Patents

Literature

697results about "Shielding gas supply/evacuation devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

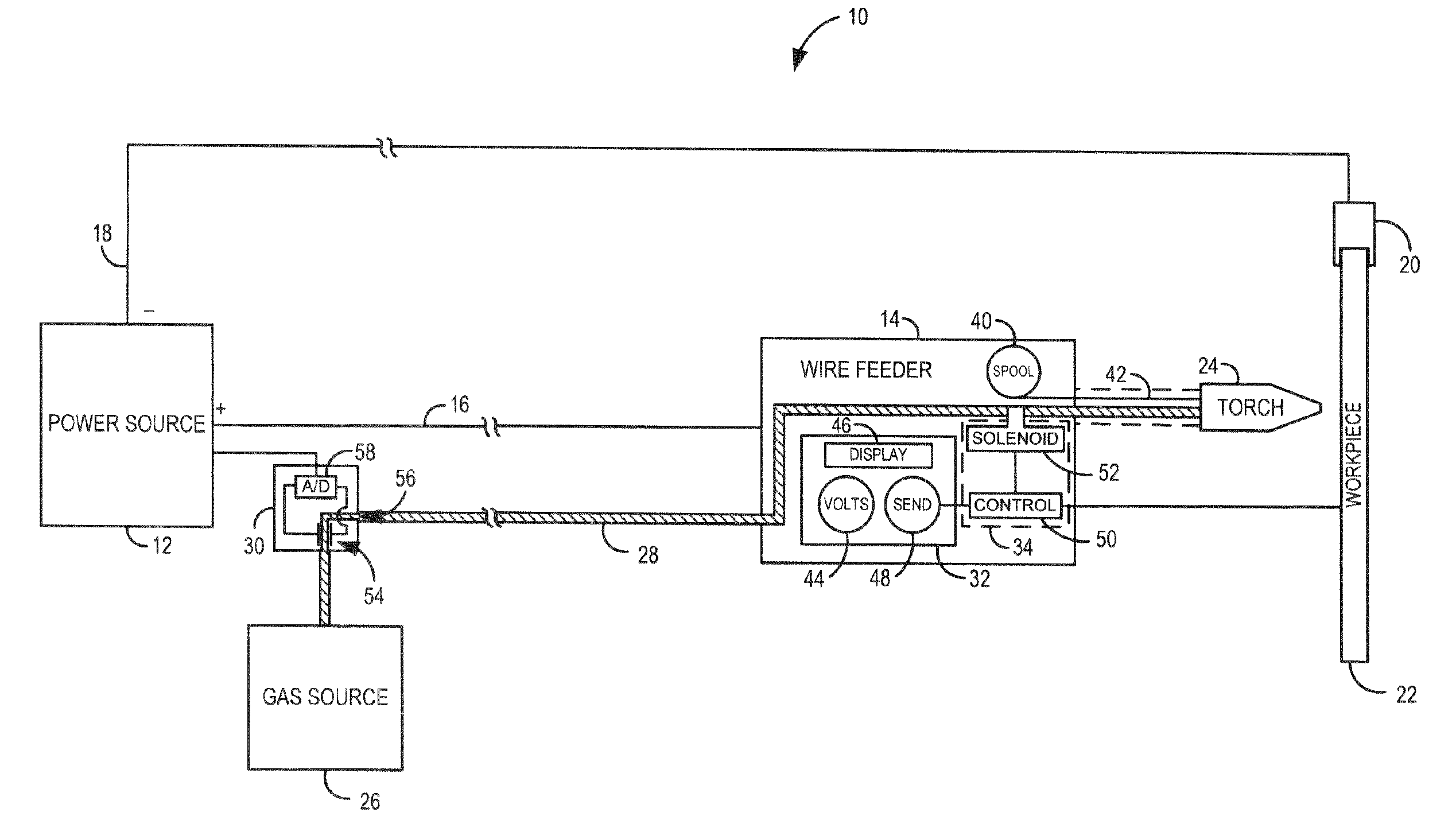

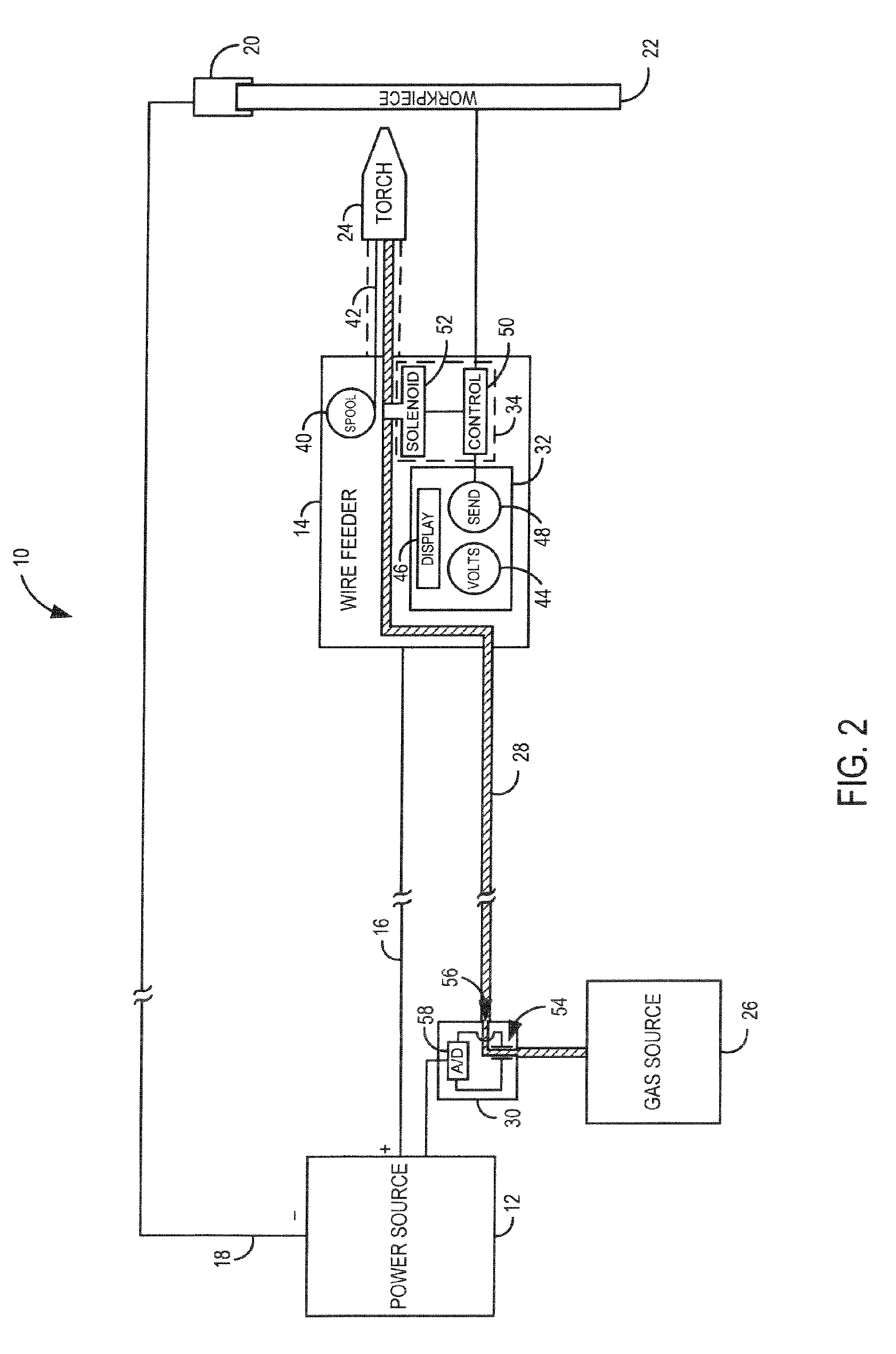

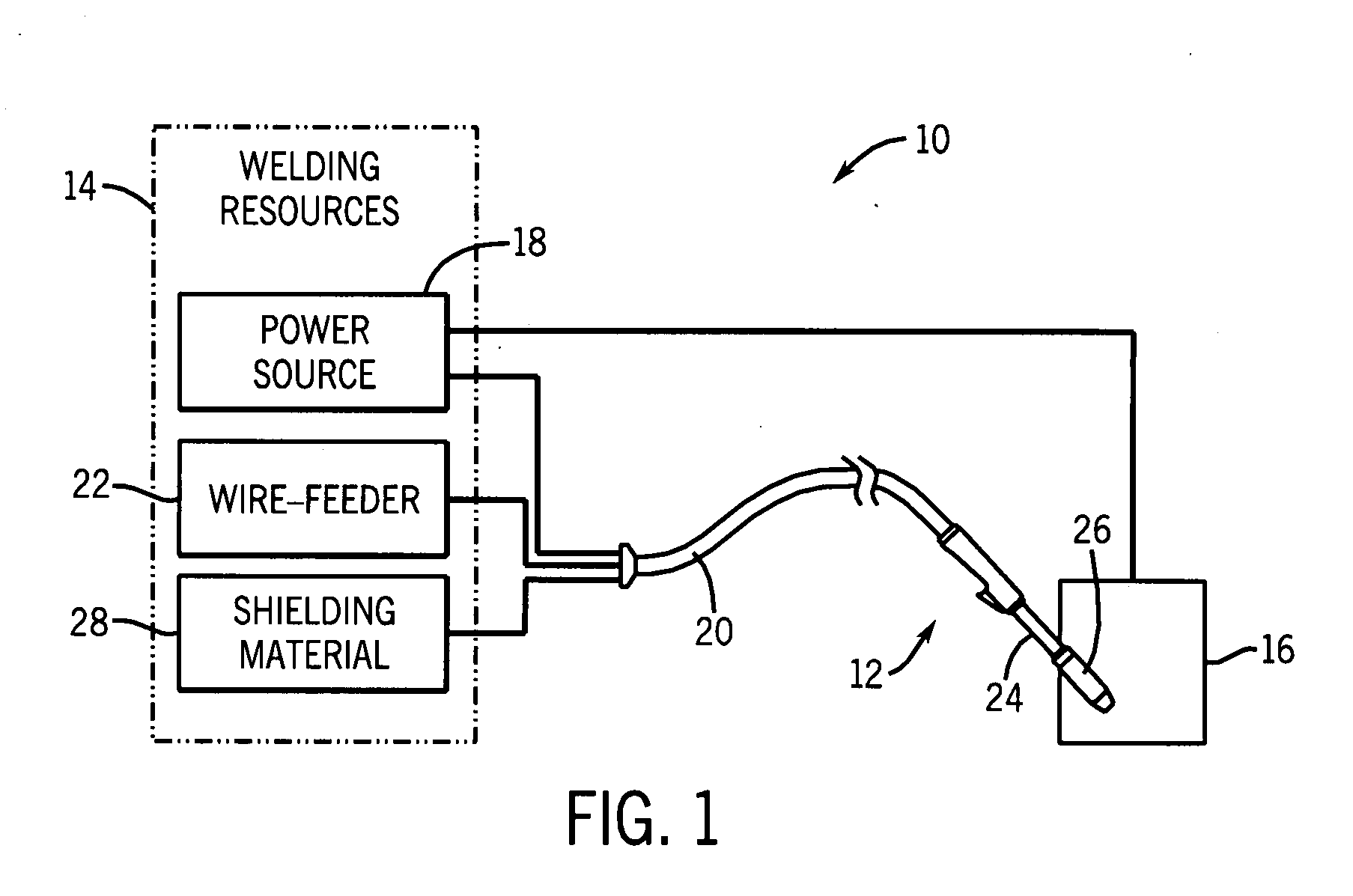

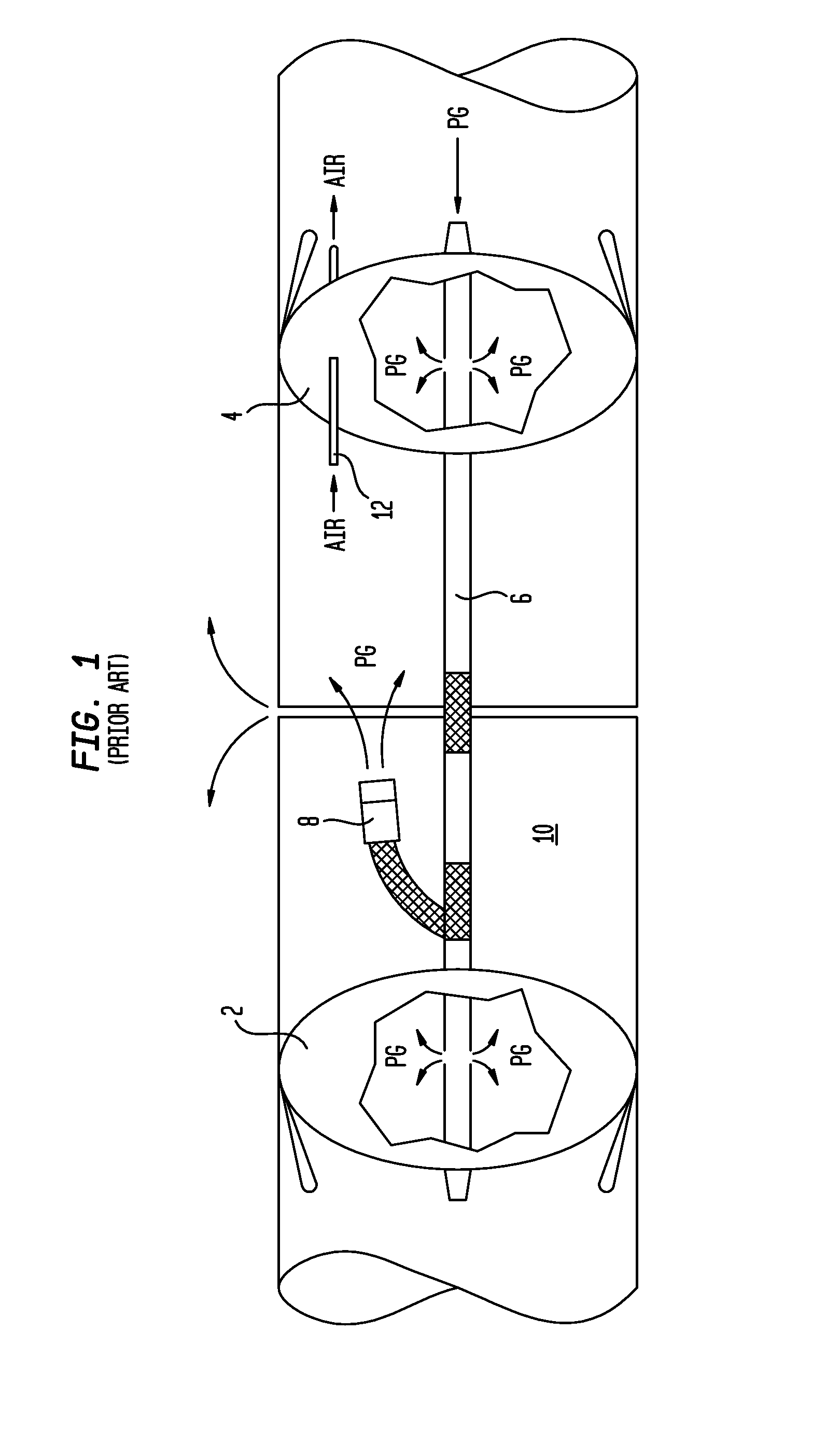

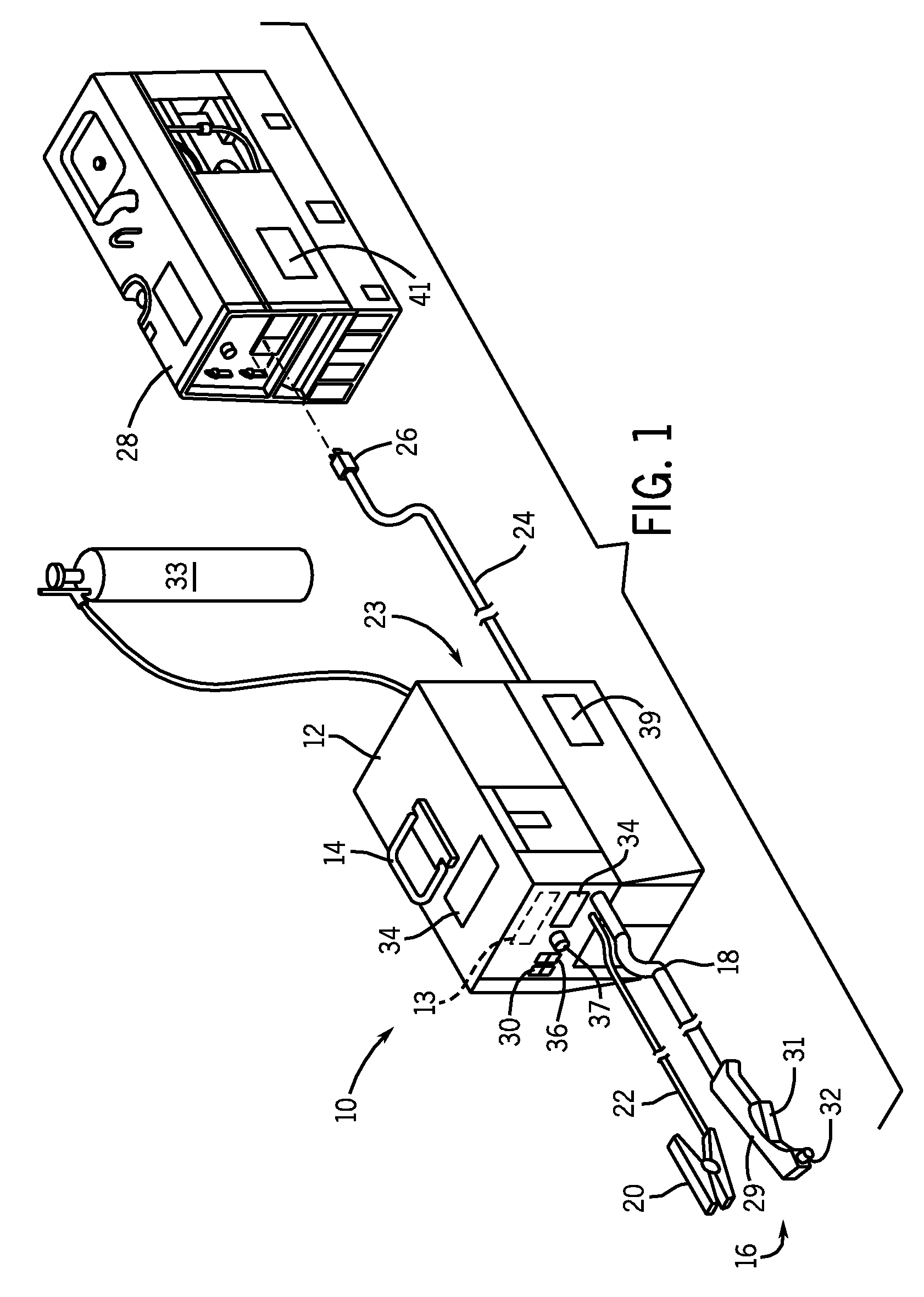

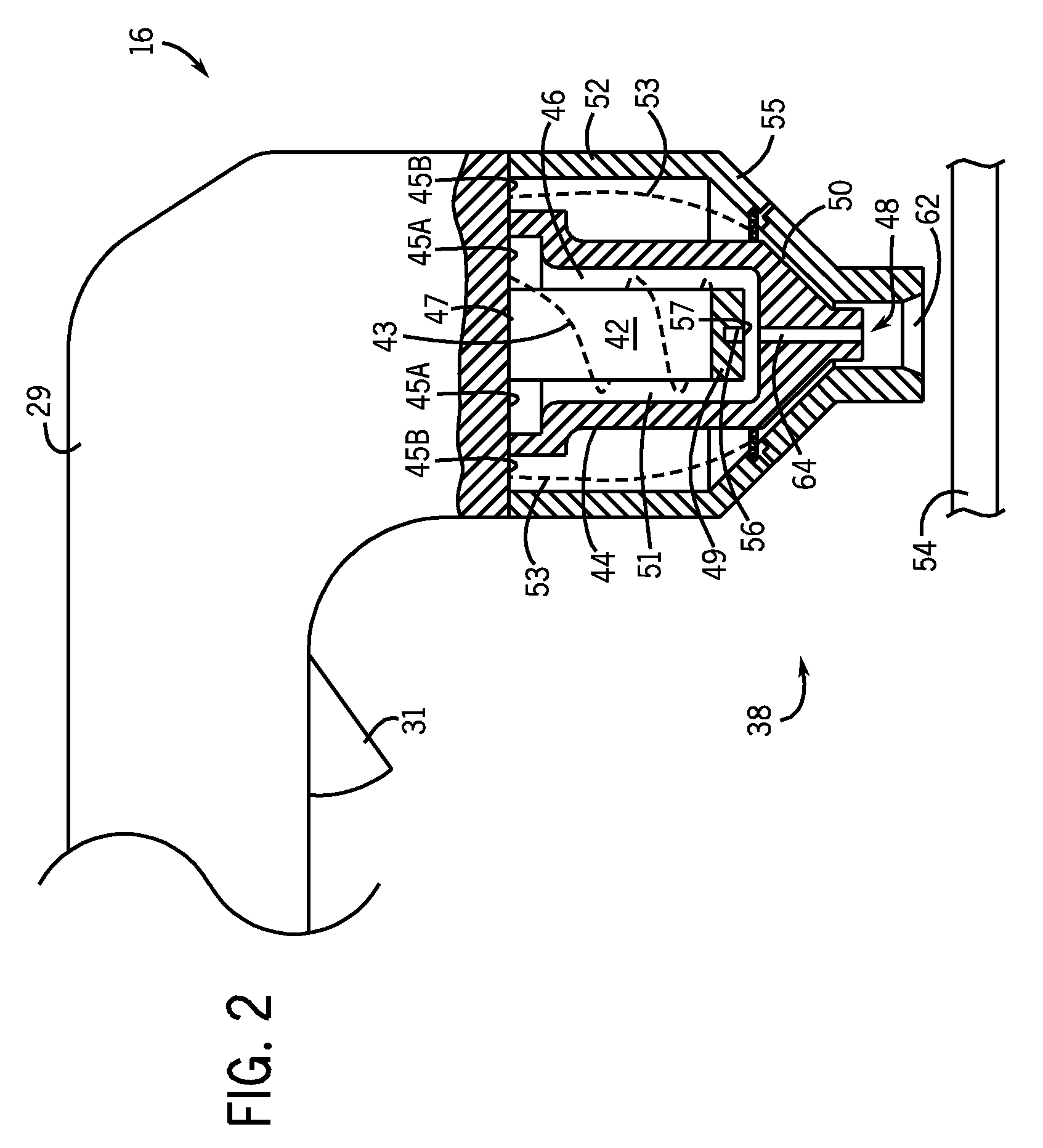

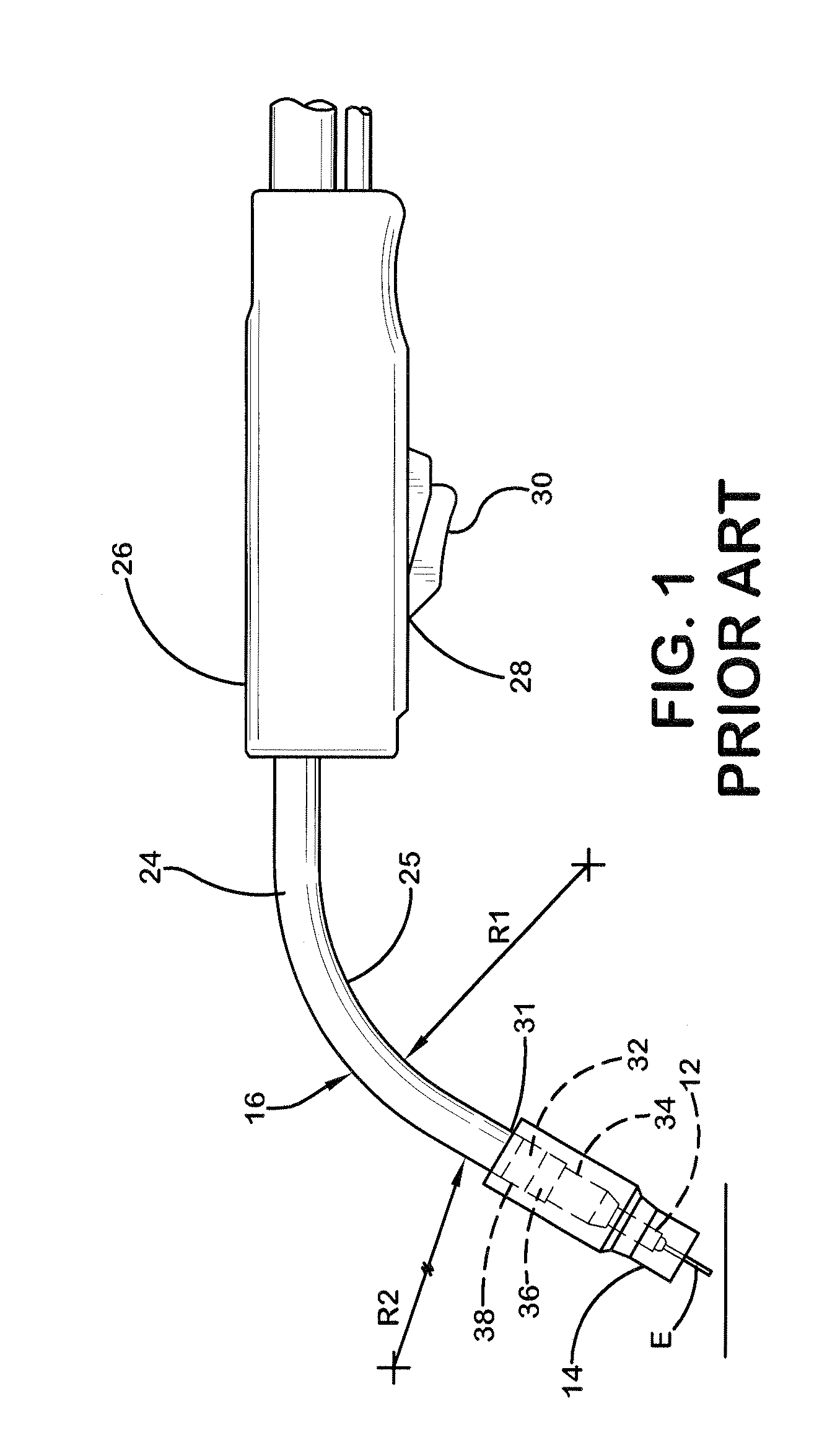

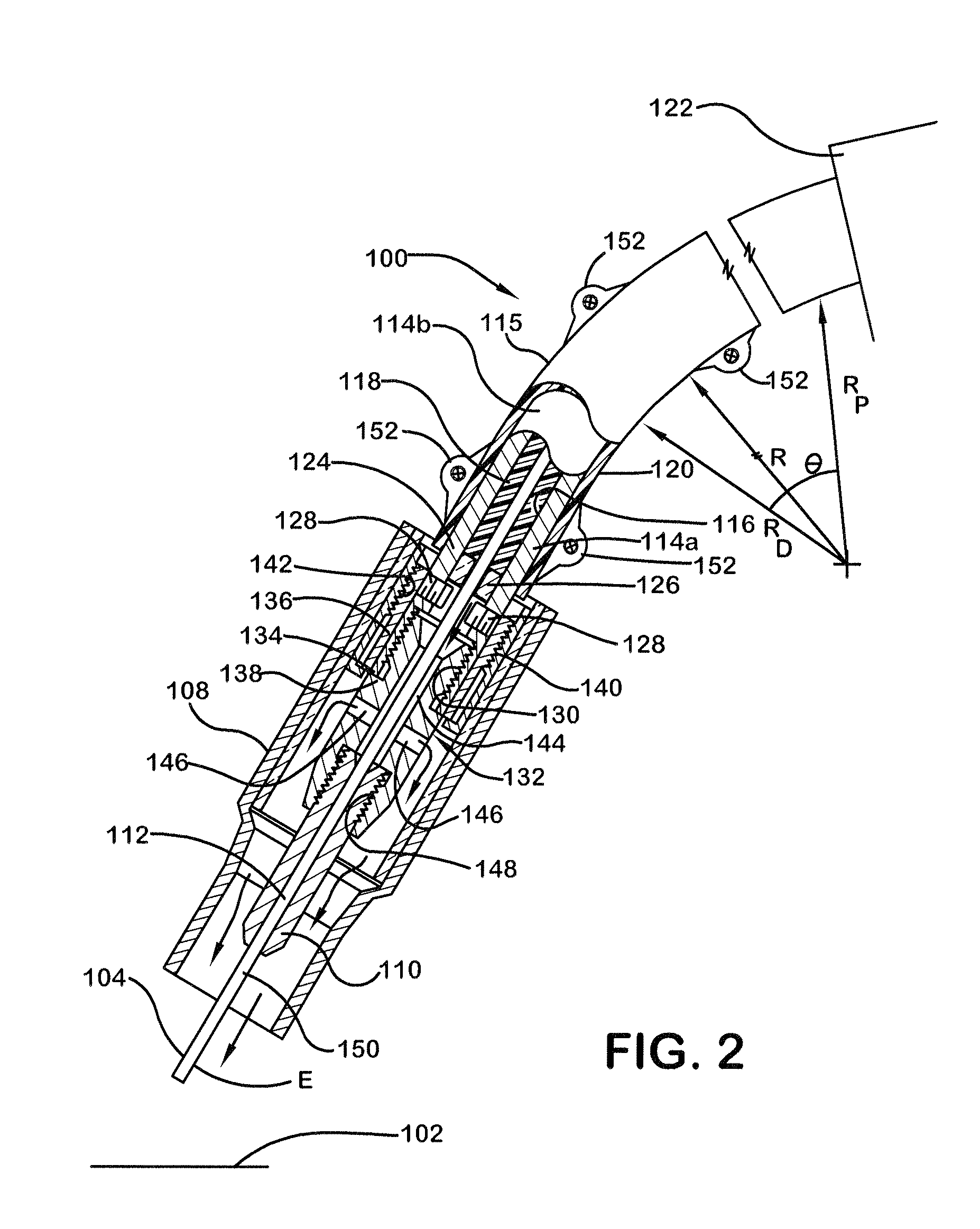

System and method for data communications over a gas hose in a welding-type application

ActiveUS20060213892A1Shielding gas supply/evacuation devicesElectric discharge heatingLine tubingCommunications system

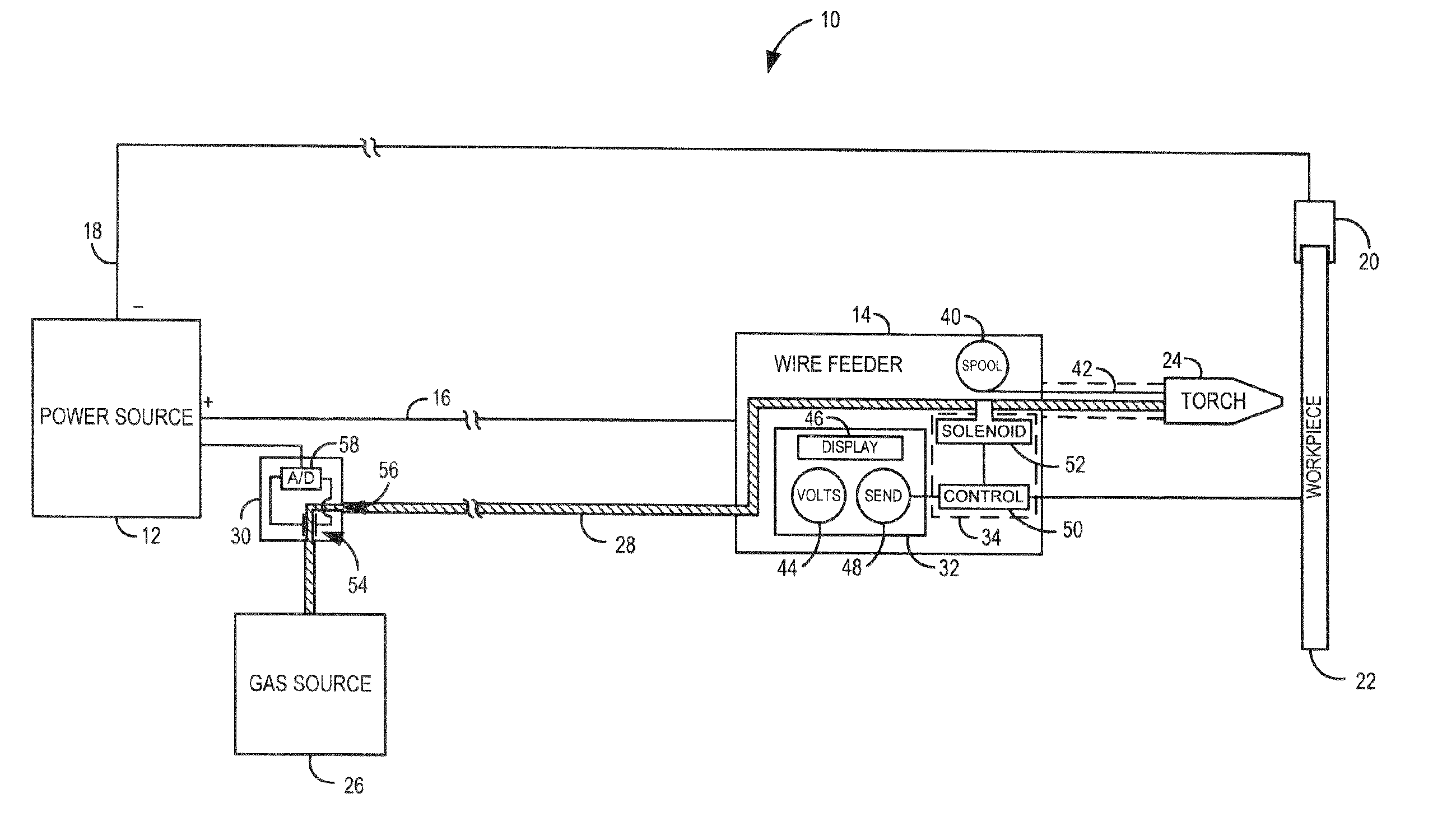

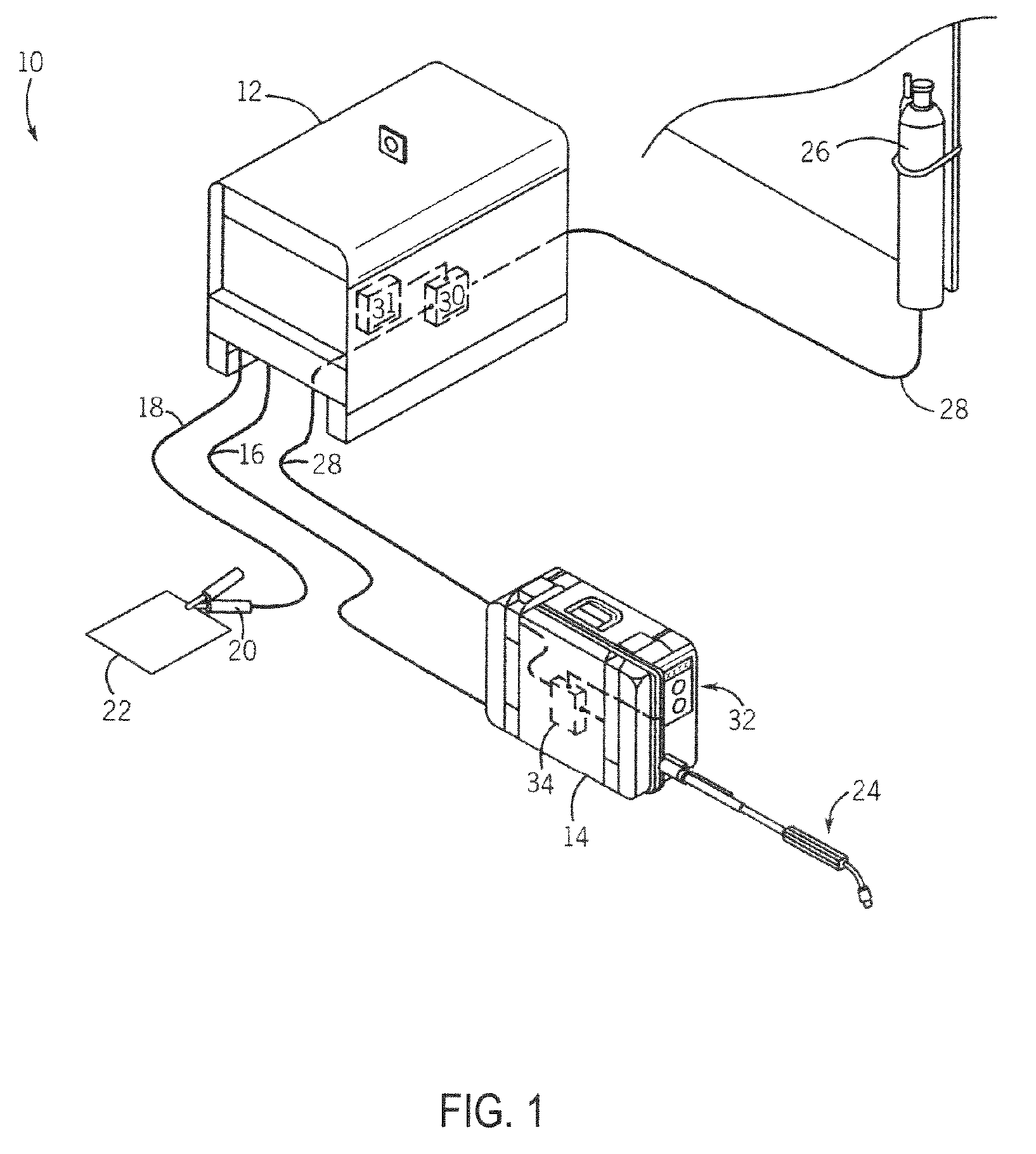

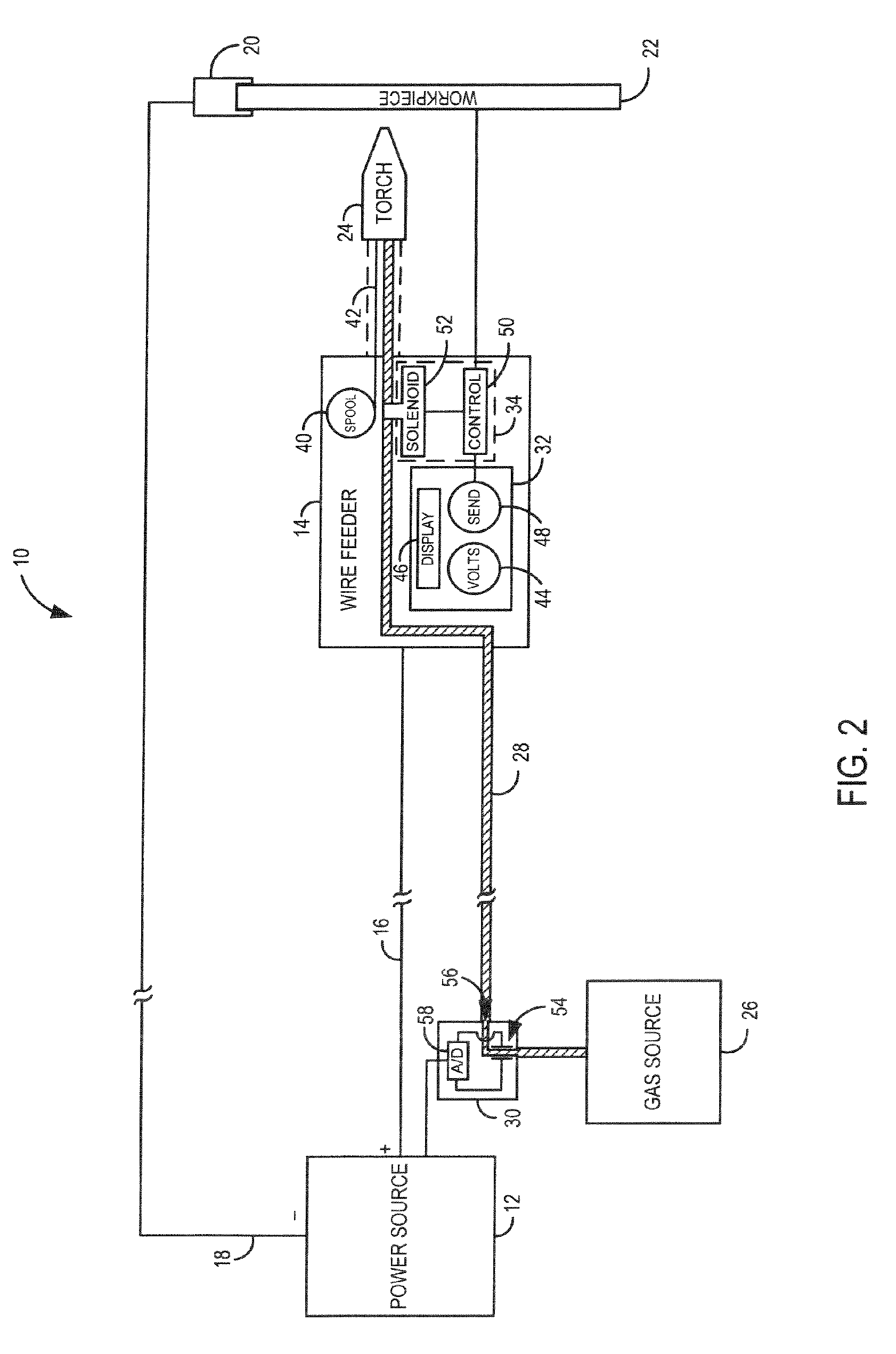

The present invention includes a system and method of controlling a remotely located welding-type power source. A communications system includes a user interface to accept a user input at a portable location and a gas purging device to systematically purge pressurized gas from a gas line connecting the portable location to a remote location based on the user input. The communications system also includes a sensor to sense pressure changes in the gas line at the remote location and a processor configured to convert the sensed pressure changes to a representation of the user input.

Owner:ILLINOIS TOOL WORKS INC

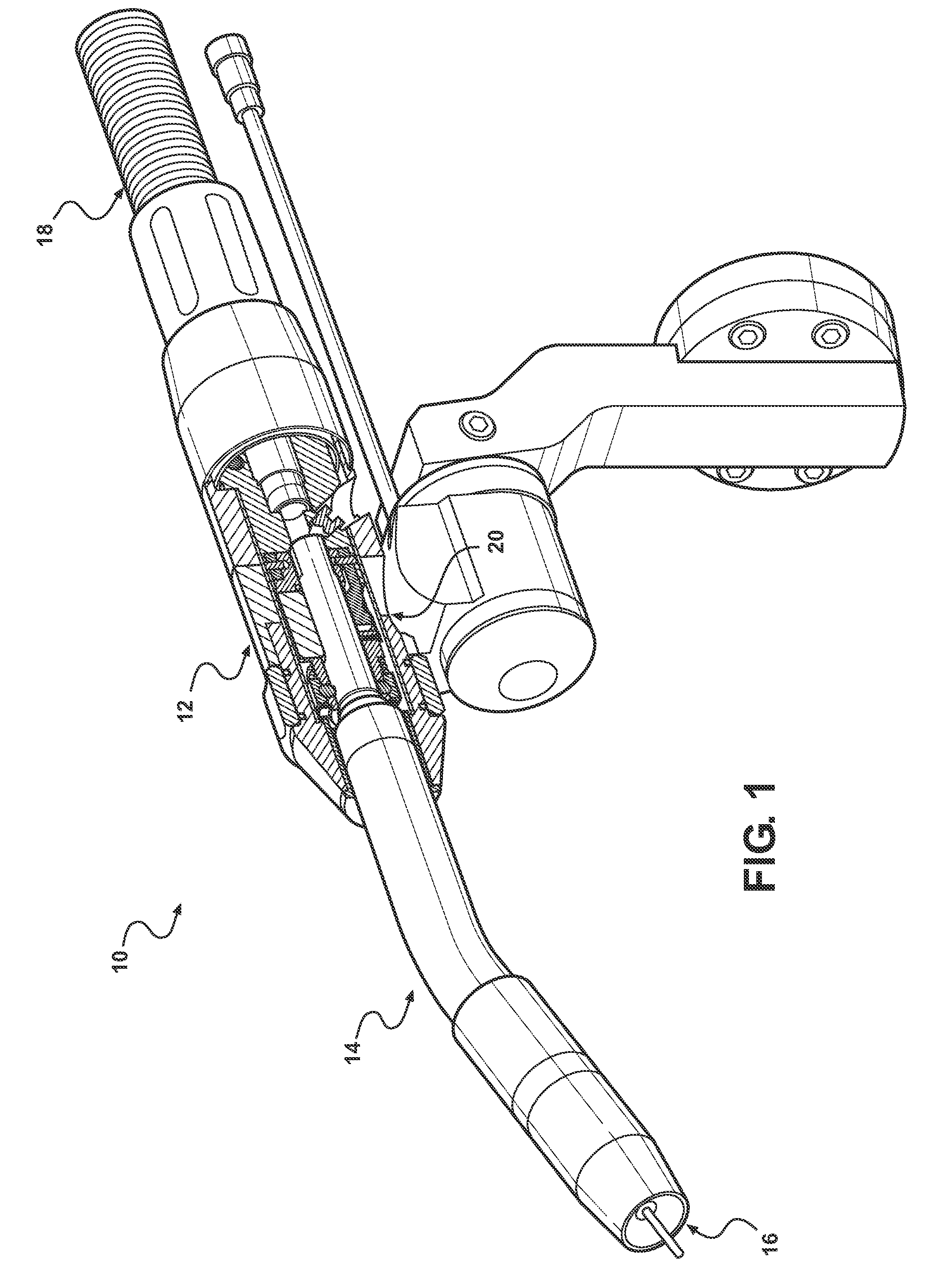

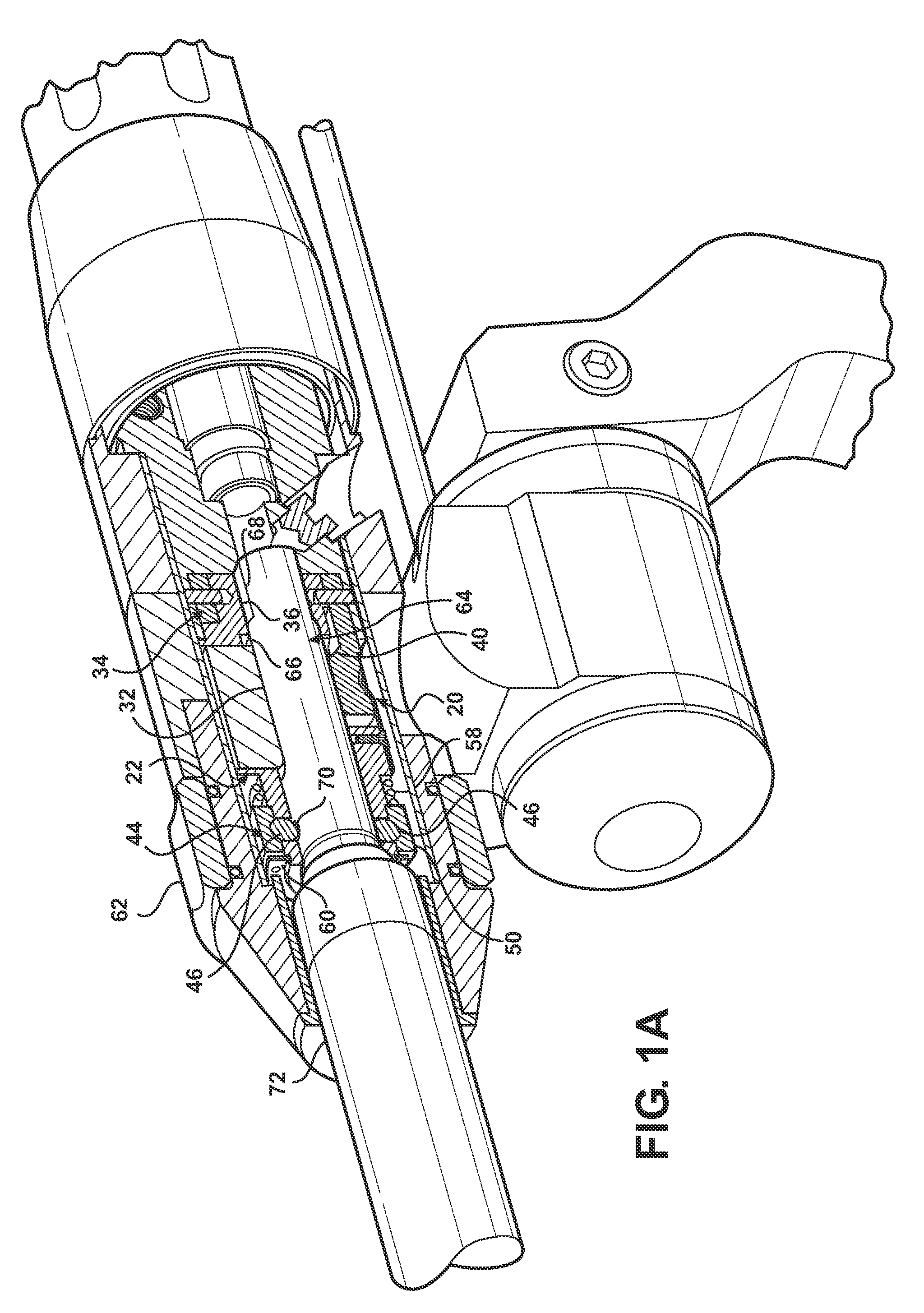

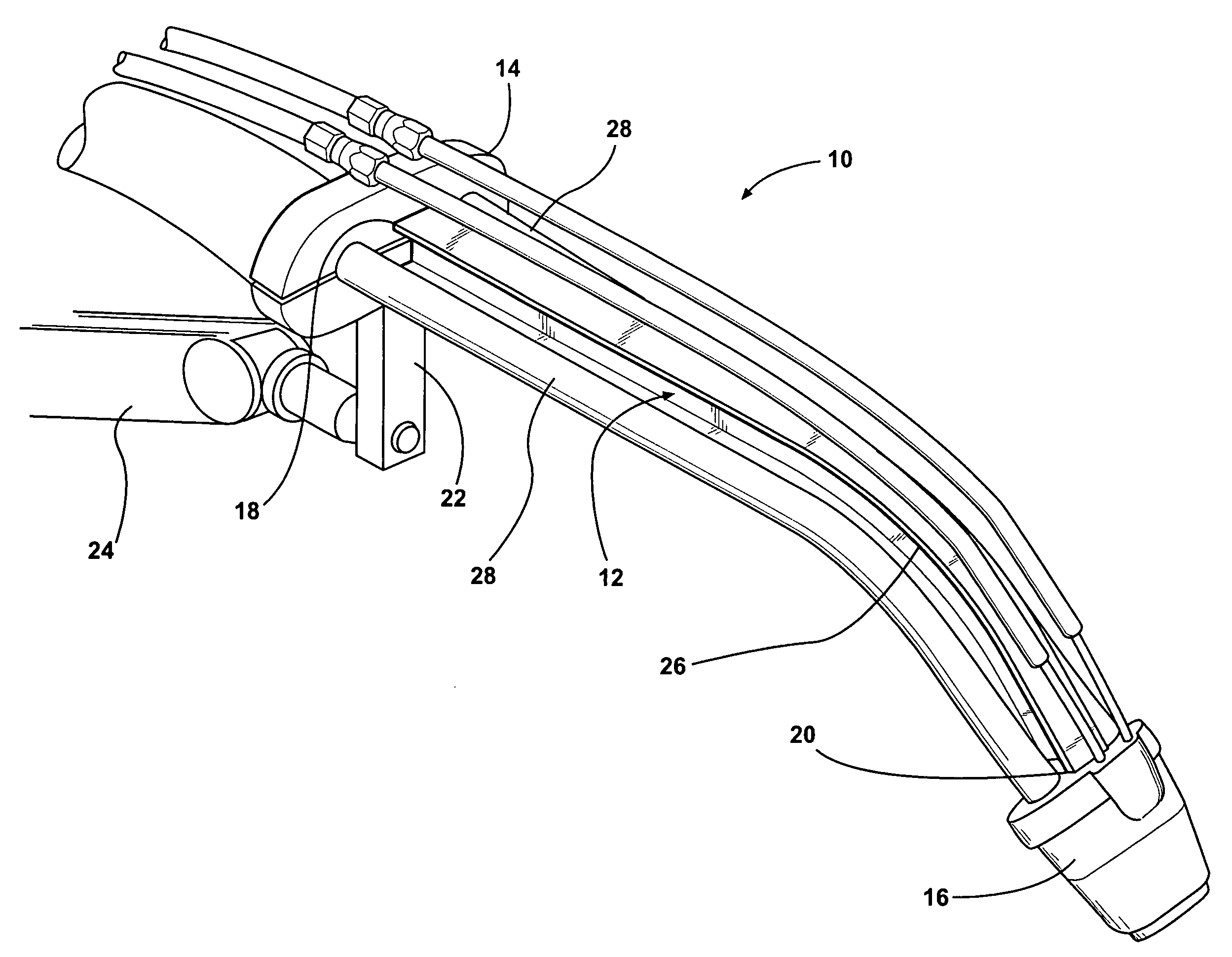

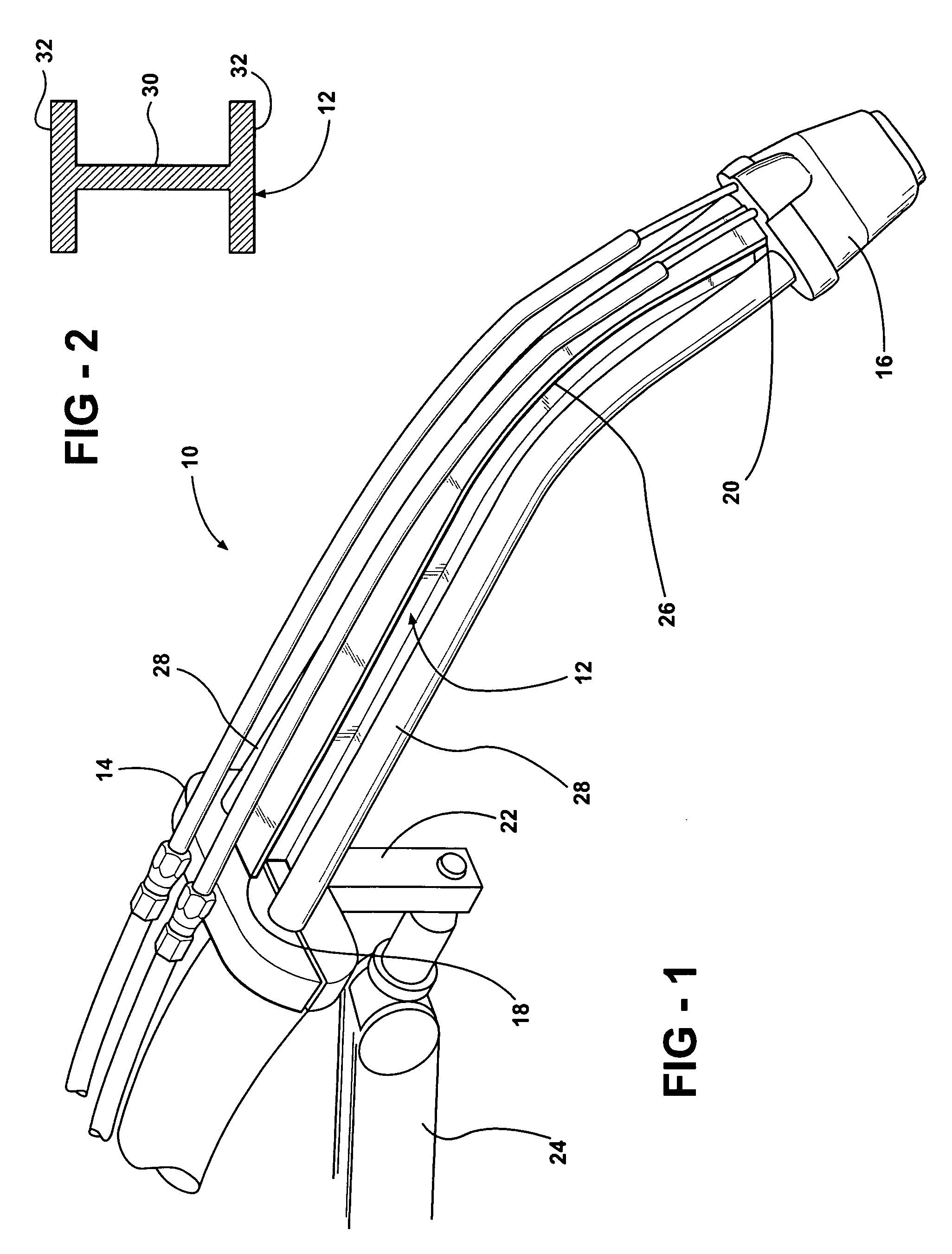

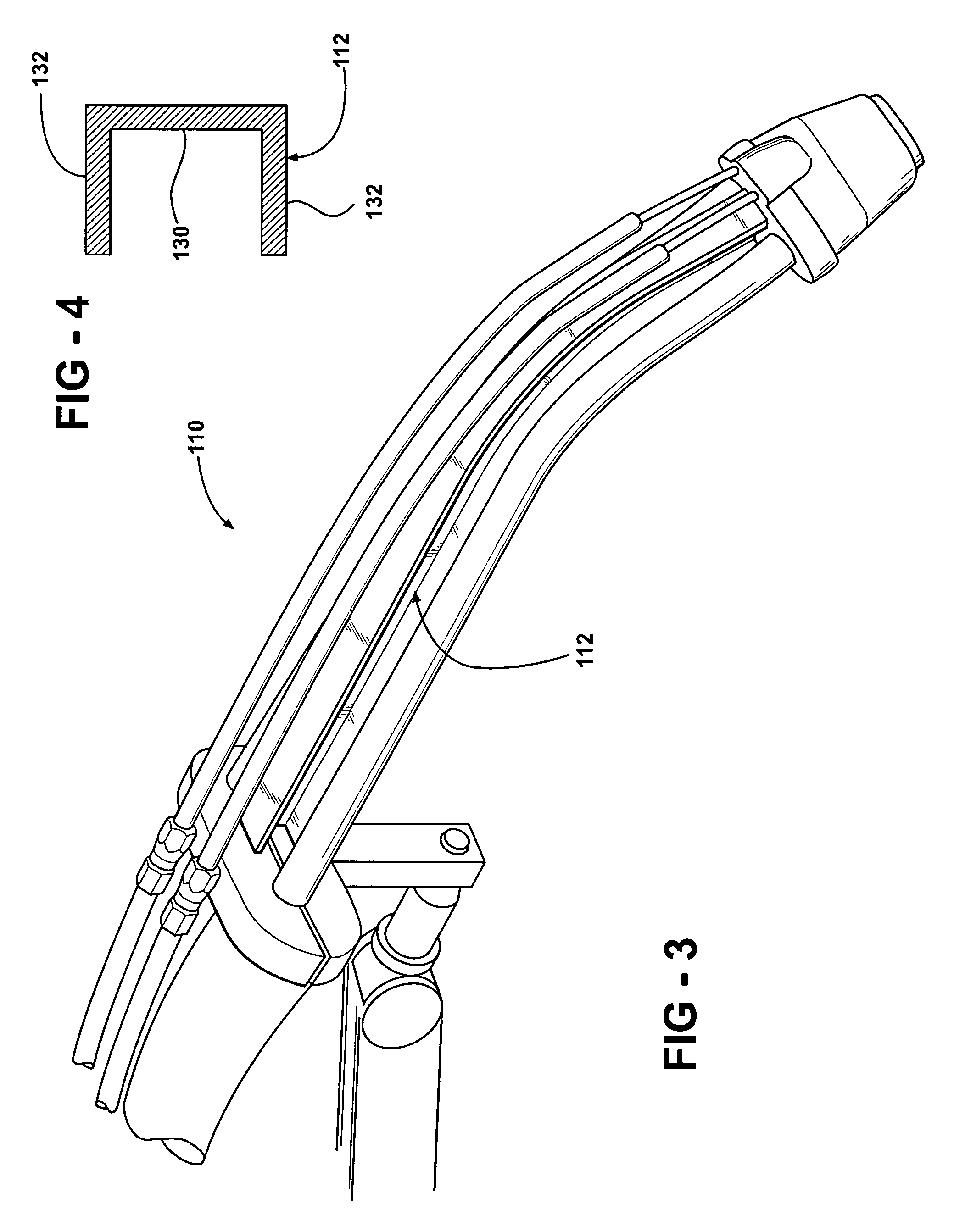

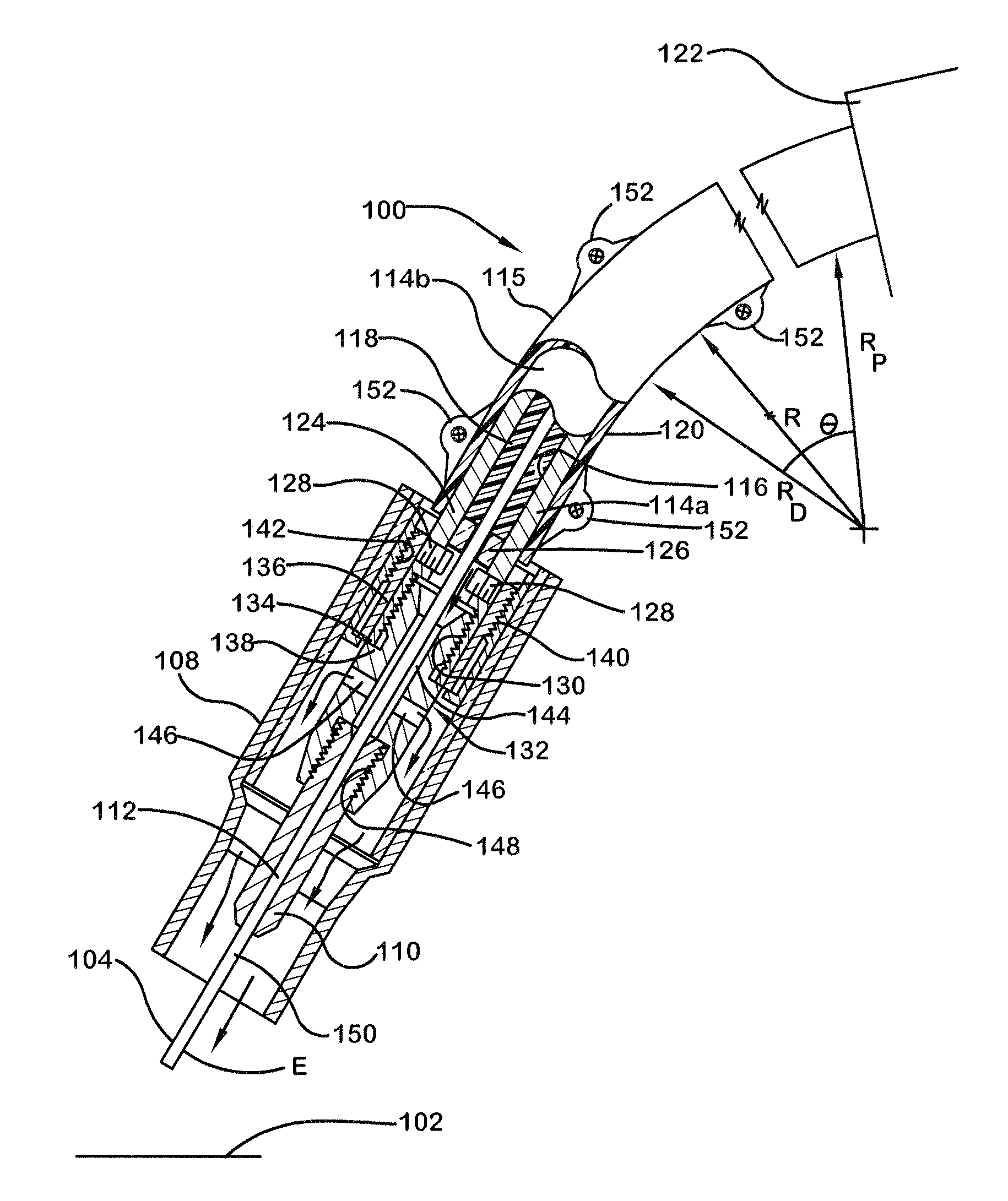

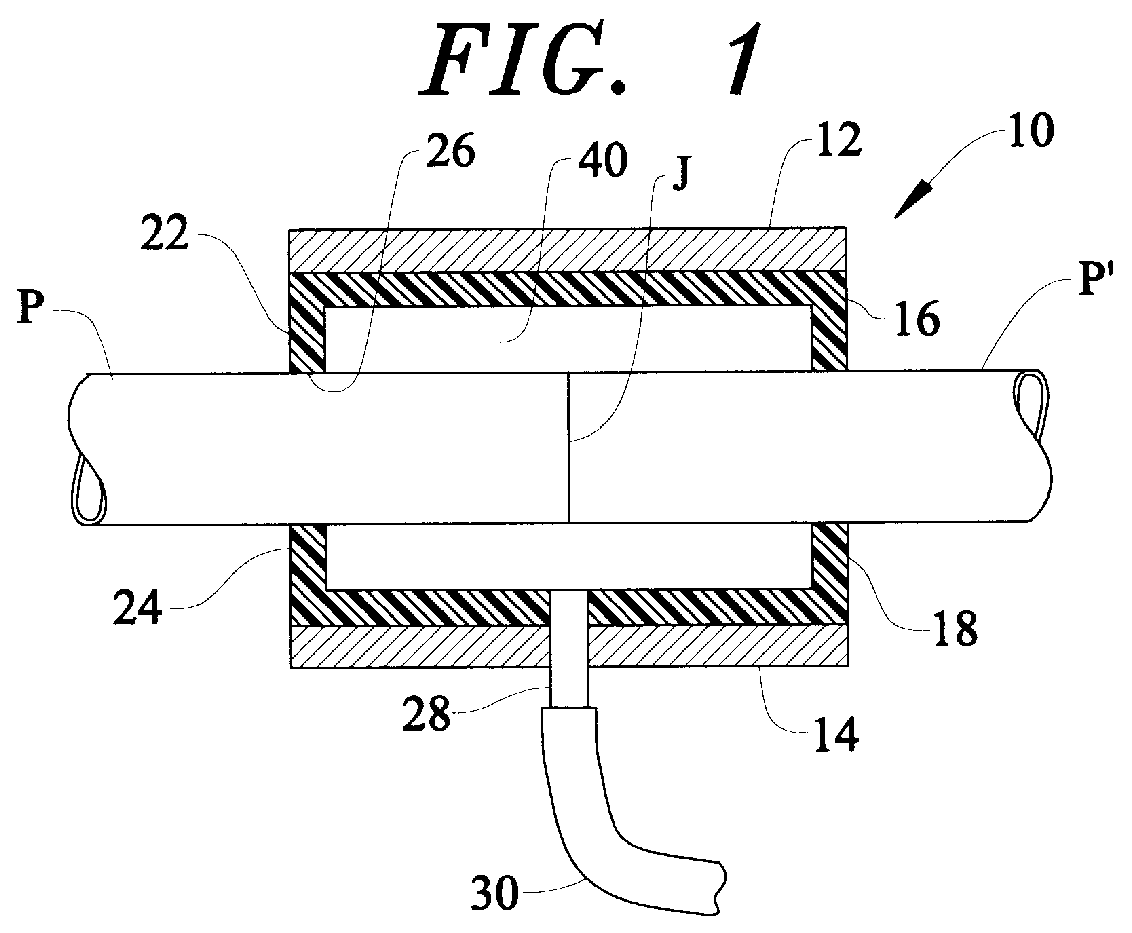

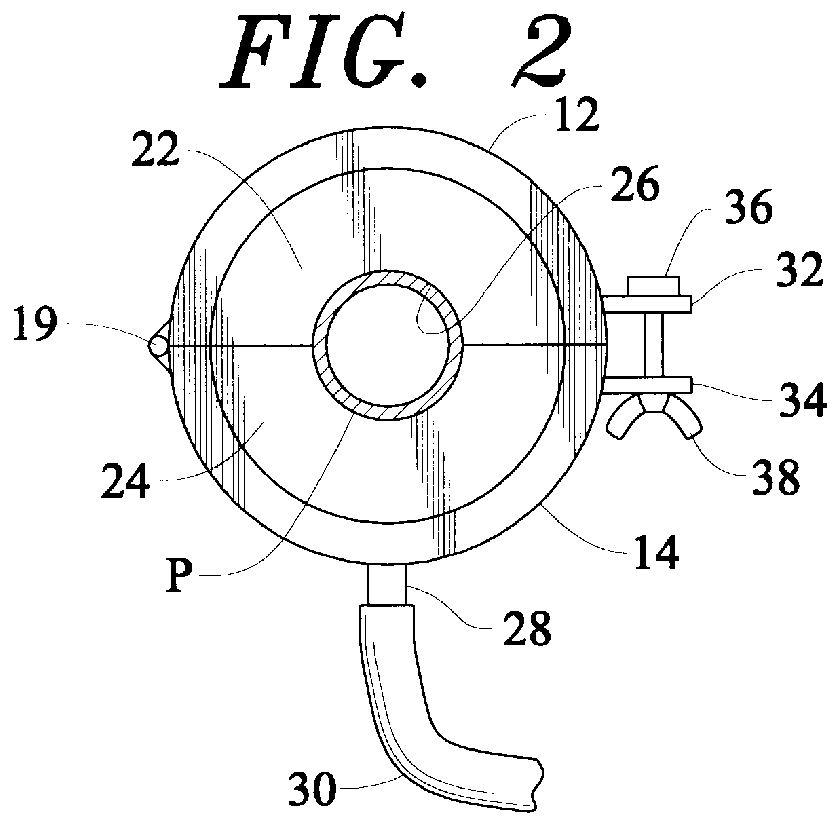

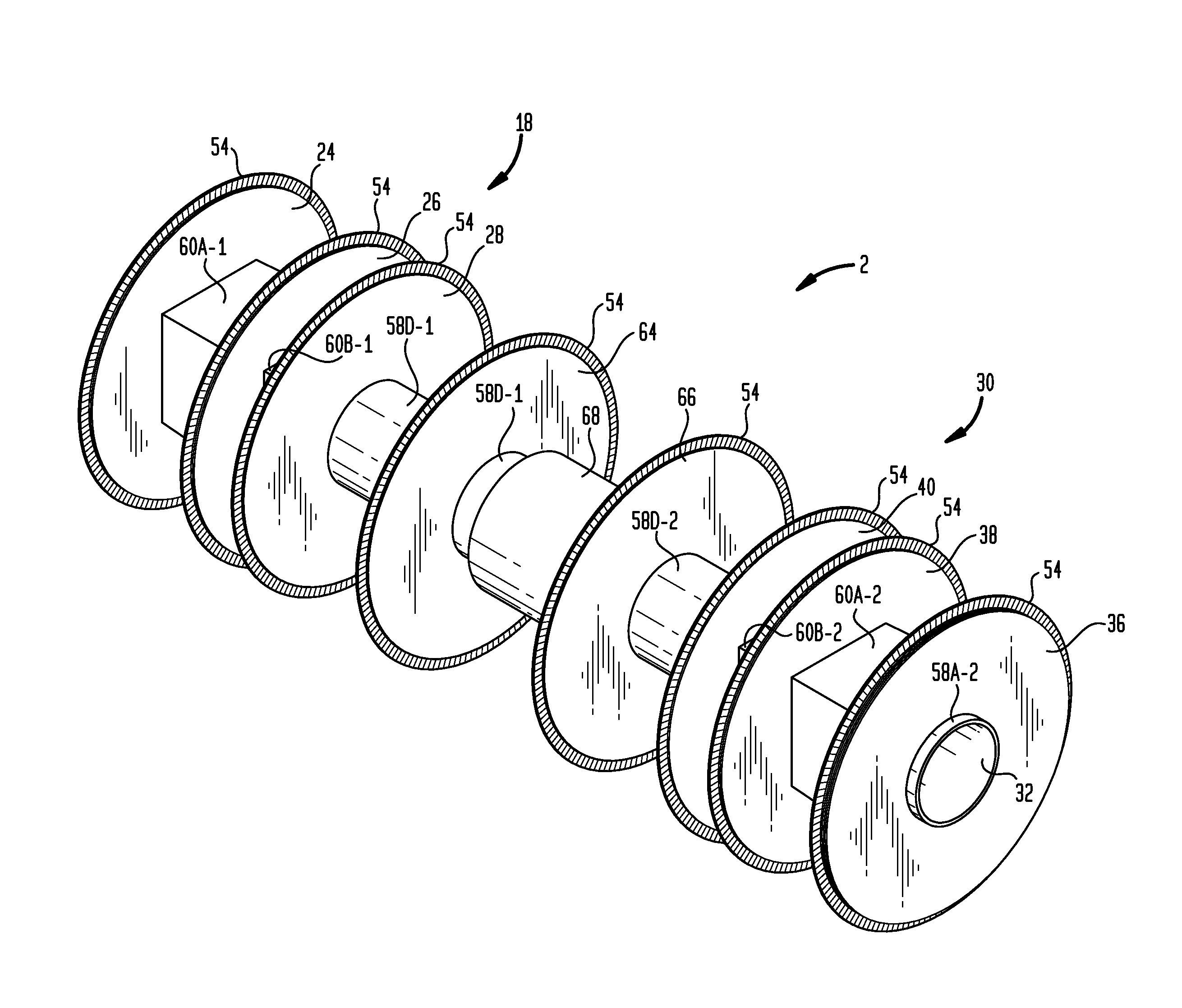

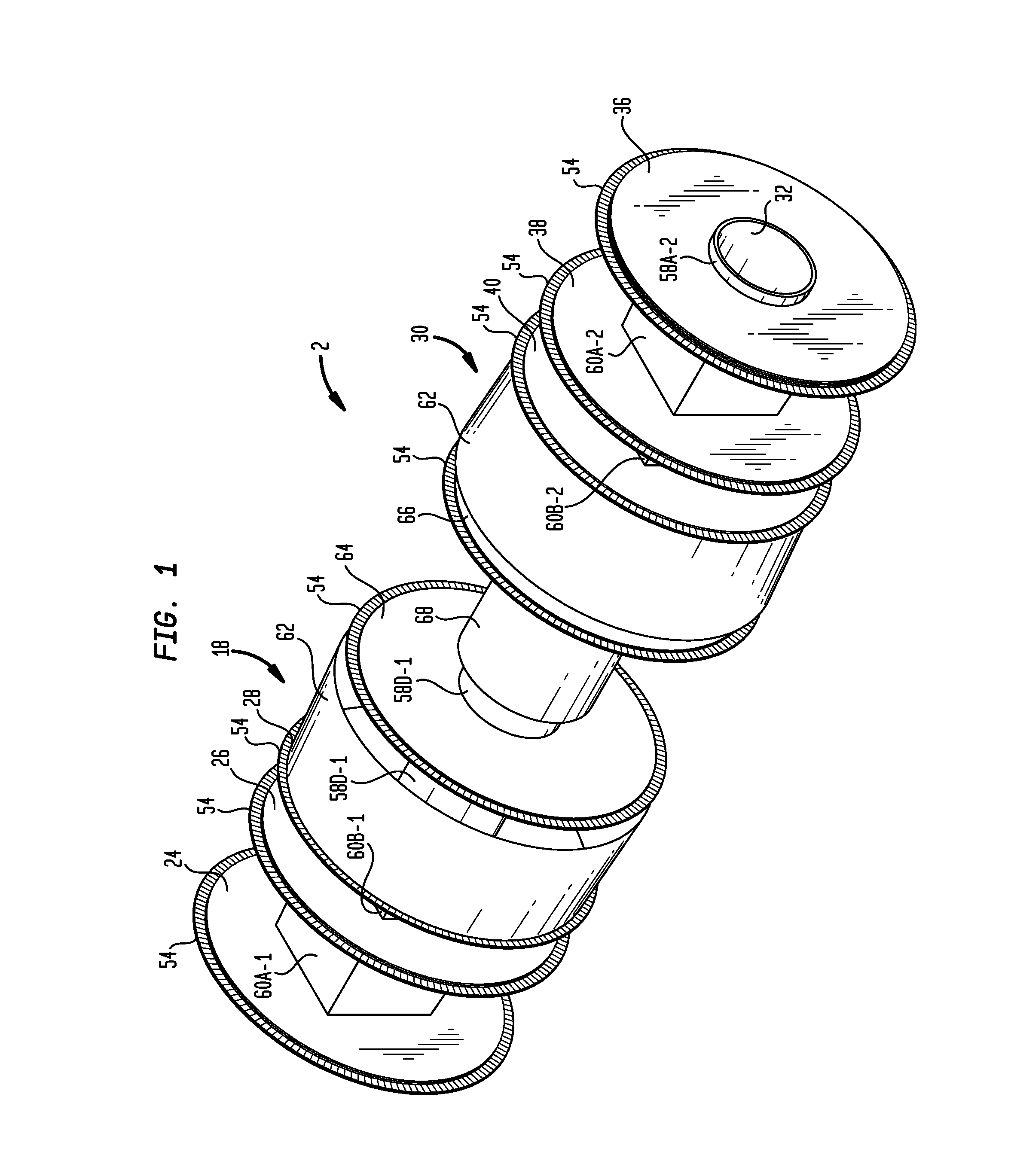

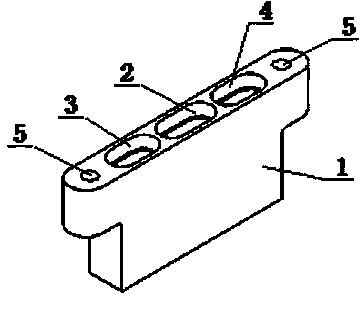

Robotic gmaw torch with quick release gooseneck locking mechanism, dual alignment features, and multiple electrical contacts

InactiveUS20100012637A1Increased durabilityImprove consistencyShielding gas supply/evacuation devicesSupport devices with shieldingLocking mechanismDetent

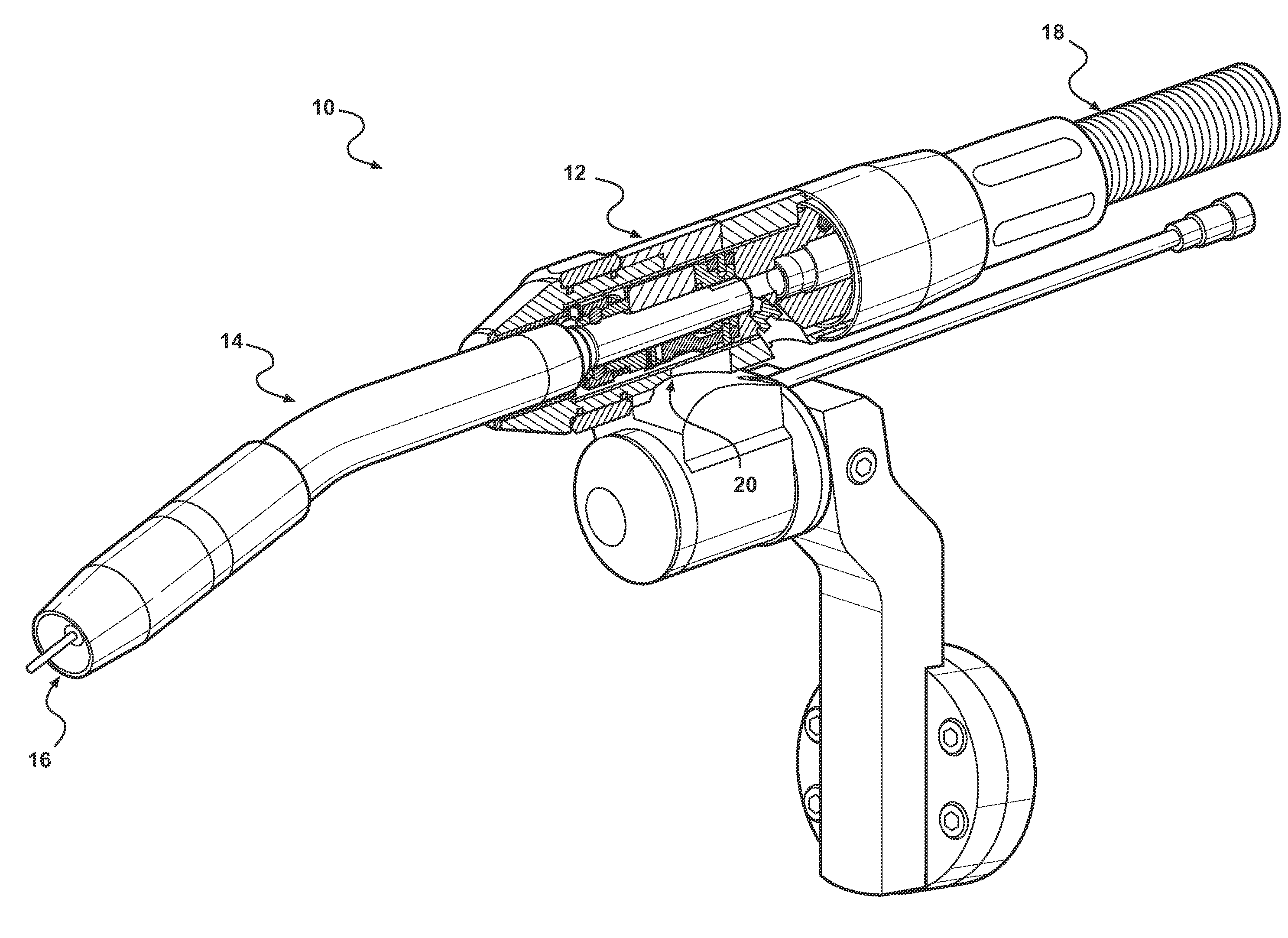

A gooseneck locking mechanism for a robotic GMAW torch having a torch body and a gooseneck includes a connector receiver disposed in the torch body. The connector receiver includes longitudinal ends and a passageway extending between the longitudinal ends. An indexing feature is disposed in the passageway. An elongated connector is mountable on a proximal end of the gooseneck. The connector includes a cooperable indexing feature. The locking mechanism further includes a detent for joining the connector receiver and the elongated connector. The indexing features align the gooseneck relative to the torch body, and the detent secures the connector in the connector receiver for quick release. The locking mechanism may include a plurality of electrical contacts in the connector receiver that are engageable with the connector to provide flow of electrical current through the connector receiver to the gooseneck.

Owner:ILLINOIS TOOL WORKS INC

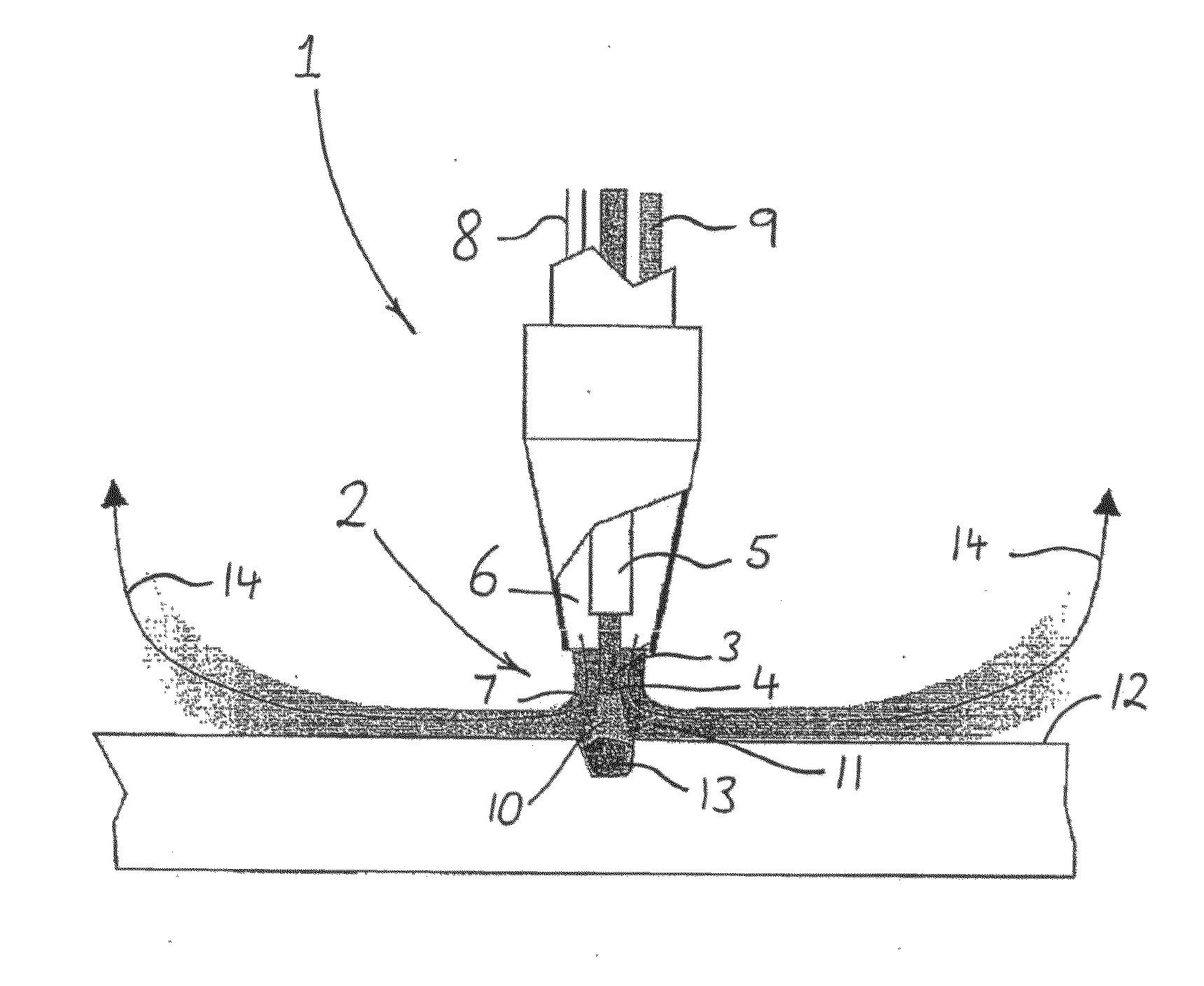

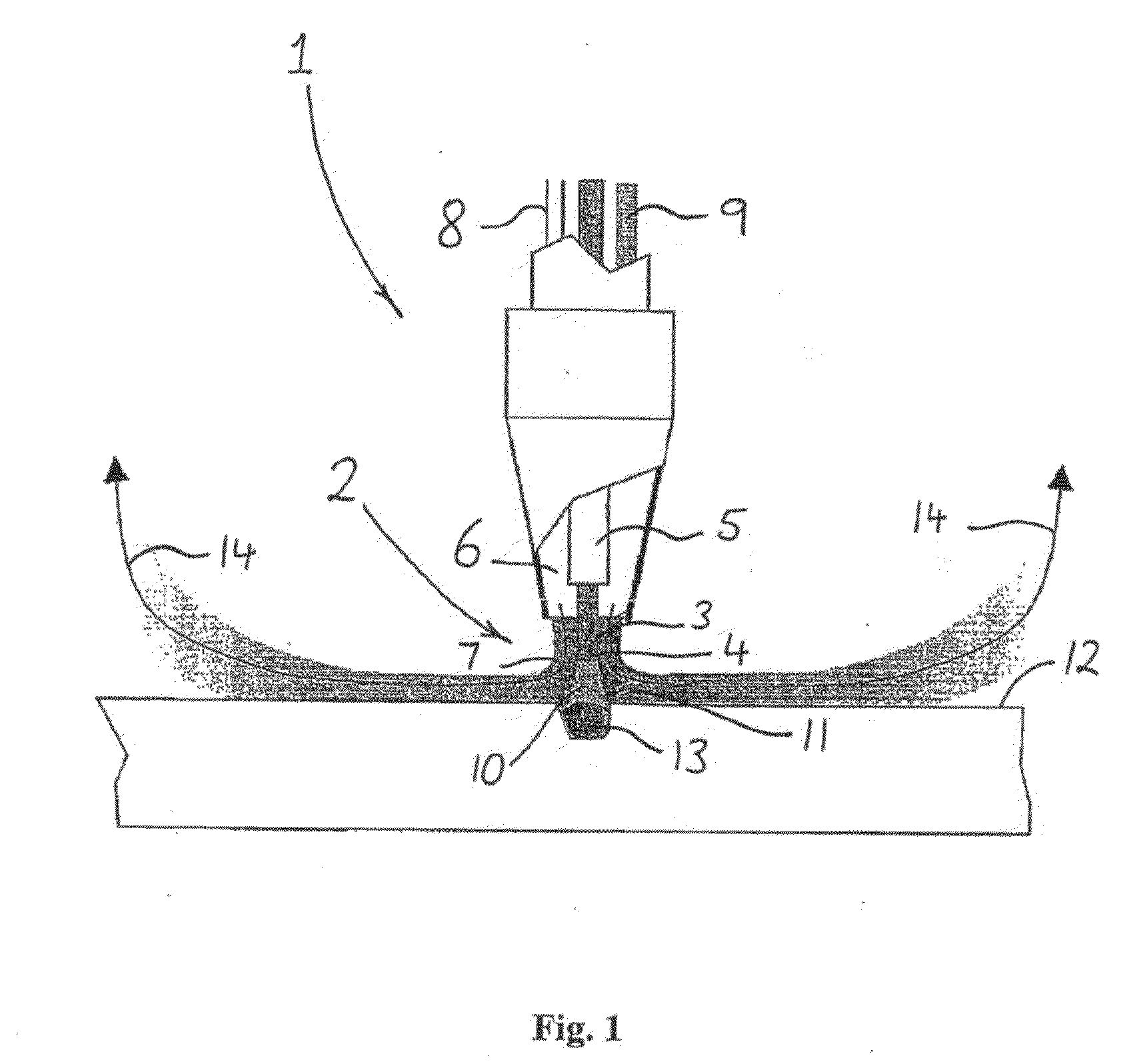

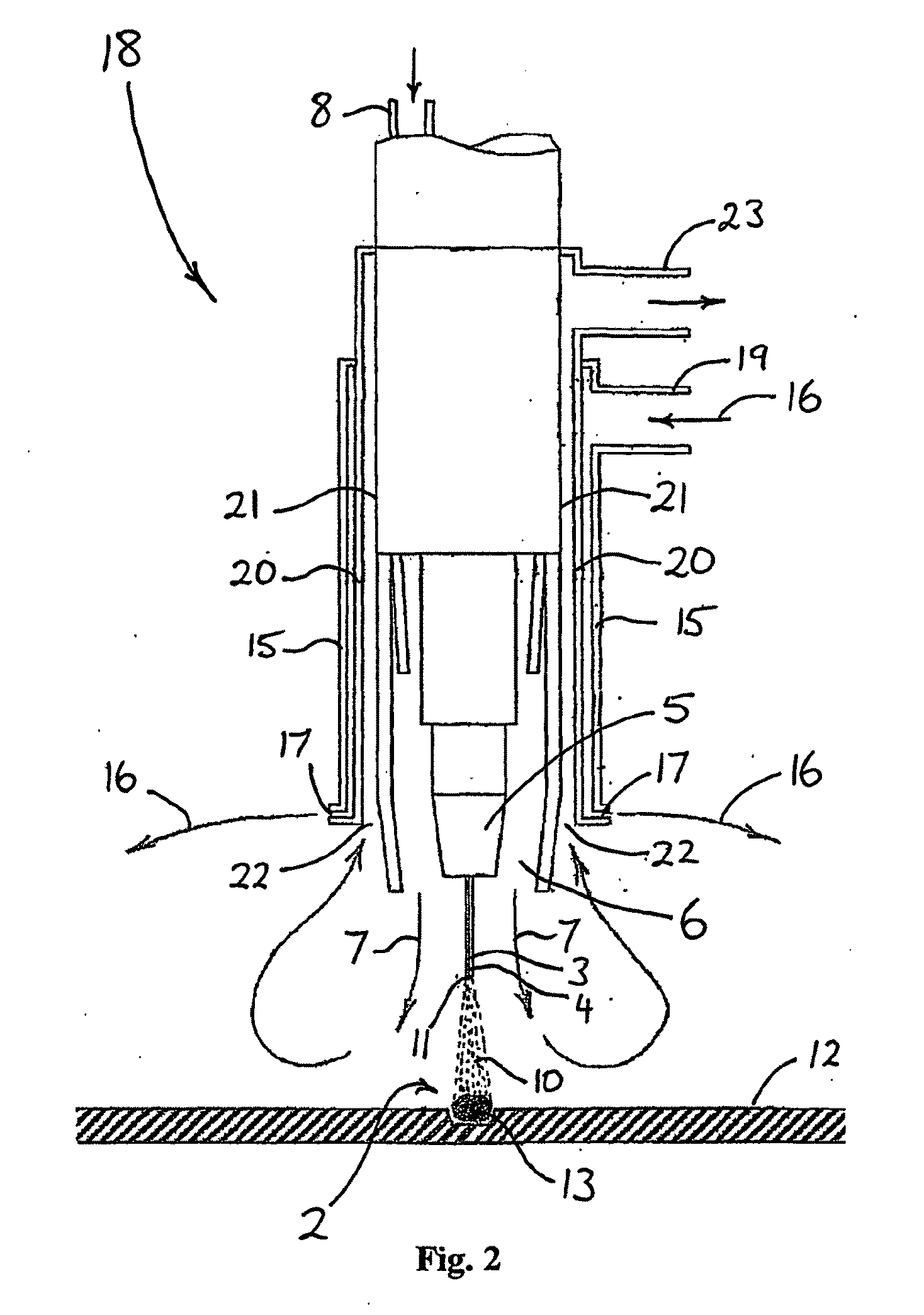

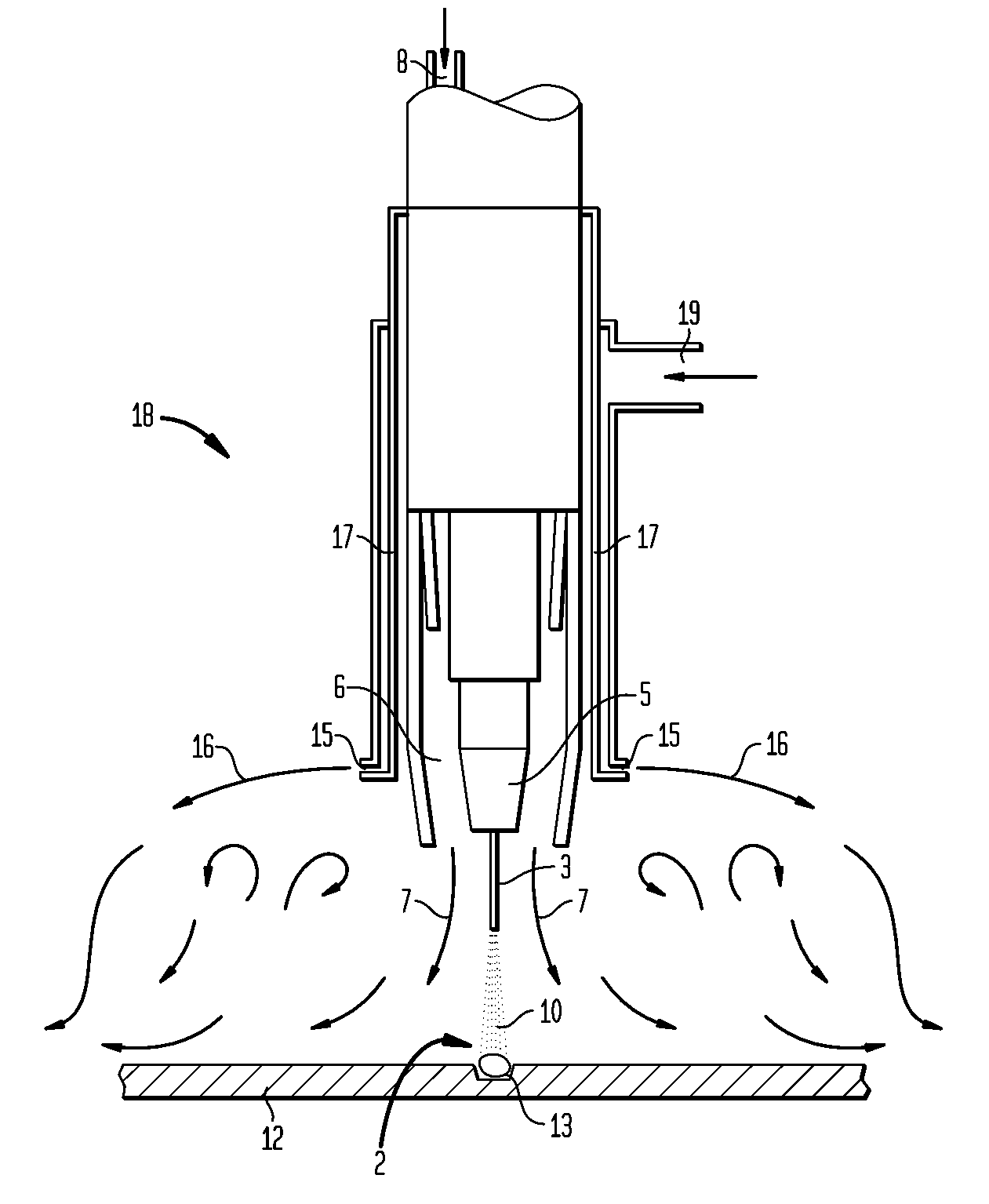

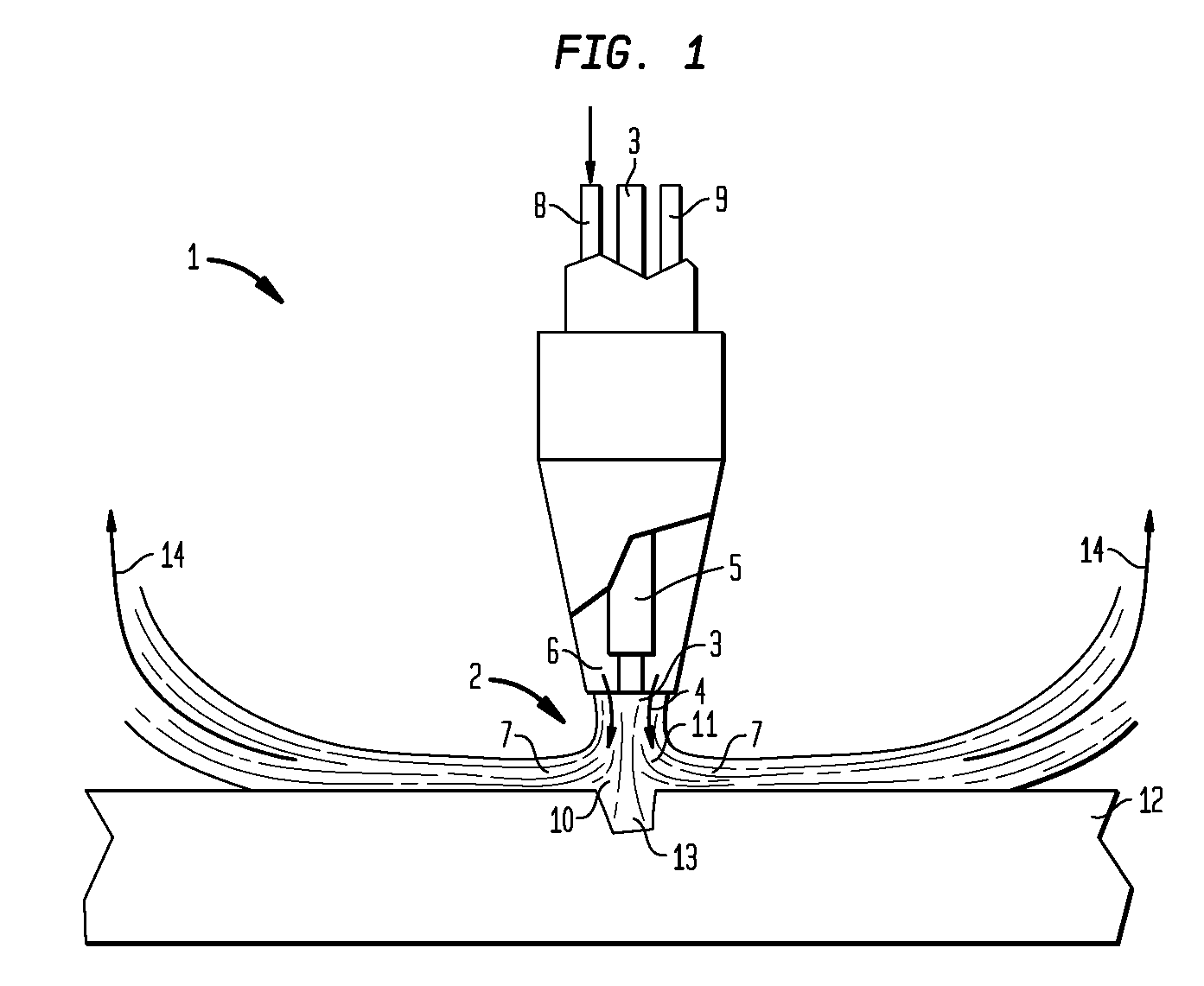

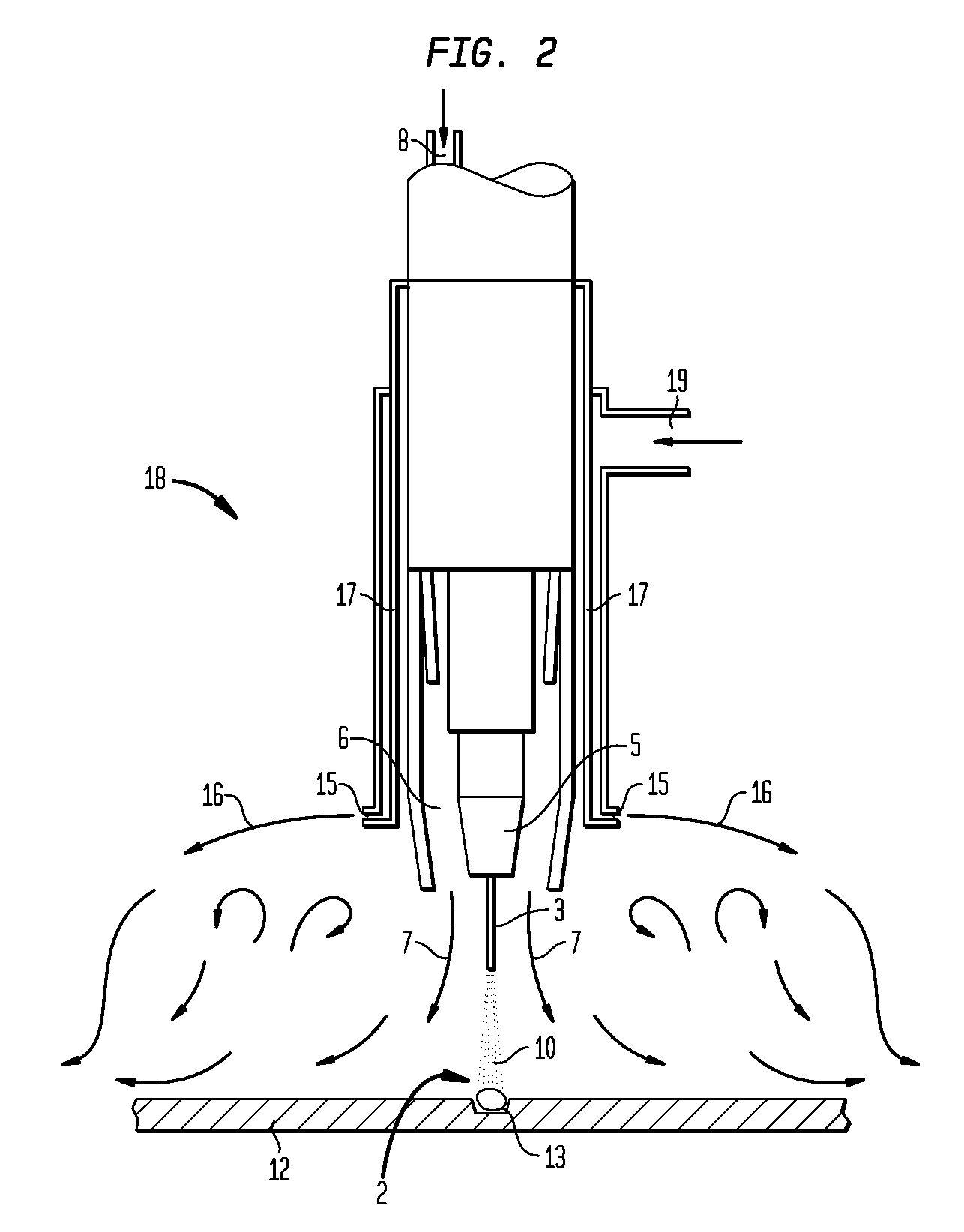

Apparatus and method for welding

InactiveUS20100276396A1Improve smoke extraction efficiencyFine-tune fume extraction efficiencyShielding gas supply/evacuation devicesDirt cleaningShielding gasCarbon Dioxide / Helium

The present invention relates to arc welding torch and a method of extracting fume gas from a welding site. The torch comprises a metal electrode and at least one shield gas port adapted to direct a shield gas curtain around the metal electrode and a welding site. At least one shroud gas port is spaced radially outward from the shield gas port and adapted to impart to an exiting shroud gas a radially outward component of velocity. Fume gas is preferably extracted from a position radially intermediate the shield gas curtain and the shroud gas curtain.

Owner:COOPER PAUL +2

System and method for data communications over a gas hose in a welding-type application

ActiveUS7247814B2Shielding gas supply/evacuation devicesElectric discharge heatingLine tubingCommunications system

Owner:ILLINOIS TOOL WORKS INC

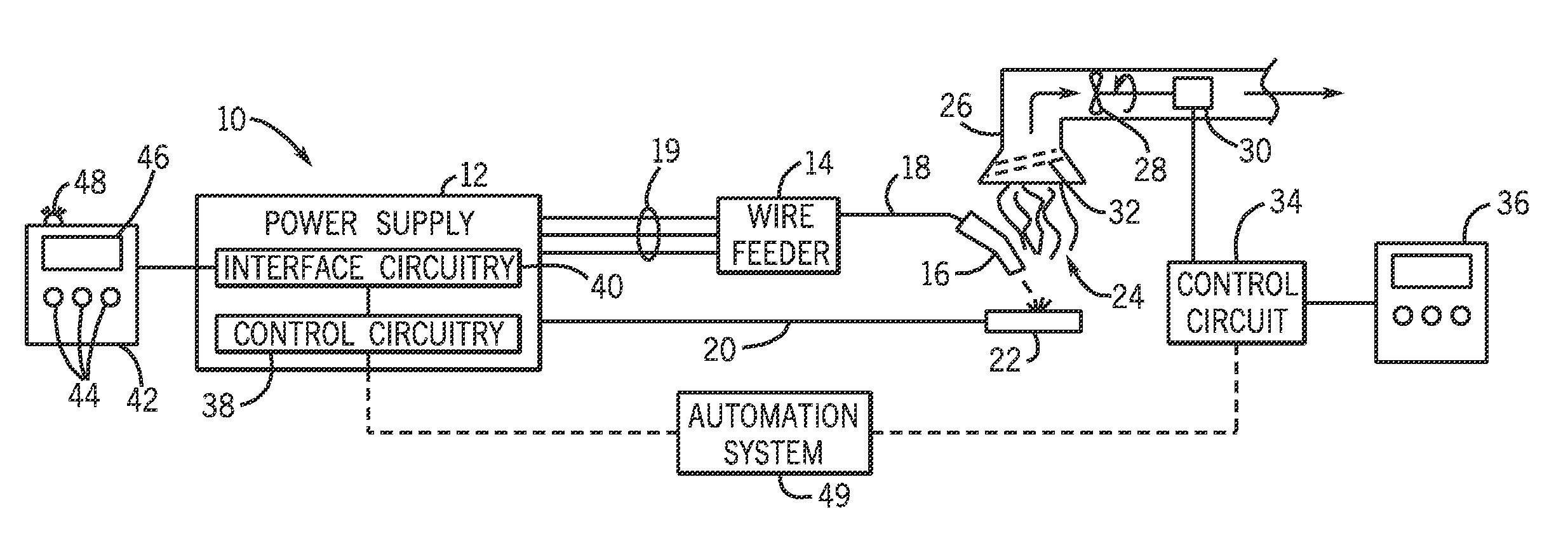

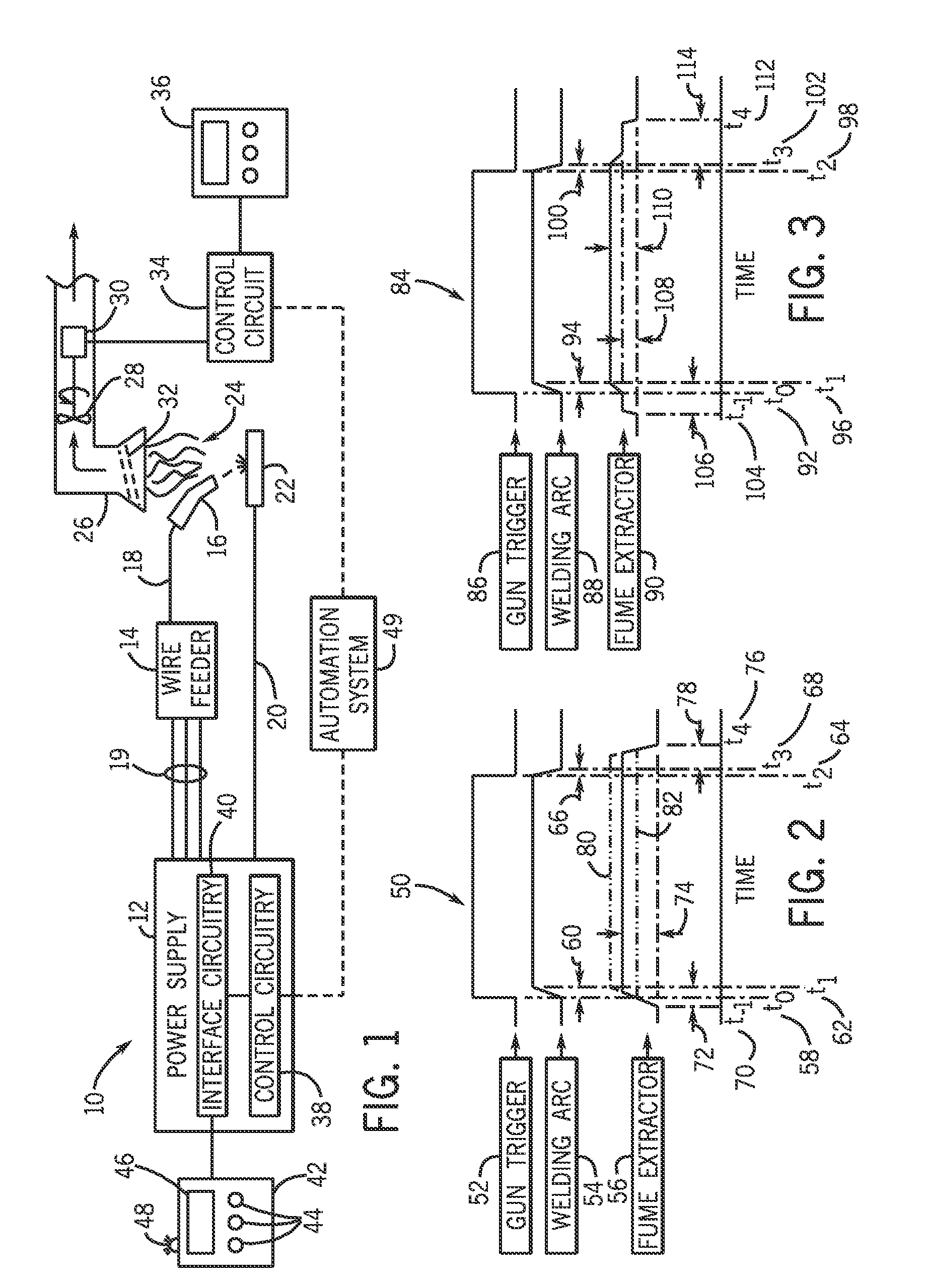

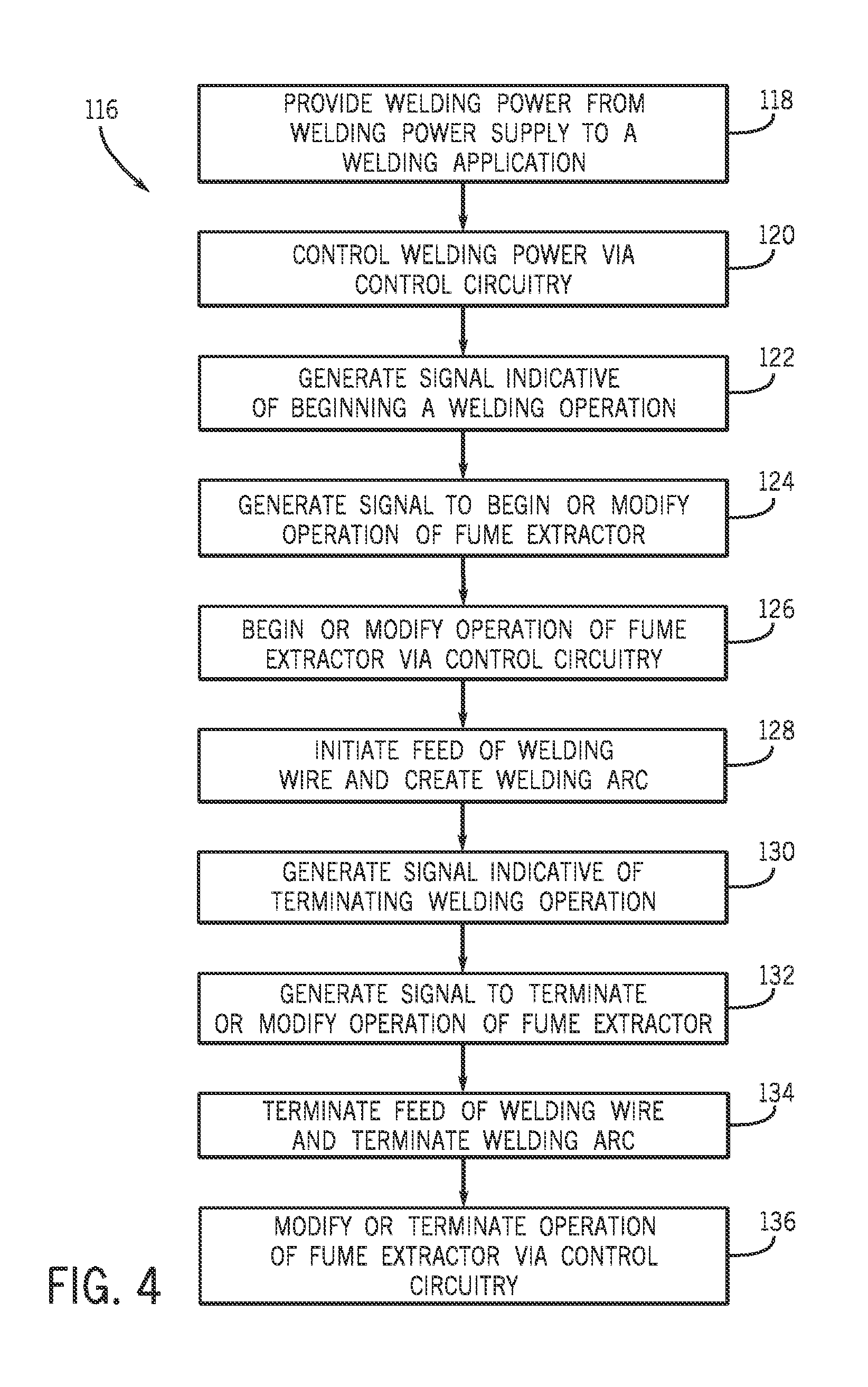

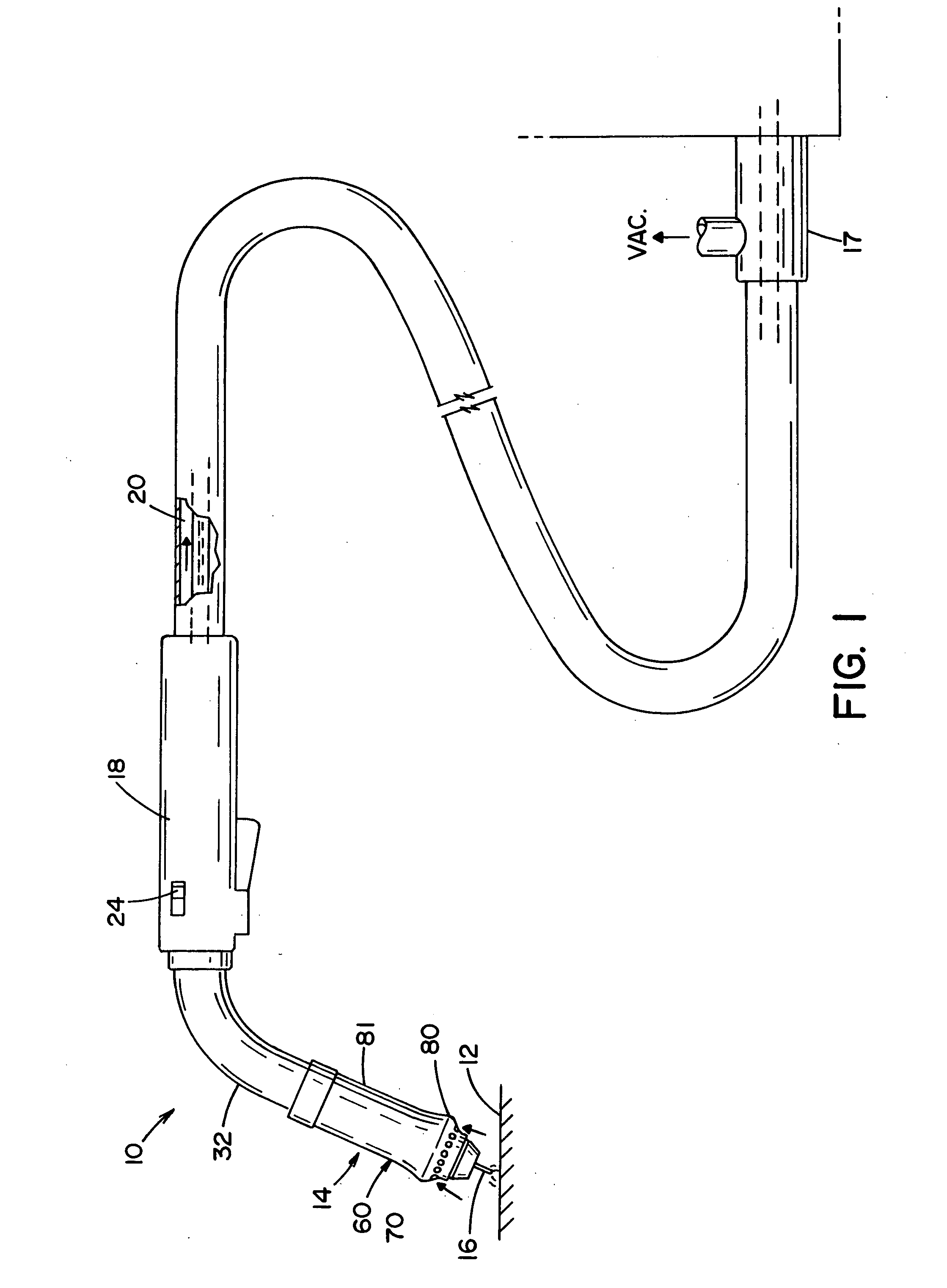

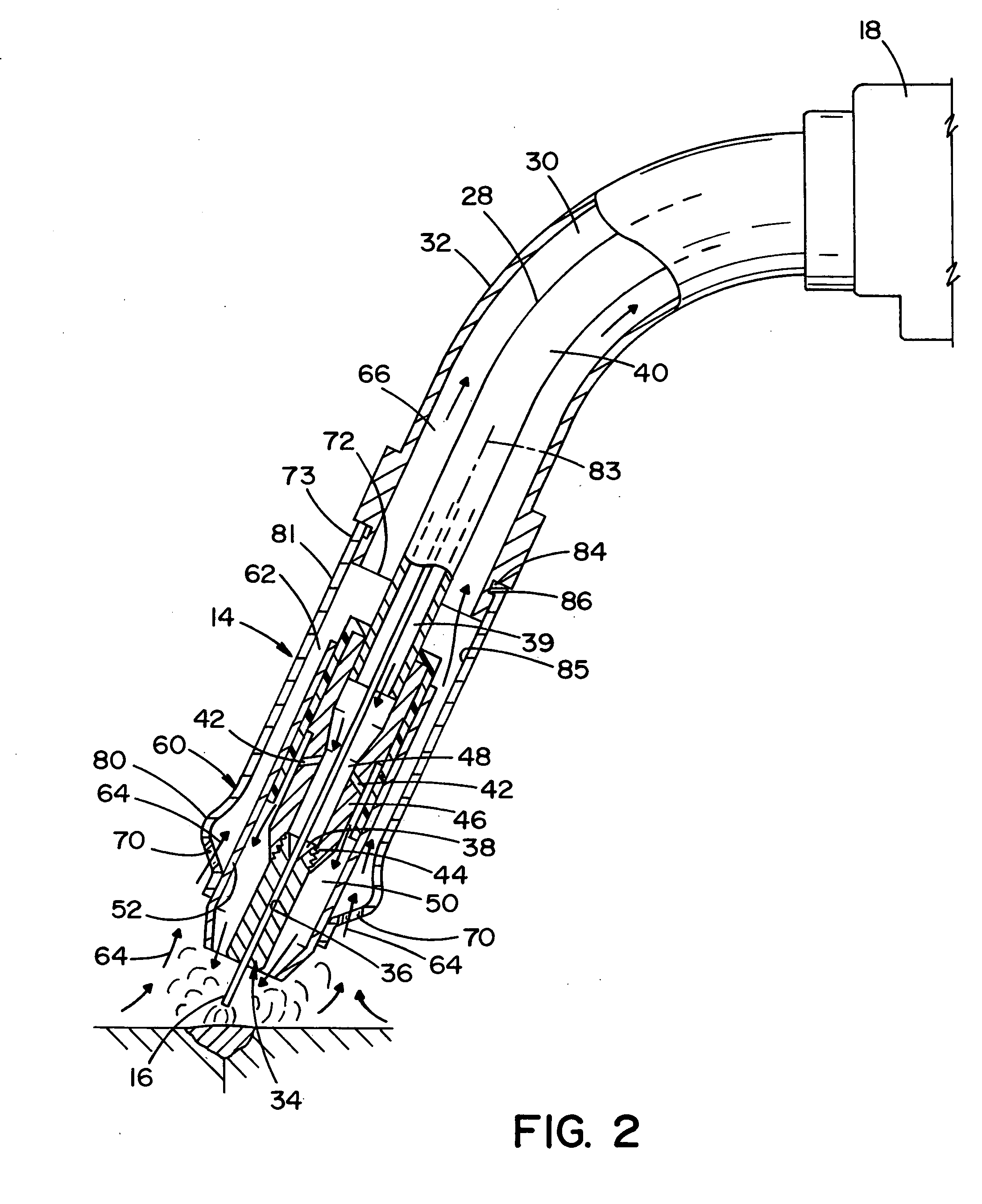

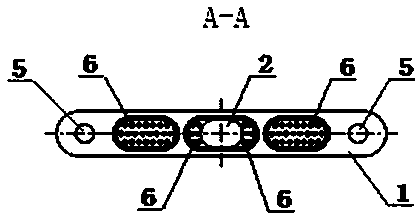

Fume extractor for welding applications

A welding system having a welding power supply coupled to a fume extractor is provided. The fume extractor may be coupled to control circuitry configured to operate the welding power supply. The control circuitry may be configured to begin, terminate or modify the operation of the fume extractor prior to the establishment of a welding arc, after the termination of the welding arc, or both. The control circuitry may be further configured to modify the operation of the fume extractor based upon a type of welding process used.

Owner:ILLINOIS TOOL WORKS INC

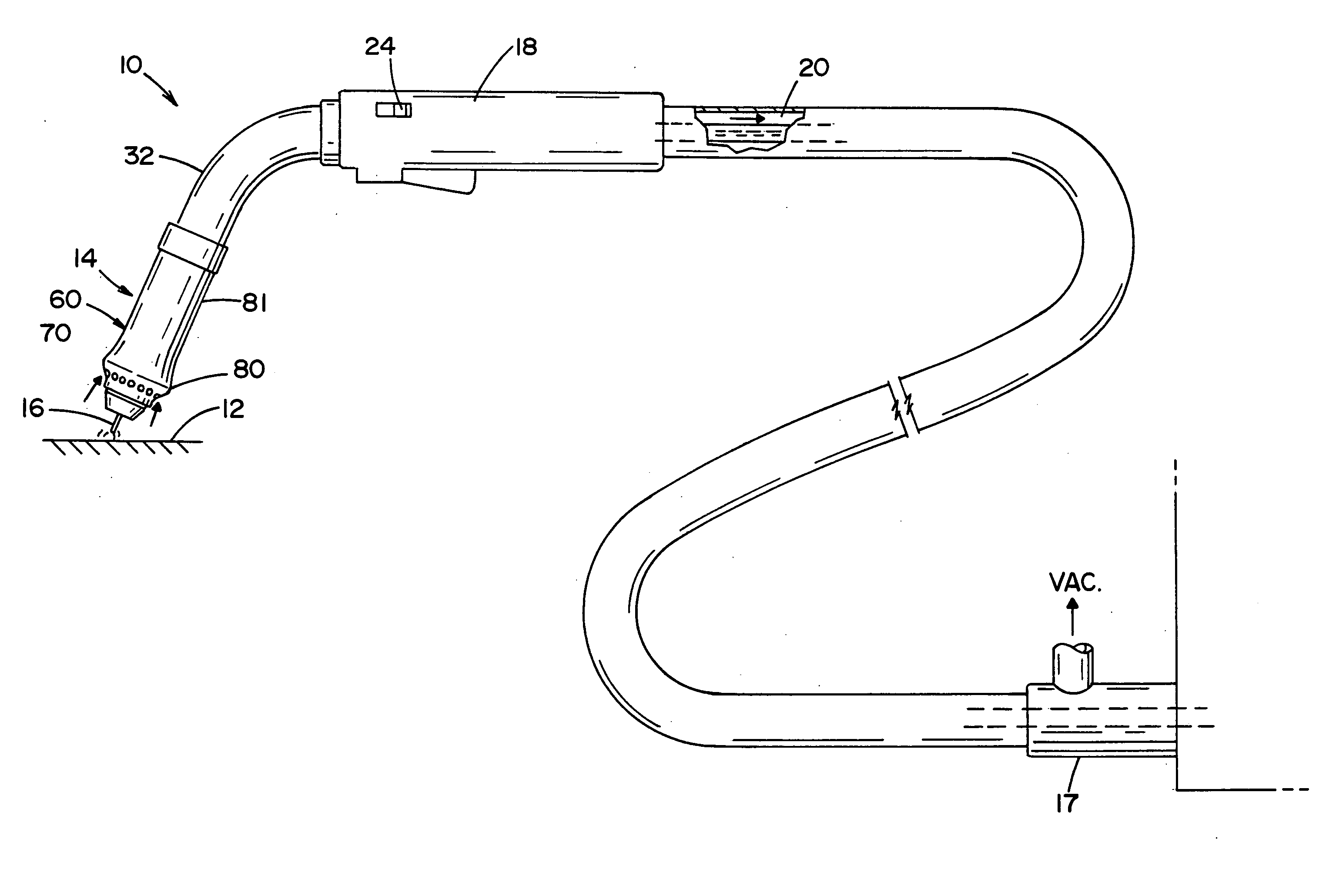

Fume gun

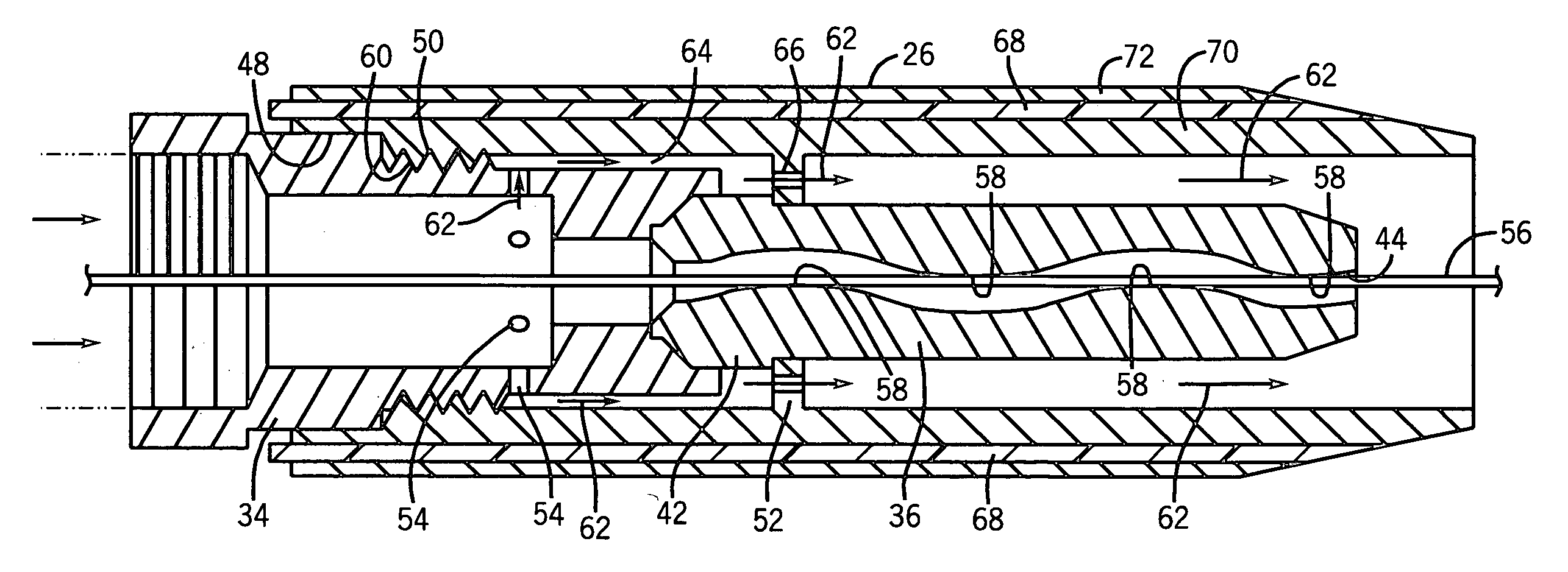

ActiveUS20060226136A1Efficient drawingCools fumeShielding gas supply/evacuation devicesDirt cleaningTorchAmbient air

A torch for use in welding operations during which smoke and / or fumes are created has a nozzle and a handle connected to a conduit extending between the handle and the nozzle. A fume extraction duct extends from the nozzle and through the handle. An annular member surrounds the axial end of the nozzle and has a plurality of openings oriented such that fumes and ambient air are extracted in a direction substantially parallel to the longitudinal axis of the nozzle. A switch is provided to control fume extraction between a full flow rate and a partial flow rate.

Owner:LINCOLN GLOBAL INC

Contact tip and assembly

InactiveUS20080035623A1Extended contact lifeLow densityShielding gas supply/evacuation devicesElectrode supporting devicesManufacturing technologyConductive materials

A contact tip for a welding torch is provided. In one embodiment, the contact tip includes a body formed of an electrically conductive material and a non-linear passage that extends through the body. The non-linear passage of this embodiment is configured to receive a wire electrode and to facilitate electrical communication between the body and the wire electrode. Various contact tip assemblies and manufacturing techniques for forming contact tips are also provided.

Owner:ILLINOIS TOOL WORKS INC

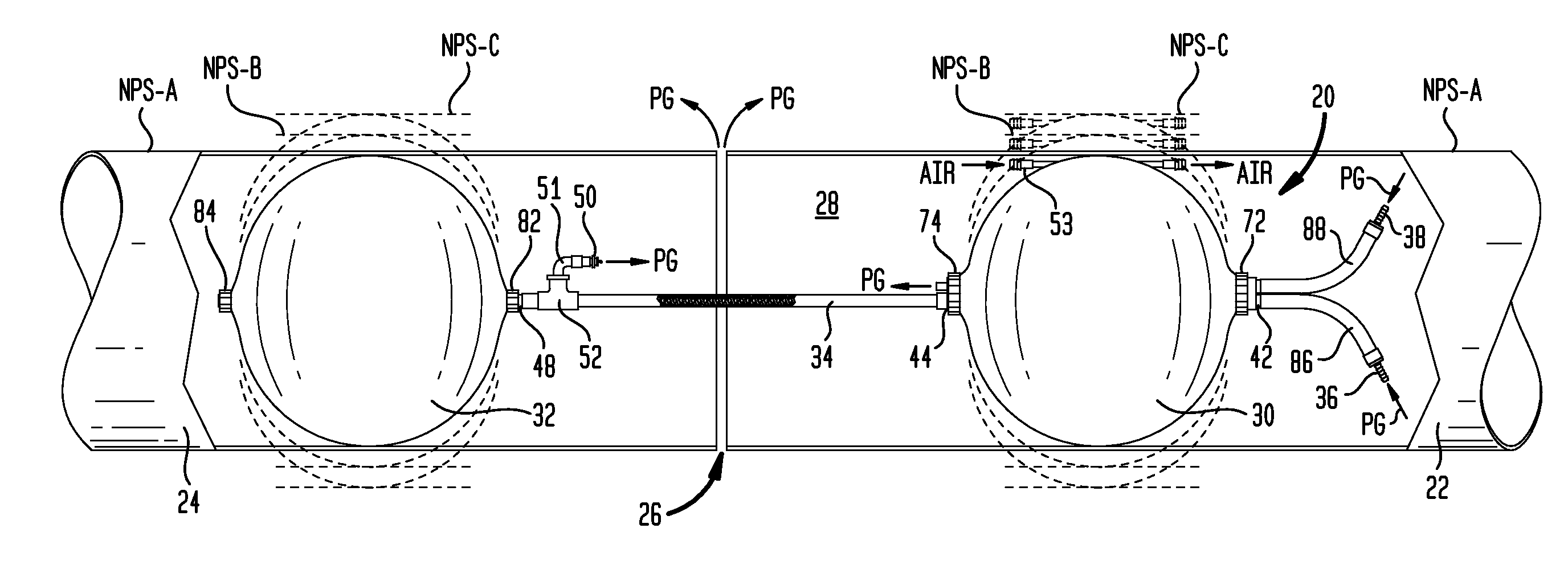

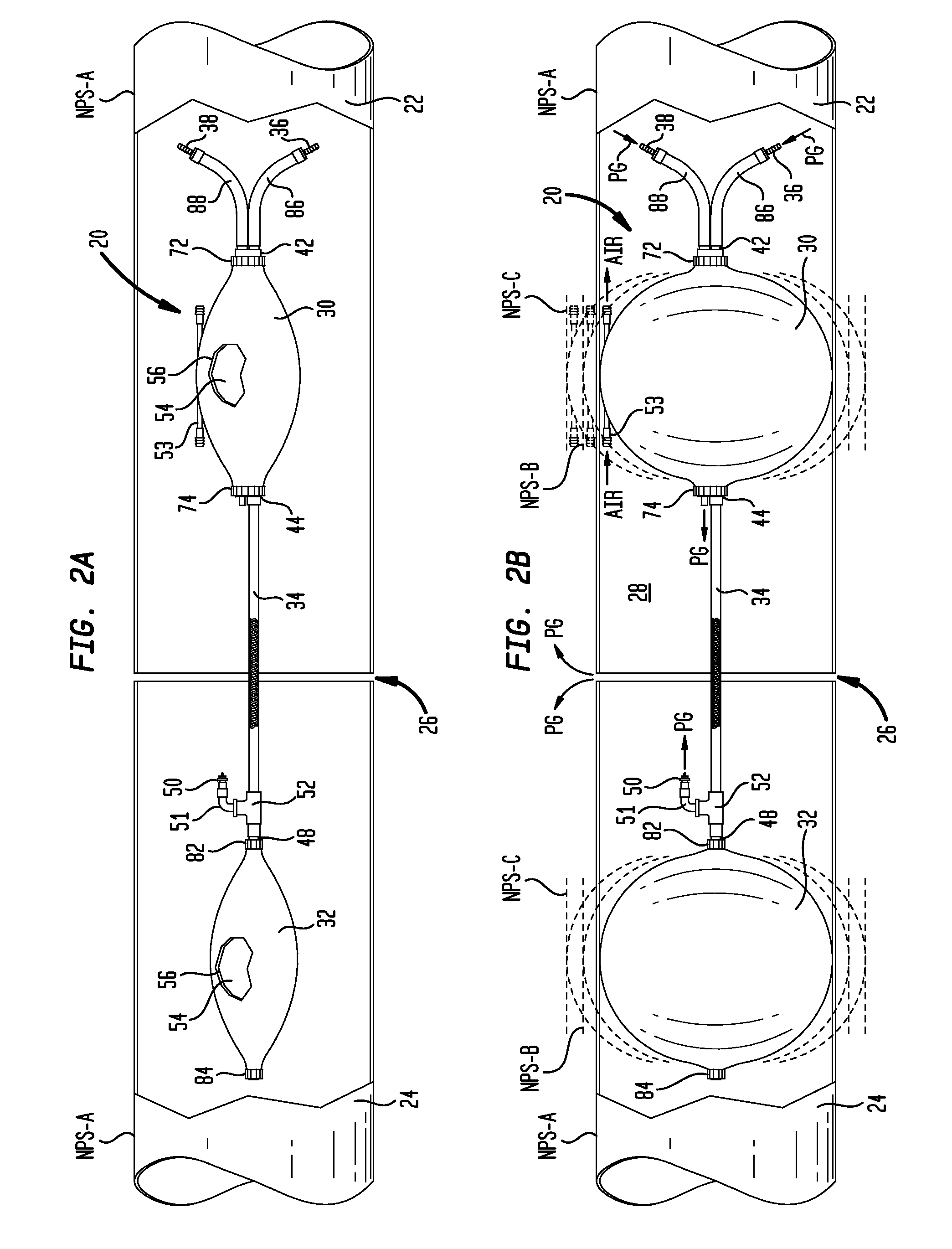

Inflatable Purge Dam Apparatus

ActiveUS20130284297A1Resistant to oxygen leakageMaintaining fluid separationShielding gas supply/evacuation devicesPipe elementsEngineeringAirbag deployment

An inflatable purge dam apparatus for use with pipes of different nominal pipe size (NPS) includes first and second inflatable purge bladders, and an intermediate bridge conduit. In a first aspect, the purge bladders each comprise an expandable inner purge gas retaining liner and a heat-resistant stretchable outer protective cover. The protective covers comprise a heat-resistant stretchable material that is constructed to undergo variable stretching to increase the size of the purge bladders as they are inflated with purge gas to a desired sealing pressure, thereby allowing the purge bladders to form an effective weld zone seal in pipes of different NPS. In a second aspect, an air vent conduit extends between first and second ports located proximate to a longitudinal centerline of the first purge bladder. The air vent conduit provides a vent pathway for venting air from the weld zone through the first purge bladder.

Owner:AQUASOL CORP LLC +1

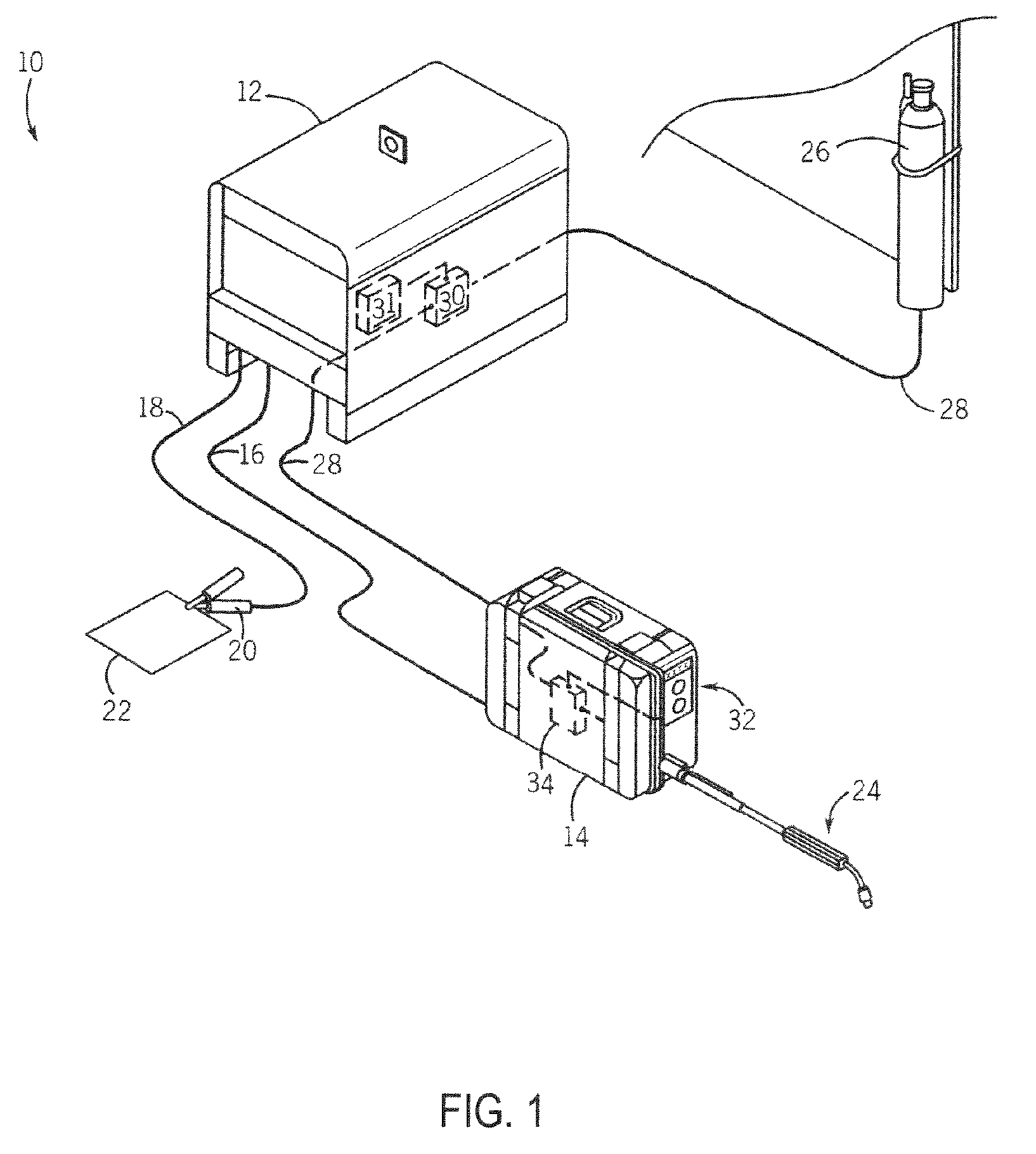

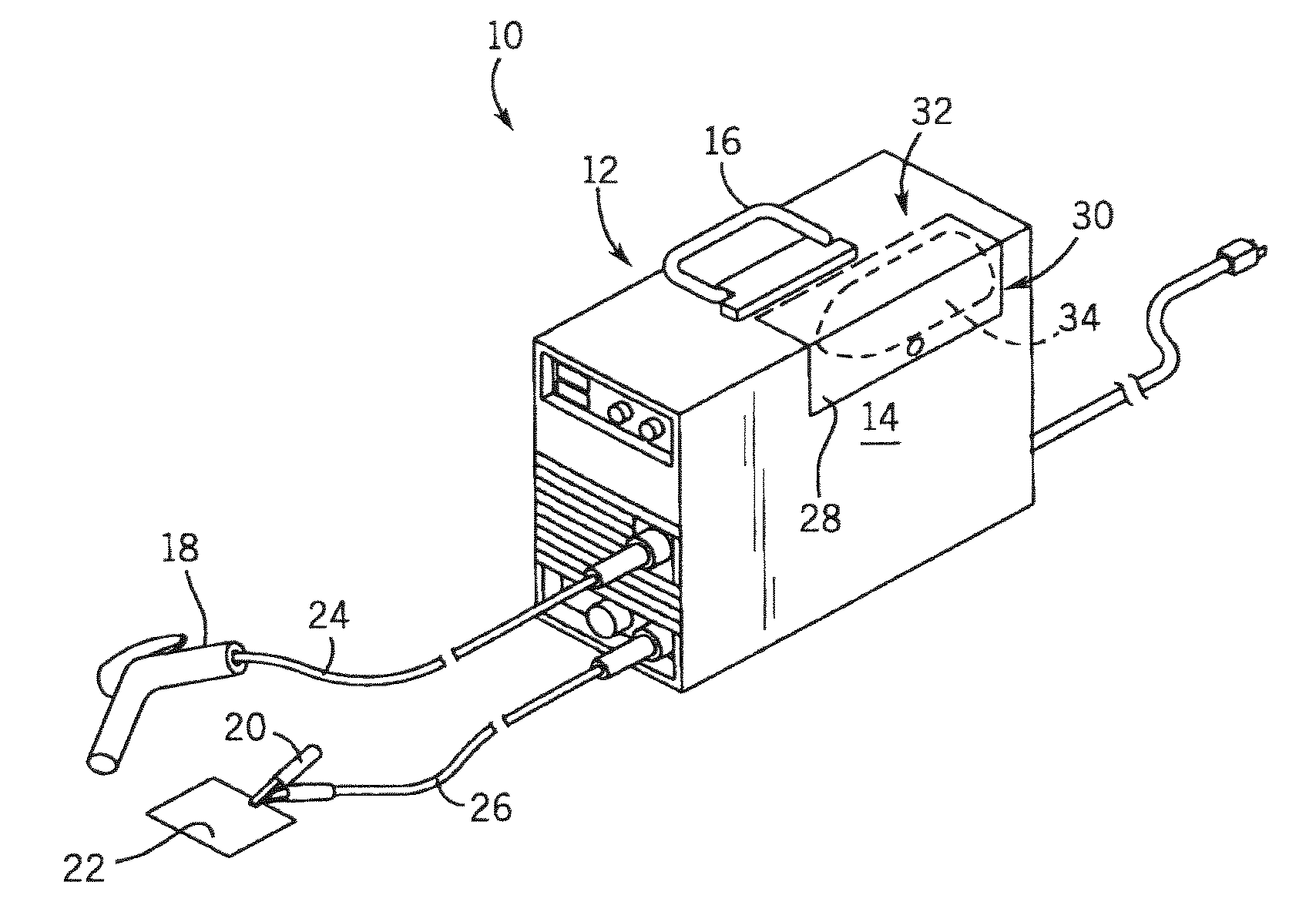

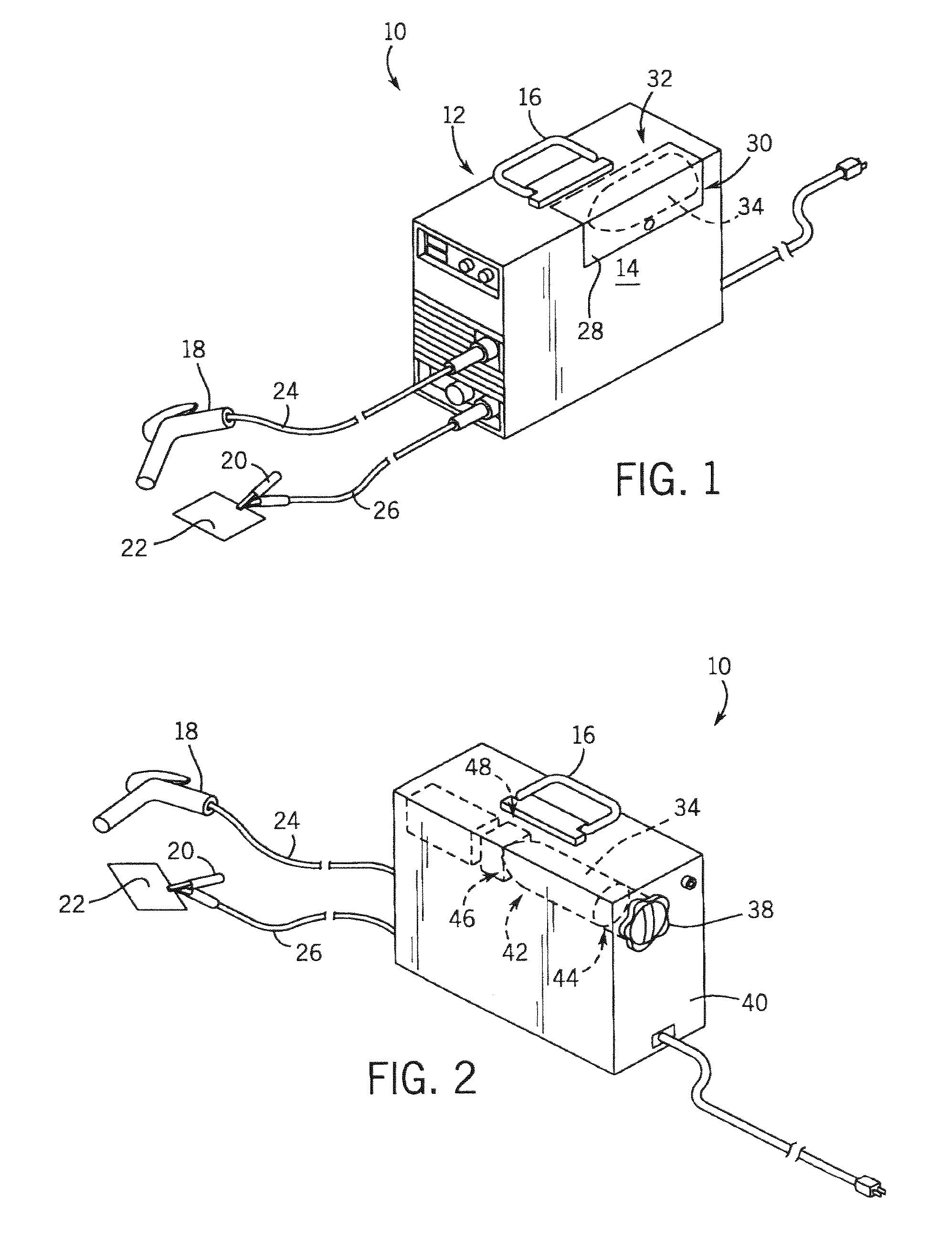

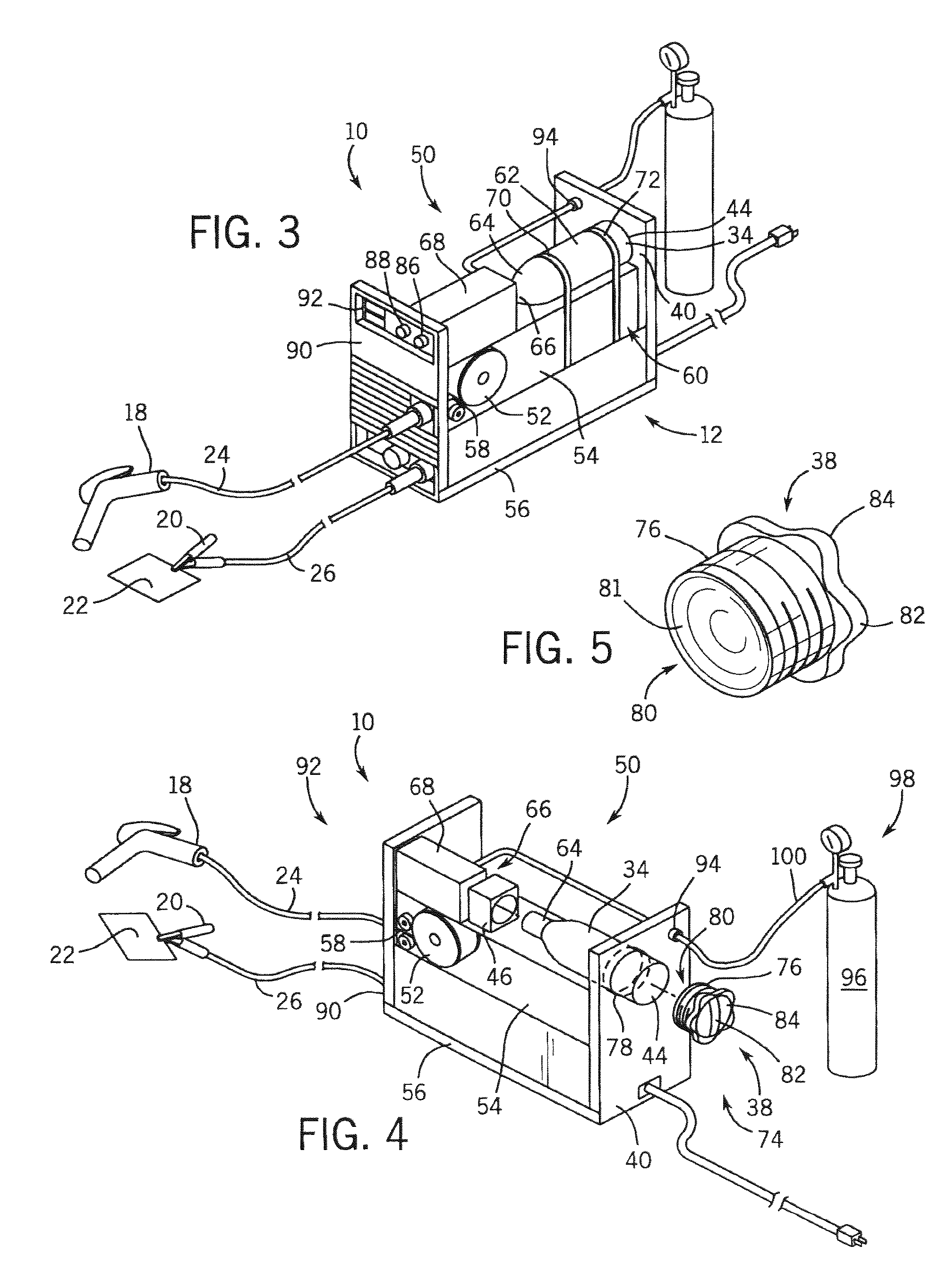

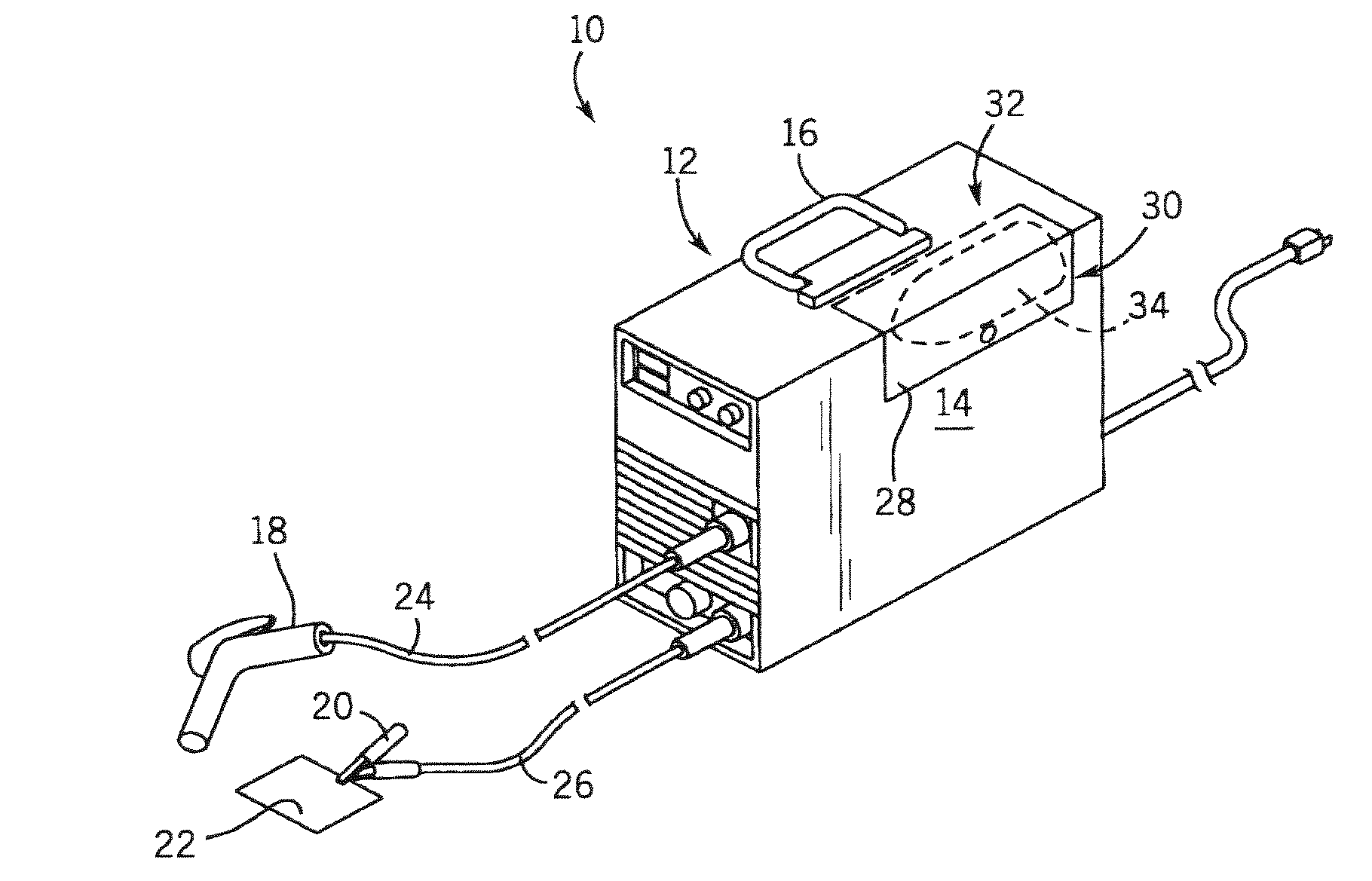

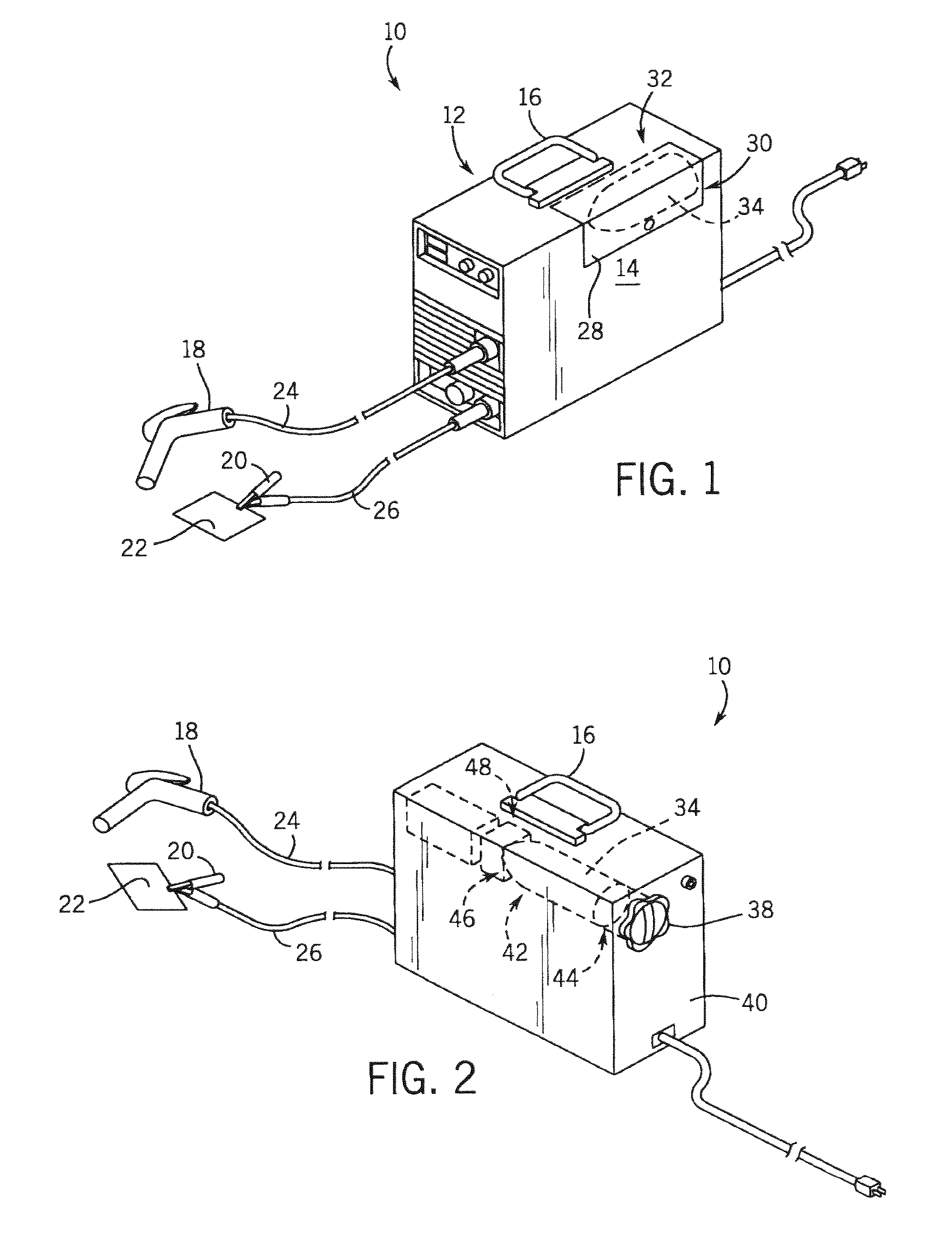

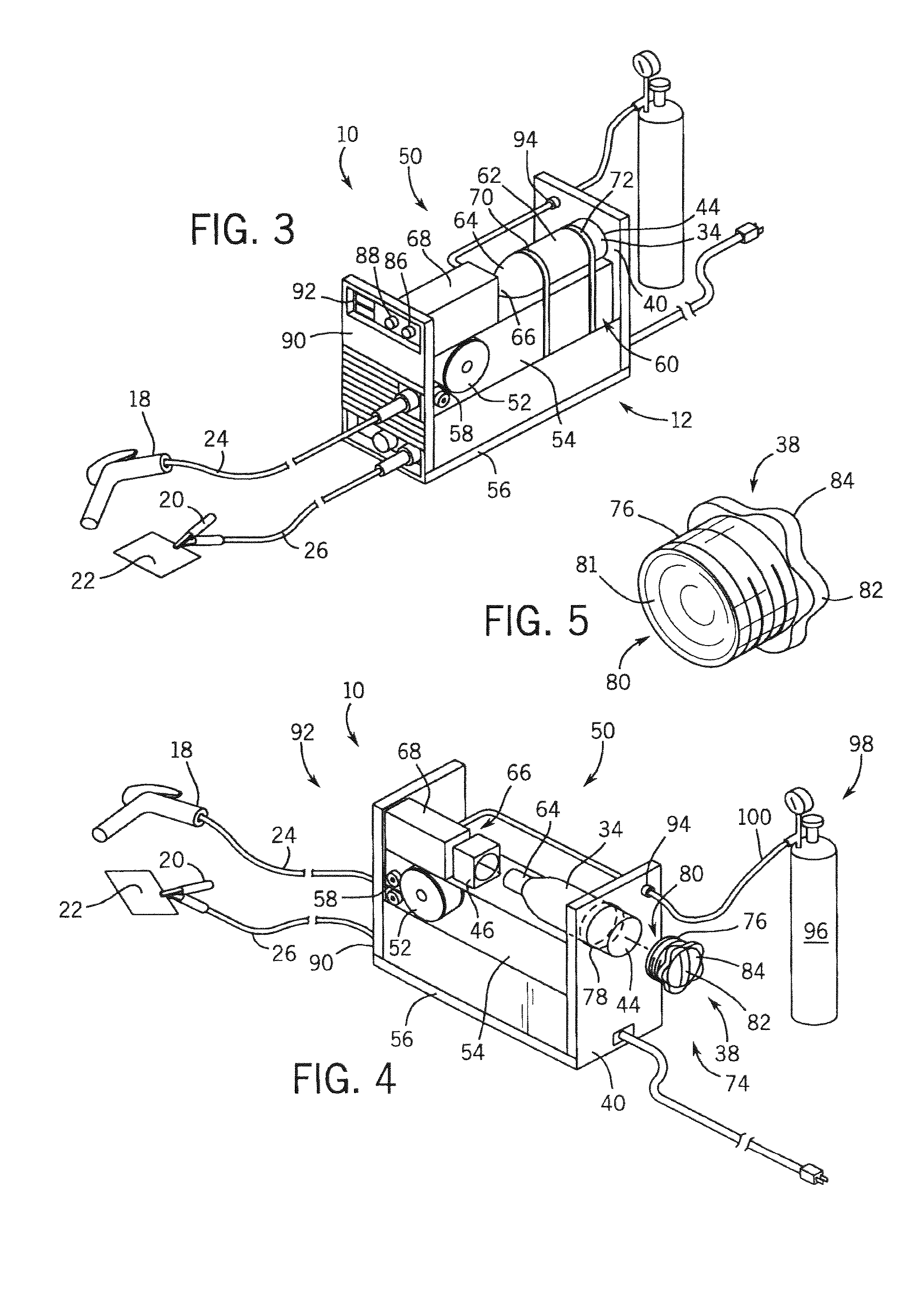

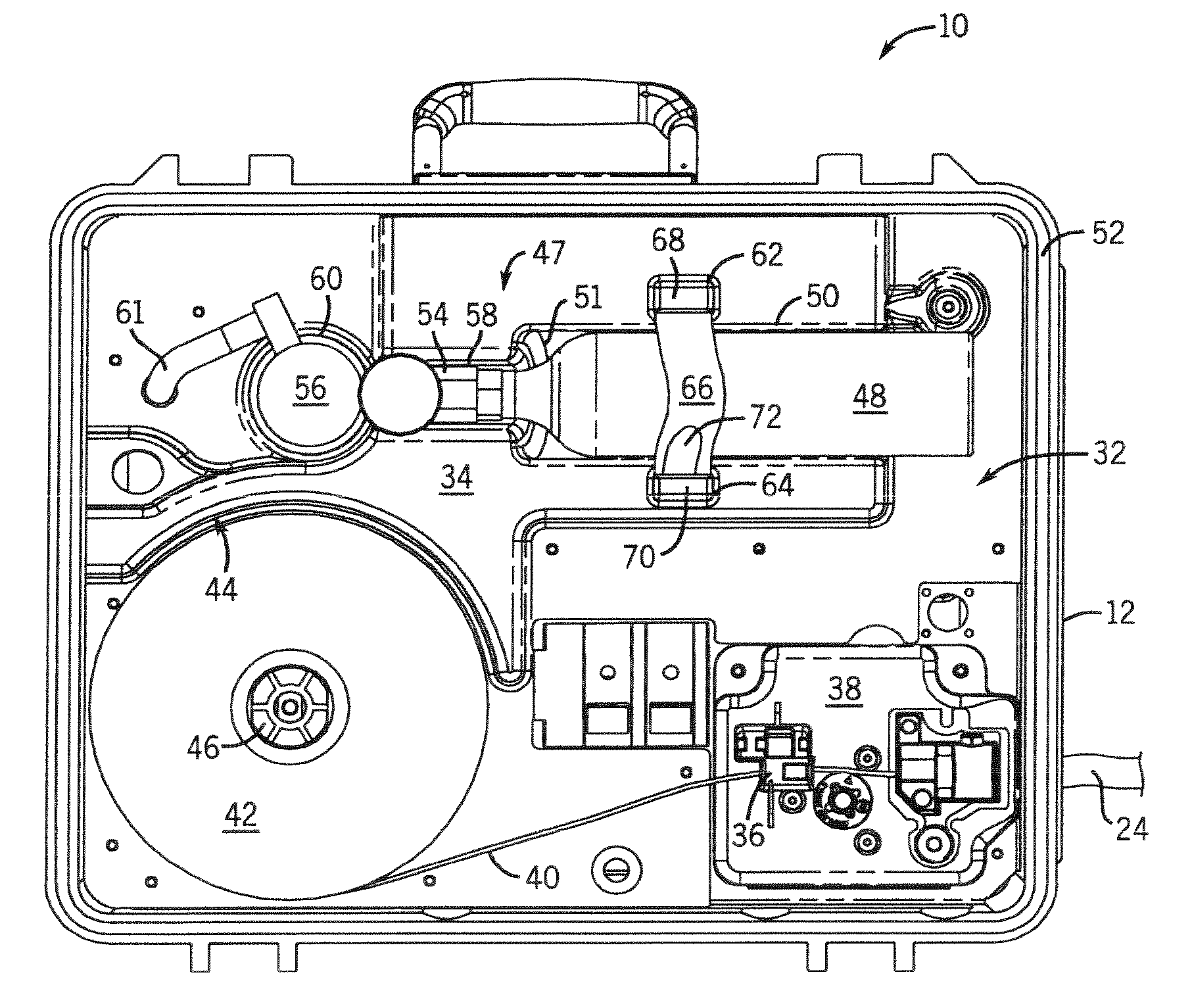

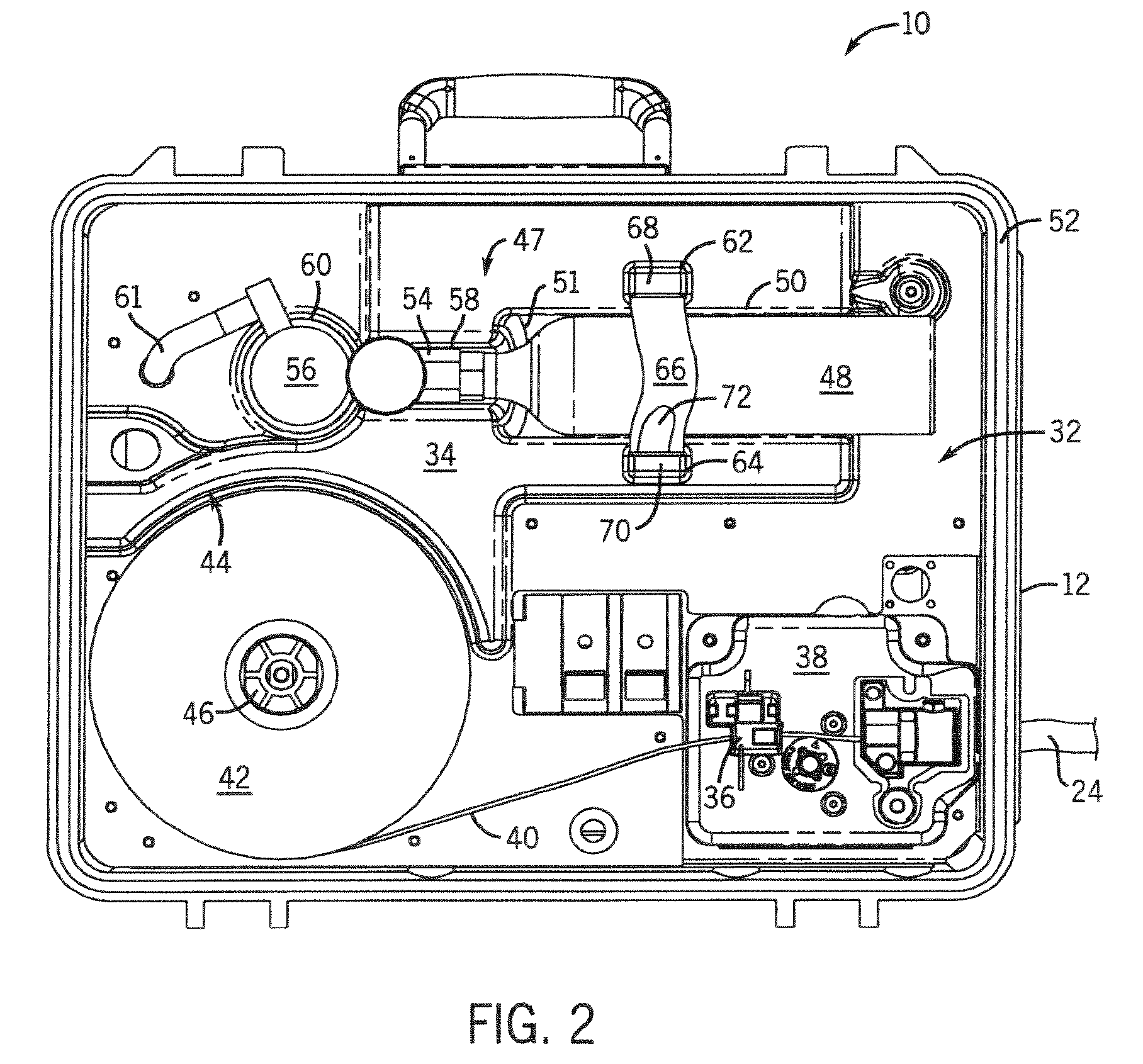

Welder with integrated gas bottle

ActiveUS6977358B2Easy to storeShielding gas supply/evacuation devicesVessel mounting detailsGas cylinderEngineering

A welder having an integrated gas cylinder is disclosed. The welder has a power source constructed to condition and output an electrical signal suitable to welding and a gas cylinder disposed in an enclosure.

Owner:ILLINOIS TOOL WORKS INC

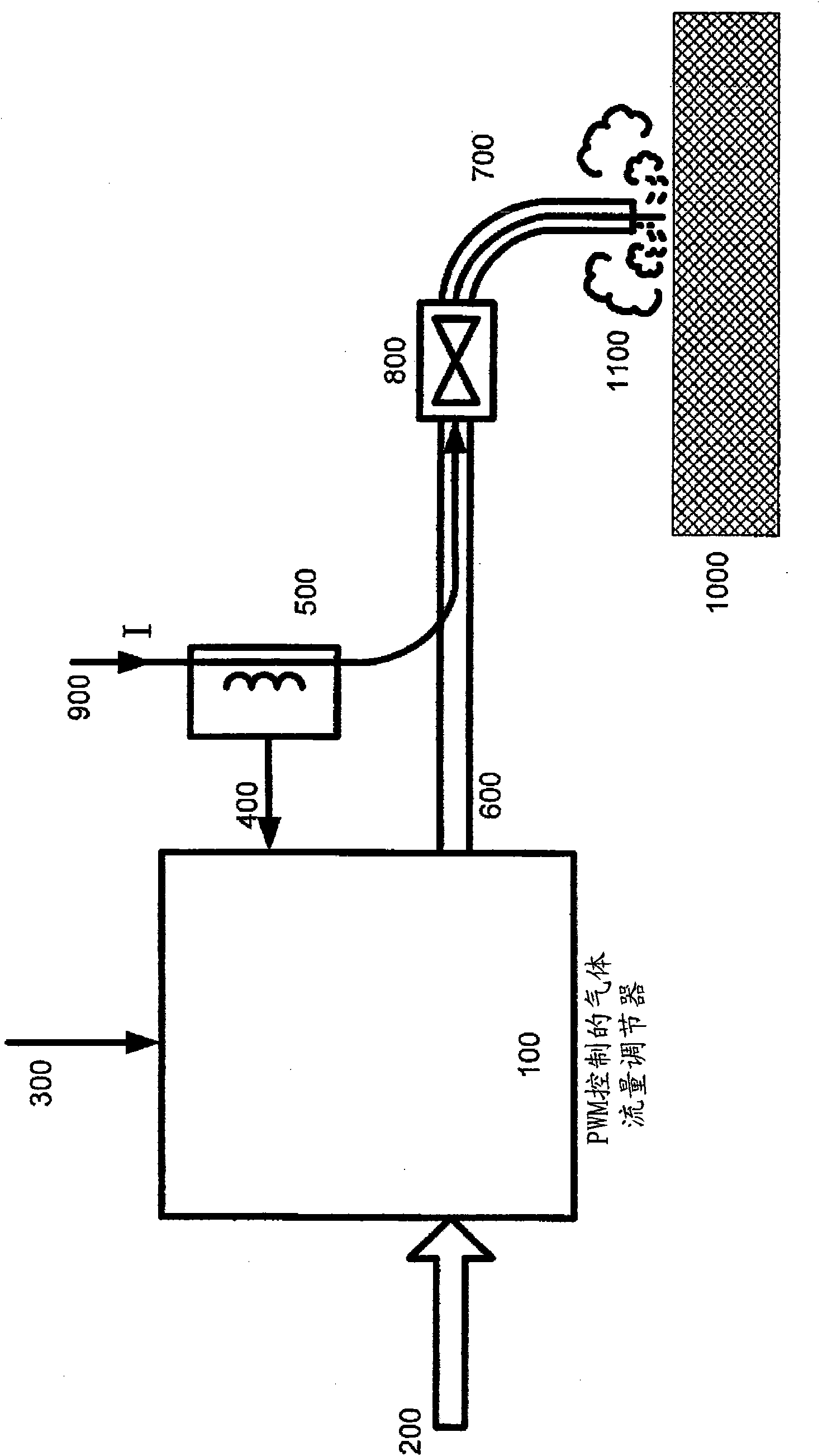

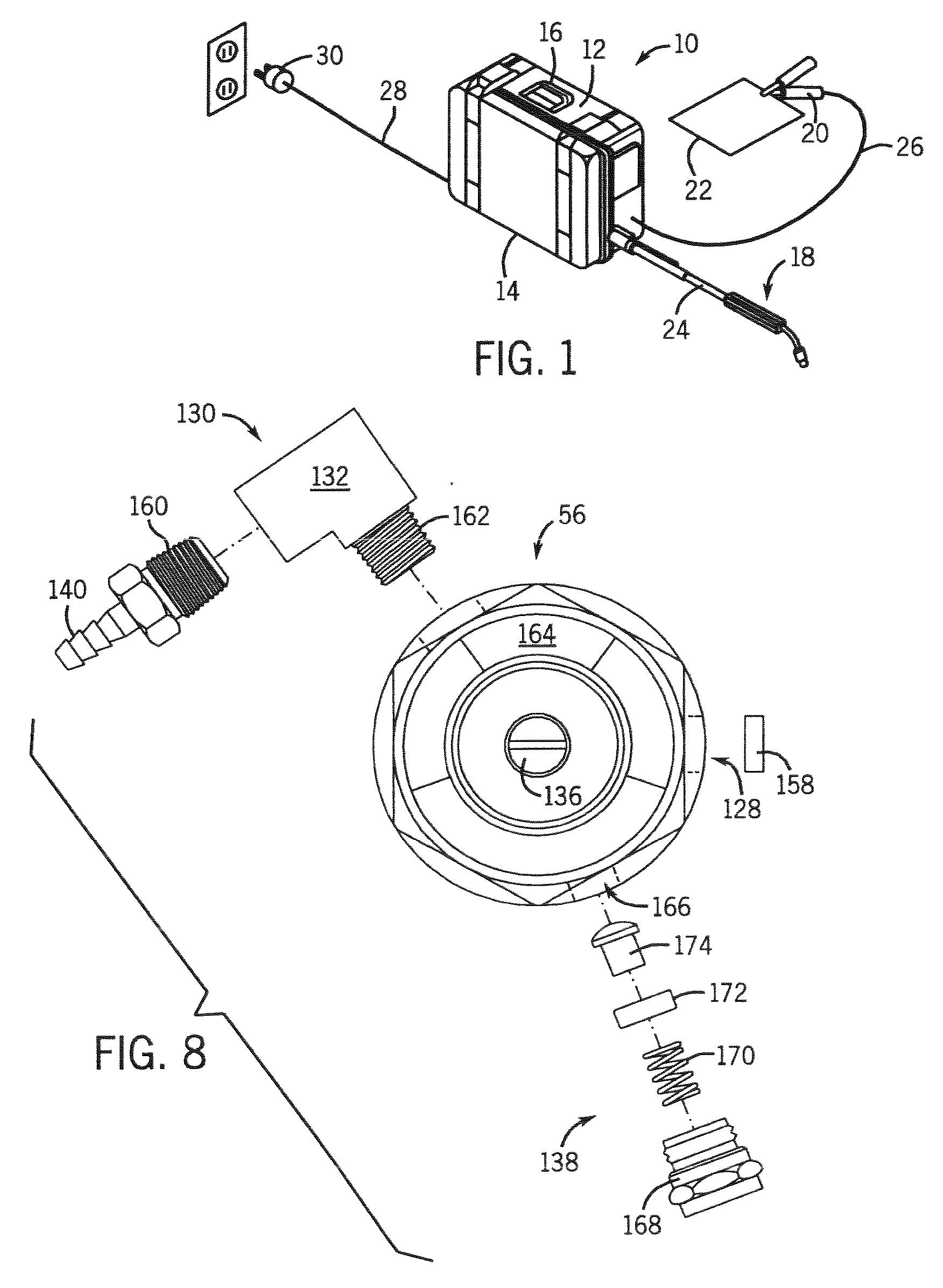

Shielding gas flow controller for a welding apparatus

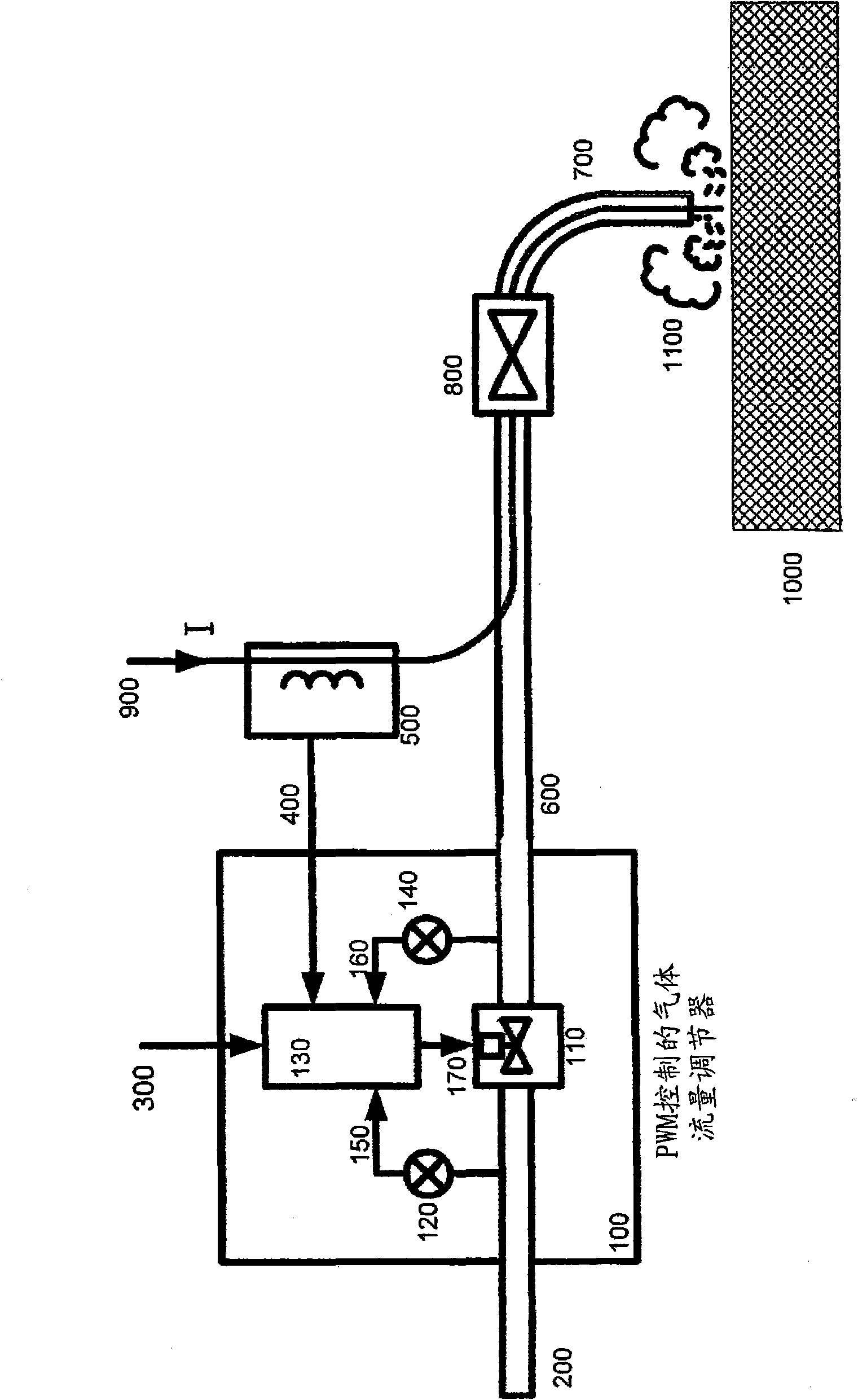

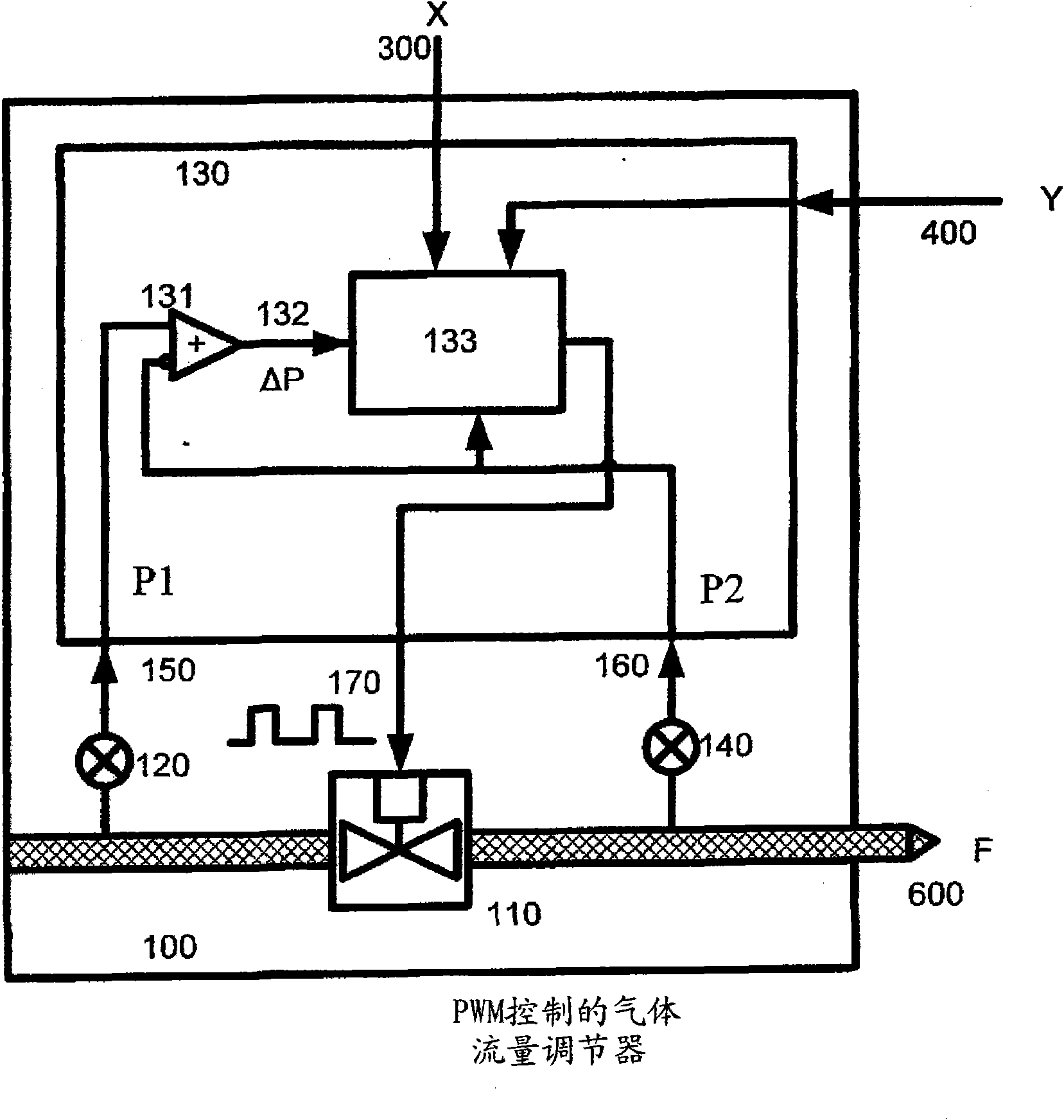

ActiveCN101855039ASolving the same problem of controllingOvercoming Pressure Drop Related IssuesShielding gas supply/evacuation devicesFlow control using electric meansProcess engineeringElectric arc

A shielding gas flow controller (100) for an electric arc welding apparatus for insertion into a shielding gas supply line between a shielding gas source (200) and a shielding gas valve (800) of the electric arc welding apparatus, the flow controller having a shielding gas (200) input and a shielding gas output (600), a controllable gas valve (110) connected between the shielding gas in- and outputs and having a control input (170), and a controller means having a first input (400) for receiving a welding signal representing an electrical welding arc current (900) of the welding apparatus during a welding operation and a gas flow setting control (300) means adapted to generate a flow setting output being function of the welding signal and representing a desired shielding gas flow. The shielding gas flow controller further comprises an input pressure sensor (120) connected to the shielding gas input and arranged to provide a shielding gas input pressure measurement (150) to a second controller means input, and an output pressure sensor (140) connected to the shielding gas output and arranged to provide a shielding gas output pressure measurement to a third controller means input (160), and a flow setting output modifying means adapted to modify the flow setting output of the gas flow setting control means based on the shielding gas input and output pressure measurements, the welding signal, and a charateristic of the controllable valve into a control signal (170) for input to the control input of the controllable gas valve so as to maintain during the welding operation a substantially constant shielding gas flow in the shielding gas supply line to the welding apparatus corresponding to the flow setting output substantially independent of actual shielding gas input and output pressures at the shielding gas in- and outputs, respectively.

Owner:ALEXANDER BINZEL SCHWEISSTECHN GMBH & CO

Welder with integrated gas bottle

ActiveUS20050000946A1Easy to storeShielding gas supply/evacuation devicesVessel mounting detailsGas cylinderEngineering

A welder having an integrated gas cylinder is disclosed. The welder has a power source constructed to condition and output an electrical signal suitable to welding and a gas cylinder disposed in an enclosure.

Owner:ILLINOIS TOOL WORKS INC

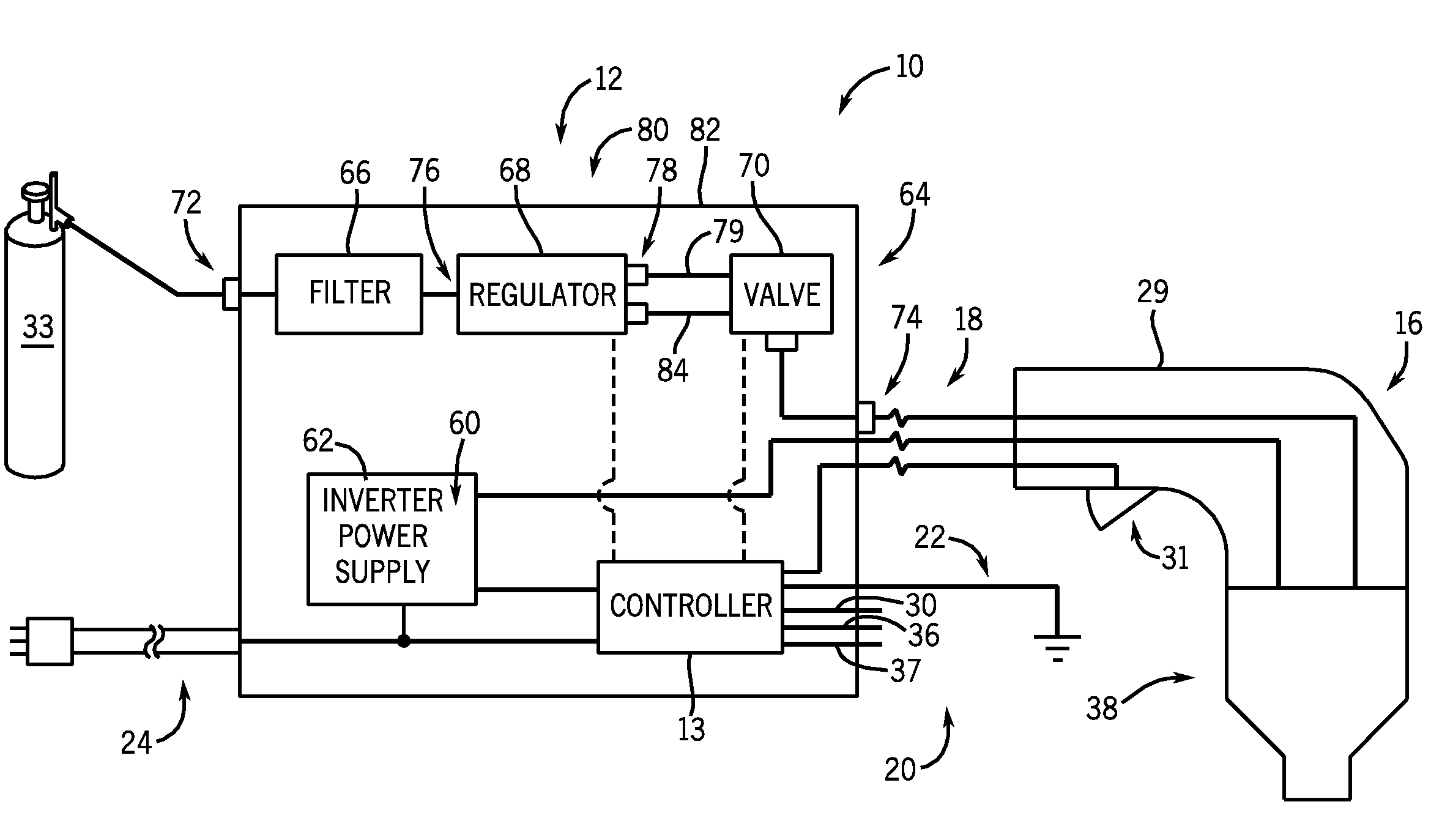

Inverter powered plasma cutting system with fixed gas flow control

ActiveUS7411149B2Selective operationShielding gas supply/evacuation devicesElectric discharge tubesPower inverterEngineering

A lightweight and compact plasma cutting system includes a power source having an inverter and a non-adjustable regulator enclosed within the power source. The inverter is configured to generate a power signal suitable for a plasma arc process and the non-adjustable regulator is preconfigured to deliver a fixed gas flow to a plasma torch for the plasma arc process.

Owner:ILLINOIS TOOL WORKS INC

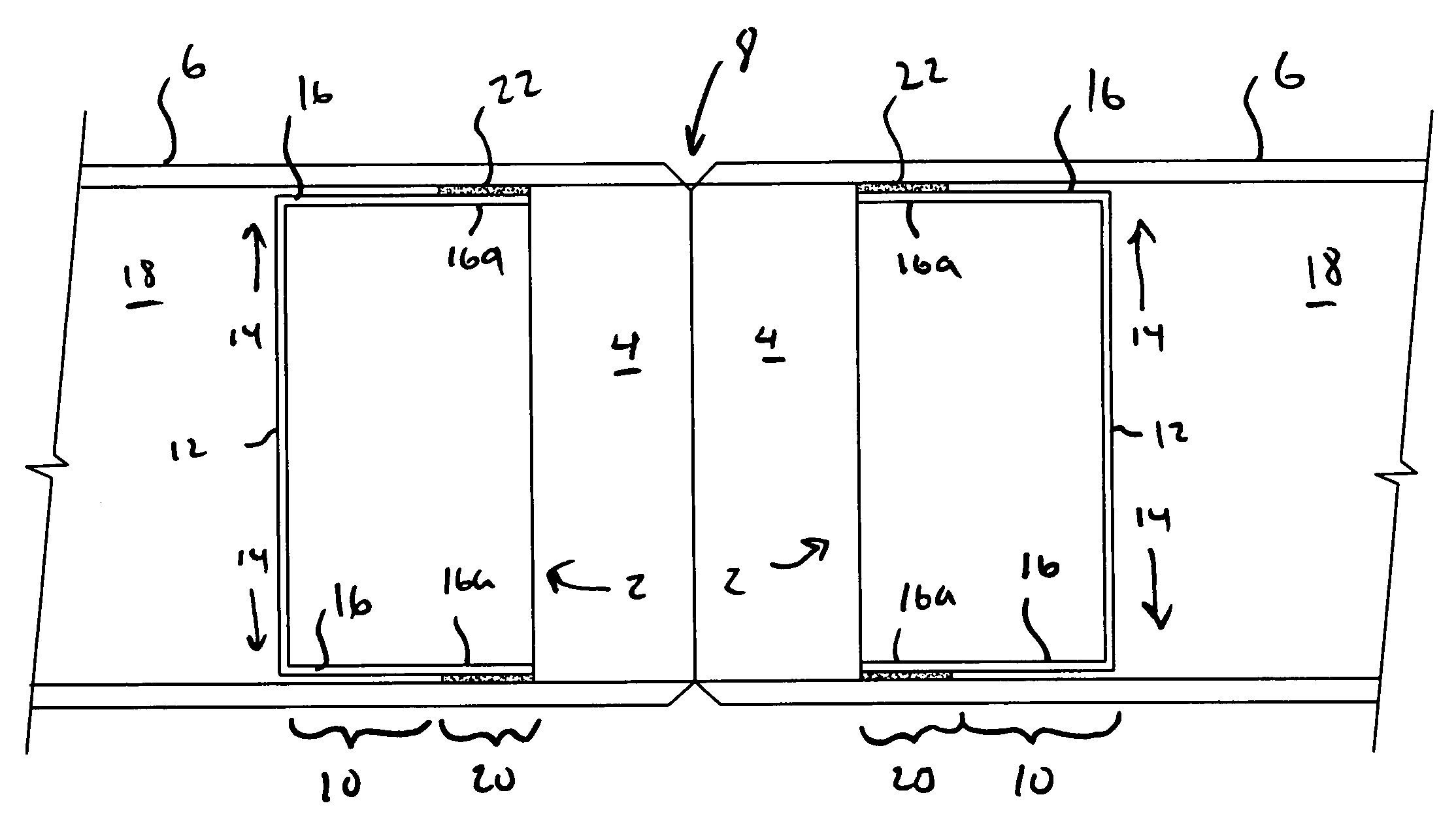

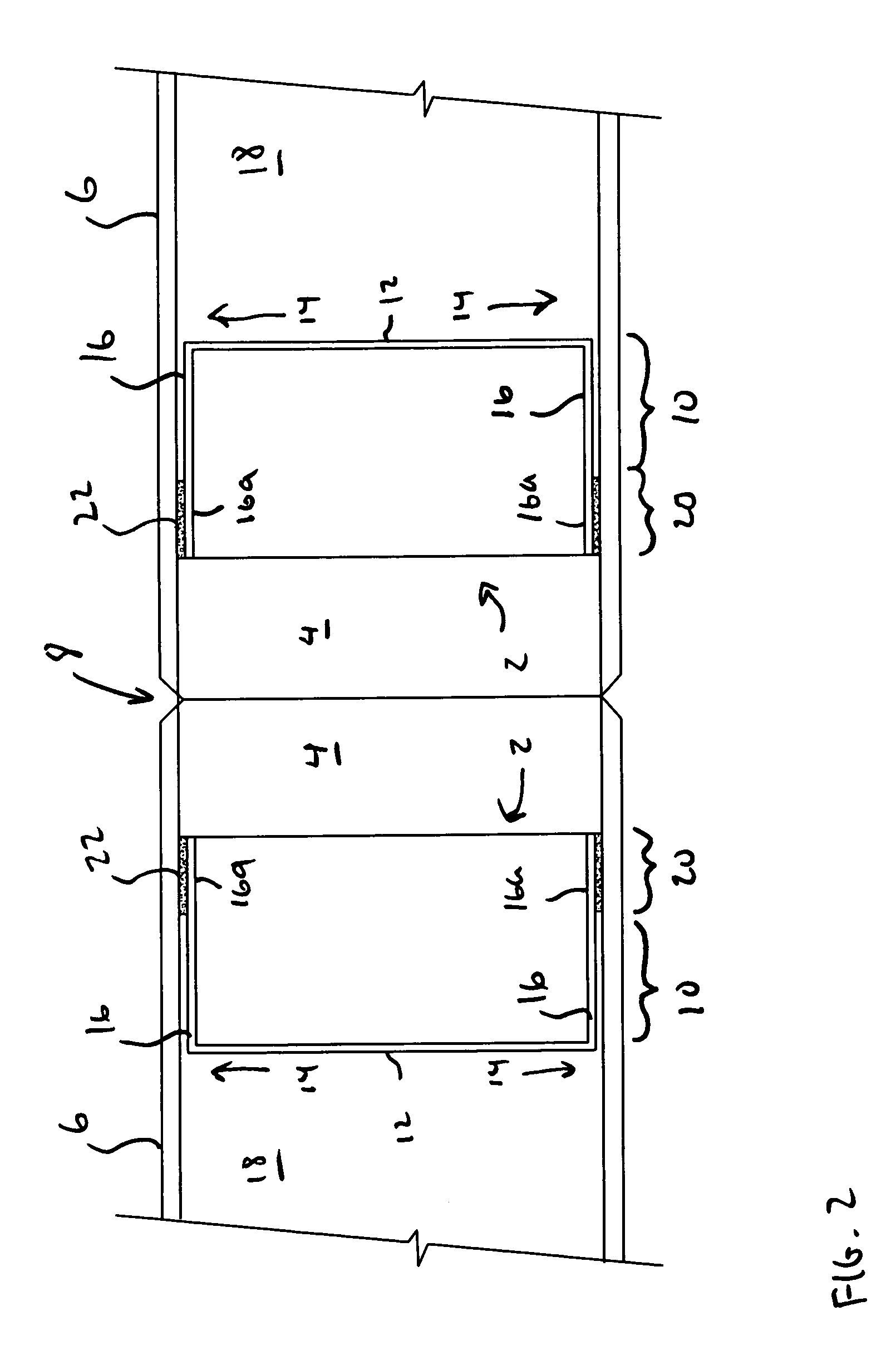

Self-adhesive purge dam for retaining purge gas around a weld zone

A self-adhesive purge dam for retaining purge gas around a weld zone includes a base configured to substantially obstruct an air passage leading to the weld zone and an adhesive skirt extending from the base and configured to engage portions of the air passage. An adhesive on the adhesive skirt allows the skirt to be adhered to the air passage. An optional removable backing covers the adhesive prior to installation. The purge dam is installed by peeling the removable backing (if present) and exposing the adhesive for adhesion.

Owner:AQUASOL CORP LLC

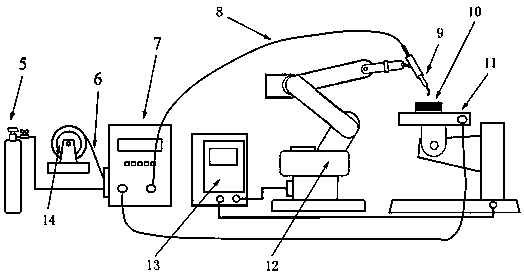

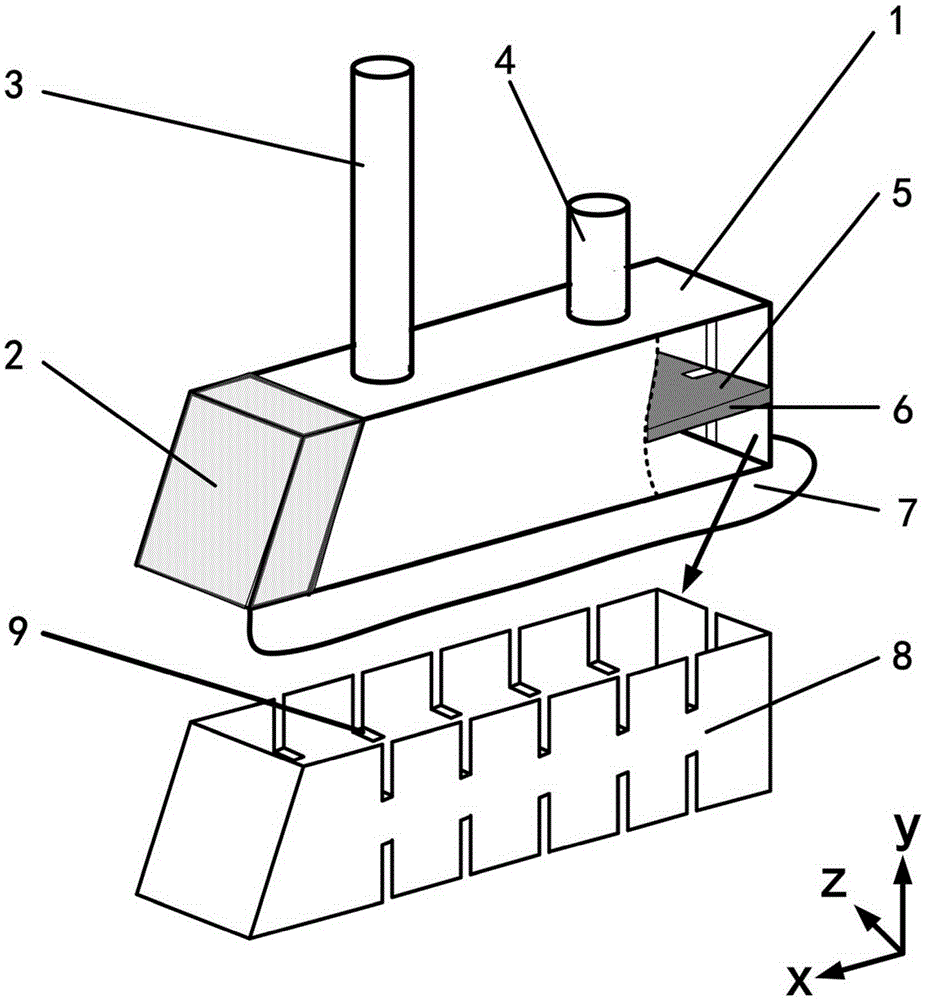

Method for additive manufacturing of high-entropy alloy part through metal wires

InactiveCN108393558ARealize the integration of 3D rapid prototypingAvoid wastingShielding gas supply/evacuation devicesNumerical controlHigh entropy alloys

The invention discloses a method for additive manufacturing of a high-entropy alloy part through metal wires. The method comprises the specific steps that (1) a three-dimensional module of the to-be-manufactured high-entropy alloy part is established on a computer, and a processing route program is established according to the three-dimensional module; (2) the metal wires of different types required by the to-be-manufactured high-entropy alloy part are combined into a wire rope which is fed into a wire feeding device or a multiple-channel wire feeding device, the wire feeding speed, heat source energy, the scanning speed and protection gas flow are set, and additive manufacturing is conducted through special additive manufacturing equipment or a robot or a numerical control machine tool ormanual work at protective atmosphere or under protection of submerged-arc welding flux; and (3) the high-entropy alloy part is obtained through subsequent treatment of machining, heat treatment, surface treatment and the like on a part blank obtained through additive manufacturing. The method disclosed by the invention is simple and easy to conduct, low in cost and suitable for industrial production of the high-entropy alloy part.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

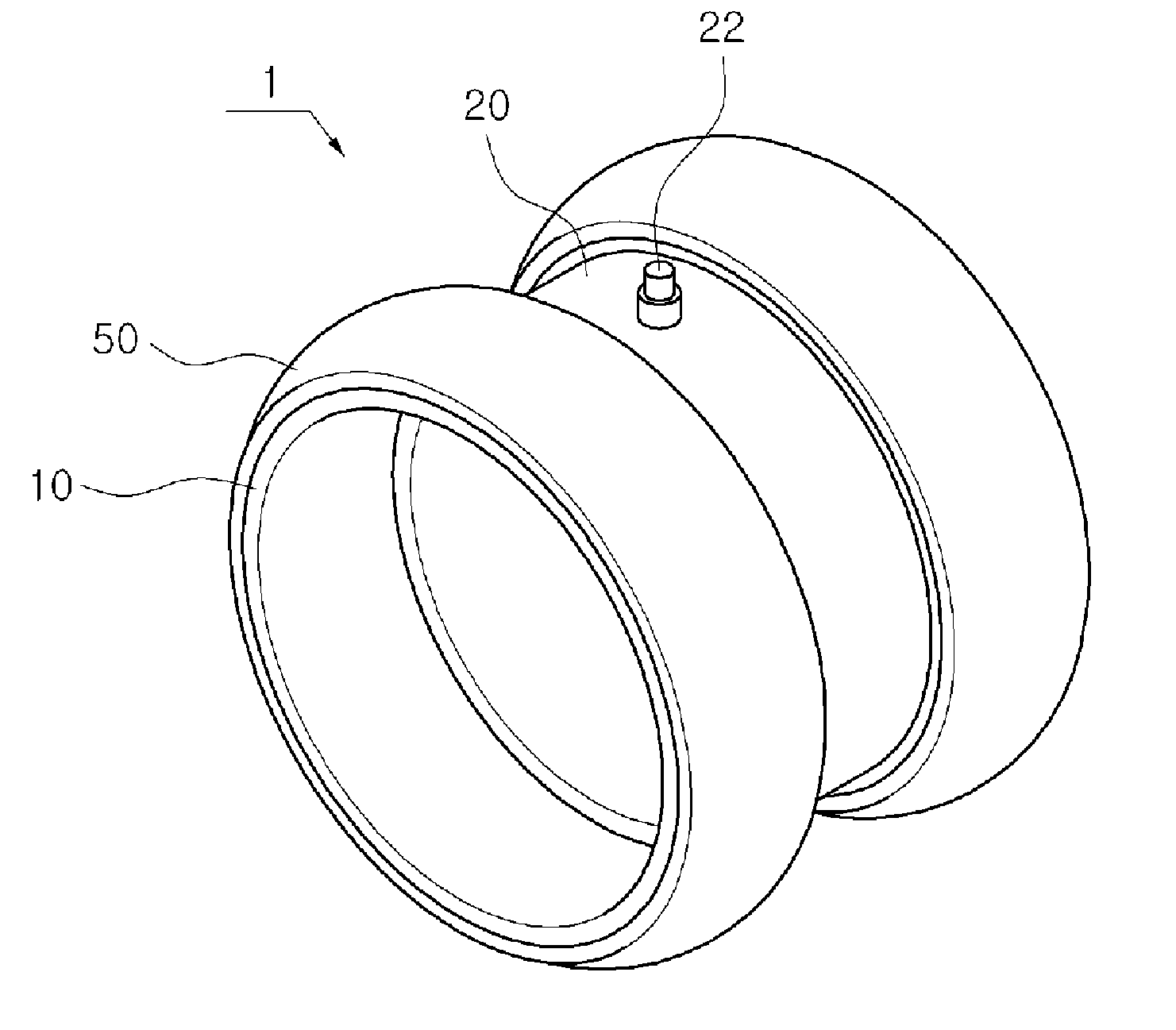

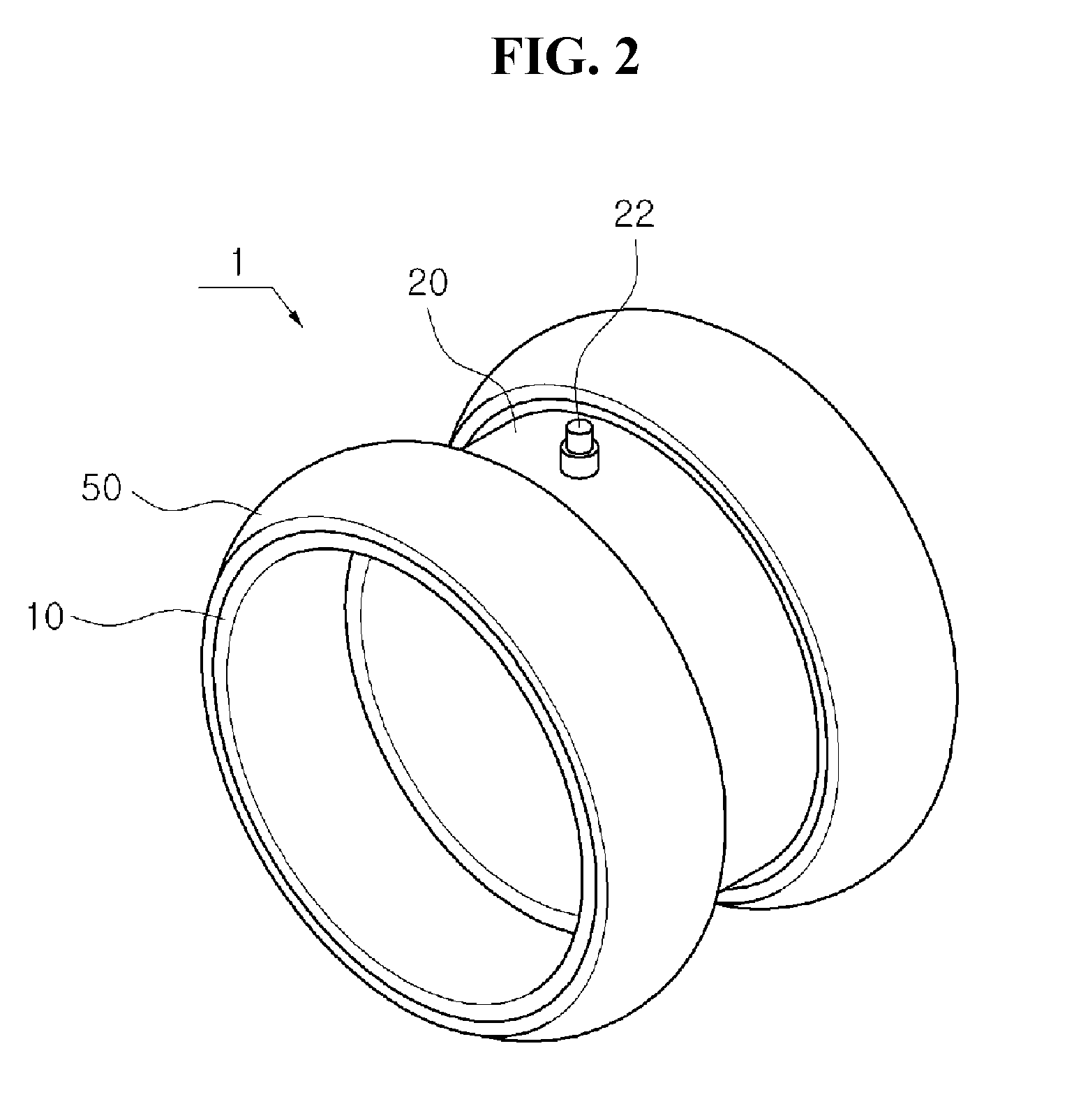

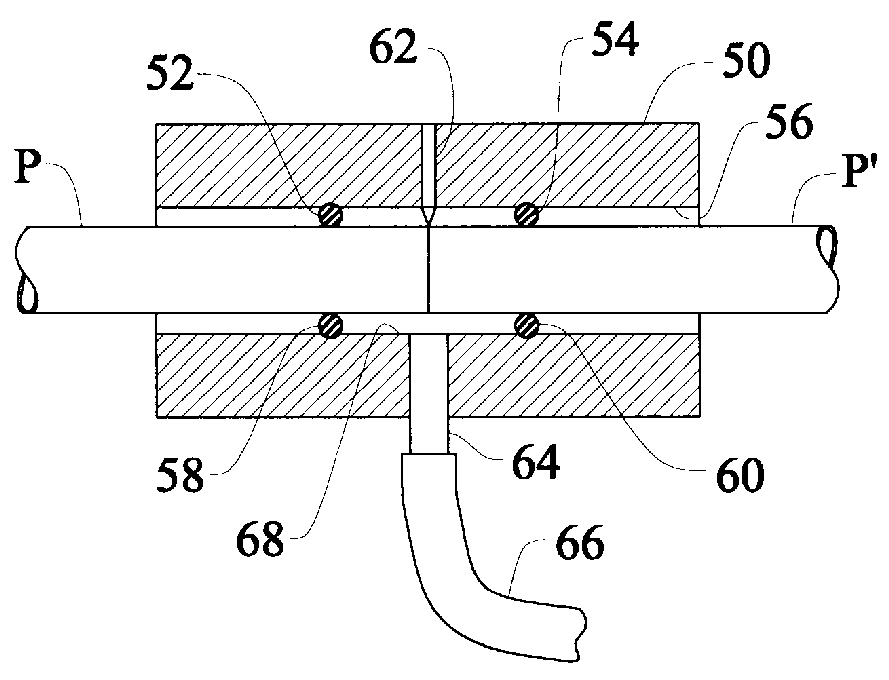

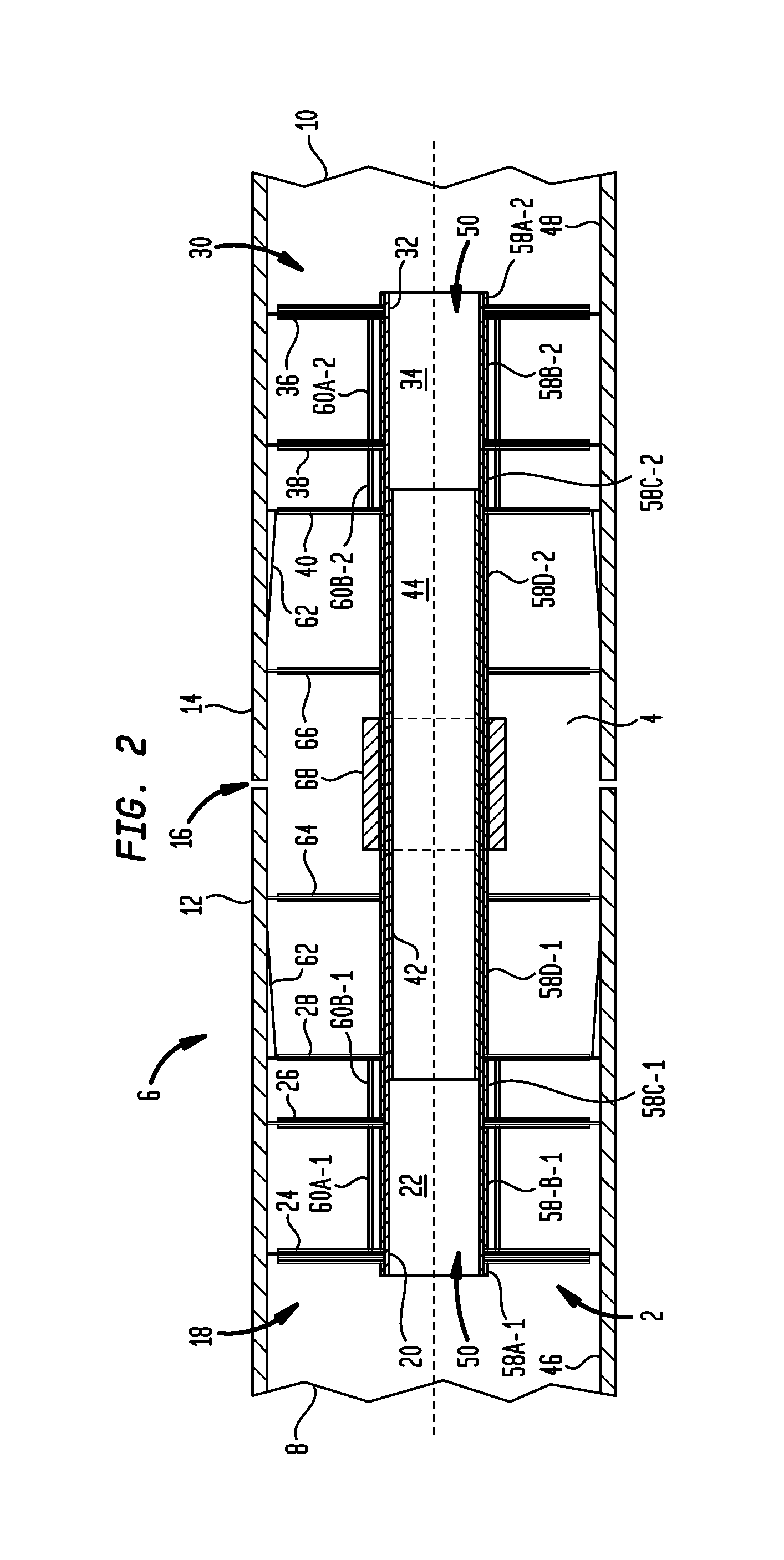

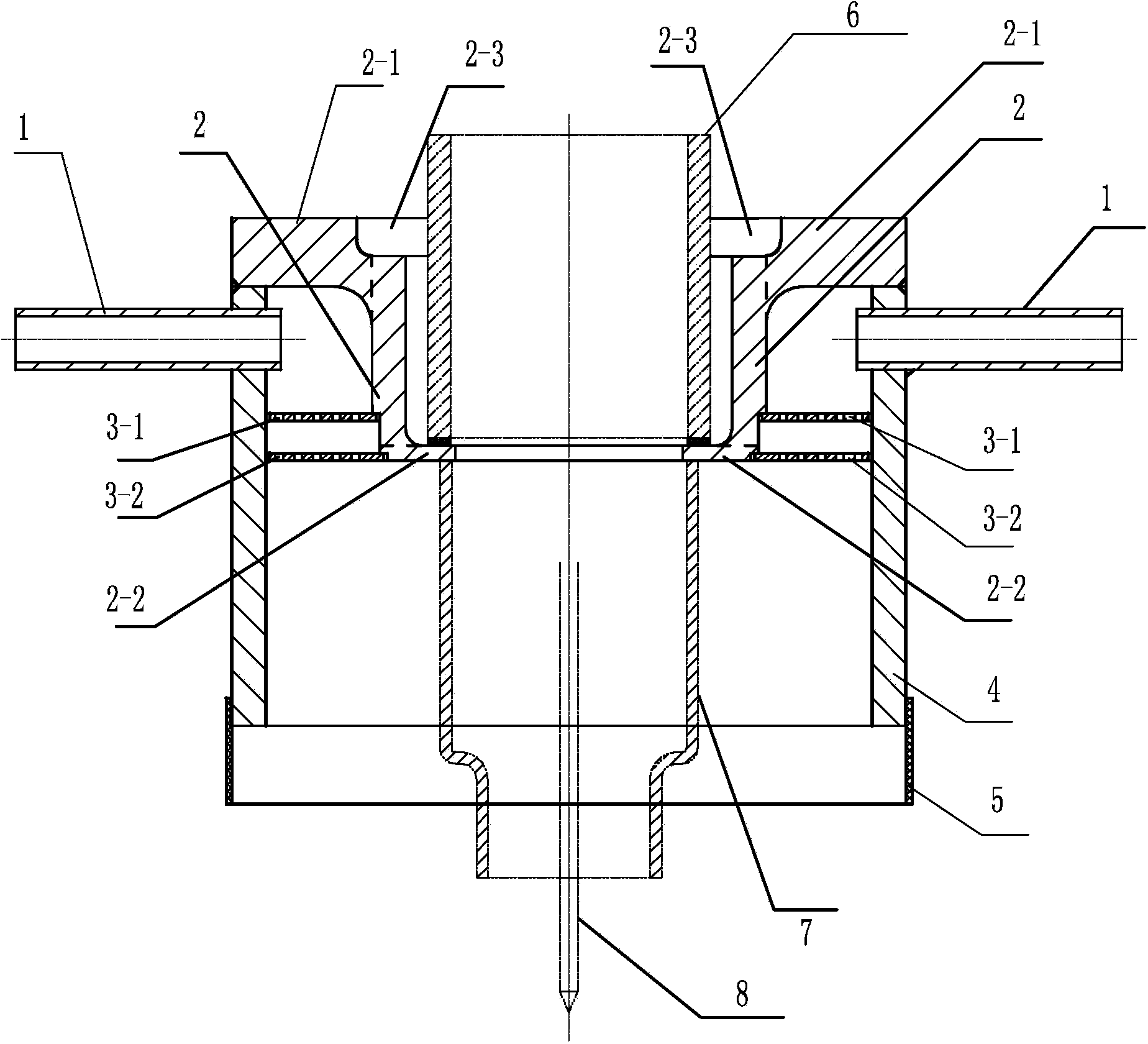

Purging device for pipe welding

InactiveUS20150083785A1Avoid damageEasy to replaceShielding gas supply/evacuation devicesWelding/cutting auxillary devicesPipe weldingBlocking layer

Disclosed is a purging device for pipe welding, comprising: a pair of sealing tools that are disposed inside a pipe, expand by supplied air and are in contact with an inner wall of the pipe; and a connection pipe that is disposed between the pair of sealing tools, is a cylindrical body, wherein the sealing tools are respectively fixed to either side end of the connection pipe and the connection pipe is provided with a gas nozzle for discharging inert gas supplied from the outside, wherein each of the sealing tools further comprises a blocking layer that is flame retardant and is coupled in such a manner as to surround an outer circumferential surface of each of the sealing tools.

Owner:PARK JIN WOO

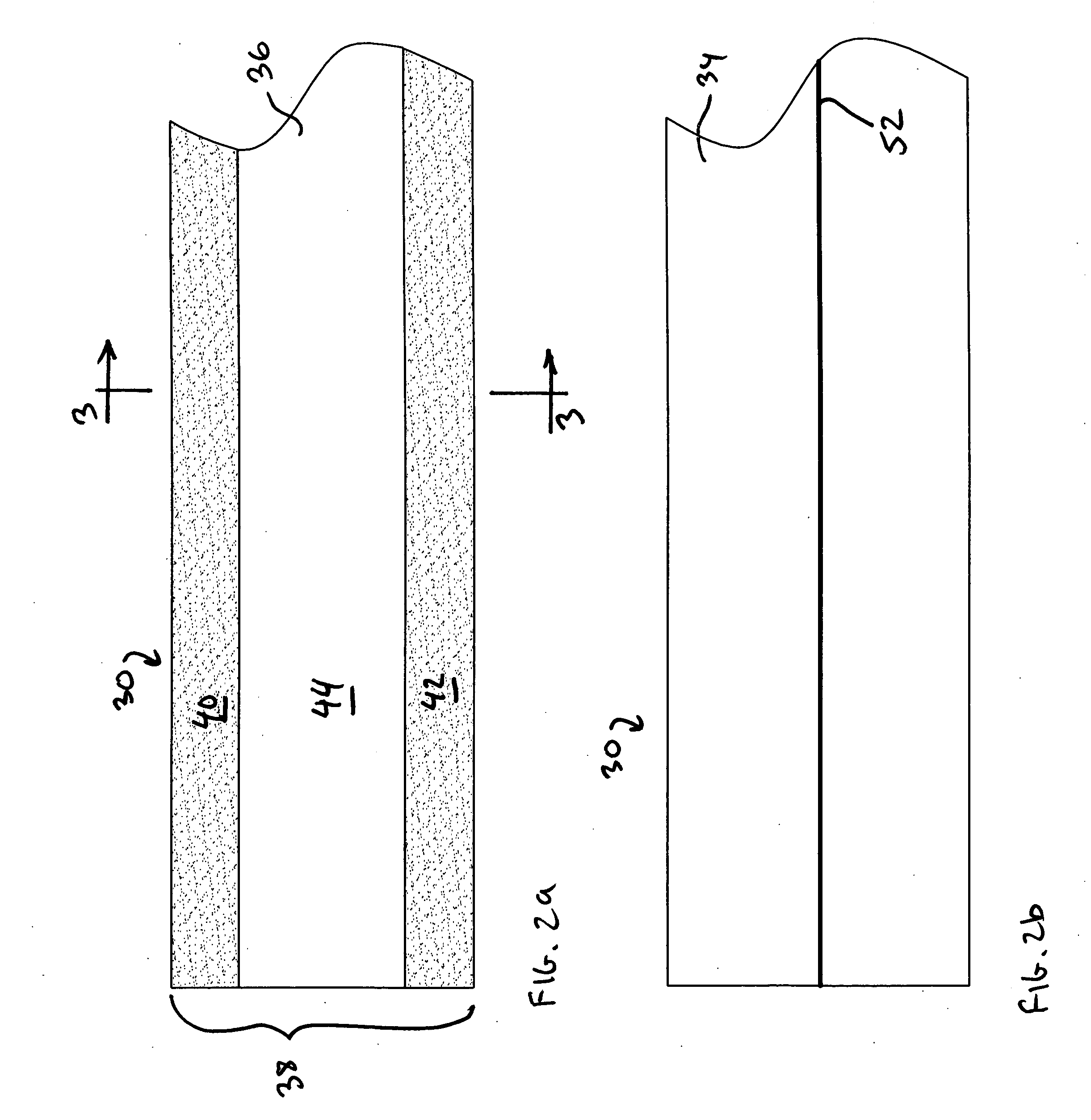

Neck for a robotic welding torch

ActiveUS20090039066A1Accurate and successful operationShielding gas supply/evacuation devicesShielding gasEngineering

A neck for a welding torch includes a rigid, non-tubular, elongated member having opposite first and second ends. The first end is connectable to a rear portion of the welding torch. The second end is connectable to a welding tip portion of the welding torch. The member locates and holds the welding tip portion in a precisely given location, and does not communicate welding power, welding wire, shielding gas, or cooling water between the first and second ends.

Owner:ILLINOIS TOOL WORKS INC

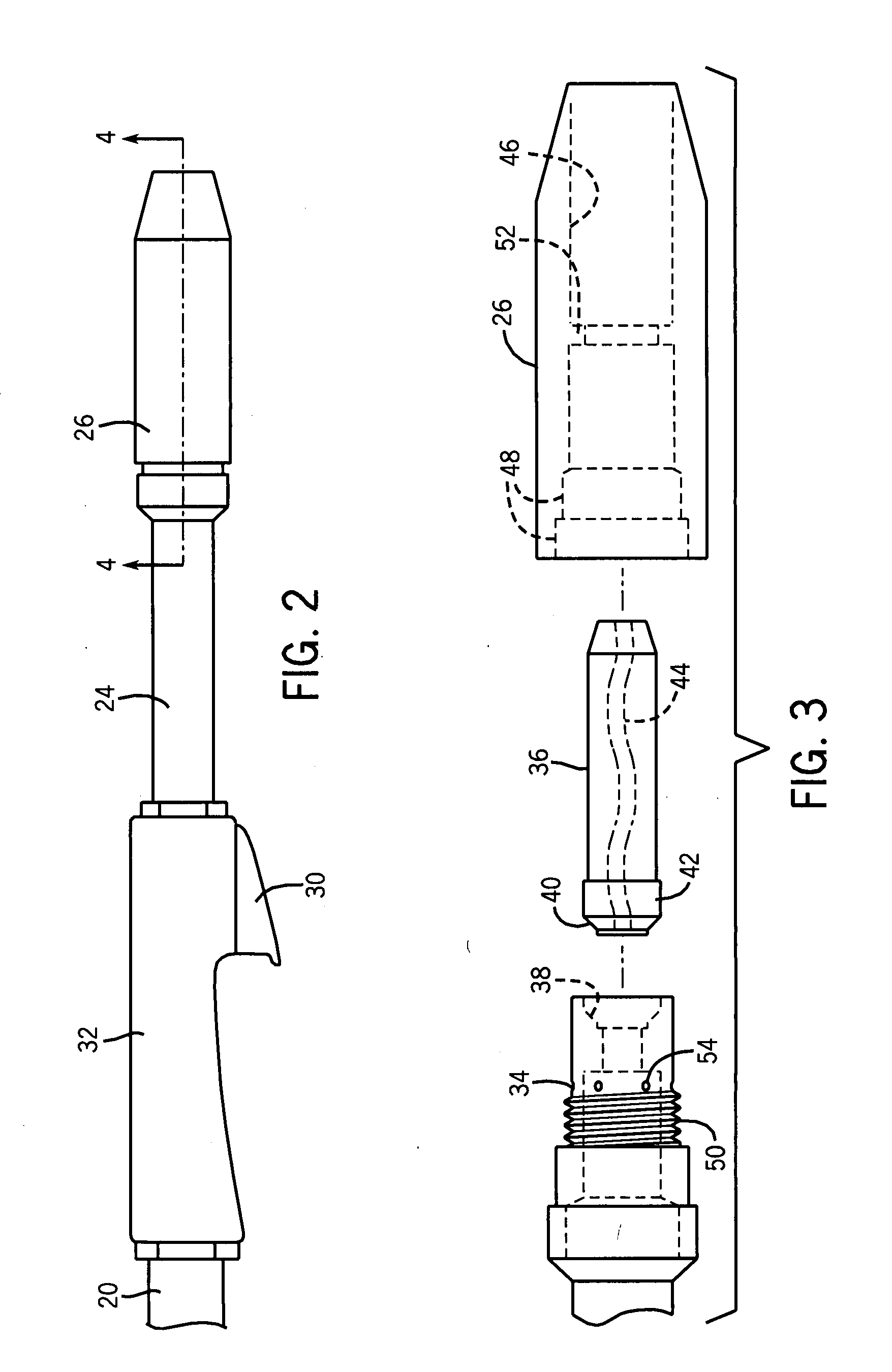

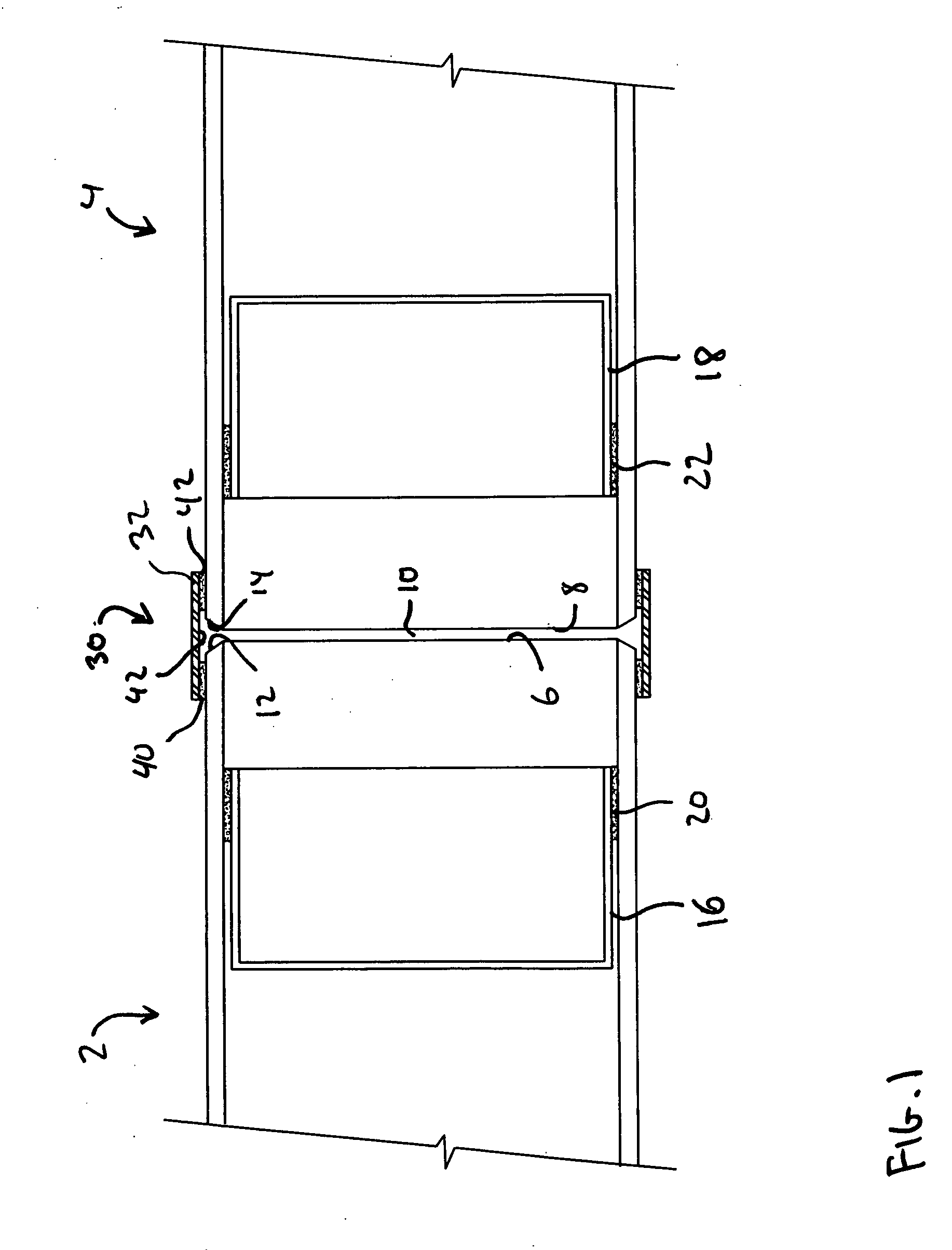

Split gooseneck for welding guns

InactiveUS20140263251A1Shielding gas supply/evacuation devicesElectrode accessoriesEngineeringWelding

Owner:LINCOLN GLOBAL INC

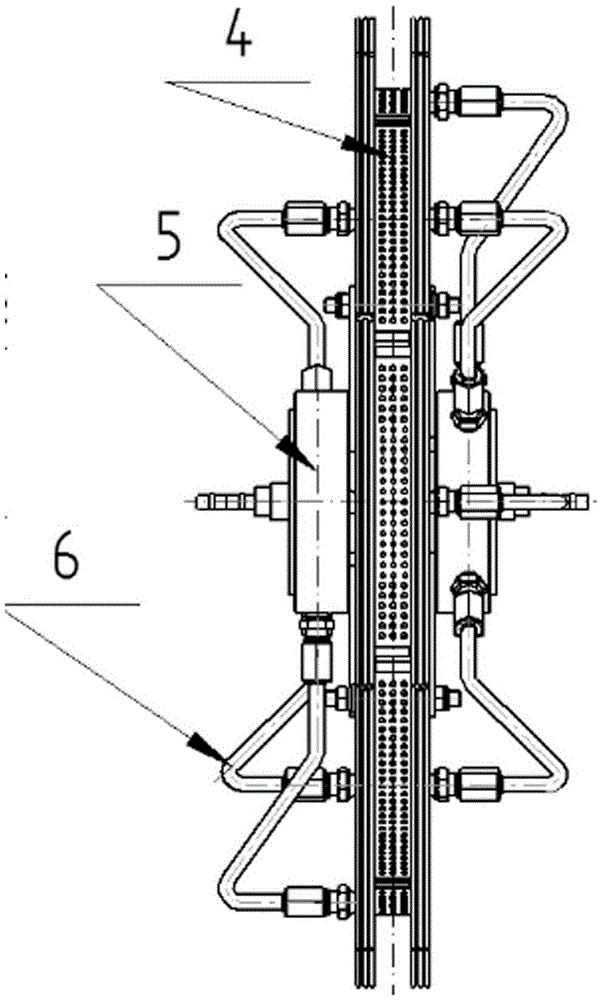

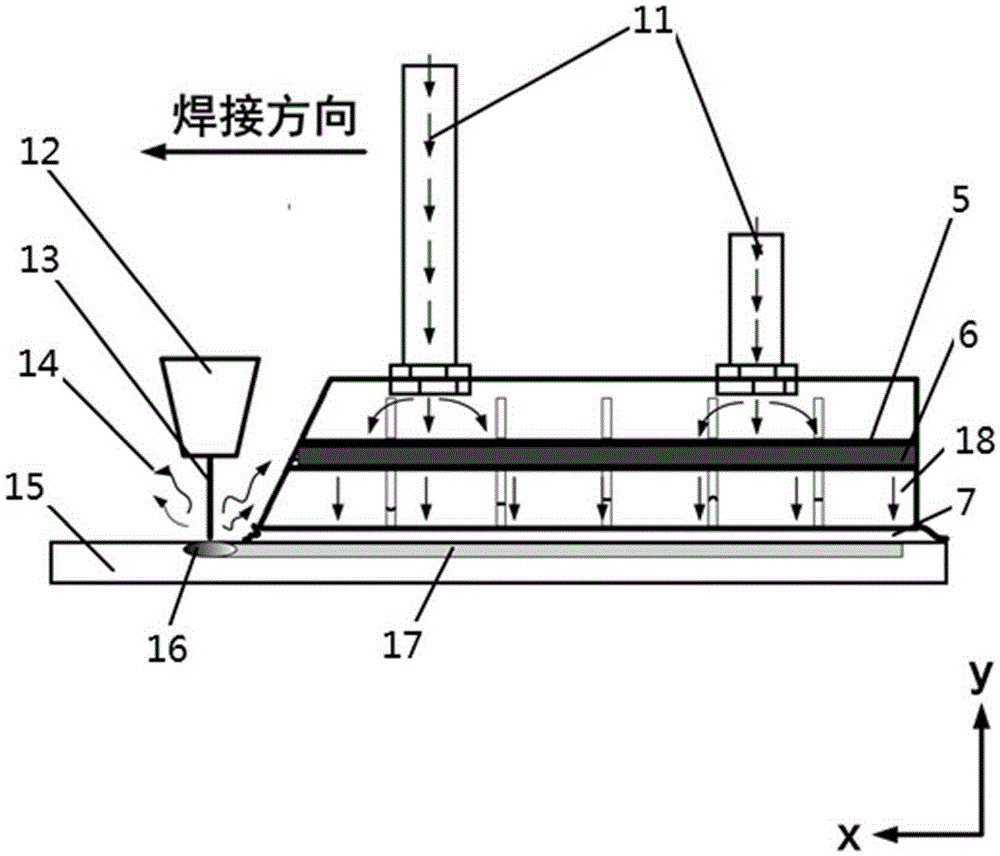

Welding structure for inner container longitudinal seam of stainless steel gas cylinder and welding method

ActiveCN105252121AReduce one-time input costsLow input costShielding gas supply/evacuation devicesWelding/cutting media/materialsButt weldingGas cylinder

The invention discloses a welding structure for an inner container longitudinal seam of a stainless steel gas cylinder and a welding method. The welding structure comprises a strip-shaped auxiliary board, wherein a main gas guide hole and a gas guide groove are formed in the strip-shaped auxiliary boar in the length direction; the main gas guide hole and the gas guide groove are arranged in parallel; a plurality of gas guide small holes are formed between the main gas guide hole and the gas guide groove; the two ends of the gas guide small holes are respectively communicated with the main gas guide hole and the gas guide groove; and the cross section of the gas guide groove and the cross section of the longitudinal seam to be welded are positioned in the same plane. The welding method comprises the following steps: rolling round; carrying out butt welding and spot welding; carrying out spot welding on run-on plates and run-off plates; clamping; and welding. According to the invention, an MIG automatic welding process is adopted, so that the primary input-cost of welding equipment is low; in a later using process, the input using and maintenance costs are relatively low and the working efficiency is improved greatly. By adopting the process in the invention, the qualification rate of nondestructive testing reaches 99.4% or above in an actual longitudinal seam welding process of an insulated gas cylinder and a cylinder for an LNG vehicle; and physical and chemical test projects completely meet standard requirements.

Owner:ANHUI DAPAN SPECIAL EQUIP VEHICLE CO LTD

Attachment for sampling purge gas pressure at weld site

InactiveUS6073481AQuickly and easily attachedQuickly and easily to and removedShielding gas supply/evacuation devicesDetection of fluid at leakage pointAbutmentProduct gas

A method and device for sampling the pressure of inert purge gas flowing in two pipes to be welded at a joint comprising a sleeve for encircling the pipes during their coaxial alignment in end to end abutment, and an associated element with the sleeve forming a sealed chamber surrounding the joint and receiving gas that leaks out from the joint at the same pressure as the gas in the pipes, and a connection for connecting the chamber for measuring the pressure of the gas therein as an indication of the pressure of the gas flowing in the pipes; the method includes clamping the device around the pipes or sliding the pipes into the device.

Owner:BAREFOOT BYRON G

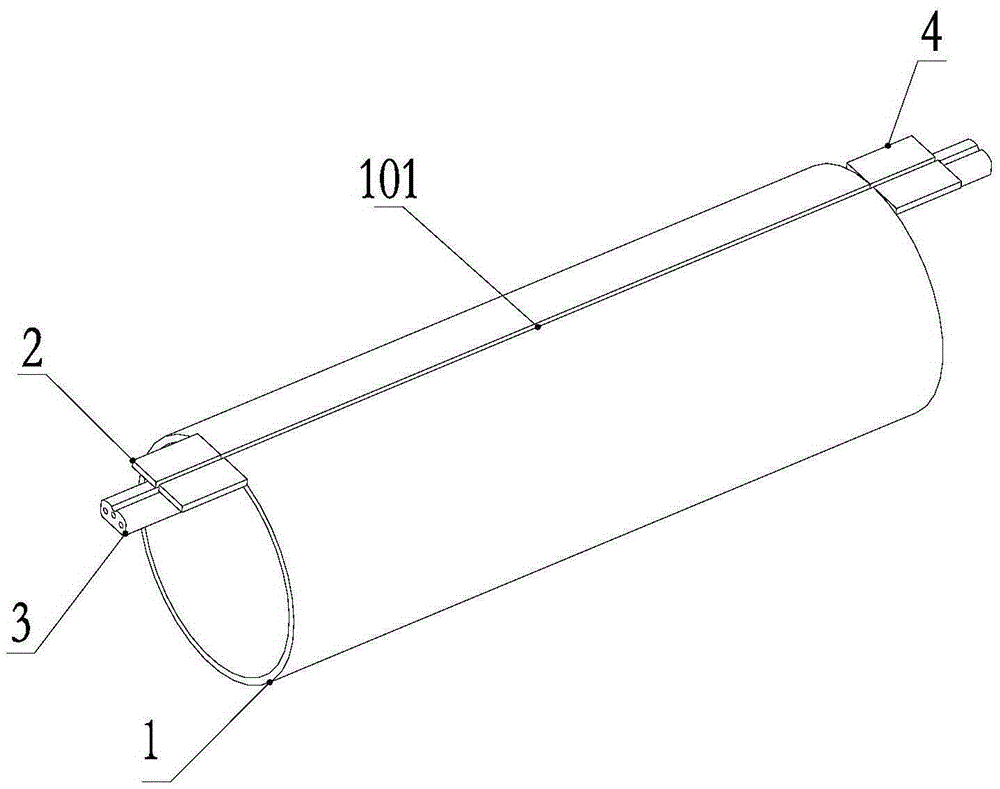

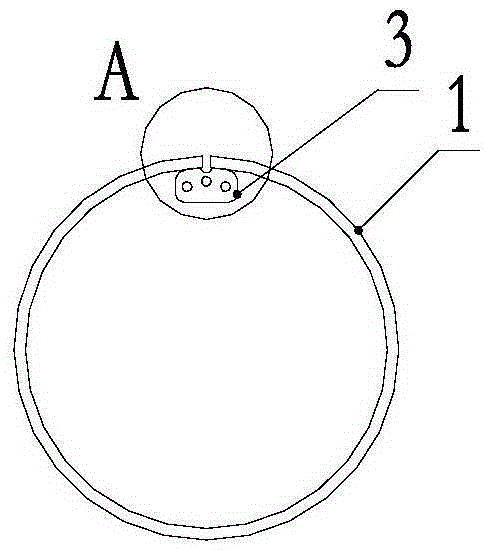

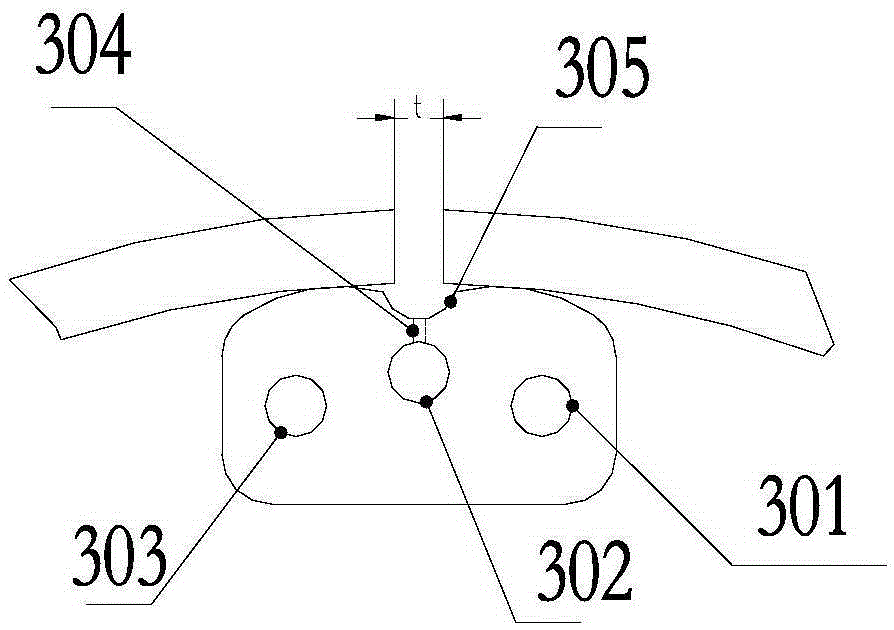

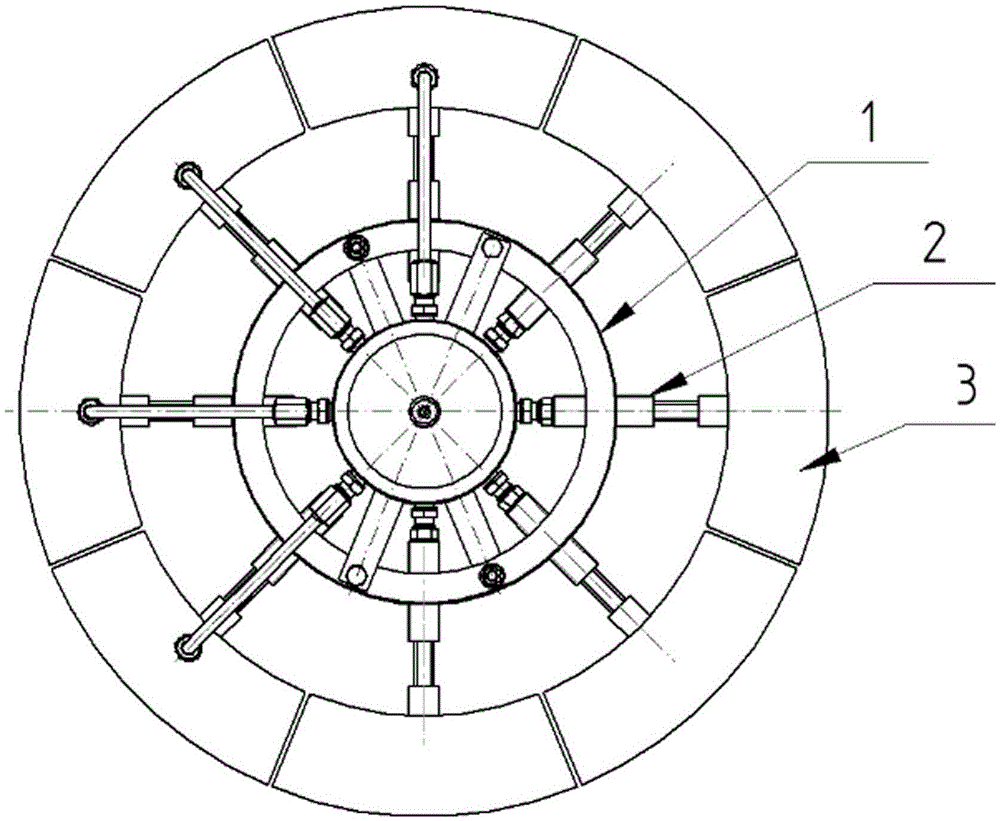

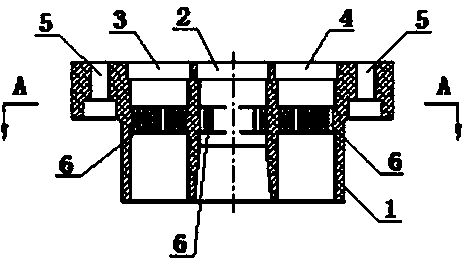

Butt joint circular seam reverse side gas shielding device for barrel fusion welding

InactiveCN105522266AImprove protectionReduce Ellipse DistortionShielding gas supply/evacuation devicesWelding/cutting auxillary devicesMelting tankButt joint

Disclosed is a butt joint circular seam reverse side gas shielding device for barrel fusion welding. The butt joint circular seam reverse side gas shielding device for barrel fusion welding is characterized by comprising a welding jig and a gas shielding channel. The welding jig comprises a supporting ring (1), eight adjusting screw rods (2) and eight arc-shaped gas shielding grooves (3), wherein the radian of each arc-shaped gas shielding groove is equal to the inner diameter of a barrel. Air inflation holes (7) are formed in the sides of the gas shielding grooves (3), perforated plates (4) which assist in uniform diffusion of gas are added to the interior of the gas shielding grooves, and sealing grooves (8) are formed in the arc-shaped surfaces, making contact with the inner wall of the barrel, of the two sides of each gas shielding groove (3). The butt joint circular seam reverse side gas shielding device for barrel fusion welding has the advantages that the whole device is flexible in structure, adjustable, and easy and convenient to operate, and adapts to barrel circular seams with different diameters, the effect of gas shielding of a welding seam molten pool and a near weld zone is good, oval deformation of barrel welding can be reduced, the shielding gas is saved, and the time needed by gas replacement in the process of gas ventilation in advance is shortened.

Owner:云南昆船机械制造有限公司

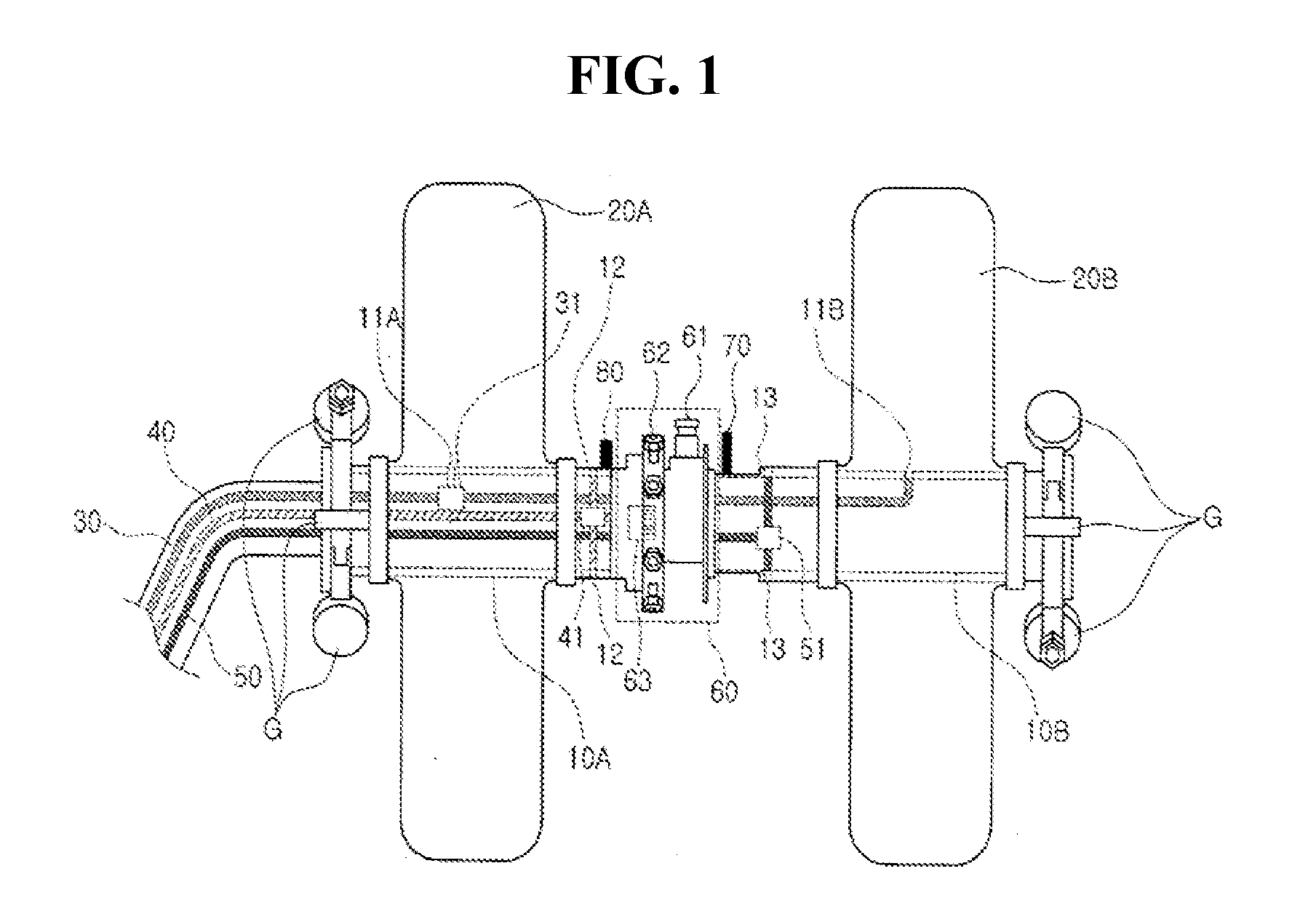

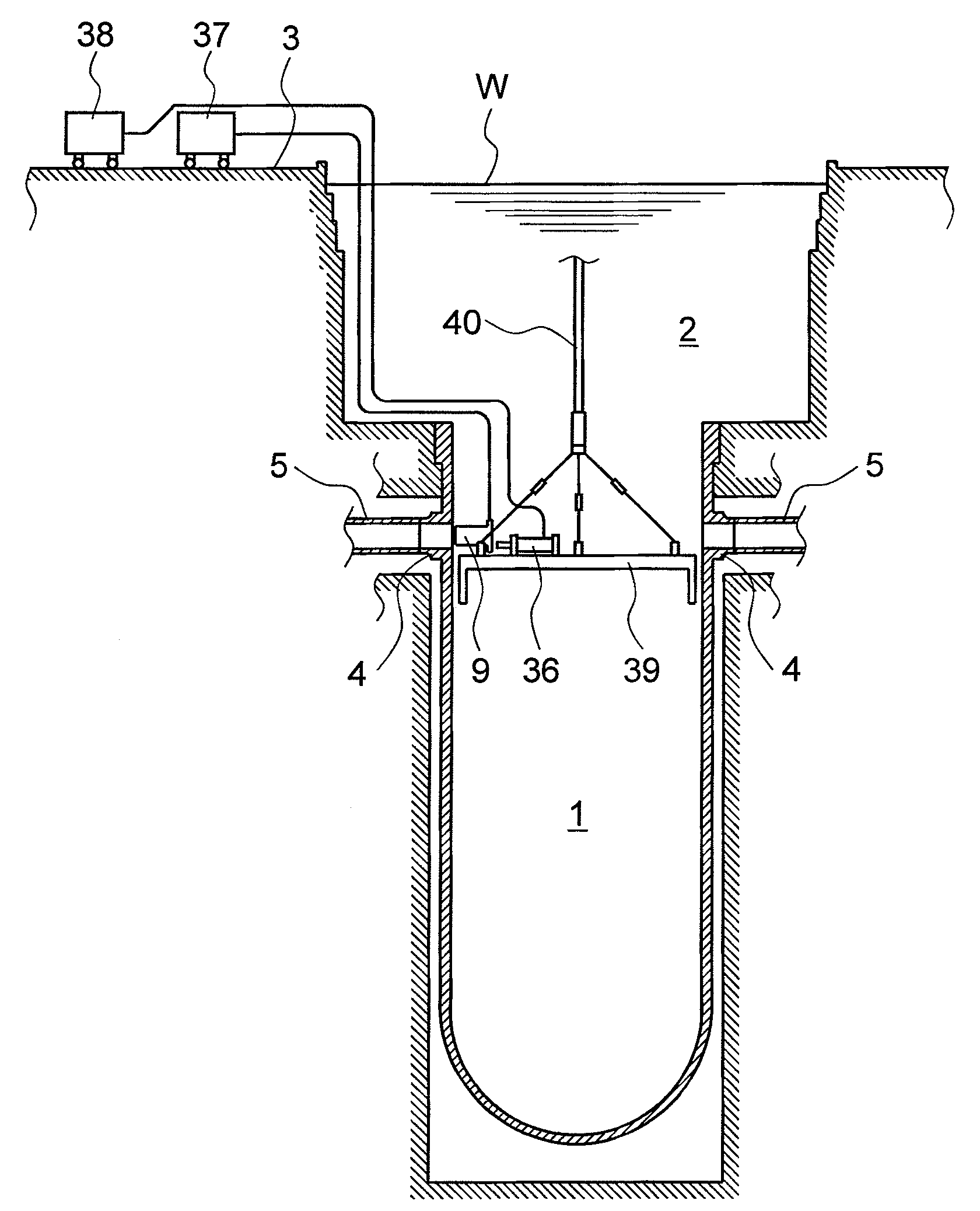

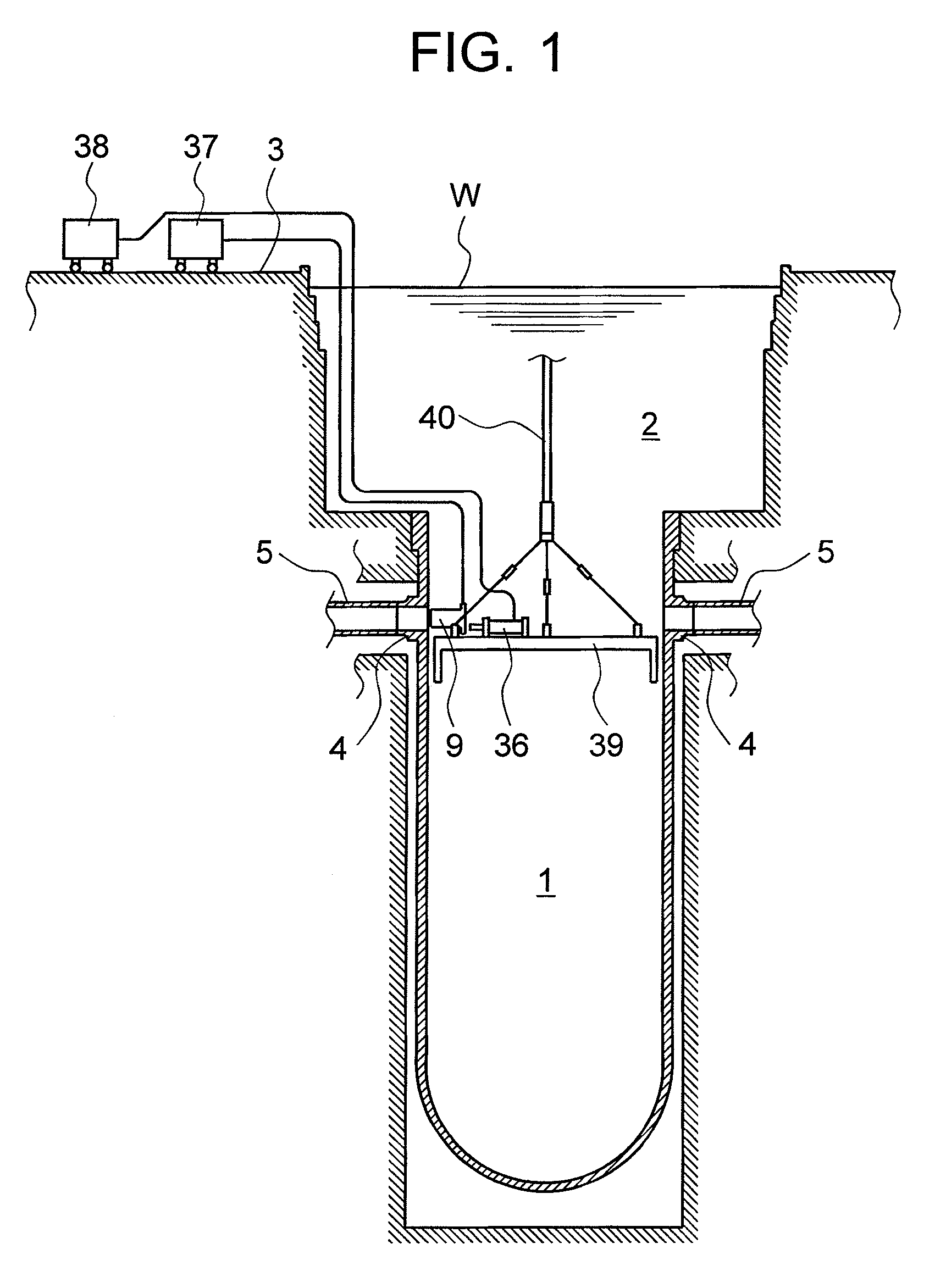

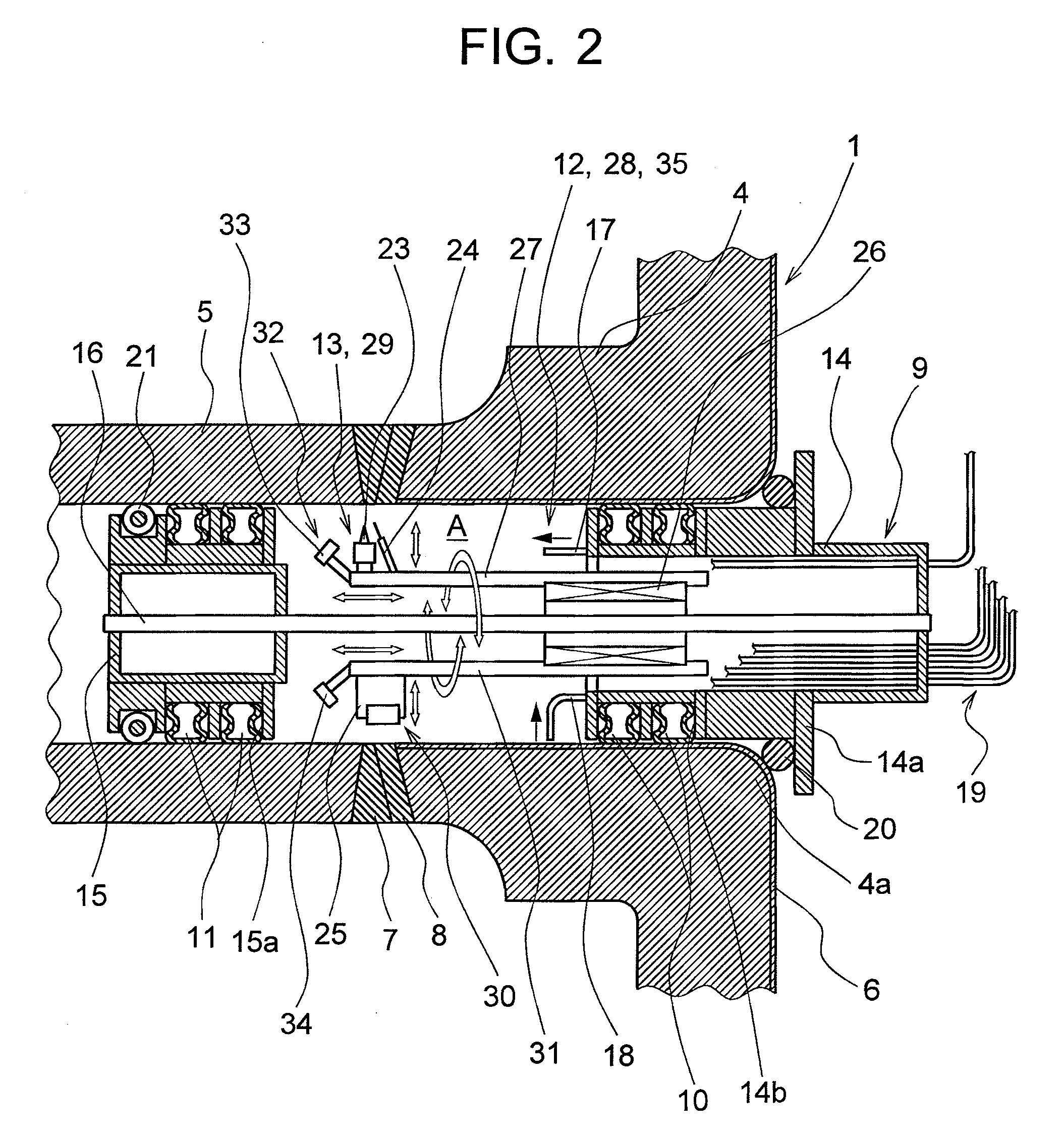

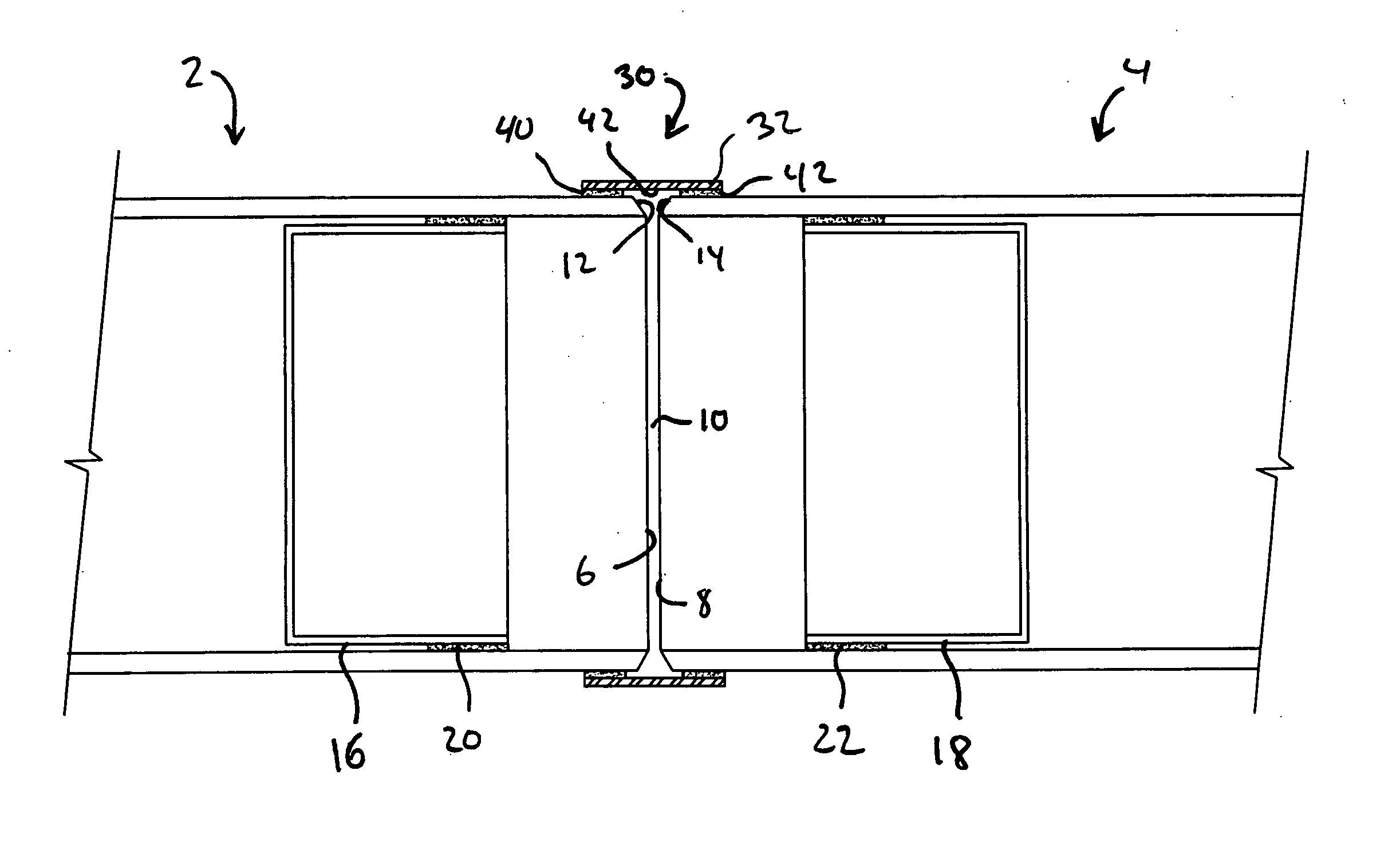

Preserving apparatus for welded joint portion and preserving method therefor

InactiveUS20090166338A1Improve welding qualityShielding gas supply/evacuation devicesSupport devices with shieldingEngineeringAtmosphere

A preserving apparatus for preserving welded joint portions 7, 8 by deposit welding on the inner surface of the welded joint portions 7, 8, in which a nozzle 4 and a pipe 5 supported under water are joined, the apparatus having: a seal member 9 that is disposed in front and behind the welded joint portions 7, 8 to be deposit welded within the nozzle 4 and pipe 5, and serves to demarcate and form a closed operation area A within the nozzle 4 and pipe 5; water drainage means 12 for draining the inside of the operation area A demarcated and formed by the seal member 9 and obtaining a gas atmosphere therein; and welding means 13 for deposit welding on the inner surface of the welded joint portions 7, 8 within the operation area A in which the gas atmosphere has been created.

Owner:IHI CORP

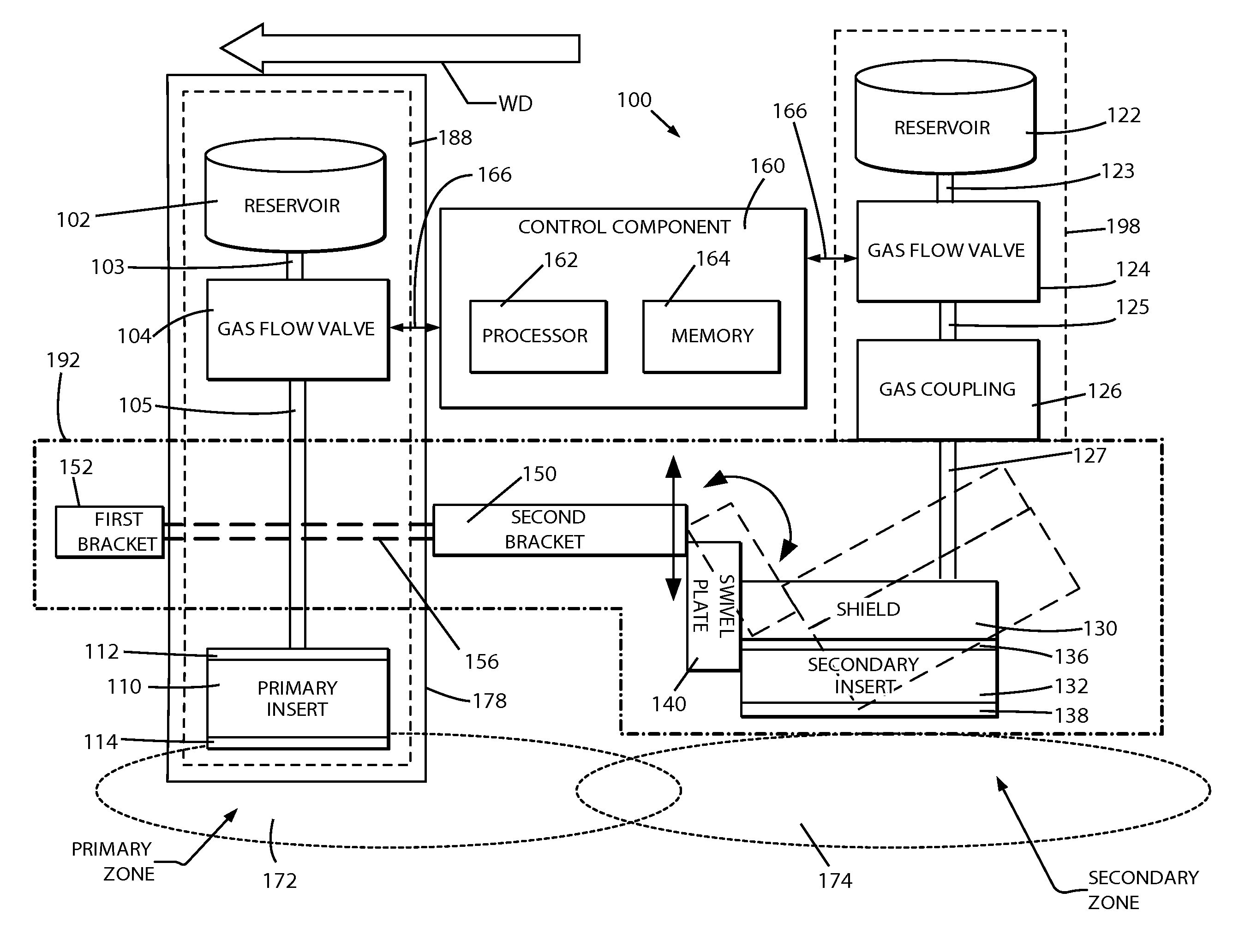

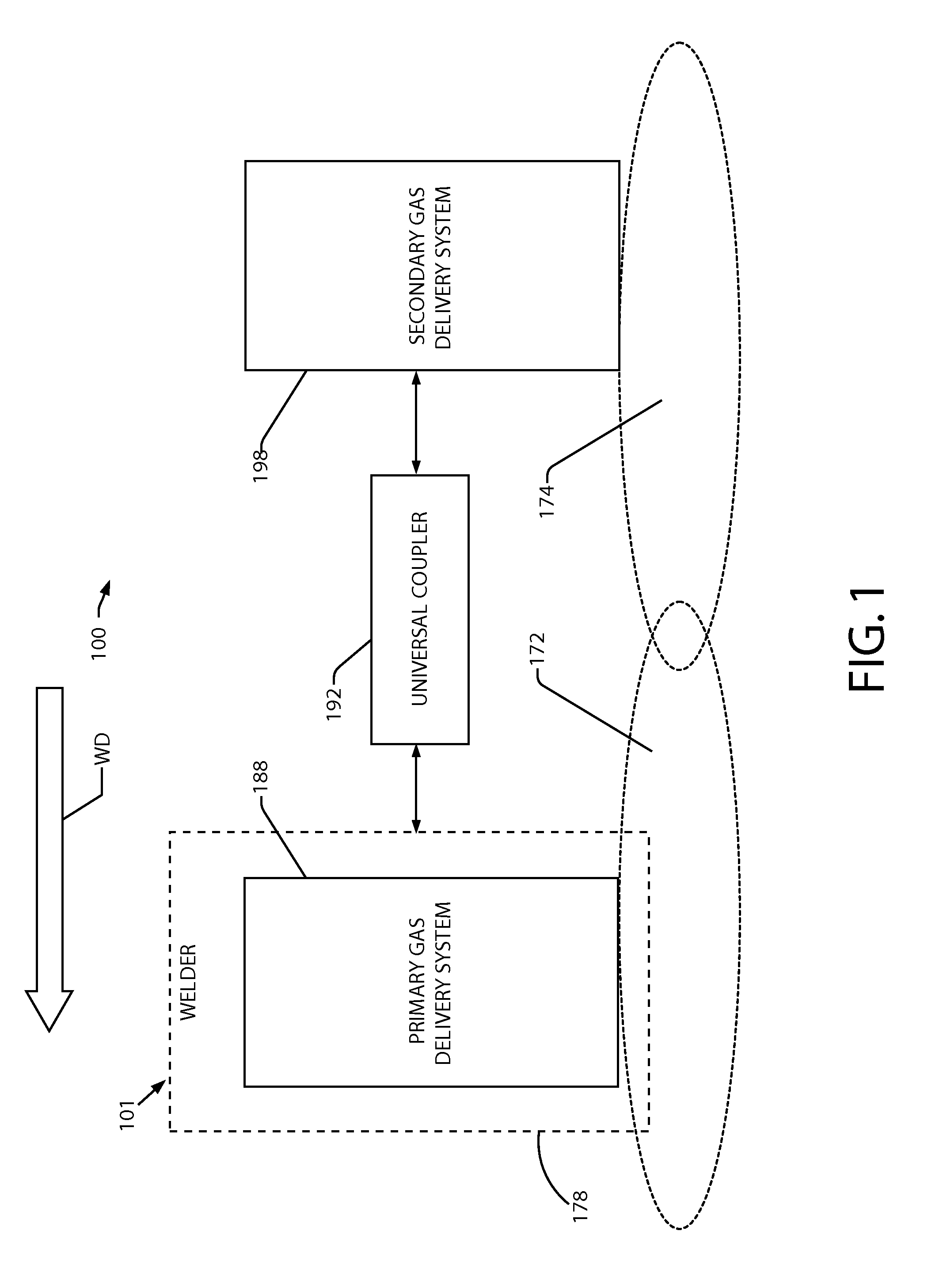

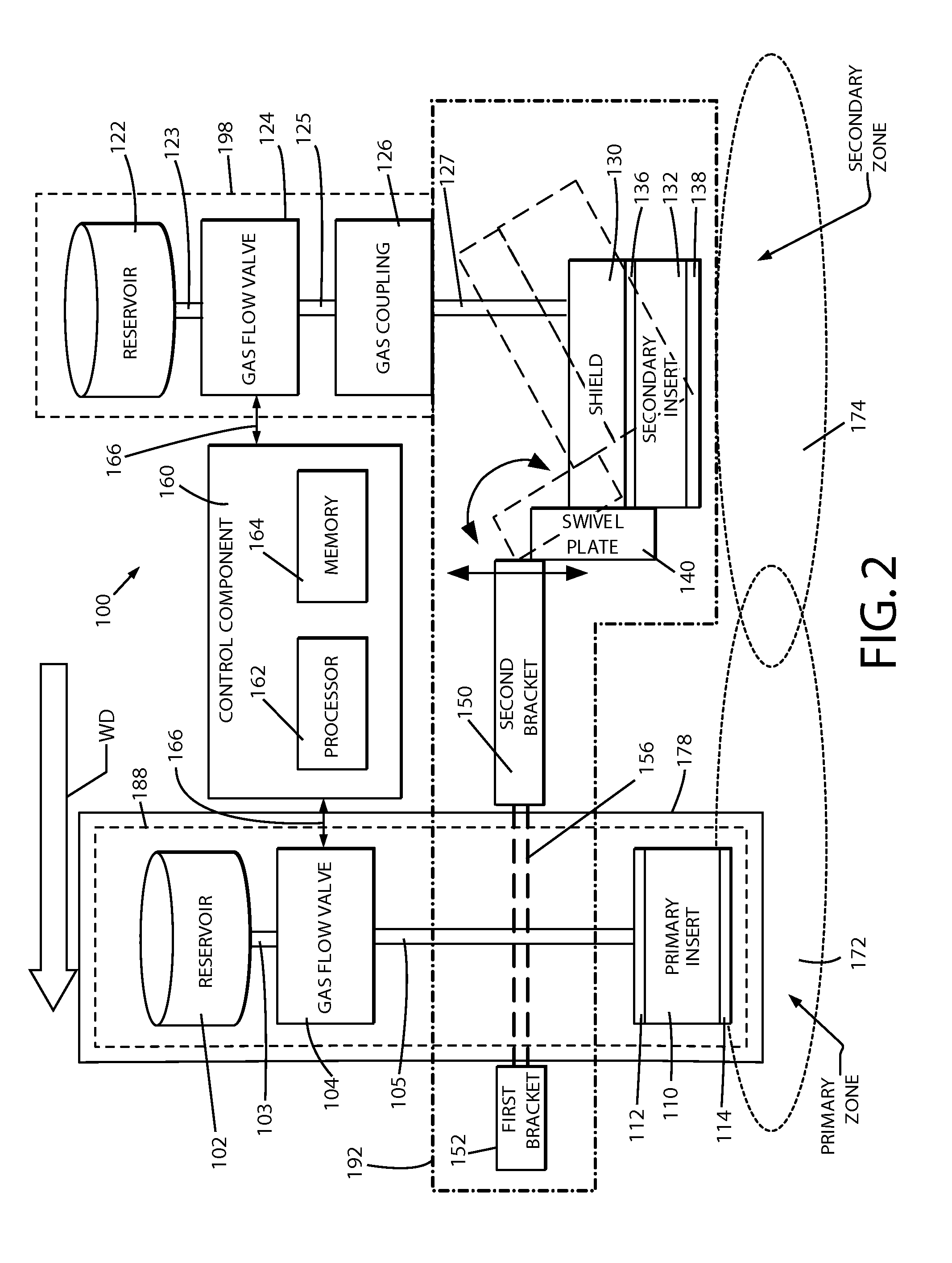

Gas shielding device for a welding system

InactiveUS20130068745A1Easy to optimizeFacilitates linearShielding gas supply/evacuation devicesShielding gasCarbon Dioxide / Helium

A welding system moves in a direction of travel, the welding system includes at least one torch directed toward a first location. The at least one torch each contains an electrode used to facilitate a weld, wherein a primary zone surrounds the electrodes in the first location. A secondary zone is located behind the primary zone with respect to the direction of travel, wherein a second gas line delivers shielding gas toward the secondary zone.

Owner:LINCOLN GLOBAL INC

Welding purge dam for high air flow environment

A water-degradable purge dam apparatus for purging a weld zone of a pipe assembly comprising first and second pipes having respective first and second ends. A first purge dam subassembly adapted for installation in the first pipe end has a hollow first conduit defining a first air flow pathway. A second purge dam subassembly adapted for installation in the second pipe end has a hollow second conduit defining a second air flow pathway. Each subassembly has one or more air flow blocking plates. A hollow third conduit, defining a third air flow pathway, is interconnectable to the first and second conduits members to span the weld zone. The first, second and third air flow pathways allow pressurized air within the pipes to pass through the purge dam apparatus and the weld zone in a sequestered by-pass zone defined by the first, second and third conduits.

Owner:AQUASOL CORP LLC

Weld joint real-time protection cover during welding

InactiveCN105269132AAvoid pollutionShielding gas supply/evacuation devicesWelding protection meansFiberEngineering

Owner:XI AN JIAOTONG UNIV

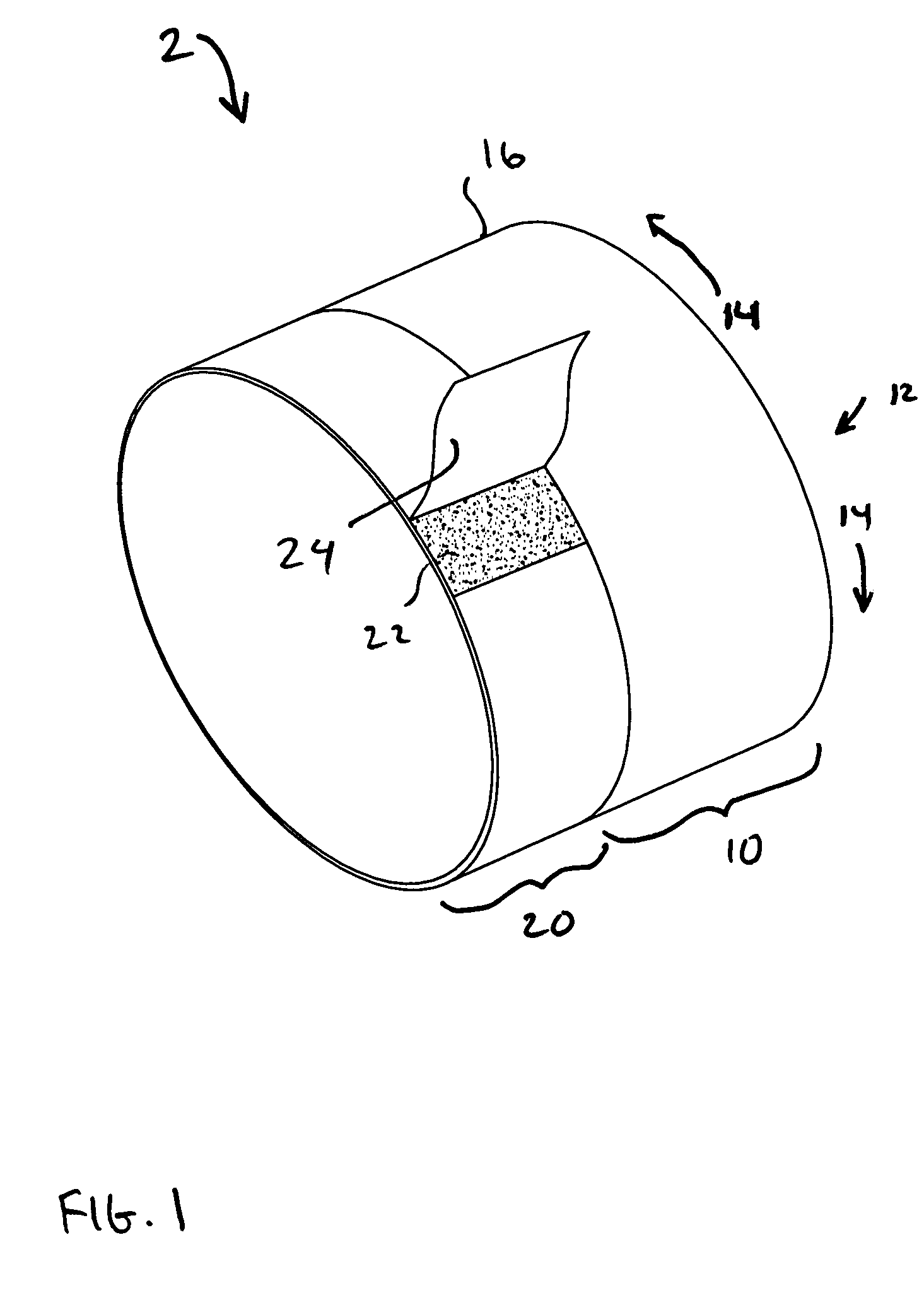

Welding tape and related taping method

InactiveUS20060068142A1Facilitate tape alignmentShielding gas supply/evacuation devicesFilm/foil adhesivesAdhesive beltAdhesive bonding

An inert gas welding tape for retaining a purge gas around a weld zone that is situated at a junction between two structures to be welded together by inert gas welding. The welding tape includes a flexible substrate and a pattern of adhesive on one side of the substrate. The adhesive pattern defines an adhesive-free zone that is substantially free of adhesive and spans the weld zone when the tape is mounted on the structures to be welded, such that substantially no adhesive will be present in the weld zone. The adhesive regions of the adhesive pattern will only contact the structures in areas that are outside of the weld zone. At installation time, a length of the welding tape is selected and any adhesive backing thereon is removed. The welding tape is then positioned over the structures to be welded, preferably with the adhesive-free zone substantially centered over the junction that forms part of the weld zone. With the welding tape in this position, the adhesive regions of the welding tape are adhered to areas of each structure that are outside of the weld zone.

Owner:HACIKYAN MICHAEL

Auxiliary protection gas hood of automatic TIC welder head

ActiveCN103934556AExpand the scope of protectionPrevent oxidationShielding gas supply/evacuation devicesArgon flowEngineering

The invention relates to an auxiliary protection gas hood of an automatic TIC welder head, and belongs to the field of machining. The auxiliary protection gas hood aims to solve the problem that oxidation of metal welding occurs easily near a welding pool in the welding process due to a small protection range of a welding nozzle of a traditional welder. According to the auxiliary protection gas hood, argon enters the auxiliary protection gas hood through a gas-guide tube, the turbulence phenomenon of the argon is reduced through filtering of a first netted plate and a second netted plate, and the argon around a welding gun forms a stable auxiliary argon flow field, so that the area outside of the nozzle of the welding gun and inside of the auxiliary protection gas hood is in the effective protection range of the argon, a good protection effect is achieved at the two sides of the welding pool in the automatic welding process of the easily oxidized metal tungsten electrode argon arc, and oxidation of titanium alloy and other easily oxidized metal is avoided. In the welding process, the auxiliary protection gas hood of the automatic TIC welder head and the welding gun form a whole, and the auxiliary protection gas hood swings along with the welding gun. The auxiliary protection gas hood of the automatic TIC welder head is suitable for the welding of the titanium alloy and other easily oxidized metal.

Owner:HARBIN TURBINE +1

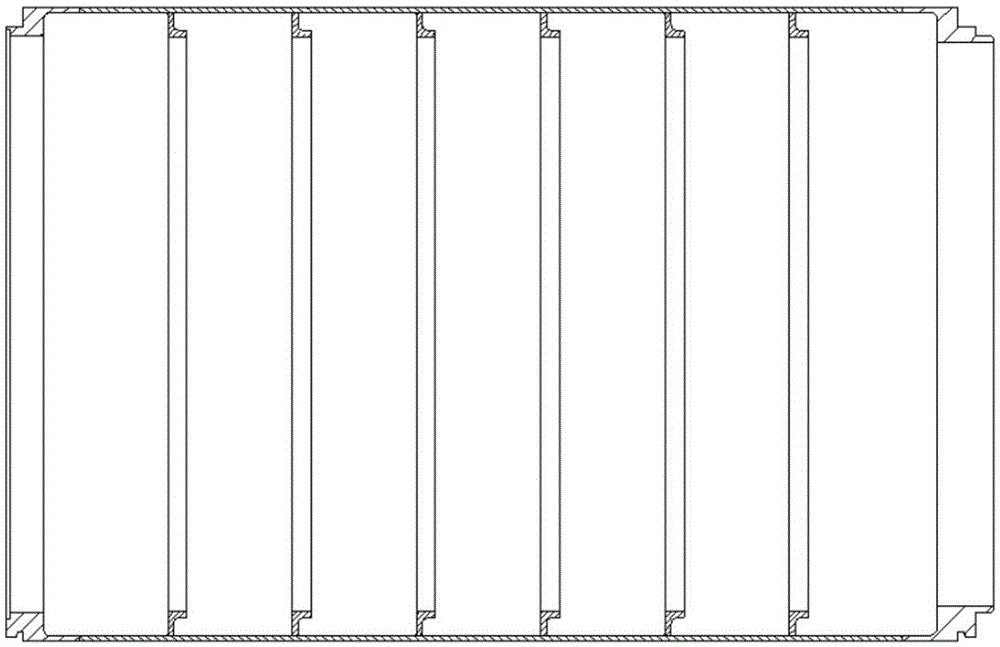

Internal/ external multi-protection narrow gap/ super-narrow gas welding nozzle

ActiveCN104162729ALow gas consumptionReduce consumptionShielding gas supply/evacuation devicesShielding gasEngineering

The invention relates to an internal / external multi-protection narrow gap / super-narrow gas welding nozzle which comprises a nozzle body with three gas inlet through holes, wherein one gas inlet through hole serves as a primary shielding gas channel, and the other two gas inlet through holes serve as secondary shielding gas channels parallel to the primary shielding gas channel in height. The internal / external multi-protection narrow gap / super-narrow gas welding nozzle further comprises pressure reduction and equalizing cavities and flow uniforming sieves, and the lower portions of the flow uniforming sieves are communicated with open gas outlet channels of a primary shielding gas area, a left secondary shielding gas area and a right secondary shielding gas area. The internal / external multi-protection narrow gap / super-narrow gas welding nozzle has the advantages that primary protection and secondary protection of filling welding passes in joints, sub-cosmetic welding passes and cosmetic welding passes can be met, protection welding of primary shielding gas and secondary shielding gas of the same gas and different gases can be met, bidirectional and unilateral backward pulling gas protection is achieved, and gas consumption is greatly reduced while welding quality is improved; the internal / external multi-protection narrow gap / super-narrow gas welding nozzle is made of ceramic materials, so that the internal / external multi-protection narrow gap / super-narrow gas welding nozzle is reliable in high-temperature insulation performance and long in service life.

Owner:HUBEI HONGLU STEEL STRUCTURE +1

Gas bottle for welding-type devices

ActiveUS20050252889A1Shielding gas supply/evacuation devicesVessel mounting detailsGas cylinderShielding gas

A gas bottle for welding-type devices, a shielding gas system, and a method for providing shielding gas to a weld are disclosed. The gas bottle has a valve constructed to be connected to a welding-type device and is preferably formed to fit within a cavity of a welding-type device. The gas bottle is constructed to provide shielding gas to the welding-type device immediately upon connection of the gas bottle to the welding-type device thereby eliminating a manual valve.

Owner:ILLINOIS TOOL WORKS INC

Method for controlling weld quality

InactiveUS20090107970A1Improve welding qualityStay focusedShielding gas supply/evacuation devicesWelding/cutting media/materialsCarbon Dioxide / HeliumShielding gas

The present invention relates to a method for controlling weld quality. The method comprises the steps of producing a shield gas curtain around the heat source and producing a shroud gas curtain spaced radially outward from the shield gas curtain, wherein the shroud gas curtain comprises a radially outward component of velocity. The shield gas curtain and the shroud gas curtain are configured to control the resultant mechanical and / or surface properties of the weld. The present invention also relates to a method for substantially confining and concentrating shield gas about the vicinity of a welding site, and a method for substantially recovering and reusing a shield gas in a welding operation.

Owner:BOC LTD +1

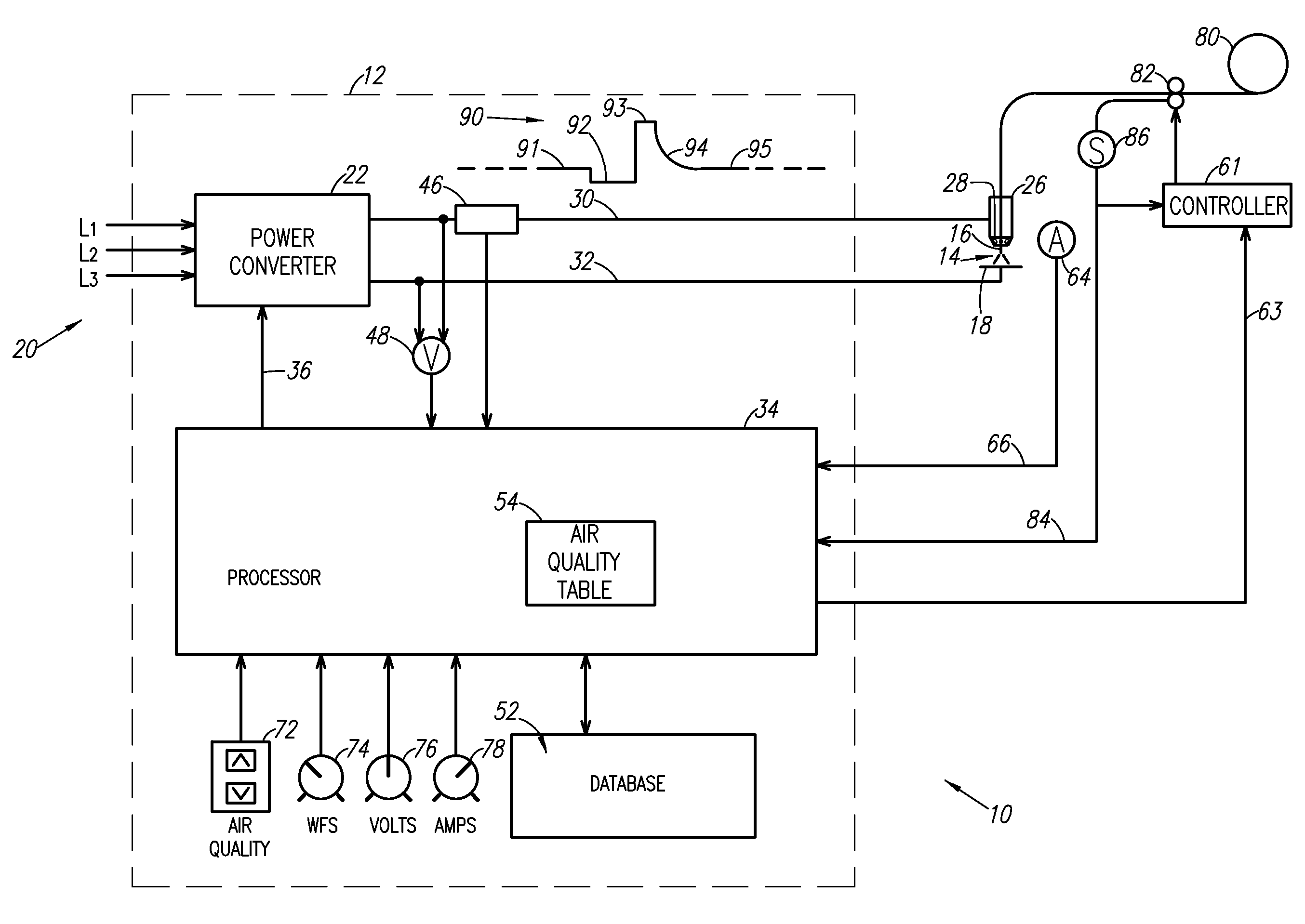

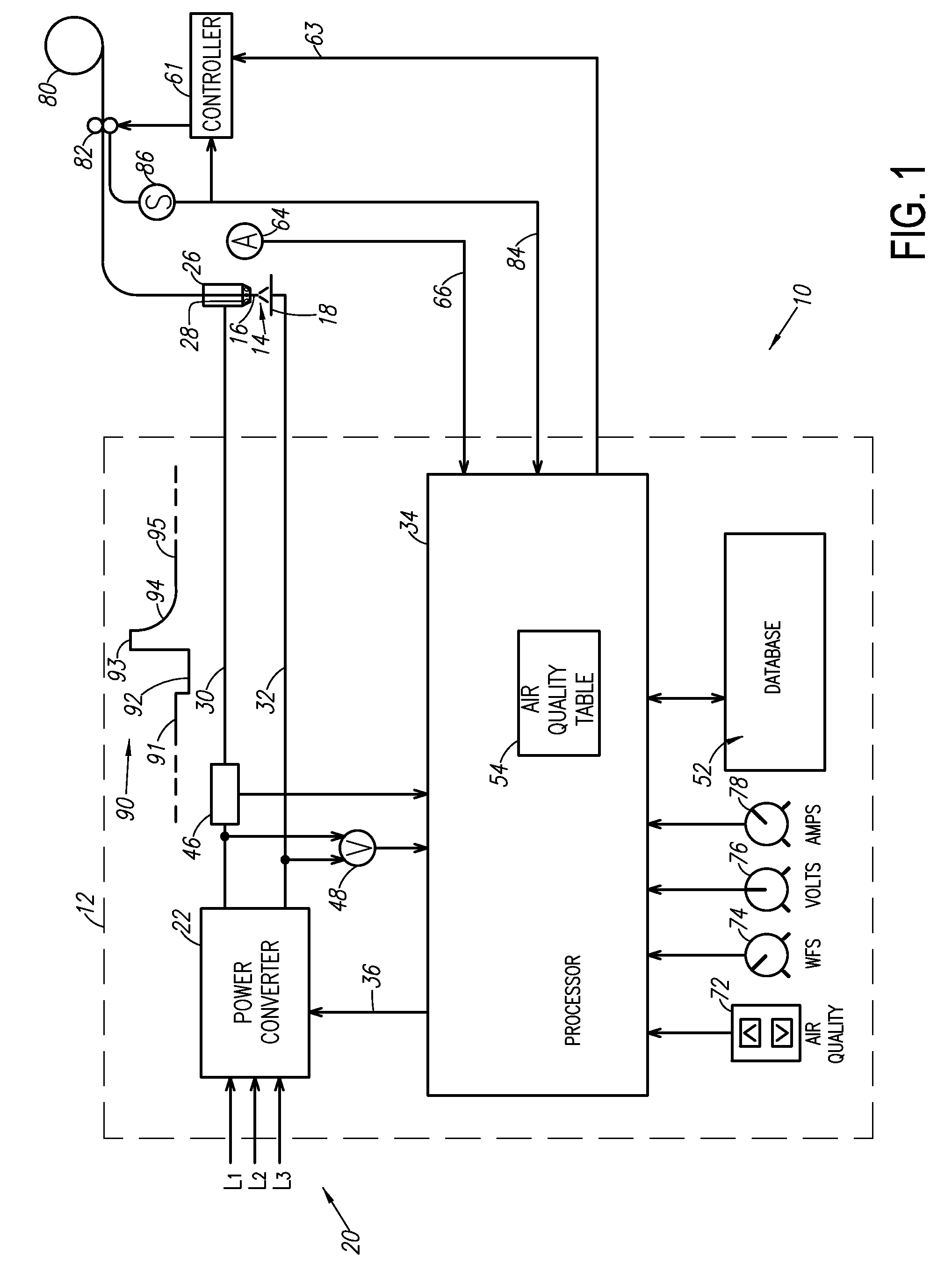

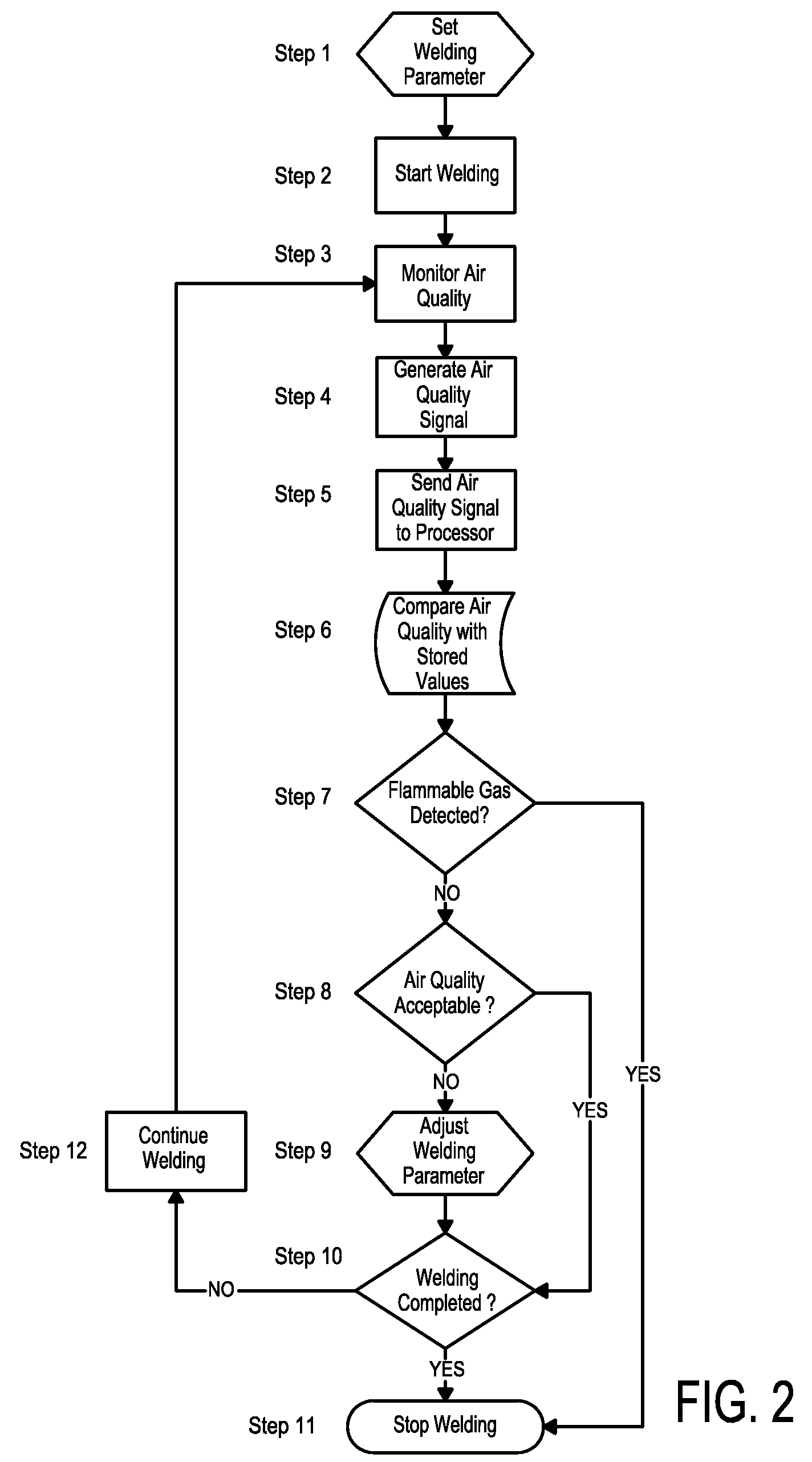

System for monitoring and controlling air quality during welding

InactiveUS20160297025A1Shielding gas supply/evacuation devicesDigital data information retrievalTorchEngineering

A fume reduction system includes an electric arc torch, a consumable wire electrode, an air quality sensor, and a power supply operatively connected to the electric arc torch and the air quality sensor. The air quality sensor monitors air quality near the electric arc torch and generates an air quality signal corresponding to the air quality. The power supply supplies electrical energy for generating the electrical arc and controls the wire feed speed of the consumable wire electrode. The power supply further receives the air quality signal and automatically reduces the wire feed speed from a first positive speed to a second positive speed based on the level of the air quality signal.

Owner:LINCOLN GLOBAL INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com