Patents

Literature

115results about How to "Lower polarization resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

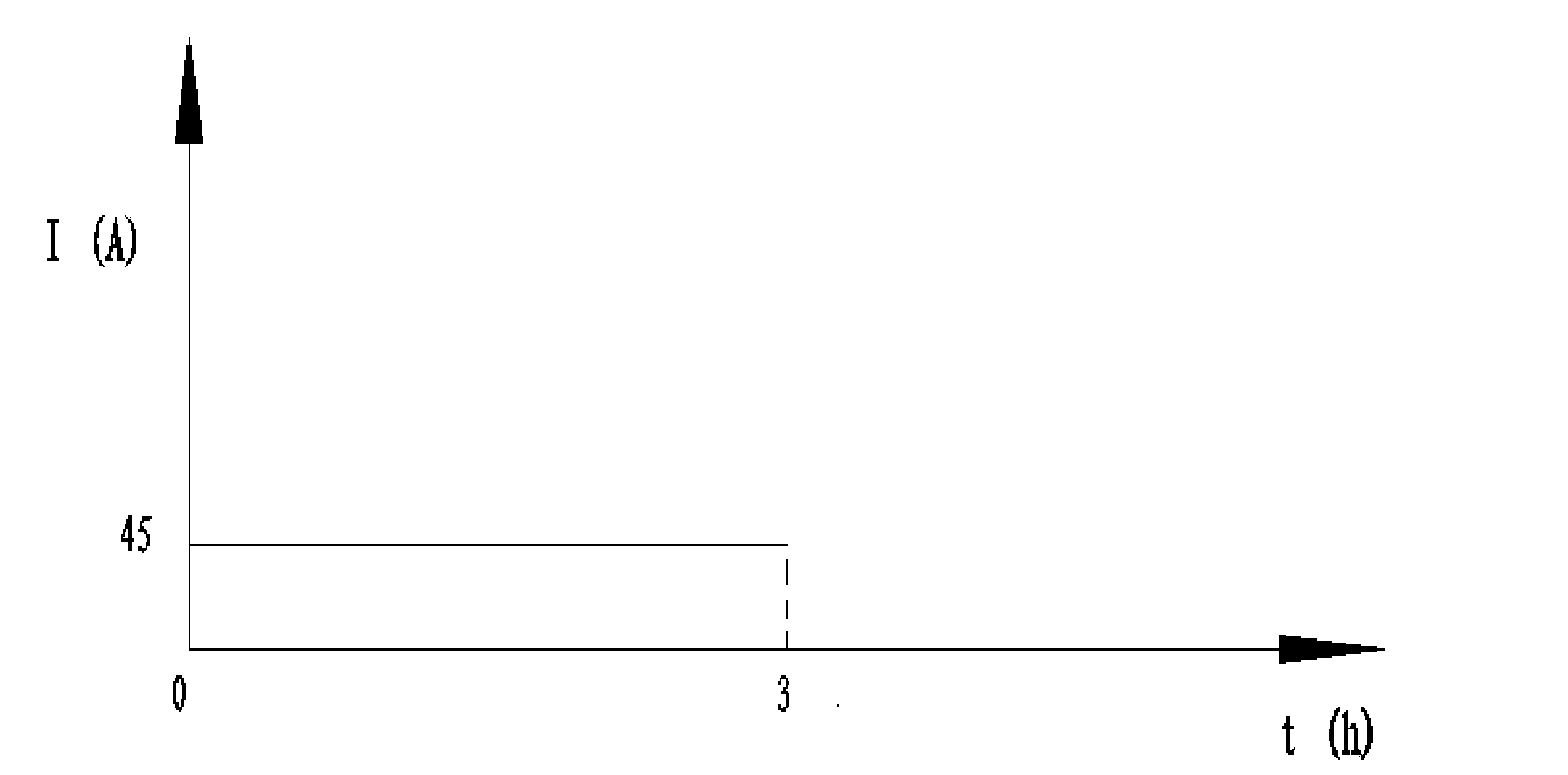

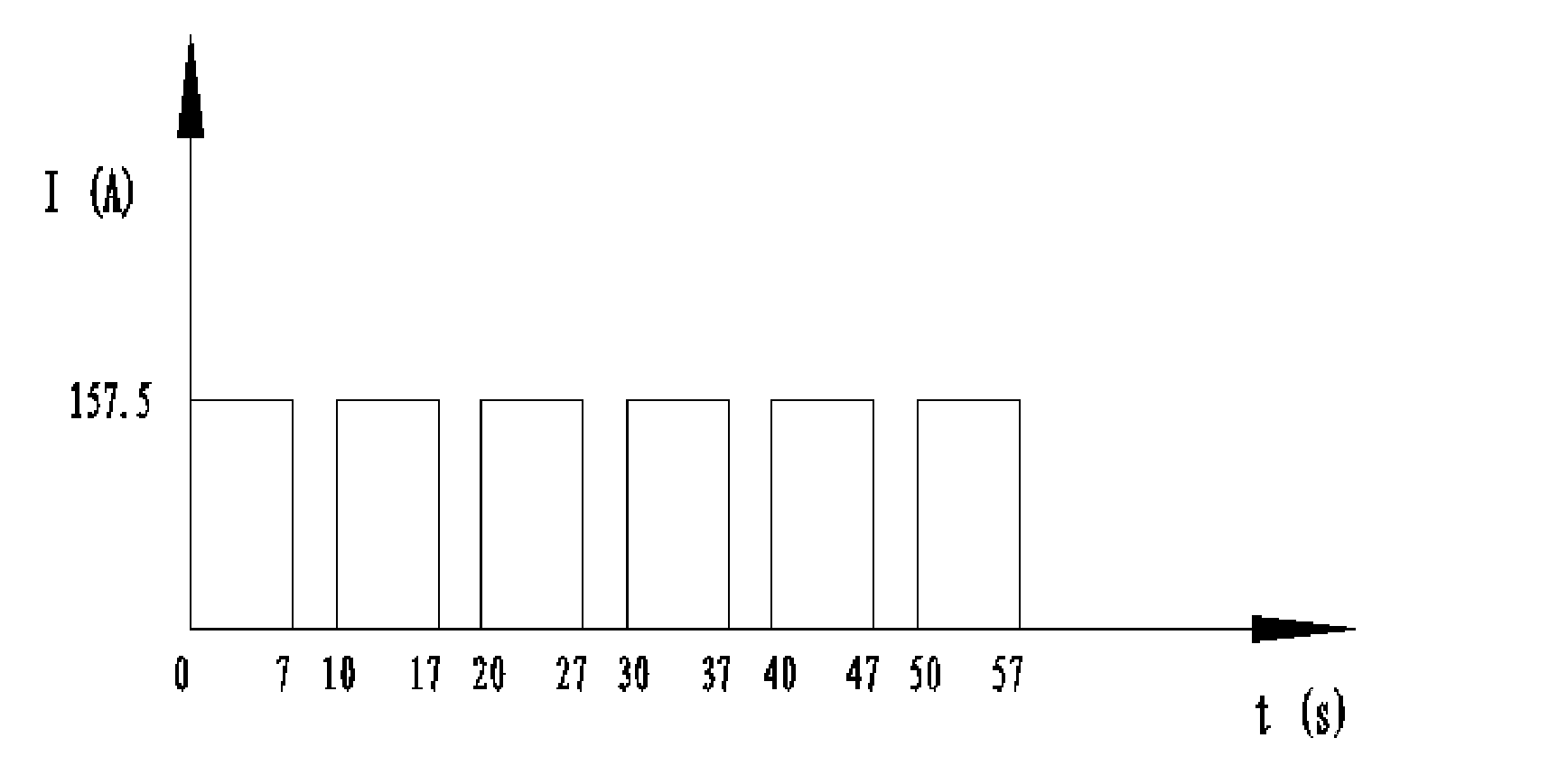

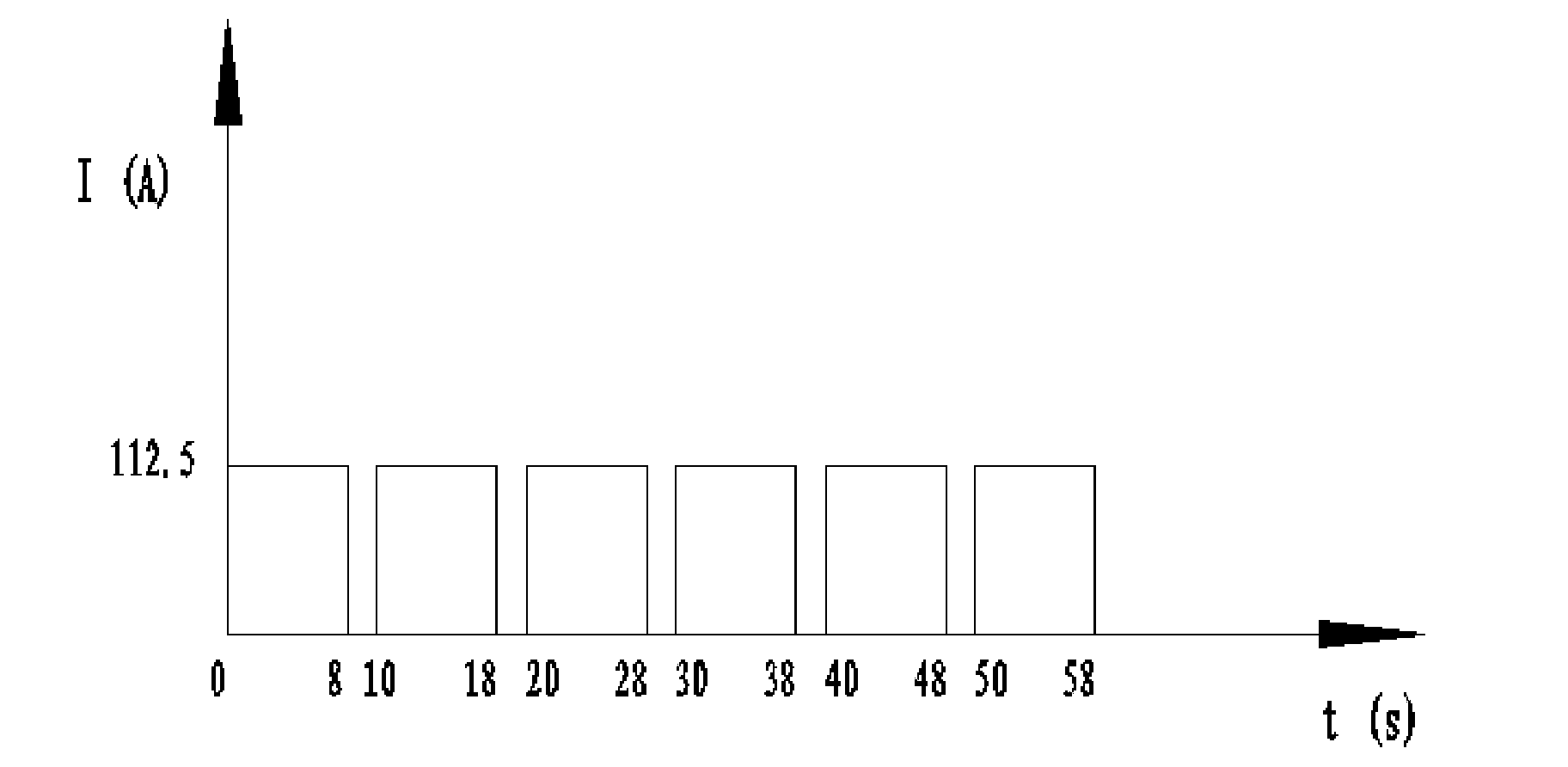

Pulse container formation method for high-capacity lead-acid battery

ActiveCN101877425AReduce shockImprove uniformityFinal product manufactureSecondary cells charging/dischargingEngineeringLow frequency

Owner:HUNAN FENGRI ELECTRIC GROUP

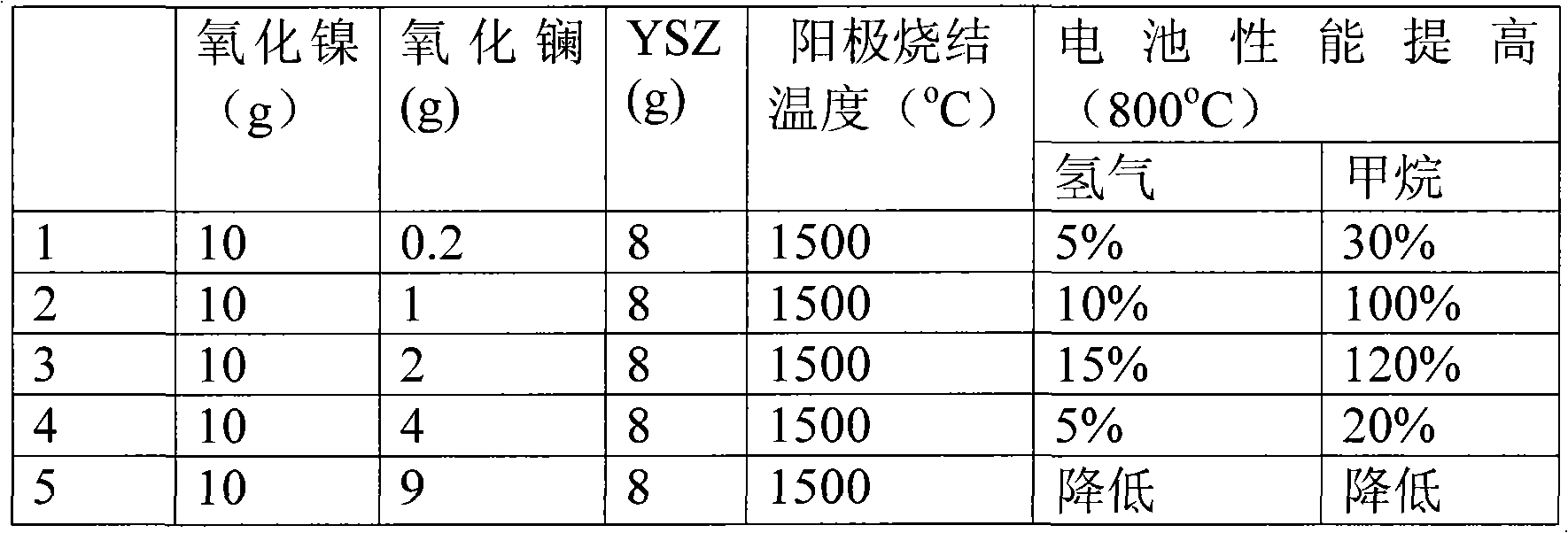

Compound anode of solid-oxide fuel battery and method for producing the same

InactiveCN101295792AGood electrode microstructureHigh activityCell electrodesSolid electrolyte fuel cellsFuel cellsRare earth

The invention relates to a solid oxide fuel cell, in particular to a composite anode of the solid oxide fuel cell and a preparation method thereof. According to weight percentage, the weight composition of the composite anode comprises 30 to 69.9 percent of NiO, 0.1 to 35 percent of rare earth materials and 30 to 69.9 percent of zirconia YSZ with stable yttrium oxide. The composite anode of the solid oxide fuel cell is compounded by adding the rare earth materials to the traditional anode of nickel oxide and zirconia with stable yttrium oxide, and the rare earth materials are added to the anode so as to improve the performance of the anode; the composite anode has the advantages of even distribution of electrode structure, tight interface contact between nickel and YSZ, low polarization impedance, high activity, etc., thus improving the output performance of the cell. The novel composite anode can be applied to flat type, tube type and flat tube type solid oxide fuel cells.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Cathode material of mid-temperature solid-oxide fuel battery and uses thereof

InactiveCN101304092AChange structureHigh activityCell electrodesSolid electrolyte fuel cellsDissociative adsorptionRare earth

The invention relates to a solid oxide fuel cell, in particular to medium temperature solid oxide fuel cell cathode material and application thereof. Being calculated by a weight percentage, the cathode material consists of 40-99 percent of perovskite-type composite oxides, 1-30 percent of CeO2 doped with rare earth oxides, and 0-59 percent of electrolyte material; the electrolyte material refers to ZrO2 stabilized by 5-20 mol percent of Y2O3 and / or ZrO2 stabilized by 5-20 mol percent of Sc2O3. The invention can change the structure of the active components of the cathode material, can improve the activity of the catalytic oxygen reduction reaction of the cathode material, can accelerate the dissociative adsorption of oxygen on the surface of the cathode material, the diffusion of oxygen species on the surface of the cathode material, the transmission process of the oxygen species in a three-phase bounded domain, charge transfer, and other electrochemical processes, and can increase the activity of the cathode of the solid oxide fuel cell.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

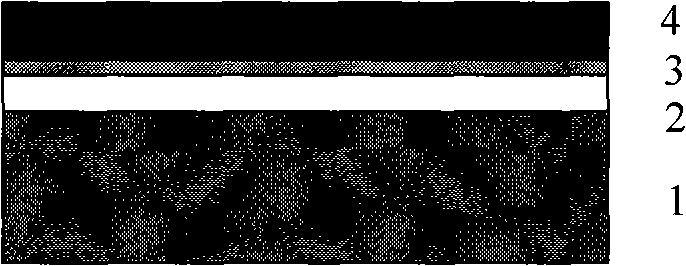

Membrane electrode component of medium temperature solid-oxide fuel cell and preparation thereof

ActiveCN101339997AGood compatibilityImprove performanceCell electrodesSolid electrolyte fuel cellsCeriumCe element

The invention relates to a solid oxide fuel cell, in particular to an intermediate-temperature solid oxide fuel cell membrane electrode component and a preparation thereof. The solid oxide fuel cell membrane electrode assembly comprises an anode substrate, a zirconium-based electrolyte membrane and an intermediate-temperature cathode, wherein, the intermediate-temperature cathode is made of 40-80% of perovskite type cathode material and 20-60% of cerium-based electrode material; and a transition layer made of 20-60% of the zirconium-based electrolyte material and 40-80% of the perovskite type cathode material is prepared between the zirconium-based electrolyte membrane and the intermediate-temperature cathode. The intermediate-temperature solid oxide fuel cell prepared by adopting the method of the invention improves the performance of the solid oxide fuel cell by more than 65% compared with that of the cell without the transition layer, and the combination of the intermediate-temperature cathode and the electrolyte membrane is more stable and reliable, which improves the operation stability and the thermal cycling stability of the cell.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

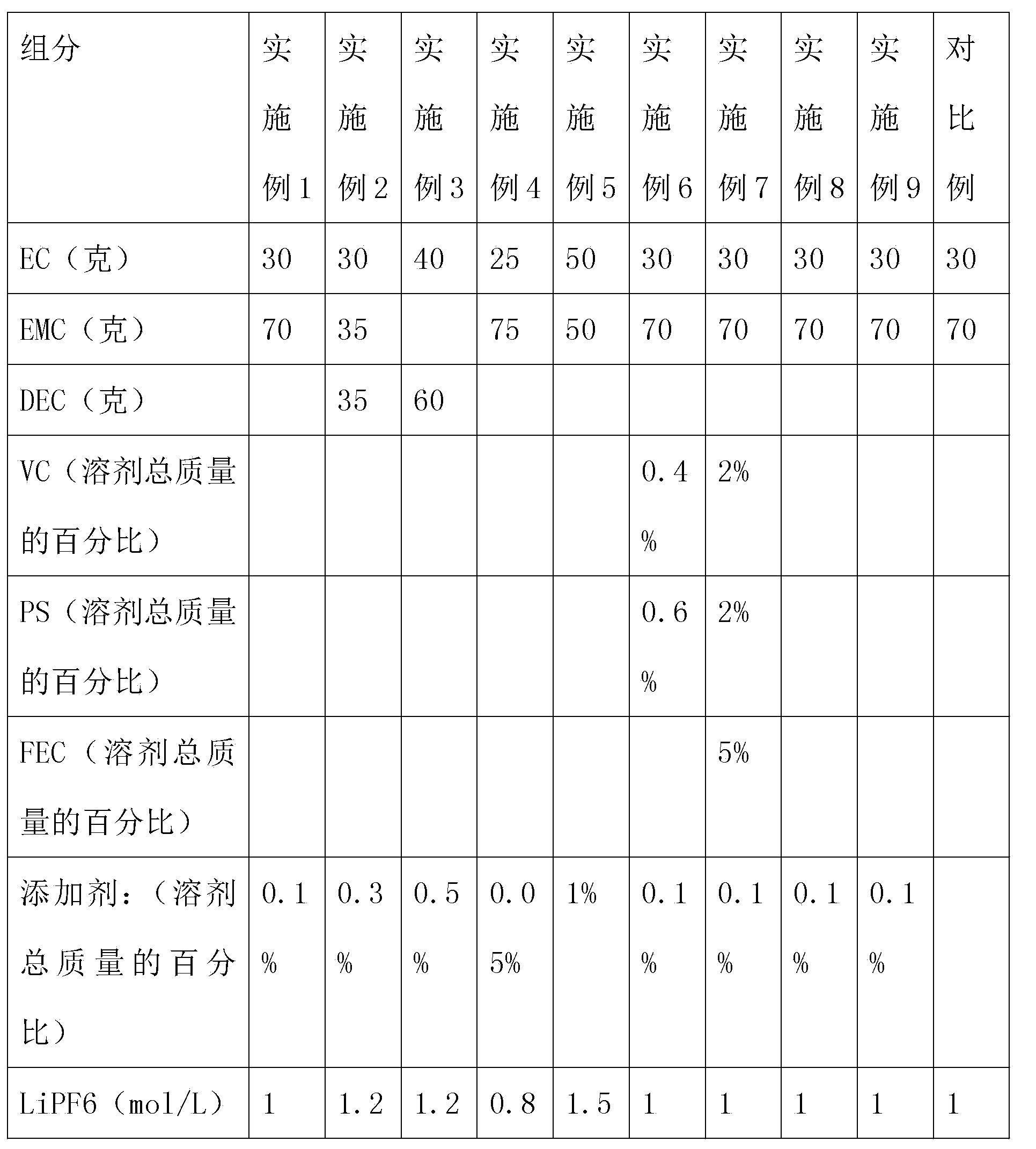

Non-aqueous electrolyte of high-voltage lithium ion batteries

ActiveCN103384017AImprove conductivityLower polarization resistanceSecondary cellsSolventLithium electrode

The invention discloses a non-aqueous electrolyte of high-voltage lithium ion batteries. The non-aqueous electrolyte comprises following ingredients: a cyclic carbonate, a linear carbonate, a lithium salt and an additive. The cyclic carbonate and the linear carbonate are mixed at a mass ratio of 1:1-3; the molar concentration of the lithium salt in the mixed solution composed by the cyclic carbonate and the linear carbonate is 0.8 to 1.5mol / L; the additive is thienyl thioether compound, and the mass of the additive is 0.01 to 1% of the mass of the solvent. The thienyl thioether compound is capable of forming a polythiophene membrane on the surface of an anode. The anode is coated by the polythiophene membrane, so that conductivity of the material is increased, electrode impedance is decreased, further contact of the electrolyte and the surface of materialis avoided, side reactions are reduced, room temperature cycling performance of the electrolyte is improve effectively, and a problem that the cycling performance of the batteries is poor under high voltage is solved.

Owner:ZHUHAI SMOOTHWAY ELECTRONICS MATERIALS

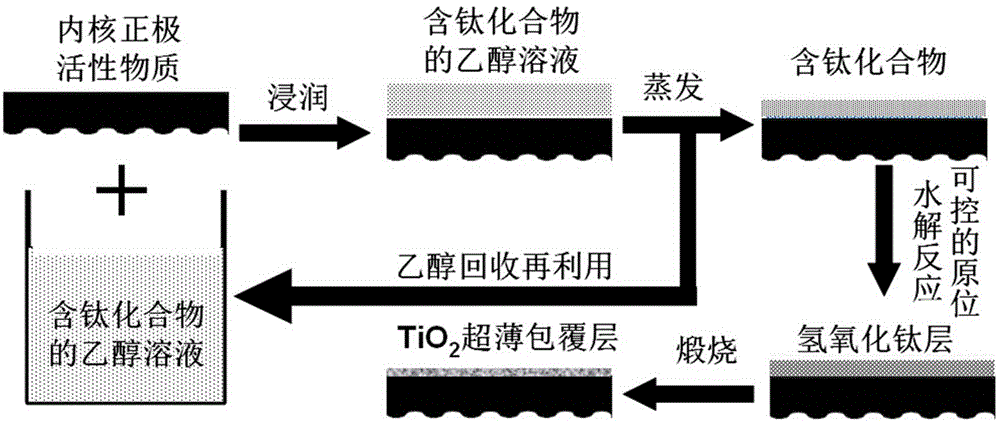

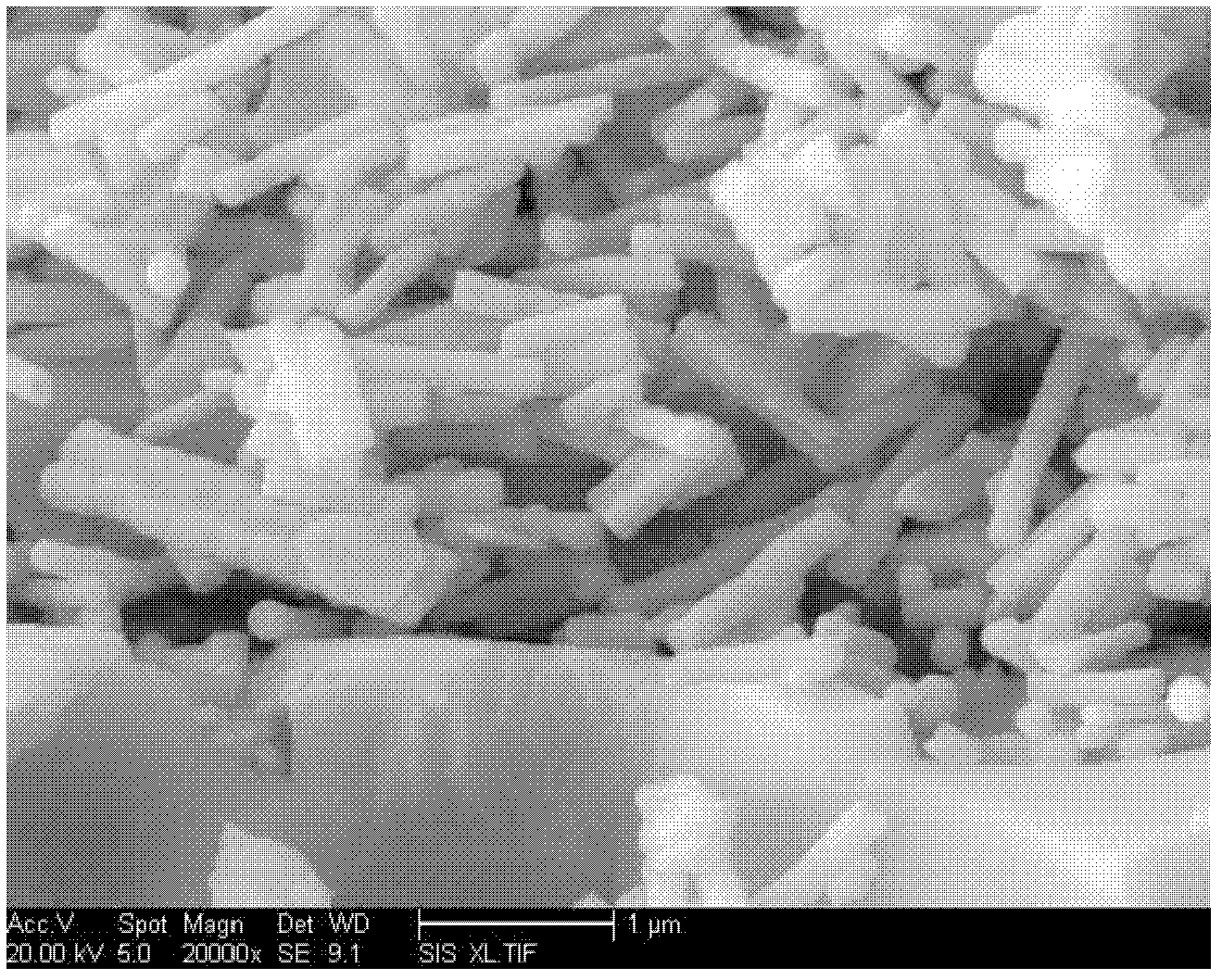

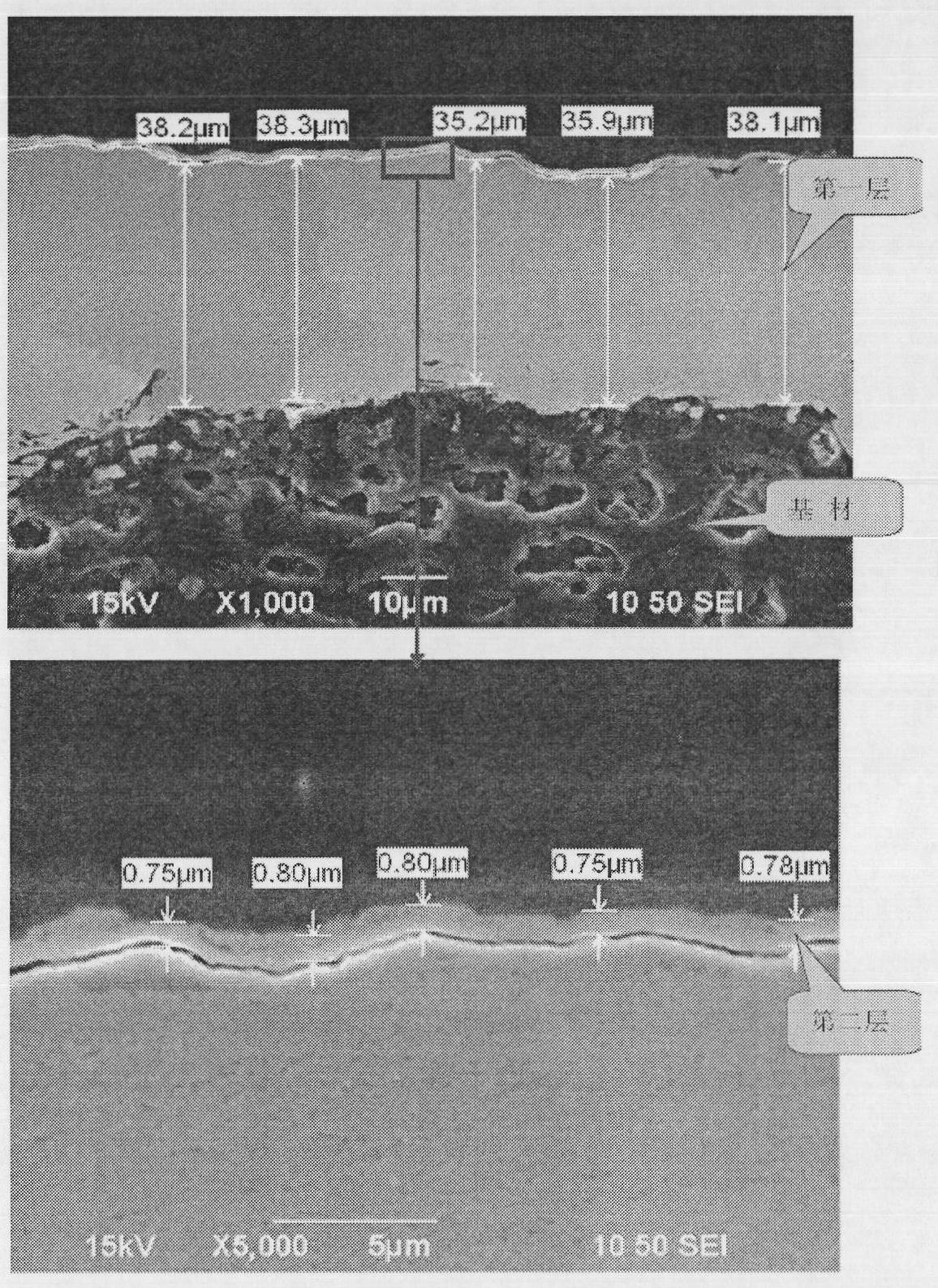

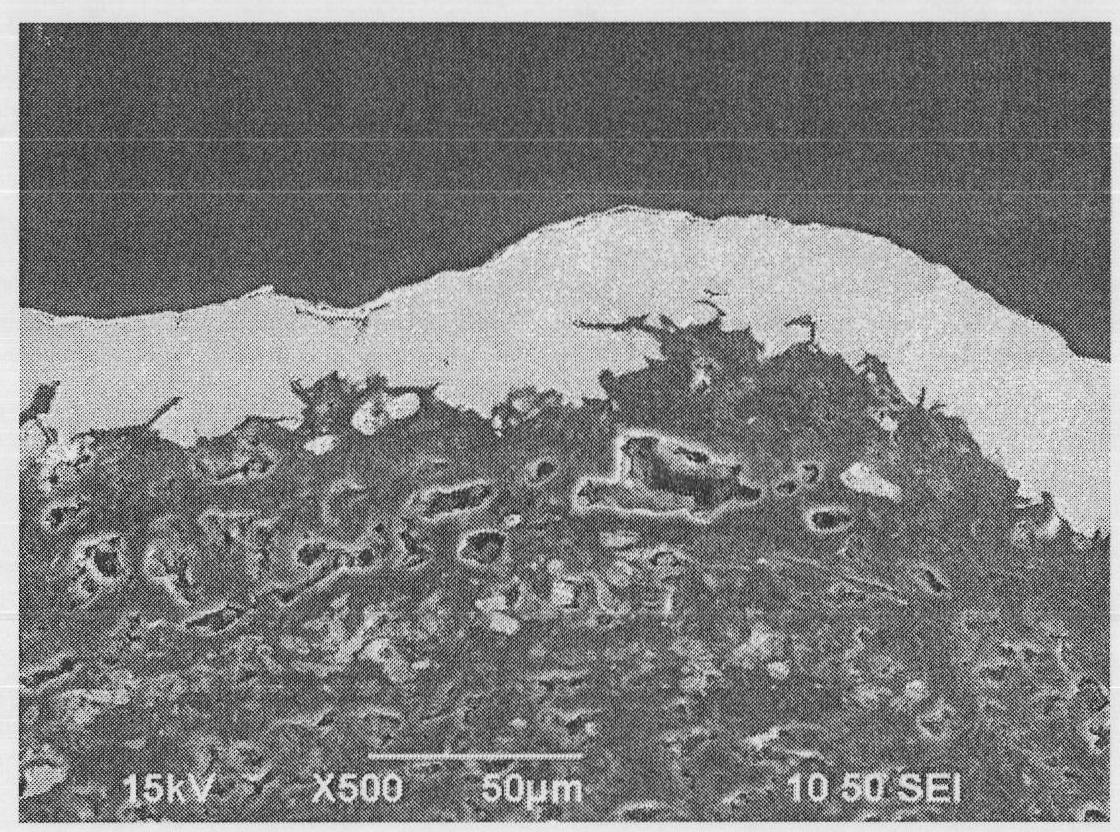

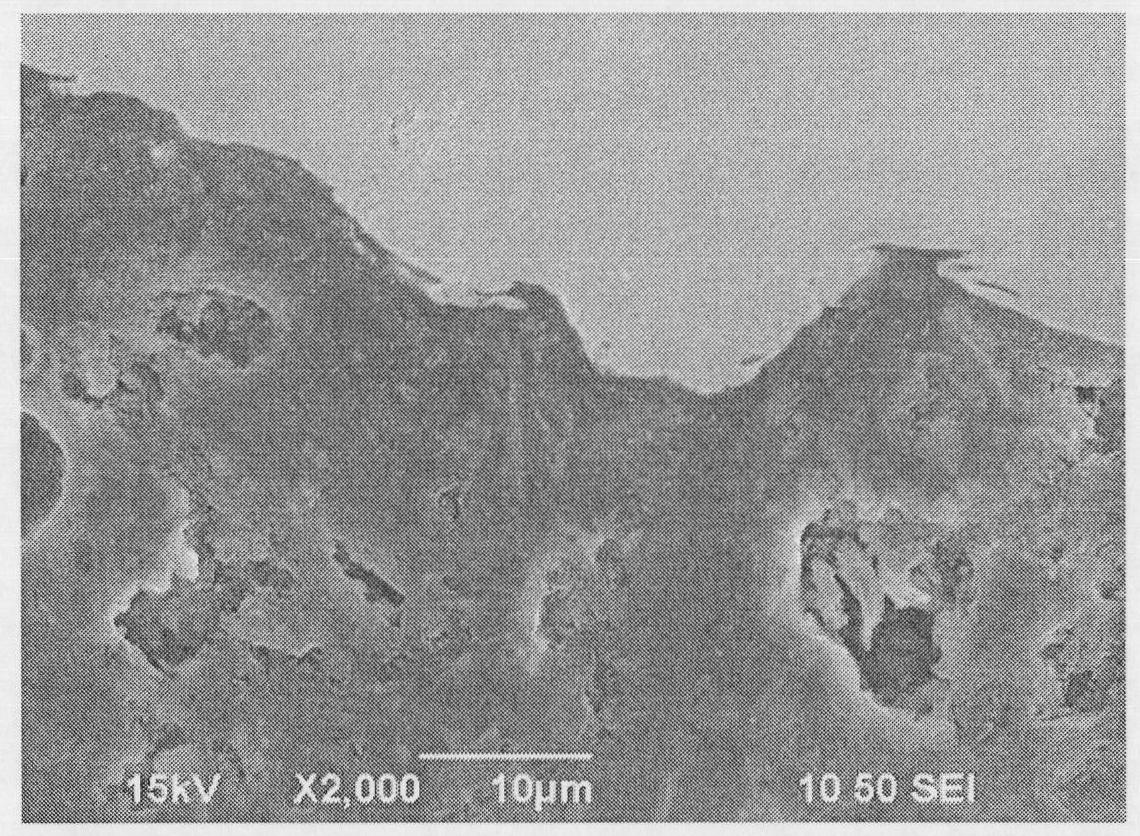

Ultrathin TiO2 coating layer of lithium battery cathode material, lithium battery cathode material and preparation method of lithium battery cathode material

ActiveCN104617267AGood conductivityLower polarization resistanceElectrode manufacturing processesSide reactionCalcination

The invention discloses an ultrathin TiO2 coating layer of a lithium battery cathode material. The coating layer is uniform and compact, and the thickness is only 0.5-20 nm. The lithium battery cathode material with a core-shell type coating structure comprises an inner-core cathode active material and the externally coated ultrathin TiO2 coating layer, wherein a mole ratio of Ti in the coating layer to a transition metal element in the inner-core cathode active material is 0.01%-3%. A preparation method of the lithium battery cathode material comprises steps as follows: a titanium contained compound is dissolved in an organic solvent; the inner-core cathode active material is added to the solution and stirred rapidly, the organic solvent is removed through heating, dry powder is obtained and is placed in dry air for standing to have in-situ hydrolysation with water molecules in air slowly and controllably, and intermediate powder is obtained and placed in an aerobic environment for calcination so as to obtain the lithium battery cathode material. The side reaction between the active material and electrolyte can be effectively inhibited, and the rate capability and the cycle performance of the lithium battery cathode material are improved.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

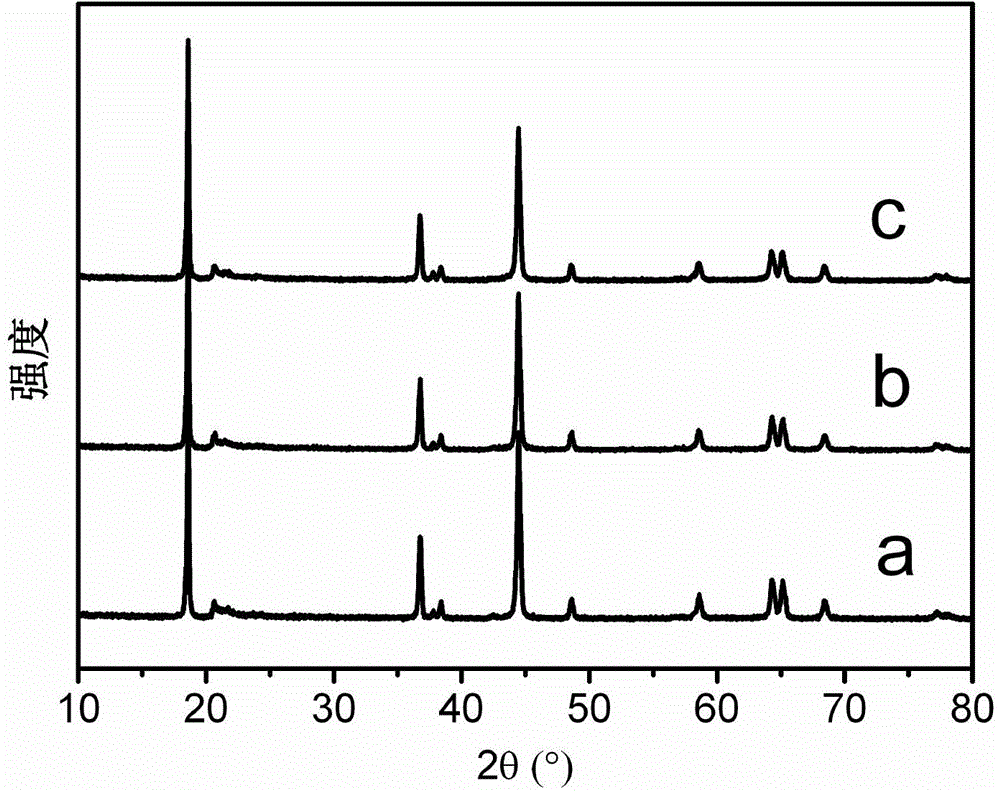

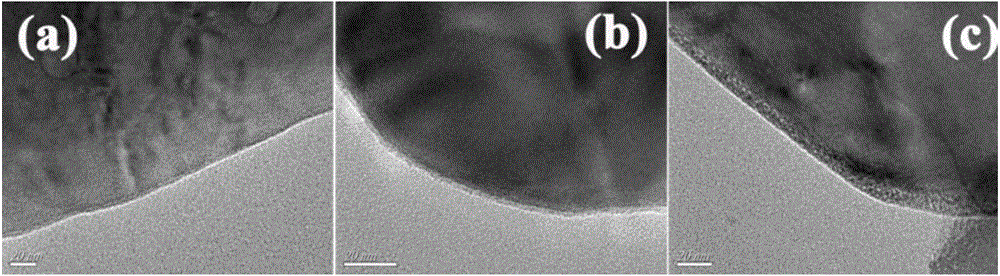

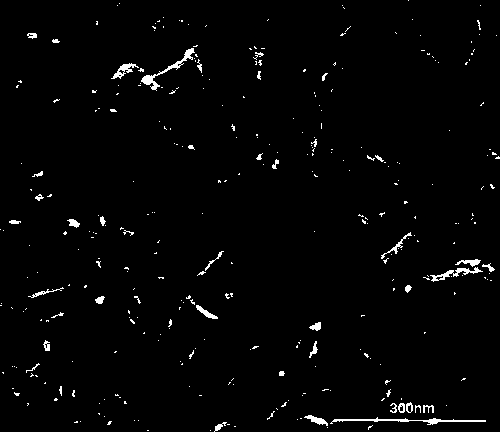

Intermediate-temperature solid oxide fuel cell one-dimensional nano composite cathode and preparation method thereof

ActiveCN102623716ALower polarization resistanceLow costMaterial nanotechnologyCell electrodesHigh resistanceElectrolysis

Disclosed are an intermediate-temperature solid oxide fuel cell one-dimensional nano composite cathode and a preparation method thereof, which relate to an intermediate-temperature solid oxide fuel cell cathode and a preparation thereof and resolve the technical problem of high resistance of exiting lanthanum strontium cobalt ferrite (LSCF) / gadolinia doped ceria (GDC) composite powder cathode polarization. Ce0.8Gd0.2O1.9 electrolyte sheets serve as a matrix of the cathode, the surface of the cathode is coated with nano rod shaped La0.8Sr0.2Co0.2Fe0.8O3 powder, and Ce0.8Gd0.2O1.9 nano granules are attached to a nano rod. The preparation method includes the steps of preparing nitrate to be a precursor solution, sintering after electrostatic spinning, obtaining nano rod shaped powder, coating the powder on electrolyte sheets for sintering, permeating a mixture liquid of gadolinium nitrate and cerium nitrate, and obtaining products after sintering; or mixing LSCF nano rod shaped powder and Ce0.8Gd0.2O1.9 nano powder to coat on electrolyte sheets for sintering, and obtaining products. The cathode and the preparation method thereof are used for intermediate-temperature solid oxide fuel cells.

Owner:HARBIN INST OF TECH

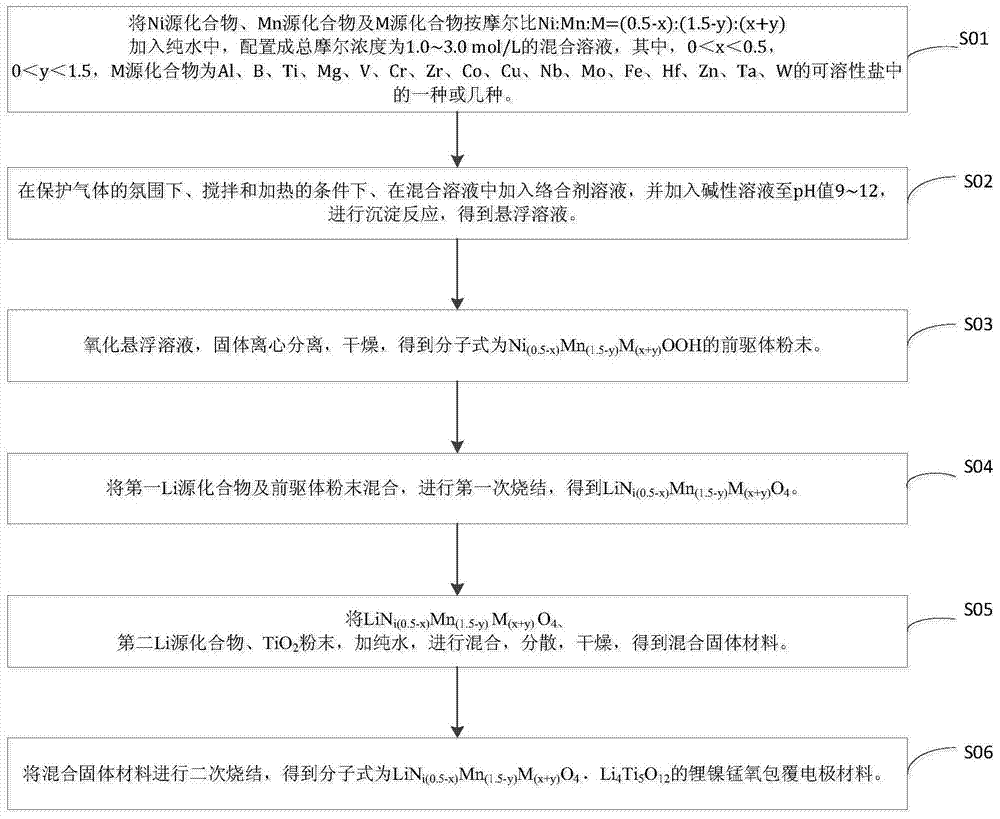

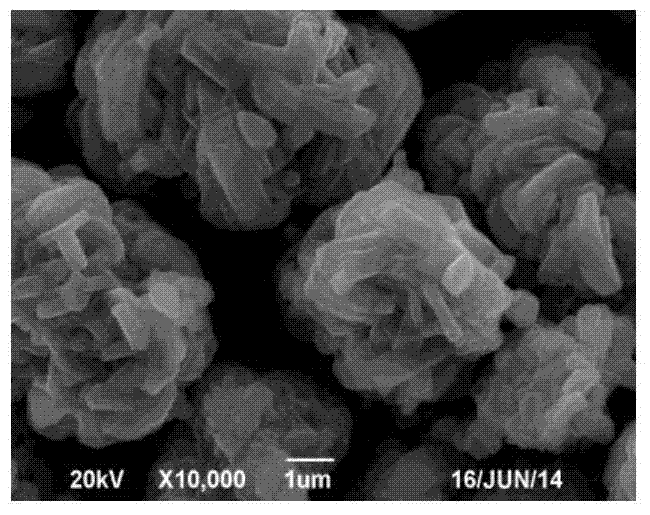

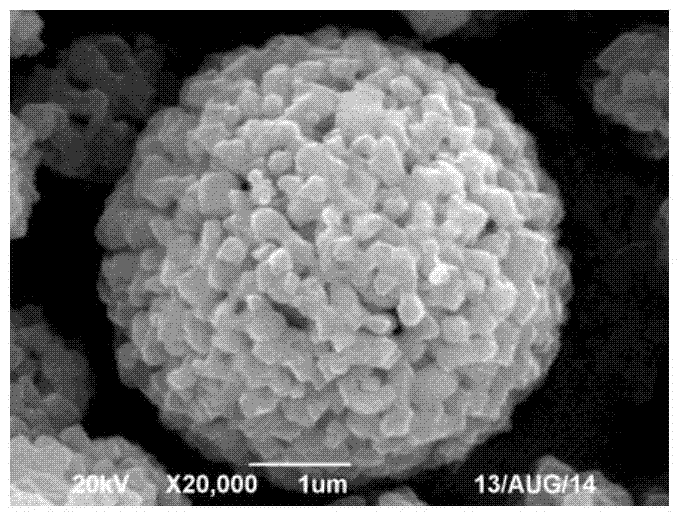

Synthetic method for lithium nickel manganese oxygen covered with lithium titanate

InactiveCN104766970ANo crystal transformationStable structureCell electrodesSecondary cellsManganeseOxygen

The invention discloses a preparing method for lithium nickel manganese oxygen covered with lithium titanate. The method comprises the following steps that firstly, Ni, Mn and M are added into pure water, and a mixed solution with the total molar concentration ranging from 1.0 mol / L to 3.0 mol / L is obtained; secondly, a complexing agent solution is added into the mixed solution, the pH value is mixed to be ranging from 9 to 12, and a supernatant solution is obtained; thirdly, the supernatant solution is oxidized, the solid centrifugal separation is carried out, drying is carried out, and precursor powder is obtained; fourthly, Li source compound is mixed with the precursor powder, a first time sintering is carried out, LiNi (0.5-x) Mn (1.5-y) M (x+y) O4 is obtained, pure water adding and the drying are carried out on the LiNi (0.5-x) Mn (1.5-y) M (x+y) O4, second Li source compound and TiO2 powder, and a mixed solid material is obtained; sixthly, secondary sintering is carried out on the mixed solid material, and an electrode material covered with the lithium titanate is obtained. According to the prepared electrode material covered with the lithium titanate, the cycle performance and the rate performance of the electrode material can be effectively improved.

Owner:HUNAN RESHINE NEW MATERIAL

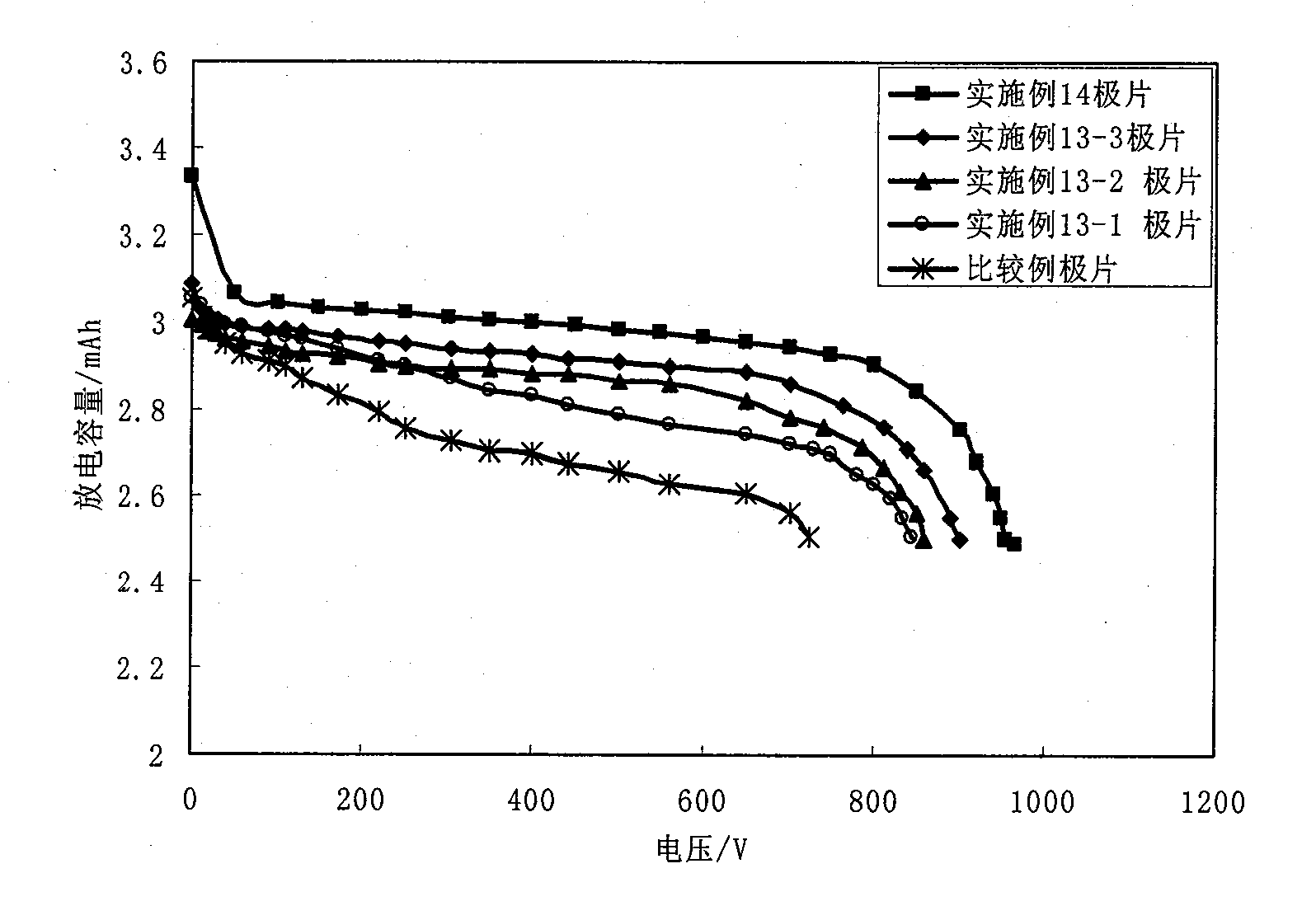

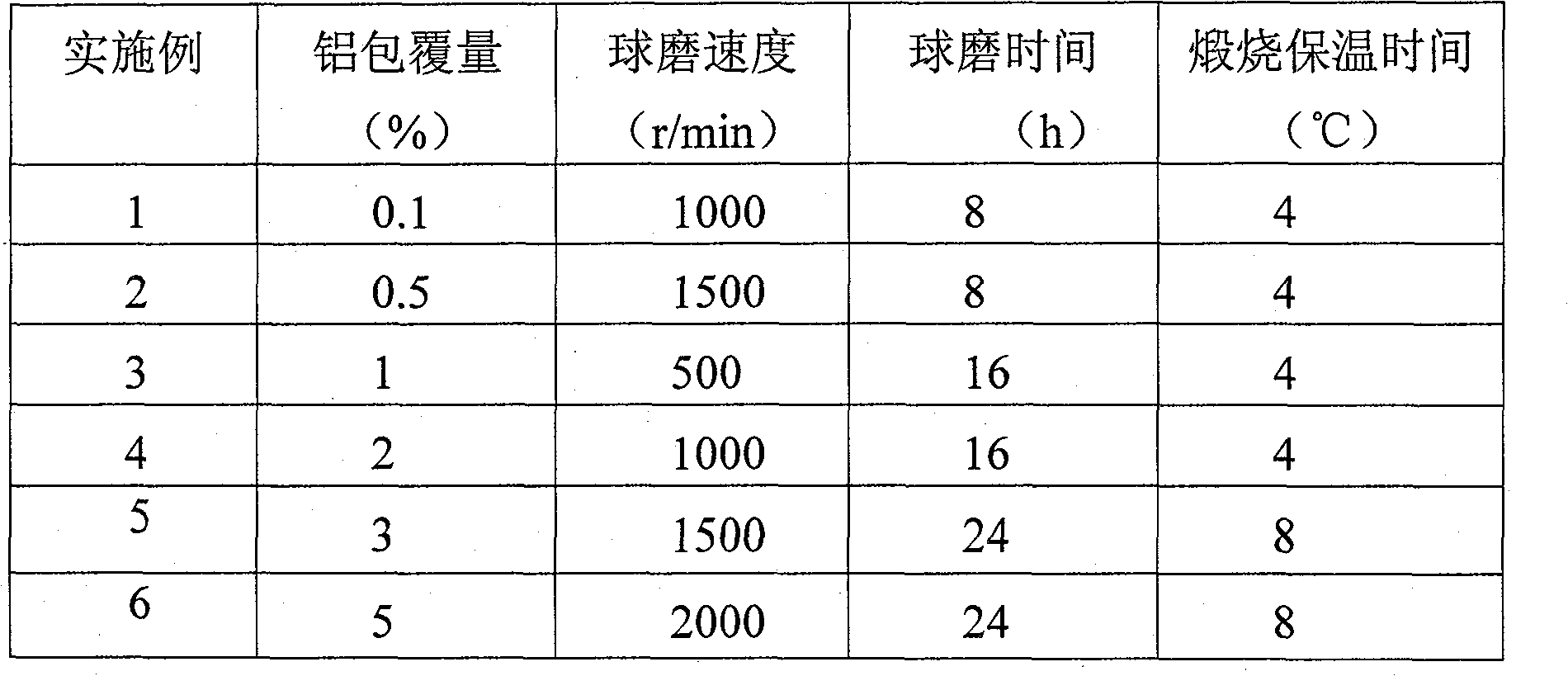

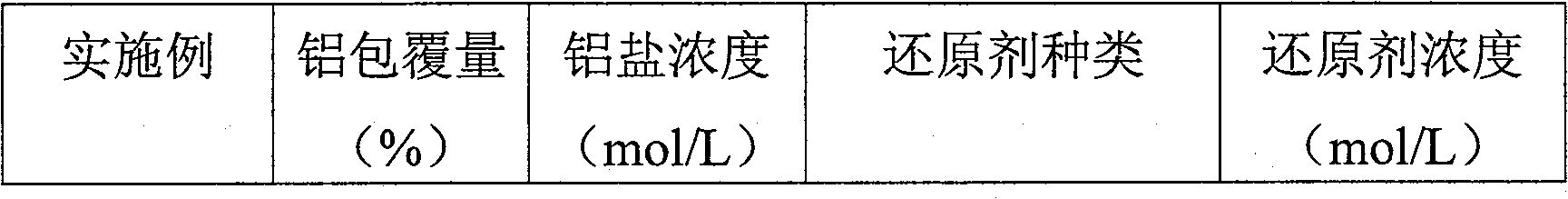

Preparation method of LiFePO material, lithium ion battery and positive plate thereof

ActiveCN101891179ALower internal resistanceImprove high current charge and discharge performanceCell electrodesSecondary cellsAluminium-ion batteryInternal resistance

The invention discloses a preparation method of a LiFePO material, a lithium ion battery using the material and a positive plate thereof. The preparation method comprises the following steps: sintering to prepare LiFePO powder; cladding aluminum on the surface of the LiFePO powder particle to form a LiFePO-Al composite material. Compared with the prior art, the LiFePO material prepared by the invention and the cladding aluminum can carry out homodisperse and surface cladding at the molecule level; the conductivity of the electrode plate prepared by the invention is improved by 101-10001 times; and the internal resistance of the LiFePO lithium ion battery is reduced greatly, and the large-current charge-discharge property is obviously improved, thus the material is particularly suitable for a high power lithium ion battery. Compared with the other cladding elementary metal, Al metal is cheaper, has lighter mass, lower melting point, more stable electrochemistry property and the like; and in additional, the aluminum in the composite material and a positive pole current collector are made of the same material, so that primary battery corrosion effect can not be formed.

Owner:STARZEON ELECTRONICS DONGGUAN +1

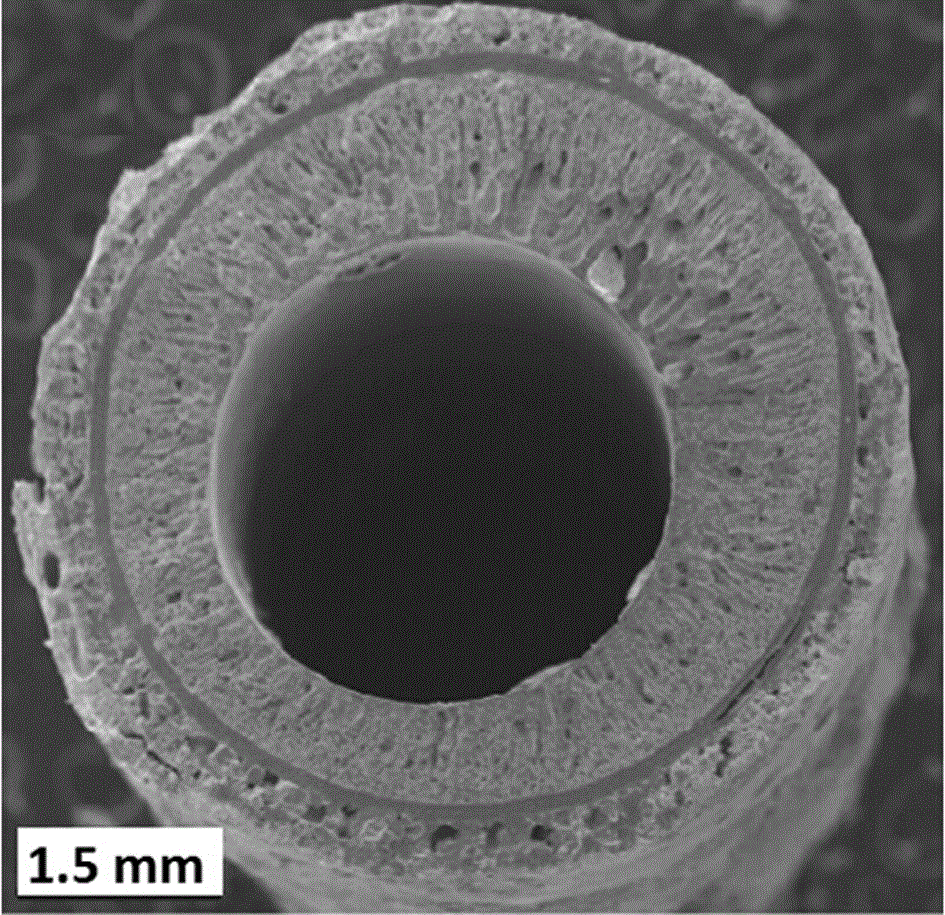

All-solid-state lithium-air battery and preparation method and application thereof

ActiveCN105742761AAll solid state implementationImprove securityFuel and primary cellsPtru catalystElectrical battery

The invention discloses an all-solid-state lithium-air battery and a preparation method and application thereof. The all-solid-state lithium-air battery provided by the invention comprises a lithium metal anode, a porous ceramic support body, a compact electrolyte thin film, a porous cathode thin film, a sealing material, a current collector and a lead, wherein the porous support body is made of garnet type lithium-ion solid electrolyte material; in an air electrode catalyst and permeation holes of the lithium metal anode, a three-phase boundary for battery reaction is expanded, and the battery polarization resistance is reduced; the thickness of the battery electrolyte thin film is smaller than 30 micrometers, a lithium ion transmission path is shortened, and the battery ohmic resistance is reduced; and the battery is a tubular structure with a closed end, the lithium metal anode is poured into a tube, and the battery is easy to seal and is easy to work in different conditions. The all-solid-state lithium-air battery prepared according to the invention has the advantages of high charging-discharging capacity, high rate performance, high cycle stability, wide working temperature range and the like, and is applicable to the field of various mobile electronic devices and power batteries.

Owner:SUZHOU UNIV

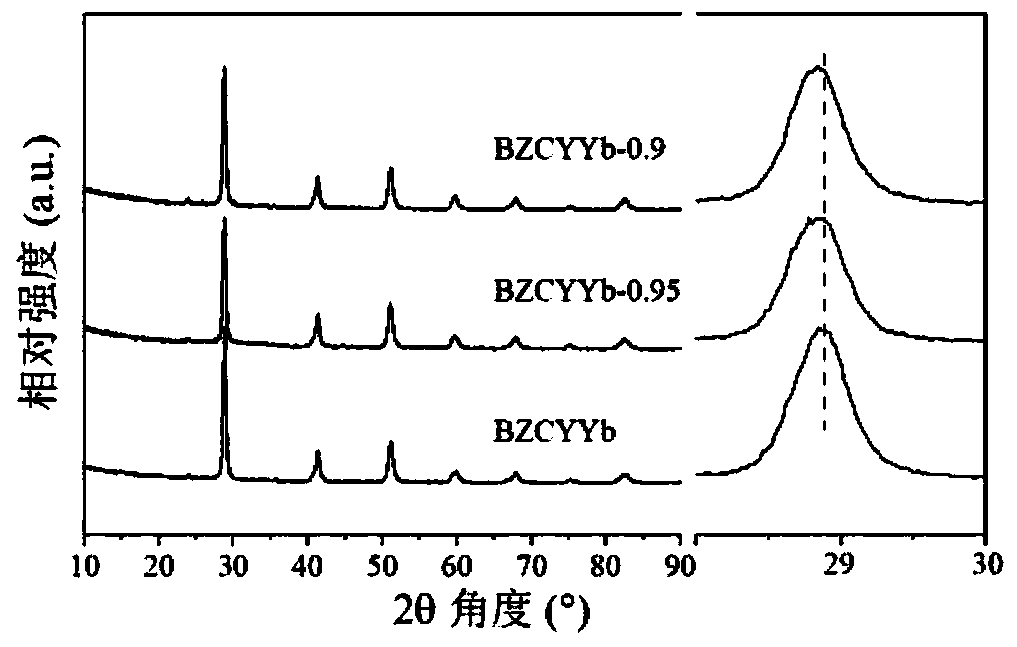

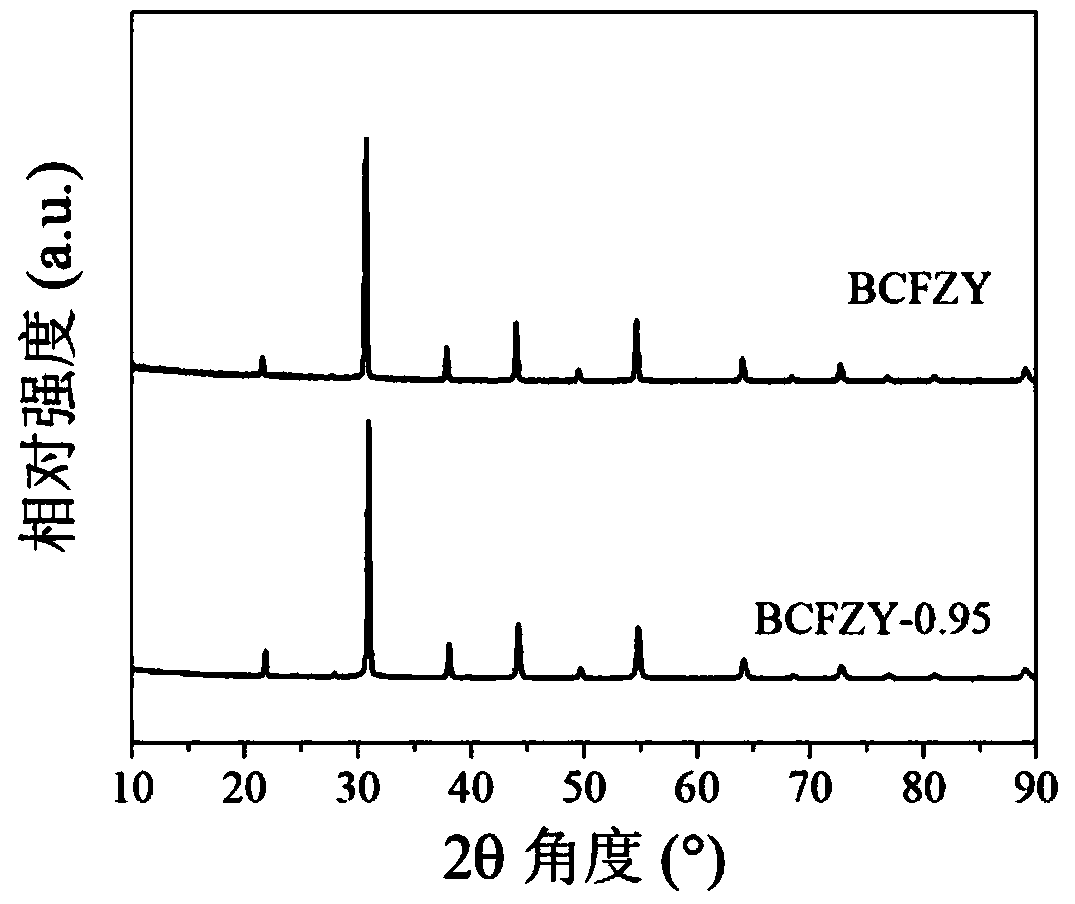

Proton conductor fuel cell cathode material with B-site defect, electrolyte and preparation method thereof

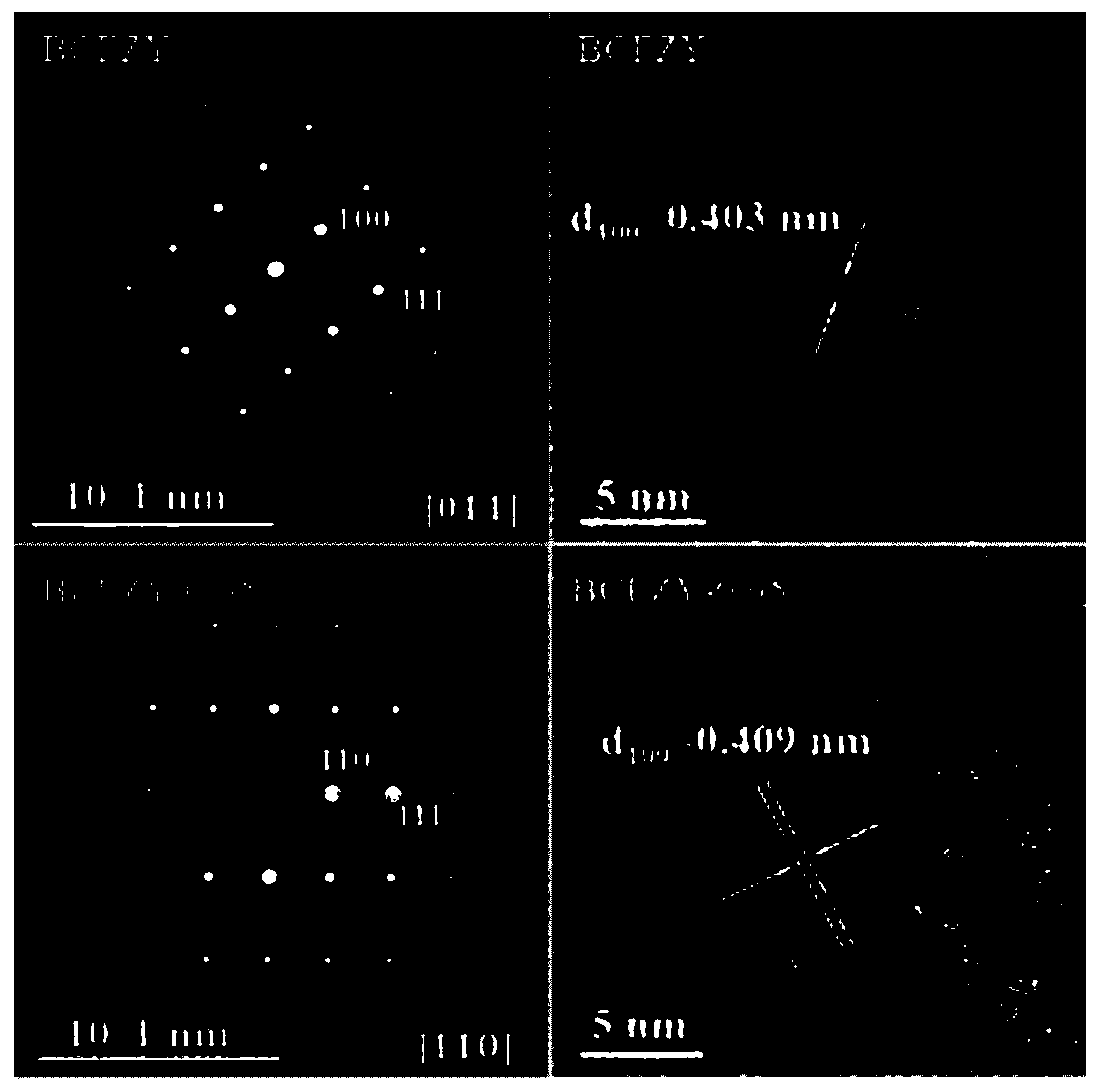

ActiveCN110429288ALower polarization resistanceLower activation energyChemical analysis using catalysisComponent separationElectrical conductorOxygen vacancy

The invention relates to a battery structure of a proton conductor fuel cell with a full B-site defect and a preparation method thereof. The constituent formula of the electrolyte material is Ba(Zr0.1Ce0.7Y0.1Yb0.1)xO3-delta(BZCYYb-x); and the constituent formula of the cathode material is Ba(Co0.4Fe0.4Zr0.1Y0.1)xO3-delta(BCFZY-x), wherein the x represents the defect amount of the B site element,0.9<=x<=1, and delta represents the oxygen vacancy content. The electrochemical performance of the fuel cell is improved by carrying out B-site ion defect on perovskite materials BaZr0.1Ce0.7Y0.1Yb0.1O3-delta and BaCo0.4Fe0.4Zr0.1Y0.1O3-delta; the Ba(Zr0.1Ce0.7Y0.1Yb0.1)xO3-delta material with the B-site defect is improved in sintering performance, oxygen permeability, proton conductivity and lowtemperature resistance; and the Ba(Co0.4Fe0.4Zr0.1Y0.1)xO3-delta material is improved in oxygen reduction reaction (ORR), area specific impedance and dual ion exchange capacity.

Owner:上海翌晶氢能科技有限公司

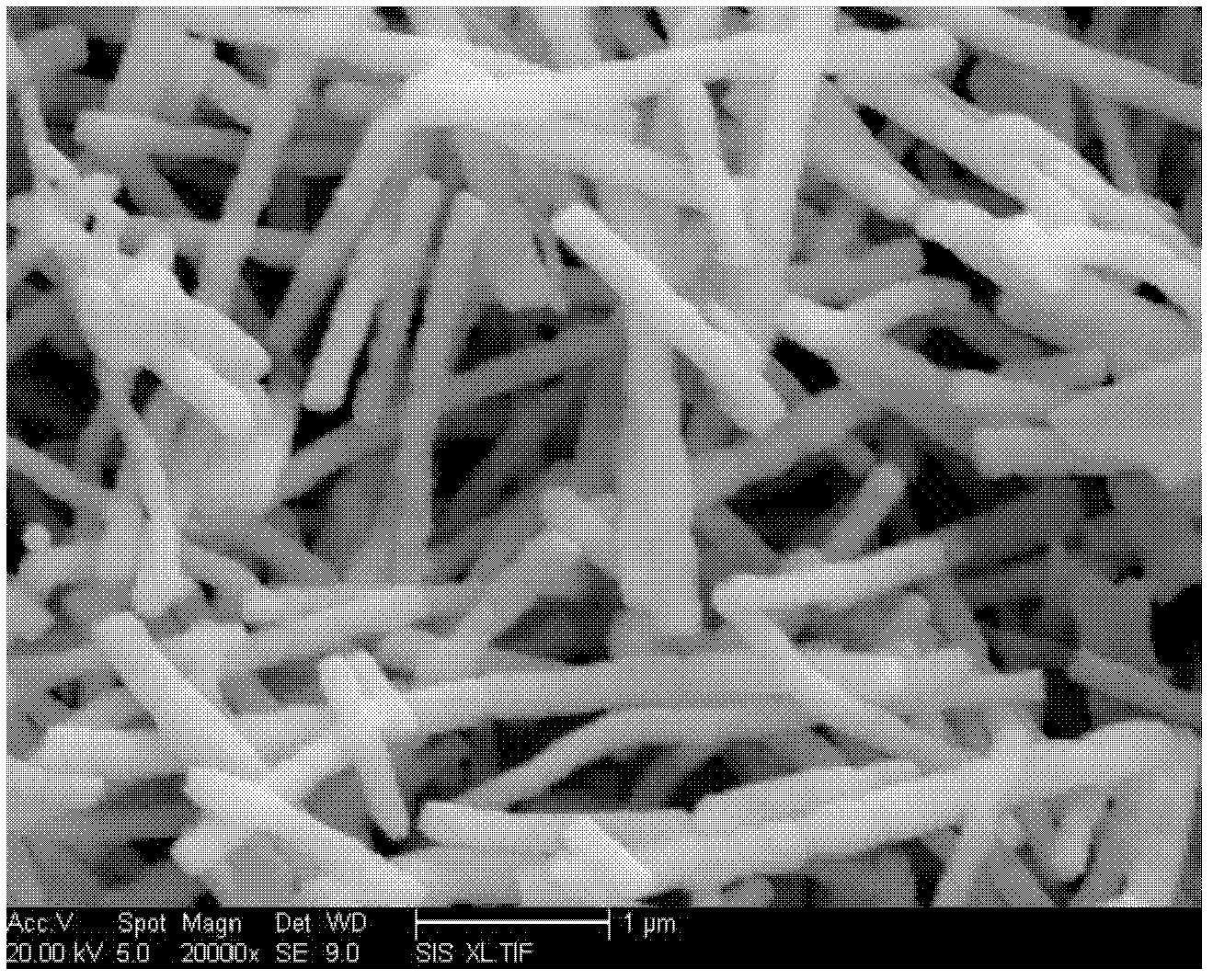

Method for making lead-acid battery pole plate

InactiveCN101841033AHigh bonding strengthTight jointElectrode carriers/collectorsLead-acid accumulator electrodesLead alloyAfter treatment

The invention relates to a method for making a lead-acid battery pole plate, which is characterized by comprising the following steps: adopting a foamy carbon with a three-dimensional structure as a skeleton, and electroplating lead or lead alloy on the skeleton to obtain a grid; coating active materials on the grid, and solidifying and drying the grid; and casting a lead or lead-alloy frame on the grid subjected to solidification and drying to obtain the lead-acid battery pole plate. The lead-acid battery pole plate is environment-friendly, can greatly reduce the lead consumption and significantly reduce the weight of the battery pole plate, and can three-dimensionally contact the active materials so as to make the current and potential distributed more uniformly on the battery pole plate, thereby reducing the electrochemical polarization and polarization resistance on the surface of the battery, facilitating the transformation of the active materials, and improving the utilization ratio and specific energy of the active materials. The lead-acid battery pole plate prepared by the method adopts the lead or lead-alloy frame, can facilitate process after-treatment, and has good process processability.

Owner:WUHAN INTEPOWER CO LTD

Preparation method of battery-grade graphite-activated carbon composite material

InactiveCN106099108AWide particle size distributionHigh porosityCell electrodesSecondary cellsMuffle furnaceActivated carbon

The invention discloses a preparation method of a battery-grade graphite-activated carbon composite material. The preparation method comprises the steps that 1, plant raw materials are washed clean with water and then contained in a metal tank, the metal tank is sealed and put into a muffle furnace, heating is conducted at the constant temperature of 450 DEG C to 650 DEG C, the temperature is naturally decreased to room temperature, and black solid activated carbon is obtained; 2, the obtained black solid activated carbon and graphite are put into a ball milling tank according to the mass ratio of 3:1-1:1, an appropriate amount of hydrochloric acid with the concentration of 0.2 M to1.0 M, an appropriate amount of sulfuric acid with the concentration of 0.1 M to 0.5 M, an appropriate amount of acetic acid with the concentration of 0.5 M to 1.2 M and an appropriate amount of water are sequentially added into the ball milling tank, ball milling is conducted for 0.5 hour to 2 hours under the condition that the ball-material ratio is equal to 1:10-1:20, and then acid washing and water washing are sequentially conducted, wherein sulfuric acid, hydrochloric acid and acetic acid are subjected to ball-milling washing three times to five times separately, and the water is subjected to ball-milling washing until the pH value of eluate is 6.8 to 7.2; 3, the washed graphite-activated carbon mixture is subjected to suction filtration and dried in an atmospheric environment, and the battery-grade graphite-activated carbon composite material is obtained. The preparation method has the advantages of being simple in process, rich in raw materials, short in manufacturing cycle and low in energy consumption and has good economic benefits, environmental benefits and social benefits.

Owner:HUBEI UEE ENERGY TECH CO LTD

High-catalytic activity composite negative electrode material of intermediate-temperature solid oxide fuel cell and preparation method of composite negative electrode material

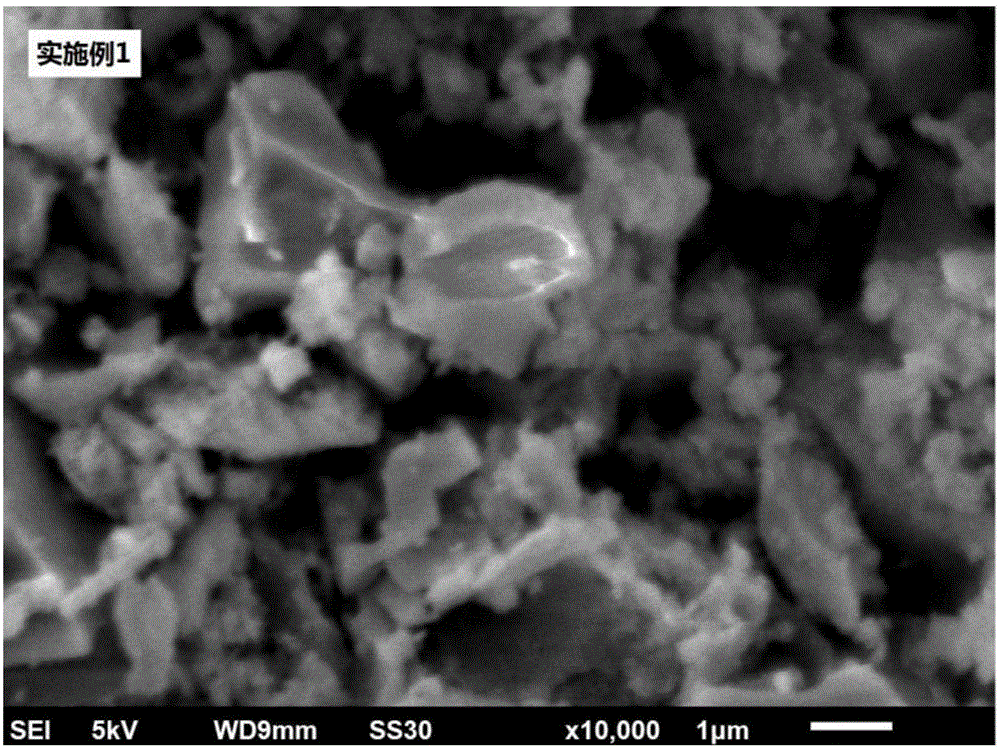

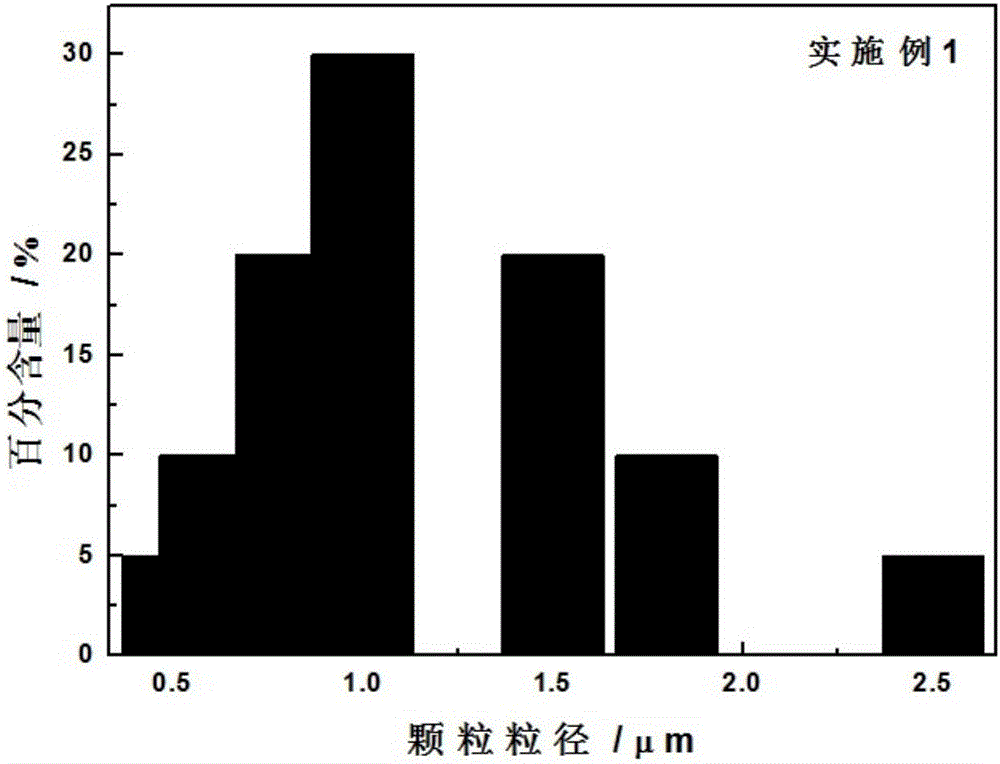

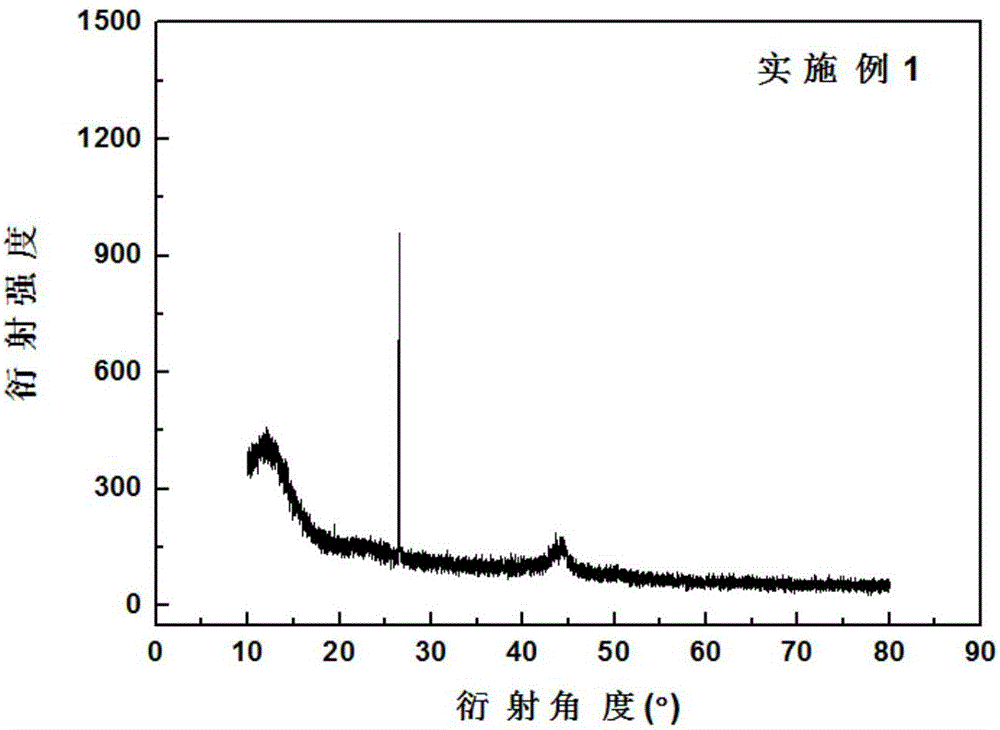

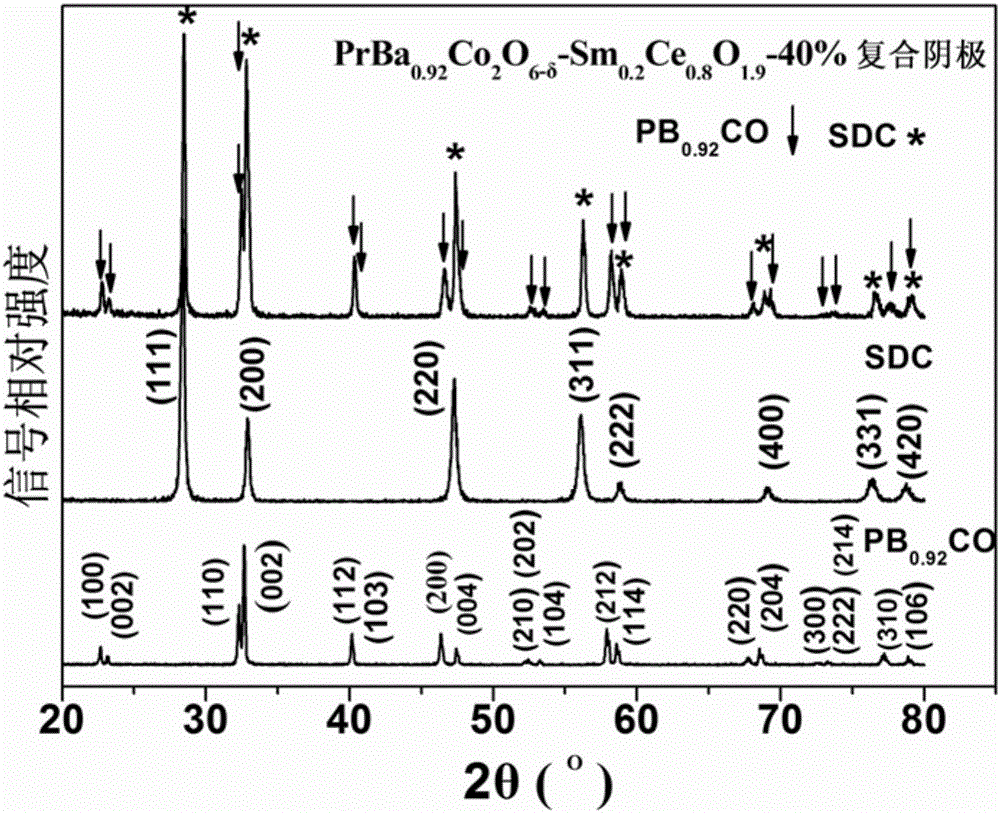

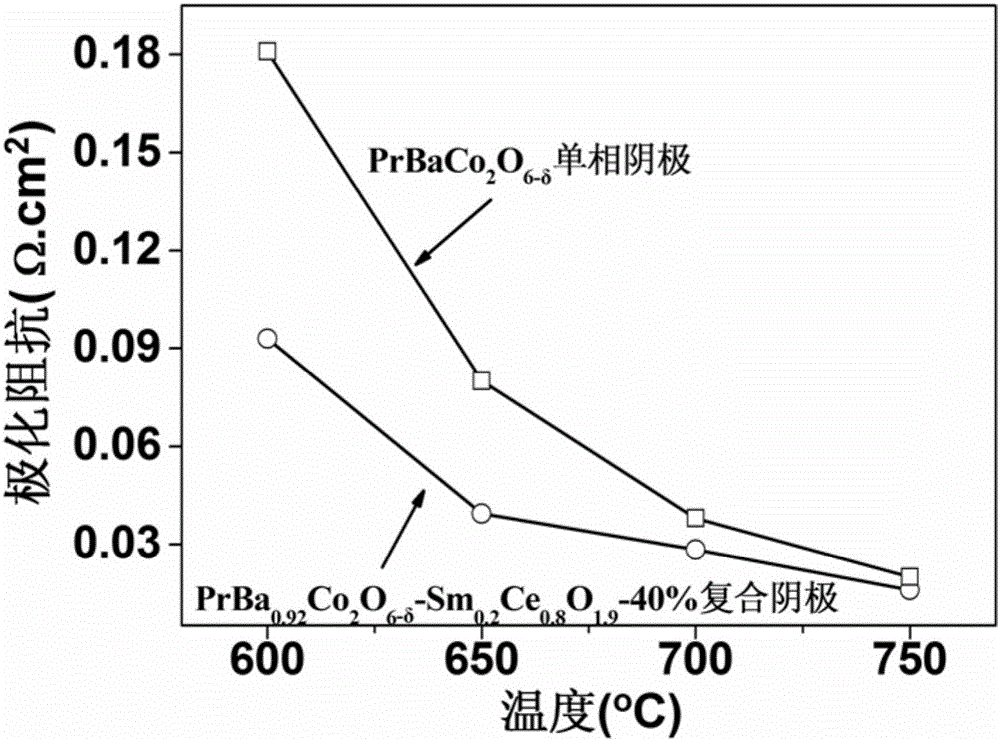

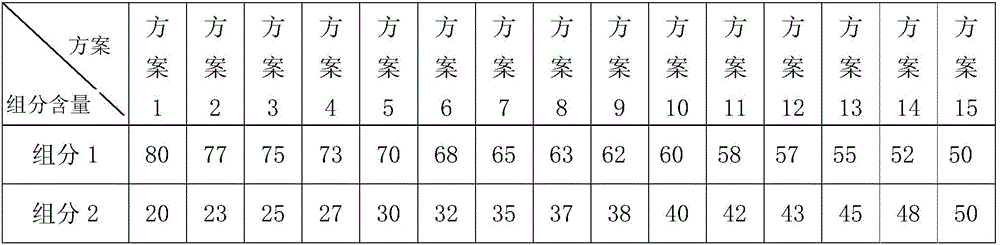

InactiveCN105870459ASimple preparation processEasy to operateCell electrodesElectrical conductorOxygen ions

The invention relates to a high-catalytic activity composite negative electrode material of an intermediate-temperature solid oxide fuel cell and a preparation method of the composite negative electrode material, and belongs to the technical field of an energy material. The composite negative electrode comprises a perovskite structured oxide PrBa<1-x>Co<2>O<6-Delta>, Pr<1-y>BaCo<2>O<6-Delta> or Pr<1-n>Ba<1-m>Co<2>O<6-Delta> in the absence of A-position cation and an oxygen ion conductor material Sm<0.2>Ce<0.8>O<1.9> or Gd<0.1>Ce<0.9>O<1.95>, wherein the mass percent of the oxygen ion conductor material accounts for 20-50%. The preparation method of the composite negative electrode material comprises the following steps of firstly, respectively preparing synthesis solutions of two constituents; secondly, mixing and uniformly stirring the two solutions to obtain a mixed synthesis solution of the two constituents, and heating the mixed synthesis solution to obtain mixed precursor gel; and finally, carrying out high-temperature sintering reaction to obtain composite negative electrode powder. The composite negative electrode material is prepared by a synchronous sintering reaction method, the preparation method has the advantages of simplicity in process, short preparation period, low cost and high efficiency, and is easy to operate, and the oxygen reduction catalytic activity of the negative electrode of the intermediate-temperature solid oxide fuel cell is effectively improved.

Owner:DALIAN UNIV OF TECH

Preparation method of textile electrode material and textile electrode material

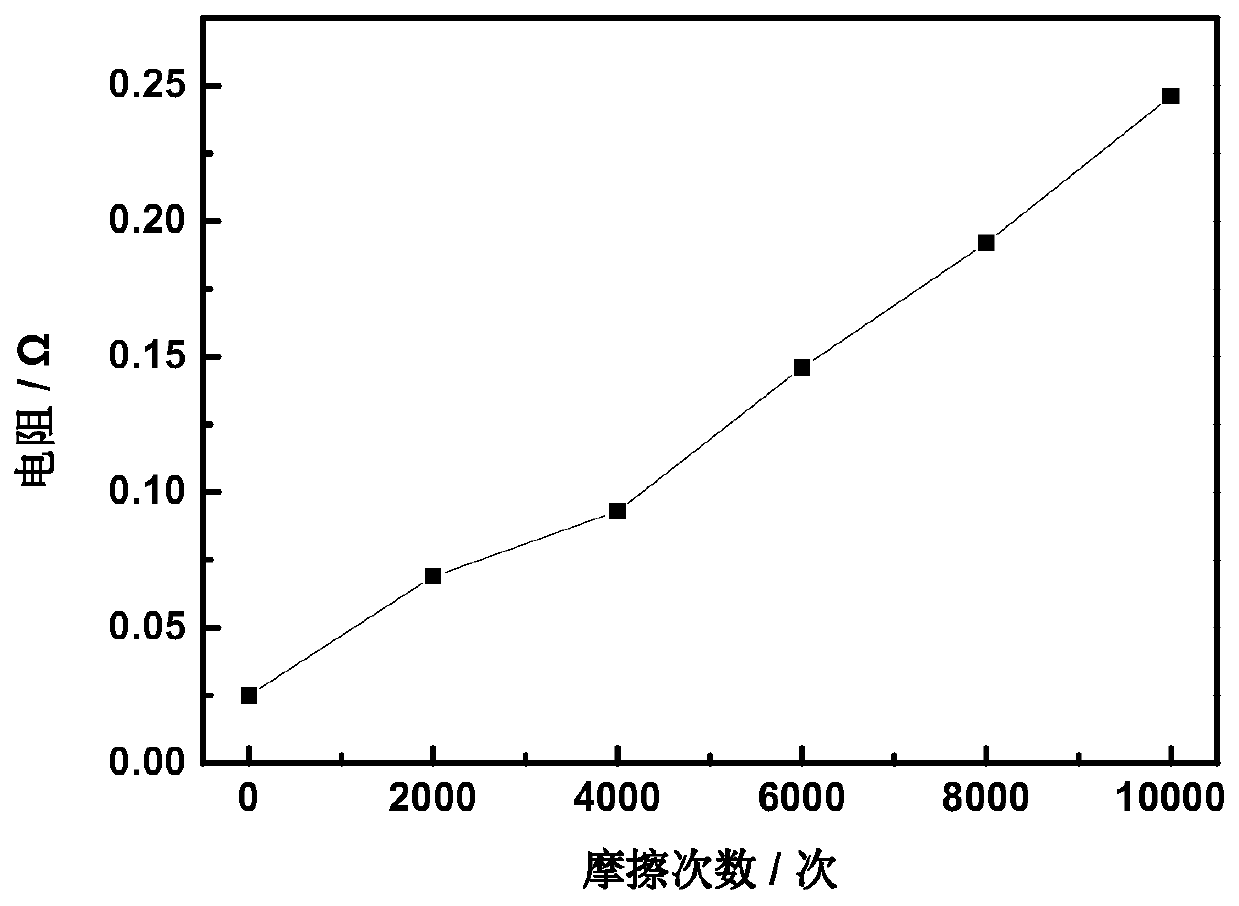

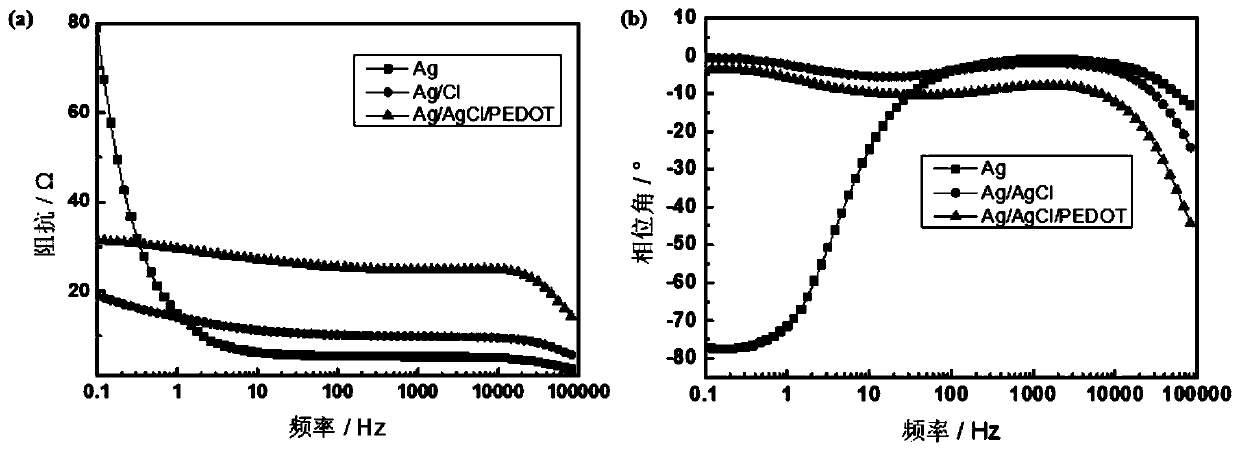

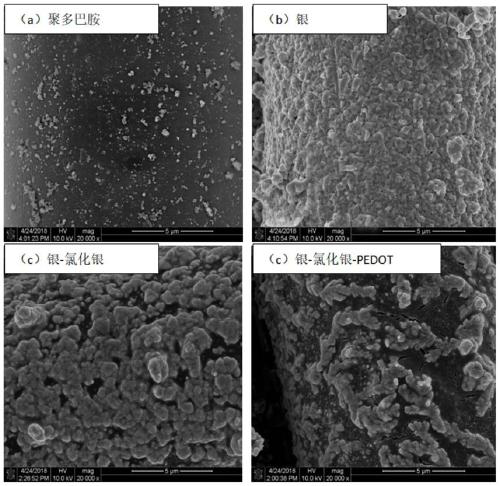

ActiveCN111395002AImprove conductivitySimplified coarseningLiquid/solution decomposition chemical coatingDiagnostic recording/measuringConductive polymer compositeSilver chloride

The invention discloses a preparation method of a textile electrode material and the textile electrode material. The preparation method comprises the steps that firstly, pretreated fabric is soaked ina dopamine hydrochloride solution, and polydopamine coated fabric is obtained; then, the polydopamine coated fabric is soaked in a silver-ammonia solution, a glucose solution is added after a certainperiod of time, and a silver-plated fabric is obtained; the silver-plated fabric is subjected to chlorination treatment in a sodium chloride solution through an electrochemical method, and a silver-silver chloride composite coating fabric is formed; finally, the silver-silver chloride composite coating fabric is modified in a conductive polymer monomer solution through an electrochemical method,and the silver-silver chloride-conductive polymer composite coating fabric is obtained. The surface specific resistance of the textile electrode material is 0.01-5 omega, the polarization impedance ina 0.9% sodium chloride solution is 10-1000 omega, the skin interface impedance is 1K omega-100M omega at 1Hz, and the phase angle variation within the frequency range of 0.5-50Hz is 0-30 degrees.

Owner:MINJIANG UNIV

Power generating apparatus

InactiveUS20090324997A1Avoid explosionAccelerating interfacial reactionFuel cell auxillariesEnergy inputHydrogenChemical reaction

This invention relates to a power generating apparatus including two systems. In one of the systems, a hydrogen gas is generated by hydrolysis, and a hydrogen demanding unit generates electric power. In the other system, electric power is generated based on an oxidation-reduction chemical reaction of an electrode and ions.

Owner:TECH BANK CO LTD

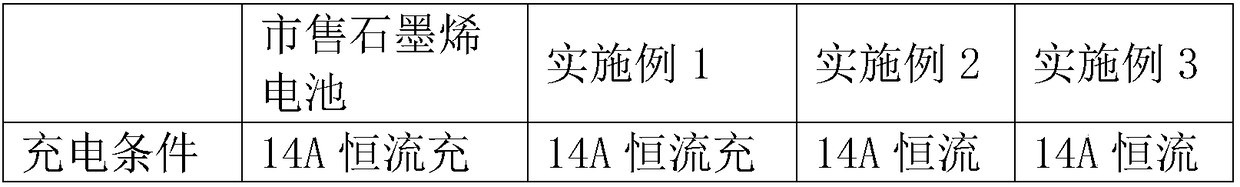

Large-capacity graphene battery capable of rapidly charging

InactiveCN108199039AImprove corrosion resistanceExtended service lifeCell electrodesSecondary cellsCorrosionEngineering

The invention provides a large-capacity graphene battery capable of rapidly charging, and relates to the technical field of batteries. The large-capacity graphene battery capable of rapidly charging,fabricated by the invention, comprises a positive pole plate, a negative pole plate, a separator, an electrolyte and a battery shell, the phenomena of small storage capacity and slow charging speed ofan existing graphene battery are solved, meanwhile, the corrosion resistance of the battery is improved, the service lifetime is prolonged, the large-capacity graphene battery is relatively good in stability, and no harm to a human body and an environment is generated; and compared with a traditional market graphene battery, it is verified that the charging time is obviously shortened by 34.94% under the same charging condition, and the charge-discharge efficiency of the battery can reach 87.73%.

Owner:长沙善道新材料科技有限公司

Solid oxide fuel cell composite cathode Ln2CuO4-Ce0.9Gd0.1O1.95 and preparation method thereof

InactiveCN103151533AImprove electrochemical performanceIncreased mixed conductivityCell electrodesComposite cathodeFuel cells

The invention relates to a solid oxide fuel cell composite cathode Ln2CuO4-Ce0.9Gd0.1O1.95 and a preparation method thereof. The invention relates to a cell composite cathode material and a preparation method thereof, aiming at solving the problem that the catalytic activity and electro-chemical property of the cathode material are pool. The solid oxide fuel cell composite cathode Ln2CuO4-Ce0.9Gd0.1O1.95 is made of Ln2CuO4 and solid electrolyte Ce0.9Gd0.1O1.95; the method comprises the steps of: I. weighing; II. preparing mixed stock; III. preparing a prefabricated body; and IV. preparing the solid oxide fuel cell composite cathode Ln2CuO4-Ce0.9Gd0.1O1.95. According to the solid oxide fuel cell composite cathode Ln2CuO4-Ce0.9Gd0.1O1.95 and the preparation method thereof, the reaction active site of the cathode is extended into the overall cathode material, the active region of the oxygen reduction reaction can be enlarged, and the electrochemical property of the cathode can be improved. The preparation method is used for preparing solid oxide fuel cell composite cathode.

Owner:HEILONGJIANG UNIV

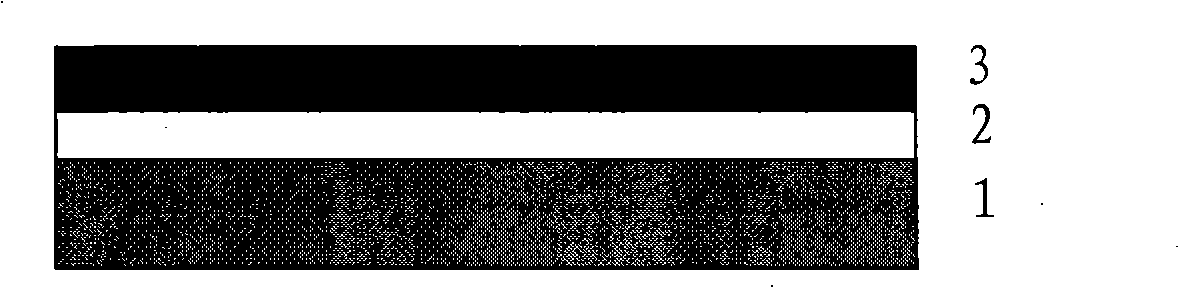

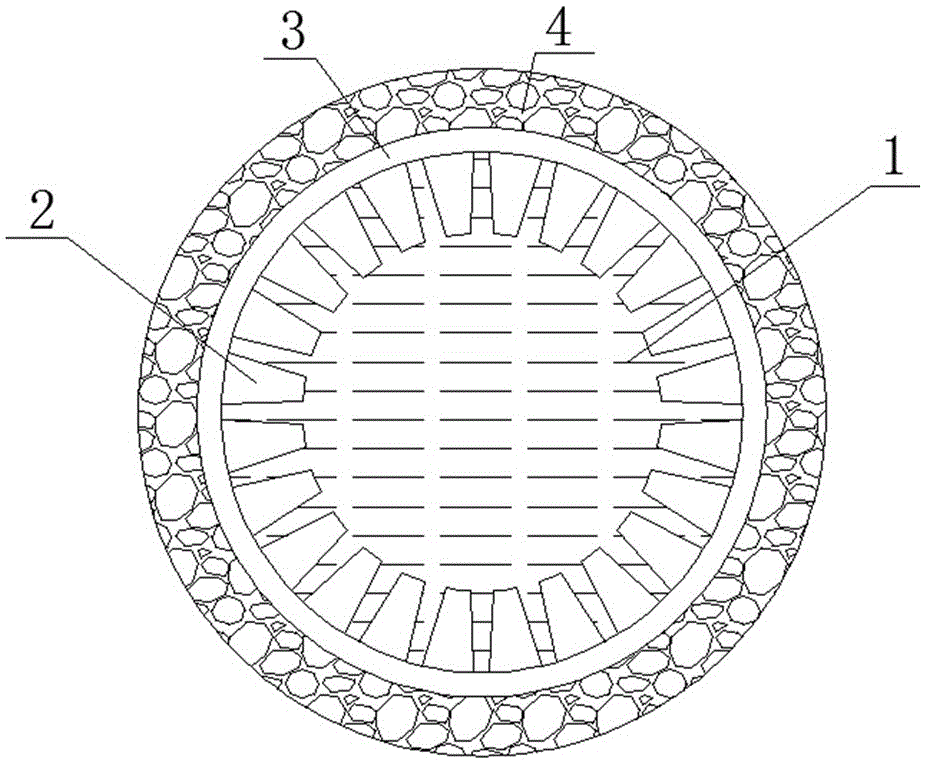

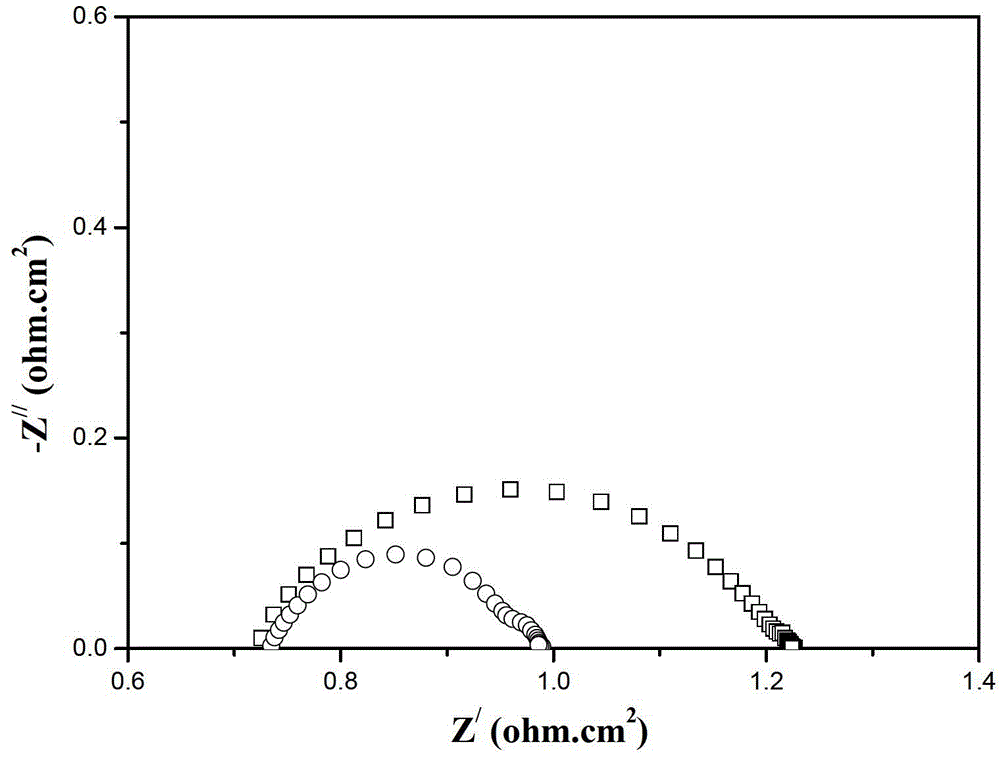

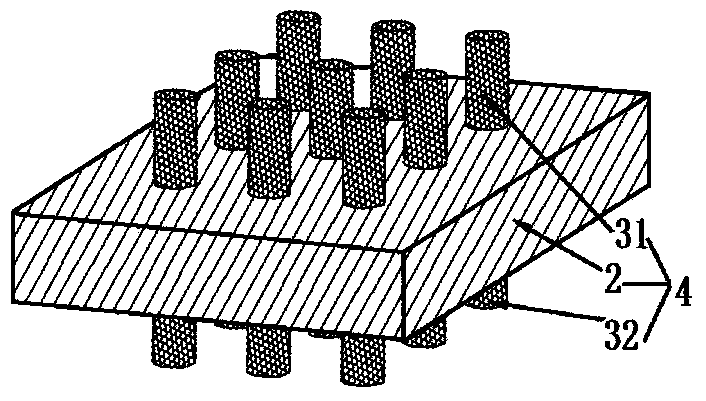

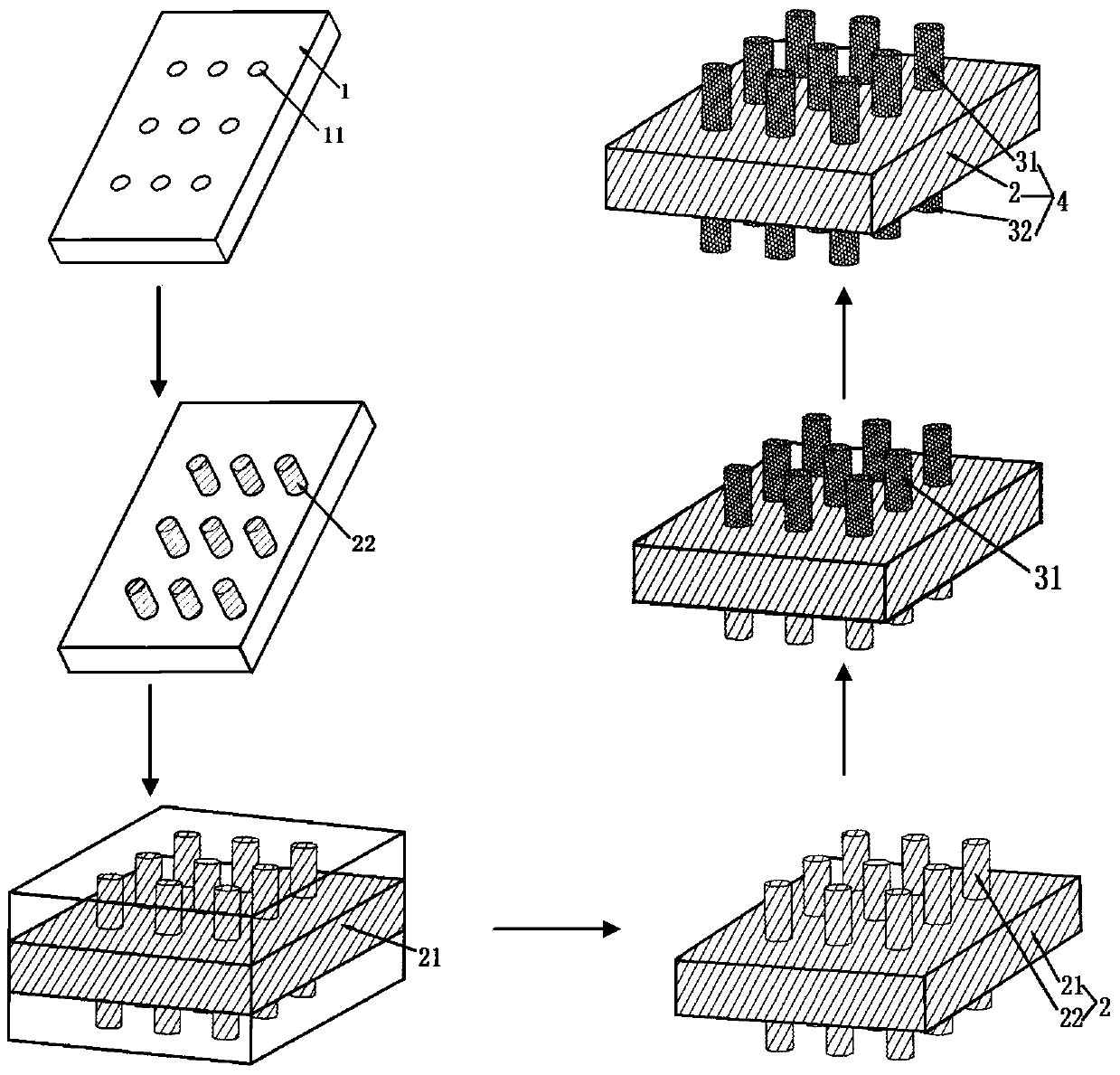

Ordered solid oxide membrane electrode

ActiveCN103515633ALower polarization resistanceIncrease the three-phase reaction interfaceCell electrodesFuel cell detailsReaction rateThree-phase

The invention belongs to the technical field of membrane electrodes, and specially relates to an ordered solid oxide membrane electrode. The support of catalysts in the ordered solid oxide membrane electrode is array solid oxide rods. The highly-ordered array solid oxide rods are capable of deciding the electrode voidage and the catalyst surface area in the ordered solid oxide membrane electrode, so that the controllable preparation on the ordered electrode is realized. The particles of anode catalysts and cathode catalyst are interpenetrated, are connected with a current collector and are highly dispersed, and the catalysts have relatively high specific surface area and catalytic activity, so that the three-phase reaction interface of SOFC and SOEC are substantially increased, the polarization resistance of the electrode is reduced, and the reaction rate of fuel and the reduction conversion rate of a raw material gas are improved. The ordered membrane electrode is expected to substantially reduce polarization electromotive force of the electrode, improve conversion efficiency and stability, and prolong operation life.

Owner:TSINGHUA UNIV

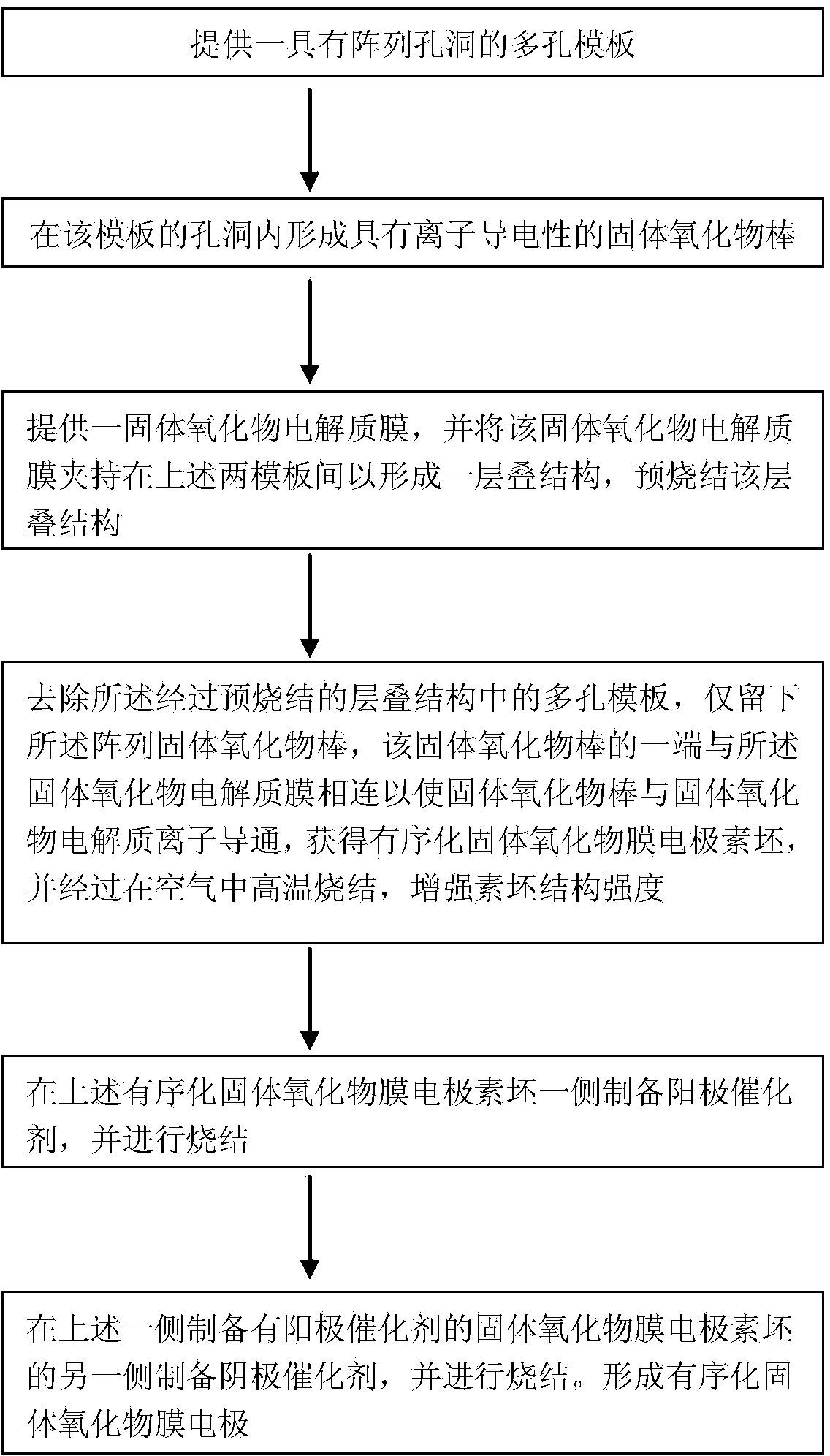

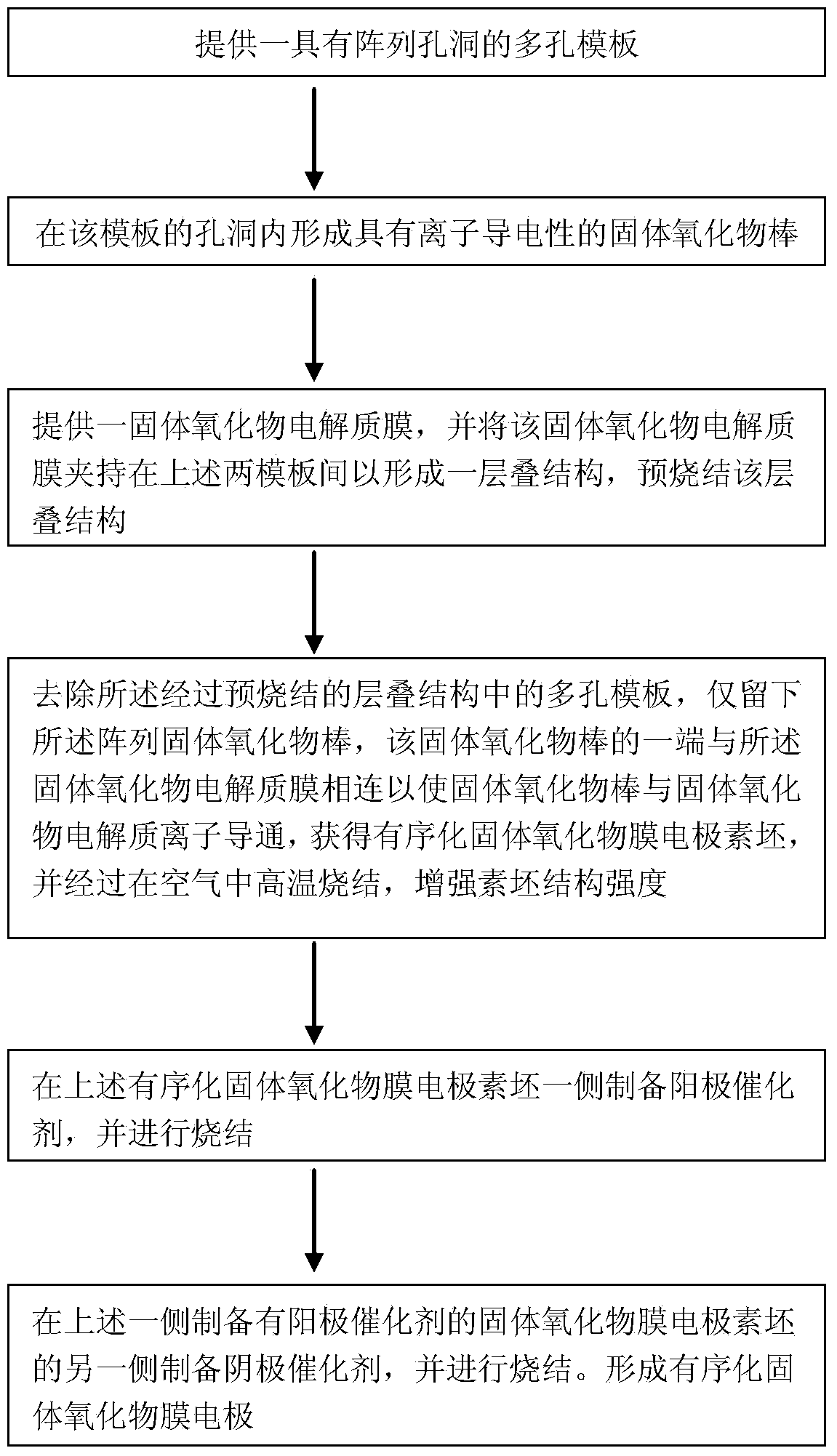

Preparation method of ordered solid oxide membrane electrode

ActiveCN103474675ALower polarization resistanceReach controllableCell electrodesVoid ratioReaction rate

The invention belongs to the technical field of an electrode preparation method, and in particular relates to a preparation method of an ordered solid oxide membrane electrode. In the method, a supporter array solid oxide bar of a catalyst can be prepared by a template method, and can be roasted and integrally fused with a compact solid oxide electrolyte membrane. The highly ordered array solid oxide bar defines the electrode void ratio and the catalyst surface size in the ordered solid oxide membrane electrode, so as to realize the controllable preparation of the ordered electrode. An anode catalyst and a cathode catalyst are prepared respectively on the array solid oxide bar, the catalysts are combined on the surface of the solid oxide bar in a nano- or micro-particle state to form a catalysis layer, the catalyst particles are communicated with each other and are connected to a collector, and the catalyst particles are dispersed highly and have higher specific surface area and catalysis activity, therefore, the three-phase reaction interface of an SOFC (solid oxide fuel cell) and an SOEC (solid oxide electrolysis cells) is increased greatly, the polarization resistance of the electrode is reduced, and consequently, the reaction rate of the fuel and the raw material gas reducing transforming rate are improved.

Owner:TSINGHUA UNIV

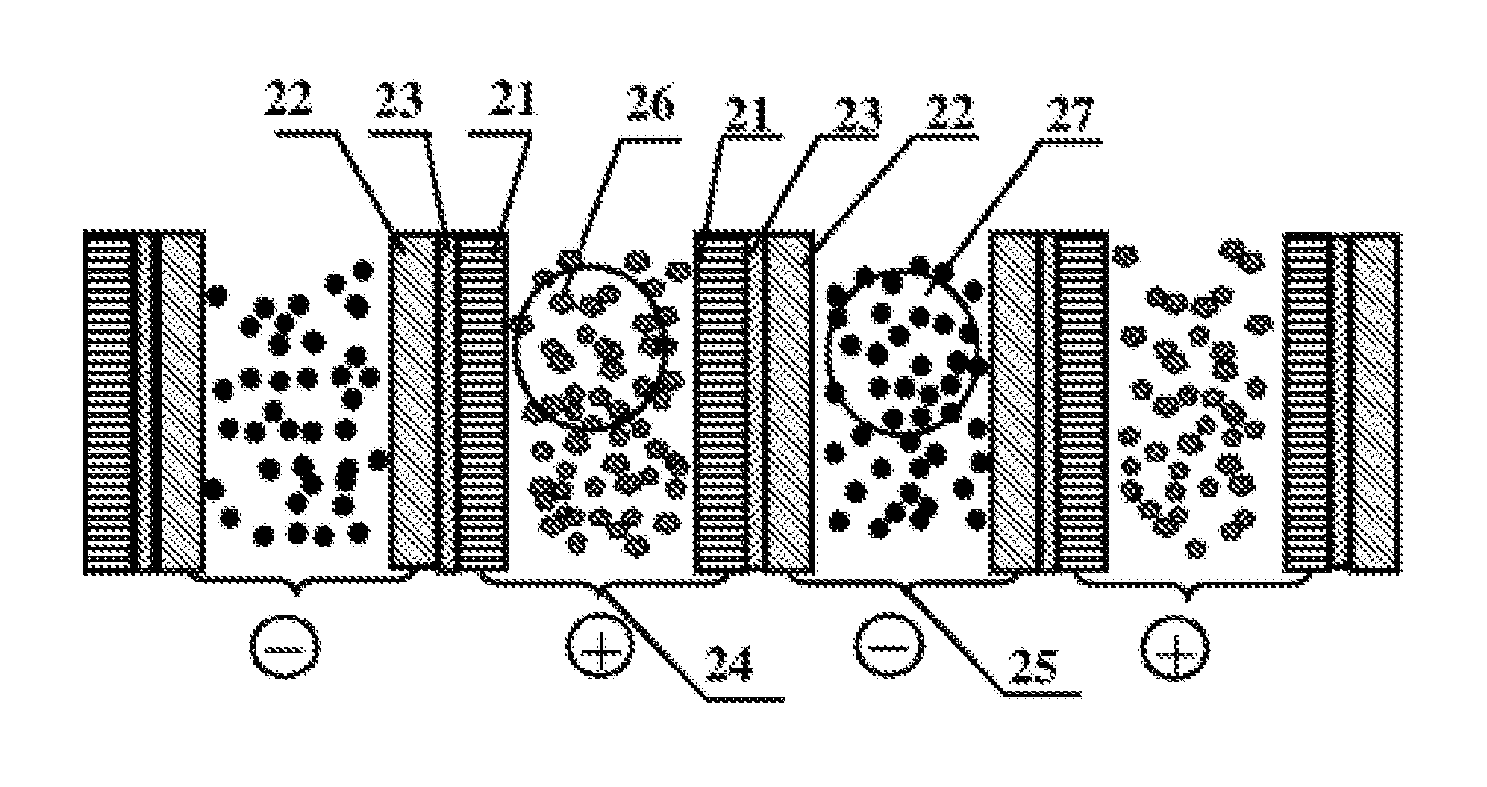

A novel lithium ion flow battery

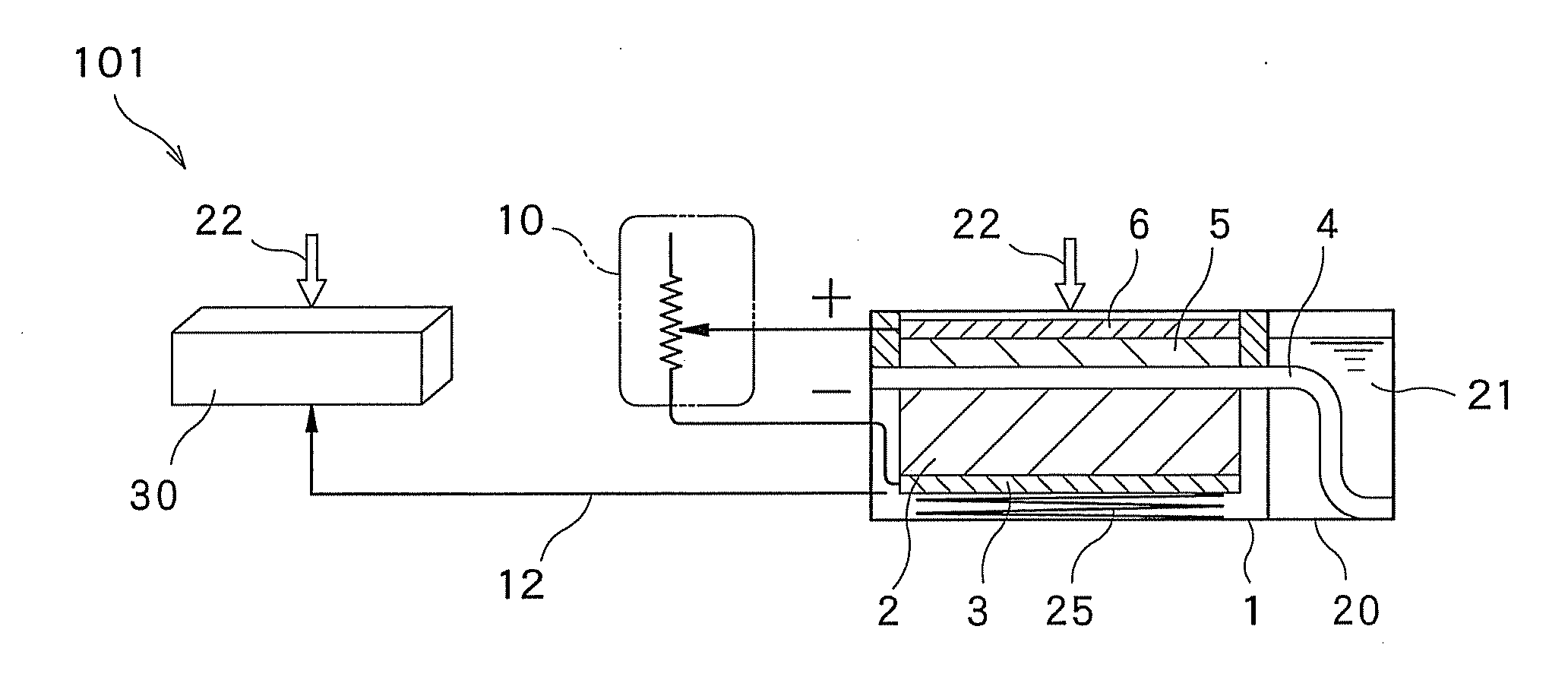

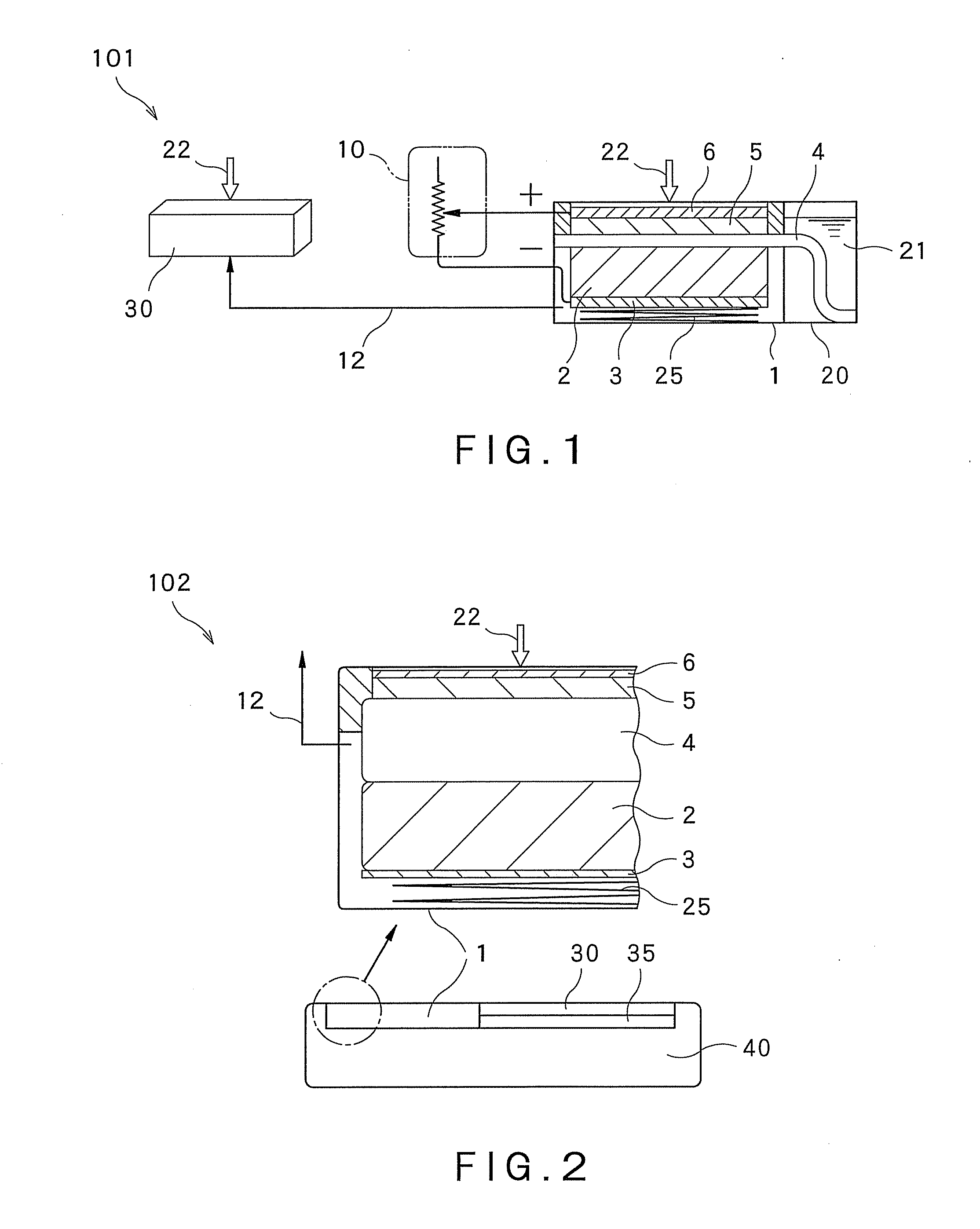

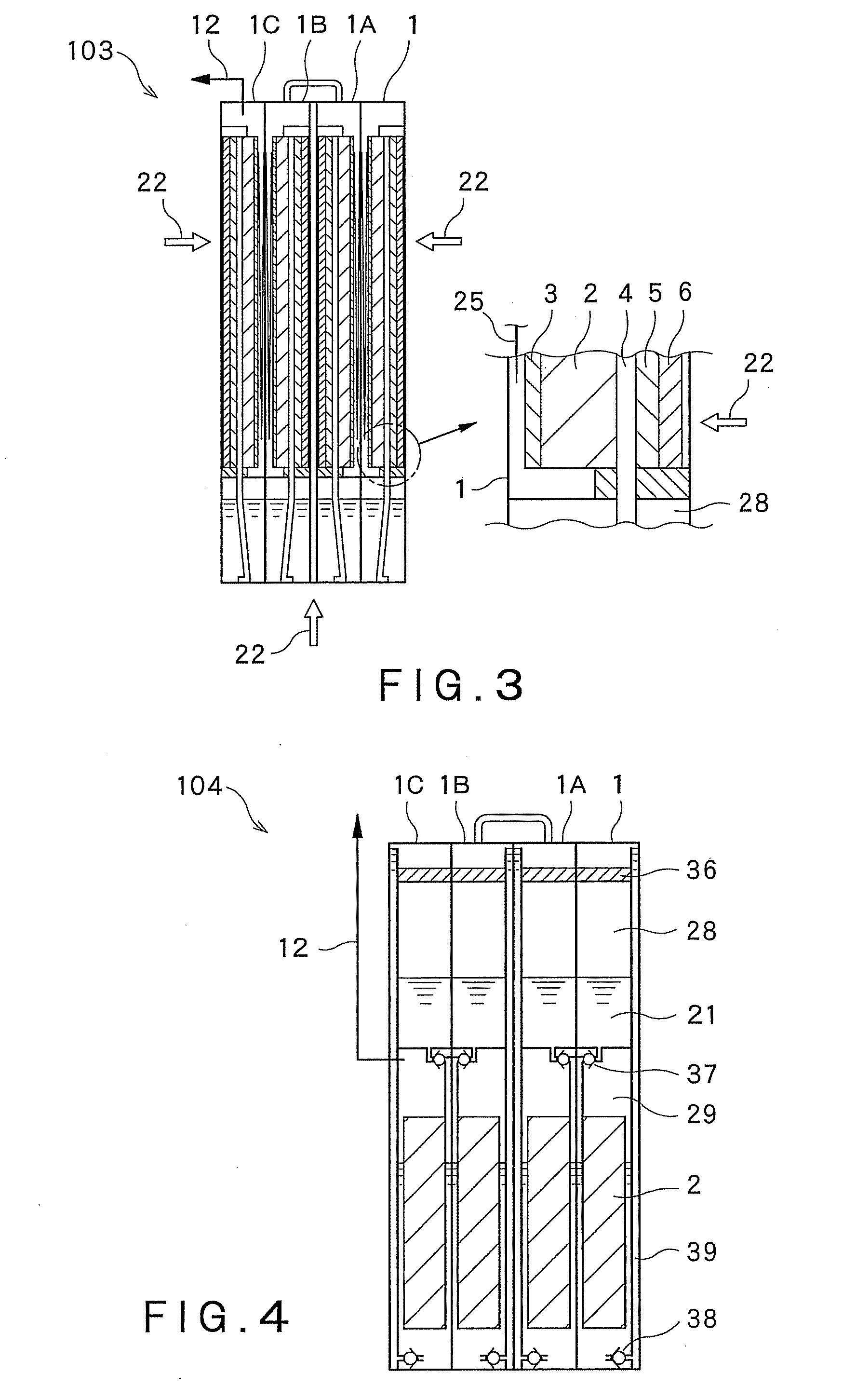

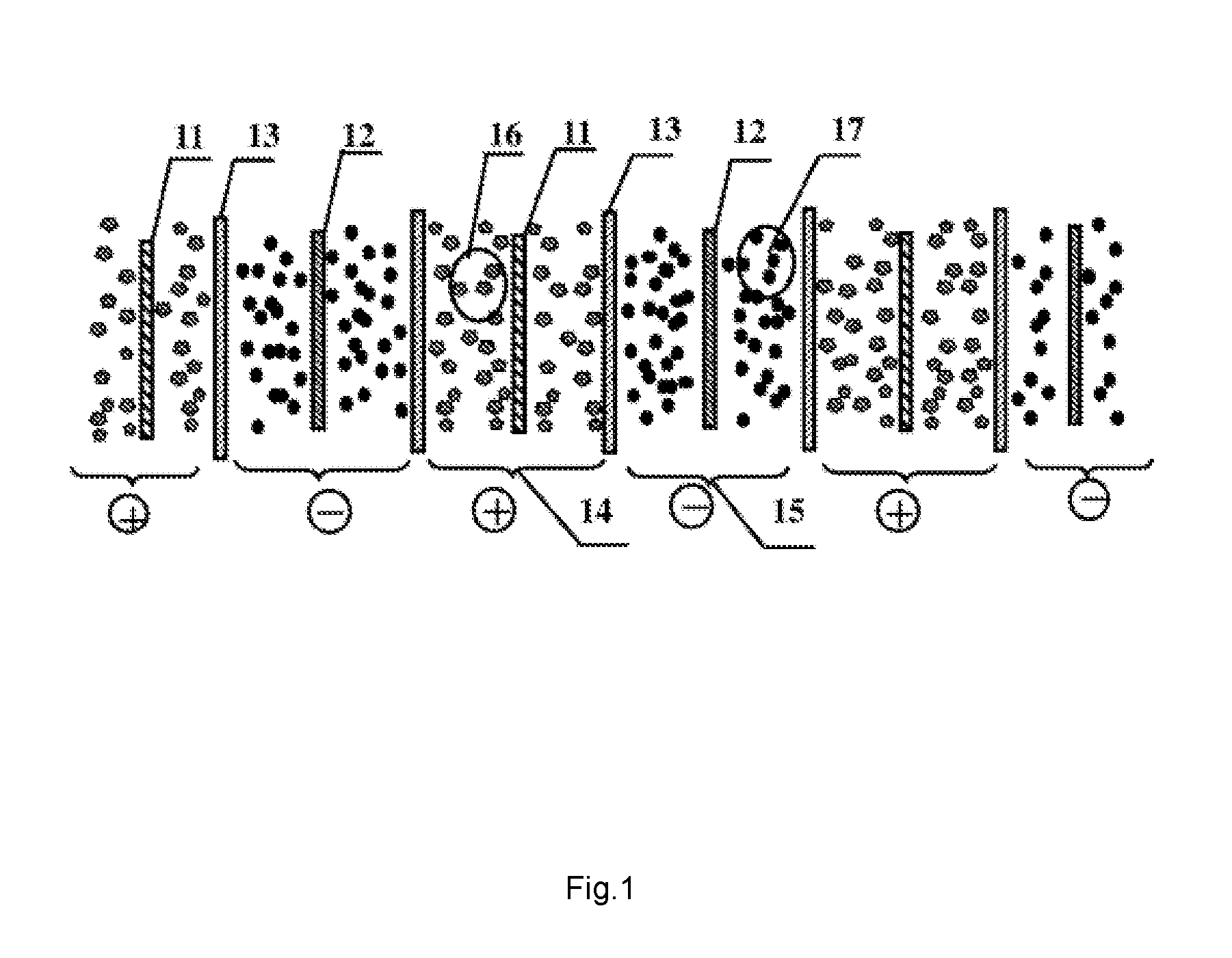

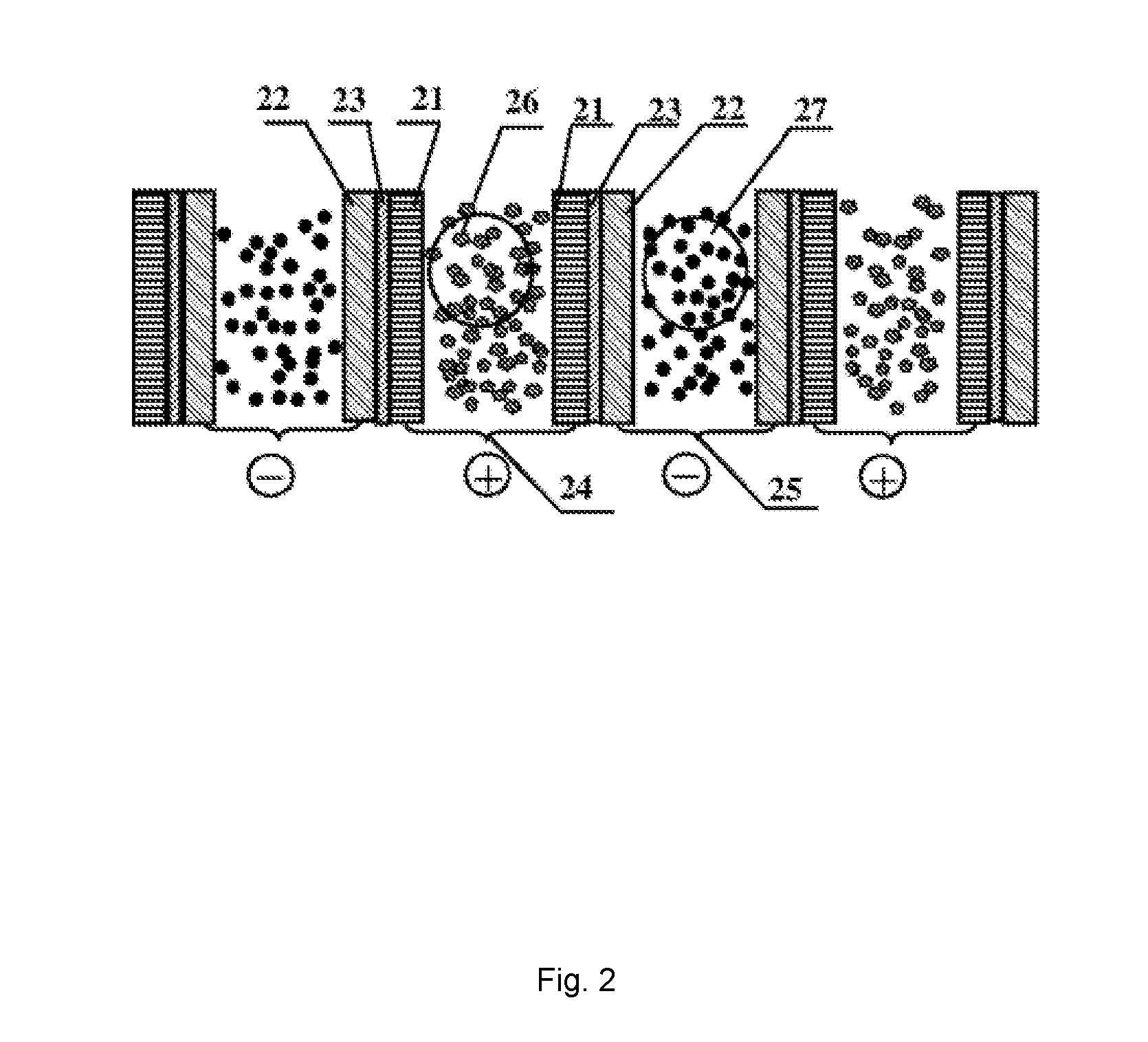

ActiveUS20160329569A1Current is limitedGood electrical conductionElectrolyte holding meansCell electrodesInternal resistanceElectrical polarity

A lithium ion flow battery comprising cathode current collectors (21), an anode current collector (22), a cathode reaction chamber (24), an anode reaction chamber (25), a separator (23), a cathode suspension solution (26) and an anode suspension solution (27), wherein the cathode and anode current collectors are located at both sides of the separator respectively and are in close contact with the separator to form sandwich composite structure layers of the cathode current collector, the separator and the anode current collector; and in that several sandwich composite structure layers are arranged in sequence in an order that current collectors with the same polarity are oppositely arranged, and the electrode suspension solution continuously or intermittently flows in a battery reaction chamber between adjacent sandwich composite structure layers. Thus, the size of the battery reaction chamber can be flexibly designed according to the viscosity of the electrode suspension solution without increasing the polarization internal resistance of the battery, thereby solving the restriction conflict existing in the existing lithium ion flow battery between the size of the battery reaction chamber and the polarization internal resistance of the battery.

Owner:BEIJING HAWAGA POWER STORAGE TECH

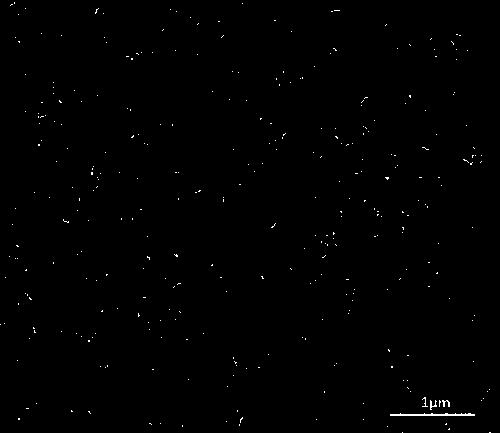

Molybdenum disulfide nanosheet and preparation method thereof

InactiveCN107512735AImprove charge-discharge cycle performanceImproved magnification performanceVacuum evaporation coatingSputtering coatingCharge dischargeLithium-ion battery

The invention discloses a molybdenum disulfide nanosheet and a preparation method thereof. The molybdenum disulfide nanosheet is prepared by adopting a magnetron reactive sputtering method, metal molybdenum is taken as a target material and argon gas is used as sputtering gas, hydrogen sulfide is taken as reactive gas, and a metal sheet is used as a substrate. As a negative electrode material for a lithium ion battery, the molybdenum disulfide nanosheet has relatively high lithium storage performance, excellent charge-discharge cycle performance and rate capability. As an electrocatalytic hydrogen evolution electrode material and a fuel cell negative electrode material, the molybdenum disulfide nanosheet effectively reduces the electrode over-voltage and reduces the polarization resistance of the electrode.

Owner:ANYANG INST OF TECH

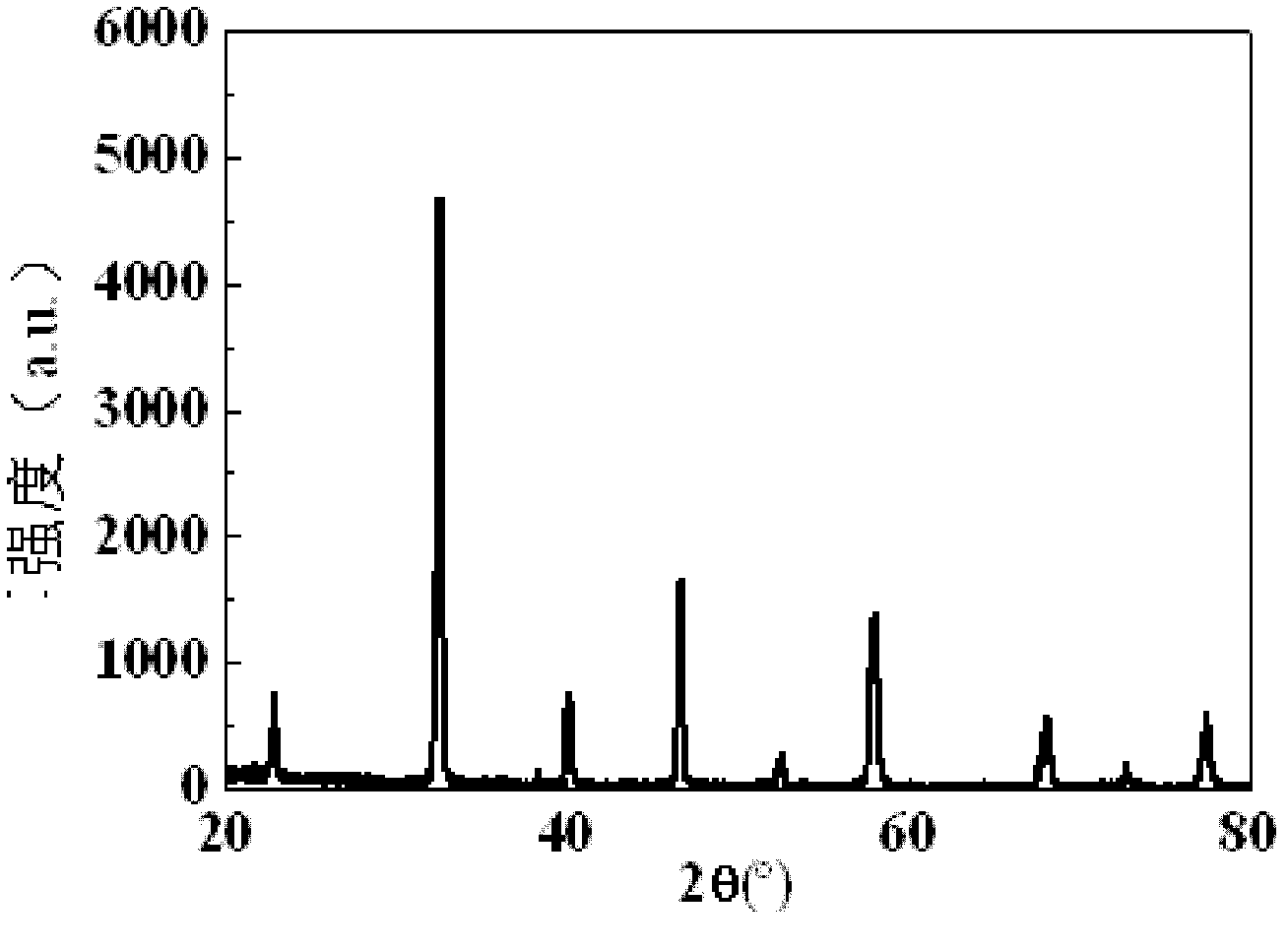

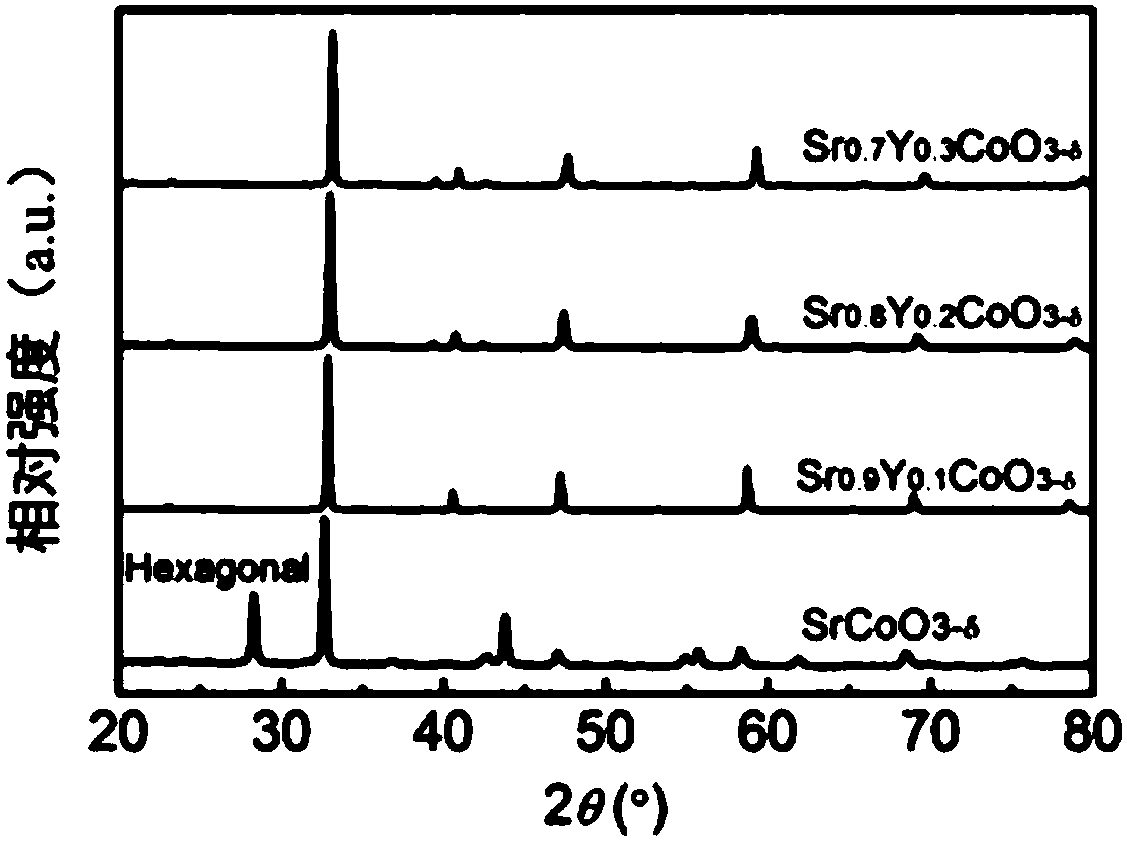

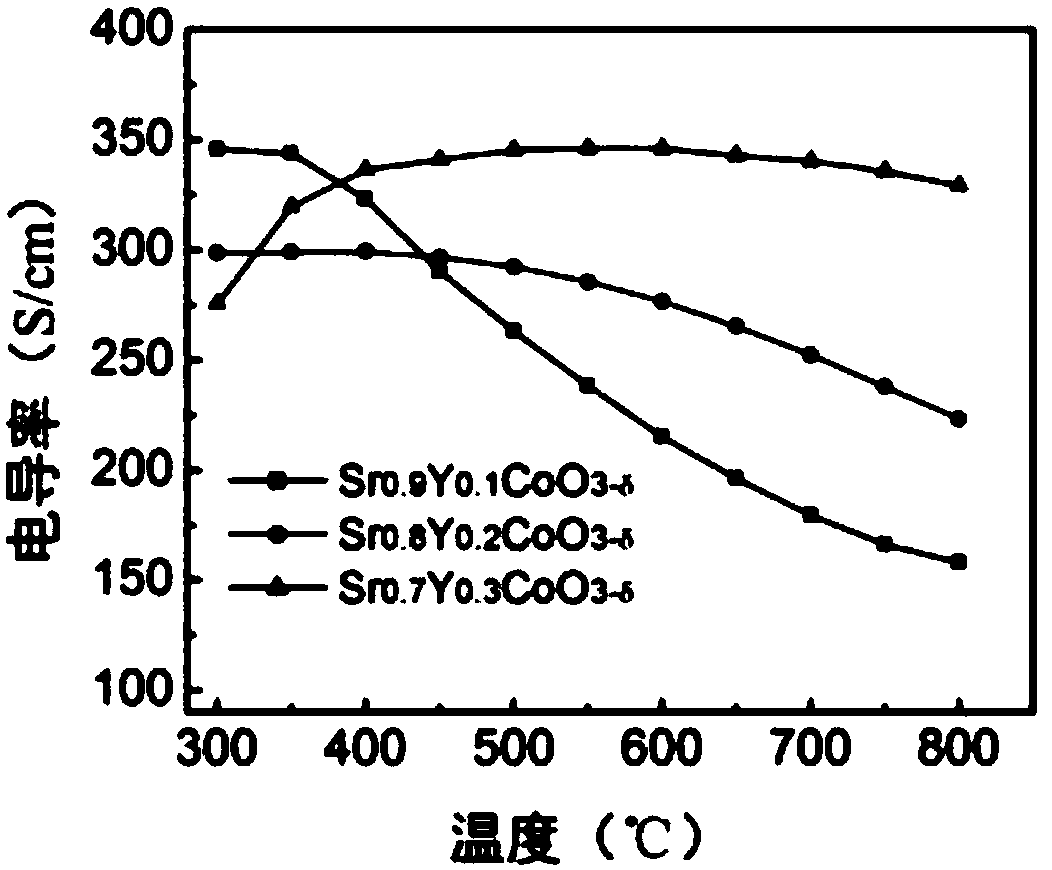

Medium-low-temperature solid oxide fuel cell negative electrode material and preparation method thereof

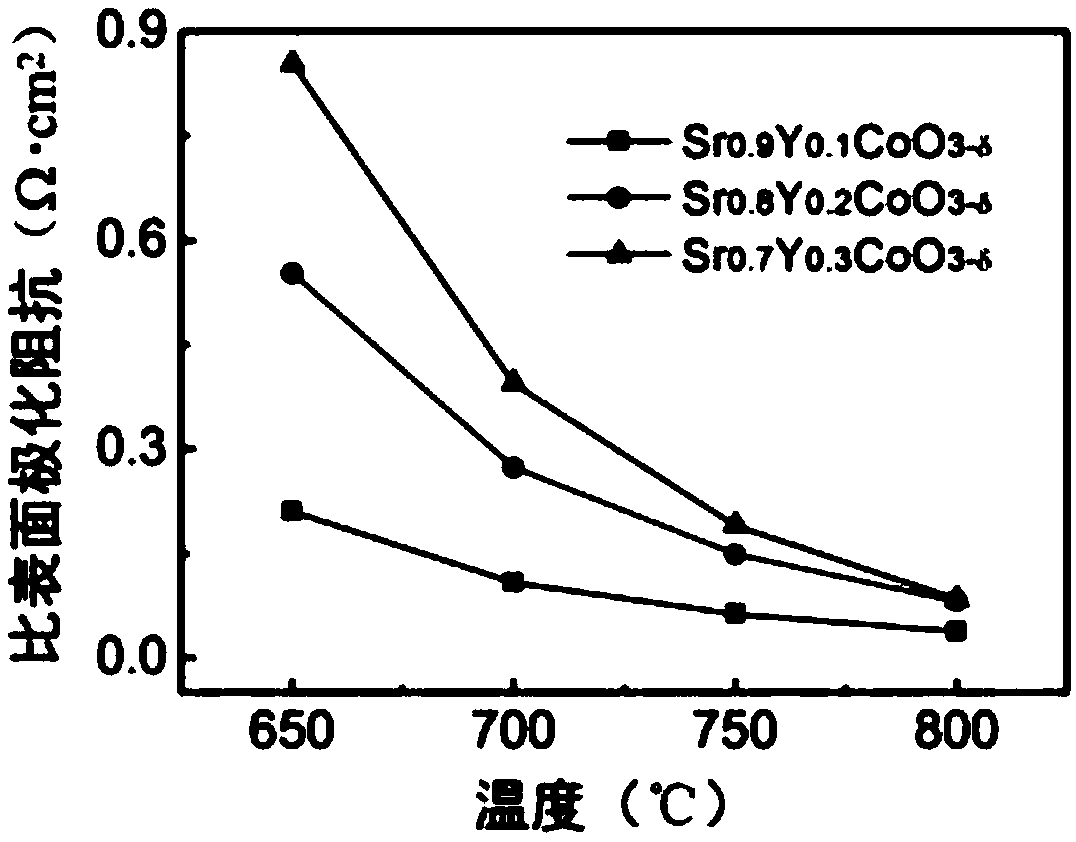

InactiveCN108400344AImprove conductivitySmall powder particlesCell electrodesRare earth metal compoundsSol-gelOxide

The invention provides a medium-low-temperature solid oxide fuel cell negative electrode material. The negative electrode material has the general formula of Sr<1-x>R<x>CoO<3-delta>, wherein x is greater than or equal to 0.01 and less than or equal to 1.0, <delta> is greater than or equal to 0 and less than or equal to 0.5; and R is Pr, Y, Nd, Dy or Gd. The invention also provides a preparation method of the medium-low-temperature solid oxide fuel cell negative electrode material. By adopting a dual chelating agent sol-gel technology, the medium-low-temperature solid oxide fuel cell negative electrode material with uniform particles is prepared, so that the perovskite structure of SrCoO<3-delta> is stabilized, relatively high electrical conductivity is achieved in the air, high catalytic activity is shown within a range of 500-800 DEG C, high compatibility with electrolytes LSGM and SDC can be achieved, and high stability and electrochemical performance are shown within a medium-low-temperature temperature.

Owner:YANGTZE UNIVERSITY

Doped cerium oxide catalytic film with preferred orientation, preparation and applications thereof

ActiveCN104934614ALower cathodic polarization resistanceImprove electrocatalytic performanceCell electrodesVacuum evaporation coatingFuel cellsFuel gas

The invention discloses a doped cerium oxide film with a preferred exposed crystal face. The film can be used as the electrode of a solid oxide fuel battery, and can also be used as a catalyst for catalytic reactions. The film is prepared through a magnetron reactive sputtering technology. The application of the doped cerium oxide film with a preferred exposed crystal face can effectively improve the electro-catalytic activity of negative electrode (for oxygen gas) and positive electrode (for fuel gas) of a solid oxide fuel battery, the battery polarization resistance is reduced, and the medium-low temperature performance of battery is effectively improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation method of solid oxide fuel cell cathode by utilizing electrical spinning method

The invention relates to a preparation method of a solid oxide fuel cell cathode by utilizing an electrical spinning method, belonging to the technological field of function materials. The preparation method is characterized in that cathode material metal cations containing the stoichiometric ratio and the precursor solution or colloidal sol of the appropriate amount of polymerizer is subjected to electrical spinning on a substrate; then the spinning precursor sample is dried and sintered to prepare the solid oxide fuel cell cathode materials with a porous structure and controllable microstructure and thickness. The SOFC (Solid Oxide Fuel Cell) cathode prepared by utilizing the electrical spinning method has the advantages of large specific surface area, high porosity, adjustable aperture and good structure homogeneity; the oxygen transmission characteristic and the catalytic activity of the cathode can be enhanced; the polarization impedance is reduced; the performance in intermediate and low temperature solid oxide fuel cells is excellent; the simple, convenient and low-cost preparation of the solid oxide fuel cell cathode is realized by omitting a powder synthesis step and reducing a high-temperature sintering step; and the method comprises the preparation of perovskite structure oxide, class perovskite structure oxide and composite cathode materials.

Owner:DALIAN UNIV OF TECH

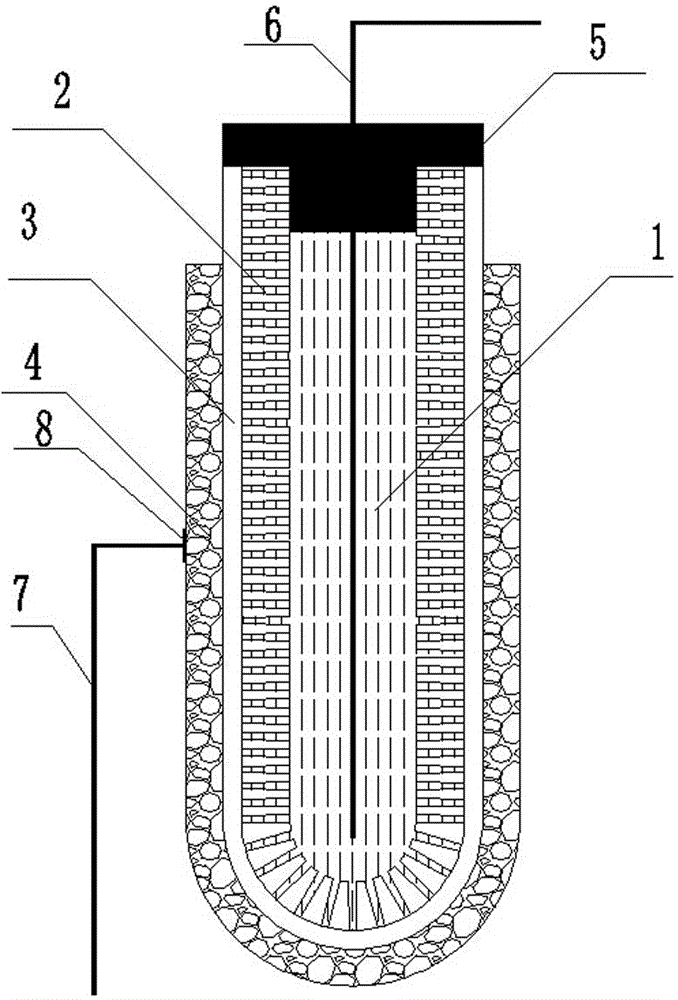

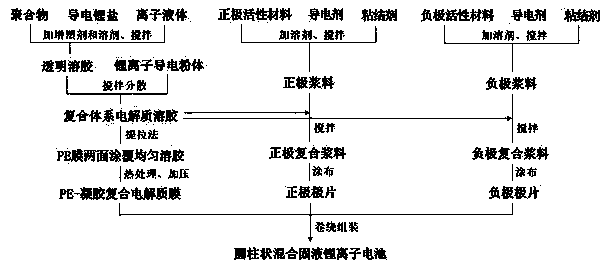

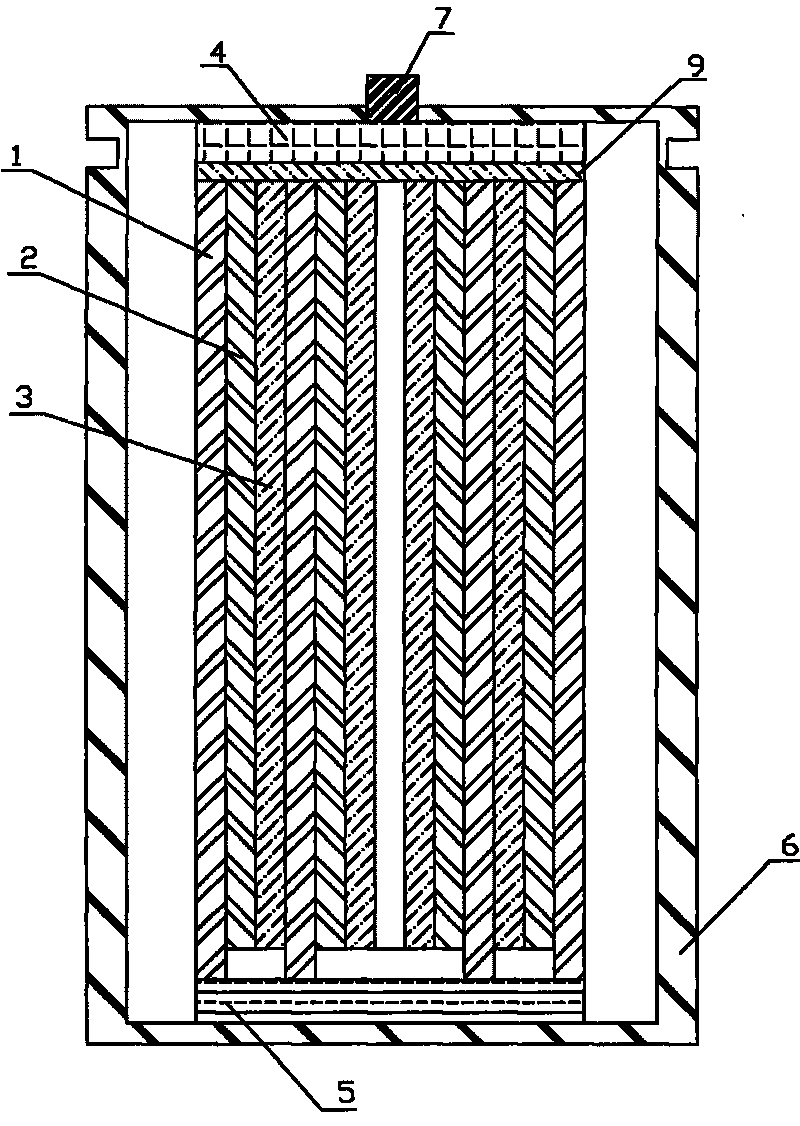

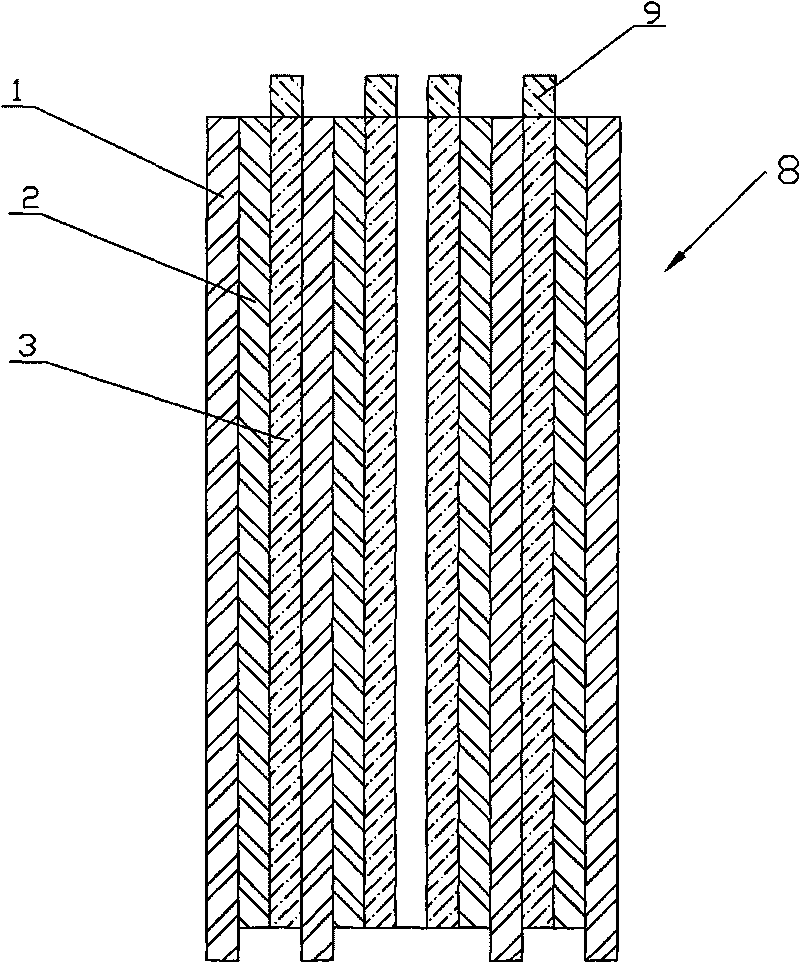

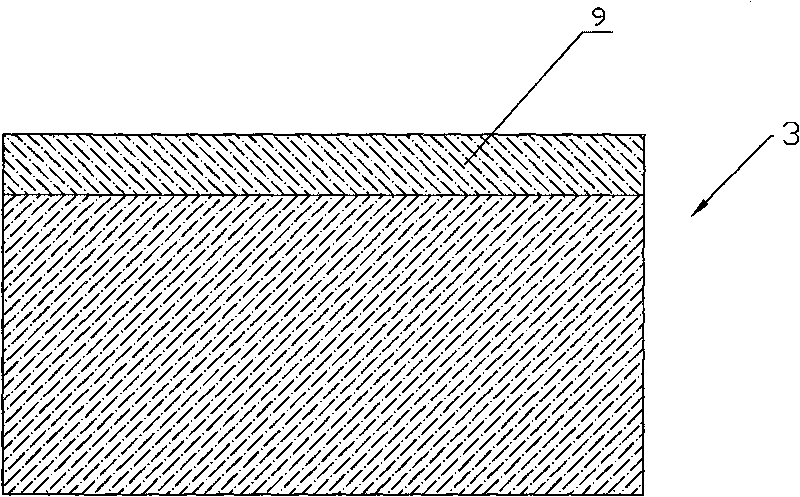

Preparation method of cylindrical mixed solid-liquid lithium ion battery

InactiveCN109698384AHigh strengthImprove lithium ion conductivityFinal product manufactureElectrolyte accumulators manufactureComposite electrolyteLithium-ion battery

The invention relates to the technical field of battery preparation, and relates to a preparation method of a cylindrical mixed solid-liquid lithium ion battery. Uniform composite electrolyte sol is applied to both sides of a PE film by pulling. A porous PE film with a mature preparation process is used as a support, and electrolyte sol is applied to both sides of the PE film (i.e. a support film). A PE film-gel composite electrolyte film is prepared through heat treatment at high temperature. The strength of the PE film is enhanced. The PE film has good lithium ion conductivity and has good property of interface binding with cathode / anode plates.

Owner:天臣新能源研究南京有限公司

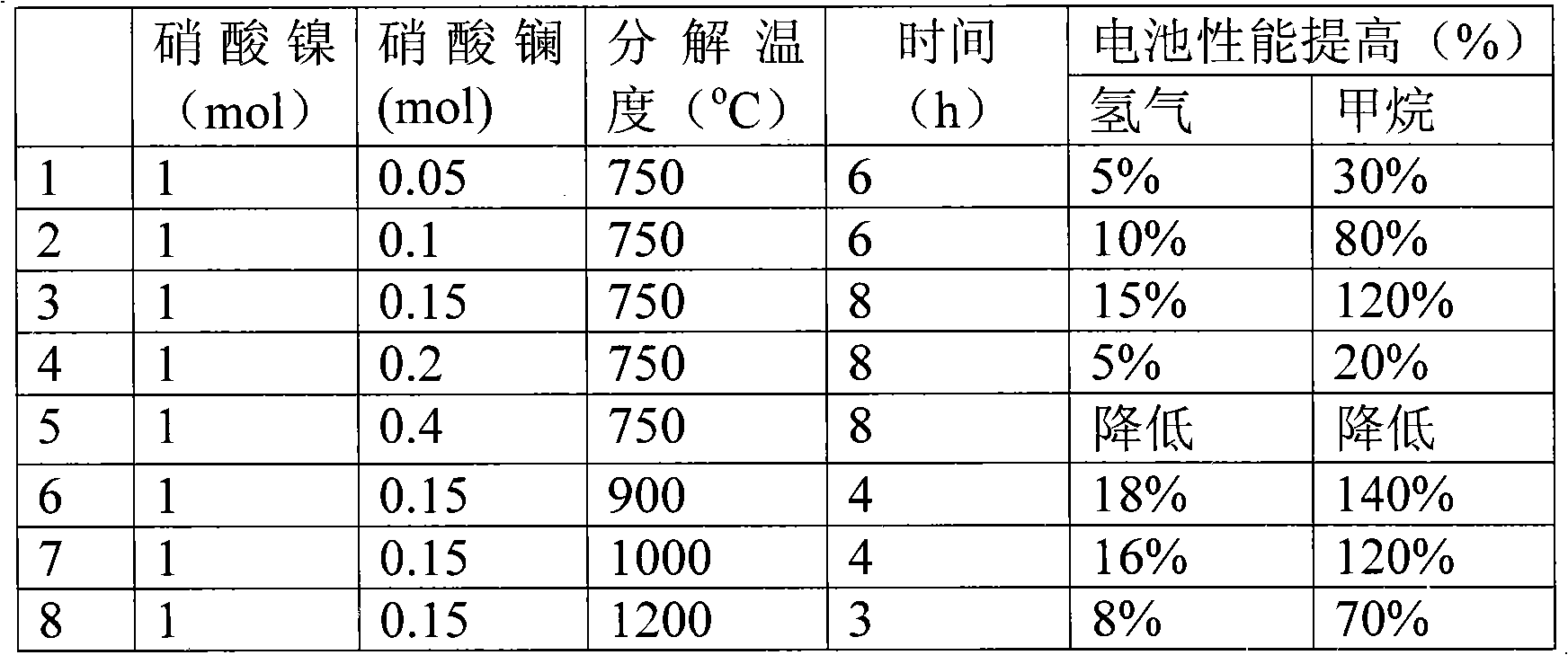

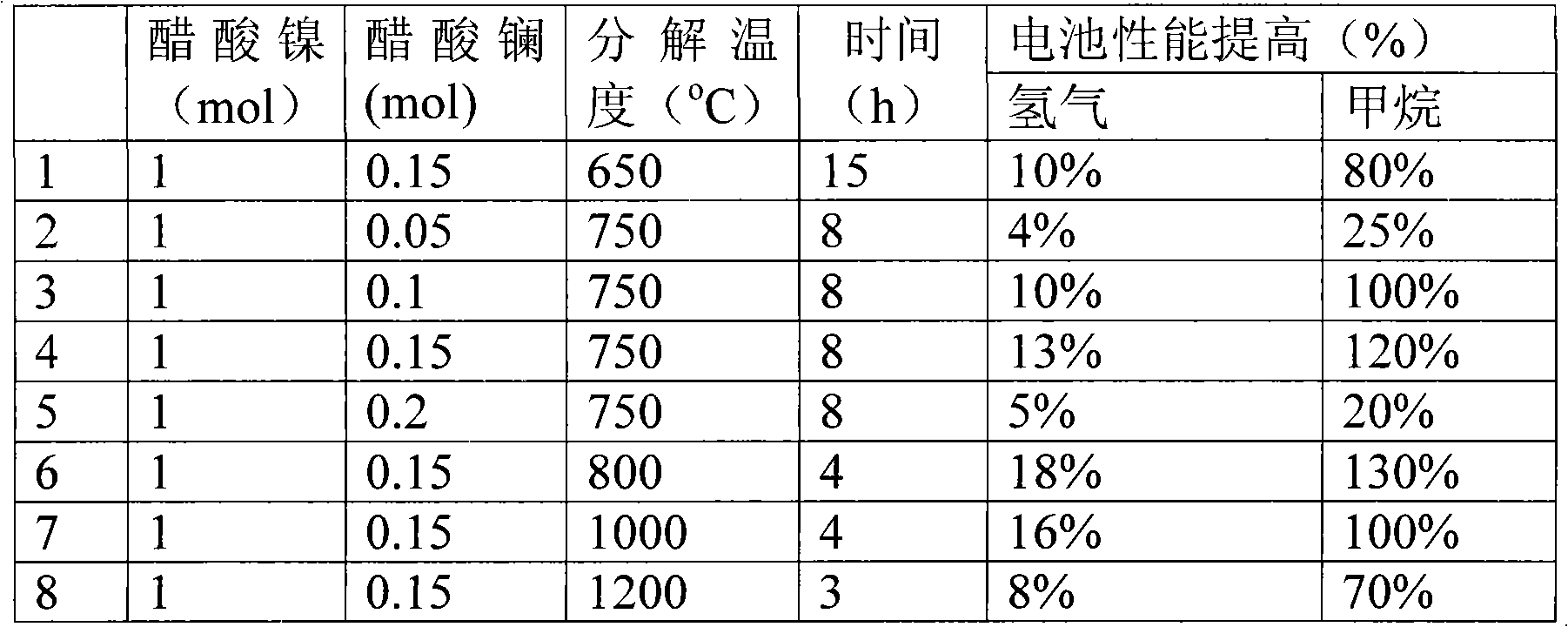

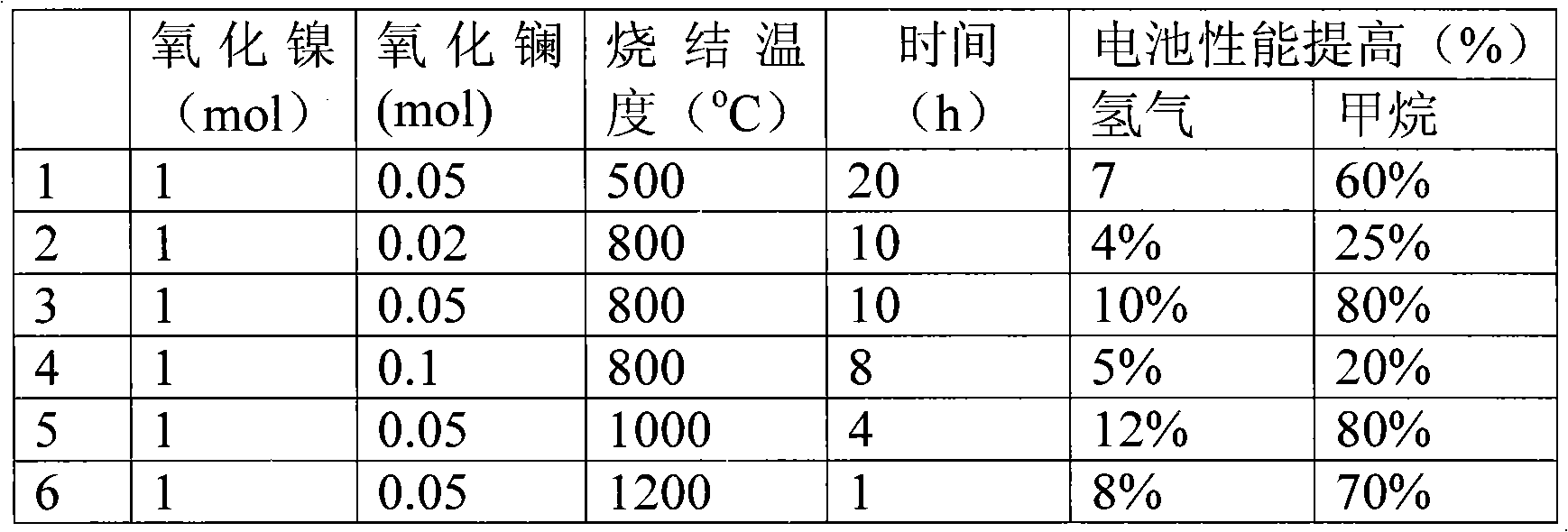

Solid-oxide fuel battery anode catalysis material containing rare earth element

InactiveCN101293207AInhibit growthImproved interface contactCell electrodesMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementCerium

The present invention relates to a solid oxide fuel battery anode catalytic material, in particular to a lanthanon-containing solid oxide fuel battery anode catalytic material. The formula comprises NiOxReyOz; wherein, Ni stands for nickel, Re stands for lanthanide rare earth element and O stands for oxygen; y is more than 0 and less than 0.5, x is more than 0 and less than 2 and z is more than 0 and less than 1. The present invention is characterized in that the anode catalytic material is modified by adding lanthanide elements such as lanthanum, cerium, praseodymium, neodymium, samarium gadolinium, etc.; in the anode made from electrolyte, the material can prevent anode catalyst particle from growing, improve the interface contact between the anode catalytic material and the electrolyte, reduce the polarization resistance of the battery, improve the activity and the output performance of the battery.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Dynamic high-capacity nickel-hydrogen battery and production process thereof

InactiveCN101719566ALower electrode resistanceLower polarization resistanceFinal product manufactureSmall-sized cells cases/jacketsInternal resistancePulp and paper industry

The invention relates to a dynamic high-capacity nickel-hydrogen battery and a production process thereof. By applying a current collecting plate and a current collecting body, the internal resistance of the battery is greatly reduced. The production process mainly comprises the following steps: preparing a nickel battery, preparing a nickel battery, coiling, welding, and moreover carrying out sulfonation treatment on a membrane. By adopting the production process, the internal resistance of the battery is greatly reduced, thereby achieving the effects of charging and discharging the nickel-hydrogen battery in a short time.

Owner:QUANZHOU JINTION ELECTRONICS

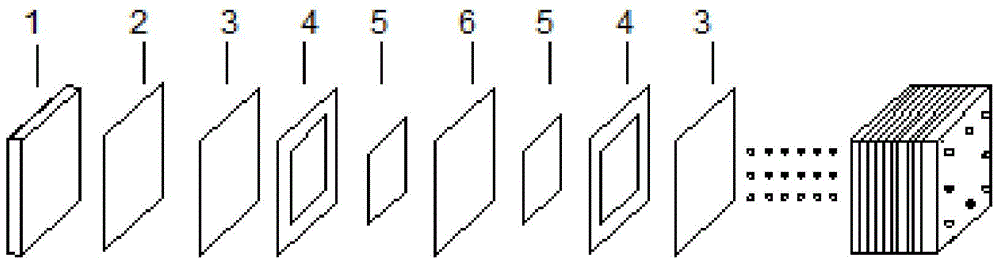

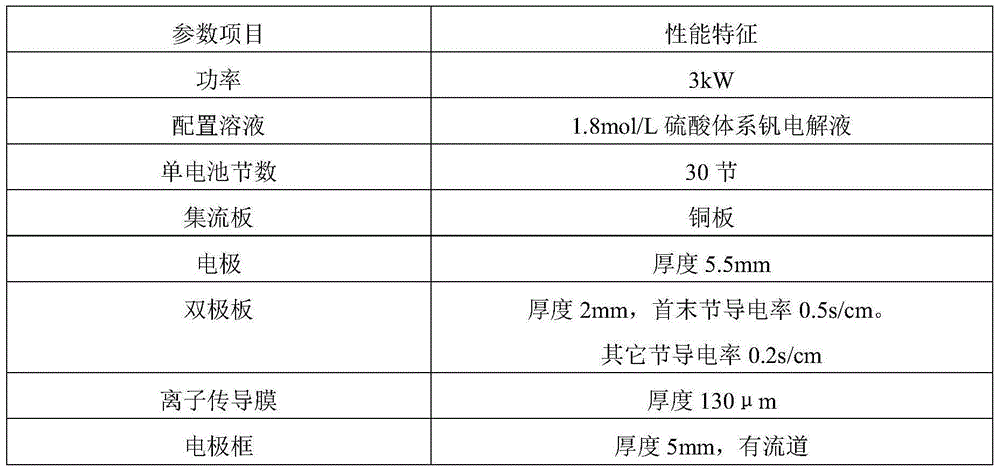

Redox flow cell stack

InactiveCN106450404ASolve the problem of excessive voltage at the first and last sectionEasy to operateCell electrodesFuel cellsElectrical resistance and conductanceFlow cell

The invention discloses a redox flow cell stack. The redox flow cell stack is formed by connecting a plurality of single batteries in series, wherein each single battery comprises a bipolar plate, an electrode, an electrode frame and an ion conduction film, and in the cell stack, a part structure comprising the single battery at an initial section and / or a tail section is different from a part structure comprising other single batteries. By improving the structures of the batteries at the initial section and the tail section, the bipolar plate of the single battery at the initial section or the tail section is changed to a material with relatively small conductivity and relatively large roughness, the ion conduction film of the battery at the initial section or the tail section is changed to a film material with relatively small resistance and more excellent performance, so that the voltage range of the refox flow cell stack is effectively reduced, the voltage consistency of the single battery in the cell tack is greatly improved, the unfavorable influence on a battery system due to long-term running of the cell stack in a relatively high voltage range is prevented, and the long-term running stability of the battery system is improved.

Owner:DALIAN RONGKE POWER

Carbon nano tube conductive agent sizing for negative electrode material of lithium ion battery and preparation method thereof

ActiveCN108461753AHigh bonding strengthShorten the diffusion pathCell electrodesSecondary cellsDispersityActivated carbon

The invention belongs to the field of lithium ion batteries, and relates to a carbon nano tube conductive agent sizing for a negative electrode material of a lithium ion battery and a preparation method thereof. The method is characterized in that activated carbon is added to the conductive agent sizing, so that the dispersity of carbon nano tubes is improved, and moreover, the adsorption capacityof a negative electrode of the lithium ion battery to electrolyte can be improved through the activated carbon dispersed in the negative electrode material, and as a result, the dispersing route of ions is reduced; a negative electrode filming agent is added to the conductive agent sizing, so that a surface SEI film can be formed on the negative electrode during charge and discharge.

Owner:南昌新苏纳米材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com