Intelligent nanometer container capable of preventing corrosion of copper and copper alloy, and preparation and application methods thereof

A technology of nano-container and copper alloy, applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problem of halloysite nanotubes with large size, limited self-healing ability of coating, corrosion inhibition Solve the problems such as small amount of agent loading, achieve good mechanical properties and thermal stability, improve mechanical properties, and achieve the effect of large loading capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

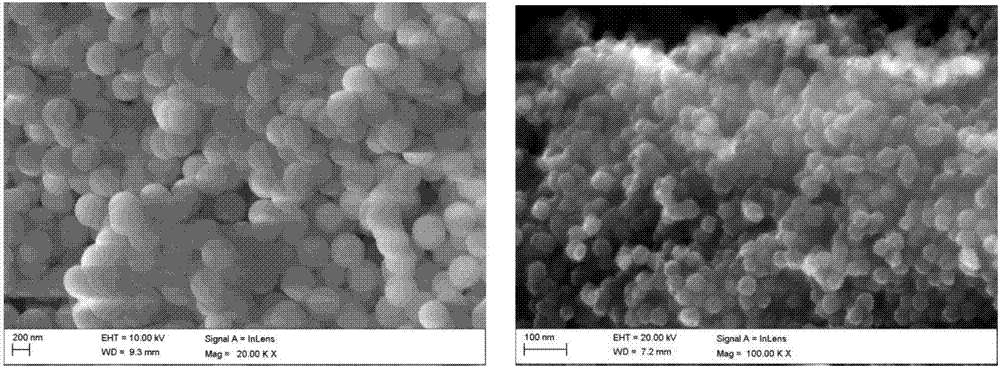

[0045] Example 1—Preparation of mesoporous nano-silica microspheres

[0046] Preparation of Mesoporous Nano-Silica Microspheres Using Triethanolamine as Catalyst

[0047] a Mix cetyltrimethylammonium chloride, water, absolute ethanol, and triethanolamine at a molar ratio of 2:103:47:8, stir magnetically for 10 min, heat to 80°C, and add a certain amount of n- Ethyl silicate, the molar ratio of ethyl orthosilicate to water in the mixture is 6:103, reflux at 80°C for 2 h, centrifuge, dry, and collect nanoparticles;

[0048] b Put the above sample into a crucible and burn it at 550°C for 6 h to decompose cetyltrimethylammonium chloride to obtain mesoporous nano-silica microspheres.

Embodiment 2

[0053] Example 2—Preparation of mesoporous nano-silica microspheres

[0054] Preparation of Mesoporous Nano-Silica Microspheres Using Triethanolamine as Catalyst

[0055] a Mix cetyltrimethylammonium chloride, water, absolute ethanol, and triethanolamine at a molar ratio of 3:100:45:10, stir magnetically for 15 minutes, heat to 85°C, and add a certain amount of n- Ethyl silicate, the molar ratio of ethyl orthosilicate to water in the mixture is 5:100, reflux at 90°C for 2.5 h, centrifuge, dry, and collect nanoparticles;

[0056] b Put the above sample into a crucible and burn it at 600°C for 7 h to decompose cetyltrimethylammonium chloride to obtain mesoporous nano-silica microspheres.

[0057] The mesoporous nano-silica microspheres prepared in Example 2 have a particle diameter between 40-70 nm.

Embodiment 3

[0058] Example 3 - Preparation of mesoporous nano-silica microspheres

[0059] Preparation of Mesoporous Nano-Silica Microspheres Using Triethanolamine as Catalyst

[0060] a Mix cetyltrimethylammonium bromide, water, absolute ethanol, and triethanolamine at a molar ratio of 4:103:50:6, stir magnetically for 12 minutes, heat to 90°C, and add a certain amount of n- Ethyl silicate, the molar ratio of ethyl orthosilicate to water in the mixture is 6:102, reflux at 85°C for 3 h, centrifuge, dry, and collect nanoparticles;

[0061] b Put the above sample into a crucible and burn it at 650°C for 8 h to decompose cetyltrimethylammonium bromide to obtain mesoporous nano-silica microspheres.

[0062] The mesoporous nano-silica microspheres prepared in Example 3 have a particle diameter between 40-70 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle diameter | aaaaa | aaaaa |

| Particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com