Patents

Literature

63results about How to "Maximizing intensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

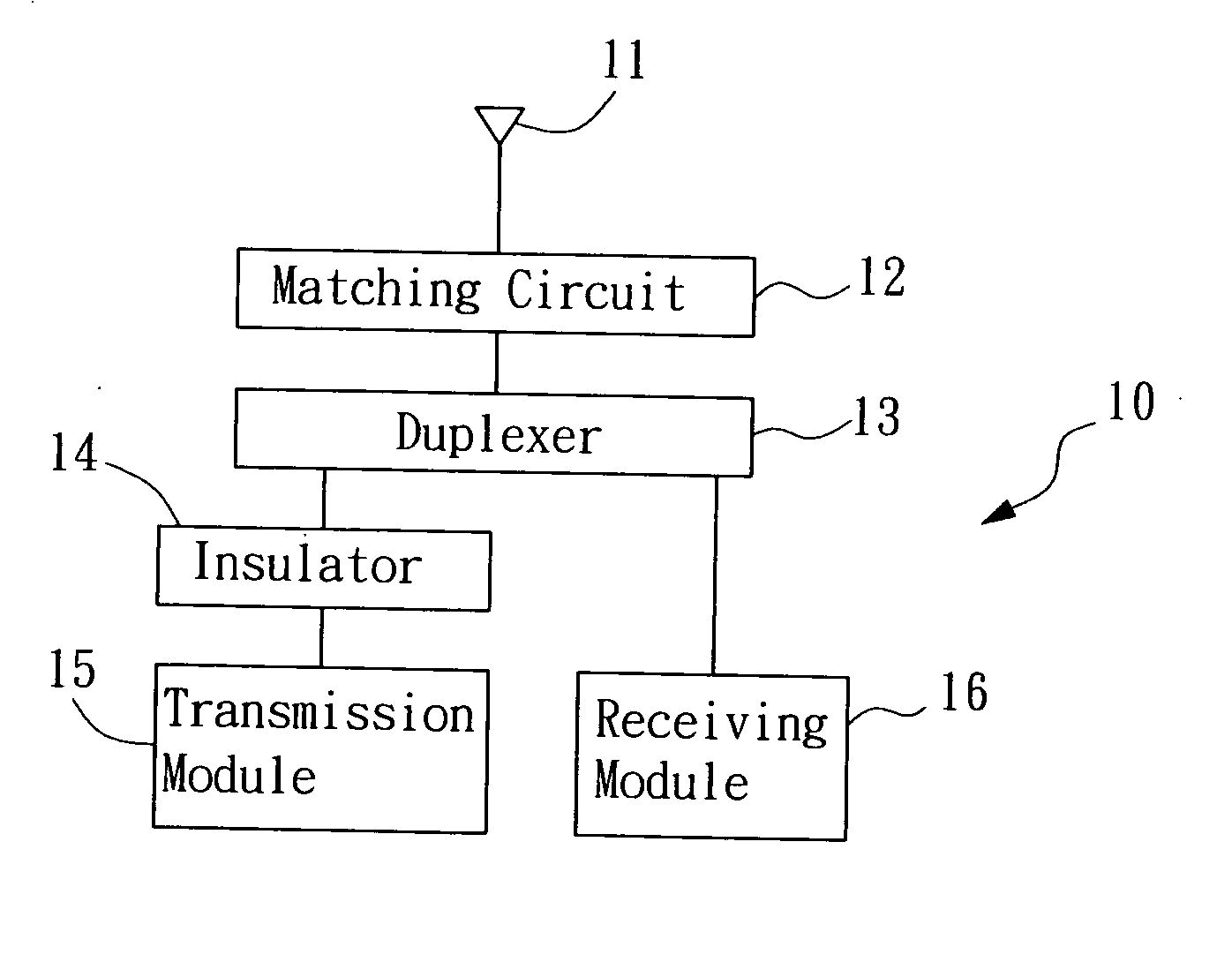

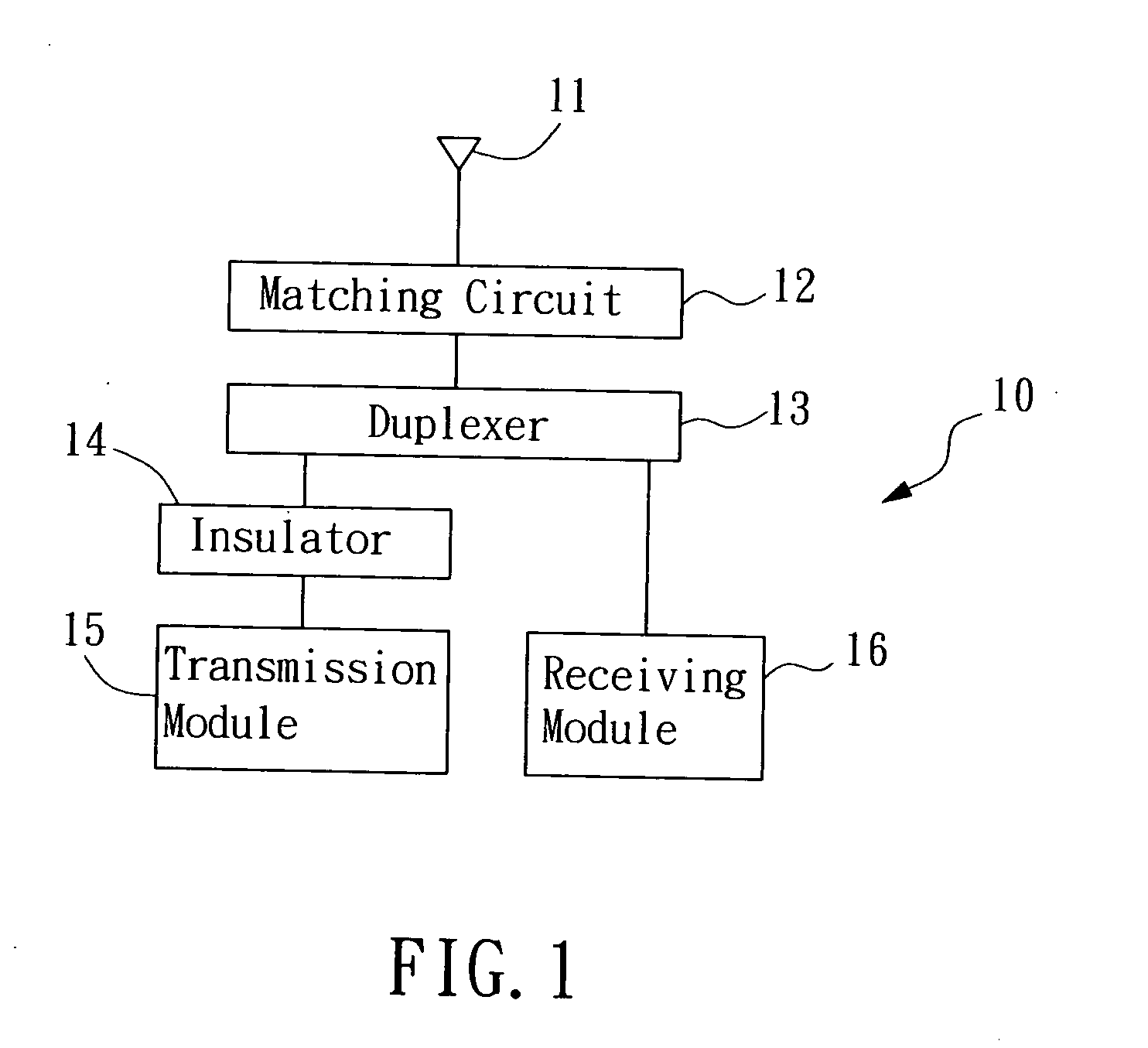

Device and method for antenna matching

InactiveUS20050042989A1Maximizing intensityIntensity of maximizedTransmissionTransceiverAntenna gain

The present invention provides a device and method for antenna matching applied in a transceiver. Wherein, the transceiver has a transmission module and a receiving module. The antenna matching device includes a matching circuit, a duplexer, a circulator, a control unit, and a coupler. Wherein, the matching circuit adjusts the matching impedance according to an adjusting signal and generates a reflection signal. The duplexer receives the reflection signal and a receiving signal and respectively sent the received two signals to the control unit and the receiving module according to their frequencies. The control unit, according to the reflection signal, estimates the adjusting signal for adjusting the matching circuit to an optimal state of the load impedance of the matching antenna, such that the antenna gain may is maximized, and a best efficiency is obtained no matter during receiving or transmission.

Owner:BENQ CORP

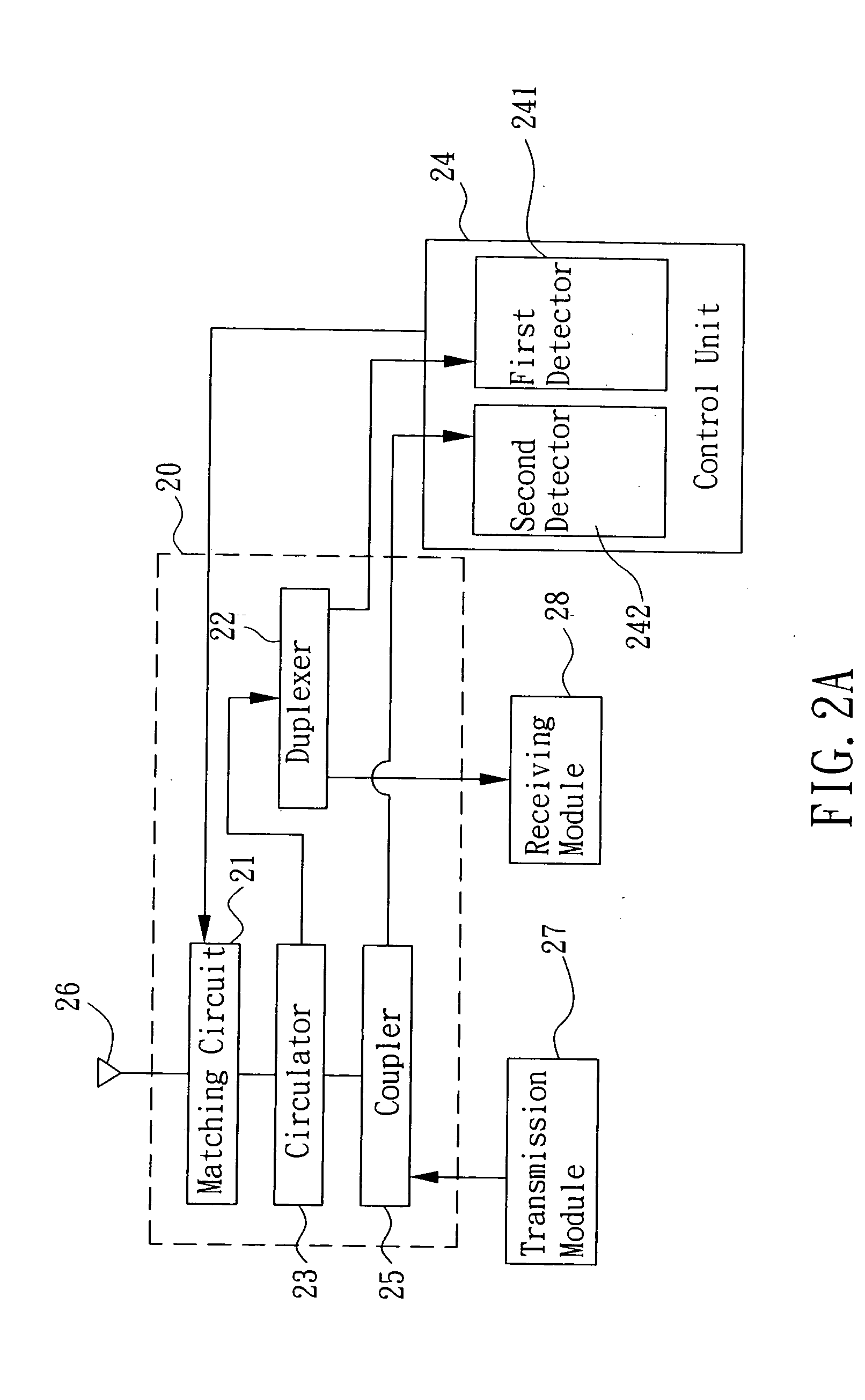

System for enhancing the television presentation of an object at a sporting event

InactiveUS6154250AMaximizing intensityImprove abilitiesTelevision system detailsColor signal processing circuitsObject basedCable television

A system for enhancing the television presentation of an object at a sporting event includes one or more sensors which are used to determine the location of the object. Based on the location of the object and the field of view of a broadcast camera, a processor determines the position of the object in a video frame of the broadcast camera. Once knowing where the object is positioned within the video frame, the television signal can be edited or augmented to enhance the presentation of the object.

Owner:SPORTSMEDIA TECH CORP

System for enhancing a video presentation

InactiveUS6252632B1Maximizing intensityImprove abilitiesTelevision system detailsColor signal processing circuitsVideo imageCable television

A system for enhancing the television presentation of an object that can highlight the object without obscuring the image of the object. The system receives a first video image, matches a second video image to a portion of the first video image corresponding to the image of the object. Specific pixels within the portion of the first video image which are not part of the image of the object are modified using a pixel from the second video image.

Owner:FOX SPORTS PRODN

Multi-fuel compression ignition engine

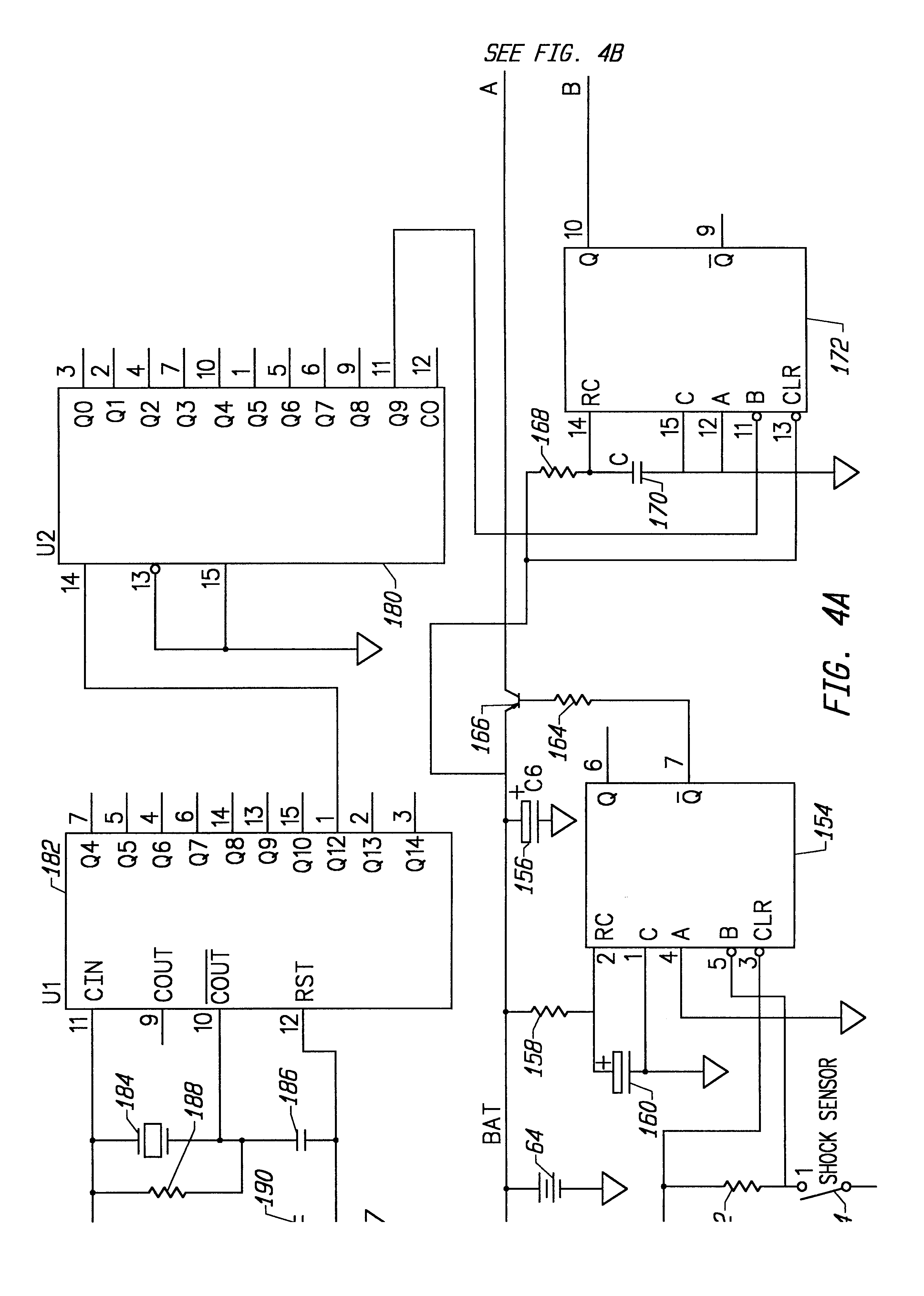

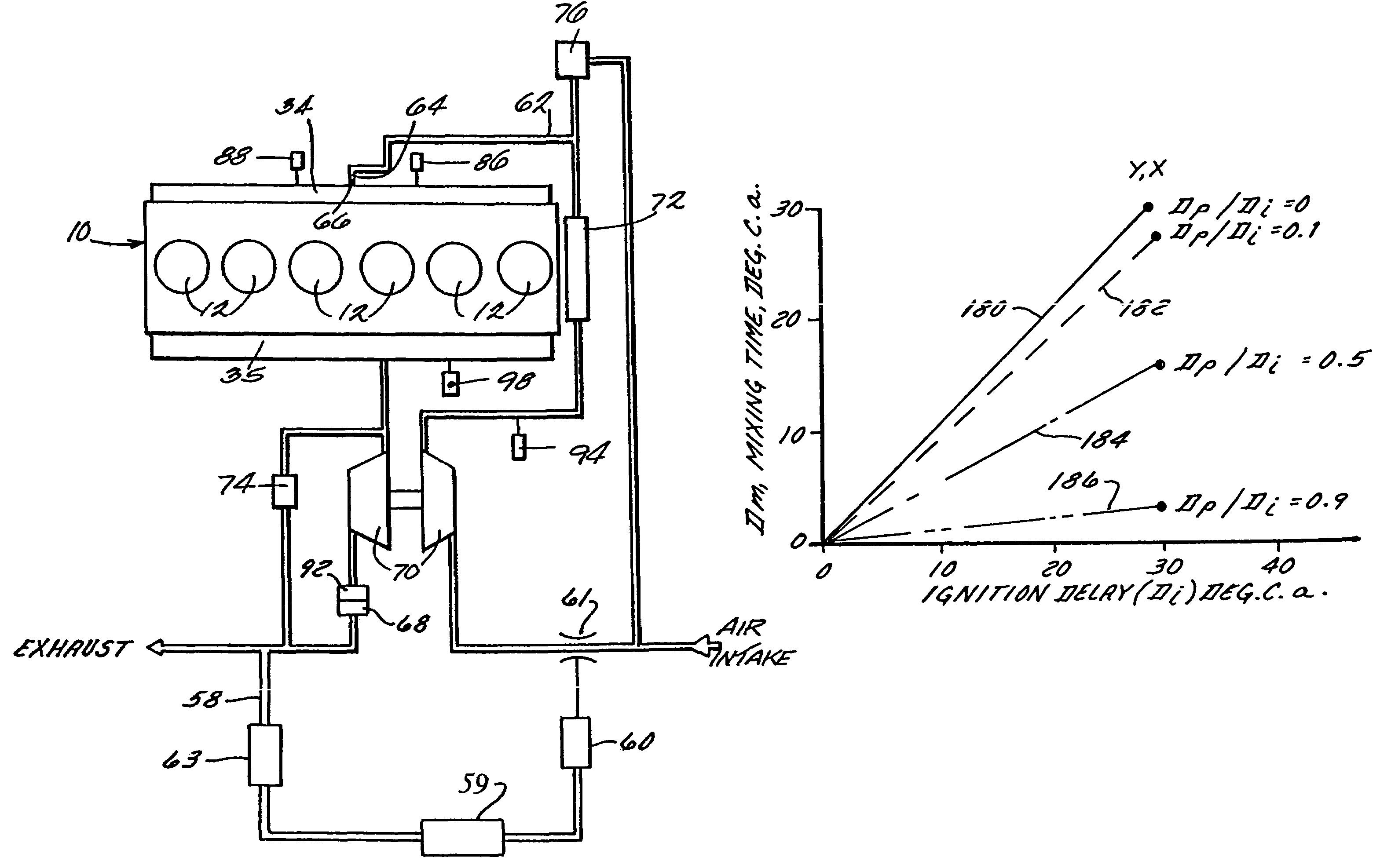

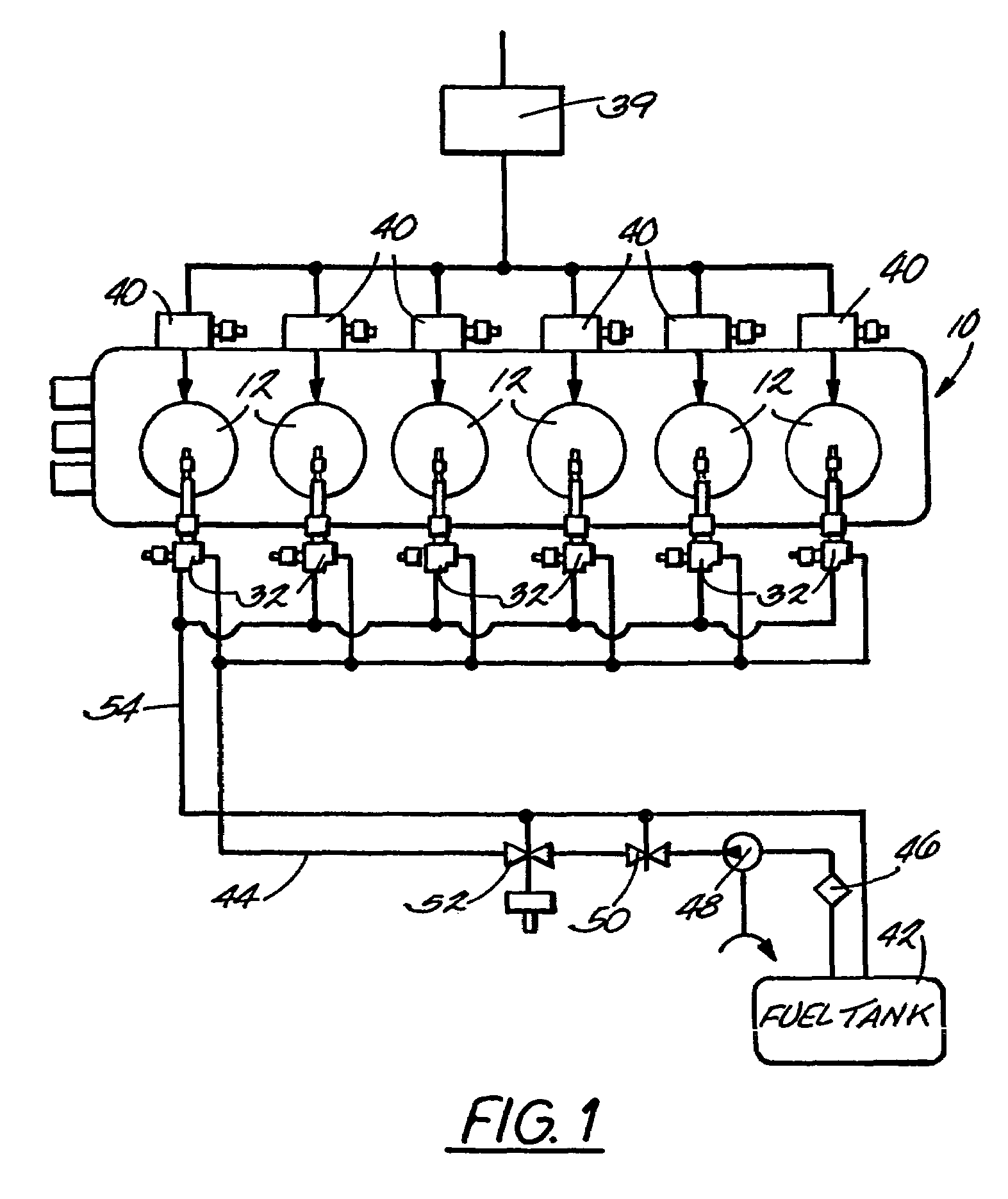

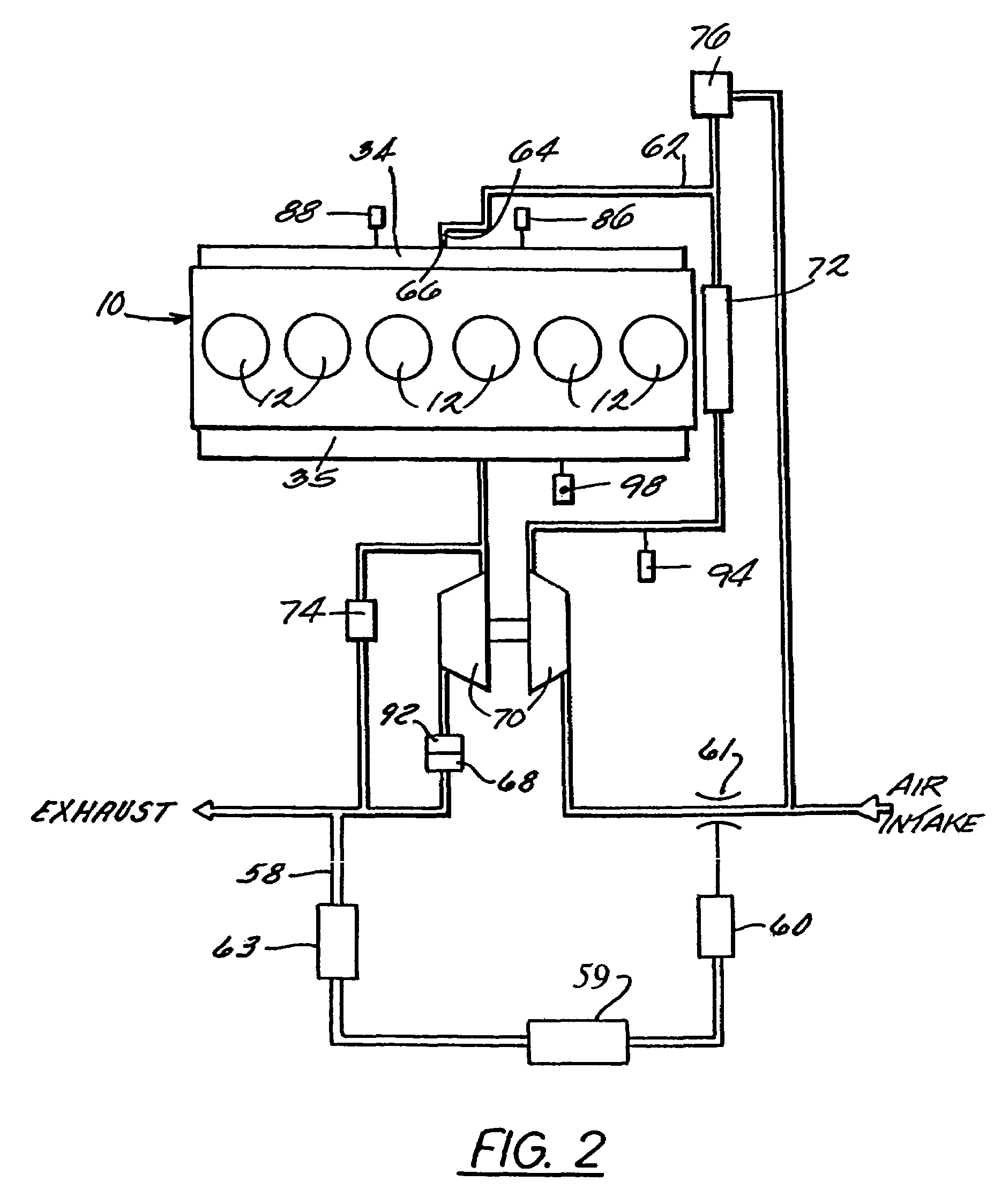

InactiveUS7036482B2Improve performanceMaximizing intensityElectrical controlInternal combustion piston enginesHcci combustionCombustion chamber

A liquid primary fuel is ignited by HCCI with the assistance of the early injection of a liquid pilot fuel. Pilot fuel injection and / or ignition are preferably controlled so as to permit the injected pilot fuel to become thoroughly distributed through and mixed with the primary fuel / air charge in the combustion chamber and vaporized prior to ignition. Pilot fuel having a lower autoignition temperature will be ignited by compression ignition, followed by the ignition of the homogeneous mixture of the primary fuel and air. HCCI combustion of the primary fuel is facilitated by 1) selection of the properties of the primary and pilot fuels and 2) obtaining a homogenous mixture of primary fuel and air by injecting primary fuel into the engine's intake air stream in the form of finely atomized droplets having a mean diameter in the micron range.

Owner:CLEAN AIR POWER

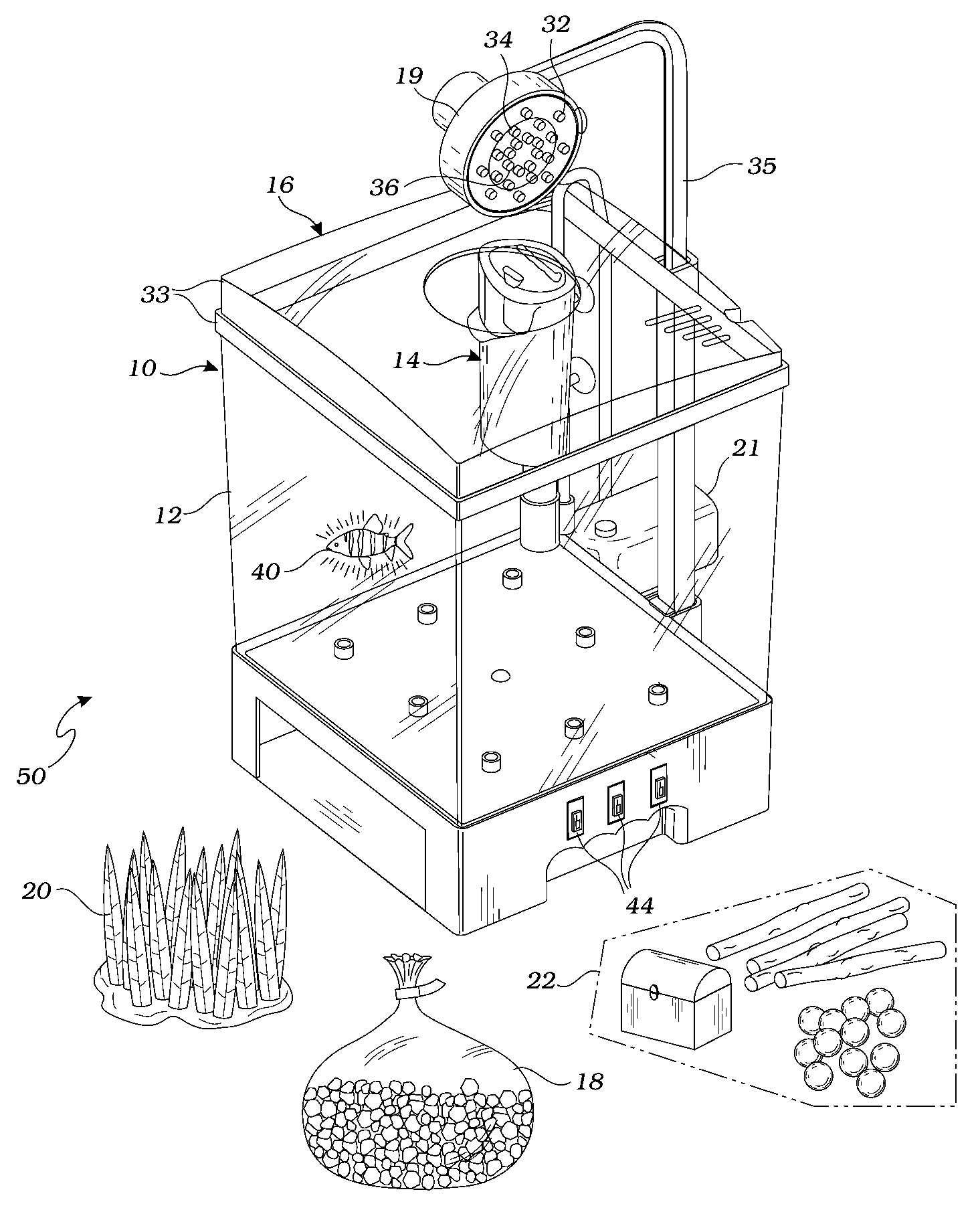

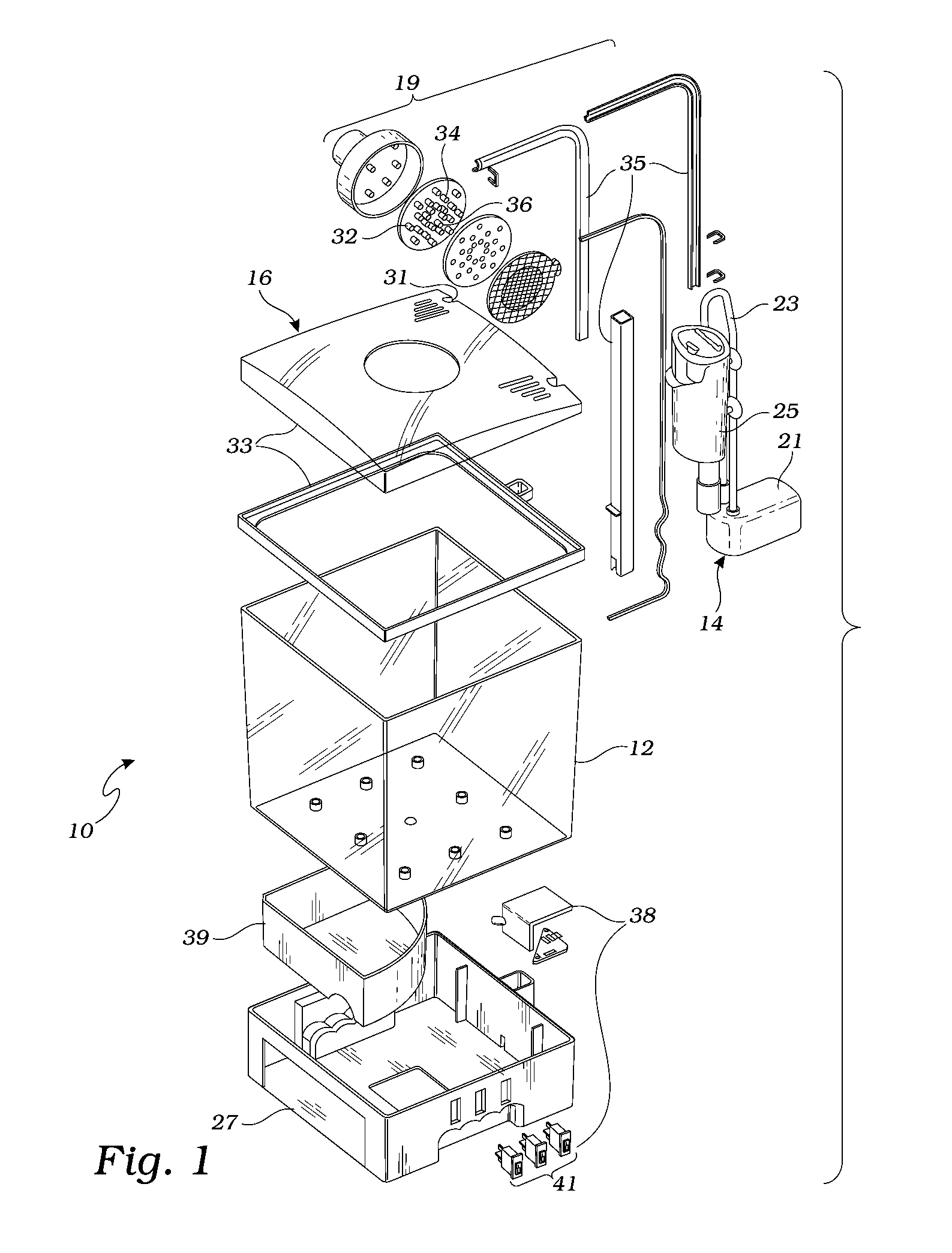

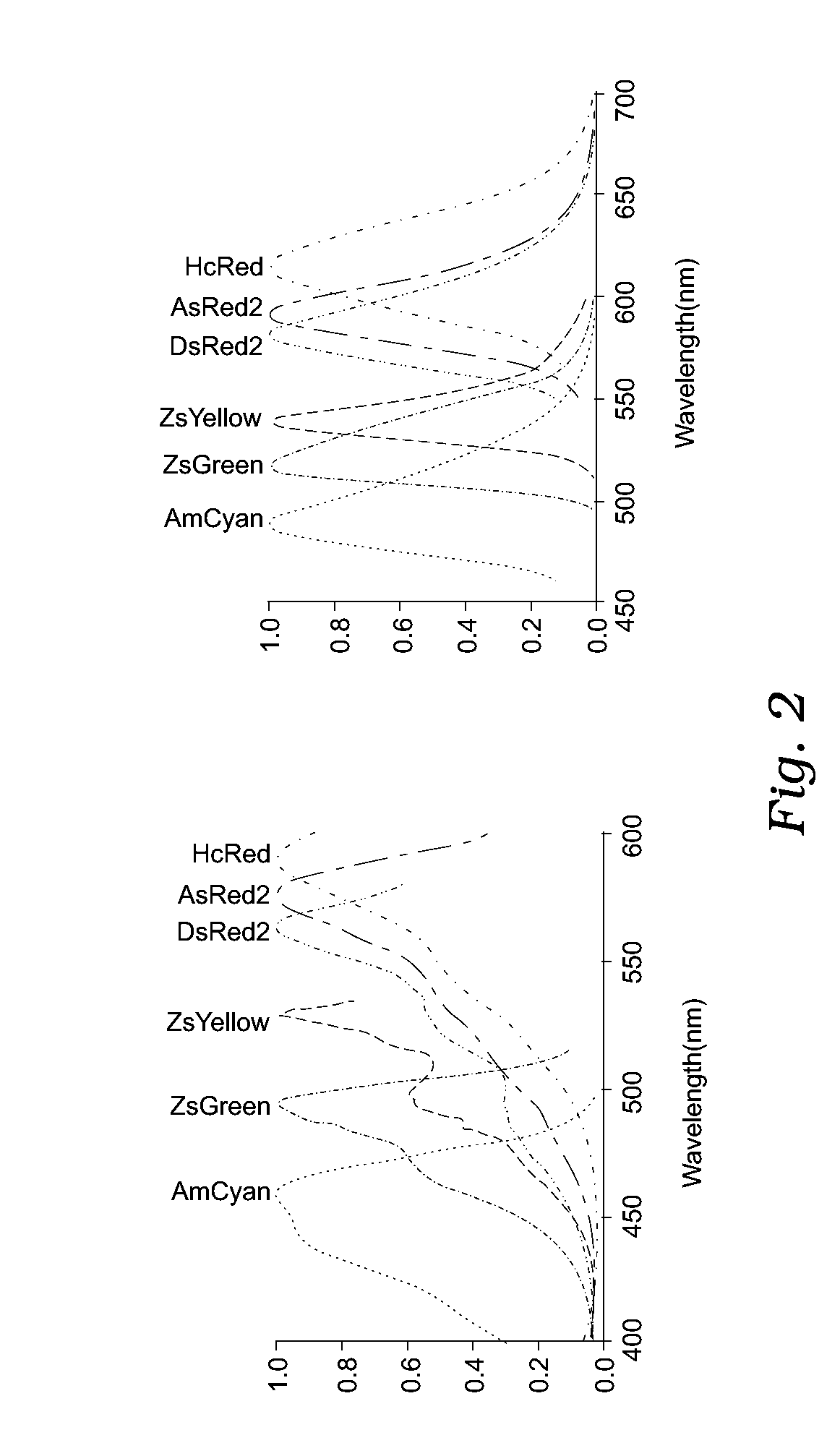

Aquarium with adjustable lighting

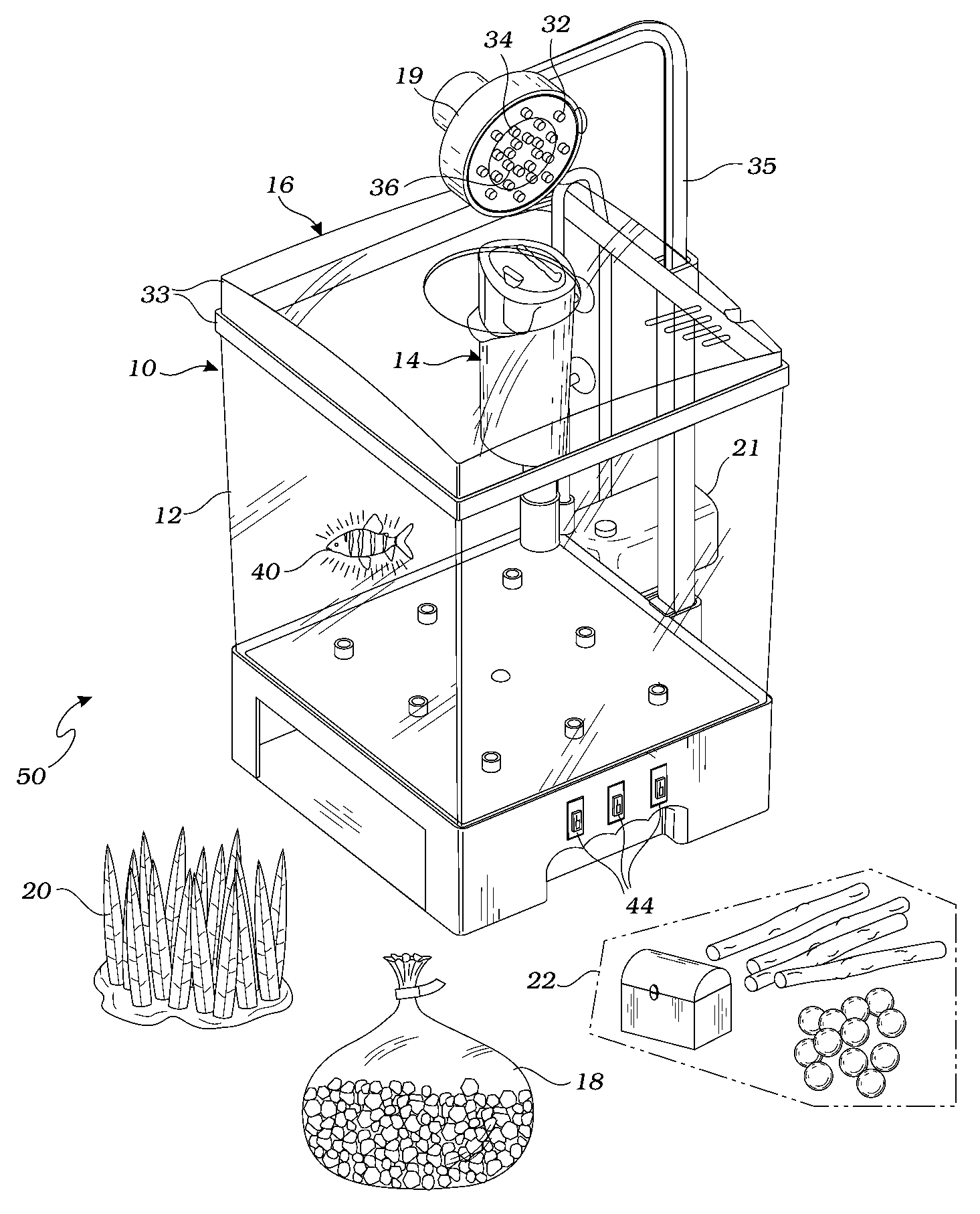

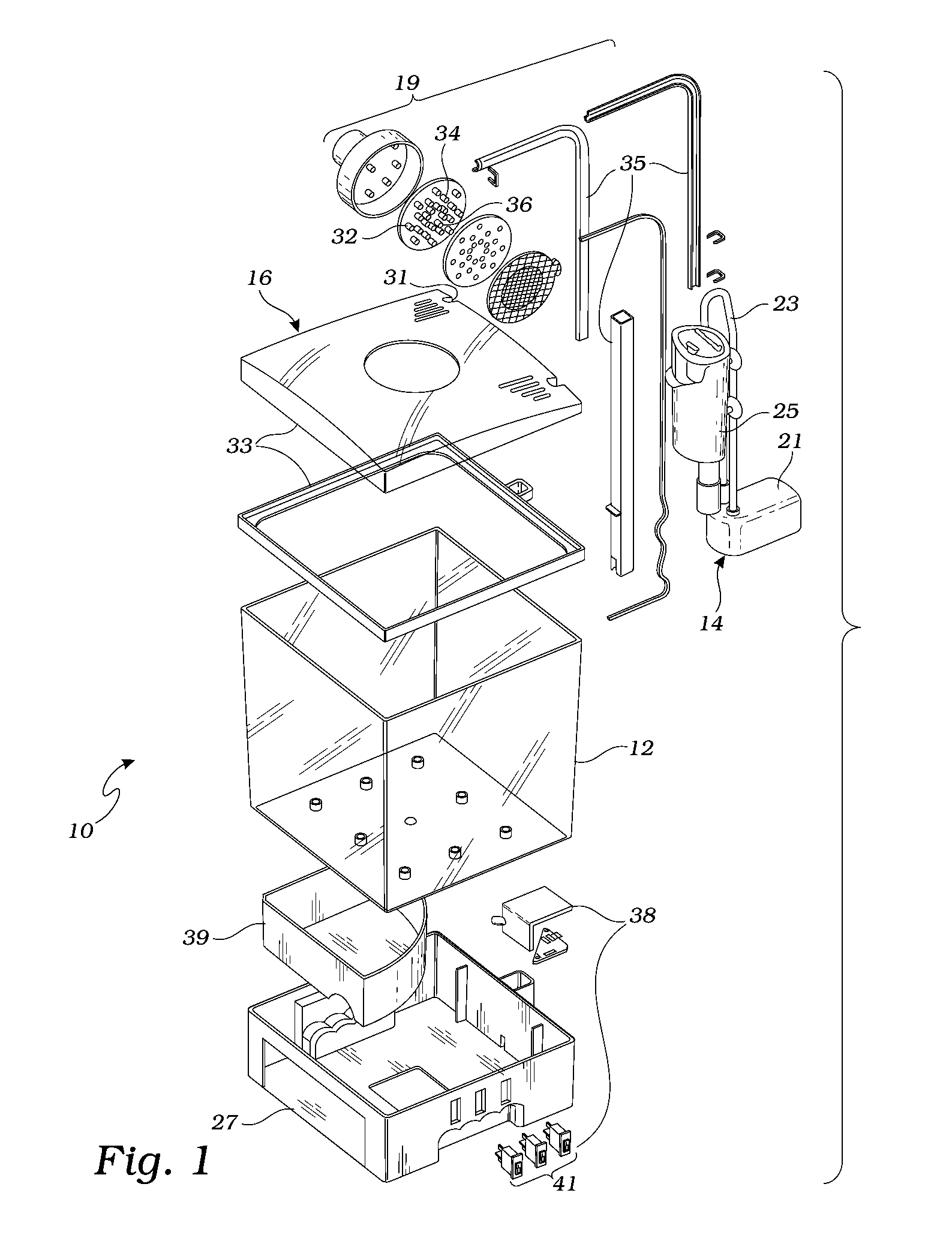

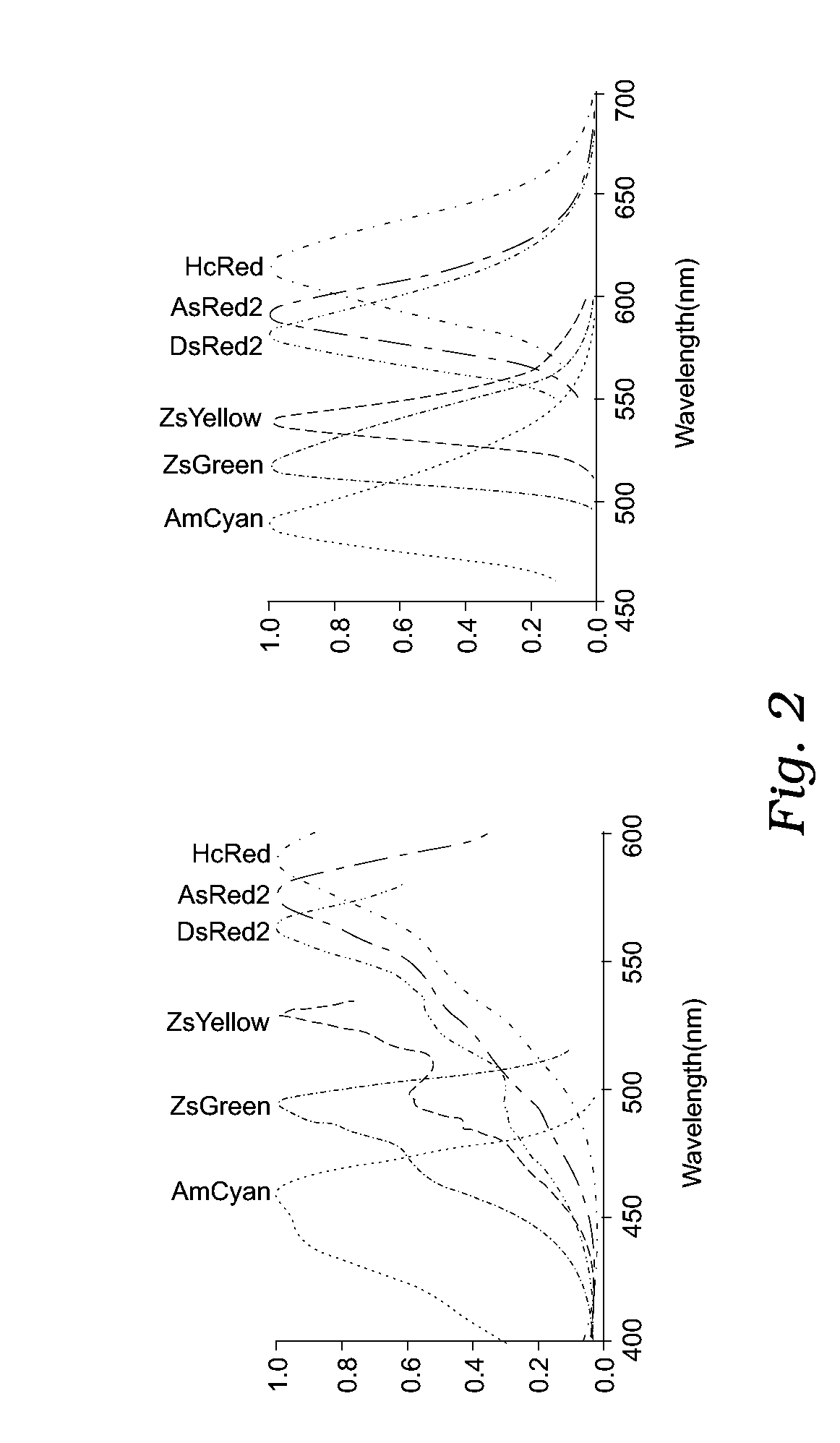

ActiveUS20080316732A1Improve the display effectMaximizing intensityMechanical apparatusDomestic lightingFluorescenceDark room

An aquarium having an adjustable lighting system for enhancing the display of fluorescent objects, such as fluorescent fish, contained within the aquarium under various external lighting conditions, such as a dark room or a brightly lit room. The aquarium comprises a tank and a plurality of light sources. Each light source emits light at a different wavelength spectrum which is selected to enhance the display of the fluorescent object under each type of external lighting condition. An electronic control is provided to control the operation of the plurality of light sources such that each light source may be selectively turned on / off based on the external lighting condition, or chronological criteria, to provide the best viewing experience.

Owner:GLOFISH LLC

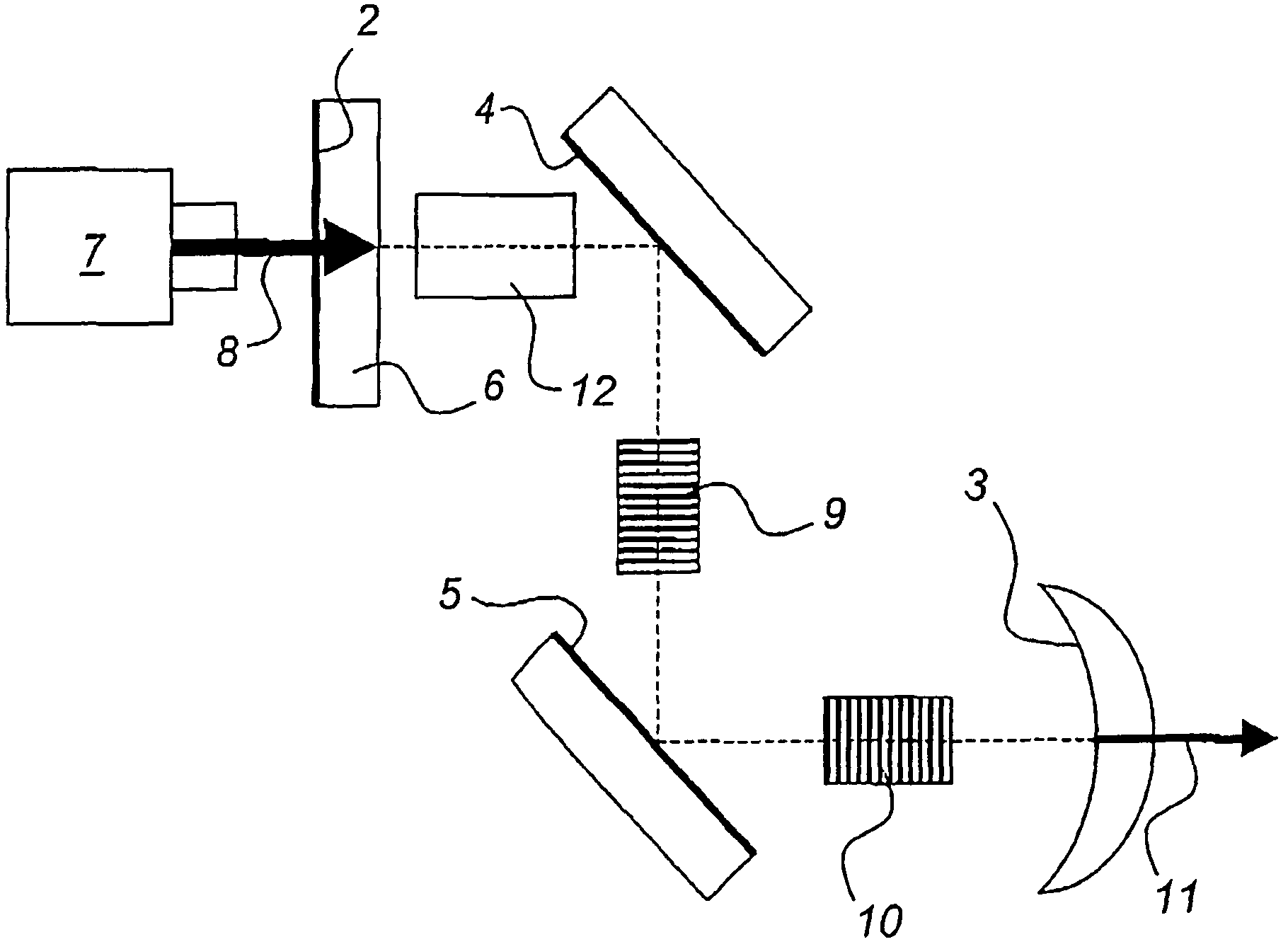

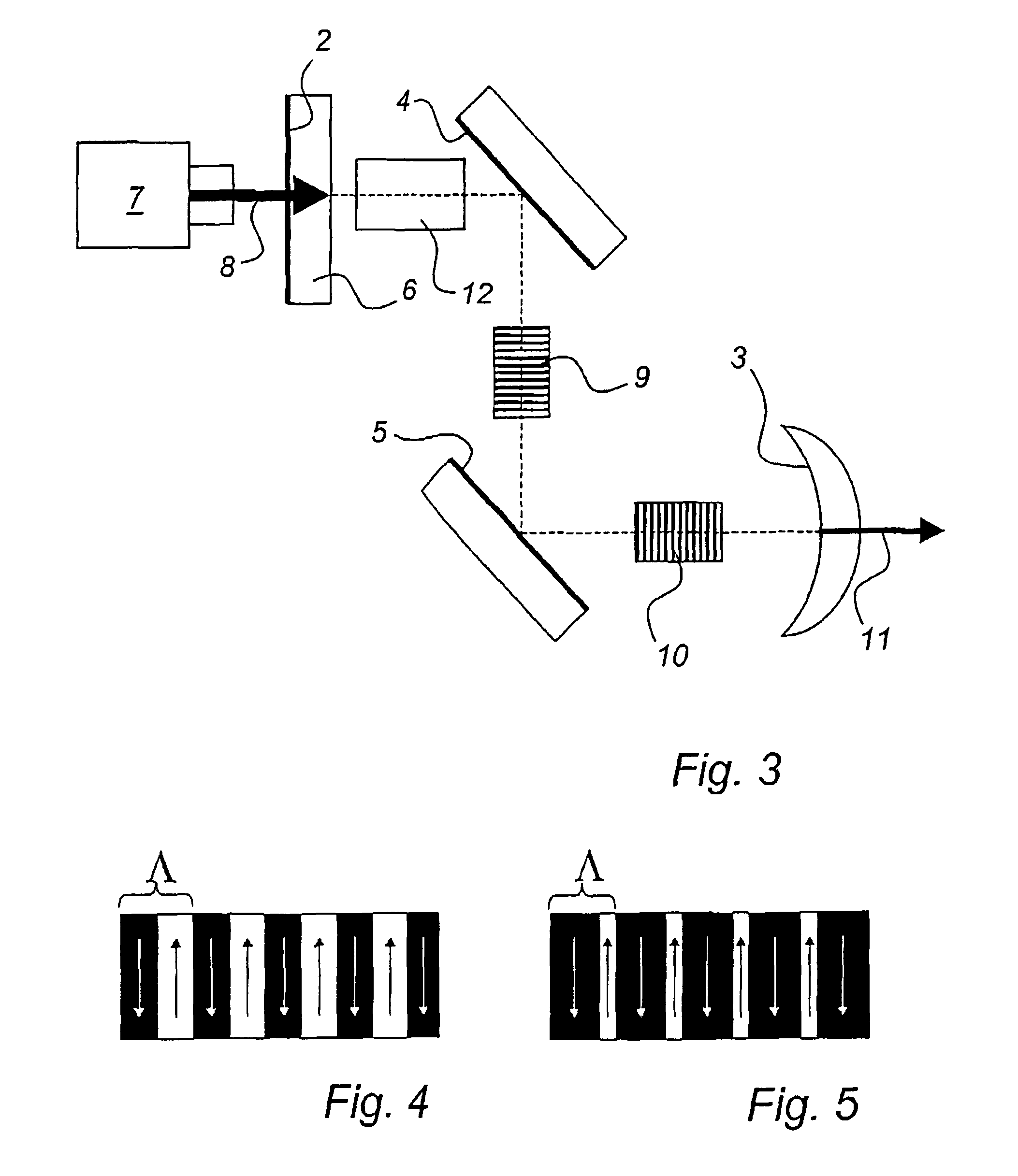

Method and system for diffractive beam combining using DOE combiner with passive phase control

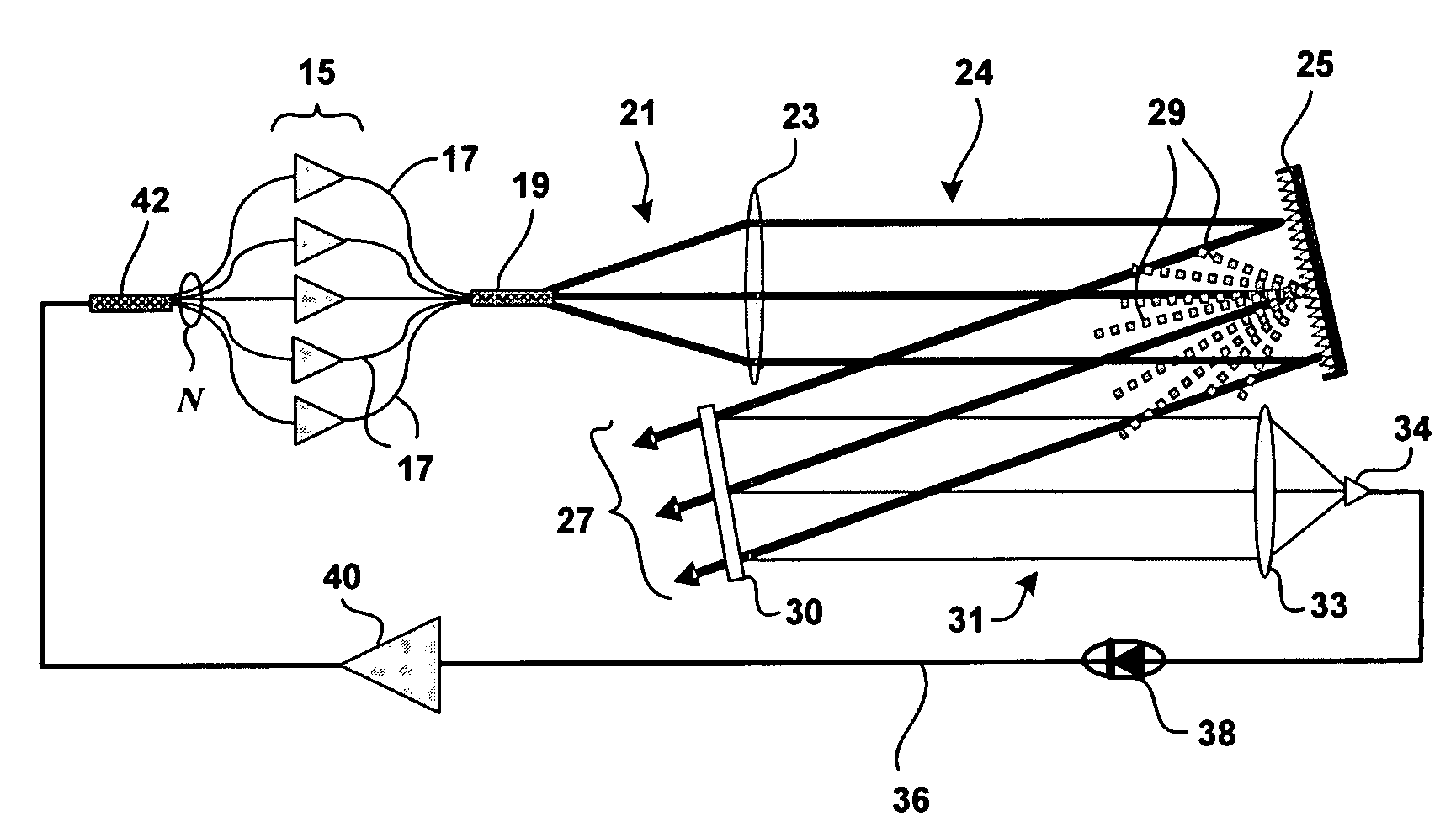

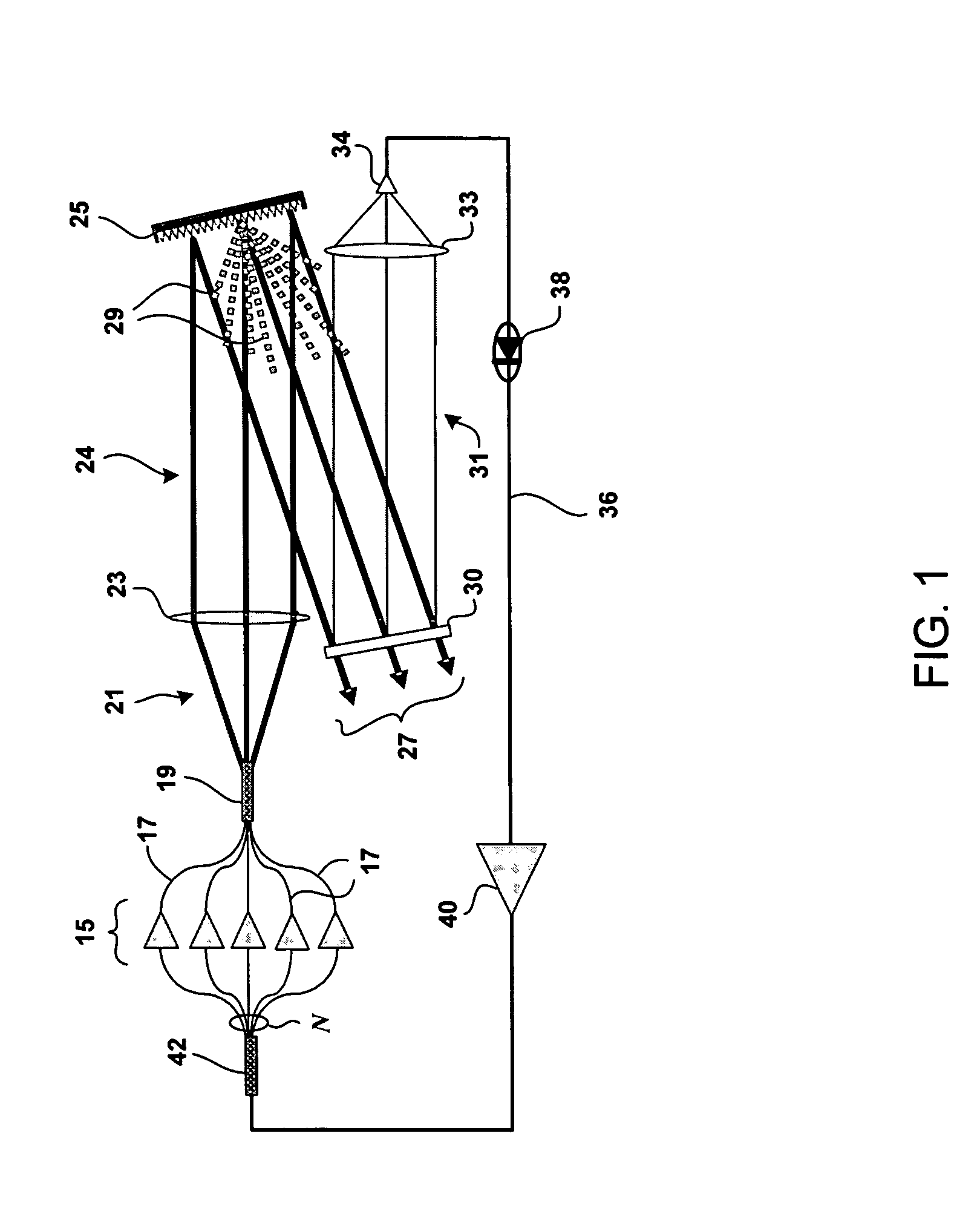

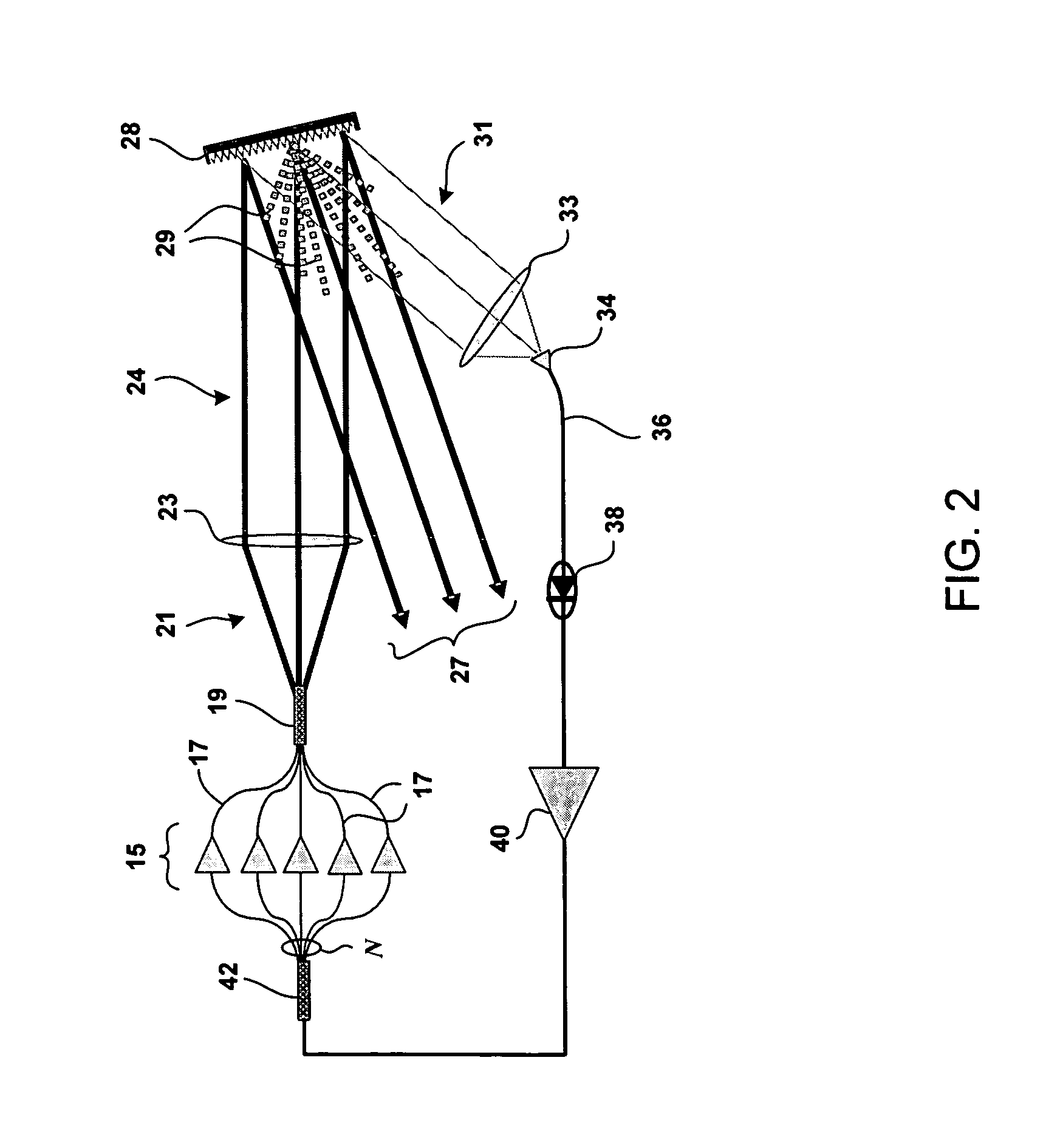

ActiveUS7339727B1Maximize round-trip gainMaximizing intensityLaser detailsOptical amplifierBeam splitter

A system and method for combining plural low power light beams into a coherent high power light beam. Optical amplifiers transmit a plurality of light beams propagating at a common wavelength through an array of optical fiber emitters. Each constituent beam is emitted from the array at a different propagation angle, collimated, and incident on a diffractive optical element operating as a beam combiner such that incident beams when properly phased and located are combined into a coherent beam at a desired diffraction order. A beam splitter or a periodic sampling grating on the diffractive optical element directs a low power sample beam to a spatial filter passing resonant mode output back to the optical amplifiers in a ring laser configuration thereby passively synchronizing phases of the constituent beams to maximize combination efficiency of the coherent beam.

Owner:NORTHROP GRUMMAN SYST CORP

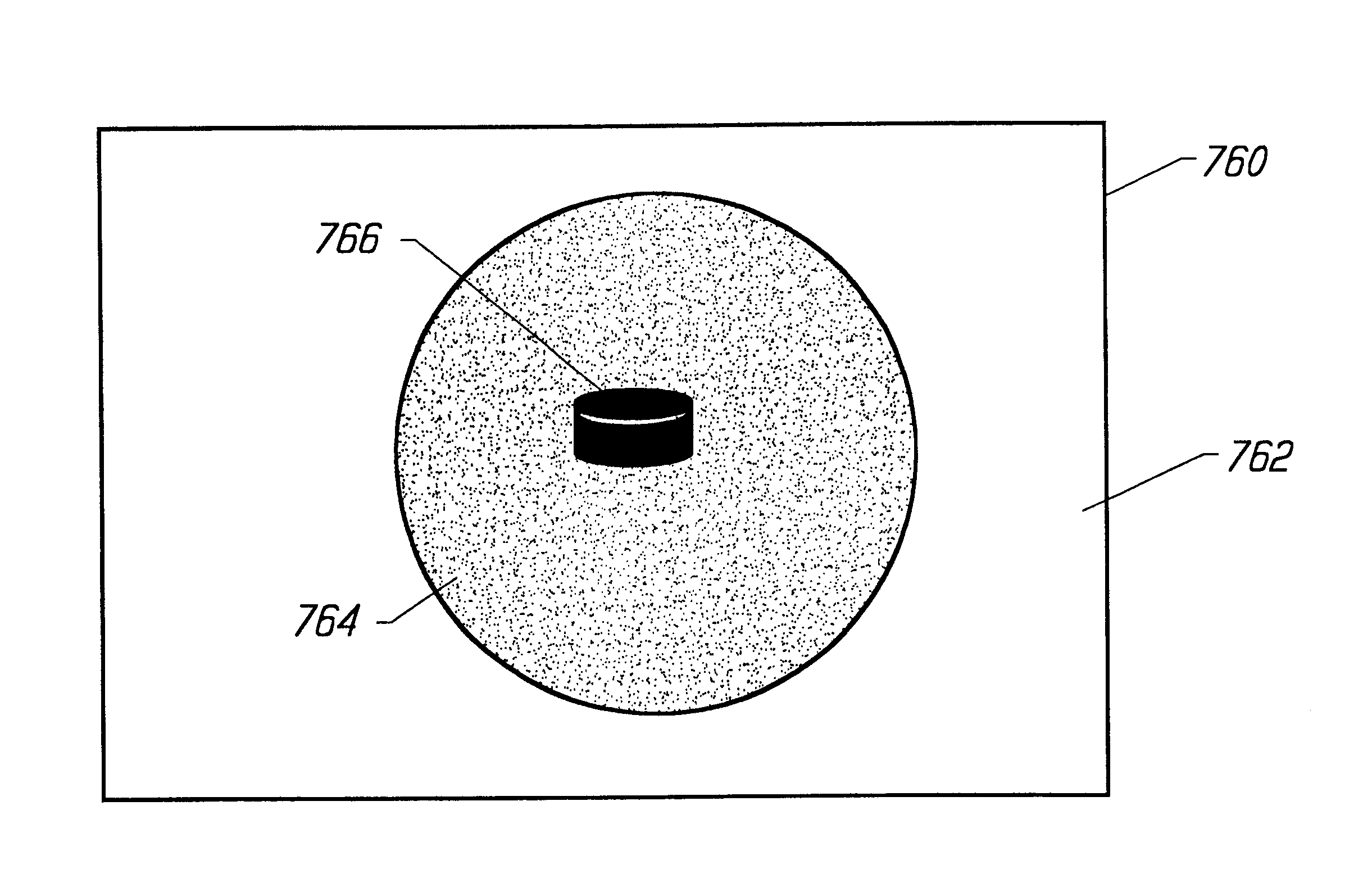

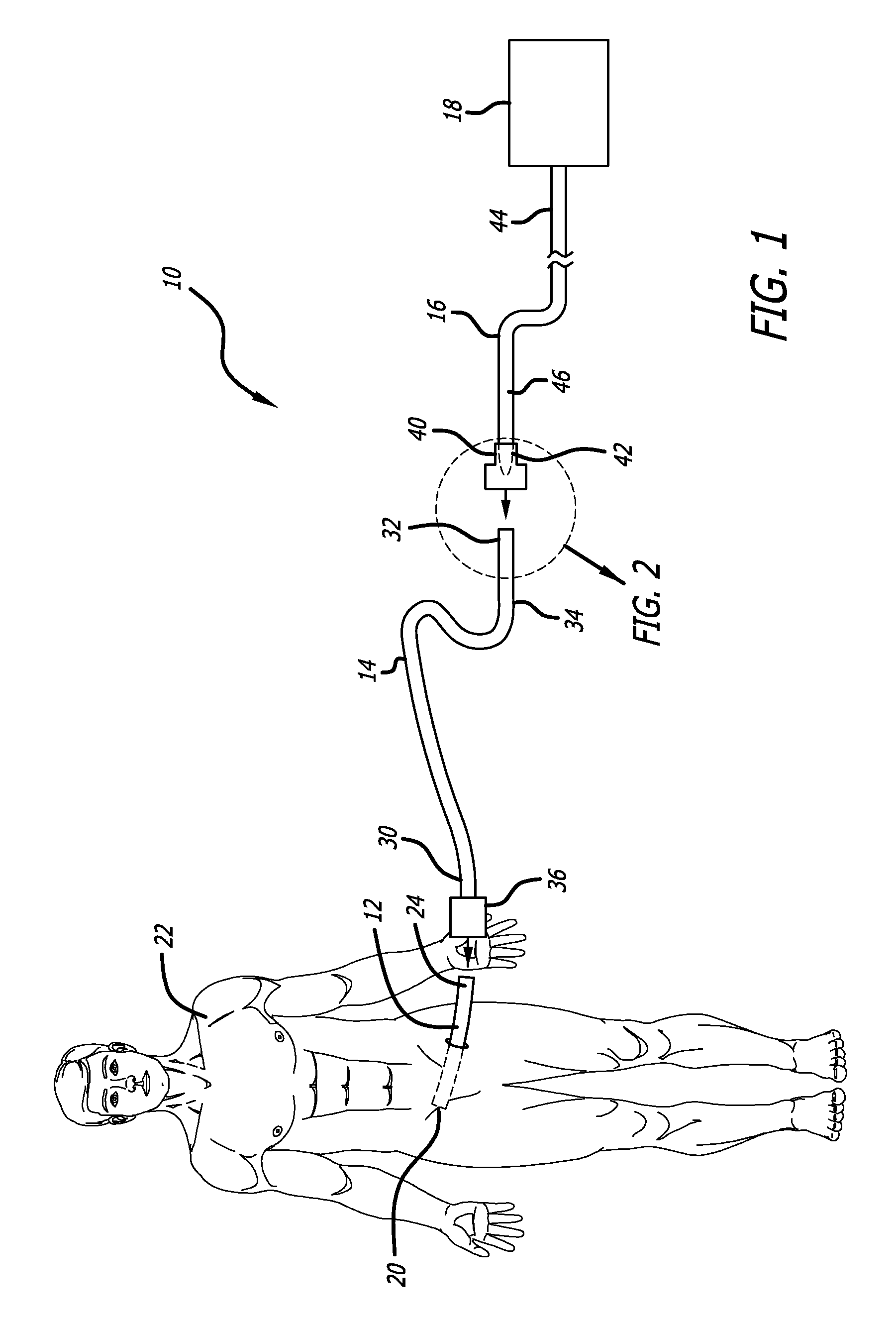

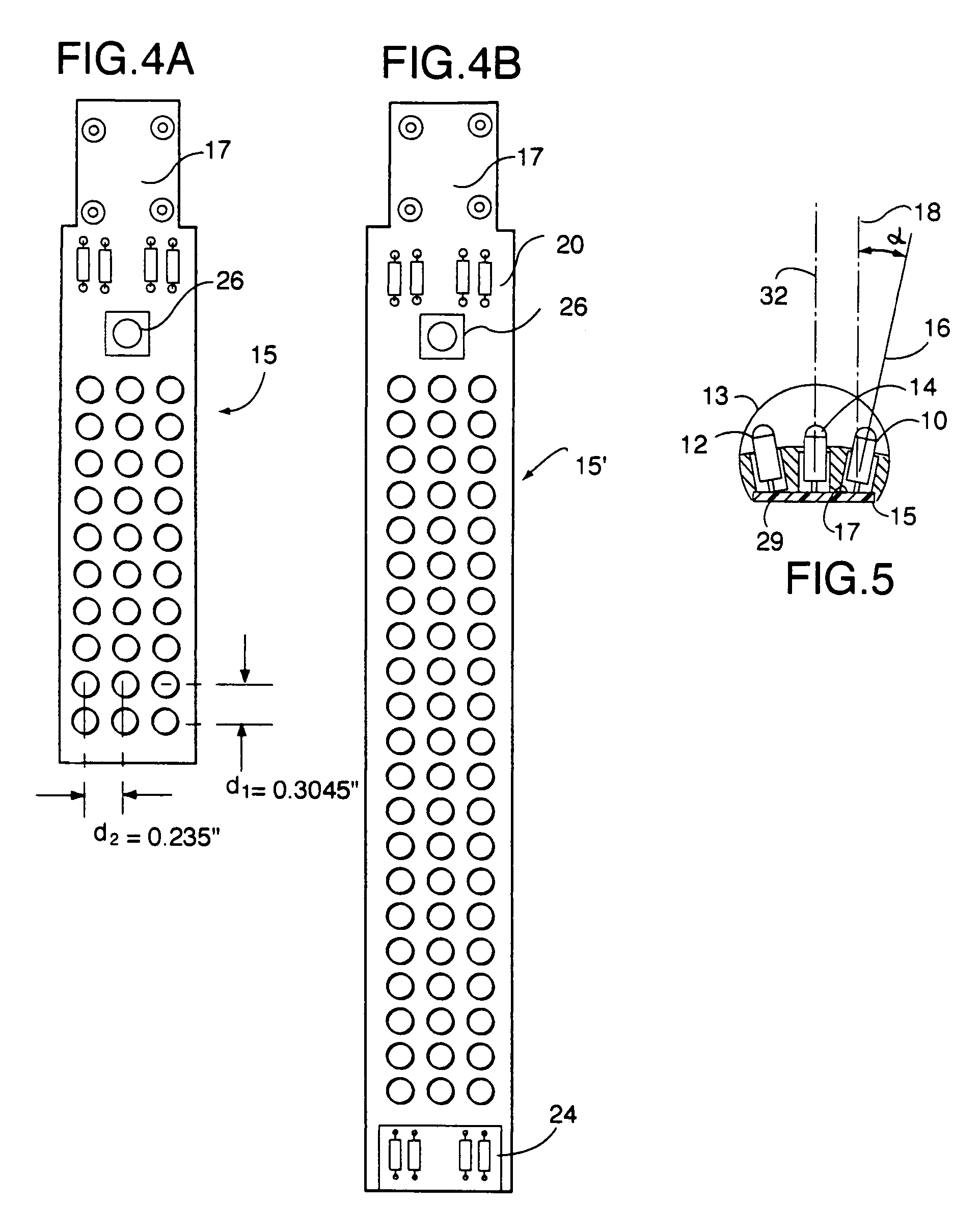

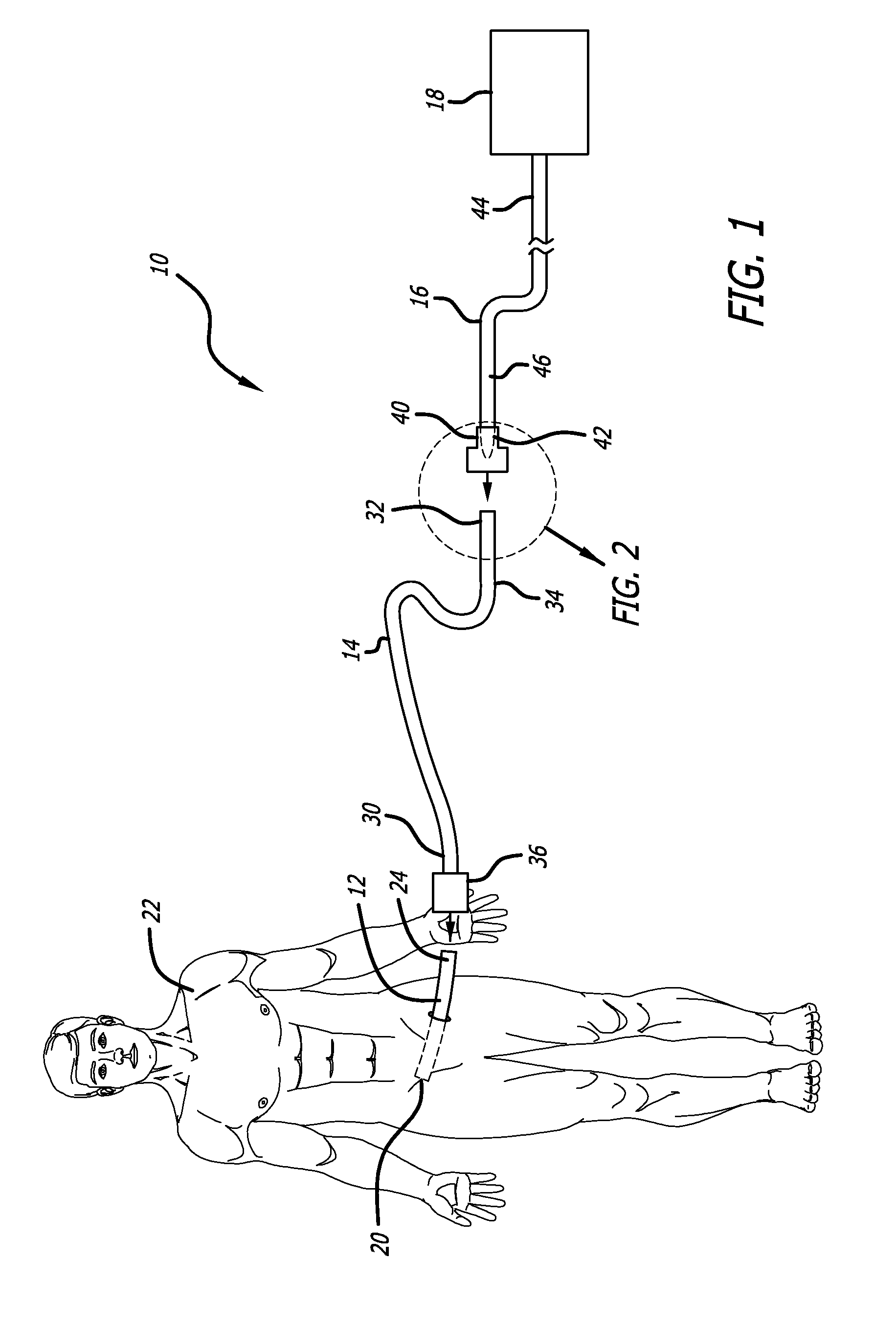

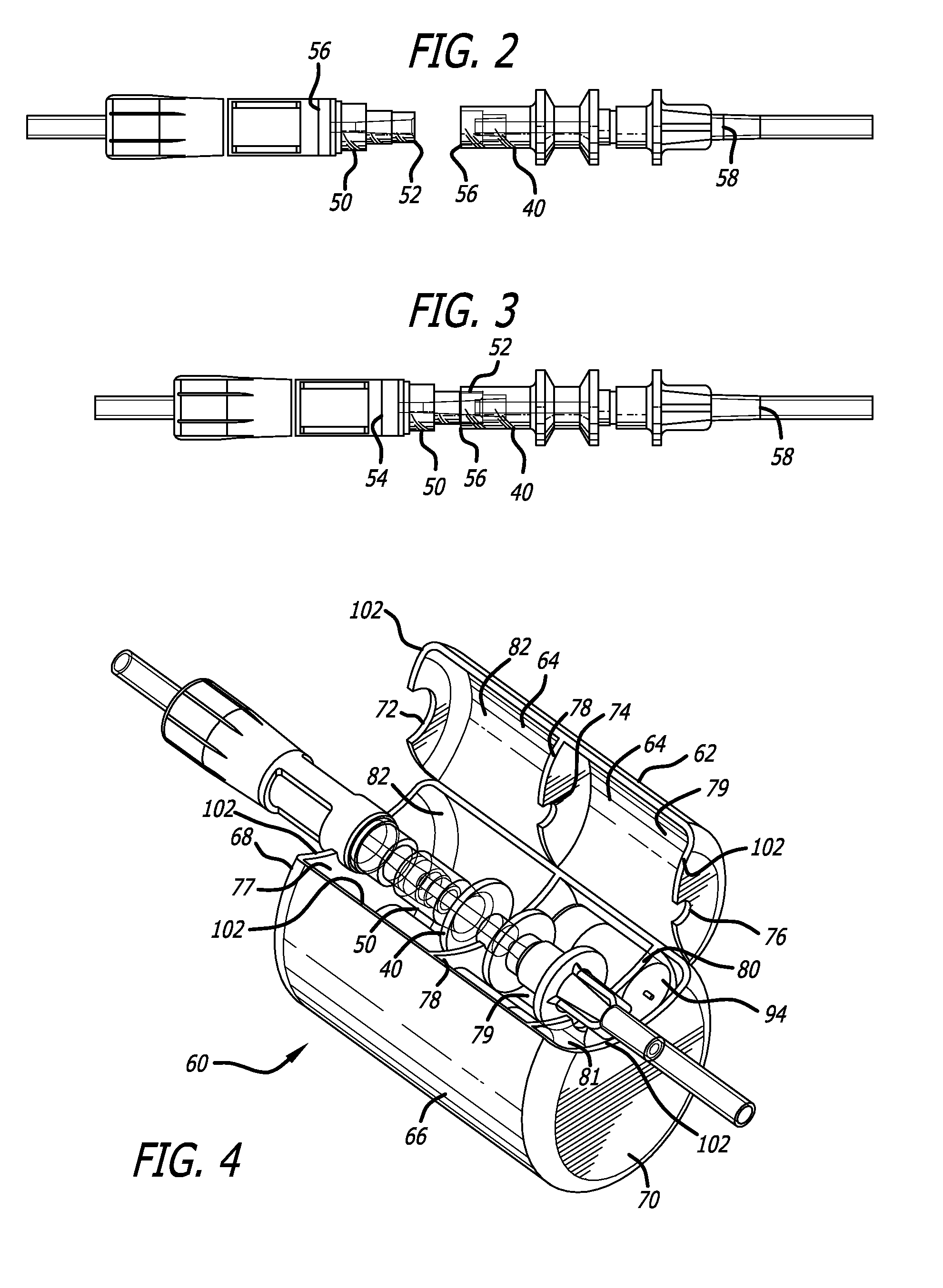

Apparatus for disinfecting or sterilizing a catheter and method of use

ActiveUS20140334974A1High strengthDisinfect connectorMaterial analysis using wave/particle radiationElectric discharge tubesUv disinfectionCatheter

An elliptical-shaped housing contains a UV light source and a power source. A connector is removably mounted in the housing and is disinfected or sterilized by UV light. A reflective coating inside the housing enhances the intensity of the UV light to disinfect or sterilize the connector.

Owner:PURACATH MEDICAL

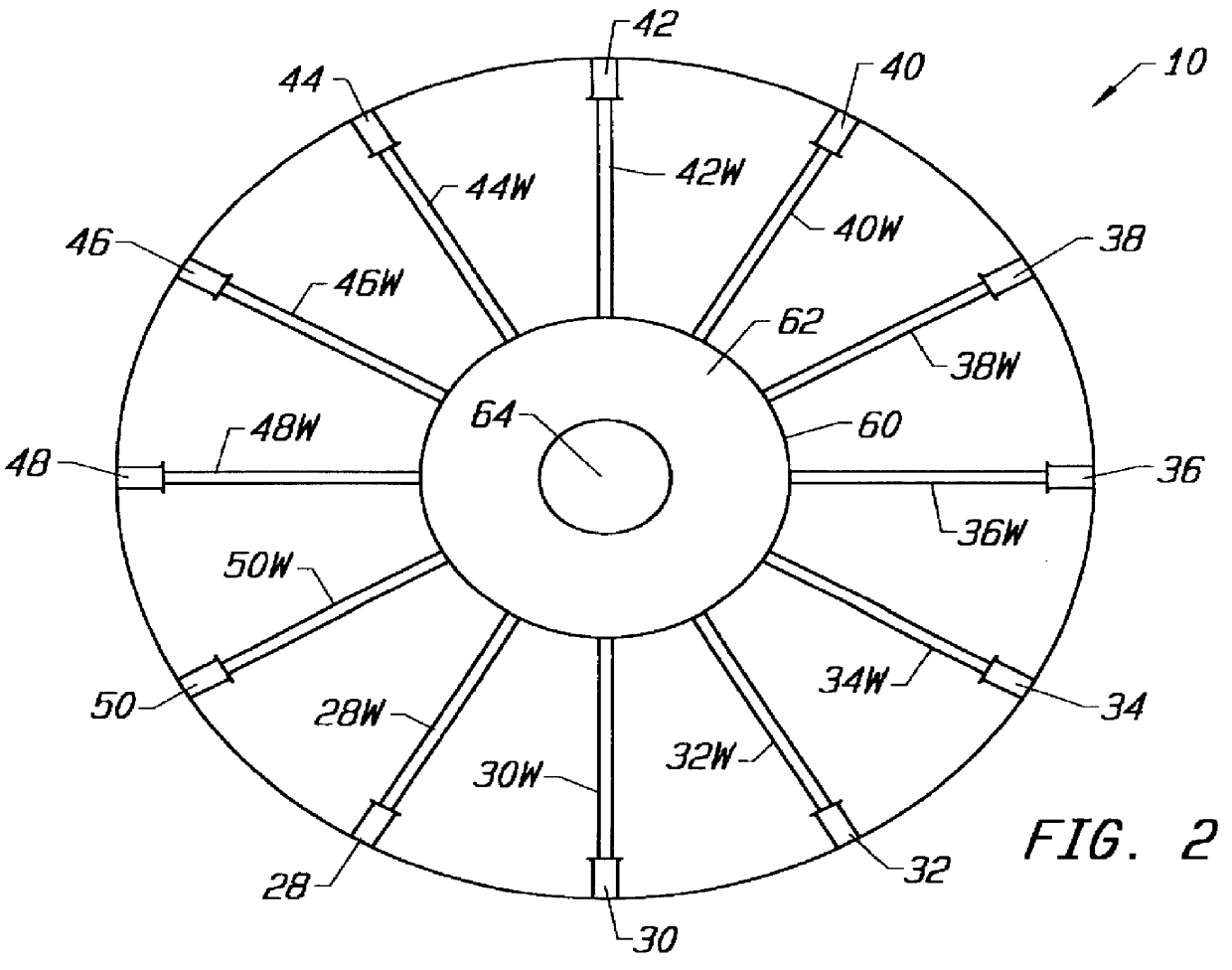

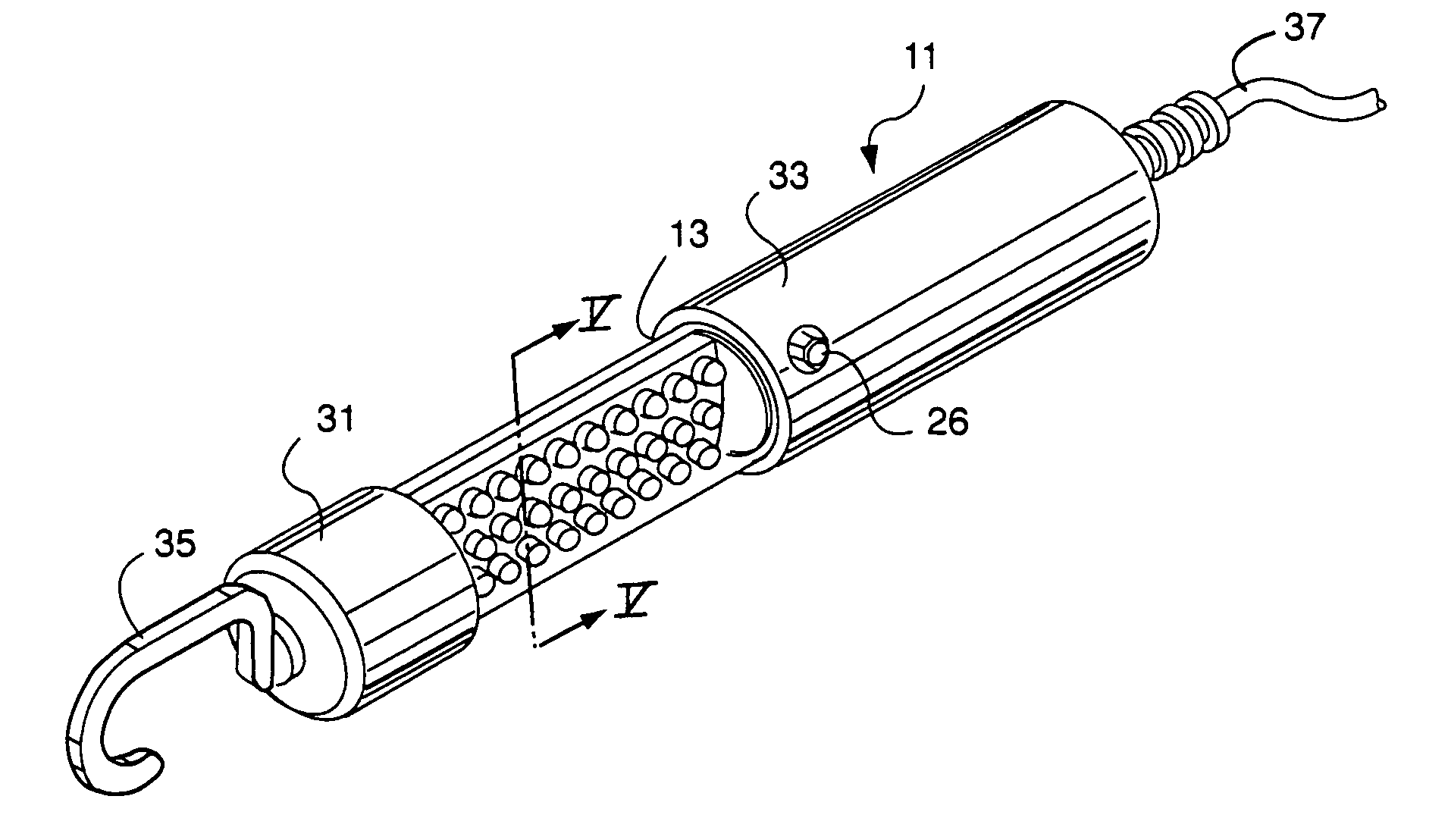

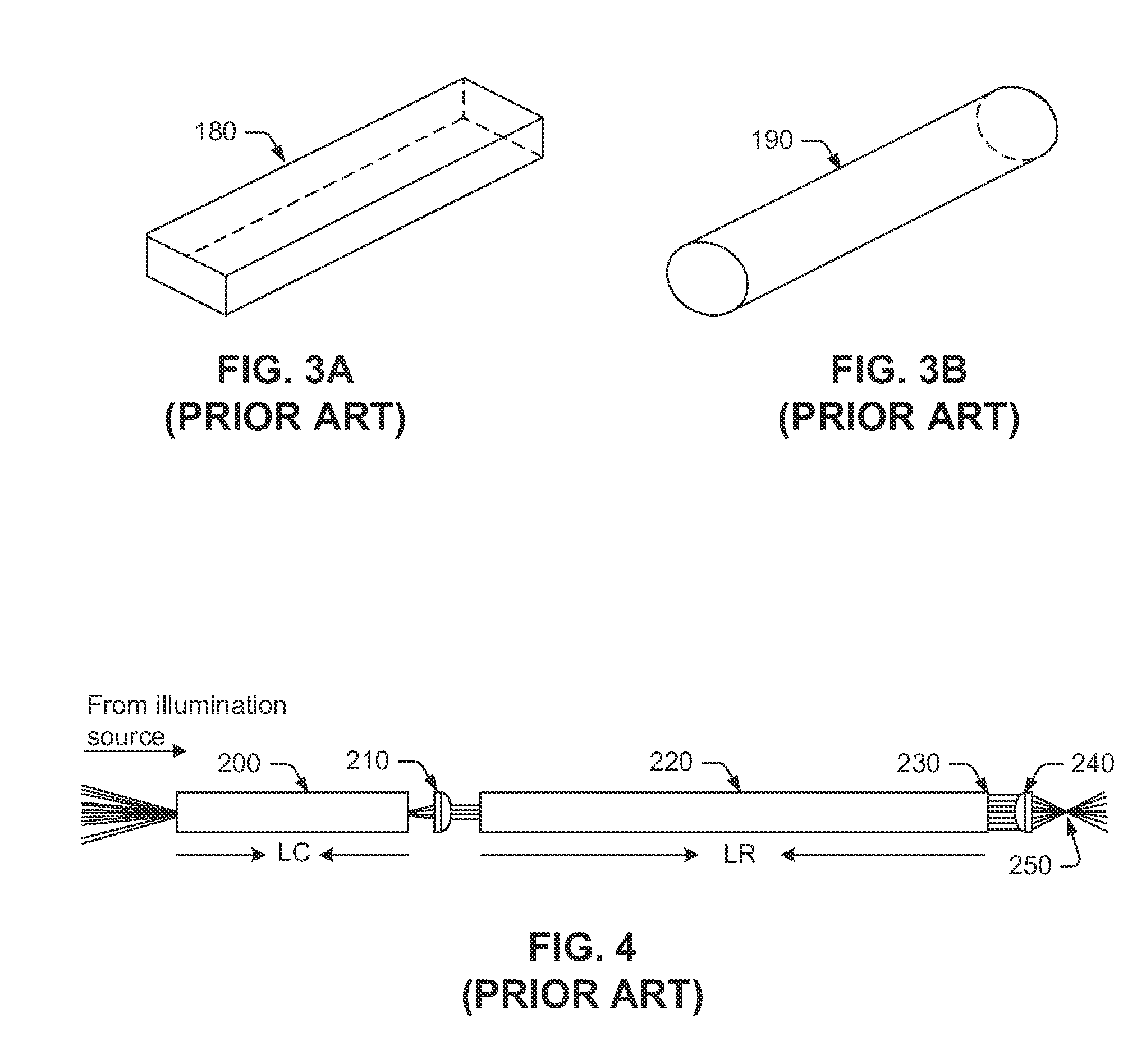

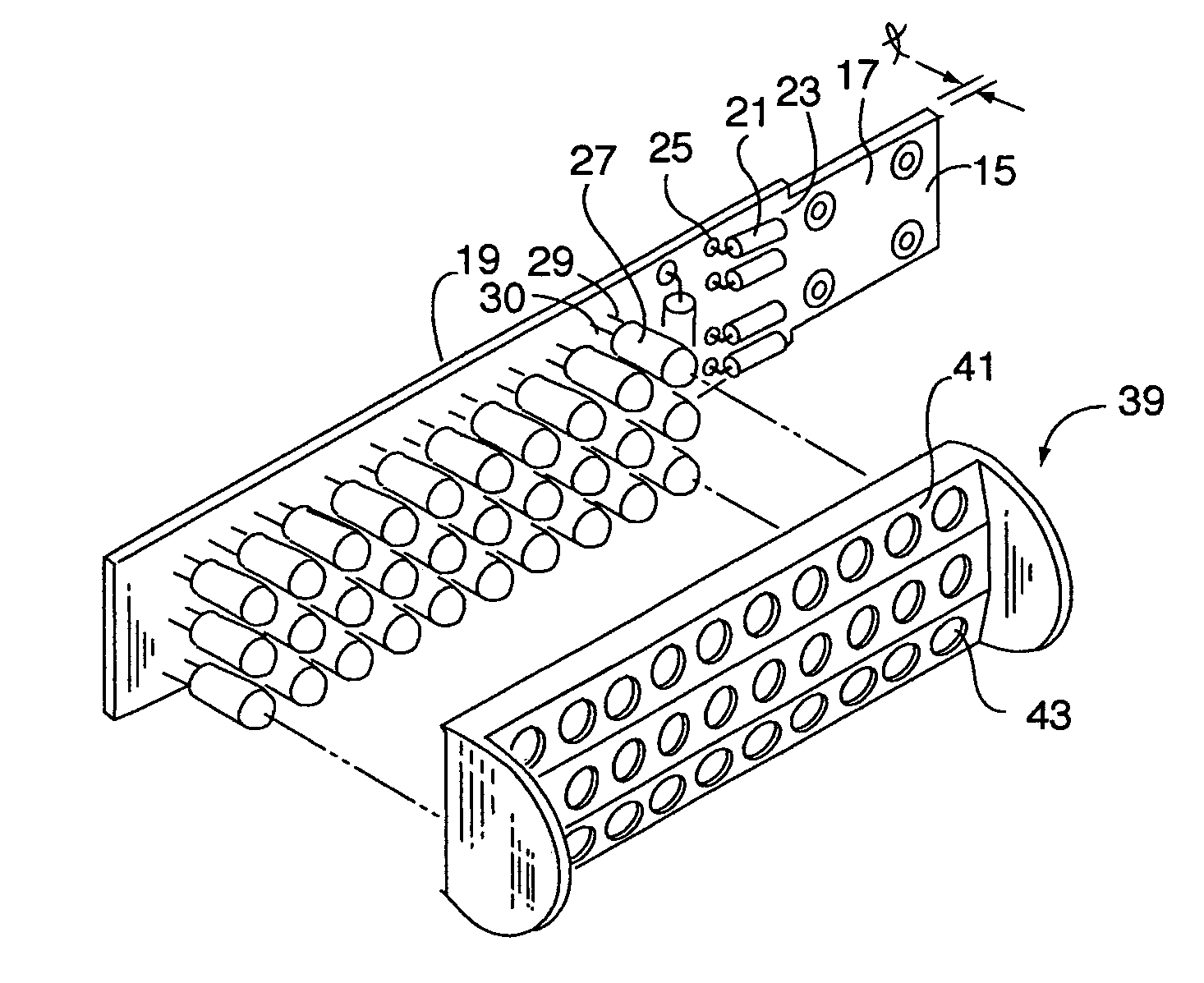

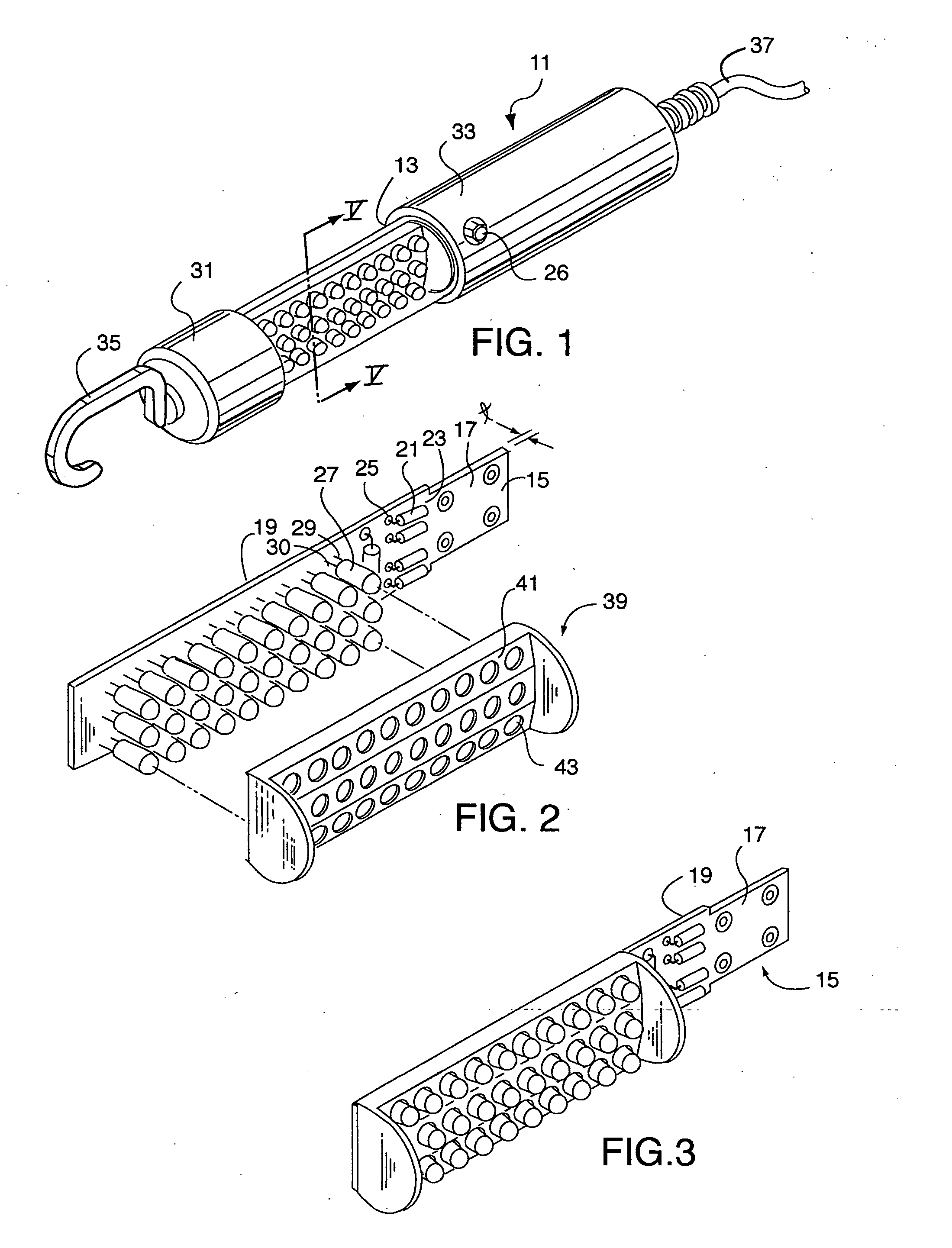

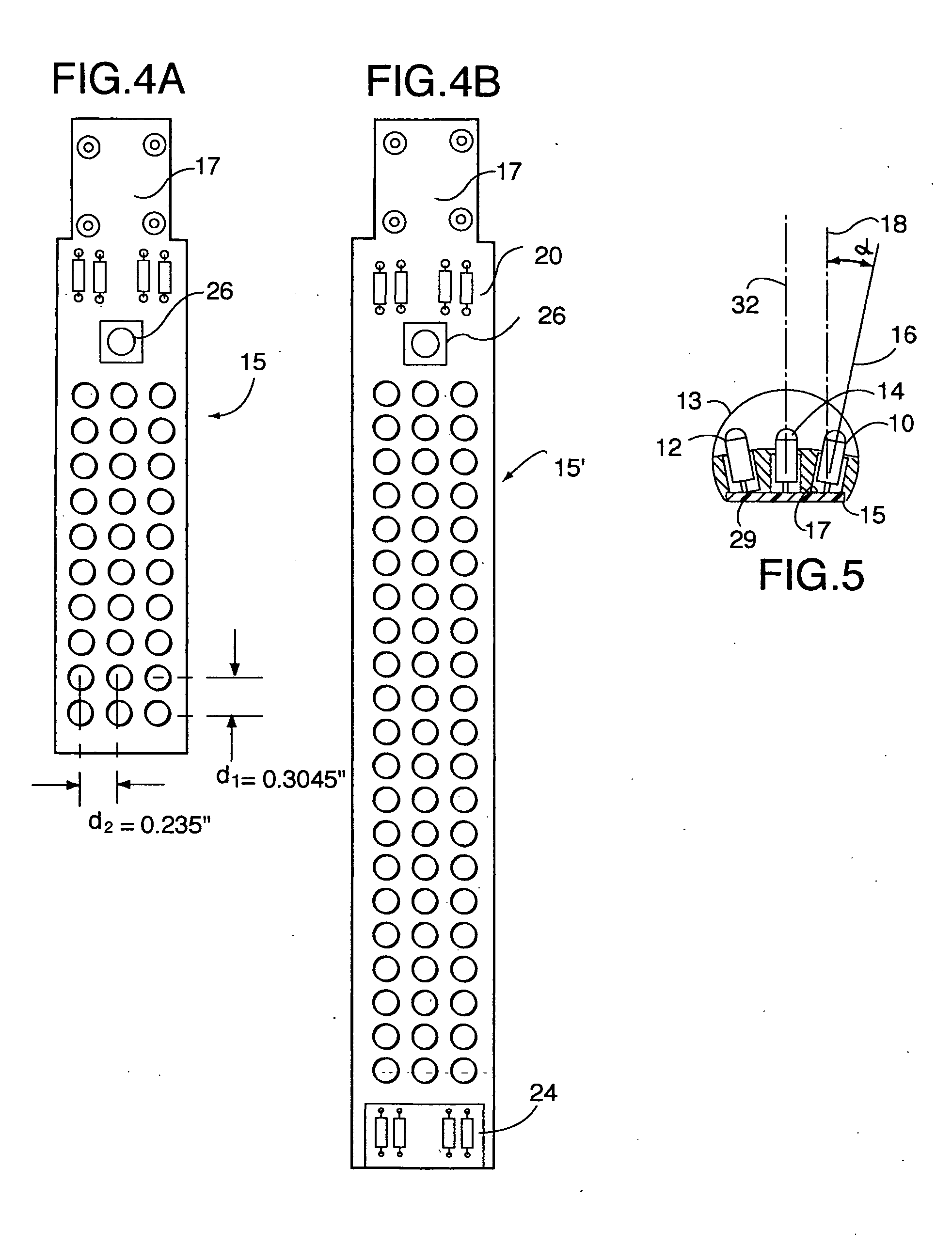

LED lighting array for a portable task light

ActiveUS7334918B2Maximize LED intensityMaximizes disk flux efficiencyElectric lighting for hand-held usePlanar light sourcesElectricityPulsed DC

An LED lighting array is disclosed wherein a plurality of light emitting devices disposed in at least first and second columns are mounted on a planar mounting surface to form an emission plane. The emission axes of all the LEDs in a first column are parallel with each other and lie in a first plane. The emission axes of the LEDs in an adjacent, second column are also parallel, but a second plane containing the emission axes of the second column is disposed at a predetermined, non-zero angle with respect to the first plane. The non-zero angle is a function of the LED beam width and the distance to a lighting target. This configuration of the LEDs provides an optimum balance at a predetermined target distance between the size of the area illuminated and the brightness of the illumination of the target. In one aspect of the invention the LED lighting array includes at least first, second and third columns of LEDs. In another aspect of the invention an LED task light includes a transparent tube and an LED lighting array disposed within the tube. An electrical drive circuit associated with the mounting substrate within the tube provides pulsed direct current for driving the LED's.

Owner:BAYCO PRODS

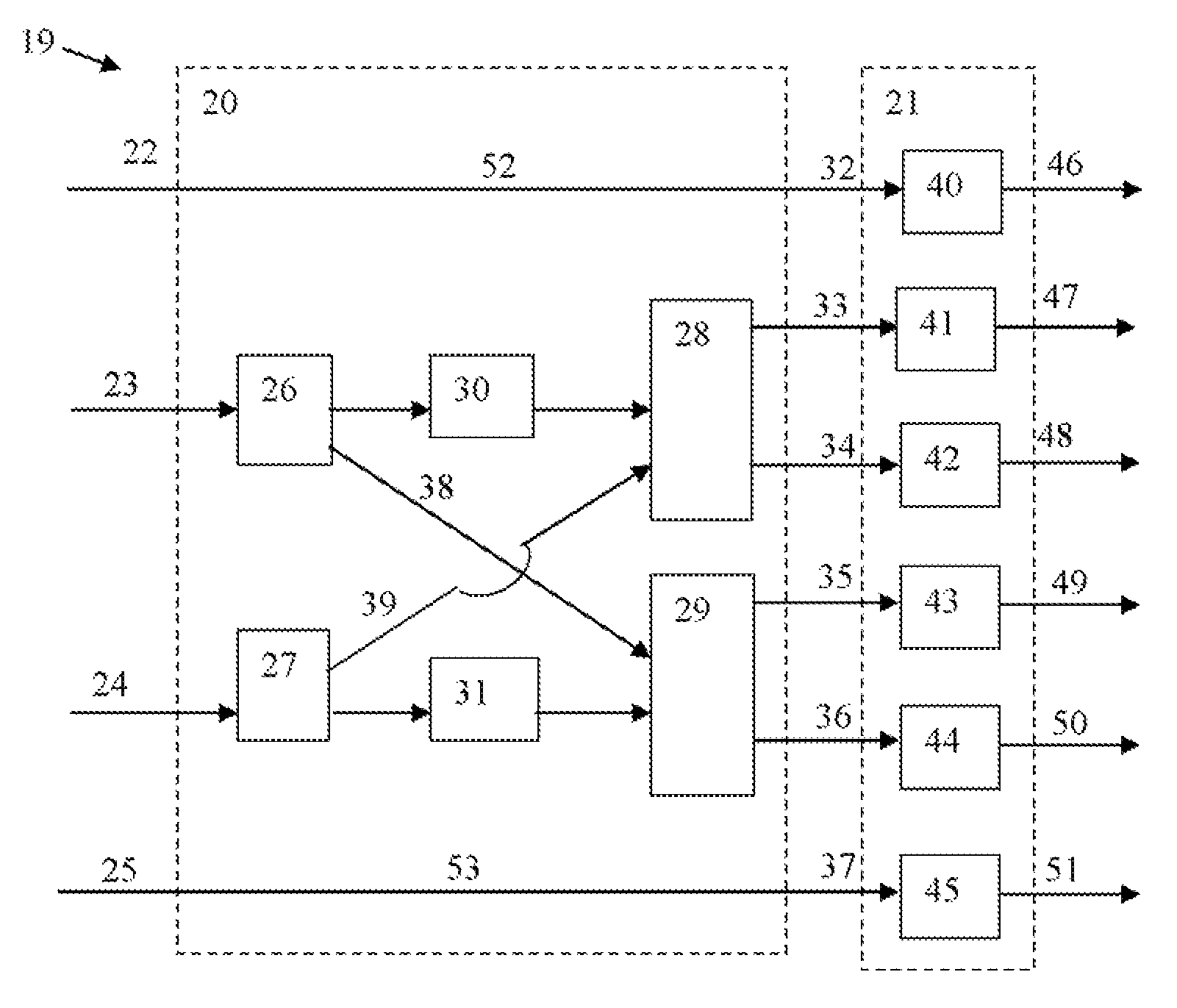

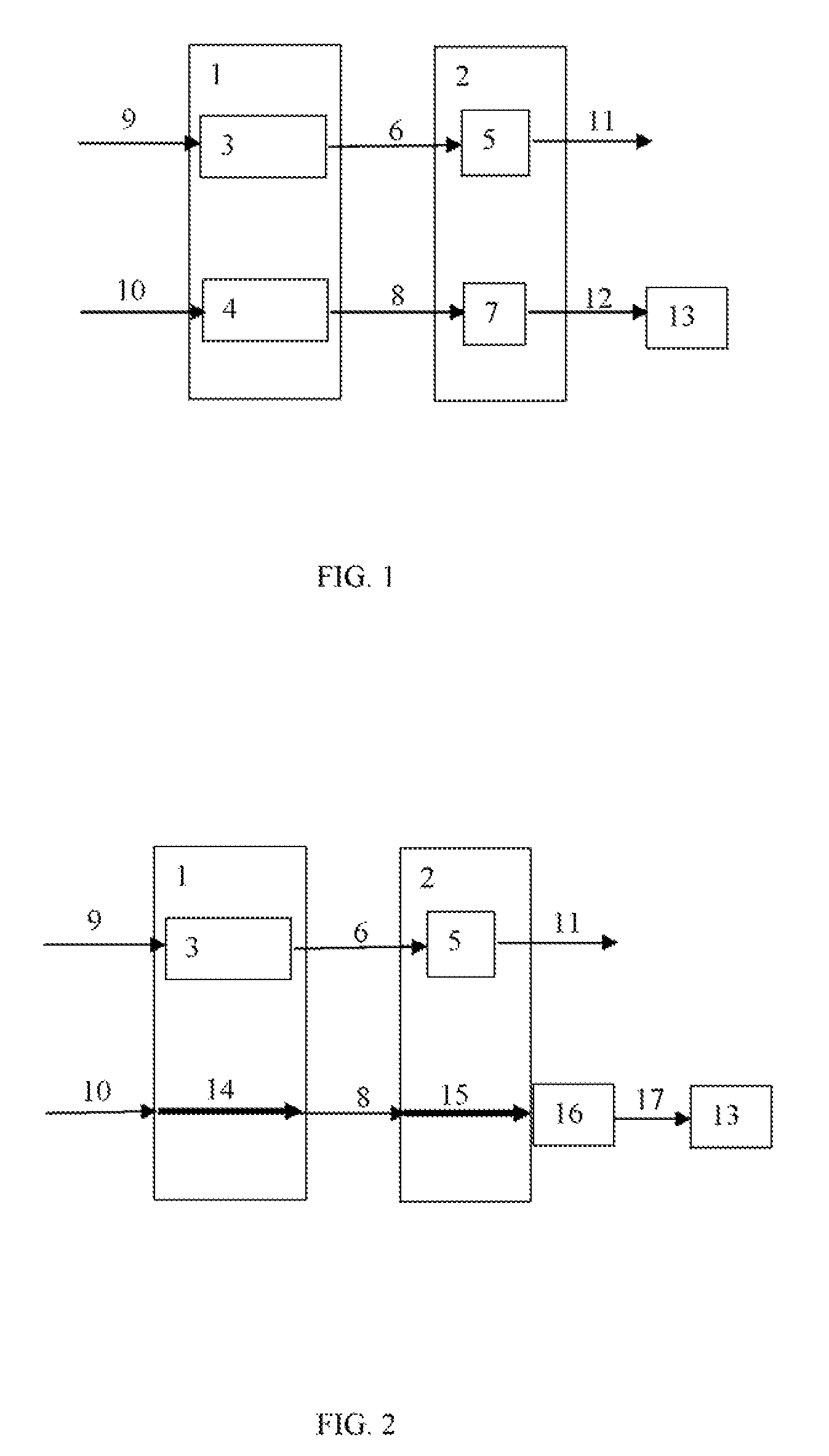

Integrated coherent optical detector

InactiveUS7483600B2Maximizing intensityPrecise positioningOptical waveguide light guideOptical communicationPhotodiode

The present invention provides an integrated device and a method of its fabrication and use. Two parts of the device each having an electronic circuit are aligned adjacent to each other with an accuracy of at least 1 micron. An alignment system includes two parts: a first part integrated with the first electronic circuit of the integrated device on the first substrate and a second part integrated with the second electronic circuit of the integrated device on the second substrate. The second part of alignment system includes at least one photodiode. The maximal value of the photodiode current indicates the best alignment of two parts of the integrated device. In one embodiment the integrated device is a coherent optical detector for high speed optical communications and chemical sensing. In another embodiment the integrated optical device is a coherent optical detector operating in two polarization states of light.

Owner:CELIGHT

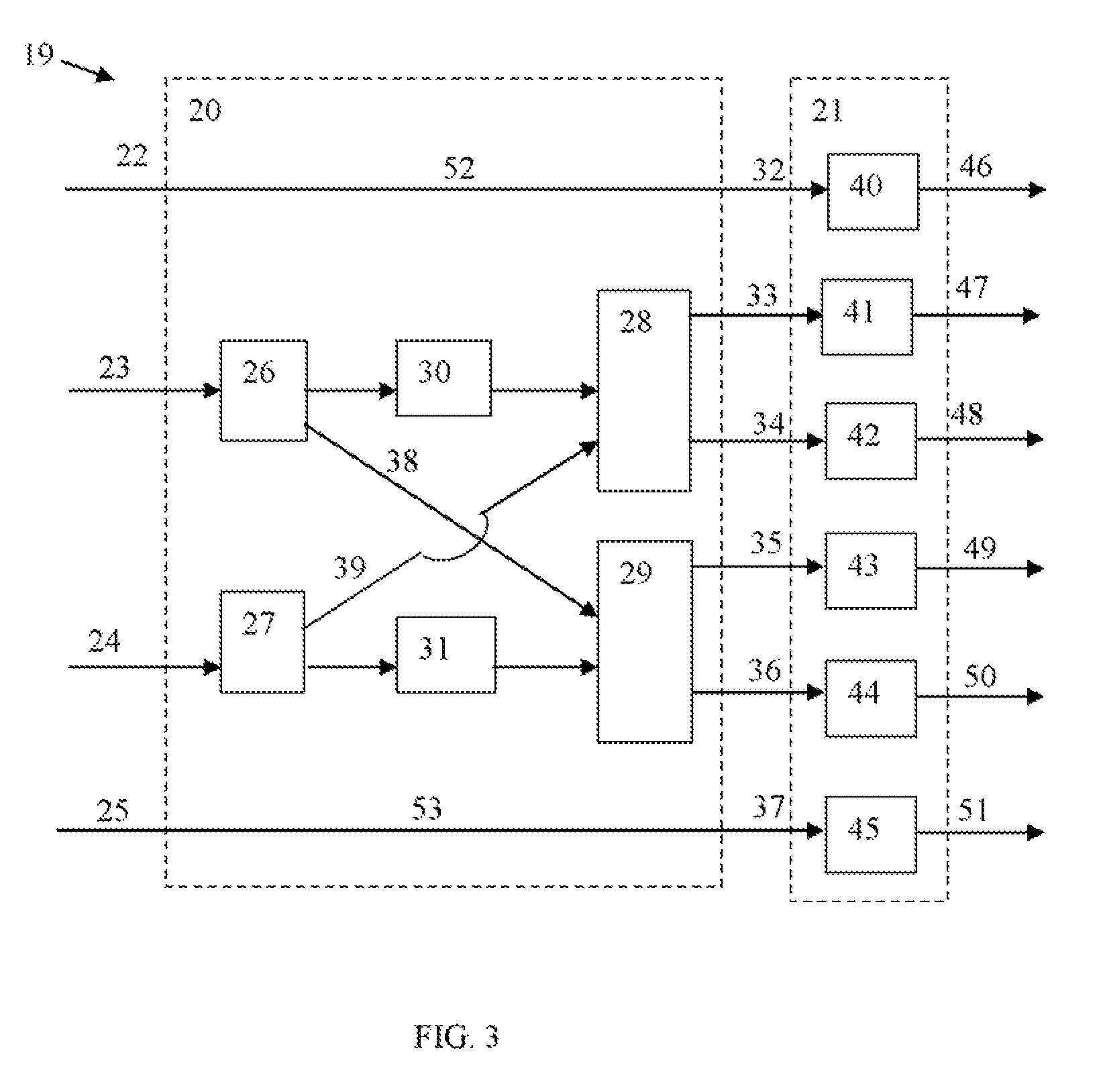

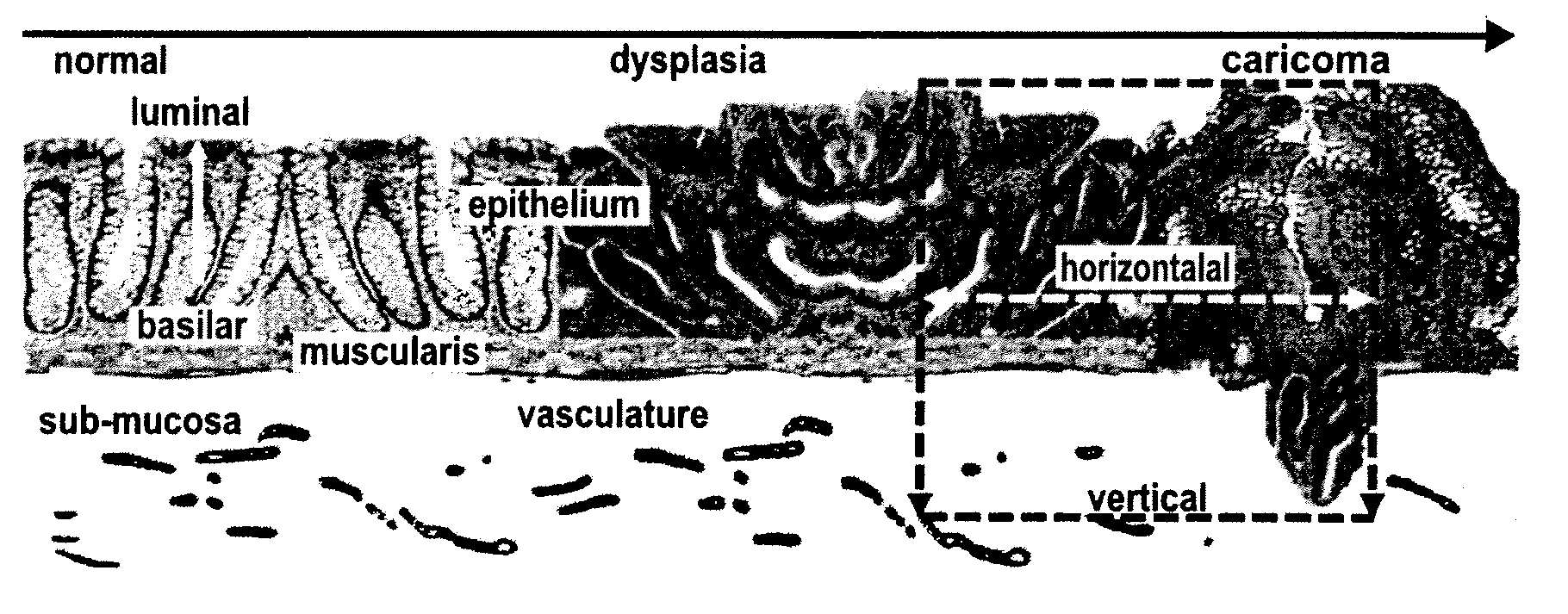

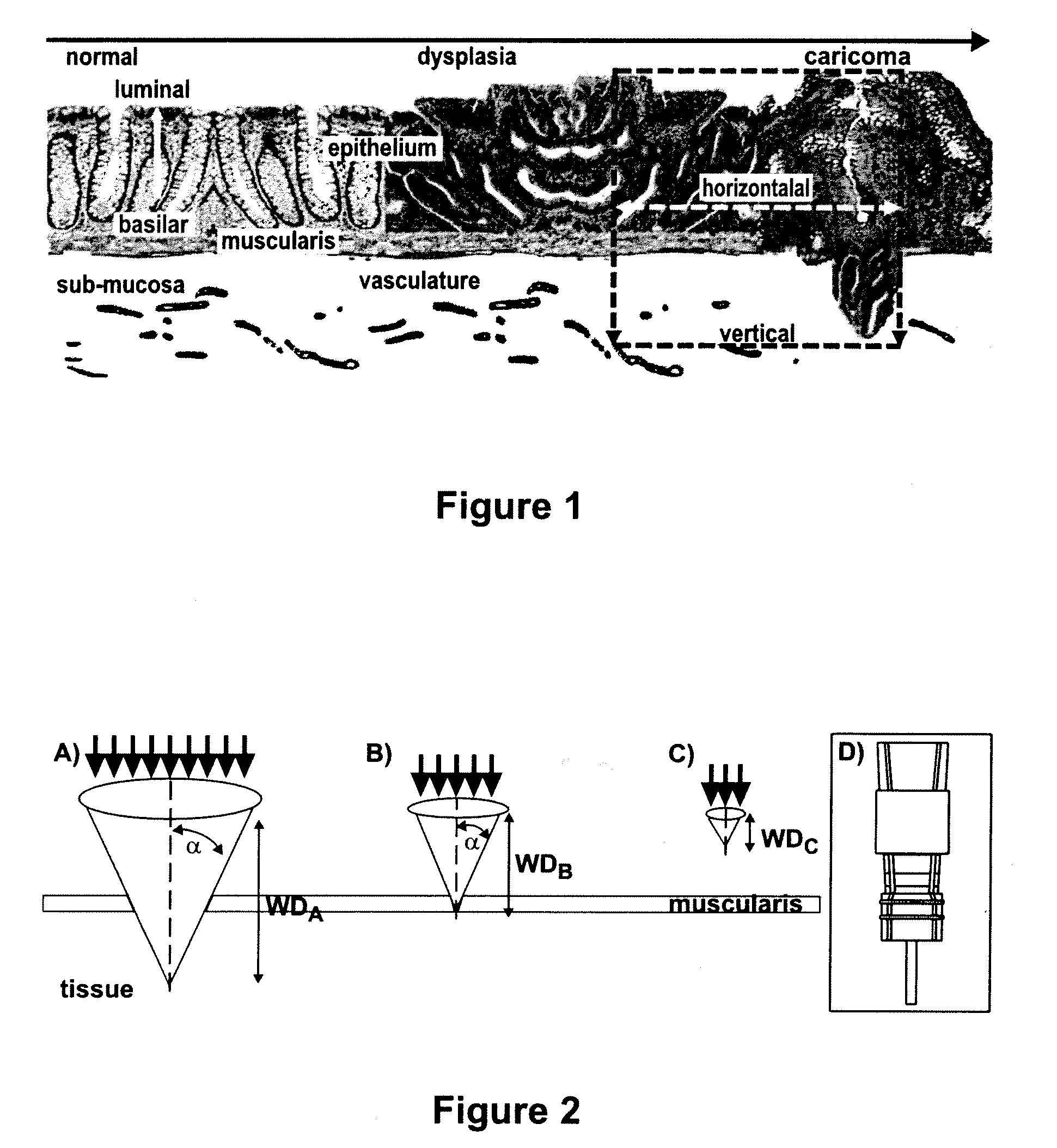

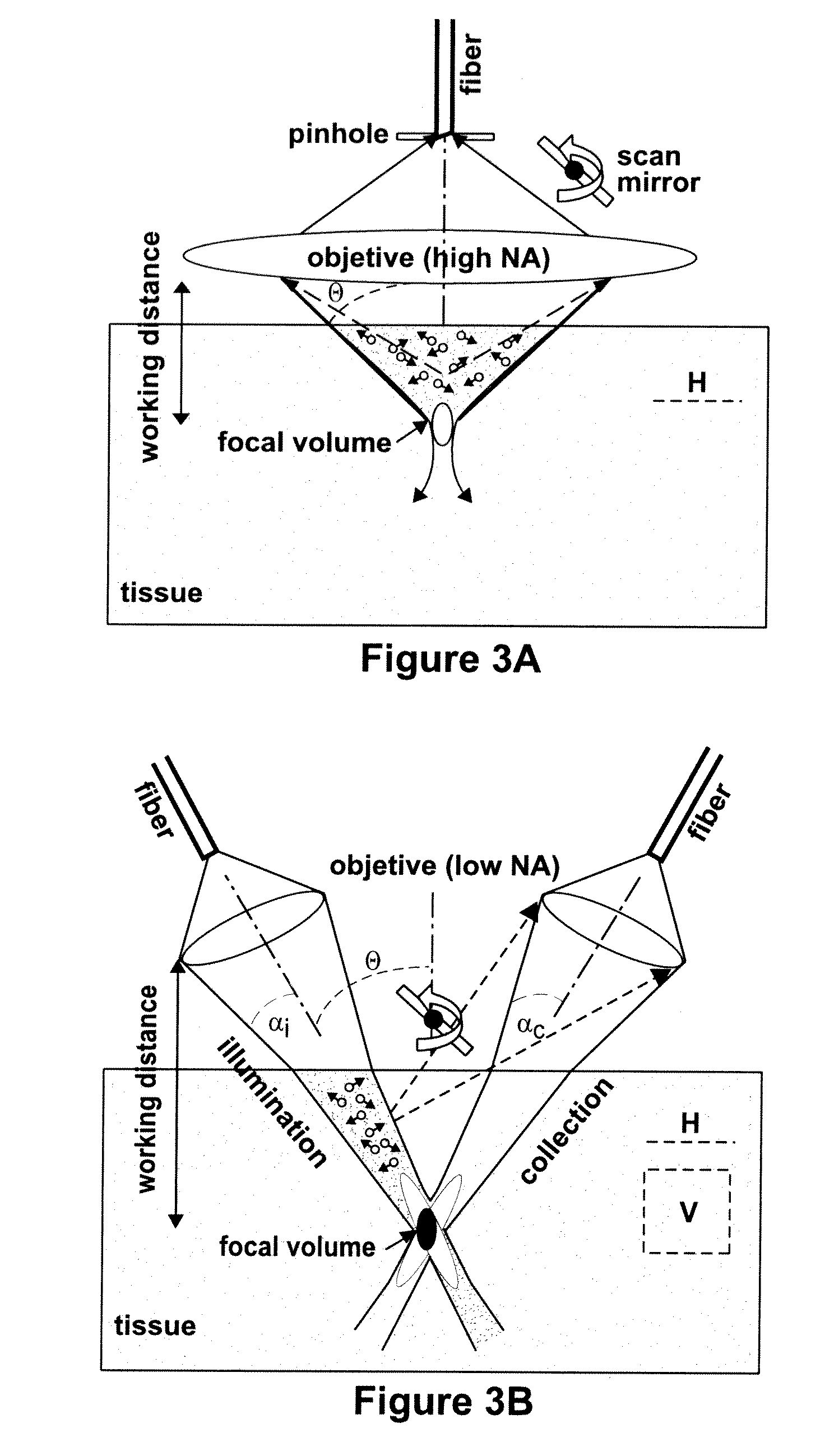

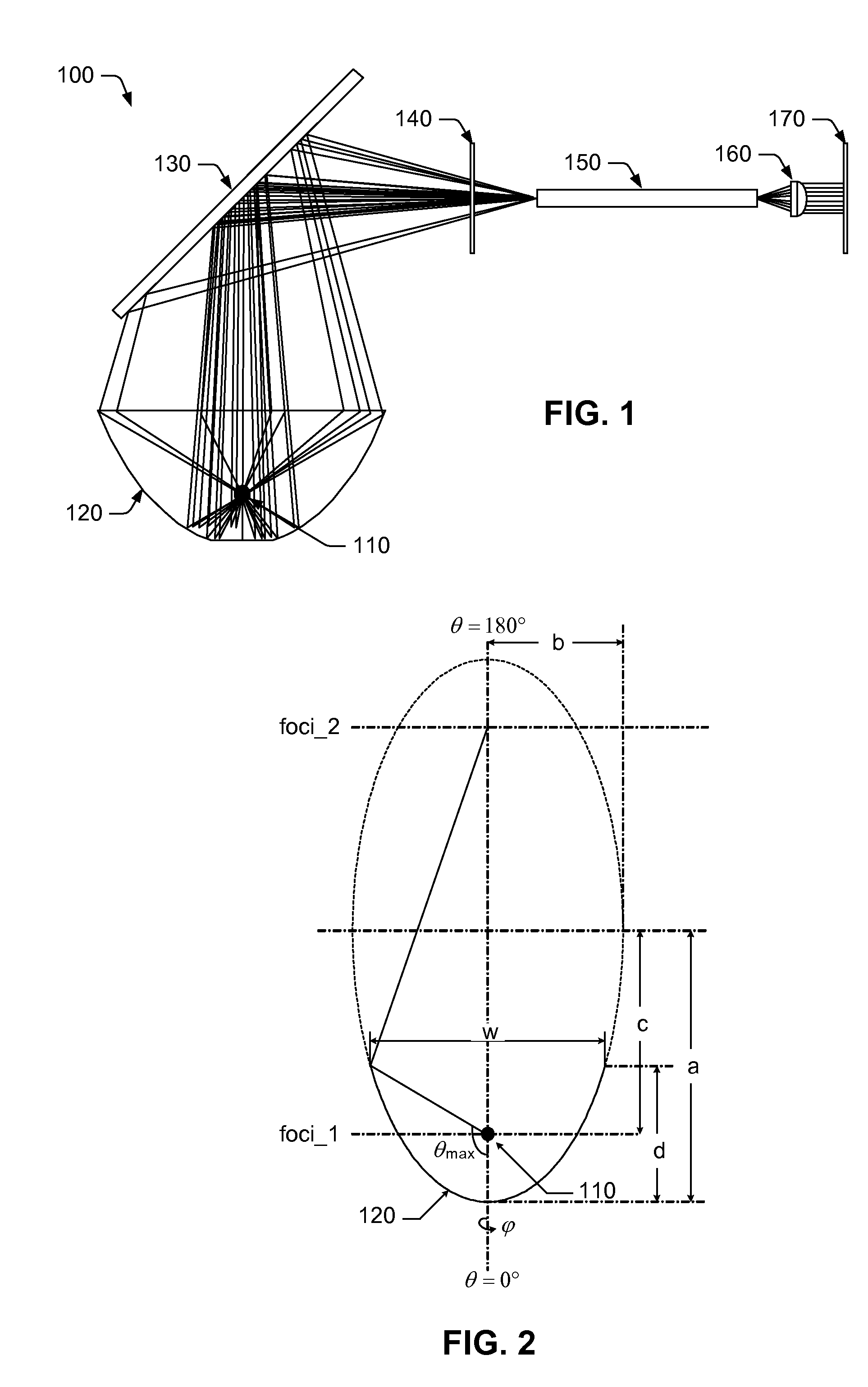

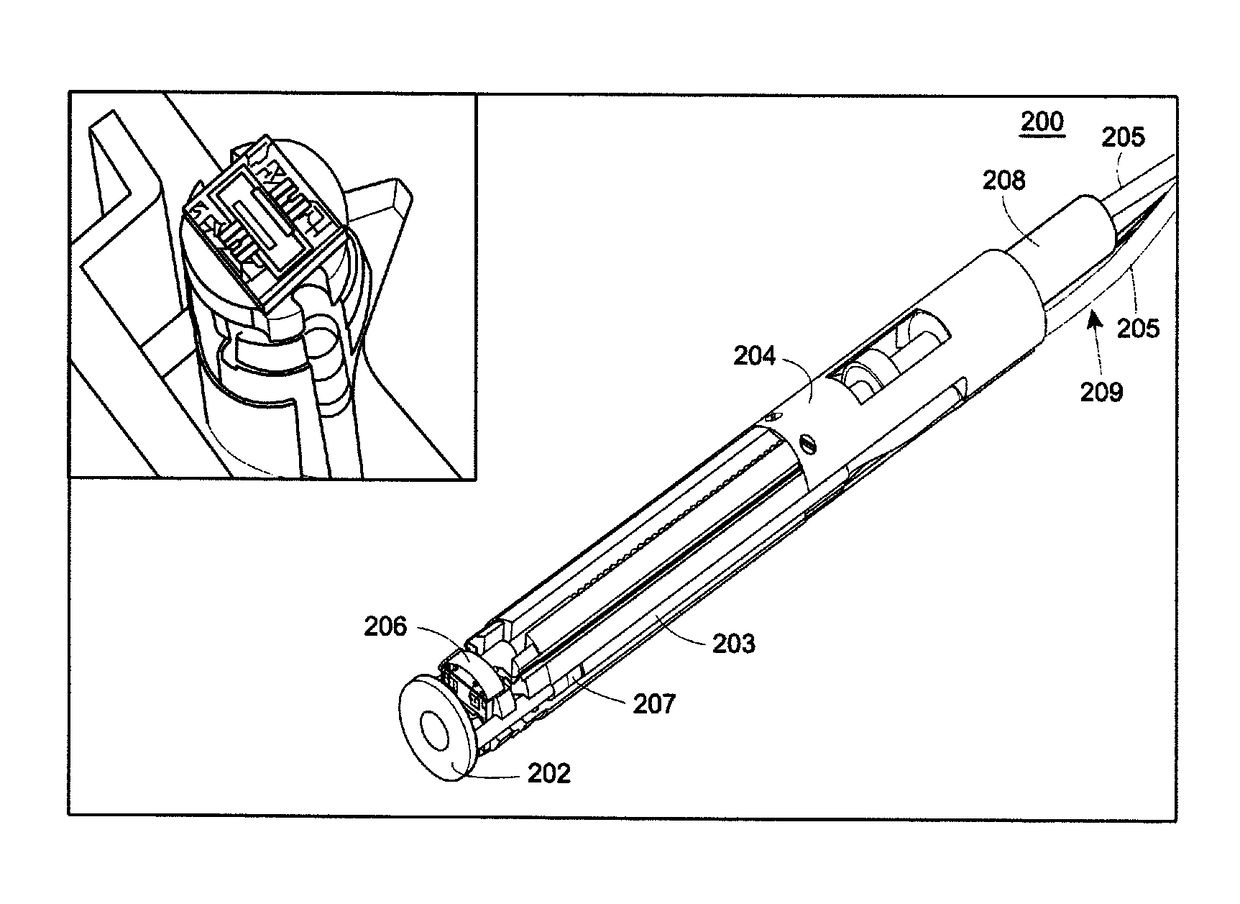

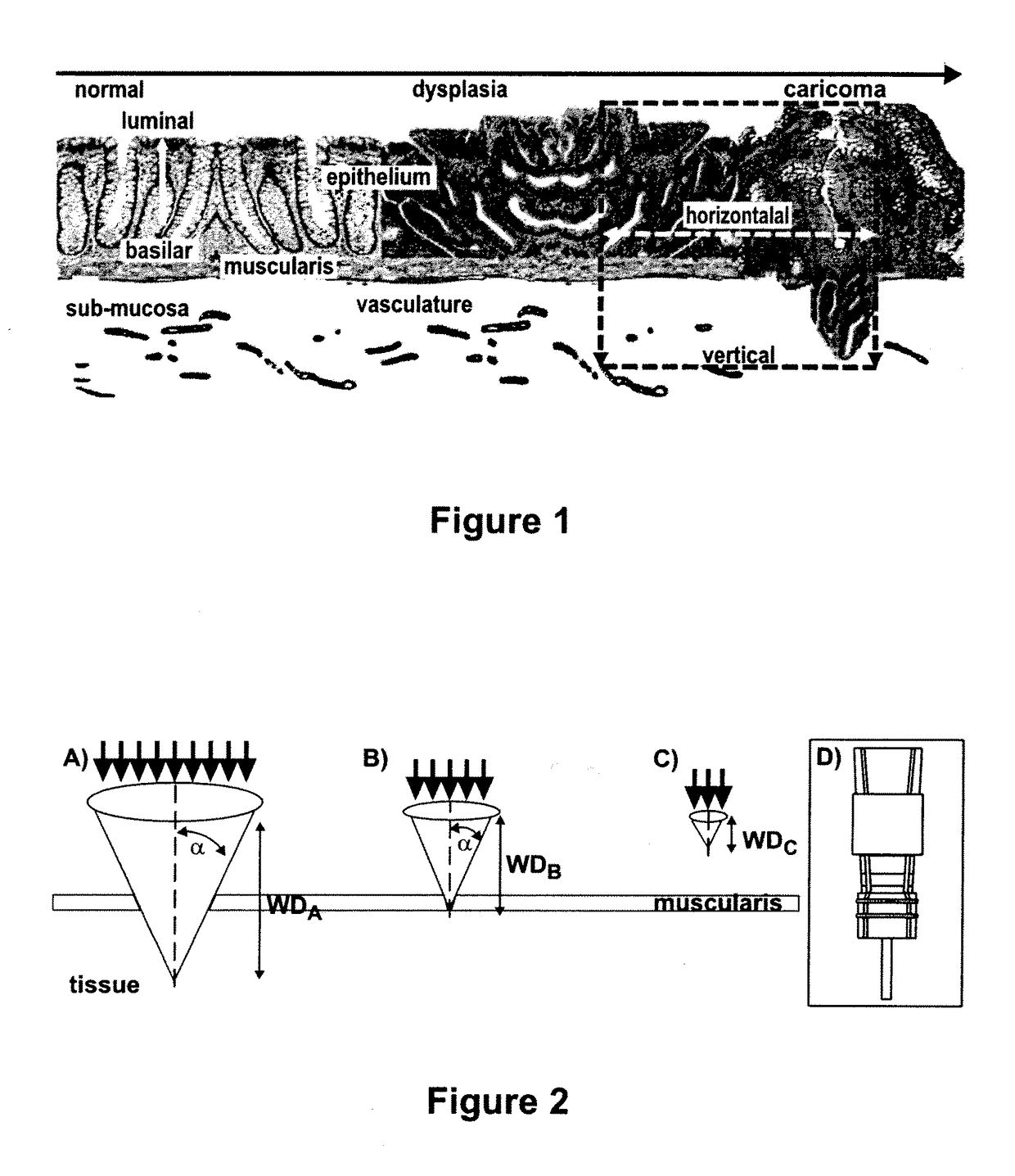

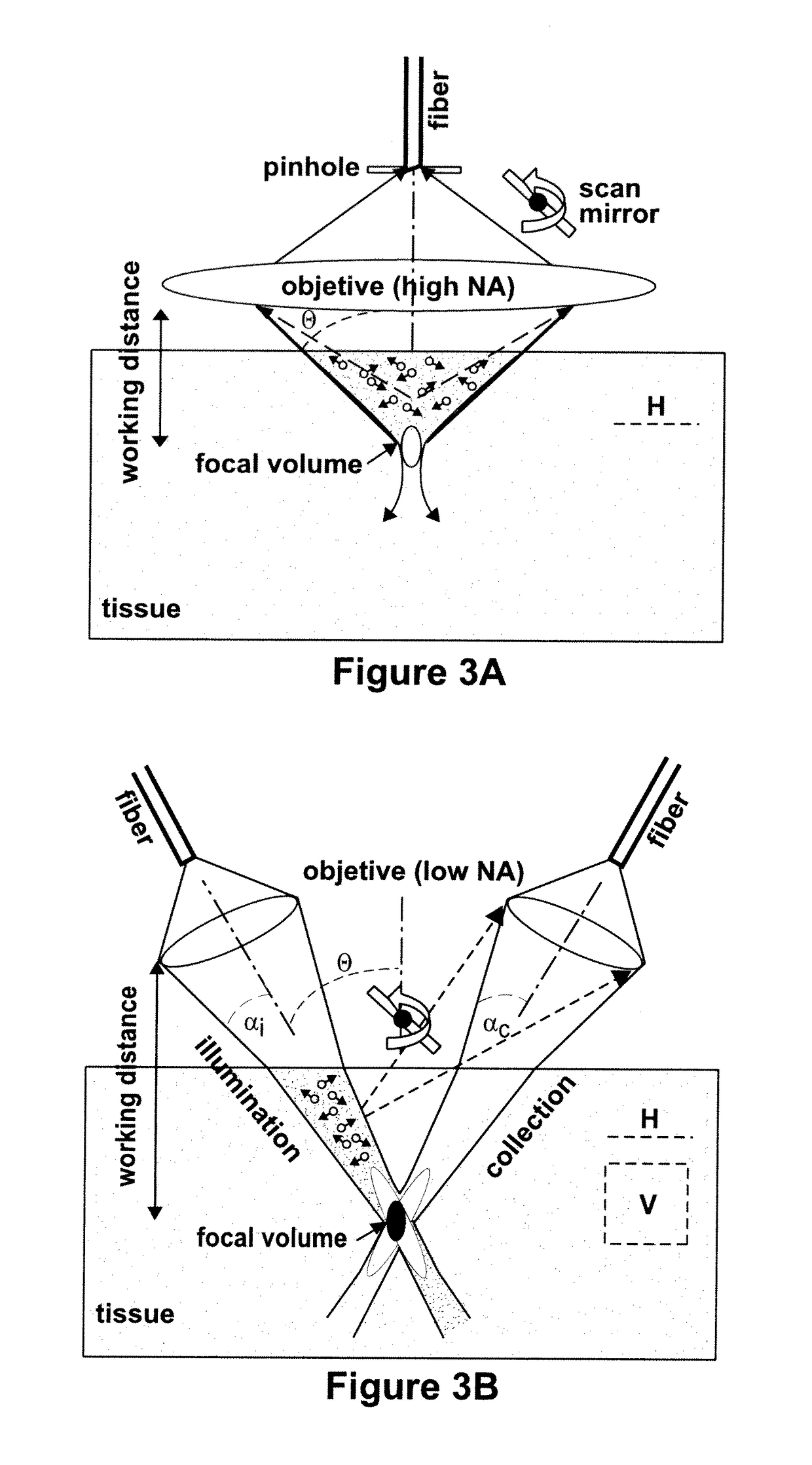

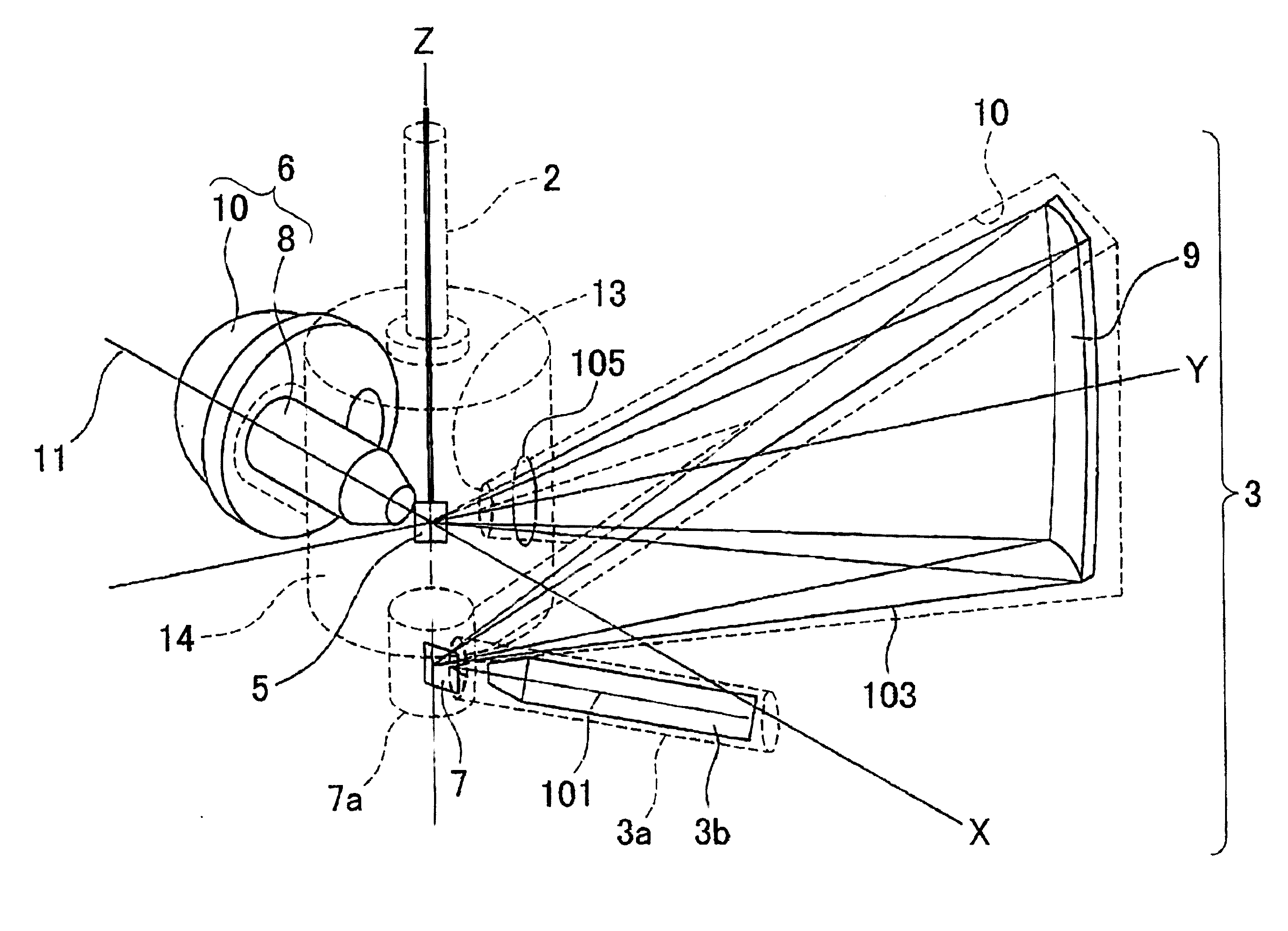

Targeted Dual-Axes Confocal Imaging Apparatus with Vertical Scanning Capabilities

ActiveUS20110125029A1Overcome blurringSuperior dynamic rangeMaterial analysis by optical meansDiagnostics using tomographyMolecular imagingEndothelium

An optical device is described that may be used as a microscope system for real-time, three-dimensional optical imaging. The device includes a miniature, fiber optic, intra-vital probe microscope that uses a dual-axes confocal architecture to allow for vertical scanning perpendicular to a surface of the sample (e.g., a tissue surface). The optical device can use off-axis illumination and collection of light to achieve sub-cellular resolution with deep tissue penetration. The optical device may be used as part of an integrated molecular imaging strategy using fluorescence-labeled peptides to detect cell surface targets that are up-regulated by the epithelium and / or endothelium of colon and breast tumors in small animal models of cancer.

Owner:THE RGT OF THE UNIV OF MICHIGAN

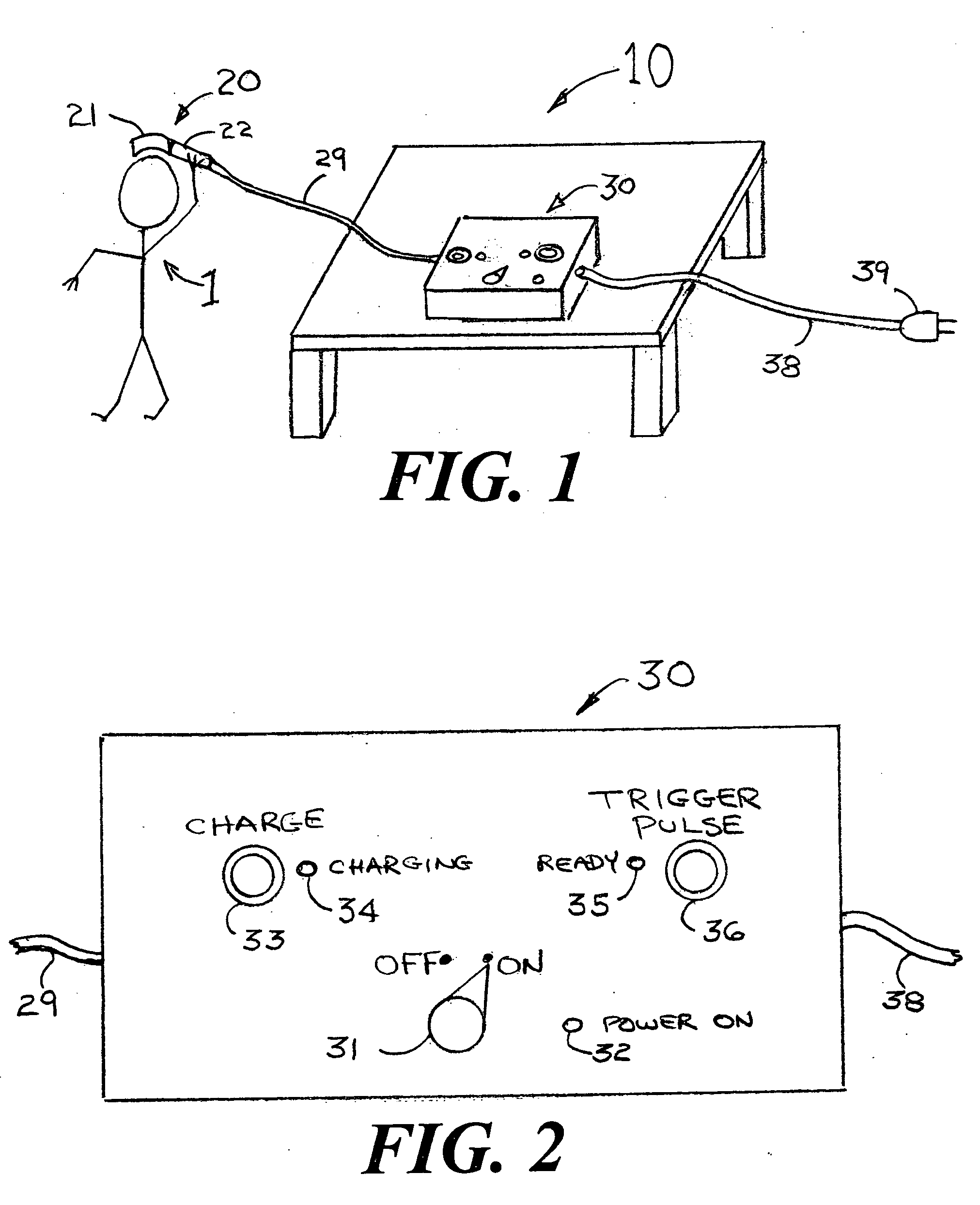

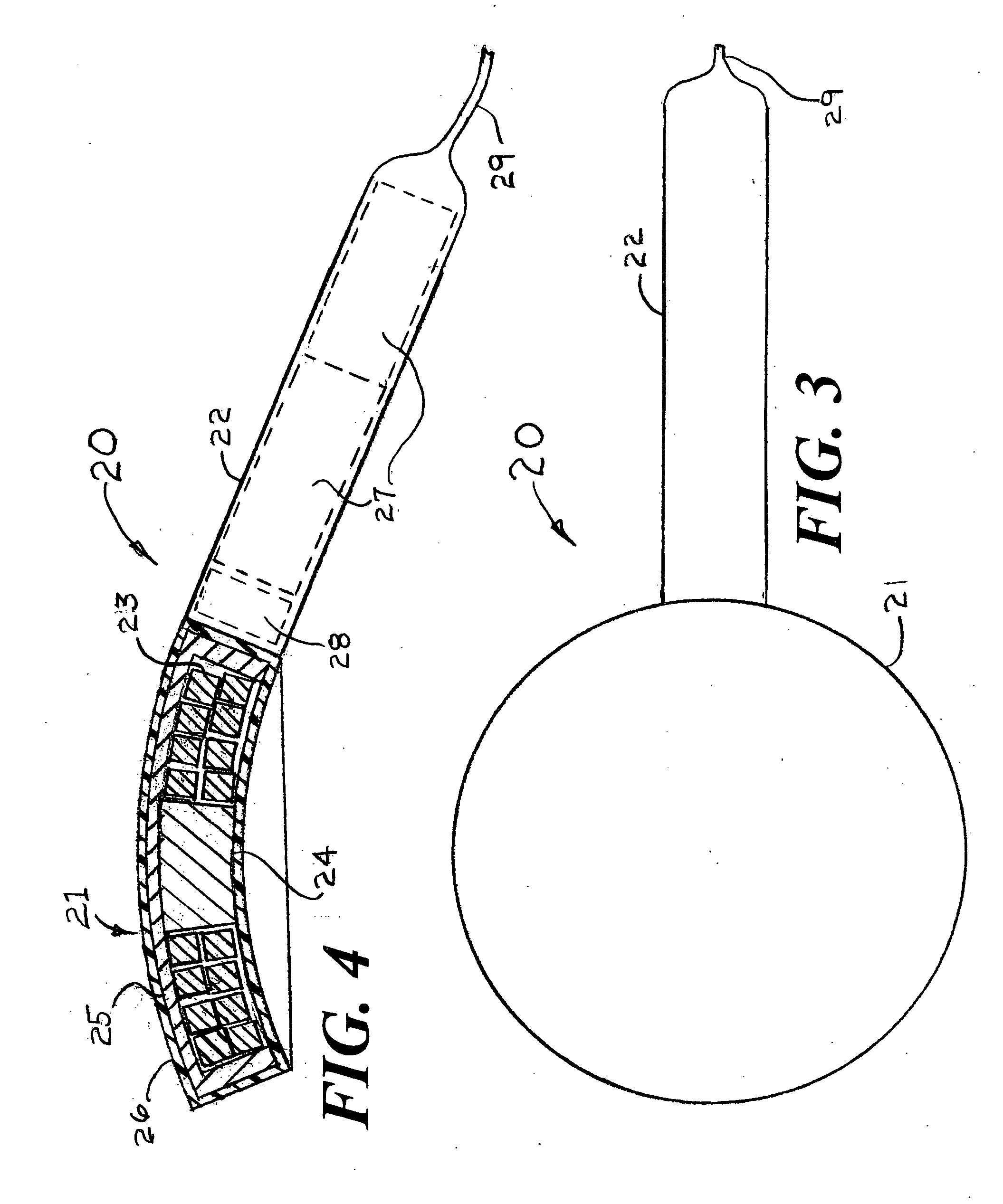

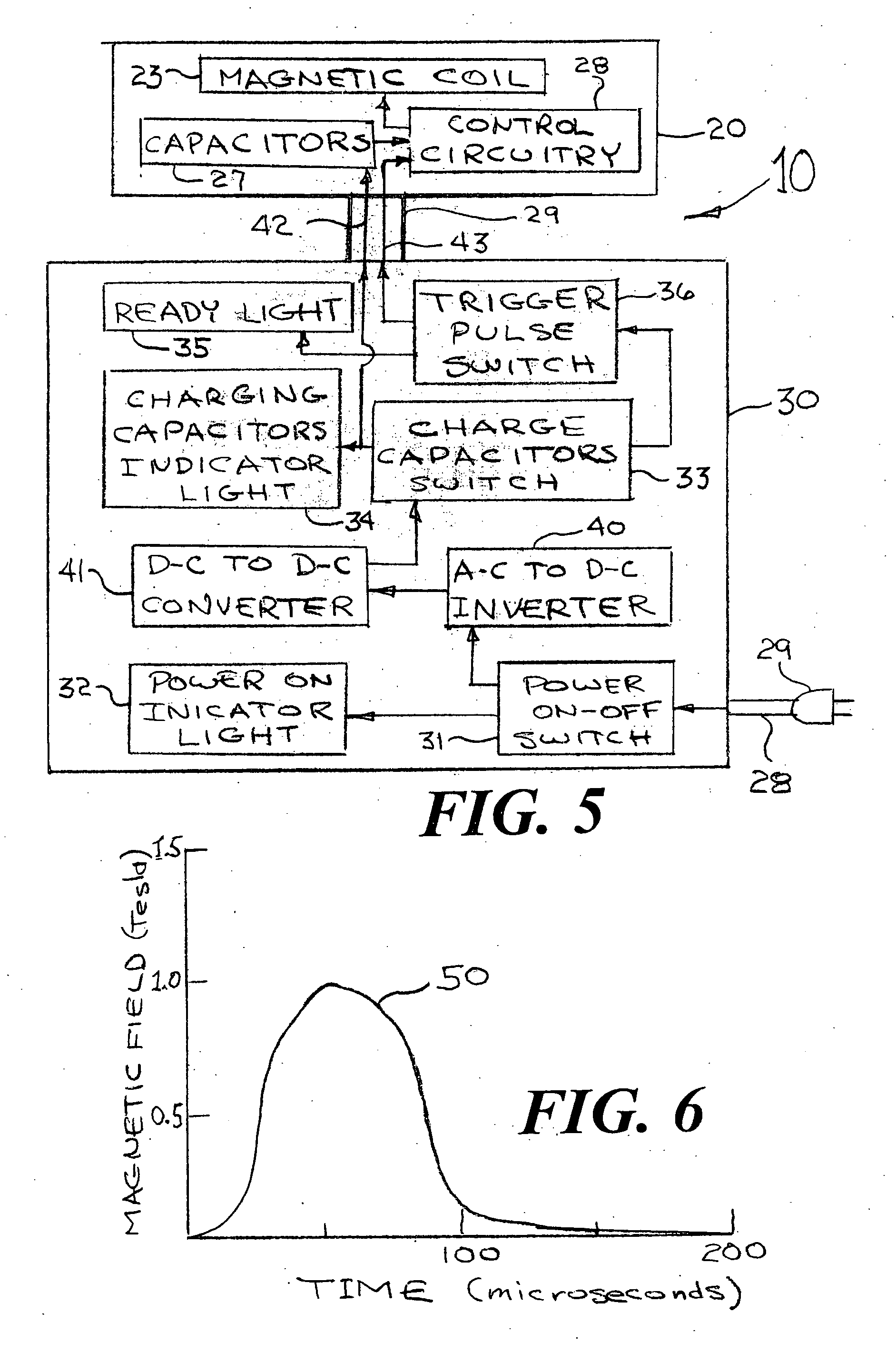

System for the treatment of migraine headaches

InactiveUS20060047316A1Eliminate the problemAvoid problemsHeart defibrillatorsMagnetotherapy using coils/electromagnetsEngineeringHeadaches

Disclosed is a system and method for treating migraine headaches employing a readily portable magnetic pulse system that has a head unit connected to a table unit by means of a connecting cable. When a patient senses either the aura of a migraine headache or an ongoing headache, he would turn the table unit on and then press a charge button to charge at least one capacitor in the head unit. When the at least one capacitor is fully charged, the patient would then place the head unit onto his head and then press a button switch that causes the at least one capacitor to discharge into an electromagnetic coil located in the head unit. The high intensity electric current in the electromagnetic coil would then create a high intensity, short duration magnetic pulse onto the patient's brain which can decrease the intensity or duration of the migraine headache.

Owner:FISCHELL ROBERT E +2

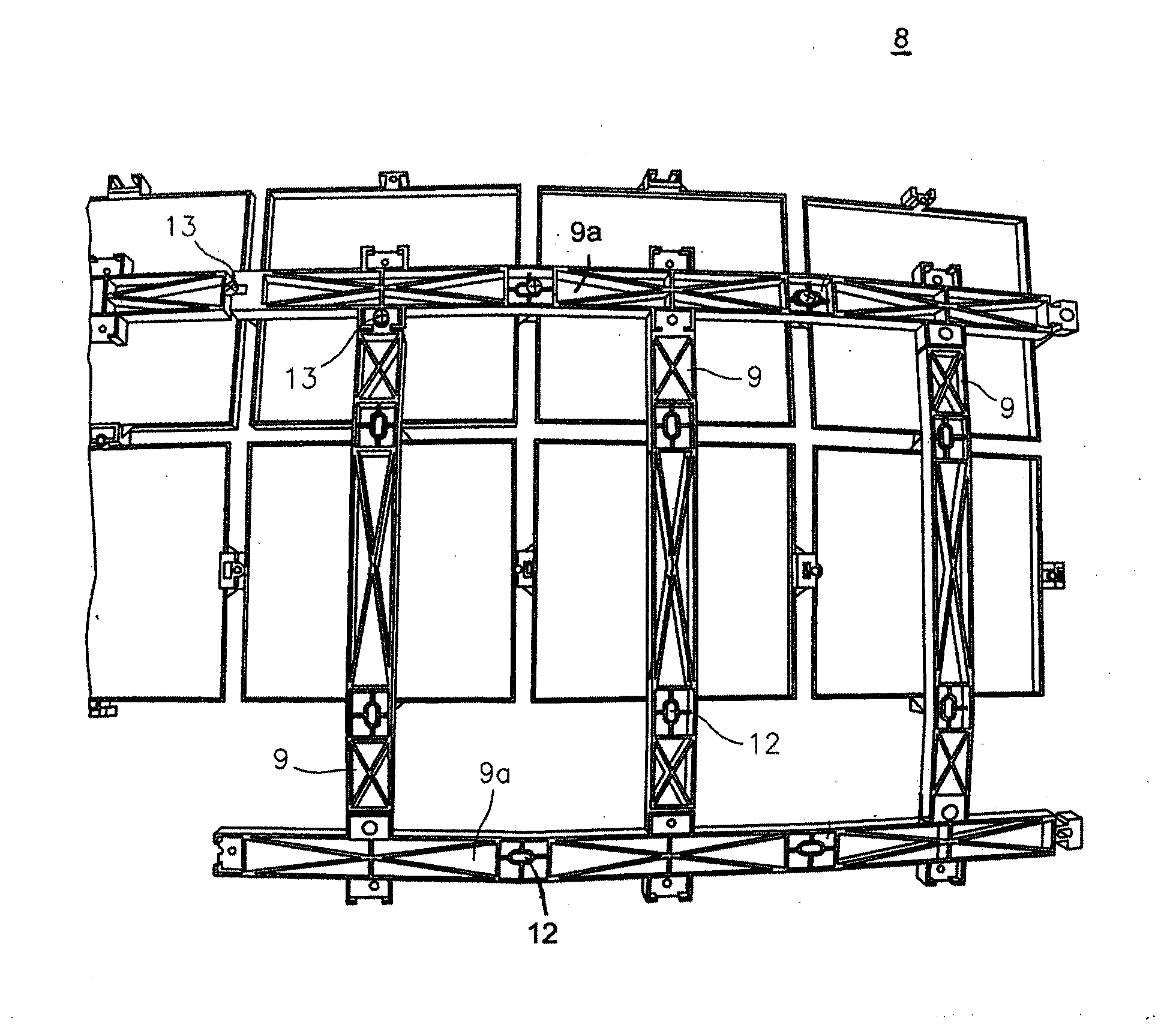

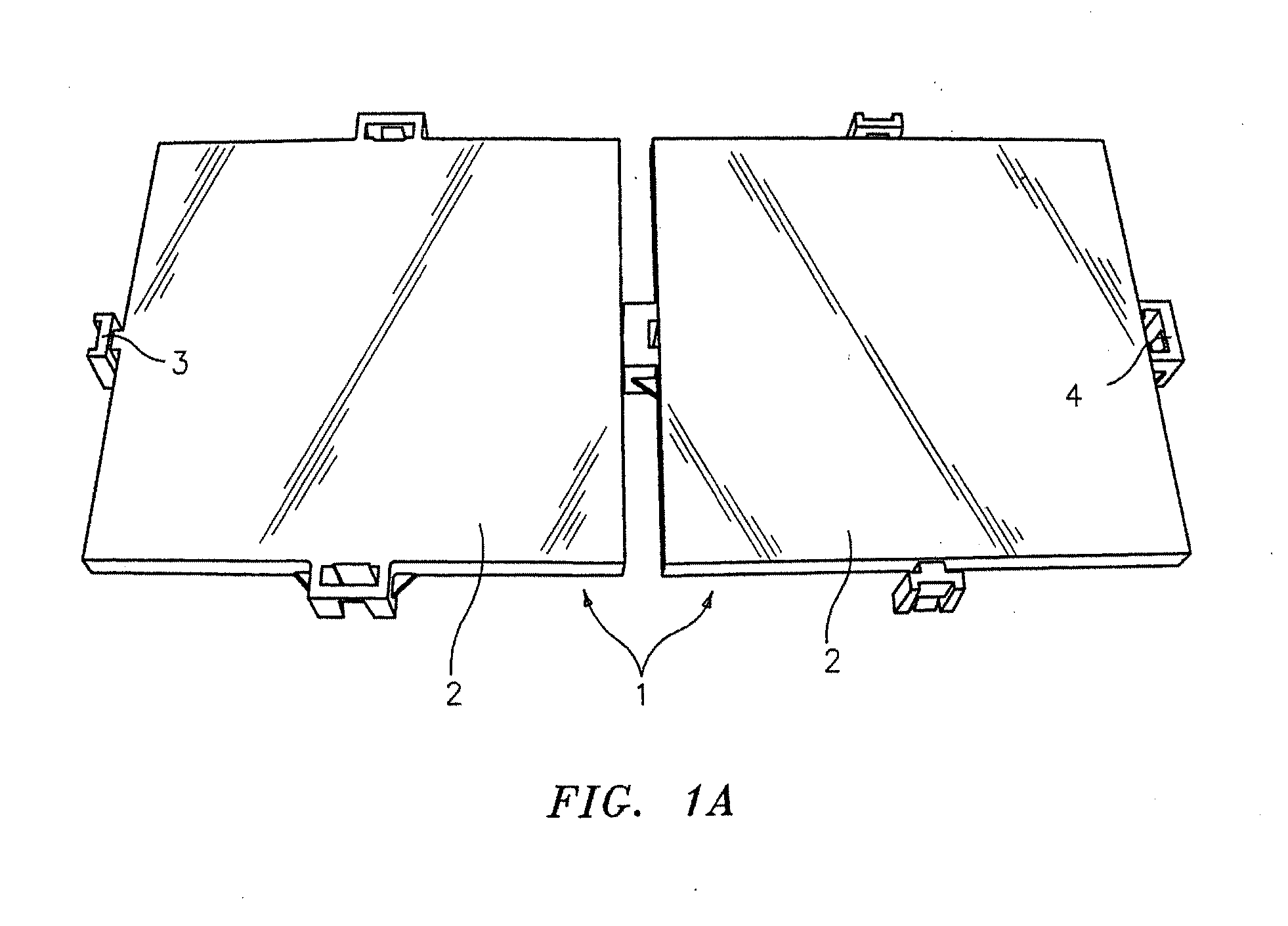

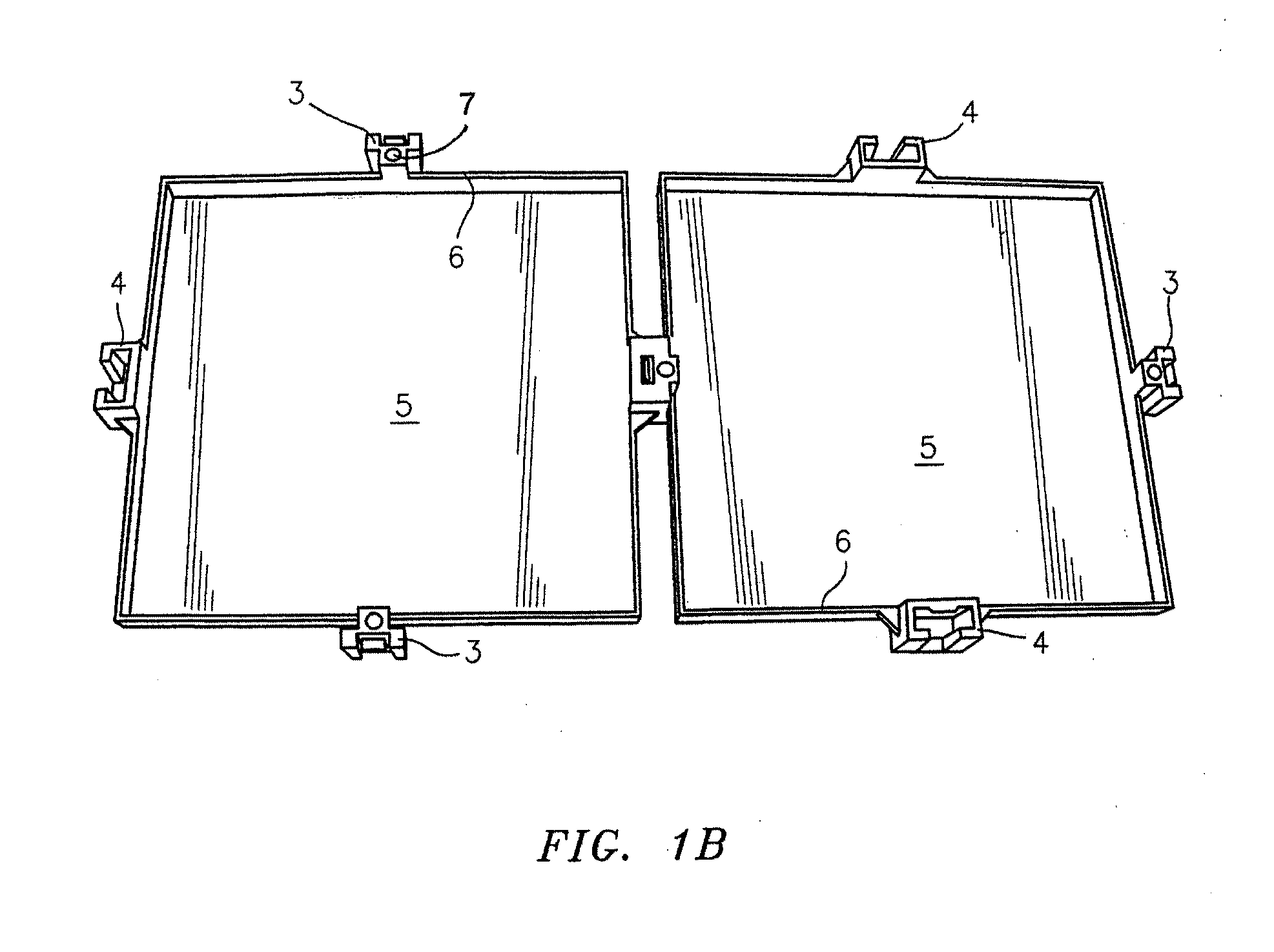

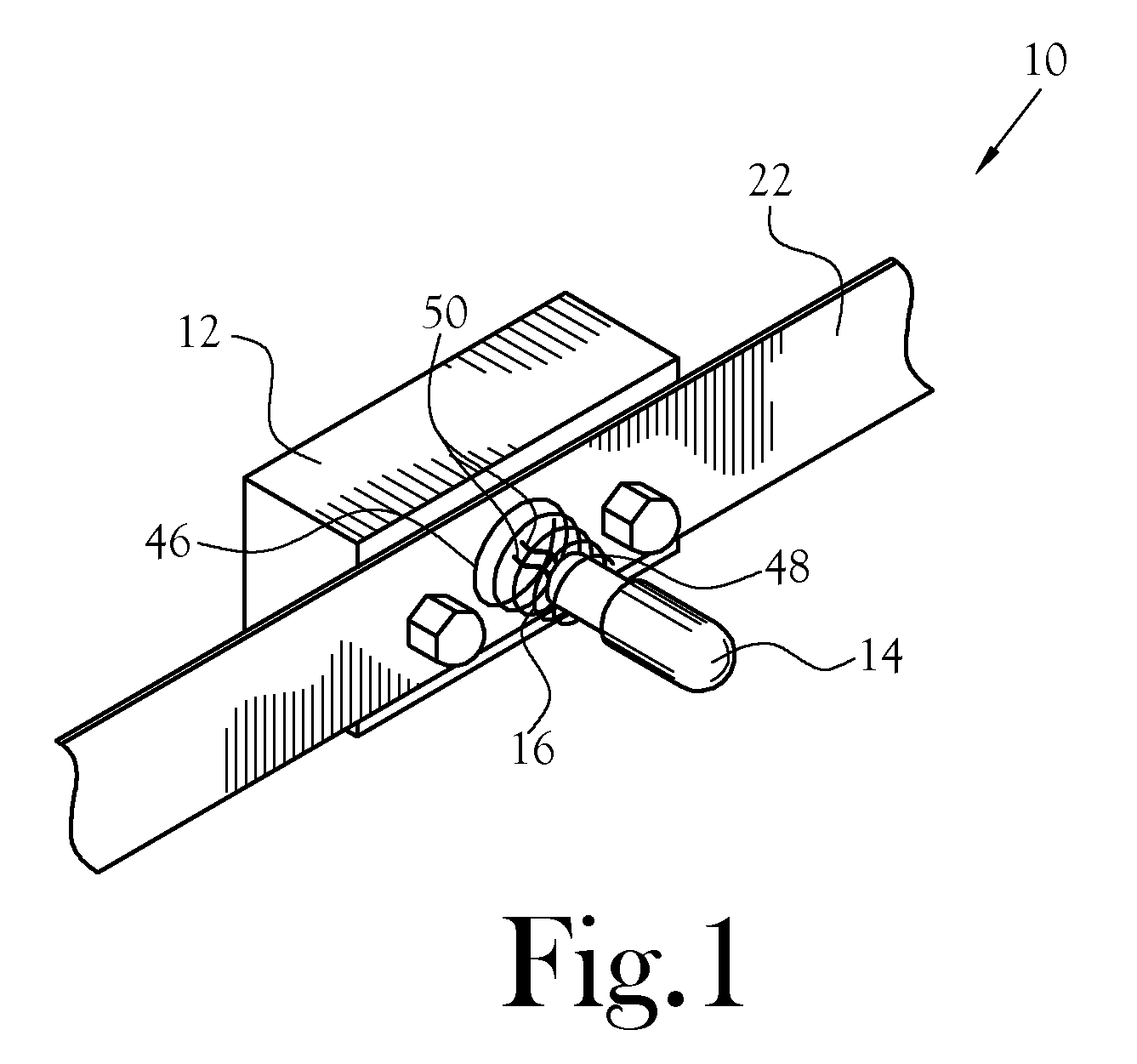

Durable, lightweight, and efficient solar concentrator

InactiveUS20100170560A1Maximize efficiencyEasy constructionSolar heating energySolar heat devicesCost effectivenessBraced frame

A solar concentrator, which is modular, durable, lightweight, and cost-efficient is described. The solar concentrator is constructed from a plurality of interconnected reflector panels that are secured to a contoured support frame assembly by means of an adjustable fastening mechanism. The reflector panels are preferably fabricated from a low-cost composite material and have an optically flat front surface. A specularly reflective front surface is formed on the reflector panel by deposition of a plurality of thin films which are highly reflective. Individual reflector panels can be interconnected and arranged into a two-dimensional grid having a predetermined degree of curvature by means of the contoured support frame assembly. Electromagnetic radiation incident upon the reflector panel arrangement is reflected to and concentrated upon a collector plate or receiving surface or receiver where it may be converted into a usable form of energy.

Owner:PERSISTENT ENERGY

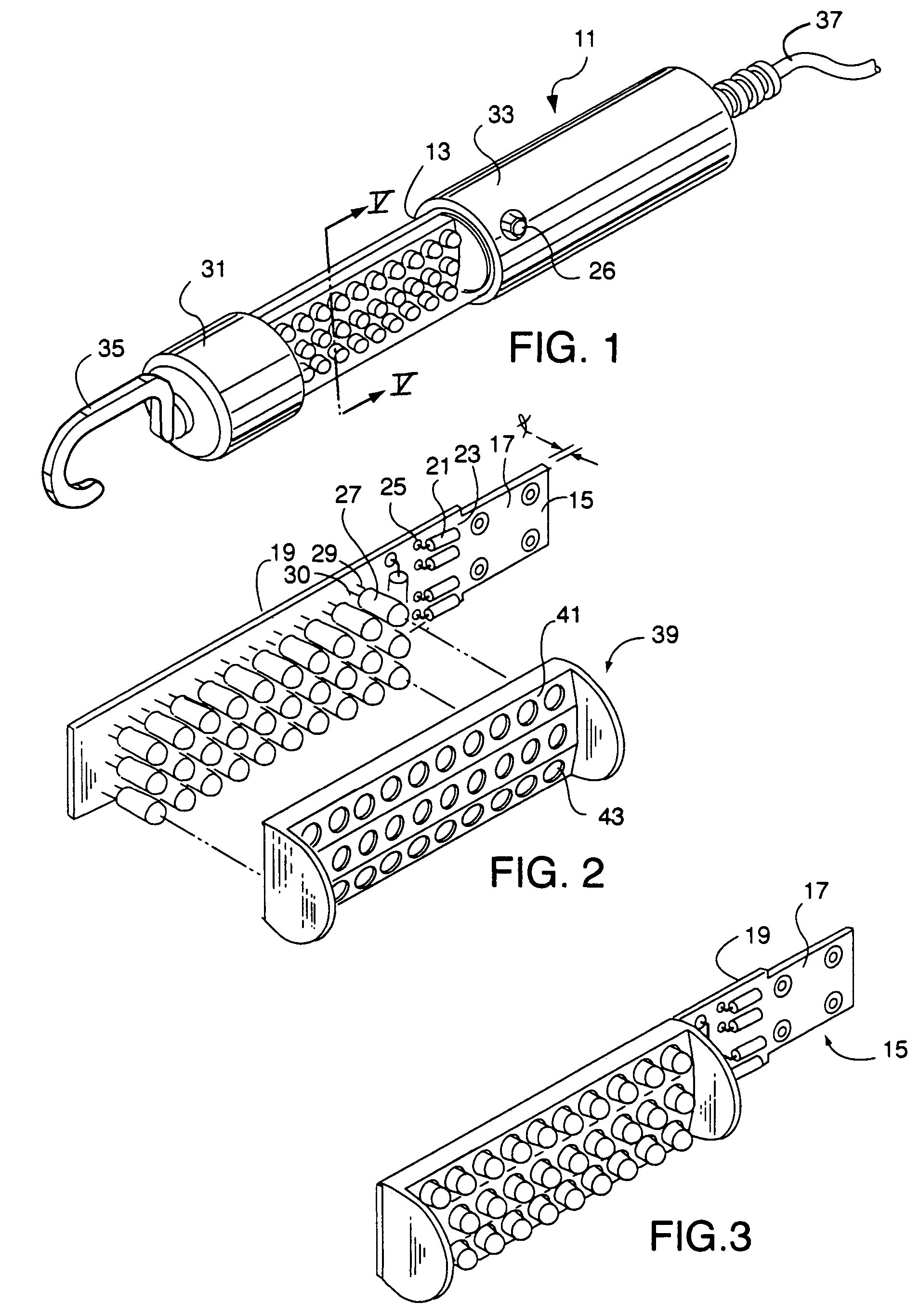

Miniature linear vibrotactile actuator

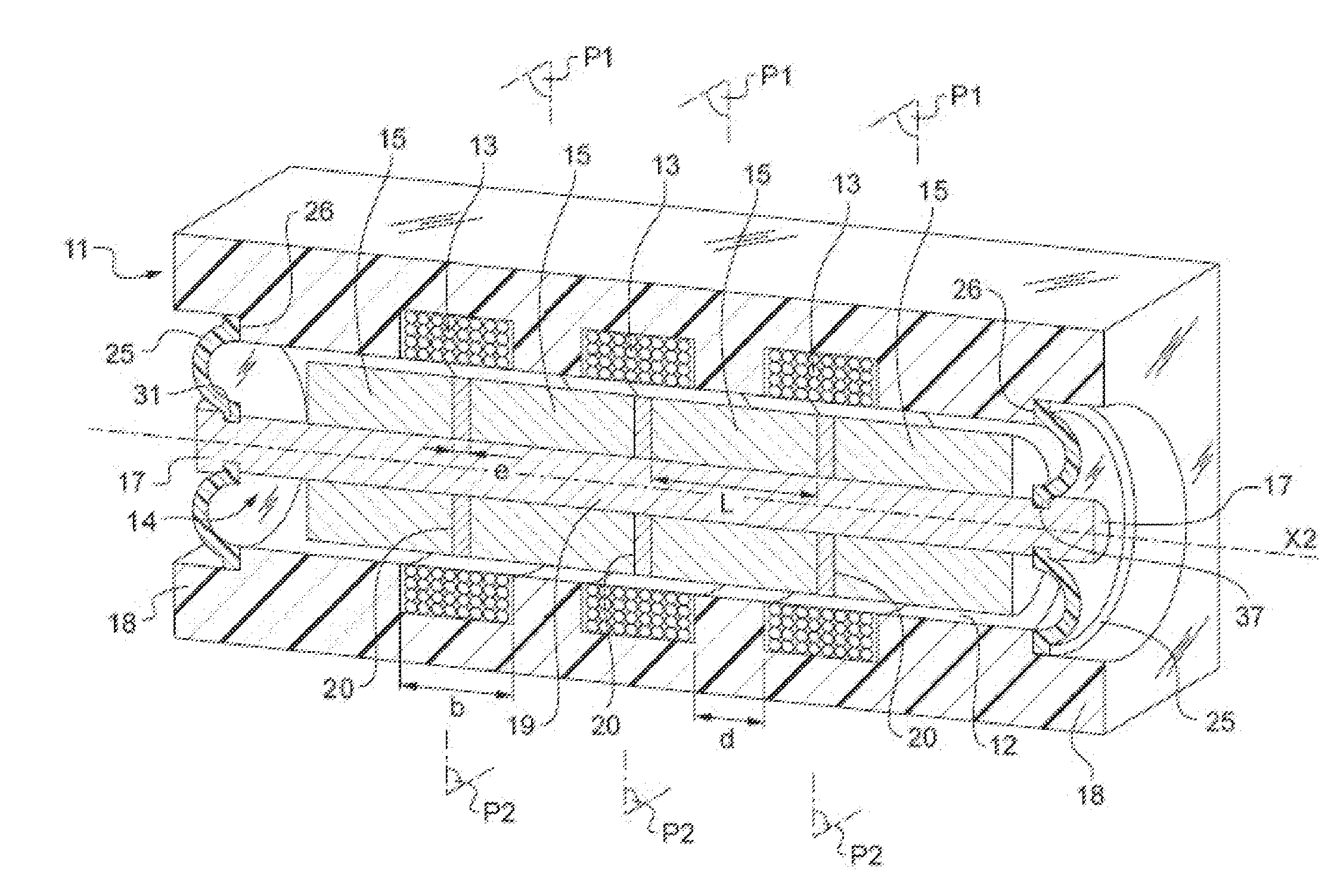

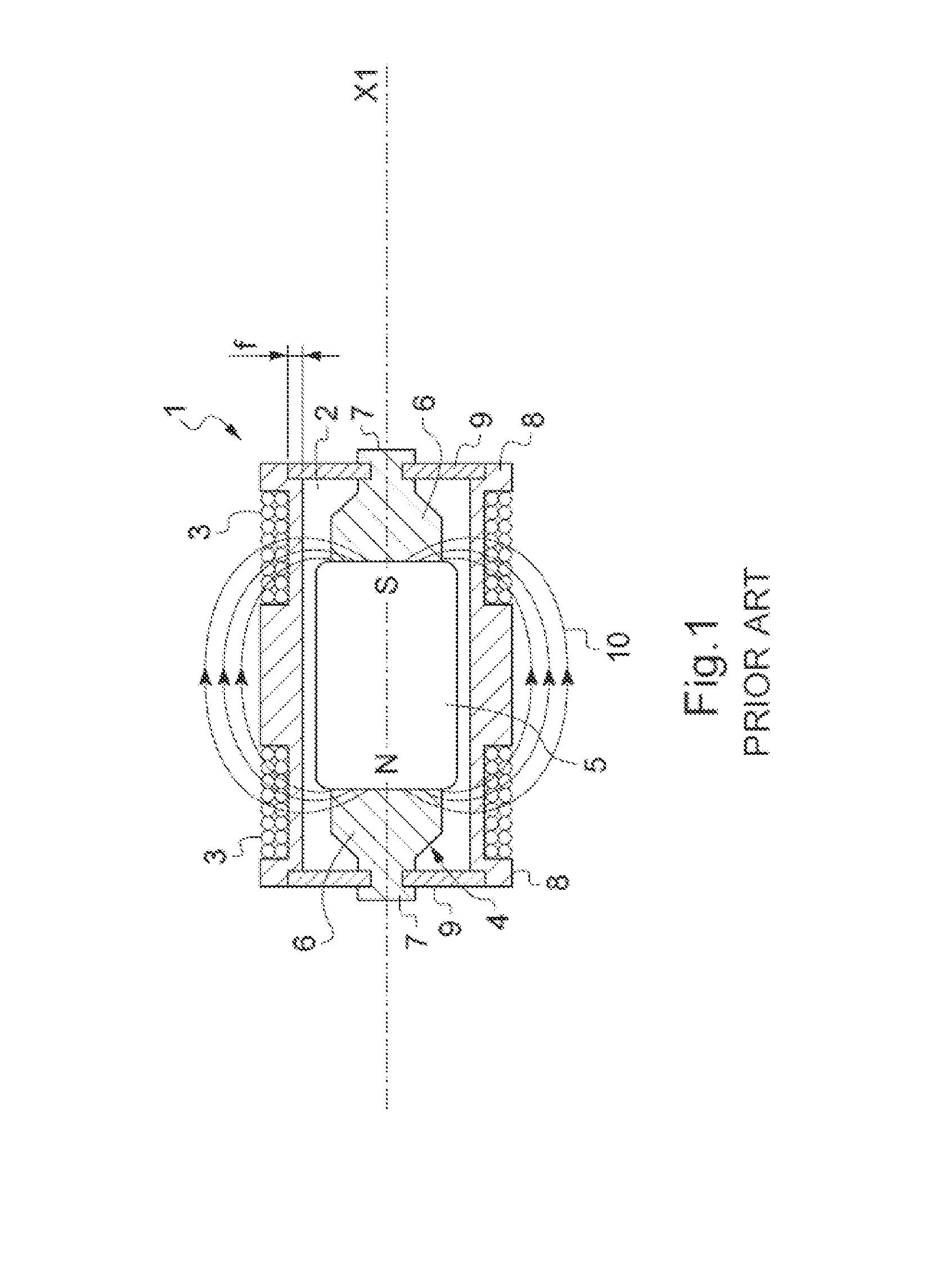

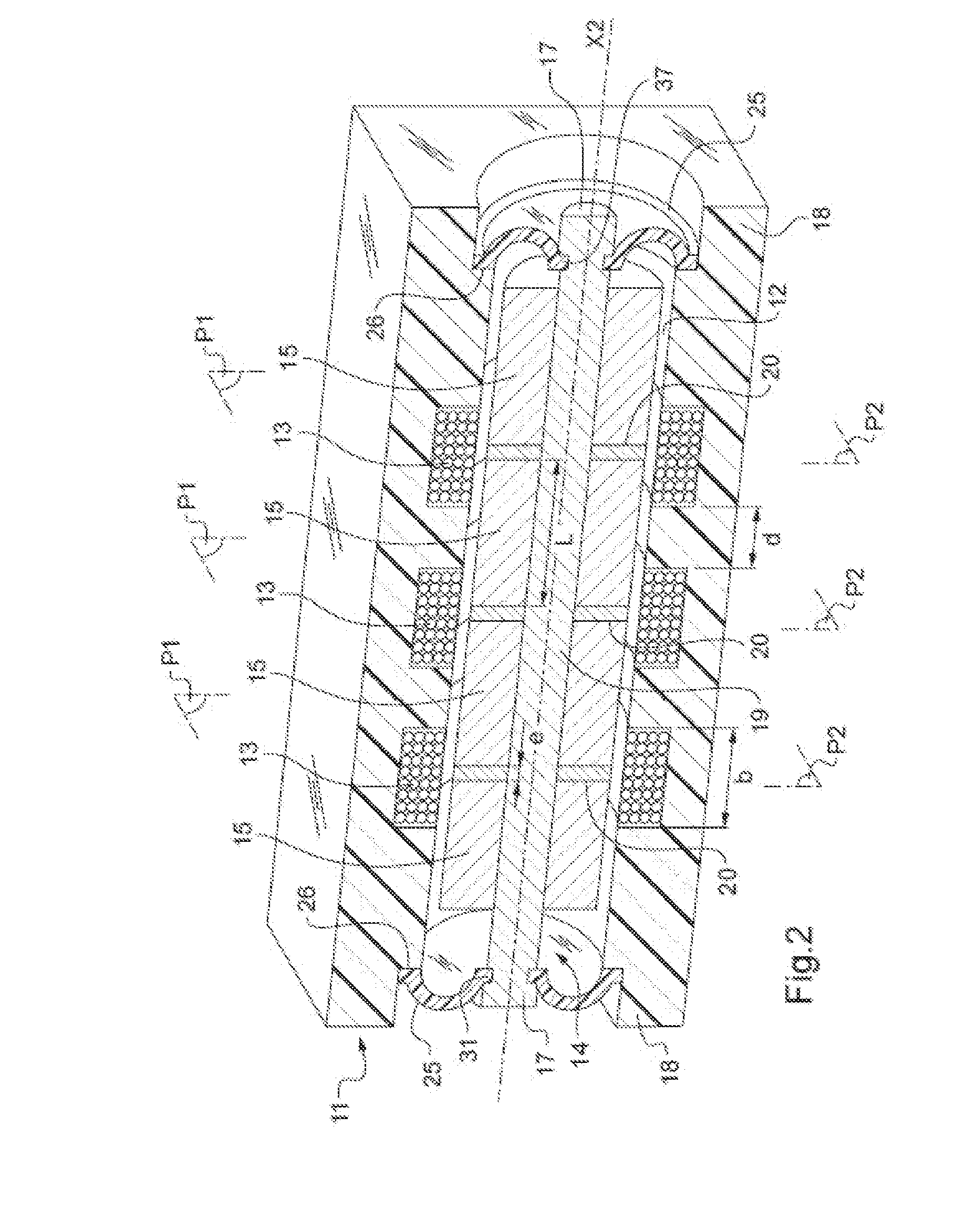

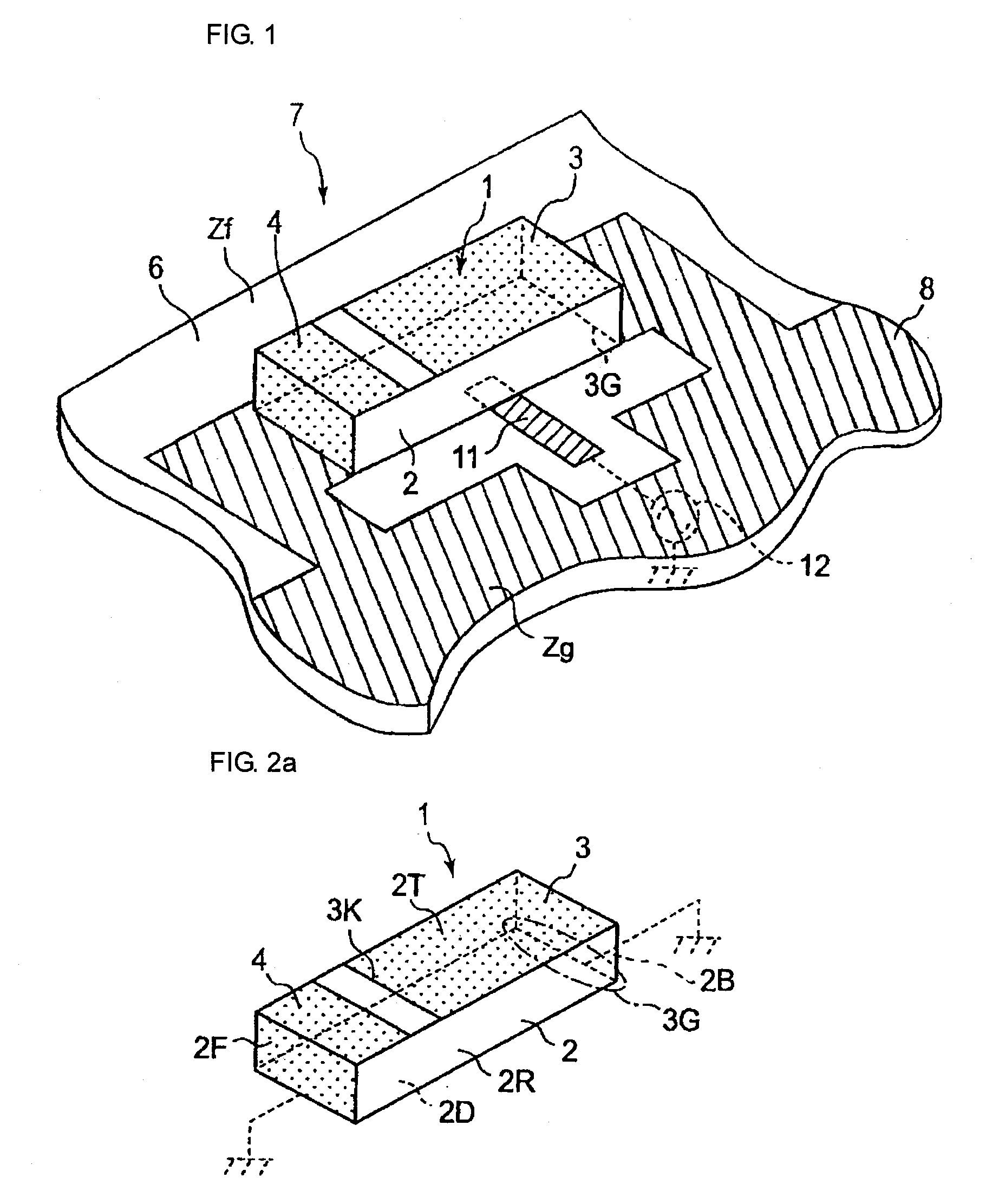

ActiveUS20140346901A1Maximizing intensityManufacturing stator/rotor bodiesEmbedding prefabricated windingsElectrical polarityEngineering

The invention relates to a miniature linear vibrotactile actuator comprising: a first element 14, 104 of generally cylindrical shape, comprising permanent magnets 15, 105 aligned so that two adjacent sides of two adjacent magnets 15, 105 have identical polarities; a second element 11, 101 defining a cylindrical cavity 12, 102 into which the first element 14, 104 is inserted with play so as to be able to slide therein in a sliding direction X2, the second element 11, 101 comprising coils 13, 103 of conductive wire having strands that extend perpendicularly to the sliding direction X2, in order to form magnetic force generators, and that are placed so as to be able to influence the first element 14, 104 electromagnetically; and means 25, 41, 125 for returning and guiding the first element 14, 104 toward an equilibrium position in the second element 11, 101, in which position a median plane P2 between two adjacent magnets substantially coincides with a median plane P1 of a facing force generator 111.

Owner:SORBONNE UNIV +1

Antenna structure and radio communication device using the same

InactiveUS20090040120A1Easy to useEasy to shareSimultaneous aerial operationsAntenna supports/mountingsCapacitanceSurface mounting

A radiation electrode is formed on a substrate of a surface mount antenna. One end of the radiation electrode forms a ground connection portion connected to ground, and the other end of the radiation electrode forms an open end. A ground connection electrode for connecting the open end of the radiation electrode to ground via a capacitance is provided on the substrate. No feeding electrode for feeding power to the radiation electrode is provided on the substrate. This surface mount antenna is mounted on a non-ground region (a region on which a ground electrode is not formed) of a board so as to constitute an antenna structure. On the board of the antenna structure, a feeding electrode for capacitively feeding power to the radiation electrode is provided at a position between the ground connection portion and the open end.

Owner:MURATA MFG CO LTD +1

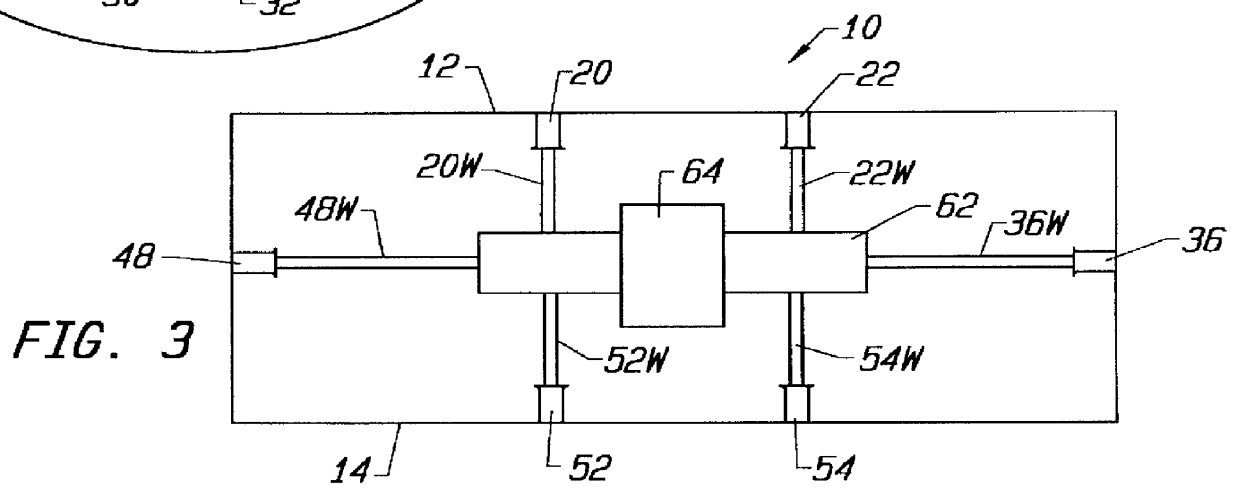

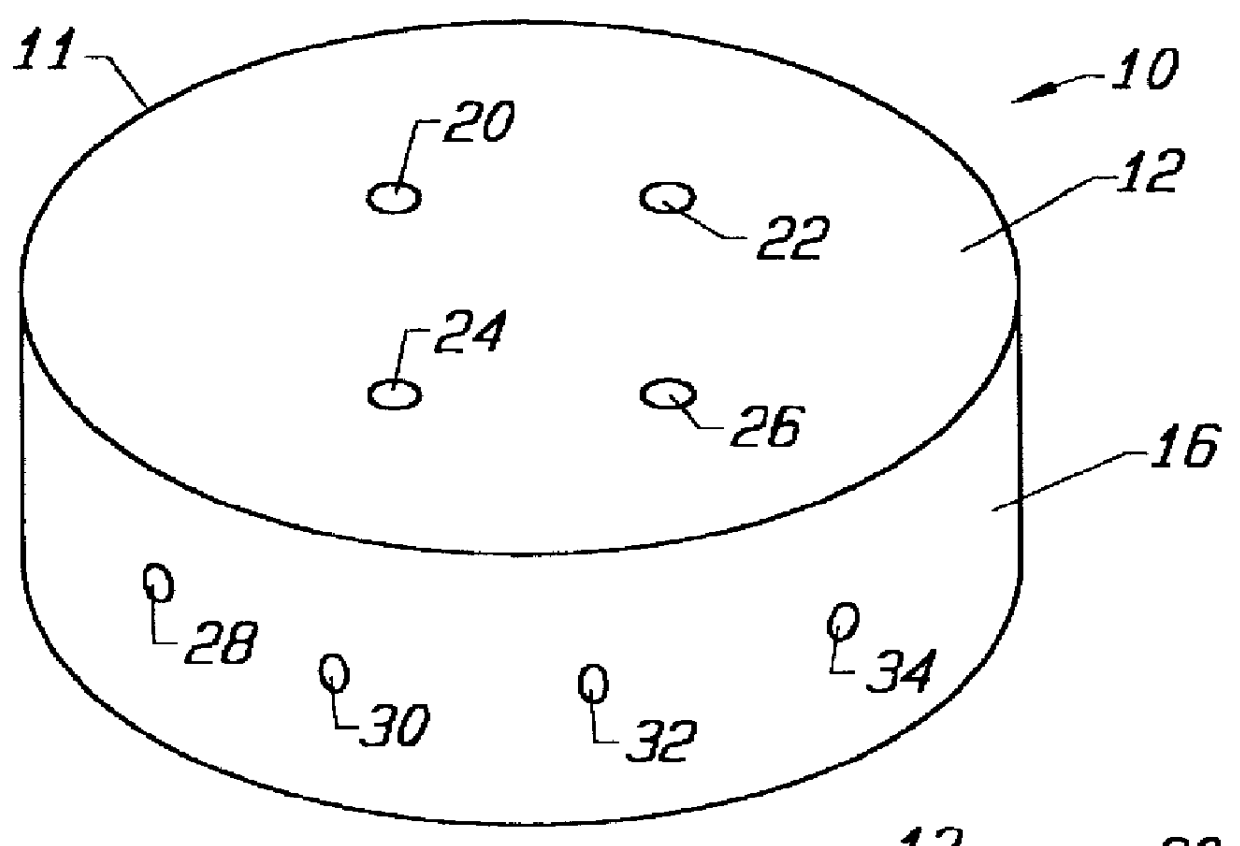

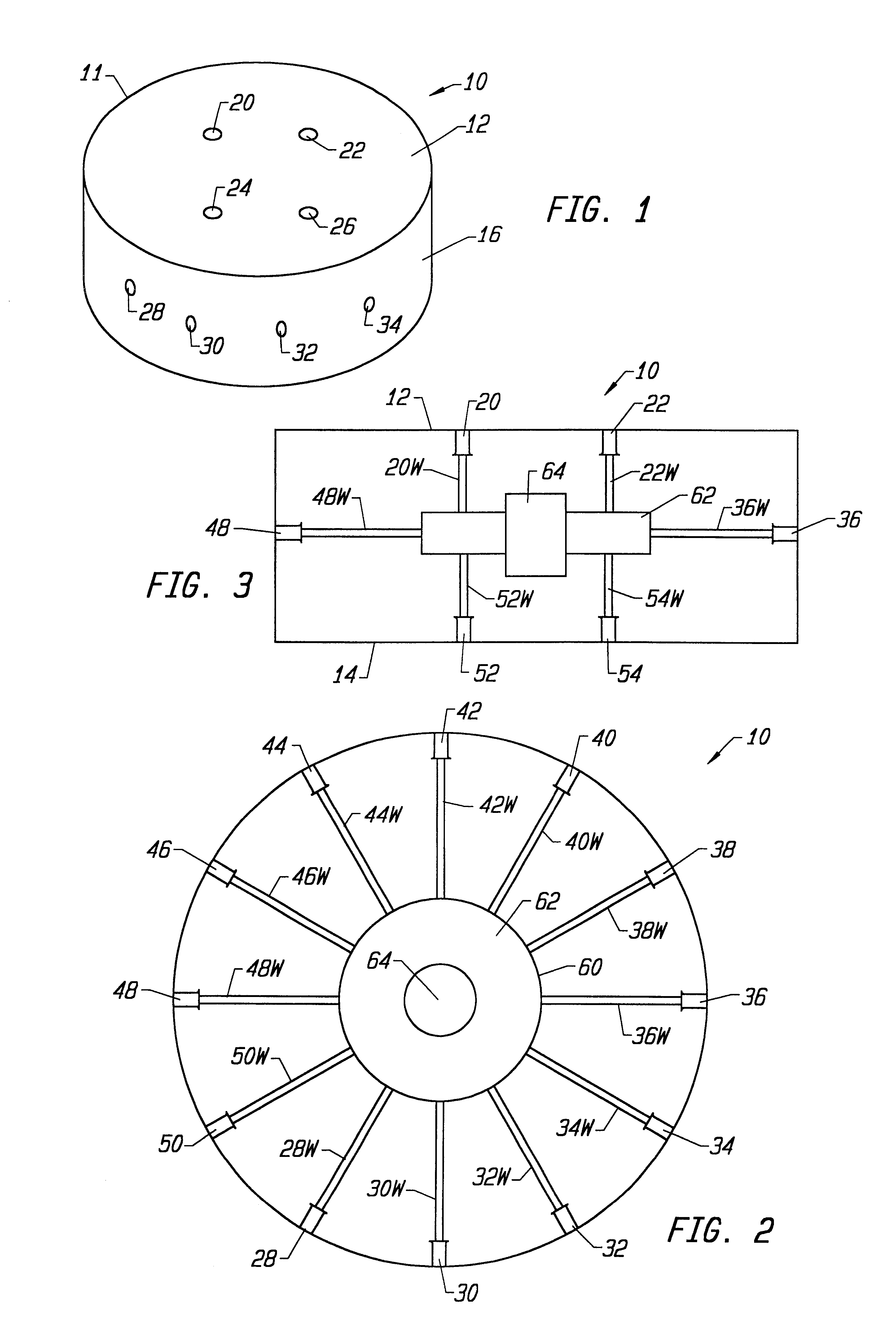

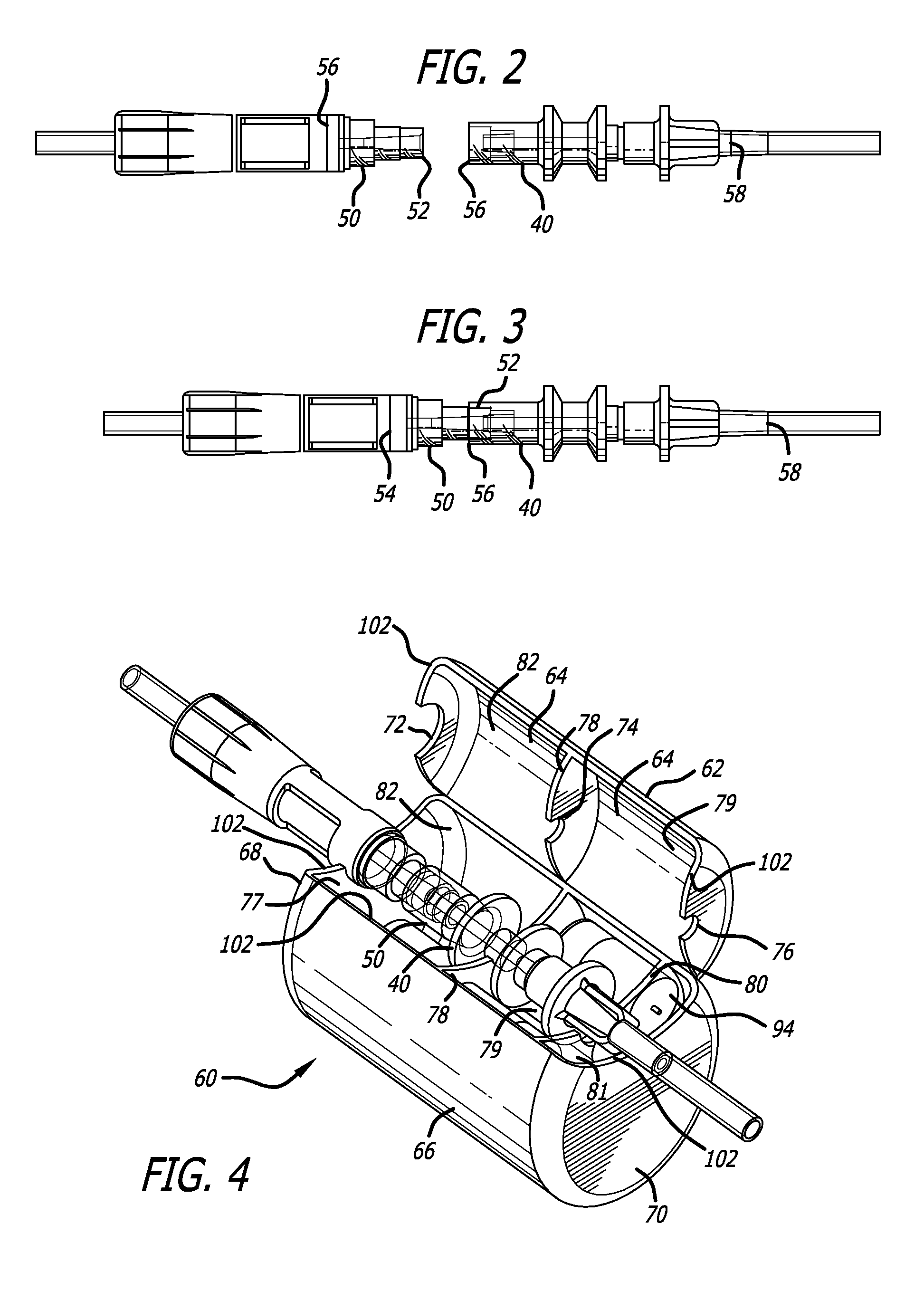

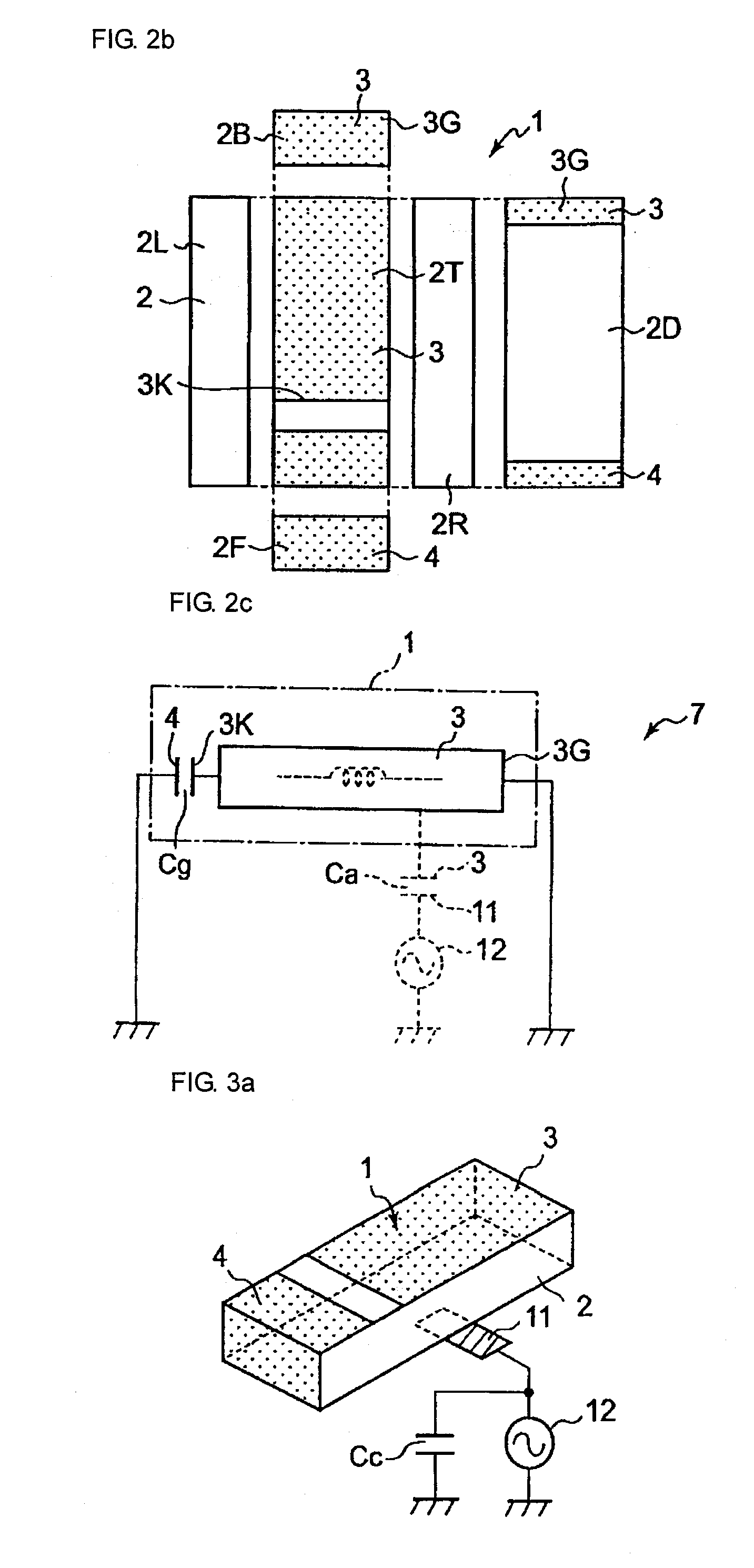

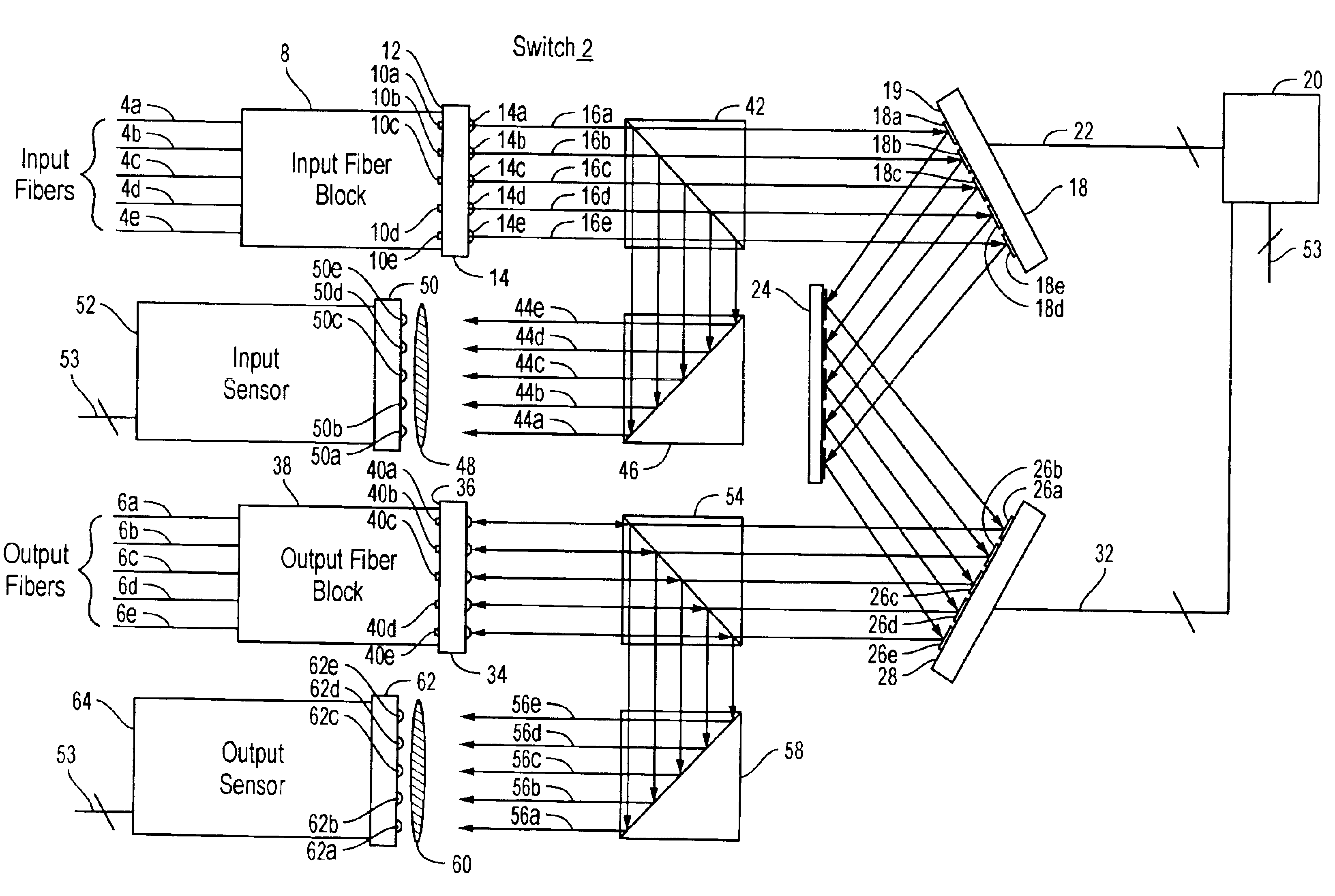

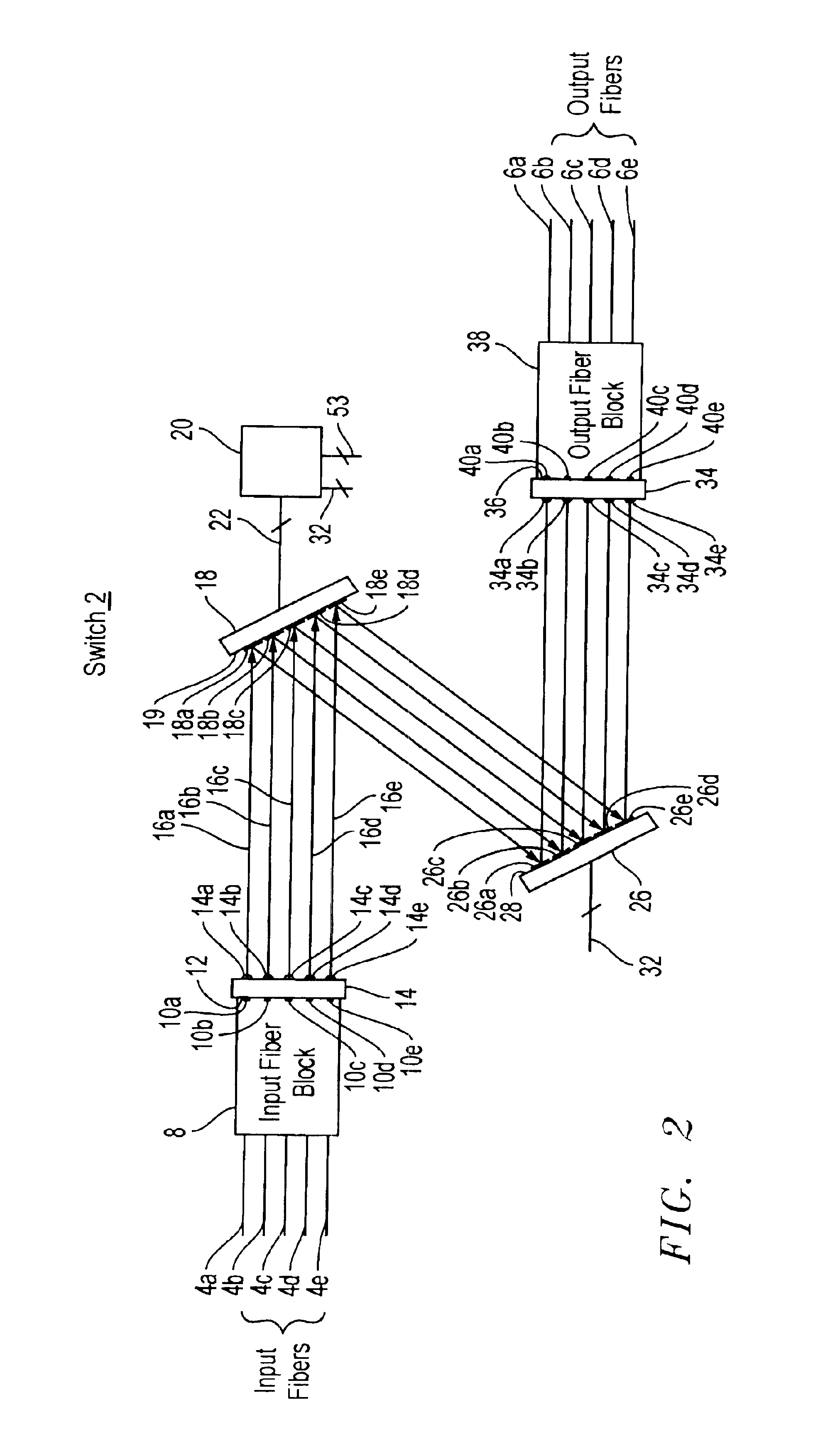

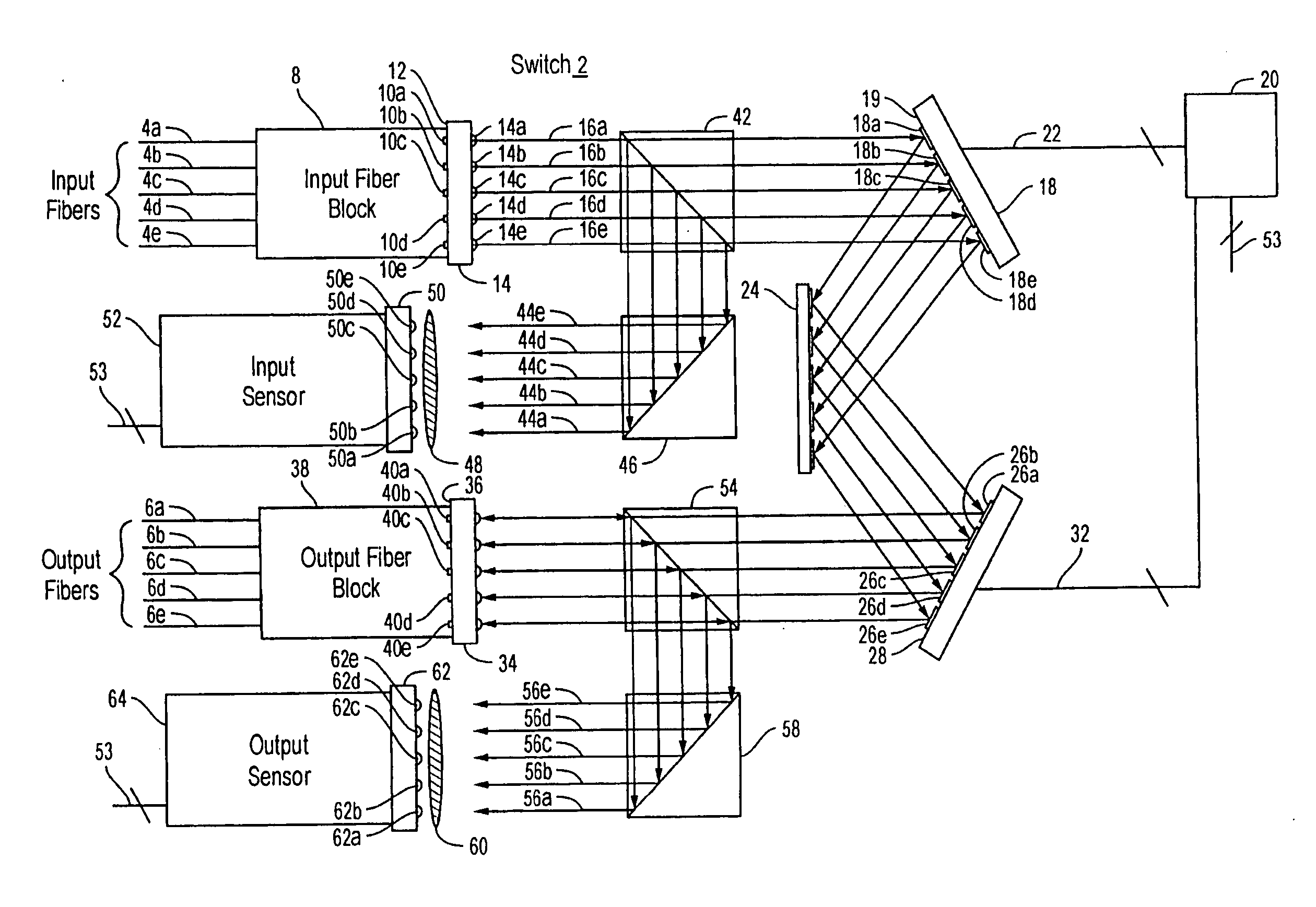

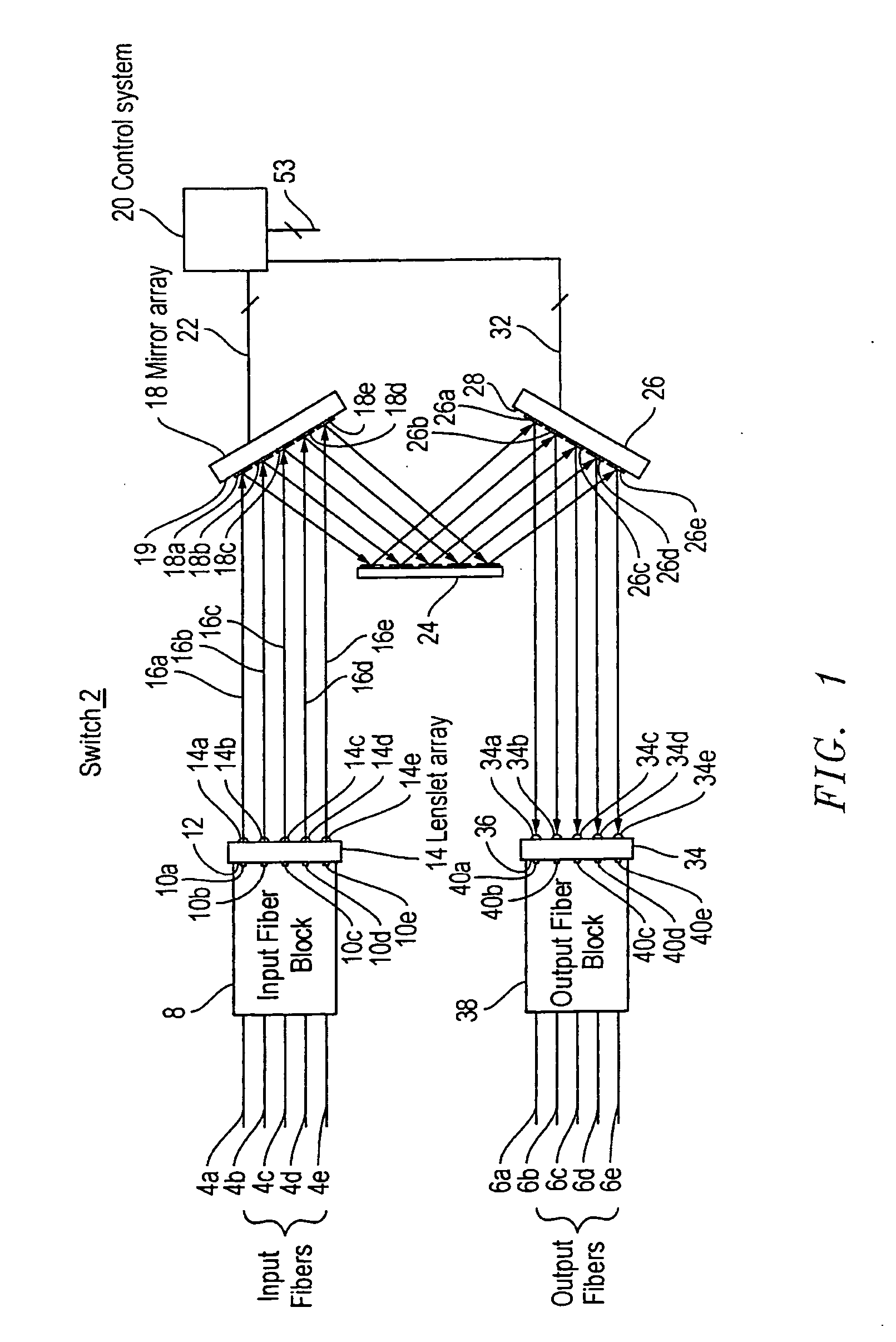

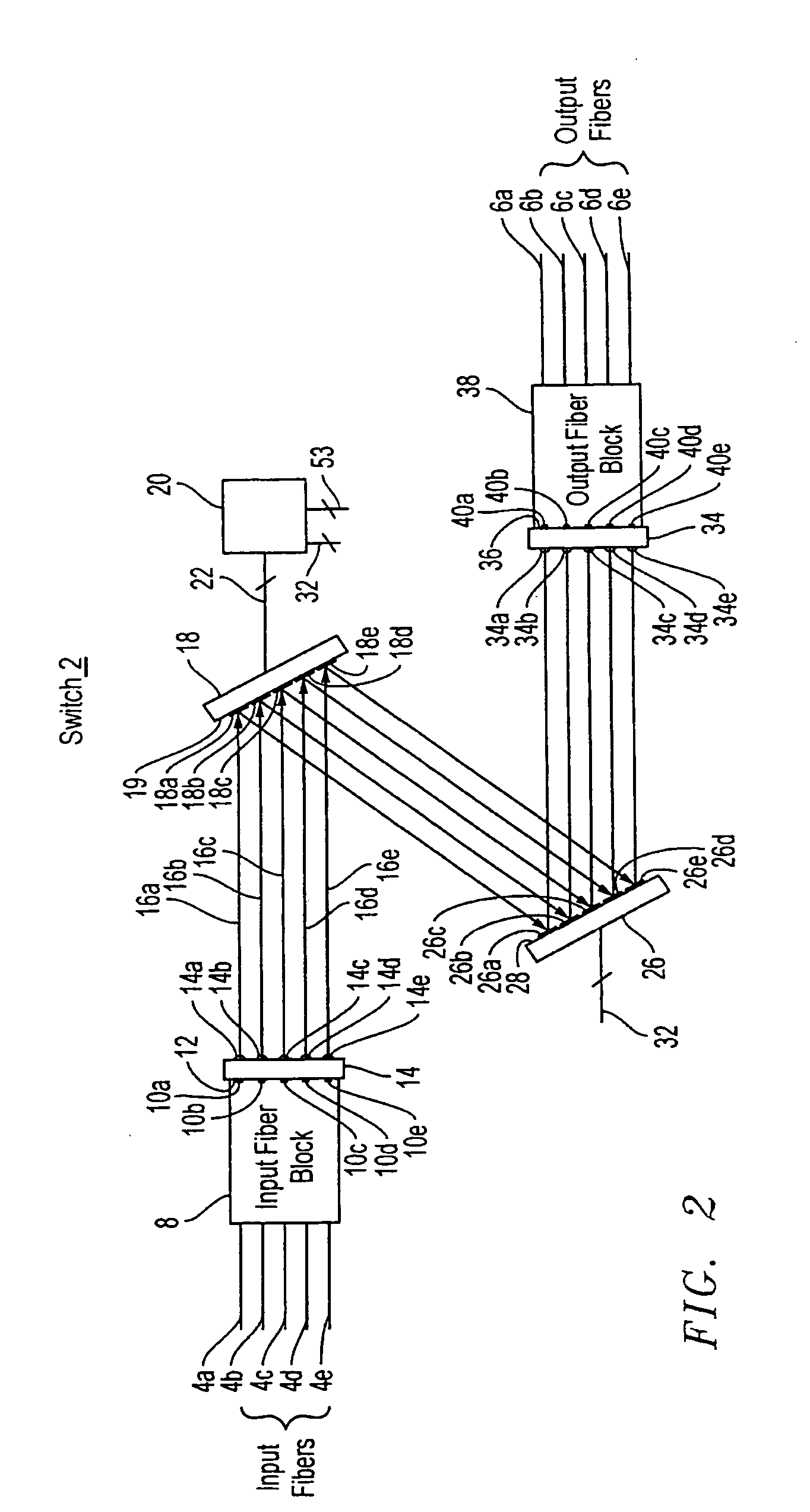

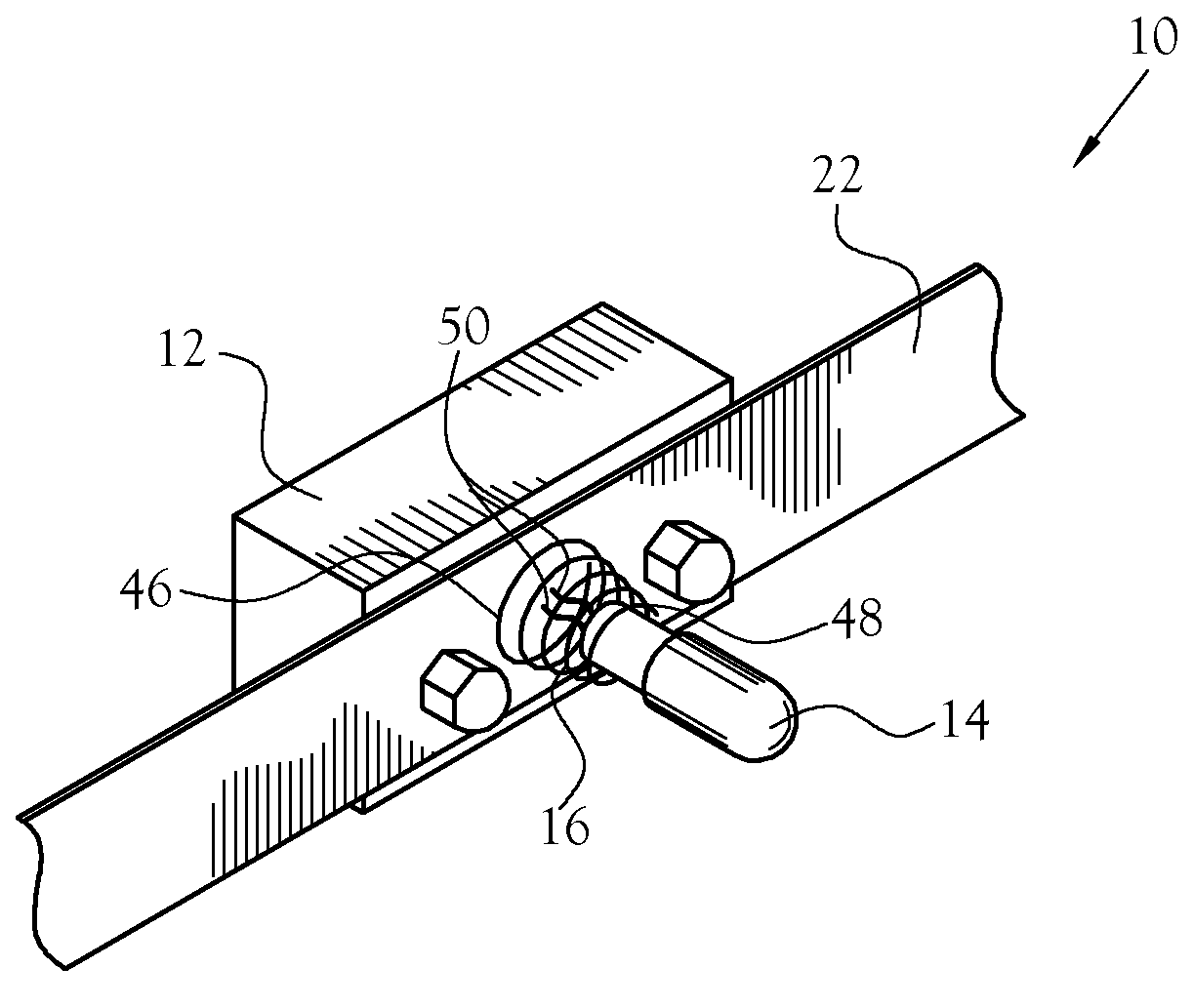

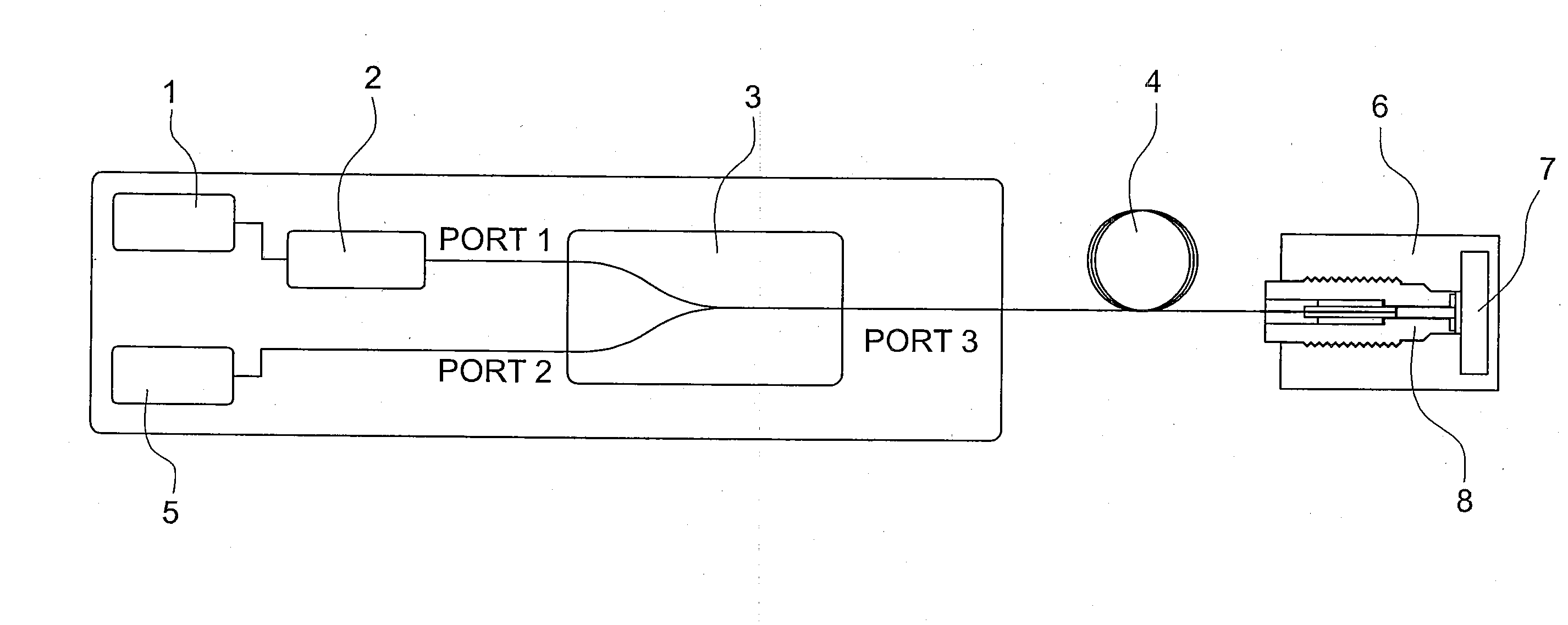

Optical system for calibration and control of an optical fiber switch

InactiveUS6898341B2Maximizing intensityImprove precision controlMultiplex system selection arrangementsCoupling light guidesCross connectionLight beam

Owner:INTEL CORP

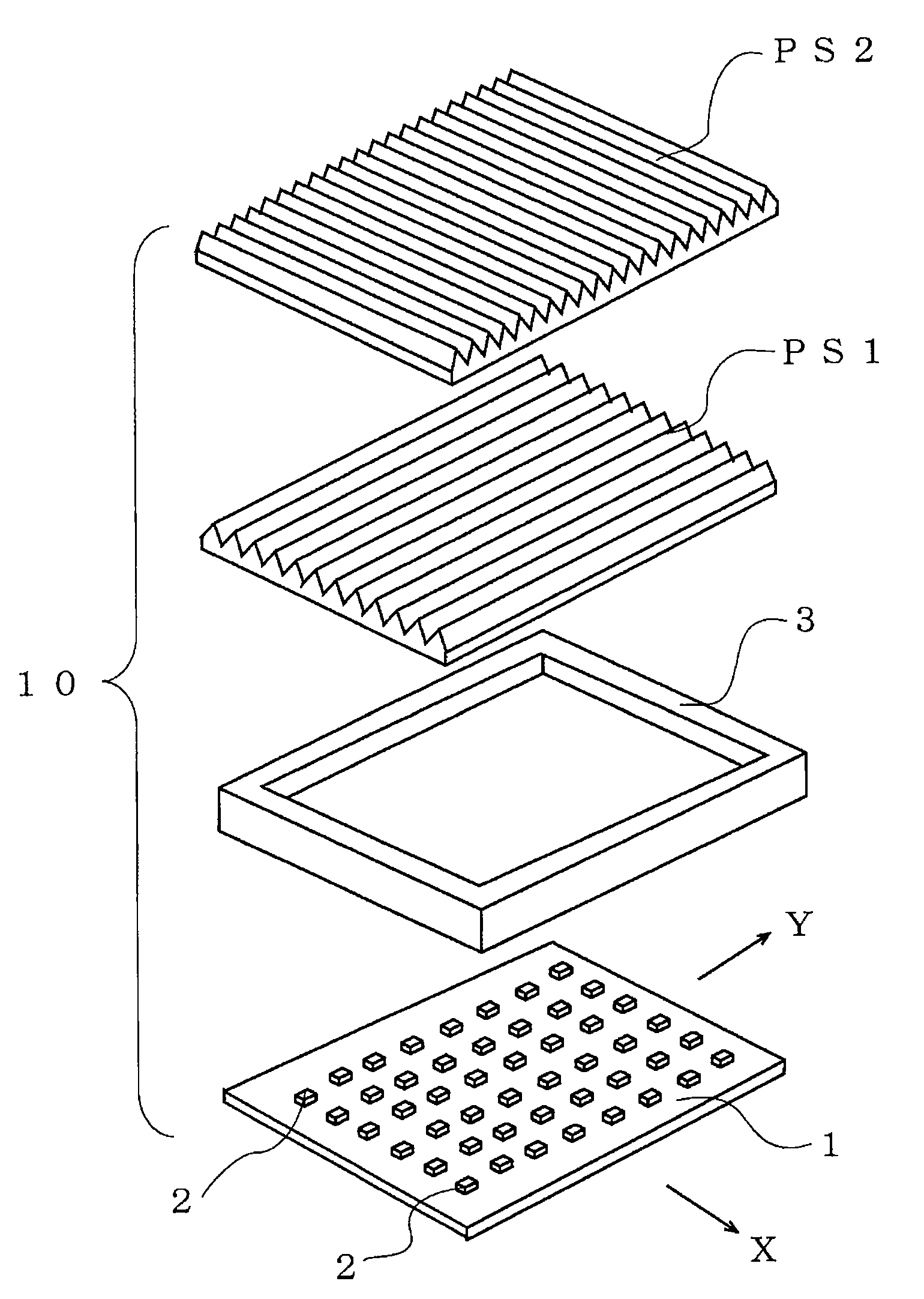

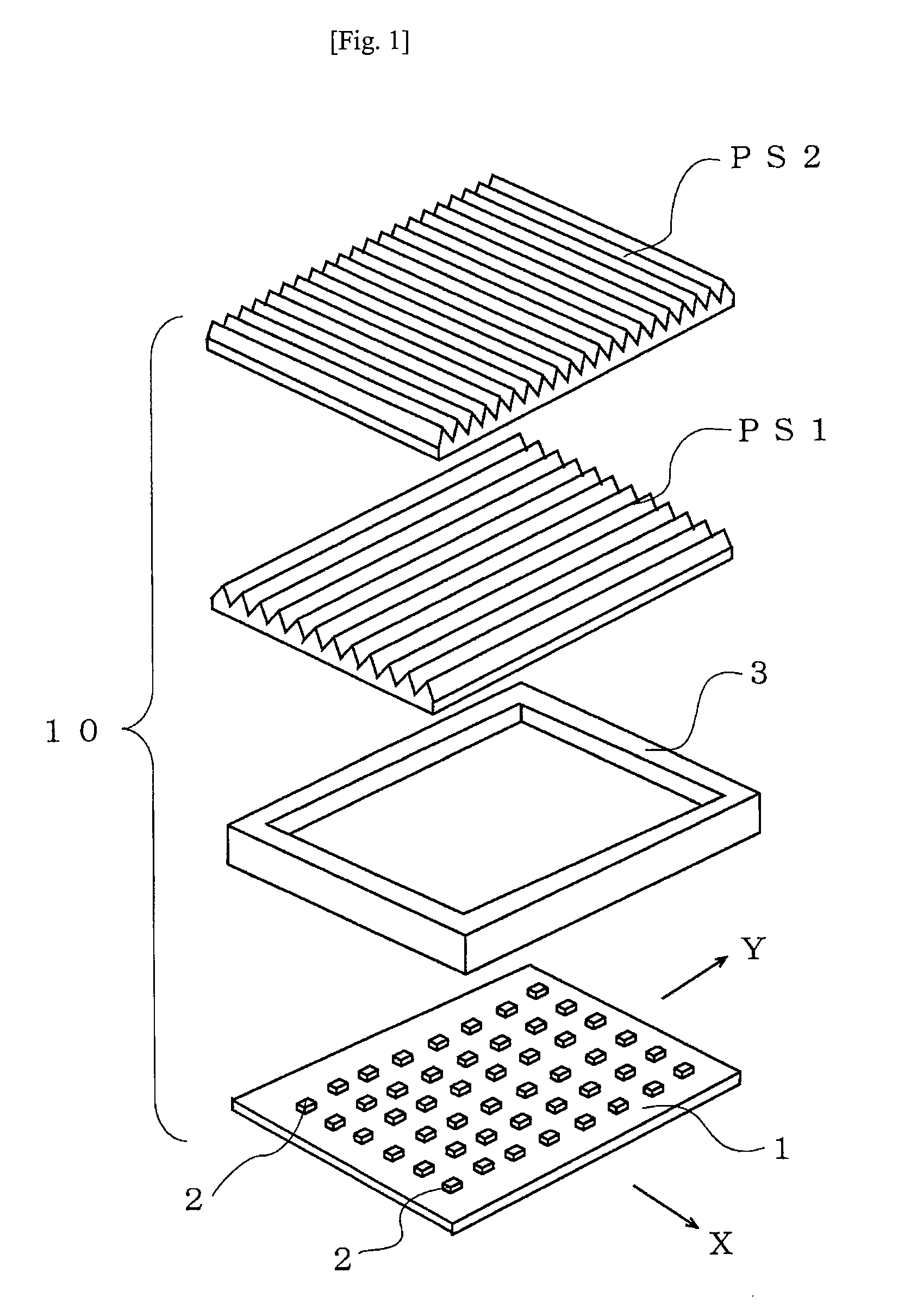

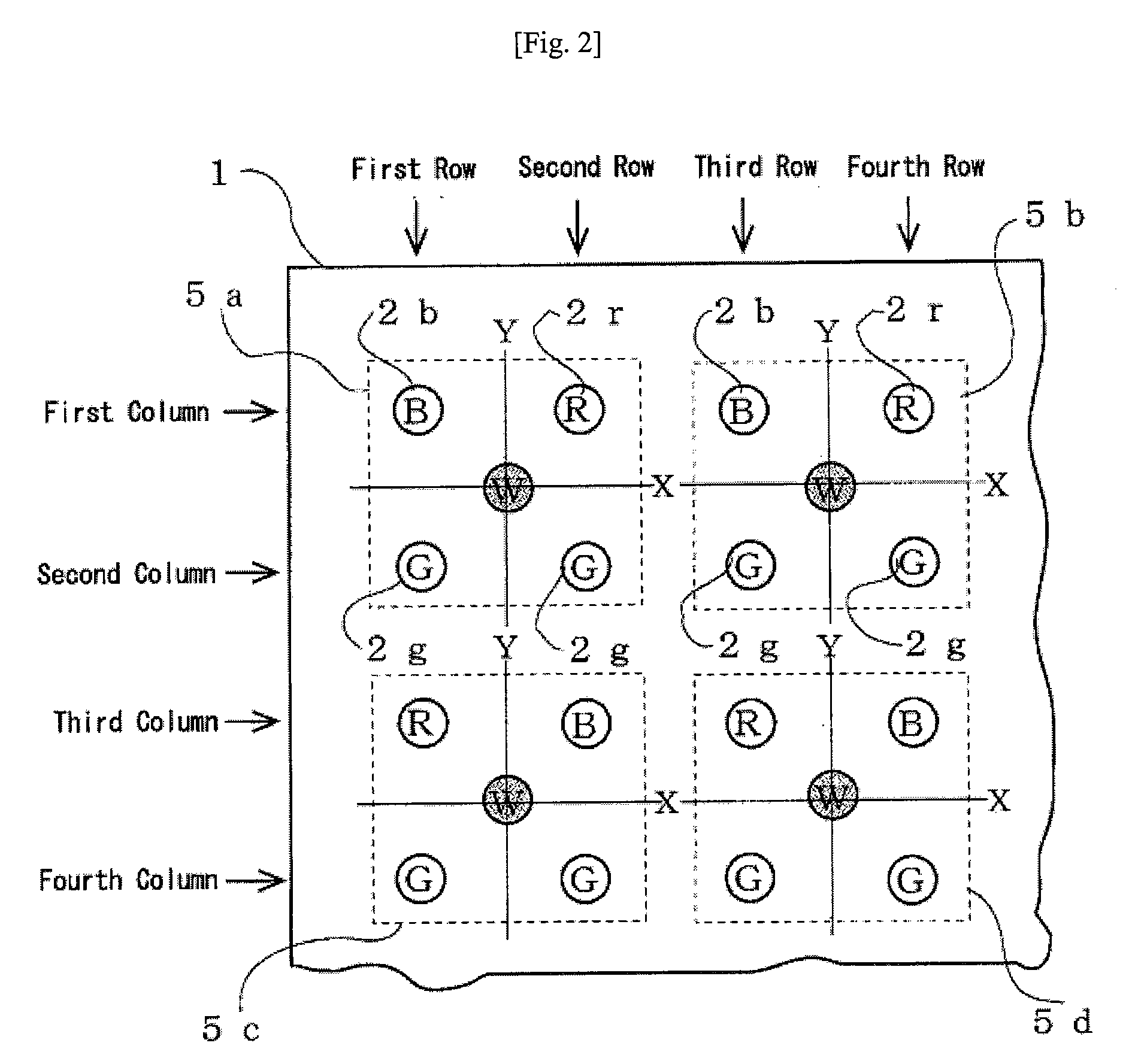

Planar light source and method of manufacturing planar light source

InactiveUS20090086477A1Small sizeReduce thicknessSpectral modifiersNon-linear opticsPrismWhite light

A planar light source directly mixes three colors of light from light-emitting diodes into white light. The planar light source has a plurality of red (2r), green (2g) and blue (2b) light-emitting diodes mounted on a mount surface of a substrate to define a plurality of light source sets, each having mutually adjacent red, green and blue light-emitting diodes, and further has first and second prism sheets (PS1 and PS2) stacked to face the mount surface. The stacked prism sheets receive and mix three colors of light from the light-emitting diodes constituting each light source set and emit lights from the red, green and blue light-emitting diodes of each of the light source sets as white light.

Owner:CITIZEN ELECTRONICS CO LTD

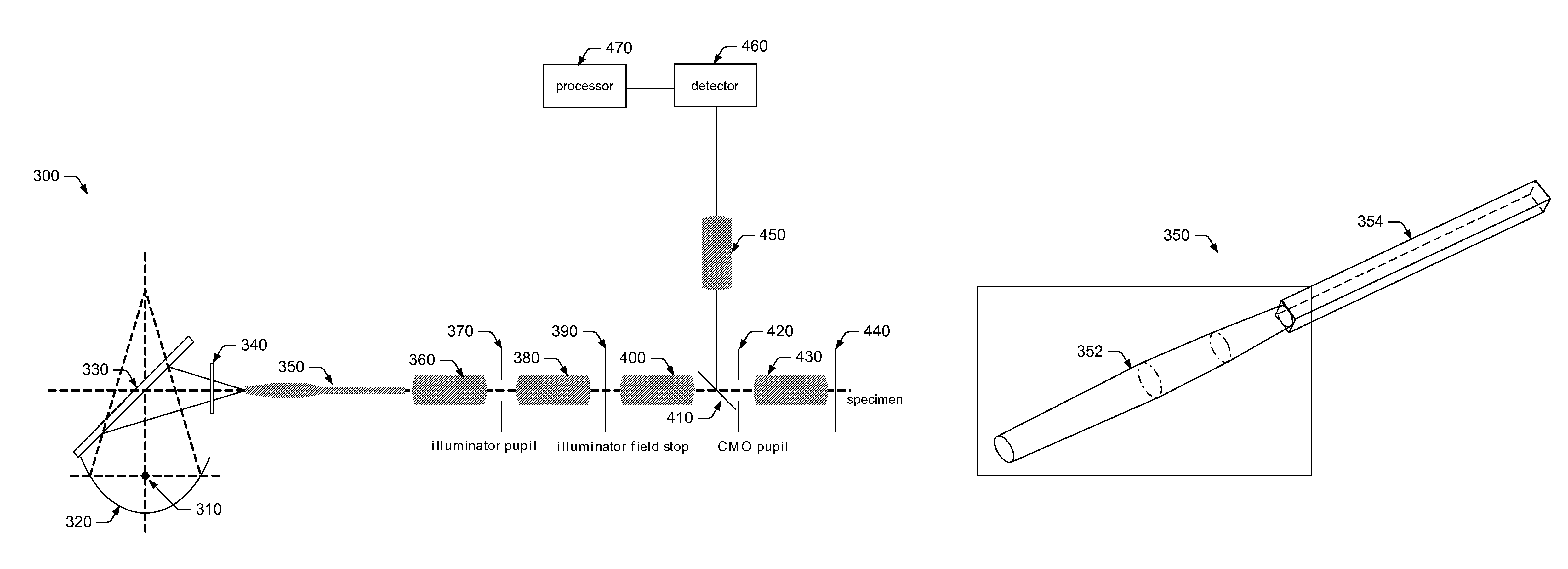

System and method for illuminating a specimen with uniform angular and spatial distribution

ActiveUS7654715B1Large numerical apertureExtensive collectionLighting elementsMaterial analysis by optical meansPupilHomogeneous distribution

A system for illuminating a specimen are disclosed herein. In general, the system may include an illumination source configured to generate light with an uneven distribution at a pupil plane and field stop of the system, a lightpipe coupled for redistributing the light across the pupil plane and field stop, and at least one optical element configured to direct the redistributed light onto a specimen. The lightpipe may generally include a cone-shaped portion and a rectangular-shaped portion. The cone-shaped portion is configured for modifying an angular distribution of the generated light, so that the redistributed light is uniformly distributed across the pupil plane of the system. The rectangular-shaped portion is formed contiguous with the cone-shaped portion and configured for modifying a spatial distribution of the generated light, so that the redistributed light is uniformly distributed across a field stop of the system. A method for illuminating a specimen and a system for inspecting a specimen are also disclosed herein.

Owner:KLA TENCOR TECH CORP

Apparatus for disinfecting or sterilizing a catheter and method of use

ActiveUS9492574B2High strengthDisinfect connectorOther blood circulation devicesCatheterMedicineCatheter device

An elliptical-shaped housing contains a UV light source and a power source. A connector is removably mounted in the housing and is disinfected or sterilized by UV light. A reflective coating inside the housing enhances the intensity of the UV light to disinfect or sterilize the connector.

Owner:PURACATH MEDICAL

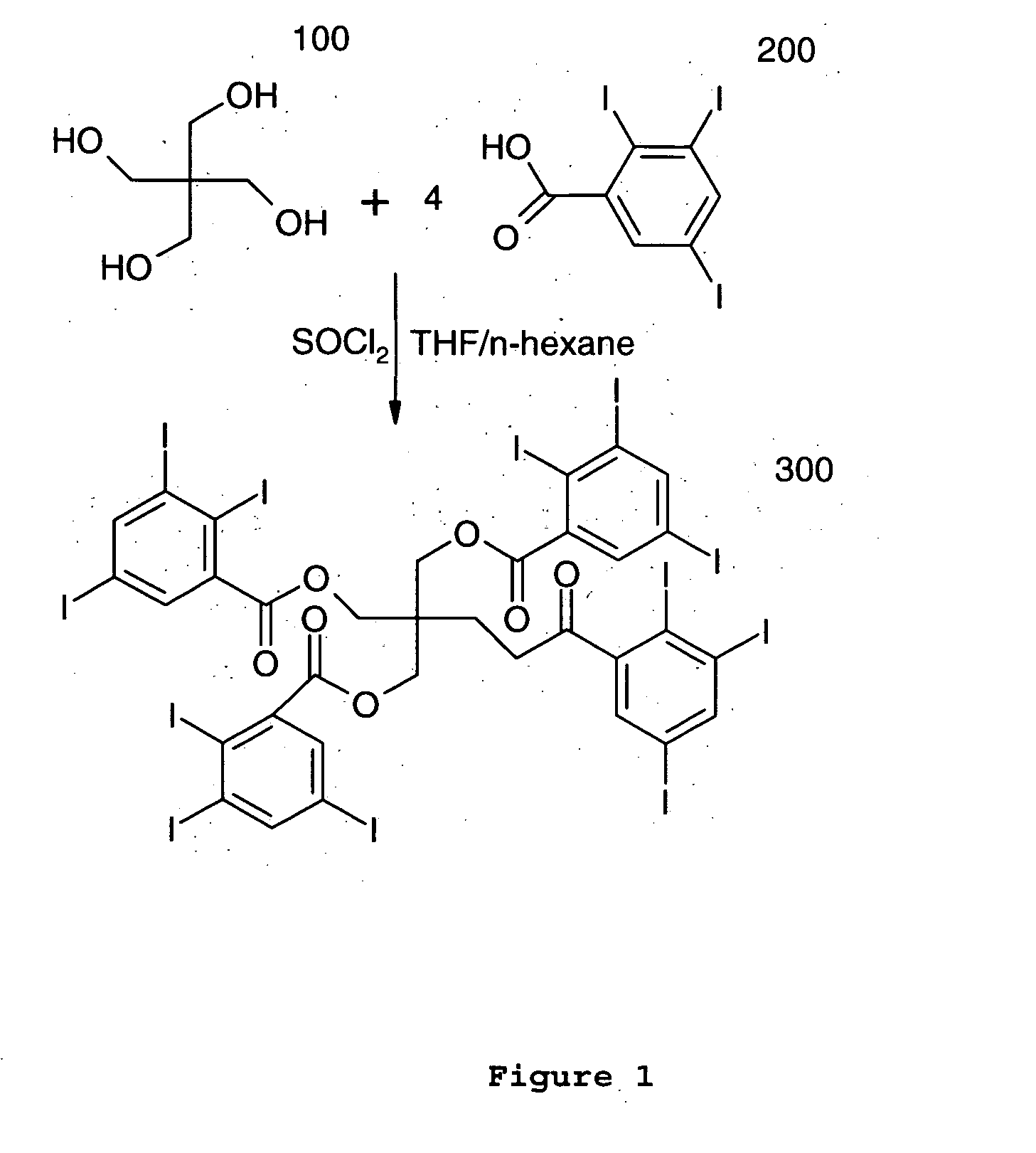

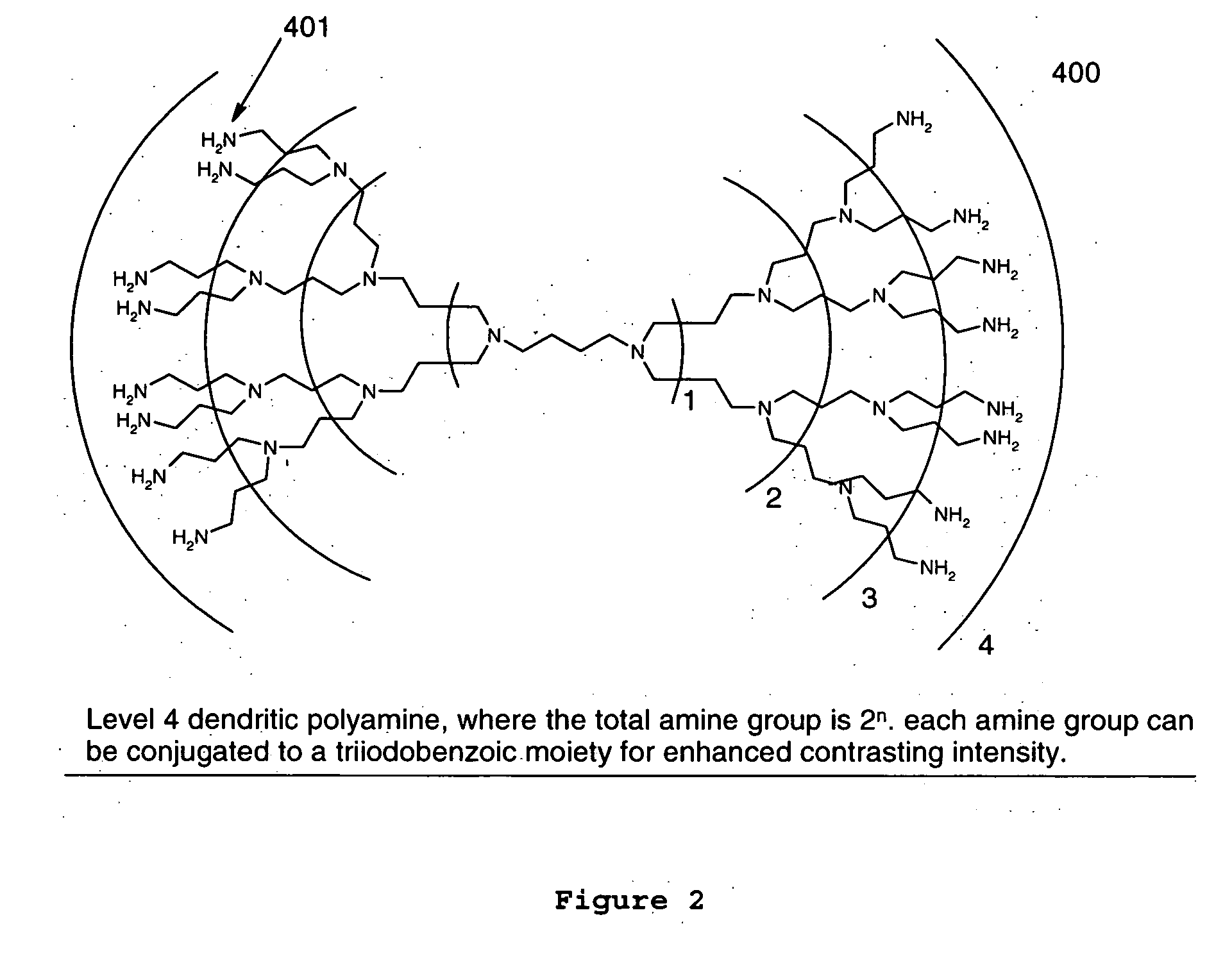

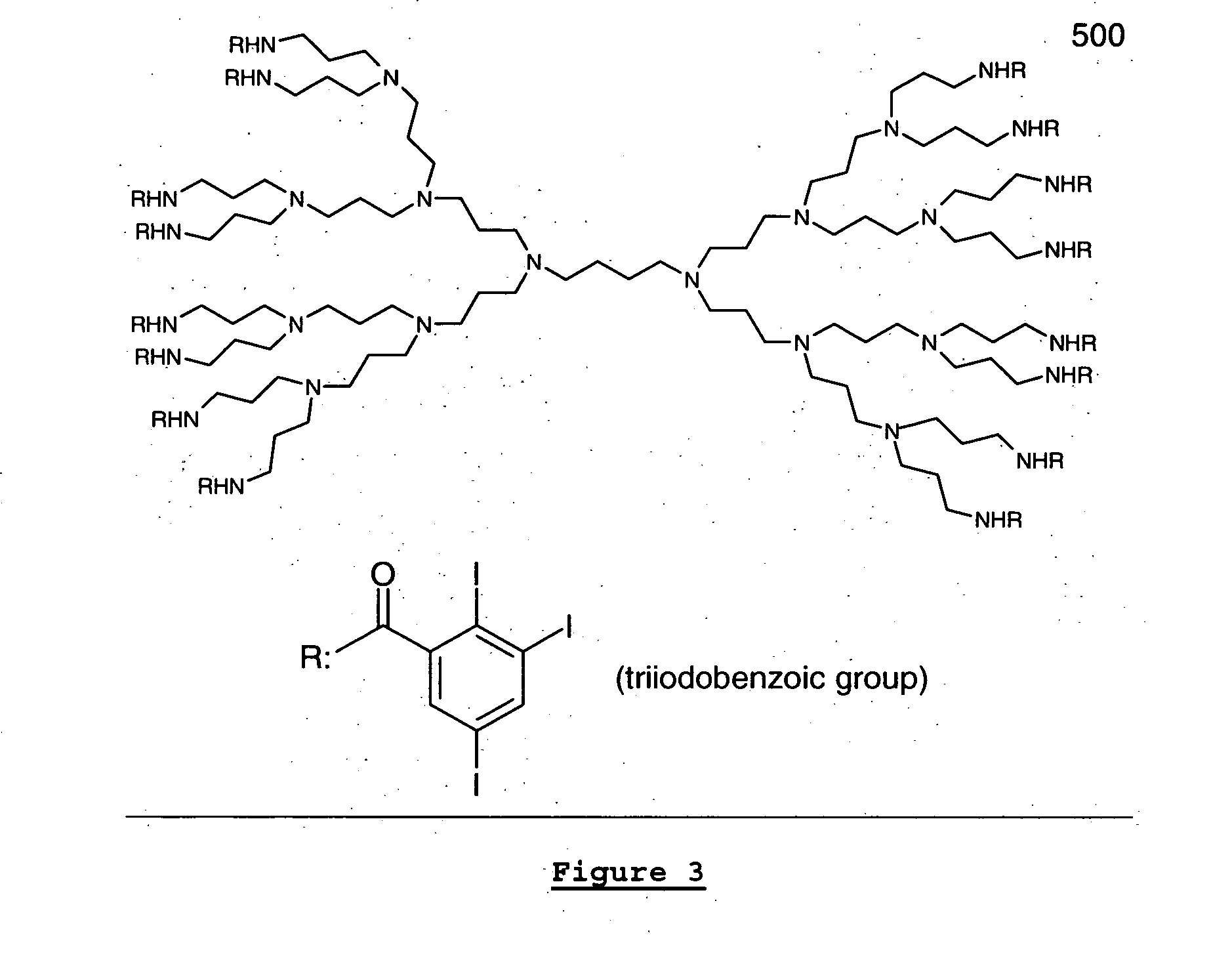

Dendritic and star-shaped contrast agents for medical devices and bioabsorbable radiopaque bulk material and method for producing same

InactiveUS20060292077A1Easy loadingPrevent thrombosisOrganic active ingredientsSurgeryDendrimerRadiopaque agent

In accordance with the present invention, a high intensity radiopaque contrast agent is disclosed. The agent may be coated on or incorporated within bulk material which may then be subsequently utilized to fabricate a radiopaque medical device. Primary effects through chemistry include higher radiopaque concentrations per unit weight of the radiopaque element or agent. Secondary effects include selective placement of the radiopaque elements which may further enhance the radiopacity of the device with reduced requirements of the radiopaque agent. Such a radiopaque contrast agent may be produced in various forms such as a dendrimer and / or incorporated as the end groups of polymeric chain. In addition one can incorporate biological and / or pharmaceutical agents in combination with the present invention.

Owner:CORDIS CORP

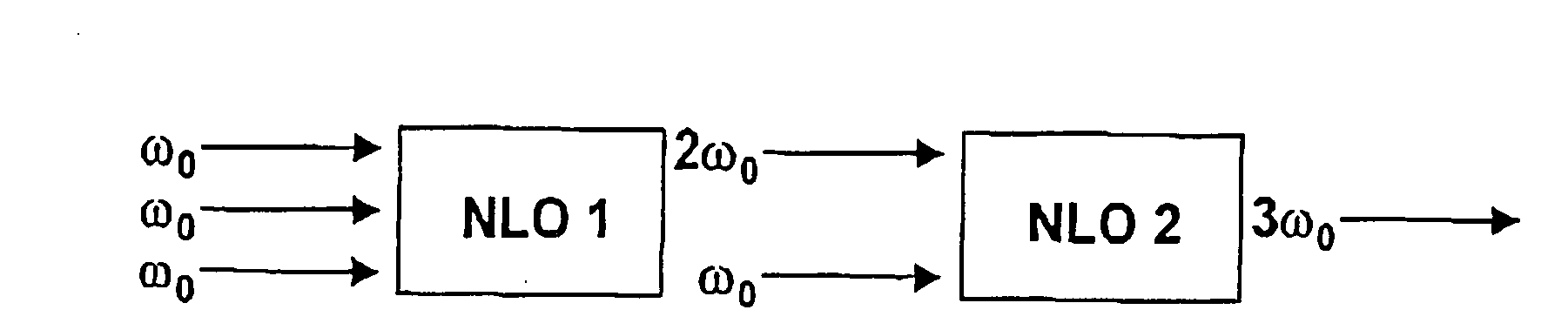

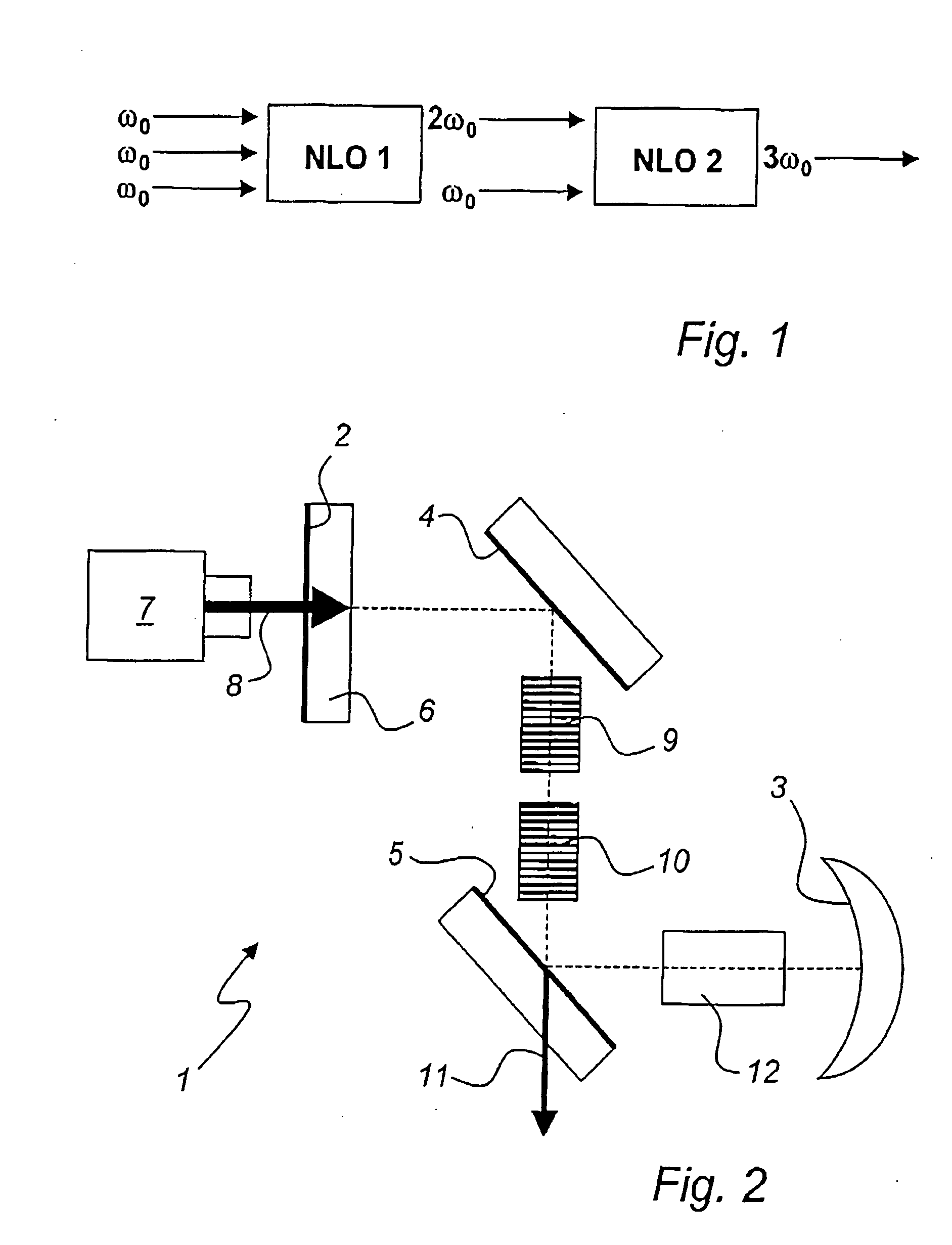

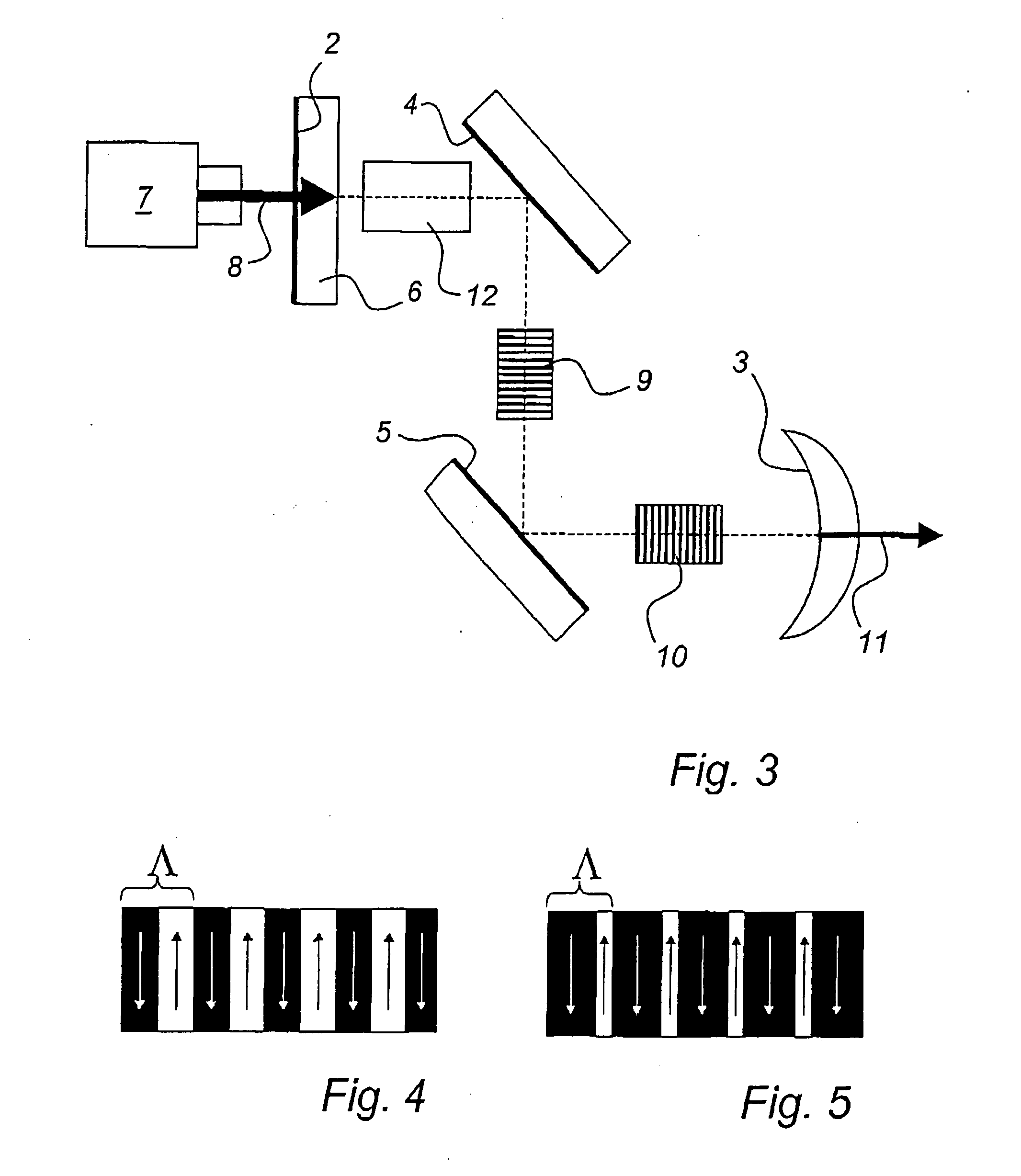

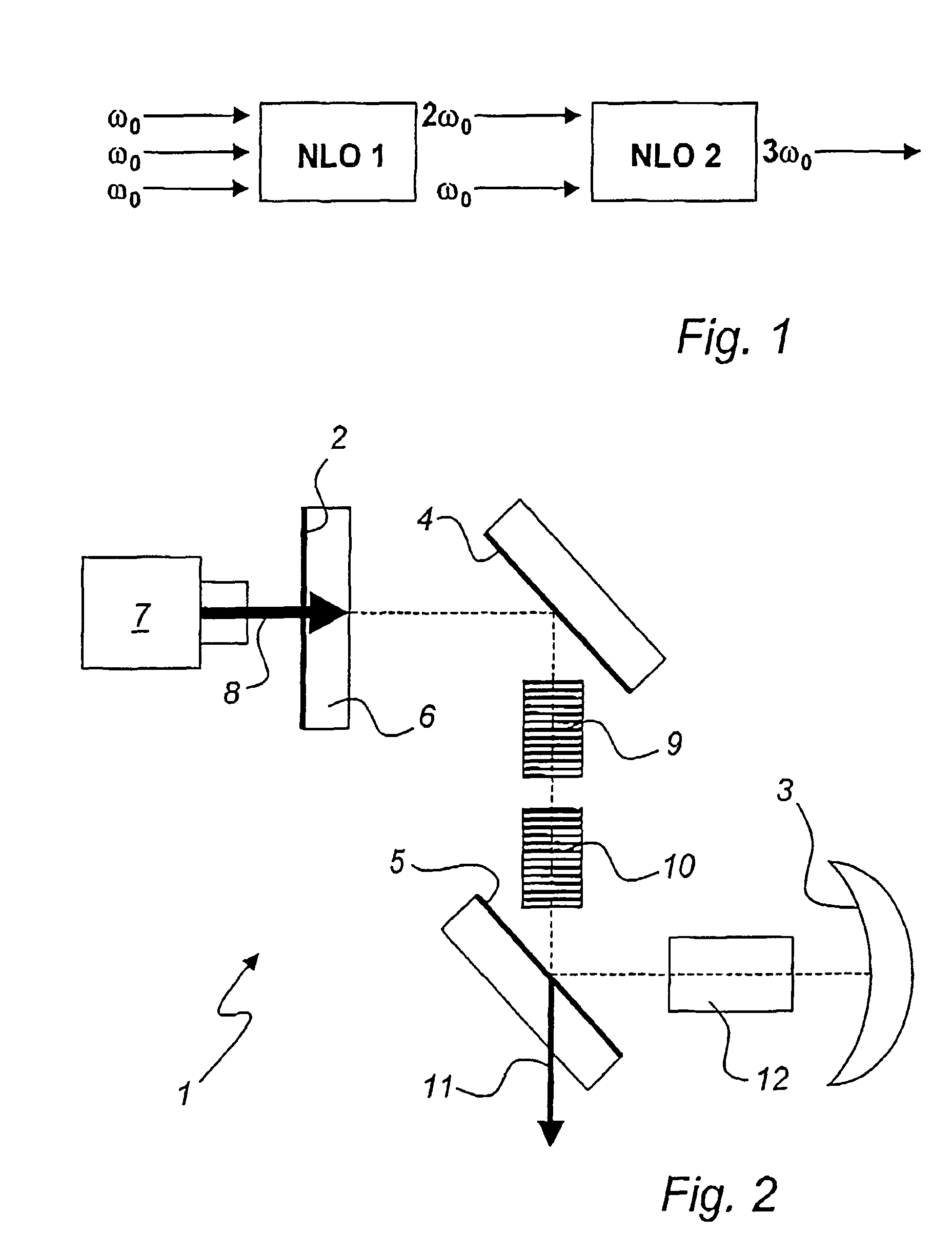

Continuous-wave ultraviolet laser

ActiveUS20080240177A1Increase stability of laserEfficient frequency conversionOptical resonator shape and constructionNon-linear opticsResonant cavityUltraviolet

A laser is disclosed, which is suitable for efficient generation of continuous-wave laser light having a wavelength of about 400 nm or less. The short-wavelength light is generated by first frequency-doubling a fundamental wave, and then sum-frequency mixing the frequency-doubled wave and the fundamental wave. The non-linear interactions are effected by means of quasi-phasematching structures inside a resonant cavity where the fundamental wave is circulating. The sum-frequency mixing is effected using second or higher order quasi-phasematching, which allows for wider domains to be inverted for the quasi-phasematching structure compared to first order quasi-phasematching. Preferably, the sum-frequency mixing is effected using periodically poled stoichiometric lithium tantalate (PPSLT) for second or third order quasi-phasematching.

Owner:COBOLT

Optical system for calibration and control of an optical fiber switch

InactiveUS20050018958A1Reduced insertion lossHigh resolution controlMultiplex system selection arrangementsCoupling light guidesLight beamEngineering

Methods of calibrating and operating optical switches as well as optical switches in which the orientations of mirrors are measured and controlled using control light beams and position sensing detectors are described. The present invention may provide high resolution control of a plurality of mirrors in an optical switch and thus allow the optical switch to cross-connect a large number of input and output ports with a low insertion loss.

Owner:INTEL CORP

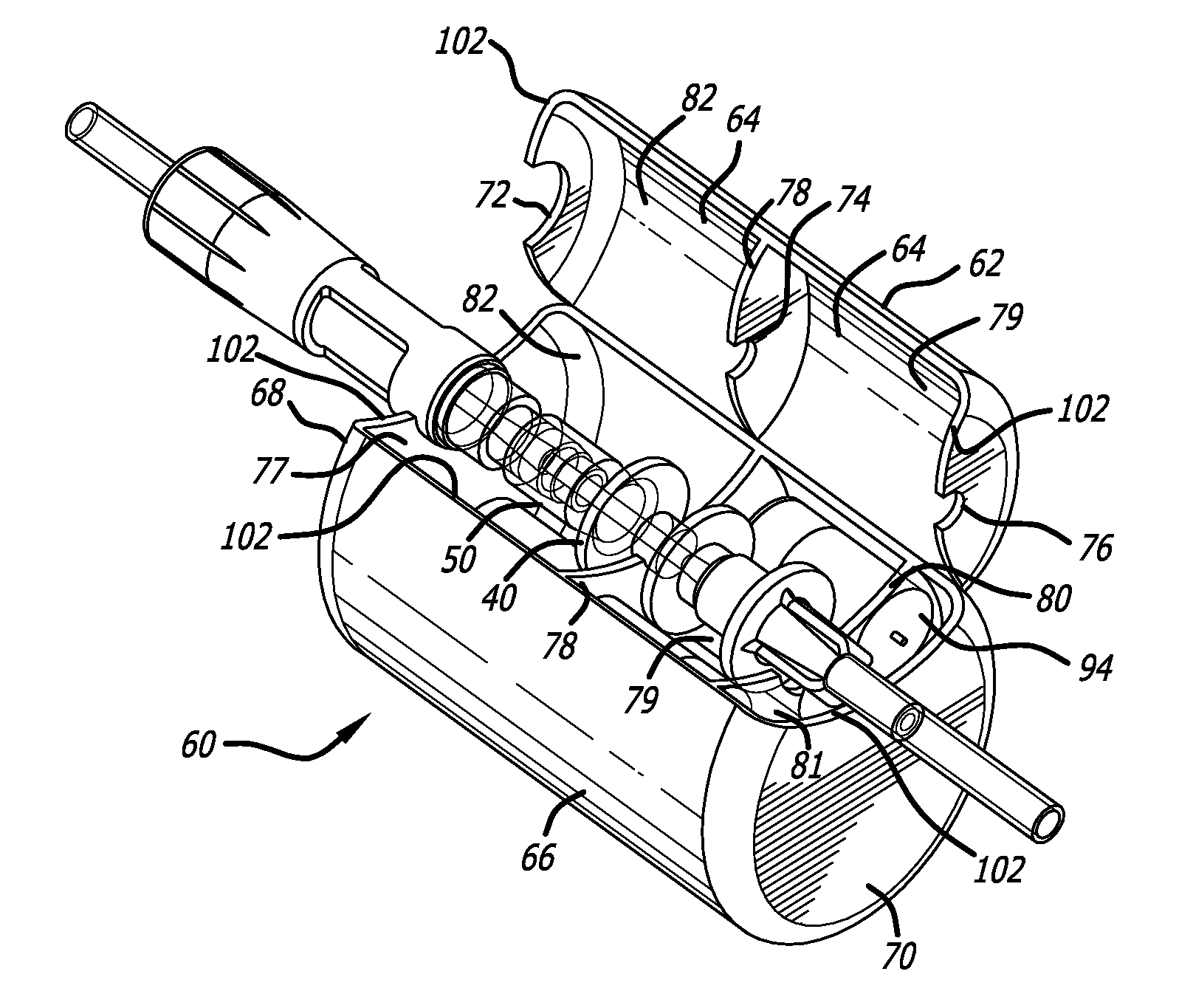

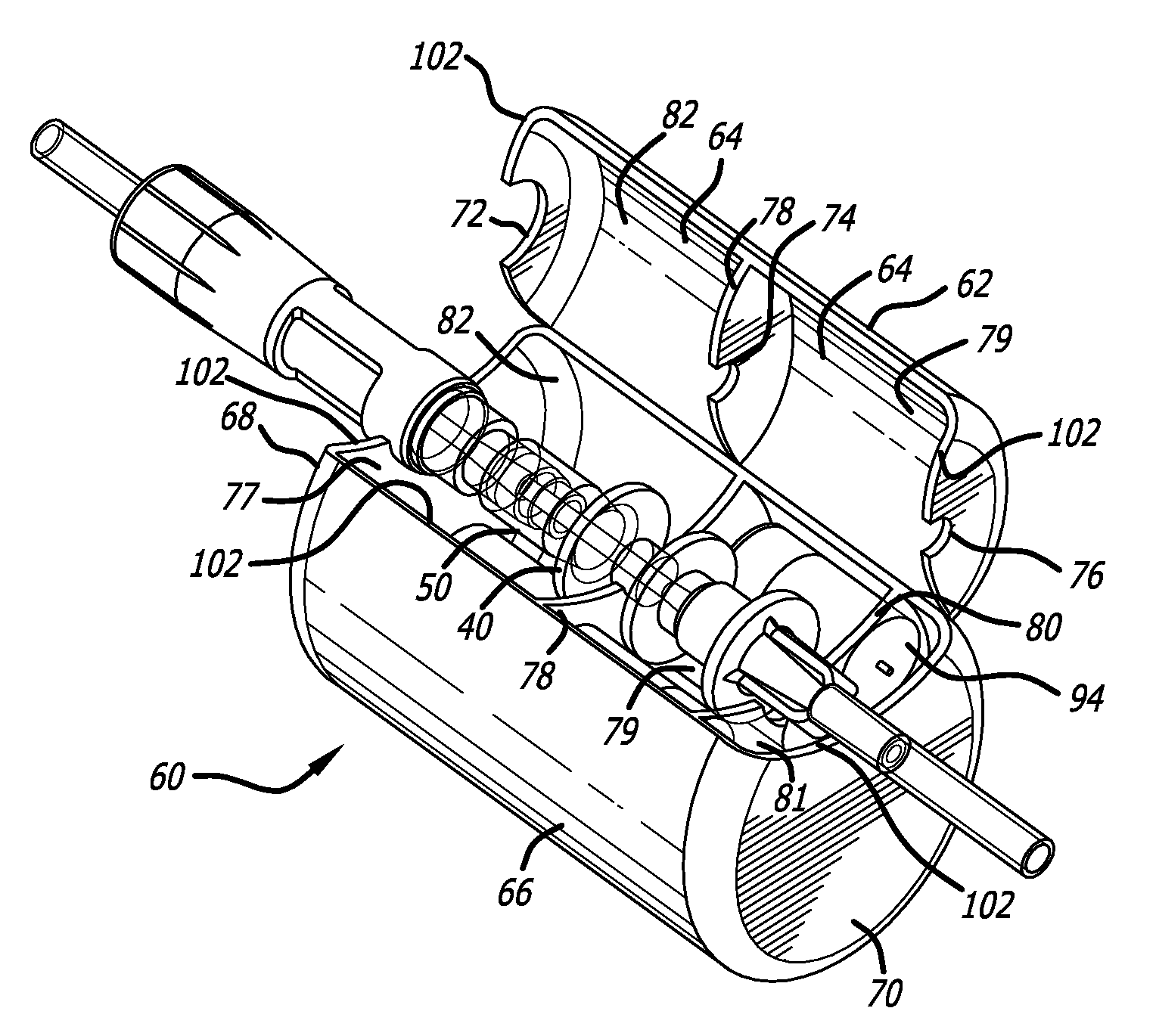

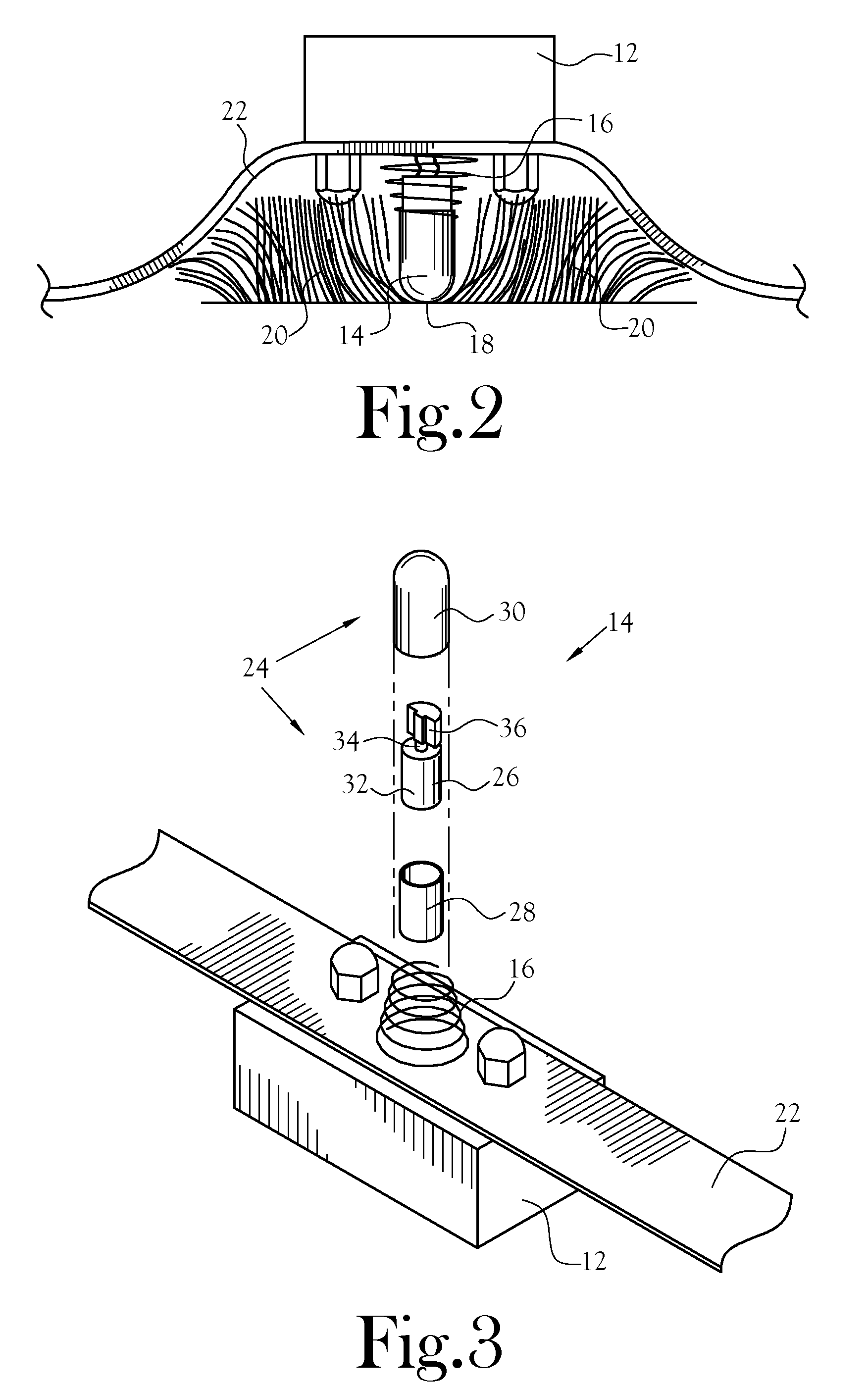

Vibration Stimulus Delivery Device

ActiveUS20080156278A1Maximizing robustnessMaximizing intensityTaming and training devicesCouplingEngineering

Described is a vibration stimulus delivery device for delivering a vibration stimulus to an animal and for maximizing the robustness and intensity of the vibration stimulus. The vibration stimulus delivery device is carried by the animal and includes a housing and a vibration probe. The vibration probe is positioned in direct contact with the skin of the animal and generates a vibration, which, when delivered to the animal, is the vibration stimulus. The vibration probe is coupled to the housing such that the coupling minimizes the inherent vibration dampening effect caused by the weight and mass of the housing. The result is a vibration stimulus delivery device that delivers a more robust and intense vibration stimulus to the animal.

Owner:RADIO SYST CORP

Targeted dual-axes confocal imaging apparatus with vertical scanning capabilities

ActiveUS9921406B2Overcome ambiguityLarge dynamic rangeDiagnostics using tomographySensorsEpitheliumFiber

An optical device is described that may be used as a microscope system for real-time, three-dimensional optical imaging. The device includes a miniature, fiber optic, intra-vital probe microscope that uses a dual-axes confocal architecture to allow for vertical scanning perpendicular to a surface of the sample (e.g., a tissue surface). The optical device can use off-axis illumination and collection of light to achieve sub-cellular resolution with deep tissue penetration. The optical device may be used as part of an integrated molecular imaging strategy using fluorescence-labeled peptides to detect cell surface targets that are up-regulated by the epithelium and / or endothelium of colon and breast tumors in small animal models of cancer.

Owner:RGT UNIV OF MICHIGAN

LED lighting array for a portable task lamp

ActiveUS20080144316A1Maximizing intensityLight weightElectric lighting for hand-held usePlanar light sourcesElectricityPulsed DC

An LED lighting array is disclosed wherein a plurality of light emitting devices disposed in at least first and second columns are mounted on a planar mounting surface to form an emission plane. The emission axes of all the LEDs in a first column are parallel with each other and lie in a first plane. The emission axes of the LEDs in an adjacent, second column are also parallel, but a second plane containing the emission axes of the second column is disposed at a predetermined, non-zero angle with respect to the first plane. The non-zero angle is a function of the LED beam width and the distance to a lighting target. This configuration of the LEDs provides an optimum balance at a predetermined target distance between the size of the area illuminated and the brightness of the illumination of the target. In one aspect of the invention the LED lighting array includes at least first, second and third columns of LEDs. In another aspect of the invention an LED task light includes a transparent tube and an LED lighting array disposed within the tube. An electrical drive circuit associated with the mounting substrate within the tube provides pulsed direct current for driving the LED's.

Owner:BAYCO PRODS

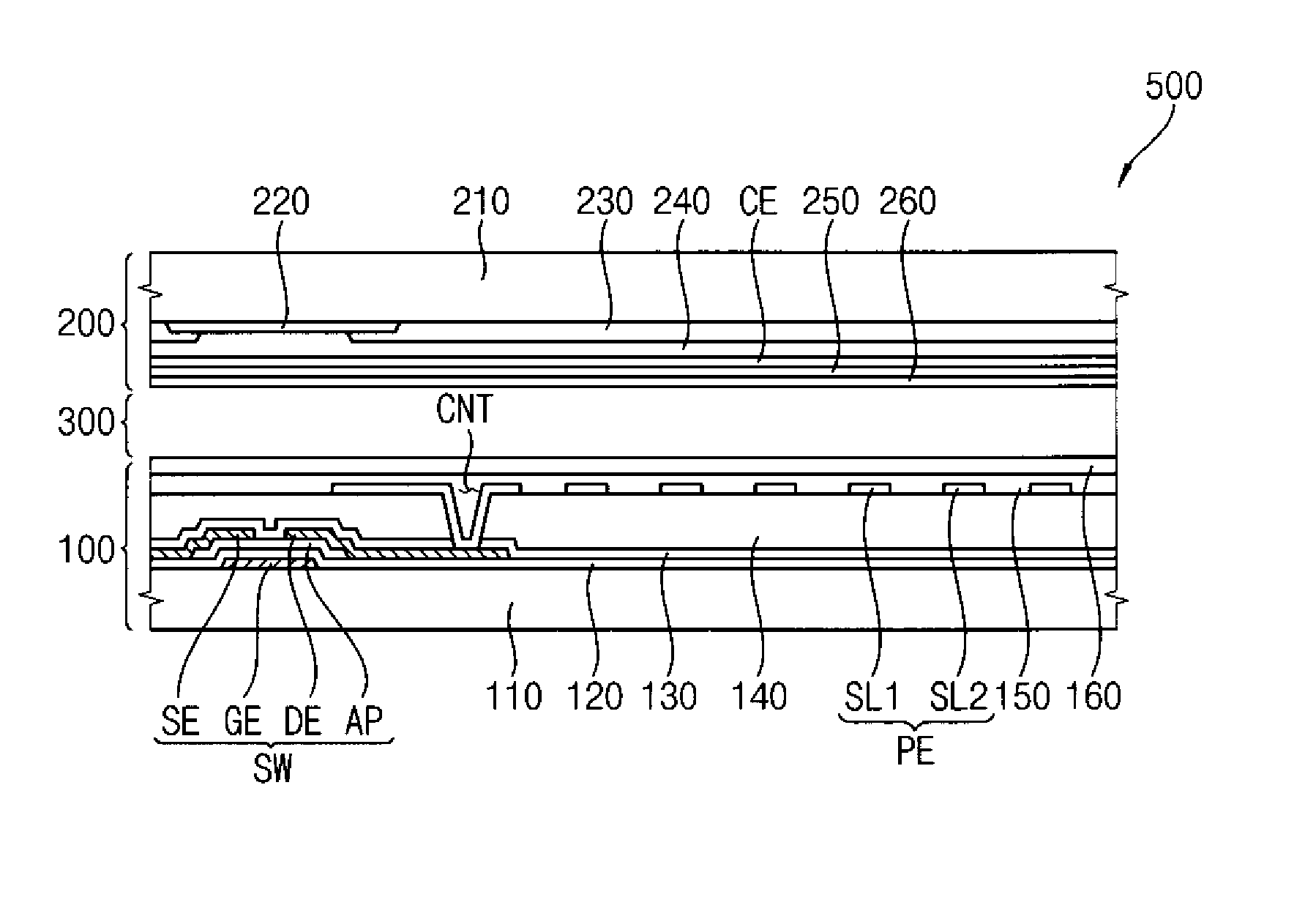

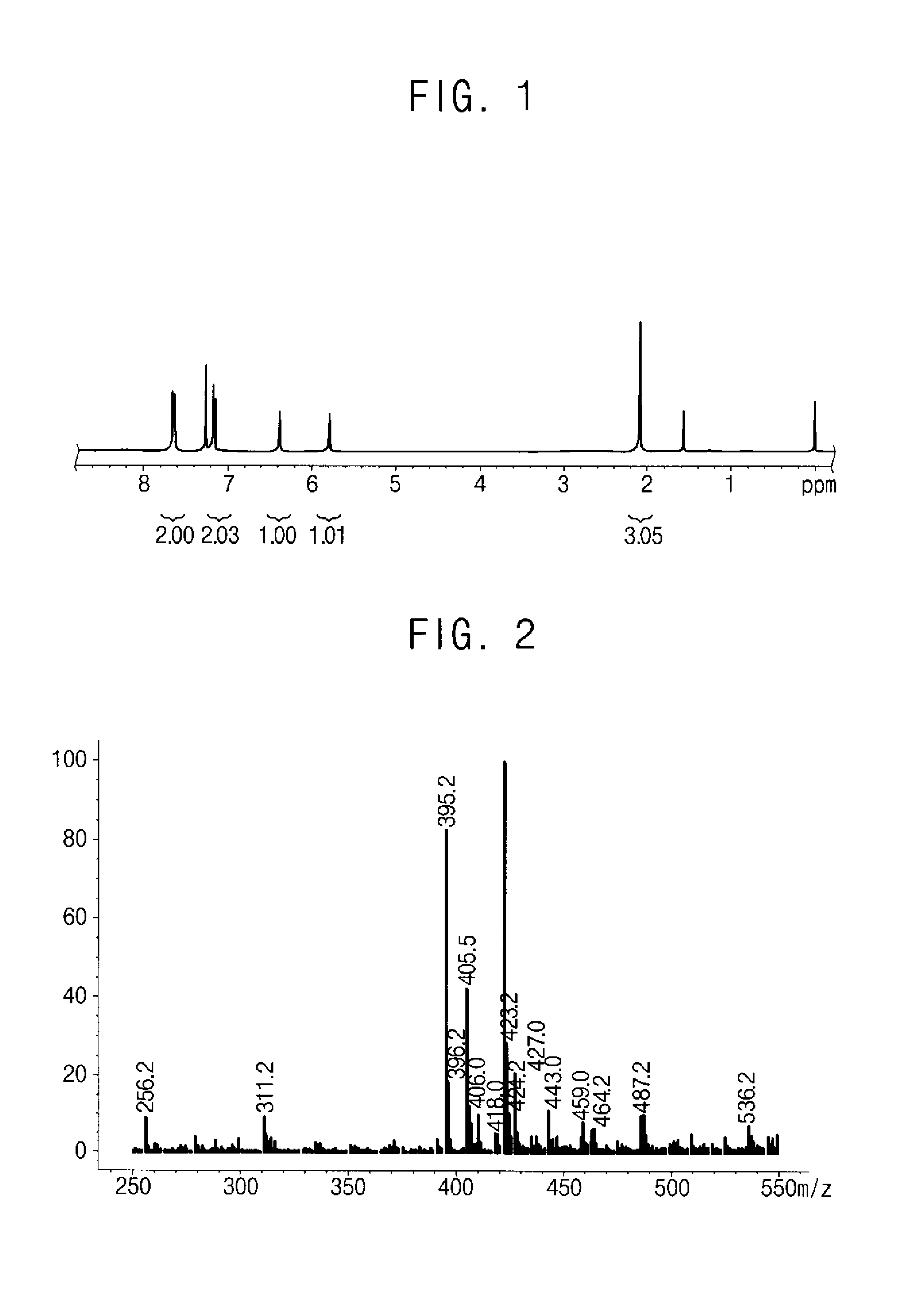

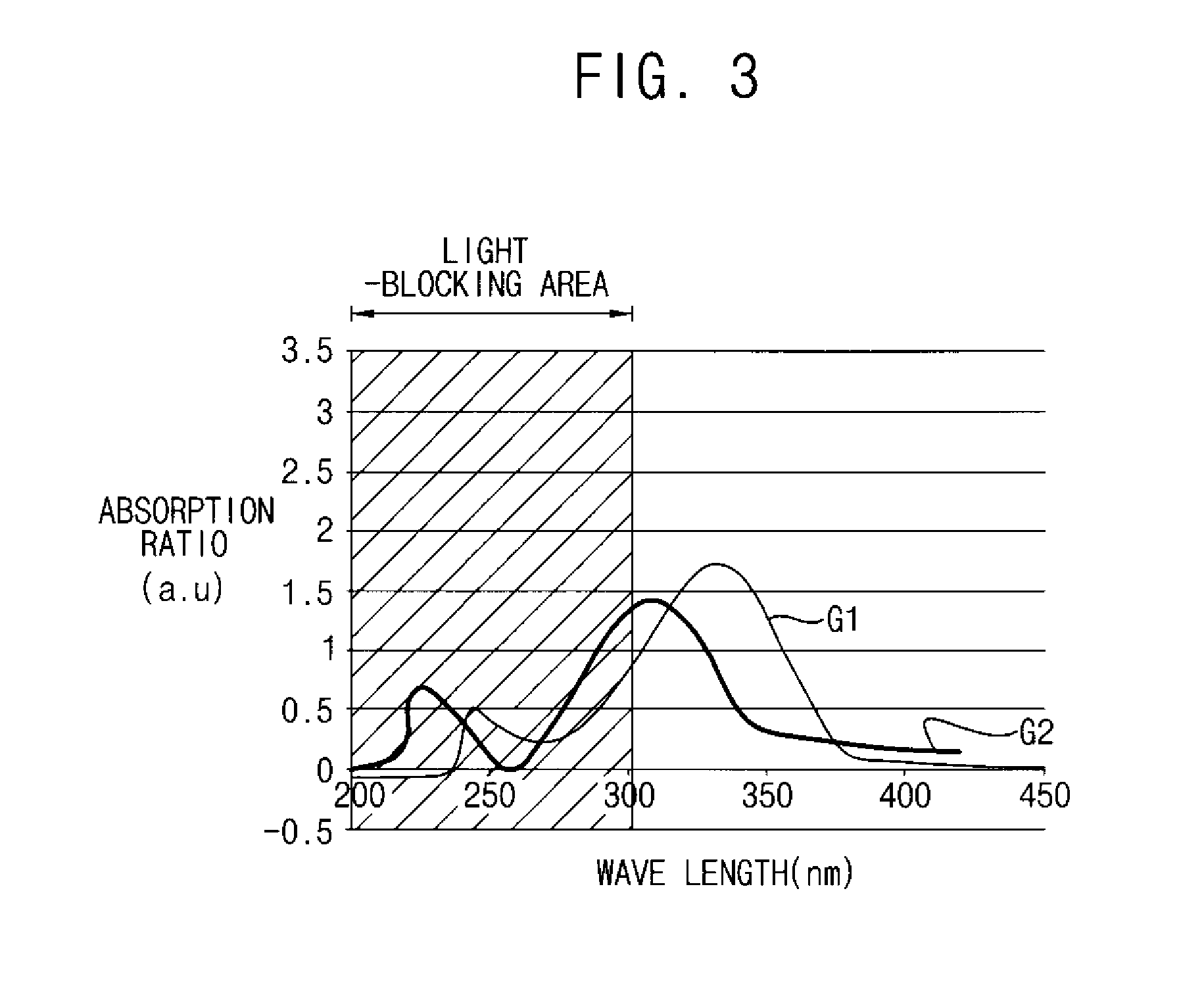

Reactive mesogen compound, liquid crystal composition including the same, method of manufacturing a display panel, and display panel

InactiveUS20130208222A1Effective compoundReduce polymerization timeLiquid crystal compositionsOrganic chemistryLength waveMesogen

A reactive mesogen compound, a liquid crystal composition including the reactive mesogen compound, a method of manufacturing a display panel, and a display panel are disclosed. The reactive mesogen compound may be activated by light having a wavelength between about 300 nm and about 700 nm.

Owner:SAMSUNG DISPLAY CO LTD

Aquarium with adjustable lighting

ActiveUS8727554B2Improve the display effectMaximizing intensityMechanical apparatusLight source combinationsFluorescenceEffect light

An aquarium having an adjustable lighting system for enhancing the display of fluorescent objects, such as fluorescent fish, contained within the aquarium under various external lighting conditions, such as a dark room or a brightly lit room. The aquarium comprises a tank and a plurality of light sources. Each light source emits light at a different wavelength spectrum which is selected to enhance the display of the fluorescent object under each type of external lighting condition. An electronic control is provided to control the operation of the plurality of light sources such that each light source may be selectively turned on / off based on the external lighting condition, or chronological criteria, to provide the best viewing experience.

Owner:GLOFISH LLC

Continuous-wave ultraviolet laser

ActiveUS7801188B2Promote generationSimple and reliable processOptical resonator shape and constructionNon-linear opticsResonant cavityUltraviolet

Owner:COBOLT

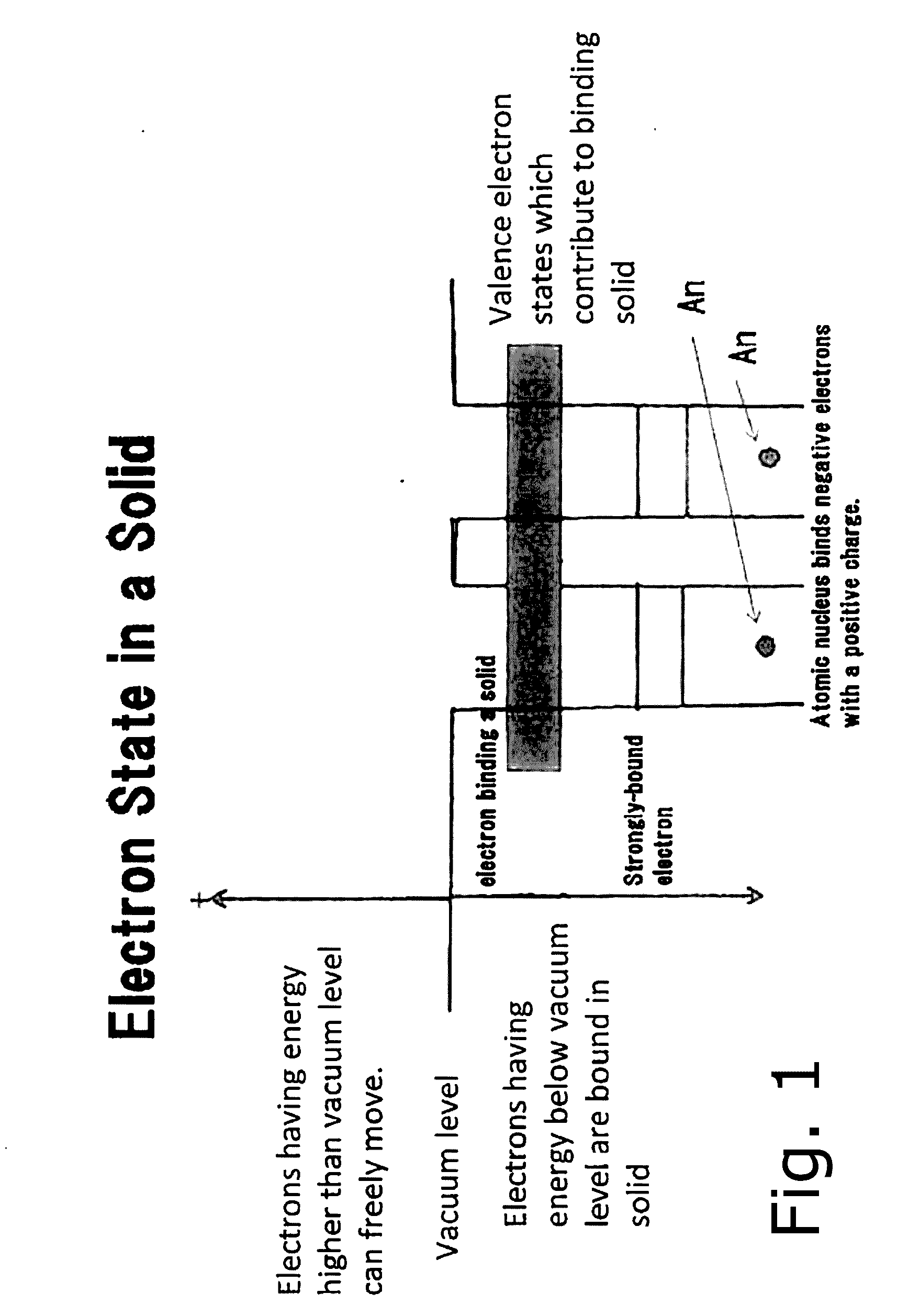

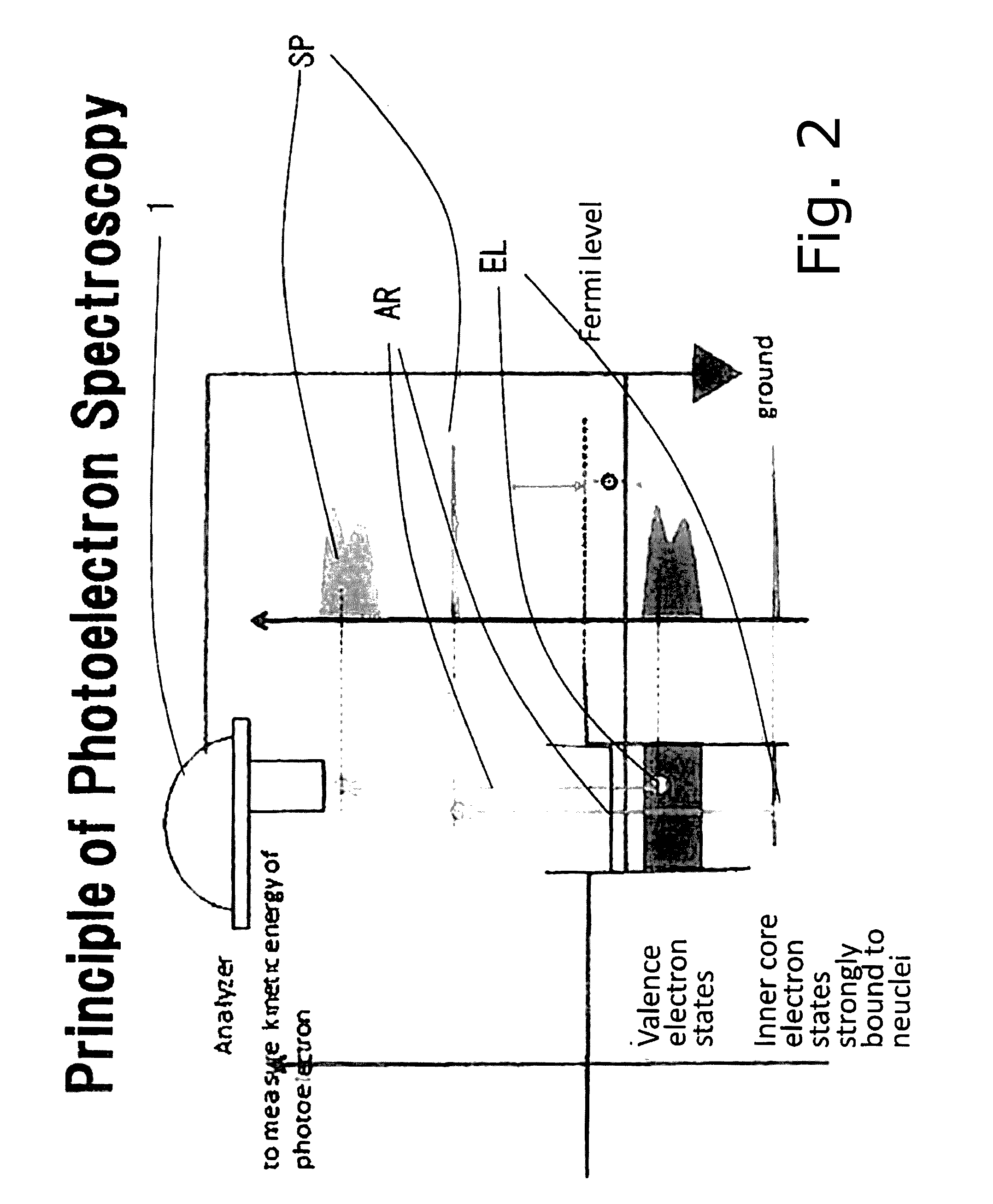

Hard X-Ray Photoelectron Spectroscopy Apparatus

InactiveUS20160327499A1Increase productionIncrease photoelectron collection efficiencyMaterial analysis by measuring secondary emissionHard X-raysFocal position

[Problem]The present invention aims to solve the problems that size of X-ray monochromater crystal assembly is restricted and the vacuum of the X-ray source and the vacuum of the analysis chamber cannot be separated.[Solution]A hard X-ray photoelectron spectroscopy apparatus comprises an X-ray source, an analyzer, a sample manipulator, an analysis chamber, and vacuum evacuation systems, wherein, in a three-dimensional space defined by a XYZ rectangular coordinate axis system, a plate-like sample is arranged to be rotatable around the Z-axis by said sample manipulator (2), wherein said X-ray source comprises an electron gun (3b) which accelerates and focuses electrons, a target which is irradiated with the electrons accelerated and focused by the electron gun to generate an X-ray, monochromater crystal assembly, wherein the monochromater crystal assembly meets the Bragg condition of X-ray diffraction in X-Y plane to diffract / reflect and monochromatize the X-ray generated in said target and extract characteristic X-rays only, and on the other hand, the electron-beam-irradiation position on the target-center of the monochromater crystal assembly-center of the sample is arranged on the Rowland circle to minimize focusing aberration to the sample, the monochromater crystal assembly is located on a circle having a radius twice as large as that of the Rowland circle in a X-Y plane, preferably electron-beam-irradiation position on said target and the center of the sample are located on each of two focuses of an ellipse coming in contact with said Rowland circle in the center of the monochromater crystal assembly, said monochromater crystal assembly has a toroidal surface in Z axial direction acquired by rotating said ellipse coming in contact with said Rowland circle around a straight line connecting the electron-beam-irradiation position on said target and the center of the sample, and, a vacuum vessel for installing these components, wherein the monochromater crystal assembly used for monochromatization with diffraction and reflection of said X-ray source is located on the Rowland circle together with said target and said sample to meet the condition that the dispersed X-ray beam concentrates on the surface of the sample with the minimum aberration, wherein said Rowland circle is located to be orthogonal to the surface of the sample, wherein an optical axis of said analyzer is placed to be perpendicular (in X axial direction) to the incident direction (in Y axial direction) of the X-ray or within a range of ±36 degree angle in a X-Y plane and within a range of ±49 degree angle in a X-Z plane, wherein the sample is such that said X-ray diffracted and reflected by a reflection surface is located on focus positions on the surface of said sample and is obliquely incident on the surface of said sample, so that the spot of said X-ray elongatedly extends along a line in substantially parallel to Y axis (substantially perpendicular to X axis), and wherein an aperture of a slit provided at the entrance of said analyzer is arranged in parallel to a direction where said X-ray spot on the sample surface elongatedly extends.

Owner:KOBAYASHI KEISUKE +1

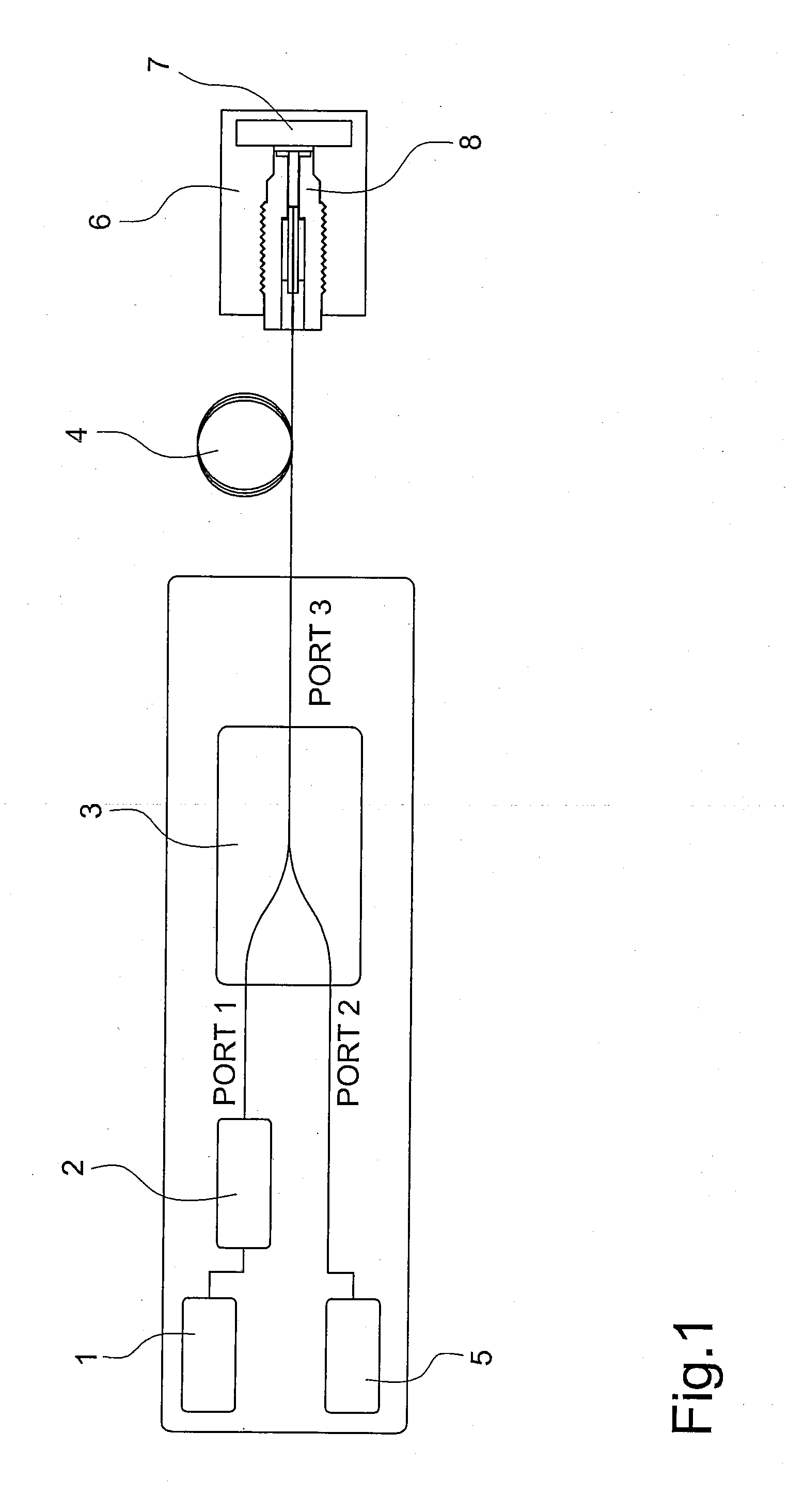

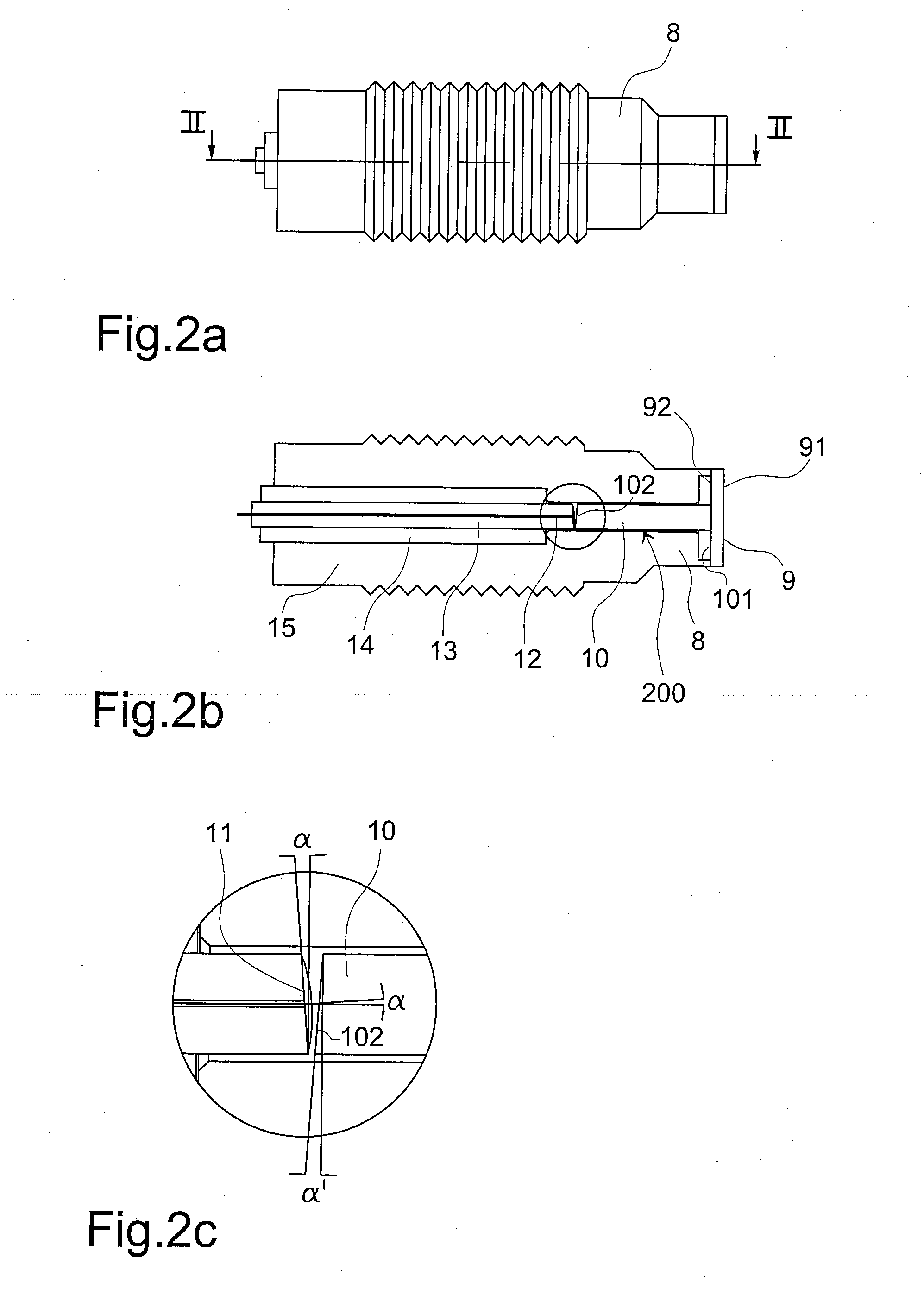

Optical sensor for contactless pressure measurements

ActiveUS20150285699A1Improve reliabilityHarsh environmentFluid pressure measurement using elastically-deformable gaugesUsing optical meansOptical axisLight beam

An optical sensor for pressure measurements is described which comprises a sensor head (8) including: -a diaphragm (9) having a first surface (91) in contact with a fluid of which the pressure has to be measured and a second surface (92) opposite to the first surface, -a body with a tubular cavity (200), -means (92, 10) arranged inside the tubular cavity, associated with the second surface of the diaphragm and movable longitudinally inside said tubular cavity in response to the deformation of the diaphragm, said means including a reflective surface (92, 102), -an end part (12) of waveguide means (4) arranged inside the tubular cavity and having the end surface (11) faced to and not in contact with the reflective surface (92, 102) of said means, said waveguide means being connected to a light source (1) and a receiver (5) respectively to send to said means the light beam (50) deriving from the light source and to collect at the receiver the light beam (60) reflected from the reflective surface of said means, the intensity of the collect light beam being dependent on the distance (D) between the end surface of the end part of waveguide means and the reflective surface. The end surface (11) of the end part (12) of waveguide means is tilted with respect to a plane orthogonal (B) to the optic axis (A) of a first angle (α) having a value such that the incident angle (θa) of the light beam deriving from the light source is less than the critical angle (θc-air) between the waveguide means and the air and greater than the critical angle (θc) of the waveguide means, and the reflective surface (102, 92) of said means is tilted with respect said plane (B) orthogonal to the optic axis (A) of a second angle (β) equal to the escaping angle of the light beam from said end surface (11) of the end part (12) of waveguide means.

Owner:LASERPOINT

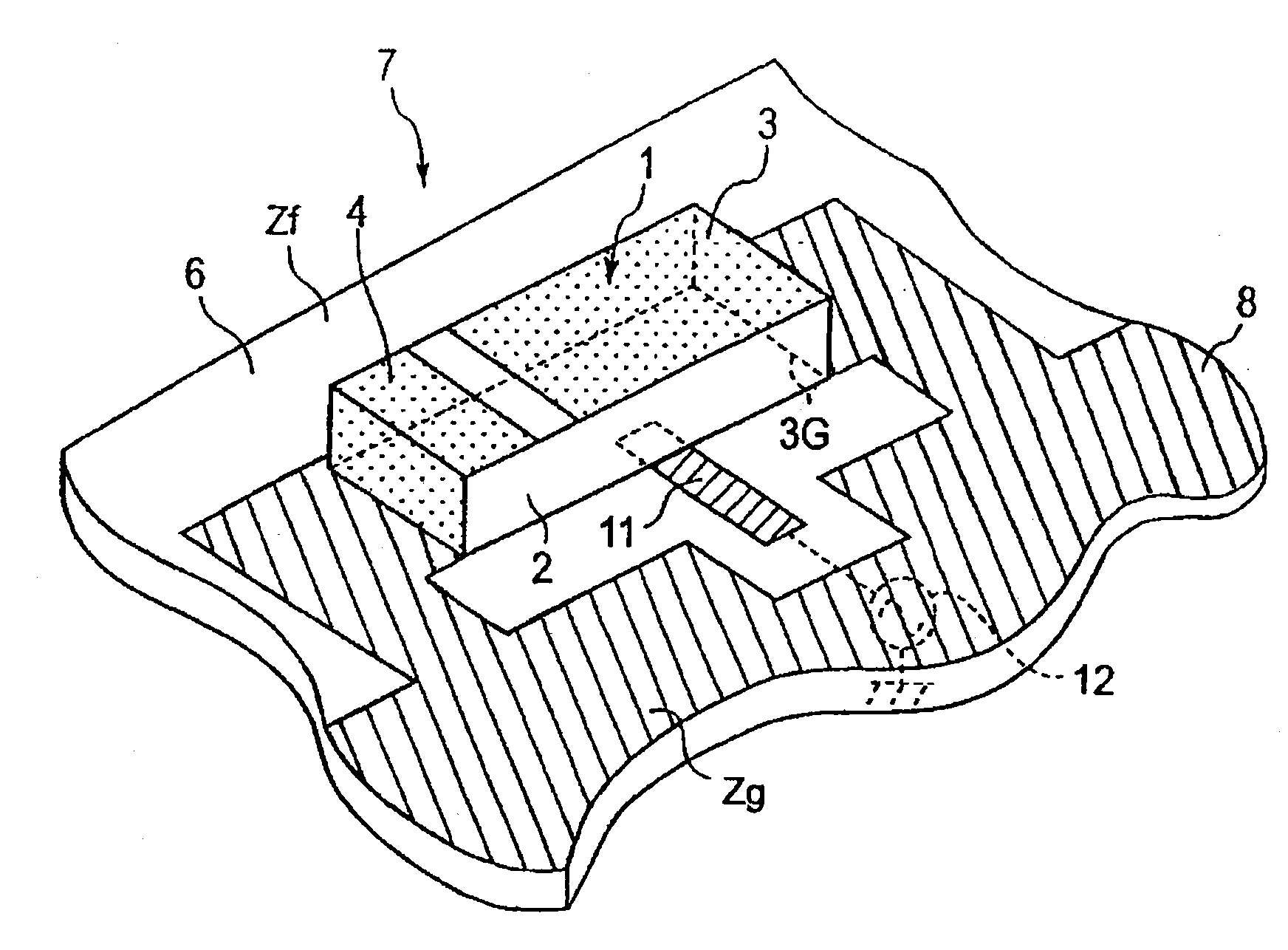

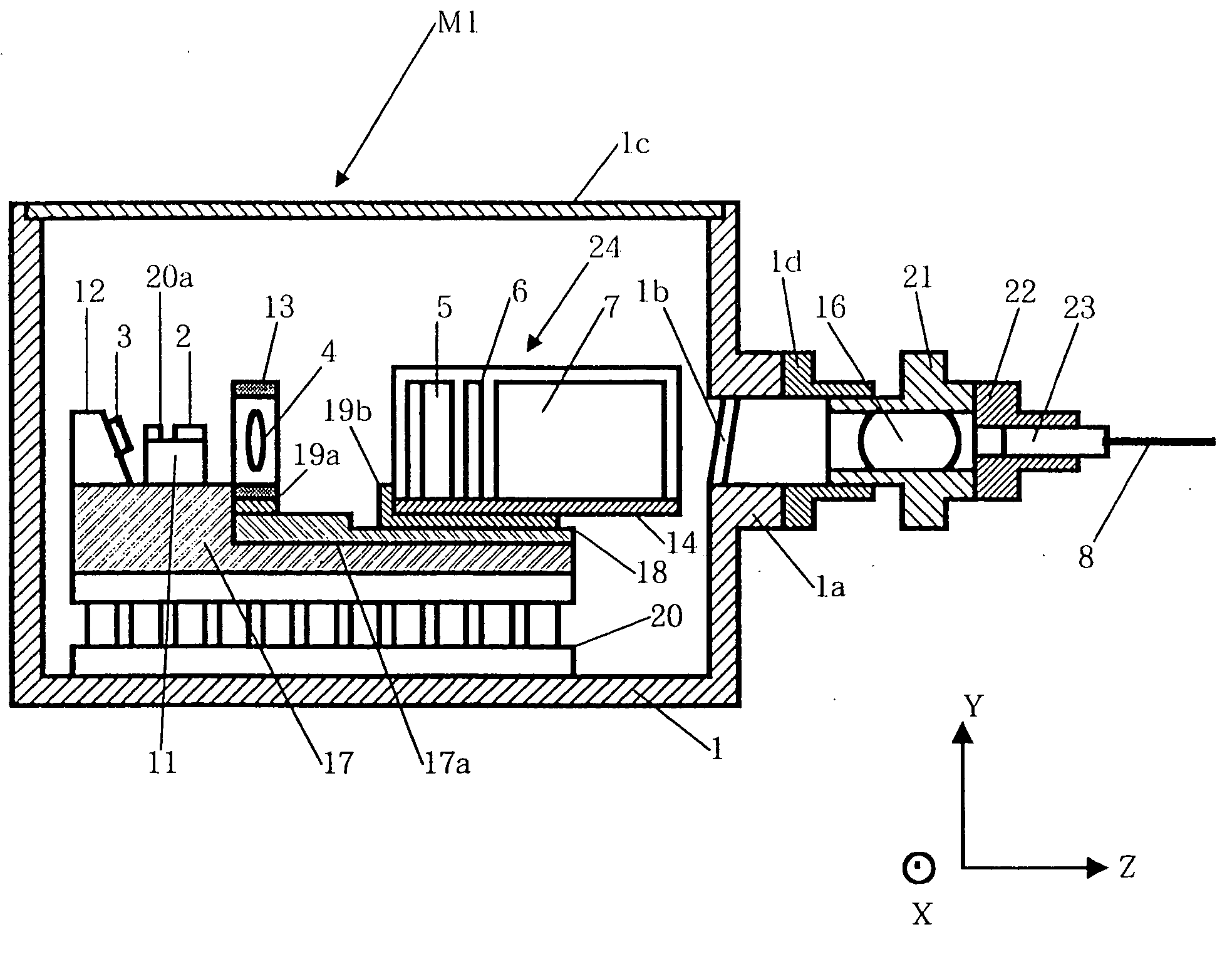

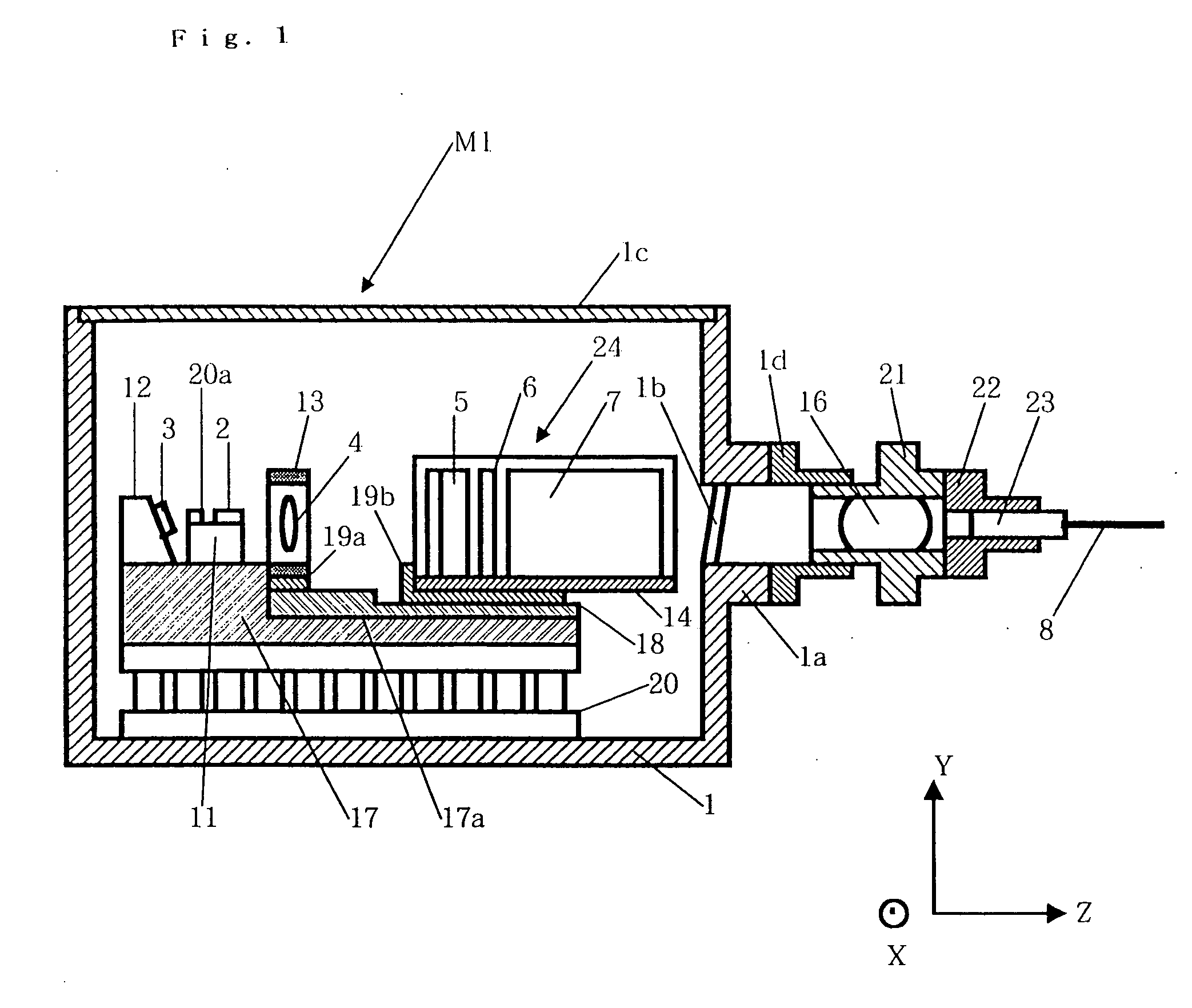

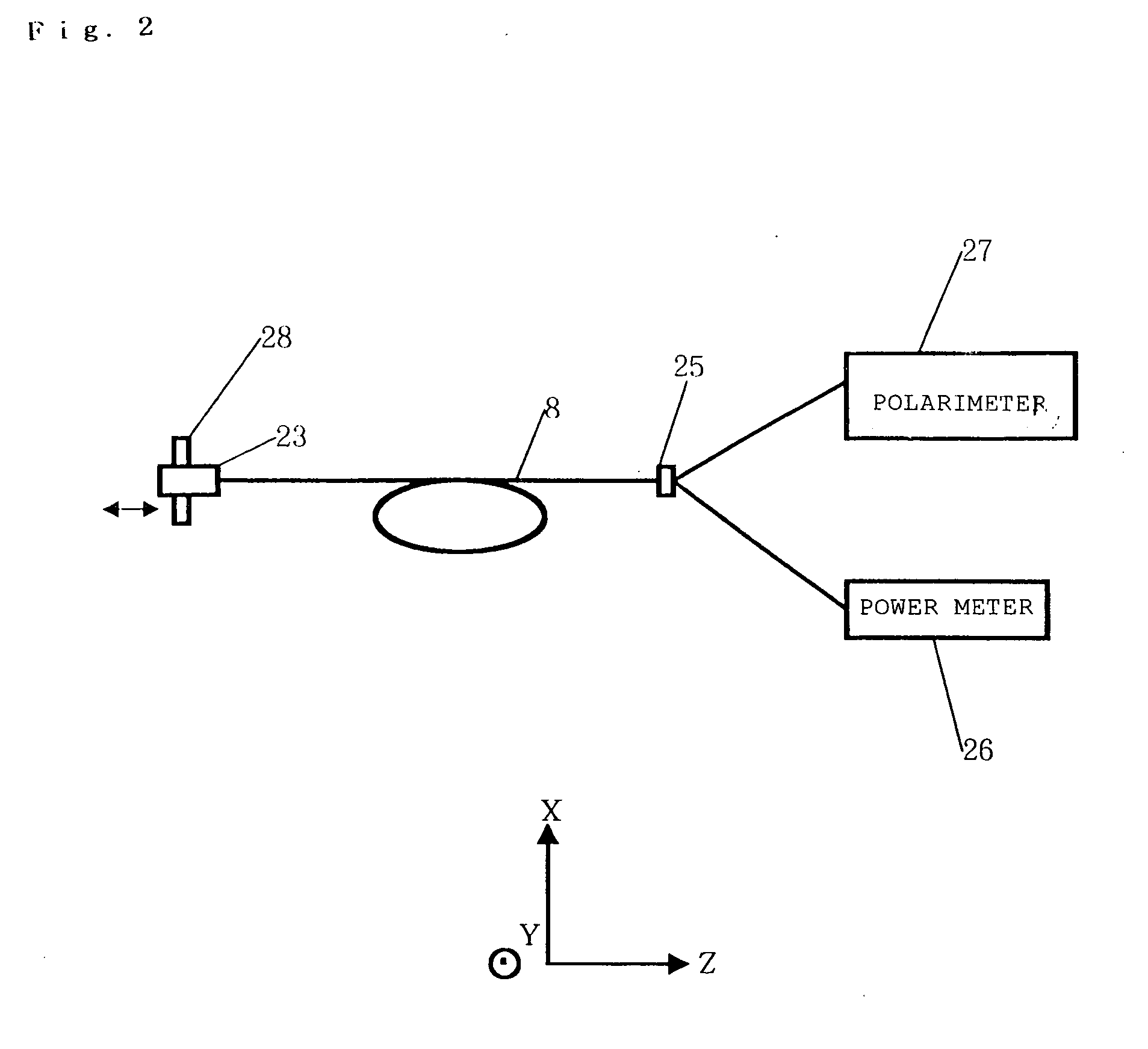

Method of aligning an optical fiber, method of manufacturing a semiconductor laser module, and semiconductor laser module

InactiveUS20050128924A1Maximizing intensityReduce polarizationSemiconductor laser arrangementsSemiconductor laser structural detailsOptical axisPolarimeter

A method of aligning an optical fiber according to the present invention has a first step of aligning an optical fiber by moving the optical fiber and finding a position that maximizes the power of beam outputted from the optical fiber with the use of a power meter, and a second step of moving and aligning the optical fiber in the optical axis direction (direction Z) from the position in which the optical fiber has been as a result of the alignment in the first step in a manner that makes the degree of polarization of two laser beams K1 and K2 equal to or lower than a given level with the use of a polarimeter.

Owner:FURUKAWA ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com