Patents

Literature

105results about How to "Good high temperature mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of high temperature and high pressure resistant rubber sealing material

InactiveCN101824172AImprove mechanical propertiesImprove heat resistanceSealing/packingPolymer scienceVulcanization

The invention belongs to the technical field of rubber sealing material, and relates to a preparation method of a high temperature and high pressure resistant rubber sealing material which can be applied to an oilfield deep oil production engineering process; first, 100 parts of hydrogenated nitrile rubber is weighed by parts in weight, put into a mixing mill to be plasticated; and then 2 to 20 parts of metal oxide, 1 to 5 parts of stearic acid, 5 to 100 parts of acrylate, 10 to 70 parts of carbon black, 1 to 6 parts of aging inhibitor, 5 to 30 parts of plasticizer, 2 to 10 parts of antiscorcher, 2 to 10 parts of vulcanizer and 2 to 10 parts of vulcanization aid are sequentially added into the mixing mill to be mixed uniformly; mixing rubber is vulcanized primarily in a plate vulcanizing press, the vulcanizing temperature is controlled to be 150 to 180DEG C, the vulcanizing time is 20 to 40min, and the vulcanizing pressure is 10 to 20MPa; after being taken out from the plate vulcanizing press, the rubber is secondarily vulcanized at 150 to 180DEG C to obtain vulcanized rubber with excellent performance; and the preparation method of the high temperature and high pressure resistant rubber sealing material has the advantages of simple process, convenient operation and use, low preparation cost, excellent mechanical performance, and in particular better high-temperature mechanical performance.

Owner:QINGDAO UNIV OF SCI & TECH +1

Preparation method of aluminum oxide metal ceramic reinforced iron-based composite

The invention relates to a preparation method of aluminum oxide metal ceramic reinforced iron-based composite, namely, aluminum-oxide-based metal ceramic is used as a structural framework and one of effective components to prepare metal ceramic iron-based composite, which is consistent in structure, even in metal phase distribution, high in mechanical performance, and high in wear resistance, under certain pressure by melt casting and further processing. The preparation method includes the steps of firstly, preparing aluminum oxide metal ceramic framework base pretreated by activated Si into surface-modified prefabricated ceramic part with a silk-screen-shaped pore structure by high-temperature sintering; secondly, preparing a pouring sand module; thirdly, placing the pouring sand module into a casting sand box for pretreating, pouring, vacuumizing, and allowing iron-based molten metal to fully permeate into pores of the prefabricated ceramic part to form a rigid integrity; and fourthly, performing heat treatment and air cooling to obtain the iron-based composite with closely combined aluminum oxide metal ceramic and iron base.

Owner:北京康盛宏达科技有限公司

Method for achieving forming of GH4738 nickel-base superalloy turbine discs

InactiveCN103341586AGood grain structureGood high temperature mechanical propertiesEngine componentsPetrochemicalAerospace

The invention discloses a method for achieving forming of GH4738 nickel-base superalloy turbine discs, and relates to a method for preparing the GH4738 nickel-base superalloy turbine discs. The method aims at solving the problems that an existing technology for preparing the GH4738 nickel-base superalloy turbine discs is complex and low in efficiency, and cannot achieve the purposes that the turbine discs are good in quality, even in grain distribution and free of surface crack. The method for achieving forming of the GH4738 nickel-base superalloy turbine discs comprises the following steps: adopting a compound insulation method with a sheath and insulation cotton, carrying out double-firing-number heating, upsetting and die forging, and carrying out solidifying solution and double aging processing at the subsolid solution temperature. By means of the method, the GH4738 nickel-base superalloy turbine discs with different diameter dimensions and disc thicknesses can be prepared. The method can be applied to preparation of nickel-base superalloy turbine discs in the field of petrochemical engineering and aerospace, and preparation of other disc forge pieces used under the high temperature condition.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Polymer electrolyte hard packaging lithium ionic cell

InactiveCN101340009ANon-flammableAvoid damageSecondary cellsCell component detailsPolymer electrolytesLiquid metal

The invention relates to a polymer electrolyte rigid package lithium ion battery which adopts a polymer electrolyte and an ultrathin metal casing, the polymer electrolyte bonds a positive electrode and a negative electrode with a membrane, thus leading a battery core to have self-strength and self-rigidity; the thickness of the battery is no longer maintained by relying on the rigidity and hardness of the metal casing, but relying primarily on self-strength and self-rigidity of the battery and secondarily relying on the rigidity and hardness of the metal casing, the two mechanisms jointly act to control the battery thickness, and the purpose of improving the battery capacity is realized by filling a plurality of active materials. The polymer electrolyte improves safety of the battery, overcomes various defects of a polymer electrolyte soft package battery and improves reliability of the battery. Compared with the existing lithium battery with a liquid metal casing, the polymer electrolyte rigid package lithium ion battery produced by adopting the method can improve the capacity by 10-30%; compared with a polymer electrolyte soft package battery, the polymer electrolyte rigid package lithium ion battery produced by adopting the method can improve the capacity by 8-20%, and the bulge and leakage rate of the battery can be less than 0.1ppm.

Owner:黄穗阳

Dampproof hydrogen sulfide stress corrosion steel and preparing method thereof

A steel for anti humid hydrogen sulfide stress corrosion and its preparation method, is characterized in the chemical ingredient (weight%) :0.04-0.08 C, 0.20-0.50 Si, 0.30-0.60 Mn, 2.00-2.30 Cr, 0.40- 0.70Al, 0.30-0.45Mo; P<=0.020, S<=0.010, Cu<=0.15, Ni<=0.20, Ti<=0.020, Sn<=0.020, As<=0.020, Pb<=0.0025, Bi<=0.010, Sb<=0.004; (N)<=0.030, (O)<=0.0025, (H)<=0.00015; surplus Fe. Adopting electric furnace primary smelt, vacuum refining in ladle oven, die-casting, heat working rolling cogging, processing with 940 DEG C normalizing and 700 DEG C tempering, finished steel product of anti humid hydrogen sulfide stress corrosion is obtained, whose metallographic structure is ferrite as well as micropearlite, actural grain size is finer than grade 6, and welding performance is good, mechanical performance is good. The inventive finished steel product has characters of high purity, matching with rigidity of crude oil smelt apparatus shell steel sheet, has good SSCC resistance,SCC resistance of chloride ion, and satisfy the need of steel for high sulfur crude oil apparatus.

Owner:SHANGHAI IRON & STEEL CO LTD NO 5 BAOSHAN IRON & STEEL GRP

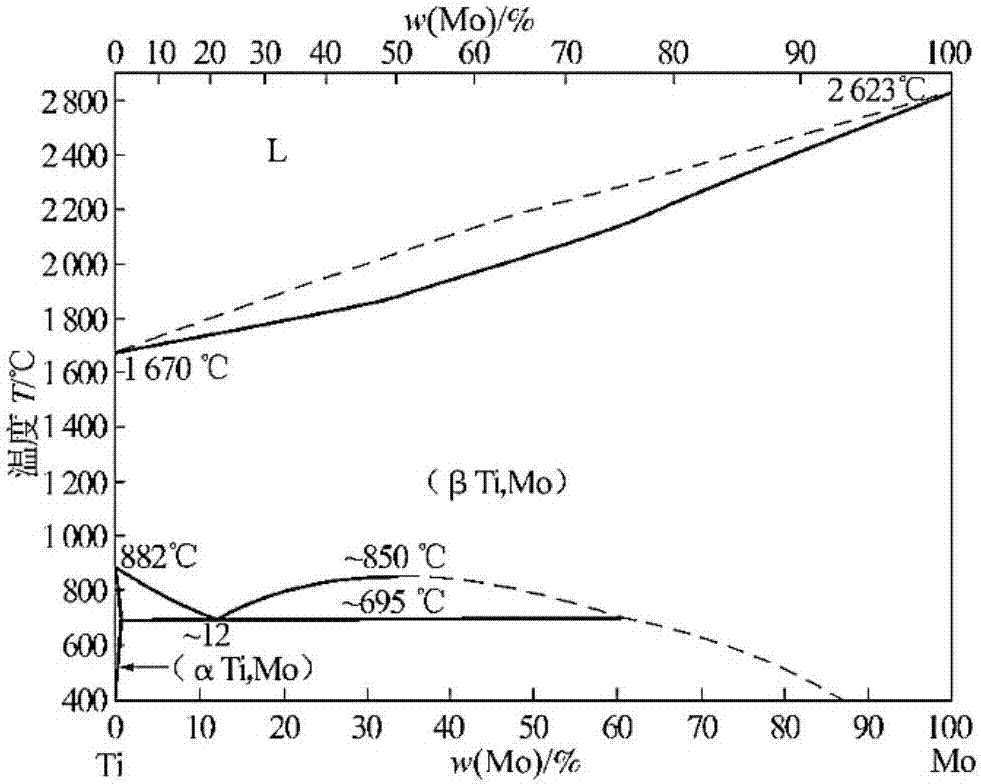

Microalloying method for improving toughness of molybdenum and molybdenum alloy fusion welding lines

ActiveCN107009025AImprove toughnessHigh bonding strengthWelding/cutting auxillary devicesArc welding apparatusRoom temperatureAlloy

The invention discloses a microalloying method for improving toughness of molybdenum and molybdenum alloy fusion welding lines. The microalloying method comprises the following steps: 1) the surfaces of areas to be welded on workpieces to be welded are pretreated, wherein the workpieces to be welded adopt materials of molybdenum or molybdenum alloys; 2) titanium layers are filled in the joined places of the workpieces to be welded; 3) the workpieces to be welded are placed in an inert gas protective atmosphere or a vacuum environment; and welding areas of the workpieces to be welded are preheated; and 4) the workpieces to be welded are welded; and welding line areas of the welded workpieces are insulated, and are cooled to reach the room temperature to finish microalloying of fusion welding lines of the workpieces. The method can eliminate the segregation problem of impurity elements in the grain boundary, and prominently improves the toughness of the molybdenum alloy fusion welding lines.

Owner:XI AN JIAOTONG UNIV

Preparation method for ZrO2 fiber with SiO2 doped

ActiveCN104141181ALow thermal conductivityHigh melting pointInorganic material artificial filamentsThermal insulationMechanical property

The invention discloses a preparation method for a ZrO2 fiber with SiO2 doped. A ZrO2-SiO2 fiber is prepared with basic zirconium carbonate (>=40%ZrO2) as a zirconium source, TEOS as a silicon source and acetic acid as stabilizers and spinning auxiliaries by means of a sol-gel method and a centrifugal spinning technology. The method is characterized in that a preparation method for a complex fiber includes the steps of precursor colloid preparation, centrifugal spinning and thermal treatment, so that the ZrO2-SiO2 composite fiber is obtained. The ZrO2-SiO2 fiber has the lowest heat conductivity coefficient, ZrO2 has high melting point, and therefore the ZrO2-SiO2 fiber can be used as a novel high-temperature thermal insulation material. Because the Y2O3 stabilized high-purity ZrO2 fiber is high in high temperature (>=1000 DEG C) pulverization rate and poor in fiber strength, growth of ZrO2 grains can be restrained by adding of a proper amount of SiO2, compared with those of pure YSZ fibers, high temperature mechanical properties of the ZrO2-SiO2 fiber are better, and the using temperature range of the YSZ fibers is expanded. Meanwhile, fiber density is lowered, so that the ZrO2 fiber has good shrinkage resistance and thermal shock resistance and is an ideal light high-temperature thermal insulation material.

Owner:南京理工宇龙新材料科技股份有限公司

12Cr2Mo1R heavy plate under critical hydrogen and heat treatment process thereof

The invention discloses a 12Cr2Mo1R heavy plate under critical hydrogen, which comprises, by weight, 0.12 to 0.15 percent of C, equal to less than 0.10 percent of Si, 0.50 to 0.60 percent of Mn, equal to or less than 0.008 percent of P, equal to or less than 0.005 percent of S, 2.35 to 2.50 percent of Cr, 0.95 to 1.05 percent of Mo, 0.020 to 0.045 percent of Al, 0.013 to 0.020 percent of Nb, equal to or less than 0.15 percent of Cu, equal to or less than 0.003 percent of Sb, equal to or less than 0.015 percent of Sn, equal to or less than 0.016 percent of As, equal to or less than 0.002 percent of O, equal to or less than 0.008 percent of N, equal to or less than 0.0002 percent of H, and the balance Fe as well as unavoidable impurities. The standard of 12Cr2Mo1R heavy plate under critical hydrogen defined by national standard GB 713-2008 has been improved. Constituent elements of 12Cr2Mo1R heavy plate under critical hydrogen and the proportion of the elements have also been optimized. The thickness of the obtained 12Cr2Mo1R heavy plate under critical hydrogen is within 155-170 mm, thereby increasing the thickness of the plate while ensuring the mechanical properties of the plate to be compatible with the standards for plates with a thickness of less than 150 mm defined by national standard 713-2008.

Owner:WUYANG IRON & STEEL +1

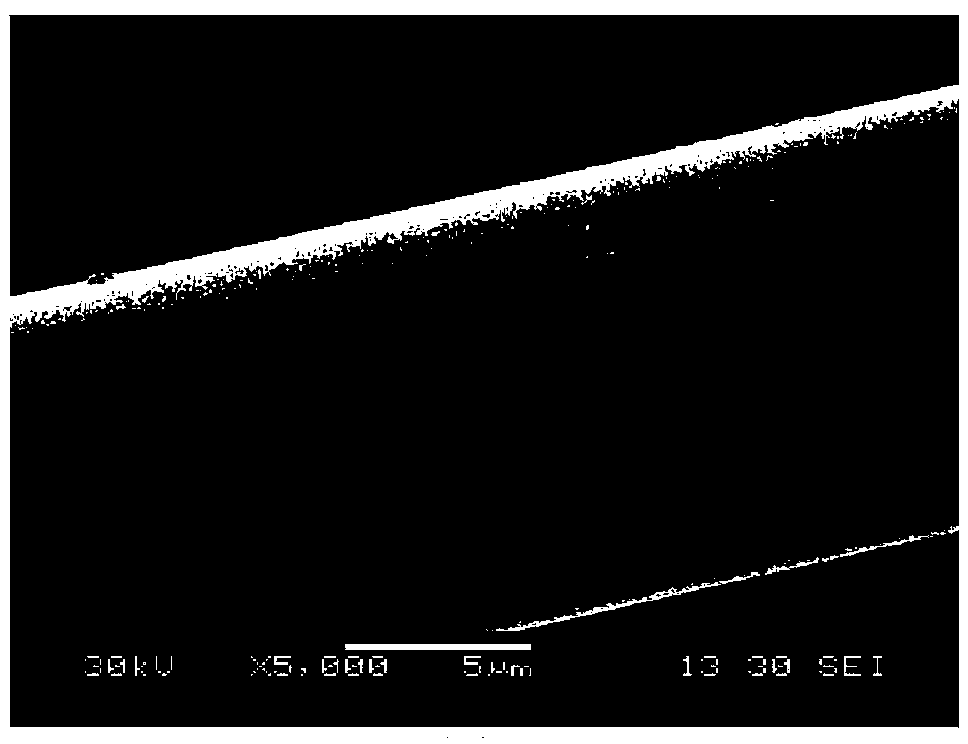

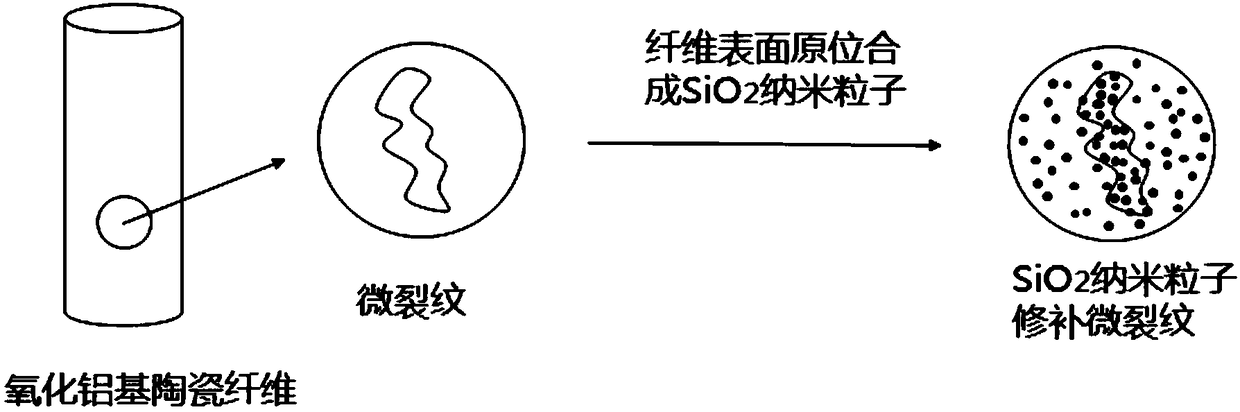

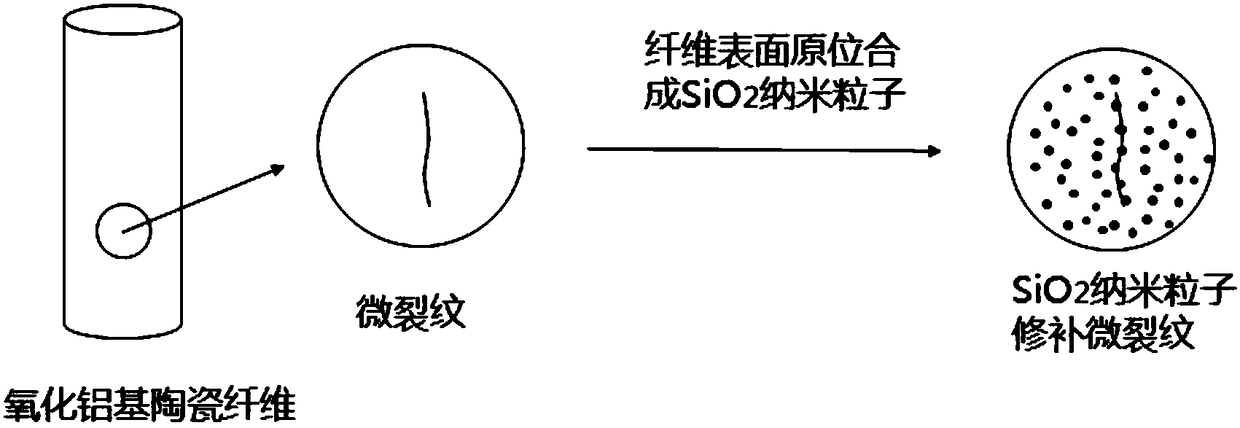

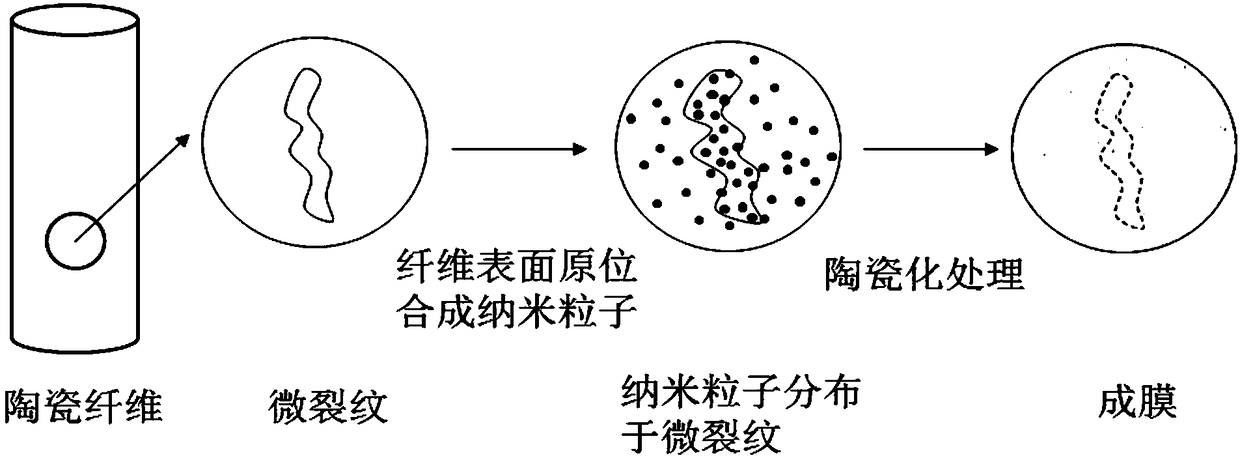

Method for surface modification of alumina-based ceramic fiber

ActiveCN108585948AHigh strengthGood high temperature mechanical propertiesSilicaNanotechnologyFiberChemical reaction

The invention relates to a method for surface modification of alumina-based ceramic fiber. The method comprises the steps of: adhering a precursor solution of SiO2 to the surface of the alumina-basedceramic fiber uniformly, and performing an in-situ chemical reaction on the surface of the fiber to form uniform SiO2 nano particles so as to complete the surface modification of the alumina-based ceramic fiber. By adopting the method to perform the surface modification of the alumina-based ceramic fiber, the strength of the fiber can be improved, and good mechanical properties of the alumina-based ceramic fiber can also be maintained at high temperature; meanwhile, surface micro cracks which can be formed during preparation of the alumina-based ceramic fiber can be repaired, and the surface state of the alumina-based ceramic continuous fiber can be improved; the method has a wide range of application, can be applied to alumina-based ceramic long fiber, alumina-based ceramic short fiber, fiber products of the alumina-based ceramic long fiber and alumina-based ceramic short fiber and the like, and is suitable for industrial production and easy to popularize.

Owner:SHANDONG UNIV

High-gamma'-content nickel-based high-temperature alloy powder for additive manufacturing, using method therefore and nickel-based high-temperature alloy component

ActiveCN112921206AGood printabilityImprove high temperature mechanical propertiesAdditive manufacturing apparatusSelective laser meltingChemical composition

The invention provides high-gamma'-content nickel-based high-temperature alloy powder for additive manufacturing, a using method therefore and a nickel-based high-temperature alloy component, and relates to the technical field of powder-based additive manufacturing. The high-gamma'-content nickel-based high-temperature alloy powder for additive manufacturing comprises the following chemical components in percentage by weight: 12-14% of Cr, 8-9% of Co, 3.8-4.2% of Al, 3.8-4.2% of Ti, 2.4-2.8% of W, 1.9-2.1% of Ta, 1.6-2.0% of Mo, 1.0-1.2% of Nb, 0.1-5% of Fe, 0.1-2.0% of Hf, 0.12% or less of C, 0.1% or less of Si, 0.02% or less of n, less than 0.03% of Zr, 0.01% or less of B, and the balance Ni and impurity elements. By using the high-temperature alloy powder, compact and crack-free complex parts meeting the strength requirement in the ultrahigh-temperature environment can be printed through the selective laser melting technology.

Owner:常州钢研极光增材制造有限公司 +1

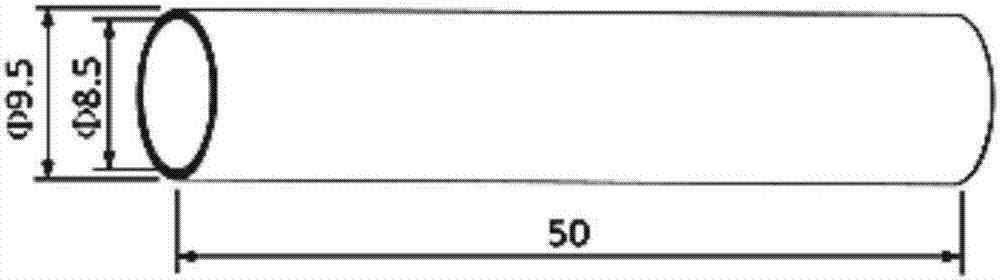

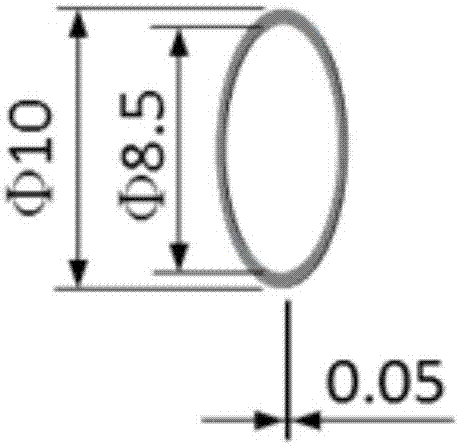

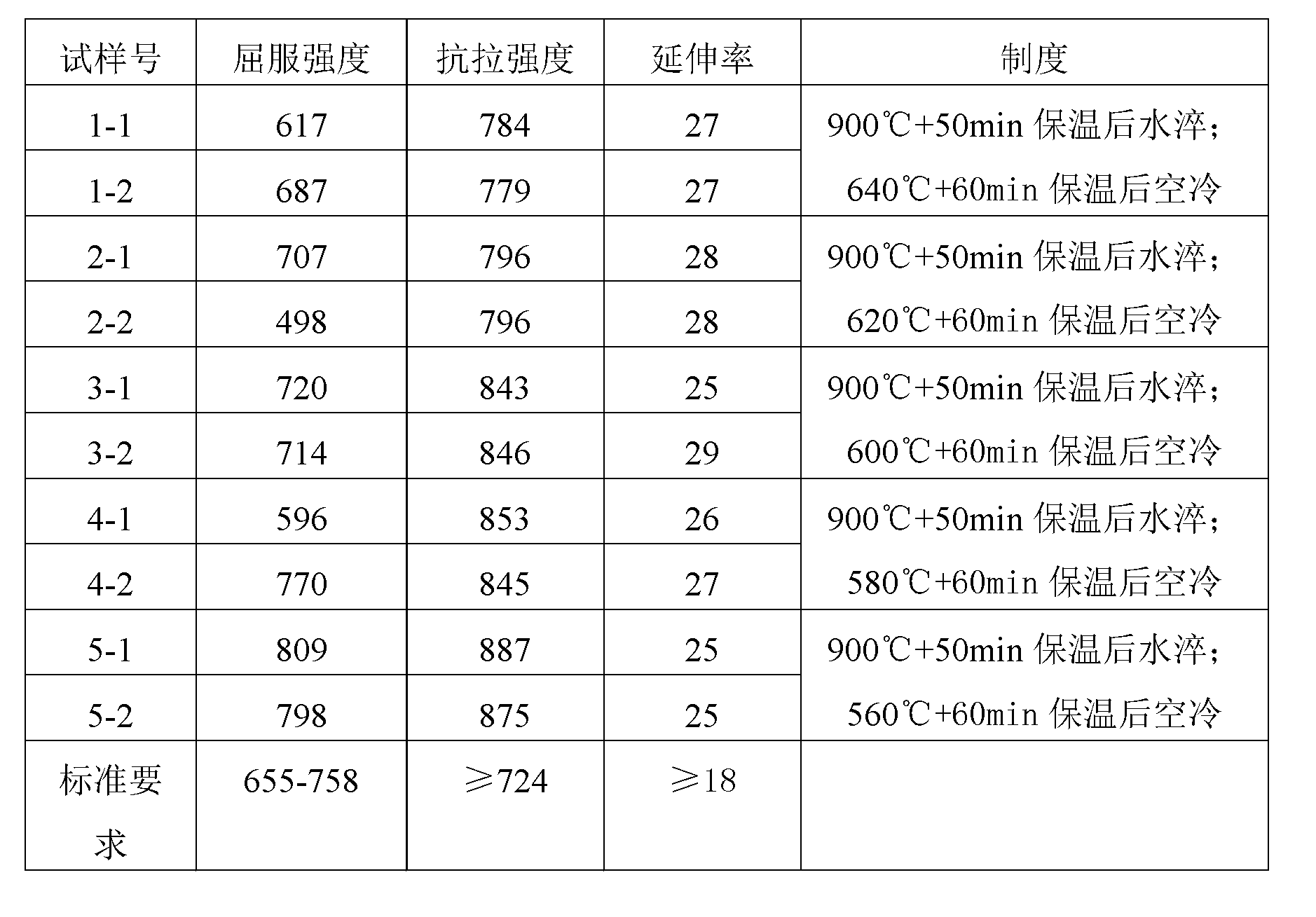

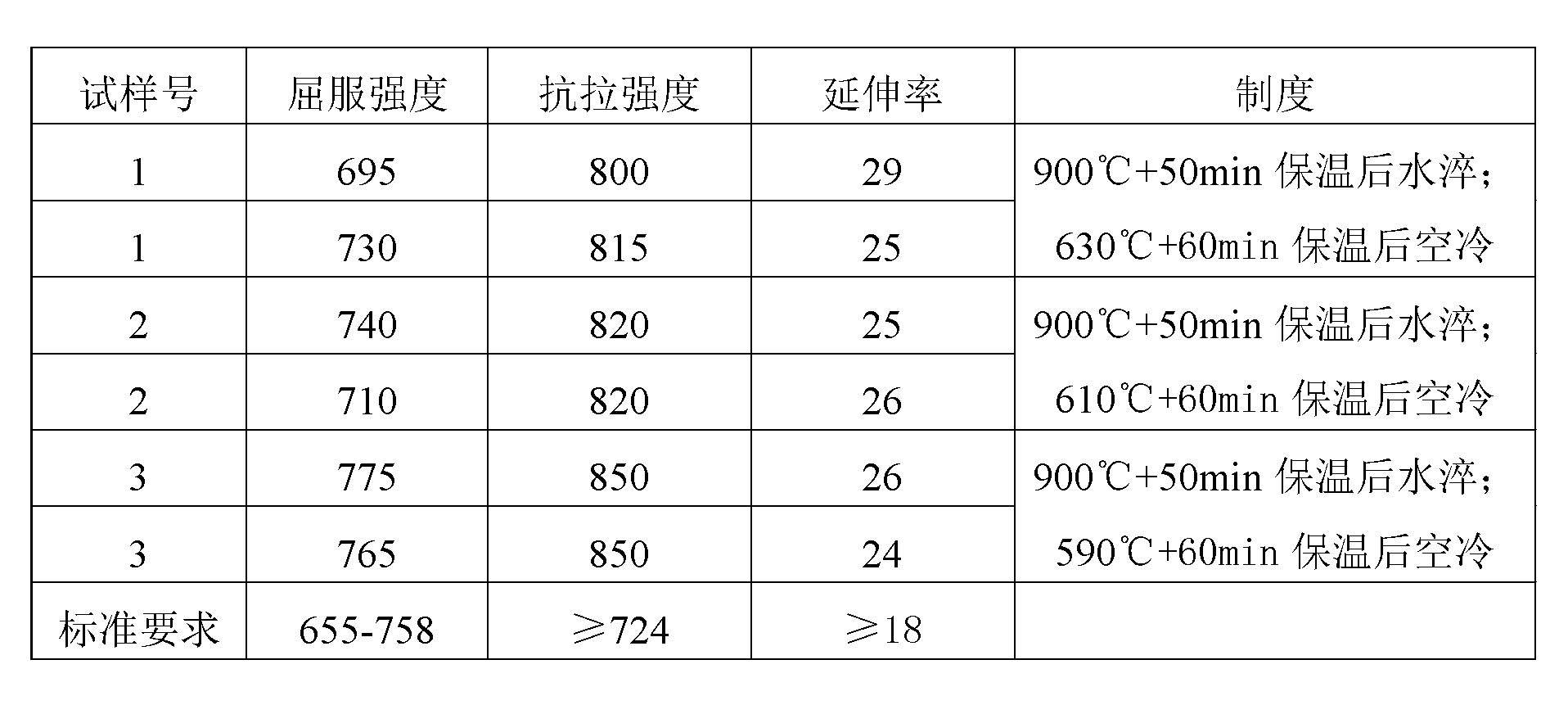

Method for manufacturing oil casings made of R95-grade steel containing rare earth

InactiveCN102936691AImprove plasticityImprove impact toughnessFurnace typesProcess efficiency improvementRare-earth elementTempering

The invention relates to a method for manufacturing oil casings made of R95-grade steel containing rare earth. The method is characterized in that each casing blank comprises, by weight, from 0.24% to 0.30% of C, from 0.15% to 0.35% of Si, from 1.35% to 1.55% of Mn, lower than or equal to 0.020% of P, lower than or equal to 0.010% of S, from 0.30% to 0.40% of Cr, from 0.02% to 0.04% of Al, from 0.0007% to 0.0110% of rare earth elements RE and the balance Fe which is a matrix. A casing heat treatment regime includes that the temperature is 910 DEG C+ / -20 DEG C and is kept for 50 minutes, and then water quenching is performed; and the tempering temperature is 630 DEG C+ / -20 DEG C and is kept for 80 minutes, then air cooling production is carried out, and the steel casings with optional sizes can meet standard requirements. The method has the advantages that the 27Mn2CrRe steel containing carbon manganese steel and the rare earth is reasonable in material constitution design, and is low in cost due to the fact that materials for manufacturing the casings do not contain precious metal elements such as molybdenum; the water quenching and tempering are combined in a heat treatment process, and the water quenching does not affect environments and is low in cost, so that the plasticity of the steel is greatly improved on the premise that the strength of the obtained oil casings made of the R95-grade steel is guaranteed, the impact toughness of the steel casings is improved, and the steel casings are excellent in high-temperature mechanical property and can meet service requirements on oil casings under different working conditions.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Liquid aromatic amine epoxy resin curing agent and preparation method thereof

InactiveCN102532486ALow toxicityGood high temperature mechanical propertiesOrganic compound preparationAmino-hyroxy compound preparationEpoxyHeat resistance

The invention discloses a liquid aromatic amine epoxy resin curing agent and a preparation method thereof. The liquid aromatic amine epoxy resin curing agent comprises the following components by weight percentage: 70-98 percent of solid aromatic amine and 2-30 percent of low-viscosity aliphatic epoxy resin. The preparation method comprises the following steps of: adding solid aromatic amine with a weight percentage of 70-98 percent in a reaction vessel, raising the temperature to a melting point above, starting an agitator after the material is molten, reducing the temperature to a melting point plus or minus 3 DEG C and dripping the low-viscosity aliphatic epoxy resin with a weight percentage of 2-30 percent for 2-3 batches through an overhead tank; agitating and reacting for 1-2 hours after the end of dripping, reducing the temperature to 50-60 DEG C, and filtering and discharging to obtain the liquid aromatic amine epoxy resin curing agent. The liquid aromatic amine epoxy resin curing agent and the preparation method thereof have the beneficial effects that the liquid aromatic amine epoxy resin curing agent prepared according to the invention can be mutually dissolved with the epoxy resin nearby the room temperature, the quicker polymerization reaction of the aromatic amine with the epoxy resin in the rubber mixing process can be avoided, and the characteristics of small toxicity, excellent curing substance heat resistance and good high-temperature mechanical property of the aromatic amine curing agent are kept.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

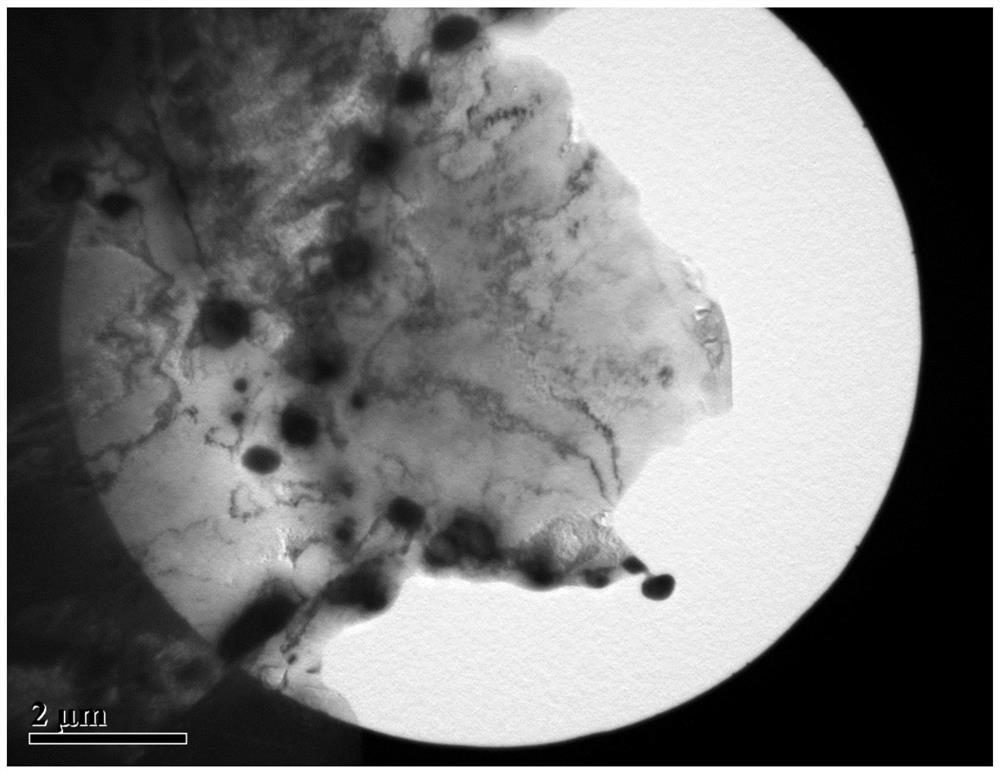

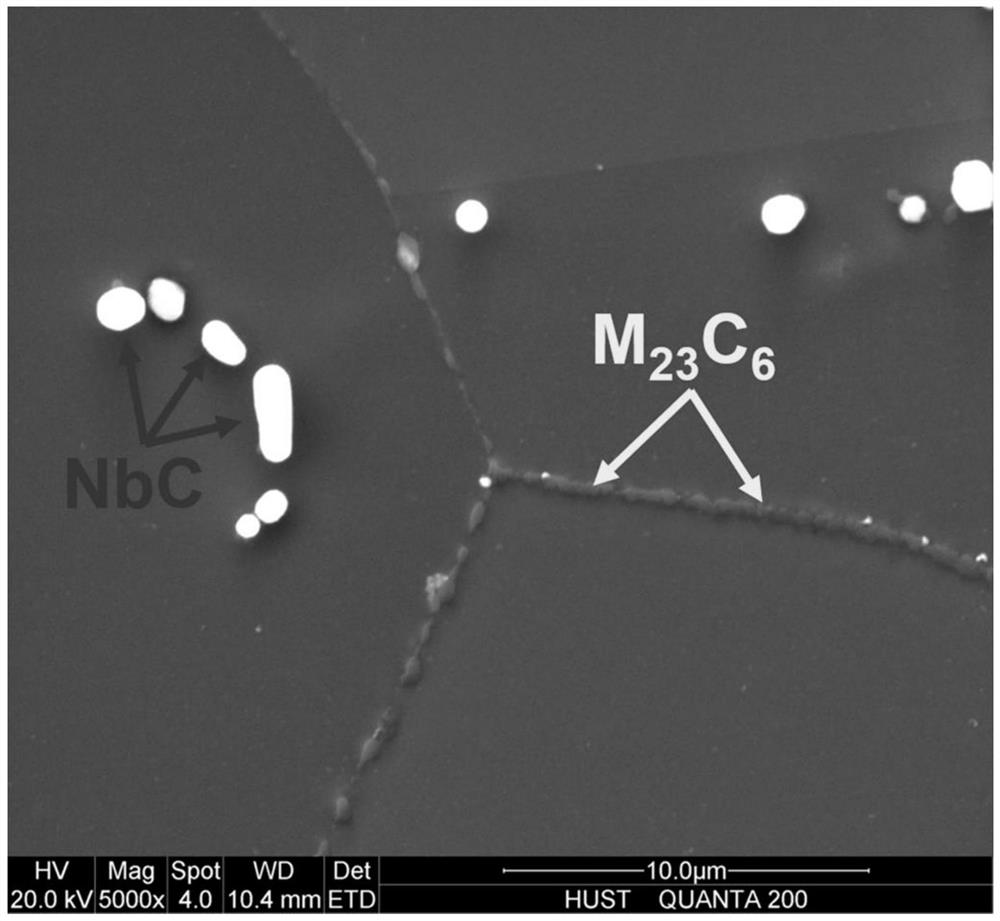

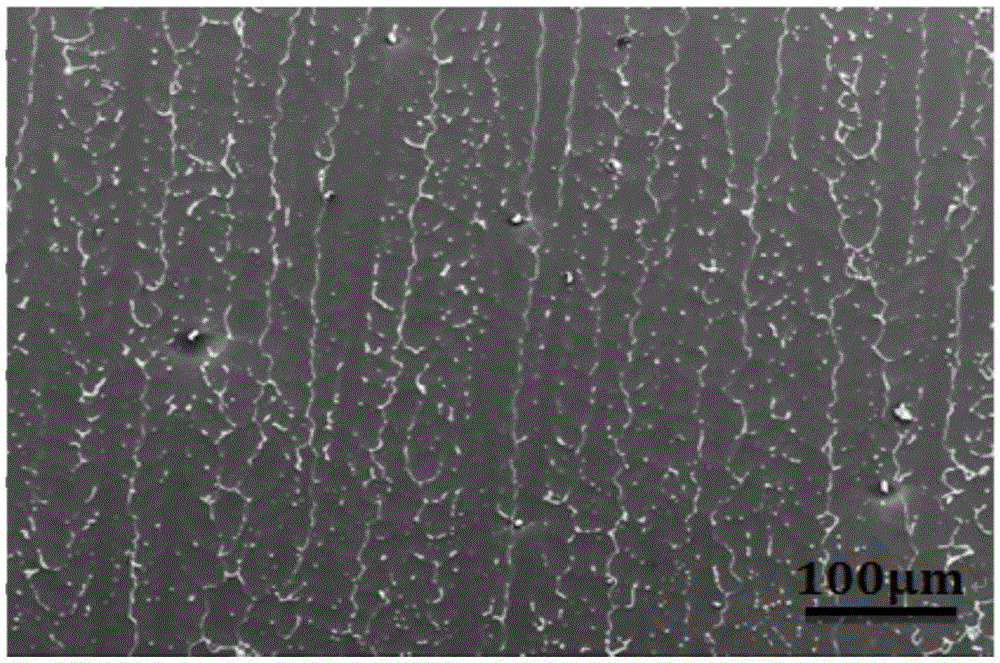

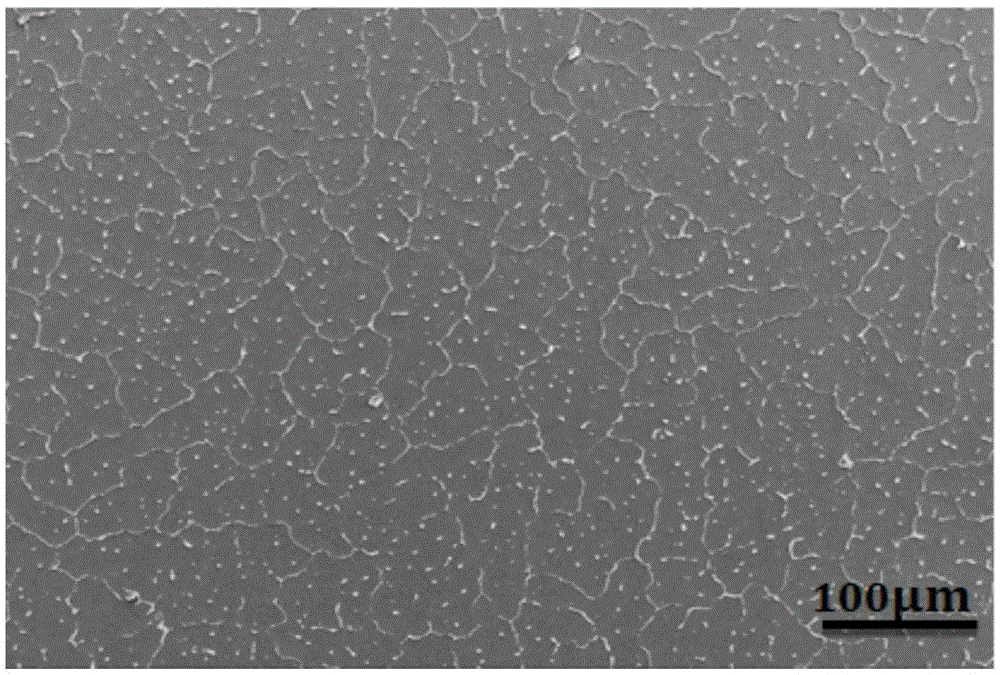

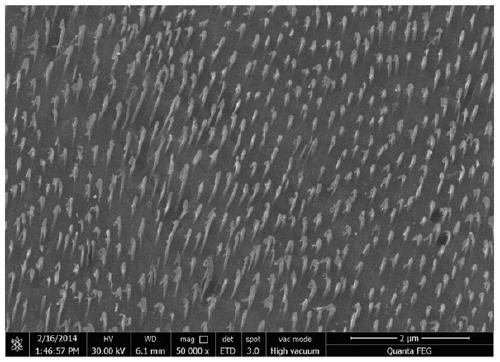

Precipitation strengthening type high-temperature high-entropy alloy for in-situ precipitation of carbide and preparation method thereof

ActiveCN111621660AGood high temperature mechanical propertiesImprove mechanical propertiesHeat stabilityCarbide

The invention discloses a precipitation strengthening type high-temperature high-entropy alloy for in-situ precipitation of carbide and a preparation method thereof, and belongs to the field of high-entropy alloy preparation. According to the method, a raw material composed of Cr, Fe, Co, Ni, Nb and Cr3C2 is fully smelted and mixed in an inert atmosphere and then subjected to solid solution agingtreatment, and the atomic percent and the atomic number of all the elements meet the requirements of 24.5% to 24.75% of Cr, 24.5% to 24.75% of Fe, 24.5% to 24.75% of Co, 24.5% to 24.75% of Ni, 0.5% to1% of Nb and 0.5% to 1% of C, wherein the atomic numbers of Cr, Fe, Co and Ni satisfy Cr = Fe = Co = Ni, and the atomic numbers of Nb and C satisfy Nb = C. According to the prepared alloy, a large number of spherical NbC carbide particles are dispersedly distributed in crystal grains, and a small number of M23C6 carbides are distributed on a crystal boundary. The crystal grains and carbide precipitated phases of the alloy have high thermal stability at high temperature, and have good effects on high-temperature structure stability and high-temperature mechanical properties of the alloy.

Owner:HUAZHONG UNIV OF SCI & TECH

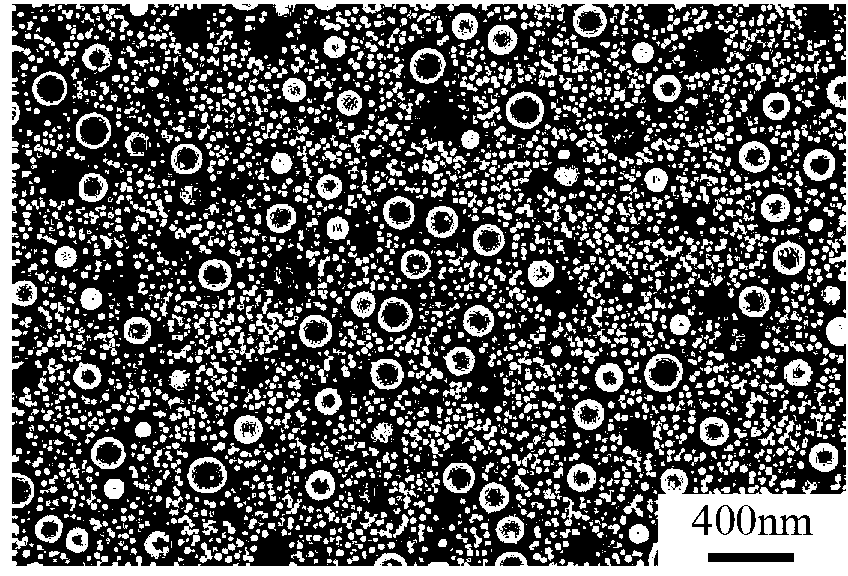

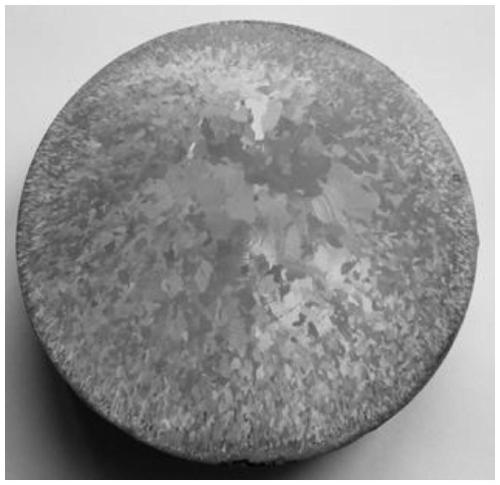

Mg-Zn-Y directional solidification alloy and preparing method thereof

The invention discloses Mg-Zn-Y directional solidification alloy and a preparing method thereof. The Mg-Zn-Y directional solidification alloy comprises, by mass, 6.00%-9.00% of Zn, 1.00%-2.00% of Y and the balance Mg. The Mg-Zn-Y directional solidification alloy and the preparing method thereof have the beneficial effects that the Mg-Zn-Y directional solidification alloy has columnar crystal tissue, has high strength and certain plasticity under the room temperature, and more importantly has high-temperature mechanical performance; particularly, the Mg-Zn-Y directional solidification alloy obtains a columnar crystal tissue with specific orientation, wherein in the columnar crystal tissue, primary arm growing is parallel, a longitudinal crystal boundary is straight, and a transverse crystal boundary does not exist. Granular phases are dispersed and distributed in crystals, and the crystal boundary phases and the crystal internal granular phases are icosahedron quasi-crystals I-Mg3Zn6Y; and the problems that in the prior art, Mg-Zn-Y alloy solidification tissue is thick, quasi-crystals are connected into a net shape in an eutectic structure form to be distributed among alpha-Mg dendritic crystals, and the quasi-crystal strengthening function cannot be developed fully are solved.

Owner:NORTHEASTERN UNIV

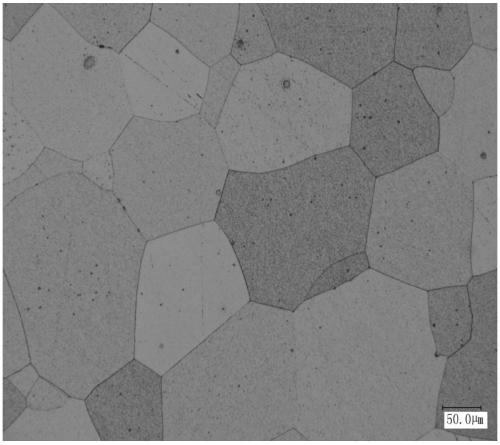

Chromium/zirconium/iron/copper alloy electrode material, and preparation and application method thereof

InactiveCN103131886AInhibition of hardness reductionHigh strengthWelding/cutting media/materialsSoldering mediaMechanical propertyImpurity

The invention relates to a chromium / zirconium / iron / copper alloy electrode material, and a preparation and application method thereof. The chromium / zirconium / iron / copper alloy contains the following components in percentage by weight: 0.8-2.0% of chromium, 0.2-0.3% of zirconium, 0.01-0.04% of iron and the balance of copper and impurity. The invention also provides a preparation method of the alloy material. The method comprises the following steps: smelting a copper alloy to form a cast ingot, performing hot rolling, and performing solution treatment at 960-980 DEG C; performing cold rolling deformation pressure processing; and finally, performing aging treatment at 430-630 DEG C. Thus, due to the improved mechanical property and heat resistance, high conductivity, high softening temperature and high yield stress at high temperature, the prepared alloy material can be used as an electrode material in welding and indicates excellent continuous welding capability.

Owner:HUNAN YINLIAN XIANGBEI COPPER IND

Aluminum alloy for pedestrian bridges and preparation method thereof

The invention relates to an aluminum alloy for pedestrian bridges and a preparation method thereof. The invention is characterized in that the aluminum alloy is composed of the following chemical components in percentage by mass: 0.55-1.0% of Mg, 0.55-0.8% of Si, 0.18-0.55% of Mn, 0.1-0.2% of Cr, 0.05-0.2% of Ta, 0.10-0.3% of Ni, 0.10-0.50% of V, 0.1-0.3% of Cu, at most 0.05% of Zn, at most 0.20% of Fe, at most 0.05% of Ti, at most 0.15% of other impurity elements (at most 0.05% of each of other impurity elements), and the balance of Al. The preparation method comprises the following steps: smelting, refining, casting and uniformizing. By optimizing the alloy composition, trace amounts of Ta, Ni and V are added to obviously enhance the strength, toughness, fatigue resistance, corrosion resistance and processability of the aluminum alloy.

Owner:ALNAN ALUMINIUM CO LTD

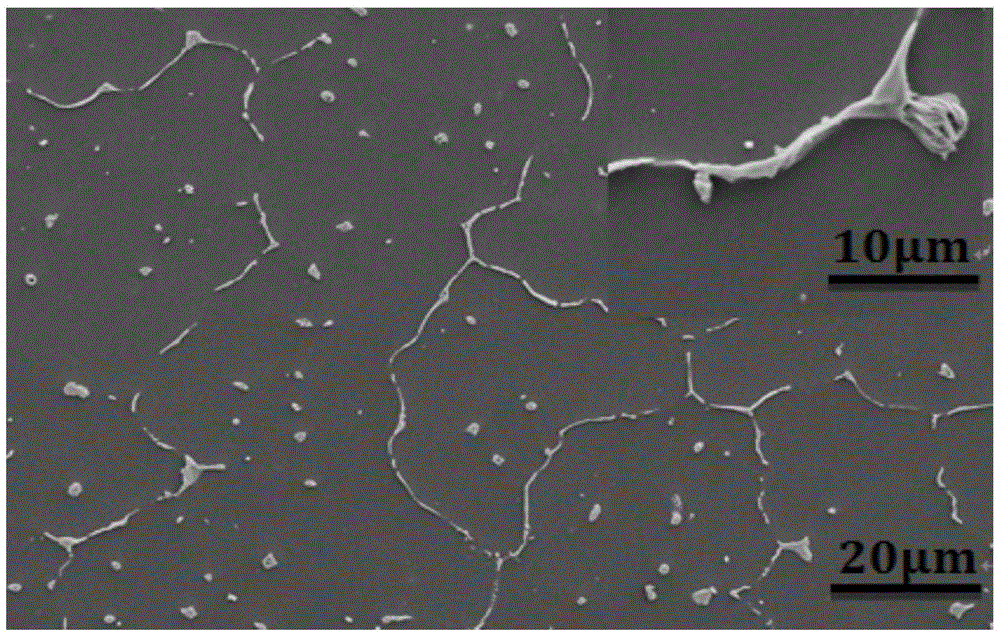

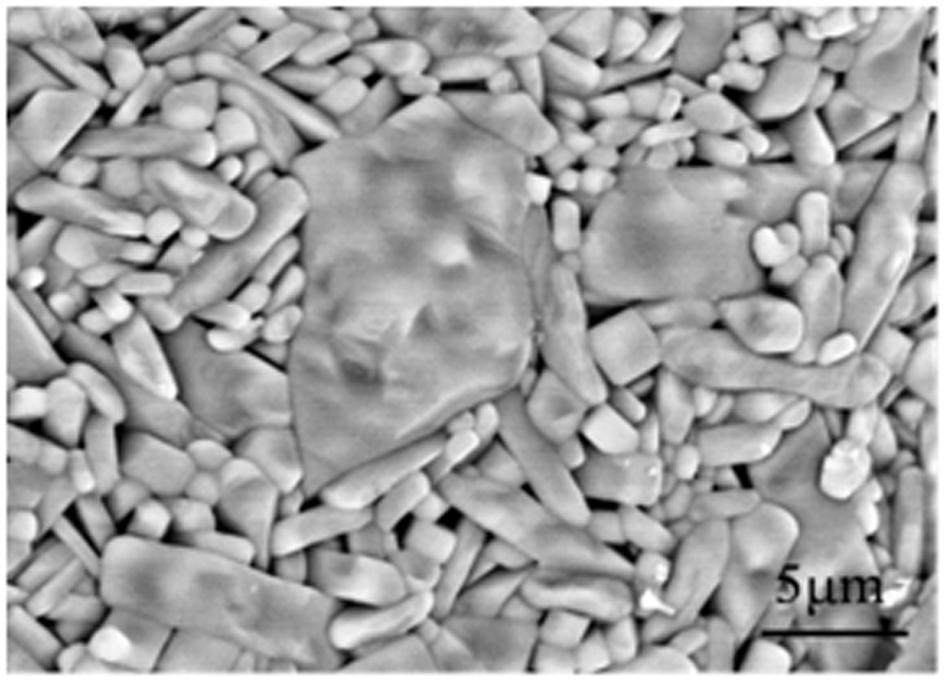

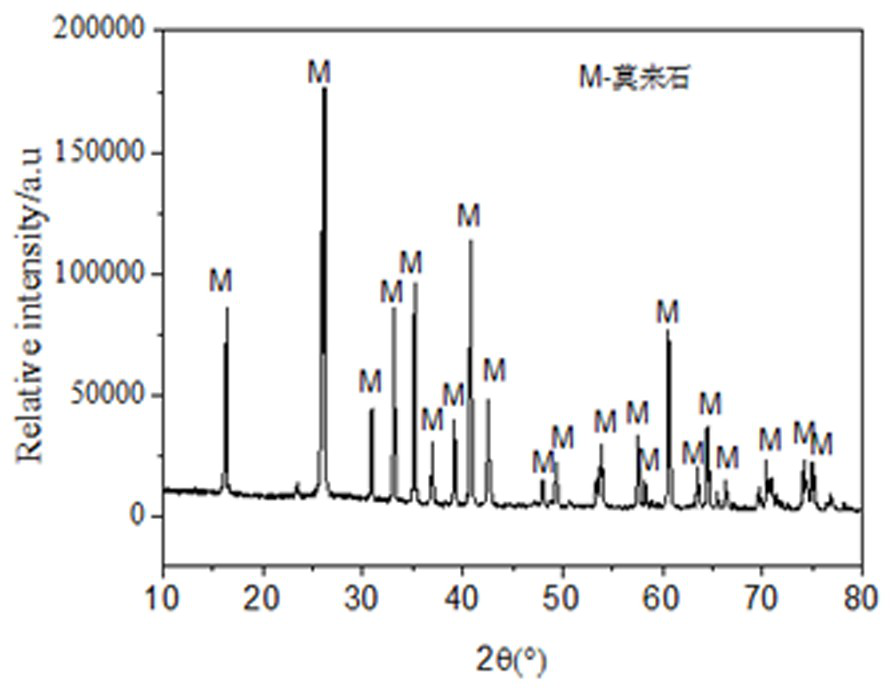

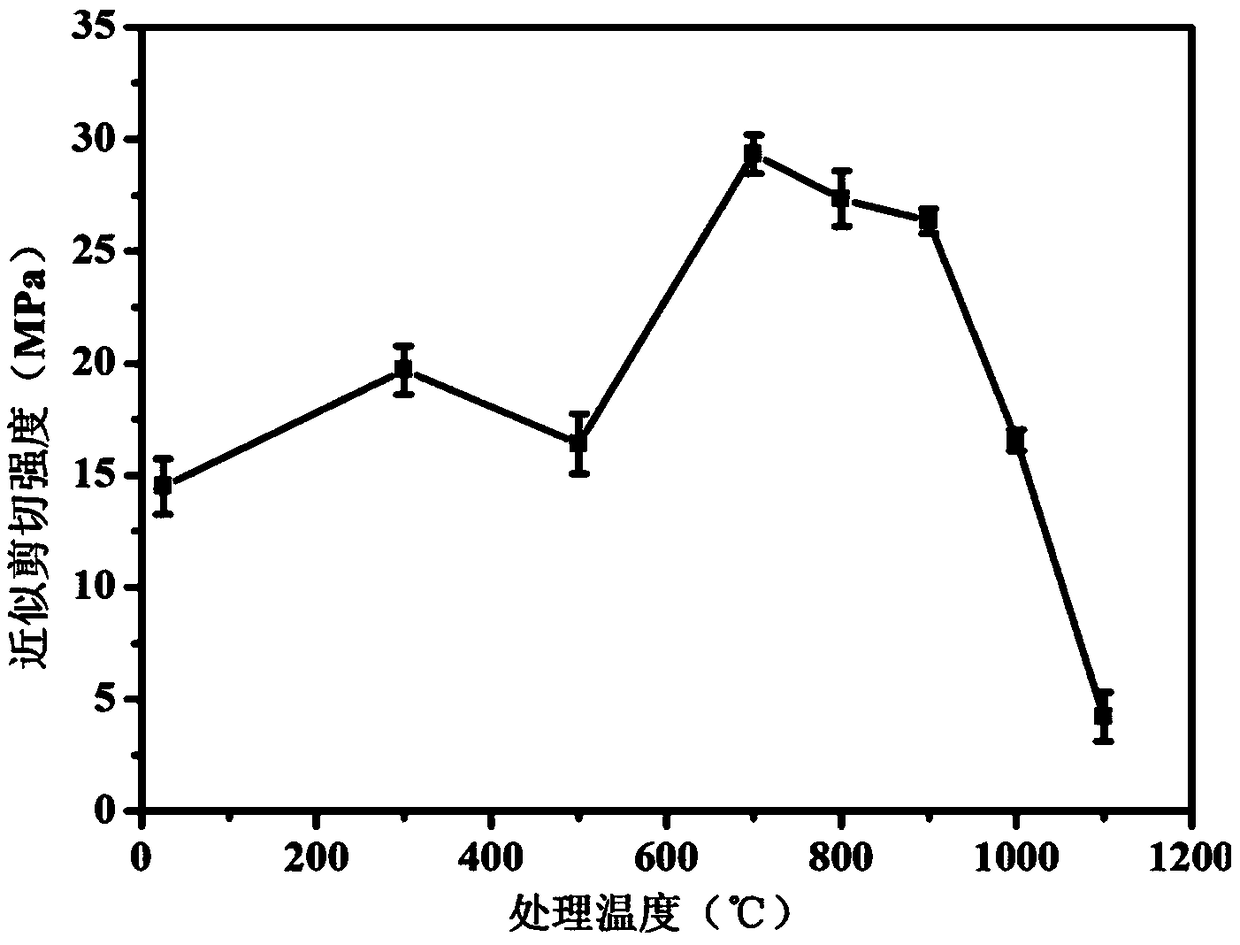

Method for preparing high-purity mullite material by taking molten silicon dioxide as silicon source

The invention discloses a method for preparing a high-purity mullite material by taking molten silicon dioxide as a silicon source. The method is characterized by comprising the following steps: a, mixing, in percentage by mass, 75-94 wt% of a silicon dioxide raw material, 4-20 wt% of an aluminum-silicon raw material and 0.1-2 wt% of a sintering aid; carrying out ball milling, drying and forming,conducting calcining in a 1500-to-1600 DEG C high-temperature furnace for 0.5-1 hour, firing the mixed raw materials to a molten state, and conducting cooling to obtain a molten silicon dioxide raw material; b, crushing the molten silicon dioxide raw material prepared in the step a, mixing the crushed molten silicon dioxide raw material with an alumina raw material according to a molar ratio of Al2O3 / SiO2 of 3: 1, co-grinding the mixed raw materials, adding a binding agent accounting for 4 wt% of the total weight of the raw materials, carrying out molding under a pressure of 80-150 MPa, carrying out calcining at 1550-1650 DEG C for 3-8 hours, and carrying out cooling to obtain the high-purity mullite crystal material. According to the invention, molten silicon dioxide is used as a siliconsource, the sintering temperature for synthesizing the high-purity mullite material is low, the addition amount of the sintering aid is small, and columnar mullite and lamellar mullite crystals are formed; and the high-purity mullite material has the characteristics of low impurity content, high density and good high-temperature mechanical properties.

Owner:临沂利发耐火材料有限公司

Preparation method of high temperature adhesive for nickel based alloy

ActiveCN108822792AGood thermal expansionLow decomposition shrinkageNon-macromolecular adhesive additivesMacromolecular adhesive additivesSilanesAdhesive

The invention discloses a preparation method of a high temperature adhesive for a nickel based alloy. The preparation method comprises following steps: mixing following raw materials: ultrafine nickelpowder, ultrafine aluminum powder, ultrafine boron carbide powder, ultrafine low temperature molten glass powder, and high activity copper oxide powder to prepare a raw material mixture; subjecting the raw material mixture to ball milling; preparing a resin solution from silane MK resin and isopropanol; and finally mixing the raw material mixture with the resin solution to prepare a gel solution.The prepared high temperature adhesive can realize partial alloying, can tolerate a high temperature as high as 1000 DEG C, and has the advantages of high thermal expansion, low decomposition rate and low shrinking percentage; high temperature resistant metal compounds and ceramic dually enhance the performance, the high temperature mechanical properties are excellent; the high temperature adhesive has the prominent characteristics that after curing the adhesive does not need any post treatment, can be used at a temperature of 1000 DEG C, and is especially suitable for a high temperature nickel based alloy (GH2132) at a temperature of 600 to 1000 DEG C.

Owner:天津航大翼安科技发展有限公司

Ceramic-embedded plate valve

InactiveCN102121537AGood high temperature mechanical propertiesGood chemical resistanceSlide valveValve housingsEngineeringGraphite

The invention discloses a ceramic-embedded plate valve, which comprises a left valve body, a right valve body, an upper flange, a lower flange, disc springs, a valve rod outer sealing member, a valve body pipe orifice outer sealing member and an inner sealing member, wherein the inner sealing member consists of a ceramic flat plate, a flat plate frame and fixing valve plates; a first disc spring is tightly attached to one side of a left fixing valve plate and one side of a right fixing valve plate; a second disc spring of which the outer diameter is larger than that of the first disc spring is arranged among the first disc spring, the left valve body and the right valve body; a third disc spring of which the outer diameter is larger than that of the second disc spring is arranged among the second disc spring, the left valve body and the right valve body; the inner peripheries of the outer sides of the left valve body and the right valve body are provided with annular grooves; and a component force flat washer and a graphite packing are fixed in the annular grooves in turn respectively by using a gland bush from outside to inside. The ceramic-embedded plate valve has the advantages of high performance, balanced stress on the fixing valve plates due to tower combination of the disc springs and component force action of the packing, and difficulty in smashing.

Owner:淄博汇华阀业有限公司

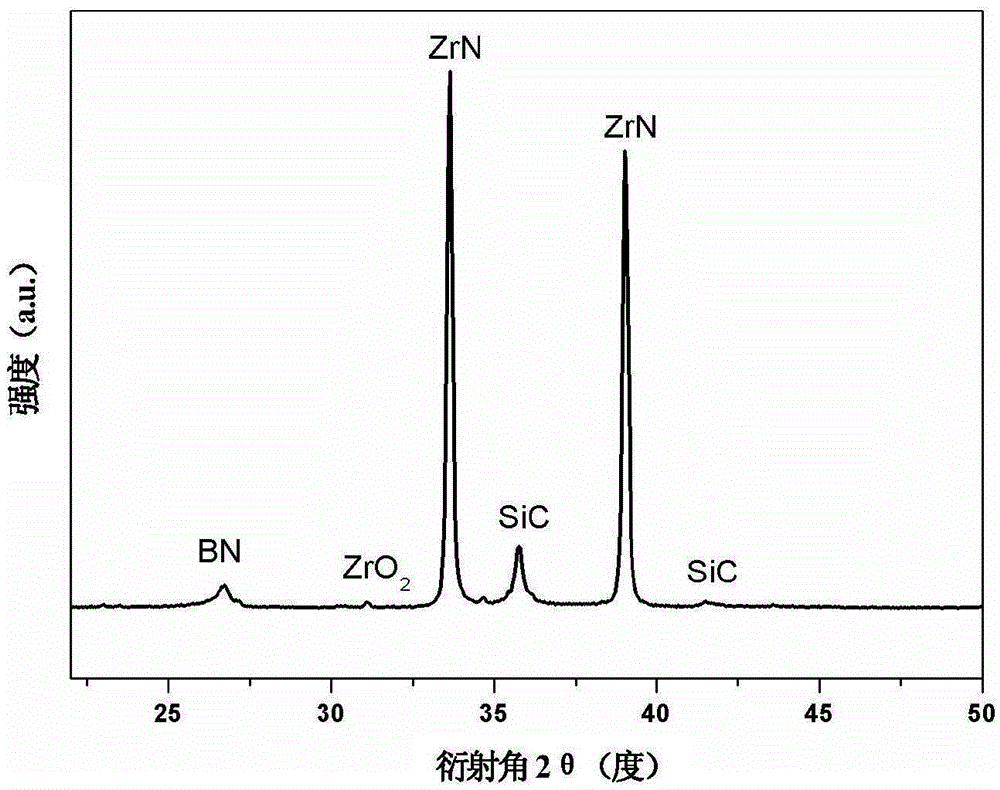

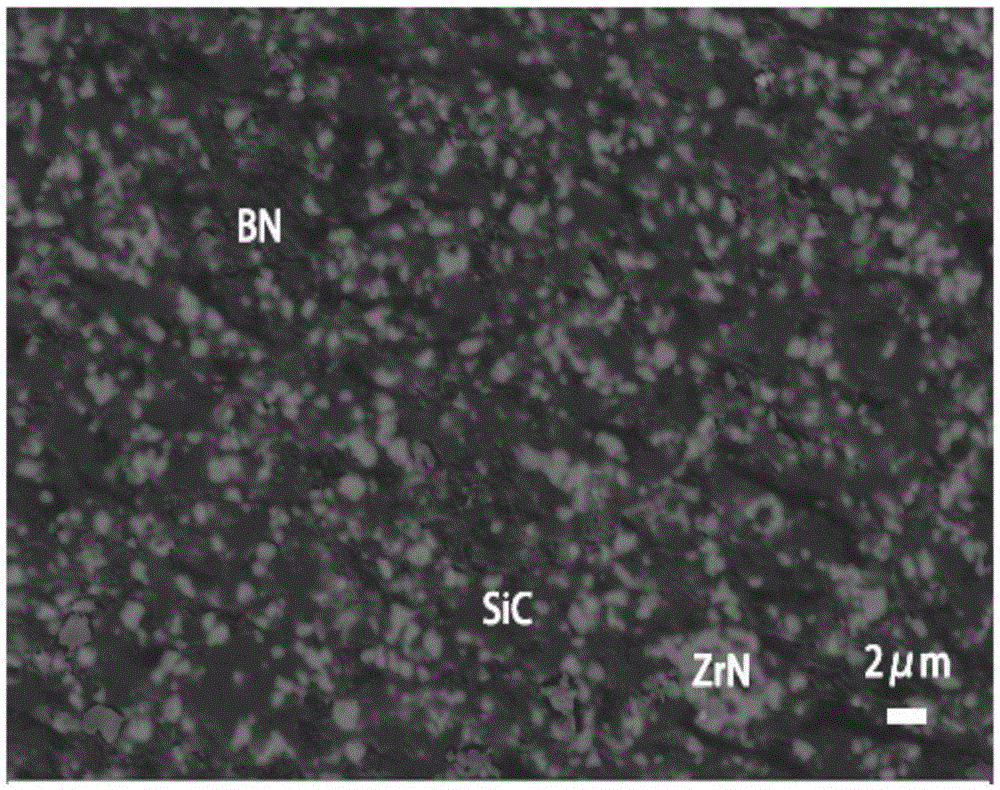

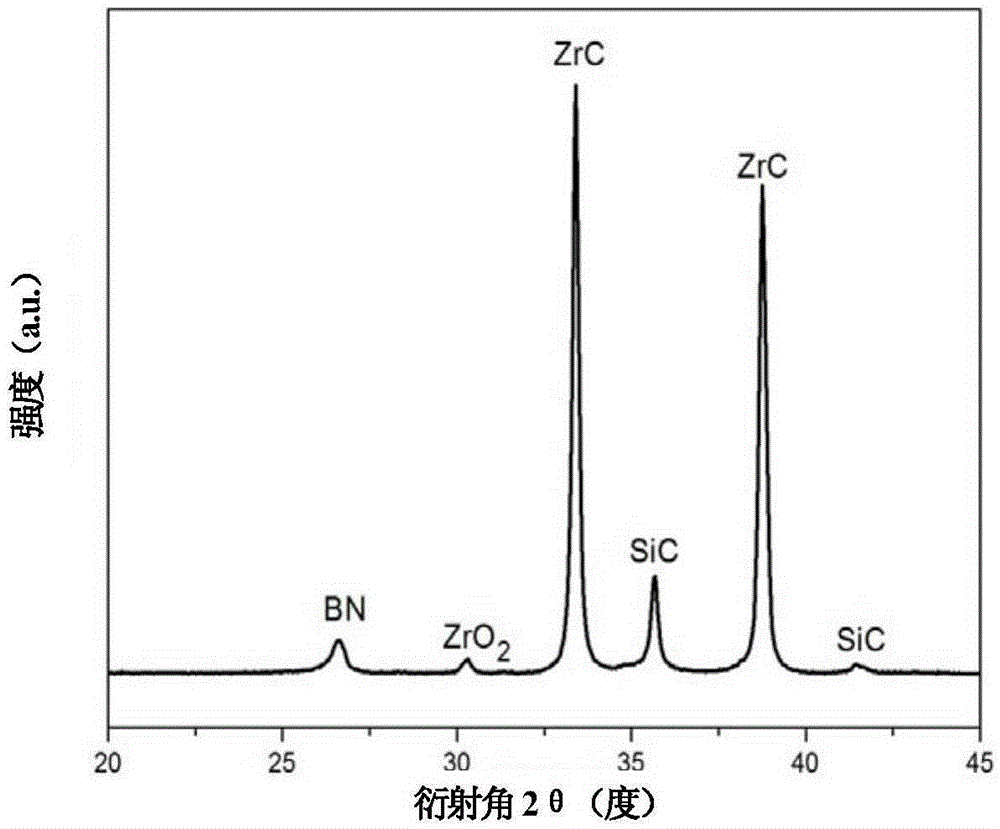

Method for preparation of ultra-high temperature ceramic matrix composite material containing boron nitride by in-situ reaction

Belonging to the field of ultra-high temperature ceramics, the invention in particular relates to a method for preparation of an ultra-high temperature ceramic matrix composite material containing boron nitride by in-situ reaction. Raw materials include zirconium boride or hafnium boride powder, silicon nitride powder and graphite powder, and are mixed, and then the mixture is subjected to in-situ reaction hot pressing sintering or reaction sintering in a discharge plasma sintering furnace. Under a nitrogen atmosphere, the heating rate is 10-100DEG C / min, the sintering temperature is 1800DEG C-2100DEG C, the sintering time is 10min-2h, and the sintering pressure is 20MPa-40MPa. Therefore, a BN phase is uniformly introduced into an ultra-high temperature ceramic matrix through in-situ reaction so as to finally obtain a ZrN(HfN)-SiC-BN composite material or ZrC(HfC)-SiC-BN composite material. The composite material can be used a nozzle throat liner and jet vane of a solid rocket engine, and a nose cone, end, wing leading edge of ultra high speed aircrafts and other high temperature resistant structural components.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Novel nitride-reinforced martensite heat-resisting steel

InactiveCN102758141AImprove thermal stabilityGood high temperature mechanical propertiesAlloyThermal stability

The invention provides a novel nitride-reinforced martensite heat-resisting steel. The steel is characterized in that main alloy components of the martensite heat-resisting steel comprises, by weight, 0.8-1.5% of Mn; 8.0-10.0% of Cr; no more than 1.5% of W; no more than 1.5% of Mo (wherein wherein the sum of the weight percentages of W and Mo is 1.5-2.0%); no more than 0.06% of Nb; no more than 0.15% of Ta (wherein Nb+Ta accounts for 0.05-0.15%); 0.1-0.3% of V; 0.03-0.05% of N; and balance of Fe. According to the invention, the content of the element Mn is increased. On a basis that a phase change point of a material AC1 is almost not reduced, heat-resisting steel original martensite tissues reinforced by high-thermal-stability nitride precipitate is obtained. With the controlling over the contents of elements Co, W, Mo, N, and the like, Laves phase and Z phase precipitation of steel during long-term high-temperature service can be retarded. Therefore, the obtained steel has relatively high tissue stability and good high-temperature mechanical properties.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

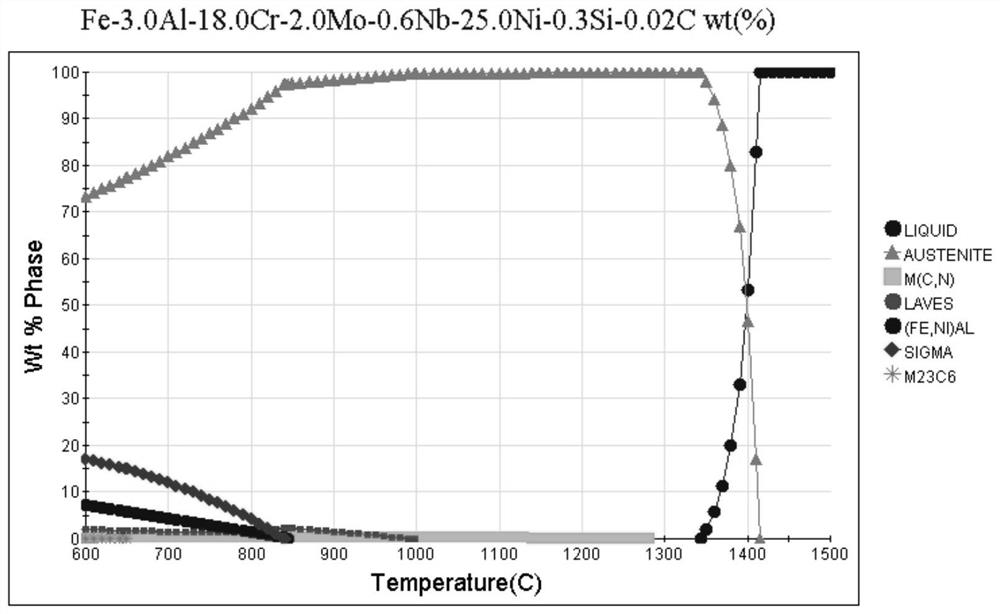

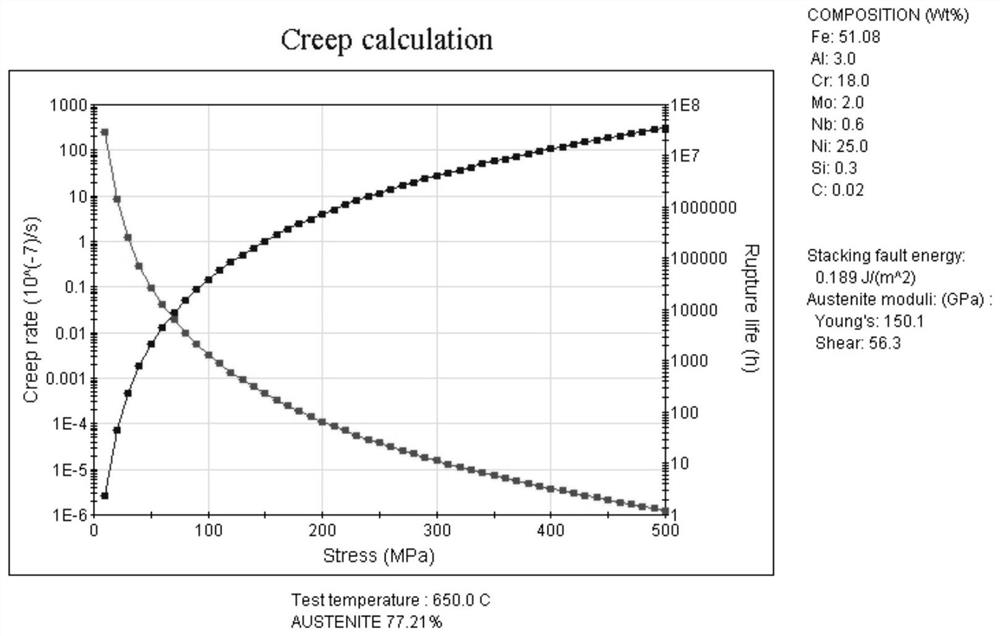

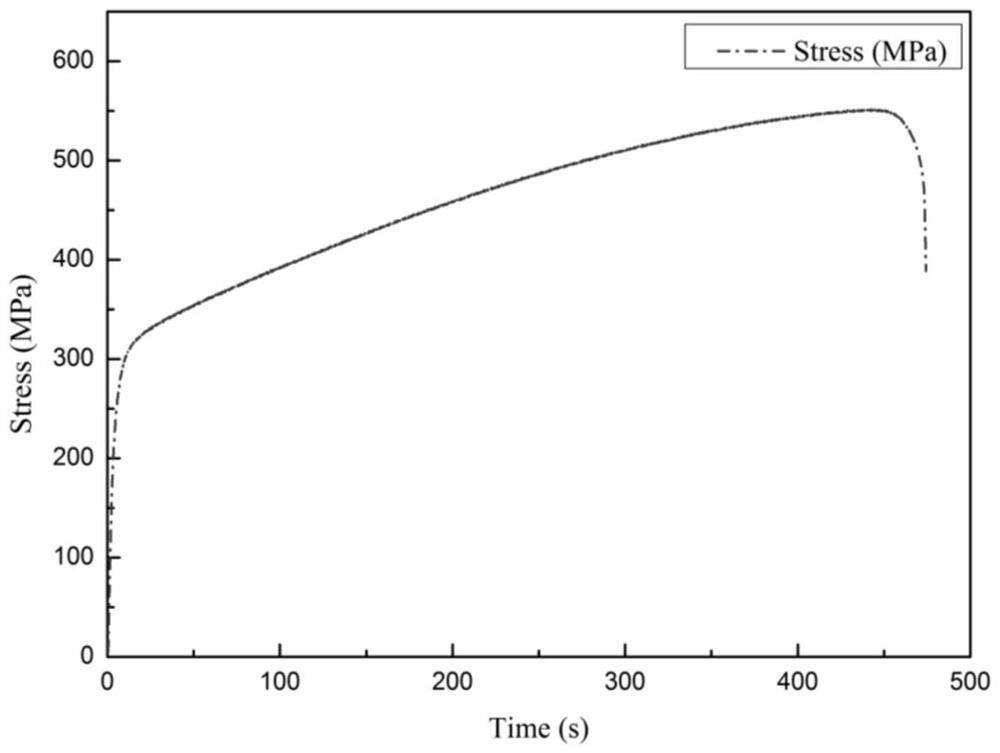

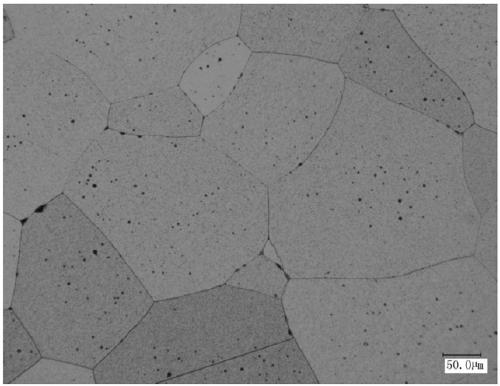

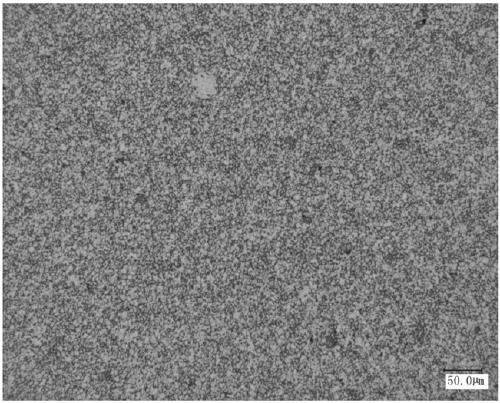

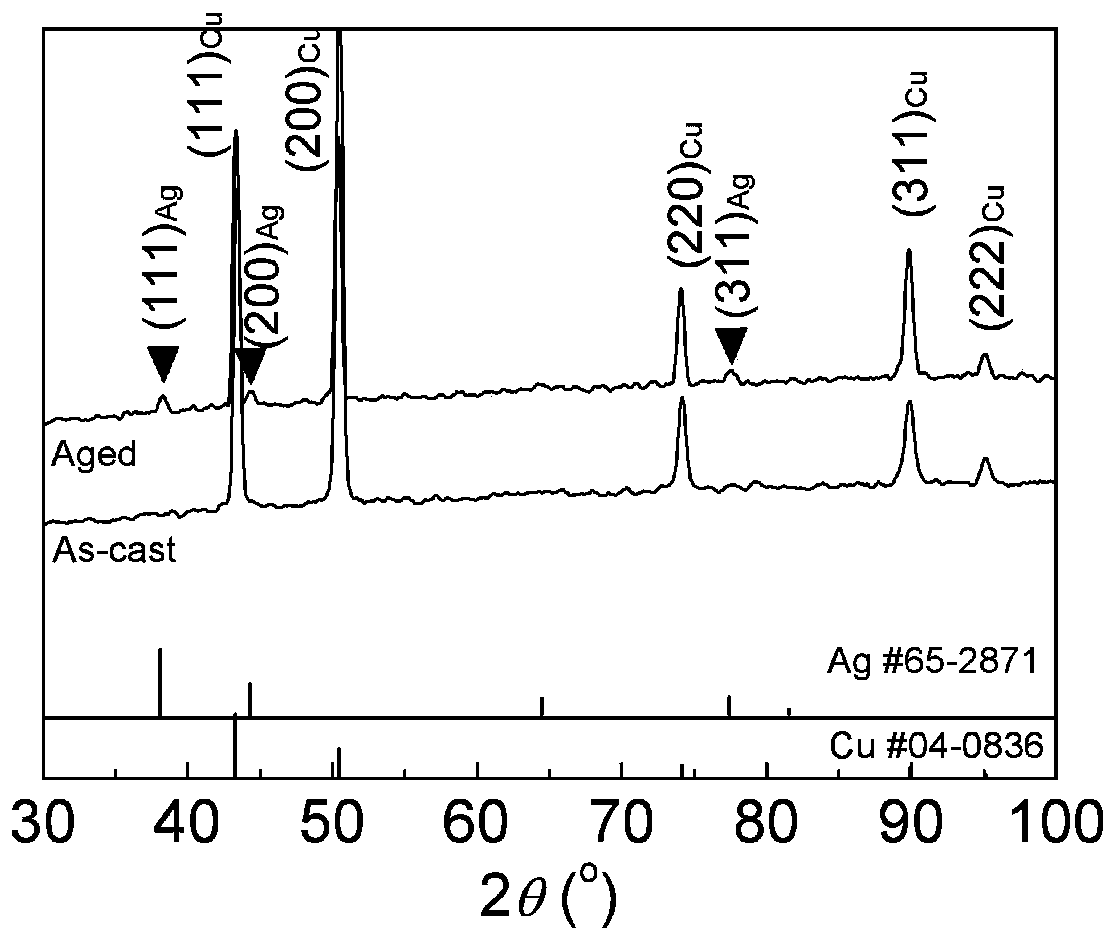

High-temperature and corrosion resistant aluminum-containing austenitic stainless steel and preparation method

InactiveCN113151747AImprove corrosion resistanceGood high temperature mechanical propertiesNuclear energy generationCooling arrangementSS - Stainless steelOxidation resistant

The invention discloses high-temperature and corrosion resistant aluminum-containing austenitic stainless steel and a preparation method. The high-temperature and corrosion resistant aluminum-containing austenitic stainless steel comprises, by weight, 15%-30% of Ni, 15%-25% of Cr, 2.5%-8% of Al, 1%-3% of Mo, 0.1%-1% of Si, 0.1%-2% of Nb, 0.02%-0.2% of C, 0.02%-0.2% of Y / Hf and the balance Fe. According to the aluminum-containing austenitic stainless steel, the content of Cr is increased to 15-25 wt.%, the content of Al is increased to 2.5-8 wt.%, the aluminum-containing austenitic stainless steel contains Cr and Al elements with the enough high content, both Cr and Al are key elements for improving the oxidation resistance, and the high content of Cr and Al contributes to formation of an Al-Cr oxidation film. A stable and compact Cr2O3 oxidation film can be formed on the surface of the alloy, and the oxidation resistance of the material is improved; and meanwhile, the Al2O3 oxidation film can be formed on the surface of the alloy in an oxidizing atmosphere, the Al2O3 layer is good in thermodynamic stability, low in growth rate and more protective in an extreme environment, and the Al can further form a large number of B2-NiAl phases in a matrix. The using temperature of the material in a high-temperature oxidizing atmosphere is increased, the corrosion resistance of the material is improved, and the material can be used in a high-temperature extreme environment.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

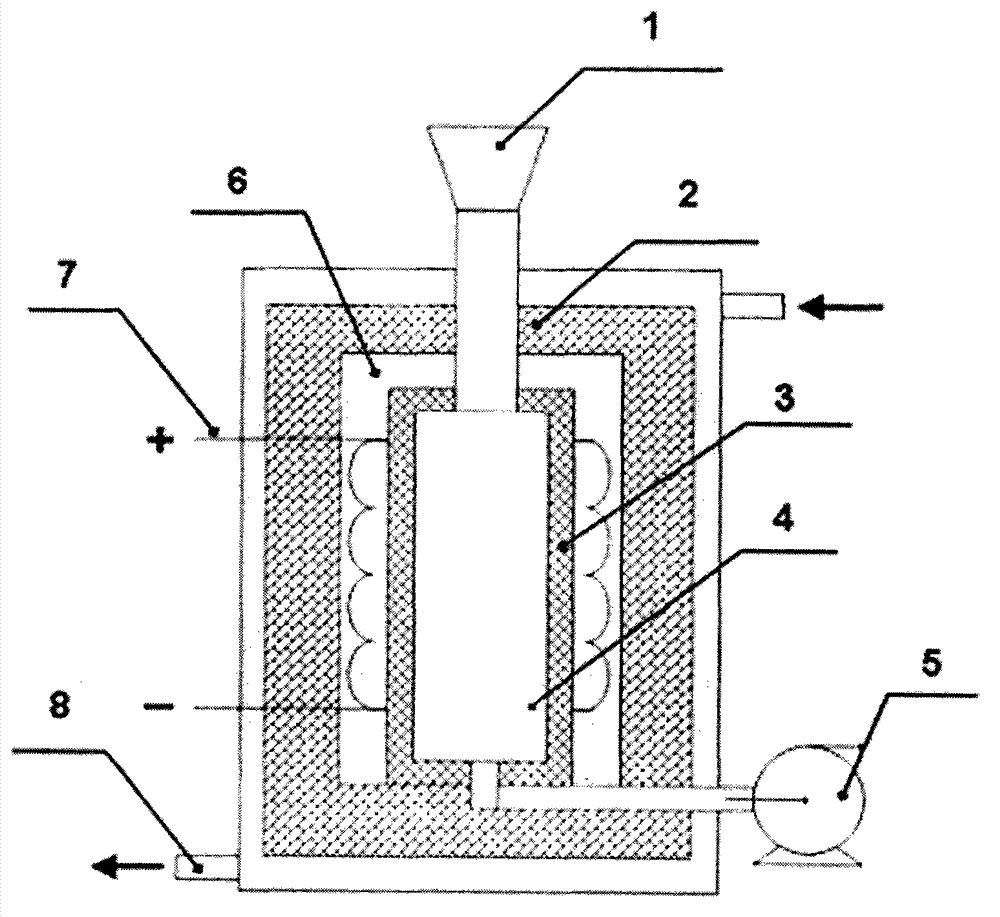

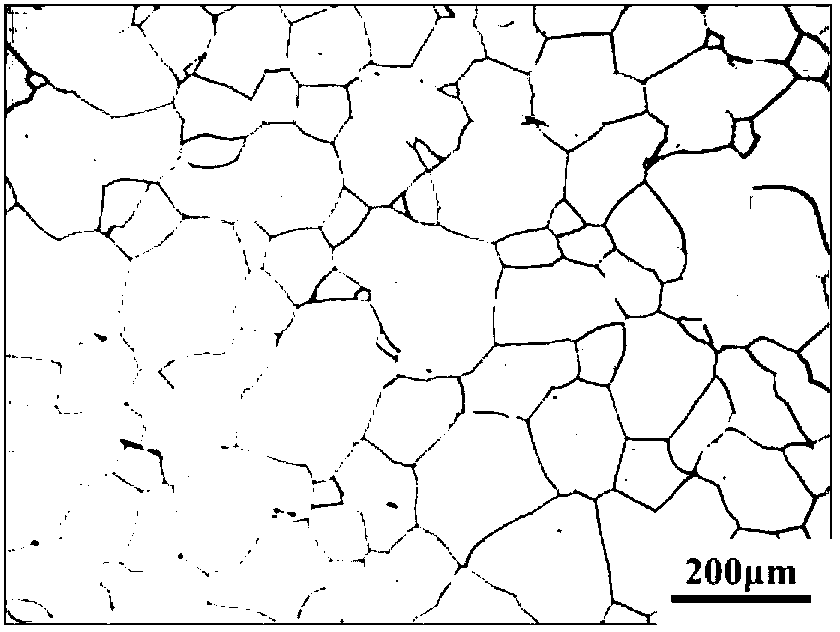

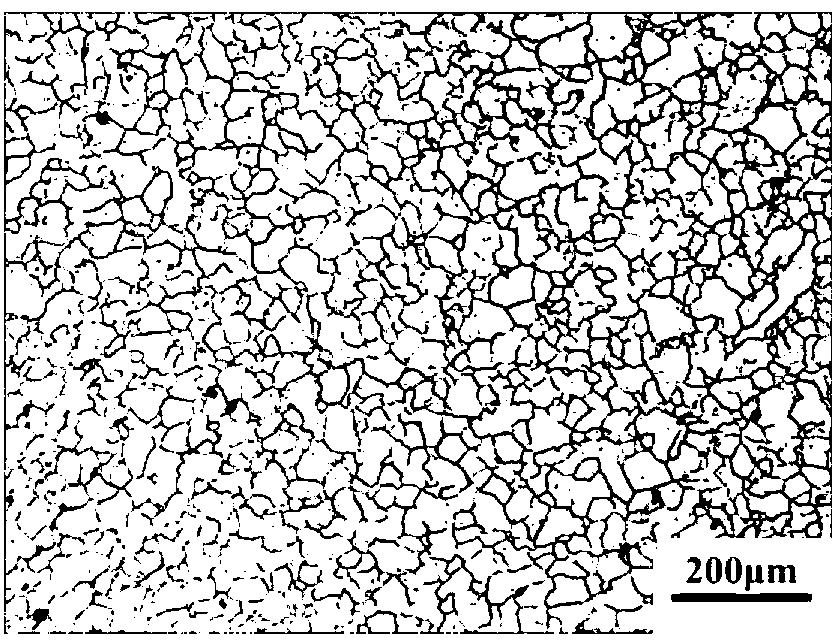

Anti-erosion molybdenum alloy electrode and manufacturing method thereof

ActiveCN109306421AStrong corrosion resistanceRaise the recrystallization temperatureElectric furnaceAlloyImpurity

The invention discloses an anti-erosion molybdenum alloy electrode and a manufacturing method thereof. The anti-erosion molybdenum alloy electrode is prepared by means of solid-liquid doping and multi-element ball-milling doping. The recrystallization temperature of the electrode is higher than 1300 DEG C, the microstructure of the electrode is uniform crystal grains, the dimensions of which are 20-70 [mu]m, and the electrode is prepared from the following components in percent by weight: 3-5wt% of ZrO2, 0.8-1.2wt% of Si, 0.1-0.5wt% of B, 0.001-3wt% of GeO2, 0.001-3wt% of SnO2, 0.001-3wt% of Bi2O3, 0-5wt% of W and 0-4wt% of Al2O3 and the balance of Mo and inevitable impurities. By controlling the content of zirconium oxide and the proportion of silicon and boron in a Mo-Si-B alloy reasonably, the alloy has good anti-erosion capacity, high recrystallization temperature and high-temperature behavior and also has good processing capacity. In addition, other targeted microelements are alsodoped in the molybdenum alloy electrode, so that the anti-erosion capacity to different molten glass is improved.

Owner:XIAMEN HONGLU TUNGSTEN MOLYBDENUM IND CO LTD +1

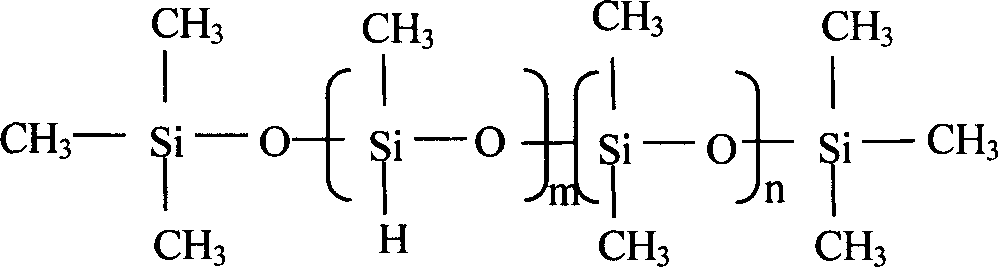

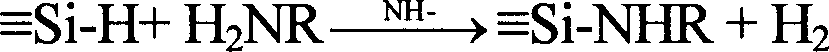

High temperature structured ceramic material SiBONC and preparation method

The material related by this invention is amorphous and crystallite ceramics composed of Si, B, O, N, C is mole ratio (1-6):1:(2-8):(1-2):(0.2-0.5). The prepn. steps are: a. silicon tetrachloride and benzaldehyde are mixed and illuminated by ultraviolet lamp to react to generate silica compound; b. alkylamine is put into the silicon compound to generate organic polymer Si-O-N, C. boron compound is put into into the organic polymer Si-O-N to generate organic polymer Si-B-O-N-C; d. organic polymer Si-B-O-N-C is splited to Si-B-O-N-C powder in pipe-type air protecting furnace; e. the prepared Si-B-O-N-C powder is fired to produce compacted ceramics Si-B-O-N-C by vacuum air heat pressing.

Owner:HARBIN INST OF TECH

Continuous extrusion process of high-strength and high-conductivity copper alloy, application of continuous extrusion process and die material

ActiveCN111394609AHigh crystal defectsHigh strength propertiesExtrusion diesQuenching devicesElectro conductivitySupersaturated solid solution

The invention discloses a continuous extrusion process of a high-strength and high-conductivity copper alloy, application of the continuous extrusion process and a die material. The die material is made of a forged high-temperature nickel-based alloy, and the alloy comprises 0.05% of C, 15% of Cr, 6% of Mo, 5% of W, 2% of Ti, 5.5% of Al and the balance Ni. The continuous extrusion process of the copper alloy comprises the following steps that (1.1) an extrusion die adopts the forged high-temperature nickel-based alloy; (1.2) the extrusion die is preheated to 500 - 600 DEG C before extrusion isstarted, a copper alloy casting blank is preheated to 700 - 750 DEG C, then the copper alloy casting blank is fed into a die cavity to be subjected to continuous extrusion to obtain a blank, whereinthe rotating speed of an extrusion wheel is controlled to be 3 - 8 rpm, the extrusion ratio is controlled to be 3-8 and the extrusion gap is controlled to be 0.6 - 2 mm; and (1.3) the blank obtained in the step (1.2) is subjected to high-strength cooling water spraying at an outlet of the extrusion die, and the blank is obtained. The invention provides the application of the continuous extrusion process in preparation of the copper alloy. The die material has very good high-temperature mechanical properties, and the continuous extrusion process solves the problem of desolvation and decomposition of a supersaturated solid solution in the continuous extrusion process and ensures the high strength and high conductivity of the copper alloy.

Owner:ZHEJIANG UNIV

Process for preparing SiBONC ceramic with high temp stabilized

A process for preparing the SiBONC ceramic with high high-temp (1500-1800 deg. C) stability includes such steps as dissolving organic silica oil and alkylamine in organic solvent, stirring while heating at 70-100 deg. C for 20-30 hr to obtain precursor SiONC, preparing precursor SiBONC, and cracking to obtain SiBONC ceramic powder. Its advantages are high bending strength and breaking toughness, and high high-temp performance.

Owner:HARBIN INST OF TECH

Process for preparing high temperature texture ceramic material SiBONC

The present invention relates to preparation process of ceramic material. The preparation process of high temperature structural ceramic material SiBONC includes the following steps: A. mixing silicon tetrachloride and benzaldehyde and irradiating the mixture with ultraviolet lamp for reaction to obtain Si-O polymer; B. adding alkyl amine into the silica polymer to obtain organic Si-O-N polymer; C. adding boride into the organic Si-O-N polymer to obtain organic Si-B-O-N-C polymer; D. cracking organic Si-B-O-N-C polymer in tubular protecting atmosphere furnace to obtain Si-B-O-N-C powder; E. sintering the Si-B-O-N-C powder in vacuum / atmospheric pressure to obtain compact Si-B-O-N-C ceramic. The Si-B-O-N-C ceramic has simple preparation process, and low cost.

Owner:HARBIN INST OF TECH

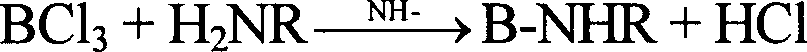

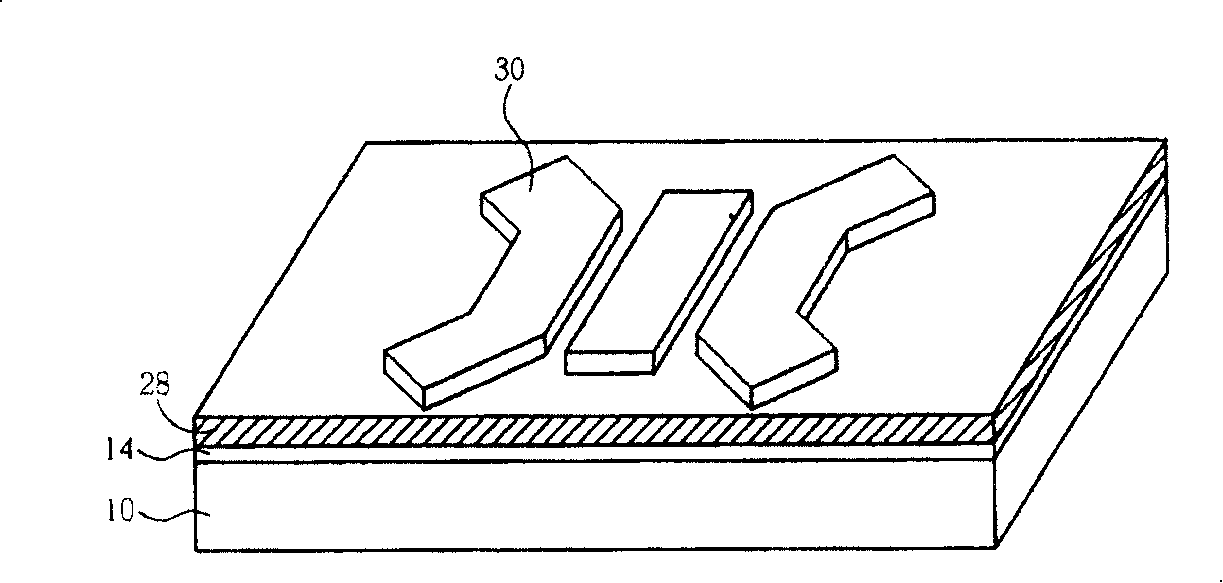

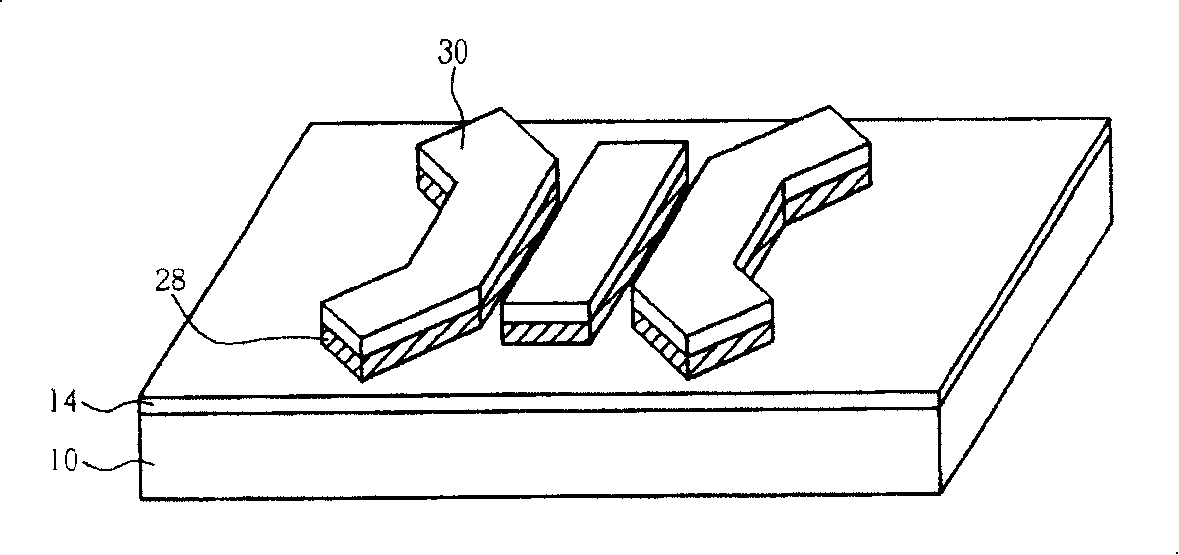

Ultra-alloy minitype heater and method for making

InactiveCN101203074AHeat resistantGood high temperature mechanical propertiesHeating element materialsElectrical componentsHigh resistanceBasement

The invention includes a superalloy micro-heater, comprising a basement, an insulating layer arranged on the front side of the basement, a patterned heating resistance arranged on the insulating layer and a contact electrode arranged on the heating resistance, wherein, the heating resistance which is made of superalloy material has the advantages of corrosion resistance, high resistance, fast temperature rising and high temperature resistance and can greatly enhance the reliability and repeatability of the superalloy micro-heater.

Owner:TOUCH MICRO SYST TECH

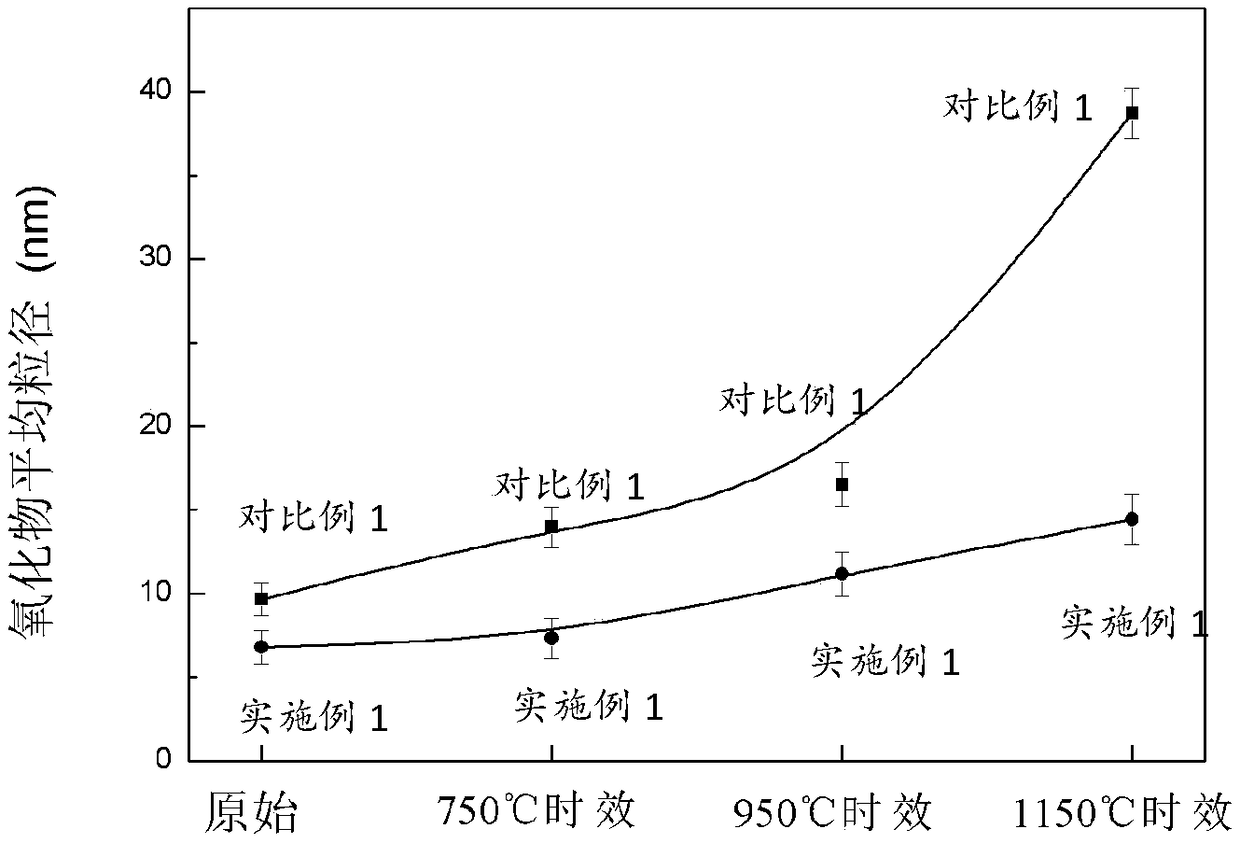

Oxidation dispersion strengthened steel and preparation method thereof

The invention provides oxidation dispersion strengthened steel comprising the following components of, by mass, 15%-17% of Cr, 2%-4% of Al, 1%-2% of W, 0.3%-1.0% of Y2O3, 0.3%-0.8% of Hf, and the balance Fe. According to records of the embodiment, oxide in the 16 Cr-oxidation dispersion strengthened (ODS) steel is refined effectively with the Hf element, and the oxide in the ODS steel provided bythe invention has better size stability and tensile strength performance in a high temperature environment.

Owner:TIANJIN UNIV

Alloy powder for die steel laser cladding remanufacturing and preparation method of alloy powder

InactiveCN110238383AImprove high temperature mechanical propertiesGood high temperature mechanical propertiesMetallic material coating processesCrack resistanceAlloy

The invention discloses alloy powder for die steel laser cladding remanufacturing and a preparation method of the alloy powder. The alloy powder comprises the following components of, in percentage by weight, 0.45%-0.60% of C, 4.20%-8.50% of Co, 3.20%-4.80% of Cr, 1.20%-3.35% of Mo, 0.60%-2.40% of Mn, 0.40%-0.85% of Nb, 0.50%-2.40% of Si, 0.8%-3.2% of B, 0.01%-0.03% of Y2O3, 0.01%-0.03% of La2O3, less than or equal to 0.035% of P, less than or equal to 0.025% of S and the balance Ni. According to the alloy powder for die steel laser cladding remanufacturing and the preparation method of the alloy powder, the crack resistance, the formability, the process stability and the component uniformity of the alloy powder in the laser cladding process can be improved, the high-temperature mechanical property of 4Cr5Mo3V die steel is improved, the service life of the 4Cr5Mo3V steel is prolonged, and the economical efficiency is good.

Owner:CHANGSHAN SHUANGMING BEARING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com