Steel wear-resistant copper alloy composite sheet, and preparation device and preparation method thereof

A composite plate and preparation device technology, applied in the field of its preparation device and preparation, steel-wear-resistant copper alloy composite plate, can solve the problems of poor composite quality, specific gravity segregation of copper-lead alloy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

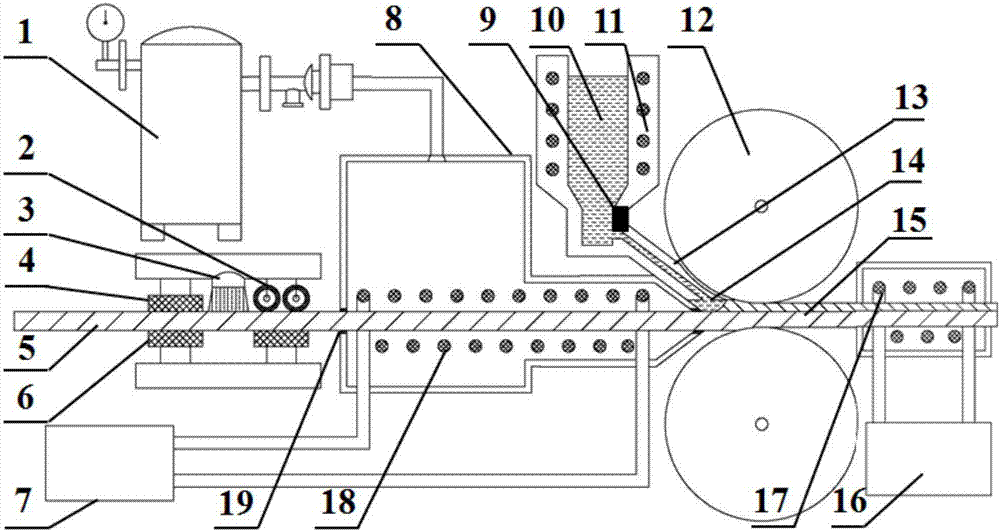

[0074] This embodiment discloses a preparation device for a steel-wear-resistant copper alloy composite plate, such as image 3 As shown, it includes a surface treatment unit, a shielding gas induction preheating unit, an induction melting unit and a semi-solid rolling compound unit arranged in sequence, and the surface treatment unit, the shielding gas induction preheating unit and the semi-solid rolling compound unit are worn There is a rectangular channel for the lower steel plate to pass through, and the size of the rectangular channel in the surface treatment unit and the shielding gas induction preheating unit is consistent with the cross-sectional size of the steel plate to be treated;

[0075] The surface treatment unit includes an upper surface grinding device 4, a lower surface grinding device 6, a cleaning device 3 and a drying device 2; the upper surface grinding device 4, the cleaning device 3 and the drying device 2 are sequentially arranged above the rectangular ...

Embodiment 2

[0093] This embodiment discloses a method for preparing a steel-wear-resistant copper alloy composite plate, using the preparation device for the steel-wear-resistant copper alloy composite plate described in Example 1.

[0094] Taking Cu-20Pb and No. 45 steel as examples, a composite plate with a thickness of 9 mm (3 mm for steel plate and 6 mm for copper alloy) was prepared. The preparation method of the steel-wear-resistant copper alloy composite plate comprises the following steps:

[0095] Step 1: Before the steel plate is used, use a cleaning solution for deoxidation pretreatment. The etching time is 2 minutes. After washing with clean water, dry it. The drying temperature is 100 ° C for 20 minutes;

[0096] Step 2: Close the closed switch below the induction melting unit, put in the raw materials according to the ratio of Cu-20%Pb, and turn on the power to perform electromagnetic induction melting of the copper-lead alloy;

[0097] Step 3: After the copper alloy is mel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com