Patents

Literature

213results about How to "Eliminate segregation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cast iron inoculant and method for production of cast iron inoculant

InactiveUS6102983AEliminate segregationIncrease the number ofBlast furnace componentsBlast furnace detailsCeriumManganese

The invention relates to an inoculant for the manufacture of cast iron with lamellar, compacted or spheroidal graphite. The inoculant comprises between 40 and 80% by weight of silicon, between 0.5 and 10% by weight of calcium and / or strontium and / or barium, between 0 and 10% by weight of cerium and / or lanthanum, between 0 and 5% by weight of magnesium, less than 5% by weight of aluminium, between 0 and 10% by weight of manganese and / or titanium and / or zirconium, between 0.5 and 10% by weight of oxygen in the form of one or more metal oxides, the balance being iron, said inoculant further comprising between 0,1 and 10% by weight of sulphur in the form of one or more metal sulphides. The invention further relates to a method for the production of the inoculant.

Owner:ELKEM

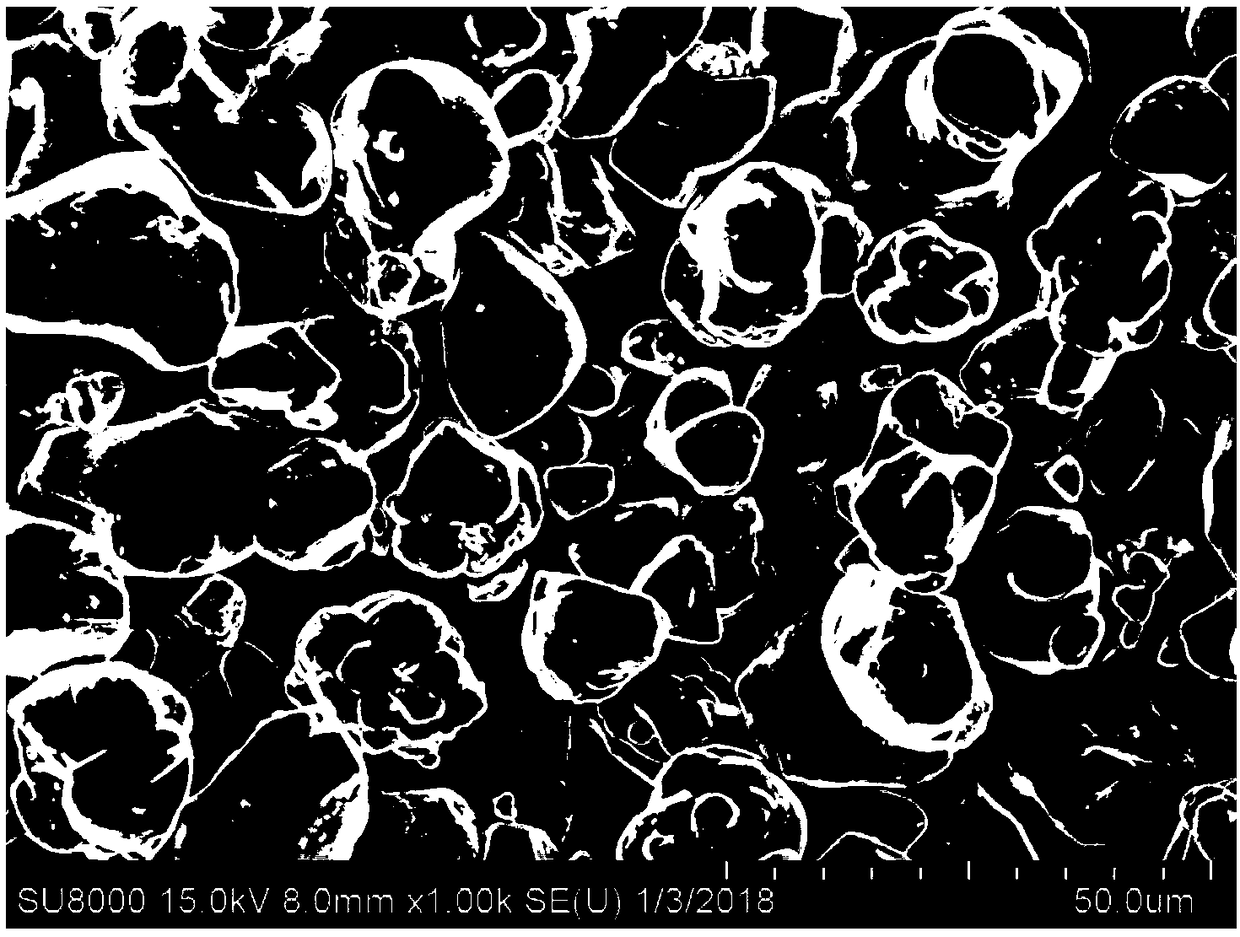

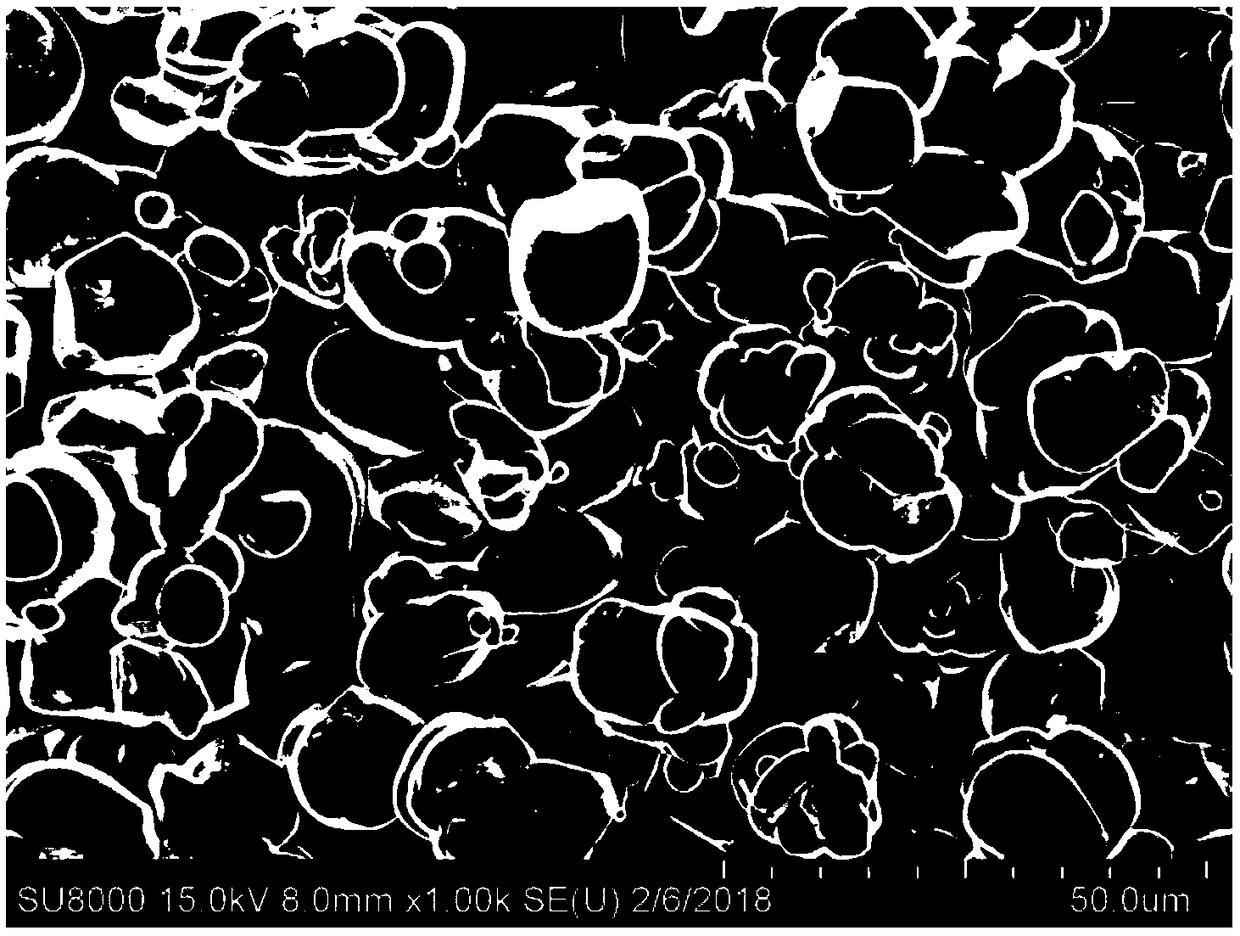

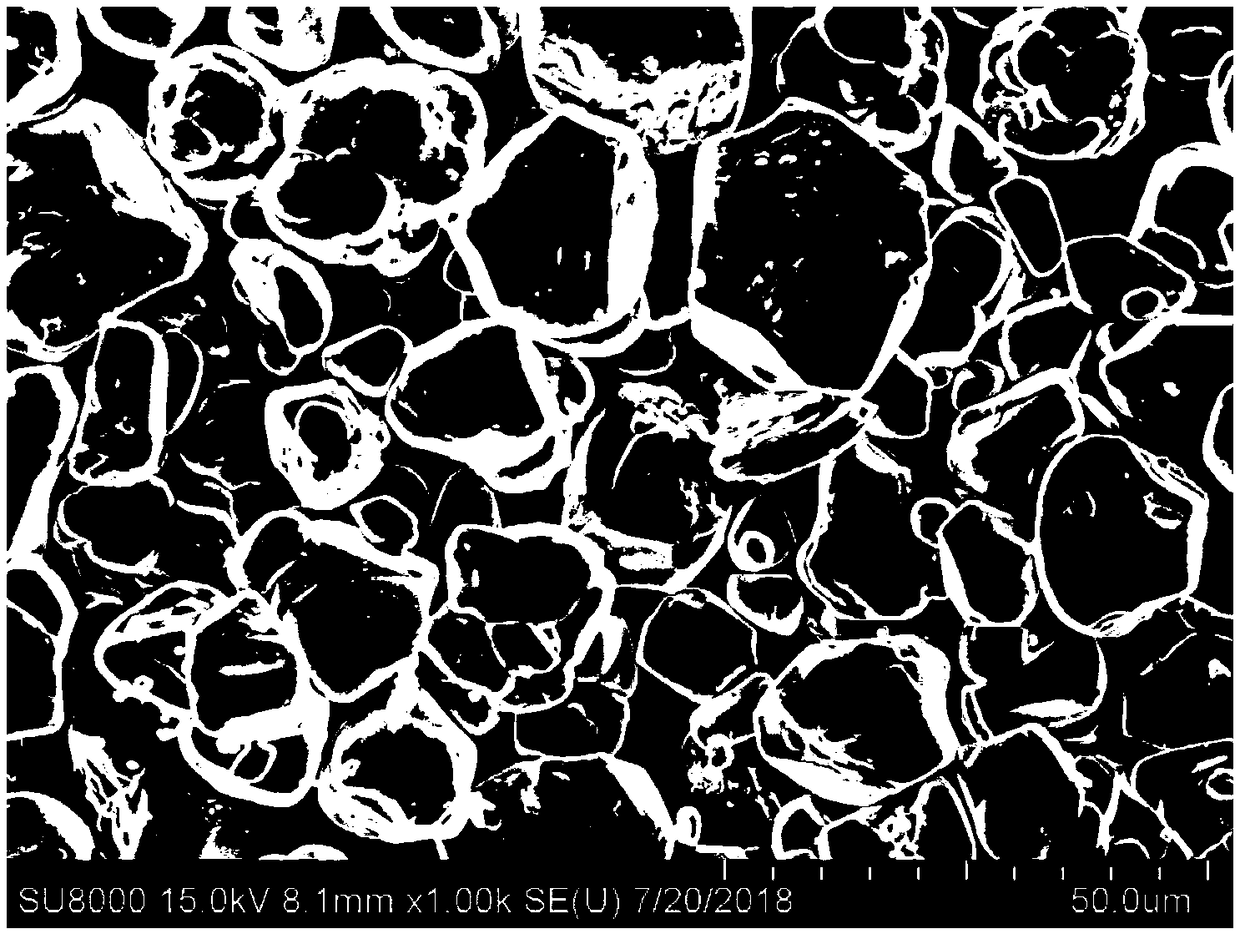

Preparation method of high-voltage lithium cobalt oxide cathode material

ActiveCN109326781AEvenly distributedWell mixedSecondary cellsPositive electrodesDual effectCobalt(II,III) oxide

The invention discloses a preparation method of a high-voltage lithium cobalt oxide cathode material which comprises the steps: (1) mixing cobaltosic oxide containing doped element M, a lithium source, oxide containing doped element M', a grain refiner and a fluxing agent to obtain a primary mixture; (2) sintering and smashing the primary mixture to obtain primary sintered powder; (3) mixing the primary sintered powder with a coating material to obtain a secondary mixture; (4) sintering and smashing the secondary mixture to obtain the lithium cobalt oxide cathode material. According to the preparation method disclosed by the invention, the problem of microscale segregation of distribution of doped elements in the product is solved by two modes of doped element premixing and dry-method mixing; a coulter type mixing technology is utilized to solve the problem of segregation of different matters in material mixing; the grain refiner and the fluxing agent are combined for use to synthesizea material in a mixed morphology; technologies such as dual effects of doped element surface crystallization catalysis and the coating material and the like are utilized; thus, performance of the high-voltage lithium cobalt oxide is obviously improved.

Owner:HUNAN CHANGYUAN LICO CO LTD

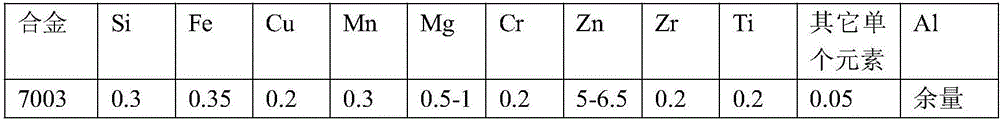

Method for manufacturing aluminum alloy hollow section for sedan bumper

The invention discloses a method for manufacturing an aluminum alloy hollow section for a sedan bumper, relates to a method for manufacturing an aluminum alloy hollow section, and aims to solve the problem that domestic limousine bumpers are low in tensile strength and non-proportional extension strength and dependent on import. The method comprises the following steps of: 1, preparing alloy melt; 2, casting an alloy cast rod; 3, cutting the cast rod off; 4, turning the cast rod to remove oxide; 5, performing homogenizing annealing; 6, heating a cast ingot; 7, extruding; 8, pre-straightening;9, quenching; 10, straightening; 11, aging; and 12, cutting according to length to obtain the aluminum alloy hollow section for an automobile bumper. The straightness and size of the hollow section prepared by the method completely meet the standards of imported bumpers, and the hollow section has high comprehensive mechanical properties. The method can be used for processing and manufacturing sections for limousine bumpers.

Owner:NORTHEAST LIGHT ALLOY CO LTD

Aluminum alloy for 480 MPa-class aluminum alloy oil pipe and pipe manufacturing method thereof

The invention discloses an aluminum alloy for a 480 MPa-class aluminum alloy oil pipe. The aluminum alloy comprises the following components by weight percent: 5.10-6.90% of Zn, 1.10-1.80% of Mg, 0.05-0.20% of Cu, 0.10-0.30% of Mn, 0.10-0.30% of Cr, 0.01-0.02% of Ti, 0.15-0.2% of Zr and the balance of Al and unavoidable impurities, wherein in the unavoidable impurities, the content of the Si is not greater than 0.15 of the total weight of the aluminum alloy and the content of Fe is not greater than 0.15 of the total weight of the aluminum alloy. The manufacture method of the aluminum alloy pipe comprises the following steps: (1) smelting the raw materials according to the weight percentage, performing external refining and casting to obtain a pipe blank; (2) performing three-stage homogenization treatment; (3) squeezing under high temperature; (4) performing twin-stage solid solution treatment, quenching and cooling; (5) prestretching and deforming; and (6) performing twin-stage artificial aging treatment.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

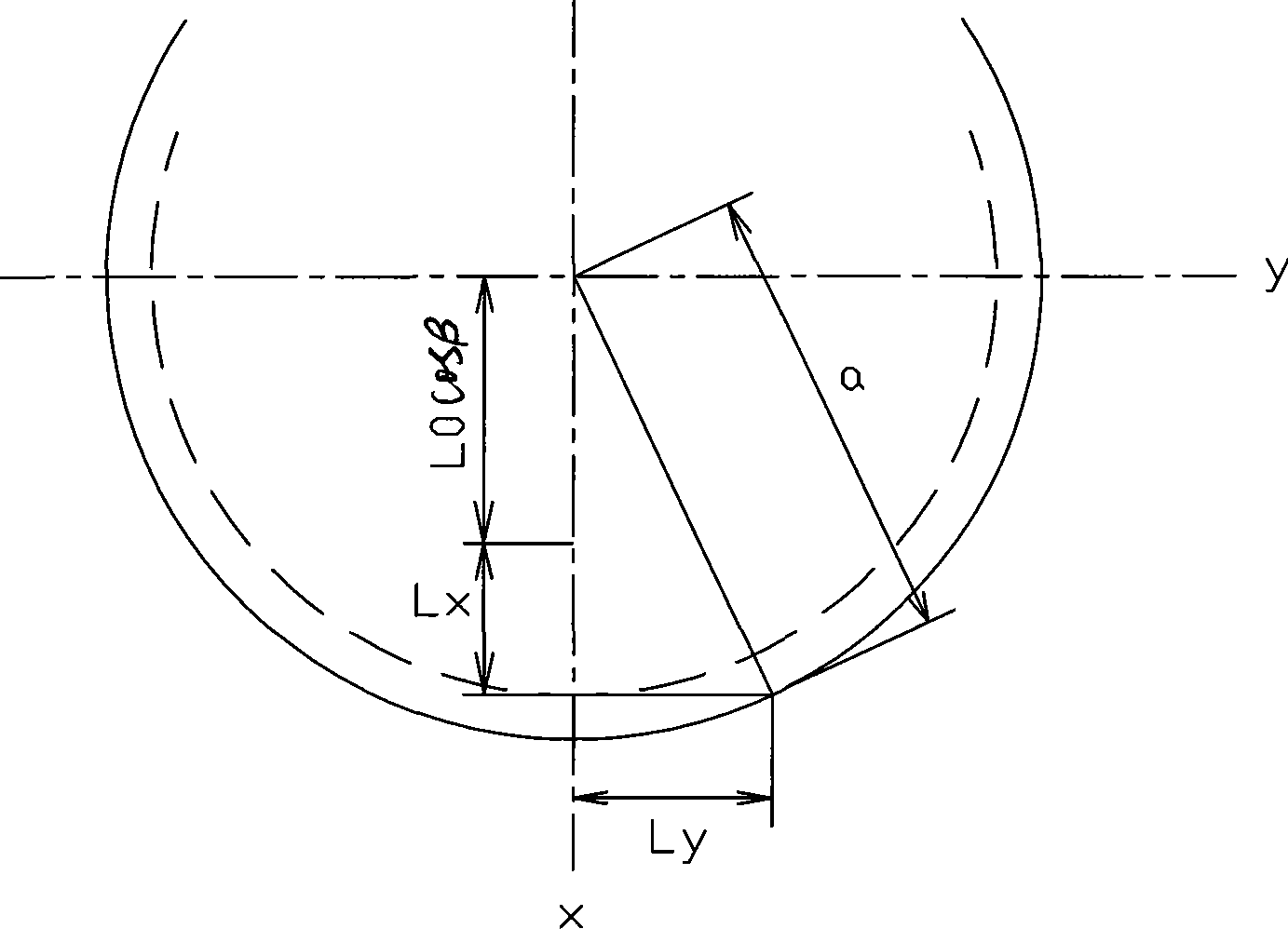

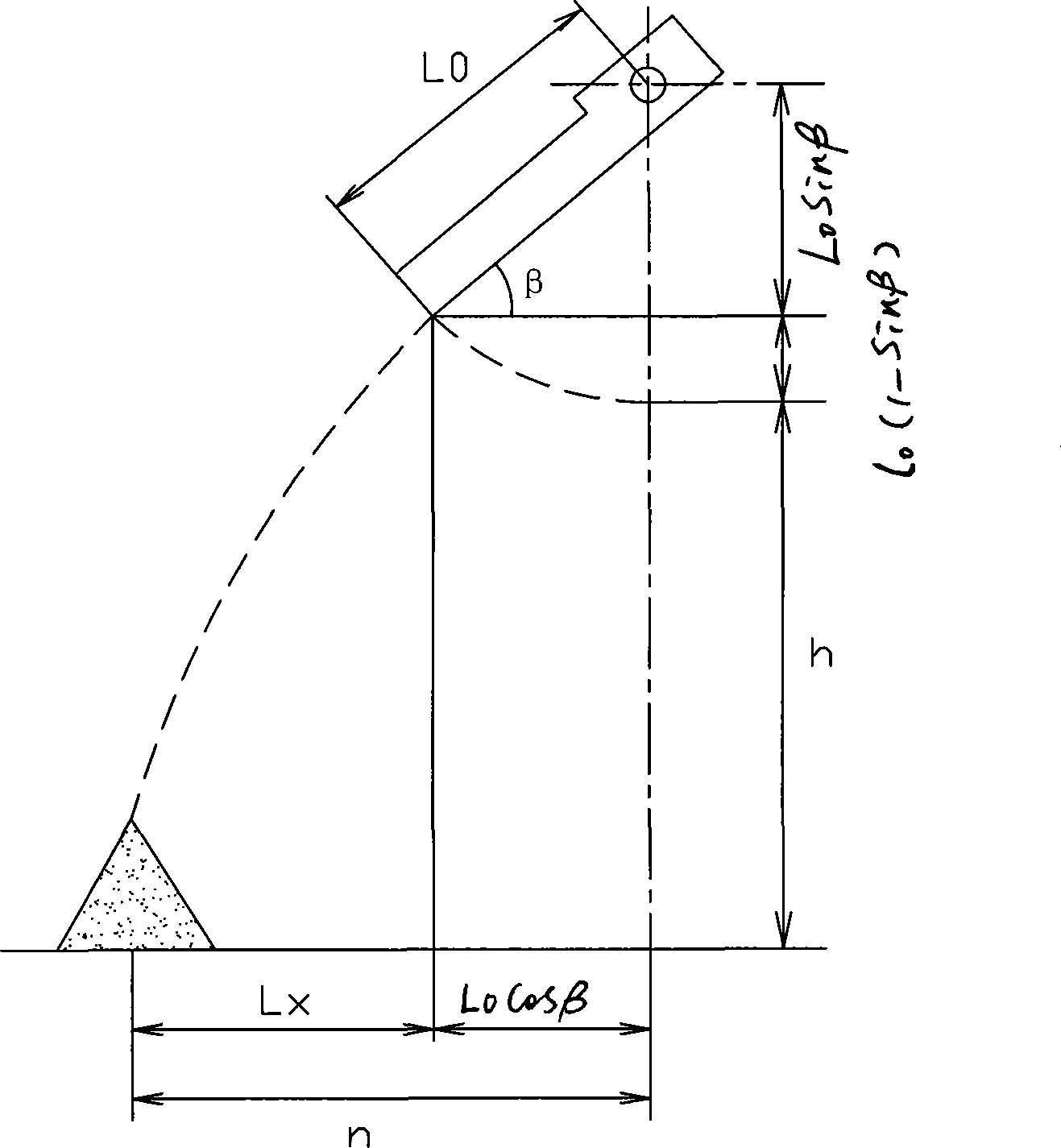

Blast furnace chute polycyclic distributing method

InactiveCN101250602AIncrease production capacityUniform material layerBell-and-hopper arrangementBlast furnace detailsRing numberGravitation

The invention discloses a blast furnace chute multi-ring burden distribution, which comprises firstly calculating the distance from the center of furnace burden from the center of a blast furnace after furnace burden fell into an xy plane, secondly deciding largest and smallest burden distribution angles in theory, thirdly deciding the actual burden distribution angles of outer ring and inner ring of ores and coke, fourthly deciding the burden distribution ring number of ores and coke, determining the burden distribution angle of middle ring of ores and coke and the angel difference of adjacent rings, and sixthly determining the burden distribution rings of each ring in ores and coke. The process largely enriches the regulating method on the upper portion of the blast furnace, changes coal gas distribution, effectively increases the coal gas usage of the blast furnace, reduces coke ratio, realizes the stable and long term operation of the blast furnace, has strong loading material capacity, can eliminate furnace burden gravity segregation and the existing of pile top, much reasonably distributes furnace burden, is beneficial for strengthening smelting, and improves the press amount relationship and further increases the air quantity of the blast furnace.

Owner:CHONGQING IRON & STEEL (GRP) CO LTD

Lignosulfonate series air entraining and water reducing admixture for concrete and its prepn process and application

The present invention relates to preparation process of serial lignosulfonate air entraining and water reducing admixtures for concrete. The preparation process includes the following steps: dissolving solid lignosulfonate in water of the same weight, adding catalyst and oxidant, heating after reaction, adding amine and partial aldehyde to aminate, and dropping the rest aldehyde for condensation reaction to obtain the product; adding surfactant and polymer through stirring, and cooling to obtain liquid phase lignosulfonate as air entraining and water reducing admixture. The present invention is used as the admixture for concrete, and has relatively high water reducing rate, capacity of raising the strength of concrete, and certain setting retarding effect to delay the appearance of cement setting heat peak and reduce crack caused by temperature change.

Owner:SOUTH CHINA UNIV OF TECH

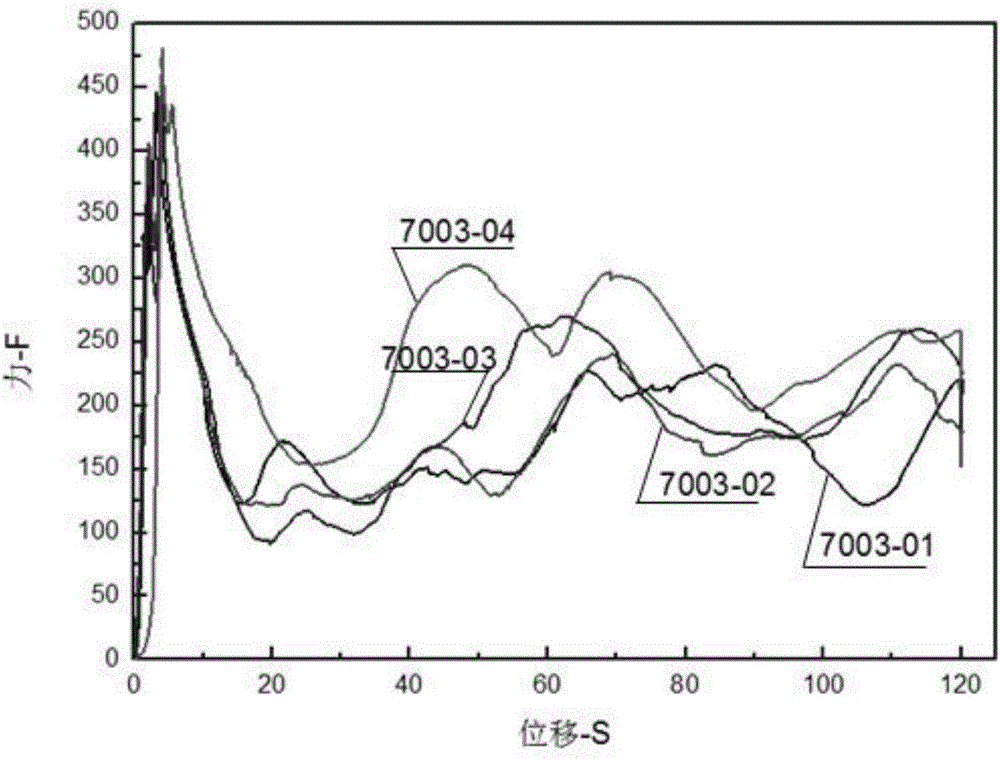

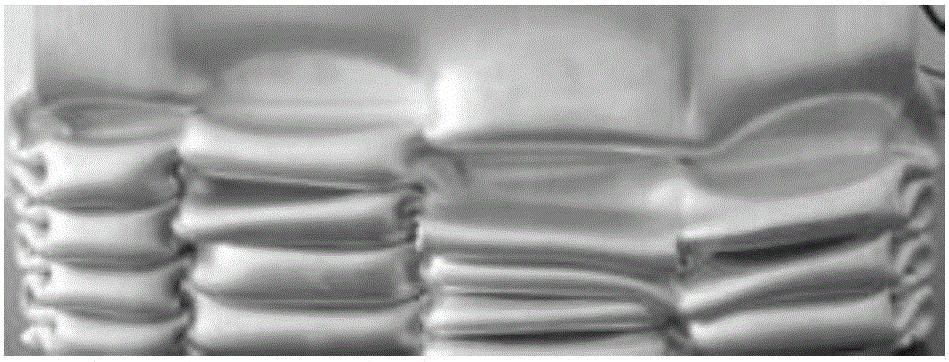

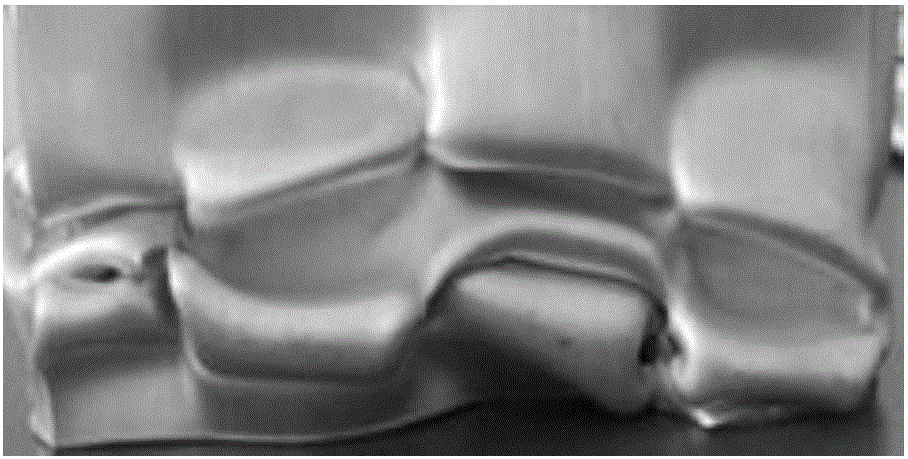

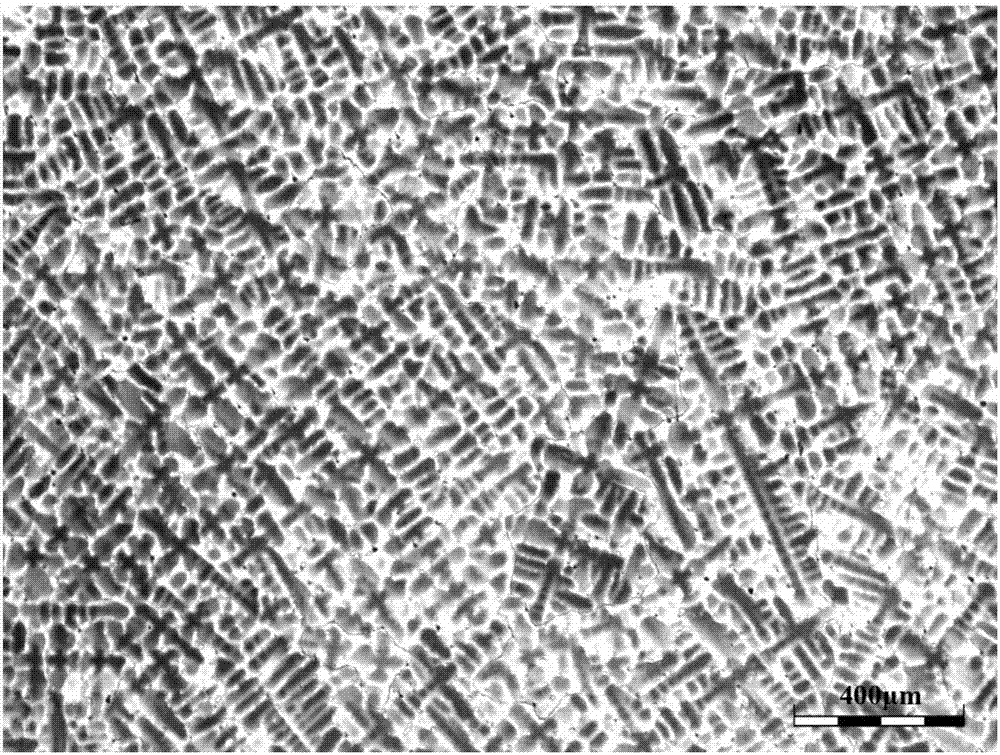

Manufacturing method of 7000-series aluminum alloy section for vehicular bodies

The invention discloses a manufacturing method of a 7000-series aluminum alloy section for vehicular bodies. The 7000-series aluminum alloy section comprises alloy elements including, by mass, 0.145%-0.155% of Si, 0.145%-0.155% of Fe, 0.09%-0.11% of Cu, 0.045%-0.055% of Mn, 0.58%-0.8% of Mg, 0.019%-0.021% of Cr, 5.5%-5.8% of Zn, 0.15%-0.19% of Zr, 0.028%-0.031% of Ti and the balance aluminum, wherein other single element content is smaller than or equal to 0.045%, other element total content is smaller than or equal to 0.15%, and a Zn / Mg ratio is controlled to be 7-10. The manufacturing method includes procedures of smelting, purification, casting for rod forming, homogeneous annealing, extruding, stretching, natural aging, manual aging treatment and the like, great static collision effects of materials can be achieved, the 7000-series aluminum alloy section is especially suitable for manufacturing of aluminum alloy energy absorption boxes and longitudinal beams for vehicular bumper systems, and comprehensive requirements of light weight of the vehicular bodies and energy absorption in low-speed and high-speed collision can be met.

Owner:CYMA PRECISION ALUMINUM

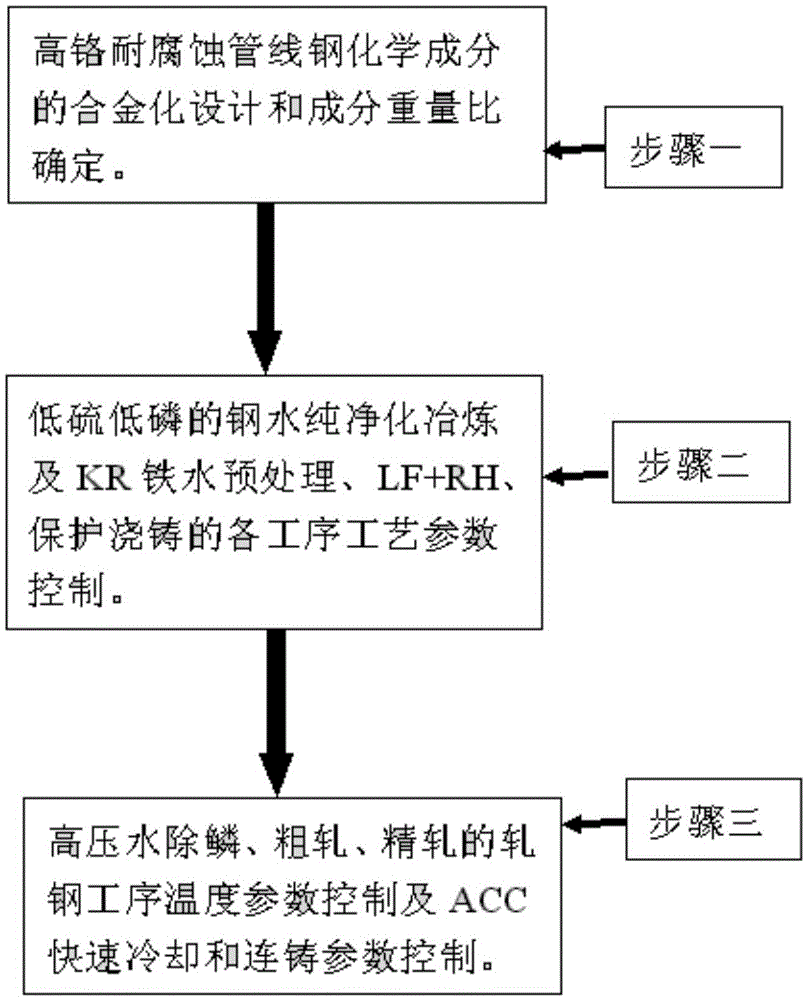

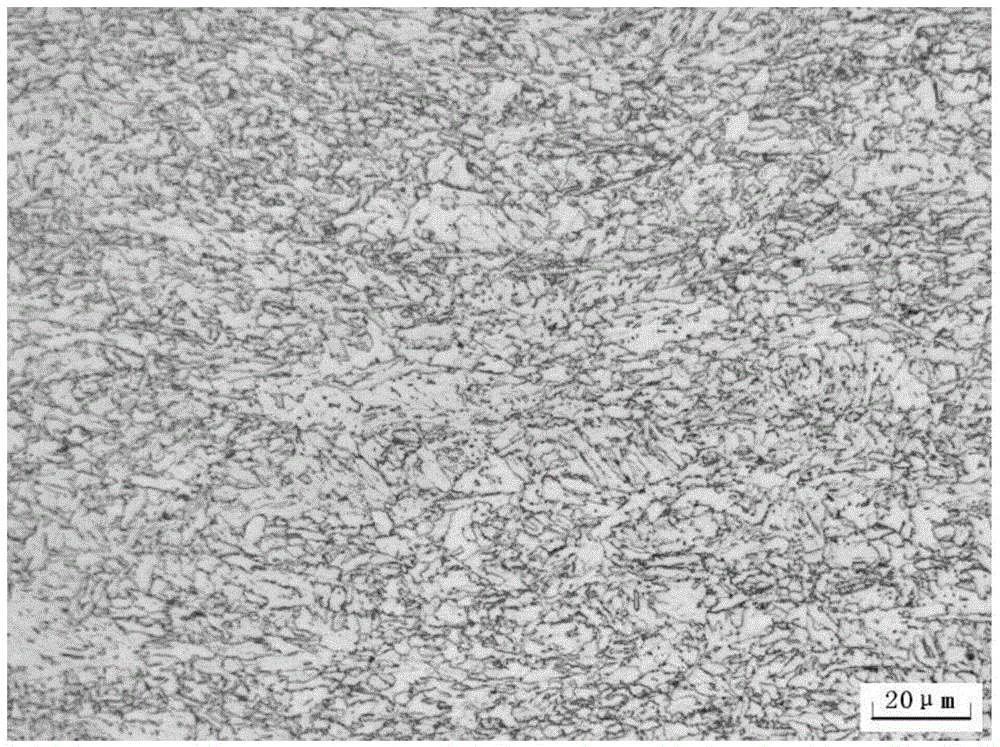

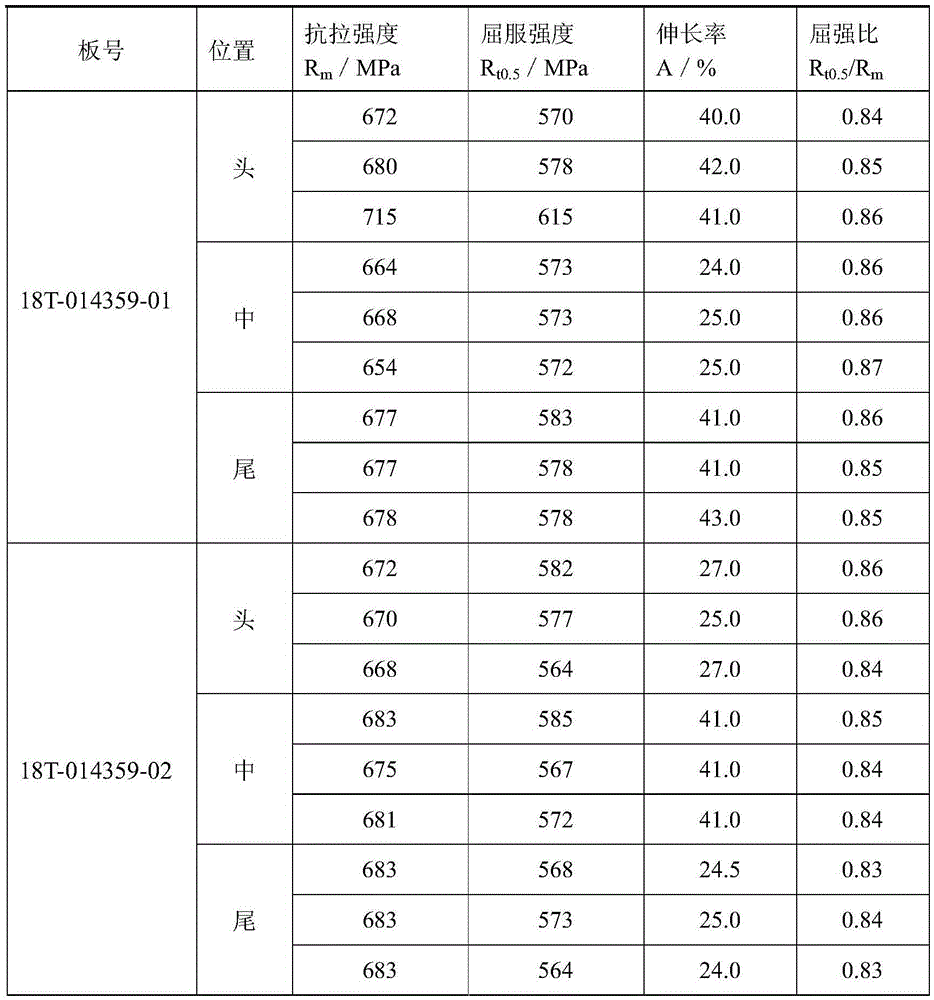

High-chrome corrosion-resisting high-strength pipeline steel and manufacturing method thereof

InactiveCN105483521AEliminate segregationAvoid formingManufacturing convertersProcess efficiency improvementAlloy elementCorrosion resistant

The invention discloses high-chrome corrosion-resisting high-strength pipeline steel and a manufacturing method thereof. The high-chrome corrosion-resisting high-strength pipeline steel is prepared from, by weight percent, 0.04%-0.08% of carbon, 0.15%-0.55% of silicon, 0.15%-0.95% of manganese, 0.030% of phosphorus or less, 0.006% of sulfur or less, 0.8%-2.0% of chrome, 0.15%-0.55% of copper, 0.020%-0.090% of niobium, 0.008%-0.035% of titanium, 0.010% of nitrogen or less and the balance iron and inevitable impurities. The high-chrome corrosion-resisting high-strength pipeline steel is different from universal low-carbon high-manganese composition design, a low-carbon, low-manganese and high-chrome alloying composition system is adopted, the manganese alloy element segregation problem caused by a high-manganese system is eliminated from compositions, and band segregation structure forming is avoided. During molten steel smelting, the refining means of KR molten iron pretreatment deep desulfuration, LF and RH refining and the like are adopted, a dual slag stopping method dephosphorization technology is adopted, a rolling control and cold control rolling process is adopted for controlling phase change temperature, the grain structure is refined, and toughness matching of the pipeline steel is guaranteed; and the produced pipeline steel has excellent corrosion resistance and higher strength and toughness.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Oxidation-resistant alloying grey cast iron and preparation method thereof

The invention discloses an oxidation-resistant alloying grey cast iron and a preparation method of the oxidation-resistant alloying grey cast iron. The cast iron comprises the following components by mass percentage: 3.0-3.2% of C, 1.8-2.0% of Si, 0.50-0.70% of Mn, 0.10-0.50% of Cr, 0.20-0.30% of Ni, 0.03-0.50% of Mo, 0.5-3.0% of Al, 0.05-0.08% of Sr, 0.005-0.15% of Zn, and the balance of Fe and inevitable impurities. The preparation method comprises the steps of melting raw materials, culturing and processing, and pouring, wherein the tapping is carried out at 1450 to 1550 DEG C after melting; the molten iron is processed by being flushed in a ladle and cultured and processed along with the flow, and then slagged and casted. According to the oxidation-resistant alloying grey cast iron provided by the invention, the organization of the grey alloying cast iron material is structured by distributing 6-8 grades of D type graphite with little graphite of A type on a ferrite substrate, so that higher toughness, high heat conductivity and high-temperature oxidization resistance can be achieved, and good casting technical performance can be ensured as well; and the oxidation-resistant alloying grey cast iron can be applied to manufacturing a glass die and a light alloy metal type casting die which can bear the heat impacting of high-temperature formed liquid and cold-heat alternating stress for a long time.

Owner:SUZHOU DONGHAI GLASS MOLD

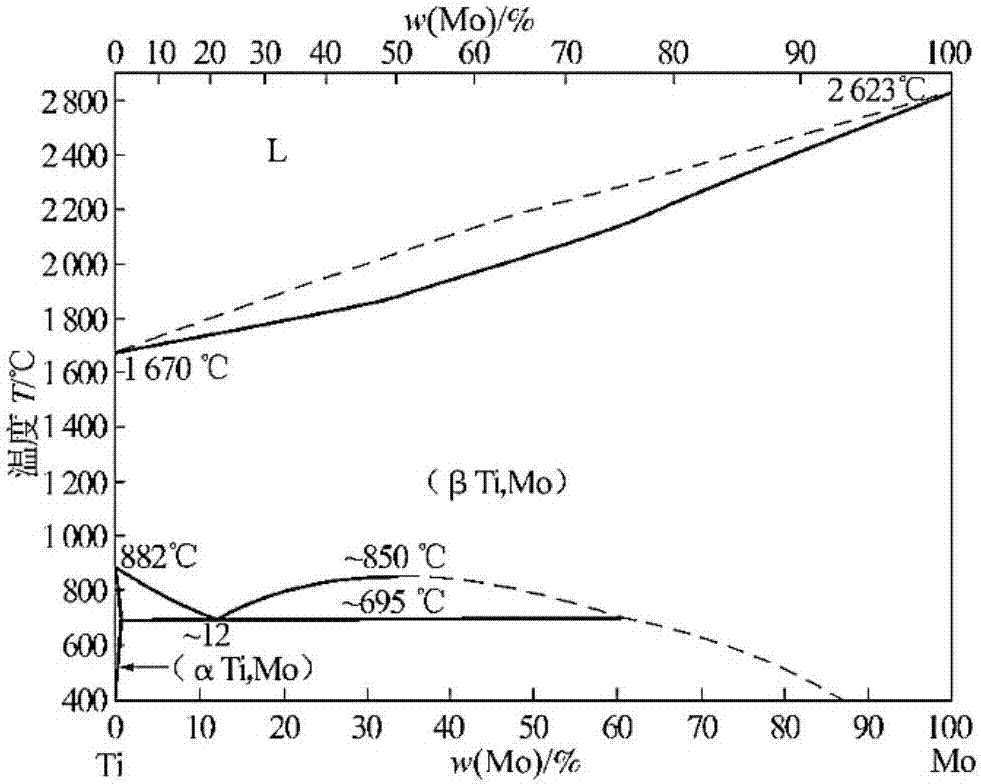

Microalloying method for improving toughness of molybdenum and molybdenum alloy fusion welding lines

ActiveCN107009025AImprove toughnessHigh bonding strengthWelding/cutting auxillary devicesArc welding apparatusRoom temperatureAlloy

The invention discloses a microalloying method for improving toughness of molybdenum and molybdenum alloy fusion welding lines. The microalloying method comprises the following steps: 1) the surfaces of areas to be welded on workpieces to be welded are pretreated, wherein the workpieces to be welded adopt materials of molybdenum or molybdenum alloys; 2) titanium layers are filled in the joined places of the workpieces to be welded; 3) the workpieces to be welded are placed in an inert gas protective atmosphere or a vacuum environment; and welding areas of the workpieces to be welded are preheated; and 4) the workpieces to be welded are welded; and welding line areas of the welded workpieces are insulated, and are cooled to reach the room temperature to finish microalloying of fusion welding lines of the workpieces. The method can eliminate the segregation problem of impurity elements in the grain boundary, and prominently improves the toughness of the molybdenum alloy fusion welding lines.

Owner:XI AN JIAOTONG UNIV

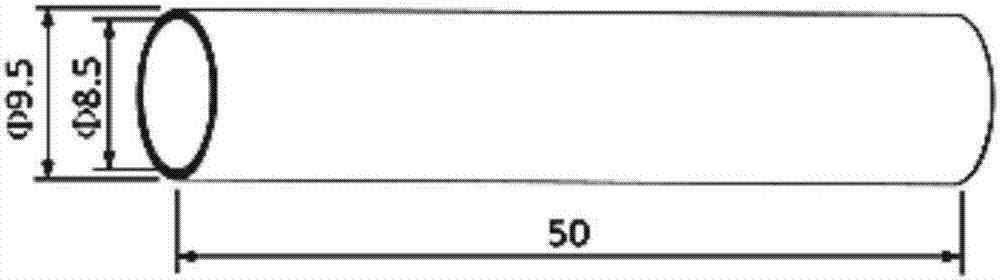

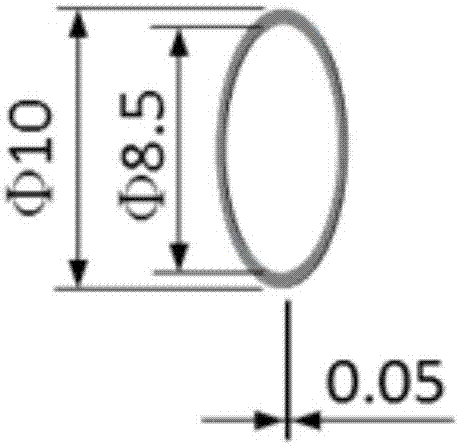

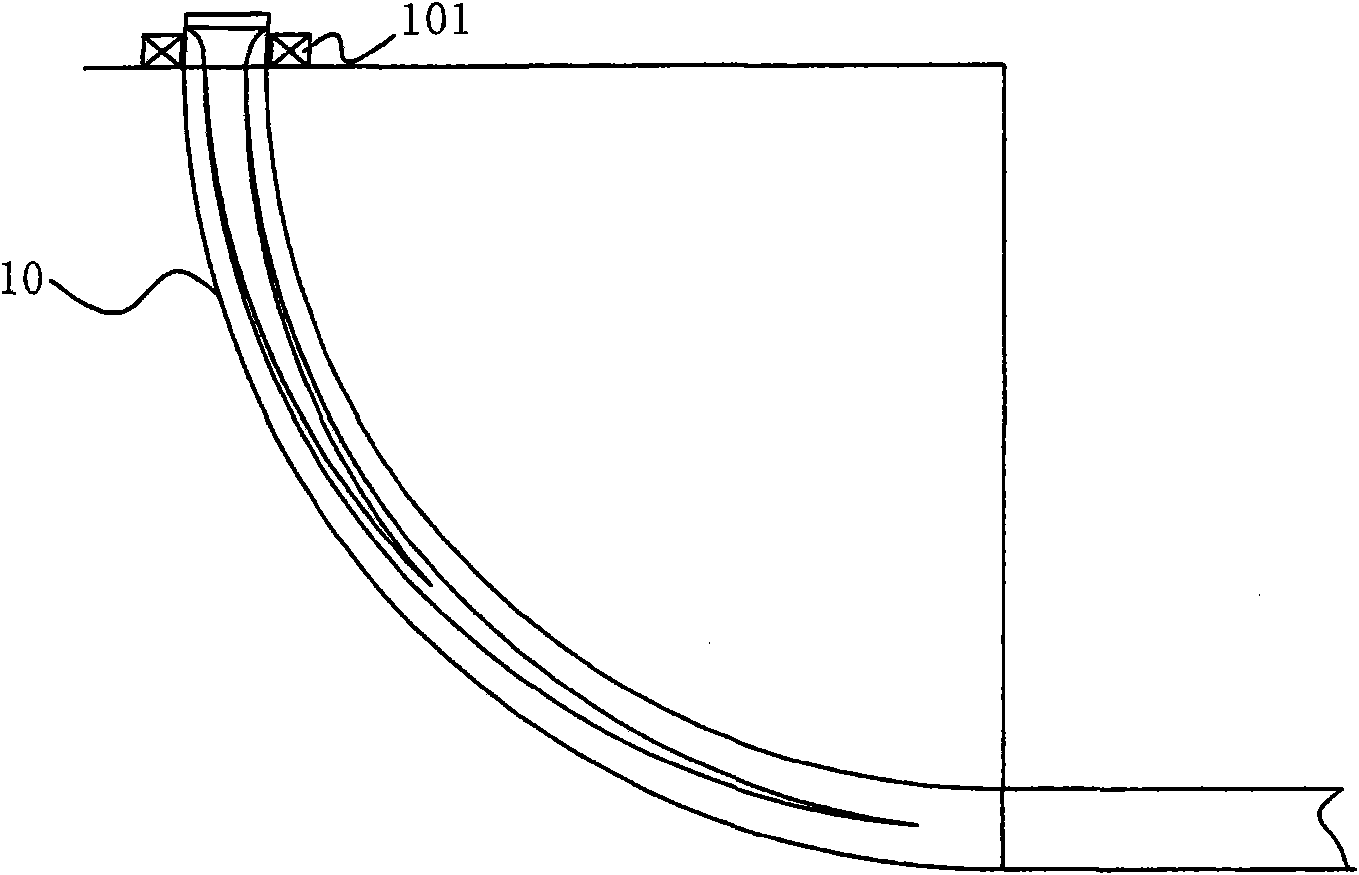

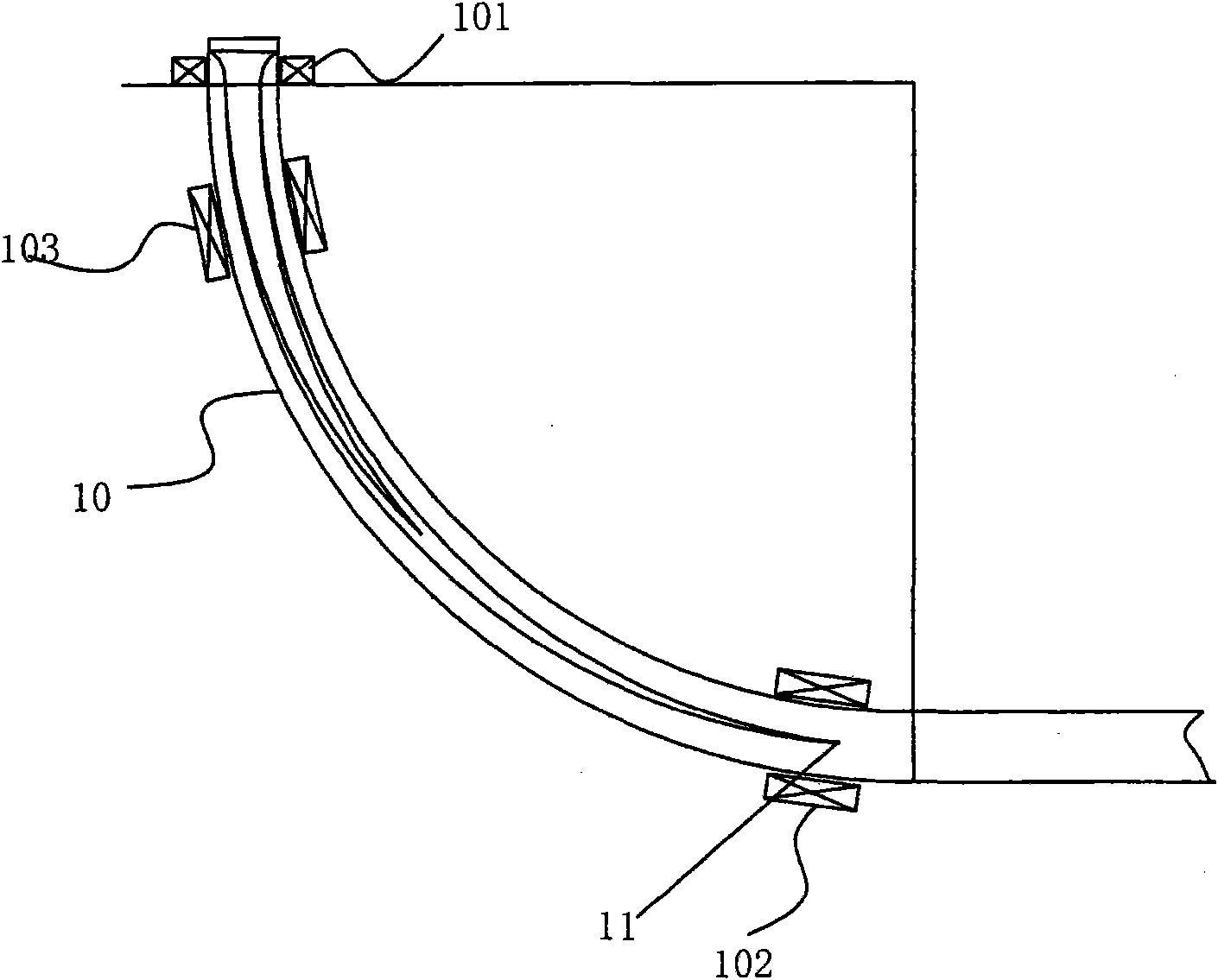

Method for improving internal organization of casting blank of continuous casting machine and electromagnetic stirring device

The invention provides a method for improving the internal organization of a casting blank of a continuous casting machine and an electromagnetic stirring device, wherein the method is as follows: atthe tail end of a continuous casting bank liquid core on a secondary cooling zone of the continuous casting machine, carrying out electromagnetic stirring and generating forward and reverse alternantspiral rotating force which causes molten steel to rotate and flow along the casting direction of the continuous casting machine and appends static pressure to a solid-liquid phase zone of the tail end of the liquid core. The method and the electromagnetic stirring device of the invention can provide enough molten steel for supplying the volume contraction during the solidification of the liquid core and eliminating shrinkage cavity and loose, thus increasing the quality of the continuous blank.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

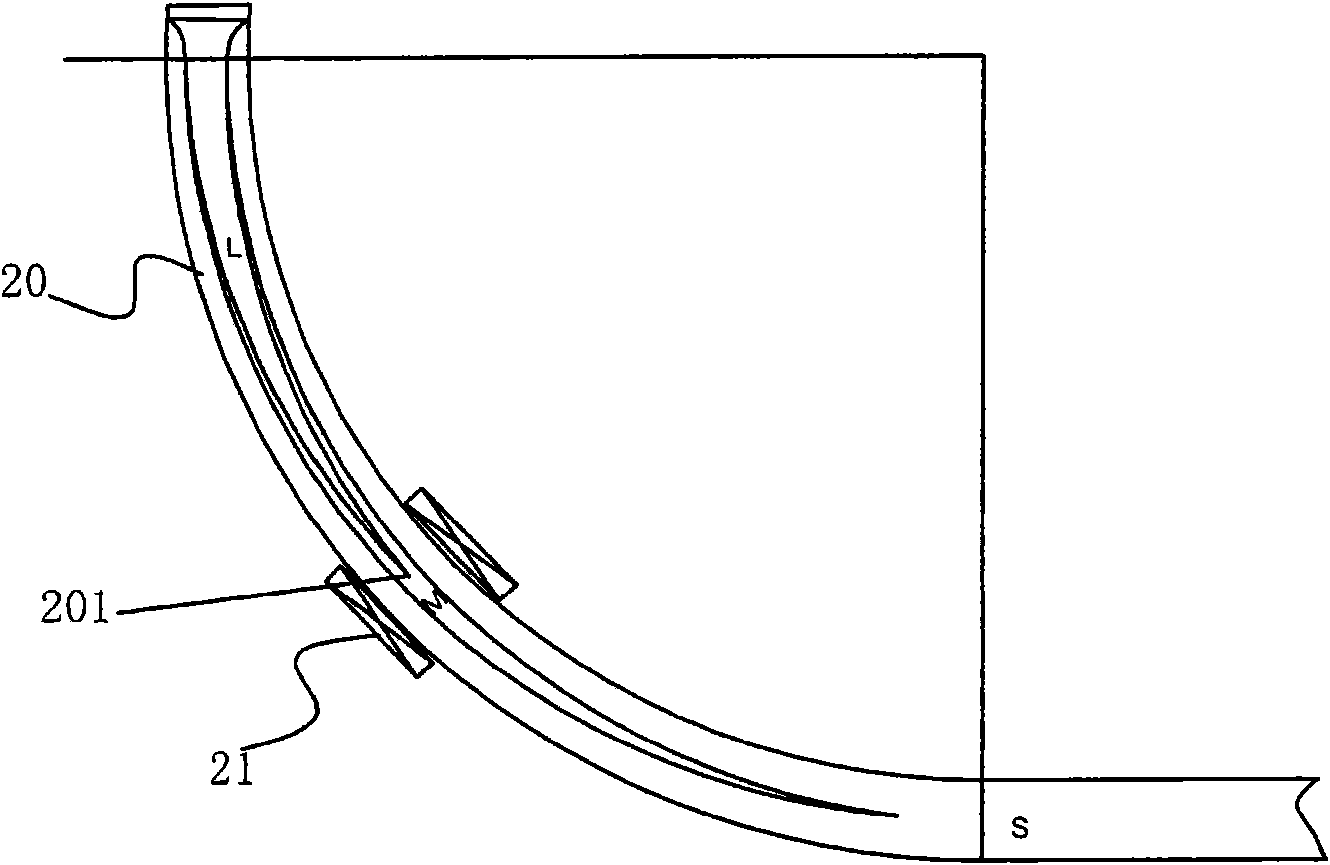

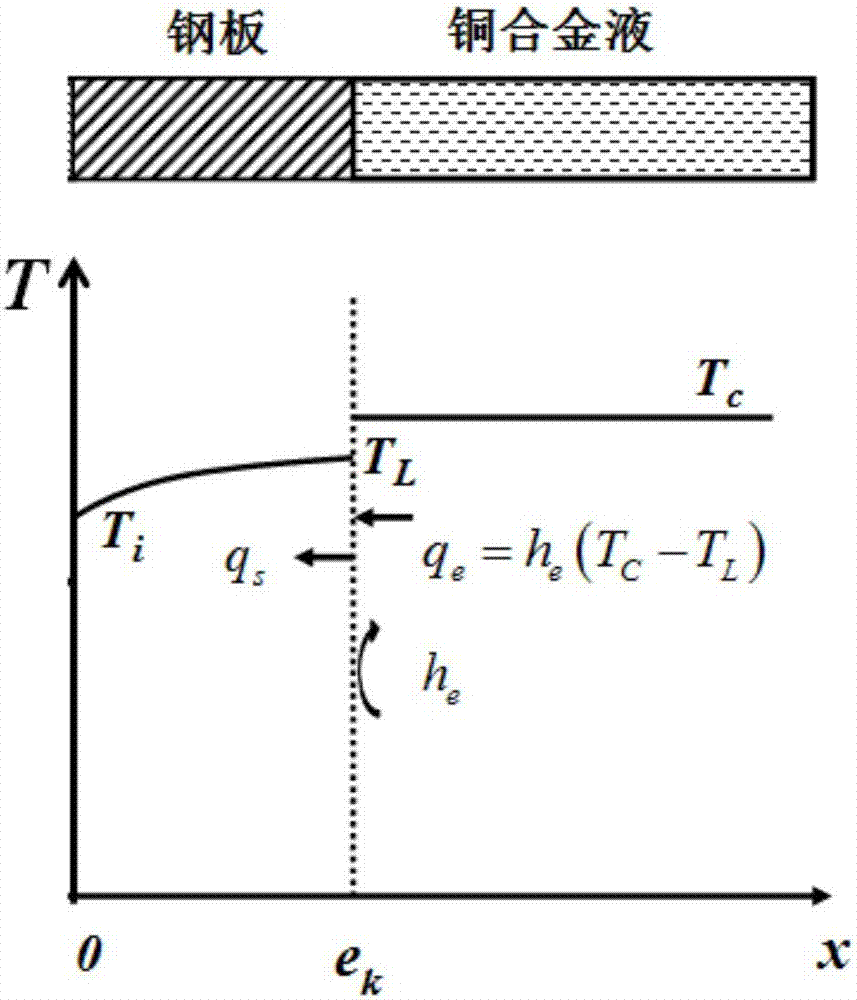

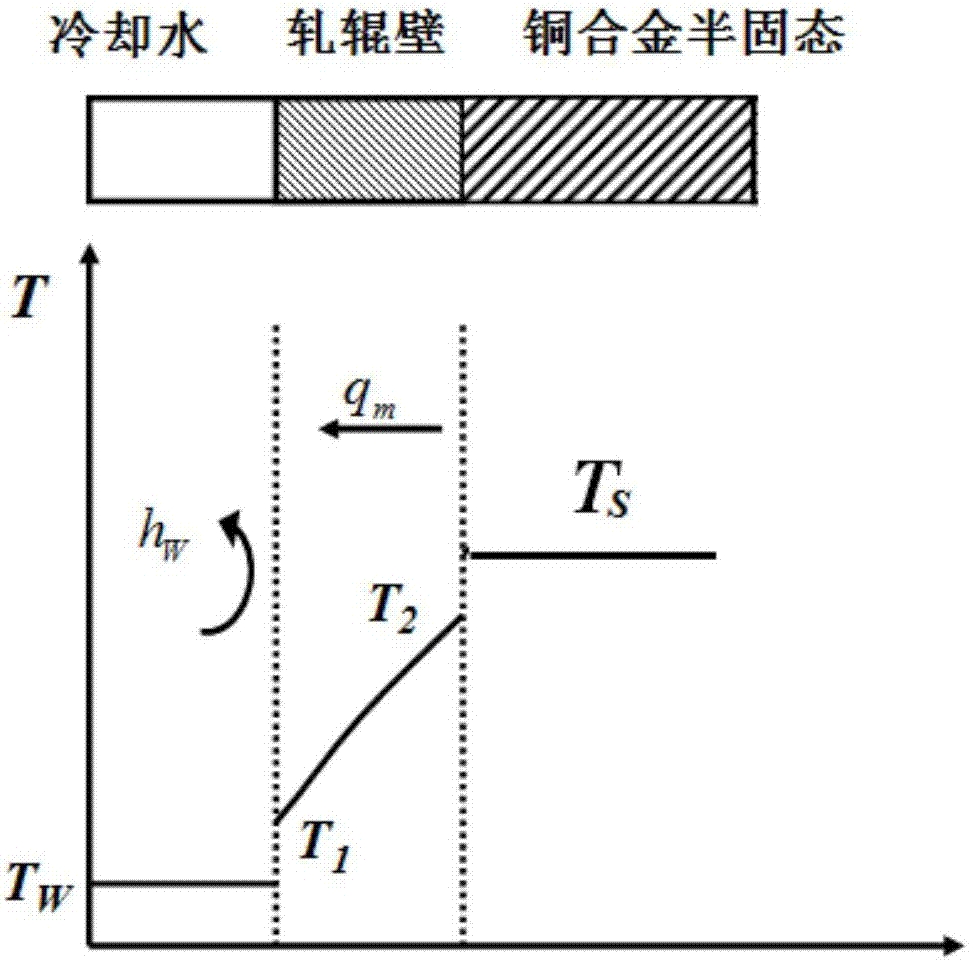

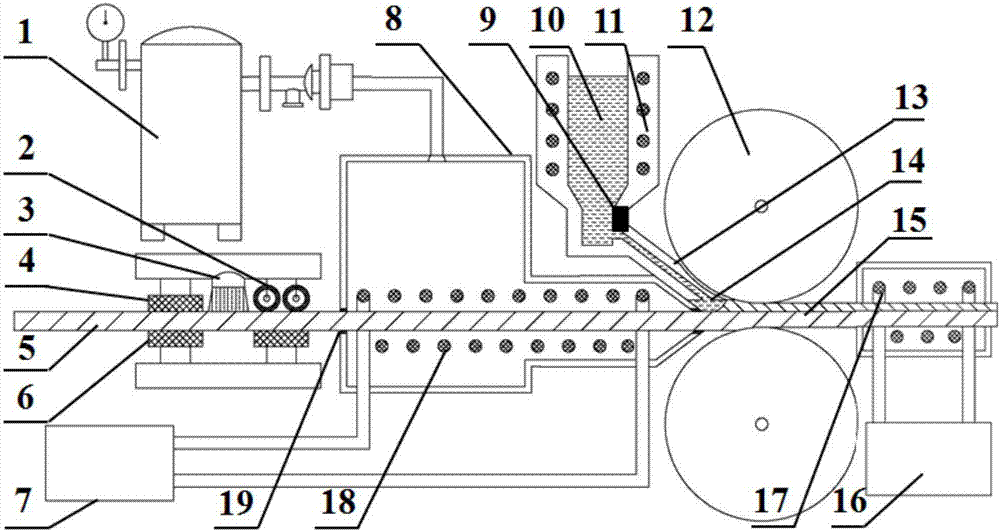

Steel wear-resistant copper alloy composite sheet, and preparation device and preparation method thereof

The invention provides a steel wear-resistant copper alloy composite sheet, and a preparation device and a preparation method thereof. The preparation device of the steel wear-resistant copper alloy composite sheet comprises a surface processing unit, a shielding gas induction preheating unit, an induction melting unit and a semisolid rolling compound unit which are arranged in turn. The surface processing unit, the shielding gas induction preheating unit and the semisolid rolling compound unit are provided with rectangular channels for lower steel plates to penetrate, and the size of the rectangular channels in the surface processing unit and the shielding gas induction preheating unit is consistent with the section size of the steel plate to be processed. The invention also provides a preparation method of the steel wear-resistant copper alloy composite sheet, and the steel wear-resistant copper alloy composite sheet prepared with the method. The preparation method provided by the invention has the characteristics of continuous production, high finished steel rate, less defects, etc., and is a technological method for producing high-quality composite sheets efficiently.

Owner:DALIAN UNIV OF TECH

Preparation method for spherical metal-based rare-earth nano composite powder capable of being used for three-dimensional printing and product prepared through same

InactiveCN107096924ASolve uneven particle size distributionHigh strengthAdditive manufacturing apparatusTransportation and packagingRare earthHigh pressure

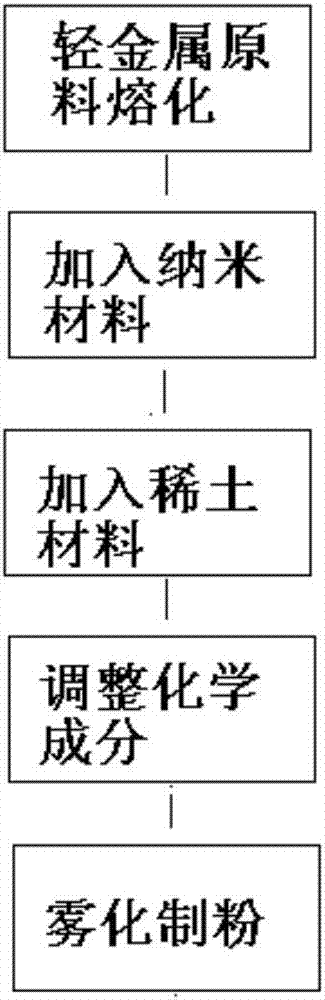

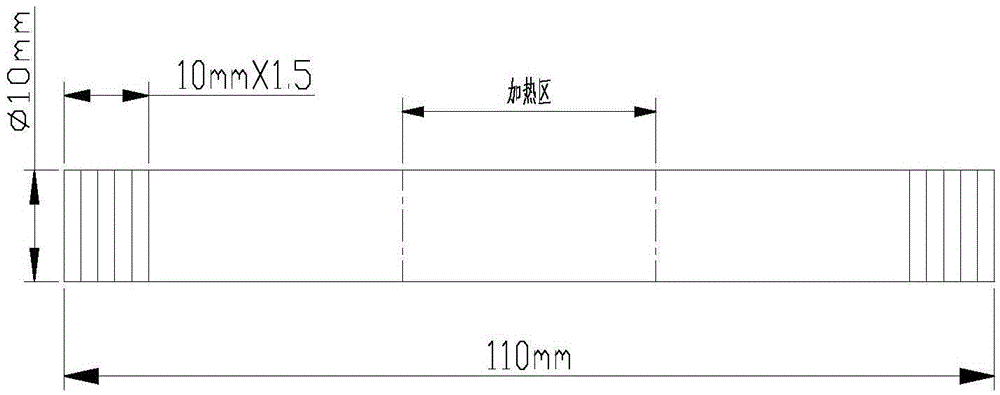

The invention discloses a preparation method for spherical metal-based rare-earth nano composite powder capable of being used for three-dimensional printing. The preparation method comprises the steps that (1) light metal raw materials are added into a crucible of an electric induction furnace, and the induction current is regulated and controlled for heating the light metal raw materials so as to enable the light metal raw materials to be melted into a liquid melt; (2) the temperature of the light metal melt is controlled to be higher than the melting point of the light metal melt by 50-100 DEG C, and 0-20.0wt% of nano materials are added into the metal melt and are ensured to be uniformly dispersed so as to form a mixed melt; (3) 0-1.0wt% of rare earth materials are added into the mixed melt formed in the step (2) and are ensured to be uniformly dispersed; (4) elements subjected to burning loss are compensated so as to adjust chemical components of an alloy; and (5) high-purity argon gas is started and is concentrated to reach an atomizing nozzle in one branch, the atomizing gas pressure and the power are kept, and the uniformly-mixed composite material melt flows out from an infusion tube, is broken into small spherical droplets under the action of high-pressure gas after falling off freely for a certain distance and rapidly condenses into spherical powder particles. A product prepared by adopting the method can be more effectively applied to a three-dimensional printing technology.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

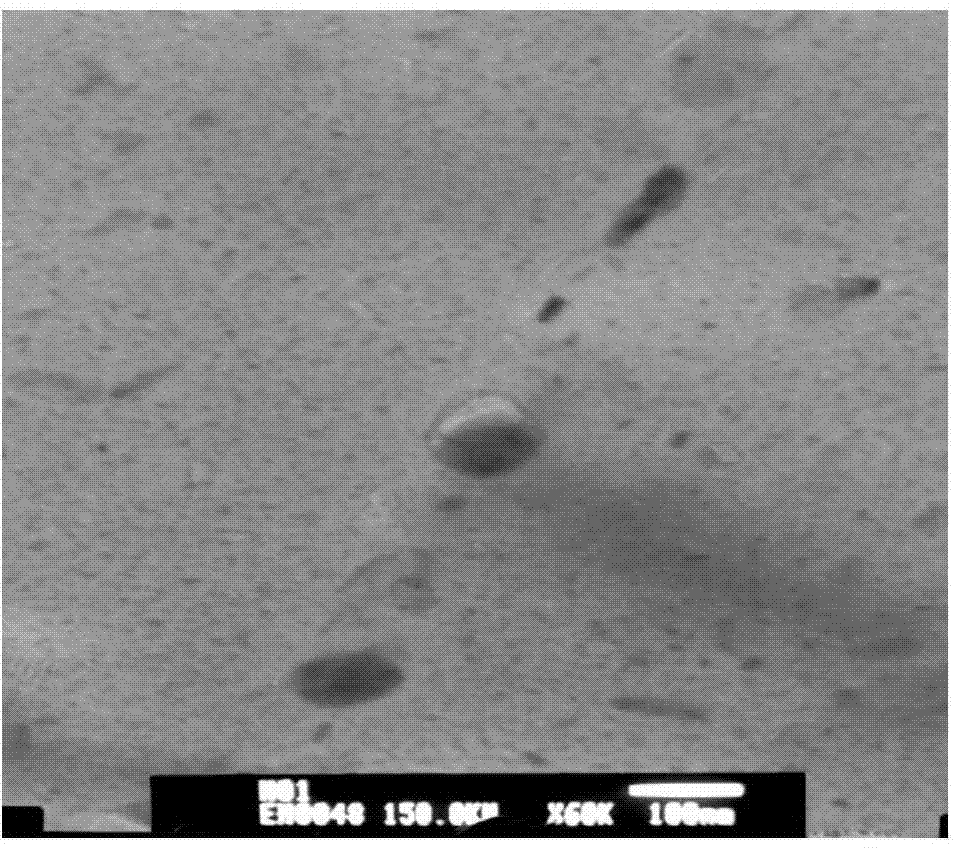

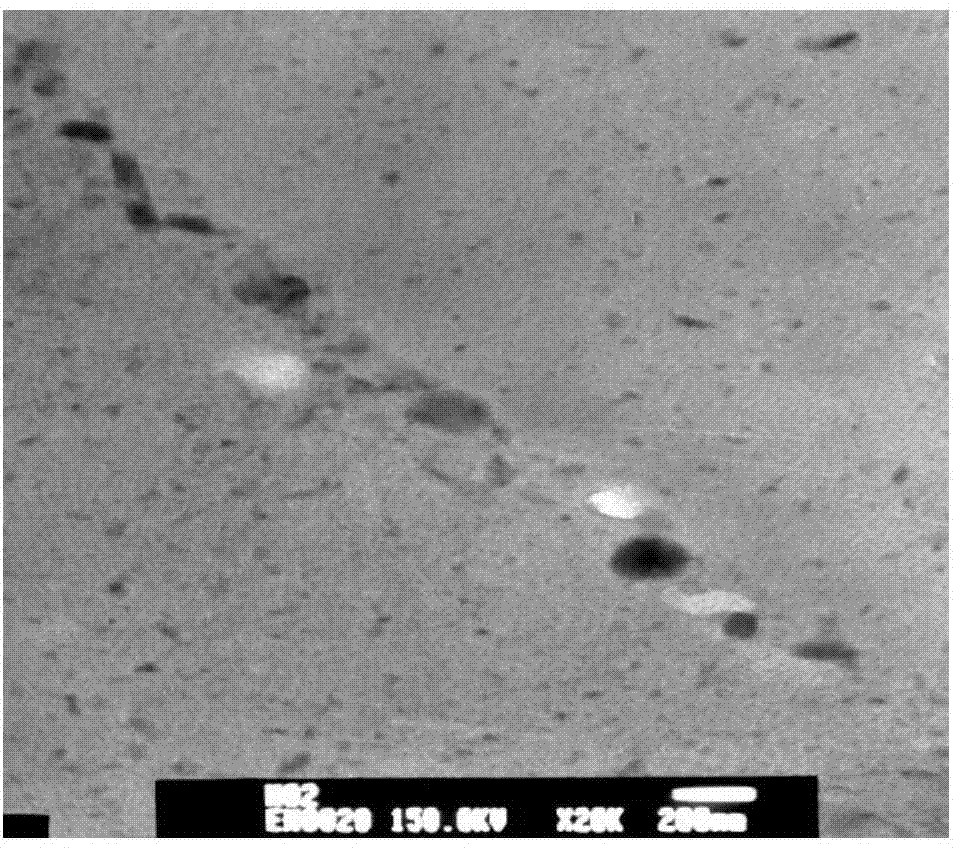

Nitride semiconductor laser device and method of manufacturing the same

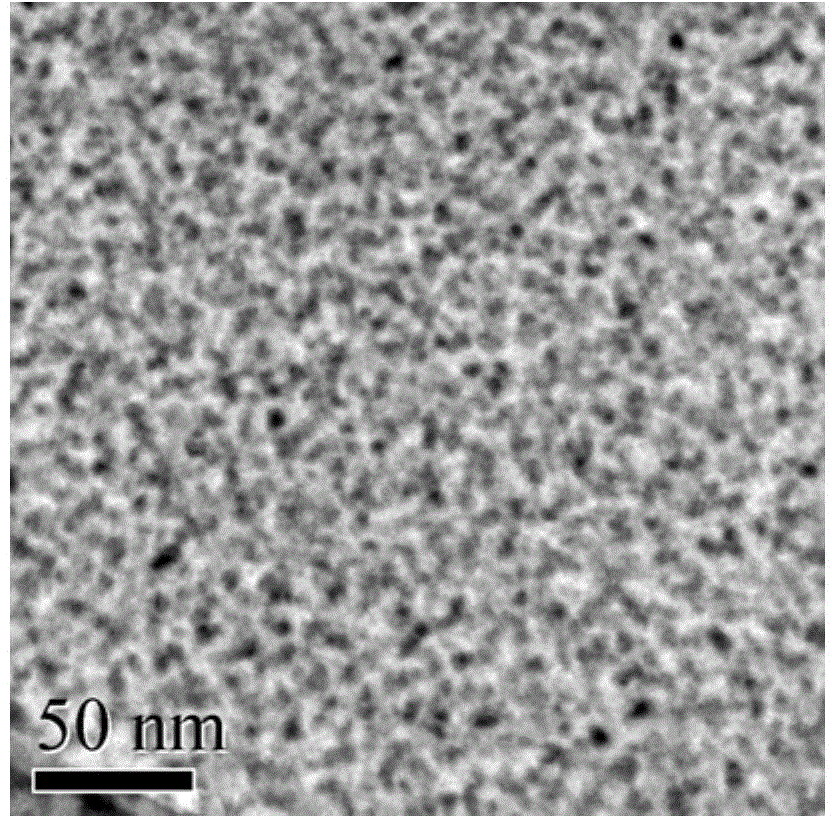

InactiveUS20070098030A1Eliminate degradationEliminate segregationOptical wave guidanceNanoopticsThin metalLow voltage

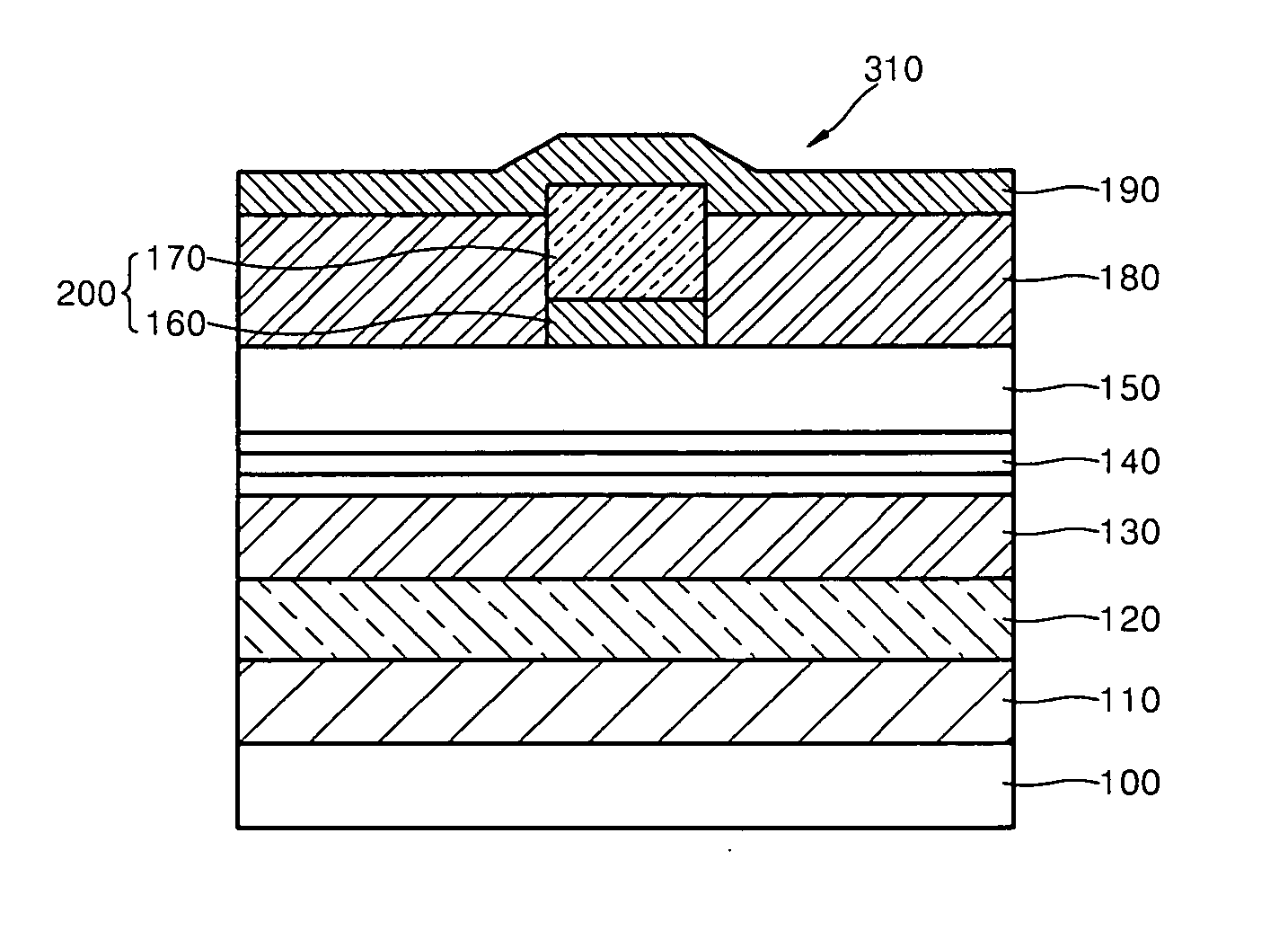

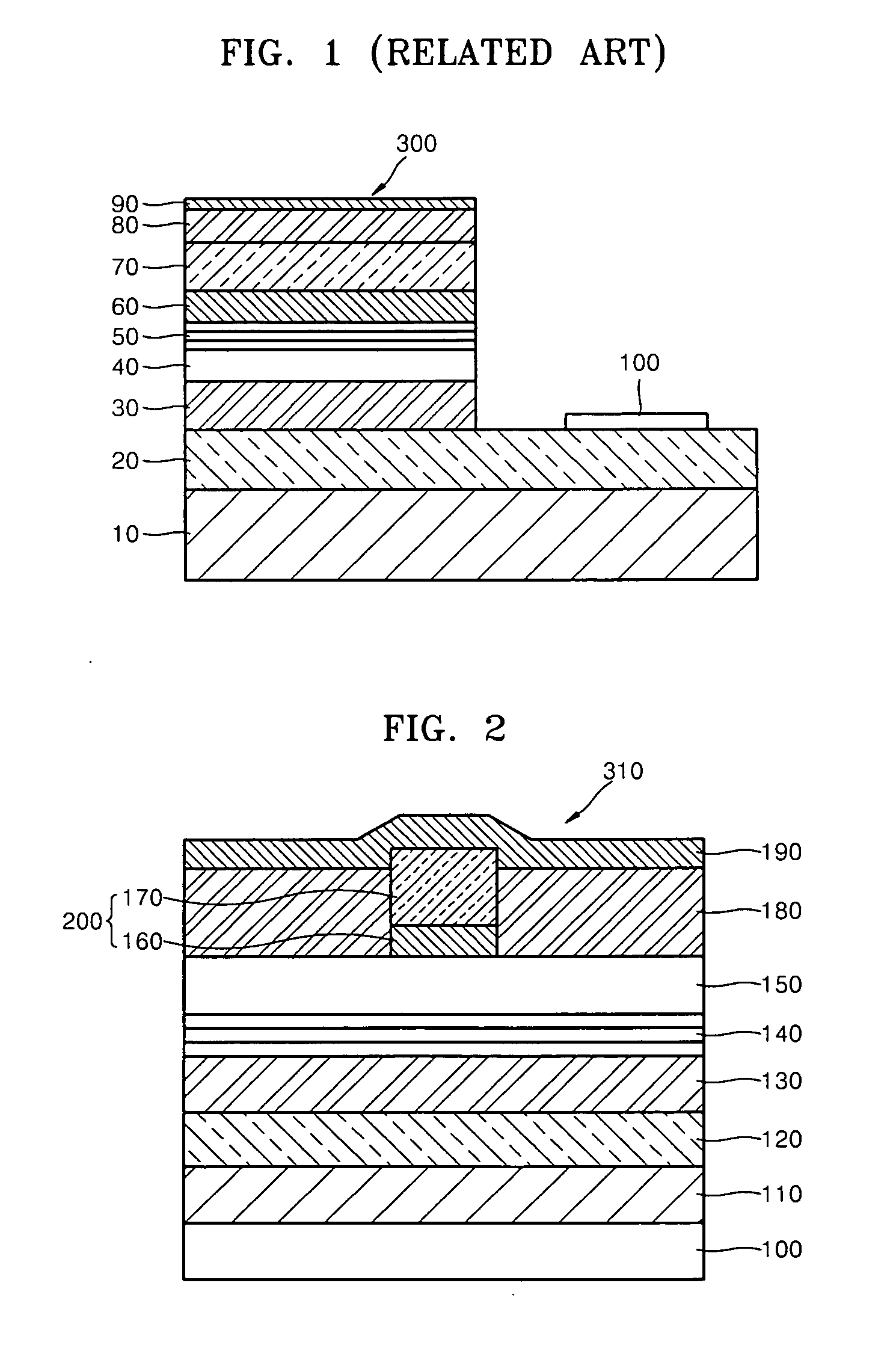

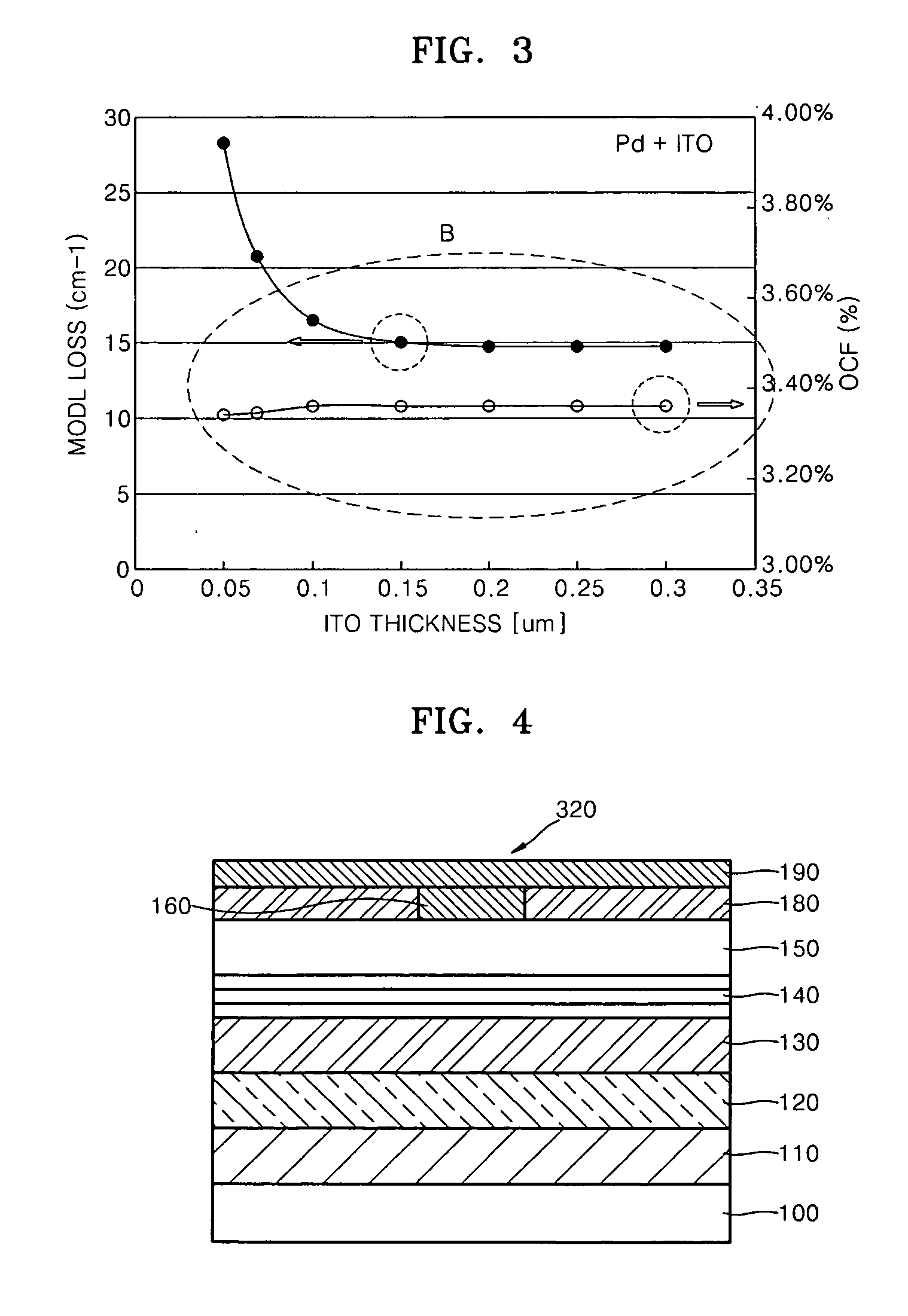

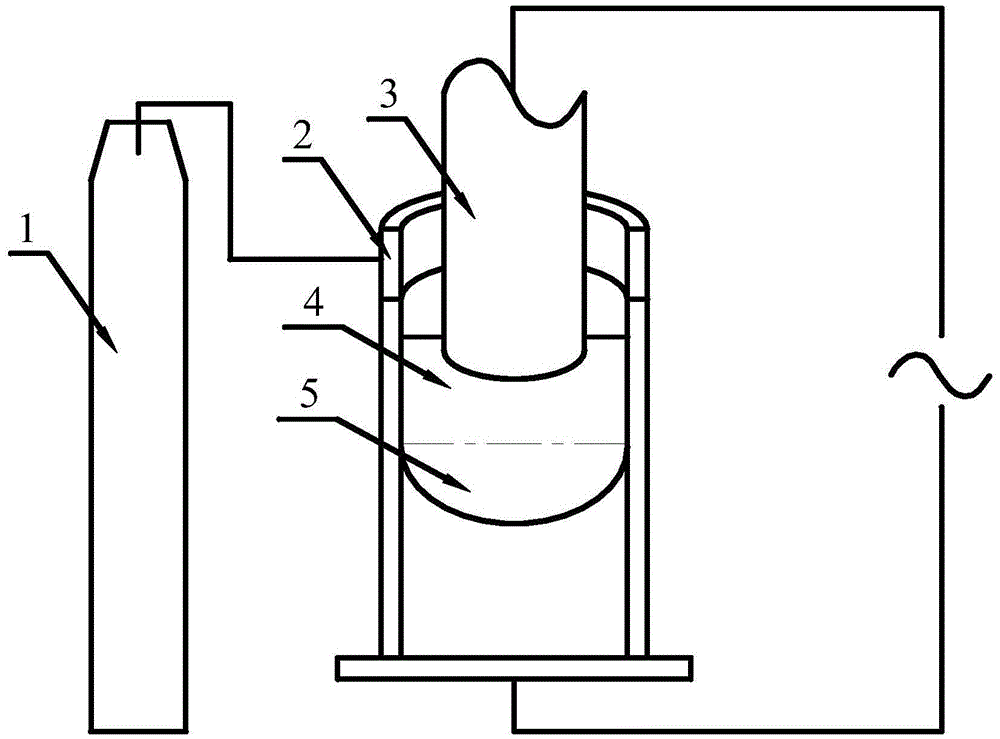

A semiconductor laser device is provided. The semiconductor laser device includes a substrate, and an n-material layer, an n-clad layer, an n-light waveguide layer, an active region, a nitride semiconductor layer, a metal layer and a metal-based clad layer sequentially formed on the substrate. The metal layer and the metal-based clad layer have a ridge shape and a current blocking layer is formed on sidewalls of the metal layer and the metal-based clad layer and an exposed surface of the nitride semiconductor layer. A p-electrode layer is formed on the ridge shaped metal layer and the current blocking layer. The semiconductor laser device uses the metal-based clad layer instead of AlxInyGa1-x-yN-based p-clad layer, thus preventing degradation of the active region. The semiconductor laser device also includes the thin metal layer between the metal-based clad layer and a p-GaN material of the nitride semiconductor layer, thus reducing contact resistance therebetween. Thus, it is possible to fabricate a high power, low voltage semiconductor laser device having a visible light wavelength.

Owner:SAMSUNG ELECTRONICS CO LTD

Heat treatment process of high-carbon chromium bearing steel

The invention provides a heat treatment process of high-carbon chromium bearing steel and belongs to the technical field of steel materials and heat treatment. The heat treatment process comprises the steps of smelting, forging, incomplete annealing, normalizing, quenching and tempering, double-refining processing, carbonitriding and surface chromizing. According to the invention, repeated quenching, tempering and other heat treatment, surface carbonitriding and surface chromizing processes are mainly adopted to reinforce the hardness and strength and prolong the service life of a bearing, so that the finally produced bearing is higher in strength, stronger in hardness and longer in service life.

Owner:ANQING YINTAI BEARING

Method for improving hot-working performance of Mn18Cr18N steel

The invention discloses a method for improving hot-working performance of Mn18Cr18N steel and belongs to the technical field of metallurgy. The method specifically includes the steps that firstly, materials are matched, wherein after electroslag remelting pre-melted slag and rare earth oxide are evenly mixed according to the mass ratio of (2-5):1, drying is performed; secondly, in the electroslag remelting preparation stage, nitrogen is introduced, and raw materials are weighed; thirdly, electroslag remelting is performed; fourthly, in the stage that electroslag remelting ends, the rare earth oxide in electroslag remelting rare earth slag is reduced into rare earth elementary substances through a reduction agent and enters molten steel through the diffusion effect, rare earth reacts with sulfur in steel so that rare earth sulfide can be generated, the content of the sulfur element in the steel is reduced, segregation of the sulfur element in the steel can be eliminated, the hot shortness of the steel is relieved, fine sphere shapes are formed due to the morphology of doping of the rare earth sulfide and doping of rare earth oxygen sulfide, and the mechanical property of the Mn18Cr18N steel can be improved.

Owner:NORTHEASTERN UNIV

Al-Zn-Mg-Cu aluminum alloy profile with high stress corrosion resistance and preparation method thereof

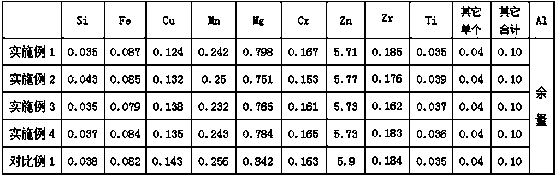

ActiveCN110184513AImprove mechanical propertiesAccelerated corrosionStress relievingUltimate tensile strength

The invention aims to provide an Al-Zn-Mg-Cu aluminum alloy profile with high stress corrosion resistance and a preparation method thereof. The aluminum alloy material is prepared from, by mass, smaller than or equal to 0.1% of Si, smaller than or equal to 0.1% of Fe, 0.12%-0.14% of Cu, 0.23%-0.25% of Mn, 0.75%-0.8% of Mg, 0.15%-0.17% of Cr, 5.7%-5.8% of Zn, 0.16%-0.19% of Zr, 0.02%-0.04% of Ti, wherein the ratio of Fe to Si ranges from 1.8 to 2.5, and the ratio of Zn to Mg is controlled to range from 7.1 to 7.7. The preparation method comprises the steps of smelting, refining, essence melting, casting, homogenization annealing, extruding, solid solution quenching, stress relieving and aging treatment. According to the Al-Zn-Mg-Cu aluminum alloy profile with the high stress corrosion resistance and the preparation method thereof, the material shows good mechanical strength and stress corrosion resistance, and the material is especially suitable for aluminum alloy structural members which are prone to stress corrosion and failure, in particular to aluminum alloy structural members subjected to tensile stress at the bottom of a rail transit or a vehicle body.

Owner:广西南南铝加工有限公司

3004 aluminum foil and preparing method and application thereof

The invention discloses 3004 aluminum foil and a preparing method and application thereof. The aluminum foil comprises chemical elements: by mass, 0.15-0.25% of Si, smaller than or equal to 0.55% of Fe, 0.14-0.2% of Cu, 1.02-1.15% of Mn, 0.95-1.1% of Mg, smaller than or equal to 0.05% of Cr, smaller than or equal to 0.15% of Zn, 0.015-0.025% of Ti, smaller than 0.1% of other chemical elements andthe balance Al. The 3004 aluminum foil is obtained by performing 3004 aluminum alloy smelting, refining, standing, online degassing and deslagging, casting, face-milling, uniform heating treatment, hot rolling, cold rolling, intermediate annealing, cold foil rolling and finished product annealing. With the combination of the various elements and the preparing process, the prepared aluminum foil has high strength and toughness, the thickness is greatly reduced when the aluminum foil is used as a container, use is convenient, and the consumption of the raw materials is reduced; and waste ring-pull cans can be adopted as a raw material, the consumption of the raw material is reduced, resources are reutilized, the source of the raw materials for preparing the aluminum foil is widened, meanwhile the burdens on the environment are avoided, the production cost is reduced, and the 3004 aluminum foil has quite good social economic benefits.

Owner:河南明泰科技发展有限公司

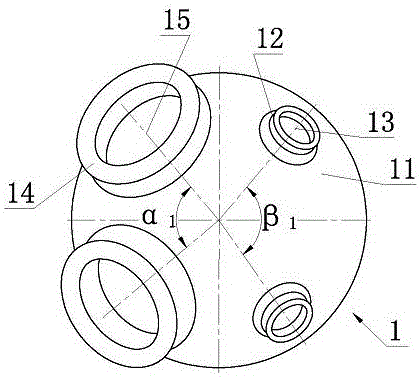

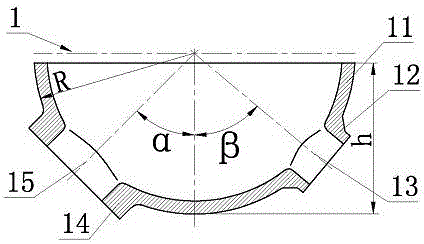

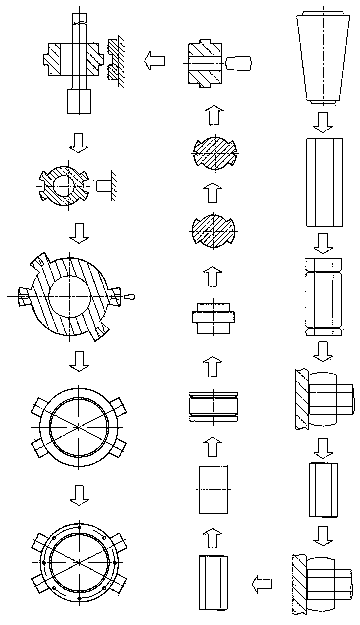

Pressure vessel integrated end socket for nuclear power, end socket plate blank of pressure vessel integrated end socket and forging method of pressure vessel integrated end socket

ActiveCN106051721AImprove mechanical propertiesImprove operational safetyMetal-working apparatusSteam boilersFiberPunching

The invention discloses a pressure vessel integrated end socket for nuclear power, an end socket plate blank of the pressure vessel integrated end socket and a forging method of the pressure vessel integrated end socket. According to the pressure vessel integrated end socket for nuclear power, a manhole base and a pipe hole base are arranged on an end socket body which is of a spherical crown structure; the manhole base and the pipe hole base are integrated with the end socket body in a forged mode; and the intersection point of the hole center line of a manhole and the hole center line of a pipe hole is located in the center of the sphere where the end socket body is located. A plate blank body of the end socket plate blank is of a circular plate structure, one surface of the plate blank body is provided with two manhole circular truncated cones and two pipe hole circular truncated cones, and the other surface of the plate blank body is a large-cone-angle circular truncated cone surface. The forging method comprises the following steps of steel ingot heating, forged blank blanking, forged blank upsetting and drawing, die forging formation, plate blank heat treatment, plate blank rough machining, end socket formation, end socket punching, forge piece heat treatment, machining of a forge piece, performance heat treatment and finished product machining. The integrated formation of the end socket of a vapor generator is achieved, the forge piece is uniform and compact in texture, the metal flow line is complete, and the fiber texture and the appearance of the forge piece tend to be more coincident.

Owner:SHANGHAI XINMIN DONGTAI HEAVY FORGING

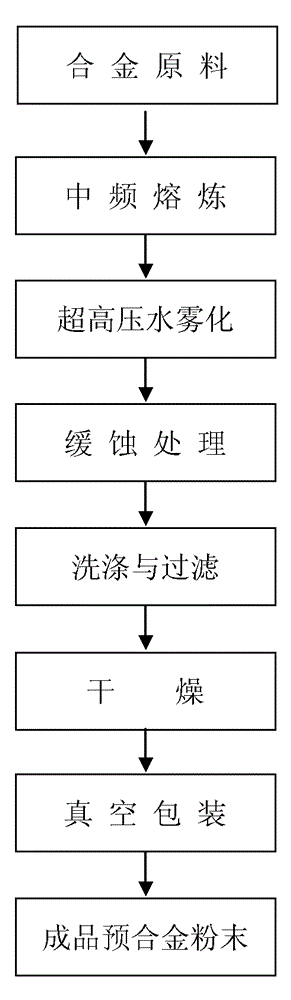

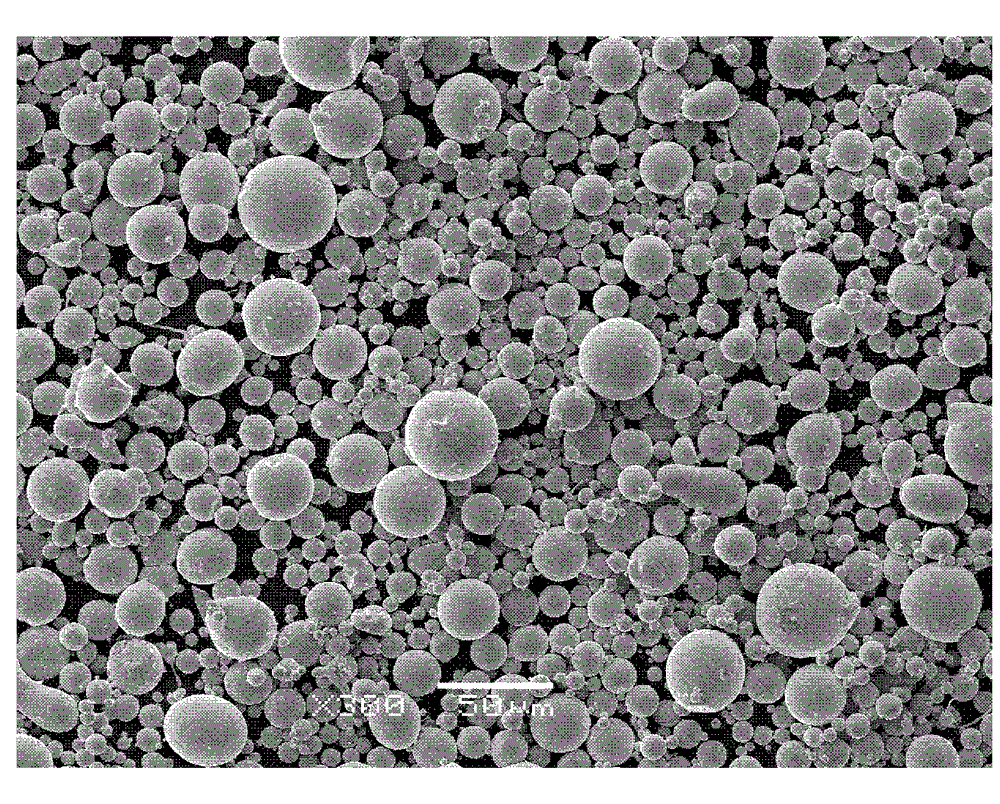

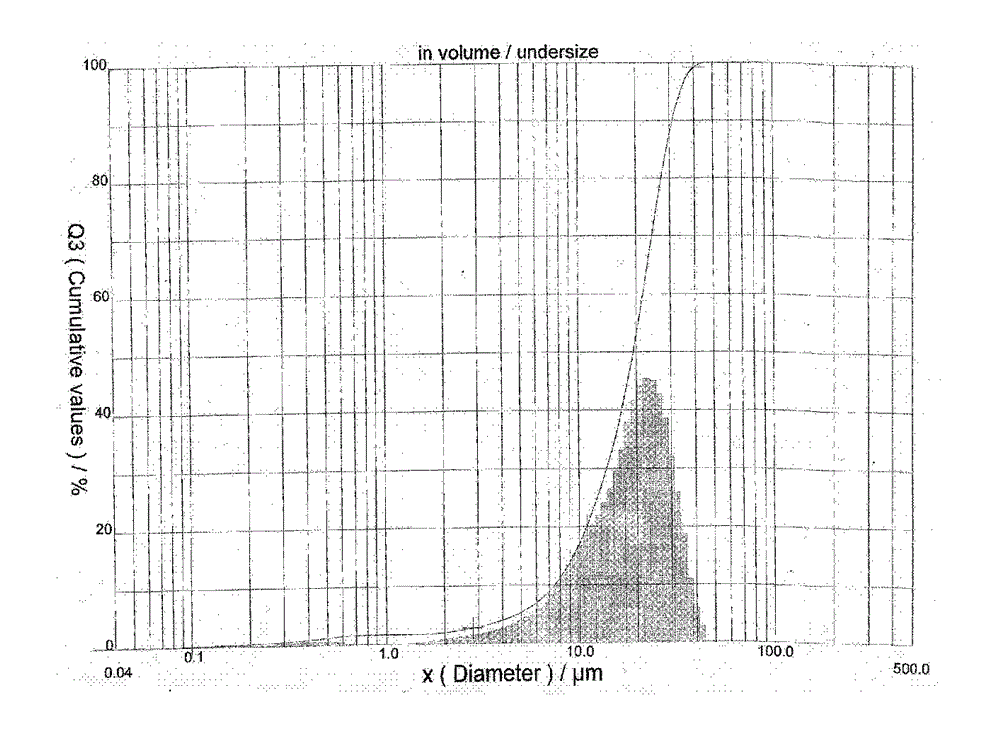

Method for preparing prealloy powder for low-oxygen-content micro-diamond product and using ultrahigh-pressure water atomization

The invention relates to a method for preparing prealloy powder for a low-oxygen-content micro-diamond product and using ultrahigh-pressure water atomization. The method comprises the technological processes of prealloy smelting, ultrahigh-pressure water atomization, quick solidification, cooling, powder corrosion inhibition process, powder collection, powder drying, powder property detection, product packaging and the like. The method has the advantages that the product is low in oxygen content, fine in granularity, controllable in particle morphology, and even and non-segregation in component, prealloy of powder elements is achieved, production process device and technology are simple, and operation is convenient.

Owner:HUNAN METALLURGY MATERIAL RES INST

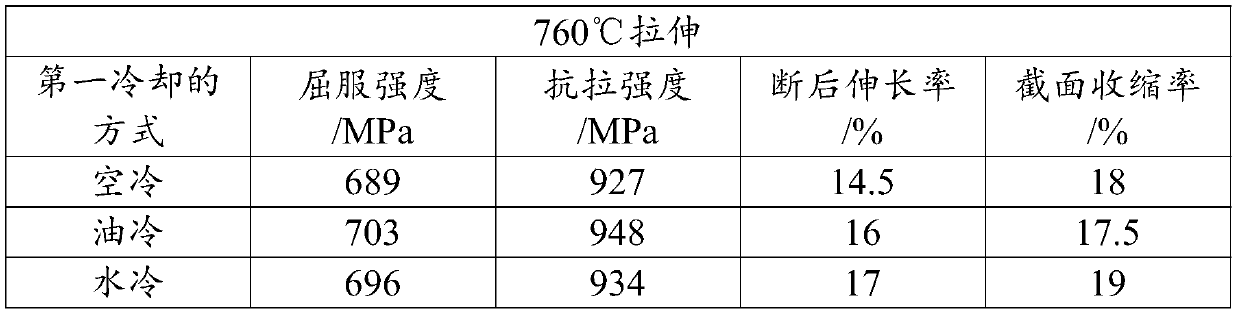

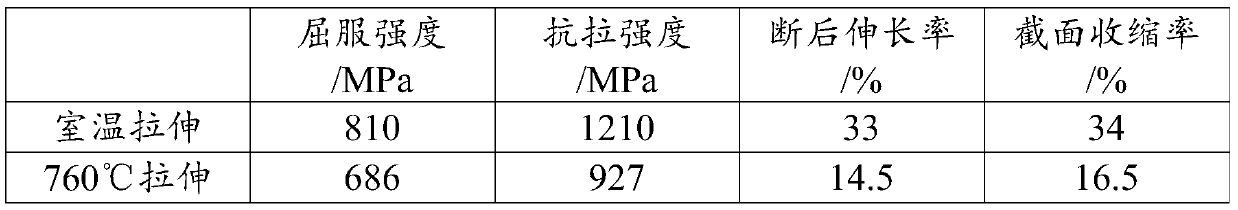

Heat treatment method of GH4780 alloy forging

ActiveCN110484841AHigh strengthImprove plasticityBlade accessoriesStatorsSmelting processUltimate tensile strength

The invention provides a heat treatment method of a GH 4780 alloy forging, and relates to the technical field of alloy manufacturing. The method comprises the following step: carrying out solution heat treatment on the GH 4780 alloy forging, wherein the temperature of the solution heat treatment is 1020-1170 DEG C. The GH 4780 alloy forging subjected to heat treatment not only can effectively eliminate the segregation of alloy elements such as Ti, Al and Cr in the smelting process and eliminate metallurgical defects such as cavities, but also can break columnar crystals and promote dynamic recrystallization, thereby refining the crystal grains and improving the strength and plasticity of the alloy forging.

Owner:BEIJING CISRI GAONA TECH +3

GH4700 alloy ingot homogenizing treatment method

InactiveCN103484649AEliminate segregationImprove hot working plasticityFurnace typesHeat treatment furnacesRoom temperatureIngot

A GH4700 alloy ingot homogenizing treatment method is characterized in that cast-condition alloy is placed into a resistance heated furnace with the temperature lower than 400 DEG C, the temperature is raised to 1130-1150 DEG C at the speed of 100 DEG C / hour, the temperature of 1130-1150 DEG C is kept for 8-10 hours, then the temperature is raised to 1180-1210 DEG C in half an hour, the temperature of 1180-1210 DEG C is kept for 24-32 hours, then the temperature is lowered to 1000 DEG C in a furnace, and the cast-condition alloy is moved out of the furnace to be cooled to room temperature in air. According to the method, Nb and Ti elements of the alloy are made to undergo segregation, the alloy is made to undergo Laves phase elimination, and hot-working plasticity of the alloy is improved.

Owner:TAIYUAN IRON & STEEL GROUP

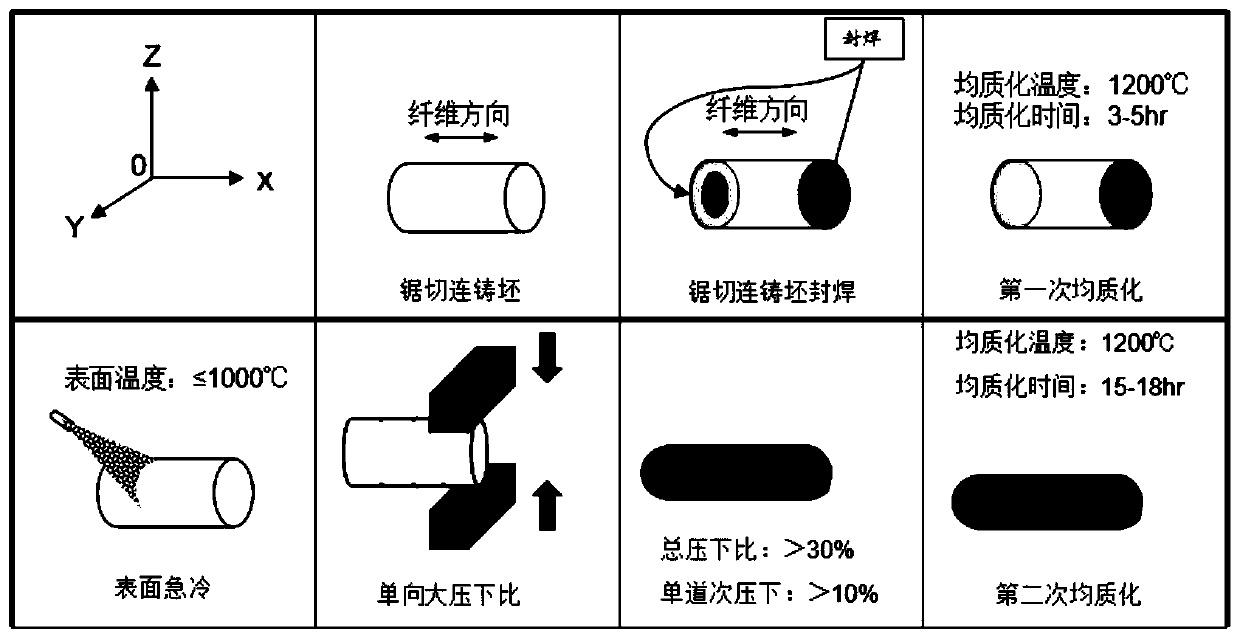

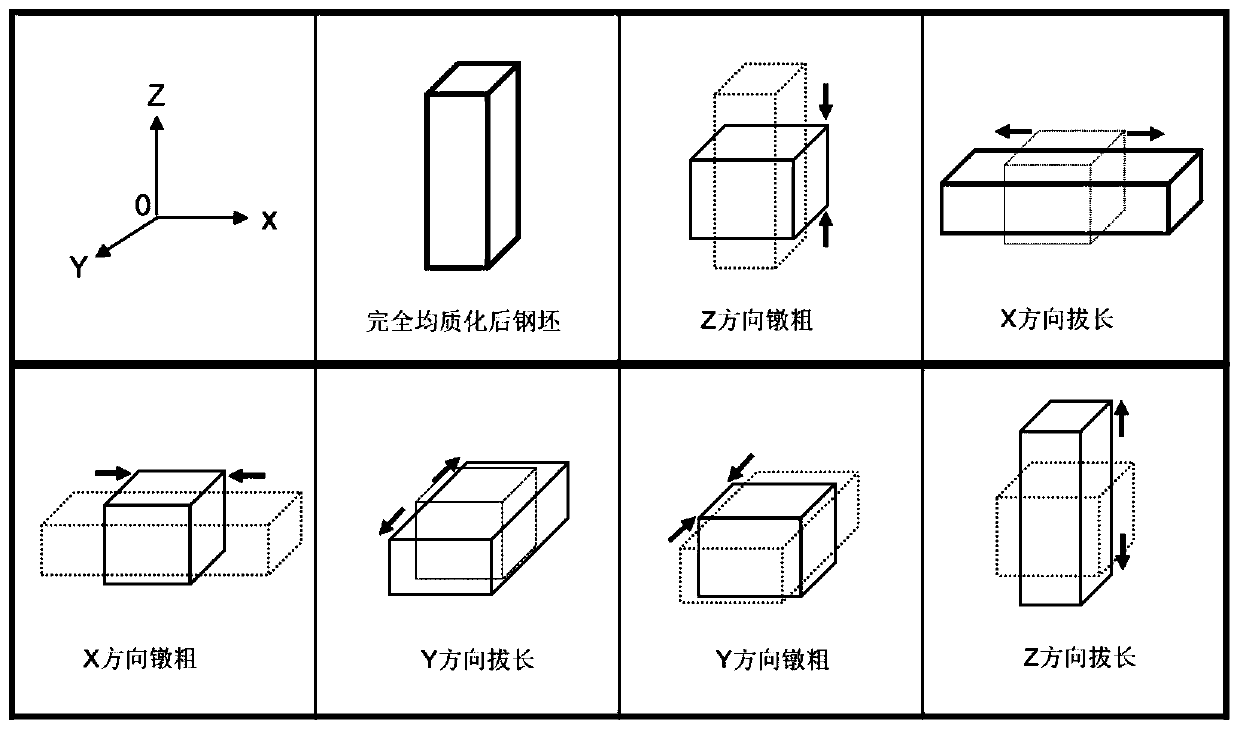

Method for producing hot work mold steel adopting continuous casting billet direct forging

ActiveCN109894473AQuality improvementUniform qualityTemperature control deviceWork treatment devicesDecompositionCarbide

The invention provides a method for producing hot work mold steel adopting continuous casting billet direct forging. The method specifically comprises the steps that end face seal welding or overlaying is performed on a sawed and cut continuous casting billet, after that, first-time homogenization is performed, and the homogenization is performed for 3-6 h with the temperature being 1150-1320 DEGC; the surface of the continuous casting billet after the first-time homogenization is quenched to 1050 DEG C or below to perform one-way large press down ratio deformation, and second-time homogenization is performed for 10-20 h with the temperature being 1150-1320 DEG C; three-way forging is performed on the steel billet after the second-time homogenization; the initial forging temperature of the three-way forging is 1250 DEG C or below, and the final forging temperature is 800-950 DEG C; and a product is obtained through grain refining and annealing. According to the method for producing the hot work mold steel adopting the continuous casting billet direct forging, by means of organic combination of continuous casting billet special treatment, the two times of homogenization and two times of the forging, kinetic conditions favorable to diffusion of carbon and alloy elements are created, and continuous casting billet central continuity loose pores and other defects, decomposition liquid chromatography carbides and banded structures generated by dendritic segregation are completely eliminated.

Owner:江阴华润制钢有限公司

Integrated forging and forming method for reactor pressure vessel barrel flange adapter tube section

ActiveCN110090914AReduce potential riskWork stress homogenizationEngine componentsReactor pressure vesselIngot

The invention discloses an integrated forging and forming method for a reactor pressure vessel barrel flange adapter tube section. The integrated forging and forming method for the reactor pressure vessel barrel flange adapter tube section comprises the steps of (1) heating a steel ingot, and pressing the steel ingot to obtain an eight-edge prism steel billet; (2) blanking a forging billet: cutting a head part and a tail part of the eight-edge prism steel billet so as to obtain an eight-edge prism forging billet; (3) upsetting and drawing the forging billet: upsetting and drawing out the forging billet; (4) carrying out upsetting and rolling: upsetting and rolling the forging billet to obtain a short cylindrical forging billet; (5) carrying out marking and dividing in the circumferential direction: cutting two marking and dividing grooves at two ends of the short cylindrical forging billet; (6) carrying out rolling and necking: forming an adapter tube billet with a convex ring in the middle section; (7) carrying out marking and dividing in the axial direction: cutting four axial dividing grooves arranged along the axial direction; (8) circularly pressing a hemline; (9) marking anddividing a hemline boss: forming four sections of bosses on a hemline adapter tube billet; (10) punching a main hole; (11) carrying out chambering and forming; (12) carrying out shaping and chambering; (13) punching an adapter tube hole; (14) carrying out heat treatment after forging; (15) roughly machining the billet; (16) carrying out quenching; (17) carrying out hardening and tempering; and (18) processing a finished product. According to the method, integrated forming and forming is realized, the structure is uniform and dense, and a metal flow line is complete.

Owner:SHANGHAI XINMIN DONGTAI HEAVY FORGING

Aluminum alloy sectional material used for automotive body and manufacturing method

The invention discloses an aluminum alloy sectional material used for an automotive body and a manufacturing method. The aluminum alloy sectional material is composed of the raw materials of, by mass, 0.13-0.17% of Si, 0.13-0.17% of Fe, 0.09-0.12% of Cu, 0.04-0.06% of Mn, 0.6-0.8% of Mg, 0.018-0.022% of Cr, 5.5%-5.8% of Zn, 0.15-0.195% of Zr, 0.027-0.033% of Ti and the balance Al, wherein the content of other single element is less than or equal to 0.05%, and the total content of other elements is less than or equal to 0.15%. The manufacturing method comprises the steps of smelting, purification treatment, rod forming through casting, homogenizing annealing, extruding, drawing, natural aging treatment, artificial aging treatment and other procedures, so that the material achieves good static collision effect, is quite suitable for manufacturing aluminum alloy crash boxes and longitudinal beams of automobile bumper systems, has the good mechanical performance and good abrasion resistance, fatigue resistance and anti-crash performance (static and dynamic collision impact performance), and can be put into mas production.

Owner:CYMA PRECISION ALUMINUM

Super-austenitic stainless steel high-temperature homogenization processing method

The invention provides a super-austenitic stainless steel high-temperature homogenization processing method, and aims to improve the uniformity and the high-temperature thermoplasticity of the component and the organization of a cast ingot or cast blank and control the size of crystal grains. The super-austenitic stainless steel high-temperature homogenization processing method is suitable for processing a target grade of steel, wherein the steel comprises, by weight, smaller than or equal to 0.02% of C, smaller than or equal to 4.00% of Mn, 19.5%-25.0% of Cr, 17.5%-23.0% of Ni, 6.0%-8.0% of Mo, 0.18%-0.55% of N, 0.30%-1.00% of Cu, smaller than or equal to 0.80% of Si, smaller than or equal to 0.030% of P, smaller than or equal to 0.01% of S and the balance Fe. The super-austenitic stainless steel high-temperature homogenization processing method is characterized by comprising the steps that the surface of the cast ingot or cast blank is brused with a high-temperature oxidation resistant coating; and the cast ingot or cast blank is put into a heating furnace, heating is conducted at the speed lower than 160 DEG C / h to enable the temperature to the range from 1240 DEG C to 1280 DEG C, the temperature is kept for 16-24 hours, and then hot working is directly conducted, or furnace cooling is conducted to enable the temperature to be 1000 DEG C, and the cast ingot or cast blank is discharged from the heating furnace and cooled in an air-cooling mode. The super-austenitic stainless steel high-temperature homogenization processing method is convenient to use, and reasonable and efficient, obviously eliminates element segregation and dendritic structures of the cast ingot or cast blank, achieves full re-dissolution of the Sigma phase and controls the size of the crystal grains, and therefore the hot-working performance is remarkably improved, and the technical guarantee is provided for acquisition of super-austenitic stainless steel products with high surface quality and excellent performance.

Owner:NORTHEASTERN UNIV

Super-strength aluminum alloy drill rod pipe body for super-deep well and manufacturing method for super-strength aluminum alloy drill rod pipe body

ActiveCN104404321ASimple ingredientsElements that increase heat resistanceAlloy substrateSolid solution

The invention discloses a super-strength aluminum alloy drill rod pipe body for a super-deep well and a manufacturing method for the super-strength aluminum alloy drill rod pipe body. The super-strength aluminum alloy drill rod pipe body comprises the following components in percentage by weight: 2.1 to 3.0 percent of Cu, 2.8 to 3.1 percent of Mg, 10.0 to 12.9 percent of Zn, 0.1 to 0.3 percent of Mn, 0.1 to 0.5 percent of Ni, 0.1 to 0.5 percent of Cr, 0.05 to 0.20 percent of Ti, 0.2 to 0.5 percent of Zr, 0.001 to 0.01 percent of B, 0.02 to 0.05 percent of Yb and the balance of Al and inevitable impurities. According to the super-strength aluminum alloy drill rod pipe body and the manufacturing method, heat treatment processes of multistage homogenization treatment, multistage solid solution treatment, aging and the like are adopted, segregation, heterogeneousness and the like in a substrate are greatly eliminated, and the melting-back of an un-melted eutectic phase in the aluminum alloy substrate is remarkably promoted, so that high strength is maintained, hot strength is improved, and the problems of insufficient strength, low surface hardness, insufficient hot strength and the like of the conventional aluminum alloy drill rod pipe body are solved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Thermo-magnetic coupling field cooperated selective laser-melting device and heating method thereof

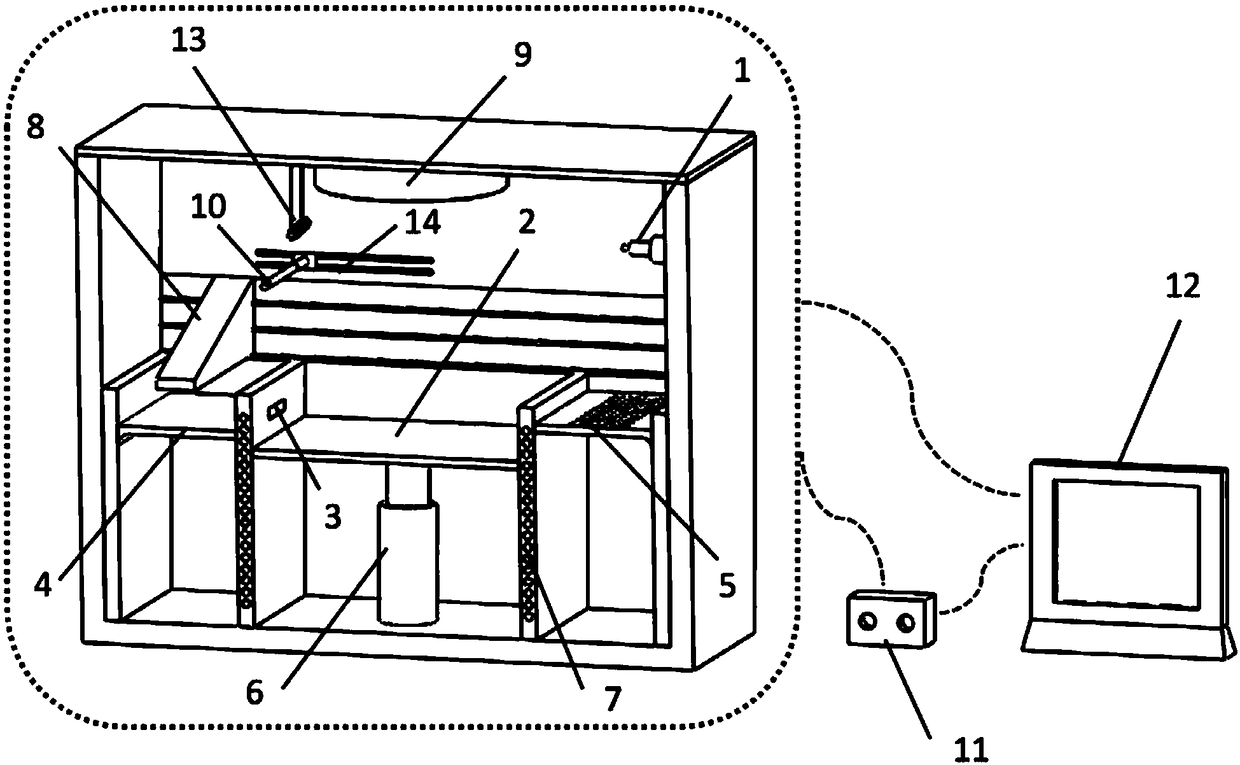

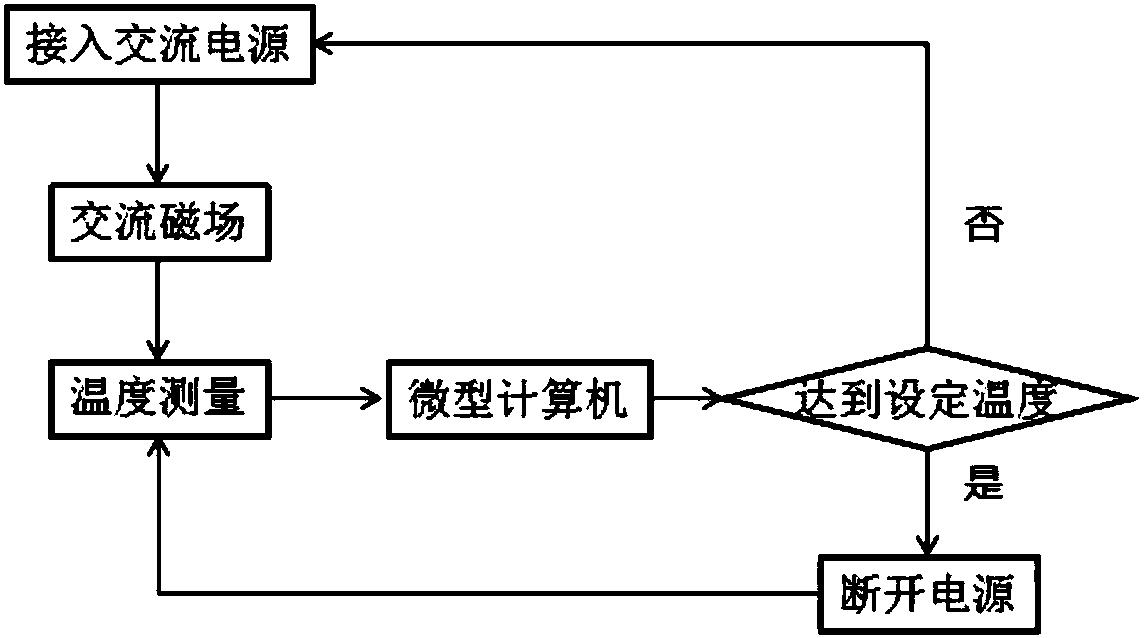

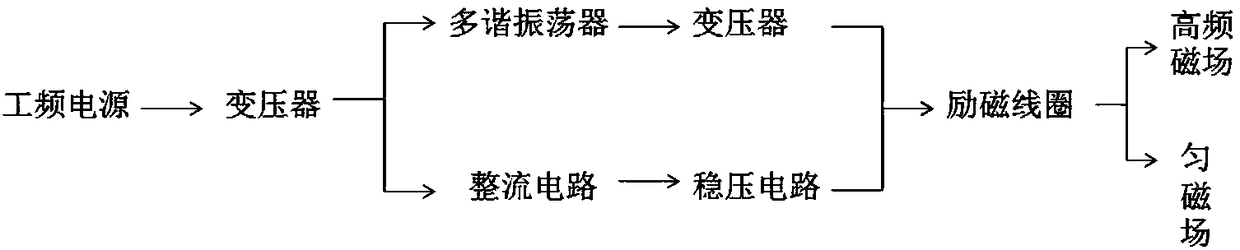

ActiveCN108421976AImprovement is difficult to control, and there are defects such as coarse dendritesImprove the mechanical properties of defectsAdditive manufacturing apparatusIncreasing energy efficiencyMelting tankSelective laser melting

The invention discloses a thermo-magnetic coupling field cooperated selective laser-melting device and a heating method thereof. The thermo-magnetic coupling field cooperated selective laser-melting device is characterized in that a magnetic field generator is introduced on the basis of conventional laser selective sintering and heating; during normal printing, a control system controls the magnetic field generator to generate stable static magnetic fields; the static magnetic fields provide lorentz force to change flow field distribution, in a workpiece printing process, of a molten pool; when a workpiece is printed and accumulated to certain thickness, the magnetic field generator is controlled to generate alternating magnetic fields for heating, tempering and thermally treating the workpiece, and then naturally cooling the workpiece to the room temperature; and workpiece printing is continued according to the method until workpiece printing is ended. In a printing process, an unevenworkpiece effect generated by the Marangoni effect can be reduced, various defects caused by the printing process further can be eliminated, crystalline grains are refined, segregation is eliminated,and internal stress is reduced, so that the structure and the performance of the workpiece are more uniform, and therefore, growth of a metallographic structure of a printing material is promoted, and hardness and strength of the workpiece are improved.

Owner:湖南珞佳智能科技有限公司

Aluminum alloy and casting method thereof

The invention provides an aluminum alloy and a casting method thereof. According to the aluminum alloy and the casting method thereof, pure silicon is added into molten aluminum, an aluminum alloy silicon ingot is acquired, and the manufactured silicon ingot serves as an intermediate alloy to be added into the molten aluminum so that an aluminum alloy cast ingot can be acquired. According to the aluminum alloy and the casting method thereof, purification treatment of the pure silicon and a homogenizing working procedure are added, the content of impurities in the molten aluminum is reduced, moreover, due to the fact that the aluminum alloy silicon ingot is the intermediate alloy, the melting point is low, during component adjusting, Si elements are scattered more uniformly, segregation ofthe Si elements is greatly eliminated, and the acquired cast ingot is more uniform in component.

Owner:苏州铭恒金属材料科技有限公司

Preparation method for high-strength and high-plasticity magnesium-zinc-manganese-yttrium alloy

The invention relates to a preparation method for a high-strength and high-plasticity magnesium-zinc-manganese-yttrium alloy and belongs to the technical field of production of a magnesium alloy of nonferrous metal. The preparation method specifically comprises the following steps that (1) smelting is conducted, specifically, a magnesium ingot and a magnesium-manganese master alloy are smelted together, a zinc ingot and a magnesium-yttrium master alloy are added, and after 20-30 min, argon is introduced for 10-20 min, finally, an alloy melt is subjected to deslagging and stood till impurities settle, and semicontinuous casting is conducted to prepare a semicontinuous cast ingot; and (2) extrusion treatment is conducted, specifically, the prepared semicontinuous cast ingot is subjected to homogenization treatment, then cooled to 25-30 DEG C and subjected to sheet turning, and finally, the cast ingot subjected to sheet turning is subjected to extrusion forming according to the extrusion ratio of 16:30 at 400-450 DEG C to prepare the magnesium-zinc-manganese-yttrium alloy. By adoption of the preparation method, the mechanical performance and the plasticity of the alloy can be simultaneously improved, and the use range of the magnesium alloy is effectively enlarged, and the magnesium alloy can replace some zirconium-containing and rare-earth-containing magnesium alloy materials and can be applied to aerospace, military and industrial fields and the like.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com