Patents

Literature

225results about How to "Component distribution is even" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

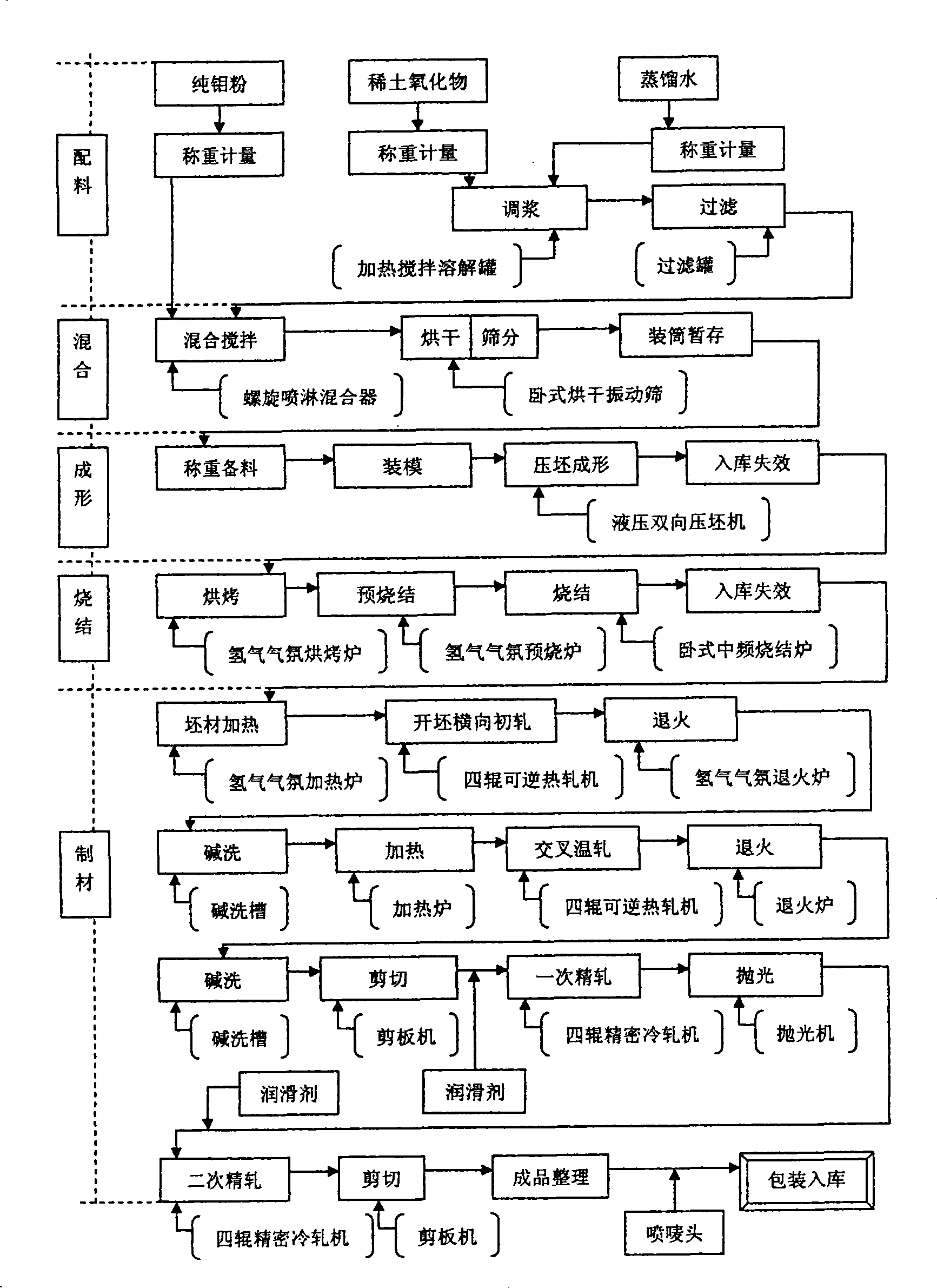

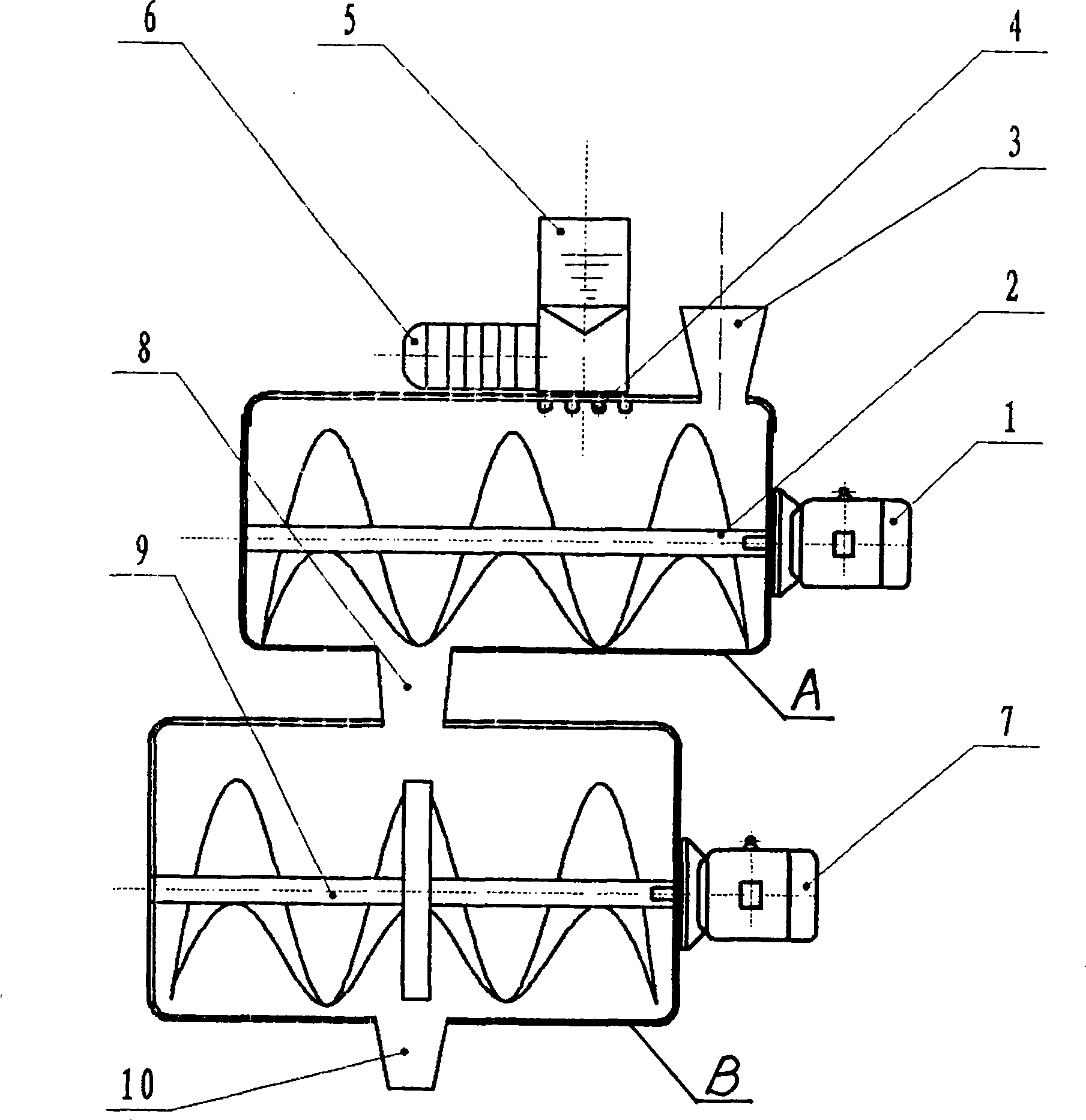

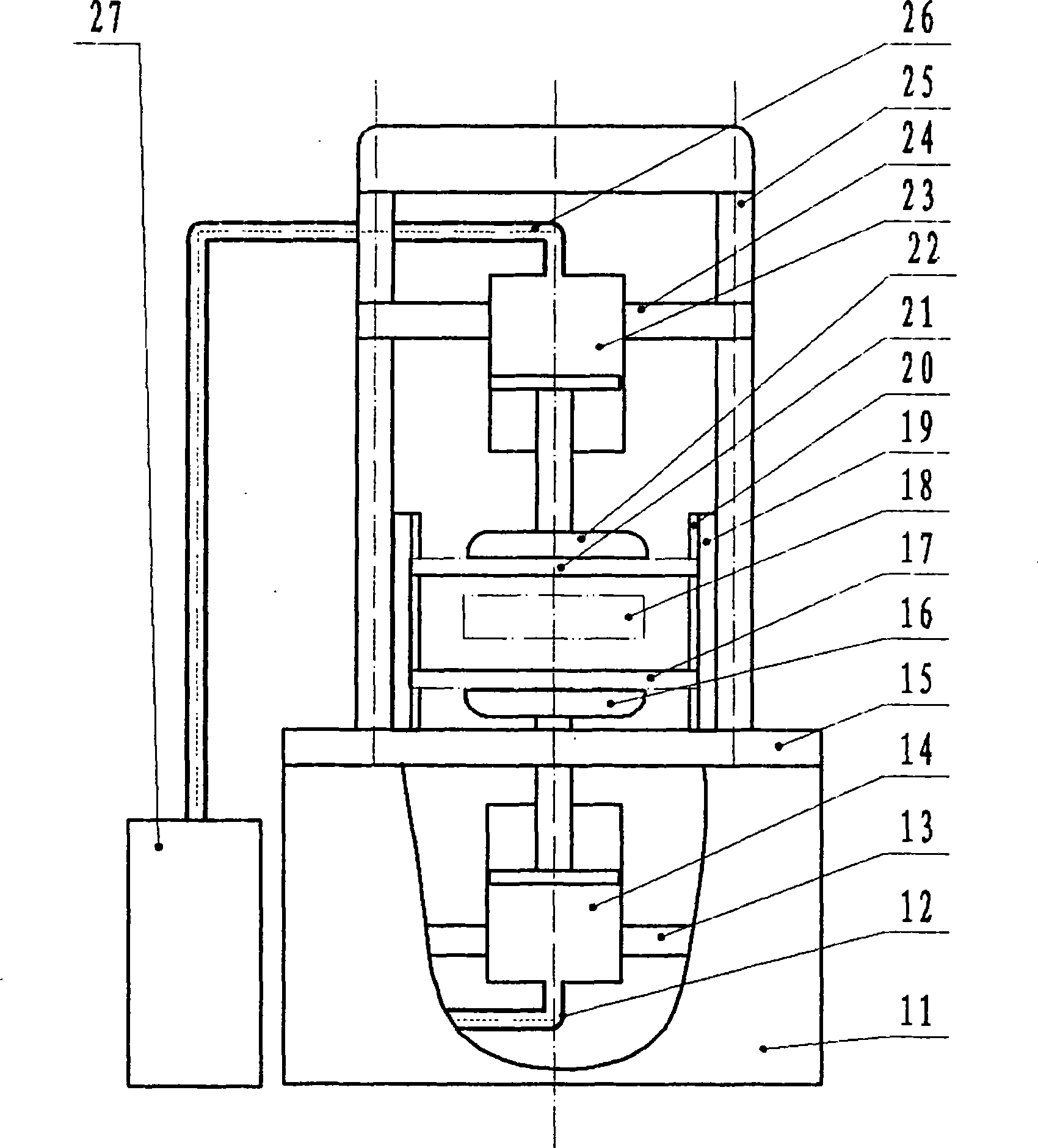

Manufacturing technology of molybdenum-based rare-earth alloy slab and equipment thereof

ActiveCN101423911AFull atomic diffusionFull liquidityRoll mill control devicesMetal rolling arrangementsExtensibilityManufacturing technology

The invention relates to a process for manufacturing the molybdenum based rare earth alloy plate and equipment for manufacturing the same, wherein pure molybdenum powder is simultaneously added with four rare earth oxides of ZrO2, Y2O3, La2O3 and Nd2O3 according to certain ratio, by utilizing the chrematistics of long and large crystal grain and strong sag resistance and anti-creep property of rare earth alloy elements and the dispersion strengthening function, the re-crystallization temperature of the metal molybdenum is increased, the mechanical performances of the molybdenum based material such as tensile property, yielding behavior and extensibility are improved, and the application range of the molybdenum based material is widened; and the manufacturing process comprises production procedures of material preparation treatment, mixing treatment, forming treatment, sintering treatment, material making treatment and the like and the setting of various technical parameters of special technical equipment and process. With the preparation process, the molybdenum based rare earth alloy plate which has the advantages of good electric conductivity and heat conductivity, excellent high-temperature resistance and corrosion resistance and better mechanical performances such as tensile property, yielding behavior and extensibility, and fills in domestic blank and can replace the imported material can be manufactured.

Owner:四平市北威钼业有限公司

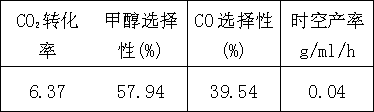

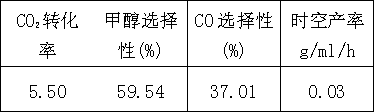

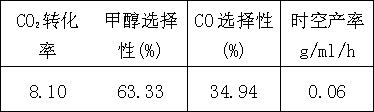

Catalyst for synthesising methanol by hydrogenation of carbon dioxide as well as preparation method and application thereof

ActiveCN103252241AEasy to prepareEasy to operateOrganic compound preparationHydroxy compound preparationMetalMethanol

The invention discloses a catalyst for synthesising methanol by hydrogenation of carbon dioxide. The catalyst is composed of oxides with the following molar ratio based on metal: 20-50% of La, 0-10% of M, 15-35% of Cu, and 2-15% of Zn, wherein M is one or more of Zr, Y, K, Ag, Ce, Pd, Mn, Mg, Fe, Co, Ni or Cr. The catalyst disclosed by the invention has the advantages that preparation is simple, operation is easy, catalyst performance repeatability is good, industrial amplification is easy to realize, and reaction conversion rate and reaction selectivity are high.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

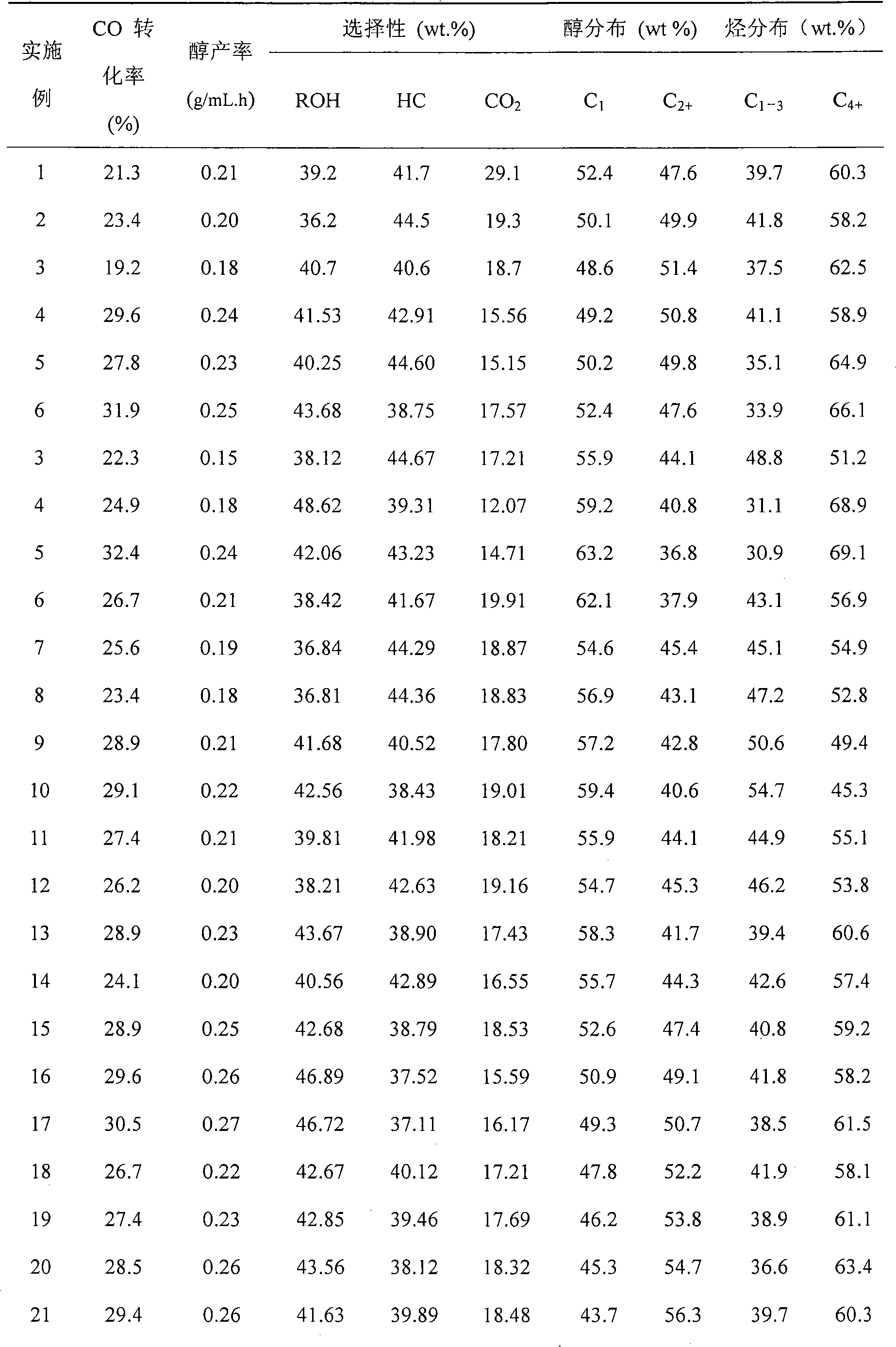

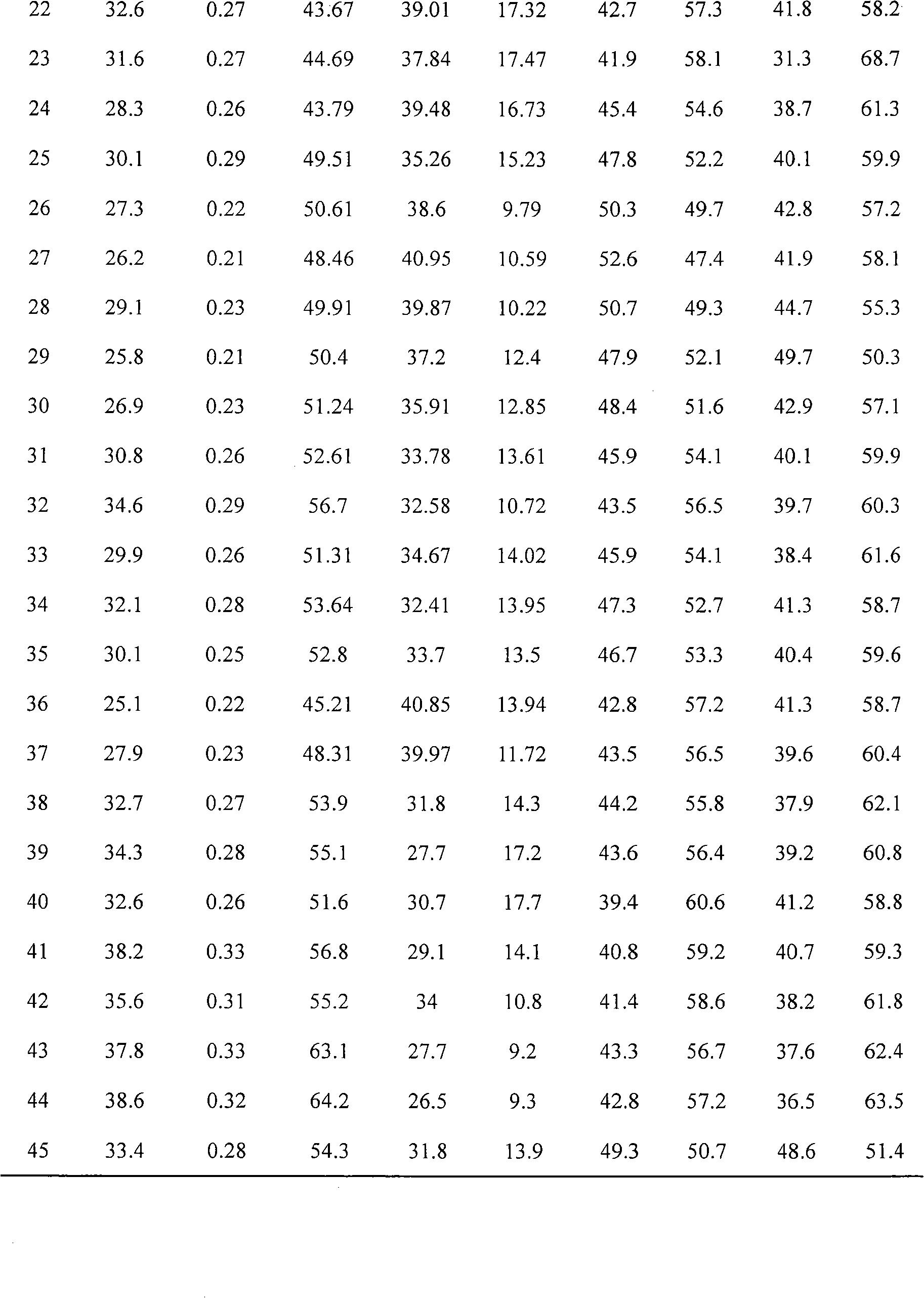

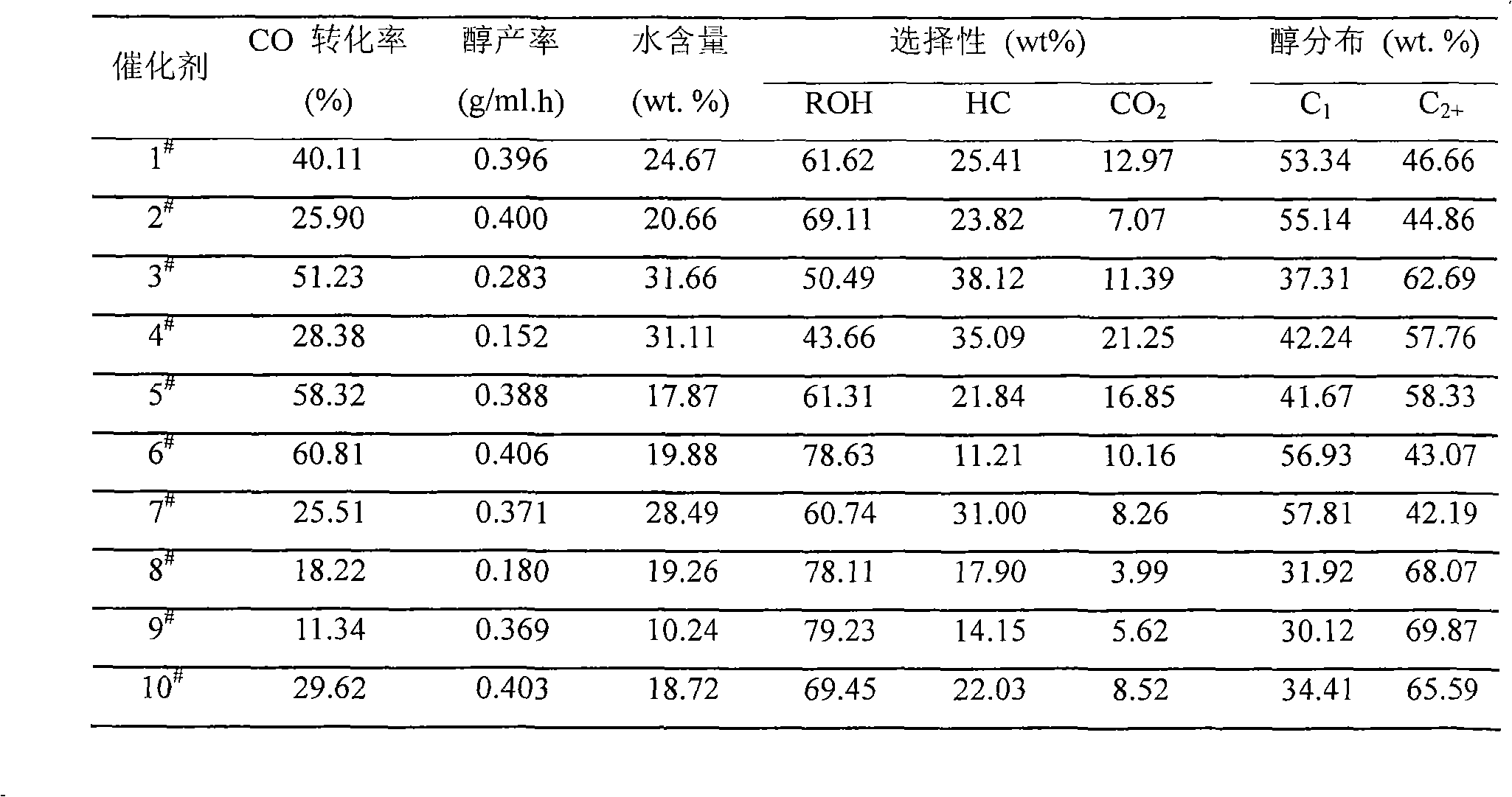

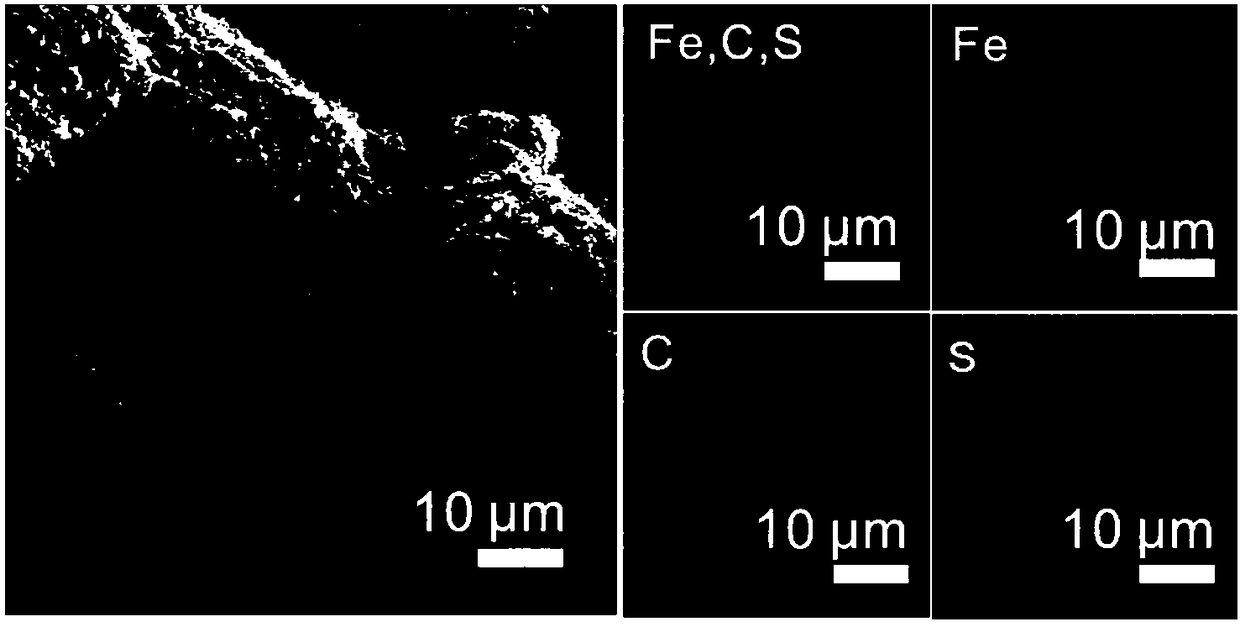

Catalyst for synthesizing low carbon mixed alcohol by synthetic gas and its preparation method

InactiveCN1631527AHas low hydrocarbon selectivityHigh activityOrganic compound preparationHydroxy compound preparationAcetic acidAlcohol

This is about a kind of catalyst to make complexes ether of low carbon, whose weight rate is: Mo: 20--40%, soil: 15--30%, Ma: 5--20%, K: 5--15%, S: 20--40%. Take the changing S reactivity to the S hua ammonia solution and Mo acid ammonia, add heavy Acetic acid, filter, dry, and make S dai Mo acid ammonia ether solution: make Ma salt ether solution, mixing them and take supersonic reaction, then get the precipitation, wash, dry and mix with K salt, crash, fire after taking protection air, add soil, mix, press to sheet, shape. The way of the invention is simple, easy to operate, high activity, high choosing ability of ether and low choosing ability of Hydrocarbon.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Catalyst for jointly producing low carbon mixed alcohol and gasoline fraction from synthesis gas and production method and use

InactiveCN101327434AEasy to prepareEasy to operateOrganic compound preparationHydroxy compound preparationCoprecipitationHigh selectivity

The present invention relates to a catalyst for making low-carbon mixed alcohol co-produced gasoline fraction from synthesis gas. The catalyst is characterized in that in weight percentage, the catalyst consists of 20 percent to 40 percent of Cu, 15 percent to 40 percent of Fe, 5 percent to 25 percent of Mn, 5 percent to 25 percent of Zn, 5 percent to 15 percent of Zr, 5 percent to 10 percent of Co and 0.01 percent to 5 percent of M, wherein, M is one kind or multiple kinds of alkali metals, alkaline earth metals or transition metal elements. The catalyst is prepared by a coprecipitation method. The catalyst has the advantages of low cost, good stability, long life and high selectivity of the low-carbon mixed alcohol co-produced gasoline fraction made from the synthesis gas under mild reaction condition.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

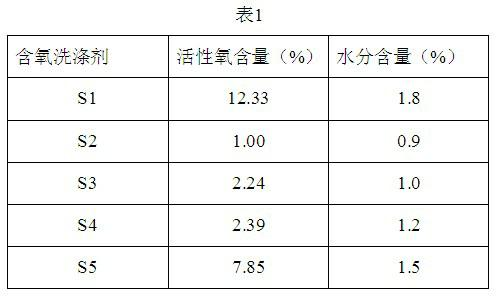

Preparation method of oxygen-containing washing agent and oxygen-containing washing agent prepared by same

ActiveCN102634422AImprove performanceImprove washabilityOrganic/inorganic per-compounds compounding agentsDetergent bleaching agentsSodium bicarbonateSilicic acid

The invention provides a preparation method of an oxygen-containing washing agent. The preparation method comprises the following steps of: A, adding 1-10 parts by weight of surfactant, 10-70 parts by weight of sodium carbonate, 1-40 parts by weight of sodium sulfate and a raw material combination containing or not containing additional assistant into a reactor, wherein the additional assistant contains 0-20 parts by weight of sodium bicarbonate, 0-30 parts by weight of silicious sodium salt and 0-10 parts by weight of an anti-dirt redeposition agent; and B, adding an aqueous hydrogen peroxide solution in the reactor, controlling the reaction temperature of the reactor to be 0-60 DEG C, shaping and drying after reaction to obtain 100 parts by weight of the oxygen-containing washing agent the active oxygen content of which is 1-12.33%. The invention also provides the oxygen-containing washing agent prepared by using the preparation method. The preparation method provided by the invention is safe and environment-friendly, and can prepare the oxygen-containing washing agent which has the advantages of uniform component distribution, variable active oxygen content, stable performance,and excellent washing effect.

Owner:HUNAN JIEYU DAILY CHEM NEW TECH

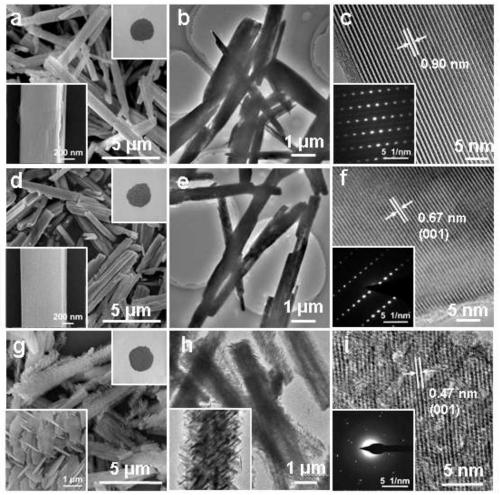

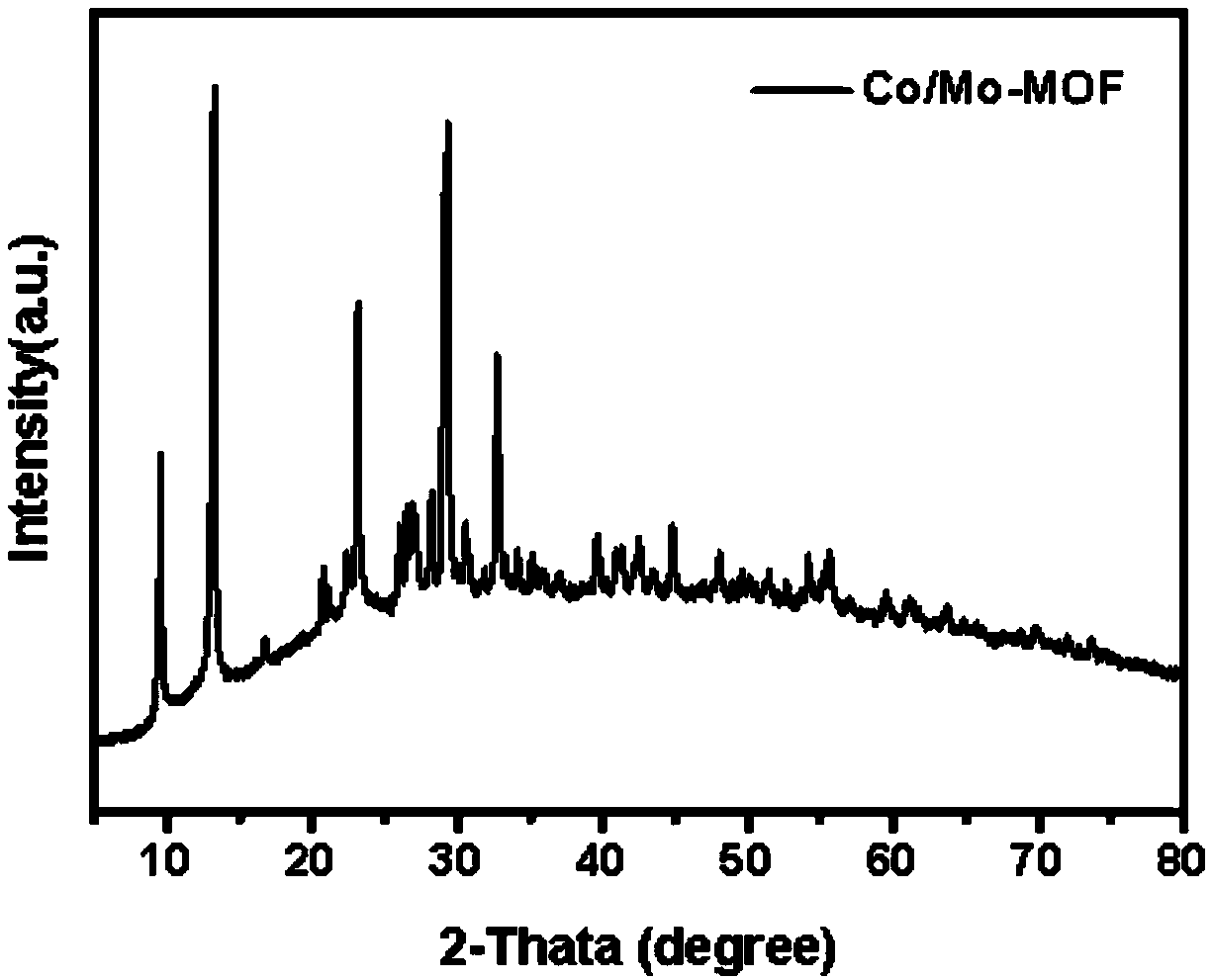

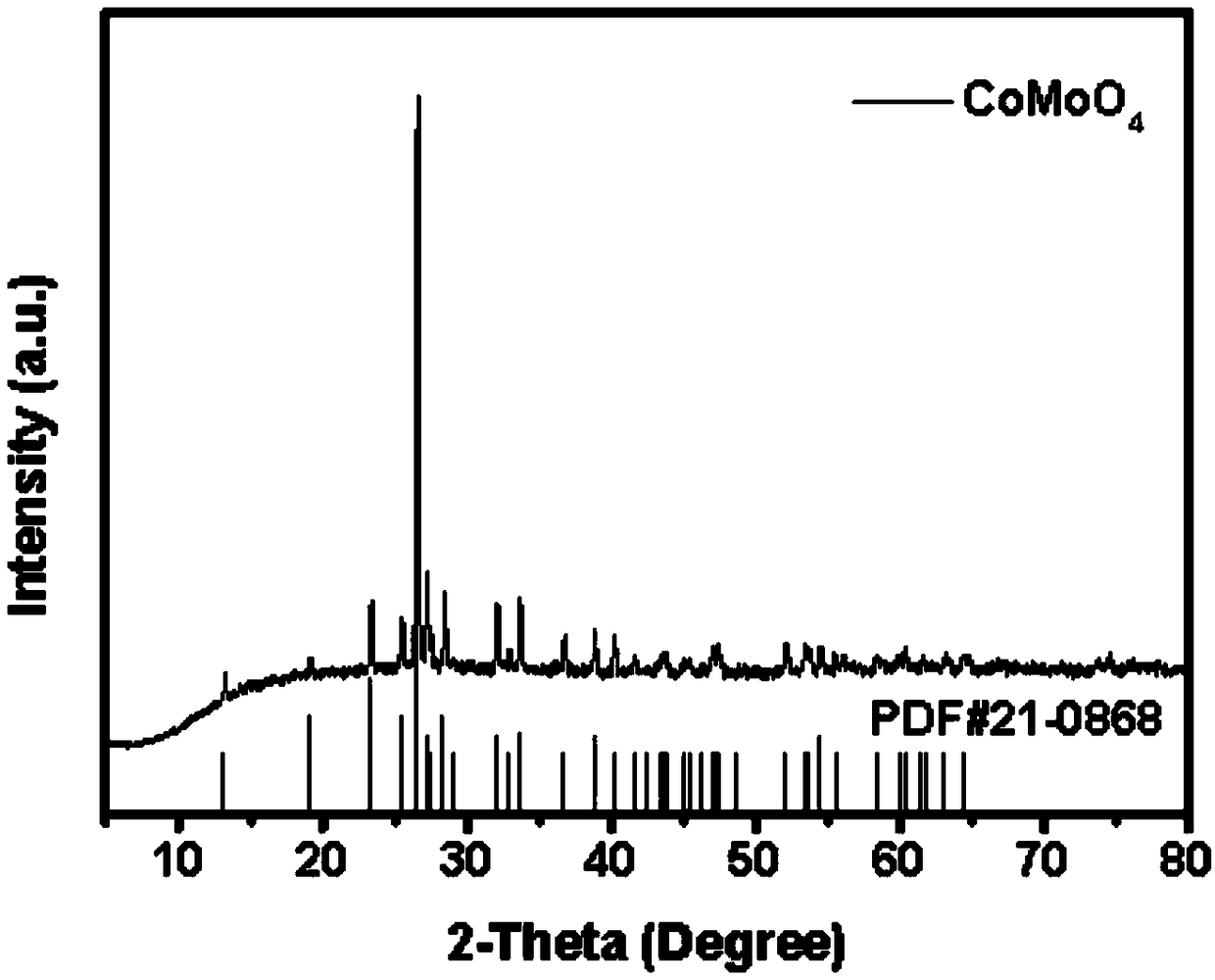

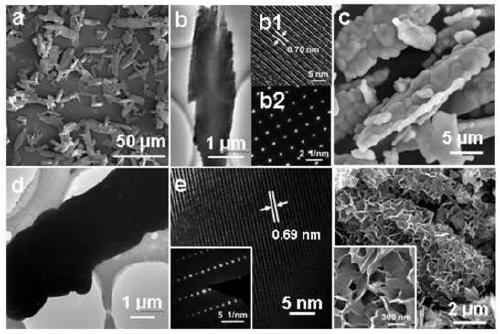

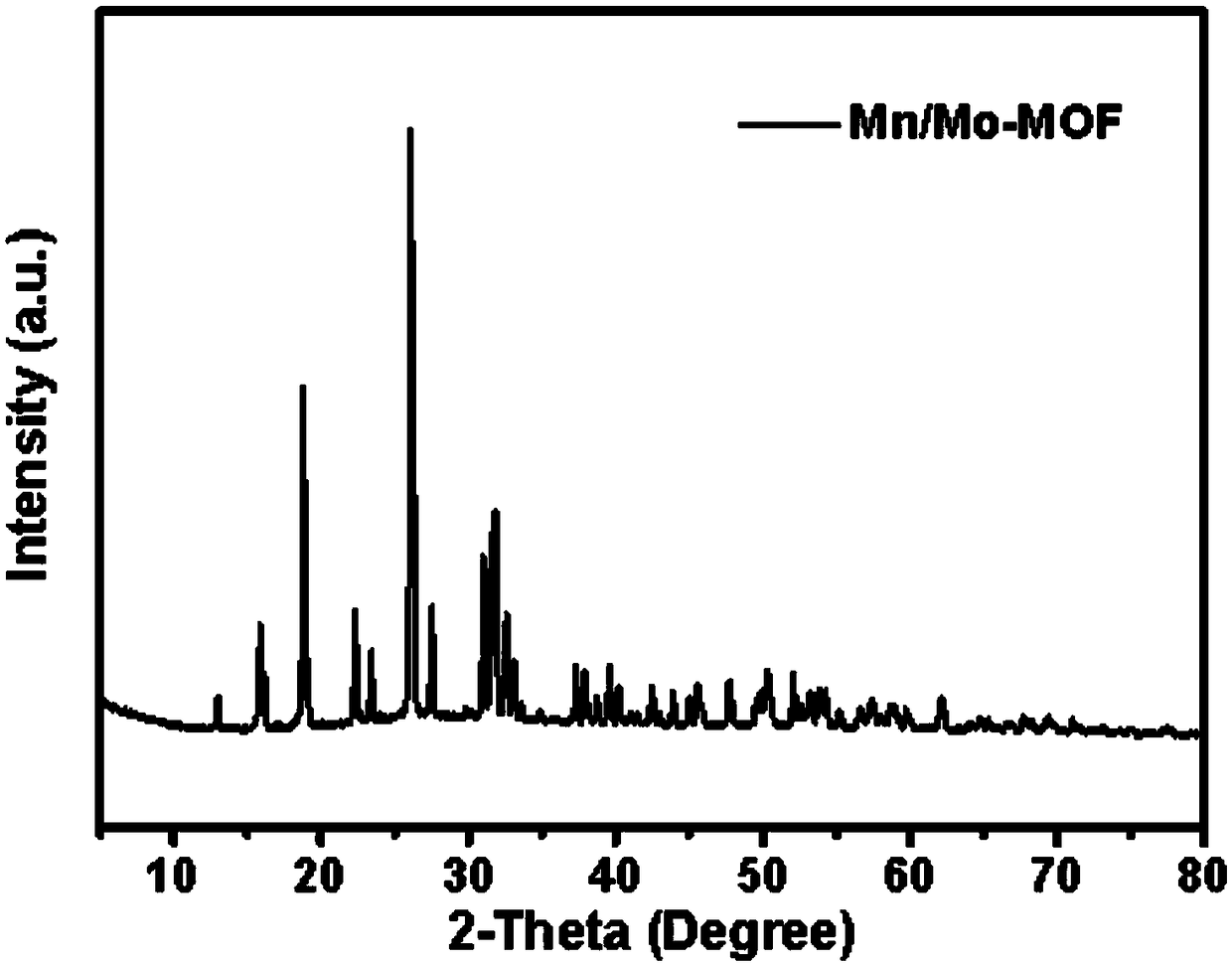

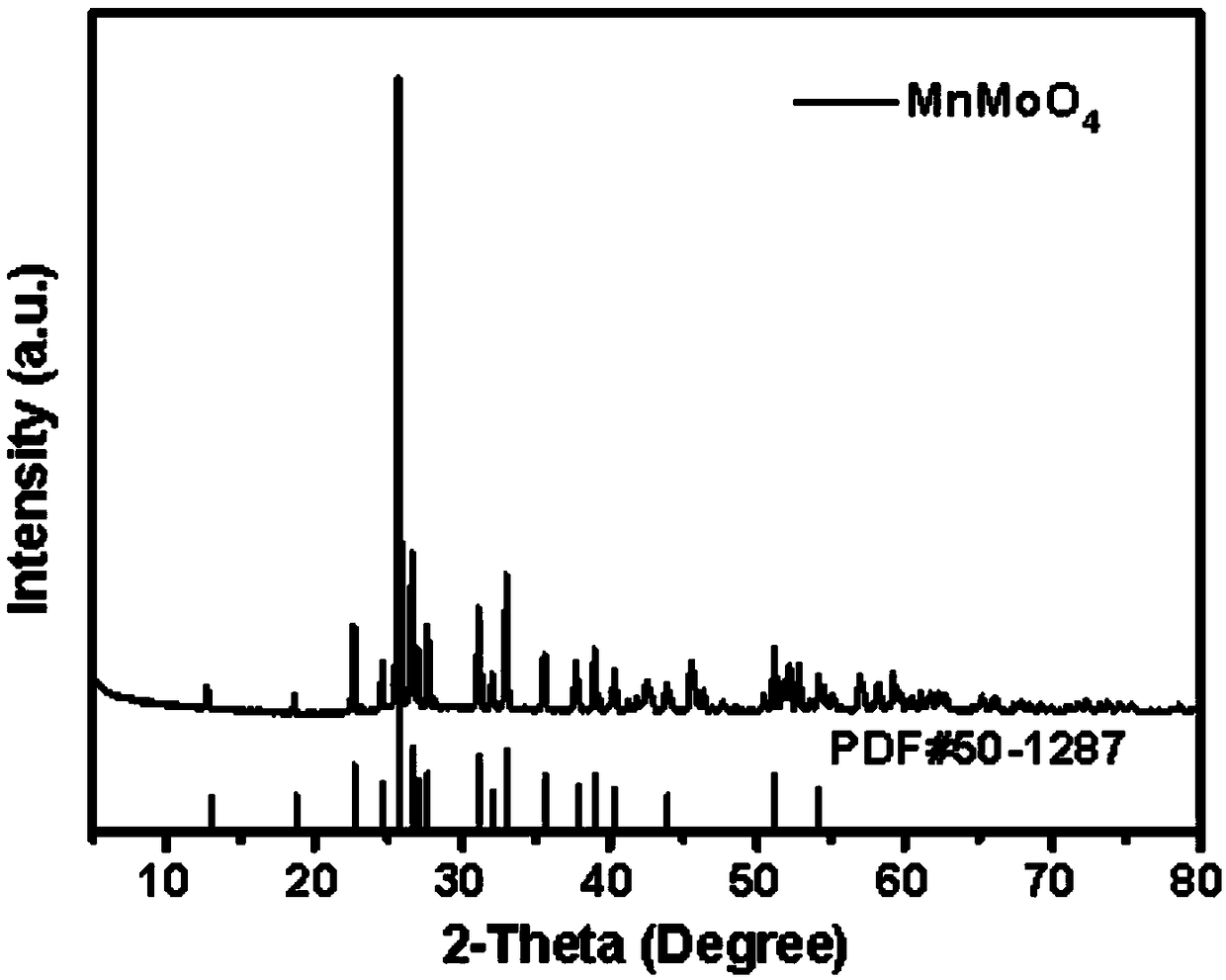

Method for preparing metal hydroxide multi-stage structure through MOF derivative bimetallic oxide template

ActiveCN109133193ASimple preparation processGentle preparation processNickel oxides/hydroxidesCobalt oxides/hydroxidesSURFACTANT BLENDMetal hydroxide

The invention relates to the technical field of nanometer materials, in particular to a method for preparing a metal hydroxide multi-stage structure through an MOF derivative bimetallic oxide template. Alkali treatment is conducted on the MOF derivative bimetallic oxide template to obtain the metal hydroxide multi-stage structure, M is set into metal in the metal hydroxide multi-stage structure, the MOF derivative bimetallic oxide template is set into MMoO4-MOF derivative bimetallic oxide, and the metal hydroxide multi-stage structure is M(OH)x. The method is simple, mold and universal in preparing process, has no special requirements for equipment, does not use surfactants, and can conduct large-scale industrial production; the metal hydroxide multi-stage structure prepared through the method is uniform in size, stable in structure and even in component distribution and has excellent OER performance and constant-current stability.

Owner:ZHEJIANG UNIV OF TECH

Iron-copper based catalyst for synthesizing low carbon mixed alcohol and production method and use

InactiveCN101327435AEasy to prepareEasy to operateOrganic compound preparationHydroxy compound preparationAlcoholCoprecipitation

The present invention relates to an iron-copper base catalyst synthesizing mixture of lower alcohols. In weight percentage, the iron-copper base catalyst consists of 20 percent to 60 percent of Cu, 15 percent to 60 percent of Fe, 0.4 percent to 20 percent of Mn, 0.4 percent to 30 percent of Zn and 0 percent to 5 percent of MA. The catalyst is prepared by a coprecipitation method. The iron-copper base catalyst has the advantages of simple preparation, easy operation, good reaction performance repeatability of the catalyst, realizing industrial amplification easily, good stability and high total alcohol selectivity.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Methanation catalyst for fluidized bed and preparation method of methanation catalyst for fluidized bed

ActiveCN106391028ACheap and easy to getLarge specific surface areaHydrocarbon from carbon oxidesHeterogenous catalyst chemical elementsMethanationAdhesive

The invention discloses a methanation catalyst for a fluidized bed and a preparation method of the methanation catalyst for the fluidized bed. The methanation catalyst for the fluidized bed comprises a carrier, an active component and auxiliary agents, and the active component and the auxiliary agents are loaded on the carrier. The carrier is a compound of Al2O3, ZrO2 and NiO or a compound of Al2O3, TiO2 and NiO; the active component is NiO; the auxiliary agents are oxides of at least one of Mg, Ca, La, Ce, Mn, Fe, Cu, Cr and Co. A co-precipitation method is adopted for preparation of the carrier of the catalyst, and uniformity in component distribution is realized; then spray forming is adopted to obtain the micro-spherical catalyst carrier which is high in fluidity and suitable for the fluidized bed. In preparation of the carrier of the catalyst, silicon sol or silicon-aluminum composite sol is added to serve as an adhesive; in a process of quick preparation of the micro-spherical carrier by spray forming, the silicon sol or silicon-aluminum composite sol is dispersed among carrier components, and after high-temperature calcination, the catalyst carrier is high in mechanical strength, abrasion resistance and impact resistance.

Owner:CHINA NAT OFFSHORE OIL CORP +1

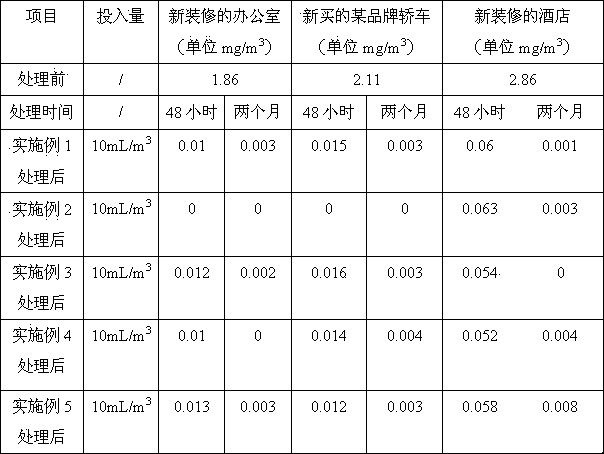

Catching agent of benzene series compounds and preparation method thereof

InactiveCN103752157AAdapt to the initial concentrationImprove stabilityDispersed particle separationSodium sorbateOtic Agents

The invention belongs to the technical field of chemical preparations and in particular relates to a catching agent of benzene series compounds and a preparation method thereof. The catching agent of the benzene series compounds comprises the following raw materials in parts by weight: 5-8 parts of polyacrylamide, 10-20 parts of starch, 8-15 parts of sorbic acid, 10-15 parts of sodium sorbate, 30-45 parts of plant flower extractive, 5-10 parts of penetrating agent, 15-20 parts of sepiolite powder, 1-3 parts of cerium manganese compound oxide catalyst, 5-10 parts of cross-linked rectorite, 10-20 parts of chitosan and 80-100 parts of deionized water. The catching agent of the benzene series compounds is good in absorption and long in service life, so that the pollution caused by the benzene series compounds after decoration of a house is solved; meanwhile, the catching agent of the benzene series compounds is also capable of effectively inhibiting or killing some bacteria and viruses in influenza, intestinal tract and skin; the catching agent of the benzene series compounds is beneficial to the health of people.

Owner:HEBEI UNIV OF ENG

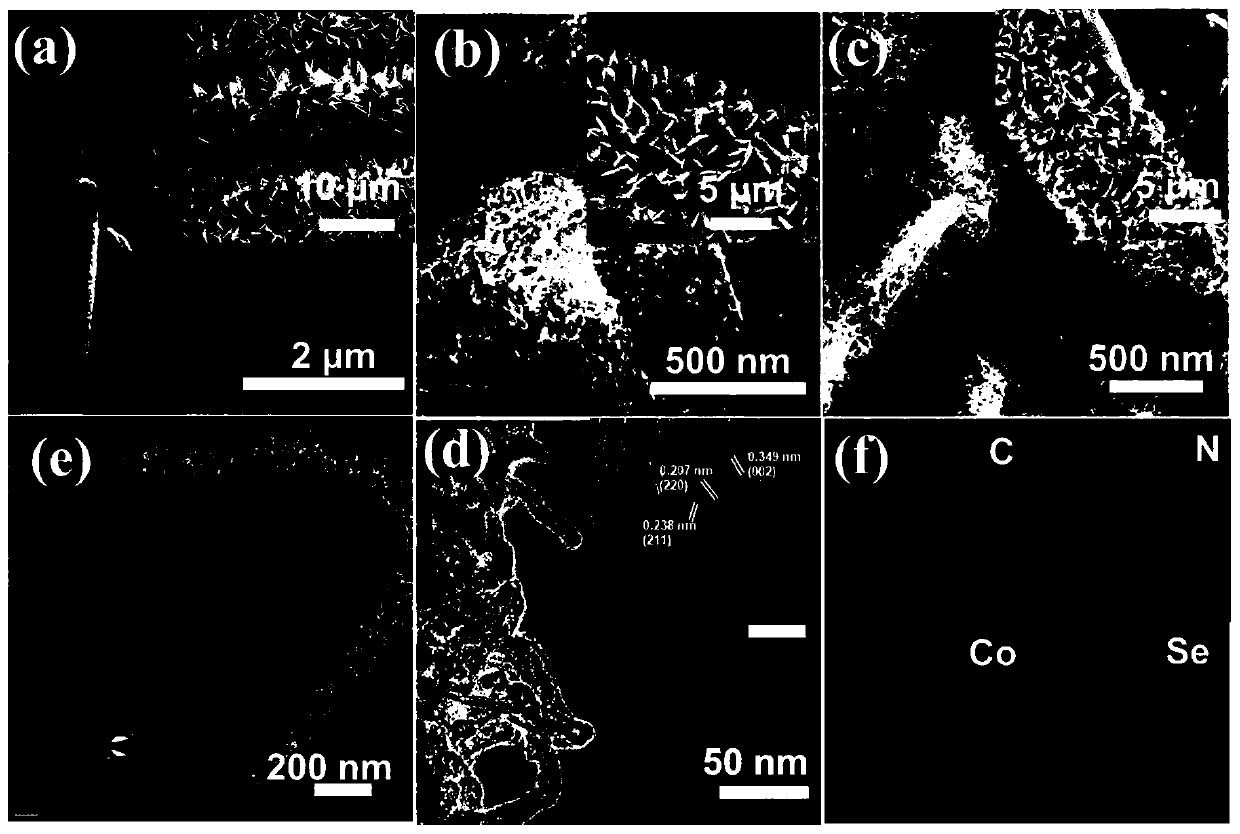

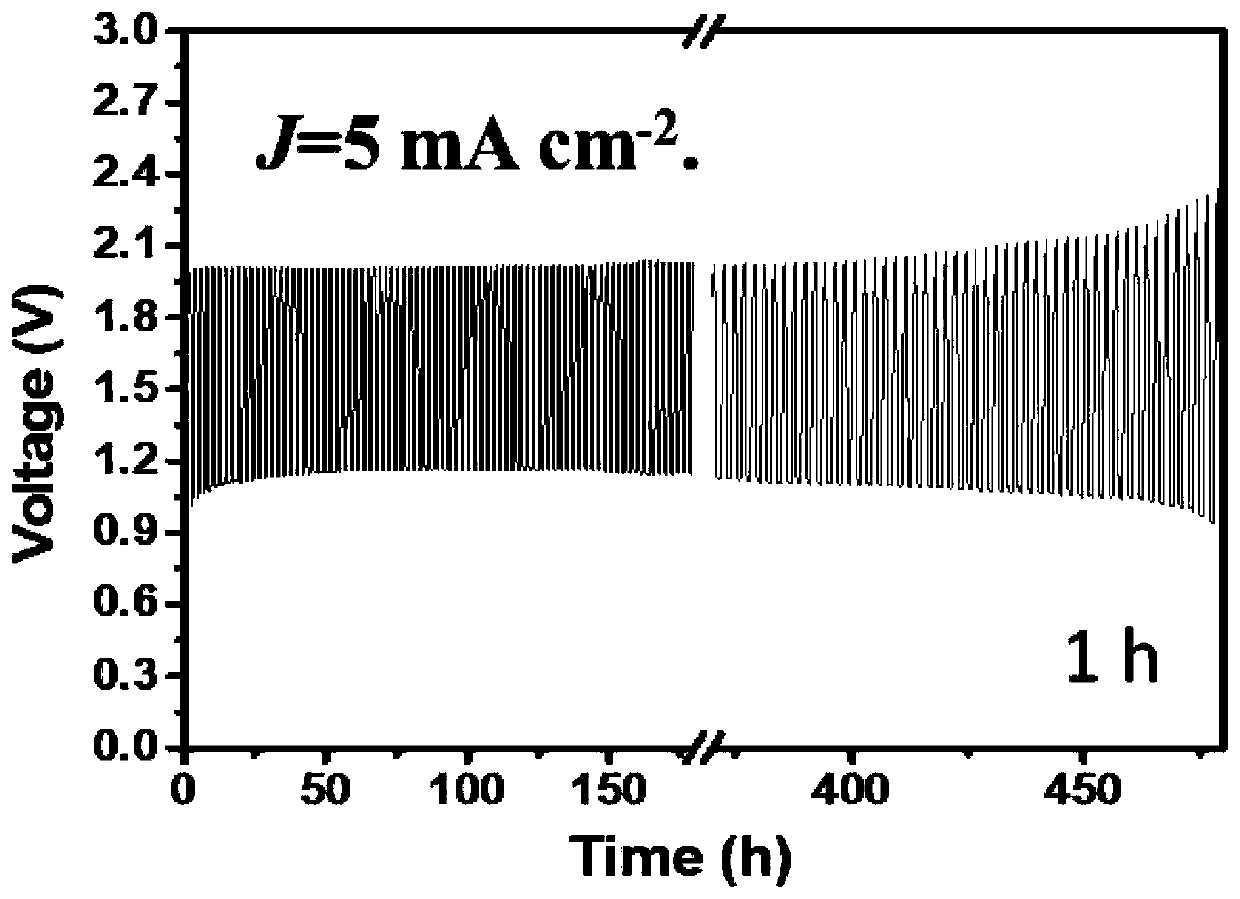

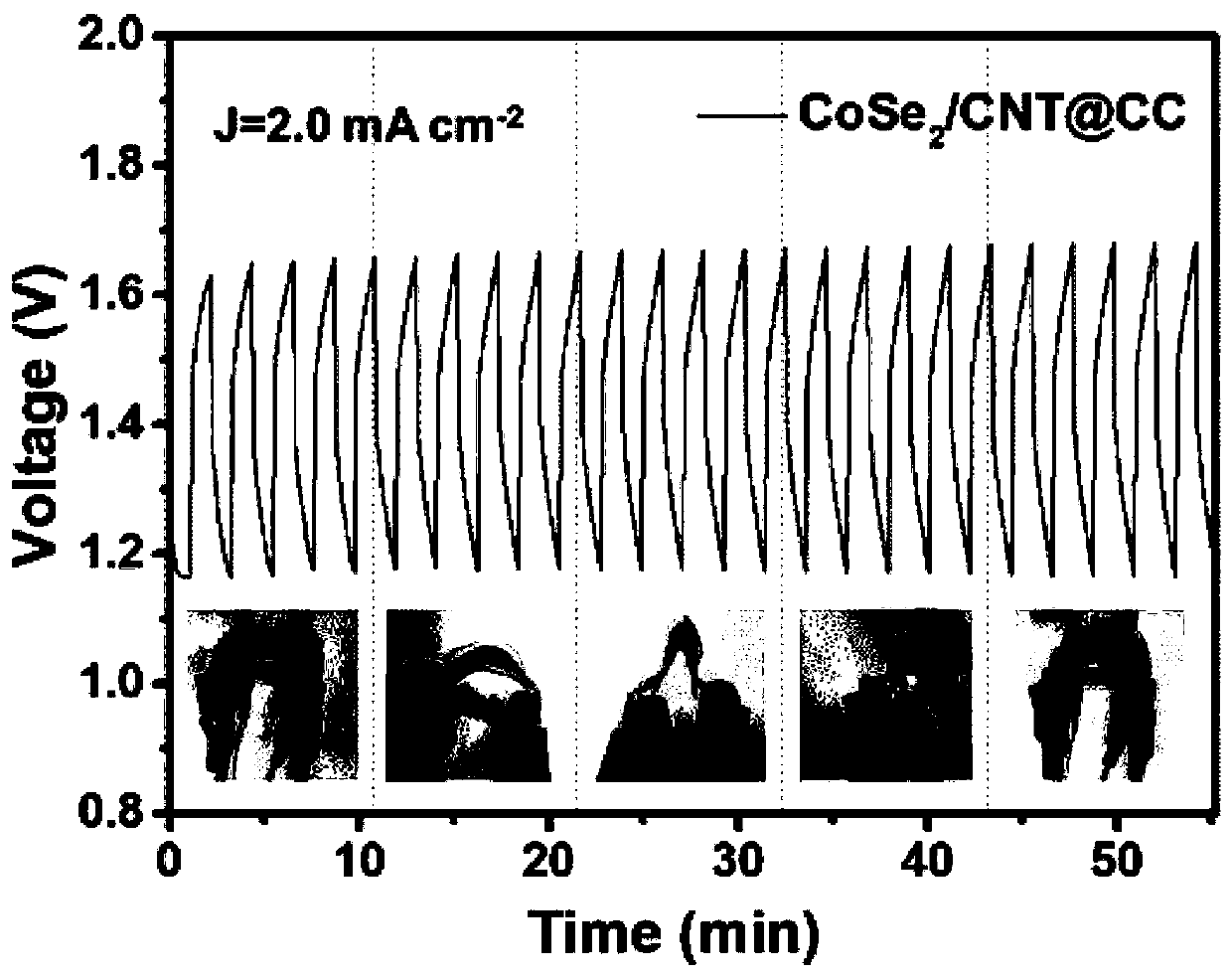

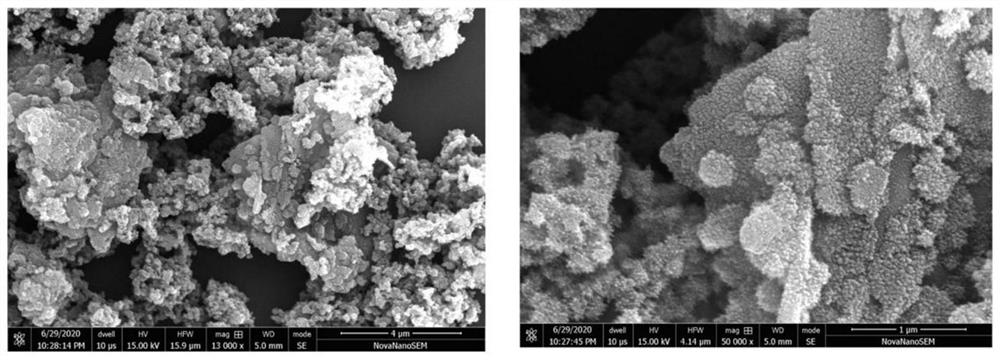

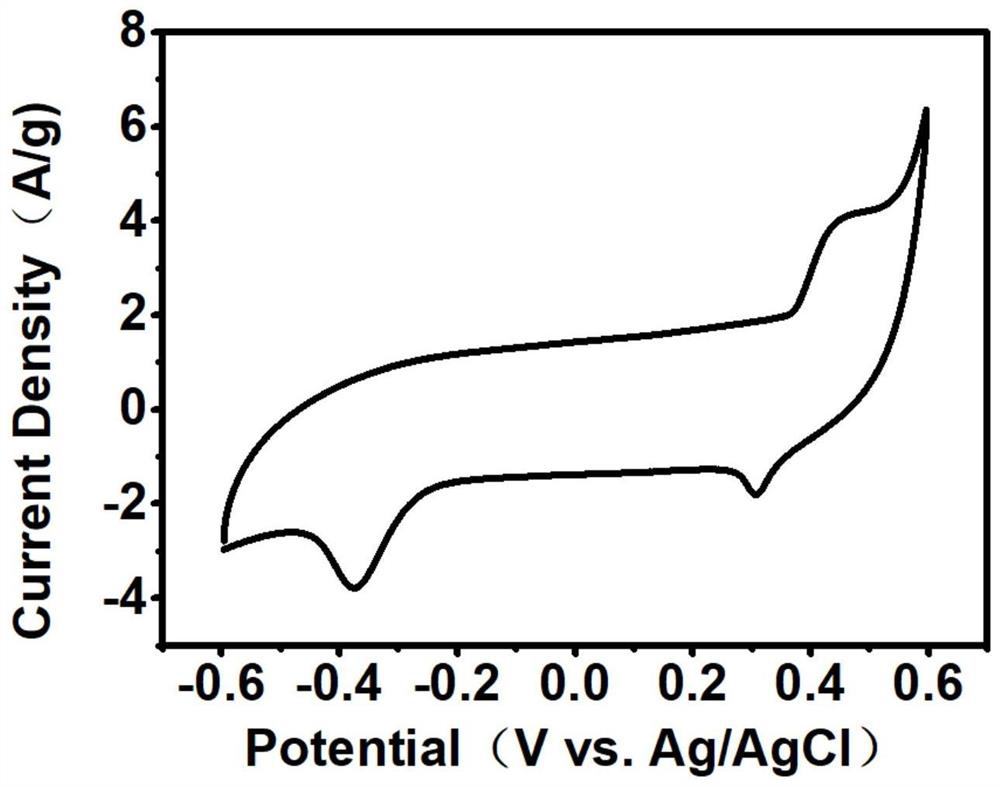

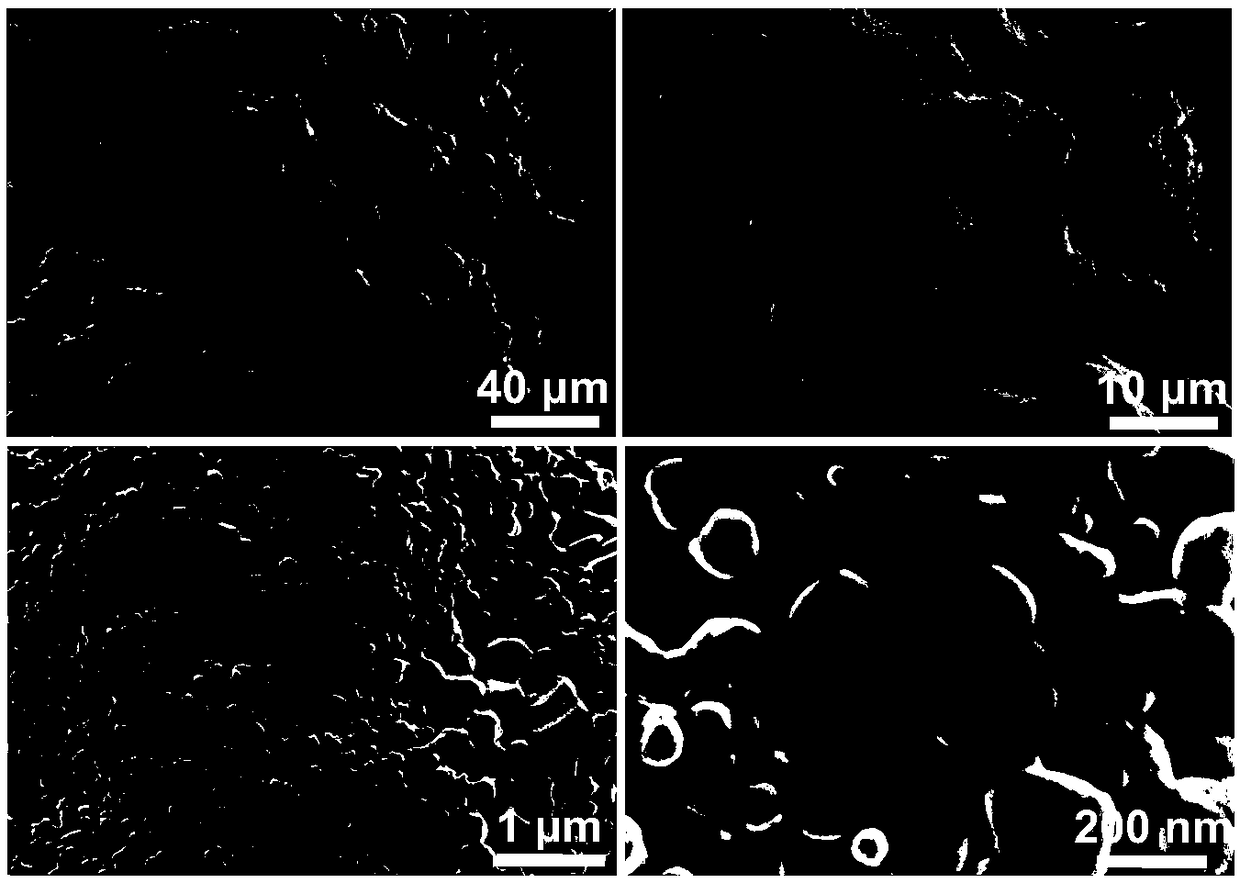

Cobalt diselenide/nitrogen-doped carbon nanomaterial composite electrode catalytic material, preparation method and application thereof

ActiveCN110787819AMass productionThe preparation method is mildFuel and primary cellsPhysical/chemical process catalystsNanotubeCobalt selenide

Relating to the technical field of composite materials, in order to solve the problems of high price and low catalytic activity of electrode catalytic materials in existing zinc-air batteries, the invention provides a cobalt diselenide / nitrogen-doped carbon nanomaterial composite electrode catalytic material, a preparation method and application thereof. The preparation method includes the steps of: (1) growing Co-MOF on carbon cloth subjected to hydrophilization treatment; (2) growing a nitrogen-doped carbon nanomaterial through CVD process to obtain a Co / nitrogen-doped carbon nanomaterial; wherein the nitrogen-doped carbon nanomaterial is a combination of nitrogen-doped carbon nanotube and nitrogen-doped carbon nanosheet; and (3) carrying out selenylation treatment to obtain the cobalt diselenide / nitrogen-doped carbon nanomaterial composite electrode catalytic material. The composite material provided by the invention retains the structural integrity of the cobalt diselenide porous frame / carbon nanosheet array obtained by taking the triangular lamellar MOF crystal as a template, has excellent properties of both the carbon nanotube and the cobalt diselenide porous frame, and has wide application prospects in the fields of adsorption, sensing, energy storage, catalysis and the like.

Owner:ZHEJIANG UNIV OF TECH

In-situ preparation method of three-dimensional conductive MOF@MXene composite electrode

ActiveCN112053861AAchieve growthUniversal preparation methodHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceChloroacetic acids

The invention relates to the field of the synthesis of composite materials, and provides an in-situ preparation method of a three-dimensional conductive MOF@MXene composite electrode in order to solvethe problem of poor conductivity of MOFs, which comprises the following steps: adding MAX phase powder into an HF solution, etching for 5-24 hours, centrifugally washing with deionized water until the pH value of the upper solution is 6-7, and carrying out vacuum drying to obtain multilayer MXene powder; uniformly dispersing the powder in the deionized water, adding chloroacetic acid, stirring atroom temperature, adding a NaOH solution, carrying out stirring reaction for 1-12 hours, carrying out centrifugal washing, and carrying out vacuum drying to obtain MXene-COOH powder; dispersing the powder into the deionized water, adding a metal salt, a ligand and ammonia water in order, carrying out air-blowing stirring reaction at 50-70 DEG C, and finally, carrying out centrifugal washing and drying to obtain the three-dimensional conductive MOF@MXene composite powder. The method is efficient and stable in process and simple in process, the prepared composite powder can serve as a super-capacitor electrode material, and the stable and efficient energy storage is achieved.

Owner:ZHEJIANG UNIV OF TECH

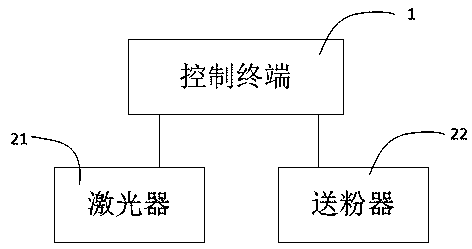

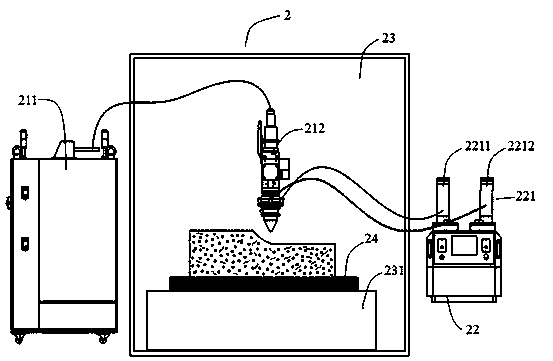

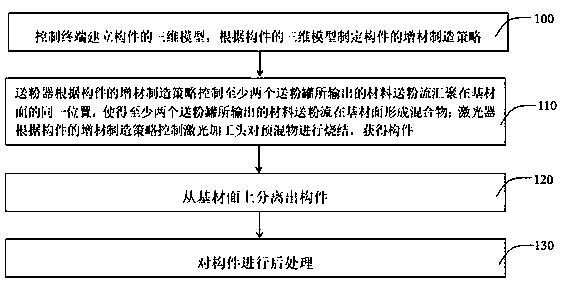

Method for preparing component through laser additional material and system for preparing laser additional material

ActiveCN111036906AEvenly distributedImprove performanceAdditive manufacturing apparatusIncreasing energy efficiencyLaser processingPhysical chemistry

The invention discloses a method for preparing a component from a laser additional material and a system for preparing the laser additional material, and relates to the technical field of preparing ofthe additional material. The problems that when the additional material is prepared through coaxial feeding and laser precipitating of premixed powder, due to the different ratio and the long-term and long-distance conveying, the airborne conveying segregation phenomenon and heavy-light separation phenomenon occur before the powder reaches a molten bath, and compositions in the composite component formed through laser precipitating are not evenly distributed are solved. A device for preparing the additional material through lasers is applied to the method. The method includes the steps that apowder feeder controls different types of material powder output by at least two powder feeding tanks to converge at a same position of a base material face according to the additional material preparing strategy of the component so that the different types of material powder output by at least two powder feeding tanks can flow on the base material face to form a mixture; and a laser device controls a laser machining head to perform melting and sintering on the mixture according to the additional material preparing strategy of the component to obtain the component. The method for preparing the component from the laser additional material and the system for preparing the laser additional material are used for preparing the additional material.

Owner:TSC LASER TECH DEV BEIJING CO LTD

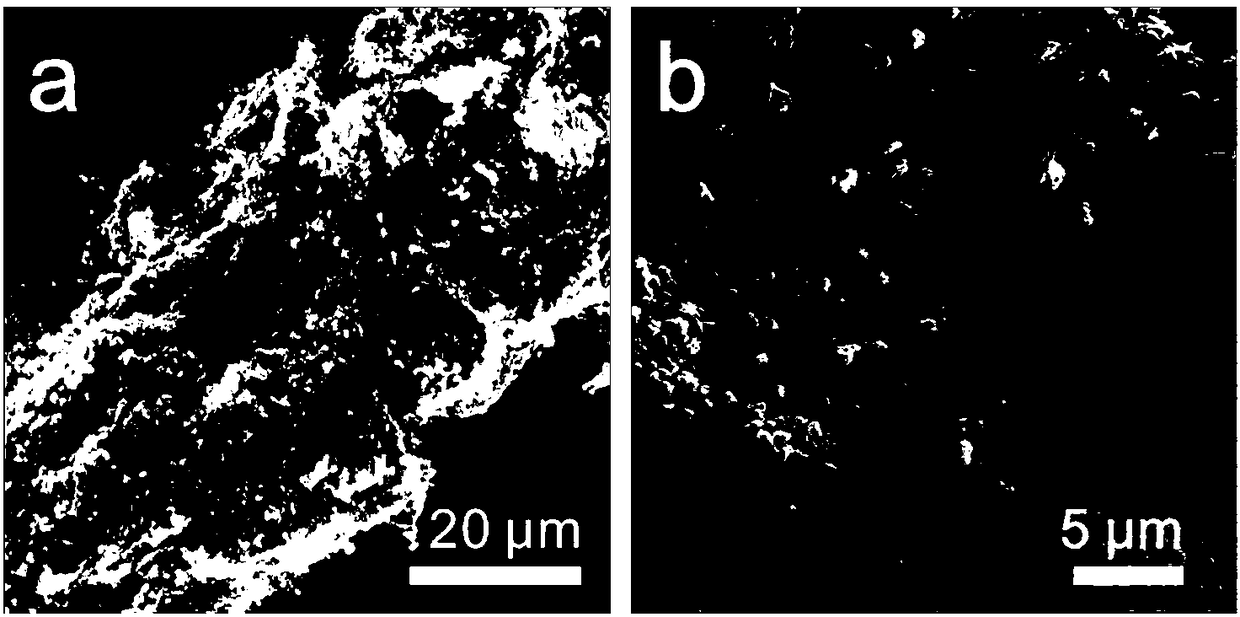

Method for preparing metal oxide multistage structure by MOF-derived bimetallic oxide template

ActiveCN109205567ASimple preparation processUniform sizeOxide/hydroxide preparationZinc oxides/hydroxidesOxideMetal

The invention relates to the technical field of nanomaterials, and in particular, relates to a method for preparing a metal oxide multistage structure by an MOF-derived bimetallic oxide template; theMOF-derived bimetallic oxide template is treated by an alkali to obtain the metal oxide multistage structure; M is set as a metal in the metal oxide multistage structure, the MOF-derived bimetallic oxide template is MMoO4-MOF-derived bimetallic oxide, and the metal oxide multistage structure is MxOy. The preparation process is simple, mild and universal, has no special requirements for equipment,does not use surfactants, and can be industrialized and produced in large scale. The metal oxide multi-stage structure prepared by the method is uniform in size, stable in structure and uniform in component distribution.

Owner:ZHEJIANG UNIV OF TECH

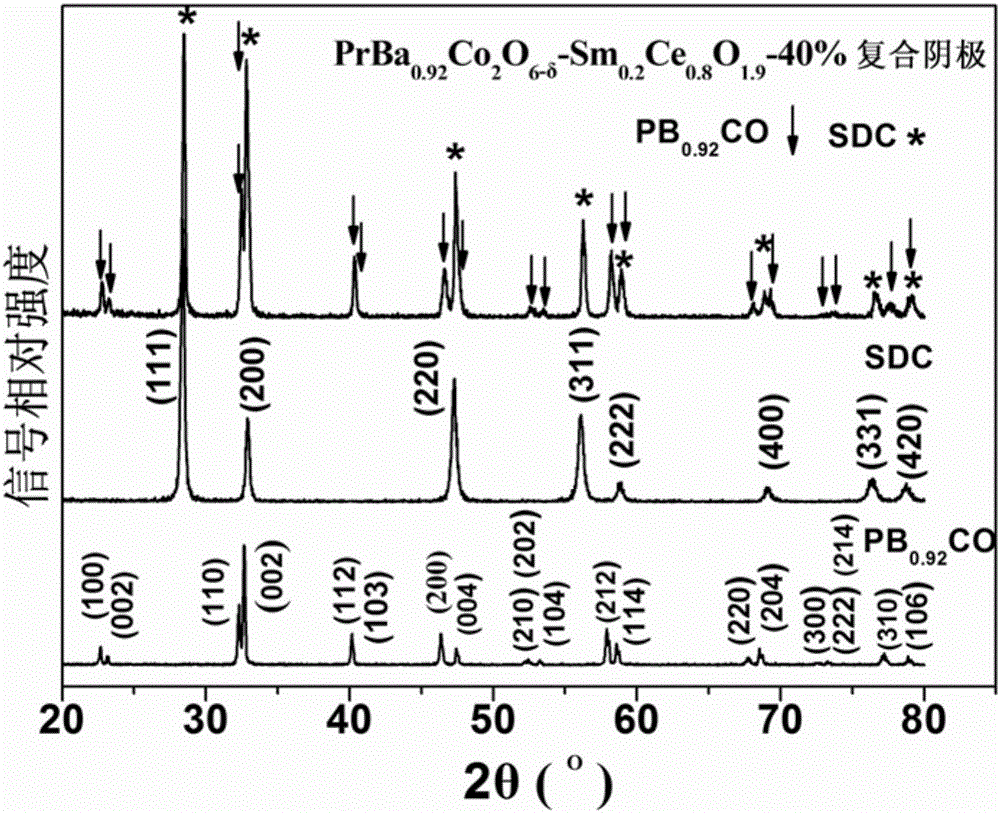

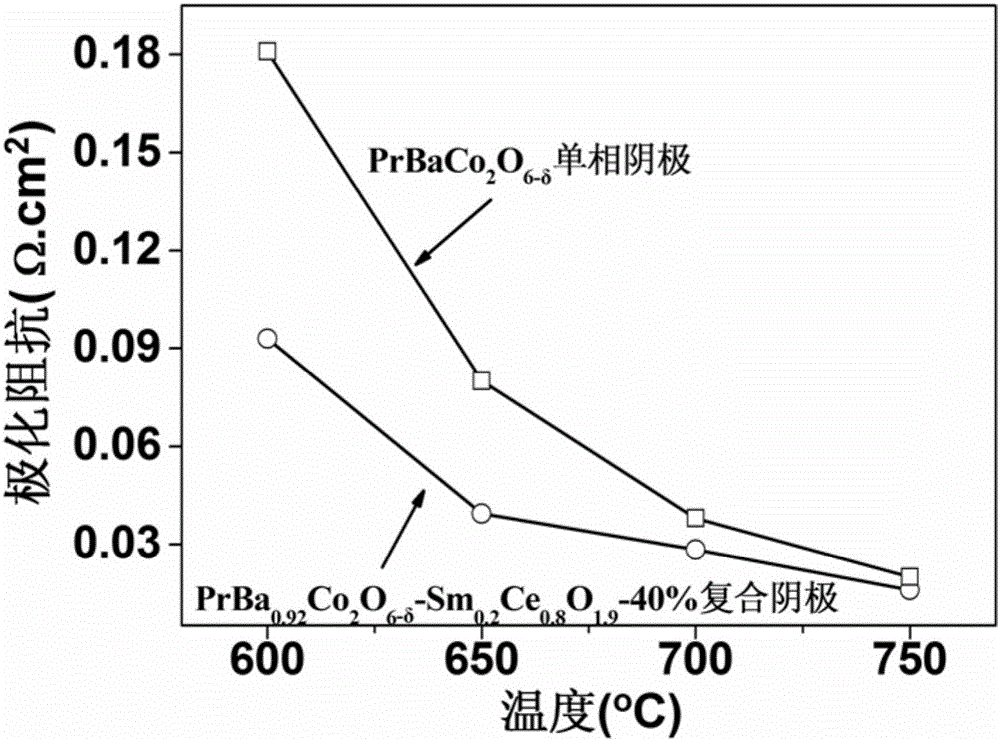

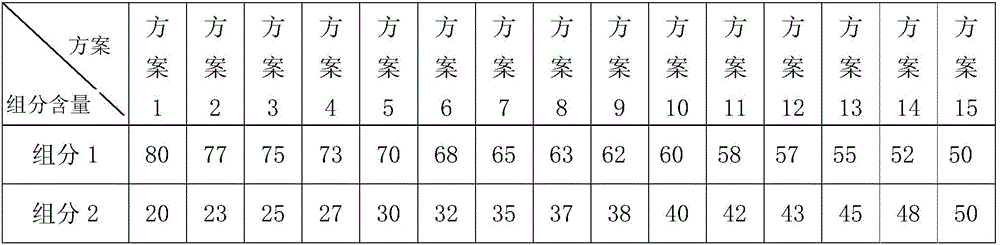

High-catalytic activity composite negative electrode material of intermediate-temperature solid oxide fuel cell and preparation method of composite negative electrode material

InactiveCN105870459ASimple preparation processEasy to operateCell electrodesElectrical conductorOxygen ions

The invention relates to a high-catalytic activity composite negative electrode material of an intermediate-temperature solid oxide fuel cell and a preparation method of the composite negative electrode material, and belongs to the technical field of an energy material. The composite negative electrode comprises a perovskite structured oxide PrBa<1-x>Co<2>O<6-Delta>, Pr<1-y>BaCo<2>O<6-Delta> or Pr<1-n>Ba<1-m>Co<2>O<6-Delta> in the absence of A-position cation and an oxygen ion conductor material Sm<0.2>Ce<0.8>O<1.9> or Gd<0.1>Ce<0.9>O<1.95>, wherein the mass percent of the oxygen ion conductor material accounts for 20-50%. The preparation method of the composite negative electrode material comprises the following steps of firstly, respectively preparing synthesis solutions of two constituents; secondly, mixing and uniformly stirring the two solutions to obtain a mixed synthesis solution of the two constituents, and heating the mixed synthesis solution to obtain mixed precursor gel; and finally, carrying out high-temperature sintering reaction to obtain composite negative electrode powder. The composite negative electrode material is prepared by a synchronous sintering reaction method, the preparation method has the advantages of simplicity in process, short preparation period, low cost and high efficiency, and is easy to operate, and the oxygen reduction catalytic activity of the negative electrode of the intermediate-temperature solid oxide fuel cell is effectively improved.

Owner:DALIAN UNIV OF TECH

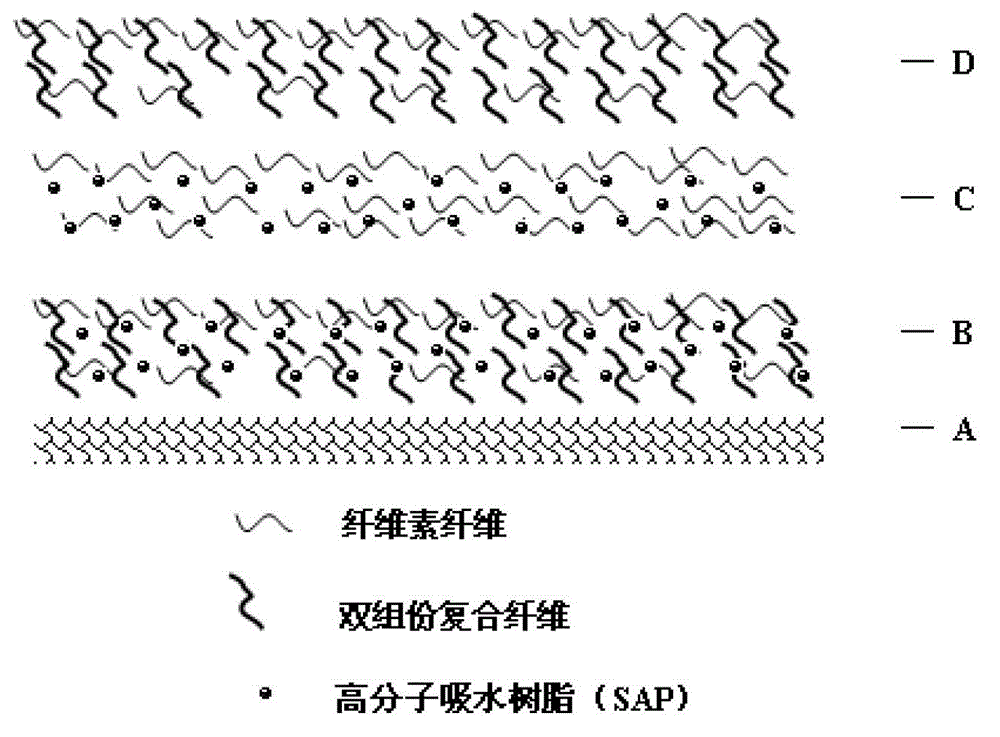

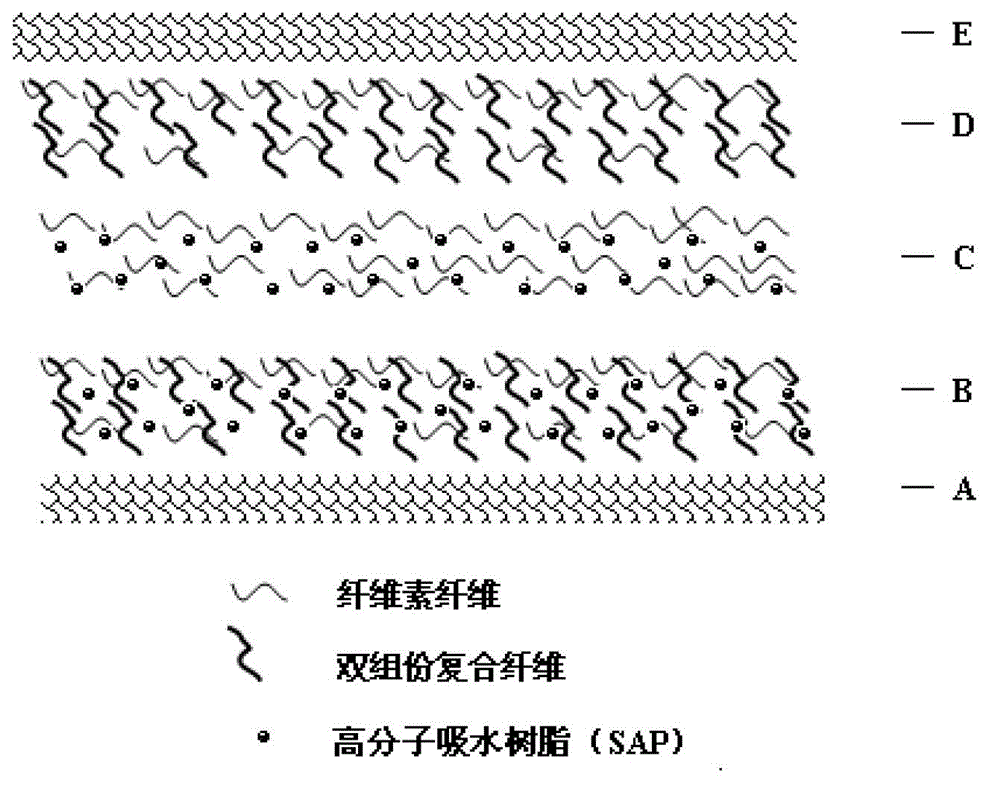

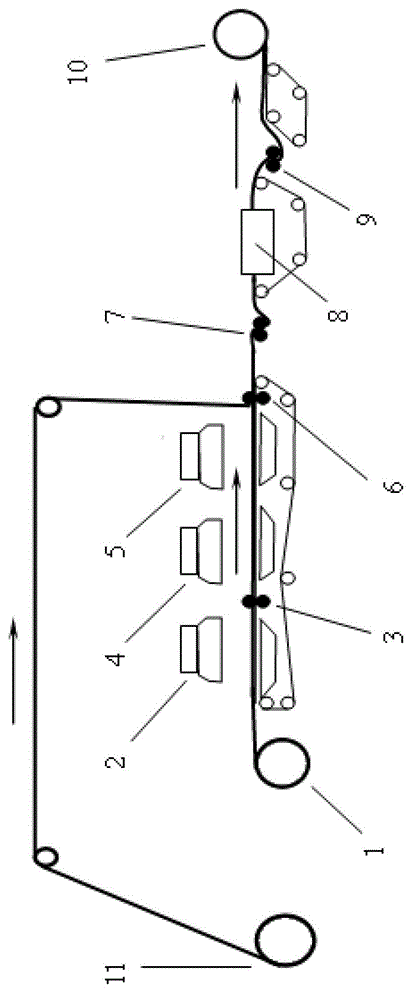

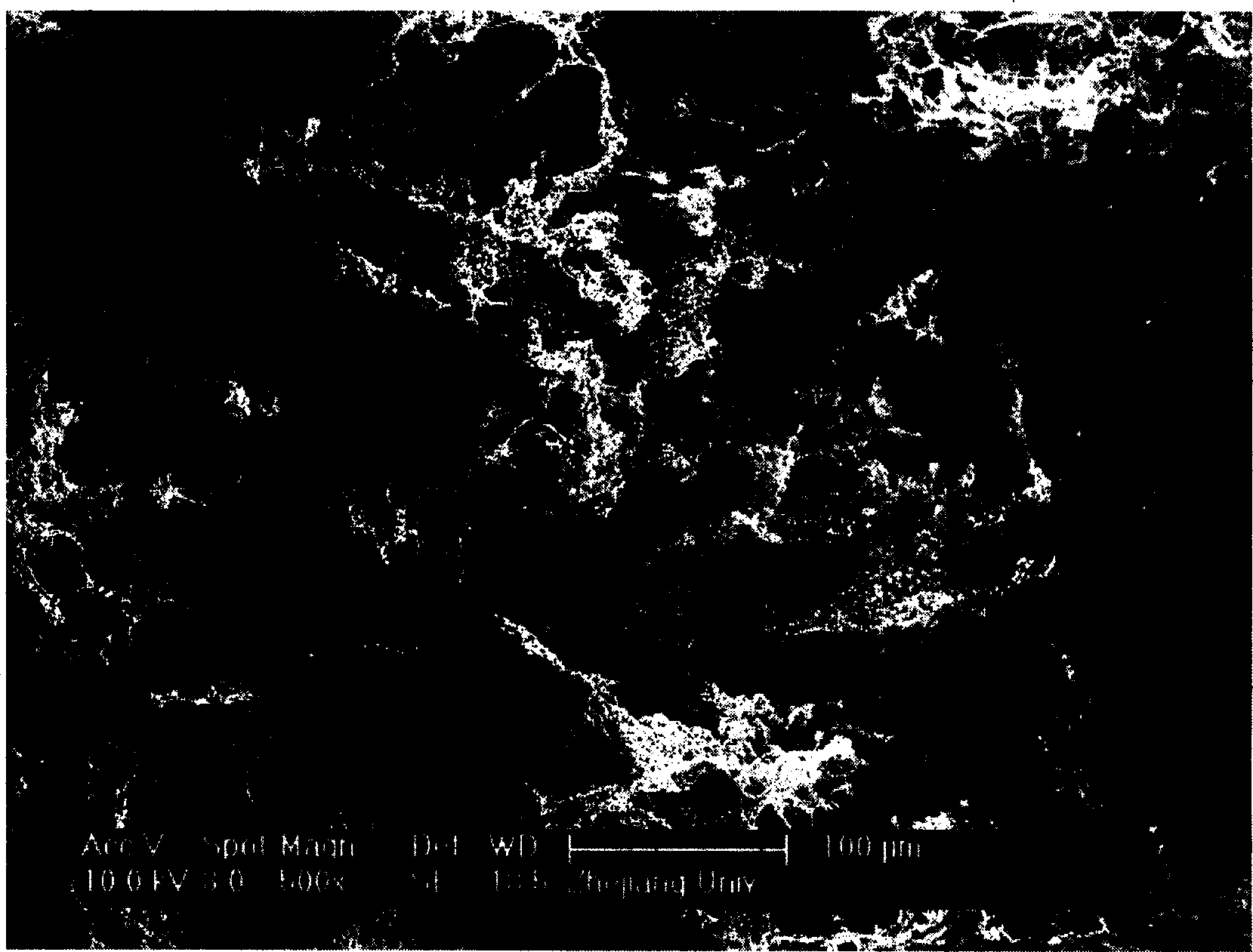

Multi-group press polish treating thin dust-free paper used for absorbing liquid, and manufacturing method and purposes thereof

ActiveCN103144368AHigh densityAbsorbentNon-fibrous pulp additionPersonal careFiberProcess engineering

Owner:FITESA CHINA AIRLAID

Medical beta phase tricalcium phosphate/collagen cmposite material and its preparing method

InactiveCN1647826AComponent distribution is evenGood biocompatibilityProsthesisBeta phaseRestorative material

The medical composite beta-tricalcium phosphate / collagen material consists of nano level beta-tricalcium phosphate in 50-67 wt% and collagen 33-50 wt%. Through in-situ complexing of collagen and beta-tricalcium phosphate, nanometer level beta-tricalcium phosphate powder is deposited on collagen substrate, and under the action of glutaraldehyde, the composite material has raised mechanical strength. The composite beta-tricalcium phosphate / collagen material of the present invention has homogeneous components, close combination, excellent biocompatibility, proper pore size and other features, and is suitable for use as the medical bone repairing material.

Owner:翁文剑 +7

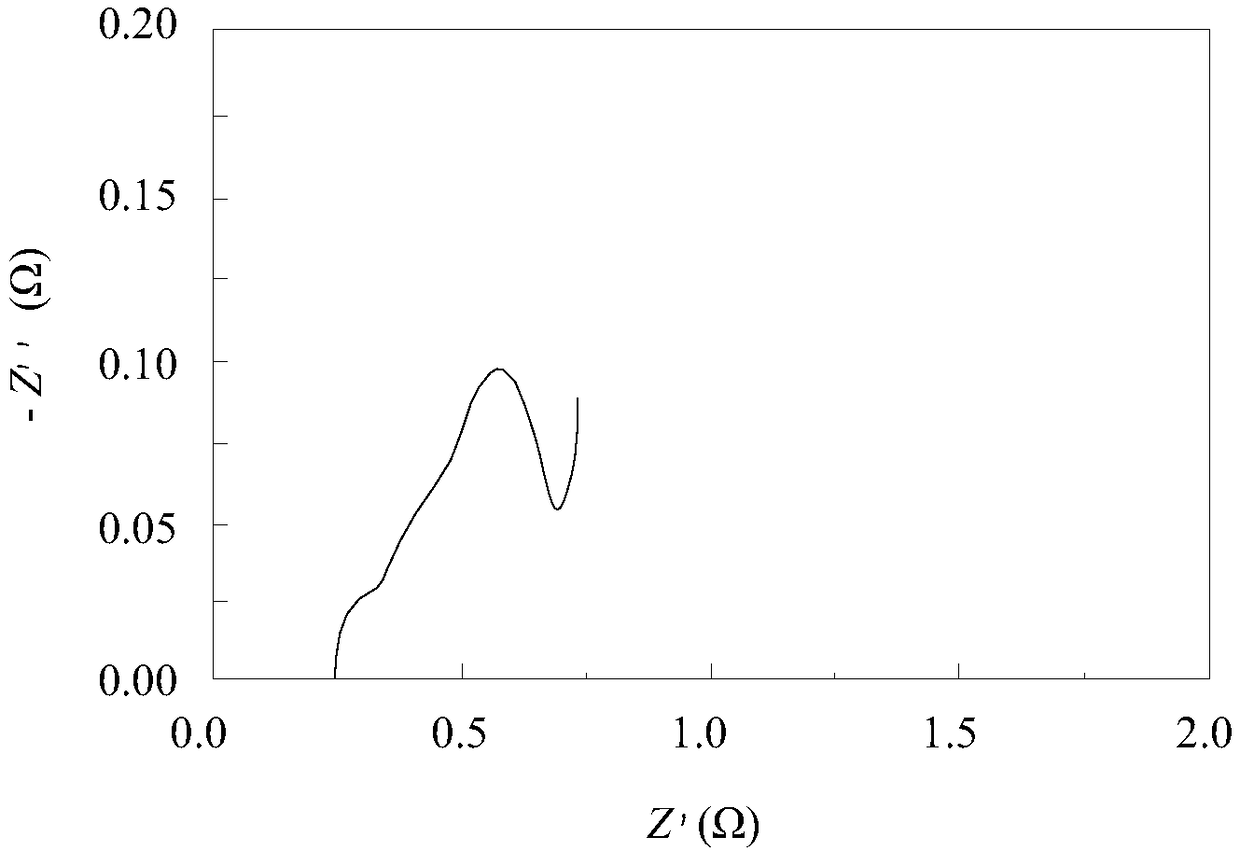

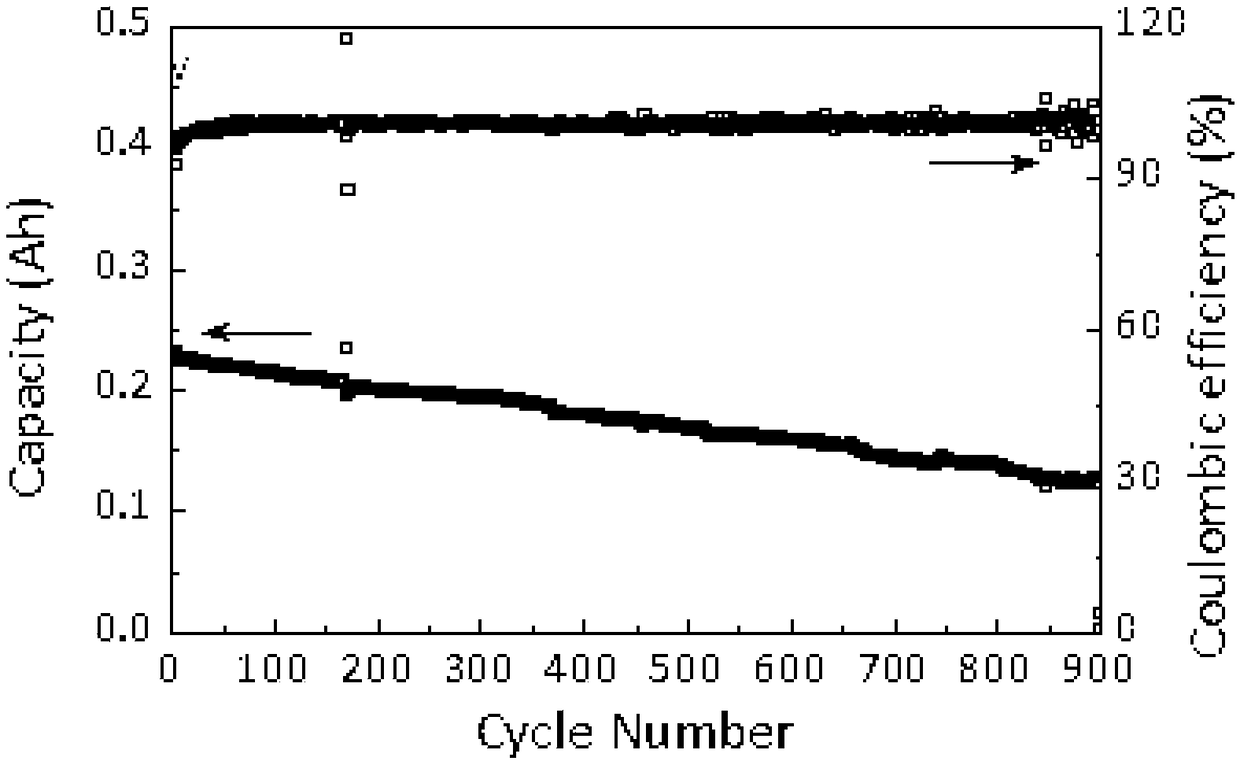

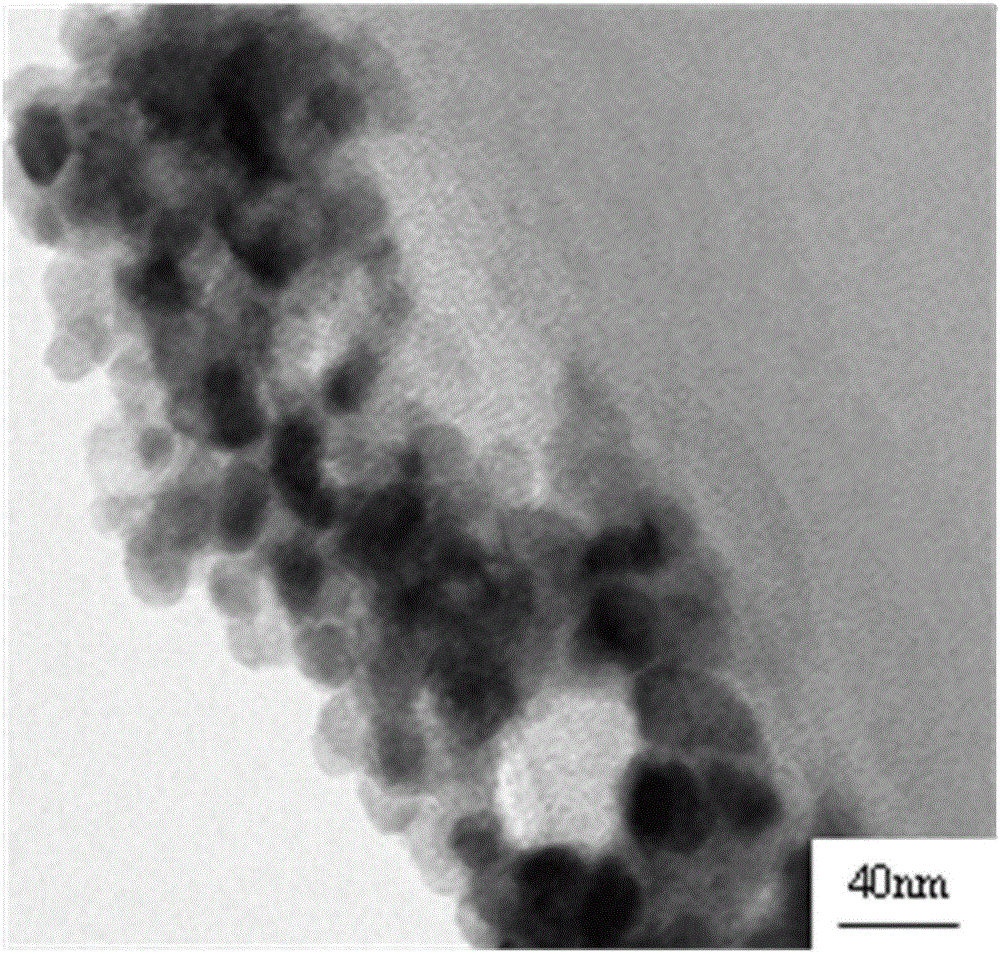

Preparation method and application of metal selenide porous frame/graphene composite fiber

InactiveCN108360090AFlexibleEnsure Structural IntegrityInorganic material artificial filamentsFiberMetal-organic framework

The invention discloses a preparation method of a metal selenide porous frame / graphene composite fiber. The metal selenide porous frame / graphene composite fiber is prepared from a fibrous compound asa precursor by calcining, and the fibrous compound is prepared from MOF (metal-organic framework) crystal powder and graphene oxide by compounding. The preparation method is simple to operate and mildin condition, the composite fiber is adjustable in morphology, controllable in structure and uniform in component distribution, structural integrity of graphene and a metal selenide porous frame obtained by taking MOF crystals as the template is retained, excellent performance of graphene and excellent performance of the metal selenide porous frame are combined, and the composite fiber can be produced in batches or industrially, has excellent performance as a lithium ion battery anode material and has good application prospect.

Owner:ZHEJIANG UNIV OF TECH

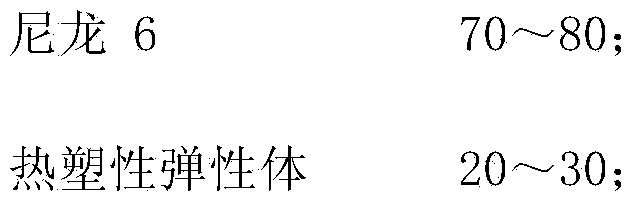

Toughened reinforced nylon 6 ternary composite material and preparation method thereof

The invention discloses a toughened and reinforced nylon 6 ternary composite material and a preparation method thereof, belongs to the field of polymer composite materials and relates to a nylon 6 ternary composite material applied to automotive trim and some parts. The toughened and reinforced nylon 6 ternary composite material comprises the following components in parts by weight: 70-80 parts of nylon 6, 20-30 parts of thermoplastic elastomer and 0.5-1.5 parts of carbon nano tube. The prepared nylon 6 ternary composite material has excellent gap impact property and thermal property, the defect of nylon 6 that gap impact property is low can be overcome; meanwhile, bending property and tensile property of the nylon 6 still can be maintained; application field of the nylon 6 is further expanded; meanwhile, experimental raw materials are simple and easily available, and the preparation method is practicable.

Owner:EAST CHINA UNIV OF SCI & TECH

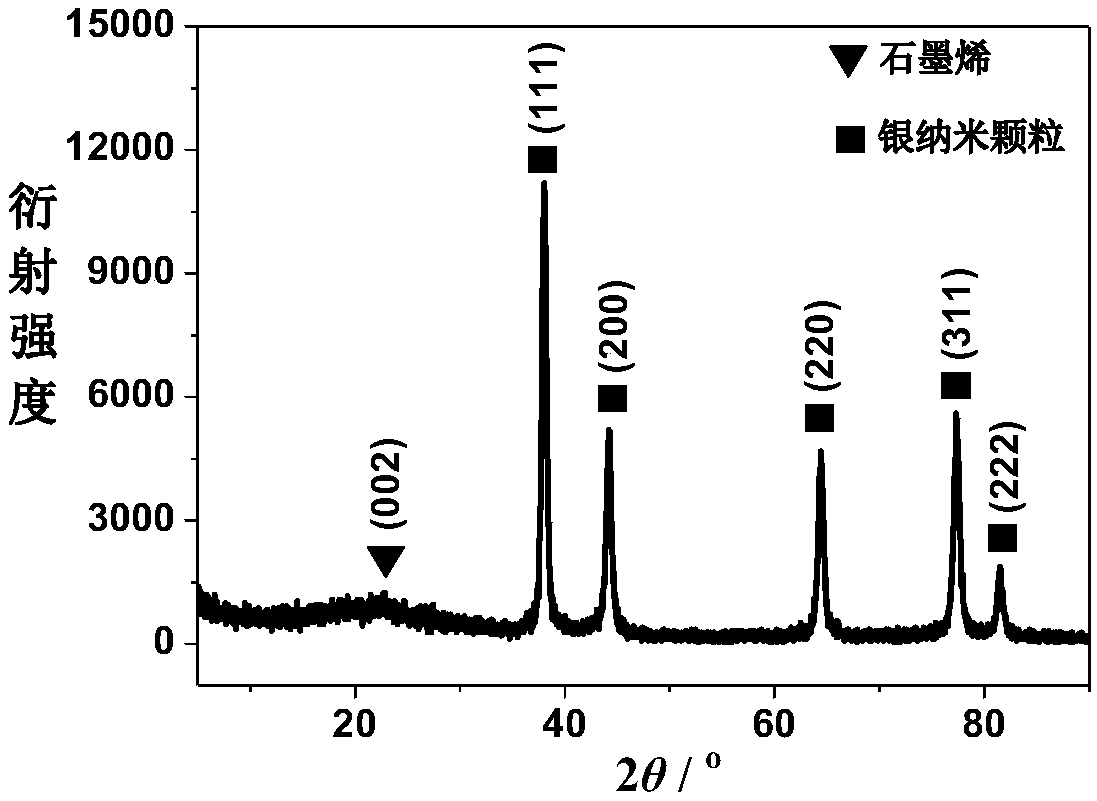

Composite thin film for flexible electrode and preparation method thereof

ActiveCN108962619AGood distribution continuityImprove conductivityHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceHigh current density

A flexible graphene-based conductive composite thin film is disclosed. The composite thin film is composed of cellulose fibers, graphene and silver nanoparticles; the surface layer structure is a continuous silver nanoparticle film formed by mutually stacking silver nanoparticles, and the interior is composed of cellulose, graphene and silver nanoparticles. The cellulose fibers are skeletons, andthe inner silver nanoparticles are wrapped by graphene. The cellulose fiber-graphene-silver nanoparticle composite thin film of the structure has excellent conductivity with the square resistance being only 0.17 [omega]sq<-1>, and has excellent electrochemical performance; the maximum area specific capacitance is up to 1242.7 mF cm<-2>, and the rate performance is good; there is almost no loss ofcapacitance (the capacitance retention rate can still reach 99.7%) after 6000 times of repeated charge and discharge under the high current density of 60 mA cm<-2>, showing excellent the stability ofrepeated charge and discharge; and the energy density is high and the specific capacitance area is large.

Owner:SHENZHEN KANGSHENG PHOTOELECTRIC TECH

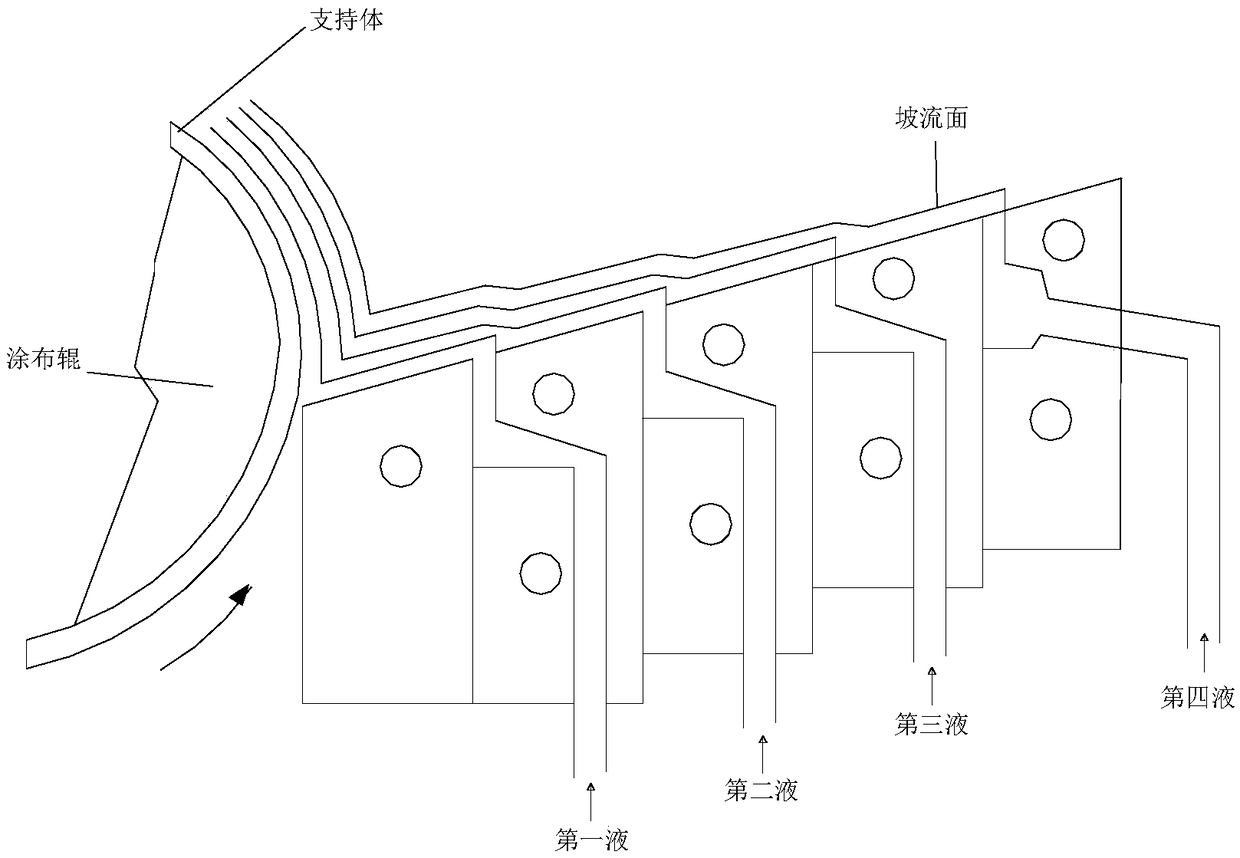

Preparation method for composite electrolyte membrane of solid-state battery

ActiveCN108767311AUniform thicknessPoor uniformity and thickness controlSecondary cellsElectrolyte immobilisation/gelificationComposite electrolytePhysical chemistry

The invention discloses a preparation method for a composite electrolyte membrane of a solid-state battery. By a multi-layer slope flowing coating process, multi-layer organic-inorganic composite electrolyte paste is synchronously coated on a surface of a carrier, and the composite electrolyte membrane of the multi-layer structure solid-state battery can be prepared. The multi-current coating process comprises the following steps of preparing paste of different constituents, allowing the organic-inorganic composite electrolyte paste to downwards flow along a slope flowing current after flowingout of a gap of a coating module according to an arrangement sequence, forming a liquid bridge in a gap between a coating roller and a slope flowing coating module, taking away by the running carrier, forming one or more layers of coating, performing, and stripping the carrier, thereby obtaining the composite electrolyte membrane of the solid-state battery.

Owner:ZHEJIANG FUNLITHIUM NEW ENERGY TECH CO LTD

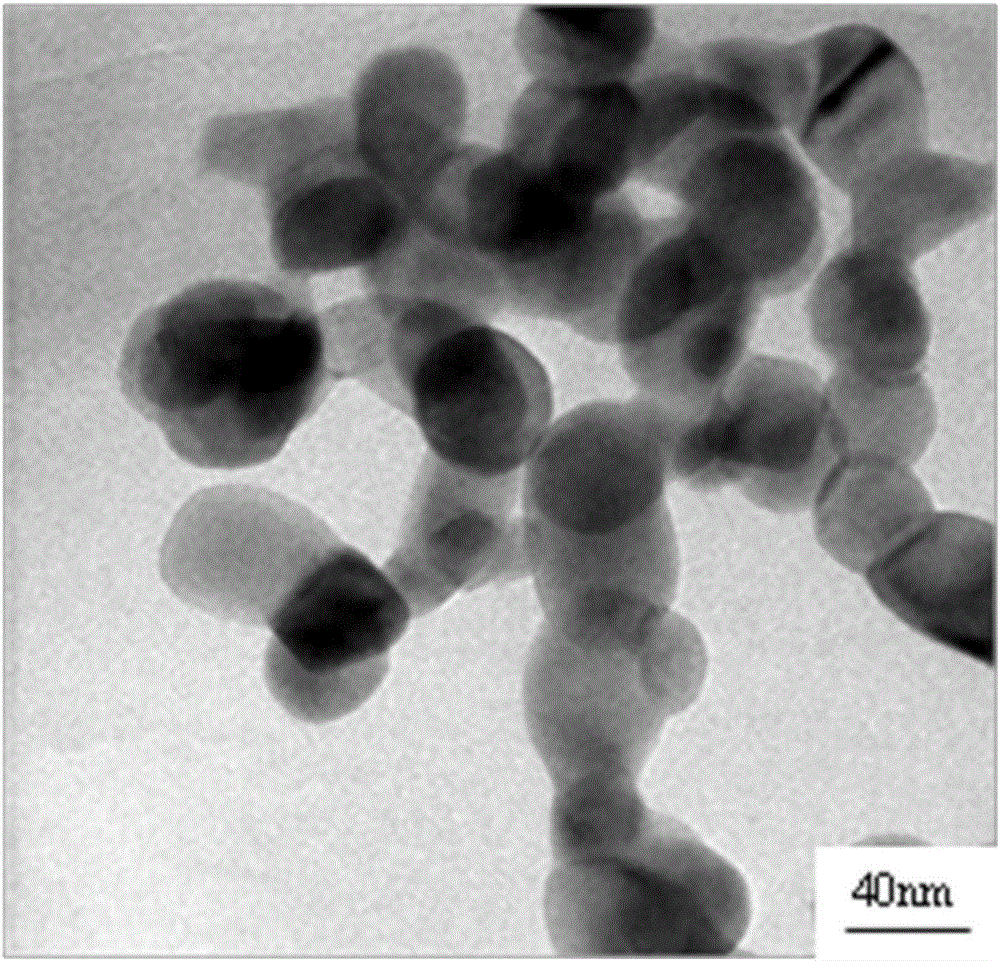

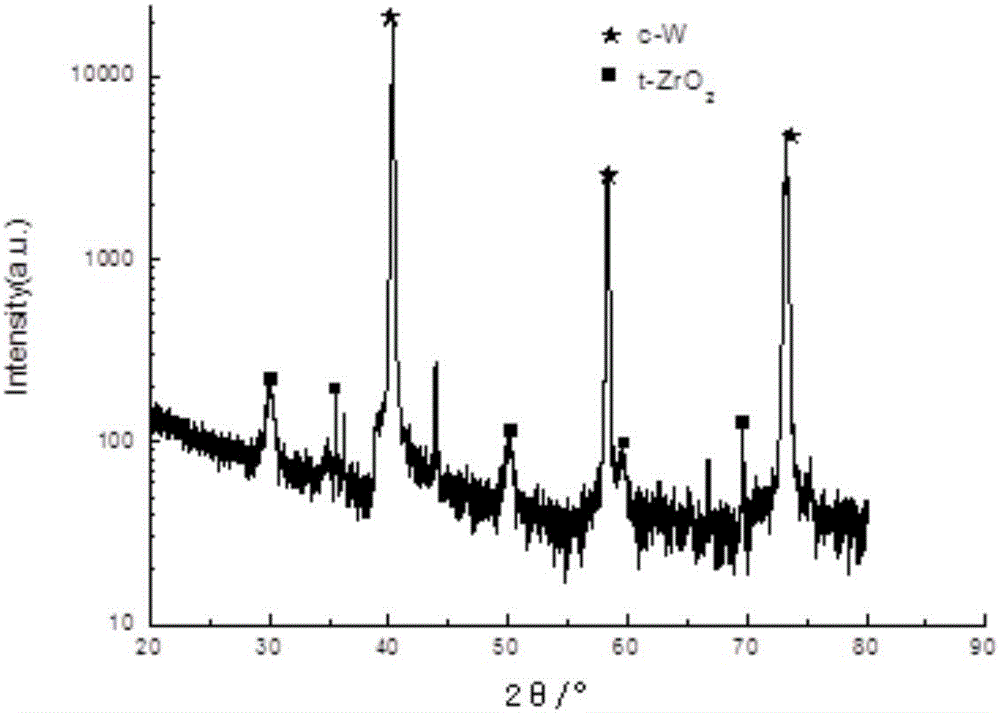

Tungsten-doped alloy powder and preparing method thereof

The invention relates to tungsten-doped alloy powder and a preparing method thereof and belongs to the field of tungsten-based alloy materials. The preparing method of the tungsten-doped alloy powder comprises the following steps: 1, preparing a suspension A and a suspension B, wherein the suspension A is prepared by carrying out hydrothermal reaction on ammonium paratungstate under the condition that the pH is 1-1.2 and carrying out washing and sedimentation, and the suspension B is prepared by separately adding ammonium hydroxide into a zirconium nitrate solution and a yttrium nitrate solution and carrying out mixing, hydrothermal reaction, washing and sedimentation; 2, uniformly mixing the suspension A and the suspension B which are obtained in the step 1, and then, filtering and drying sediments so as to obtain precursor powder; and 3, forging the precursor powder obtained in the step 2 and carrying out reduction at a hydrogen atmosphere so as to obtain the tungsten-doped alloy powder. The tungsten-doped alloy powder which is obtained by adopting the preparing method has the advantages that the granularity of all components is small, the sizes of particles are more uniform, and the distribution of the components is more uniform.

Owner:HENAN UNIV OF SCI & TECH

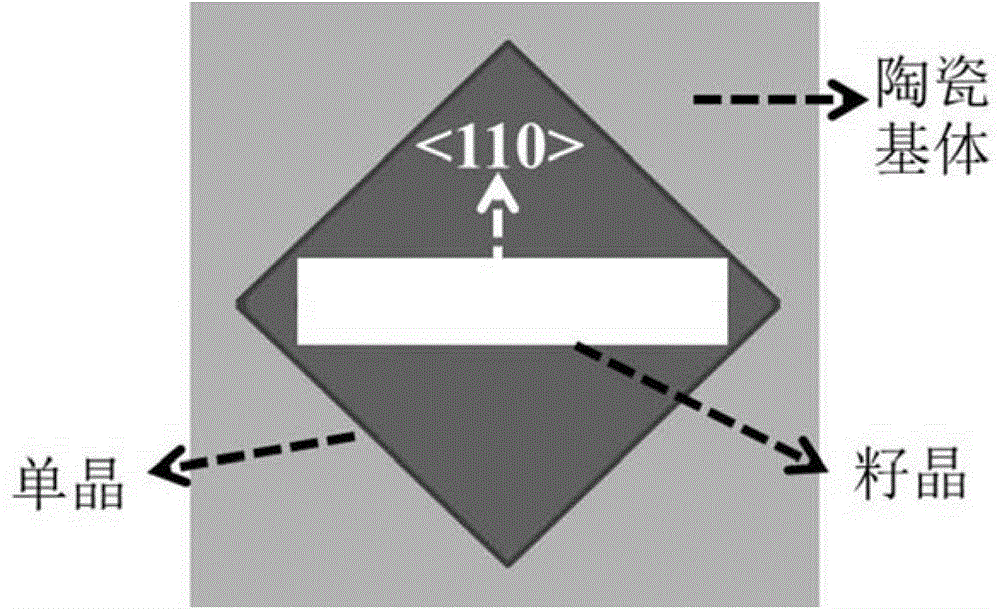

Potassium sodium niobate based single crystal and preparation method thereof

InactiveCN104357910ASimple growth processLow costPolycrystalline material growthFrom solid stateCeramic sinteringCombustion

The invention relates to a potassium sodium niobate based single crystal and a preparation method thereof. The potassium sodium niobate based single crystal has a chemical formula of (K0.45Na0.55)[1-x]Li[x]NbO3, wherein x is not less than 0 and not more than 0.1, and the size of the potassium sodium niobate based single crystal is more than 10 mm. In combination with single crystal preparation and ceramic sintering processes, a small amount of combustion-supporting agent is introduced and single crystal seeds are adopted for induction, so that a ceramic matrix is converted into single crystals at the temperature lower than the melting point of the ceramic matrix, and the potassium sodium niobate based lead-free piezoelectric single crystal with the size of more than 10 mm is successfully prepared.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Method for preparing fluorinated hydroxyapatite/ zirconium oxide (FHA/ZrO2) composite ceramic powder with good heat stability by hydrothermal synthesis

The invention provides a method for preparing fluorinated hydroxyapatite / zirconium oxide (FHA / ZrO2) composite ceramic powder with good heat stability by hydrothermal synthesis, relates to a preparation method of the composite ceramic powder, and aims at solving the problems that all components in the composite ceramic powder are not evenly dispersed and mixed, and composite ceramic powder is poor in heat stability. The method comprises the steps of: 1, preparing yttrium-stabilized hydrous zirconium oxide powder Y2O3-Zr(OH)4; 2, preparing FHA / ZrO2 composite precursor powder by hydrothermal synthesis; and 3, carrying out heat treatment on the FHA / ZrO2 composite ceramic powder to obtain the FHA / ZrO2 composite ceramic powder with the phase composition including FHA and yttrium-stabilized tetragonal phase ZrO2. The method is applied to the field of preparing the composite ceramic powder by hydrothermal synthesis.

Owner:HARBIN INST OF TECH

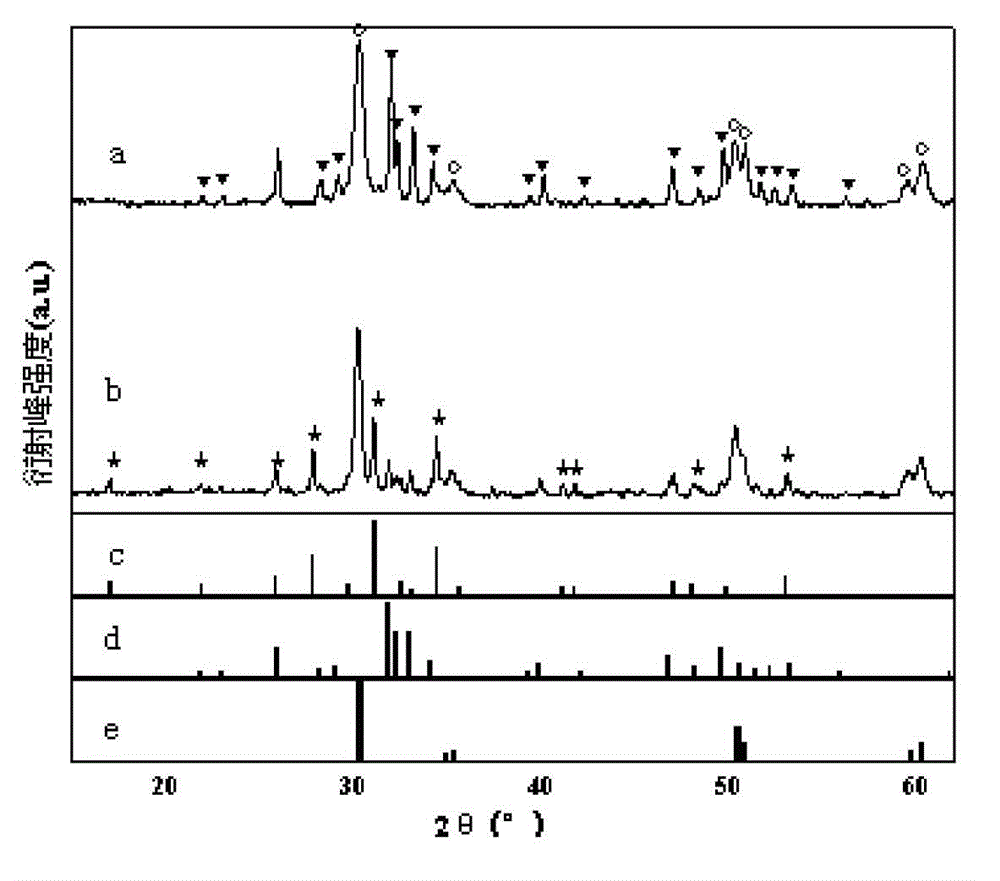

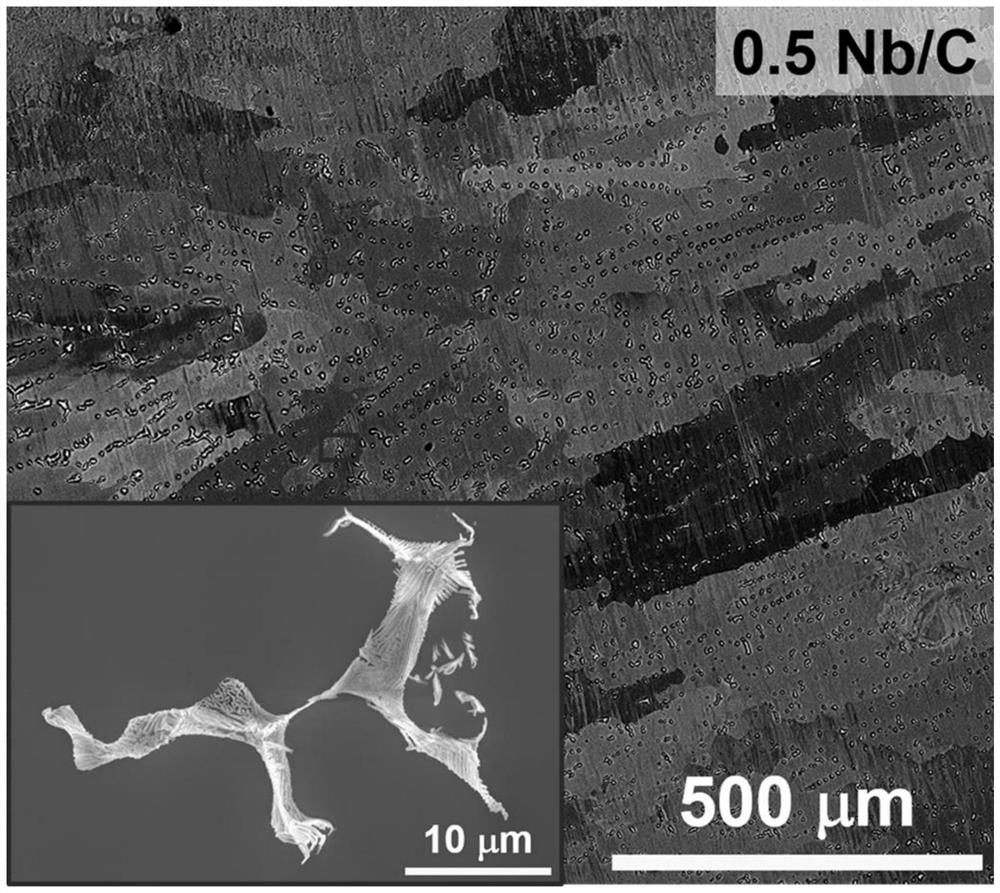

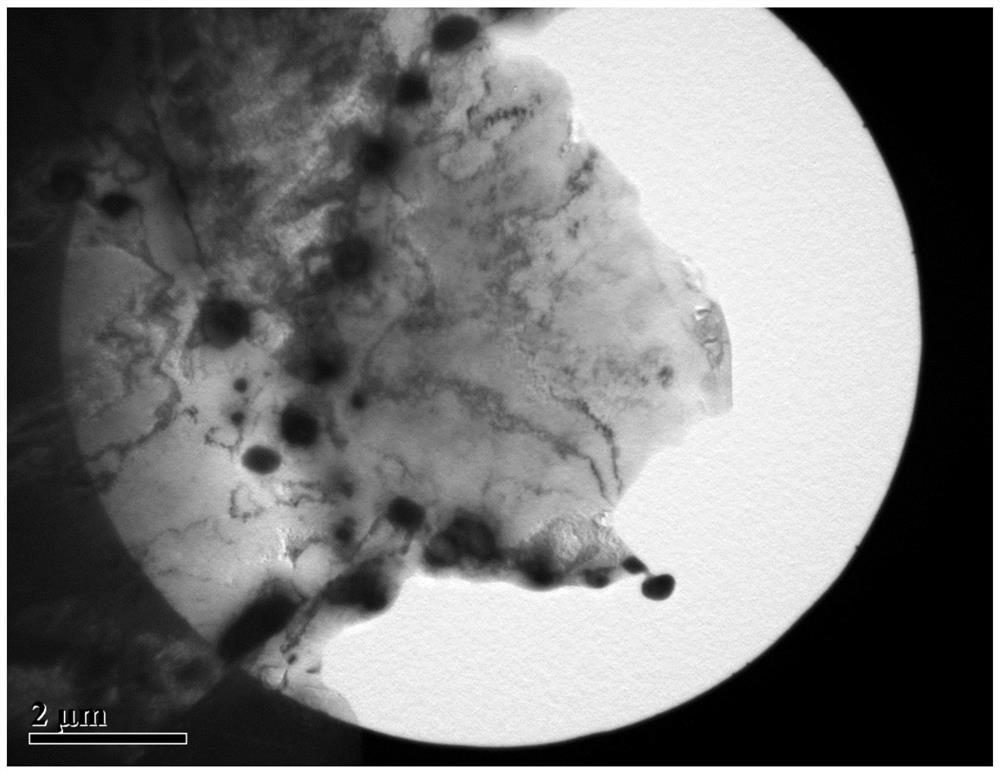

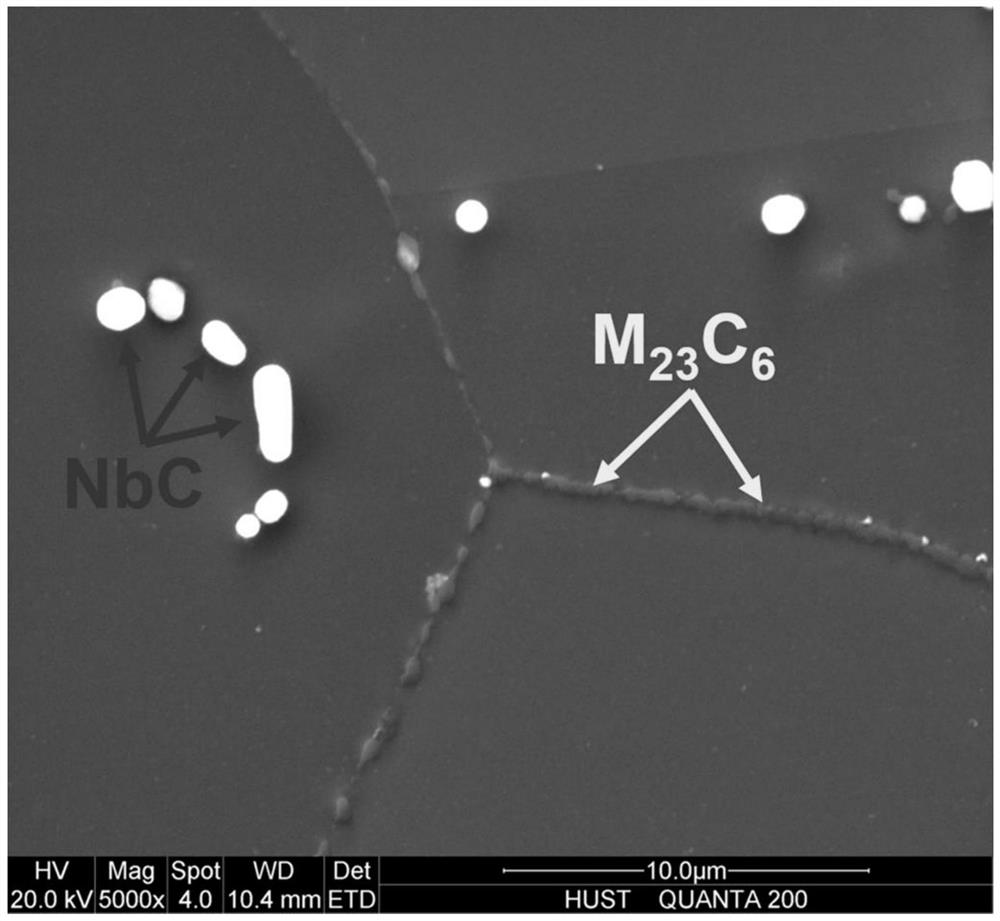

Precipitation strengthening type high-temperature high-entropy alloy for in-situ precipitation of carbide and preparation method thereof

ActiveCN111621660AGood high temperature mechanical propertiesImprove mechanical propertiesHeat stabilityCarbide

The invention discloses a precipitation strengthening type high-temperature high-entropy alloy for in-situ precipitation of carbide and a preparation method thereof, and belongs to the field of high-entropy alloy preparation. According to the method, a raw material composed of Cr, Fe, Co, Ni, Nb and Cr3C2 is fully smelted and mixed in an inert atmosphere and then subjected to solid solution agingtreatment, and the atomic percent and the atomic number of all the elements meet the requirements of 24.5% to 24.75% of Cr, 24.5% to 24.75% of Fe, 24.5% to 24.75% of Co, 24.5% to 24.75% of Ni, 0.5% to1% of Nb and 0.5% to 1% of C, wherein the atomic numbers of Cr, Fe, Co and Ni satisfy Cr = Fe = Co = Ni, and the atomic numbers of Nb and C satisfy Nb = C. According to the prepared alloy, a large number of spherical NbC carbide particles are dispersedly distributed in crystal grains, and a small number of M23C6 carbides are distributed on a crystal boundary. The crystal grains and carbide precipitated phases of the alloy have high thermal stability at high temperature, and have good effects on high-temperature structure stability and high-temperature mechanical properties of the alloy.

Owner:HUAZHONG UNIV OF SCI & TECH

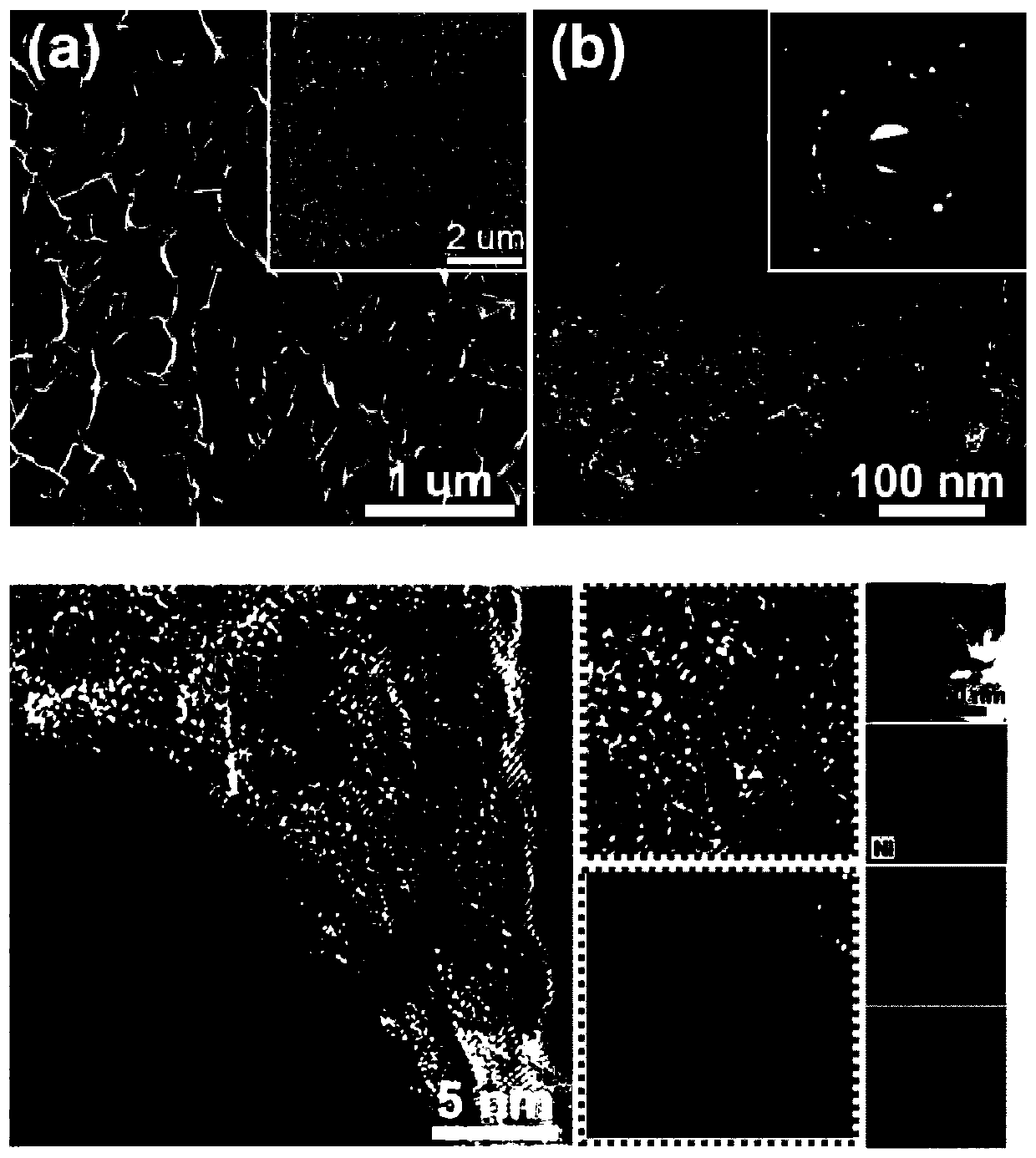

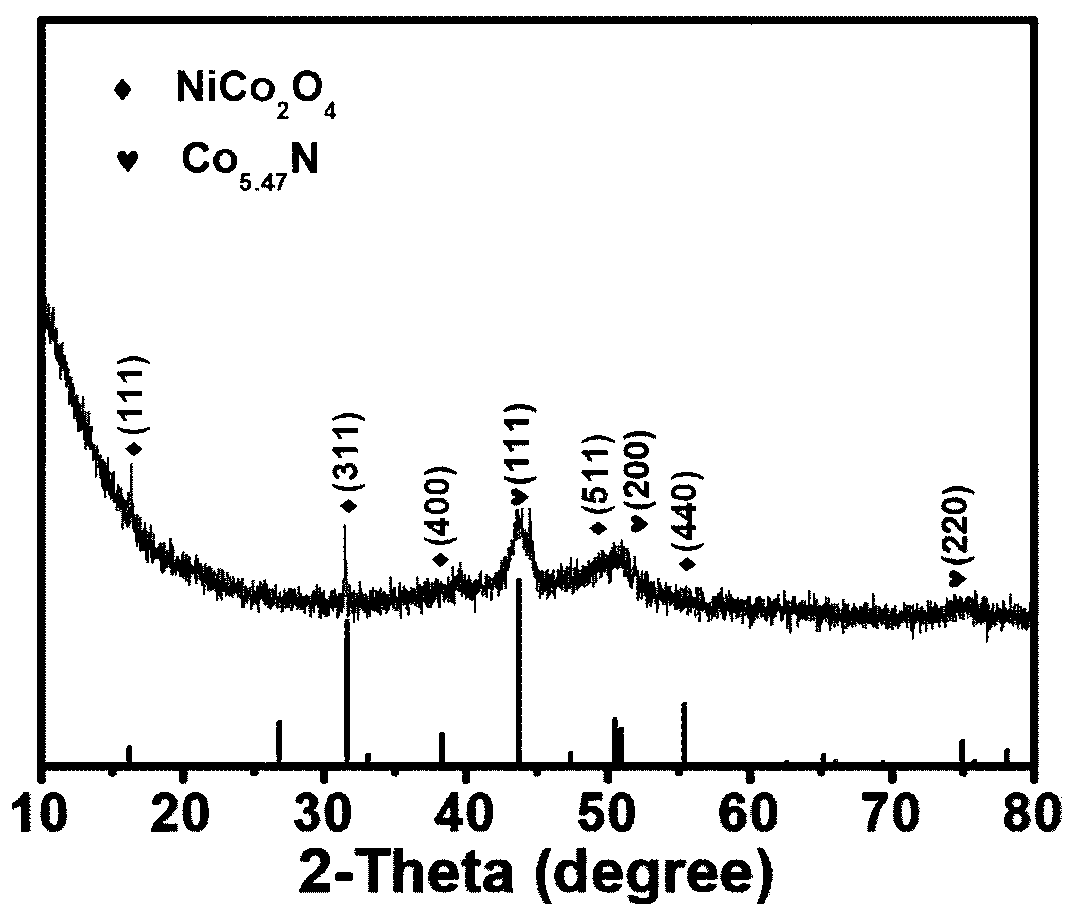

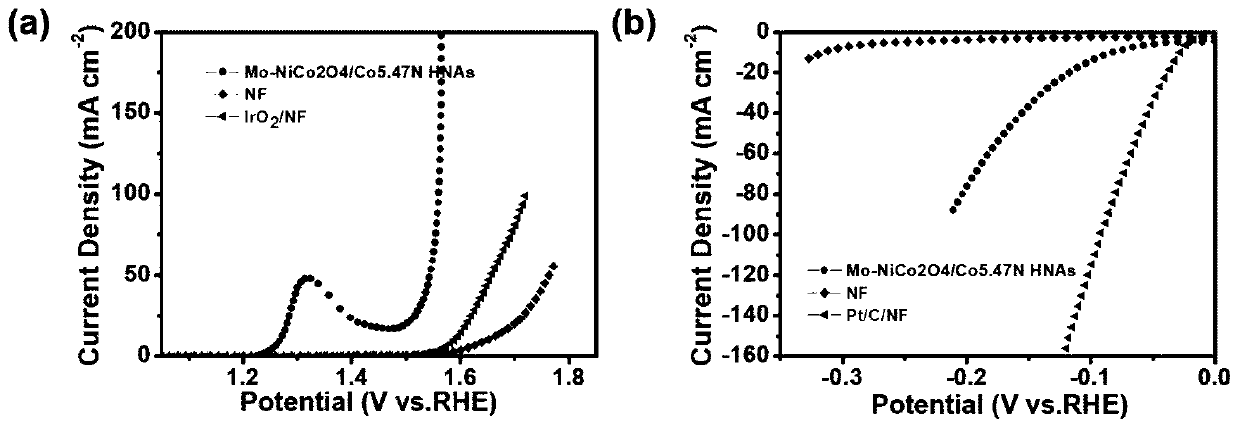

Preparation method of full water electrolysis catalyst with heterojunction structure

ActiveCN110787806AEasy to manufactureReduce demandMetal/metal-oxides/metal-hydroxide catalystsElectrodesPtru catalystElectrolysis

The invention relates to the technical field of nano-materials, in particular to a preparation method of a full water electrolysis catalyst with a heterojunction structure. The preparation method includes: 1) preparing a precursor solution, and putting a pretreated conductive substrate into the precursor solution for hydrothermal reaction to obtain a trimetal precursor; and 2) placing the trimetalprecursor in a reducing atmosphere, carrying out first-step heating to a first-stage temperature and then carrying out heat preservation for a period of time, then carrying out second-step heating toa second-stage temperature, and then conducting heat preservation for a period of time, thus obtaining the full water electrolysis catalyst with a heterojunction structure. The preparation method isconcise and efficient, low in equipment requirement, and convenient to popularize and realize industrial production; meanwhile, the catalyst has the double functions of hydrogen evolution and oxygen evolution, can be directly used as a self-supporting electrode, and has wide universality; and the prepared full water electrolysis catalyst with a heterojunction structure has stable microstructure, homogeneous nano-structure size and uniform component distribution, and has good electro-catalytic performance and mechanical performance.

Owner:ZHEJIANG UNIV OF TECH

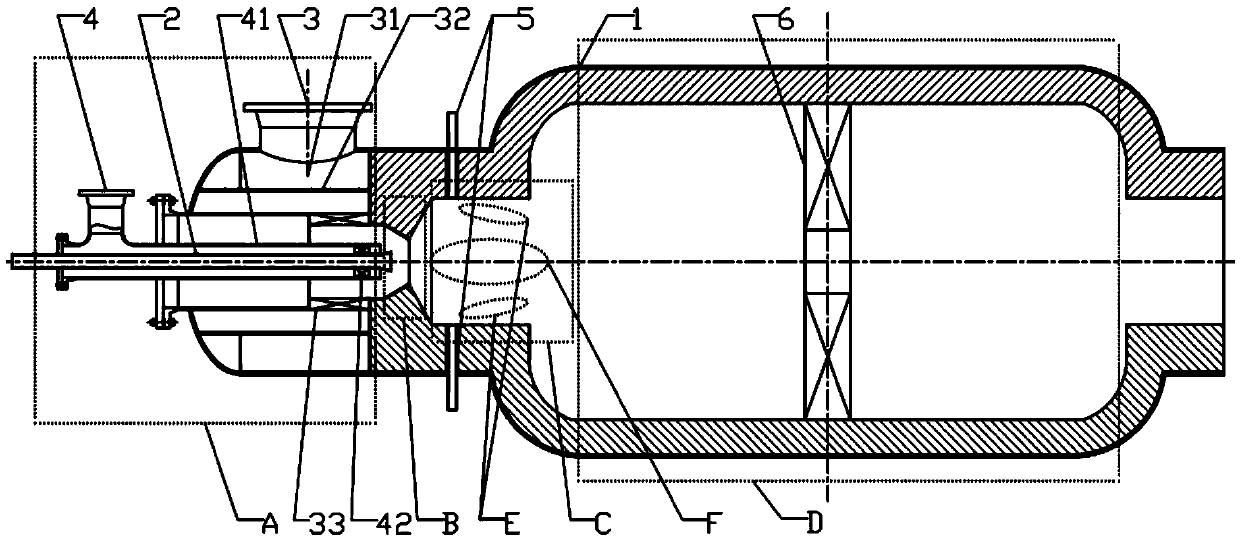

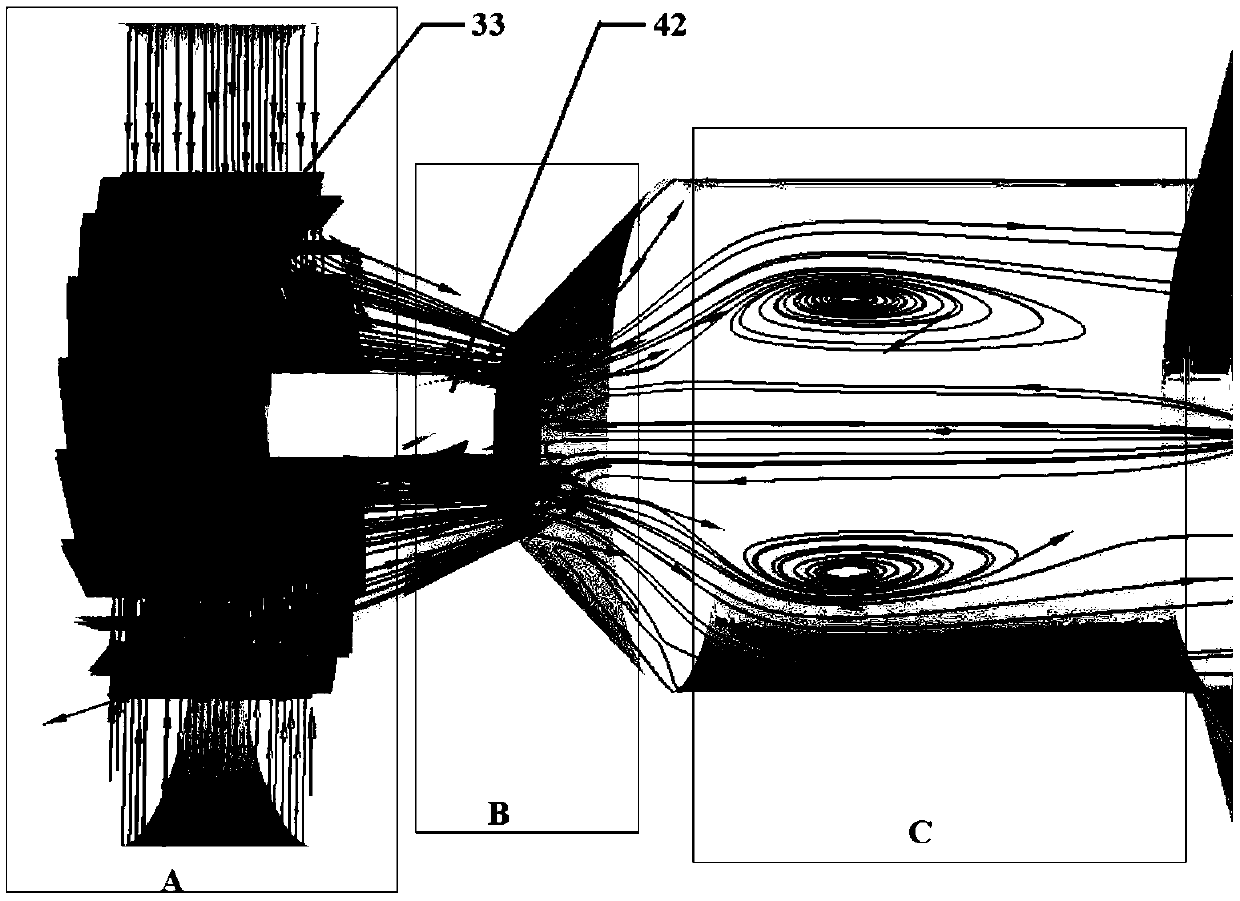

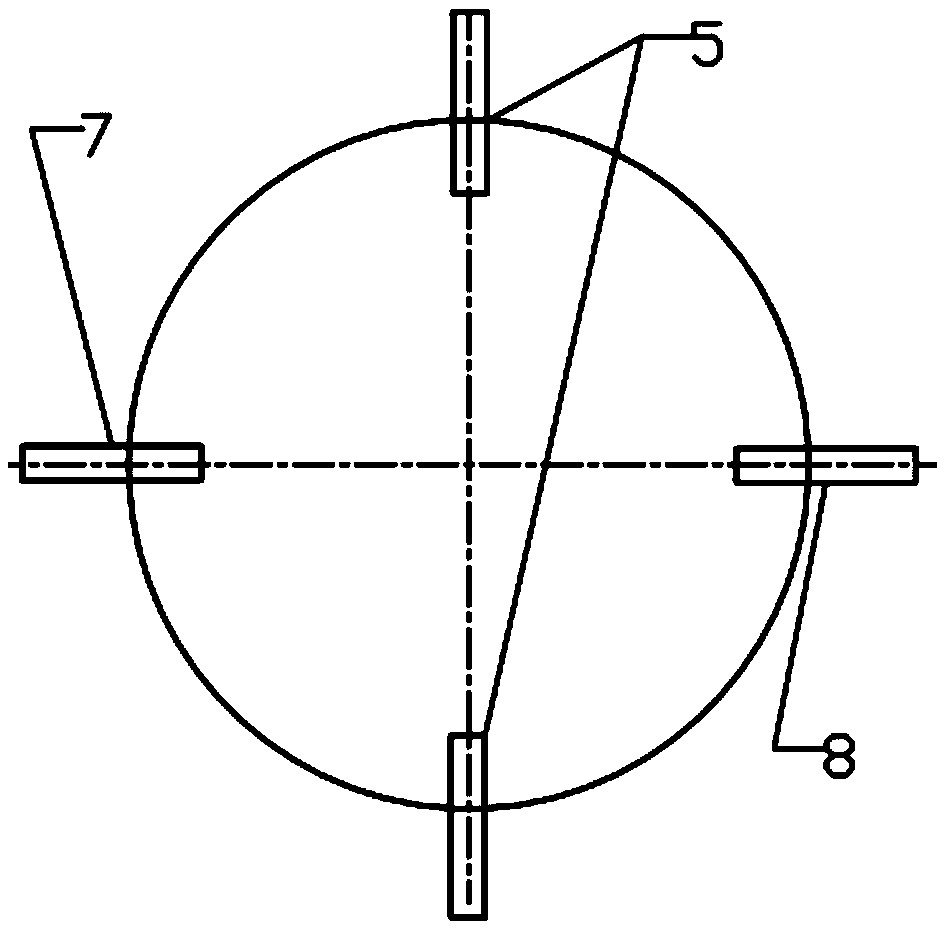

Industrial combustion furnace for treating exhaust gas and waste liquid and treatment method

ActiveCN105509071AReduce generationImprove combustion efficiencyIncinerator apparatusExhaust fumesProcess engineering

The invention discloses an industrial combustion furnace for treating exhaust gas and waste liquid and a treatment method. The combustion furnace comprises a furnace body, and the furnace body sequentially comprises a feeding area, a mixing area, a main combustion area and a rear combustion area; a center air gun, an air inlet pipeline and a waste pipeline are arranged in the feeding area; the air enters the mixing area from the center air gun and the air inlet pipeline and sequentially flows through an outer air cavity, an air deflector and a first swirling device; the exhaust gas and the waste liquid enter the mixing area from the waste pipeline and sequentially flow through a waste gun and a second swirling device; the waste gun is arranged on the outer side of the center air gun in a sleeving mode, and the waste gun and the center air gun are uniform in extension direction and are communicated with the mixing area. The method comprises the steps that a, the air enters the mixing area from the center air gun and the air inlet pipeline; b, fuel gas enters the main combustion area and is mixed with the air for combustion; c, the exhaust gas and the waste liquid enter the mixing area from the waste pipeline; d, the mixtures of the air, the exhaust gas and the waste liquid enter the main combustion area and are ignited; e, the exhaust gas and the waste liquid enter the rear combustion area after being ignited. According to the invention, the reaction area of the exhaust gas and the waste liquid and the reaction area of the oxygen are separated, the combustion time of the exhaust gas and the waste liquid and the combustion time of the oxygen are separated, the combustion efficiency is improved, and pollutant residues in tail gas are reduced.

Owner:KEYON PROCESS +1

Preparation method and application of metal sulfide porous framework/graphene composite fiber

InactiveCN108456936AFlexibleEnsure Structural IntegrityCell electrodesSecondary cellsFiberMetallic sulfide

The invention discloses a preparation method of metal sulfide porous framework / graphene composite fiber. The metal sulfide porous framework / graphene composite fiber is obtained through calcination with a fiber-like compound prepared by compounding MOF crystal powder and graphene oxide as a precursor. The preparation method is simple to operate, conditions are mild, the shape is adjustable, the structure is controllable, component distribution is uniform, the structural integrity of a metal sulfide porous framework obtained with graphene and MOF crystals as templates is kept, excellent properties of graphene and properties of the metal sulfide porous framework are integrated, the fiber can be produced in batches or industrially produced, and the fiber serves as a lithium ion battery negative electrode material, is excellent in performance and has a good application prospect.

Owner:ZHEJIANG UNIV OF TECH

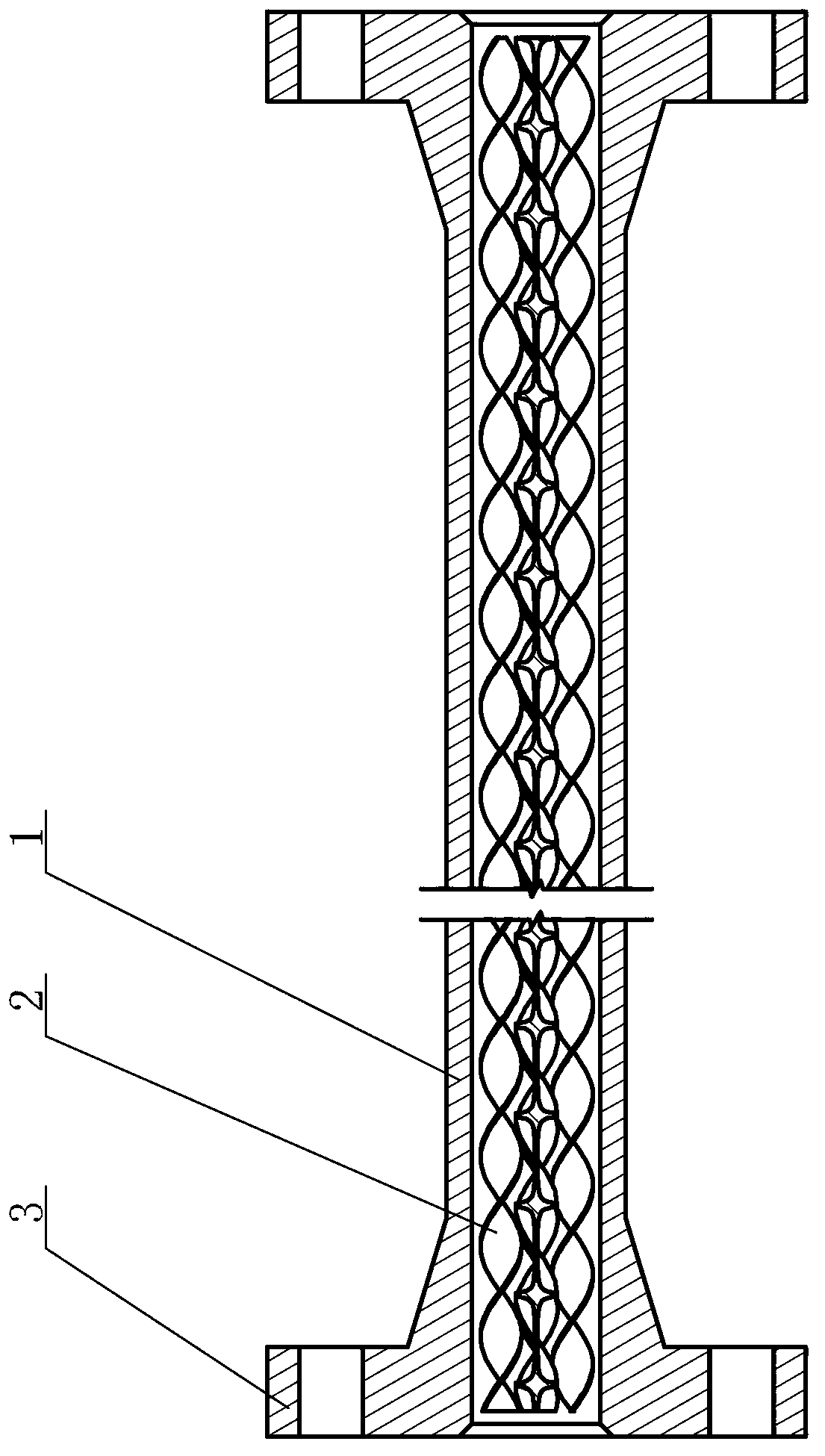

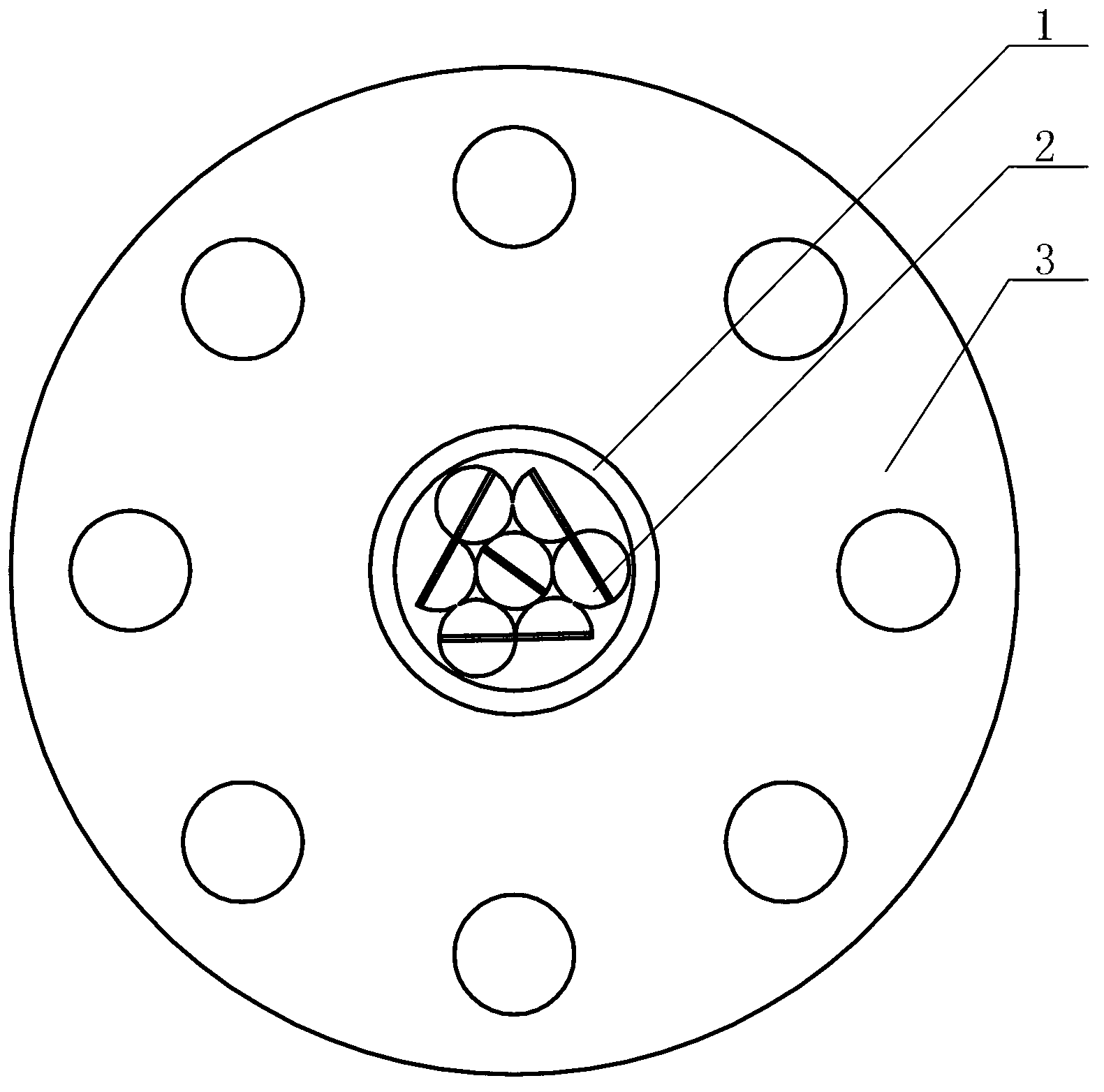

Spiral low-shear static mixer

InactiveCN103252182AAvoid mechanical shearComponent distribution is evenFlow mixersPulp and paper industryStatic mixer

The invention discloses a spiral low-shear static mixer, relates to a static mixer and in particular relates to a spiral low-shear static mixer. The invention aims to solve the problem that the conventional static mixer is high in viscosity loss and non-ideal in uniform mixing effect. The spiral low-shear static mixer comprises a tube shell and seven spiral mixing units, wherein the seven spiral mixing units are inserted into the tube shell; and the central line of each spiral mixing unit along the length direction is parallel to the central line of the tube shell along the length direction. The spiral low-shear static mixer is used for mixing polymer mother solution and water.

Owner:HARBIN BOHUA TECH

Nanometer copper catalyst for synthetizing hydrogen peroxide by direct method and preparation method thereof

InactiveCN1557544AComponent distribution is evenGood dispersionPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesMetal/metal-oxides/metal-hydroxide catalystsMetal particleCopper

The present invention belongs to the field of chemical technology, and is new type of nano metal copper catalyst for direct hydrogen peroxide preparing process with CO, O2 and water as material and its preparation process. The catalyst consists of copper 5-20 wt%, metal modifier 1-5 wt% and carrier material the rest, and the copper component is nano metal particle of 5-20 nm size highly dispersed in carrier. The catalyst is prepared through reducing chemically the carrier containing Cu ion and metal modifier and subsequent impurity elimination. The catalyst is used for direct hydrogen peroxide preparing process with CO, O2 and water as material, and has raised hydrogen peroxide yield and excellent industrial application foreground compared with noble metal Pd catalyst.

Owner:FUDAN UNIV

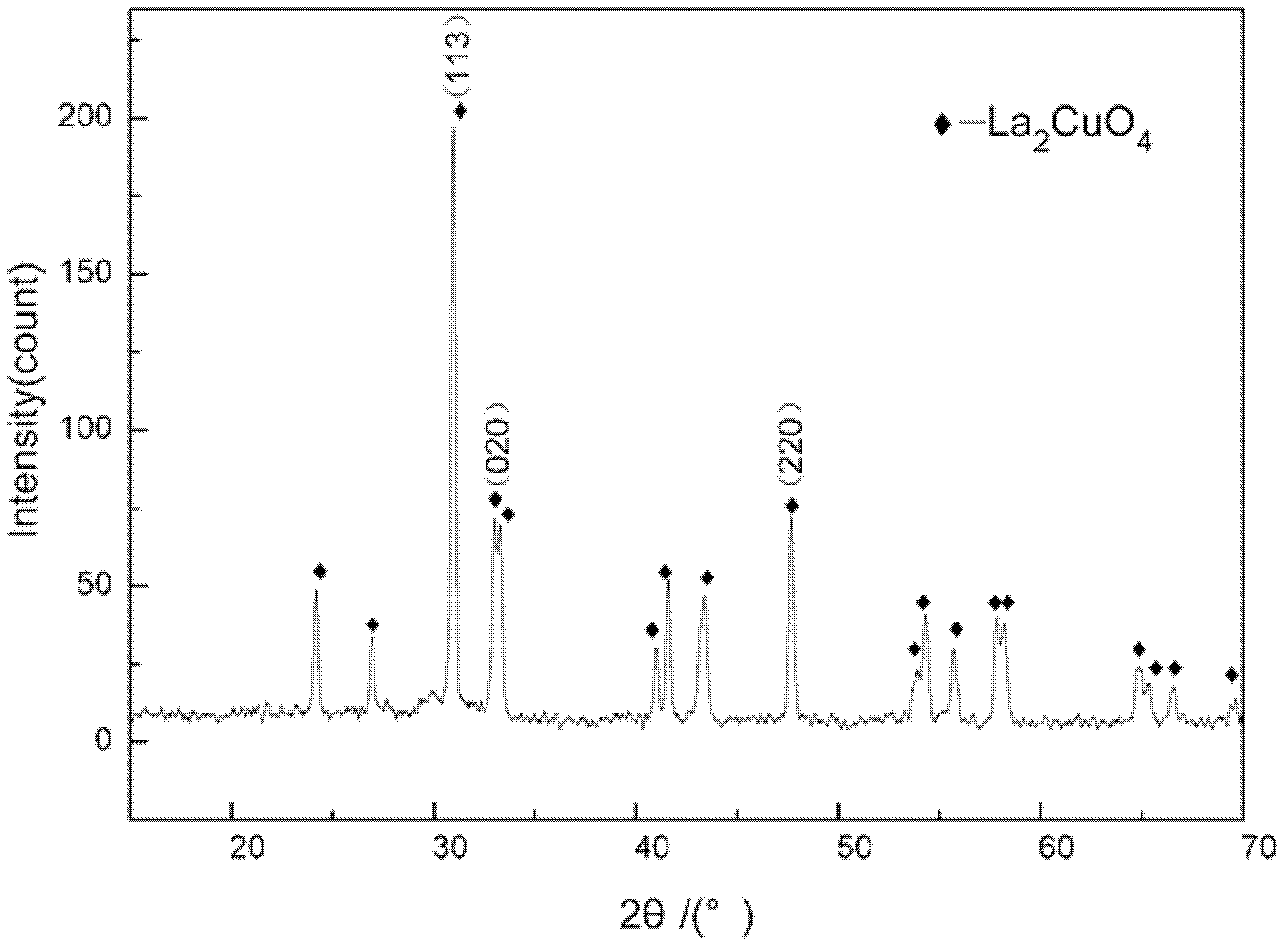

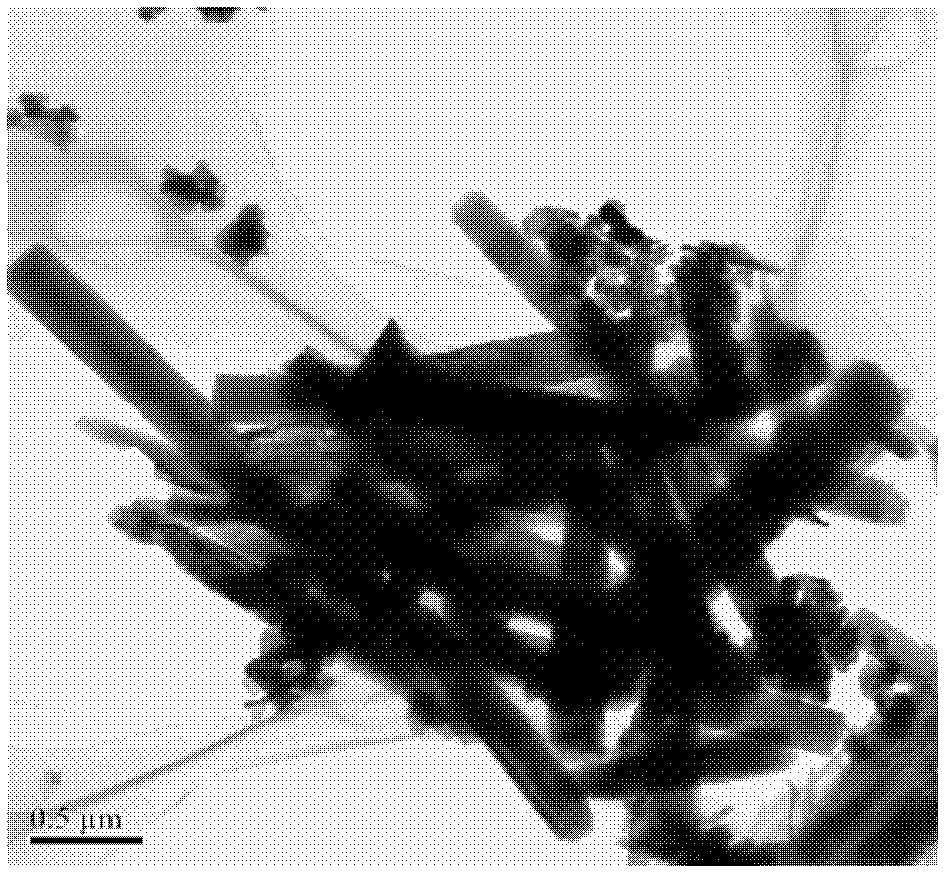

Method for preparing special-shaped lanthanum cuprate (La2CuO4) powder bodies by sol-gel method

ActiveCN102502768AFine particleShape is easy to controlCopper compoundsMetal/metal-oxides/metal-hydroxide catalystsReaction temperatureCopper nitrate

The invention relates to a method for preparing special-shaped lanthanum cuprate (La2CuO4) powder bodies by a sol-gel method. The method comprises the steps of: dissolving lanthanum nitrate and copper nitrate by de-ionized water to obtain a solution A; sequentially adding glycine and dispersants into the solution A, and adjusting the pH to be 1.5 to 4.5 with urea to obtain a solution B; standing, aging and drying the solution B to obtain dry gel; and grinding the dry gel into powders by a mortar, placing into a muffle furnace for calcining and grinding into powder to obtain the special-shaped La2CuO4 powder bodies. According to the method, the special-shaped La2CuO4 powder bodies are prepared by using the sol-gel method; EDTA (Ethylene Diamine Tetraacetic Acid), stearic acid and oxalic acid are used as dispersants respectively, so that the needle-like, rod-like and spindle-like La2CuO4 powder bodies can be obtained; the prepared La2CuO4 has the advantages of good crystallization, complete shape, good repeatability and low reaction temperature, so that the energy consumption is greatly reduced, the cost is saved; and the method is simple to operate and is suitable for large scale production.

Owner:山东格新精工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com