Patents

Literature

564 results about "Copper matrix" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

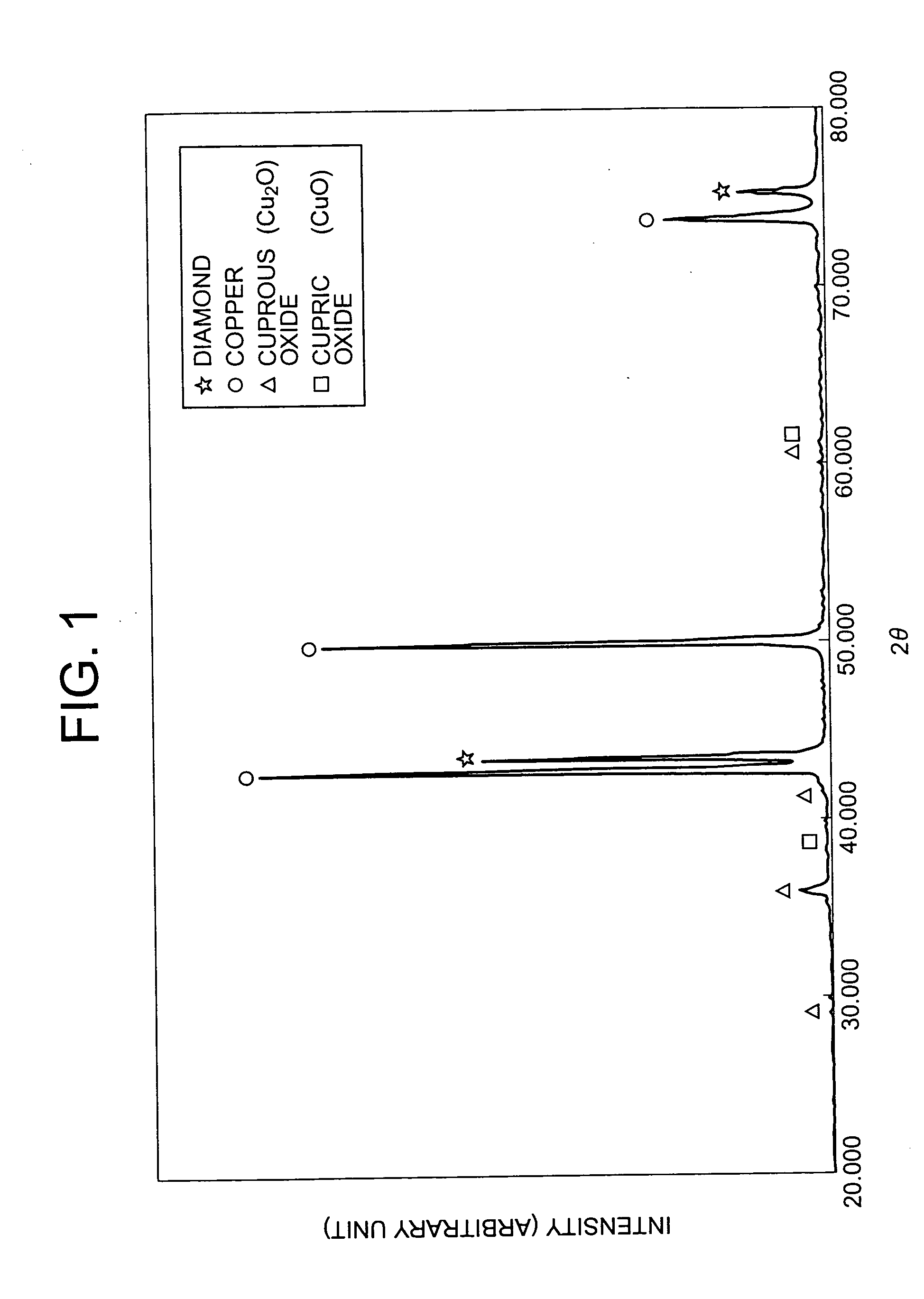

Sintered diamond having high thermal conductivity and method for producing the same and heat sink employing it

ActiveUS20050051891A1Improve performanceProlong lifeSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipThermal expansion

This invention relates to a high thermal conductivity composite material which comprises diamond particles and a copper matrix useful as electronic heat sinks for electronics parts, particularly for semiconductor lasers, high performance MPUs (micro-processing units), etc., also to a process for the production of the same and a heat sink using the same. According to the high thermal conductivity diamond sintered compact of the present invention, in particular, there can be provided a heat sink having a high thermal conductivity as well as matching of thermal expansions, most suitable for mounting a large sized and high thermal load semiconductor chip, for example, high output semiconductor lasers, high performance MPU, etc. Furthermore, the properties such as thermal conductivity and thermal expansion can freely be controlled, so it is possible to select the most suitable heat sink depending upon the features and designs of elements to be mounted.

Owner:SUMITOMO ELECTRIC IND LTD

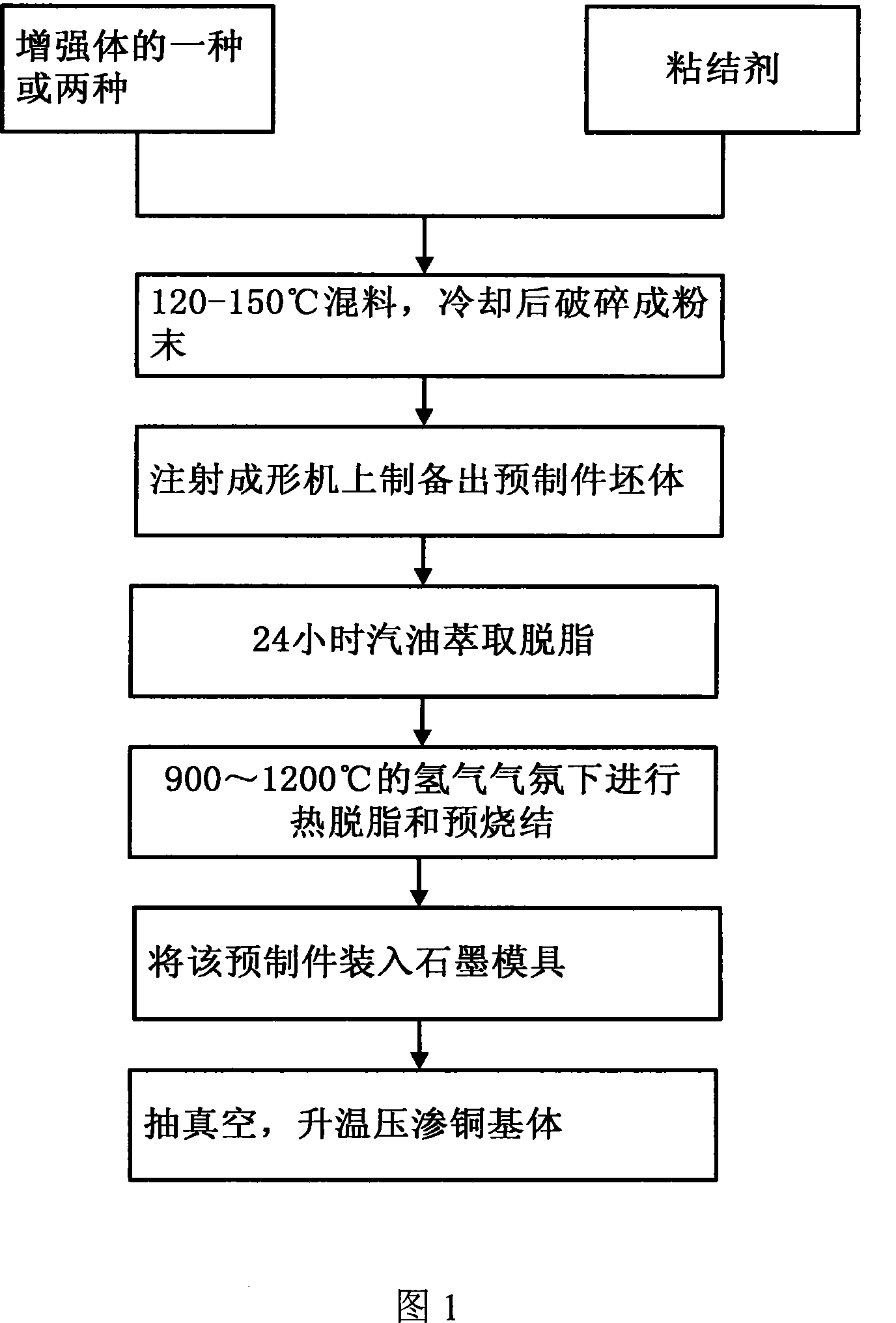

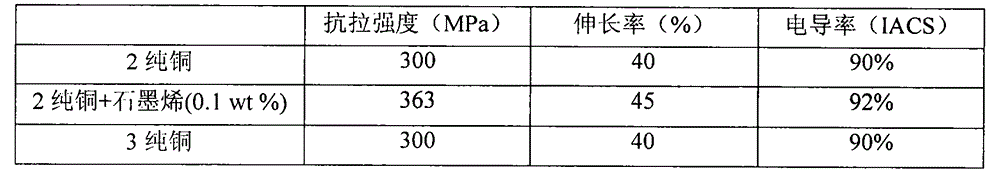

High heat conductivity copper-base composite material and preparation method thereof

The invention belongs to the technical field of preparation of electronic packaging materials, and particularly designs a copper-based composite material with high thermal conductivity and a preparation method thereof. The copper-based composite material is made of a reinforcement and a binder through a prefabricated injection molding process to make a reinforcement prefabricated part, wherein the size of the reinforcement particle is 7-60 μm, and it is composed of silicon carbide particles, diamond particles or aluminum nitride particles. One or two of them; the copper matrix is directly placed on the reinforcement preform, wherein the copper matrix is electrolytic copper or oxygen-free copper, and the volume ratio of the reinforcement to the copper matrix is 50-75%: 25-50 %, made by pressure infiltration process. The preparation method adopts the injection molding process of the prefabricated part and the pressure impregnation process to prepare the high thermal conductivity copper matrix composite material. The thermal conductivity of the copper-based composite material in the present invention is higher than that of the aluminum-based composite material with the same reinforcement system, the material itself has low density and small thermal expansion coefficient, which meets the requirement of light weight of the packaging material.

Owner:GRIMAT ENG INST CO LTD

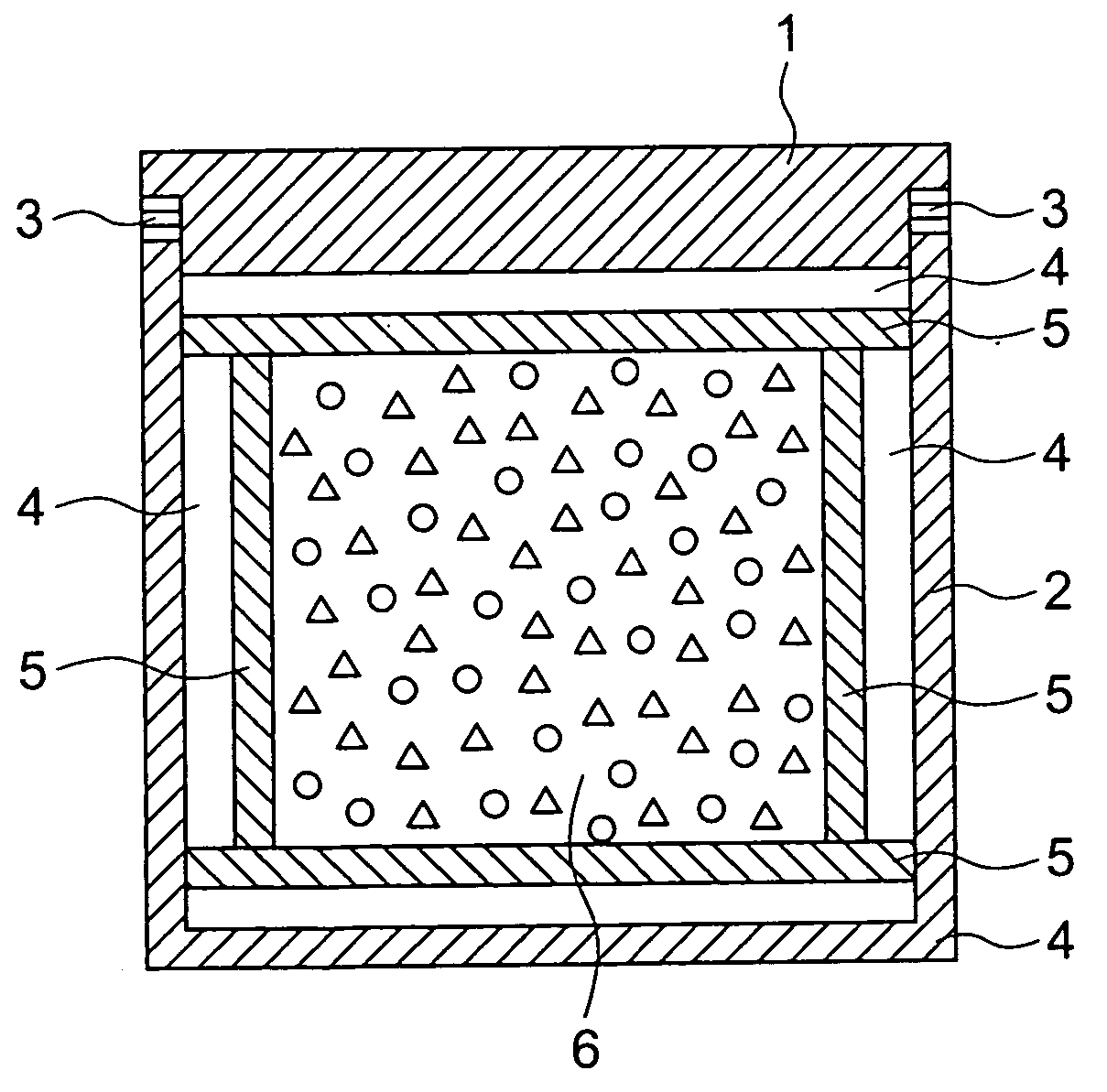

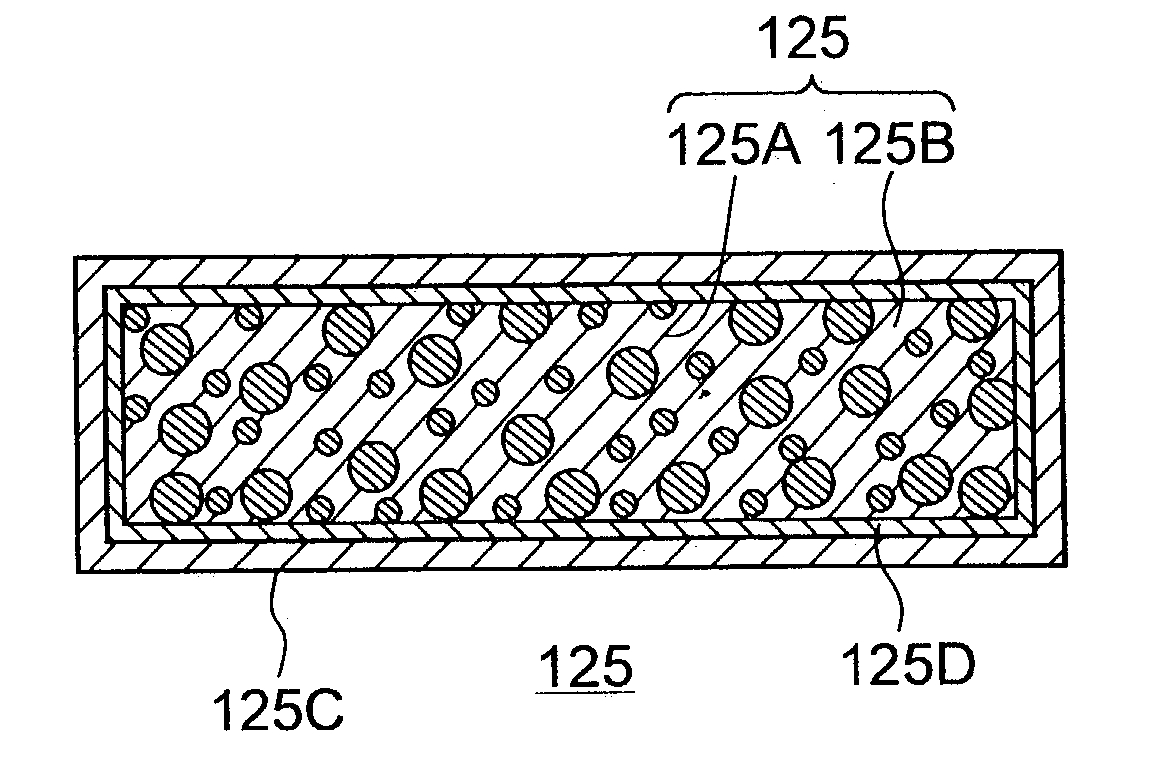

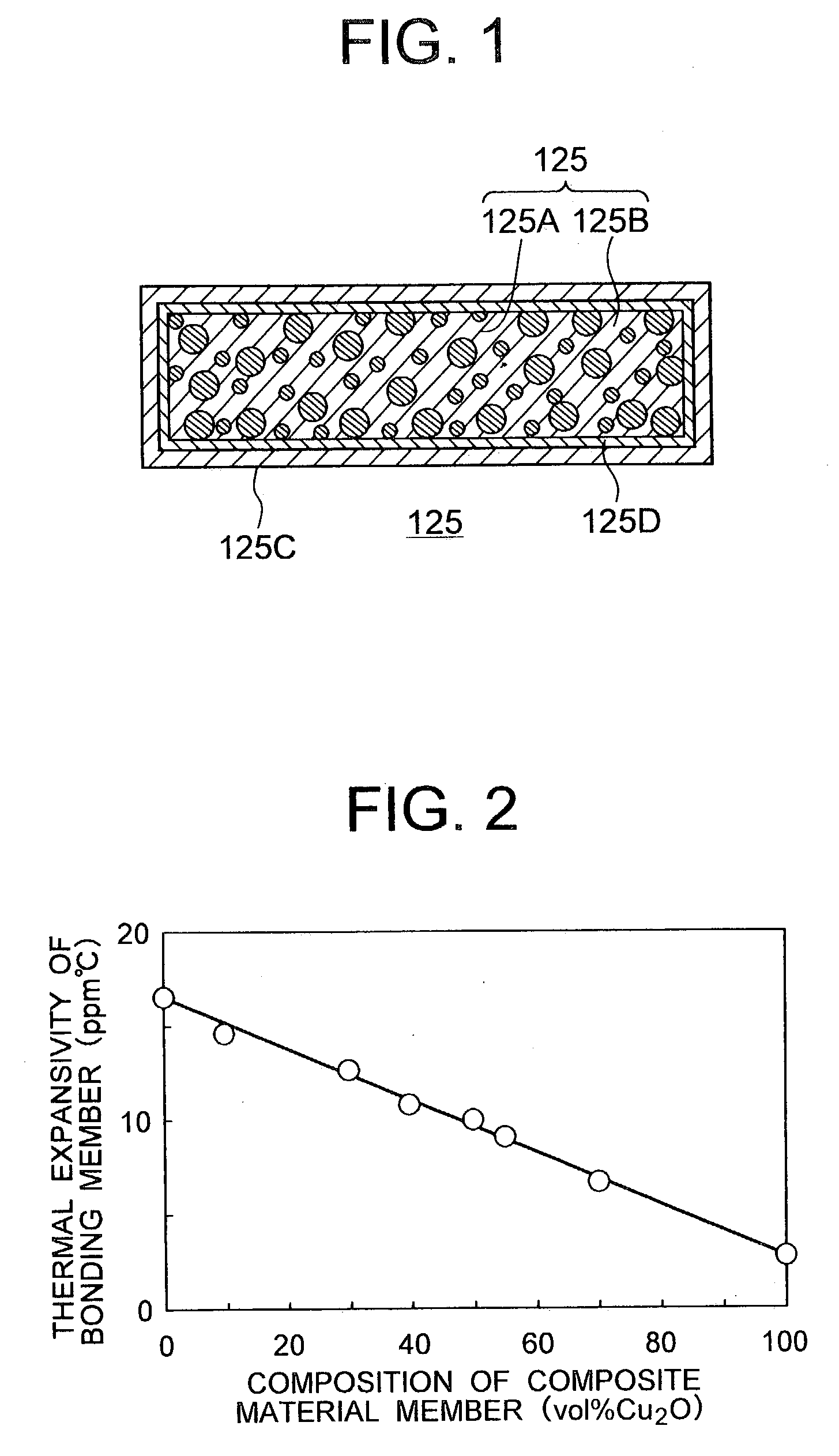

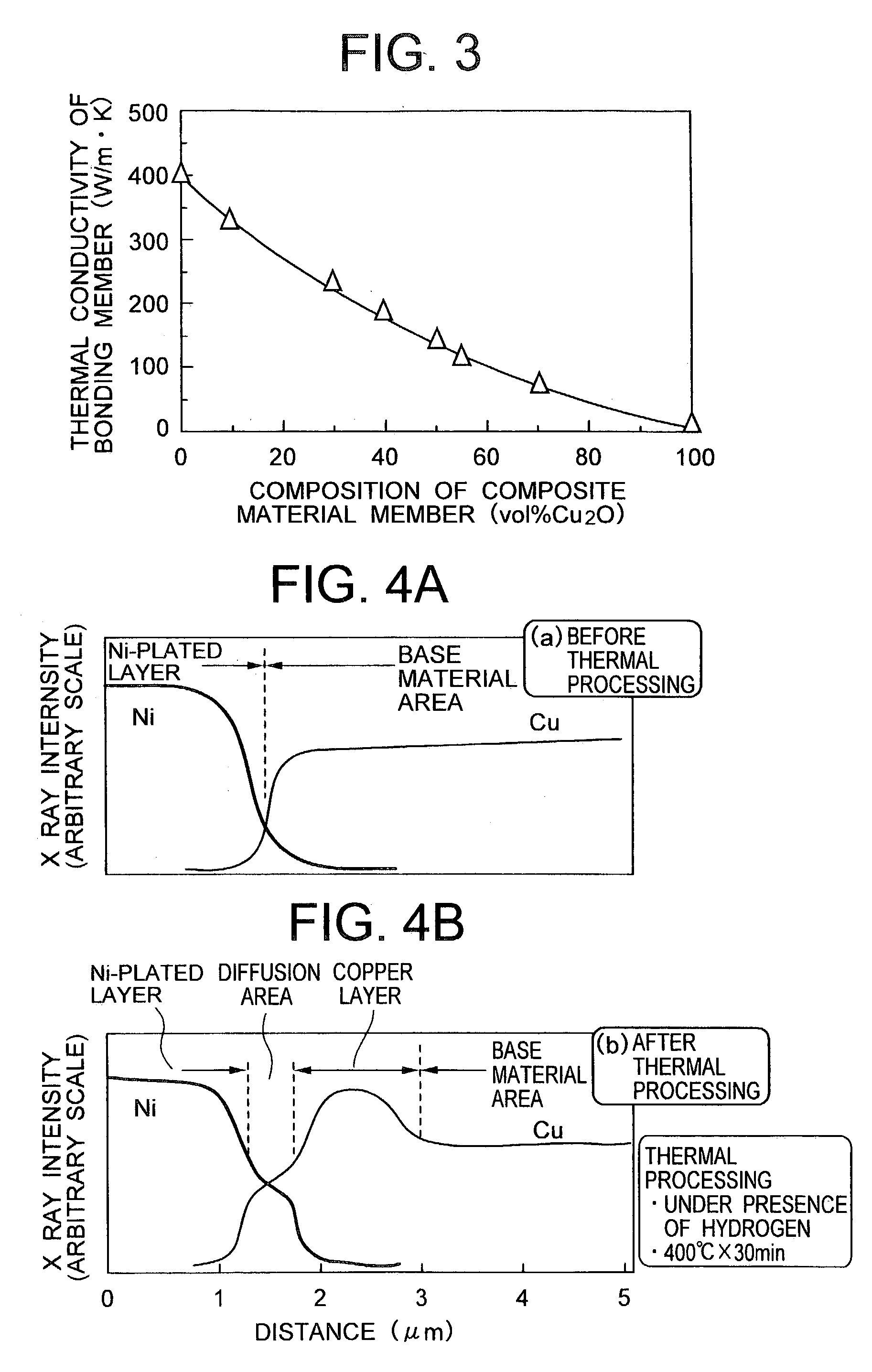

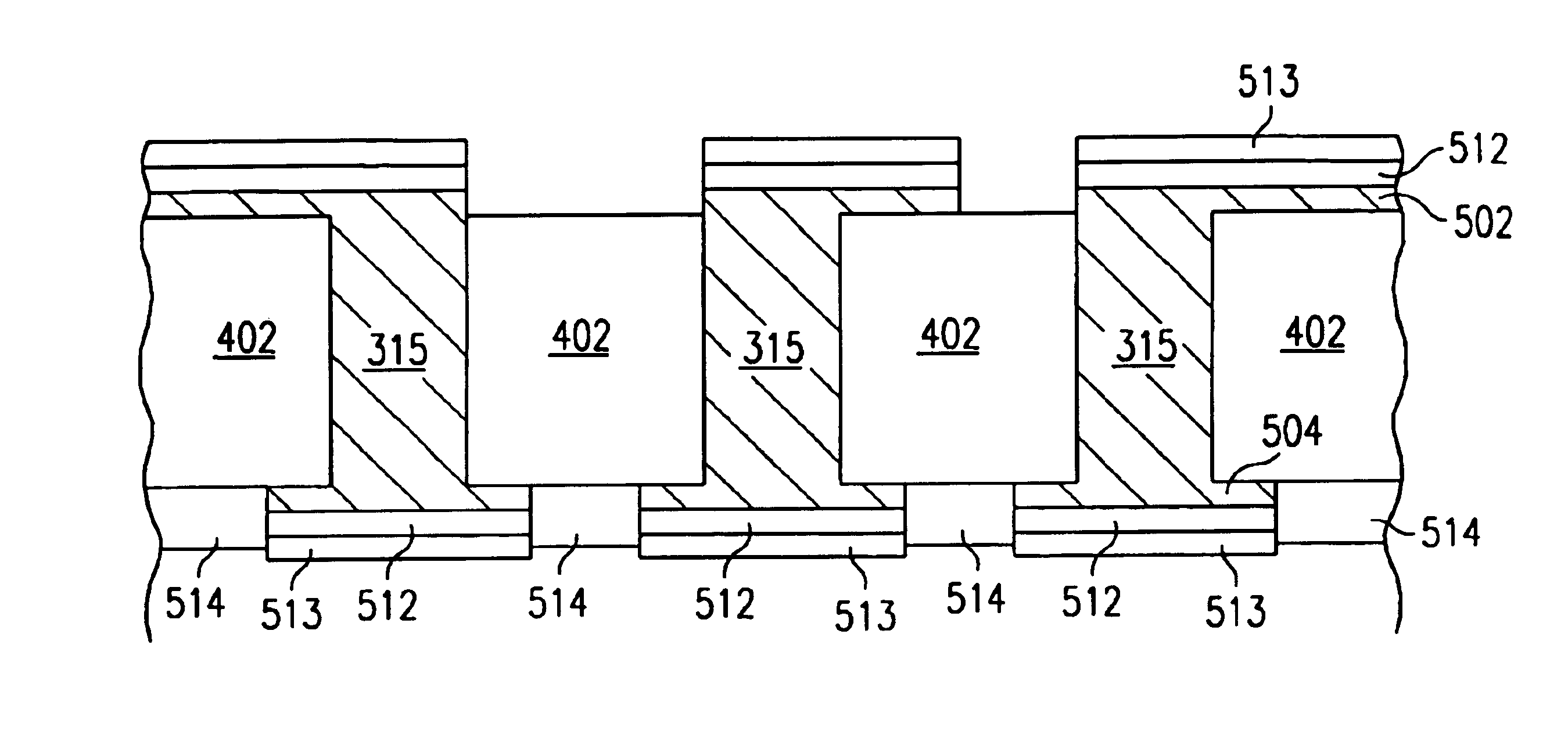

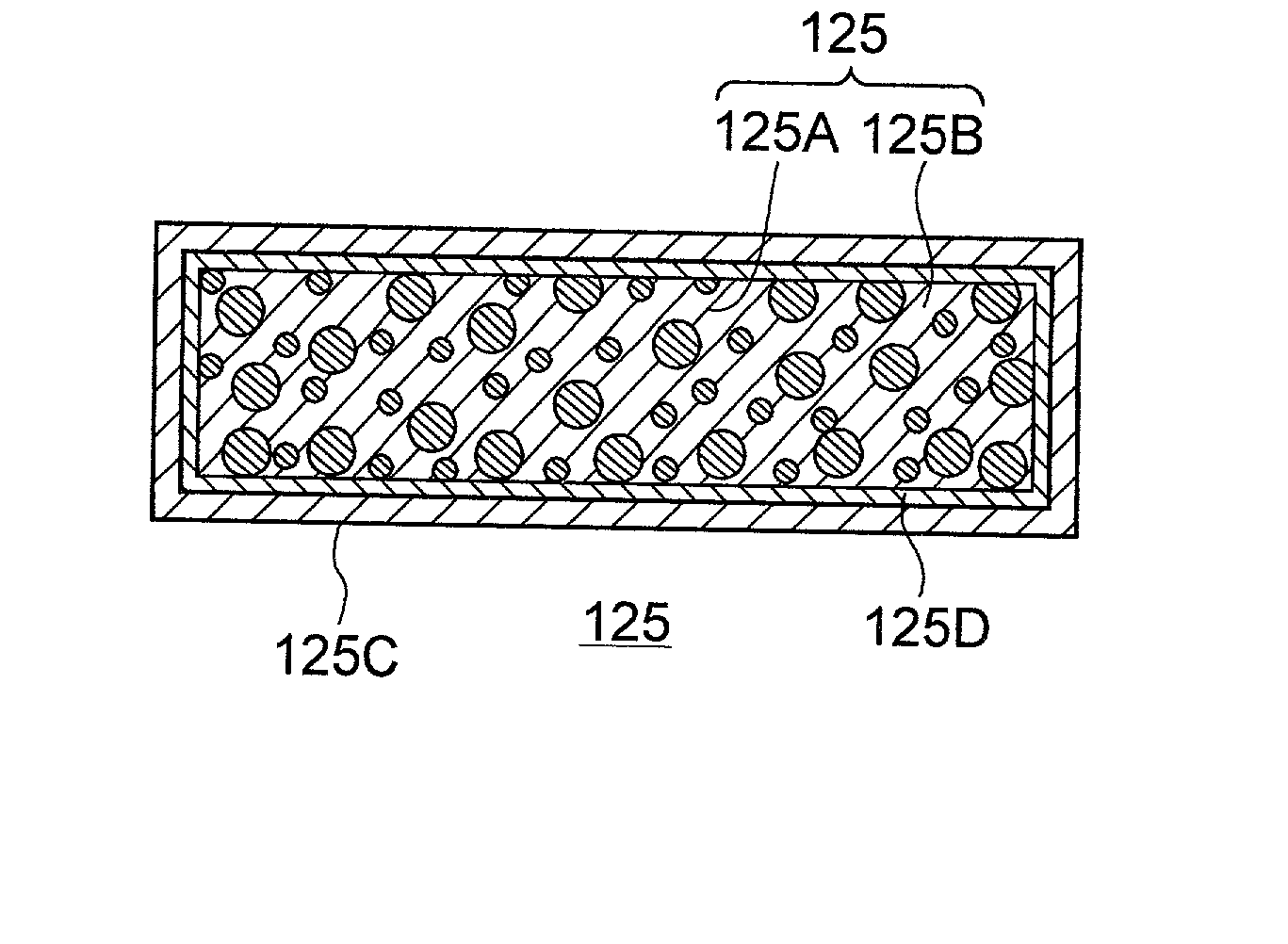

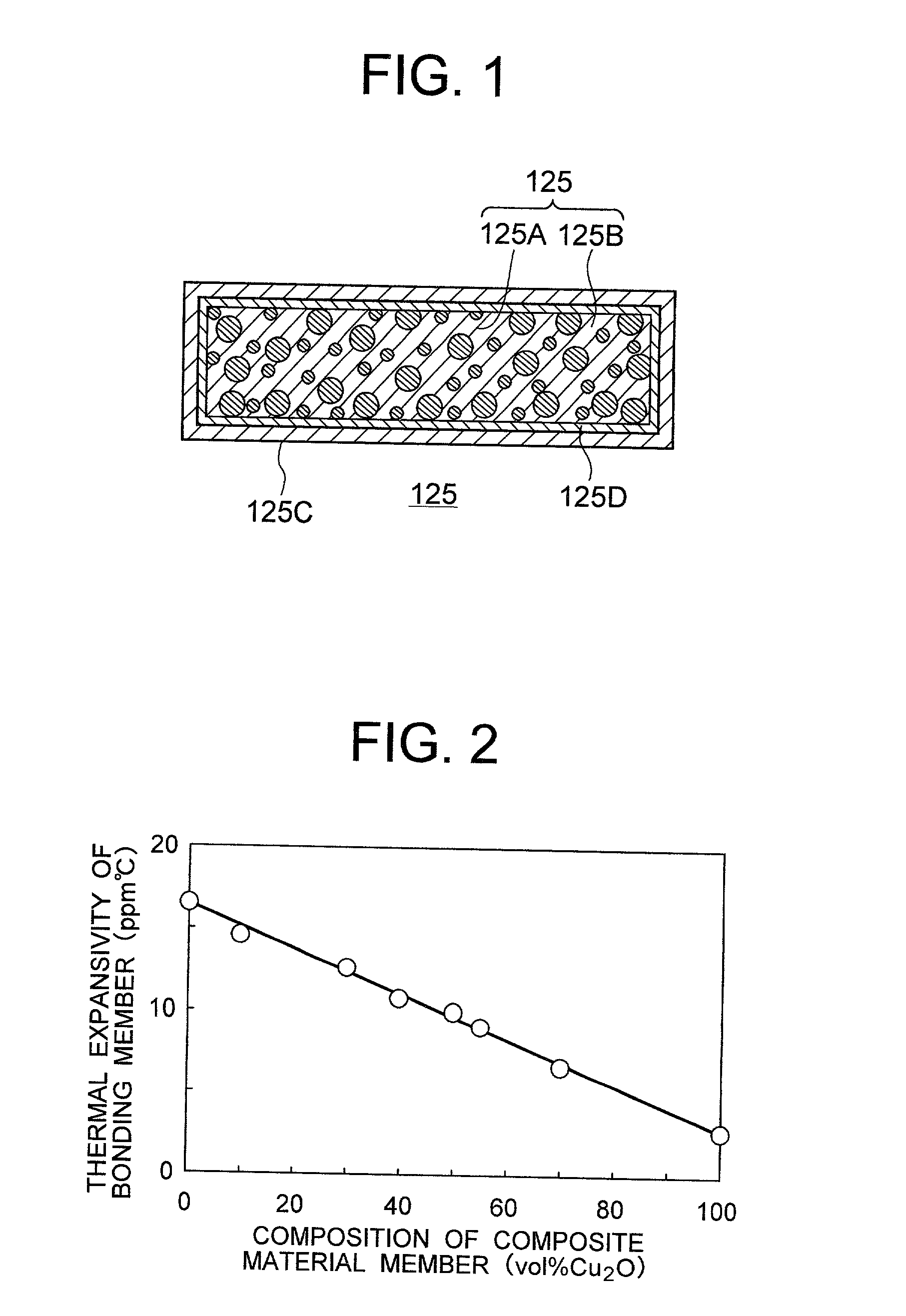

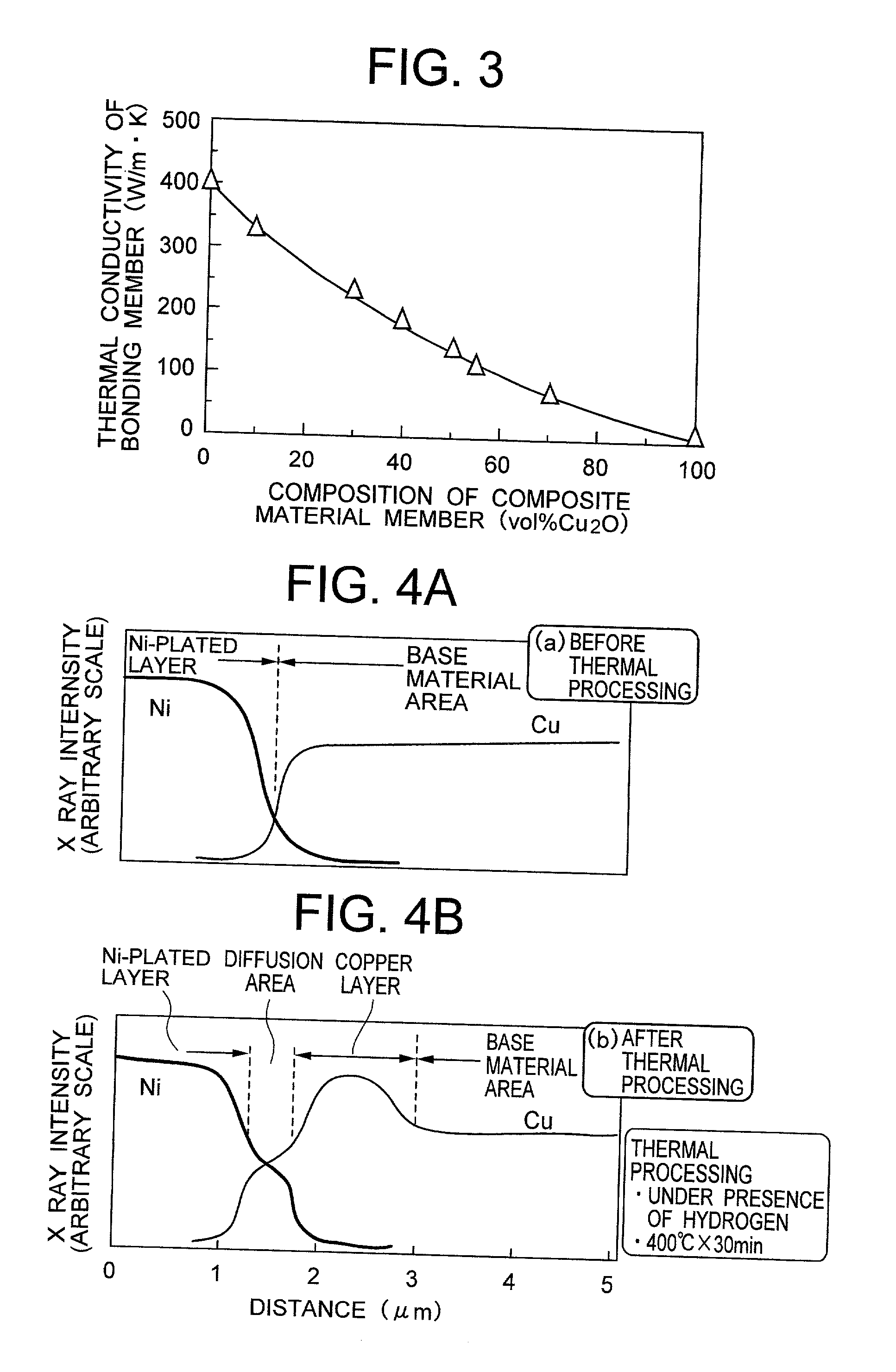

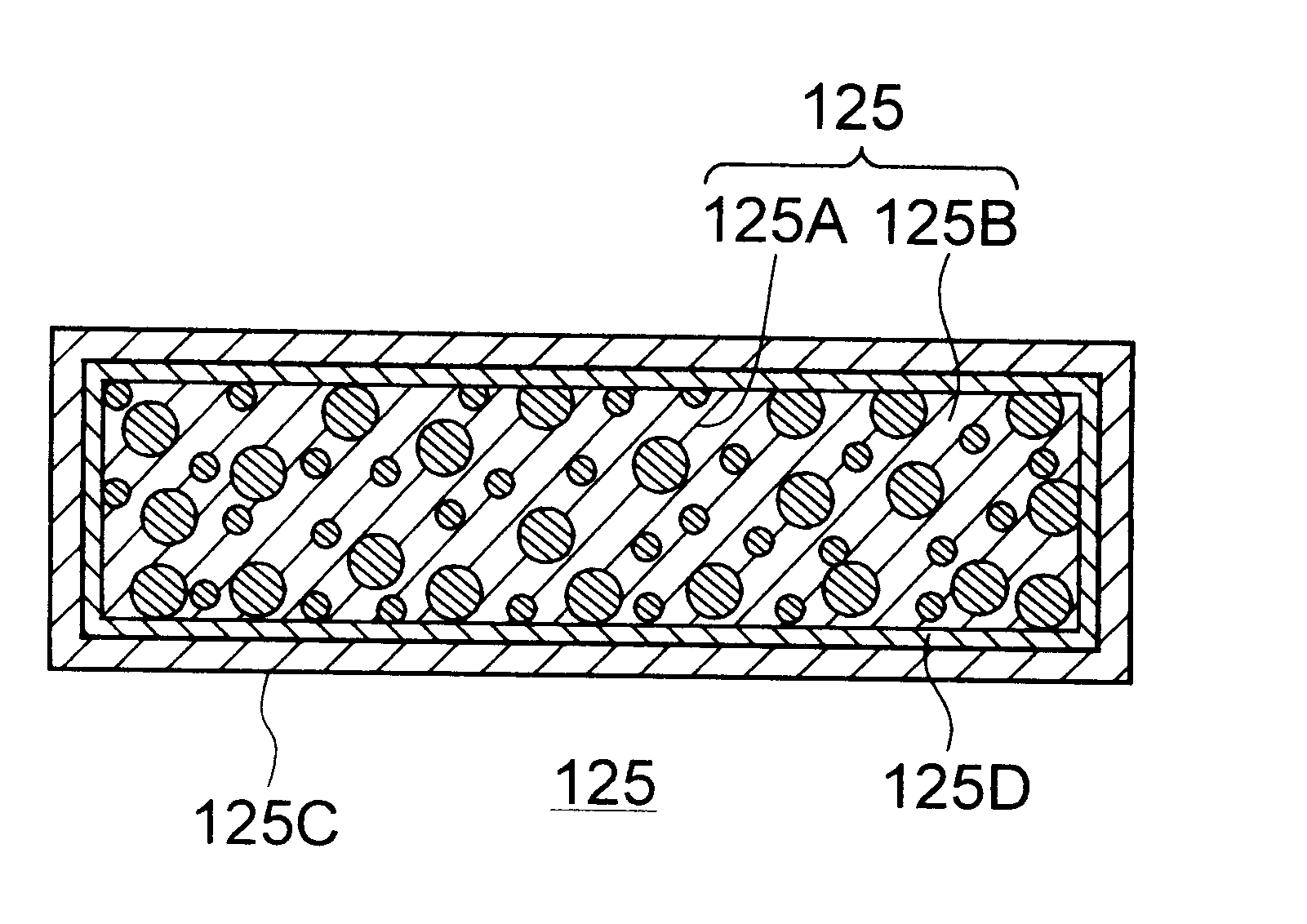

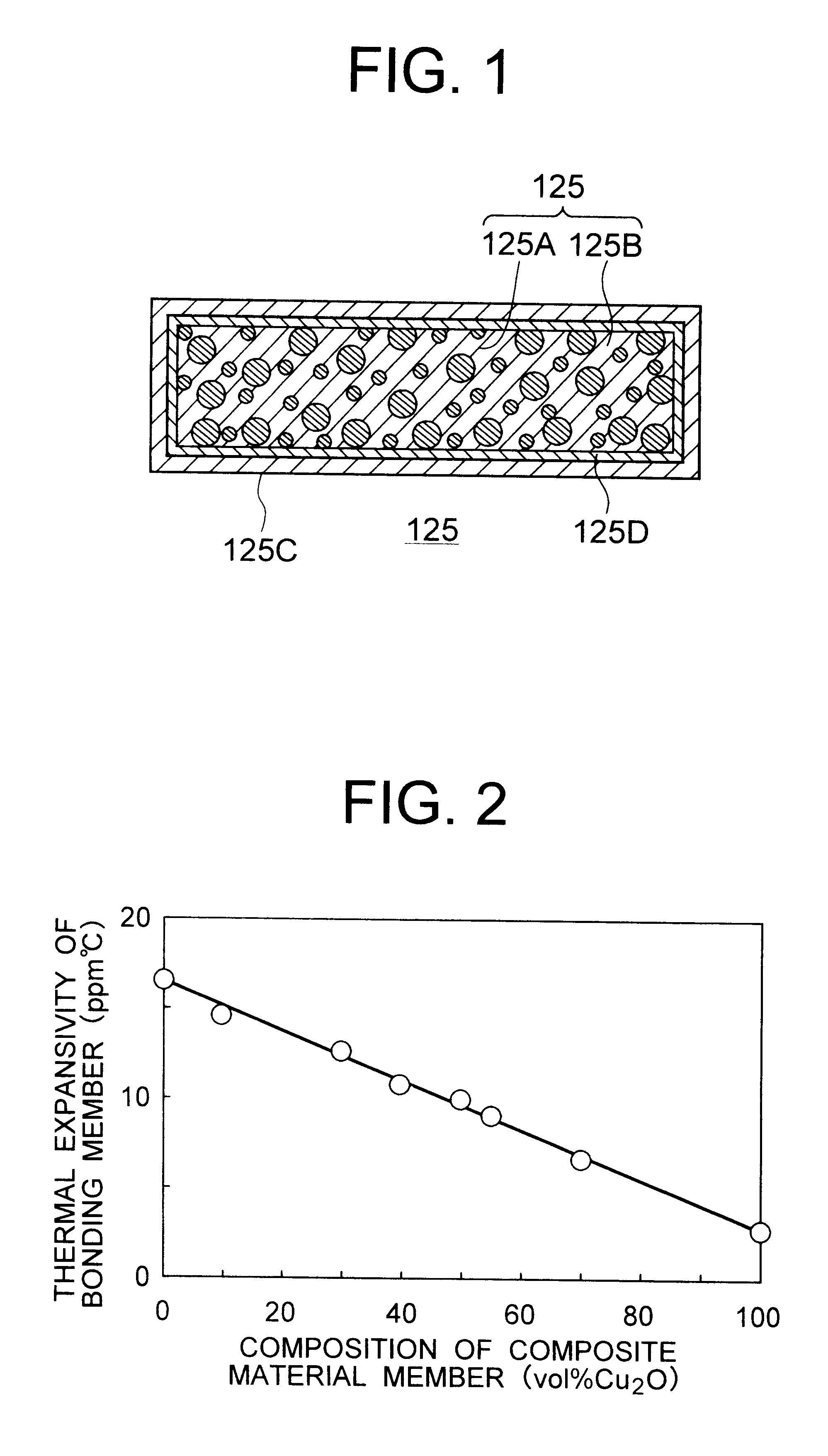

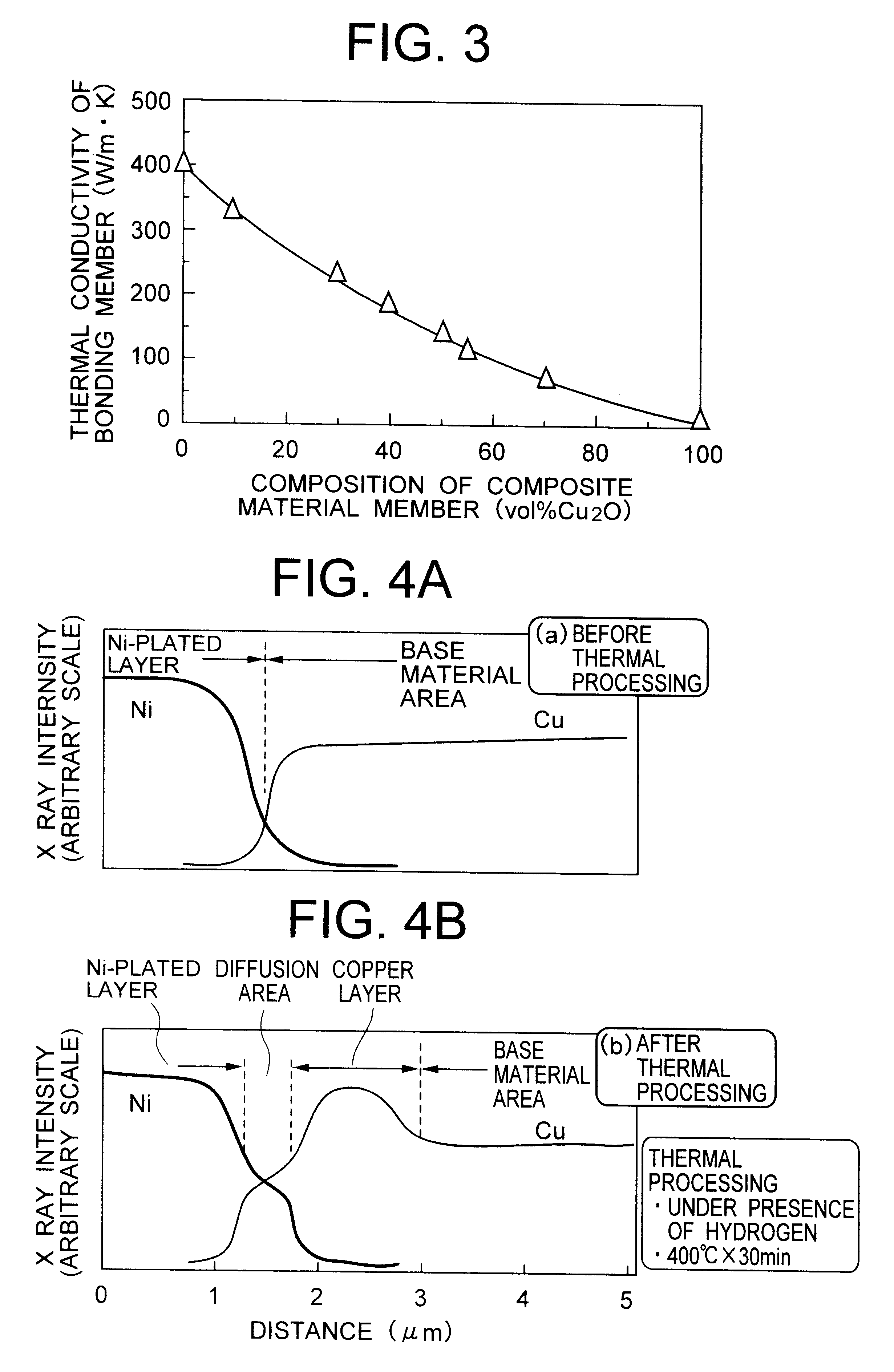

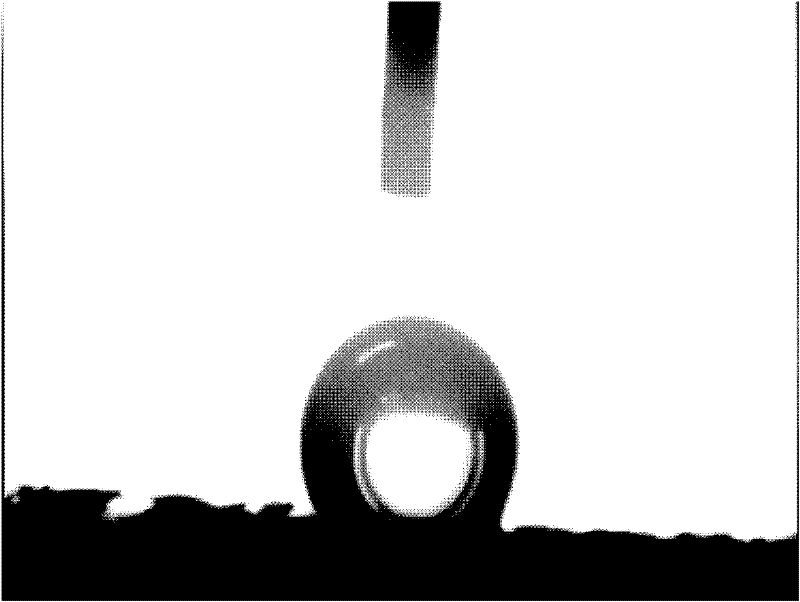

Composite material member for semiconductor device and insulated and non-insulated semiconductor devices using composite material member

InactiveUS20030201530A1Semiconductor/solid-state device detailsSolid-state devicesSemiconductorSurface cover

To provide a composite material member for semiconductor device, an insulated semiconductor device and non-insulated semiconductor device using the composite material member, which are effective for obtaining a semiconductor device that alleviates thermal stress or thermal strain occurring during production or operation, has no possibilities of deformation, degeneration and rupture of each member, and is highly reliably and inexpensive. The composite material member for semiconductor device is characterized by being a composite metal plate with particles composed of cuprous oxide dispersed in a copper matrix, in which a surface of the composite metal plate is covered with a metal layer, and a copper layer with thickness of 0.5 mum or larger exists in an interface formed by the composite metal plate and the metal layer.

Owner:HITACHI LTD

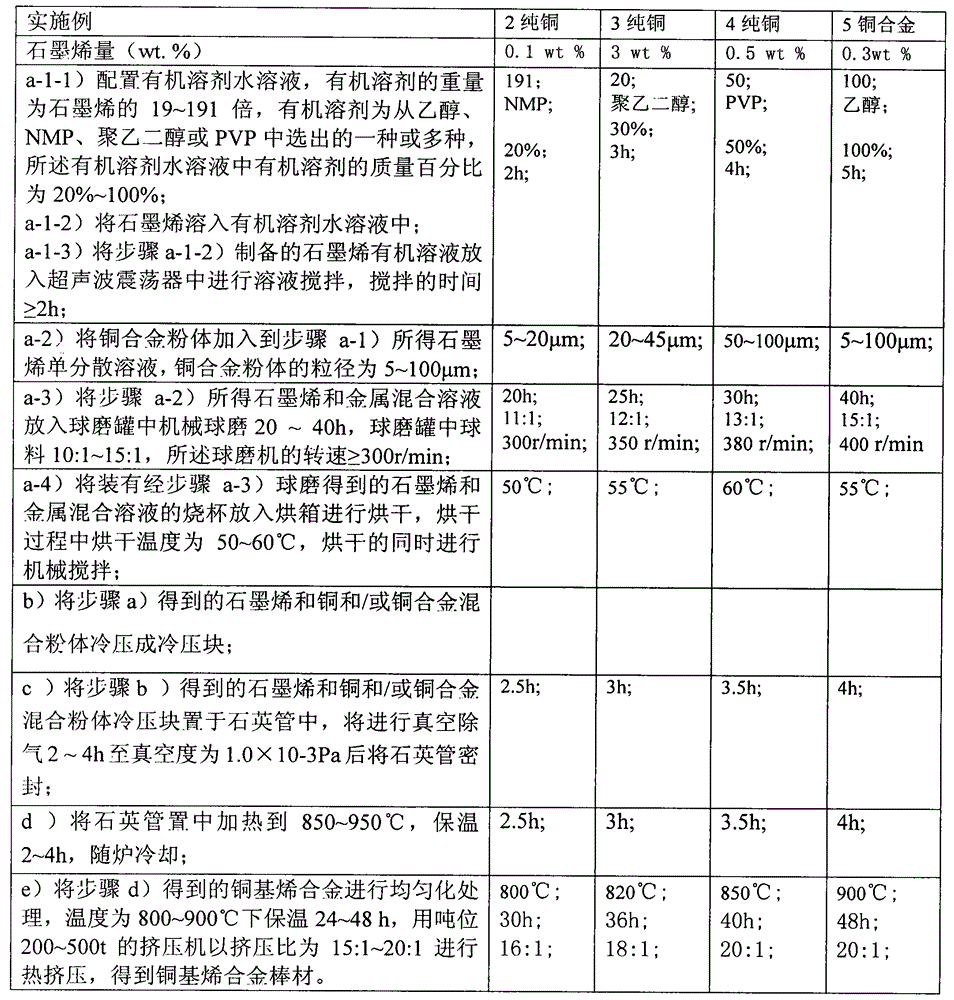

Preparation method of copper matrix graphene alloy

InactiveCN105063403AEvenly dispersedSolve the problem of easy reunion and difficult dispersionCvd grapheneCopper alloy

The invention provides a preparation method of copper matrix graphene alloy. The method comprises the following steps: preparing graphene and copper and / or copper alloy mixed powder, carrying out cold pressing, and carrying out sintering molding. The method improves an original preparation technology of the copper matrix graphene alloy, and has the advantages of production period and cost reduction, simple process operation, simple required device, high production efficiency, low preparation cost, and easy realization of large-scale industrialization.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

High heat-conducting copper-based composite material and preparation method thereof

InactiveCN101831584ALow densitySmall coefficient of thermal expansionVacuum evaporation coatingSputtering coatingInterfacial thermal resistanceThermal expansion

The invention relates to a high heat-conducting copper-based composite material and a preparation method thereof, belonging to the technical field of electronic packaging materials. The copper-based composite material consists of 50-80 percent by volume of electroplated diamond particles and 20-50 percent by volume of copper. The electroplated diamond particles and a caking agent are mixed according to the volume ratio of 1:1-4:1 and are produced into a diamond prefabricated part by using an injection forming process of the prefabricated part; and a copper matrix is directly placed on the diamond prefabricated part or is melt and poured on the diamond prefabricated part to be produced into the high heat-conducting copper-based composite material by using a pressure infiltration process. The copper-based composite material has higher heat conductivity ratio than that of an aluminum-based composite material; by plating the surface of diamond, the interface bonding of the matrix copper and the diamond can be improved and the interface heat resistance can be reduced; in addition, the material has low density and small thermal expansion coefficient and meets the requirement for light quality of packaging materials.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

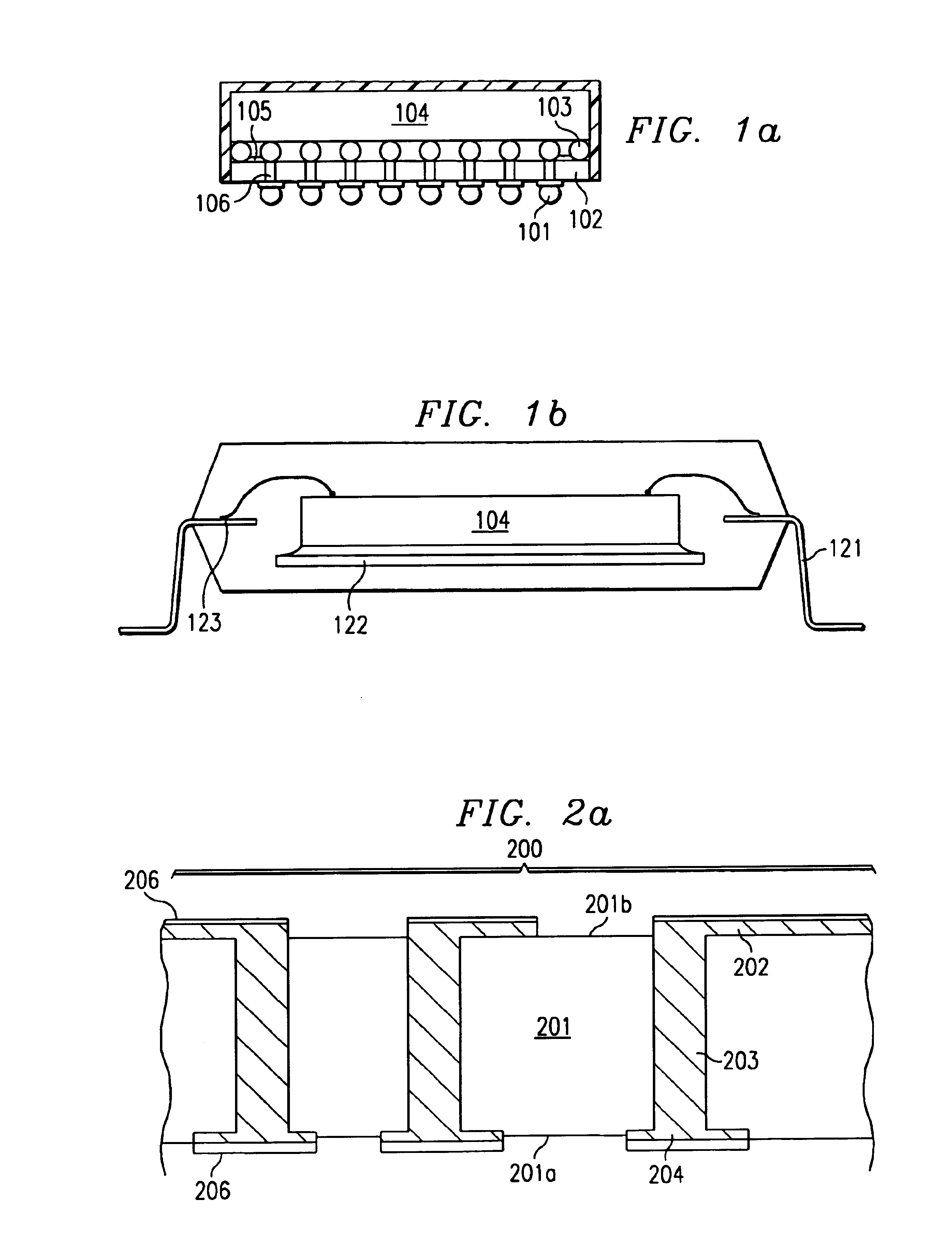

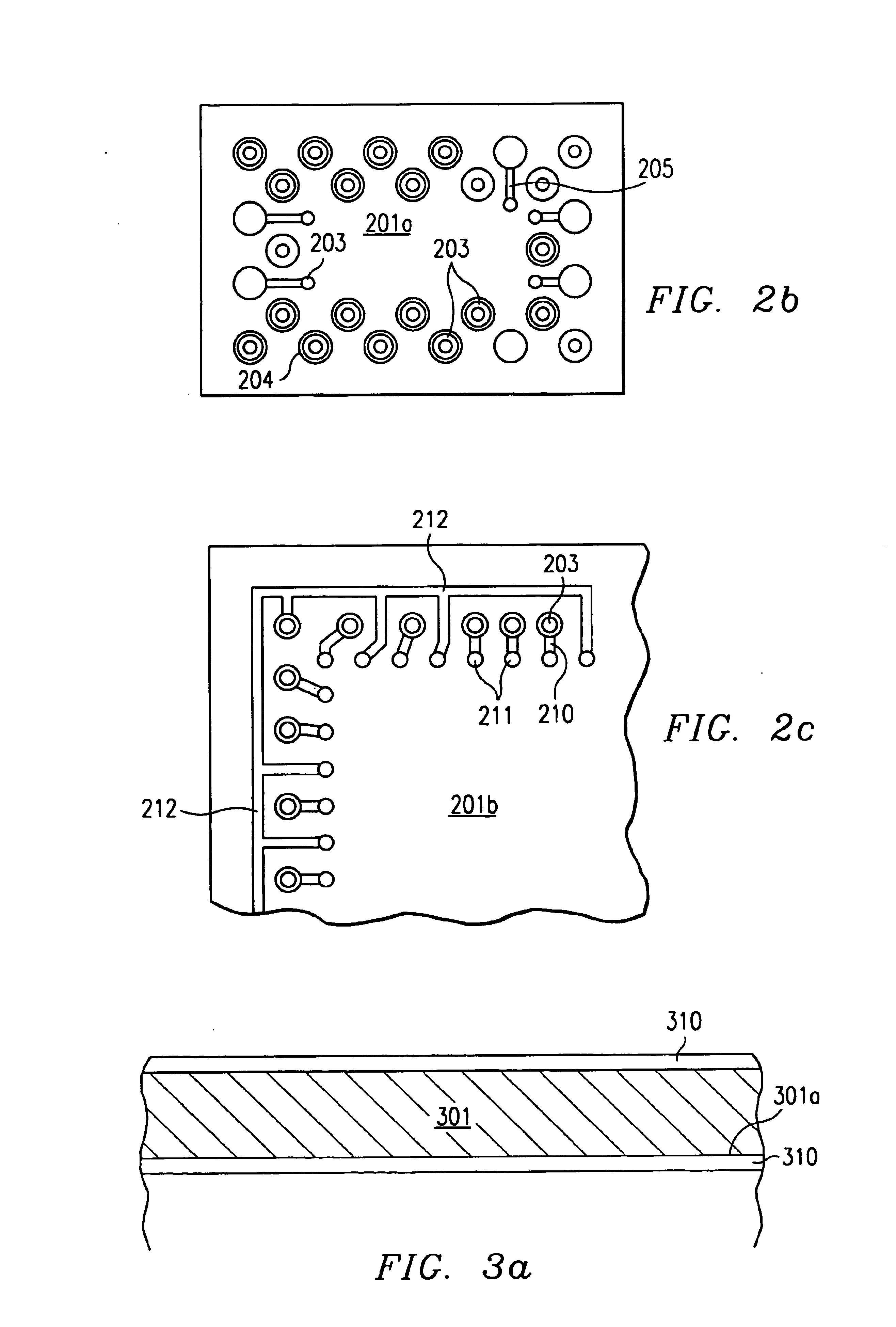

Method of fabricating flexible circuits for integrated circuit interconnections

InactiveUS6915566B2Increases conductor thicknessConnection sealPrinted circuit assemblingLine/current collector detailsIntegrated circuit interconnectFlexible circuits

A method for the fabrication of a double-sided electrical interconnection flexible circuit (200) particularly useful as a substrate for an area array integrated circuit package. A copper matrix with studs (203) is pressed through a dielectric film (201) having a copper layer on the opposite surface, thereby forming an intermediate structure for a flex circuit with self-aligned solid copper vias in a one step process. The contacts are reinforced by plating both surfaces with a layer of copper, and conventional processes are used to complete the circuit patterning.

Owner:TEXAS INSTR INC

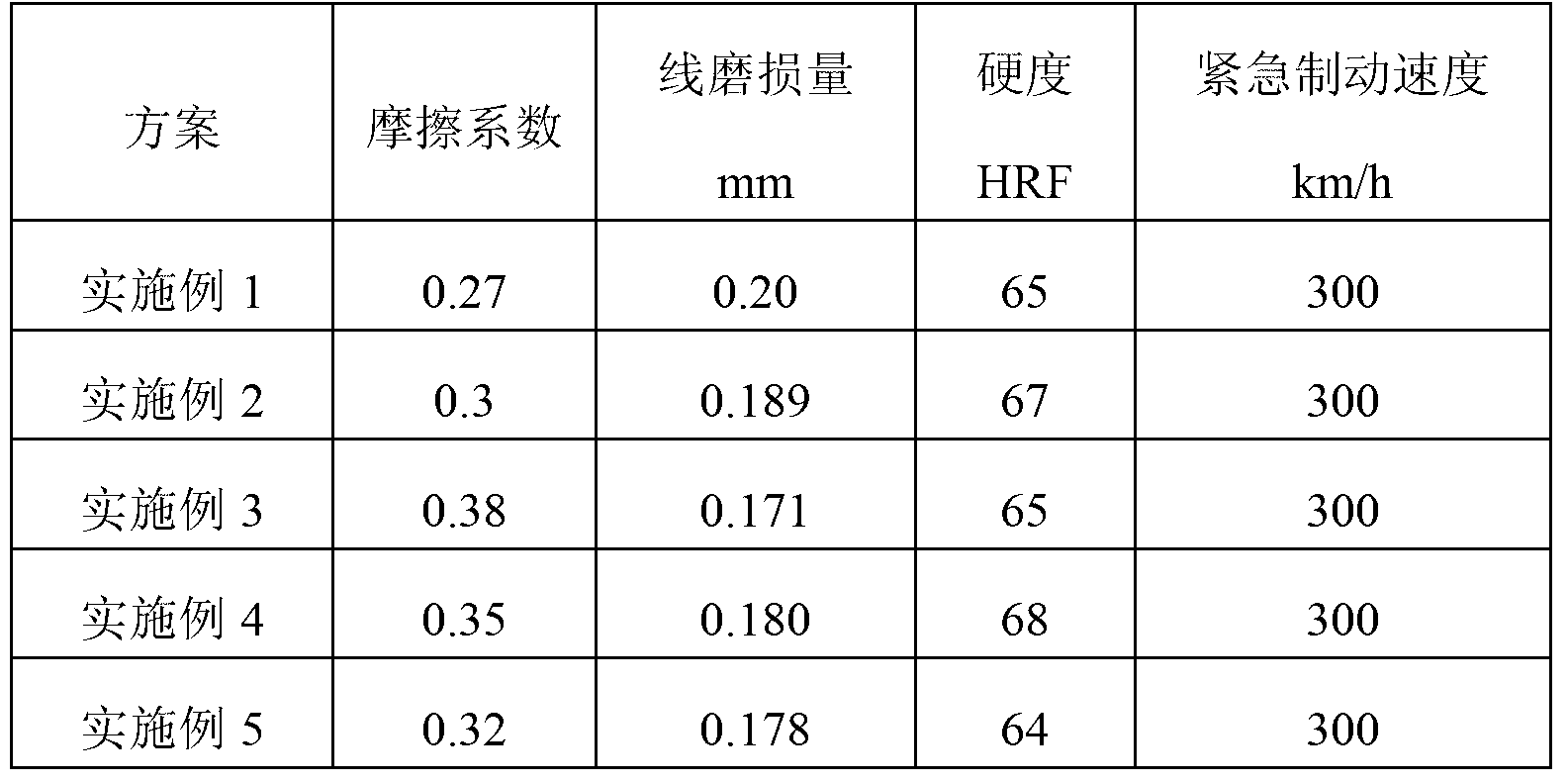

Dispersion-strengthened copper-based powder metallurgy brake pad and preparation for same

The invention discloses preparation for the brake pad of a high-speed train via a powder metallurgy method and by taking dispersion-strengthened copper as a matrix material. According to the oxide dispersion-strengthened copper, a copper matrix is strengthened by oxide dispersion particles, and the dispersion-strengthened copper chooses dispersion-strengthened copper powder in which nanometre Al2O3 is in a ratio of 0.03-5% by weight; and the formula of the brake pad comprises 50-70wt% of dispersion-strengthened copper powder, 5-20wt% of Fe powder, 4-15wt% of (flaky) C powder, 1-10wt% of SiO2 powder, 1-7wt% of Al2O3 powder, 1-7wt% of Sn powder, 1-3wt% of Pb powder, and 1-10wt% of MoS2 powder. The dispersion-strengthened copper-based brake pad is obtained by uniformly mixing the powders in a ratio, moulding by cold-pressing, then performing pressure sintering with a steel backing. Compared with the traditional copper-based brake pad, the brake pad taking the dispersion-strengthened copper as a matrix is enhanced in matrix strength, high in thermal conductivity, good in stability, good in fatigue performance and wear resistance, and less in wear on dual discs.

Owner:UNIV OF SCI & TECH BEIJING

High-conductivity high-strength copper-iron alloy and preparation method thereof

The invention provides a high-conductivity high-strength copper-iron alloy and a preparation method thereof. The Fe precipitation phase in the alloy is uniformly distributed in a sub-micron level in acopper matrix, and the content of Fe is 5-25 wt%; and the conductivity is 45-60% IACS, and the tensile strength is 620-1360 MPa. The preparation method of the alloy comprises the following steps of firstly, preparing alloy powder by an atomization method; then, carrying out sintering treatment on the alloy powder, so as to obtain a sintered blank; carrying out wire drawing treatment on the sintered blank to obtain the wire material; and finally, carrying out aging treatment on the wire material to obtain the copper-iron alloy. The high-conductivity high-strength copper-iron alloy prepared cansolve the problem that iron-phase distribution in the high-strength and high-conductivity copper-iron alloy is not uniform, the sub-micron level uniform distribution of the Fe precipitation phase inthe copper matrix can be realized, and the alloy strength is improved to the maximum extent on the premise that the high conductivity of the alloy is kept.

Owner:CENT SOUTH UNIV

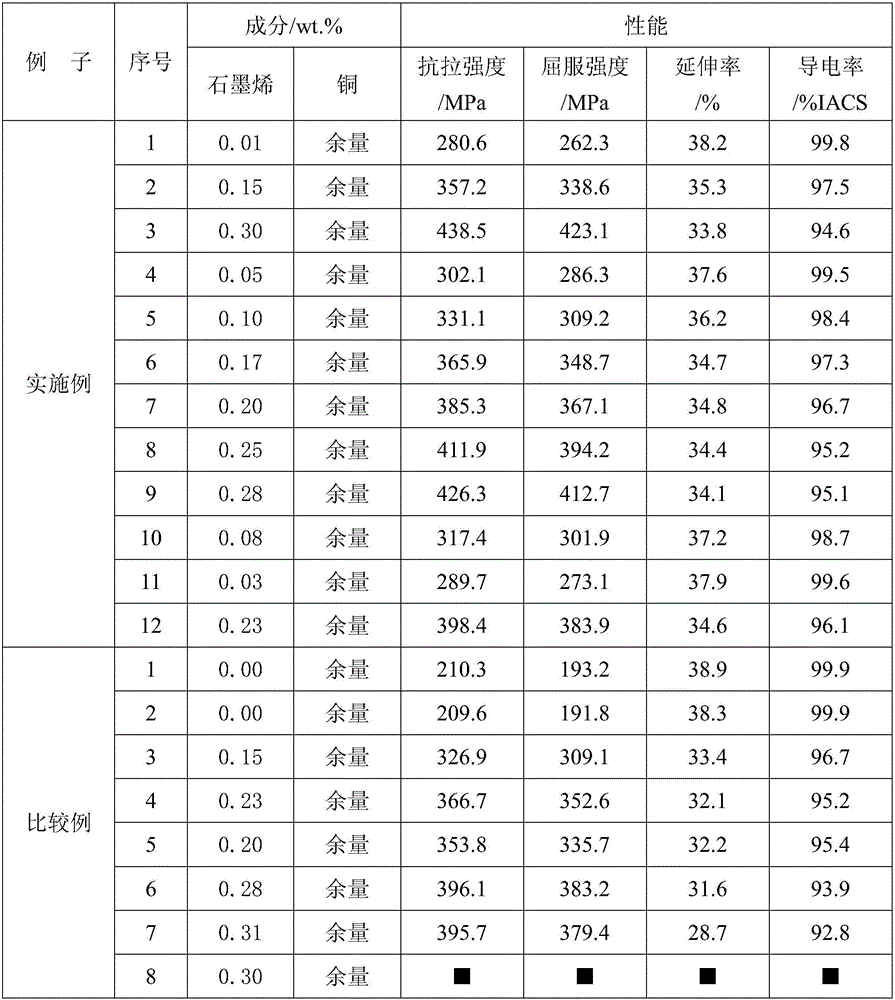

Copper-graphene composite material and preparation method thereof

ActiveCN105714139APrevent oxidationControllable distribution densityLead frameUltimate tensile strength

The invention relates to a copper-graphene composite material and a preparation method thereof. The copper-graphene composite material comprises graphene and copper, and is characterized in that the graphene is evenly distributed in a copper matrix in a sheet structure; distribution density of the graphene is 100 sheets per square centimeter to 3000 sheets per square centimeter; and preferably, the content of the graphene is 0.01 wt% to 0.30 wt%, and the balance is Cu. The copper-graphene composite material disclosed by the invention is prepared by adding the graphene into the copper; the copper matrix can be served as an electrical conduction main body to enable electrical conductivity of the composite material to be close to pure copper, and the graphene is served as a reinforcement phase, so that tensile strength performance and yield strength performance are both increased; therefore the copper-graphene composite material can be widely applied to the fields of consumer electronics, electrics, aeronautics and astronautics, high-speed rails, lead frames, electronic connector preparation; and the preparation method provided by the invention is suitable for industrial and scale production.

Owner:NINGBO POWERWAY ALLOY MATERIAL

Composite material member for semiconductor device and insulated and non-insulated semiconductor devices using composite material member

InactiveUS20020192488A1Semiconductor/solid-state device detailsSolid-state devicesSemiconductorSurface cover

To provide a composite material member for semiconductor device, an insulated semiconductor device and non-insulated semiconductor device using the composite material member, which are effective for obtaining a semiconductor device that alleviates thermal stress or thermal strain occurring during production or operation, has no possibilities of deformation, degeneration and rupture of each member, and is highly reliably and inexpensive. The composite material member for semiconductor device is characterized by being a composite metal plate with particles composed of cuprous oxide dispersed in a copper matrix, in which a surface of the composite metal plate is covered with a metal layer, and a copper layer with thickness of 0.5 mum or larger exists in an interface formed by the composite metal plate and the metal layer.

Owner:HITACHI LTD +1

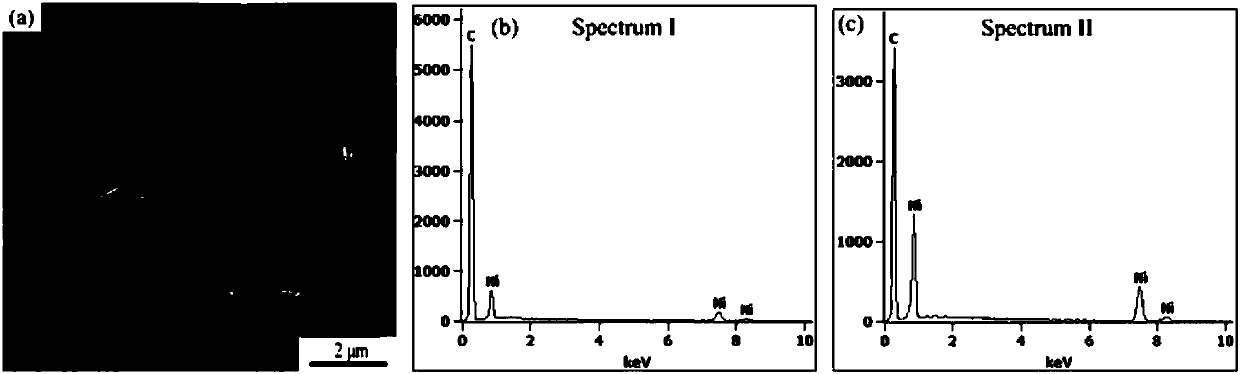

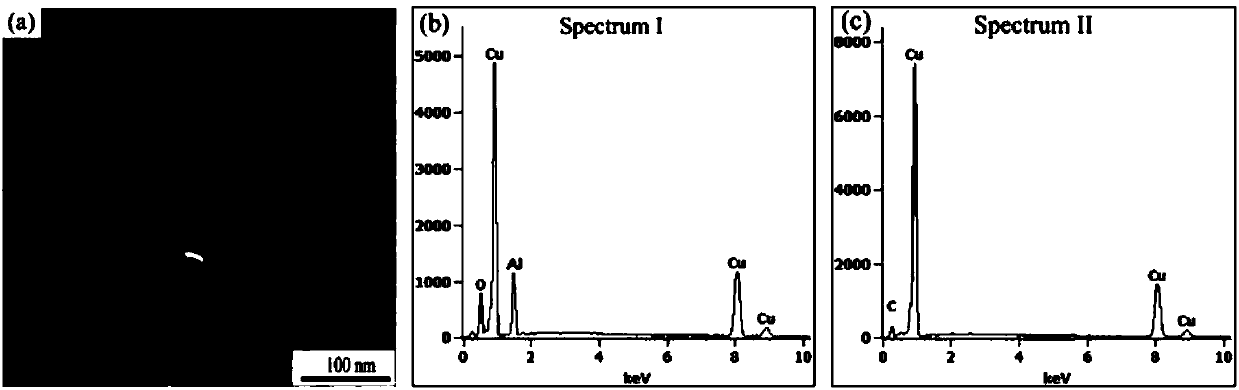

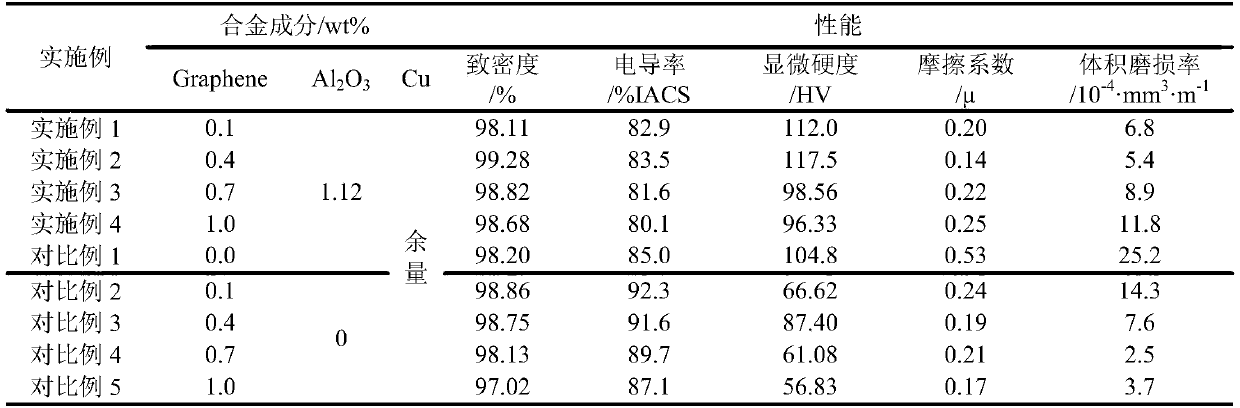

Graphene-aluminum oxide hybrid reinforced copper-based composite material and preparation method thereof

The invention discloses a graphene-aluminum oxide hybrid reinforced copper-based composite material. The composite material comprises 0.1-1.0 wt% of graphene, 1.0-1.2 wt% of Al2O3, and the balance copper. According to the copper-based composite material, the graphene and the aluminum oxide are adopted as complex-phase reinforcement bodies, zero-dimensional aluminum oxide particles can be effectively pinned through a special two-dimensional structure of a nano graphene sheet, a steric-hinerance effect is generated, accordingly, the agglomeration phenomenon of the particles is effectively reduced, and the particles are uniformly scattered; and the surface of the graphene is subjected to chemical nickel-plating and modification treatment, thus, the wettability and the interface bonding situation between the graphene / copper matrixes can be obviously improved, ideal interface bonding is achieved, accordingly, the synergistic effect between the graphene and the aluminum oxide particles is realized to the greatest extent, and the combination properties including strength, hardness, electrical conductivity, and friction and wear properties of the copper-based composite material are comprehensively improved.

Owner:ZOLTRIX MATERIAL GUANGZHOU

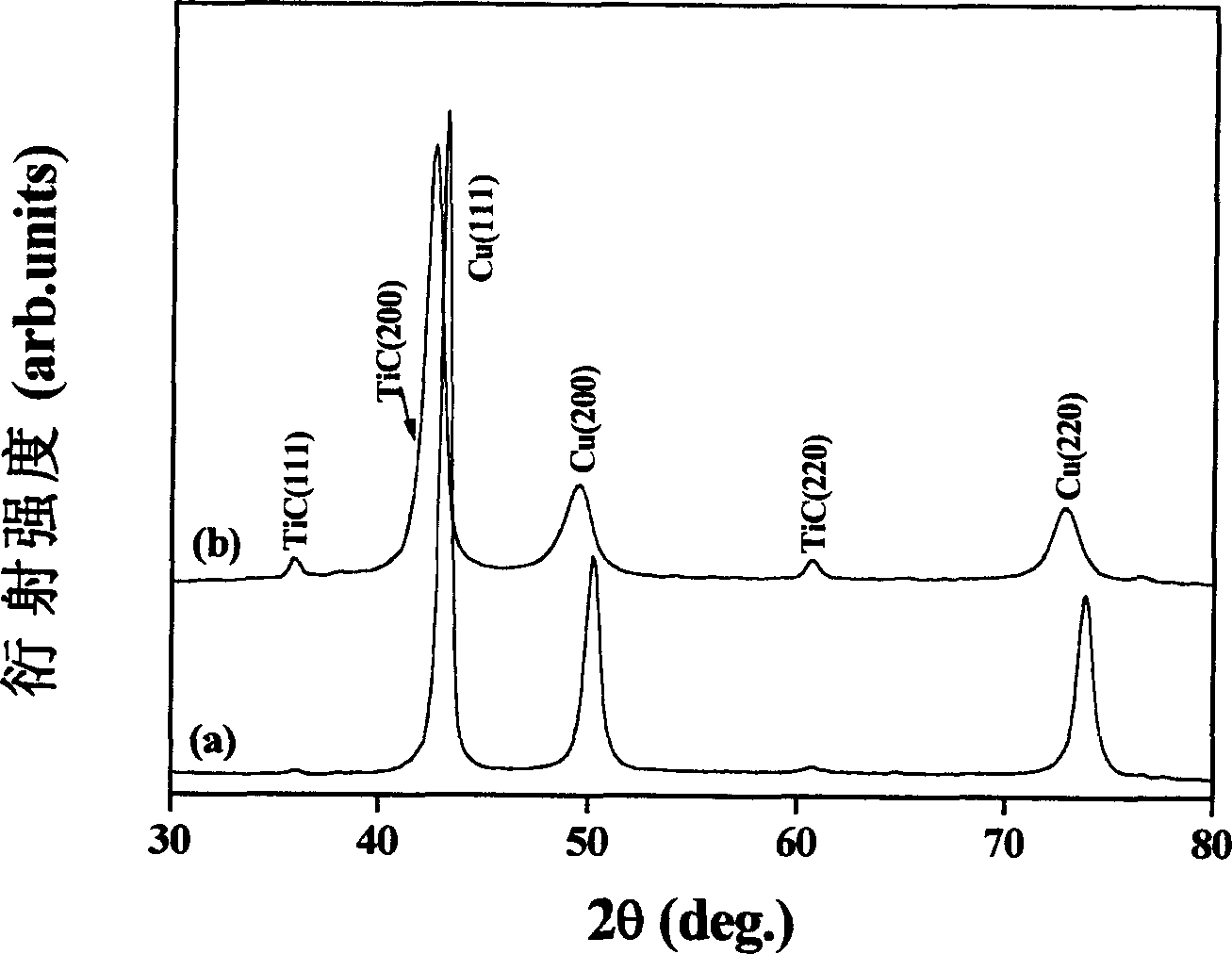

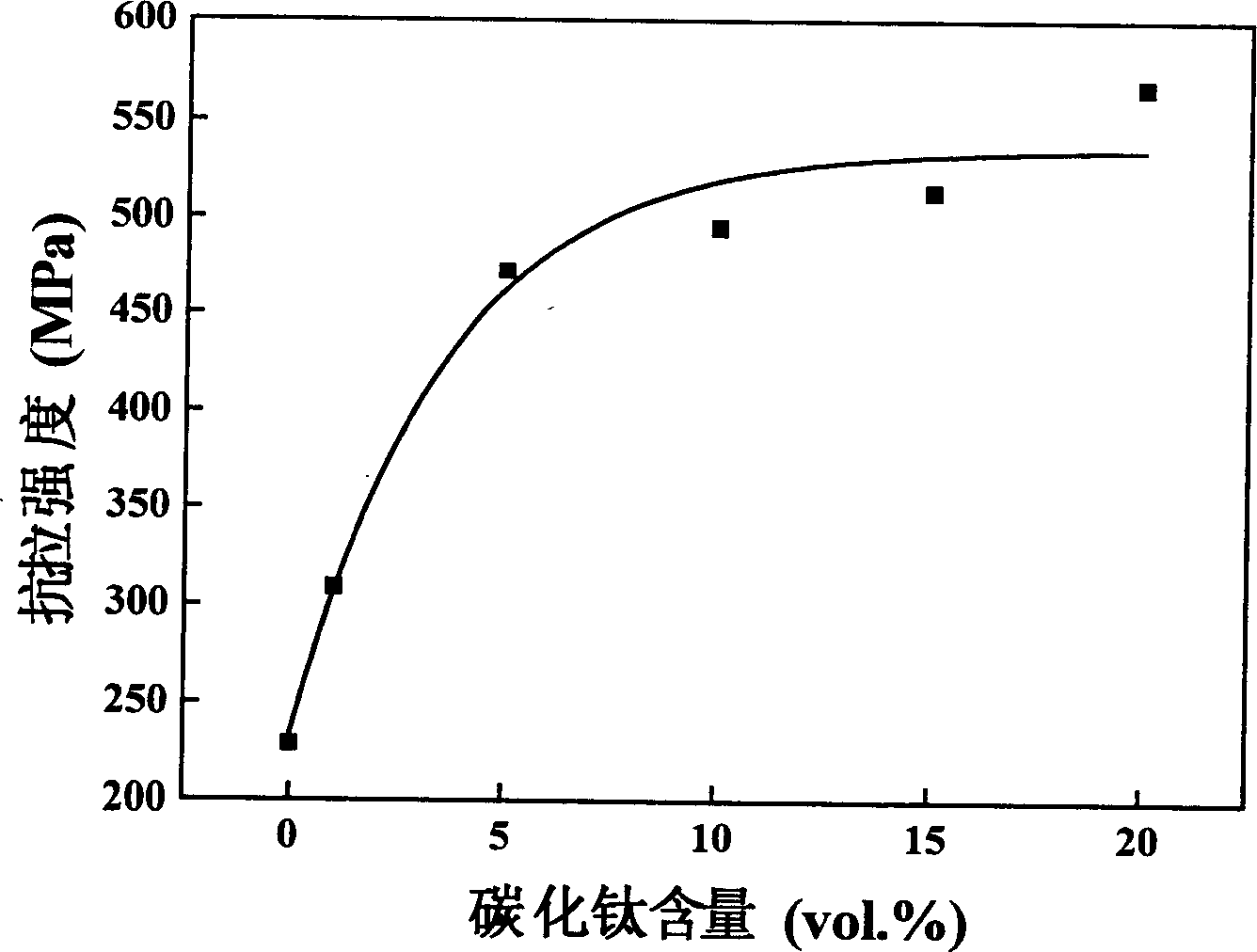

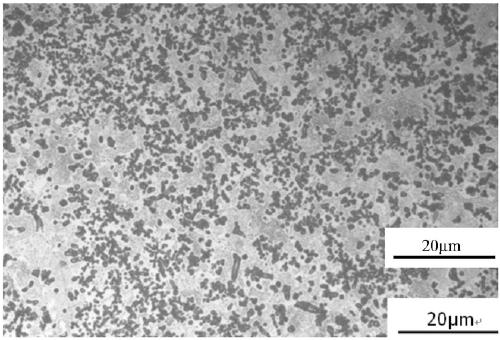

In-situ produced titanium carbide dispersion strengthening copper based composite material and method for preparing the same

The preparation method to decompose Ti2SnC dispersed in Cu-matrix and in-situ generate 1-20vol.% TiCx dispersion-strengthened Cu-base series composite material comprises: mixing Ti2SnC ultrafine powder with copper as given ratio to grind for 5-15h and then load into graphite mould; cold pressing on 5-15MPa; sintering in hot-pressing furnace with protective atmosphere for 0.5-3h on condition of 30-50MPa and 800-900Deg; finally, annealing at 950-1050Deg for 2-8h. This invention can prepare the composite with high hardness and strength with simple technique.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Carbon nanotube-metal composite enhanced copper-based composite material and preparation method thereof

The invention relates to a carbon nanotube-metal composite enhanced copper-based composite material and a preparation method thereof, and belongs to the field of preparation of composite materials. The preparation method comprises the following steps: preparing colloidal sol by using soluble salts containing metallic elements and copper ions and carbon nanotube as raw materials, carrying out spray granulation by using the colloidal sol through a spray dryer so as to obtain nanoscale mixed powder, calcining the mixed powder in an oxygen-free atmosphere so as to obtain black powder, reducing the black powder in a hydrogen atmosphere so as to obtain carbon nanotube-metallic element composite enhanced copper-based powder, carrying out isostatic press moulding on the mixed powder, and then sintering in the hydrogen atmosphere so as to obtain the carbon nanotube-metallic element composite enhanced copper-based composite material, wherein the content of a metallic element X in the composite material is 0.1-2wt%, and the content of the carbon nanotube in the composite material is 0.1-2wt%. The preparation method has the advantages that corresponding carbides can be formed, the problem of reinforcement agglomeration caused by poor interface bonding between reinforcement and a copper matrix is solved, and the copper-based composite material with excellent combination properties can be obtained.

Owner:NINGBO CPX ELECTRONICS TECH

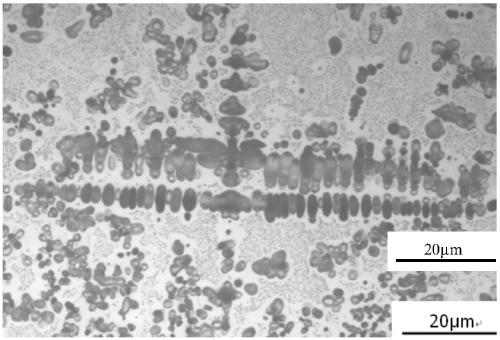

High-strength and high-conductivity heat-resistant Cu-Fe-Y-Mg alloy material with electromagnetic wave shielding performance and preparation method thereof

The invention discloses a high-strength and high-conductivity heat-resistant Cu-Fe-Y-Mg alloy material with electromagnetic wave shielding performance and a preparation method thereof, and the copperalloy comprises Cu, Fe, Mg and Y elements; and the mass percentage of Fe is greater than or equal to 5% and is smaller than the mass percentage of Cu, and the Fe is uniformly distributed in the alloymaterial. The copper alloy uses a large amount of inexpensive iron element in the composition design; due to the immiscibility of copper and iron in the molten state, the starting alloy is mainly copper in the smelting process, a small amount of iron is added for melting, and after melting, Cu-Fe master alloy is added in a master alloy manner, alloy elements yttrium and magnesium are jointly addedin the smelting, which acts as a modificator and promotes the uniform distribution of the iron phase in the copper matrix in the solidified state, so that the alloy product finally has uniform properties, electromagnetic wave shielding performance and high strength and high thermal conductivity. The copper alloy material is suitable for non-vacuum large-scale industrial manufacturing.

Owner:CENT SOUTH UNIV

Method for synthesizing nanometer Ni2O3/Co3O4 cathode material on copper sheet current collector through two-step method

InactiveCN104009208AIncrease capacityGood capacity valueElectrode carriers/collectorsSecondary cellsAdhesiveLithium-ion battery

The invention discloses a method for synthesizing a nanometer Ni2O3 / Co3O4 cathode material on a copper sheet current collector through a two-step method. According to the method, a nanowire array directly grows on the current current collector matrix, so that the process treatment is greatly simplified, and an adhesive and a conductive additive are not used in the electrode. The method comprises the following steps: electroplating a nano-scale granular nickel layer on a copper matrix subjected to acid treatment to serve as a seed, generating a nano array through a hydrothermal reaction, and preparing a final product through high-temperature calcining. The proper nickel electroplating time is selected, the combination degree between the substrate and the material is improved, and the nickel is hard to drop, so that the cycling stability of the lithium ion battery is improved. Meanwhile, compared with a nickel plating-free pure Co3O4 array, the Ni2O3 / Co3O4 array has the advantages that the capacity value of unit area is improved. When the electrochemical performance is tested, the prepared cathode material reflects high charging and discharging capacity and long cycle life.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Composite material member for semiconductor device and insulated and non-insulated semiconductor devices using composite material member

InactiveUS6579623B2Mosaic printer telegraph systemSemiconductor/solid-state device detailsSemiconductorMetal

To provide a composite material member for semiconductor device, an insulated semiconductor device and non-insulated semiconductor device using the composite material member, which are effective for obtaining a semiconductor device that alleviates thermal stress or thermal strain occurring during production or operation, has no possibilities of deformation, degeneration and rupture of each member, and is highly reliably and inexpensive. The composite material member for semiconductor device is characterized by being a composite metal plate with particles composed of cuprous oxide dispersed in a copper matrix, in which a surface of the composite metal plate is covered with a metal layer, and a copper layer with thickness of 0.5 mum or larger exists in an interface formed by the composite metal plate and the metal layer.

Owner:HITACHI LTD +1

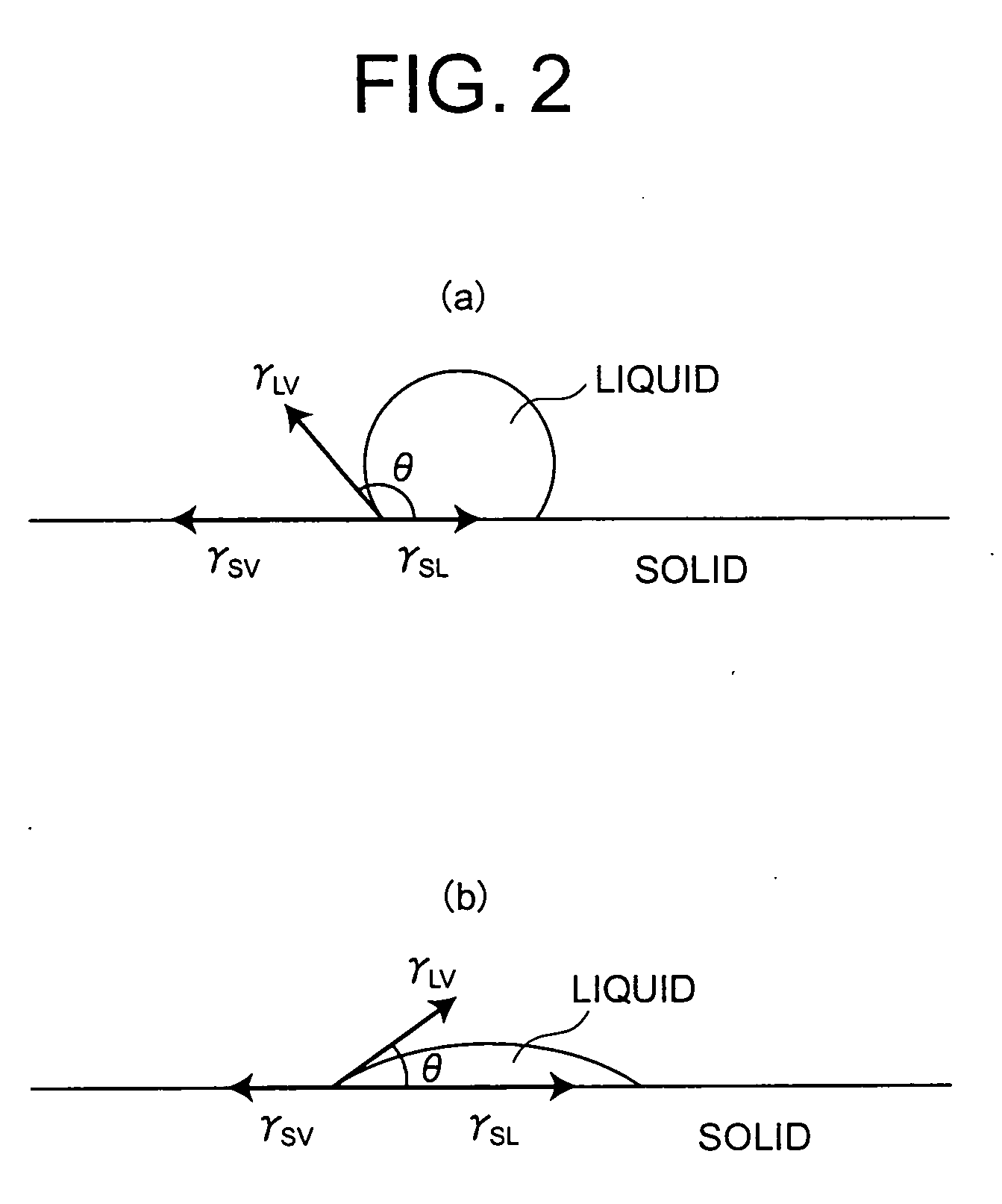

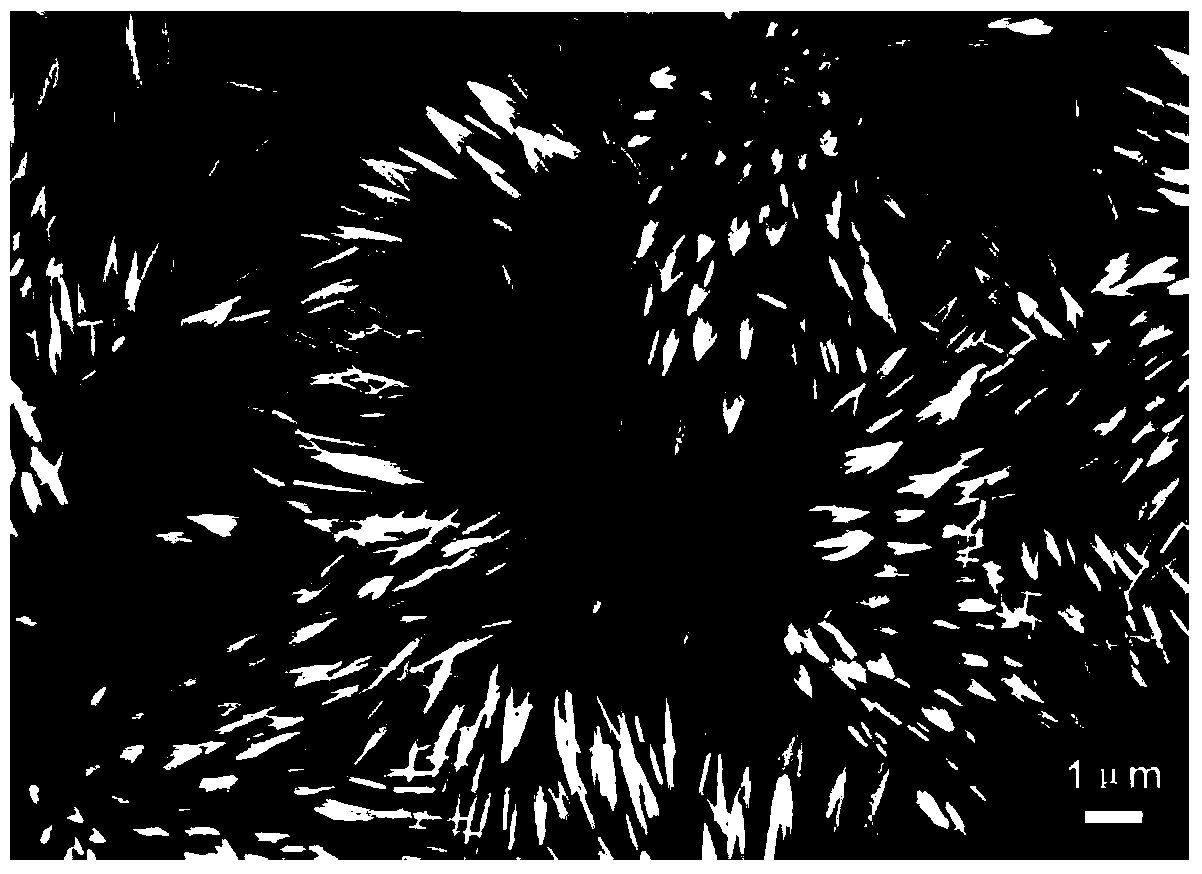

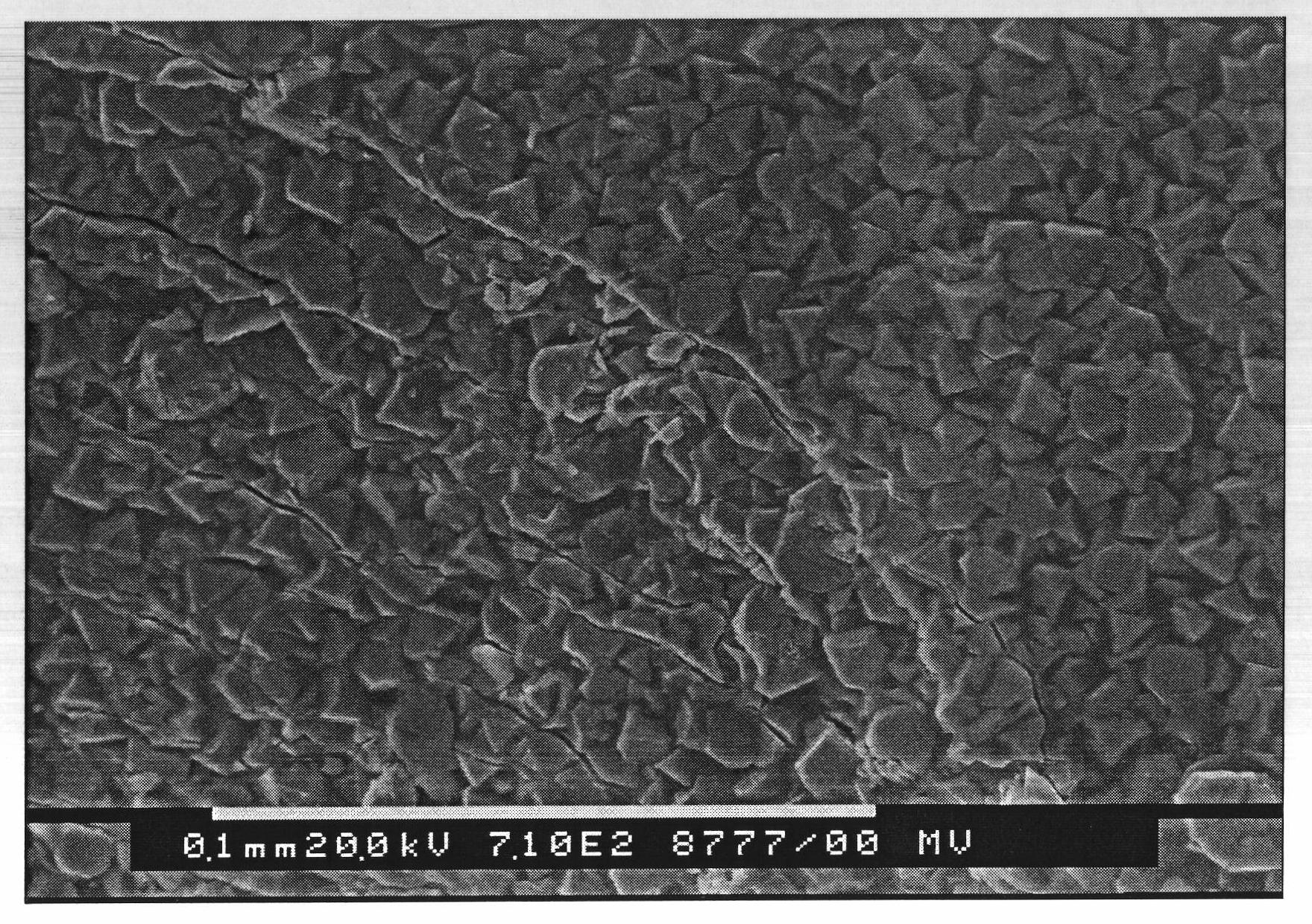

Method for constructing super-hydrophobic membrane on surface of copper matrix

InactiveCN102230169ALow toxicityExcellent superhydrophobic propertiesLiquid/solution decomposition chemical coatingCarboxylic acidSurface modification

The invention relates to a method for constructing a super-hydrophobic membrane on the surface of a copper matrix, and relates to a method for constructing a super-hydrophobic membrane, which solves the problems of complex steps of constructing the super-hydrophobic surface and large toxicity of raw materials in the conventional method. In the method, a sliver layer with a micro-nanometer structure is generated by replacement reaction of copper and silver nitrate, a rough surface is constructed on the copper matrix, and a self-assembly membrane is formed on a silver surface by utilizing long-chain carboxylic acid to reduce surface energy. When the method is used, the construction of the rough surface and surface modification are completed in one step, equipment and a process is simple, and the method is easy to operate; and the toxicity of the raw materials is low, and environmental pollution is small. The method is suitable for the large-scale industrial production of the super-hydrophobic membrane.

Owner:HARBIN INST OF TECH

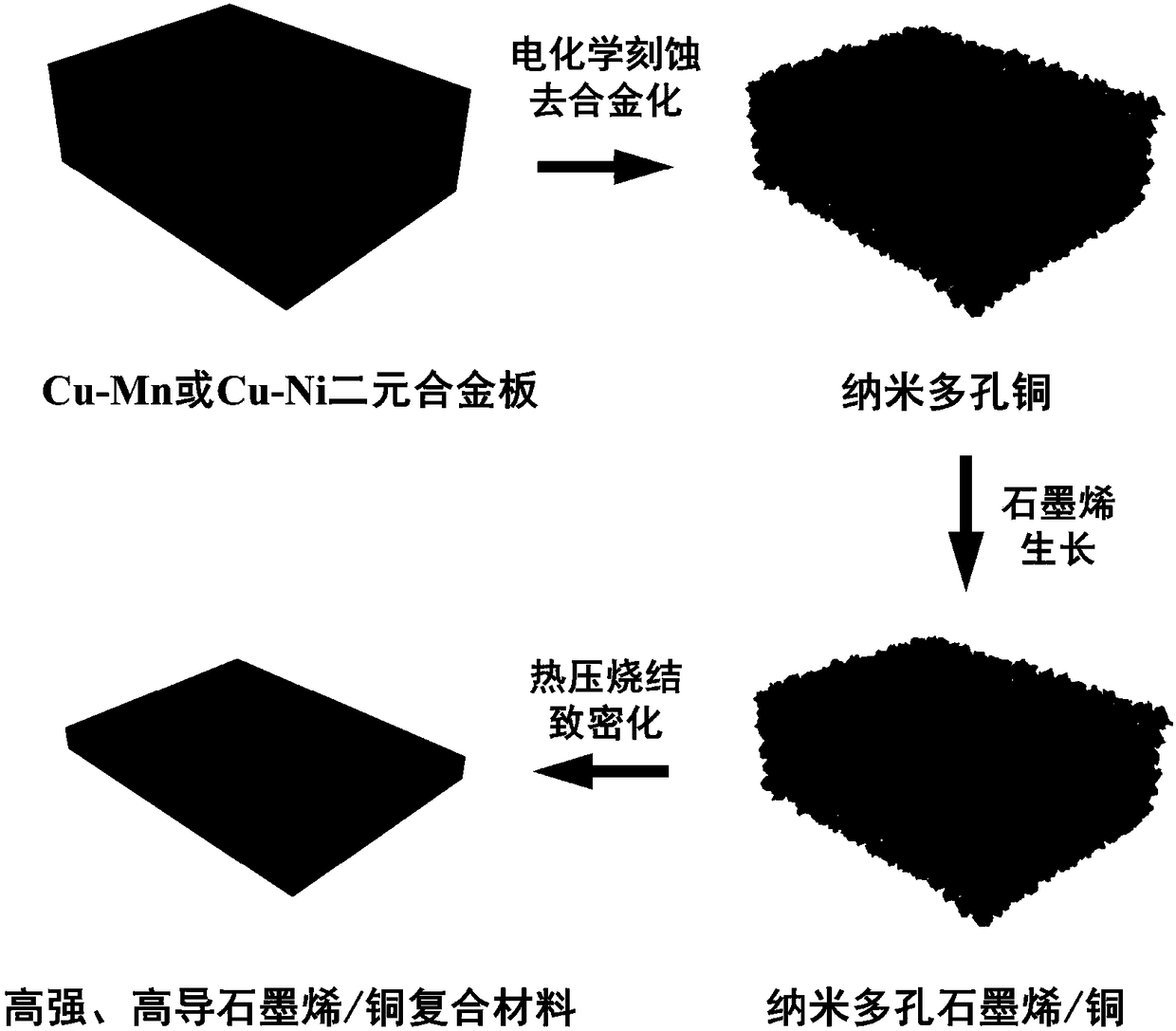

High strength, high conductivity graphene/copper nanocomposite material and preparation method and application thereof

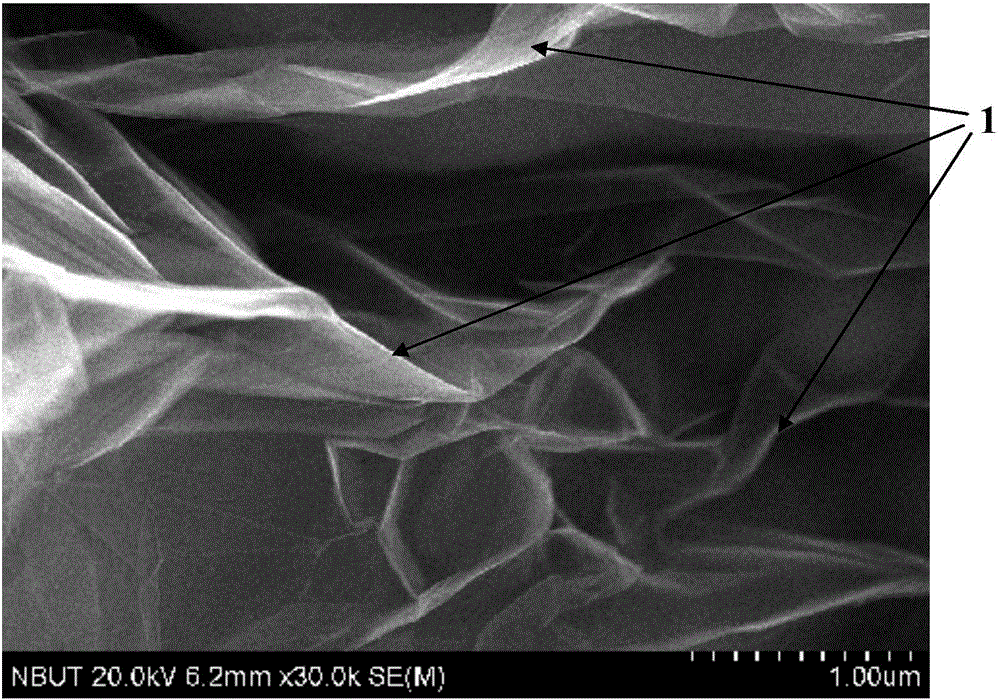

ActiveCN108149046AHigh strengthHigh densityChemical vapor deposition coatingNetwork structureInterconnection

The invention relates to a high strength, high conductivity graphene / copper nanocomposite material and a preparation method and application thereof. A copper matrix of the composite material is uniformly distributed in three-dimensional nanometer scale, the scale is between 10-100 nm, preferably, 30nm-80nm; and graghene is of a three-dimensional interconnection network structure in the composite material, and the number of average layers is 1-100. The obtained graphene / copper nanocomposite material has the characteristics of high strength, high modulus and high conductivity, and can be used asvarious types of conductive materials.

Owner:CRRC IND INST CO LTD +1

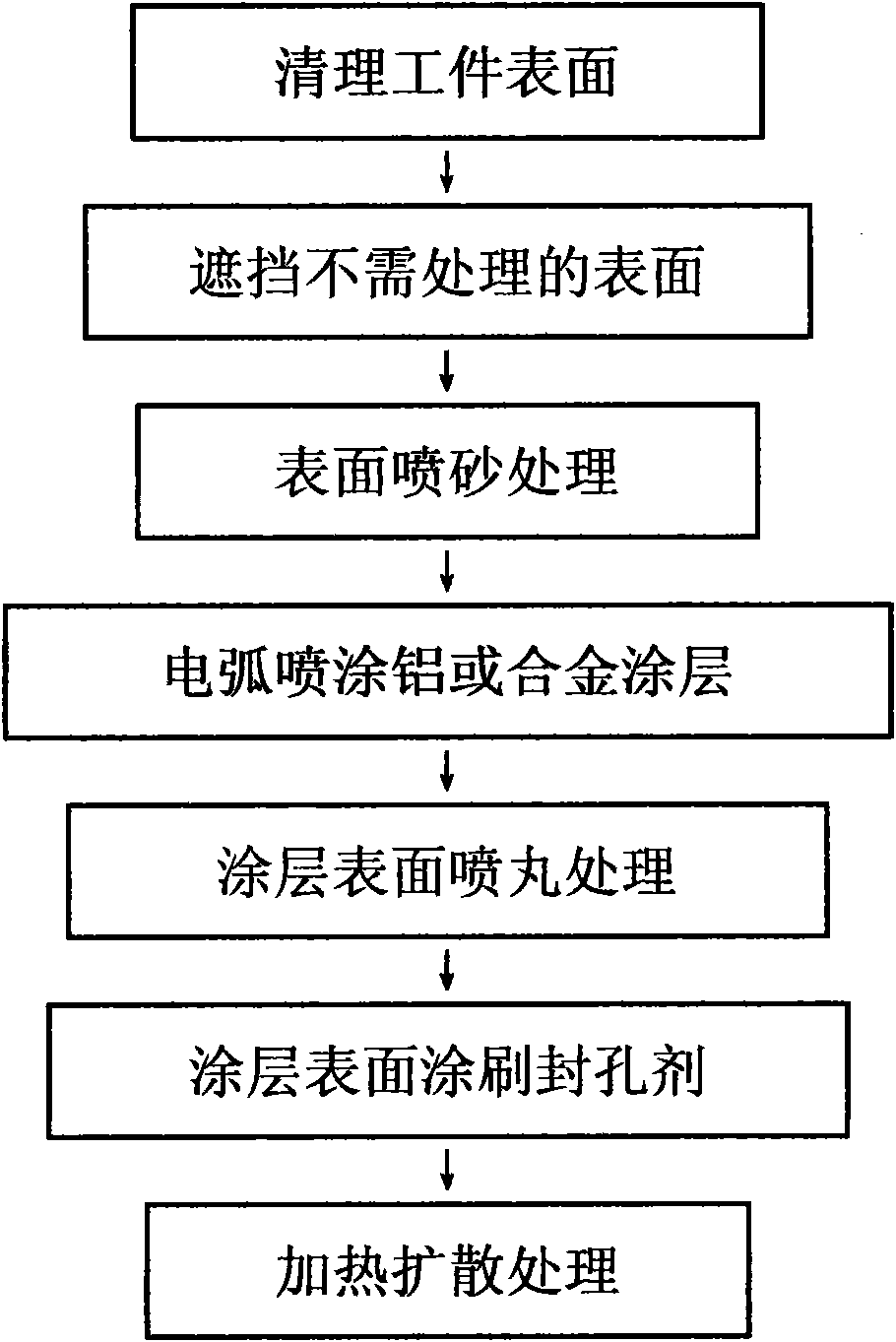

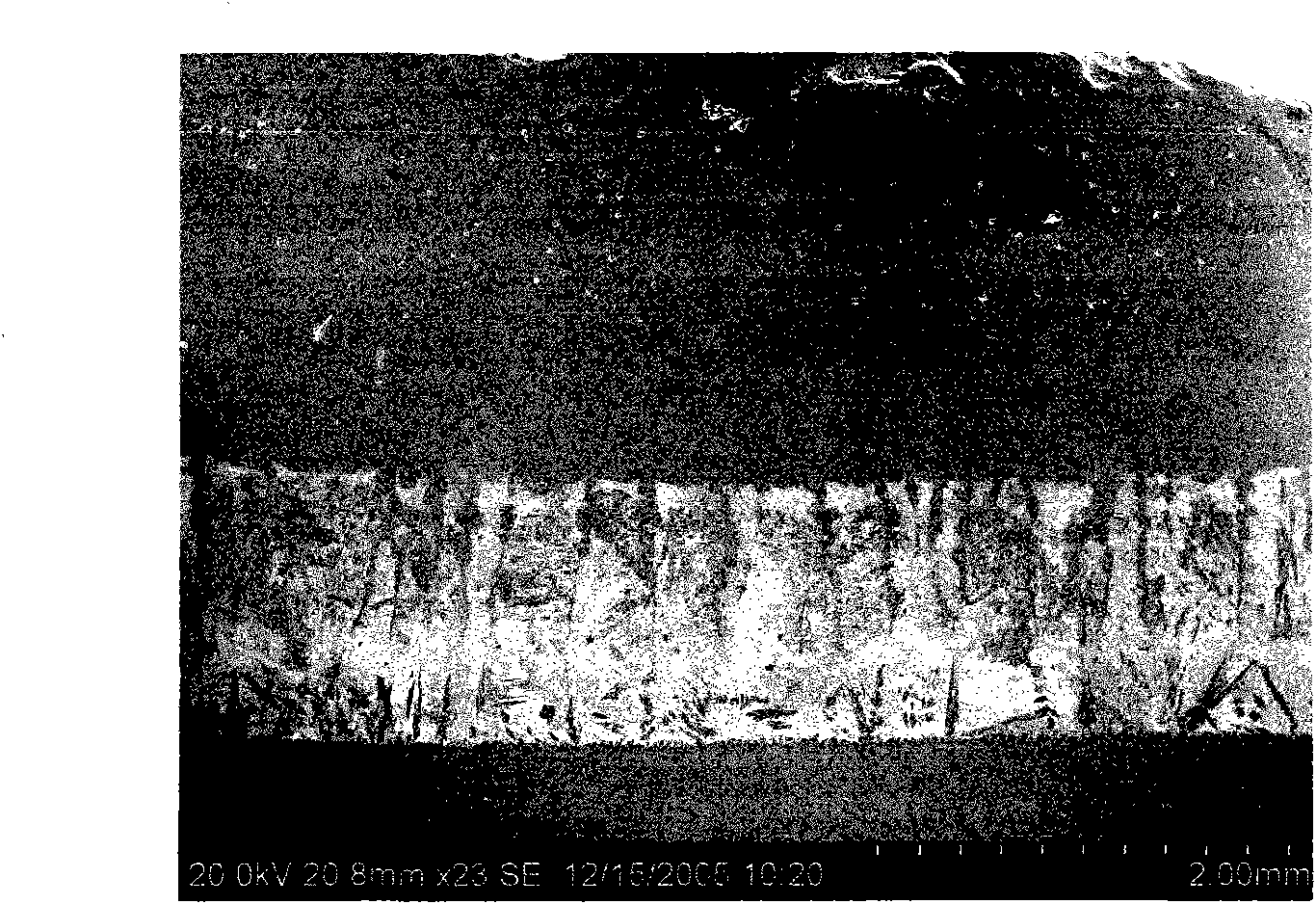

Process for preparing antioxidant and wear-resistant layer on surface of copper

InactiveCN101638788AImprove the protective effectExtend protection lifeMolten spray coatingThermal sprayingWear resistant

The invention provides a process method for preparing an aluminide penetrating layer on the surface of pure copper or a copper alloy by combining the thermal spraying technology and the thermal treatment technology, which comprises the following steps: firstly, spraying a layer of pure aluminium coating on the surface of a copper product through arc; secondly, performing shot blasting and sealingagent coating treatment on the surface of the coating; and finally, performing thermal treatment at a temperature of between 800 and 900 DEG C, maintaining the temperature for 2 to 4 hours, and obtaining an aluminide layer over 3mm on the surface of the pure copper. The aluminide layer prepared by the method has good combination with a copper substrate, good antioxidant performance and good wear resistance. The method can prepare the aluminide penetrating layer, and also can prepare aluminium-molybdenum, aluminium-silicone, aluminium-chromium binary or multi-metallic diffusion layers.

Owner:SHENYANG POLYTECHNIC UNIV

A method for preparing tungsten-copper or molybdenum-copper high-voltage contact materials by direct forming

InactiveCN102286740ASimple processPrevent high temperature deformationElectric switchesPressure inorganic powder coatingCopper highHigh pressure

A method for preparing tungsten-copper or molybdenum-copper high-voltage contact materials by direct forming. Firstly, the raw material powder is uniformly mixed according to the composition ratio of the high-voltage contact, and then the mixed raw material powder is input into the powder feeding system of the cold spraying system. Or spraying with heated gas, under the action of high-pressure gas, the raw material powder collides with the copper substrate to undergo plastic deformation, and then deposits on the surface of the copper base to form a high-voltage contact material, and finally the formed tungsten copper or molybdenum copper high-voltage contact material Use directly or after annealing at 1000-1400°C for 30-60 minutes. The invention simplifies the process, overcomes the high-temperature deformation of the copper base, distributes the copper solidified phase finely and uniformly, reduces the equipment cost of cold spraying, improves the safety of the working process, is suitable for online processing, and saves spraying cost.

Owner:SHENYANG GOLDEN HEADPOWER NEW MATERIALS

Method for laser cladding Co-based alloy coating at blast-furnace tuyere

ActiveCN101519704AAvoid crackingReduce temperature gradientTuyeresMetallic material coating processesSuperalloyAlloy coating

The invention discloses a method for laser cladding Co-based alloy coating on the surface of a blast-furnace tuyere, which includes the following steps of: (1) preprocessing the surface of an air outlet of the blast-furnace tuyere; (2) praying predeposited base alloy on the surface of the air outlet; (3) before being fed into a CO2 laser, preprocessing a blast-furnace tuyere workpiece; (4) feeding powder in a backward synchronous way or a coaxial way, and then multi-pass cladding Co-based alloy powder at the work layer of the air outlet of the blast-furnace tuyere which is predeposited by the gas argon arc welding by the CO2 laser; simultaneously, protecting the region which is processed in the laser cladding way by inert gases; and (5) follow-up processing. Under the premise of not affecting the thermal conductance of the copper matrix, the method can obtain the coating with high-hardness, wear-resistance and high temperature oxidation-resistance and can make the coating firmly bonded with the matrix in a metallurgical way; therefore, the method can significantly prolong the service life of the blast-furnace tuyere. In addition, the method has the advantage of low cost and can be used in the partial restoration of a waste blast-furnace tuyere.

Owner:BAOSHAN IRON & STEEL CO LTD +1

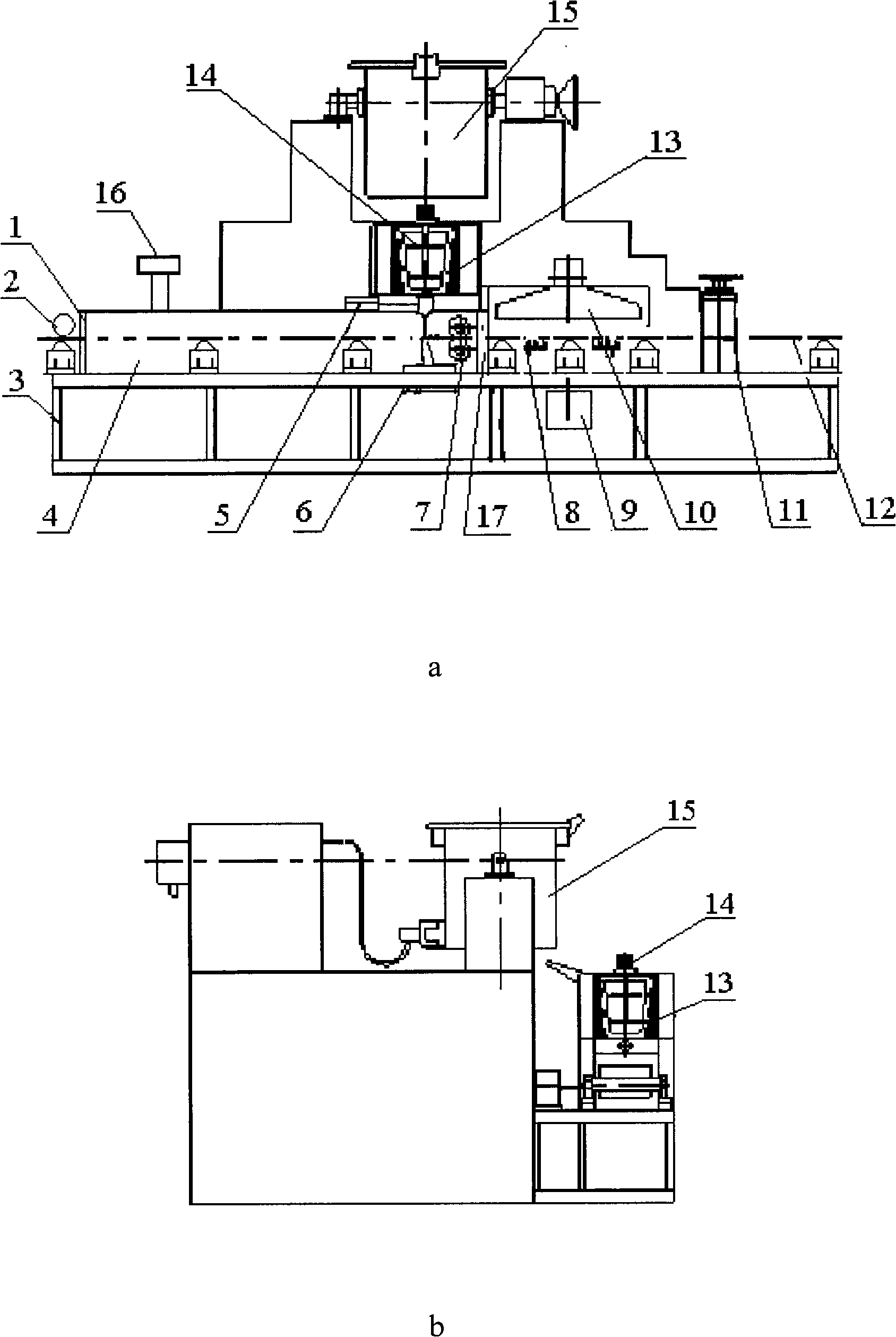

Abrasive feeding method for electroplate grinding wheel

The invention discloses an abrasive feeding method for an electroplate grinding wheel. The method comprises (1) a step of surface treatment of an abrasive; (2) a step of abrasive distribution, wherein the abrasive after being treated and a magnetic fluid containing a plating solution are mixed uniformly to form a suspension liquid, and then the magnetic fluid carrying the abrasive is controlled by magnetic field changes to motion on the surface of an electroplate grinding wheel matrix, thus completing distribution of the abrasive on the surface of an electroplate grinding wheel matrix; and (3) a step of abrasive fixation. The electroplate grinding wheel matrix is a steel matrix, a copper matrix, a bronze matrix, an aluminum matrix, an aluminum alloy matrix or a cemented carbide matrix. According to the method, the precision of abrasive distribution is improved and the strength between the abrasive and the matrix is enhanced. The grinding wheel prepared by the method has a good heat dissipation effect and a long service lifetime, and causes no surface burns of workpieces during machining processes.

Owner:赛尔科技(如东)有限公司

Preparing method for silver plating graphene enhanced copper-based electric contact material

ActiveCN105950904AGood electrical and thermal conductivityImprove welding resistanceTransportation and packagingMetal-working apparatusSilver plateChemical plating

The invention relates to a copper-based electric contact material used in a middle-low-voltage electric appliance switch, in particular to a preparing method for a silver plating graphene enhanced copper-based electric contact composite material. The copper-based composite material comprises, 0.5 wt.%-4 wt.% of bismuth, 0.05 wt.%-0.5 wt.% of yttrium, 0.1 wt.%-0.5 wt.% of graphene (silver plating), 1wt.%-5wt. / % of silver and the balance copper and other inevitable impurities. Copper-yttrium alloy powder is prepared and subjected to chemical silver plating, the copper-yttrium alloy powder and graphene subjected to silver plating treatment are subjected to ball milling and mixed evenly, and the electric contact material is finally prepared through pressing and sintering. The surface of copper powder is subjected to silver plating so that the anti-oxidation performance of the material can be improved, the graphene is subjected to silver plating treatment so that combination between the graphene and a copper base body can be enhanced, and therefore the comprehensive performance of the material is improved, and the copper-based electric contact material good in electric conductivity, resistant to electric arc erosion and excellent in welding resistance is finally obtained.

Owner:UNIV OF JINAN

Continuous casting heat composite apparatus and method for preparing copper lead alloy-steel shaft bushing material

ActiveCN101298082AControl cooling rateNo segregationMetal rolling arrangementsThermal insulationAlloy

The invention discloses a continuous casting thermal compound device which comprises a bracket, a steel plate conveying device fixedly connected with the bracket, a sealing and heating device, an alloy metal thermal-insulation device, an alloy layer rolling and leveling device, a cooling device, a rolling roll device and an alloy melting device; an outlet at the bottom of the alloy metal thermal-insulation device is communicated with a chute runner at the top of a steel plate conveyer belt; an ultrasonic device is arranged below the chute runner; the cooling device is composed of multi-row orientated nozzles; all parts are regulated by a control system. The continuous casting thermal compound device is utilized for continuous casting and thermal compound of the copper lead alloy and the steel to produce a bimetallic bearing material; the copper lead-steel bearing material produced by the device of the invention has slender alloy structure, where the lead shows a short-shoot shape and a small part thereof has a shape of ball and is distributed uniformly on the copper matrix, without net-like structure or discontinuous net-like structure; the bearing material also has good homogeneity of structure, with relatively high bonding strength between duplex metals and stable and reliable quality.

Owner:CSIC NO 12 RES INST

Preparation method of three-dimensional structure CNTs reinforced Cu-based composite

ActiveCN105441711AEvenly dispersedNo agglomerationChemical vapor deposition coatingGas phaseUltimate tensile strength

The invention relates to a preparation method of a CNTs (Carbon Nano Tubes) reinforced copper-based composite, and discloses a preparation method of a three-dimensional structure CNTs reinforced Cu-based composite, so as to solve the problems that three-dimensional CNTs are not dispersed uniformly by the traditional preparation method, and the strength of the composite is low due to the fact that a binding force between CNTs and a matrix is low. The preparation method of the three-dimensional structure CNTs reinforced Cu-based composite comprises the steps that first, by adopting a chemical vapor deposition method, three-dimensional graphene is prepared on a foamy copper matrix; then, by adopting a plasma reinforced chemical vapor deposition method, CNTs grow on graphene, and three-dimensional structure CNTs are prepared; finally, a three-dimensional CNTs / foamy copper material and copper powder are subjected to spark plasma sintering, and the three-dimensional structure CNTs reinforced Cu-based composite is obtained. The above scheme is applied to the preparation method of the three-dimensional structure CNTs reinforced Cu-based composite.

Owner:HARBIN INST OF TECH

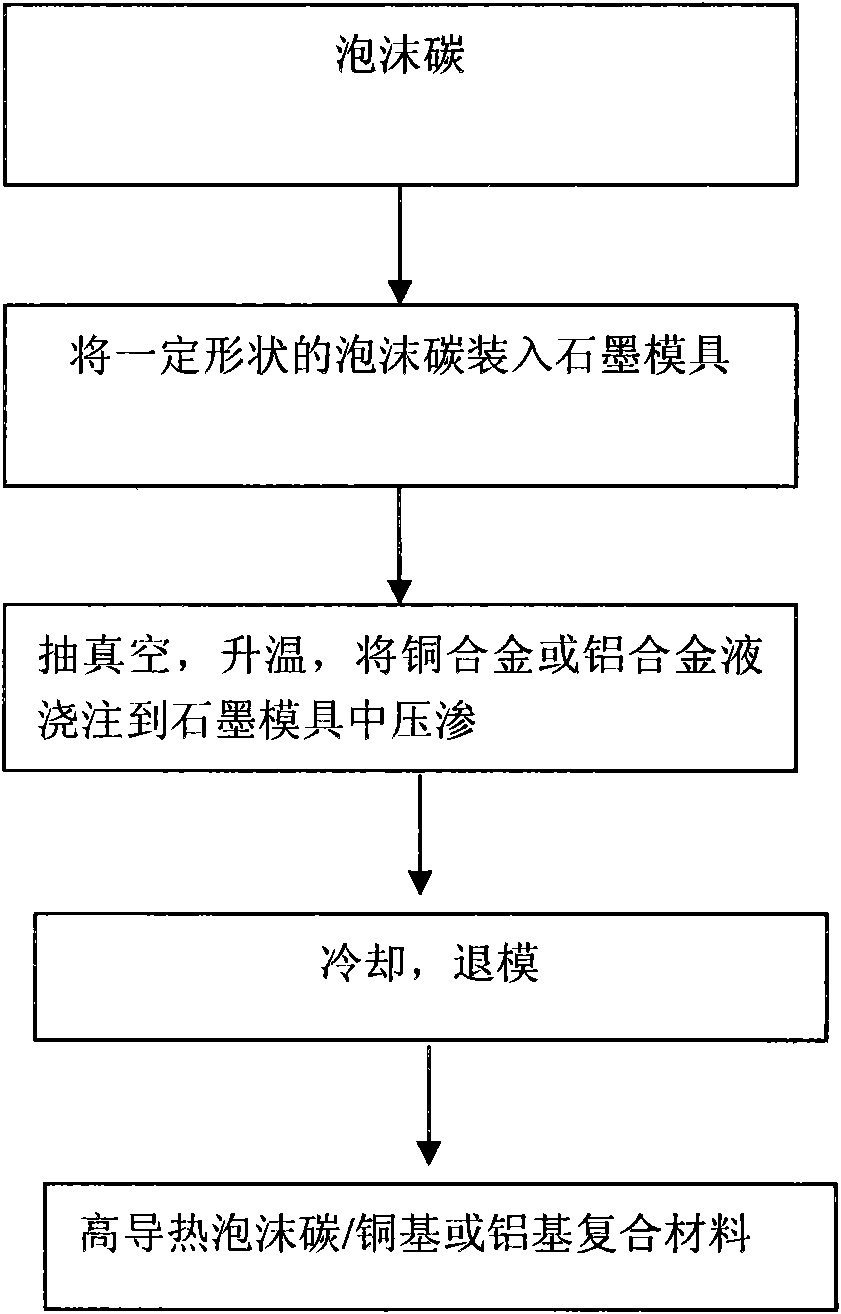

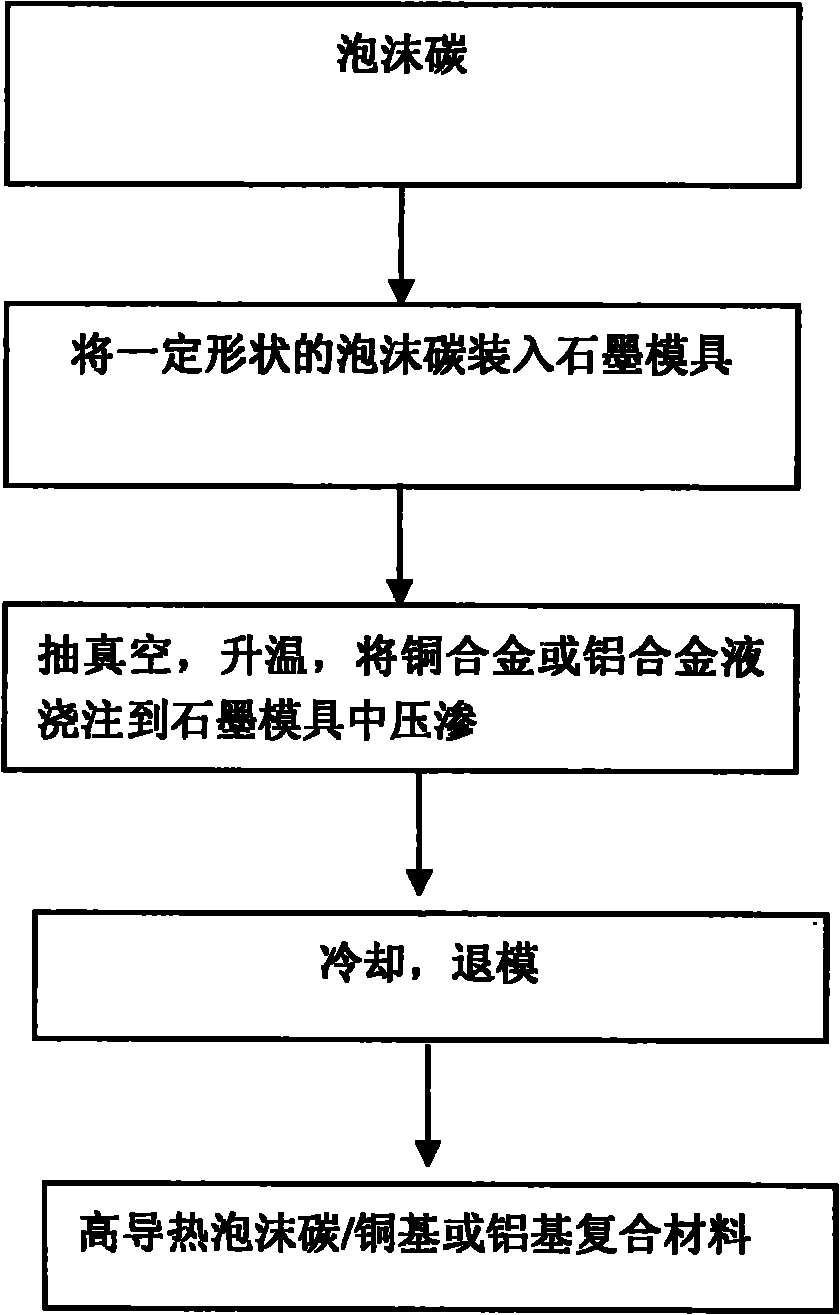

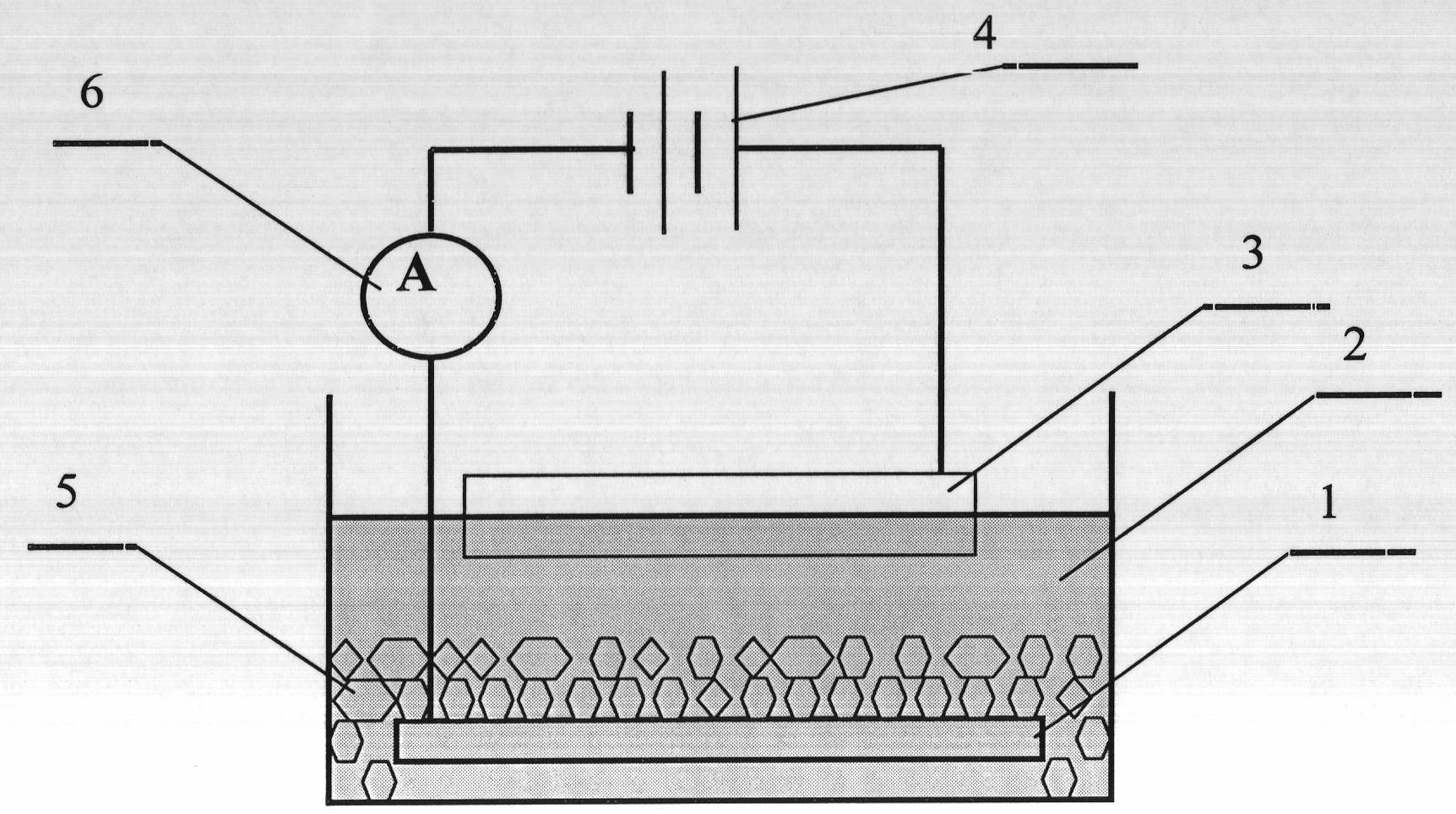

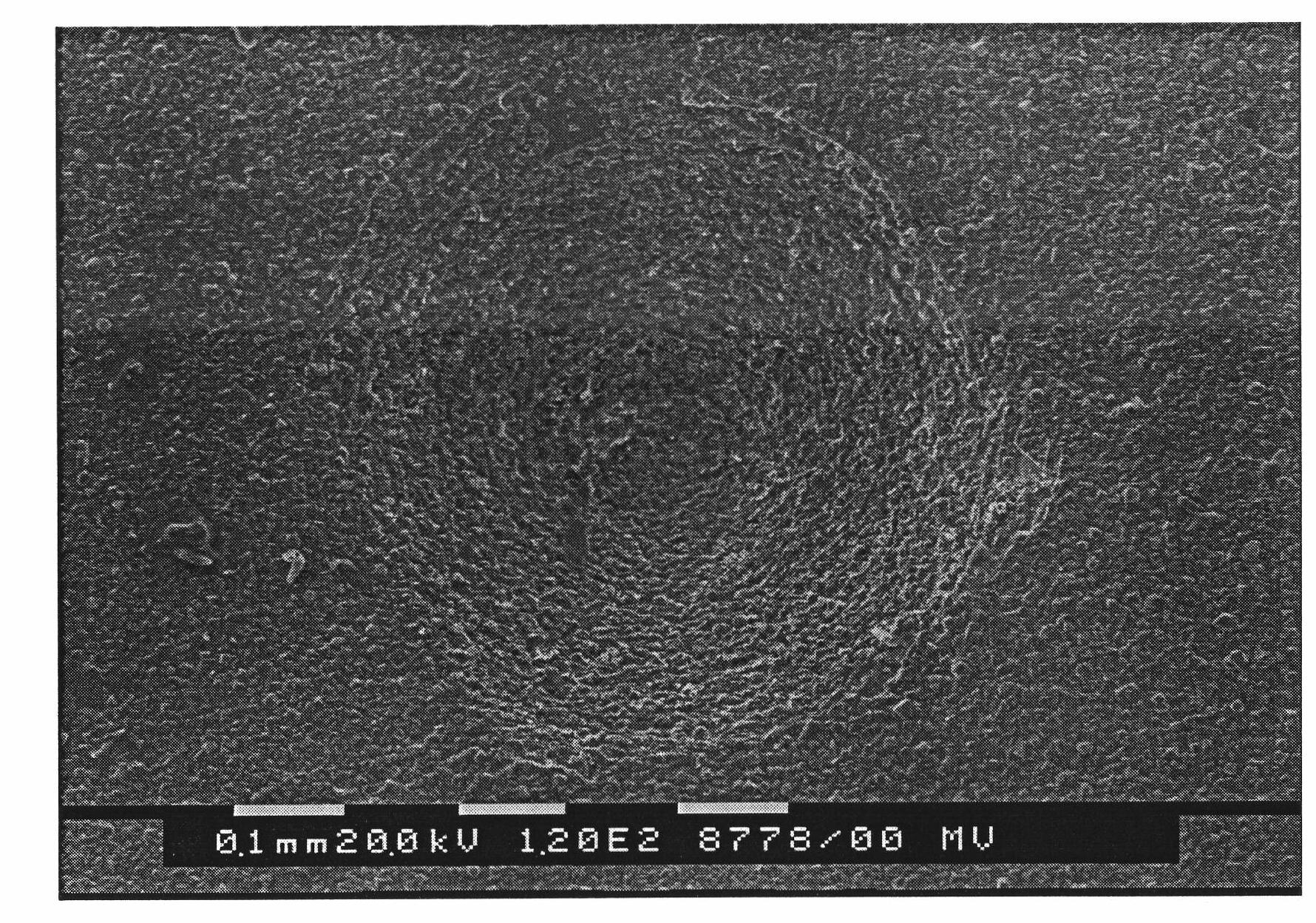

Foamy carbon/copper matrix or aluminum matrix composite material and preparation method thereof

ActiveCN102400006AHigh specific thermal conductivitySmall coefficient of thermal expansionPorosityInduction furnace

The invention relates to a foamy carbon / copper matrix or aluminum matrix composite material with high thermal conductivity and a preparation method thereof, belonging to the technical field of electronic packaging materials. The composite material comprises 30 to 50 (v)% of foamy carbon and 50 to 70 (v)% of copper alloy or aluminum alloy, wherein, the porosity of foamy carbon is 50 to 70% and is identical with the value of the the content of copper alloy or aluminum alloy expressed as volume percent. According to the invention, a graphite die filled with foamy carbon is put in a vacuum pressure infiltration furnace, when a degree of vacuum reaches 0.01 to 1 Pa and temperature rises to be 100 to 300 DEG C higher than the melting point of the matrix, i.e., copper alloy or aluminum alloy, molten copper alloy or aluminum alloy liquid is casted into the graphite die from a medium frequency induction furnace for pressure infiltration, and the composite material is obtained after the vacuum pressure infiltration furnace is cooled and the die is removed. The composite material prepared in the invention has low density, isotropic thermal conduction performance and excellent workability, and can meet requirements of lightweight, high thermal conductivity, good dimensional stability and the like for electronic packaging materials.

Owner:GRIMAT ENG INST CO LTD

Method for preparing graphene reinforced copper base composite material

The invention discloses a method for preparing a graphene reinforced copper base composite material. Uniformly mixed graphene and copper powder are covered by a thin pure copper chip; the pouring speed is not higher than 1 mm / s; the influence on the graphene dispersing process by flowing of molten copper in the pouring process is controlled; and the temperature of the poured molten copper is not lower than 1080 DEG C and not higher than 1200 DEG C. The method can prominently improve distribution of graphene in a copper matrix in the process of using a casting method to prepare the graphene reinforced copper base composite material, and enhances the material strength and hardness; the average hardness of the graphene reinforced copper base composite material in the method can reach above 80 HV; the electric conductivity under normal temperature is not lower than 80% IACS; and the heat conducting coefficient under normal temperature is not lower than 339 w / (mK).

Owner:JIANGXI UNIV OF SCI & TECH +1

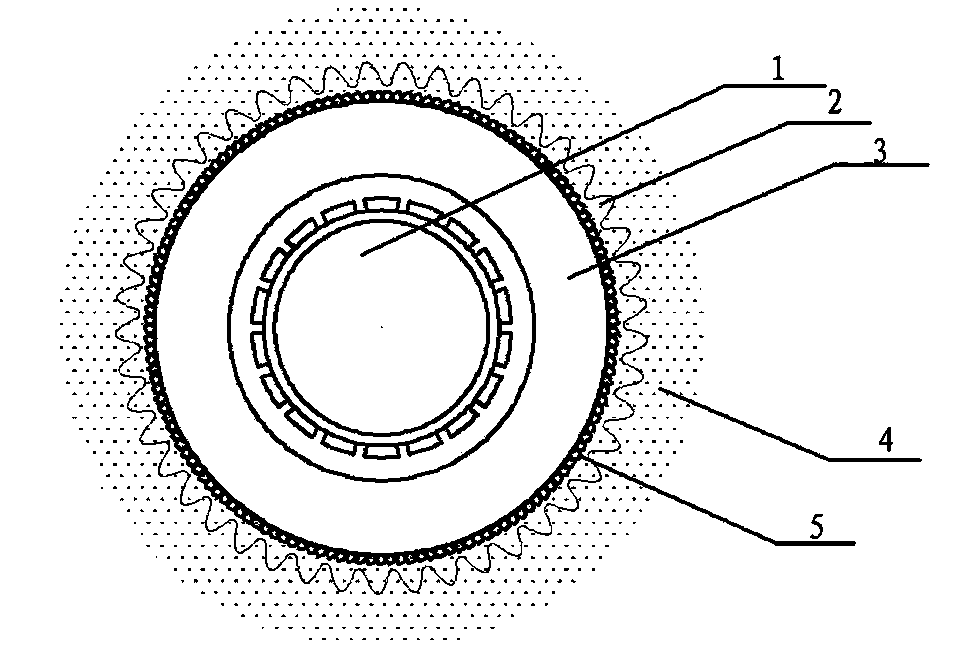

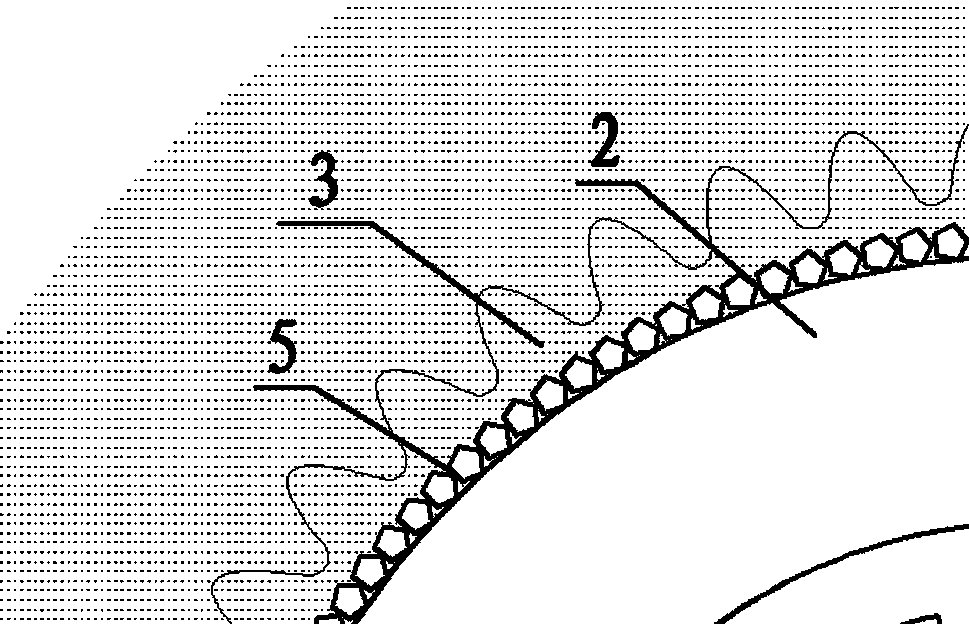

Copper-based mosaic structure interface diamond coating and preparation method and application thereof

InactiveCN101935837AImprove bindingReduce defectsElectrolytic coatingsChemical vapor deposition coatingHeat sinkImpurity

The invention discloses a copper-based mosaic structure interface diamond coating and a preparation method and application thereof. The coating consists of a copper-diamond composite coarse sanding plating layer, a copper reinforcing layer, a copper-diamond composite thin sanding layer and a CVD diamond epitaxial growth layer from the bottom to the top. The preparation method comprises the following steps of: 1, depositing the copper-diamond composite coarse sanding plating layer, the copper reinforcing layer and the copper-diamond composite thin sanding layer on a copper matrix in turn to obtain a workpiece deposited with the copper-diamond composite plating layer; and 2, performing homogeneous epitaxial growth on the diamond exposed on the surface of the workpiece deposited with the copper-diamond composite plating layer in a CVD diamond deposition system to obtain the continuous diamond coating. The copper-based mosaic structure interface diamond coating has the advantages of high purity, few impurities, low thermal stress and firm combination with the matrix, and is an ideal choice of a microelectronic heat sink material.

Owner:SOUTH CHINA UNIV OF TECH

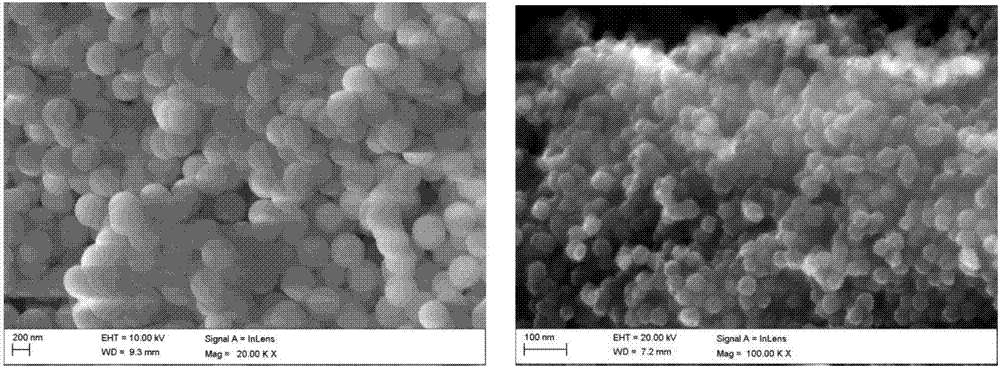

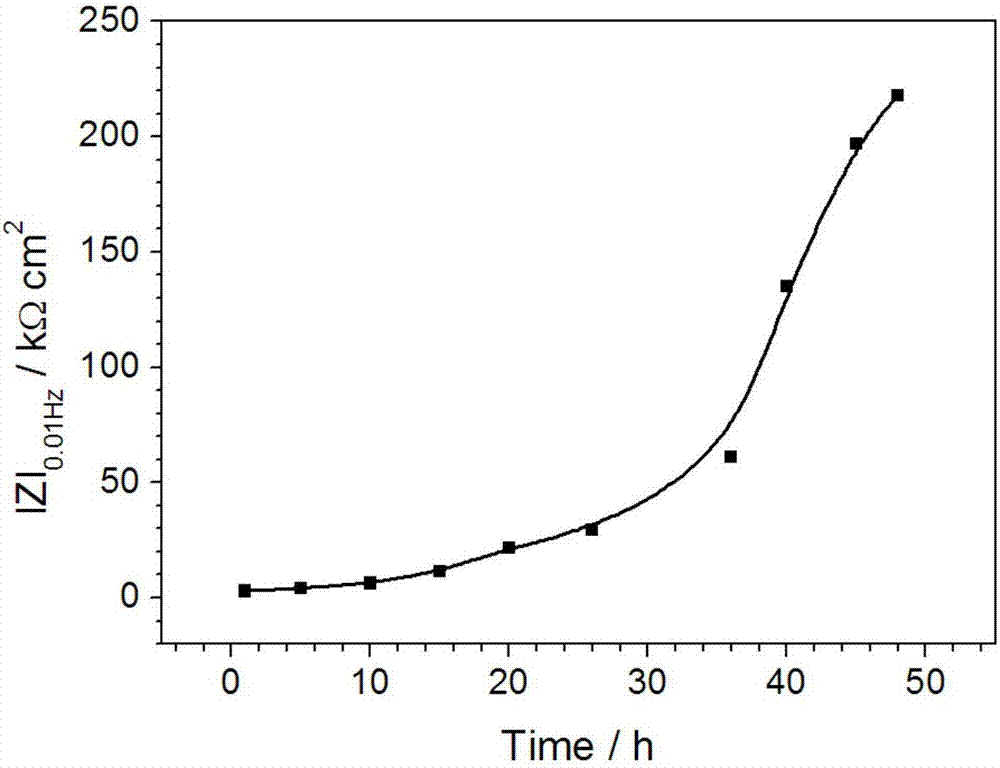

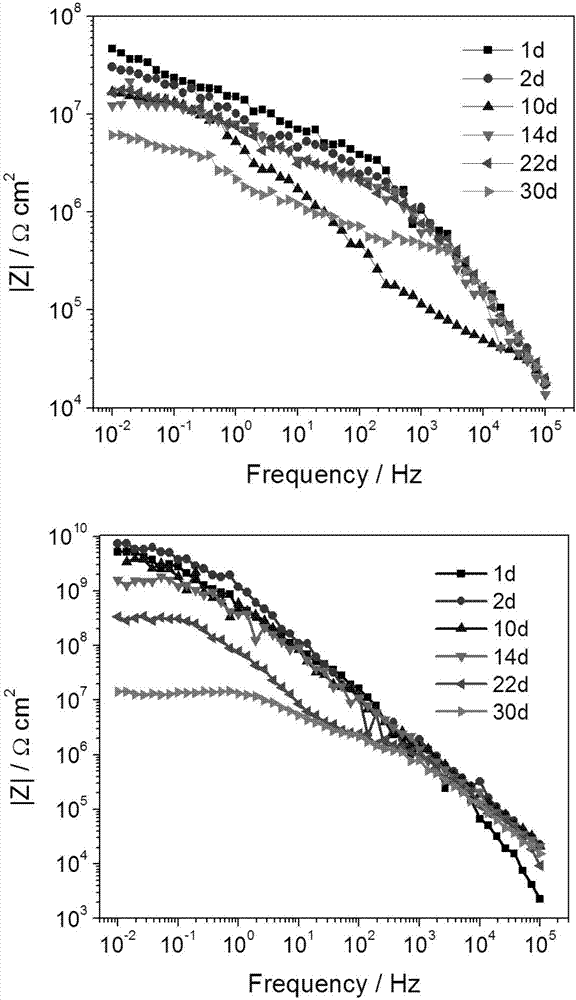

Intelligent nanometer container capable of preventing corrosion of copper and copper alloy, and preparation and application methods thereof

InactiveCN106928806AAvoid corrosionExtended duration of actionMaterial nanotechnologySilicaAutomatic controlMicrosphere

The invention provides an intelligent nanometer container capable of preventing corrosion of copper and copper alloy, and preparation and application methods thereof, belonging to the technical field of corrosion prevention. Mesoporous silica microspheres with controllable particle size can be obtained by adjusting preparation conditions; by supporting a corrosion inhibitor reacting with a copper matrix, a protective film can be formed on the surfaces of copper and copper alloy thereof, so as to effectively inhibit the corrosion of the copper and copper alloy thereof; the surface of the mesoporous silica microspheres supported with large-capacity high-efficiency corrosion inhibitor is modified, and after the modified mesoporous silica microspheres are applied to an intelligent self-restoration anti-corrosion coating, not only can the compatibility of the mesoporous silica microspheres with the coating resin be further improved, but also the purpose of automatically controlling release rate of the corrosion inhibitor can be realized, and the purpose of remarkably improving the prevention effect of the common organic anti-corrosion coating and prolonging the prevention service life can be achieved. Especially when the coating is damaged, the coating has self-restoration function, and the prevention service life of the coating can be prolonged.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

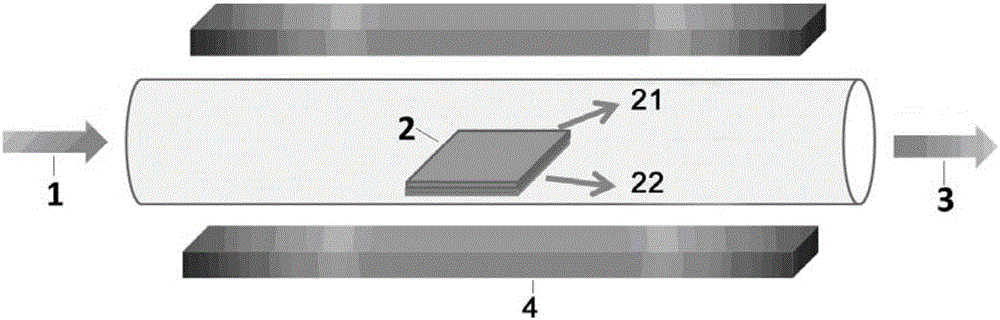

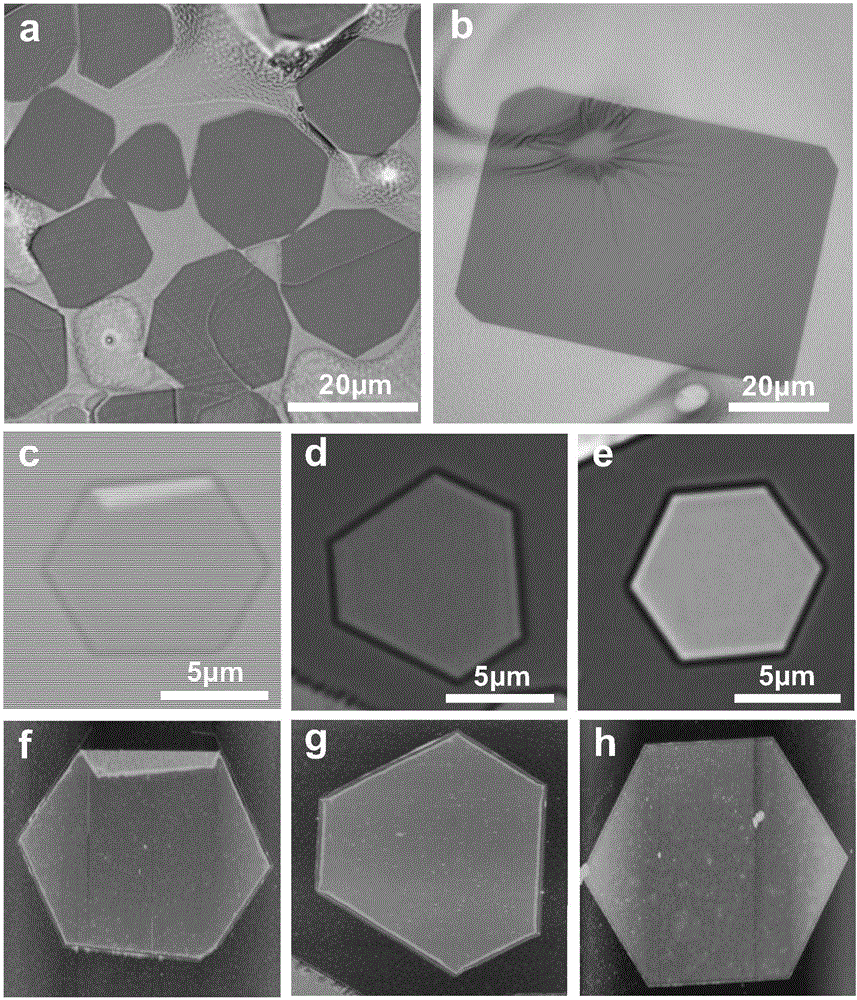

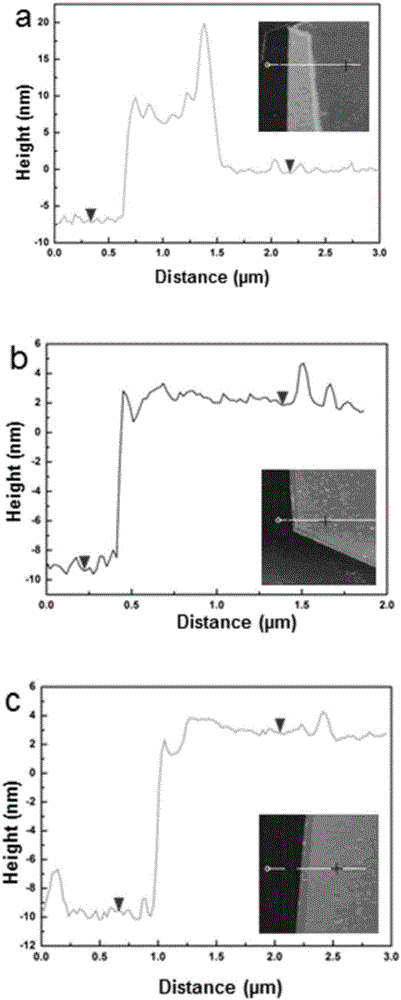

High-quality ultrathin two-dimensional transition-group metal carbide crystal and preparation method thereof

ActiveCN106319628ARealize large area preparationImprove crystal qualityPolycrystalline material growthFrom chemically reactive gasesMetal foilWear resistant

The invention relates to the field of preparation of two-dimensional transition-group metal carbide new materials and preparation thereof by chemical vapor deposition (CVD), particularly a high-quality ultrathin two-dimensional transition-group metal carbide crystal and a preparation method thereof. The preparation method is suitable for preparing large-area high-quality ultrathin two-dimensional transition-group metal carbides. The preparation method comprises the following steps: by using a copper foil (top layer) / transition group metal foil (bottom layer) bimetal lamination as a growth matrix, carrying out catalytic cracking on a carbon source at high temperature by a CVD technique to grow the ultrathin two-dimensional transition metal carbide crystal, and etching to remove the copper matrix, thereby obtaining the ultrathin two-dimensional transition group metal carbide crystal. The high-quality ultrathin two-dimensional transition-group metal carbide crystal has the characteristics of simple preparation technique, controllable product thickness and size and the like, and is suitable for large-area preparation, thereby laying a foundation for the research and application of the high-quality ultrathin two-dimensional transition-group metal carbide crystal in the fields of catalysis, energy storage, wear-resistant coatings, transparent conducting films, heat management and two-dimensional superconduction.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com