Patents

Literature

146 results about "Autoignition temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

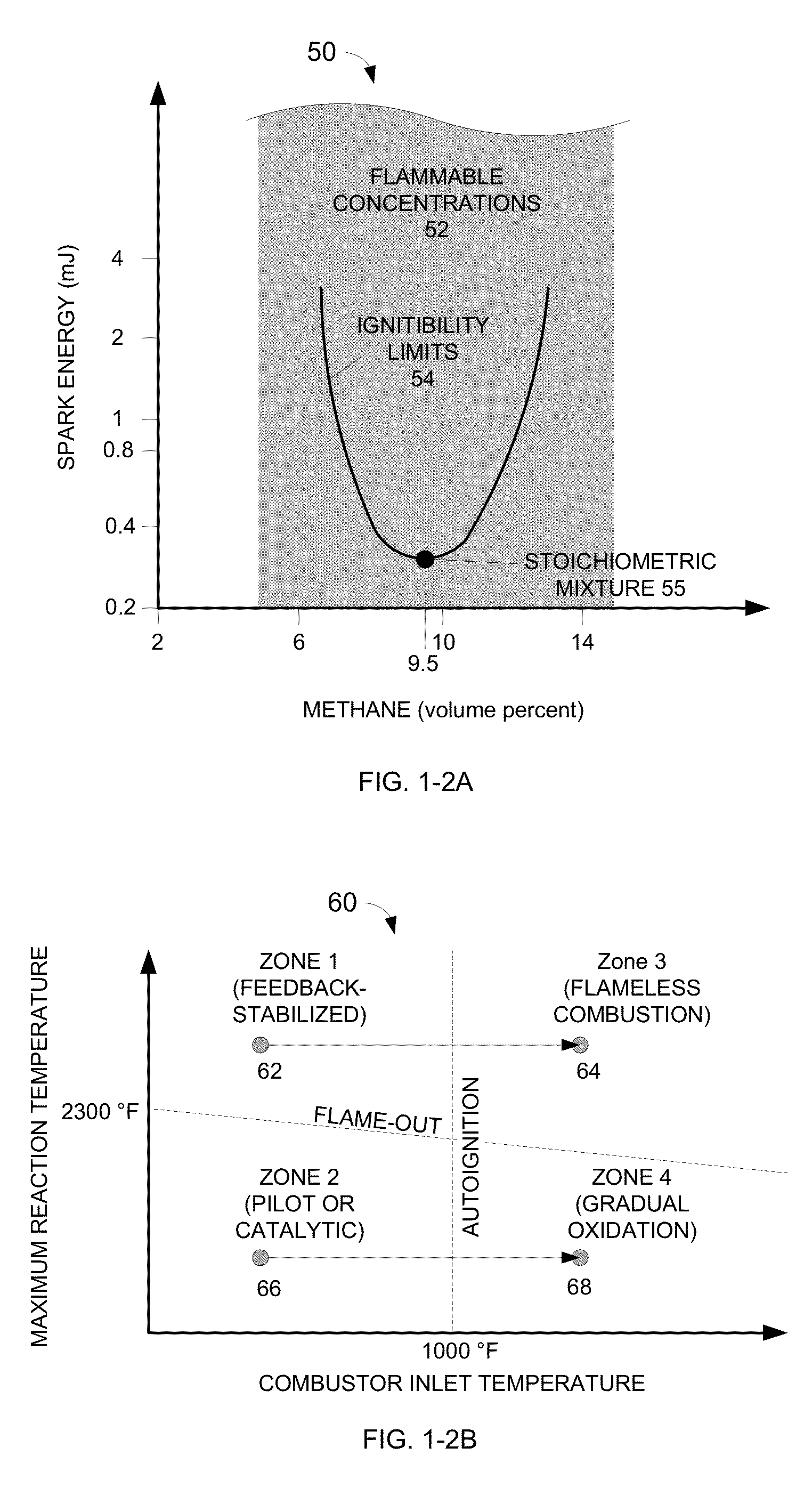

The autoignition temperature or kindling point of a substance is the lowest temperature at which it spontaneously ignites in normal atmosphere without an external source of ignition, such as a flame or spark. This temperature is required to supply the activation energy needed for combustion. The temperature at which a chemical ignites decreases as the pressure or oxygen concentration increases. It is usually applied to a combustible fuel mixture.

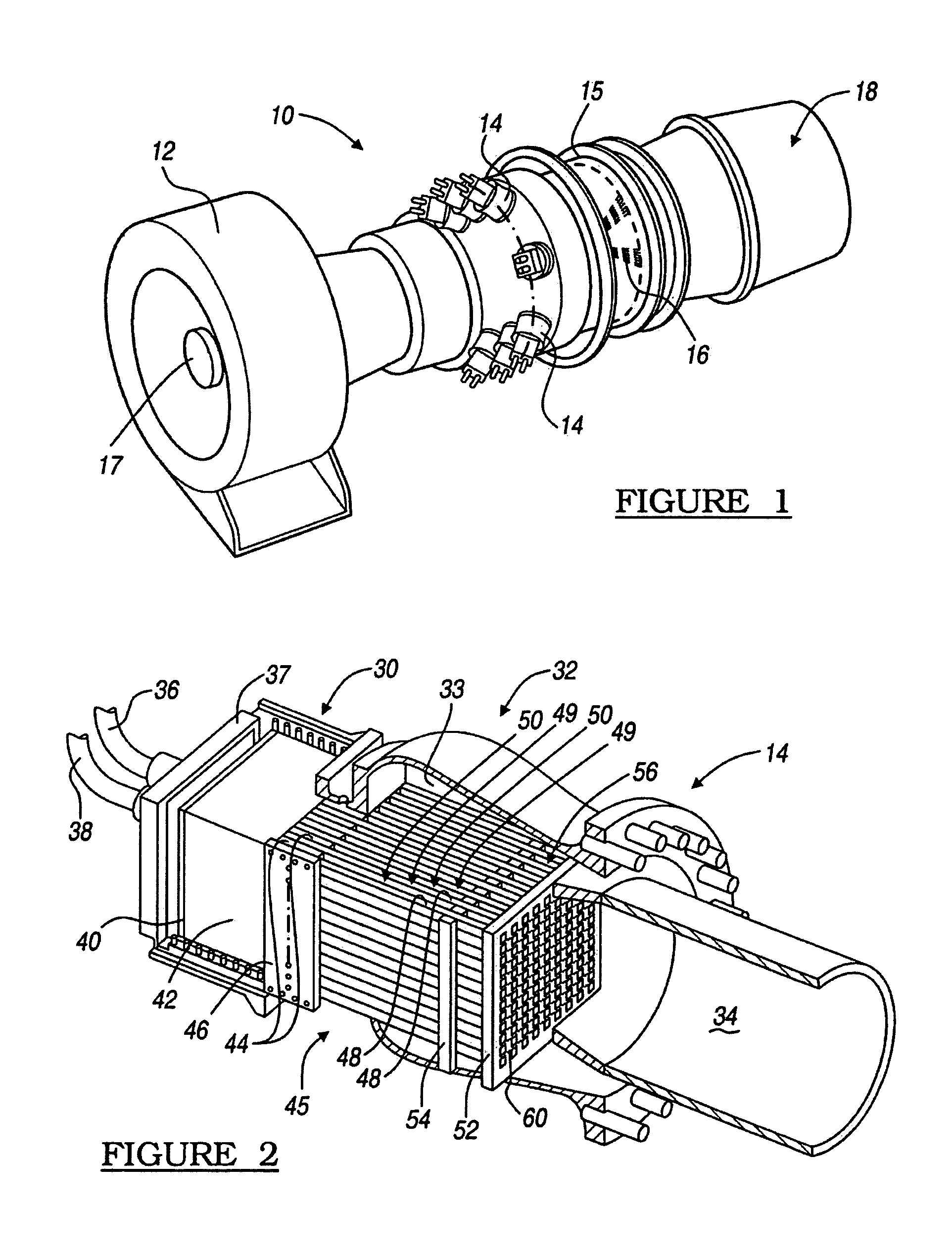

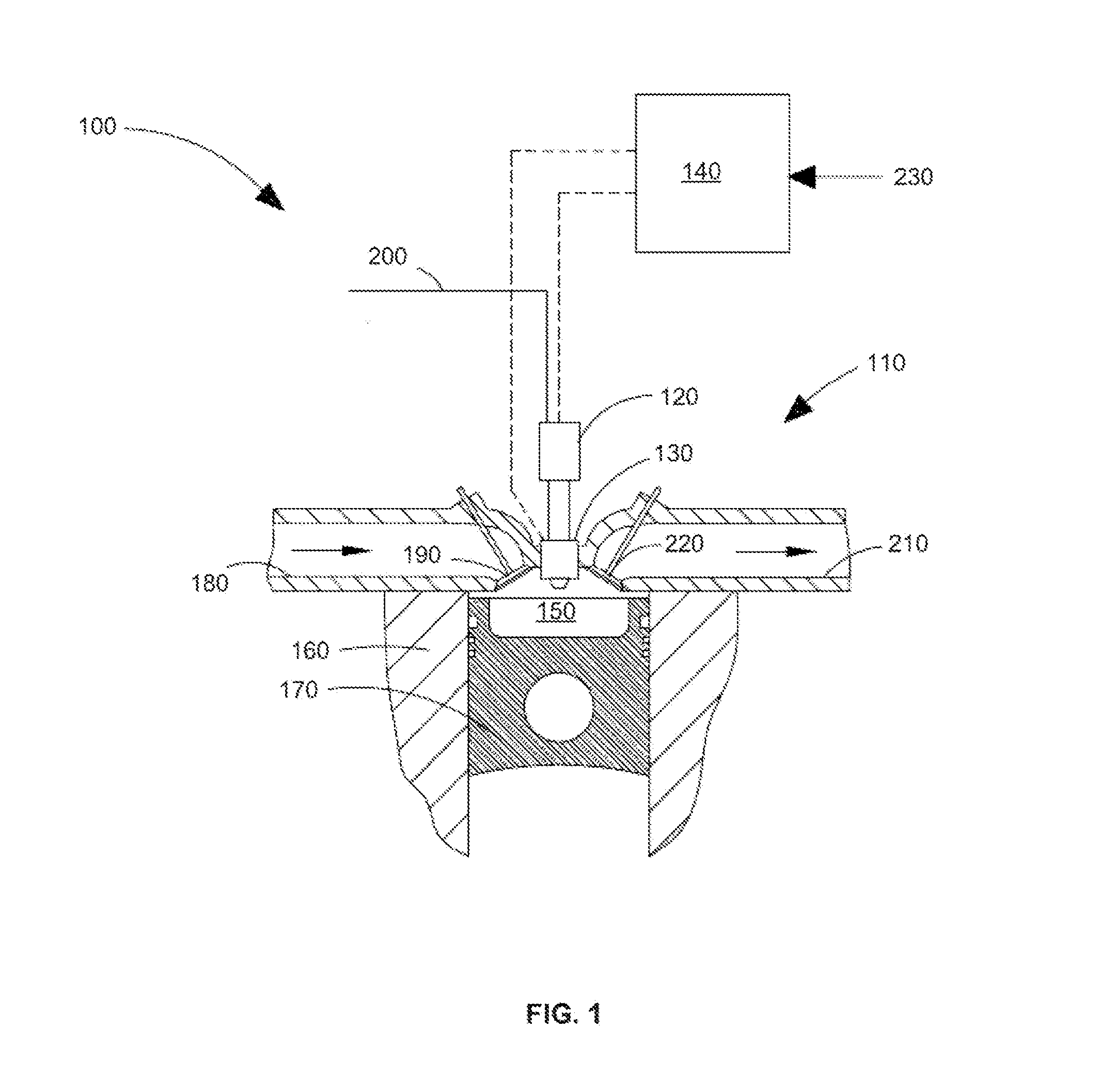

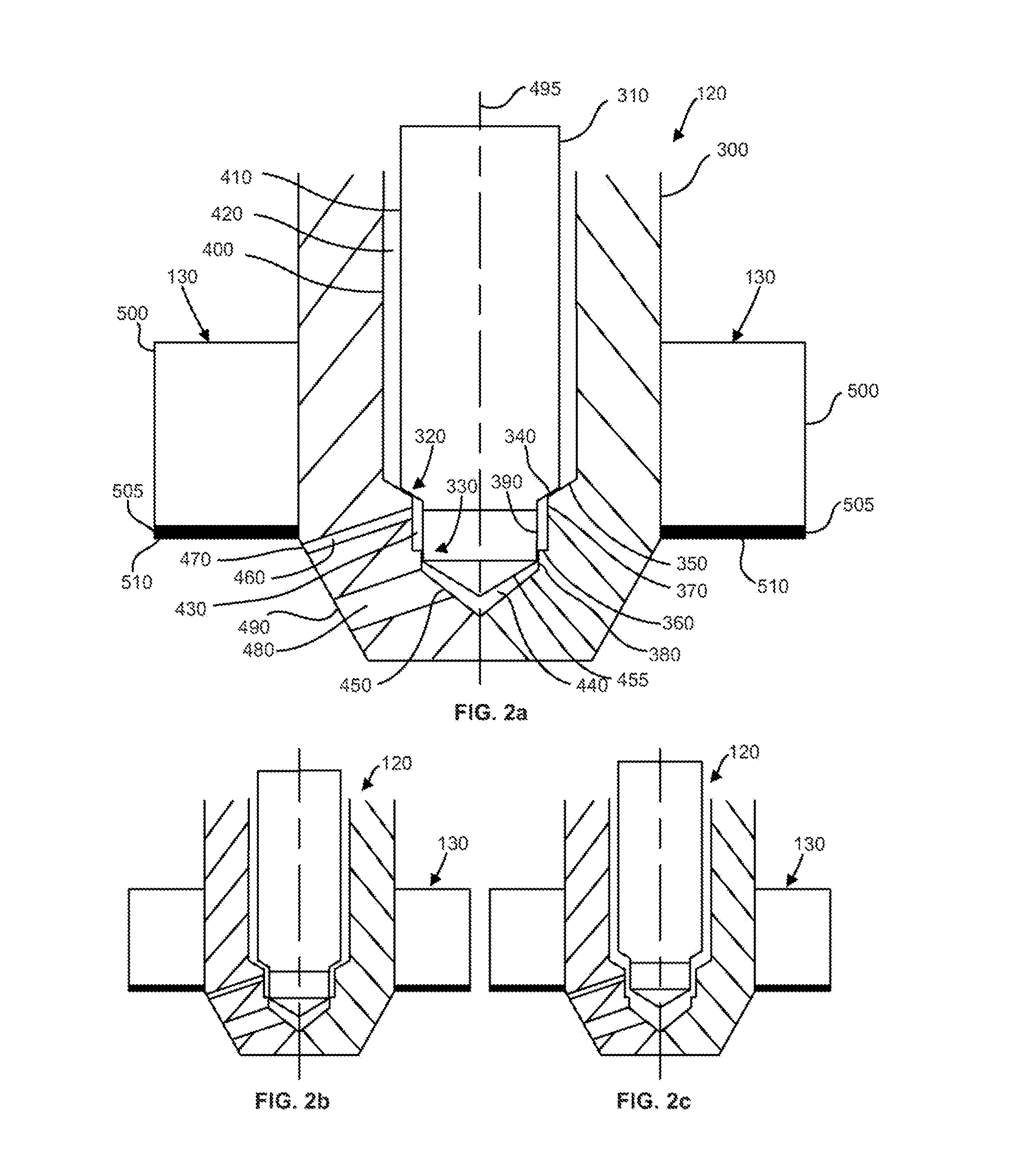

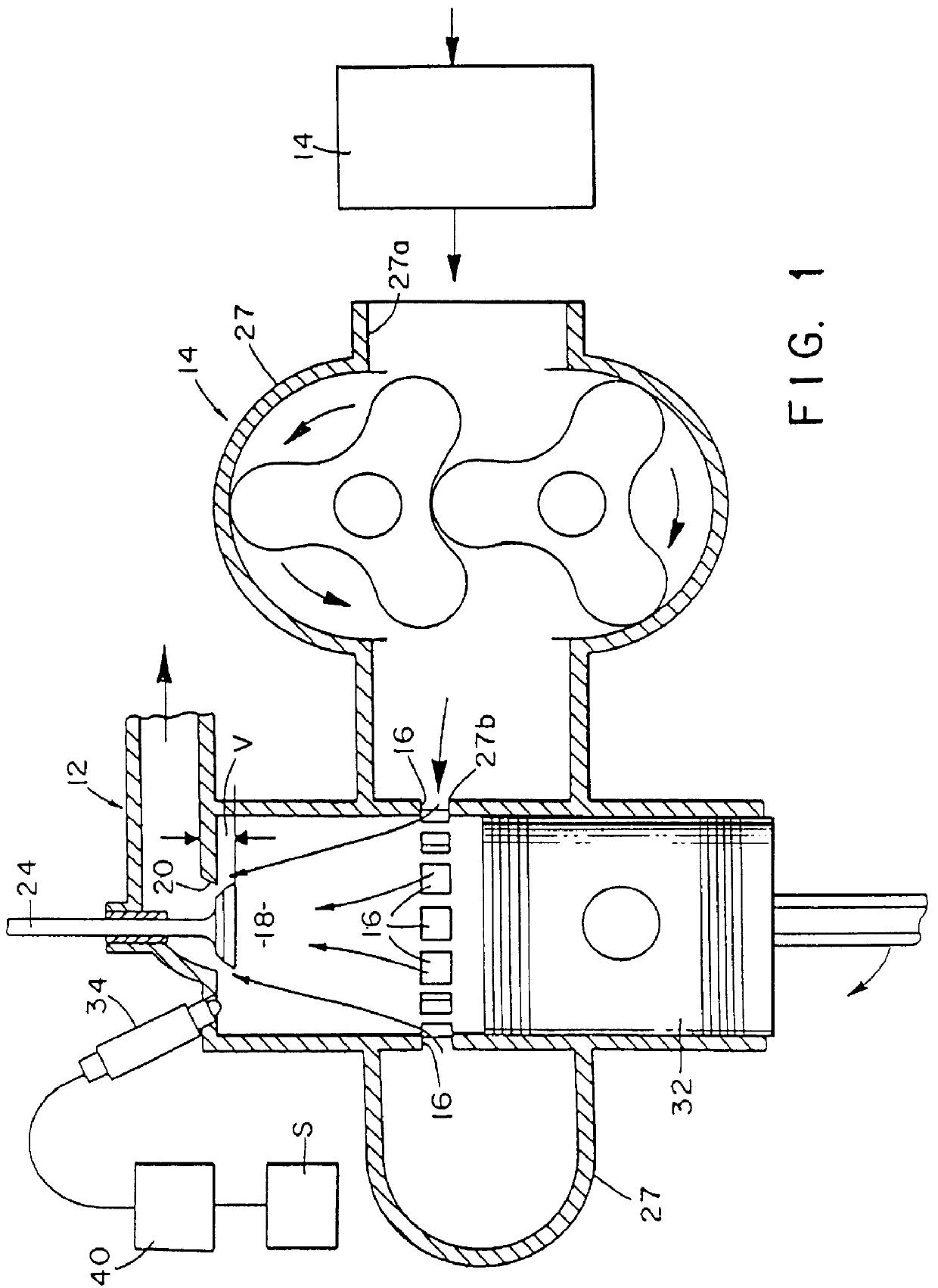

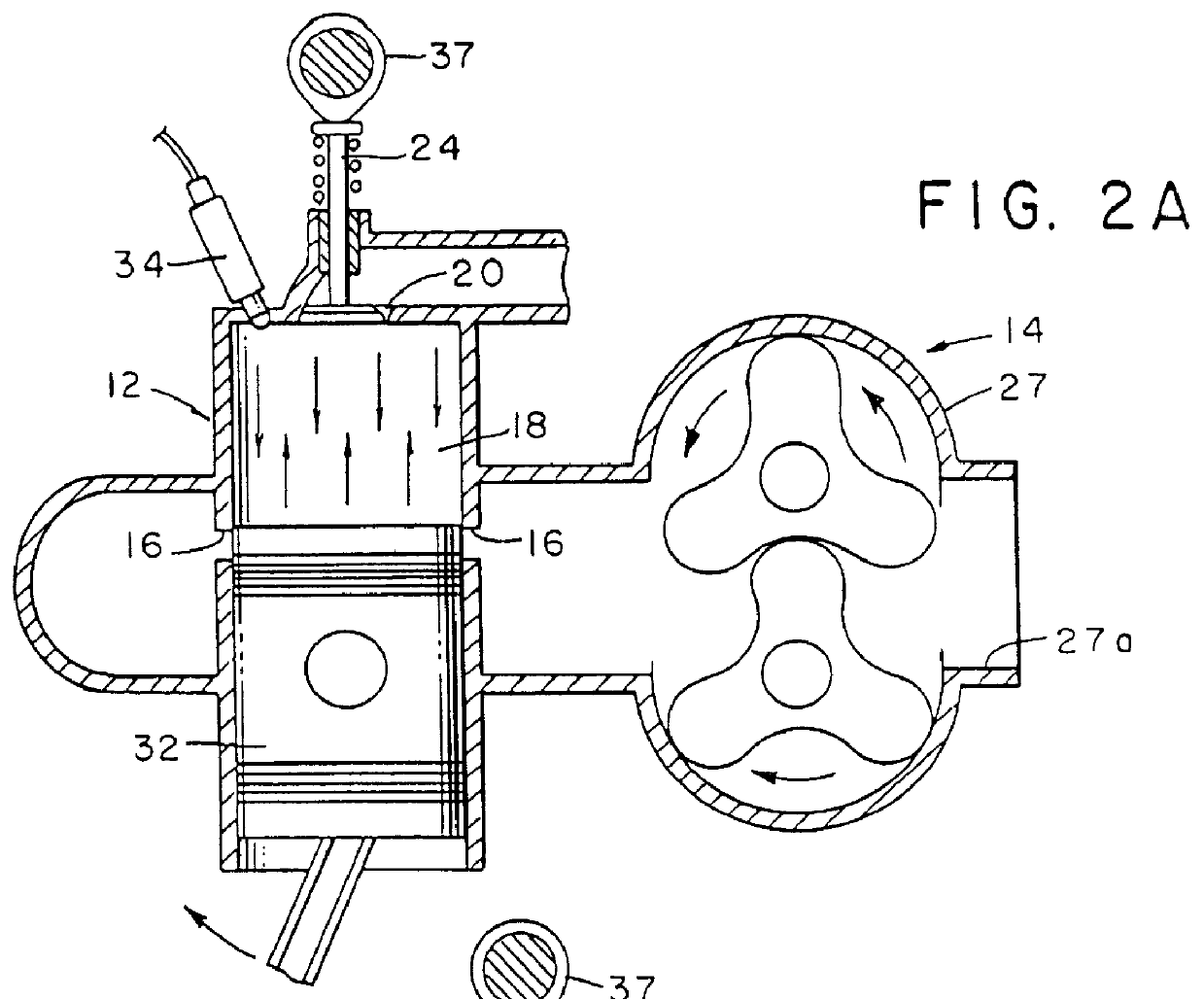

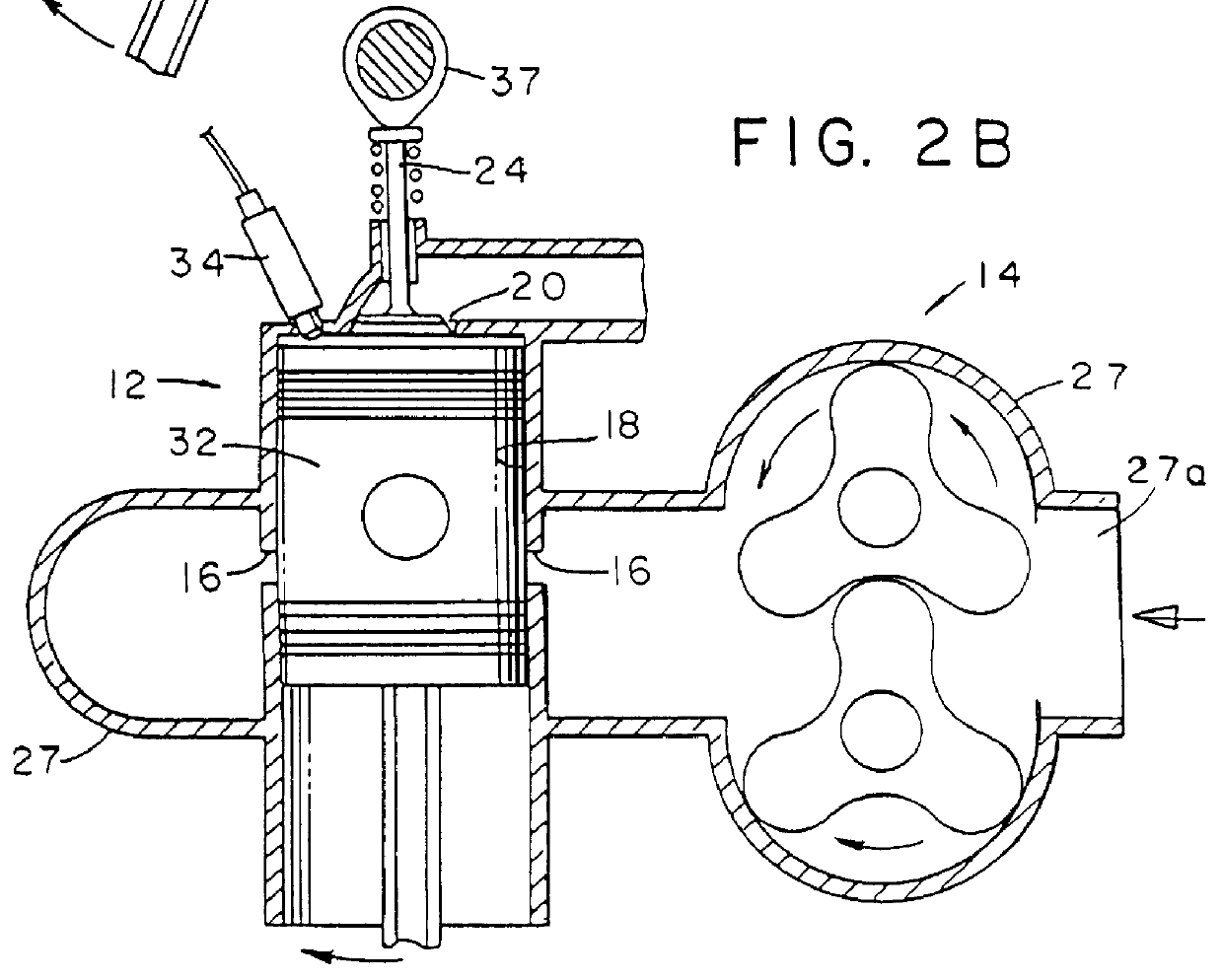

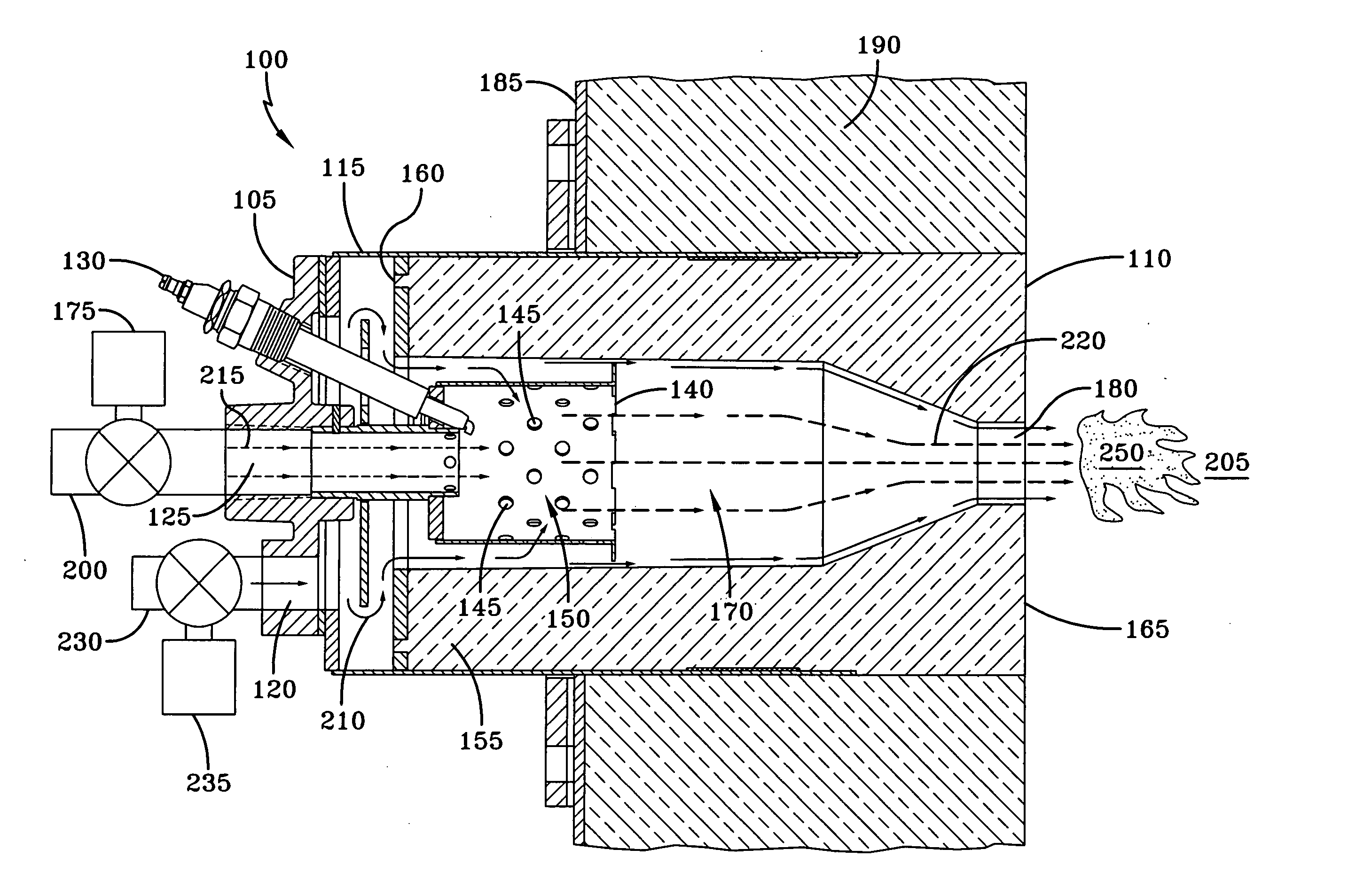

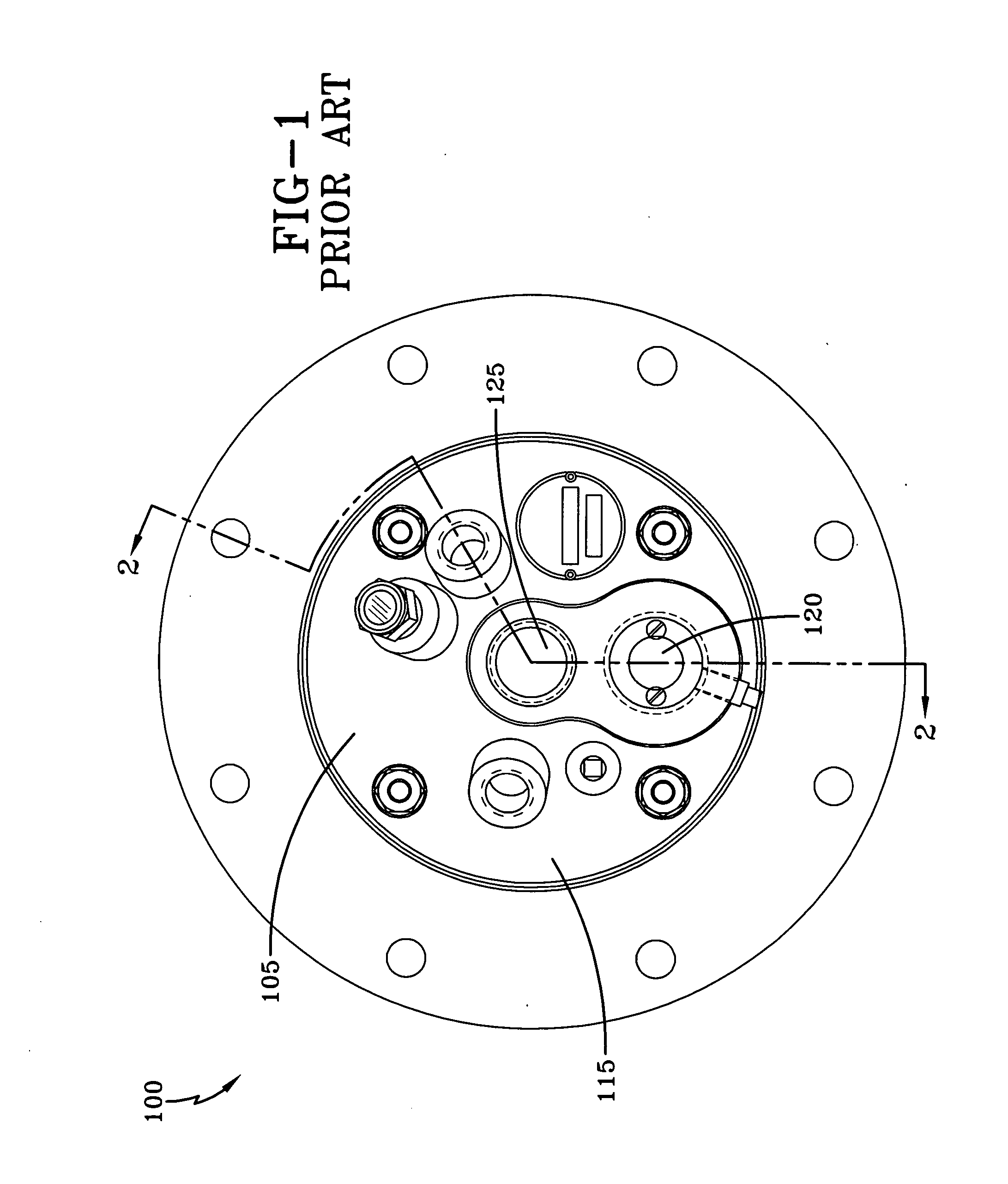

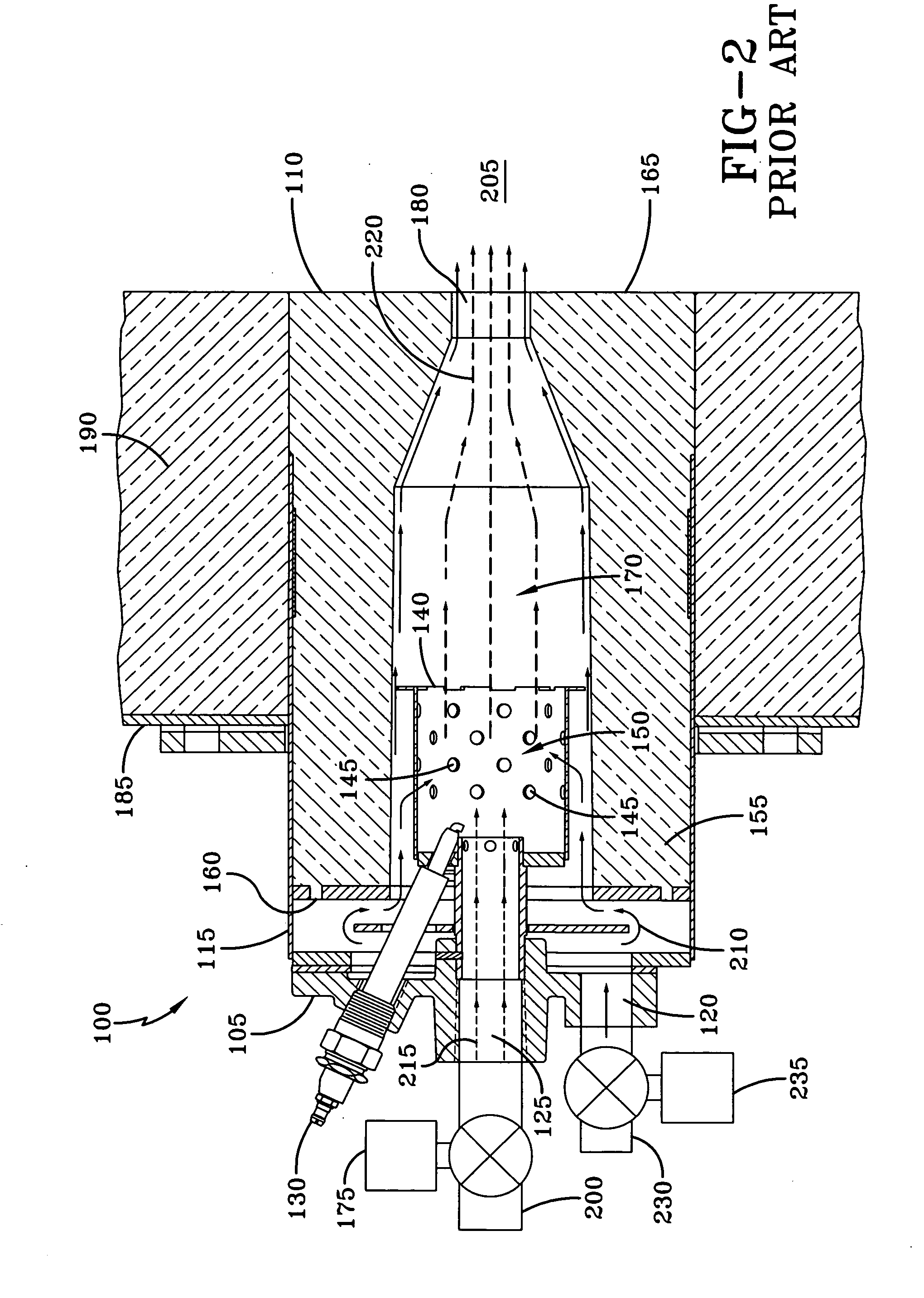

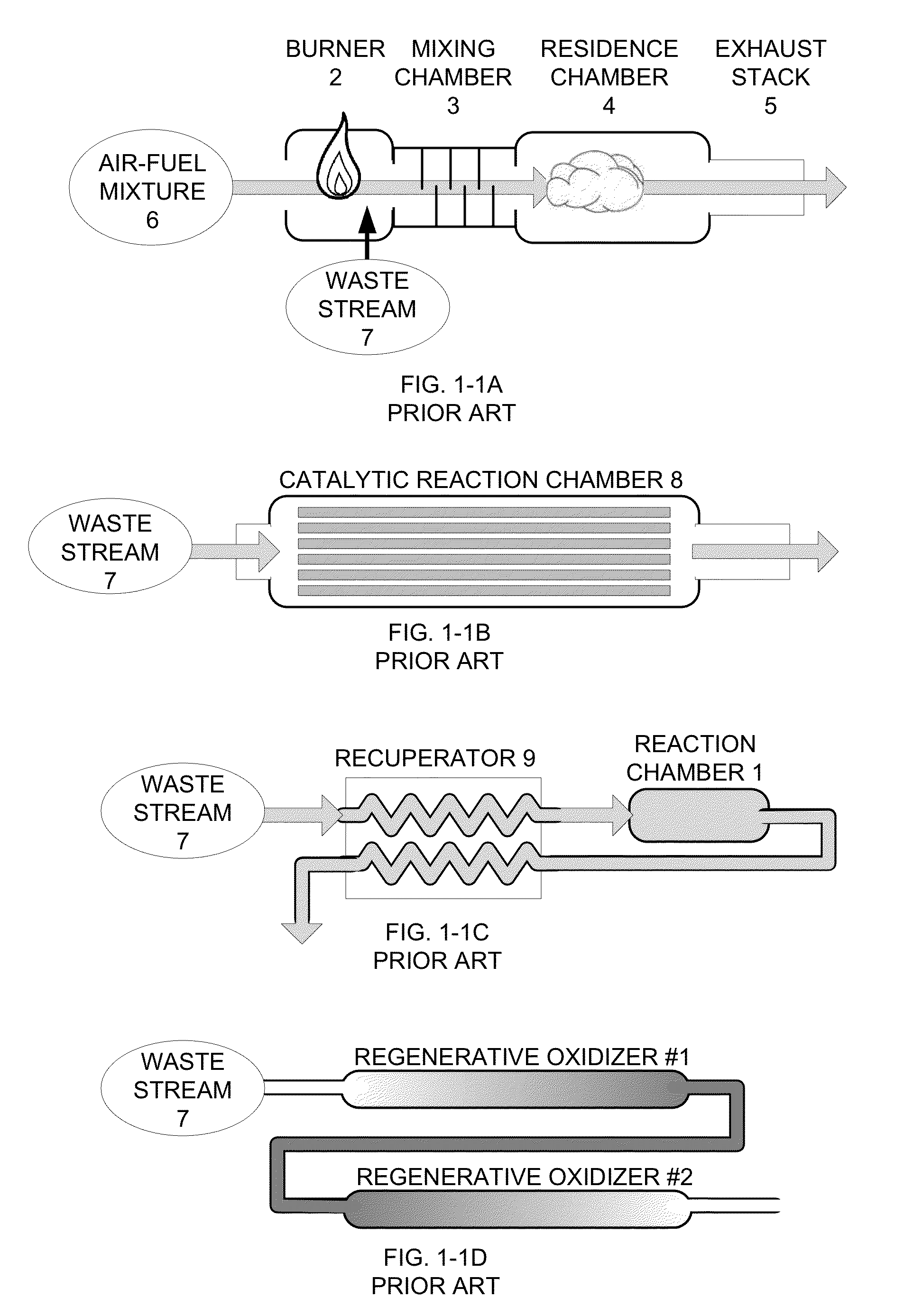

Flameless combustor

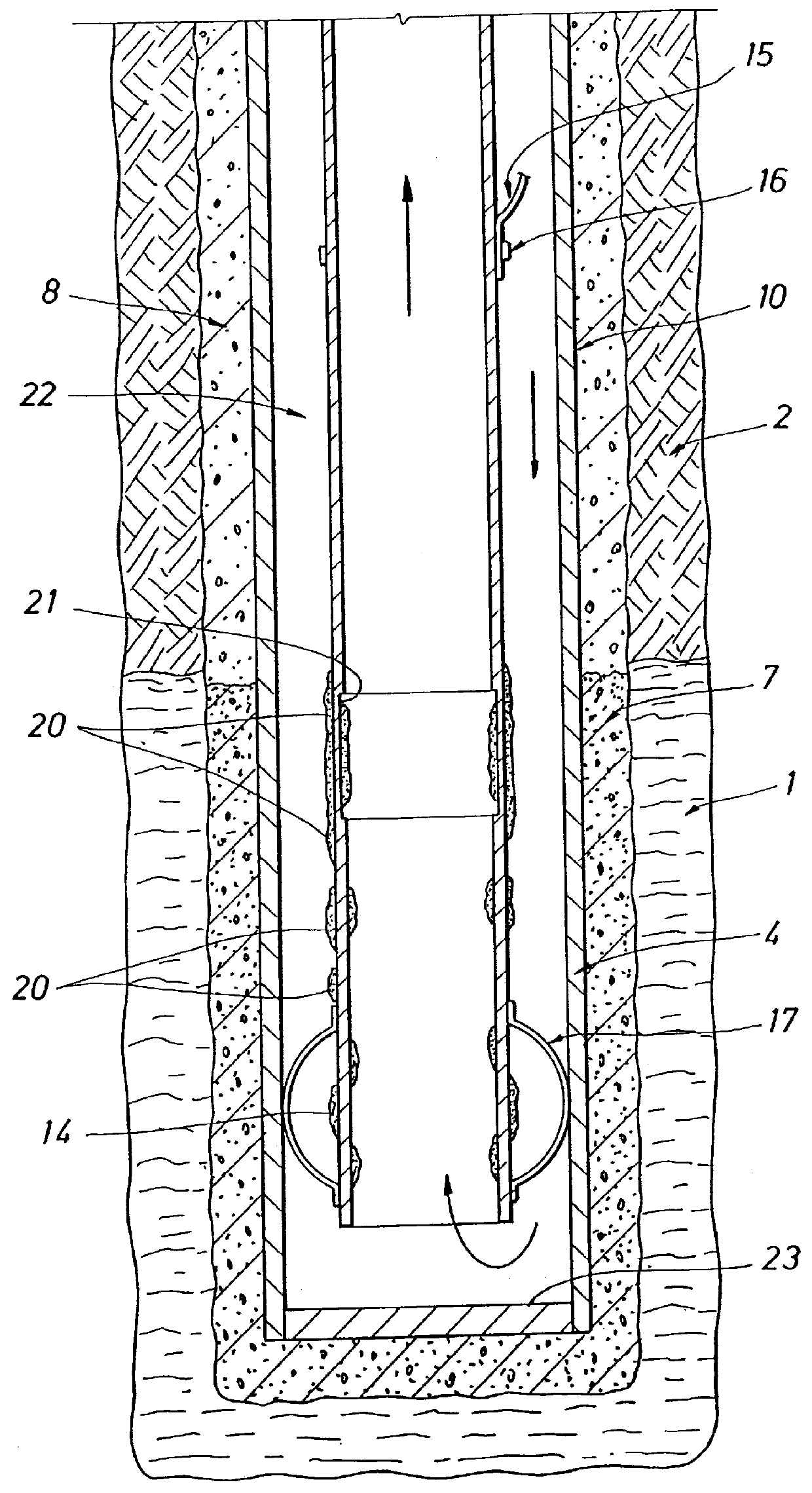

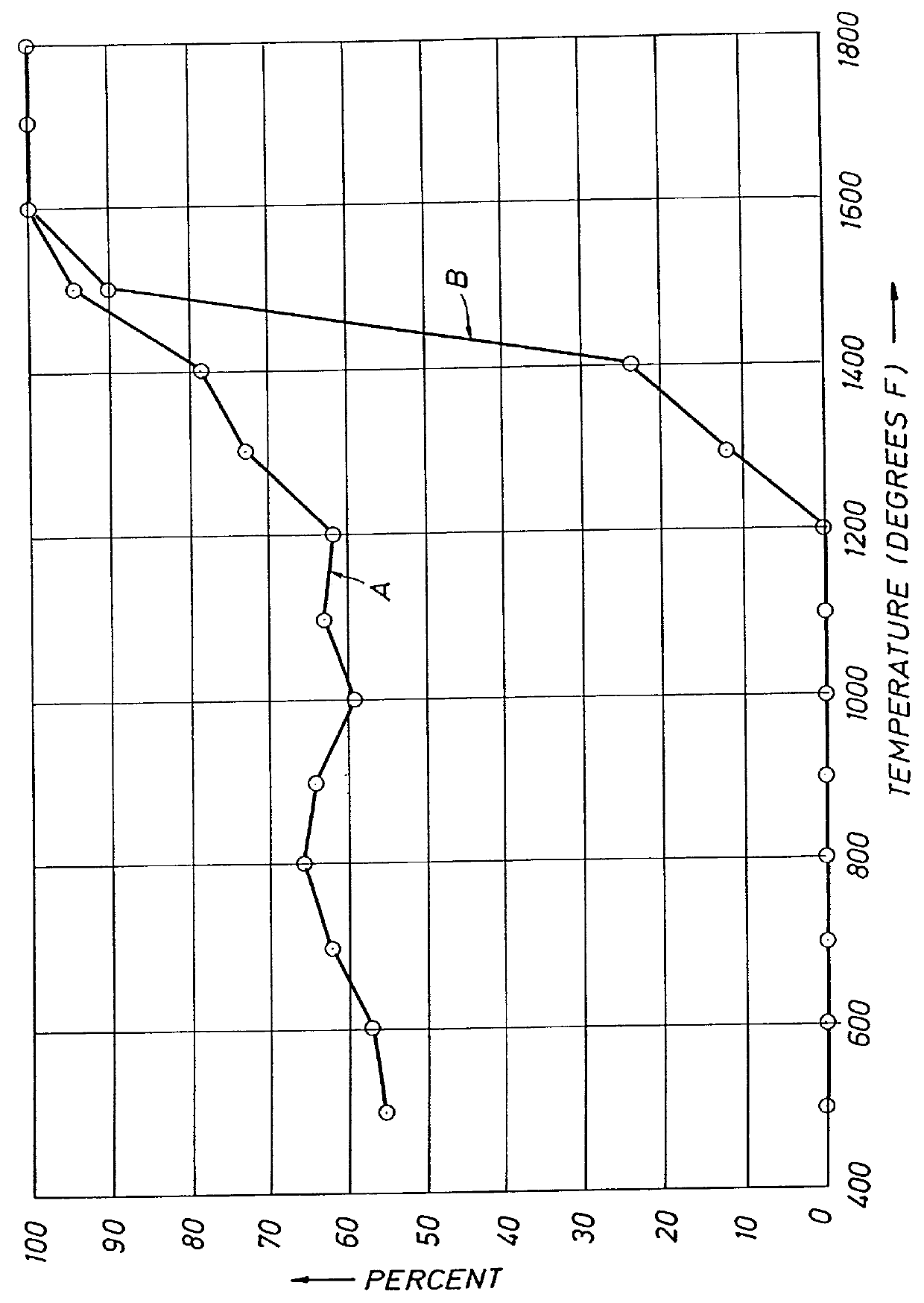

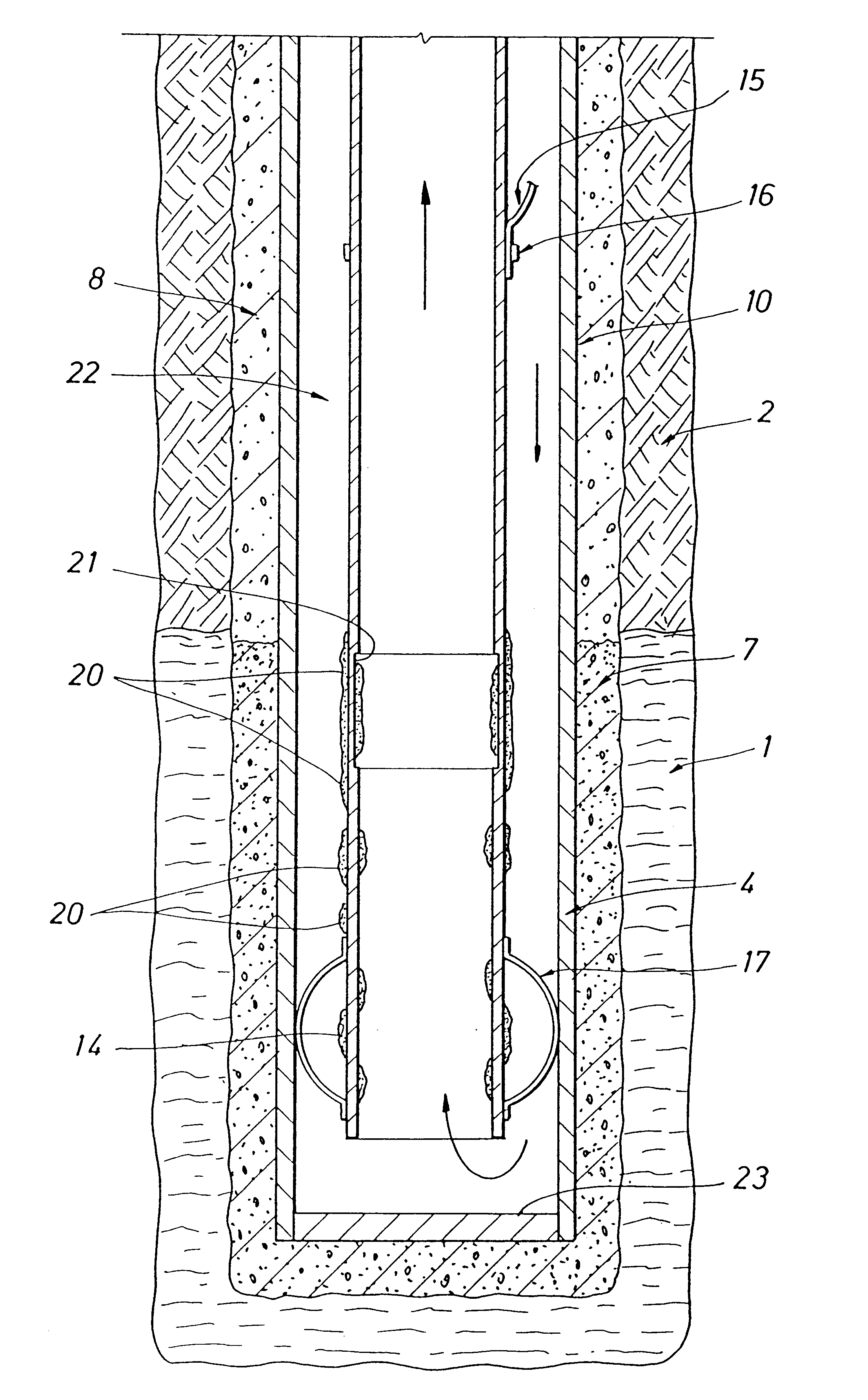

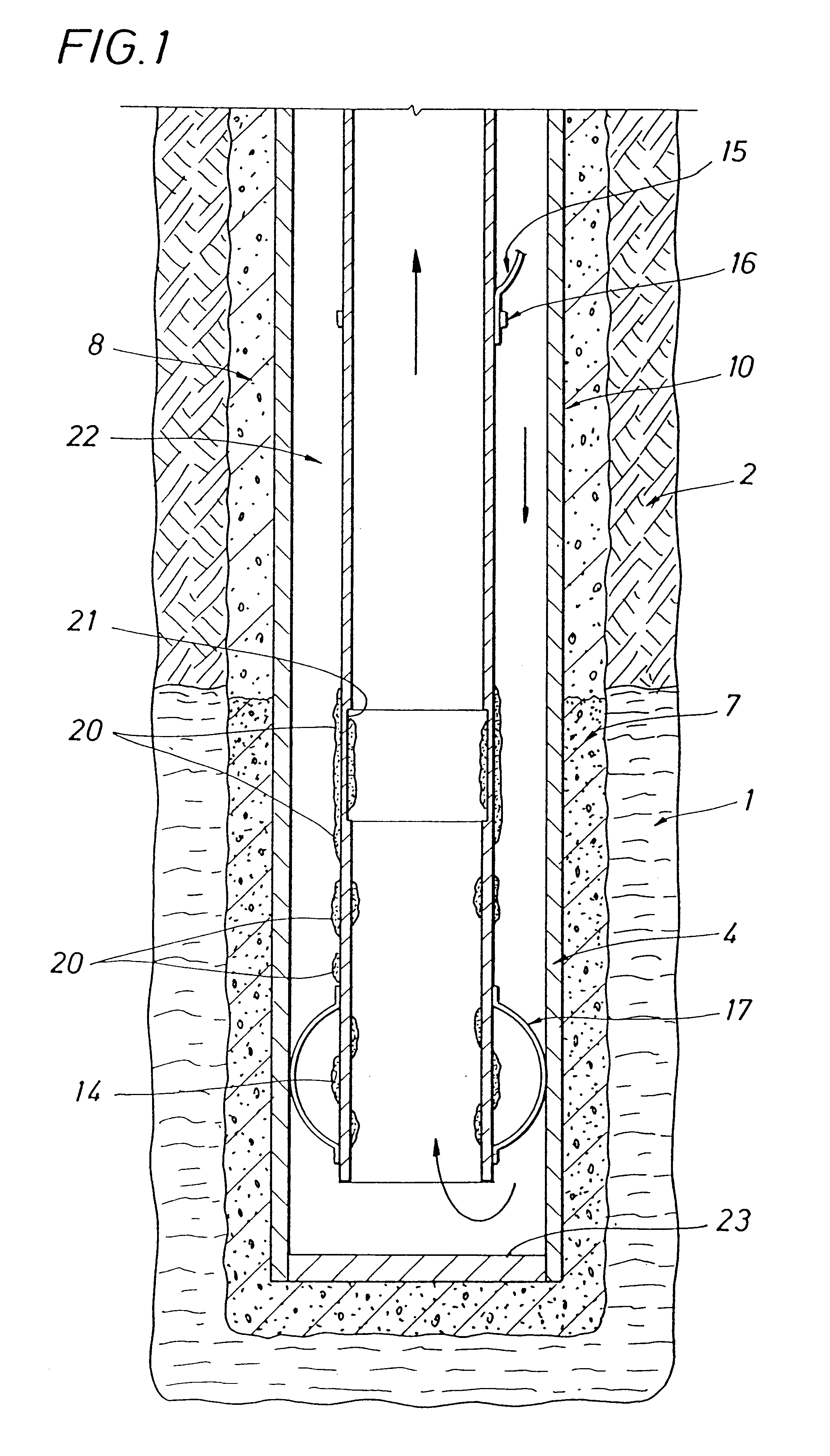

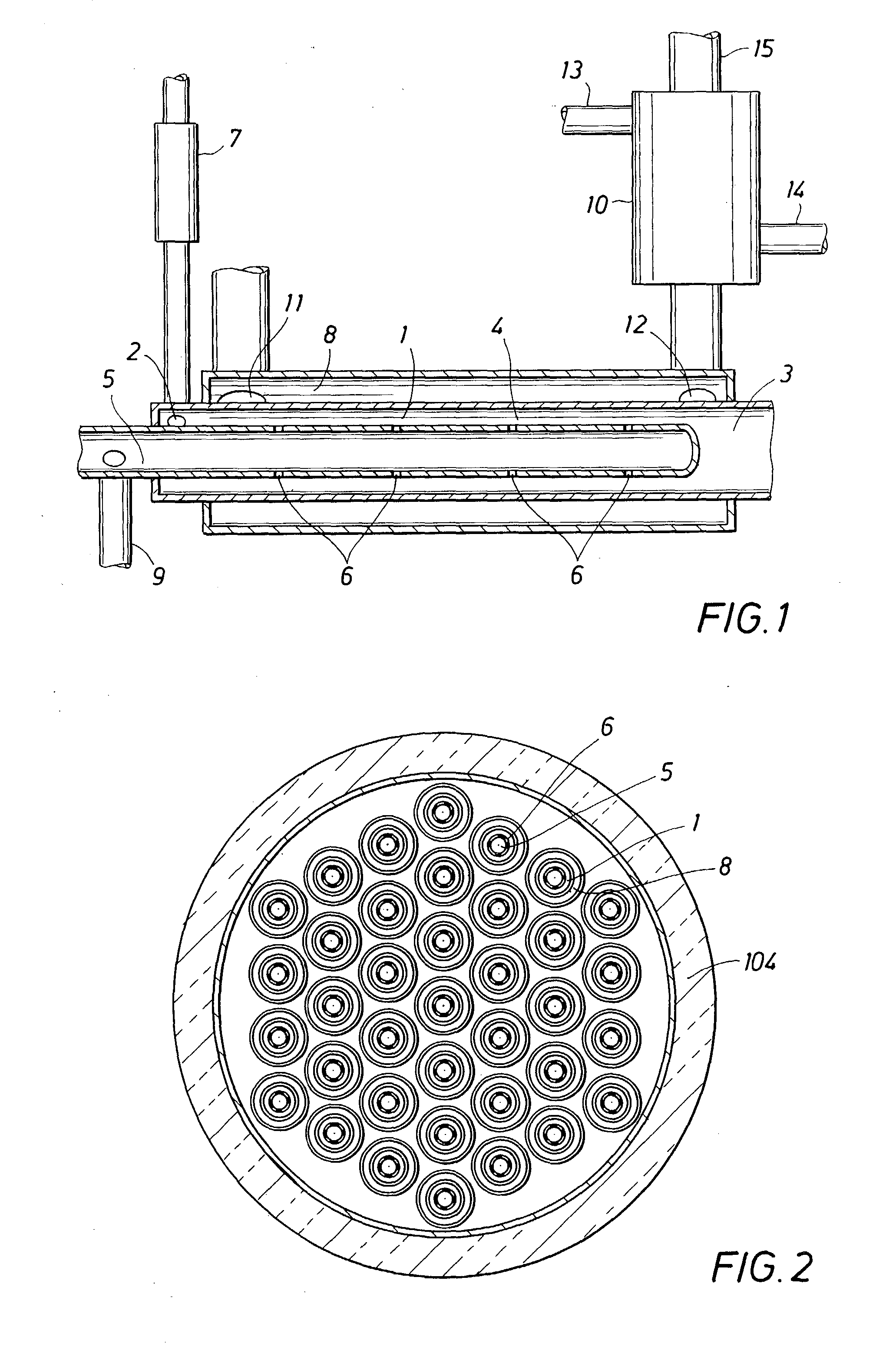

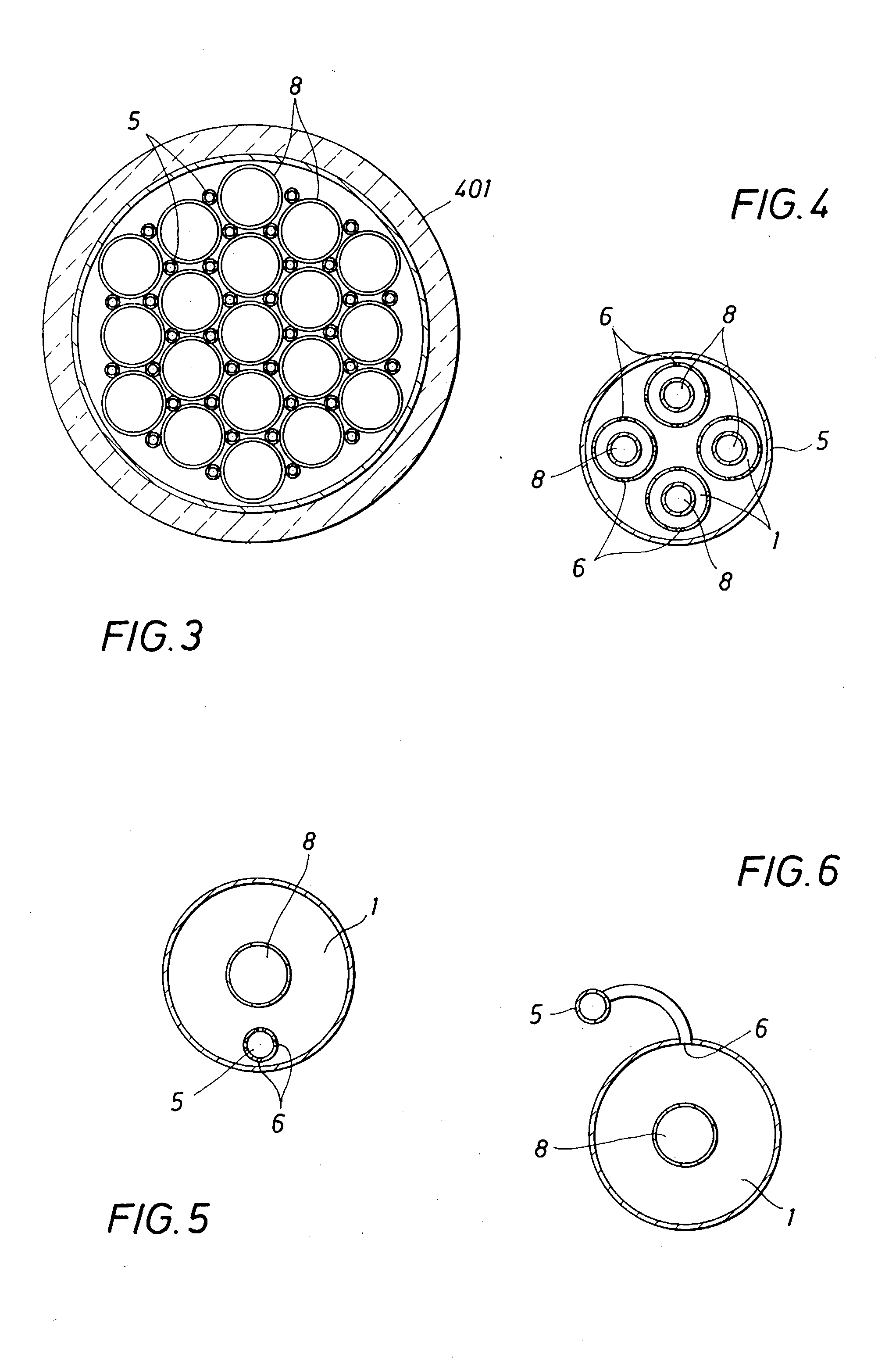

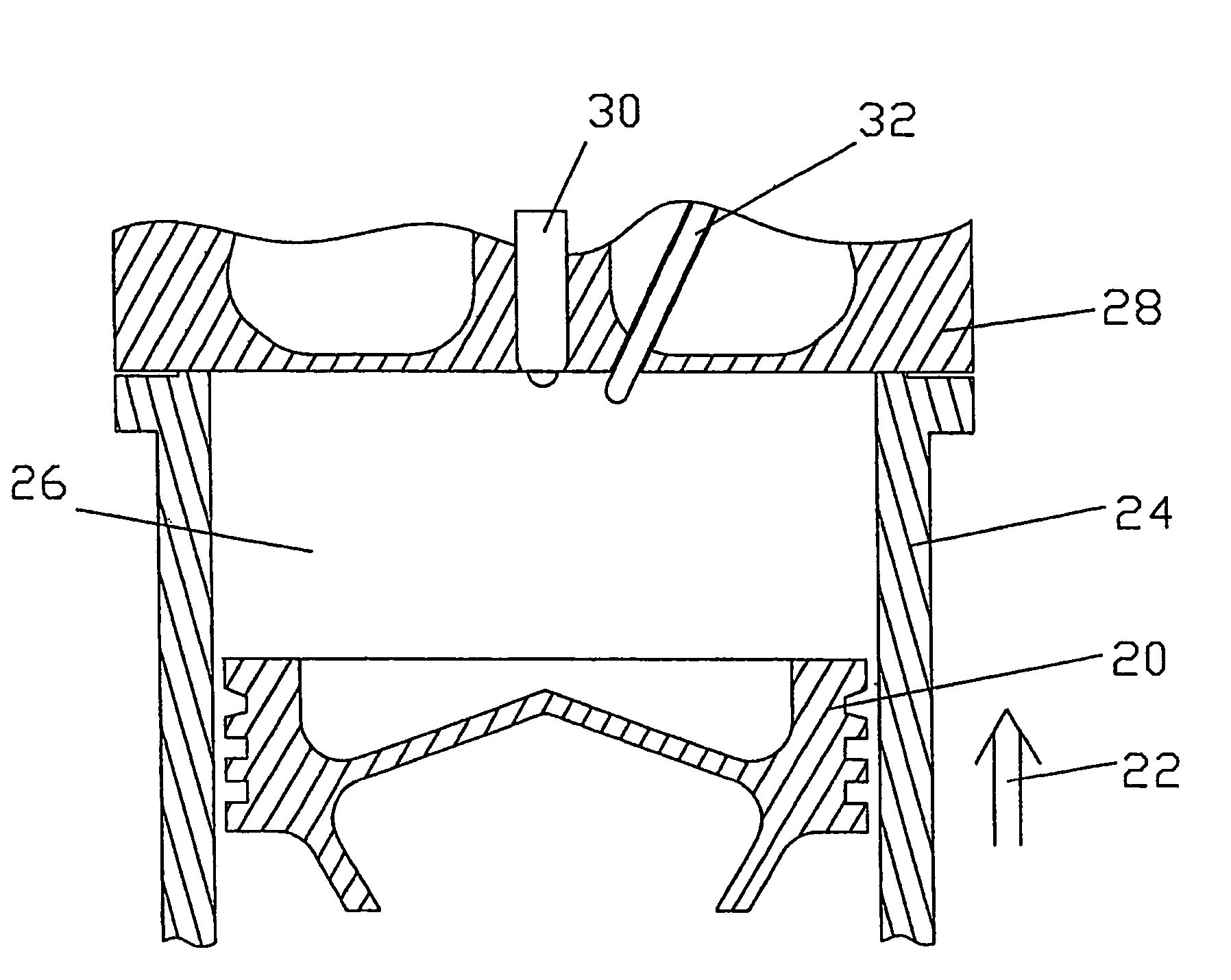

InactiveUS6019172AEasy to igniteImprove the level ofApparel holdersInsulationCombustorCombustion chamber

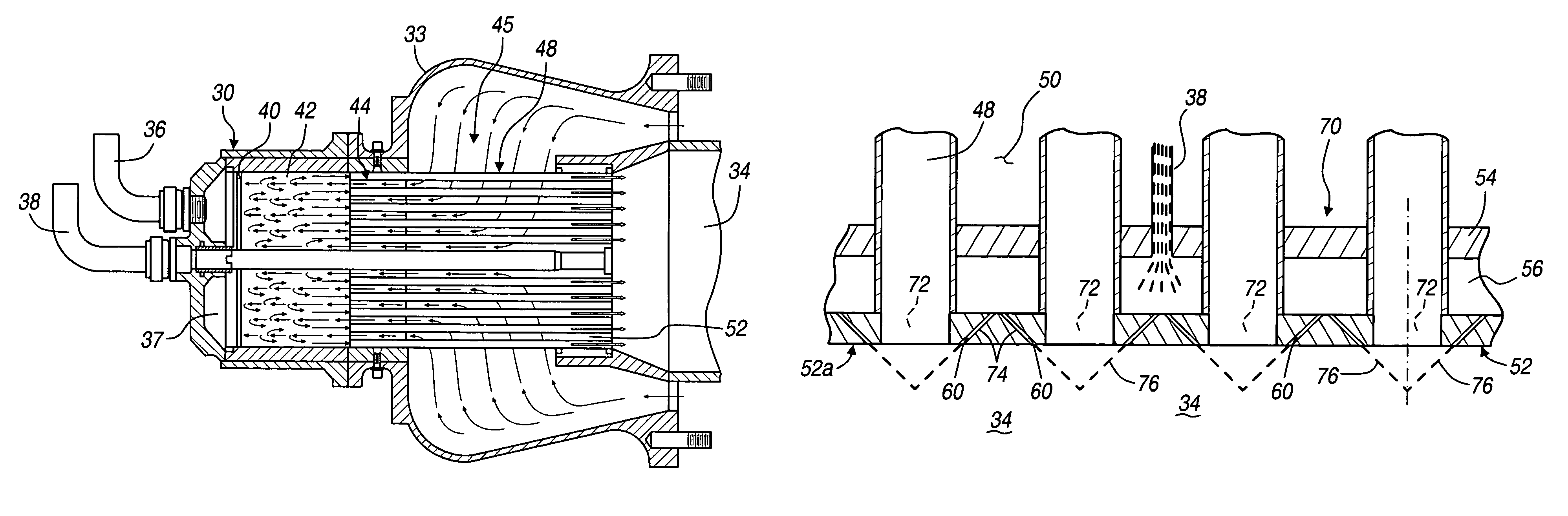

A combustor method and apparatus is provided. The method utilizes flameless combustion with one or more of three improvements to enhance ignition of the flameless combustor. A catalytic surface can be provided within a combustion chamber to provide flameless combustion at least in the vicinity of the catalytic surface at a temperature that is much lower than the autoignition temperature of fuel in air without the presence of the catalytic surface. Nitrous oxide or supplemental oxygen may also be used as an oxidant either instead of air or with air to reduce ignition temperatures. Further, electrical energy can be passed through the fuel conduit, raising the temperature of the conduit to a temperature above which the fuel will ignite when combined with the oxidant.

Owner:SHELL OIL CO

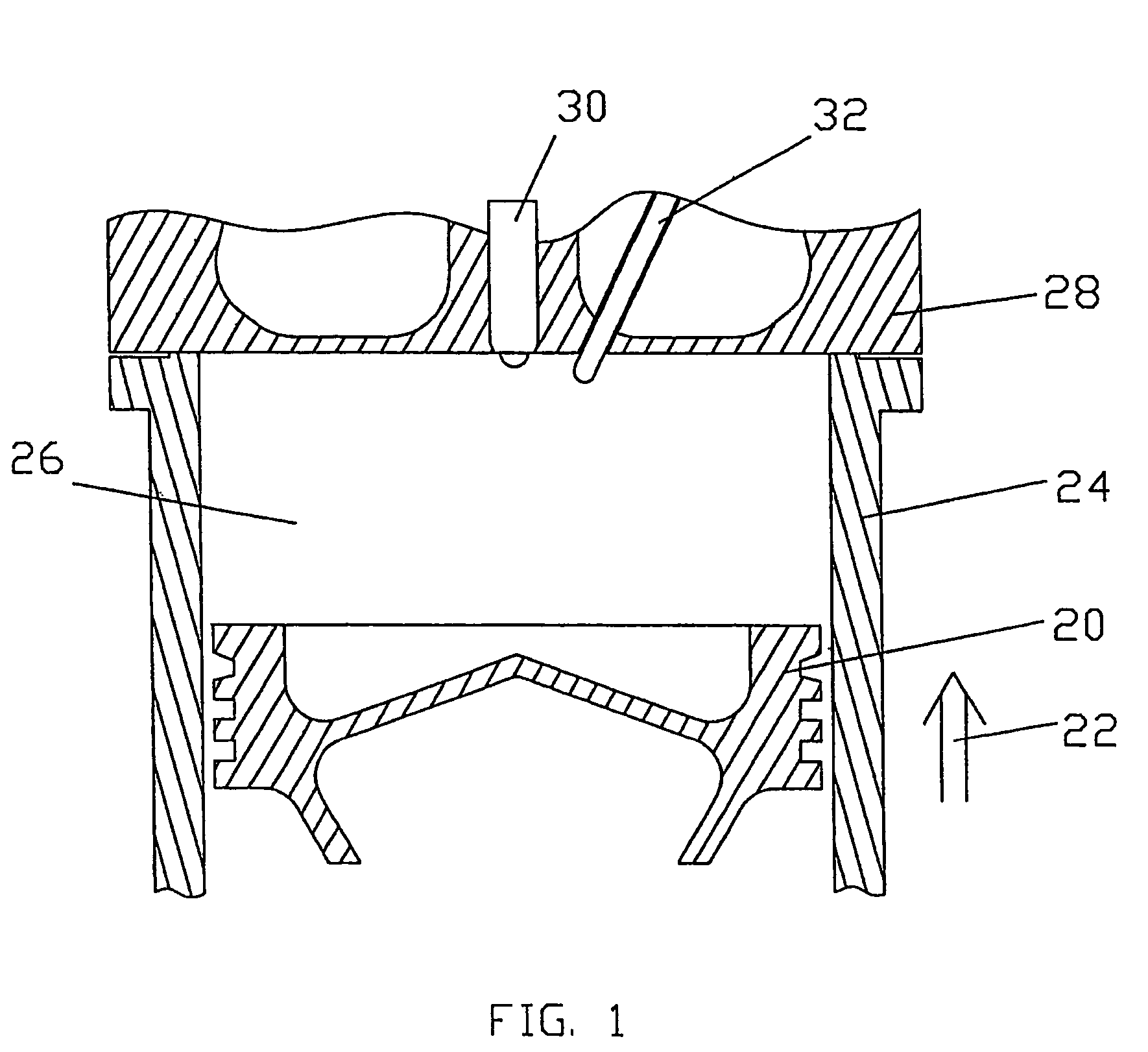

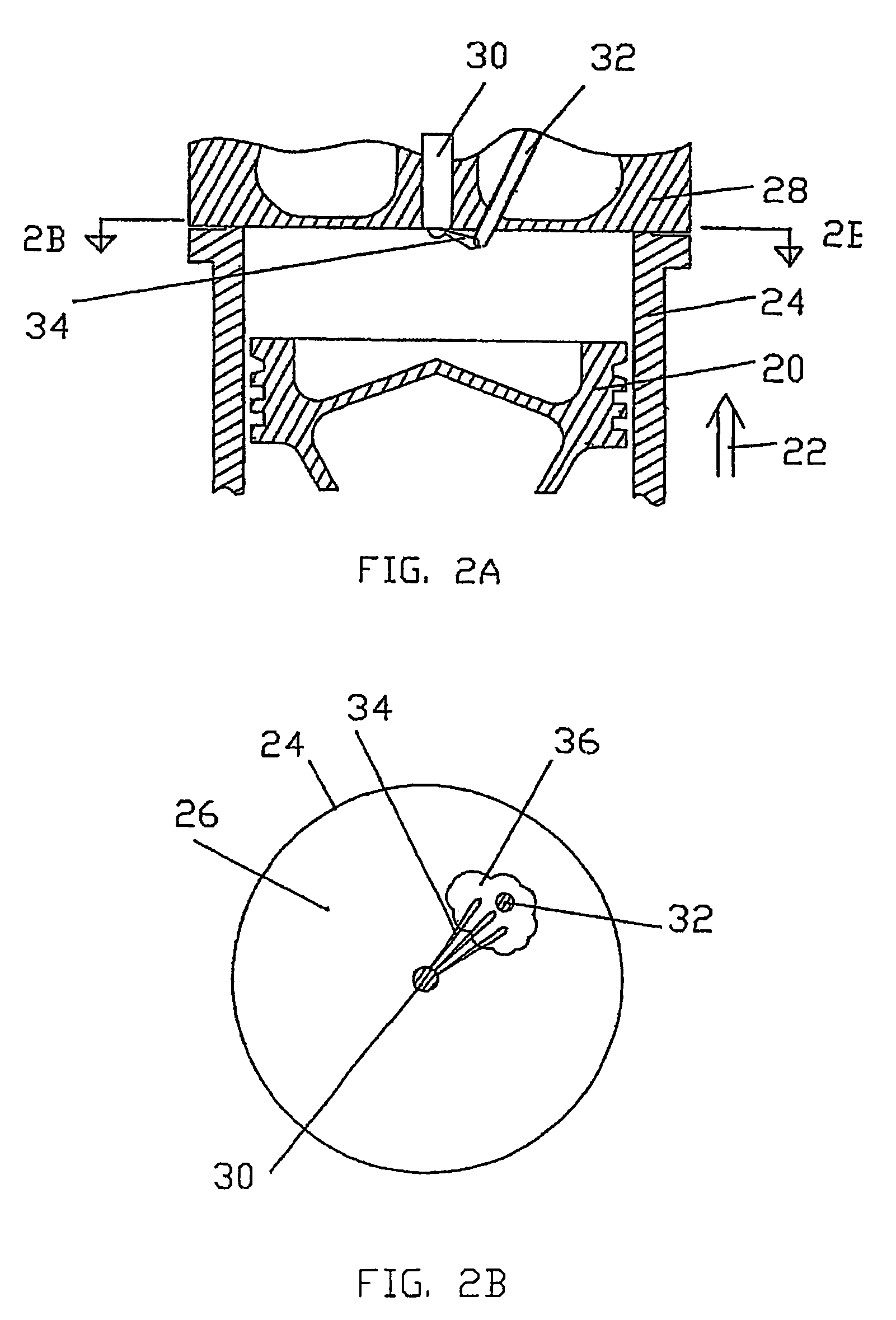

Method for ignition of flameless combustor

InactiveUS6269882B1Easy to igniteImprove the level ofApparel holdersIncandescent ignitionCombustorCombustion chamber

A combustor method and apparatus is provided. The method utilizes flameless combustion with one or more of three improvements to enhance ignition of the flameless combustor. A catalytic surface can be provided within a combustion chamber to provide flameless combustion at least in the vicinity of the catalytic surface at a temperature that is much lower than the autoignition temperature of fuel in air without the presence of the catalytic surface. Nitrous oxide or supplemental oxygen may also be used as an oxidant either instead of air or with air to reduce ignition temperatures. Further, electrical energy can be passed through the fuel conduit, raising the temperature of the conduit to a temperature above which the fuel will ignite when combined with the oxidant.

Owner:SHELL OIL CO

Flameless combustor process heater

InactiveUS20020015670A1Reduce the temperatureLow costThermal non-catalytic crackingBurnersAutoignition temperatureEngineering

A process heater is provided utilizing flameless combustion, the process heater having: an oxidation reaction chamber, the oxidation reaction chamber having an inlet for oxidant, an outlet for combustion products, and a flow path between the inlet and the outlet; a fuel conduit capable of transporting a fuel mixture to a plurality of fuel nozzles within the oxidation reaction chamber, each nozzle providing communication from within the fuel conduit to the oxidation chamber, with each nozzle along the flowpath between the inlet and the outlet; a preheater in communication with the oxidation chamber inlet, the preheater capable of increasing the temperature of the oxidant to a temperature resulting in the combined oxidant and fuel from the fuel nozzle closest to the oxidation chamber inlet being greater than the autoignition temperature of the combined oxidant and fuel from the fuel nozzle closest to the oxidation chamber inlet; and a process chamber in a heat exchange relationship to the oxidation reaction chamber wherein the heat transferred from the oxidation section does not causes the temperature of the mixture within the oxidation reaction chamber in the vicinity of each fuel nozzle to decrease below the auto ignition temperature of the combined mixture in the oxidation chamber in the vicinity of that fuel nozzle.

Owner:SHELL OIL CO

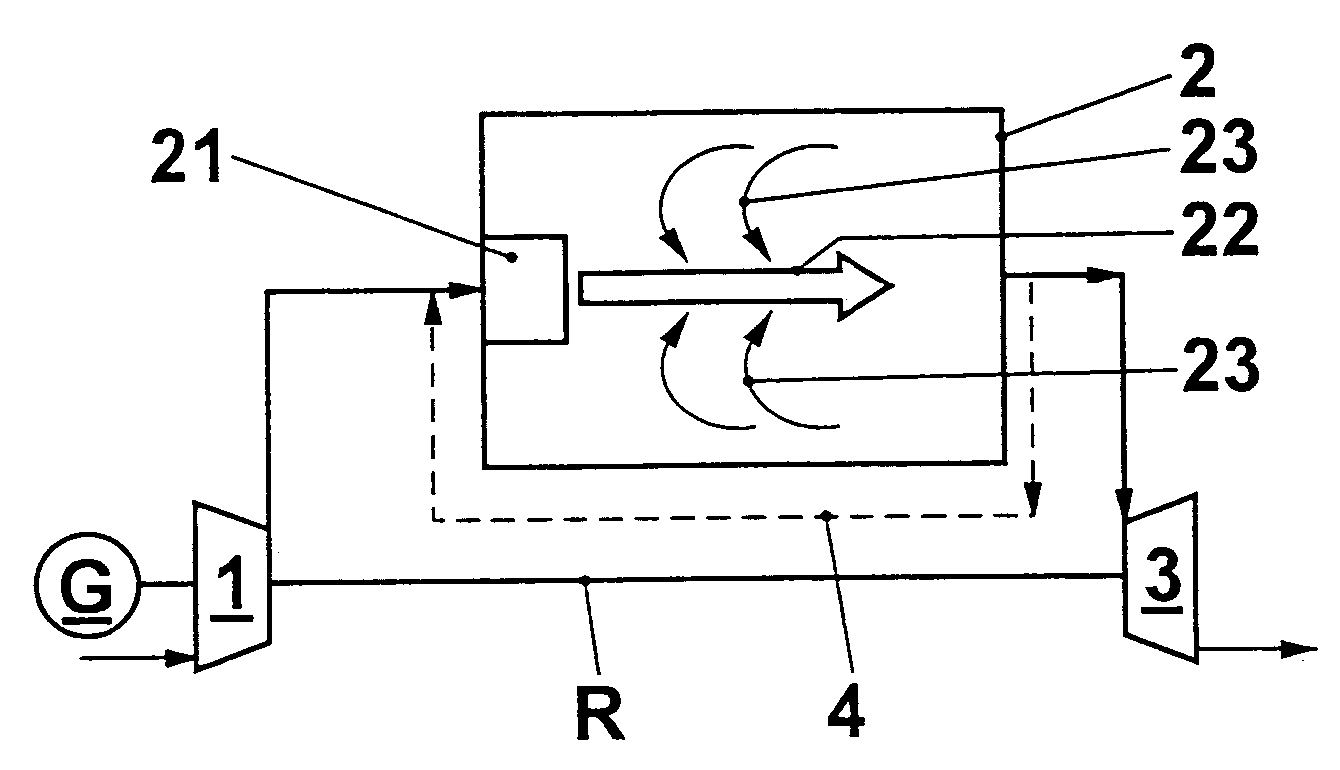

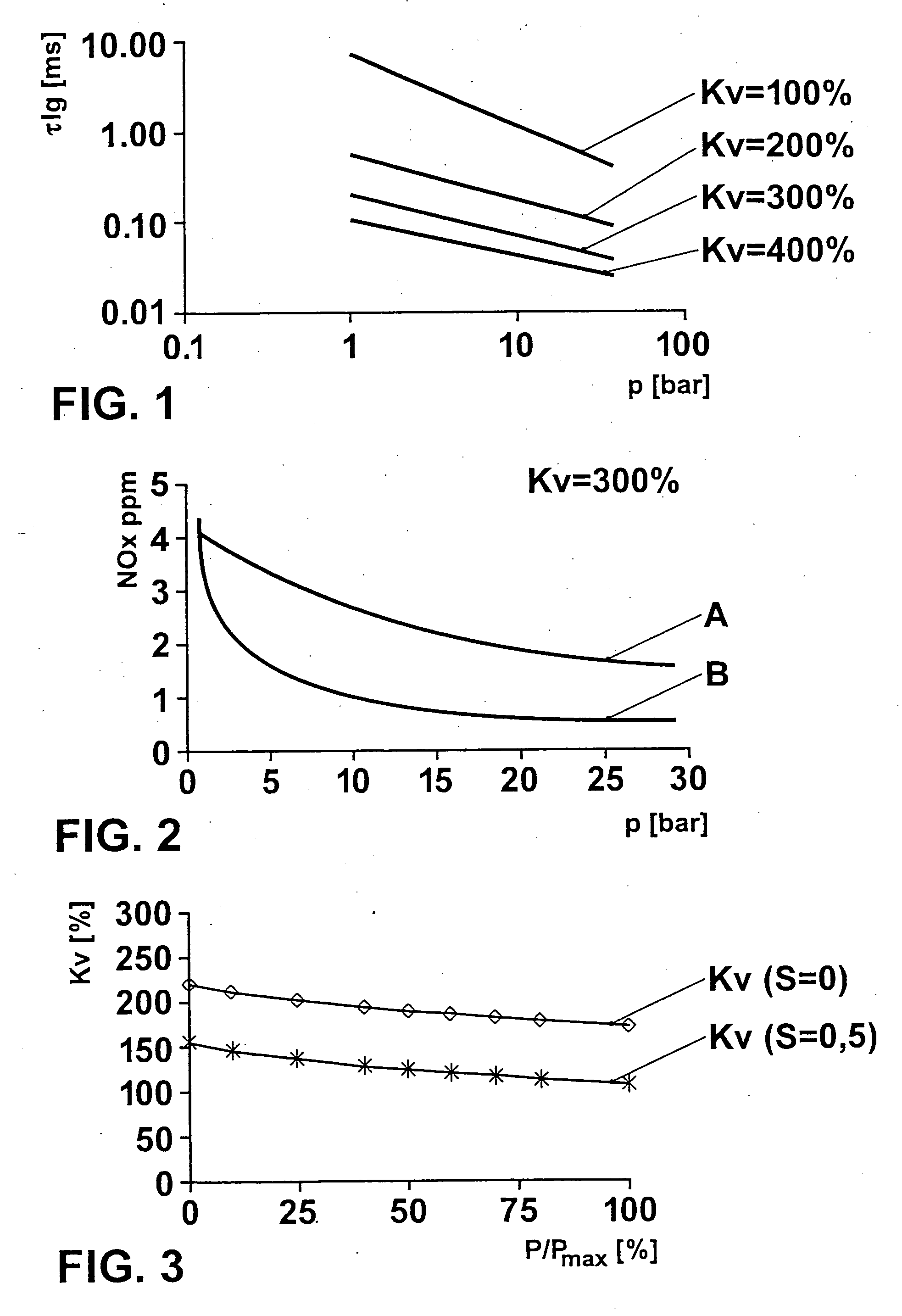

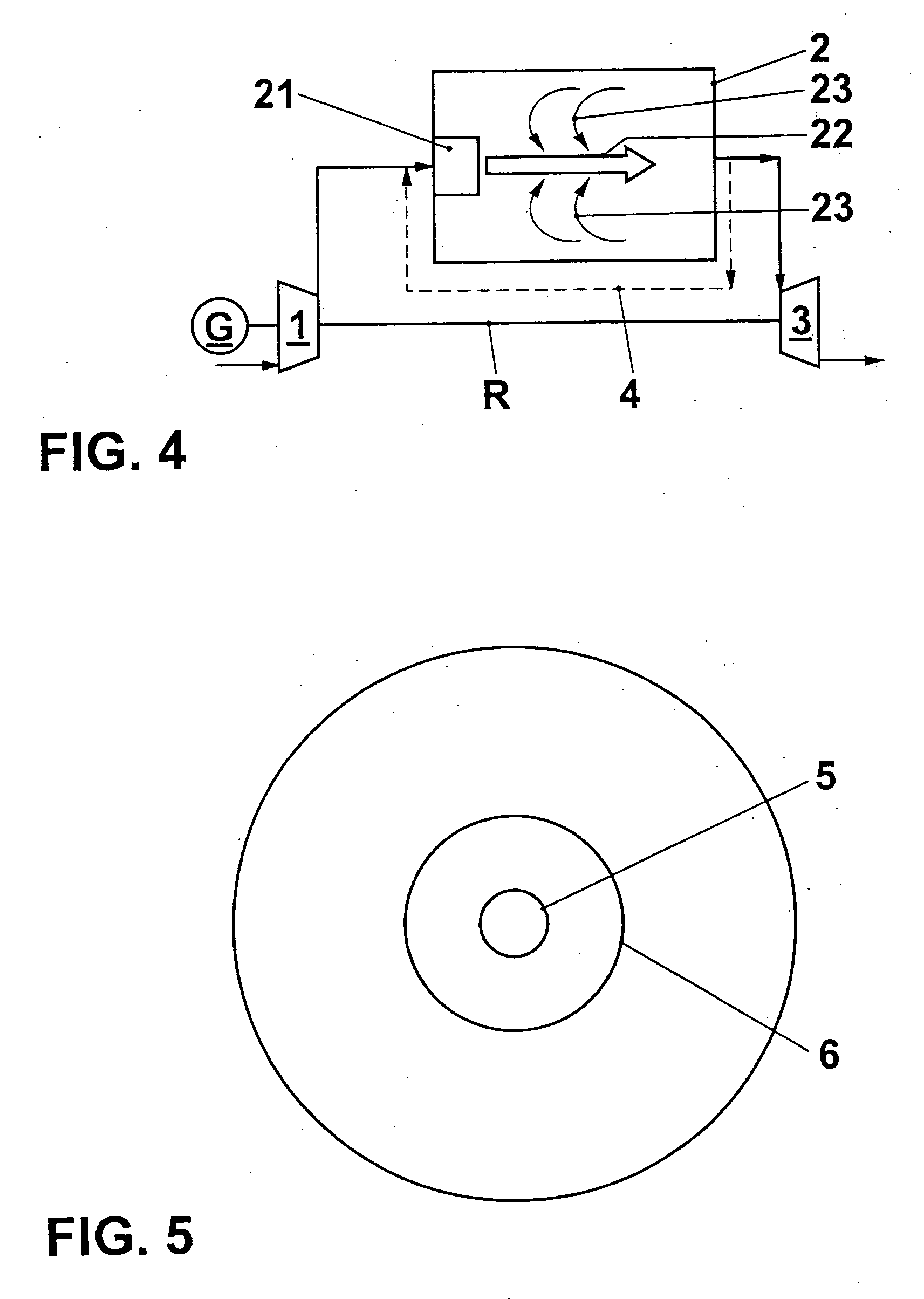

Method for combustion of a fuel

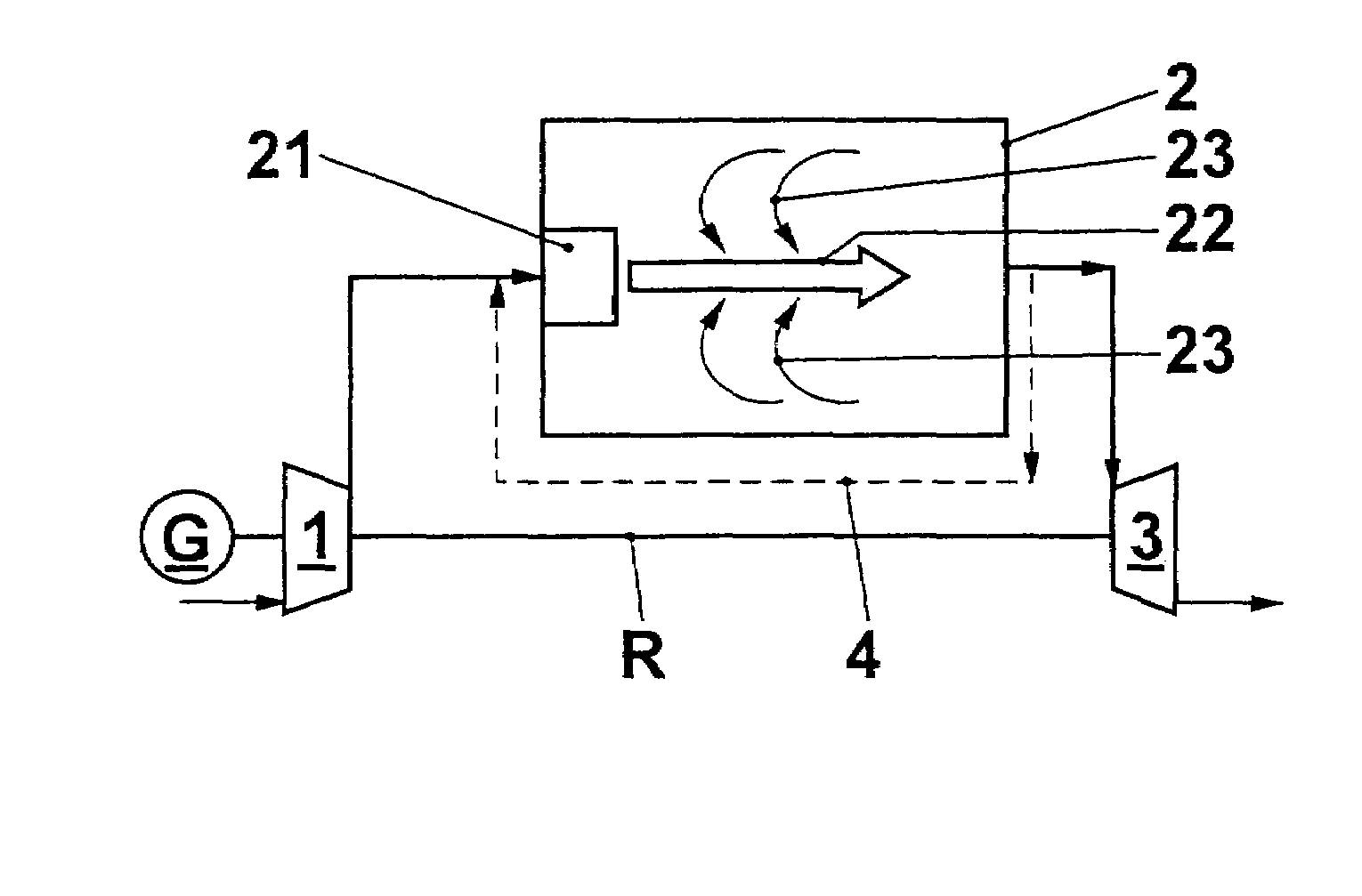

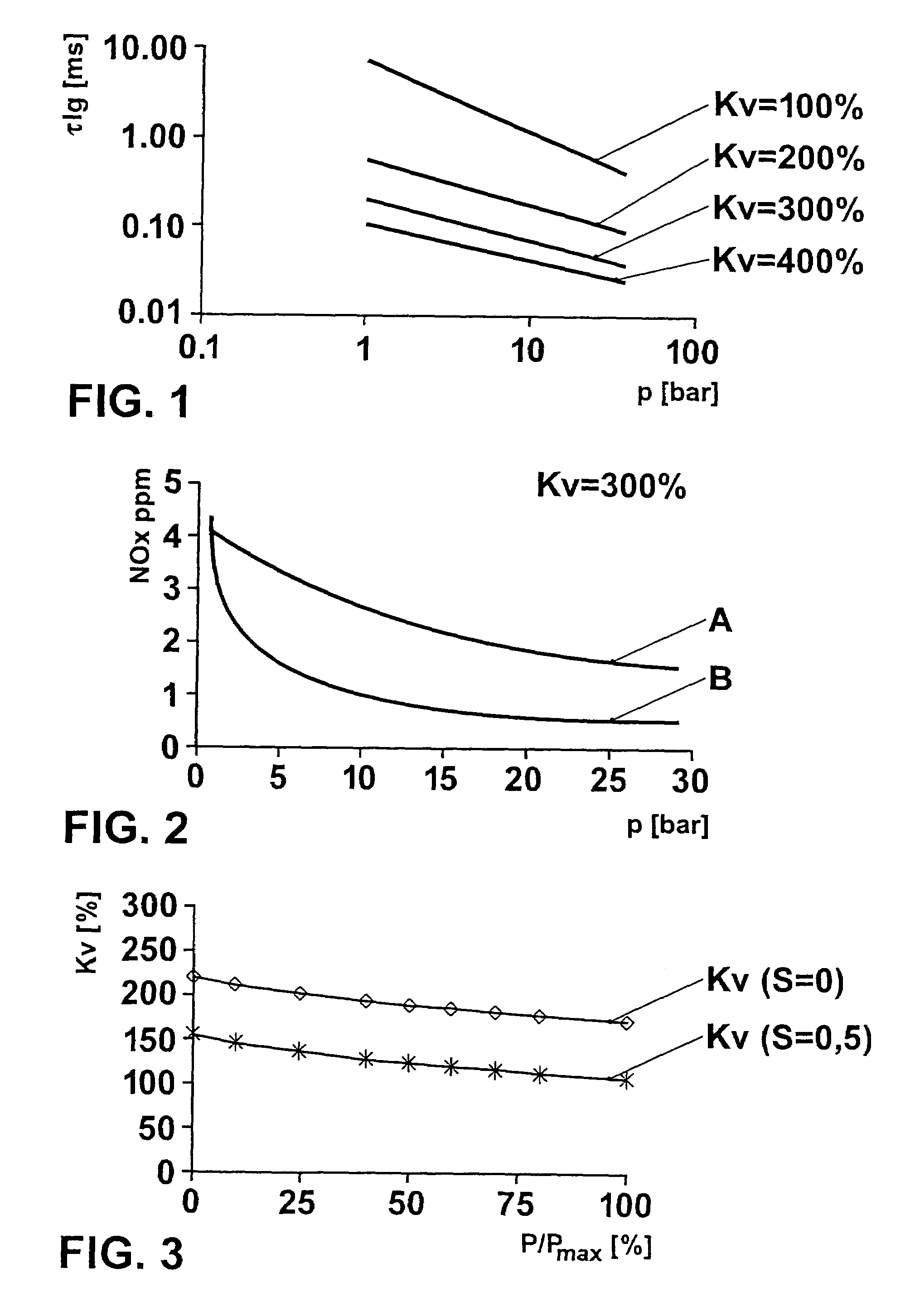

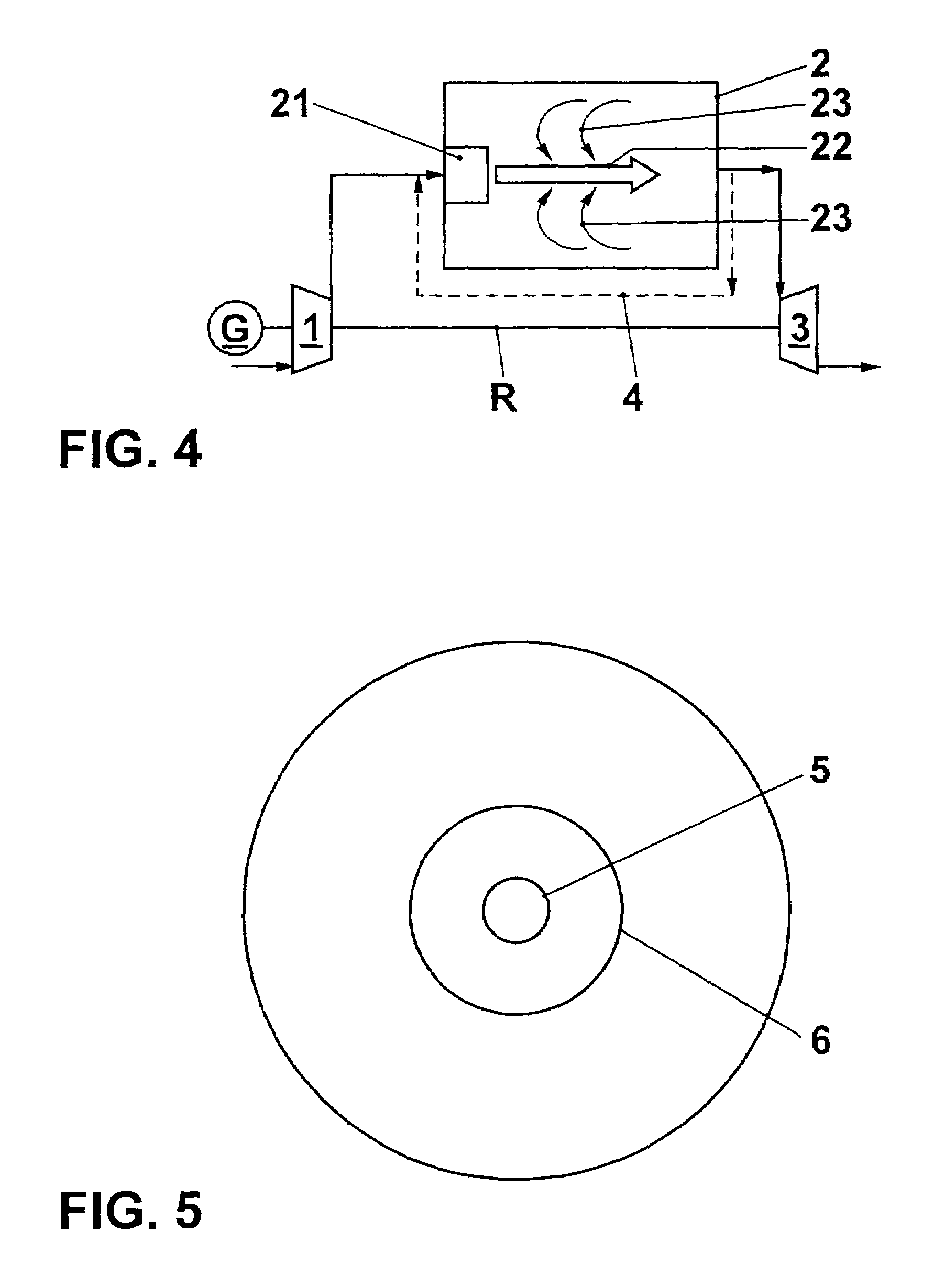

InactiveUS7363756B2Increase speedAccelerated dilutionContinuous combustion chamberGas turbine plantsCombustion chamberFront velocity

In a method for the combustion of a fuel, a fuel or a premixed combustible mixture is introduced into a combustion space as a combustible fluid open jet. The velocity of the open jet is selected in such a way that it is impossible for a stable flame front to form, i.e. is in any event greater than the flame front velocity, and that, on account of a jet pump effect, flue gas is mixed into the combustible fluid jet from the combustion chamber in a jet-induced recirculation internally within the combustion chamber. The admixed flue gas dilutes and heats the combustible fluid. The heating causes the spontaneous ignition temperature to be exceeded, and a low-pollutant volumetric flame is formed in a highly dilute atmosphere.

Owner:ANSALDO ENERGIA SWITZERLAND AG

Gas generants comprising transition metal nitrite complexes

InactiveUS6077371AMetal azide explosive compositionsAlkali metal salt explosive compositionsNitriteHydrazine compound

High nitrogen gas generant compositions, useful for inflating passenger restraint gas inflator bags, comprise a nitrogen rich coordination compound selected from coordination complexes comprised of anionic nitro and nitrito ligands coordinated with a transitional metal template, and nonmetallic or nonmetallic / metallic cations. The gas generant compositions generate relatively more gas and less solids, and are safer than known gas generant compositions. Certain gas generant compositions ignite at lower autoignition temperatures thereby facilitating the use of an aluminum or light weight metal pressure vessel. Other gas generants self-deflagrate eliminating the need for other constituents in the composition. Novel methods for the synthesis of nonmetal derivative coordination complexes, guanidine and hydrazine for example, are also presented.

Owner:AUTOMOTIVE SYST LAB +1

Method and apparatus for injecting a fuel into a combustor assembly

InactiveUS7469544B2Eliminating selectedTurbine/propulsion fuel supply systemsContinuous combustion chamberCombustorAutoignition temperature

Owner:THE BOEING CO

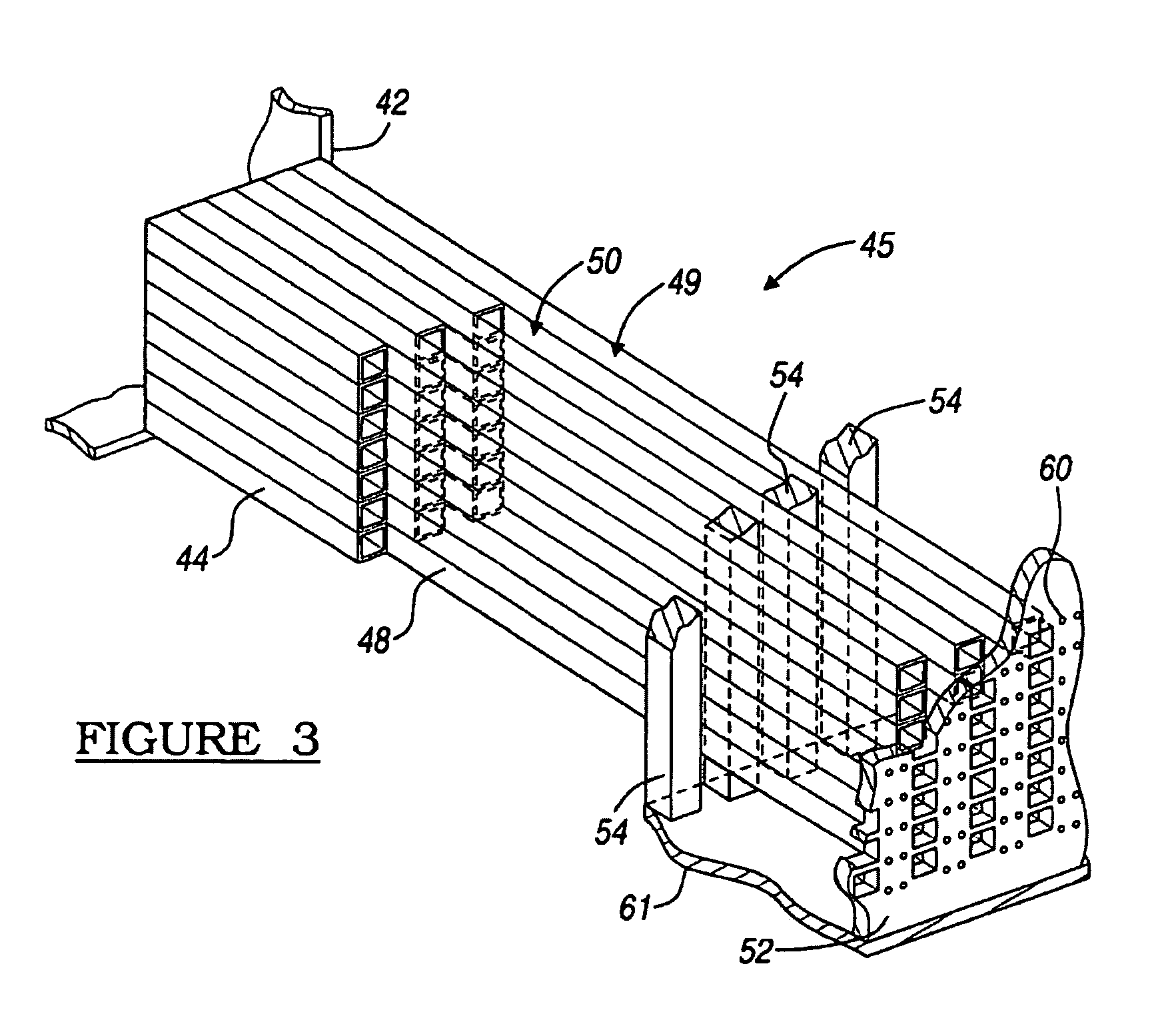

Multi-fuel compression ignition engine

InactiveUS7036482B2Improve performanceMaximizing intensityElectrical controlInternal combustion piston enginesHcci combustionCombustion chamber

A liquid primary fuel is ignited by HCCI with the assistance of the early injection of a liquid pilot fuel. Pilot fuel injection and / or ignition are preferably controlled so as to permit the injected pilot fuel to become thoroughly distributed through and mixed with the primary fuel / air charge in the combustion chamber and vaporized prior to ignition. Pilot fuel having a lower autoignition temperature will be ignited by compression ignition, followed by the ignition of the homogeneous mixture of the primary fuel and air. HCCI combustion of the primary fuel is facilitated by 1) selection of the properties of the primary and pilot fuels and 2) obtaining a homogenous mixture of primary fuel and air by injecting primary fuel into the engine's intake air stream in the form of finely atomized droplets having a mean diameter in the micron range.

Owner:CLEAN AIR POWER

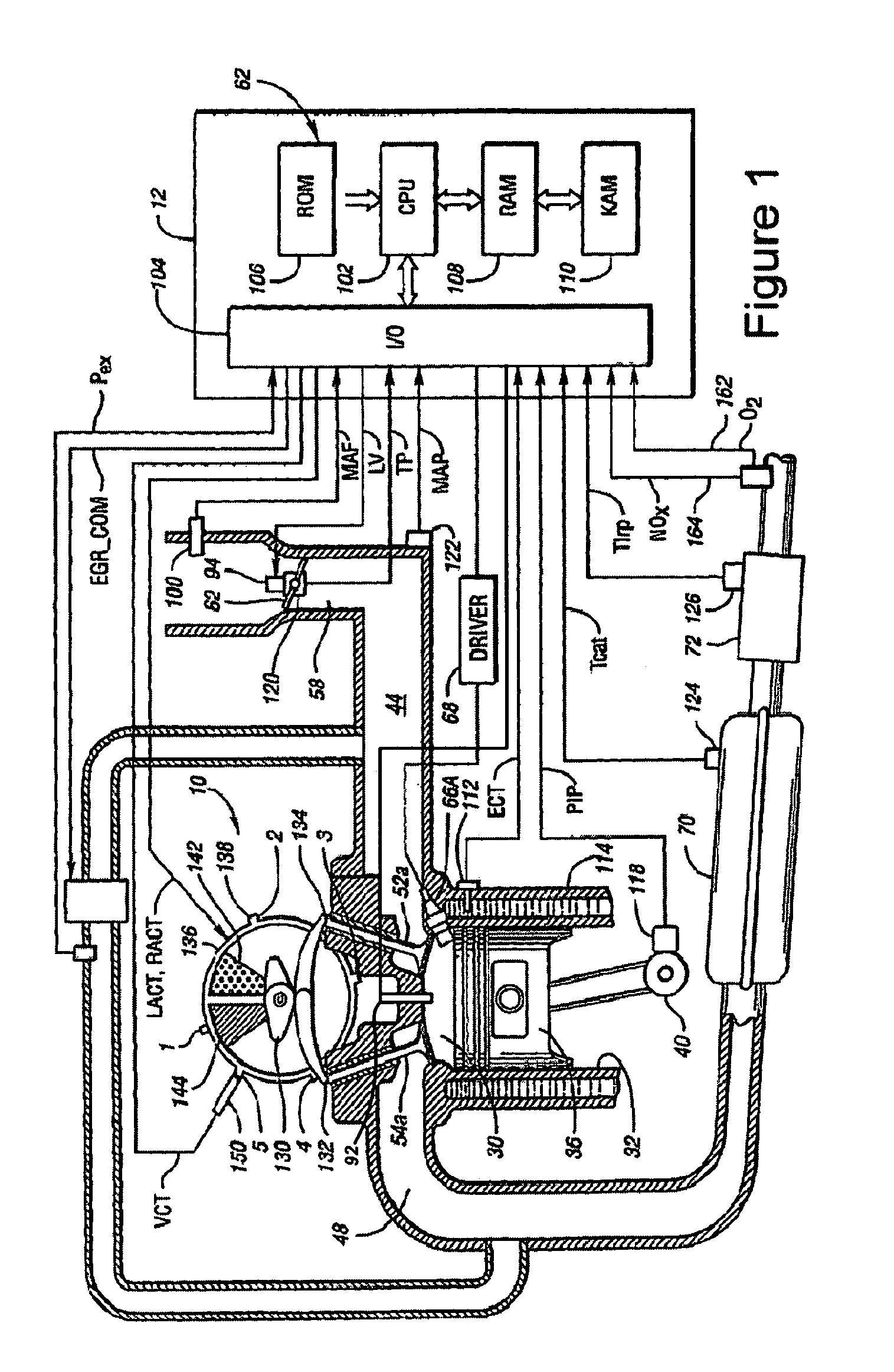

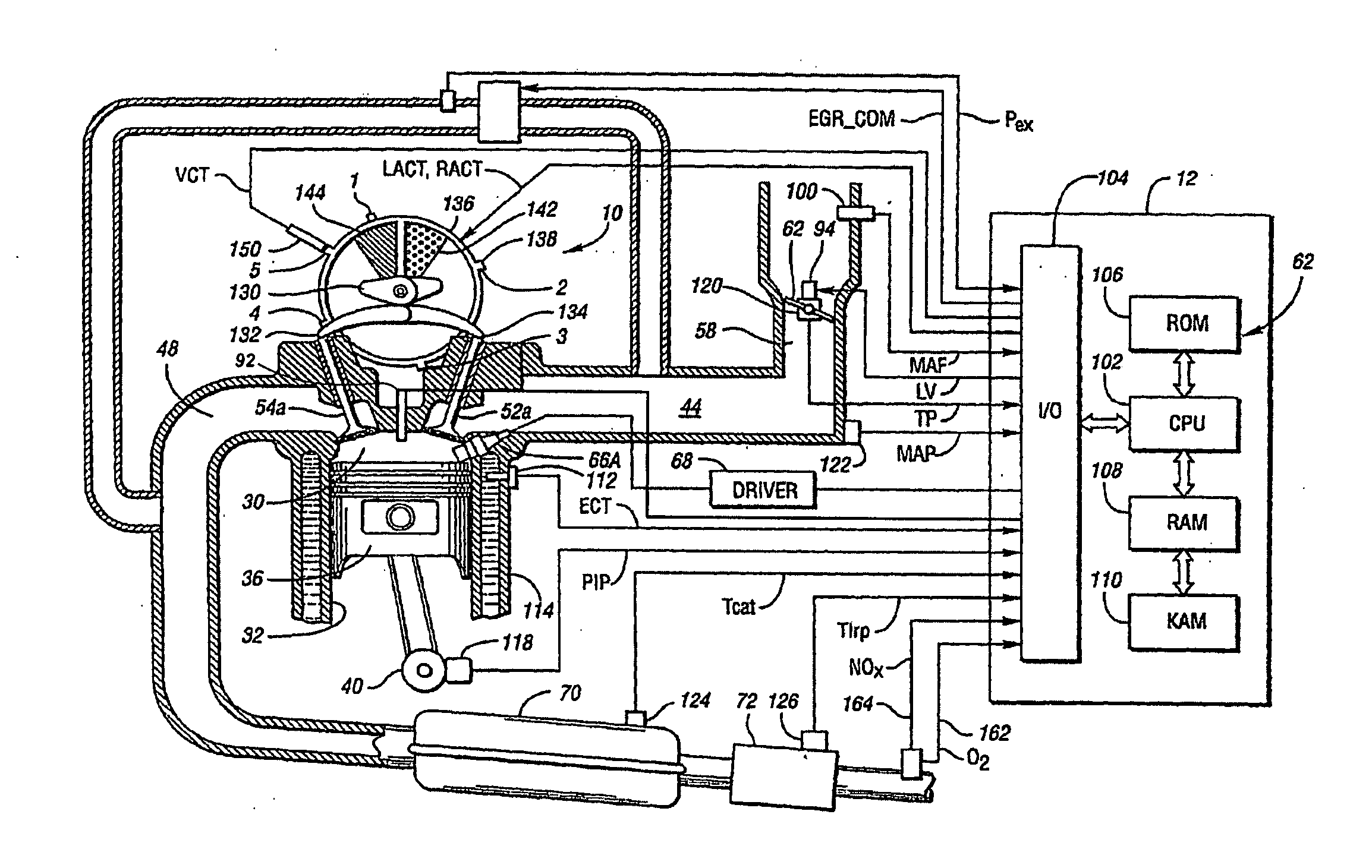

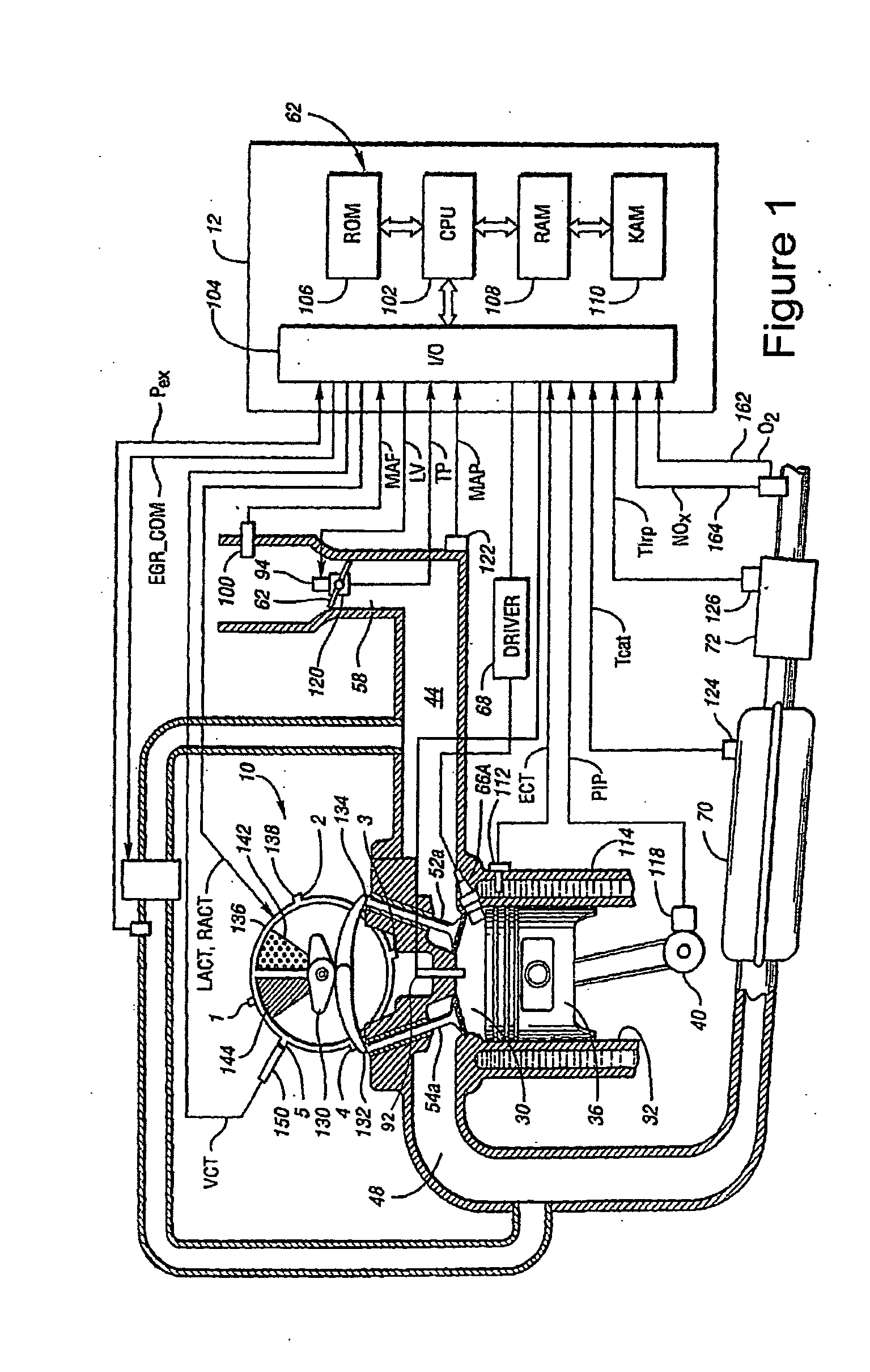

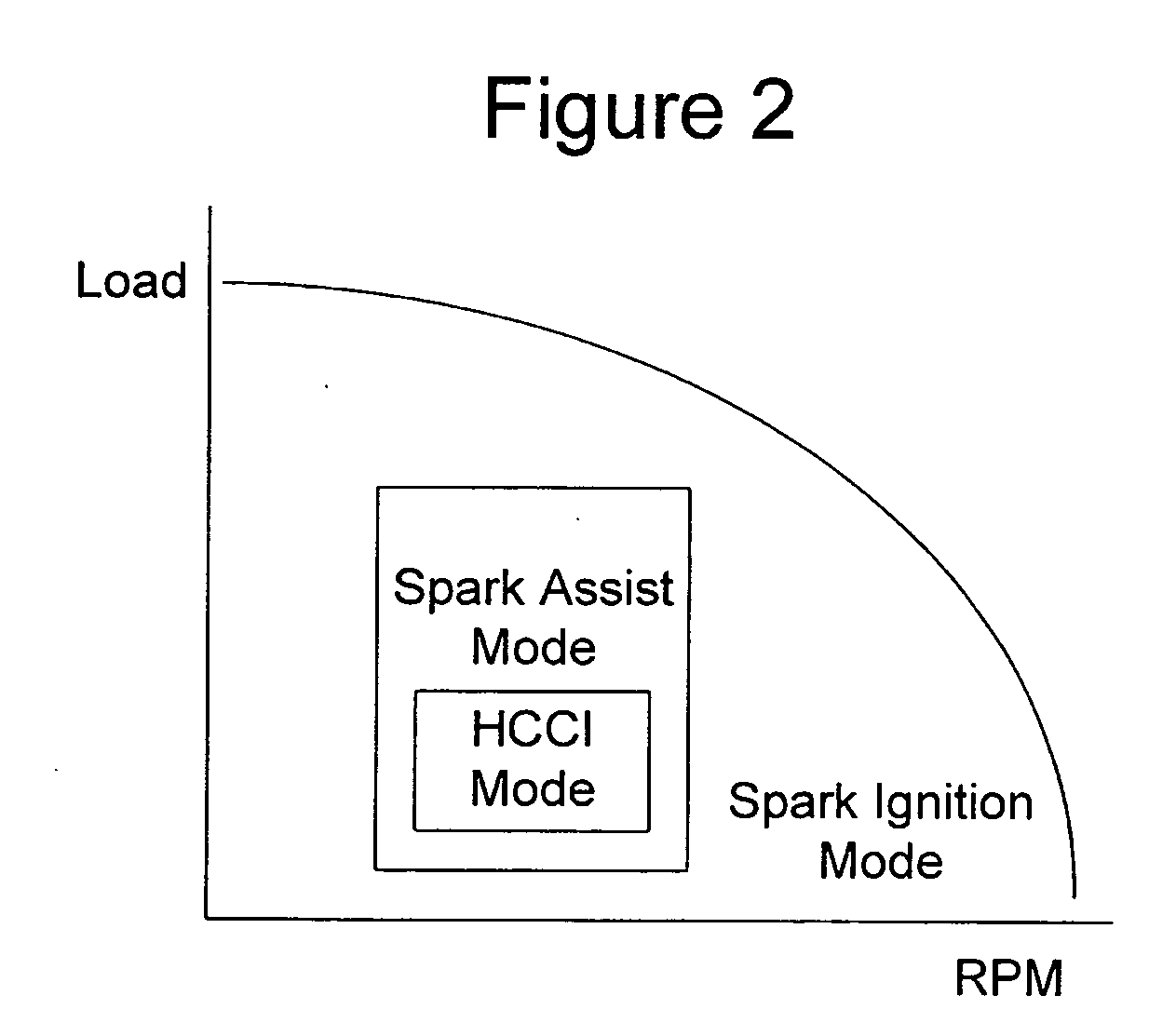

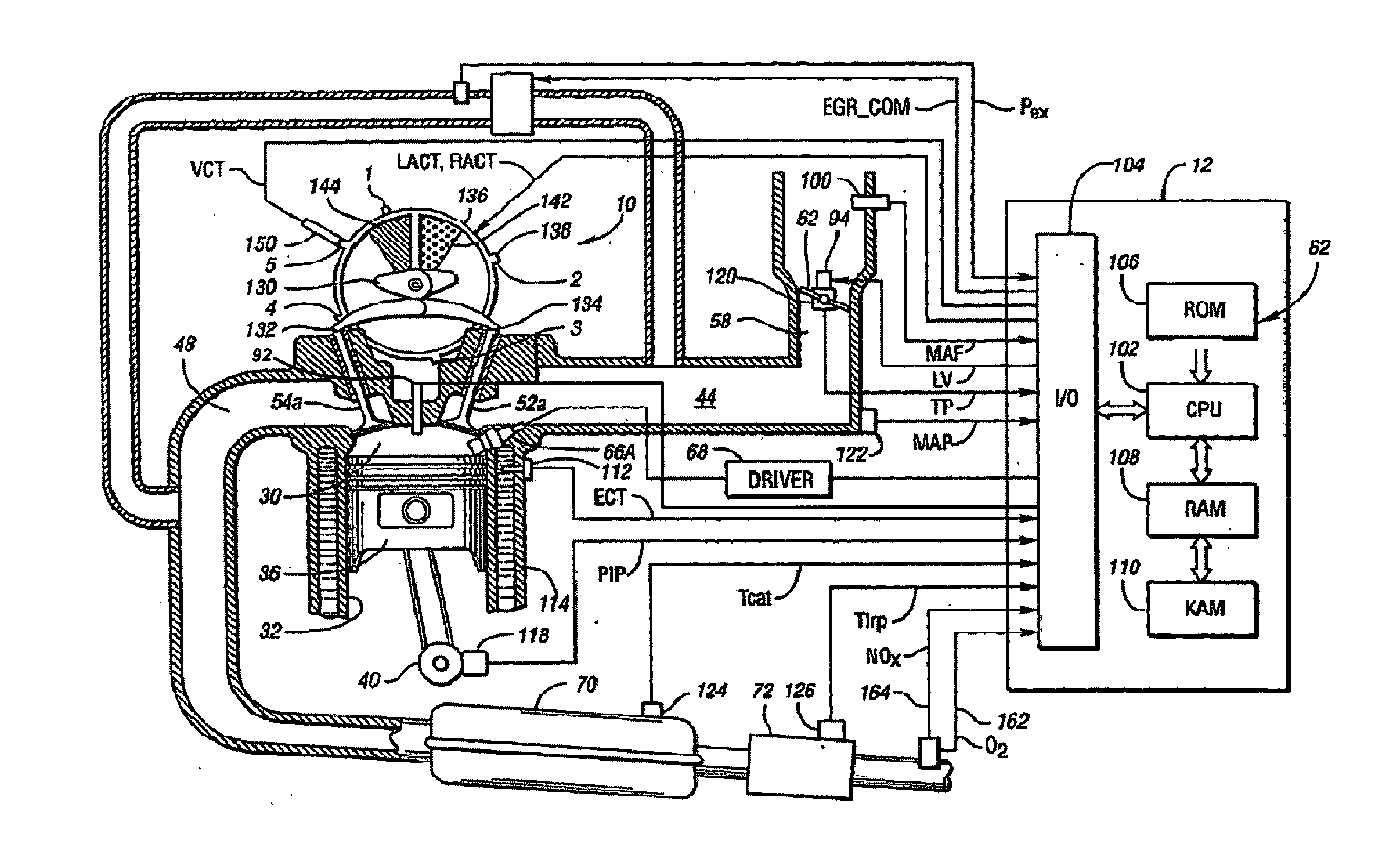

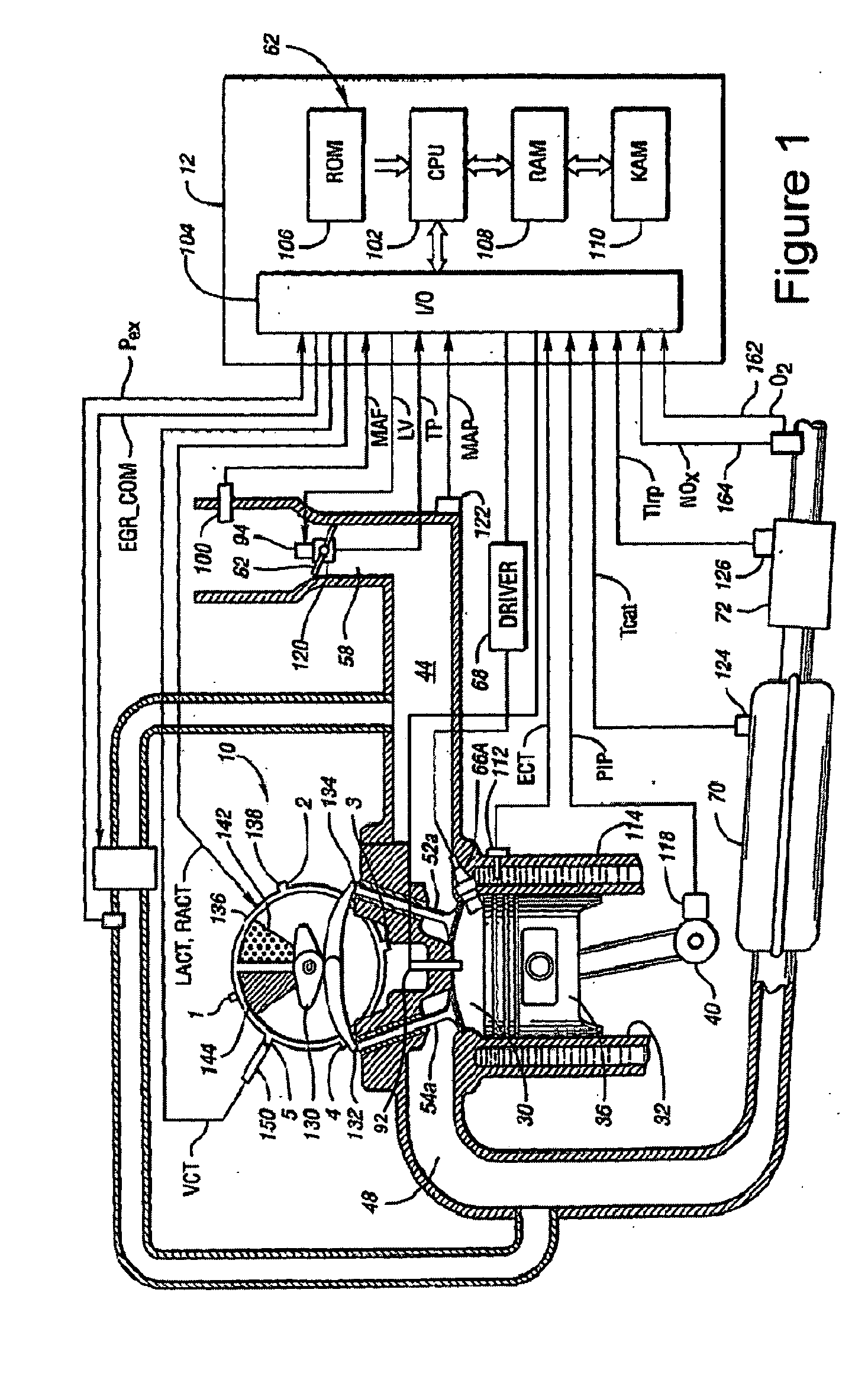

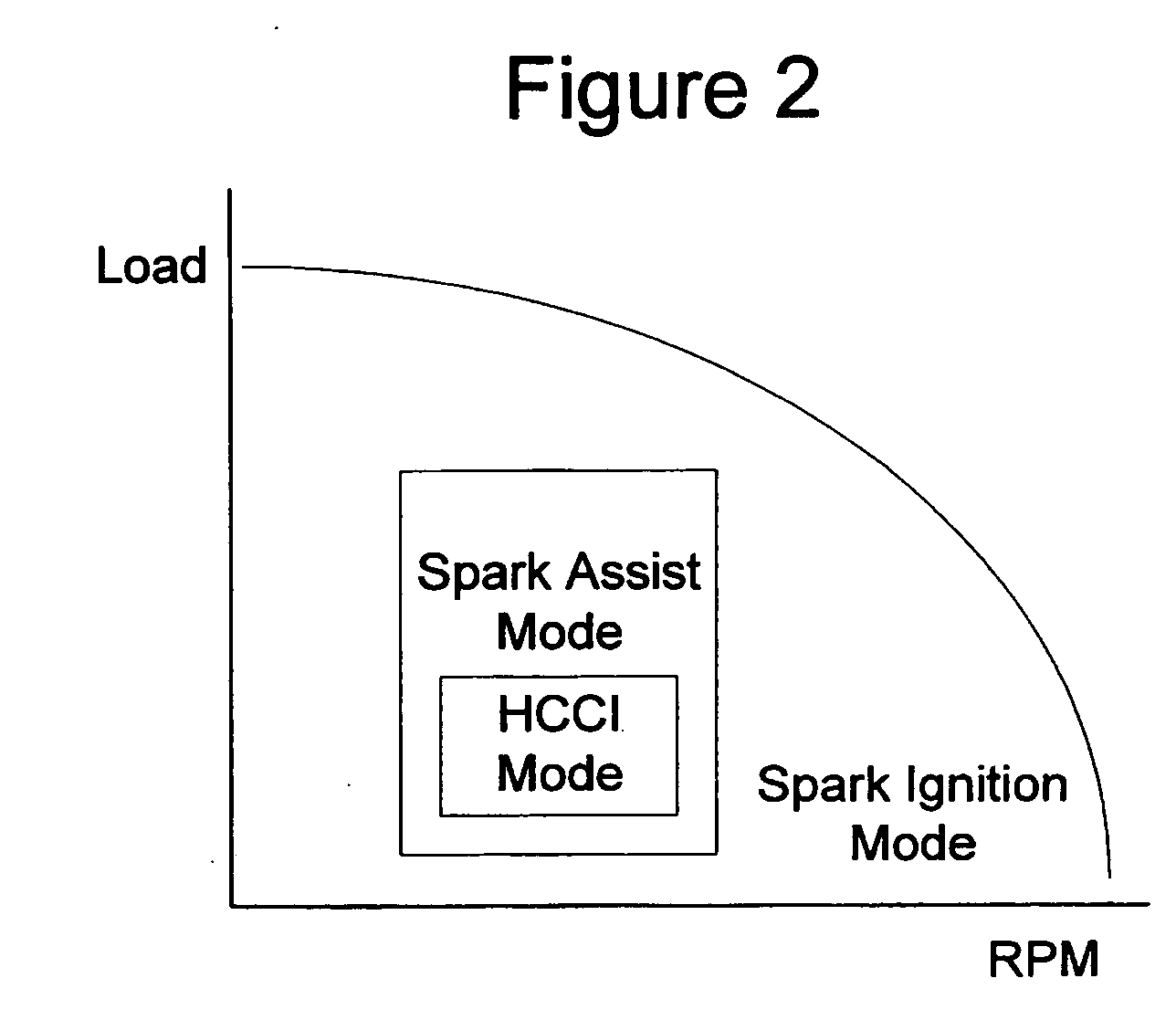

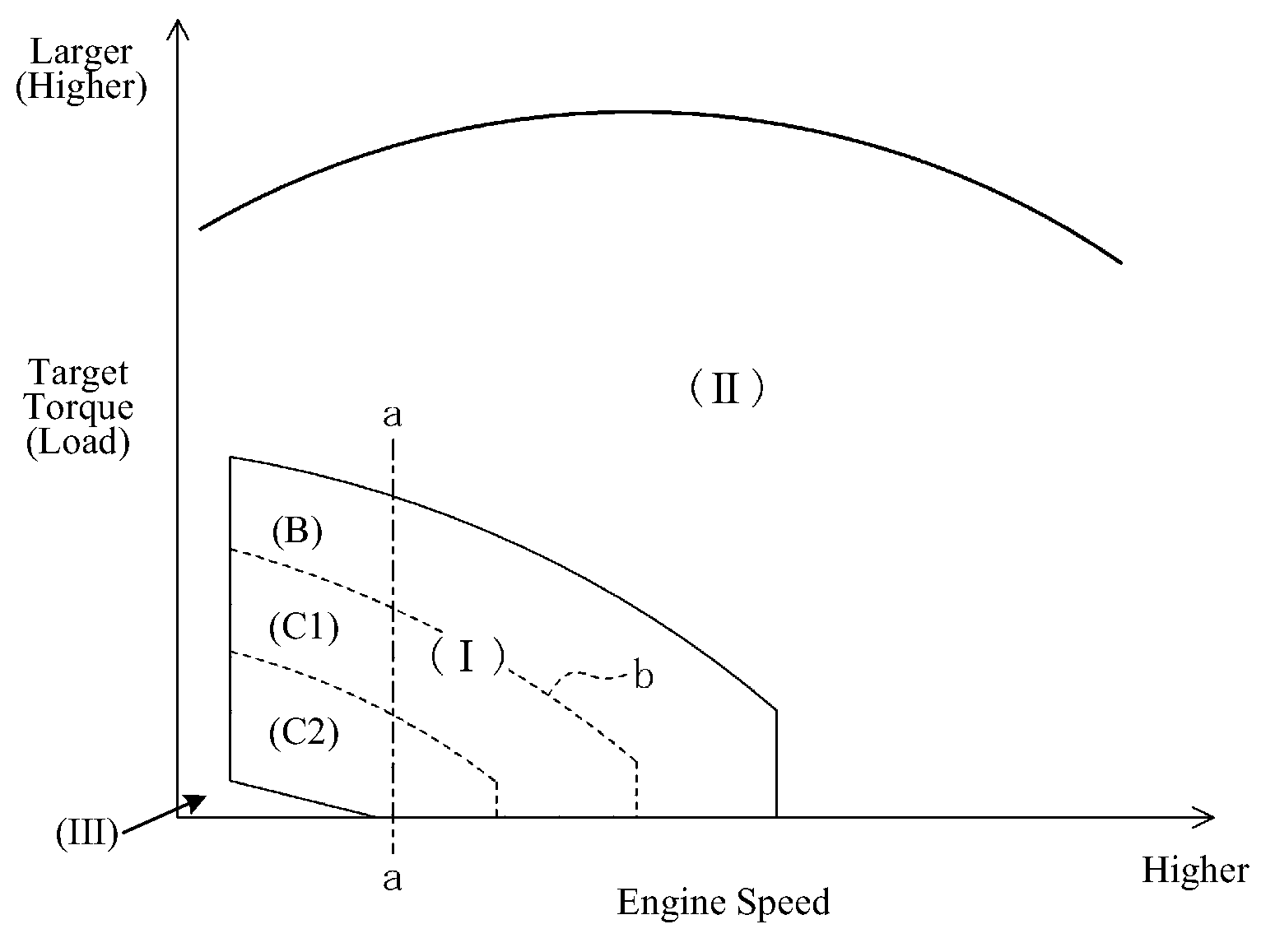

Load transient control methods for direct-injection engines with controlled auto-ignition combustion

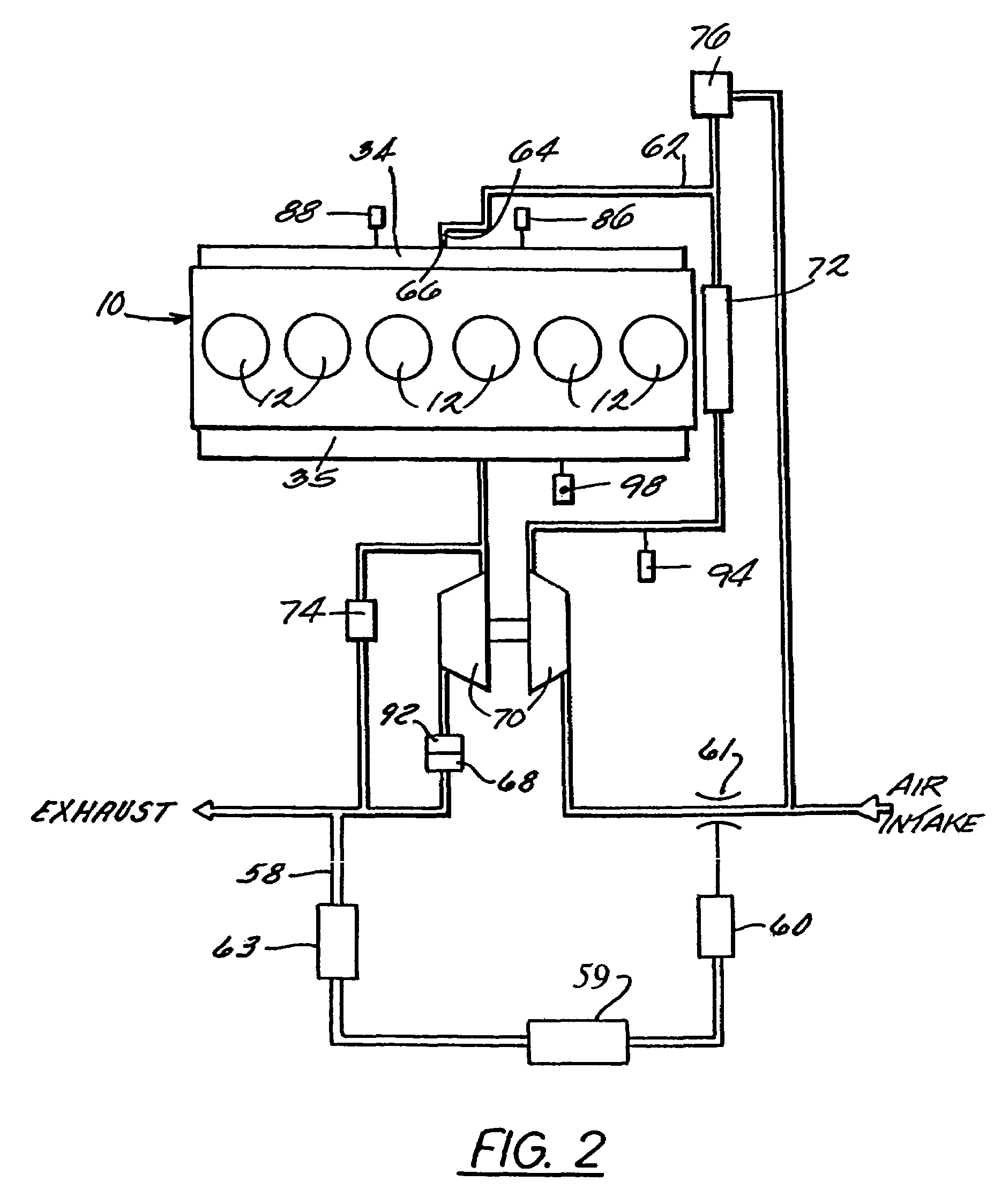

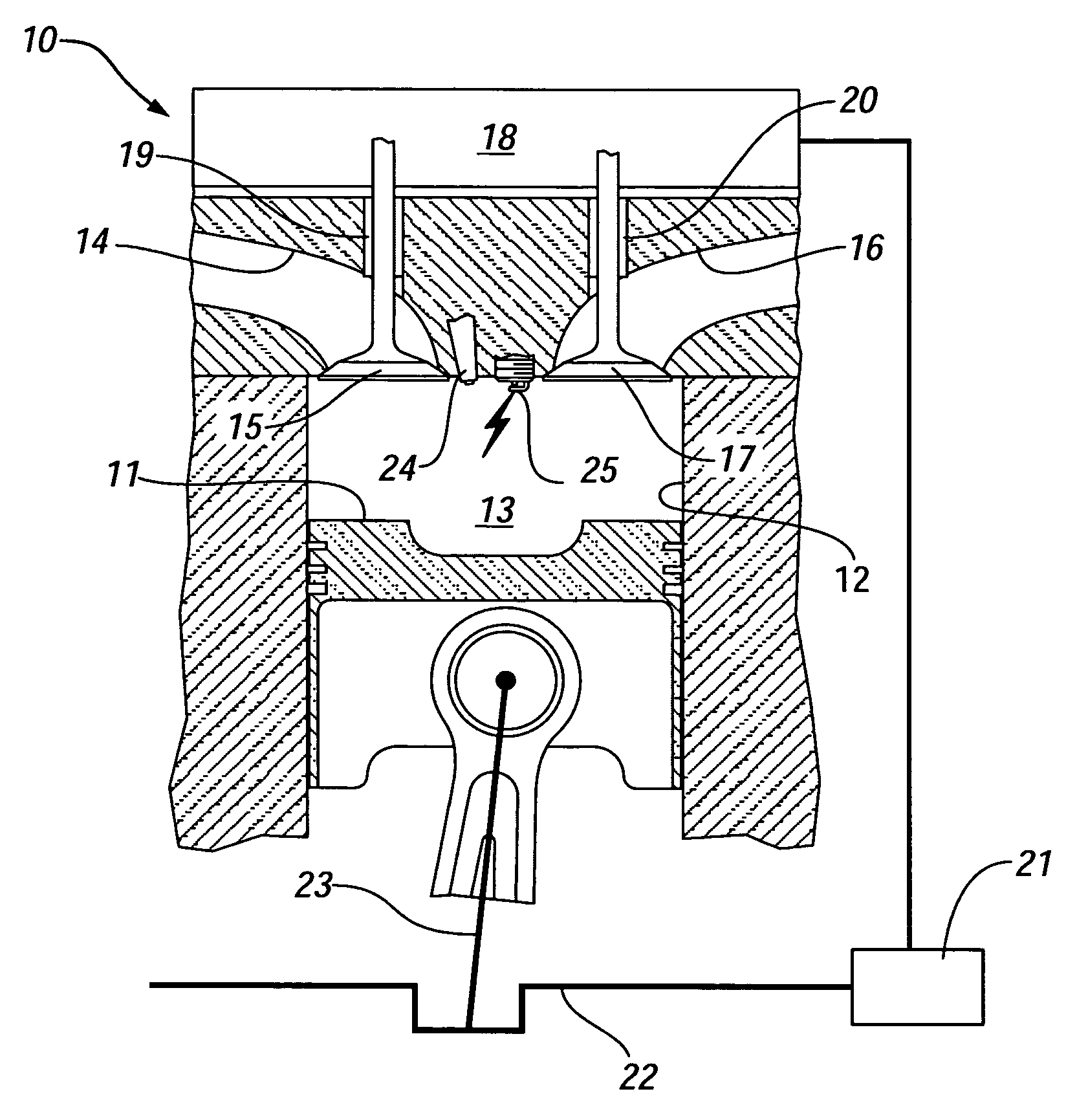

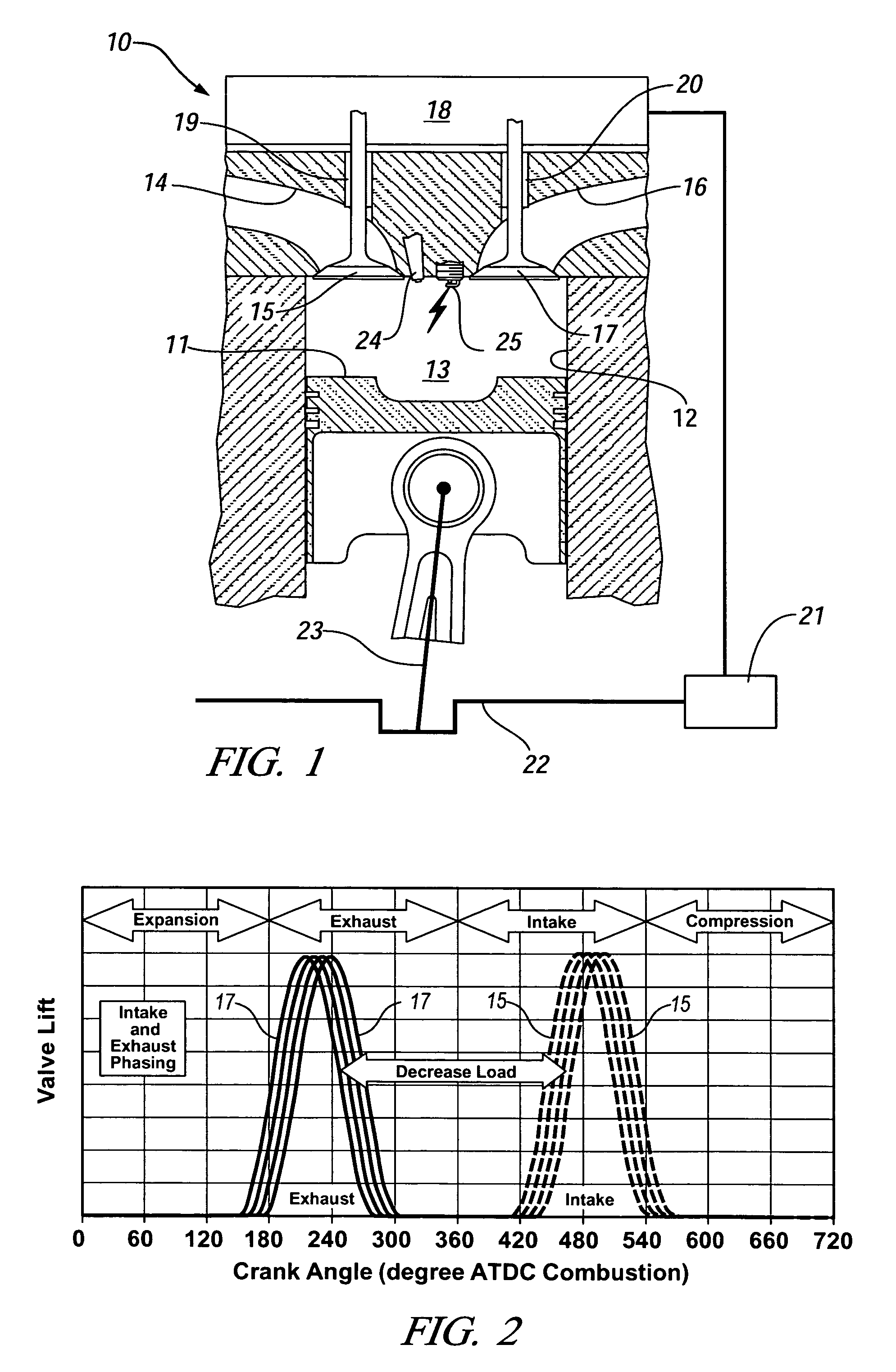

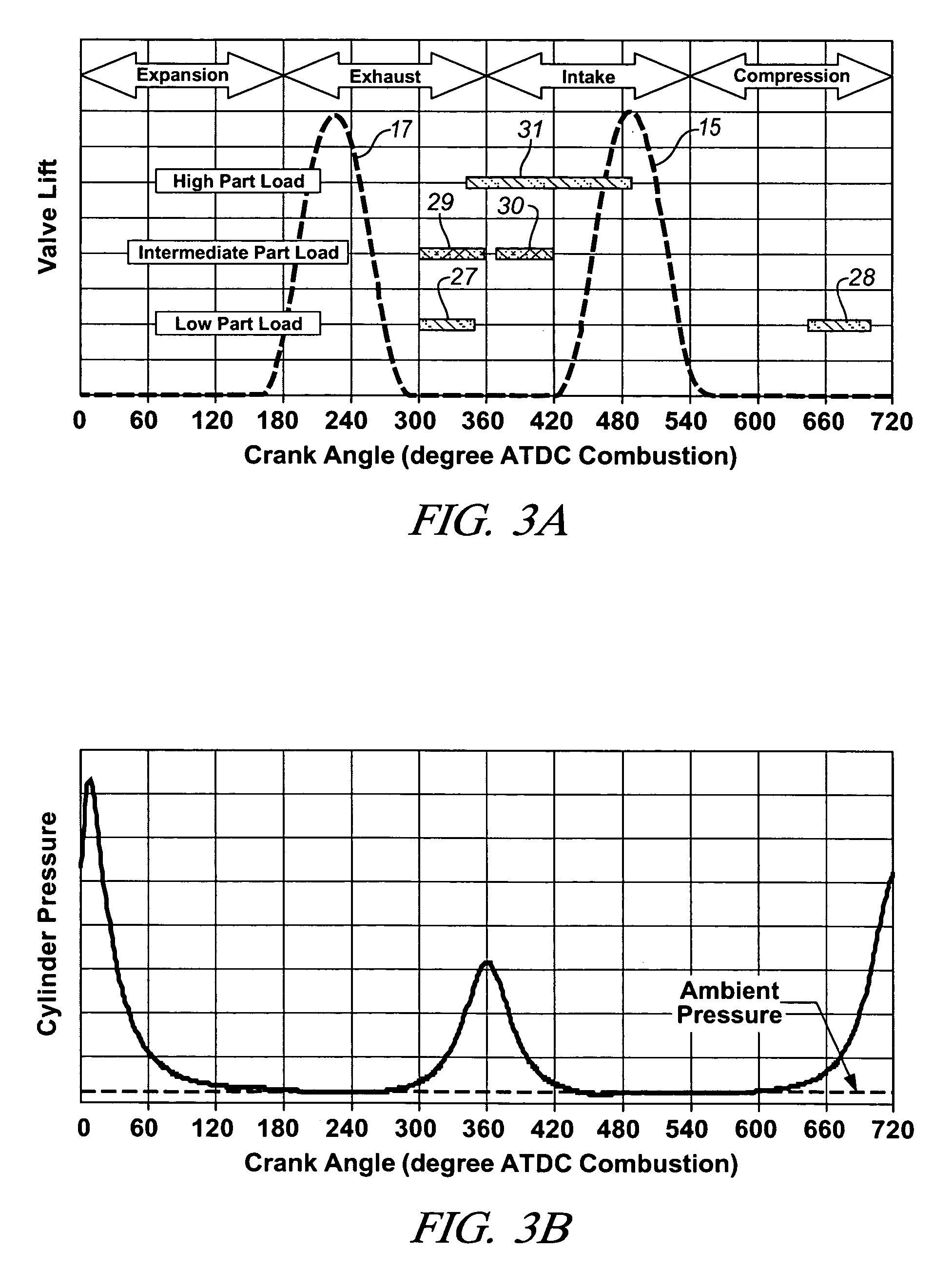

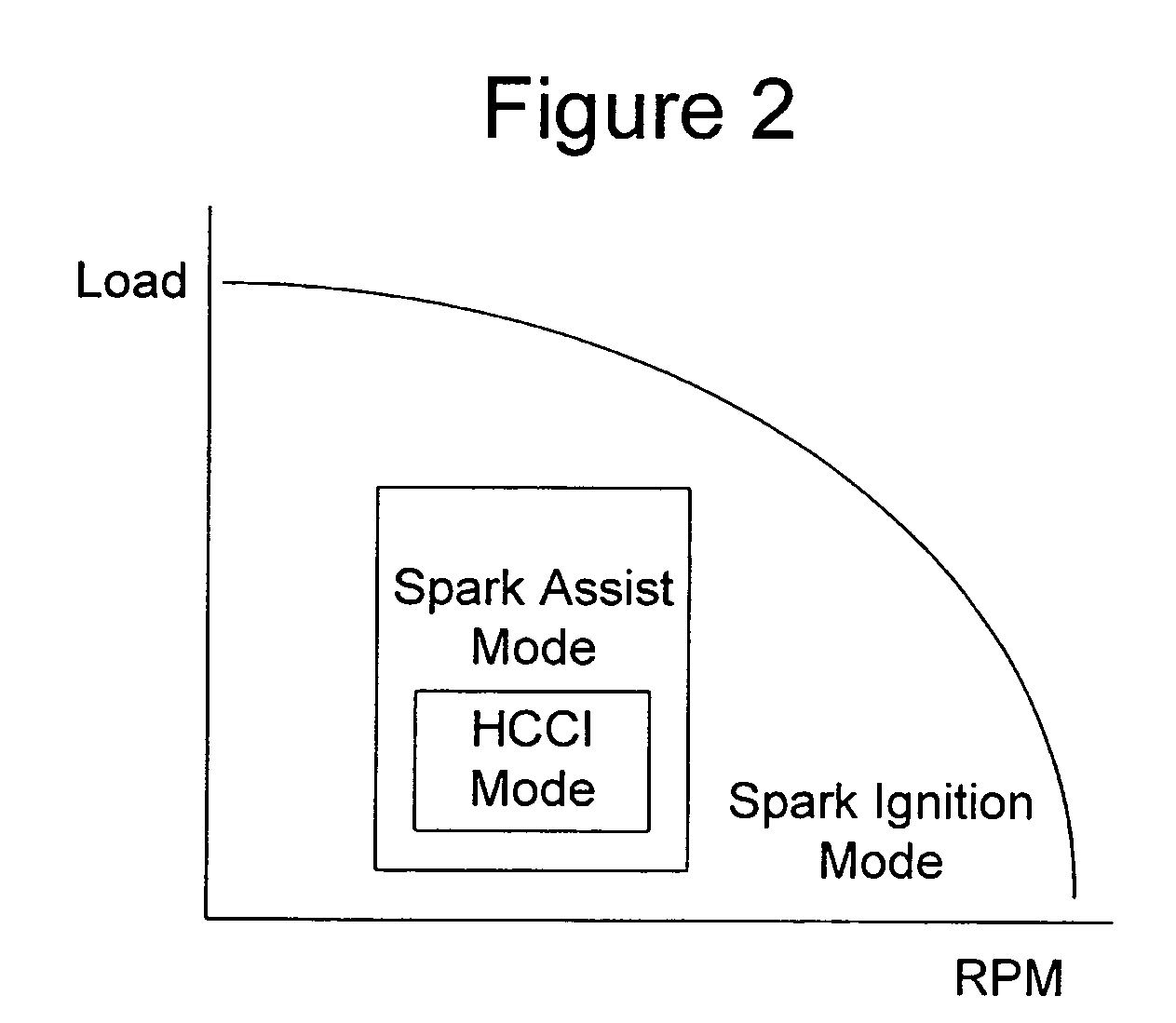

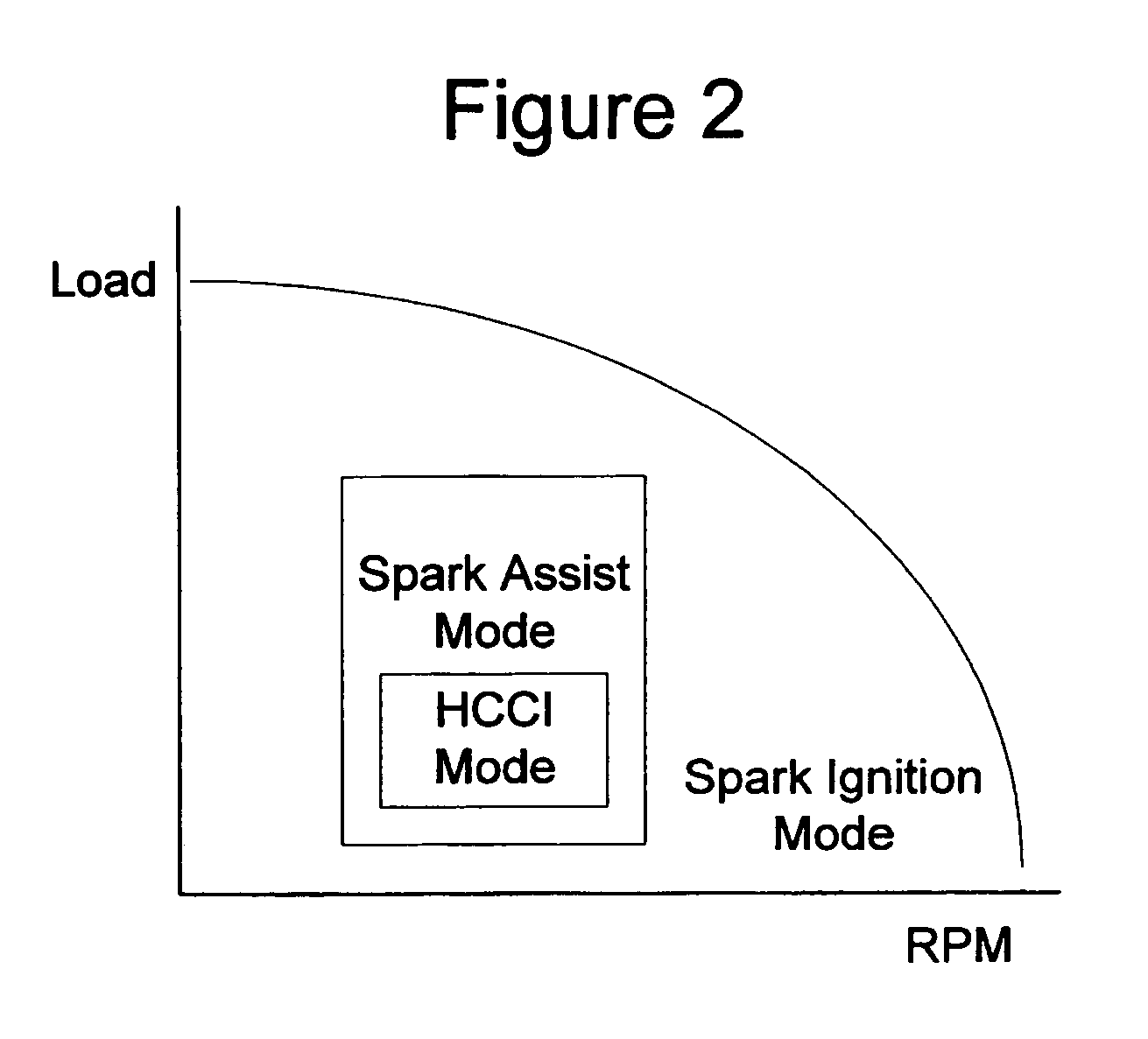

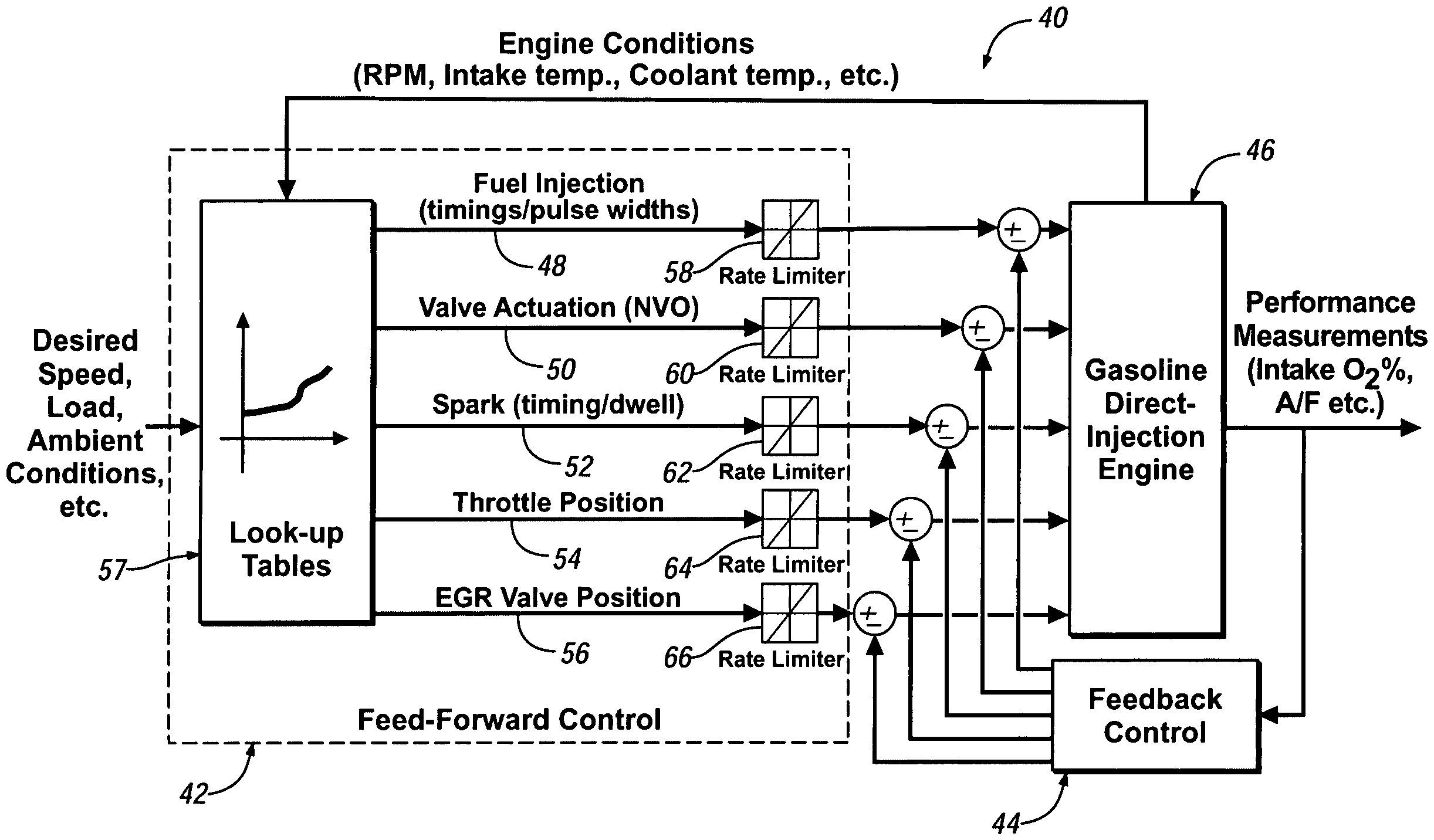

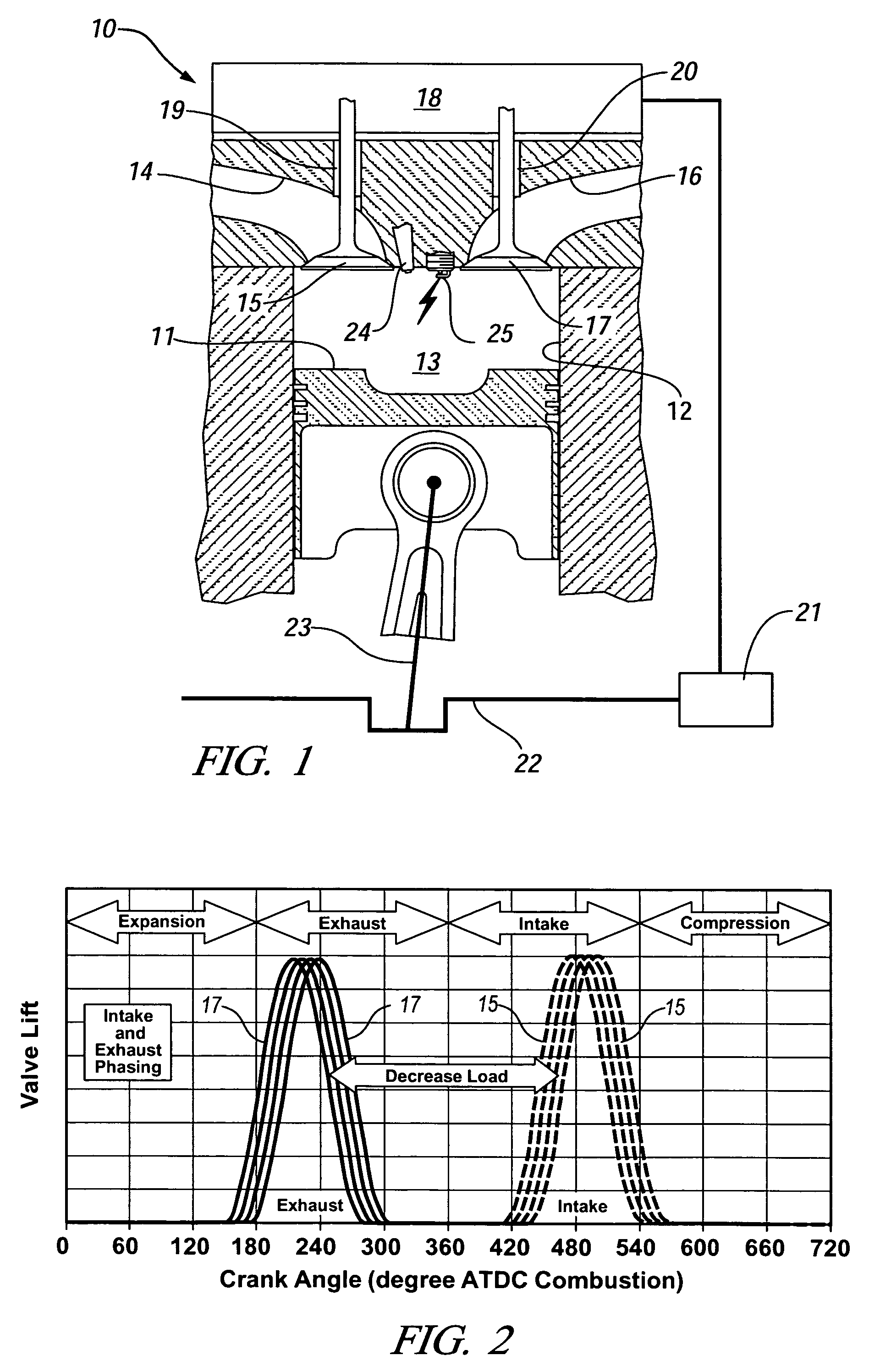

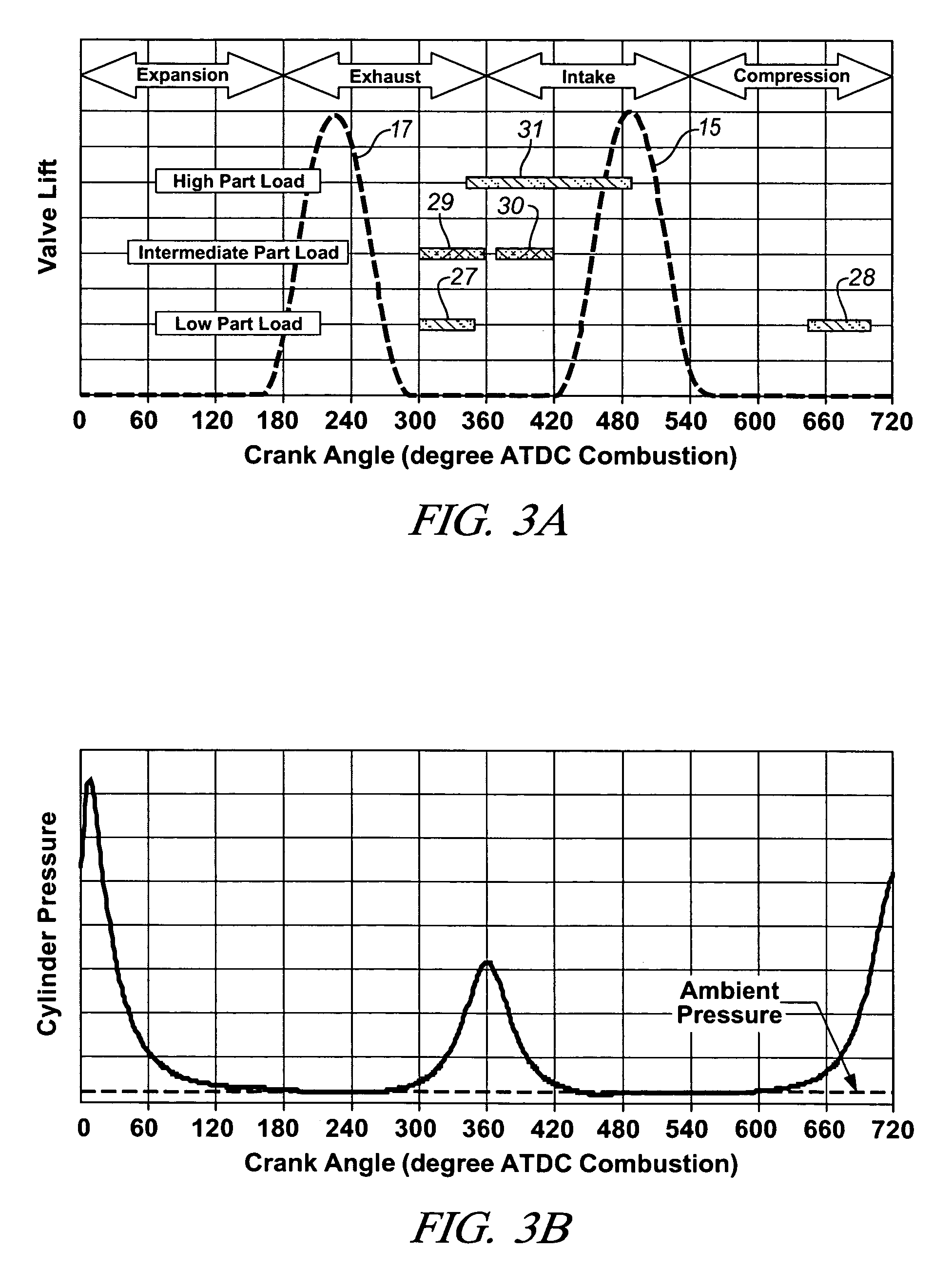

InactiveUS20060196467A1Electrical controlNon-fuel substance addition to fuelHomogeneous charge compression ignitionLow load

A direct injection controlled auto-ignition engine is operated at steady state, within a homogeneous charge compression-ignition (HCCI) load range and with fuel-air-diluent mixtures at predetermined conditions, for each speed and load, of engine control inputs, including at least fueling mass flow rate, injection timing (FI), spark timing (SI) and exhaust recompression obtained by negative valve overlap (NVO). During load change rates below a predetermined threshold, SI, FI and NVO change rates are synchronized to current changes in the fueling mass flow rate. For fast load increases above the threshold, the cylinder charge is temporarily enriched by increasing the percentage of residual gas or reducing the percentage of fresh air mass in the charge sufficiently to maintain auto-ignition temperature during the load change. This may be done by delaying NVO action for a predetermined speed-dependent number of engine cycles. At very low loads, stable fuel rate reduction may require an alternate method involving deceleration fuel cut-off followed by a step change during refire.

Owner:GM GLOBAL TECH OPERATIONS LLC

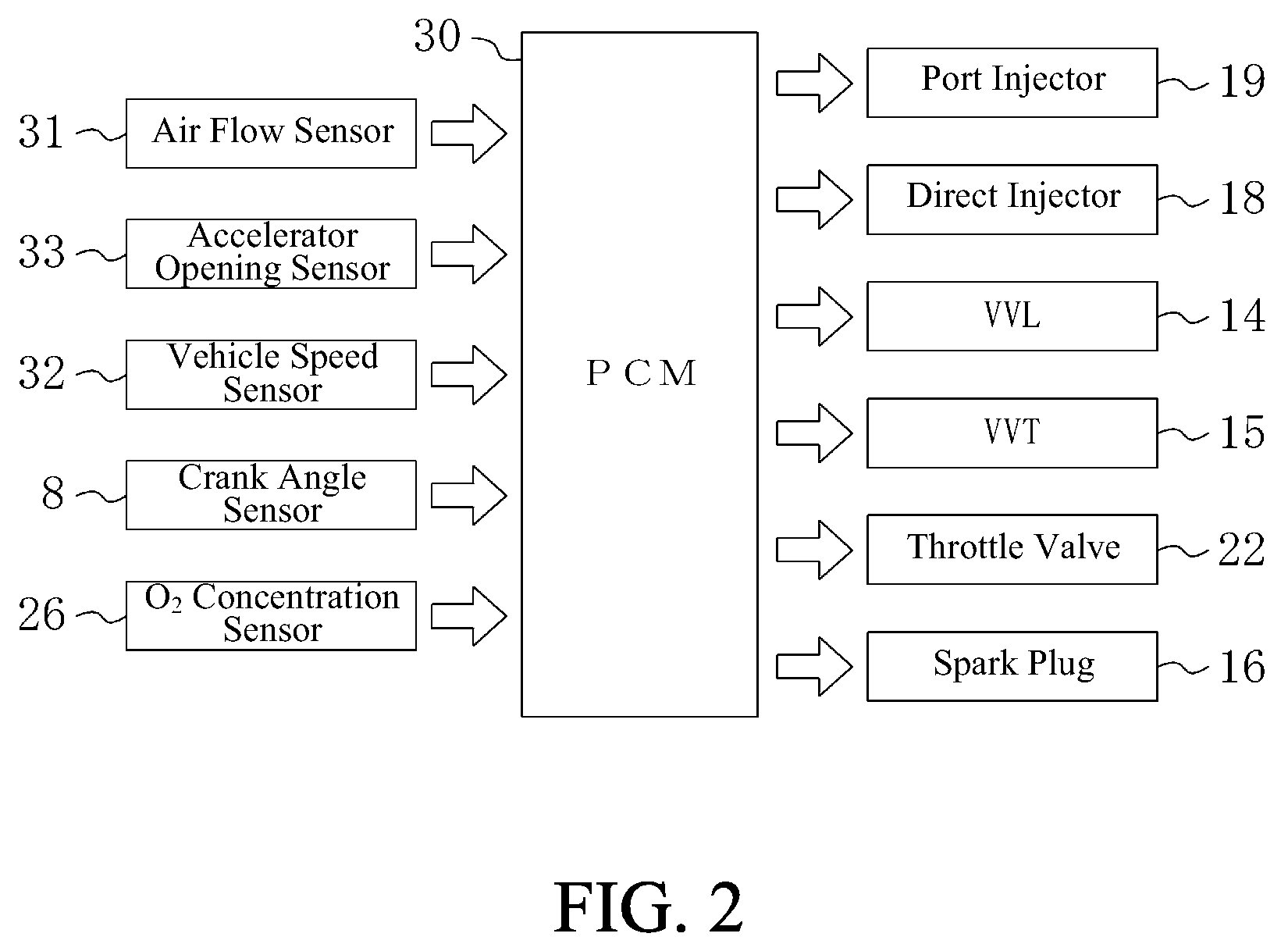

Method of operating an internal combustion engine

ActiveUS20080178836A1Overcome disadvantagesAccelerate emissionsValve arrangementsElectrical controlExternal combustion engineInternal combustion engine

A method of operating an internal combustion engine having a combustion chamber with a piston and a spark plug, comprising during a first mode, bringing the temperature of the combustion chamber to auto-ignition temperature by adjusting engine operating conditions and producing auto-ignition in said combustion chamber without requiring spark from said spark plug; and during a second mode, bringing the temperature of the combustion chamber close to auto-ignition temperature by adjusting engine operating conditions, forming a small cloud of stratified air-fuel mixture near said spark plug, igniting said fuel cloud by a spark form said spark plug, and then causing cylinder pressure to rise, thereby producing auto-ignition at other sites in said combustion chamber wherein said first mode is implemented in a first operating range and said second mode is implemented only in a second operating range where engine speed and load are lower than said first operating range.

Owner:MAZDA MOTOR CORP

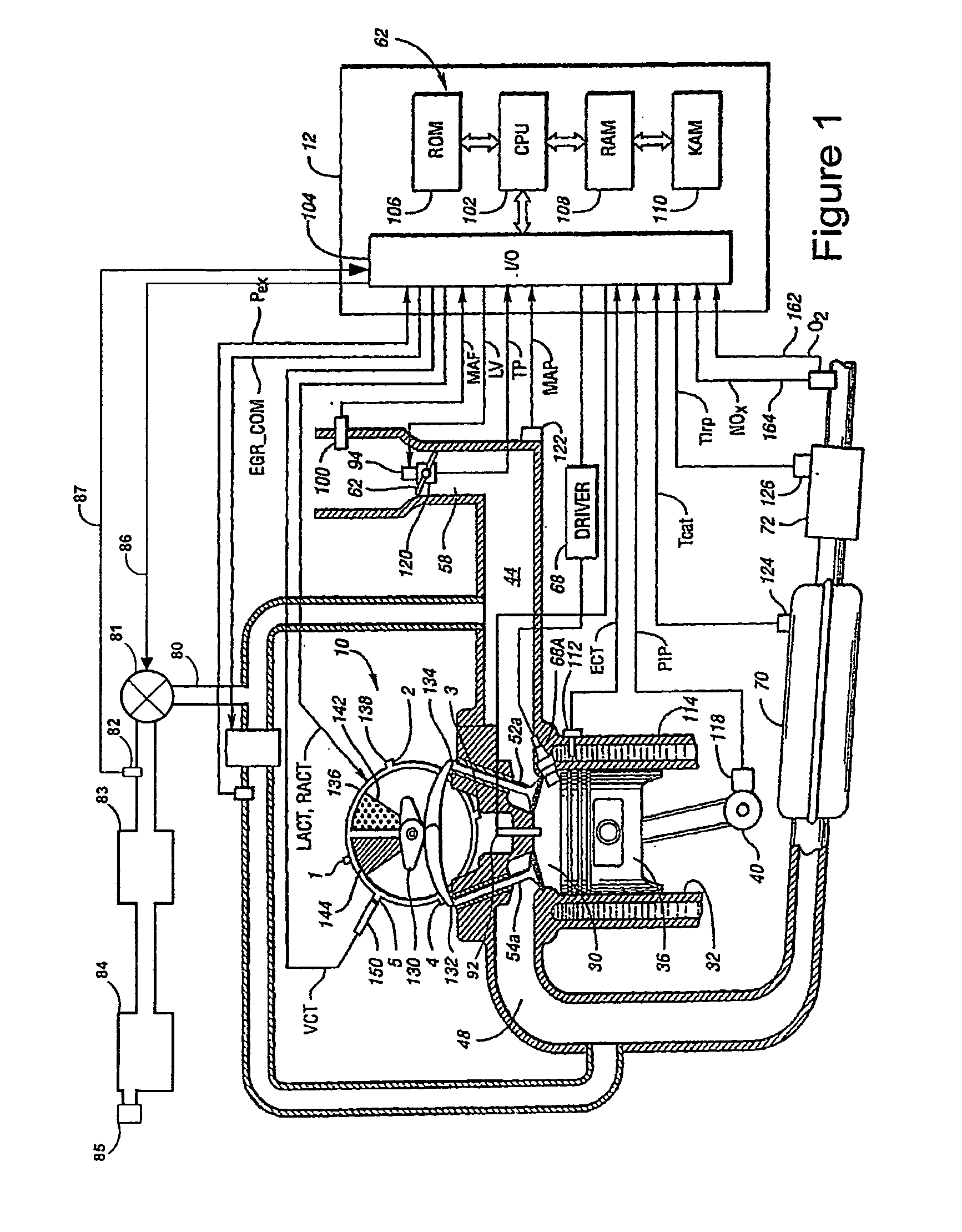

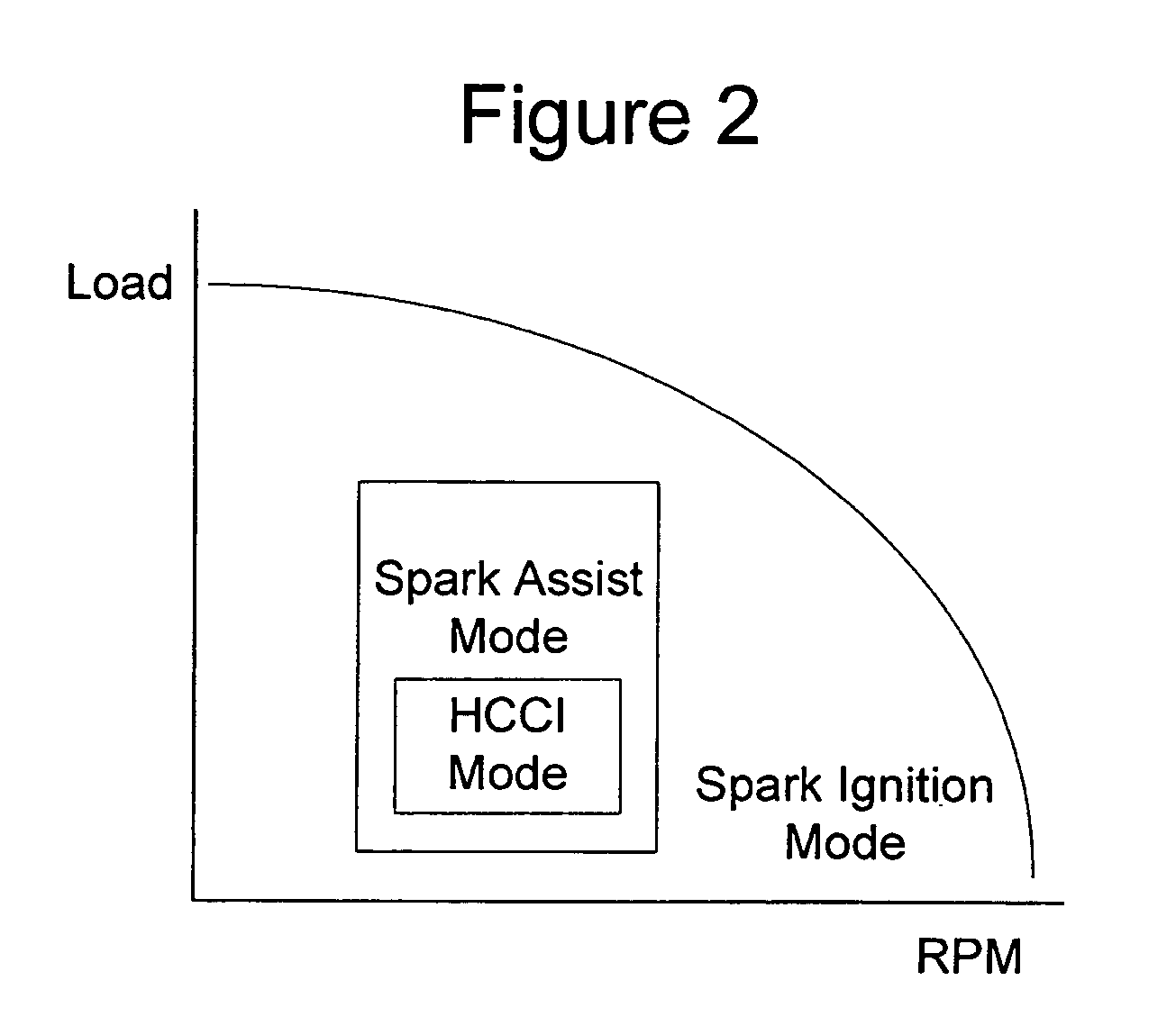

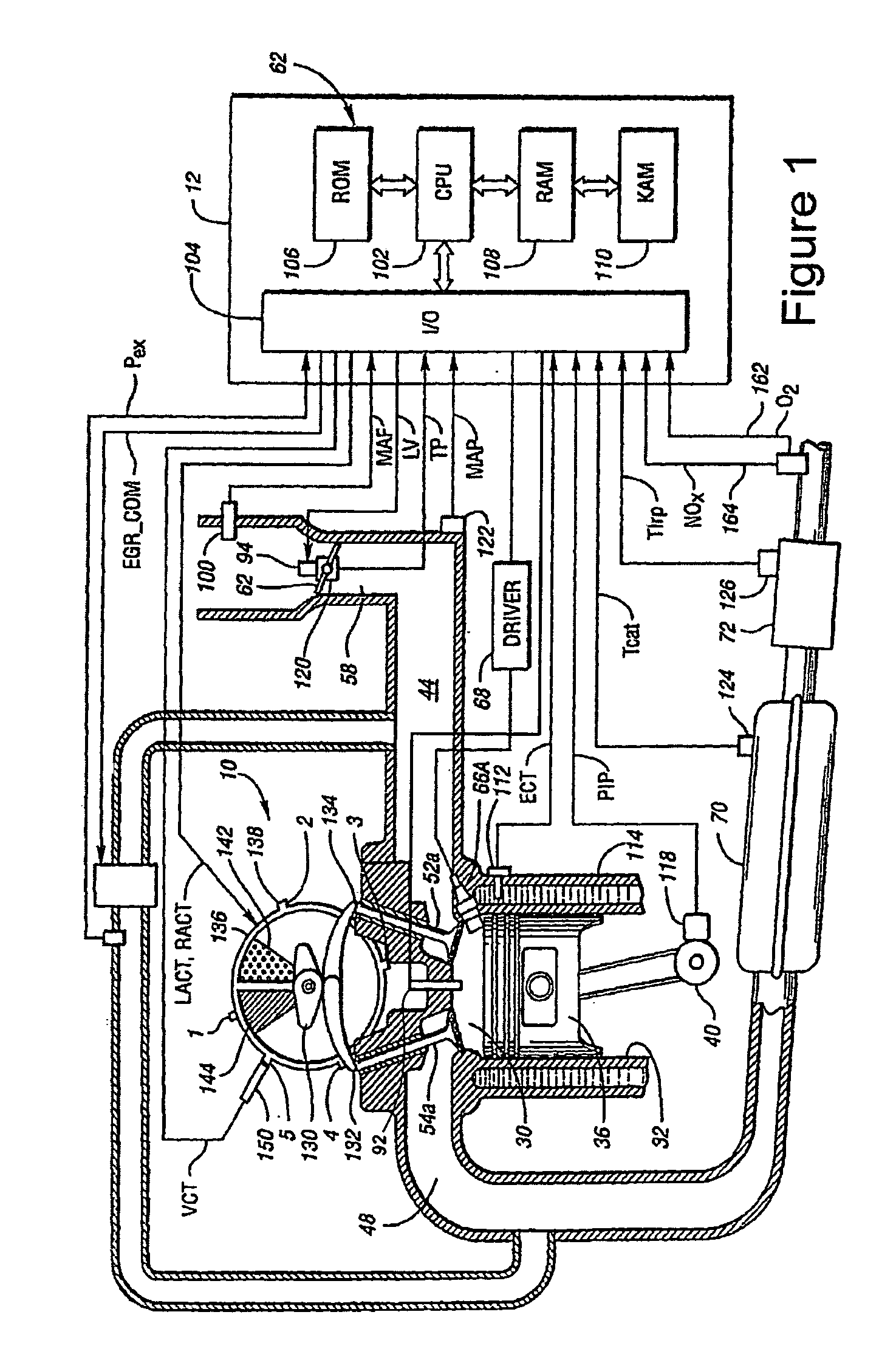

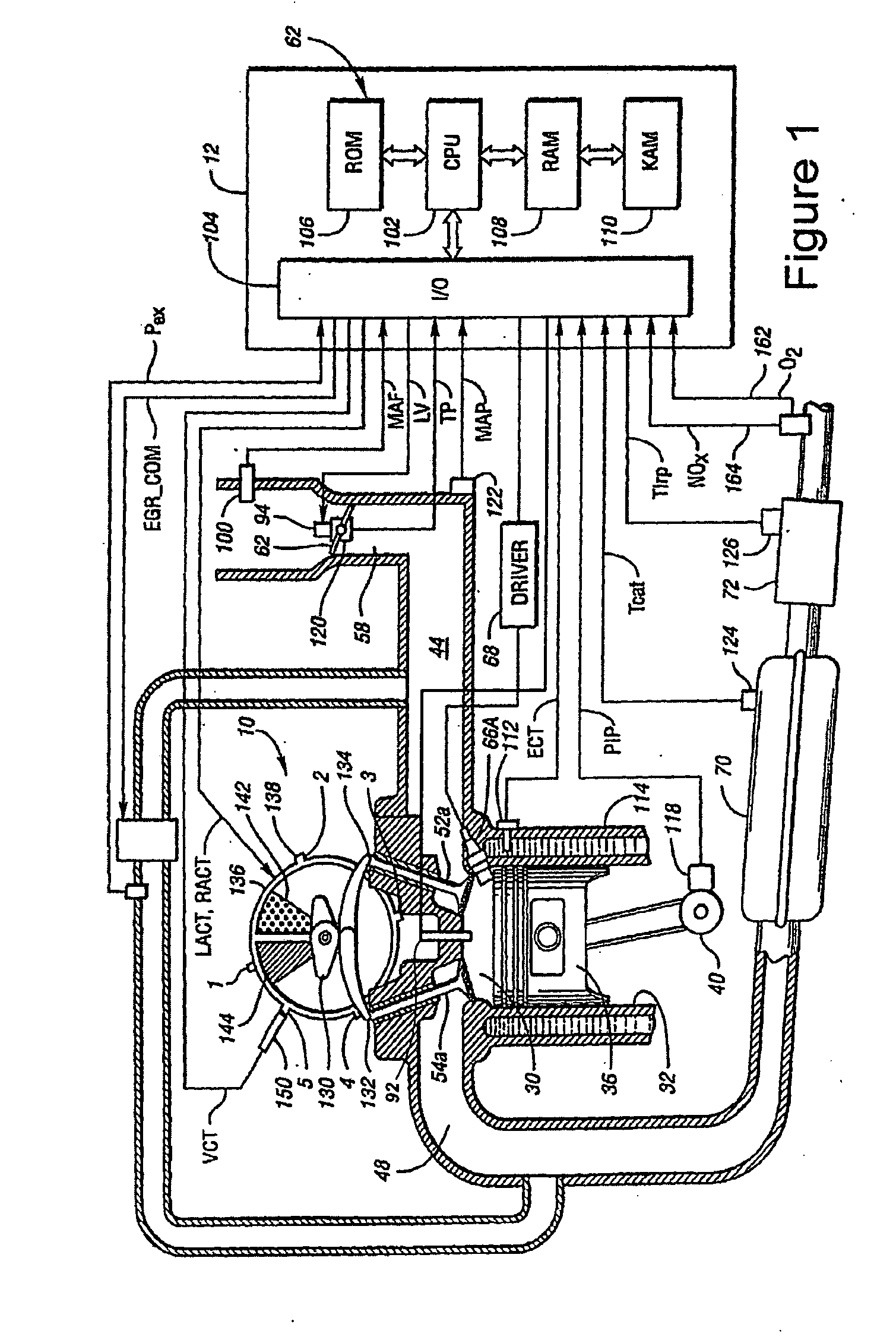

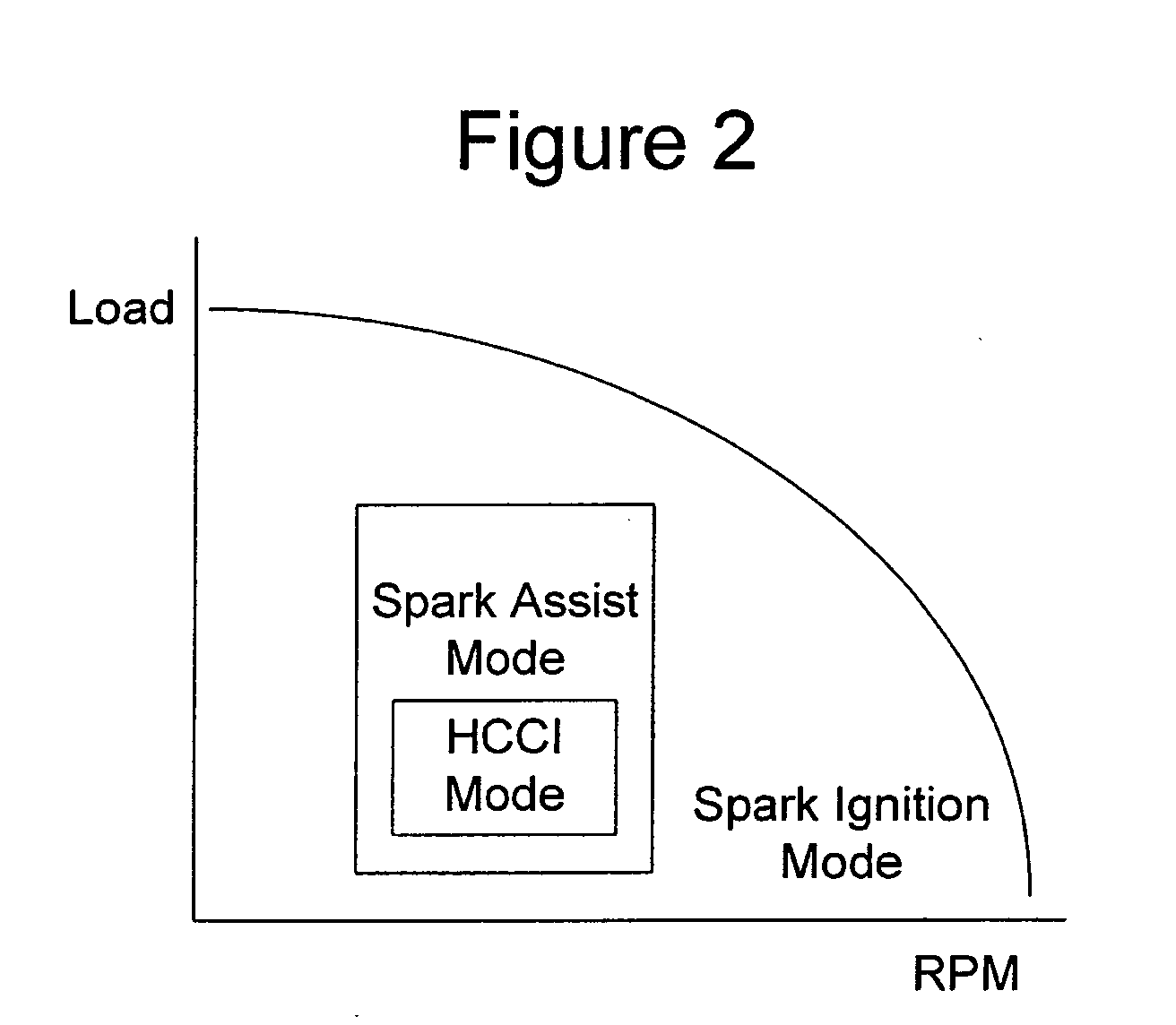

System and method for engine operation with spark assisted compression ignition

ActiveUS7168420B1Accelerate emissionsReduce fuel savingElectrical controlNon-fuel substance addition to fuelCombustion chamberInternal combustion engine

A method of operating an internal combustion engine having a combustion chamber with a piston, comprising: inducting at least air and fuel vapors from a fuel vapor system; and adjusting an operating condition of the engine so that a mixture of air and fuel in the combustion chamber, including said fuel vapor, approaches, but does not achieve, said autoignition temperature; and performing a spark from the spark plug so that said mixture substantially auto-ignites.

Owner:FORD GLOBAL TECH LLC

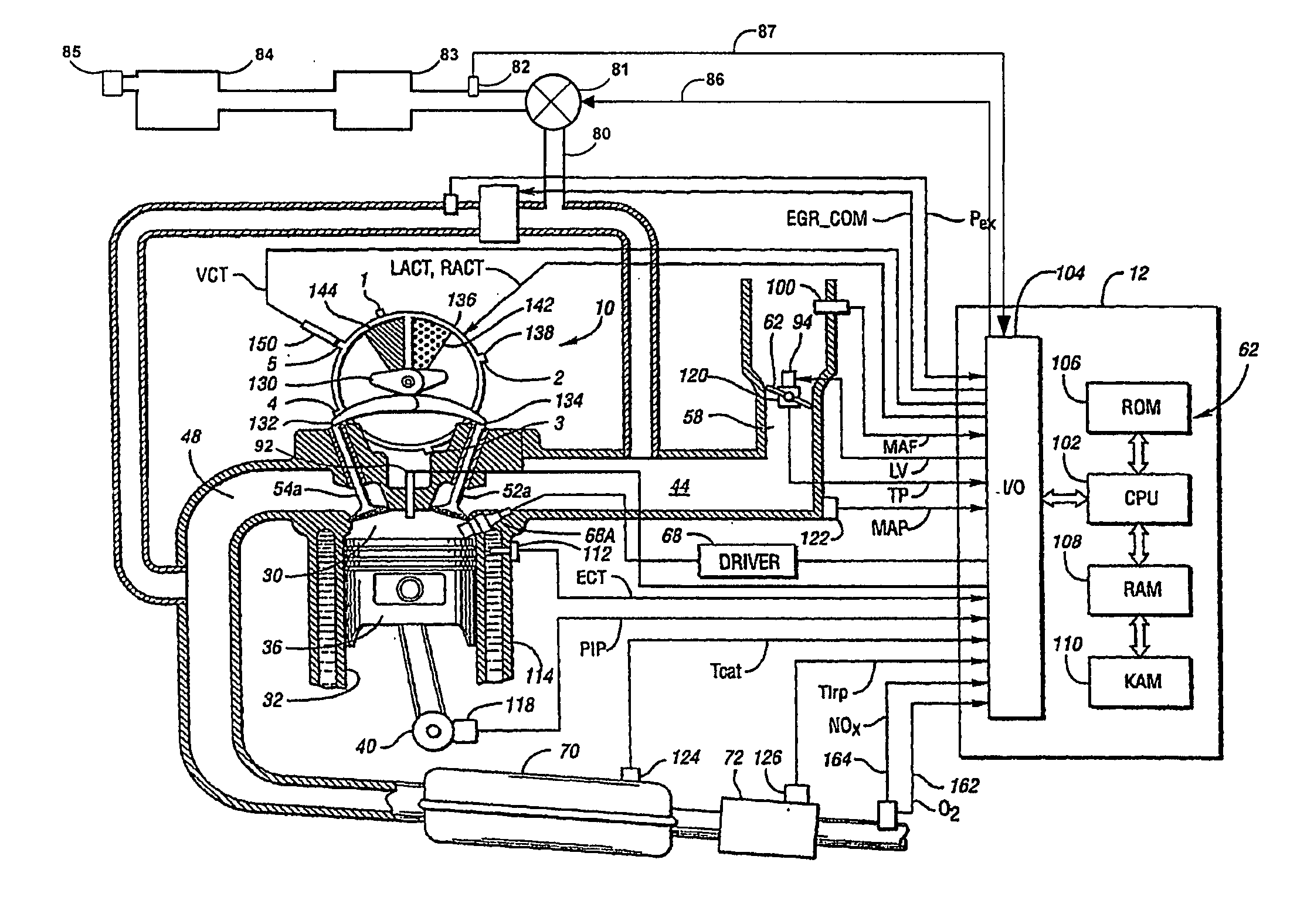

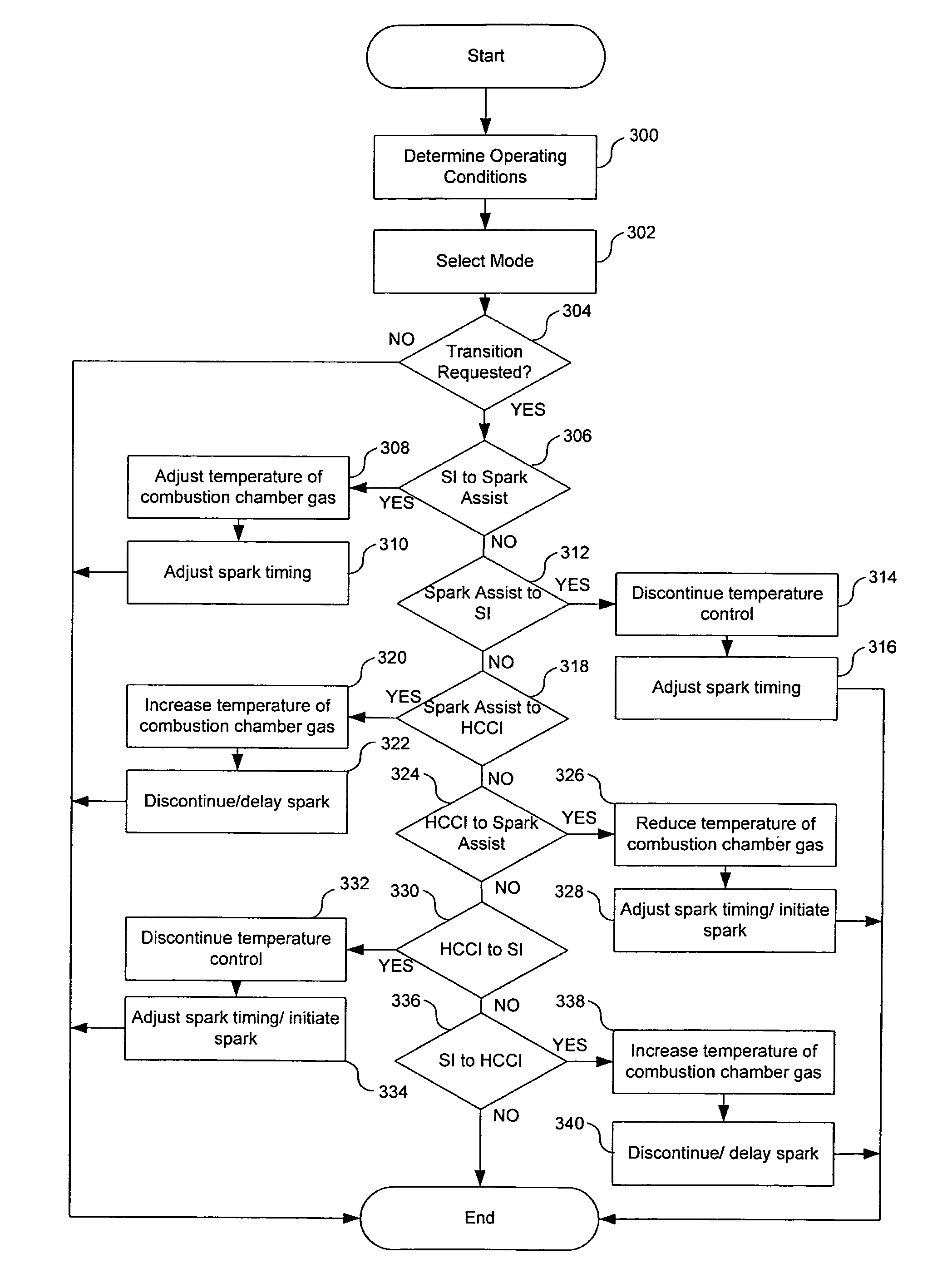

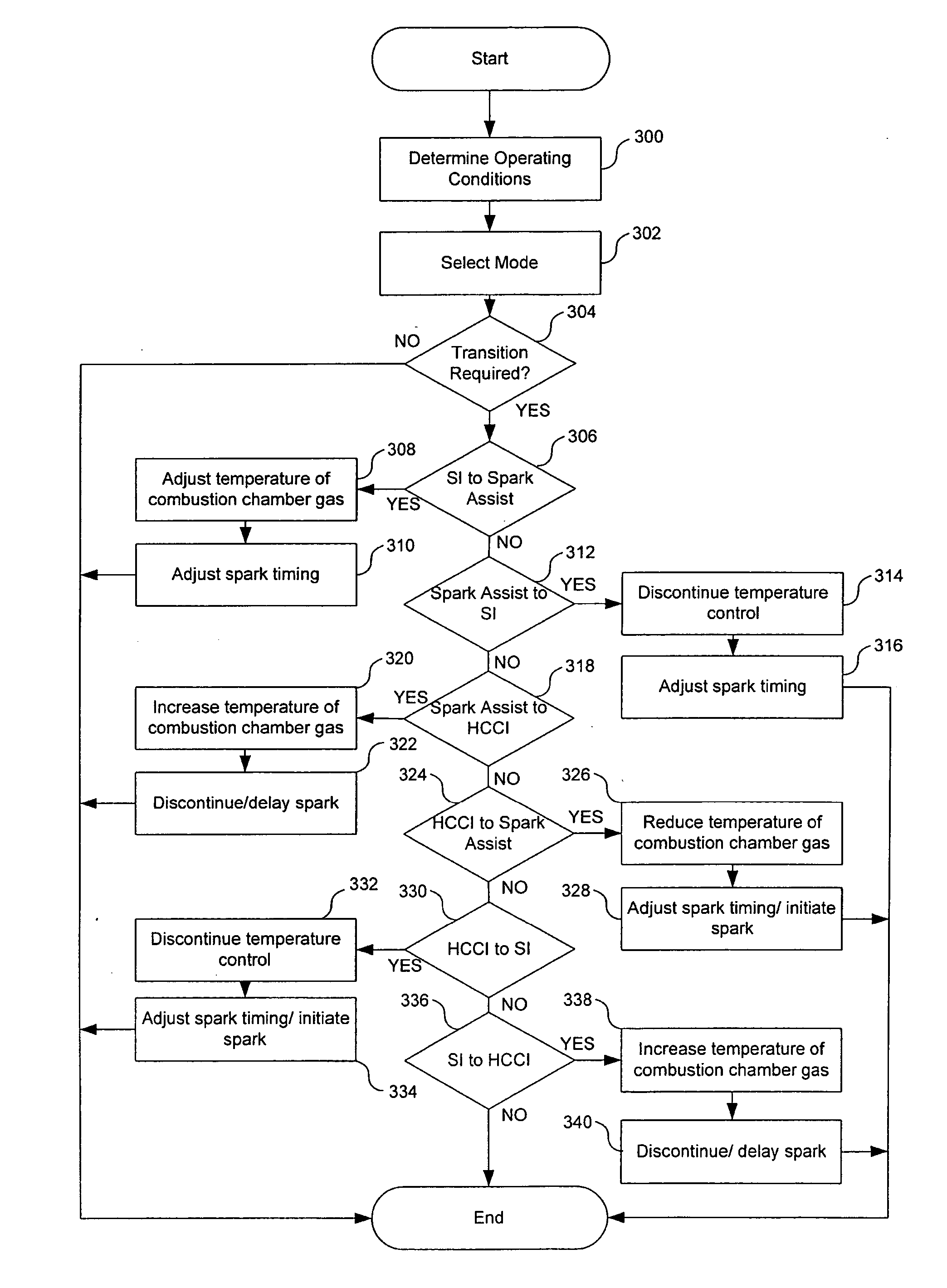

Transition strategy for engine operation with spark ignition and homogeneous charge compression ignition modes

ActiveUS7240659B2Improve efficiencyReduce the production of nitrogen oxidesElectrical controlInternal combustion piston enginesHomogeneous charge compression ignitionExternal combustion engine

A method of operating an internal combustion engine having a combustion chamber with a piston and a spark plug, when transitioning between spark ignition combustion and autoignition combustion, creating a first mixture of air and fuel, adjusting an operating condition of the engine so that said first mixture of air and fuel in the combustion chamber approaches, but does not achieve, the autoignition temperature, and performing a spark from the spark plug so that at least a portion of said first mixture combusts to raise a remaining portion of said first mixture to said autoignition temperature.

Owner:FORD GLOBAL TECH LLC

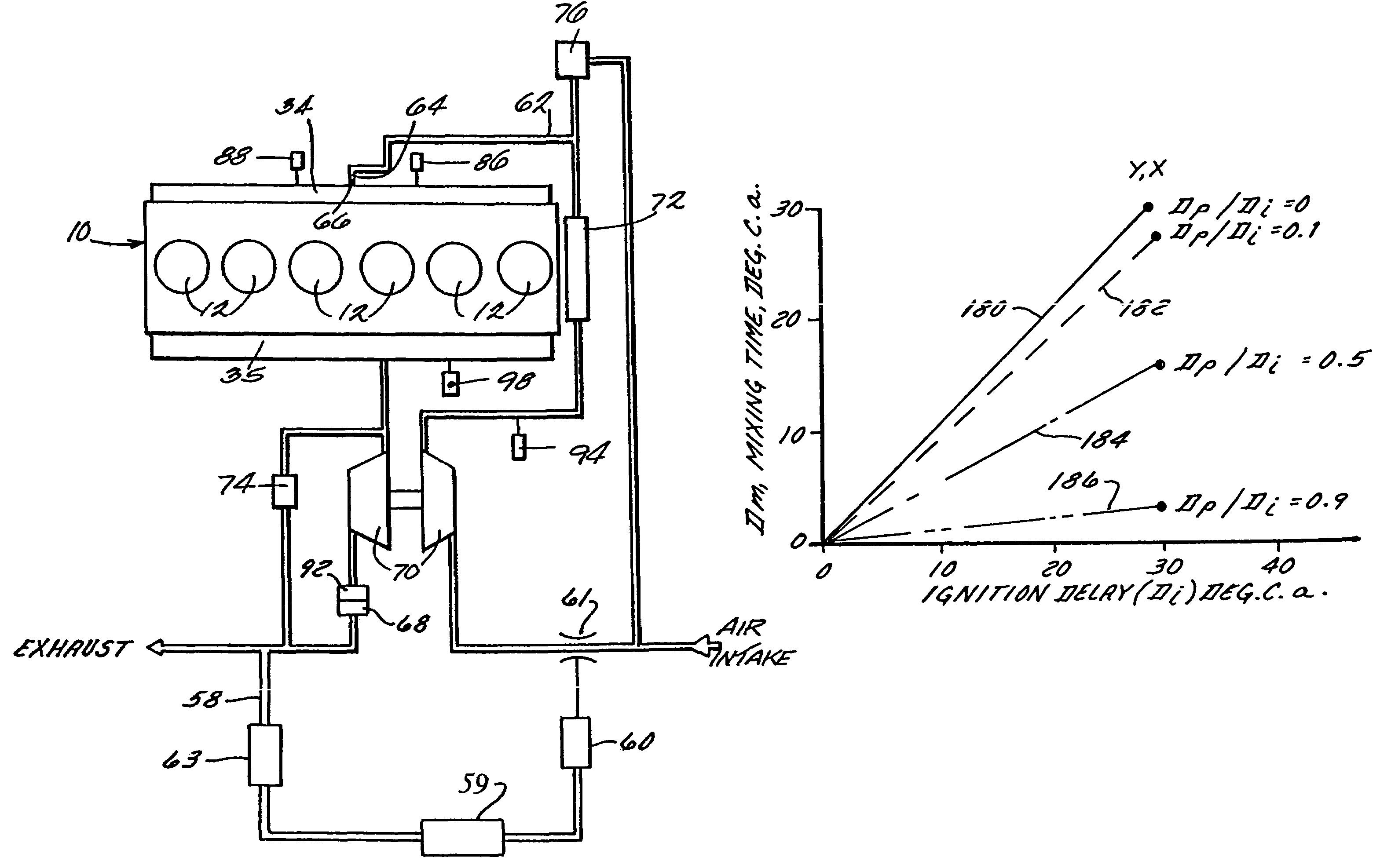

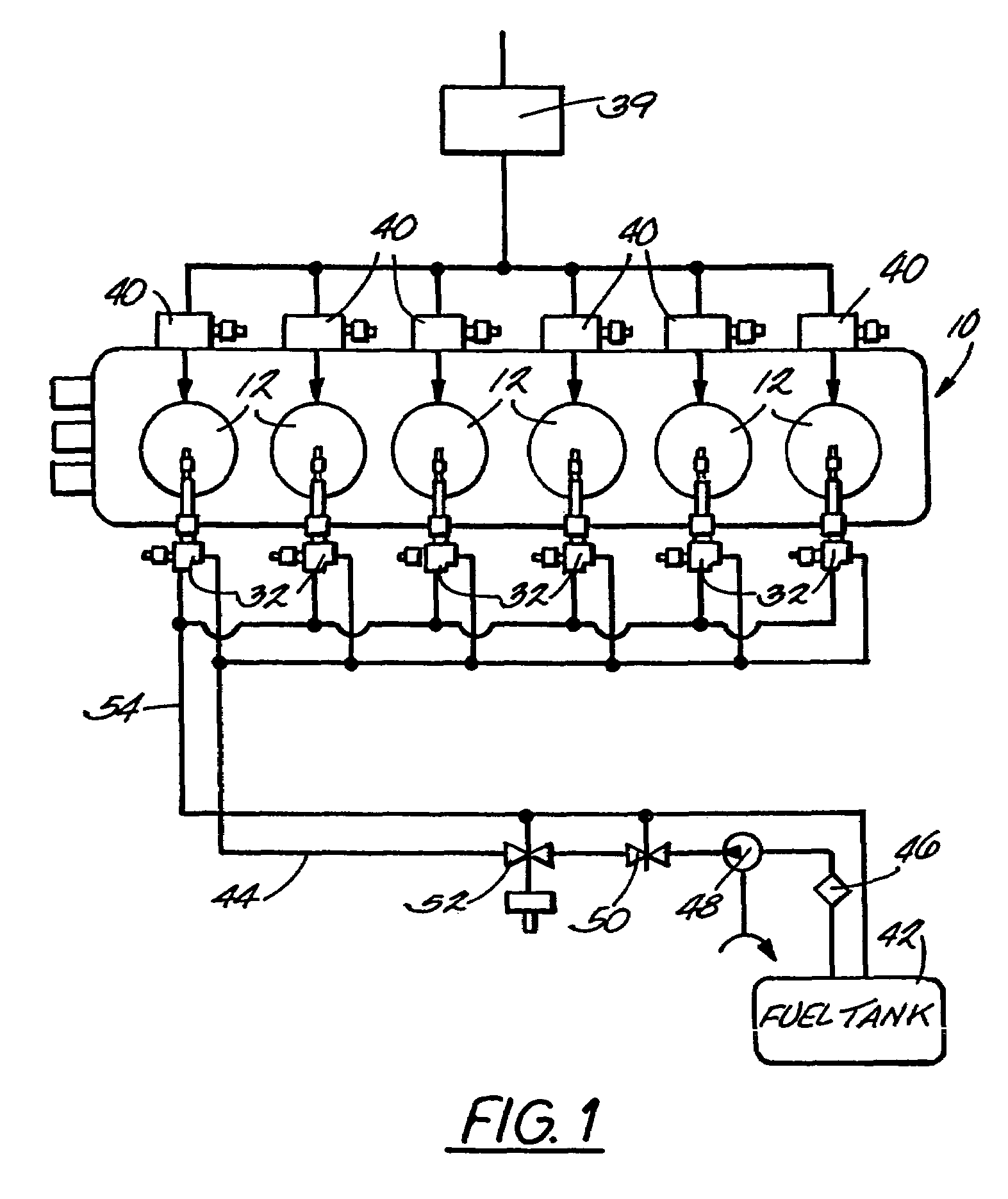

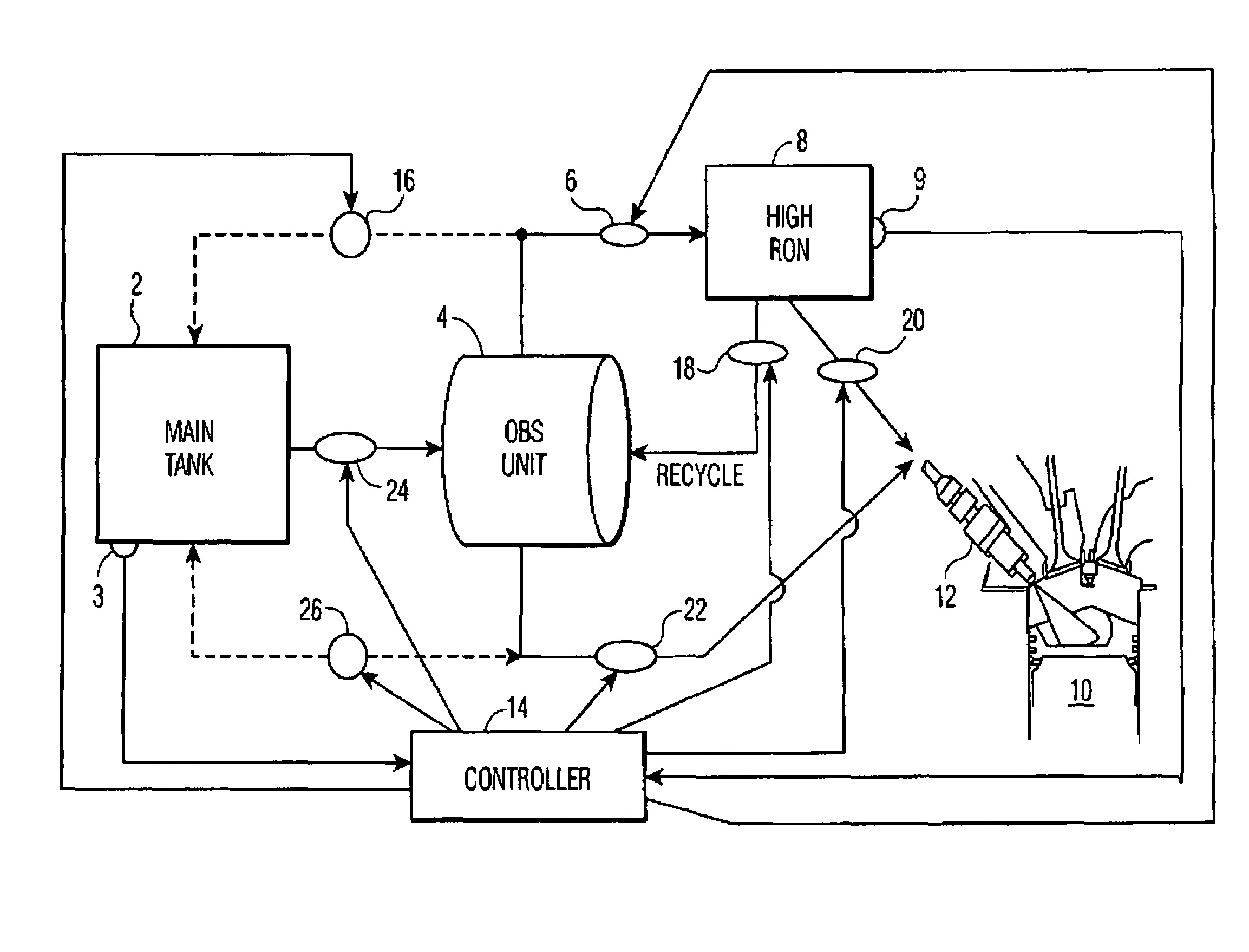

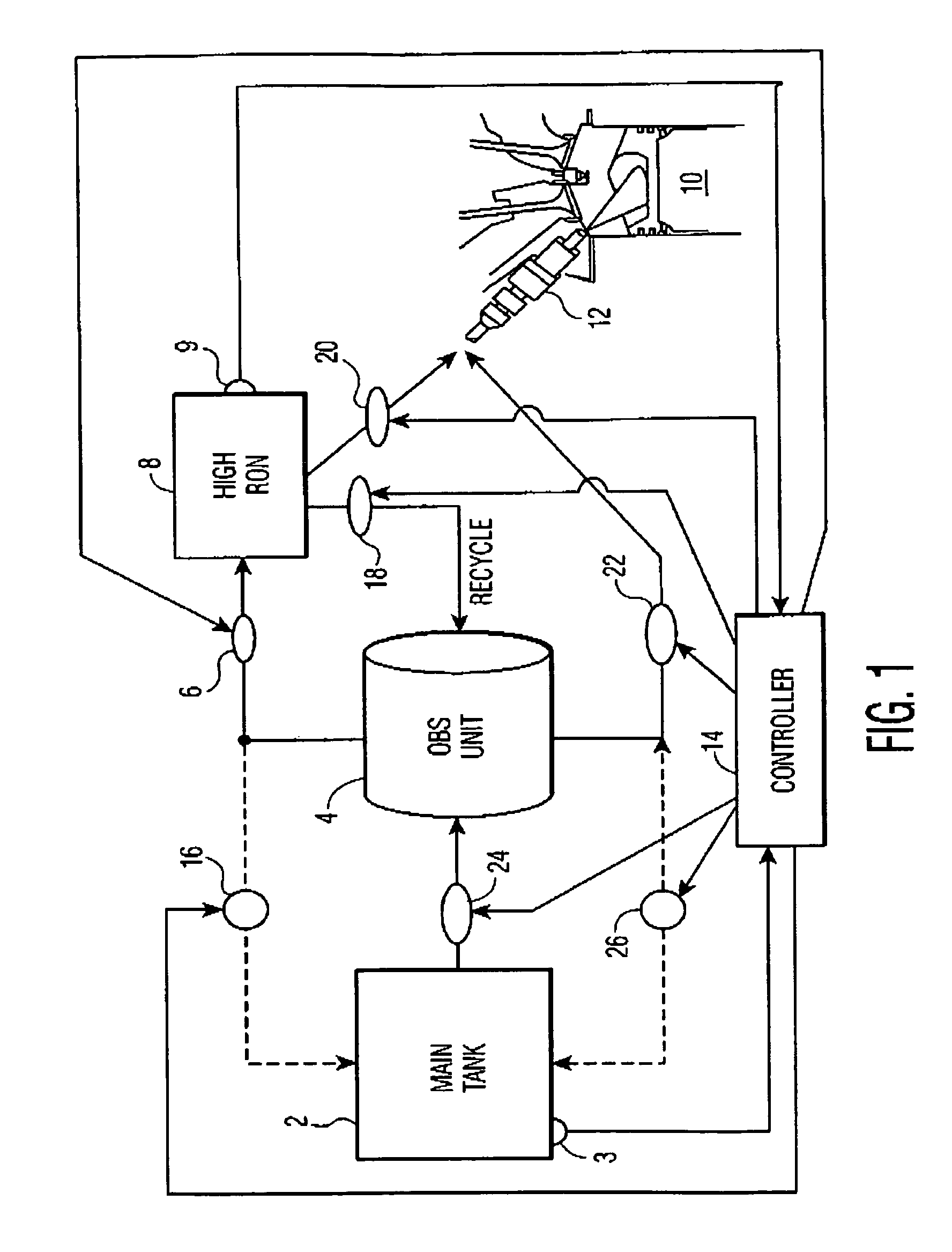

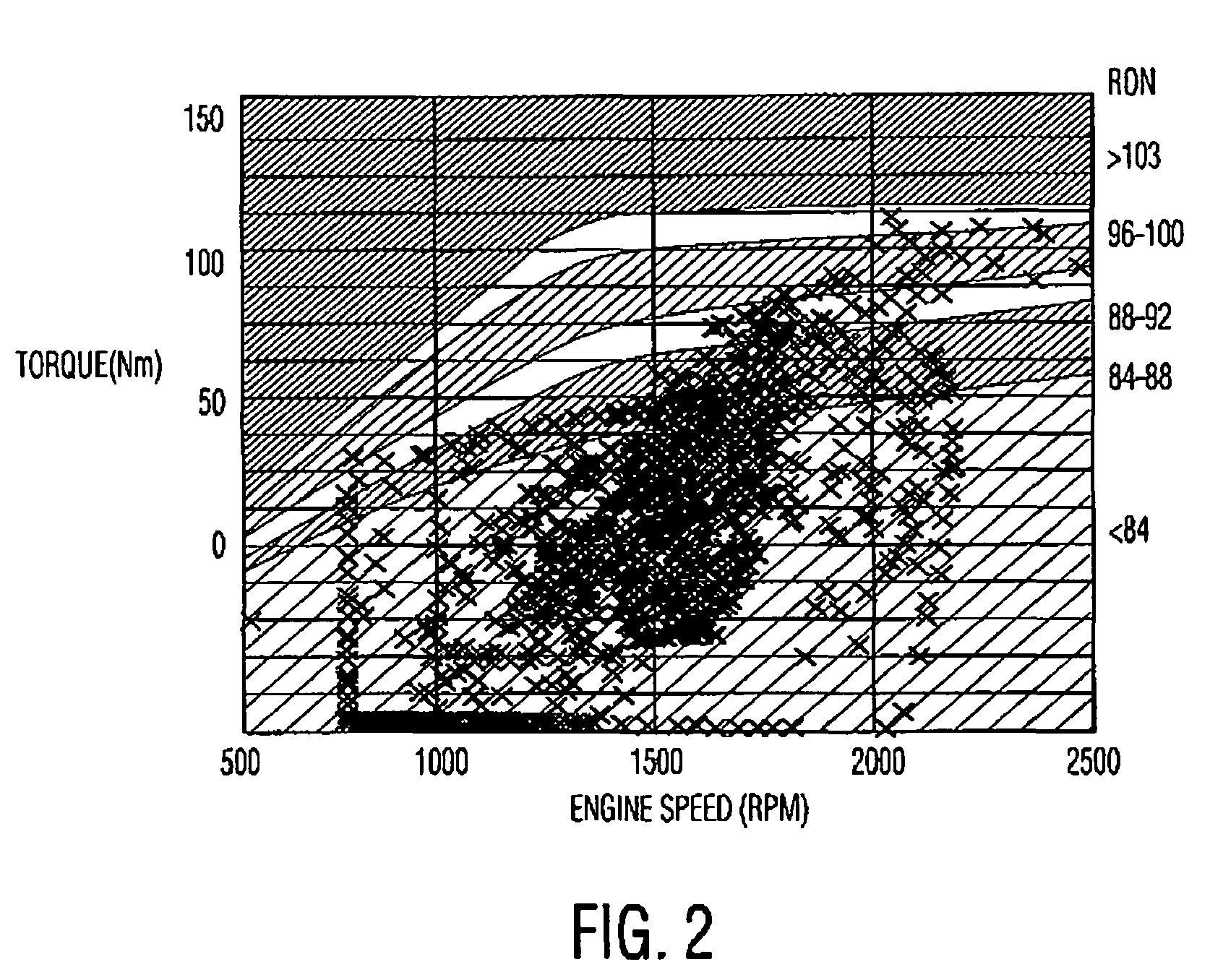

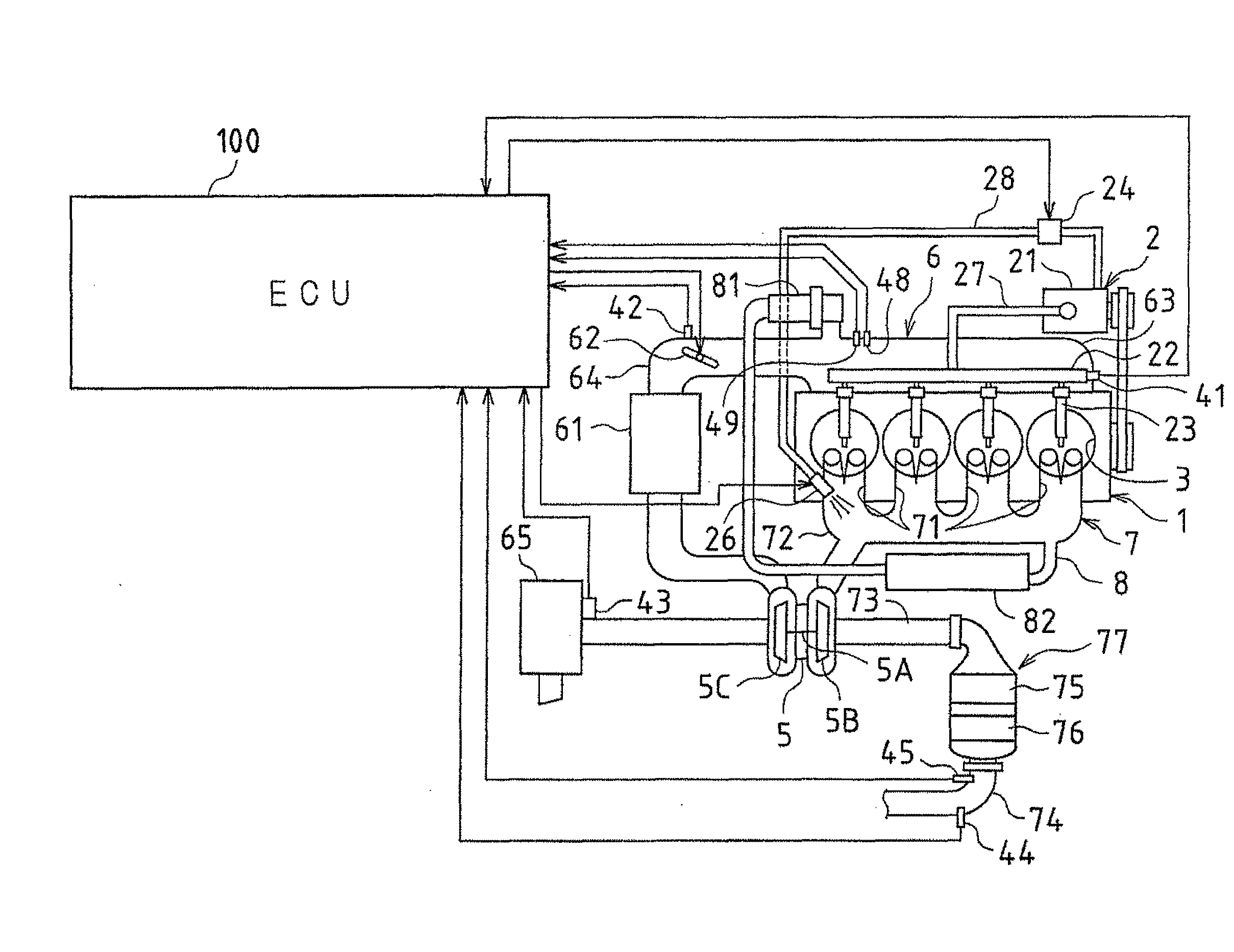

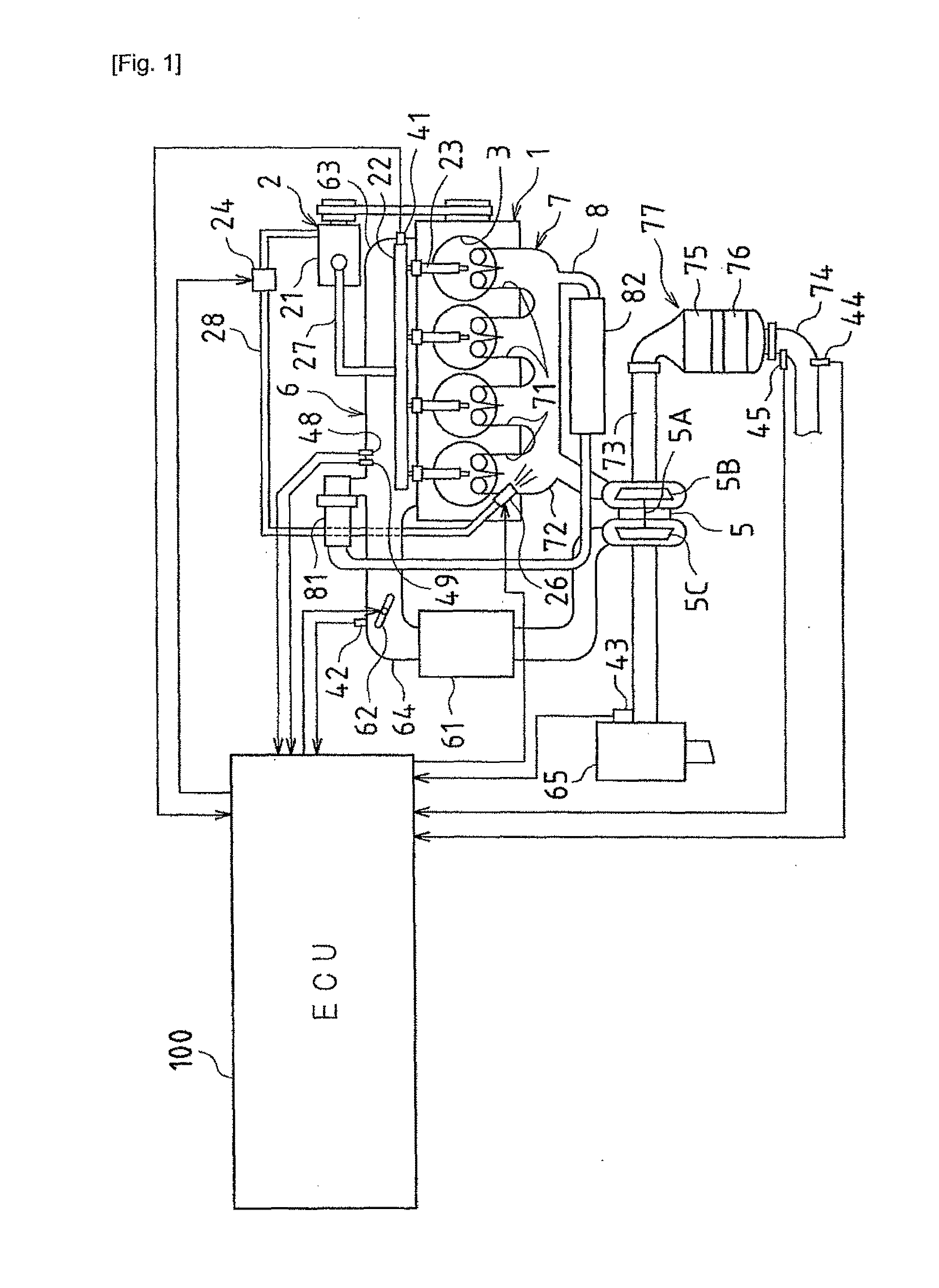

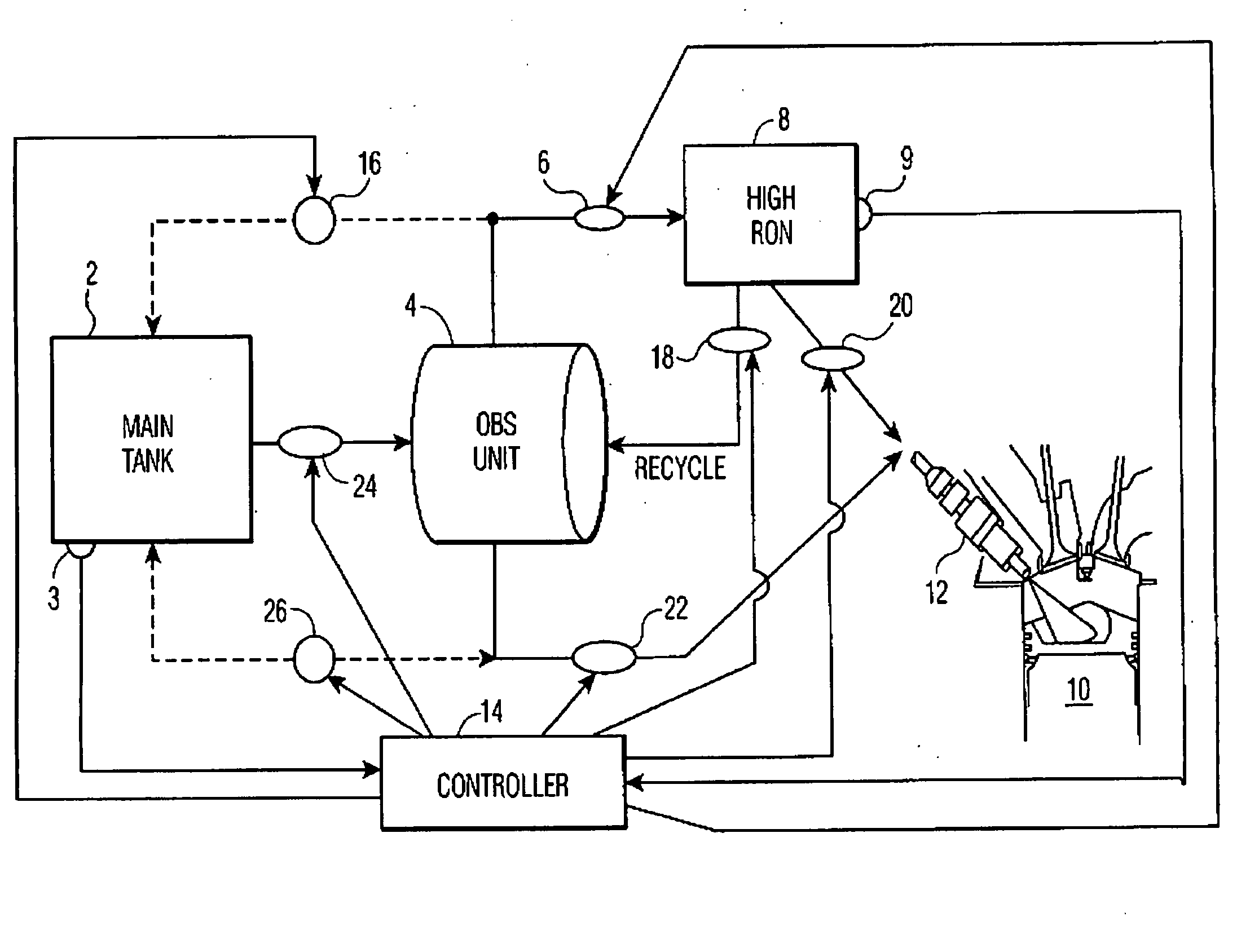

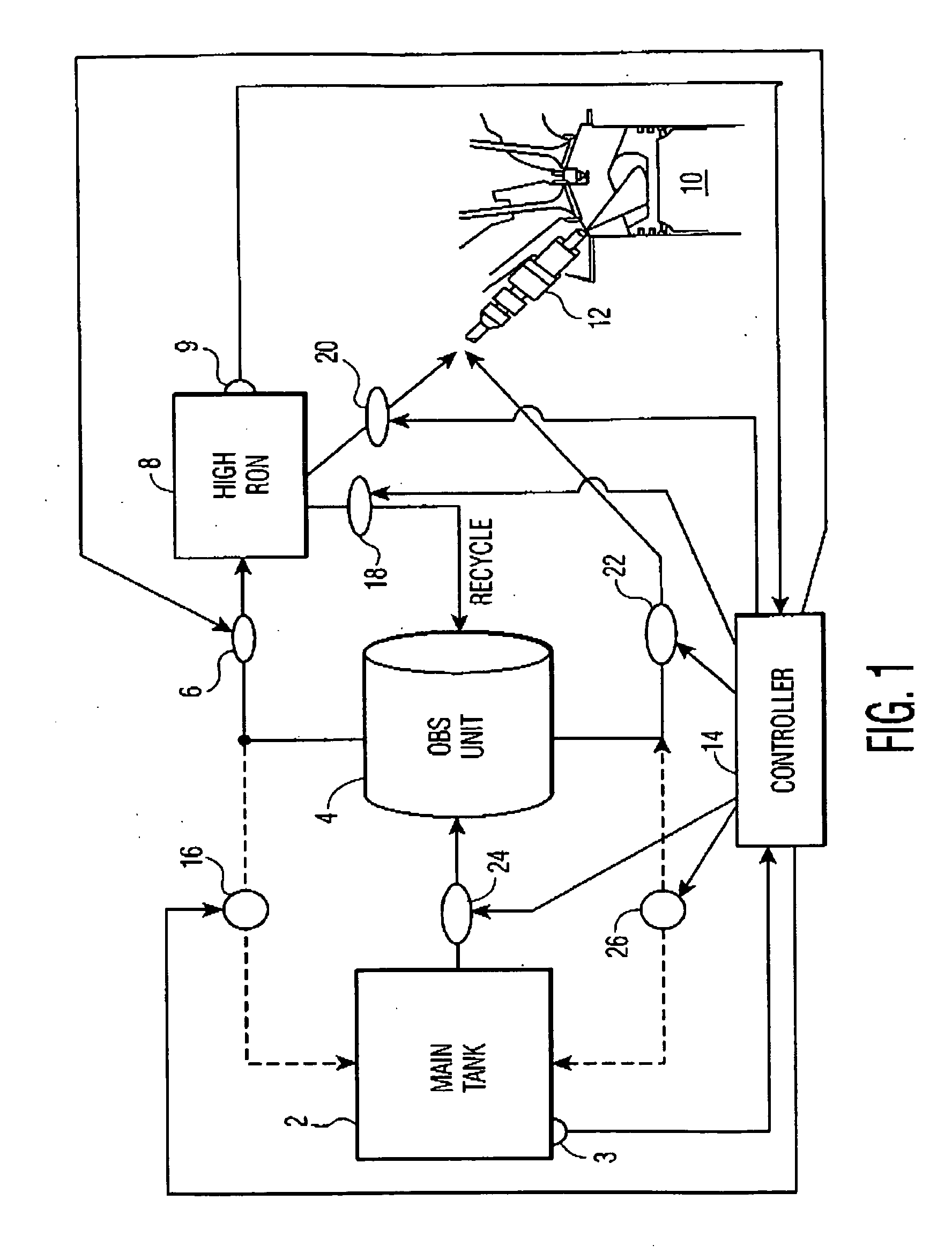

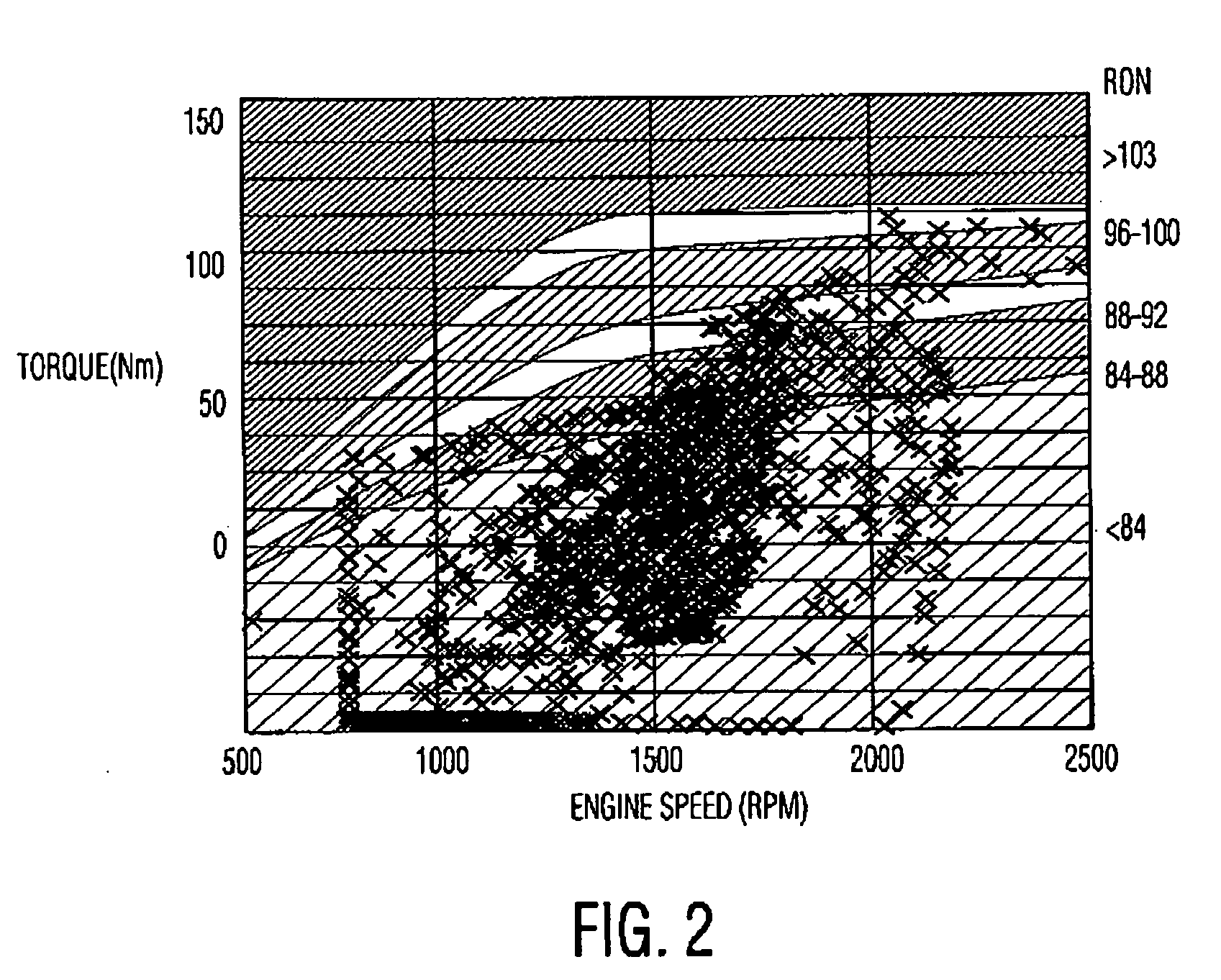

Multiple fuel system for internal combustion engines

InactiveUS8051828B2Electrical controlInternal combustion piston enginesProduction rateAutoignition temperature

A fuel management system mounted on a vehicle is operative to feed individually or a mixture of grades of relatively low, intermediate, and high autoignition temperature fuels to an associated internal combustion engine. The system includes an on board separation unit (OBS unit) for receiving and separating intermediate autoignition temperature (IAT) fuel into low and high autoignition temperature fuels, LAT and HAT, respectively. The production rate of the LAT and HAT fuels by the OBS unit is controlled to substantially match the consumption requirements of the engine at any given time for the LAT and HAT fuels.

Owner:TOYOTA JIDOSHA KK +1

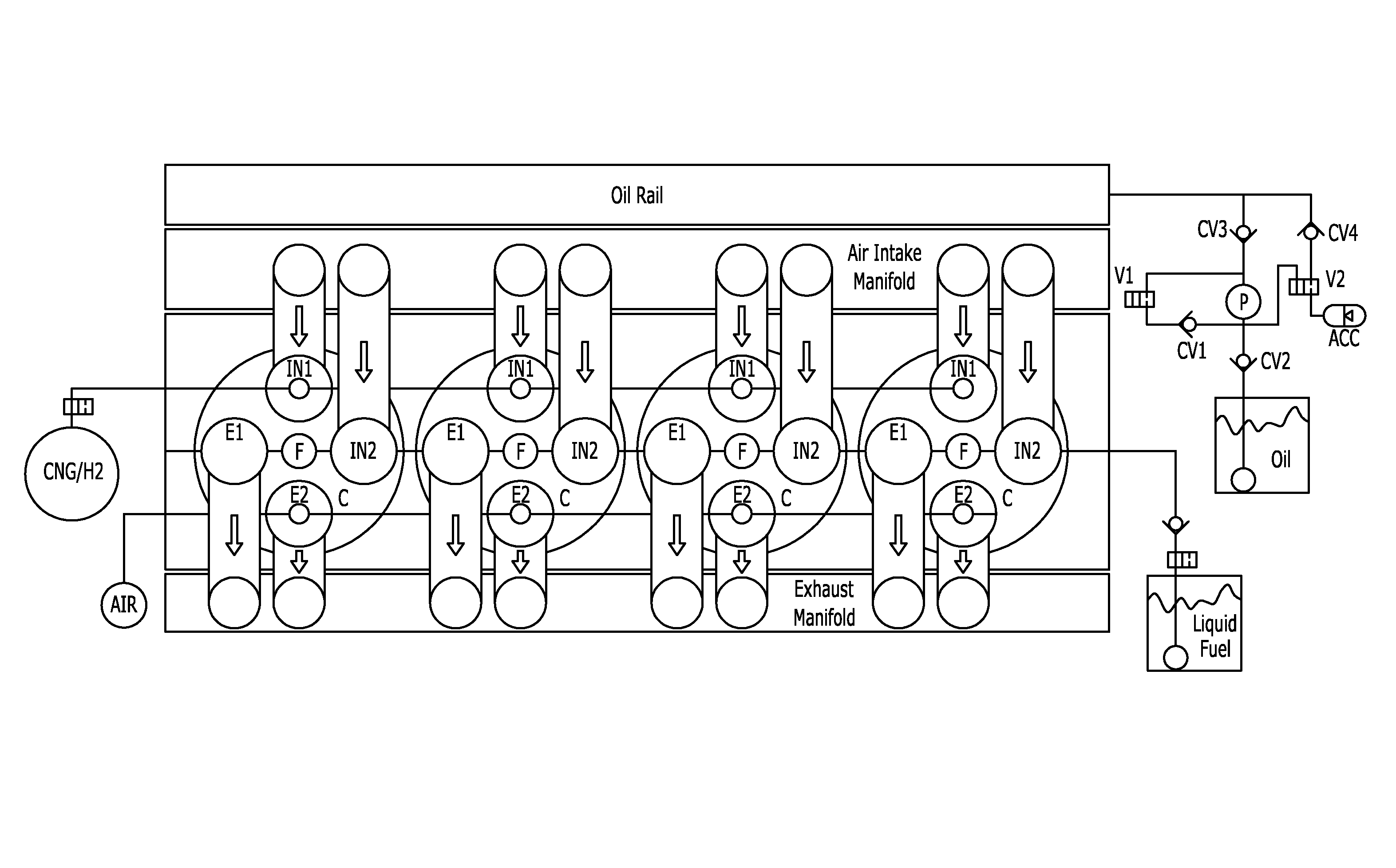

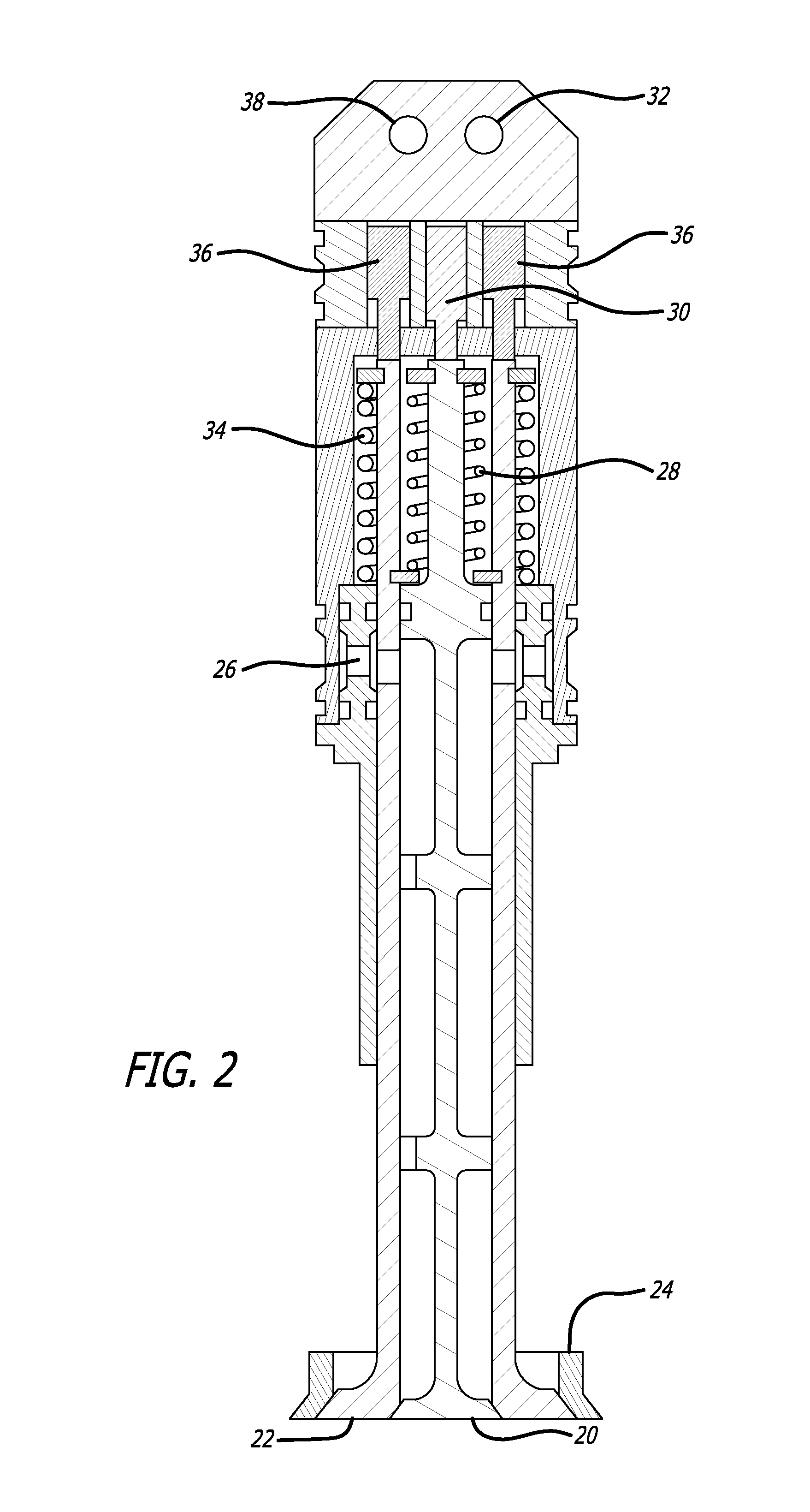

Dual Fuel Compression Ignition Engines and Methods

ActiveUS20100229838A1Non-fuel substance addition to fuelInternal combustion piston enginesHydrogenCompressed natural gas

Dual fuel compression ignition engines and methods that allow compression ignition on gaseous fuels like compressed natural gas, hydrogen and ammonia, yet will run on liquid fuels, including diesel fuels for such purposes as starting or when the gaseous fuel is not available or has been consumed and greater range or operating time is needed. Ignition of fuels having a high self ignition temperature is assured by recirculating high temperature exhaust gas back into the intake charge before compression. Existing engines may be converted to run as a dual fuel engine by replacement of the engine head or heads. Various embodiments are disclosed.

Owner:STURMAN DIGITAL SYST

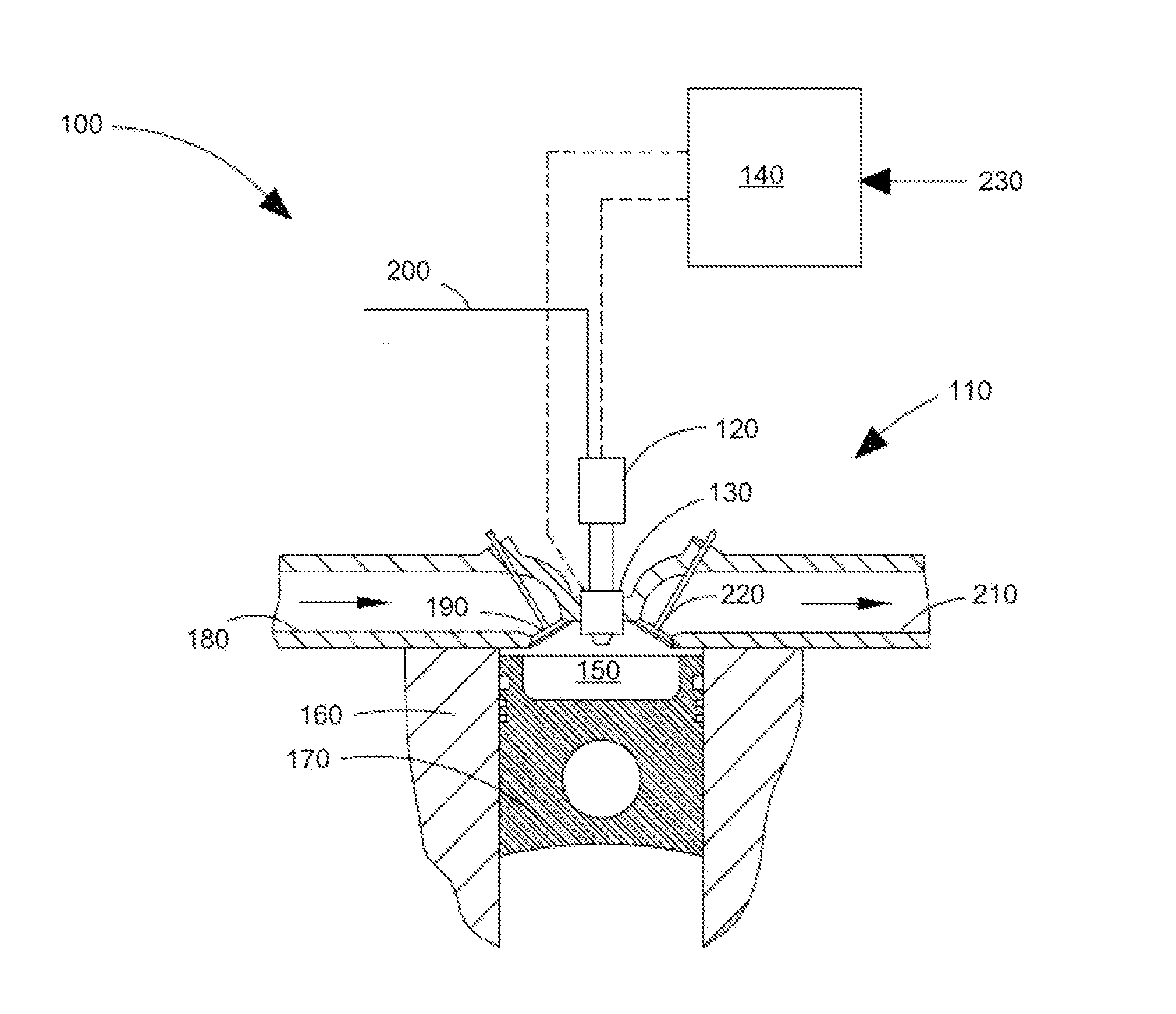

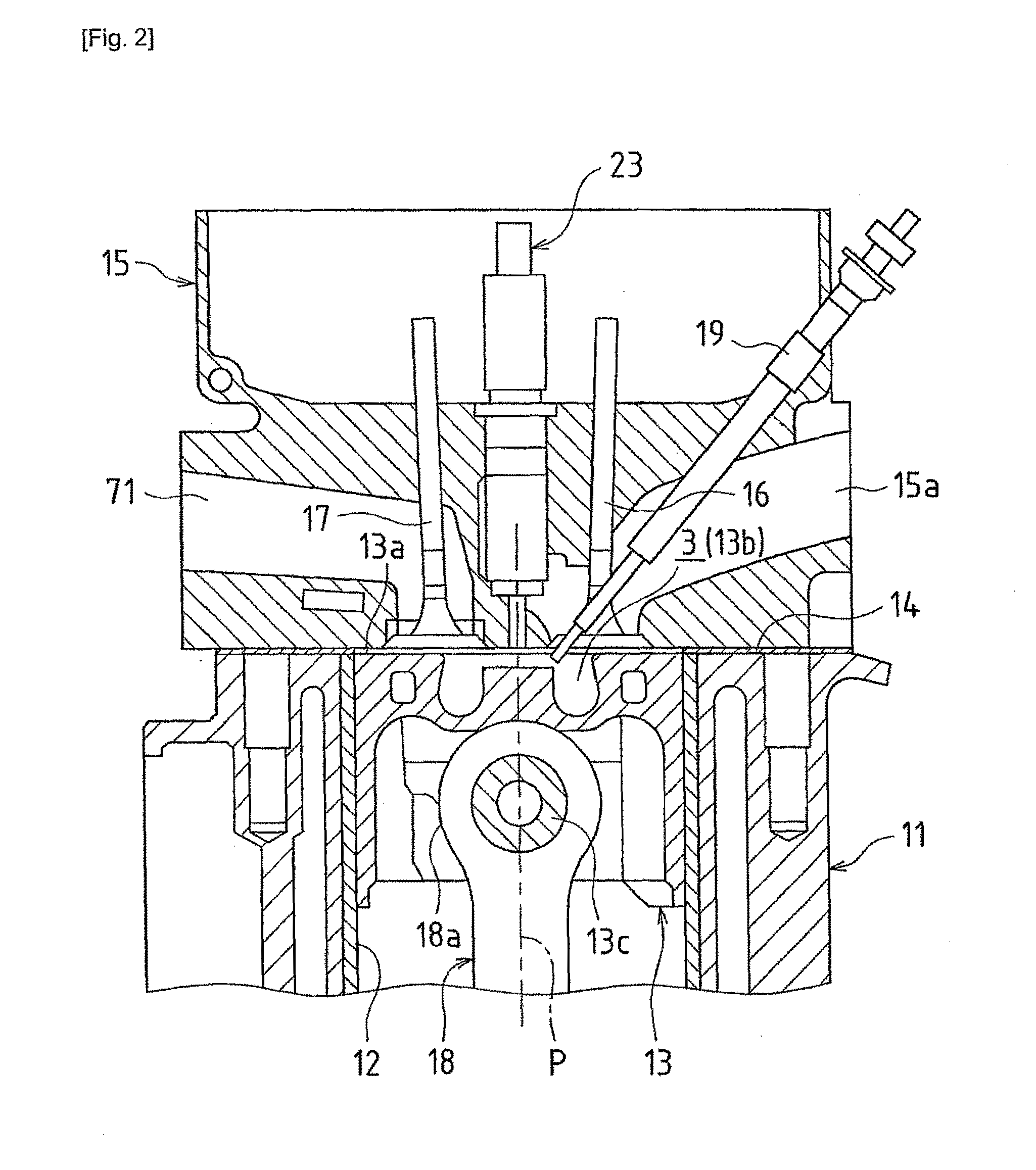

Apparatus And Method For Igniting A Gaseous Fuel In A Direct Injection Internal Combustion Engine

ActiveUS20150020769A1Retard in spaceImprove flammabilityElectrical controlIncandescent ignitionCombustion chamberAutoignition temperature

An apparatus and method for igniting a gaseous fuel directly introduced into a combustion chamber of an internal combustion engine comprises steps of heating a space near a fuel injector nozzle; introducing a pilot amount of the gaseous fuel in the combustion chamber during a first stage injection event; controlling residency of the pilot amount in the space such that a temperature of the pilot amount increases to an auto-ignition temperature of the gaseous fuel whereby ignition occurs; introducing a main amount of the gaseous fuel during a second stage injection event after the first stage injection event; and using heat from combustion of the pilot amount to ignite the main amount.

Owner:WESTPORT FUEL SYST CANADA INC

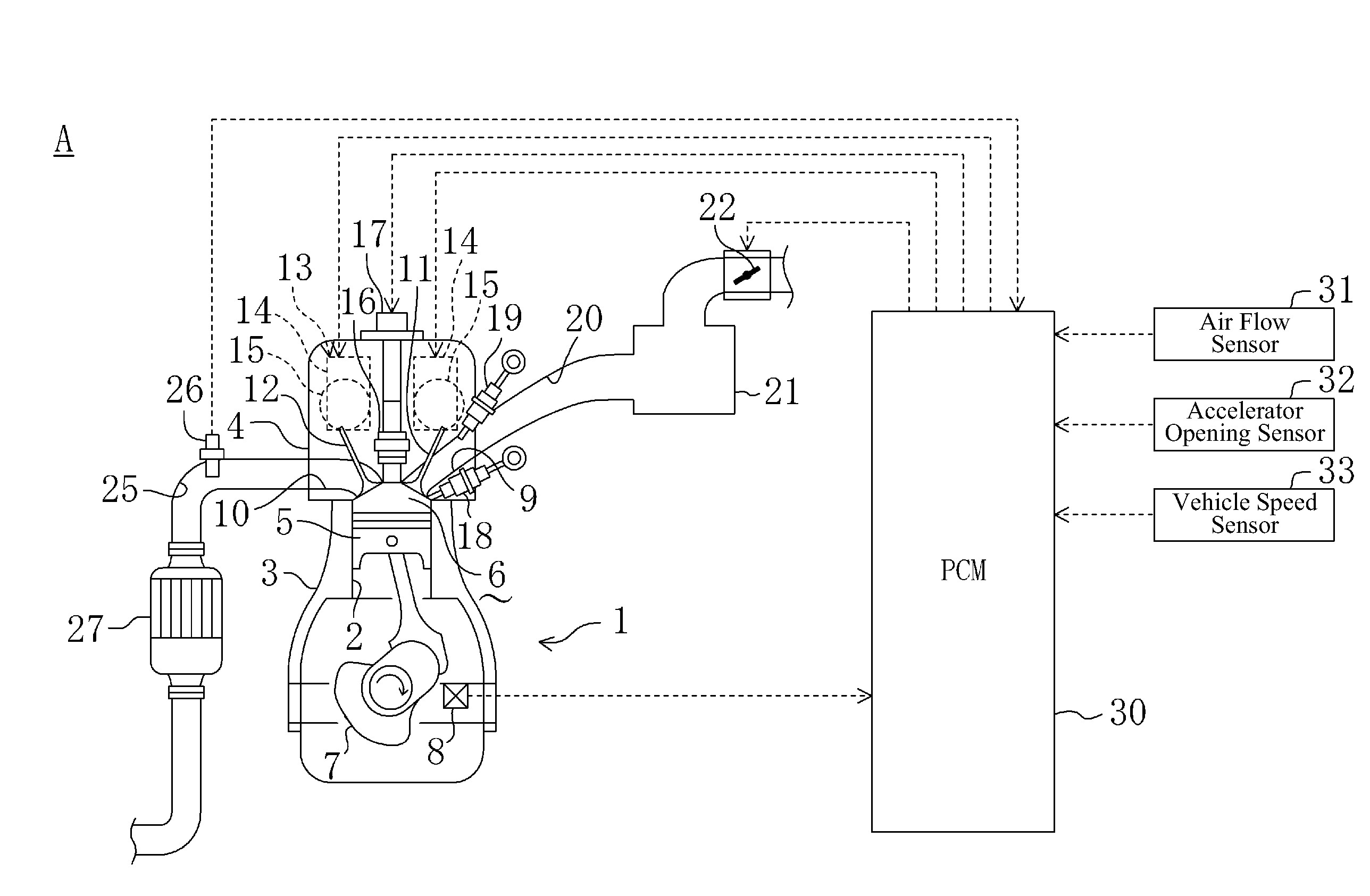

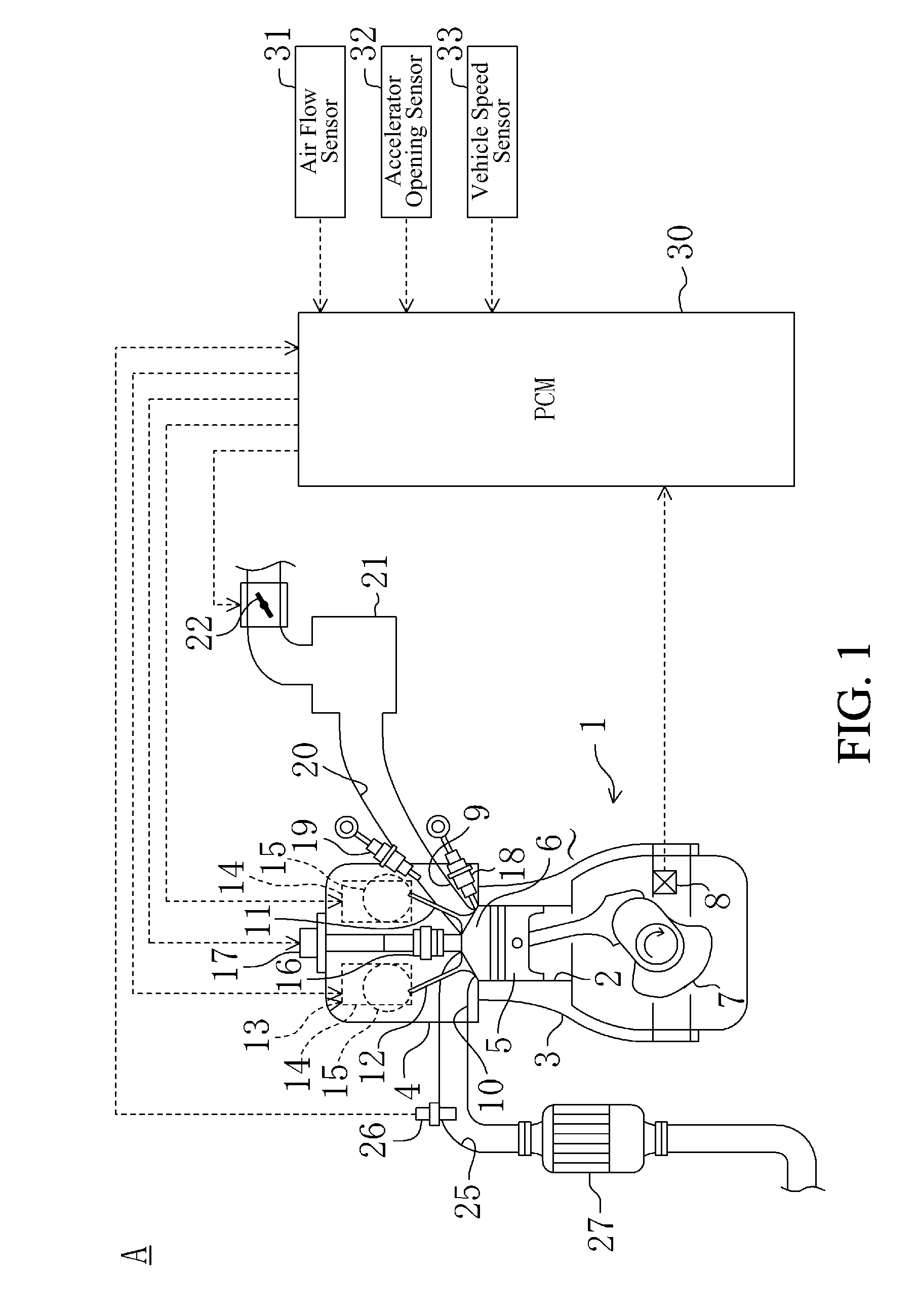

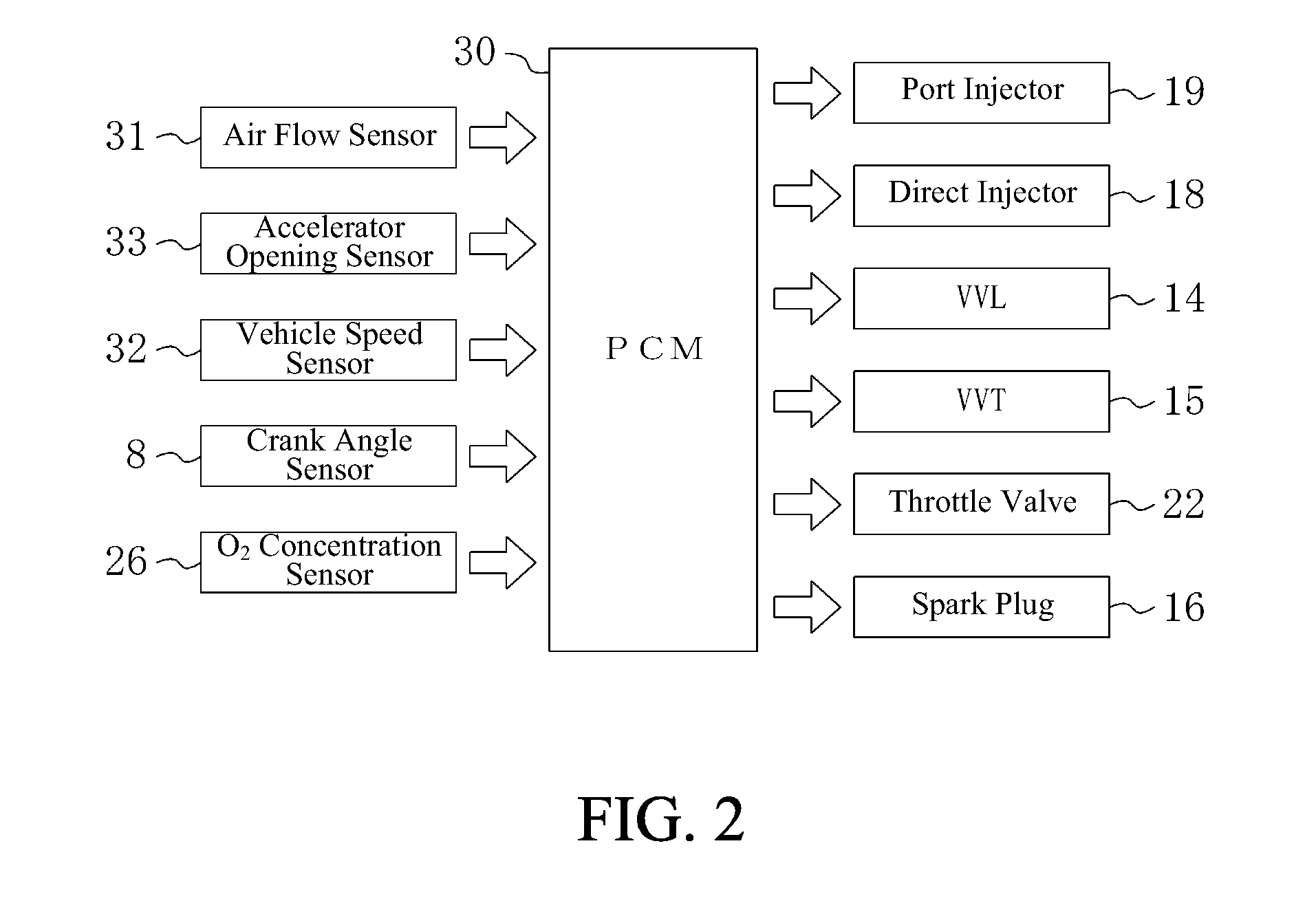

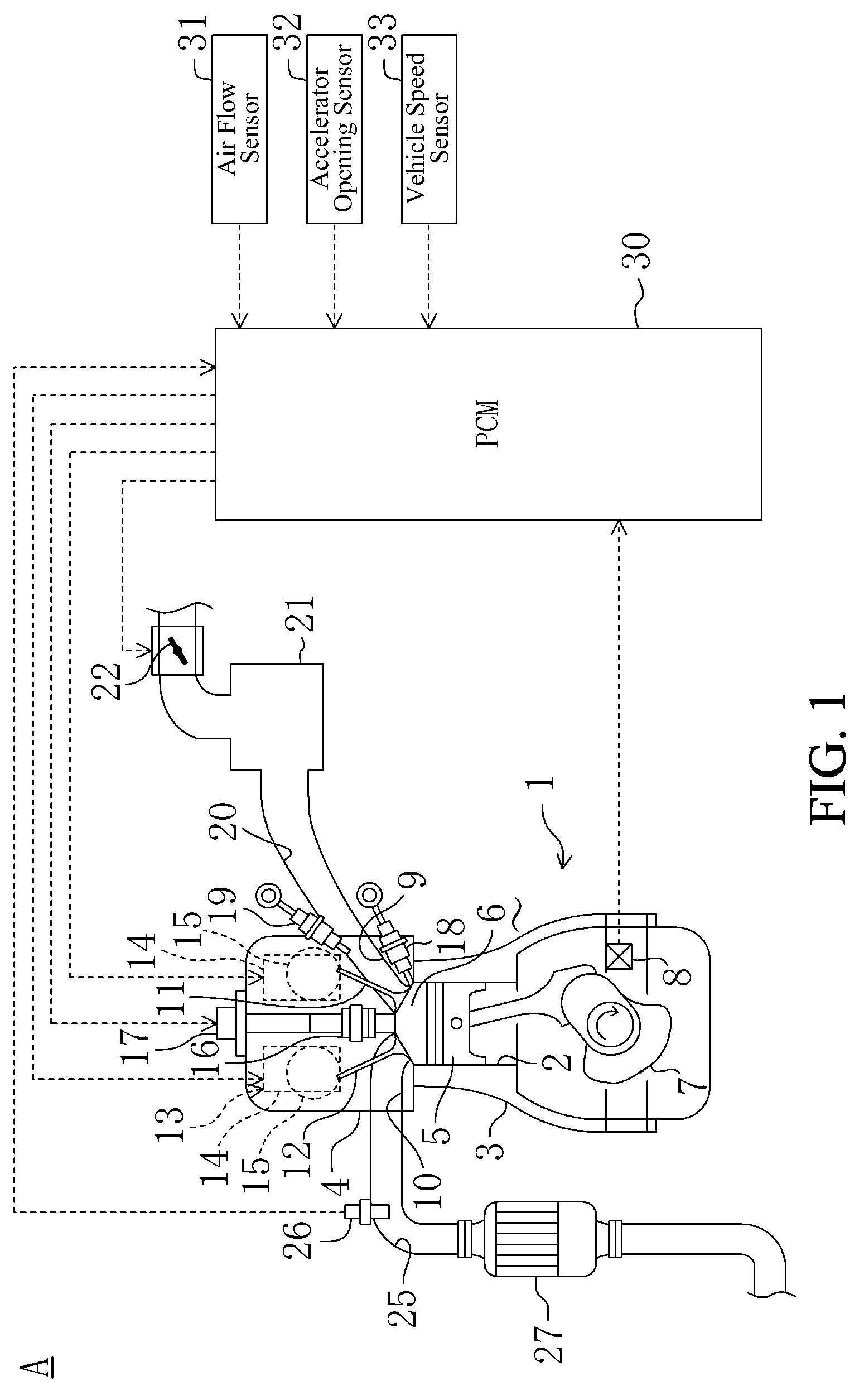

Fuel injection control apparatus of internal combustion engine

InactiveUS20110005491A1Improve exhaust emissionsImprove stabilityElectrical controlInternal combustion piston enginesExternal combustion engineEngineering

In one embodiment, a total pilot injection amount is calculated from the difference between a compressed gas temperature in a cylinder and a fuel self-ignition temperature. As pilot injection, a plurality of instances of divided pilot injection are performed, and by setting the injection amount per one instance of divided pilot injection to an injector minimum limit injection amount, each divided pilot injection amount is suppressed, and the penetration of fuel is suppressed to a low level so that attachment of fuel to a wall face is avoided, and also, fuel is caused to accumulate in the center portion of the cylinder.

Owner:TOYOTA JIDOSHA KK

Low emission power plant and method of making same

InactiveUS6101989AReduce the amount of solutionLower than normal exhaust valve liftNon-fuel substance addition to fuelInternal combustion piston enginesParticulatesCombustion chamber

A low emission power generating apparatus which comprises a modified two-stroke diesel engine component and a modified turbocharger component which has a relatively low aspect ratio. The diesel engine component is a modification of a conventional two-stroke diesel engine design and includes an exhaust valve cam of unique design that has a cam profile which results in a later than-normal exhaust valve opening and an earlier-than-normal valve closing so that the time during which the exhaust valve remains open is shorter than normal, thereby causing a substantially greater volume of residual gases to remain in the combustion chamber following the scavenge stroke. This increase in the volume of the residual exhaust gases within the chamber leads to an increase in compression temperature and effectively increases the compression ratio and consequently the compression pressure. Because of the heat absorption capacity of these residual exhaust gases, the exhaust gases remaining in the chamber following the scavenge stroke tend to absorb combustion heat and thereby effectively reduce the peak combustion temperature. This reduction in peak combustion temperature advantageously results in the lower than normal formation of nitrogen oxide (NOx) and, therefore, allows advancement of the injection timing, while still maintaining the NOx emissions coming from the engine lower than those legislatively mandated. Advantageously, the advance in injection timing, which increases NOx emissions, by definition has the effect of also reducing particulate matter emissions. Thus, by increasing the volume of residual exhaust gases within the cylinder, substantial particulate matter emission reductions can be achieved, while at the same time maintaining NOx emissions well below mandated limits. The modified turbocharger component provides an additional charge of oxygen-rich air into the combustion chamber which effectively increases the compression pressure, which, in turn, leads to an earlier start of combustion because of the combustible mixture reaching its auto-ignition temperature at an earlier point in the cycle. This phenomenon leads to more thorough combustion of the fuel and also generally leads to higher exhaust temperatures. Higher exhaust temperatures, in turn, lead to a greater oxidation rate of the soluble organic fraction thus lowering the level of emission from the engine of undesirable particulate matter.

Owner:CLEAN CAM TECH SYST

Reduced NOx method of combustion

InactiveUS20060246388A1Lowering NO<sub>xIndirect carbon-dioxide mitigationGaseous fuel burnerCombustorCombustion chamber

The present invention is a method for achieving low NOx single-stage combustion. A high velocity burner is run normally, with combustion occurring within both the burner combustion chamber and furnace chamber, until the gases within the furnace exceed the auto-ignition temperature of the gaseous fuel. The gaseous fuel is then shut off until the temperature within the burner combustion chamber drops below the auto-ignition temperature of the gaseous fuel. The gaseous fuel is then turned back on and the gaseous fuel auto ignites within the furnace chamber. The combustion then occurs only within the furnace chamber and not in the burner combustion chamber.

Owner:HAUKE MFG

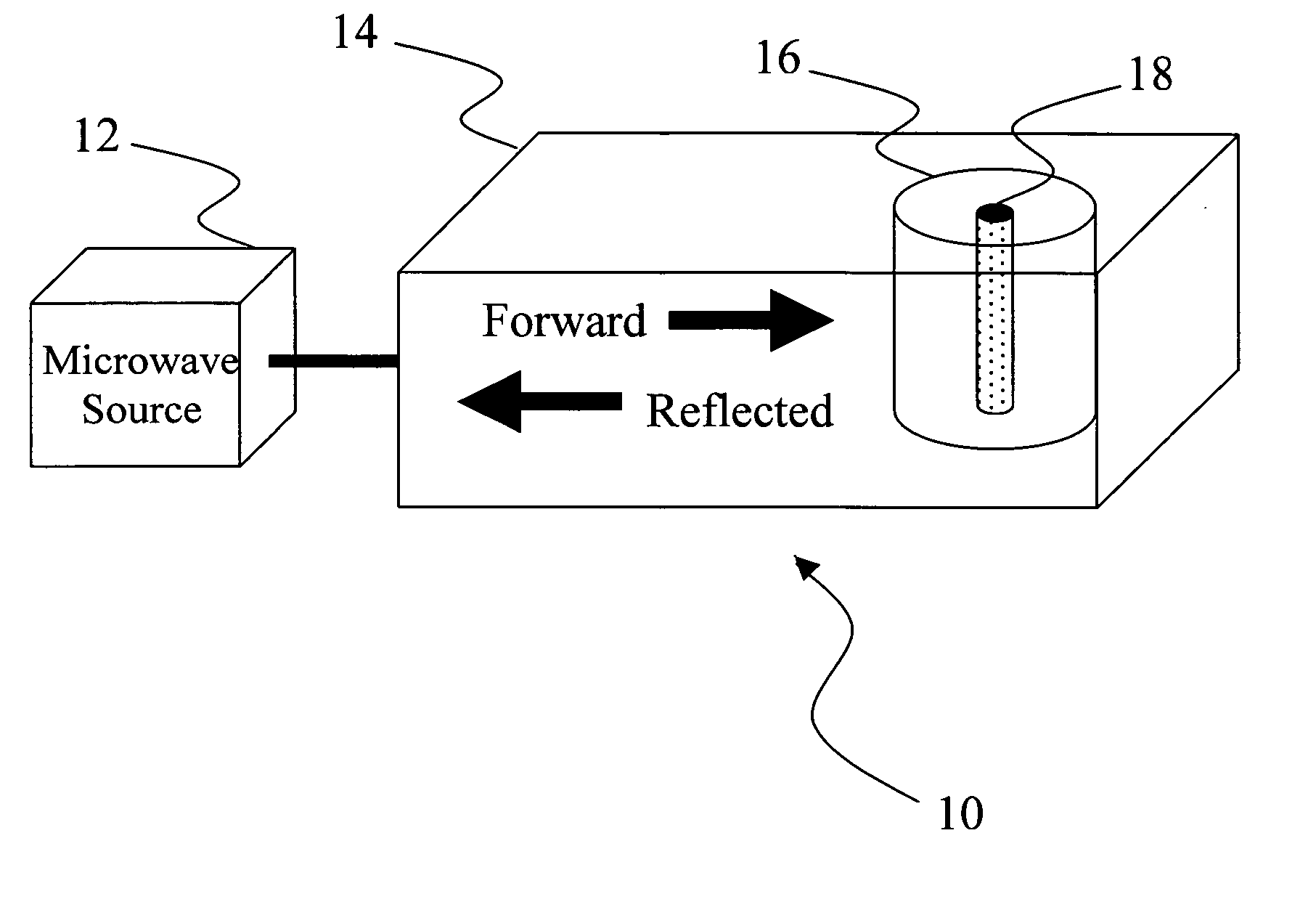

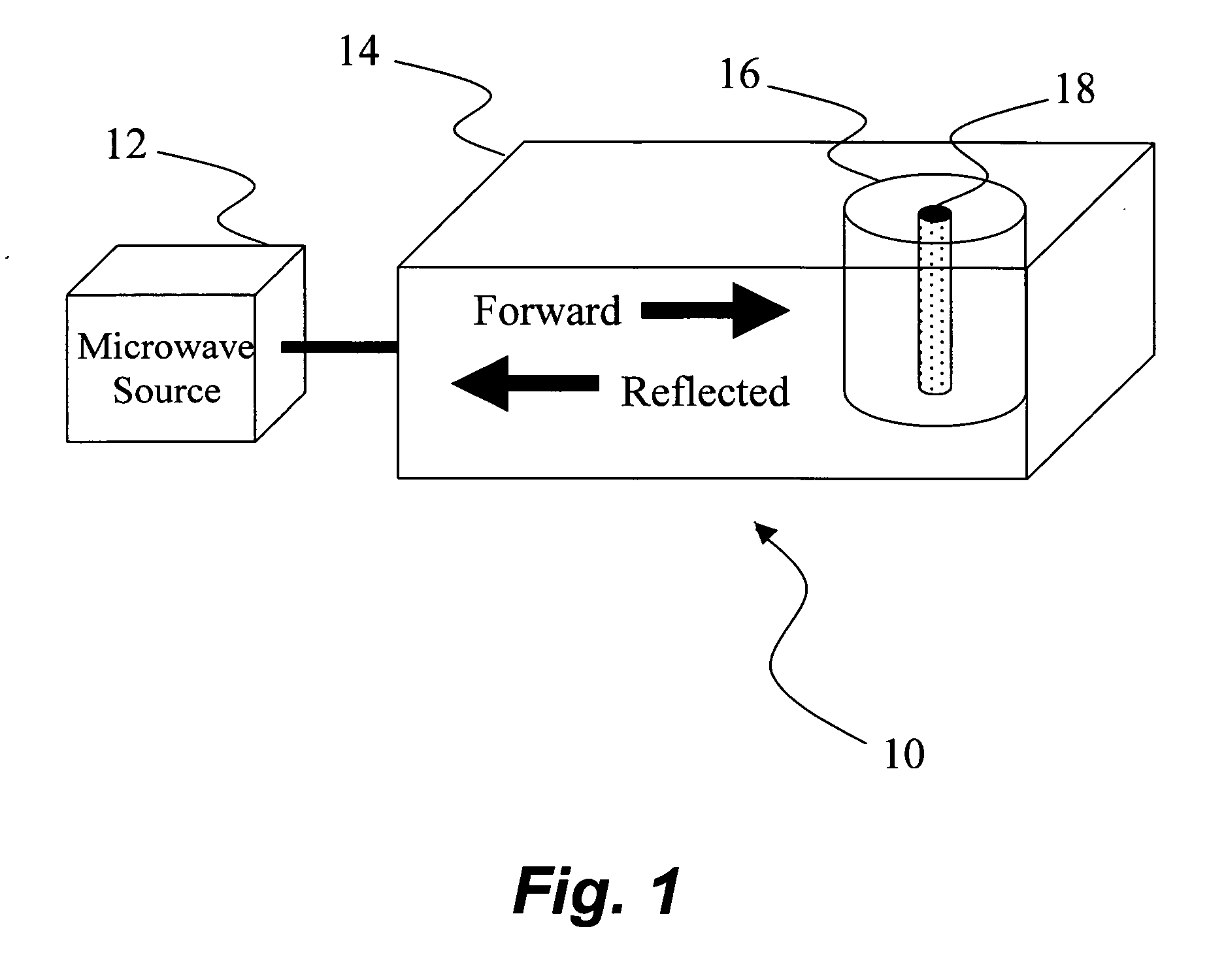

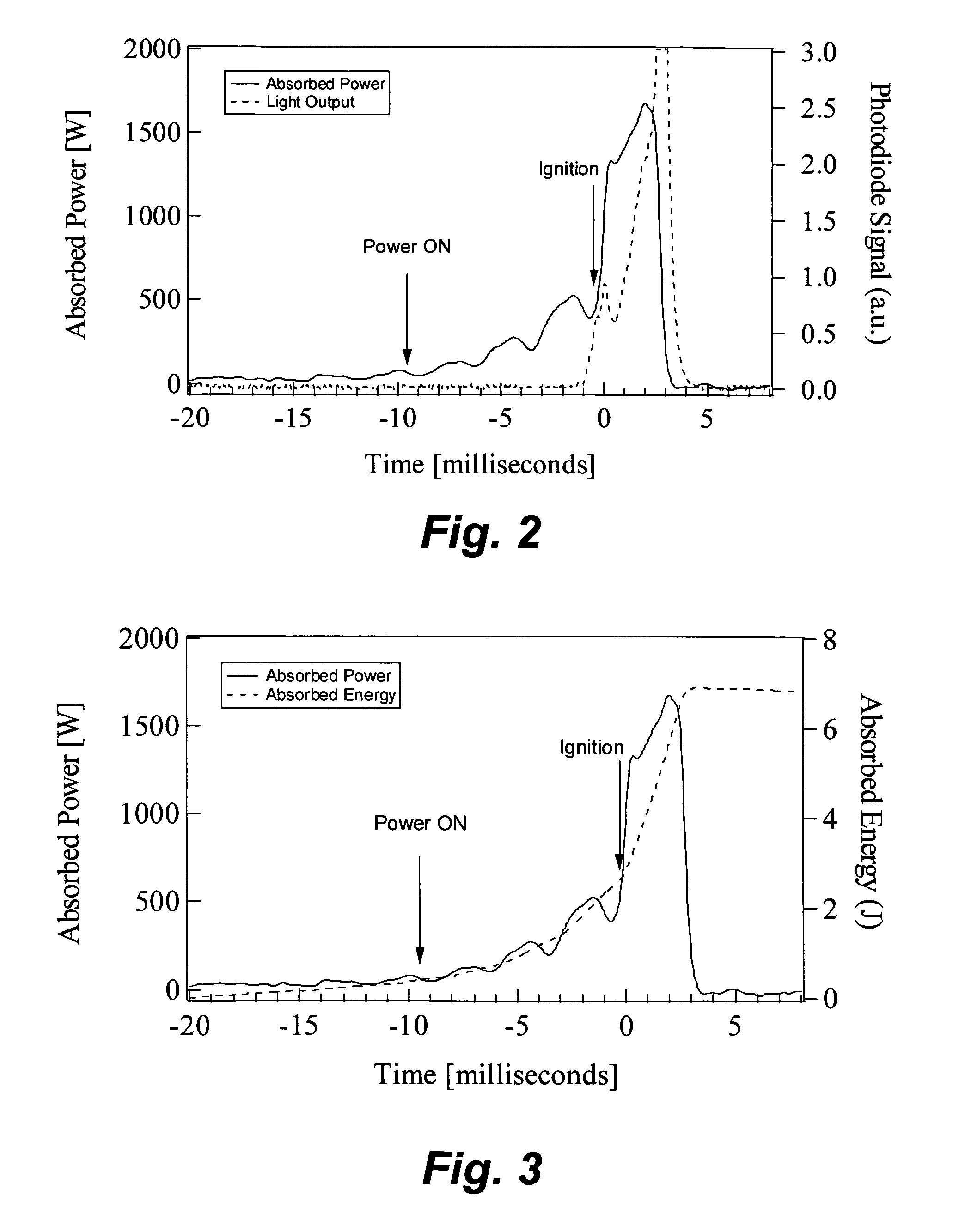

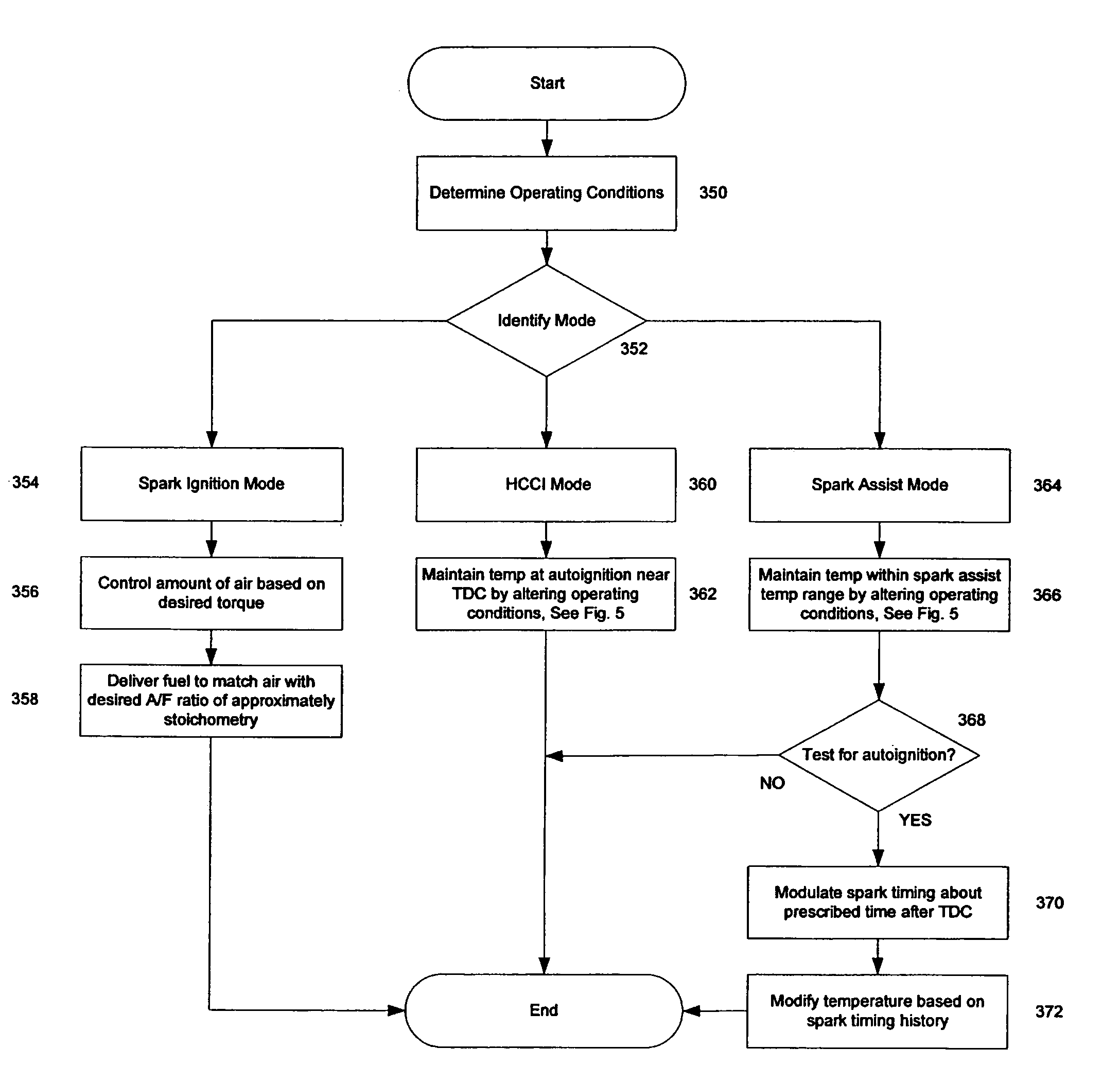

Microwave heating of energetic materials

InactiveUS20060011083A1Material nanotechnologyNon-explosive fillers/gelling/thickening agentsGramDegree Celsius

Mixtures of high explosives with materials that readily absorb microwaves ignite more readily when exposed to microwave energy than the corresponding neat explosives. A charge of HMX (0.5 gram) mixed with carbon nanotubes (1 percent by mass) ignited with 7.5 joules at an average rate of 750 W for 10 milliseconds. To raise a charge of the same mass of neat HMX to an autoignition temperature of 200 degrees Celsius would require much more energy (about 110 joules) for a longer duration (about 150 milliseconds).

Owner:LOS ALAMOS NATIONAL SECURITY

System and method for engine operation with spark assisted compression ignition

InactiveUS7234438B2Improve efficiencyReduce the production of nitrogen oxidesElectrical controlCombustion enginesCombustion chamberTop dead center

A method of operating an internal combustion engine having a combustion chamber with a piston is disclosed. The method comprising during a first mode, adjusting an operating condition of the engine so that a first mixture of air and fuel in the combustion chamber attains an autoignition temperature and therefore combusts without performing a spark from the spark plug; and during a second mode, adjusting said operating condition of the engine so that a second mixture of air and fuel in the combustion chamber approaches, but does not achieve, said autoignition temperature; and performing a spark from the spark plug after top dead center of piston position so that said second mixture combusts.

Owner:FORD GLOBAL TECH LLC

Load transient control methods for direct-injection engines with controlled auto-ignition combustion

InactiveUS7370633B2Electrical controlInternal combustion piston enginesHomogeneous charge compression ignitionLow load

A direct injection controlled auto-ignition engine is operated at steady state, within a homogeneous charge compression-ignition (HCCI) load range and with fuel-air-diluent mixtures at predetermined conditions, for each speed and load, of engine control inputs, including at least fueling mass flow rate, injection timing (FI), spark timing (SI) and exhaust recompression obtained by negative valve overlap (NVO). During load change rates below a predetermined threshold, SI, FI and NVO change rates are synchronized to current changes in the fueling mass flow rate. For fast load increases above the threshold, the cylinder charge is temporarily enriched by increasing the percentage of residual gas or reducing the percentage of fresh air mass in the charge sufficiently to maintain auto-ignition temperature during the load change. This may be done by delaying NVO action for a predetermined speed-dependent number of engine cycles. At very low loads, stable fuel rate reduction may require an alternate method involving deceleration fuel cut-off followed by a step change during refire.

Owner:GM GLOBAL TECH OPERATIONS LLC

Multiple fuel system for internal combustion engines

InactiveUS20090242038A1Easy to operateElectrical controlInternal combustion piston enginesProduction rateAutoignition temperature

A fuel management system mounted on a vehicle is operative to feed individually or a mixture of grades of relatively low, intermediate, and high autoignition temperature fuels to an associated internal combustion engine. The system includes an on board separation unit (OBS unit) for receiving and separating intermediate autoignition temperature (IAT) fuel into low and high autoignition temperature fuels, LAT and HAT, respectively. The production rate of the LAT and HAT fuels by the OBS unit is controlled to substantially match the consumption requirements of the engine at any given time for the LAT and HAT fuels.

Owner:TOYOTA JIDOSHA KK +1

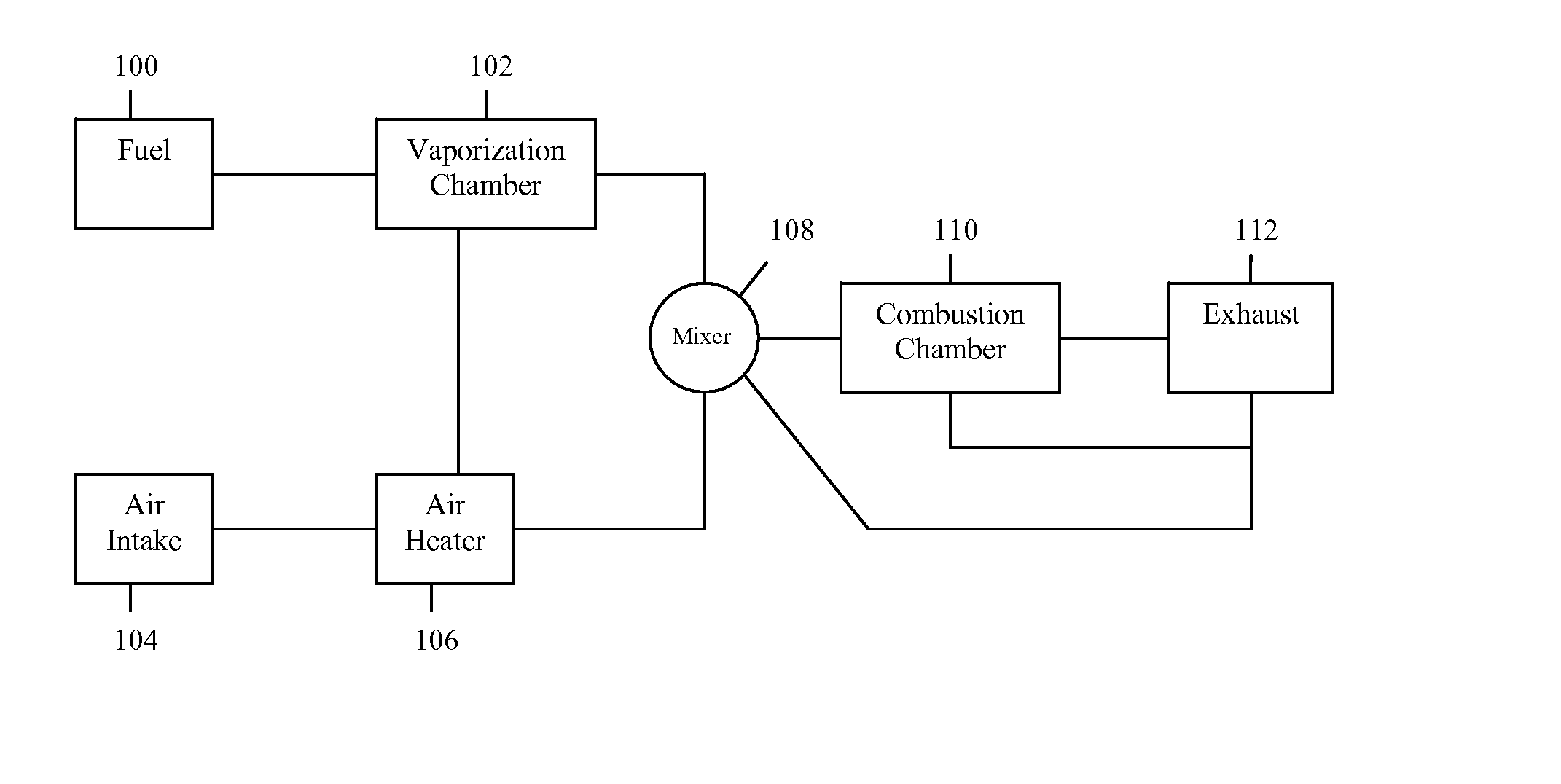

Method for providing controlled heat to a process

InactiveUS20030182858A1Low costIncrease temperatureThermal non-catalytic crackingBurnersHeat fluxEngineering

This invention relates to a method for providing controlled heat to a process utilizing a flameless distributed combustion. The method of the invention comprises providing an oxidation chamber, with an inlet for oxidant, an outlet for combustion products, and a flowpath between the inlet and the outlet; transporting fuel in a fuel conduit containing a plurality of fuel nozzles distributed along substantially the entire length of the oxidation reaction chamber, each nozzle providing communication from within the fuel conduit to the oxidation chamber, the fuel nozzles being spaced so that no flame results when the fuel is mixed with the oxidant flowing through the flowpath in the oxidation chamber; preheating the oxidant to a temperature at which when the oxidant and fuel are mixed in the oxidation chamber, the temperature of resulting mixture exceeds the autoignition temperature of said mixture; and conducting a process in a process chamber which is in a heat exchange relationship with the oxidation chamber, whereby a controlled heat flux is provided to the process chamber at a desired temperature profile and at a rate of heat flux sufficient to complete the process being conducted therein.

Owner:SHELL OIL CO

Transition strategy for engine operation with spark ignition and homogeneous charge compression ignition modes

ActiveUS20070062483A1Improve fuel efficiencyReduce the production of nitrogen oxidesElectrical controlInternal combustion piston enginesPistonAutoignition temperature

A method of operating an internal combustion engine having a combustion chamber with a piston and a spark plug, when transitioning between spark ignition combustion and autoignition combustion, creating a first mixture of air and fuel, adjusting an operating condition of the engine so that said first mixture of air and fuel in the combustion chamber approaches, but does not achieve, the autoignition temperature, and performing a spark from the spark plug so that at least a portion of said first mixture combusts to raise a remaining portion of said first mixture to said autoignition temperature.

Owner:FORD GLOBAL TECH LLC

System and method for engine operation with spark assisted compression ignition

InactiveUS20070062486A1Improve fuel economyEmission reductionElectrical controlCombustion enginesCombustion chamberTop dead center

A method of operating an internal combustion engine having a combustion chamber with a piston is disclosed. The method comprising during a first mode, adjusting an operating condition of the engine so that a first mixture of air and fuel in the combustion chamber attains an autoignition temperature and therefore combusts without performing a spark from the spark plug; and during a second mode, adjusting said operating condition of the engine so that a second mixture of air and fuel in the combustion chamber approaches, but does not achieve, said autoignition temperature; and performing a spark from the spark plug after top dead center of piston position so that said second mixture combusts.

Owner:FORD GLOBAL TECH LLC

System and method for engine operation with spark assisted compression ignition

ActiveUS20070062484A1Reliable spark assisted HCCI operationImprove fuel economyElectrical controlInternal combustion piston enginesCombustion chamberInternal combustion engine

A method of operating an internal combustion engine having a combustion chamber with a piston, comprising of adjusting an operating parameter of the engine so that a mixture of air and fuel in the combustion chamber approaches, but does not achieve, an autoignition temperature, and performing a spark from the spark plug so that said second mixture combusts; adjusting a timing of said spark from the spark plug; and adjusting an operating parameter to increase a correlation between said adjusted spark timing and timing of said combustion.

Owner:FORD GLOBAL TECH LLC

Gradual oxidation with heat transfer

ActiveUS20130232985A1Reduce formationAvoid and decrease expenseFuel supply regulationContinuous combustion chamberFlameoutReaction temperature

Described herein are embodiments of systems and methods for oxidizing gases. In some embodiments, a reaction chamber is configured to receive a fuel gas and maintain the gas at a temperature within the reaction chamber that is above an autoignition temperature of the gas. The reaction chamber may also be configured to maintain a reaction temperature within the reaction chamber below a flameout temperature. In some embodiments, heat and product gases from the oxidation process can be used, for example, to drive a turbine, reciprocating engine, and injected back into the reaction chamber.

Owner:REDUCTONOX CORP

Method of operating an internal combustion engine

ActiveUS7669578B2Improve fuel economy and emissionReduce the formation of nitrogen oxidesValve arrangementsElectrical controlExternal combustion engineEngineering

A method of operating an internal combustion engine having a combustion chamber with a piston and a spark plug, comprising during a first mode, bringing the temperature of the combustion chamber to auto-ignition temperature by adjusting engine operating conditions and producing auto-ignition in said combustion chamber without requiring spark from said spark plug; and during a second mode, bringing the temperature of the combustion chamber close to auto-ignition temperature by adjusting engine operating conditions, forming a small cloud of stratified air-fuel mixture near said spark plug, igniting said fuel cloud by a spark form said spark plug, and then causing cylinder pressure to rise, thereby producing auto-ignition at other sites in said combustion chamber wherein said first mode is implemented in a first operating range and said second mode is implemented only in a second operating range where engine speed and load are lower than said first operating range.

Owner:MAZDA MOTOR CORP

Method for combustion of a fuel

InactiveUS20050282097A1Increase in flame volumeMinimize residence timeContinuous combustion chamberGas turbine plantsCombustion chamberFront velocity

In a method for the combustion of a fuel, a fuel or a premixed combustible mixture is introduced into a combustion space as a combustible fluid open jet. The velocity of the open jet is selected in such a way that it is impossible for a stable flame front to form, i.e. is in any event greater than the flame front velocity, and that, on account of a jet pump effect, flue gas is mixed into the combustible fluid jet from the combustion chamber in a jet-induced recirculation internally within the combustion chamber. The admixed flue gas dilutes and heats the combustible fluid. The heating causes the spontaneous ignition temperature to be exceeded, and a low-pollutant volumetric flame is formed in a highly dilute atmosphere.

Owner:ANSALDO ENERGIA SWITZERLAND AG

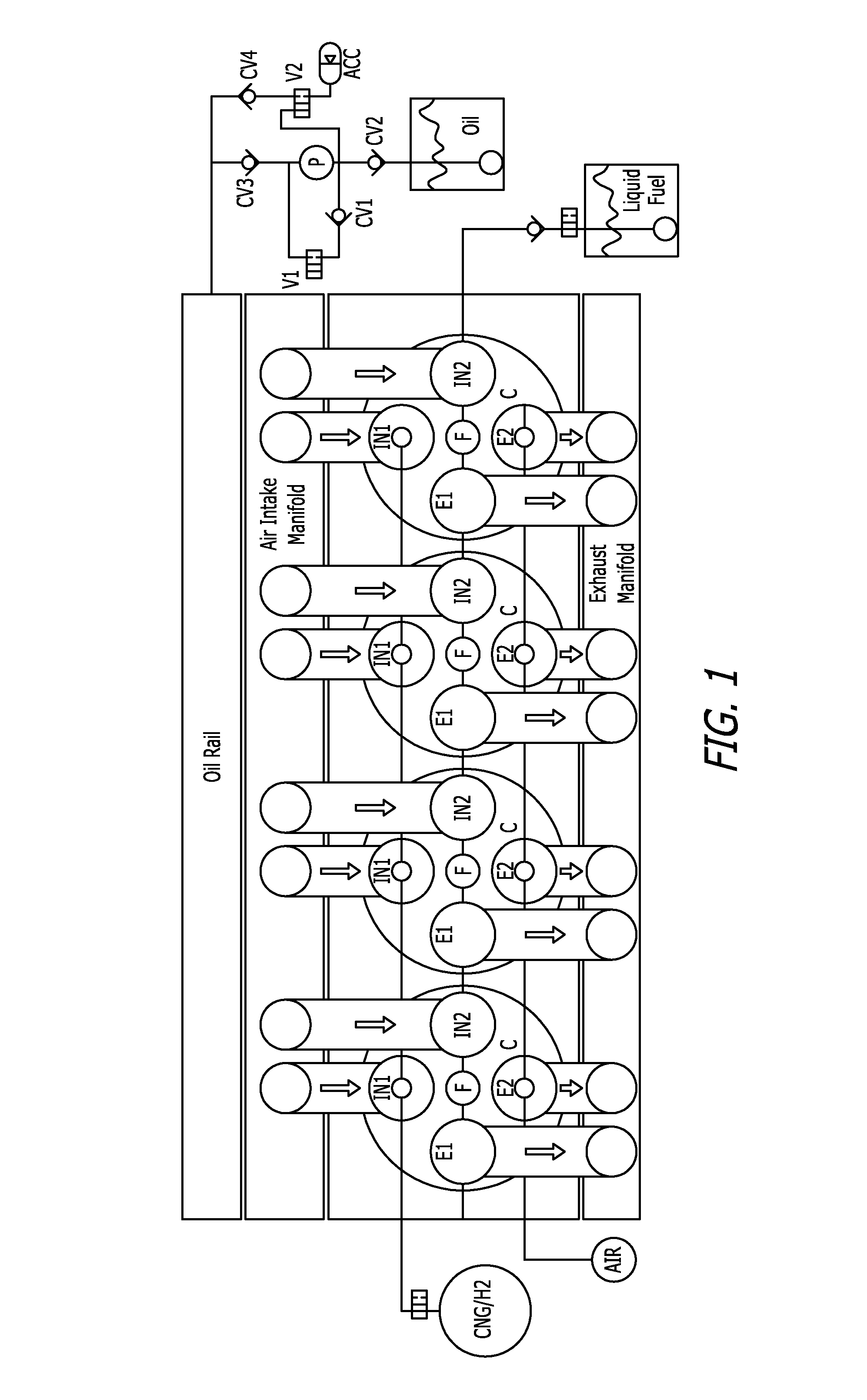

Control method and apparatus for gaseous fuelled internal combustion engine

InactiveUS7162994B2Increase the cross-sectional areaPrevent exitElectrical controlInternal combustion piston enginesTop dead centerExternal combustion engine

A method and apparatus create an environment within a combustion chamber of an internal combustion engine suitable for auto-ignition and combustion of a fuel that will not otherwise auto-ignite. Under high-load conditions, a pilot quantity of the fuel is injected in the combustion chamber of an internal combustion engine during the compression stroke of the piston. The quantity and timing of the fuel are chosen to heat an intake charge within the combustion chamber to a temperature at or above the auto-ignition temperature of the fuel by the time required for a main injection of the fuel to drive the piston during the power stroke. Generally, auto-ignition temperatures should be reached at or near top dead center of the piston. An injector design delivers fuel in manner carried out by the method.

Owner:WESTPORT POWER

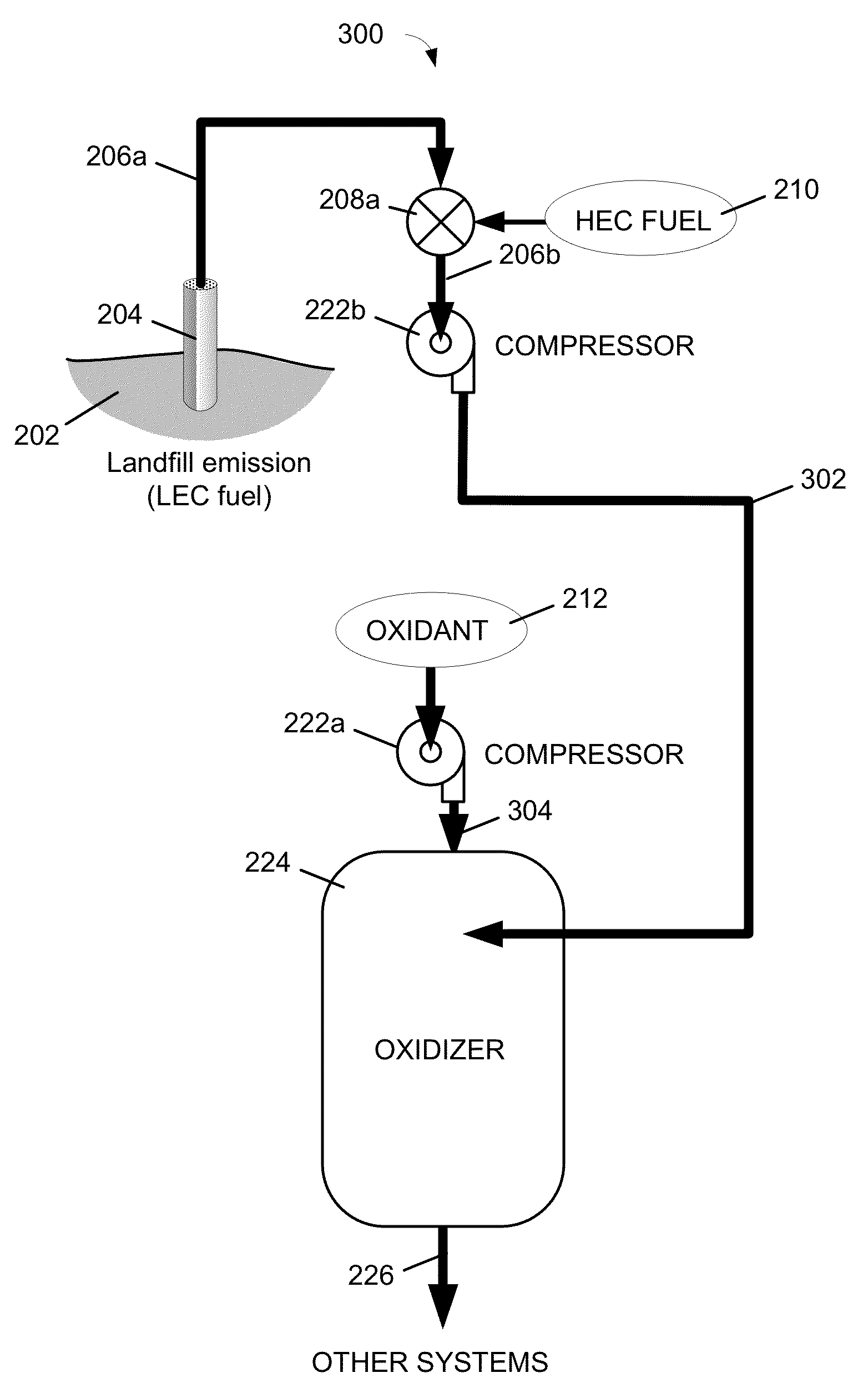

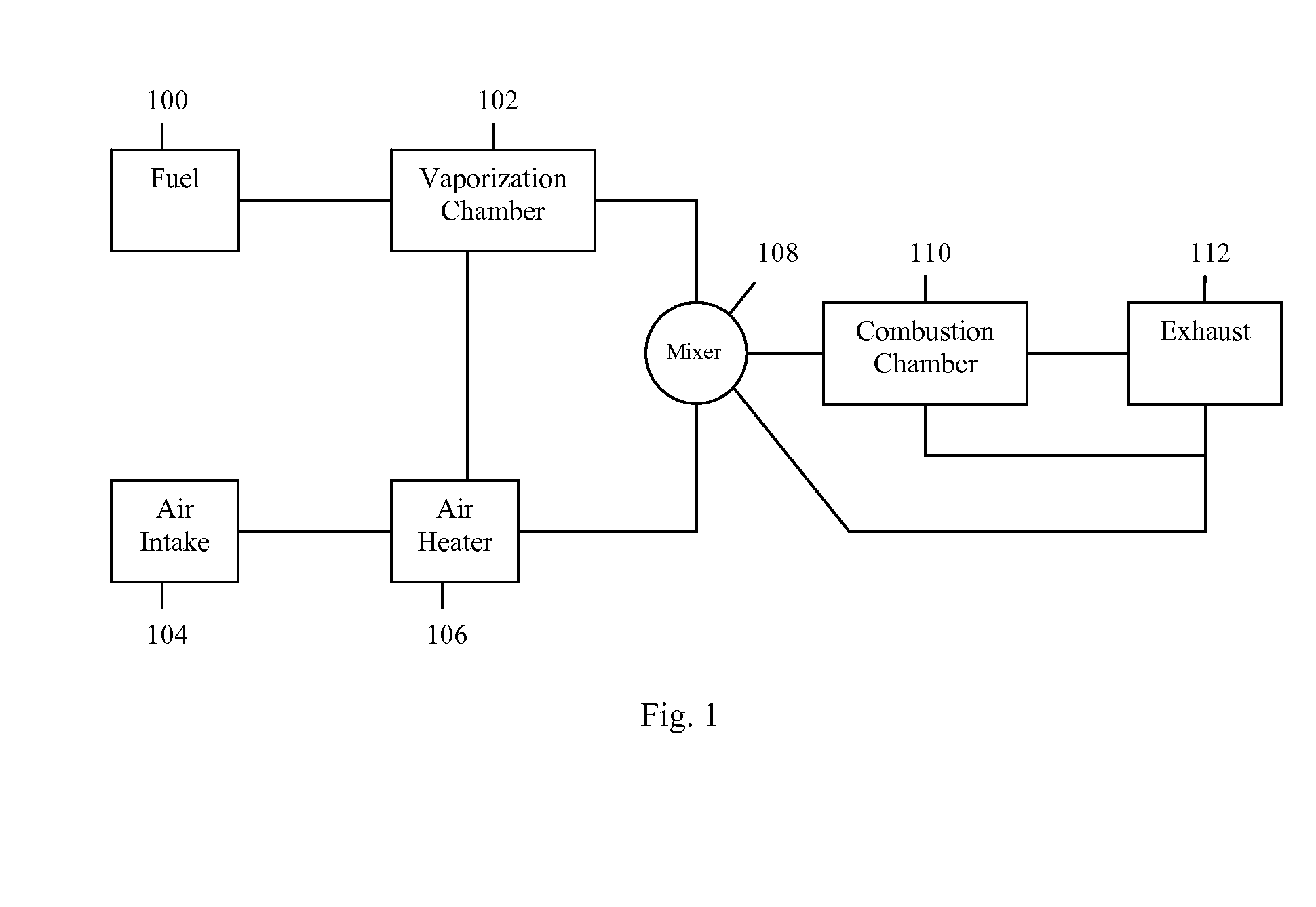

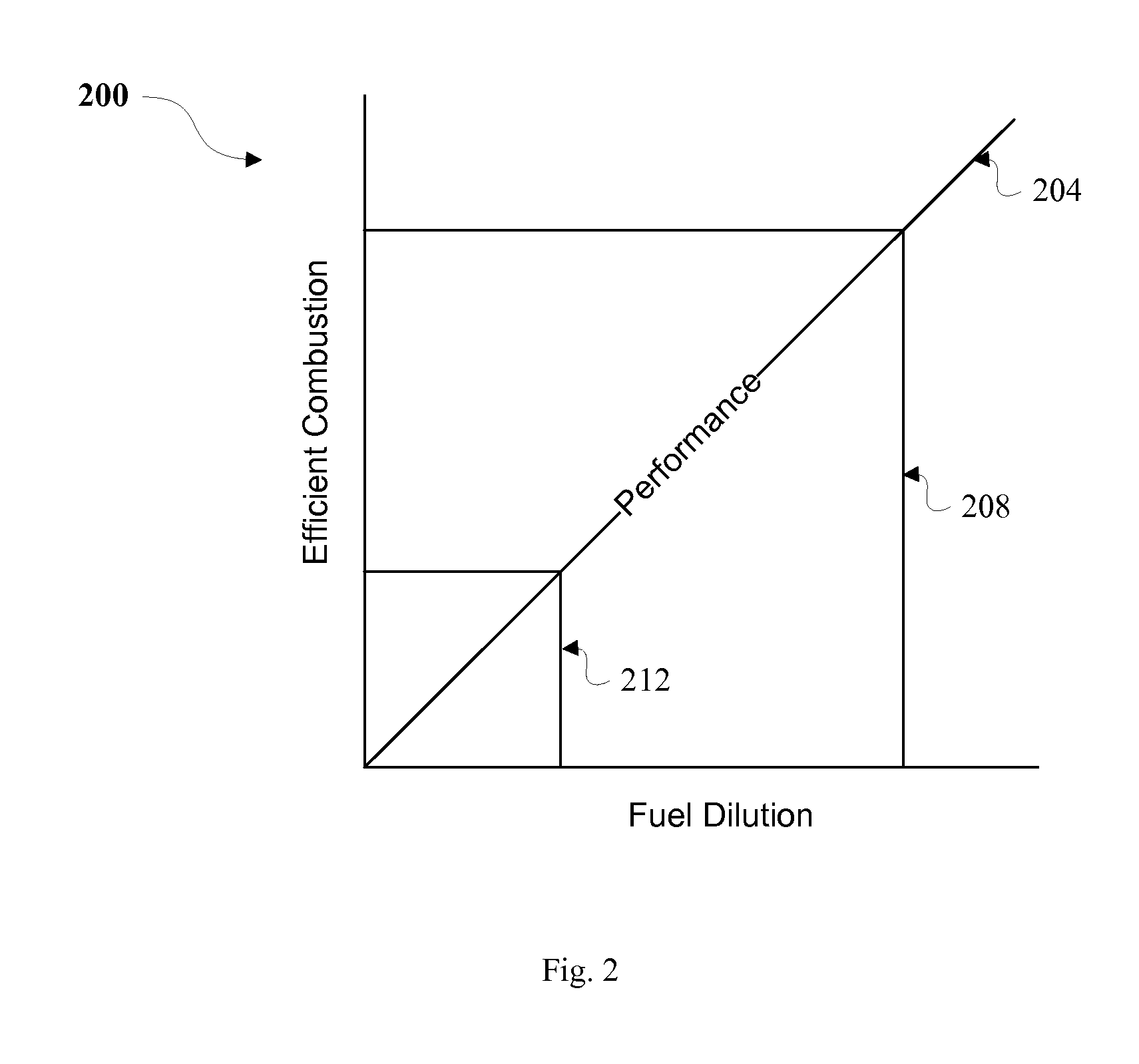

Fuel utilization

InactiveUS20080032245A1Less timeEfficient workBurnersLiquid fuel feeder/distributionFuel efficiencyEngineering

Embodiments of the present invention provide a fuel supply system for combustion engines, whereby the temperatures of an oxidizer and fuel may be increased so that the temperatures approach but do not achieve an auto-ignition temperature for the fuel charge. The fuel charge may result in substantial improvements in fuel efficiency.

Owner:VAPOR FUEL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com