Multistage atomization gas-liquid two-phase large-caliber mist nozzle

An atomized gas and large-diameter technology, which is applied in the direction of liquid spraying devices and spraying devices, can solve the problems of uneven spray distribution and unequal liquid volume, and achieve uniform droplet distribution, reduced gas consumption, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

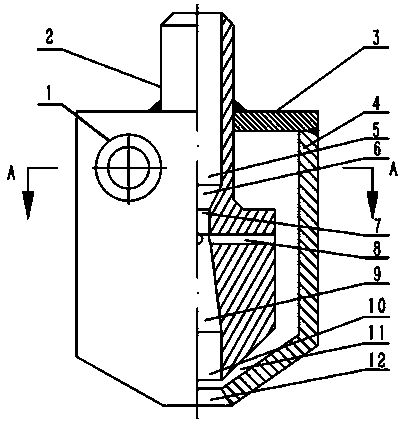

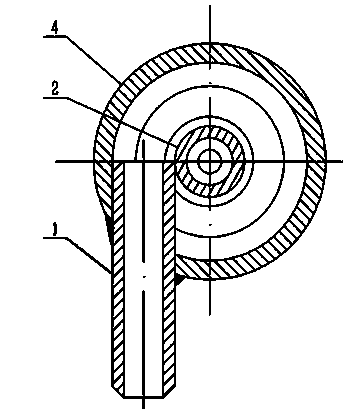

[0035] A multi-stage atomizing gas-liquid two-phase large-diameter fine mist nozzle. Such as figure 1 , image 3 and Figure 5 As shown, the nozzle includes an inlet pipe 1 , a liquid inlet pipe 2 , a top cover 3 and a swirl tube 4 .

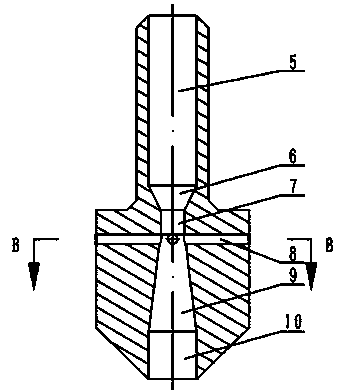

[0036] Such as figure 2 As shown, the shape of the liquid inlet pipe 2 is that the upper part is a small cylinder, the middle part is a large cylinder and the lower part is a truncated cone; the center of the liquid inlet pipe 2 is provided with a through hole, and the through holes are sequentially from top to bottom. The straight pipe section 5, the reducer pipe section 6 of the Venturi pipe, the throat section 7 of the Venturi pipe, the expanding pipe section 9 of the Venturi pipe and the lower straight pipe section 10 are composed.

[0037] Such as figure 1 and Figure 5 As shown, the swirl tube 4 is composed of a hollow cylinder in the upper section and a hollow truncated cone in the lower section.

[0038] Such as figure 1 and F...

Embodiment 2

[0044] A multi-stage atomizing gas-liquid two-phase large-diameter fine mist nozzle. Except following technical statement, all the other are with embodiment 1:

[0045] The distance between the outer wall of the large cylinder of the liquid inlet pipe 2 and the inner wall of the hollow cylinder of the swirl tube 4 is 5-8 mm; the minimum distance of the annular seam 11 is 0.7-1.0 mm.

[0046] The cone angle of the frustum of the liquid inlet pipe 2 is 45-50°; the diameter of the upper straight pipe section 5 of the liquid inlet pipe 2 is 10-15 mm.

[0047] The cone angle of the hollow frustum of the cyclone 4 is 30 ~ 35 °

[0048] Such as Figure 5 As shown, the small cylinder of the liquid inlet pipe 2 is composed of two sections of cylinders whose diameter is small at the top and large at the bottom; the fixed connection method is threaded connection; There is a sealing ring at the connection.

[0049] The compressed air in this specific embodiment enters the swirl cylind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cone angle | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com