Hydraulic excavating energy saving system

An energy-saving system and hydraulic accumulator technology, which is applied to mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., can solve the problems that affect the energy recovery efficiency of the system and have many energy conversion links. Achieve the effects of reduced power level, high power density, and avoiding energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

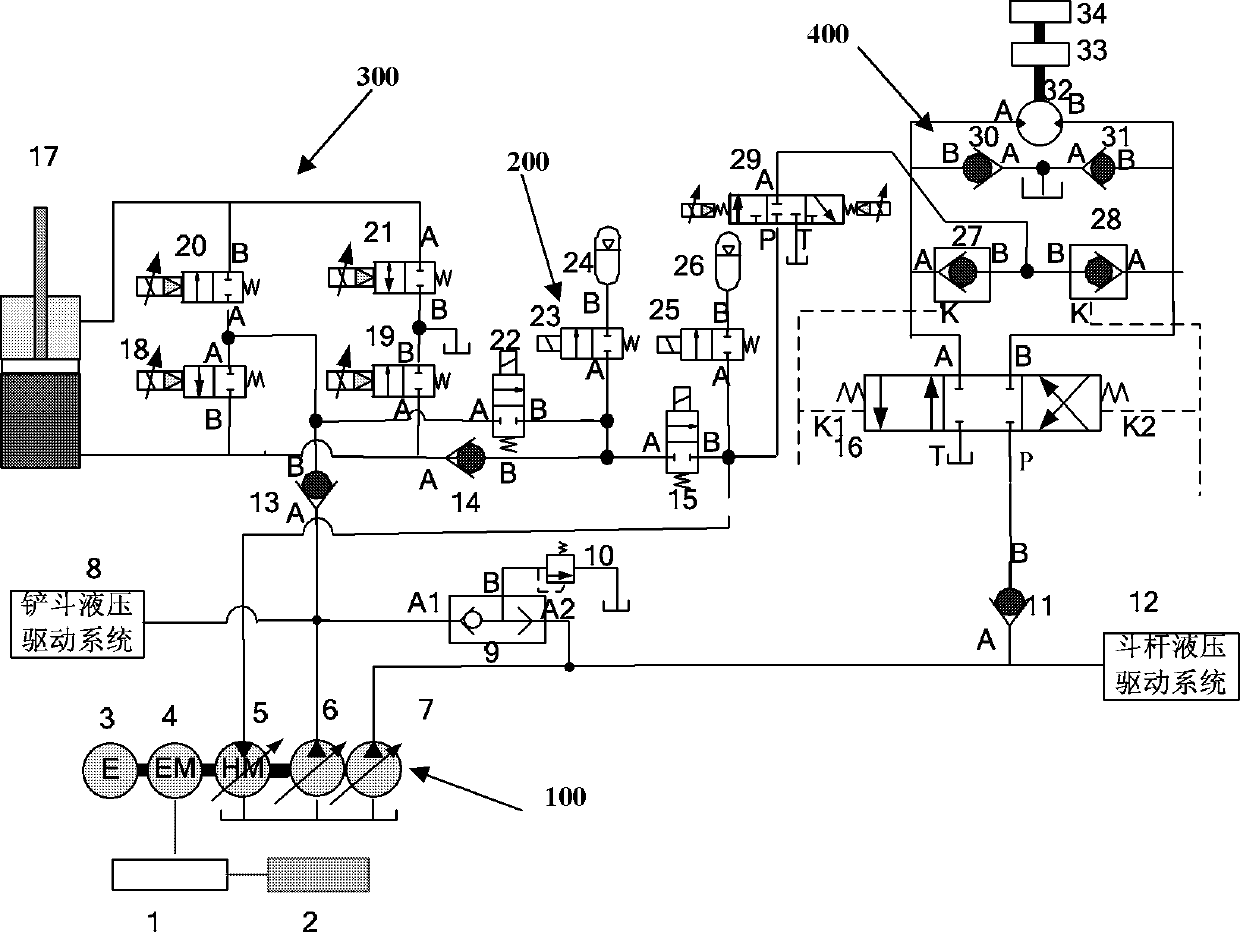

[0052] Please refer to the attached figure 1 As shown, it shows the specific structure of the preferred embodiment of the present invention, which includes the boom drive cylinder 17 and the boarding mechanism 34, and also includes the oil-electric-hydraulic hybrid drive system 100, the hydraulic accumulator control unit 200, the dynamic Arm drive cylinder hydraulic control unit 300, boarding mechanism hydraulic control unit 400, inverter 1, battery 2, first check valve 11, second check valve 13, third check valve 14, shuttle valve 9, safety valve 10. Bucket hydraulic drive system 8 , stick hydraulic drive system 12 , first hydraulic accumulator 24 , second hydraulic accumulator 26 , and reducer 33 mechanically connected to boarding mechanism 34 .

[0053] Specifically, the interconnection relationship of each component is as follows:

[0054] The oil-electric-hydraulic hybrid drive system 100 includes an engine 3 connected to a coaxial mechanical transmission, an electric / ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com