Excavator energy-recuperation system

An energy recovery and excavator technology, which is applied in the direction of mechanically driven excavators/dredgers, etc., can solve the problems of heavy weight of hydraulic excavators, shortened life of hydraulic components, and increased system temperature, so as to improve energy utilization. , prolong life, reduce the effect of throttling energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

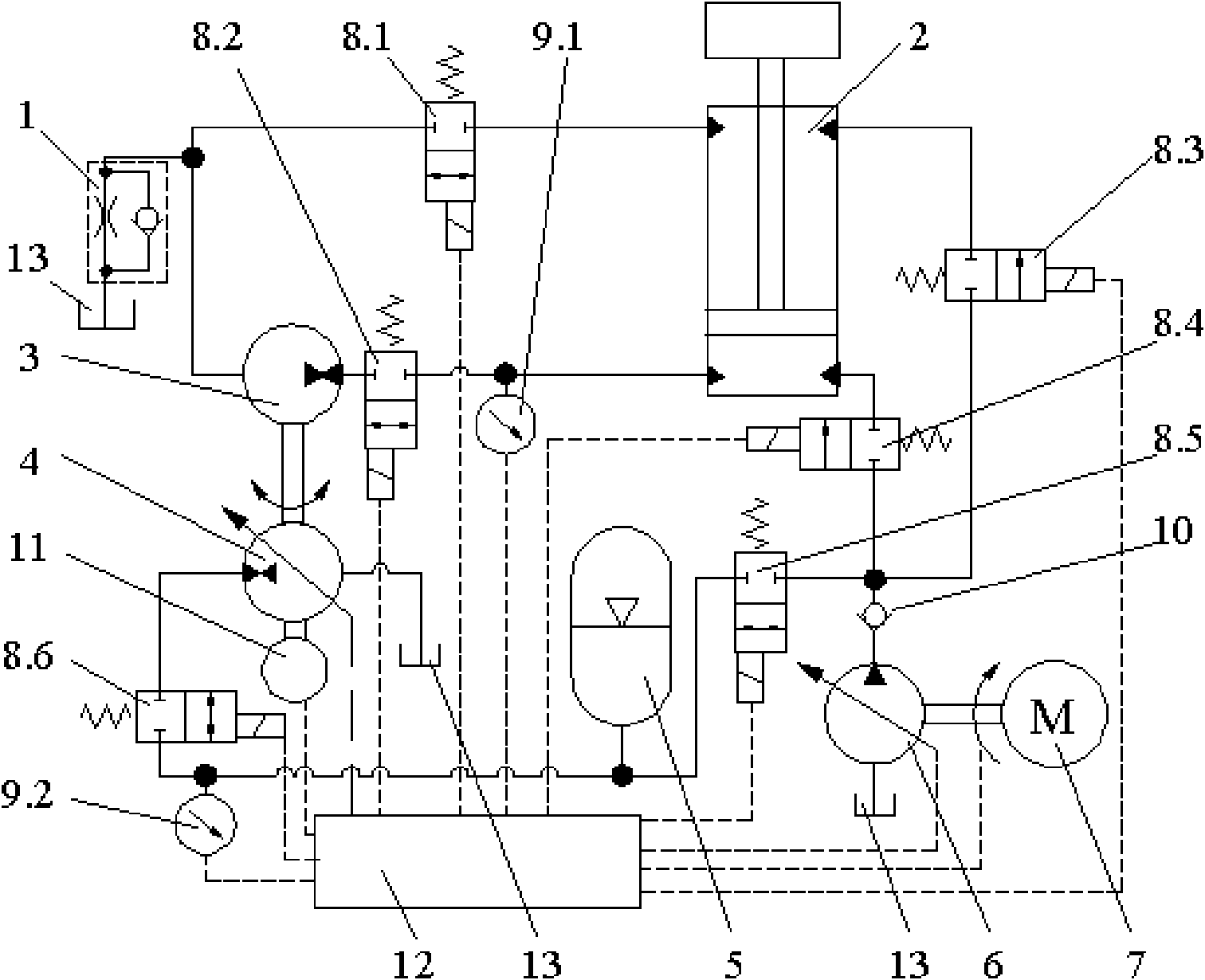

Embodiment 1

[0014] see figure 1 , This embodiment includes a hydraulic cylinder 2, an oil tank 13, a quantitative pump / motor 3, a valve and an engine 7. The key technology is to install the first variable pump / motor 4 and the speed measuring photoelectric encoder 11 coaxially with the quantitative pump / motor 3, the quantitative pump / motor 3 and the first variable pump / motor 4 form a hydraulic transformer; one end of the quantitative pump / motor 3 The second reversing valve 8.2 is connected with the lower chamber of the hydraulic cylinder 2, and the second reversing valve 8.2 is also connected with the first pressure sensor 9.1; Oil tank 13, the other way is connected with the upper cavity of hydraulic cylinder 2 through the first reversing valve 8.1, and the one-way throttle valve 1 is used to increase the fluid pressure returned to the oil tank 13 output by the quantitative pump / motor 3, so that the fluid pressure returned to the oil tank 13 Part of the fluid is supplied back to hydrauli...

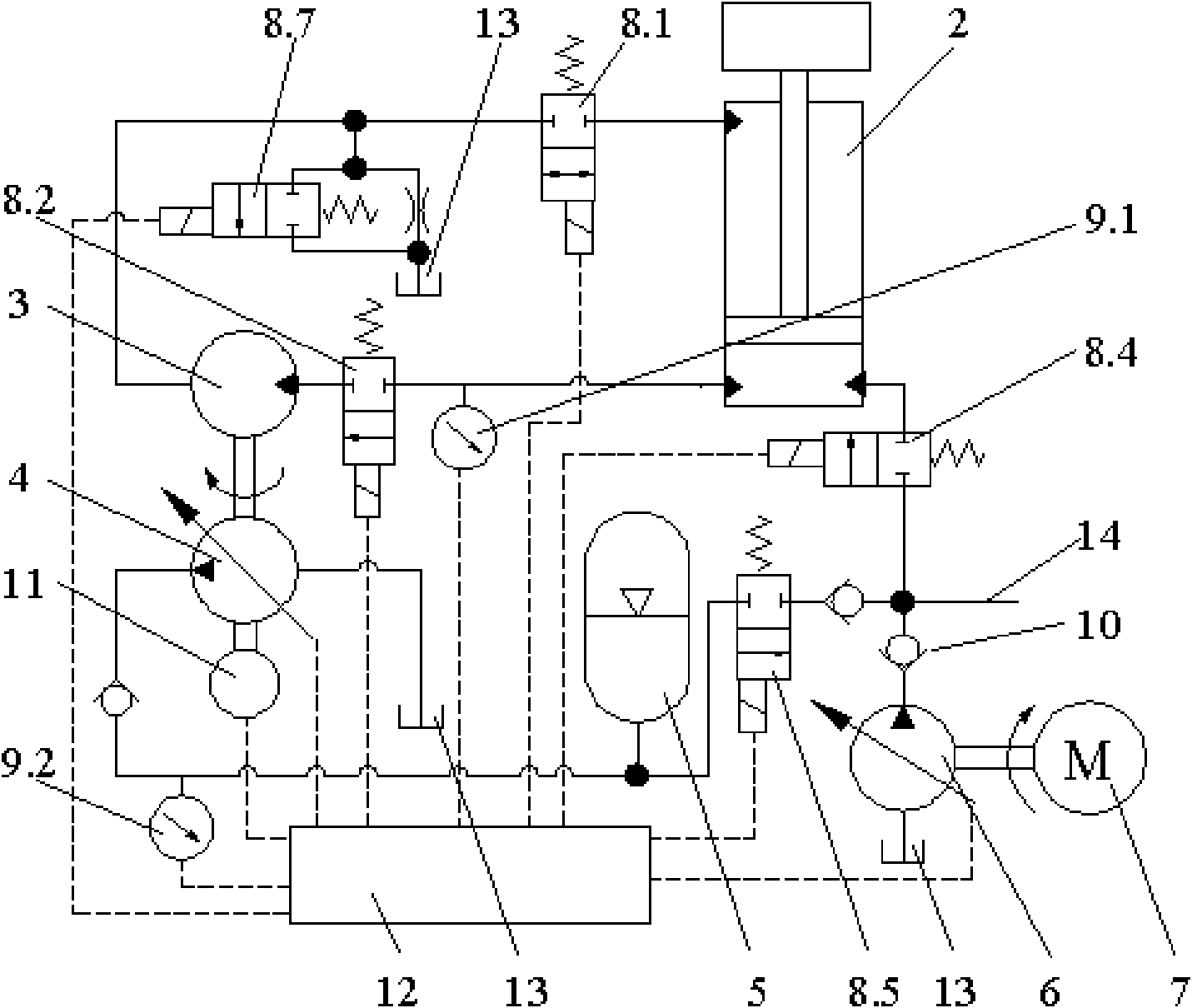

Embodiment 2

[0016] see figure 2 , This embodiment includes a hydraulic cylinder 2, an oil tank 13, a quantitative pump / motor 3, a valve and an engine 7. The key technology is to install the first variable pump / motor 4 and the speed measuring photoelectric encoder 11 coaxially with the quantitative pump / motor 3, the quantitative pump / motor 3 and the first variable pump / motor 4 form a hydraulic transformer; one end of the quantitative pump / motor 3 The second reversing valve 8.2 is connected to the lower chamber of the hydraulic cylinder 2, and the second reversing valve 8.2 is also connected to the first pressure sensor 9.1; the other end of the quantitative pump is divided into two circuits, and the first one is connected through the seventh reversing valve 8.7 Oil tank 13, the other way is connected with the upper chamber of hydraulic cylinder 2 through the first reversing valve 8.1, and the seventh reversing valve 8.7 is used to increase the fluid pressure returned to the oil tank 13 ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com