High-catalytic activity composite negative electrode material of intermediate-temperature solid oxide fuel cell and preparation method of composite negative electrode material

A solid oxide, high catalytic activity technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problem of poor catalytic activity of oxygen reduction, and achieve the effect of short preparation cycle, simple preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

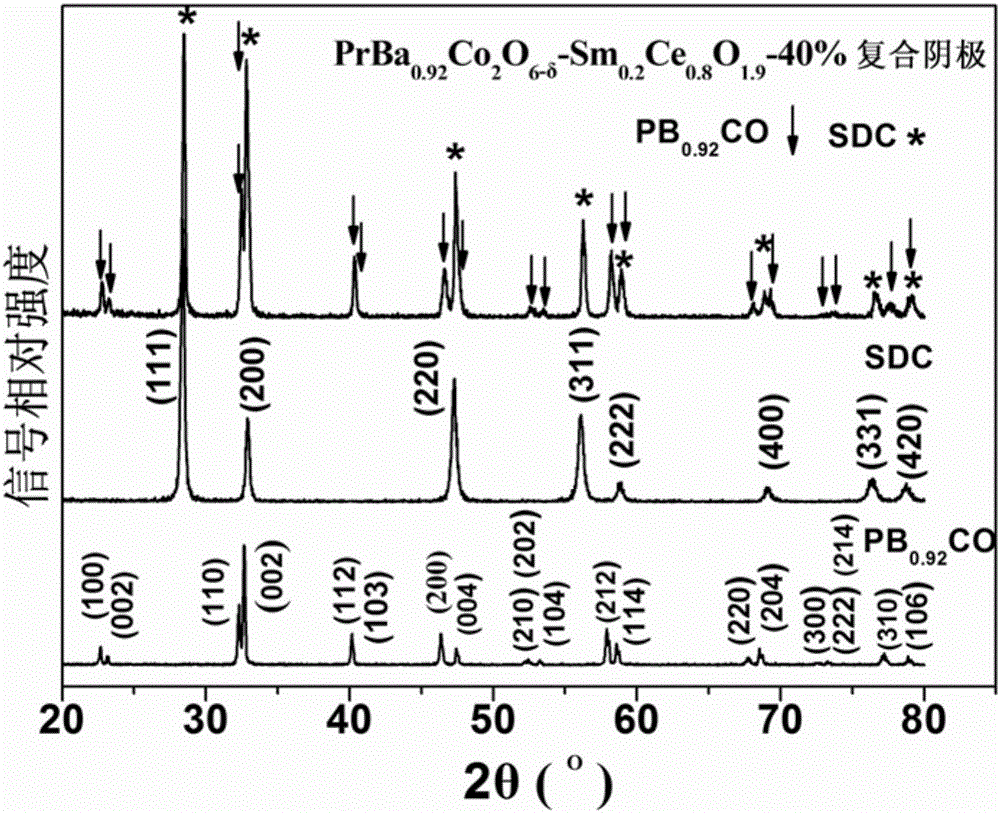

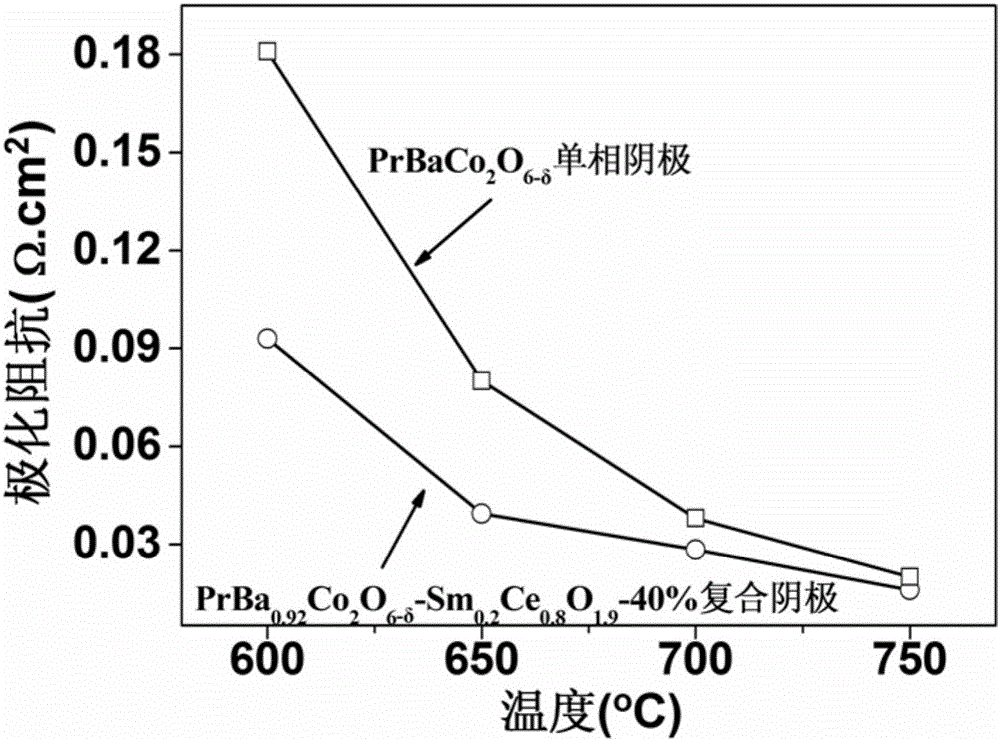

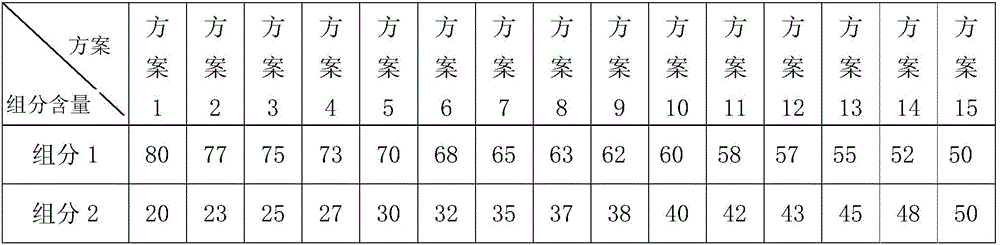

[0023] Example 1: Preparation of medium temperature SOFC composite cathode PrBa by synchronous sintering reaction method 0.92 co 2 o 6-δ -Sm 0.2 Ce 0.8 o 1.9 , Sm in the composite cathode 0.2 Ce 0.8 o 1.9 The mass percent content is 40%.

[0024] (1) PrBa 0.92 co 2 o 6-δ Synthetic solution (solution I) preparation

[0025] According to the preparation of 16.036g PrBa 0.92 co 2 o 6-δ -Sm 0.2 Ce 0.8 o 1.9 Composite cathode, weigh 22.91g EDTA, dissolve in 100ml deionized water under magnetic stirring, add NH 3 ·H 2 O adjusts pH ≈ 6 to form EDTA-NH 3 solution; then weigh Pr(NO 3 ) 3 ·6H 2 O 8.70g, Ba(NO 3 ) 2 4.809g, Co(NO 3 ) 3 ·6H 2 O 11.641g, it was completely dissolved in the above EDTA-NH under magnetic stirring 3 In the solution, an EDTA-metal salt solution is formed, and the molar amount of EDTA in the solution is related to the metal ion Pr 3+ 、Ba 2+ with Co 3+ the same total molar weight; then weigh 32.95g citric acid and dissolve it in 100...

Embodiment 2

[0031] Example 2: Preparation of medium temperature SOFC composite cathode Pr by synchronous sintering reaction method 0.95 BaCo 2 o 6-δ -Gd 0.1 Ce 0.9 o 1.95 , Gd in the composite cathode 0.1 Ce 0.9 o 1.95 The mass percentage content of is 50%.

[0032] (1)Pr 0.95 BaCo 2 o 6-δ Synthetic solution (solution I) preparation

[0033] According to the preparation of 9.701g Pr 0.95 BaCo 2 o 6-δ -Gd 0.1 Ce 0.9 o 1.95 Composite cathode, weigh 11.544g EDTA, dissolve it in 150ml deionized water under magnetic stirring, add NH 3 ·H 2 O adjusts pH ≈ 6 to form EDTA-NH 3 solution; then weigh Pr(NO 3 ) 3 ·6H 2 O 4.133g, Ba(NO 3 ) 2 2.613g, Co(NO 3 ) 3 ·6H 2 O 5.821g, it was completely dissolved in the above EDTA-NH under magnetic stirring 3 In the solution, an EDTA-metal salt solution is formed, and the molar amount of EDTA in the solution is related to the metal ion Pr 3+ 、Ba 2+ with Co 3+ the same total molar weight; then weigh 16.601g of citric acid and diss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com