Patents

Literature

1478 results about "Carbon Dioxide / Helium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

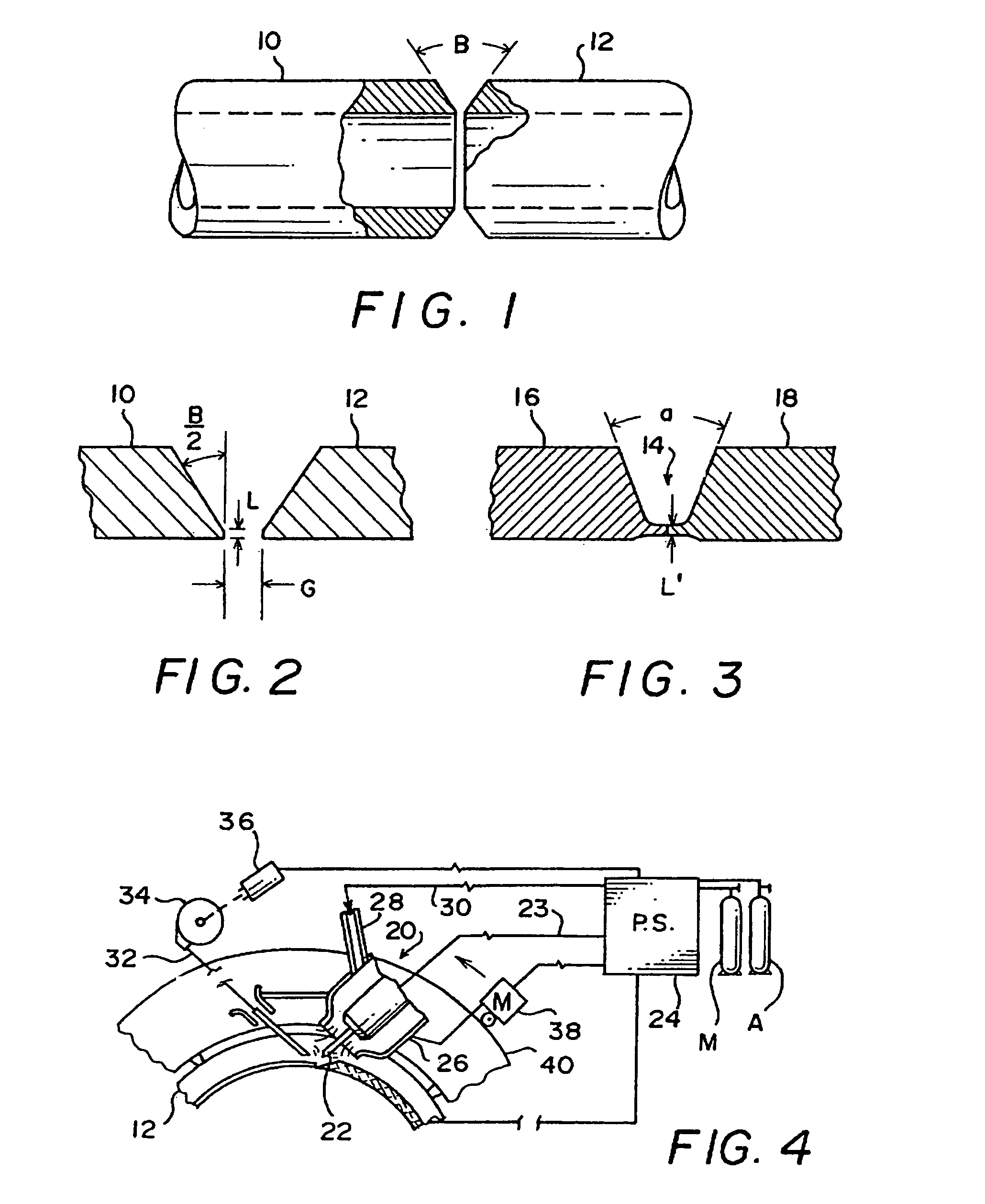

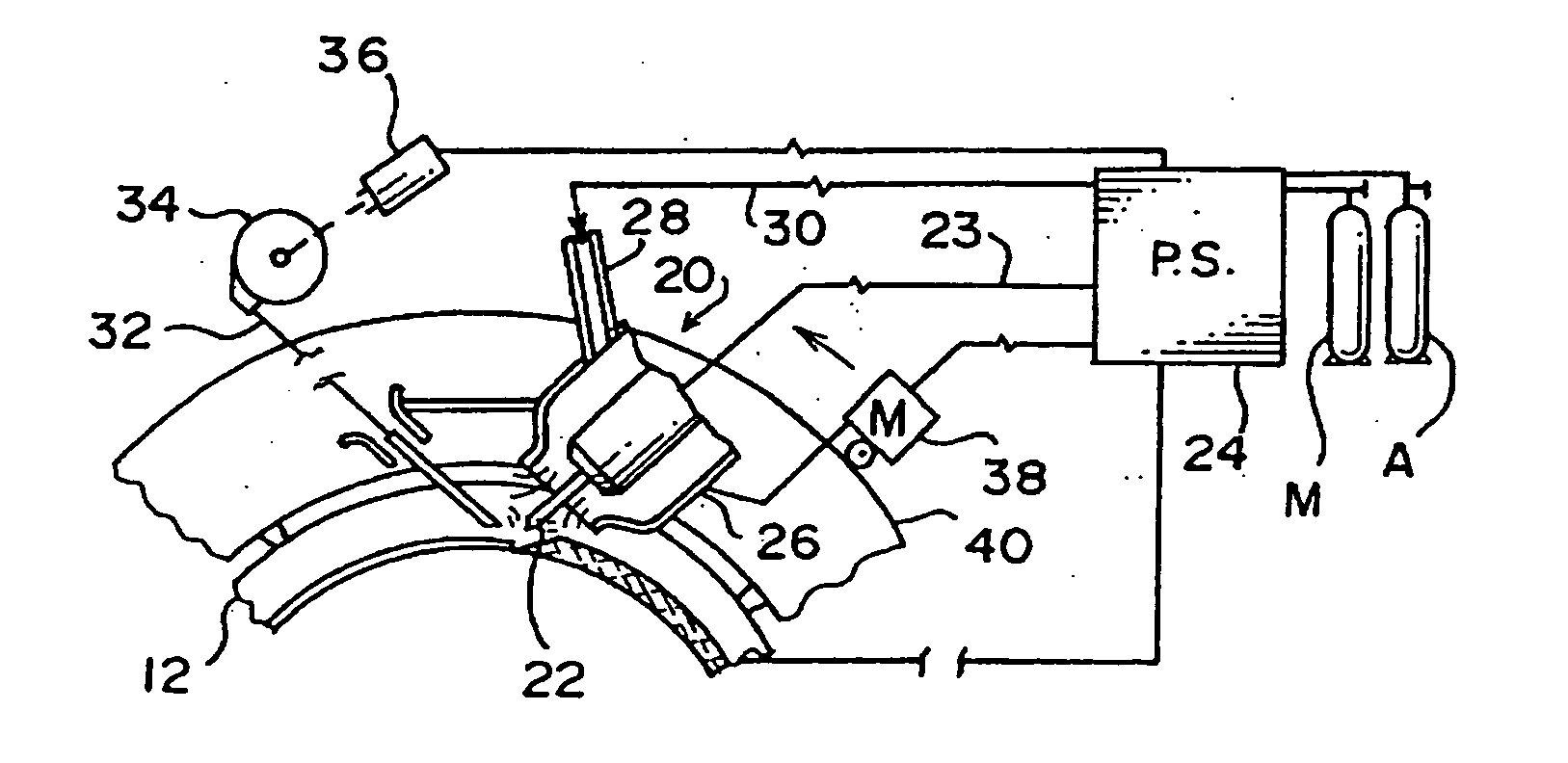

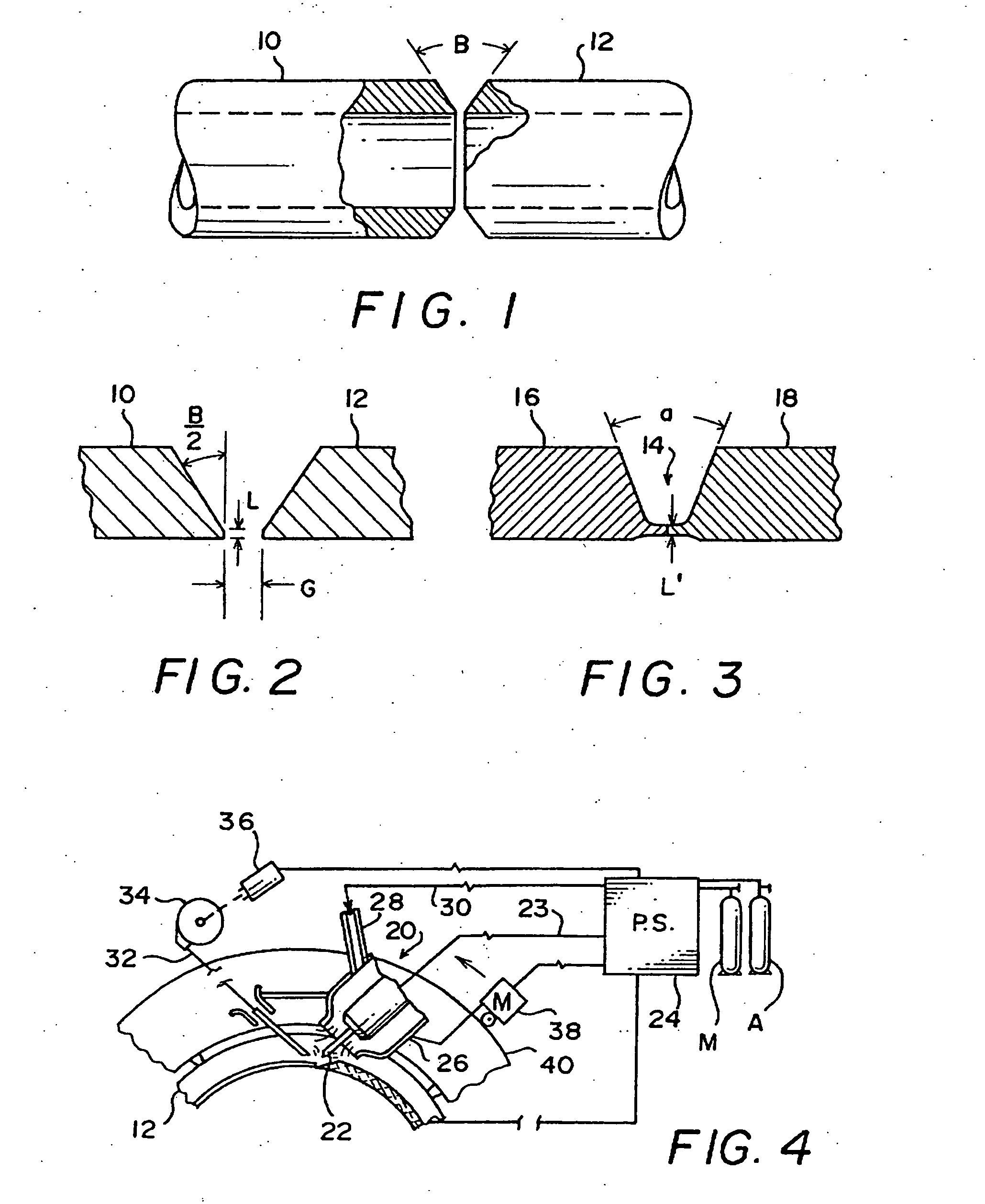

Carbon dioxide in concentration of 1-2% is commonly used in the mix with argon to reduce the surface tension of the molten metal. Another common blend is 25% carbon dioxide and 75% argon for GMAW. Helium is lighter than air; larger flow rates are required.

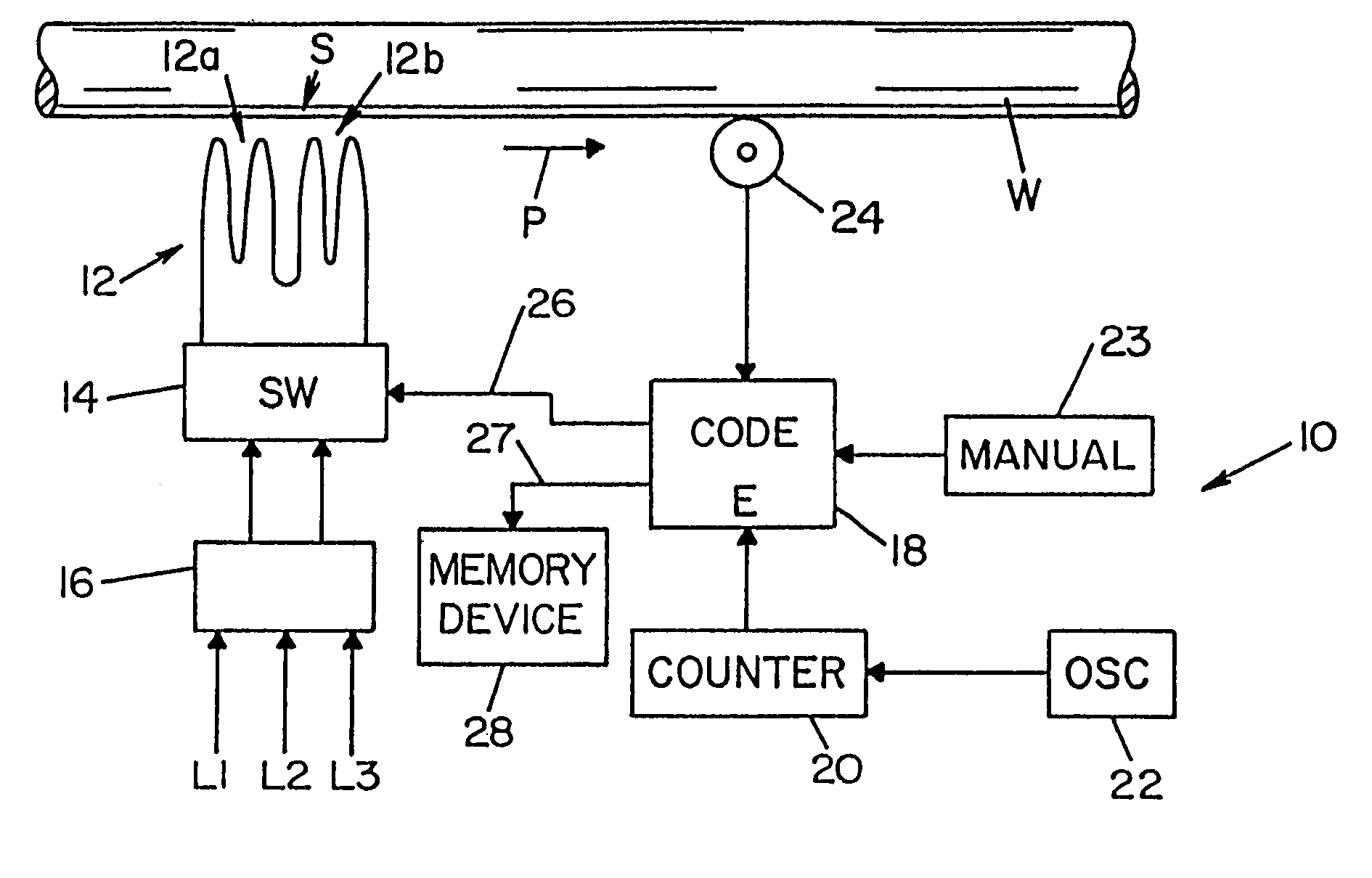

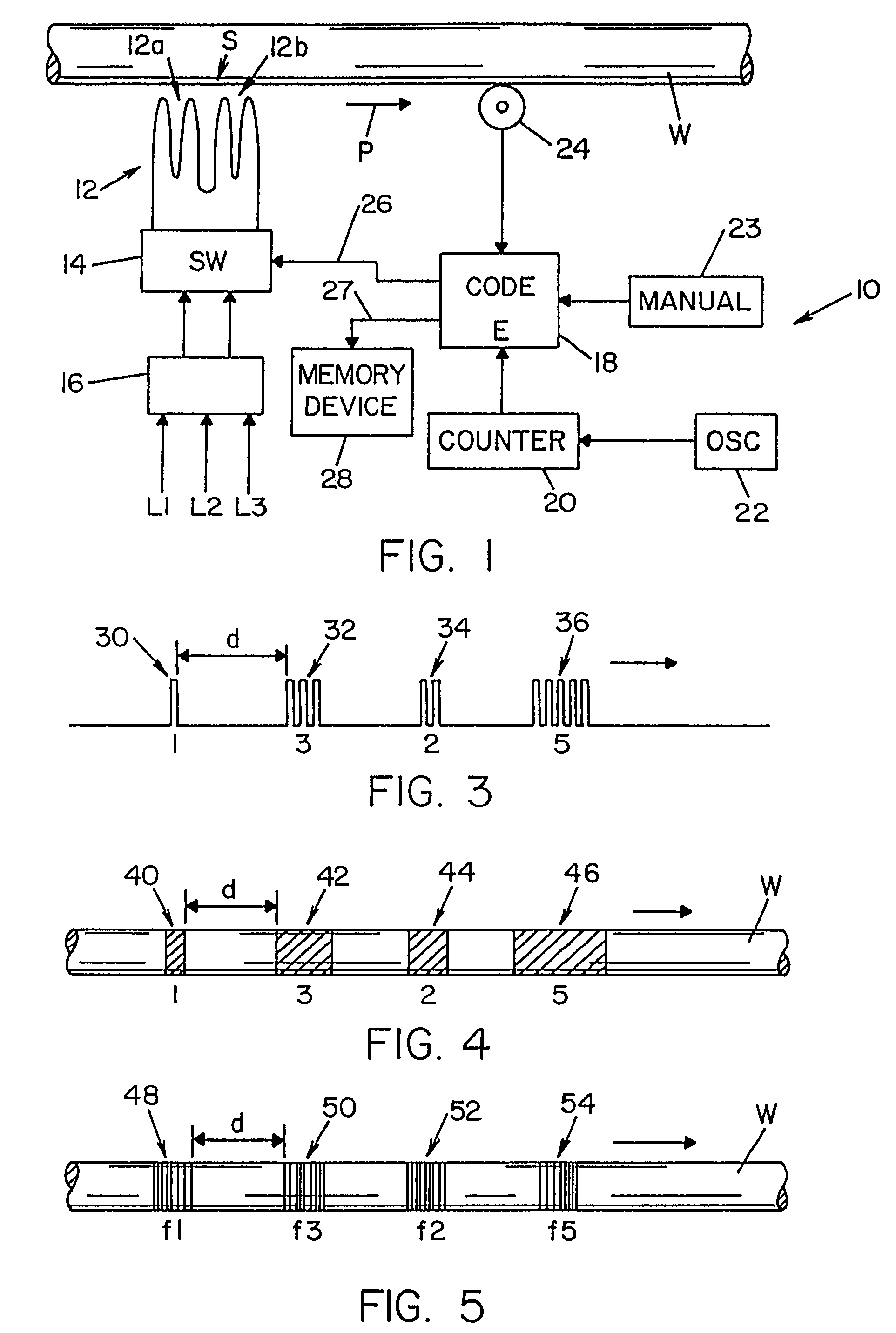

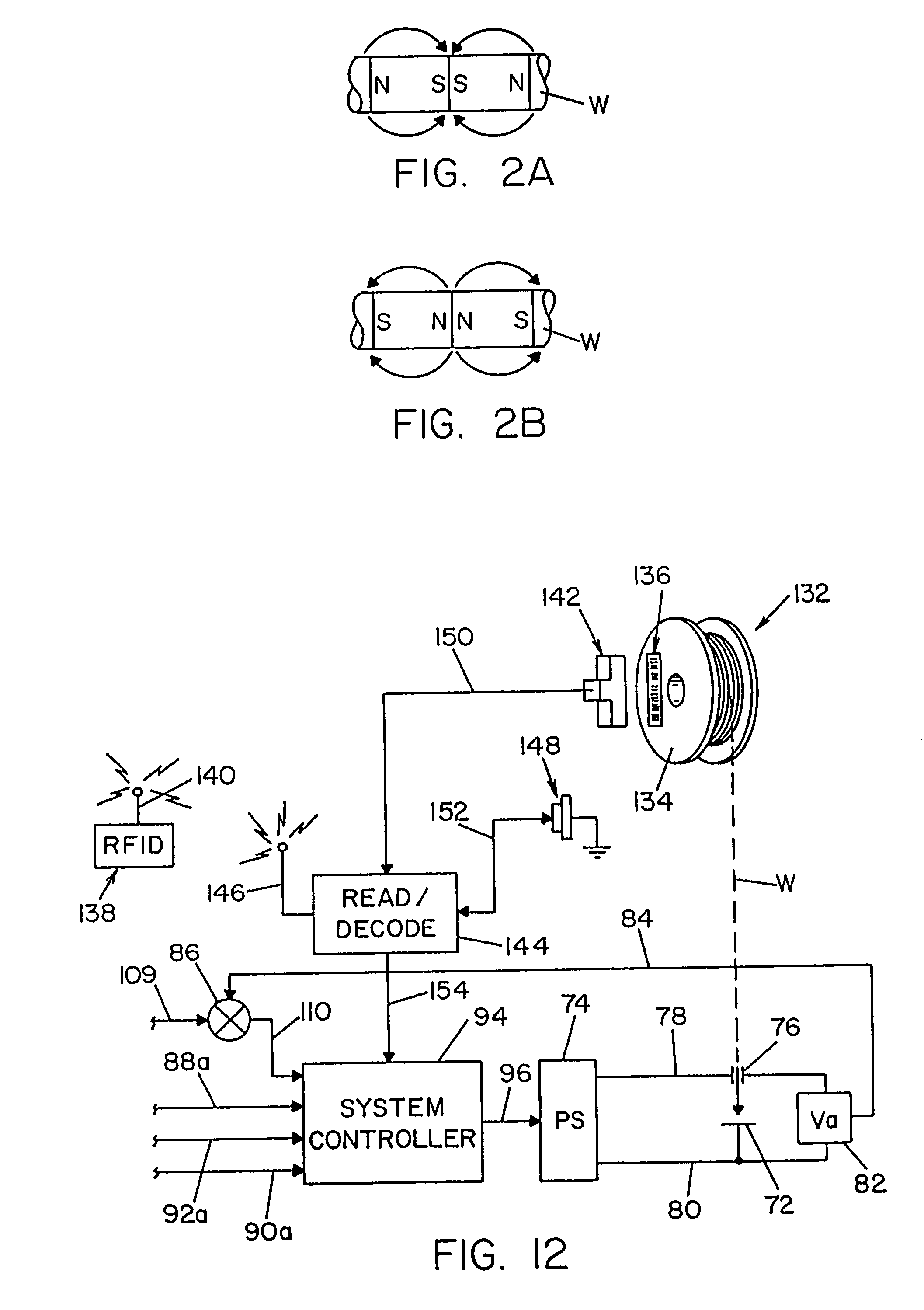

Coded welding consumable

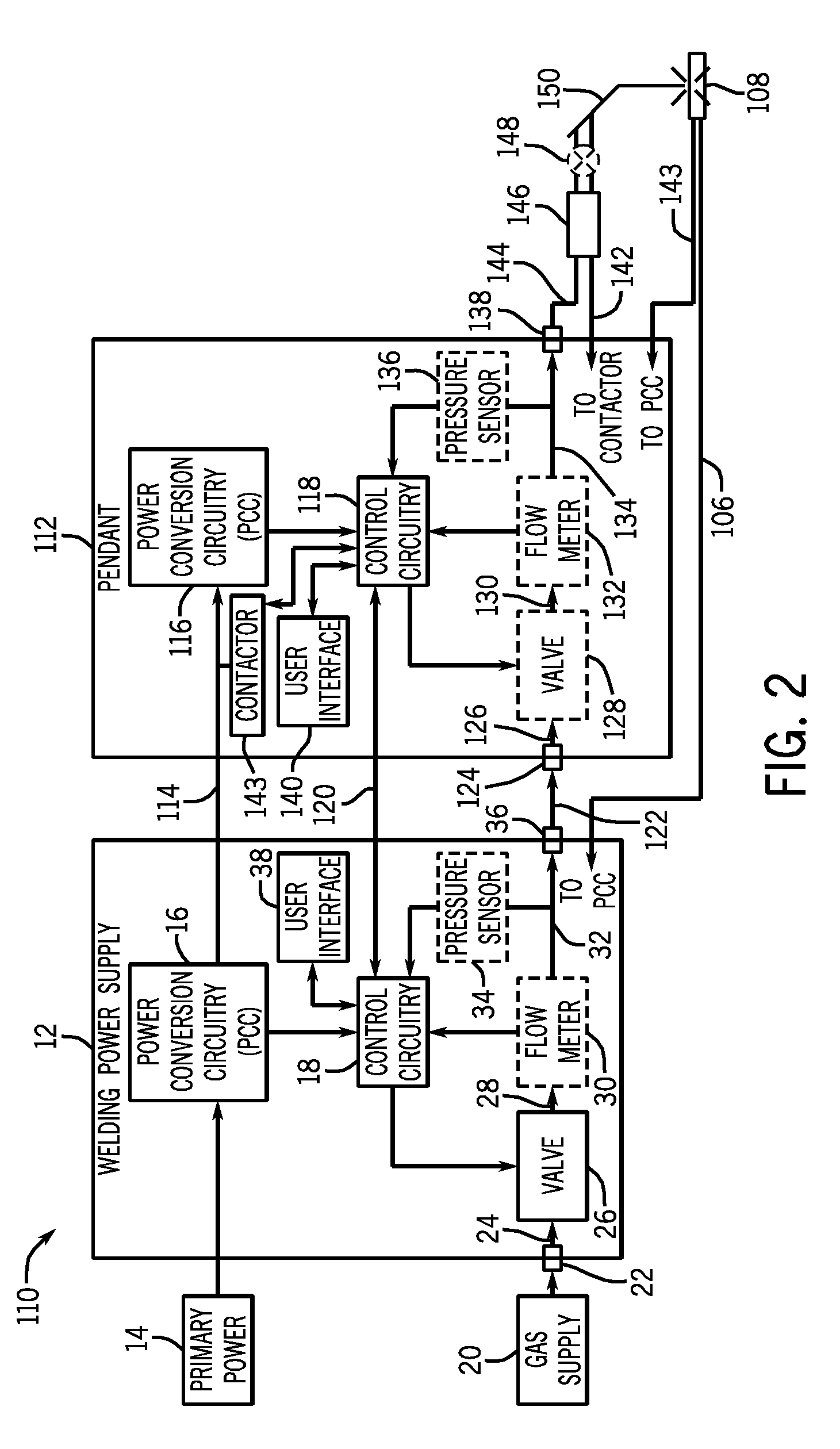

InactiveUS7032814B2Quality improvementImprove welding efficiencyArc welding apparatusCo-operative working arrangementsCarbon Dioxide / HeliumShielding gas

Information pertaining to characteristics of consumables such as metal welding electrode wire and shielding gas and which characteristics are useful in connection with adjusting welding parameters in an arc welding process and / or selecting between operating modes in a welding system are encoded on welding wire and / or on other memory components such as bar code labels and tags, RFID cards and tags, IC cards, and Touch Memory buttons, and the memory device is scanned prior to and / or at the point of use of the welding wire or shielding gas for enabling tracking of product distribution, manual and / or automatic selection of an operating mode for the welding system, manual and / or automatic adjustment of welding parameters in a given operating mode, consumables inventory, and the like.

Owner:LINCOLN GLOBAL INC

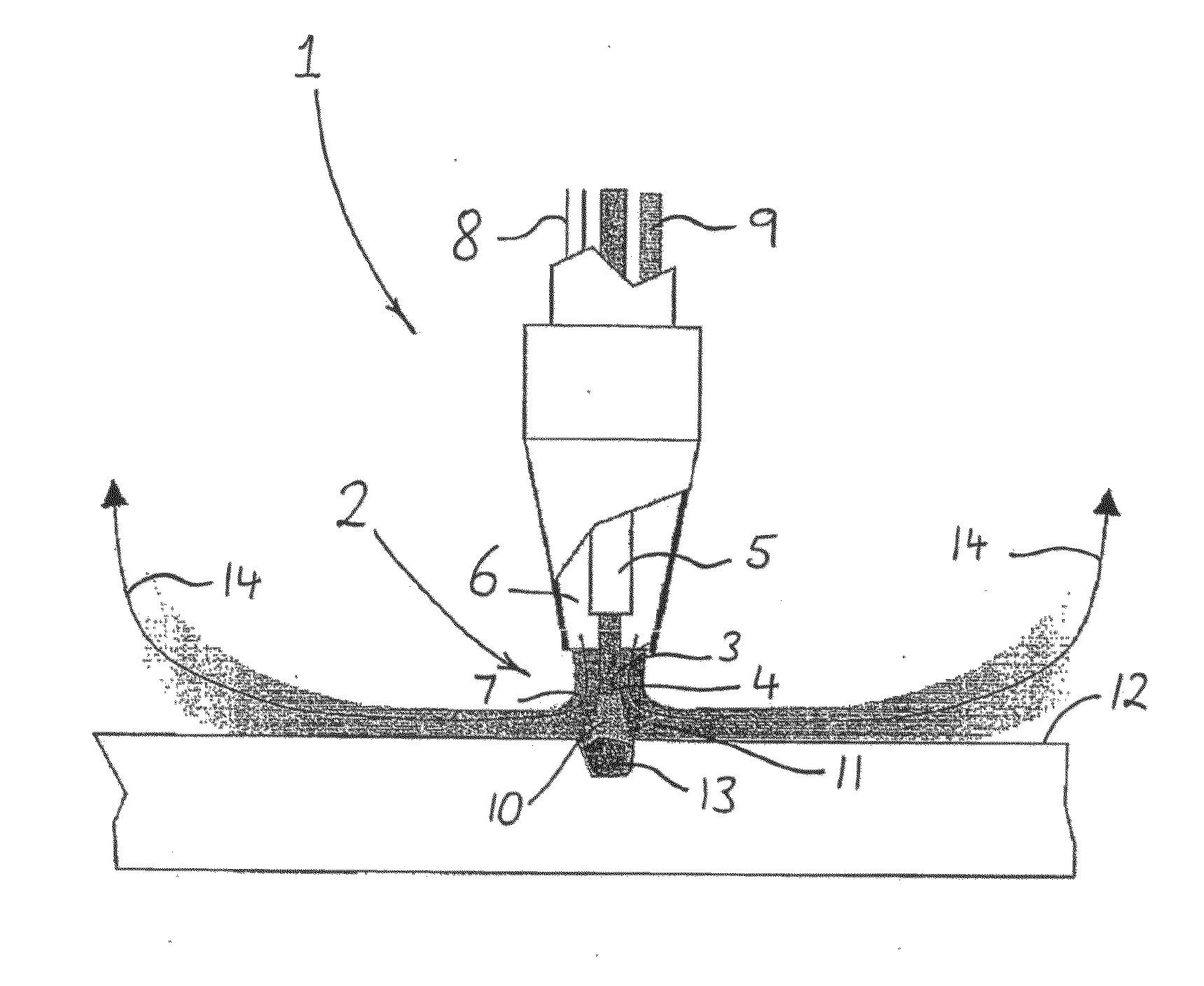

Apparatus and method for welding

InactiveUS20100276396A1Improve smoke extraction efficiencyFine-tune fume extraction efficiencyShielding gas supply/evacuation devicesDirt cleaningShielding gasCarbon Dioxide / Helium

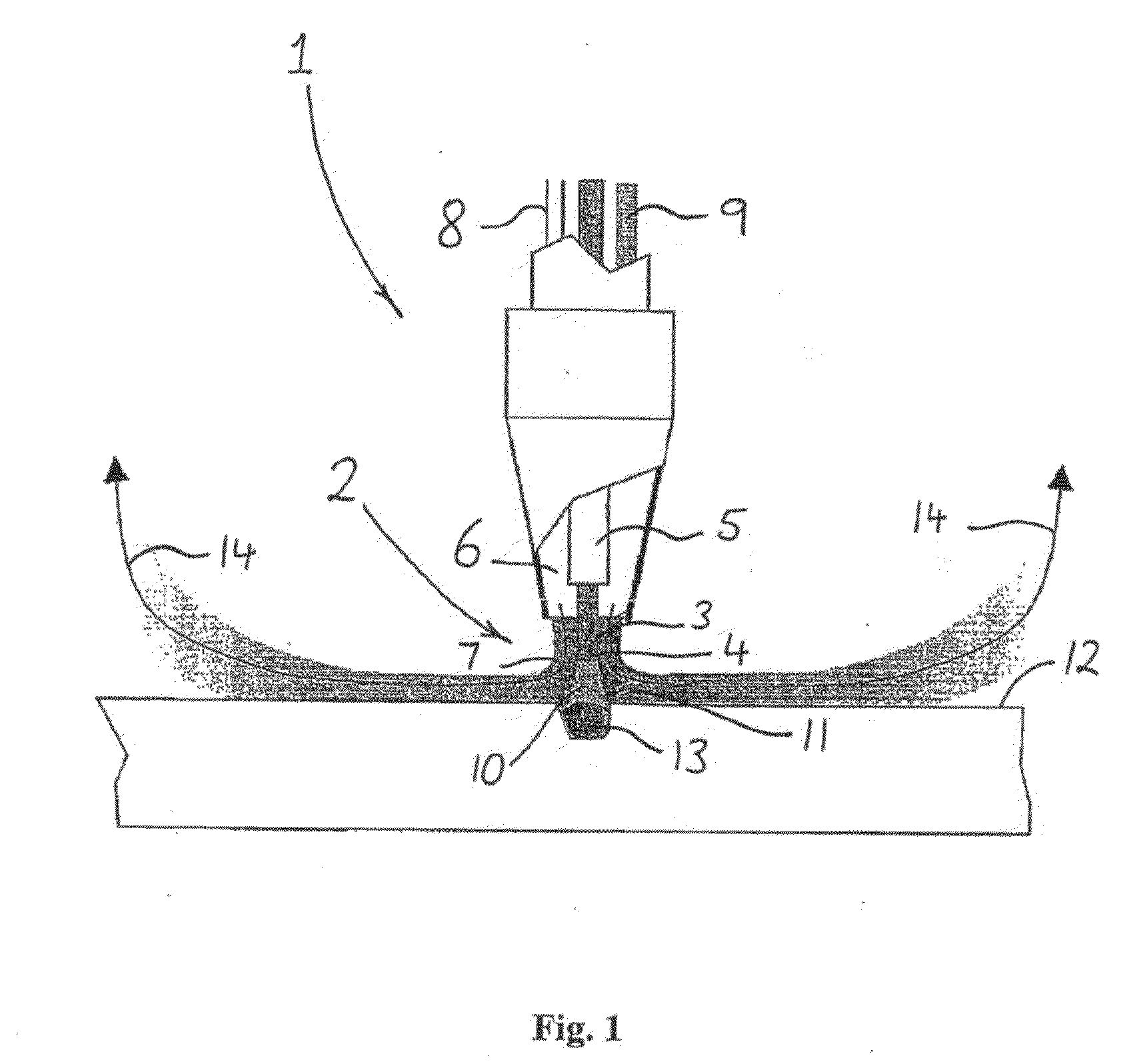

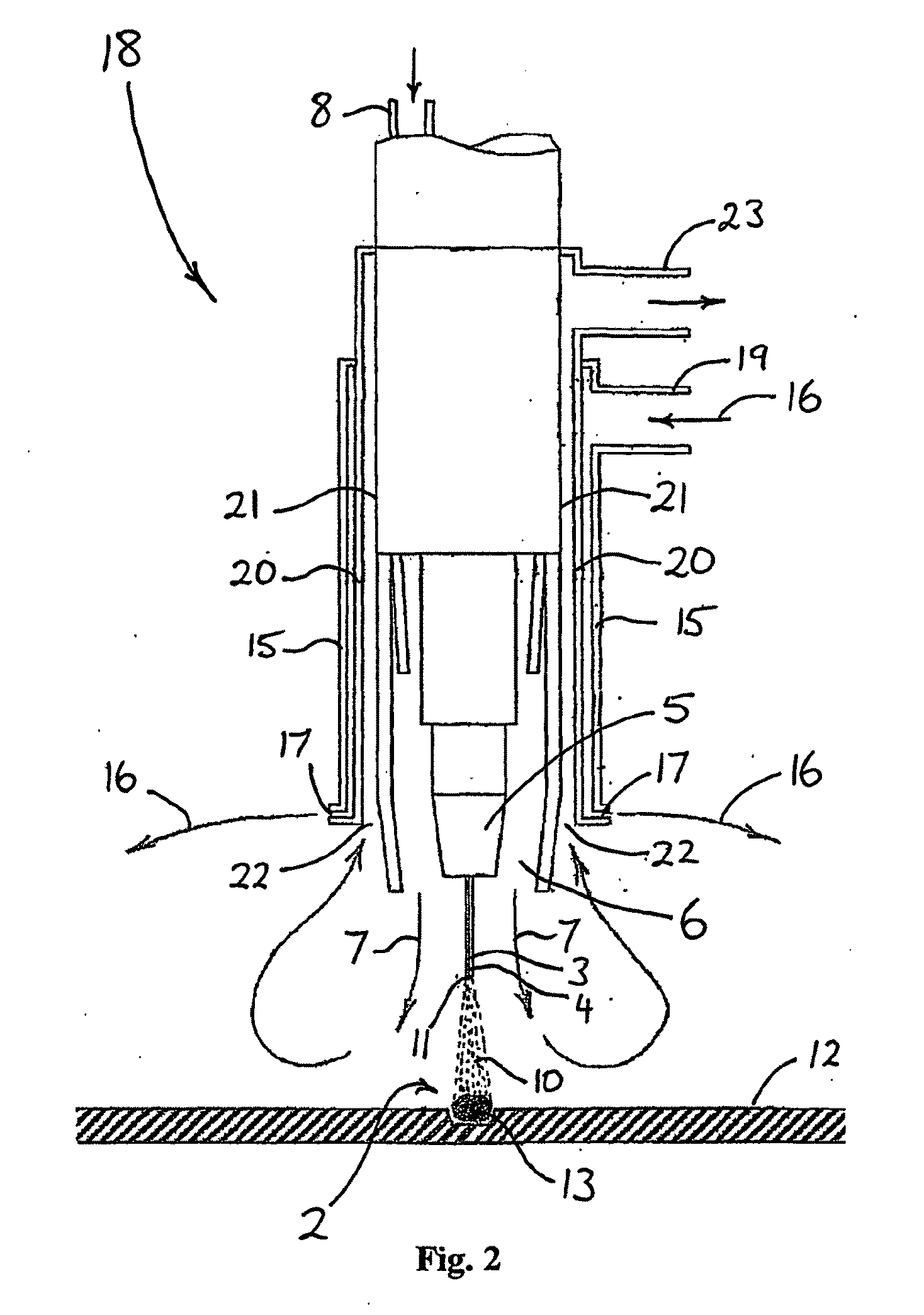

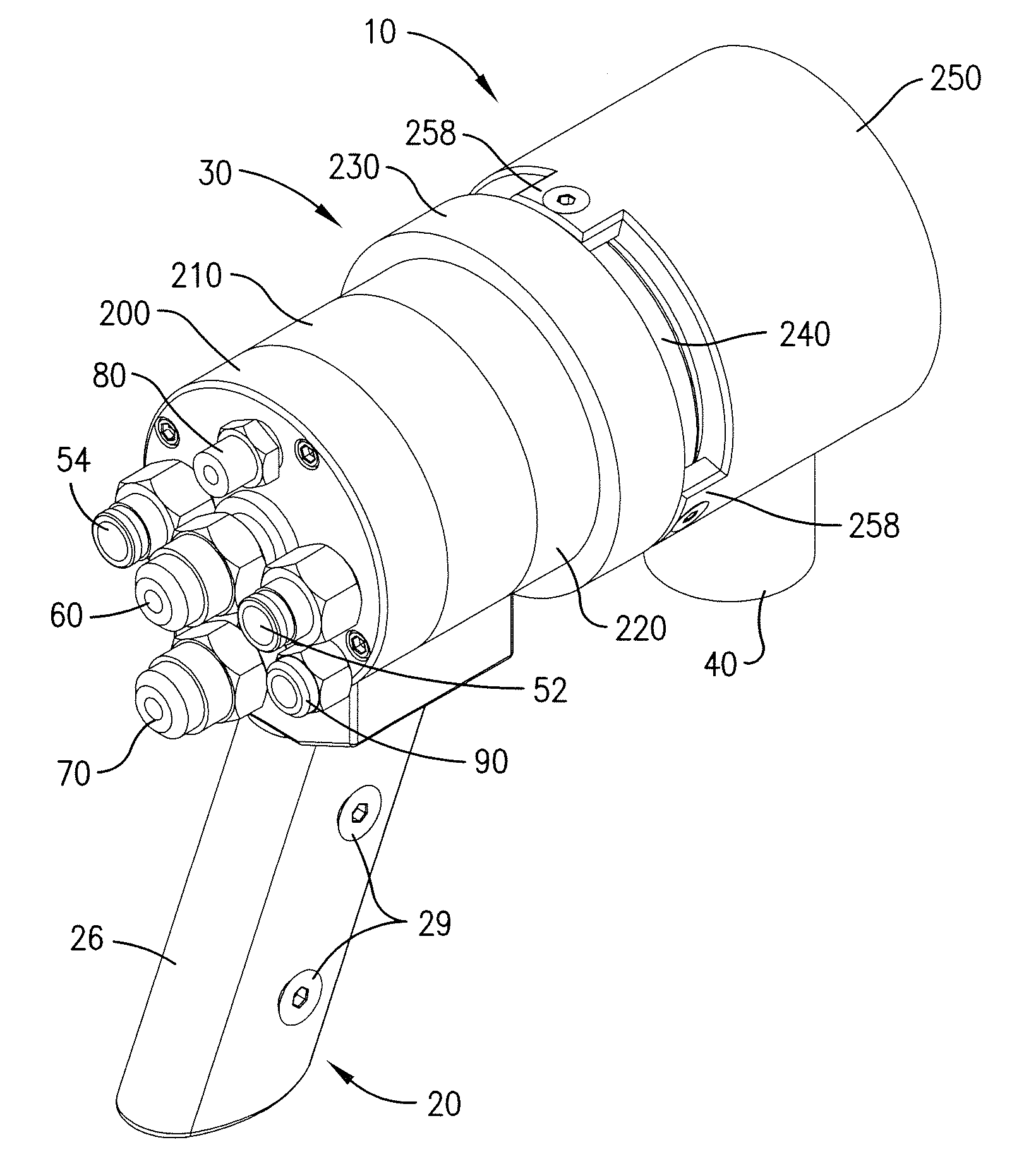

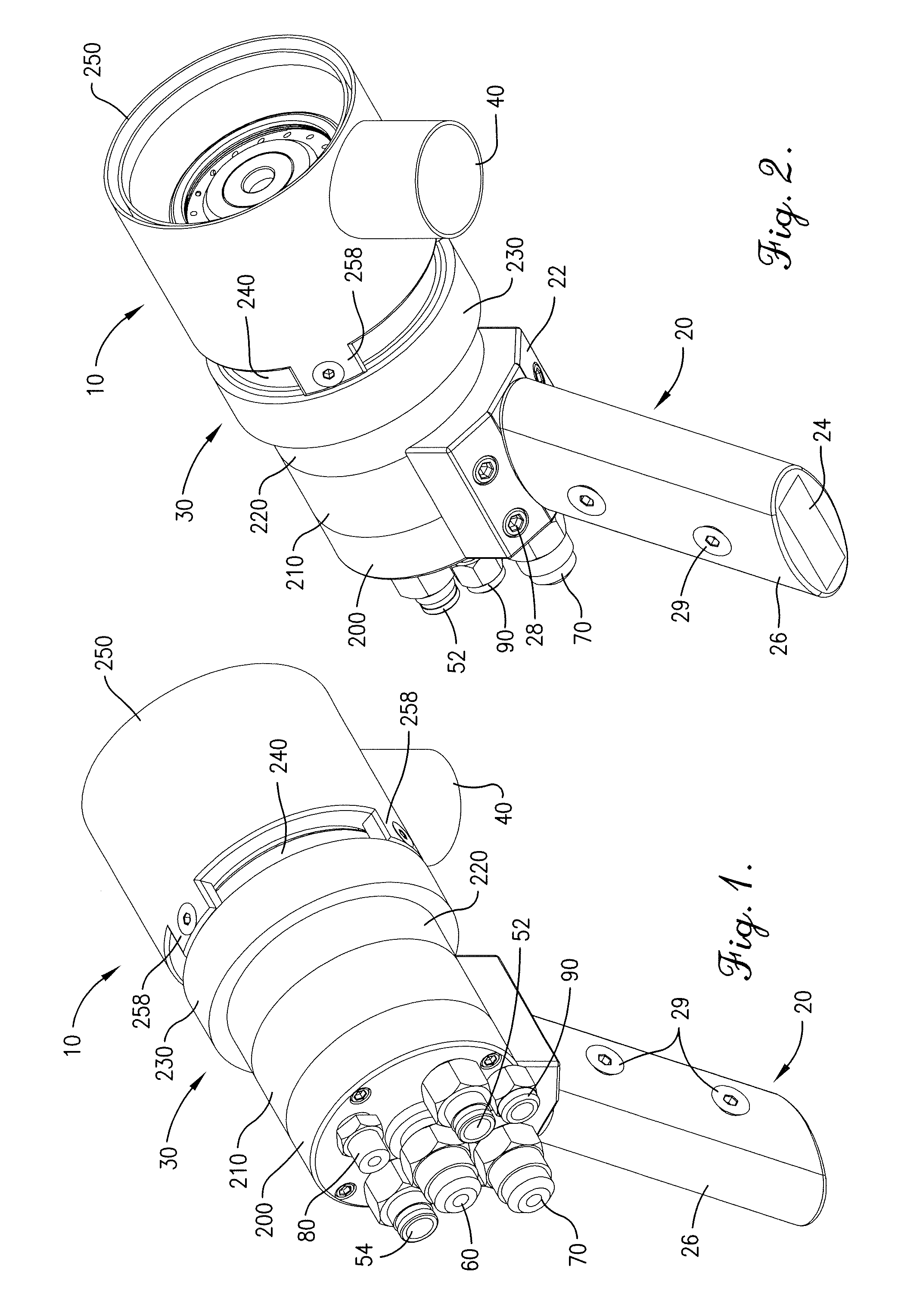

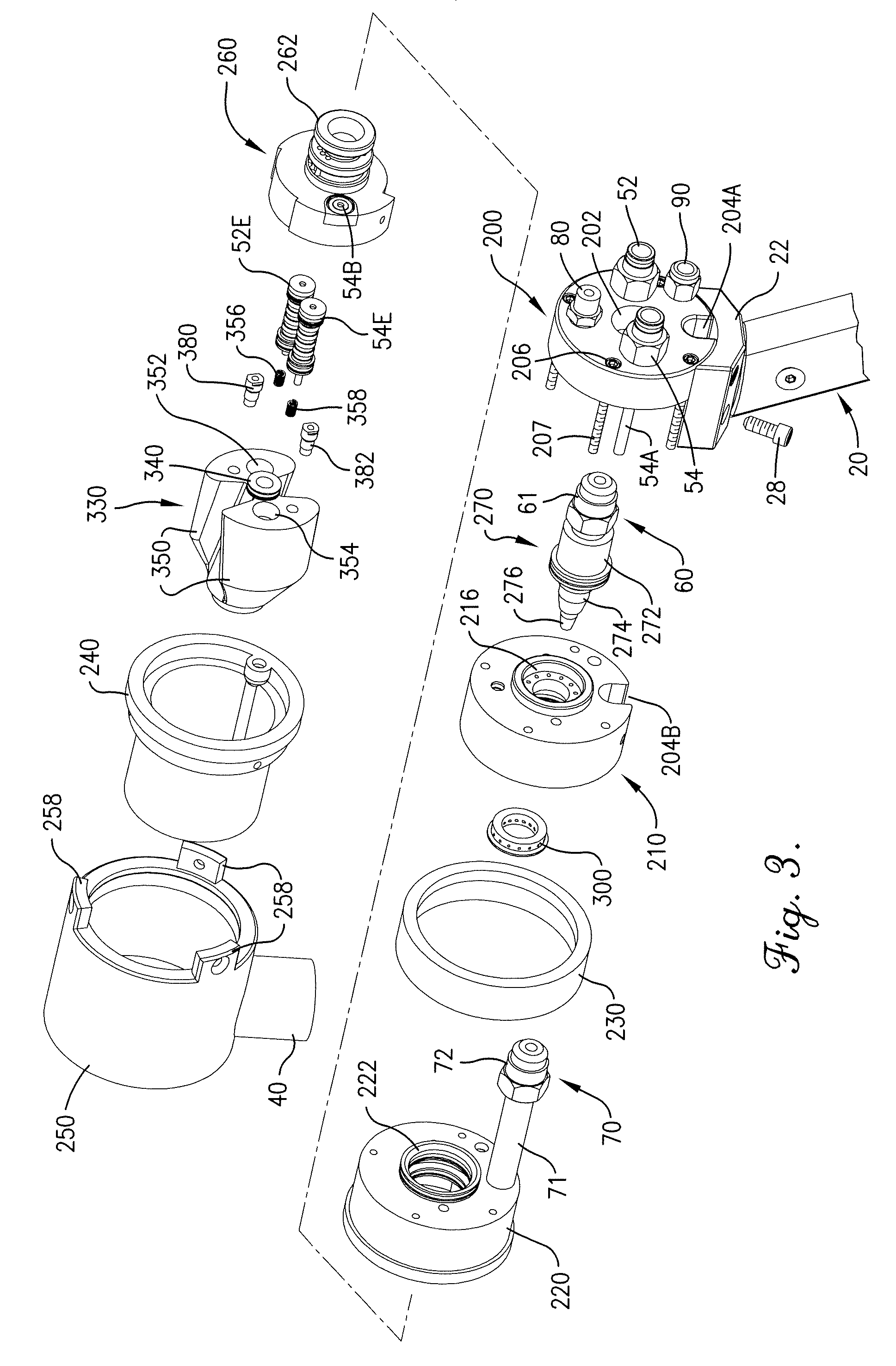

The present invention relates to arc welding torch and a method of extracting fume gas from a welding site. The torch comprises a metal electrode and at least one shield gas port adapted to direct a shield gas curtain around the metal electrode and a welding site. At least one shroud gas port is spaced radially outward from the shield gas port and adapted to impart to an exiting shroud gas a radially outward component of velocity. Fume gas is preferably extracted from a position radially intermediate the shield gas curtain and the shroud gas curtain.

Owner:COOPER PAUL +2

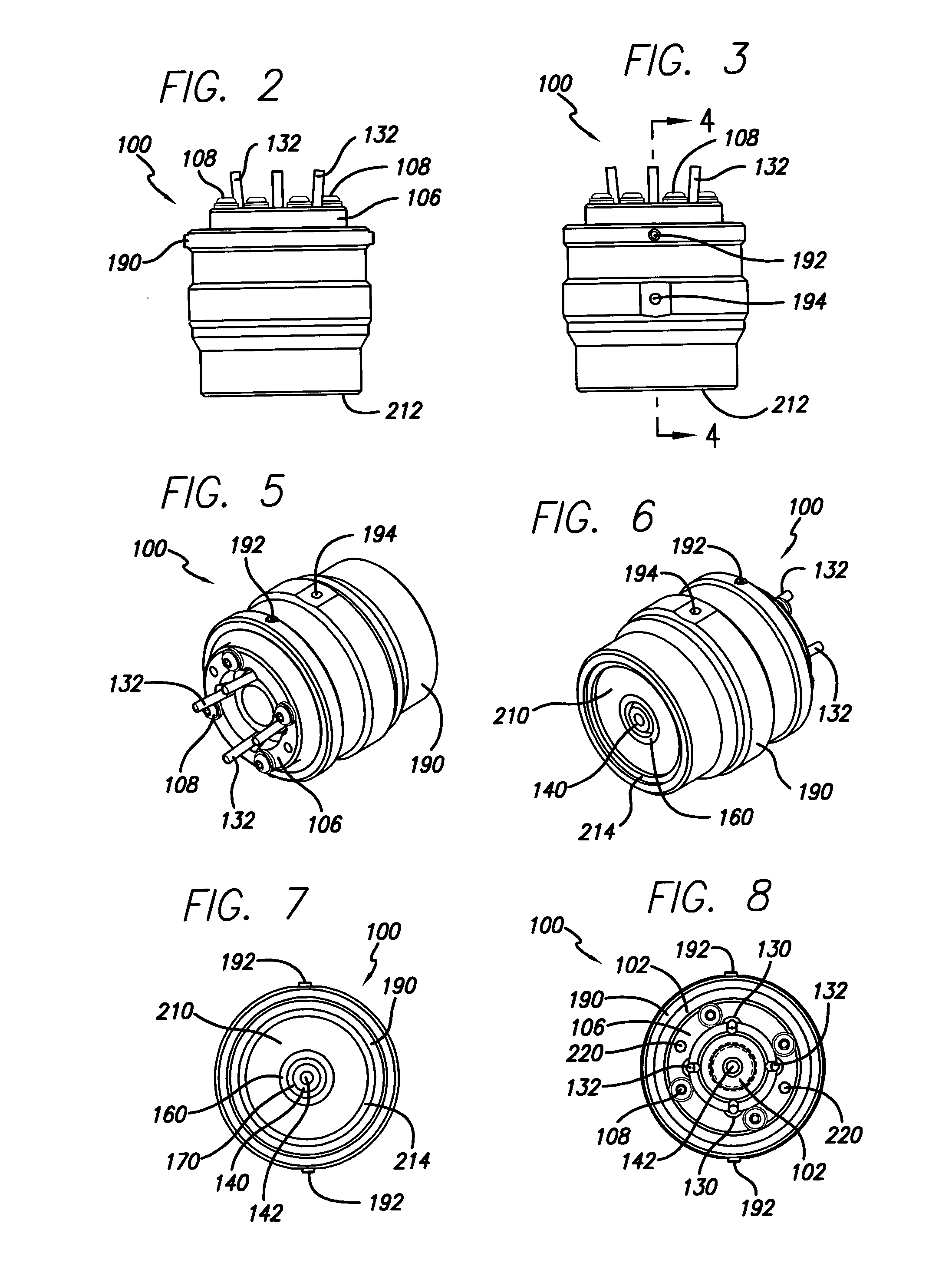

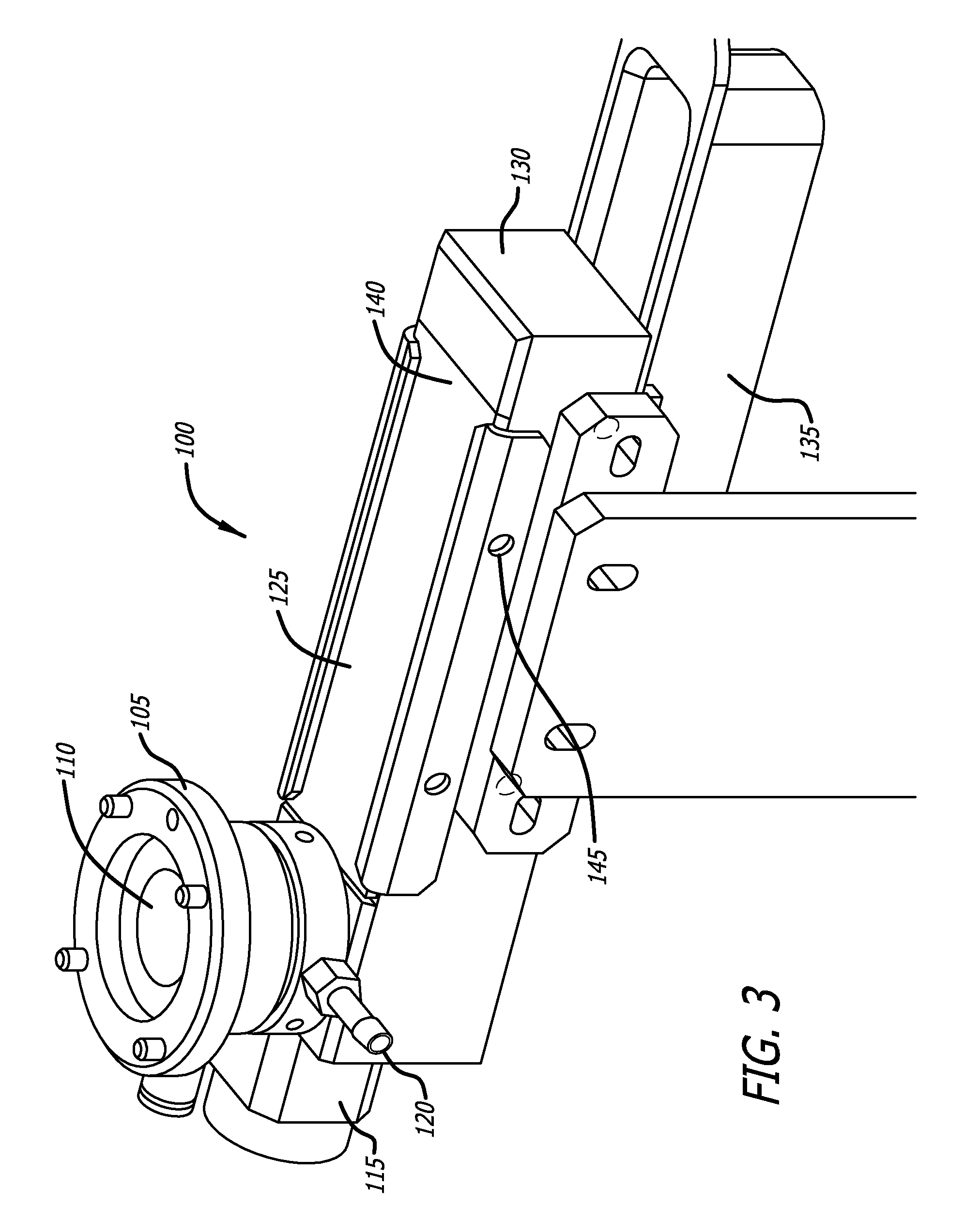

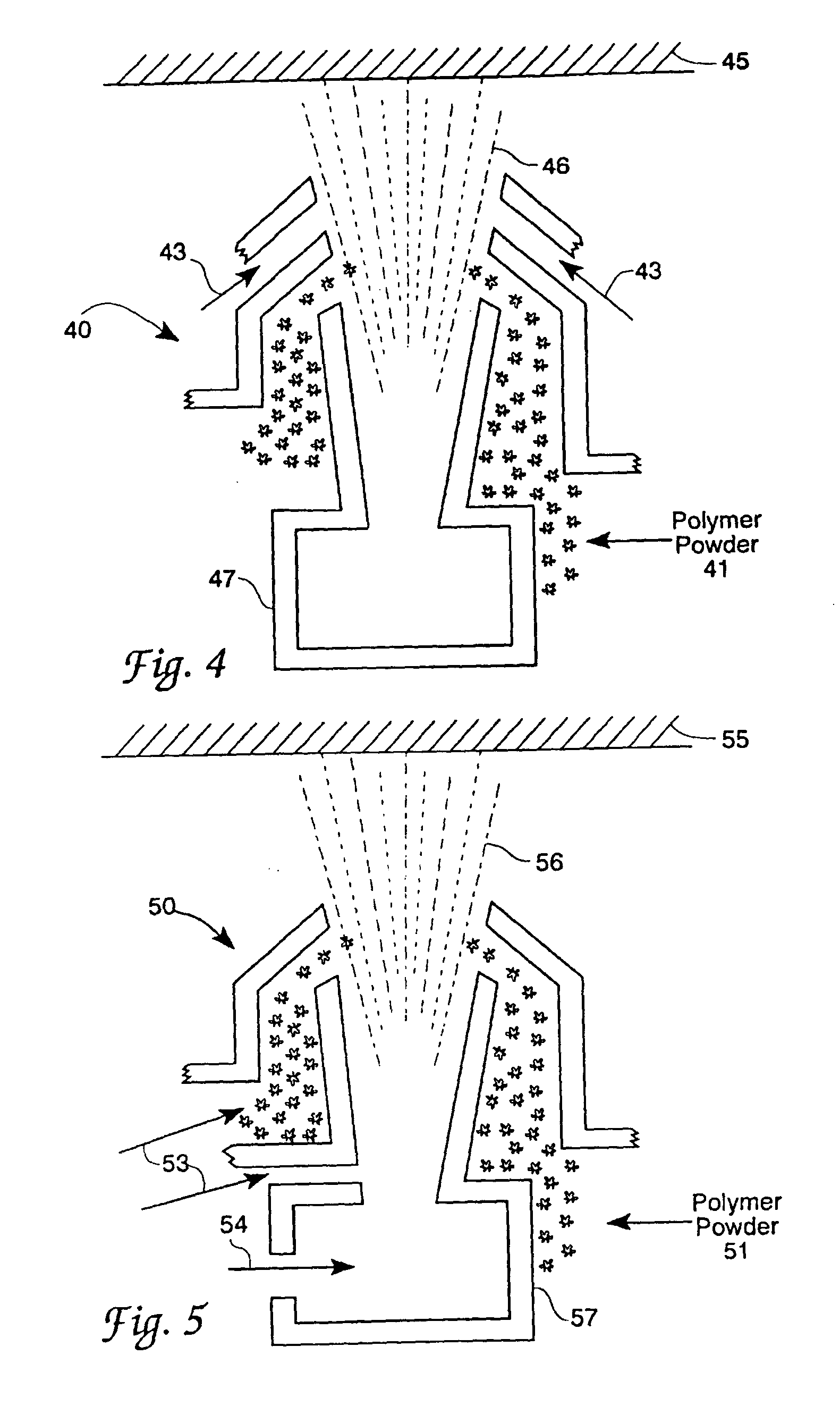

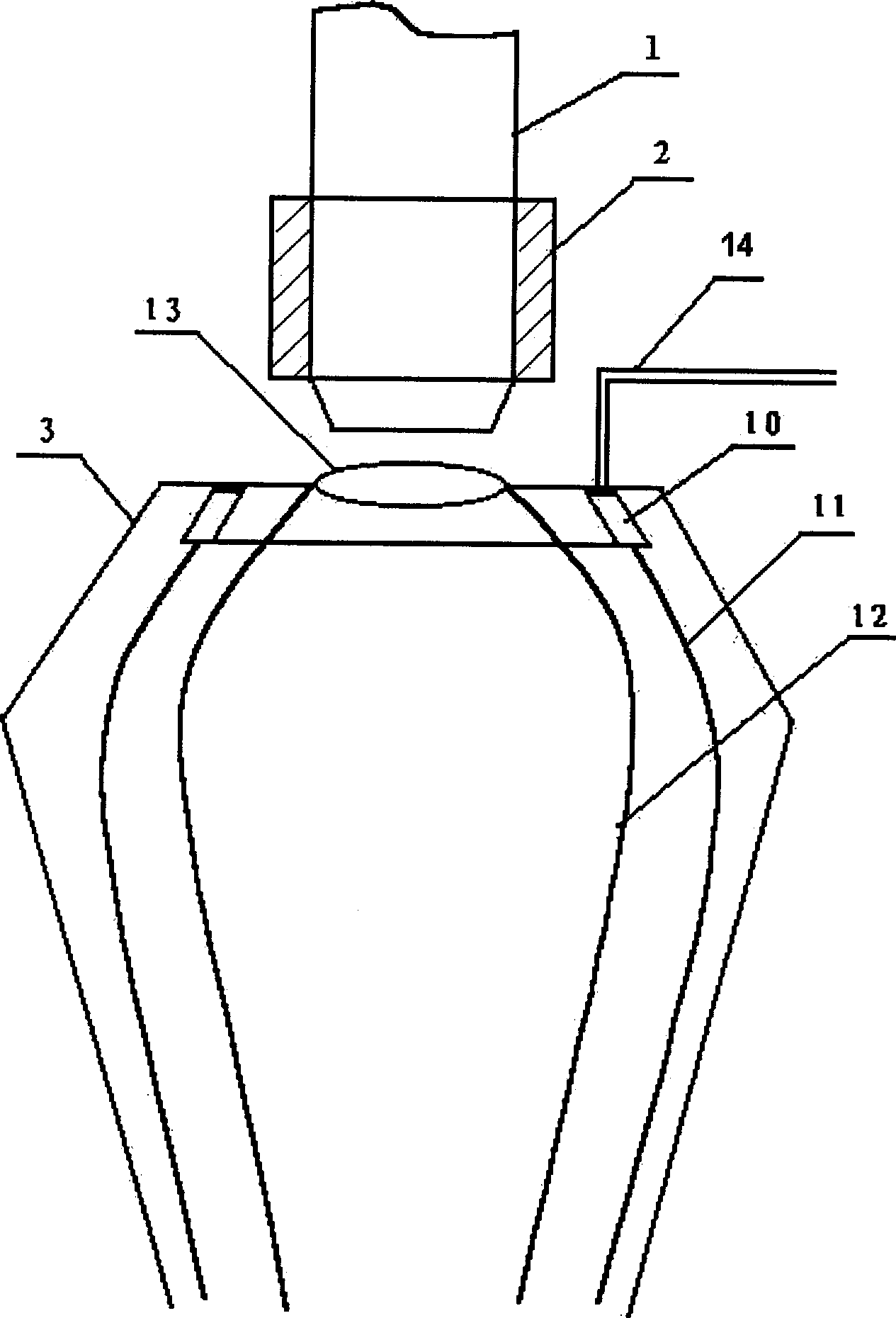

Coaxial nozzle design for laser cladding/welding process

InactiveUS20050056628A1Reliably-symmetric powder flowLong-term useLaser beam welding apparatusLaser NozzleShielding gas

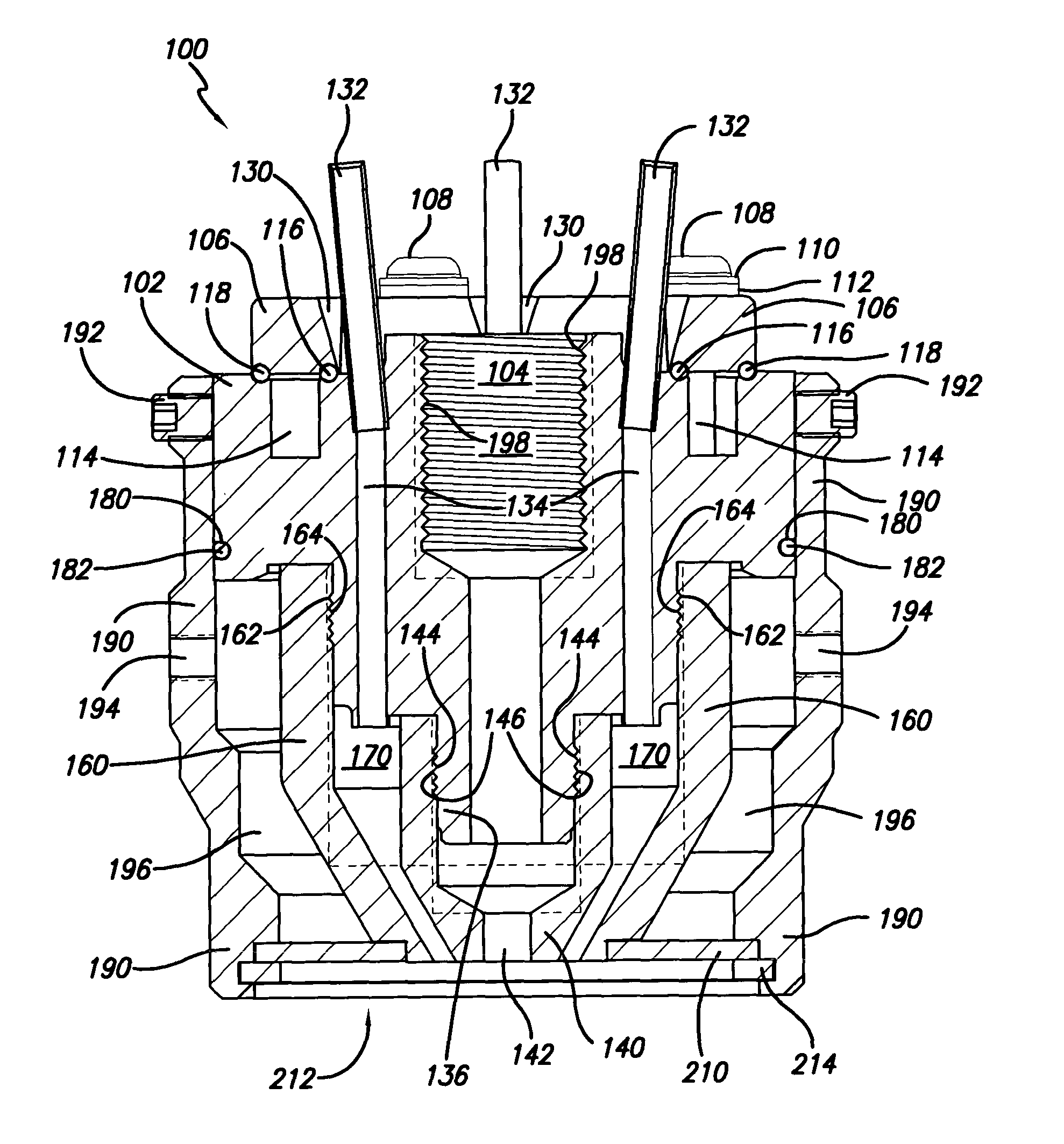

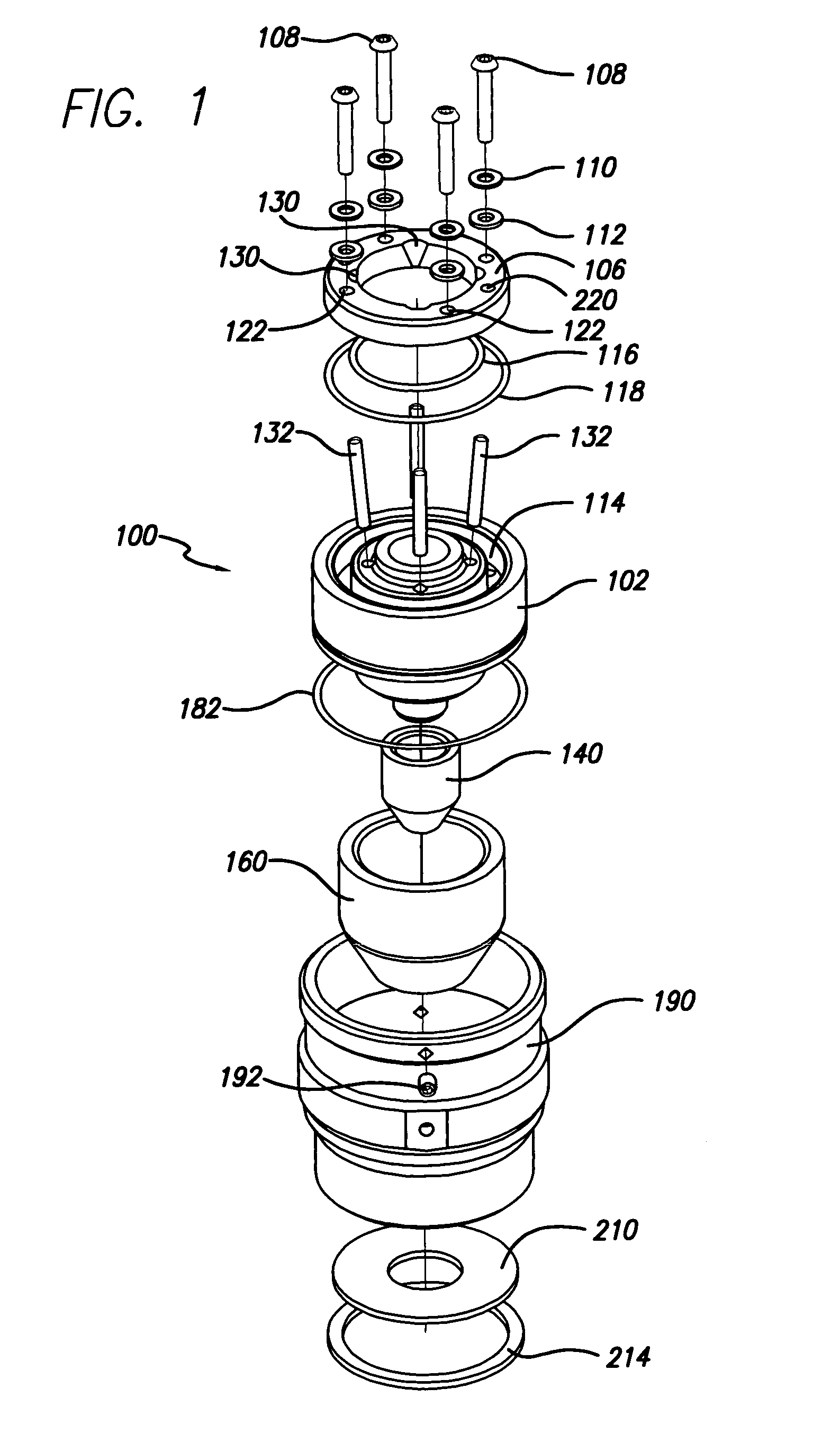

A laser nozzle for use in a laser powder fusion (LPF) welding process provides longer service life and ease of maintenance. Eliminating the use of laser nozzle inserts, the laser nozzle uses an inner tip that is less subject to damage from the welding process. The laser beam travels down an open central passage to exit out the inner tip in focused alignment with a conical powder flow stream ending in a point generally coincident with the laser beam. The powder supply travels through a passage that is generally coaxial to the central laser passage. A circumscribing passage for inert shielding gas or the like is coincidentally coaxial with both the laser powder flow channel and the central laser channel. Coolant is circulated through a main body portion of the nozzle in order to keep the entire assembly cool. Both the laser and the flow of powder may be adjusted according to operating preferences. A porous shielding cover prevents ejecta and other materials from entering into the shielding gas flow channel. The entire assembly is easily constructed from readily available materials and is easily disassembled for cleaning. Reassembly is also easily achieved in order to enable rapid refurbishment and reconstitution of an optimal LPF welding nozzle.

Owner:HONEYWELL INT INC

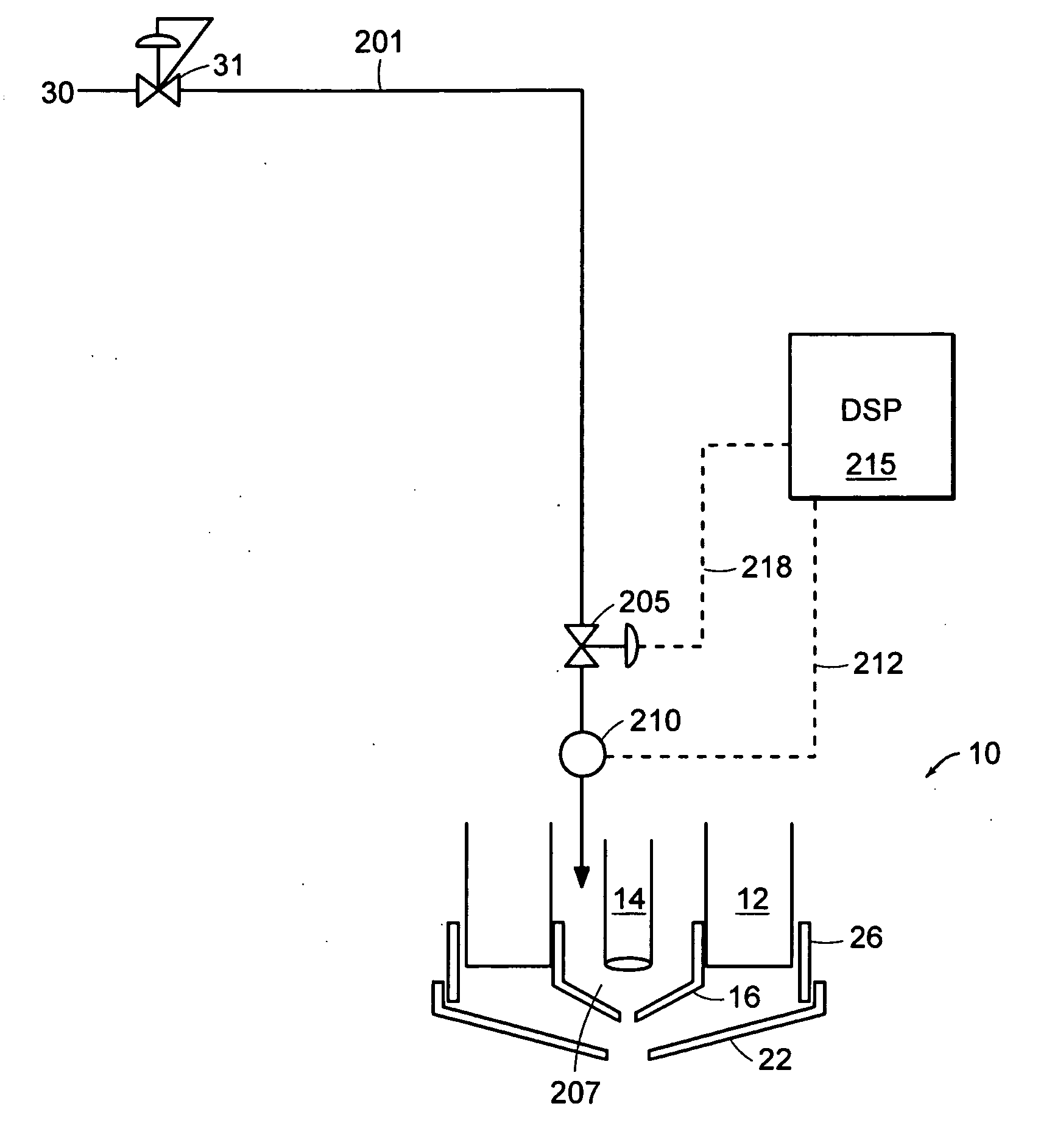

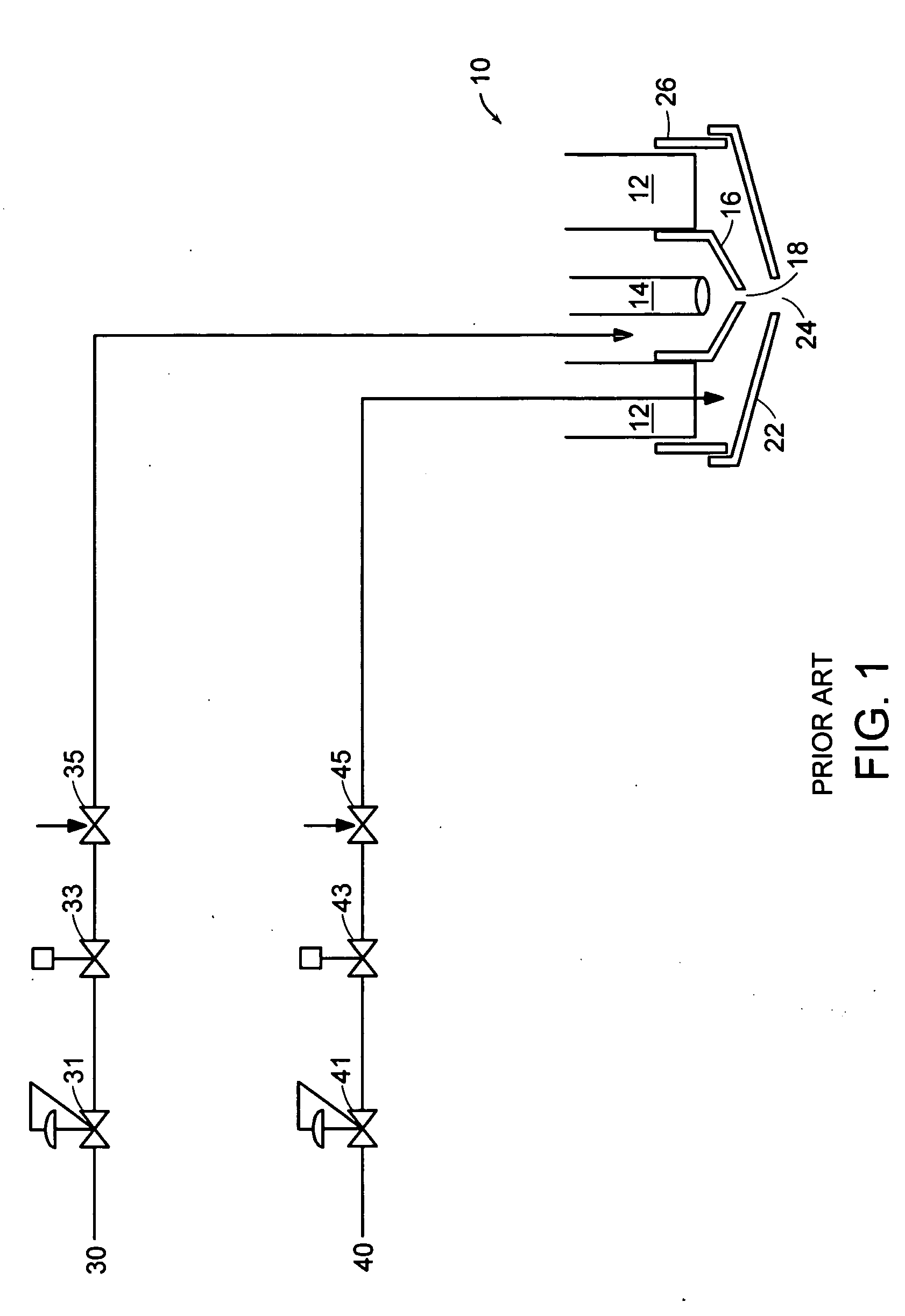

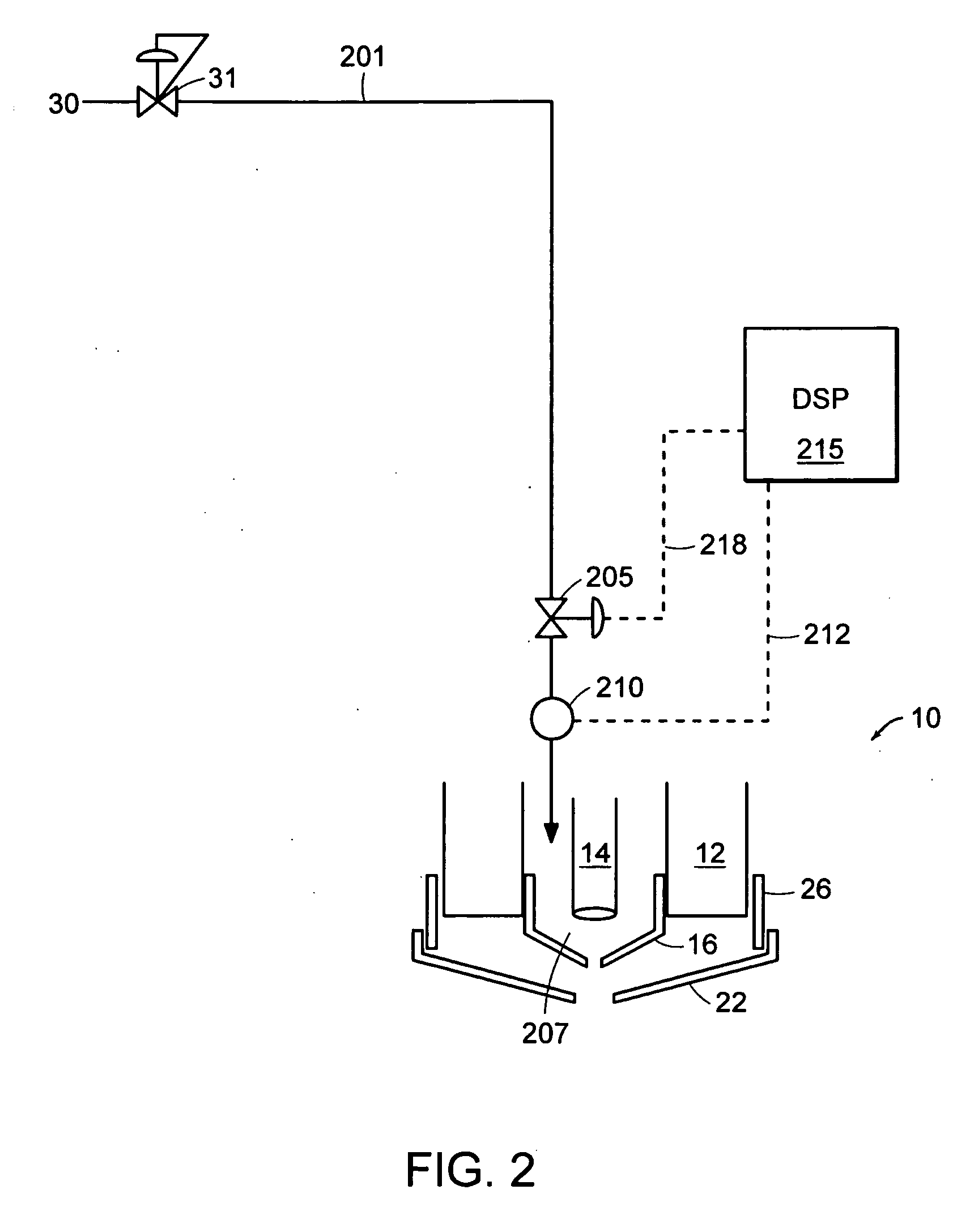

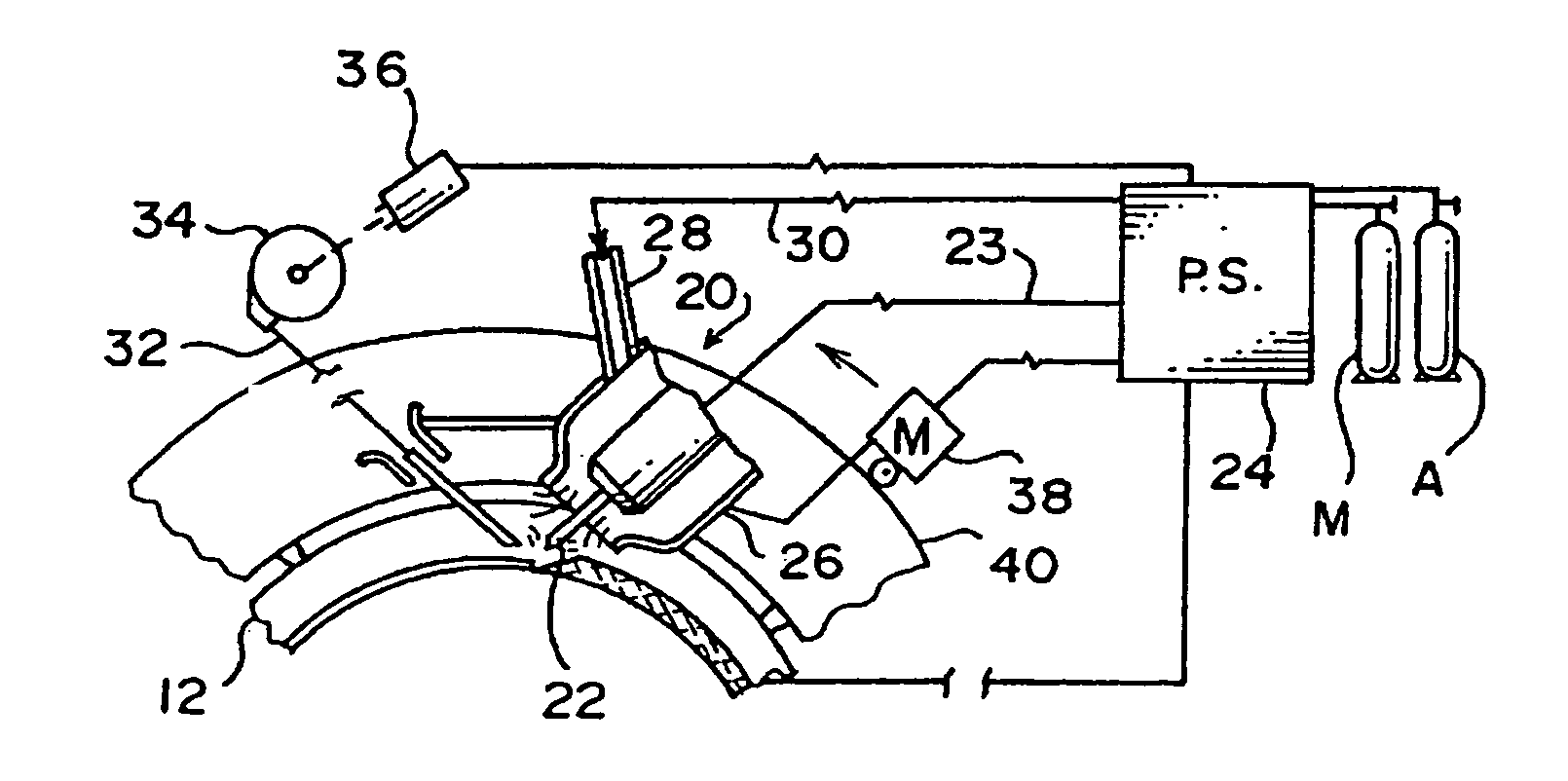

Automatic gas control for a plasma arc torch

InactiveUS20060163216A1Prolong lifeHigh operating current levelArc welding apparatusPlasma welding apparatusProportional controlSolenoid valve

A method and apparatus for controlling a gas supply to a plasma arc torch uses a proportional control solenoid valve positioned adjacent the torch to manipulate the gas flow to the torch, thereby extending electrode life during arc transfer and shutdown. Swirl ring design can be simplified and gas supply and distribution systems become less complicated. The invention also allows manipulation of shield gas flow to reduce divot formation when making interior cuts. The system can be controlled with a digital signal processor utilizing a feedback loop from a sensor.

Owner:HYPERTHERM INC

Laser cutting system

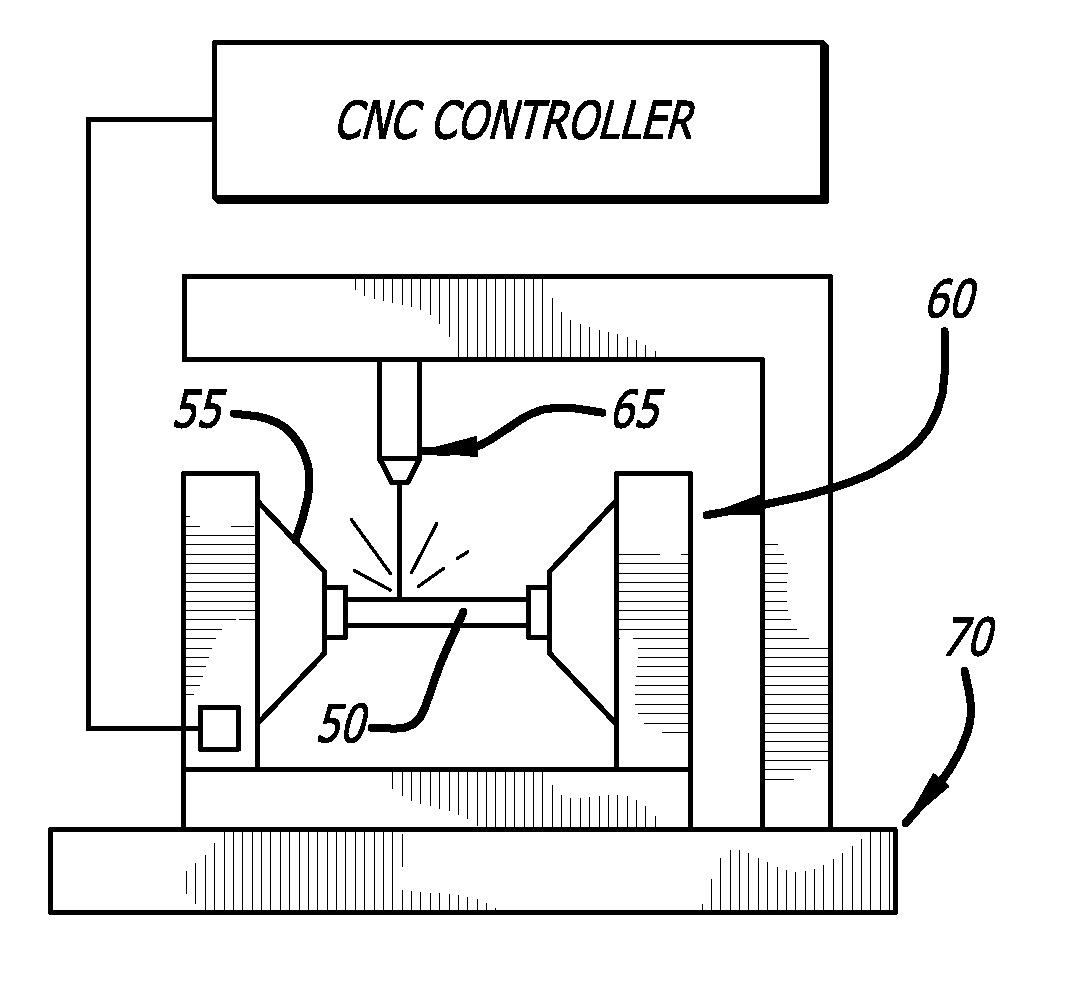

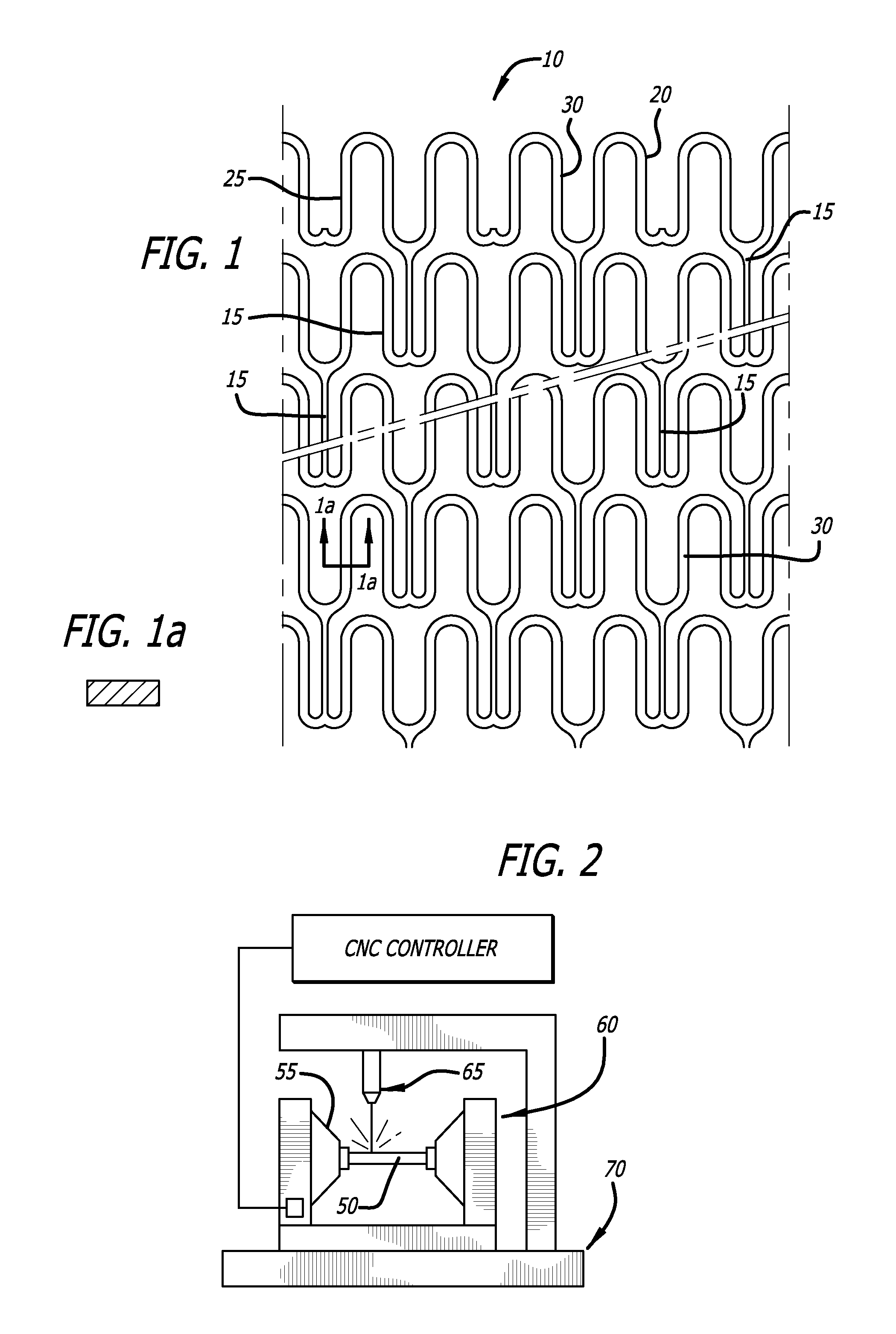

InactiveUS20100193482A1Reduce and eliminate heat and oxygen related changeAvoid damageLaser beam welding apparatusCarbon Dioxide / HeliumShielding gas

A laser cutting system including a chamber configured to provide a controlled environment while the laser is being used to cut a pattern into a material to reduce or eliminate heat and oxygen related changes to the mechanical characteristics of the material. A system for providing a gas to the controlled environment within the chamber, as well as a means for exhausting gas and cutting debris from the chamber is also described. A cutting mandrel that provides for flow of a shielding gas and also provides a means for dispersing a laser beam before it can produce unwanted damage to a section of tubing is also described.

Owner:ABBOTT CARDIOVASCULAR

Process for welding

InactiveUS7170032B2Long electrode lifeEvacuating shieldingWelding/cutting media/materialsElastomerShielding gas

A welding process for non-stainless steel workpieces using GTAW equipment and hydrogen containing shield gas on a first root pass is improved by using a shield gas delivery system comprising hoses or conduits made of elastomeric material having a moisture permeability coefficient of less that 275, preferably less than 100, and using a tungsten electrode composition comprising at least tungsten and lanthanum oxide, and preferably tungsten, lanthanum oxide, yttrium oxide and zirconium oxide. Preventing moisture permeation through the elastomeric hoses delivering hydrogen containing shield gas eliminates expulsion of fused weld metal during second pass filler welding over the root pass weld. Electrode life is enhanced using the tungsten compounds.

Owner:JV IND CO LLC

Process for welding

InactiveUS20050109735A1Long electrode lifeEvacuating shieldingWelding/cutting media/materialsElastomerShielding gas

A welding process for non-stainless steel workpieces using GTAW equipment and hydrogen containing shield gas on a first root pass is improved by using a shield gas delivery system comprising hoses or conduits made of elastomeric material having a moisture permeability coefficient of less that 275, preferably less than 100, and using a tungsten electrode composition comprising at least tungsten and lanthanum oxide, and preferably tungsten, lanthanum oxide, yttrium oxide and zirconium oxide. Preventing moisture permeation through the elastomeric hoses delivering hydrogen containing shield gas eliminates expulsion of fused weld metal during second pass filler welding over the root pass weld. Electrode life is enhanced using the tungsten compounds.

Owner:JV IND CO LLC

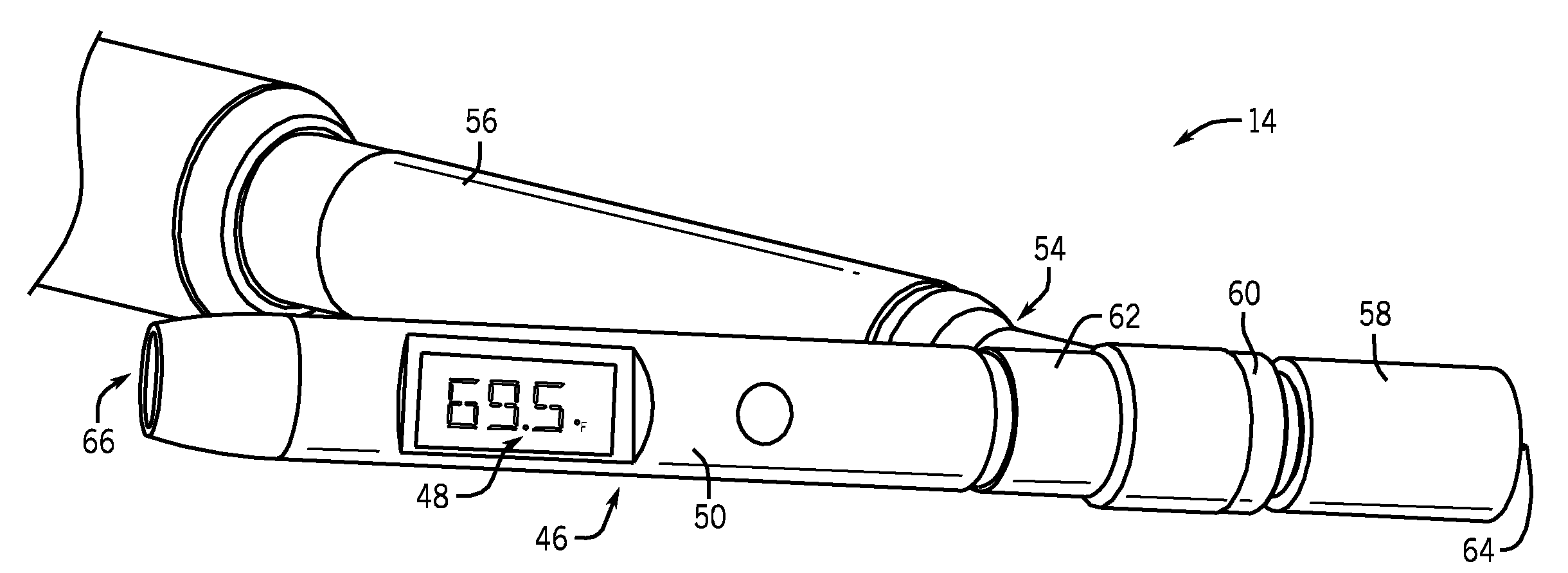

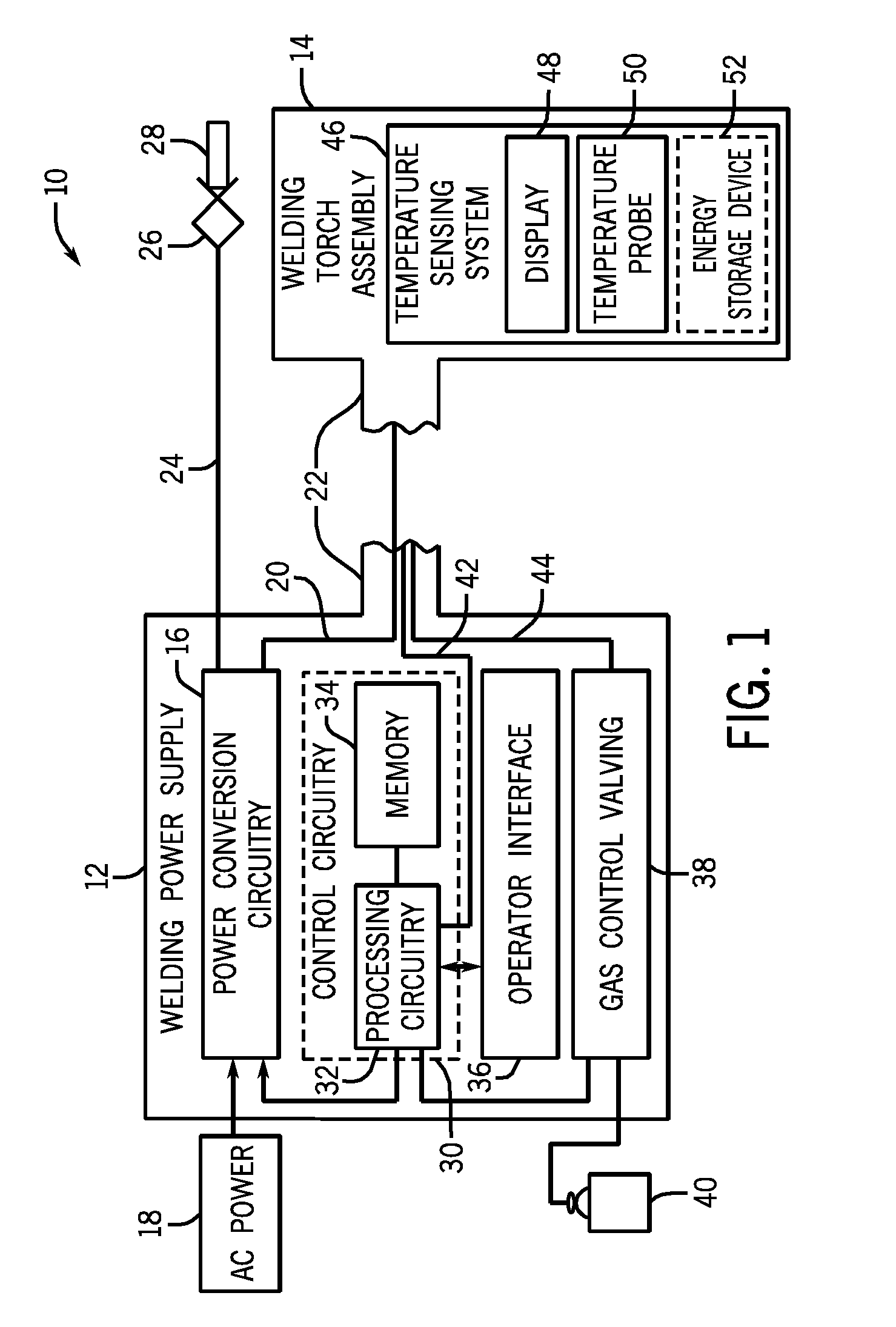

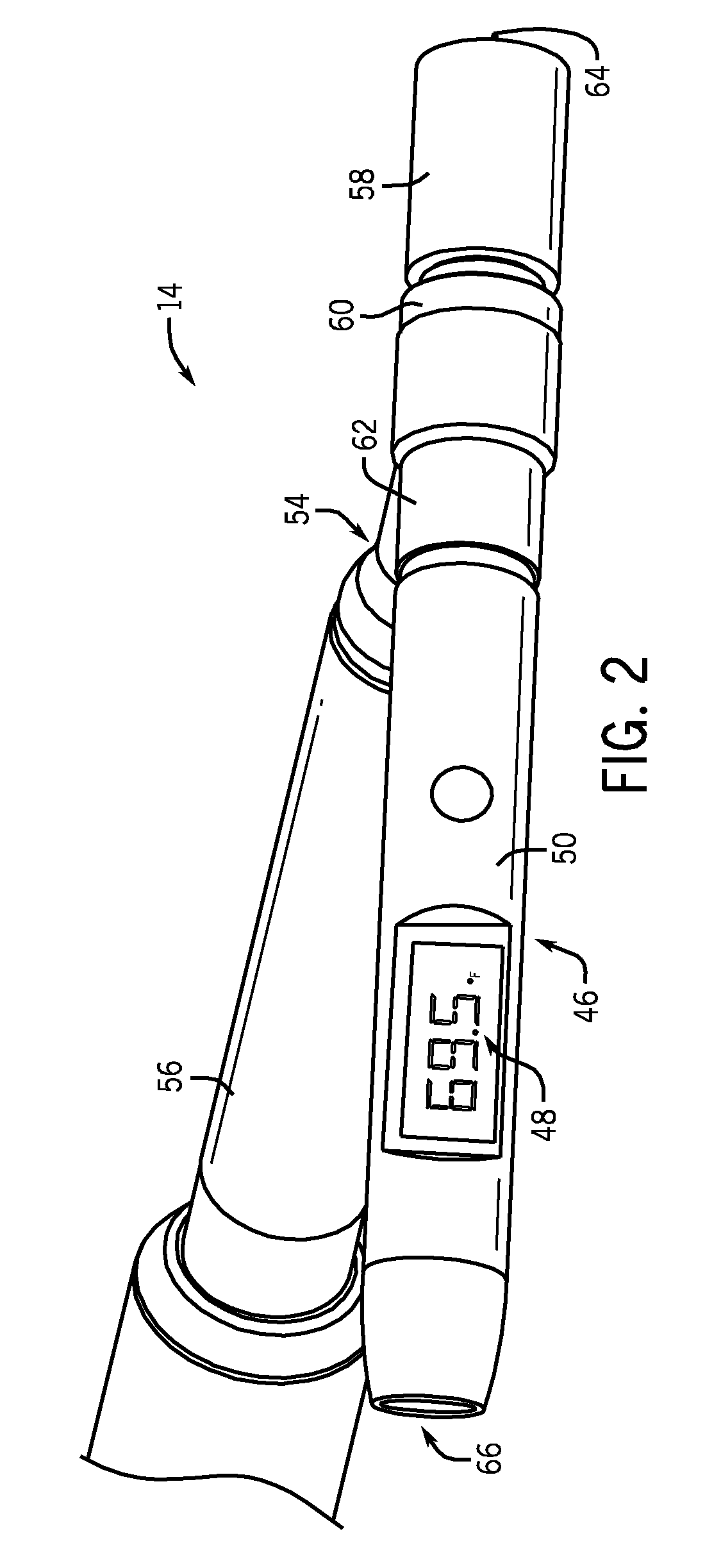

Welding systems having non-contact temperature measurement systems

ActiveUS20130264322A1Pyrometry using electric radation detectorsWelding accessoriesShielding gasCarbon Dioxide / Helium

Welding systems including welding torch assemblies are provided. The welding torch assembly may include a welding torch adapted to be utilized in a welding operation to establish a welding arc between the welding torch and a workpiece. Shielding gas may be supplied to the welding torch for establishment of a gas shielding area around a weld pool. The welding torch assembly may also include a temperature sensing system having a non-contact temperature sensor coupled to the welding torch and adapted to sense a temperature of the workpiece at a location outside of the molten weld pool.

Owner:ILLINOIS TOOL WORKS INC

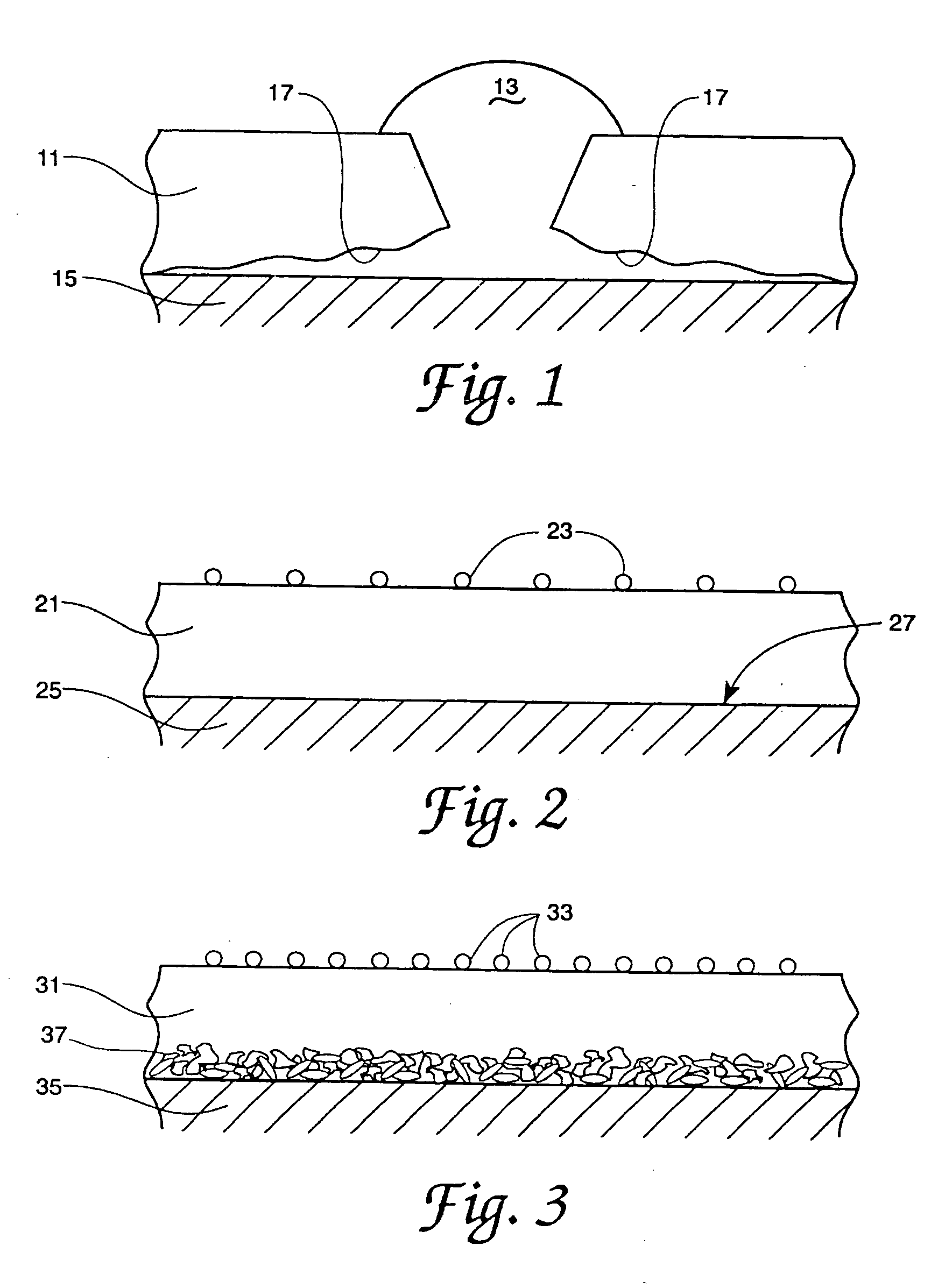

Process for coating substrates with polymeric compositions

InactiveUS20050048218A1Eliminate the problemElimination of free volumeLiquid surface applicatorsMolten spray coatingMetallurgyFuel tank

Corrosion resistant non-polar polymer coatings and methods for applying the coatings to substrates are described, wherein a source of non-polar polymer powder is deposited as a coating onto the surface of a substrate by high temperature thermal spray. The non-polar character of the powder and any additives thereto is substantially preserved during the high temperature thermal spray process by the use, at one or more locations along the thermal spray route, of at least one non-oxidizing shielding gas, at least one reducing gas, or a combination of the two types of gases to displace or react with ambient oxygen. High velocity impact force (HVIF) spraying techniques are preferred. Similarly processes and materials for low permeability and non-corrosive HVIF coatings for steel fuel tanks are disclosed.

Owner:WEIDMAN LARRY G

Apparatus and method for applying antifoulants to marine vessels

ActiveUS20080116178A1Avoid pollutionPrevent flame conditionLiquid surface applicatorsElectric heatingBond coatingPlasma generator

A plasma spray apparatus in the form of a gun is utilized to apply an antifoulant coating to marine vessels. The apparatus includes a plasma generator, an electrophoresis element, a heating element, a shield gas element, a liquid cooling system, a forced air system, and a vacuum system. The plasma generator ionizes gas to create a plasma stream, which is utilized in part to supply energy to the heating element that heats a powder material. The heated powder material is exposed to the electrophoresis element to create a covalently bonded coating material. The coating material is injected into the plasma stream and is applied to a target surface. The shield gas element injects a gas flow to surround and protect the plasma and coating material stream as the stream is in flight to the target surface. The liquid cooling system cools portions of the plasma generator and heating element. The forced air system cools a portion of the target surface as the coating material is being applied. The vacuum system removes fumes and stray particles during the application process.

Owner:REINTJES MARINE SURFACE TECH

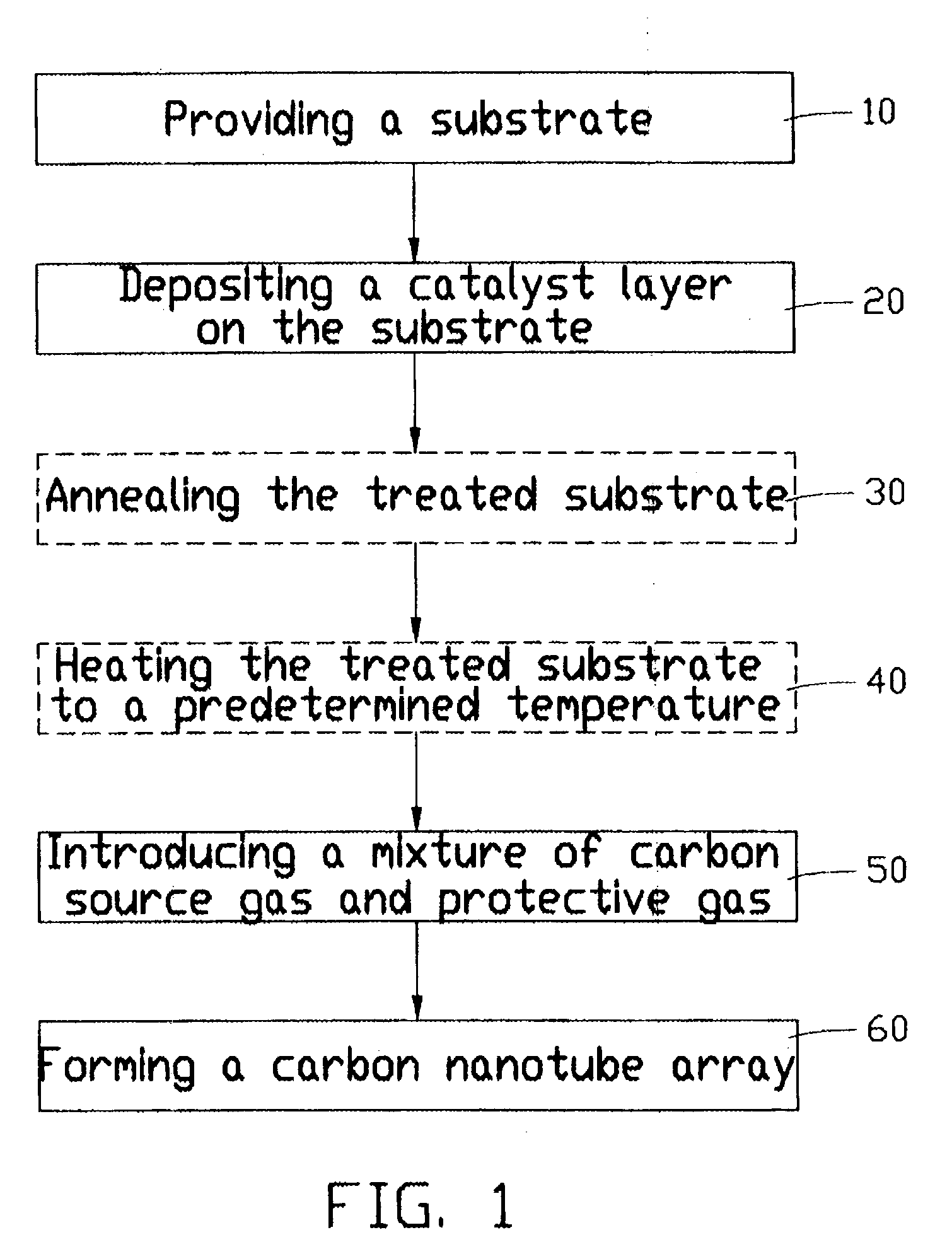

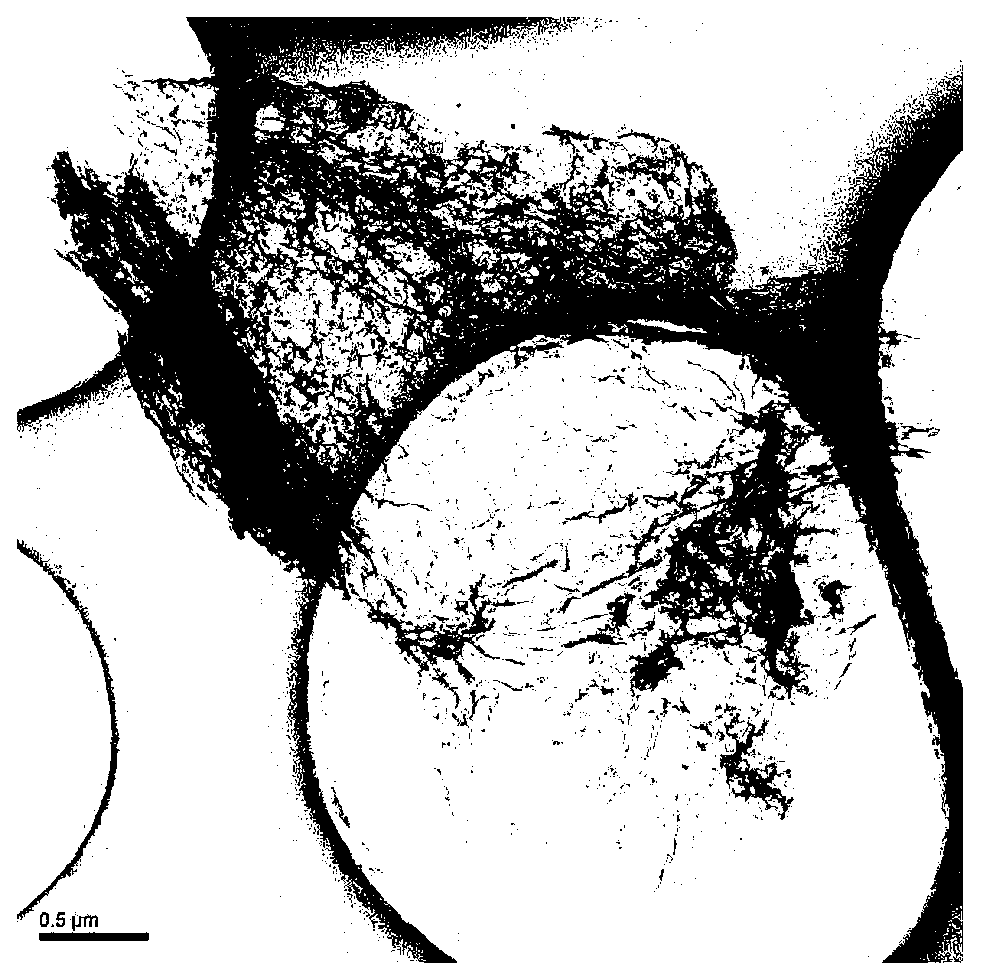

Carbon nanotube array and method for forming same

ActiveUS20040053053A1Reduce partial pressureEasy to bundleMaterial nanotechnologyPolycrystalline material growthMetal catalystCarbon nanotube

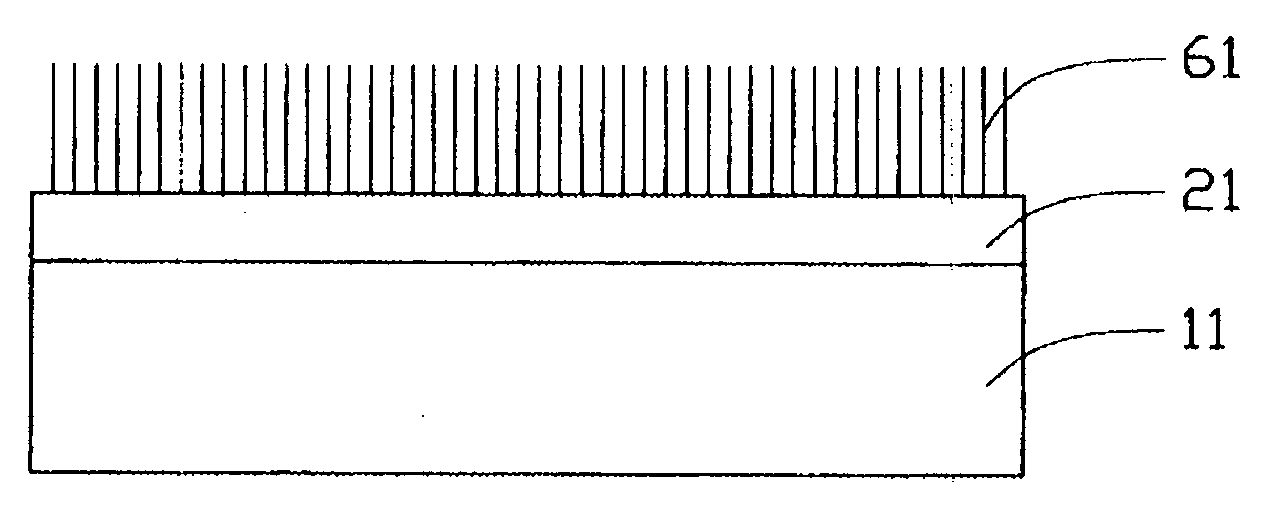

A method for forming a carbon nanotube array includes the following steps: providing a smooth substrate (11); depositing a metal catalyst layer (21) on a surface of the substrate; heating the treated substrate to a predetermined temperature in flowing protective gas; and introducing a mixture of carbon source gas and protective gas for 5-30 minutes, thus forming a carbon nanotube array (61) extending from the substrate. When the mixture of carbon source gas and protective gas is introduced, a temperature differential greater than 50° C. between the catalyst and its surrounding environment is created by adjusting a flow rate of the carbon source gas. Further, a partial pressure of the carbon source gas is maintained lower than 20%, by adjusting a ratio of the flow rates of the carbon source gas and the protective gas. The carbon nanotubes formed in the carbon nanotube array are well bundled.

Owner:HON HAI PRECISION IND CO LTD +1

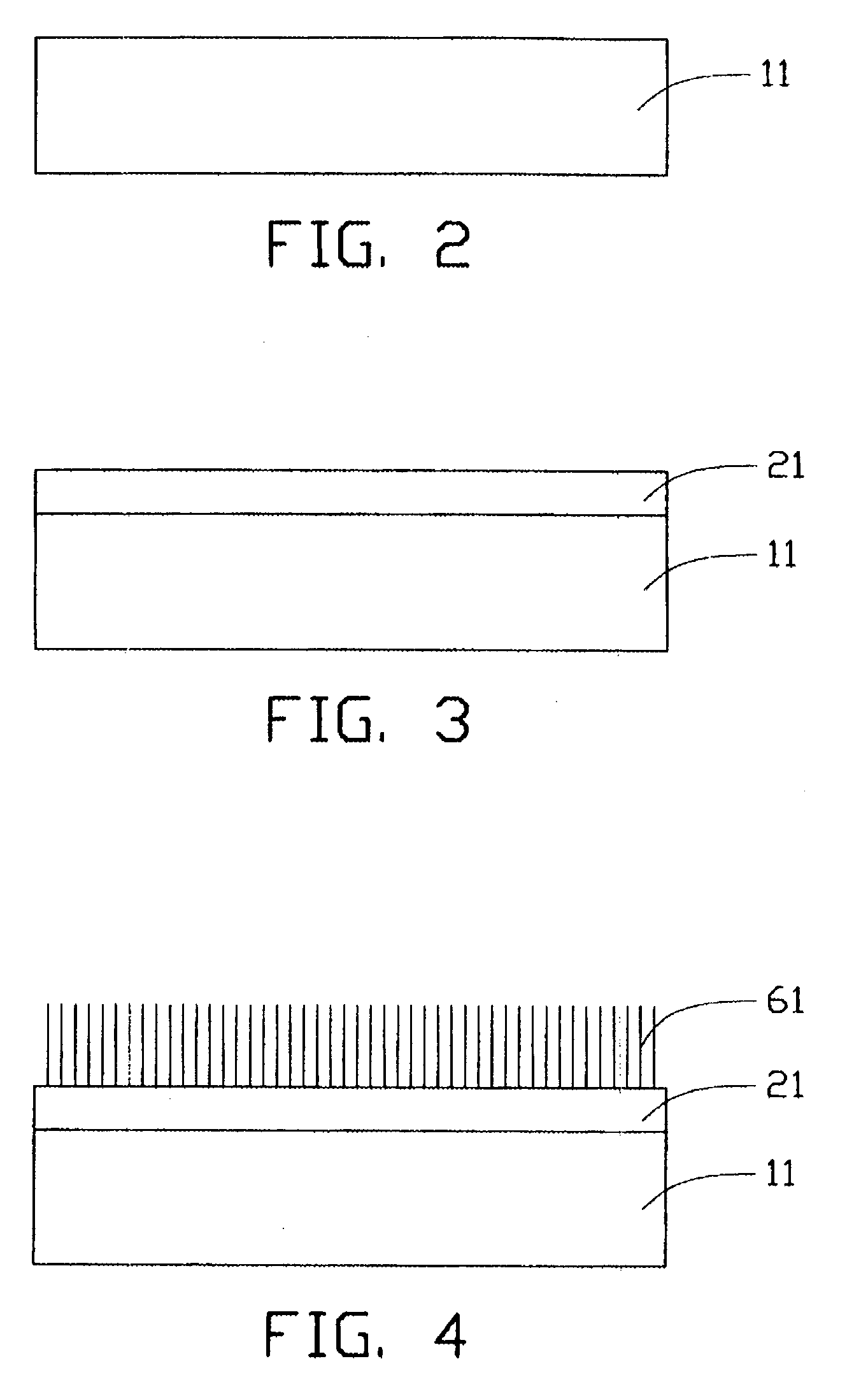

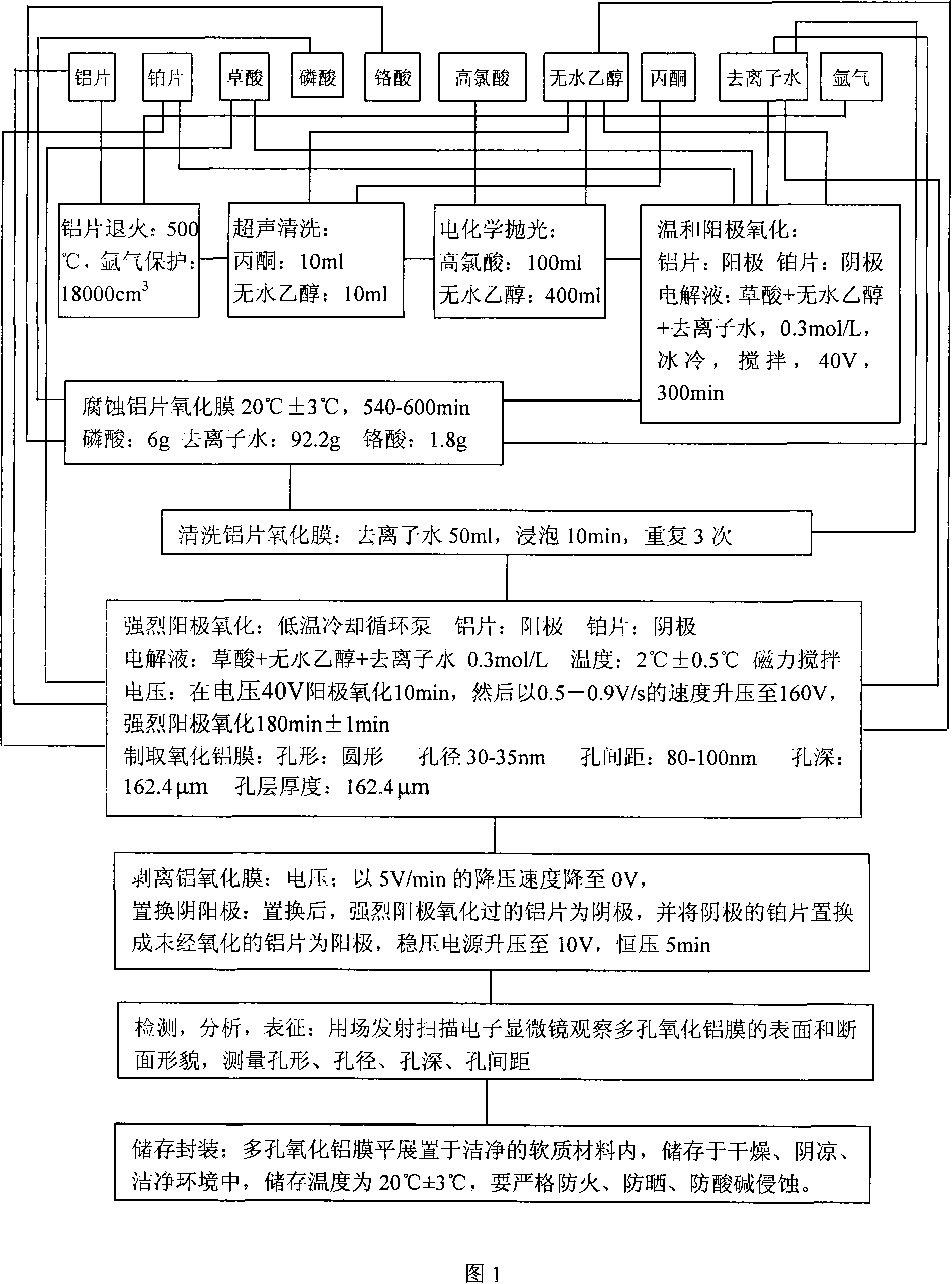

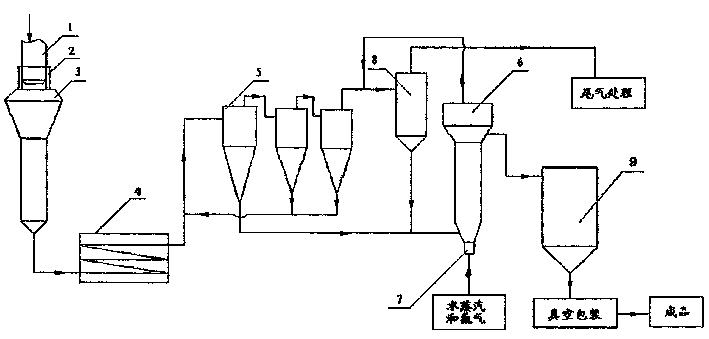

Strong anodic oxidation method for preparing porous pellumina

InactiveCN101139730AReduce pollutionRich sourcesSurface reaction electrolytic coatingShielding gasPhosphoric acid

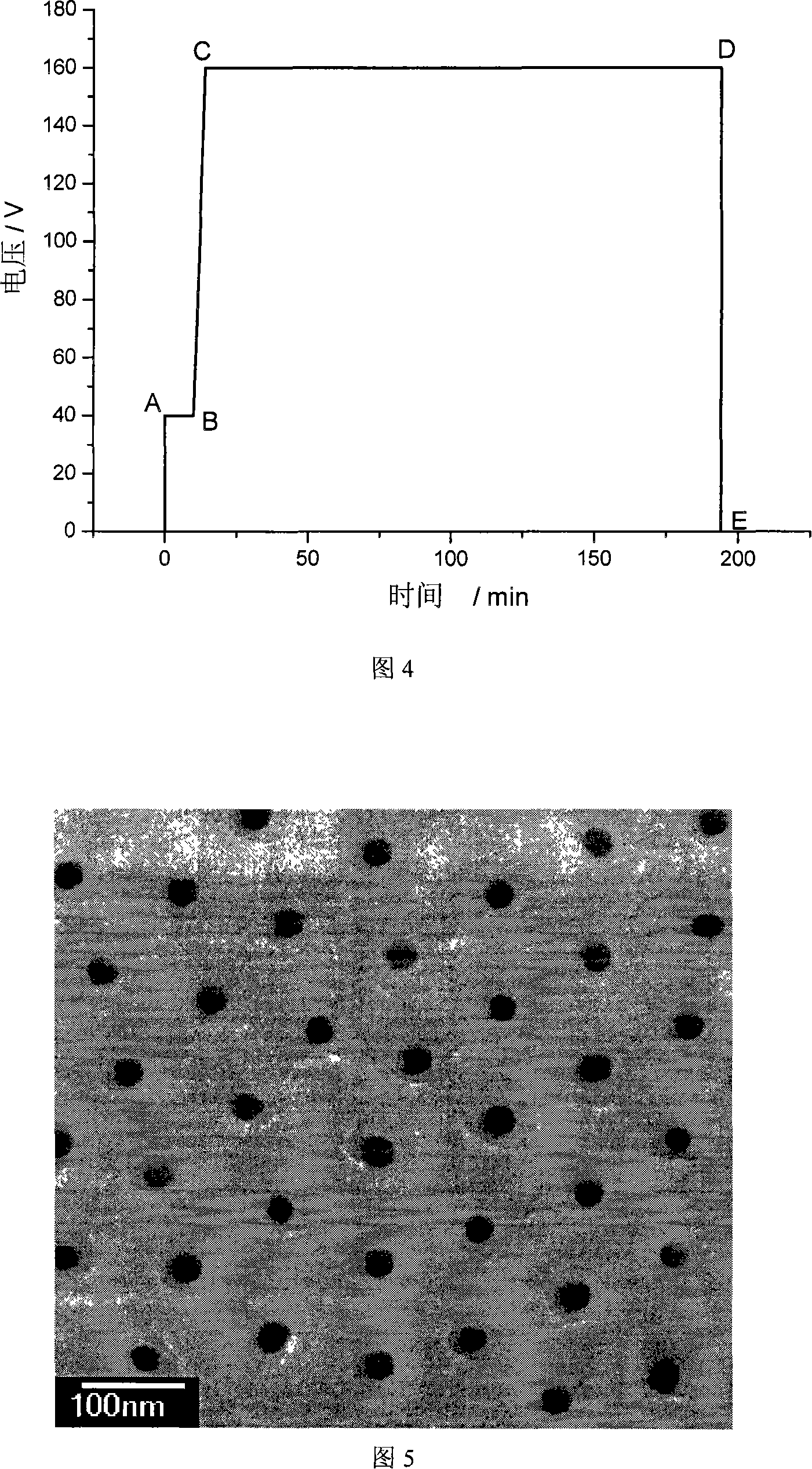

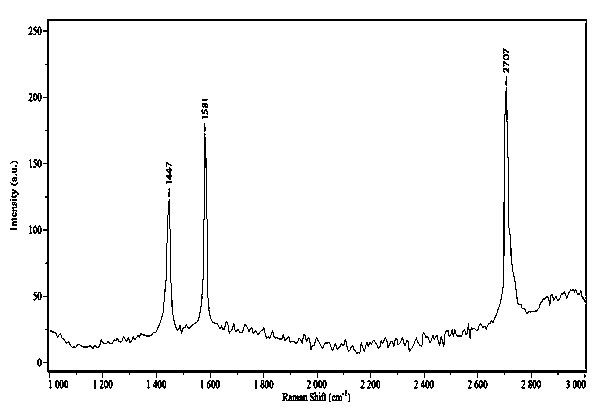

The invention relates to an intensive anodic oxidation process to prepare porous anodic alumina film. An aluminum sheet is as an anode; a platinum sheet as a cathode; argon as shielded gas; mixed solution of perchloric acid with absolute alcohol as electrochemical polishing compound for the aluminum sheet; mixed solution of oxalic acid, absolute alcohol and deionized water as electrolyte; and mixed solution of phosphoric acid, chromic acid and deionized water as alumina film corrodent. Through aluminum sheet annealing, purging, electrochemical polishing, mild anodic oxidation, corrosion on aluminum sheet oxide film, intensive anodic oxidation and stripping oxide film, and finally, pale yellow, high purity and ordered porous-structured nanometer-leveled alumina film is achieved; The alumina film pore is in circular shape sized in 30 to 35nm, pore distance in 80 to100nm and pore depth in 162.4 micrometers; growth rate of the alumina film is 54 micrometers / h, which is 27 times higher than 2 micrometers / h of growth rate of anodic oxidation aluminum film prepared through mild anodic oxidation process.

Owner:TAIYUAN UNIV OF TECH

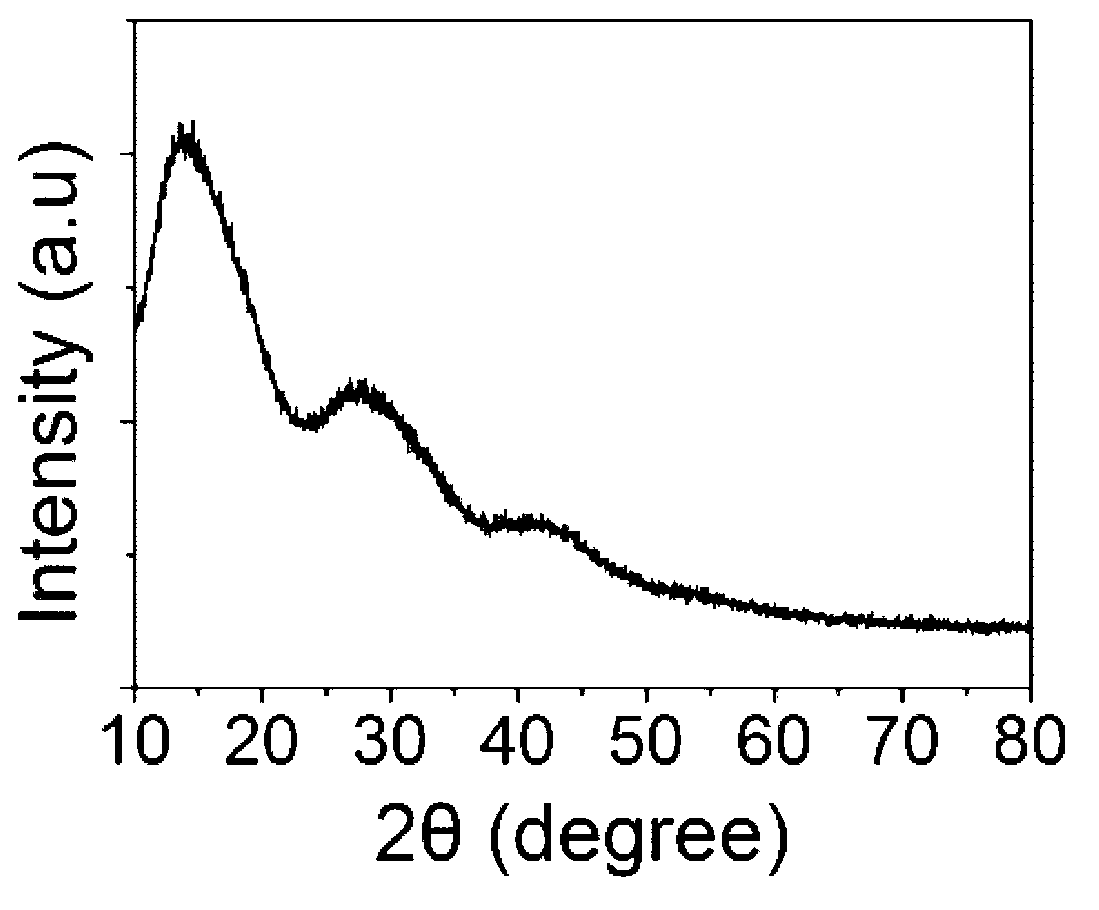

Method for preparing graphene from lignin

The invention discloses a method for preparing graphene from lignin, which comprises the following steps: putting a porcelain sample boat filled with lignin and a catalyst into a hinge pipe furnace, introducing shielding gas at uniform speed while heating the sample in the furnace from room temperature to the target temperature at a constant heating speed, and keeping at the target temperature; and after the sample is cooled to room temperature, taking out the sample, washing with deionized water, carrying out vacuum filtration, and drying at low temperature to obtain the graphene. The preparation technique is simple and convenient; and the obtained graphene has the advantages of high quality and considerable yield.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

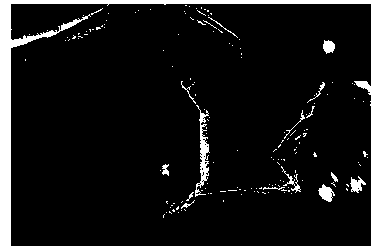

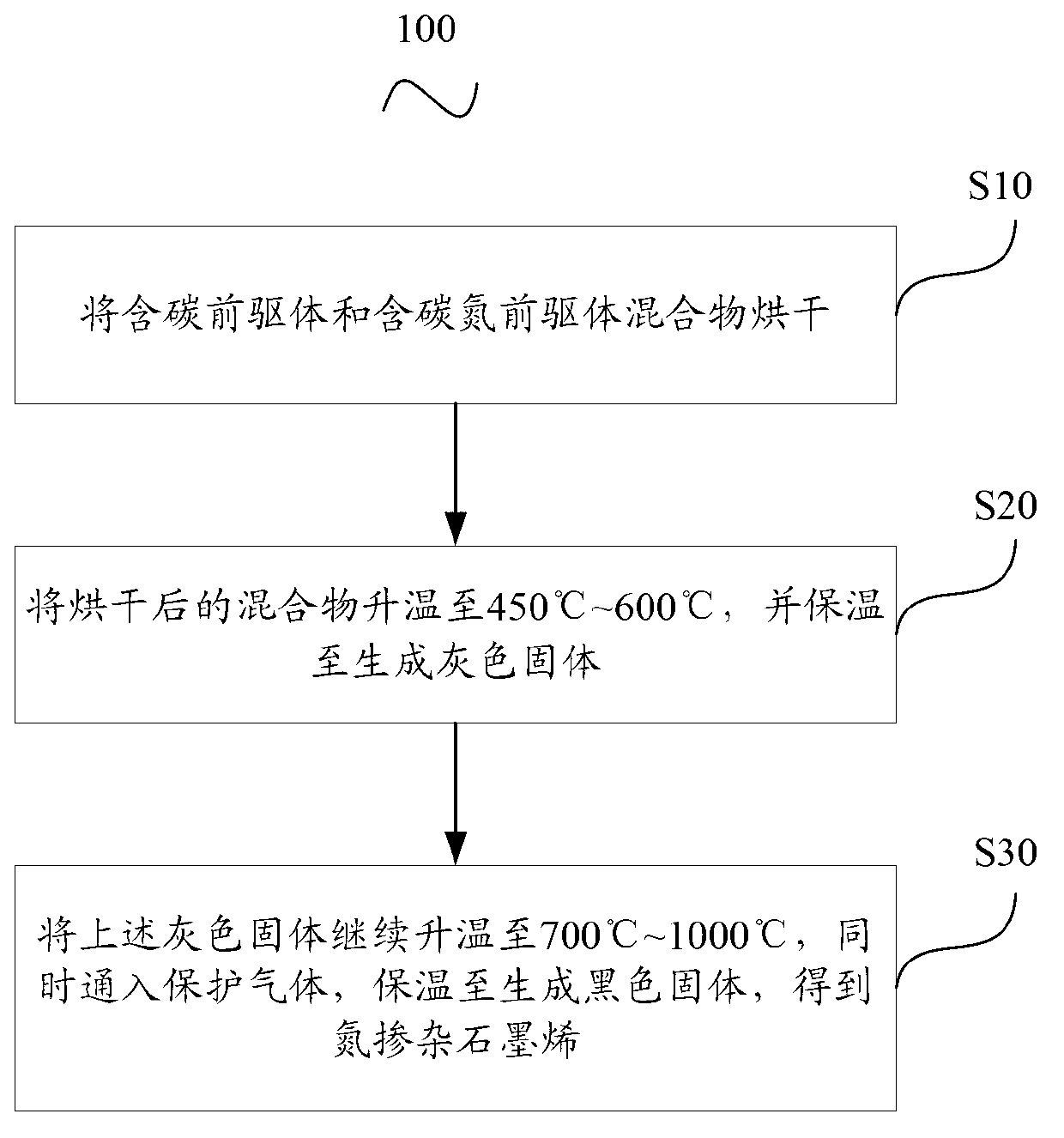

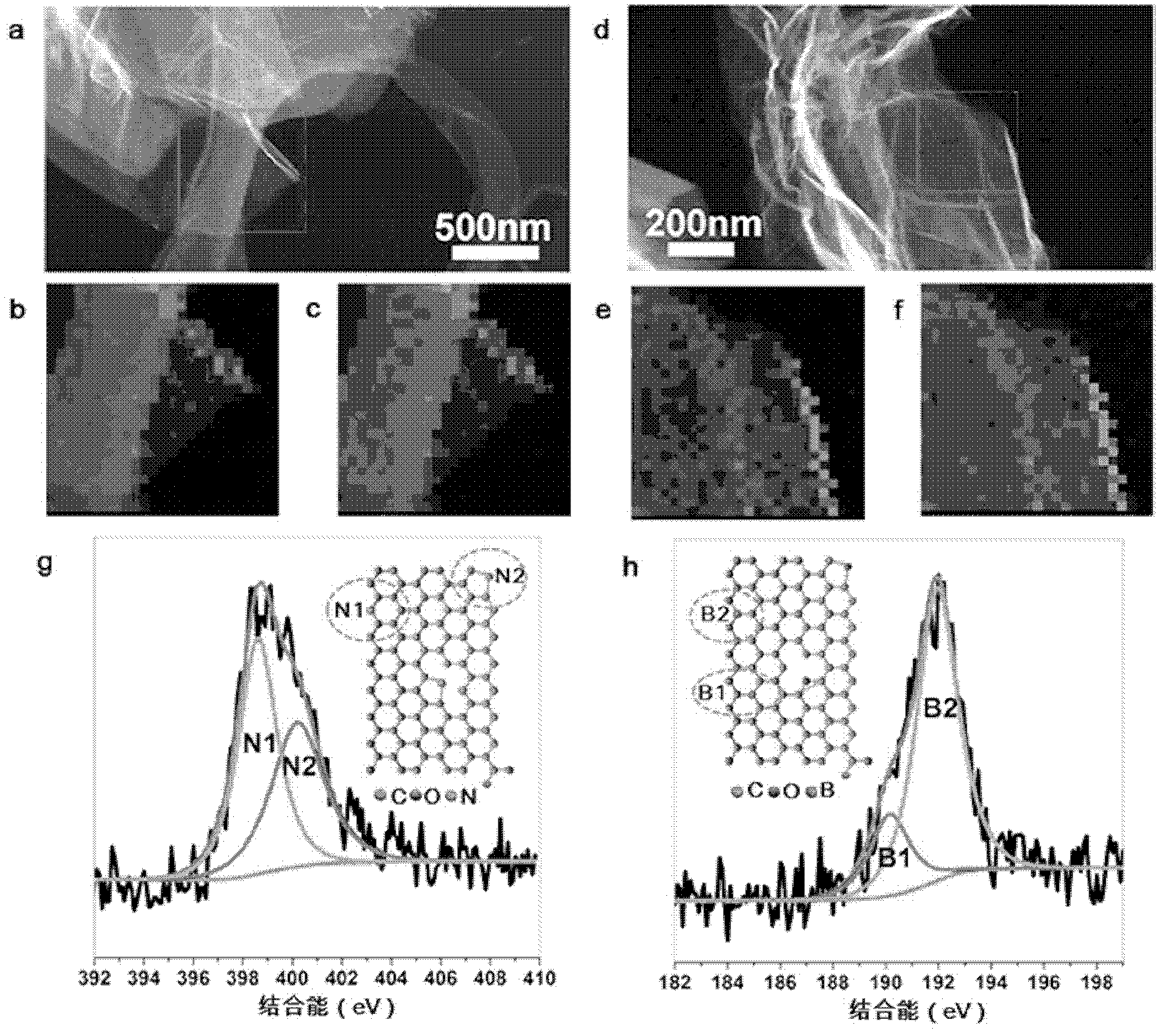

Method for preparing nitrogen-doped graphene and nitrogen-doped graphene

InactiveCN103274393ASimple processEase of industrial productionGrapheneSolid reactionCarbon Dioxide / Helium

The invention discloses a method for preparing nitrogen-doped graphene which comprises the following steps of: drying a mixture of a carbon-containing precursor and a carbon-nitrogen-containing precursor; raising the temperature of the dried mixture to be 450-600 DEG C, and keeping the temperature to generate gray solid; and continuously raising the temperature of the gray solid to be 700-1000 DEG C, introducing protective gas, keeping the temperature to generate black solid, and obtaining the nitrogen-doped graphene. According to the method for preparing nitrogen-doped graphene in the embodiment, the nitrogen-doped graphene is obtained under normal pressure and high temperature through a solid-phase reaction, the whole preparation method is simple in process, the nitrogen-doped graphene can be obtained without complex equipment, and industrial production is easily performed. In addition, the invention also provides nitrogen-doped graphene.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Steel wire for carbon dioxide shielded arc welding and welding process asing the same

InactiveCN1533315AAchieve Jet TransitionGood effectArc welding apparatusWelding/cutting media/materialsRare-earth elementBead shape

In carbon dioxide arc welding by use of shielding gas comprised of carbon dioxide as main component, a welding wire that enables spray transfer of globules, and provides an excellent bead shape in addition to reduction of amount of spatters even in a high-speed welding, and a welding method using the welding wire are proposed. As the specific means, a welding steel wire for use in carbon dioxide arc welding in DC-electrode negative, comprising a bar steel having a composition that contains 0.003 to 0.20% by mass of C, 0.05 to 2.5% by mass of Si, 0.25 to 3.5% by mass of Mn, 0.015 to 0.100% by mass of REM (rare-earth elements), 0.001 to 0.05% by mass of P, and 0.001 to 0.05% by mass of S, or further contains 0.0100% by mass or less of O, or further contains one or two or more of 0.02 to 0.50% by mass of Ti, 0.02 to 0.50% by mass of Zr, and 0.02 to 3.00% by mass of Al, or further contains 0.0001 to 0.0150% by mass of K, or further contains 3.0% by mass or less of Cr, 3.0% by mass or less of Ni, 1.5% by mass or less of Mo, 3.0% by mass or less of Cu, 0.015% by mass or less of B, 0.20% by mass or less of Mg, 0.5% by mass or less of Nb, 0.5% by mass or less of V, and 0.020% by mass or less of N, and contains Fe and unavoidable impurities as residue is used.

Owner:JFE STEEL CORP

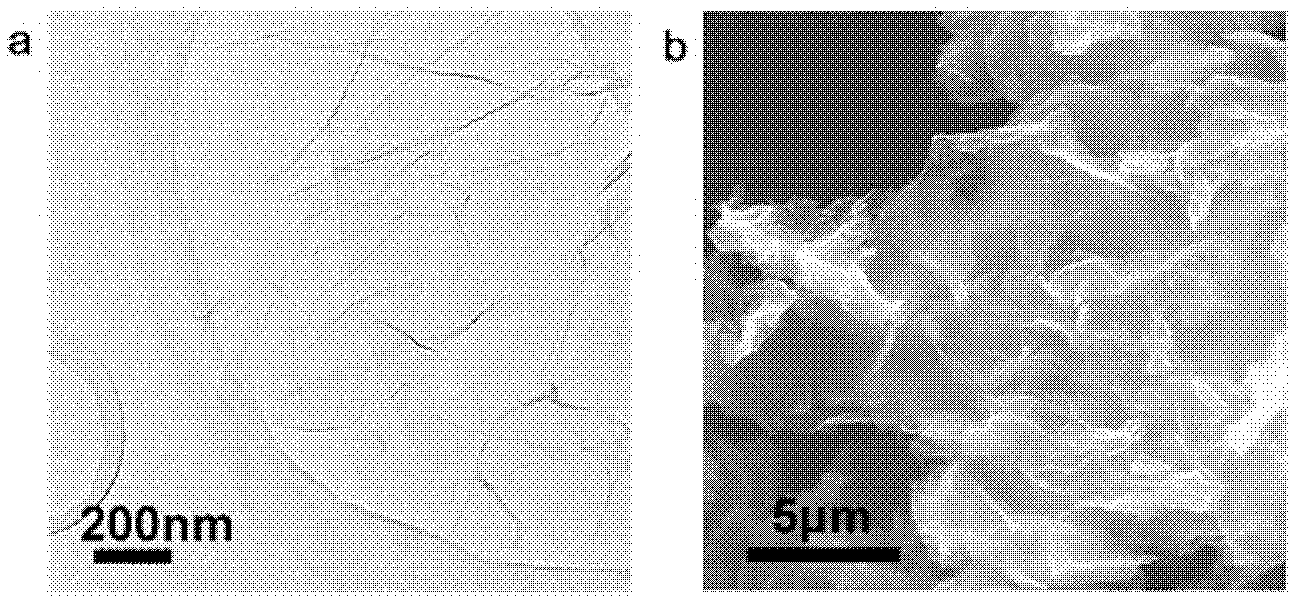

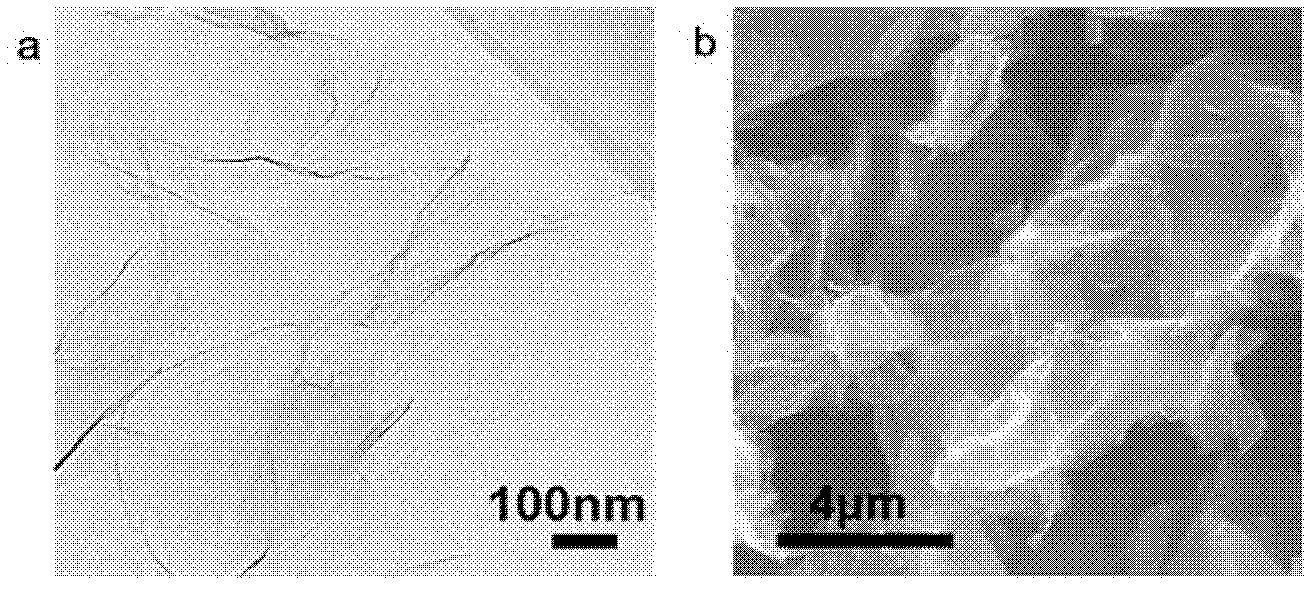

Doped graphene electrode material, macro preparation method and application of doped graphene electrode material

InactiveCN102306781AImprove conductivityGood thermal stabilityCell electrodesHigh current densityDoped graphene

The invention relates to the field of graphene electrode materials, and in particular relates to a doped graphene electrode material, a macro preparation method as well as an application of the doped graphene electrode material in a high-capacity high-multiplying-power lithium ion battery. In the invention, graphene is taken as a raw material. The preparation method comprises the following steps: controlling the temperature rising speed rate through shielding gas; introducing gas containing nitrogen or boron elements in different concentrations at high temperature so as to realize the doping of heteroatoms of the graphene, and get the nitrogen or boron doped graphene; mixing the doped graphene, conductive carbon black and a bonding agent; adding a solvent; coating the mixture on a current collector after grinding; taking the mixture after drying, shearing and tabletting as a working electrode; adding electrolyte containing a lithium salt by taking a lithium plate as a counter electrode / reference electrode; assembling into a button-type lithium ion half-battery in a glove box; and carrying out constant current charge and discharge tests under the condition of high current density. According to the invention, the electrode stability of the material under the condition of high current density is improved, and the fact that the doped graphene has higher specific capacity and excellent cycle performance in a shorter time is realized.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

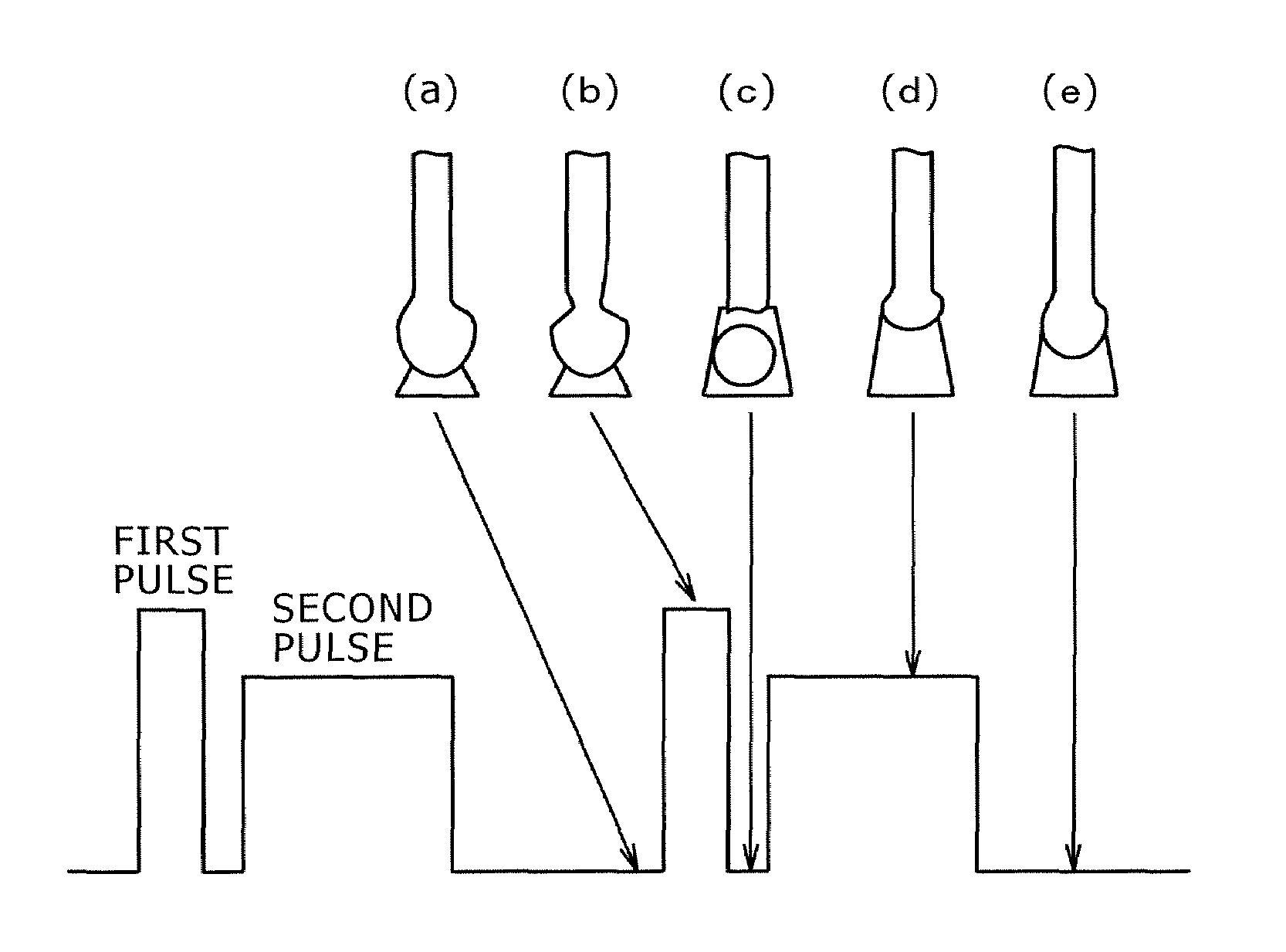

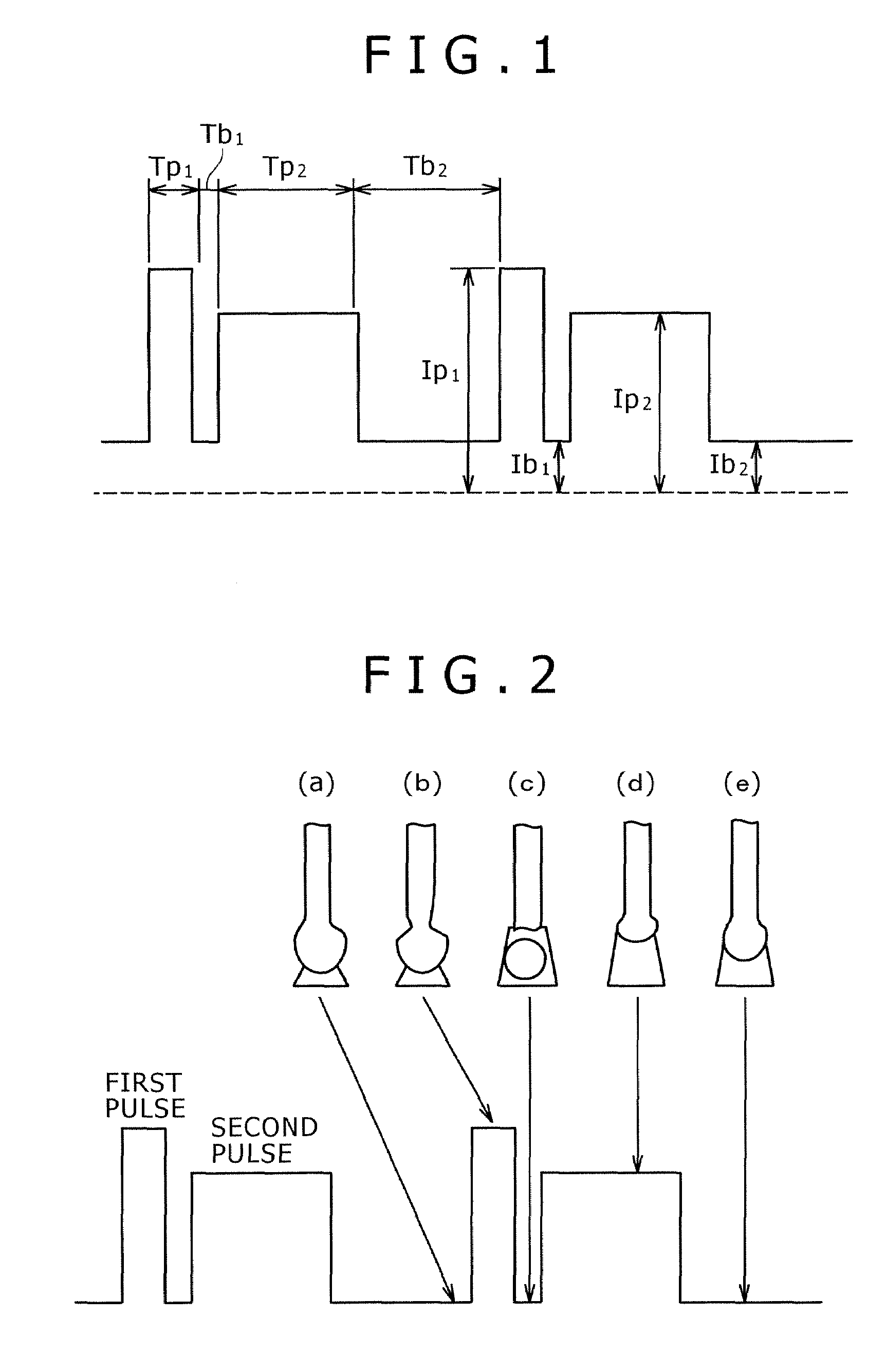

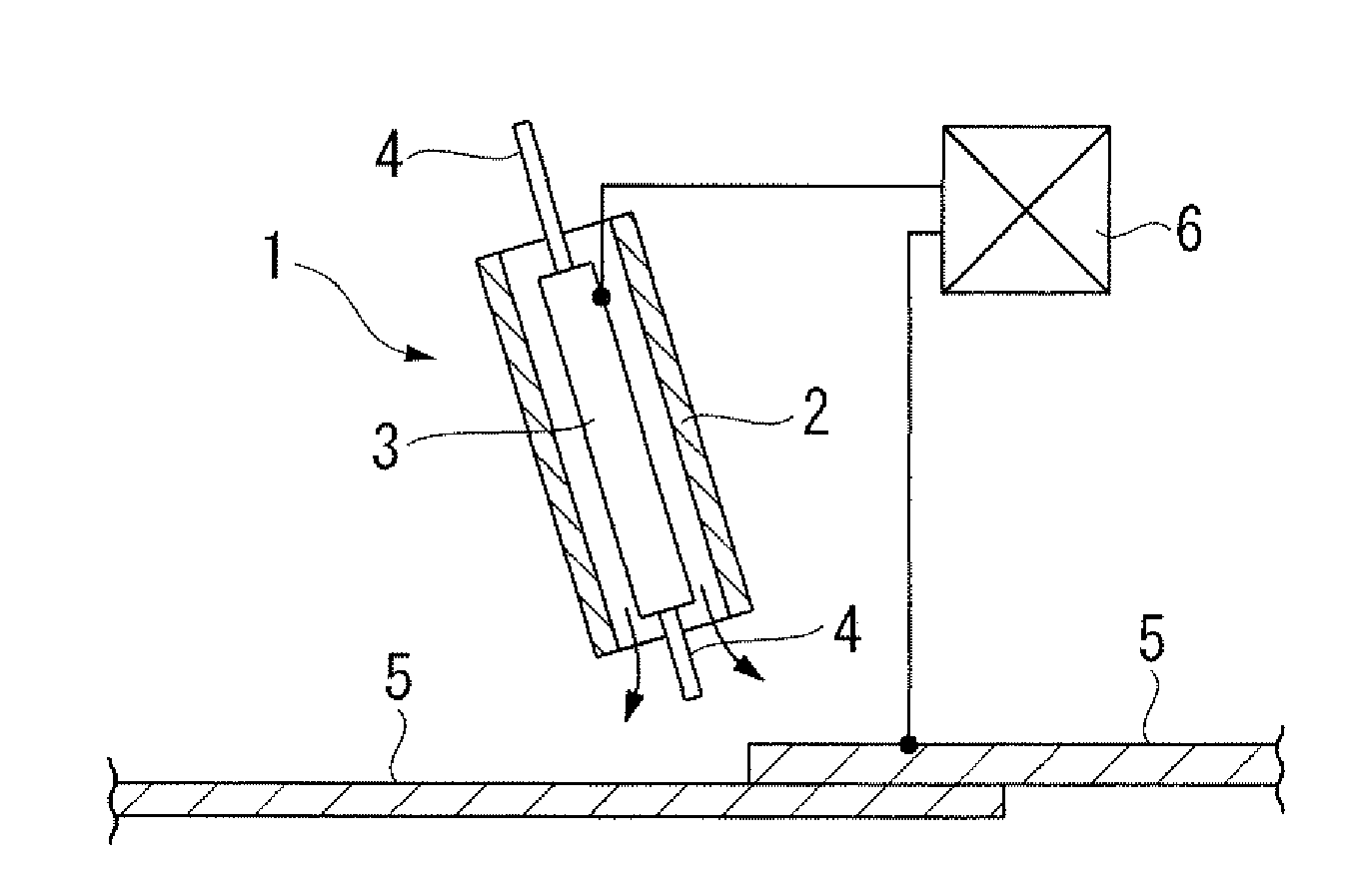

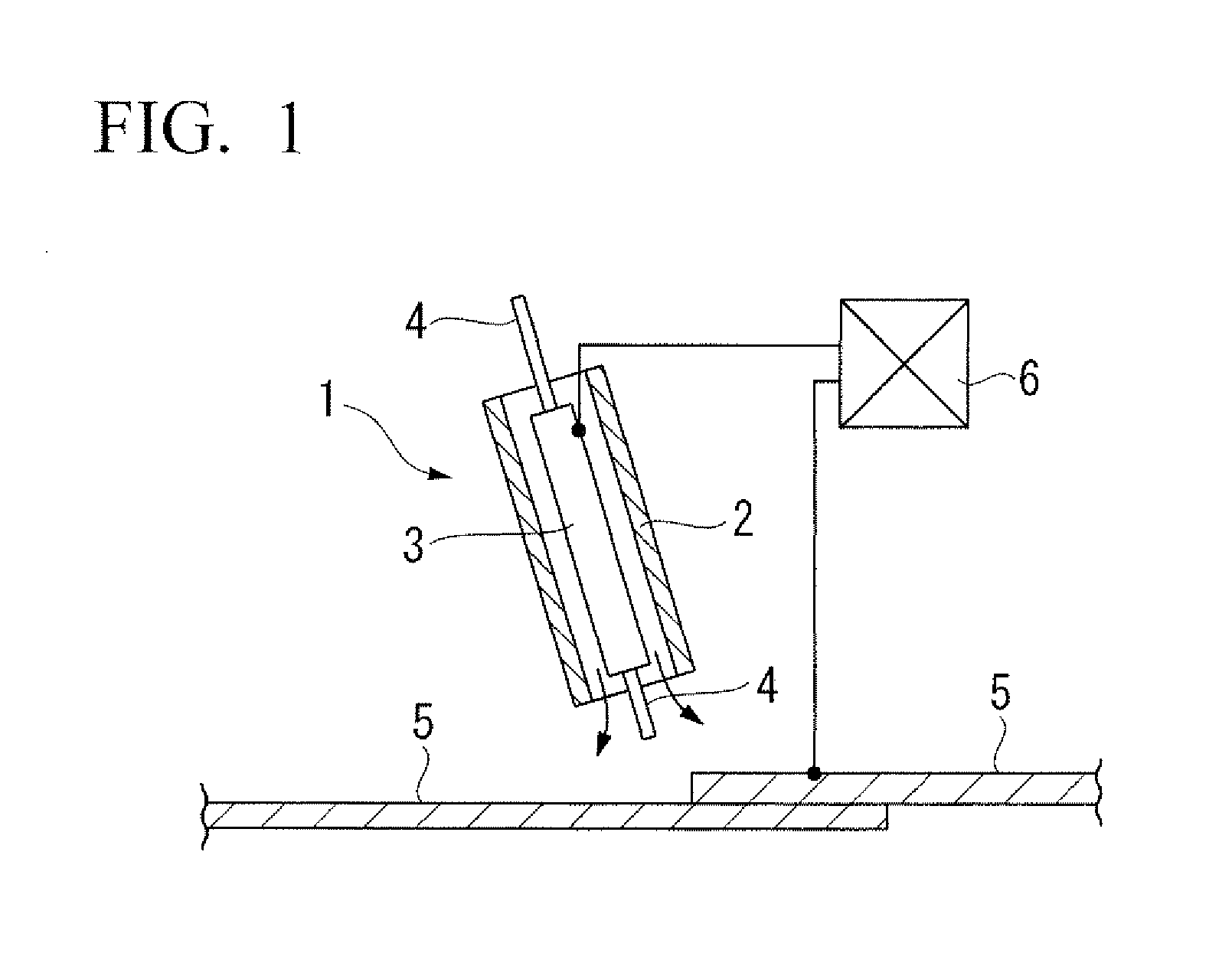

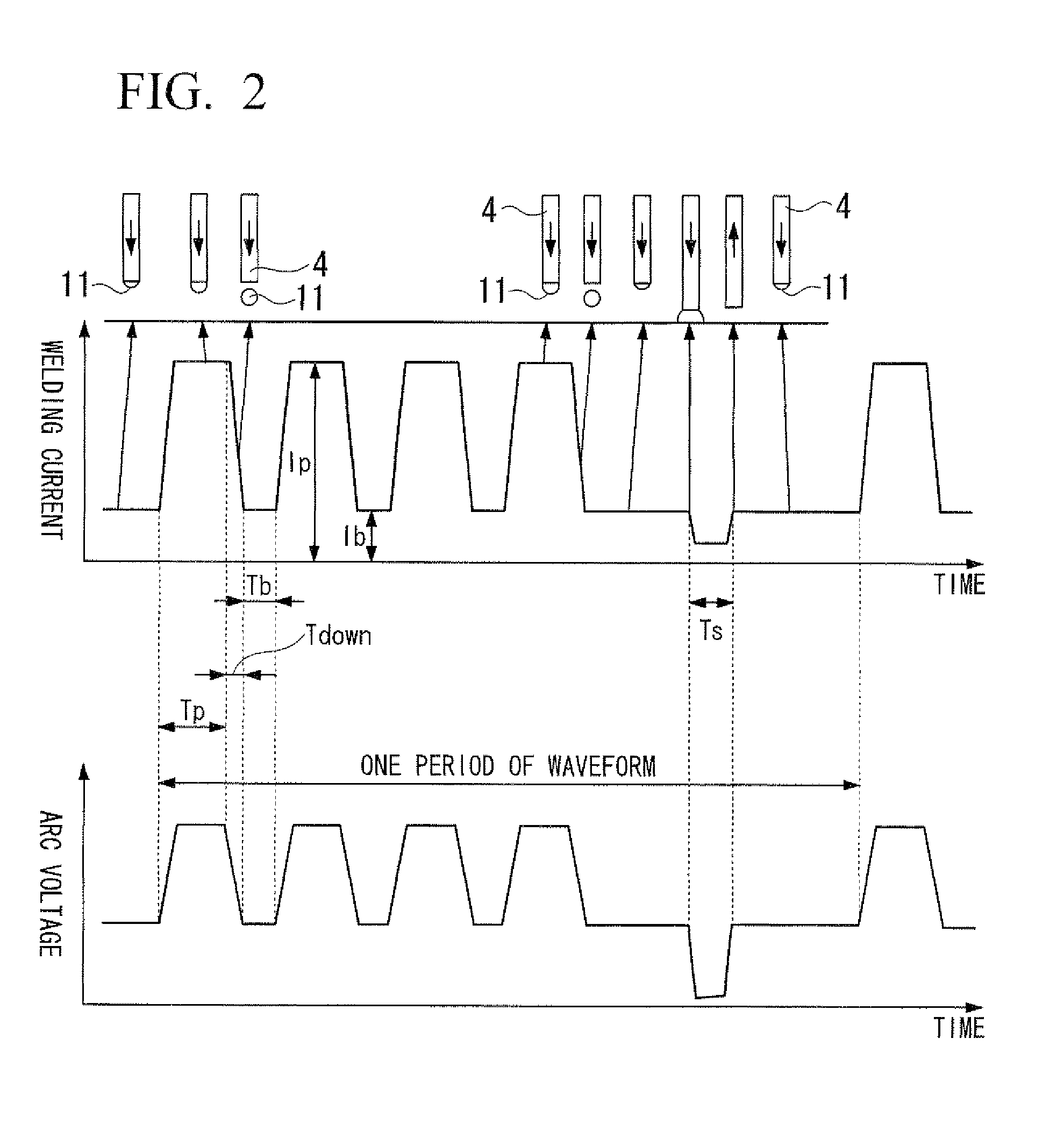

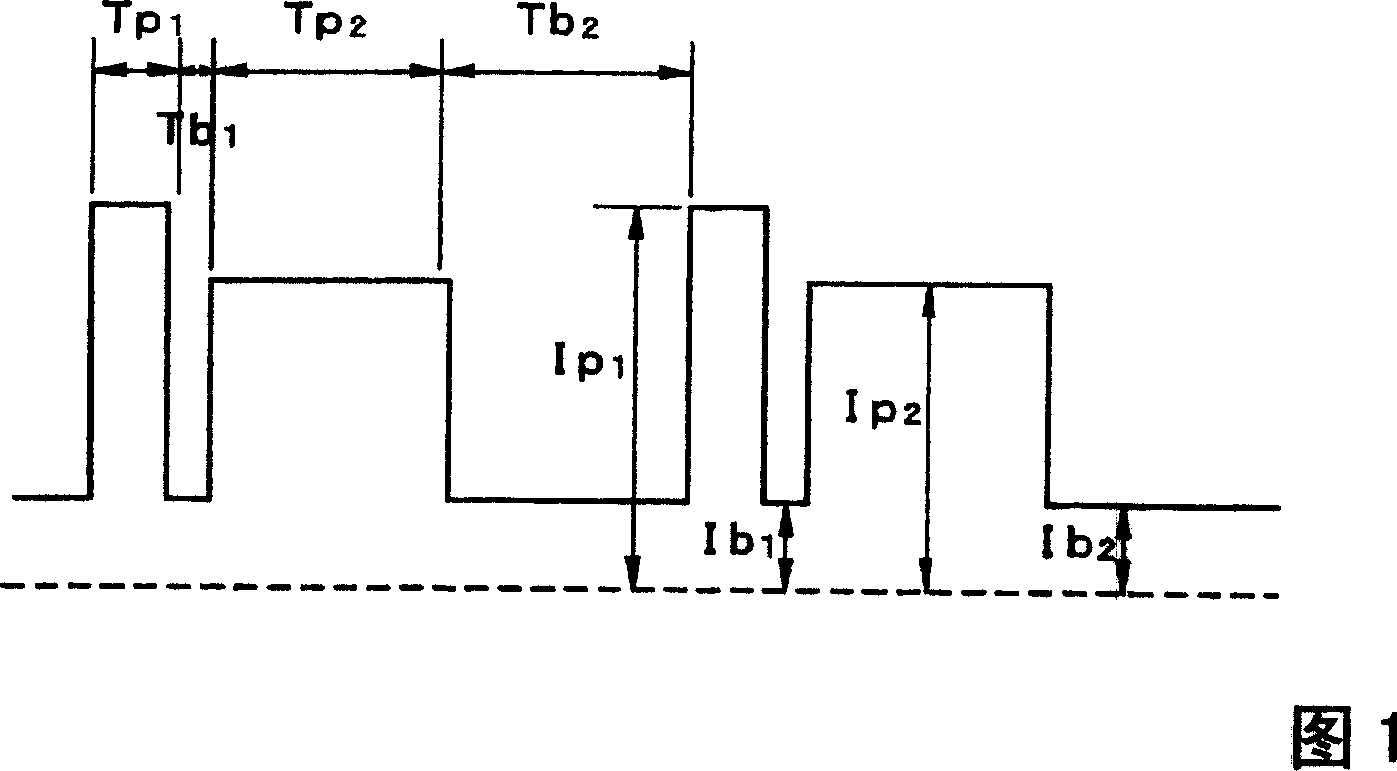

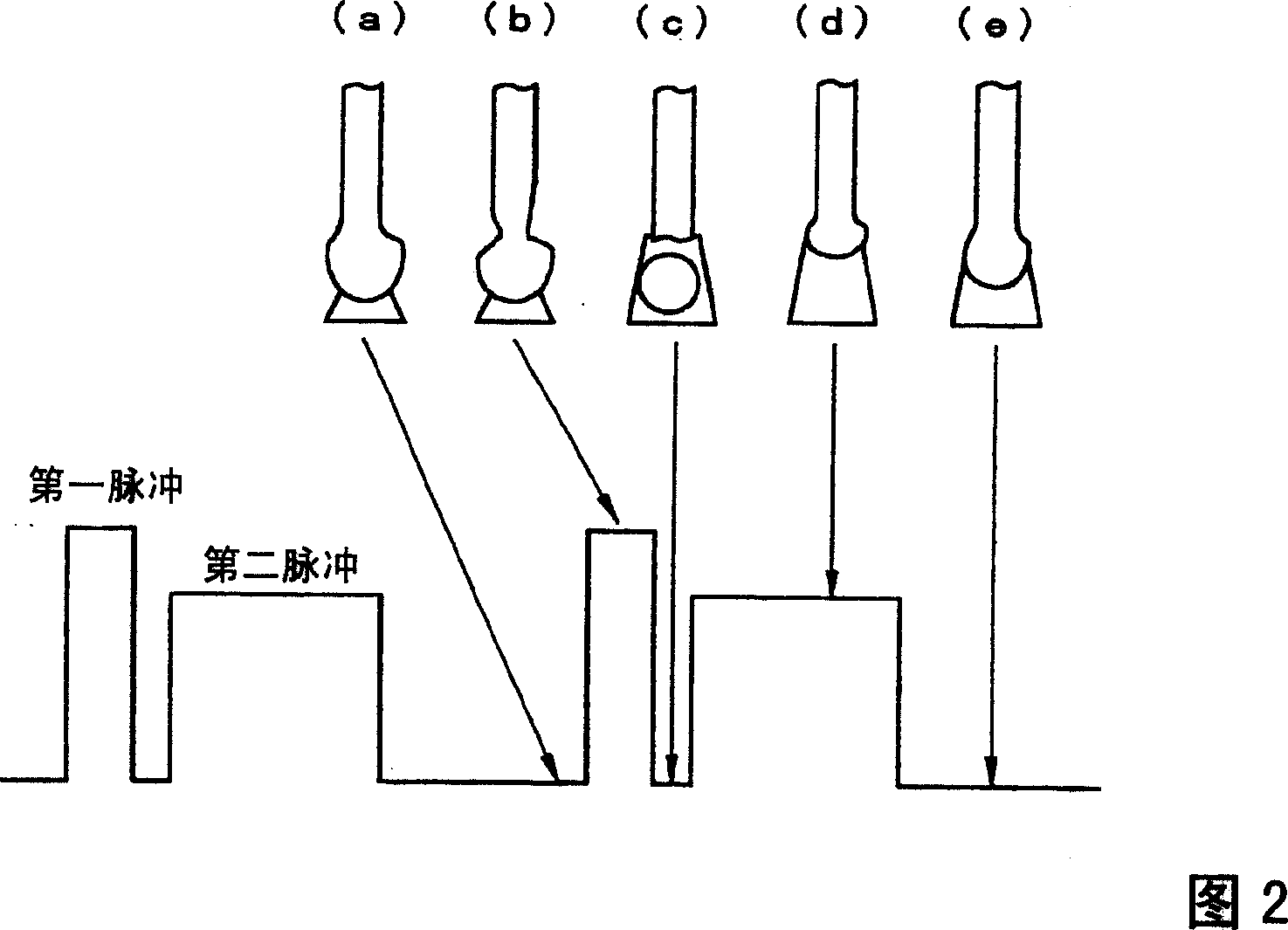

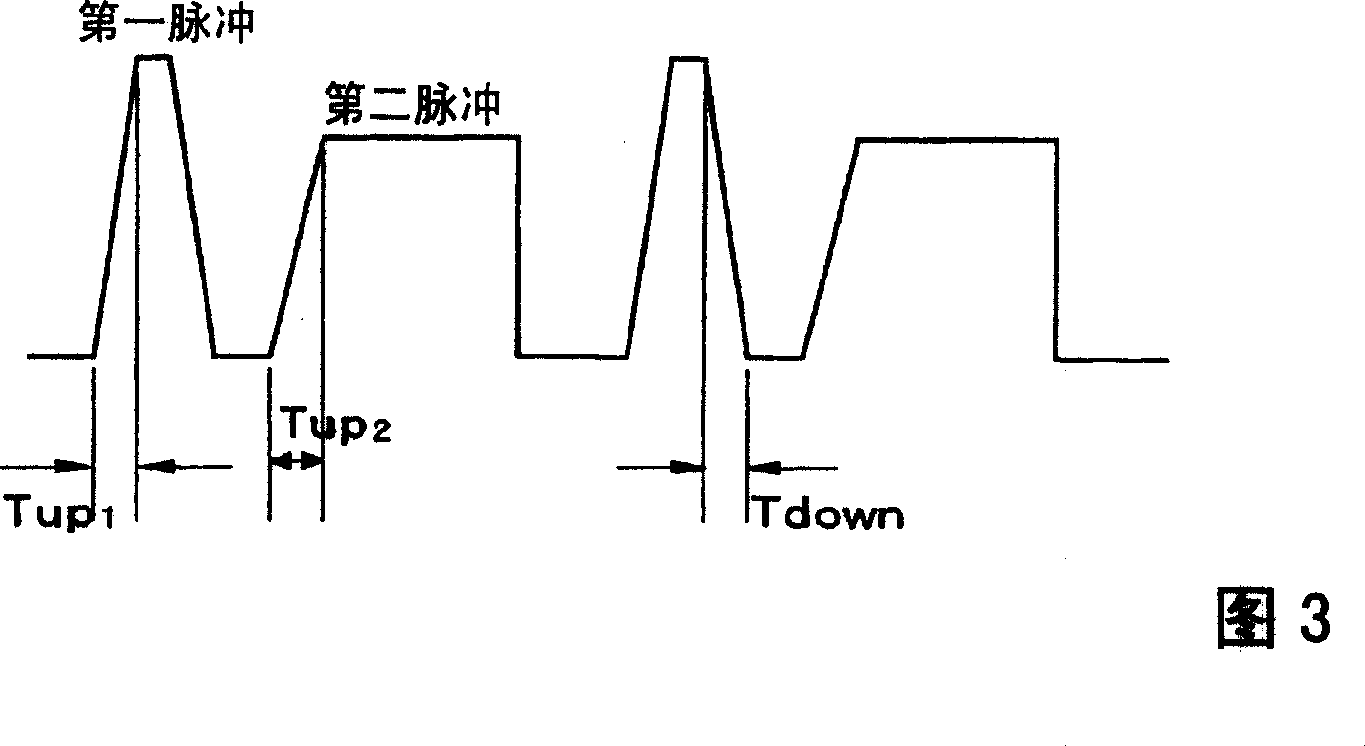

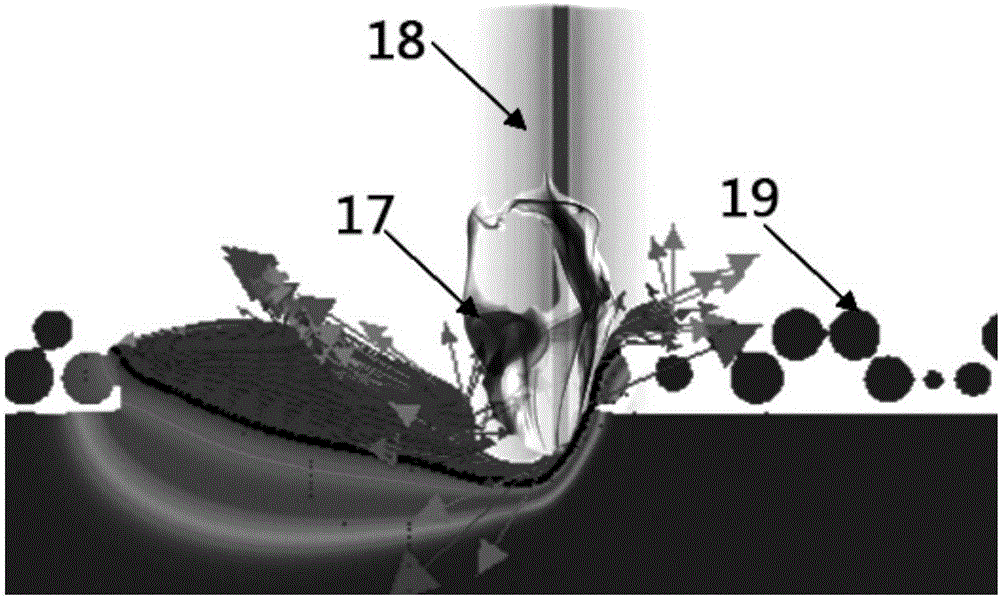

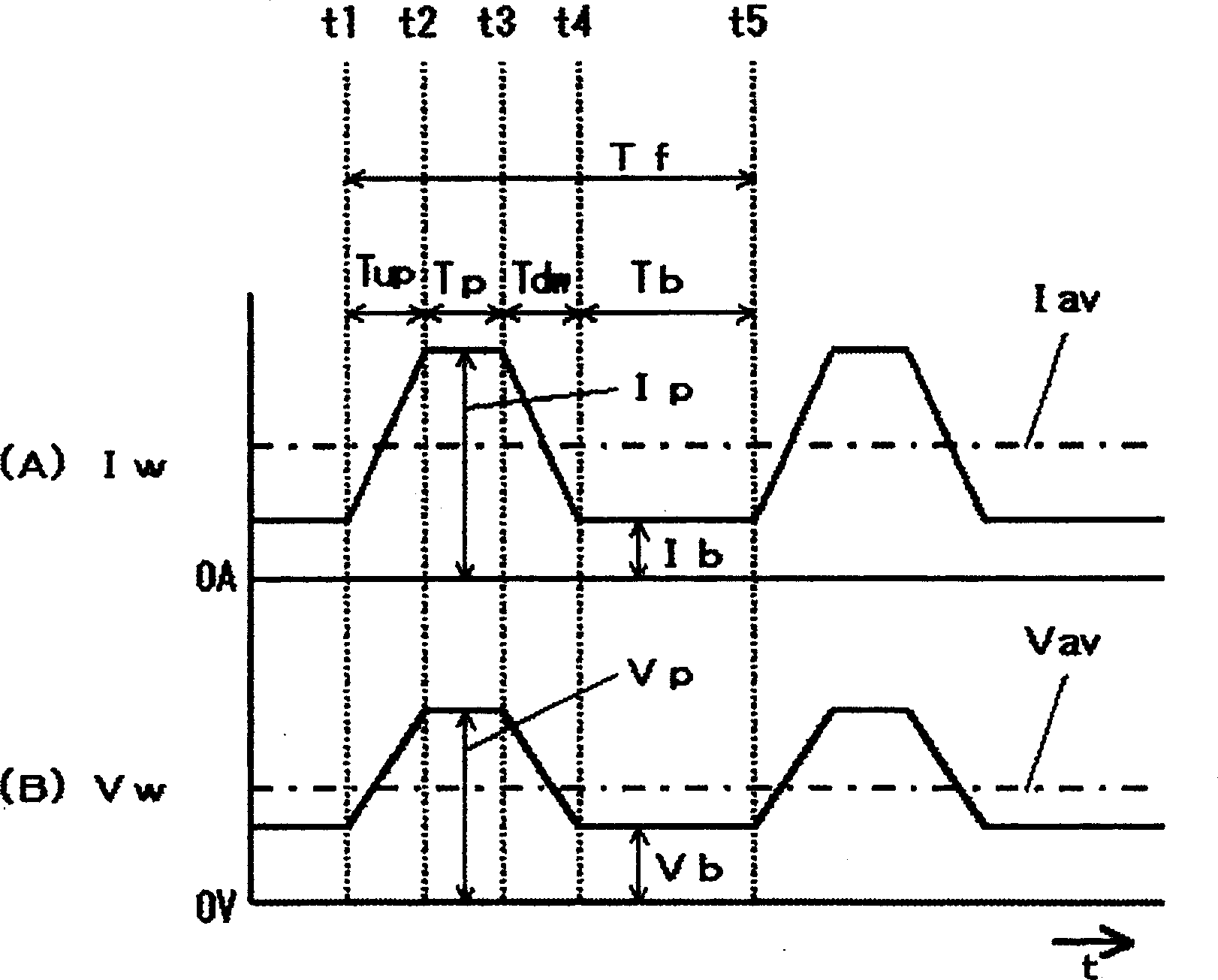

Pulsed arc welding method

ActiveUS20070210048A1Good saveImprove stabilityArc welding apparatusShielding gasCarbon Dioxide / Helium

Disclosed is a pulsed arc welding method using a pulse current of alternately repeating first and second pulses as a weld current, wherein the first pulse and the second pulse have a pulse waveform of a different pulse peak current level and a different pulse width, respectively, and the following conditions are satisfied: peak current of the first pulse (Ip1)=300 to 700A; peak period (Tp1)=0.3 to 5.0 ms; base current Ib1=30 to 200A, base period (Tb1)=0.3 to 10 ms; peak current of the second pulse (Ip2)=200 to 600A; peak period (Tp2)=1.0 to 15 ms; base current (Ib2)=30 to 200A; and base period (Tb2)=3.0 to 20 ms. In this manner, the consumable electrode arc welding using carbon dioxide gas alone or a mixed gas made mainly of carbon dioxide gas as a shield gas can benefit from stabilized welding arc, improved regularity of droplet transfer, and significantly reduced generation rates of spatters and fumes.

Owner:KOBE STEEL LTD

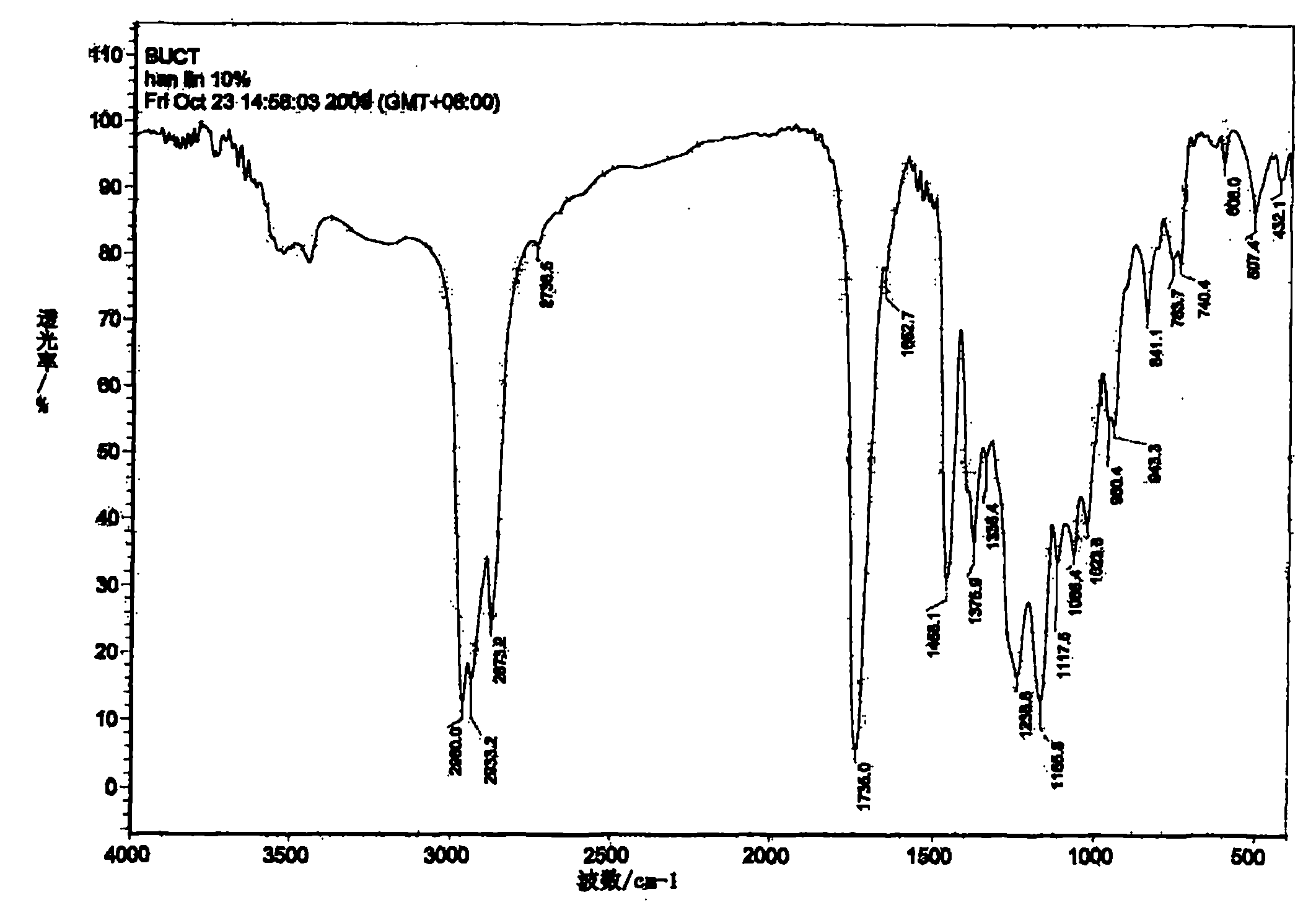

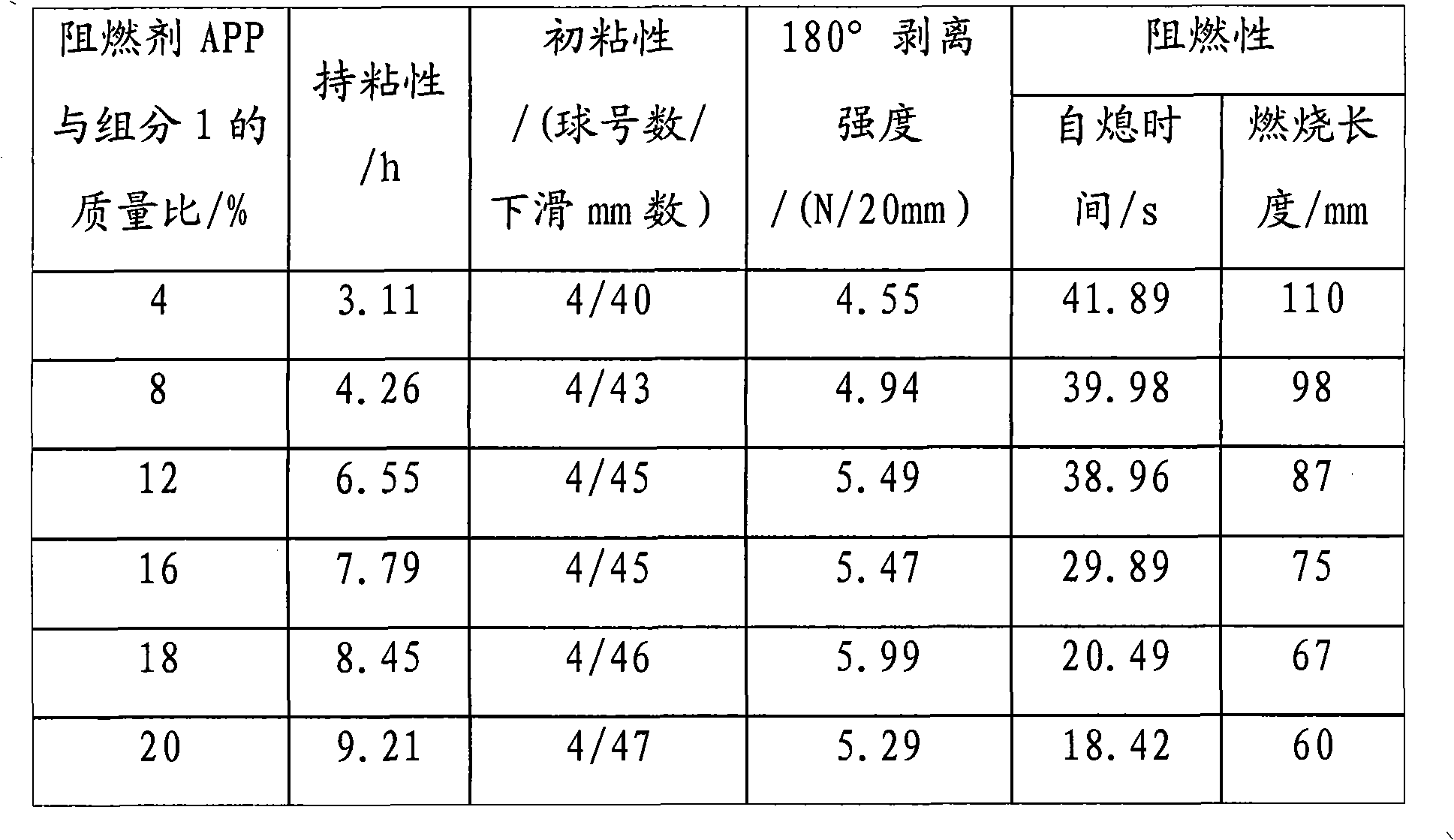

Preparation method of combined phosphorus type flame-retardant acrylate pressure-sensitive adhesive

InactiveCN101805567AImprove flame retardant performanceImprove stabilityFilm/foil adhesivesEster polymer adhesivesCarbon Dioxide / HeliumShielding gas

The invention discloses a preparation method of a combined phosphorus type flame-retardant acrylate pressure-sensitive adhesive. The preparation method comprises the following steps: adopting a free radical solution polymerization process and a multistep polymerization process to polymerize flame-retardant phosphorous acrylate monomers and common acrylate monomers to prepare a combined phosphorus type flame-retardant acrylate pressure-sensitive cement by using N2 as shielding gas under the conditions of normal pressure and the temperature of 70-85 DEG C; coating the pressure-sensitive cement, and drying to prepare the combined phosphorus type flame-retardant acrylate pressure-sensitive adhesive; and in order to better enhance the flame retardant property of the pressure-sensitive adhesive, optionally adding flame-retardant sizing to the pressure-sensitive cement, then coating, and drying. The method has a simple process, and the prepared pressure-sensitive adhesive has excellent properties and avoids the environmental pollution caused by a halogenated flame retardant.

Owner:BEIJING UNIV OF CHEM TECH

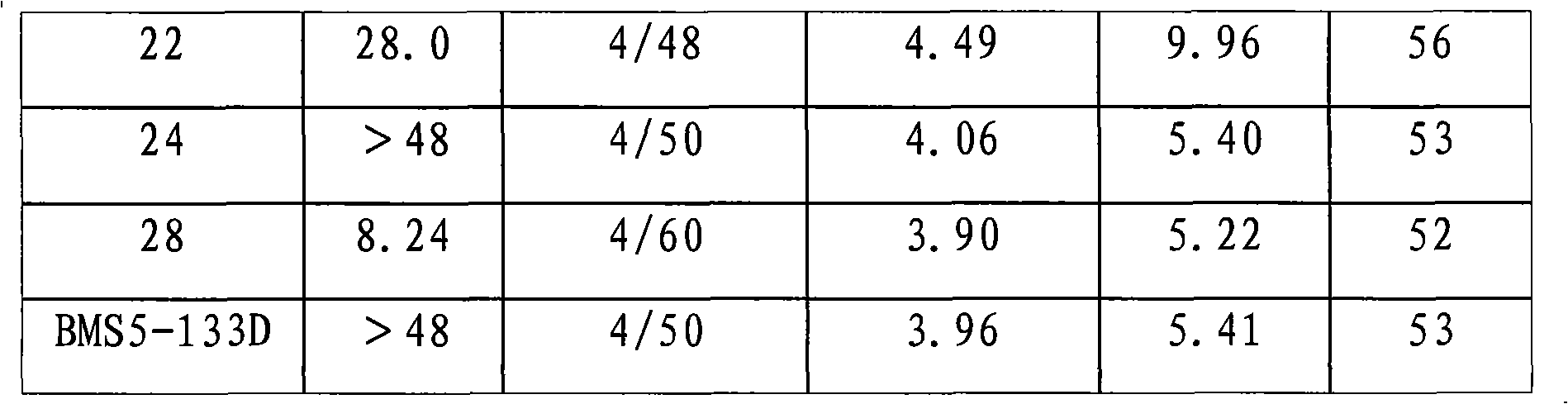

High-dispersion nano silicon dioxide preparation method

InactiveCN1422805AImprove continuityImprove stabilityOxide/hydroxide preparationSilicaWater vaporSilanes

The invention discloses a method to prepare high-disperse nano SiO2, imputting O2-H2 organic halogen silane in a certain proportion into reaction room to make burning reaction, at the same time inputting a protective gas, vapor and inert gases, adopting the produced water and heat to make high-temperature hydrolytic condensation reaction and making the late process such as aggregative gas-solid separation deacidification on the reaction product to obtain it, primary particle dimaeter 7-40 nm, ratio surface area 100-400 m2 / g, pH value 3.8-4.5, SiO2 receiving rate >99%.

Owner:ZHEJIANG KAIHUA SYNTHETIC MATERIAL

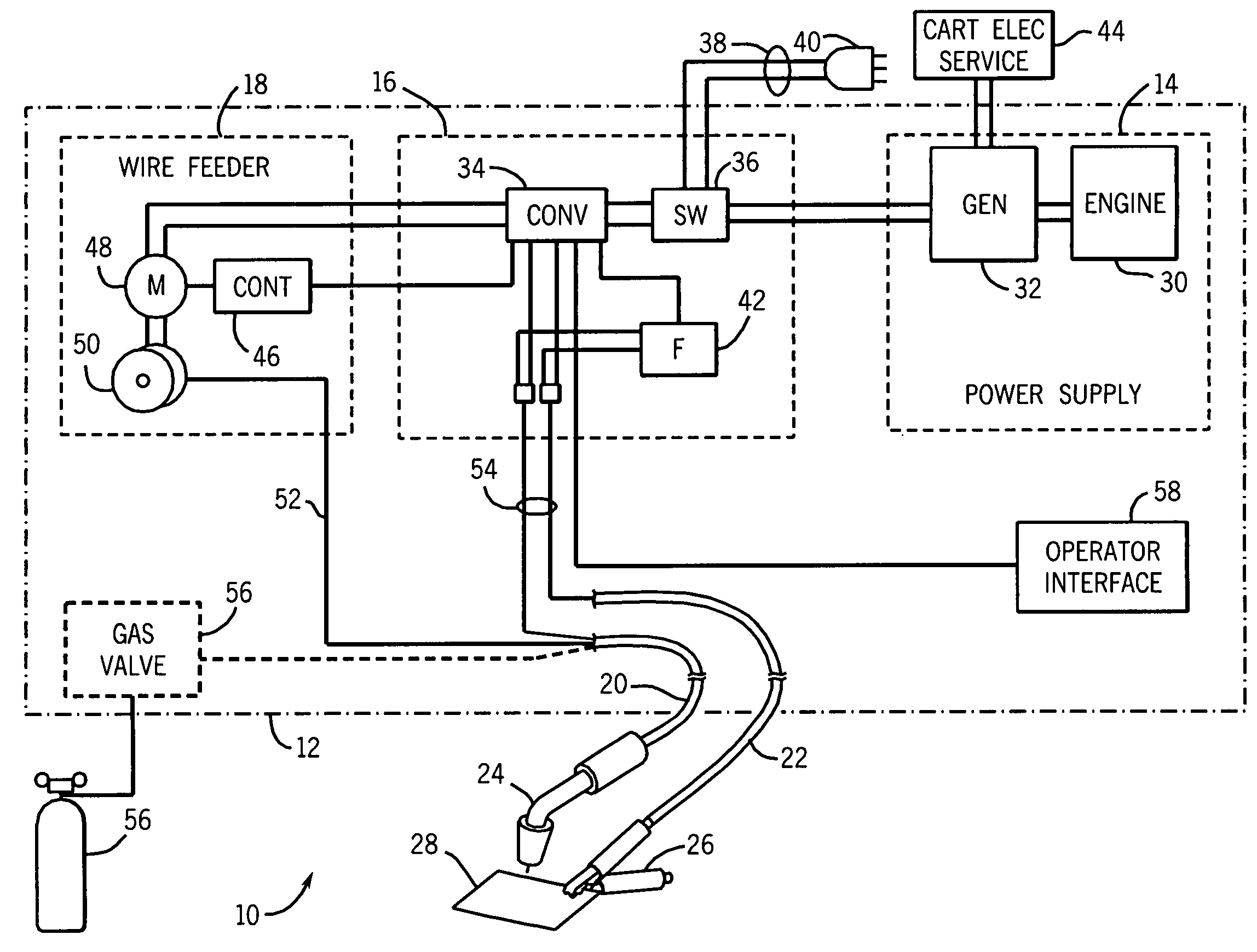

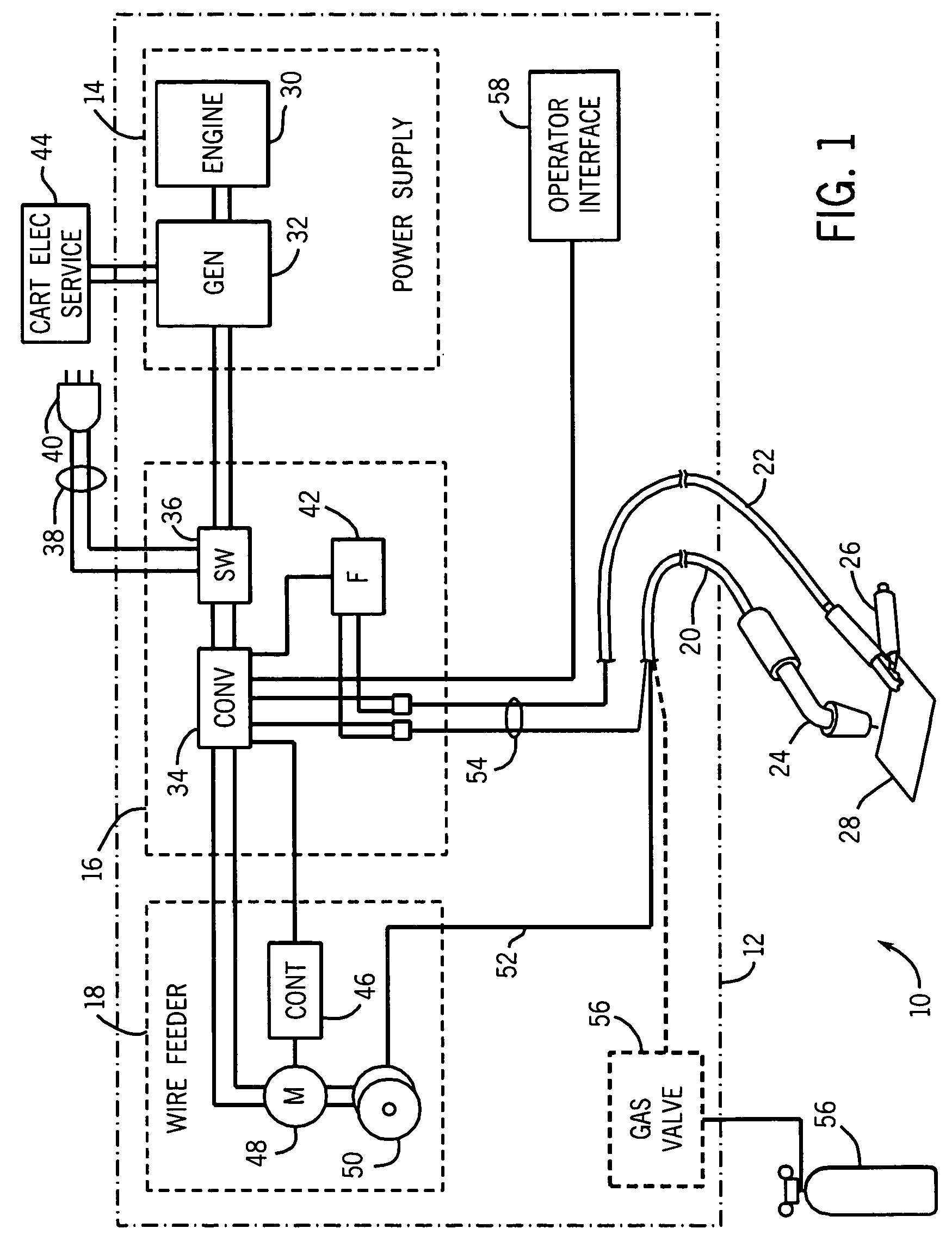

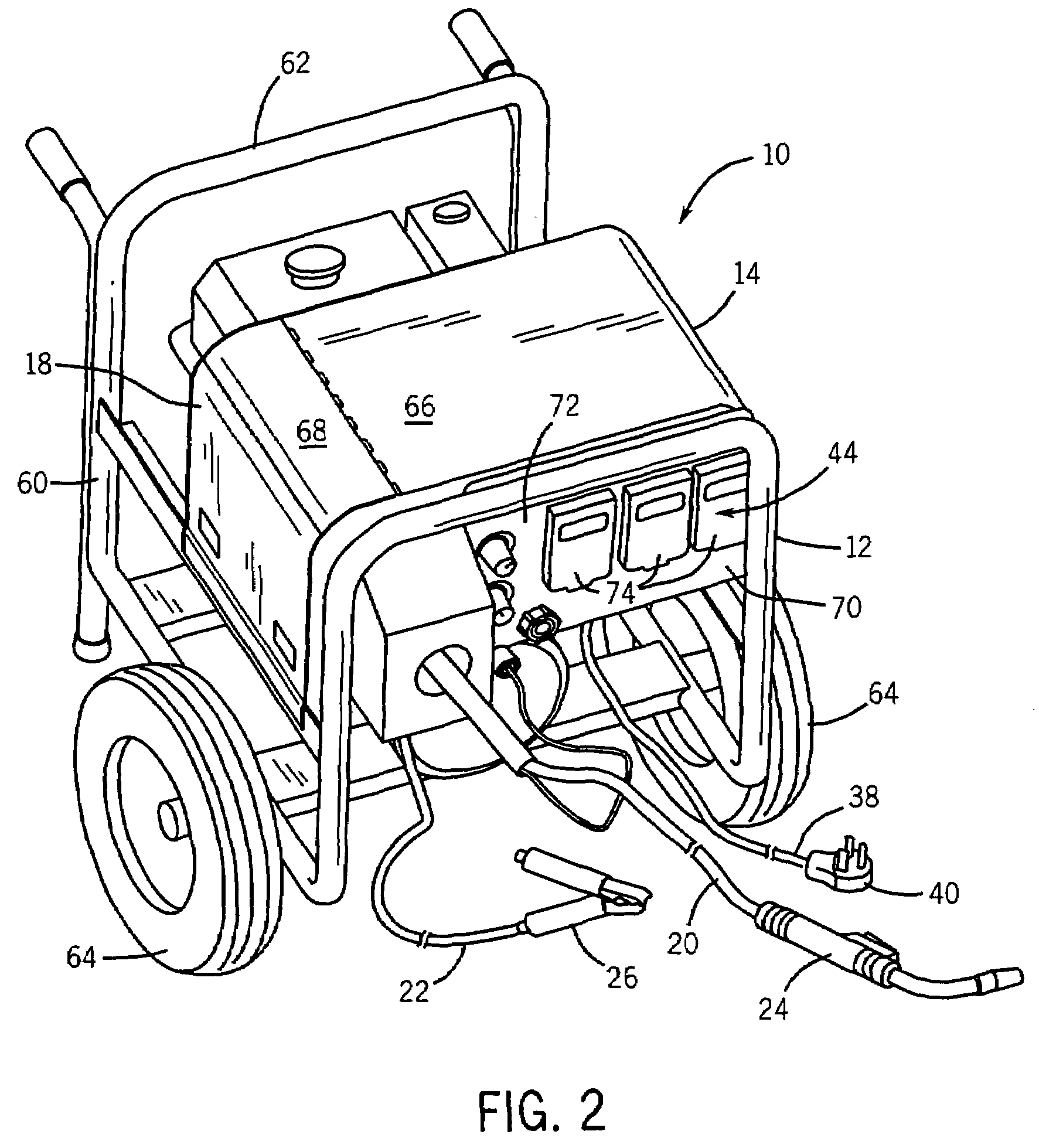

Dual power integrated MIG welder and generator system

An integrated welding system is described that includes an engine-driven power supply, control circuitry for regulating power from the power supply and for delivering power suitable for welding, and a wire feeder driven by the generated power for delivering a continuous feed of wire electrode. The system is suitable for MIG and flux core welding applications, and may further include an optional gas supply for a shielding gas. Other power is available in the system, such as for running conventional 120V and 240V power tools, lights and so forth. The unit may also be operated from an external power source, typically the power grid. The unit may be designed to permit selective operation in accordance with constant voltage and constant current regimes for MIG, TIG and stick welding.

Owner:ILLINOIS TOOL WORKS INC

Method for gas-shielded arc brazing of steel sheet

InactiveUS20110174784A1Reduce generationReduce arc voltageArc welding apparatusWelding/cutting media/materialsSheet steelShielding gas

Owner:NIPPON SANSO CORP

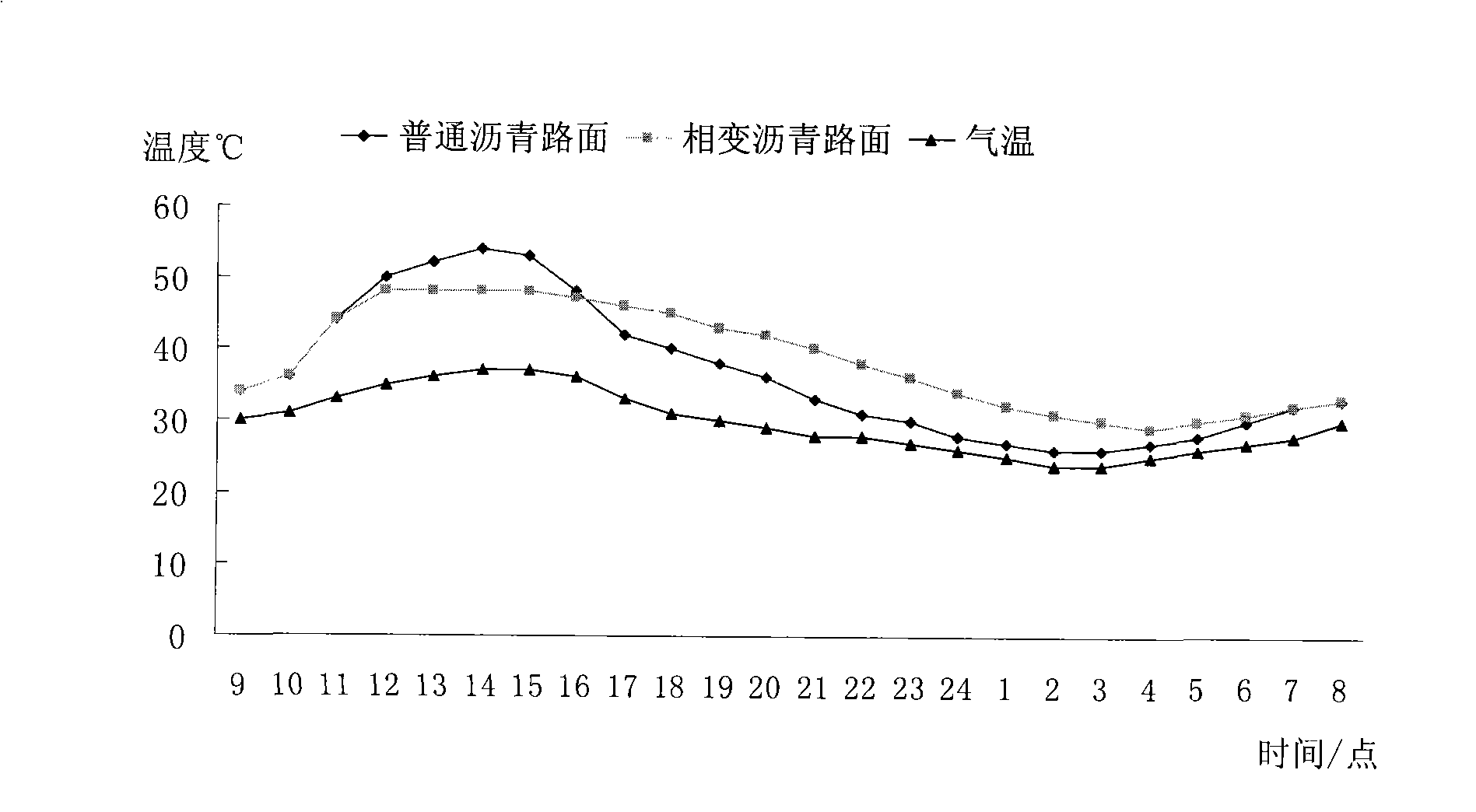

Method for preparing phase change asphalt pavement material

The invention relates to a preparation method for phase-change asphalt pavement material and is characterized in that the method comprises the following steps: (1), the preparation of phase-change asphalt modifier: firstly, selecting the materials based on the mass ratio among phase change material, coagulant, support material and coupling agent which is equal to 100:1-5:10-50:1-5; secondly, adding the phase change material into the silica sol, and then adding the coagulant dropwise to form gel; drying the gel, cooling the gel to room temperature and then taking out and mashing the gel to get powder through mixing; vacuuming the powder at 30-50 DEG C for 2-4 hours, then adding the support material under the protection of shielding gas; at 80-100 DEG C, adding the coupling agent for hydrophobic modification; then granulating to get the phase-change asphalt modifier; (2), the preparation of phase-change asphalt pavement material: firstly, selecting the materials based on the mass ratio among coarse aggregate: fine aggregate: filler, asphalt, fiber and phase change asphalt modifier which is equal to 100:10-20:1-8:2-6:0.2-0.5:2-10; then stirring the materials to get the phase-change asphalt pavement material. The phase-change asphalt pavement material prepared through the invention can improve the high temperature stability of pavement surface.

Owner:WUHAN MUNICIPAL CONSTR GROUP

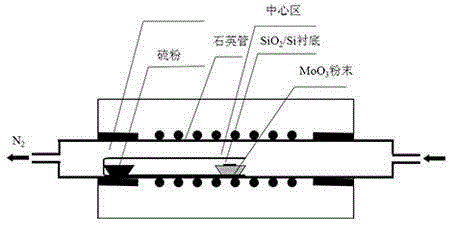

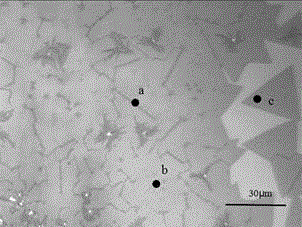

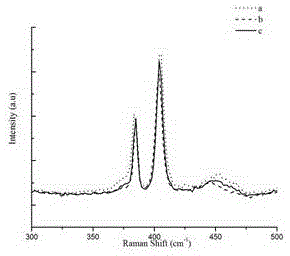

Preparation method for a large-area single-layer or few-layer molybdenum disulfide film

The invention discloses a preparation method for a large-area single-layer or few-layer molybdenum disulfide film. The main steps of the preparation method are as follows: firstly, sulfur powder and molybdenum trioxide powder are placed in two quartz boats respectively, a substrate is placed on the quartz boat loaded with molybdenum trioxide powder, and the obverse surface faces downwards; secondly, the two quartz boats loaded with sulfur powder and molybdenum trioxide powder are placed at a bottom end and an orifice of a quartz test tube respectively; thirdly, the above quartz test tube is placed in a tubular furnace, the bottom end and the orifice of the test tube are located at the edge area and the central area of the tubular furnace respectively; fourthly, protection gas argon or nitrogen is inputted into the tubular furnace, a normal pressure is kept until the experiment is over; fifthly, the tubular furnace is heated at a certain heating speed, thus the edge area and the central area of the tubular furnace are in proper temperatures respectively, the temperatures are kept for some time, sulfur powder sublimates and reacts with gas phase molybdenum trioxide, and a large-area single-layer or few-layer molybdenum disulfide film is generated on the substrate; sixthly, the tubular furnace is cooled to the room temperature, and the preparation process is finished. The method is slightly affected by air flow, the repetition rate is high, preparation of high-quality large-area single-layer or few-layer molybdenum disulfide film can be achieved at a normal pressure.

Owner:XIANGTAN UNIV

Pulsed arc welding method

ActiveCN101032778AInevitable formationReduce splashArc welding apparatusWelding/cutting media/materialsGeneration rateShielding gas

Disclosed is a pulsed arc welding method using a pulse current of alternately repeating first and second pulses as a weld current, wherein the first pulse and the second pulse have a pulse waveform of a different pulse peak current level and a different pulse width, respectively, and the following conditions are satisfied: peak current of the first pulse (Ip1)=300 to 700A; peak period (Tp1)=0.3 to 5.0 ms; base current Ib1=30 to 200A, base period (Tb1)=0.3 to 10 ms; peak current of the second pulse (Ip2)=200 to 600A; peak period (Tp2)=1.0 to 15 ms; base current (Ib2)=30 to 200A; and base period (Tb2)=3.0 to 20 ms. In this manner, the consumable electrode arc welding using carbon dioxide gas alone or a mixed gas made mainly of carbon dioxide gas as a shield gas can benefit from stabilized welding arc, improved regularity of droplet transfer, and significantly reduced generation rates of spatters and fumes.

Owner:KOBE STEEL LTD

Production method of large polycrystalline ingot

ActiveCN102021650AIncrease production capacityIncrease profitPolycrystalline material growthSingle crystal growth detailsCooking & bakingShielding gas

The invention relates to the technical field of ingot casting of solar energy batteries, in particular to a production method of a large polycrystalline ingot. Silicon nitride and water are mixed uniformly through electric mixing for 15-30 minutes, and the mixture is used as a coating liquid, the coating liquid is uniformly coated on the inner surface of a crucible after the crucible is preheated, and then high-temperature baking is carried out on the crucible, a silicon material is loaded in the baked crucible, and then charging is carried out on the crucible loaded with the silicon material, shielding gas-argon passes through a polycrystalline furnace after vacuumizing is carried out on the polycrystalline furnace, the polycrystalline furnace is heated to melt the silicon material, and then, the melted silicon material is gradually crystallized from the bottom part to the top part through directional solidification, and then discharging is carried out after gradual cooling is carried out through high-temperature annealing, the crucible is disassembled after the discharged polycrystalline ingot is cooled at room temperature, so as to obtain the polycrystalline silicon ingot which is sliced to prepare the battery. The large charging amount is realized, the capacity of the casting ingot is improved, the utilization rate of the polycrystalline ingot is improved, the cost is reduced, the requirements of a high-load slicer are met, and the crystal quality is kept to be unchanged.

Owner:TRINA SOLAR CO LTD

Preparation method of carbon-coated cobalt oxygen evolution reaction electro-catalyst

InactiveCN104056630AImprove catalytic performanceImprove stabilityMaterial nanotechnologyCell electrodesWater bathsCarbon layer

The invention relates to a preparation method of a carbon-coated cobalt oxygen evolution reaction electro-catalyst and belongs to the preparation field of electrochemical catalysts. The preparation method includes the steps that firstly, a carbon source and cobalt salts in proportion are placed into water for dissolving and mixing, and then evaporation to dryness is performed at the water bath condition at the temperature of 50 DEG C-80 DEG C to obtain powder evenly mixed; then the powder is heated to 400 DEG C-1000 DEG C under the shielding gas condition and then calcinated for 30 minutes-120 minutes to obtain a carbon-coated cobalt elementary substance; finally, an electrochemical pretreatment method is used for obtaining a nano-particle of carbon layer-cobaltic oxide-elementary substance cobalt, wherein the nano-particle is of an electric conduction core-shell structure. The method is simple in process, convenient to implement and low in requirement for preparation equipment and improves safety in the experiment process. The carbon layer-cobaltic oxide-elementary substance cobalt prepared through the method is even in diameter and good in electric conduction and has good electro-catalysis water oxidation performance.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

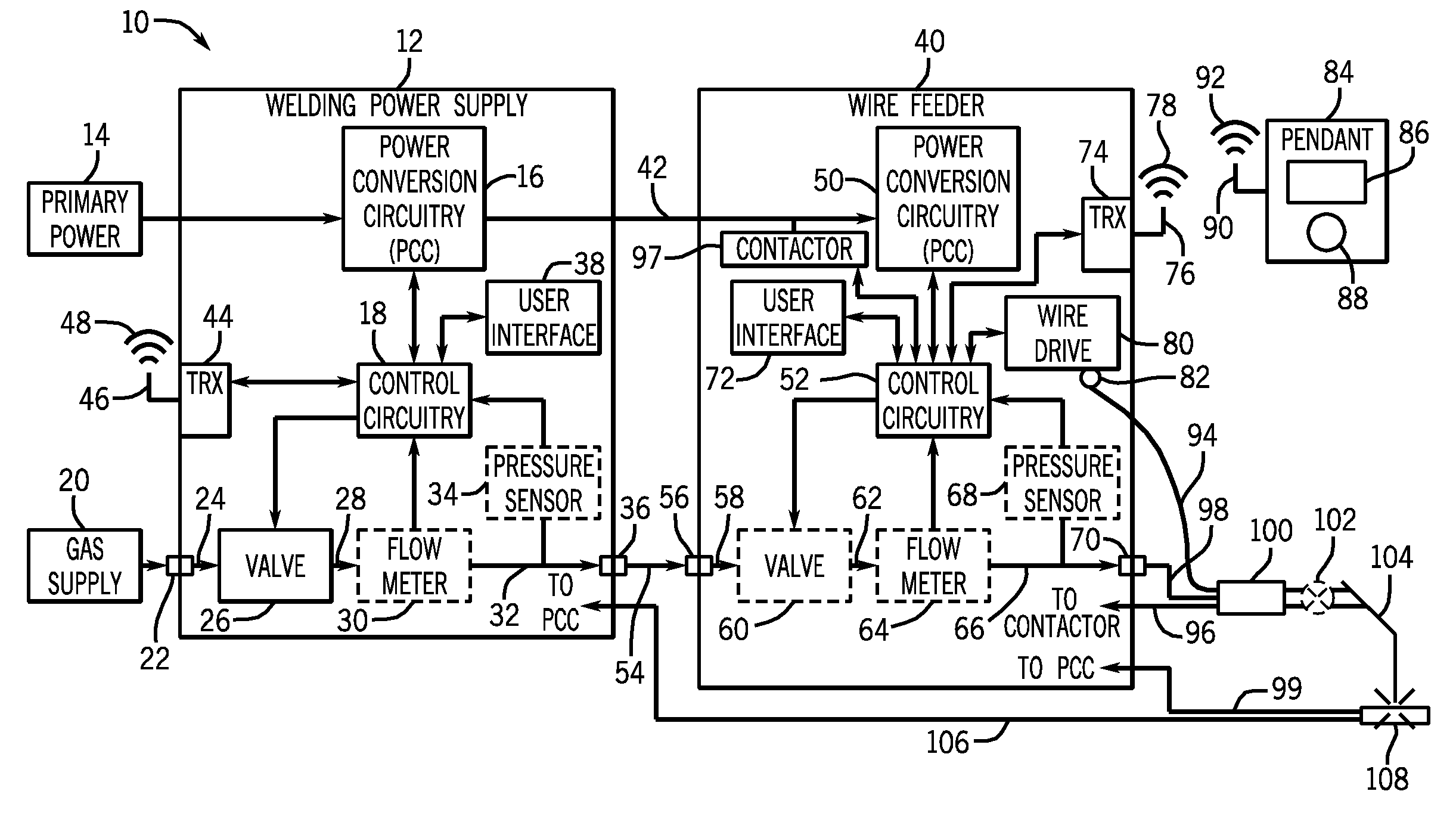

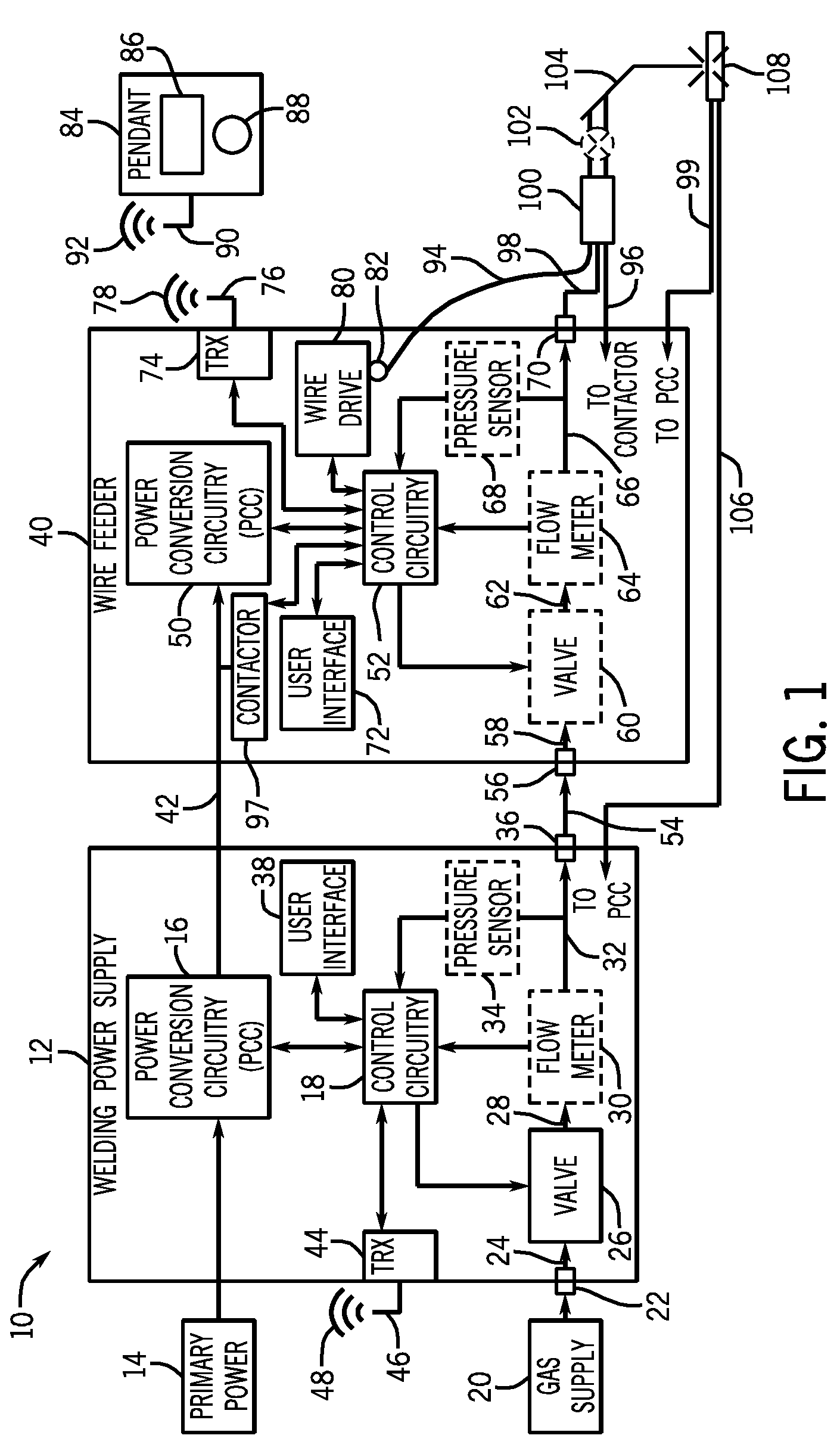

Welding gas leak detection system and method

ActiveUS20110284500A1Arc welding apparatusFluid-tightness measurementWelding power supplyShielding gas

A method and system for detecting a welding gas leak is provided. One welding power supply includes a gas valve configured to control the flow of shielding gas to a welding device through a gas line. The welding power supply also includes a sensor coupled to the gas line and configured to detect a parameter of the shielding gas. The welding power supply includes control circuitry coupled to the gas valve and to the sensor, and configured to control the operation of the gas valve, and to receive device value representative of the detected parameter. The control circuitry is further configured to determine a leak test result based upon the parameter value, and to provide an operator indicator of the leak test result.

Owner:ILLINOIS TOOL WORKS INC

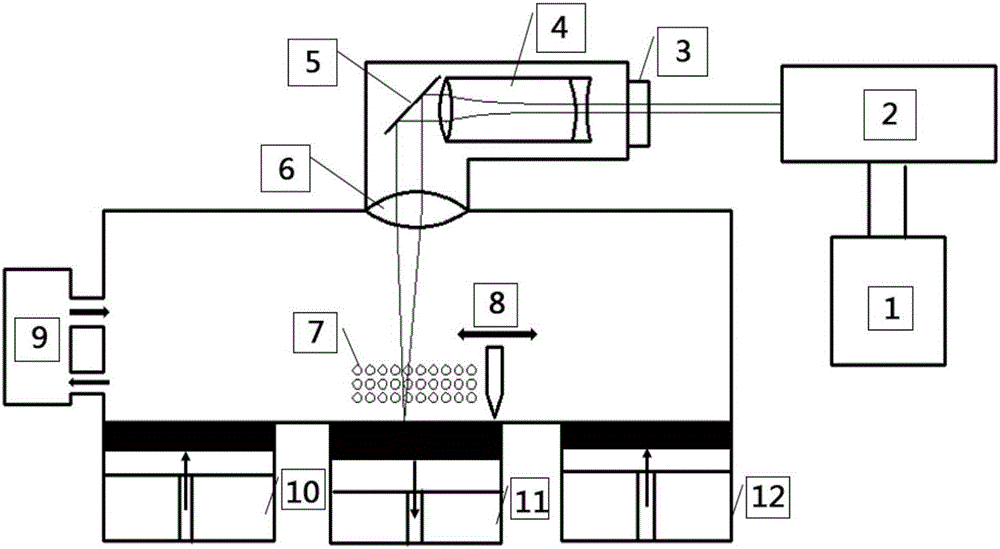

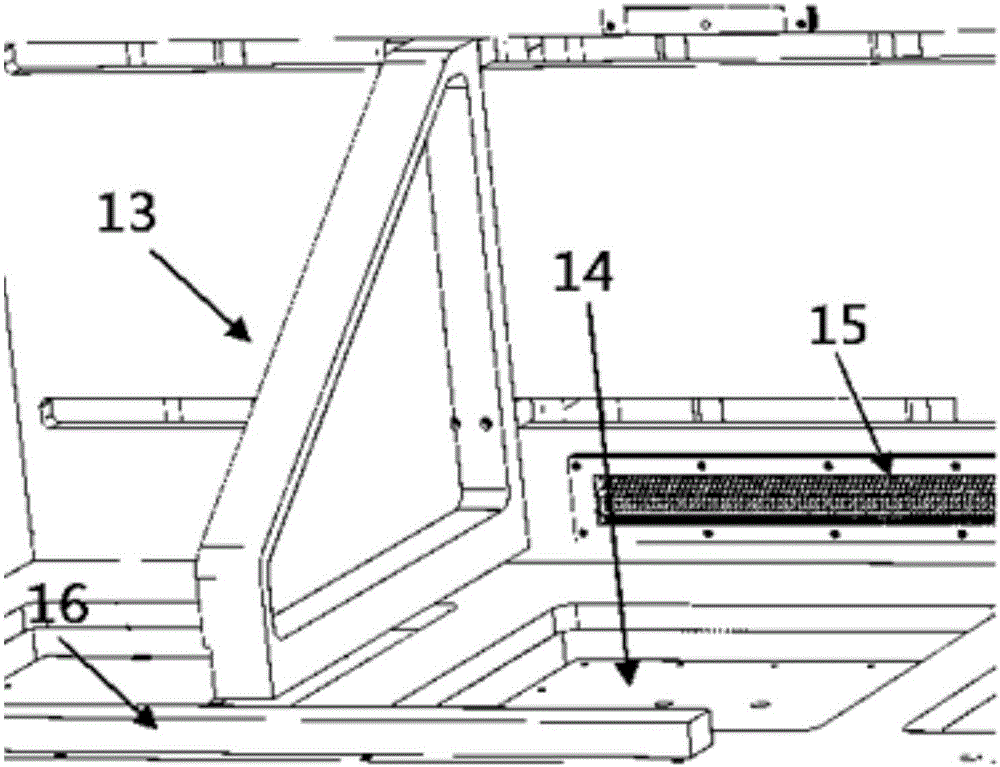

Device for entering and exiting of shielding gas on two sides of forming bin of metal 3D printing equipment

ActiveCN106623928AIncrease profitAdditive manufacturing apparatusIncreasing energy efficiencyMelting tankShielding gas

The invention provides a device for entering and exiting of shielding gas on two sides of a forming bin of metal 3D printing equipment. Gas exiting and entering devices for working bins in metal selective forming equipment are generally simple pore channel devices or rectangular devices, have common problems that gas flow produced at a gas inlet in a laser sintering process for powder cannot blow away black smoke and metal vapor plasma produced under mutual action of laser and powder, and then larger power loss of laser and irregular shape of a weld pool are caused and result in severe influence on forming quality and forming precision of formed parts, or have the problem that powder sintering black smoke close to the gas inlet and is blown to be scattered on a powder layer close to a gas outlet and printing work is affected. The specific device is mainly designed to enable gas flow to form stable laminar flow and effectively blow away the black smoke and metal vapor plasma produced during laser sintering of the powder, the laser energy utilization rate can be increased by about 10%-15%, the quality and the precision of the formed parts can be improved effectively, and the density of the formed parts approaches 100%.

Owner:BEIJING UNIV OF TECH

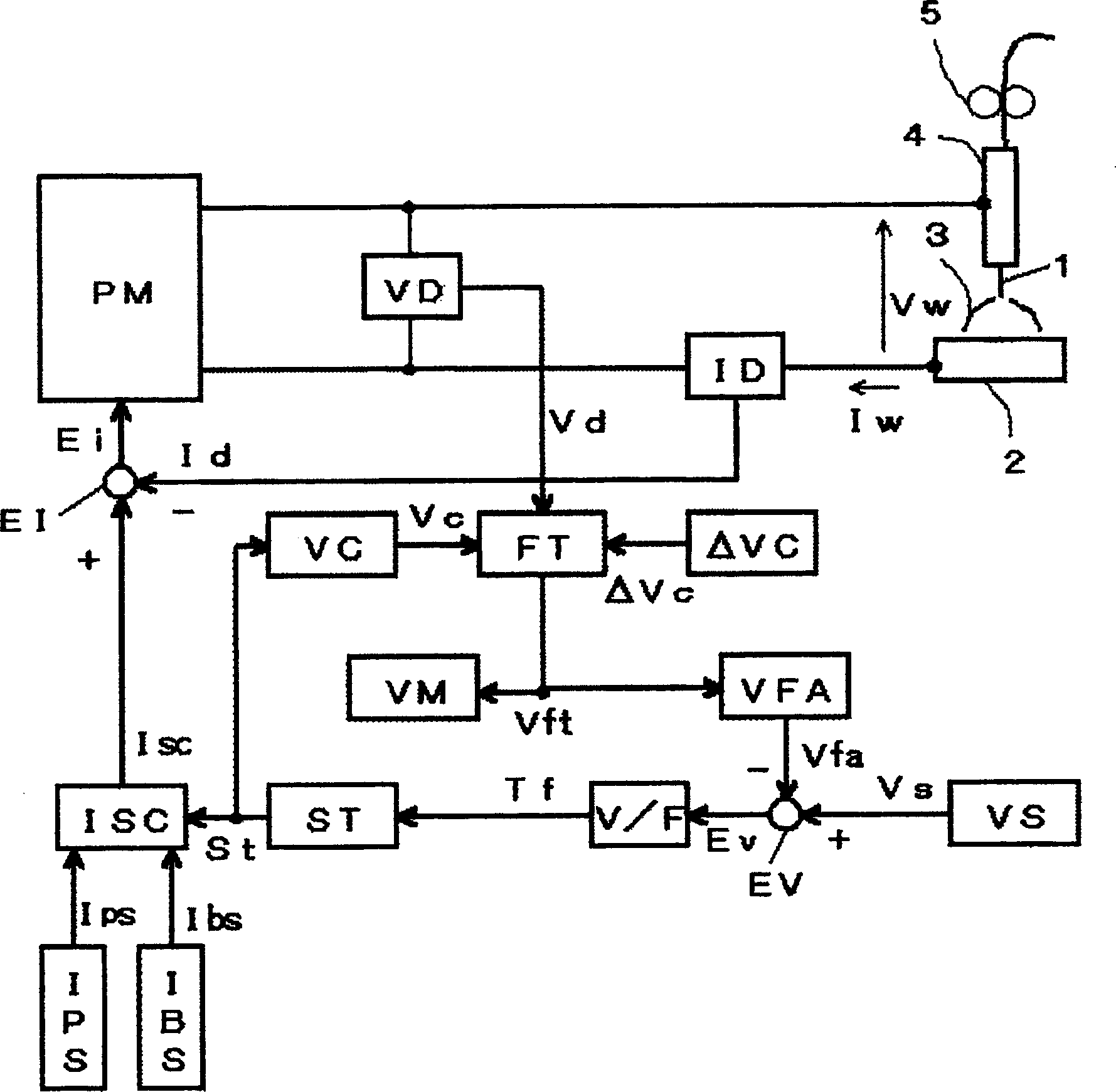

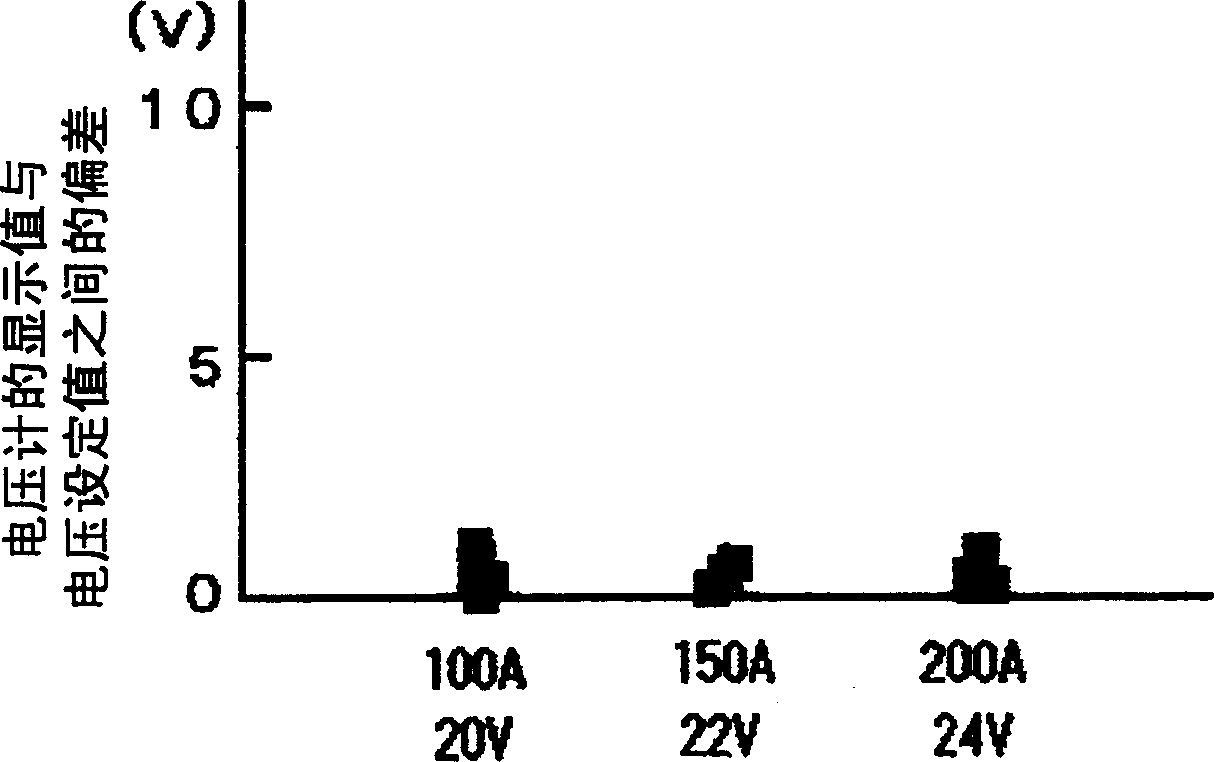

Impulsive arc welding powder supply

Use only inert gas in the shielding gas, pass the pulse waveform welding current (Iw) consisting of peak current and base current, and detect the welding voltage (Vw) between the melting electrode (1) and the base metal (2) , limit the welding voltage detection value (Vd) within the specified fluctuation range (Vc±ΔVc) from the reference voltage waveform (Vc) of the pulse waveform, calculate the welding voltage limit value (Vft), and control the output of the welding power source so that In a pulsed arc welding power source in which the welding voltage limit average value (Vfa) after averaging the welding voltage limit value (Vft) is approximately equal to the preset voltage setting value (Vs), even if an abnormal voltage is superimposed, the arc The length-proportional voltage value is displayed on the welding power source's voltmeter.

Owner:DAIHEN CORP

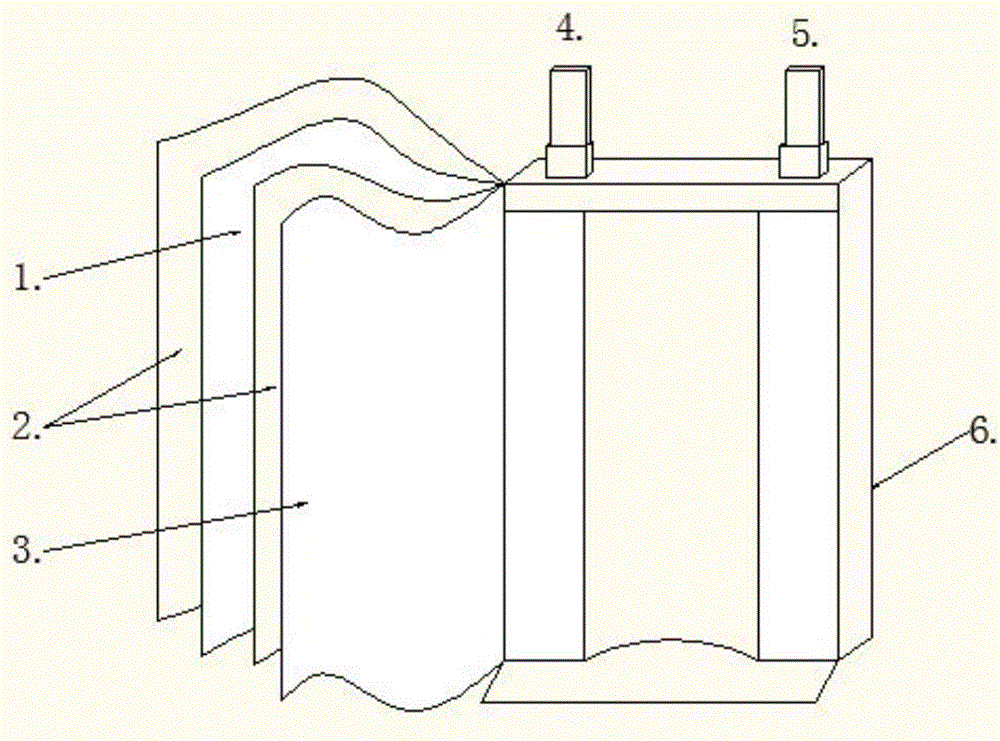

Rechargeable aluminum ion battery and preparation method thereof

InactiveCN104810544AAchieve practical purposesCell seperators/membranes/diaphragms/spacersFinal product manufactureAluminum IonShielding gas

The invention discloses a rechargeable aluminum ion battery and a preparation method thereof, and belongs to the technical field of batteries. The rechargeable aluminum ion battery can be widely used in the electronics industry and communications industry, and can also be used as a power battery for an electric vehicle. The invention provides a novel aluminum ion battery device, especially a soft bagged battery. The aluminum ion battery device adopts a membrane to separate the positive and negative electrodes of the aluminum ion battery, and uses an insulating soft bag to wrap the positive and negative electrodes of the aluminum ion battery; the enclosed battery is assembled in a shielding gas atmosphere, and only the positive and negative electrode leads which are conductive are exposed for being connected with an external circuit; according to different electrode making technologies, the battery can be assembled into square or round or other shapes. The soft bagged aluminum ion storage battery provided by the invention has the benefits that the capacity is high, the charge and discharge efficiency is high, the cycling stability is good, and the charge and discharge features are excellent; in addition, the electrode materials are extensive in source, and the battery is easy to prepare, low in cost, green and environment-friendly, and low in price.

Owner:UNIV OF SCI & TECH BEIJING +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com