Microalloying method for improving toughness of molybdenum and molybdenum alloy fusion welding lines

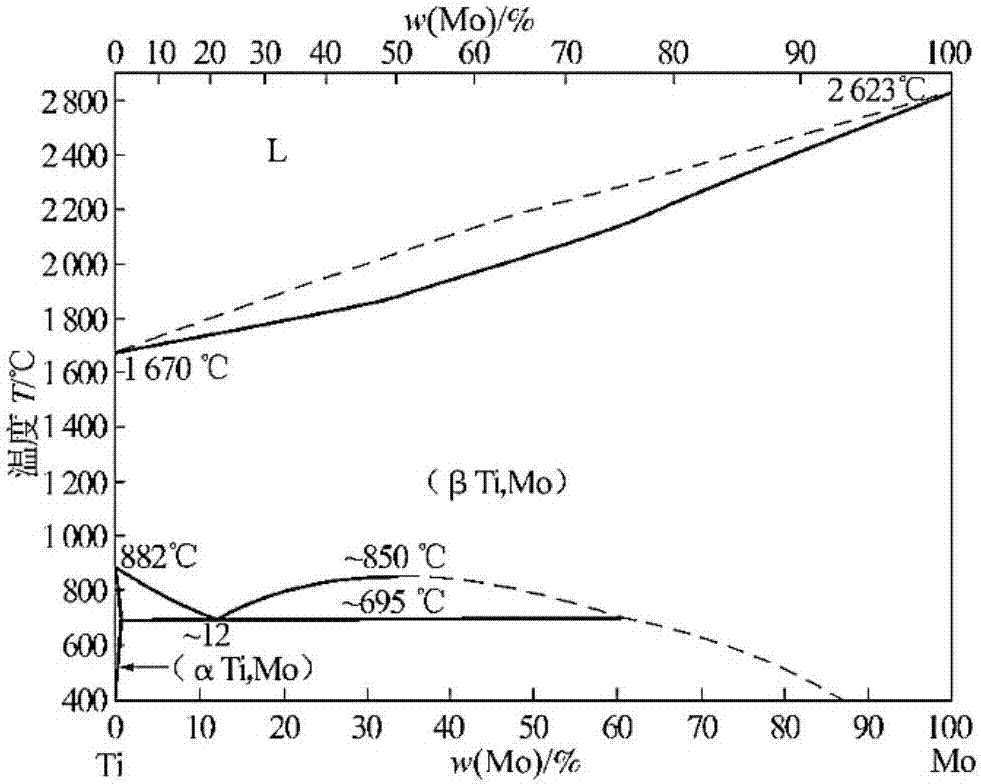

A micro-alloying and molybdenum alloy technology, applied in welding equipment, welding equipment, arc welding equipment, etc., can solve the problems of segregation of impurity elements, and achieve the effect of improving toughness, strong affinity, and eliminating segregation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

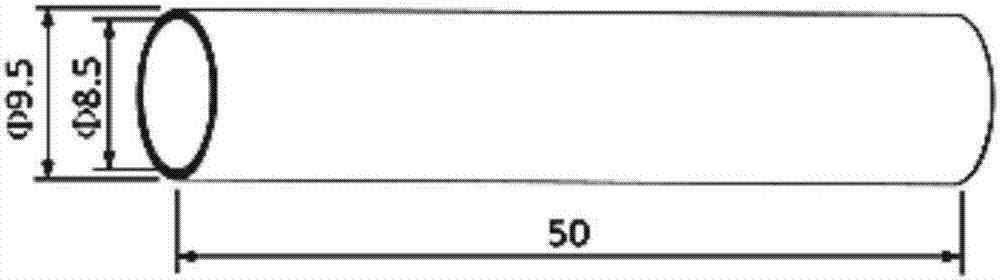

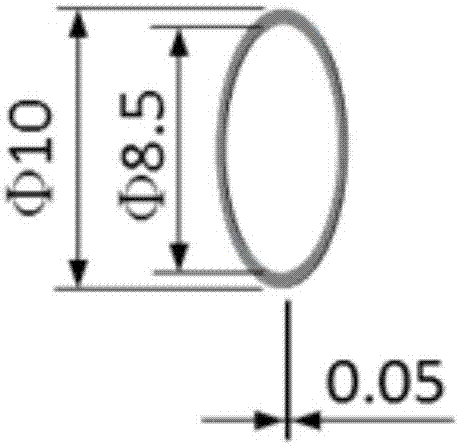

[0044] With 0.25wt% La 2 o 3 The butt laser welding of high-performance molybdenum alloy thin-walled tube with end plug in dispersion-strengthened phase is taken as an example. The dimensions are shown in Fig. 2(a), Fig. 2(b) and Fig. 2(c). ), Figure 2(b) and Figure 2(c) are marked in mm; the main operation process of welding is as follows: 1) use 240# sandpaper, 600# sandpaper, 1000# #Sandpaper for grinding, then alkali washing with dilute sodium hydroxide aqueous solution, and finally ultrasonic cleaning with acetone, drying for later use; 2) Process TA1 titanium foil with a thickness of 0.05mm into a ring with an outer diameter of 10mm and an inner diameter of 8.5mm spacer, again with 12 mL of HNO 3 , 6mL of HF and 82mL of H 2 The solution prepared by O is pickled to remove the oxide film on the surface of the titanium foil, and finally ultrasonically cleaned with acetone and dried for later use; 3) Assemble the molybdenum tube and the end plug, and fill the joint with t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com