Patents

Literature

427results about "Spectrometer circuit arrangements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

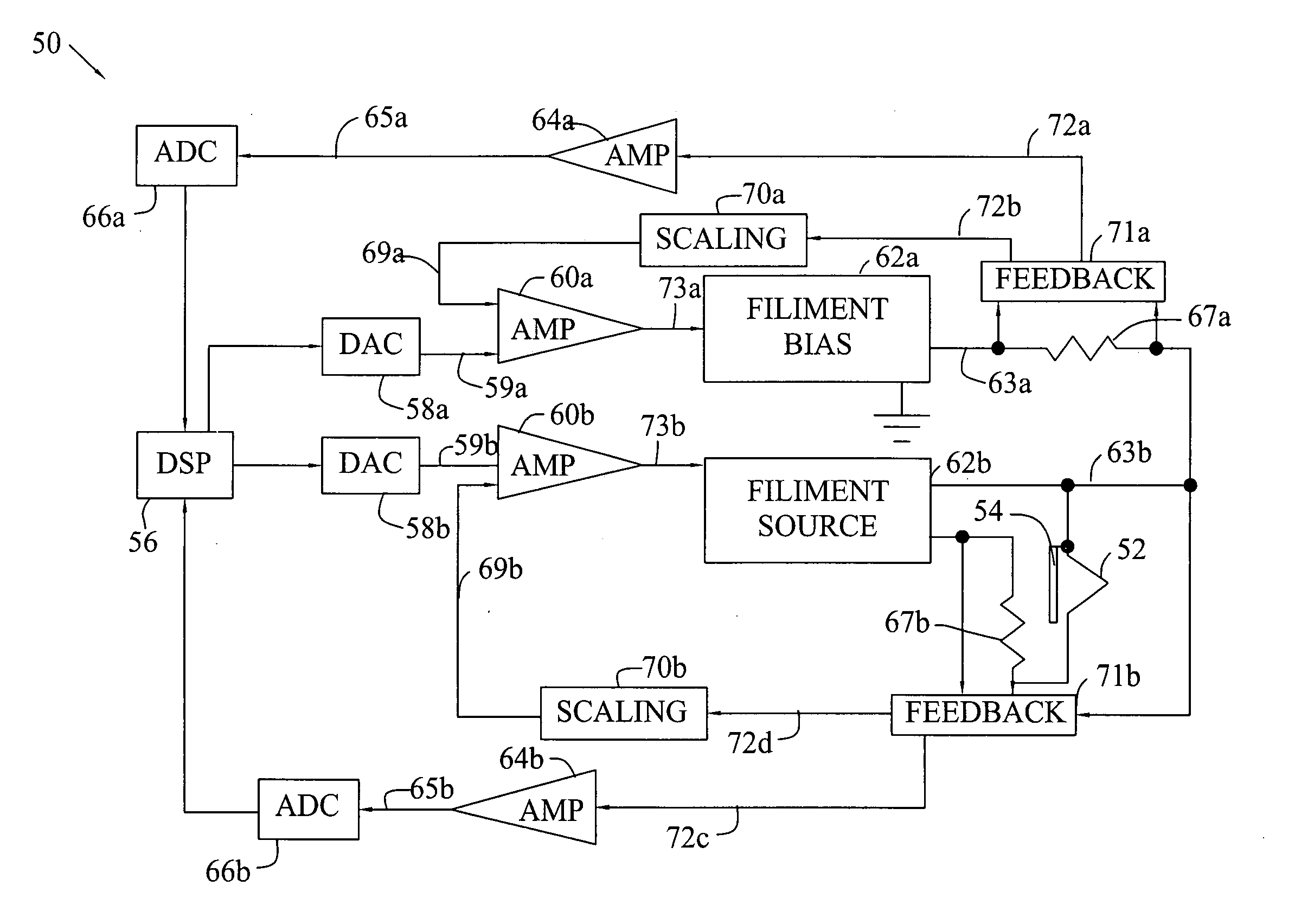

Programmed electron flux

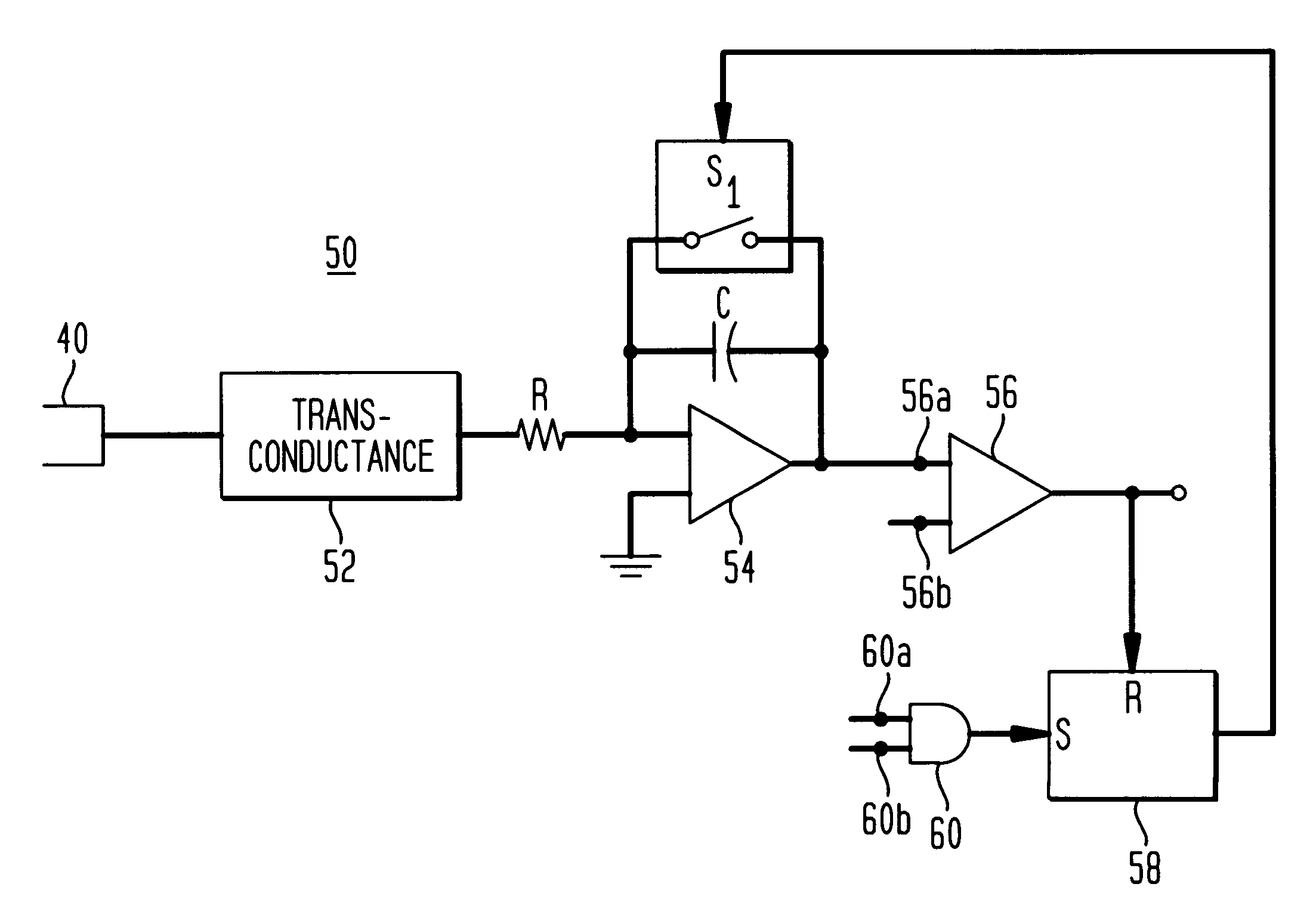

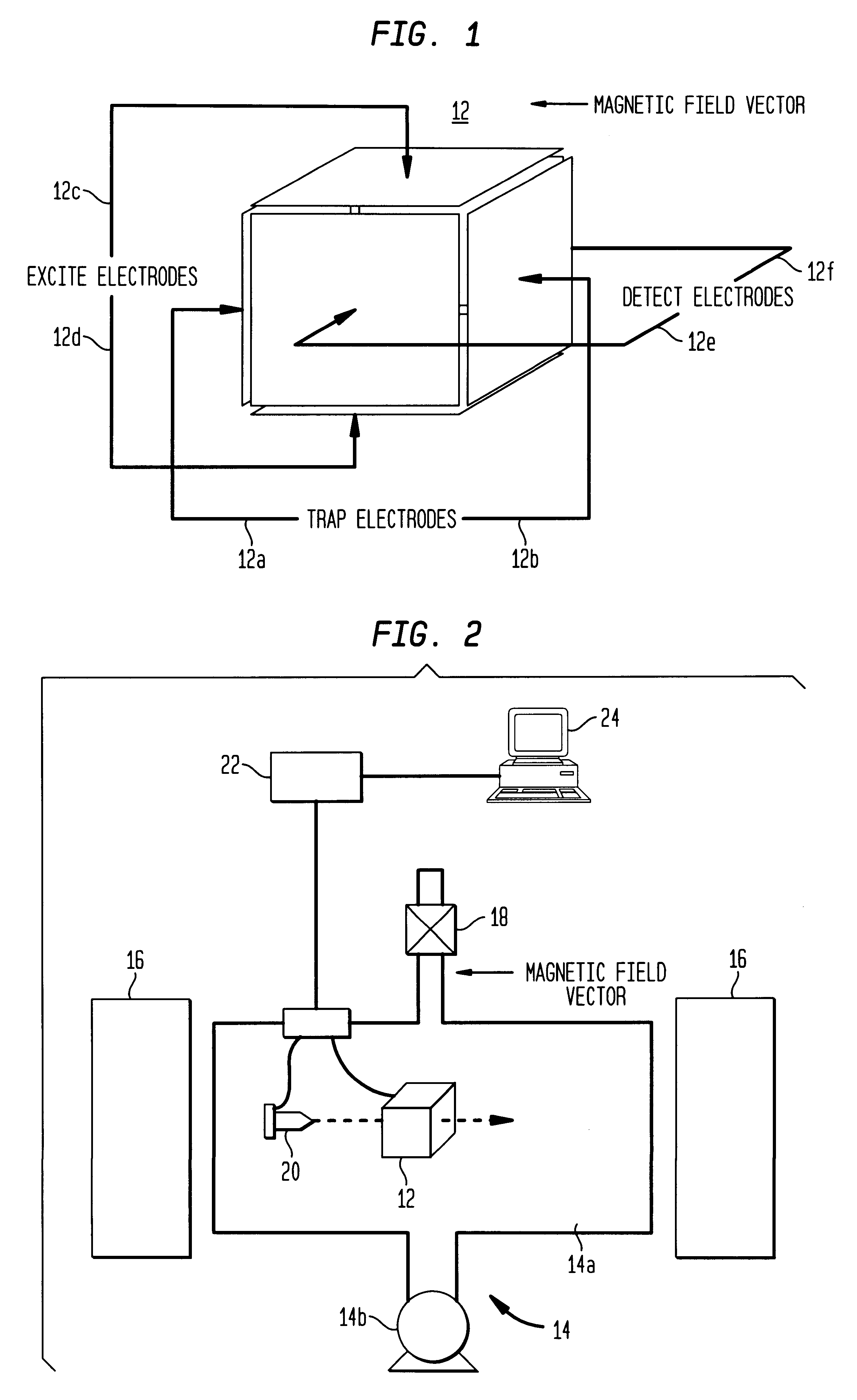

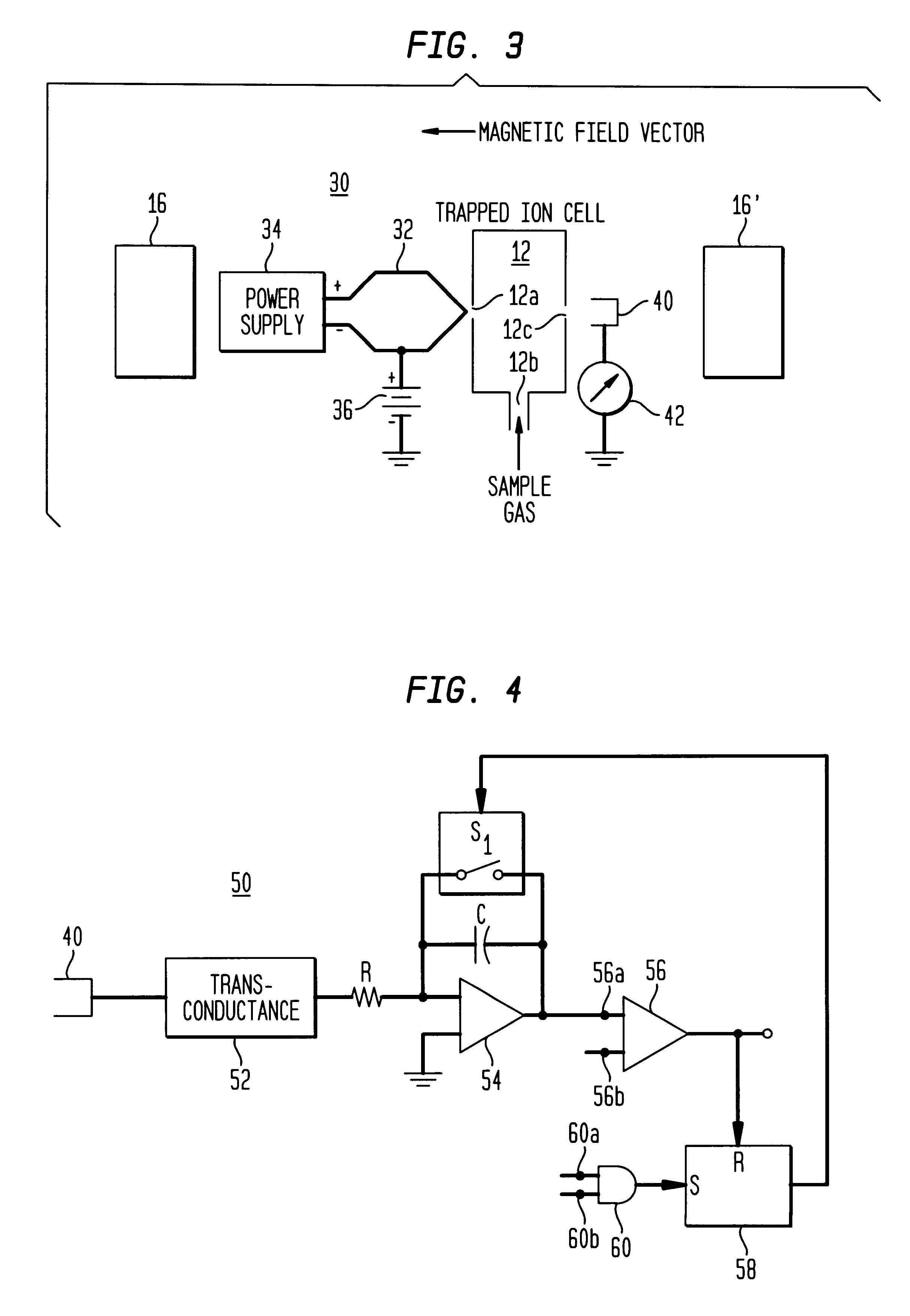

InactiveUS6255648B1Spectrometer circuit arrangementsStability-of-path spectrometersElectron fluxIonization

A quantity of electrons that will be used in the ionization event in an FTICR MS is preprogrammed. When the number of electrons produced reaches that number, the electron beam is turned off. This approach assures that the same number of electrons are used for every measurement and eliminates the variations due to fundamental characteristics of the electron sourcere and the variations in temperature due to changing ambient conditions.

Owner:SIEMENS AG

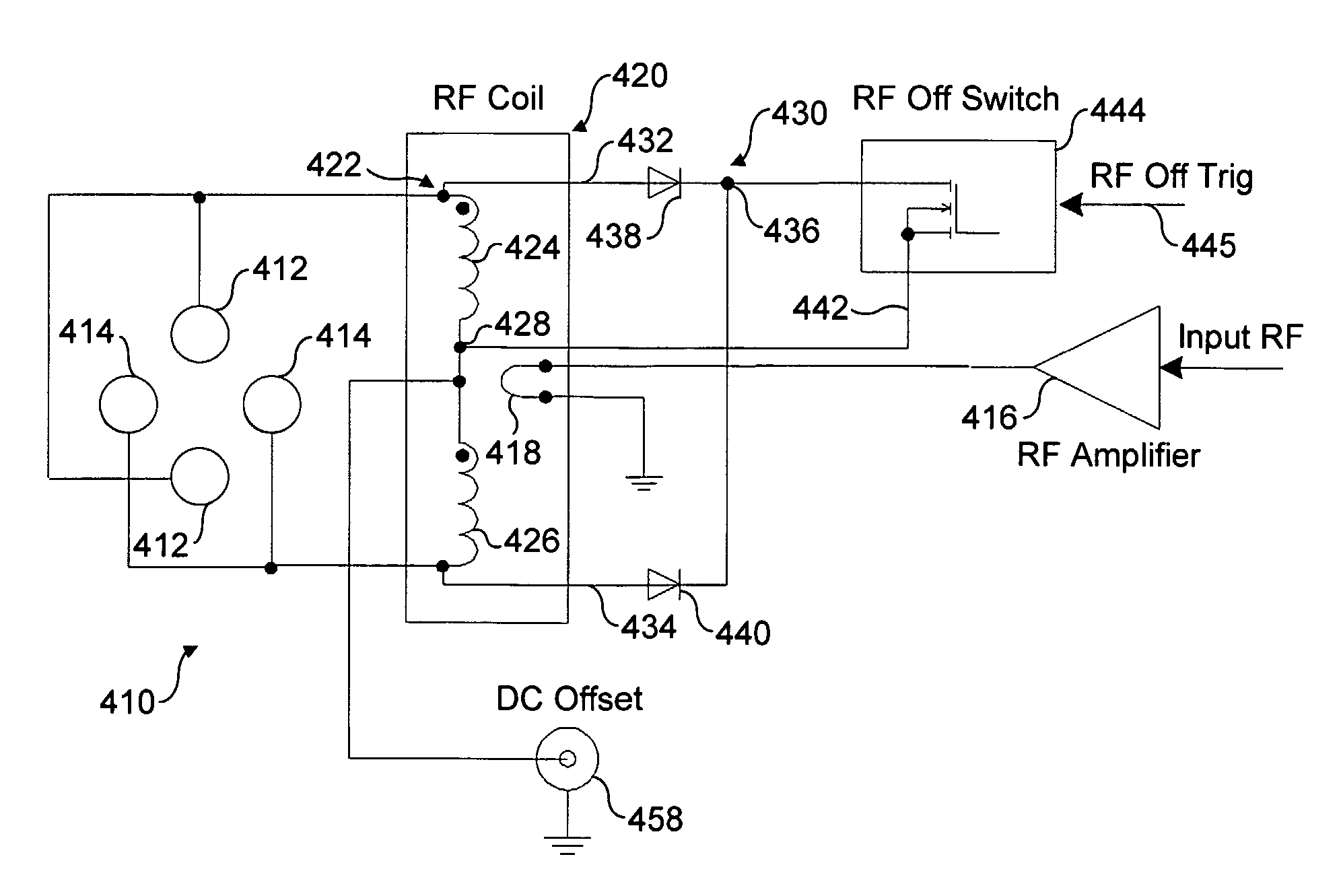

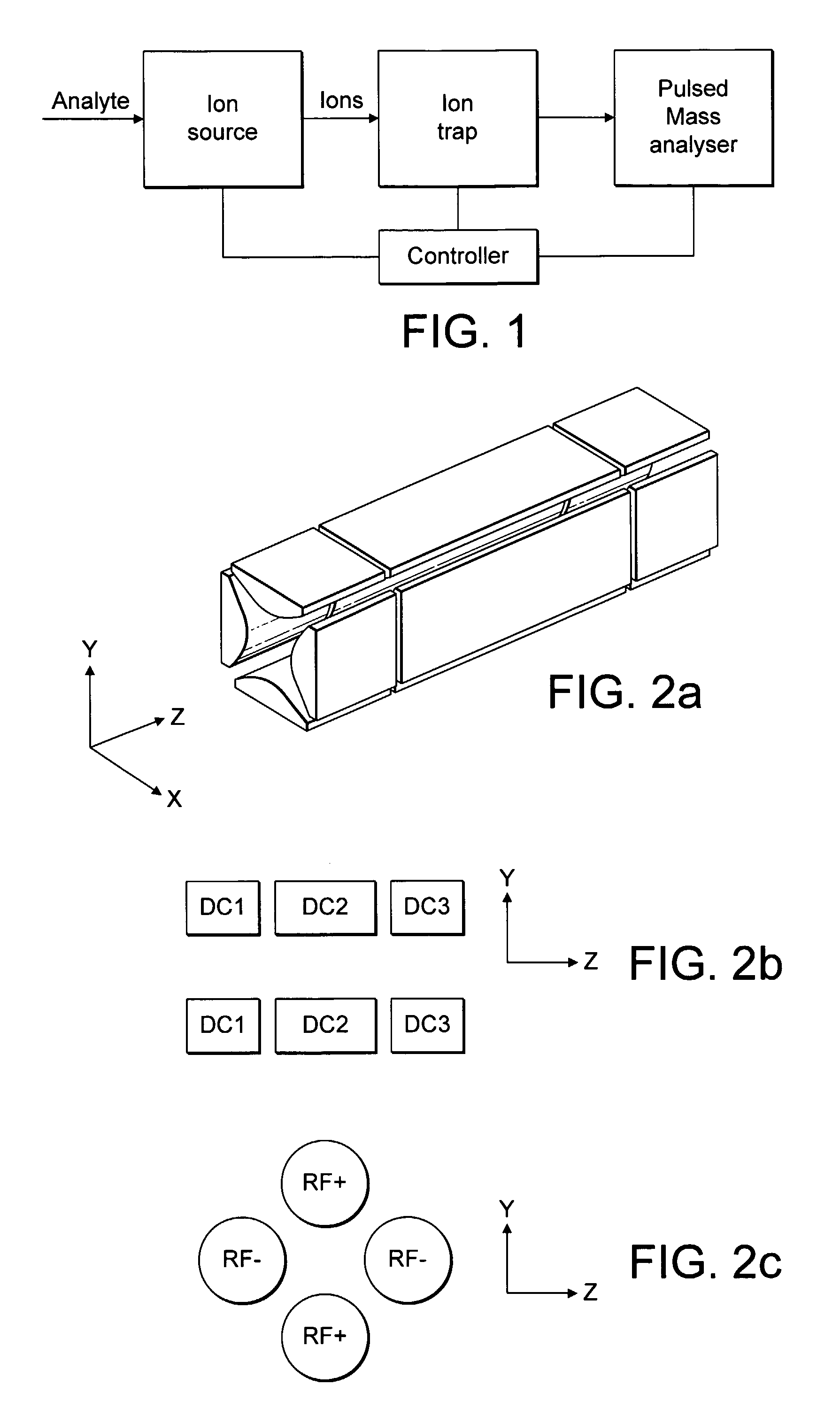

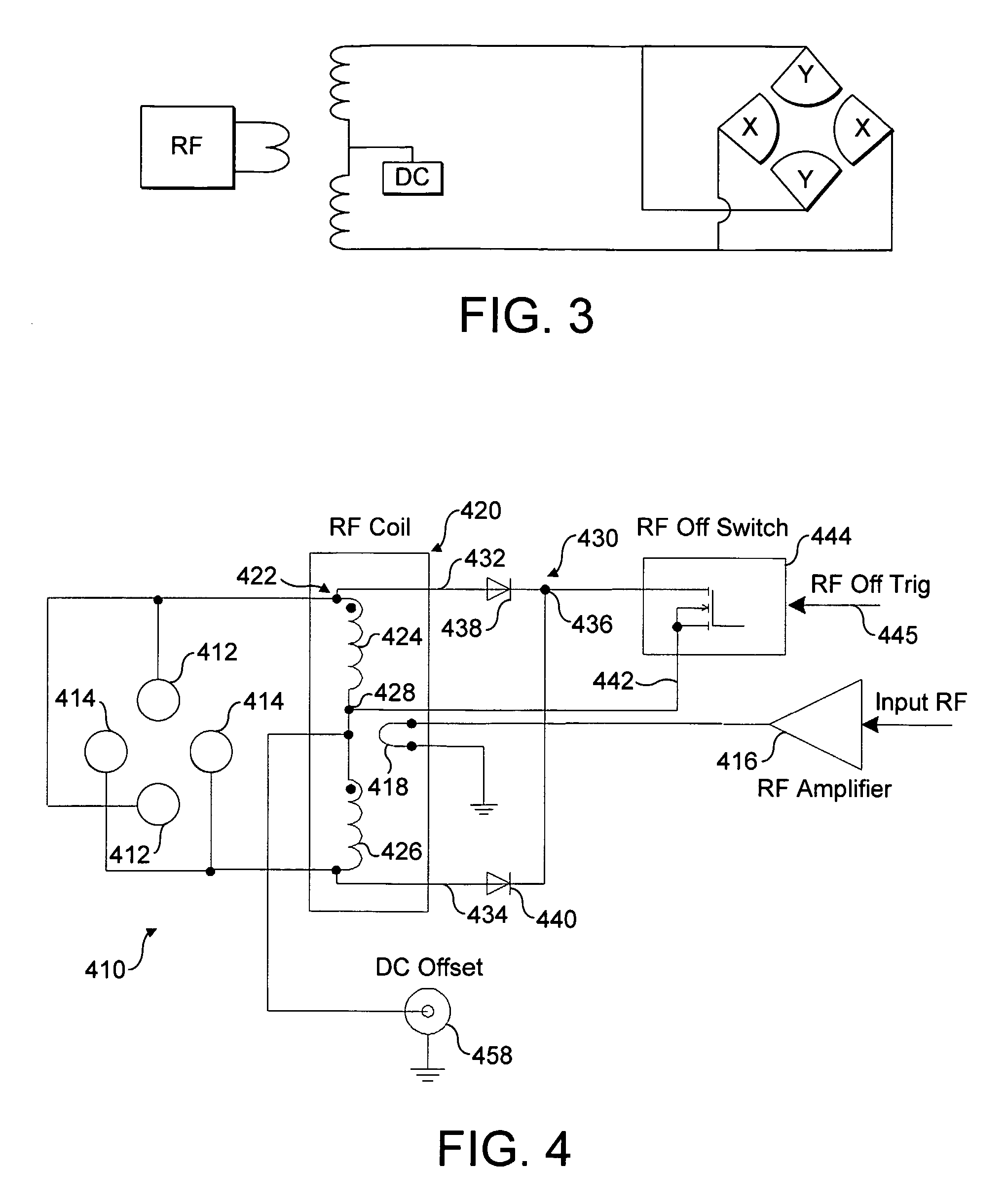

RF power supply for a mass spectrometer

ActiveUS7498571B2Promote recoveryStability-of-path spectrometersSpectrometer circuit arrangementsShunt DeviceRf field

The present invention provides a radio frequency (RF) power supply in a mass spectrometer. The power supply provides an RF signal to electrodes of a storage device to create a trapping field. Such ion storage devices are often used to store ions prior to ejection to a subsequent mass analyzer. The RF field is usually collapsed prior to ion ejection. The present invention provides a RF power supply comprising: a RF signal supply, a coil arranged to receive the signal provided by the RF signal supply and to provide an output RF signal for supply to electrodes of an ion storage device, and a shunt including a switch operative to switch between a first open position and a second closed position in which the shunt including a switch operative to switch between a first open position and a second closed position in which the shunt shorts the coil output.

Owner:THERMO FINNIGAN

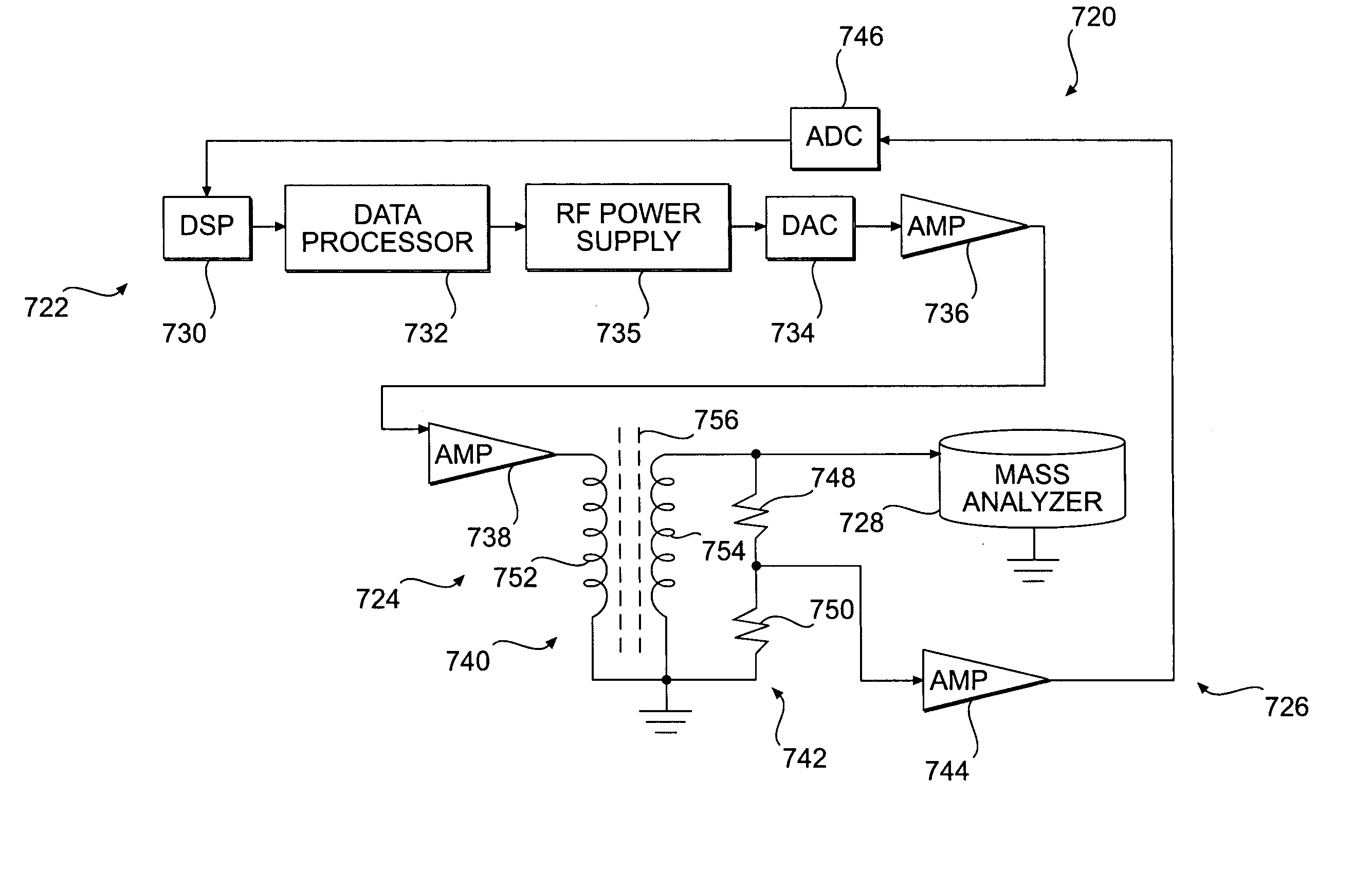

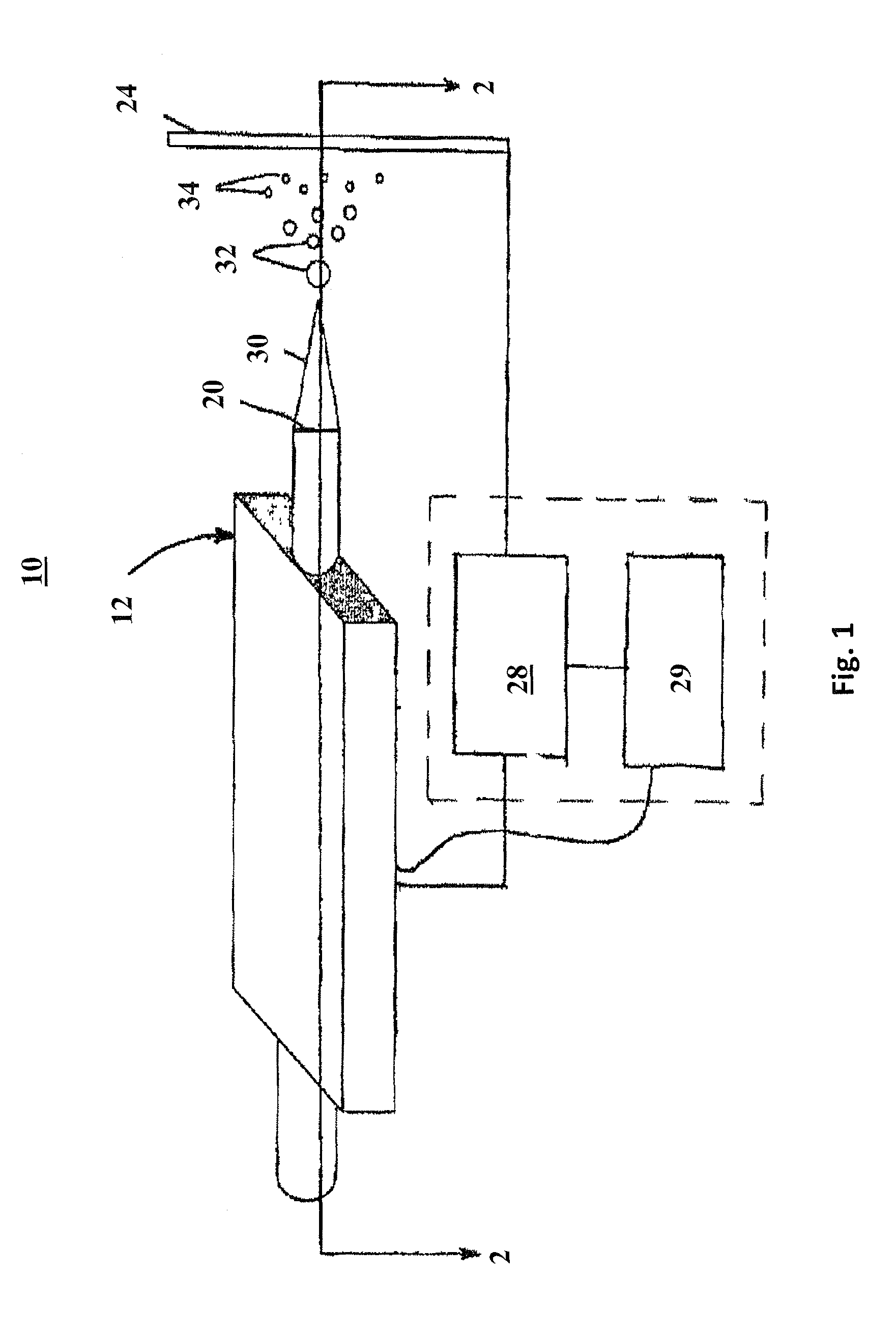

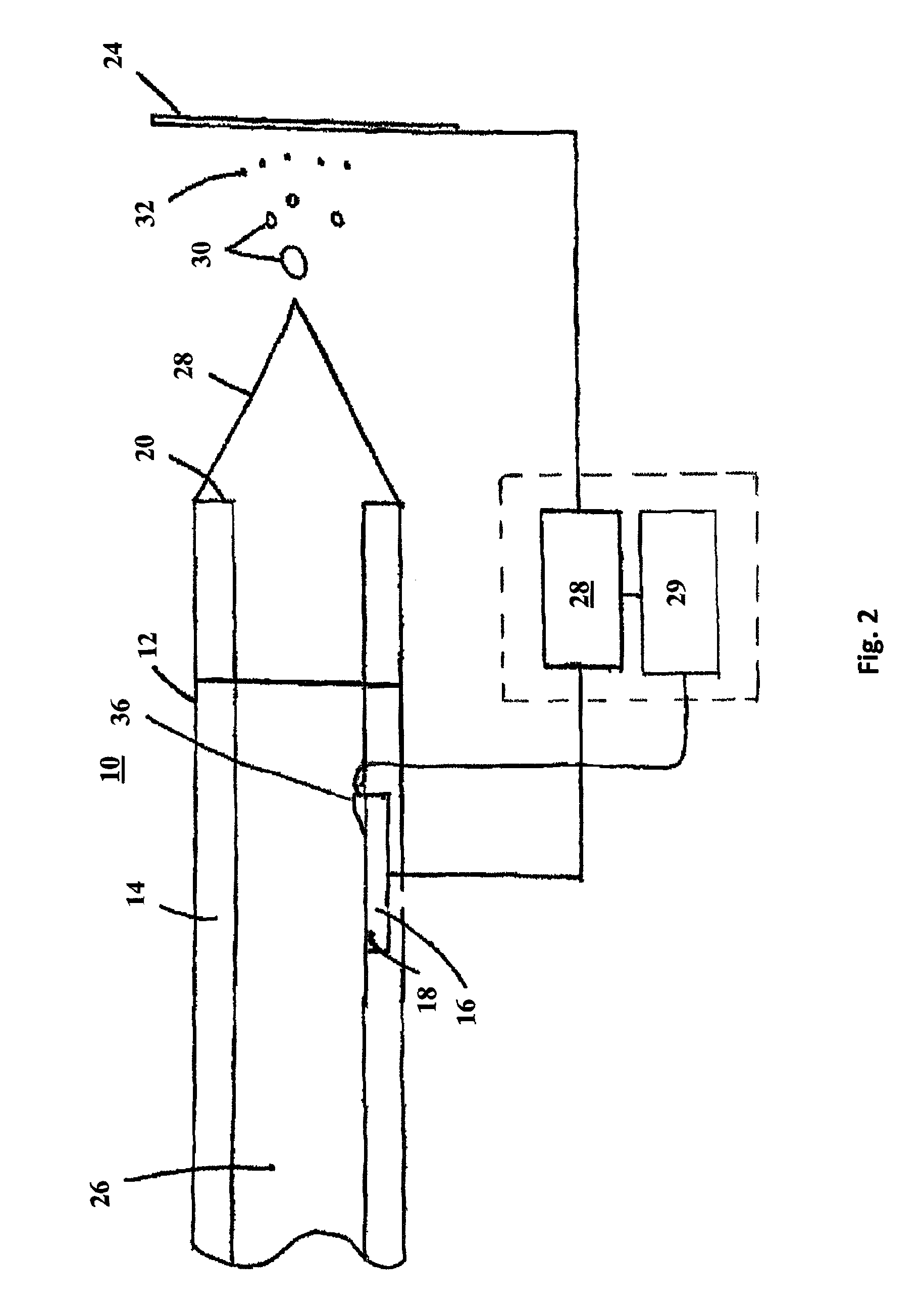

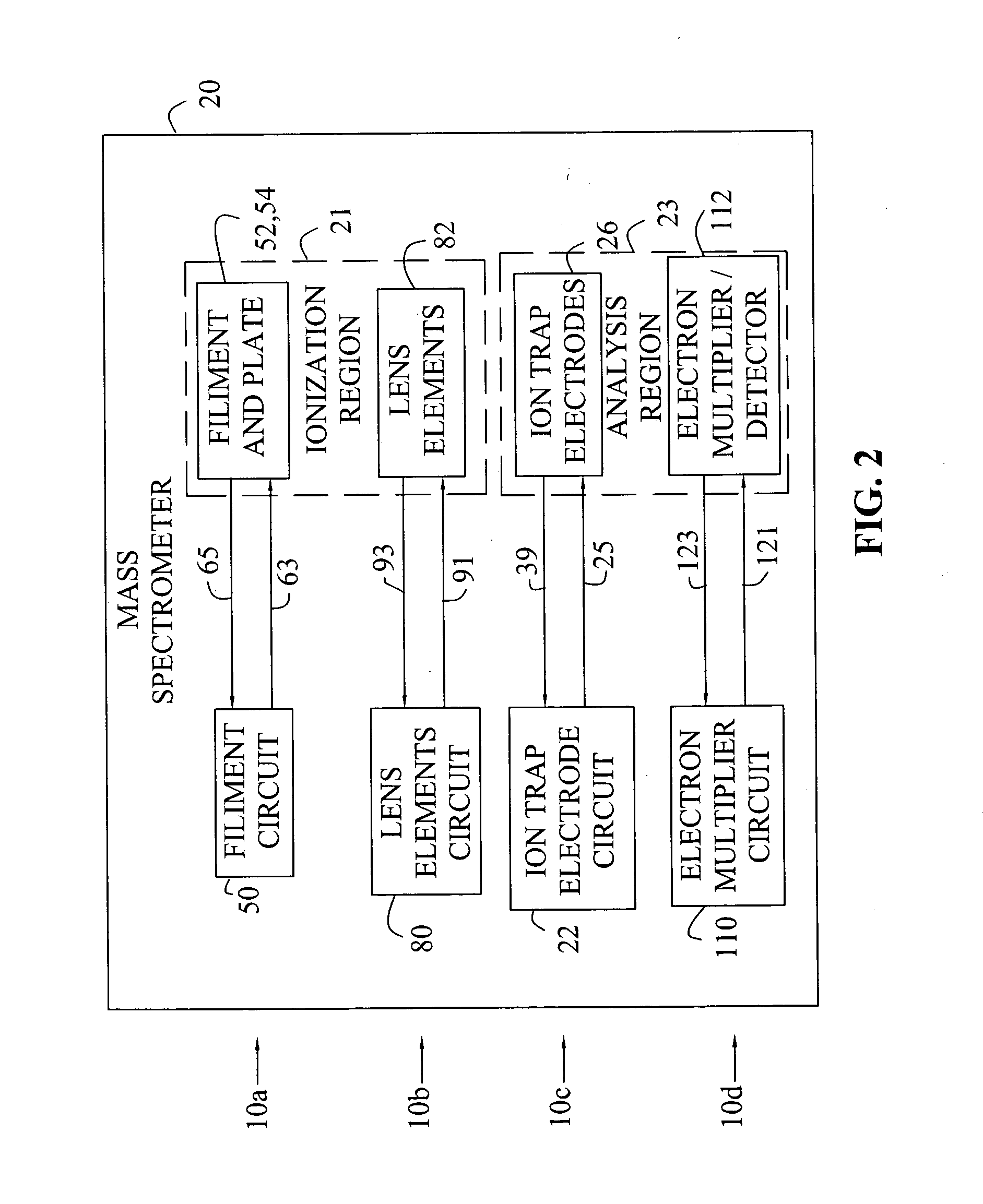

Portable mass spectrometers

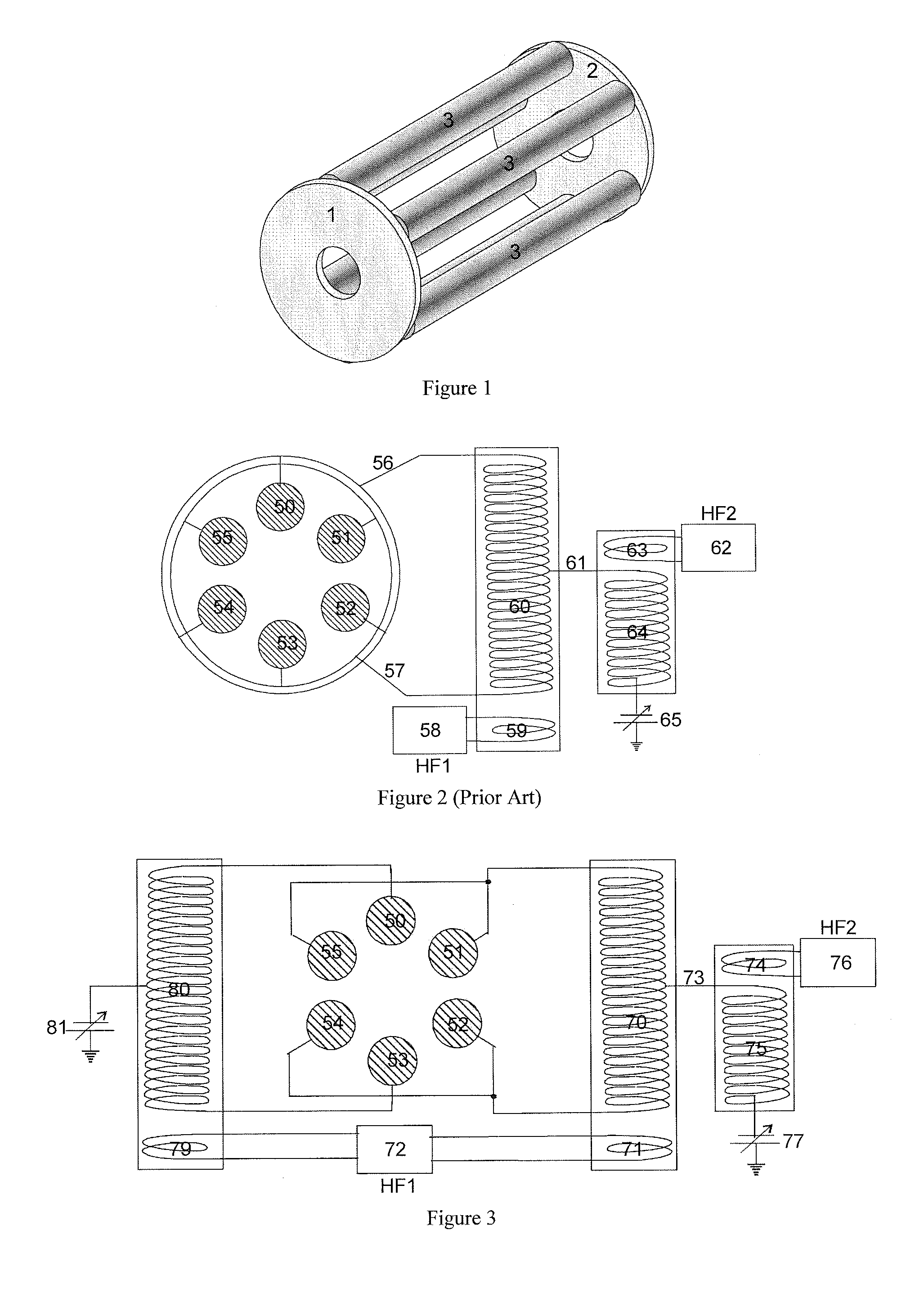

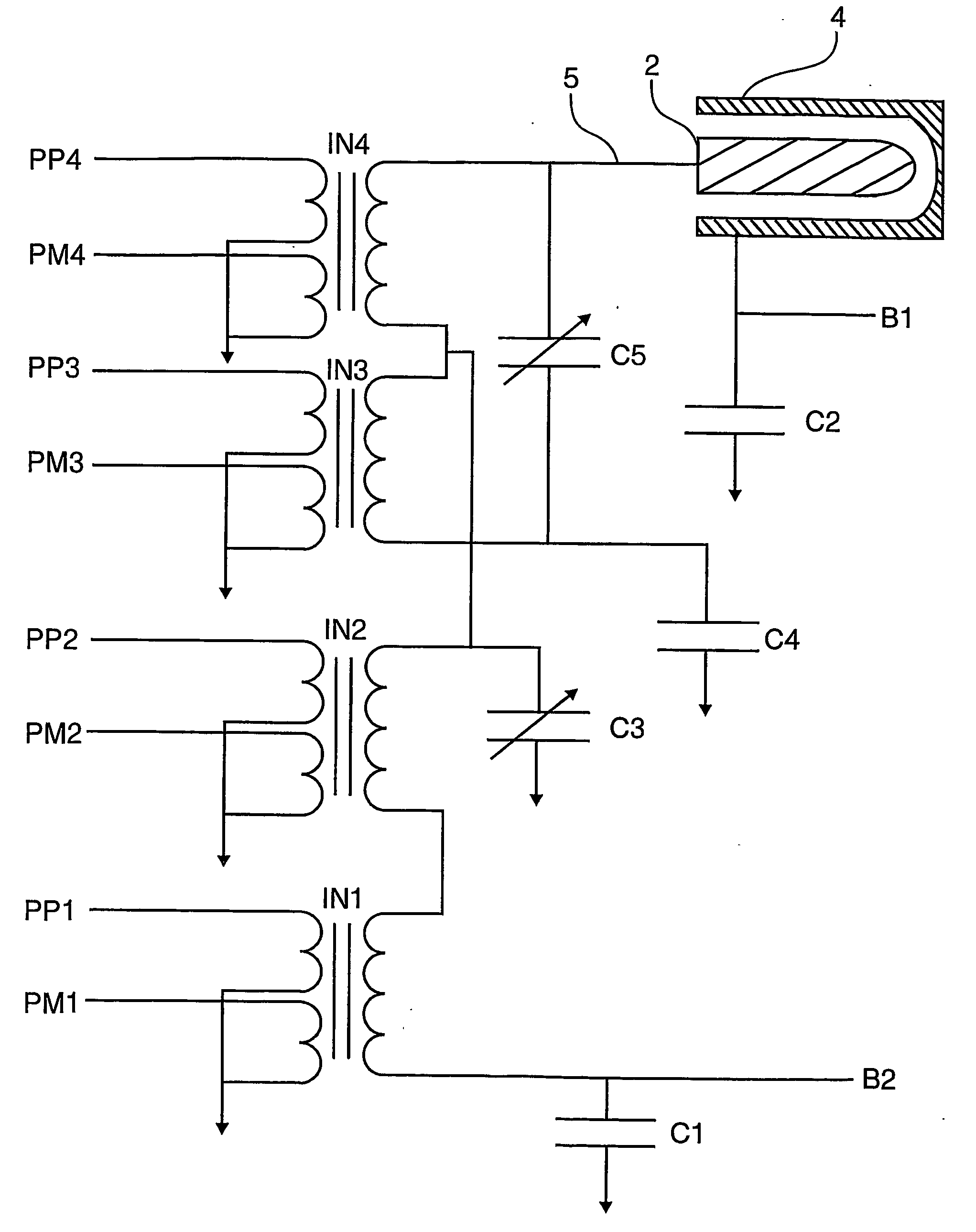

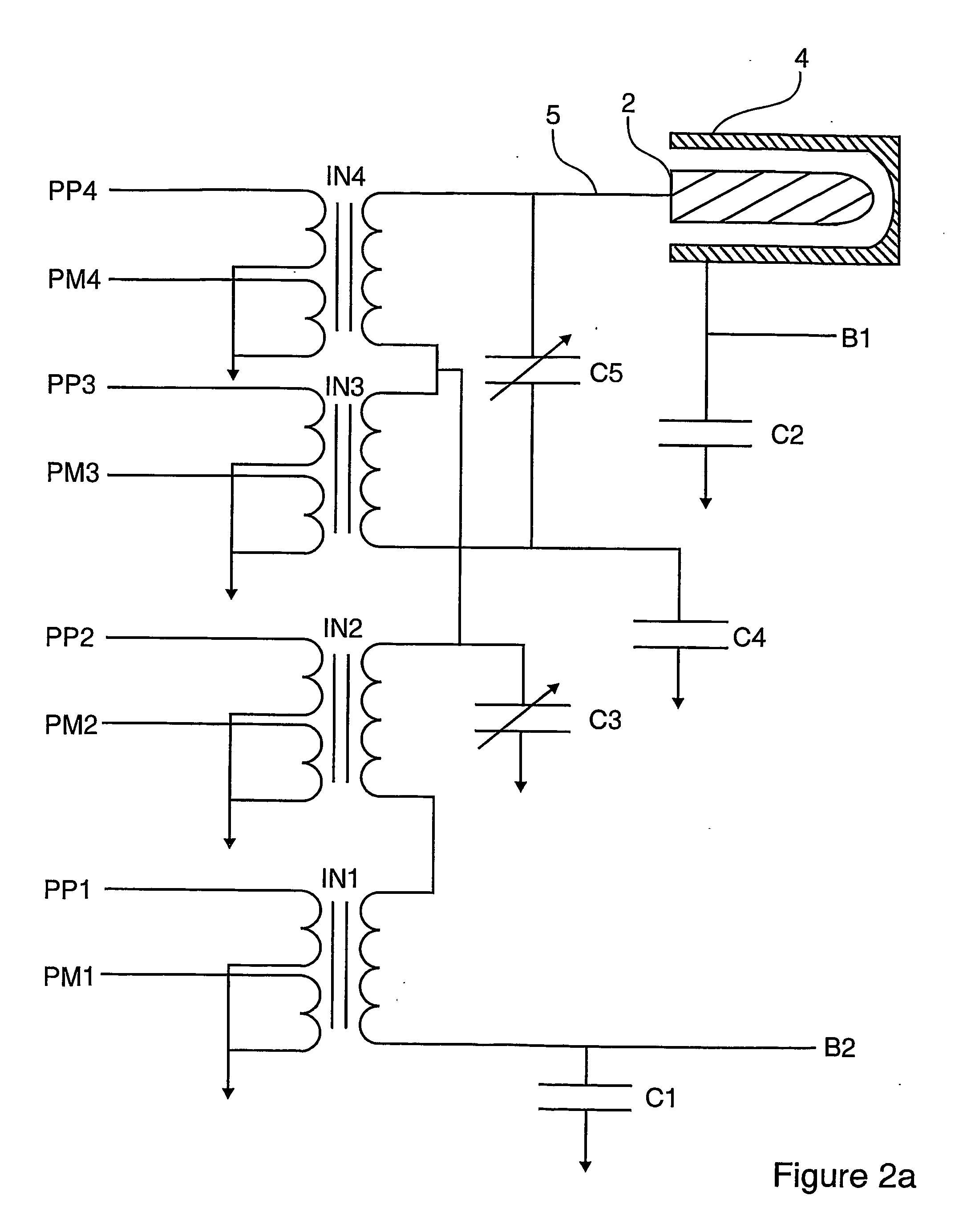

InactiveUS7161142B1Improved calibration techniqueSpectrometer circuit arrangementsIsotope separationQuantum electrodynamicsTransformer

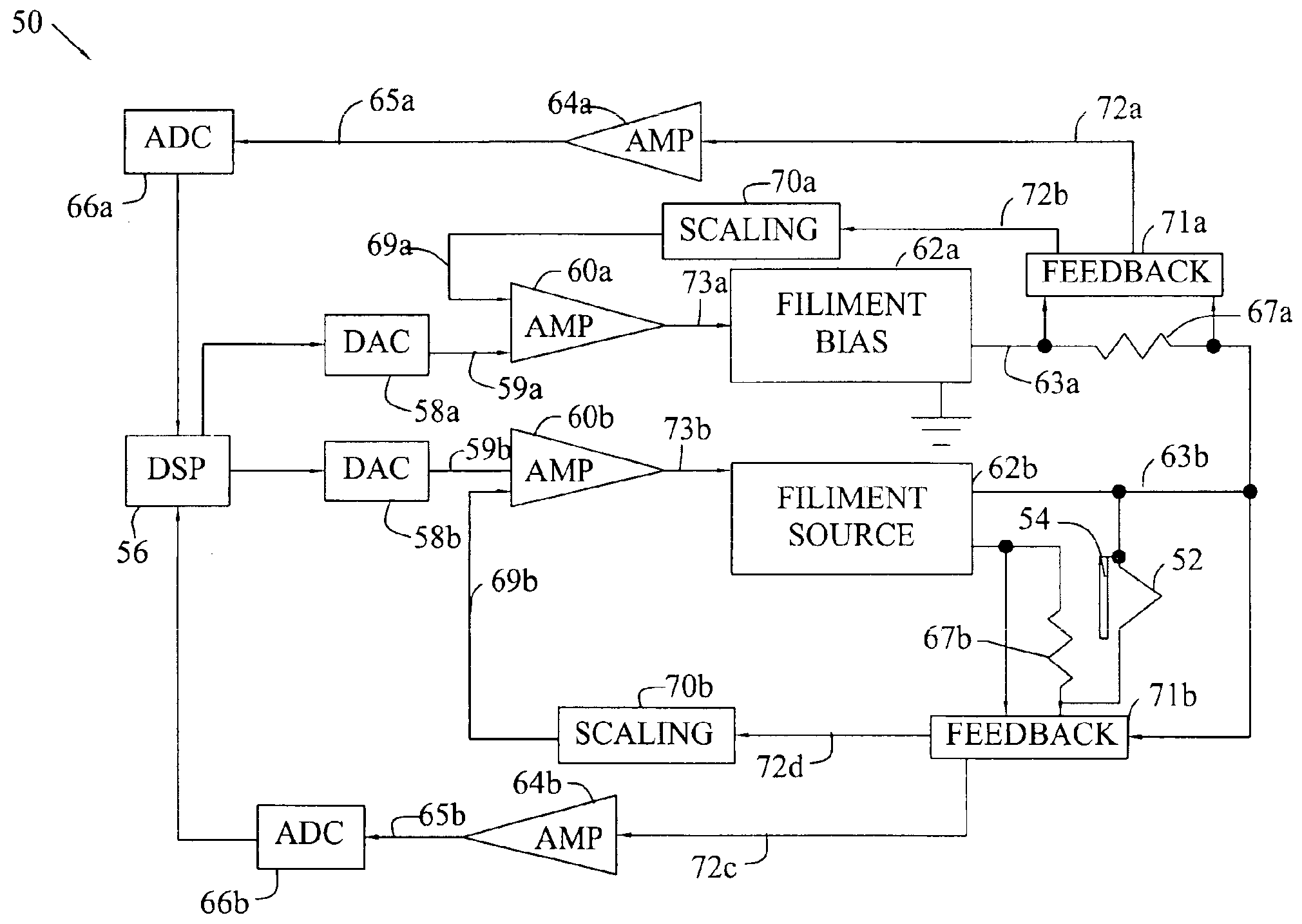

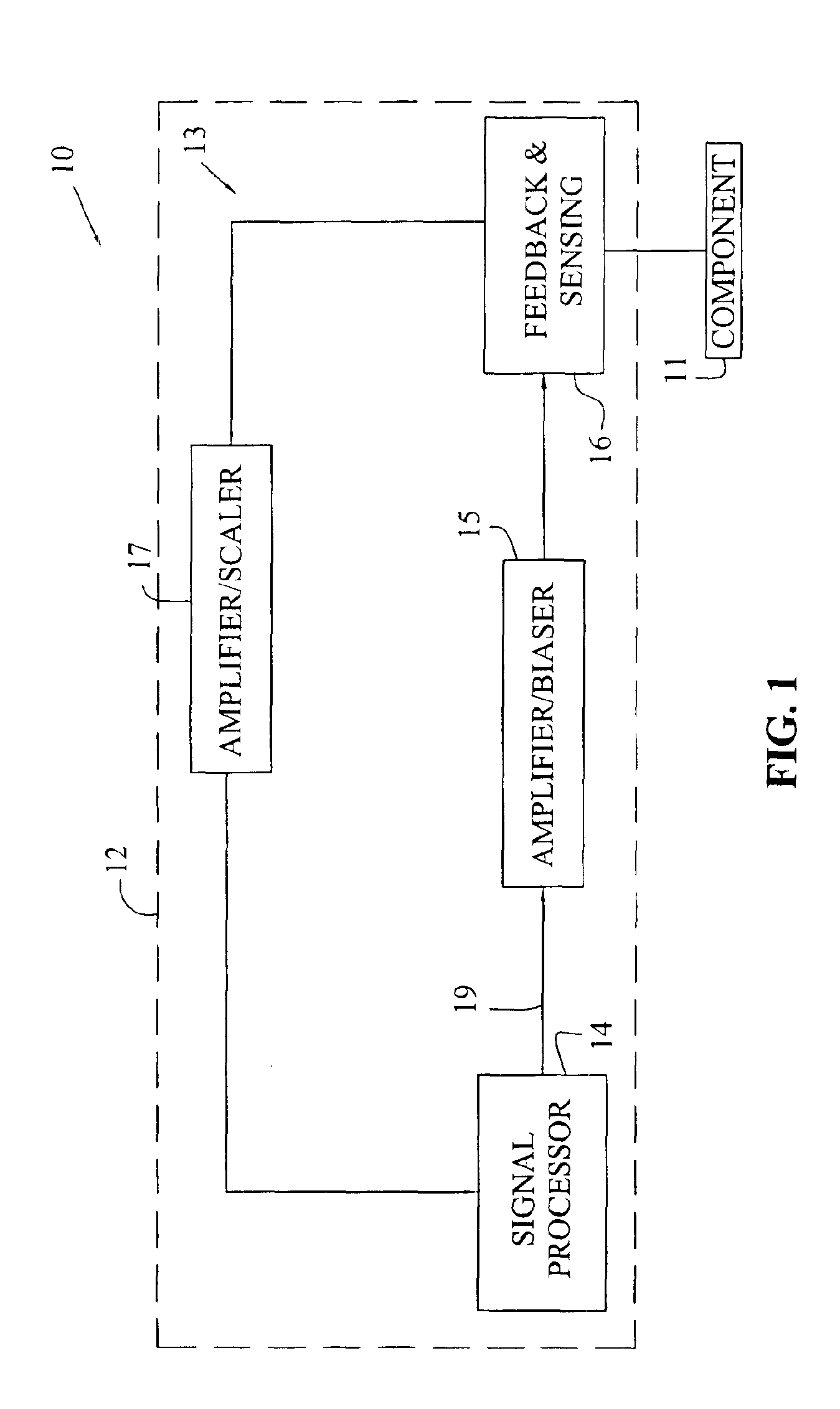

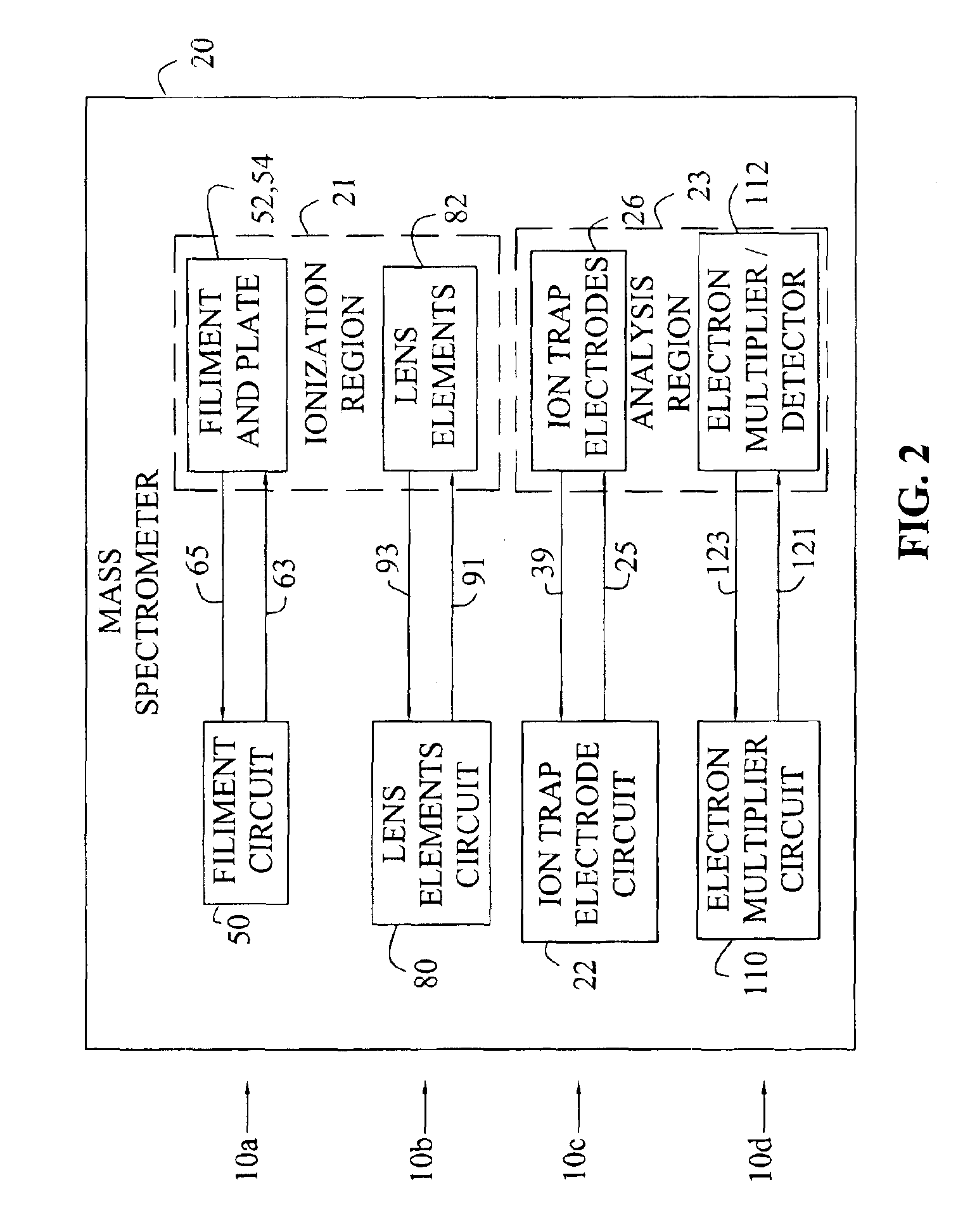

The present invention relates to a mass spectrometer, and more specifically a portable mass spectrometer. In one implementation, the mass spectrometer includes a toroidal transformer. In another implementation, the mass spectrometer includes feedback circuitry to monitor signals applied in the mass spectrometer.

Owner:FLIR DETECTION

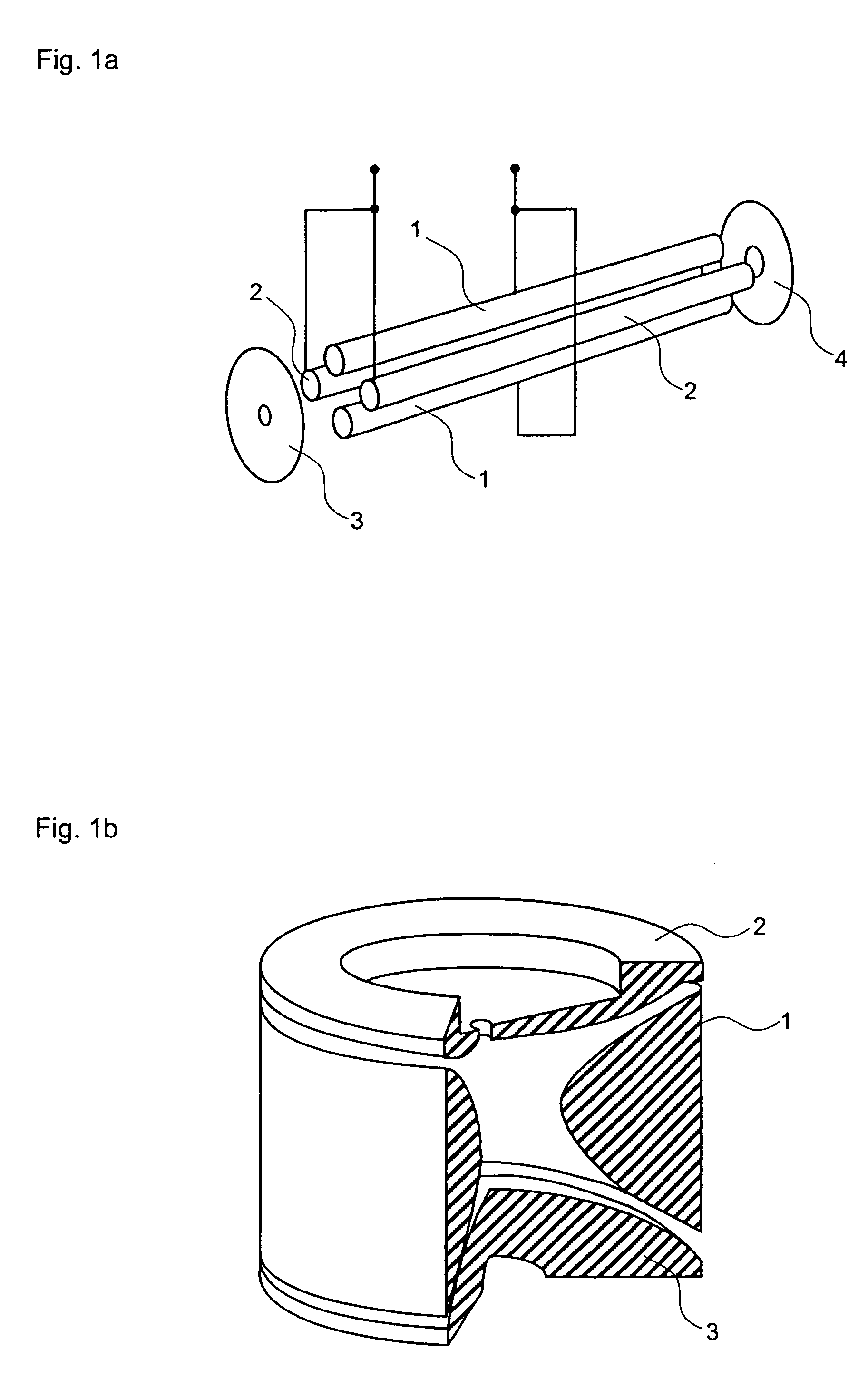

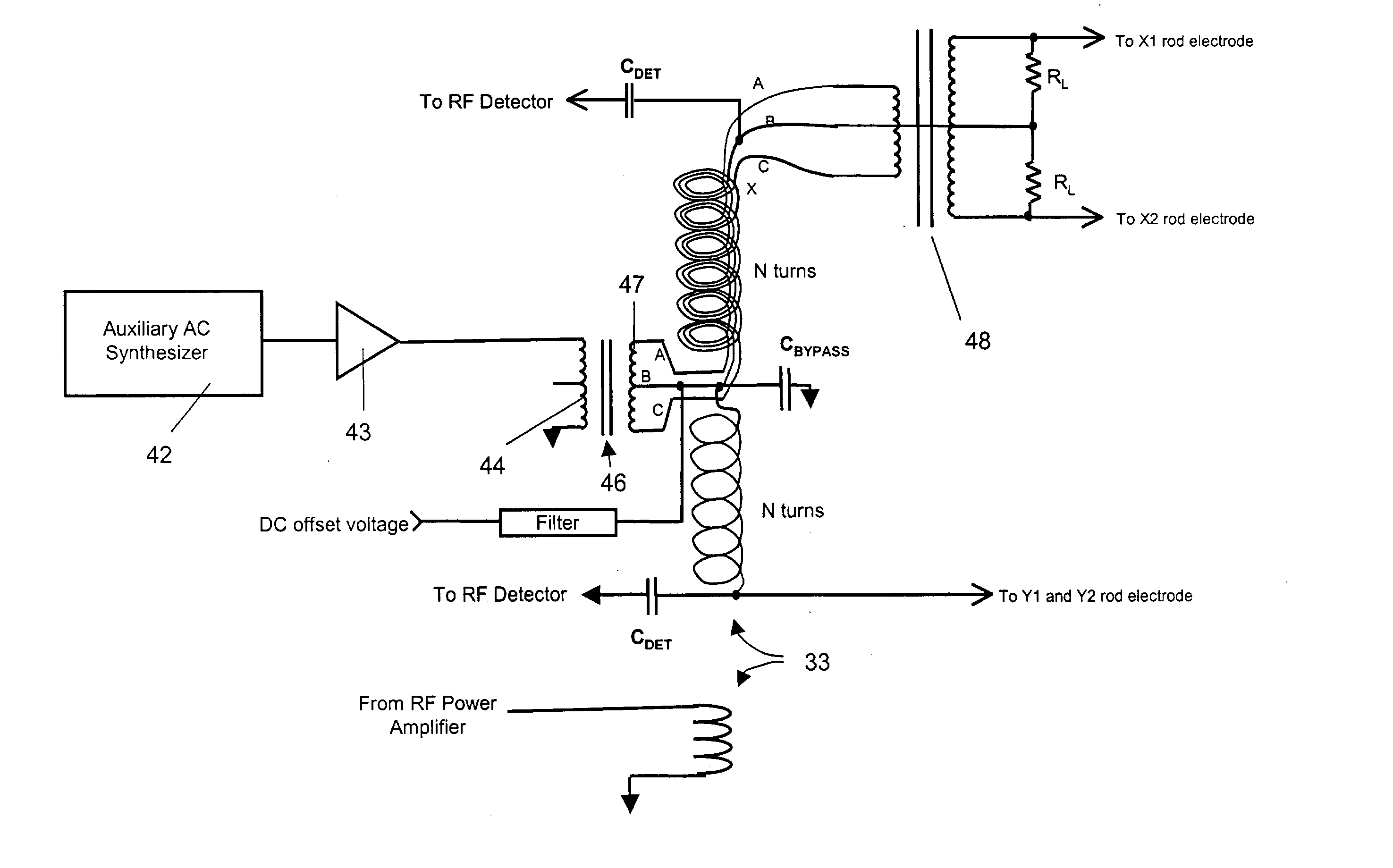

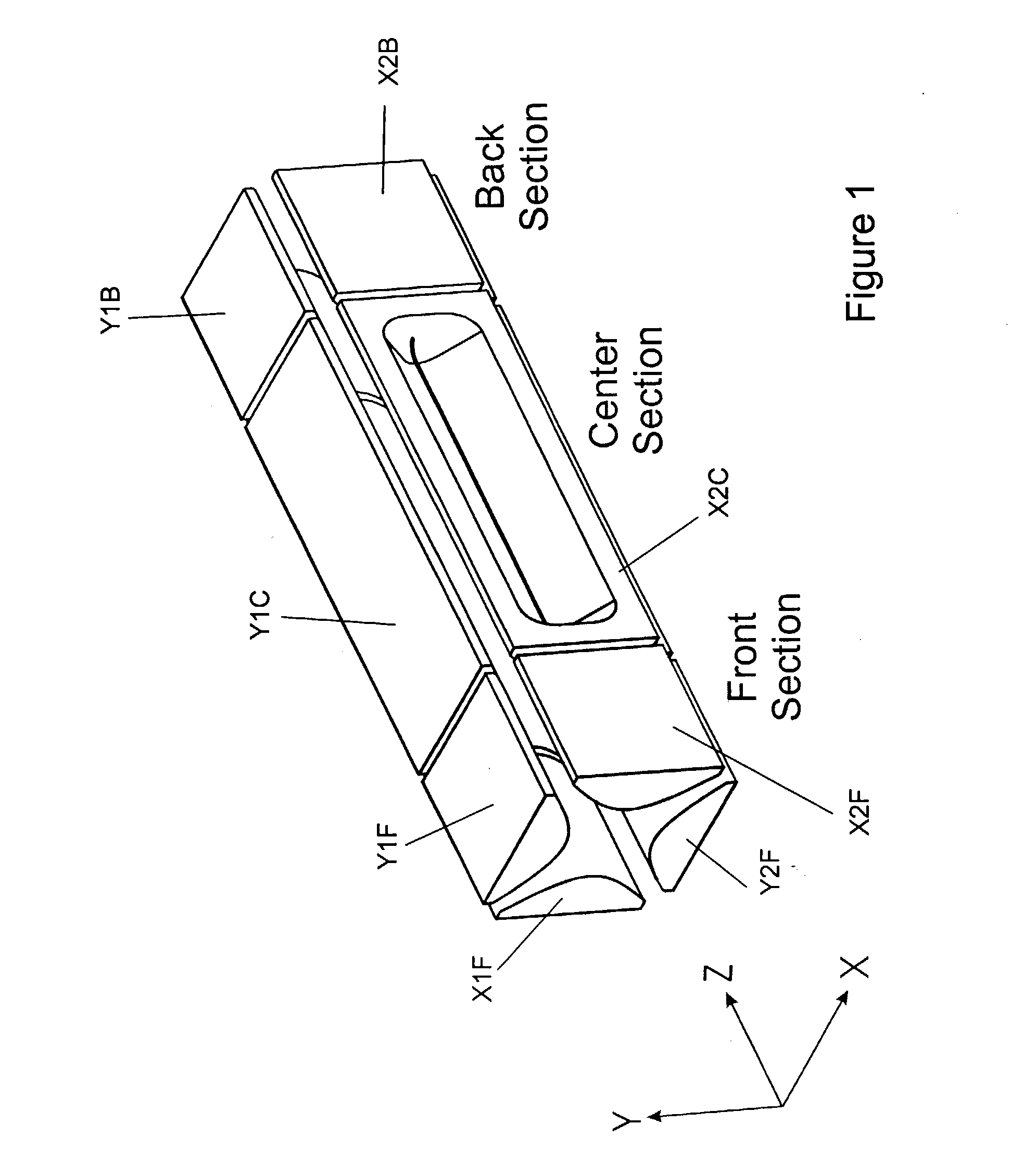

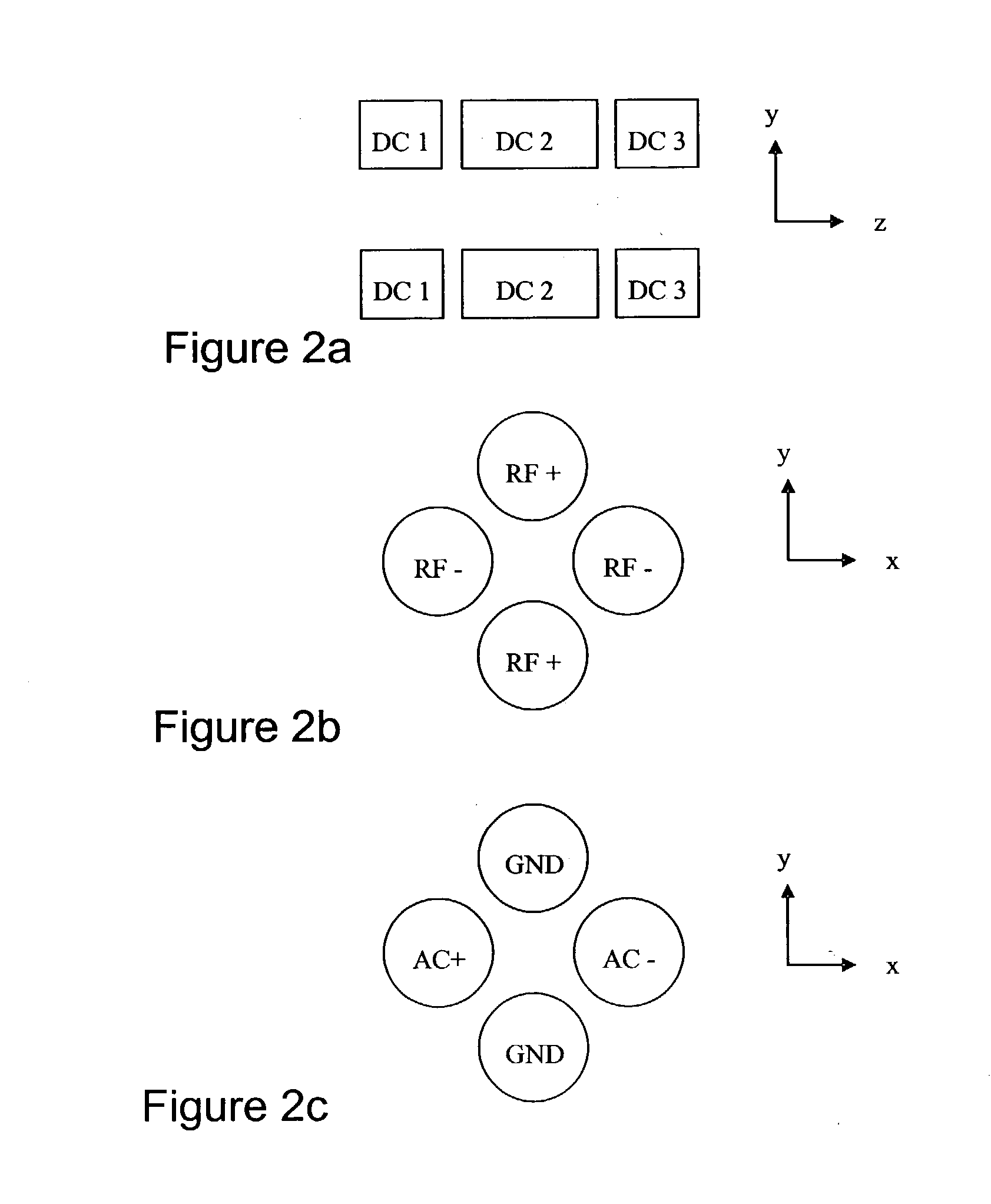

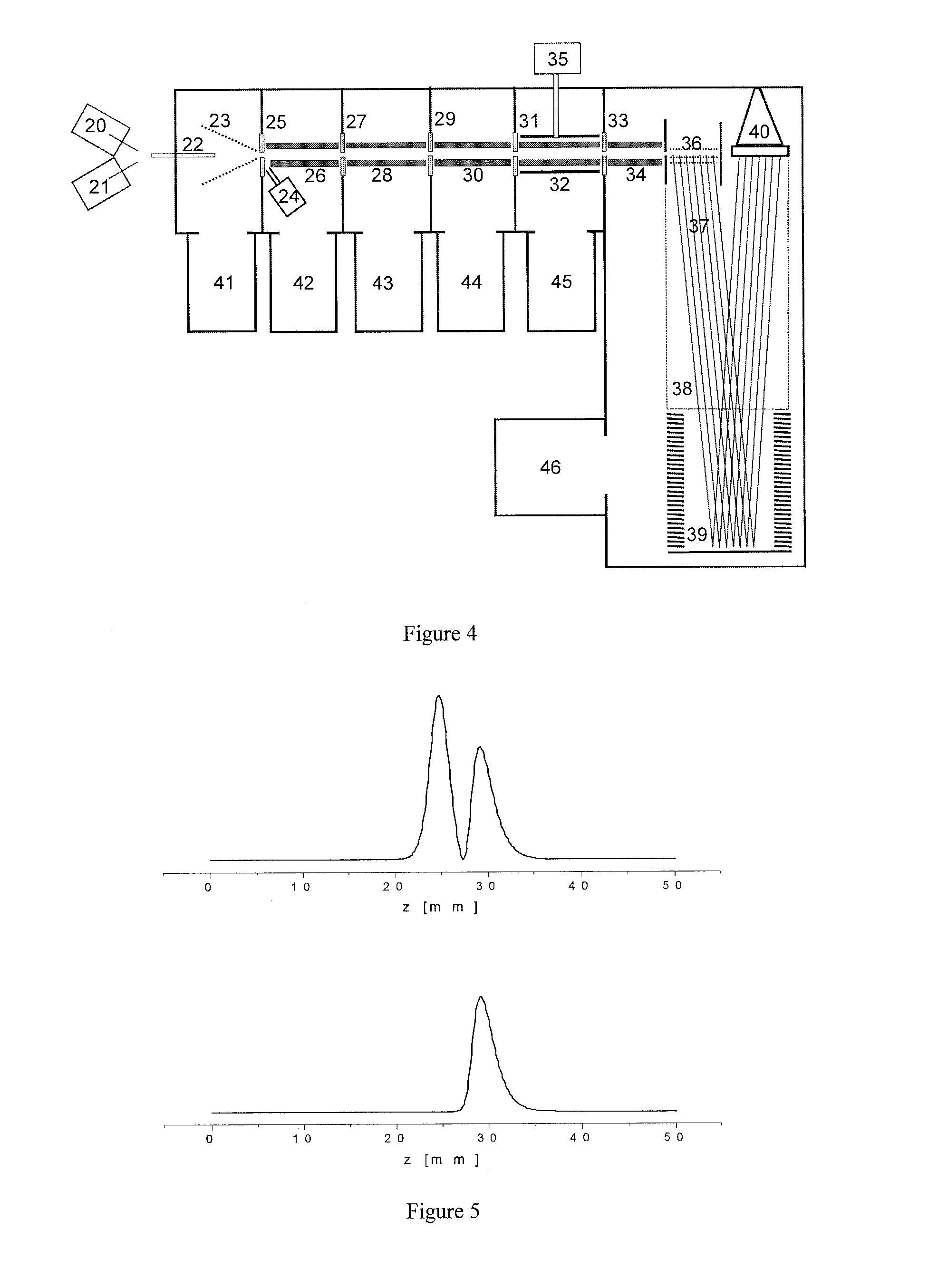

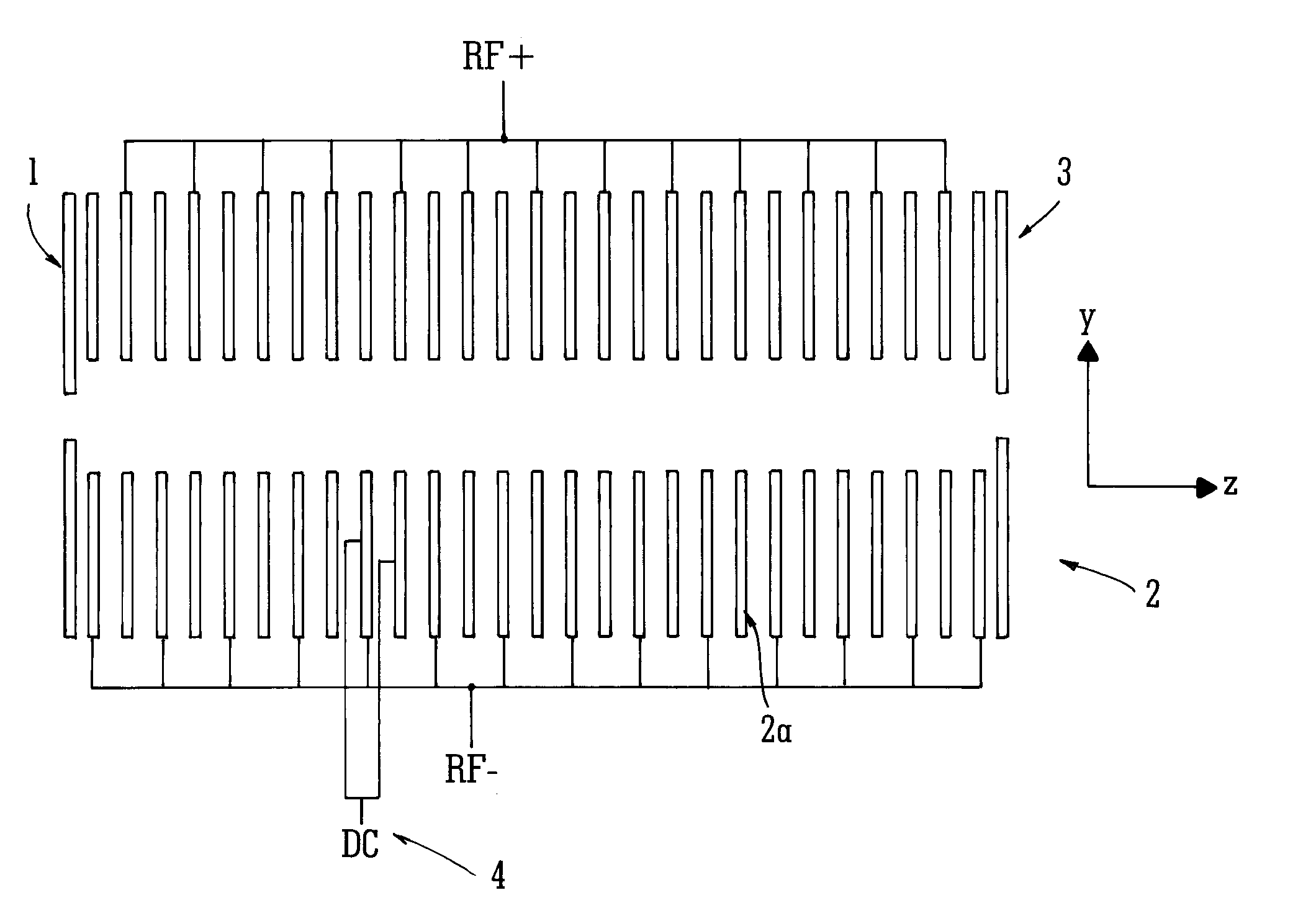

Circuit for applying supplementary voltages to RF multipole devices

InactiveUS6844547B2Spectrometer circuit arrangementsStability-of-path spectrometersLow voltageTransformer

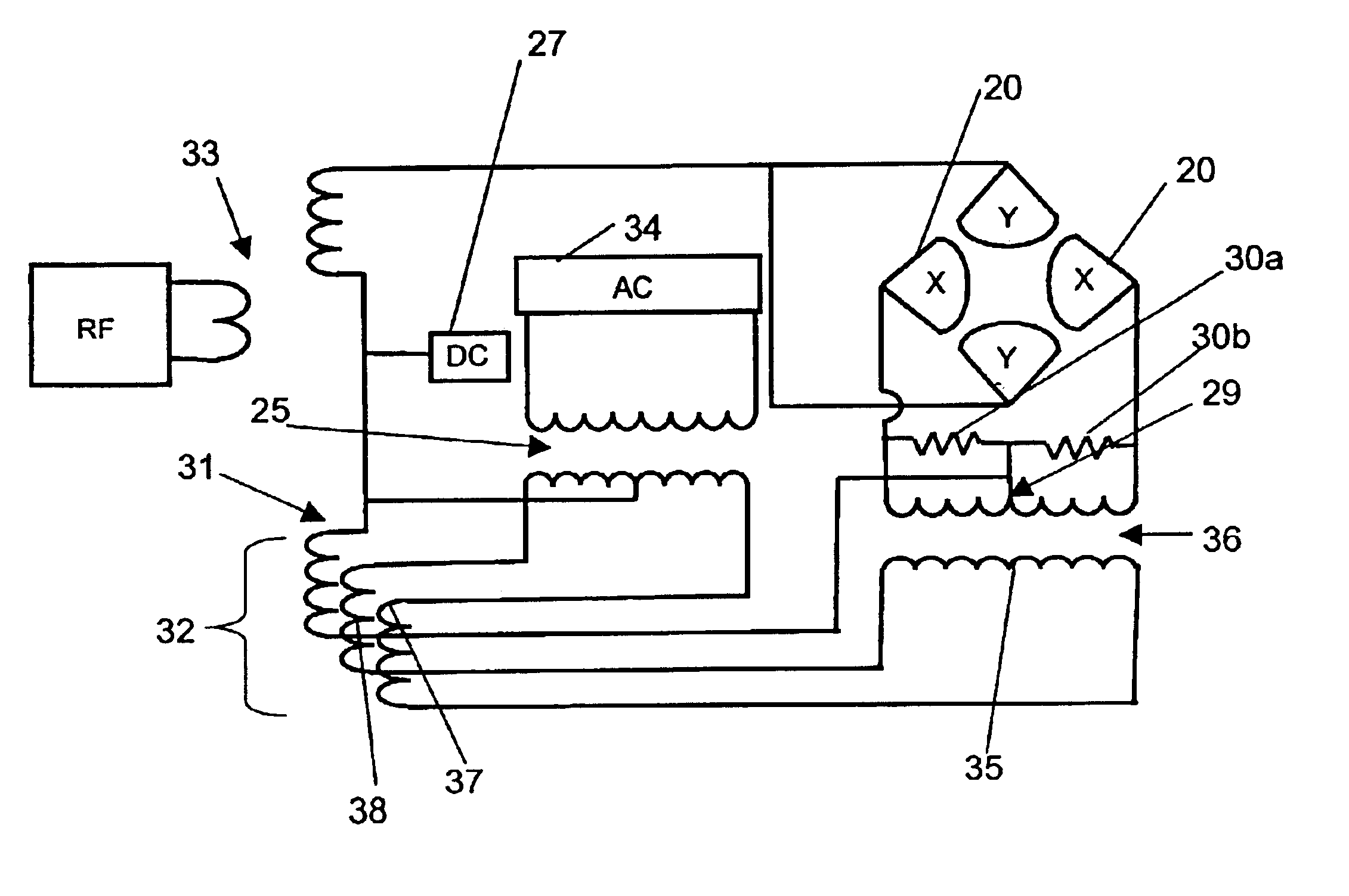

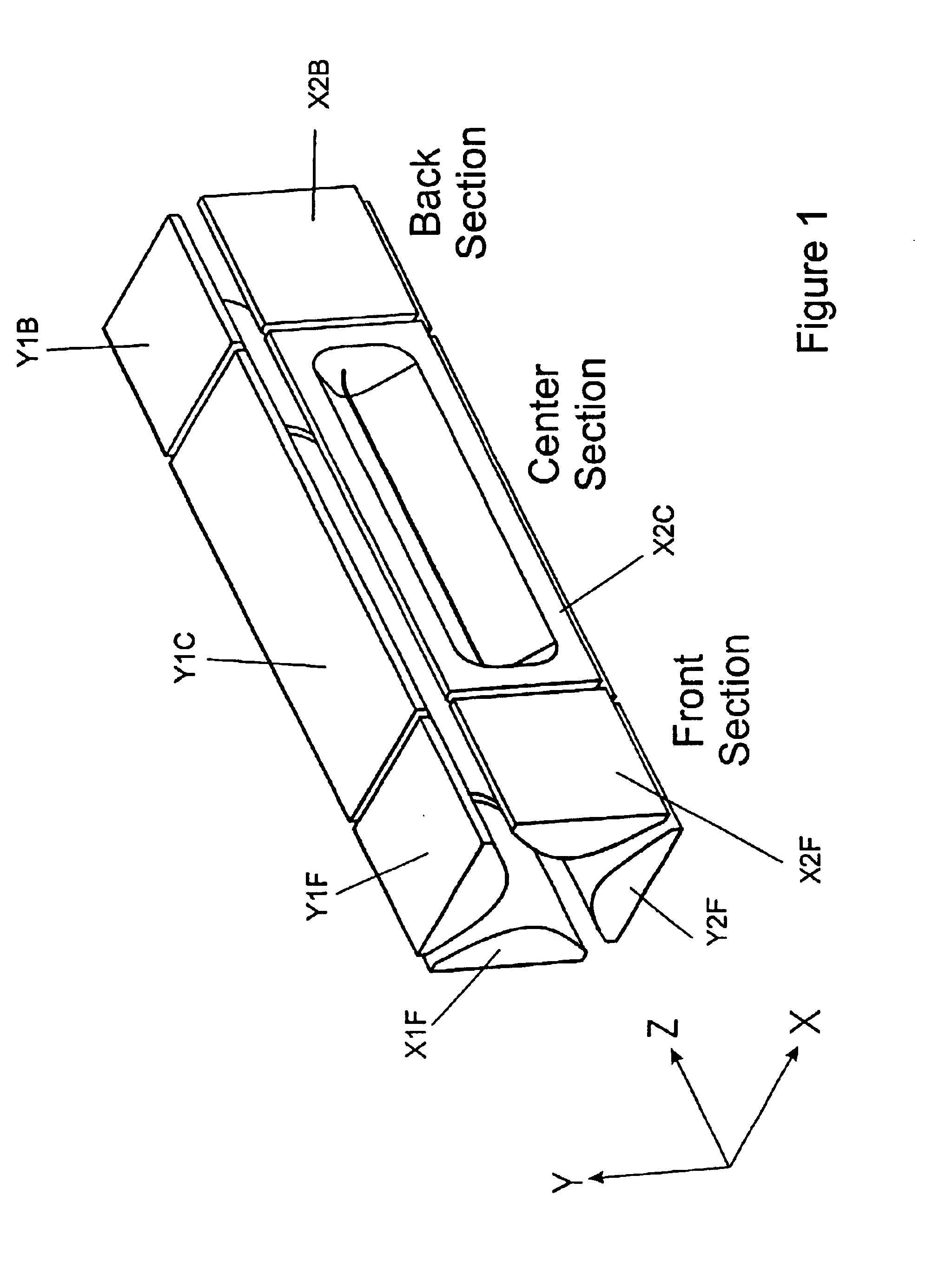

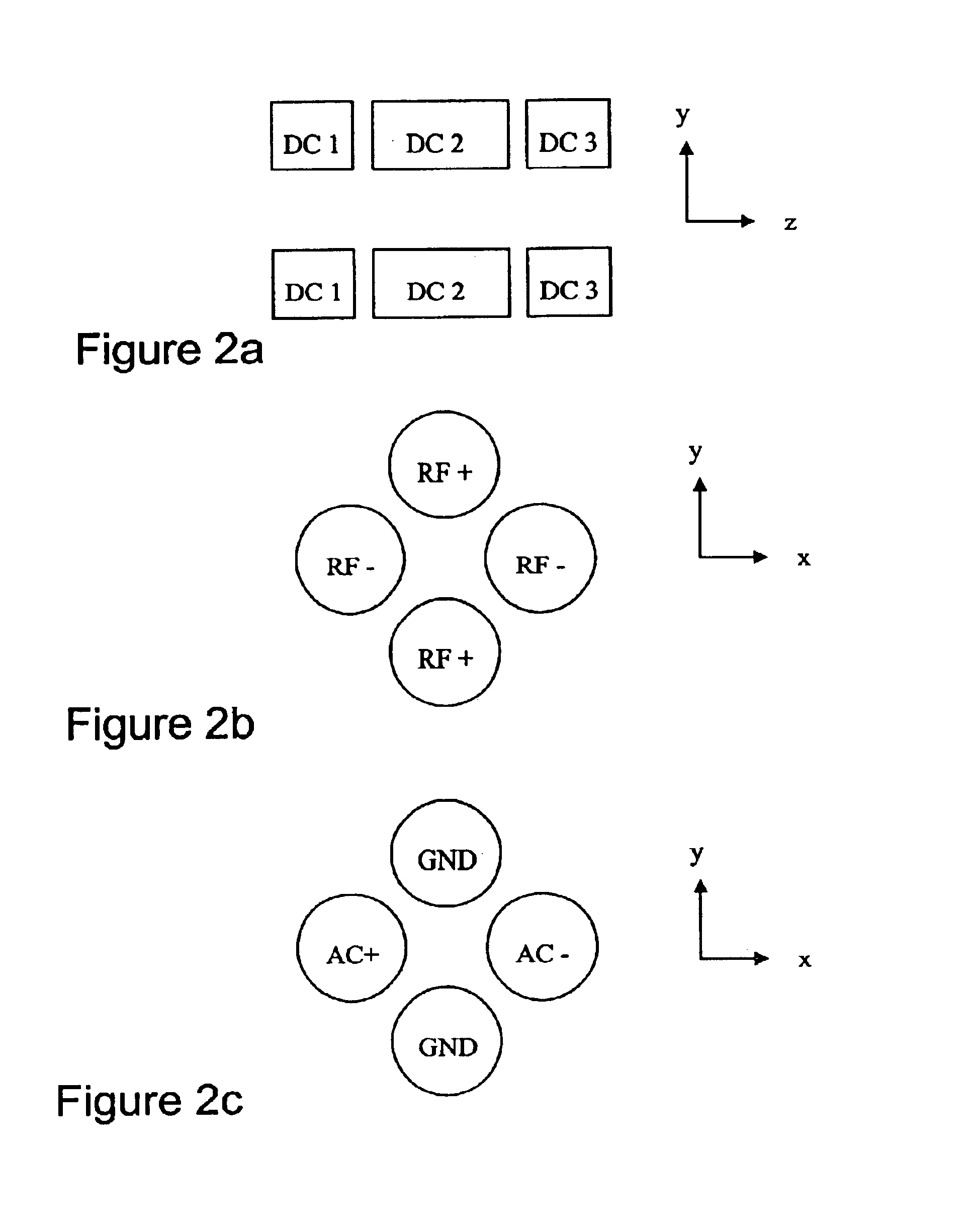

A circuit is described for applying RF and AC voltages to the elements or electrodes of an ion trap or ion guide. The circuit includes an RF transformer having a primary winding and a secondary winding. The secondary winding includes at least two filars. A broadband transformer adapted to be connected to a source of AC voltage applies AC voltage across the low-voltage end of two of the filars. Another broadband transformer connected to the filars at the high-voltage end provides a combined RF and AC output for application to selected electrodes. Also described is a circuit employing a multi-filar RF transformer and broadband transformers for applying RF and AC voltages to spaced rods of a linear ion trap. Also described is a circuit employing a multi-filar RF transformer and broadband transformers for applying RF and AC voltages to the electrodes in each section of a linear ion trap of the type having a center section and end sections, and different DC voltages to the electrodes in the end sections.

Owner:THERMO FINNIGAN

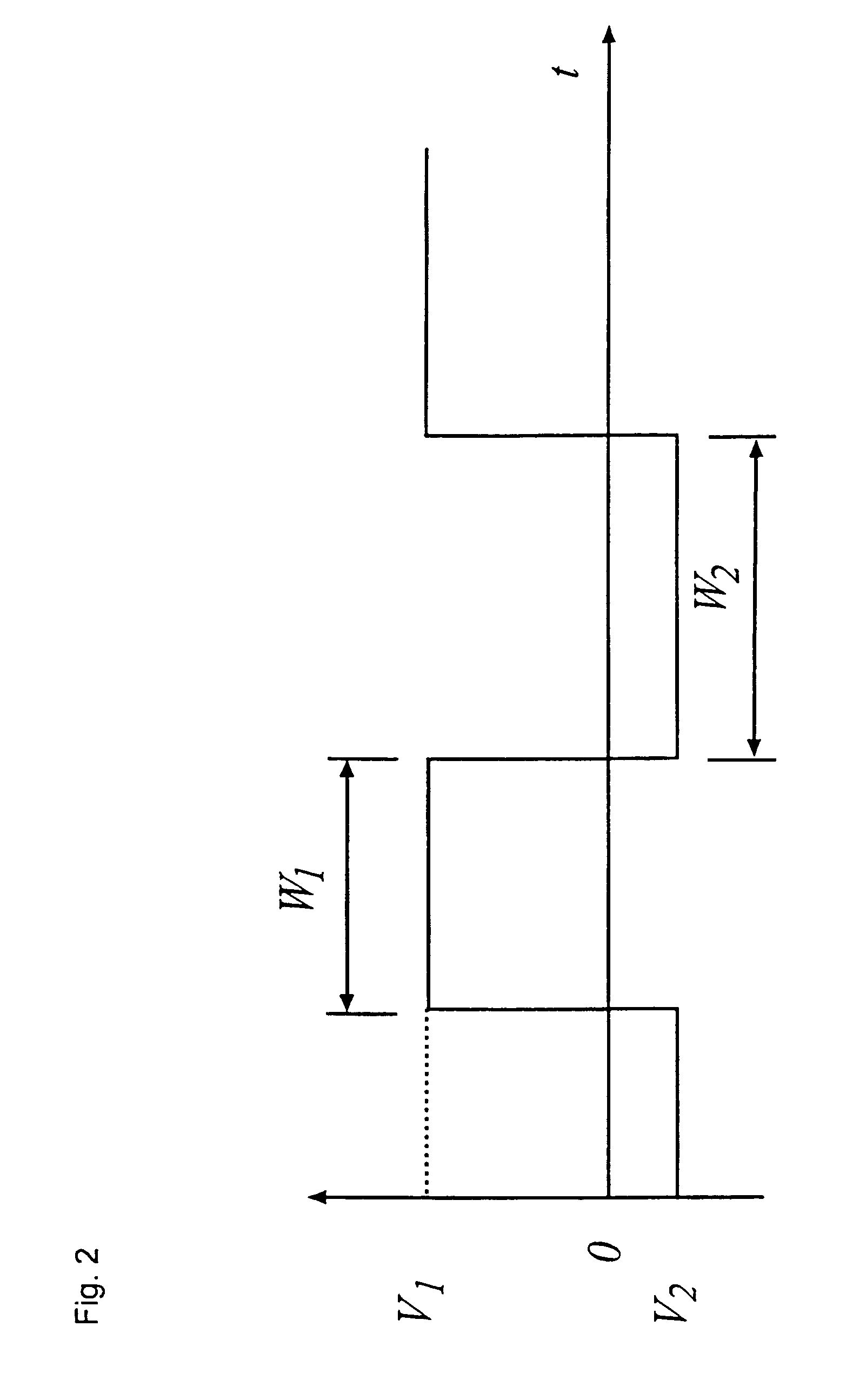

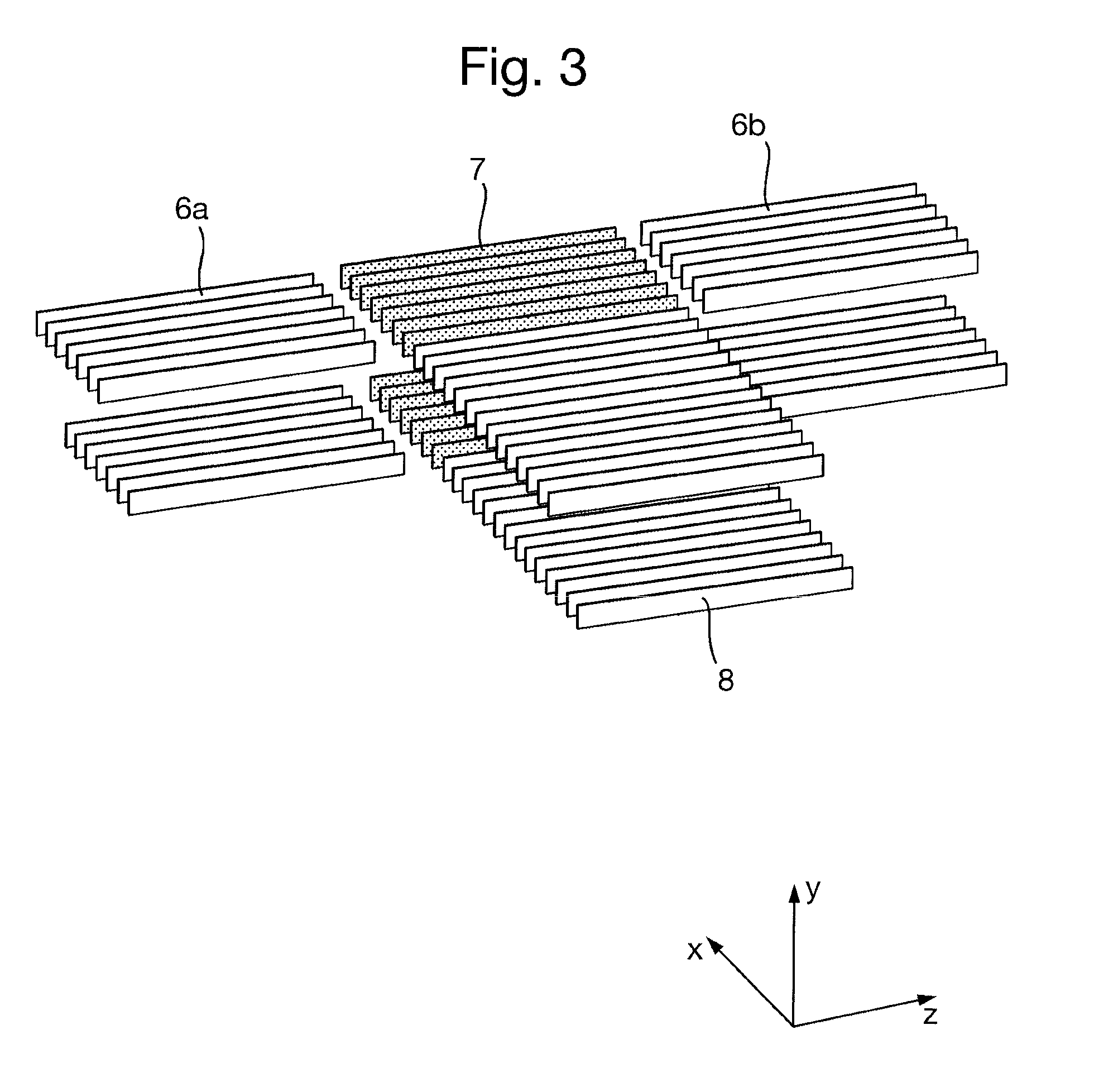

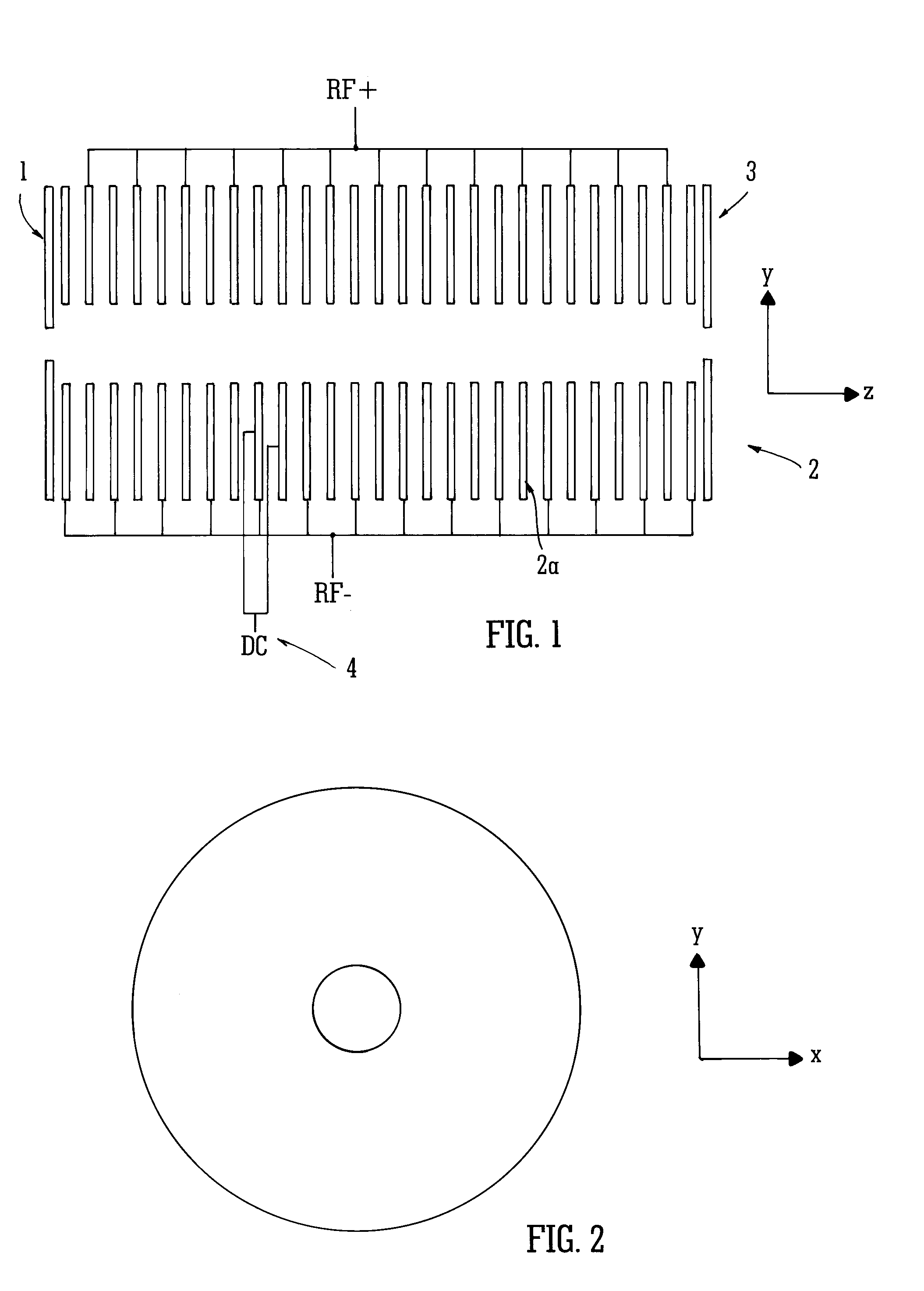

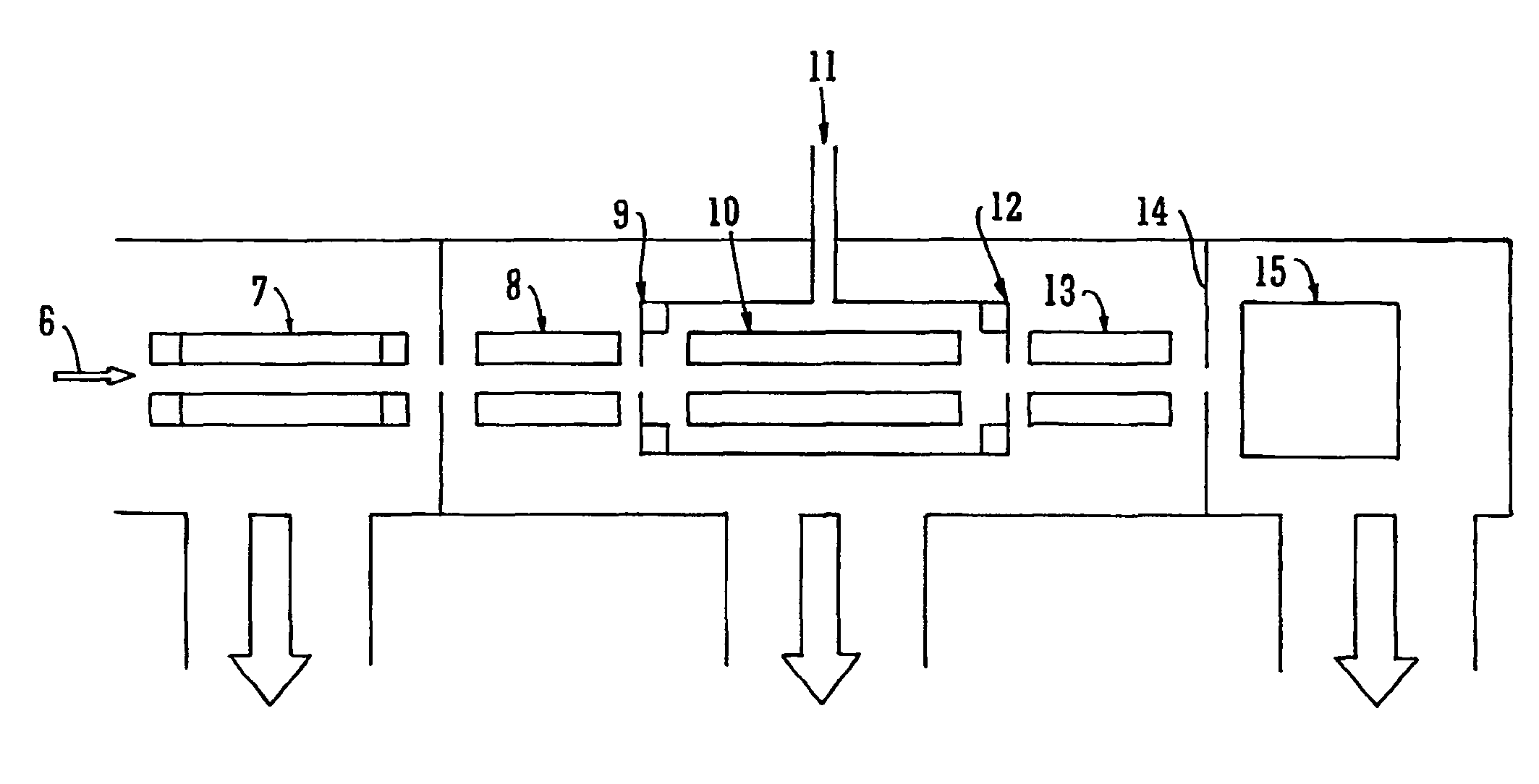

Methods and apparatus for driving a quadrupole ion trap device

InactiveUS7193207B1Spectrometer circuit arrangementsStability-of-path spectrometersLow voltageDipole excitation

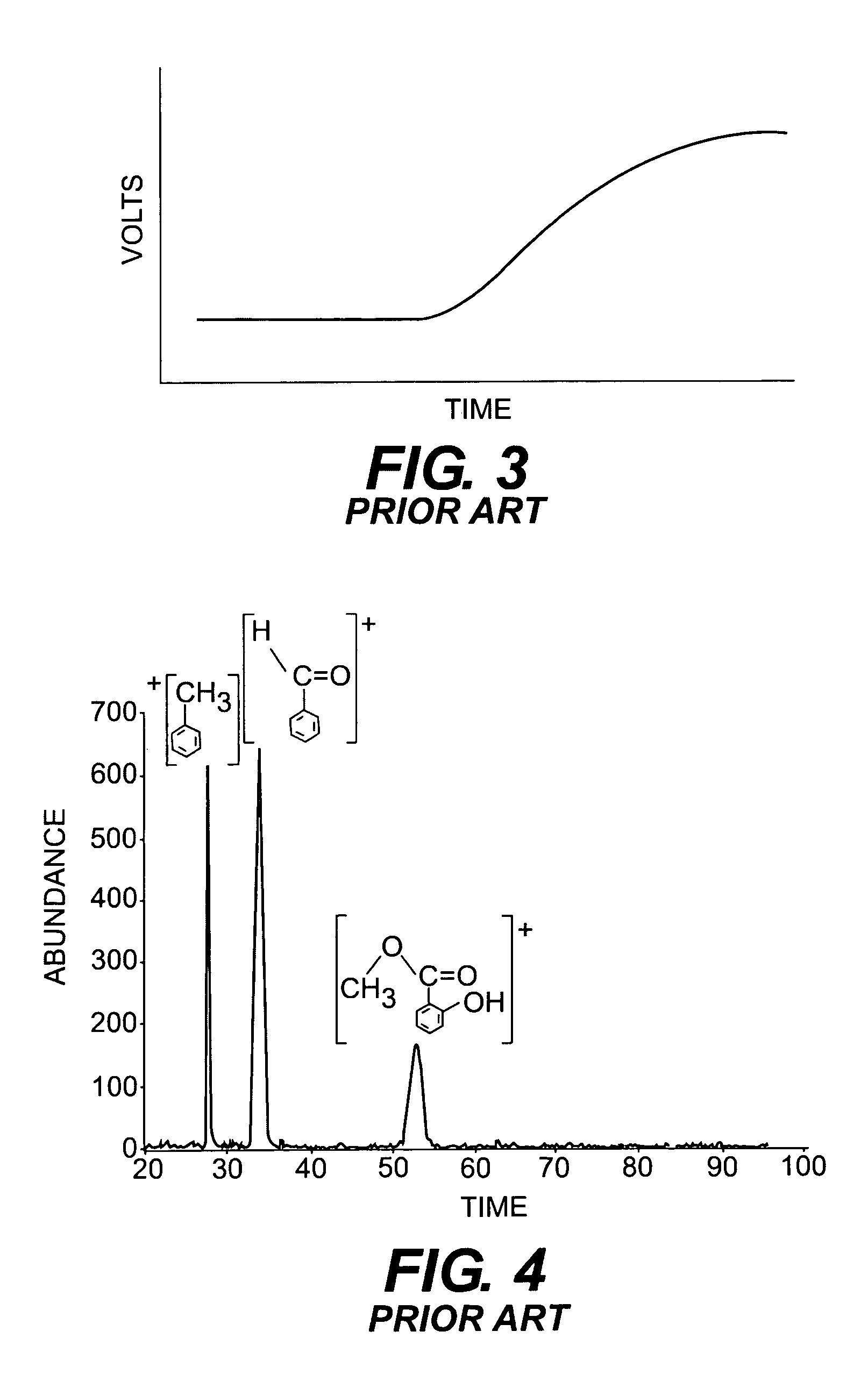

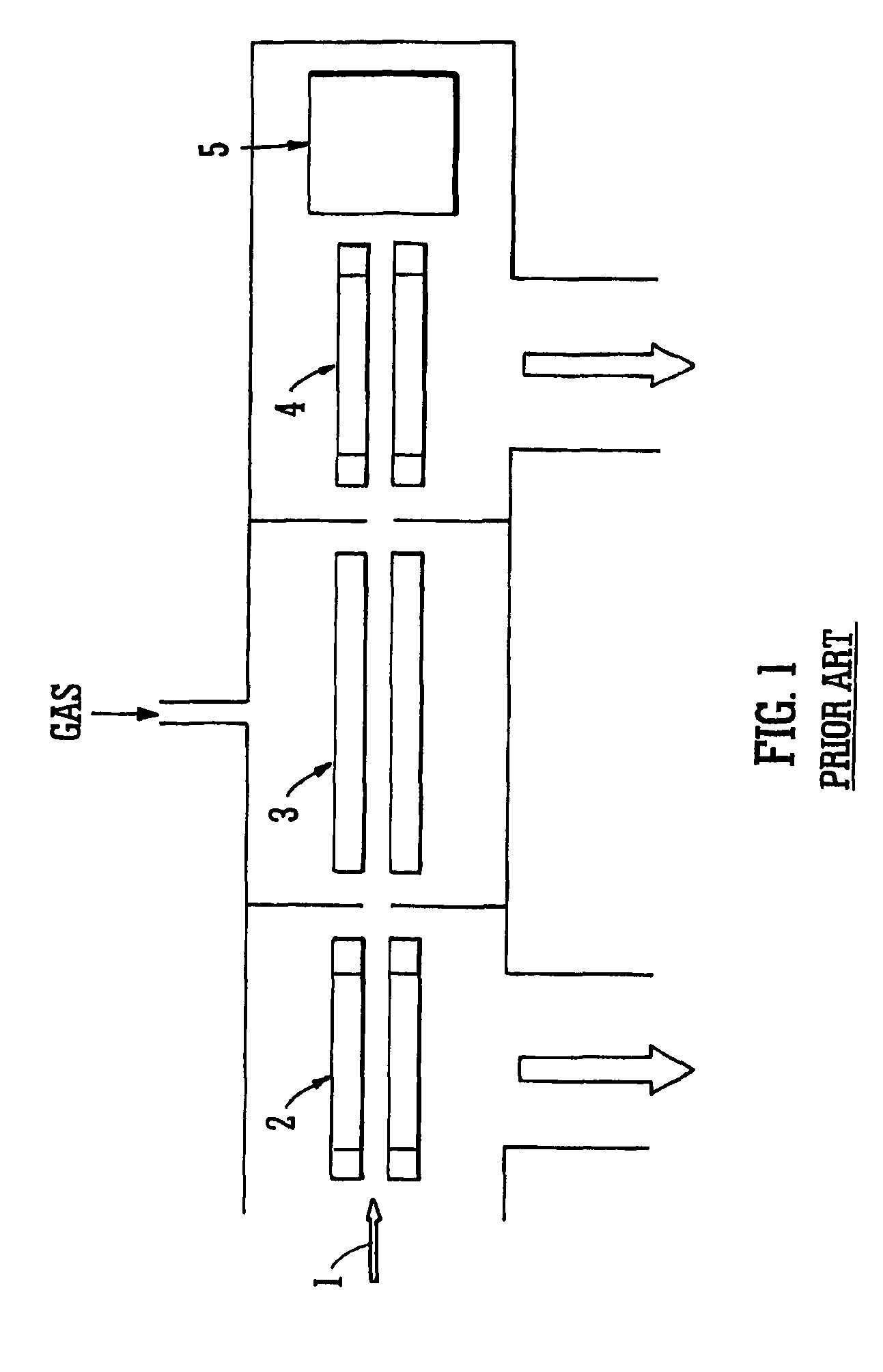

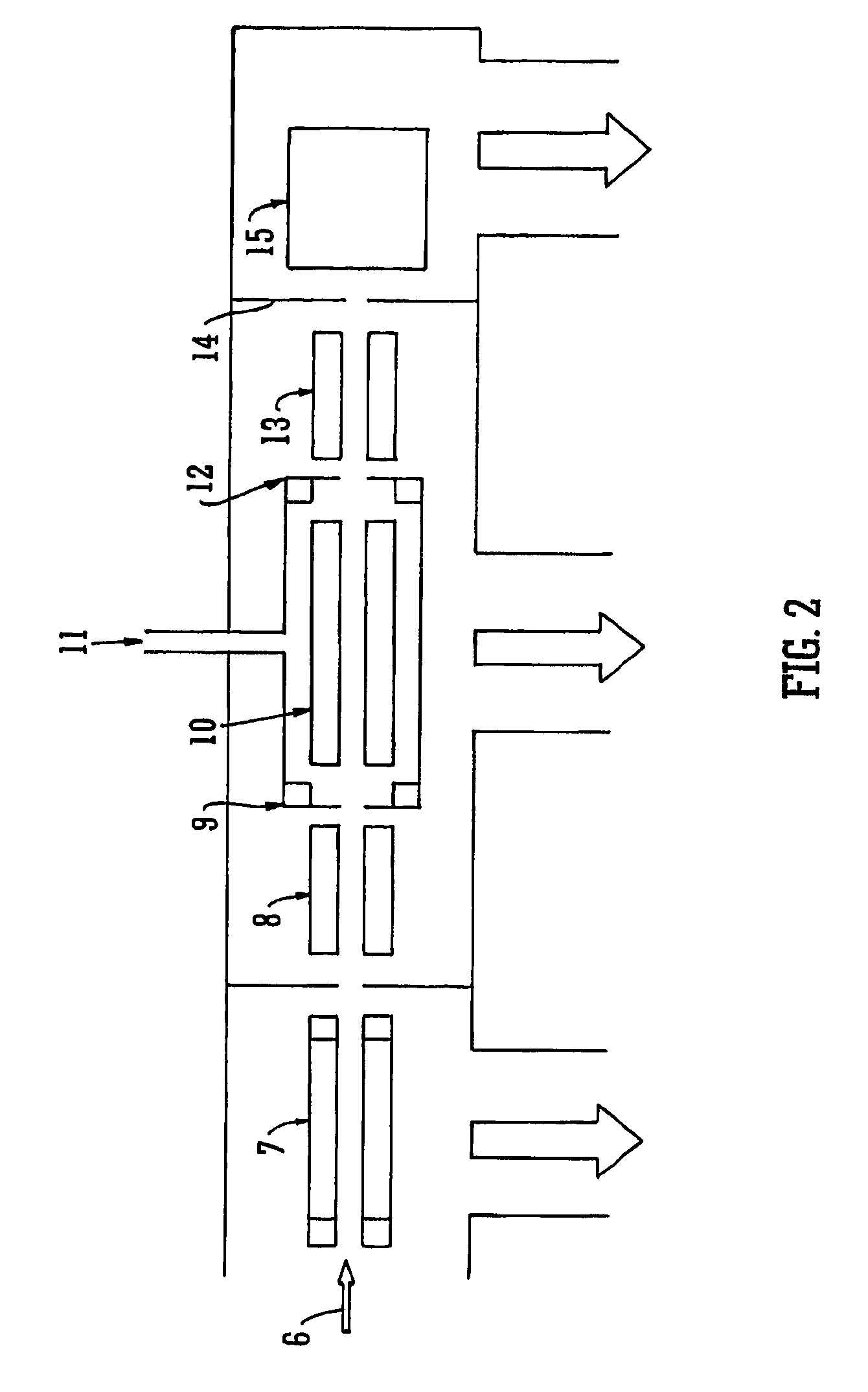

A digital drive apparatus (FIG. 3) for quadrupole device such as a quadrupole ion trap has a digital signal generator (11, 13, 14; 24, 25, 26) and a switching arrangement (16, 17) which alternately switches between high and low voltage levels (V1, V2) to generate a rectangular wave drive voltage. A dipole excitation voltage is also supplied to the quadrupole device to excite resonant oscillatory motion of ions.

Owner:SHIMADZU RES LAB EURO

Circuit for applying suplementary voltages to RF multipole devices

InactiveUS20030173524A1Minimizes axis potentialStability-of-path spectrometersSpectrometer circuit arrangementsLow voltageTransformer

A circuit is described for applying RF and AC voltages to the elements or electrodes of an ion trap or ion guide. The circuit includes an RF transformer having a primary winding and a secondary winding. The secondary winding includes at least two filars. A broadband transformer adapted to be connected to a source of AC voltage applies AC voltage across the low-voltage end of two of the filars. Another broadband transformer connected to the filars at the high-voltage end provides a combined RF and AC output for application to selected electrodes. Also described is a circuit employing a multi-filar RF transformer and broadband transformers for applying RF and AC voltages to spaced rods of a linear ion trap. Also described is a circuit employing a multi-filar RF transformer and broadband transformers for applying RF and AC voltages to the electrodes in each section of a linear ion trap of the type having a center section and end sections, and different DC voltages to the electrodes in the end sections.

Owner:THERMO FINNIGAN

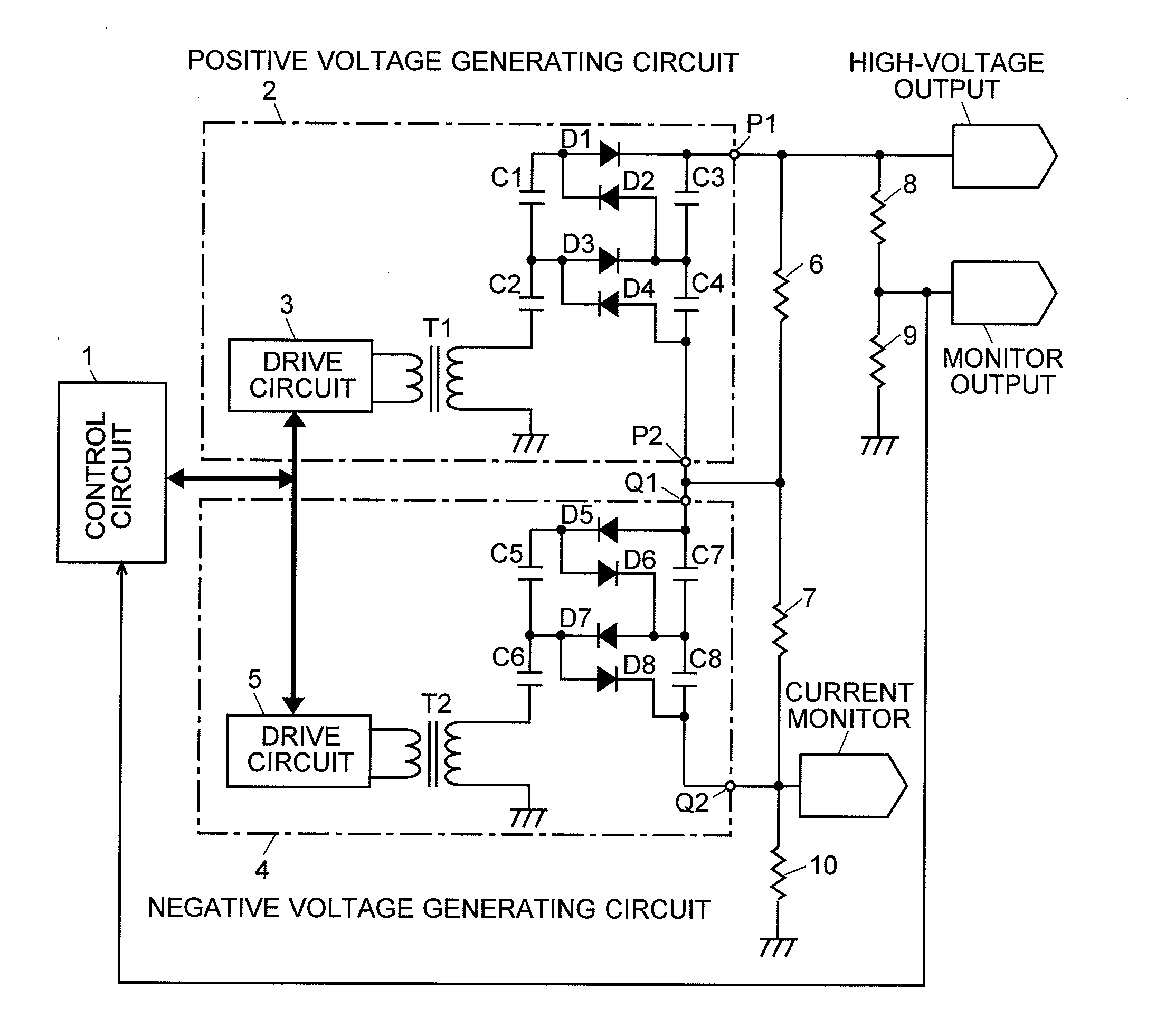

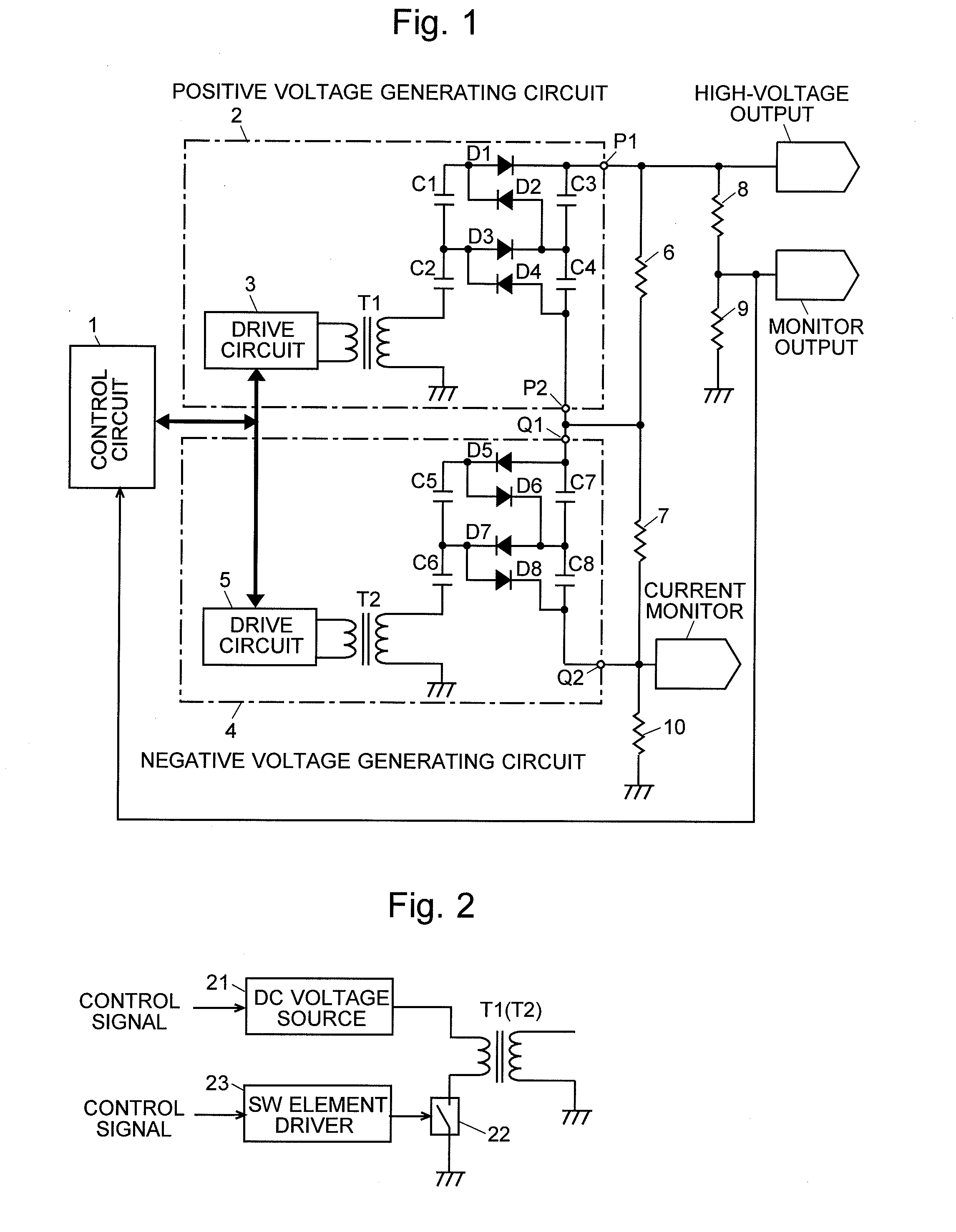

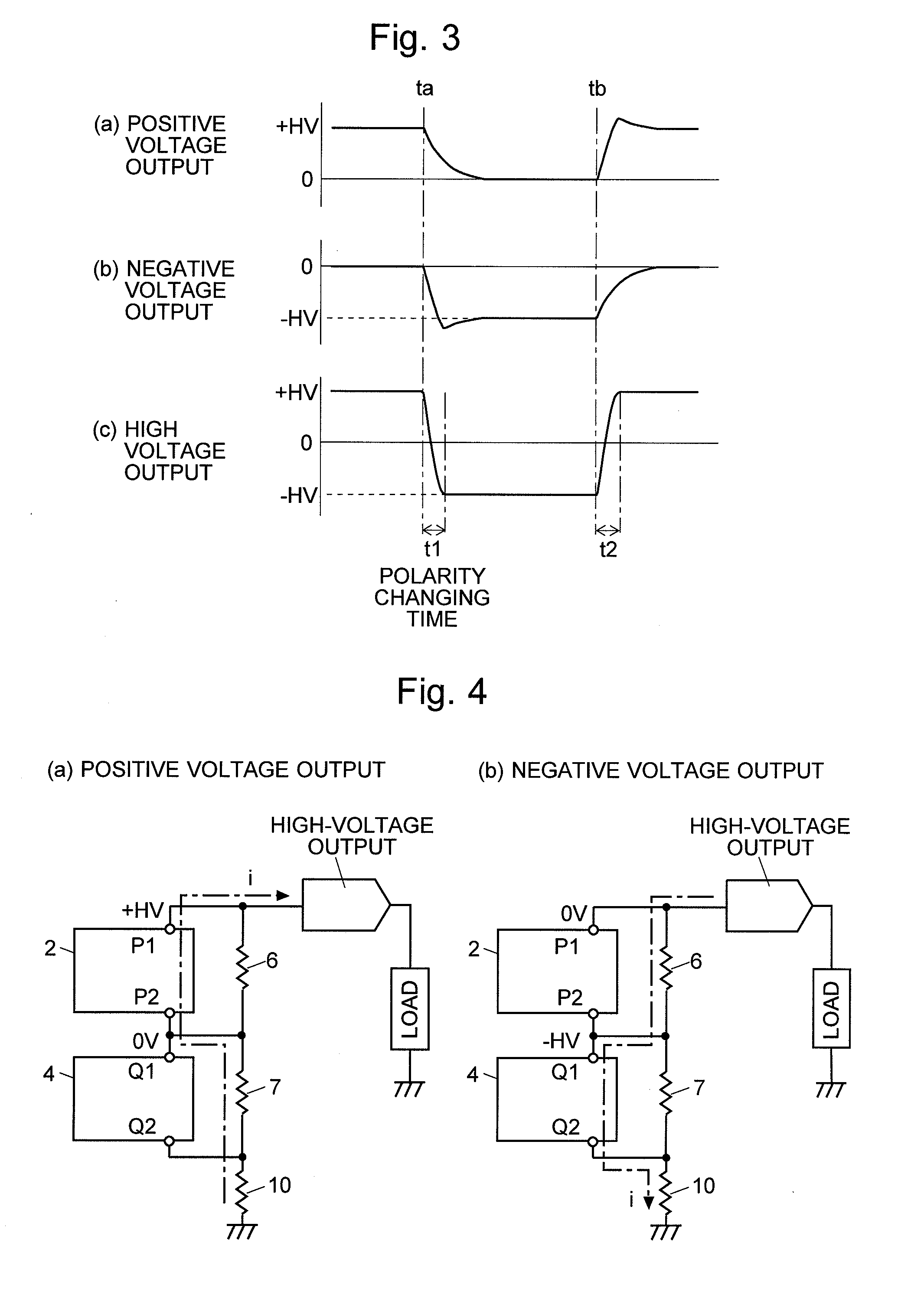

High-voltage power unit and mass spectrometer using the power unit

ActiveUS20090230297A1Not easily occurLow costSpectrometer circuit arrangementsDc network circuit arrangementsEngineeringHigh pressure

The output terminal P2 of the positive voltage generating circuit 2 and the output terminal Q1 of the negative voltage generating circuit 4 are connected in series. The output terminal Q2 of the negative voltage generating circuit 4 is connected to the ground via the resistor 10. Each of the resistors 6 and 7 is respectively connected in parallel to the voltage generating circuits 2 and 4. A high voltage whose polarity is changed is taken from the output terminal P1 of the positive voltage generating circuit 2. For changing the output voltage from positive to negative one, the control circuit 1 controls each of the drive circuits 3 and 5 so that the output of the positive voltage generating circuit 2 changes from the voltage +HV to zero and the output of the negative voltage generating circuit 4 simultaneously changes from zero to −HV. Accordingly, the output voltage changes in a short period of time. Although a high-voltage-resistance resistor is required in this configuration, it is far more inexpensive and has higher reliability compared to a high-voltage relay or a semiconductor switch which has been conventionally used.

Owner:SHIMADZU CORP

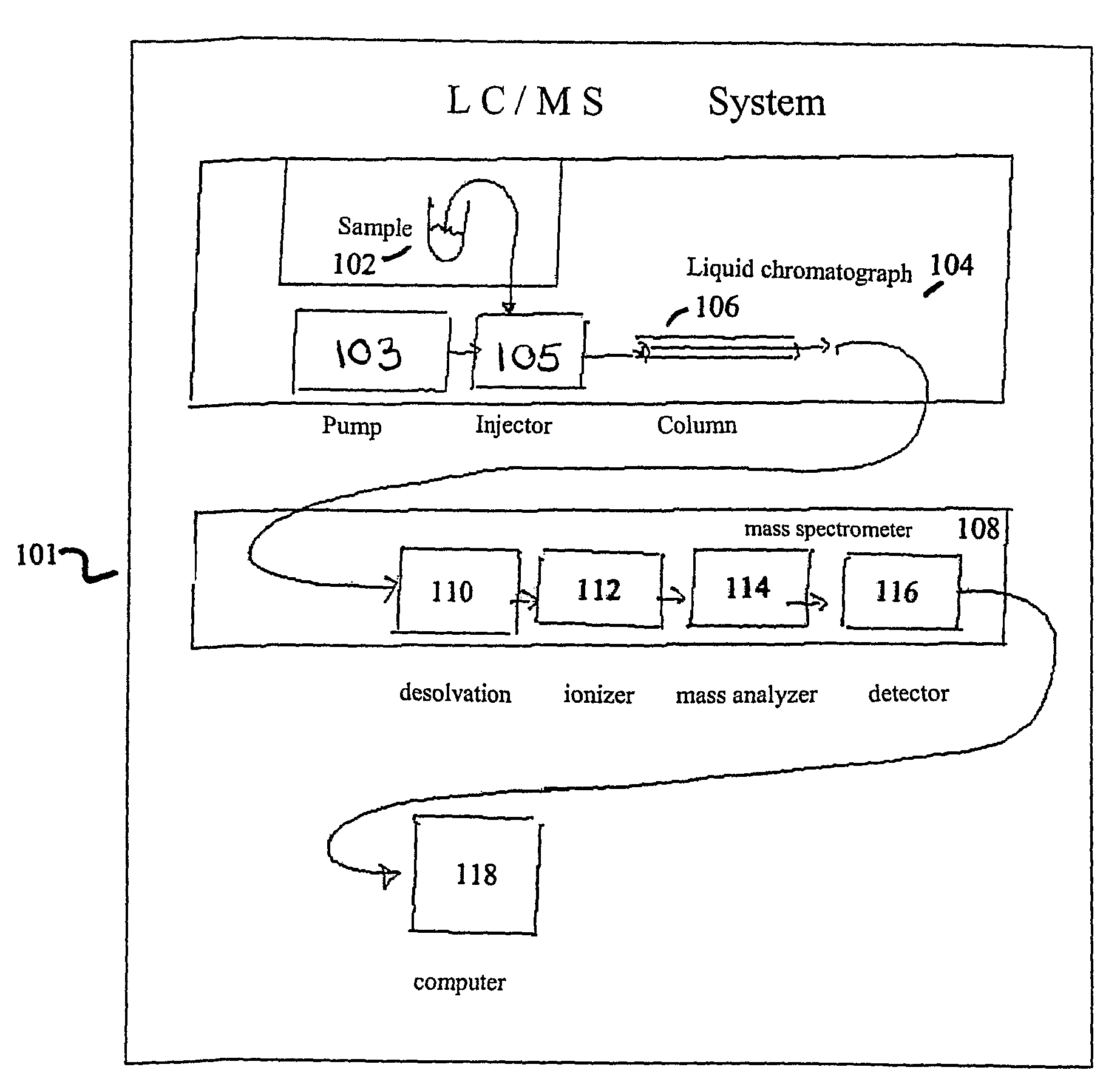

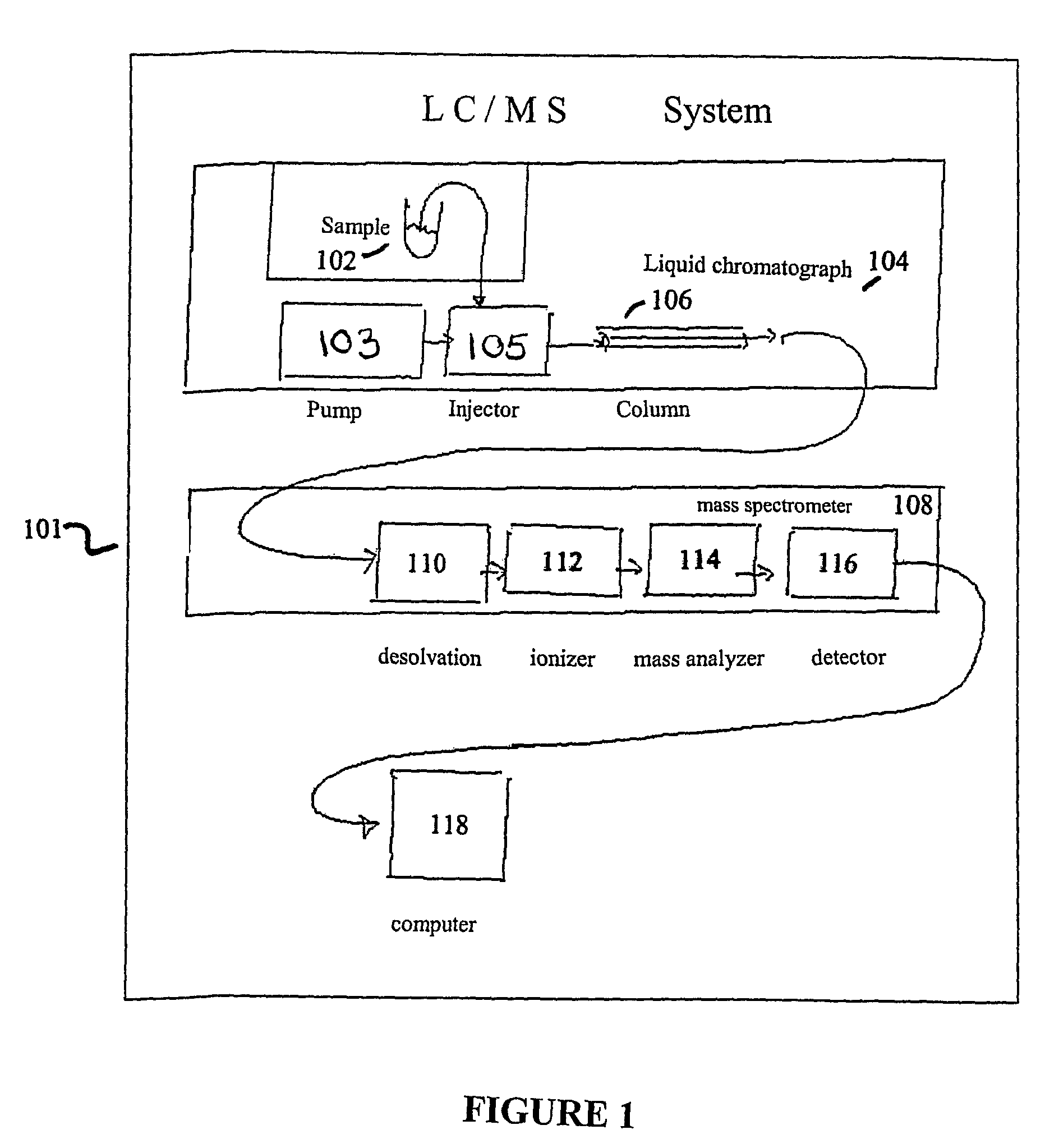

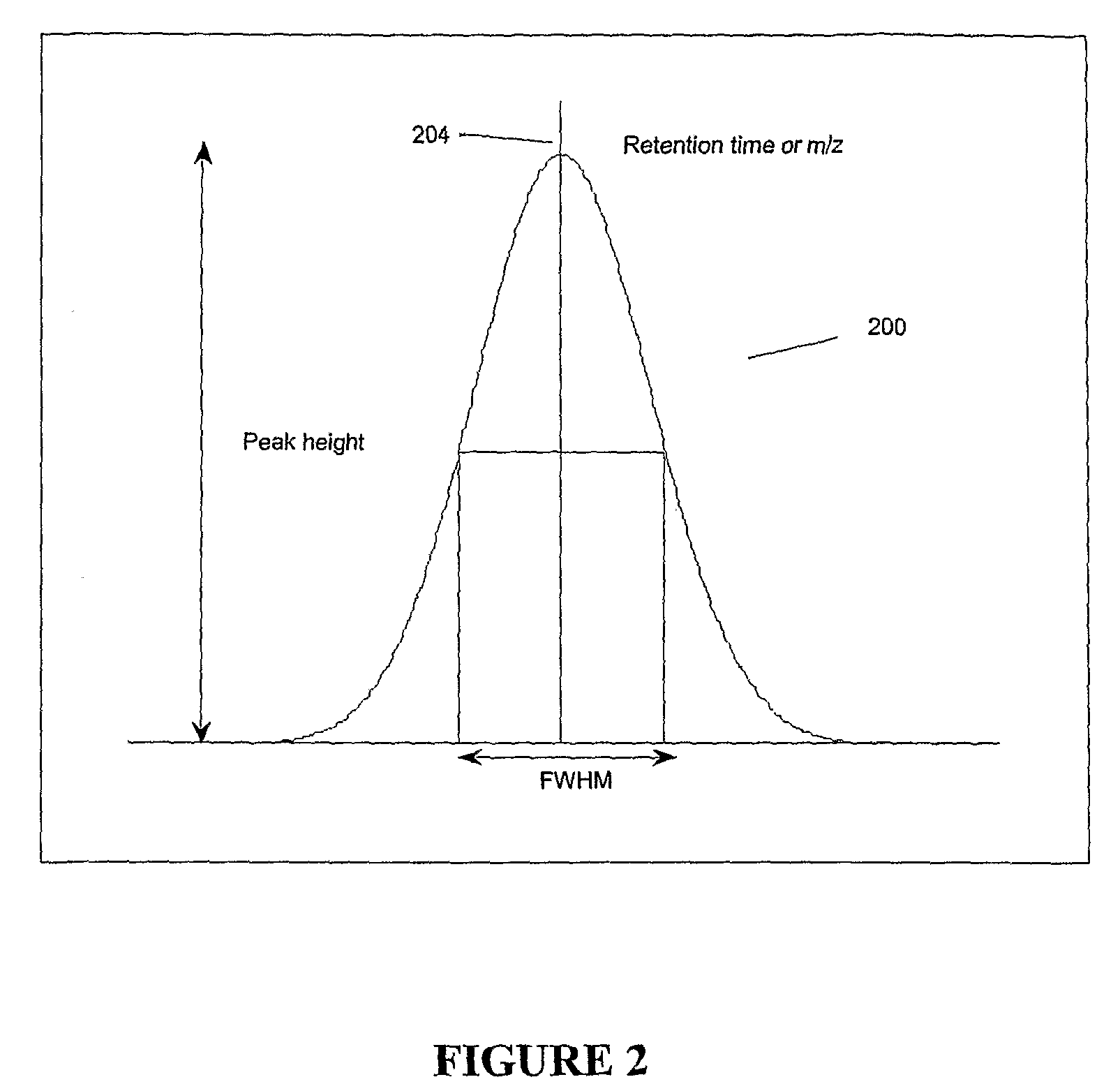

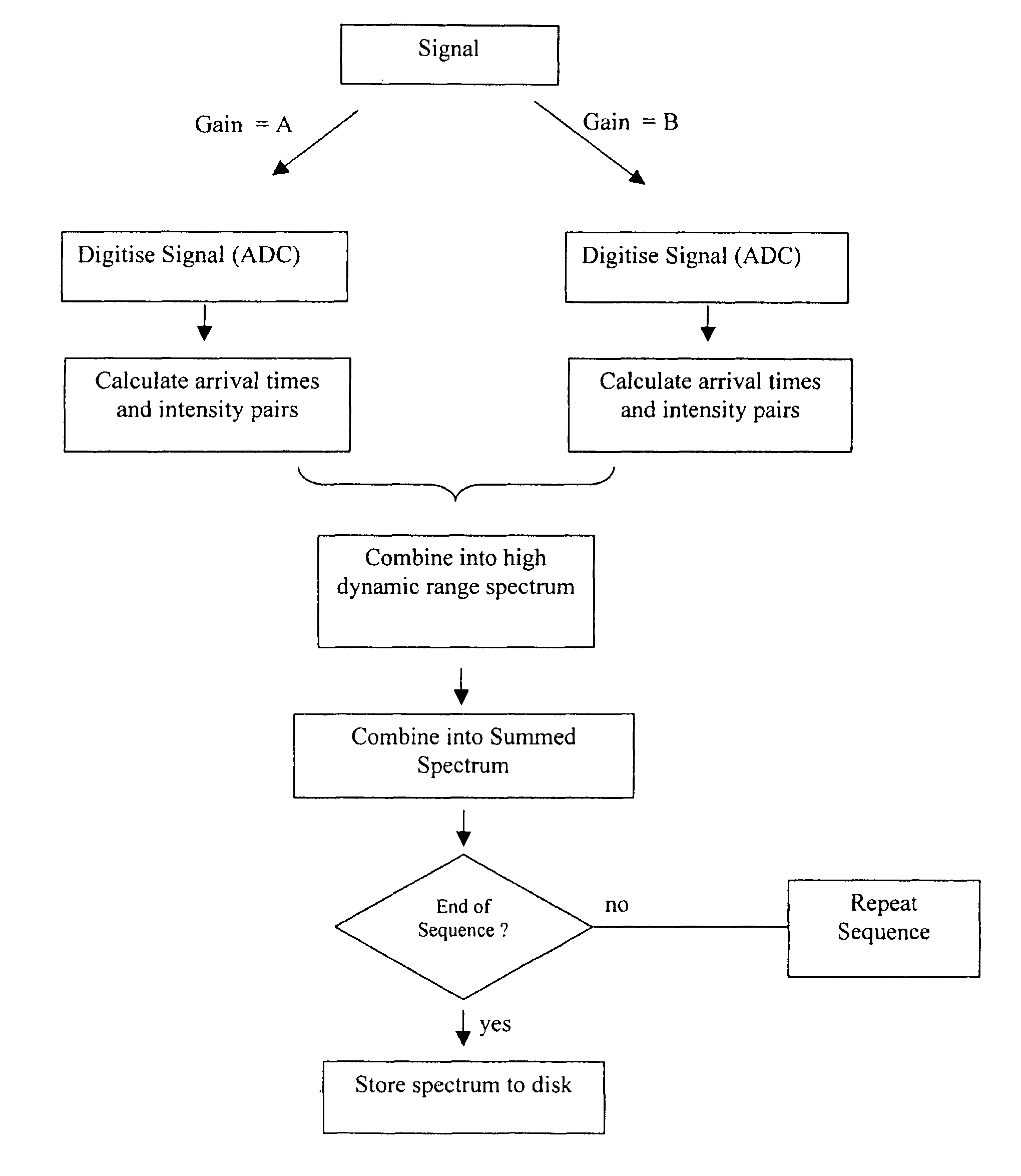

Apparatus and method for identifying peaks in liquid chromatography/mass spectrometry data and for forming spectra and chromatograms

ActiveUS7645984B2Accurately and optimally estimatedReduce impactThermometer detailsSpectral/fourier analysisRetention timeLiquid chromatography mass spectroscopy

Chromatograms and mass spectra produced by an LC / MS system are analyzed by creating a two-dimensional data matrix of the spectral and chromatographic data. The two-dimensional matrix can be created by placing the spectra generated by the mass spectrometer portion of the LC / MS system in successive columns of the data matrix. In this way, the rows of the data matrix correspond to chromatographic data and the columns of the data matrix correspond to the spectra. A two-dimensional filter is specified and applied to the data matrix to enhance the ability of the system to detect peaks associated with ions. The two-dimensional filter is specified according to desired criteria. Rank-1 and rank-2 filters can be specified to improve computational efficiency. One method of applying the two-dimensional filter is through convolution of the data matrix with the two-dimensional filter to produce an output data matrix. Peaks corresponding to detected ions are identified in the output data matrix. Parameters of the peaks are determined and stored for later processing including quantitation, or simplification of chromatograms or spectra by, for example, identifying peaks associating with ions having retention times falling within a specified retention time window or having mass-to charge ratios falling within a specified mass-to-charge ratio window.

Owner:WATERS TECH CORP

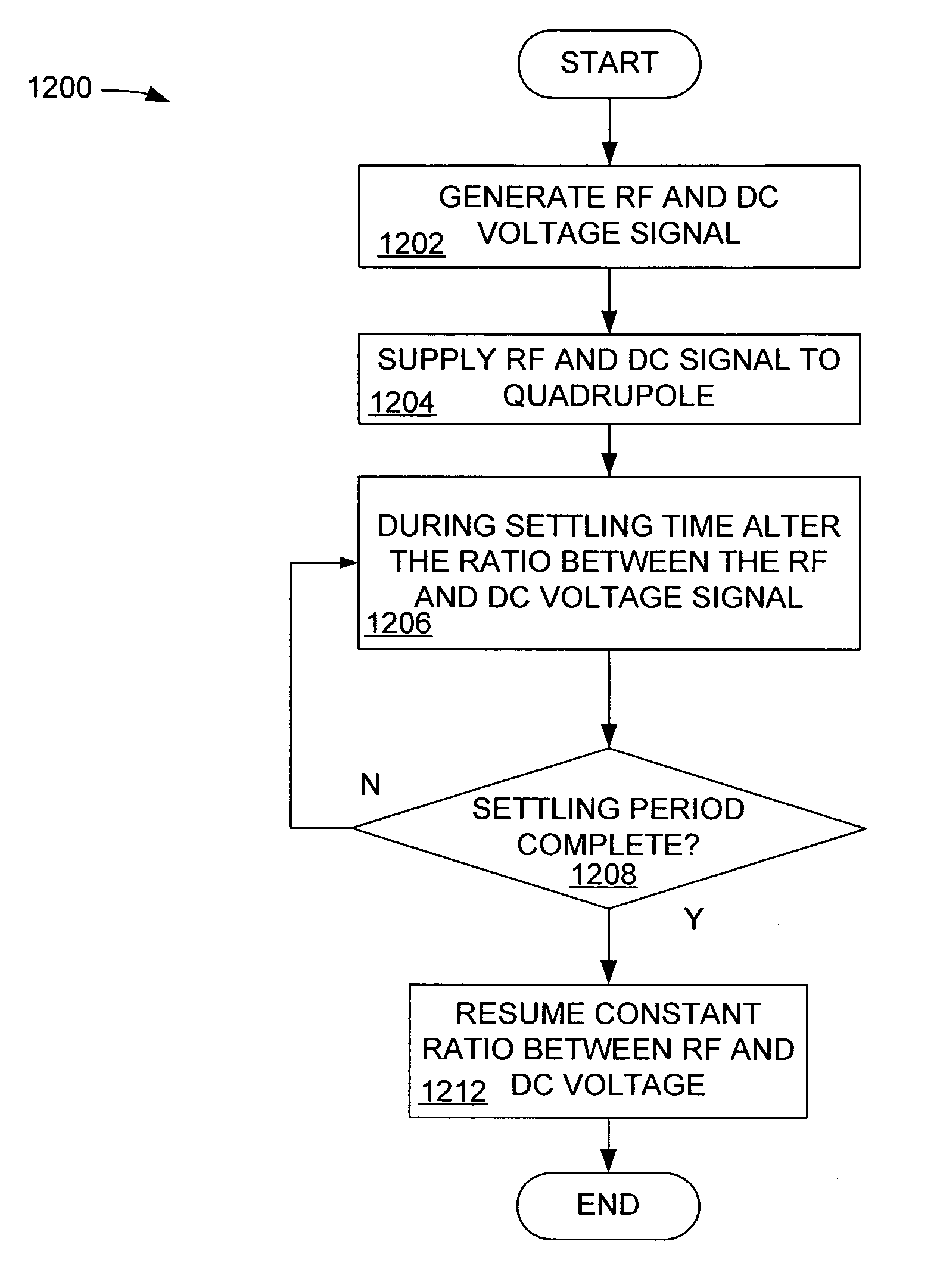

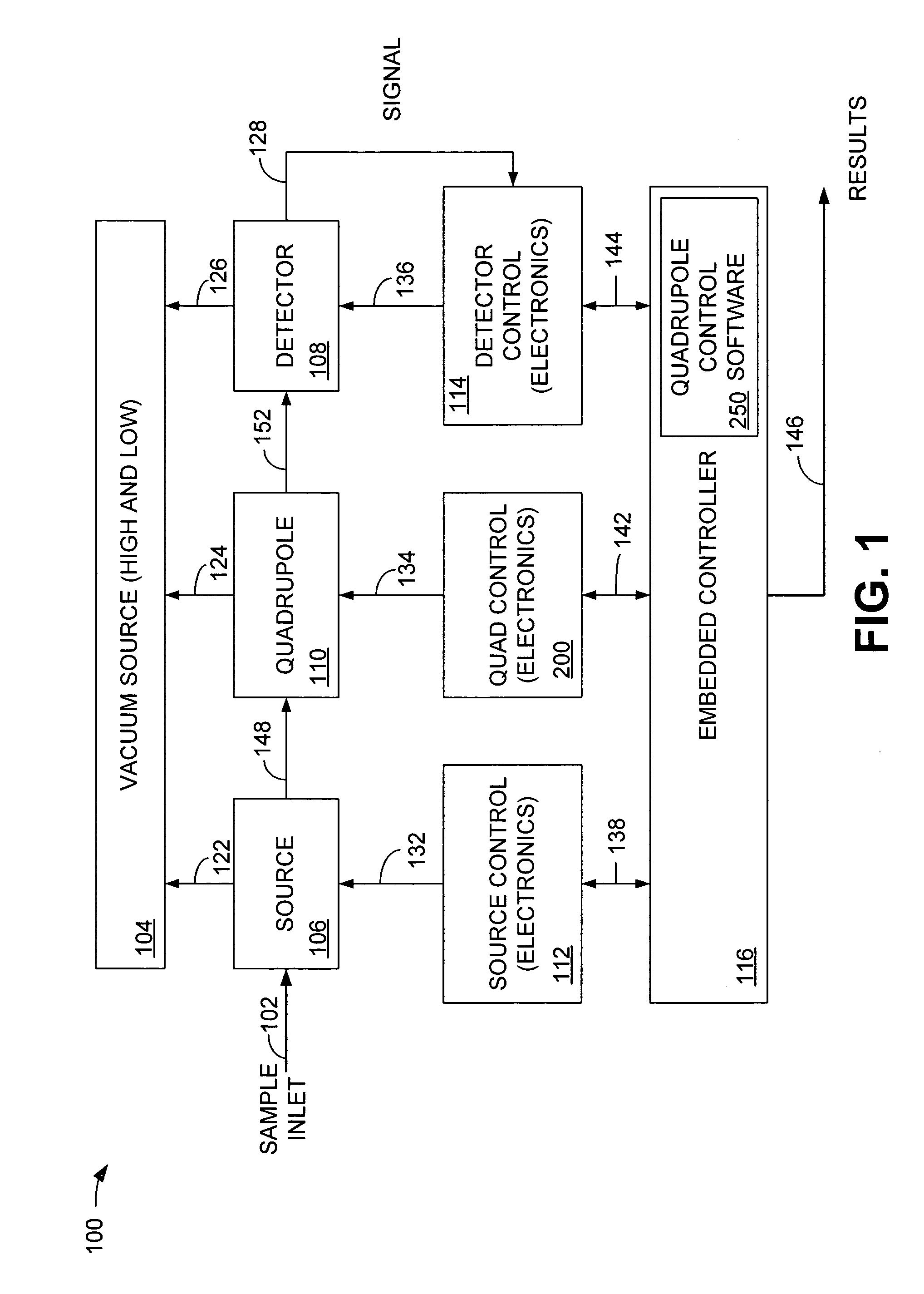

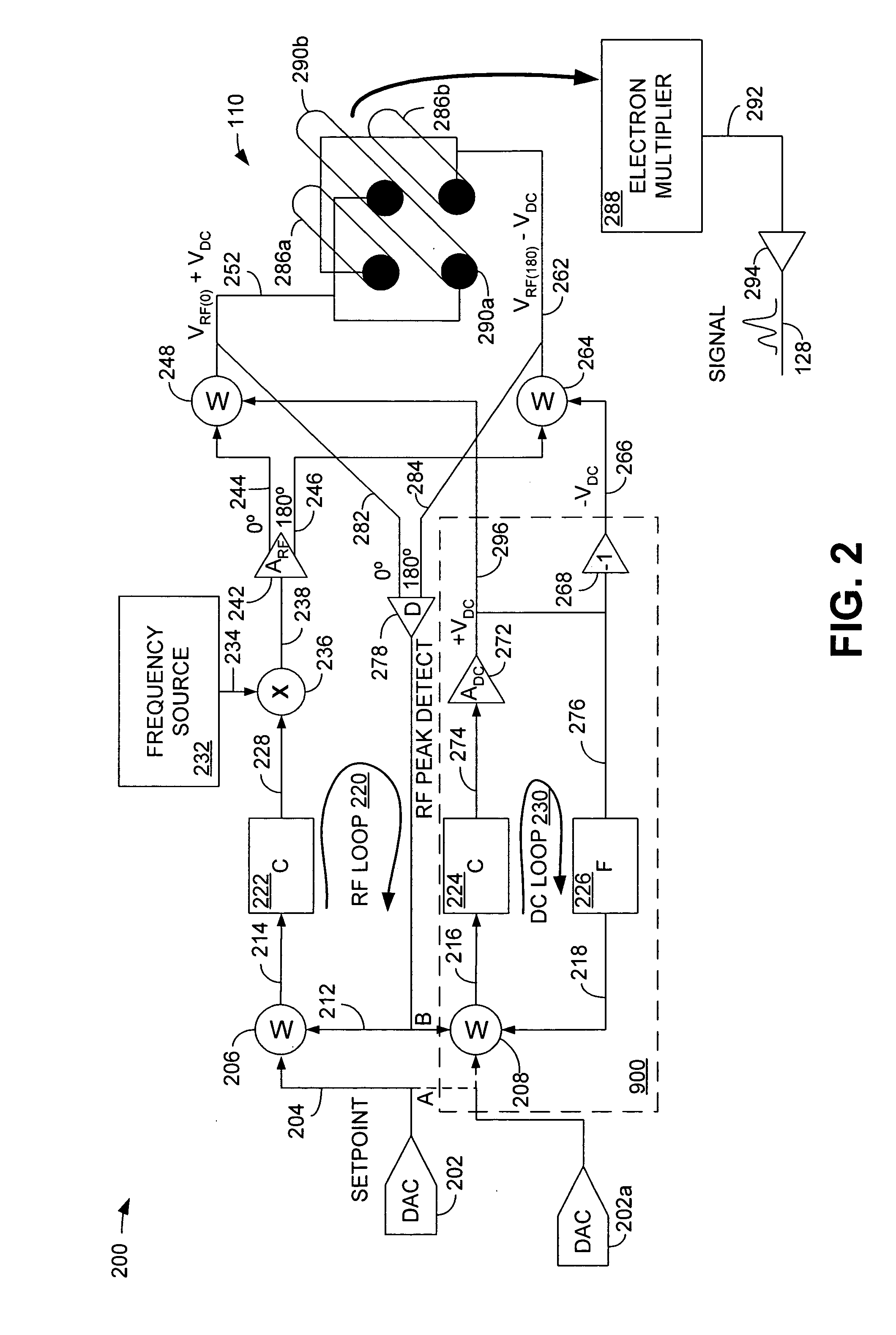

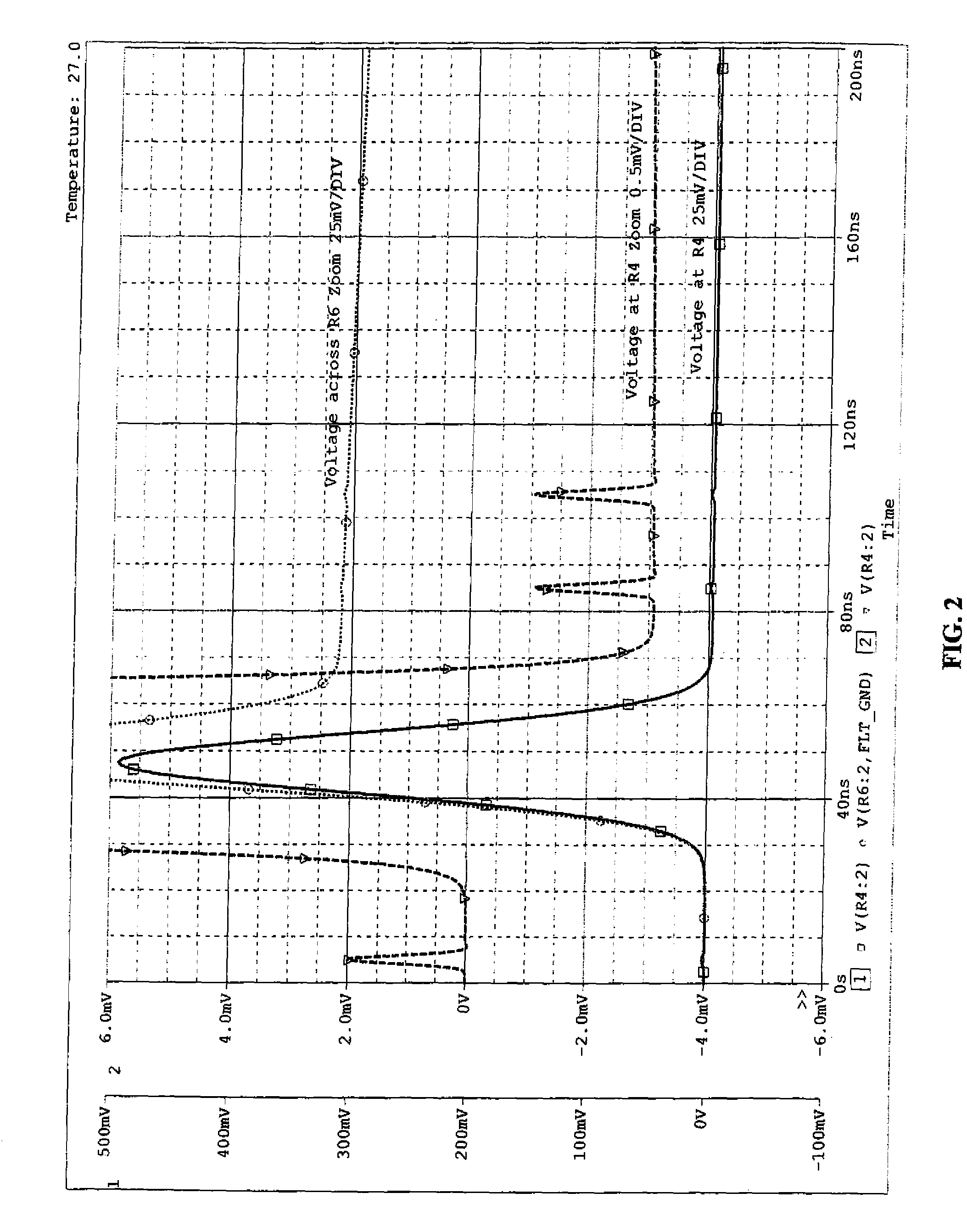

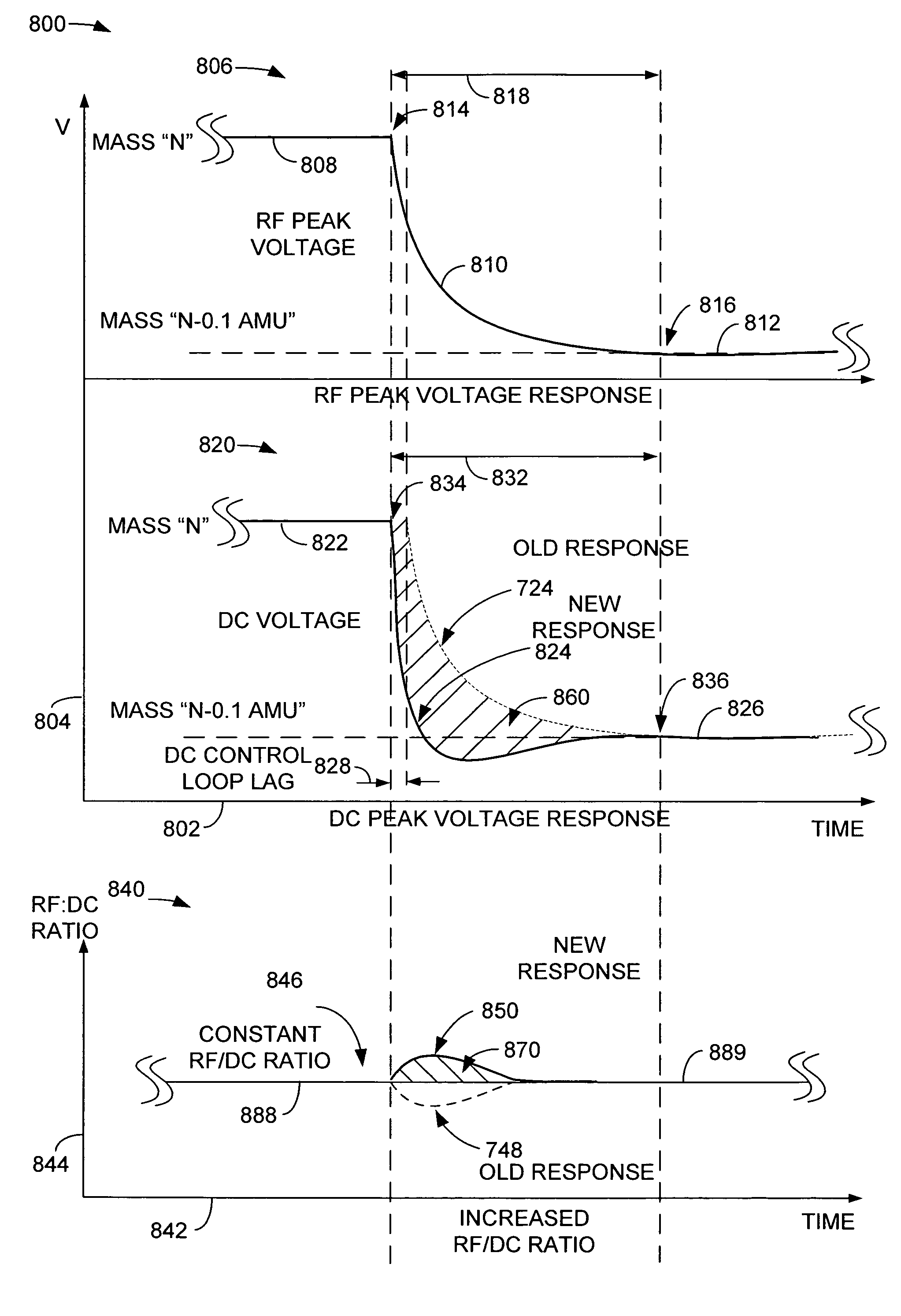

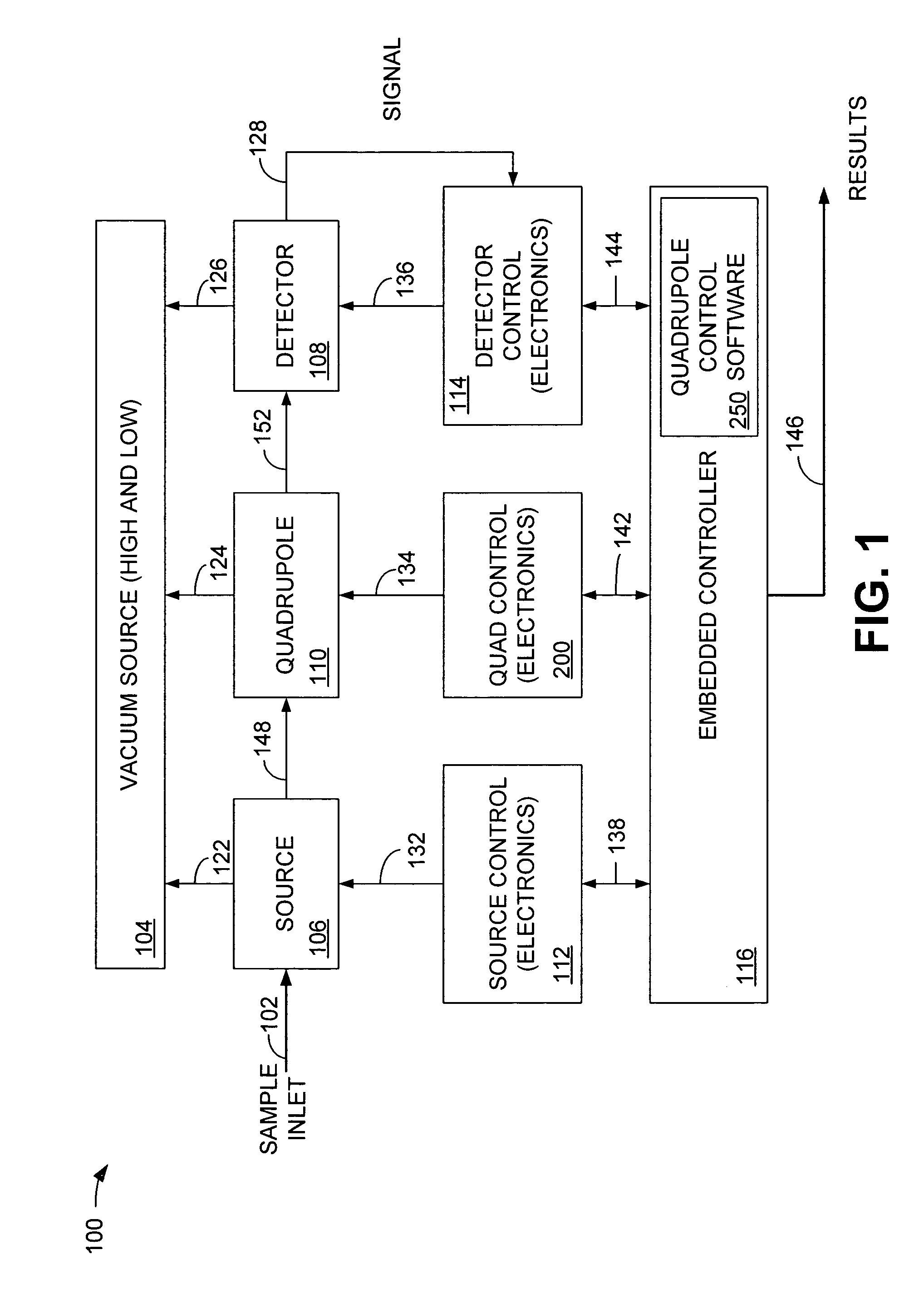

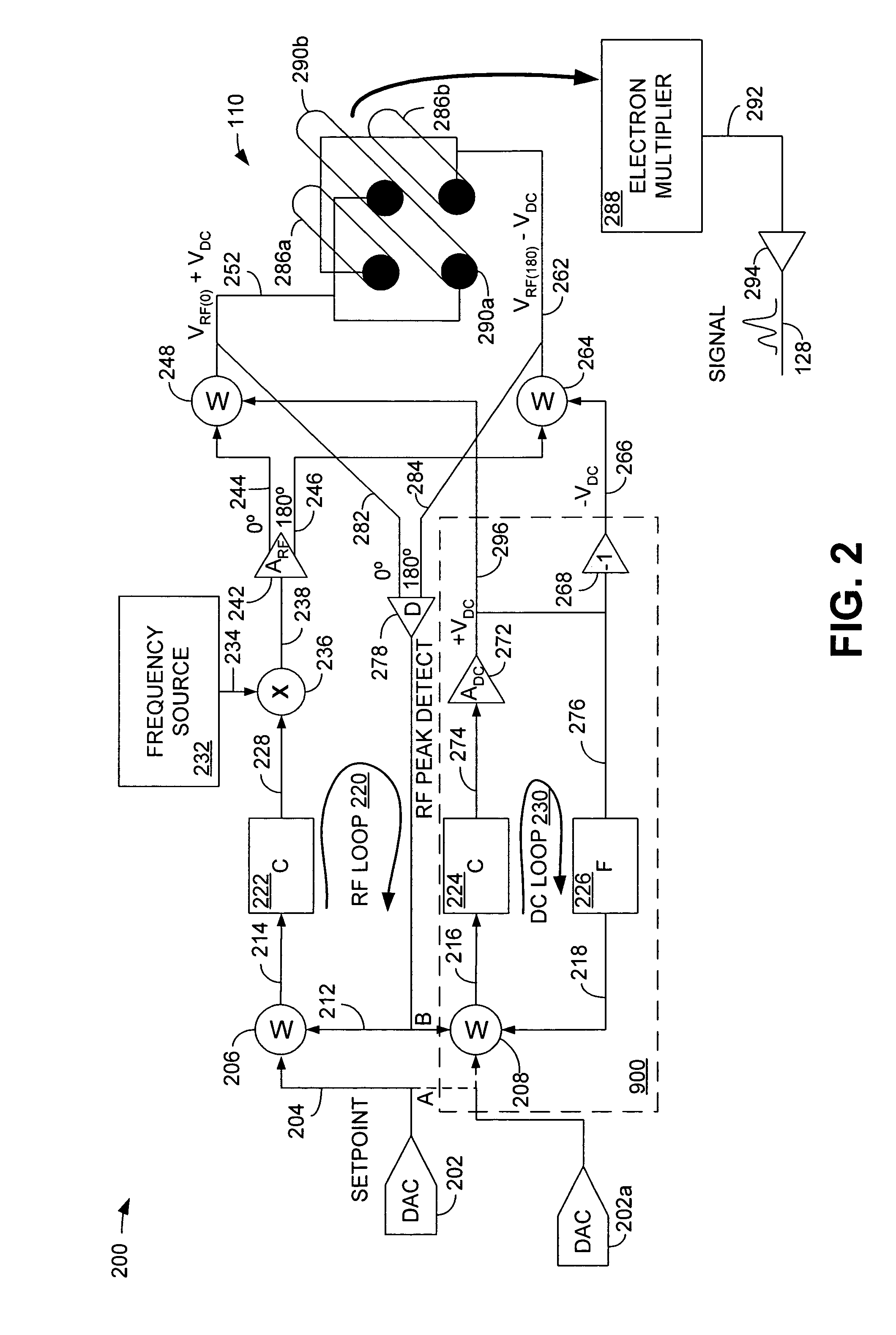

Apparatus and method for electronically driving a quadrupole mass spectrometer to improve signal performance at fast scan rates

ActiveUS20060016985A1Altering responseStability-of-path spectrometersSpectrometer circuit arrangementsEngineeringMass analyzer

An apparatus for electronically controlling a quadrupole in a mass spectrometer, comprises radio frequency (RF) drive circuitry and direct current (DC) drive circuitry coupled to a quadrupole, an RF control loop associated with the RF drive circuitry, a DC control loop associated with the DC drive circuitry, and control loop circuitry associated with the DC control loop, the control loop circuitry configured to alter a response of the DC control loop during a settling time period of a step response such that ion transmission through the quadrupole is greater during the settling time than if the response of the DC control loop during the settling time is unaltered.

Owner:AGILENT TECH INC

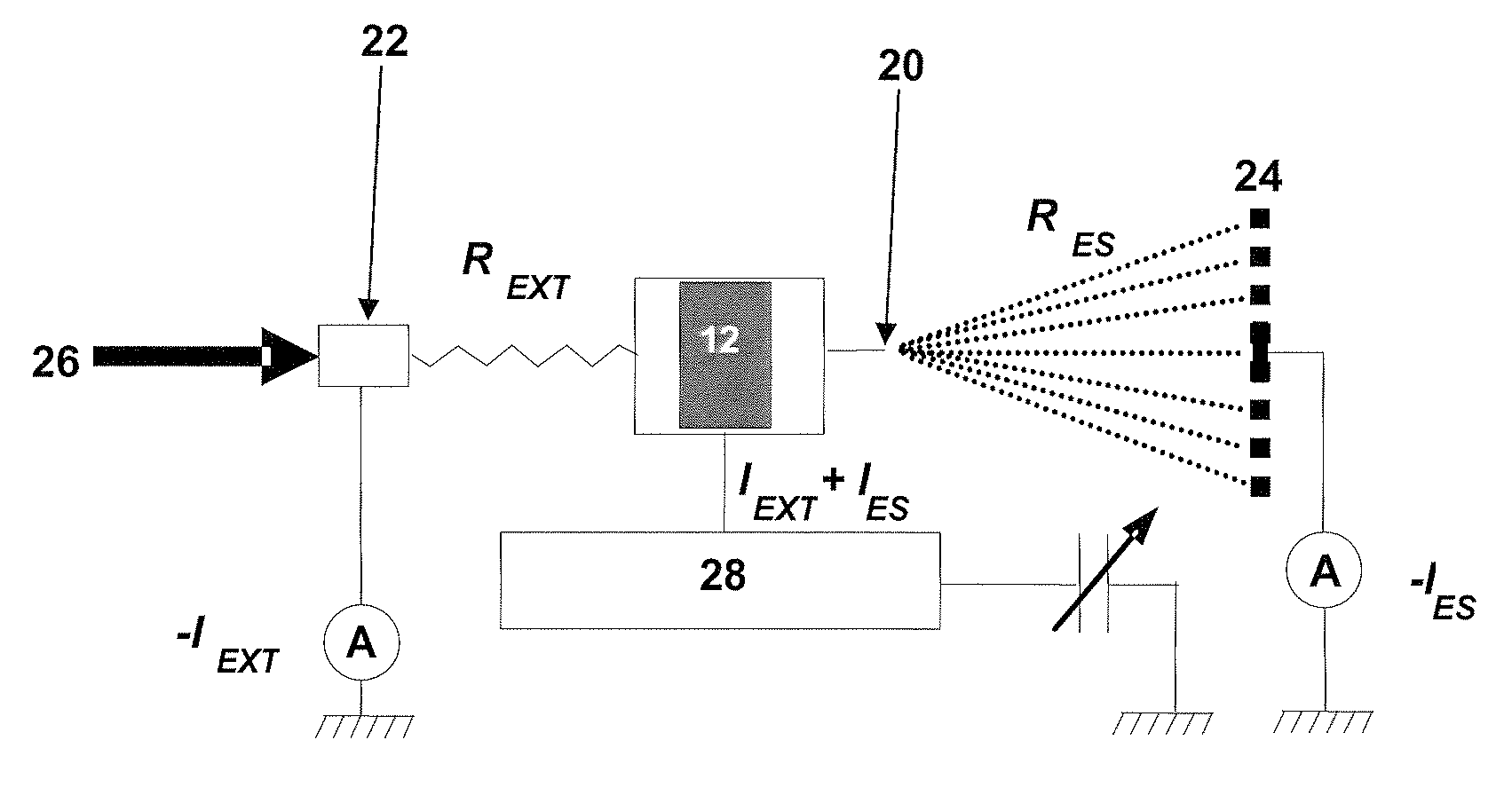

Pulsed voltage electrospray ion source and method for preventing analyte electrolysis

InactiveUS8084735B2Spectrometer circuit arrangementsMaterial analysis by optical meansElectrolysisAnalyte

An electrospray ion source and method of operation includes the application of pulsed voltage to prevent electrolysis of analytes with a low electrochemical potential. The electrospray ion source can include an emitter, a counter electrode, and a power supply. The emitter can include a liquid conduit, a primary working electrode having a liquid contacting surface, and a spray tip, where the liquid conduit and the working electrode are in liquid communication. The counter electrode can be proximate to, but separated from, the spray tip. The power system can supply voltage to the working electrode in the form of a pulse wave, where the pulse wave oscillates between at least an energized voltage and a relaxation voltage. The relaxation duration of the relaxation voltage can range from 1 millisecond to 35 milliseconds. The pulse duration of the energized voltage can be less than 1 millisecond and the frequency of the pulse wave can range from 30 to 800 Hz.

Owner:UT BATTELLE LLC

Auxiliary frequency parametric excitation of quadrupole mass spectrometers

ActiveUS20120145892A1Improve dynamic rangeImprove power efficiencySpectrometer circuit arrangementsDynamic spectrometersFundamental frequencySpectrometer

The apparatus introduces a second adjustable resonant point in a QMS at a frequency that is close to a multiple of the fundamental frequency by adjusting driving point impedance characteristics of the QMS. The apparatus measures the first and second resonant point of the QMS to account for changes in the operational characteristics of the QMS.

Owner:RGT UNIV OF MICHIGAN

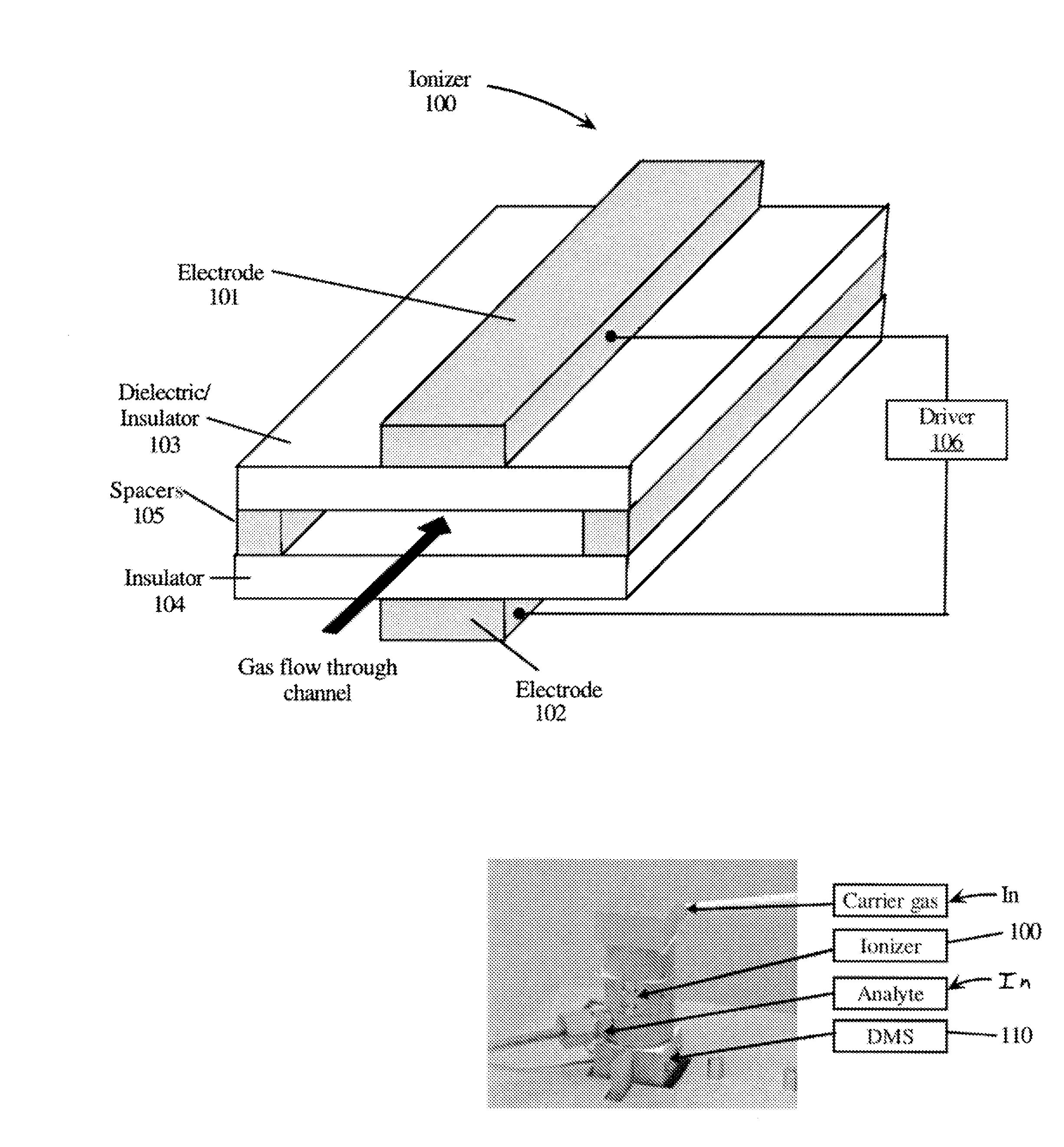

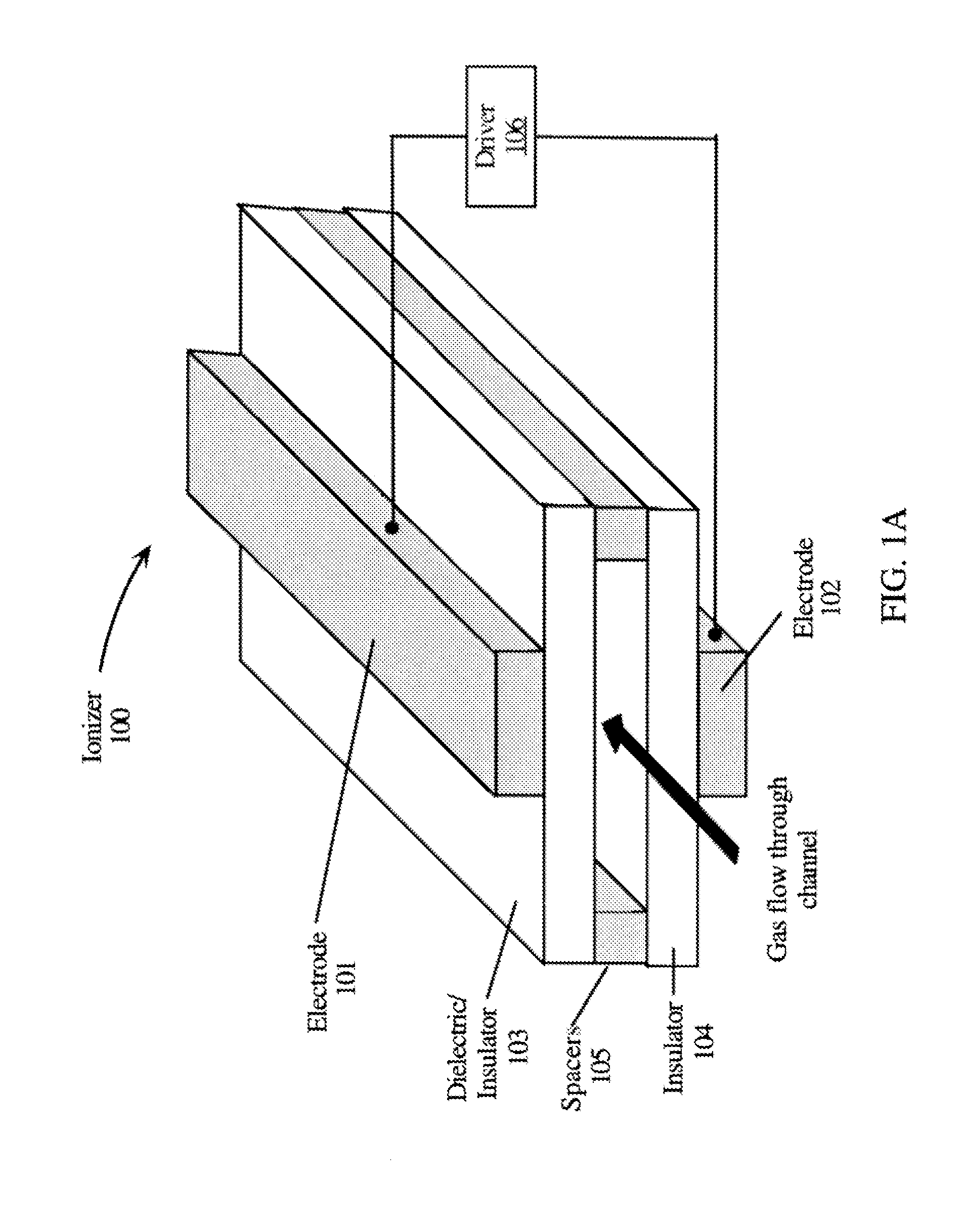

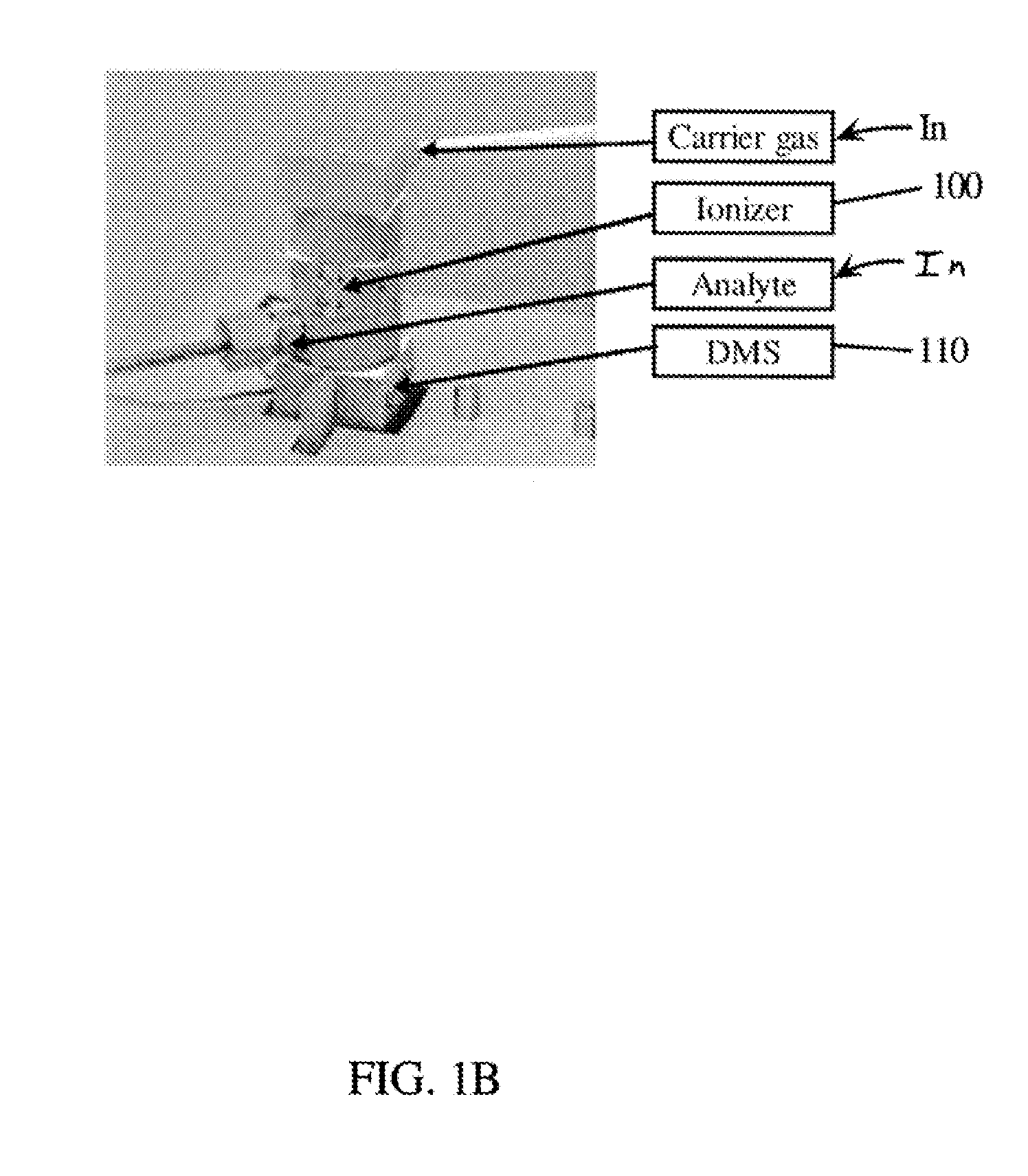

Nonradioactive ionization source driver

InactiveUS20140291506A1Spectrometer circuit arrangementsMaterial analysis by electric/magnetic meansSpectroscopyIon density

System and method for operating an ionizer using a combination of amplitude modulation and pulse width modulation to control the plasma temperature and the type of ions needed for analytic equipment. Ion density can be controlled by the repetition rate. The ionizer may utilize a non-radioactive ionization source, and be coupled to a differential mobility spectroscopy (DMS) analyzer.

Owner:PEN

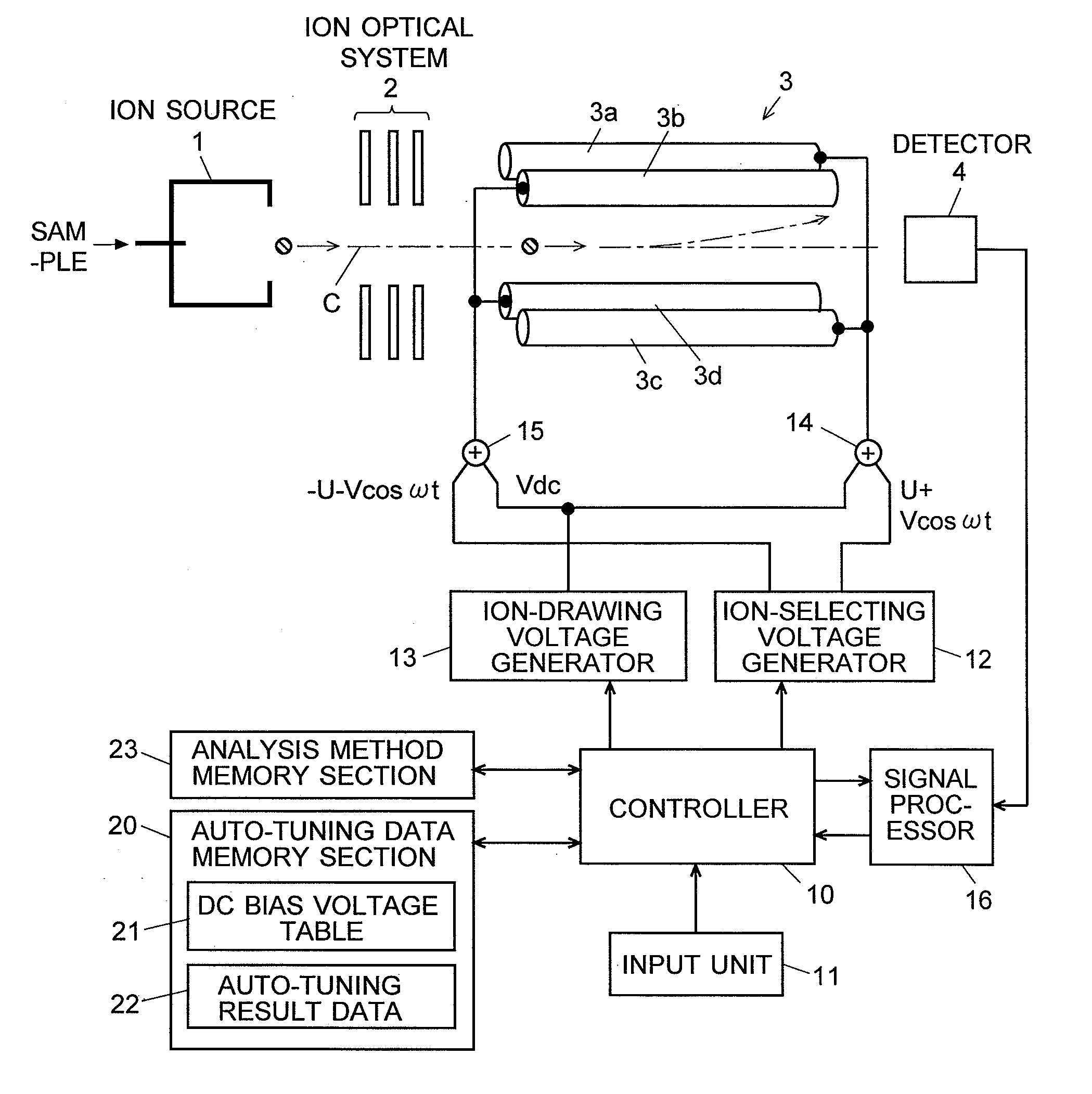

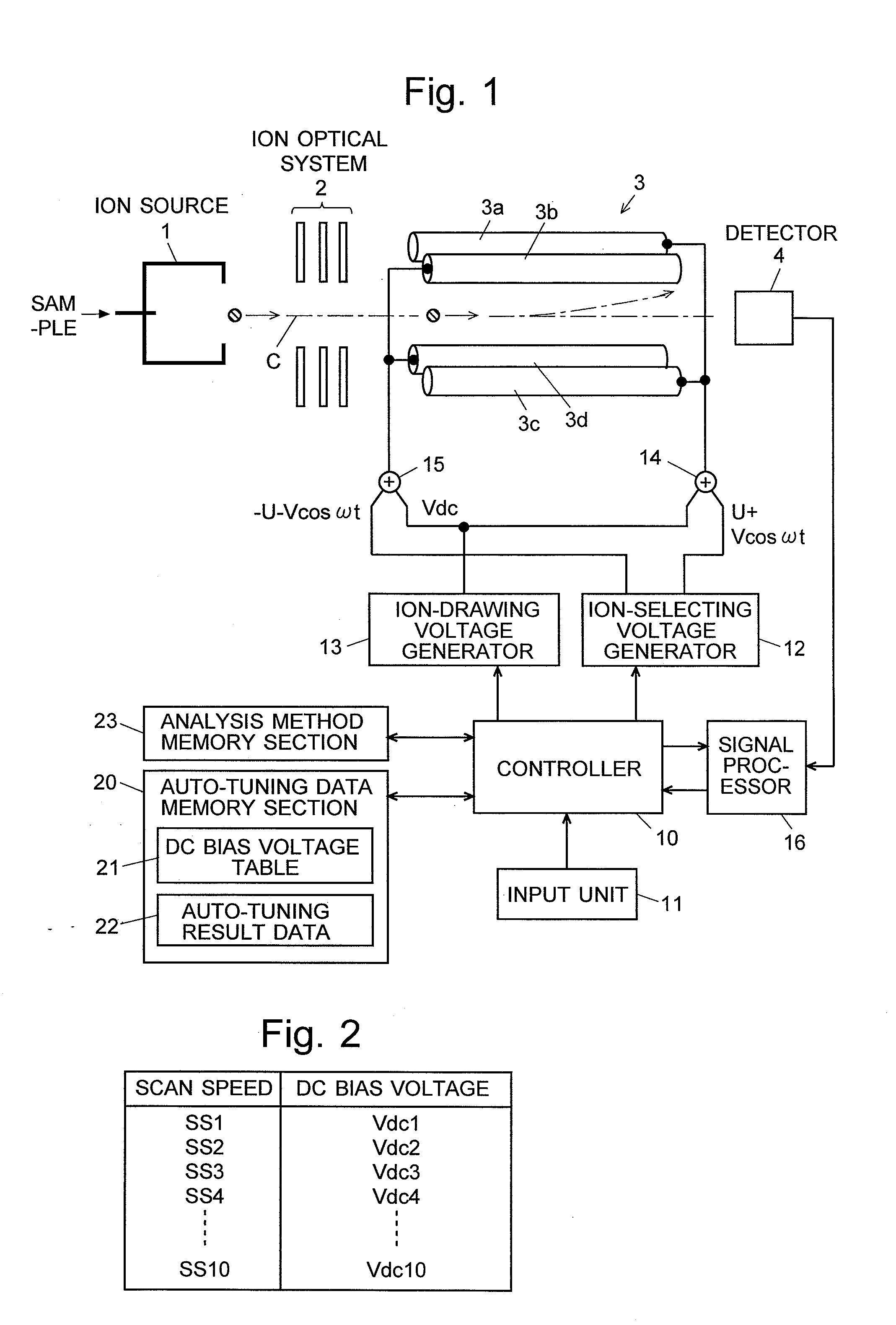

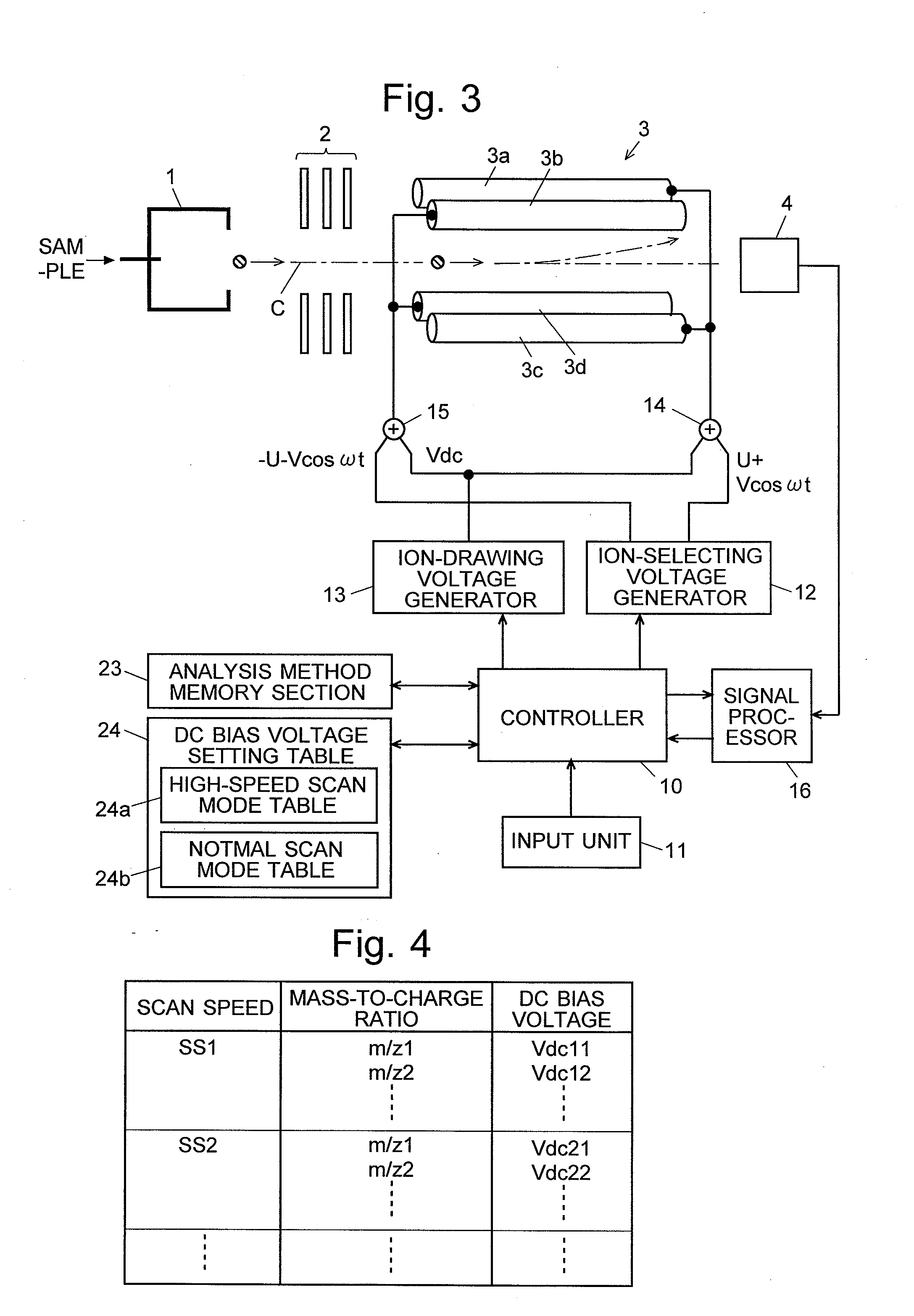

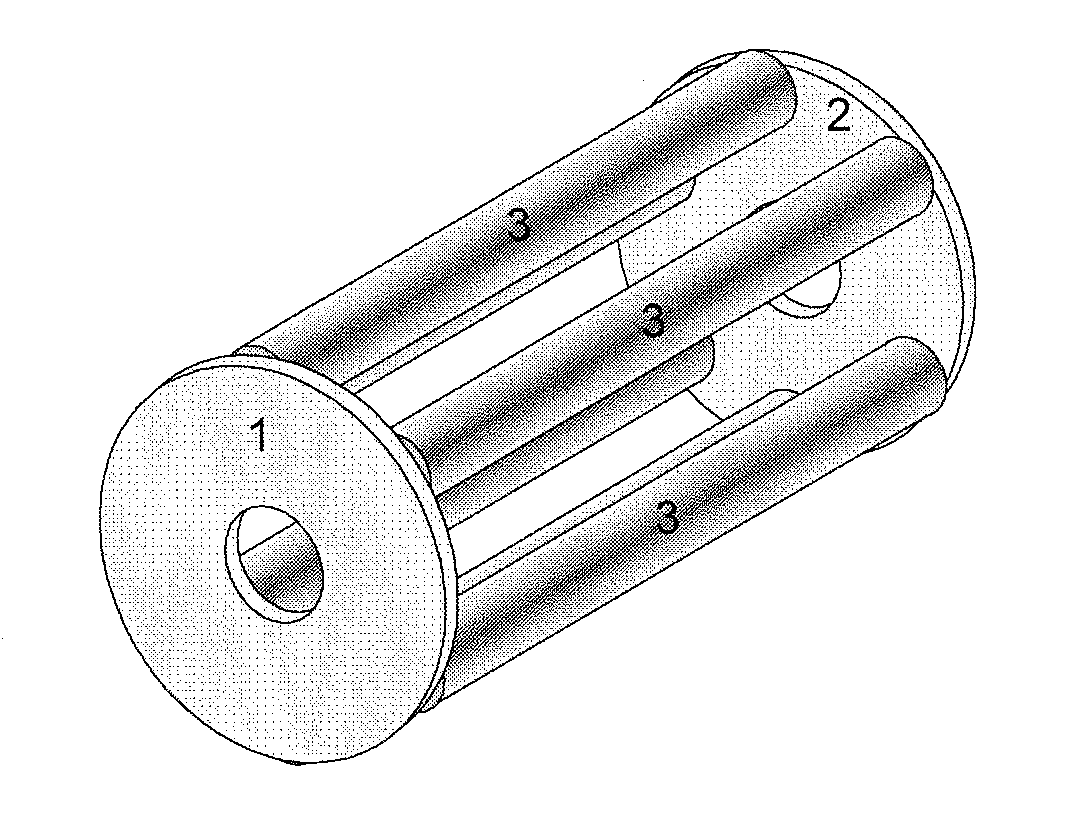

Quadrupole mass spectrometer

ActiveUS20100193684A1Maximizing intensityMaintaining detection sensitivityStability-of-path spectrometersSpectrometer circuit arrangementsVoltage generatorData memory

A table (21) for relating an appropriate DC bias voltage to each of a plurality of selectable scan speeds is stored beforehand in an auto-tuning data memory section (20). In an auto-tuning operation, a controller (10) determines the DC bias voltage corresponding to each scan speed by referring to the table (21) and fixes the output of an ion-drawing voltage generator (13) at that voltage. Subsequently, while changing the voltages applied to relevant sections such as an ion optical system (2), the controller (10) finds voltage conditions under which the detection signal is maximized. The conditions thus found are stored in an auto-tuning result data (22). In an analysis of a target sample, a DC bias voltage corresponding to a scan speed specified by an operator is obtained from the DC bias voltage table (21), and the optimal conditions for this voltage are obtained from the auto-tuning result data (22). Based on these items of information, conditions for the scan measurement are determined. This method prevents the deterioration in detection sensitivity, which will otherwise take place if the scan measurement is performed at a high scan speed.

Owner:SHIMADZU CORP

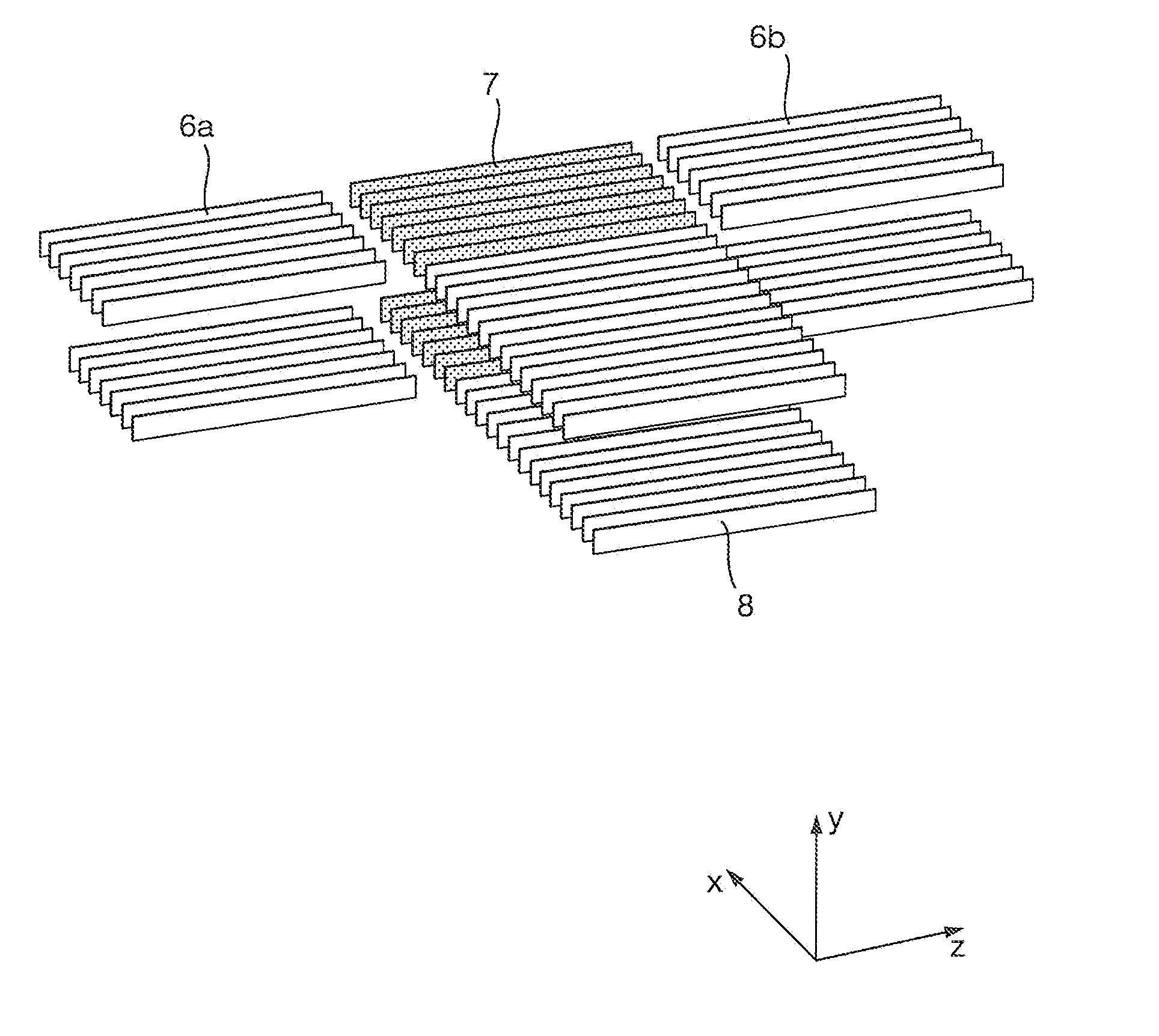

Mixed radio frequency multipole rod system as ion reactor

ActiveUS20110284741A1High fragmentation yieldEasy to fillSpectrometer circuit arrangementsIsotope separationElectrical polarityFrequency oscillation

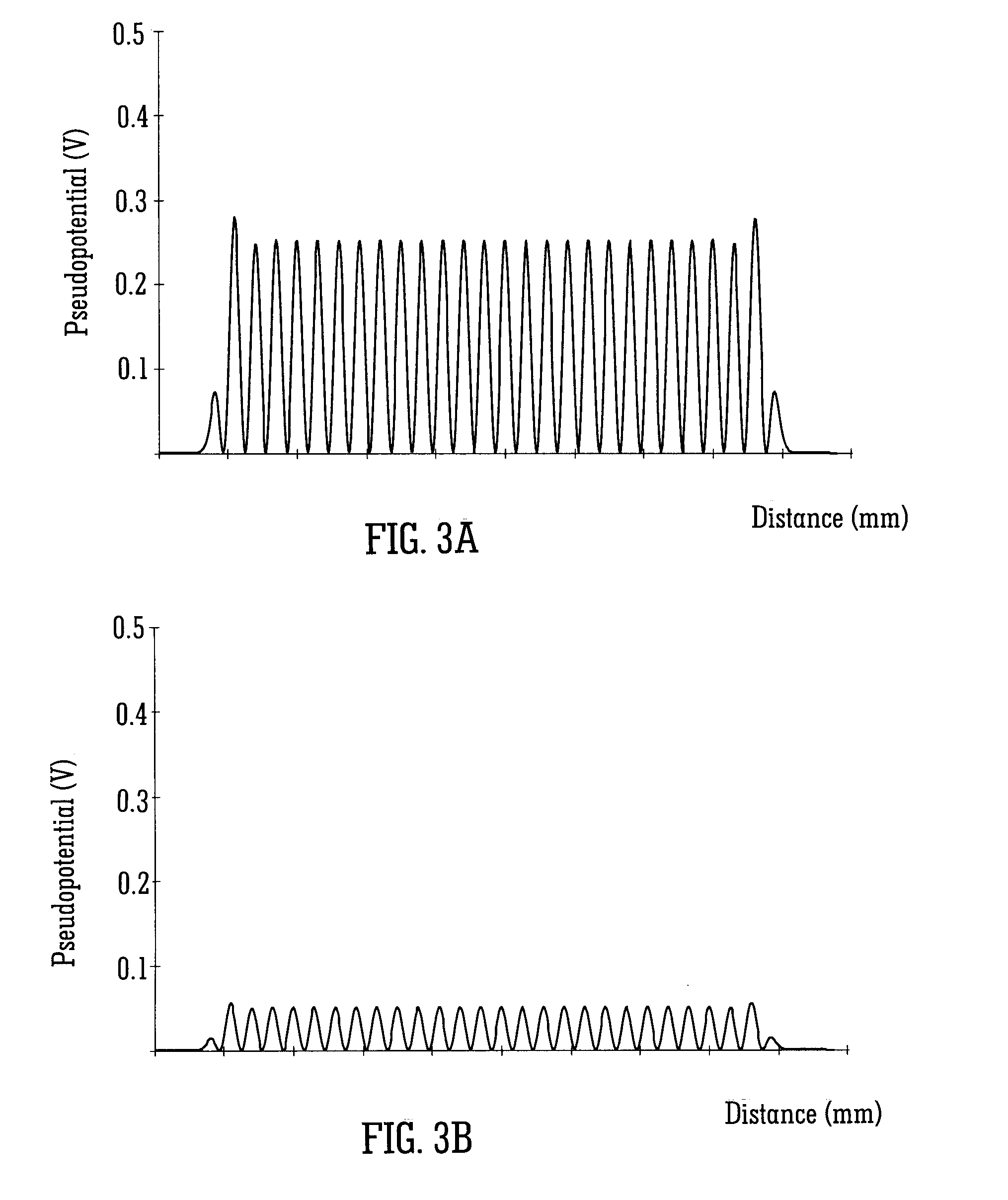

The invention relates to a linear multipole ion storage device which is suitable for reactions between positive and negative ions, and for fragmentation reactions by electron transfer dissociation (ETD) in particular. The invention uses a linear RF ion trap with at least three pairs of rods with a new type of electronic power supply. The two phases of a first RF voltage are applied to the pole rods alternately around the circumference and confine positive as well as negative ions in the radial direction. A second RF voltage is either applied single-phase to some of the pole rods, but not to all of them, or two-phase to unequal numbers of pole rods so that the axis potential oscillates with the frequency of this second RF voltage and generates a pseudopotential barrier which acts axially on ions of both polarities at the ends of the ion storage device. In the interior, the second RF produces a complex superposition field resulting in an increased fragmentation yield for ETD.

Owner:BRUKER DALTONIK GMBH & CO KG

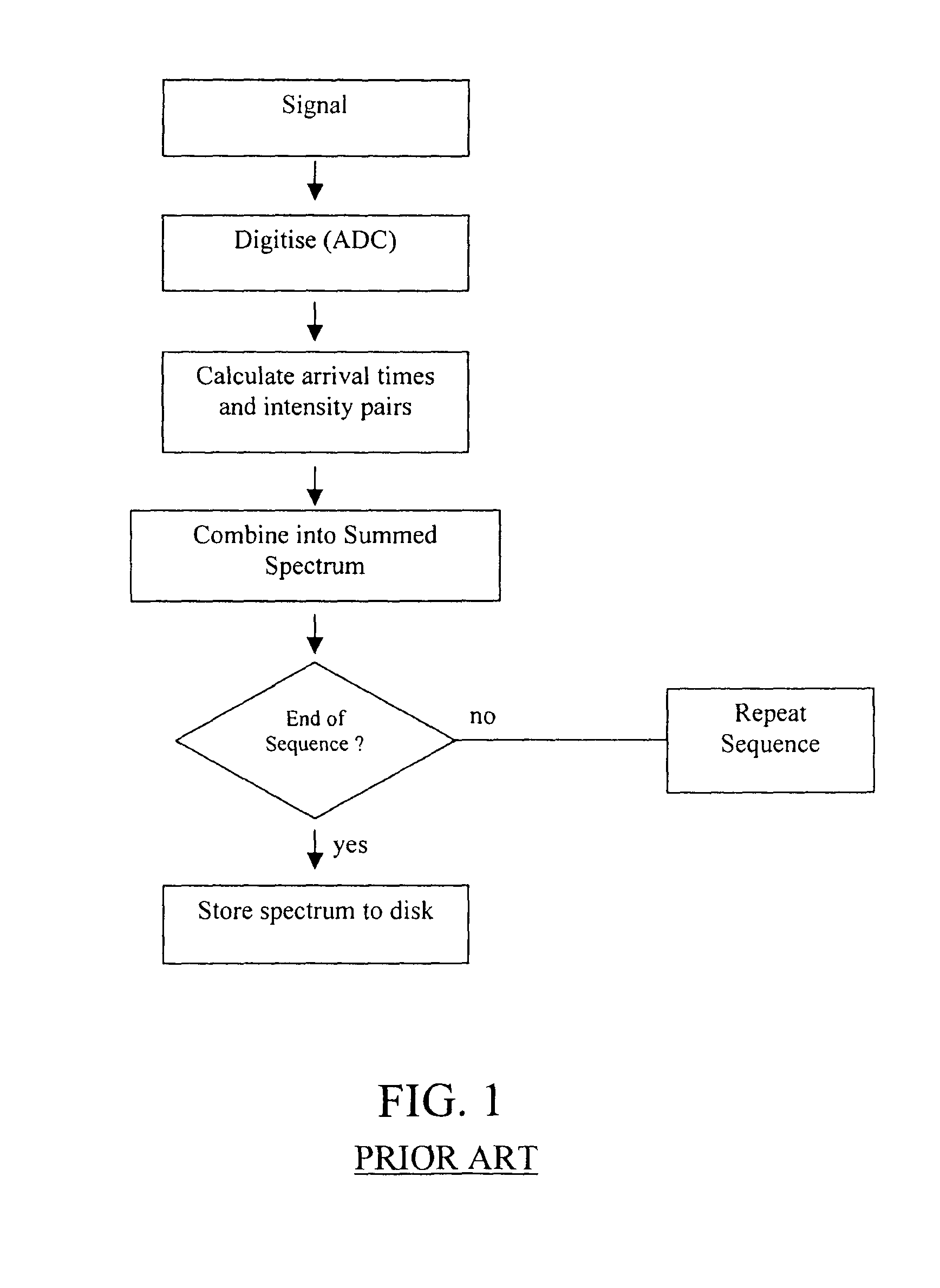

Mass spectrometer

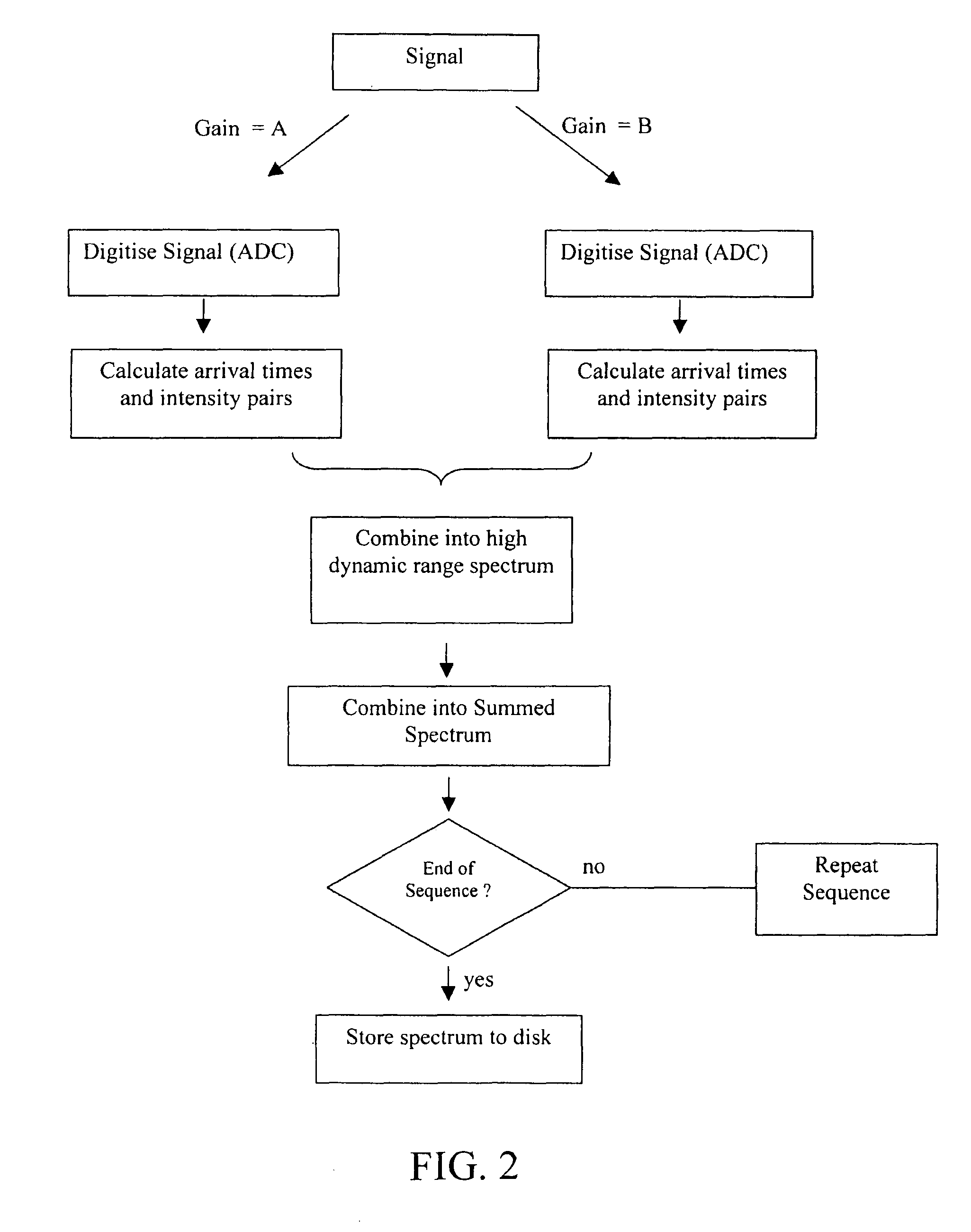

A mass spectrometer is disclosed wherein an ion signal is split into a first and second signal. The first and second signals are multiplied by different gains and are digitised. Arrival time and intensity pairs are calculated for both digitised signals and the resulting time and intensity pairs are combined to form a high dynamic range spectrum. The spectrum is then combined with other corresponding spectra to form a summed spectrum.

Owner:MICROMASS UK LTD

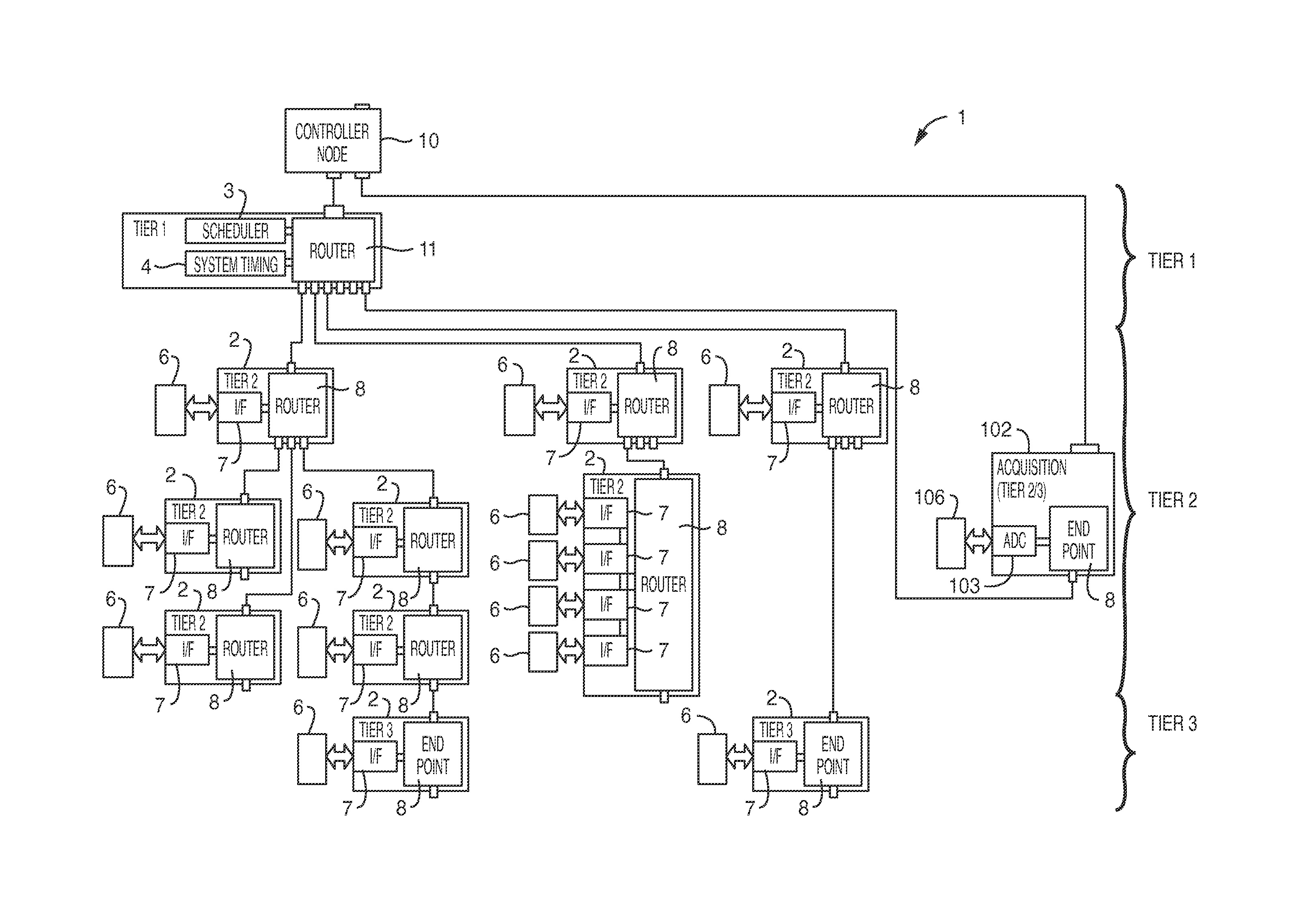

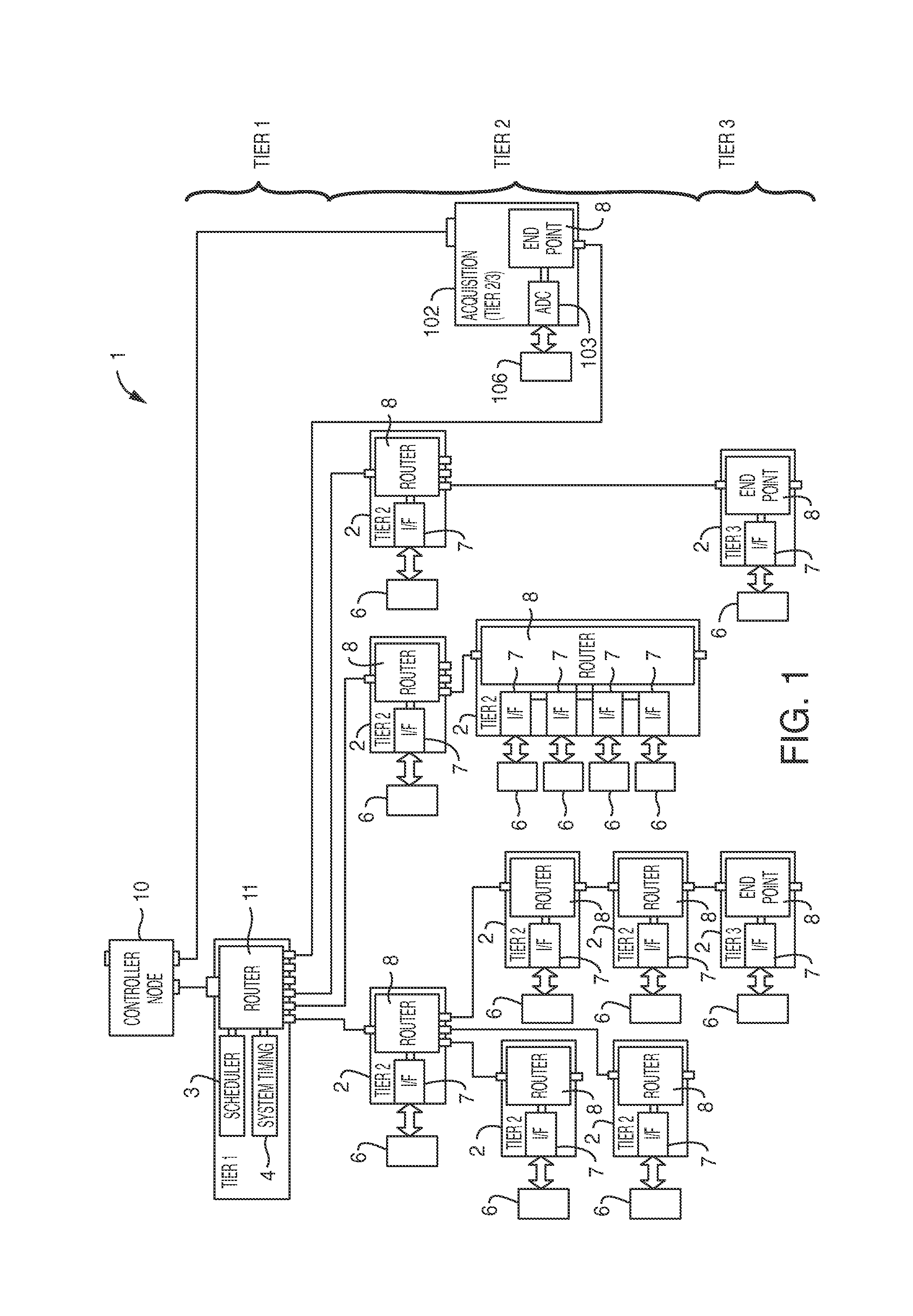

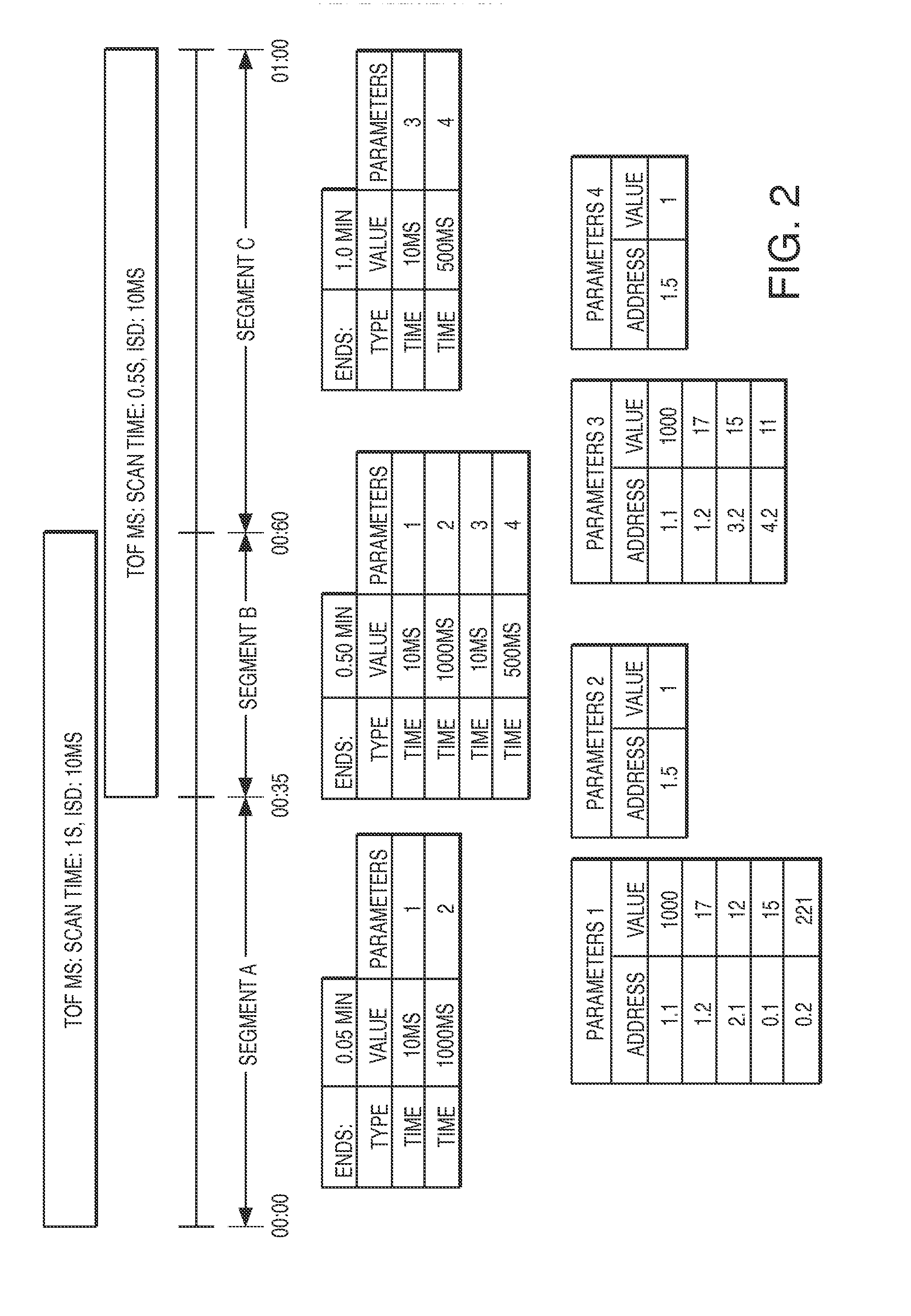

Mass spectrometer, control system and methods of operating and assembling a mass spectrometer

ActiveUS20150076338A1Spectrometer circuit arrangementsLine/current collector detailsControl systemMass spectrometric

A mass spectrometer and methods for controlling a mass spectrometer are provided. In an exemplary embodiment, the mass spectrometer includes a plurality of discrete functional modules, each operable to perform a predetermined function of the mass spectrometer, wherein the modules are individually addressable and connected in a network. The mass spectrometer can also include a scheduler operable to introduce discrete packets of instructions to the network at predetermined times to instruct at least one module to perform a predetermined operation.

Owner:MICROMASS UK LTD

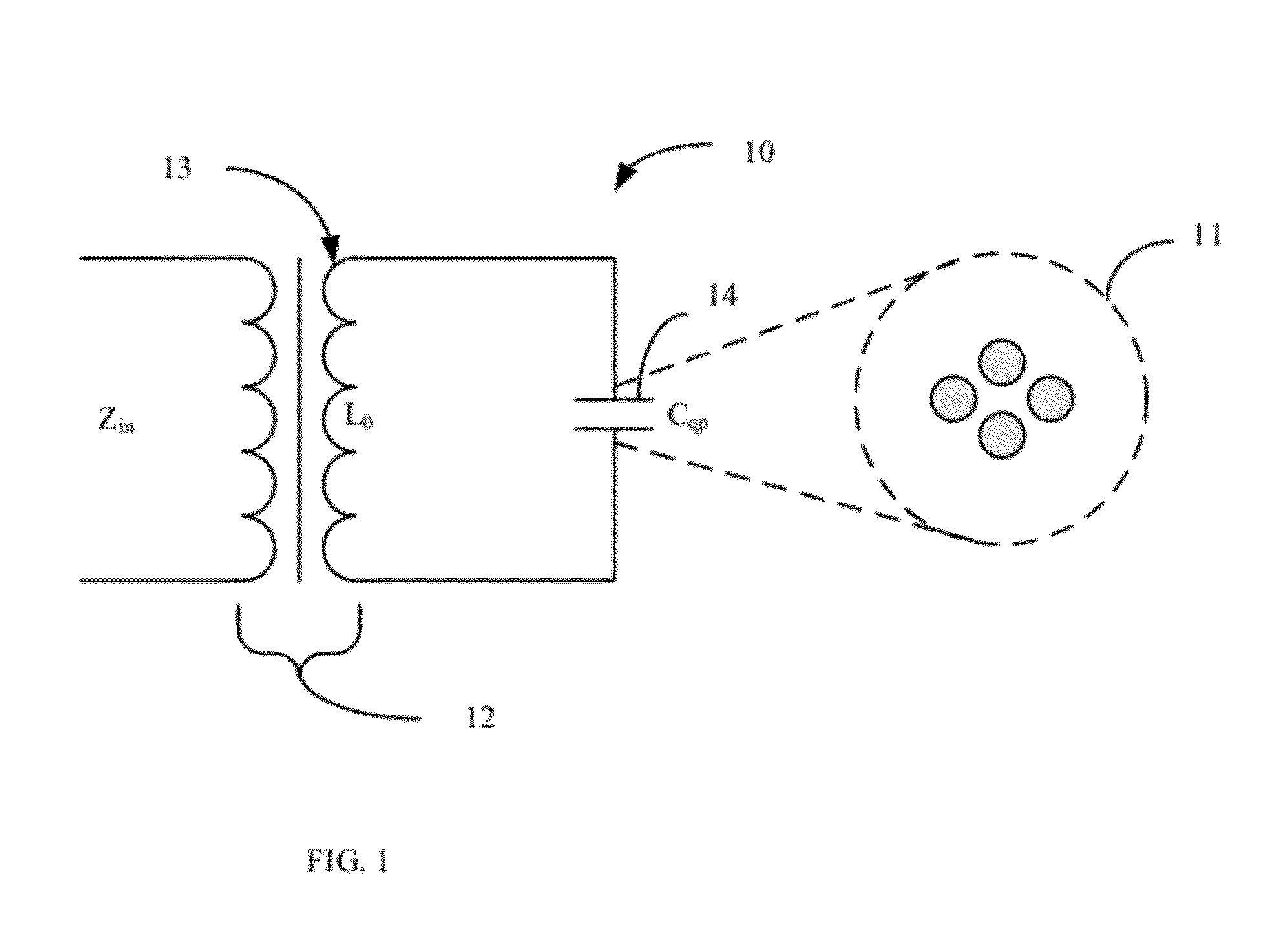

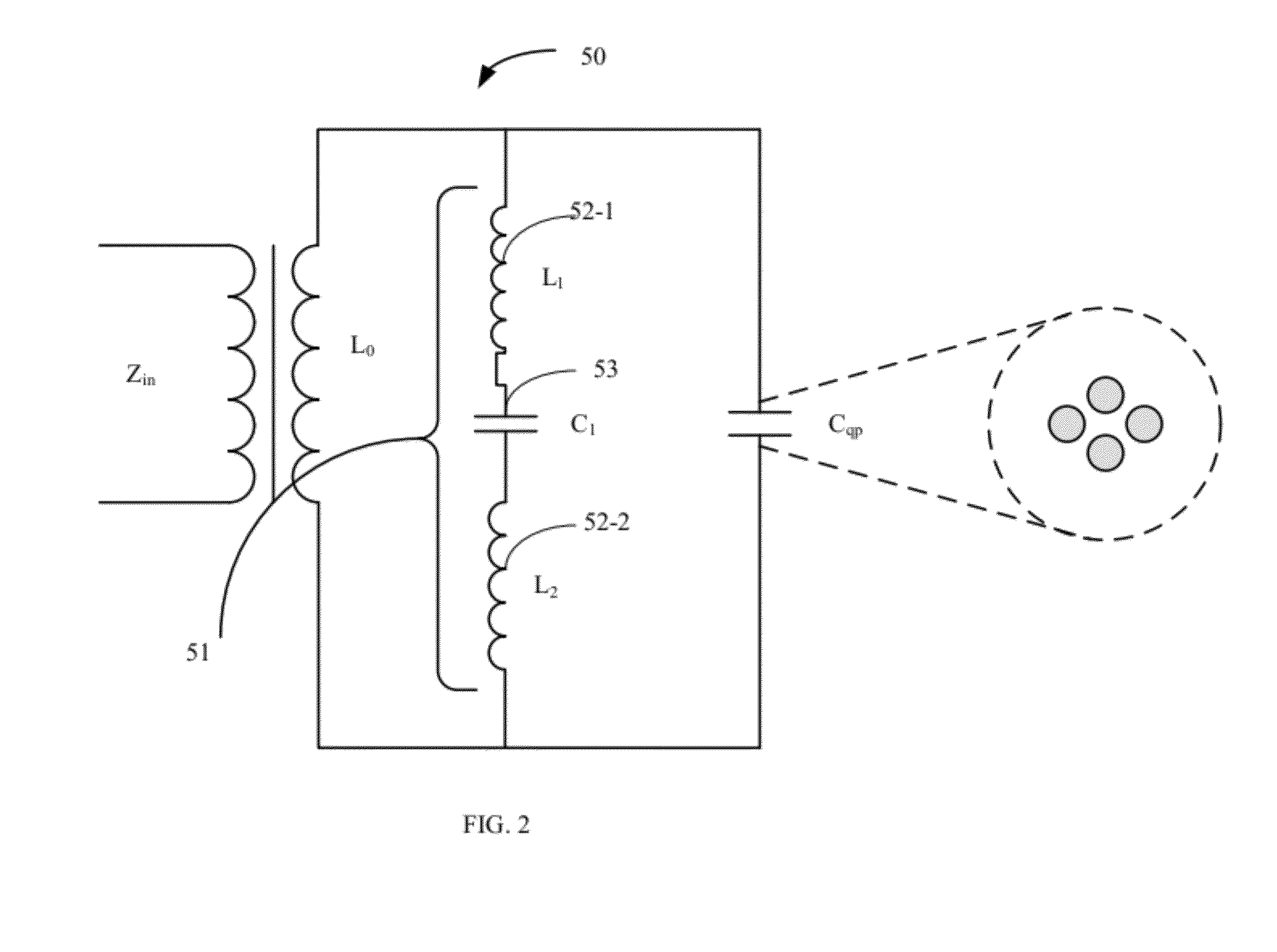

Waveform generator electronics based on tuned lc circuits

InactiveUS20050269500A1Spectrometer circuit arrangementsStability-of-path spectrometersElectricityWave shape

Disclosed is an apparatus for generating a periodically varying electrical signal for creating a periodically varying electrical field between electrodes of an ion mobility spectrometer. The apparatus includes an output port. A first tuned circuit is provided for being electrically coupled to an external power source and for, in isolation, providing a first periodically varying electrical signal having a first frequency. The first tuned circuit is coupled to the output port for providing an output electrical signal having a component at the first frequency thereto. A second tuned circuit is provided for being electrically coupled to an external power source and for providing a second periodically varying electrical signal having a second frequency different from the first frequency. The second tuned circuit is coupled to the first tuned circuit for varying the output electrical signal about the first periodically varying electrical signal.

Owner:THERMO FINNIGAN

Ion manipulation method and device

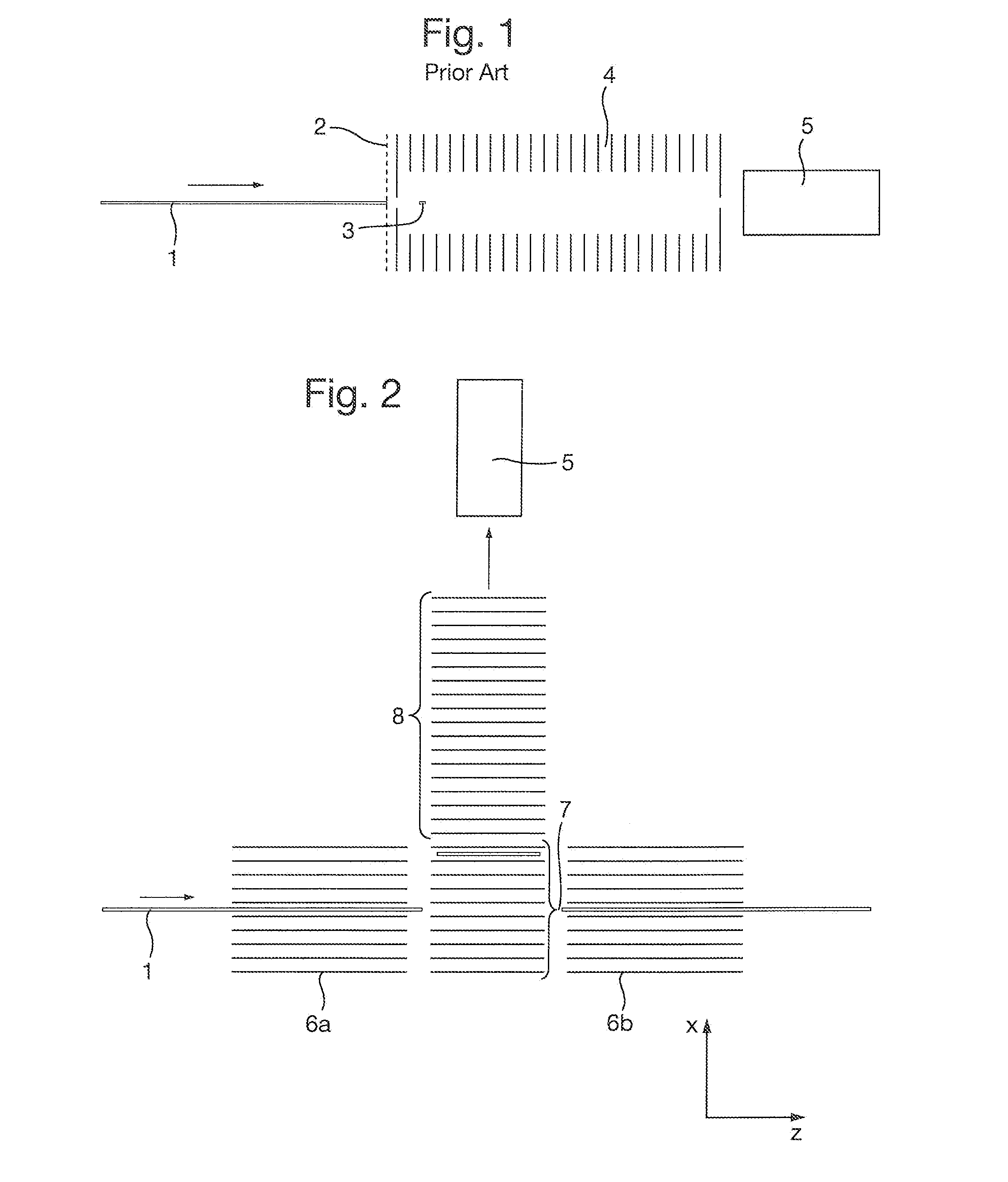

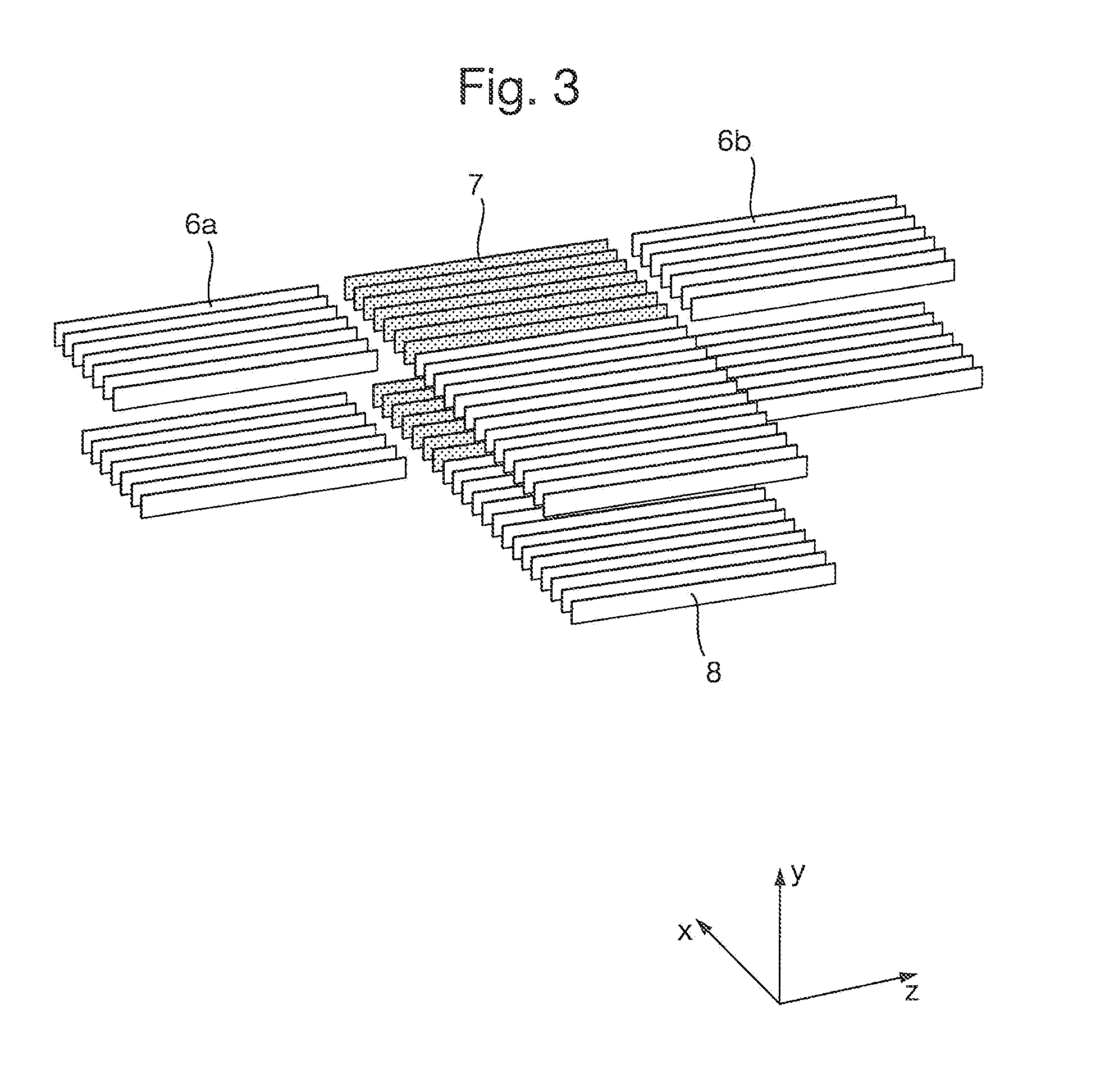

ActiveUS20160071715A1Improve performanceReduction of trapping effectSpectrometer circuit arrangementsElectron/ion optical arrangementsDc voltageElectric field

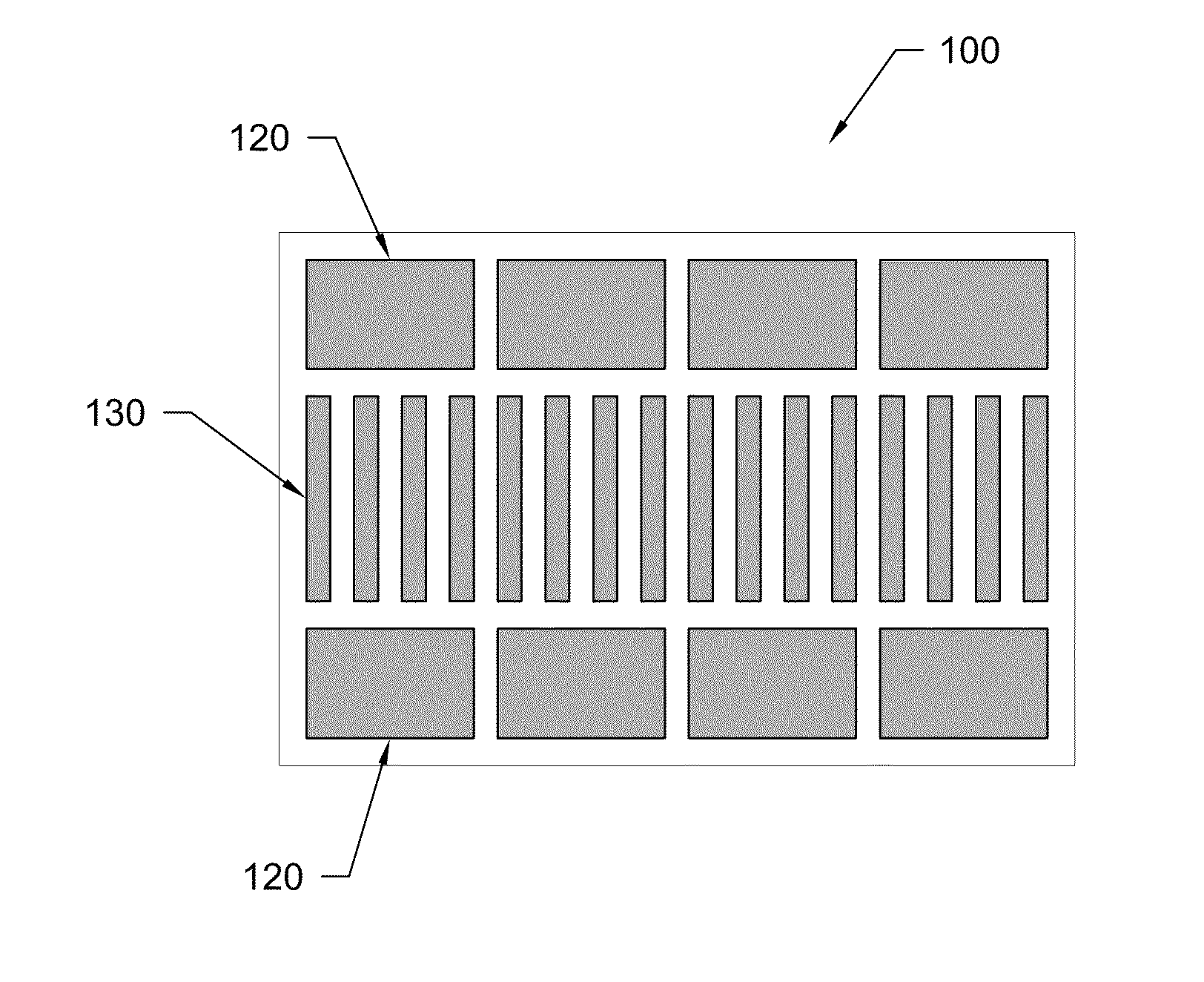

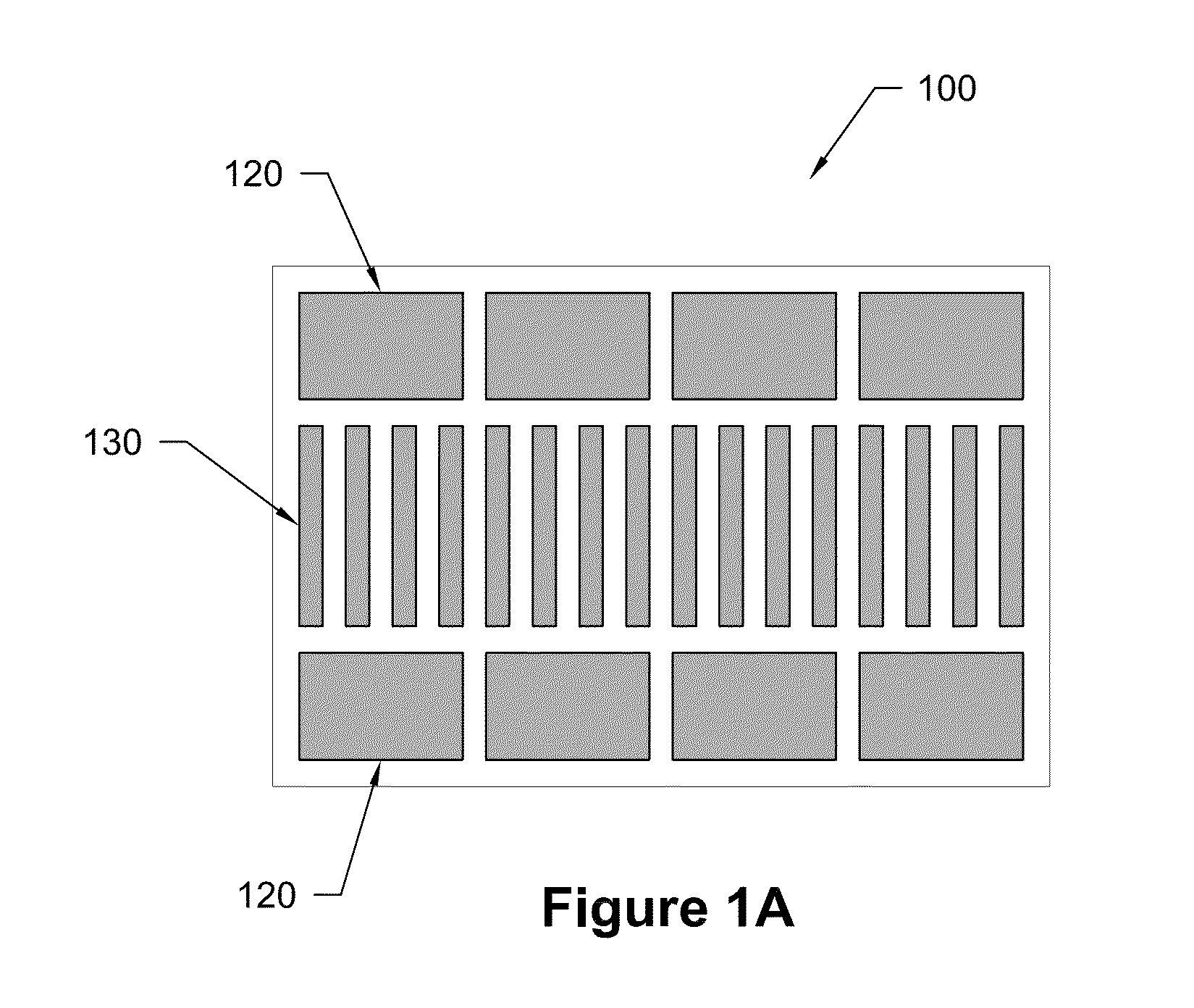

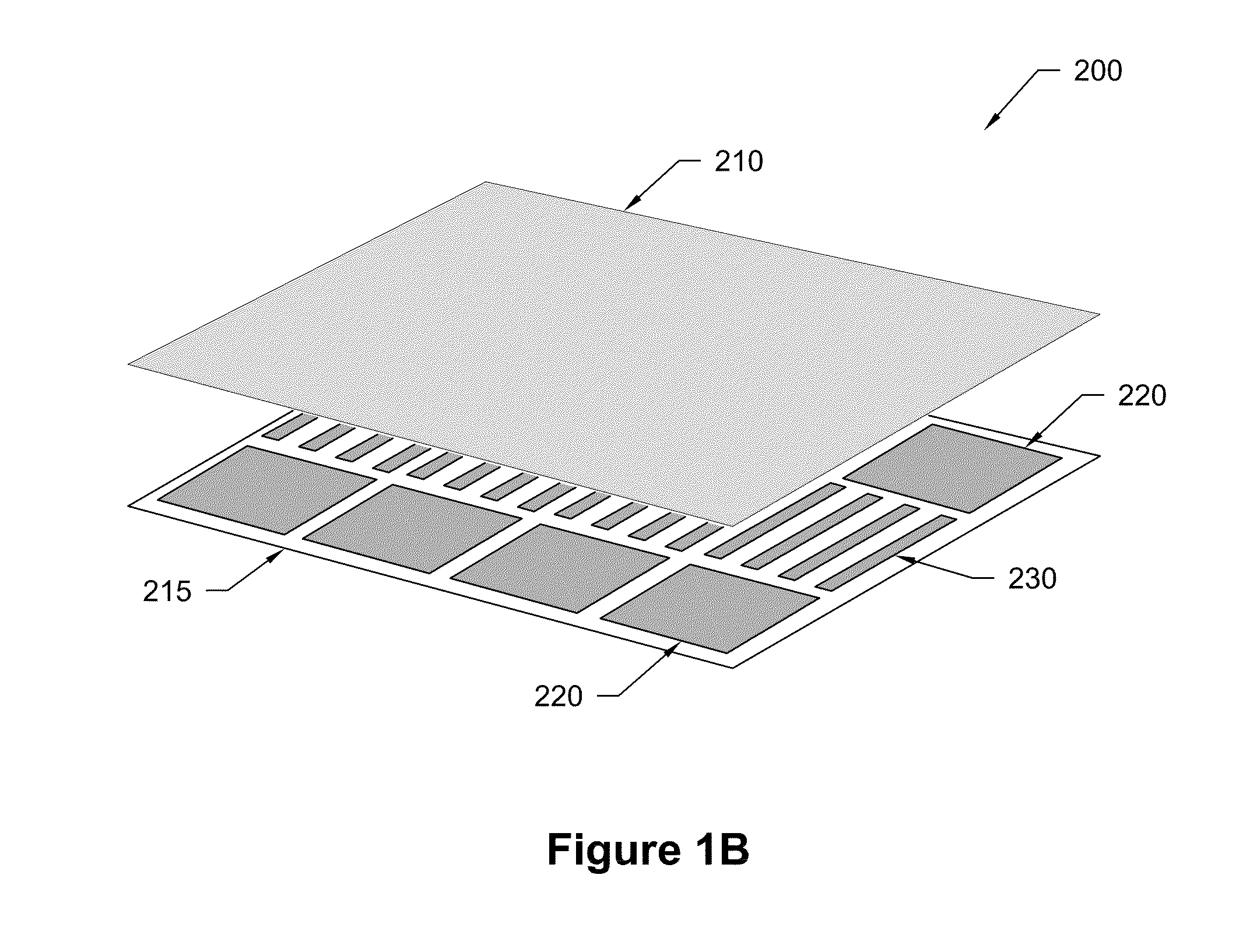

An ion manipulation method and device is disclosed. The device includes a pair of substantially parallel surfaces. An array of inner electrodes is contained within, and extends substantially along the length of, each parallel surface. The device includes a first outer array of electrodes and a second outer array of electrodes. Each outer array of electrodes is positioned on either side of the inner electrodes, and is contained within and extends substantially along the length of each parallel surface. A DC voltage is applied to the first and second outer array of electrodes. A RF voltage, with a superimposed electric field, is applied to the inner electrodes by applying the DC voltages to each electrode. Ions either move between the parallel surfaces within an ion confinement area or along paths in the direction of the electric field, or can be trapped in the ion confinement area.

Owner:BATTELLE MEMORIAL INST

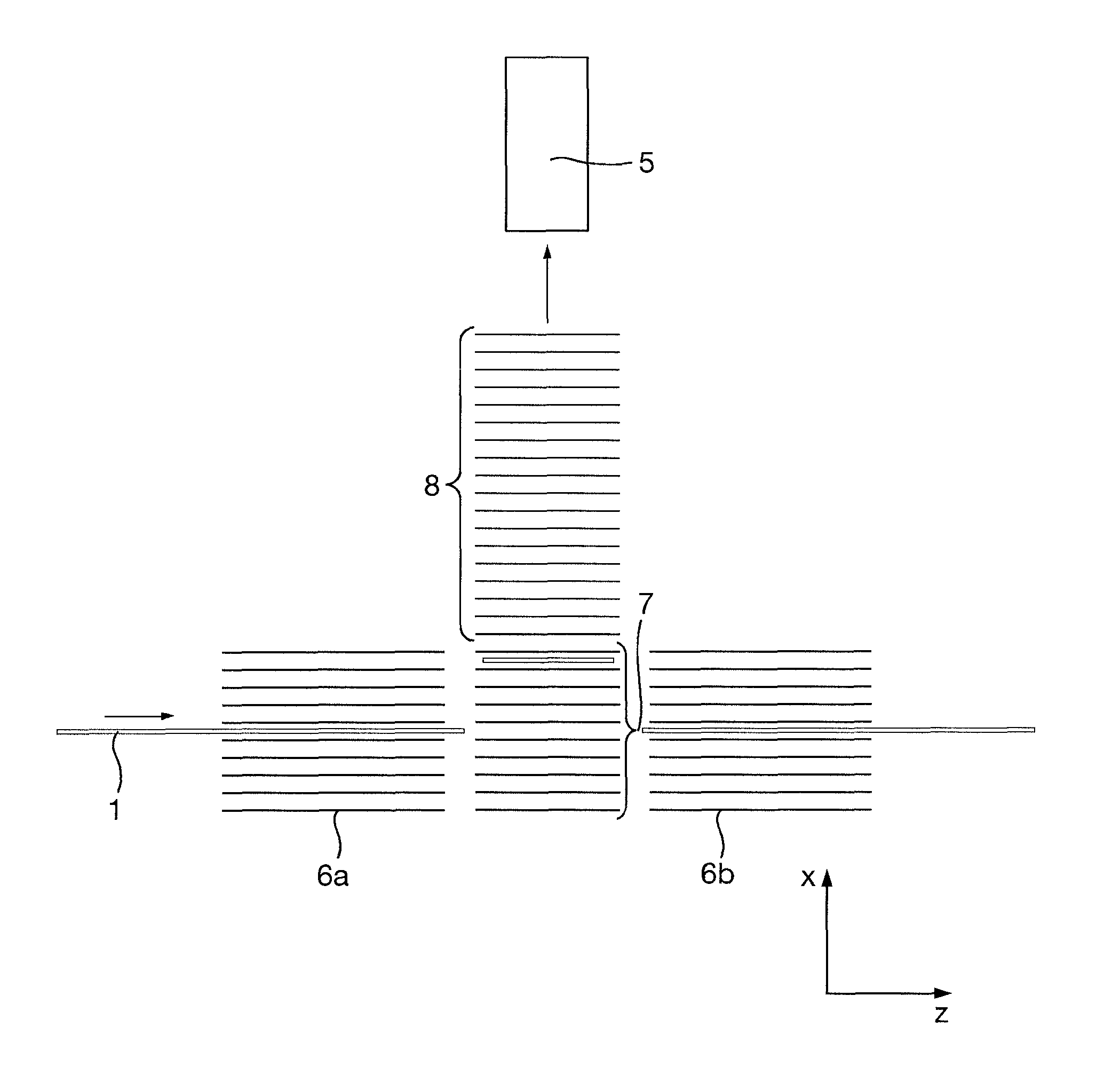

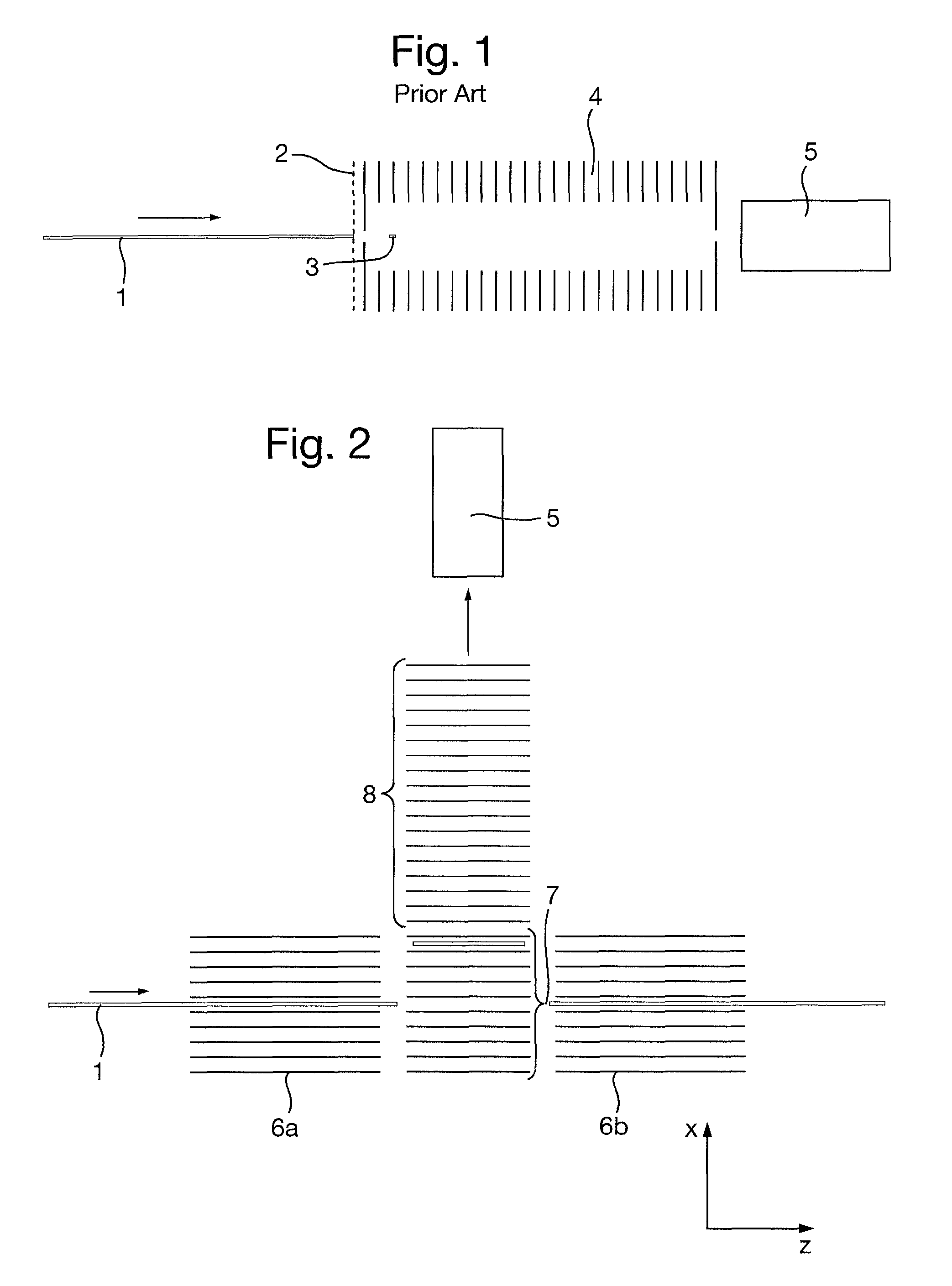

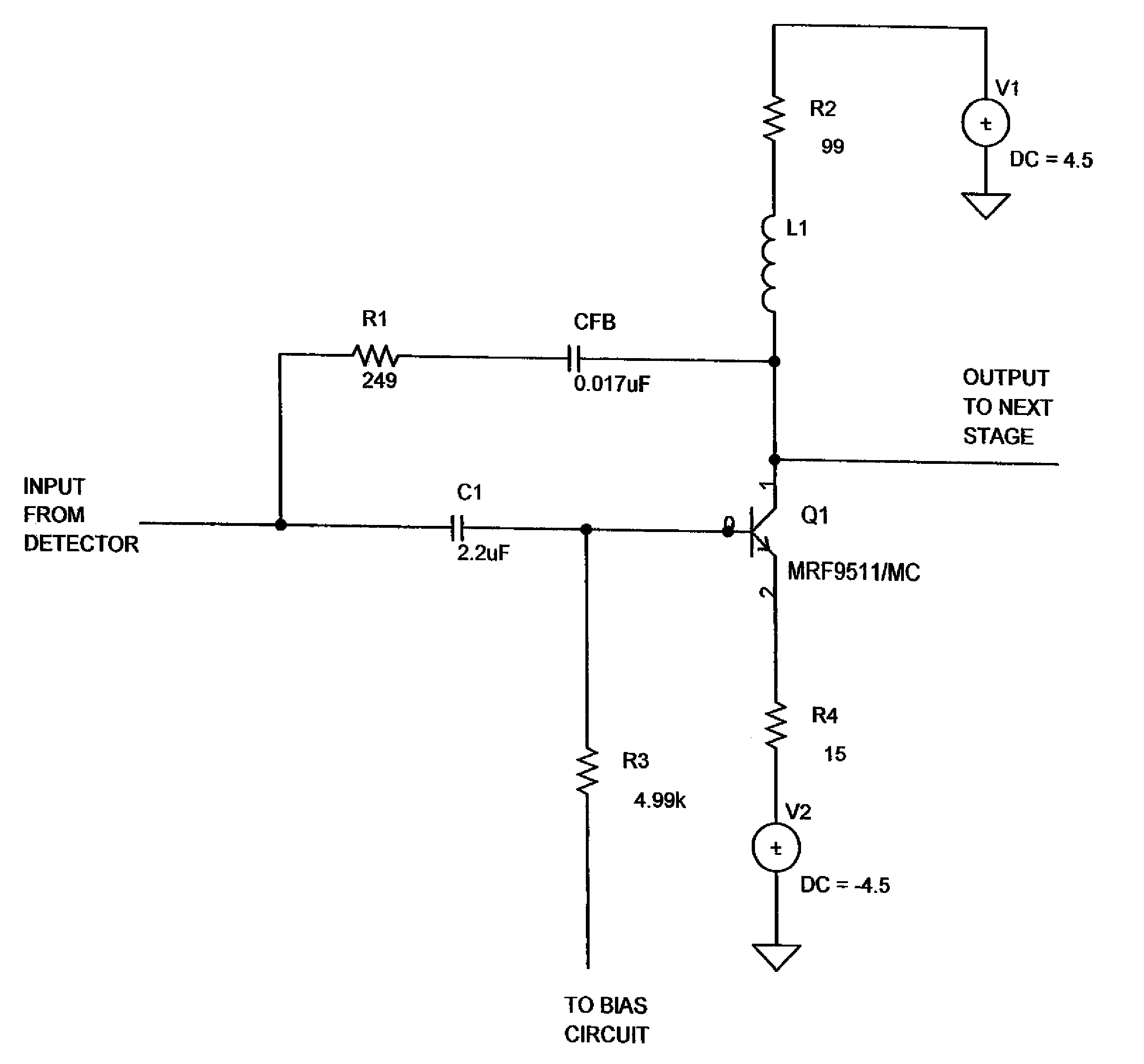

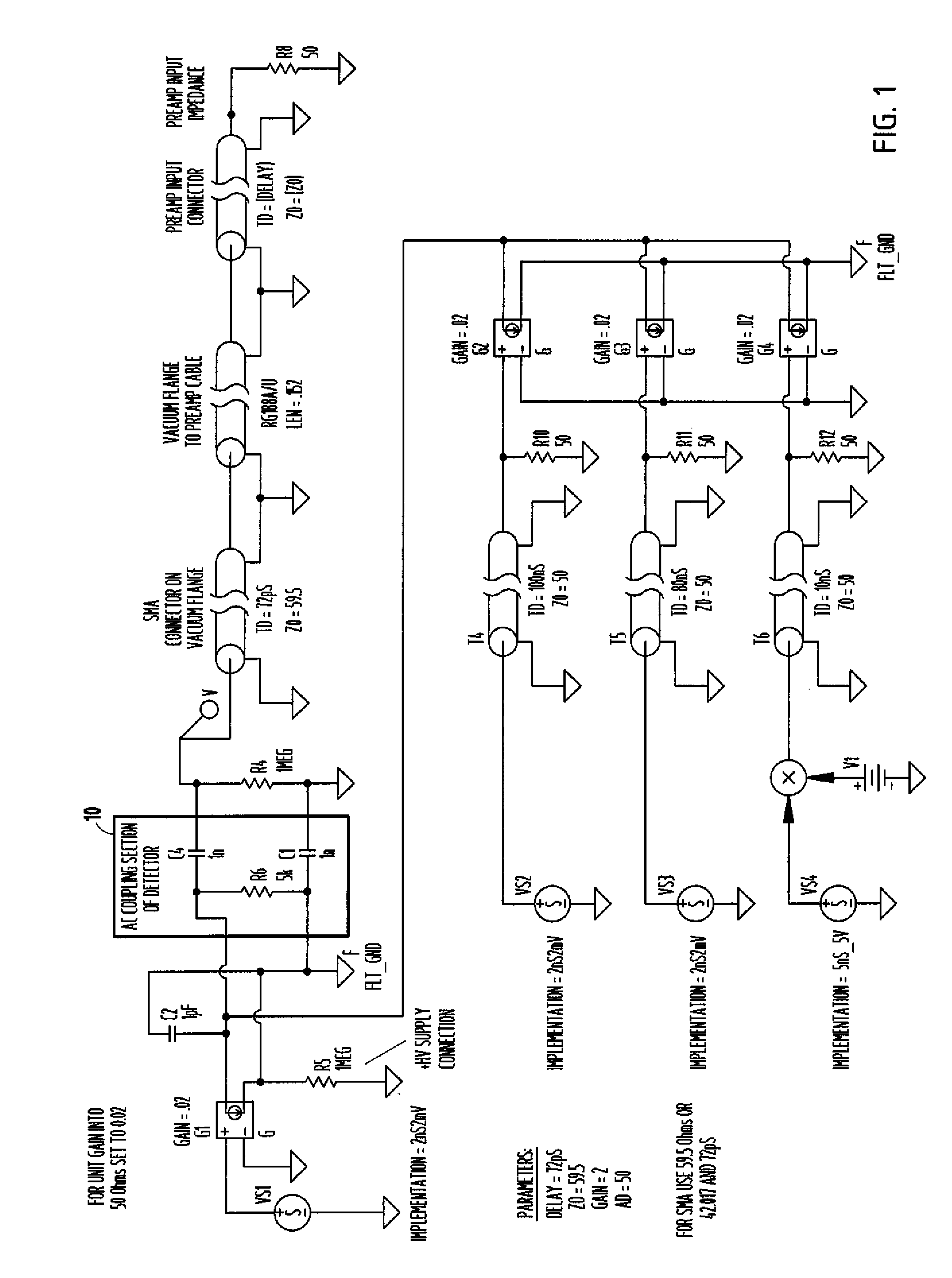

Ion guide with orthogonal sampling

ActiveUS8716660B2Spectrometer circuit arrangementsTime-of-flight spectrometersPulse beamPhysical chemistry

A mass spectrometer is disclosed comprising a RF ion guide wherein in a mode of operation a continuous, quasi-continuous or pulsed beam of ions is orthogonally sampled from the ion guide and wherein the continuous, quasi-continuous or pulsed beam of ions is not axially trapped or otherwise axially confined within the RF ion guide. The ion guide is maintained, in use, at a pressure selected from the group consisting of: (i) 0.0001-0.001 mbar; (ii) 0.001-0.01 mbar; (iii) 0.01-0.1 mbar; (iv) 0.1-1 mbar; (v) 1-10 mbar; (vi) 10-100 mbar; and (vii) >100 mbar.

Owner:MICROMASS UK LTD

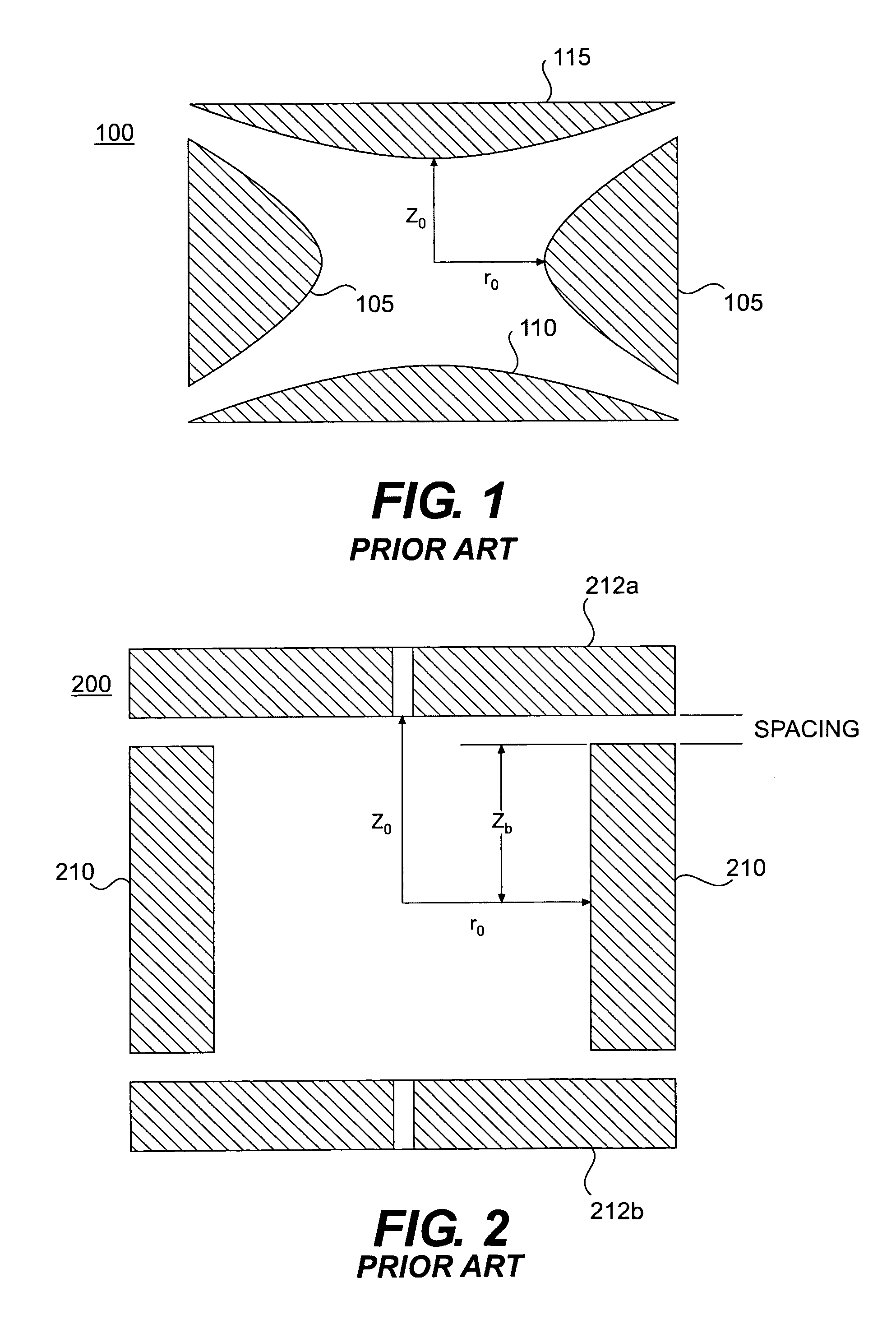

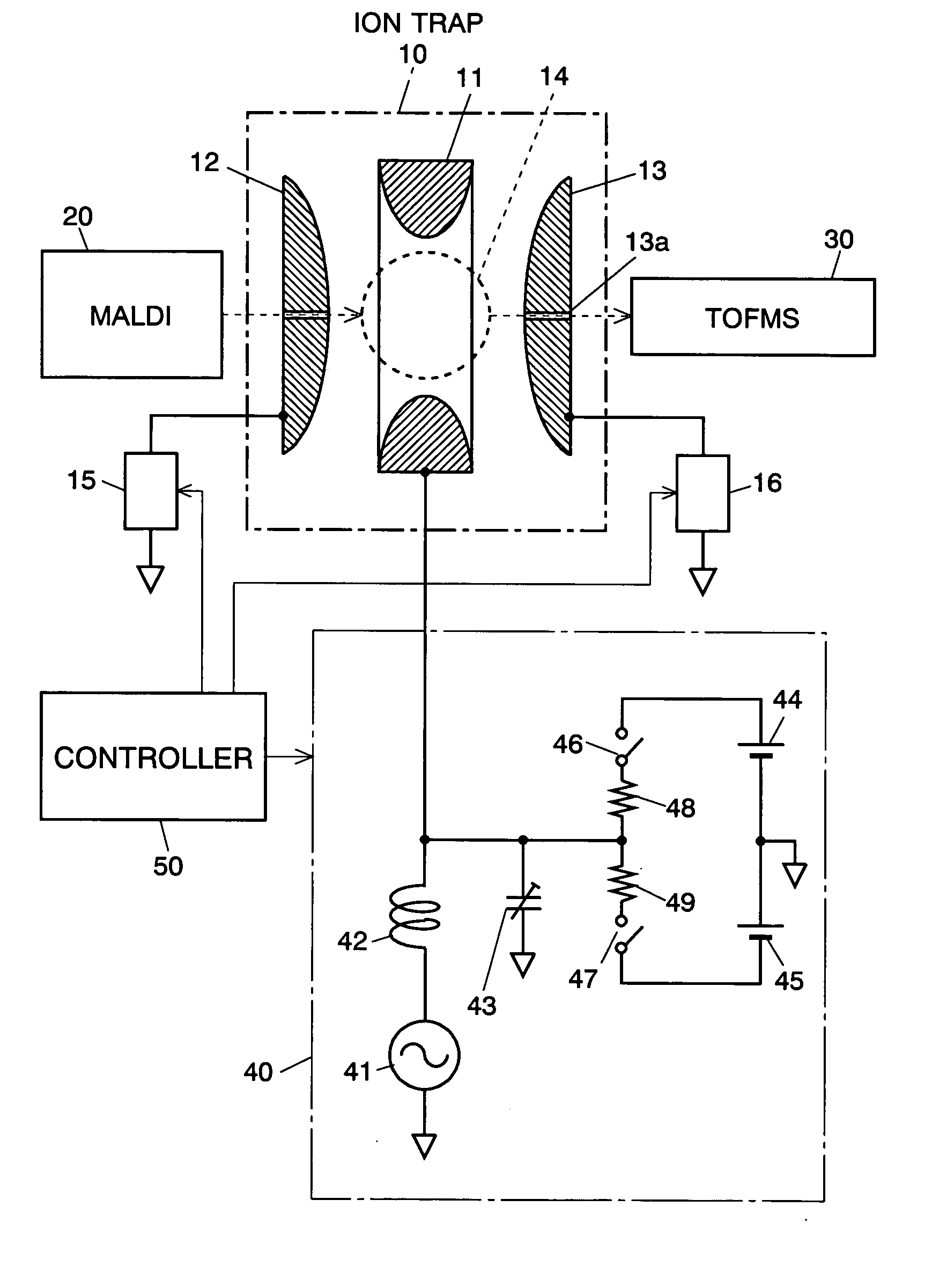

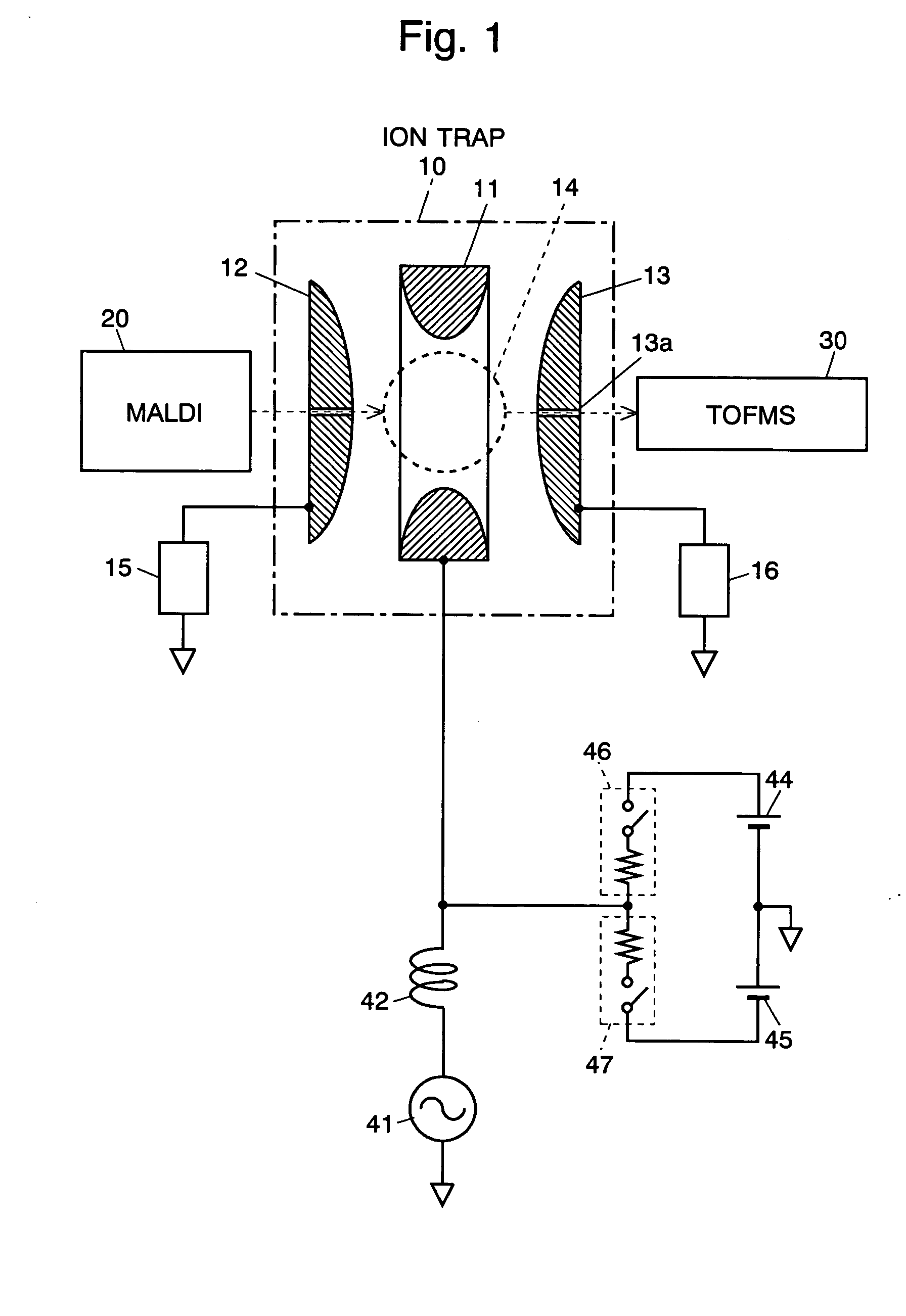

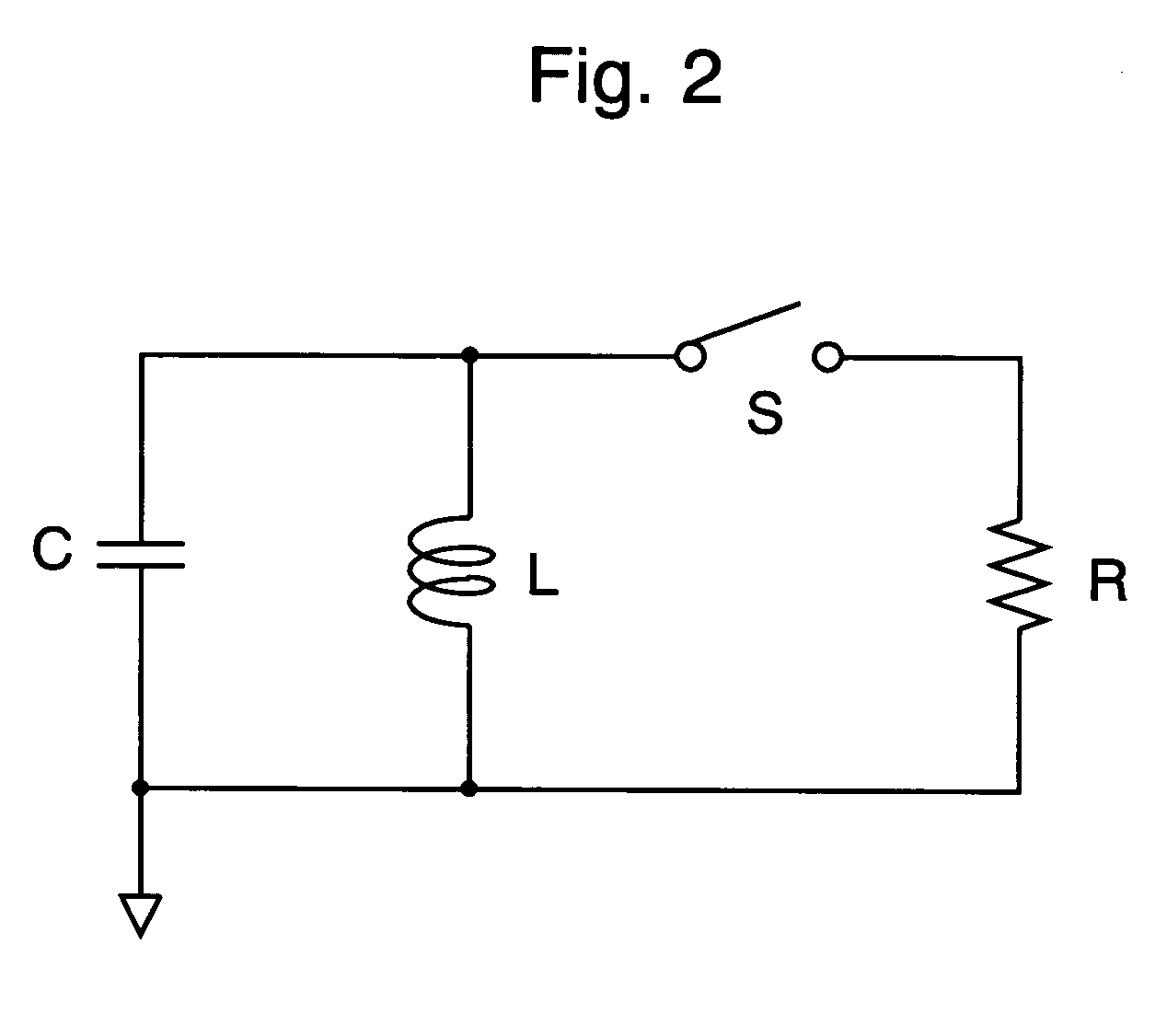

Ion storage device

InactiveUS20050127291A1Reduce the total massNot easy to flowSpectrometer circuit arrangementsStability-of-path spectrometersCapacitanceLc resonant circuit

In the ion storage device 10 according to the present invention, an LC resonant circuit 40 for generating an RF voltage for trapping ions is connected to at least one of the electrodes 11, 12 and 13 surrounding the ion storing space 14. The LC resonant circuit 40 includes switching devices 46, 47 and resistances 48, 49 for stopping the RF voltage when the ions stored in the ion storing space 14 are ejected. The inductance L, the capacitance C and the resistance R of the LC resonant circuit are set to substantially satisfy the critical damping condition, which means that R=X / 2 where X=ω0L=(ω0C)−1. According to this configuration, the RF voltage damps fast when the RF voltage is stopped by the switching devices 46, 47, and the deterioration of the mass resolution of the mass analyzer or the peak shift in the mass spectrum is prevented.

Owner:SHIMADZU CORP

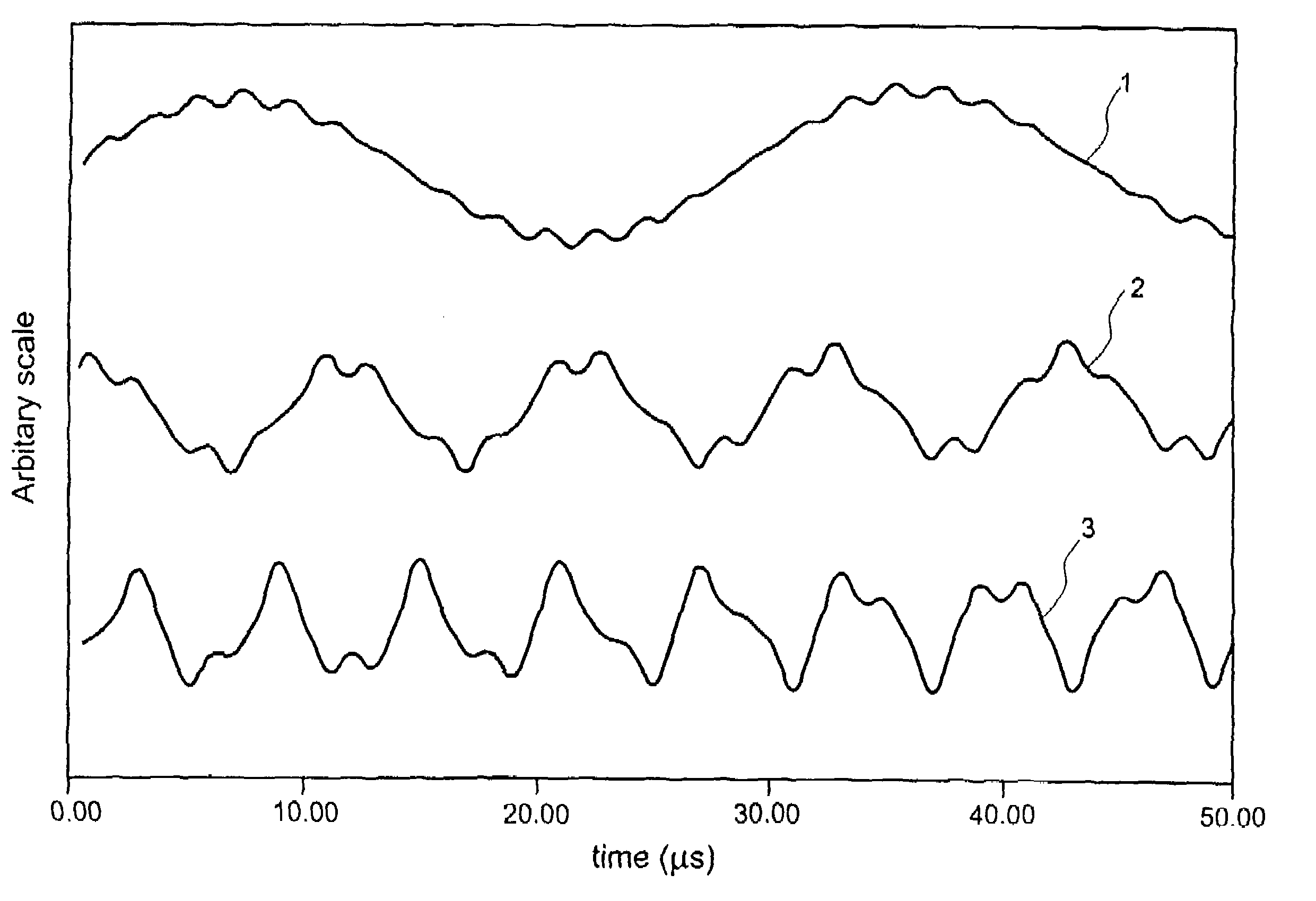

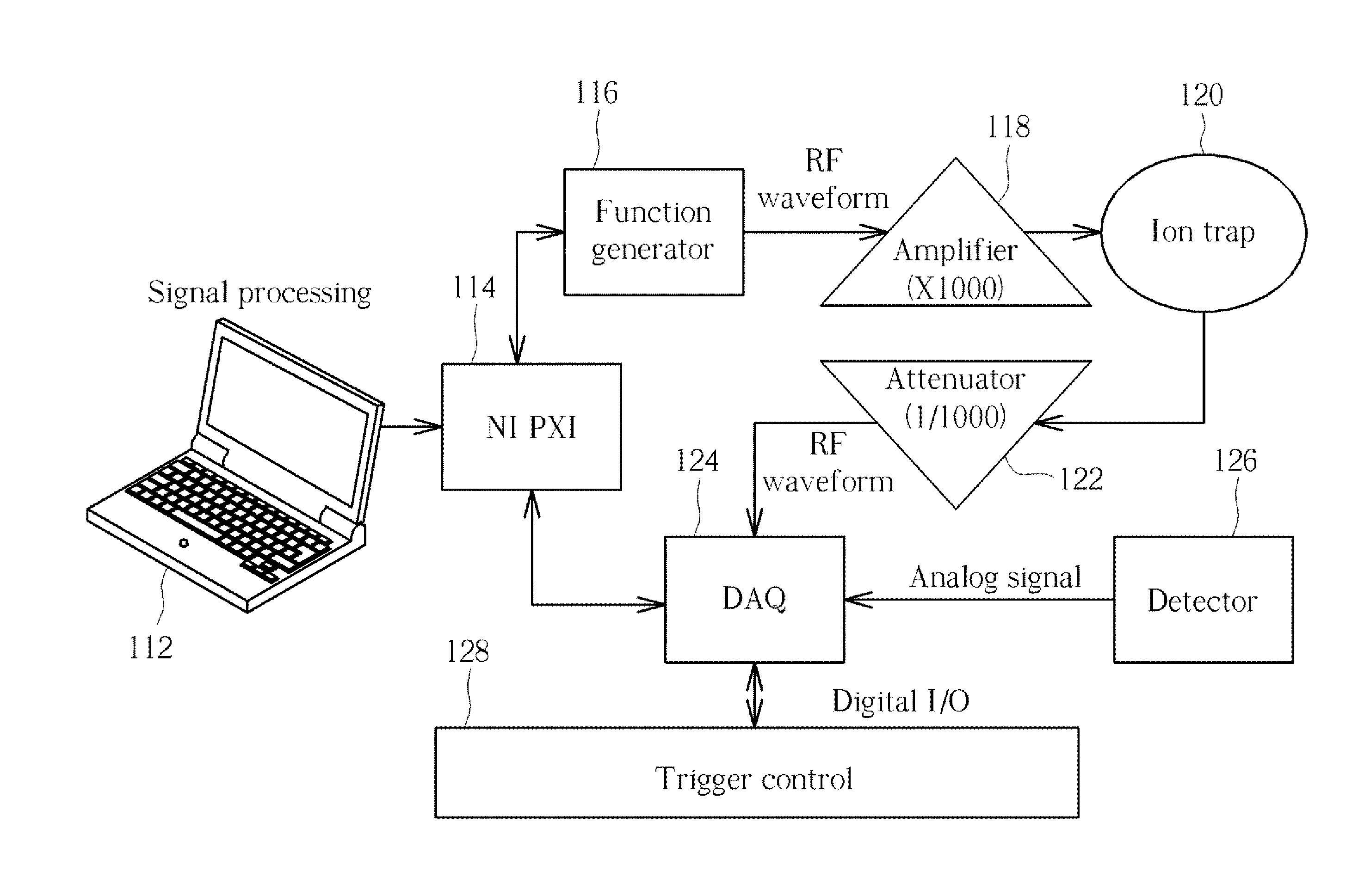

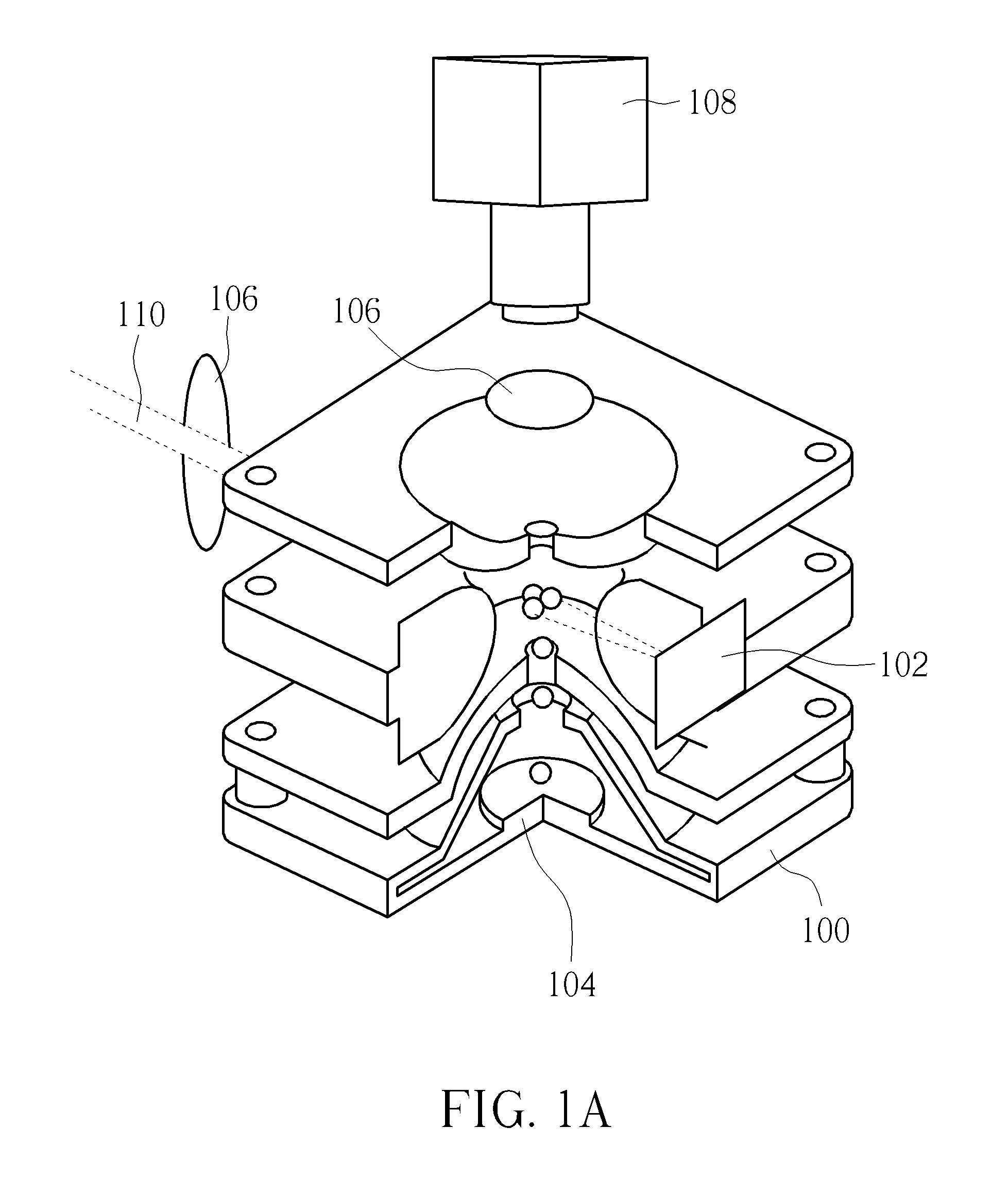

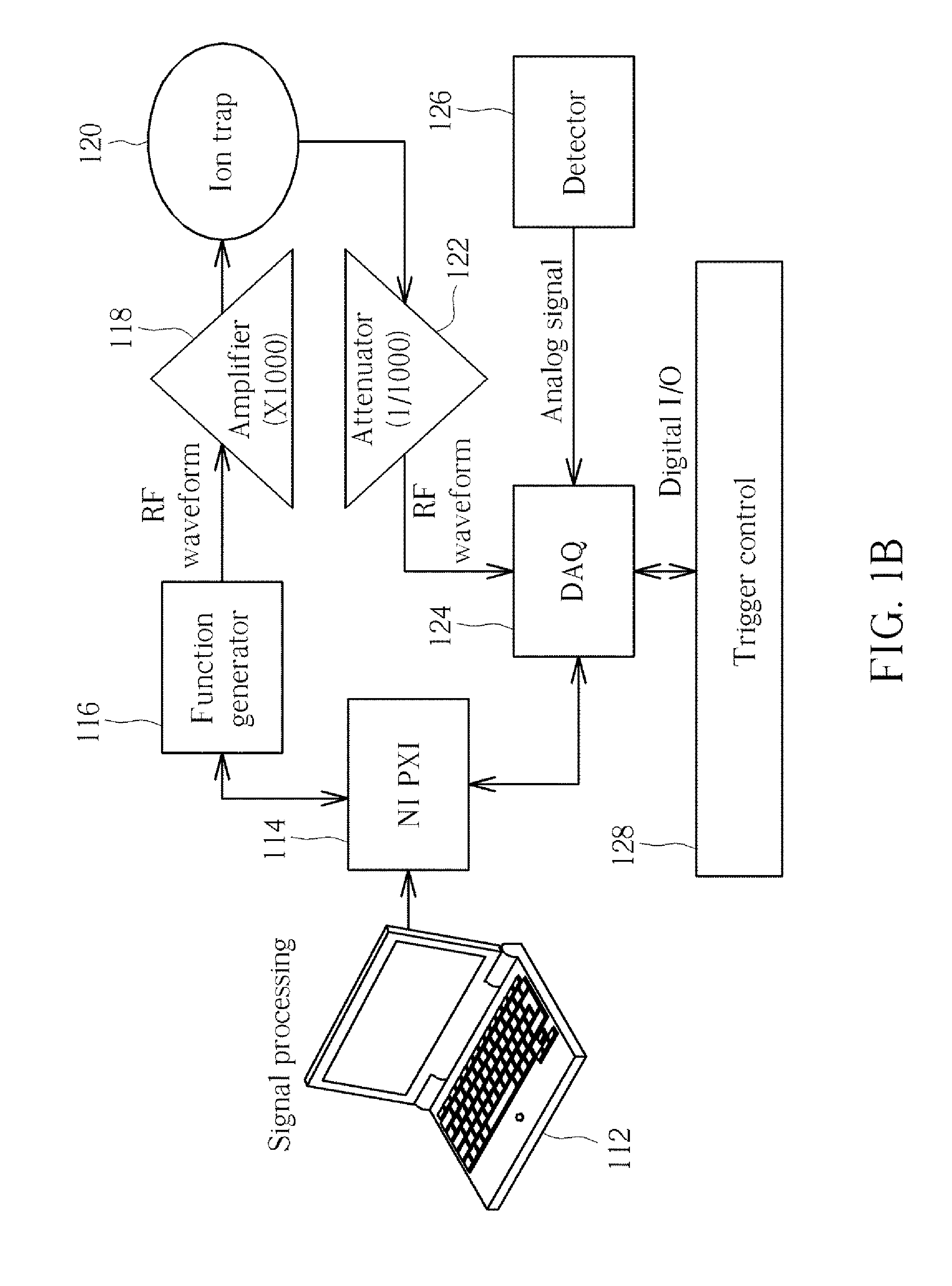

Signal denoising methods for a charge detection frequency-scan/voltage-scan quadrupole/linear/rectilinear ion trap mass spectrometer

InactiveUS20130311141A1Induced decreaseRemove radio frequency interferenceSpectrometer circuit arrangementsAmplifier modifications to reduce noise influenceIon trap mass spectrometryCharge detection

A signal denoising method for a frequency-scan ion trap mass spectrometer includes reading a signal raw data array observed in the spectrometer. The signal raw data array is processed by Boxcar averaging method to obtain a first signal array. Then the first signal array is processed by a harmonic interference cancellation method to obtain a second data array. Next the second signal array is processed by a radio frequency interference reduction method and a third signal array without the background induced from driving voltage of ion trap is reconstructed according to the second signal array.

Owner:NATIONAL DONG HWA UNIVERSITY

Ion Guide With Orthogonal Sampling

ActiveUS20140048702A1Spectrometer circuit arrangementsMaterial analysis by electric/magnetic meansPulse beamIon beam

A mass spectrometer is disclosed comprising a RF ion guide wherein in a mode of operation a continuous, quasi-continuous or pulsed beam of ions is orthogonally sampled from the ion guide and wherein the continuous, quasi-continuous or pulsed beam of ions is not axially trapped or otherwise axially confined within the RF ion guide. The Ion guide is maintained, in use, at a pressure selected from the group consisting of: (i) 0.0001-0.001 mbar; (ii) 0.001-0.01 mbar; (iii) 0.01-0.1 mbar; (iv) 0.1-1 mbar; (v) 1-10 mbar; (vi) 10-100 mbar; and (vii) >100 mbar.

Owner:MICROMASS UK LTD

Base line restoration circuit

InactiveUS7884317B2Correction errorSpectrometer circuit arrangementsNegative-feedback-circuit arrangementsPower flowIntegrator

Owner:LECO CORPORATION

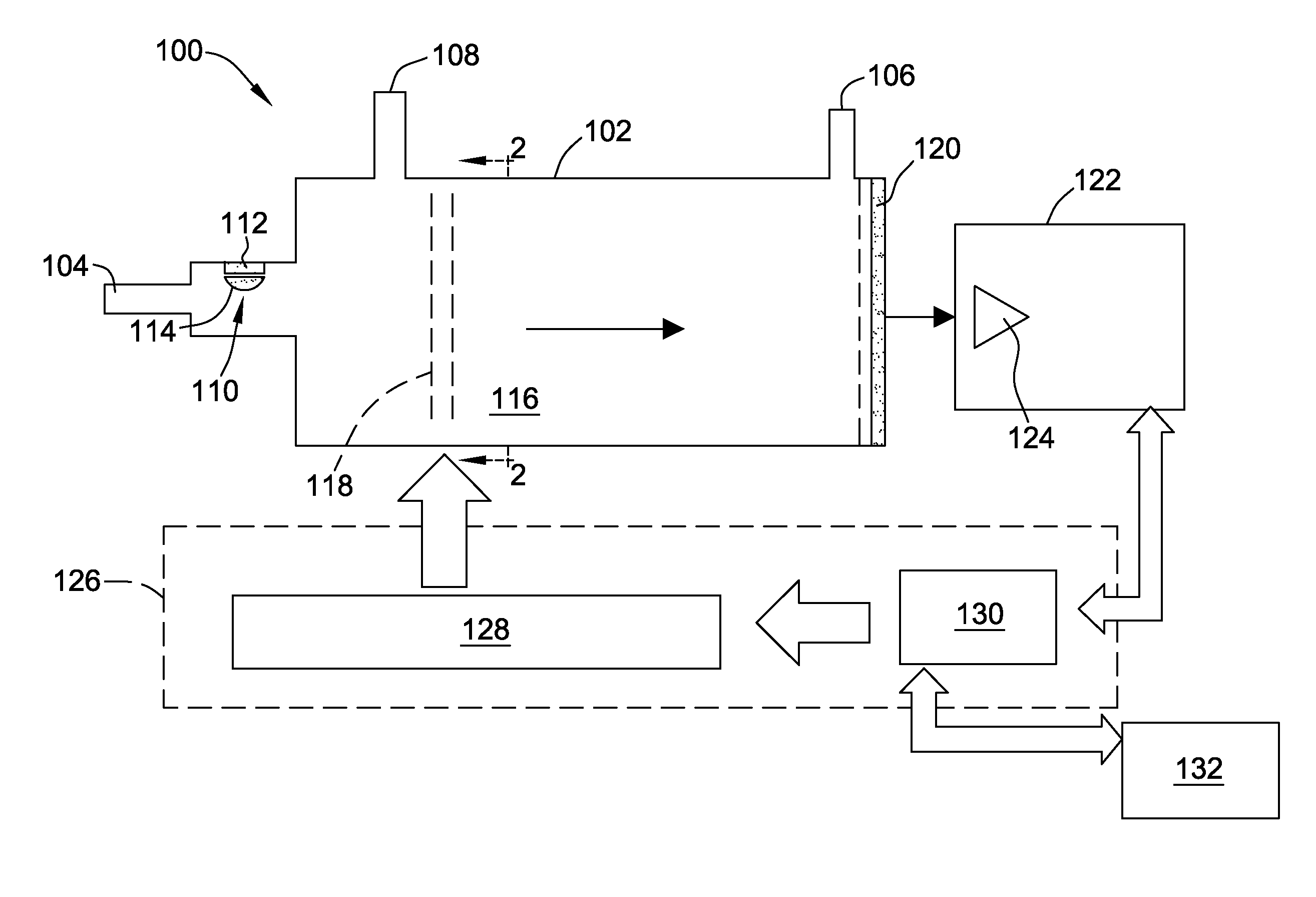

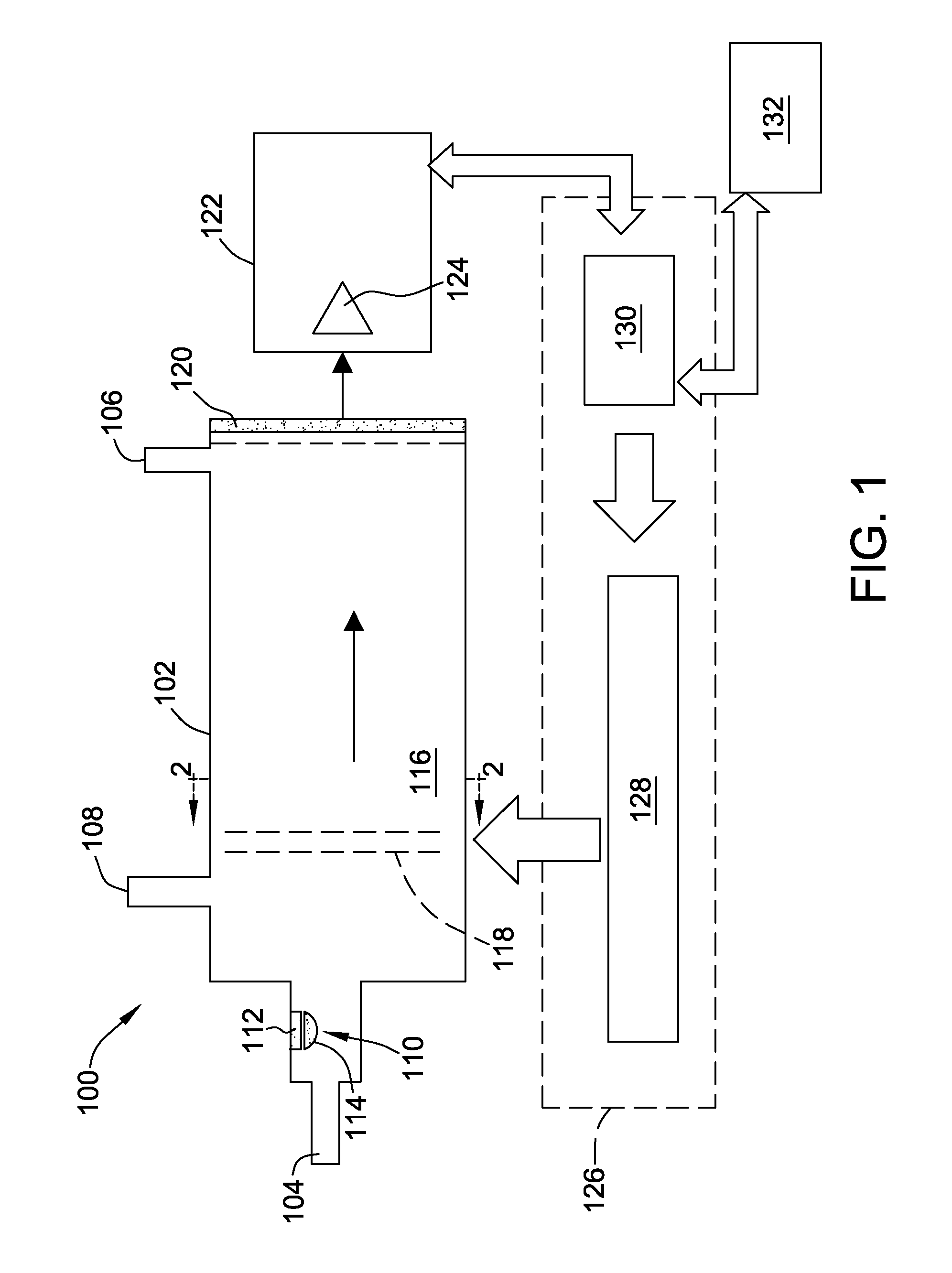

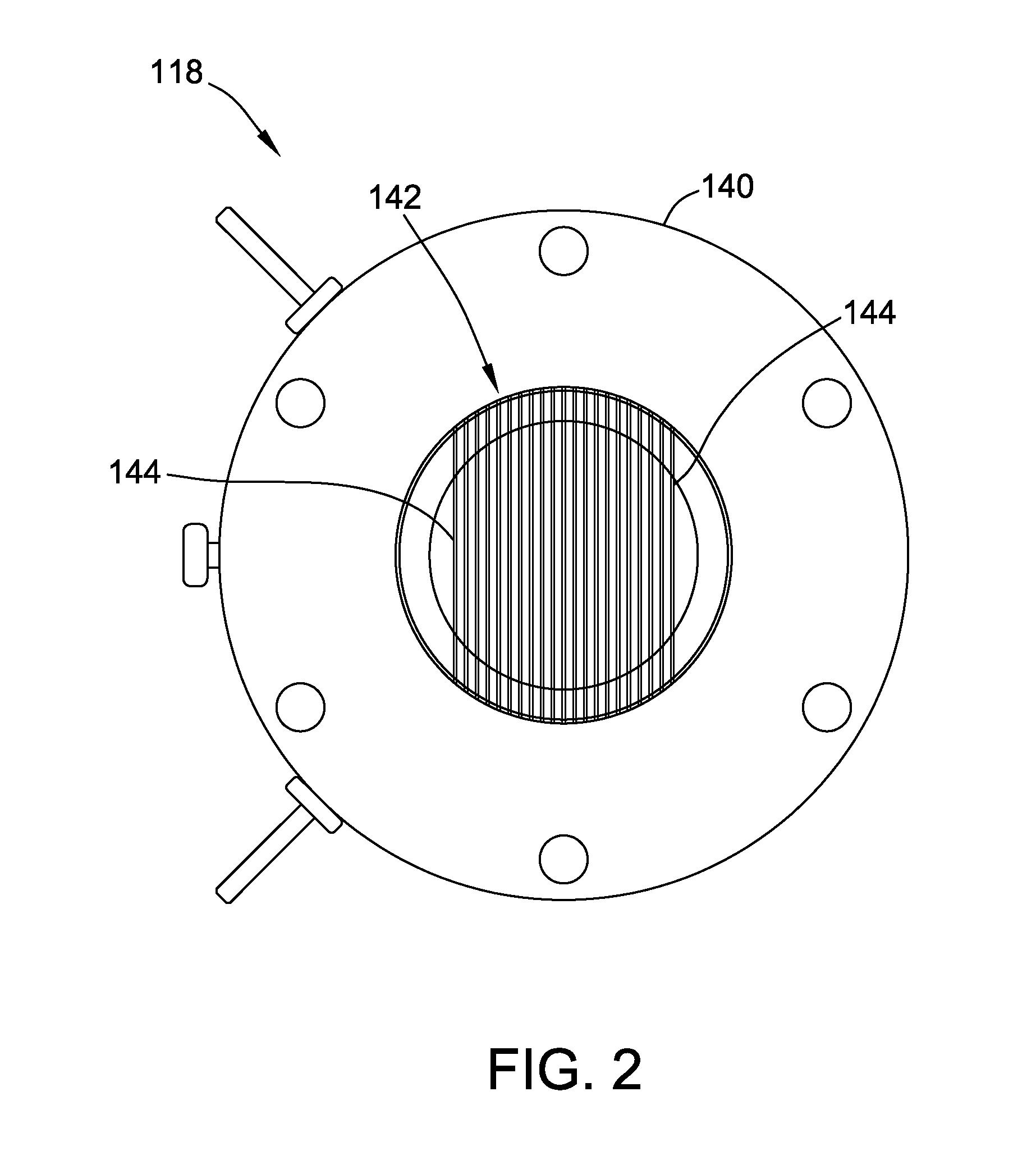

Ion mobility spectrometer and method of using the same

ActiveUS9147565B1Avoid flowEasy to solveSpectrometer circuit arrangementsTime-of-flight spectrometersVoltage regulationTemporal periods

A method of detecting constituents in a sample includes generating a plurality of ions in an ionization region. The method also includes preventing the plurality of ions in the ionization region from flowing into a drift region through inducing a first voltage in a device positioned between the two regions. The method further includes injecting at least a portion of the ions from the ionization region into the drift region. The method also includes regulating the voltage in the device to a second voltage for a first predetermined temporal period, the second voltage less than the first voltage. The method further includes regulating the voltage in the device to the first voltage. The method also includes regulating the voltage in the device to the second voltage for a second predetermined temporal period, the second predetermined temporal period different from the first predetermined temporal period.

Owner:RAPISCAN SYST INC (US)

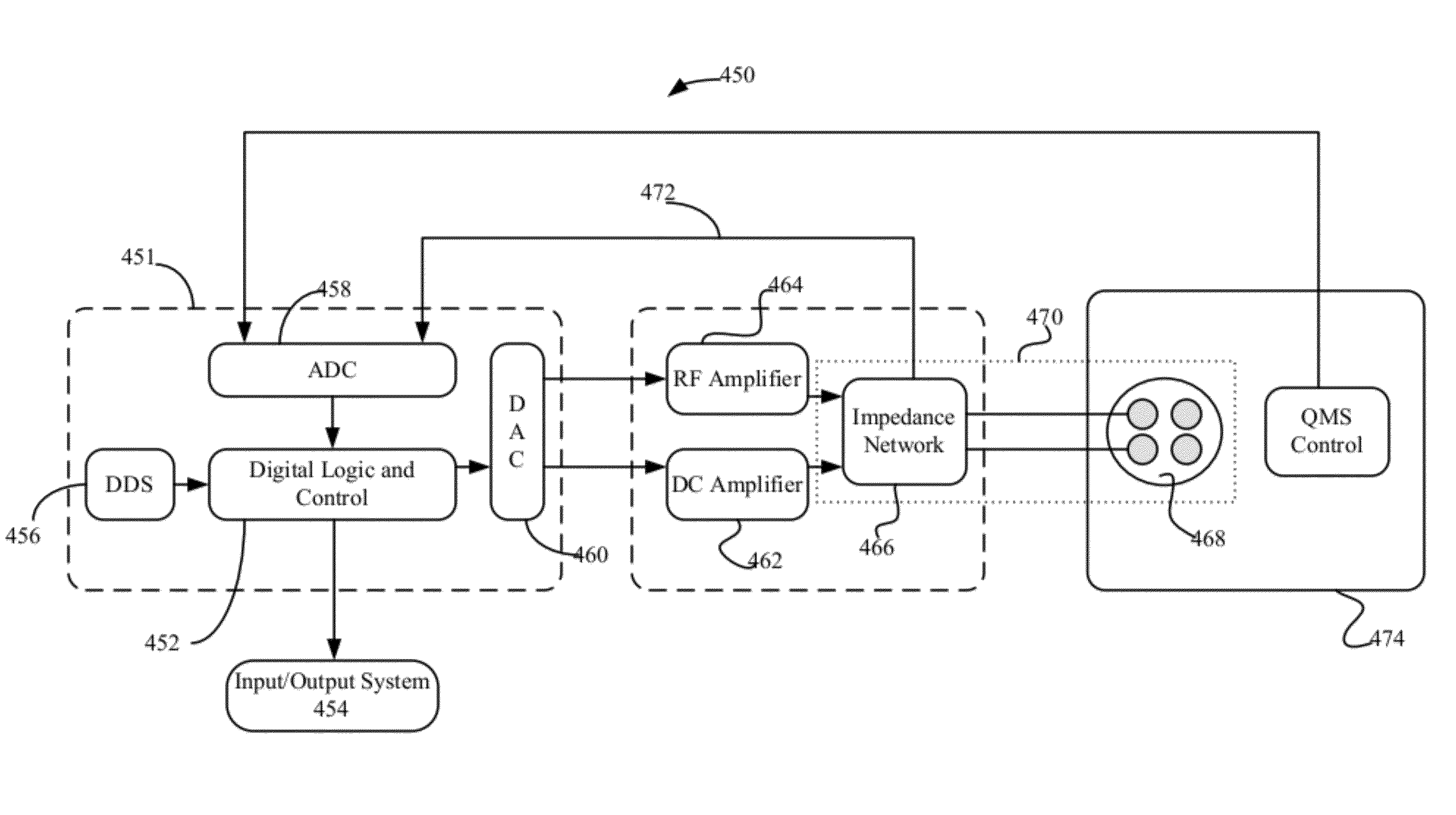

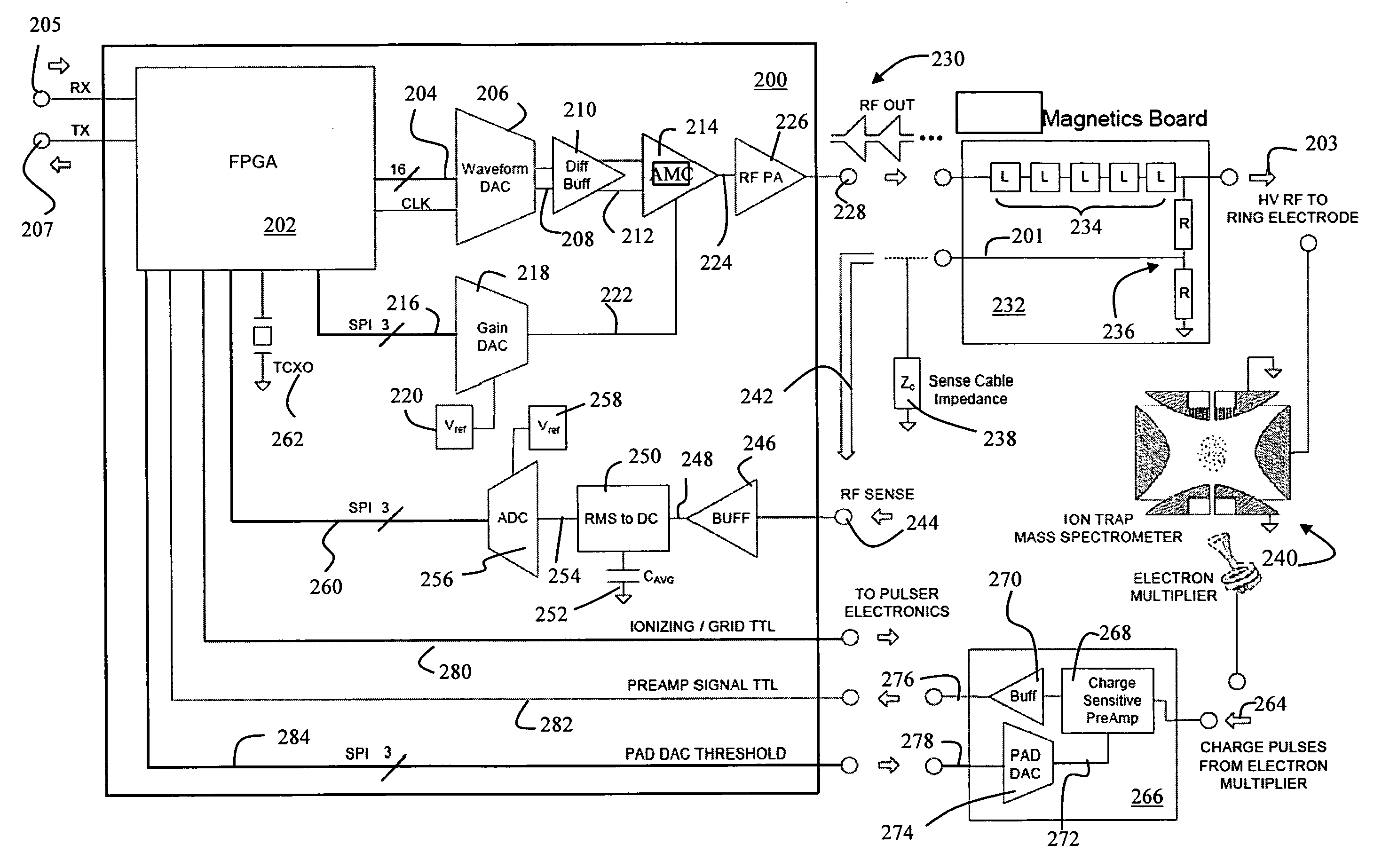

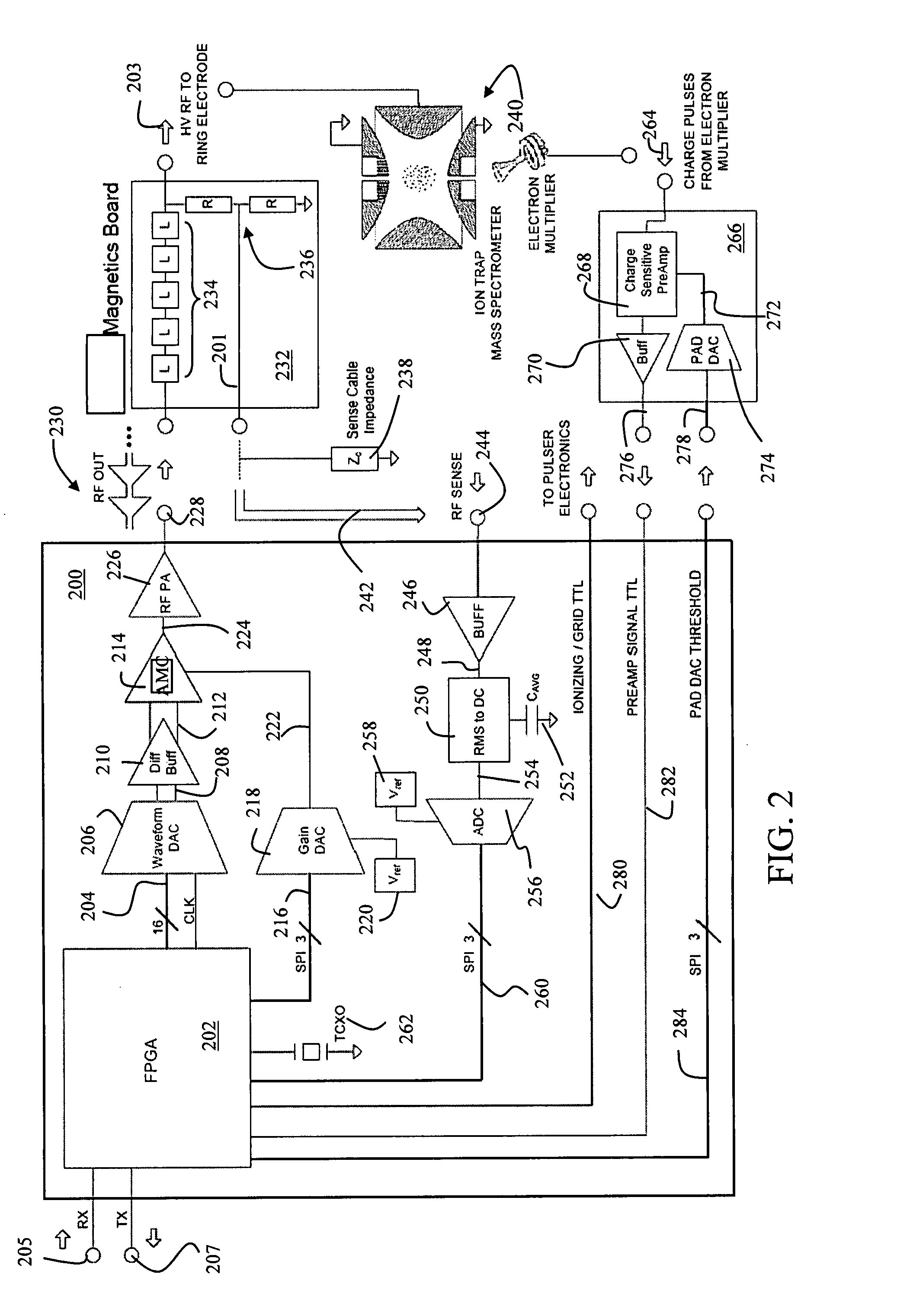

Electronic drive and acquisition system for mass spectrometry

InactiveUS20080001083A1Avoid dataSpectrometer circuit arrangementsIsotope separationMass Spectrometry-Mass SpectrometryEngineering

The present invention discloses an mixed signal RF drive electronics board that offers small, low power, reliable, and customizable method for driving and generating mass spectra from a mass spectrometer, and for control of other functions such as electron ionizer, ion focusing, single-ion detection, multi-channel data accumulation and, if desired, front-end interfaces such as pumps, valves, heaters, and columns.

Owner:CALIFORNIA INST OF TECH

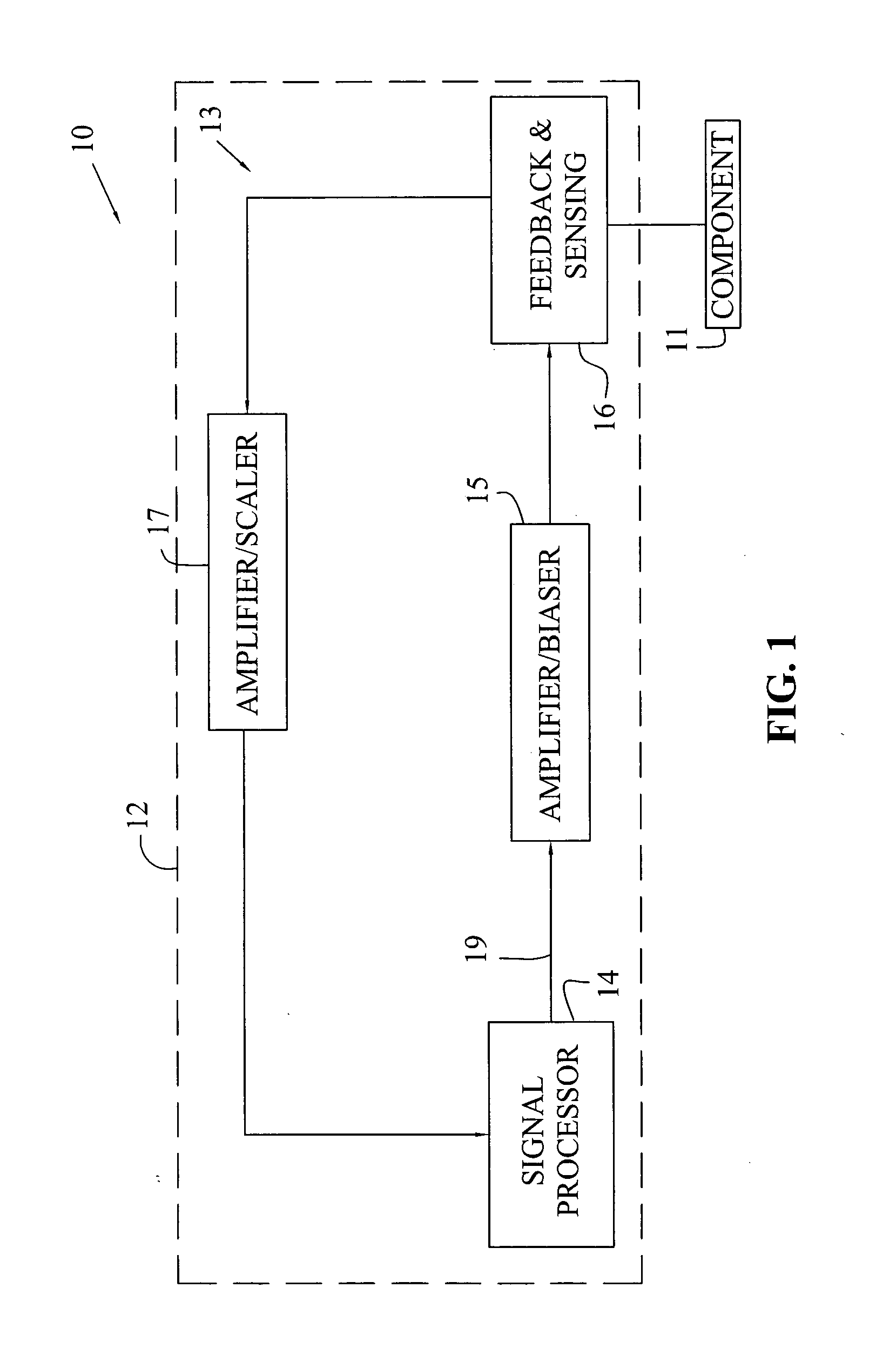

Method of automatically calibrating electronic controls in a mass spectrometer

ActiveUS20050051720A1Increase in mass accuracyImprove accuracyStability-of-path spectrometersSpectrometer circuit arrangementsElectronic circuitMass analysis

The present invention provides methods and electronic circuits for a chemical analyzer, for example, a mass spectrometer, which provide generated signals that are maintained to a required level of precision. A user may specify the required precision for the signals which operate the spectrometer and may specify the required precision for the mass analysis, either explicitly or by choosing a predefined configuration. The spectrometer will then generate the signals to the required precision despite changes in operating conditions, environmental conditions, component aging and degradation, or other nonfailure effects that otherwise affect analyzer calibration and signal output. The electronic circuits incorporate signal monitoring to maintain closed-loop signal control. The closed-loop control includes a feedback path which may include discrete components and may include software enabling a processor to adjust the generated signals to maintain the required precision of the signals and analysis. Further, the spectrometer may monitor signals and analyze and store data in order to predict future performance, including precision, analysis limitations, impending component degradation or failure, or another parameter associated with a component or signal of the spectrometer. Specifically, a range for a particular parameter may be specified and a indication provided to a user when the parameter exceeds the specified range.

Owner:FLIR DETECTION

Mass Spectrometer

ActiveUS20110180704A1Increase amplitudeEffective amplitudeStability-of-path spectrometersSpectrometer circuit arrangementsReverse orderMass-to-charge ratio

An ion guide or mass analyser is disclosed comprising a plurality of electrodes having apertures through which ions are transmitted in use. A pseudo-potential barrier is created at the exit of the ion guide or mass analyser. The amplitude or depth of the pseudo-potential barrier is inversely proportional to the mass to charge ratio of an ion. One or more transient DC voltages are applied to the electrodes of the ion guide or mass analyser in order to urge ions along the length of the ion guides or mass analyser. The amplitude of the transient DC voltage applied to the electrode may be increased with time so that ions are caused to be emitted from the ion guide or mass analyser in reverse order of their mass to charge ratio.

Owner:MICROMASS UK LTD

Method of automatically calibrating electronic controls in a mass spectrometer

ActiveUS6982413B2Calibration reducedMeet cutting requirementsSpectrometer circuit arrangementsStability-of-path spectrometersClosed loopMass analyzer

The present invention provides methods and electronic circuits for a chemical analyzer, for example, a mass spectrometer, which provide generated signals that are maintained to a required level of precision. A user may specify the required precision for the signals which operate the spectrometer and may specify the required precision for the mass analysis, either explicitly or by choosing a predefined configuration. The spectrometer will then generate the signals to the required precision despite changes in operating conditions, environmental conditions, component aging and degradation, or other nonfailure effects that otherwise affect analyzer calibration and signal output. The electronic circuits incorporate signal monitoring to maintain closed-loop signal control. The closed-loop control includes a feedback path which may include discrete components and may include software enabling a processor to adjust the generated signals to maintain the required precision of the signals and analysis. Further, the spectrometer may monitor signals and analyze and store data in order to predict future performance, including precision, analysis limitations, impending component degradation or failure, or another parameter associated with a component or signal of the spectrometer. Specifically, a range for a particular parameter may be specified and a indication provided to a user when the parameter exceeds the specified range.

Owner:FLIR DETECTION

Apparatus and method for electronically driving a quadrupole mass spectrometer to improve signal performance at fast scan rates

ActiveUS7078686B2Stability-of-path spectrometersSpectrometer circuit arrangementsMass analyzerQuadrupole

An apparatus for electronically controlling a quadrupole in a mass spectrometer, comprises radio frequency (RF) drive circuitry and direct current (DC) drive circuitry coupled to a quadrupole, an RF control loop associated with the RF drive circuitry, a DC control loop associated with the DC drive circuitry, and control loop circuitry associated with the DC control loop, the control loop circuitry configured to alter a response of the DC control loop during a settling time period of a step response such that ion transmission through the quadrupole is greater during the settling time than if the response of the DC control loop during the settling time is unaltered.

Owner:AGILENT TECH INC

Mass spectrometer

ActiveUS9012840B2Loss of sensitivityWithout any loss in duty cycle and sensitivitySpectrometer circuit arrangementsTime-of-flight spectrometersMass spectrometricSpectrometer

A mass spectrometer is disclosed comprising a first quadrupole rod set mass filter, a collision cell, an ion mobility spectrometer or separator, an ion guide or collision cell arranged downstream of the ion mobility spectrometer or separator, a second quadrupole rod set mass filter and an ion detector.

Owner:MICROMASS UK LTD

Popular searches

Omegatrons Radio frequency spectrometers Transformers/inductances magnetic cores Portable spectrometers Fixed transformers Beam/ray focussing/reflecting arrangements Beam/ray deflecting arrangements Beam deviation/focusing by electric/magnetic means Ac-dc conversion without reversal Ac network circuit arrangements

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com