Patents

Literature

317results about How to "Uniform preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Device for mixing powder and liquid and method thereof

InactiveCN1459328AContinuous preparationUniform preparationFlow mixersMixing methodsMetallurgyMixed approach

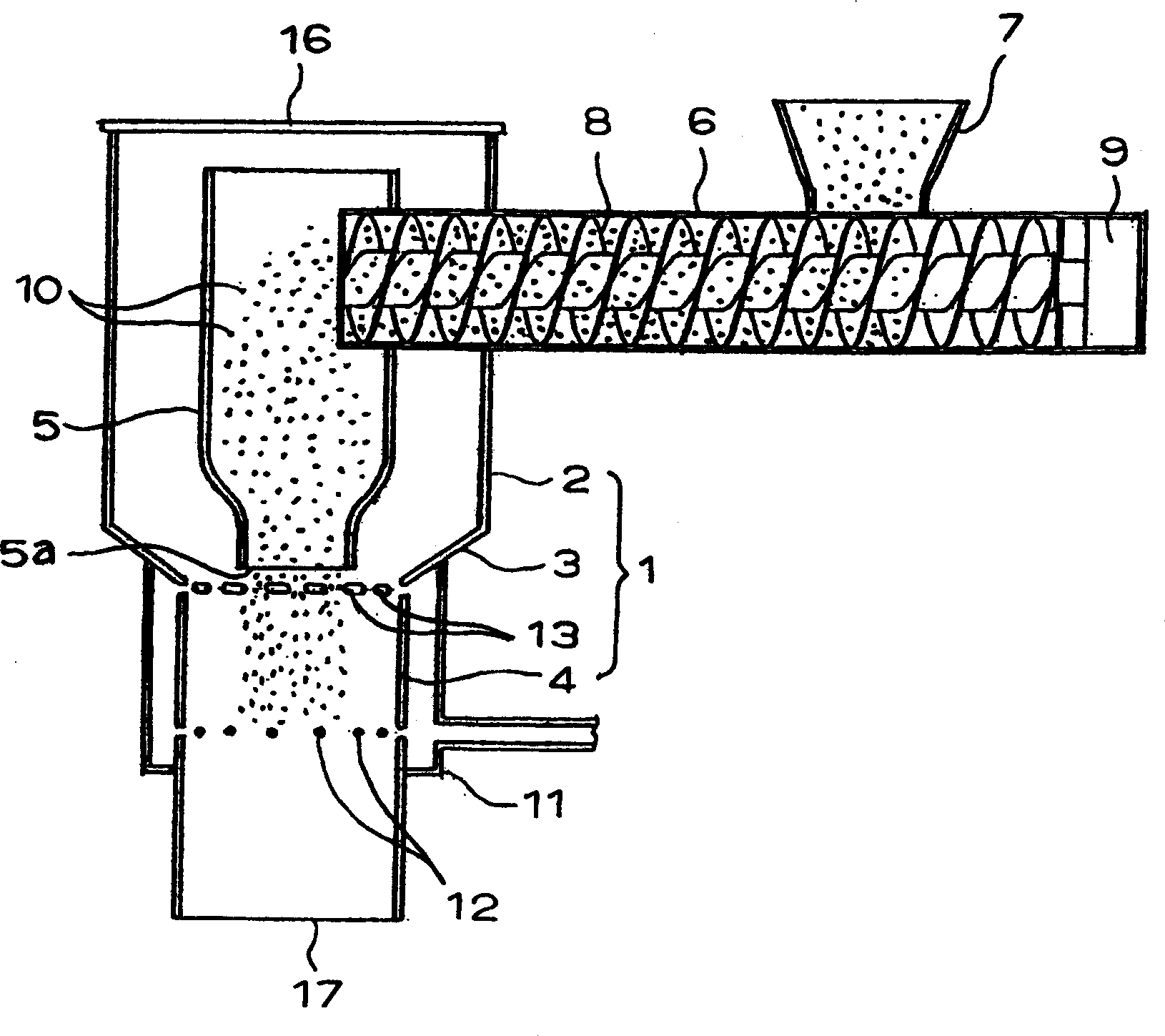

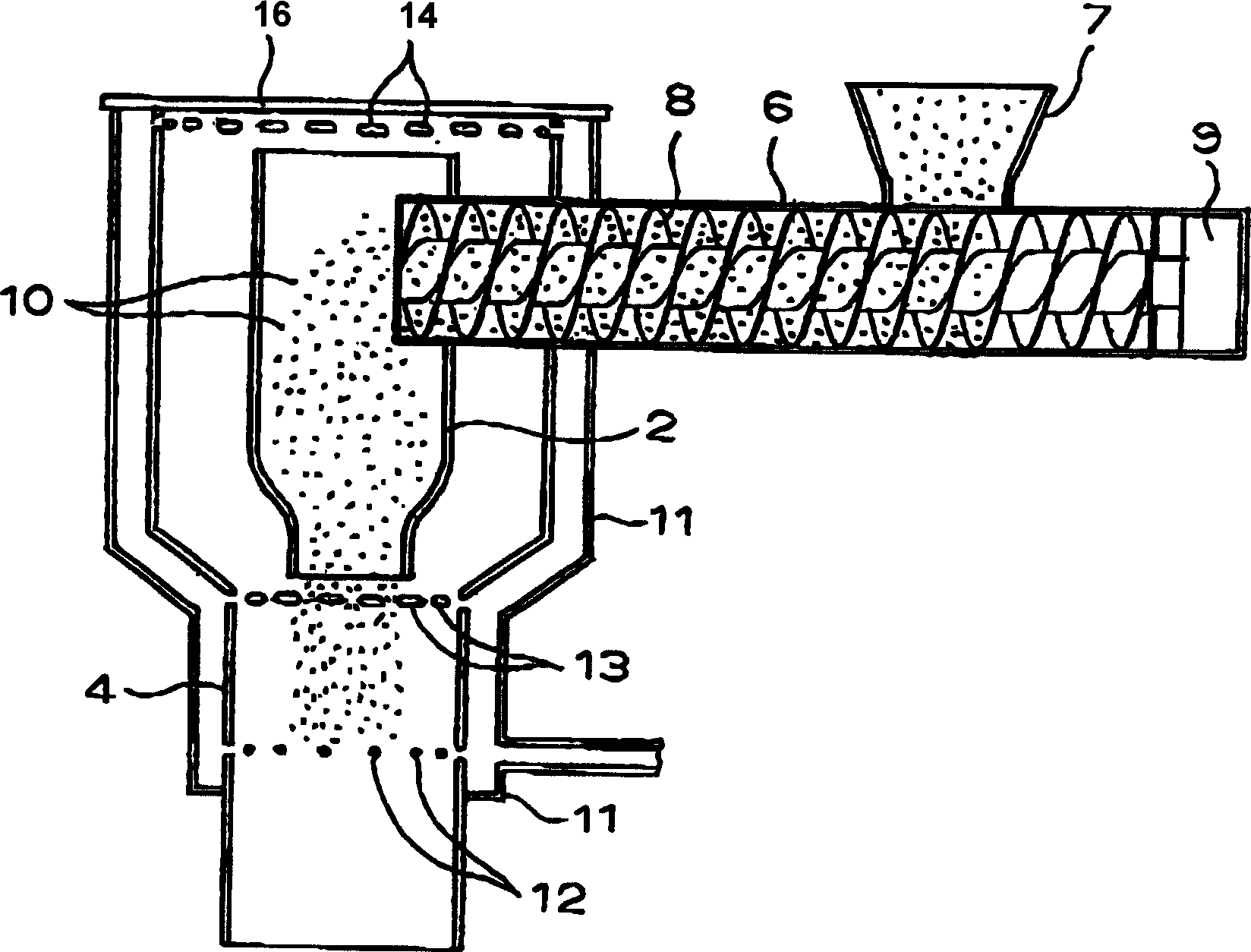

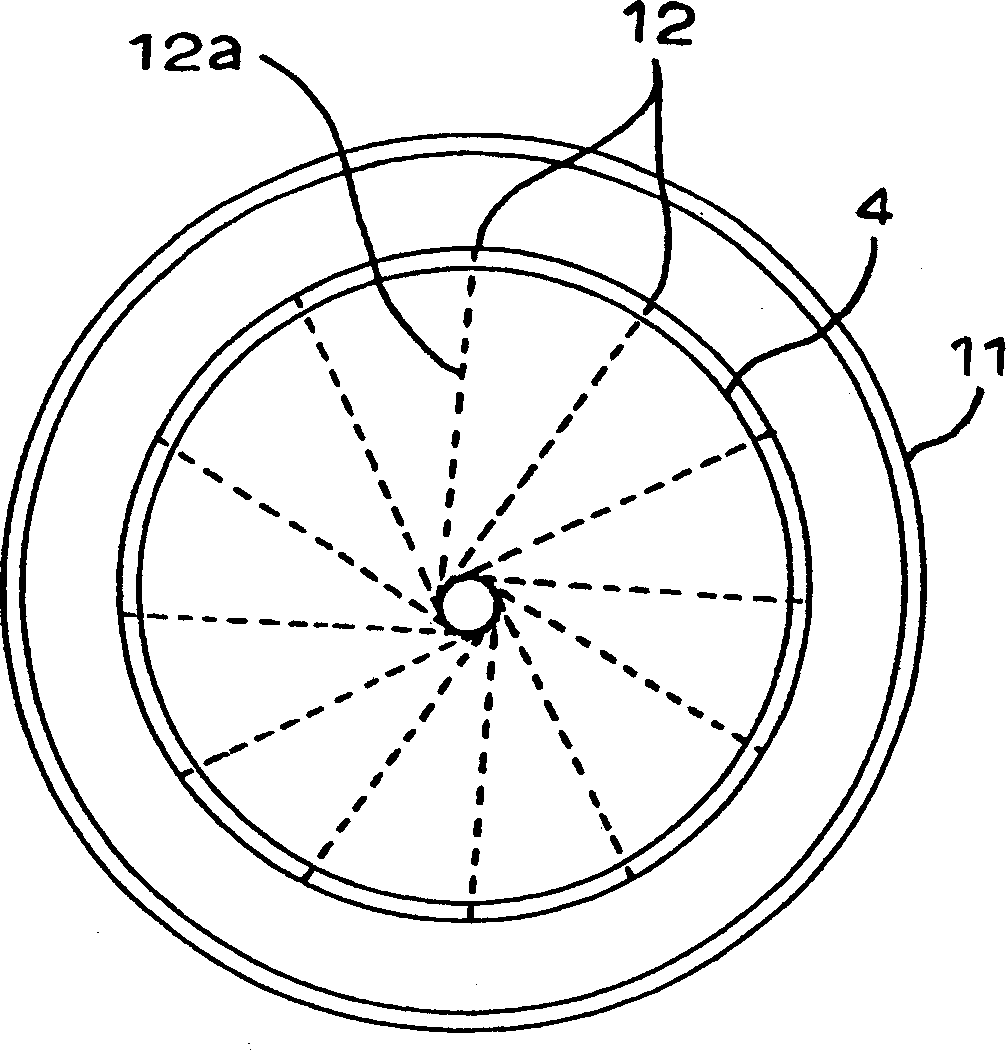

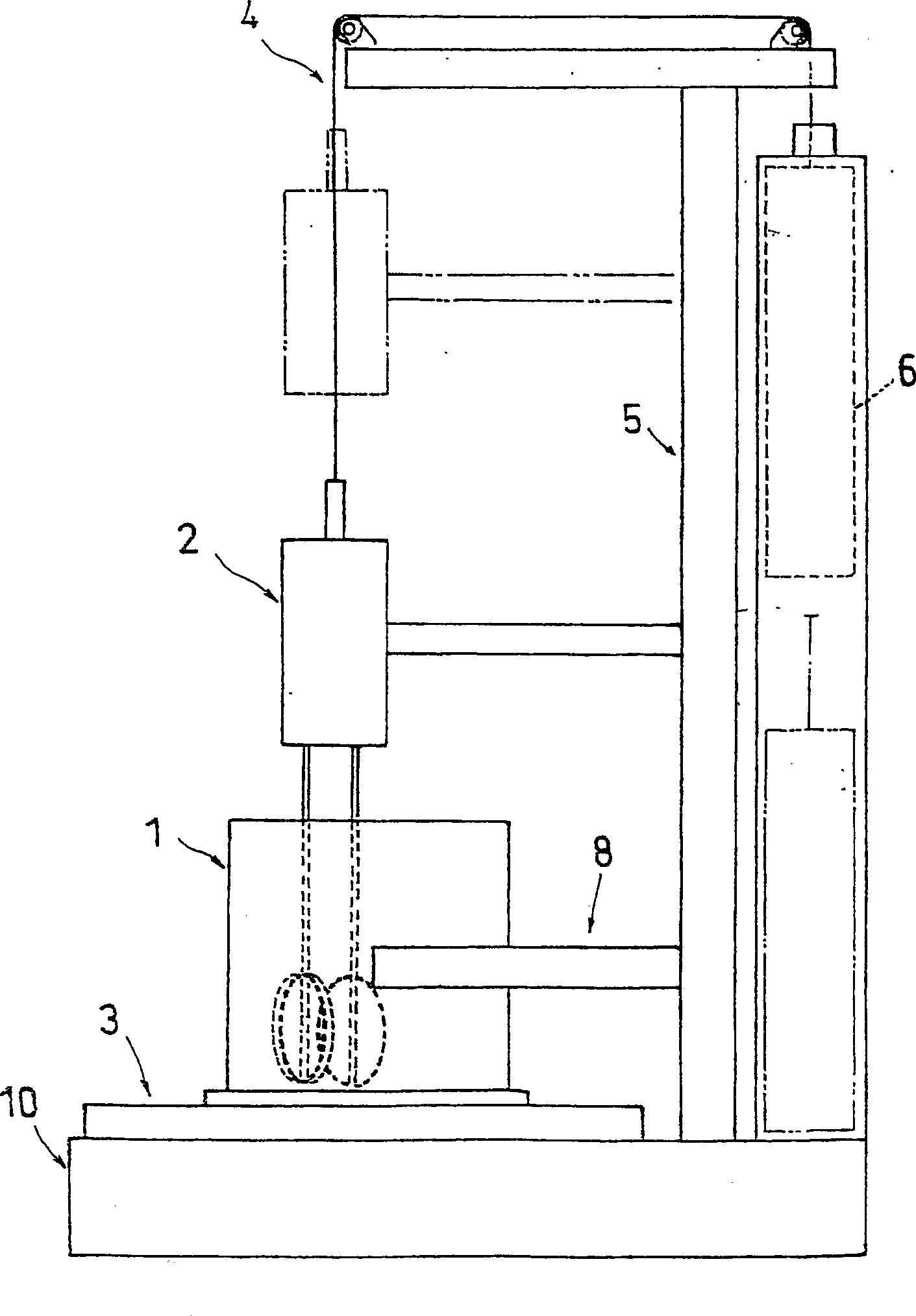

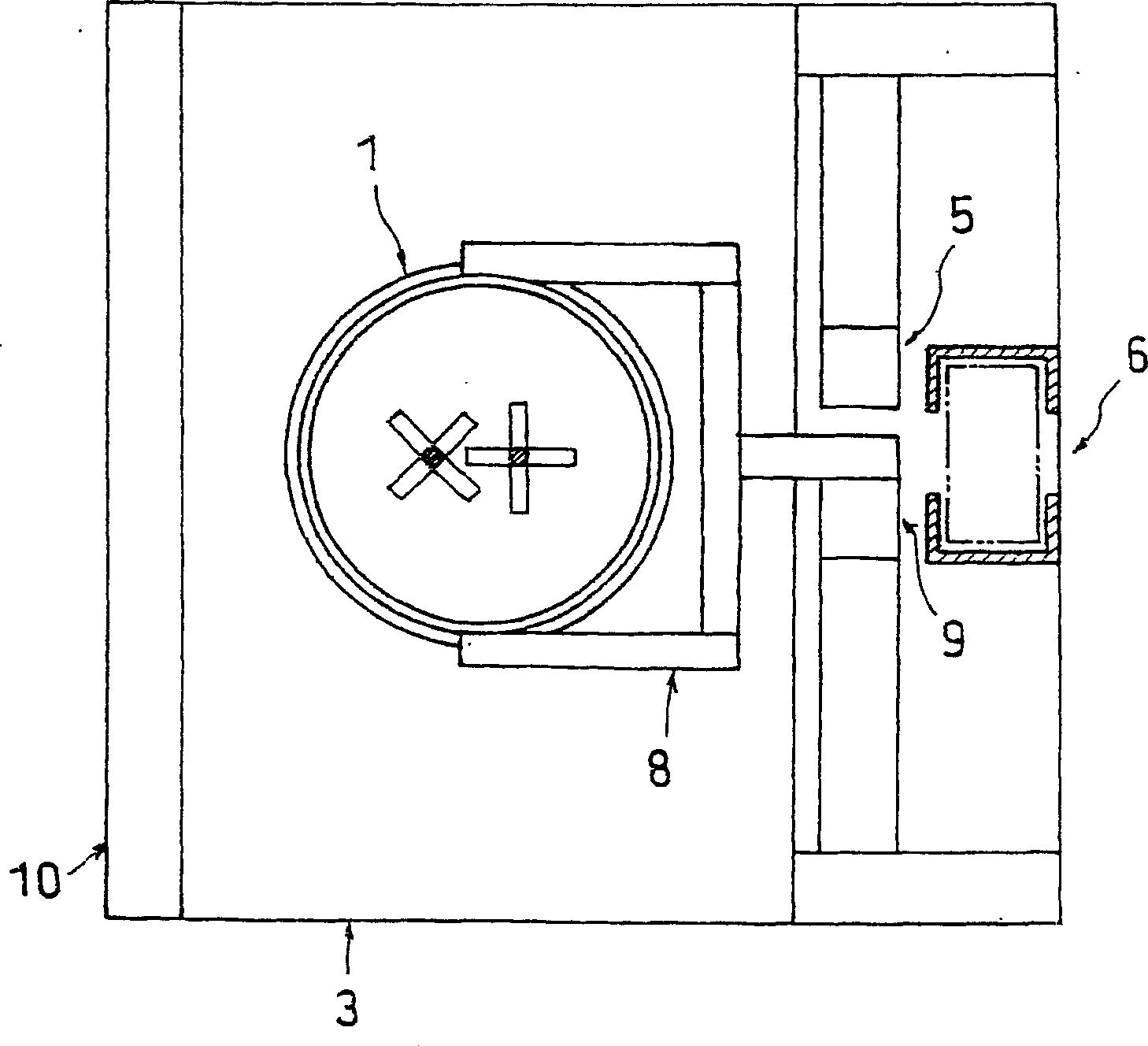

To provide a mixing device which prevents generation of lumps and undissolved powder in mixing the powder and liquid, and can continuously mix them and uniformly at a desired concentration, and to provide a method therefor. The constant quantity of powder 10 is fallen continuously by gravity into the central part of a cylindrical vessel 1 and the falling powder is mixed with the injection-flow liquid by injecting the liquid from an injection opening 12 installed along the peripheral direction of the lower cylindrical part 4 of the cylindrical vessel 1.

Owner:MITSUBISHI CHEM CORP

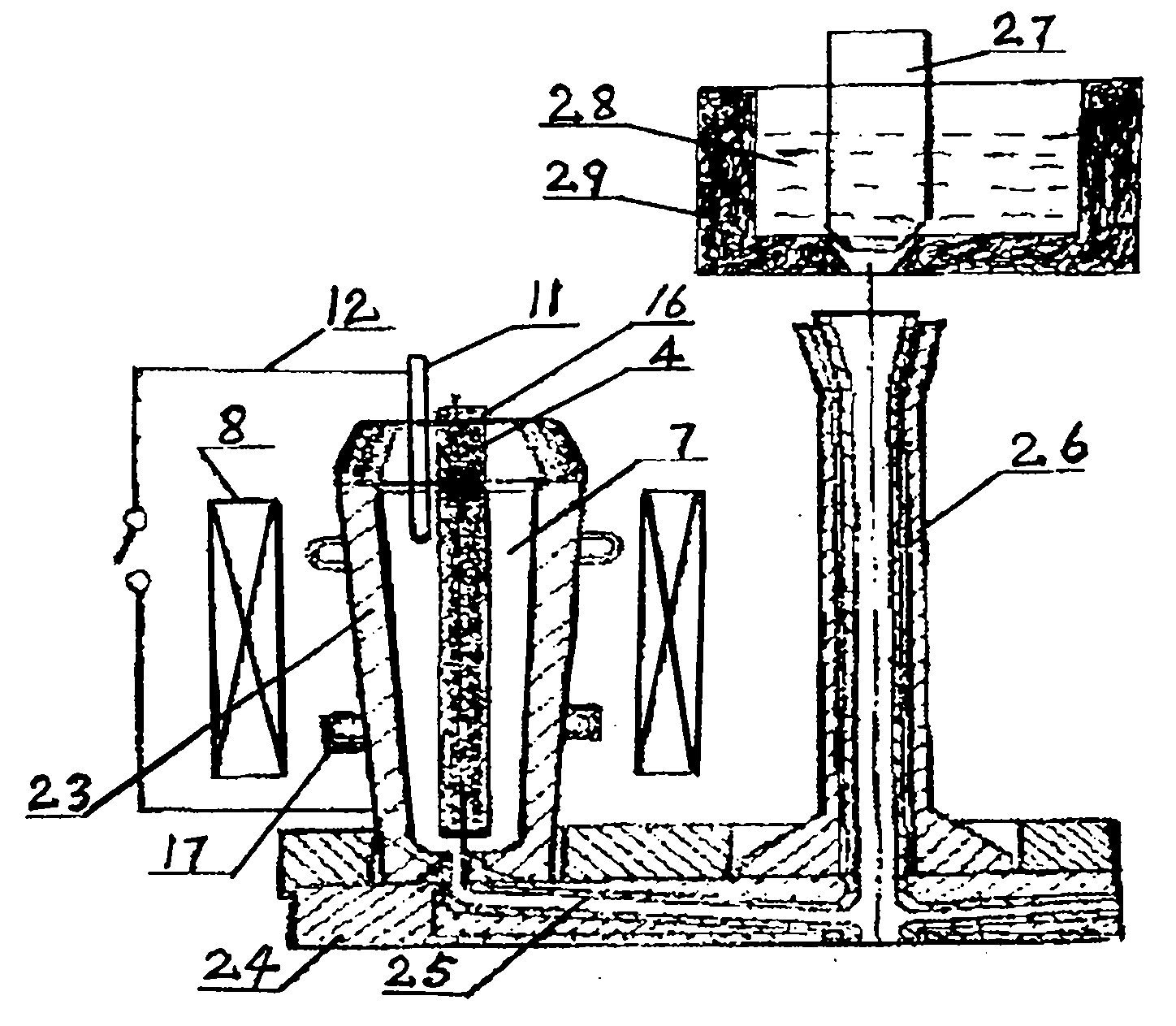

Process and equipment for preparing nanoparticle-reinforced metal matrix composite material

The invention discloses a process and equipment for preparing a nanoparticle-reinforced metal matrix composite material. The process comprises the following steps of: mixing reinforcing nanoparticles with matrix metals and a grain growth inhibitor in a stirring ball mill together, and then loading the mixture into a steel pipe; casting the mixture together with the matrix metals in a water cooling crystallizer or casting and forming the mixture together with a molten metal in a casting mould; and performing quick solidification and crystallization after electromagnetic stirring and ultrasonic vibration to ensure that the two phase materials achieve complete metallurgical bonding, wherein because of the electromagnetic stirring and the ultrasonic vibration, the two phase materials are mixed more uniformly, and all properties of the composite material can be further improved. by using the process and the equipment, a production process is simple, the cost is low, the efficiency is high, the product performance is high, the process is easy to control, the external dimensions of products are not limited by the process, and large-sized nanoparticle-reinforced metal matrix composite materials can be manufactured.

Owner:丁家伟

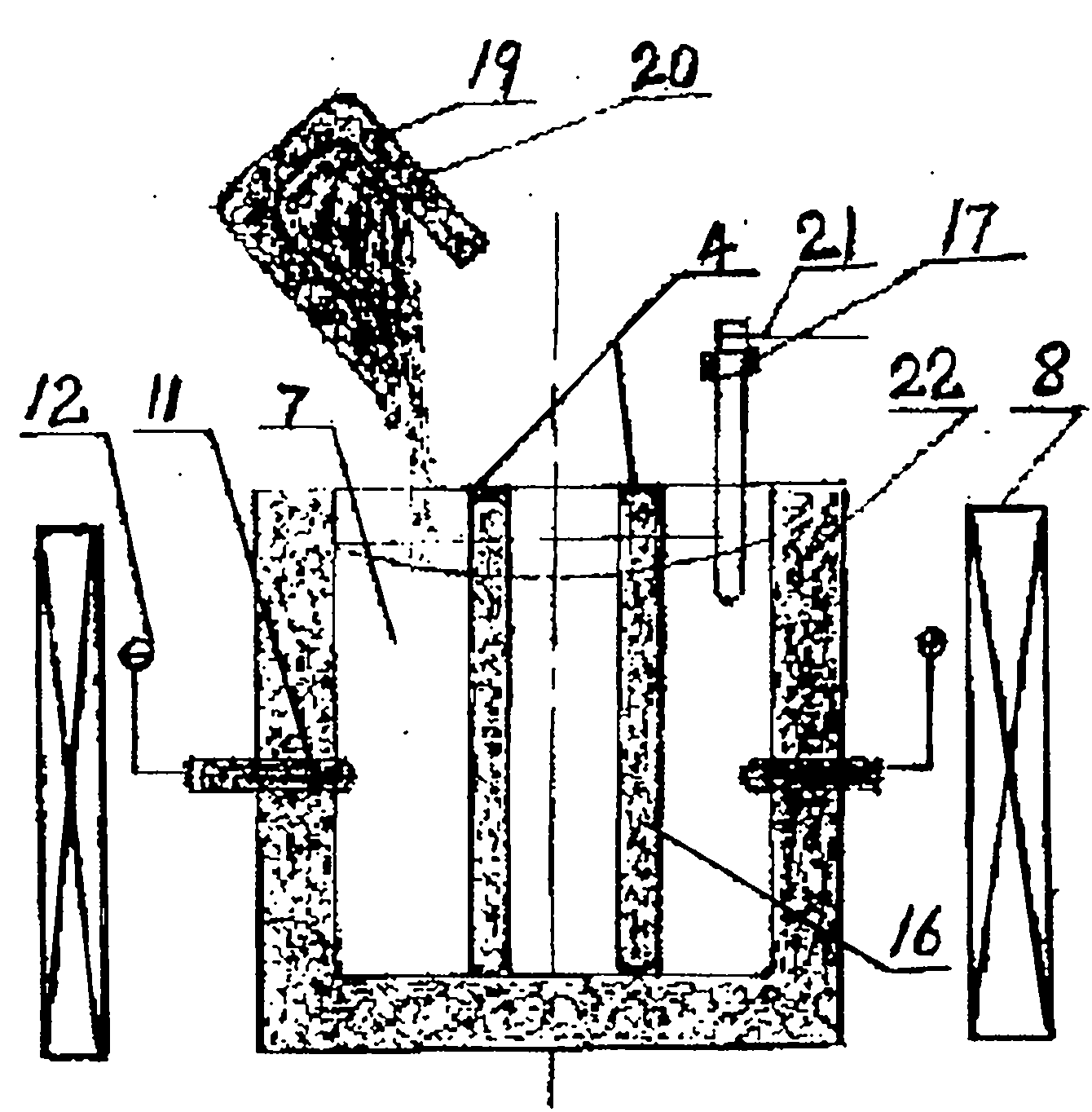

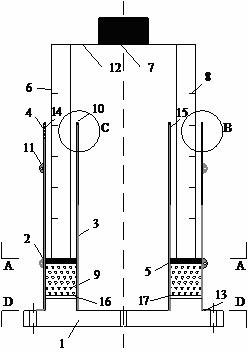

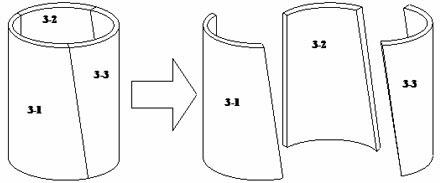

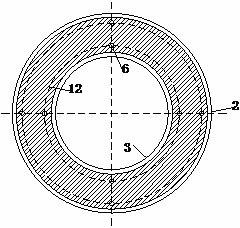

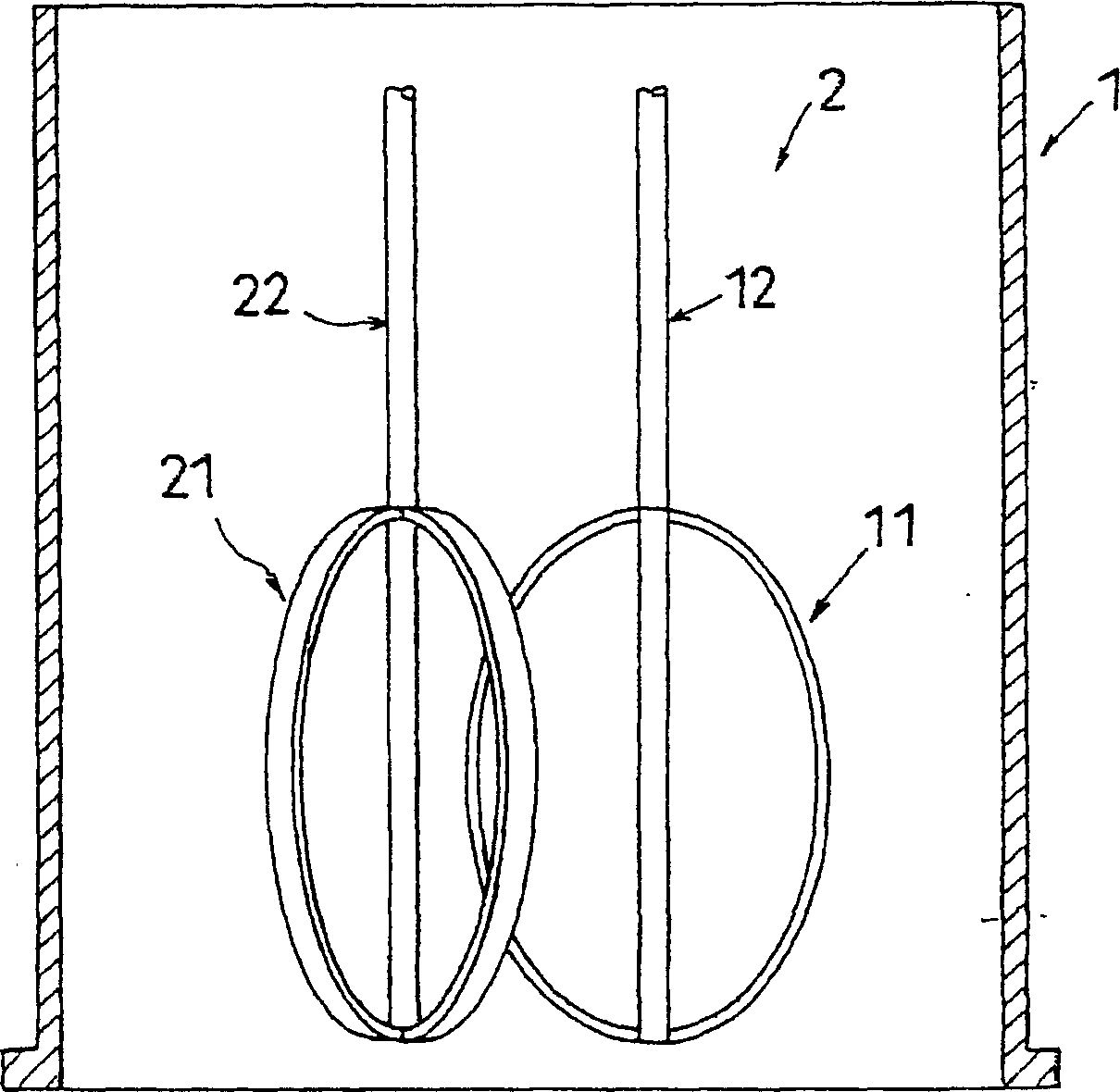

A large hollow cylinder sample maker for coarse-grained soil and its use method

ActiveCN102288461AAvoid uneven forceFlexible accessPreparing sample for investigationSoil scienceTest sample

The invention discloses a large-sized hollow cylindrical sampler for coarse grained soil and a use method thereof. The sampler comprises an annular sleeve and a vibrating compacter, two parts in all, wherein the annular sleeve comprises an annular base (1), an annular outer sleeve (2), an annular inner sleeve (3) and an annular extension barrel (4); and the vibrating compacter comprises a vibrating motor (7), a circular iron plate (12), a dowel bar (6), a positioner (8) and an annular iron plate (5). While using the instrument, a soil sample (9) is paved at first and then put into the annulariron plate (5); next, the vibrating motor (7) is turned on; when the edge of the annular outer sleeve (2) is level with the positioner (8), the vibrating motor (7) stops vibration and the next layer of soil sample (9) is added; and then vibration compaction is performed until the soil samples reach a predetermined height. The sampler is simple to use, convenient for operation and control, and capable of preparing a highly compact and even test sample, so that the time and labour for preparing the test sample are saved.

Owner:HOHAI UNIV

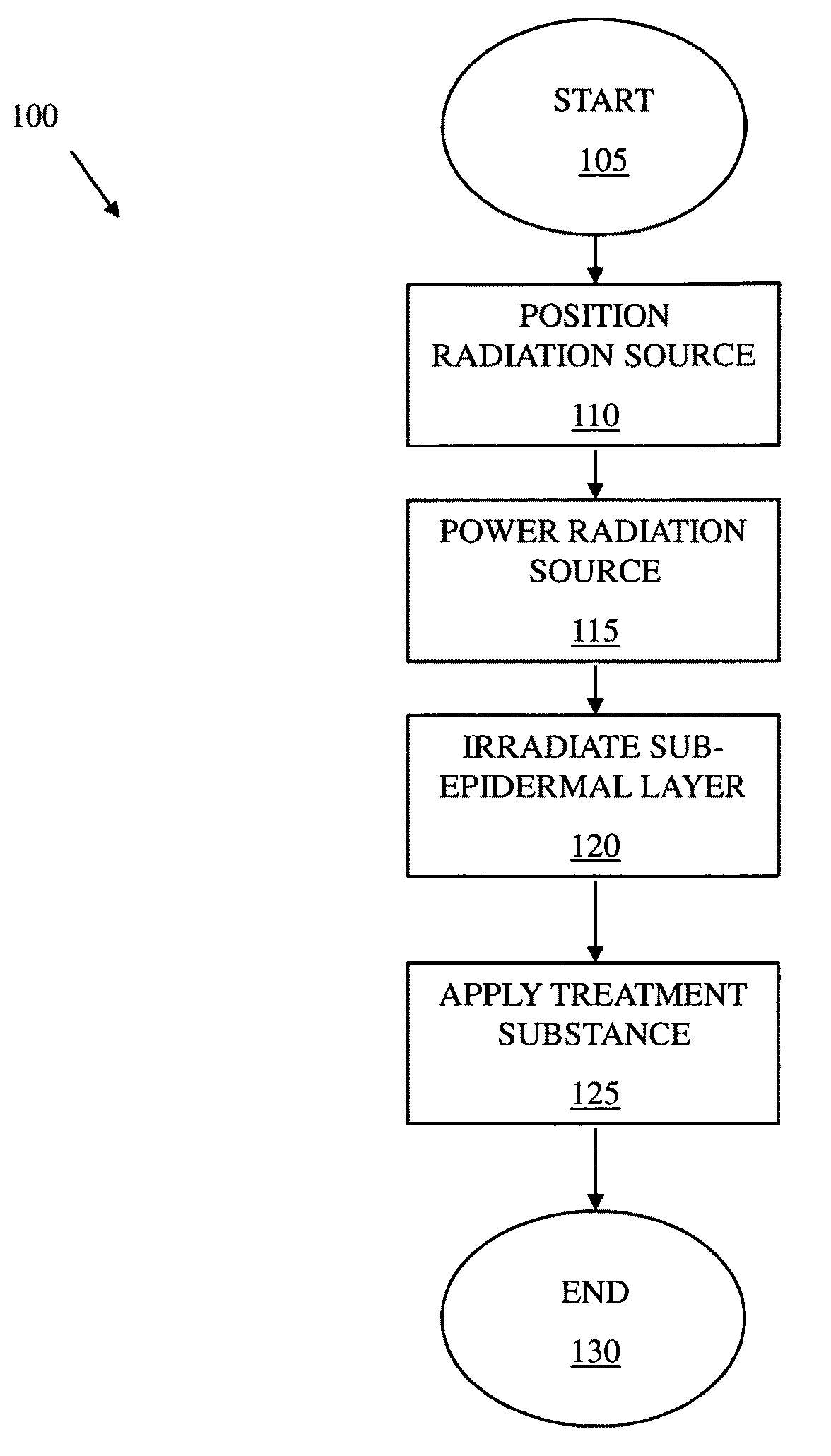

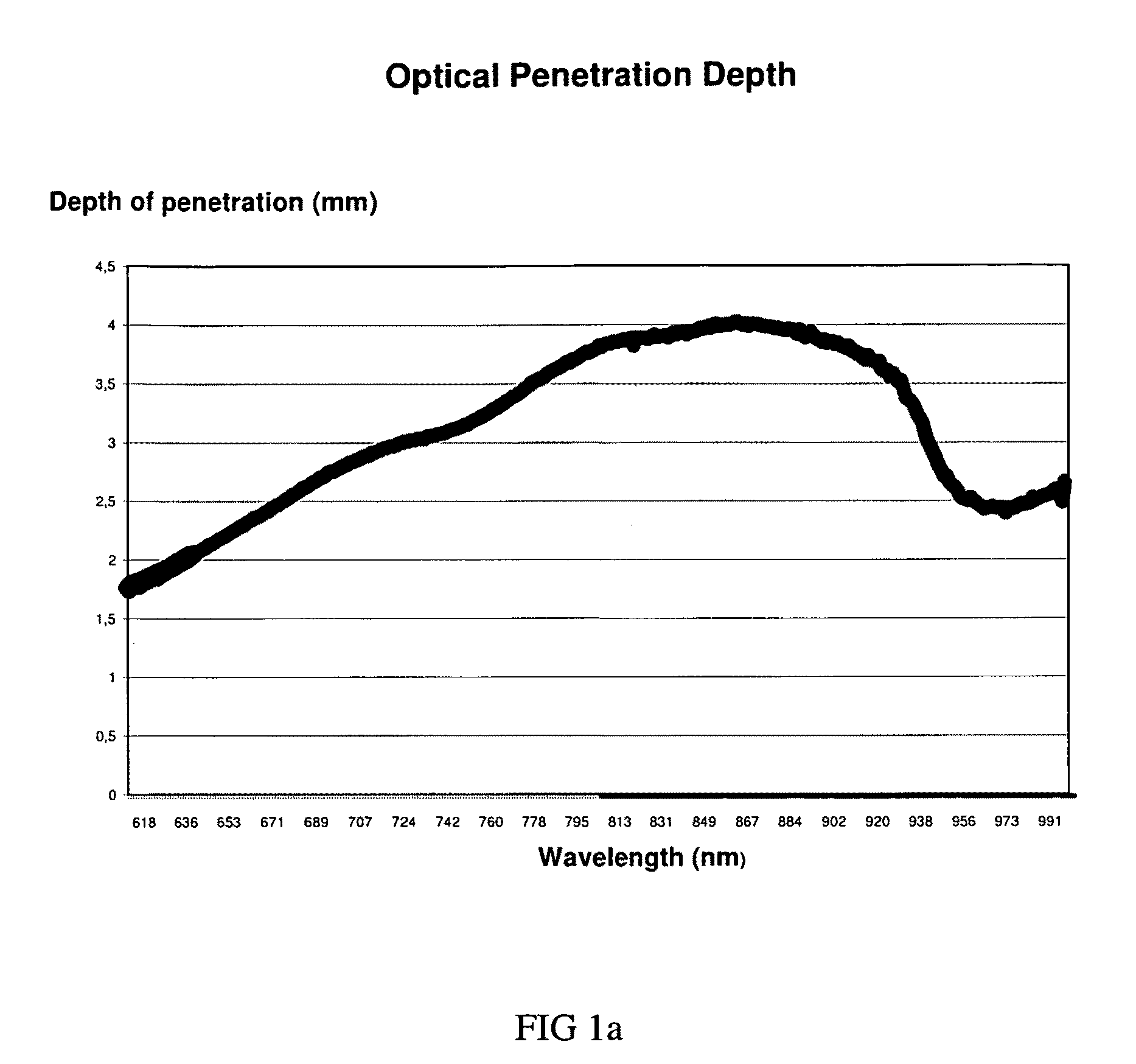

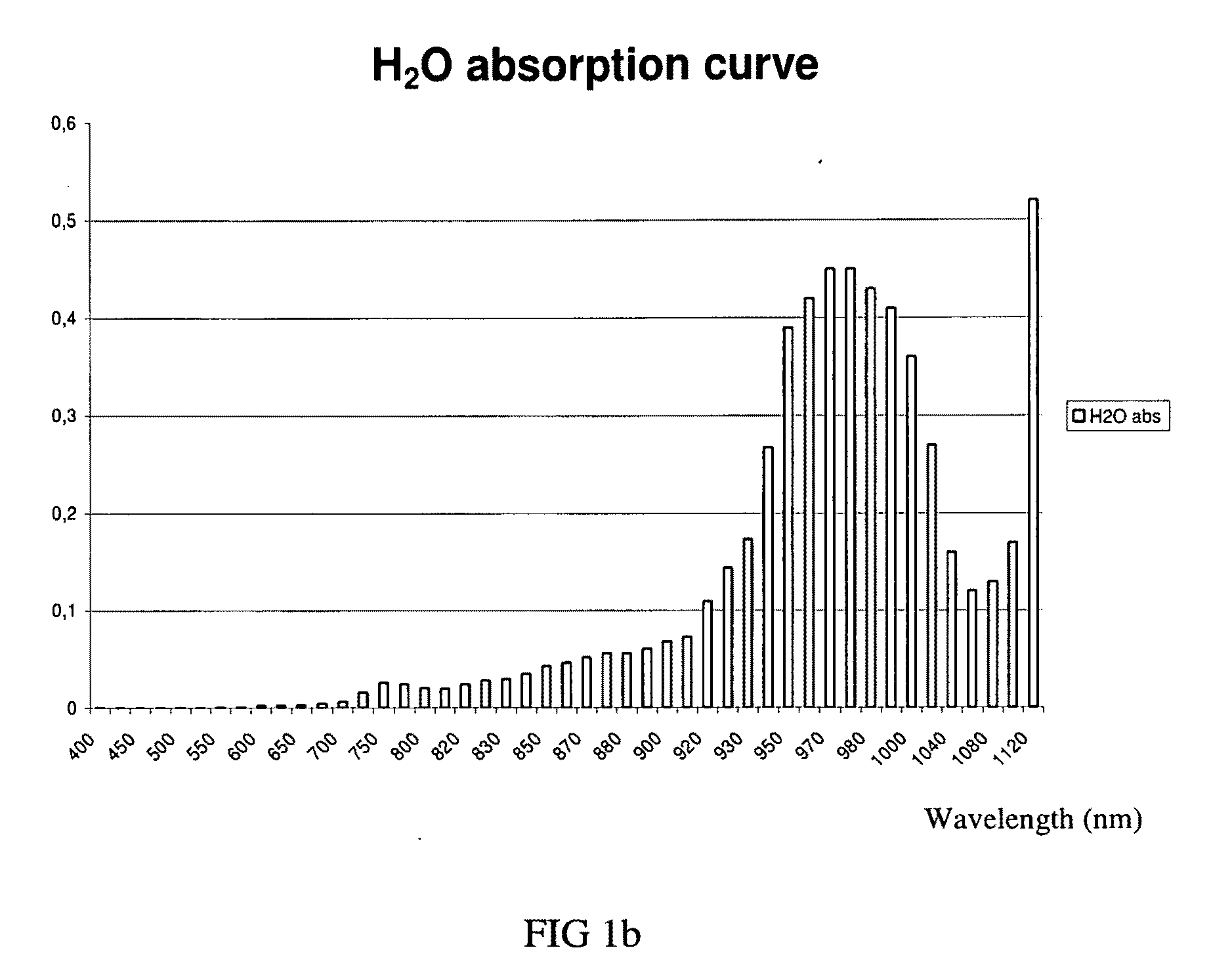

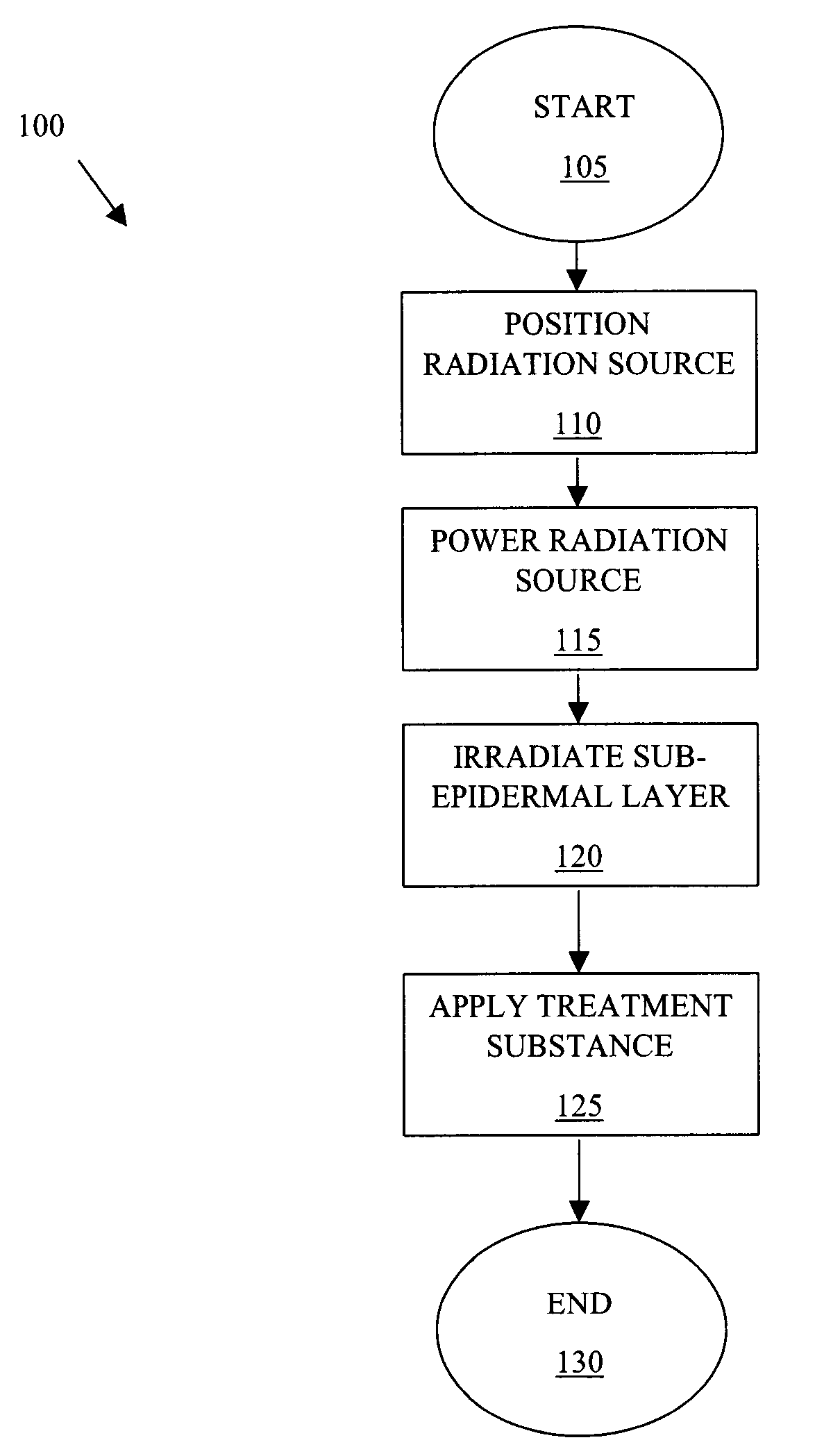

Method for the treatment of skin tissues

InactiveUS20090247932A1Without any damage to skinEasy to useElectrotherapyLight therapySkin surfaceSkin tissue

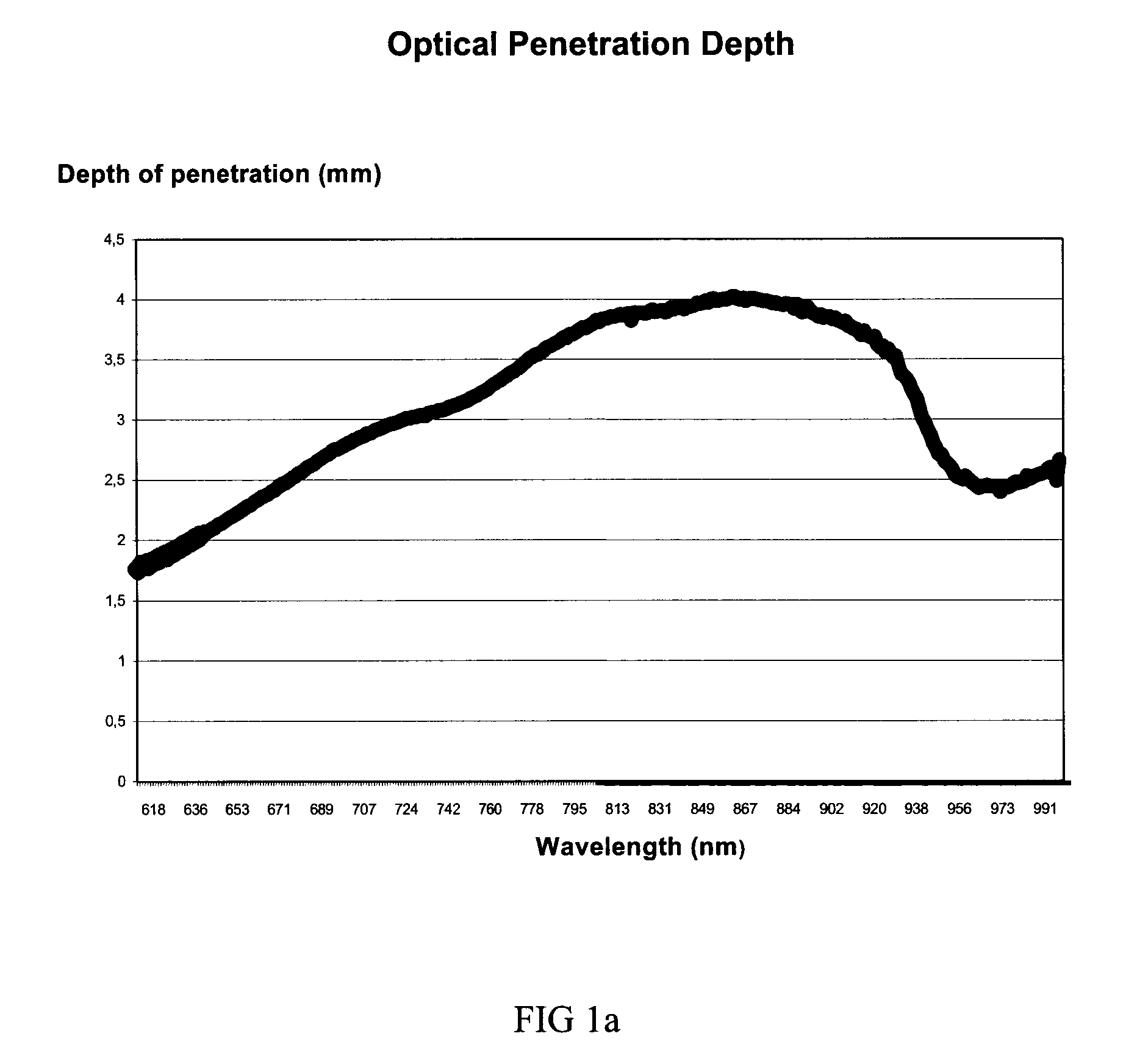

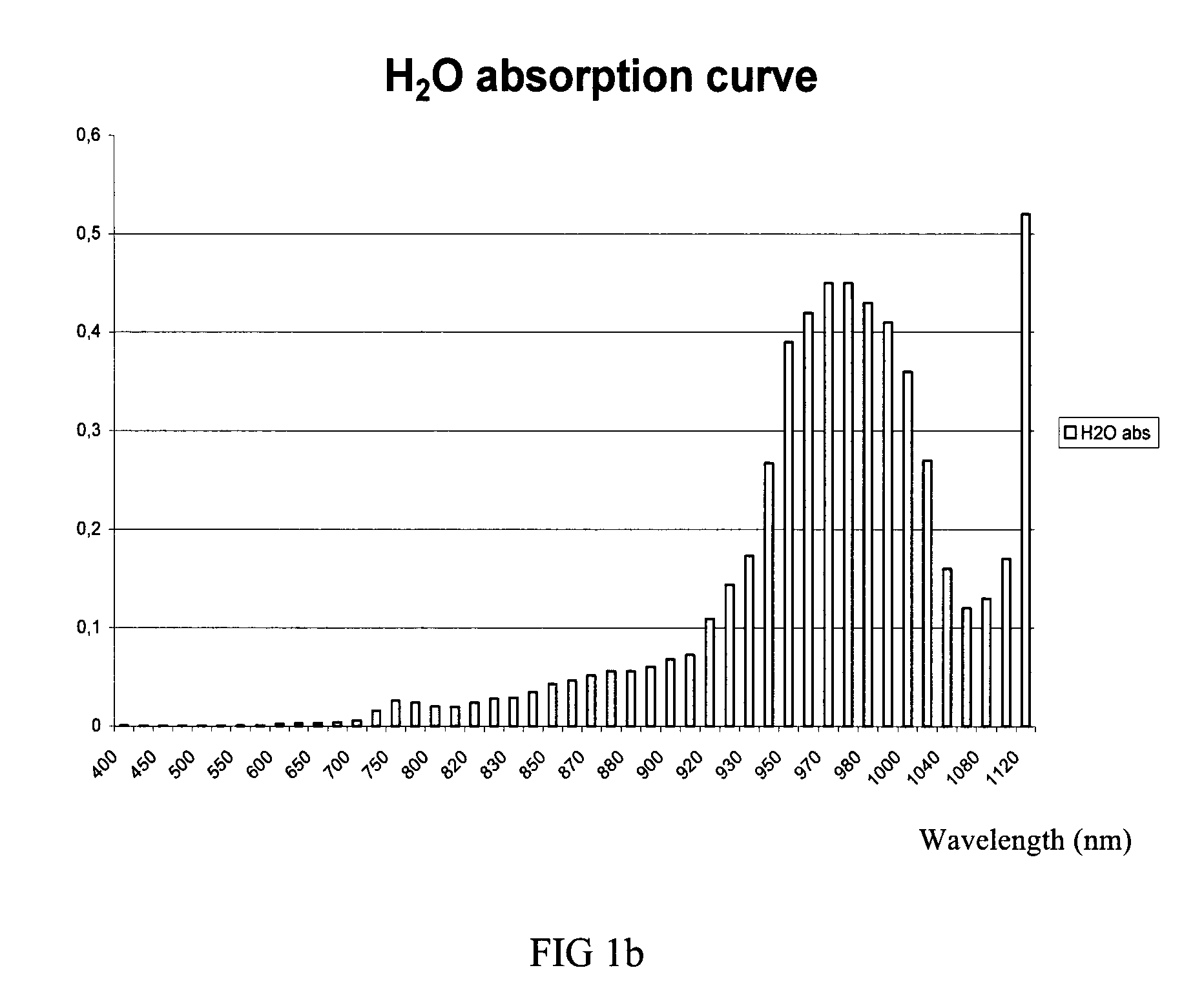

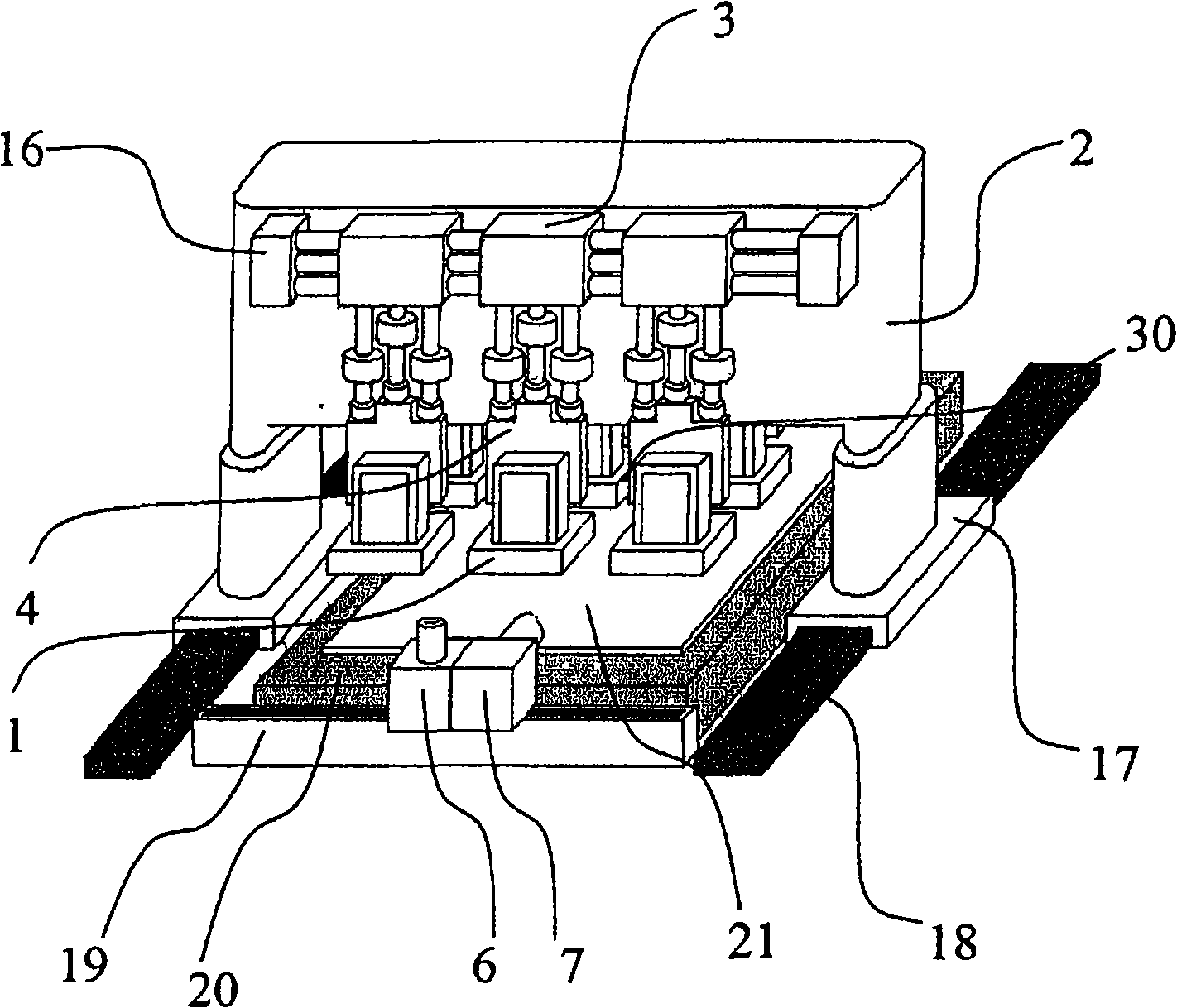

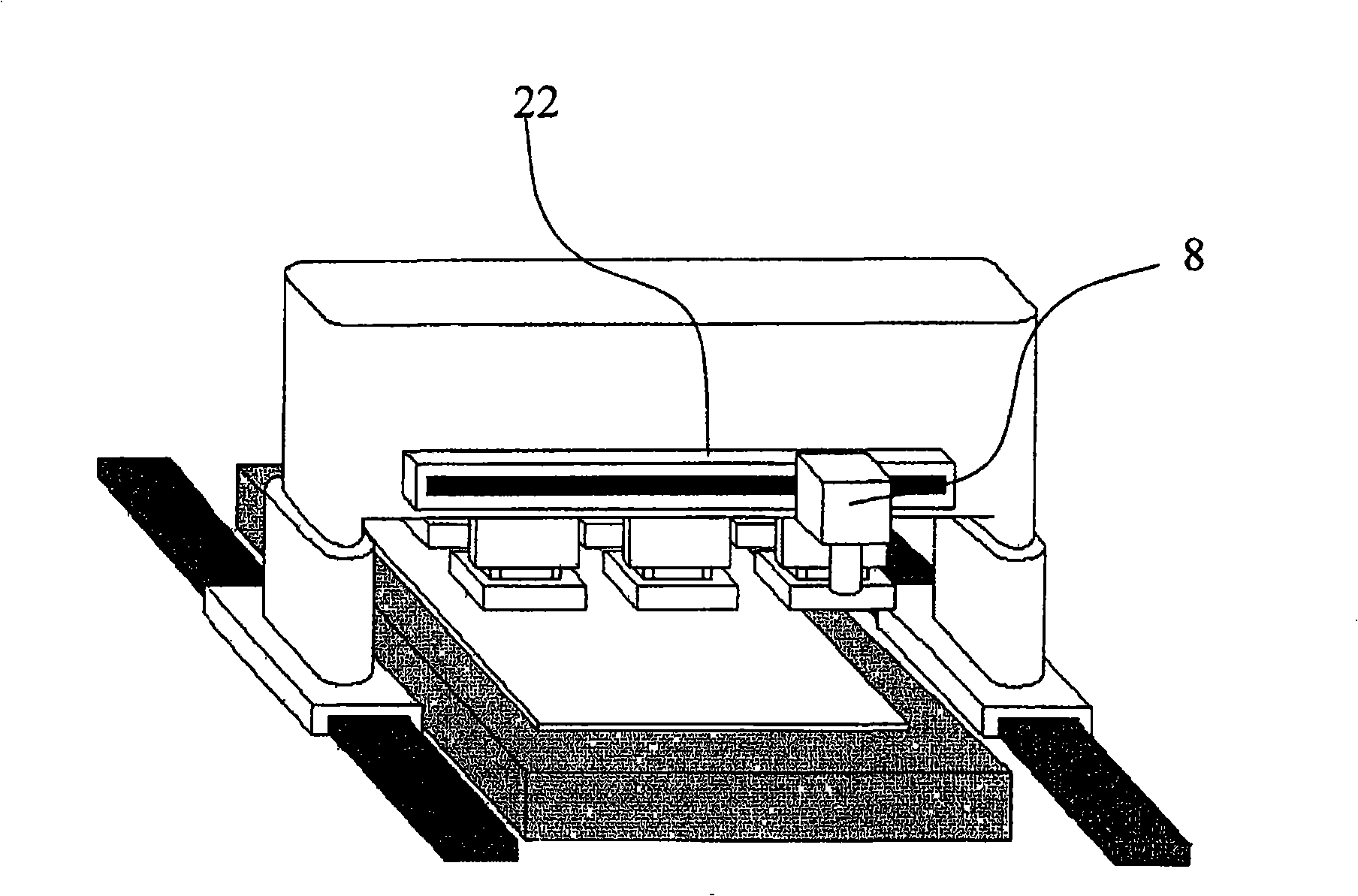

A method for treating skin tissues, the skin tissues defining an epidermal layer and a sub-epidermal layer, the epidermal layer defining a skin surface and the sub-epidermal layer extending from the epidermal layer substantially opposite to the skin surface, the method comprising: positioning a radiation source outside of the skin tissues at a predetermined distance from the skin surface; powering the radiation source so as to produce infrared radiation having a predetermined spectrum and a predetermined power; and irradiating the sub-epidermal layer with the infrared radiation through the epidermal layer, the predetermined spectrum and the predetermined power being such that the infrared radiation is absorbed to a larger degree in the sub-epidermal layer than in the epidermal layer.

Owner:BAROLET DANIEL

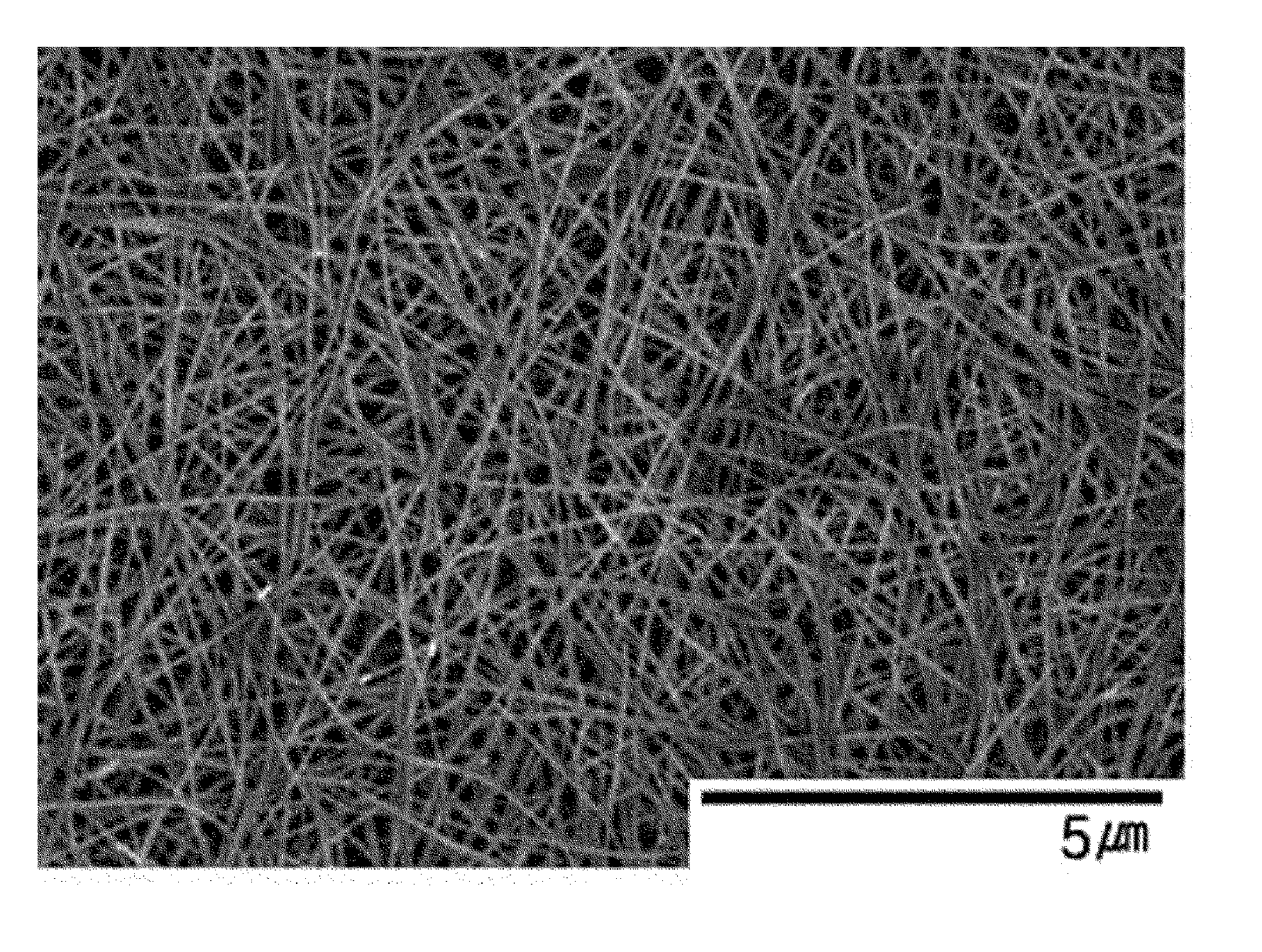

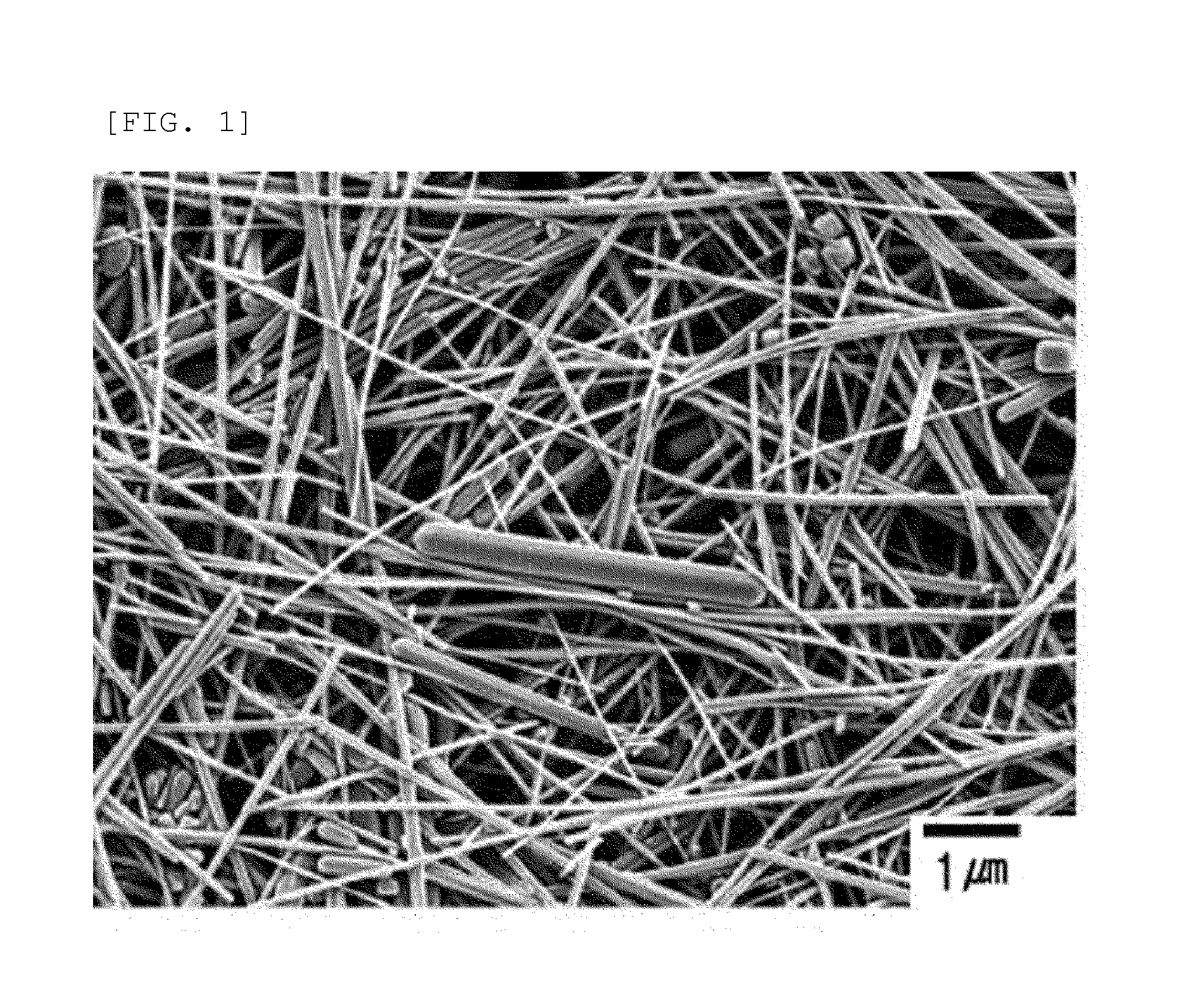

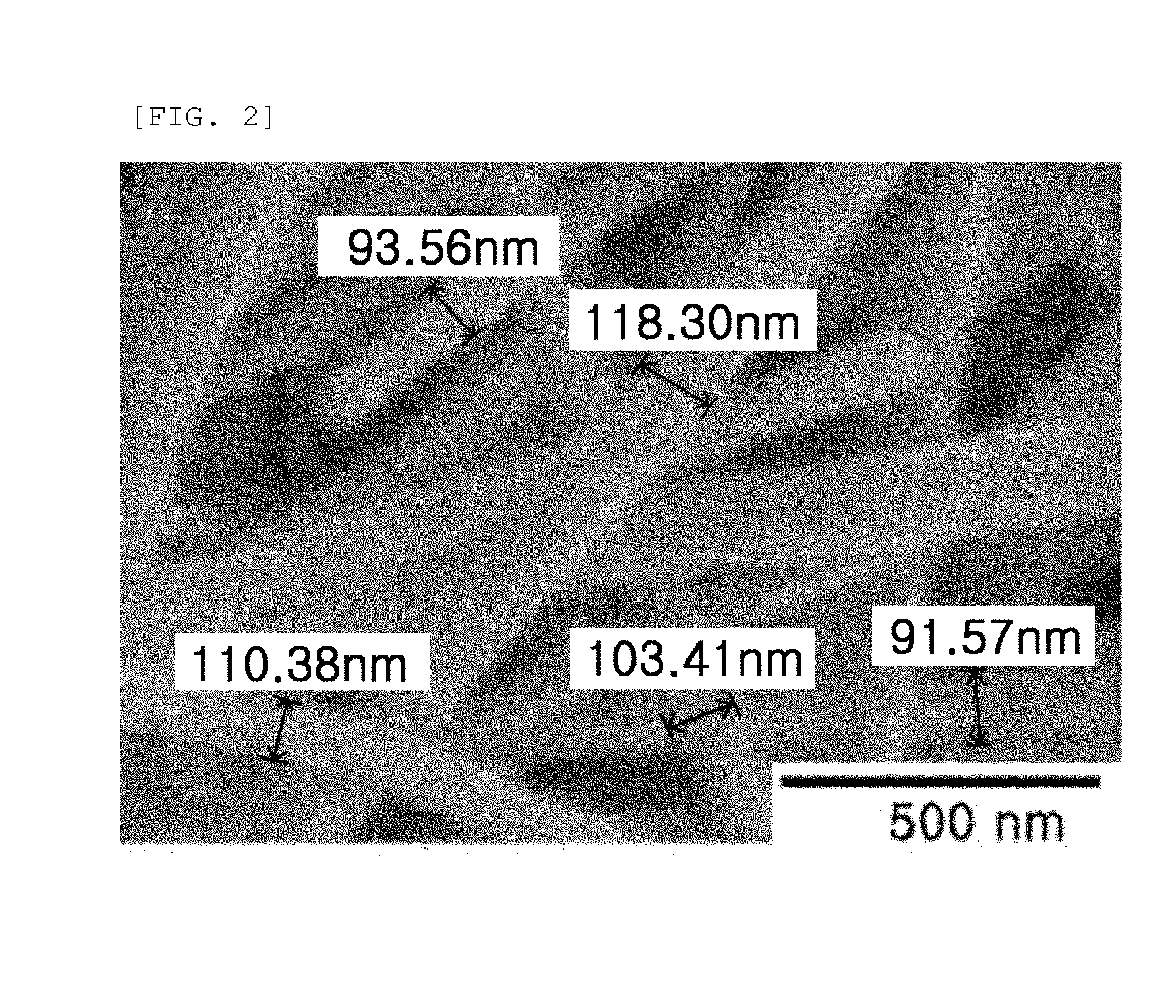

Method for manufacturing silver nanowires using ionic liquid

InactiveUS20150321257A1Low surface resistivityHigh light transmittanceMaterial nanotechnologyTransportation and packagingIonSolvent

The present invention relates to a method of preparing silver nanowires having a diameter of less than 100 nm and a length of 10 μm or more, and, more particularly, to a method of uniformly preparing silver nanowires having a high aspect ratio using an ionic liquid as an additive in addition to a silver salt precursor, a reducing solvent and a capping agent in a polyol process. When the technology of the present invention is used, silver nanowires having a diameter of less than 100 nm and a length of 10 μm or more can be uniformly prepared. Further, when a transparent conductive film is formed by applying a silver nanowire-dispersed solution onto a base film, the transparent conductive film has a surface resistivity of 101˜103Ω / □ and a light transmittance of 90% or more to the base film.

Owner:INSCON TECH +1

Method for the Treatment of Skin Tissues

InactiveUS20090112192A1Without any damage to skinEasy to useSurgical instrument detailsLight therapySkin surfaceSkin tissue

A method for treating skin tissues, the skin tissues defining an epidermal layer and a sub-epidermal layer, the epidermal layer defining a skin surface and the sub-epidermal layer extending from the epidermal layer substantially opposite to the skin surface, the method comprising: positioning a radiation source outside of the skin tissues at a predetermined distance from the skin surface; powering the radiation source so as to produce infrared radiation having a predetermined spectrum and a predetermined power; and irradiating the sub-epidermal layer with the infrared radiation through the epidermal layer, the predetermined spectrum and the predetermined power being such that the infrared radiation is absorbed to a larger degree in the sub-epidermal layer than in the epidermal layer.

Owner:BAROLET DANIEL +1

Inkjet head device

ActiveCN101407131AUniform preparationNo spotsPower drive mechanismsOther printing apparatusEngineeringCoating

The technical problem the invention object to resolve is to measure the bias starting from the target location from the initial installation, and to manufacture product substrates with high yield after effective and high precision correction, in an apparatus of using an ink jet head with a plurality of nozzles to coat the material on the substrate. In the invention, a nozzle camera is used to process position correction to all the heads beforehand by taking the central head as a benchmark in the a plurality of ink jet heads provided on the apparatus and measuring the position of the two terminal nozzles (a space d) of the head 1. Furthermore, the material pattern is coated on a substrate for modulation, the bias (a space D) from the target location is measured by observing the position of the coating points, and then XYtheta direction position correction of the nozzle between heads is performed by calculating the moving quantity from the bias.

Owner:艾美柯技术株式会社

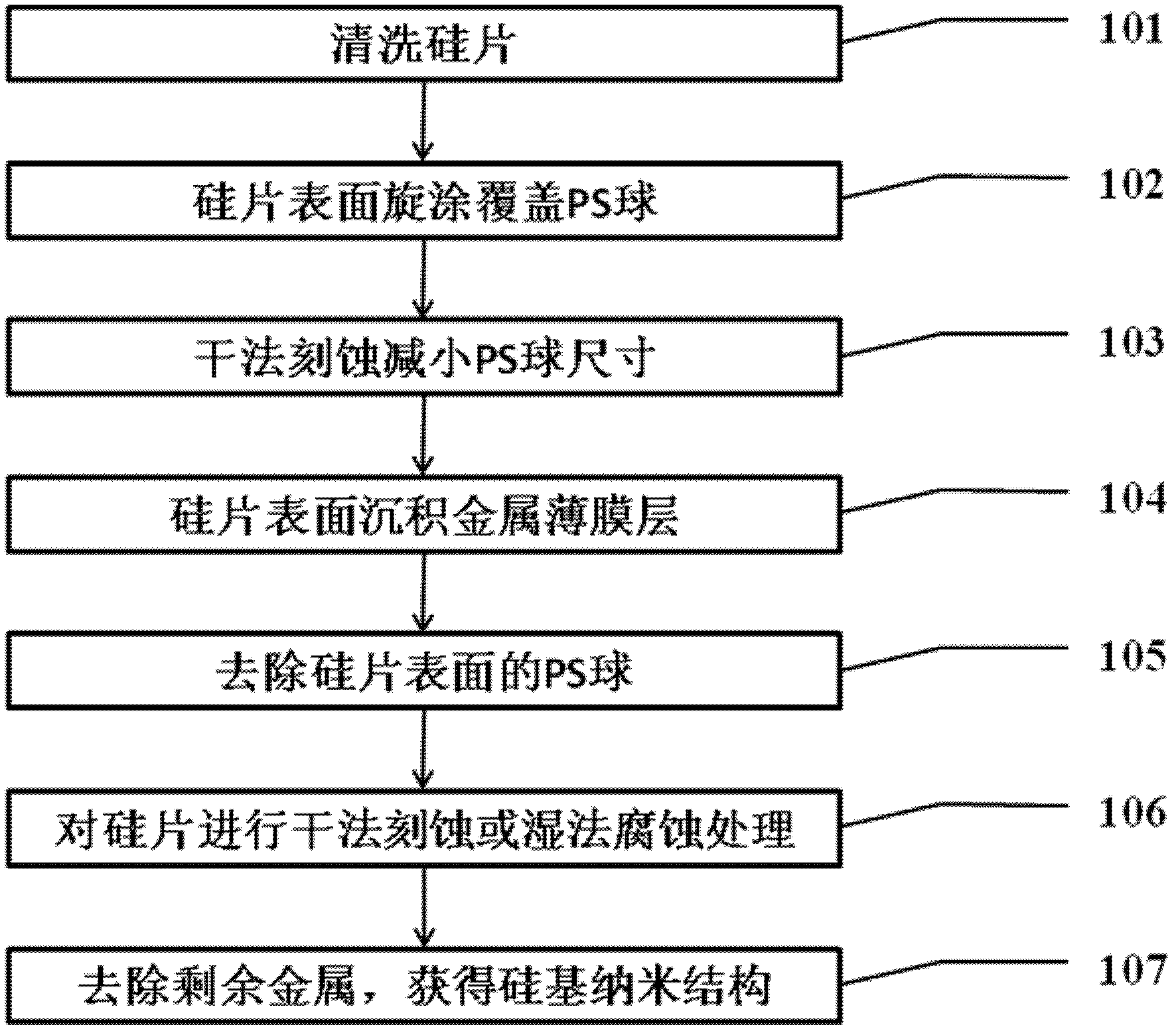

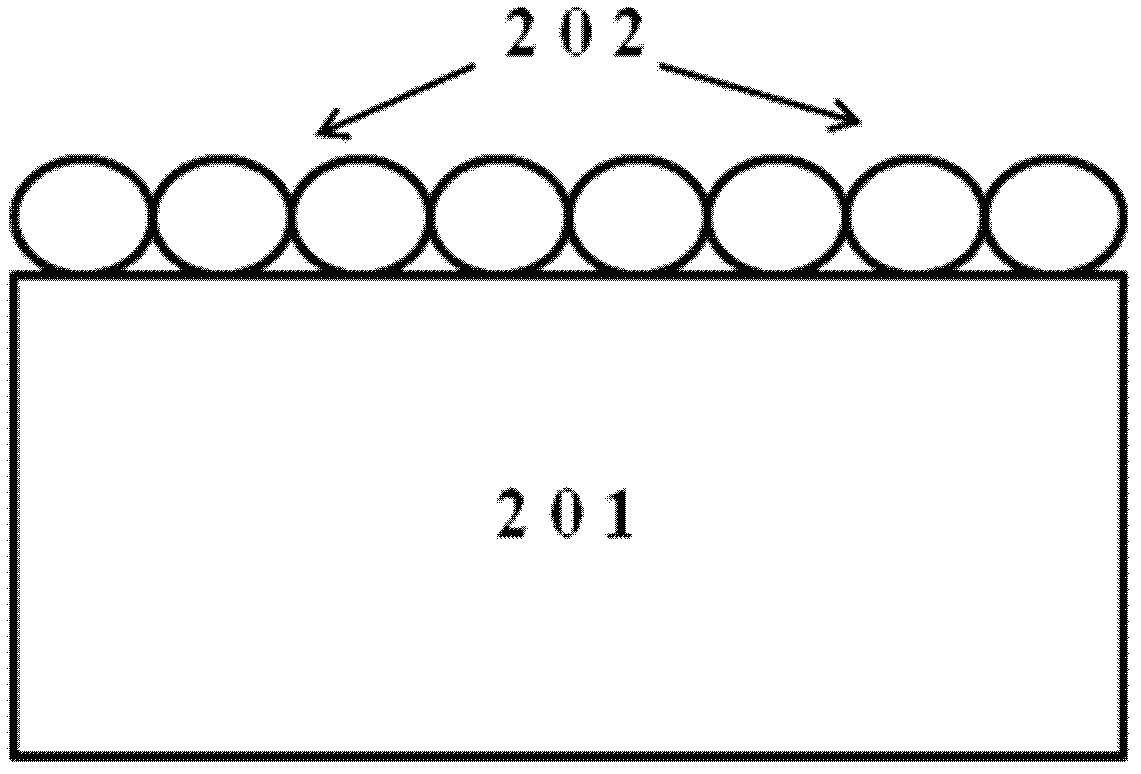

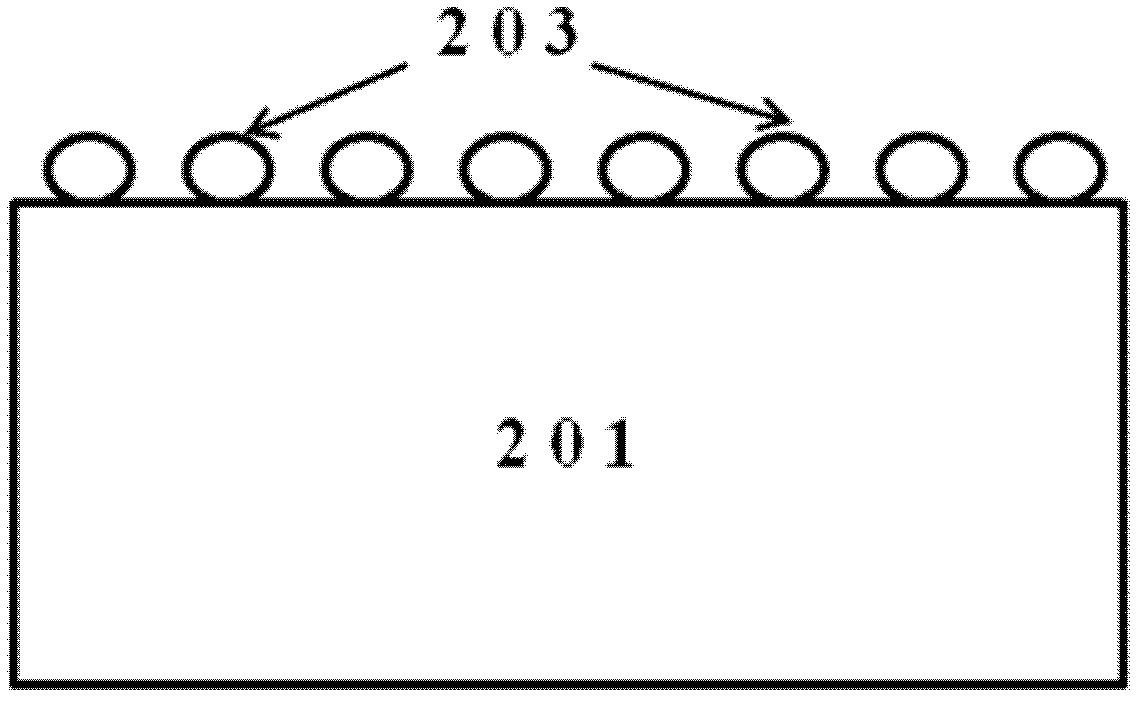

Silicon substrate nano-structure for solar cell and preparing method thereof

InactiveCN102593261AImprove conversion efficiencyUniform sizeFinal product manufactureNanoinformaticsPolystyreneSolar cell

The invention discloses a silicon substrate nano-structure for a solar cell and a preparing method thereof, and the method includes: cleaning silicon chips; spin-coating and covering single layer polystyrene (PS) spheres on the surface of the silicon chips; etching the PS spheres and reducing the sizes of the PS spheres; depositing a metal film layer on the surface of the silicon chip surface and forming metal mask; removing residual PS spheres on the silicon chip surface and remaining for the left metal masking layer; forming the silicon substrate nano-structure by using a dry etching or wet etching method; treating the silicon chips by heated concentrated acid and removing the residual metal and finishing the preparation of the silicon substrate nano-structure. According to the silicon substrate nano-structure for the solar cell and the preparing method thereof, PS spheres masking and metal film growth are utilized and the dry etching method and the wet etching method are combined so that a preparing method of silicon substrate nano-structure for the solar cell is provided. According to the silicon substrate nano-structure, the reflectivity is low, the light trapping ability is of high efficient, the light absorption of the solar cell is enhanced and the efficiency of the solar cell is improved.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Environment-friendly straw feed manufacturing equipment

The invention discloses environment-friendly straw feed manufacturing equipment. The equipment comprises a feeding pipe, a box body, an electric telescopic rod, a camera, a stir-frying knife, a pressing plate, an air blower, a crushing box, a heater, a drying box and a rotary conical roller, wherein the feeding pipe is arranged on the top of the box body, the electric telescopic rod is arranged on the top of the box body, and the pressing plate is arranged at the bottom of the electric telescopic rod; a cutter is arranged on the lower surface of the pressing plate, a rotating shaft is arranged in the box body, and the stir-frying knife is arranged at the bottom of the rotating shaft; a pressure bearing plate is arranged in the box body, a cam is arranged at the bottom of the pressure bearing plate, and a timer is arranged on the outer wall of the box body; the top of the box body is communicated with the air blower, an inclined guide plate is arranged below the pressure bearing plate, and the crushing box is arranged at the outlet end of the inclined guide plate; the bottom of the crushing box is connected with the drying box, and a discharging pipe is arranged at the bottom of the drying box. The equipment guarantees reasonable utilization of straw, straw feed particles can be conveniently stored, the breeding feed cost is reduced, and the equipment is simple in structure, convenient to use and easy to popularize.

Owner:邹铁梅

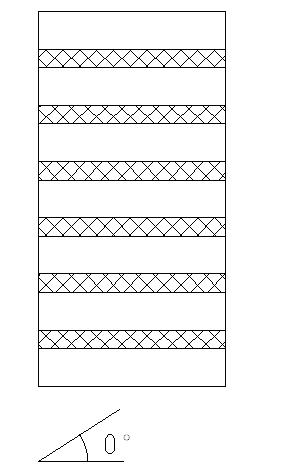

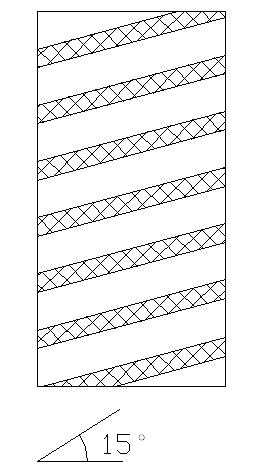

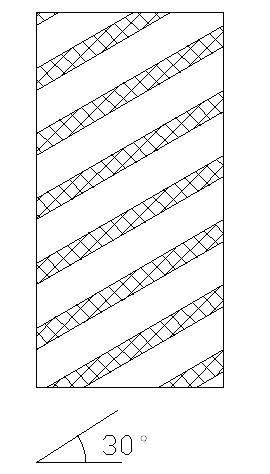

Method for preparing interactive laminar modeling material test piece

InactiveCN101913818ASimple processImprove efficiencyLaminationLamination apparatusBLENDER/MIXEREngineering

The invention discloses a method for preparing an interactive laminar modeling material test piece. The method comprises the following steps of: A, preparing a modeling material: (1) preparing a material a, namely placing loess and barite powder in a stirrer, uniformly stirring the materials and adding water into the mixture to obtain a plastic mixed material a; (2) preparing a material b, namely placing cement and loess into the stirrer, uniformly stirring the materials and adding water into the mixture to obtain the plastic mixed material b; B, assembling detachable boxes; C, pre-pressing: placing the prepared material a and material b in the boxes, arranging pressing plates on the boxes respectively and placing the boxes on an MTS pressure tester for pressing; D, slicing; E, adsorbing, translating and superposing; F, repairing and repressing; G, solidifying; and H, machining the test piece: manufacturing the interactive laminar standard test pieces with different bed inclinations. The method has the advantages of simple and definite process flow, high efficiency, reduction in manufacturing period, high reliability, uniform manufacturing of thin modeling material layer at each layer, broad application prospect and obvious economic benefit.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

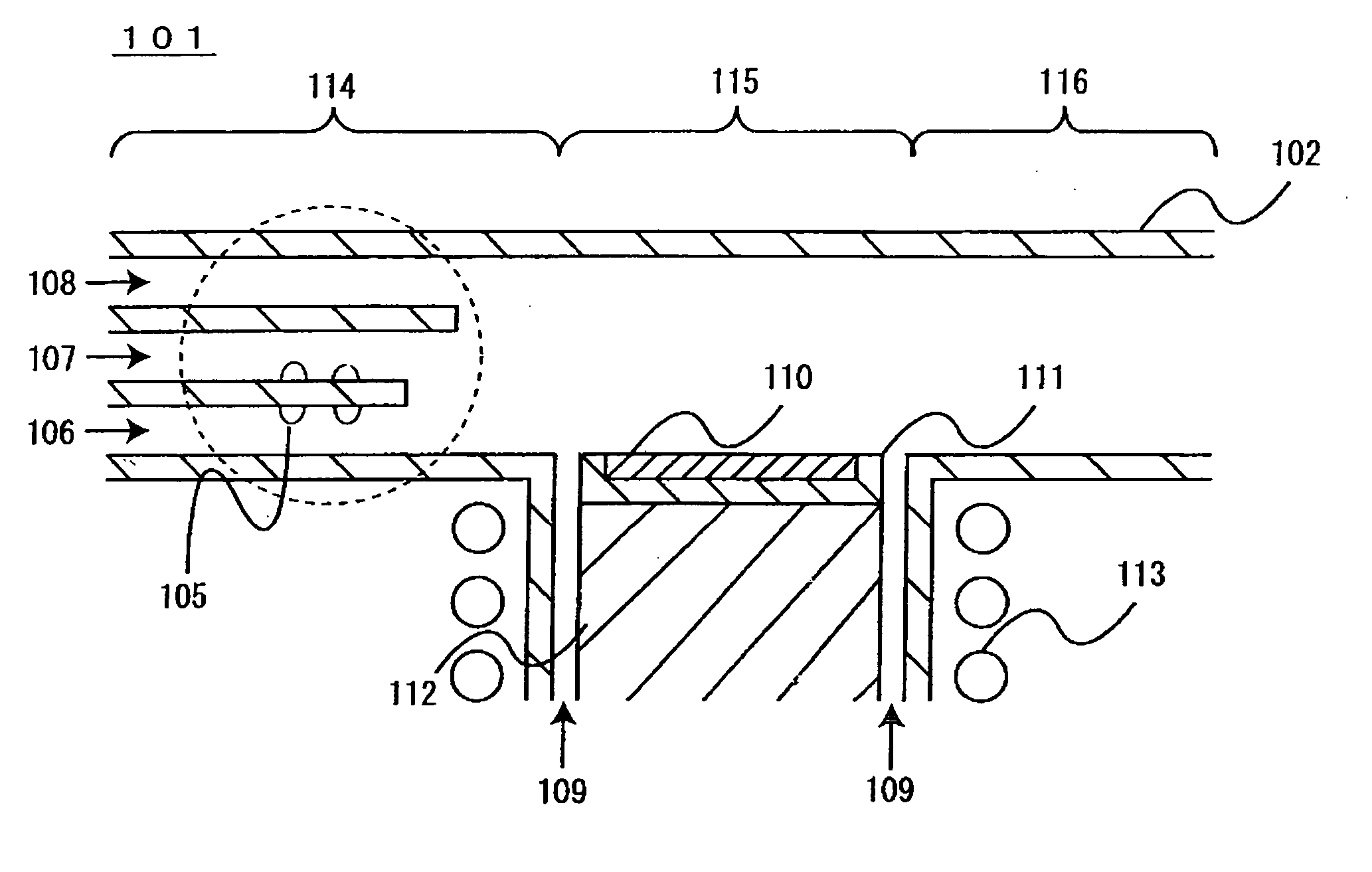

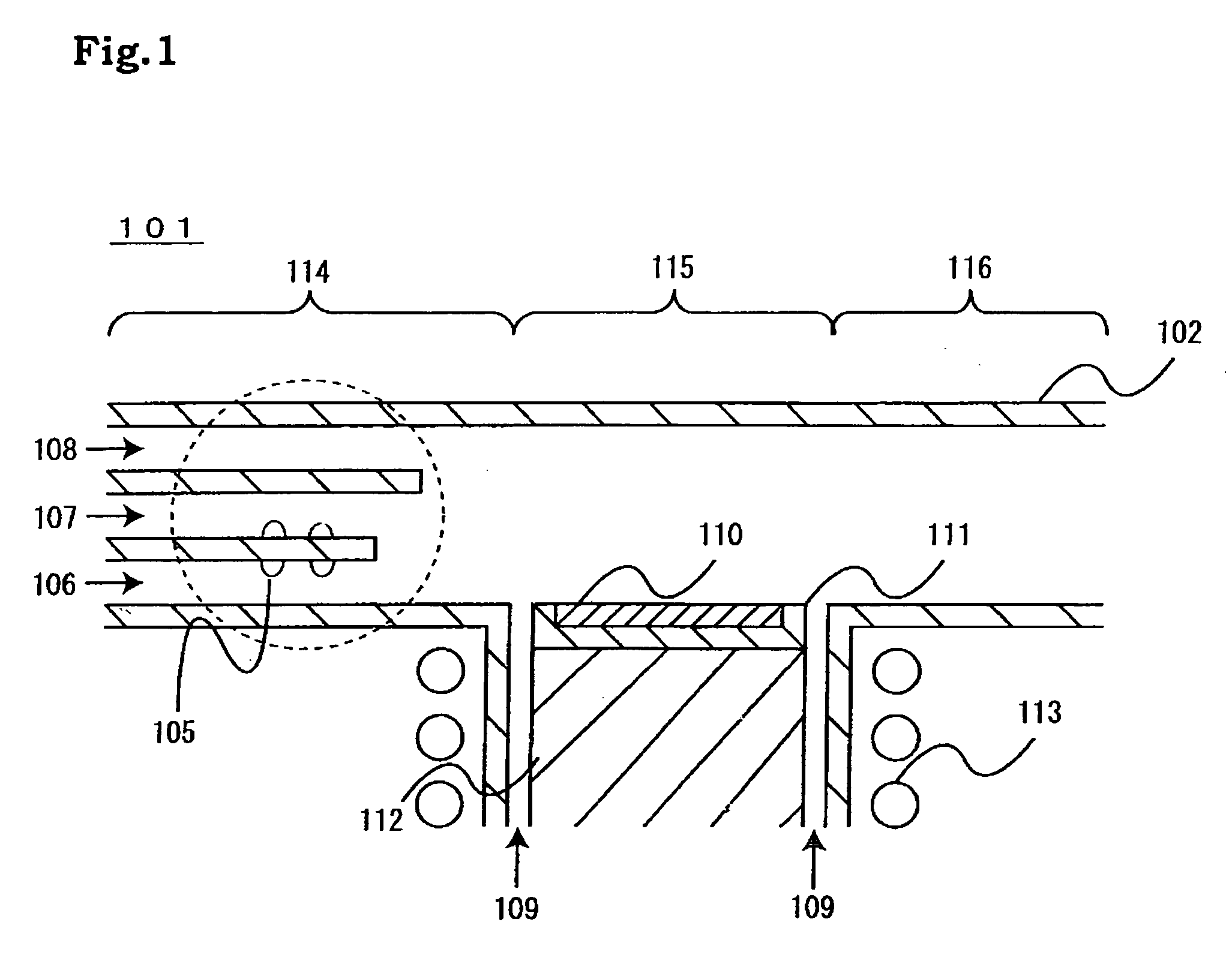

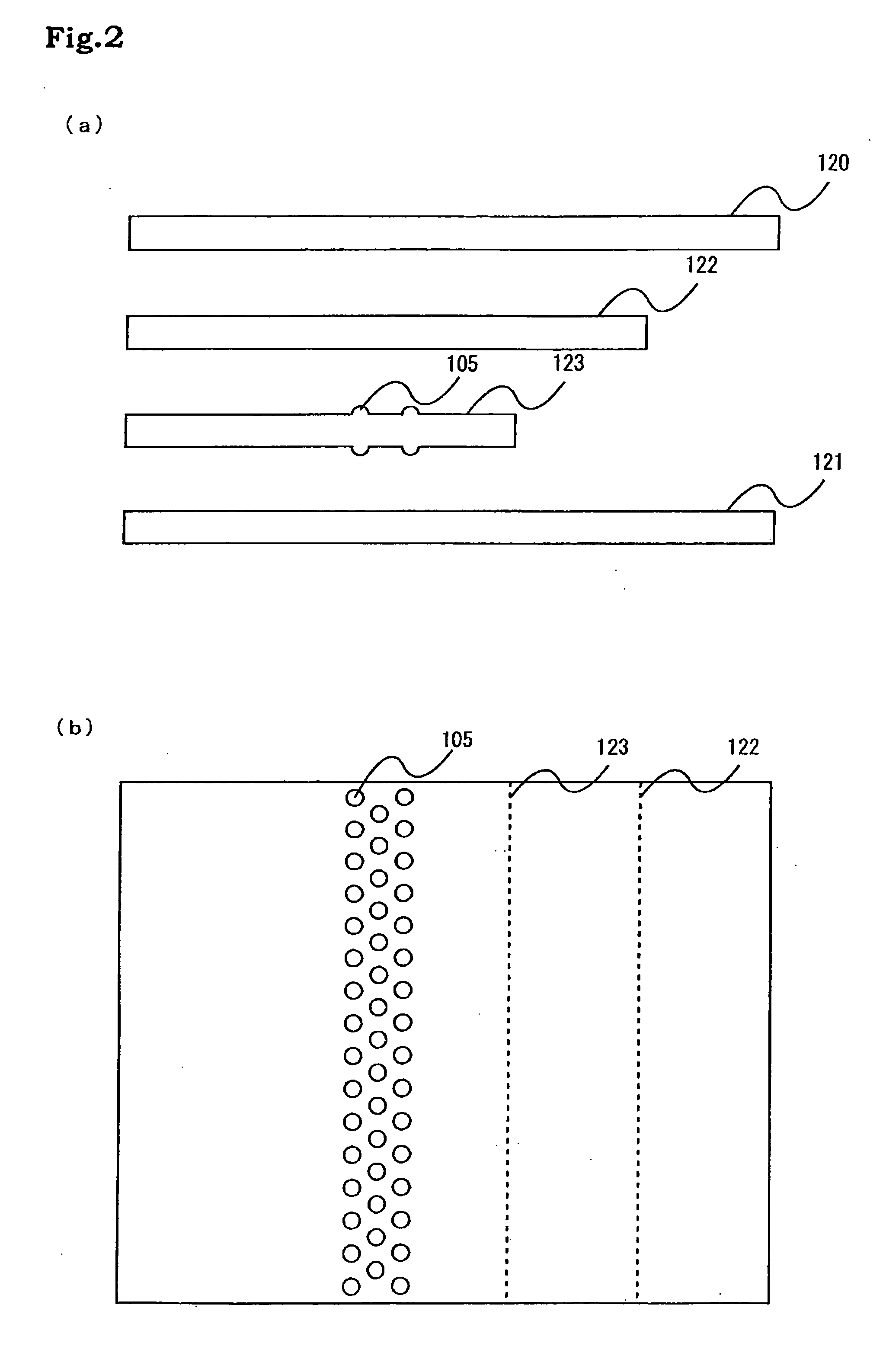

Apparatus for producing nitride semiconductor, method for producing nitride semiconductor, and semiconductor laser device obtained by the method

InactiveUS20060057824A1Increase productionFew characteristicPolycrystalline material growthSemiconductor/solid-state device manufacturingNitride semiconductorsLaser

The present invention relates to an apparatus for producing a nitride semiconductor by crystal-growing the nitride semiconductor on a substrate by diffusing a gas containing a source gas of group III element and a source gas of group V element. The gas is diffused in parallel with the substrate and from upstream to downstream. The apparatus has the substrate housed in the apparatus and a flow channel for allowing the gas to flow in the flow channel. The apparatus also has a plurality of protrusions provided on an inner wall of the flow channel. A partition for causing the source gas of group III element and the source gas of group V element to be introduced separately into the flow channel is provided on the upstream portion of the flow channel and in a horizontal direction. The protrusions are formed on the upper and lower surfaces of the partition. With this structure, the source gas of group III element and the source gas of group V element are more uniformly mixed before the source gases are supplied.

Owner:SHARP KK +1

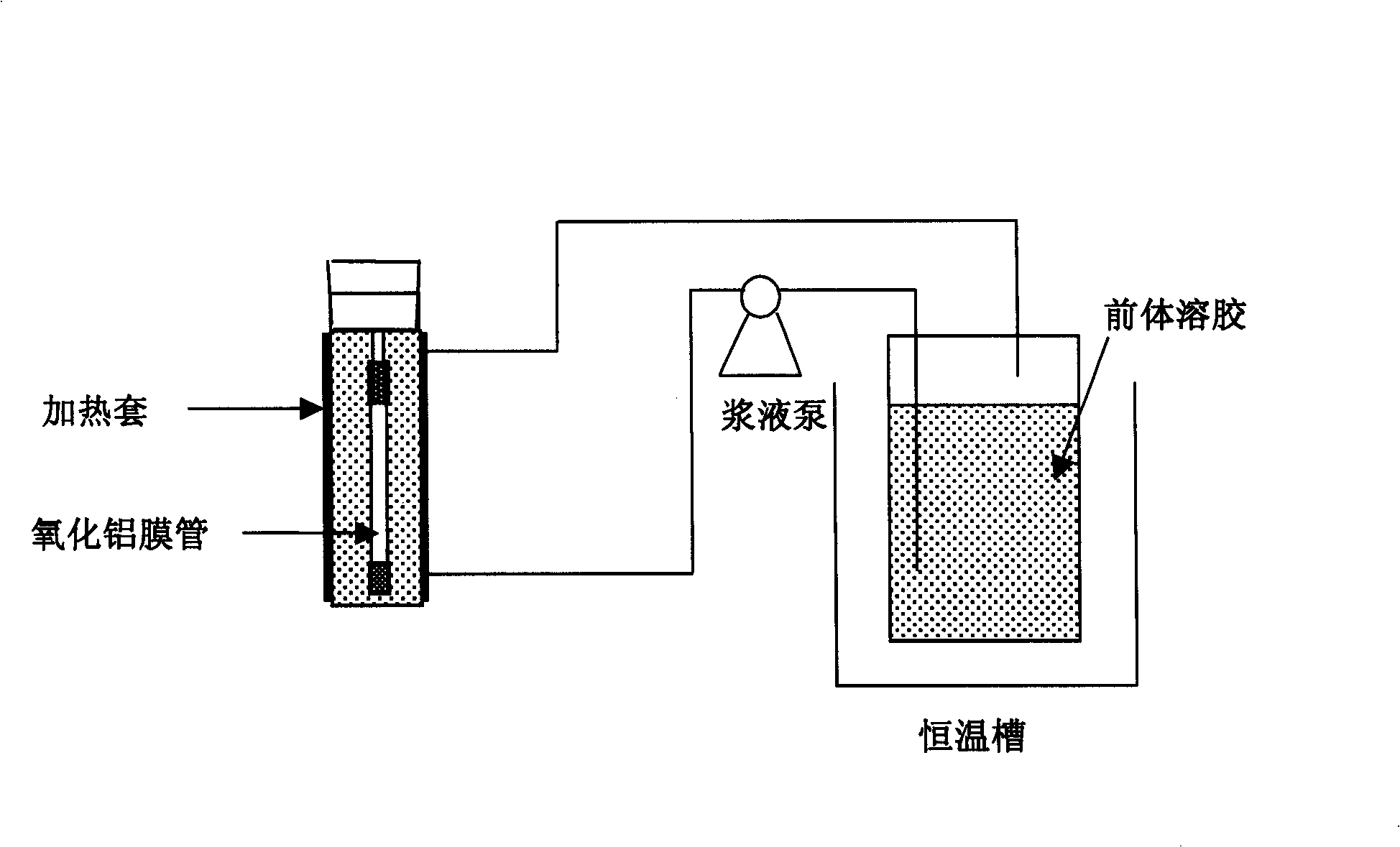

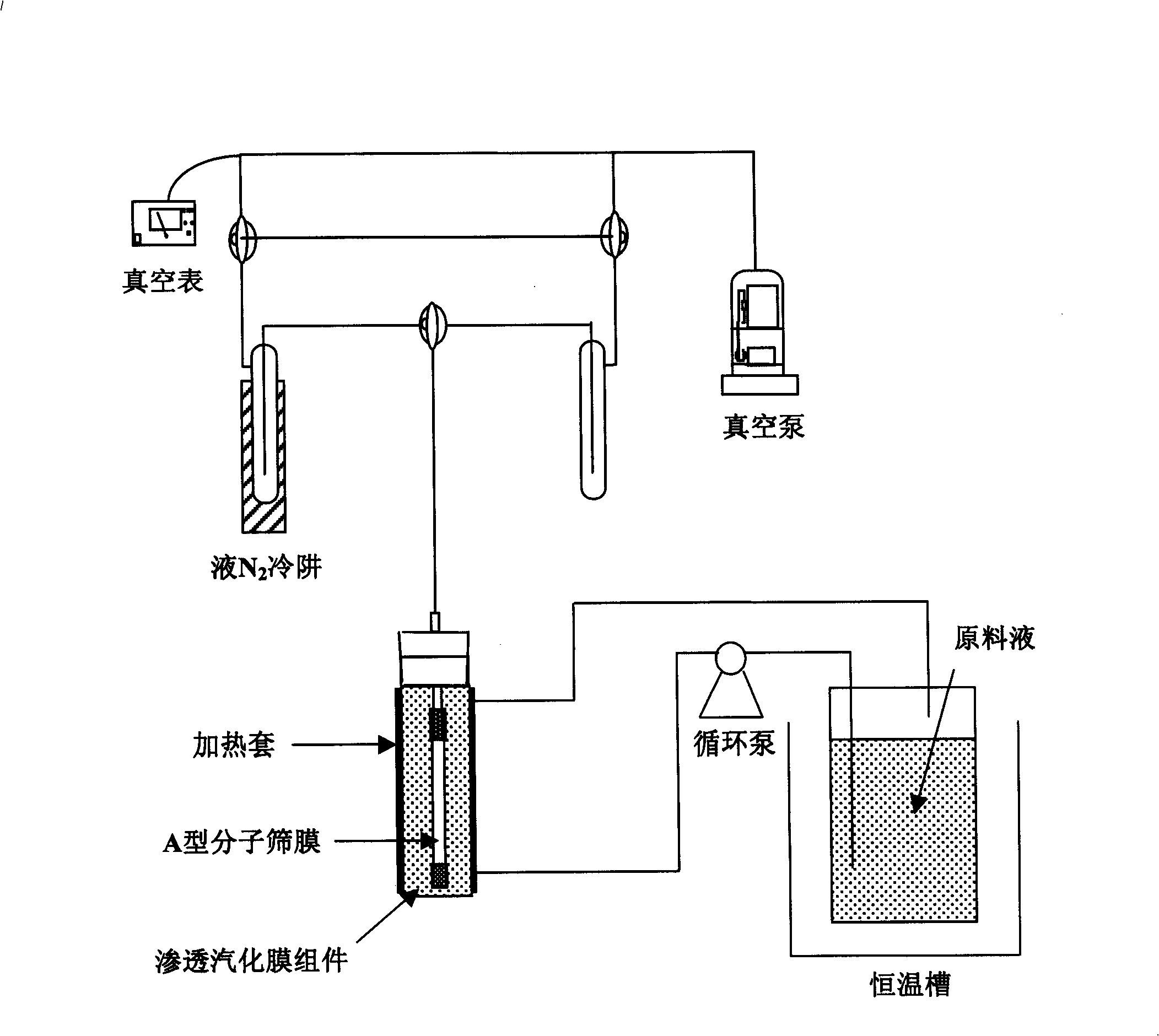

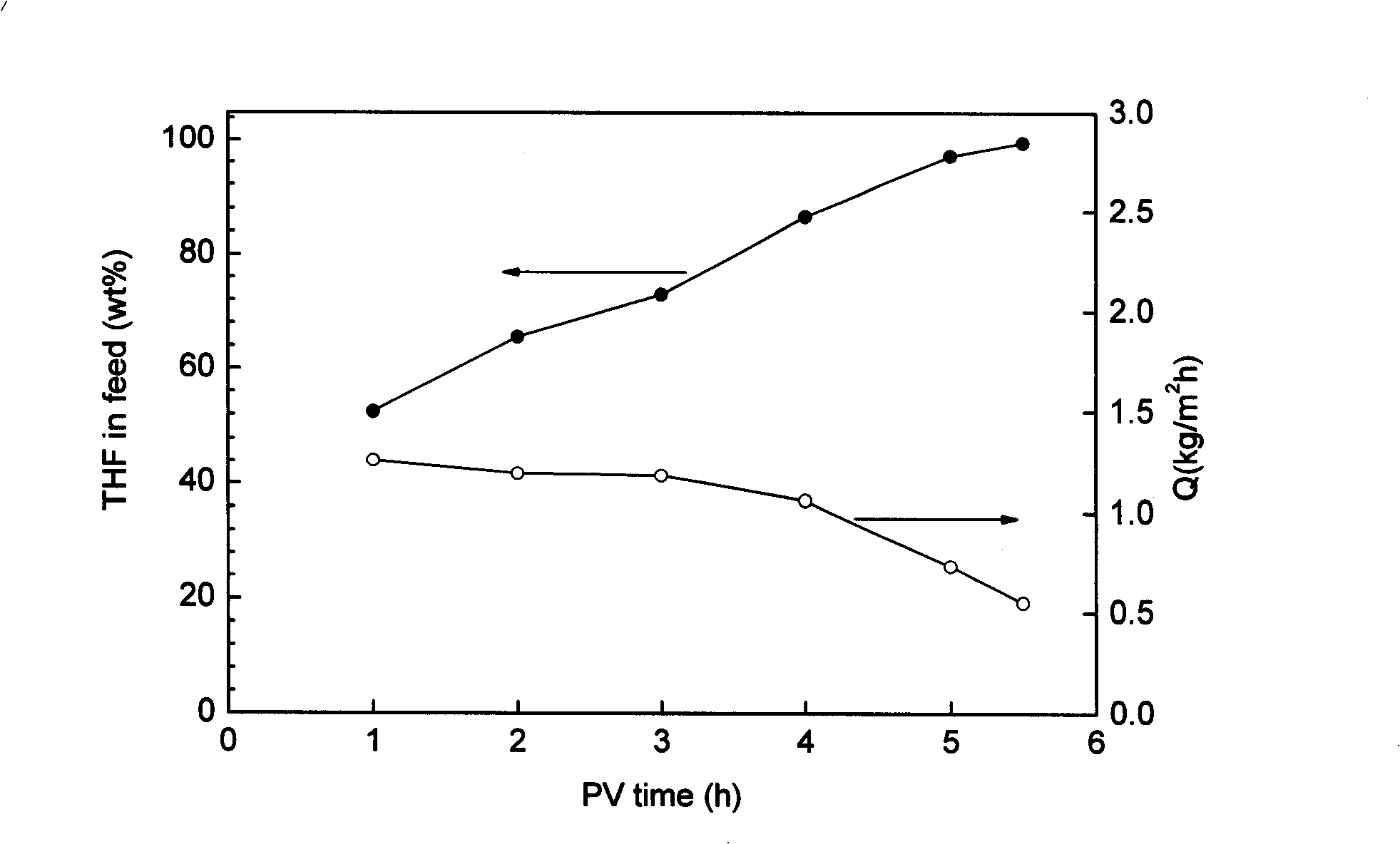

Novel methods for producing type A molecular sieve film in current system

InactiveCN101402022AUniform preparationContinuous preparationSemi-permeable membranesMolecular sieveDefinite time

The invention provides a novel method for preparing an A-type molecular sieve membrane, which adopts preparation of the molecular sieve membrane in a flow system. The method comprises the following steps: a silicon source, an aluminum source, an alkali source and deionized water are prepared into precursor sol of A-type molecular sieve according to certain proportion first; a vector membrane tube which is precoated with A-type molecular sieve crystal seeds is fixed inside a synthesis reactor; the molecular sieve precursor sol which is heated to a given temperature is conveyed into the synthesis reactor through a slurry pump, and the precursor sol is driven to flow and circulate on the surface of an outer membrane of the vector membrane tube; and the A-type molecular sieve membrane can be obtained after flowing, circulating and crystallization for a definite time at the given temperature. The preparation method provided by the invention has the advantages that the preparation method can basically solve the problem of concentration gradient during the synthetic process of he molecular sieve, is favorable to the preparation of the uniform, continuous and compact molecular sieve membrane with superior separation performance, and is particularly suitable for preparing the molecular sieve membrane for industrial application.

Owner:中科院嘉兴中心成都有机所分中心 +1

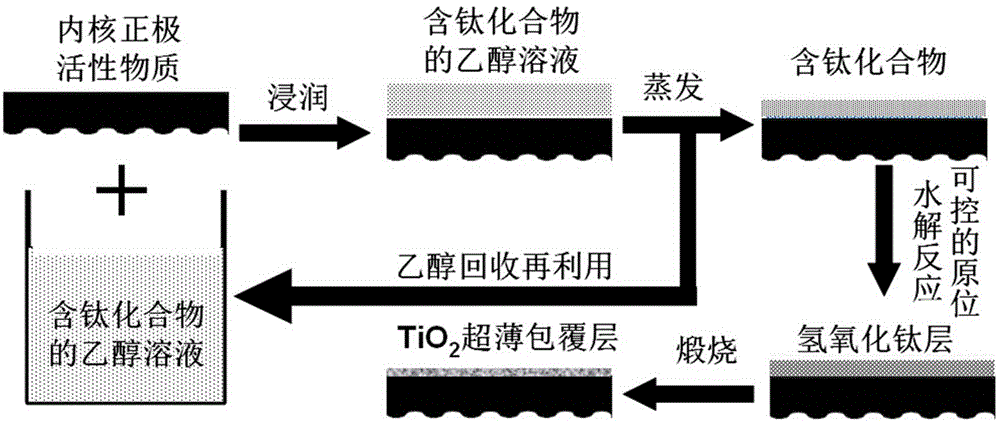

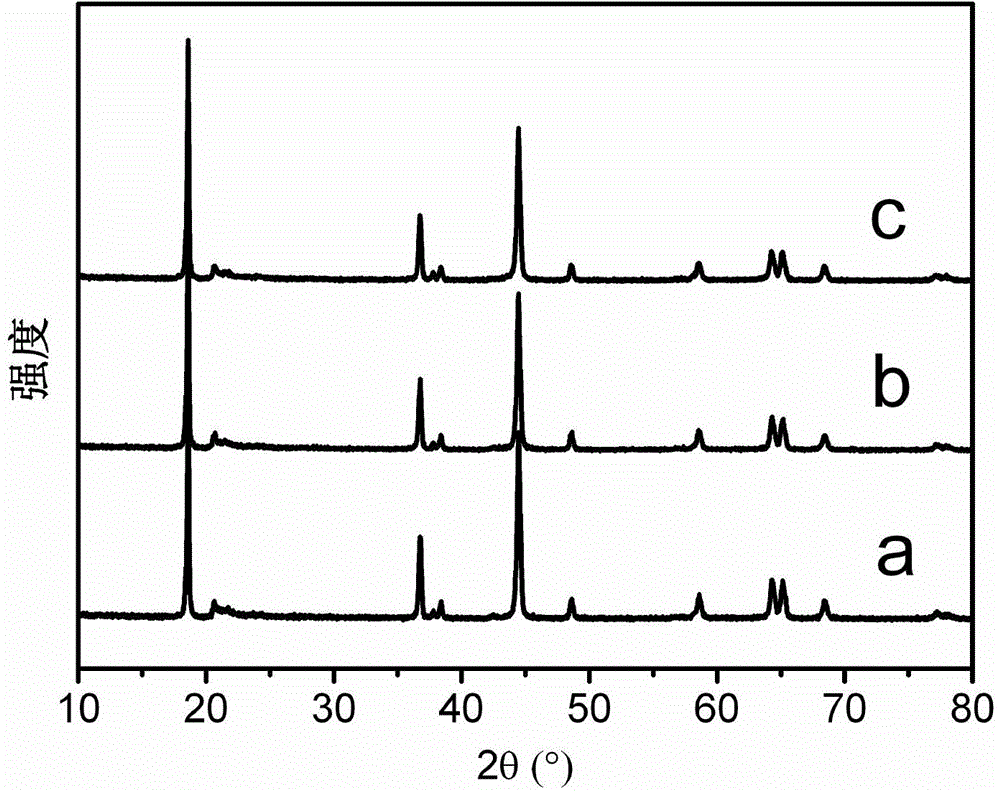

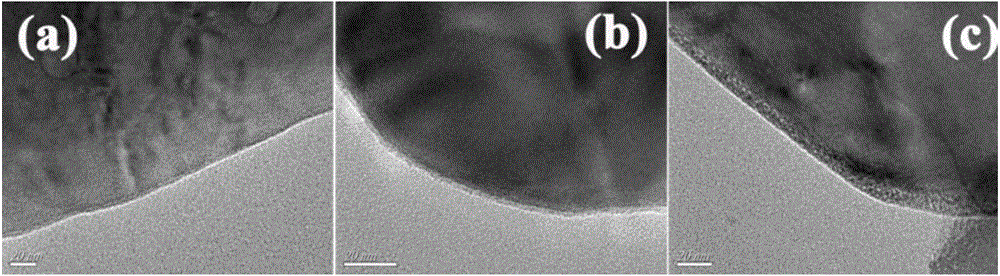

Ultrathin TiO2 coating layer of lithium battery cathode material, lithium battery cathode material and preparation method of lithium battery cathode material

ActiveCN104617267AGood conductivityLower polarization resistanceElectrode manufacturing processesSide reactionCalcination

The invention discloses an ultrathin TiO2 coating layer of a lithium battery cathode material. The coating layer is uniform and compact, and the thickness is only 0.5-20 nm. The lithium battery cathode material with a core-shell type coating structure comprises an inner-core cathode active material and the externally coated ultrathin TiO2 coating layer, wherein a mole ratio of Ti in the coating layer to a transition metal element in the inner-core cathode active material is 0.01%-3%. A preparation method of the lithium battery cathode material comprises steps as follows: a titanium contained compound is dissolved in an organic solvent; the inner-core cathode active material is added to the solution and stirred rapidly, the organic solvent is removed through heating, dry powder is obtained and is placed in dry air for standing to have in-situ hydrolysation with water molecules in air slowly and controllably, and intermediate powder is obtained and placed in an aerobic environment for calcination so as to obtain the lithium battery cathode material. The side reaction between the active material and electrolyte can be effectively inhibited, and the rate capability and the cycle performance of the lithium battery cathode material are improved.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

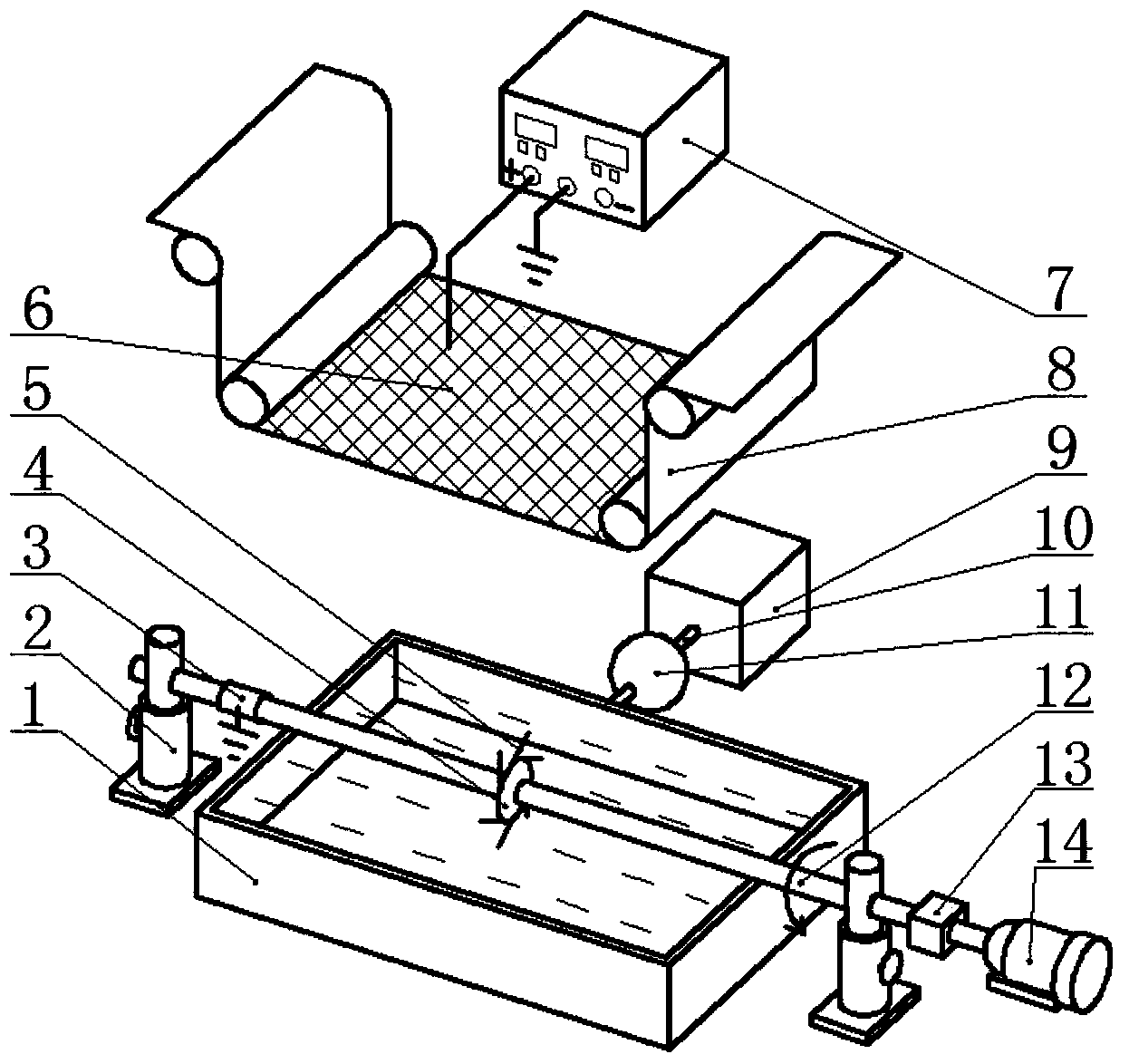

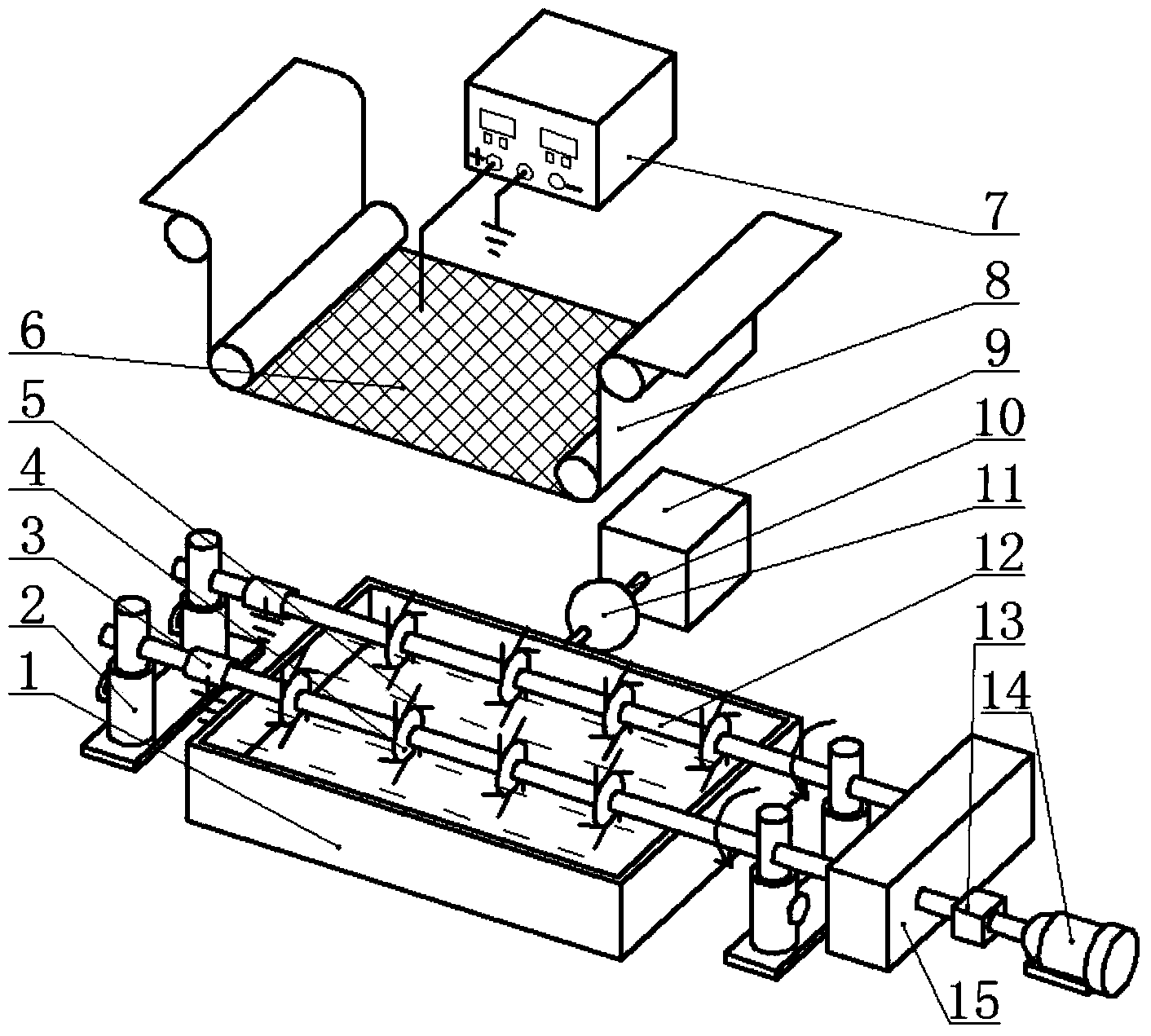

Fiber jetting device

The invention discloses a fiber jetting device, and relates to a fiber manufacturing device. The device is provided with a rotary wheel, a throwing rope, a rotary shaft, a solution tank, a driving motor, a lifting platform, an electric brush, a liquid storage box, a liquid supplying pipe, a metering pump, a coupler, a fiber collecting and conveying device, a high-voltage electrode net, a high-voltage power source and a control circuit. Electrostatic spinning liquid feeding is performed through the throwing rope, the defects that in a needle head type electrostatic spinning technology, a sprayer is blocked easily, the device is difficult to clean, the spinning efficiency is low and the spinning quality is poor are avoided, and meanwhile electric field interference phenomena such as the fringe effect happening in the multi-sprayer electrostatic spinning process are avoided. By changing the material, the diameter, the length and the shape of the cross section of the throwing rope, the shape, the arrangement and the output of fibers can be controlled. Further, by controlling the immersion length of the throwing rope, the rotation speed of the rotary wheel, the distance between the rotary wheel and the fiber collecting and conveying device, the electric field intensity and other electric spinning technological parameters, the electrostatic spinning efficiency and the quality of the fibers are improved, the nanometer fibers can be manufactured fast and evenly, and large-scale industrial production of the nanometer fibers is facilitated.

Owner:XIAMEN UNIV

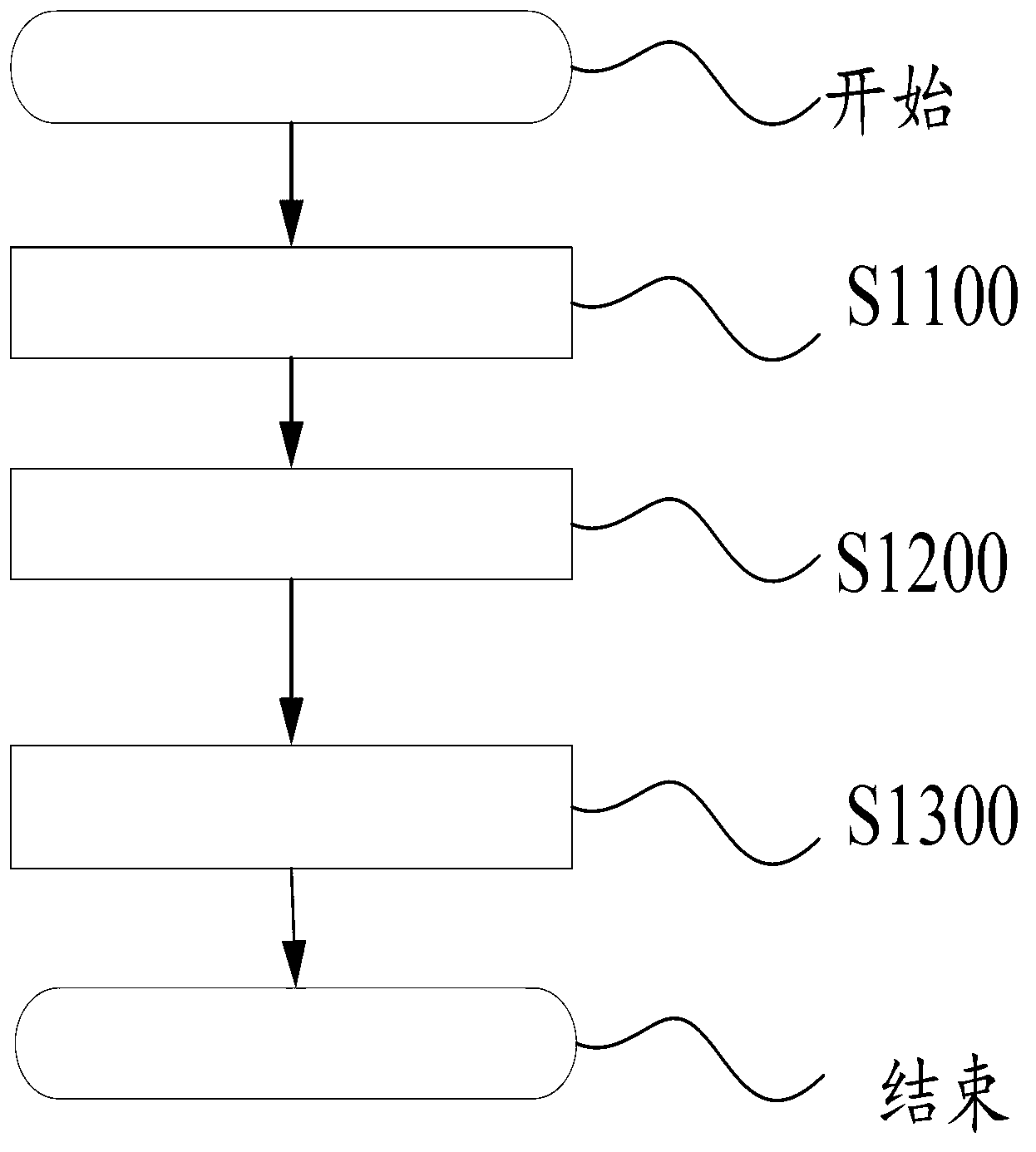

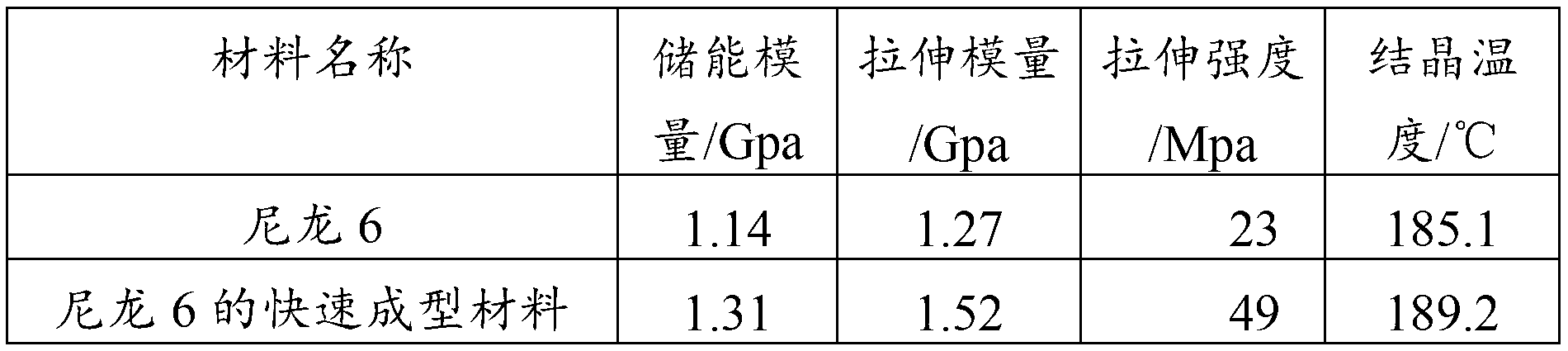

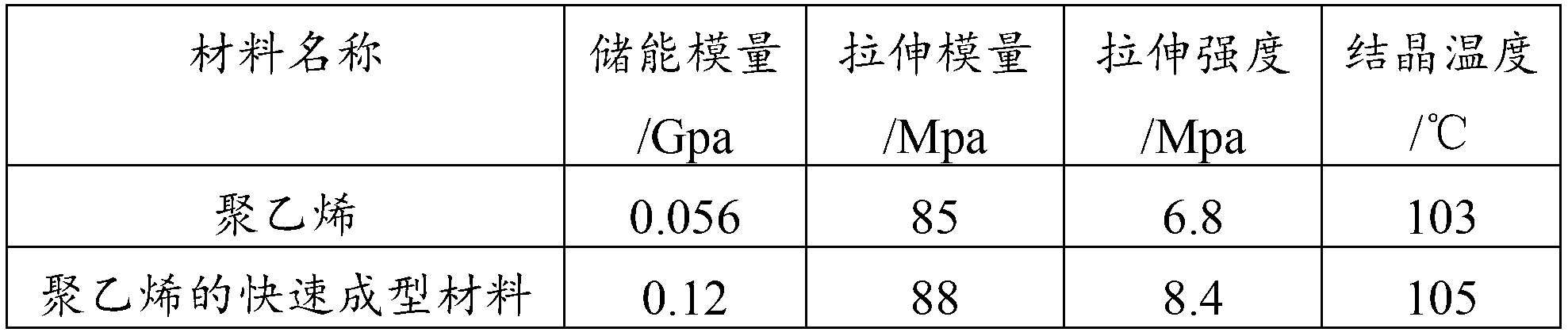

Rapid prototyping material and preparation method thereof

The invention discloses a preparation method of a rapid prototyping material. The preparation method comprises the steps of providing raw materials, wherein raw materials comprise the following ingredients in parts by weight: 85-97.5 parts of engineering plastics, 0.5-5 parts of nanocellulose and 2-10 parts of viscosity reducer; (S1100) weighing the raw materials: drying the raw materials for 4-10 hours at the temperature of 105 DEG C, and then, weighing the raw materials according to a weight ratio; (S1200) carrying out blending modification: carrying out three-dimensional stirring and blending on the weighed raw materials for 30-90 min; and (S1300) sieving: sieving the blended raw materials by using a sieve of 70-140 meshes. The invention further discloses the rapid prototyping material obtained through the preparation method. According to the rapid prototyping material disclosed by the invention, the preparation process is simple, and the industrialization is easy to realize; and the material is short in prototyping cycle, good in thermal stability and high in mechanical strength.

Owner:珠海市红旌发展有限公司

Somatic human cell line mutations

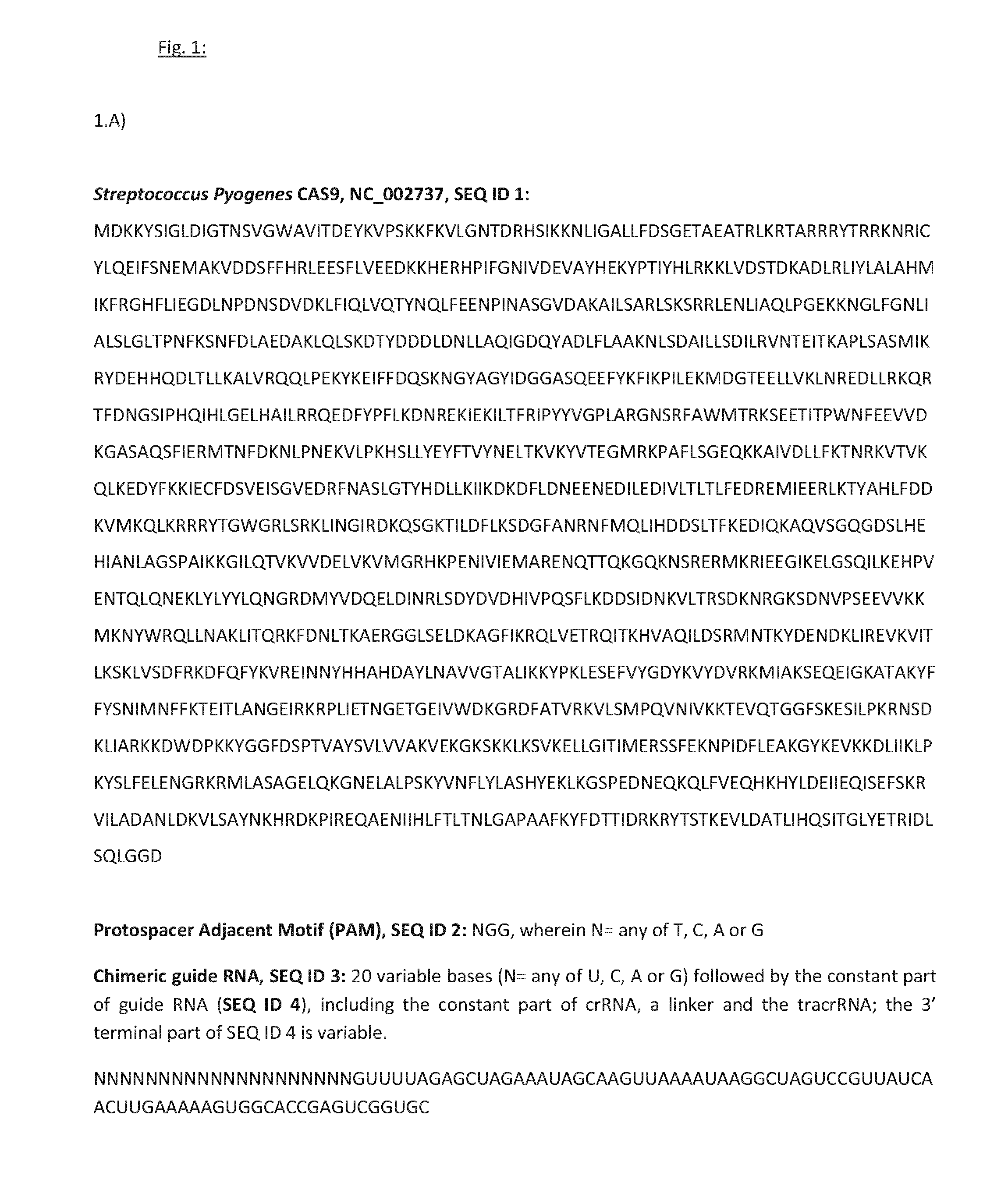

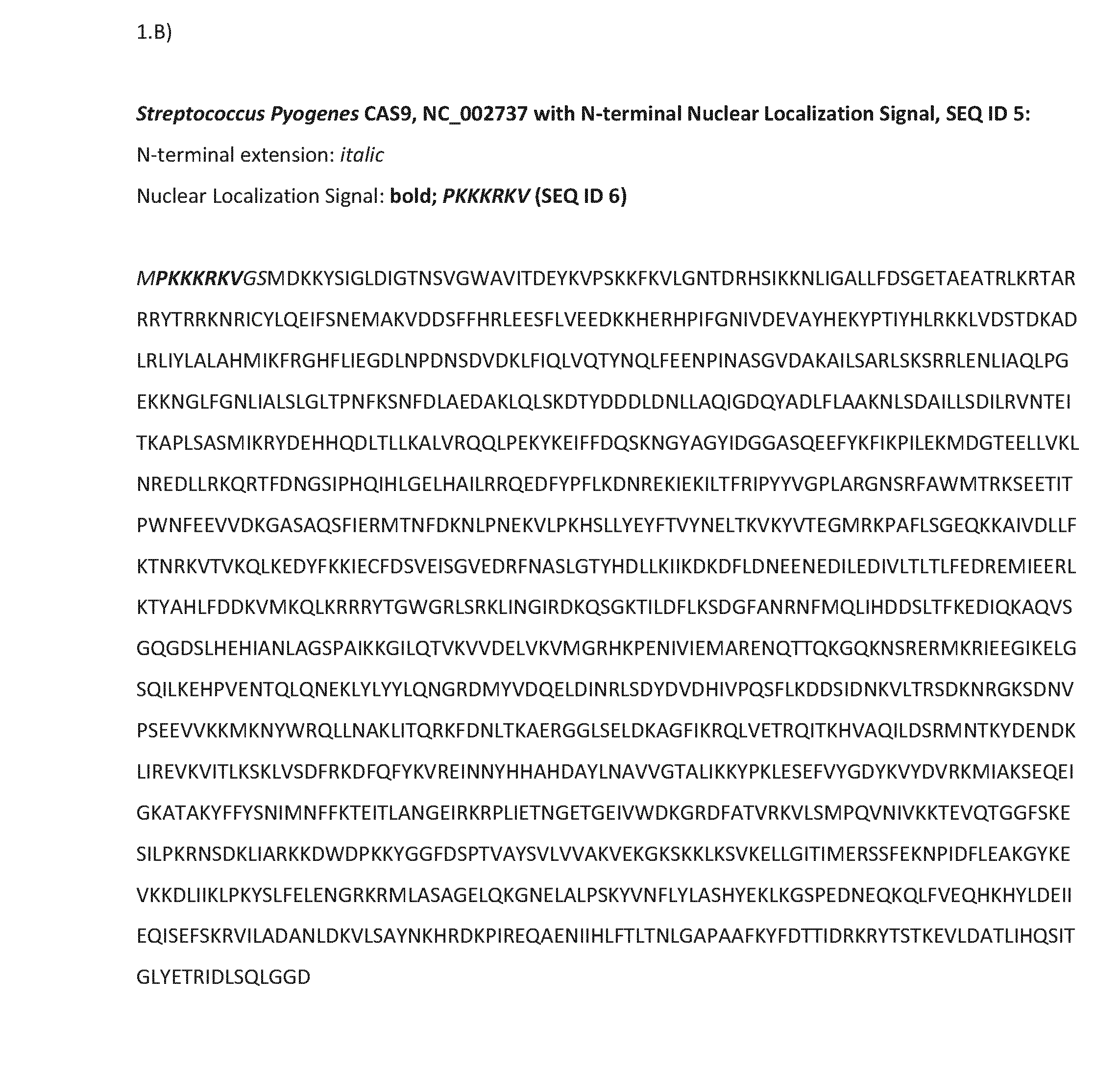

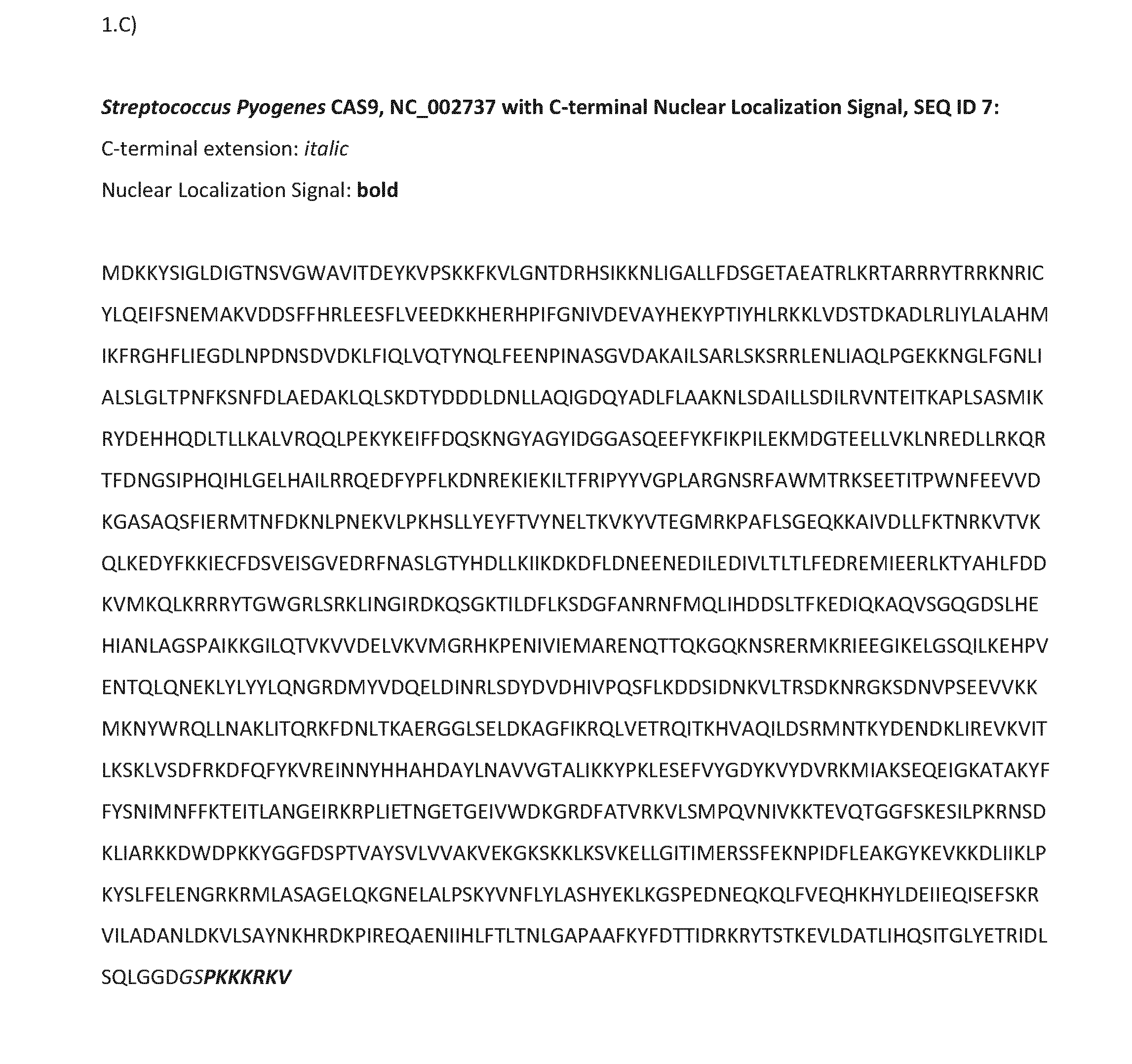

ActiveUS20170009256A1Even mixtureDifferenceMicrobiological testing/measurementStable introduction of DNAGenomic mutationDna breakage

The invention provides for a method of producing a mutant somatic human cell line of cells comprising a genomic mutation of interest (MOI) at a predefined genomic site of interest (GOI) in close proximity to a genomic target site, which comprises: a) providing a guide RNA (gRNA) comprising a tracrRNA in conjunction with crRNA including an oligonucleotide sequence that hybridizes with the target site; b) providing an RNA-guided endonuclease which catalyzes the DNA break at the target site upon hybridizing with the gRNA; c) introducing the gRNA into the cells in the presence of the endonuclease to obtain a repertoire of cells comprising a variety of genomic mutations at the target site; d) selecting a cell from said repertoire which comprises a MOI; wherein the cell is haploid for the genomic locus of the target site; and e) expanding the cell to obtain the mutant cell line. The invention further provides for a mutant human somatic cell line obtainable by such method; and libraries of mutant human somatic cell lines of isogenic cells with a variety of genomic mutations at different predefined genomic target sites.

Owner:HORIZON DISCOVERY

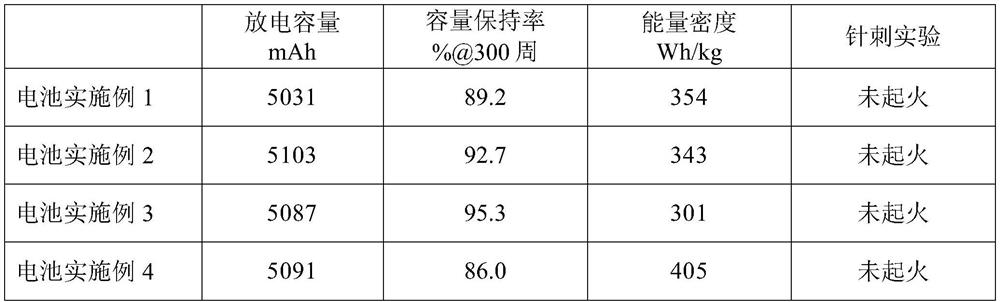

In-situ polymerized organic-inorganic composite solid-state battery

ActiveCN111933894AIncrease elasticityGood compatibilityFinal product manufactureSecondary cellsElectrical conductorIn situ polymerization

The invention discloses an in-situ polymerized organic-inorganic composite solid-state battery, which is characterized in that a polymer solid-state electrolyte monomer or oligomer small molecule is compactly connected with an electrode active material, an inorganic fast ion conductor and a lithium salt in an in-situ polymerization manner, wherein the polymer solid electrolyte monomer or oligomersmall molecule at least comprises one compound containing an unsaturated carbon-carbon bond and carbonyl or sulfonyl or sulfinyl; the polymer solid electrolyte monomer or oligomer small molecule at least comprises one compound containing two or more unsaturated carbon-carbon bonds. The battery is small in interface resistance, high in conductivity and resistant to high voltage, the problem that asolid-state battery is poor in room-temperature and low-temperature performance is solved, and the production technological process is simple and reliable.

Owner:安普瑞斯(无锡)有限公司

Graphene foam aluminum composite metal material and preparing method

ActiveCN107442775AGood effectLow densityIncreasing energy efficiencyFoaming agentVolumetric Mass Density

The invention provides a graphene foam aluminum composite metal material and a preparing method. The preparing method comprises the following steps that a foaming agent and graphene are evenly dispersed by grinding and then mixed with aluminum metal powder; and the foaming agent is uniformly decomposed and releases gas through laser sintering, so that aluminum alloy is in a foam state by expanding of the gas, graphene is dispersed on the interface of the foam, and then the graphene foam aluminum composite metal material is obtained after cooling; the metal aluminum foaming process and the graphene strengthening process are conducted at the same time, so that the technical defects that the performance is not stable and the strengthening effect is not ideal of graphene foam aluminum composite material prepared through an existing method are overcome; the graphene foam aluminum composite metal material with characteristics of being stable, uniform, low in density and high in strength is prepared; and the prepared graphene foam aluminum composite metal material is stable in property, easy to store and convey and realize large-scale industrial production.

Owner:德州市洛泰商贸有限公司

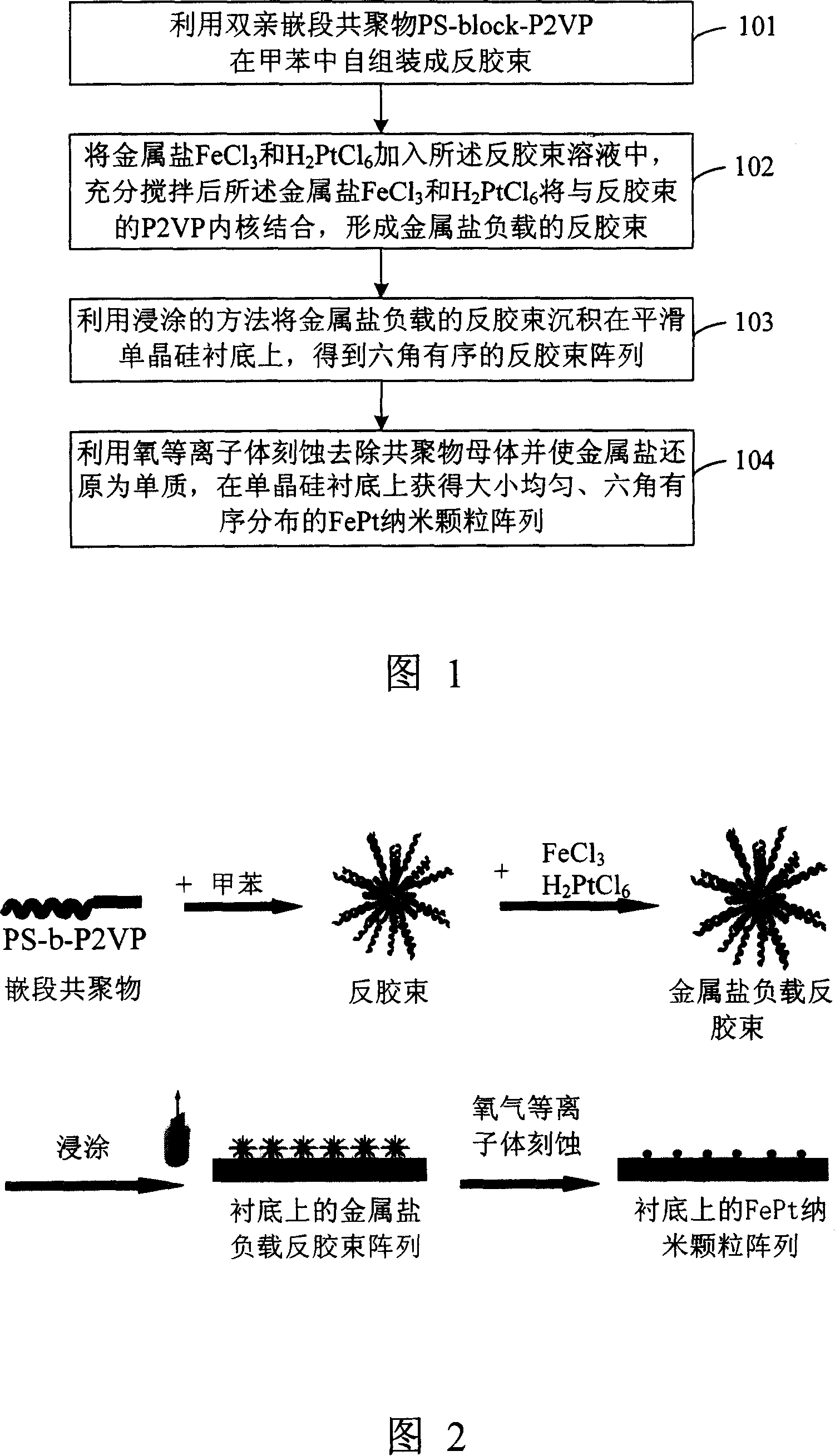

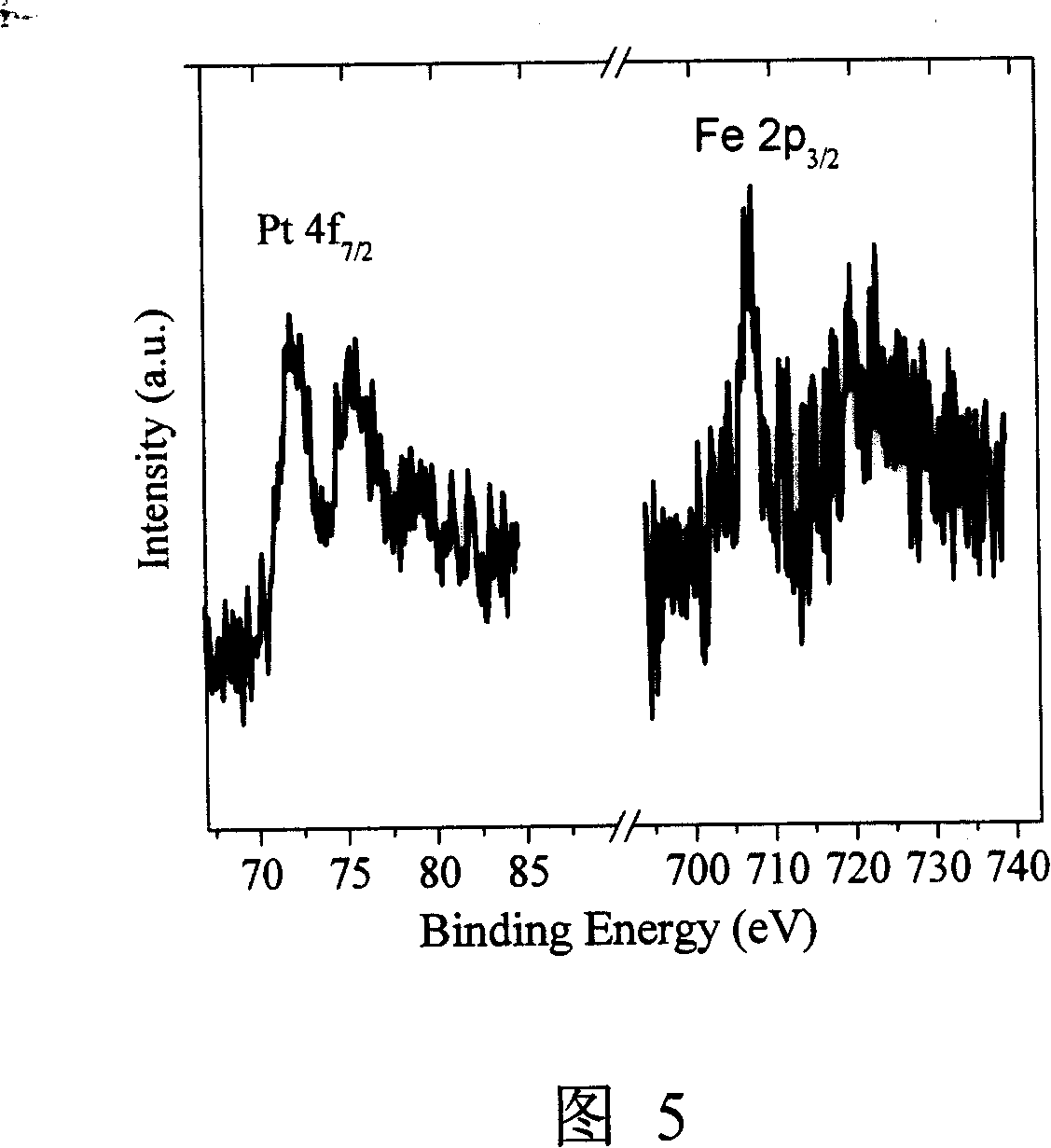

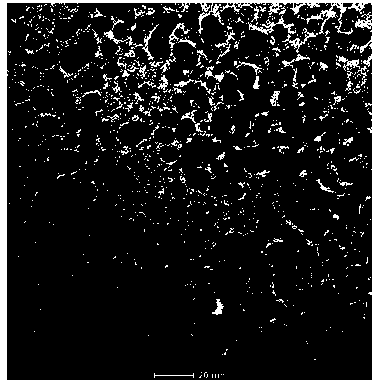

Method for preparing hexangular ordered FePt nano particle array

InactiveCN101148710AEvenly distributedParticle size is easy to controlInductances/transformers/magnets manufactureNanoparticleDip-coating

The process of preparing ordered hexagonal nanometer FePt particle array includes the following steps: 1. self-assembling inverse micelle with amphiphilic block copolymer PS-block-P2VP intoluene; 2. adding metal salts FeCl3 and H2PtCl6 into the inverse micelle solution through stirring for the metal salts FeCl3 and H2PtCl6 to be combined with the P2VP kernel of the inverse micelle to form inverse micelle with supported metal salts; 3. depositing the inverse micelle with supported metal salts onto smooth monocrystalline substrate through dip coating to obtain ordered hexagonal inverse micelle array; and 4. oxygen plasma etching to eliminate copolymer substrate and reduce metal salt into simple substance so as to obtain homogeneous ordered hexagonal nanometer FePt particle array on the monocrystalline substrate.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

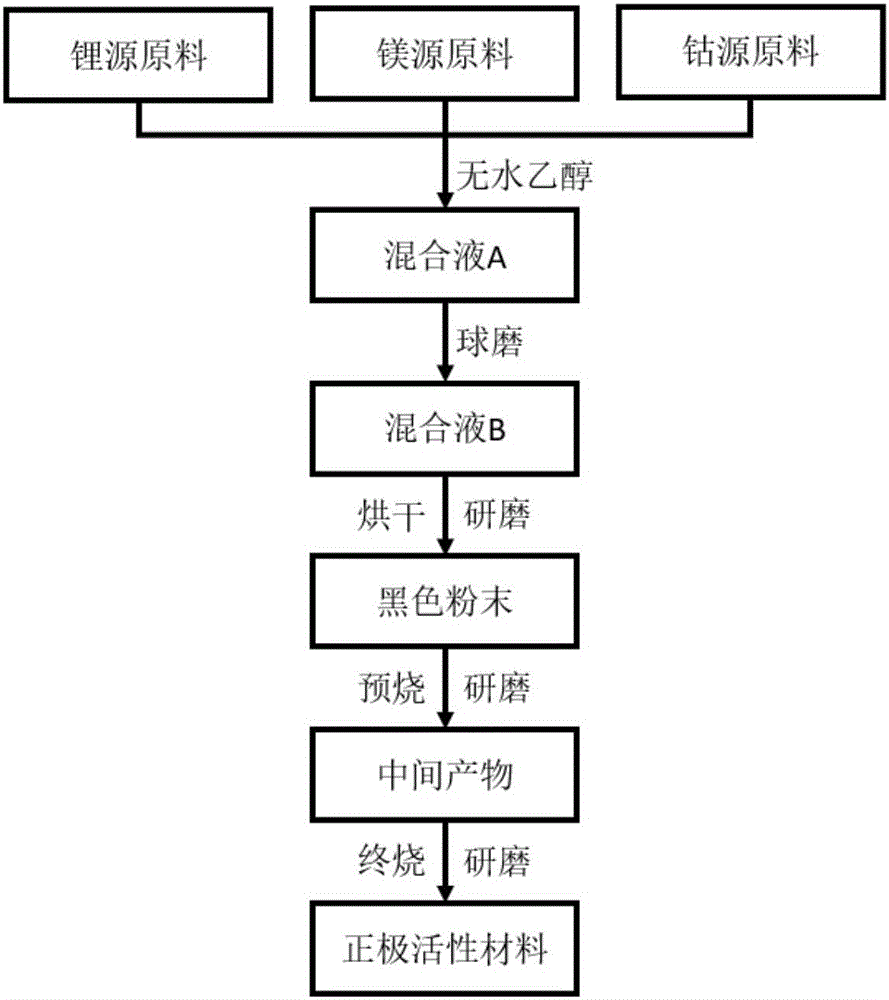

High-voltage cathode material Li delta Co(1-x)MgxO2@AlF3 of lithium ion battery and preparation method of high-voltage cathode material

ActiveCN106099098AImprove conductivityImprove high current charge and discharge performanceCell electrodesHigh voltage cathodeLithium electrode

The invention belongs to the field of lithium ion batteries, and provides a cathode material Li delta Co(1-x)MgxO2@AlF3 of a lithium ion battery and a preparation method of the cathode material. According to the cathode material Li delta Co(1-x)MgxO2@AlF3, delta is larger than or equal to 1 and smaller than or equal to 1.05, x is larger than 0 and smaller than or equal to 0.05, and the defect of poor electrochemical performance of laminar LiCoO2 under high potential is overcome. The bulk-phase doping modification and surface coating combined laminar cathode material Li delta Co(1-x)MgxO2@AlF3 has higher specific discharge capacity and very stable circulation performance; at the room temperature, at 0.5 C rate and within the charge-discharge voltage range of 2.75-4.4 V (vs.Li / Li<+>), the first specific discharge capacity can reach 187.6 mAh / g, the 3.8V platform capacity approaches 100%, the capacity can reach 180 mAh / g after 30 times of circulation, and the capacity retention ratio is 96%. Besides, the provided material preparation method adopts a simple preparation process, the preparation cost is low, and large-scale industrial production is easy to realize.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Manufacturing method of potishing pad use polyurethane foam and polyurethane foam

InactiveCN1625575AUniform preparationSmall deviation of specific gravitySemiconductor/solid-state device manufacturingLapping machinesFoaming agentHydrogen

A production method comprising the step of charging prepolymer, a foaming agent and an active hydrogen-containing compound in specified amounts into a tank and foaming / mixing them for a specified time by a mixer, and the subsequent step of pouring the mixture liquid into a metal mold.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

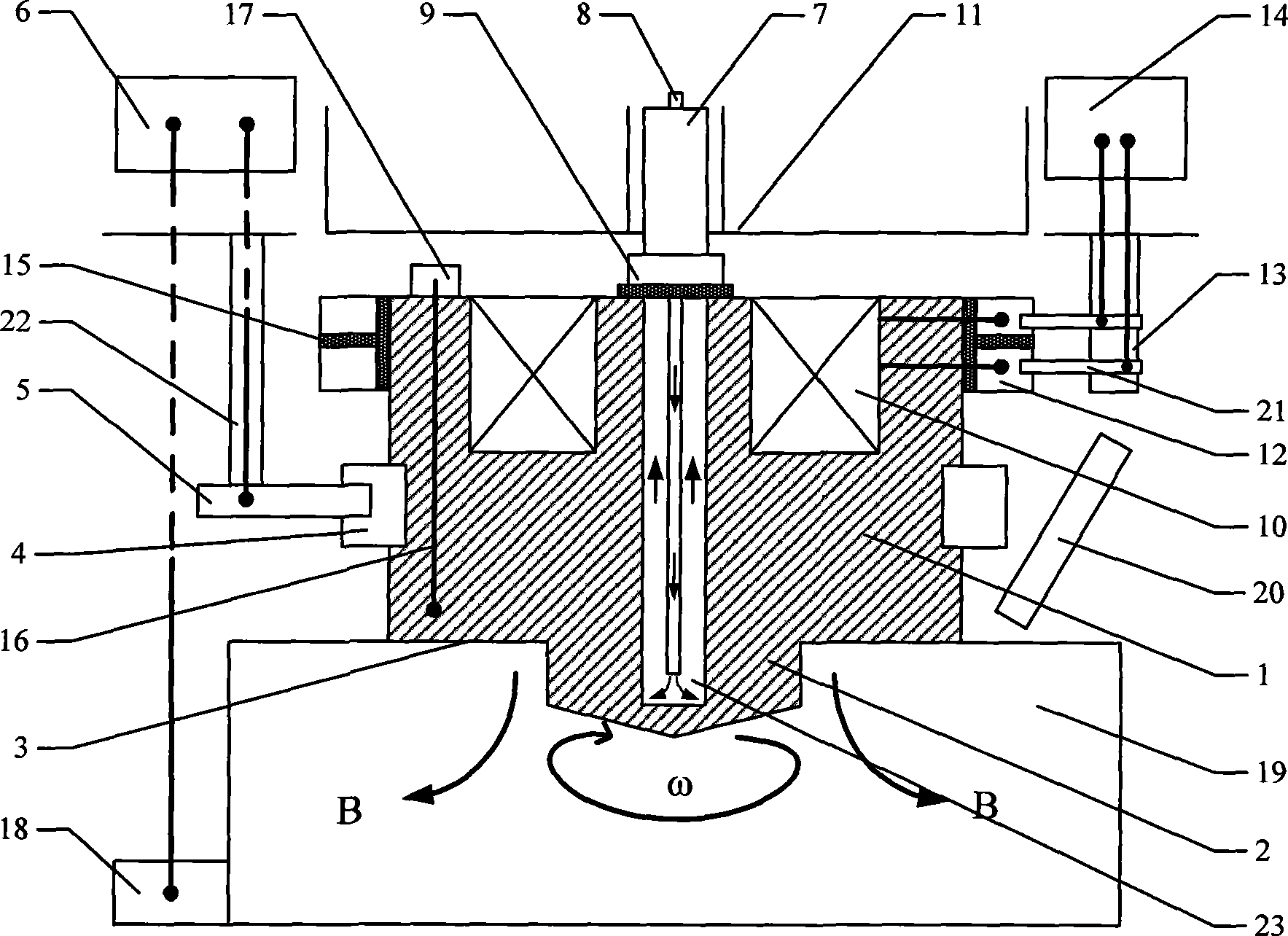

Method and equipment for preparing nano material with large thickness and area through acute plastic deformation

InactiveCN101544352AEffective protectionPrevent oxidationNanostructure manufactureSlice thicknessElectromagnetic field

The invention relates to a method for preparing a nano material with large thickness and area through acute plastic deformation. The method comprises the following steps: adopting carrying current acute stirring friction forced highly undercooled control technology under the action of electromagnetic vibration in-situ compound electromagnetic field to prepare a metallic nano grain material and a ultrafine grain material with large thickness and area; adopting an electromagnetic vibration coil to ensure that a stirring head carries out high-speed stirring and electromagnetic vibration stirring friction composite motion combined with electromagnetic vibration at a certain frequency; and forming an alternating electromagnetic field of a certain intensity inside a workpiece. Under the joint action of carrying current stirring friction and a forced highly undercooled control temperature mechanism, coarse grain structure of the metal surface in a certain thickness undergoes acute plastic deformation and breaks to form stable nano grain and ultrafine grain structure; thus, the method realizes the preparation or surface modification of the metallic nano material with large thickness and area and uniform structure, and can also be used in stirring friction welding.

Owner:CHONGQING UNIV

Method for preparing grinding wheel according to wet method

The invention belongs to the technical field of grinding wheel preparation and particularly relates to a method for preparing a grinding wheel according to a wet method. The method comprises the following steps: respectively adding powder glue, water, starch, binder, foaming agent and curing agent in proportion at different time, and then controlling the stirring speed, temperature and pouring speed in different preparing steps. The method provided by the invention has the advantages of simple technology and production equipment; the prepared grinding wheel is uniform in pore size and distribution; the mechanical strength, the abrasive resistance and the grinding property of the grinding wheel are greatly increased; and especially, the maximum porosity can reach 75%.

Owner:东莞市脉拓表面处理科技有限公司 +1

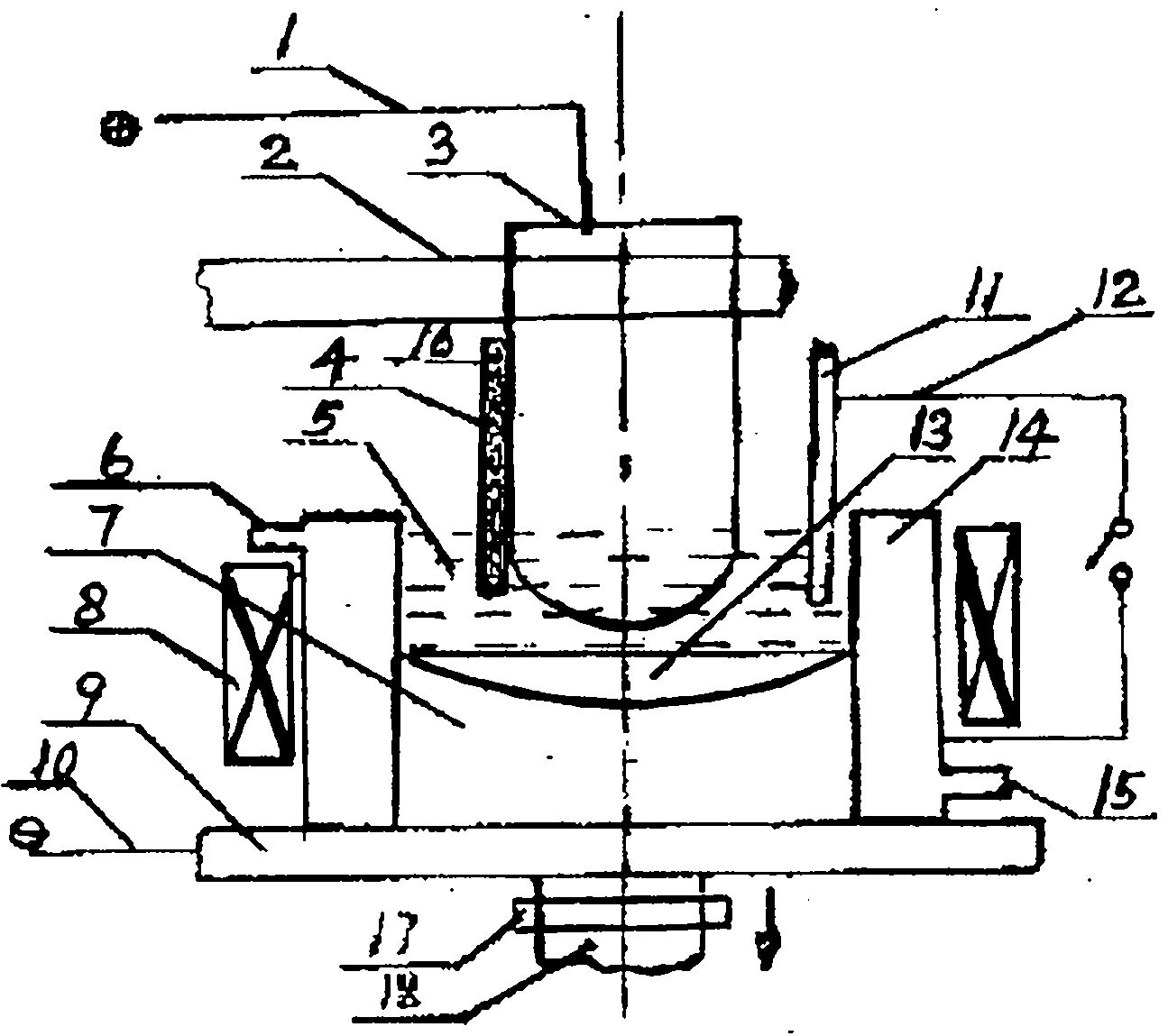

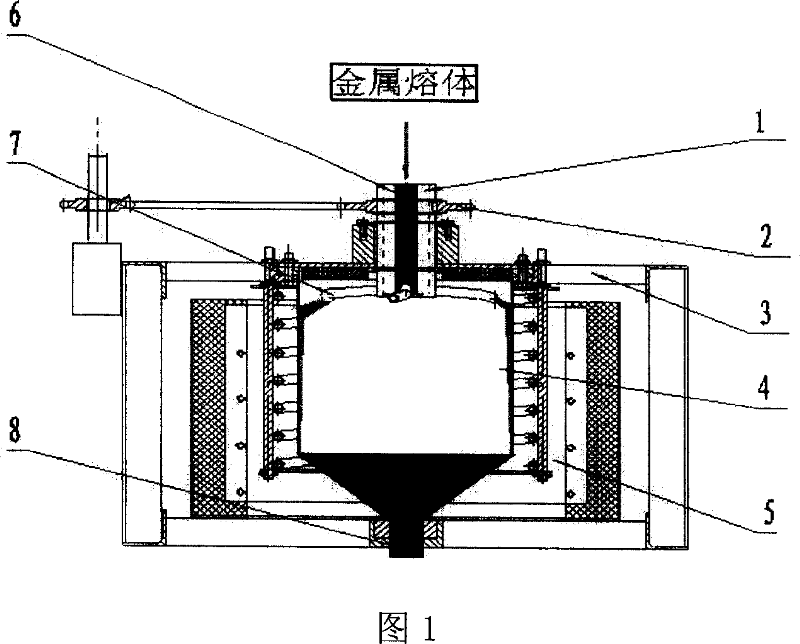

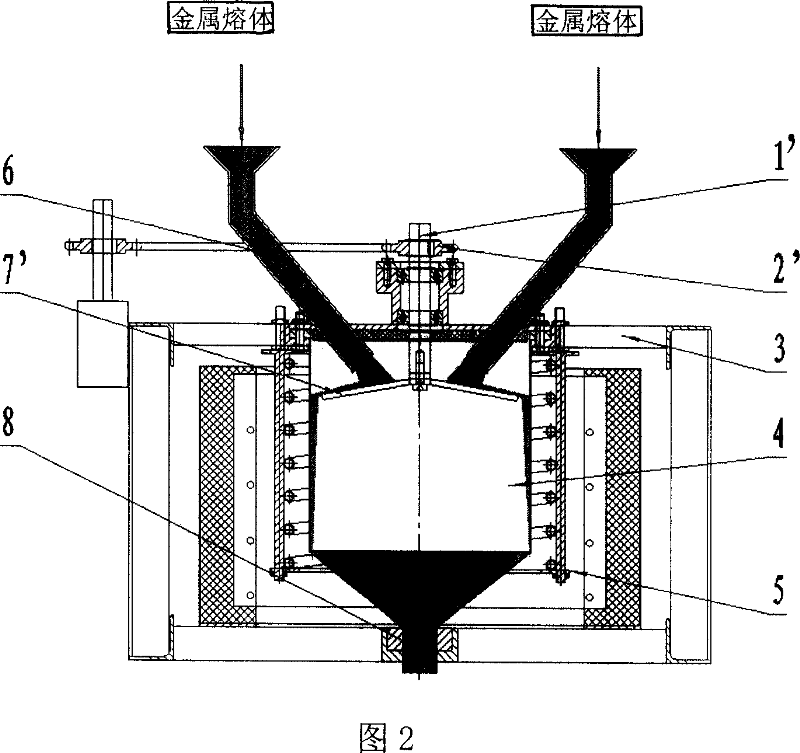

Method for preparing metal sizing agent by a compelling, equal-freezing and continuous method

The invention relates to a method for forced uniform solidified continuous preparing metal slurry, comprising that (1) melting overheat metal with the temperature more than the liquidus temperature about 0-100deg.C is poured into upper guide flow pipe; (2) the liquid metal flows into the melting deconcentrator and the liquid metal is injected on the inner round wall of melting deconcentrator; the temperature control system out of pulping room make the wall temperature of pulping room be controlled lower than the liquidus temperature about 0-100deg.C; the liquid metal is collected at the cone bottom to obtain the metal slurry with solid fraction smaller than 30%; the metal slurry flows out through the lower guide flow pipe and the temperature is controlled in -10-10deg.C of liquidus temperature; (3) the metal slurry flows into the collector or is sent into the common equipment such as die-casting, rolling and forging so on directly to carry rheological forming out and or is cast into the mould continuously to produce semi-solid continuous casting slab. The merit of invention is that the preparation of metal slurry is uniform, mass and continuous, and it can satisfy the demand of huge industrial production easily.

Owner:有研金属复材技术有限公司

Separation method of graphene oxide different in sizes in graphene oxide preparation process

The invention provides a separation method of graphene oxide different in sizes in a graphene oxide preparation process, and relates to graphene oxide preparation. According to the separation method, graphene oxide prepared by using an oxidation reduction method is separated according to difference of dispersibility of the graphene oxide different in sizes in a solvent so as to obtain the following graphene oxide different in sizes: precipitates B-COSs1 which are graphene oxide products, the sizes of which are greater than 25 micrometers, precipitates GOSs2 which are graphene oxide products, the sizes of which are greater than 15 micrometers and are less than or equal to 25 micrometers, precipitates GOSs3 which are graphene oxide products, the sizes of which are greater than 5 micrometers and less than or equal to 15 micrometers, and precipitates F-COSs4 which are graphene oxide products, the sizes of which are less than or equal to 5 micrometers. The separation method can be used for overcoming the defects that the graphene oxide products which are prepared by using the conventional various oxidation reduction methods and different in sizes are completely mixed and irregular in distribution.

Owner:HEBEI UNIV OF TECH

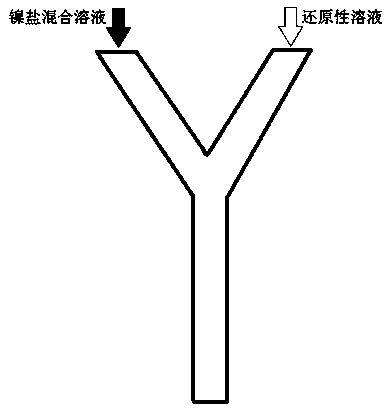

Method for continuous and rapid preparation of nano nickel by microfluidics technology

InactiveCN103737018AUniform preparationUniform particle size distributionNanotechnologyNickel saltActive agent

The invention relates to a method for continuous and rapid preparation of nano nickel by the microfluidics technology and belongs to the technical field of synthesis of nanomaterial by microfluidics and microreactor technology. The method includes: dissolving NiS04.6H21 into distilled water, regulating PH (power of Hydrogen) of a solution, adding a surfactant, and mixing well for configuration to obtain a nickel salt mixed solution; dissolving a reducing agent into the distilled water for configuration to obtain a reducing solution; pumping the nickel salt mixed solution and the reducing solution obtained in the above steps into a Y-shaped microreactor channel for micro-mixing reaction, and subjecting the mixed solution to cleaning, separating and vacuum low-temperature drying treatment to obtain black nickel nanoparticles. The method has the advantages of being high in mixed mass transfer rate, even in reaction, continuously stable and the like by combining the microfluidics technology; featuring in wet reduction, the nano nickel is subjected to micro-mixing in the Y-shaped microreactor channel, so that the continuous and rapid preparation of the nano nickel is realized.

Owner:KUNMING UNIV OF SCI & TECH

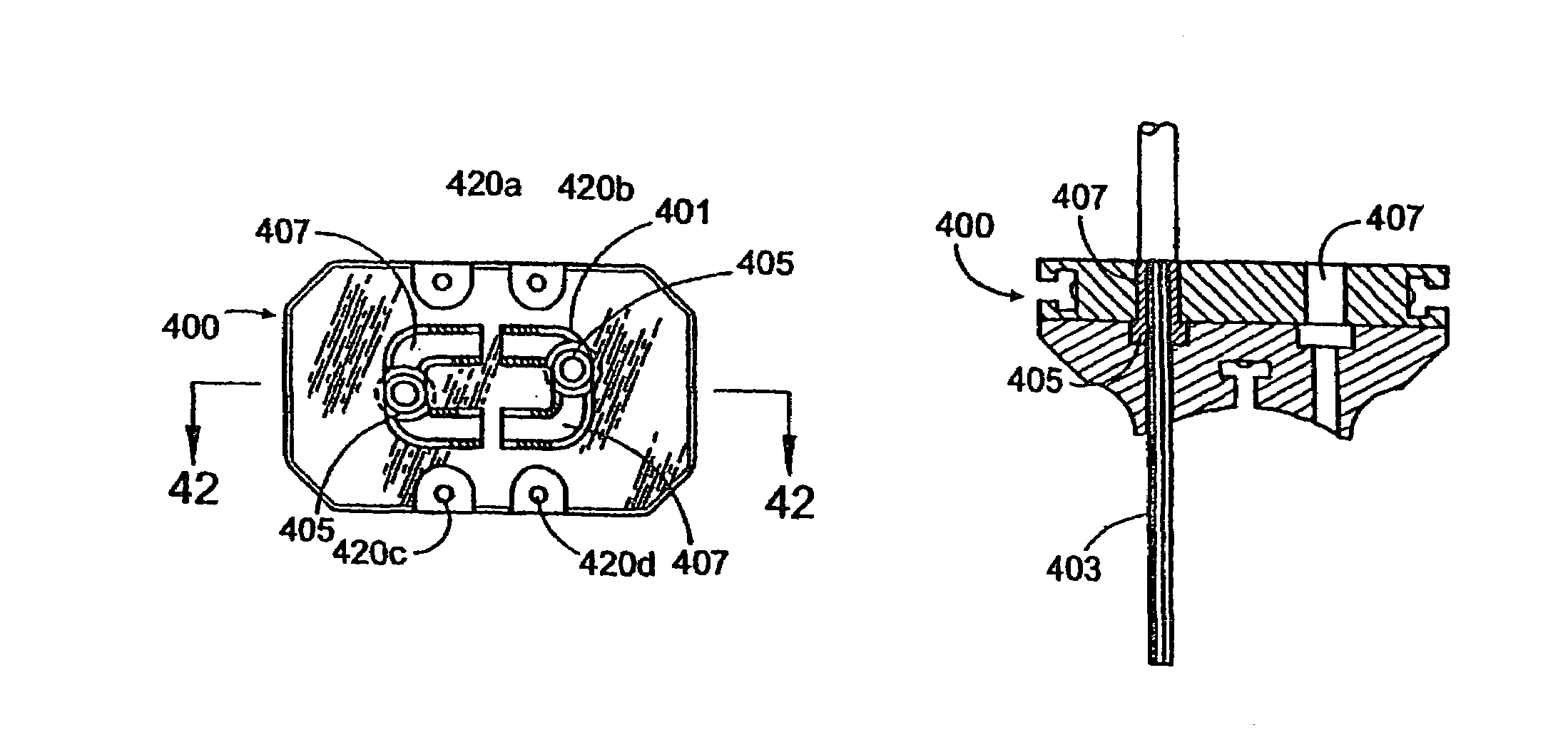

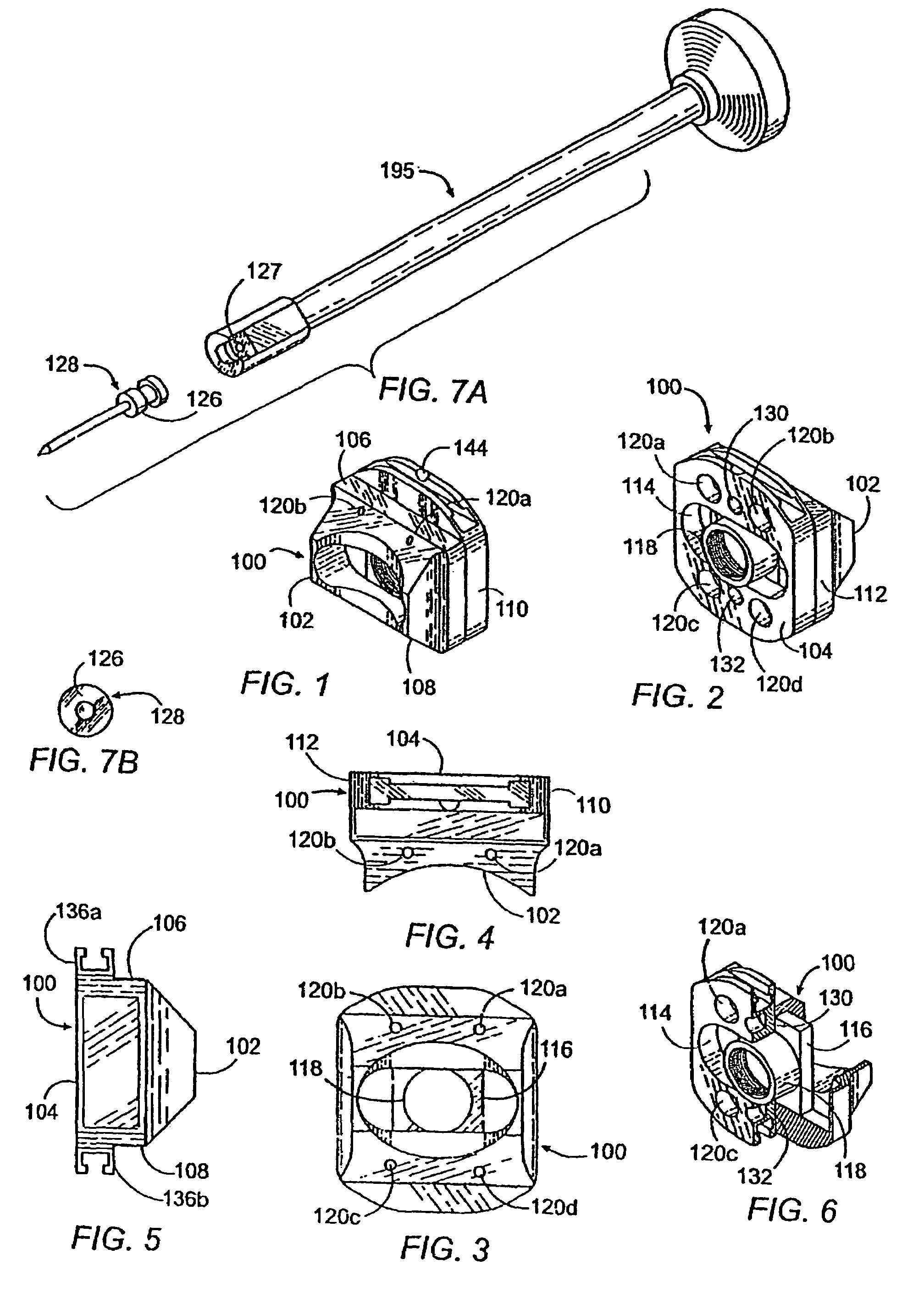

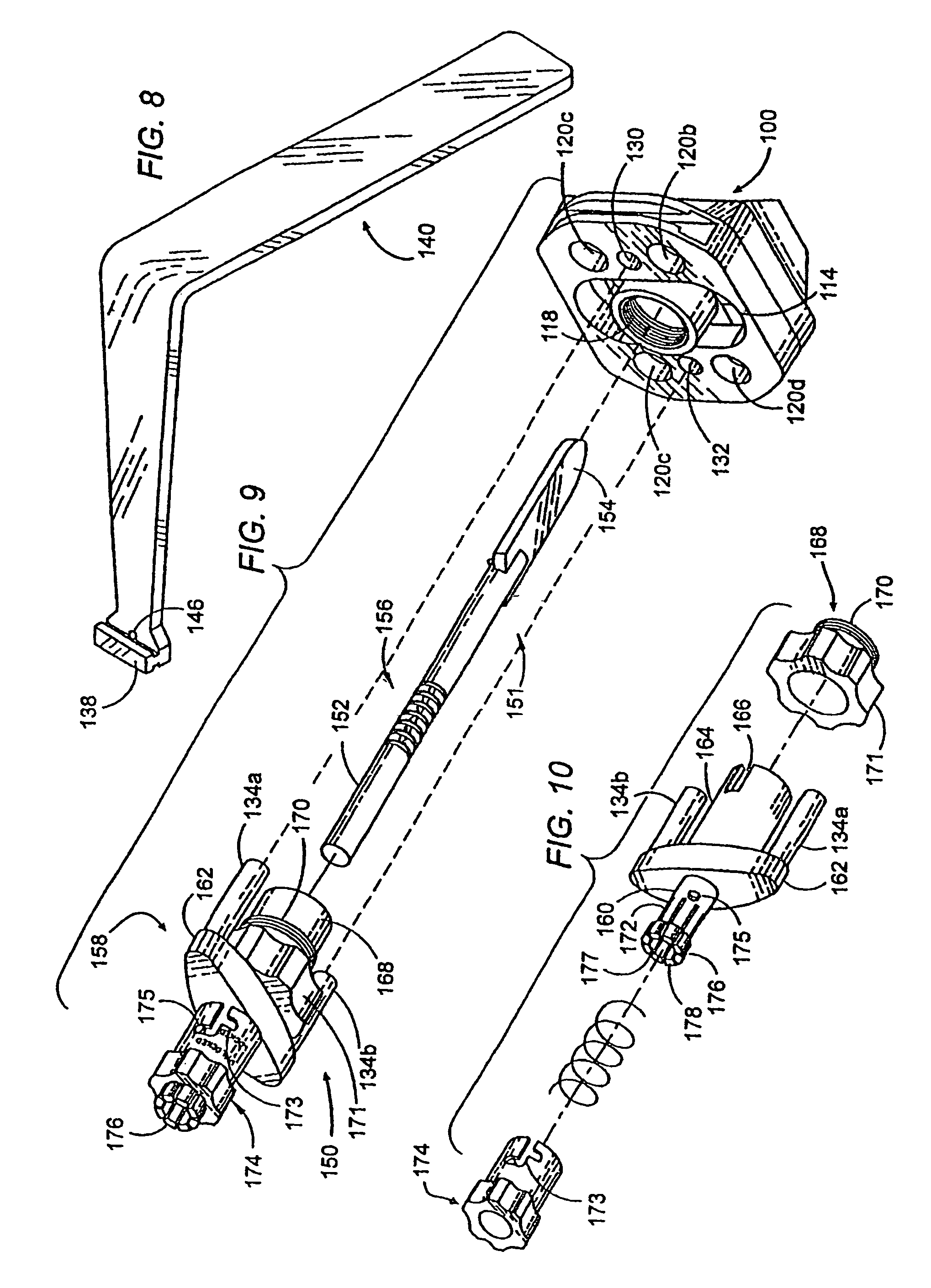

Bone removal device

InactiveUS7635370B2Improve stabilityThe relationship is accurateJoint implantsSpinal implantsDefining lengthVertebral bone

An apparatus and method for placing adjacent vertebrae at a fixed distance and angular relationship relative to each other, fixing said vertebrae in said position by use of a milling block engaging each of said adjacent vertebrae and then using a milling means, the depth, length and excursion of which from side to side are controlled by said apparatus to machine out a defined thickness of bone and a space of defined length, height, width and shape in preparation for receiving an interbody spinal implant or graft of known size and configuration are disclosed.

Owner:WARSAW ORTHOPEDIC INC

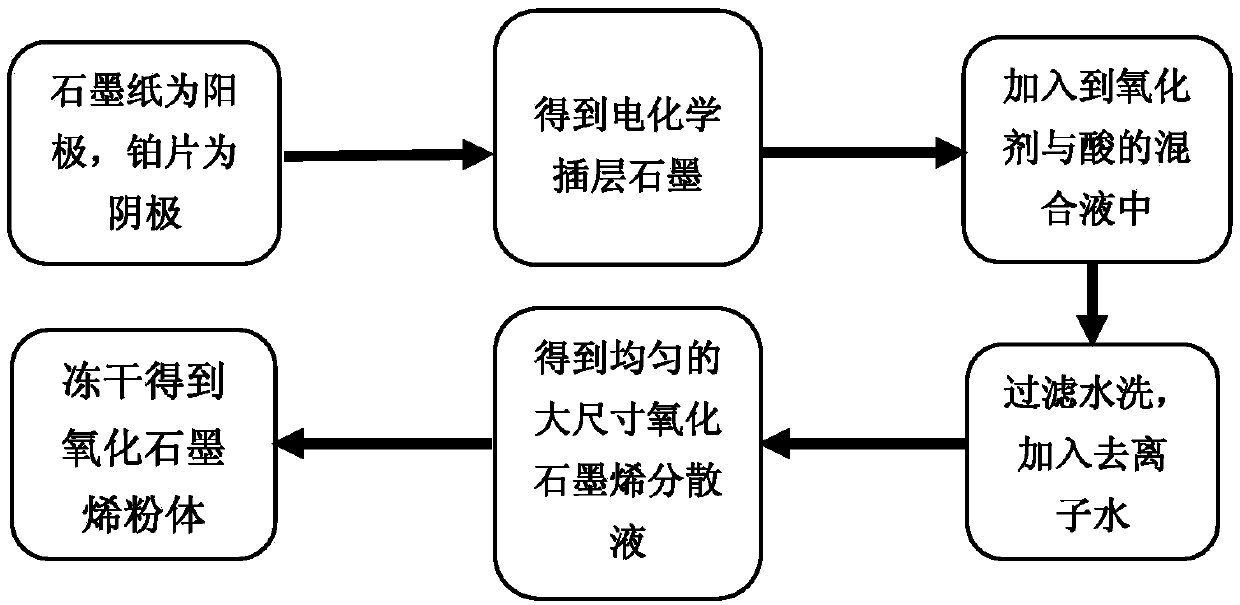

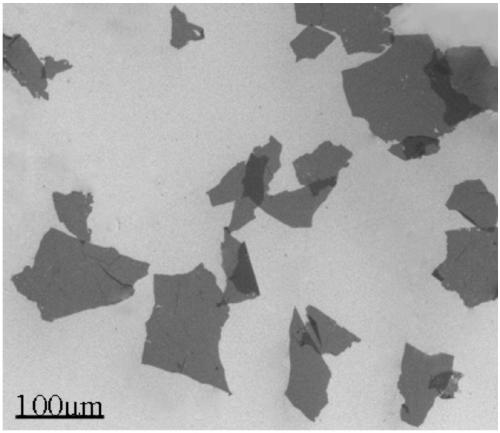

Preparation method of large-dimension graphene oxide and large-dimension graphene oxide obtained by method

The invention relates to a preparation method of large-dimension graphene oxide. The method comprises the following steps of using graphite paper as an anode; using a platinum sheet as a cathode; performing electrochemical pretreatment in electrolyte; performing intercalation on an anode material; peeling graphite; adding the materials into a mixed solution of an oxidizing agent and acid for oxidization reaction; peeling the graphene oxide under the oscillator oscillation or magnetic power stirring conditions, so that the multilayer graphene oxides are peeled into single-layer and few-layer graphene oxides and are dispersed into deionized water to form large-dimension graphene oxide dispersion liquid; performing centrifugal separation to obtain graphene oxide slurry; performing freeze drying treatment to obtain large-dimension graphene oxide powder. The invention also provides the large-dimension graphene oxide obtained by the preparation method. The electrochemical intercalation graphene is used as raw materials to perform oxidization reaction to realize the fast oxidization on the graphene; through natural settling cleaning and mild mechanical peeling, the fast peeling on the large-dimension graphene oxide is realized; the characteristics of high efficiency, high yield and low cost are achieved.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI +1

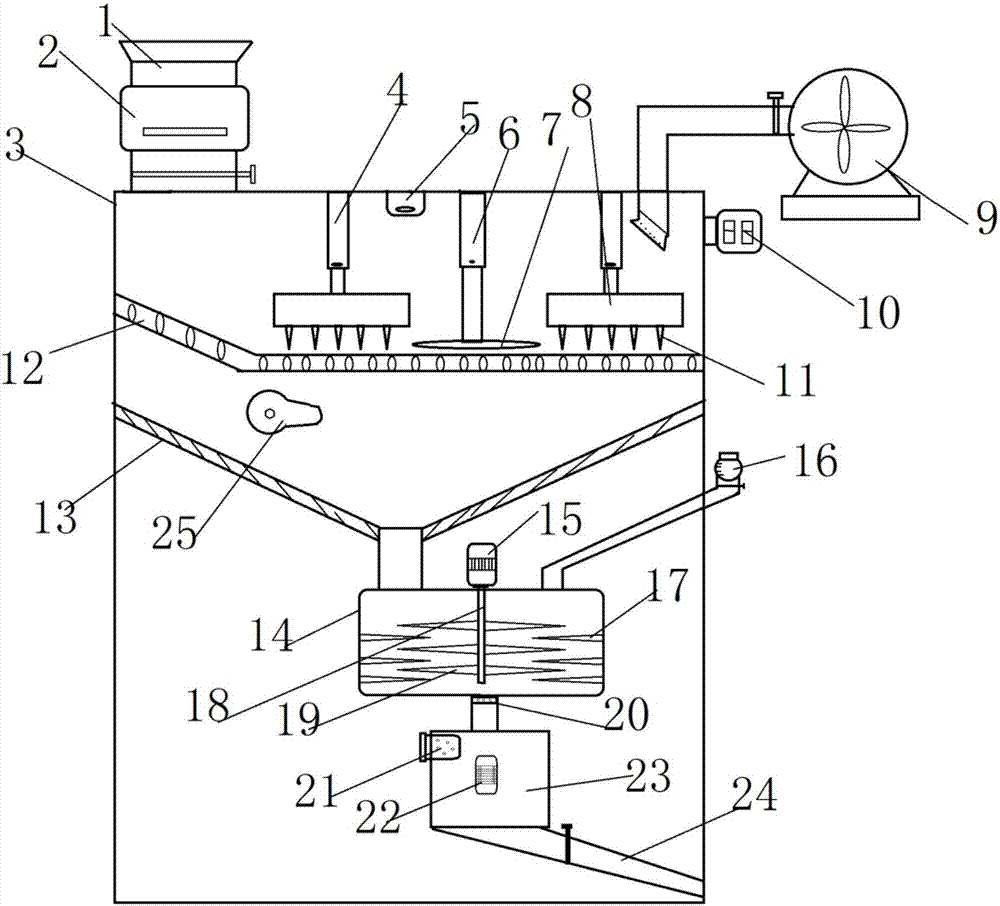

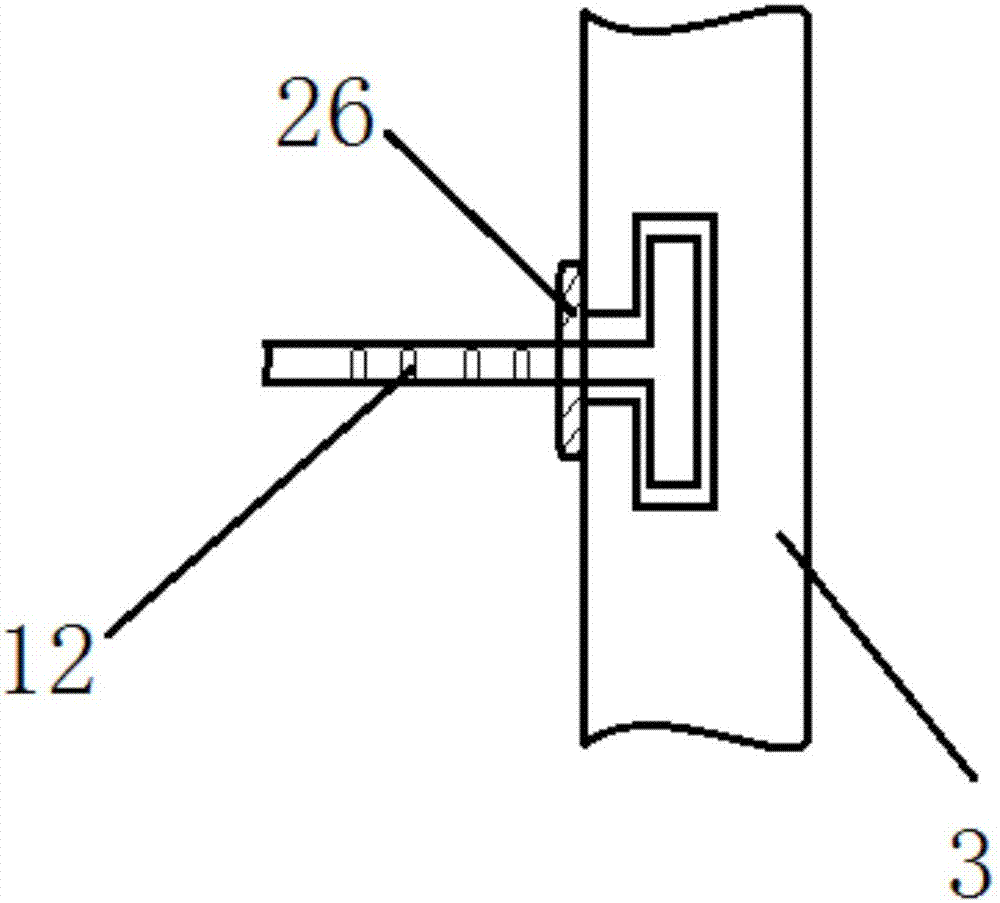

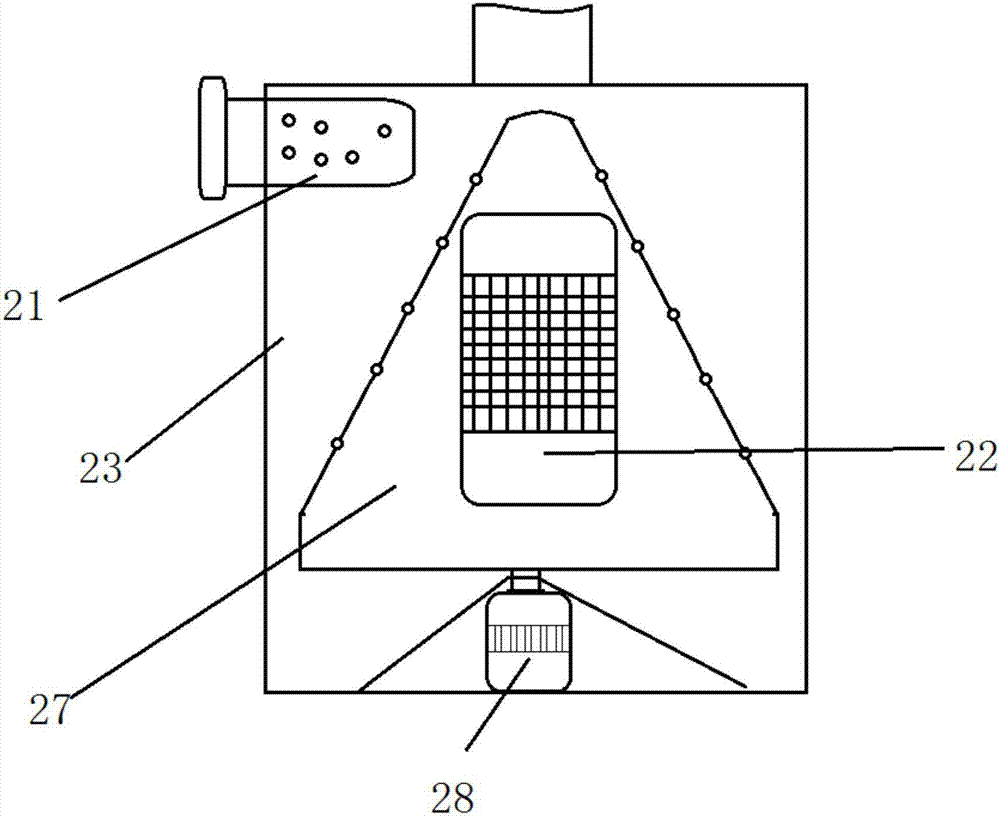

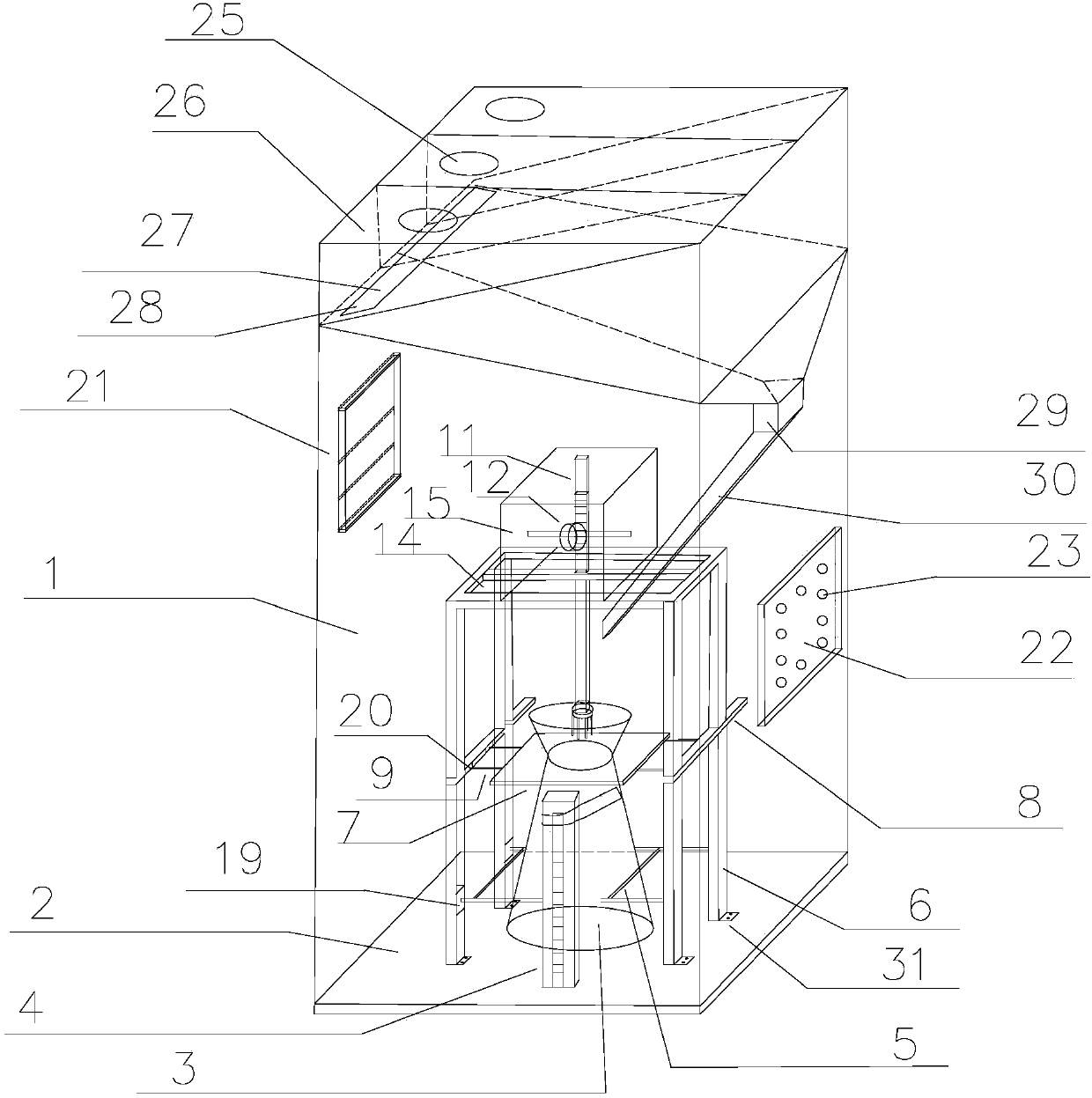

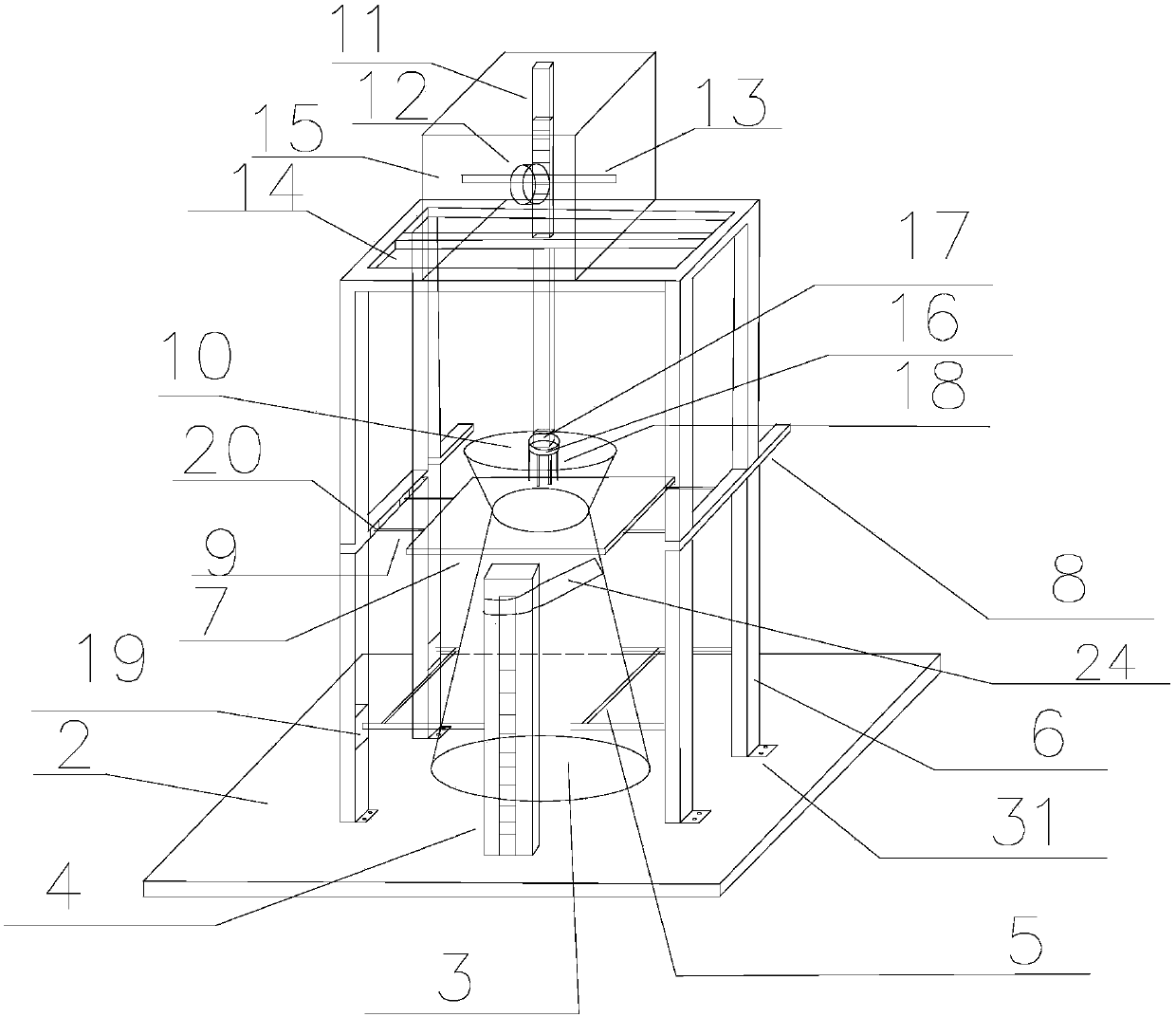

Full-automatic tester for slump degree of cement concrete

PendingCN108051574AThe testing process is simpleAccurate measurementFlow propertiesMaterial testing goodsEngineeringPower apparatus

The invention relates to a full-automatic tester for a slump degree of cement concrete. The full-automatic tester comprises an environmental box, as well as a slump degree cylinder, a scraping apparatus and an inserting and pounding apparatus which are successively arranged in the environmental box from bottom to top, wherein the slump degree cylinder is connected with a vertical traction apparatus; the scraping apparatus is provided with a through hole capable of being communicated with the upper end of the slump degree cylinder, and the scraping apparatus is connected with the horizontal traction apparatus; the lower end of the inserting and pounding apparatus can stretch into the slump degree cylinder, and the upper end of the inserting and pounding apparatus is connected with a liftingapparatus; a feeding apparatus for feeding materials into the slump degree cylinder is also arranged above the slump degree cylinder; the vertical traction apparatus, the horizontal traction apparatus and the lifting apparatus are respectively connected with a power apparatus, and the power apparatus is connected with a controller; and a measurement apparatus for acquiring a slump degree of cement concrete is also installed in the environmental box. By adopting the full-automatic tester for the slump degree of the cement concrete, the accuracy of a test result can be ensured, the automatic operation can be realized, the experiment continuity is good, and the accuracy and reality of a measured result are good.

Owner:CHANGAN UNIV

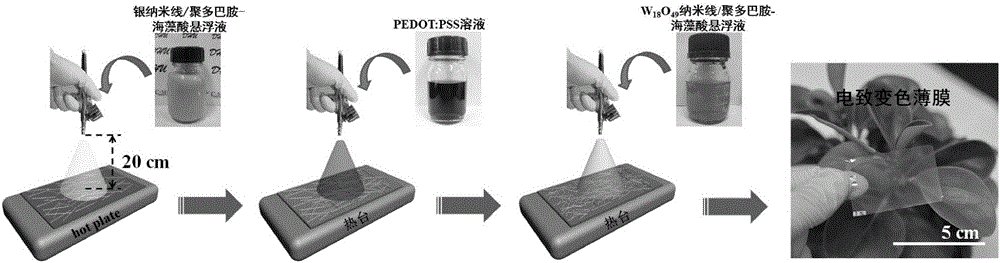

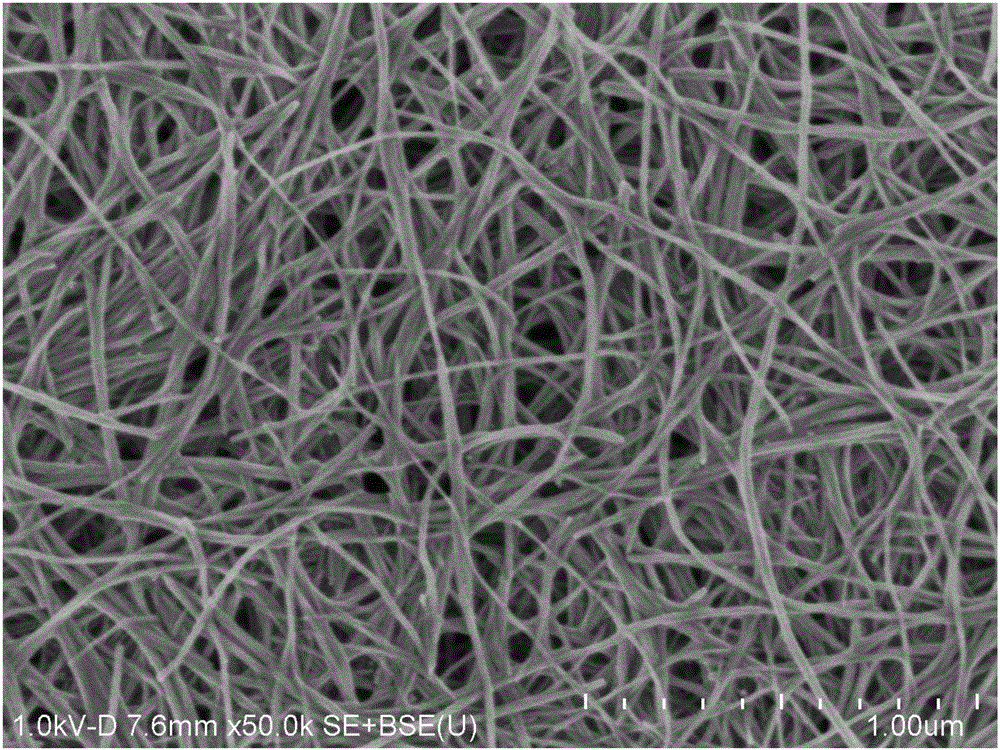

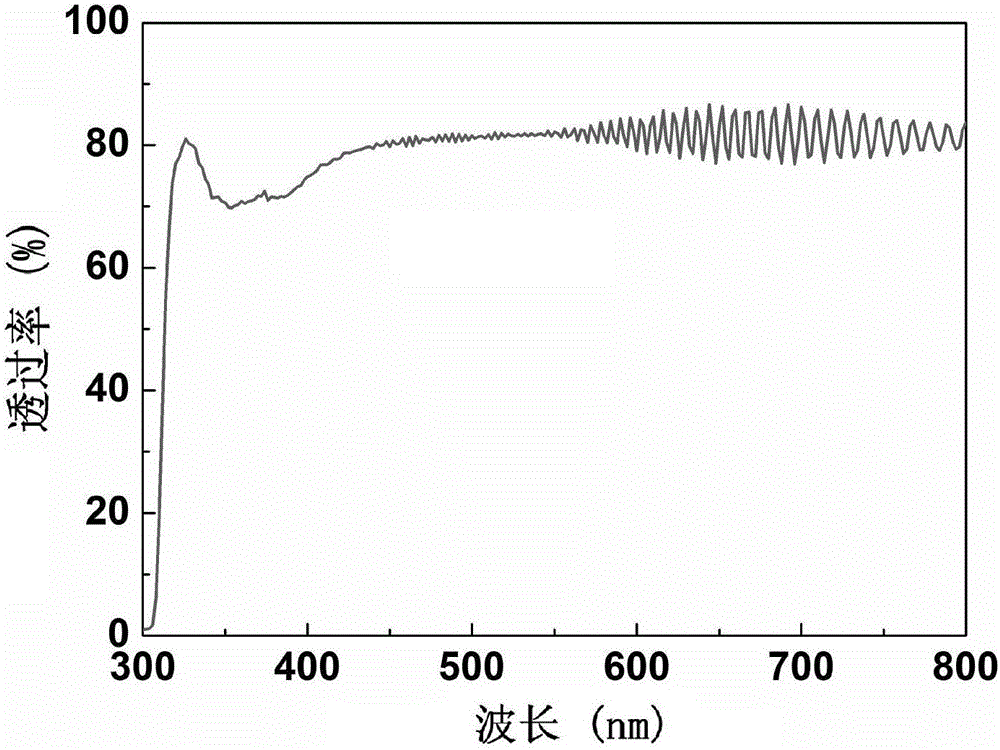

Preparation method of high-flexible light W18O49 electrochromic film

ActiveCN105001436AFast transition rateFast flexibilitySynthetic resin layered productsAnhydrous ethanolElectrochromism

The invention relates to a preparation method of a high-flexible light W18O49 electrochromic film. The method includes: dissolving a polydopamine / alginic acid compound in a water / ethanol mixed solution to obtain a mixed solution, dispersing silver nanowires and W18O49 nanowires in the mixed solution respectively to obtain a spraying liquid A containing silver nanowires and polydopamine / alginic acid and a spraying liquid B containing W18O49 nanowires and polydopamine / alginic acid; mixing PEDOT:PSS water solution with anhydrous ethanol to obtain a PEDOT:PSS diluent; placing a PET film on a hot stage, arranging an airbrush above the PET film vertically, and under nitrogen pressure, spraying the spraying liquid A, the PEDOT:PSS diluent and the spraying liquid B to the PET film in order, thus obtaining the high-flexible light W18O49 electrochromic film. The method provided by the invention is simple and is suitable for large area preparation, realizes high bendability and light weight of an electrochromic film electrode, and enlarges the range of application.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com