Patents

Literature

2110results about "Non-aqueous electrolyte accumulators" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

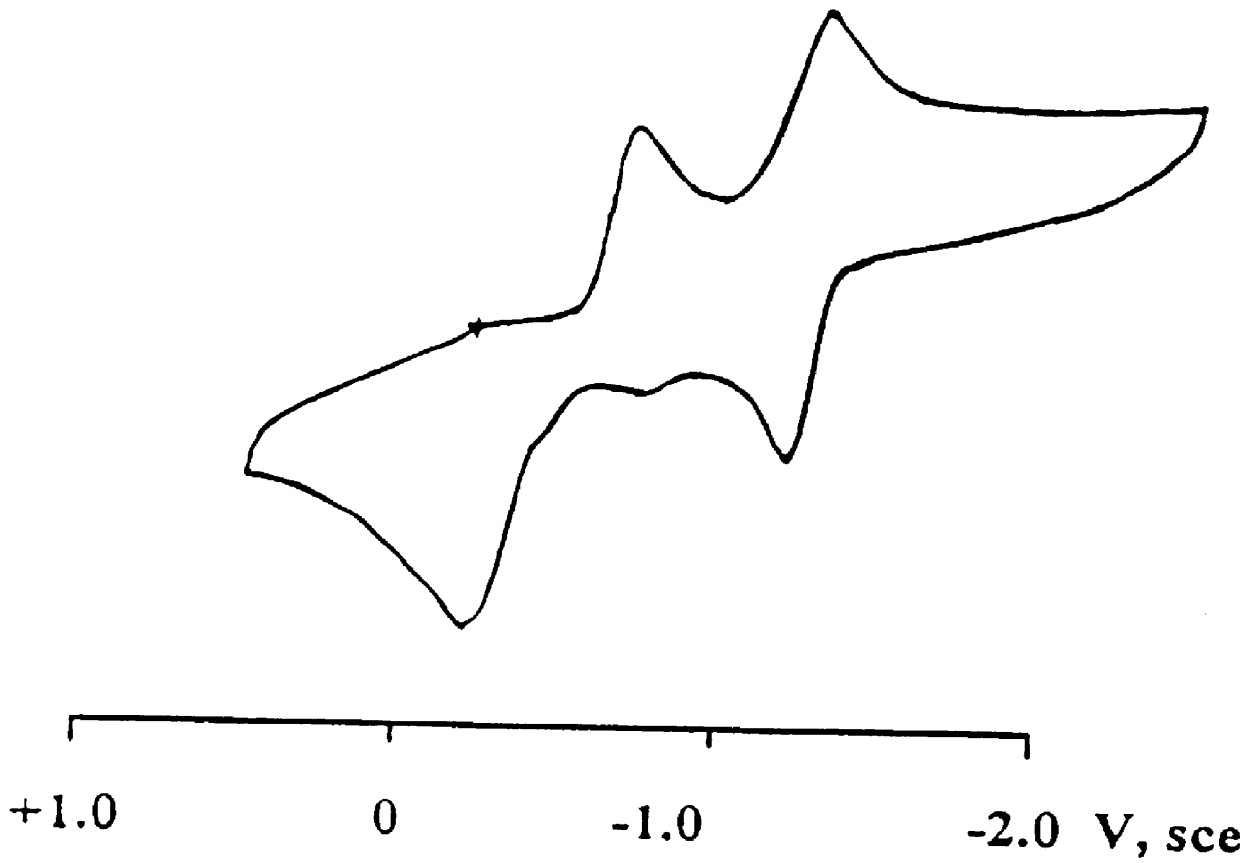

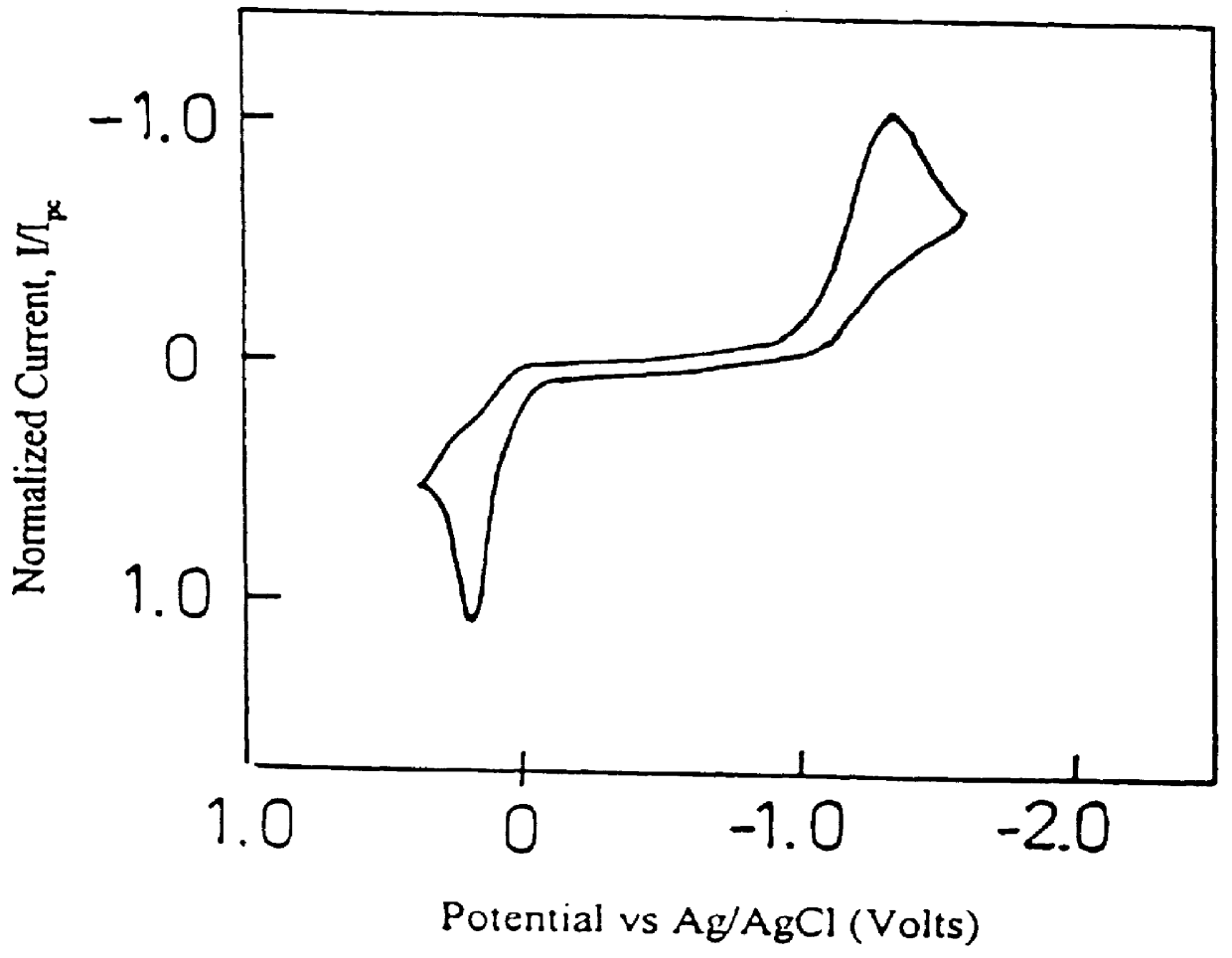

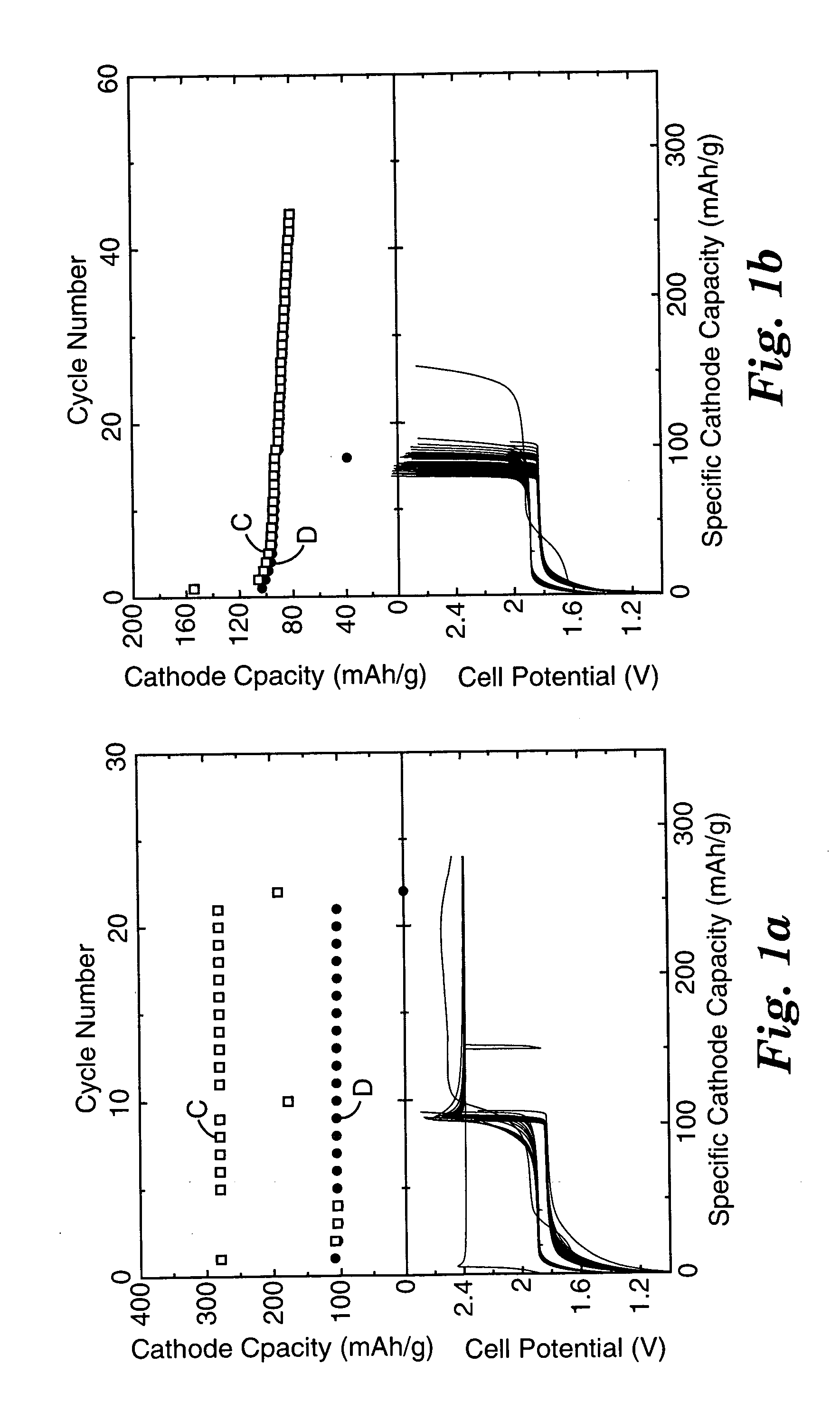

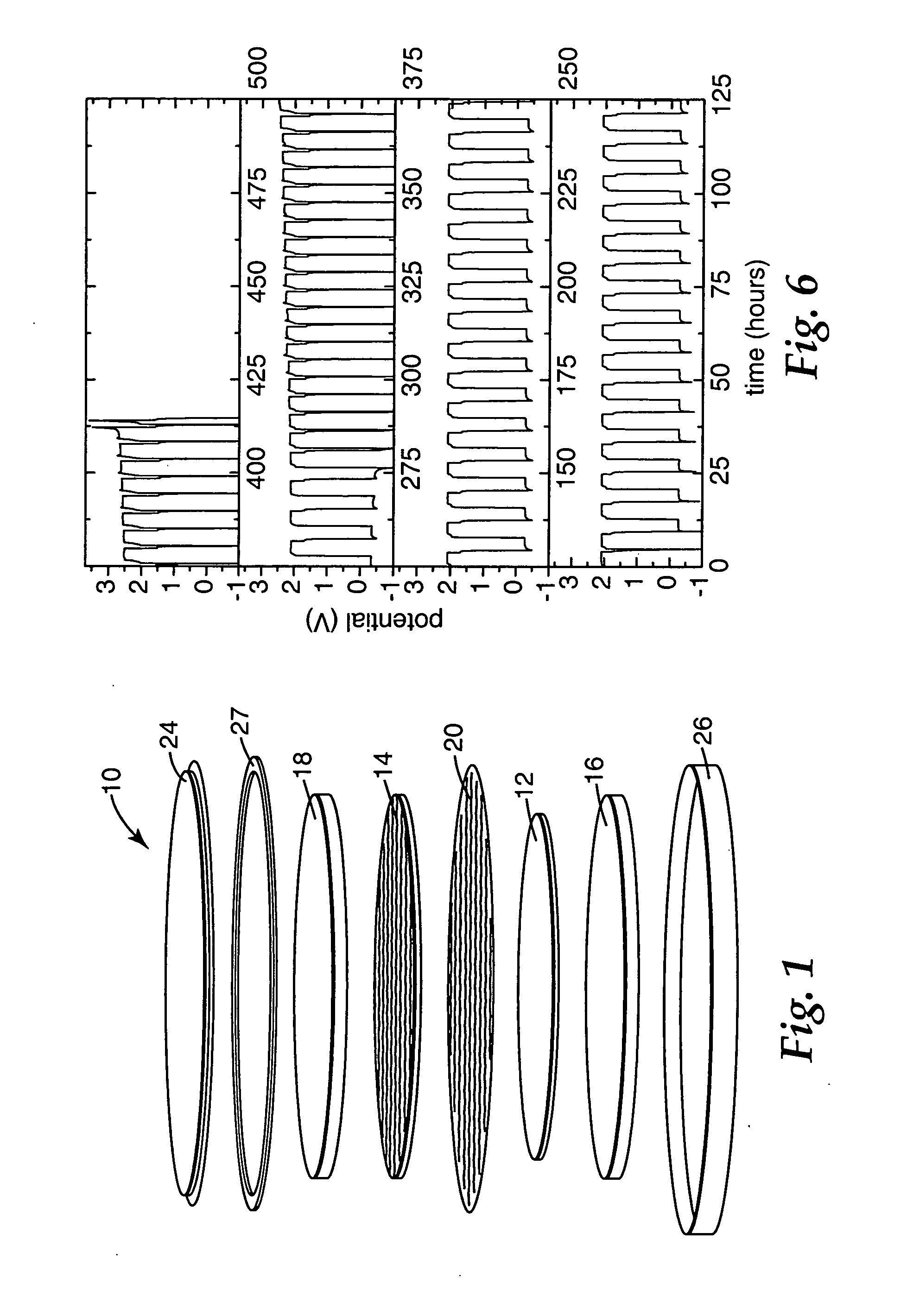

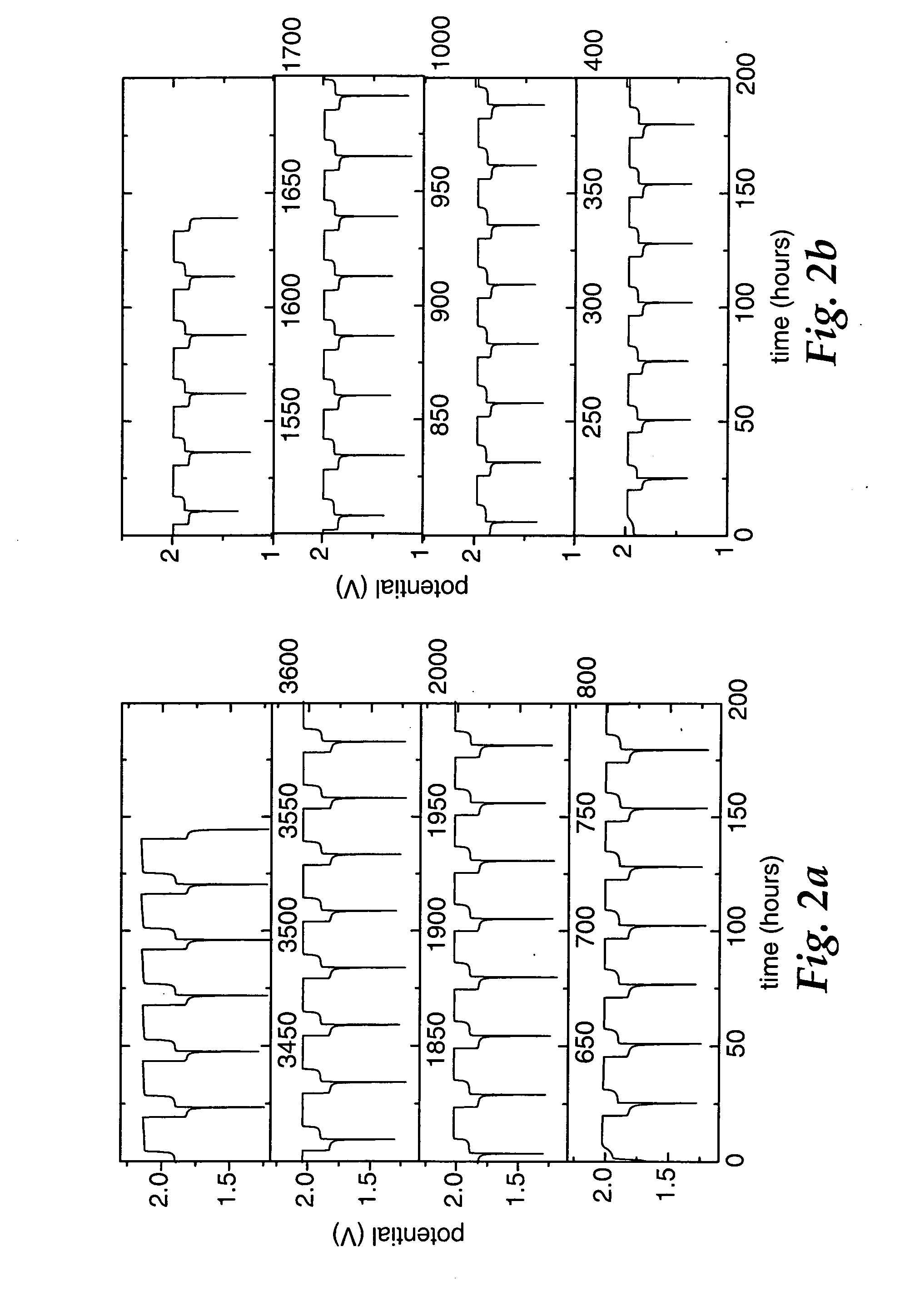

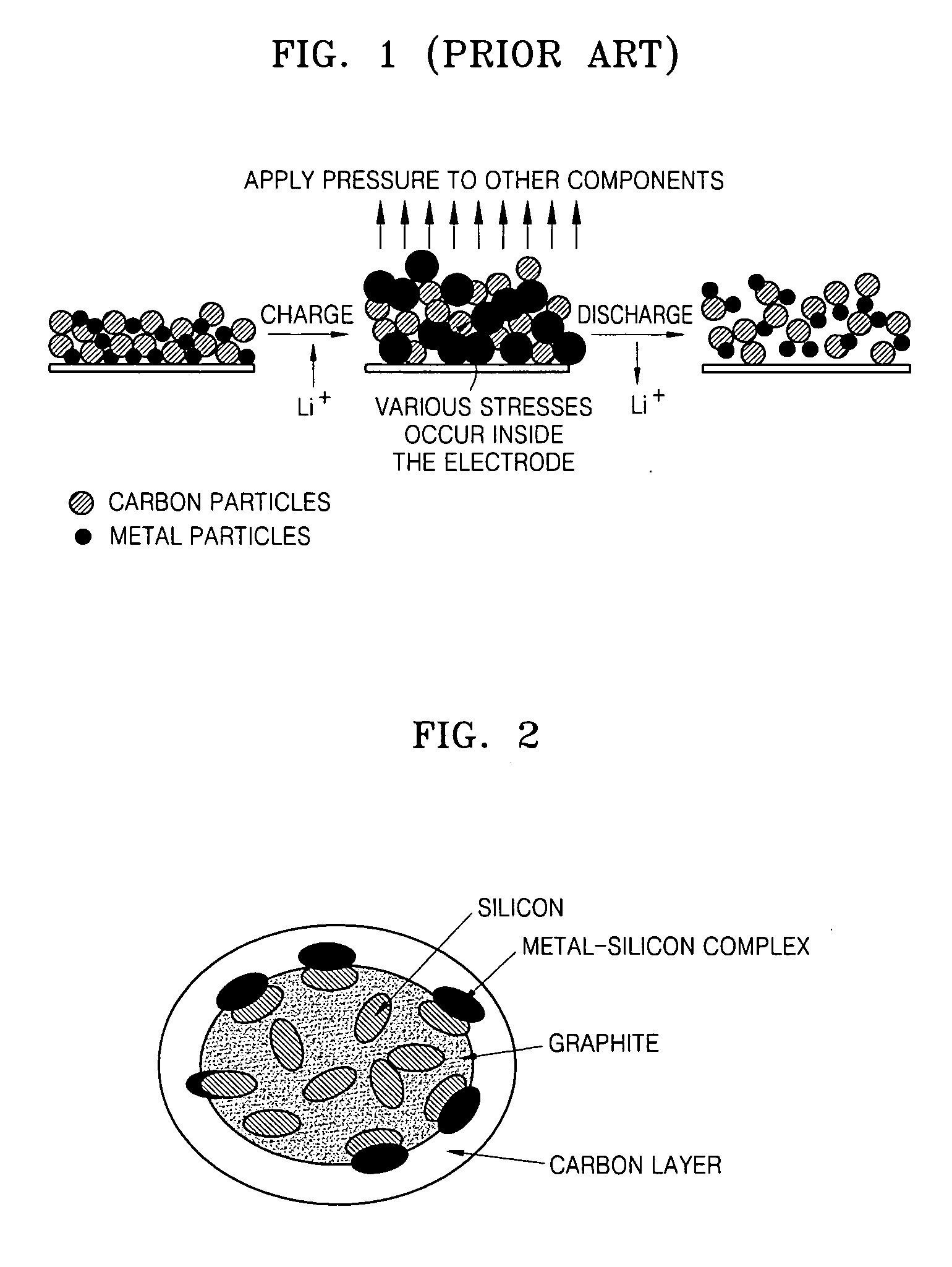

Electroactive high storage capacity polyacetylene-co-polysulfur materials and electrolytic cells containing same

InactiveUS6117590AHigh storage capacity per unit weightFacilitates electron transportElectrode manufacturing processesNon-aqueous electrolyte accumulatorsElectrochemical cellElectrode material

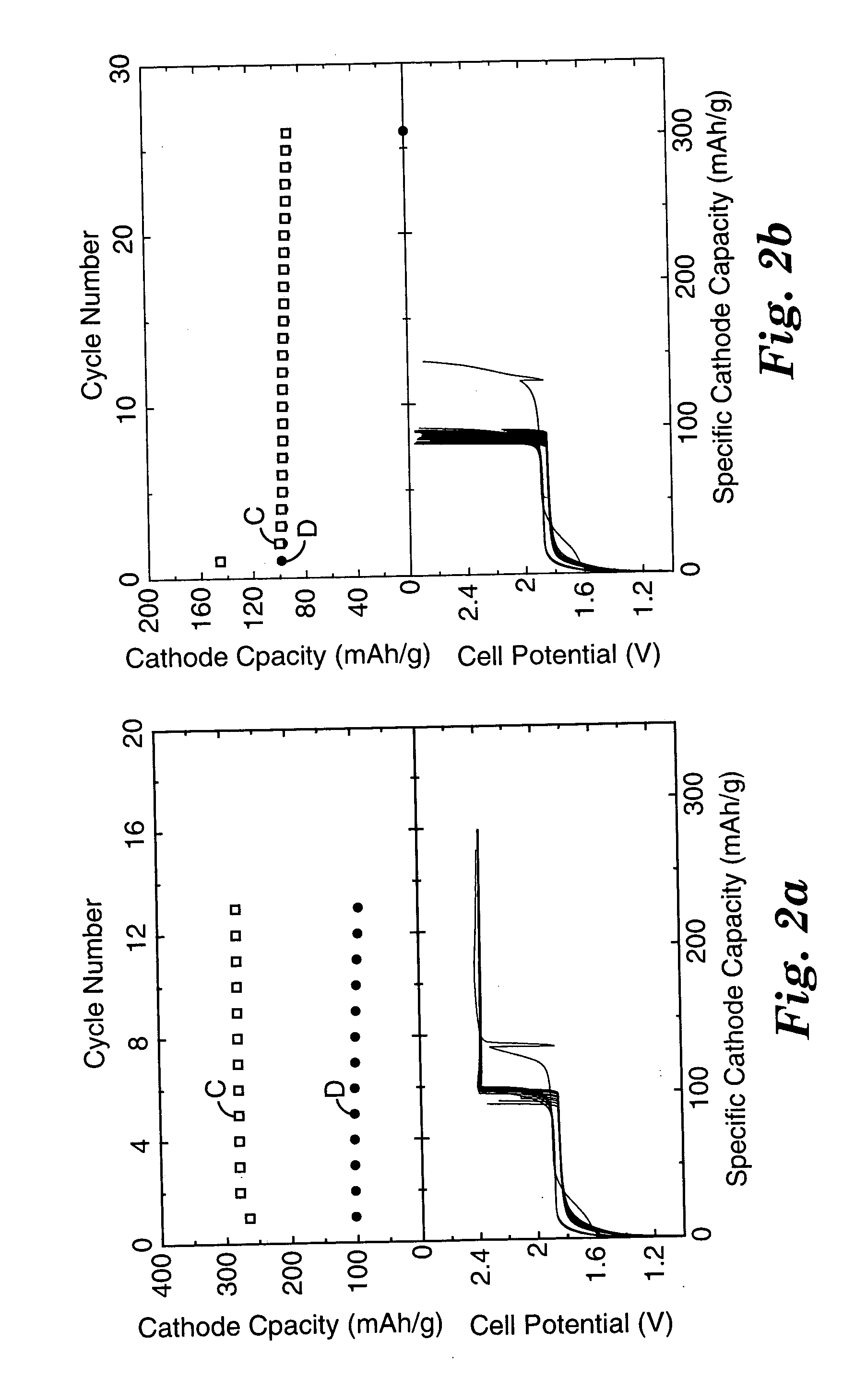

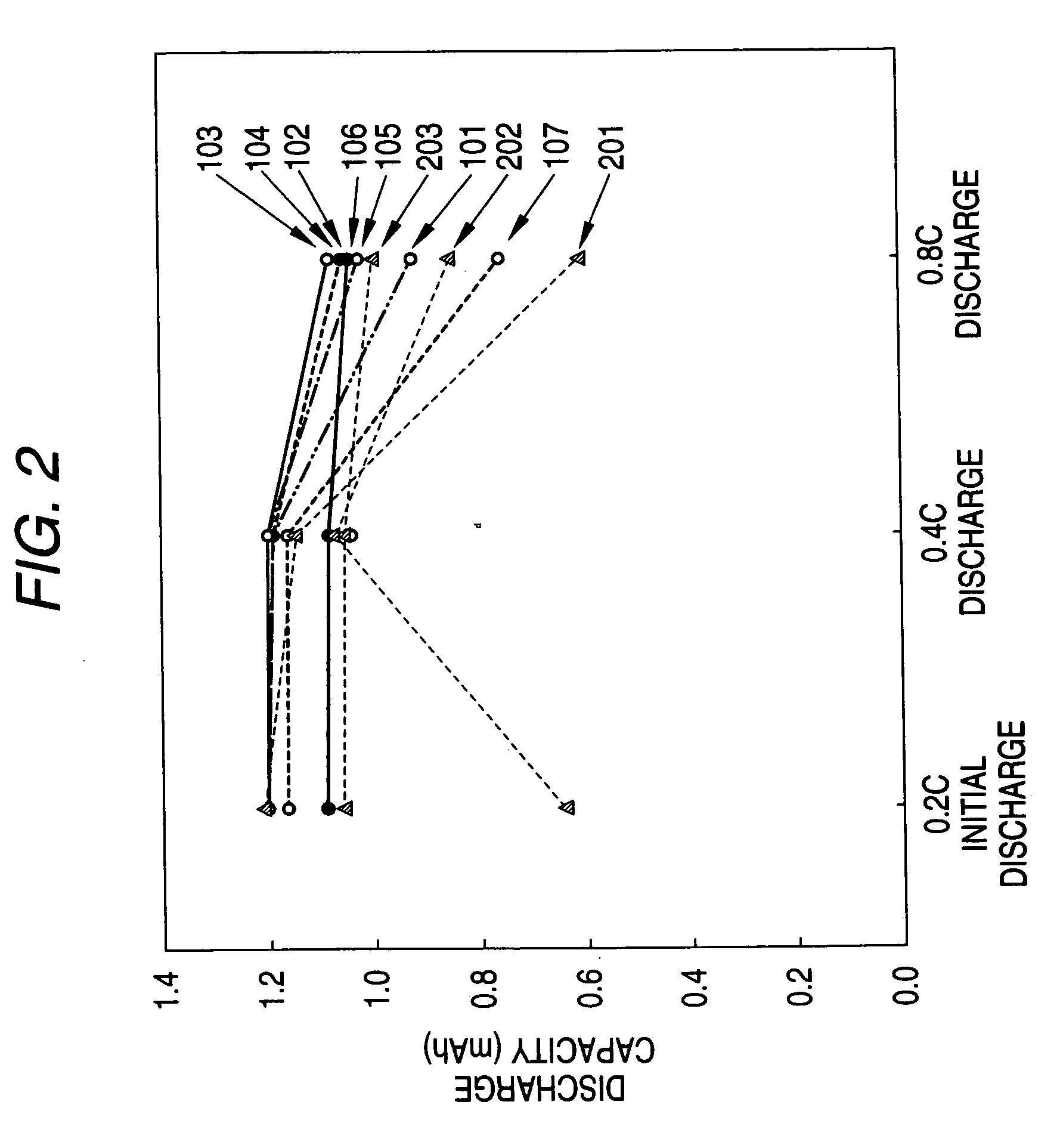

The present invention relates to novel electroactive energy storing polyacetylene-co-polysulfur (PAS) materials of general formula (C2Sx)n wherein x is greater than 1 to about 100, and n is equal to or greater than 2. This invention also relates to novel rechargeable electrochemical cells containing positive electrode materials comprised of said polyacetylene-co-polysulfur materials with improved storage capacity and cycle life at ambient and sub-ambient temperatures.

Owner:THE BANK OF NEW YORK +1

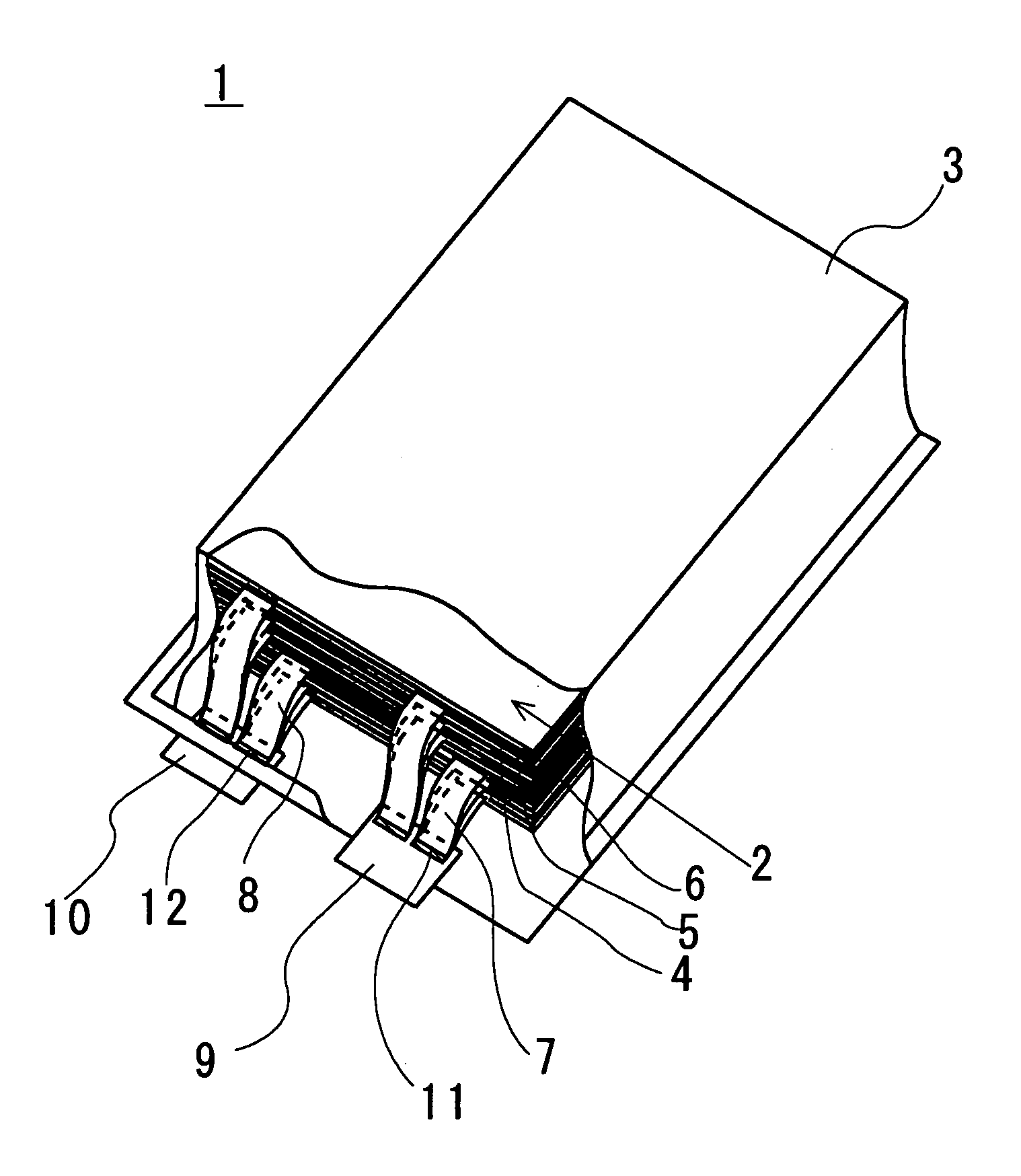

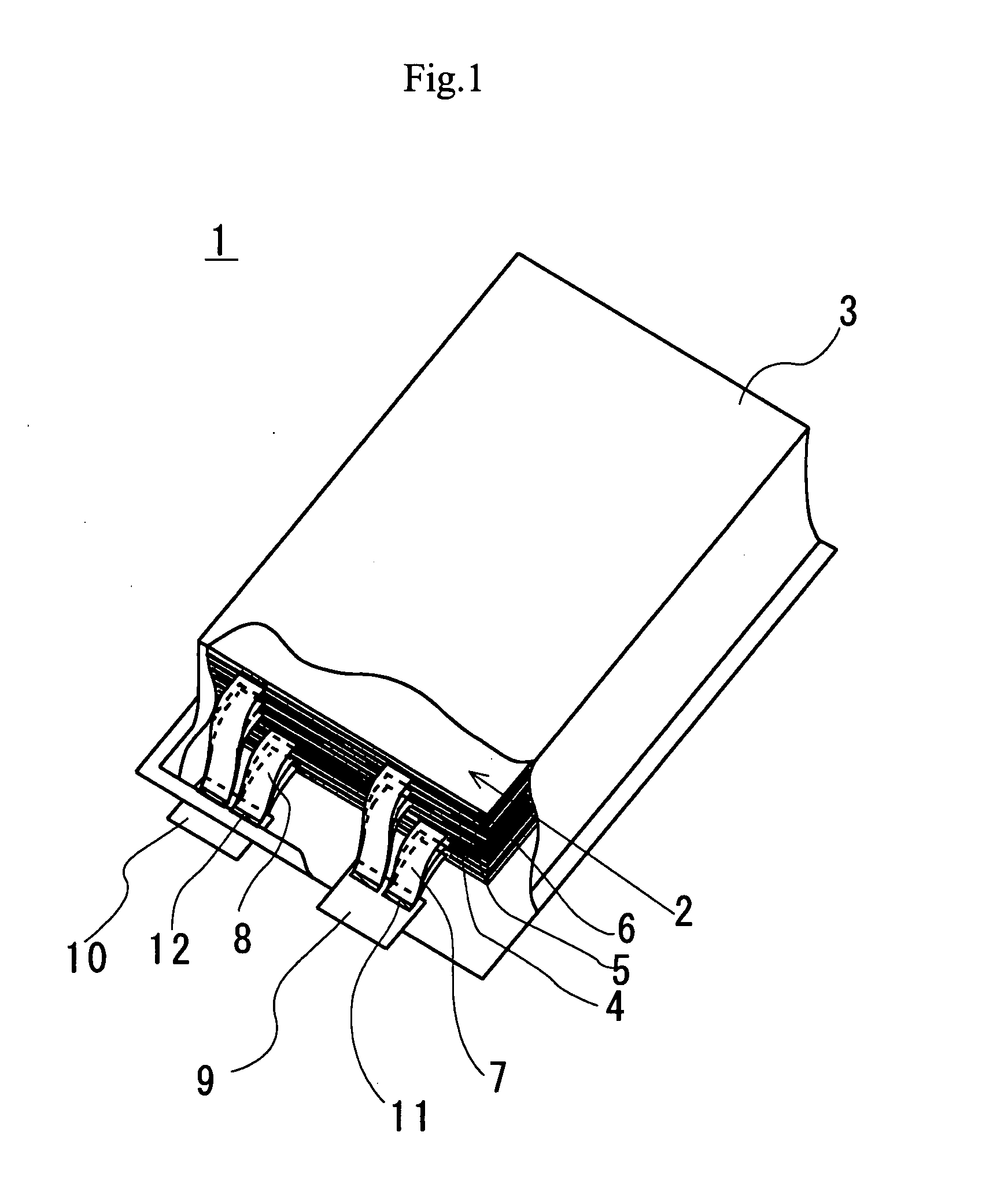

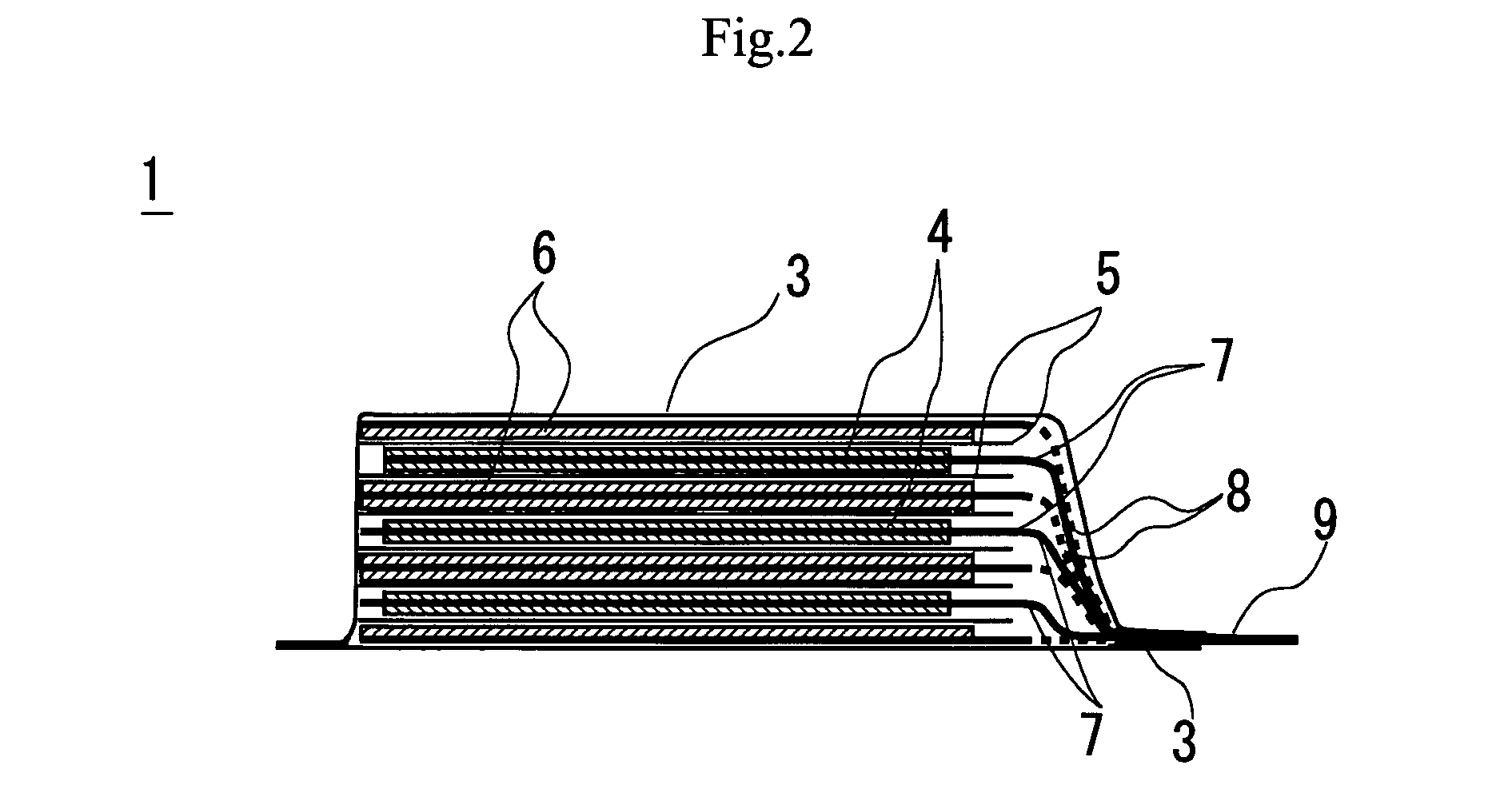

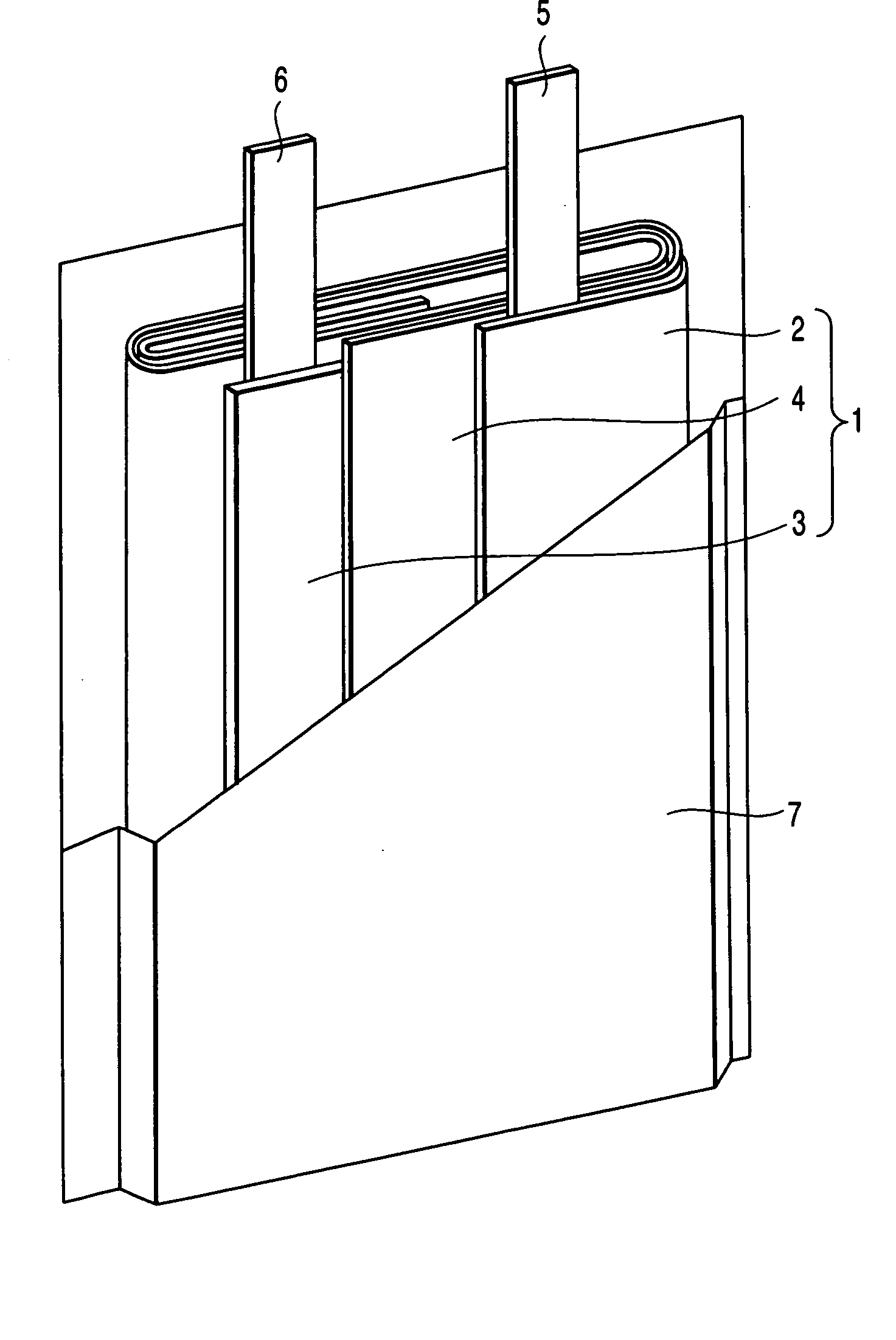

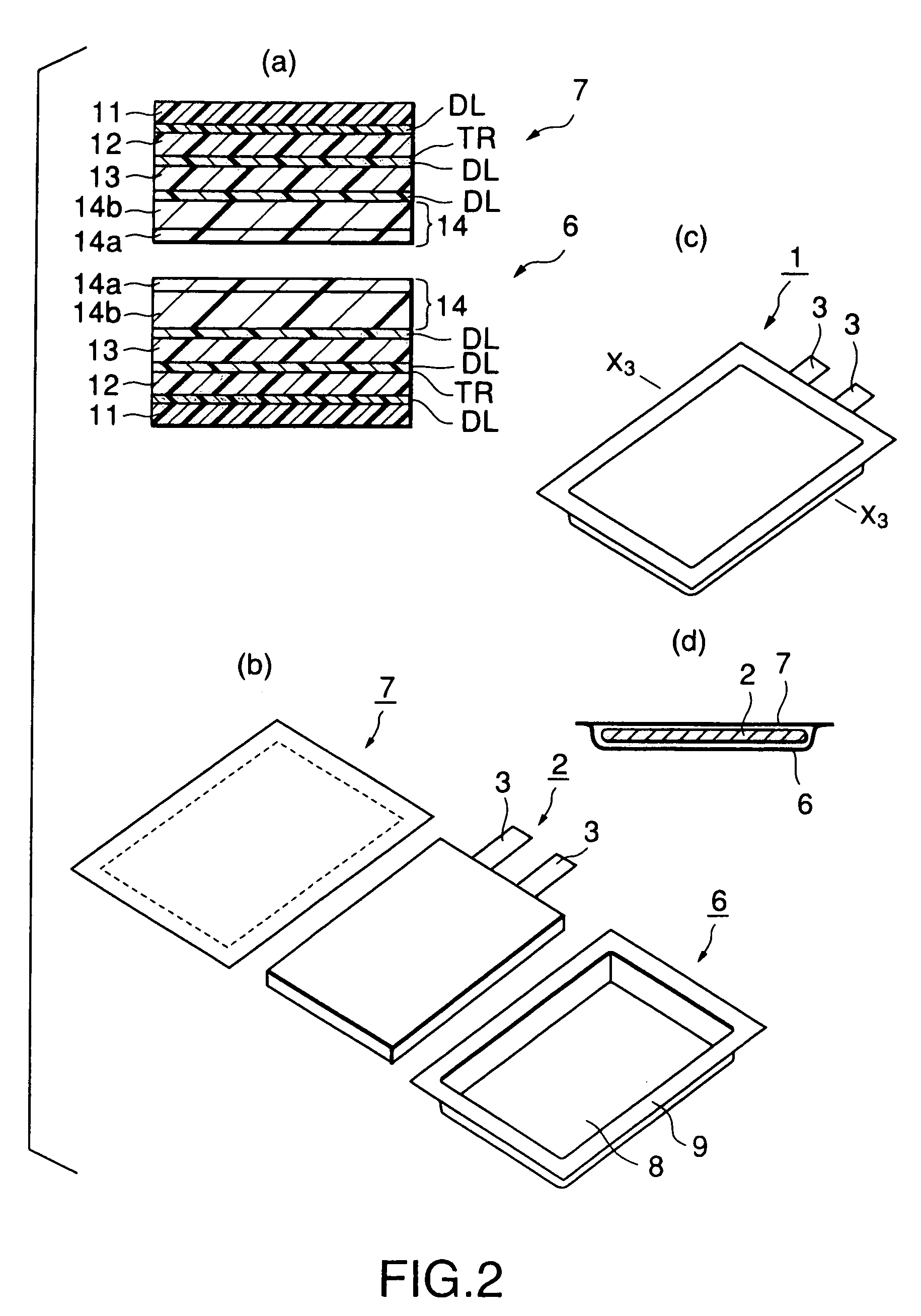

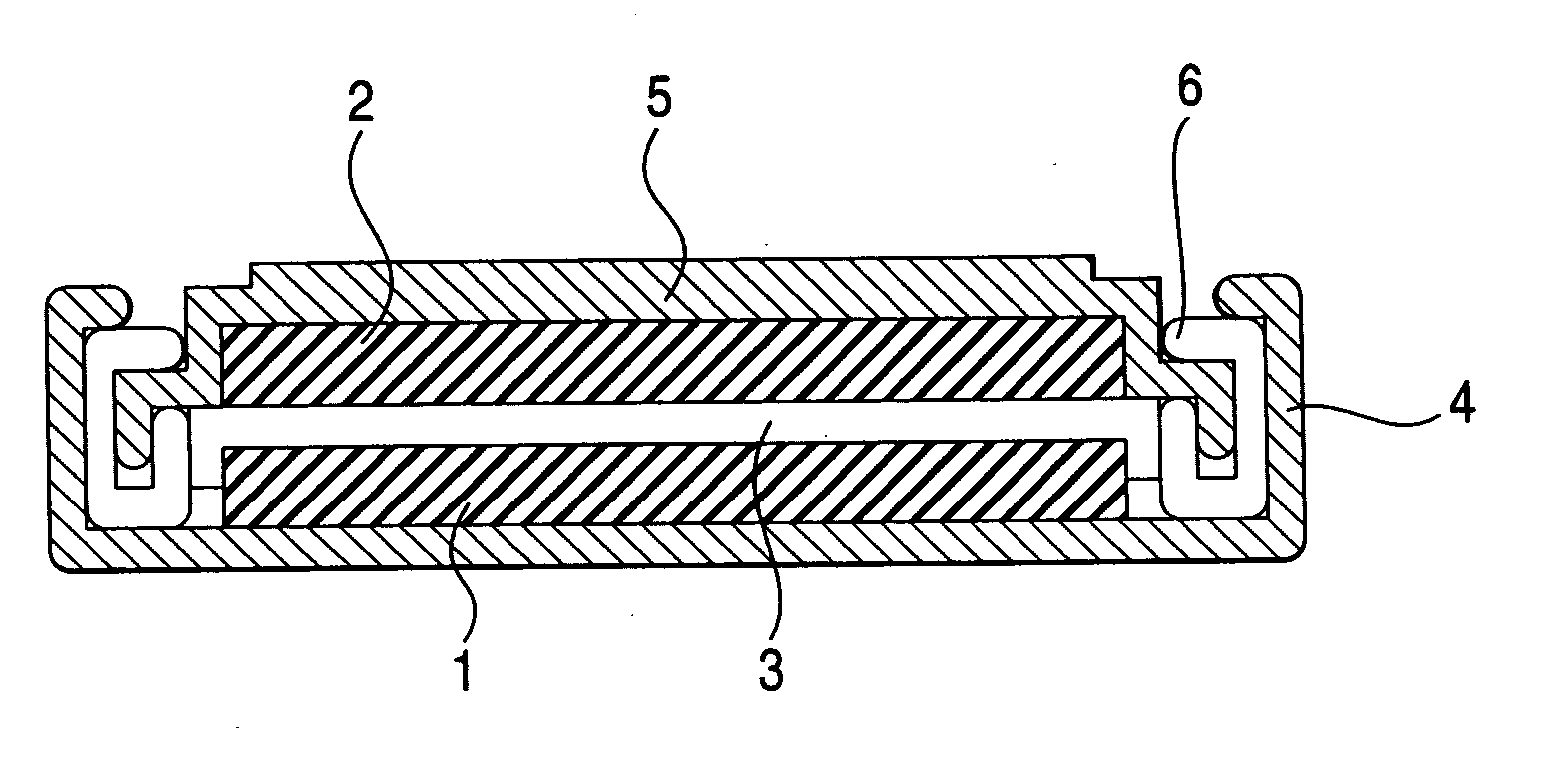

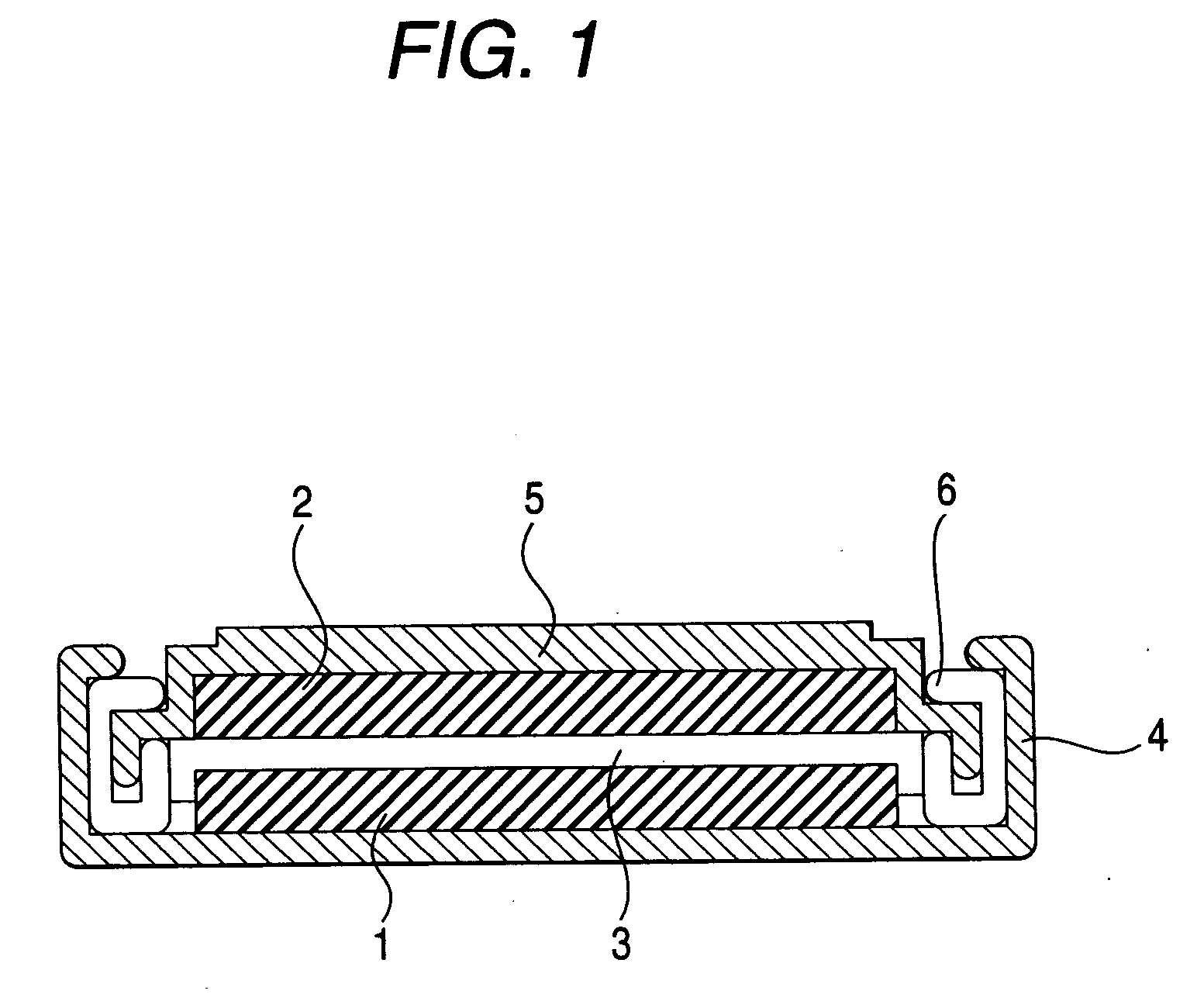

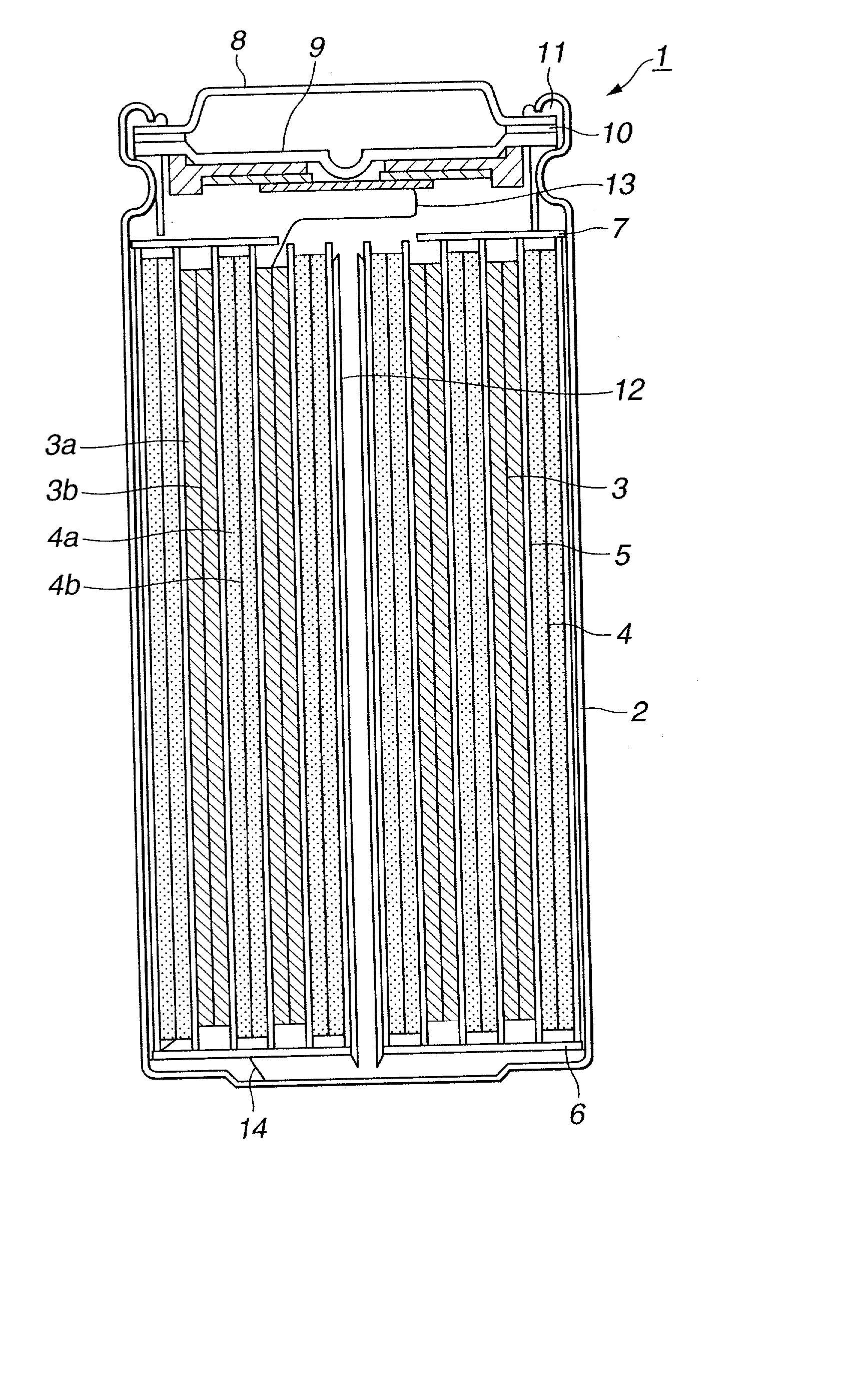

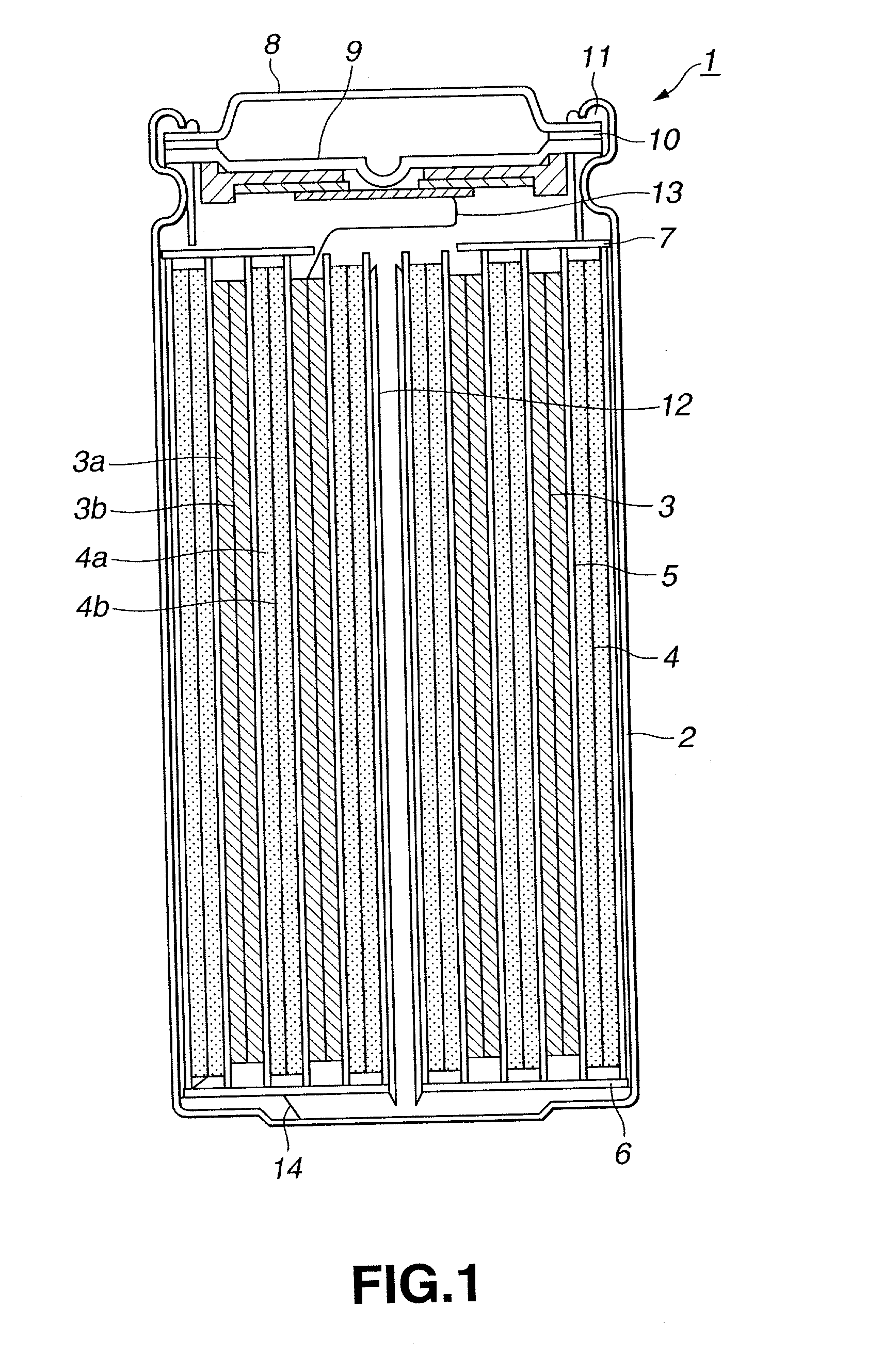

Method for production of stacked battery

ActiveUS20080060189A1Improve reliabilityShorten the lengthNon-aqueous electrolyte accumulatorsLarge-sized flat cells/batteriesEngineeringElectrical and Electronics engineering

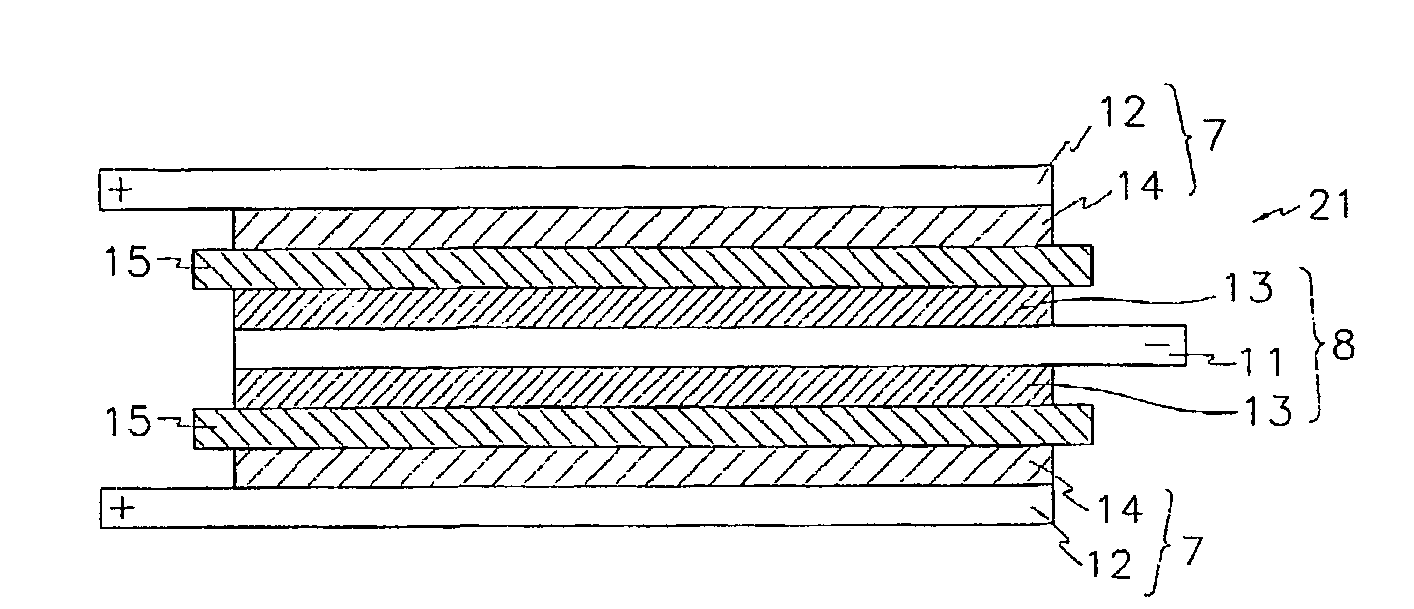

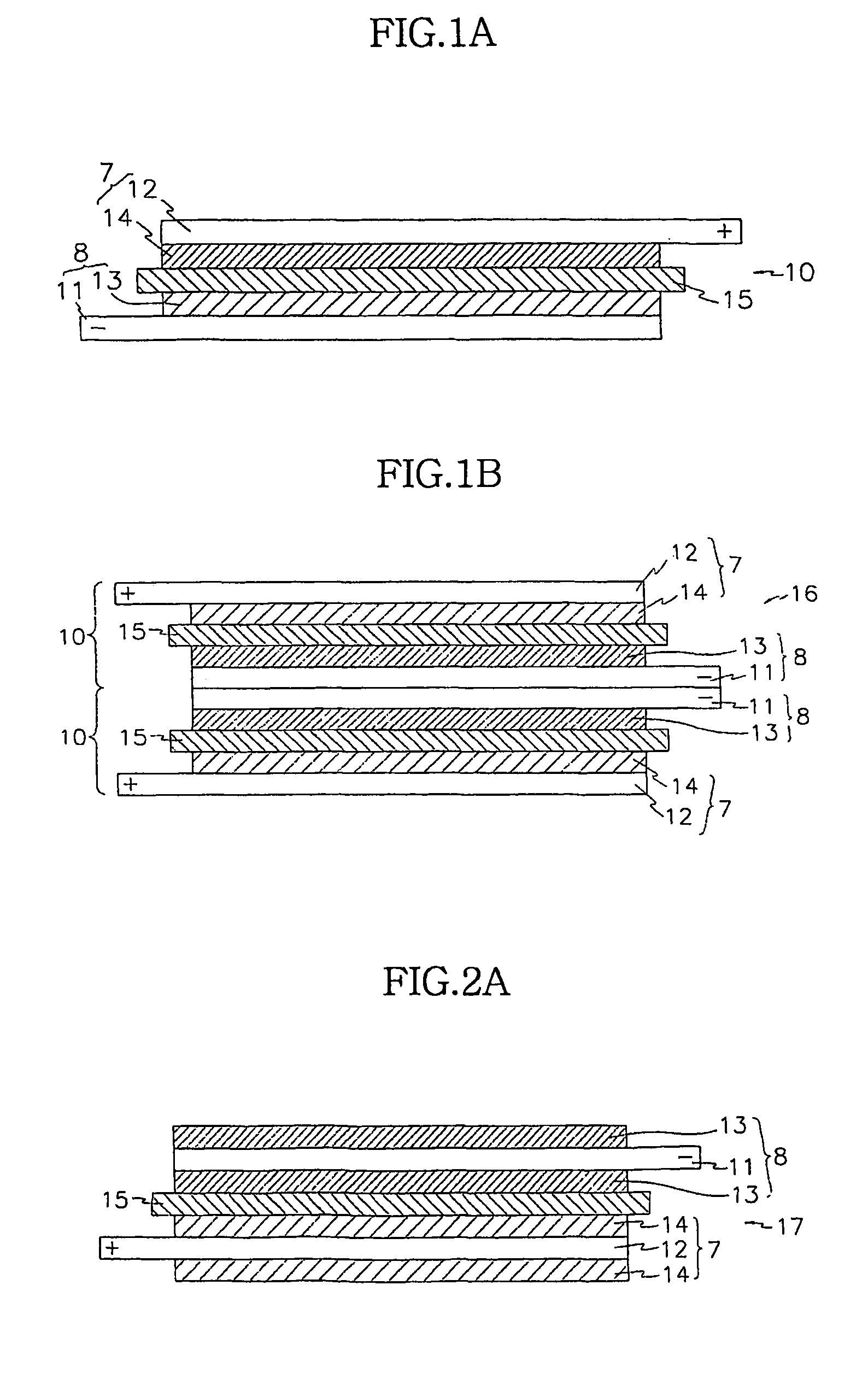

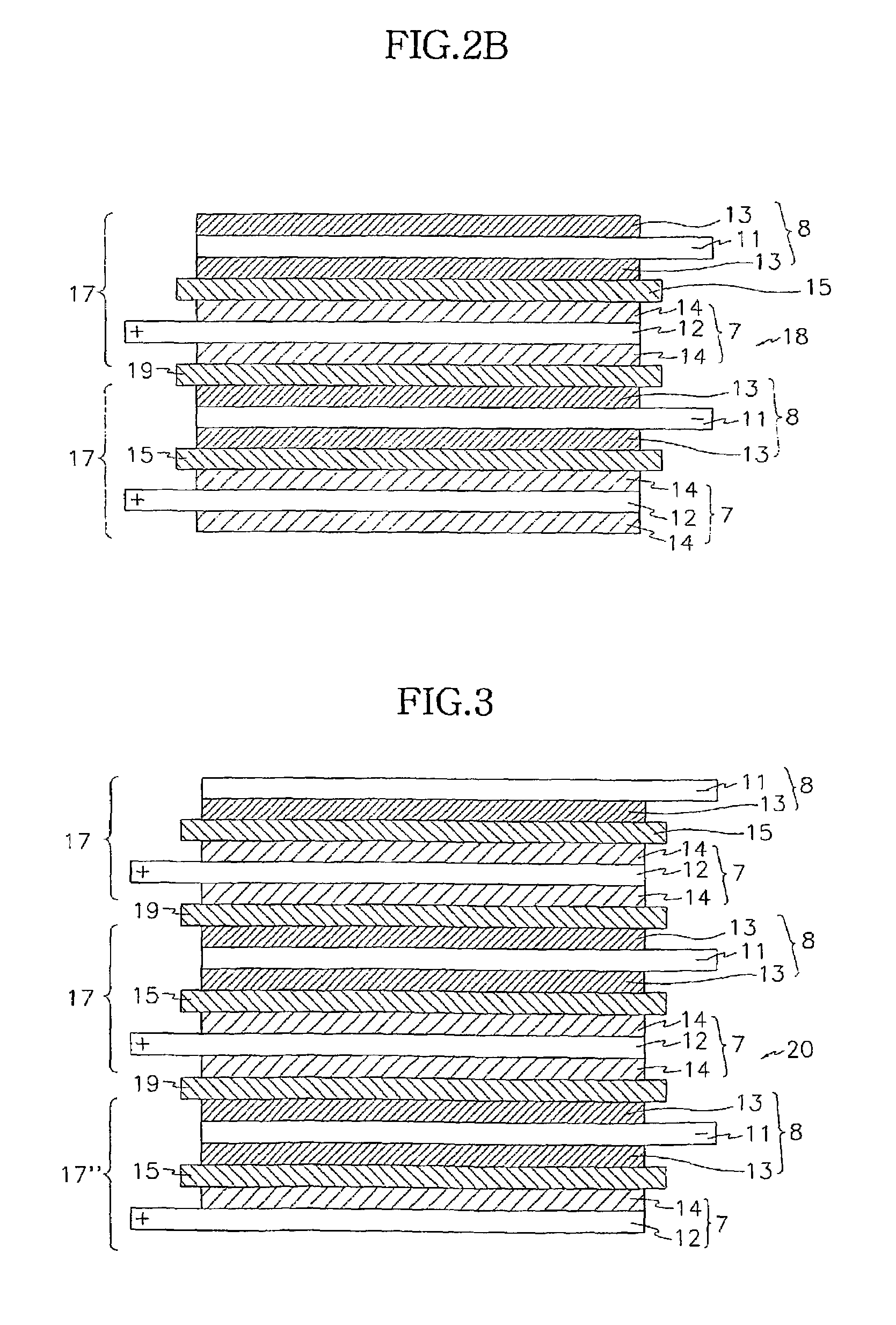

A method for production of a stacked battery having a plurality of positive electrode current collection tabs and a plurality of negative electrode current collection tabs drawn out from a stacked member formed by laying positive electrodes and negative electrodes alternately one on the other with separators interposed between them and bonded respectively to a positive lead terminal and a negative lead terminal comprises a step of determining in advance a simultaneously bondable number, or the number of positive electrode current collection tabs and the number of negative electrode current collection tabs that can be laid one on the other and collectively bonded, and bonding conditions for bonding them and a step of forming groups of current collection tabs, each group being formed by laying a number of current collection tabs not exceeding the simultaneously bondable number one on the other, displacing the bonding positions of the groups of positive electrode current collection tabs or those of negative electrode current collection tabs relative to each other in the direction of drawing out the positive electrode current collection tabs or the negative electrode current collection tabs, whichever appropriate, or in a direction perpendicular to the direction on the surface of the positive lead terminal or the negative lead terminal, whichever appropriate, and collectively bonding the positive electrode current collection tabs or the negative electrode current collection tabs of each group under the bonding conditions.

Owner:ENVISION AESC ENERGY DEVICES LTD

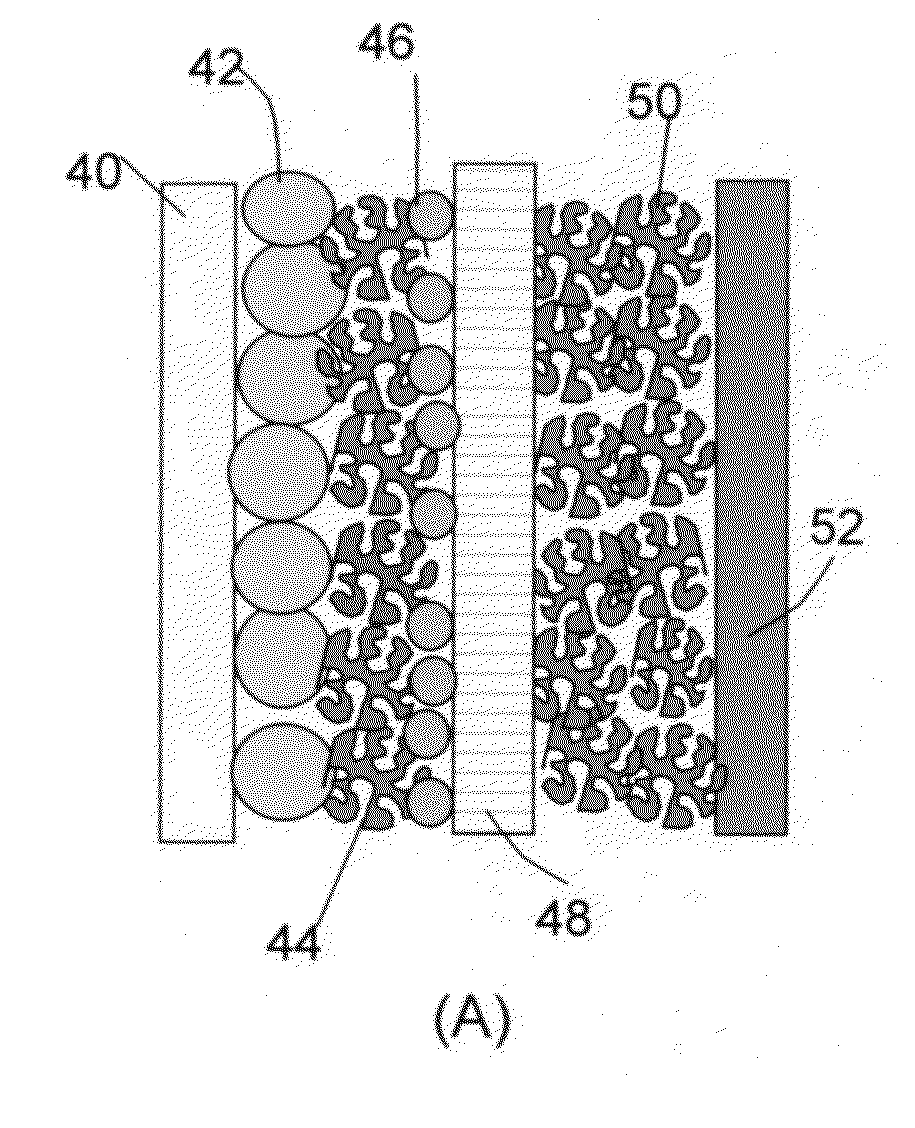

Hybrid electrode and surface-mediated cell-based super-hybrid energy storage device containing same

PendingUS20130171502A1Primary cell to battery groupingMaterial nanotechnologyHigh energyLithium metal

The present invention provides a multi-component hybrid electrode for use in an electrochemical super-hybrid energy storage device. The hybrid electrode contains at least a current collector, at least an intercalation electrode active material storing lithium inside interior or bulk thereof, and at least an intercalation-free electrode active material having a specific surface area no less than 100 m2 / g and storing lithium on a surface thereof, wherein the intercalation electrode active material and the intercalation-free electrode active material are in electronic contact with the current collector. The resulting super-hybrid cell exhibits exceptional high power and high energy density, and long-term cycling stability that cannot be achieved with conventional supercapacitors, lithium-ion capacitors, lithium-ion batteries, and lithium metal secondary batteries.

Owner:GLOBAL GRAPHENE GRP INC +1

Negative active material for a rechargeable lithium battery, a method of preparing the same, and a rechargeable lithium battery comprising the same

ActiveUS20050233213A1Improved cycle-life characteristic and charge and discharge characteristicIncrease chanceElectrode manufacturing processesNon-aqueous electrolyte accumulatorsHigh rateSilicon oxide

The present invention relates to a negative active material for a rechargeable lithium battery, which includes a silicon-based composite having a silicon oxide of the form SiOX where x≦1.5 and at least one element selected from the group consisting of B, P, Li, Ge, Al, and V, and a carbonaceous material. The negative active material of the present invention can improve the cycle-life and high-rate charge / discharge characteristics of a rechargeable lithium battery.

Owner:SAMSUNG SDI CO LTD

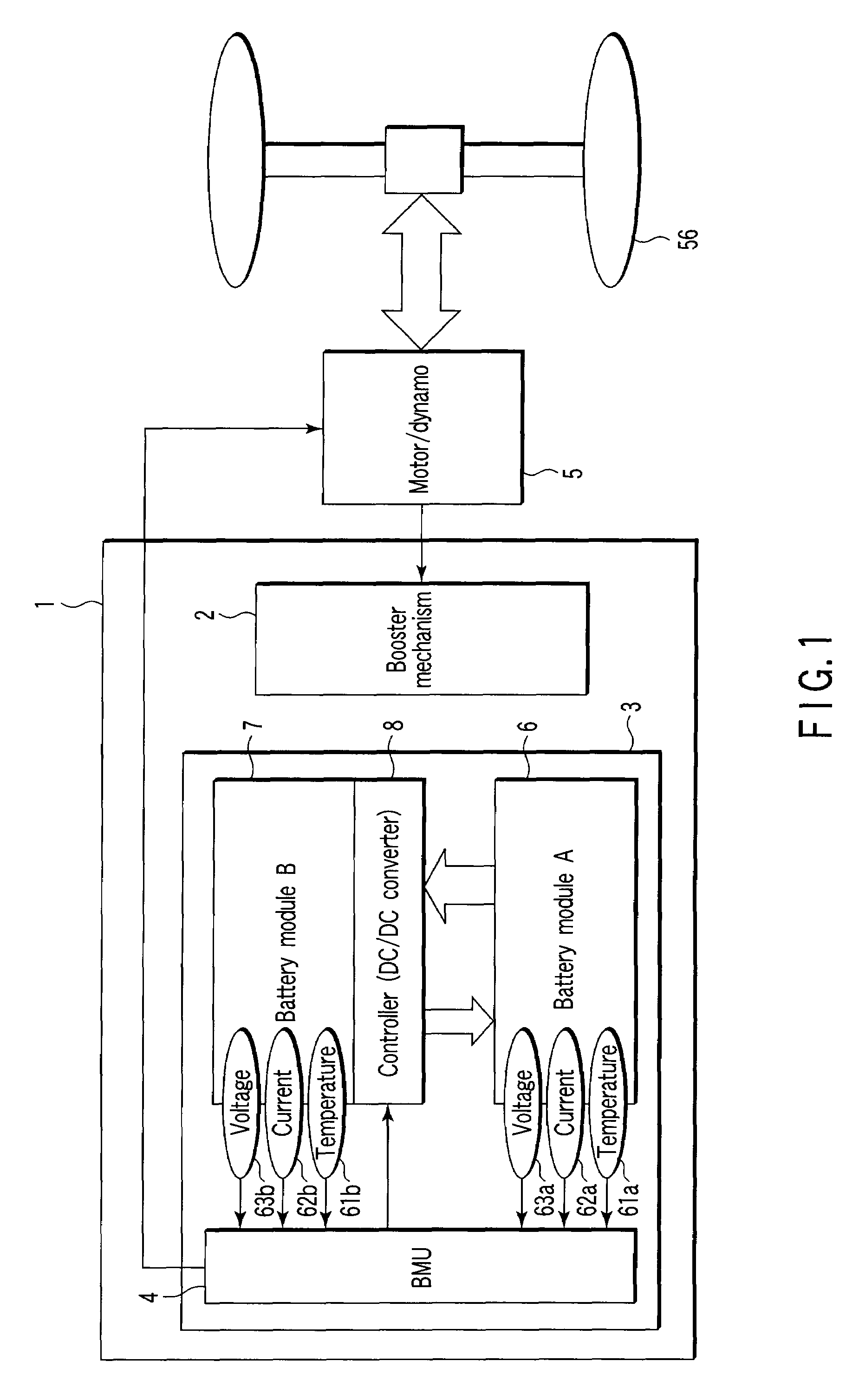

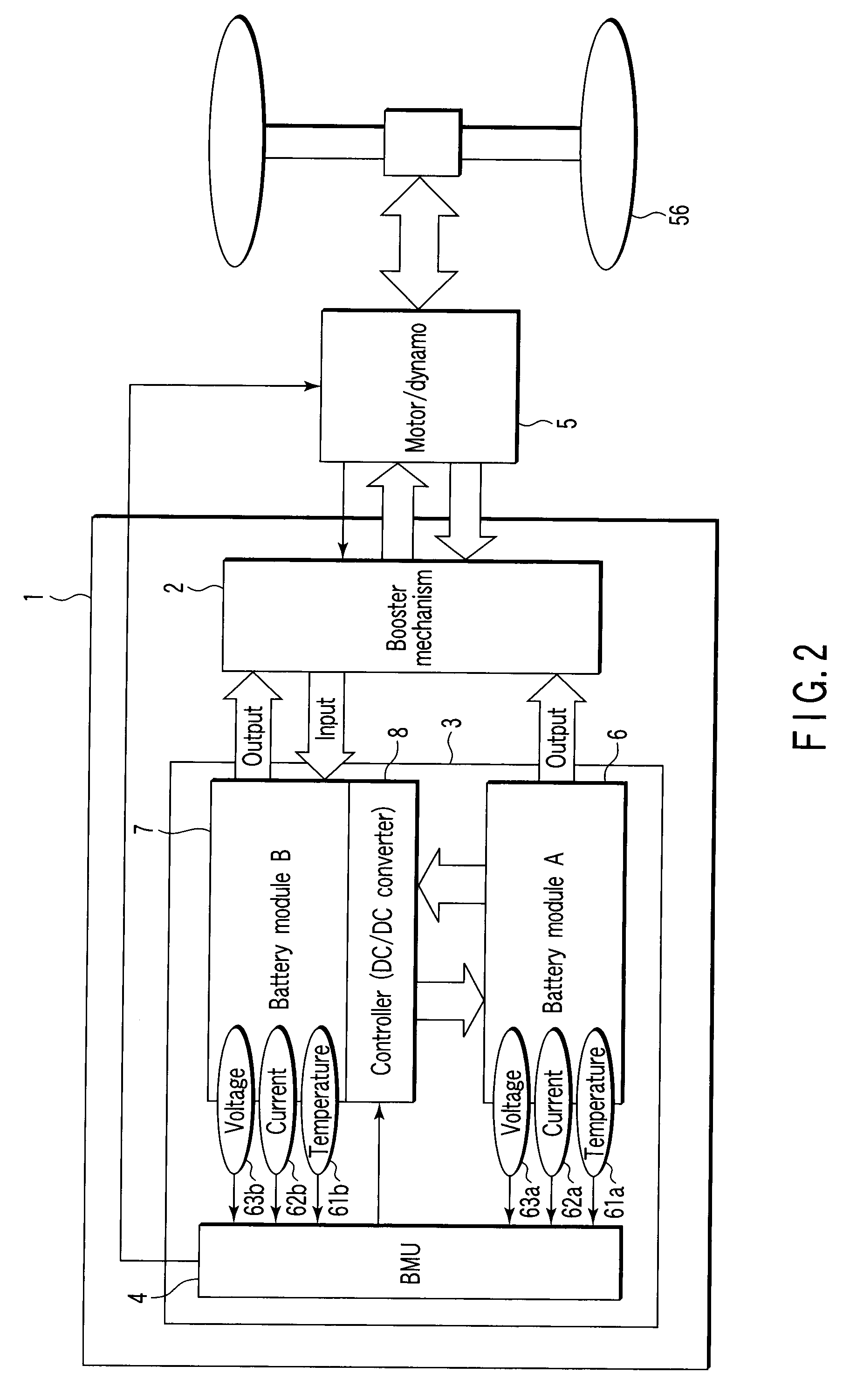

Storage battery system, on-vehicle power supply system, vehicle and method for charging storage battery system

ActiveUS20070284159A1Efficient chargingKeep for a long timeBatteries circuit arrangementsRailway vehiclesLithiumElectrical battery

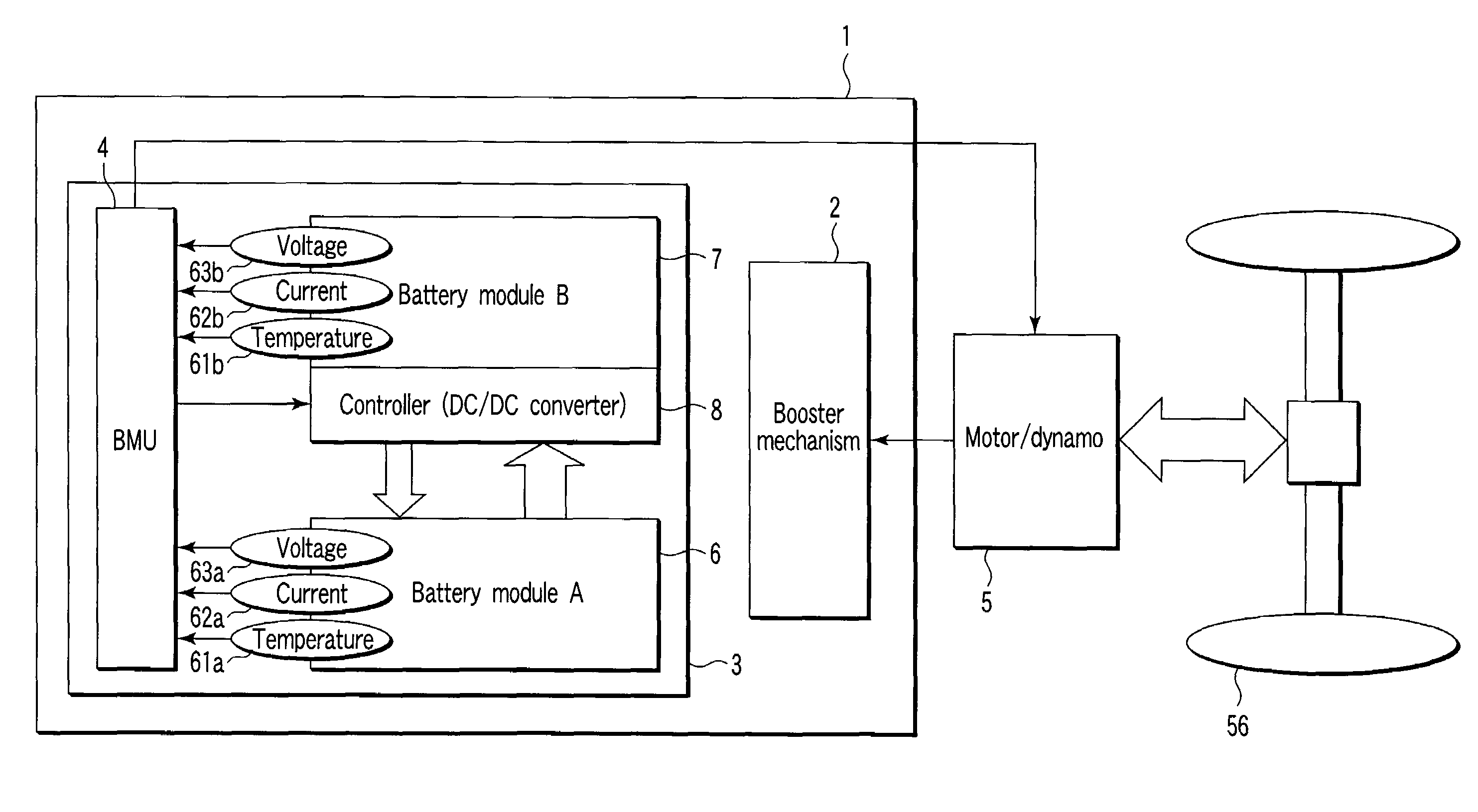

A storage battery system includes a battery module A with a first nonaqueous electrolyte battery including a negative-electrode material which has an average grain size of 2 μm or more and is used to occlude and discharge lithium ions, a battery module B with a second nonaqueous electrolyte battery set at a lithium-ion-occluding potential of 0.4V (vs.Li / Li) or more, and including a negative-electrode material which has an average grain size of primary particles of 1 μm or less and is used to occlude lithium ions, and a controller configured to intermittently connect the module A to the module B to intermittently supply power from the module A to the module B to set a charge state and a discharge depth of the second nonaqueous electrolyte battery within a range of 10 to 90%, when no power is supplied to the module B at least from an outside.

Owner:KK TOSHIBA

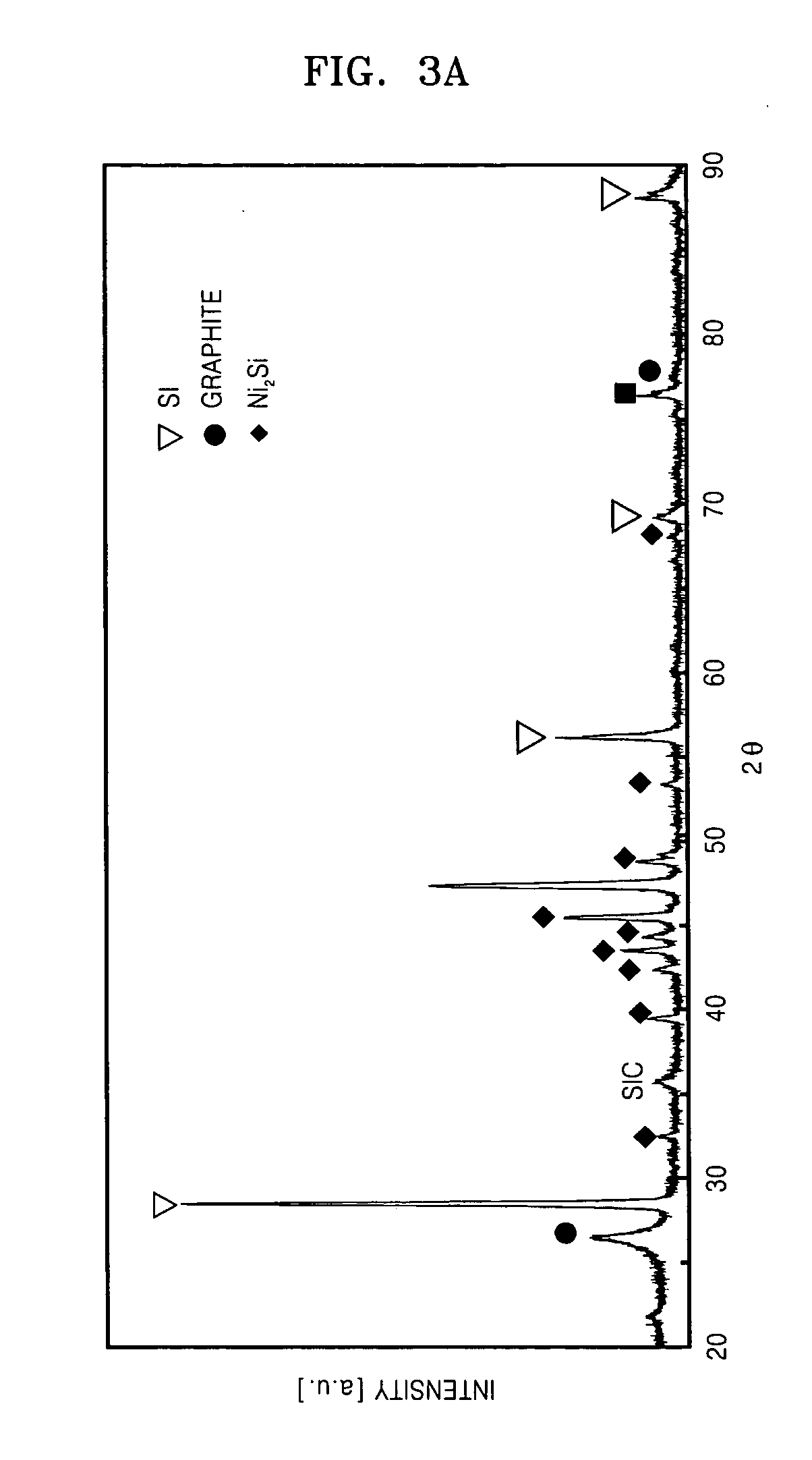

Anode active material, method of preparing the same, and anode and lithium battery containing the material

ActiveUS20060134516A1Improve capacity efficiencyImprove charge/discharge efficiencyElectrode thermal treatmentNon-aqueous electrolyte accumulatorsFiberGraphite

Owner:SAMSUNG SDI CO LTD

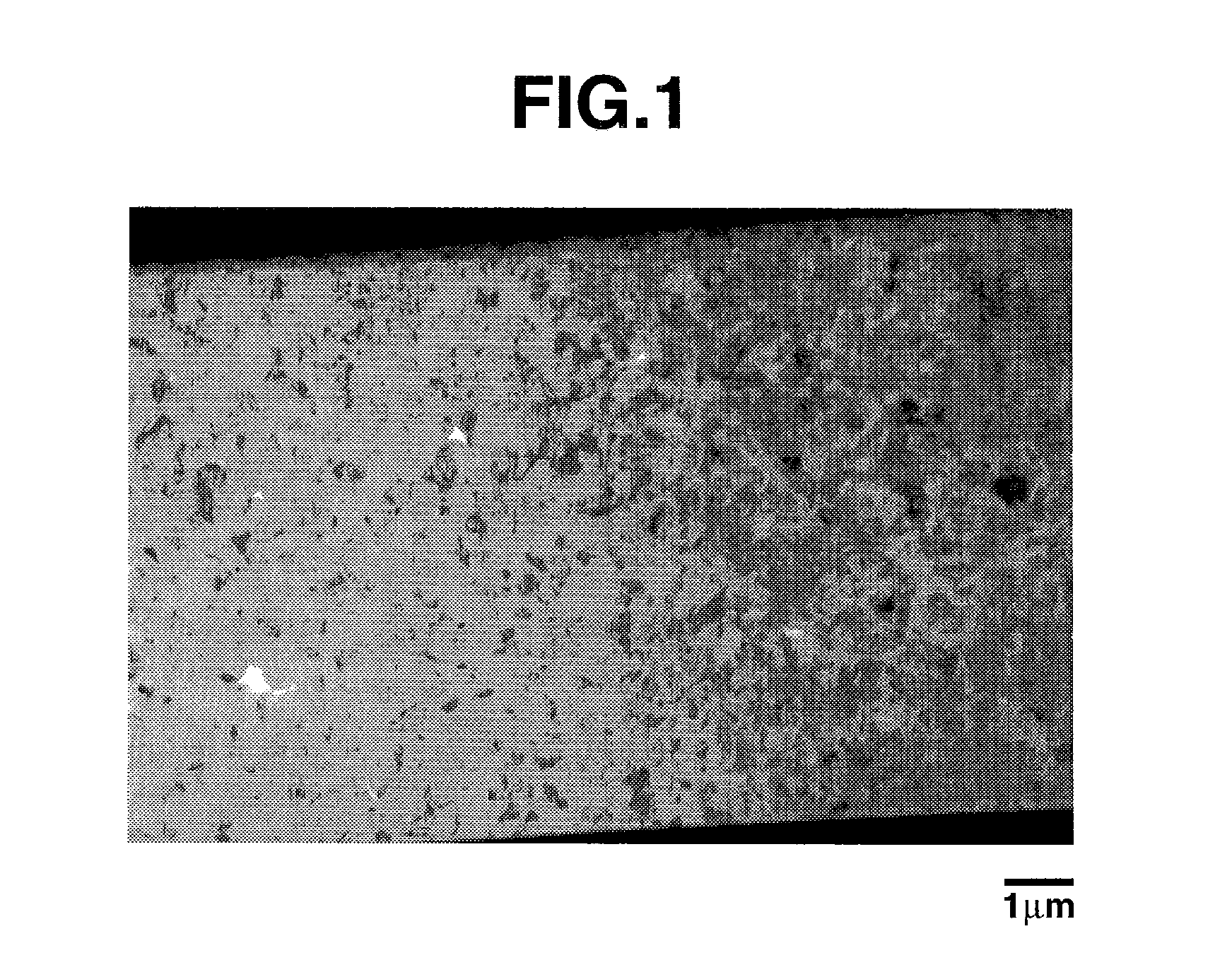

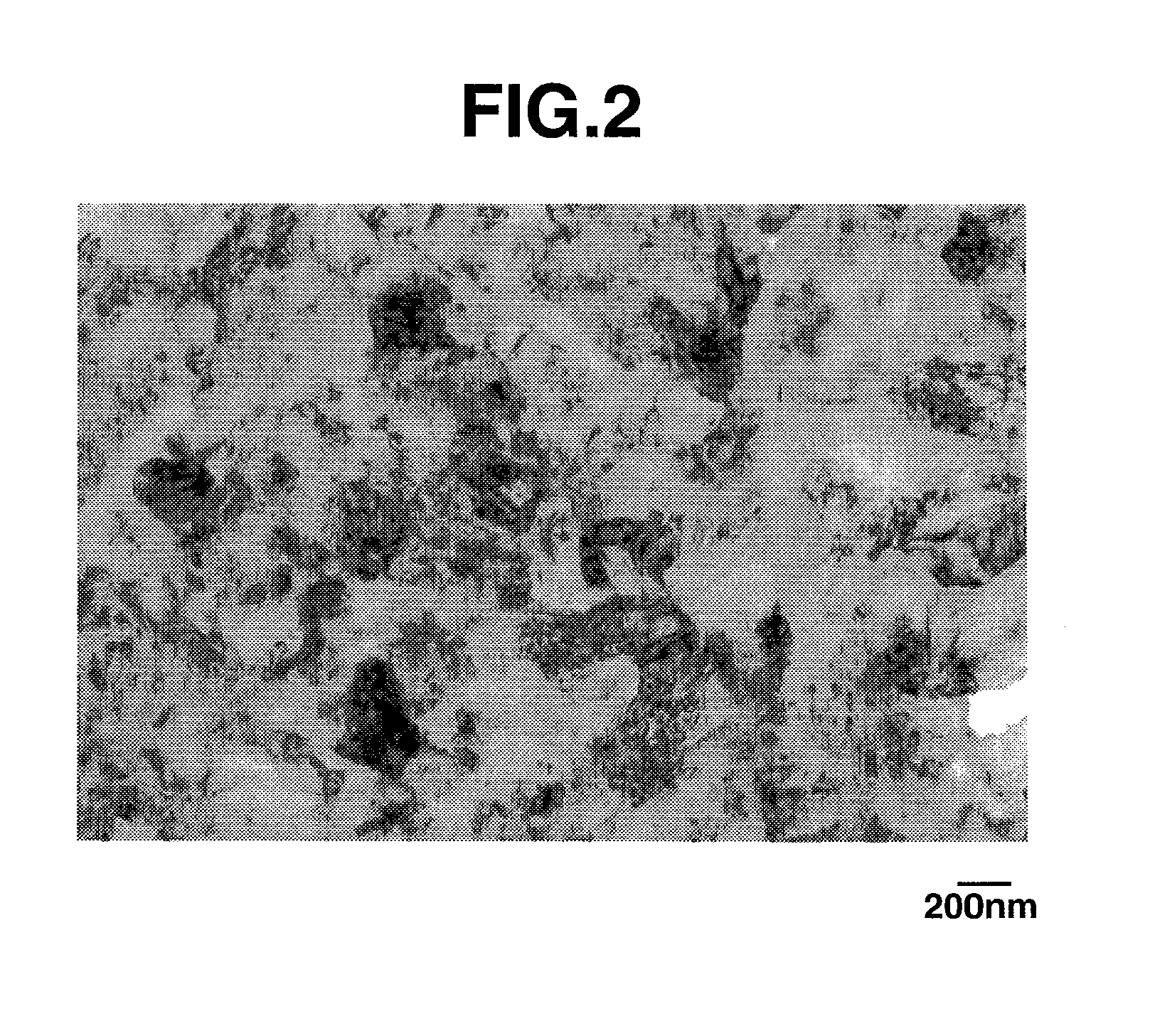

Non-aqueous electrolyte secondary battery, negative electrode material, and making method

ActiveUS20090239151A1Improve cycle performanceImprove efficiencyNon-aqueous electrolyte accumulatorsActive material electrodesSilicon oxideSilicon particle

A negative electrode material comprising an active material and 1-20 wt % of a polyimide resin binder is suitable for use in non-aqueous electrolyte secondary batteries. The active material comprises silicon oxide particles and 1-50 wt % of silicon particles. The negative electrode exhibits improved cycle performance while maintaining the high battery capacity and low volume expansion of silicon oxide. The non-aqueous electrolyte secondary battery has a high initial efficiency and maintains improved performance and efficiency over repeated charge / discharge cycles by virtue of mitigated volumetric changes during charge / discharge cycles.

Owner:SHIN ETSU CHEM IND CO LTD

Negative electrode and non-aqueous electrolyte secondary battery using the same

InactiveUS20080096110A1Good charge and discharge cycle performanceImprove cycle performanceNon-aqueous electrolyte accumulatorsElectrode carriers/collectorsPorous substrateConductive materials

The negative electrode for a non-aqueous electrolyte secondary battery of the present invention includes a conductive porous substrate, and a conductive material and an active material filled in pores of the porous substrate. The active material contains at least one of a metal element and a semi-metal element capable of reversibly absorbing and desorbing lithium.

Owner:PANASONIC CORP

Method of manufacturing solid electrolyte battery

InactiveUS20050132562A1High trafficAvoid excessive power outputNon-aqueous electrolyte accumulatorsFinal product manufacturePolymer electrolytesBattery cell

A method of manufacturing a solid electrolyte battery includes a step of thermally pressing a composite layer including a positive electrode ink layer, an electrolyte ink layer and a negative electrode ink layer that are formed by coating a positive electrode ink, an electrolyte ink and a negative electrode ink. Further, the positive electrode ink, the electrolyte ink and the negative electrode ink contain a polymer electrolyte. By this method, it is possible to improve the flow of ions across respective interlayers of a positive electrode active material layer, a solid electrolyte layer and a negative electrode active material layer.

Owner:NISSAN MOTOR CO LTD

Nonaqueous electrolyte

ActiveUS20050221188A1Excellent characteristicsNon-aqueous electrolyte accumulatorsElectrode carriers/collectorsLithiumMaterials science

A nonaqueous electrolyte battery includes a positive electrode containing an active material, a negative electrode, and a nonaqueous electrolyte, the negative electrode including a current collector and a negative electrode active material supported by the current collector, the negative electrode active material having a Li insertion potential not lower than 0.2V (vs. Li / Li+) and an average primary particle diameter not larger than 1 μm, and a specific surface area of the negative electrode, excluding a weight of the current collector, as determined by the BET method falls within a range of 3 to 50 m2 / g.

Owner:KK TOSHIBA

Separator for nonaqueous electrolyte batteries, nonaqueous electrolyte battery using it, and method for manufacturing separator for nonaqueous electrolyte batteries

InactiveUS6511774B1High tear strengthEnhanced penetration strengthNon-aqueous electrolyte accumulatorsCell seperators/membranes/diaphragms/spacersHigh energyEngineering

The present invention provides a separator for non-aqueous electrolyte batteries which neither breaks nor slips off at the time of fabrication of battery, gives excellent battery fabricability, causes no internal short-circuit caused by contact between electrodes even if the electrodes are externally short-circuited, can inhibit ignition of battery and produces high energy density and excellent cycle life, and further provides a non-aqueous electrolyte battery using the separator and a method for manufacturing the separator. That is, the present invention relates to a separator for non-aqueous electrolyte batteries which comprises a porous base containing at least one member selected from a porous film, a woven fabric or nonwoven fabric containing an organic fiber and a paper and an organometallic compound applied to the porous base; a method for the manufacture of the separator for non-aqueous electrolyte batteries which comprises allowing said porous base to contact with a solution of organometallic compound by impregnation, coating or spraying, followed by drying or curing with heating to apply the organometallic compound to the porous base; and a non-aqueous electrolyte battery using the separator.

Owner:MITSUBISHI PAPER MILLS LTD

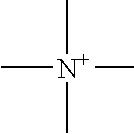

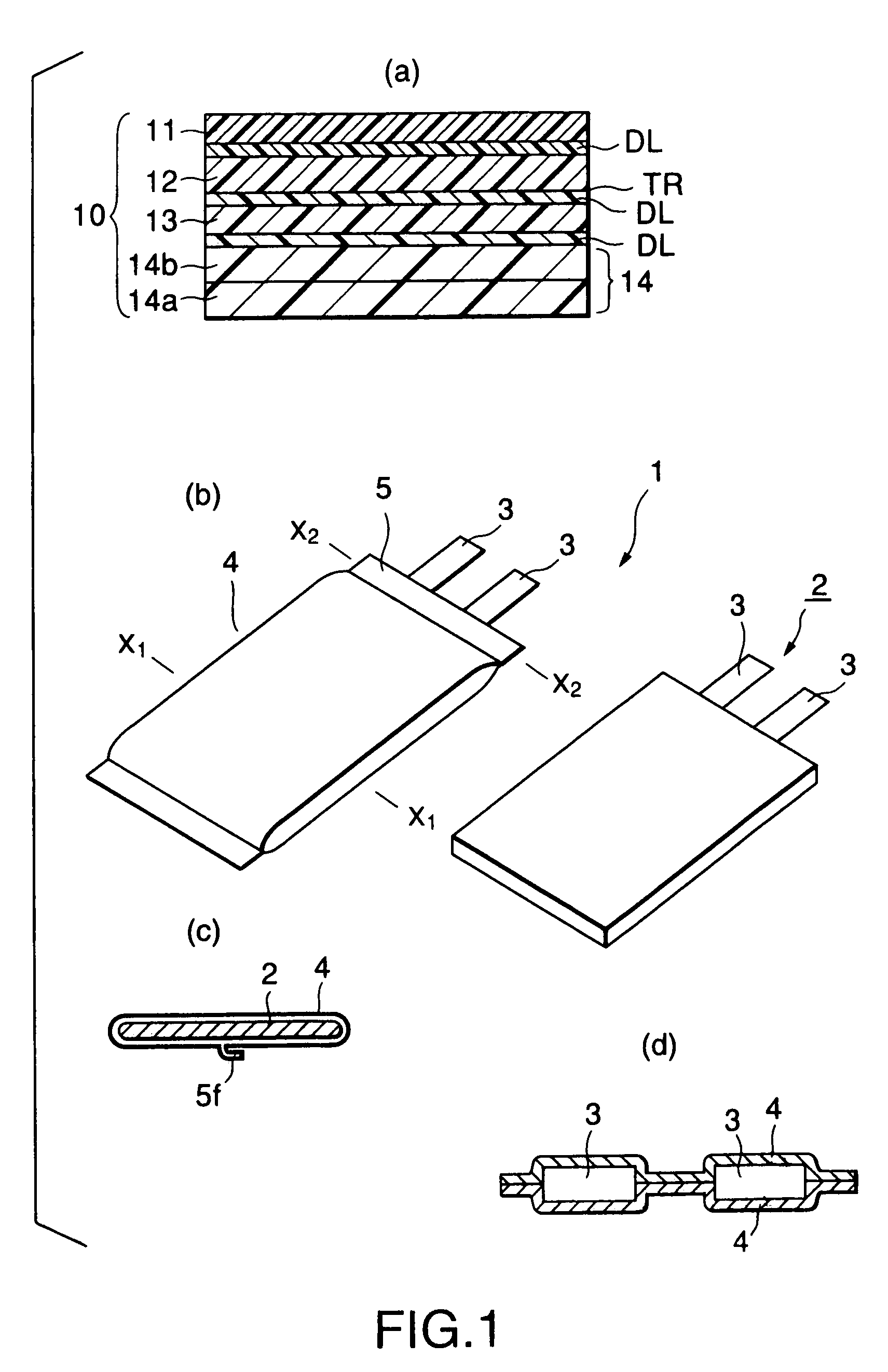

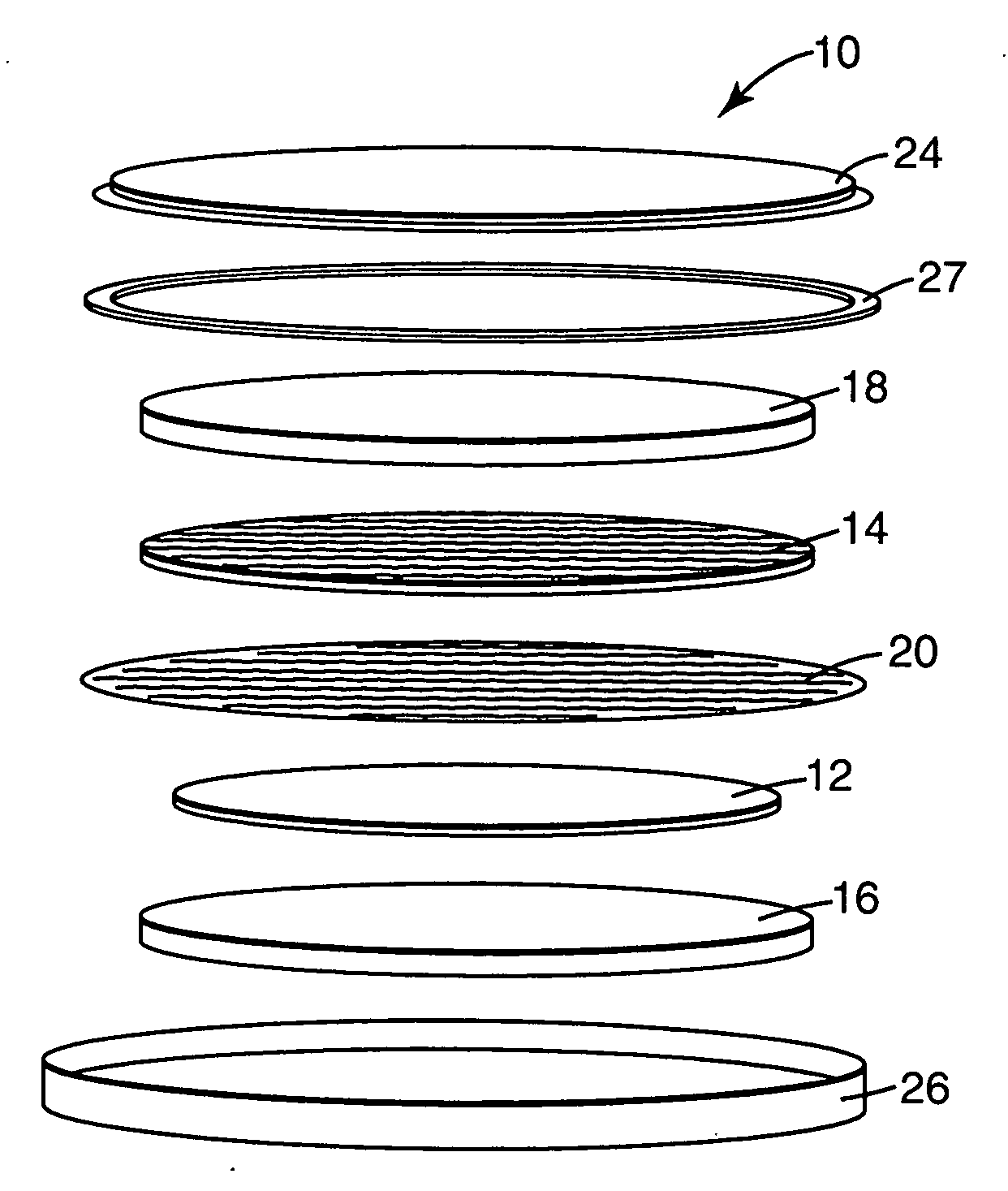

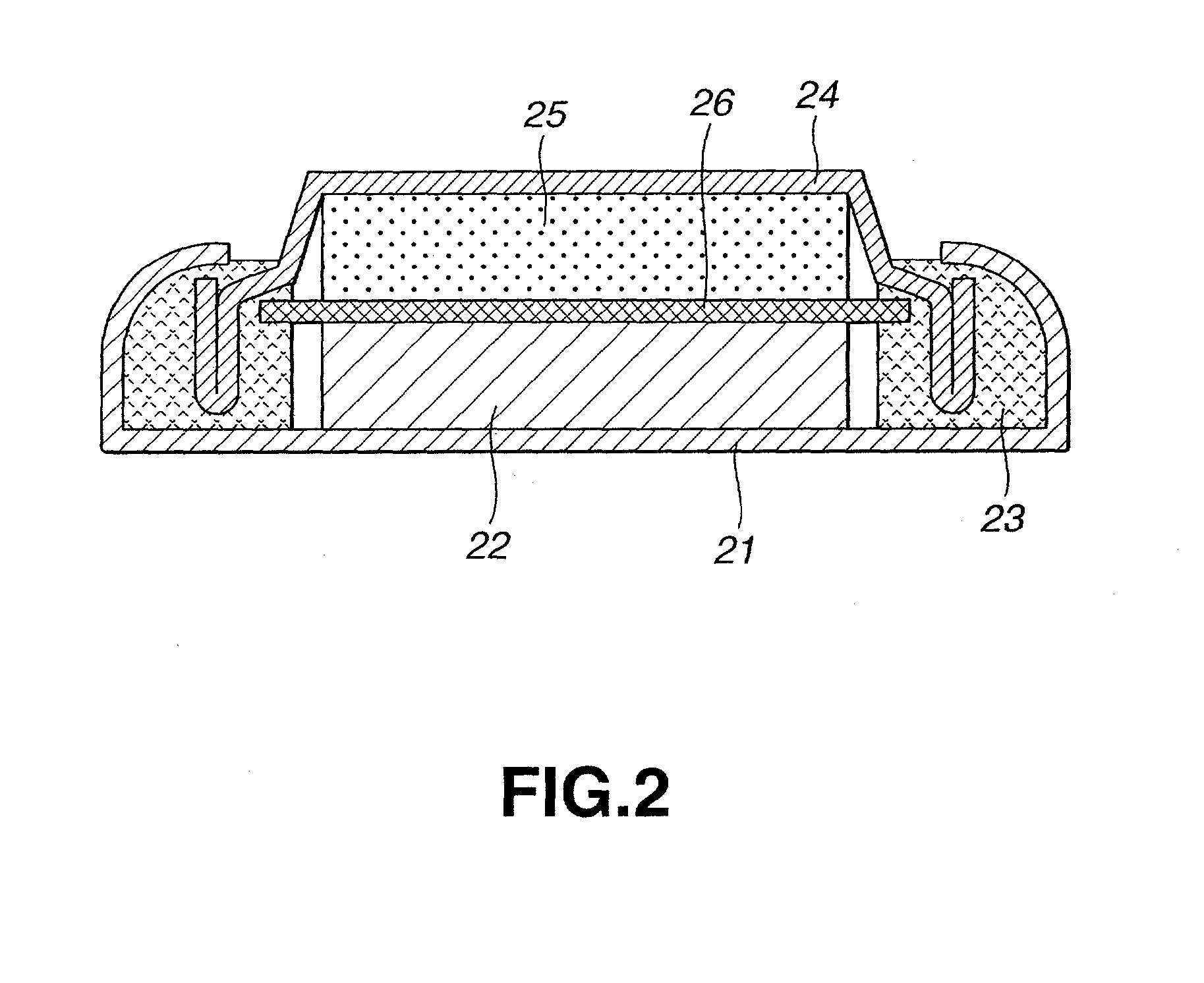

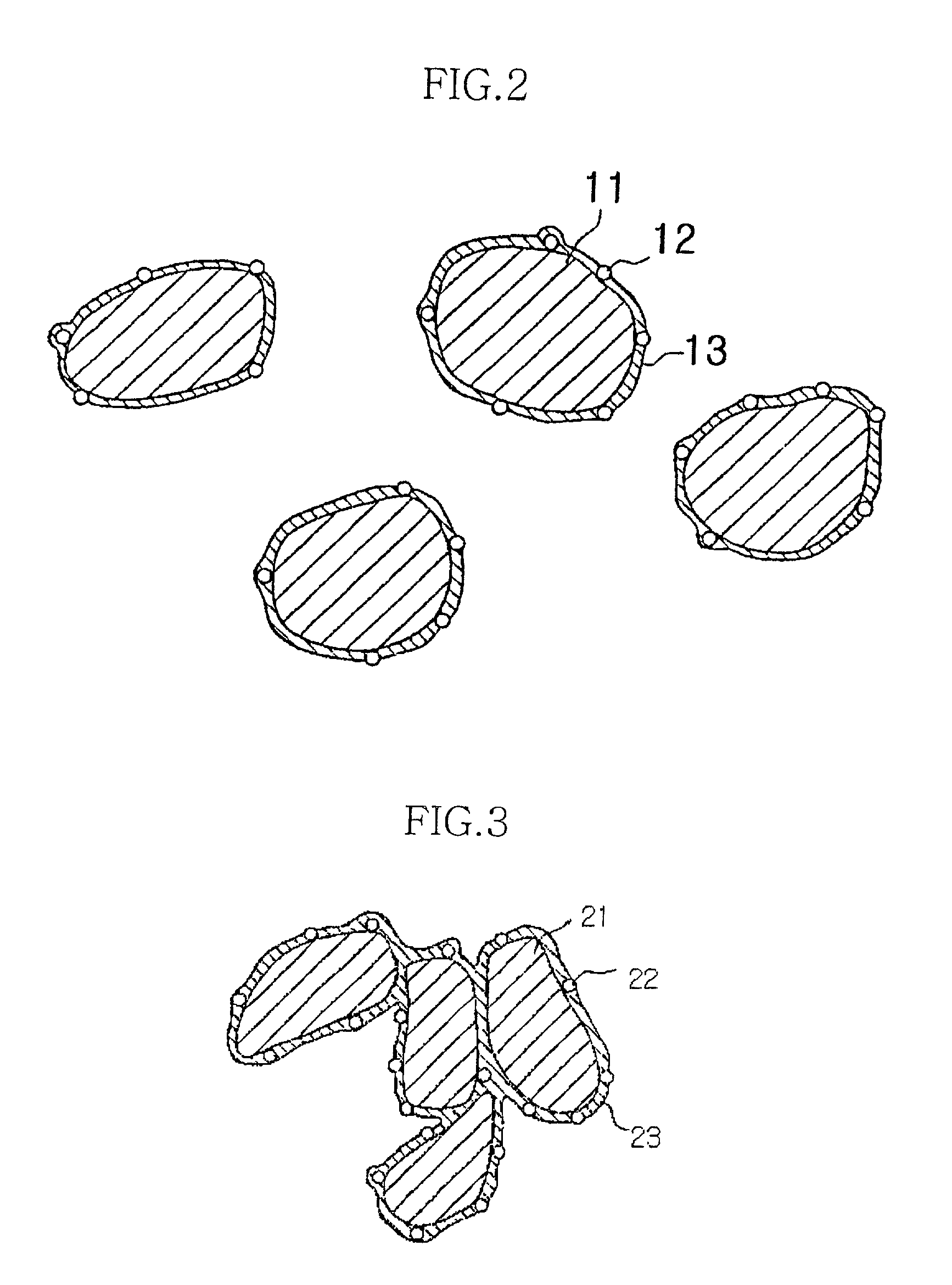

Material for packaging cell, bag for packaging cell, and its production method

InactiveUS7285334B1Excellent gas barrier performanceHigh mechanical strengthNon-aqueous electrolyte accumulatorsSynthetic resin layered productsEngineeringMethods of production

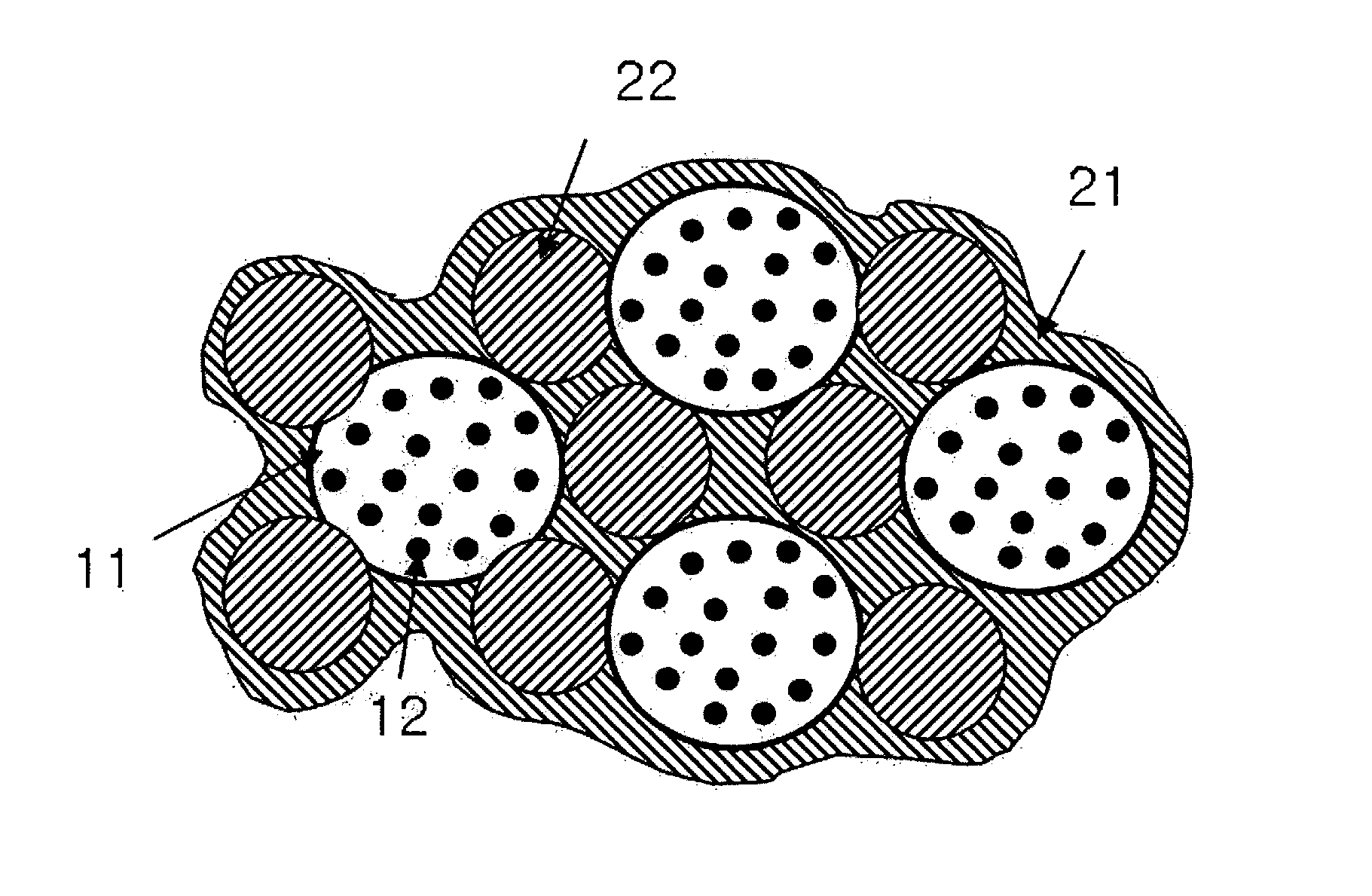

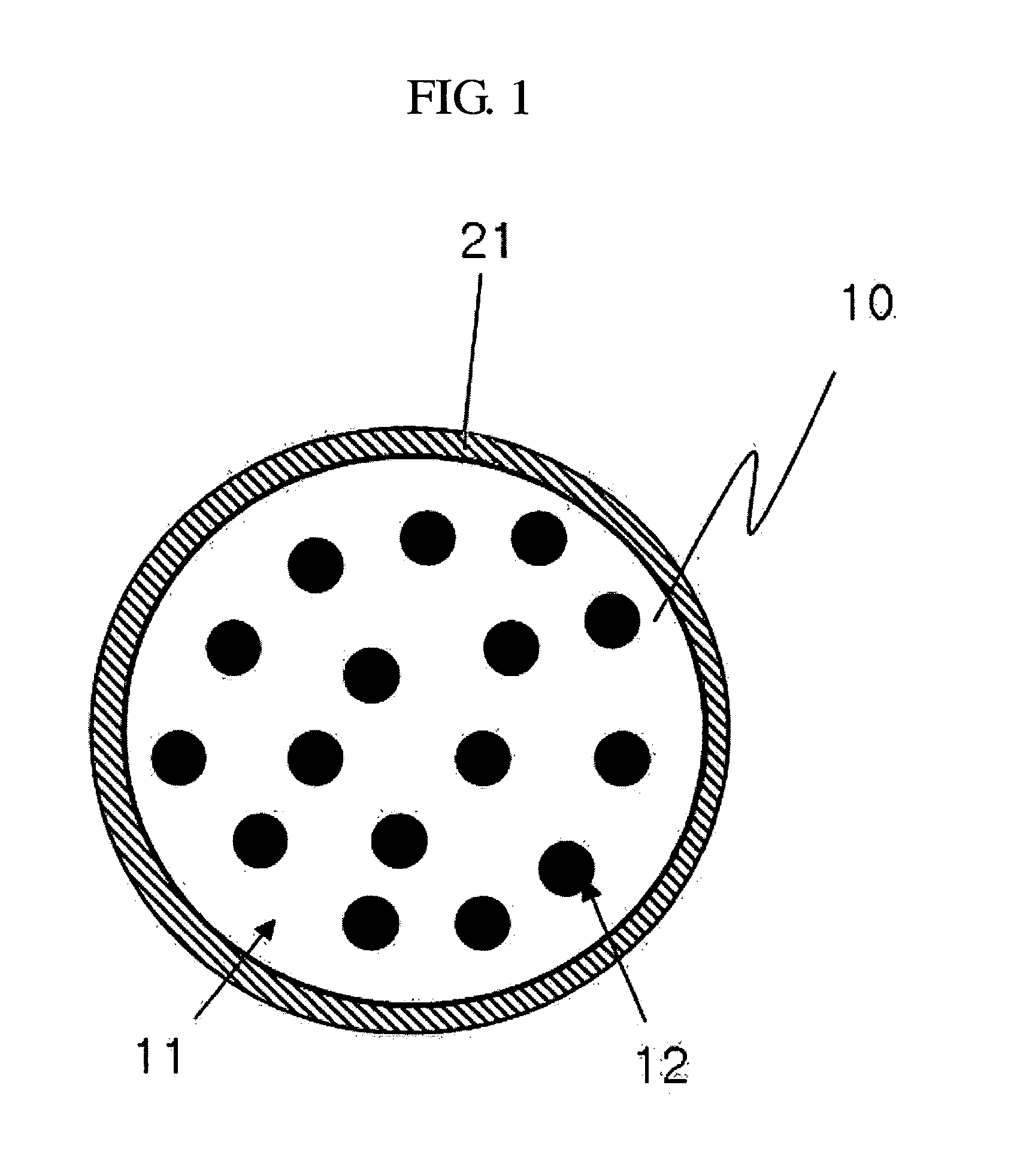

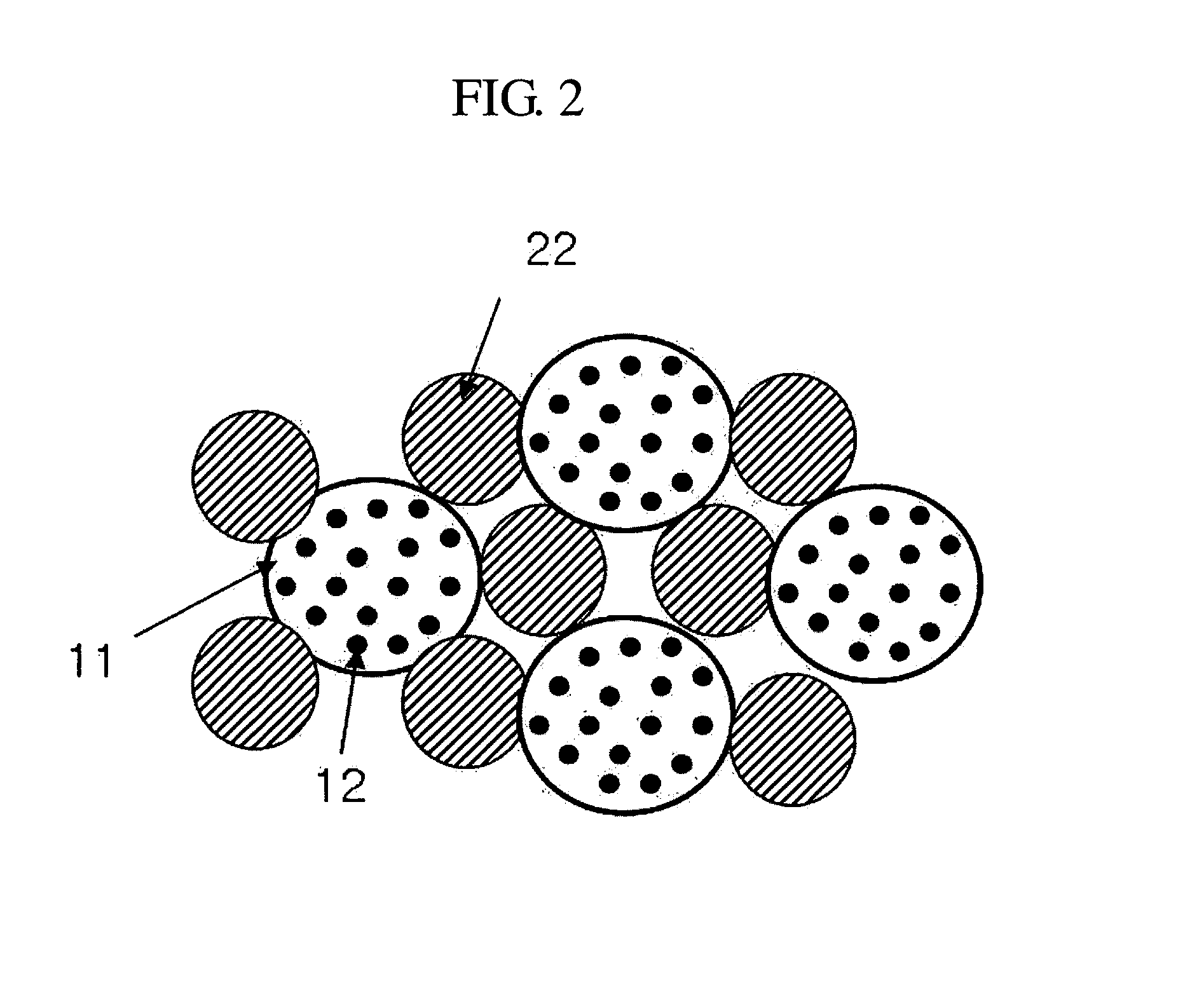

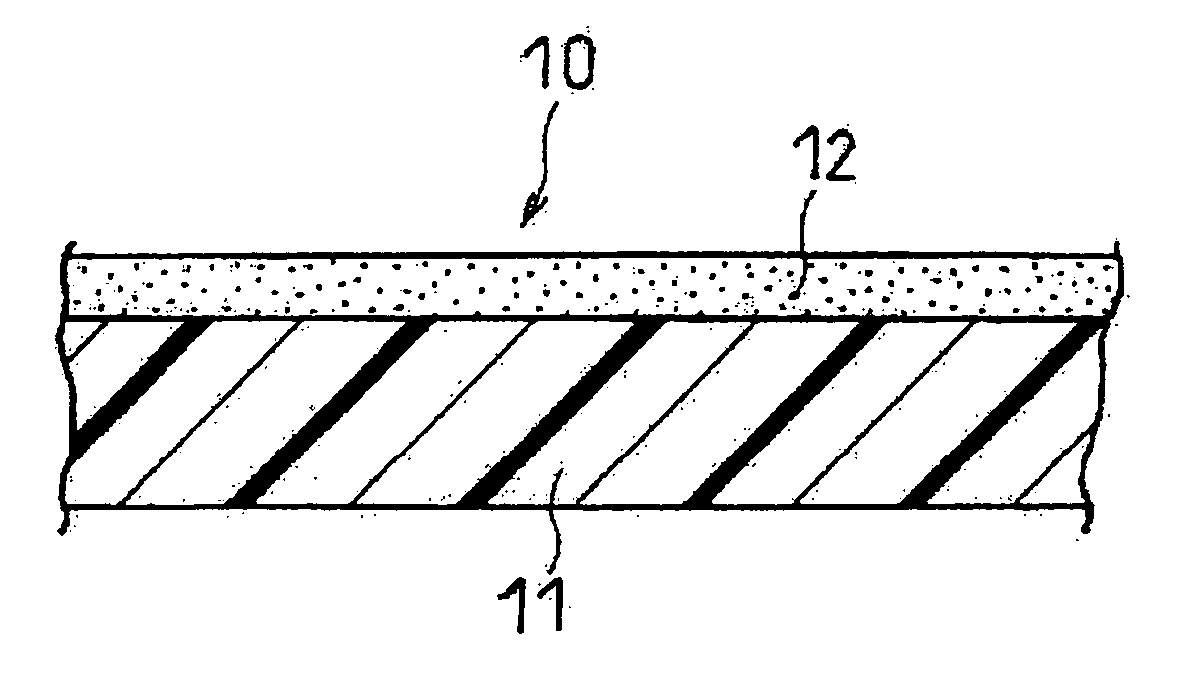

A lithium battery comprises a pouch (4) and a lithium battery module (2) packaged in the pouch (4). The pouch (4) is formed from a battery packaging laminated structure (10). The laminated structure (10) has an outermost layer (11), a barrier layer (12) and an innermost layer (14), or an outermost layer (11), a barrier layer (12), an intermediate layer (13) and an innermost layer (14) superposed in that order. The outermost layer (11) is formed of a formable base material, the barrier layer (12) is formed of a impermeable base material having a barrier property, the intermediate layer (13) is formed of a formable base material and the innermost layer (14) is formed of a heat-adhesive base material.

Owner:DAI NIPPON PRINTING CO LTD

Redox shuttle for rechargeable lithium-ion cell

InactiveUS20050221196A1Excellent repeated overcharge stabilityNon-aqueous electrolyte accumulatorsOrganic electrolyte cellsLithiumAlkoxy group

A redox chemical shuttle comprising an aromatic compound substituted with at least one tertiary carbon organic group and at least one alkoxy group (for example, 2,5-di-tert-butyl-1,4-dimethoxybenzene) provides repeated overcharge protection in rechargeable lithium-ion cells.

Owner:3M INNOVATIVE PROPERTIES CO

Prismatic battery

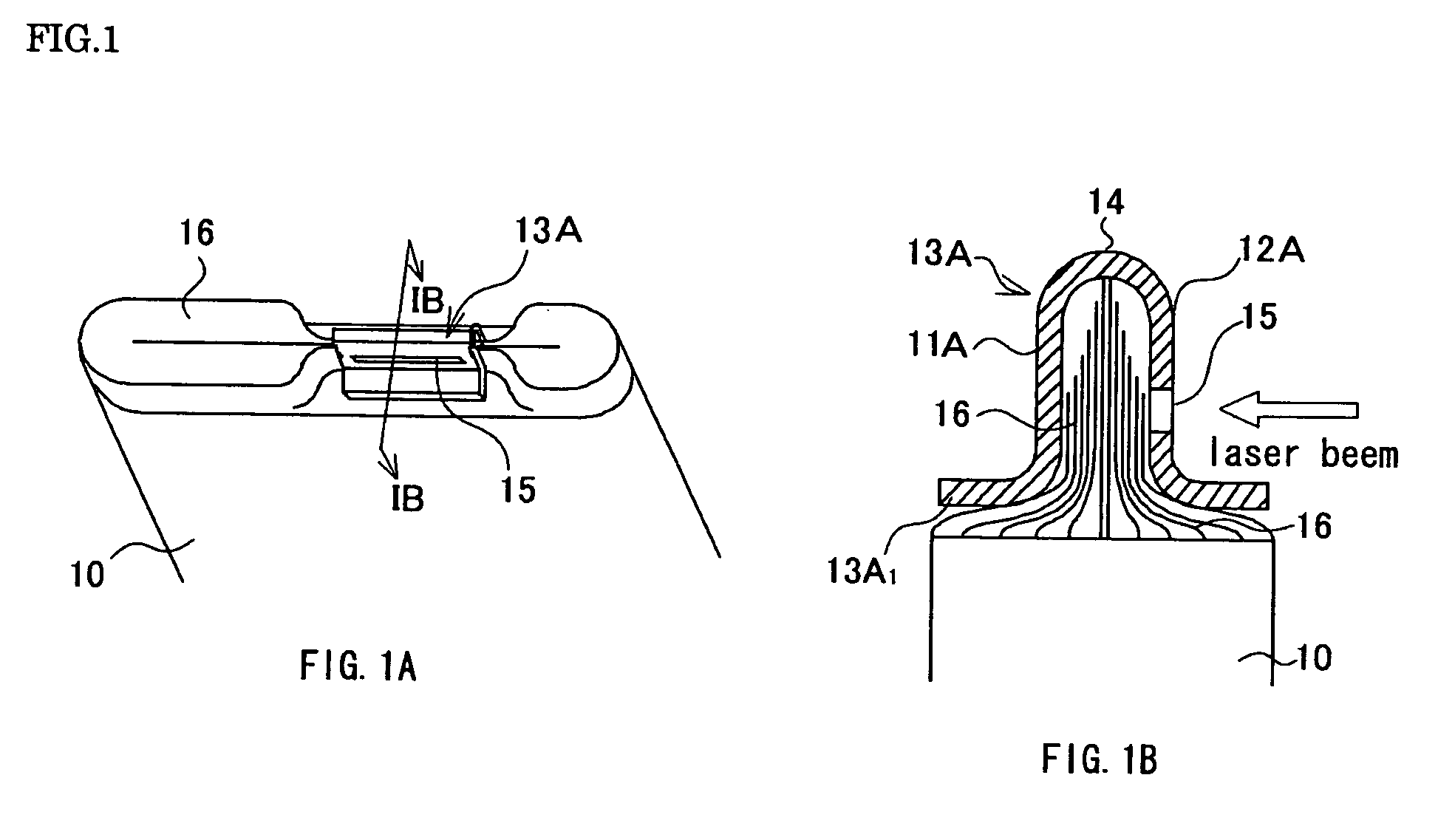

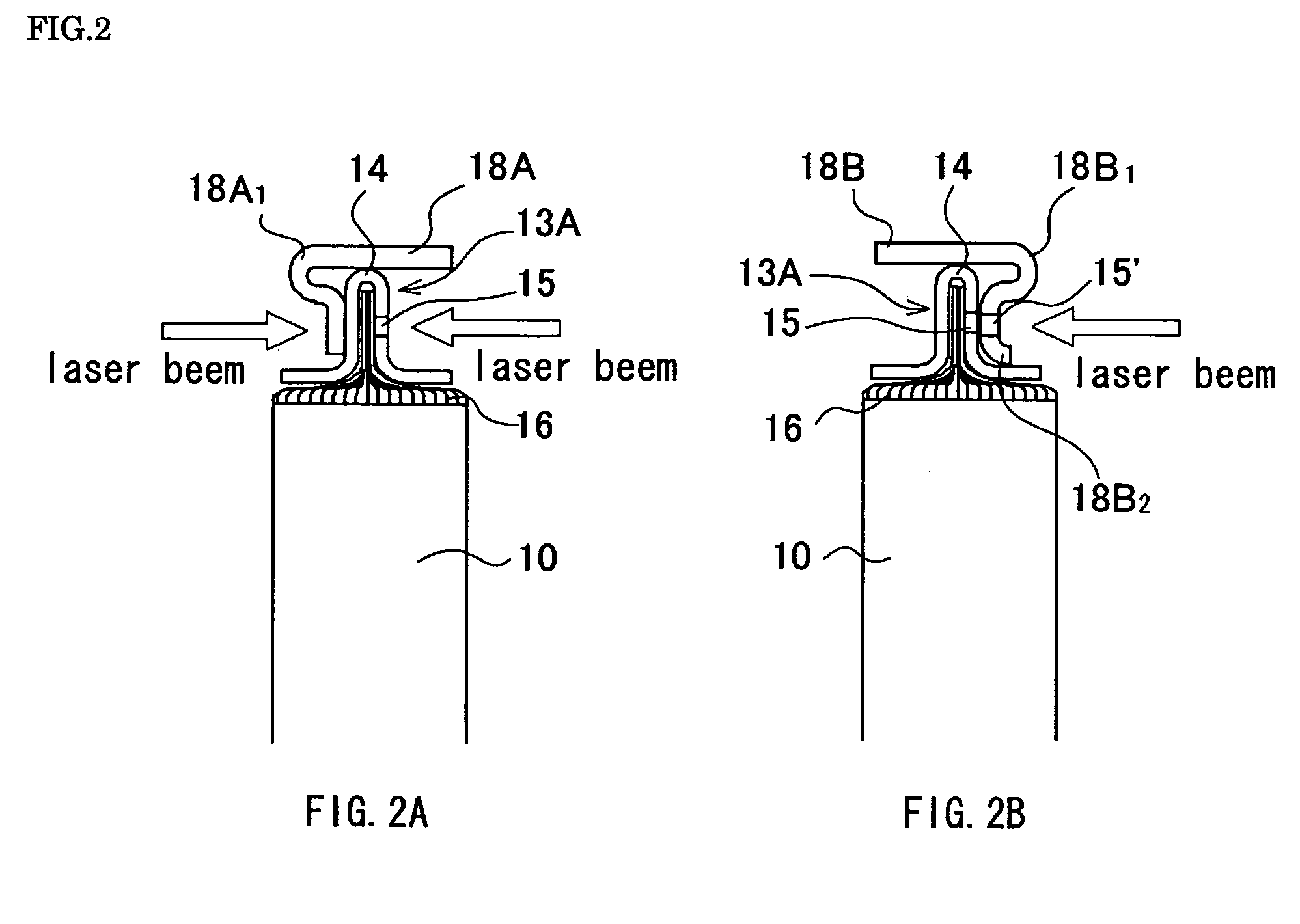

ActiveUS20070117009A1Reduce the possibilityNon-aqueous electrolyte accumulatorsCell electrodesElectric vehicleHigh energy beam

A prismatic battery according to one embodiment of the present invention includes a flat electrode group 10 stacked or rolled by mutually positive and negative electrodes with a separator therebetween, a pressing plate 13A, a current collecting body 18A or 18B and a plurality of exposed sections 16, at least one end of the positive and negative electrodes substrates in a width direction being uncoated with a positive or negative electrode mixture. The pressing plate 13A is welded to the exposed sections 16. The pressing plate 13A includes opposing surfaces with a space therebetween provided by folding back a metal plate, and includes a slit 15 along a folded back section at least to one of the opposing surface's side. The exposed sections 16 are inserted into a gap of the pressing plate 13A, and the exposed sections 16 and the pressing plate 13A are welded by a high energy beam from a transverse direction through the slit 15. This provides a prismatic battery for large current application in electric vehicles and hybrid electric vehicles.

Owner:SANYO ELECTRIC CO LTD

Layered Lithium Nickel Manganese Cobalt Composite Oxide Powder For Material Of Positive Electrode Of Lithium Secondary Battery, Process For Producing The Same, Positive Electrode Of Lithium Secondary Battery Therefrom, And Lithium Secondary Battery

ActiveUS20070202405A1Improve securityImprove battery performanceNon-aqueous electrolyte accumulatorsOrganic electrolyte cellsManganeseCobalt

A powder of a layered lithium-nickel-manganese-cobalt composite oxide for use as a positive-electrode material for lithium secondary battery is provided which, when used as a positive-electrode material for lithium secondary battery, enables a cost reduction and higher safety to be reconciled with improved battery performances. The powder of a layered lithium-nickel-manganese-cobalt composite oxide for use as a positive-electrode material for lithium secondary battery is composed of secondary particles formed by the aggregation of primary particles. It has a composition represented by the following formula (I), has a volume resistivity of 5×105 Ω·cm or lower in the state of being compacted at a pressure of 40 MPa, and has a value of C / S, wherein C is the concentration of carbon contained therein (% by weight) and S is the BET specific surface area thereof (m2 / g), of 0.025 or smaller. The powder has been regulated so as to have a volume resistivity not higher than the specified value and a considerably reduced carbon content while having a composition in a limited range, whereby a cost reduction and higher safety can be reconciled with improved battery performances. Li1+zNixMnyCo1−x−yOδ (I) (0<z≦0.91, 0.1≦x≦0.55, 0.20≦y≦0.90, 0.50≦x+y≦1, 1.9≦δ≦3)

Owner:MITSUBISHI CHEM CORP

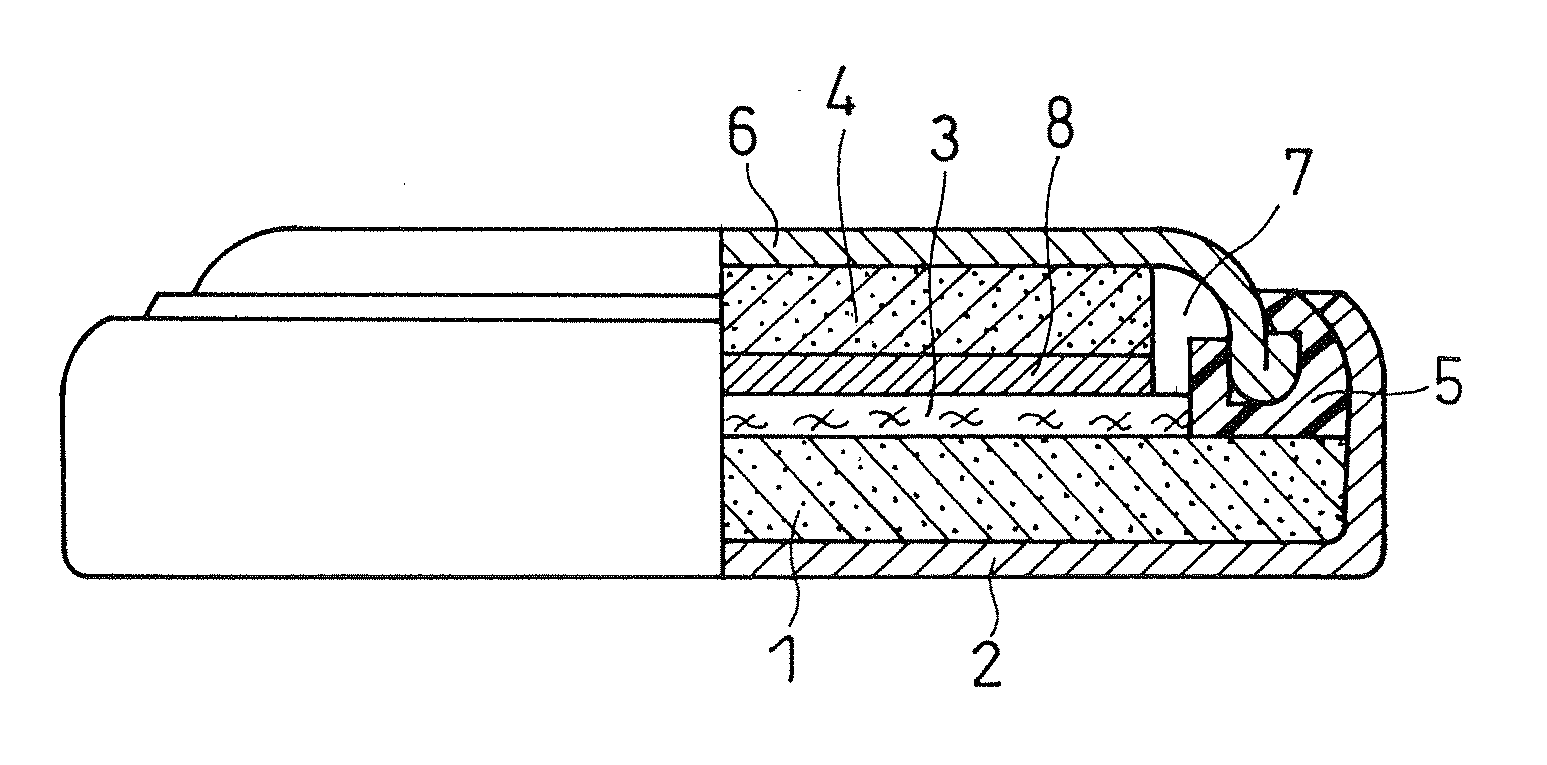

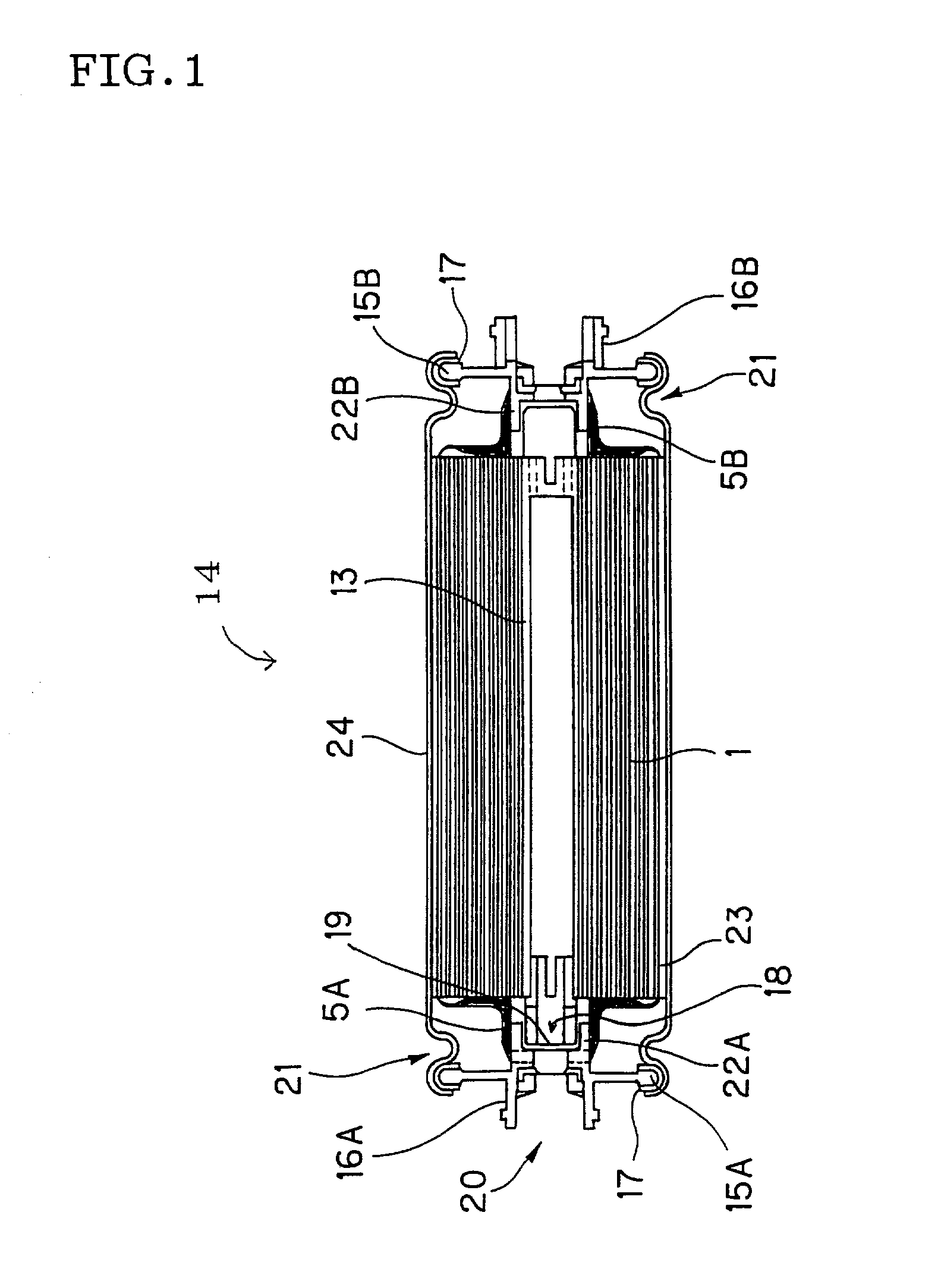

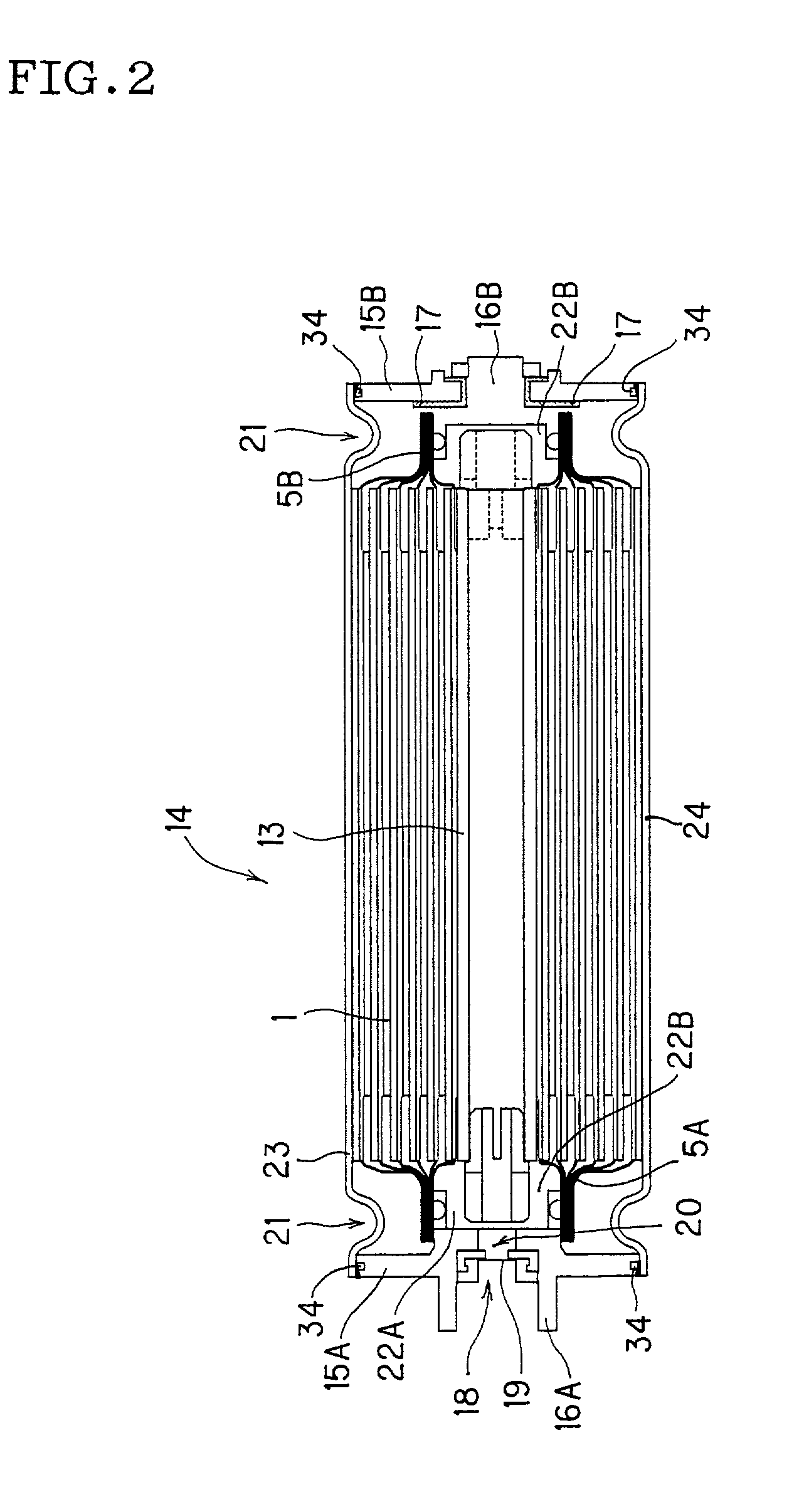

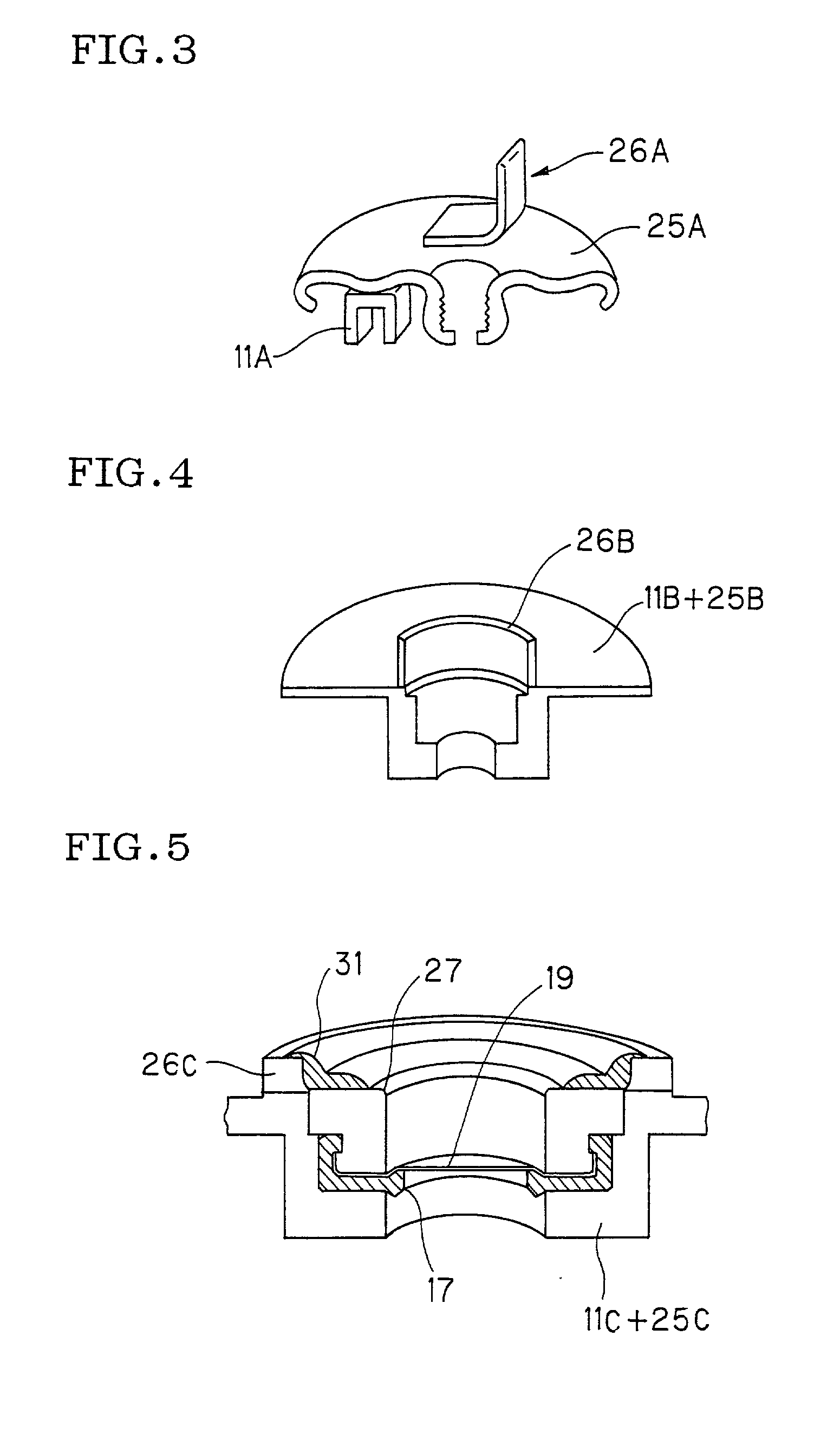

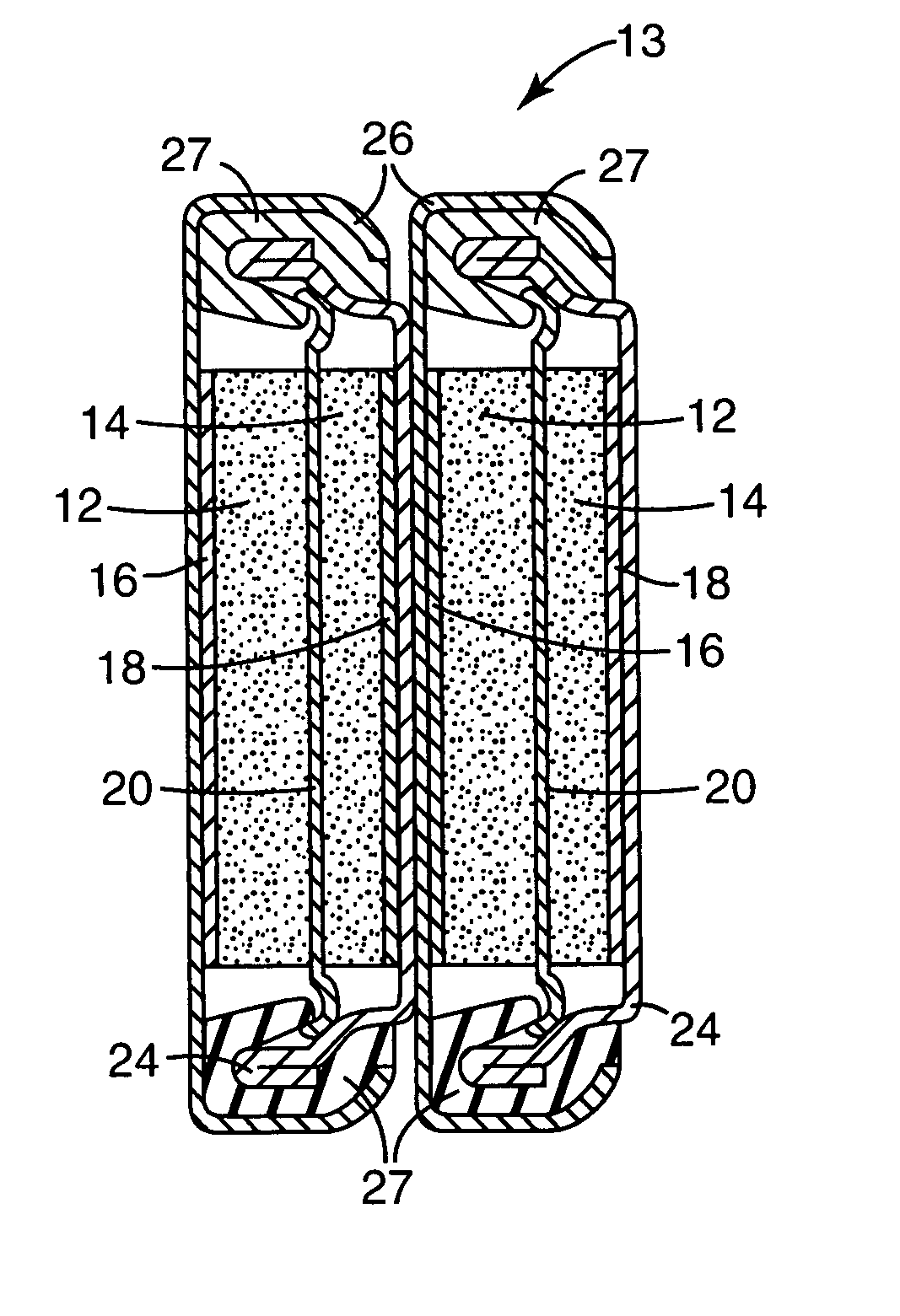

Lithium secondary cell and assembly thereof

InactiveUS20010049054A1Primary cell to battery groupingNon-aqueous electrolyte accumulatorsElastomerLithium

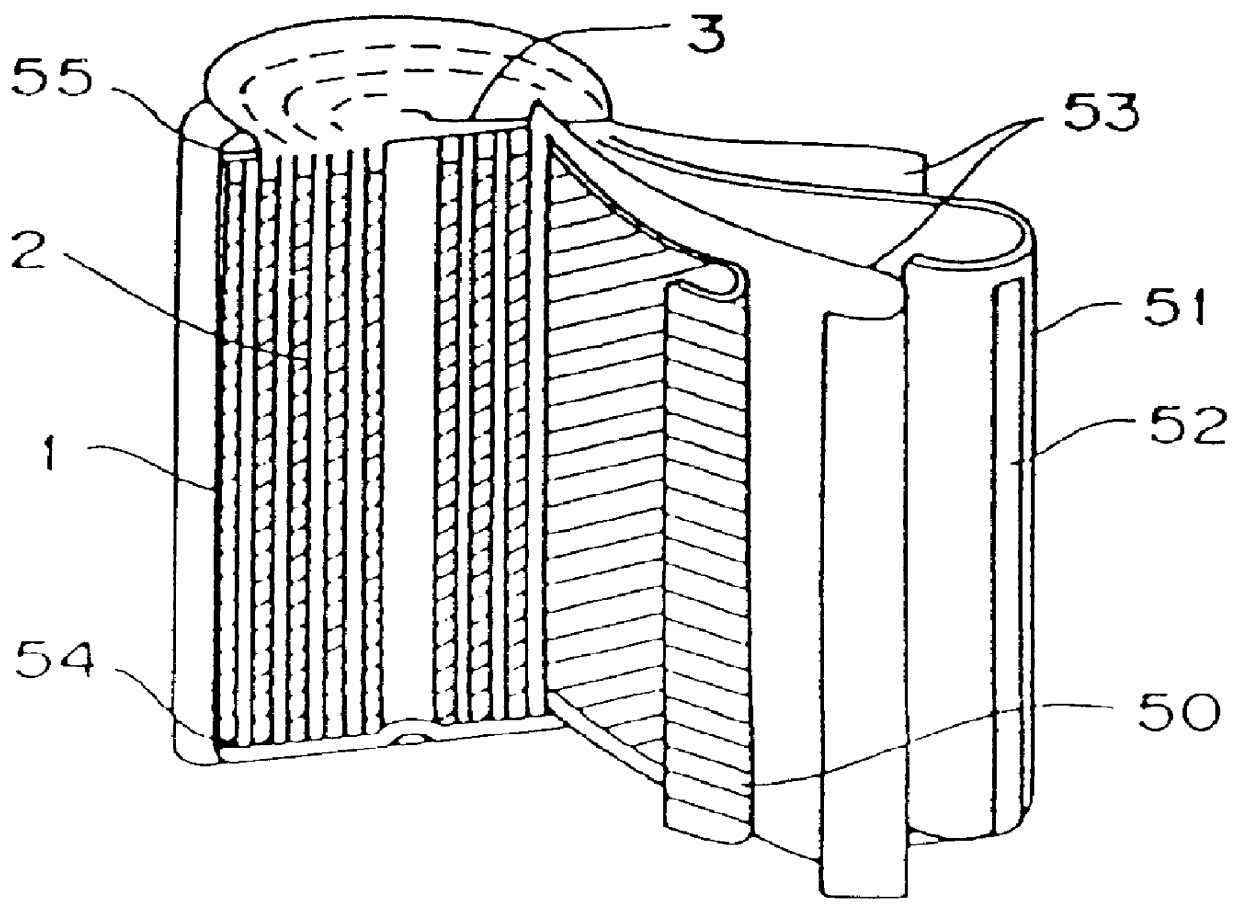

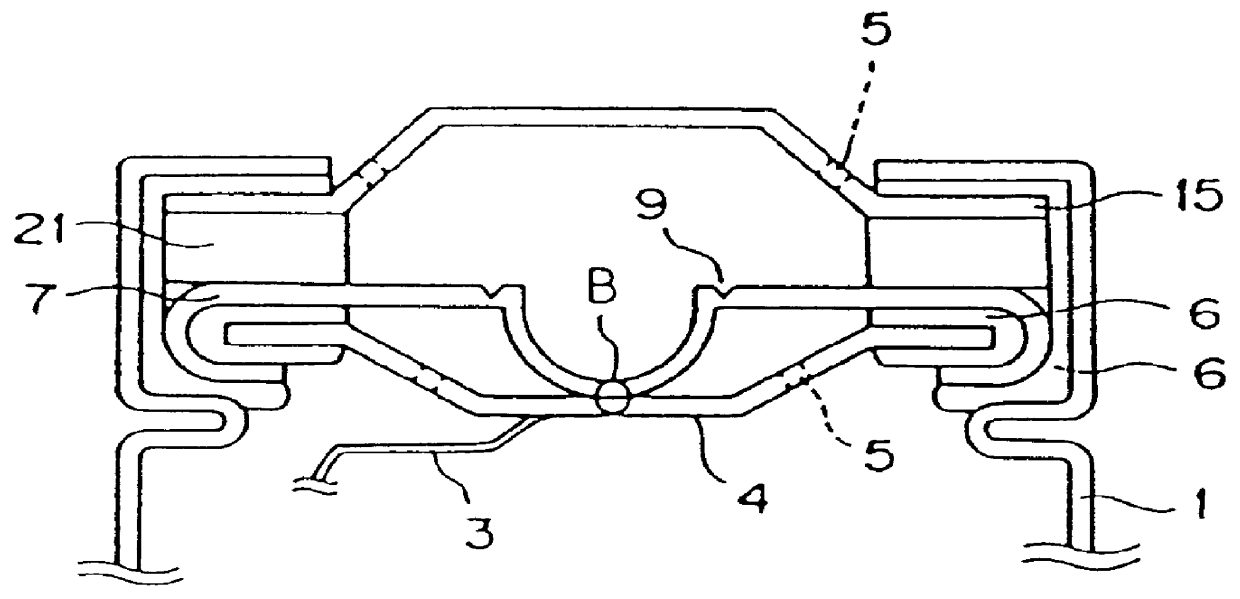

To provide a lithium secondary cell, which is excellent in productivity since a cell structure is simple and easy for assembly. Provided is a lithium secondary cell having: an internal electrode body including a positive electrode plate, a negative electrode plate, the positive electrode plate and the negative electrode plate being wound and laminated around an external periphery wall of a hollow cylindrical winding core, and inside the internal electrode body a nonaqueous electrolyte solution being impregnated, a cylindrical cell case contained in this internal electrode body 1 with both ends being opened, and two electrode caps sealing the above described internal electrode body 1 at both the open ends of this cell case. The electrode cap has a plate member sealing the internal electrode body and disposed so as to seal both the open ends of the above described cell case, an external terminal member protruding onto the surface of the electrode caps to lead out currents to outside, and an internal terminal member brought into connection with the internal electrode body and taking out currents from the internal electrode body, and an elastic body and at least two of the above described plate member, the external terminal member and the internal terminal member are joined together for construction. Furthermore, there is also provided an assembly of lithium secondary cells.

Owner:NGK INSULATORS LTD

Substituted phenothiazine redox shuttles for rechargeable lithium-ion cell

InactiveUS20060263697A1Non-aqueous electrolyte accumulatorsElectrode carriers/collectorsLithiumRedox

A rechargeable lithium-ion cell contains a positive electrode, negative electrode, charge-carrying electrolyte containing charge carrying medium and lithium salt, and an N-substituted or C-substituted phenothiazine compound dissolved in or dissolvable in the electrolyte. The substituted phenothiazine compound has an oxidation potential above the positive electrode recharged potential and serves as a cyclable redox chemical shuttle providing cell overcharge protection.

Owner:3M INNOVATIVE PROPERTIES CO

Non-aqueous electrolyte battery

InactiveUS20060068282A1Improve output performanceImprove cycle performanceNon-aqueous electrolyte accumulatorsCell seperators/membranes/diaphragms/spacersMolten saltNon aqueous electrolytes

A non-aqueous electrolyte battery that contains a molten salt electrolyte and has the enhanced output performances and cycle performances can be provided. The electrolyte has a molar ratio of lithium salt to molten salt of from 0.3 to 0.5, and the non-aqueous electrolyte battery has a positive electrode having a discharge capacity of 1.05 or more times that of a negative electrode thereof.

Owner:KK TOSHIBA

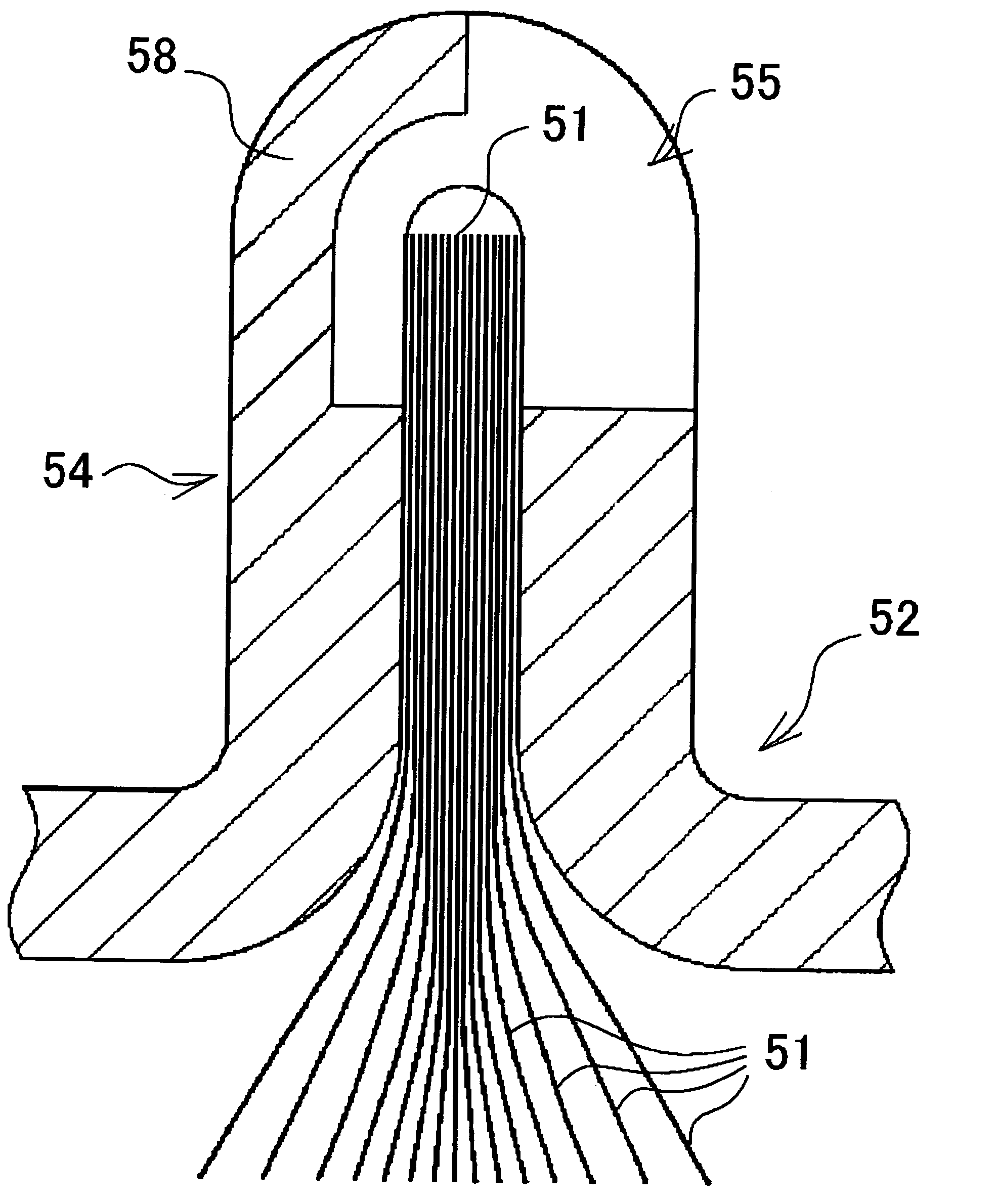

Lithium secondary battery

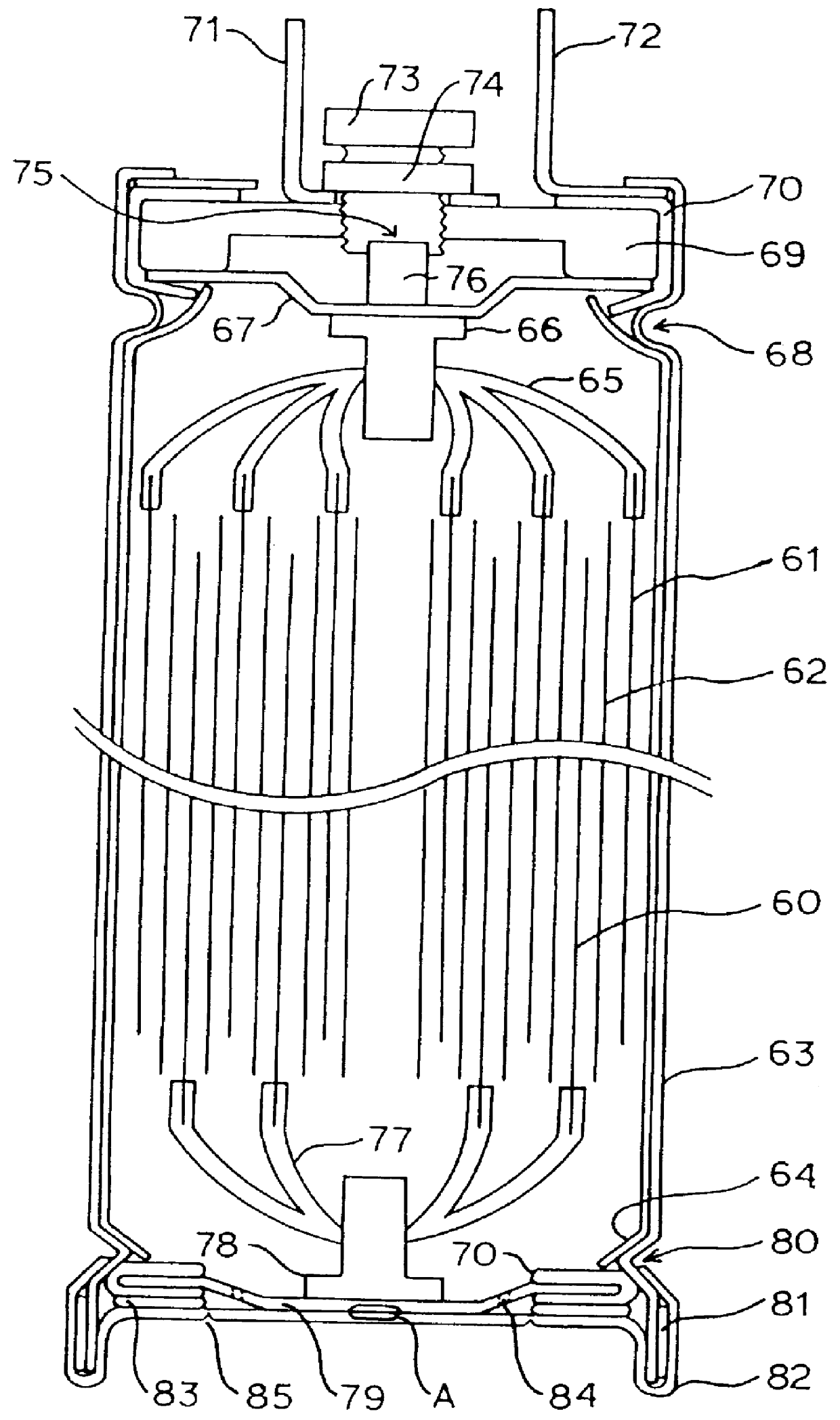

A lithium secondary battery includes an electricity generating portion in which positive electrode 60 and negative electrode 61 form a laminate through separator films 62 made of porous polymer so that the positive electrode 60 and the negative electrode 61 do not come in direct contact with each other, leads 65, 77 which are respectively connected to plural portions of the positive electrode 60 and the negative electrode 61 to make electricity collection, and a low melting point alloy member 76 as a current break mechanism being inserted in a current path of the inside of the battery, which is melted to break the current path when the temperature of the battery is raised over a predetermined temperature.

Owner:NGK INSULATORS LTD

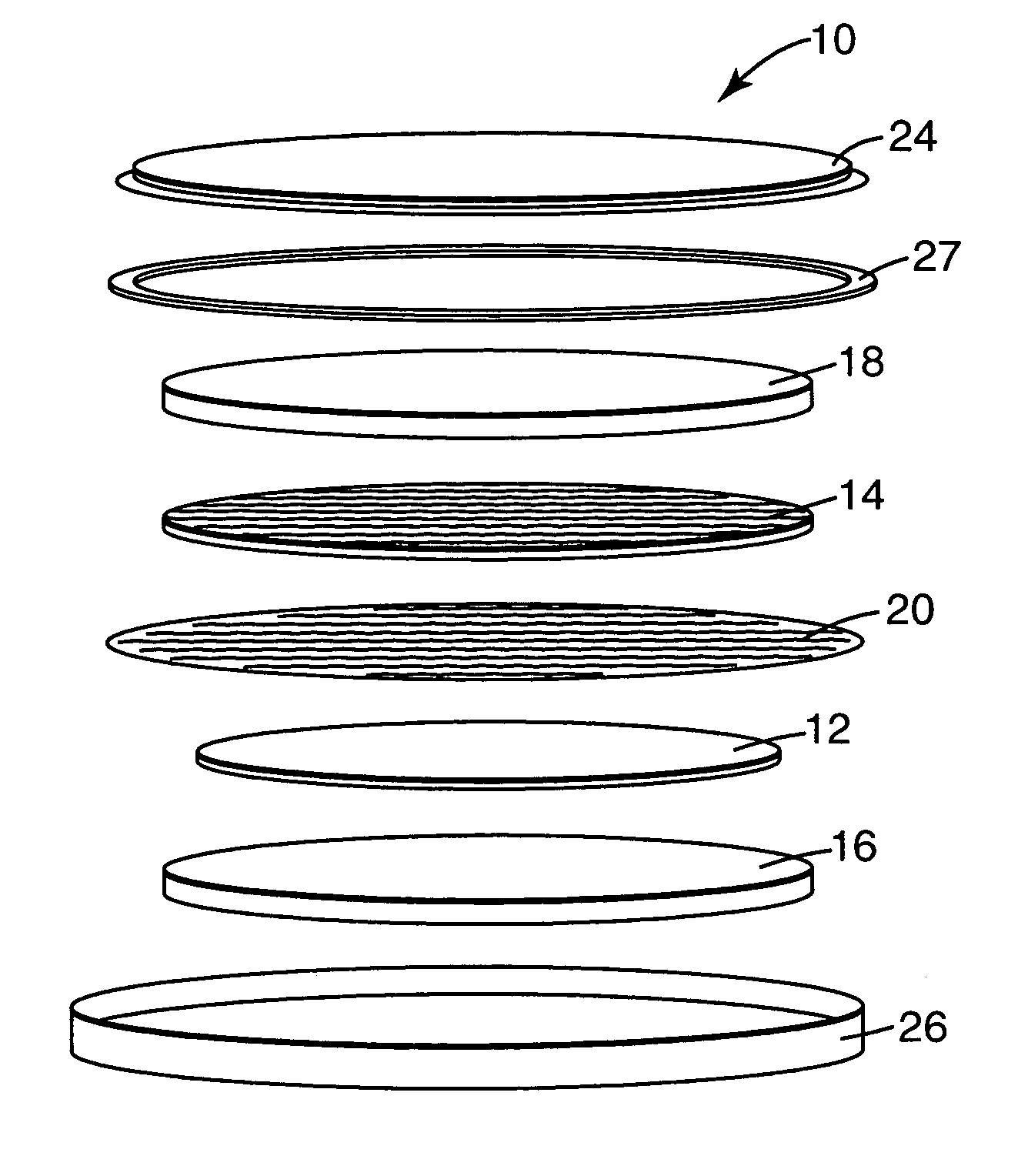

Electrochemical device using multicomponent composite membrane film

InactiveUS7014948B2Easy to manufactureImprove adhesionMembranesSemi-permeable membranesPolymer scienceElectrochemistry

The present invention provides a electrochemical element, wherein a multi-component composite film comprising a) polymer support layer film and b) a porous gellable polymer layer which is formed on either or both sides of the support layer film of a), wherein the support layer film of a) and the gellable polymer layer of b) are unified with each other without an interface between them.

Owner:TORAY BATTERY SEPARATOR FILM +1

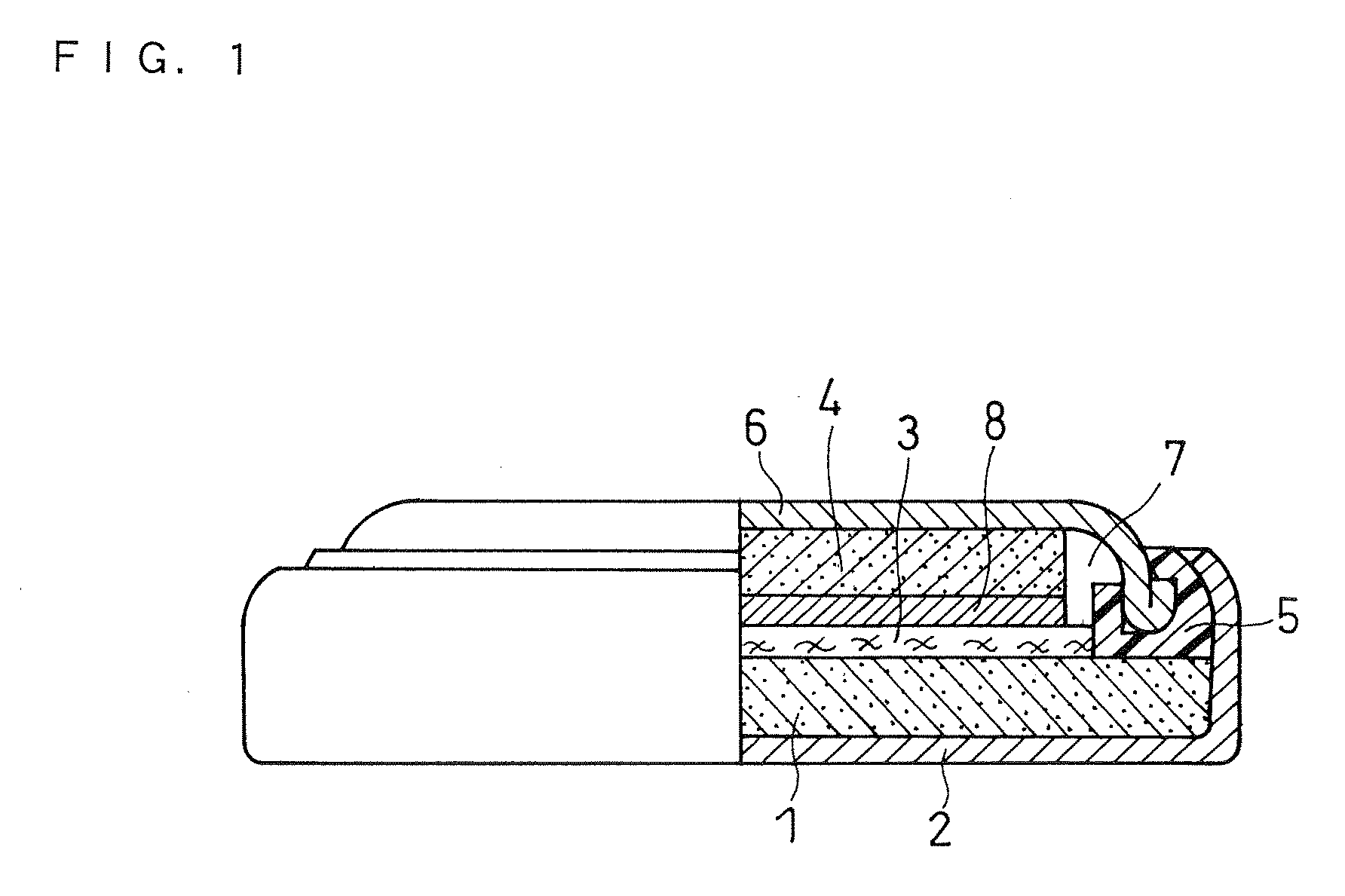

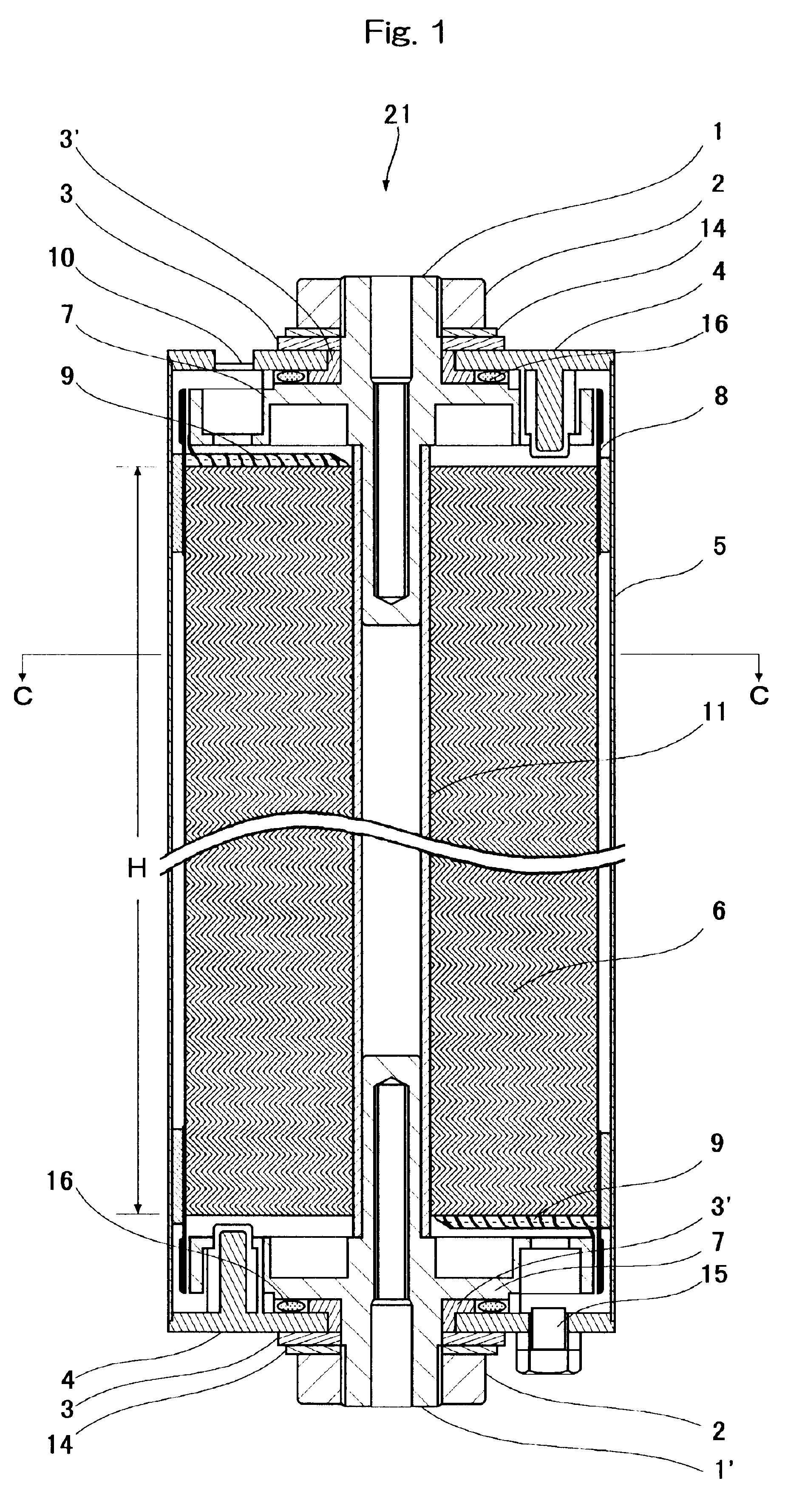

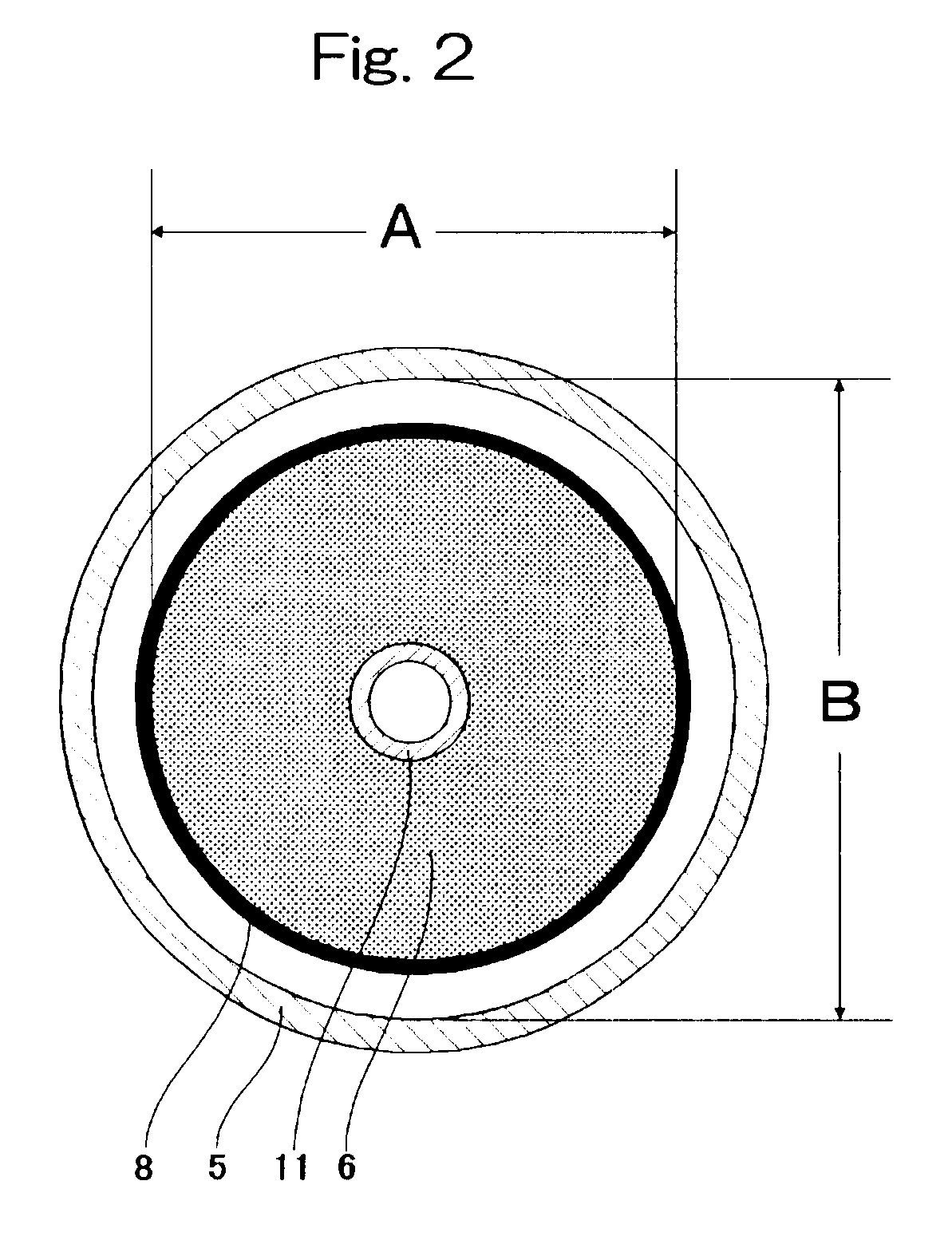

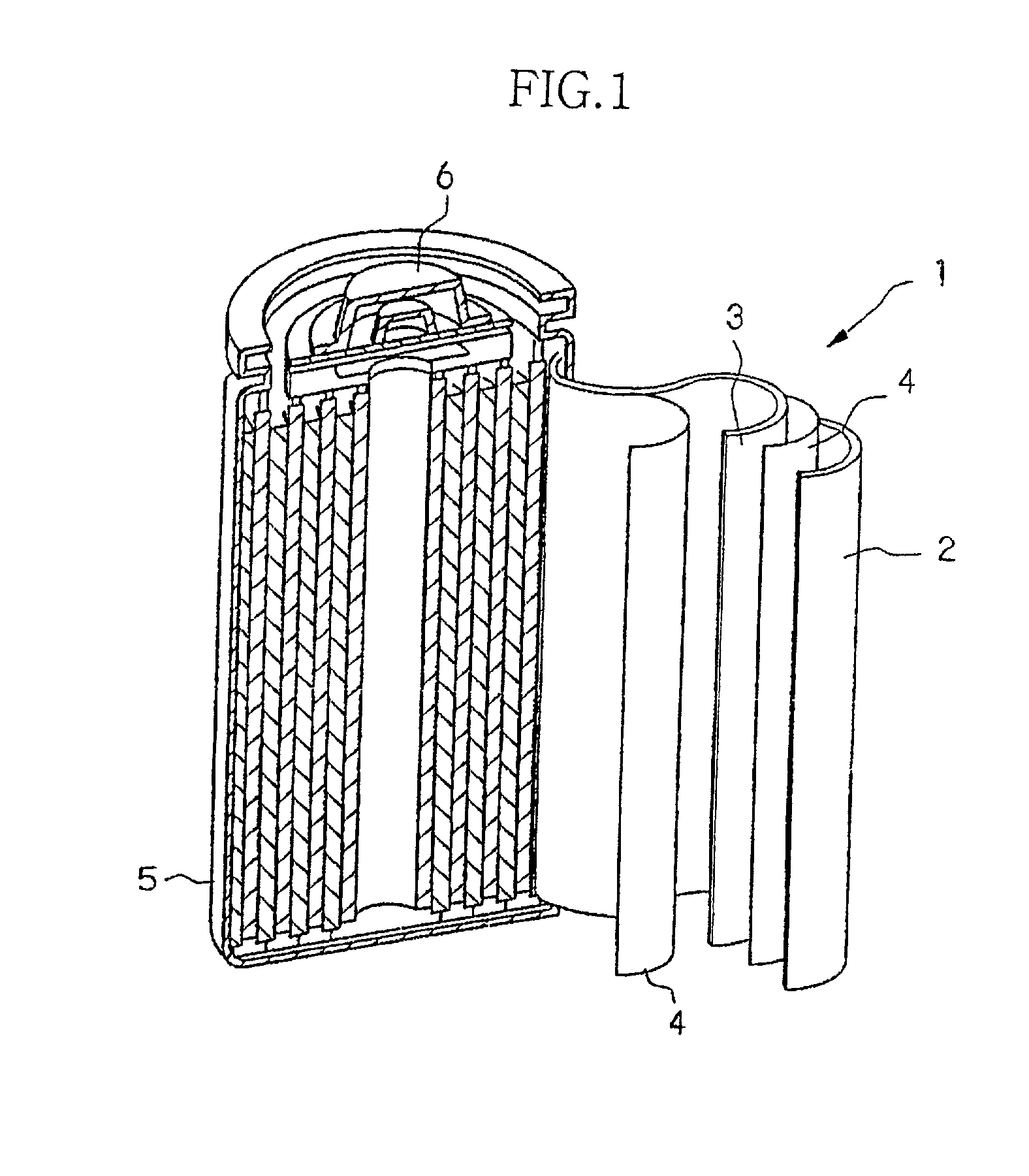

Cylindrical lithium-ion battery

InactiveUS6509114B1Non-aqueous electrolyte accumulatorsFinal product manufactureEngineeringLithium-ion battery

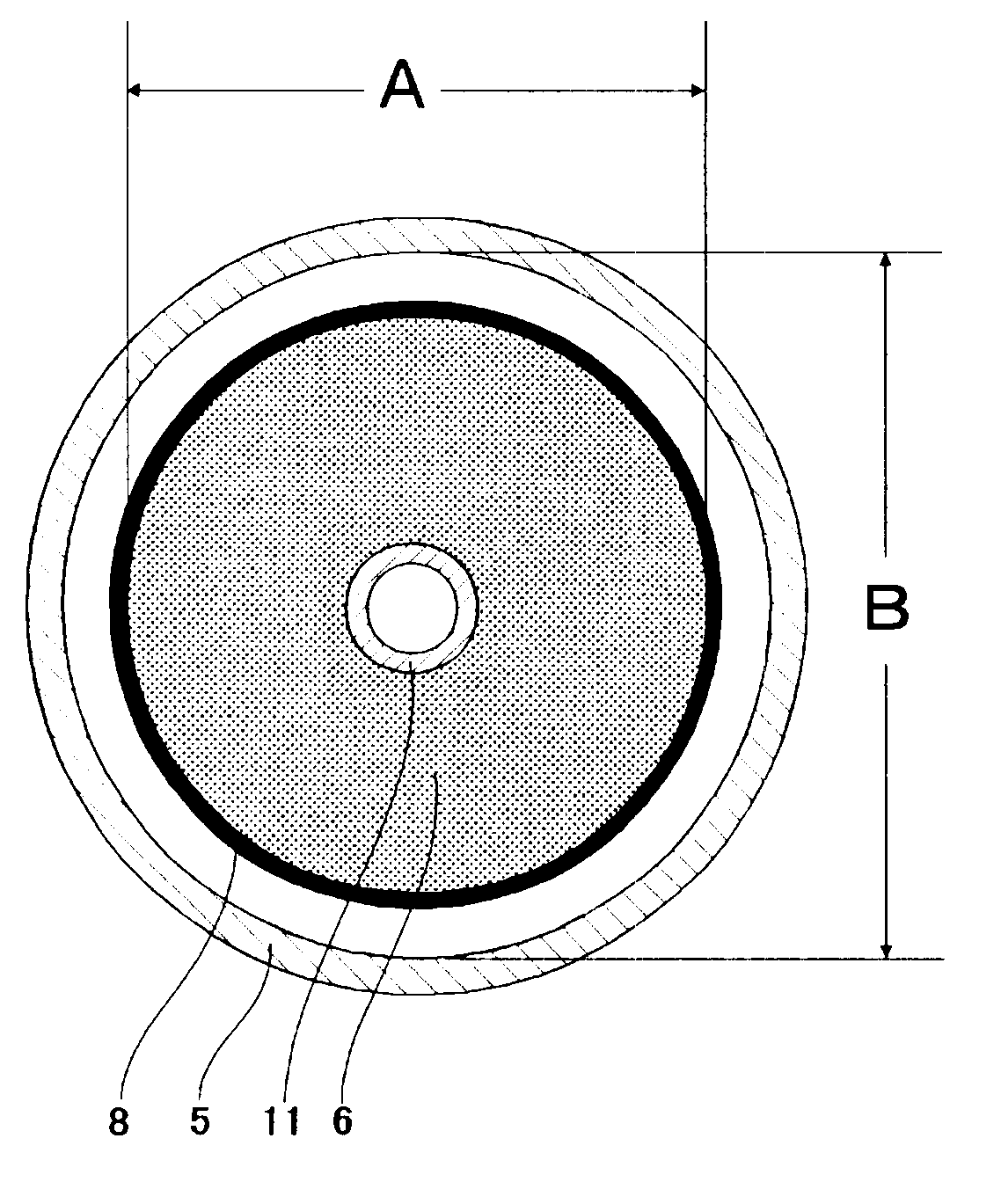

A cylindrical lithium-ion battery with excellent safety where abnormal heat generation and remarkable deformation of a battery container do not occur even at an abnormal time is provided. When an average diameter of a winding group 6 is A mm, an inner diameter of the battery container 5 is B mm, a longitudinal length of the winding group 6 except for lead pieces extending from the winding group 6 is H mm, and the number of windings where a layer of one unit comprising a negative electrode member / separator / negative electrode member / separator is wound around a shaft core 11 is W, a calculation value K obtained by a formula; K=(B-A)x(10000 / (WxH) is set to 0.89 or more. When the calculation value K is 0.89 or more, a gap (B-A) between an outer periphery of the winding group 6 and an inner periphery of the battery container 5 that enables the winding group 6 to expand in its diameter direction at an abnormal time is properly secured.

Owner:HITACHI VEHICLE ENERGY

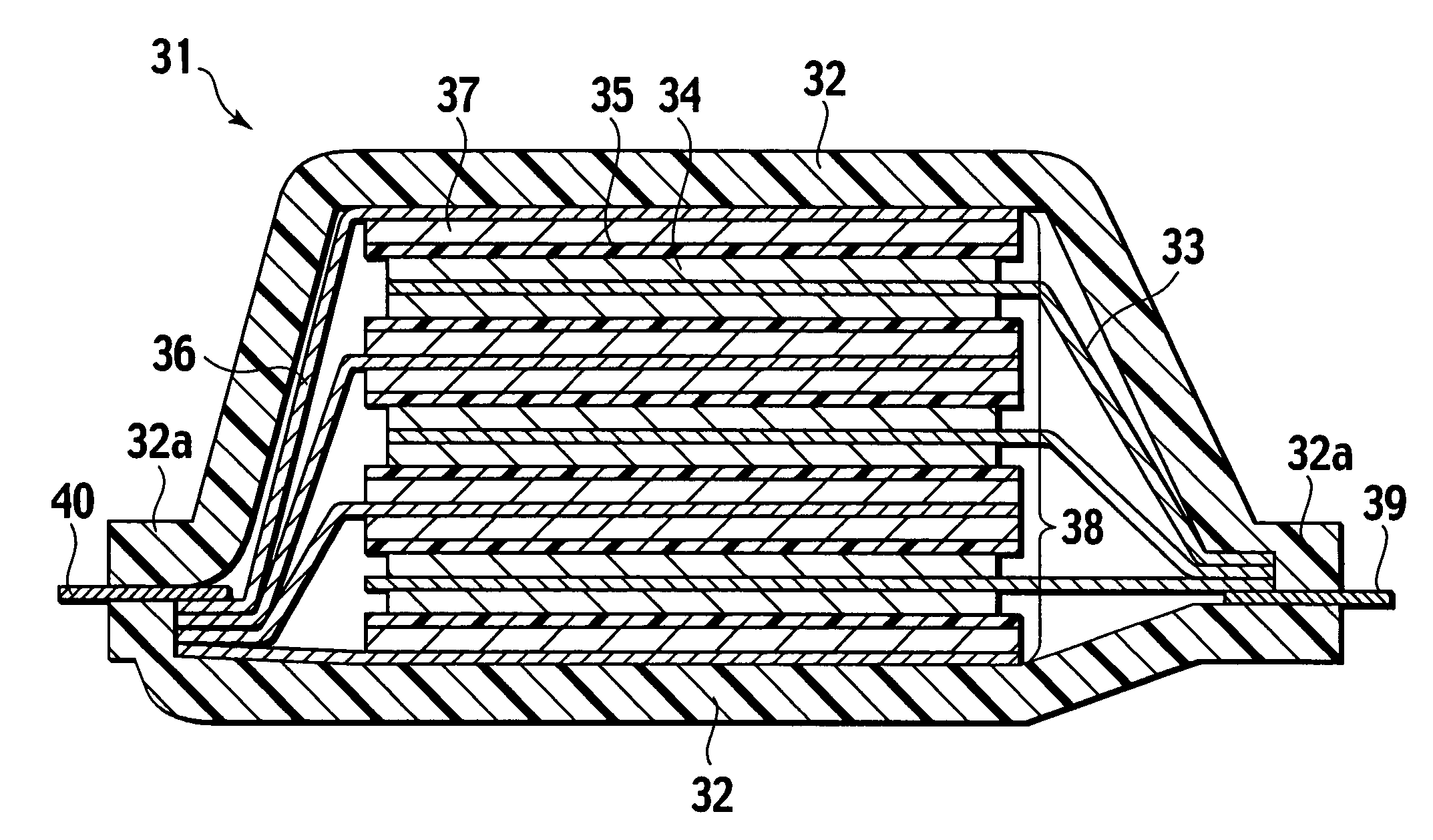

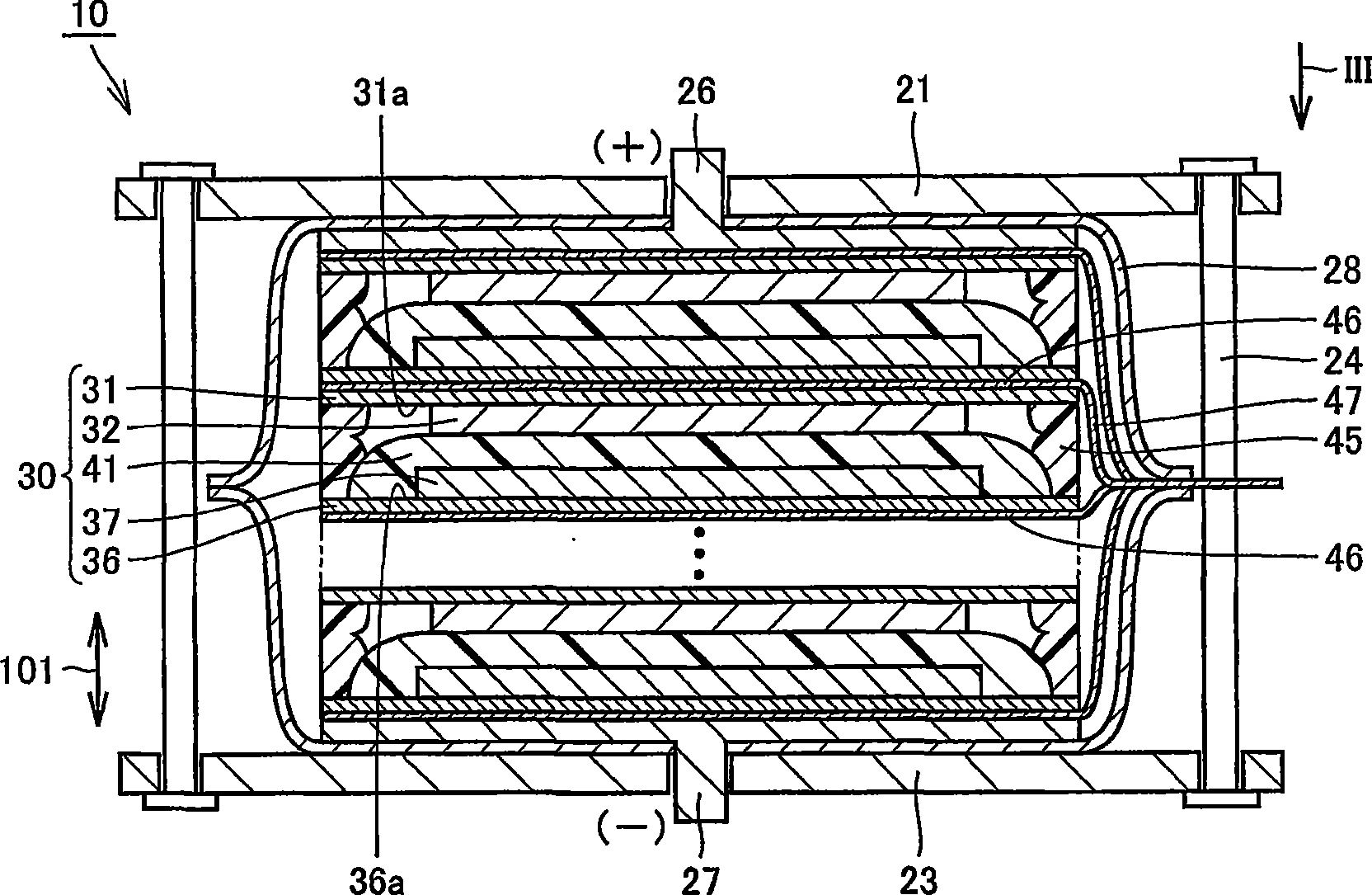

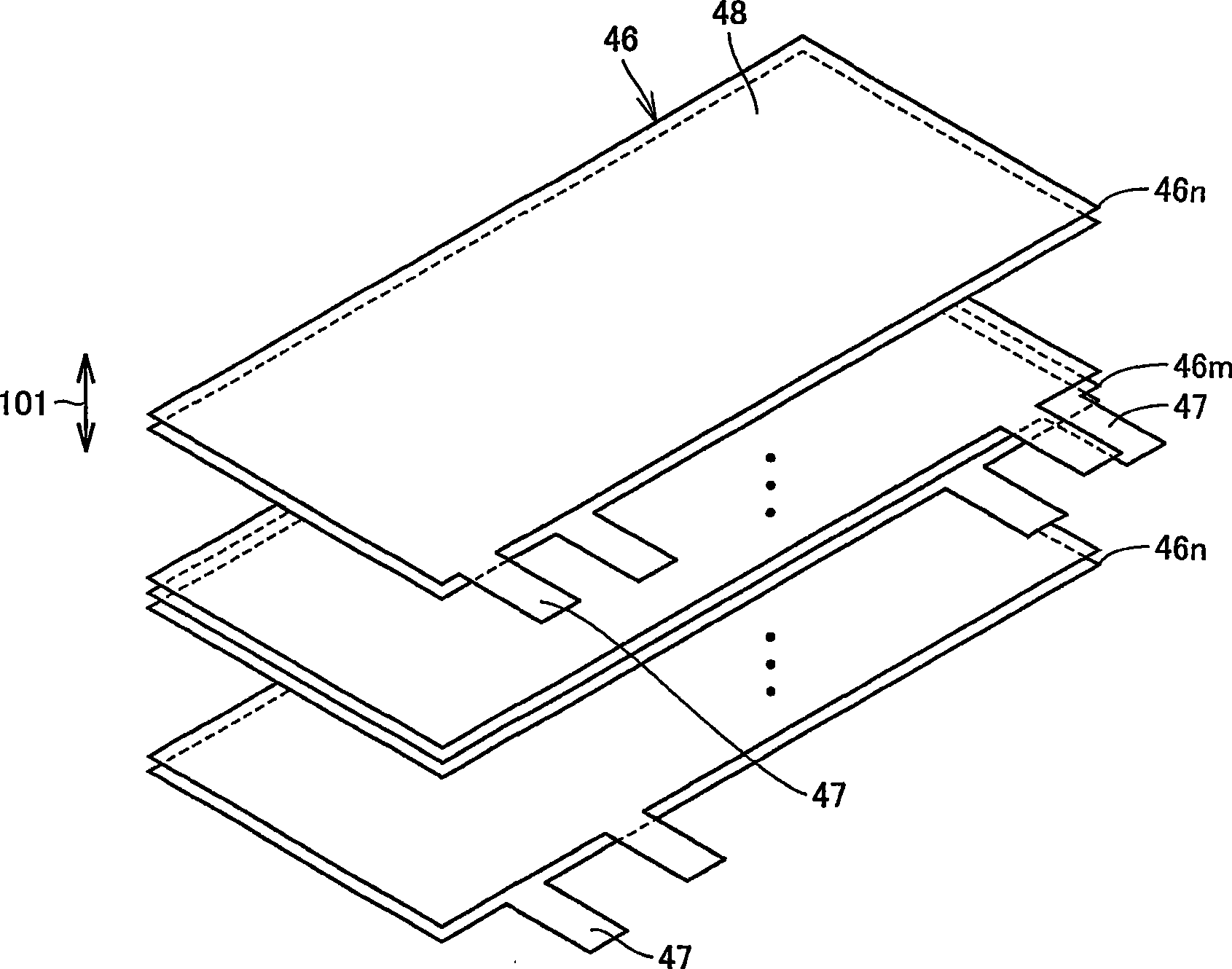

Stacked type battery

InactiveCN101416343ASpeed up heat dissipationNo drop in productivityNon-aqueous electrolyte accumulatorsLarge-sized flat cells/batteriesProduction rateEngineering

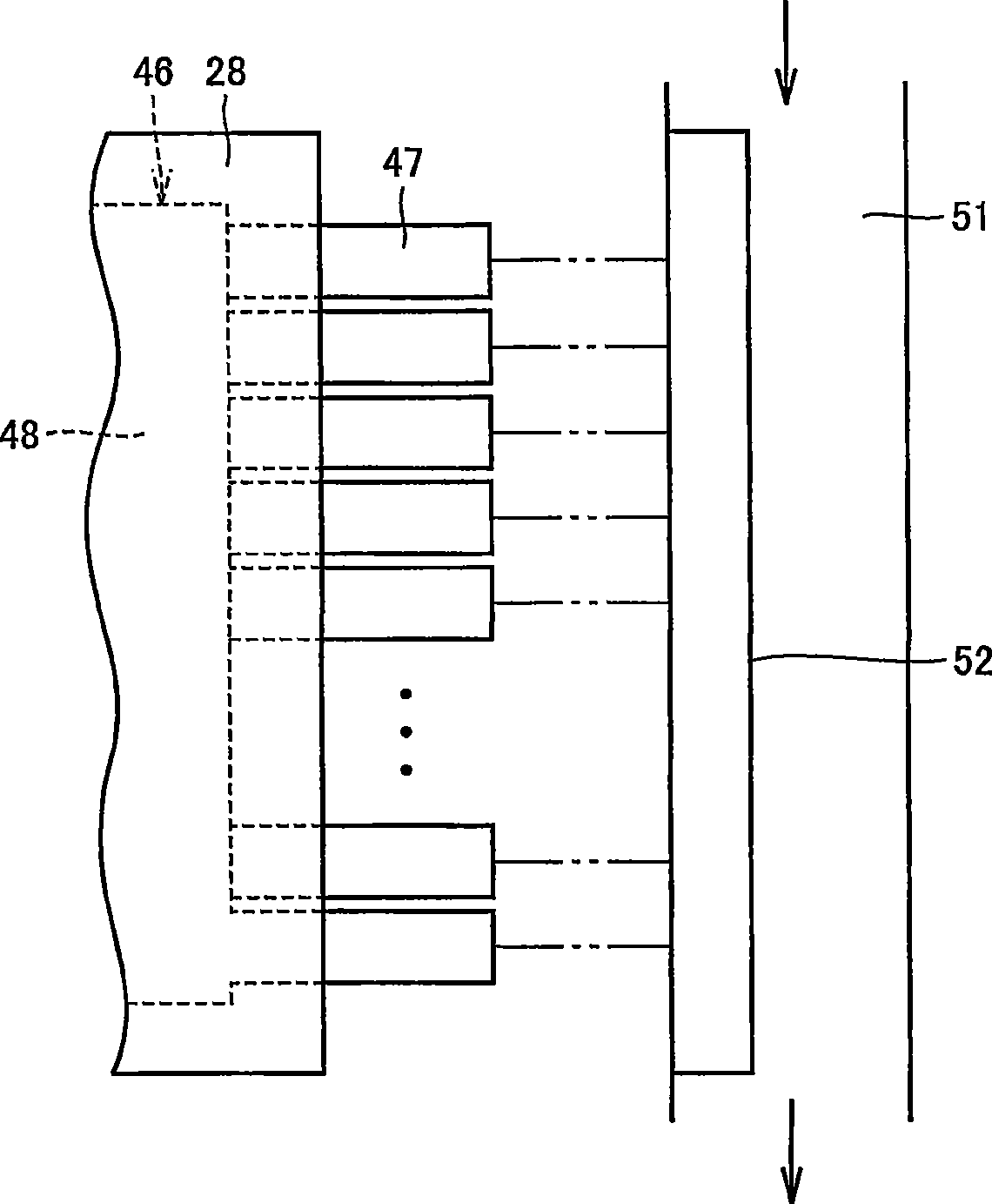

A stacked cell (10) is provided with a plurality of stacked unit cells (30), which have a positive electrode collector foil (31) and a negative electrode collector foil (36); and a sheet member (46), which is arranged between the adjacent unit cells (30) and sandwiched between the positive electrode collector foil (31) and the negative electrode collector foil (36). The positive collector foil (31) and the negative collector foil (36) are provided with a positive electrode active material layer (32) and a negative active material layer (37), respectively. The positive electrode collector foil (31) and the negative electrode collector foil (36) are laid one over another to have the positive electrode active material layer (32) and the negative electrode material layer (37) face each other through an electrolyte layer (41). The sheet member (46) has a cooling tab (47) which extends from between the positive electrode collector foil (31) and the negative electrode collector foil (36). Thus, the stacked cell having improved heat dissipation is provided without deteriorating productivity.

Owner:TOYOTA JIDOSHA KK

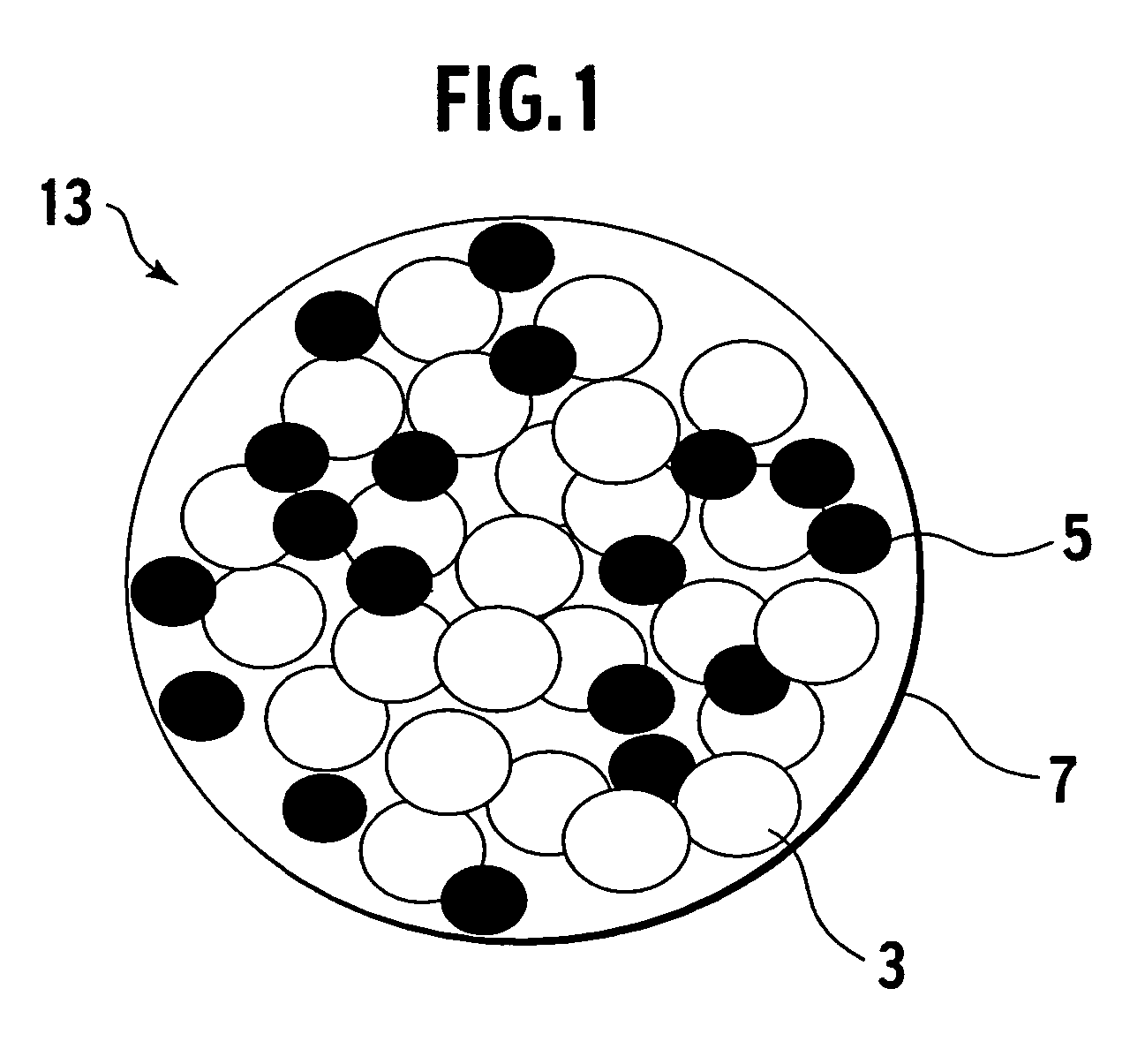

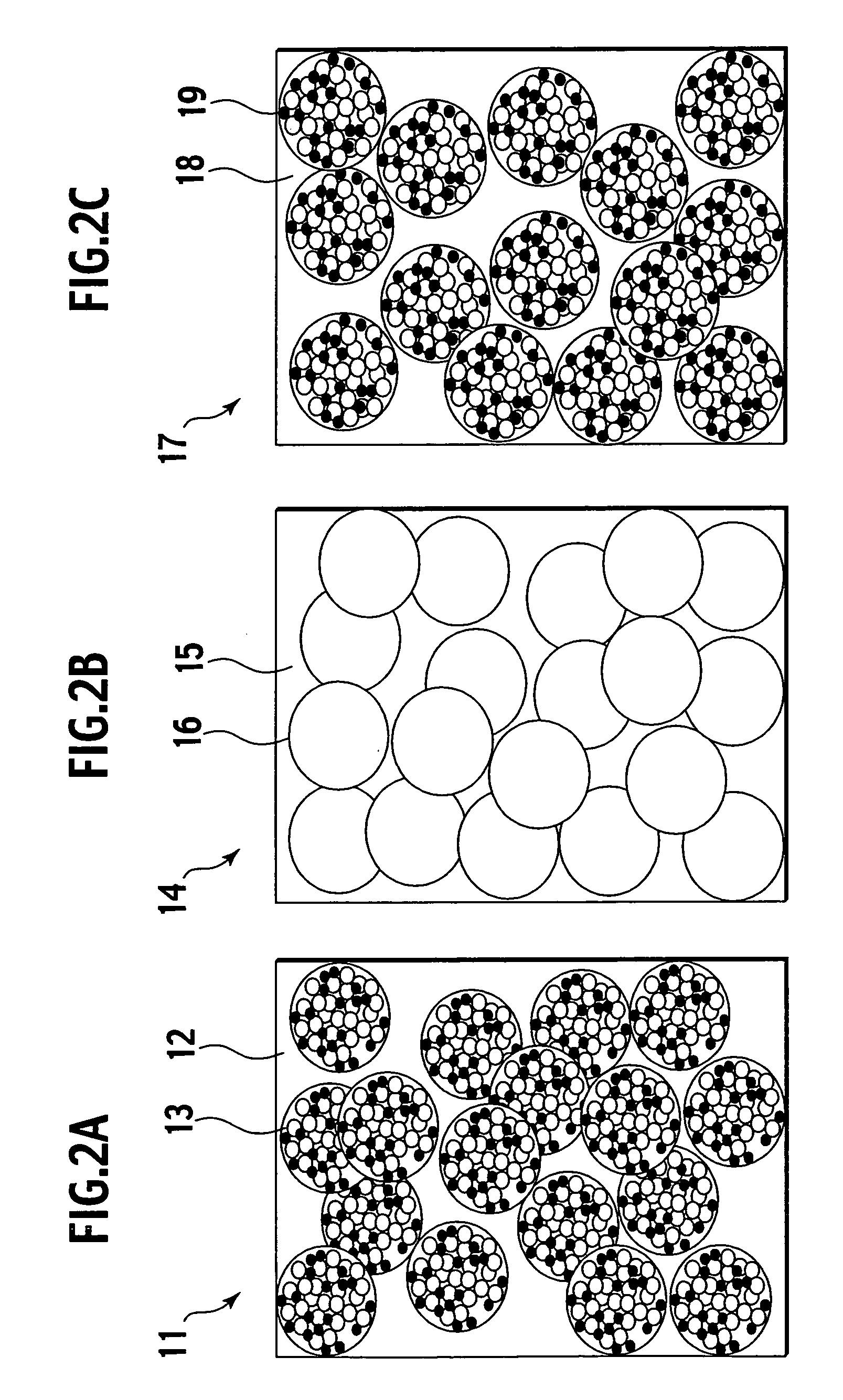

Cathode active material, method of preparing the same, and cathode and lithium battery containing the material

ActiveUS20060257745A1Improve high voltage stabilityImprove thermal stabilityWalking sticksElectrode rolling/calenderingComposite cathodeHigh rate

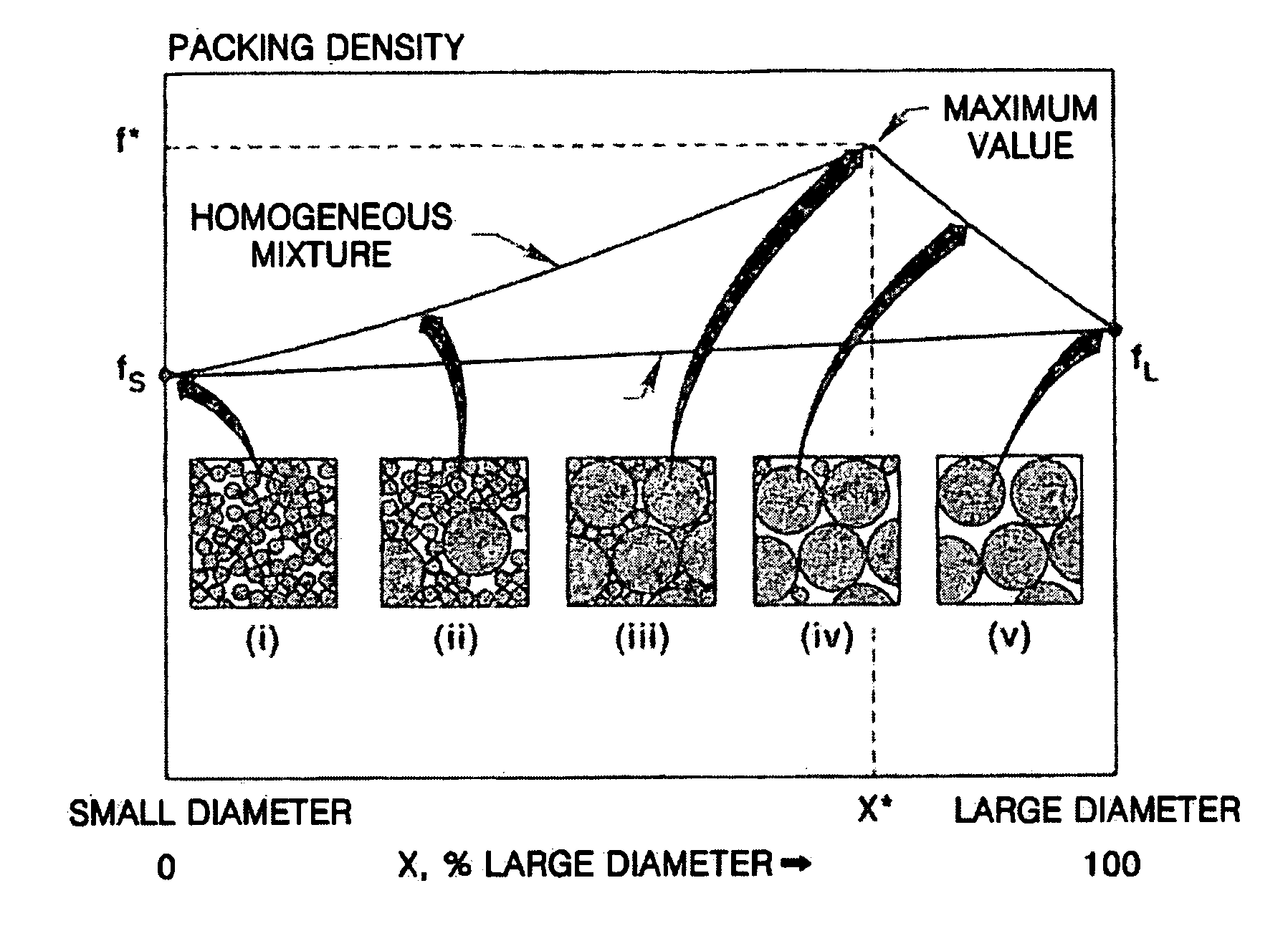

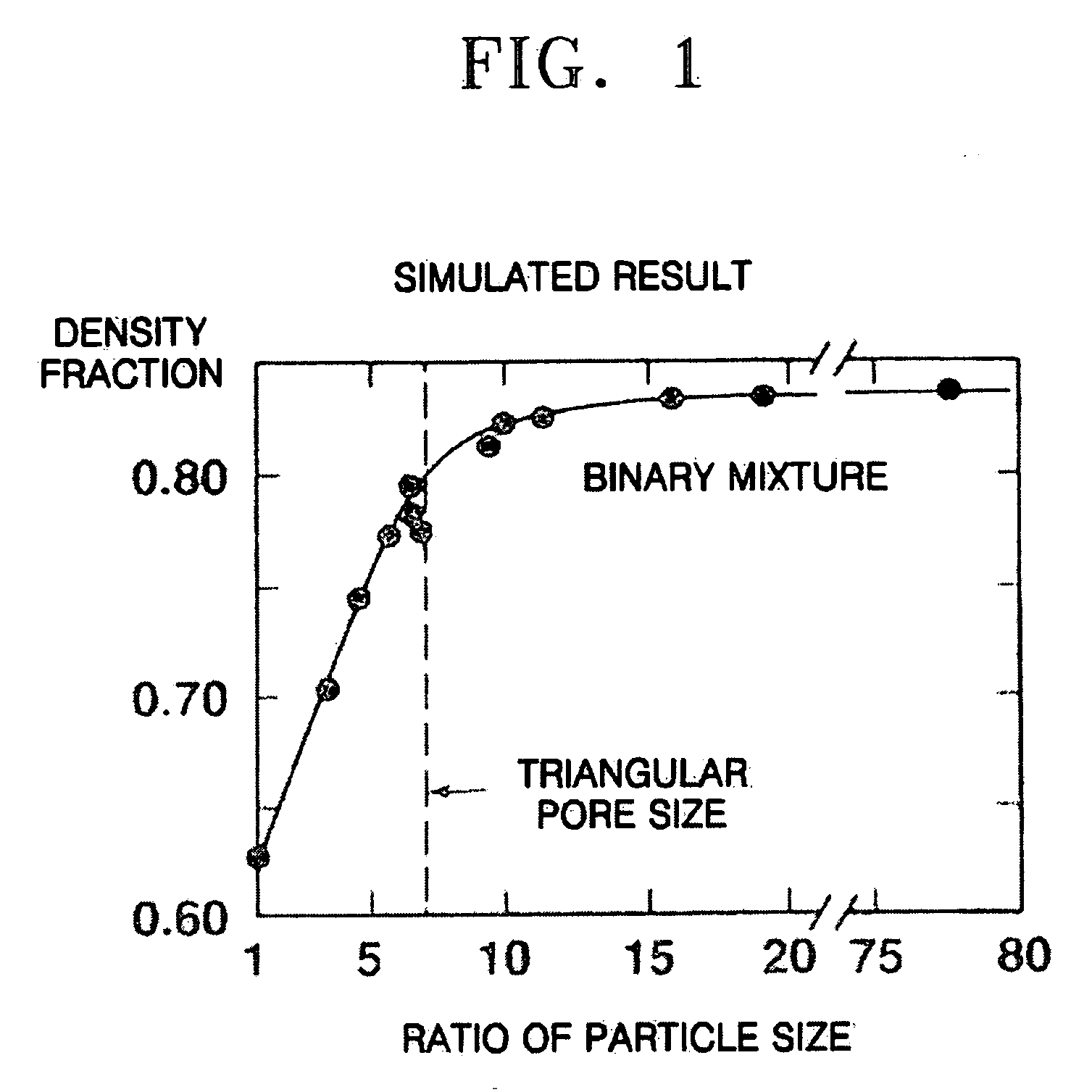

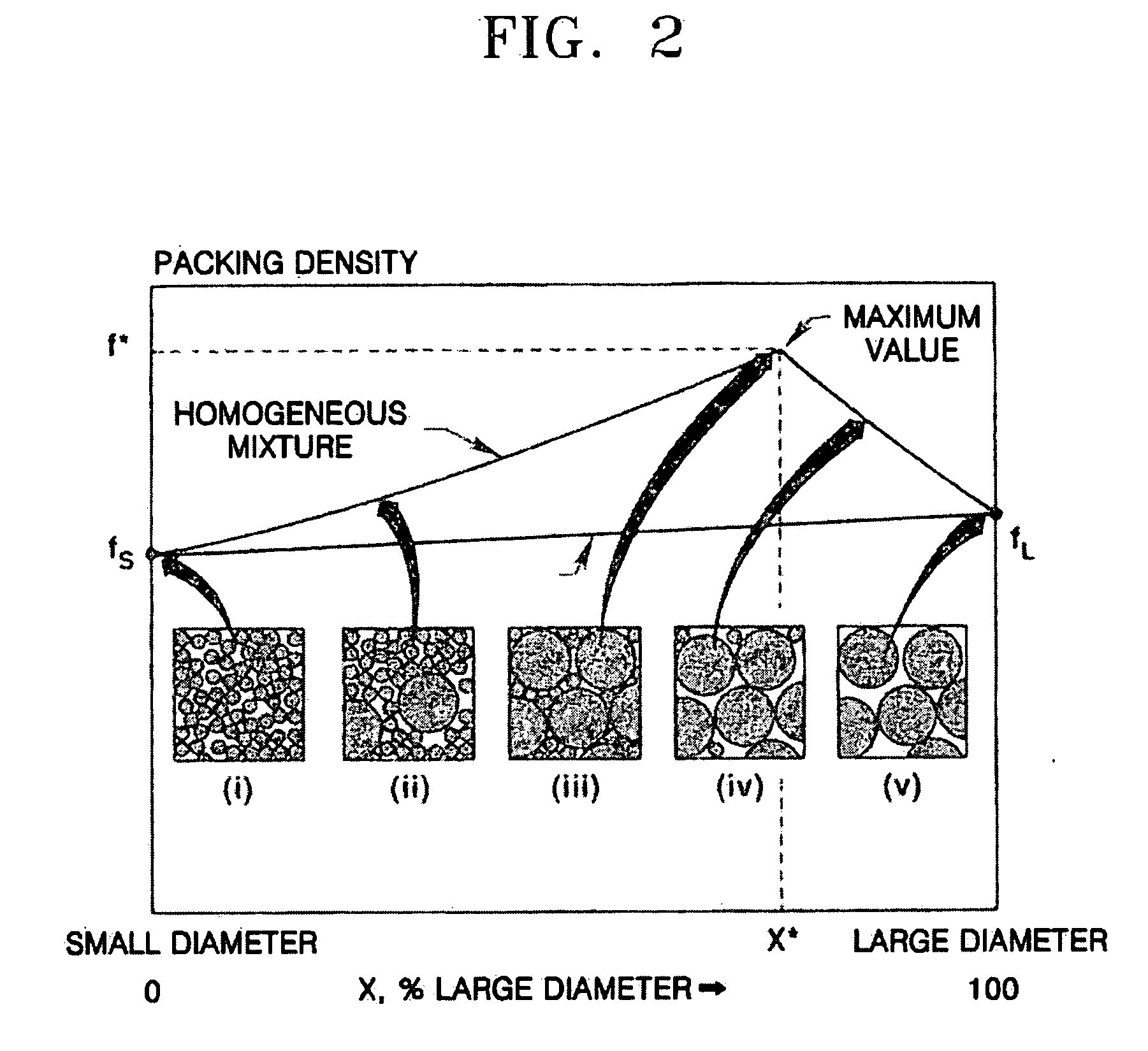

Composite cathode active materials having a large diameter active material and a small diameter active material are provided. The ratio of the average particle diameter of the large diameter active material to the average particle diameter of the small diameter active material ranges from about 6:1 to about 100:1. Mixing the large and small diameter active materials in a proper weight ratio improves packing density Additionally, including highly stable materials and highly conductive materials in the composite cathode active materials improves volume density, discharge capacity and high rate discharge capacity.

Owner:SAMSUNG SDI CO LTD

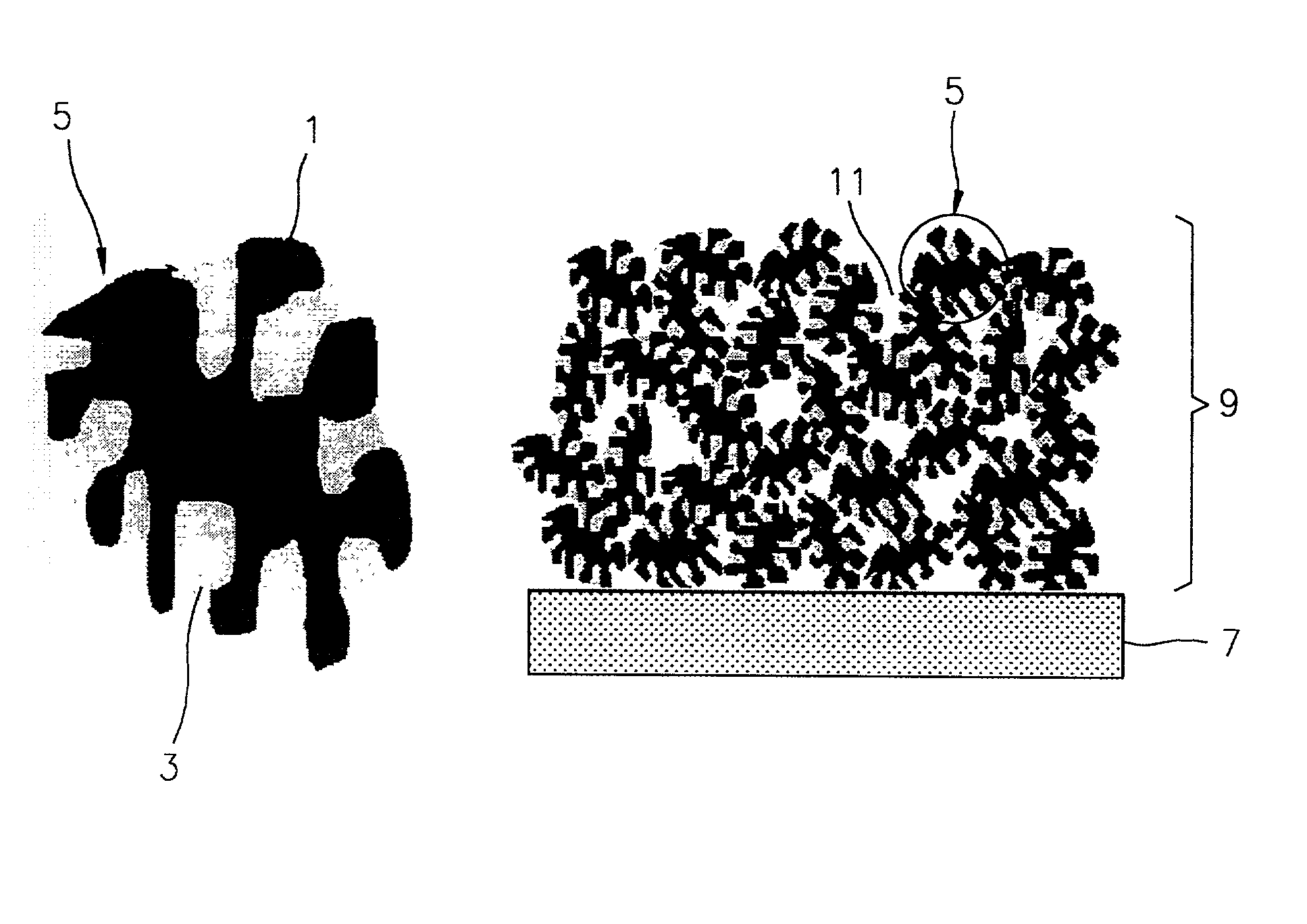

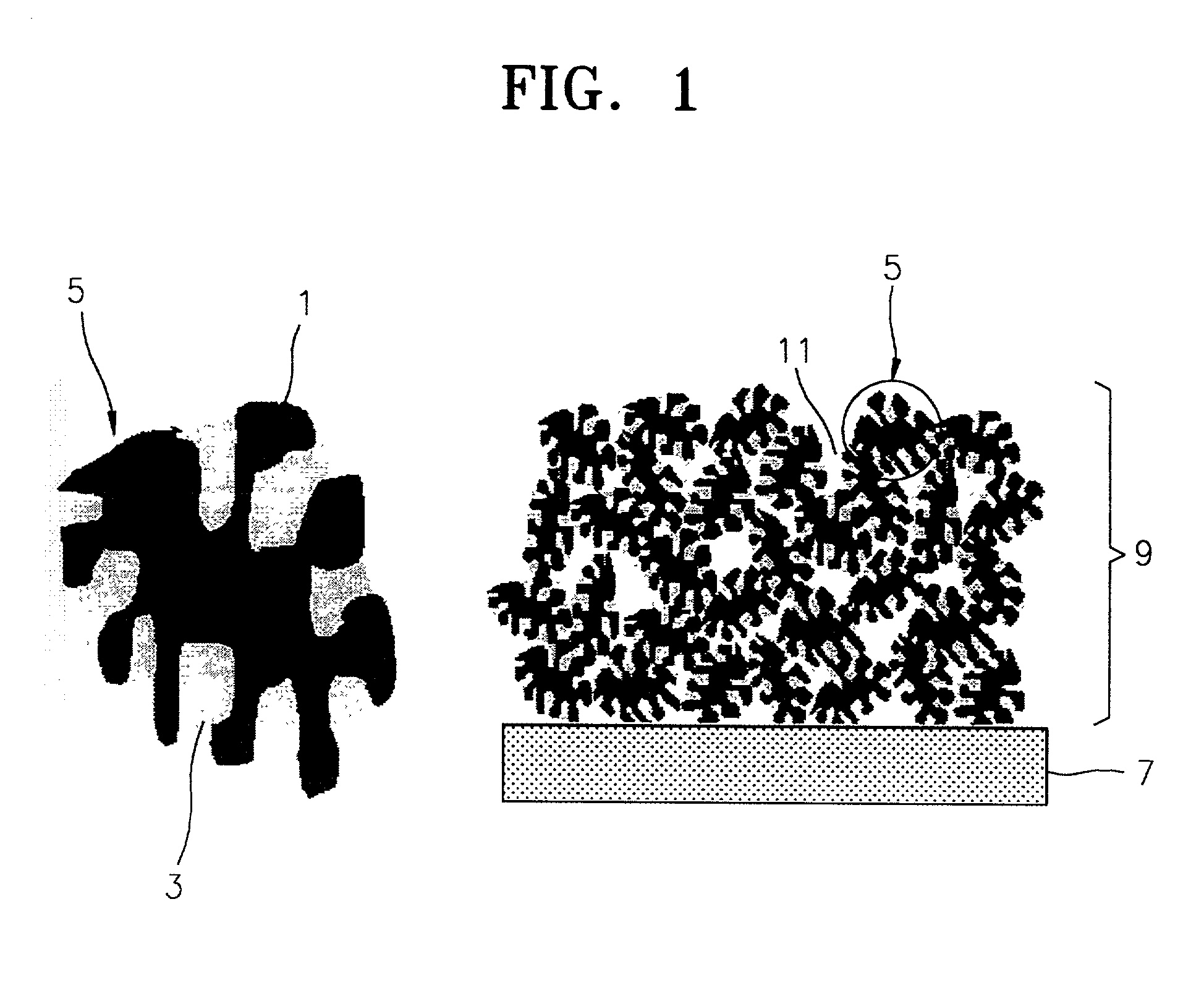

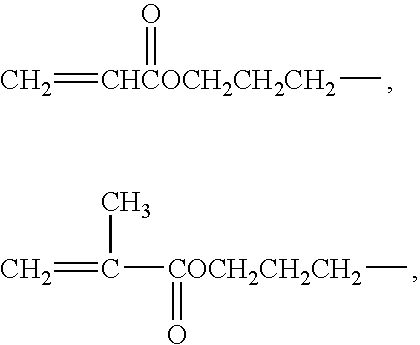

Cathode electrode, method for manufacturing the same and lithium battery containing the same

InactiveUS20030113624A1Continuous fillingNon-aqueous electrolyte accumulatorsFinal product manufactureSimple Organic CompoundsConductive materials

Disclosed is a cathode electrode having a cathode active material layer stacked on a current collector. The cathode active material layer includes a porous conductive material having a surface coated with sulfur and / or a sulfur-containing organic compound and / or pores filled with sulfur and / or a sulfur-containing organic compound. A lithium secondary battery employing the cathode electrode also is disclosed. The cathode electrode is structurally stable during charging and discharging since the structure of the cathode active material layer can be maintained even at the phase transition of sulfur during charging and discharging.

Owner:SAMSUNG SDI CO LTD

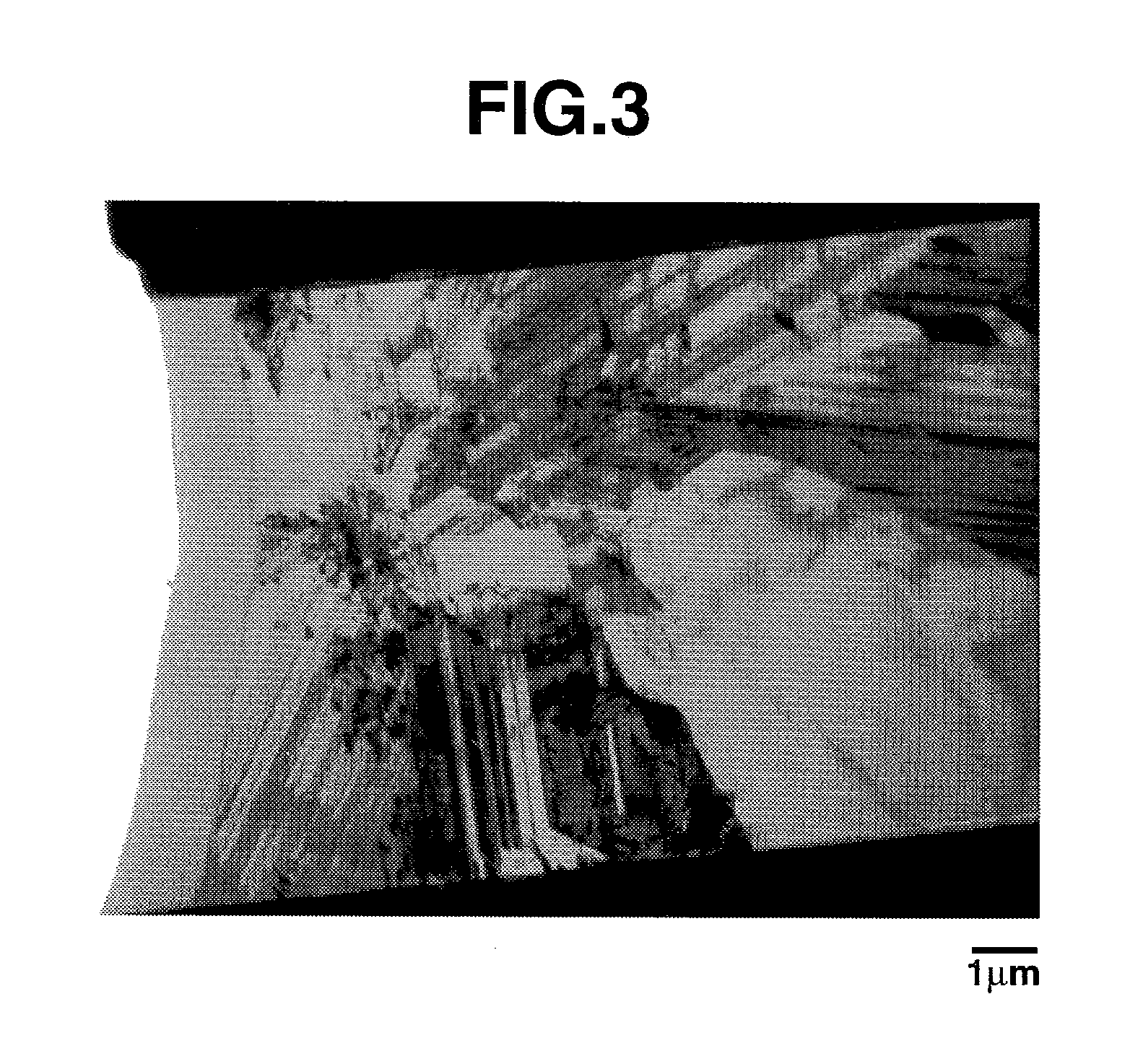

Anode active material and nonaqueous electrolyte secondary battery

InactiveUS20030008212A1Chemical deterioration of a nonaqueous electrolyte material is preventedAvoid destructionElectrode manufacturing processesPrimary cell maintainance/servicingFiberMaterials science

The present invention relates to an anode material excellent in its charging and discharging characteristics and a secondary battery excellent in its charging and discharging cyclic characteristics. An anode active material is used for a nonaqueous electrolyte secondary battery including an anode having the anode active material, a cathode having a cathode active material and a nonaqueous electrolyte. The capacity of the anode is expressed by the sum of a capacity component obtained when light metal is doped and dedoped in an ionic state and a capacity component obtained when the light metal is deposited and dissolved. The light metal includes an anode base material capable of doping and dedoping the light metal in an ionic state and a fibrous material having an electric conductivity.

Owner:SONY CORP

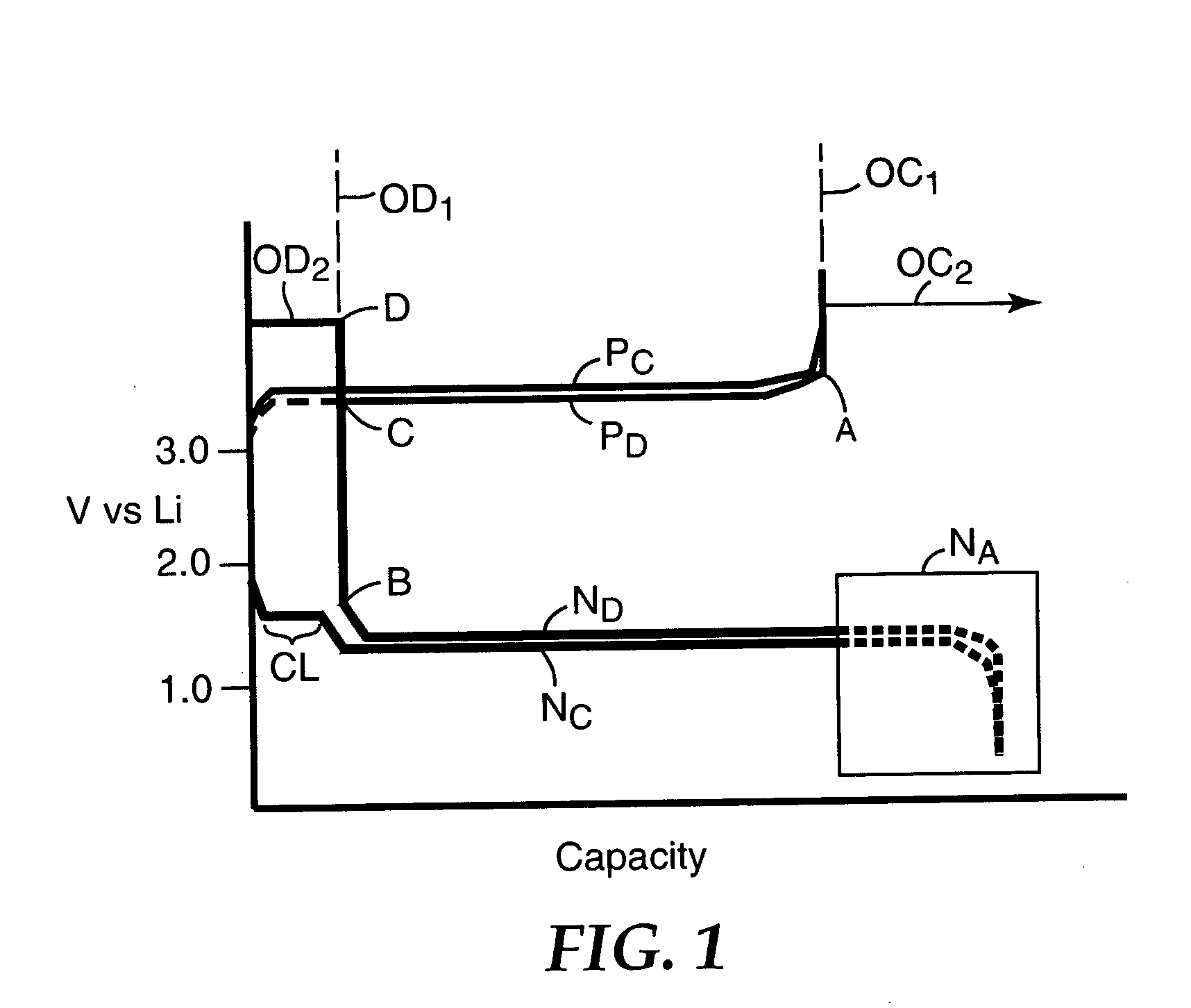

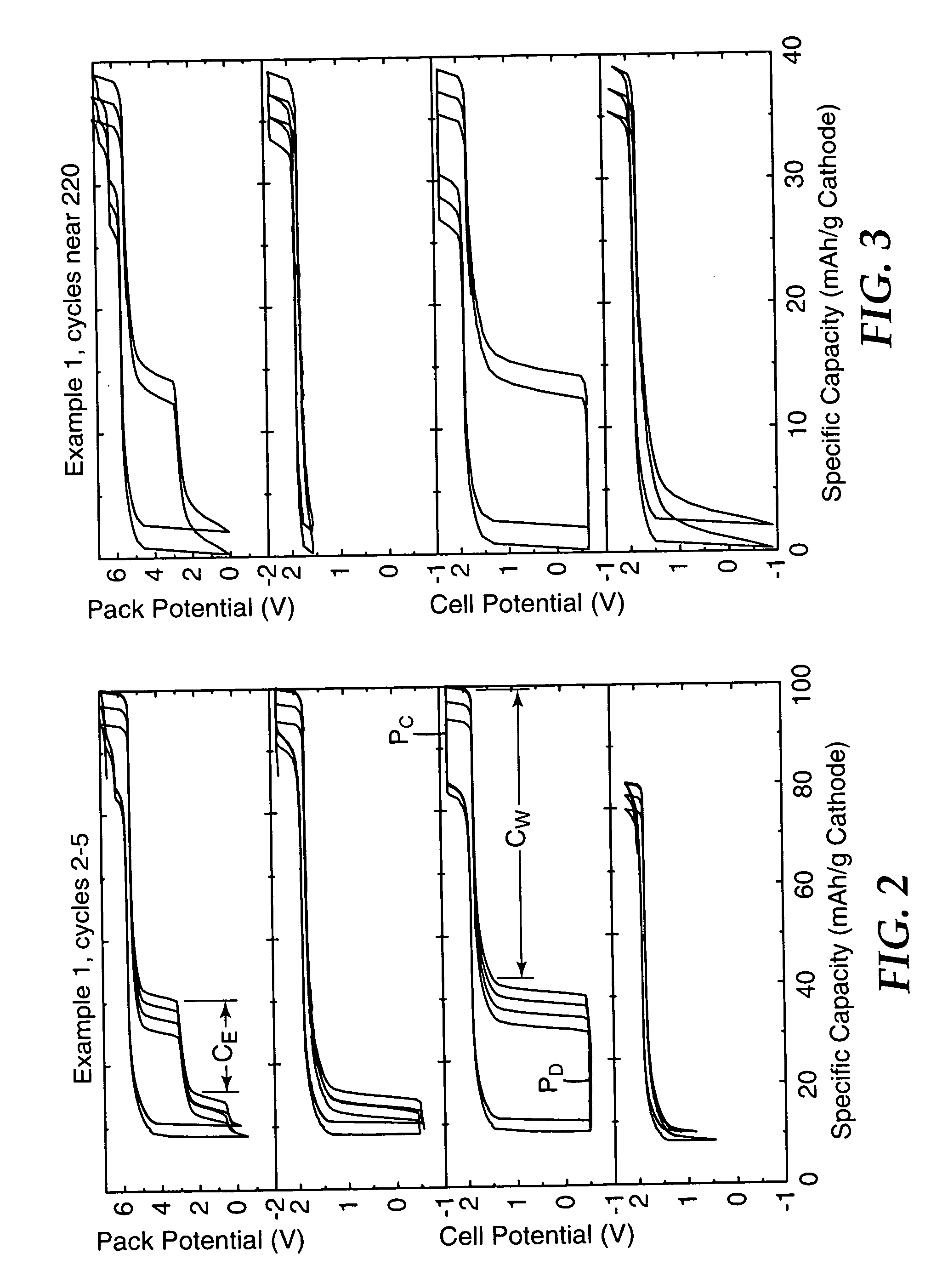

Redox shuttle for overdischarge protection in rechargeable lithium-ion batteries

InactiveUS20050221168A1Wide windowLarge capacityNon-aqueous electrolyte accumulatorsElectrolytic capacitorsElectrode potentialCapacity loss

A battery of series-connected rechargeable lithium ion cells each of which contains a negative electrode; a negative electrode current collector; a positive electrode; a positive electrode current collector; and an electrolyte comprising charge carrying medium, lithium salt and cyclable redox chemical shuttle. The negative electrode has a larger irreversible first cycle capacity loss than that of the positive electrode, and is driven to a potential above that of the positive electrode if the cell is discharged to a state of cell reversal. The shuttle has an electrochemical potential above the positive electrode maximum normal operating potential, and prevents the negative electrode potential from reaching even higher and more destructive positive values during overdischarge. The current collector has a lithium alloying potential below the negative electrode minimum normal operating potential. The battery chemically limits or eliminates cell damage due to repeated overdischarge, and may operate without electronic overdischarge protection circuitry.

Owner:3M INNOVATIVE PROPERTIES CO

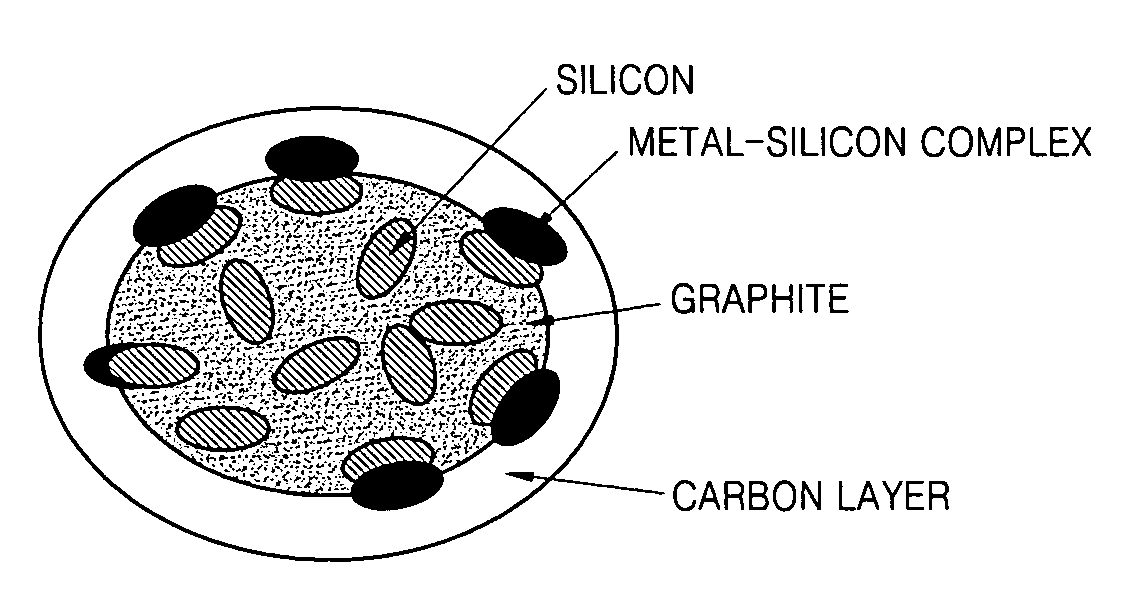

Anode active material, method of manufacturing the same, and lithium battery using the same

ActiveUS20070077490A1Large capacityGood capacity retentionNon-aqueous electrolyte accumulatorsElectrode thermal treatmentCarbon layerMetal alloy

Anode active materials, methods of producing the same and lithium batteries using the same are provided. More particularly, an anode active material having high capacity and excellent capacity retention, a method of producing the same and a lithium battery having a long lifespan using the same are provided. The anode active material comprises complex material particles comprising silicon and graphite, a carbon layer covering the surface of the complex material particles, and a silicon-metal alloy formed between the complex material particles and the amorphous carbon layer.

Owner:SAMSUNG SDI CO LTD

Separator and Non-Aqueous Electrolyte Secondary Battery Using Same

InactiveUS20080070107A1Improve securityImprove performanceNon-aqueous electrolyte accumulatorsCell seperators/membranes/diaphragms/spacersFine particulateMaterials science

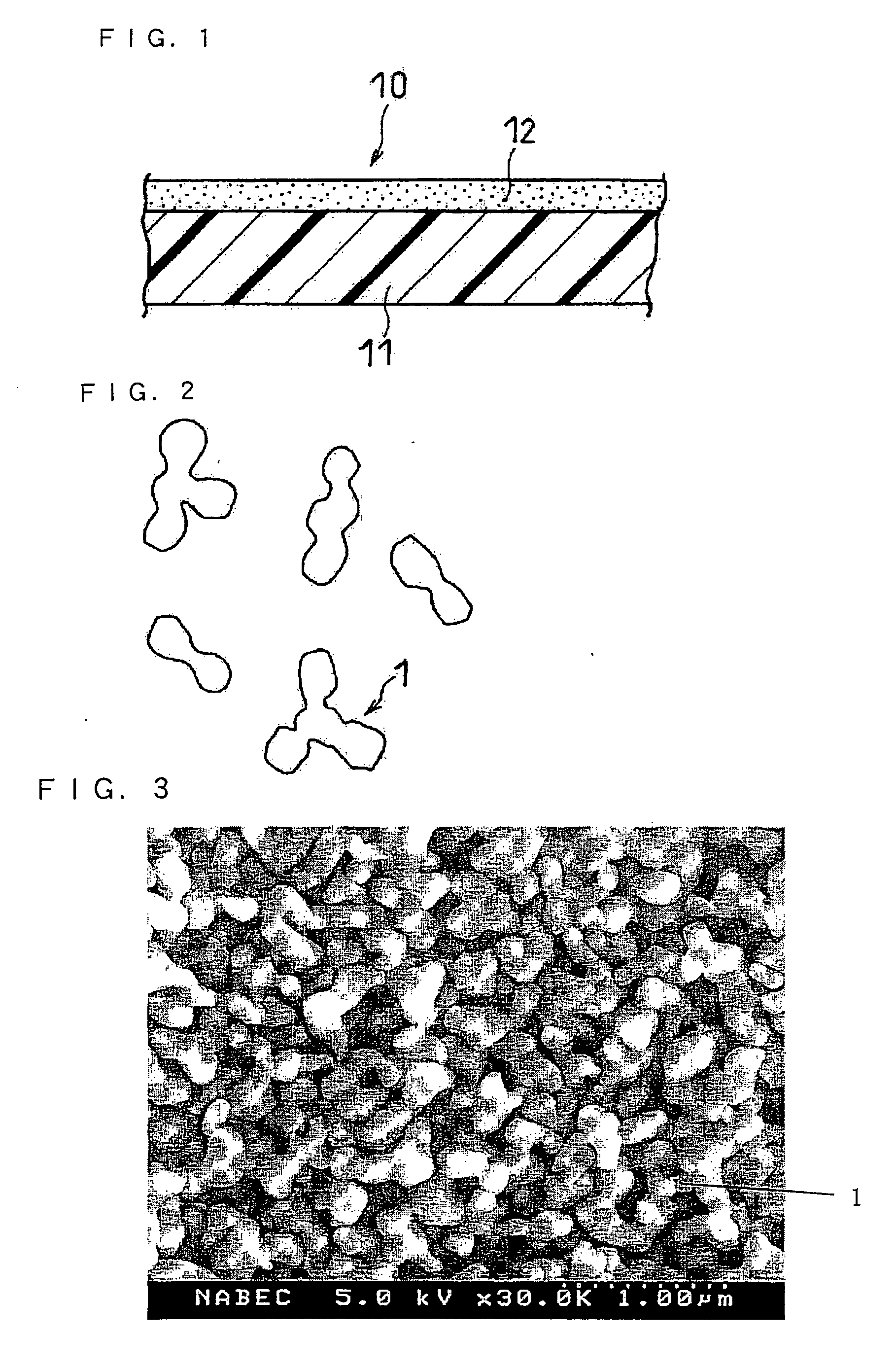

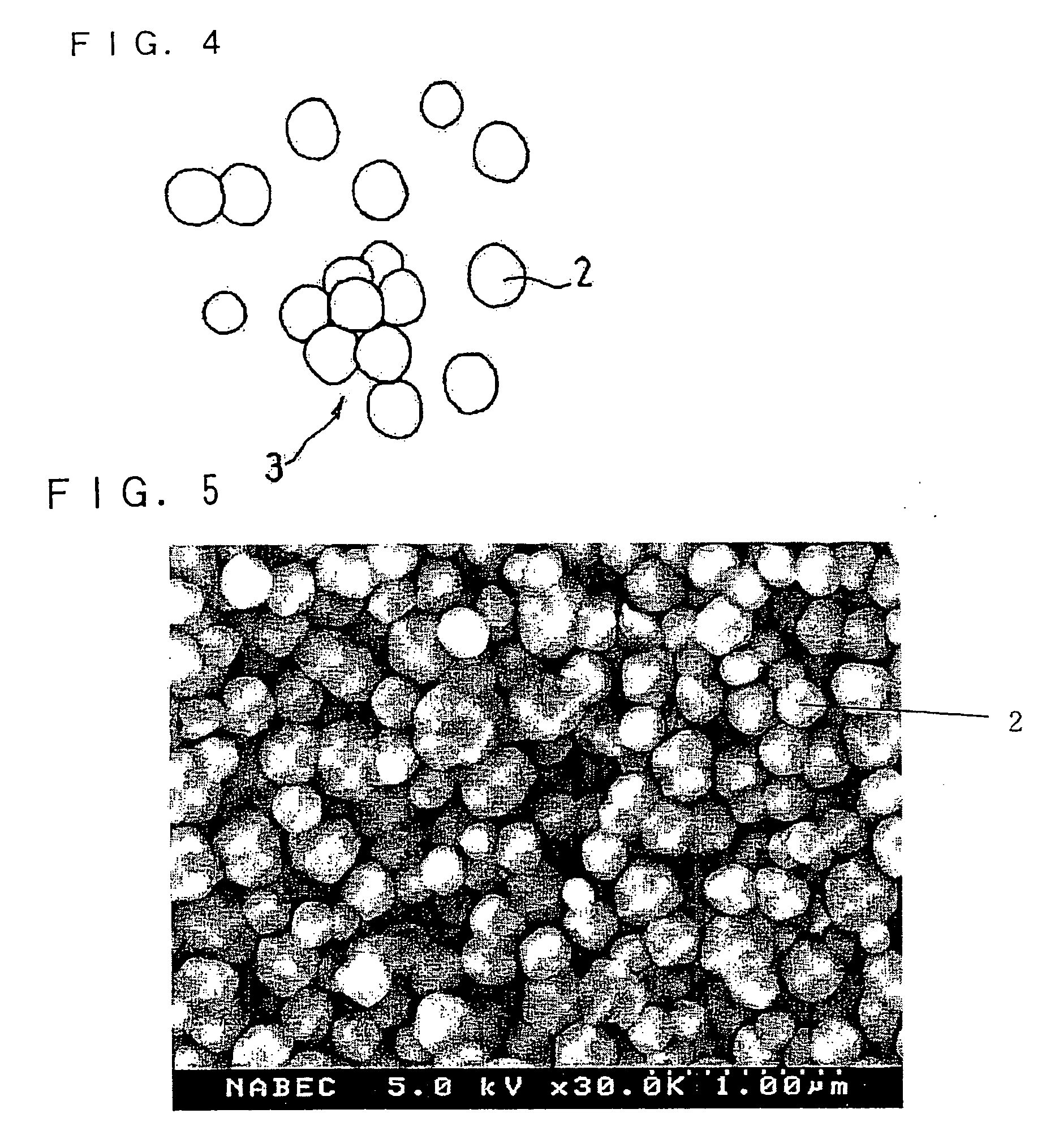

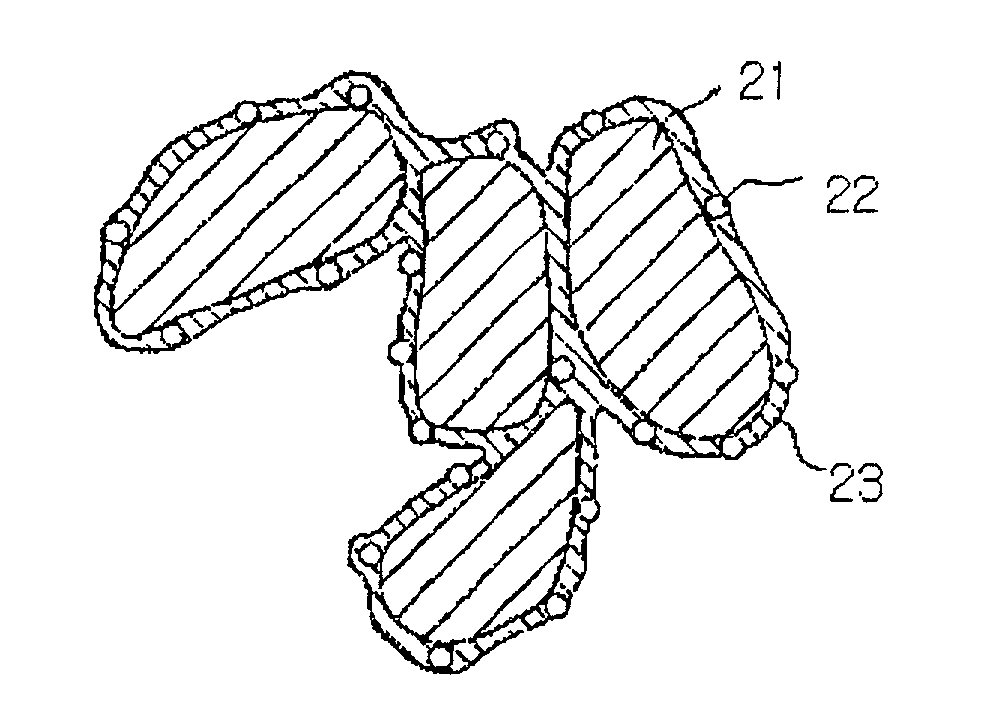

A separator including at least a layer containing a fine particulate filler and a shutdown layer. The fine particulate filler includes a joined-particle filler that is in the form of a plurality of primary particles joined and bonded to one another. A non-aqueous electrolyte secondary battery including this separator exhibits improved safety, high performance and large current discharge capability particularly at low temperatures.

Owner:PANASONIC CORP

Negative active material for rechargeable lithium battery and method of preparing same

InactiveUS20020009646A1Increase energy densityImprove cycle lifeElectrode manufacturing processesNon-aqueous electrolyte accumulatorsCarbon filmGraphite particle

Owner:SAMSUNG SDI CO LTD

Non-aqueous electrolyte secondary battery negative electrode material, making method, and lithium ion secondary battery

ActiveUS20040106040A1Large capacityImprove cycle performanceNon-aqueous electrolyte accumulatorsNegative electrodesConductive coatingMaterials science

A non-aqueous electrolyte secondary battery negative electrode material is provided wherein a negative electrode active material containing a lithium ion-occluding and releasing material which has been treated with an organosilicon base surface treating agent is surface coated with a conductive coating. Using the negative electrode material, a lithium ion secondary battery having a high capacity and improved cycle performance is obtainable.

Owner:SHIN ETSU CHEM IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com