Patents

Literature

926results about How to "Easy to drop" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

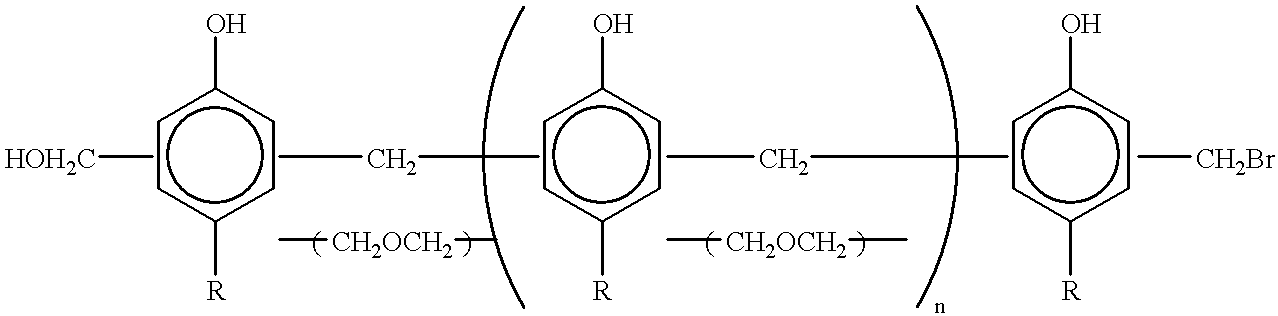

Super-hydrophobic and super-oleophobic surface preparation technology

The invention discloses super-hydrophobic and super-oleophobic surface preparation technology. In the preparation technology, aluminum or aluminum alloy sheets are subjected to two-step electrochemical treatment, and then are modified by using perfluorinated octadecyl trichlorosilane or perfluorinated polymethacrylate to prepare the super-hydrophobic and super-oleophobic surface. The surface has super-hydrophobic property on aqueous solution of which the pH value is between 1 and 14 and super-oleophobic property on various oil drops, wherein a contact angle of the surface on water is 171 degrees, and a rolling angle is less than 1 degree; the surface expresses the super-oleophobic property on various oil drops except for perfluorinated polymer liquid, and all contact angles between the oil drops and the surface are more than 150 degrees, and rolling angles are generally less than 10 degrees; and the surface can also be put in air for a long time and can still maintain the super-hydrophobic property and super-oleophobic property.

Owner:中科润泉(烟台)工业科技有限公司

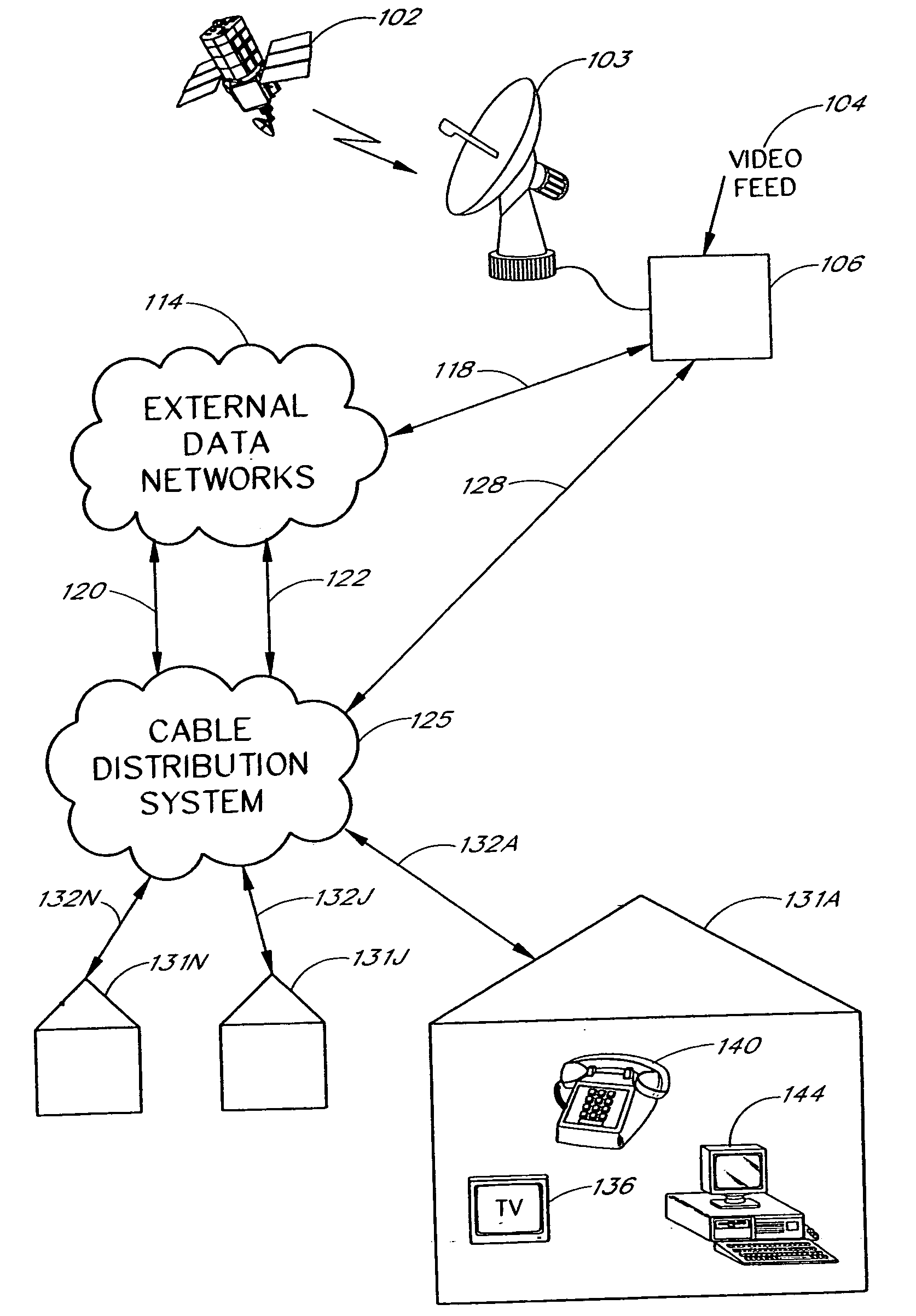

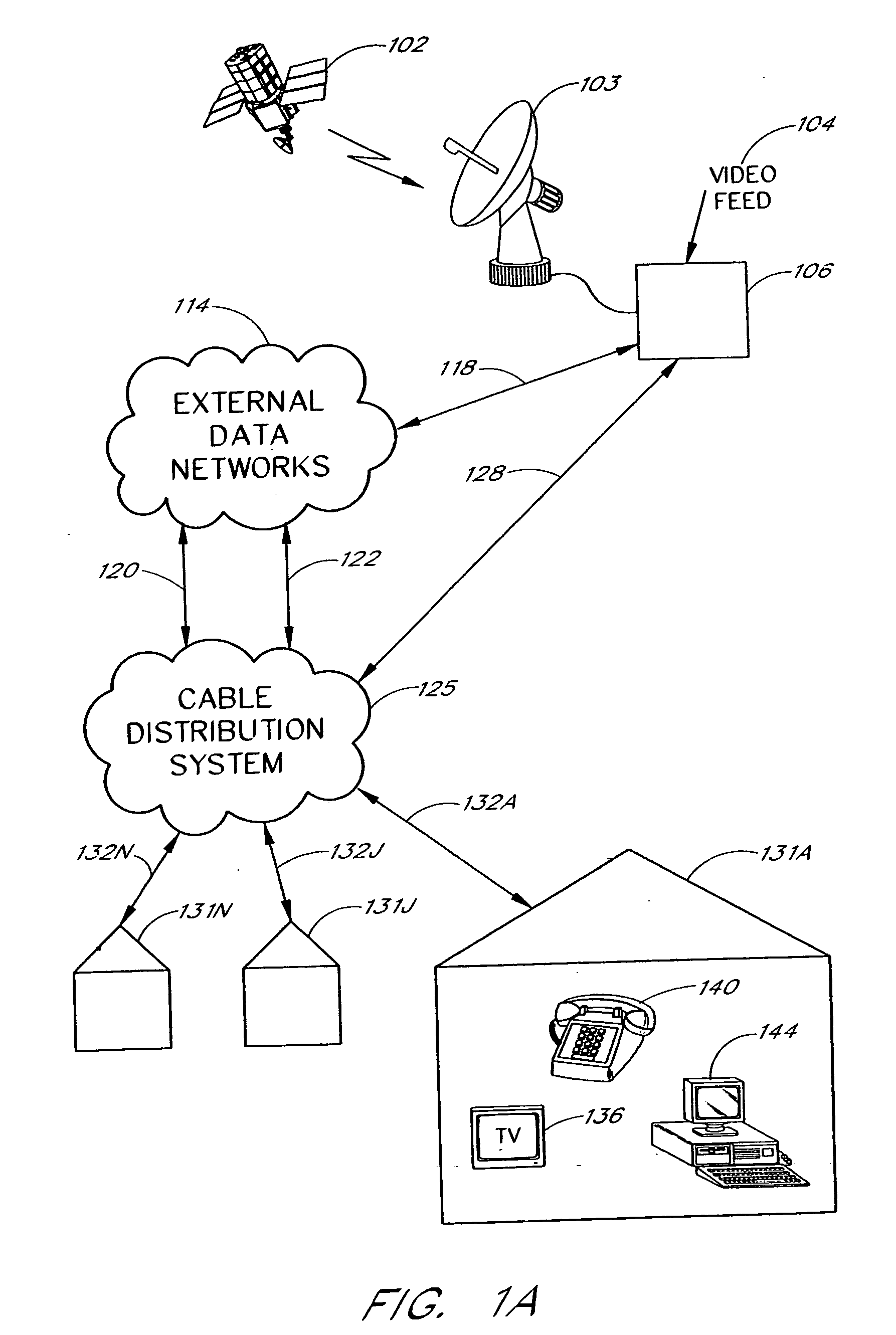

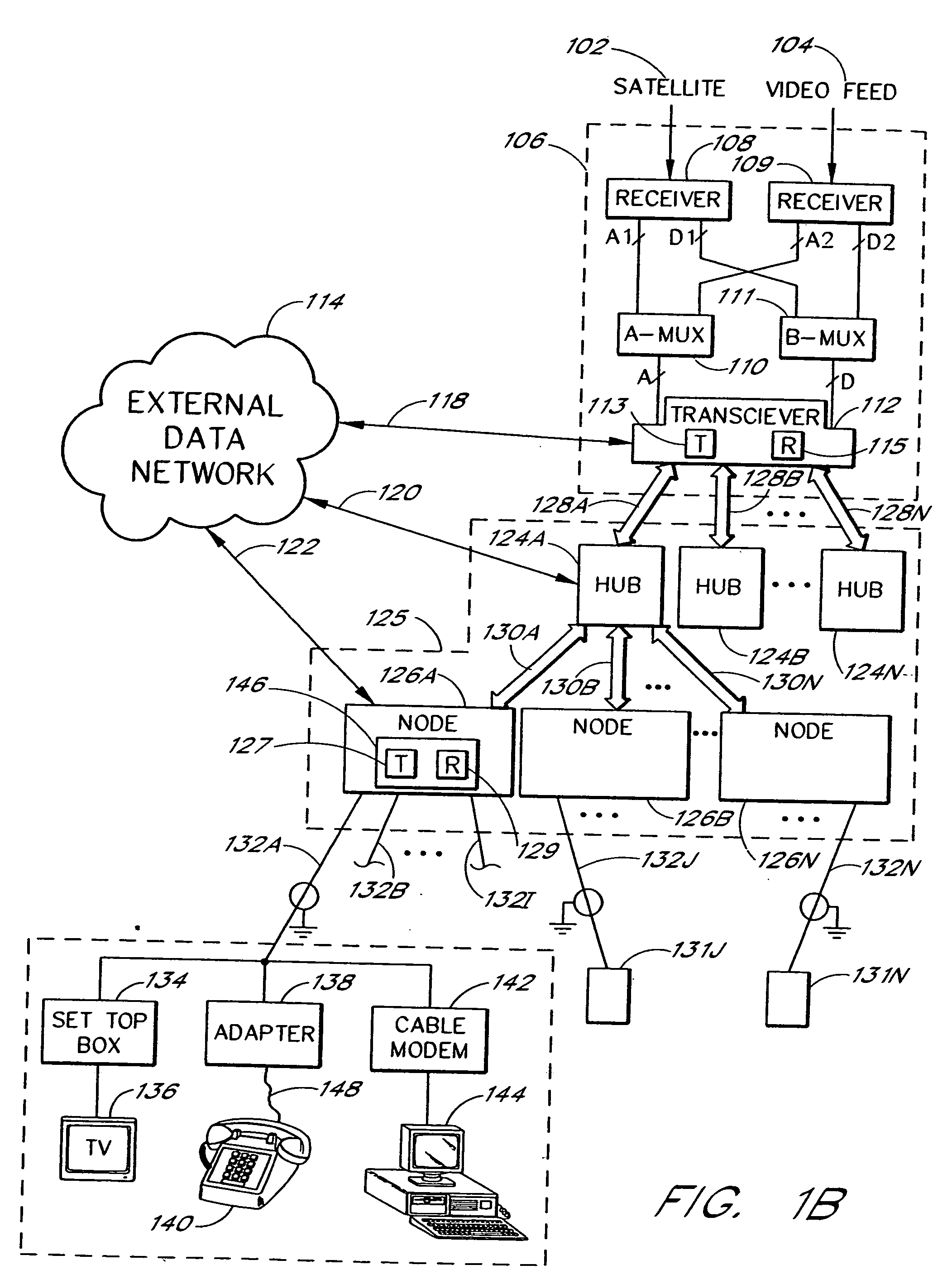

Method and apparatus for a digitized CATV network for bundled services

InactiveUS20050114903A1Easy to addEasy to dropAnalogue secracy/subscription systemsClosed circuit television systemsDigital videoSignal quality

A cost-efficient digital CATV network to improve signal quality, provide reliability, and offer the ability to meet demands for interactive services is described. Analog or digital video downstream channels are converted to a digital format by a digital headend transmitter. Relatively costly error-encoding for digital video channels is also part of the digital headend transmitter. Downstream analog and digital video channels in the digital format are transmitted using time-division multiplex technology from a headend to nodes using standard network protocols, such as SONET. Standard network protocols provide error-monitoring and status indication of transmit data, thus ensuring high signal quality and reliability. Time-division multiplexing facilitates easy adding or dropping of information to a transmit path. Flexibility to add or drop information is critical in providing interactive services. Data from interactive services can be added or dropped at points of presence throughout the digital CATV network. Subscribers to the digital CATV network can communicate with each other. A digital node transmitter receives the analog or digital video channels in digital format and converts the analog or digital video channels into an analog format. The digital node transmitter also frequency-division multiplexes multiple analog or digital video channels into one analog broadband signal for broadcast to subscribers' homes.

Owner:QUARTICS

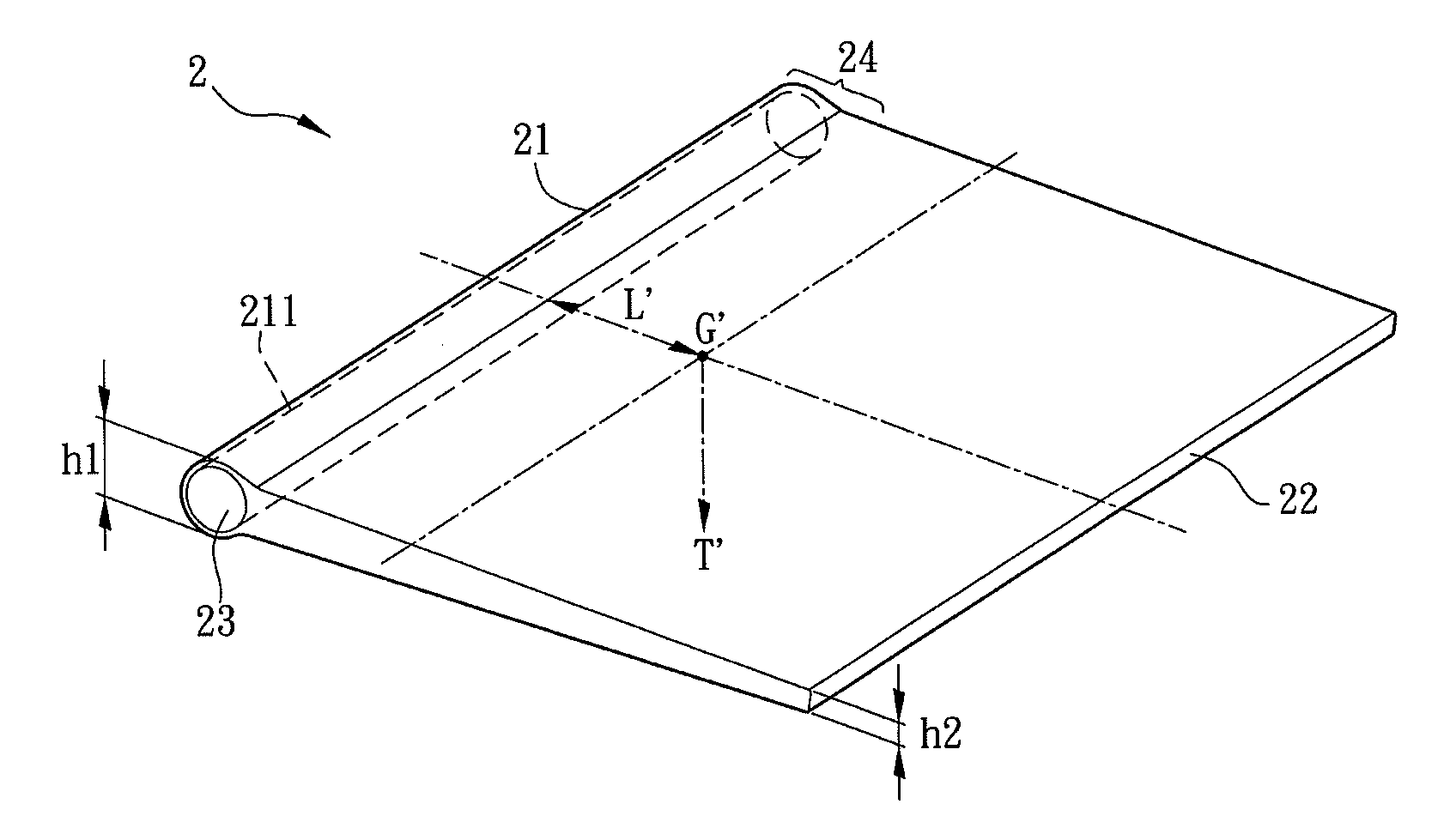

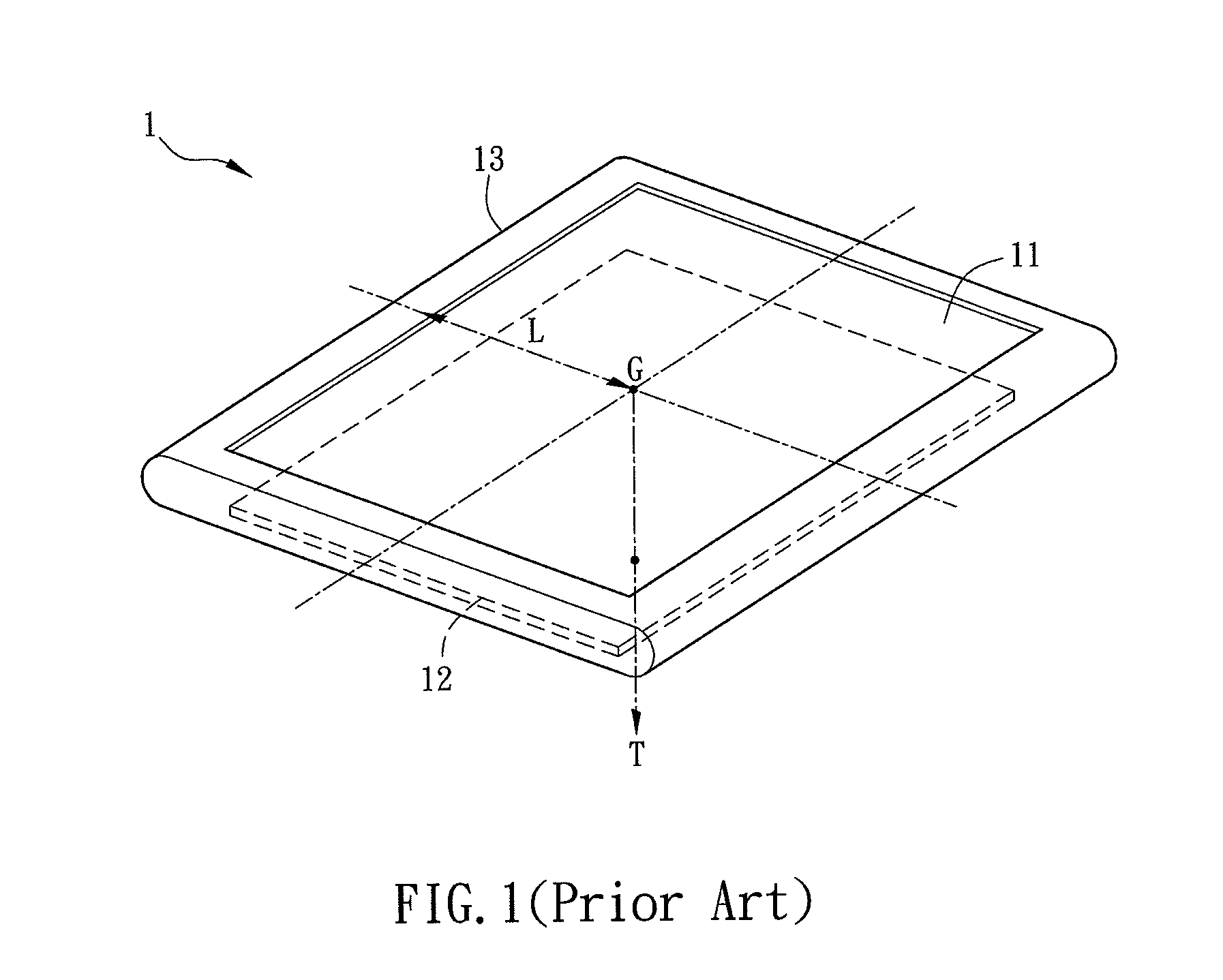

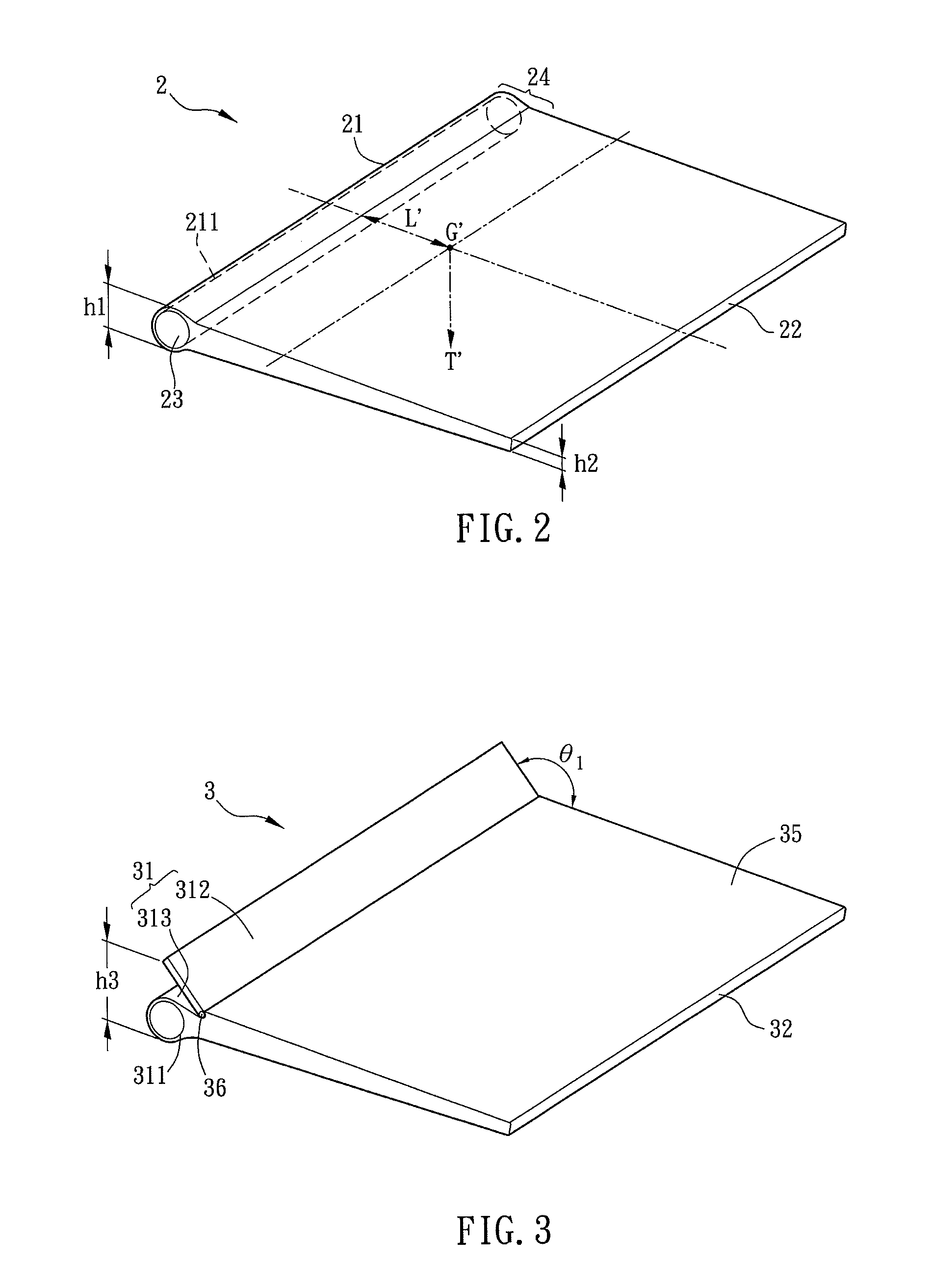

Tablet electronic device

ActiveUS20120106047A1Easy to useComfortable positionDetails for portable computersElectrical apparatus contructional detailsGravity centerEngineering

A tablet electronic device is disclosed. The tablet electronic device includes a first side, a second side and an electronic component. The first side has a first thickness. The second side is opposite to the first side and has a second thickness. The second thickness is larger than the first thickness. The second side has a recess. The electronic component is accommodated in the recess such that a gravity center of the tablet electronic device is adjusted towards the second side. The tablet electronic device has a holding portion and the center of gravity of the tablet electronic device is arranged in a suitable position, thus the tablet electronic device disclosed herein can be comfortably operated while being held in a user's hand. Furthermore, the tablet electronic device can be set in various ways for comfortable usage.

Owner:ASUSTEK COMPUTER INC

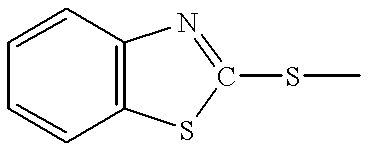

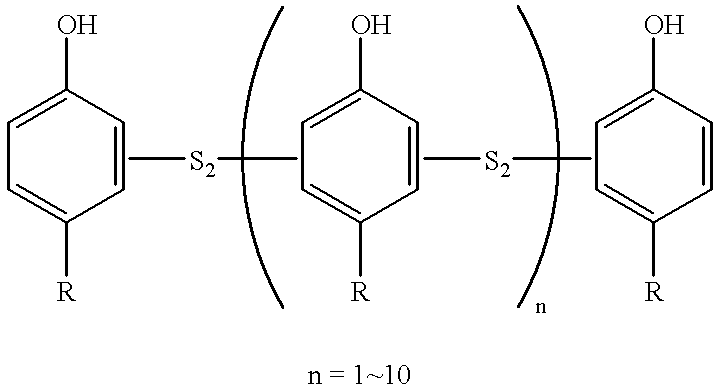

Stabilizer bushing

A cylindrical rubber elastic member for having a stabilizer bar inserted therein comprises an inner layer rubber with high sliding properties and an outer layer rubber provided outside of the inner layer rubber. Both the stability in operation and the riding comfort can be improved. Further, the rubber elastic member comprises a sliding surface made of a rubber with high sliding properties at the end face thereof. Frictional resistance can be lowered to prevent abnormal noise. A stabilizer bushing comprising a main body rubber portion of a sulfur-vulcanizable first rubber compound and a sliding rubber portion of a second rubber compound containing a sulfur-vulcanizable lubricant on the inner surface of the main body rubber portion, wherein the first rubber compound exhibits vulcanizability satisfying:and contains a crosslinking tackifier, t90 is a time to 90% vulcanization, t50 is a time to 50% vulcanization, and the vulcanizability is measured by a curastometer in accordance with JIS K 6300.

Owner:TOYO TIRE & RUBBER CO LTD

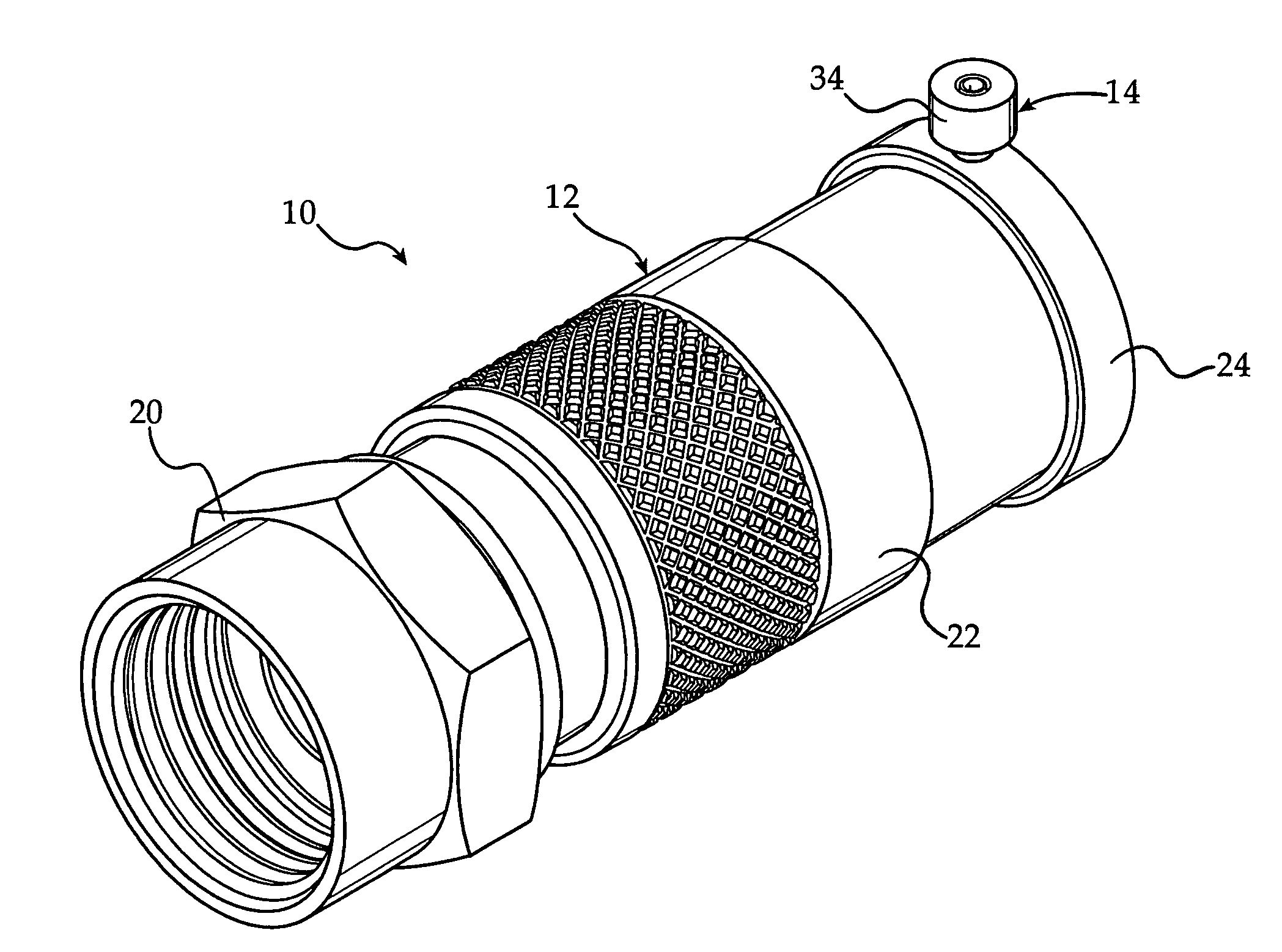

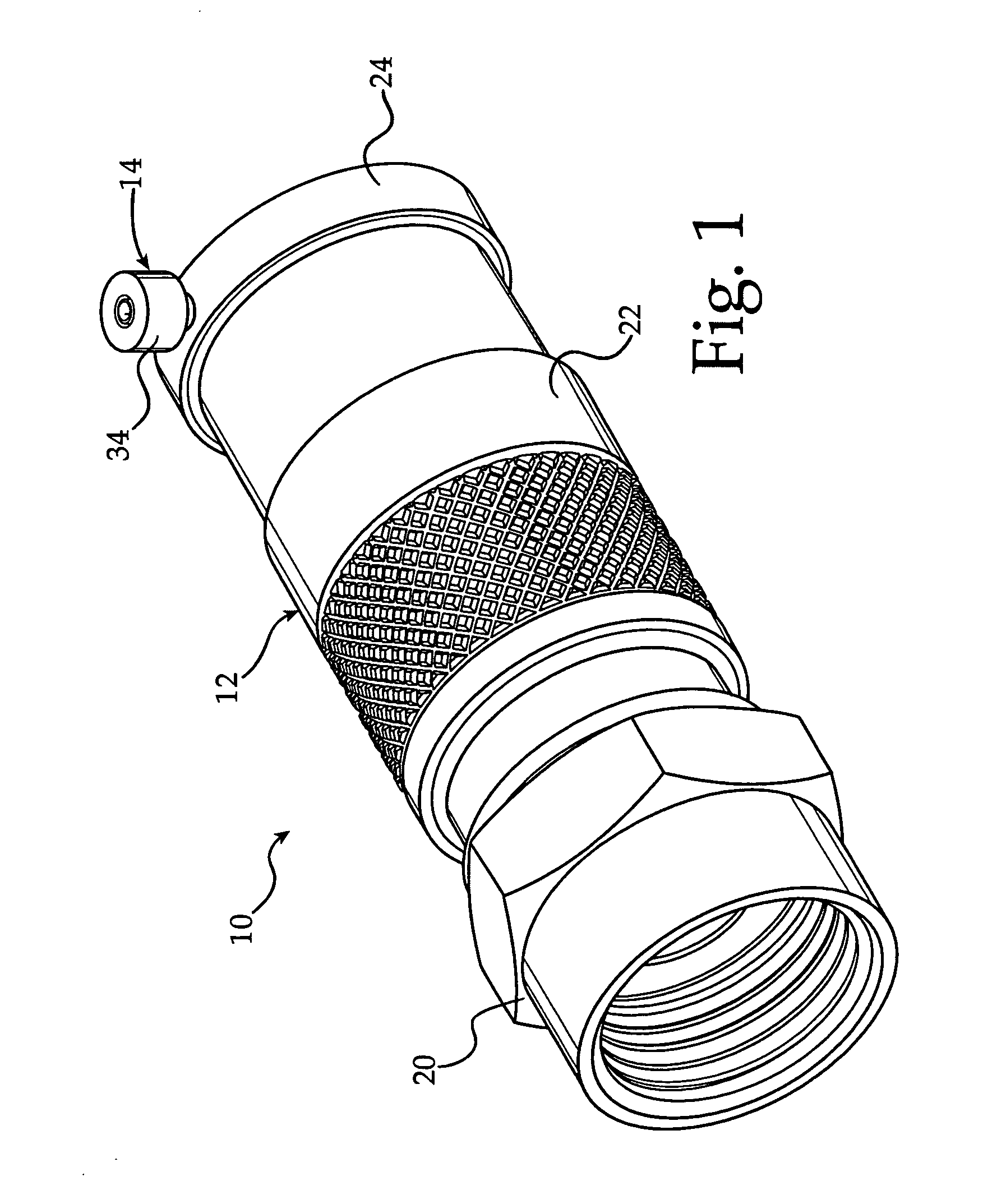

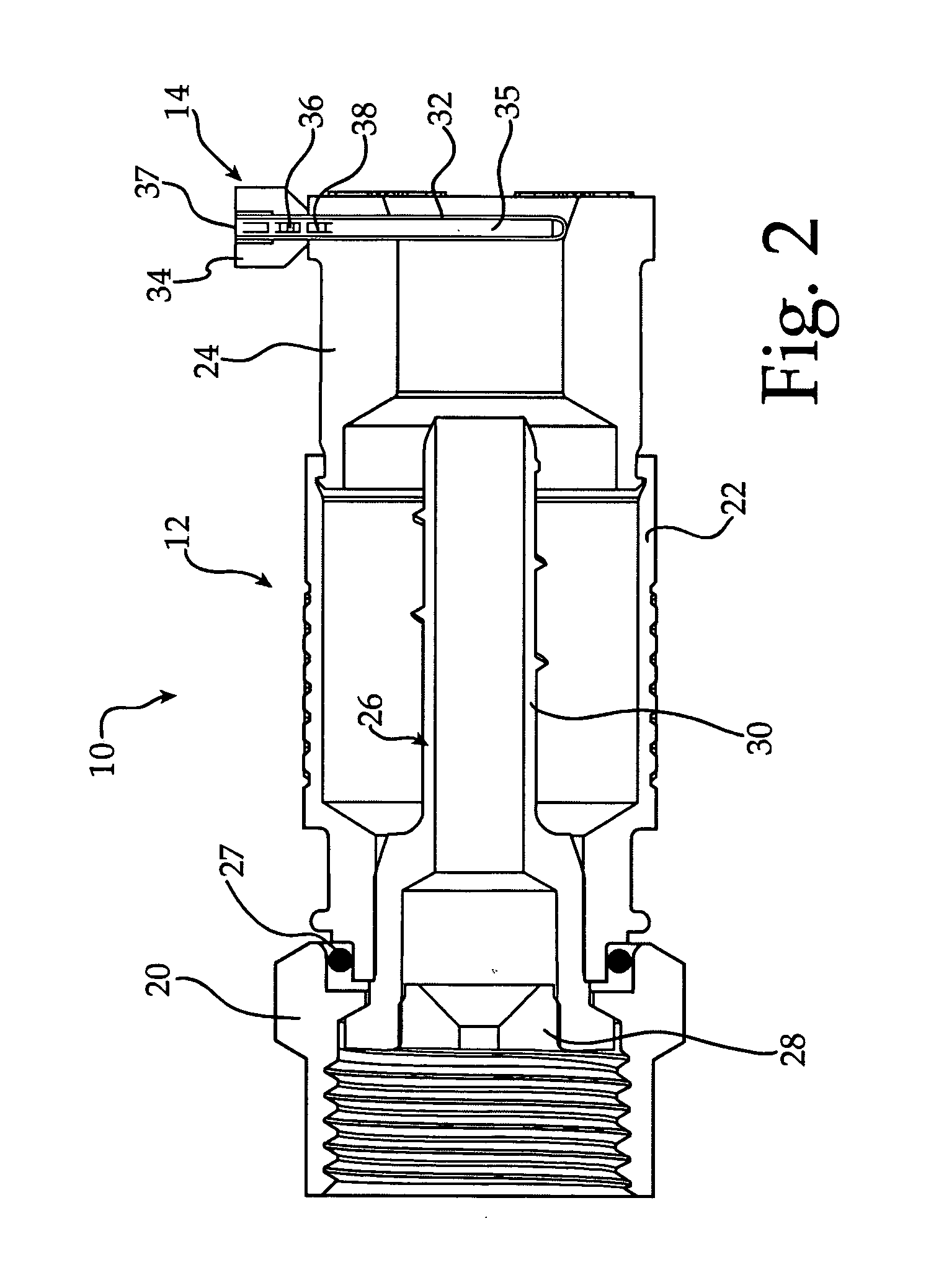

Step up pin for coax cable connector

InactiveUS20080064259A1Easy to dropEasy to loseTwo pole connectionsCoupling device detailsCoaxial cableElectrical conductor

The invention provides a coaxial cable connector having a step up pin that engages the center conductor of a coax cable to increase the diameter of the center conductor to thereby make it more manageable. The pin is stored with the connector until the pin and connector are affixed to a coax cable.

Owner:PPC BROADBAND INC

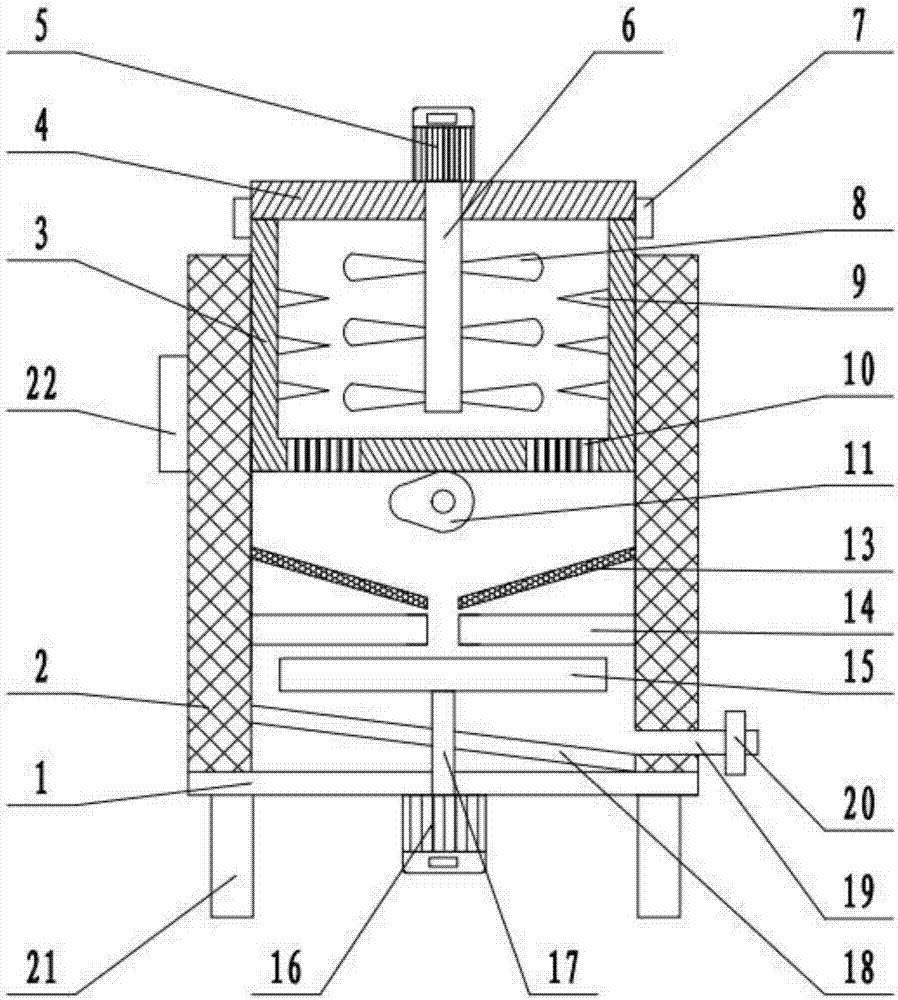

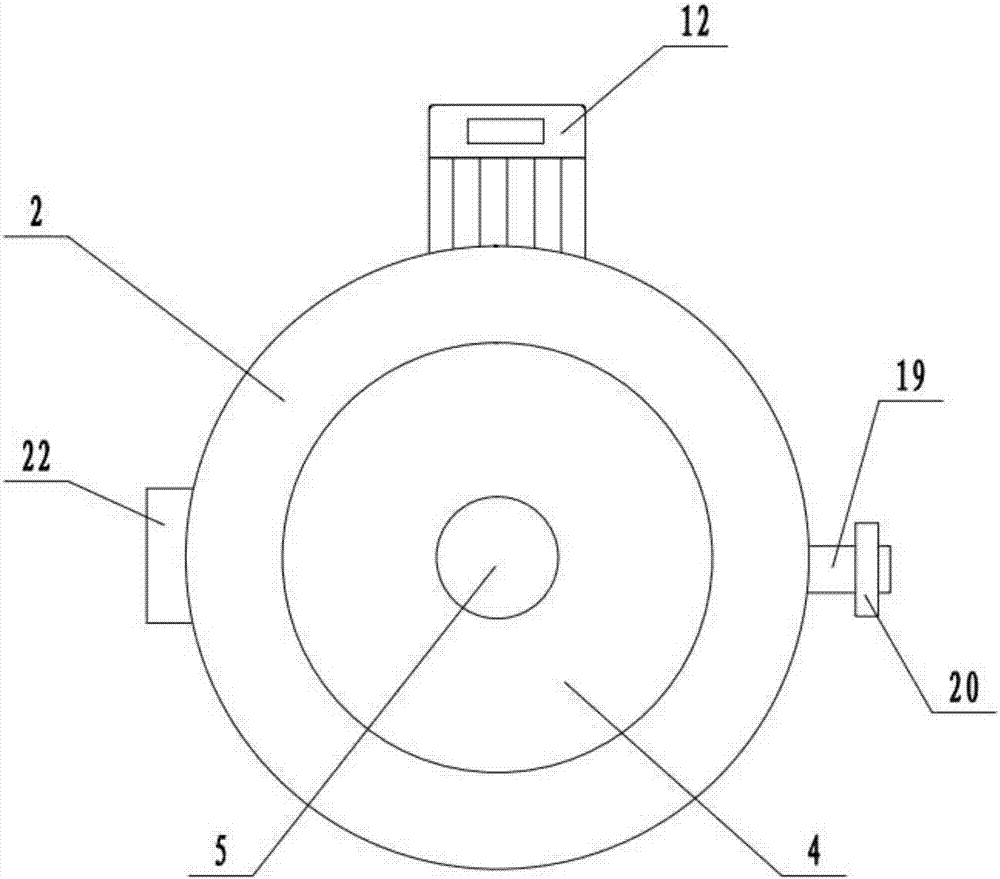

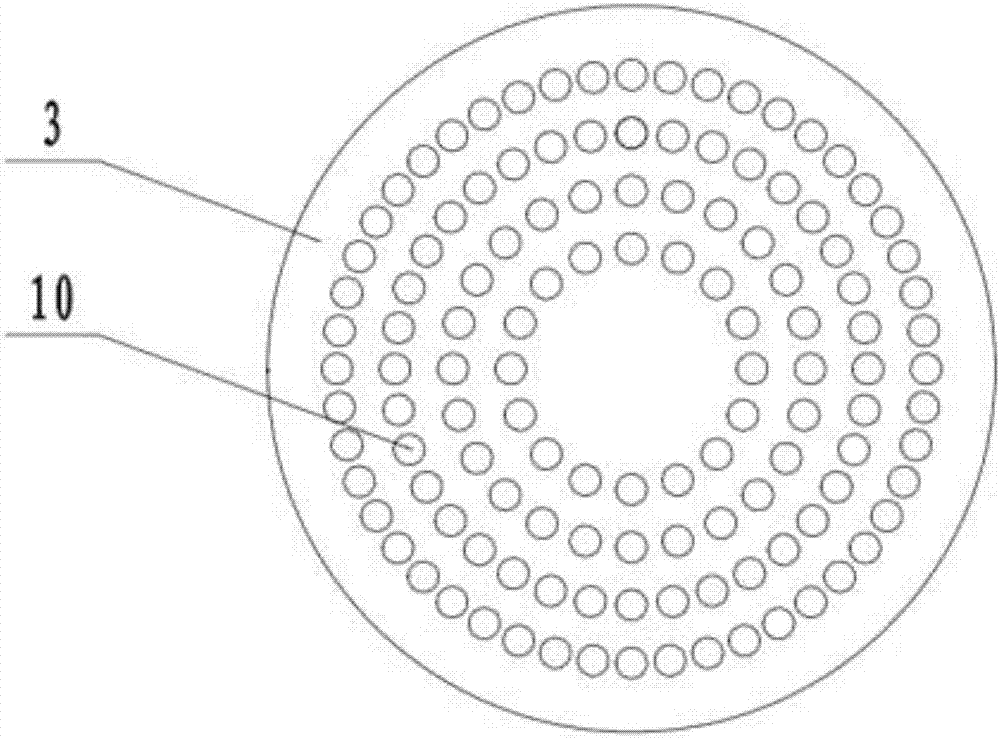

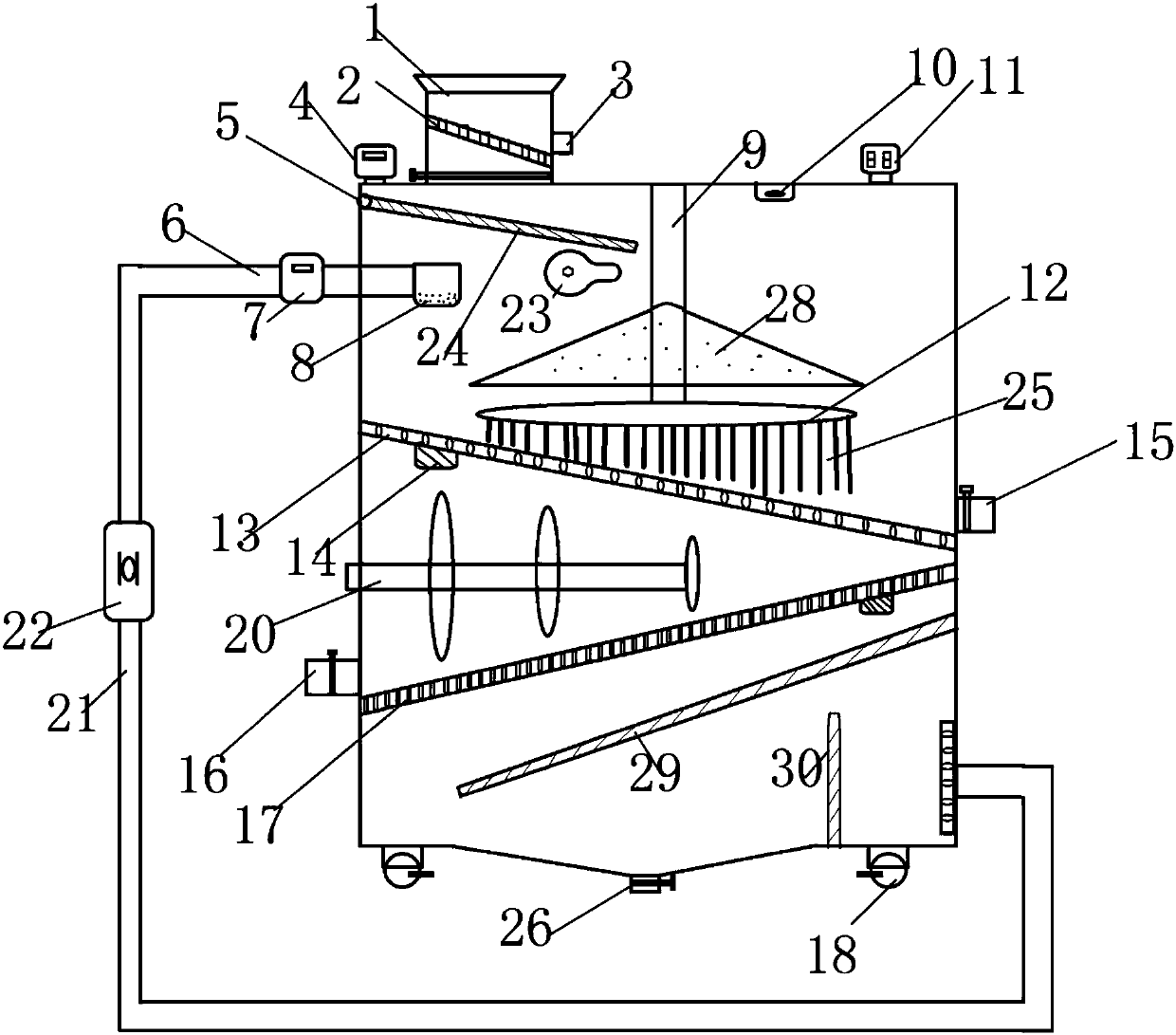

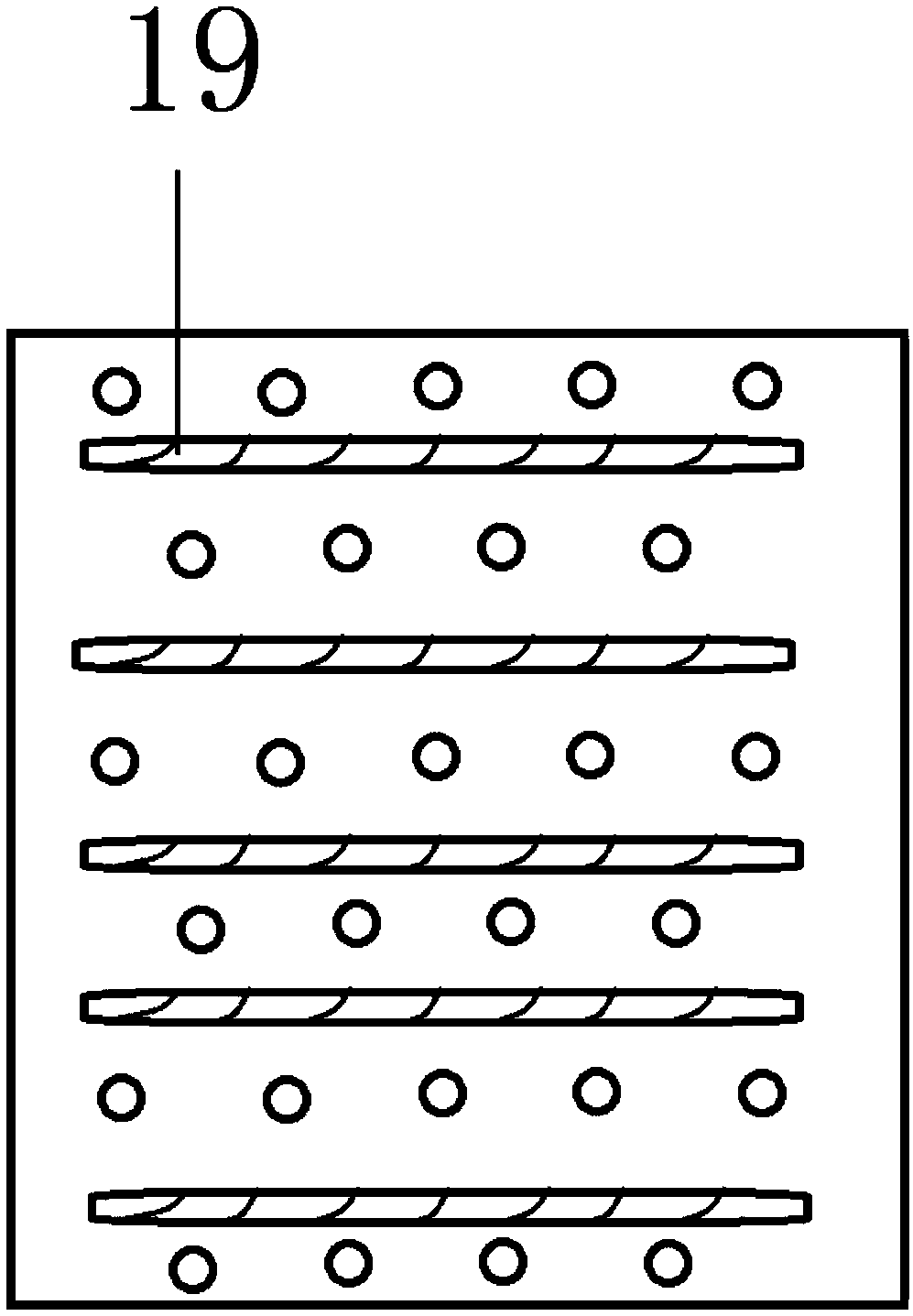

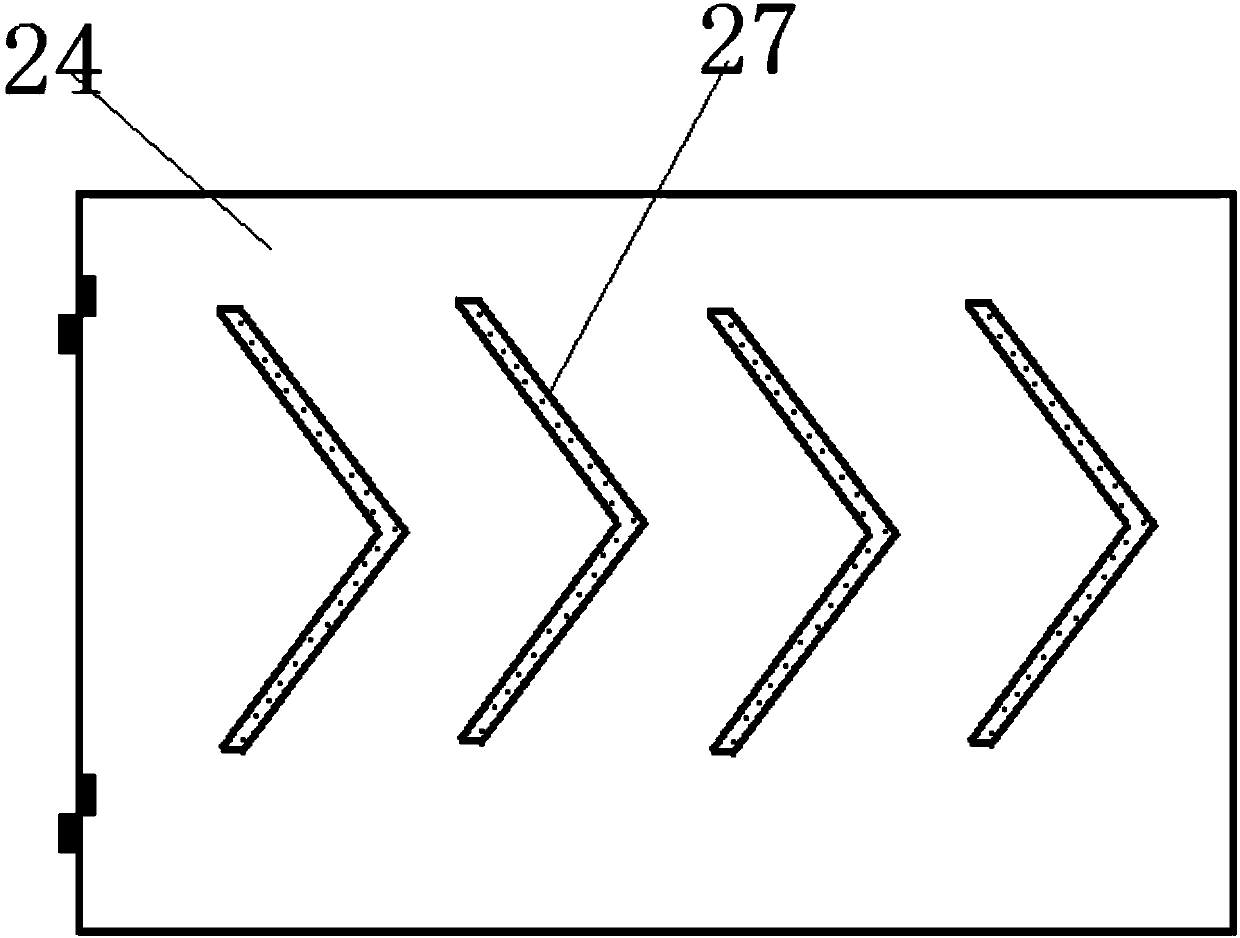

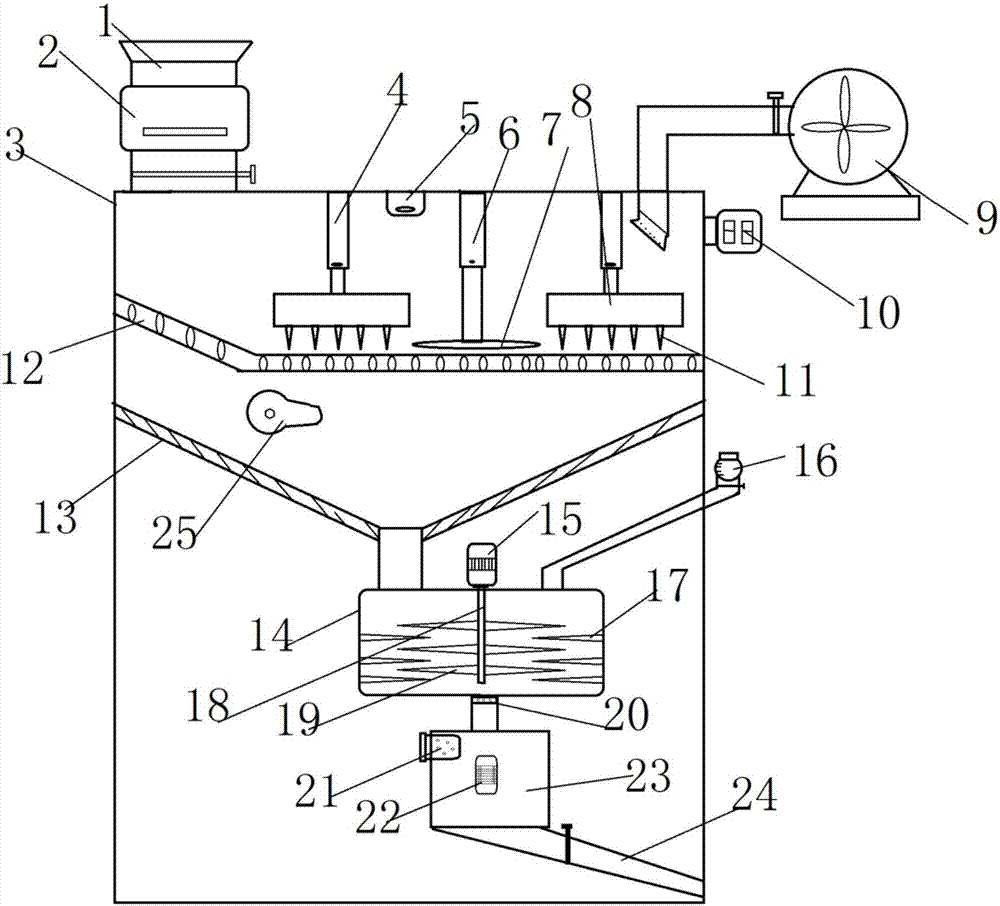

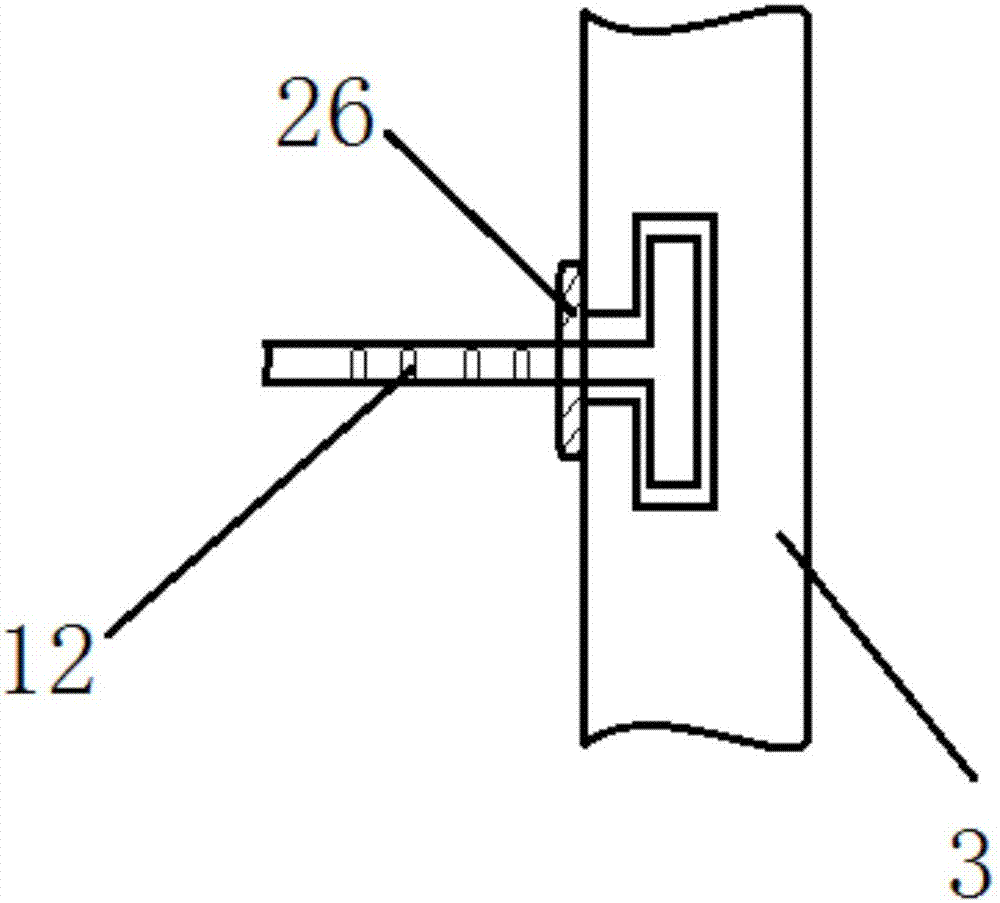

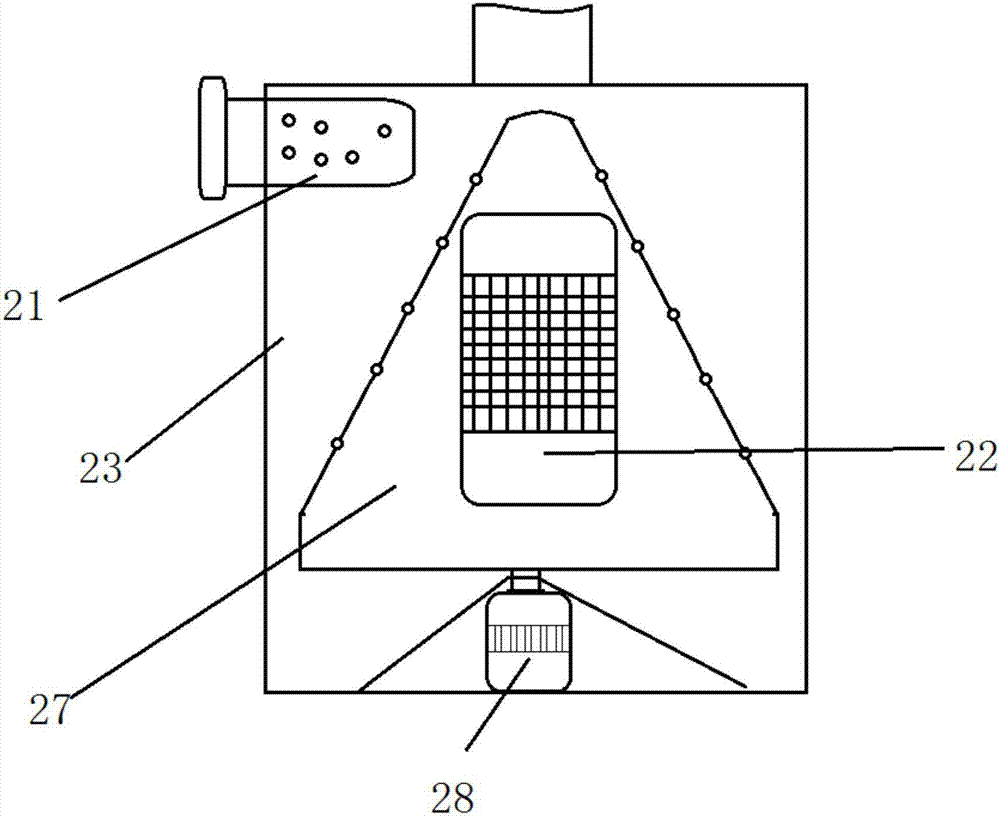

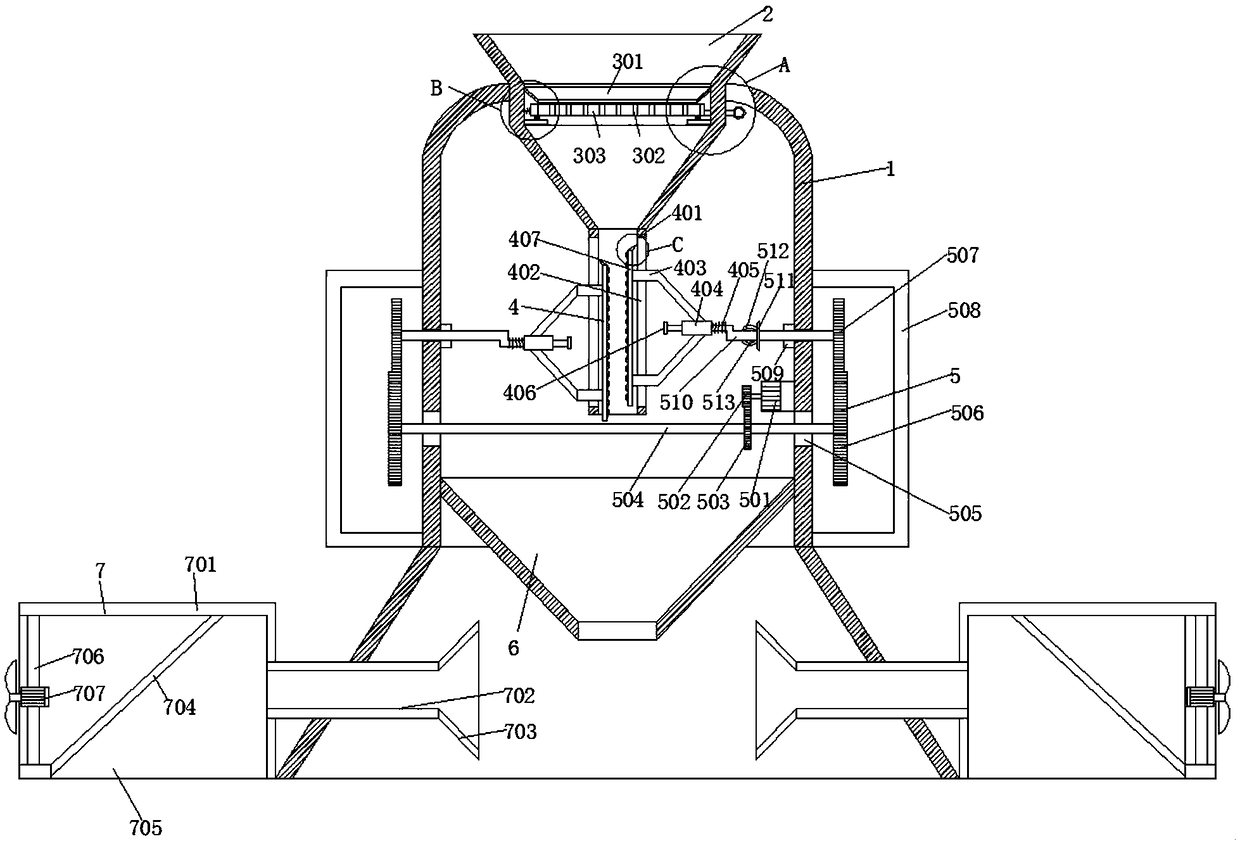

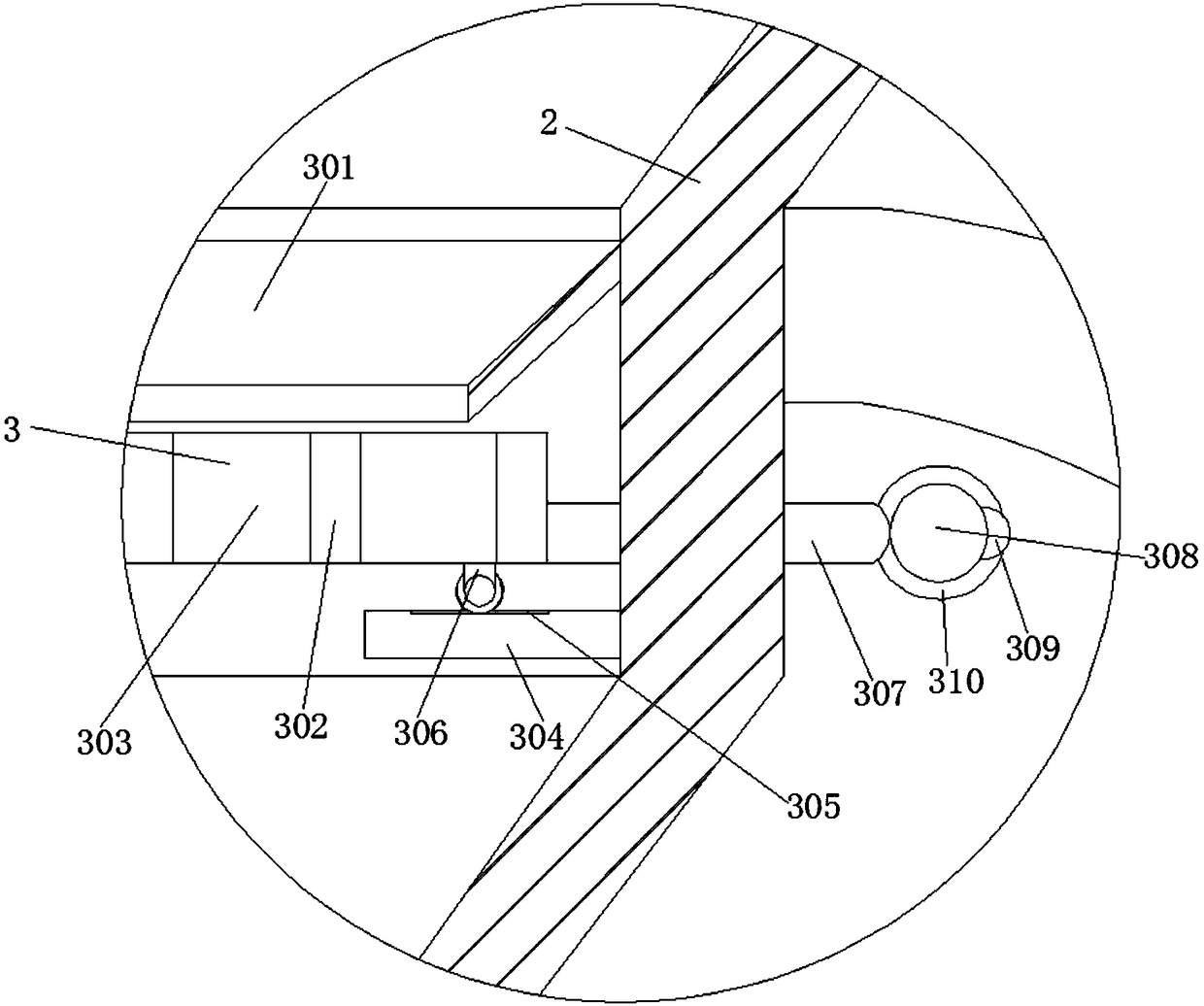

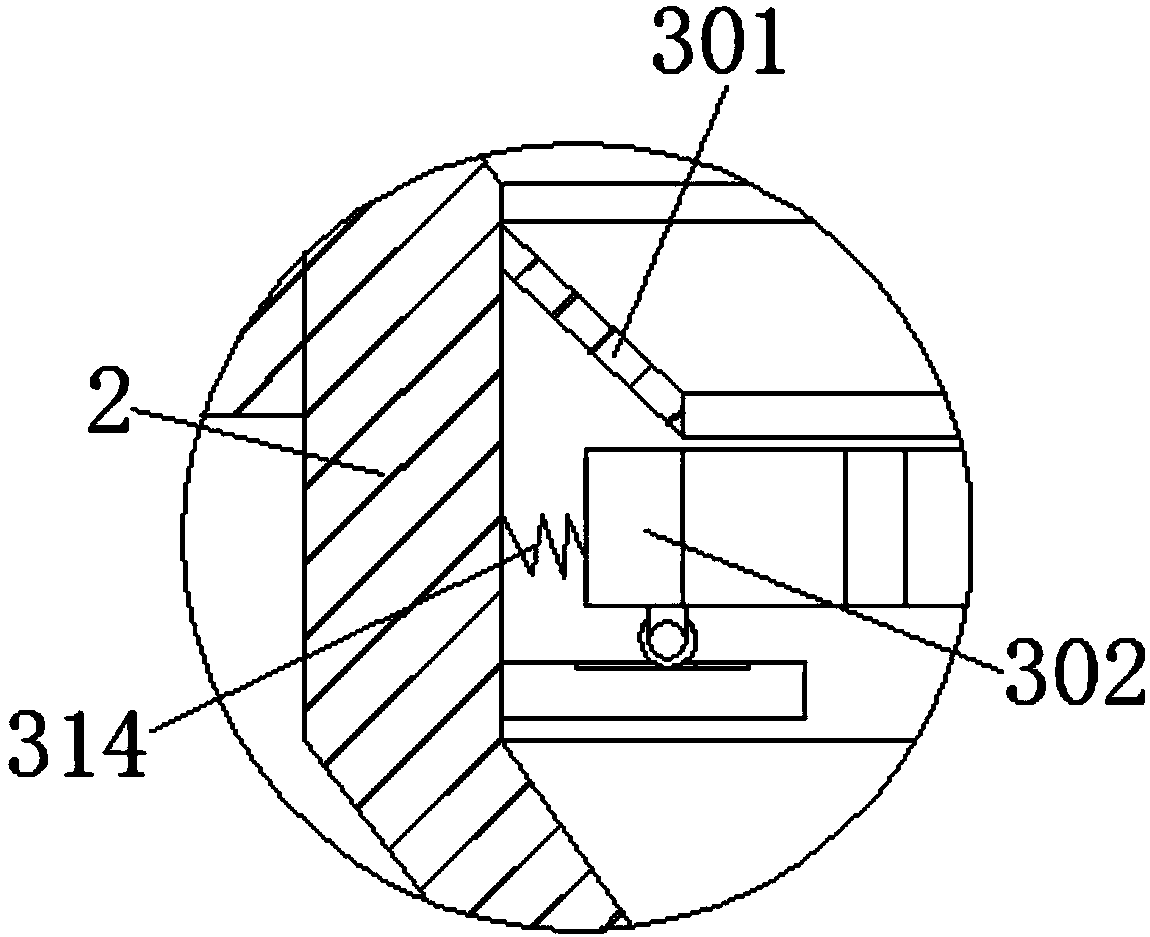

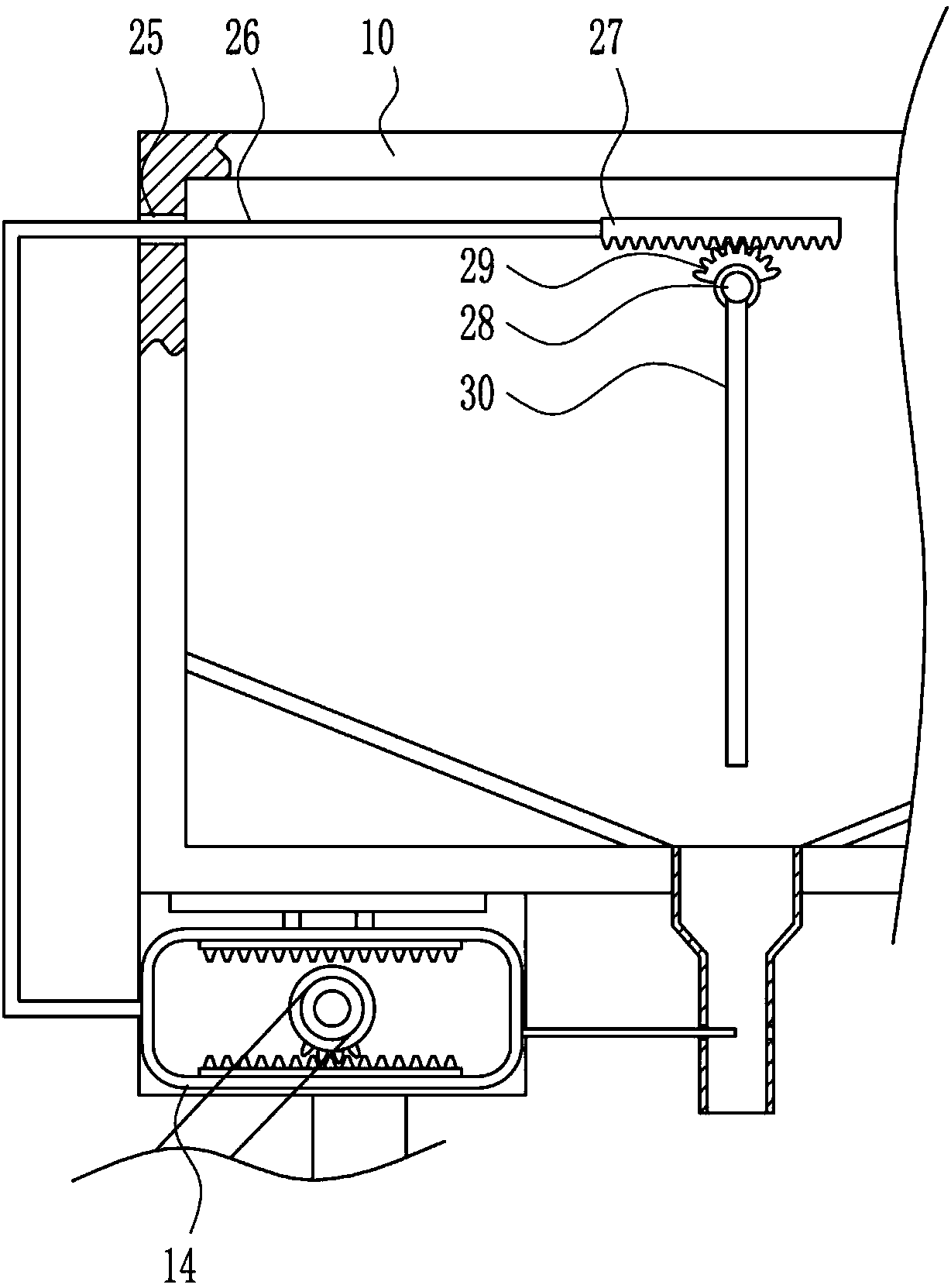

Vibration type material crushing and grinding integrated machine

The invention discloses a vibration type material crushing and grinding integrated machine which comprises a base, a sleeve, a tank, a tank cover and support legs. The vibration type material crushing and grinding integrated machine is characterized in that the lower end of the sleeve is fixedly connected with the base; the tank is mounted in the sleeve; the tank is in sliding connection with the inner wall of the sleeve; the upper surface of the tank cover is fixedly connected with a crushing motor; a shaft extending end of the crushing motor is fixedly connected with a rotary shaft; the rotary shaft is fixedly connected with crushing vanes; screening holes are formed in the bottom of the tank; a cam is arranged under the tank; a through hole is formed in the middle of a guide plate; the crushing motor drives the crushing vanes to rotate to crush materials; the crushing vanes are matched with crushing cutting blades on the inner wall of the tank, and the crushing efficiency is improved; the cam rotates to drive the tank to vibrate up and down along the inner wall of the sleeve, so that the crushing effect is further improved, and crushed materials can penetrate through the screening holes to fall off conveniently; and an upper grinding plate and a lower grinding plate are matched for use, and ridges on the surfaces of the crushed materials are ground off, so that the materials are ground into balls.

Owner:惠安县丽佳智能设备有限公司

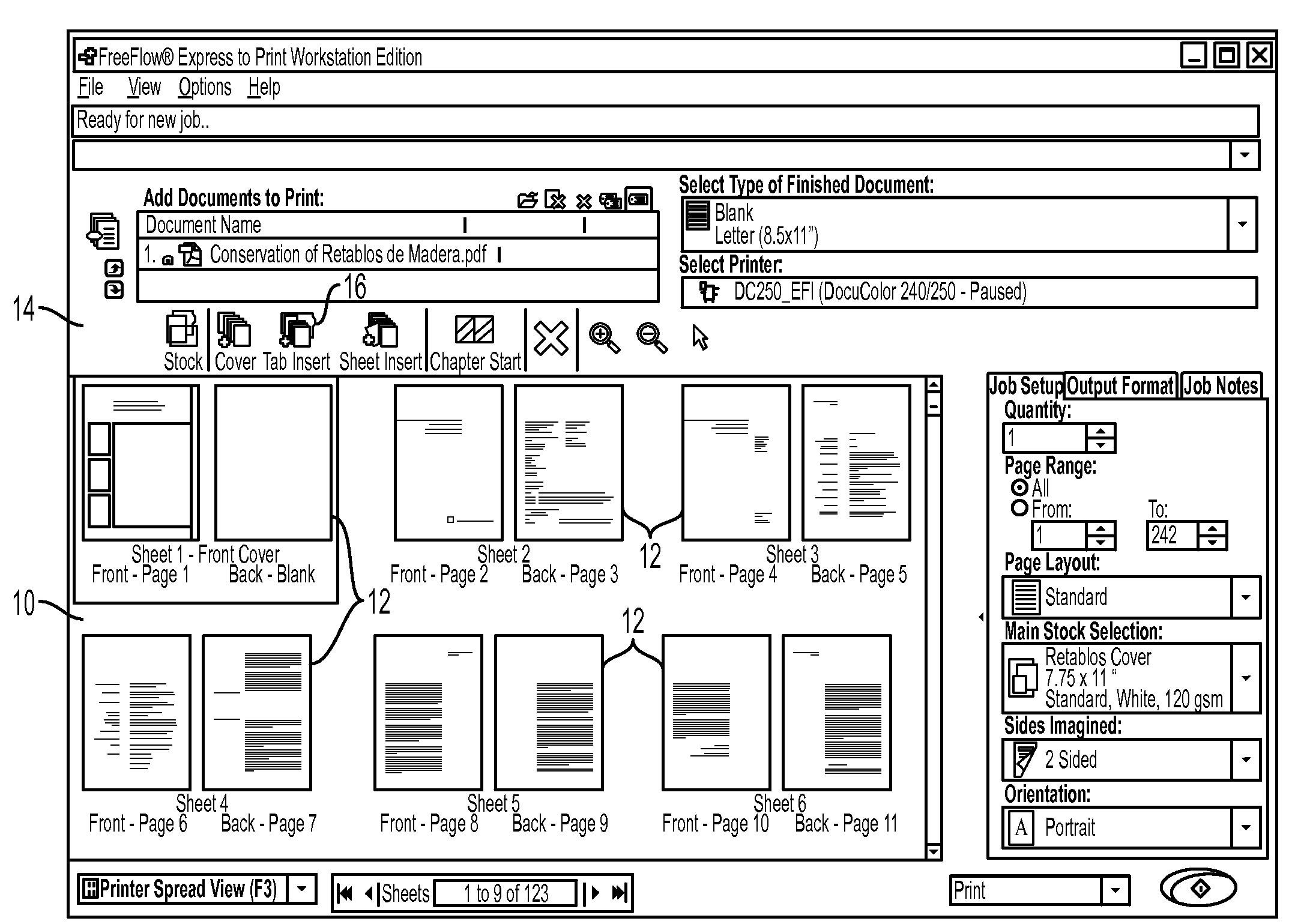

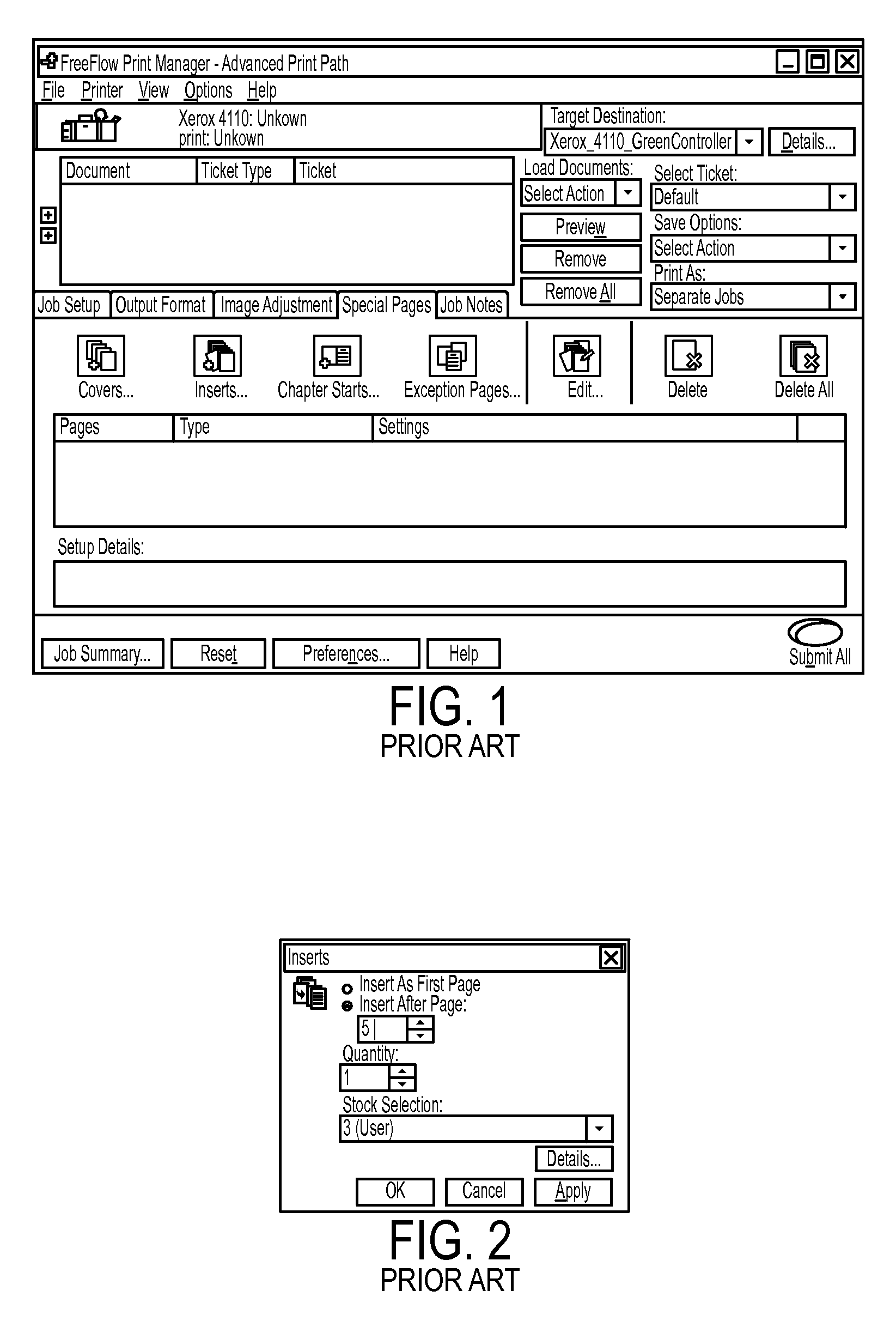

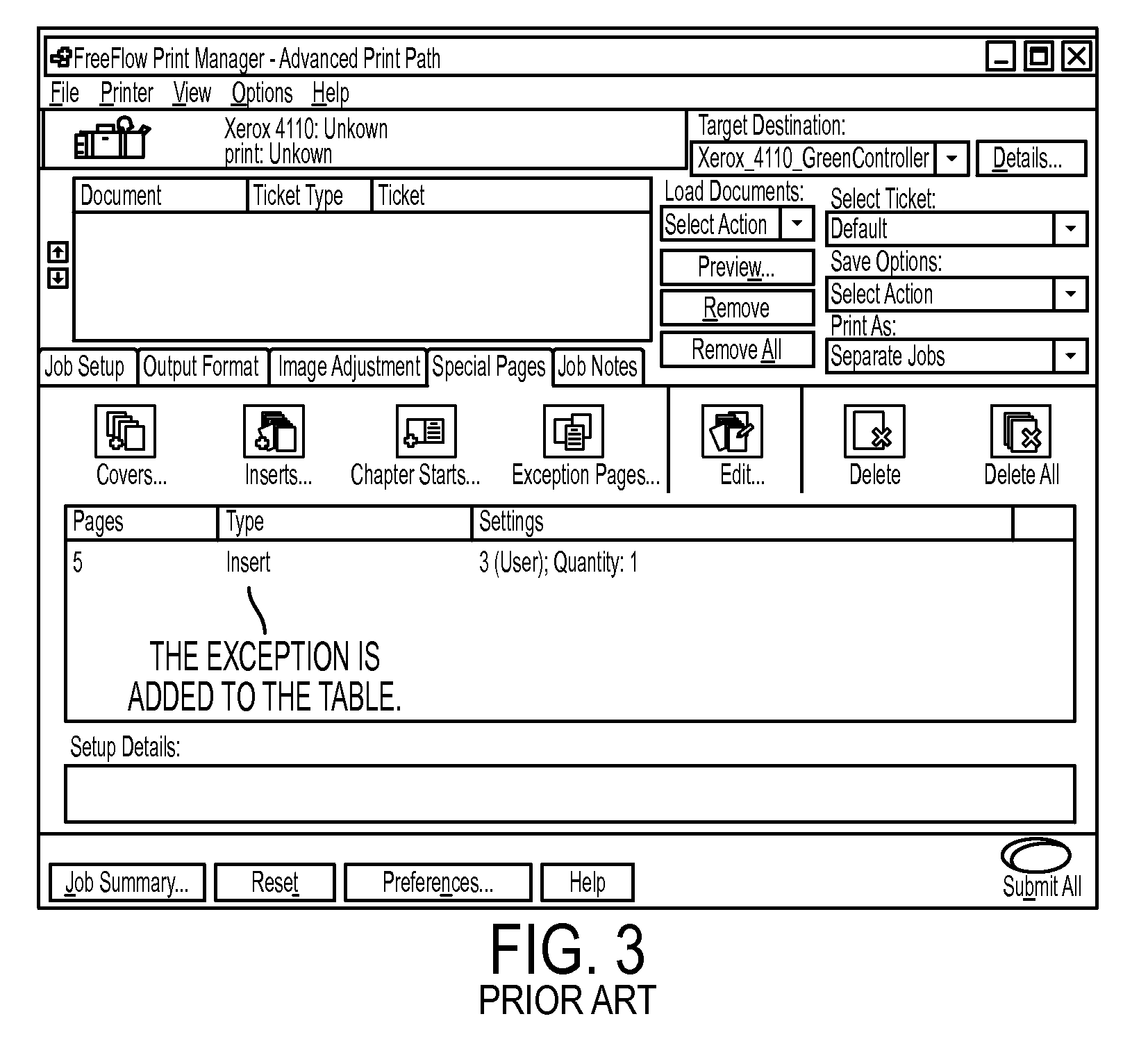

Highly visual drag and drop method to simplify programming special pages

InactiveUS20100275144A1Simple processQuick addSpecial data processing applicationsInput/output processes for data processingDrag and dropSoftware engineering

The present disclosure shows an easy to learn and easy to use drag and drop method in a highly visual user interface to simplify the process of programming special pages and to quickly add page objects to a document's pages. The results of these drag and drop operations are displayed for the user prior to printing. More specifically, a limited number of icons are preprogrammed but can be pre-programmed when applied to a document. The modifications apply to subsequent applications of the icon to provide a simple but flexible technique to accommodate numerous types of special page programming. It also provides the ability to save modifications relative to the page reference, thus making the special pages programmed reusable and useful even if the original document has been somewhat modified.

Owner:XEROX CORP

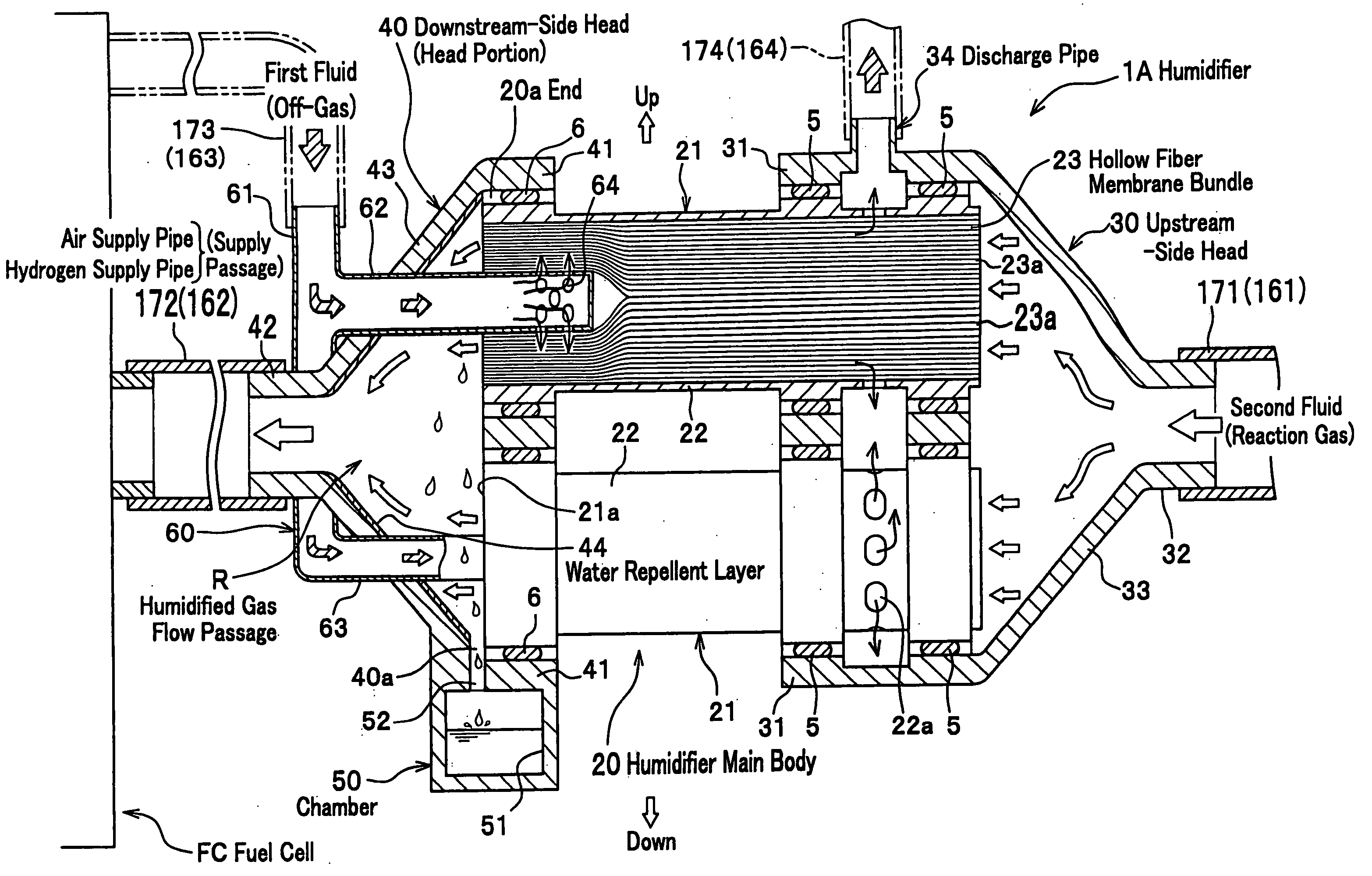

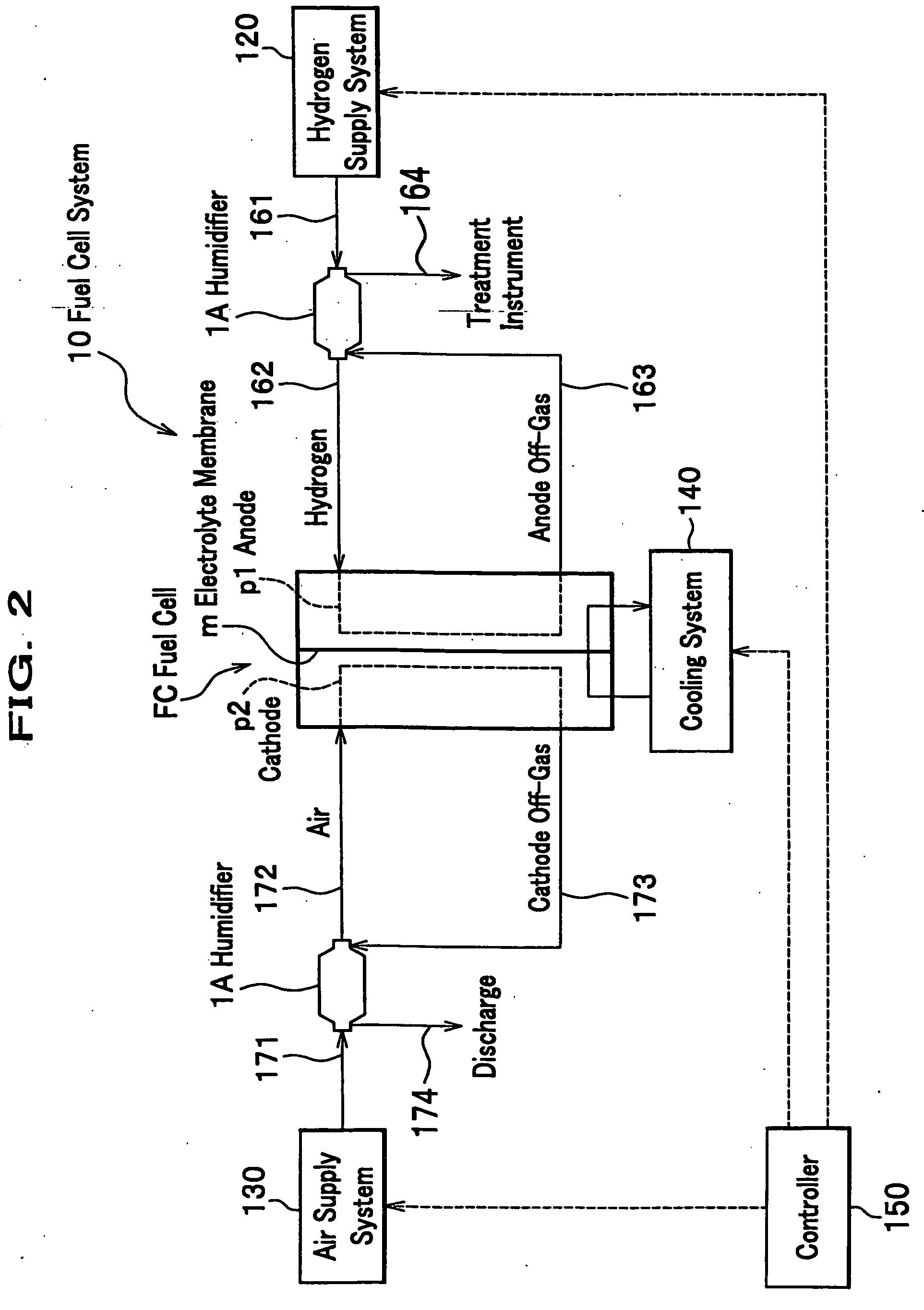

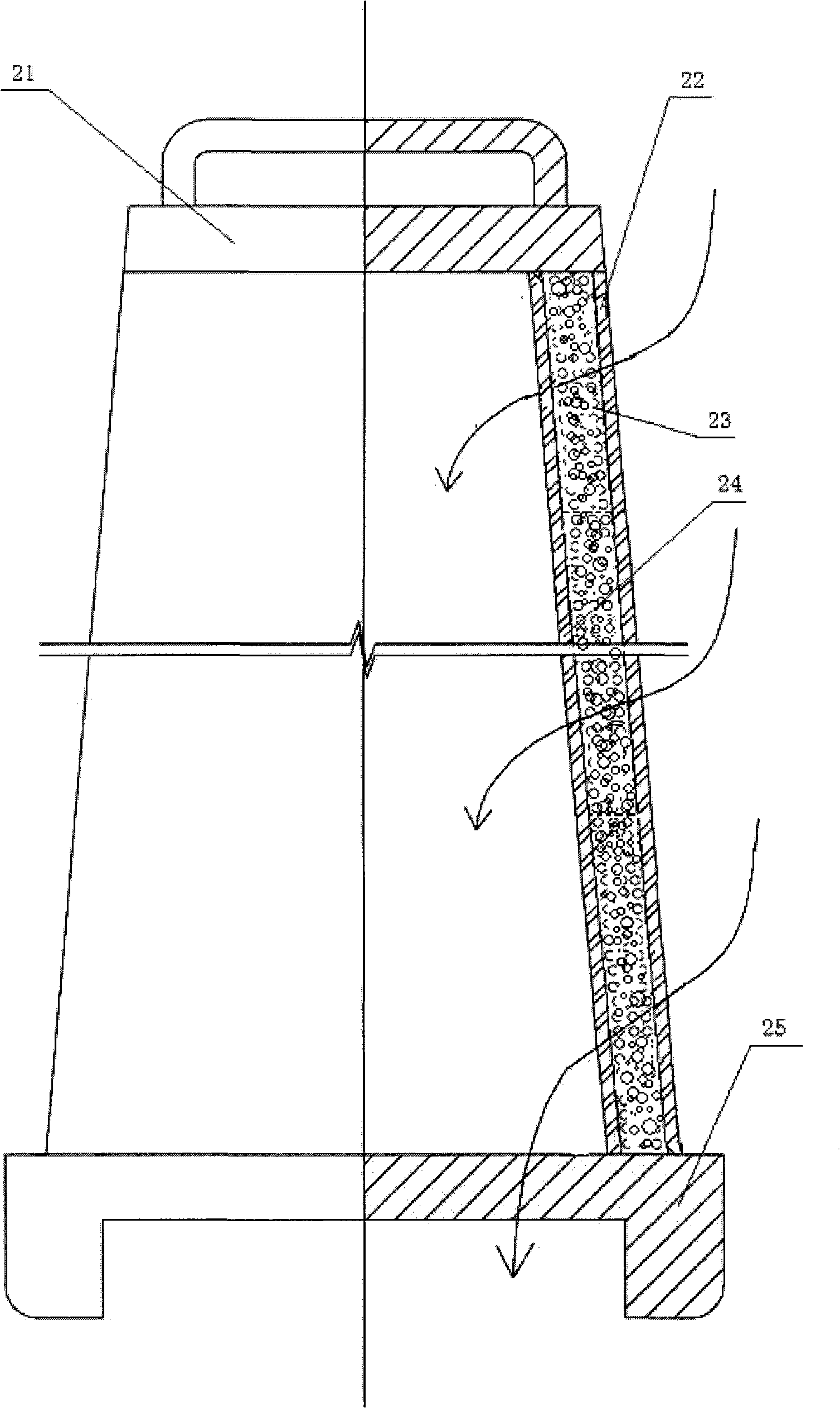

Humidifier for fuel cell system

InactiveUS20060147774A1Easy to dropEasily introducedFuel cell auxillariesIsotope separationProduct gasEngineering

A humidifier of the present invention includes a humidifier main body for humidifying a second fluid, using a humidified first fluid discharged from a fuel cell; a head portion of which one end is connected to an end of the humidifier main body and the other end is connected to the fuel cell or a supply passage extending from the fuel cell, and which supplies the second fluid after humidification to the fuel cell; and a chamber for communicating a bottom portion of a humidified gas flow passage formed within the head portion.

Owner:HONDA MOTOR CO LTD

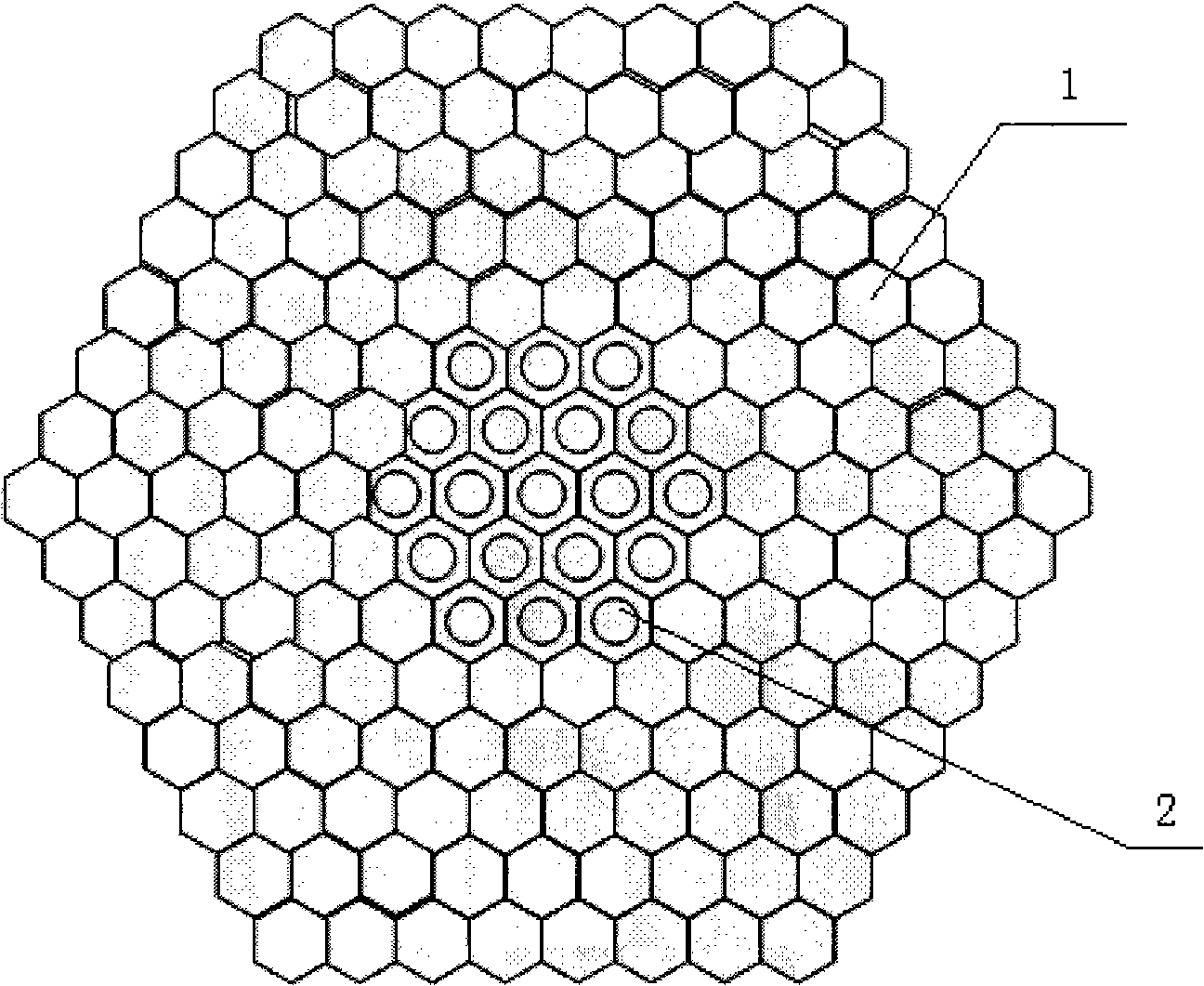

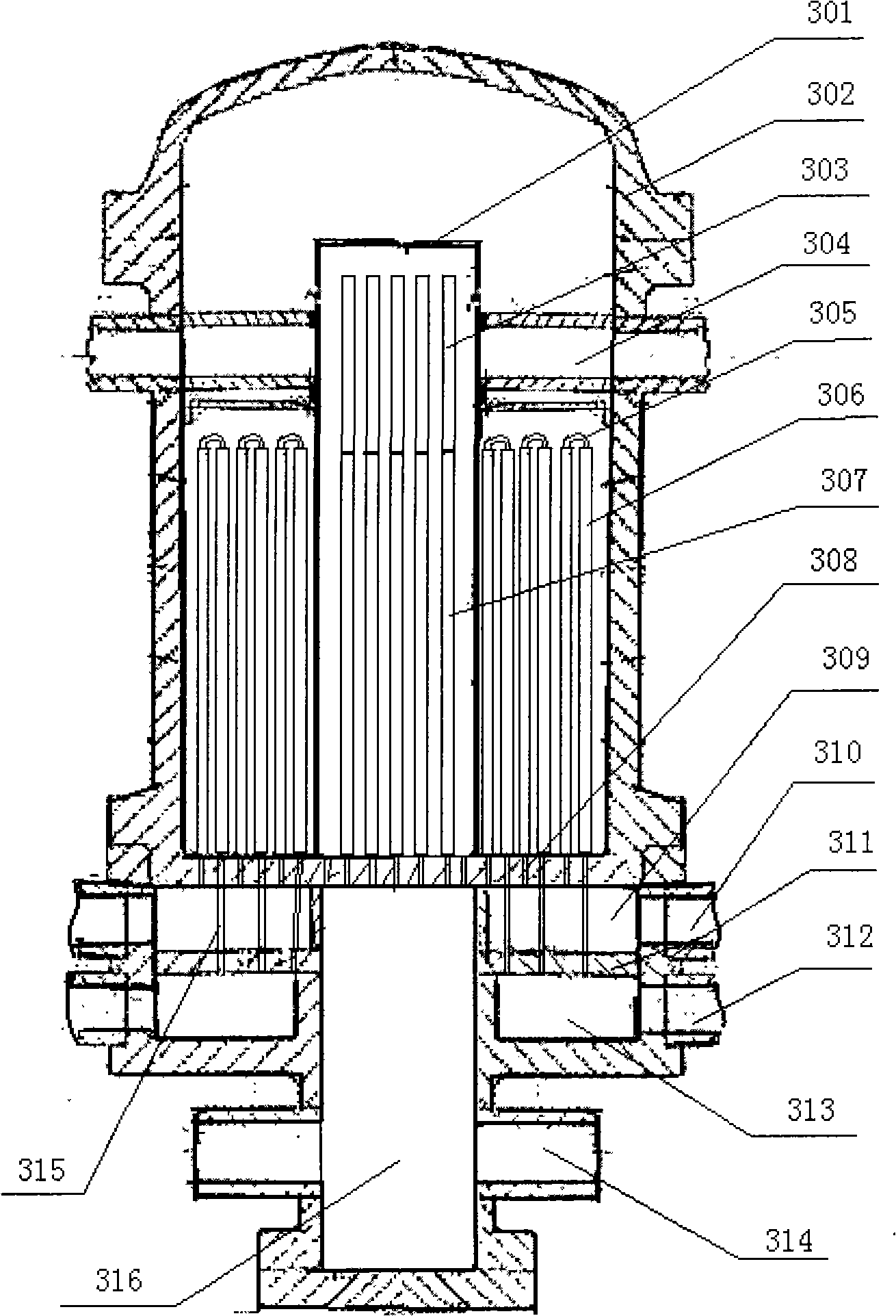

Stack core of water-cooling double-section breeding nuclear reactor as well as nuclear reactor using the same

InactiveCN101299351AIncrease temperatureInclusiveNuclear energy generationShieldingNuclear reactor coreNuclear reactor

The invention belongs to the technical field of the nuclear reactor engineering, particularly to the water-cooling two-region multiplication nuclear reactor core and the nuclear reactor adopting the same, wherein the water-cooling two-region multiplication nuclear reactor core includes a fast neutron energy spectrum area adopting the coating grain sheath fuel assembly and a thermal neutron energy spectrum area adopting the dense rod bundle fuel assembly or the coating grain sheath fuel assembly. The water-cooling two-region multiplication nuclear reactor core of the invention adopts the coating grain sheath fuel assembly, which breaks through the restrain of the stainless steel shell to the outlet scream temperature, realizes the higher coolant outlet temperature, meanwhile the fast neutron core is leaked to the thermal neutron energy spectrum core constituted by the rod bundle fuel assembly dense boom at the subcritical to be multiplied.

Owner:张育曼 +1

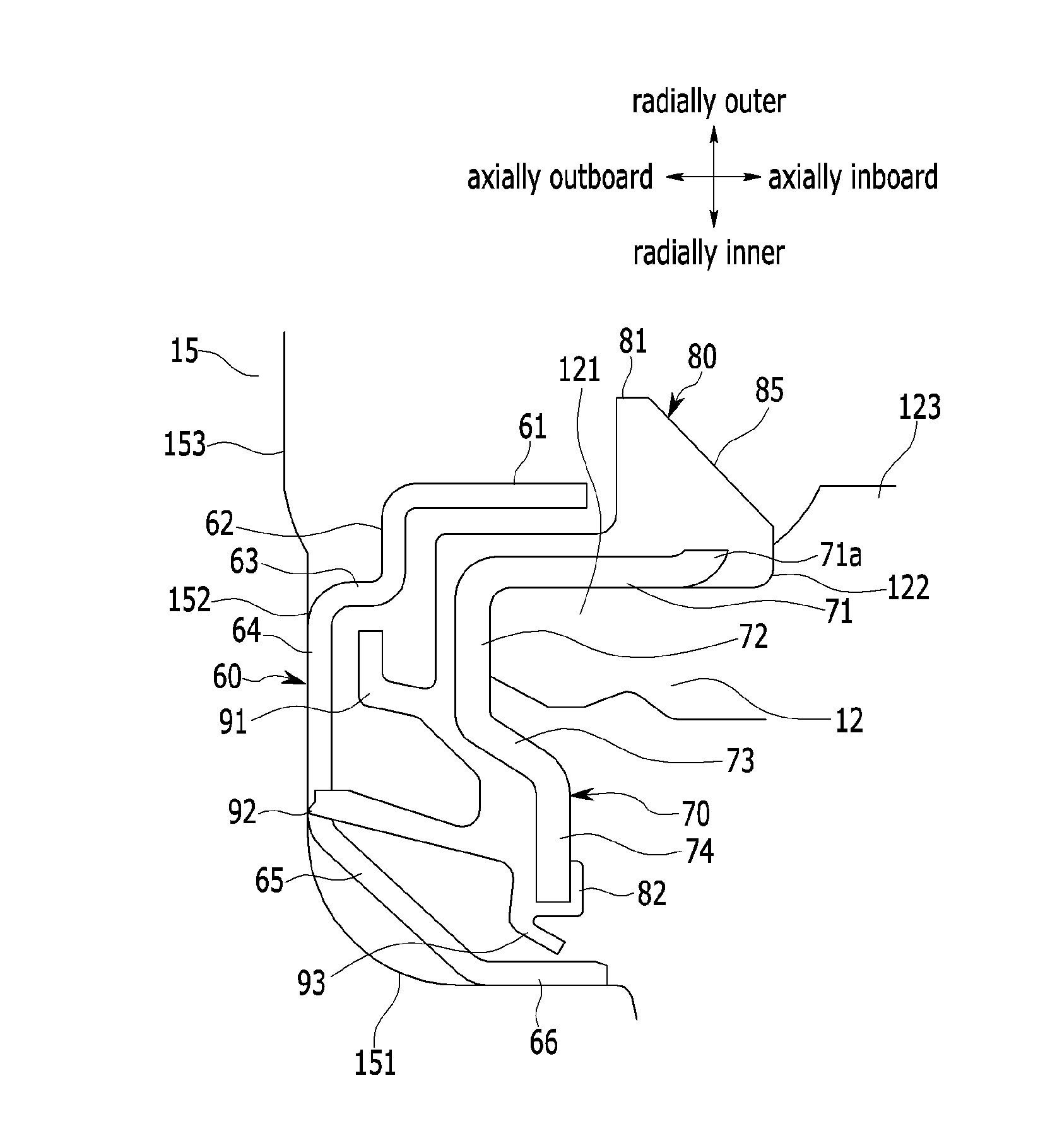

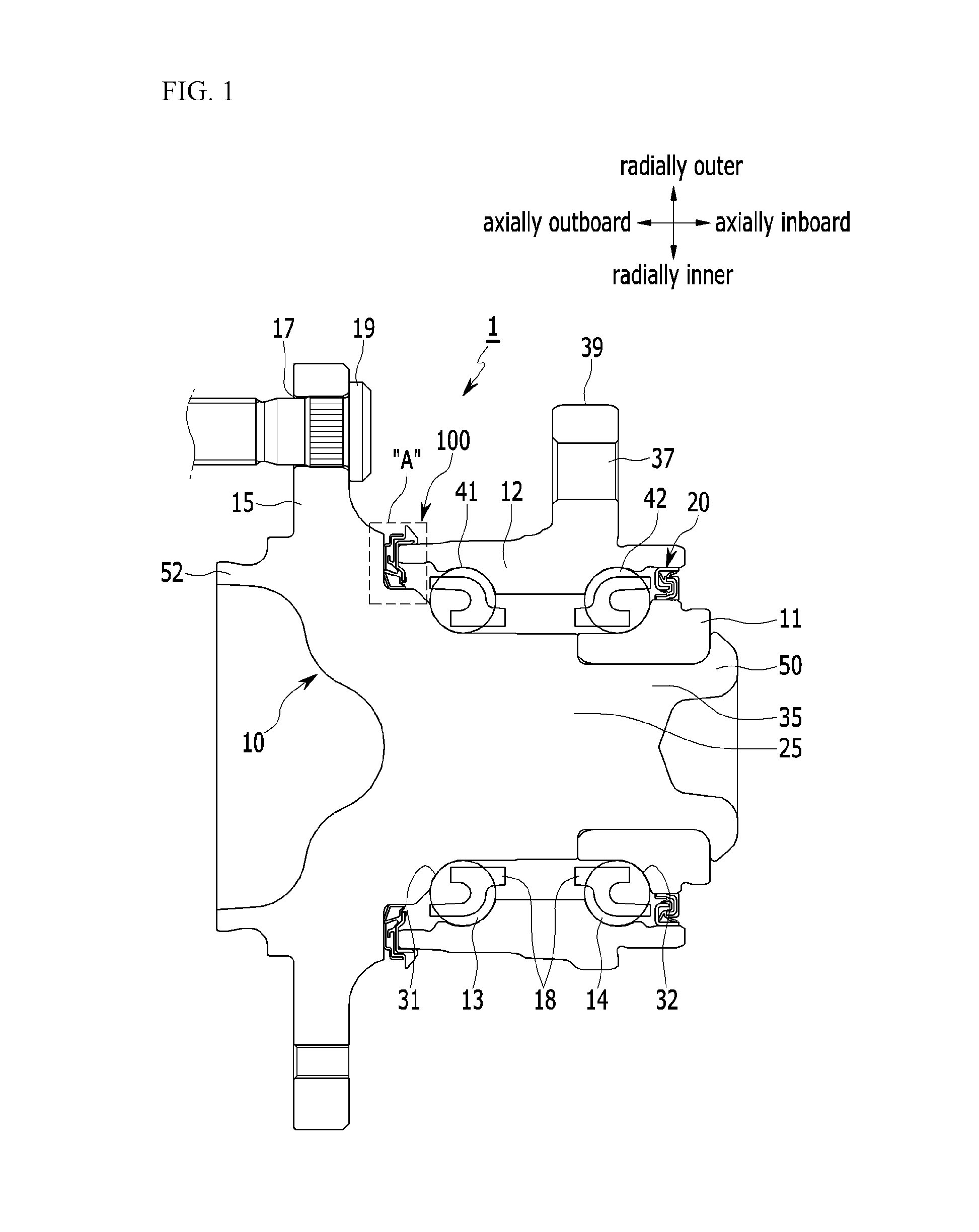

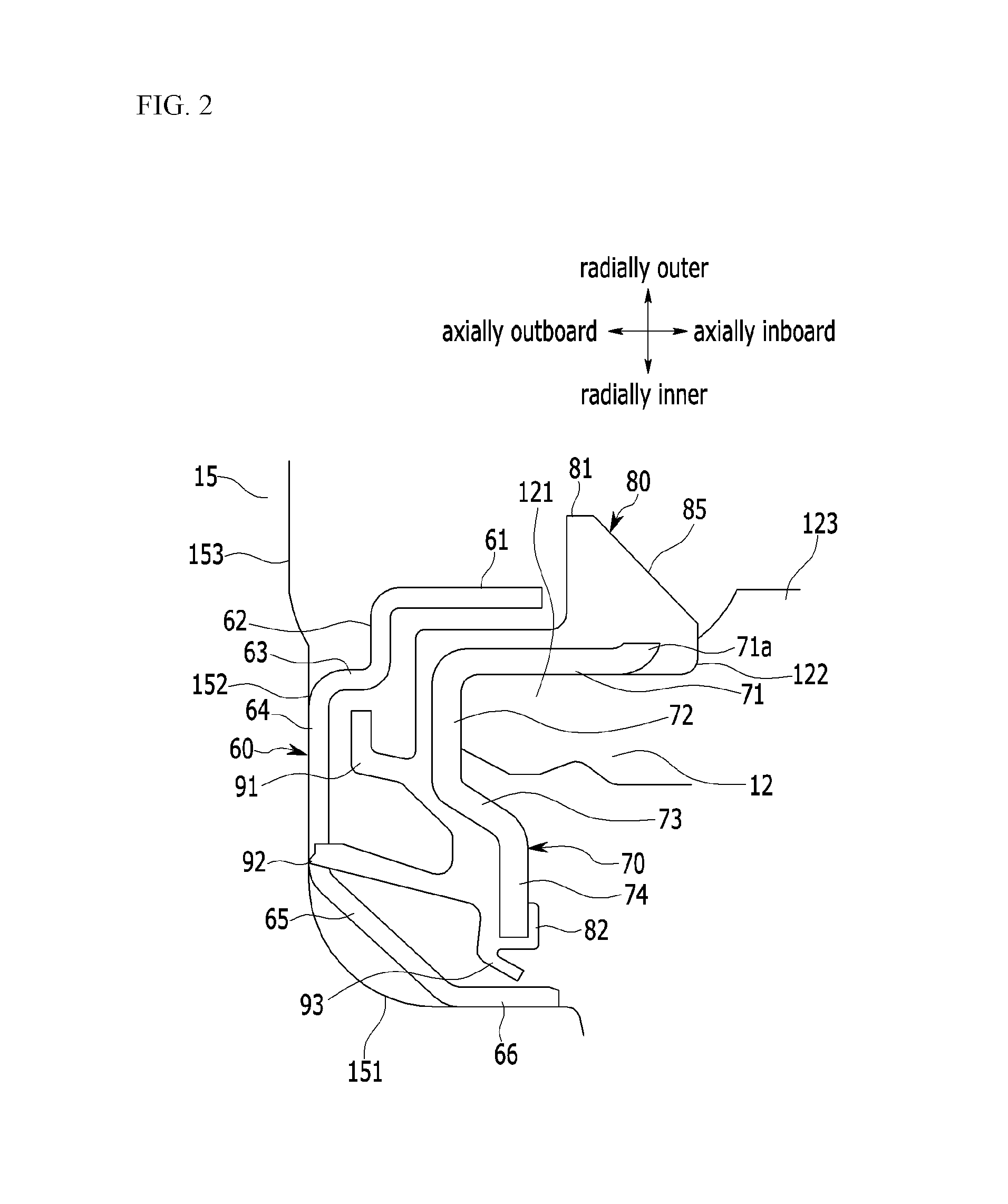

Sealing structure of wheel bearing for vehicle and wheel bearing provided with the same

ActiveUS20160221391A1Easy to dropPrevent inflowEngine sealsRolling contact bearingsEngineeringFlange

Owner:ILJIN GLOBAL

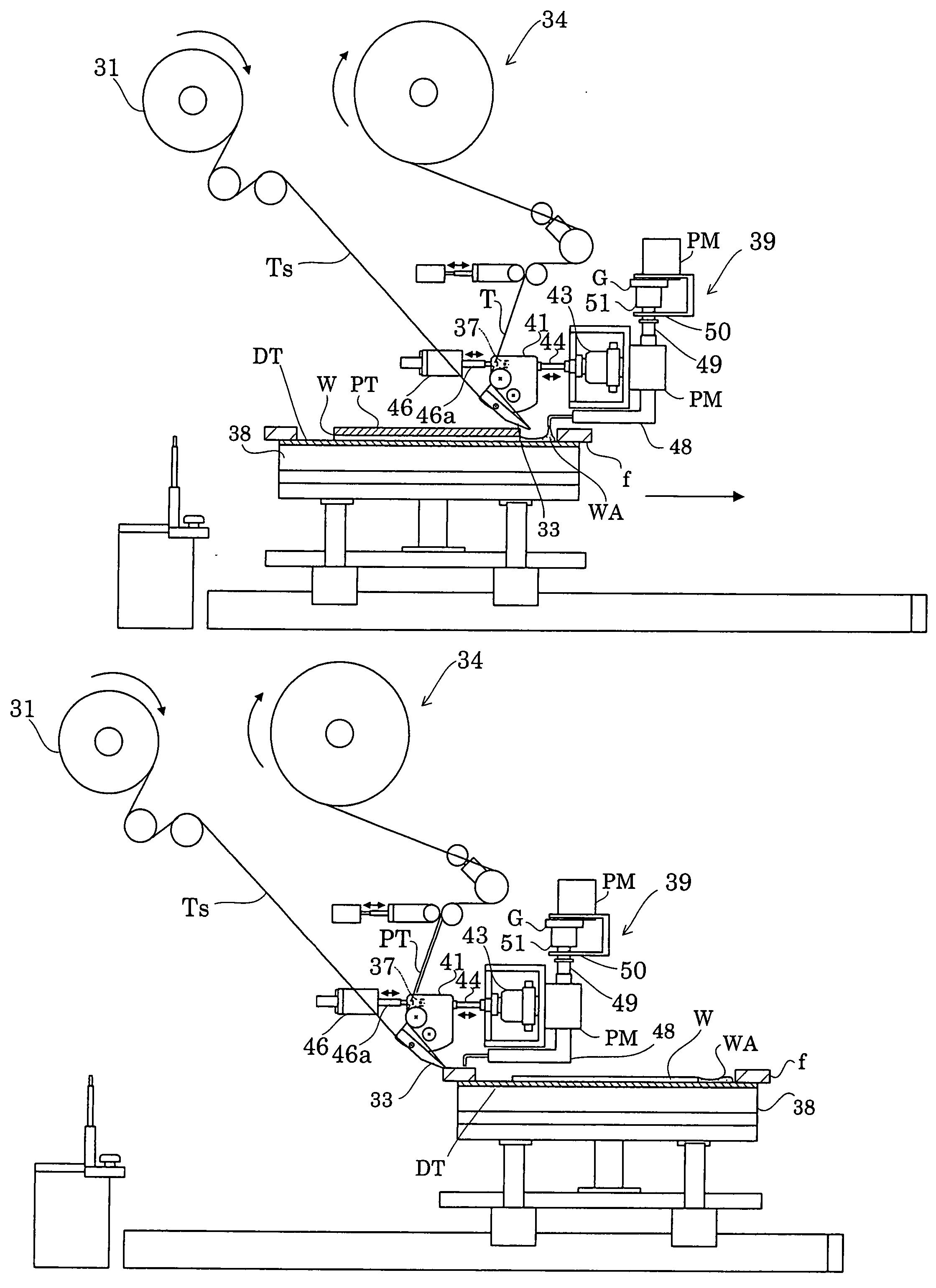

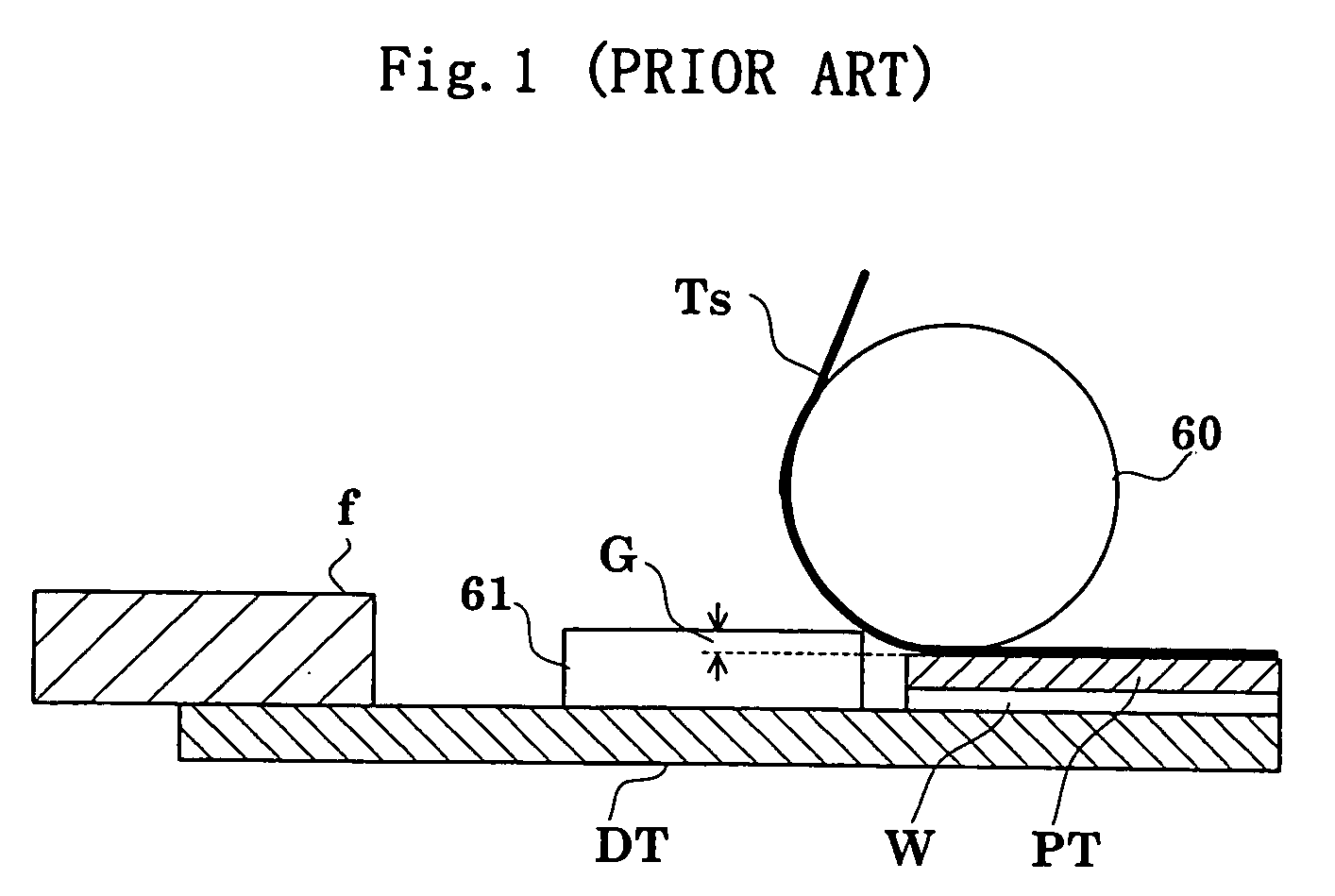

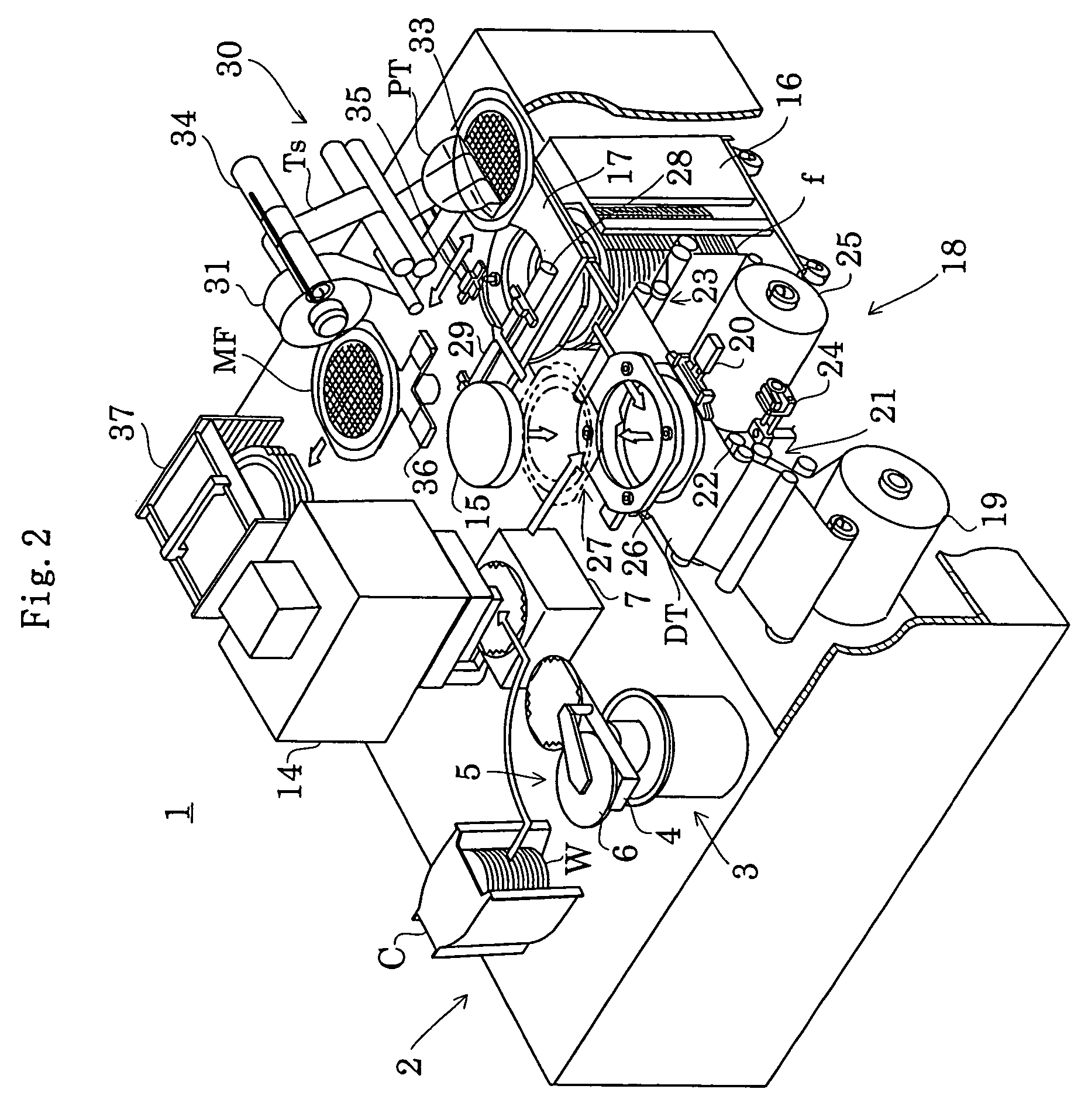

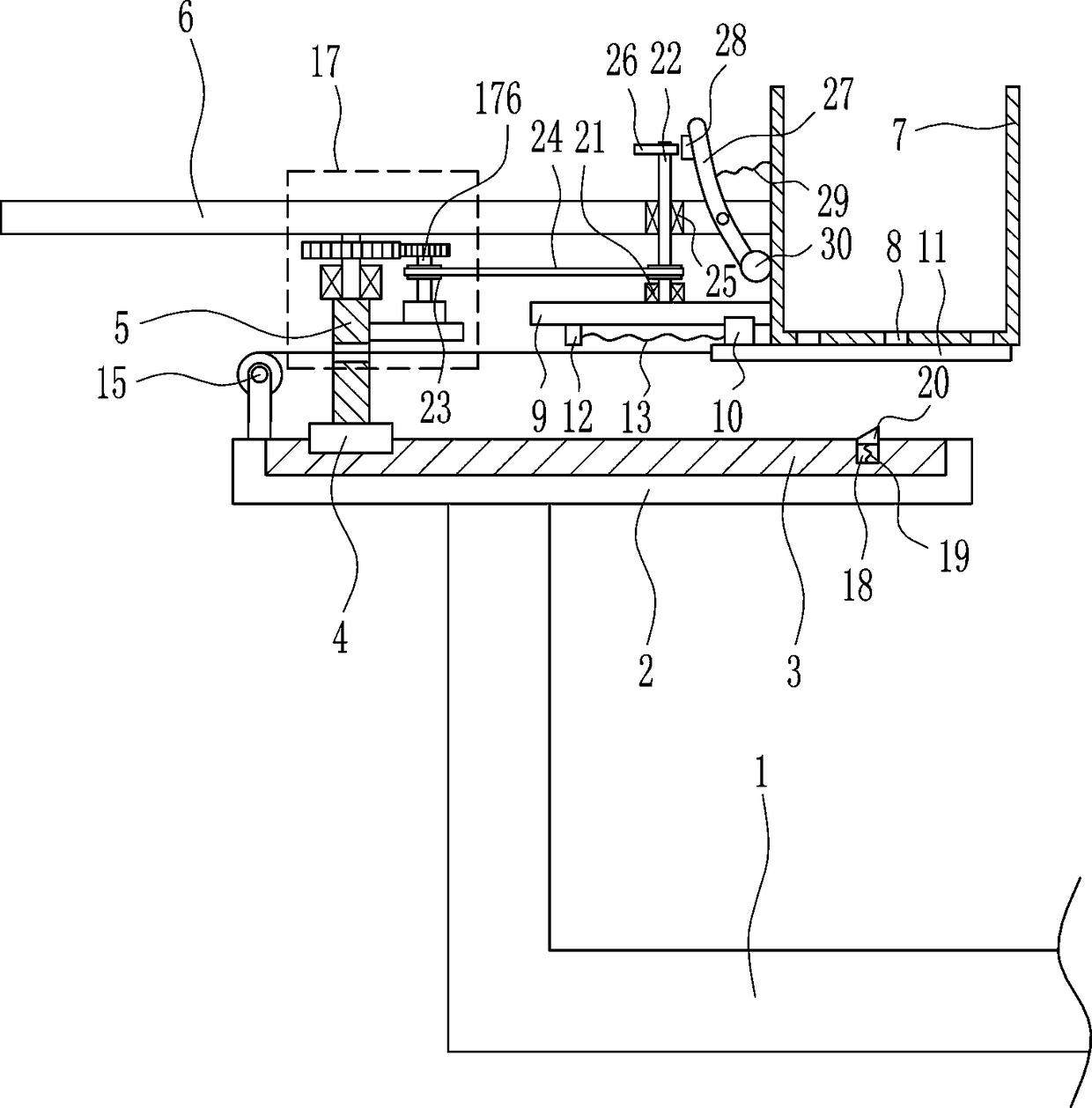

Protective tape separation method, and apparatus using the same

InactiveUS20060068524A1Improve accuracyDirect contact guaranteeLamination ancillary operationsSolid-state devicesDicing tapeEngineering

The invention relates to an apparatus for separating a protective tape joined to a semiconductor wafer. Before joining a separation tape to a protective tape on a surface of a semiconductor wafer held, from its back side, by a ring frame via a dicing tape while pressing the separation tape against the protective tape with the use of an edge member, pure water is dropped from a piston nozzle onto the back side of the dicing tape located in front of a joining start end of the separation tape.

Owner:NITTO DENKO CORP

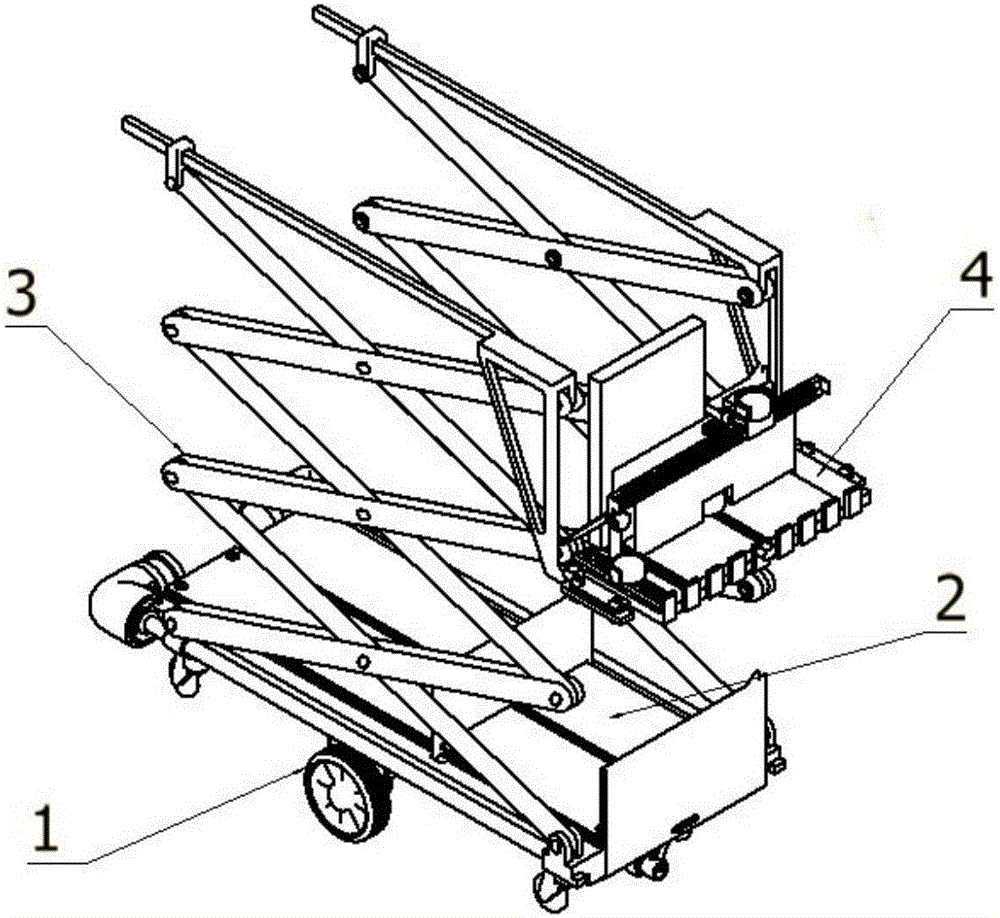

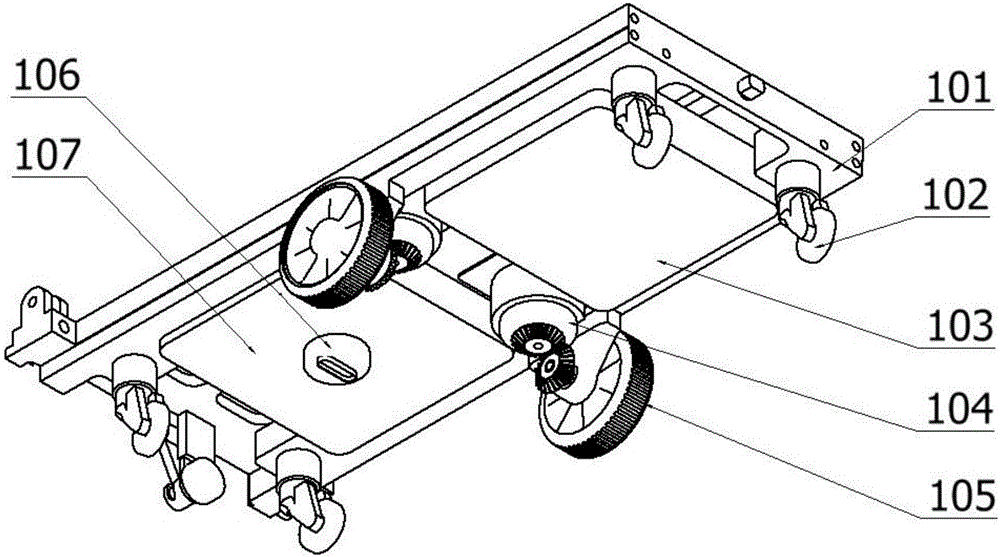

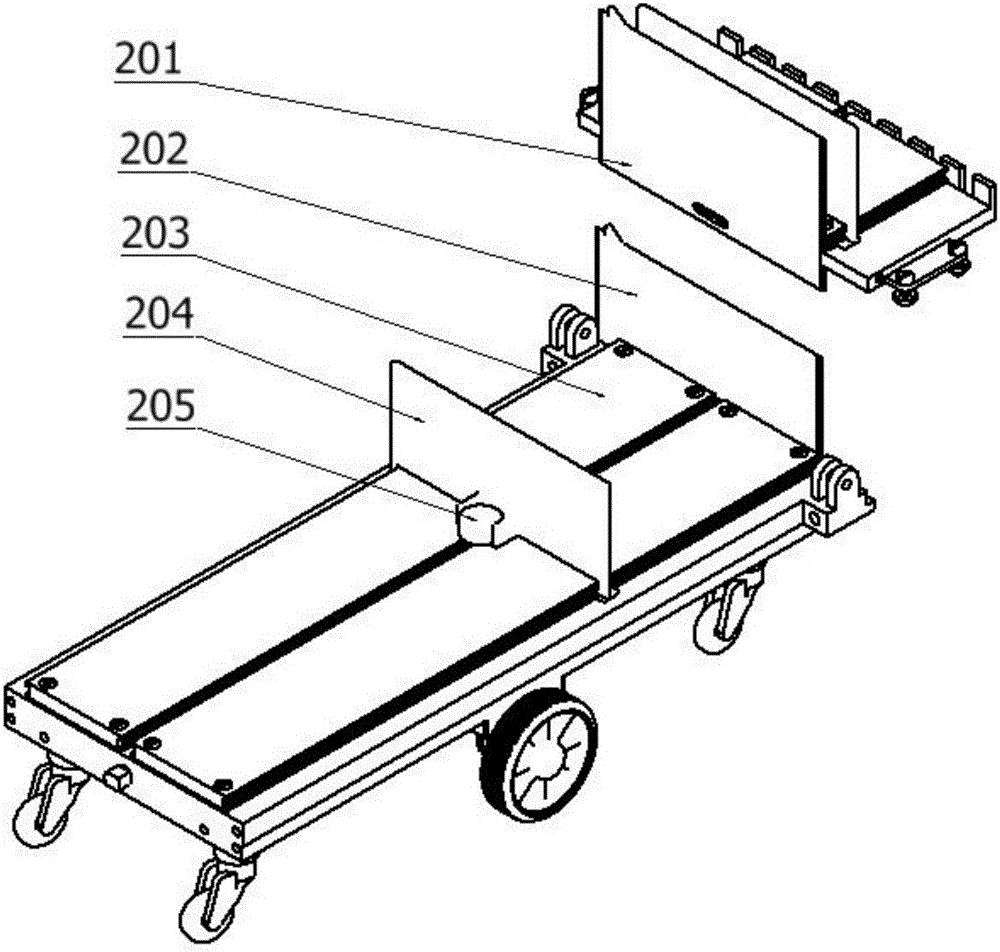

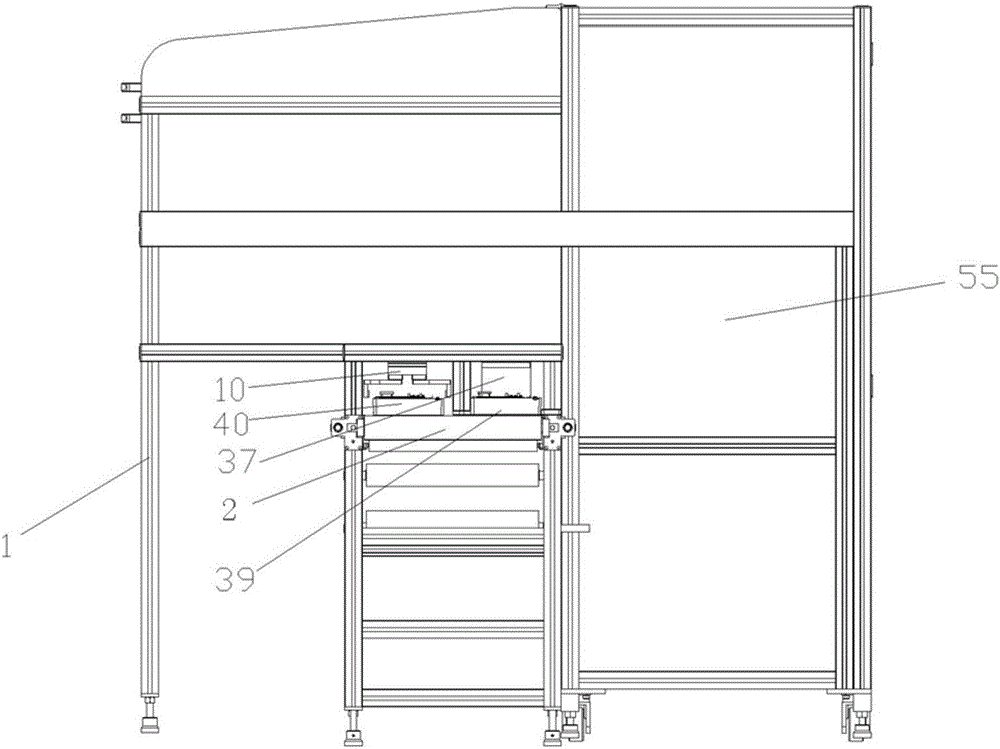

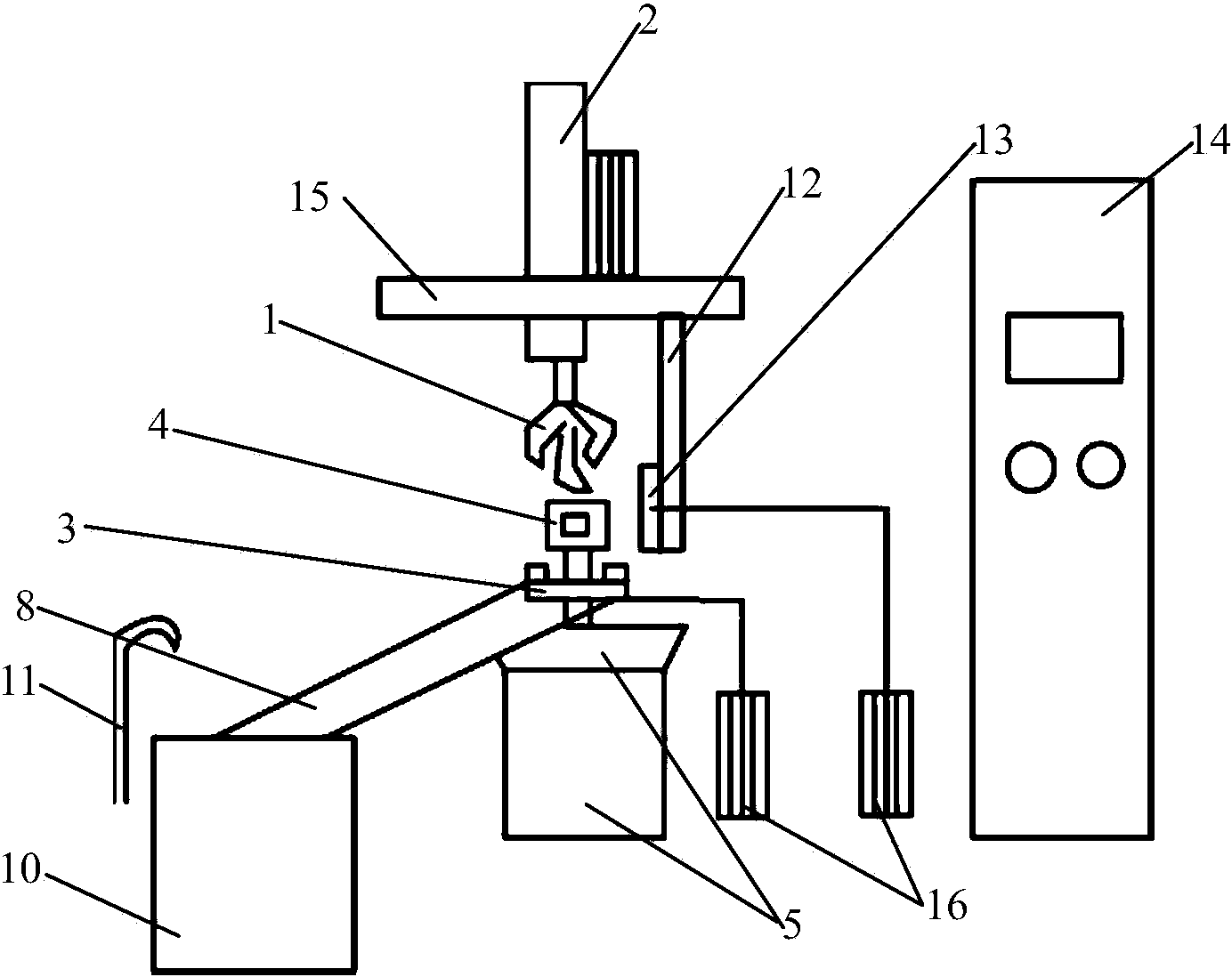

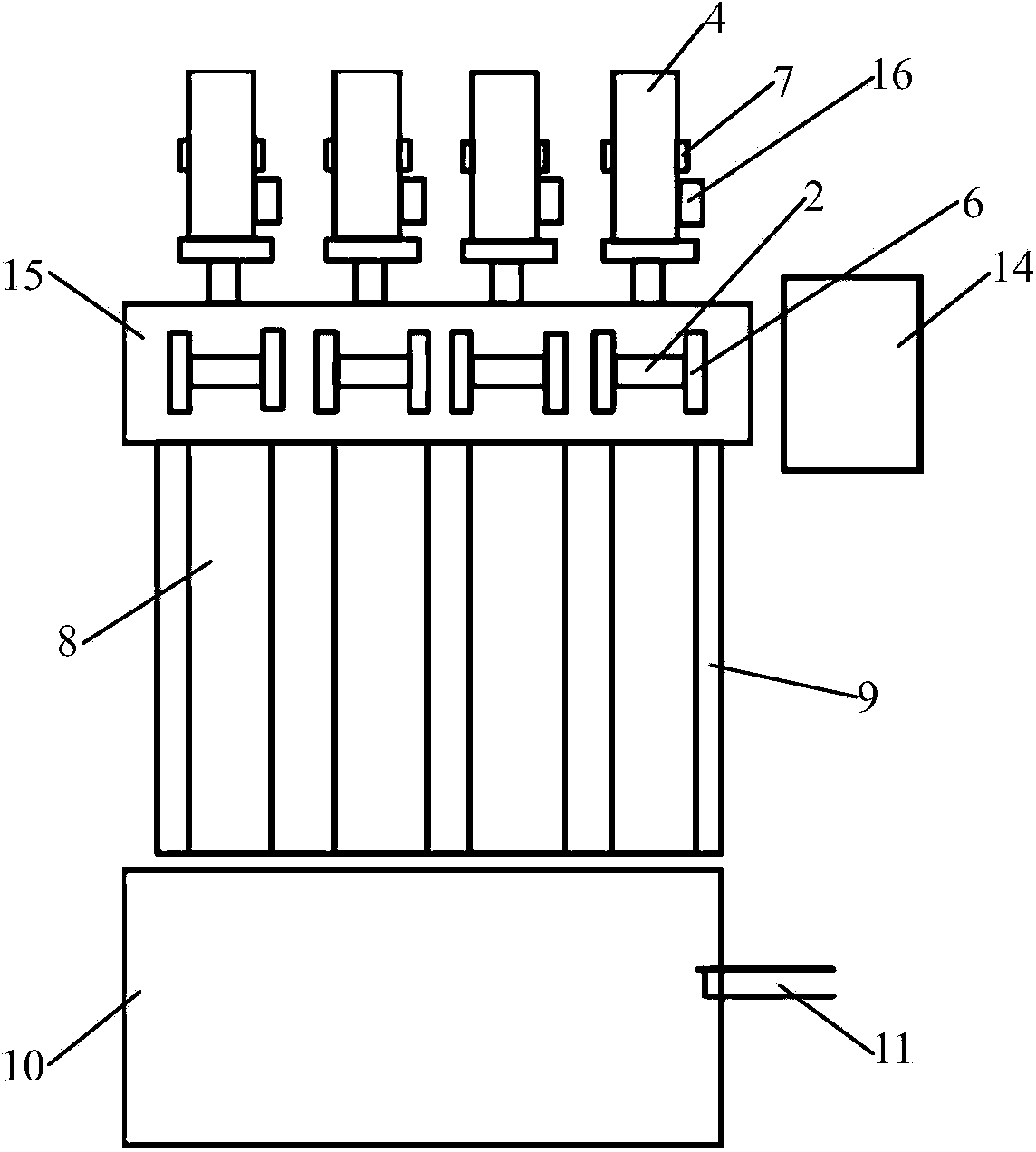

Automatic library book returning robot and book returning system thereof

InactiveCN106032196AReduce operating costsImprove efficiencyConveyorsStorage devicesEngineeringFuture of robotics

The invention discloses an automatic library book returning robot and a book returning system thereof, and belongs to the technical field of robots. The automatic library book returning robot comprises a moving assembly capable of driving the robot to move as a whole. A book loading assembly is arranged at one end of the moving assembly, a lifting assembly is arranged above the moving assembly, a book putting-in-rack assembly is installed on the lifting assembly, and the lifting assembly can drive the book putting-in-rack assembly to move vertically. The book putting-in-rack assembly comprises a lifting table, a book bottom plate and a first book pushing plate capable of sliding vertically on the book bottom plate are arranged on the lifting table, a book pushing device is arranged on the first book pushing plate, a book dividing device is further arranged on one side of the lifting table and can move along the side edge of the lifting table, and a code scanner is further installed on the book dividing device. The book returning robot is reasonable in structural design, easy to operate, capable of automatically rerunning books without manual intervention, high in efficiency and capable of reducing labor cost, emancipating productivity and reducing the operating cost of a library.

Owner:XI AN JIAOTONG UNIV

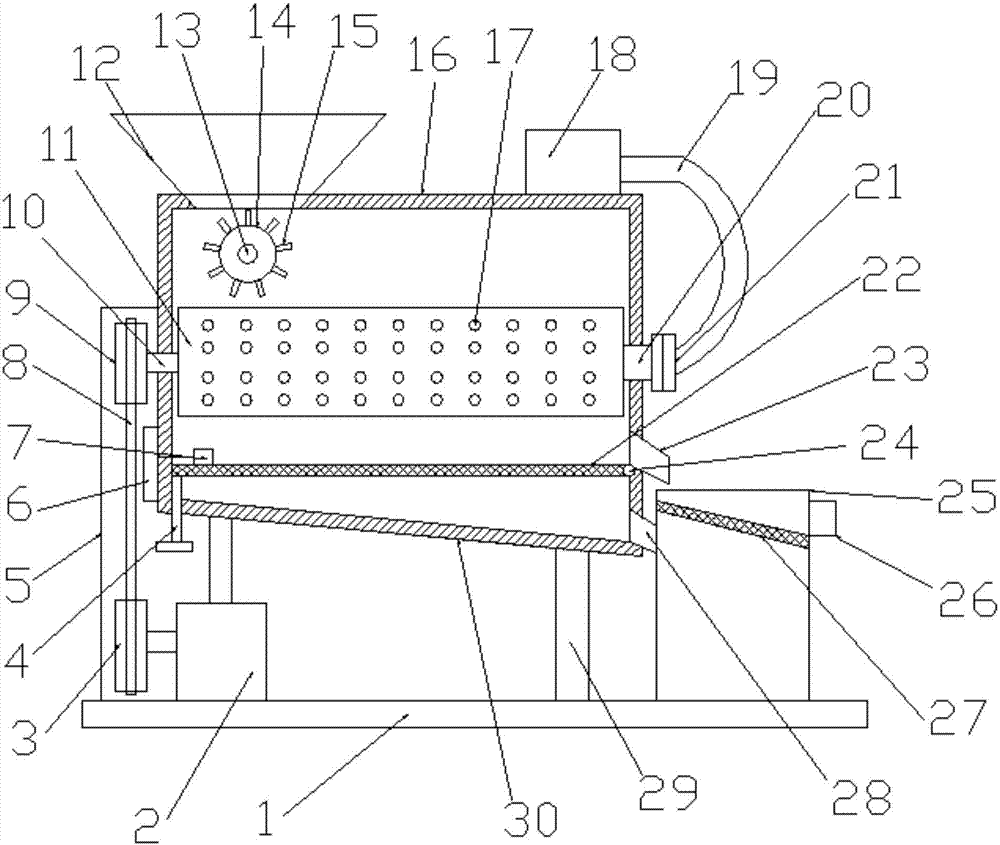

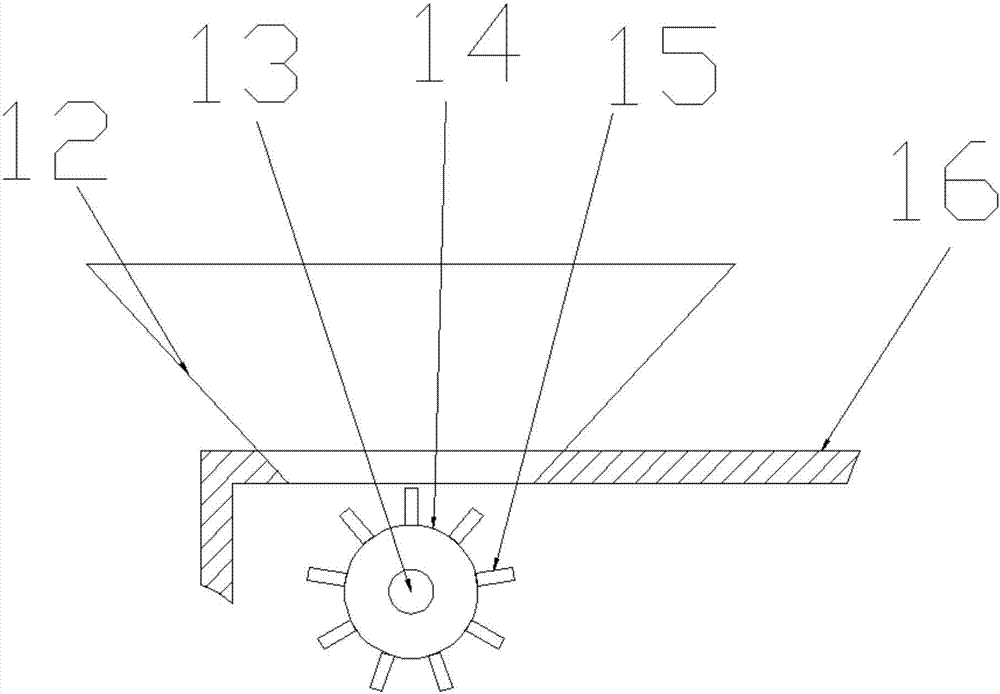

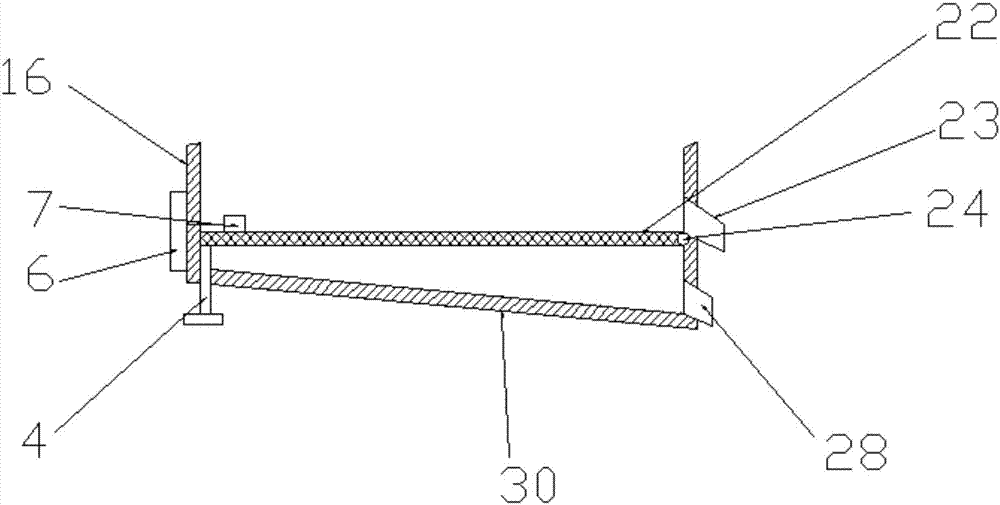

Tea drying, sieving and separating device

InactiveCN107279332AEvenly heatedEasy to dropSievingPre-extraction tea treatmentDry structureTransducer

The invention discloses a tea drying, screening and separating device, which includes a fixed plate, an organic casing is arranged on the fixed plate, and a bracket is arranged at the bottom of the casing. The invention provides a tea drying, screening and separating device, which has a novel structure; The drying structure is ingeniously set, and the material distribution mechanism is set to make the raw materials evenly dispersed. The hot air in the inner chamber of the drying drum dries the tea leaves attached to the surface from the inside to the outside through the vent holes, and the heat is even. The tea leaves are fully heated to ensure the quality and high drying efficiency. In addition, it is convenient to drop the dried tea leaves for screening. The present invention drives the transducer set on the screen through an ultrasonic power supply, and attaches ultrasonic waves to the screen to make the fine powder accept The huge ultrasonic acceleration can suppress the blocking factors such as adhesion, friction, flat drop, wedging, etc., and can greatly improve the efficiency of screening and cleaning. In addition, the invention performs secondary screening to ensure the high quality of finished products.

Owner:银川金帮手信息科技有限公司

Efficient gravel screening water recycling device

The invention discloses an efficient gravel screening water recycling device which comprises a feeding pipe, a grid, a liquid level meter, a tank, a water inlet pipe, a flow meter, a spray head, a rotating shaft, a camera, a timer, impellers, a sieve plate, a vibration exciter, a coarse sand discharging pipe, a fine sand discharging pipe and a return pipe, wherein the feeding pipe is arranged at the top of the tank, the grid is arranged obliquely in the feeding pipe, the tank is communicated with the water inlet pipe, the spray head is arranged at the outlet end of the water inlet pipe, the rotating shaft is arranged in the tank, the impeller is mounted on the rotating shaft which is connected with an external motor, the sieve plate is arranged obliquely in the tank, the lower surface of the sieve plate is provided with the vibration exciter, and the upper surface of the sieve plate is provided with a friction strip. The sieve plate comprises a first sieve plate and a second sieve plate, a stirring shaft is arranged between the first sieve plate and the second sieve plate and provided with a plurality of groups of impellers of different sizes, the bottom end of the tank is connected with one end of the return pipe, and the other end of the return pipe is communicated with the water inlet pipe. The efficient gravel screening water recycling device screens gravels, improves working efficiency, saves time and labor, and is simple in structure, convenient to use and favorable for popularization.

Owner:HUNAN WANGLONG ENTERPRISE MANAGEMENT CONSULTING CO LTD

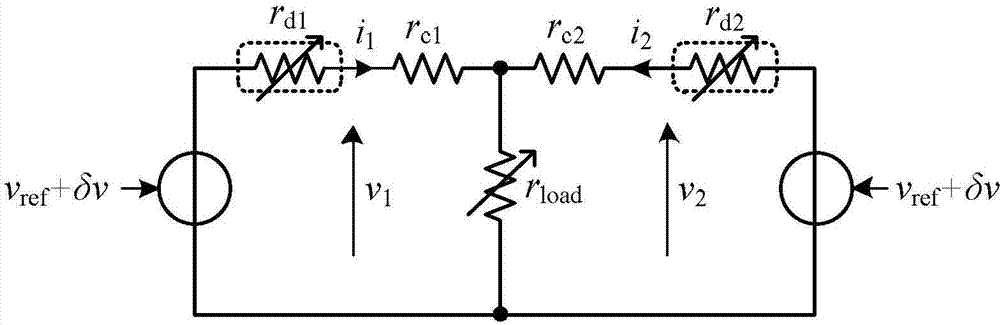

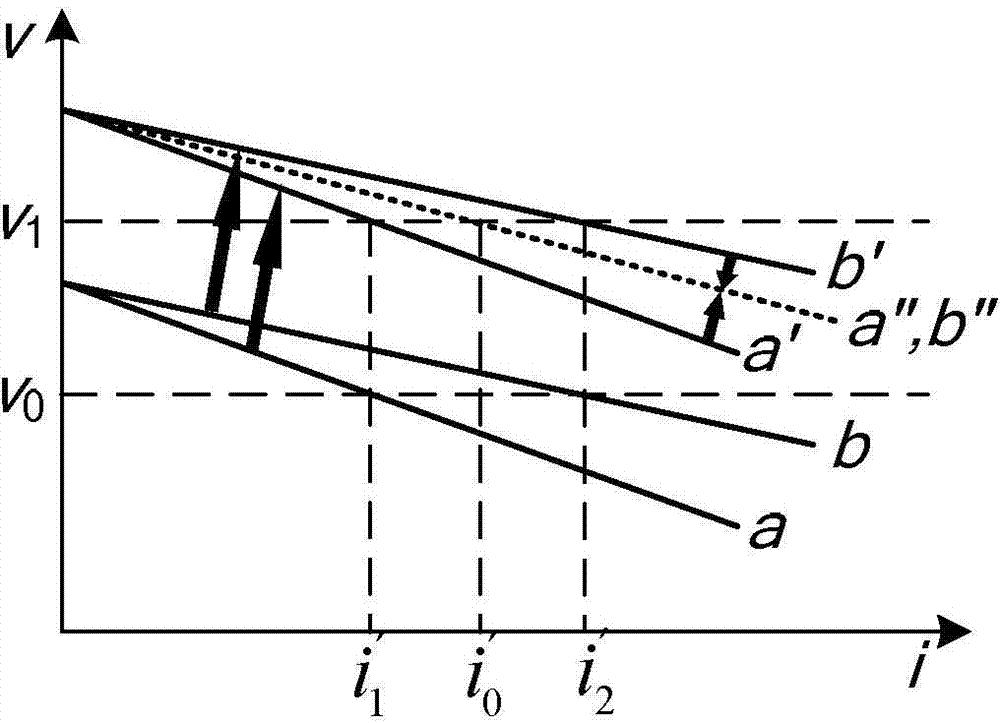

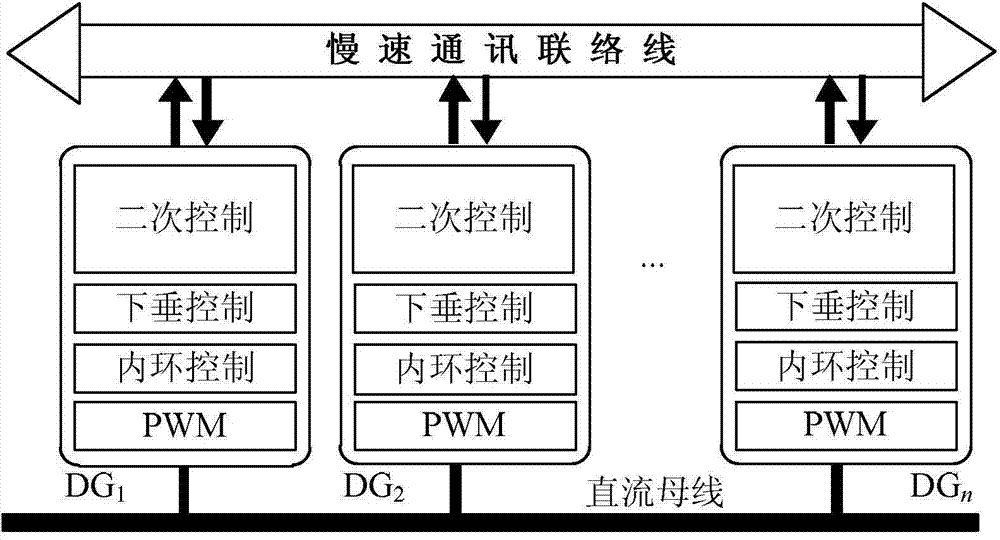

Droop control method of DC converter with function of secondary adjustment of adaptive impedance

ActiveCN104753059AEasy to dropImprove homeostasisDc source parallel operationDroop speed controlLow speed

The invention belongs to the technical field of droop control of DC converters, relates to a droop control method of a DC converter with a function of secondary adjustment of adaptive impedance, and aims to solve the problems that distributed generating unit cable impedance difference causes poor droop current homogenization effect to the DC distributed power supply system and the DC micro grid based on droop control and the parallel DC converters is low in steady state and dynamic current homogenization precision. The method has the advantages that the steady state and dynamic current homogenization precision of the parallel DC converters in the distributed DC power supply system and the DC micro grid based on droop control is improved; parameters, such as voltage, current and droop coefficient, of the parallel converters are transmitted in real time through low-speed communication, the droop coefficient is adjusted in self-controllers of the parallel converters, and finally external characteristic impedances of the parallel converters are equalized; droop curves are subjected to shifting adjustment, and bus voltage drop caused by droop control is improved.

Owner:HARBIN INST OF TECH

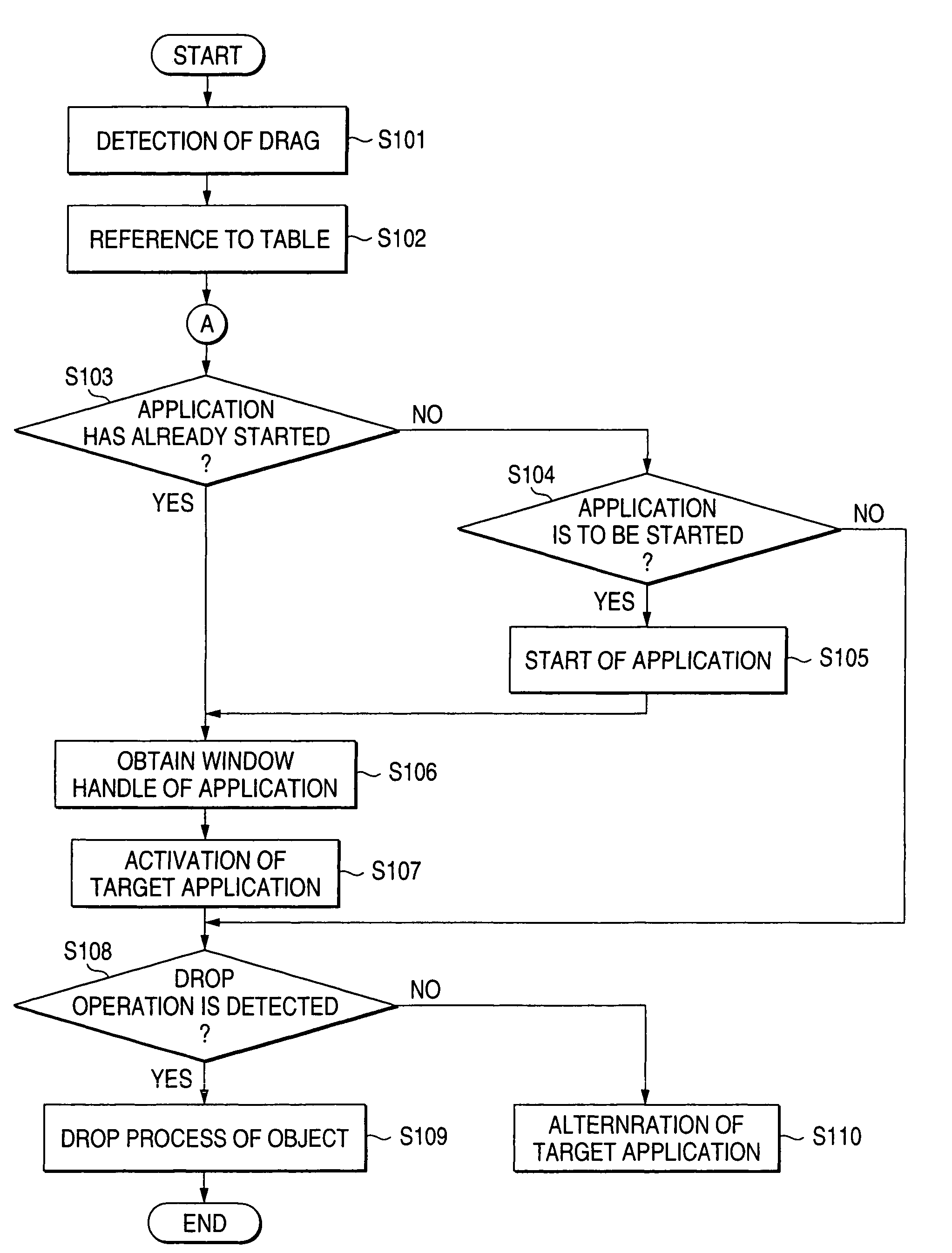

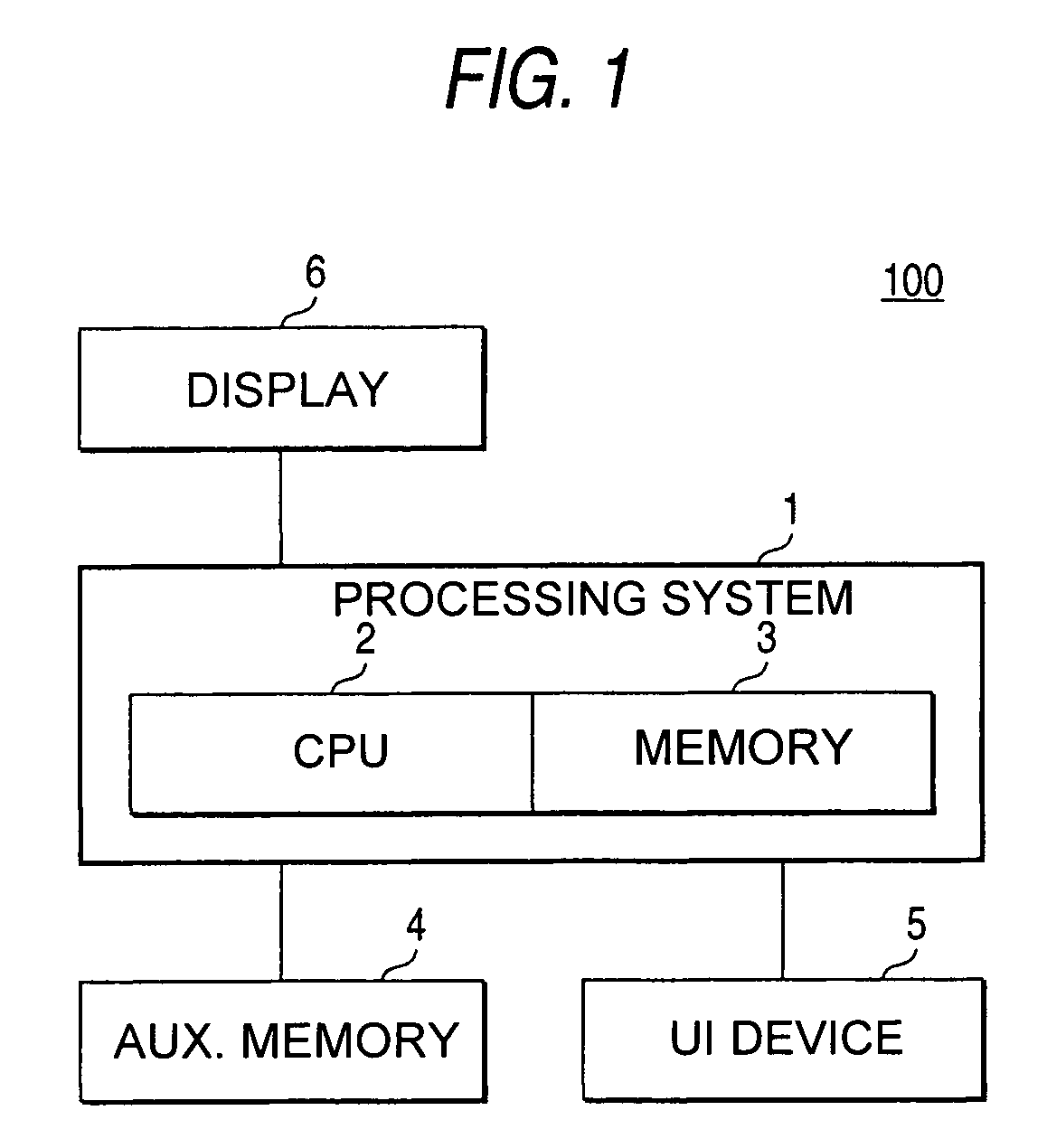

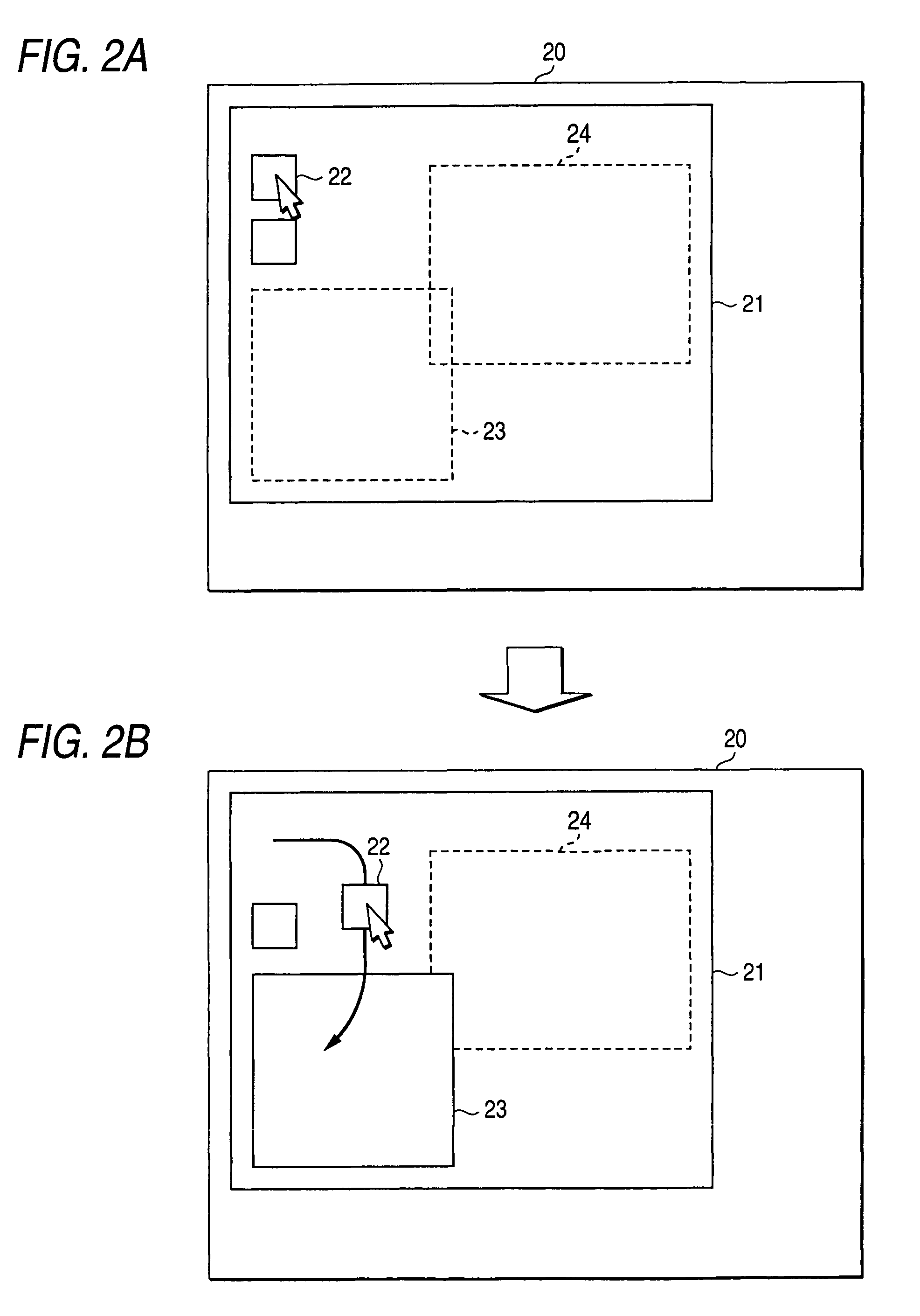

Display control method and display control processing system for concealed window on desktop

InactiveUS7458032B2Easy to dropEasily decideCathode-ray tube indicatorsDigital output to display devicePointing deviceComputer science

The object of the present invention is to make it possible to drop easily an object in a window as a destination of drop by an operator even if the window as the destination of drop is concealed on the desktop before start of the drag. When an object 22 displayed in a window 21 is dragged by a pointing device and then dropped in another window 23, start of a drag operation is detected, and the window 23 that corresponds to an application as a destination of drop of the dragged object 22 is displayed on a foremost side of a multi-window environment to activate.

Owner:FUJIFILM CORP

Environment-friendly straw feed manufacturing equipment

The invention discloses environment-friendly straw feed manufacturing equipment. The equipment comprises a feeding pipe, a box body, an electric telescopic rod, a camera, a stir-frying knife, a pressing plate, an air blower, a crushing box, a heater, a drying box and a rotary conical roller, wherein the feeding pipe is arranged on the top of the box body, the electric telescopic rod is arranged on the top of the box body, and the pressing plate is arranged at the bottom of the electric telescopic rod; a cutter is arranged on the lower surface of the pressing plate, a rotating shaft is arranged in the box body, and the stir-frying knife is arranged at the bottom of the rotating shaft; a pressure bearing plate is arranged in the box body, a cam is arranged at the bottom of the pressure bearing plate, and a timer is arranged on the outer wall of the box body; the top of the box body is communicated with the air blower, an inclined guide plate is arranged below the pressure bearing plate, and the crushing box is arranged at the outlet end of the inclined guide plate; the bottom of the crushing box is connected with the drying box, and a discharging pipe is arranged at the bottom of the drying box. The equipment guarantees reasonable utilization of straw, straw feed particles can be conveniently stored, the breeding feed cost is reduced, and the equipment is simple in structure, convenient to use and easy to popularize.

Owner:邹铁梅

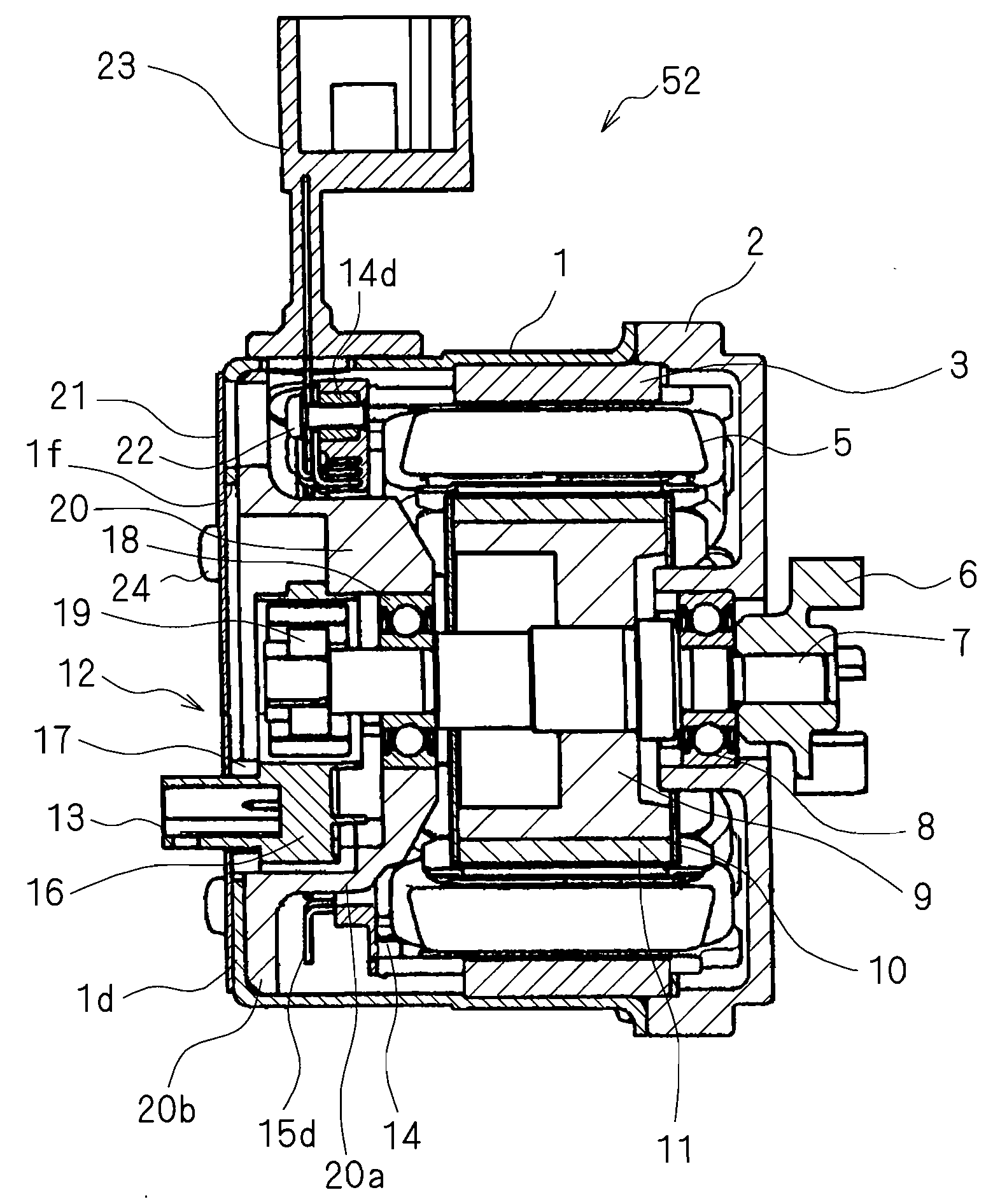

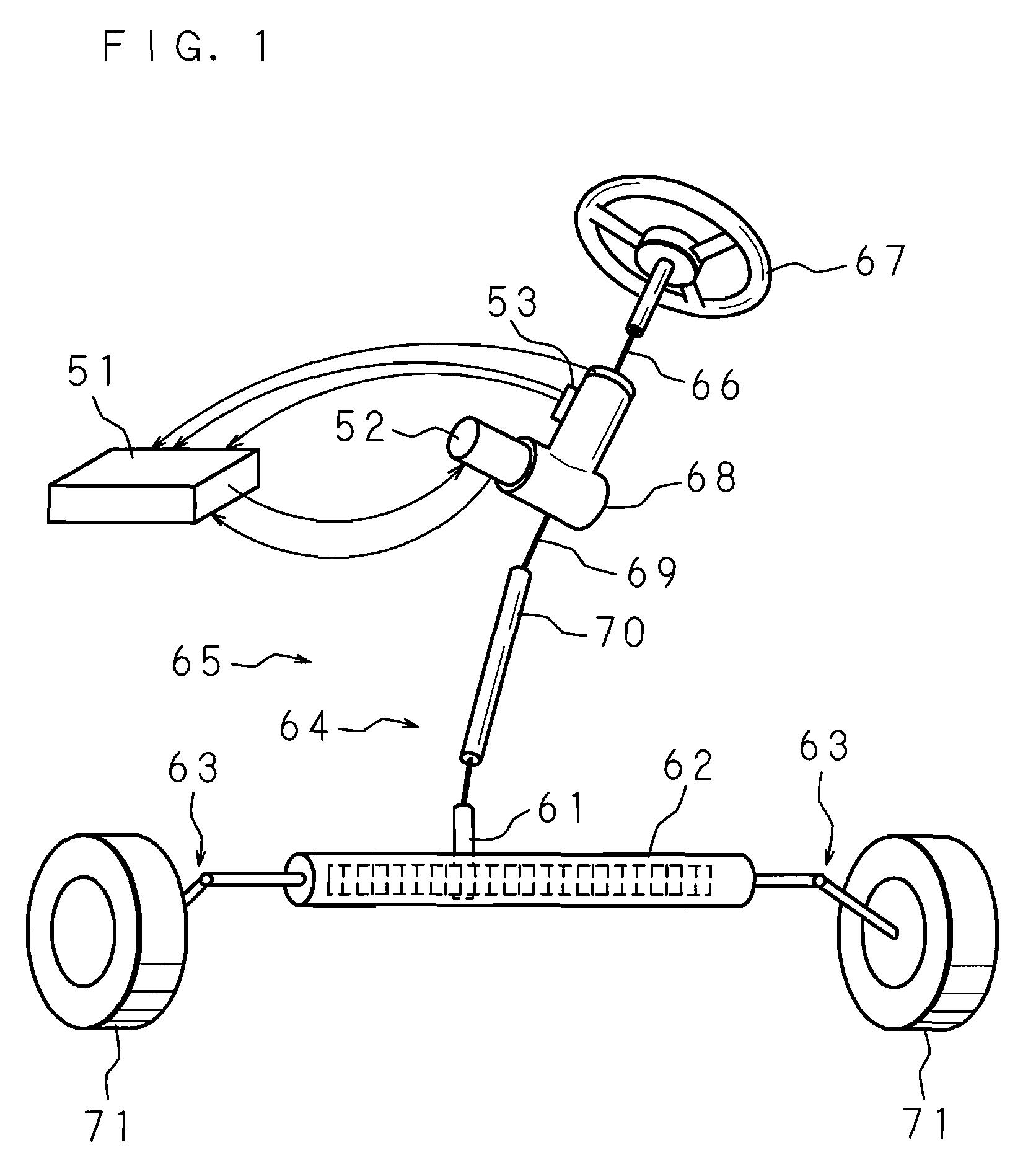

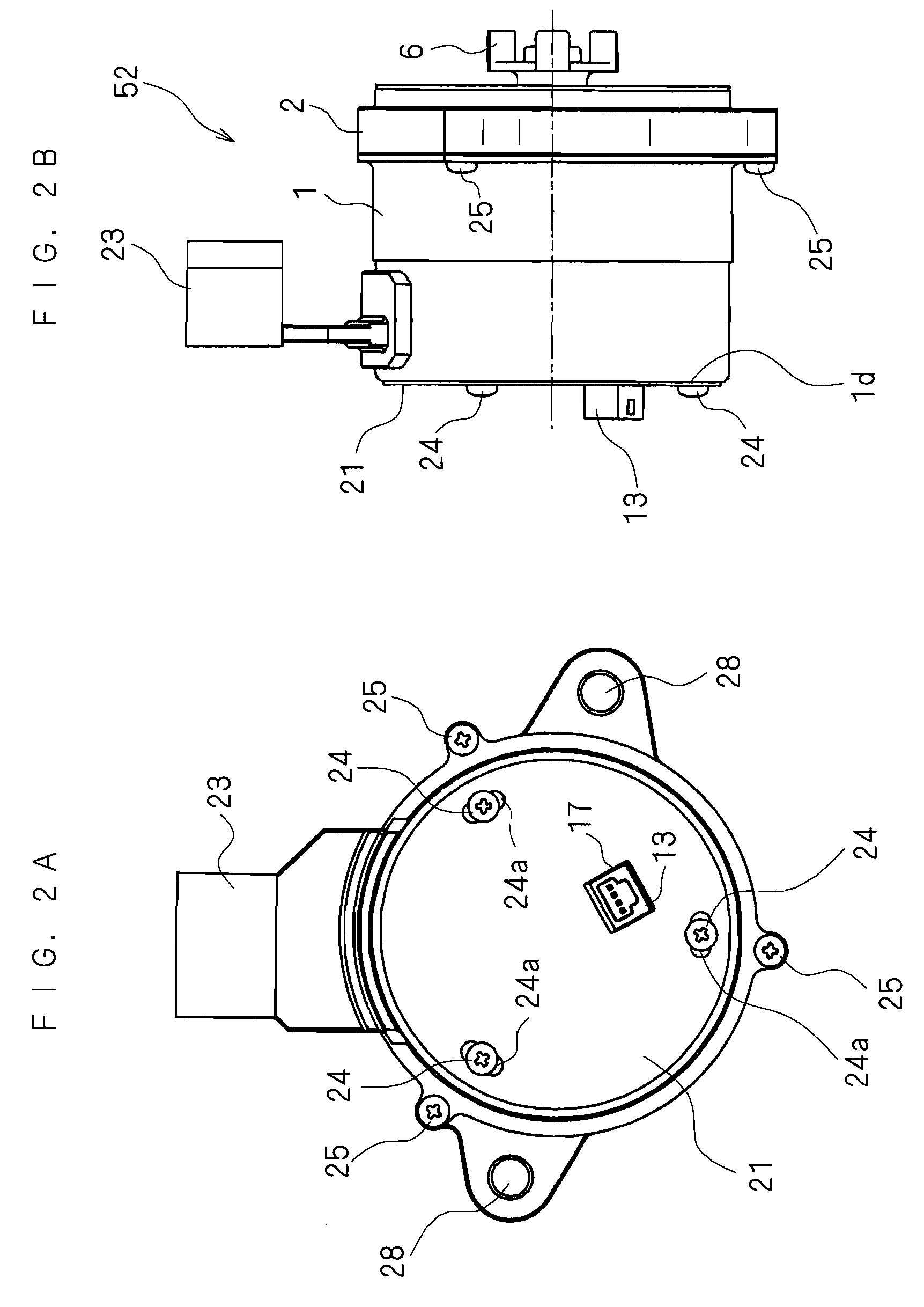

Electric power steering apparatus

InactiveUS20080017438A1Easily brokenEasy to dropWindingsManufacturing dynamo-electric machinesElectric power steeringBrushless motors

In an electric power steering apparatus which includes a brushless motor composed of a cylindrical motor case with a bottom; a bracket for covering an opening of the motor case; an end housing for supporting a non-output-shaft side bearing located on one side; a bus bar housing in a ring shape for storing a plurality of bus bars; and a rotational angle sensor, and drives the brushless motor with a flow of current according to the detected steering torque, the end housing has a cylindrical section with a flange surrounding the end on one side and is inserted into the motor case from the opening until the flange comes into contact with the bottom of the motor case, the bus bar housing is placed to surround the outer circumferential surface of the cylindrical section of the end housing, and the rotational angle sensor is placed in the cylindrical section.

Owner:JTEKT CORP

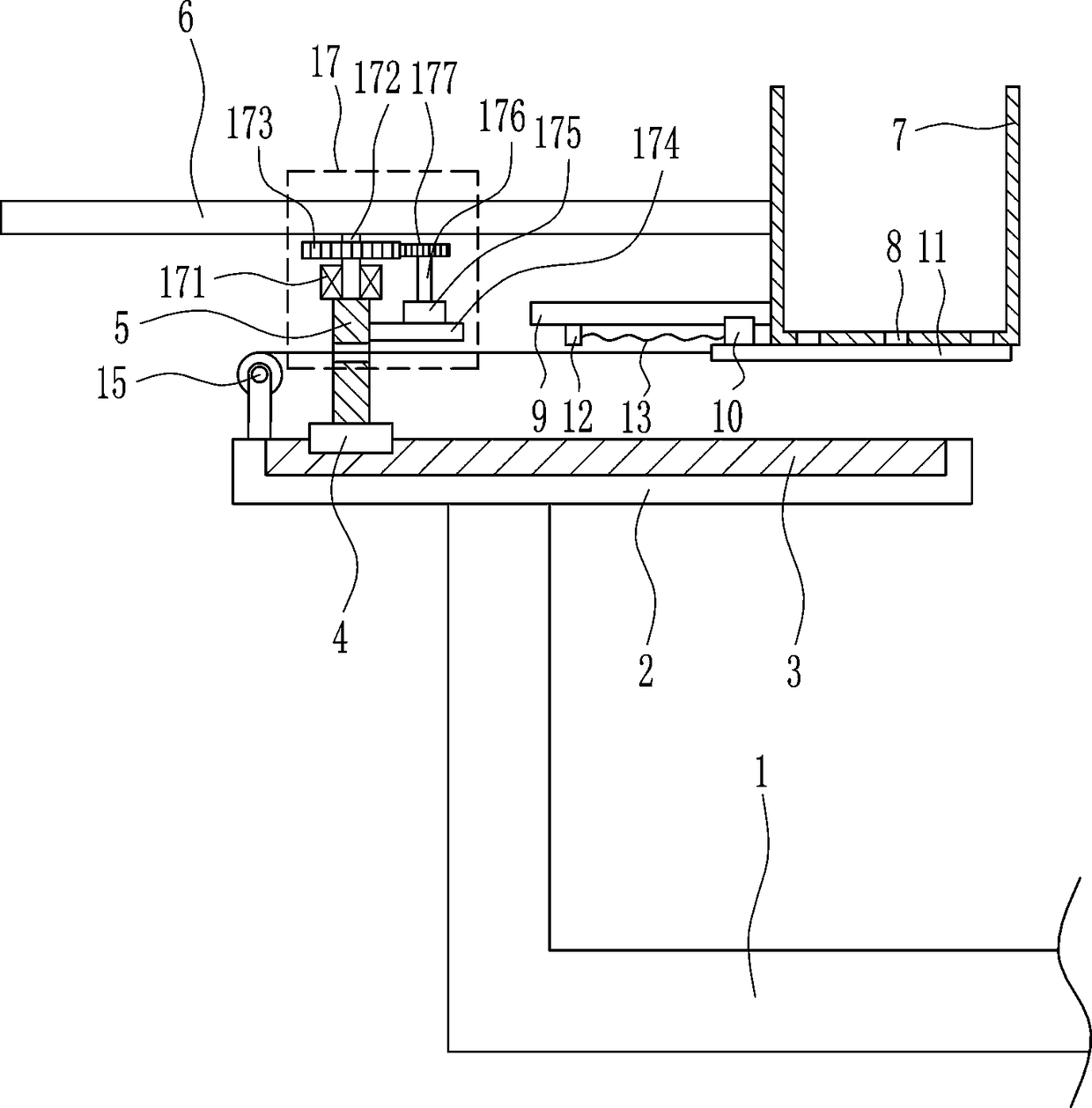

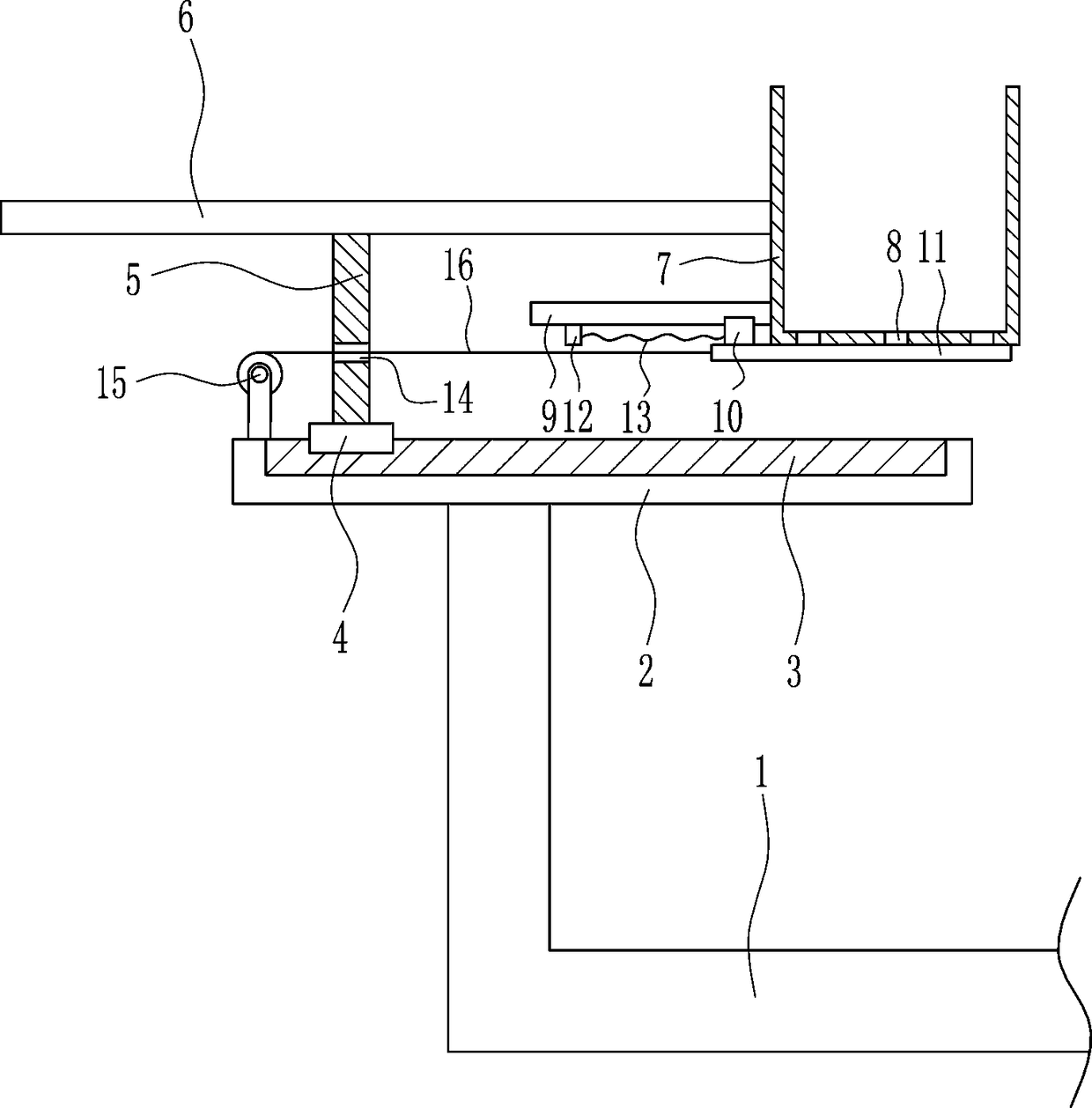

Fodder feeding equipment for ornamental fish for gardens

ActiveCN108112527ADistributionEasy to dropClimate change adaptationPisciculture and aquariaEngineeringFodder

The invention relates to feeding equipment, in particular to fodder feeding equipment for ornamental fish for gardens. The fodder feeding equipment for the ornamental fish for the gardens is capable of realizing feeding in a dispersed mode. The fodder feeding equipment provided by the invention comprises a mounting plate, a first sliding rail, a first sliding block, a support rod, a connecting rod, a frame body, a second sliding rail, a second sliding block, a first baffle plate, a connecting block, a first spring and the like, wherein the mounting plate is arranged at the top of the left wallof a water pool, the first sliding rail is embedded in the center of the top of the mounting plate, the first sliding block is connected to the first sliding rail in a sliding mode, the support rod is connected to the top of the first sliding block, the connecting rod is connected to the top end of the support rod, and the frame body is connected to the right end of the connecting rod. Accordingto the fodder feeding equipment, the effect of carrying out feeding in a dispersed mode is achieved, the frame body continuously rotate clockwise and counterclockwise so that fodder can be fed in a more dispersed mode, a plastic ball continuously knocks on the frame body so that the fodder in the frame body can drop down more quickly, and first through holes can also be prevented from being blocked.

Owner:XINCHANG LINYU MACHINERY TECH CO LTD

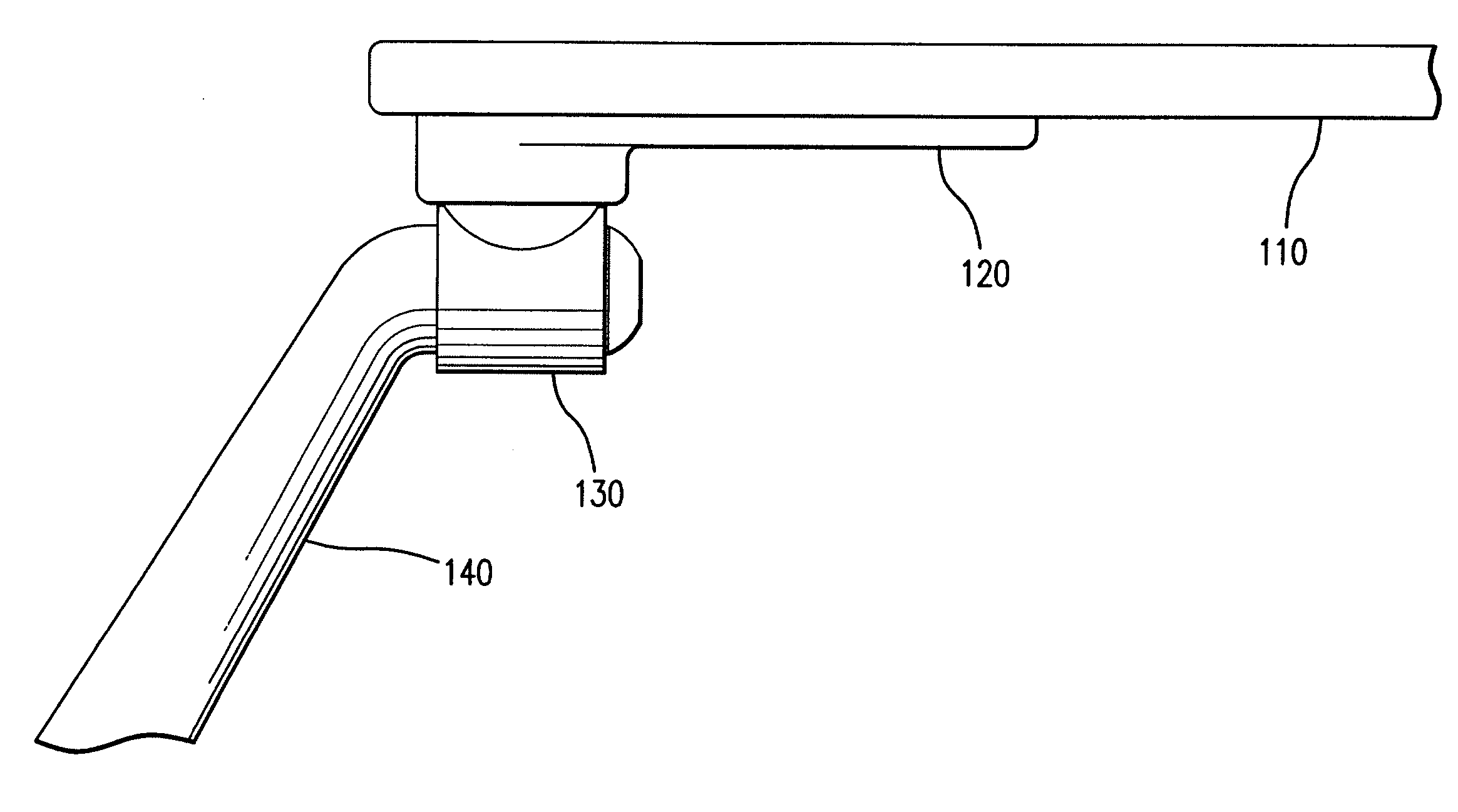

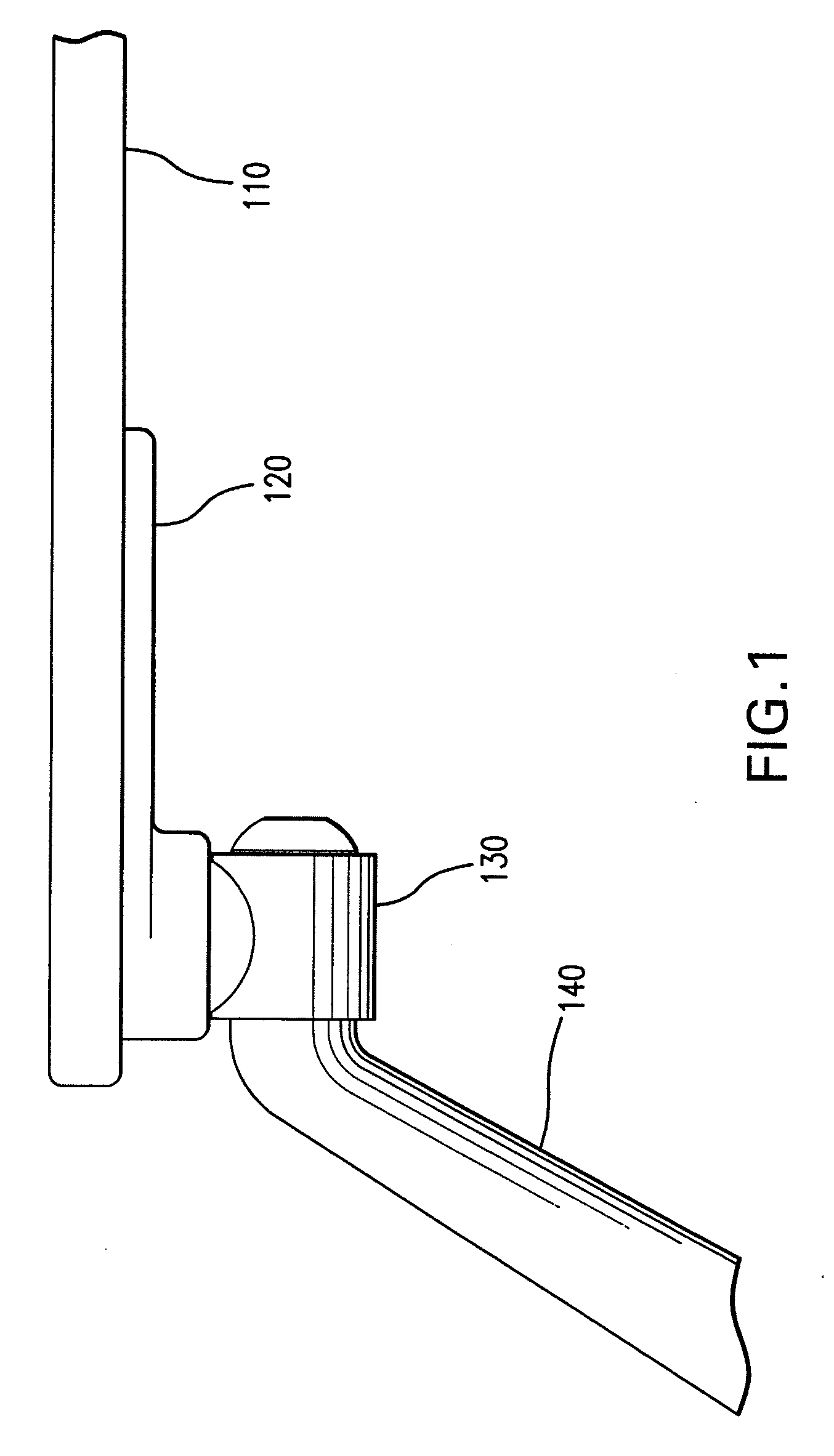

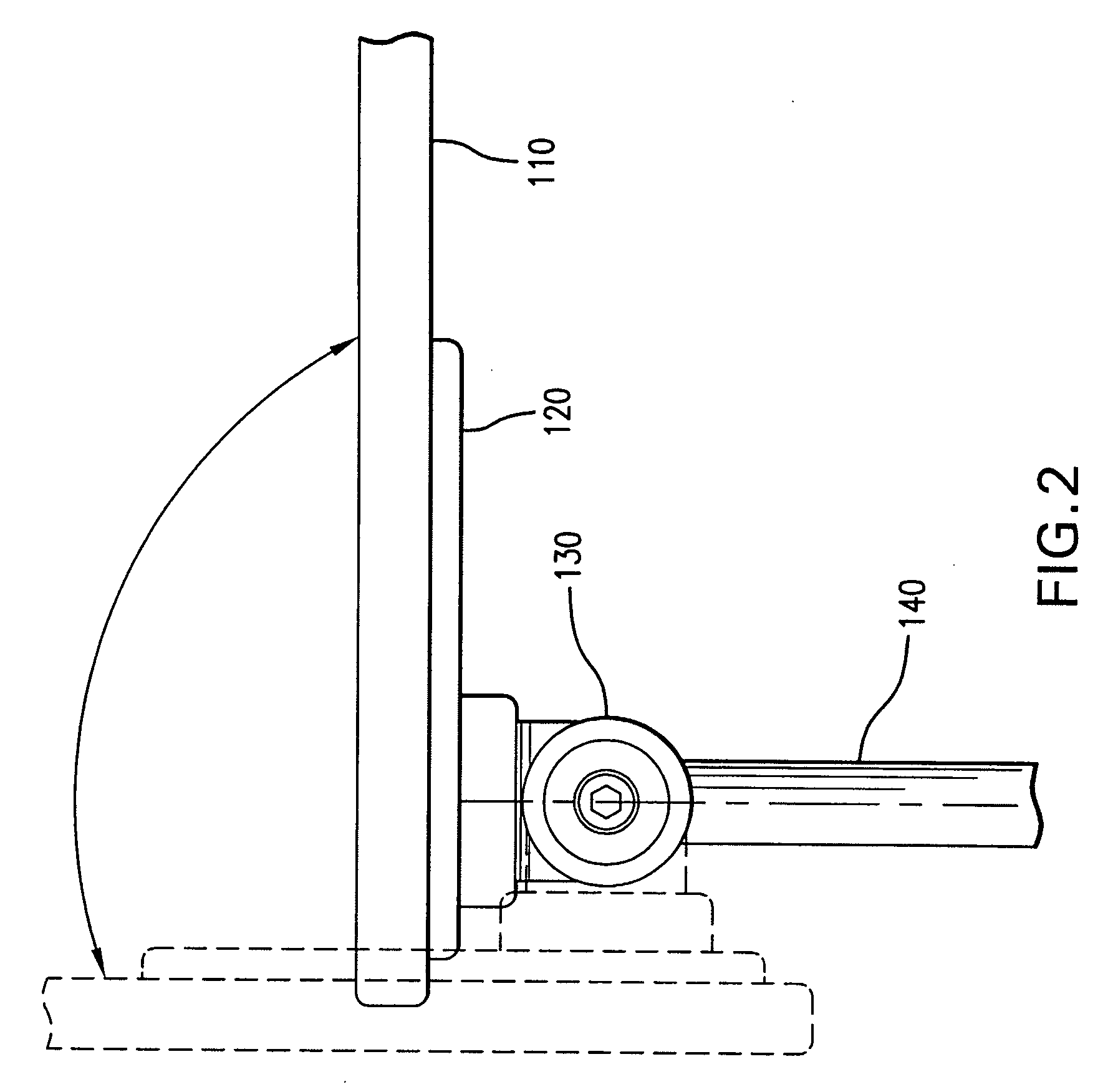

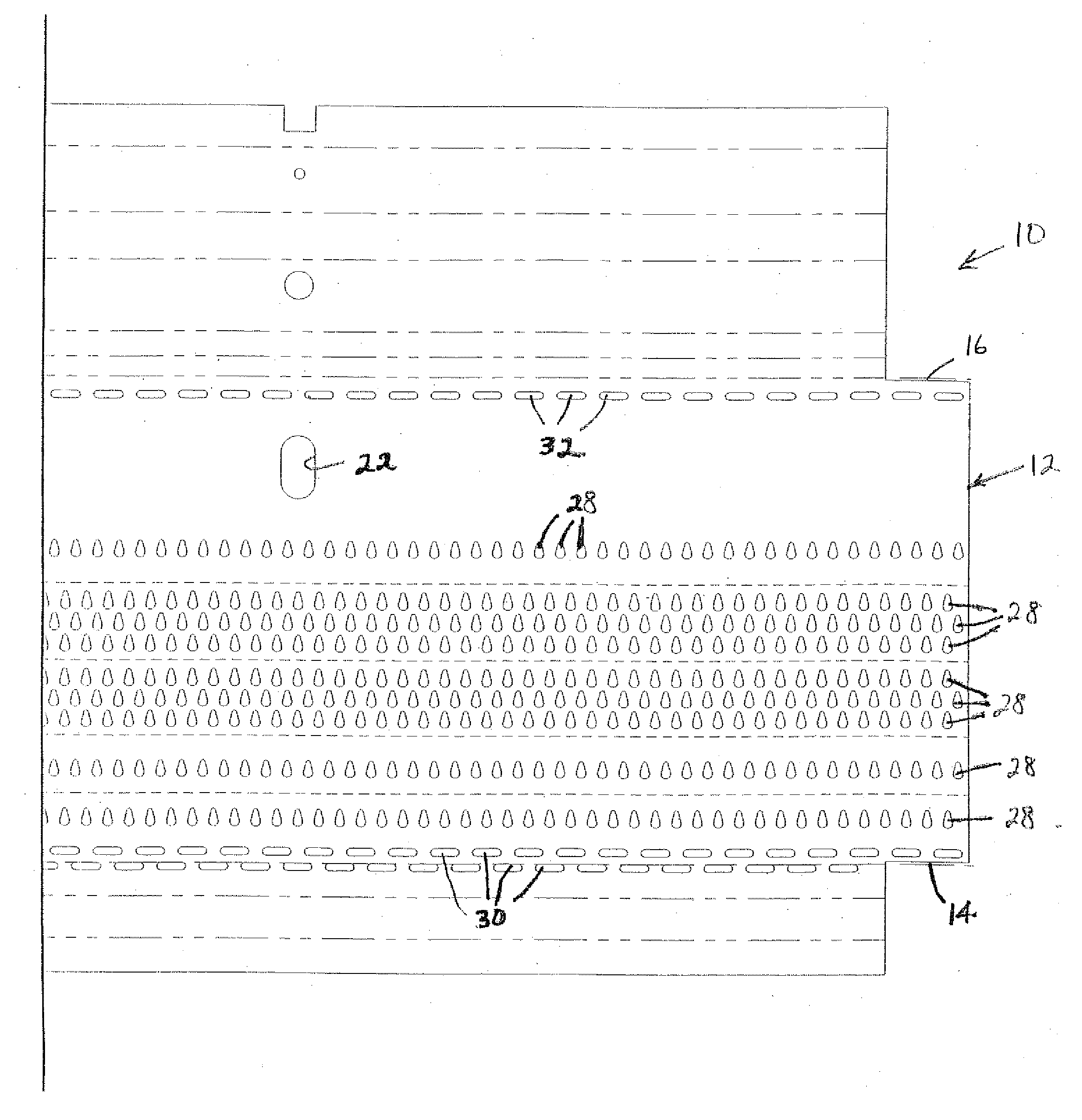

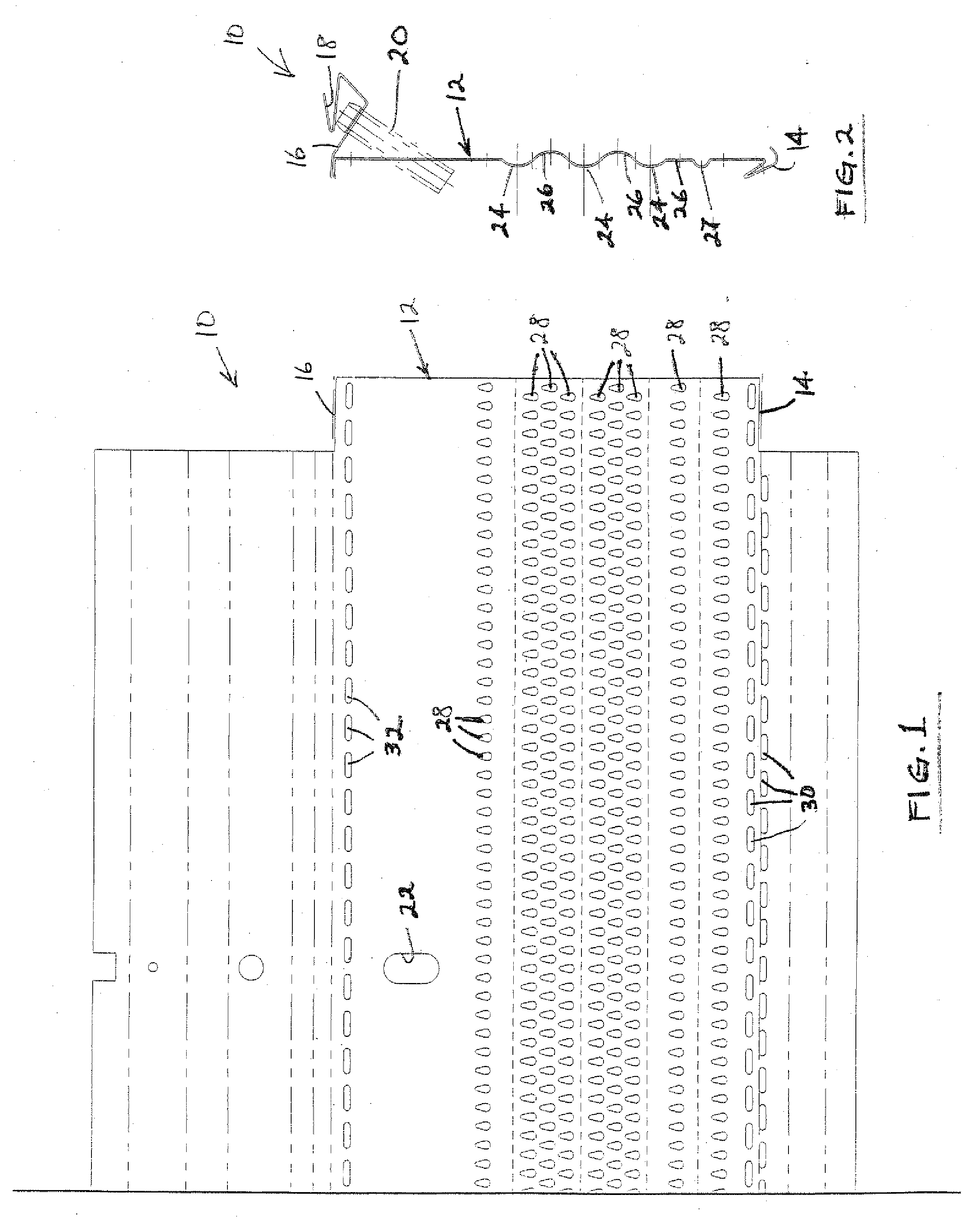

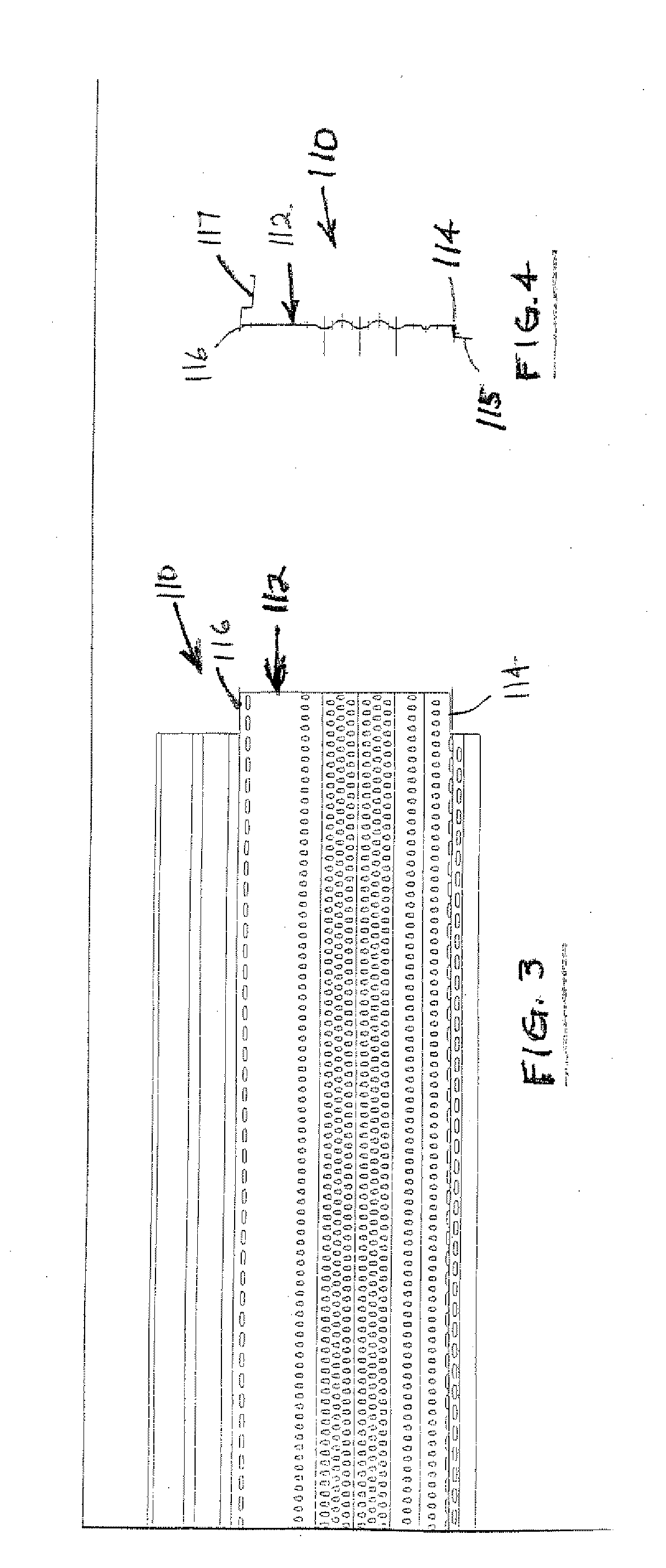

Writing tablet

A movable writing tablet for a chair comprising of a tablet mounted to a tablet support. A double rotating hinge connects to the tablet and support on one end, and is connected to a support block on the other end. The other end of the support block is connectable to a stack chair. The double rotating hinge enables the writing tablet to rotate about a horizontal and a vertical plane such that it can be positioned in the open or closed position. The tablet can be positioned in a vertical position adjacent to the support block allowing vertical stacking of chairs equipped with similar writing tablets. When the writing tablet is in the closed position it enables vertical stacking of chairs by automatically shifting from its vertical to a tilted position, allowing the tablets to stack on top of each other. Vertical stacking of two or more chairs allows their associated writing tablets to “nest” one on top of the other.

Owner:CENT FOR DESIGN RES

LED (Light-Emitting Diode) box body, LED display screen and maintenance tool

ActiveCN102314814AEasy to debugQuick releaseCasings/cabinets/drawers detailsIdentification meansLED displayEngineering

The invention discloses an LED (Light-Emitting Diode) box body, which approximately comprises a module and an installing frame, wherein the module comprises a veil, a PCB (Printed Circuit Board) lamp board and a bottom shell, and the bottom shell of the module and the installing frame are magnetically adsorbed and fixed; the veil, a PCB lamp board and the bottom shell are fixedly connected; and a bolt is arranged on the veil of the module, and a clamping space is left between a screw cap of the bolt and the outer surface of the veil. In an LED display screen disclosed by the invention, by adopting a magnetically adsorbing and fixing structure of the bottom shell of the module and the installing frame, the module is more convenient and rapider to install, the work efficiency is improved, and meanwhile, the problem that the bolt is easy to fall when the bolt is assembled and disassembled is solved; and a structure that the clamping space is left between the screw cap of the bolt and the outer surface of the veil is adopted by the invention, so that a maintenance tool can be conveniently utilized for clamping the bolt on the veil of the module, the module can be more conveniently assembled and disassembled, and the work efficiency is further improved.

Owner:UNILUMIN GRP

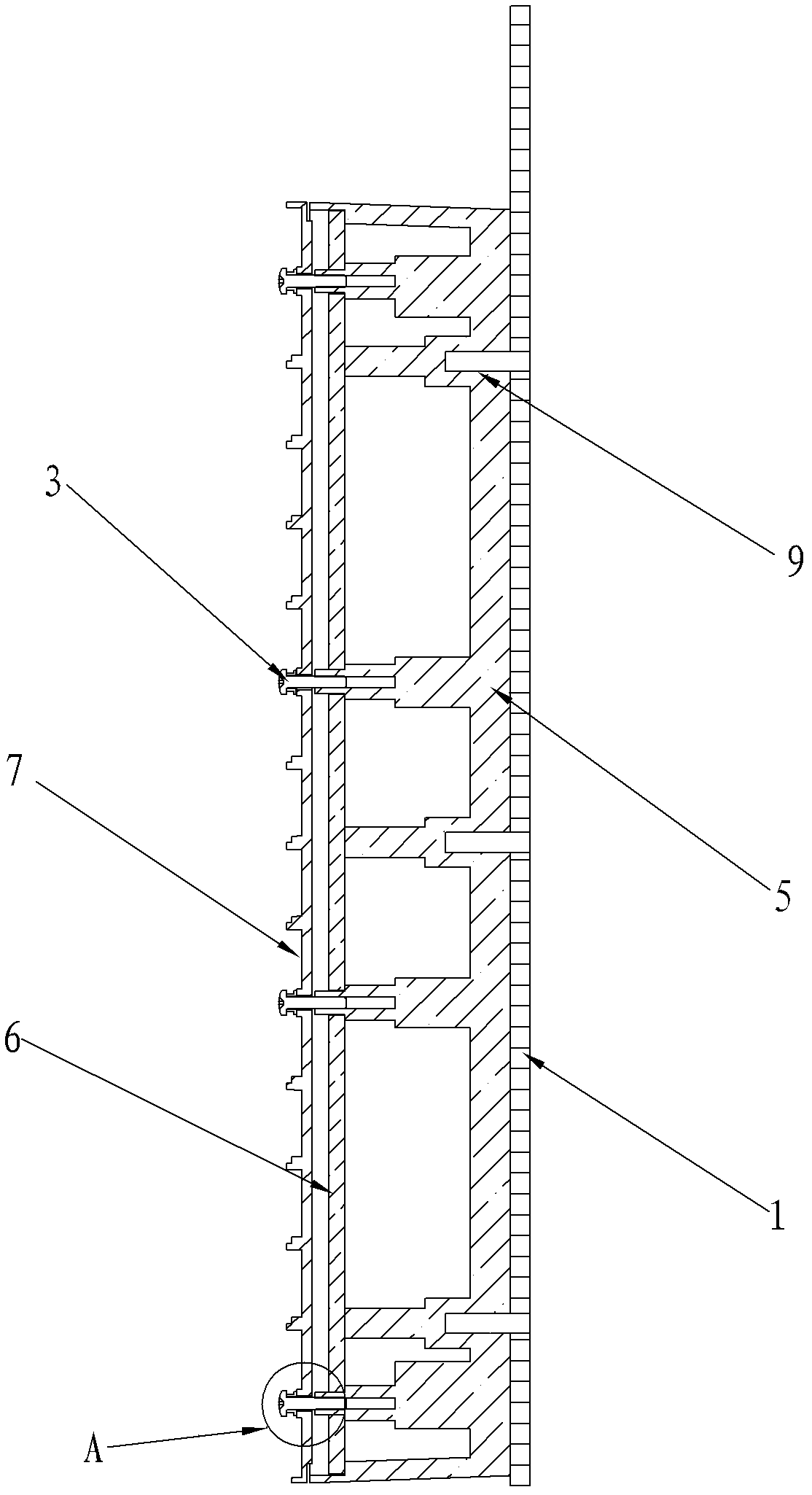

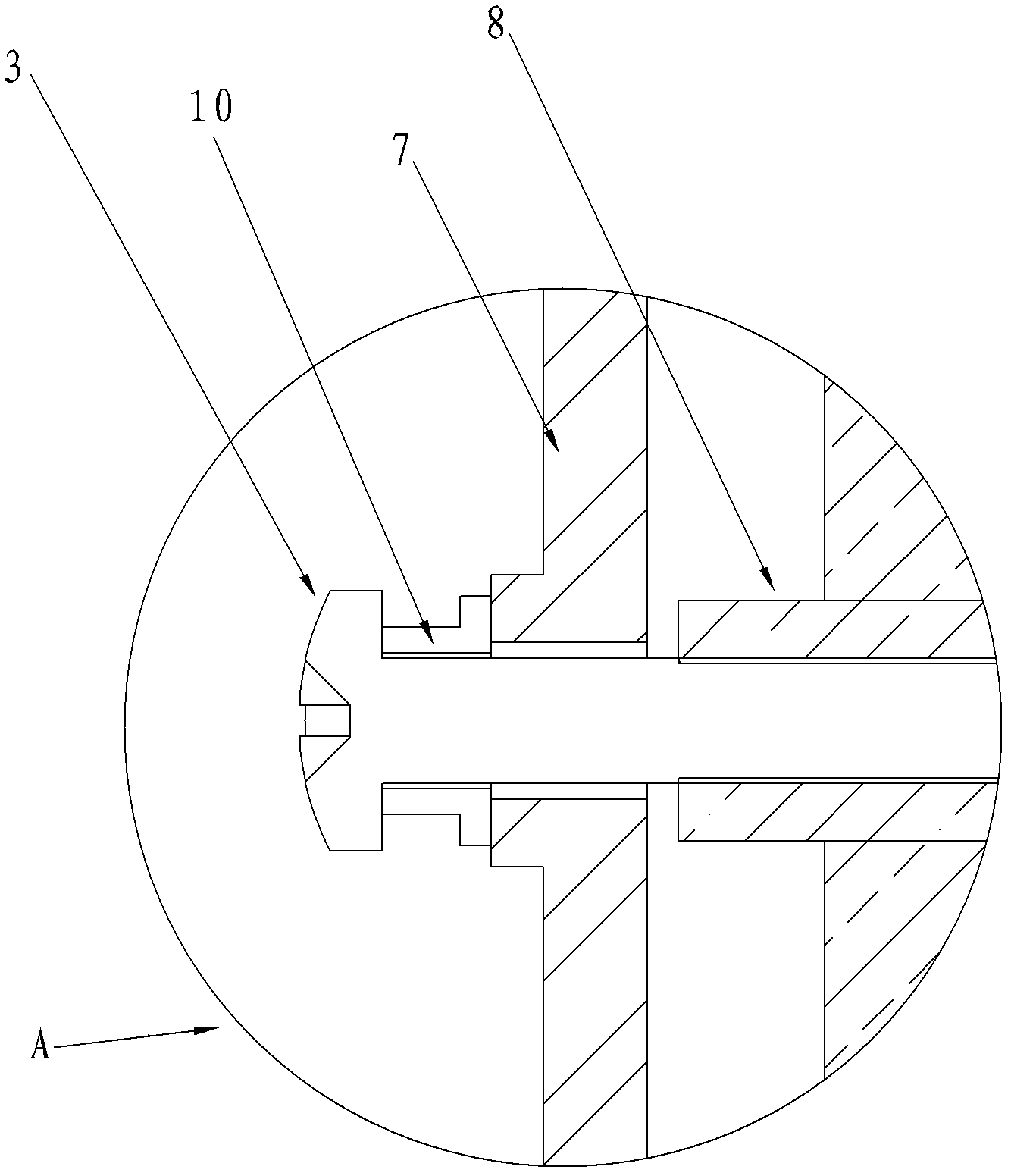

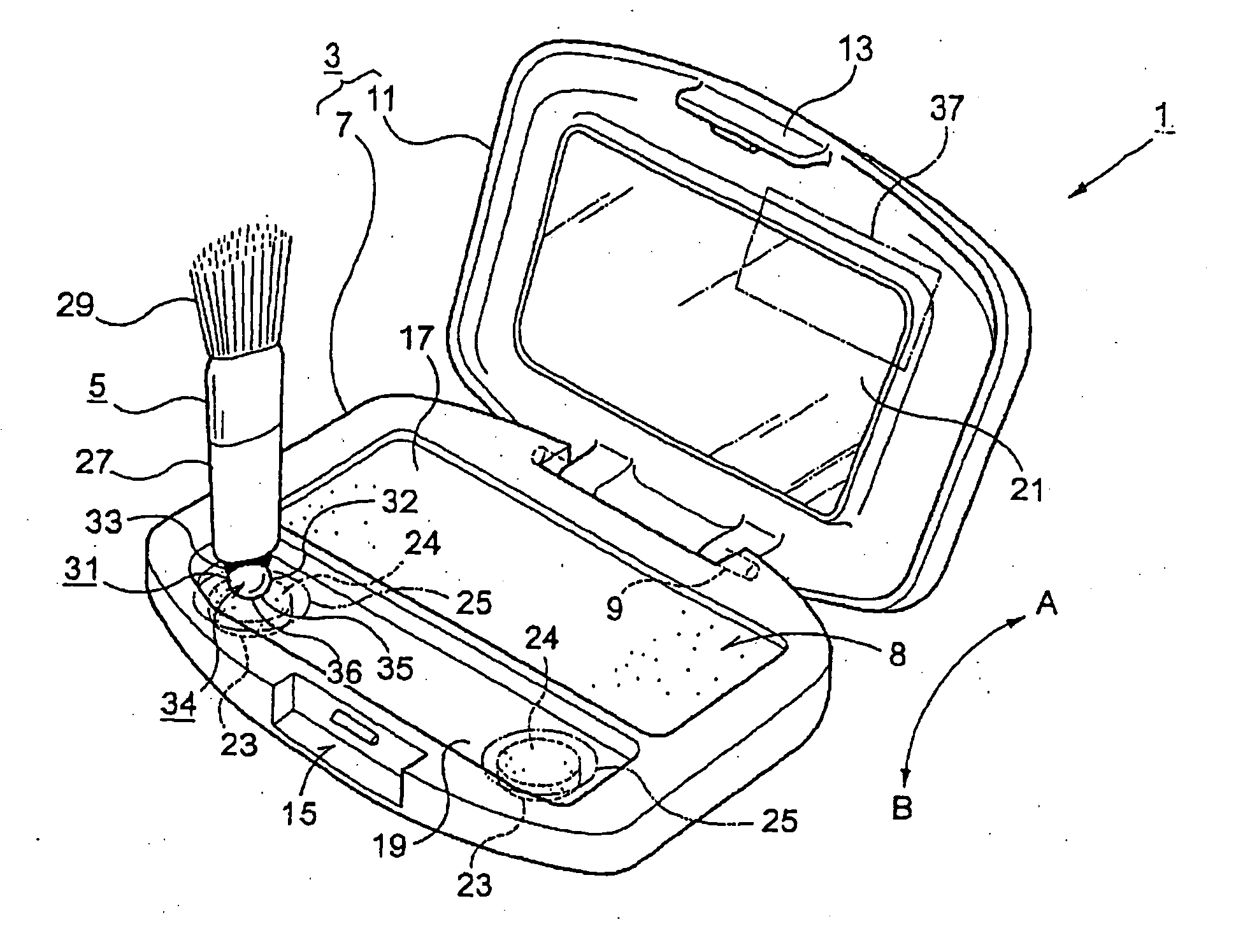

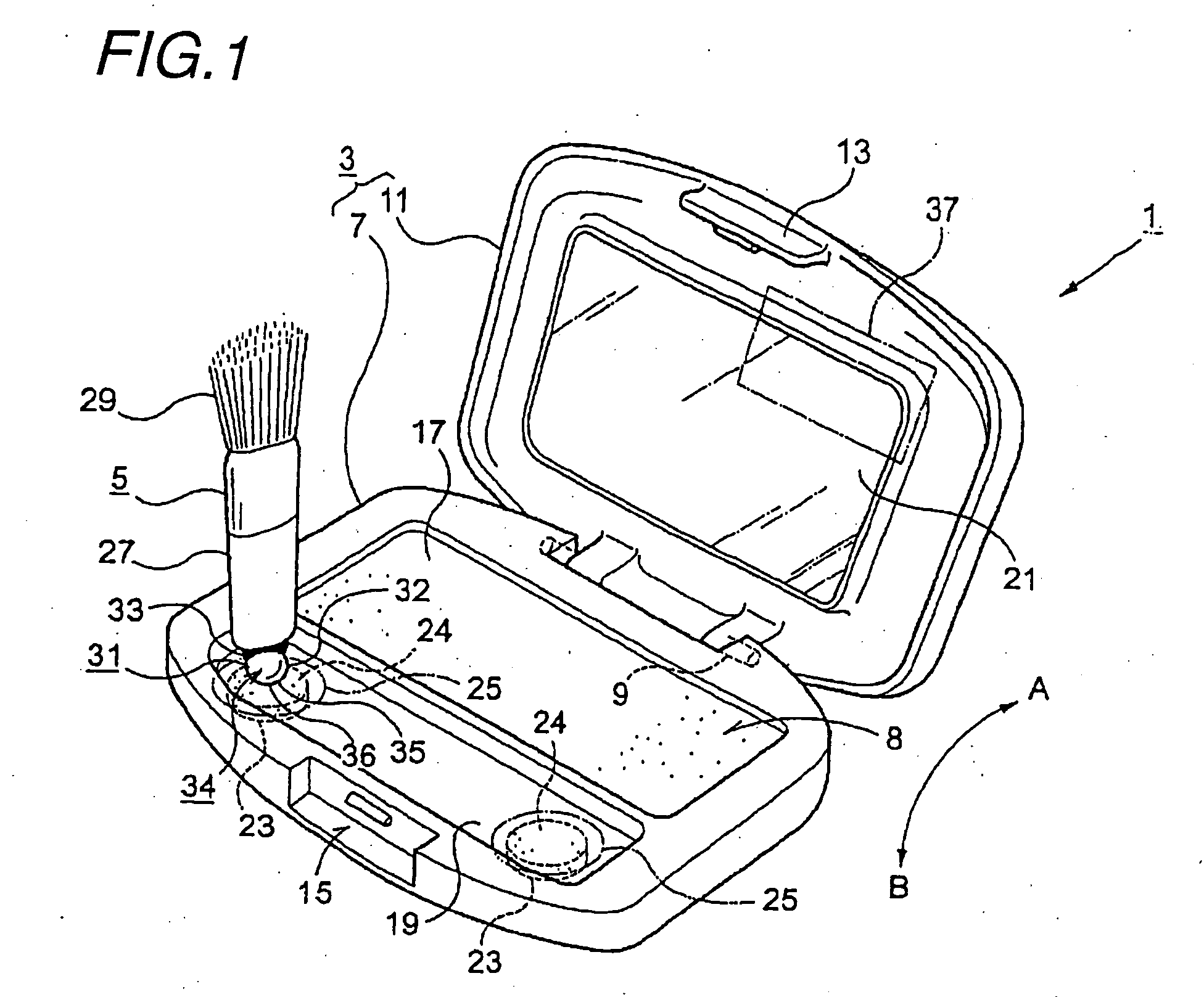

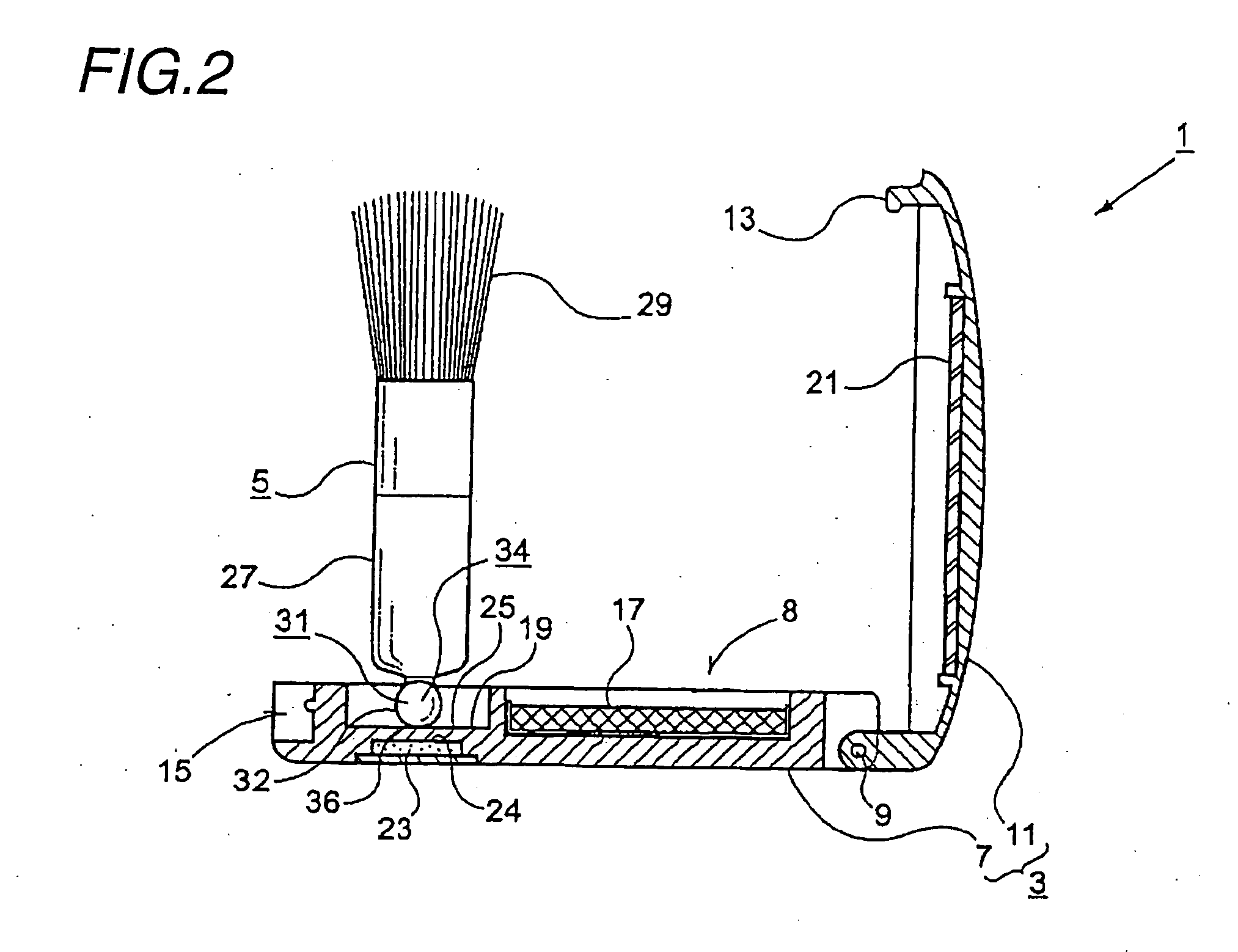

Self-erecting structure for rod-shaped member and method of producing rod-shaped member having self-erecting structure

InactiveUS20070056603A1Space minimizationEasy to dropOther accessoriesPackaging toiletriesEngineeringSupport surface

The present invention provides a self-erecting structure for a rod-shaped member, e.g. a brush, which enables the rod-shaped member to be readily taken out from an associated container while satisfying the demand that the rod-shaped member should be prevented from easily dropping from the container, and also provides a method capable of readily producing a rod-shaped member having such a structure. A rod-shaped member 5 has an erecting operation part 34 formed with a rolling surface 32 and an erection support surface 35. A first magnet 31 is provided in the vicinity of the erection support surface in a state where a first magnetic pole of the first magnet 31 faces toward one end of the rod-shaped member 5. Magnetic force from the first magnetic pole acts on the erection support surface. A second magnet 23 or a ferromagnetic material is provided in the vicinity of an erecting action surface 25. The second magnet has a second magnetic pole opposite in polarity to the first magnetic pole. The second magnetic pole faces upward so that magnetic force from the second magnetic pole acts on the erecting action surface. The rod-shaped member is constantly urged to pivot in the erecting direction by magnetic attraction force between the two magnets so that the rod-shaped member is automatically shiftable from a lying position to an erect position. A lid 11 of the container has an erection restraining part 37 capable of holding the rod-shaped member in the lying position on a mount surface 19 against the urging force when the lid 11 is closed.

Owner:HUH GENE

Coat-removing device for coat-removing oil-fried peanut kernels based on bionic kneading

InactiveCN108433120AReduce wasteReduce manufacturing costGas current separationHuskingEngineeringPeanut kernel

The present invention provides a coat-removing device for coat-removing oil-fried peanut kernels based on bionic kneading, and relates to the field. The coat-removing device for coat-removing the oil-fried peanut kernels based on the bionic kneading comprises a machine shell. The top part of the machine shell communicates with a material feeding funnel; the inside of the material feeding funnel isprovided with a stable material conveying device; a coat-removing device is arranged in the machine shell and connected with the material feeding funnel; two transmission devices are connected with the coat-removing device; a material discharging funnel is arranged inside the machine shell and fixedly connected with the lower sides of the transmission devices; and two peanut coat separation devices are arranged on the both sides of the machine shell. In the coat-removing device for coat-removing the oil-fried peanut kernels based on the bionic kneading, the operations of the transmission devices can drive two kneading plates to move up and down repeatedly; besides, the movement directions of the two kneading plates are opposite; and the opposite movement direction of the two kneading plates is similar to that of hand kneading, can ensure that the peanuts are not damaged and improves the integrity of the peanut kernels.

Owner:赵从琴

Gutter guard

ActiveUS20110265391A1Easy to assembleConveniently mountedRoof coveringStands/trestlesWater flowEngineering

Owner:PROD INNOVATION GRP

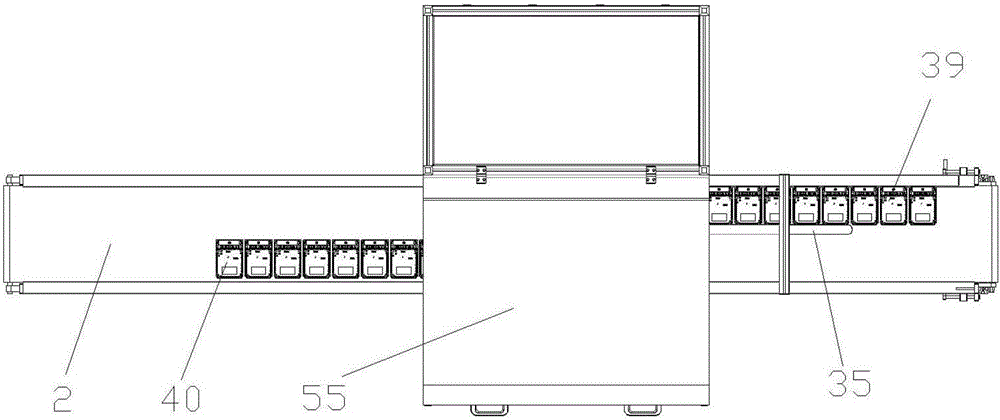

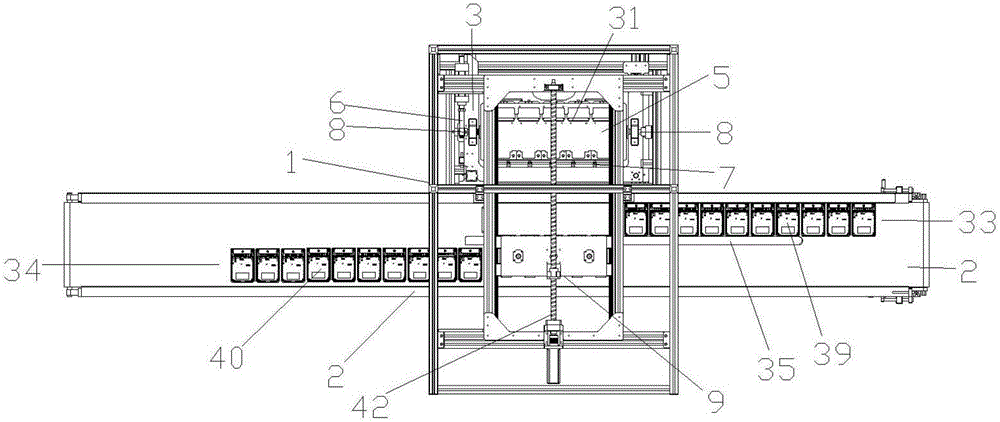

Automatic dust removal equipment for electric energy meters

The invention discloses automatic dust removal equipment for electric energy meters. The automatic dust removal equipment for the electric energy meters comprises a rack, a conveying device and a dust removal device. The automatic dust removal equipment is characterized in that the conveying device and the dust removal device are arranged on the front part and the rear part of the rack in parallel; the dust removal device comprises a location fixture used for fixing the plurality of electric energy meters, an air-blowing device and a turnover mechanism used for driving the location fixture to turn over up and down; and a transferring-loading mechanism is further arranged above the rack, and between the conveying device and the location fixture, and used for grabbing the electric energy meters to be subjected to dust removal on the conveying device and moving the electric energy meters onto the location fixture or grabbing the electric energy meters subjected to dust removal on the location fixture and moving the electric energy meters onto the conveying device. According to the automatic dust removal equipment for the electric energy meters, the conveying device and the dust removal device are mutually separated, so that dust in the electric energy meters can be adequately eliminated.

Owner:NINGBO SANXING MEDICAL & ELECTRIC CO LTD

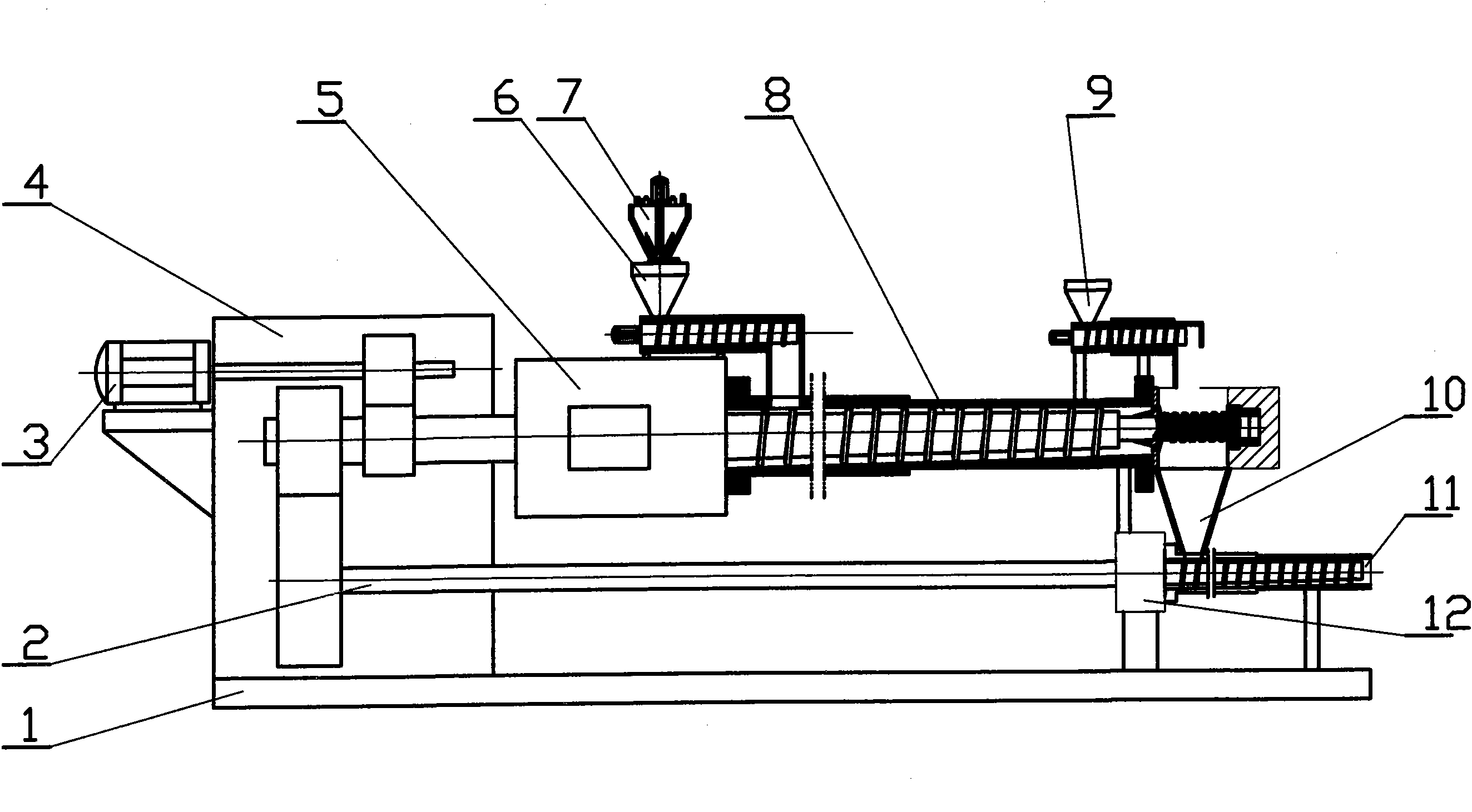

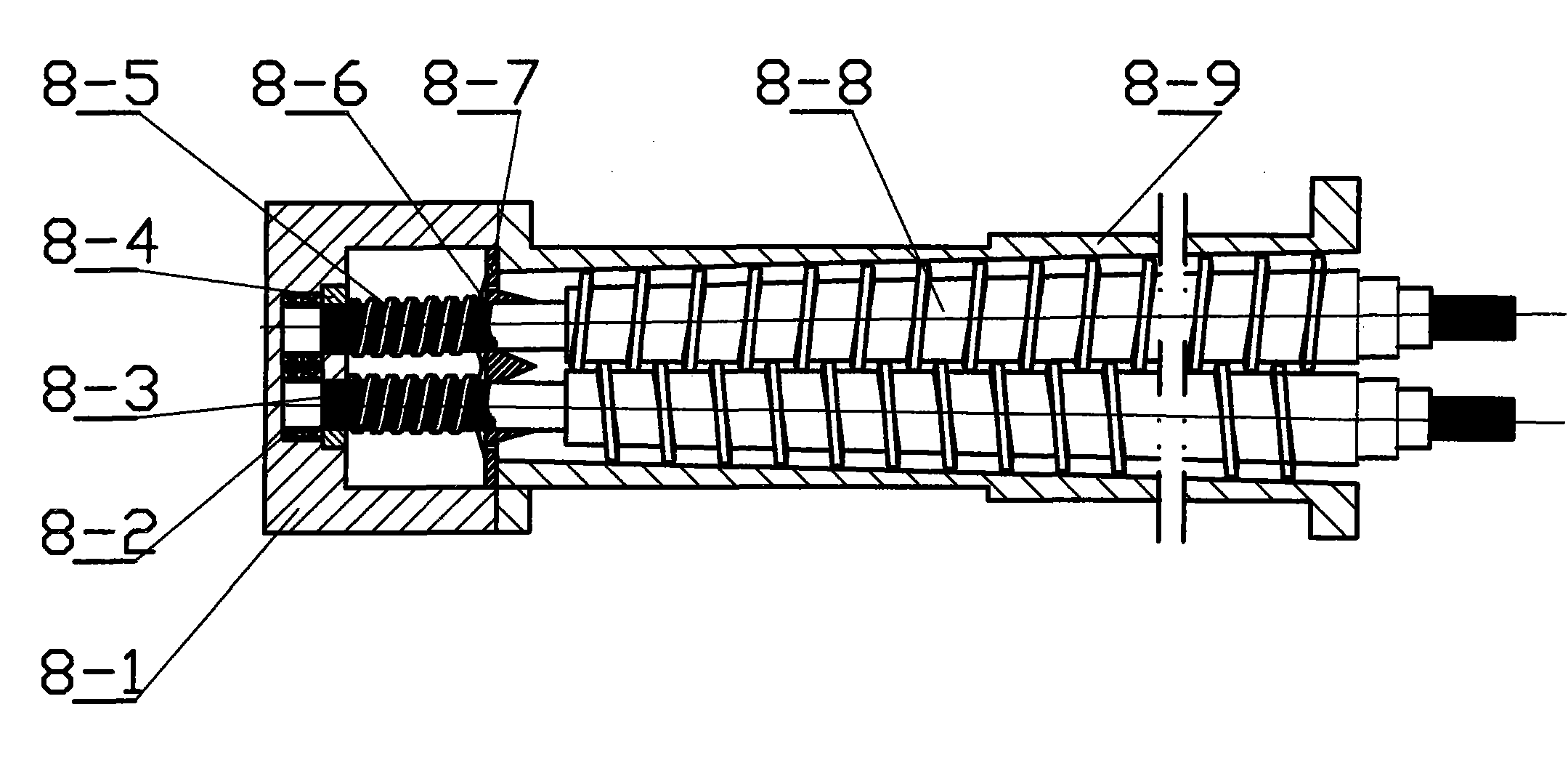

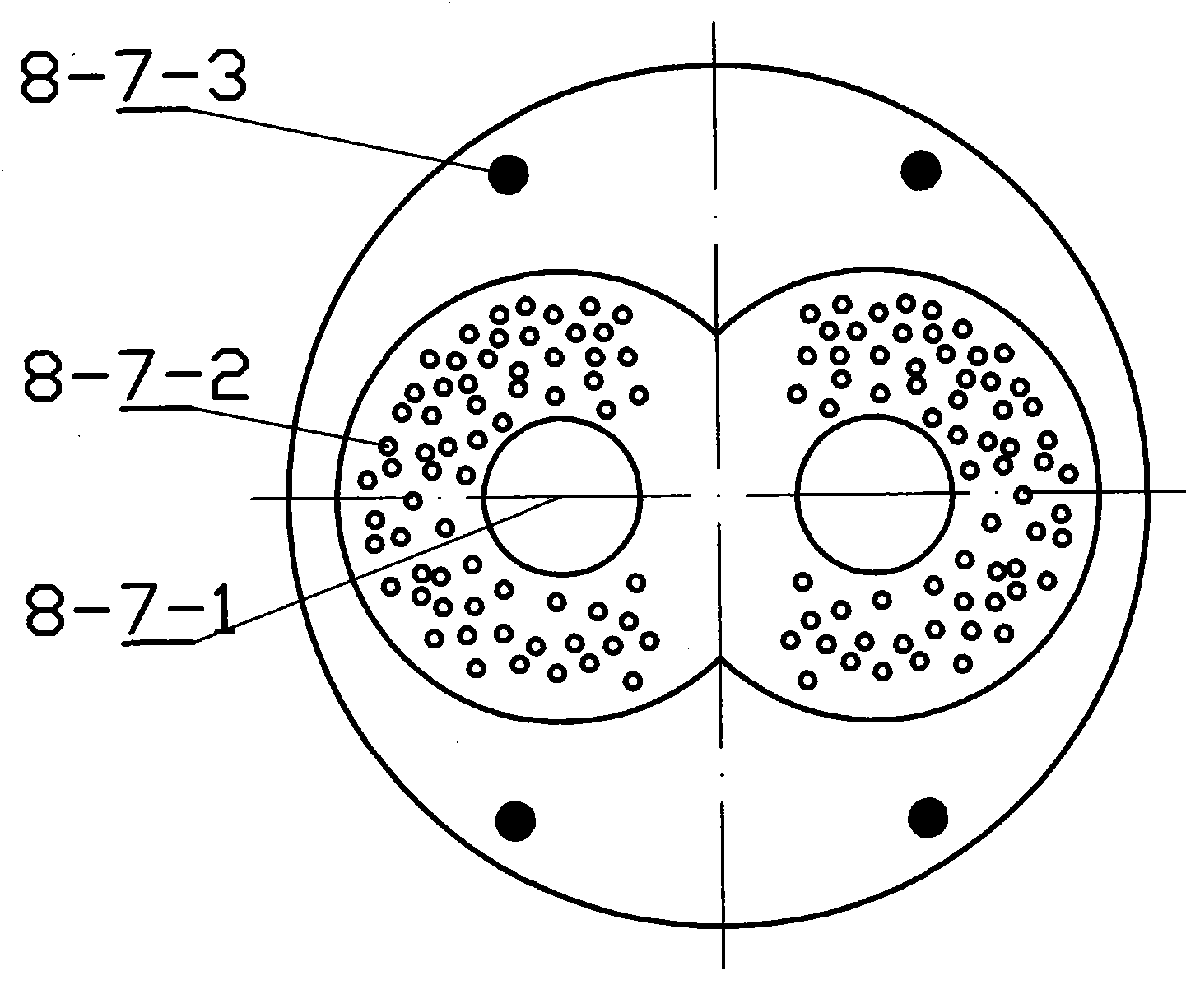

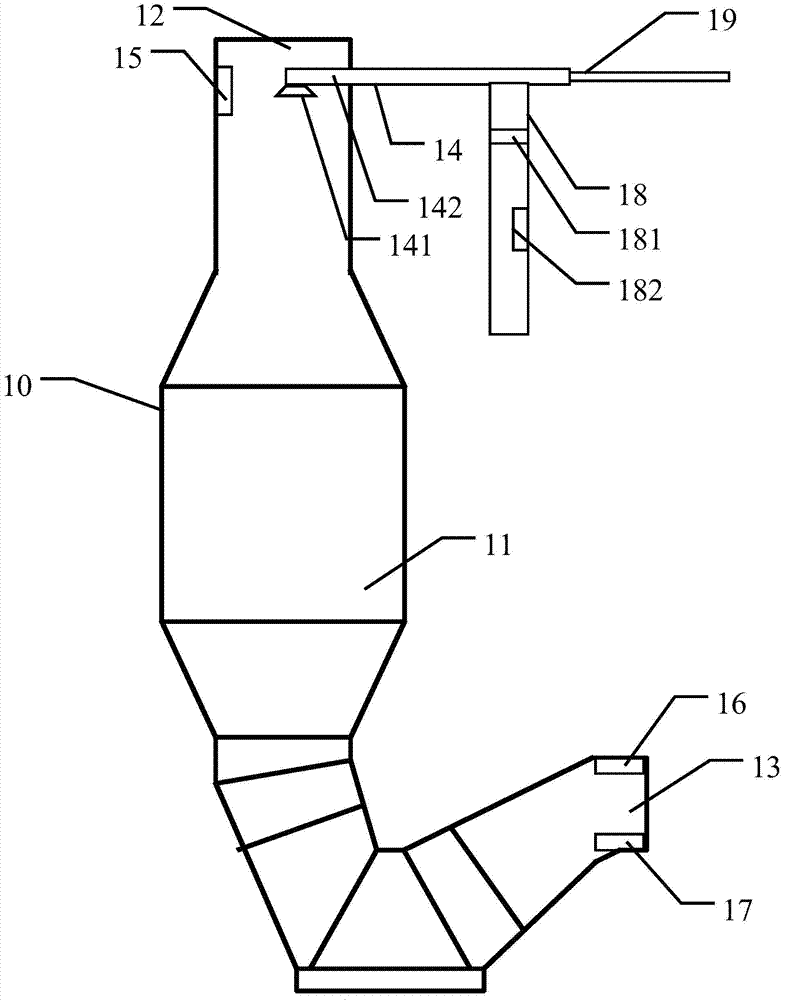

Multifunctional wood-plastic composite material one-step method extruder

A novel multifunctional wood-plastic composite material one-step method extruder is provided. A motor is connected with a twin-screw gear distribution box and a speed-adjusting speed-varying box respectively through a gear speed-varying box and an extending transmission shaft; the gear distribution box is connected with a twin-screw granulator; a material mixing device is connected with the twin-screw granulator through a twin-screw feeder; a master batch feeding device is connected with the twin-screw granulator; a connecting barrel is connected with the twin-screw granulator and a single-screw extruder; the single-screw extruder is connected with the speed-adjusting speed-varying box; all devices are connectedly arranged on a machine base. The extruder is mainly used for extrusion processing of a wood-plastic composite material and composite materials having similar properties, can also be used just for granulation, can complete production by the one-step method after raw materials are mixed, has high efficiency, and saves energy; the extruder completely avoids friction damage of screws and screw tubes, thereby improving the usage usefulness of equipment; the extruder allows extrusion processed products to have various wood imitation patterns; and the extruder can be applied to composite materials with various systems and much extrusion capacity.

Owner:江苏文嘉勄木塑装备制造有限公司

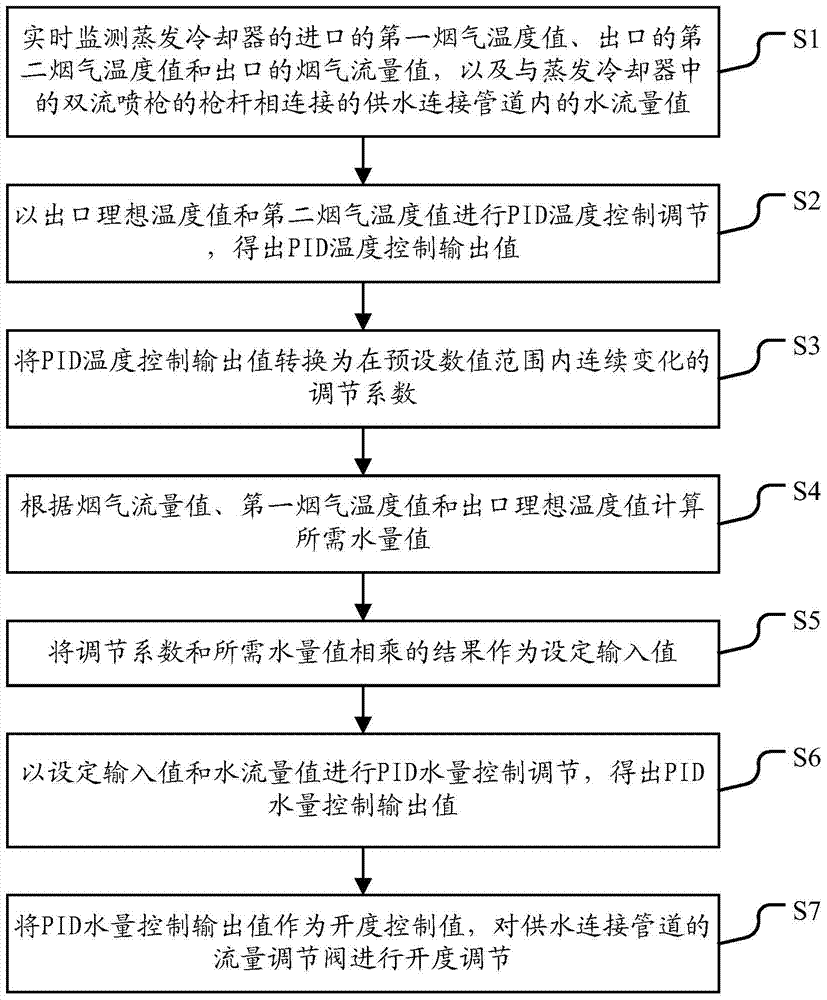

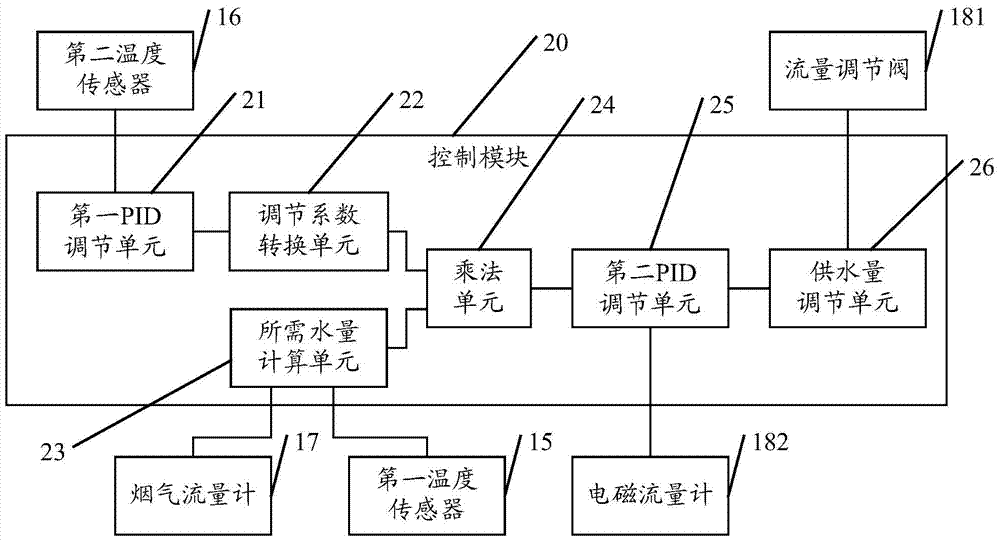

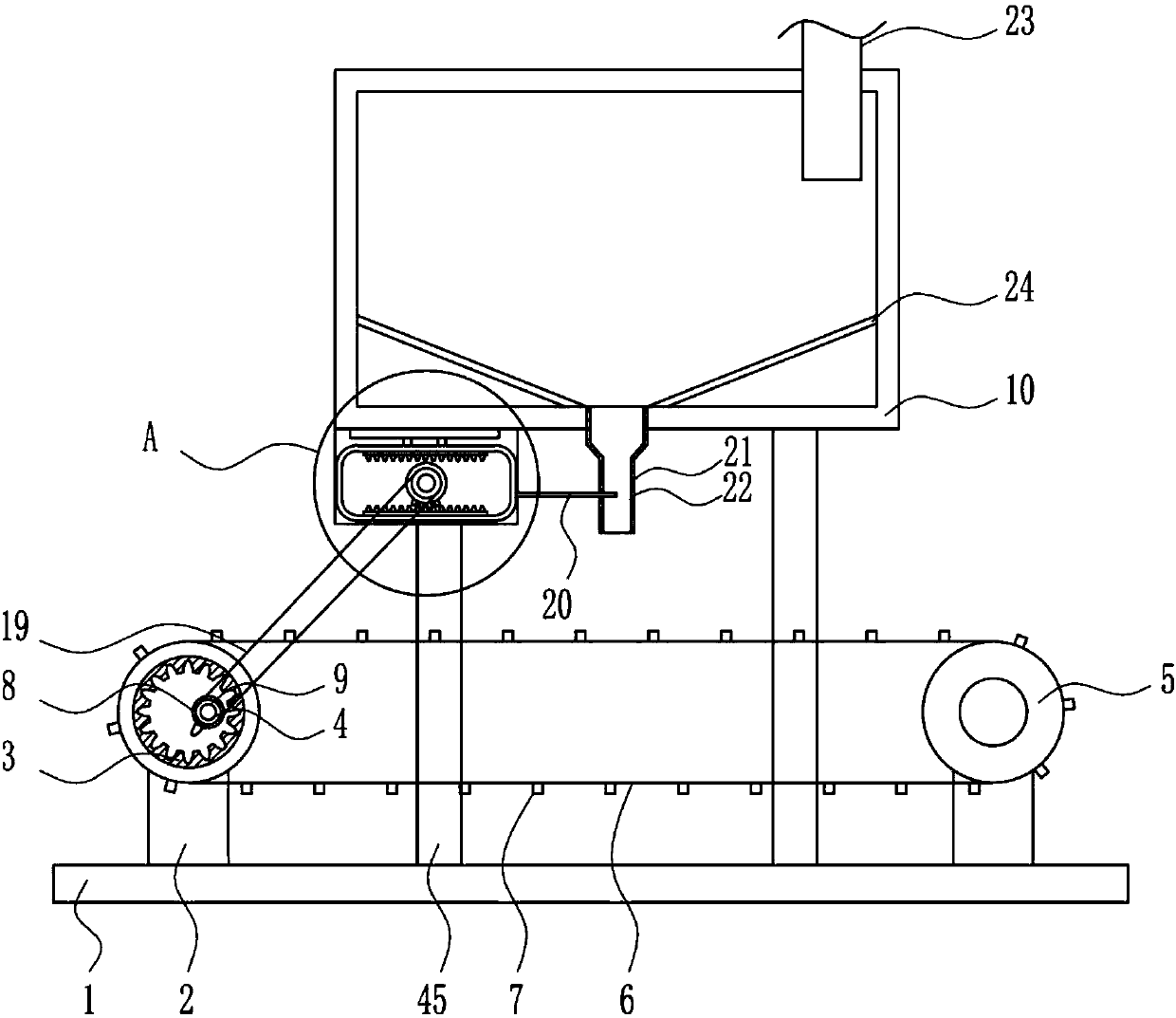

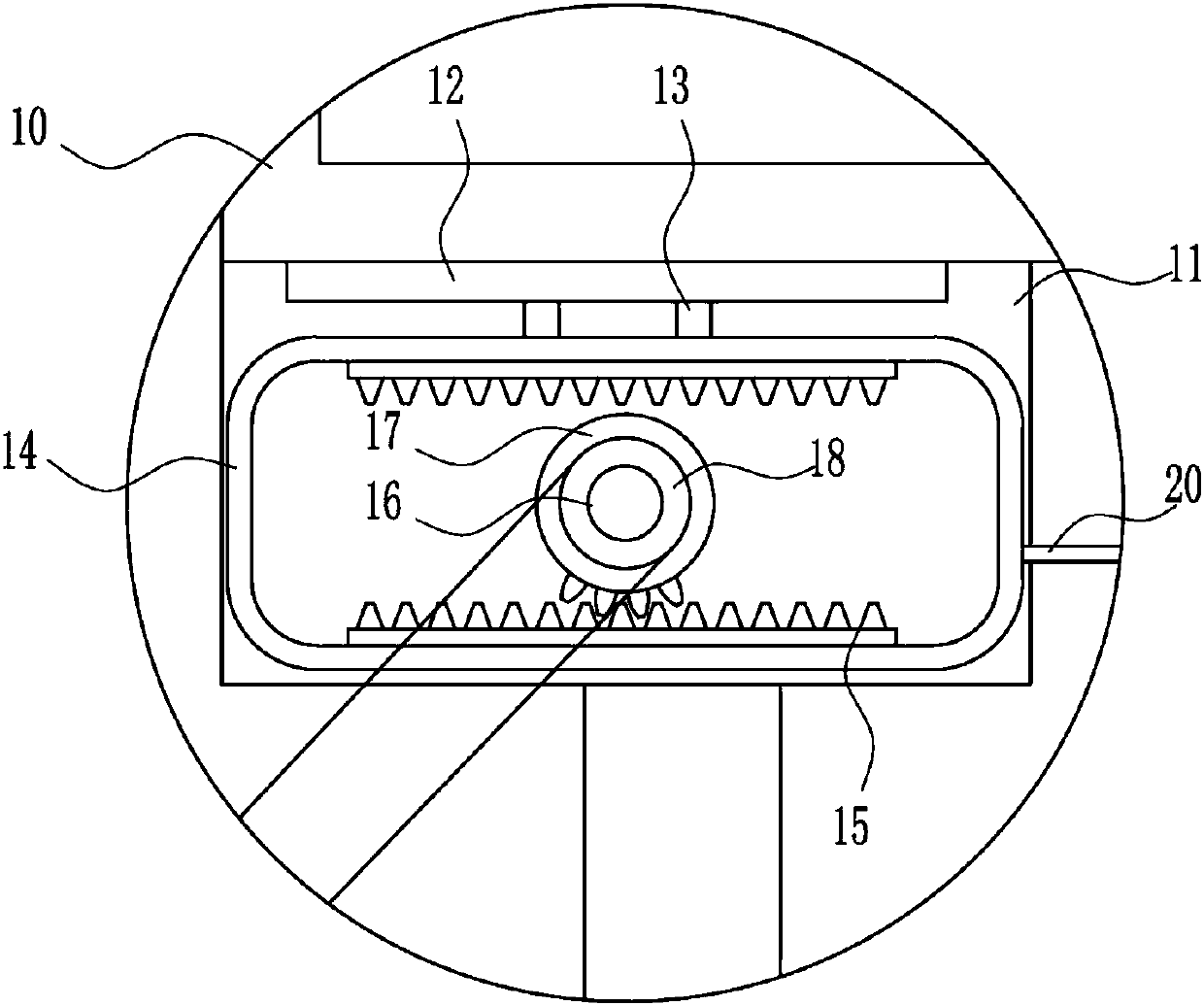

Smoke cooling control method and system in dedusting process of electric furnace

ActiveCN103673652AKeep dryEasy to dropIncreasing energy efficiencyControl devices for furnacesTemperature controlElectric arc furnace

The invention discloses a smoke cooling control method and system in the dedusting process of an electric furnace. The method includes the steps that a first smoke temperature value, a second smoke temperature value, a smoke flow value and a water flow value are detected in real time; PID temperature control and regulation are conducted according to an outlet ideal temperature value and the second smoke temperature value, and a PID temperature control output value is obtained; a PID temperature control output value is converted into a regulating coefficient which continuously changes within a preset numerical range; a required water amount value is calculated according to the smoke flow value, the first smoke temperature value and the outlet ideal temperature value; the result obtained by multiplying the regulating coefficient by the required water amount value is used as a set input value; PID water amount control and regulation are conducted according to the set input value and the water flow value, and then a PID water amount control output value is obtained; the PID water amount control output value is used as an opening control value, and then the opening of a flow regulating value of a water supply pipeline is regulated. By the adoption of the smoke cooling control method and system, the water amount can be accurately controlled to cool smoke.

Owner:BERIS ENG & RES CORP

Quantified tinning device for colorful candies

The invention relates to a tinning device, in particular to a quantified tinning device for colorful candies. The quantified tinning device for colorful candies achieves technical purposes. In order to achieve the technical purposes, the quantified tinning device for colorful candies comprises a base plate, a first support, an inner gear ring and the like; the first support and a third support arearranged on the top of the base plate, the inner gear ring is rotationally connected to the front portion of the first support, a first rotating shaft is arranged at the front portion of the first support and located inside the inner gear ring, the inner gear ring and the right first support are each provided with a first belt wheel, and a first flat belt is wound around the first belt wheels. The tinning device has the effects that during quantified tinning, the number of candies of each tin is small, and operation is easy and convenient; knocking balls continuously knock a guiding plate, candy falling is more smooth, the deviation of the numbers of candies discharged every time is lowered, the quantified precision of the device is improved, and the device is reliable and stable, and high in generalizability.

Owner:南通北外滩建设工程有限公司

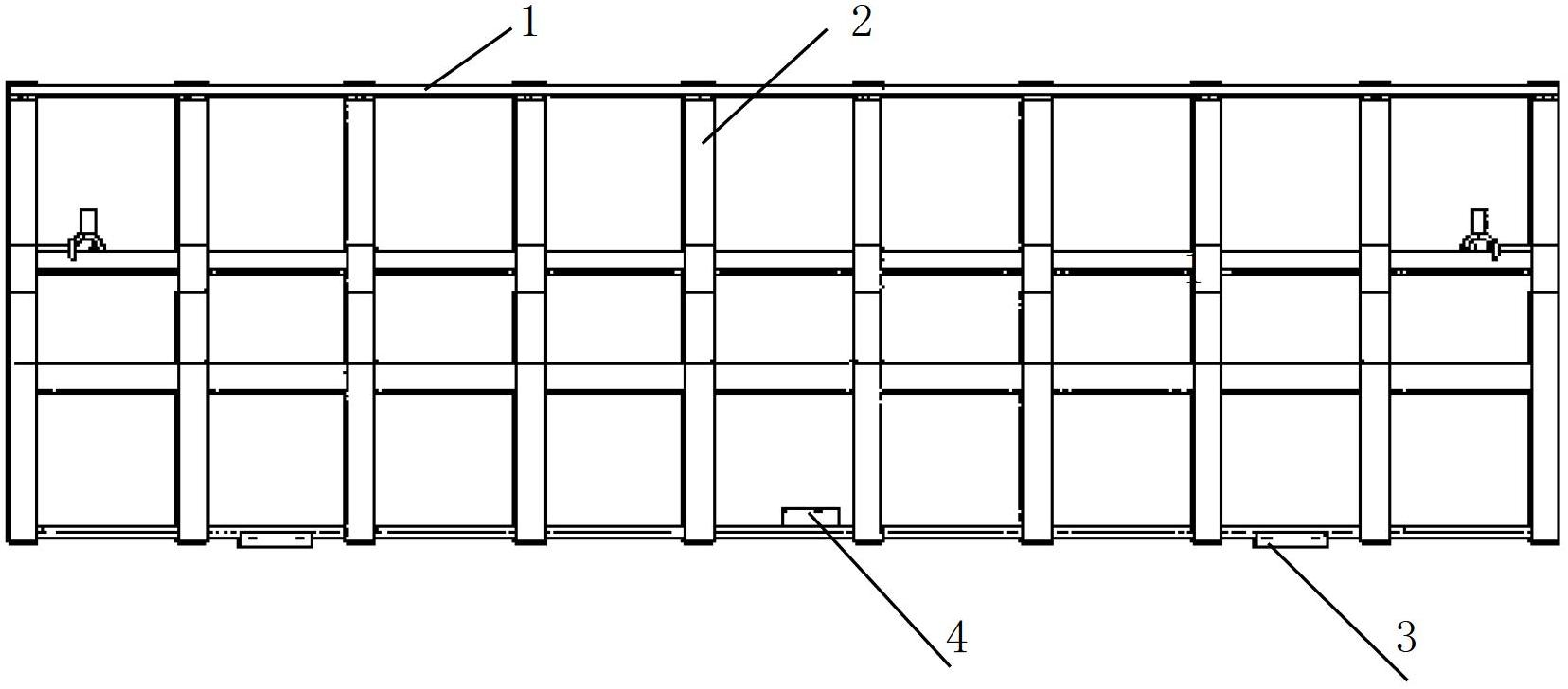

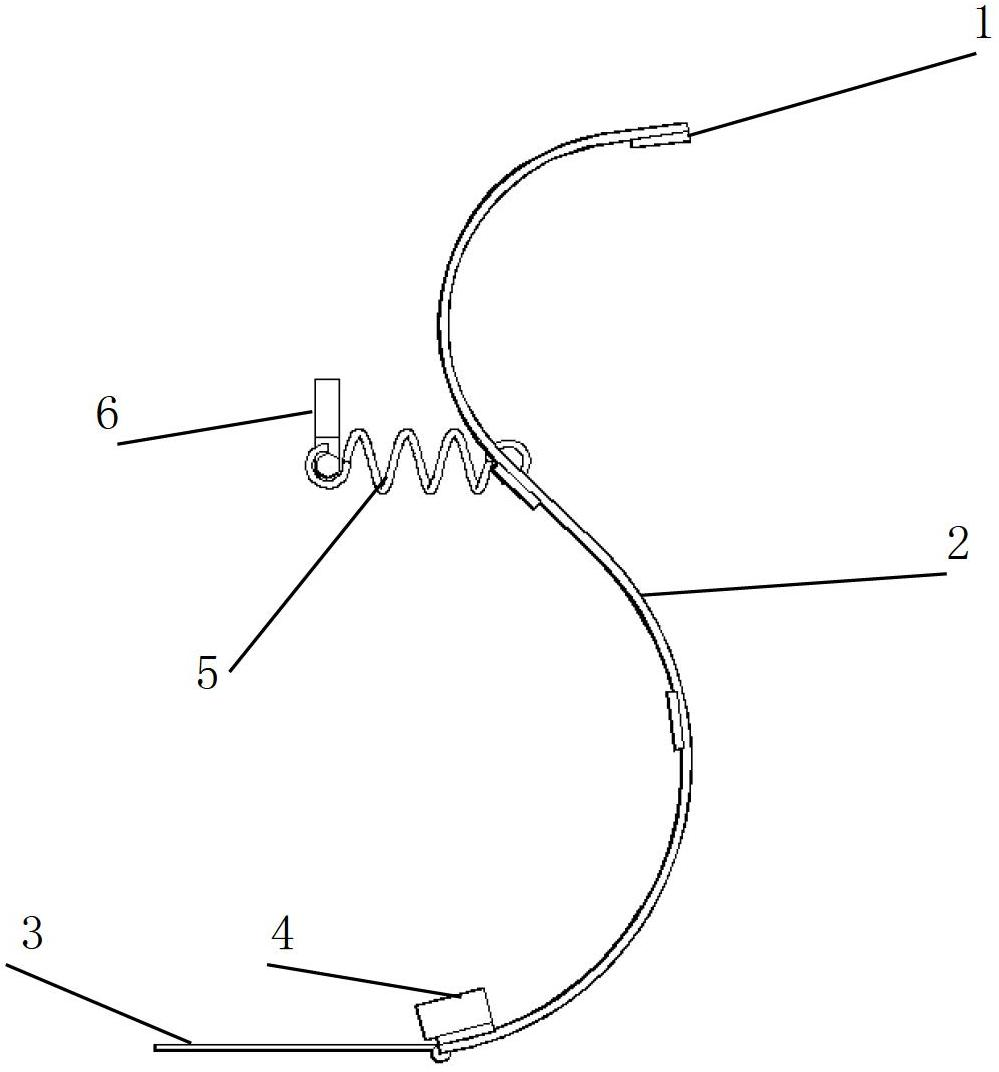

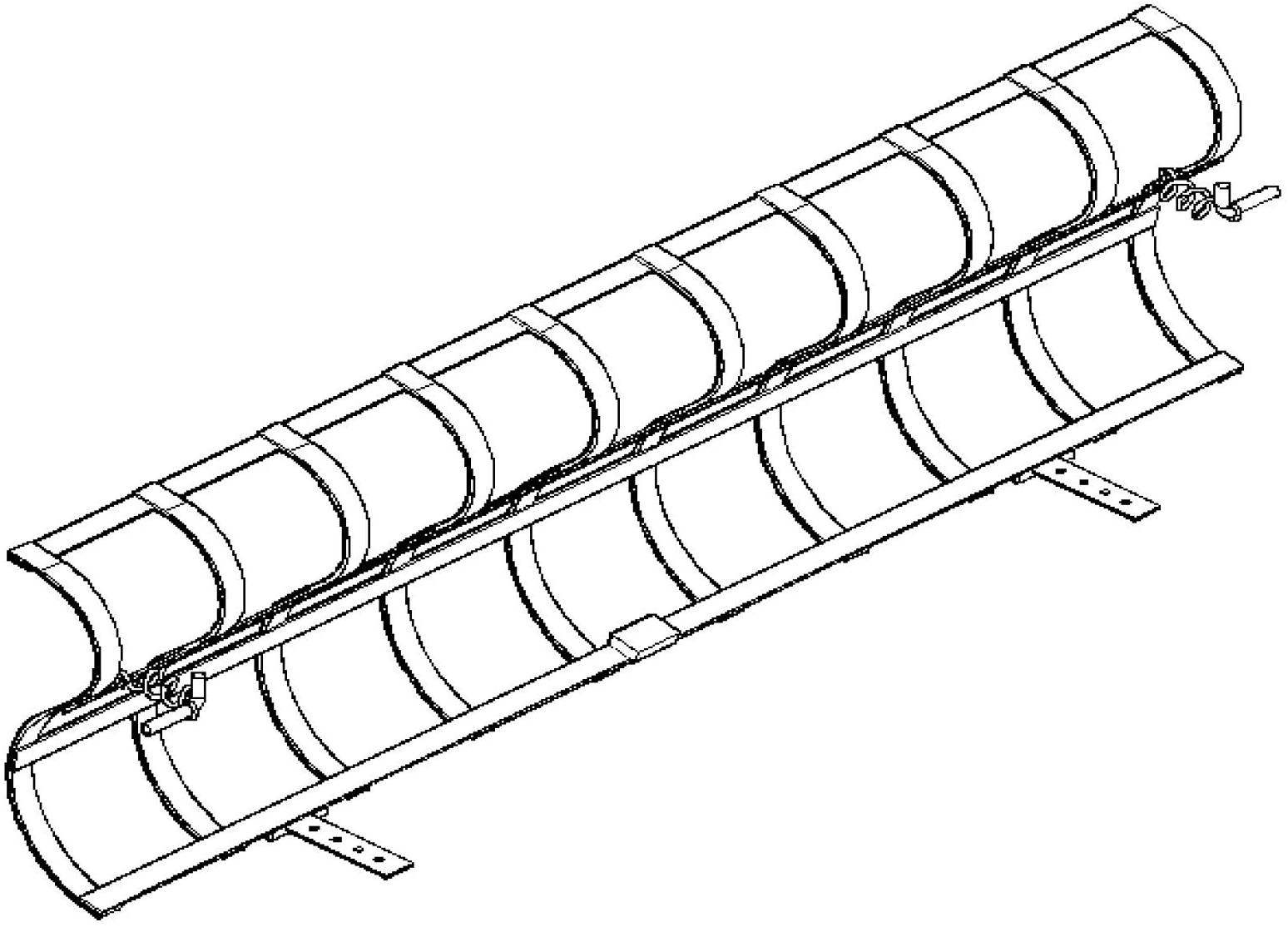

Window S-shaped alarm guardrail and manufacturing method thereof

InactiveCN102677840ABeautiful shapeStrong sense of artFixed grillesBurglar alarm mechanical actuationAlarm deviceFloor level

The invention relates to a window S-shaped alarm guardrail and the manufacturing method thereof. The window S-shaped alarm guardrail mainly comprises transverse bars, longitudinal bars and an alarm device, and is characterized in that an S-shaped guardrail comprises the plurality of transverse bars and longitudinal bars, and a switch is arranged on the guardrail body and is connected with the alarm device. The window S-shaped alarm guardrail is arranged outside a window to get in the only way for a thief, and has the anti-theft functions of preventing climbing, preventing hanging and the like, so as to nip in the bud; and the window S-shaped alarm guardrail further can prevent people and objects from falling by accidents, does not influence escape and relief, and can be widely used for anti-theft protection in various building floors.

Owner:张朝峰

Automatic potato peeling machine

InactiveCN104287062APrevent fallingEasy to dropVegetable peelingFood treatmentPush and pullPulp and paper industry

The invention belongs to the technical field of vegetable peeling, and particularly relates to an automatic potato peeling machine. The automatic potato peeling machine comprises a hoisting air cylinder, an air claw, a rotation tray, a push and pull air cylinder and a collection box, wherein the hoisting air cylinder is fixed on a support through a fixing plate, the lower portion of the hoisting air cylinder is connected with the air claw, the rotation tray is arranged at the lower end of the air claw, the collection box is arranged below the rotation tray, the push and pull air cylinder is arranged at the rear of the rotation tray, the height of the push and pull air cylinder is 3-6cm higher than the rotation tray, a conveyor belt is arranged in front of the rotation tray, the conveyor belt is obliquely arranged relatively to the horizontal direction, a washing pool is arranged in front of the conveyor belt, a water supply pipeline is arranged above the washing pool, a knife rest is fixed on one side of the rotation tray and below the fixing plate, and a peeling knife is arranged on the knife rest. The automatic potato peeling machine has the advantages of thoroughly peeling skin of potatoes, easily washing the surfaces of the potatoes after being peeled, and being capable of directly collecting the skin of the potatoes and completing washing processes, and high in overall automation degree.

Owner:天津费斯特餐饮管理有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com