Patents

Literature

138 results about "Electrochemical potential" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In electrochemistry, the electrochemical potential, μ, sometimes abbreviated to ECP, is a thermodynamic measure of chemical potential that does not omit the energy contribution of electrostatics. Electrochemical potential is expressed in the unit of J/mol.

Redox shuttle for overdischarge protection in rechargeable lithium-ion batteries

InactiveUS20050221168A1Wide windowLarge capacityNon-aqueous electrolyte accumulatorsElectrolytic capacitorsElectrode potentialCapacity loss

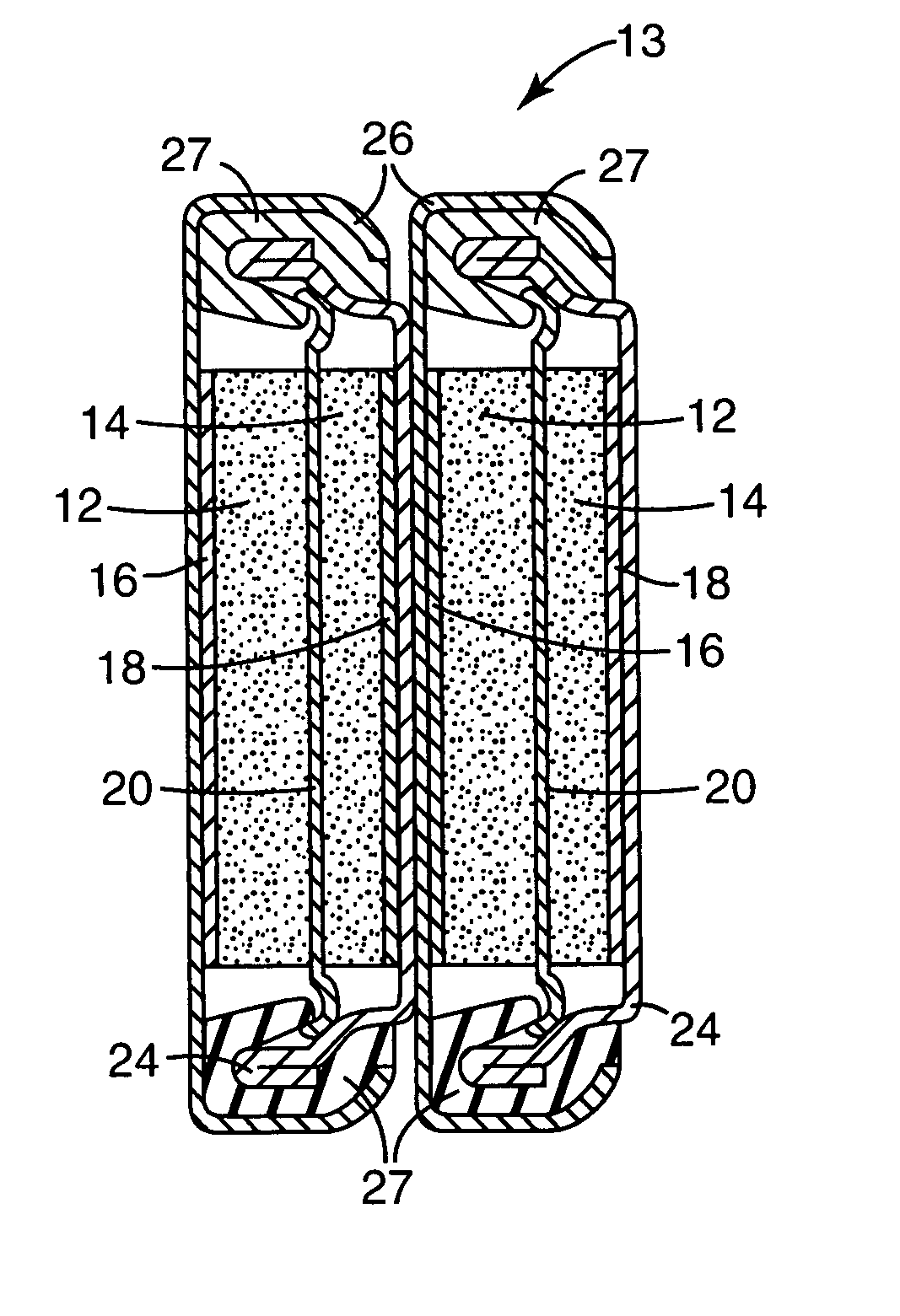

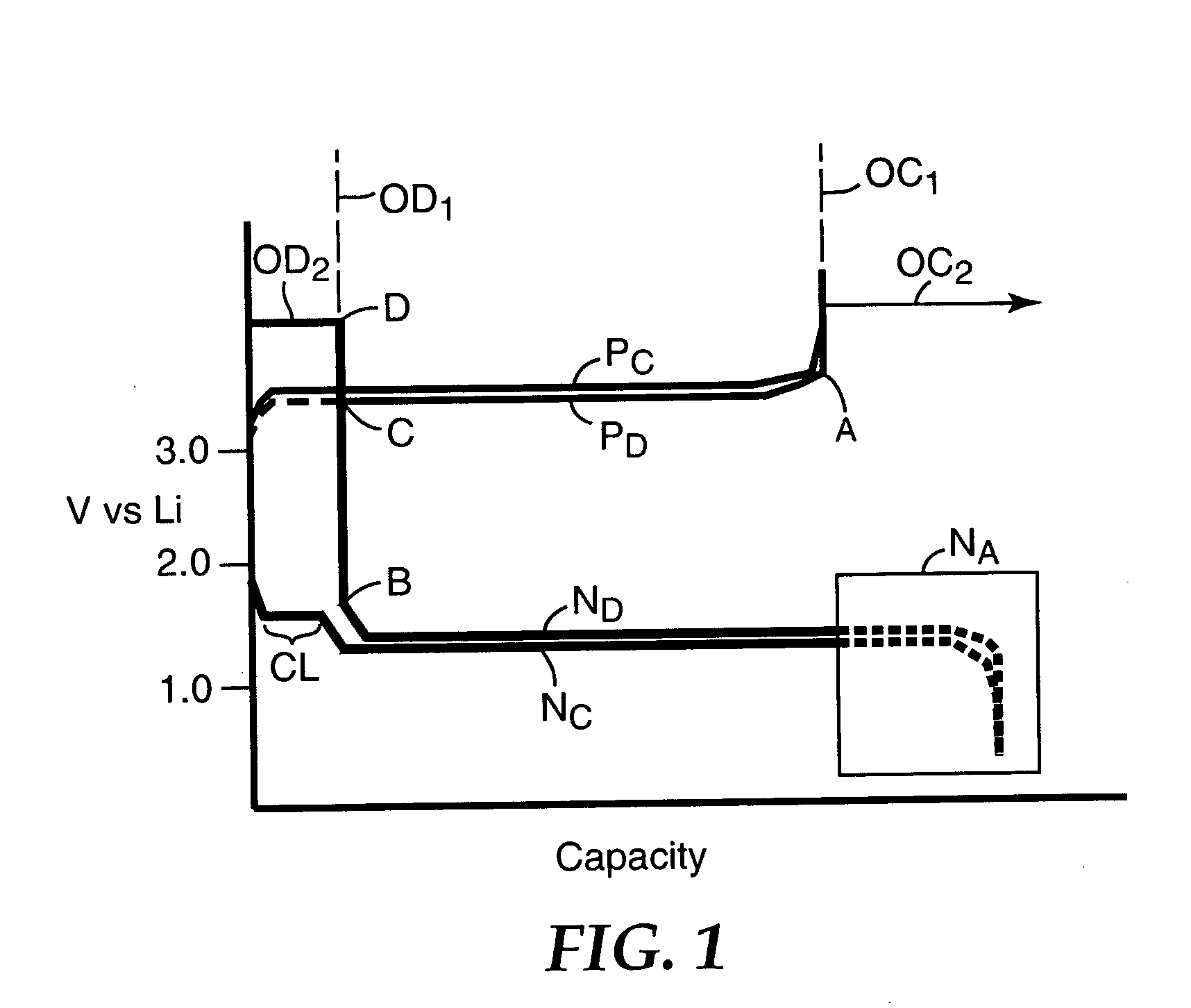

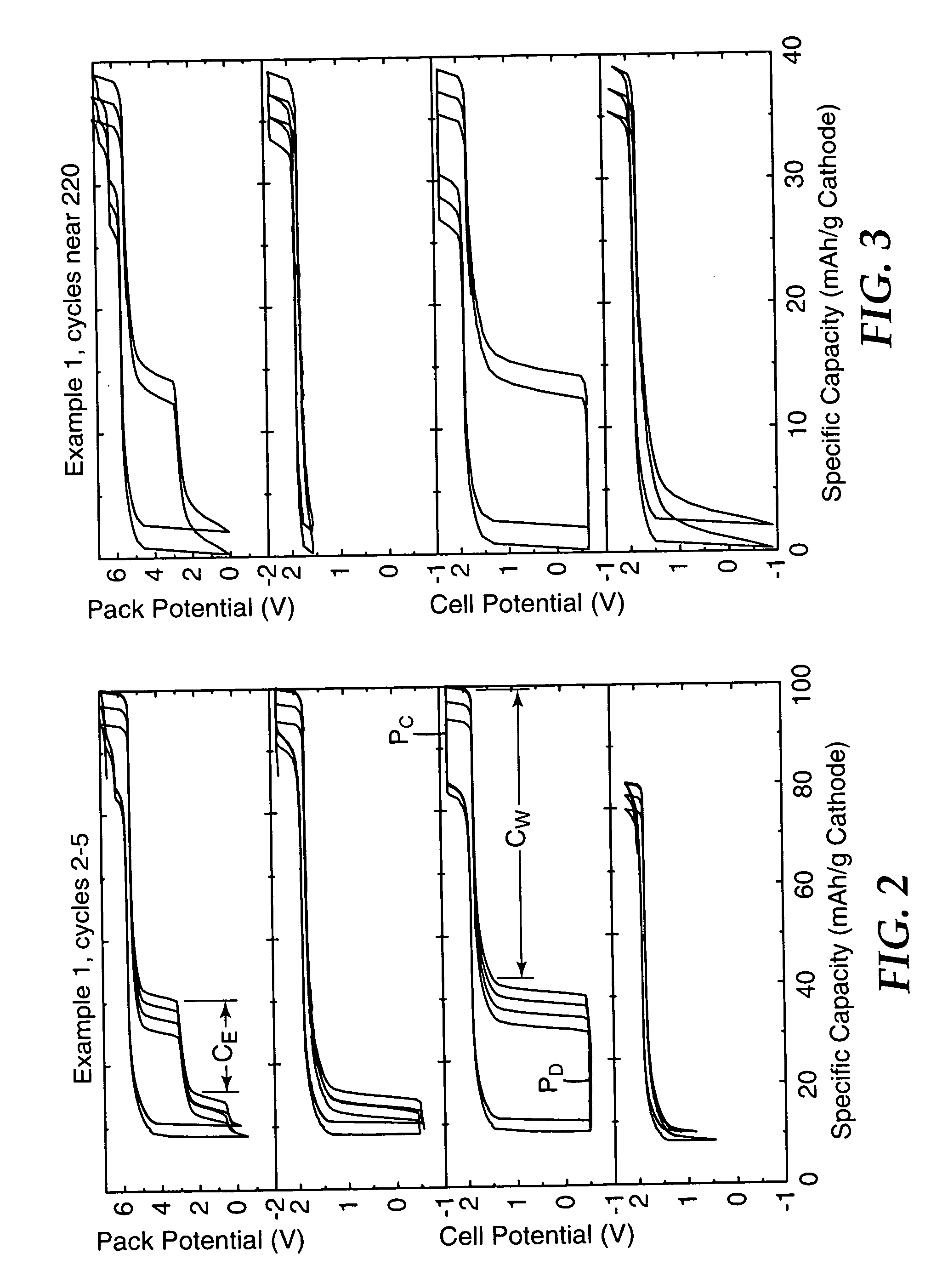

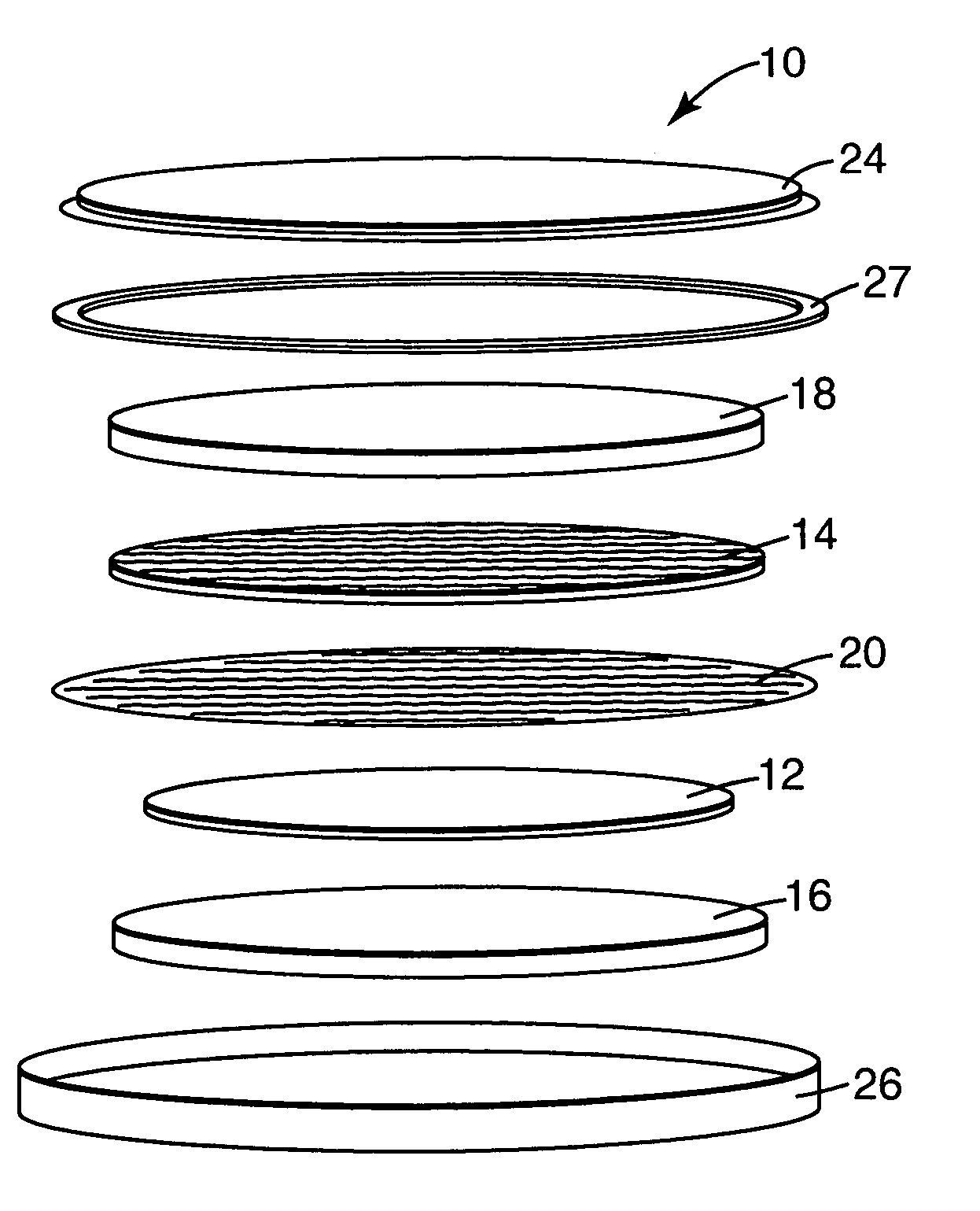

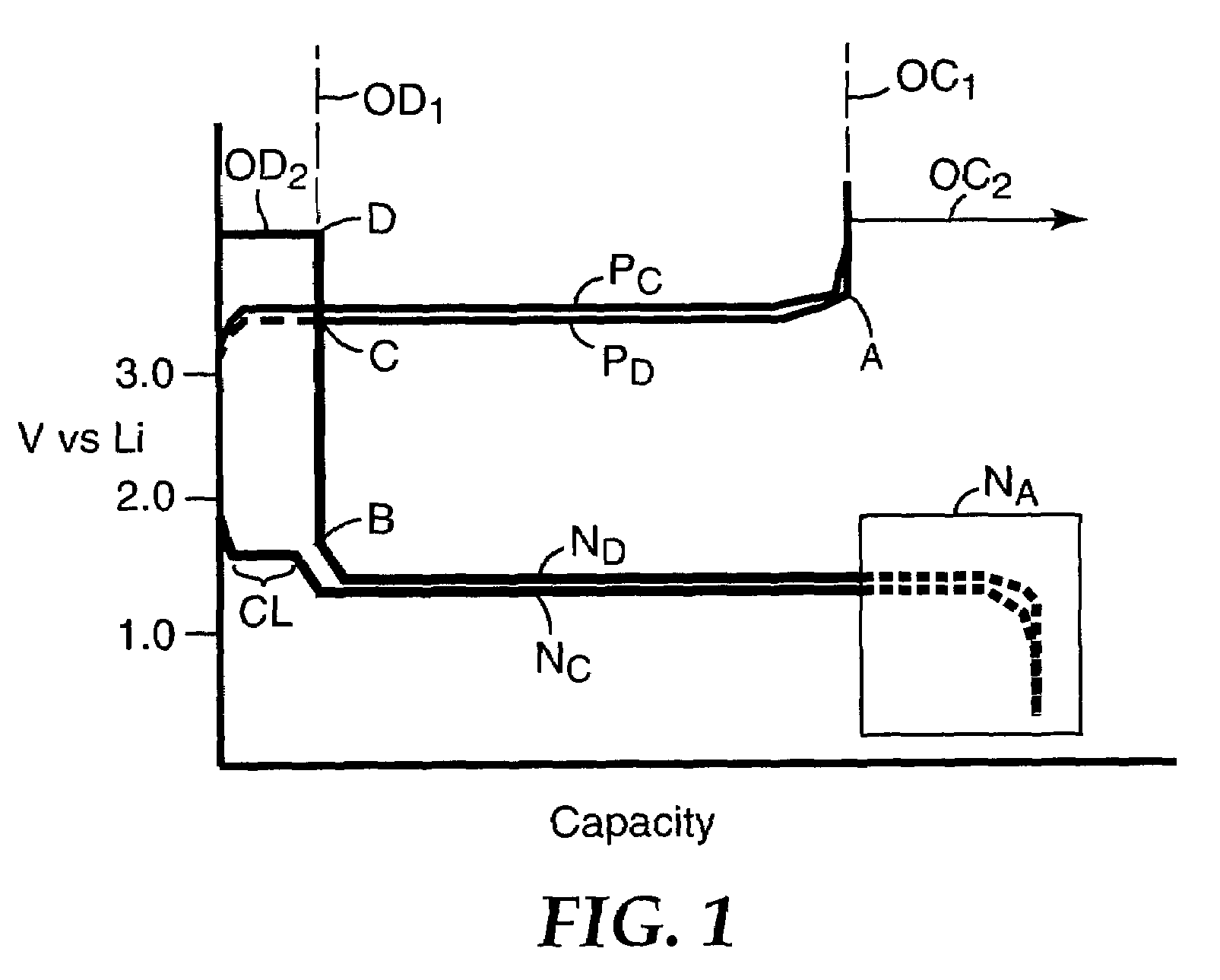

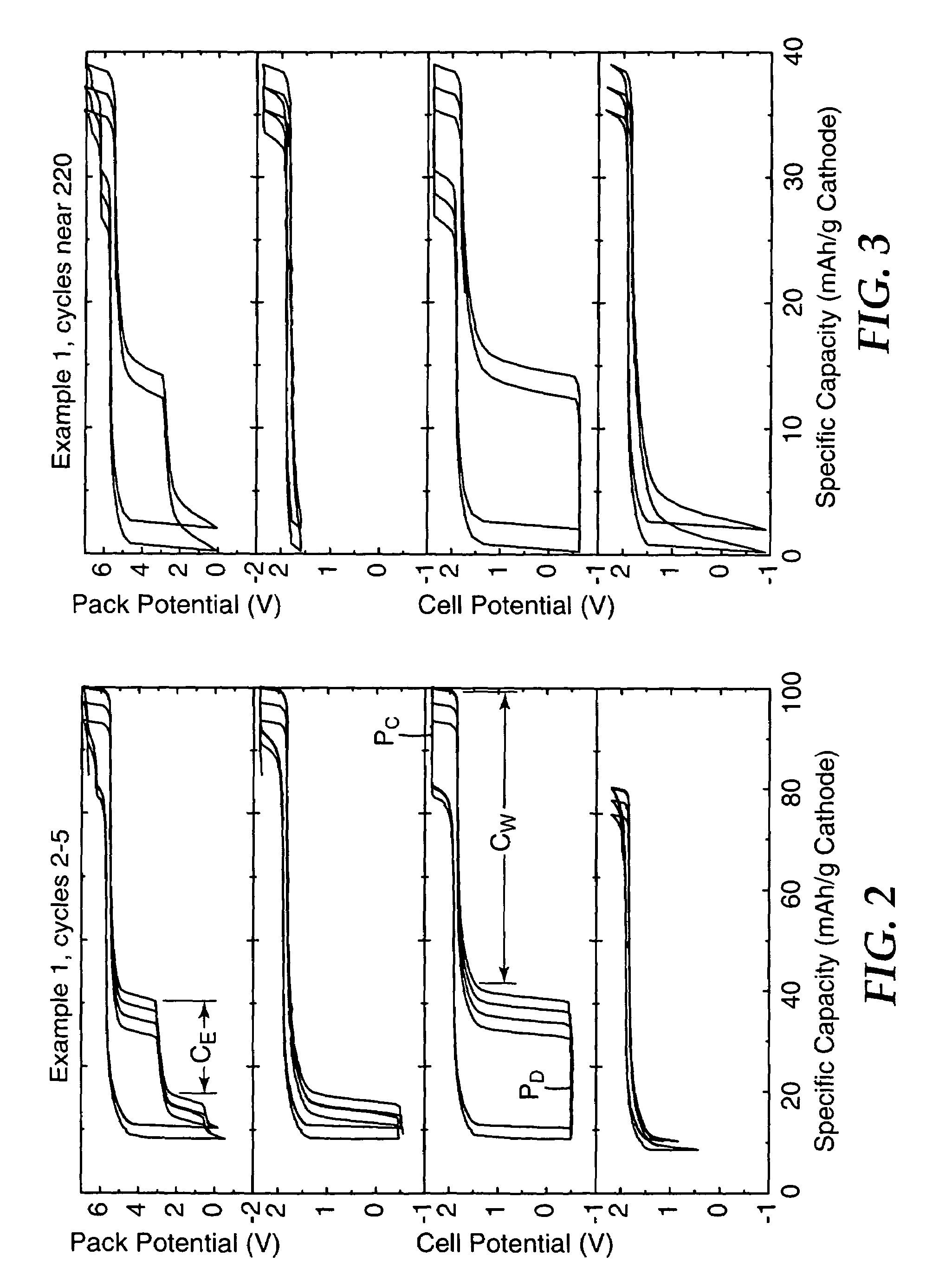

A battery of series-connected rechargeable lithium ion cells each of which contains a negative electrode; a negative electrode current collector; a positive electrode; a positive electrode current collector; and an electrolyte comprising charge carrying medium, lithium salt and cyclable redox chemical shuttle. The negative electrode has a larger irreversible first cycle capacity loss than that of the positive electrode, and is driven to a potential above that of the positive electrode if the cell is discharged to a state of cell reversal. The shuttle has an electrochemical potential above the positive electrode maximum normal operating potential, and prevents the negative electrode potential from reaching even higher and more destructive positive values during overdischarge. The current collector has a lithium alloying potential below the negative electrode minimum normal operating potential. The battery chemically limits or eliminates cell damage due to repeated overdischarge, and may operate without electronic overdischarge protection circuitry.

Owner:3M INNOVATIVE PROPERTIES CO

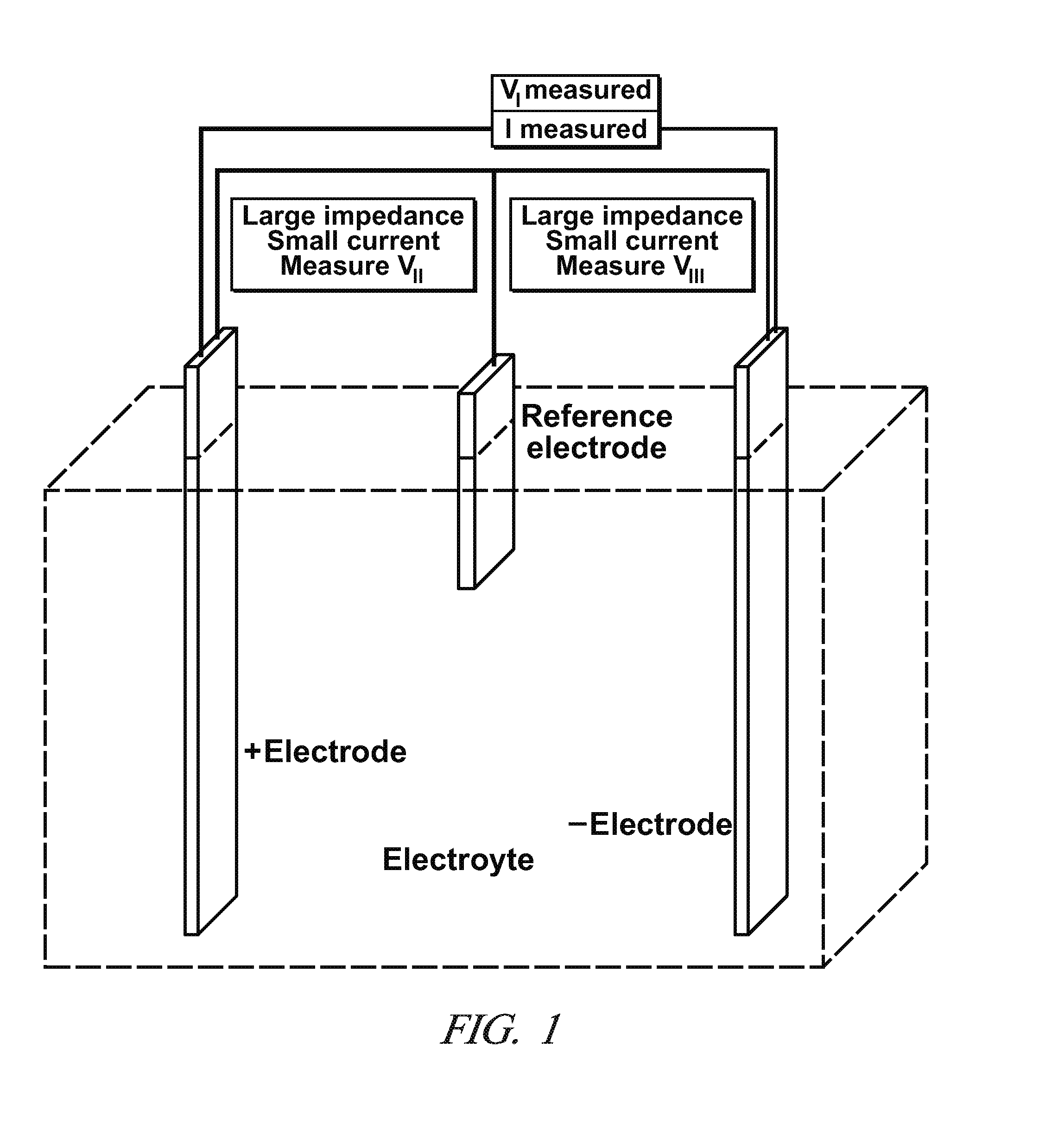

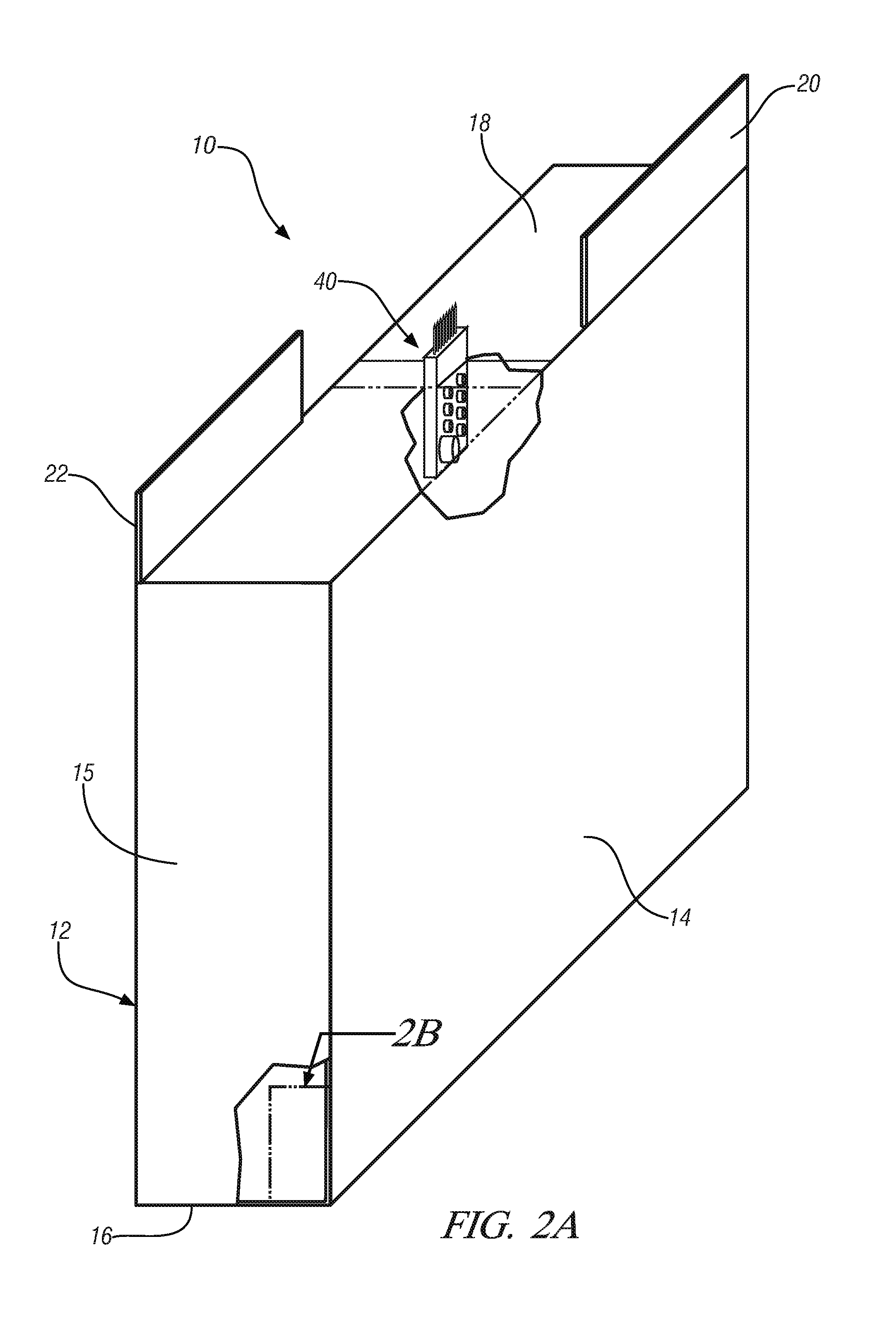

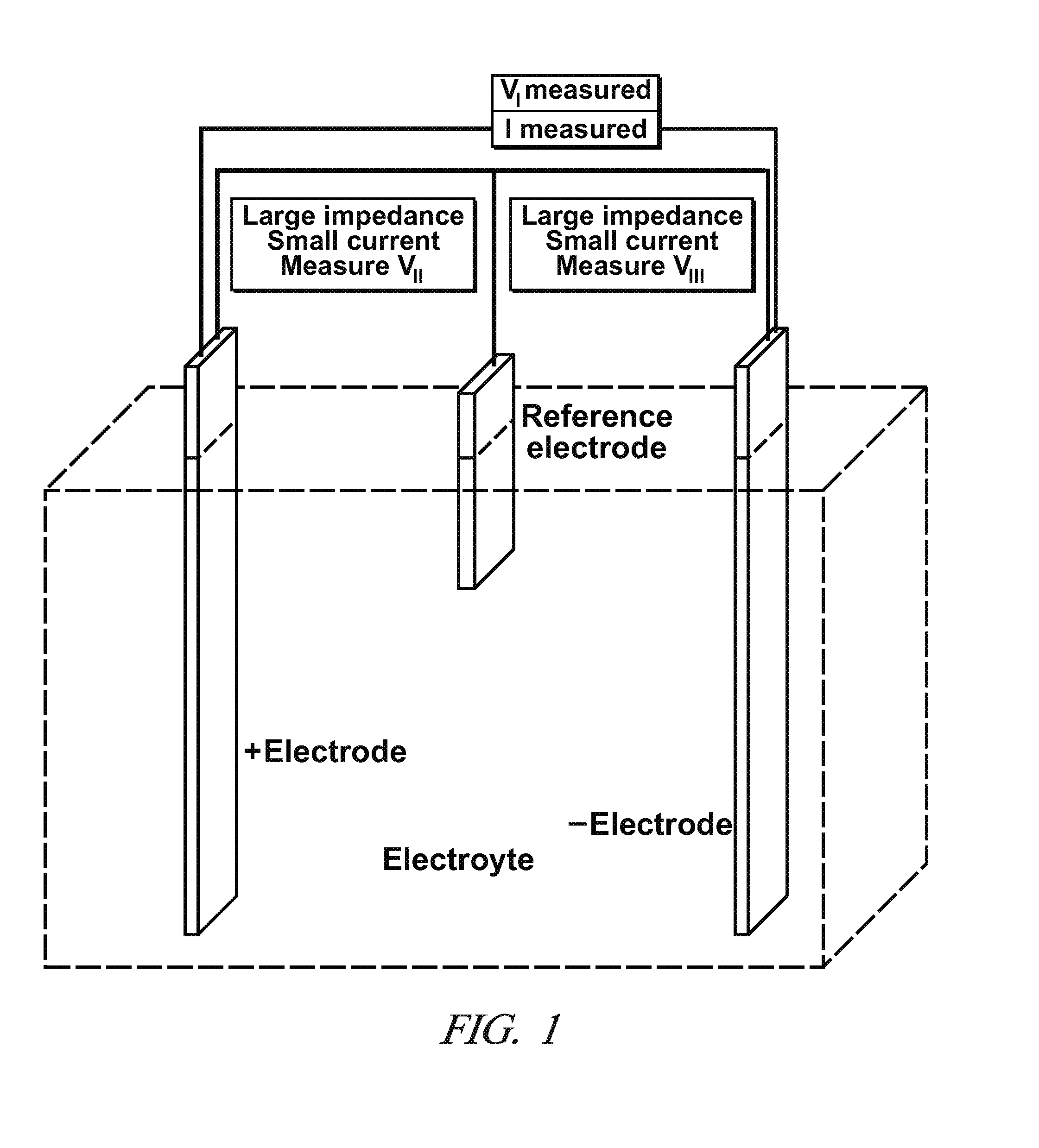

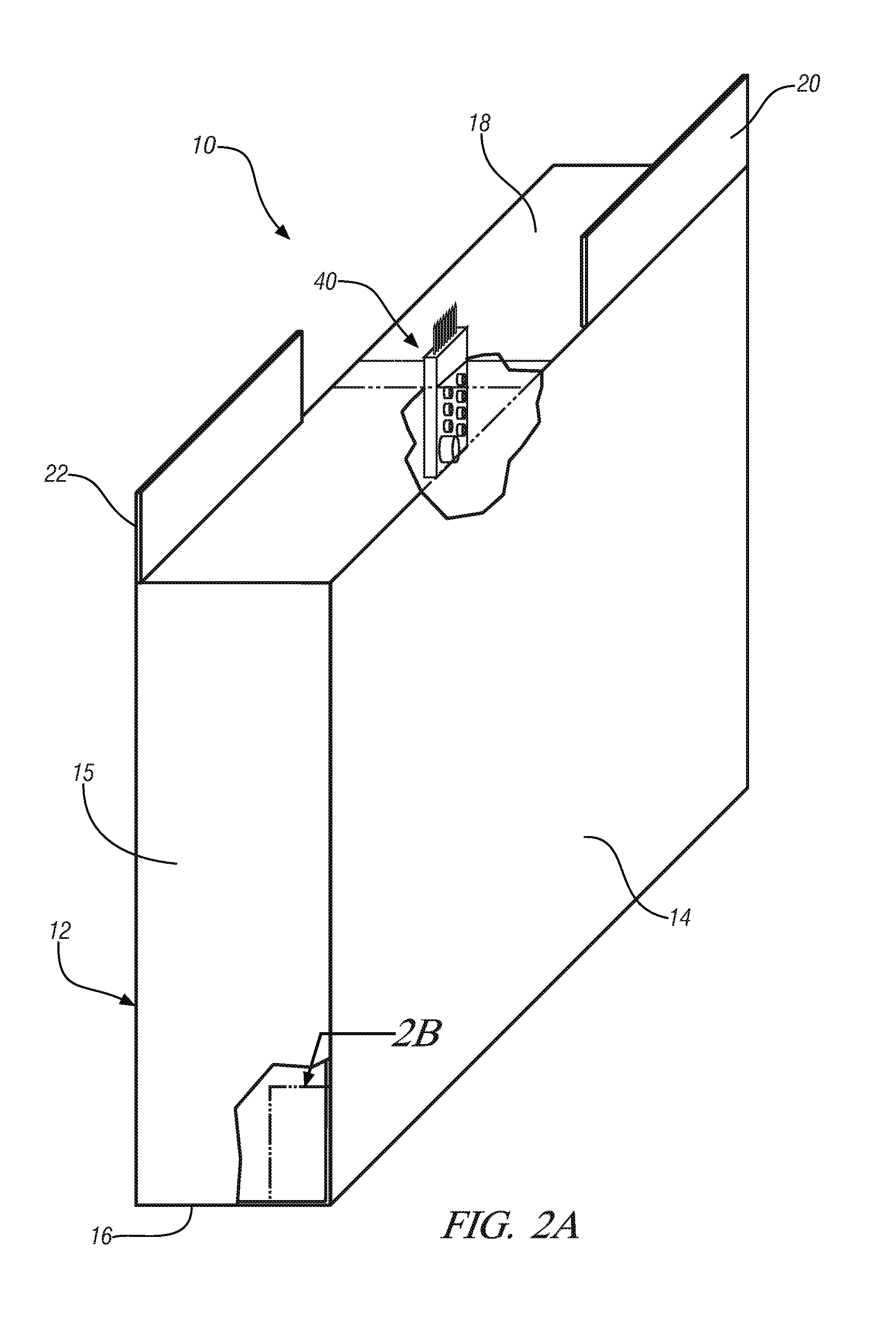

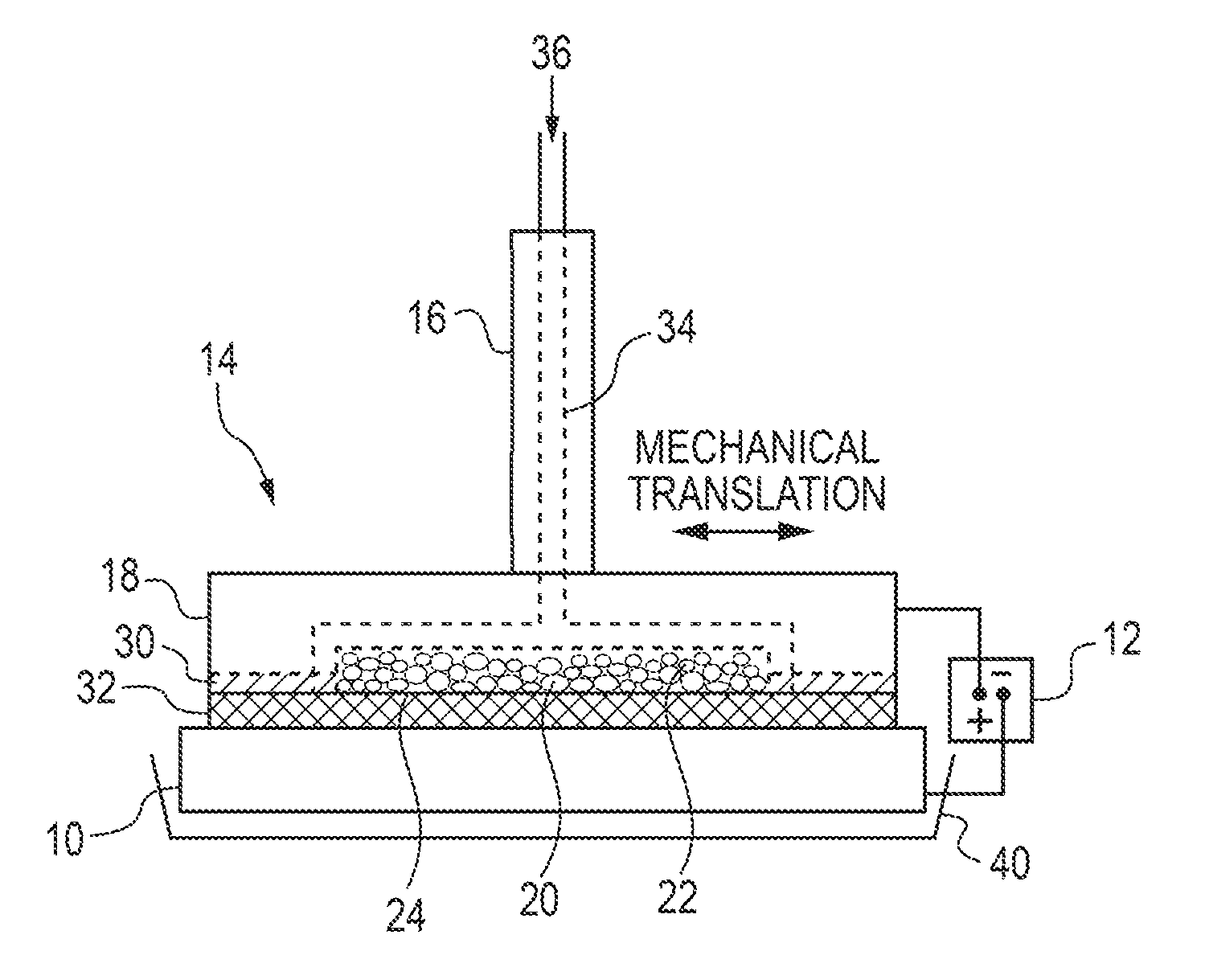

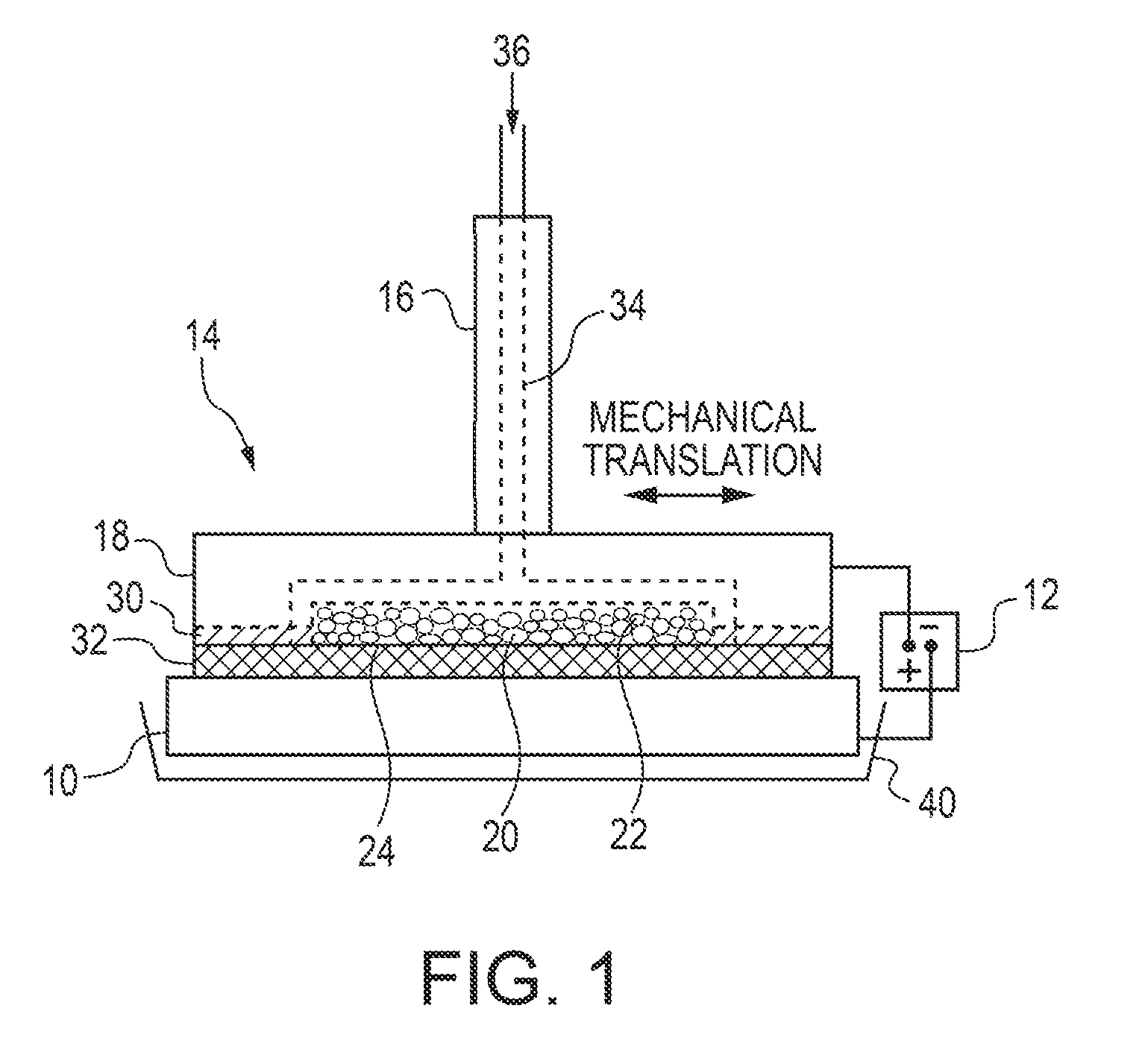

Lithium-ion cell with an array of reference electrodes

ActiveUS20110250478A1Easy to insertFinal product manufactureCell electrodesLithiumElectrical battery

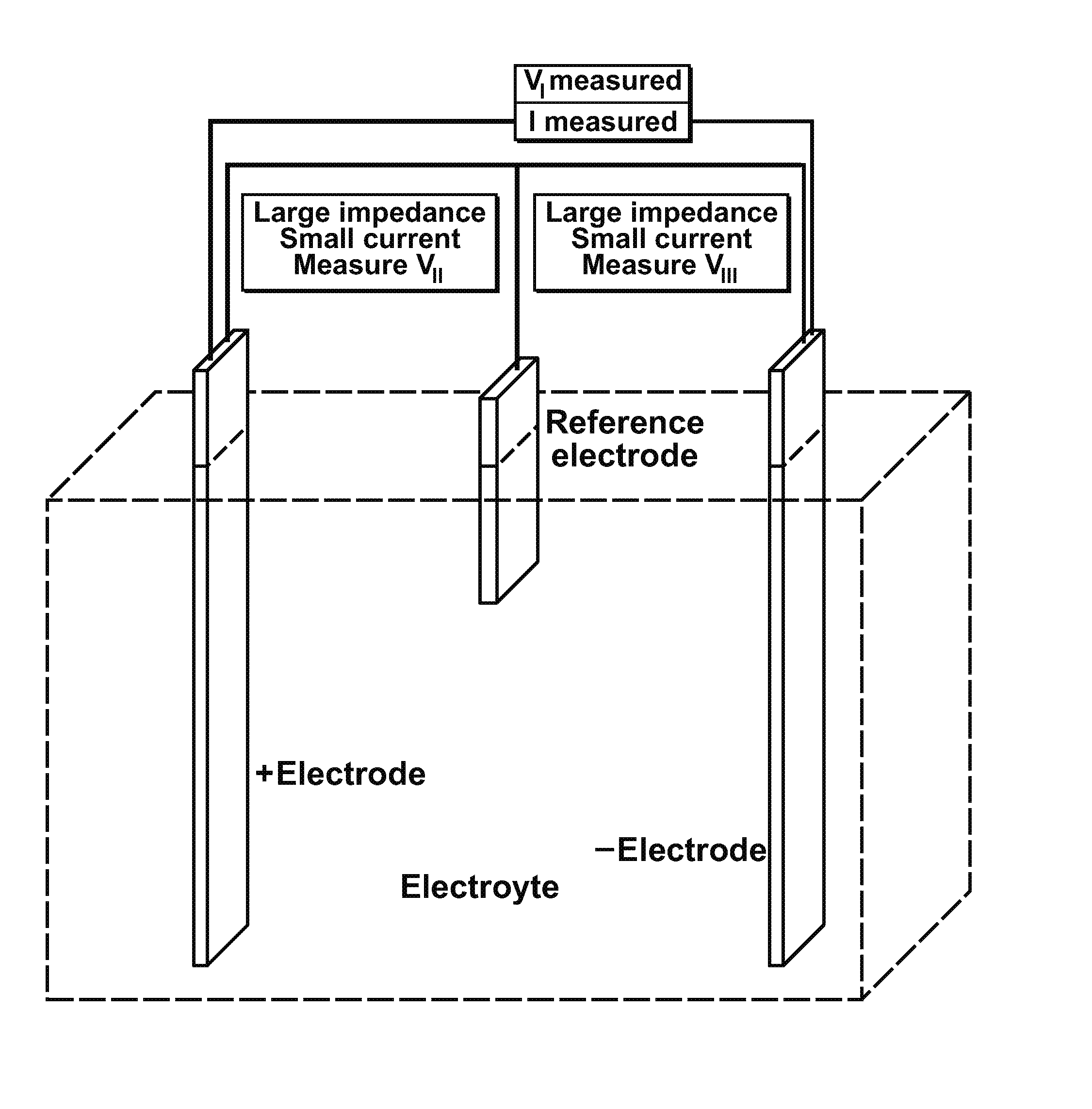

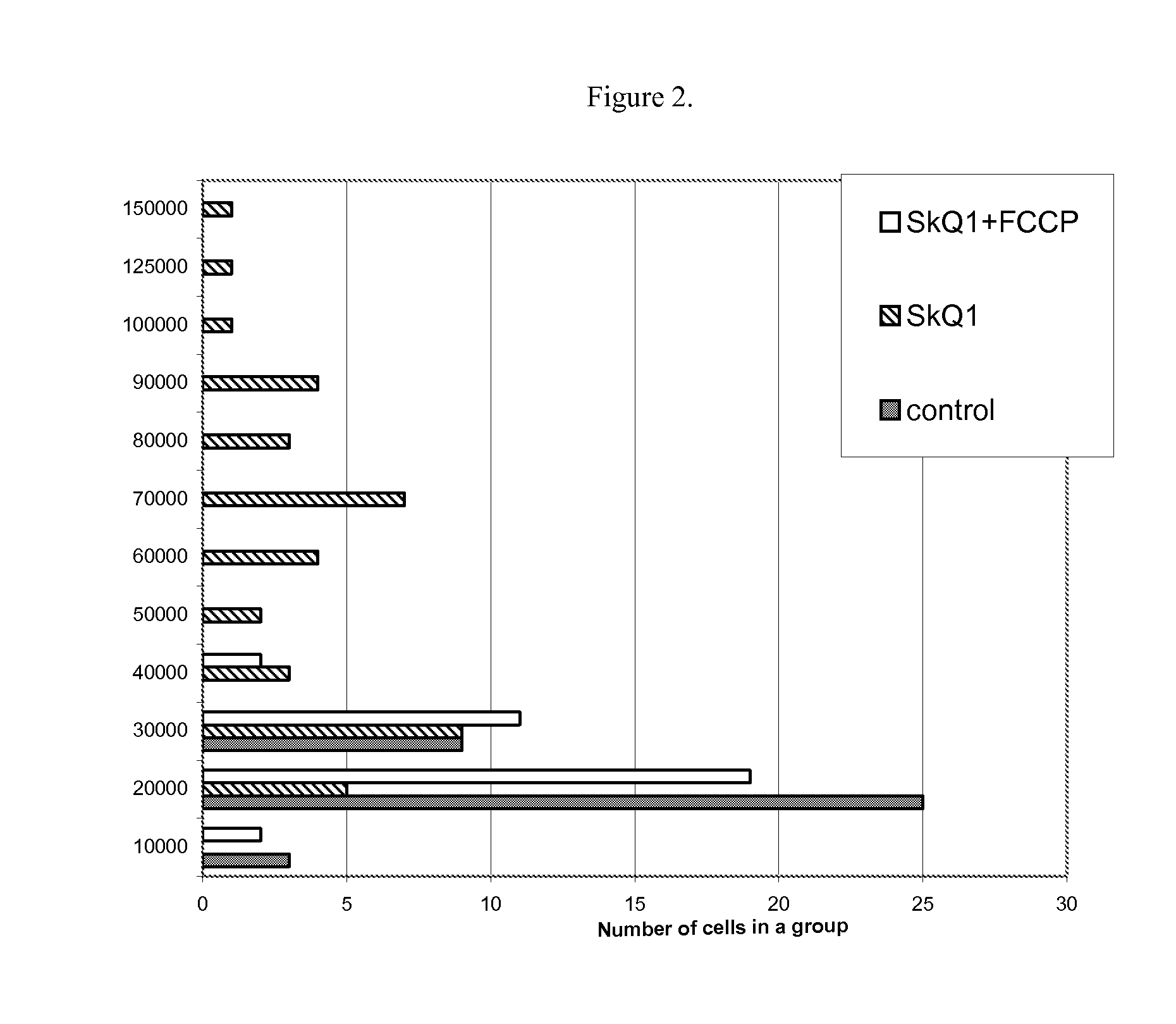

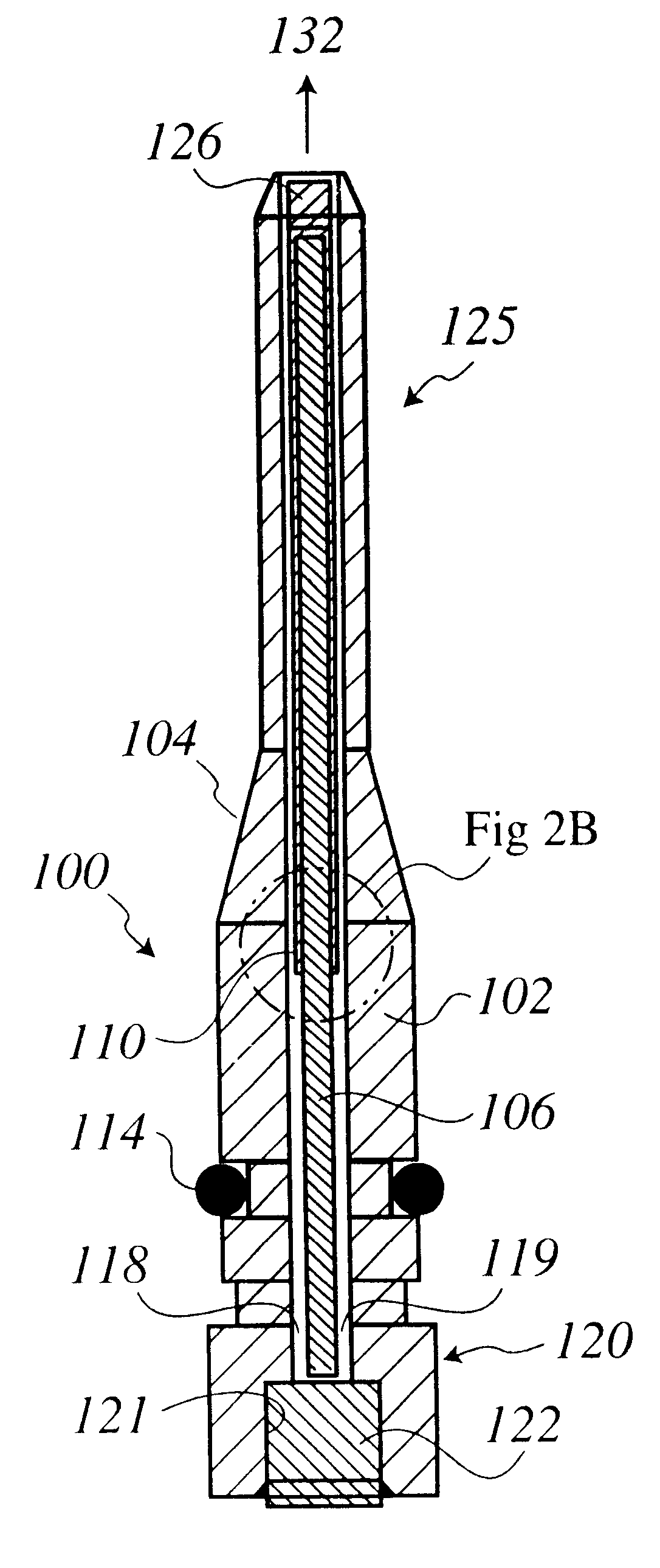

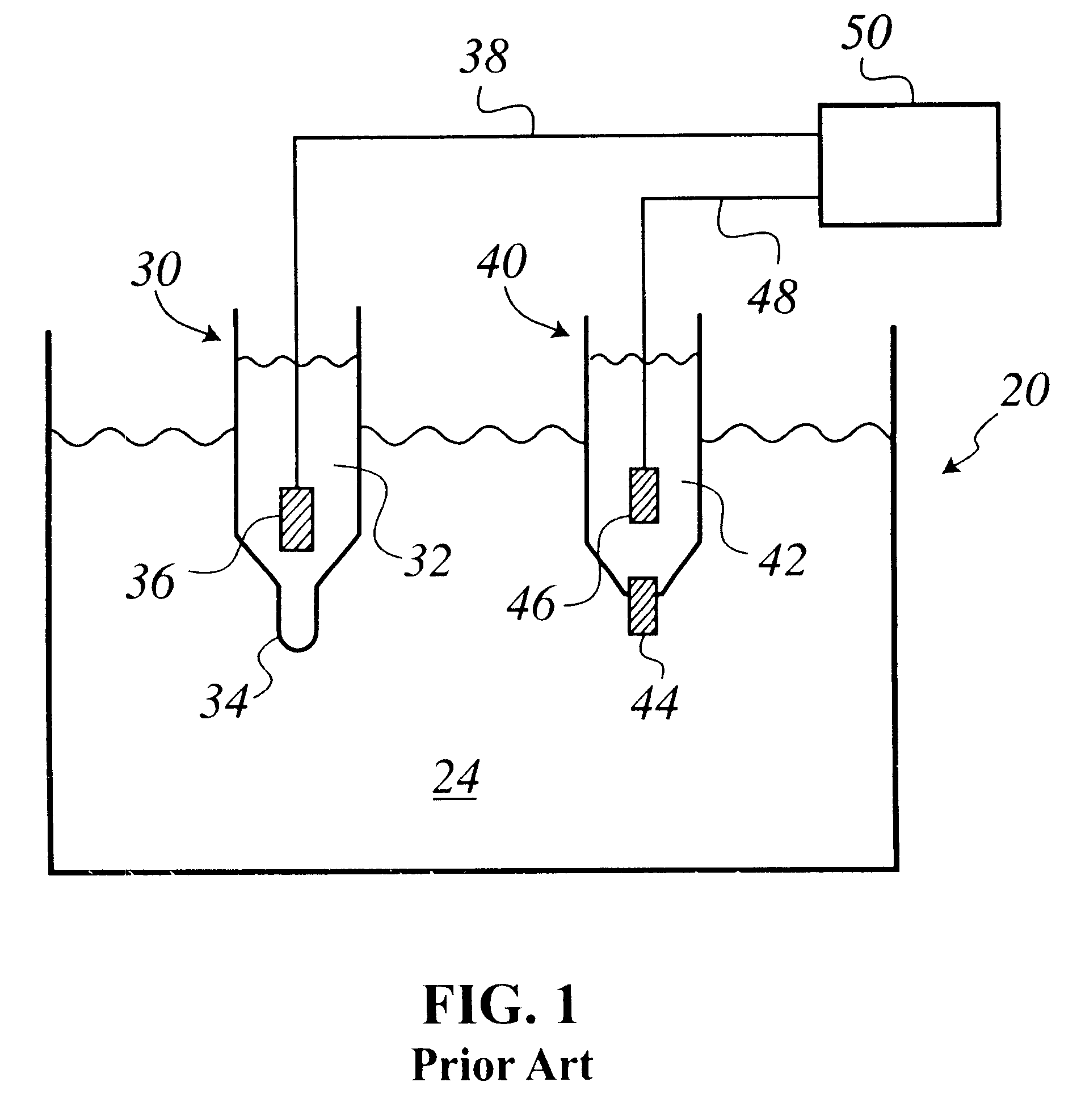

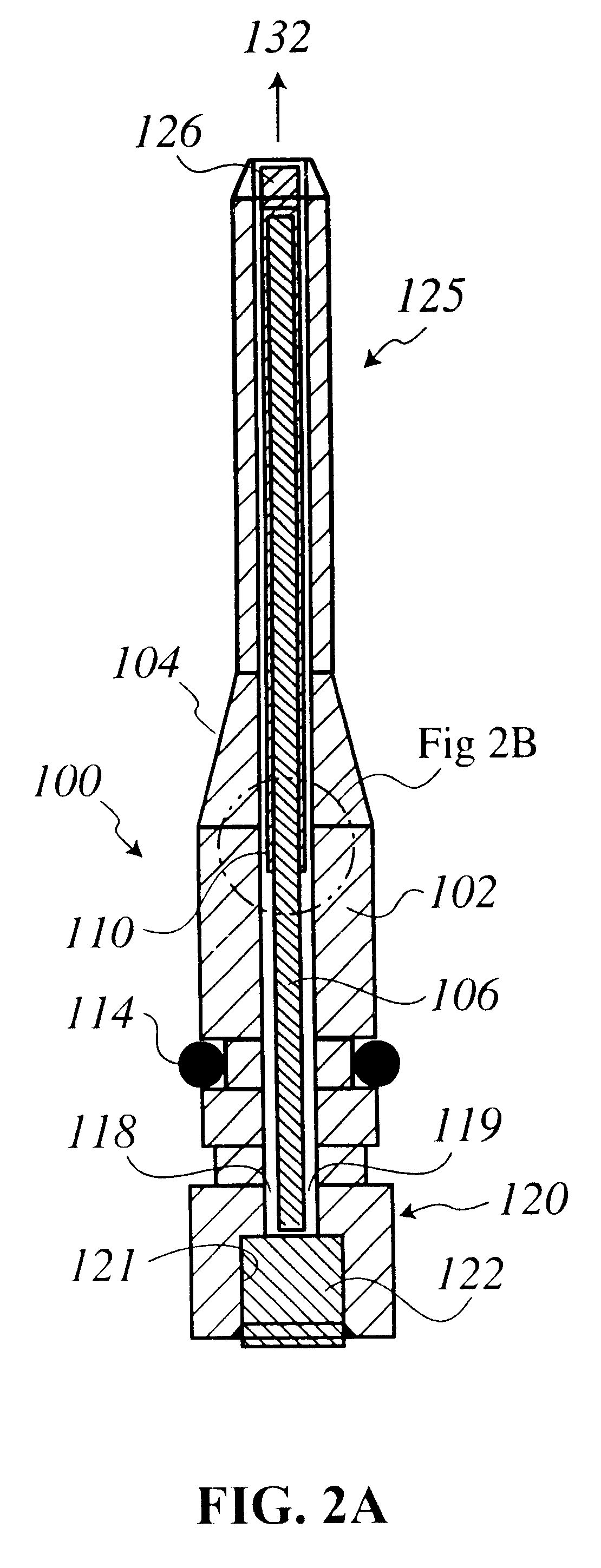

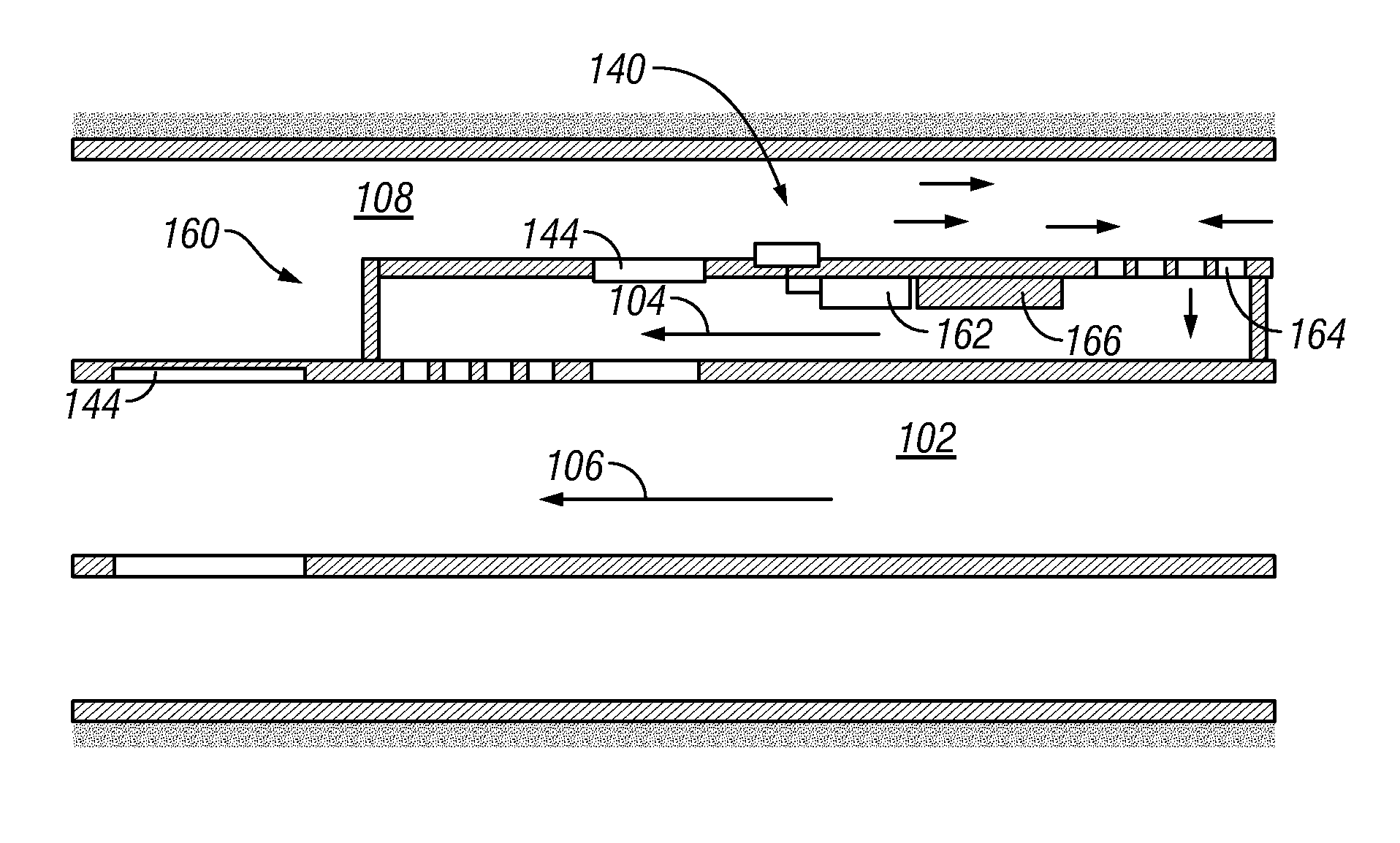

A cluster or array of reference electrode materials is prepared and used to monitor the state of charge of positive and negative active electrode materials of a lithium-ion cell. The reference electrode materials are composed so as to provide useful electrochemical potential values when placed in the same electrolyte in proximity with a positive or negative electrode. The array of reference electrodes includes at least two electrically discrete instances of reference electrode materials. Such duplication of reference material in the array permits confirmation of the present quality and activity of a reference material used for evaluation of positive and / or negative electrode material in a lithium-ion cell.

Owner:GM GLOBAL TECH OPERATIONS LLC

Controlled electrochemical polishing method

InactiveUS7998335B2Electrolysis componentsSemiconductor/solid-state device manufacturingOxidizing agentMaterials science

The invention relates to a method of polishing a substrate comprising at least one metal layer by applying an electrochemical potential between the substrate and at least one electrode in contact with a polishing composition comprising a reducing agent or an oxidizing agent.

Owner:CABOT MICROELECTRONICS CORP

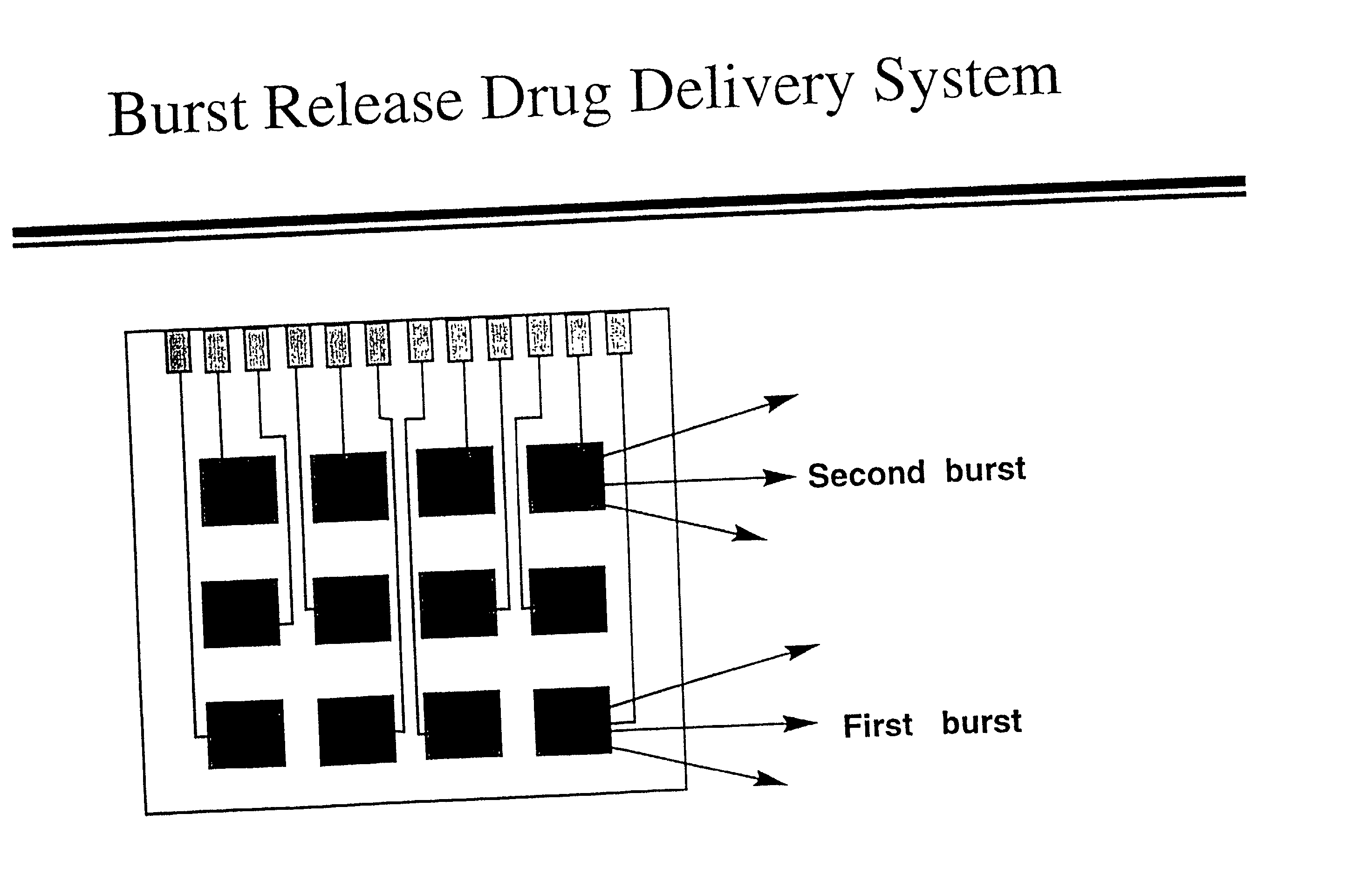

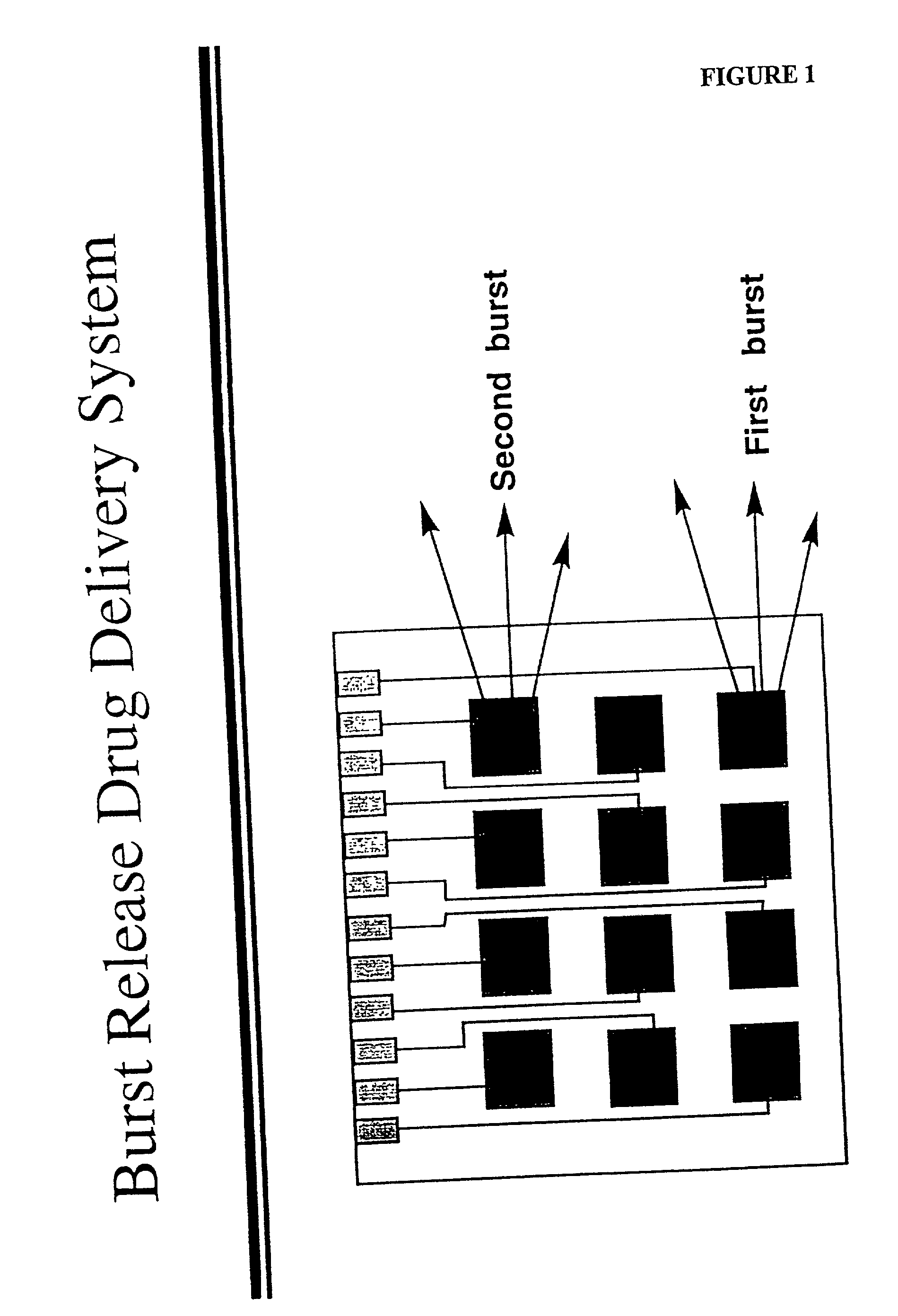

Drug release (delivery system)

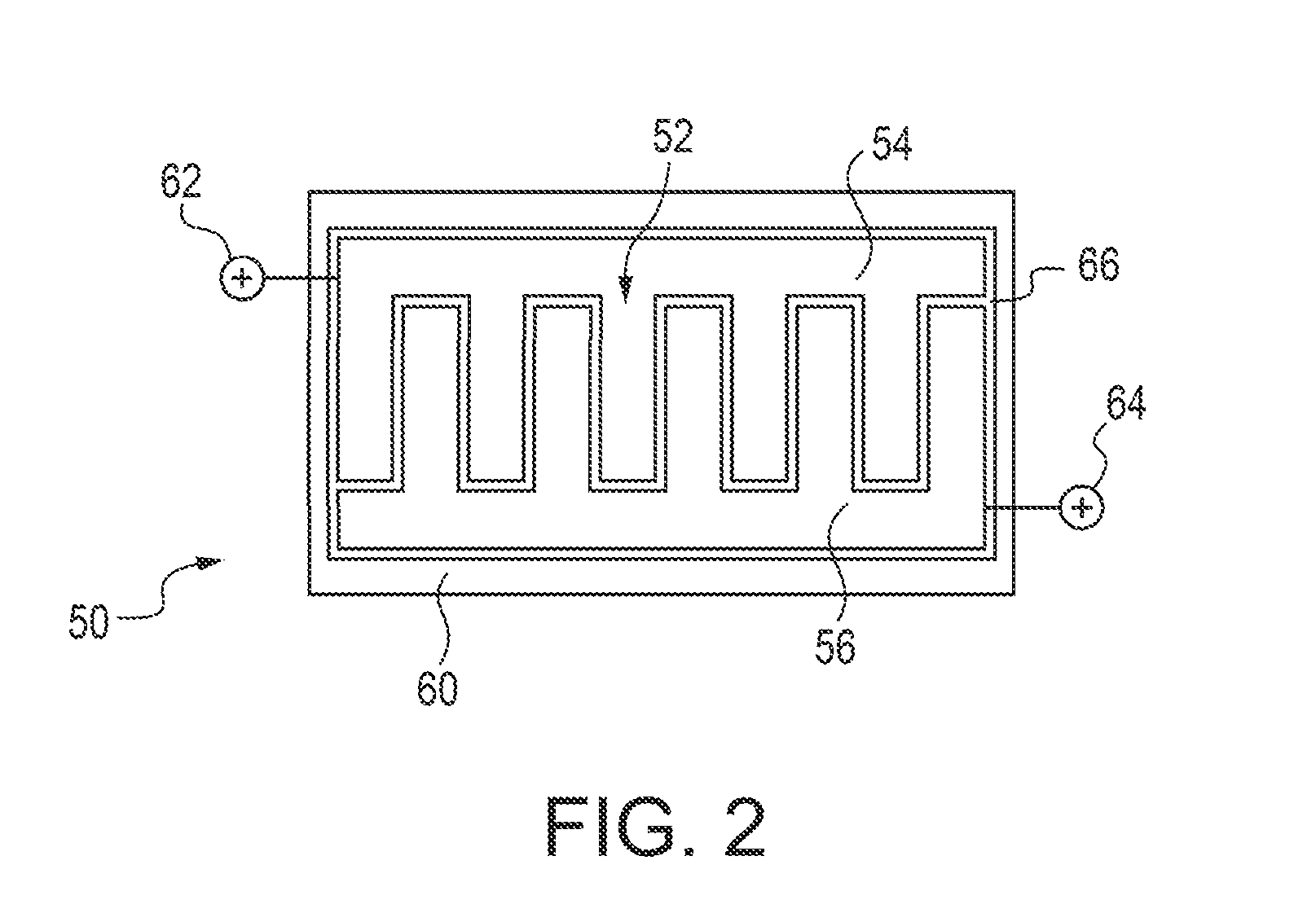

InactiveUS20020035346A1Limited medicinal wasteReduce riskElectrotherapyPharmaceutical delivery mechanismPolypyrroleDrug release

An electrically addressable release pad for use in a burst electrode drug release (delivery) system. The pad useable in this system comprises a polymer, preferably polypyrrole, which surrounds medicine. Once a section of the polymer receives an electrochemical potential sent from an electrode contained within the pad, a defined dose of medicine contained therein is released. The pad is designed to be worn by a patient, so that when the medication is released, its administered to the patient, without the patient having to do anything. The electrode typically can be a burst electrode, one with a unique electrical signature. The electrode can be triggered from a remote source.

Owner:PHARMACIA CORP +1

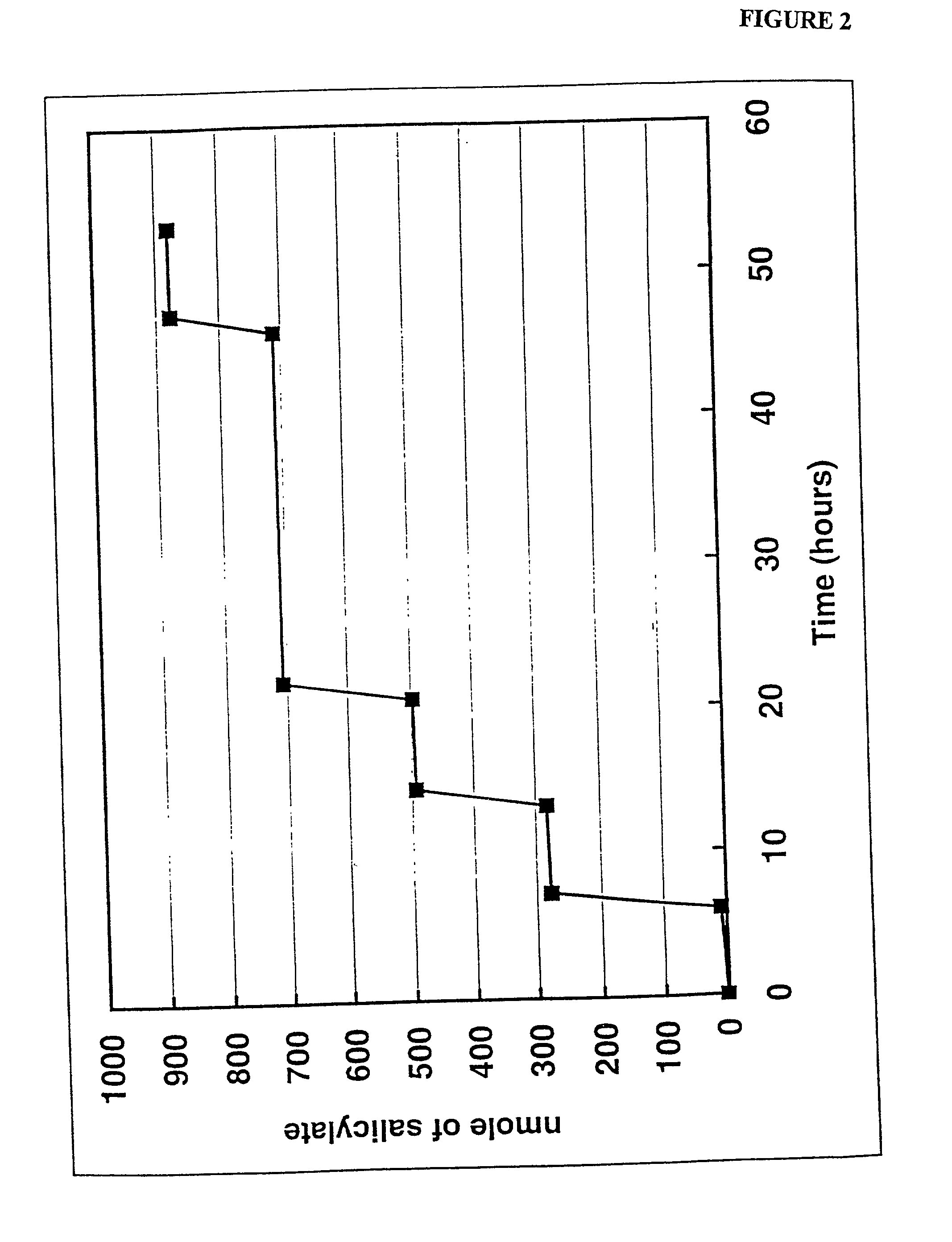

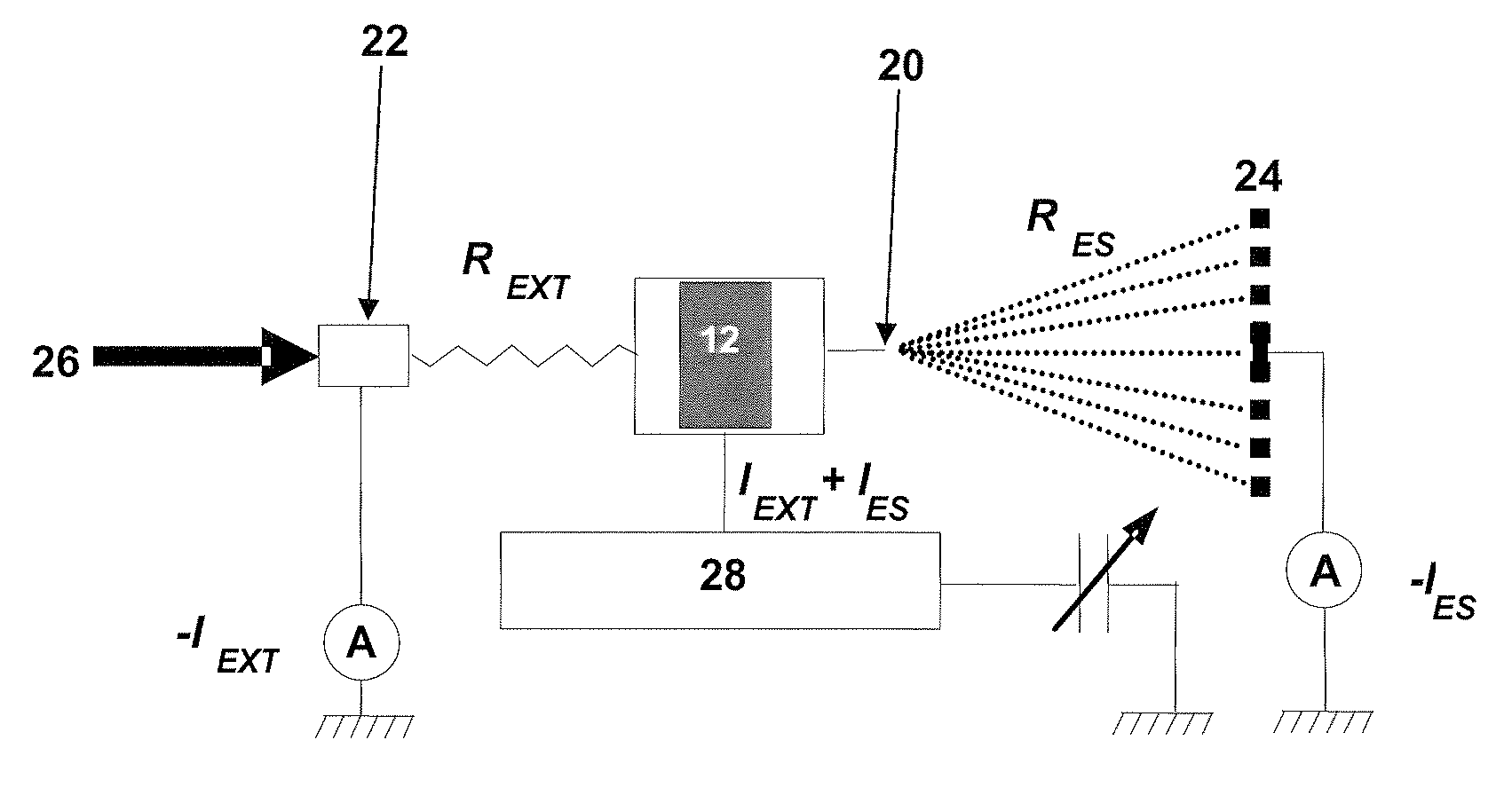

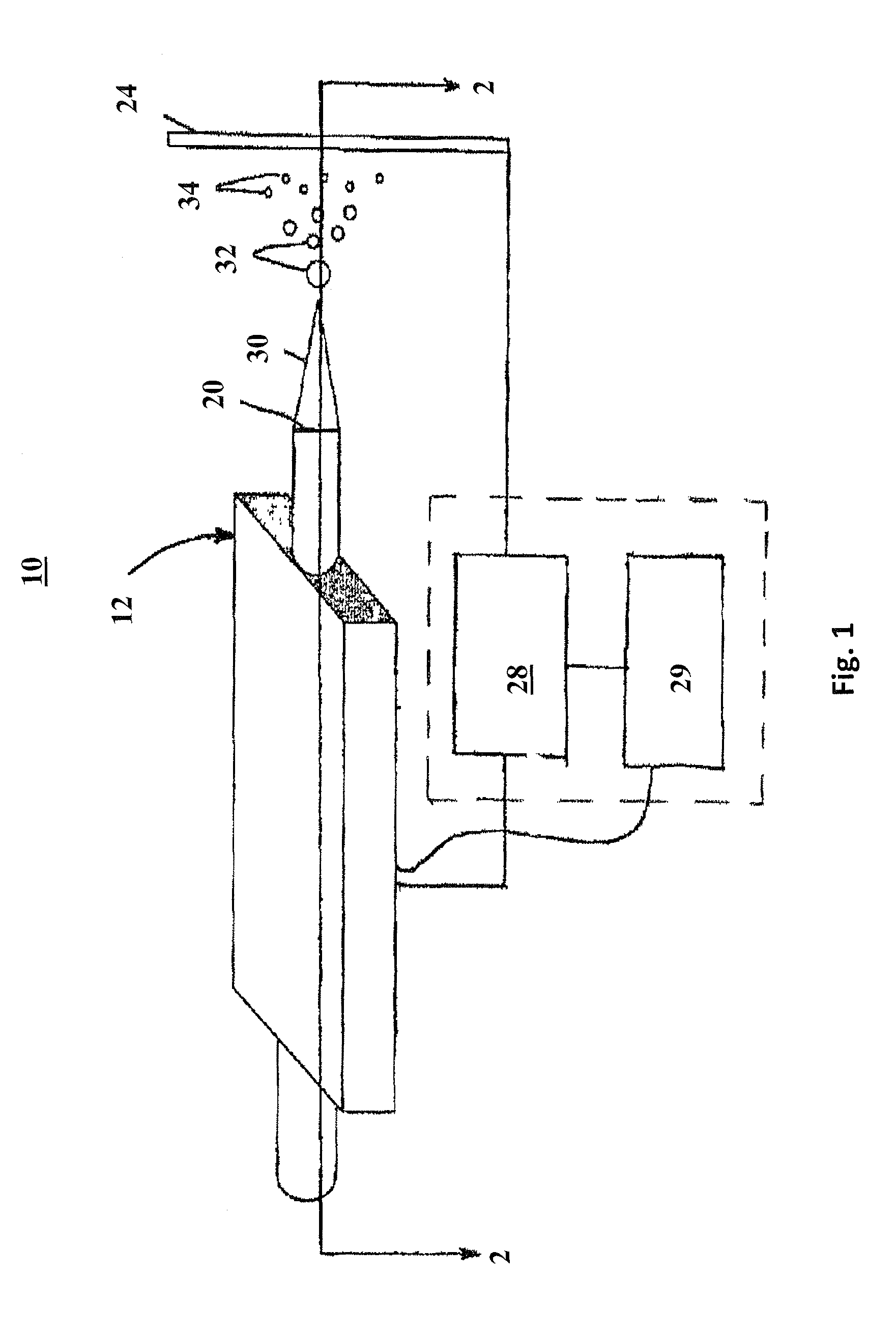

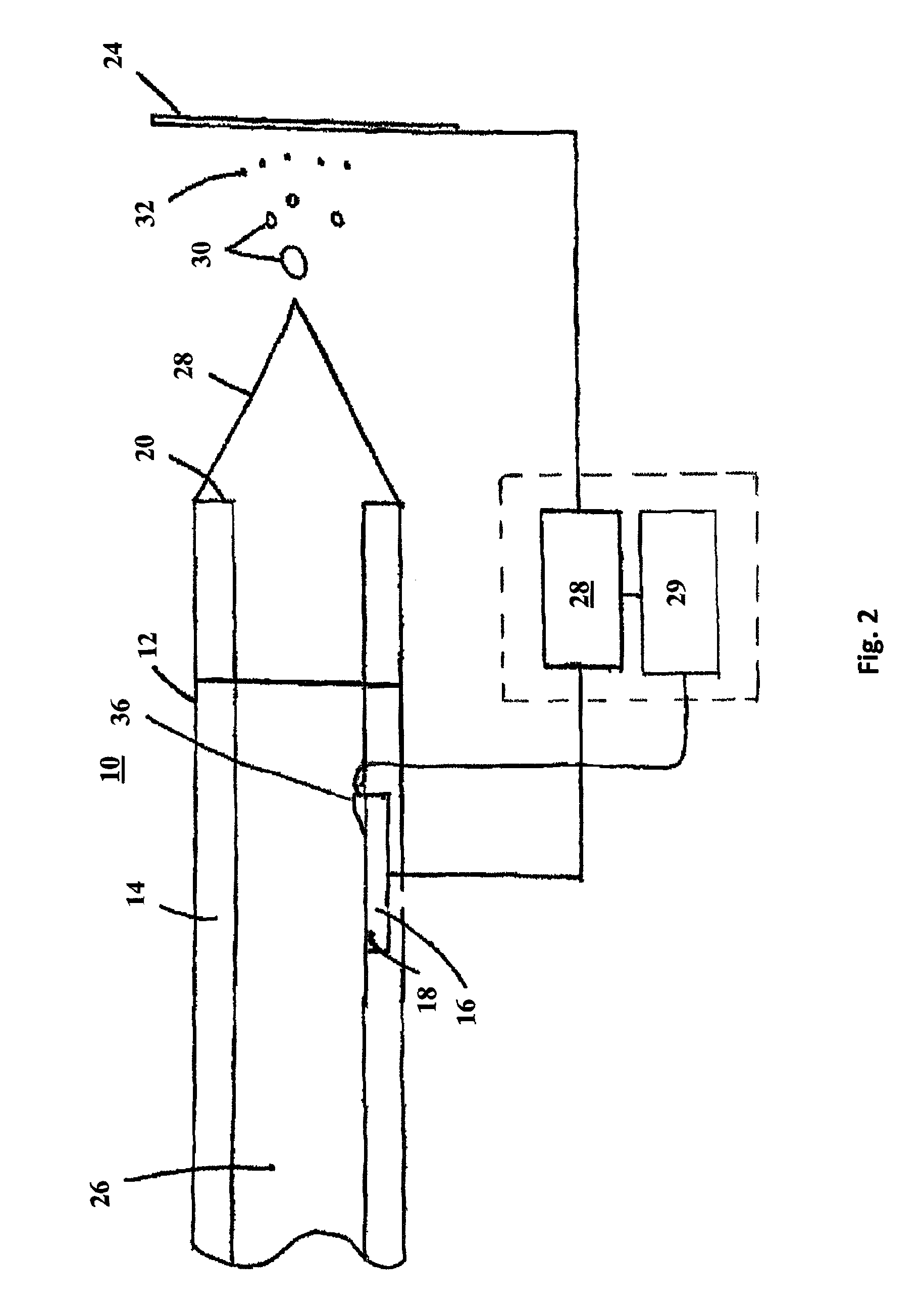

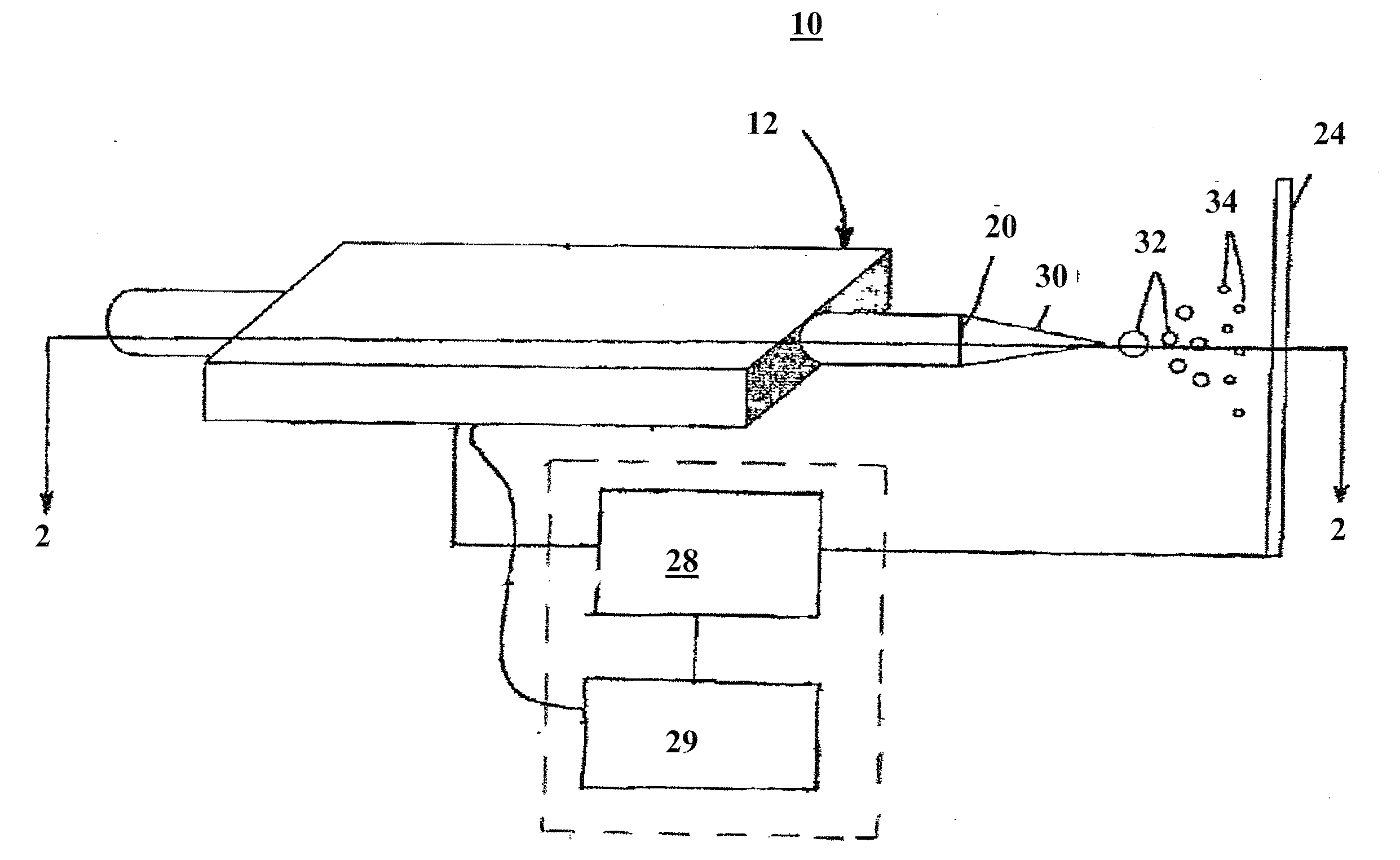

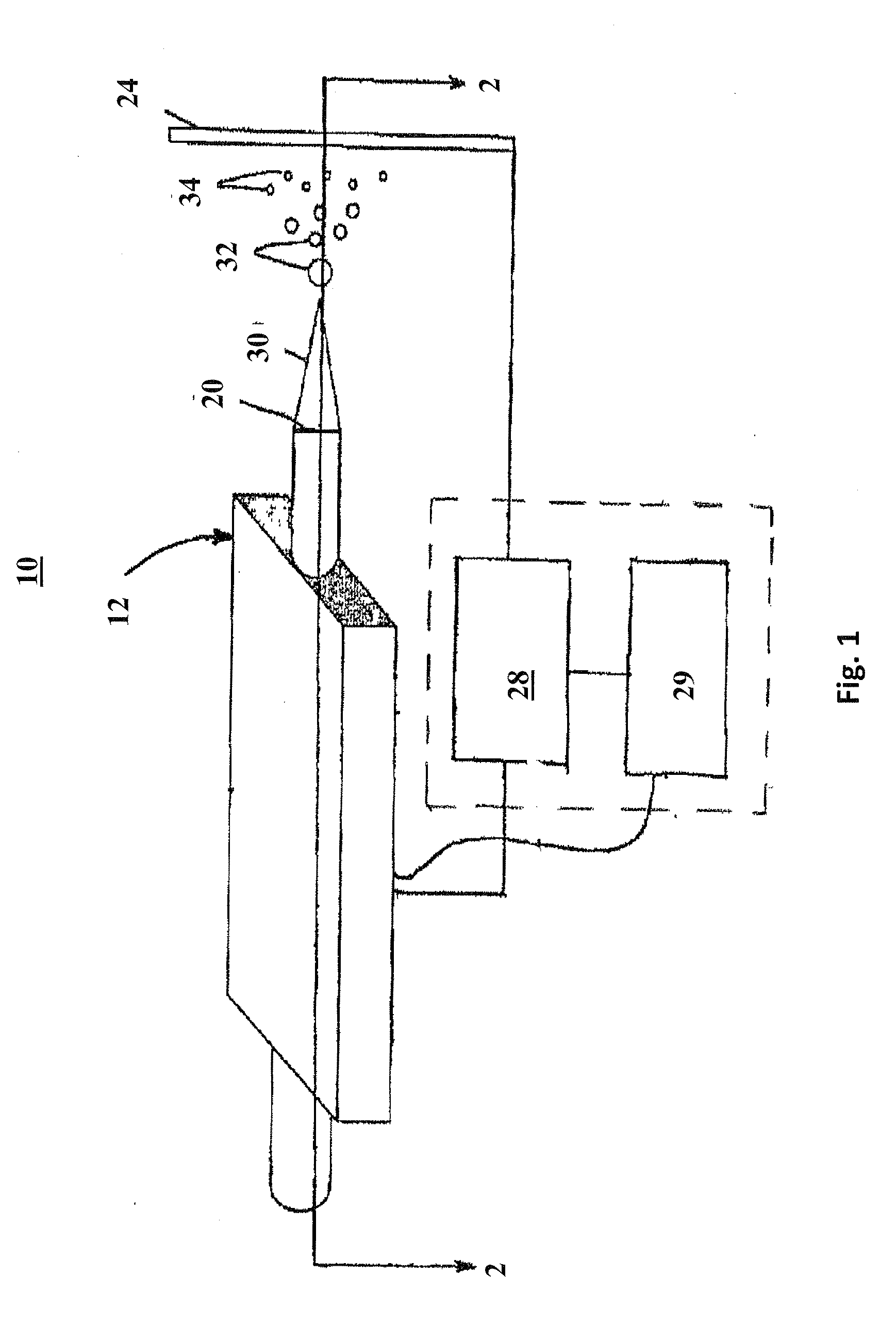

Pulsed voltage electrospray ion source and method for preventing analyte electrolysis

InactiveUS8084735B2Spectrometer circuit arrangementsMaterial analysis by optical meansElectrolysisAnalyte

An electrospray ion source and method of operation includes the application of pulsed voltage to prevent electrolysis of analytes with a low electrochemical potential. The electrospray ion source can include an emitter, a counter electrode, and a power supply. The emitter can include a liquid conduit, a primary working electrode having a liquid contacting surface, and a spray tip, where the liquid conduit and the working electrode are in liquid communication. The counter electrode can be proximate to, but separated from, the spray tip. The power system can supply voltage to the working electrode in the form of a pulse wave, where the pulse wave oscillates between at least an energized voltage and a relaxation voltage. The relaxation duration of the relaxation voltage can range from 1 millisecond to 35 milliseconds. The pulse duration of the energized voltage can be less than 1 millisecond and the frequency of the pulse wave can range from 30 to 800 Hz.

Owner:UT BATTELLE LLC

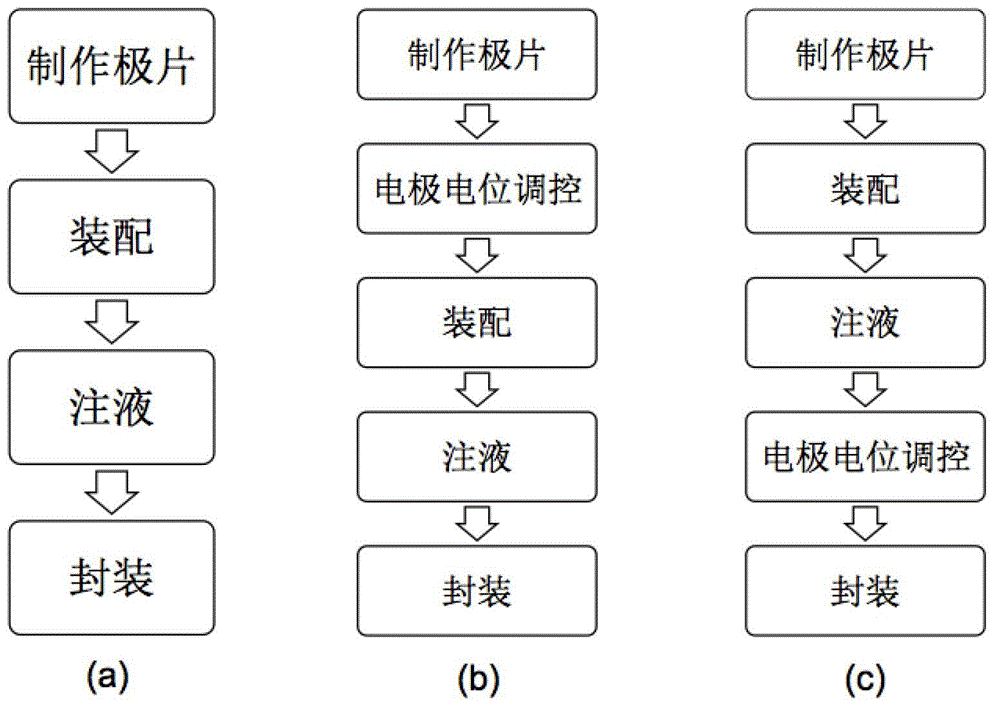

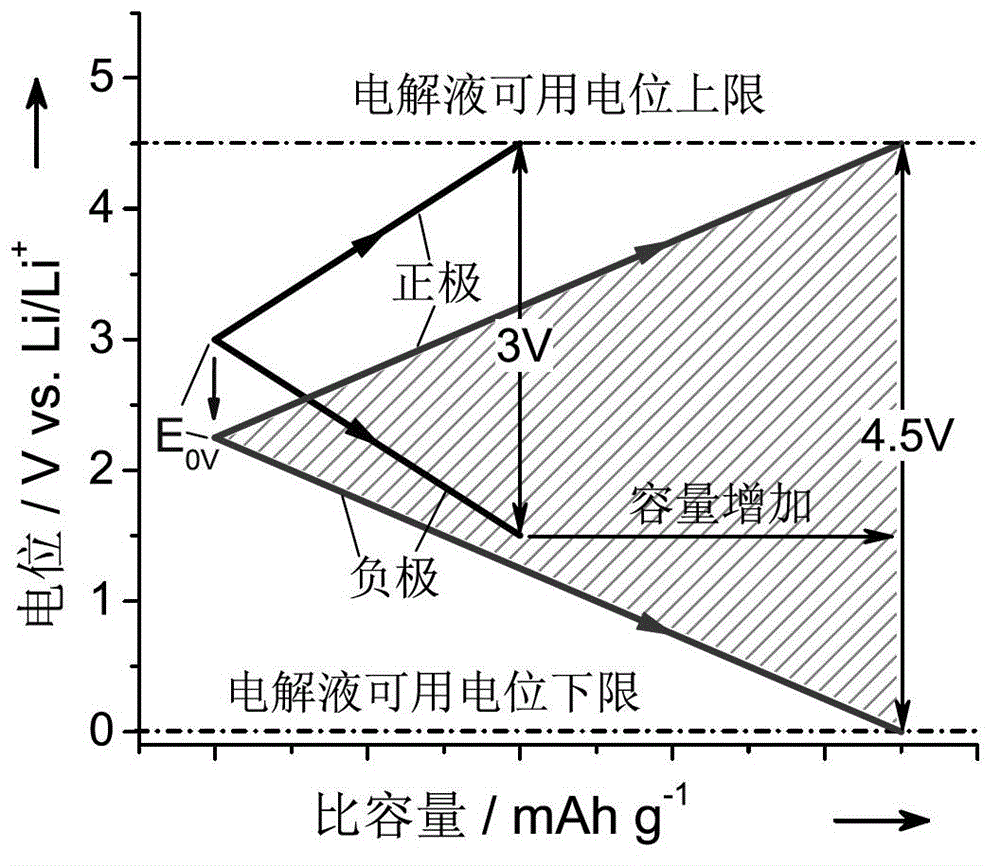

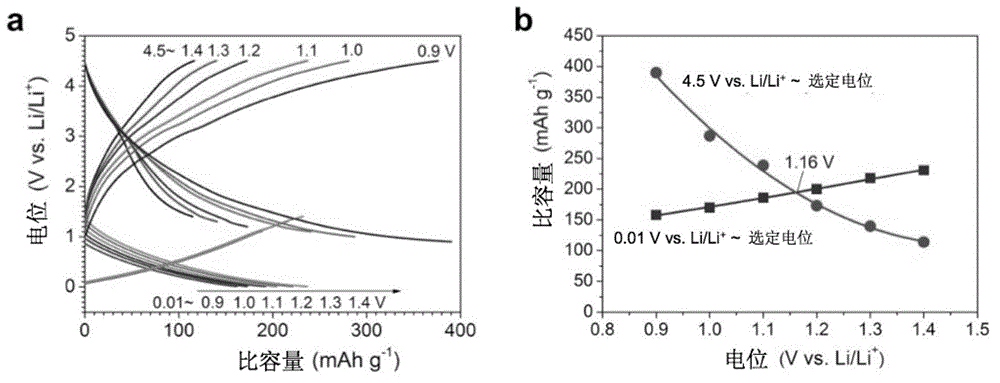

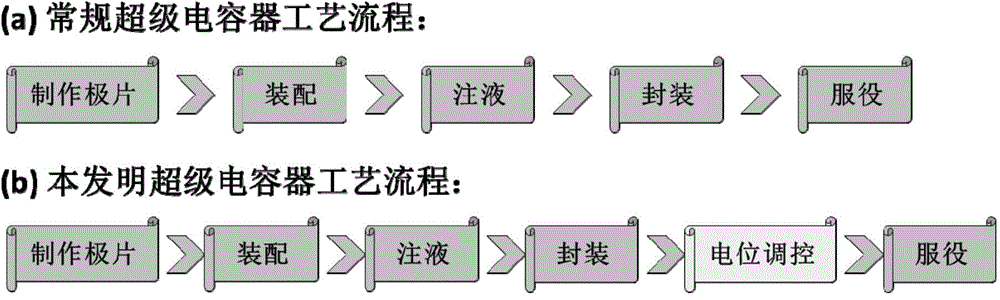

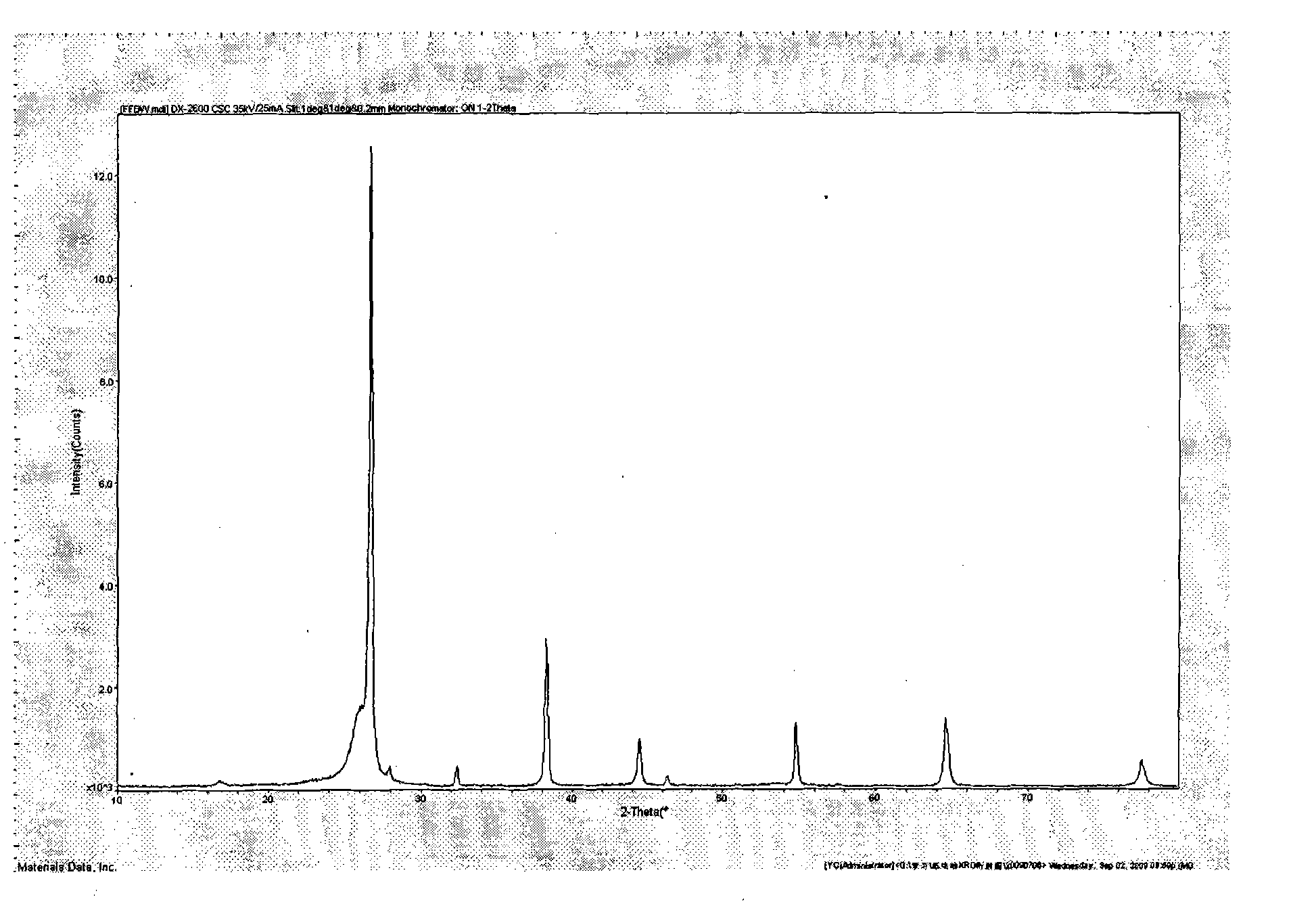

Method for realizing energy density maximization of supercapacitor

InactiveCN104064370ASolve underutilized problemsIncrease energy densityHybrid/EDL manufactureCapacitorMaterials science

The invention belongs to the field of a supercapacitor of electrochemical energy storage, and discloses a method for realizing energy density maximization of a supercapacitor, for solving the problem of energy density loss caused by high specific capacity of an electrode material and incapability of giving full play to and fully utilizing an available voltage window of an electrolyte in a conventional supercapacitor. Through an electrochemical process, charges are injected to an electrode material to realize electrochemical potential adjustment, and then the adjusted electrode material is assembled to form the supercapacitor, thus working potential windows of a positive electrode and a negative electrode in a device are optimized, the working voltages and specific capacity of the device are improved at the same time, and the energy density maximization of the supercapacitor is realized.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Controlled electrochemical polishing method

InactiveUS20060281196A1Electrolysis componentsSemiconductor/solid-state device manufacturingOxidizing agentReducing agent

The invention relates to a method of polishing a substrate comprising at least one metal layer by applying an electrochemical potential between the substrate and at least one electrode in contact with a polishing composition comprising a reducing agent or an oxidizing agent.

Owner:CABOT MICROELECTRONICS CORP

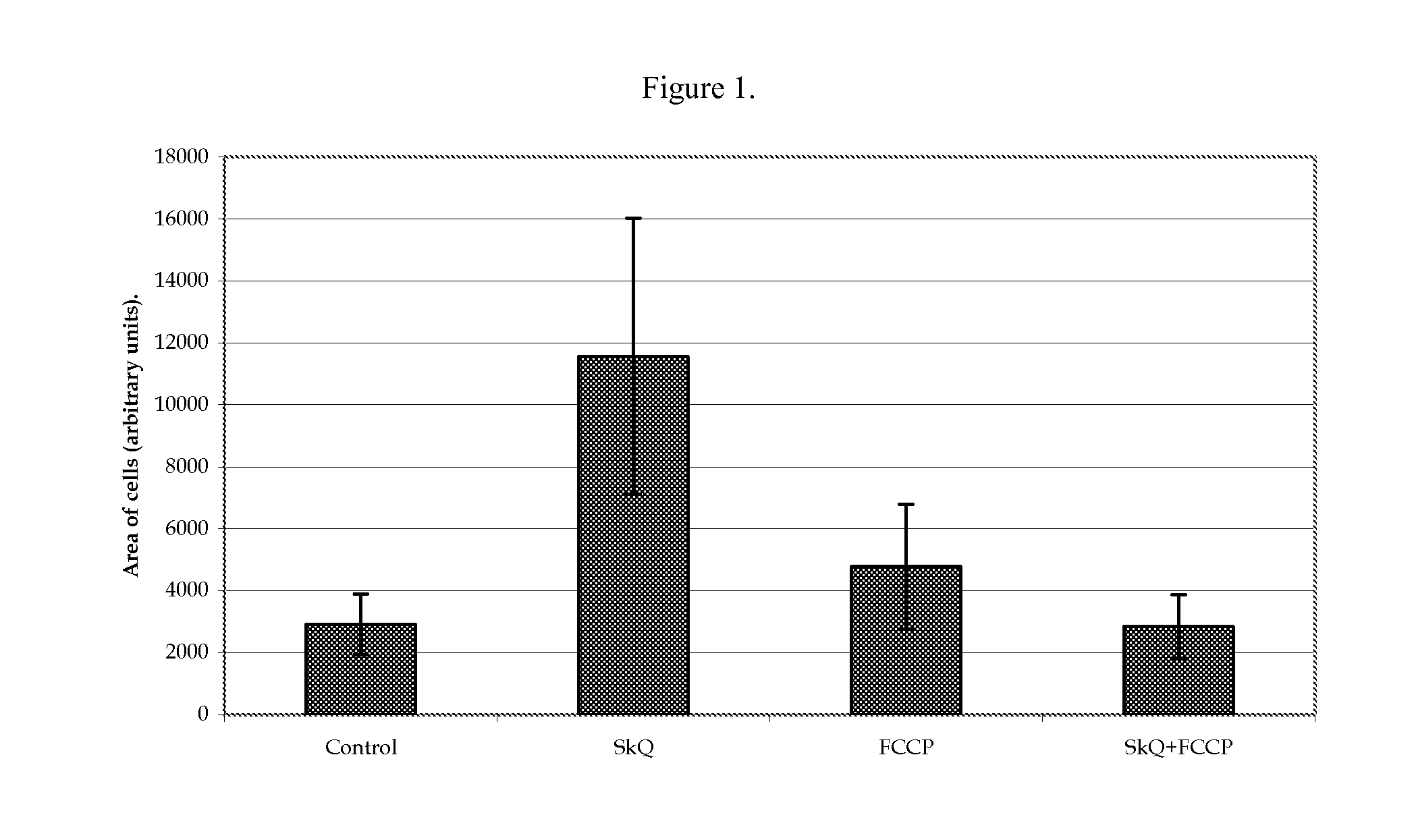

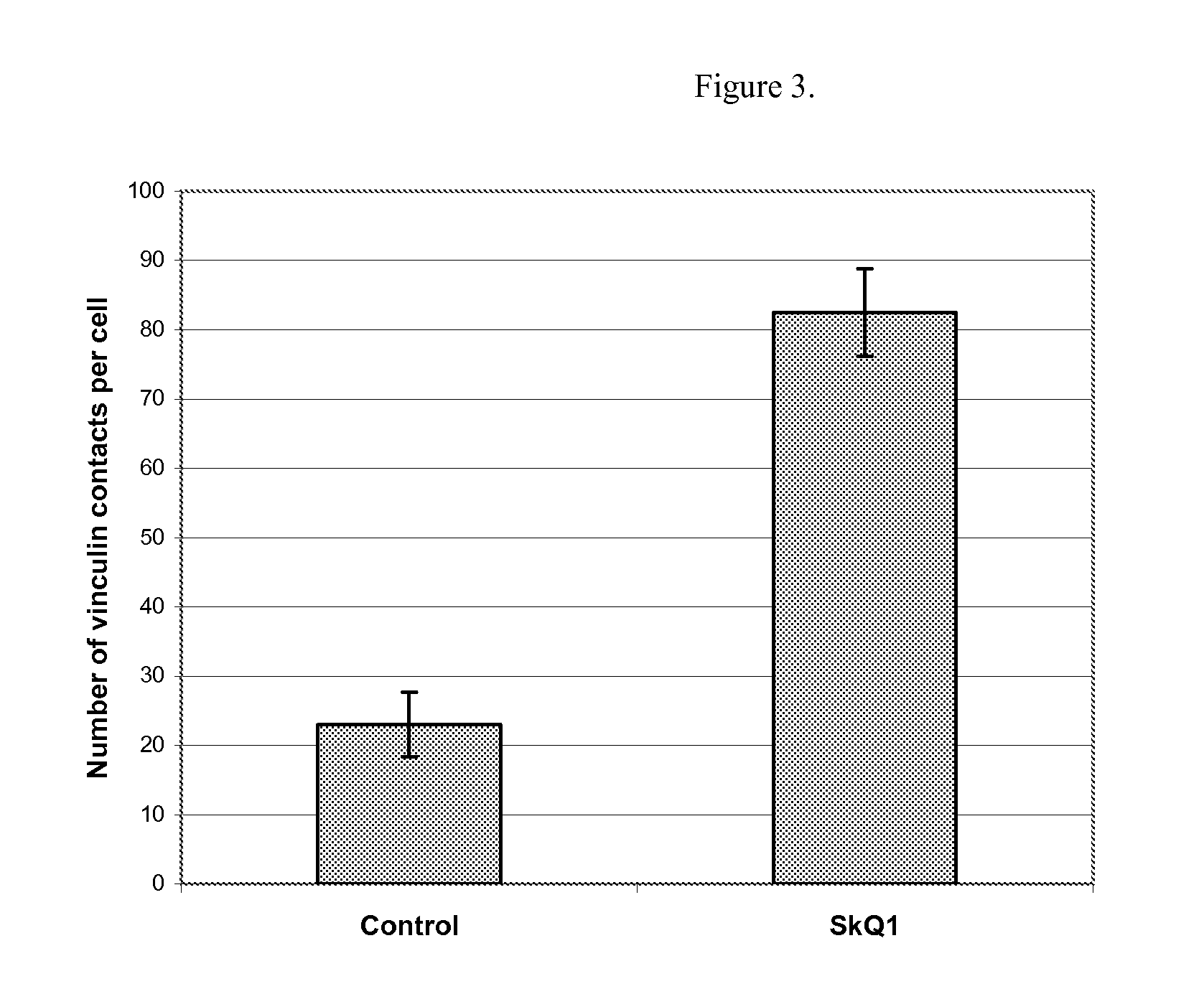

Pharmaceutical and cosmetic compositions for accelerated healing of wounds and other surface damages

ActiveUS20100292625A1Improve skin conditionImprove skin skin rejuvenationBiocideCosmetic preparationsHydrogenActive agent

The invention relates to biology and medicine, in particular, it can be used in medicine for preparing a pharmacological composition used for accelerated healing of wounds and the damages by means of addressed (directed) delivery of biologically active agents to mitochondria by means electrochemical potential of hydrogen ions contained therein. Said invention can be also used for producing a composition useful in transplantation surgery for preserving transplantation material and for inhibiting rejection. Moreover, the invention can be used for producing a cosmetic agent for improving state of the skin and for the revitalisation and regeneration thereof.

Owner:MITOTECH SA

Nickel-plated brazing product having improved corrosion performance

InactiveUS20020175205A1Improve corrosion resistanceWelding/cutting media/materialsThin material handlingFiller metalAluminide

A brazing product, e.g. a brazing sheet product, having an aluminium layer made of an aluminium alloy comprising silicon in an amount in the range of 2 to 18 weight %, and a layer comprising nickel on the outer surface of the aluminium layer such that taken together the aluminium layer and all layers exterior thereto form the filler metal for a brazing operation. The filler metal has a composition containing at least one element: (i) with a smaller exchange current density for the Hydrogen Evolution Reaction ("HER") than nickel and / or (ii) such that the electro-chemical potential difference between particles of Ni-aluminide(s) of the filler and the aluminium alloy matrix of the filler is reduced. The filler metal's mol-ratio of Ni to such element(s) is in the range of 10:(O.3-30). The invention also relates to a method of manufacturing a brazed assembly using the brazing product, and to a brazed assembly comprising at least one component made of the brazing product.

Owner:CORUS ALUMINUM WALZPRODUKTE GMBH (DE)

Lithium-ion cell with an array of reference electrodes

A cluster or array of reference electrode materials is prepared and used to monitor the state of charge of positive and negative active electrode materials of a lithium-ion cell. The reference electrode materials are composed so as to provide useful electrochemical potential values when placed in the same electrolyte in proximity with a positive or negative electrode. The array of reference electrodes includes at least two electrically discrete instances of reference electrode materials. Such duplication of reference material in the array permits confirmation of the present quality and activity of a reference material used for evaluation of positive and / or negative electrode material in a lithium-ion cell.

Owner:GM GLOBAL TECH OPERATIONS LLC

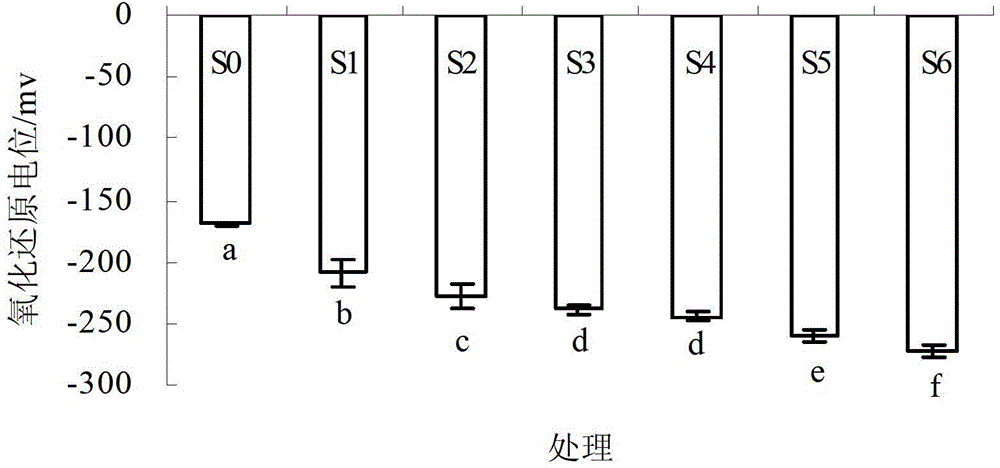

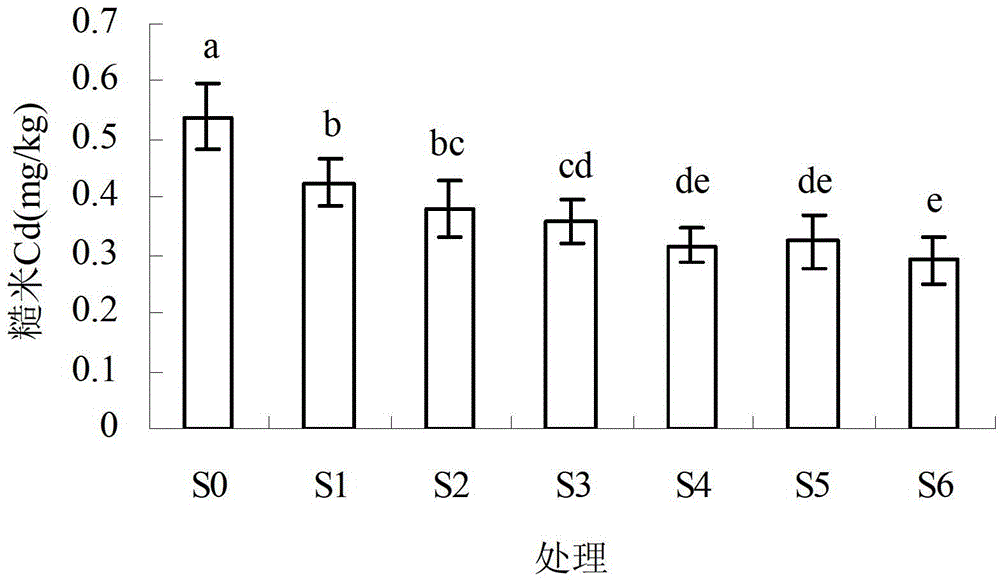

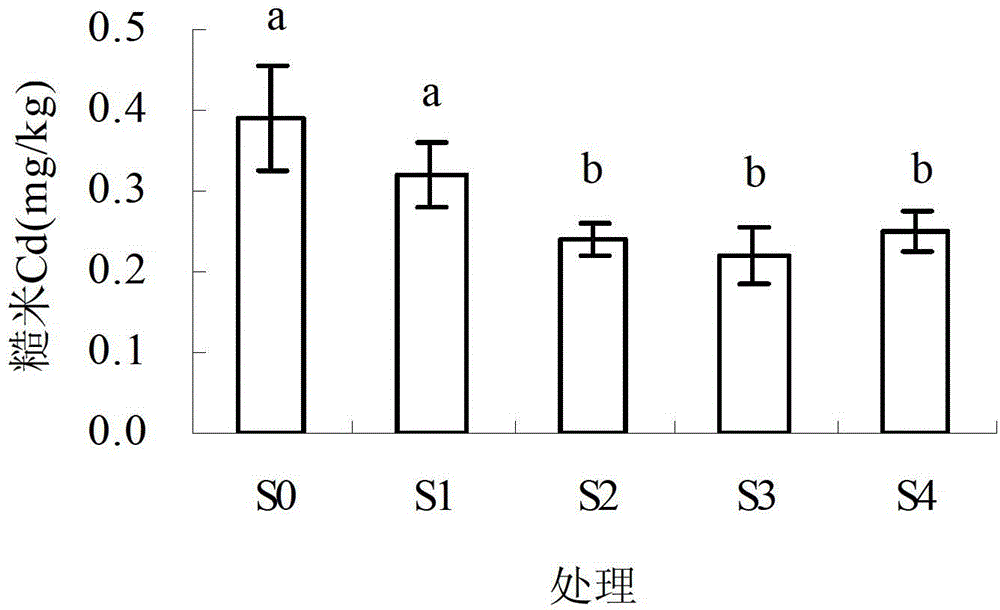

Soil conditioning method capable of reducing cadmium accumulation for paddy rice

InactiveCN102974606AWide variety of sourcesEasy to operateContaminated soil reclamationSoil heavy metalsBiology

The invention discloses a soil conditioning method capable of reducing cadmium accumulation for paddy rice. The soil conditioning method comprises the following steps of: before ploughing and fertilizing acid soil contaminated by heavy metal cadmium, uniformly spreading a soil conditioner sulfite over the surface of the acid soil contaminated by the heavy metal cadmium, then applying a base fertilizer, and blending sufficiently; and with combination of soil flooding conditioning, making the soil in a flooded state in a rice growth period so as to make the acid soil contaminated by the heavy metal cadmium in a low-electrochemical-potential reducing environment with Eh being (-150mV)-(-300mV), effectively adsorbing the cadmium in the soil by using the generated reduzate, and generating chemical precipitates, thereby completing the soil conditioning process. The soil conditioning method disclosed by the invention is simple and reliable in operation, quick in response after utilization and obvious in economic benefits, and has great significance of controlling the heavy metal cadmium contamination of the soil and guaranteeing the food safety.

Owner:湖南宇丰农科生态工程有限公司

Online water pollution source tracing method

InactiveCN110412006ARealize online traceabilityEasy accessMaterial analysis by electric/magnetic meansRaman scatteringPapermakingSource tracing

Owner:BEIJING UNIV OF CHEM TECH +1

Magnesium-zinc-calcium alloy, method for production thereof, and use thereof

A magnesium alloy includes <3% by weight of Zn, ≦0.6% by weight of Ca, with the rest being formed by magnesium containing impurities, which favor electrochemical potential differences and / or promote the formation of intermetallic phases, in a total amount of no more than 0.005% by weight of Fe, Si, Mn, Co, Ni, Cu, Al, Zr and P, wherein the alloy contains elements selected from the group of rare earths with the atomic number 21, 39, 57 to 71 and 89 to 103 in a total amount of no more than 0.002% by weight.

Owner:BIOTRONIK AG

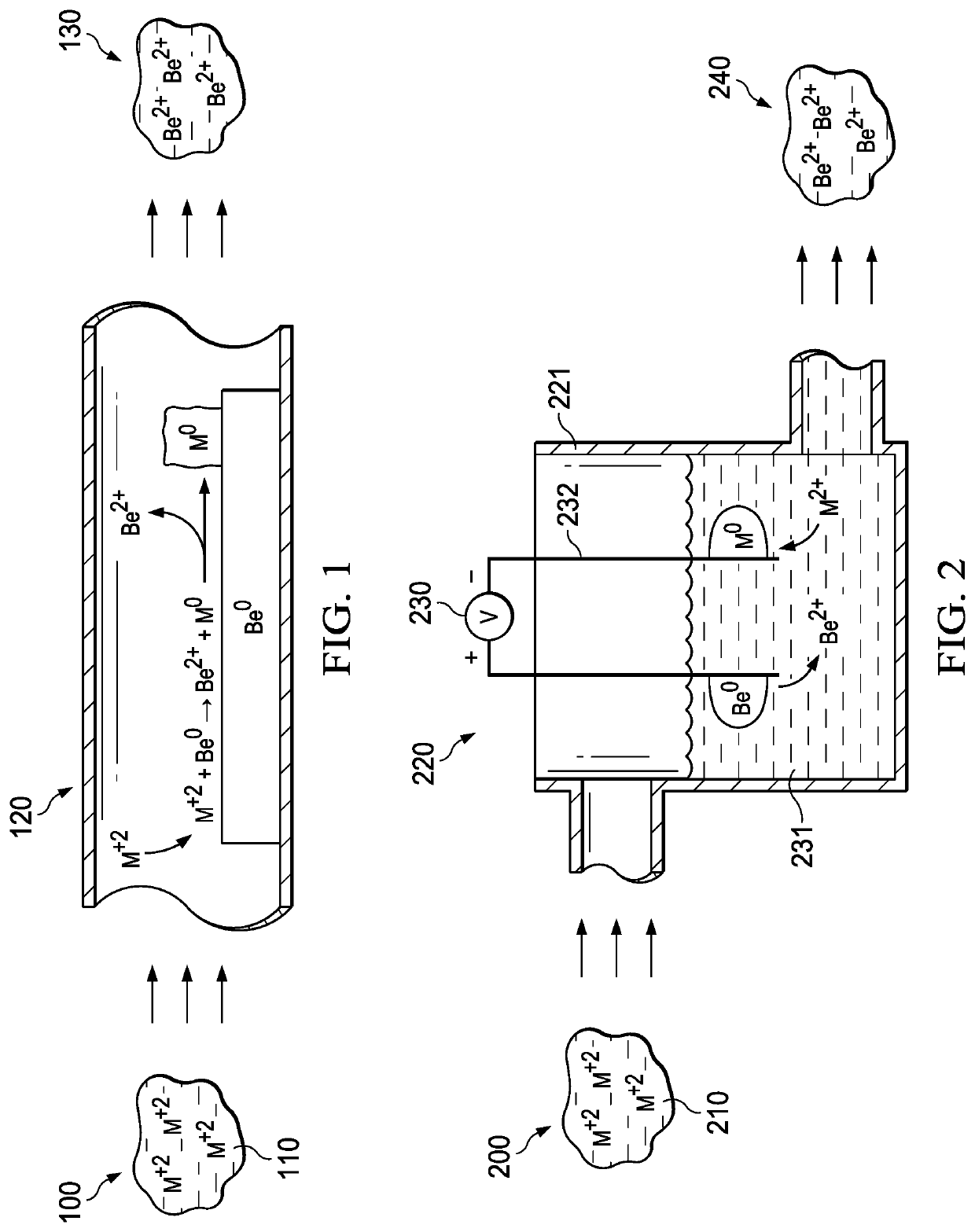

Systems and methods for maintaining chemistry in molten salt systems

InactiveUS20200122109A1Reduce solubilityFacilitate chemical reactionsElectrolysis componentsLiquid-gas reaction as foam/aerosol/bubblesChemical controlPhysical chemistry

Methods and systems for removing impurities from a molten salt stream are provided. A molten salt stream is provided that comprises a mixture of compounds selected from the group consisting of LiF, BeF2, and NaF, and ZrF4. The molten salt stream is flowed through a loop that may contain a precipitation filter, electrochemical potential, and / or a sparger, which thereby remove impurities in the molten salt stream. Various physical methods and apparatus are used to control the ability to remove impurities from the molten salt stream based on temperature, solubility, and general chemistry control.

Owner:KAIROS POWER LLC

Magnesium-zinc-calcium alloy, method for production thereof, and use thereof

ActiveUS20150129091A1Improve mechanical propertiesIncreasing proof stressSurgeryTissue regenerationRare-earth elementZinc

A magnesium alloy includes 3 to 7.0% Zn, 0.001 to 0.5% Ca, the remainder being magnesium containing impurities, which promote electrochemical potential differences and / or the formation of intermetallic phases, in a total amount of no more than 0.005 of Fe, Si, Mn, Co, Ni, Cu, Al, Zr and P, wherein the alloying elements are selected from the group of the rare earths having the ordinal numbers 21, 39, 57 to 71 and 89 to 103 in a total amount of no more than 0.001% by weight.

Owner:BIOTRONIK AG

Redox shuttle for overdischarge protection in rechargeable lithium-ion batteries

InactiveUS7648801B2Wide windowLarge capacityNon-aqueous electrolyte accumulatorsElectrode carriers/collectorsElectrode potentialCapacity loss

A battery of series-connected rechargeable lithium ion cells each of which contains a negative electrode; a negative electrode current collector; a positive electrode; a positive electrode current collector; and an electrolyte comprising charge carrying medium, lithium salt and cyclable redox chemical shuttle. The negative electrode has a larger i rreversible first cycle capacity loss than that of the positive electrode, and is driven to a potential above that of the positive electrode if the cell is discharged to a state of cell reversal. The shuttle has an electrochemical potential above the positive electrode maximum normal operating potential, and prevents the negative electrode potential from reaching even higher and more destructive positive values during overdischarge. The current collector has a lithium alloying potential below the negative electrode minimum normal operating potential. The battery chemically limits or eliminates cell damage due to repeated overdischarge, and may operate without electronic overdischarge protection circuitry.

Owner:3M INNOVATIVE PROPERTIES CO

Replaceable reference junction including an ion-barrier for an electrochemical sensor

InactiveUS6579440B2Weather/light/corrosion resistanceVolume/mass flow measurementChemical physicsElectrical battery

Owner:SCHNEIDER ELECTRIC SYST USA INC

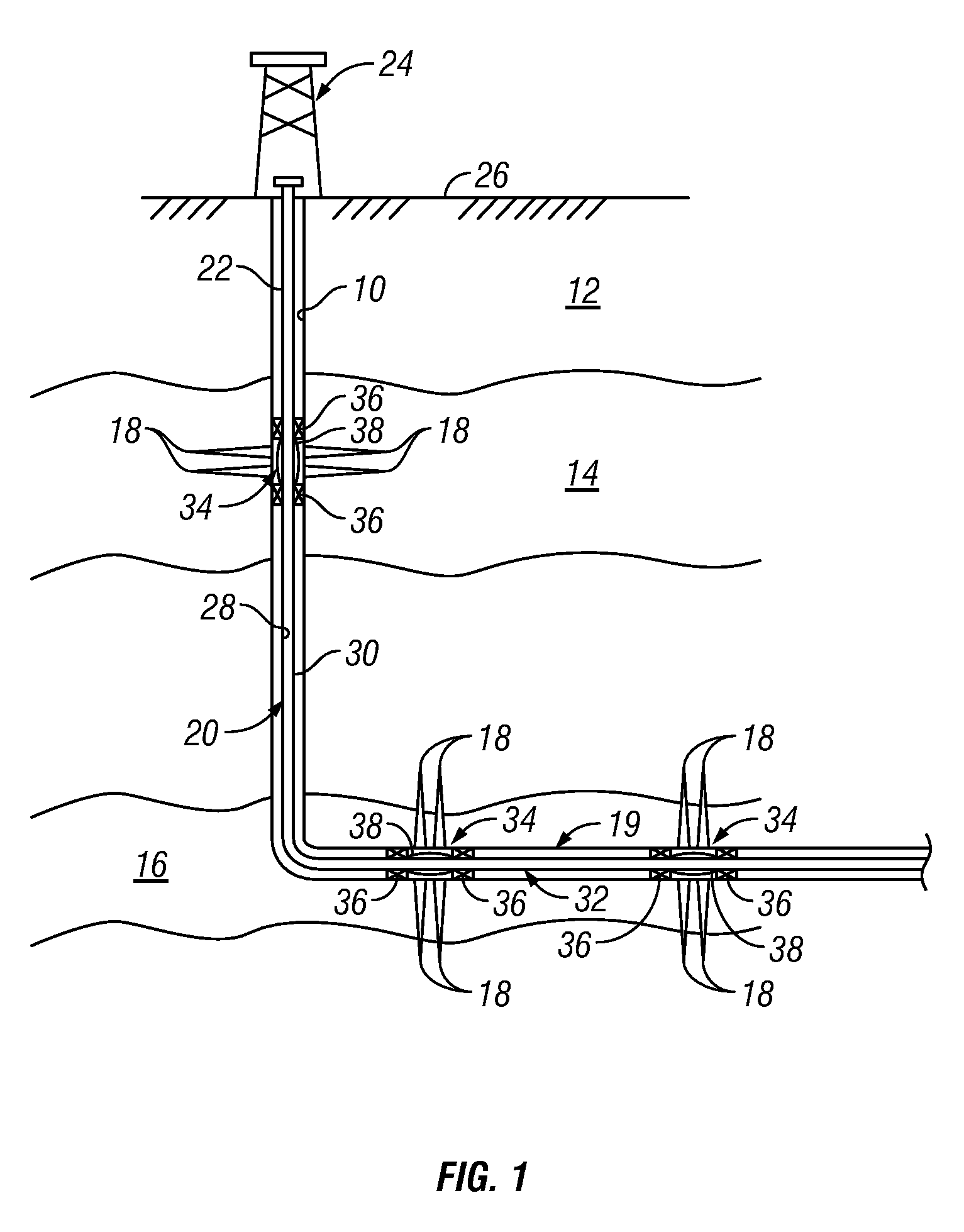

Water control device using electromagnetics

An apparatus for controlling a flow of fluid in a well includes a flow control device and a generator that generates electrical energy in response to a flow of an electrically conductive fluid. The flow control device may include an actuator receiving electrical energy from the generator, and a valve operably coupled to the actuator. The actuator may be configured to operate after a preset value for induced voltage is generated by the generator. The generator may use a pair of electrodes positioned along a flow path of the electrically conductive fluid to generate electrical energy. In one arrangement, one or more elements positioned proximate to the electrodes generate a magnetic field along the flow path of the electrically conductive fluid that causes the electrodes to generate a voltage. In another arrangement, the electrodes create an electrochemical potential in response to contact with the electrically conductive fluid.

Owner:BAKER HUGHES INC

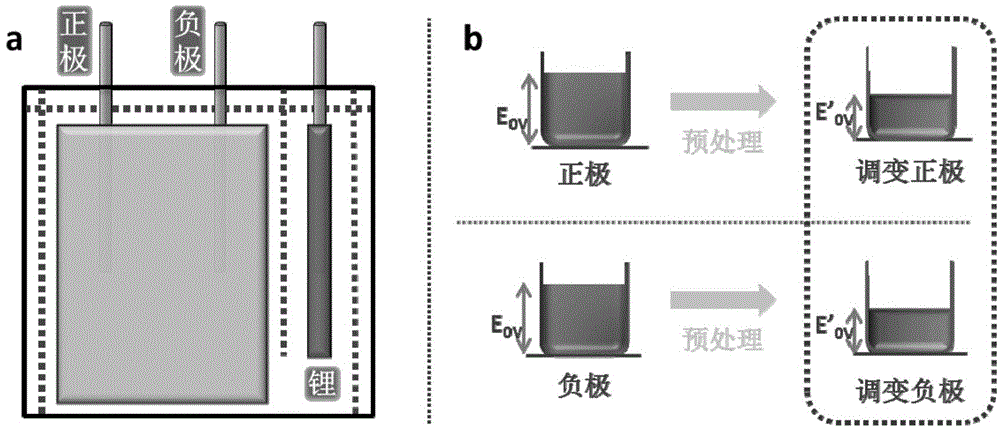

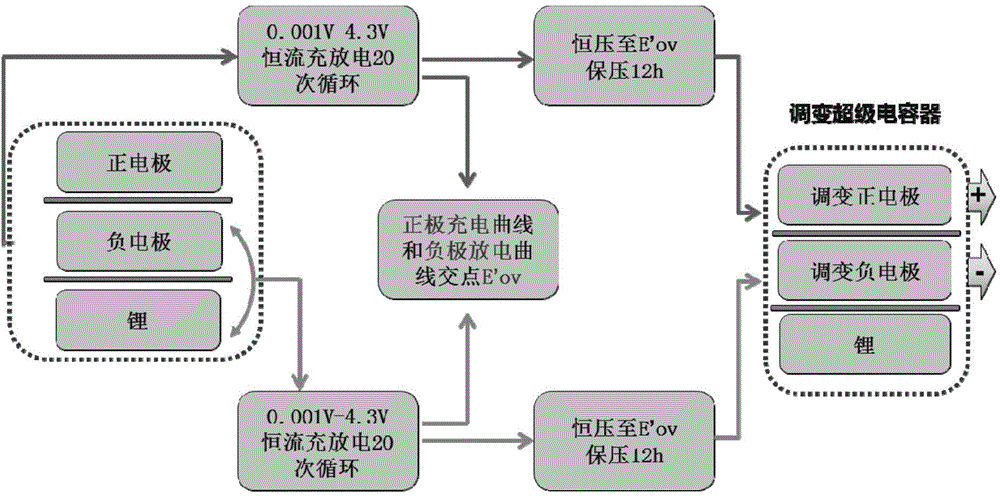

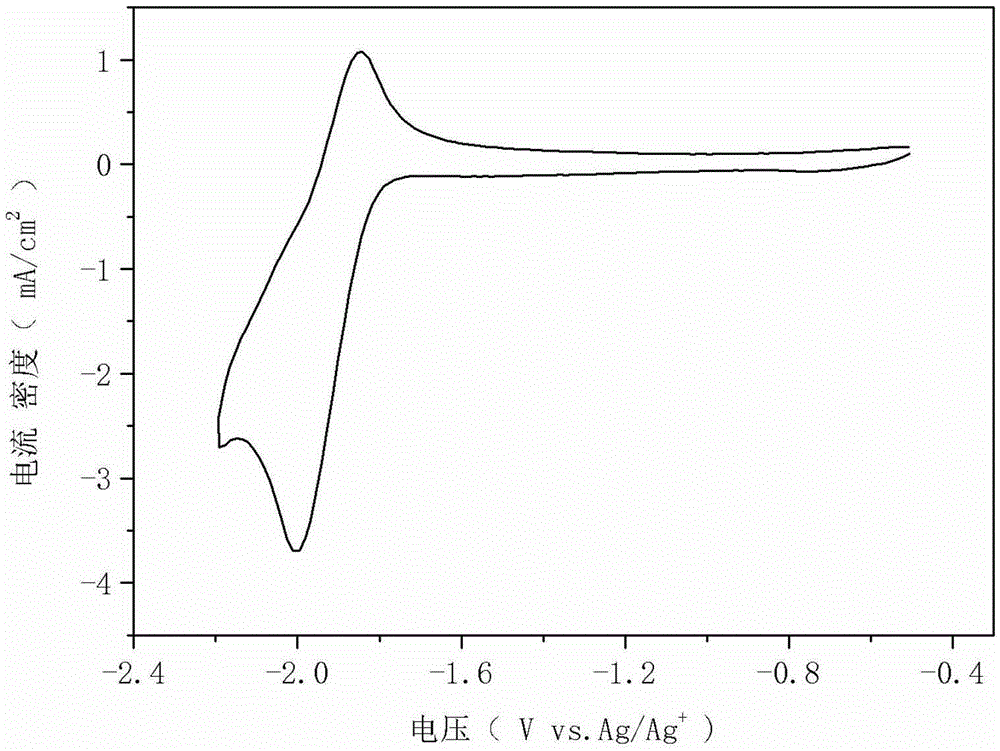

High-energy-density super capacitor and preparation method thereof

ActiveCN104916456AIncrease energy densityHas practical valueHybrid capacitor electrodesElectrolytic capacitorsHigh energyEngineering

The invention discloses a high-energy-density super capacitor and a preparation method thereof, and belongs to the field of electrochemical energy storage. Through introducing a metal lithium electrode in the assembling process of the super capacitor, the electrochemical state of an electrode material is controlled, charges are injected into the electrode material, positive and negative materials for electrochemical potential adjustment are obtained, working potential windows of positive and negative electrodes in the super capacitor are optimized, the working voltage and the specific capacity of the device are simultaneously improved, and the energy density of the super capacitor is improved. At the same time, the obtained capacitor can carry out electrochemical activation process through the metal lithium electrode to stabilize the potential windows so as to enable the super capacitor to have super long cycle life. The super capacitor and the method provided by the invention are simple in technical process, are compatible with a conventional process, and substantially improve the device performance, thereby having quite large application prospect.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for cleaning metallurgical silicon material

InactiveCN101695697ASuitable for useThe reaction electromotive force is largeCleaning using liquidsReaction rateAcid washing

The invention relates to a method for cleaning a metallurgical silicon material, which comprises the following steps: crushing a metal silicon material to below 3 centimeters; preparing acid-washing impurity removing solution, and preparing mixed acid by using hydrofluoric acid and nitric acid in a ratio of 1:12-20; soaking the crushed silicon material into the mixed acid, and stirring and cleaning the silicon material for certain time; fishing out the cleaned silicon material, cleaning the silicon material by secondary purified water, and continually turning over the silicon material; and ultrasonically cleaning the silicon material by third-grade purified water, fishing out the cleaned silicon material when the pH is equal to 7, and drying the silicon material. When the silicon material contains impurities, the electrochemical potential energy and the surface activity in an area are changed, the impurities are enriched, the reaction electromotive force of the impurities is large, the reaction rate with the acid is high, then the metal silicon material is subjected to impurity removal to a certain degree by using the principle, and the best selective corrosion effect is realized by allocating the acid matching ratio, concentration and reaction time so as to remove more impurities, realize the selective corrosion effect and meet the usage requirements of solar cells on the silicon material.

Owner:TRINA SOLAR CO LTD

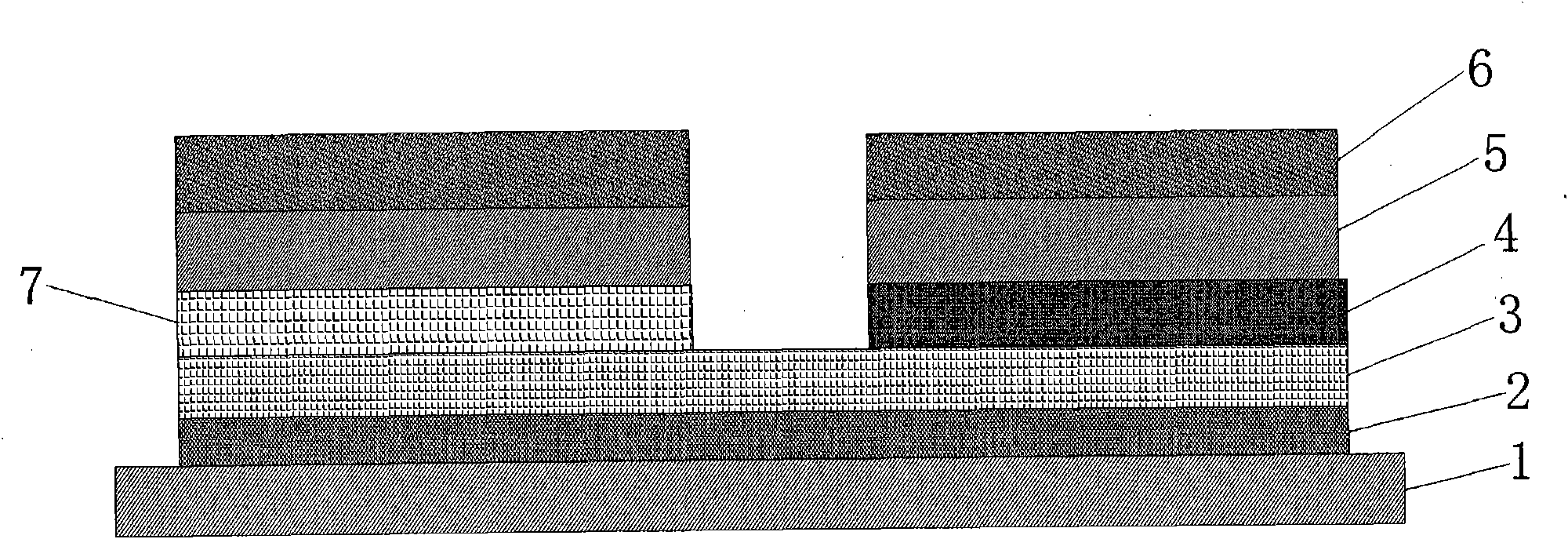

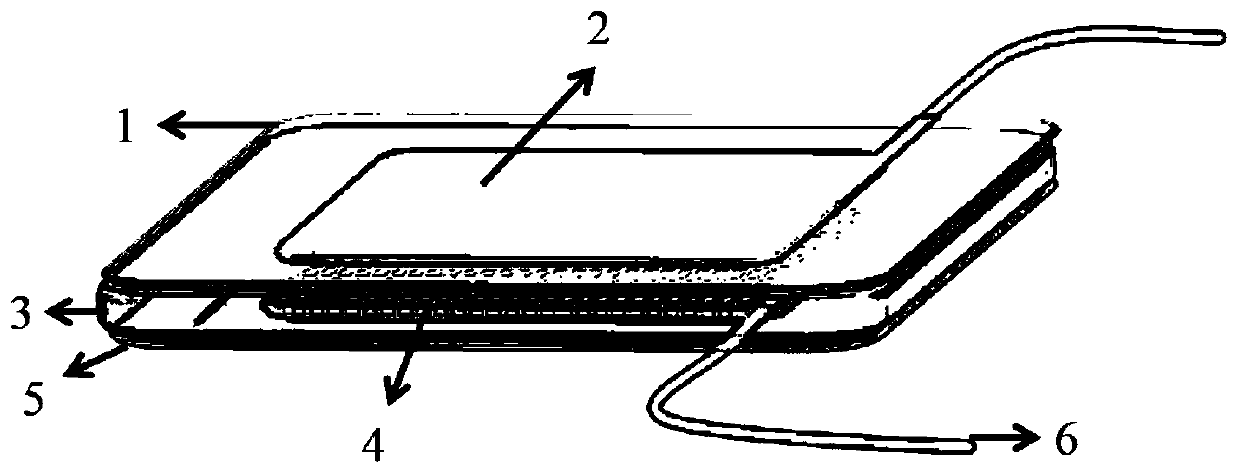

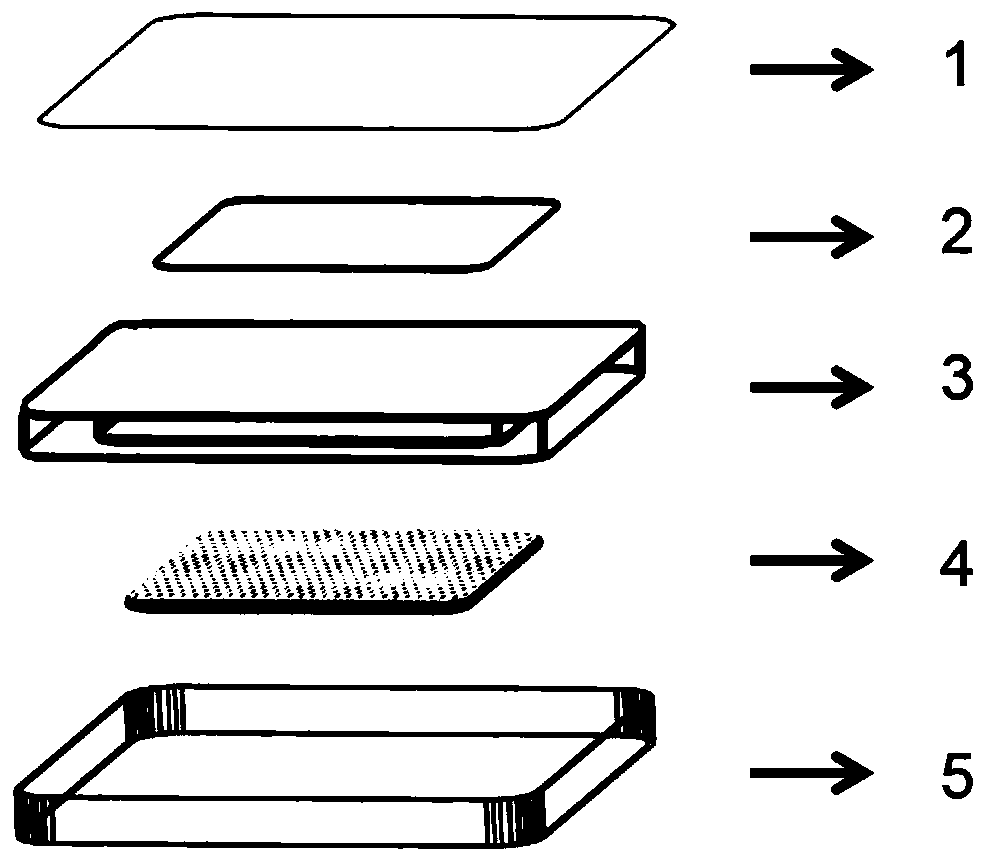

Self-electroosmosis hydrogel adhesive film

InactiveCN101862505APromote osmotic absorptionSelf-produced electroosmotic effectElectrotherapyOrganic filmAdhesive

The invention relates to a self-electroosmosis hydrogel adhesive film, which combines an electrochemical primary batter consisting of two polar materials with different electrochemical potential difference with functional active substance-containing hydrogel. A method for manufacturing the self-electroosmosis hydrogel adhesive film comprises the following steps of: printing conductive paste on an organic film to form a collector layer; producing a positive electrode layer and a negative electrode layer and printing the positive electrode layer and the negative electrode layer on the collector layer respectively; adhering all the layers on a non-woven fabric substrate; coating a conductive adhesive layer on the two electrodes respectively; and coating a functional active substance-containing hydrogel layer on the conductive adhesive layer. During use, the hydrogel adhesive film is contacted with the skin of a human body, and the two electrodes and the skin of the human body form a current loop through the hydrogel comprising a certain amount of moisture, so that permeation rate of the active substance can be increased and the adsorption rate of the skin on the active substance can be increased. The hydrogel adhesive film has the advantages of overcoming the defects that a power supply needs to be added, the film cannot be used at any time and the cost is high in the conventional ion permeation technique, and effectively increasing the permeation rate of the functional active substance, along with simple structure, low cost, convenient storage and carrying and convenient use.

Owner:SICHUAN UNIV +1

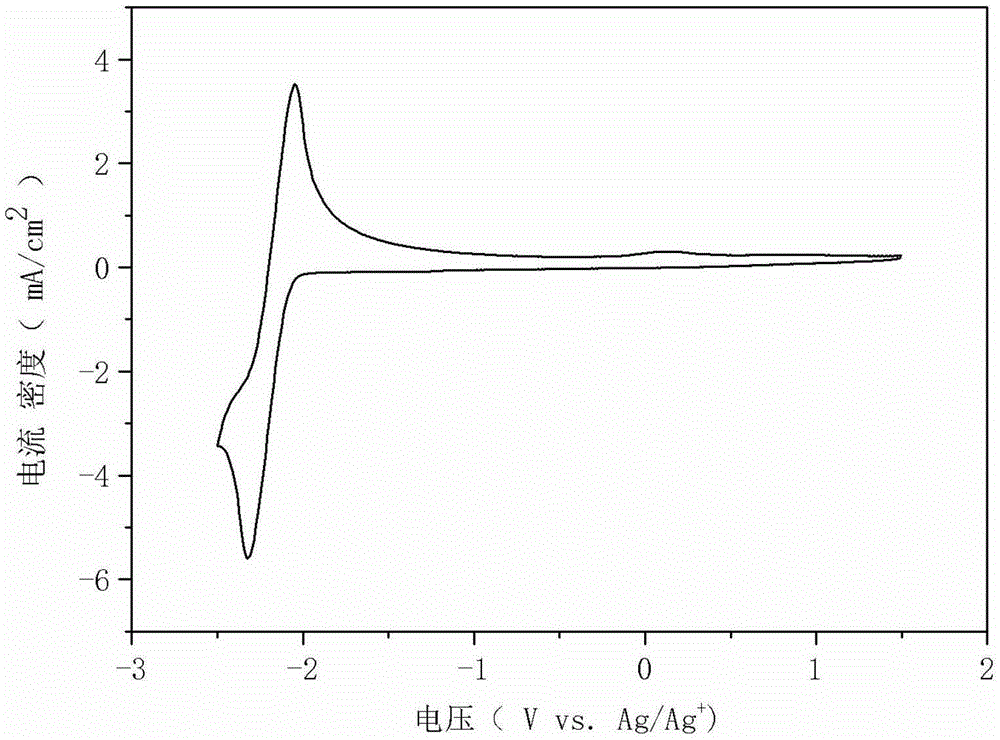

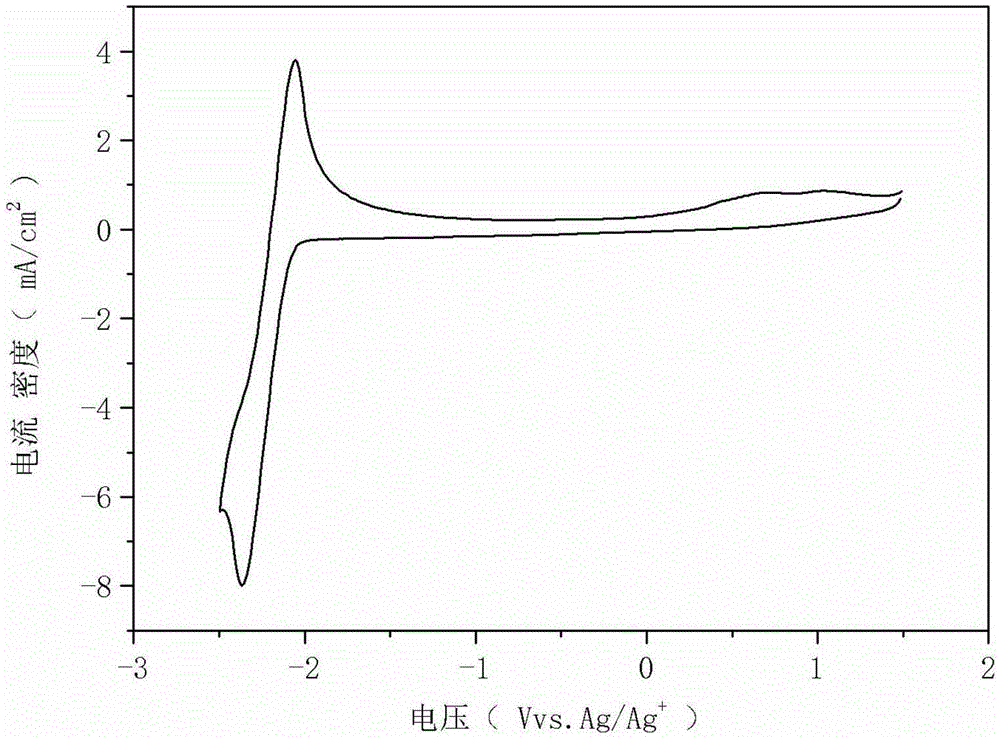

Organic phase electrolyte and application thereof in negative electrode of redox flow battery

InactiveCN106654332ALow electrochemical potentialImprove electrochemical performanceRegenerative fuel cellsTetrafluoroborateDiethyl ether

The invention discloses an organic phase electrolyte and an application thereof in a negative electrode of a redox flow battery. The organic phase electrolyte consists of active materials, a supporting electrolyte and an organic solvent, wherein the active materials are diphenyl ketone and a derivative thereof, anthrone and a derivative thereof, or dibenzoyl methane and a derivative thereof; the supporting electrolyte is selected from tetraethylammonium hexafluorophosphate, tetraethylammonium tetrafluoroborate, tetrabutylammonium hexafluorophosphate or tetrabutylammonium tetrafluoroborate; and the organic solvent is selected from acetonitrile, tetrahydrofuran, propylene carbonate, ethylene carbonate, dimethyl sulfoxide, dimethylformamide, glycol dimethyl ether or ethylene glycol diethyl ether. The organic phase electrolyte disclosed by the invention has relatively low electrochemical potential and high electrochemical property; when the organic phase electrolyte is used as the negative electrode electrolyte of the redox flow battery for assembling an organic phase redox flow battery, relatively high open-circuit voltage can be realized, so that the energy density of the battery can be improved; and meanwhile, the capacity fading of the battery can be lowered, so that the cycle life of the battery can be prolonged.

Owner:TIANJIN UNIV

Pulsed voltage electrospray ion source and method for preventing analyte electrolysis

InactiveUS20100072394A1Spectrometer circuit arrangementsMaterial analysis by optical meansElectrolysisAnalyte

An electrospray ion source and method of operation includes the application of pulsed voltage to prevent electrolysis of analytes with a low electrochemical potential. The electrospray ion source can include an emitter, a counter electrode, and a power supply. The emitter can include a liquid conduit, a primary working electrode having a liquid contacting surface, and a spray tip, where the liquid conduit and the working electrode are in liquid communication. The counter electrode can be proximate to, but separated from, the spray tip. The power system can supply voltage to the working electrode in the form of a pulse wave, where the pulse wave oscillates between at least an energized voltage and a relaxation voltage. The relaxation duration of the relaxation voltage can range from 1 millisecond to 35 milliseconds. The pulse duration of the energized voltage can be less than 1 millisecond and the frequency of the pulse wave can range from 30 to 800 Hz.

Owner:UT BATTELLE LLC

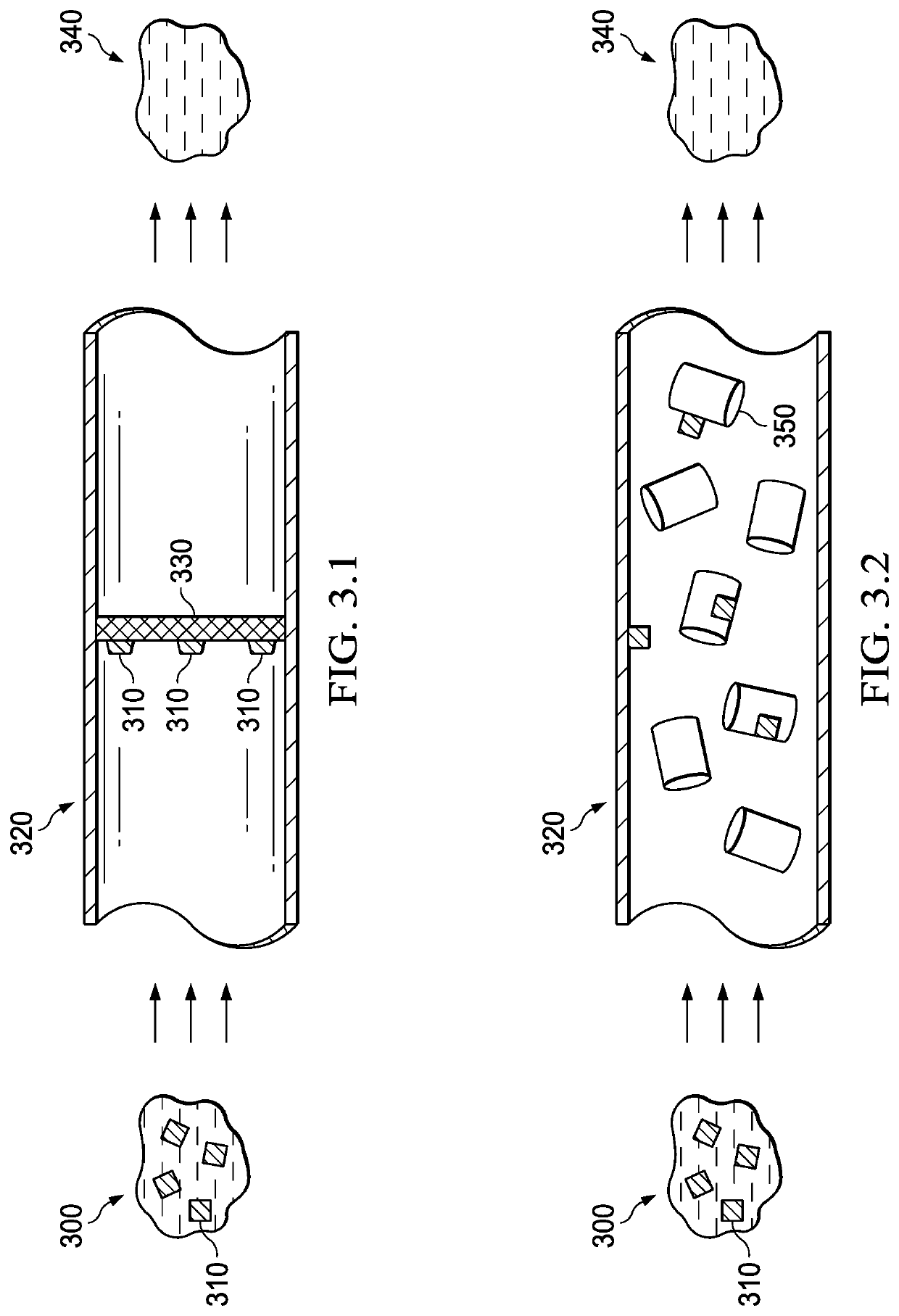

Flow-through consumable anodes

ActiveUS20130112563A1Increase surface areaAvoid disintegrationCellsElectroforming processesDissolutionConcentration gradient

Anode applicators include consumable anodes, that can be operated in a non-stationary mode and are insensitive to orientation, are used in selective plating / brush electrodeposition of coatings or free-standing components. The flow-through dimensionally-stable, consumable anodes employed are perforated / porous to provide relatively unimpeded electrolyte flow and operate at low enough electrochemical potentials to provide for anodic metal / alloy dissolution avoiding undesired anodic reactions. The consumable anodes include consumable anode material(s) in high surface area to reduce the local anodic current density. During electroplating, sufficient electrolyte is pumped through the consumable anodes at sufficient flow rates to minimize concentration gradient and / or avoid the generation of chlorine and / or oxygen gas and / or undesired reaction such as the anodic oxidation of P-bearing ions in the electrolyte. The active consumable anode material(s) can have a microstructure which is fine-grained and / or amorphous to ensure a uniform anodic dissolution.

Owner:INTEGRAN TECH

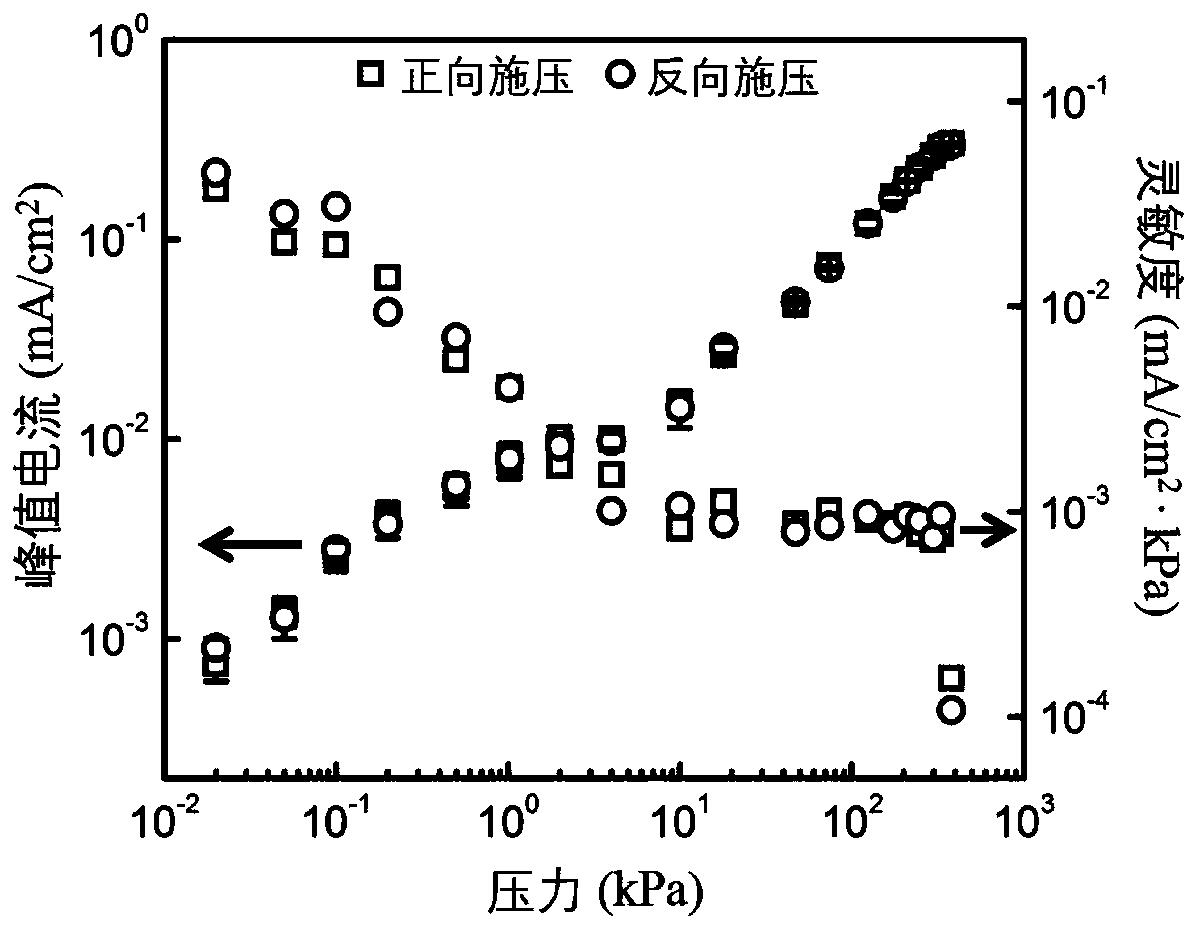

Wearable pressure sensor based on carbon nanotube film and production method thereof

ActiveCN110123271ALarge working rangeHigh sensitivityForce measurement using piezo-electric devicesDiagnostic recording/measuringCarbon nanotubePolymer thin films

The invention belongs to the technical field of a human body wearable pressure sensor, and discloses a wearable pressure sensor based on a carbon nanotube film and a production method thereof. The pressure sensor comprises a sensing mechanism comprising a sealed box, a porous ceramic plate, a working electrode, a counter electrode and a flexible polymer film, the porous ceramic plate is provided with a groove, and the counter electrode is disposed in the groove; the working electrode is disposed on the porous ceramic plate and covers the groove; the groove is used for accommodating an electrolyte; the flexible polymer film is disposed on the sealed box for sealing the porous ceramic plate, and the working electrode and the counter electrode are sealed in the sealed box; The pressure sensoruses the pressure of the carbon nanotube film to induce the change characteristic of the electrochemical potential to convert the pressure energy to electrical energy, and realizes the real-time monitoring of the pressure to-be-measured. The wearable pressure sensor has good environmental adaptability, can be applied to water environment, and has good accuracy.

Owner:HUAZHONG UNIV OF SCI & TECH

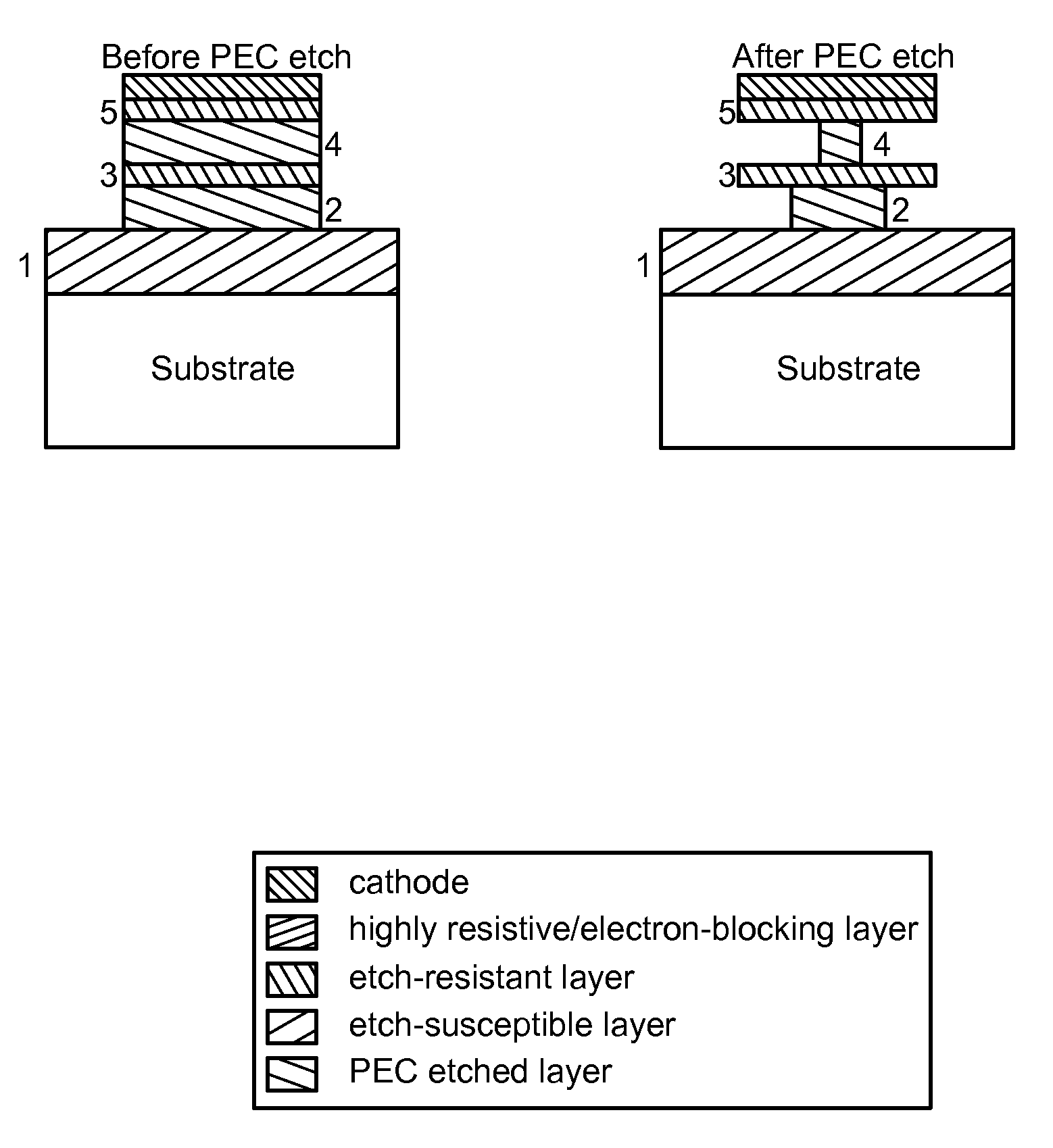

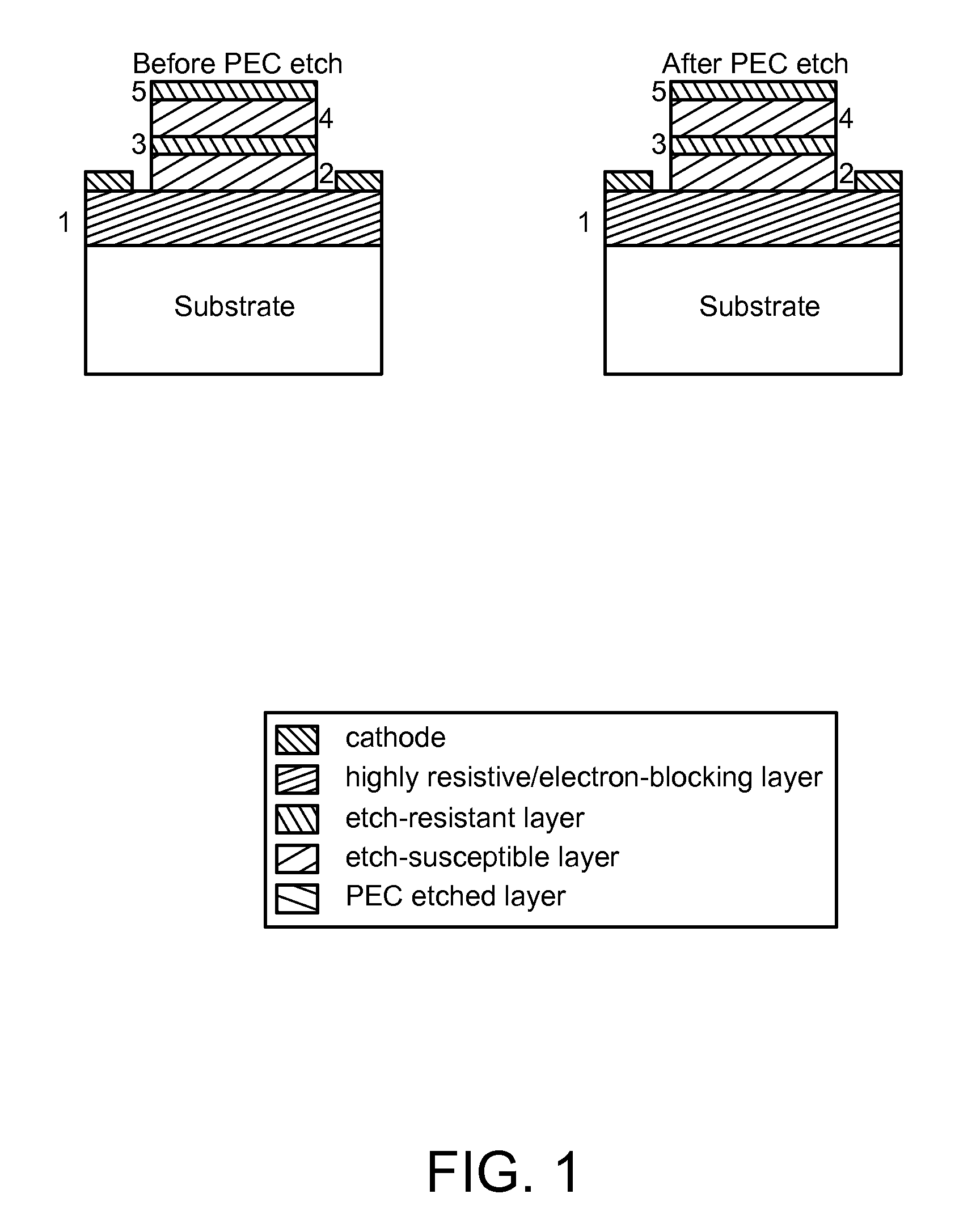

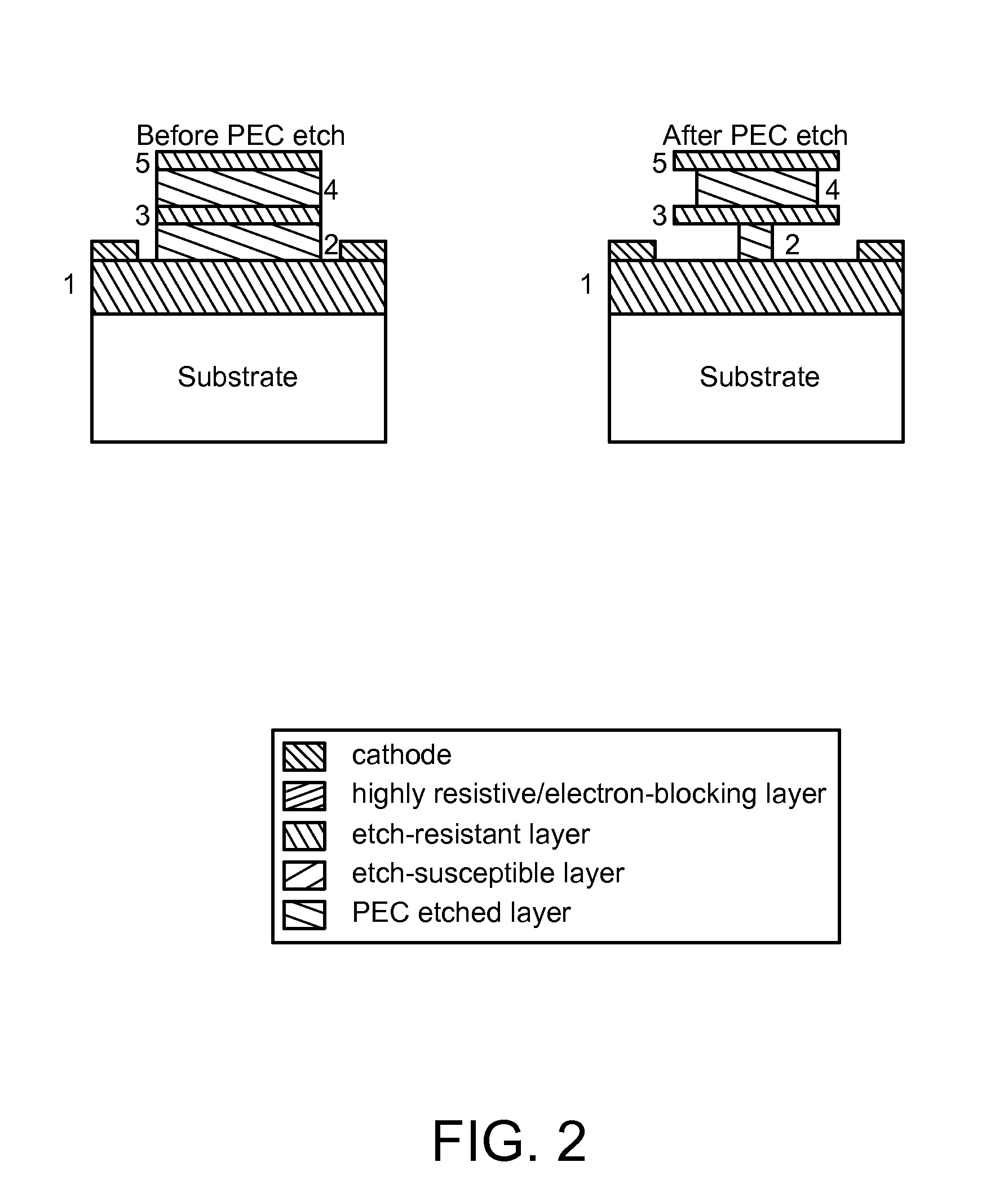

Control of photoelectrochemical (PEC) etching by modification of the local electrochemical potential of the semiconductor structure relative to the electrolyte

ActiveUS7550395B2Semiconductor/solid-state device manufacturingNanoopticsElectrical resistance and conductanceSemiconductor structure

A method for locally controlling an electrical potential of a semiconductor structure or device, and hence locally controlling lateral and / or vertical photoelectrochemical (PEC) etch rates, by appropriate placement of electrically resistive layers or layers that impede electron flow within the semiconductor structure, and / or by positioning a cathode in contact with specific layers of the semiconductor structure during PEC etching.

Owner:RGT UNIV OF CALIFORNIA

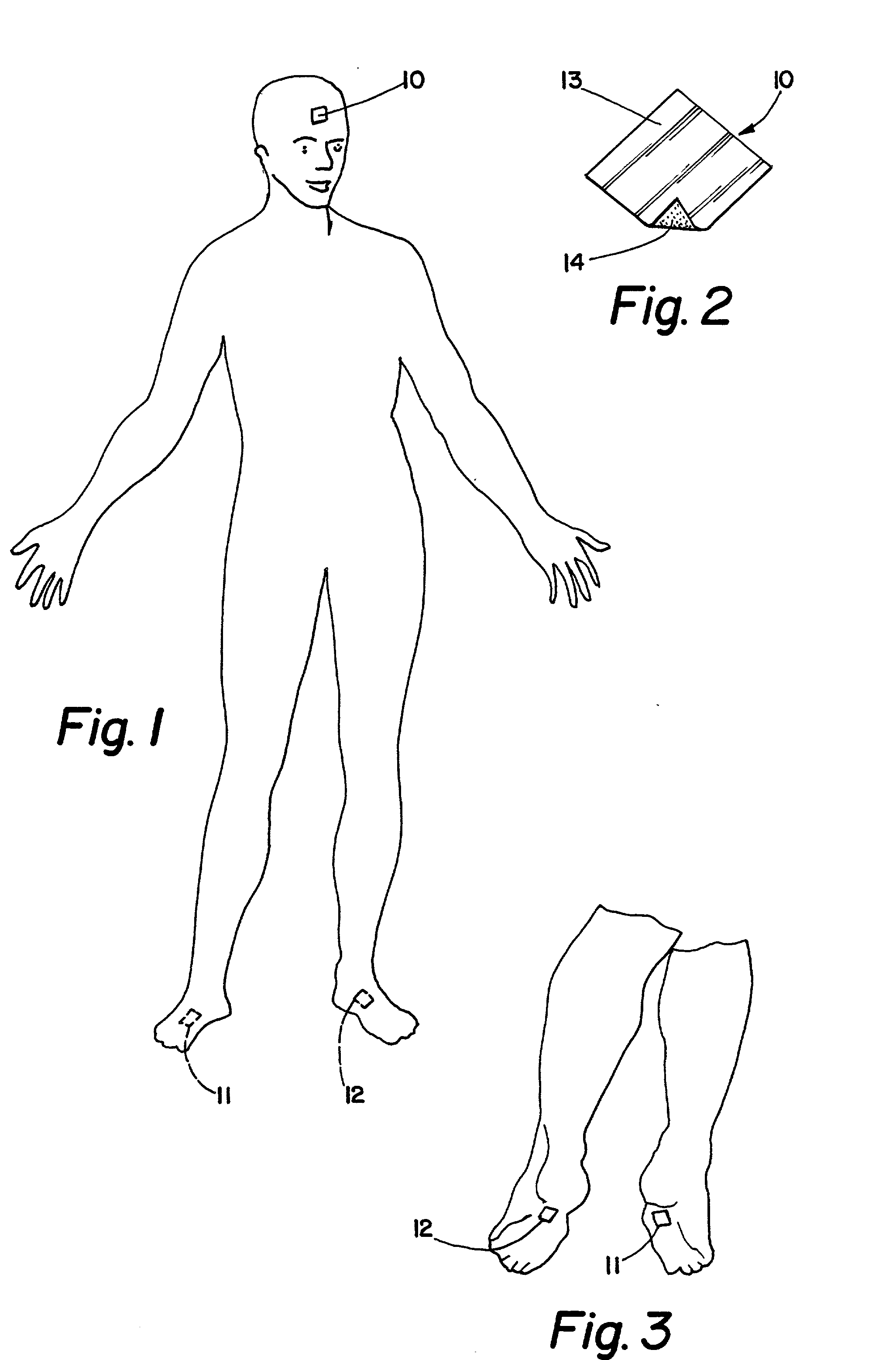

Electrical youth current cure

A device for inducing an electric current in the body to reverse and cure aging and disease. The current may be induced by means of the electrochemical potential between aluminum foil tabs (10, 11 & 12) on the forehead and feet and gold and silver dental work.

Owner:DRAKE GENE F

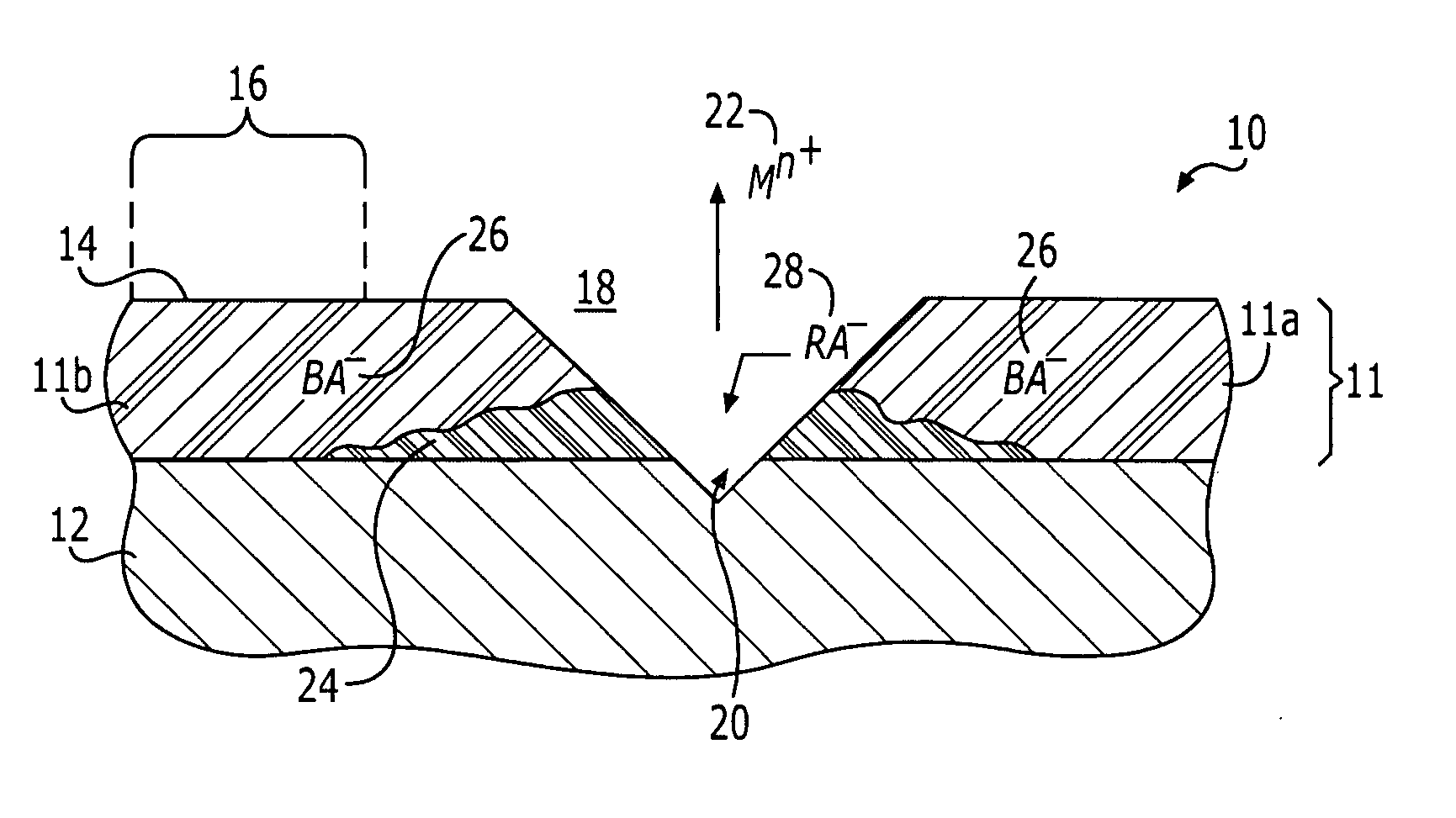

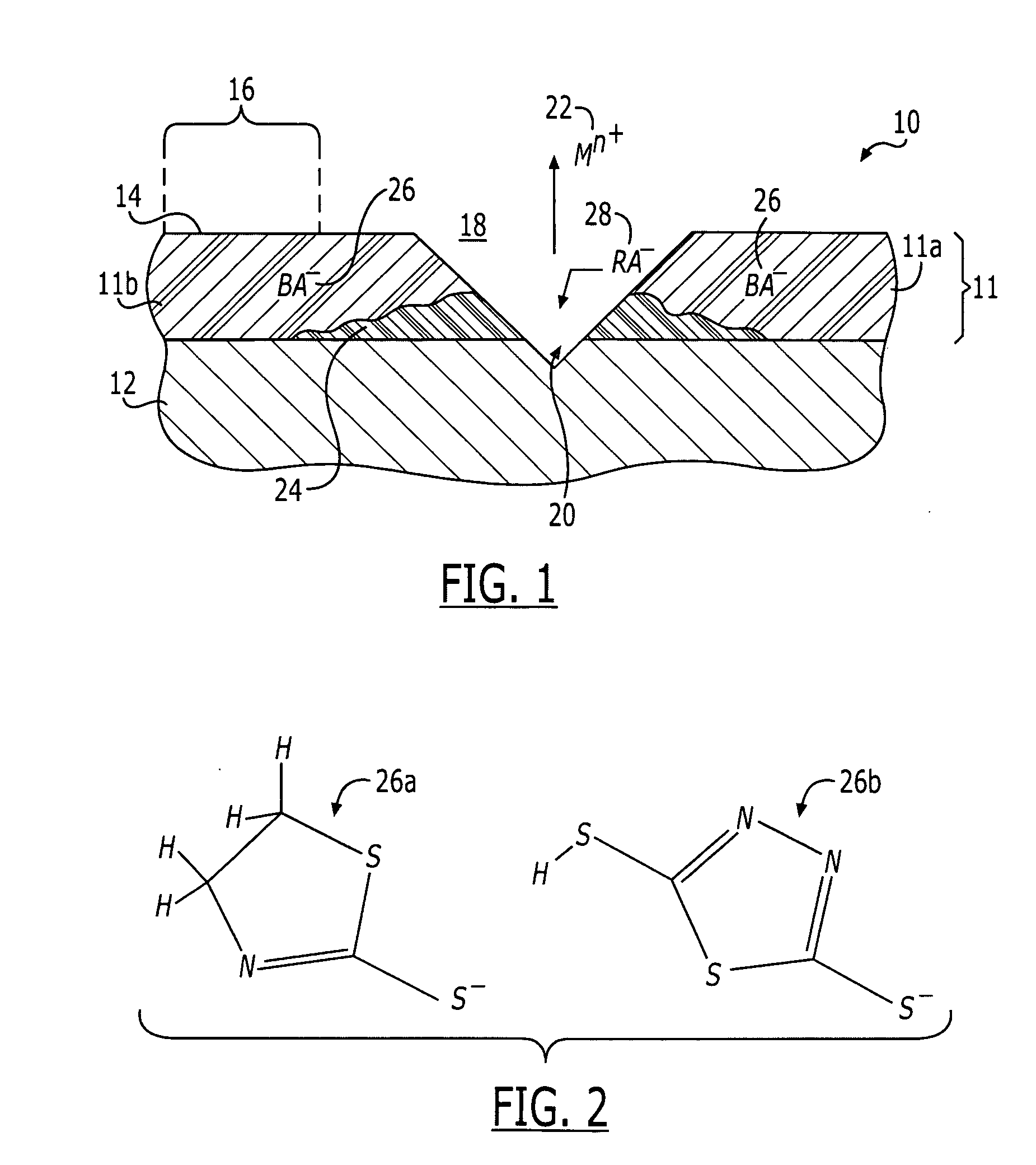

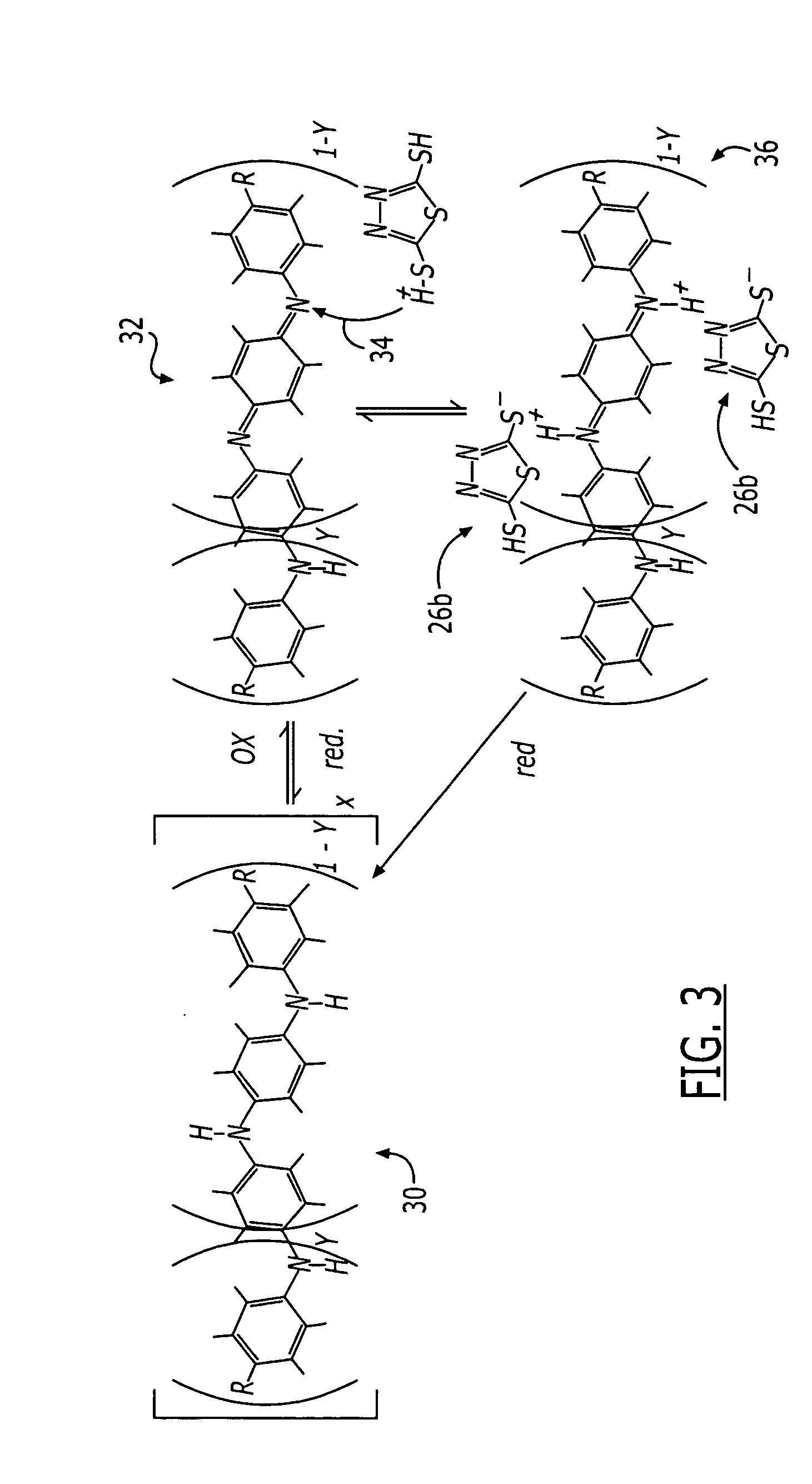

Composition for the controlled release of inhibitors for corrosion, biofouling, and scaling

InactiveUS20050201890A1Prevent corrosion of the substratePrevent scalingAnti-corrosive paintsThin material handlingDopantControlled release

A polymer composite structure, wherein the composition releases an anionic dopant upon application of an electrochemical potential, such as when in contact with a metallic substrate in a corrosive environment. The composite actively inhibits corrosion at the point of contact of the composite with a metal substrate by release of “active” or “smart” corrosion inhibitors which migrate to the corrosion area. Composites having anionic dopants having biocidal or scale-inhibiting properties may be used to inhibit biofouling and scaling wherein the dopants are released upon application of a electrochemical potential.

Owner:THE BOEING CO

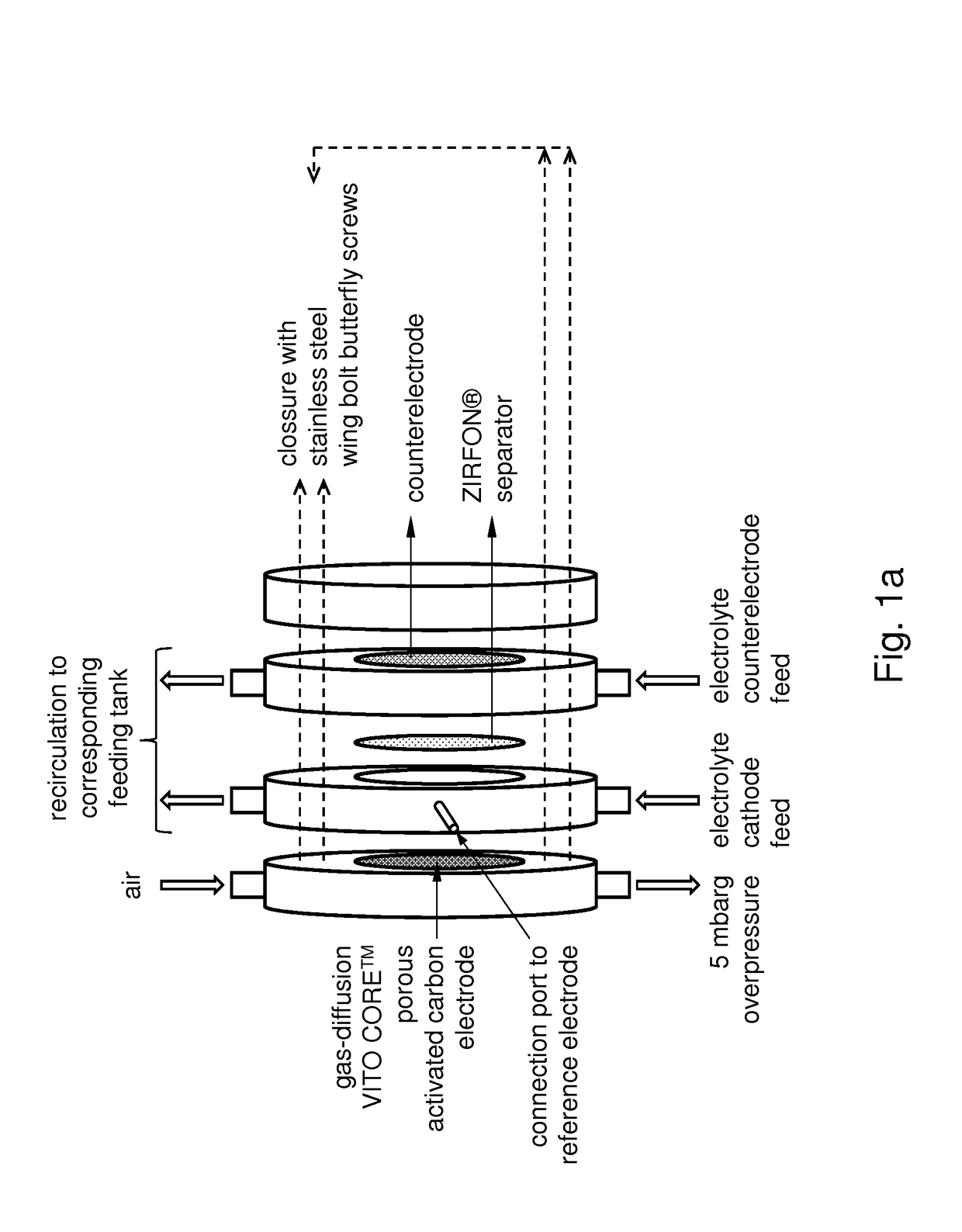

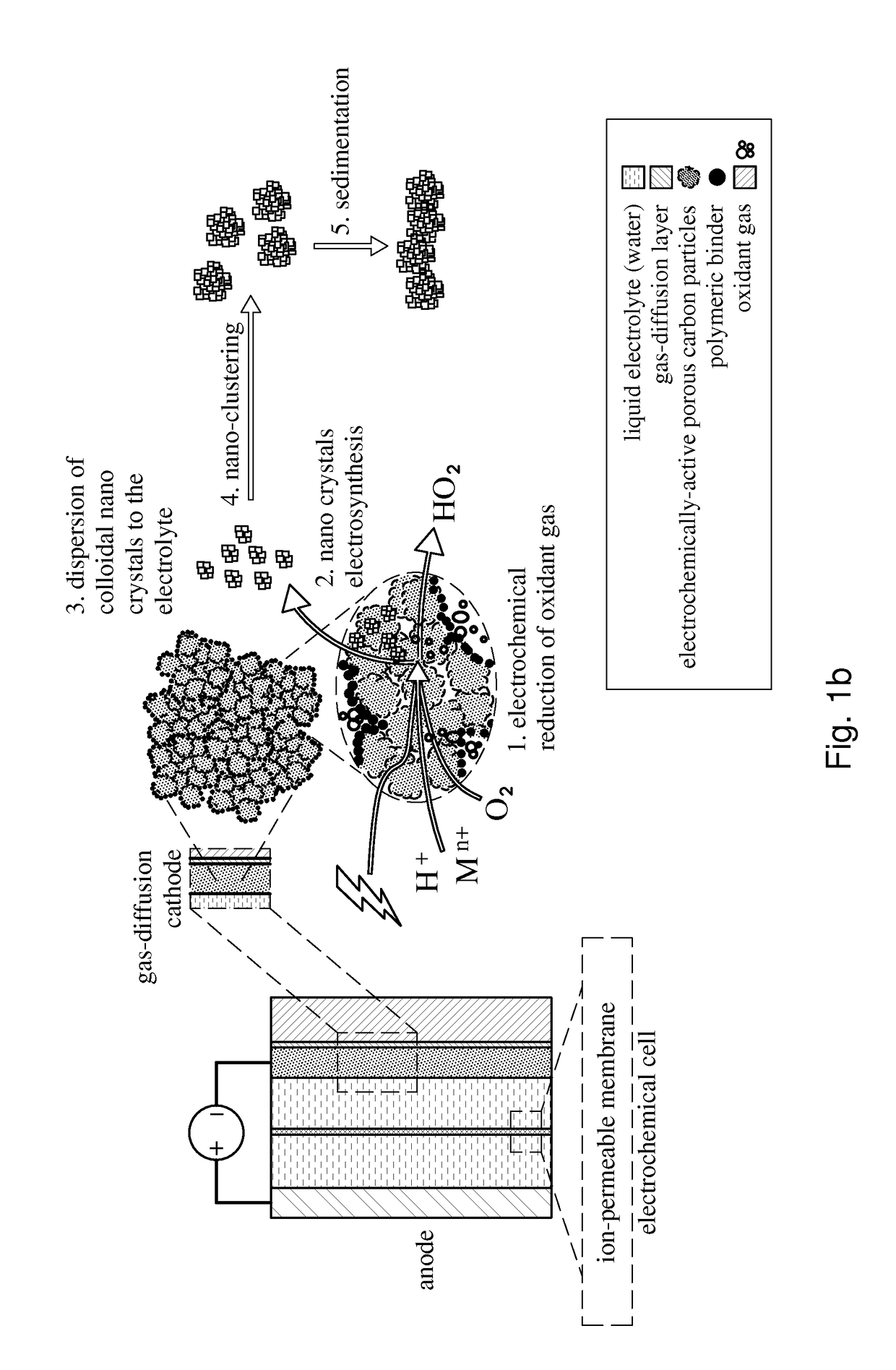

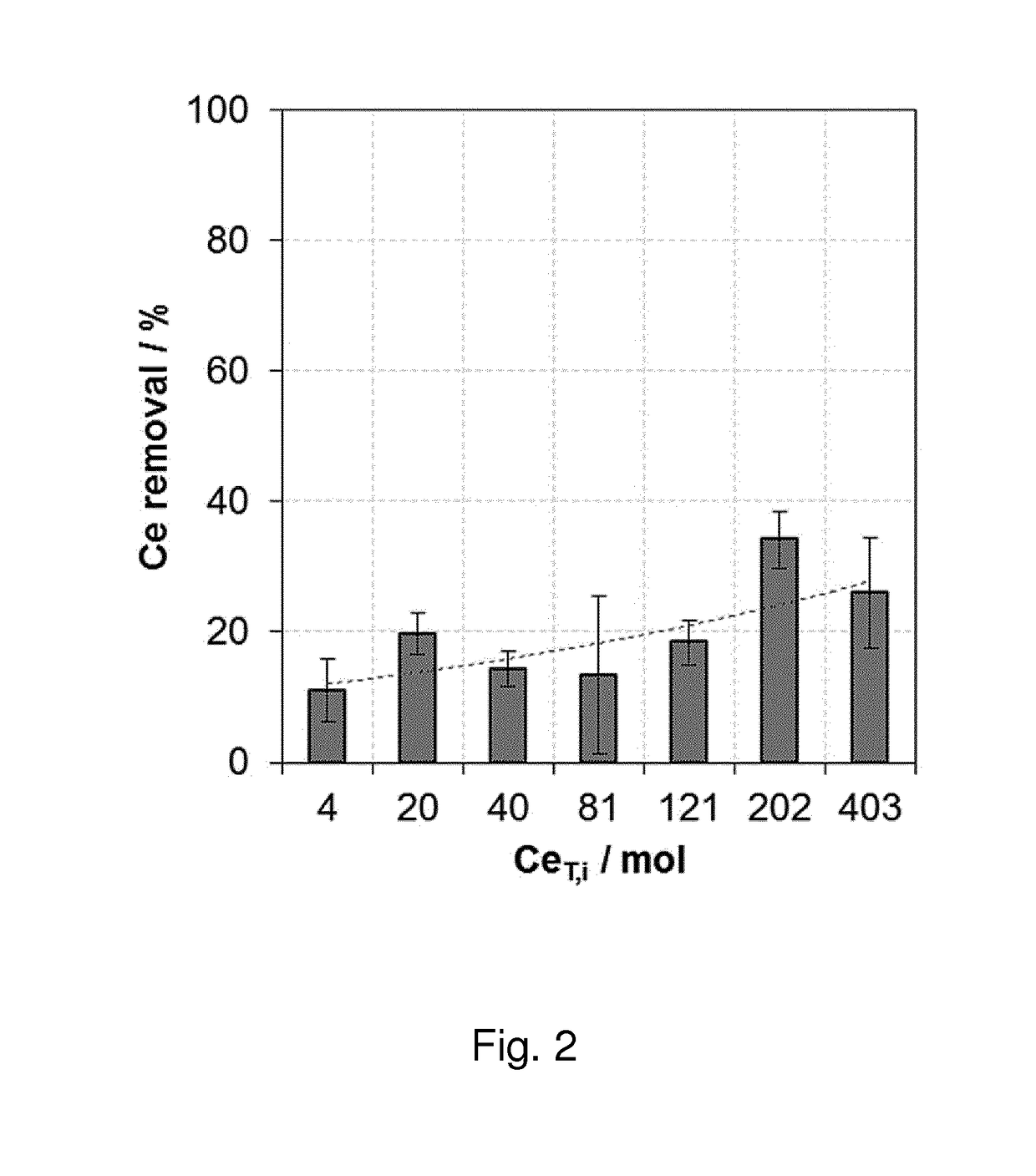

An electrochemical process for preparing a compound comprising a metal or metalloid and a peroxide, ionic or radical species

An electrochemical process is for recovering a metal element or a metalloid element or a mixture of two or more thereof from at least one water soluble precursor compound containing the metal element or a metalloid element or two or more thereof, in the form of one or more nano particles, in particular nano crystals of at least one reaction product. The process includes supplying the water soluble precursor compound to a water-based catholyte of a cathode compartment of an electrochemical cell, equipped with a cathode containing a gas diffusion electrode, adjusting the pH of the catholyte, supplying at least one oxidant gas to the gas diffusion electrode, and subjecting the cathode to an electrochemical potential to cause reduction of the at least one oxidant gas.

Owner:VLAAMSE INSTELLING VOOR TECHNOLOGISCH ONDERZOEK NV VITO

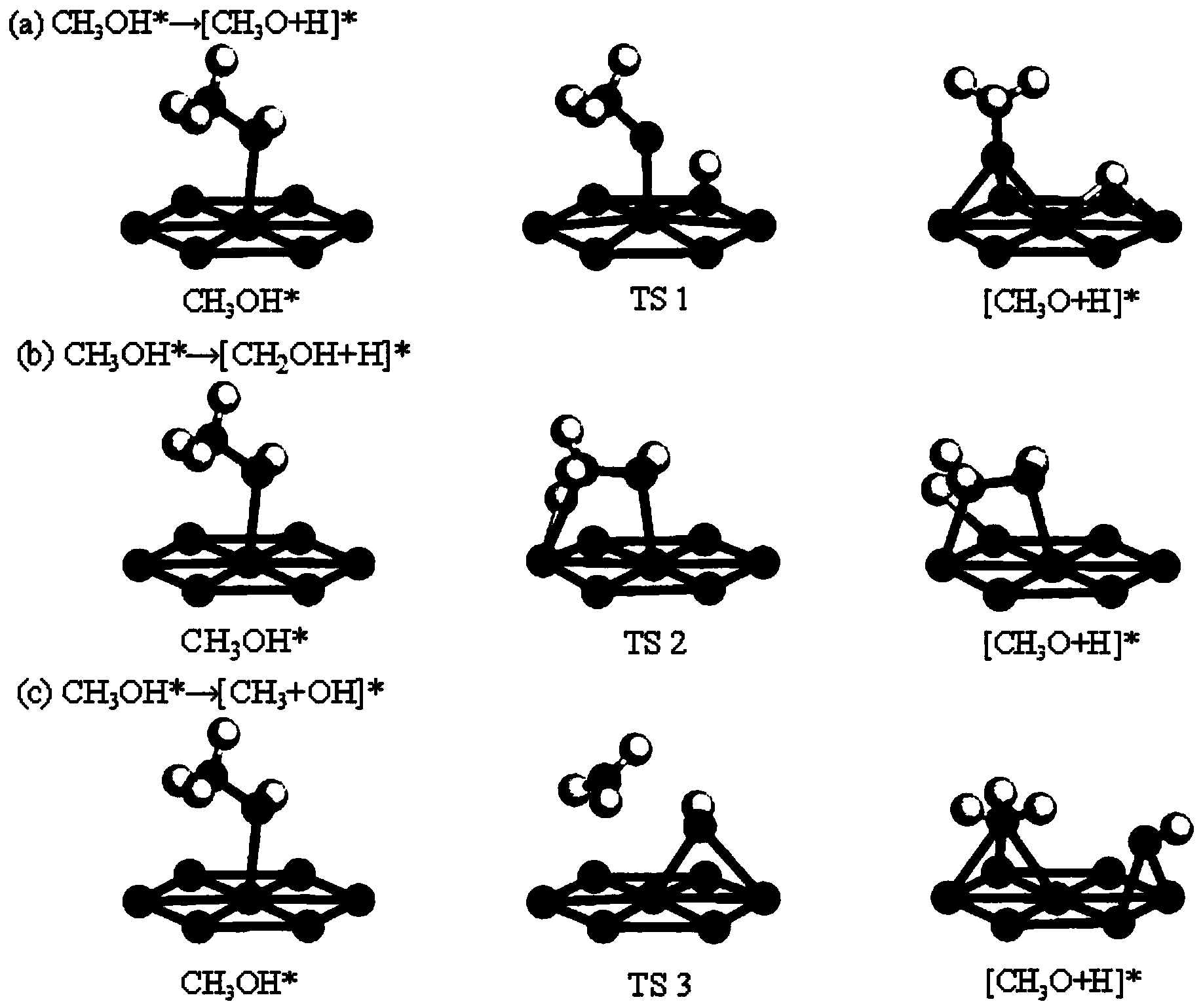

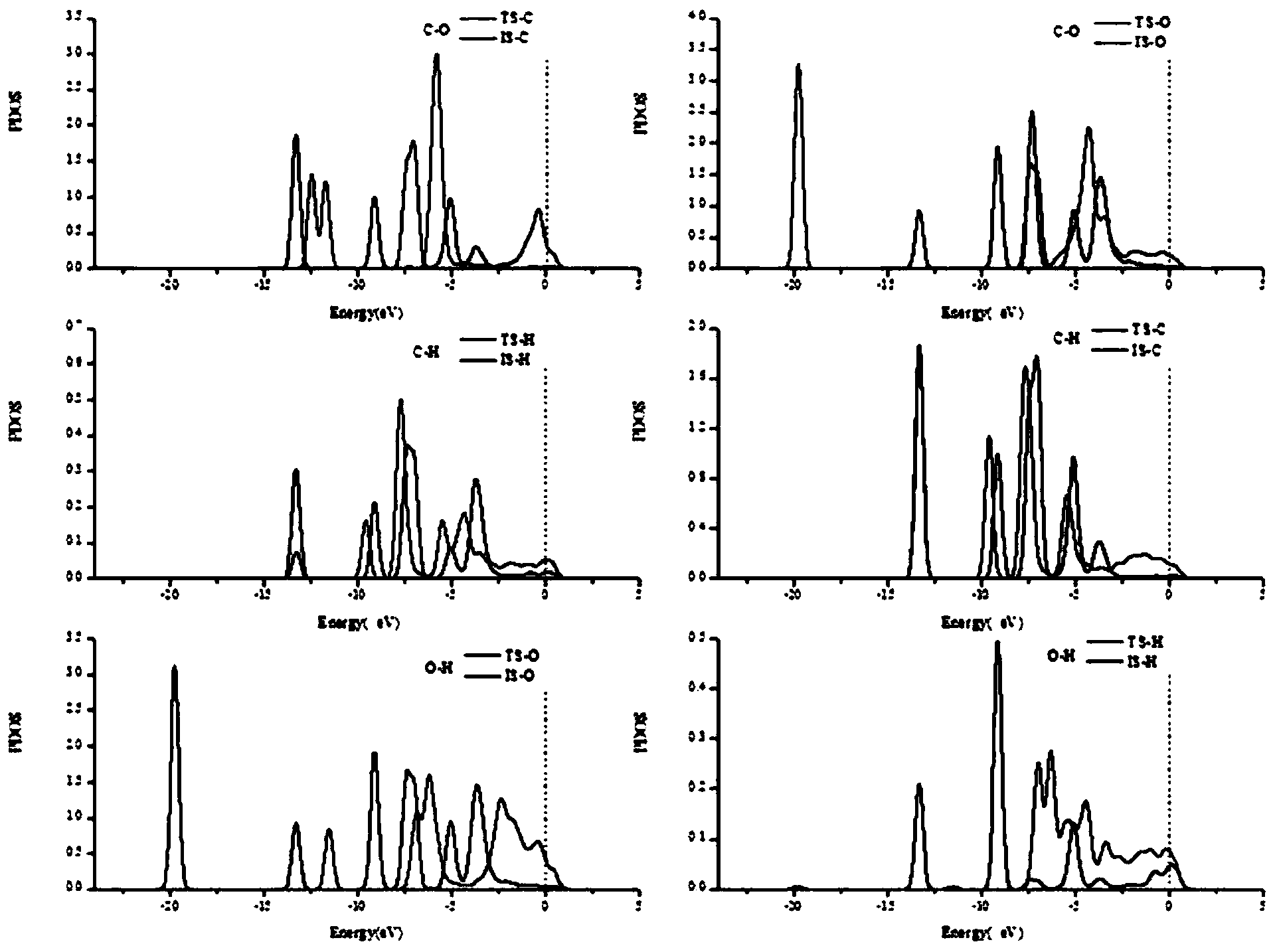

Method for testing activity of methanol fuel cell anode material

InactiveCN103869045ASolve impossible puzzlesEasy to buildMaterial analysisPartial density of statesQuantum chemistry

The invention discloses a method for testing activity of a methanol fuel cell anode material. The method is characterized in that the activity of the cell anode material is tested through special quantum chemistry calculation simulation for improving the accuracy of judging the activity and the efficiency of a cell. The method comprises the following steps: firstly, analyzing an adsorption structure, thermodynamics and kinetics parameters of an elementary reaction, and the like by researching the adsorption of the methanol on the surface of the anode material and three broken bond reaction principles of methanol; and secondly, performing comparative analysis on an energy barrier obtained by using calculation, a PDOS (Partial Density Of States) graph and an electrochemical potential to judge the activity of a catalyst. The activity of the methanol fuel cell anode material is conveniently, rapidly and accurately researched by using the method; resources are saved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com