Internal/ external multi-protection narrow gap/ super-narrow gas welding nozzle

A technology with multiple protections and narrow gaps, which is applied in the direction of providing/removing protective gas devices, welding equipment, welding accessories, etc., can solve the problems of large gas consumption, reduction, unfavorable welding production costs, etc., and achieve long life and high temperature insulation Reliable performance and reduced power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

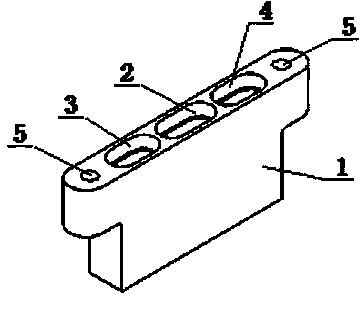

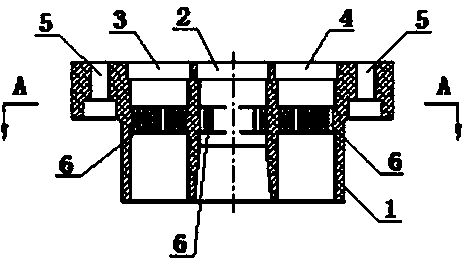

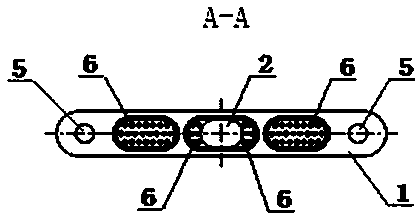

[0027] Example 1: It is a basic embodiment of the present invention. Such as Figure 1 to Figure 4 As shown, an internal / external multiple protection narrow-gap / ultra-narrow-gap welding nozzle includes a long nozzle body 1, and the upper part of the nozzle body 1 along the height direction has 3 air intake through holes side by side: the middle one It is the primary protective gas channel 2, and there is a secondary protective gas channel on the left and right sides, respectively, the left secondary protective gas channel 3 and the right secondary protective gas channel 4; the two outer ends near the nozzle body 1 have 1 screw holes 5; the primary protective gas channel 2 is a through hole in the middle that can facilitate the installation and disassembly of the contact tip; the two secondary protective gas channels are through holes parallel to the primary protective gas channel 2 in the height direction. The upper part of the hole is a decompression and equalization chamb...

Embodiment 2

[0028] Example 2: Be the further embodiment of embodiment 1. The internal / external multiple protection narrow gap / ultra-narrow gap welding nozzle, the structure of the uniform flow screen 6 in the two secondary protection gas passages is that a plurality of evenly distributed parallel straight holes are arranged on the partition, and the straight The holes are used to force the shielding gas to flow laminarly when it is ejected from the partition. The thickness of the uniform flow sieve 6 is 3 mm to 5 mm, the diameter of the sieve holes of the uniform flow screen 6 is 0.8 mm to 1.2 mm, and the hole distance is designed according to the average distribution of the uniform flow holes on the cross-sectional area of the secondary protective gas channel. The nozzle body 1 is flat, and the connection between the nozzle and the welding torch is a screw connection. The thickness of the flat-shaped nozzle: this embodiment is aimed at the narrow gap mixed gas shielded welding and i...

Embodiment 3

[0031] Example 3:is a preferred embodiment. The difference from Example 2 is that the thickness of the leveling sieve 6 is 4 millimeters, and the diameter of the mesh of the leveling sieve 6 is 1 millimeter. The thickness of the flat nozzle is manufactured according to the needs of narrow gap mixed gas shielded welding and inert gas shielded welding (MAG / MIG) where the welding groove assembly gap G is 12 mm, and the thickness of the nozzle is 8 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com