Patents

Literature

32results about How to "Improve exhaust emissions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

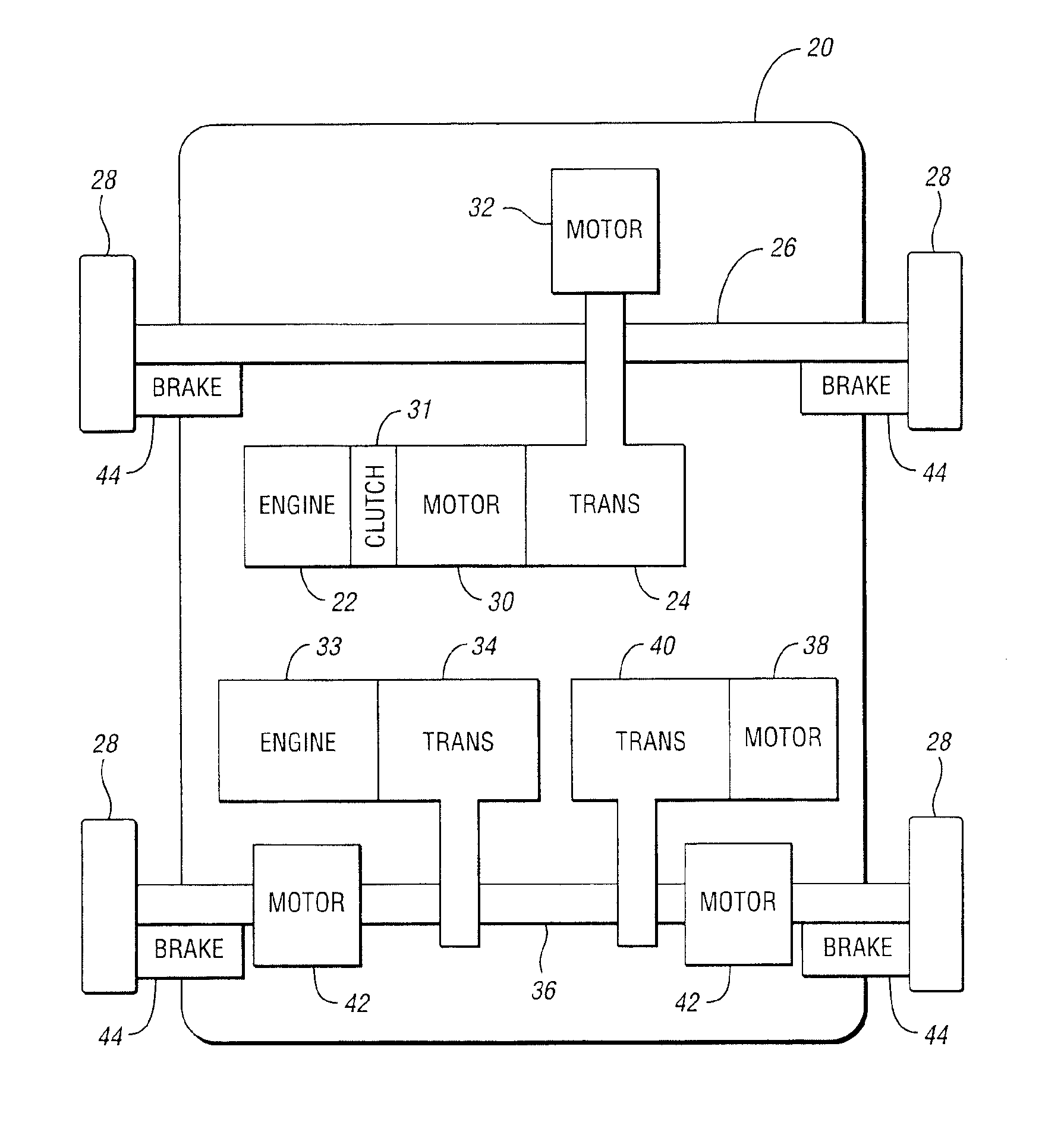

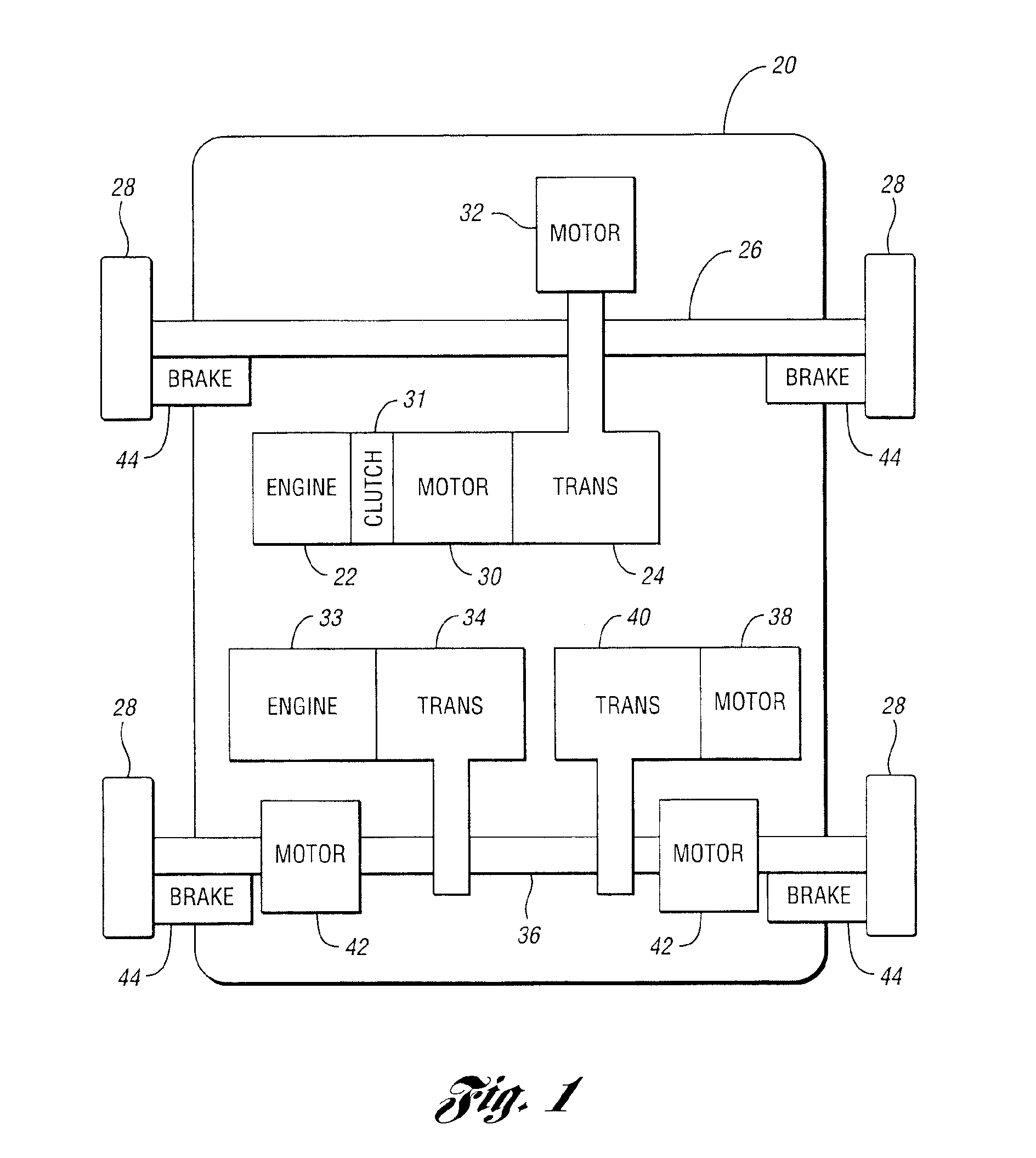

Vehicle torque coordination

InactiveUS6862511B1Less prone to failureImprove driveabilityBrake system interactionsDigital data processing detailsControl theory

Owner:FORD GLOBAL TECH LLC

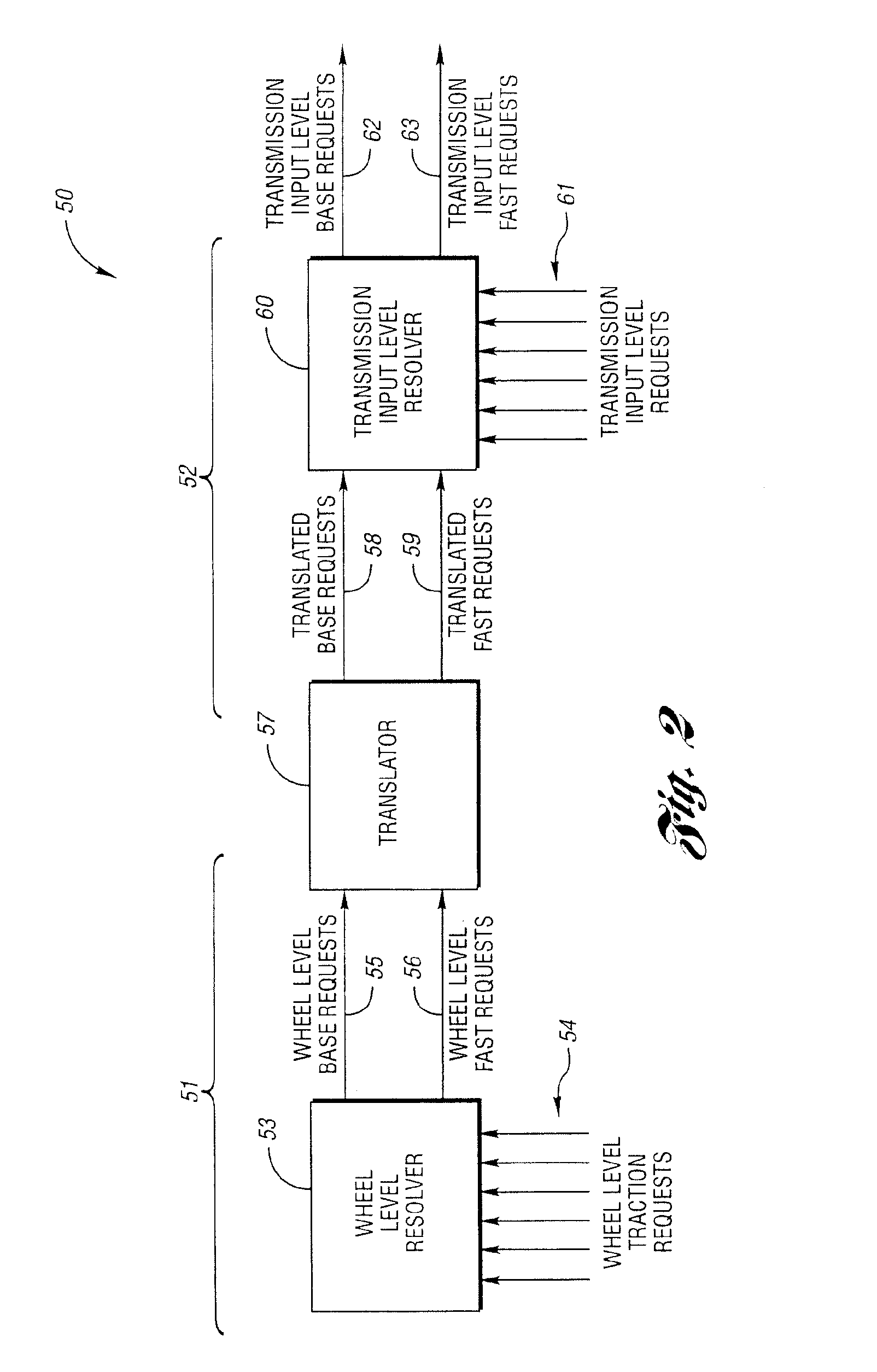

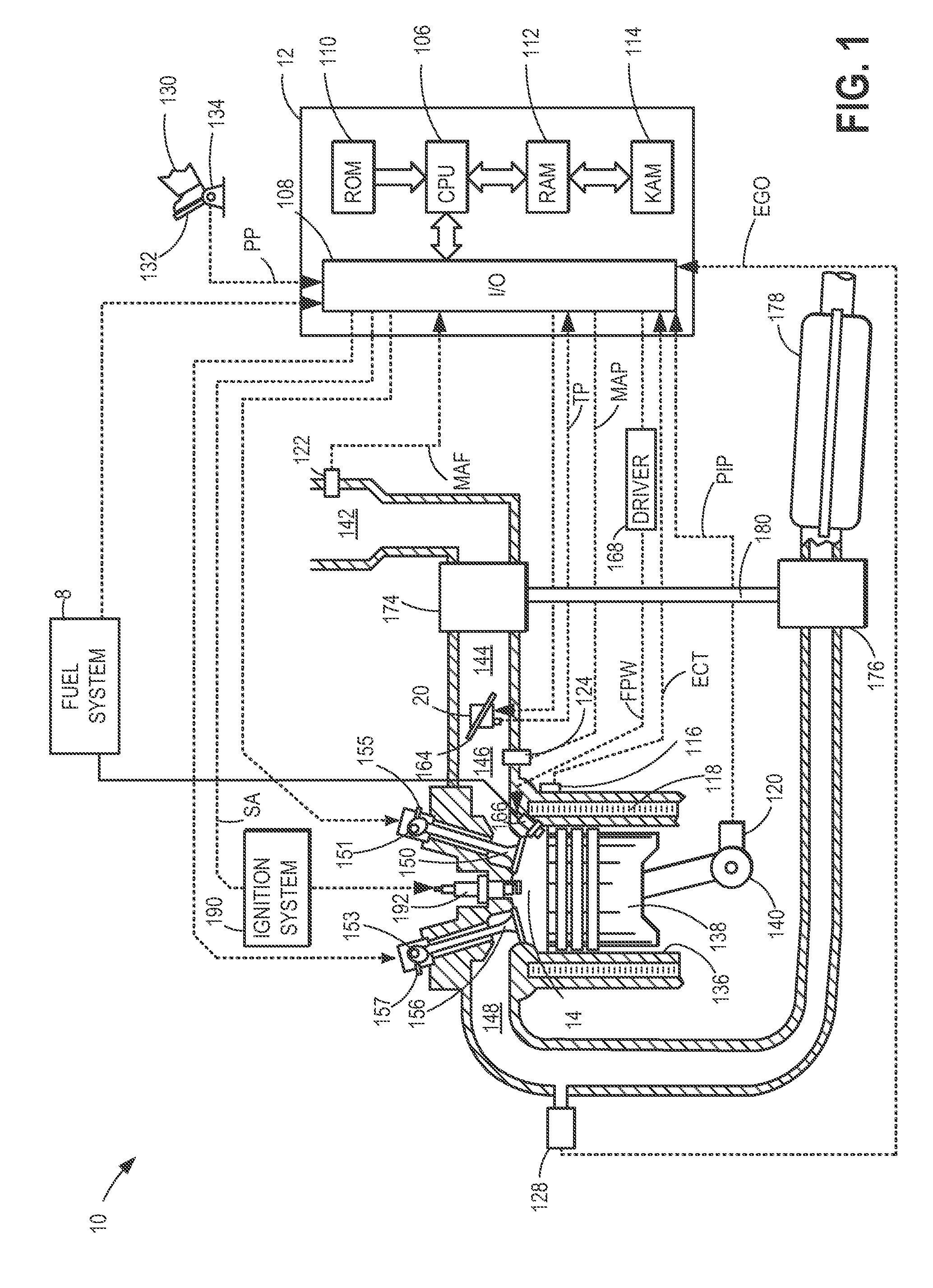

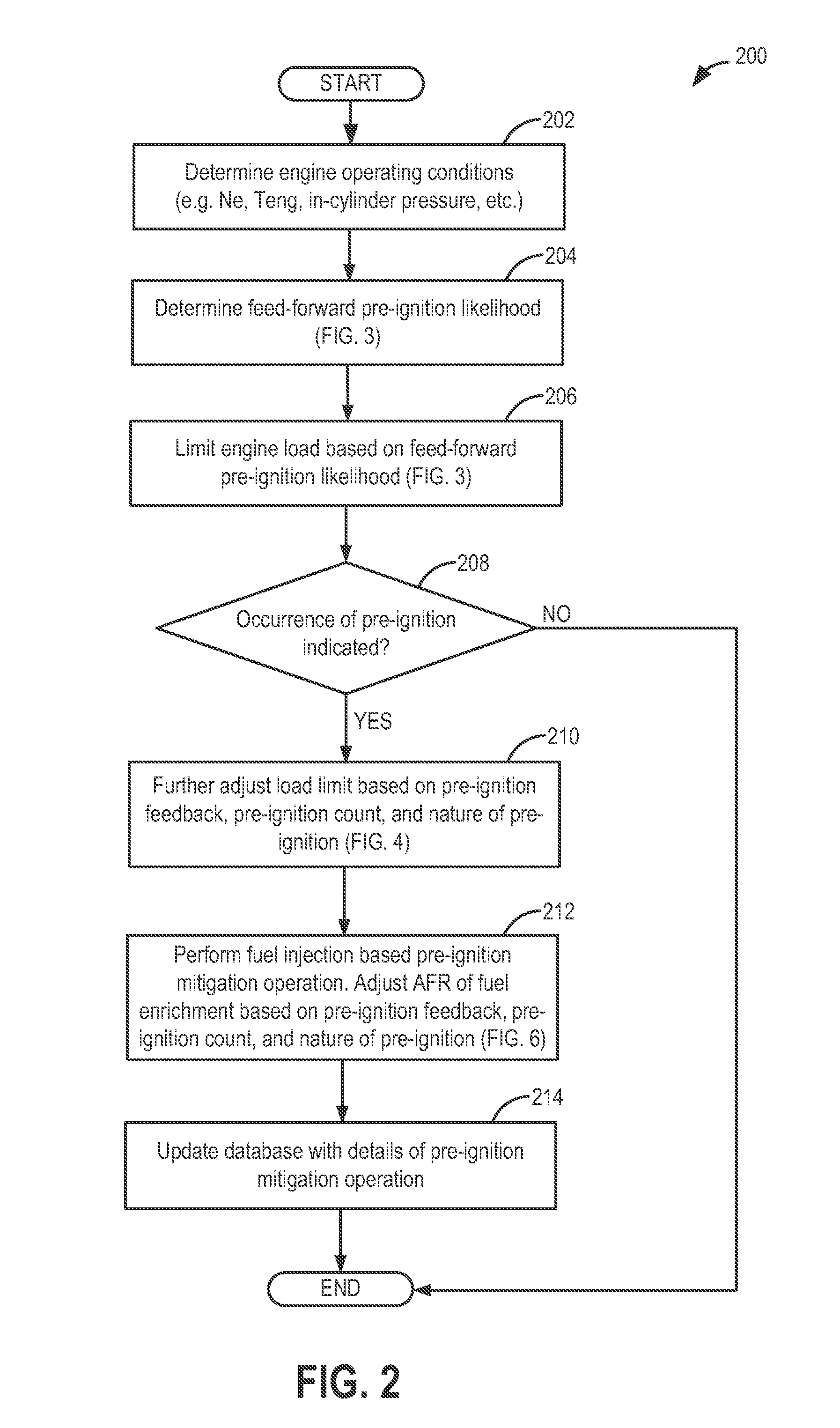

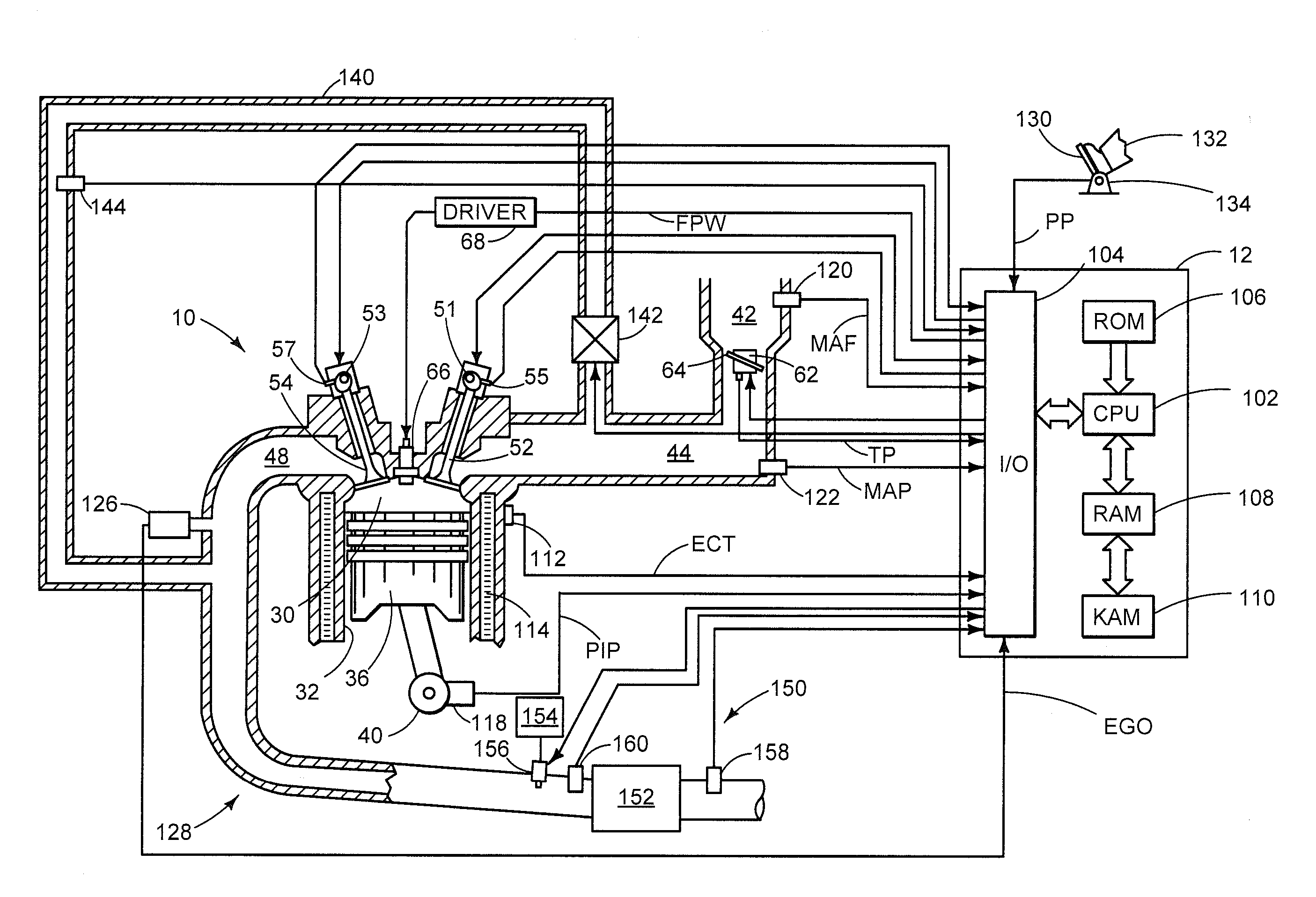

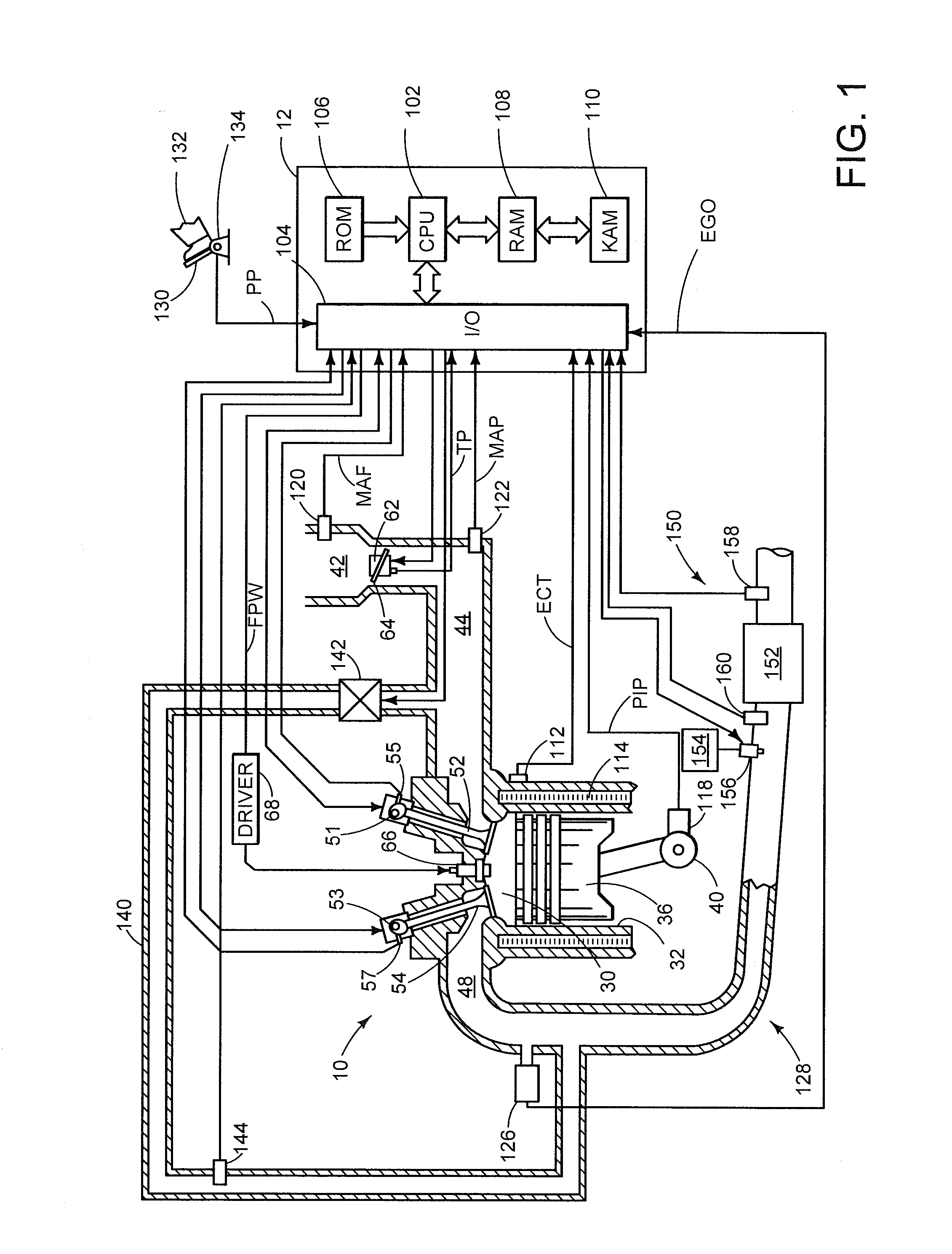

Method and system for pre-ignition control

ActiveUS20110144893A1Improve exhaust emissionsExtended durationAnalogue computers for vehiclesElectrical controlIgnition coilOperant conditioning

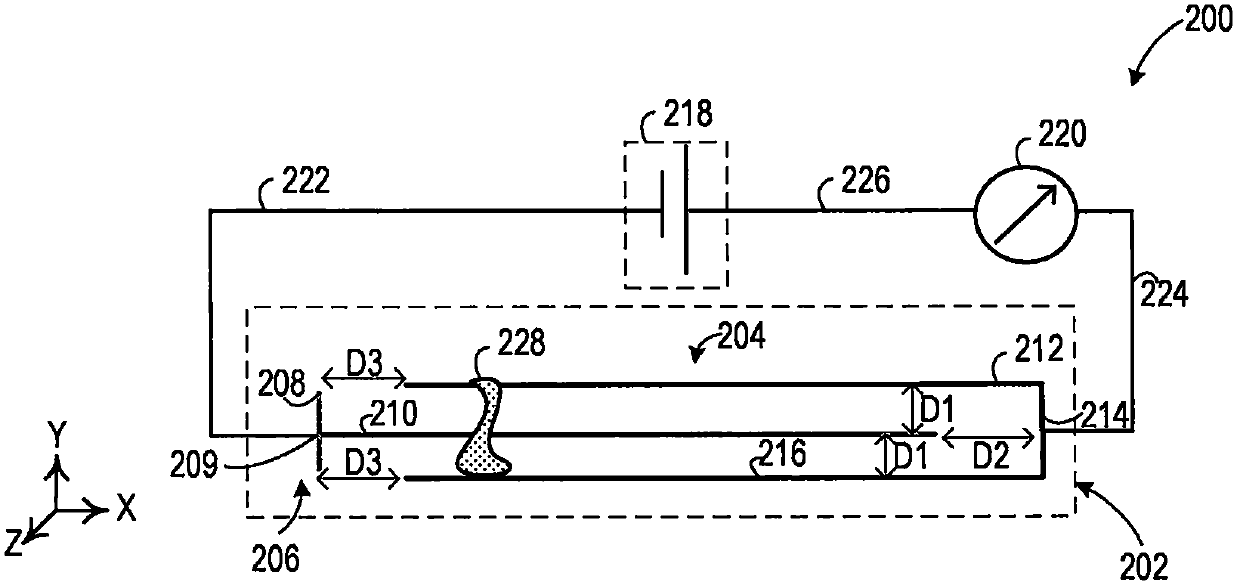

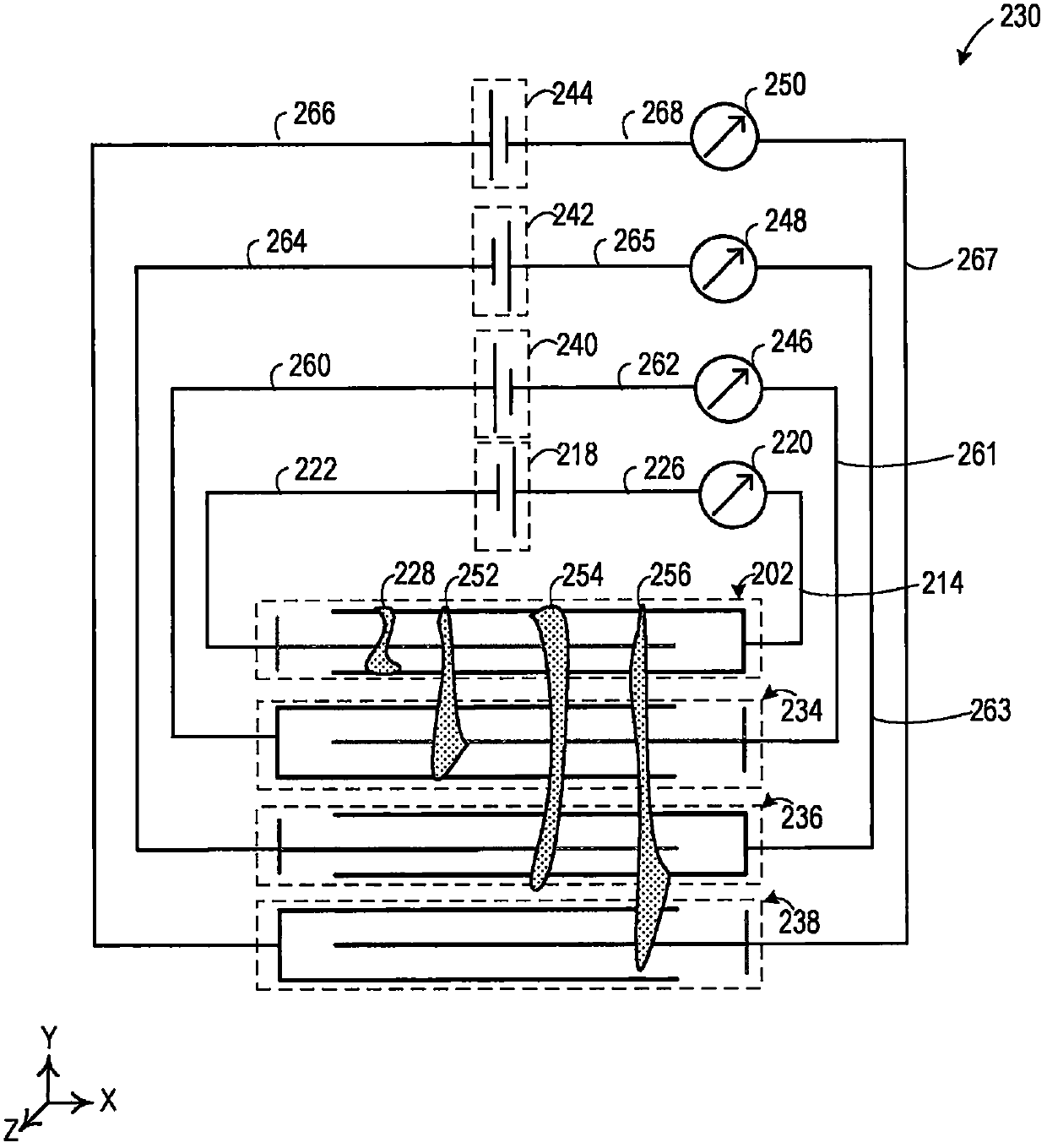

Methods and systems are provided for mitigating engine pre-ignition based on a feed-forward likelihood of pre-ignition and feedback from a pre-ignition event. In response to an indication of pre-ignition, a cylinder may be enriched while an engine load is limited. The enrichment may be followed by an enleanment to restore exhaust catalyst feed-gas oxygen levels. The mitigating steps may be adjusted based on engine operating conditions, a pre-ignition count, as well as the nature of the pre-ignition.

Owner:FORD GLOBAL TECH LLC

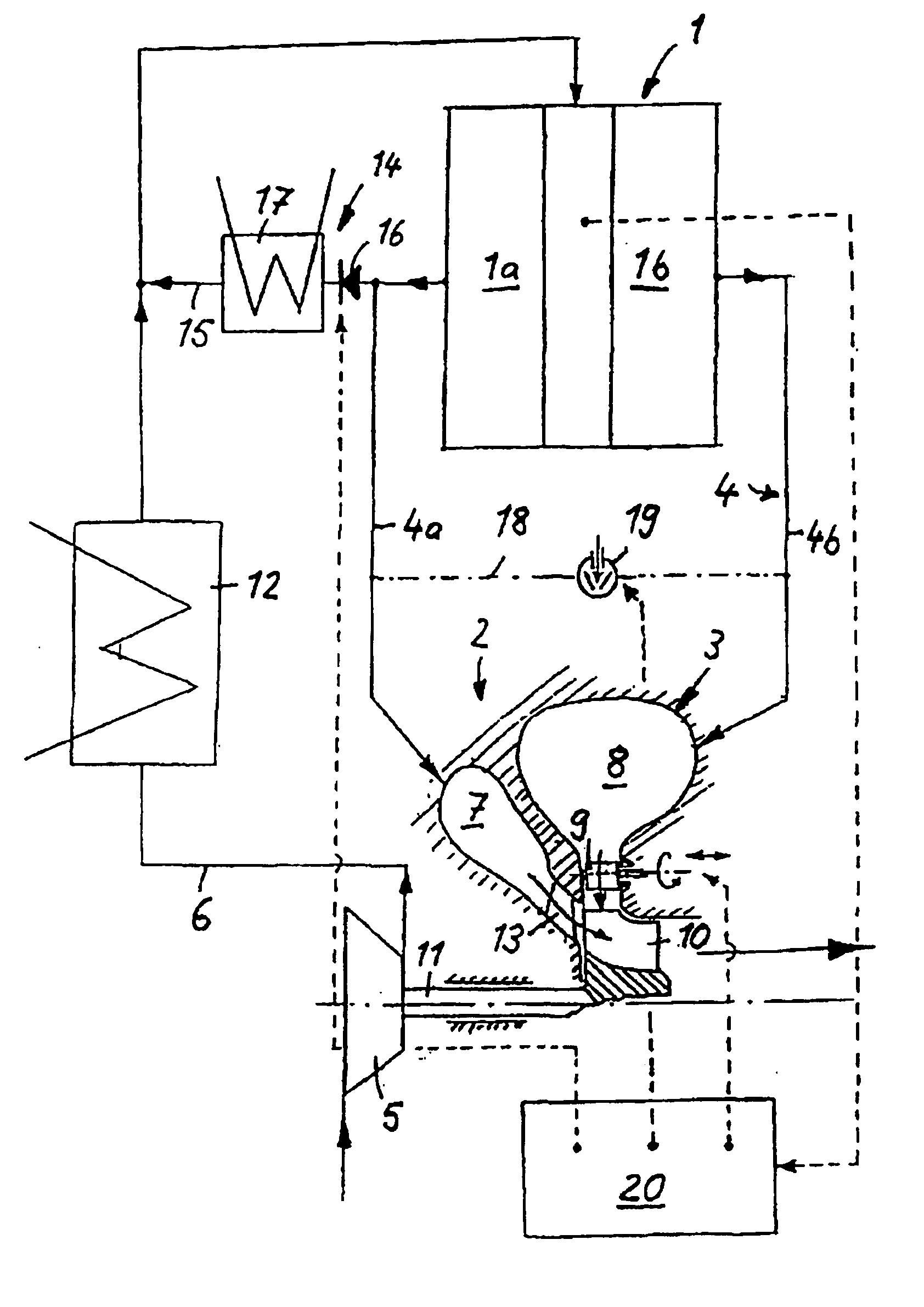

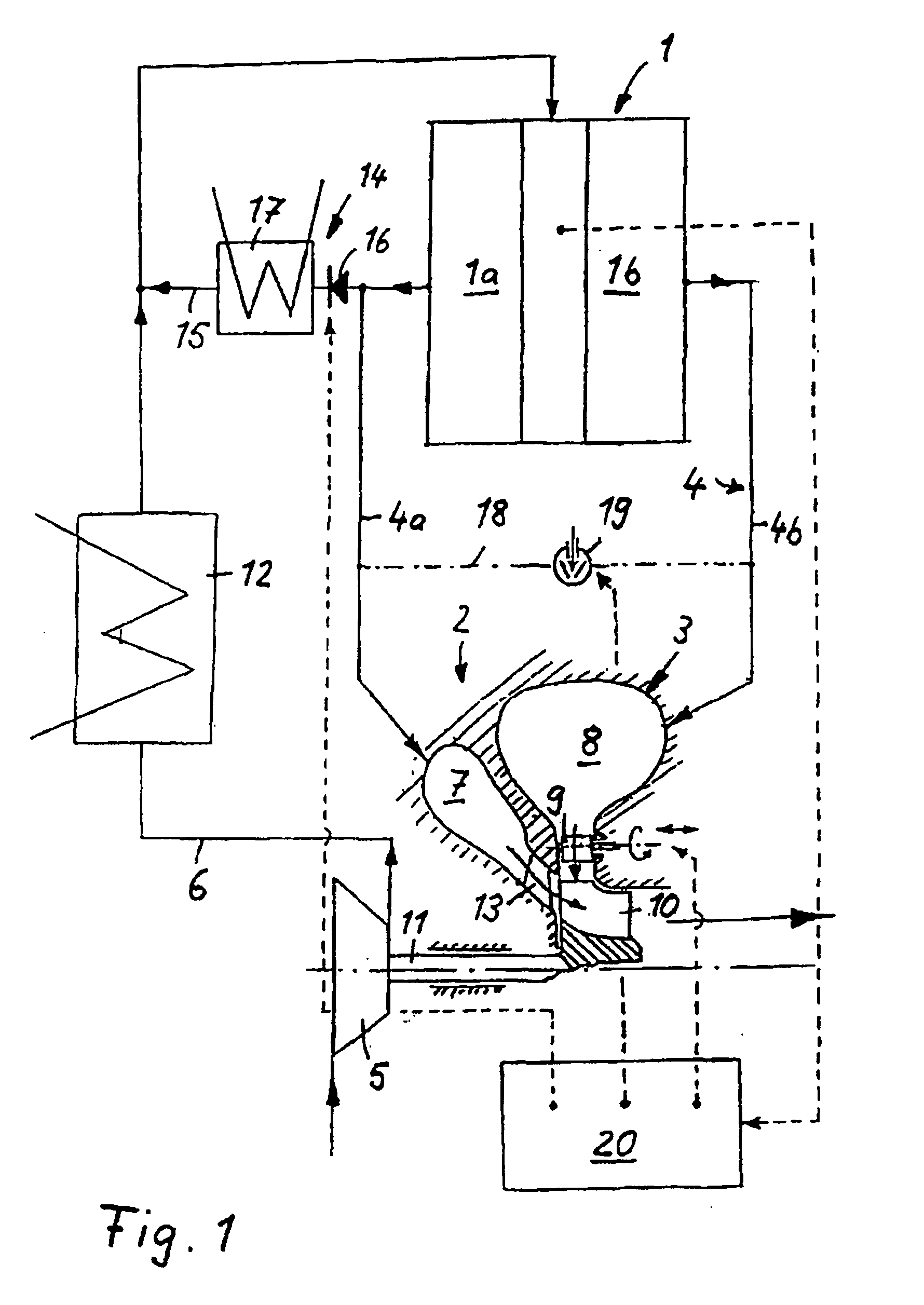

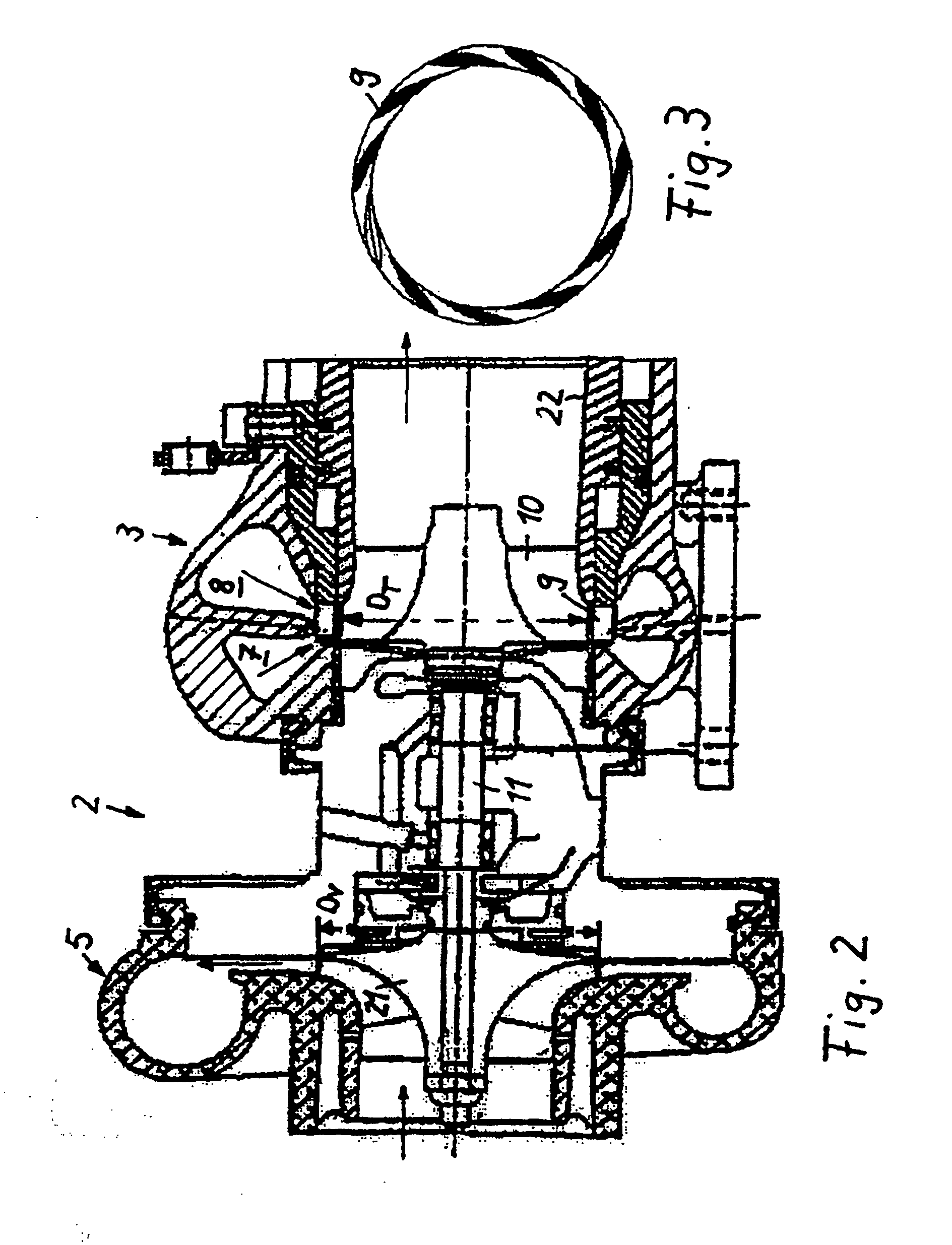

Exhaust gas turbocharger for a reciprocating internal combustion engine and corresponding reciprocating internal combustion engine

ActiveUS20070180826A1Improve turbine efficiencyImprove efficiencyInternal combustion piston enginesPump componentsImpellerExhaust valve

In an exhaust gas turbocharger for a reciprocating internal combustion engine comprising an exhaust gas turbine in the exhaust line and a compressor in the inlet line of the engine, the exhaust gas turbine has two exhaust gas flow passages, by way of which exhaust gas is fed to the turbine rotor, the ratio of the turbine rotor diameter to the compressor wheel diameter being set by a function, which is dependent on the displacement volume of the internal combustion engine.

Owner:DAIMLER TRUCK AG

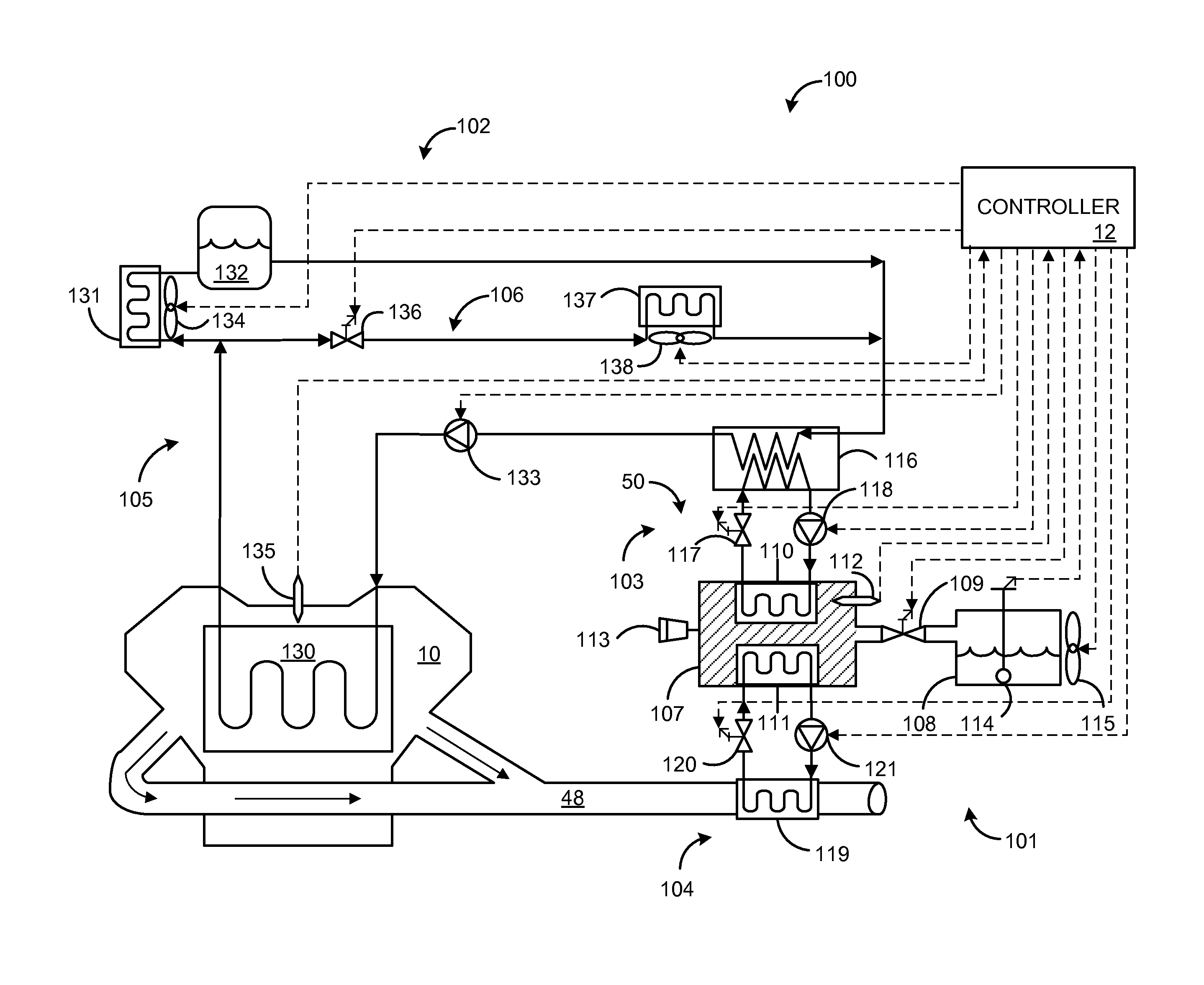

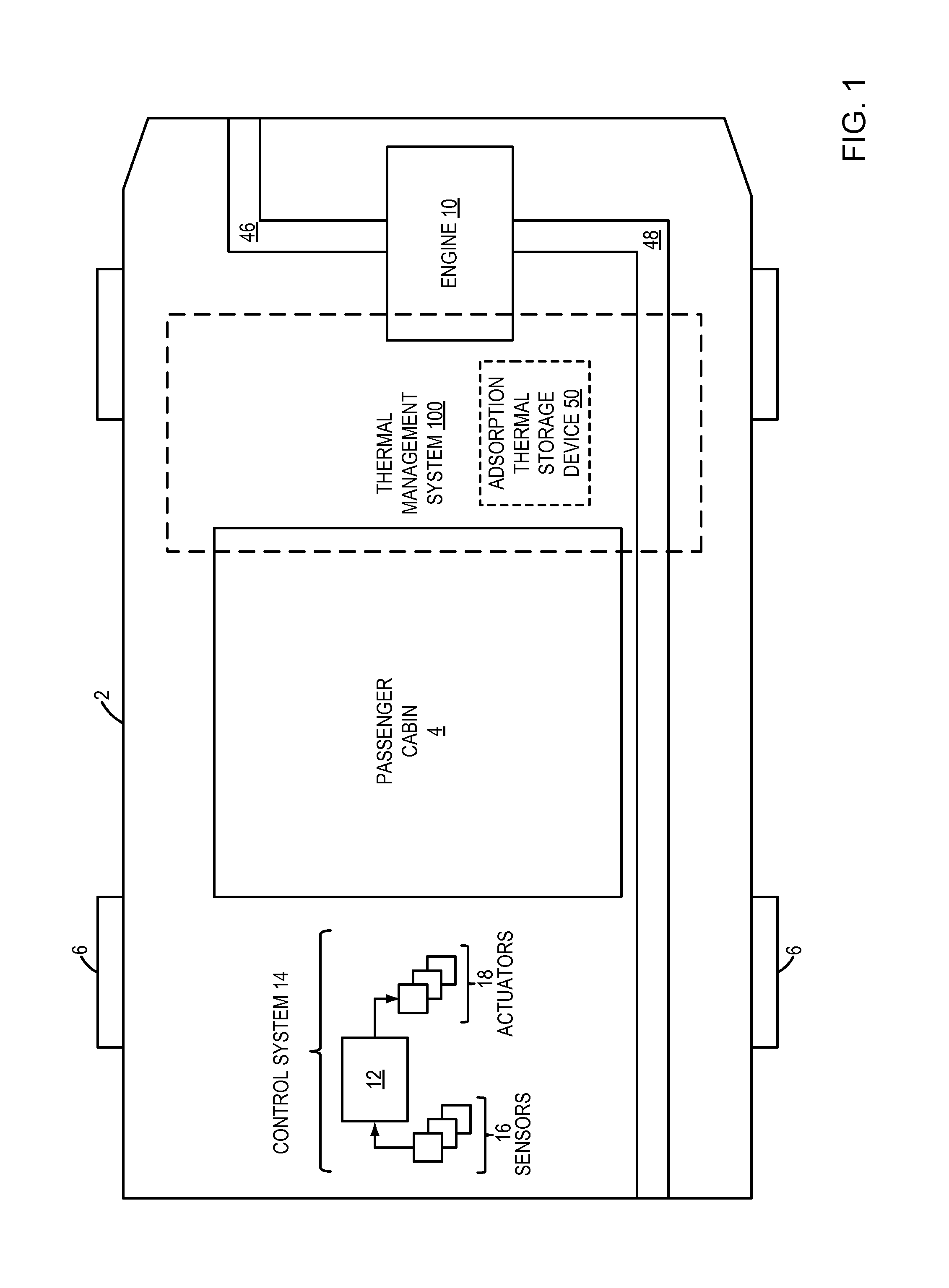

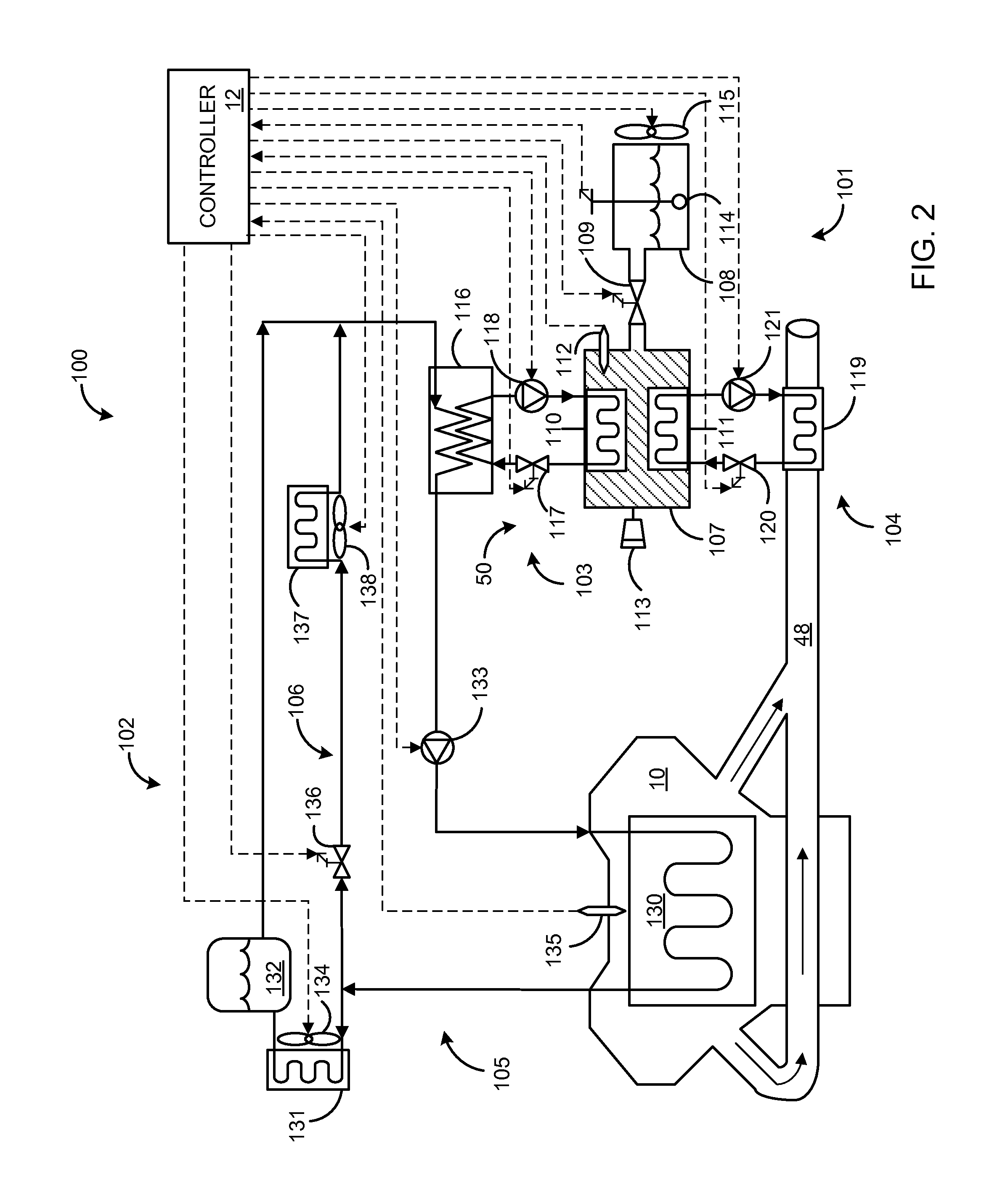

System for thermal management of a vehicle and method for vehicle cold start

InactiveUS20140374058A1Less-waste heatOptimize timingInternal combustion piston enginesExhaust apparatusHeat exchangerAutomotive engineering

A method, comprising during a vehicle engine cold start, opening a first valve coupled between a first container containing an adsorbent and a second container containing an adsorbate, circulating a first fluid through a first conduit coupled to a first heat exchanger located within the first container and a second heat exchanger located outside the first container, and circulating a second fluid through a second conduit coupled to the second heat exchanger. In this way, heat may be generated at the adsorber during a cold start and subsequently transferred to the cooling jacket of the vehicle engine and / or other vehicle compartments, thereby decreasing the warm-up time for the engine.

Owner:FORD GLOBAL TECH LLC

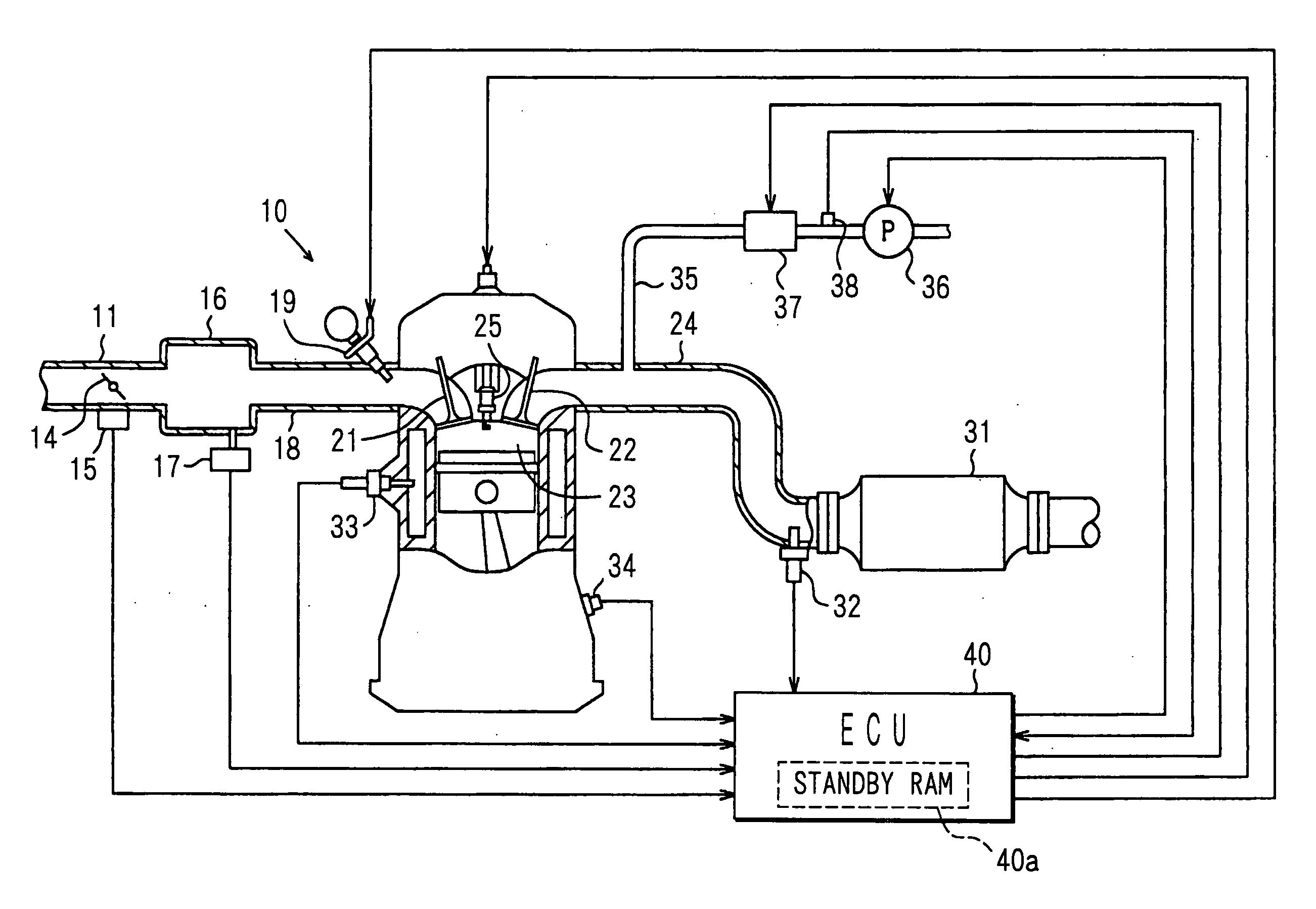

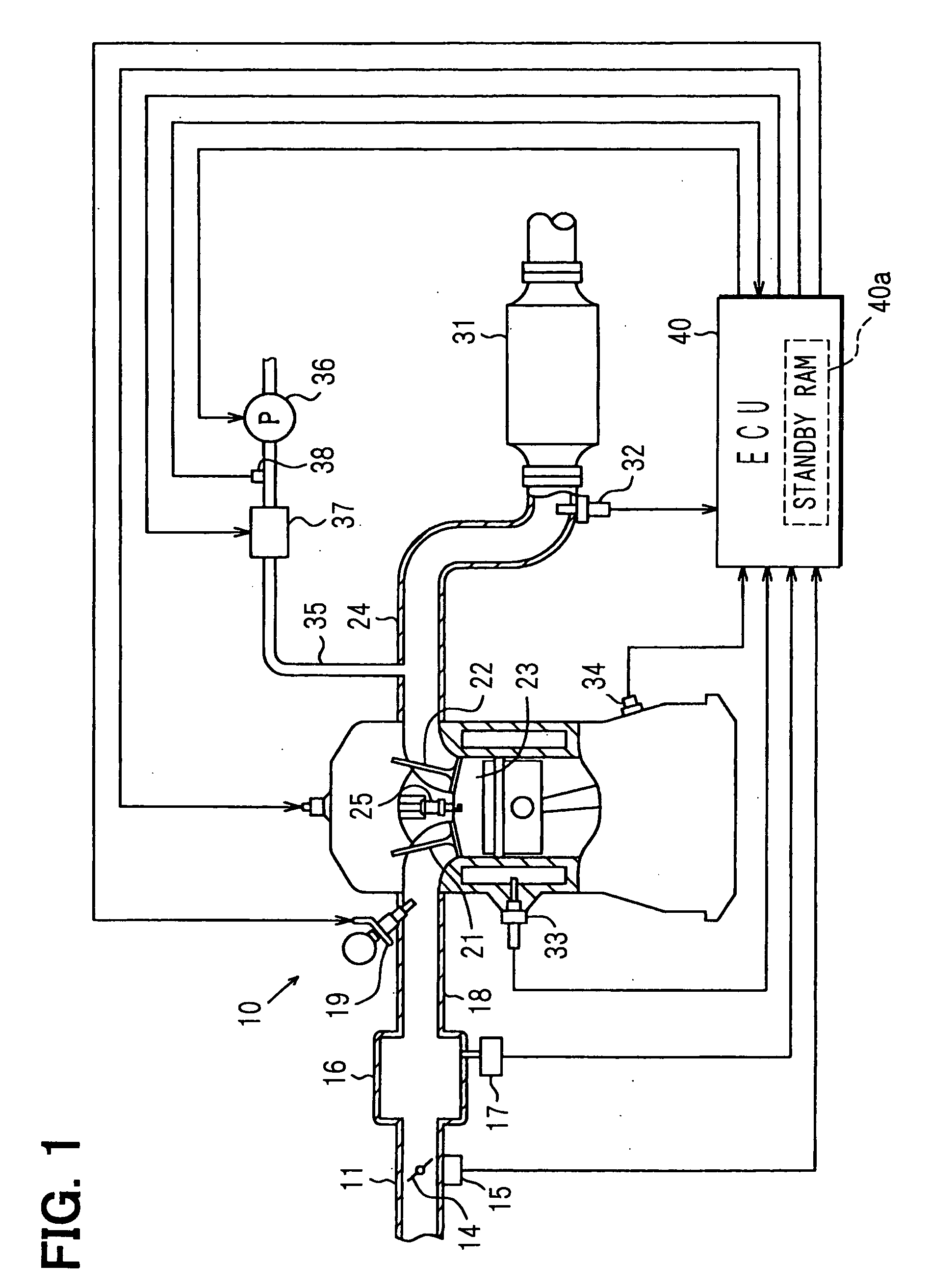

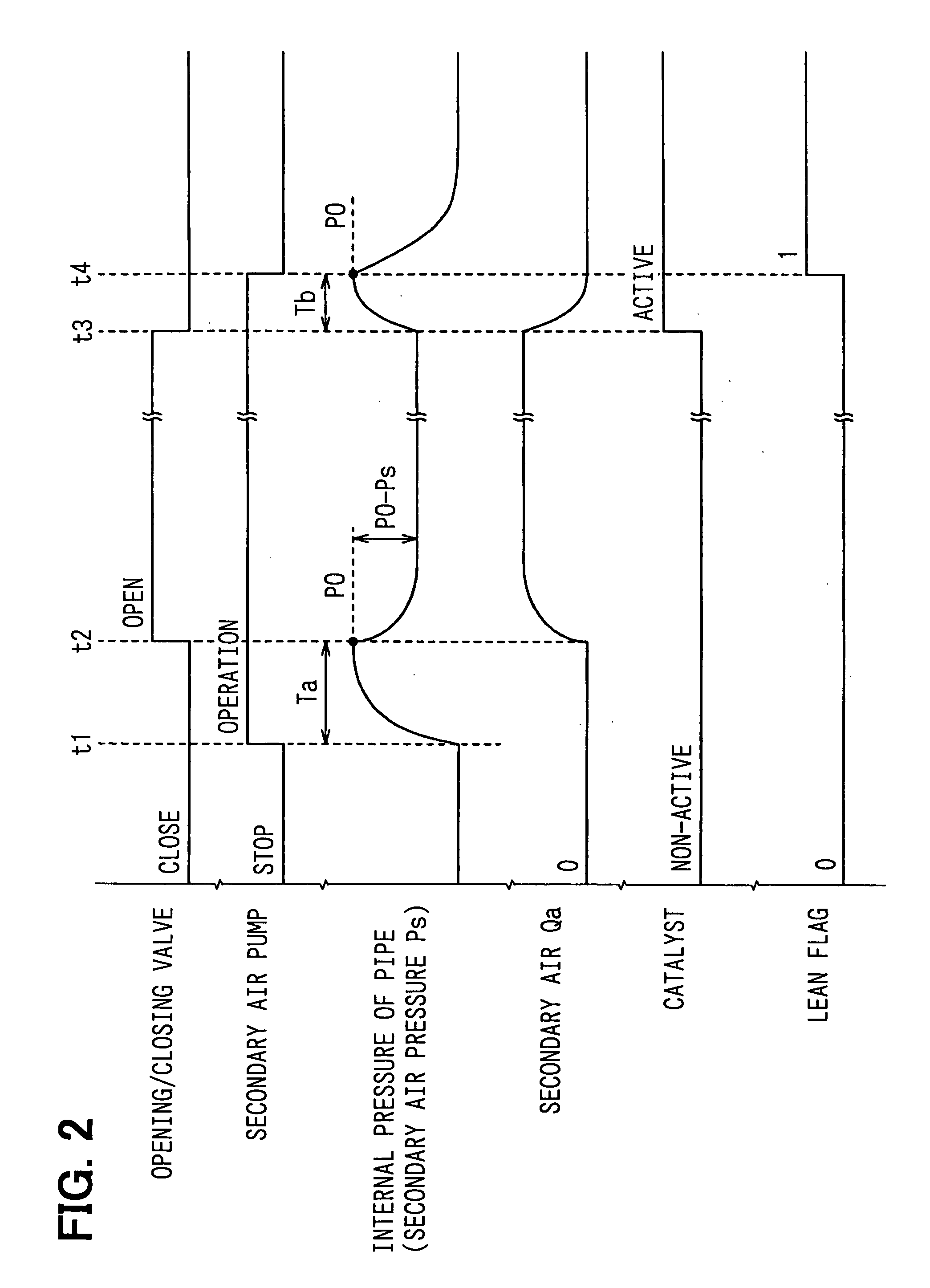

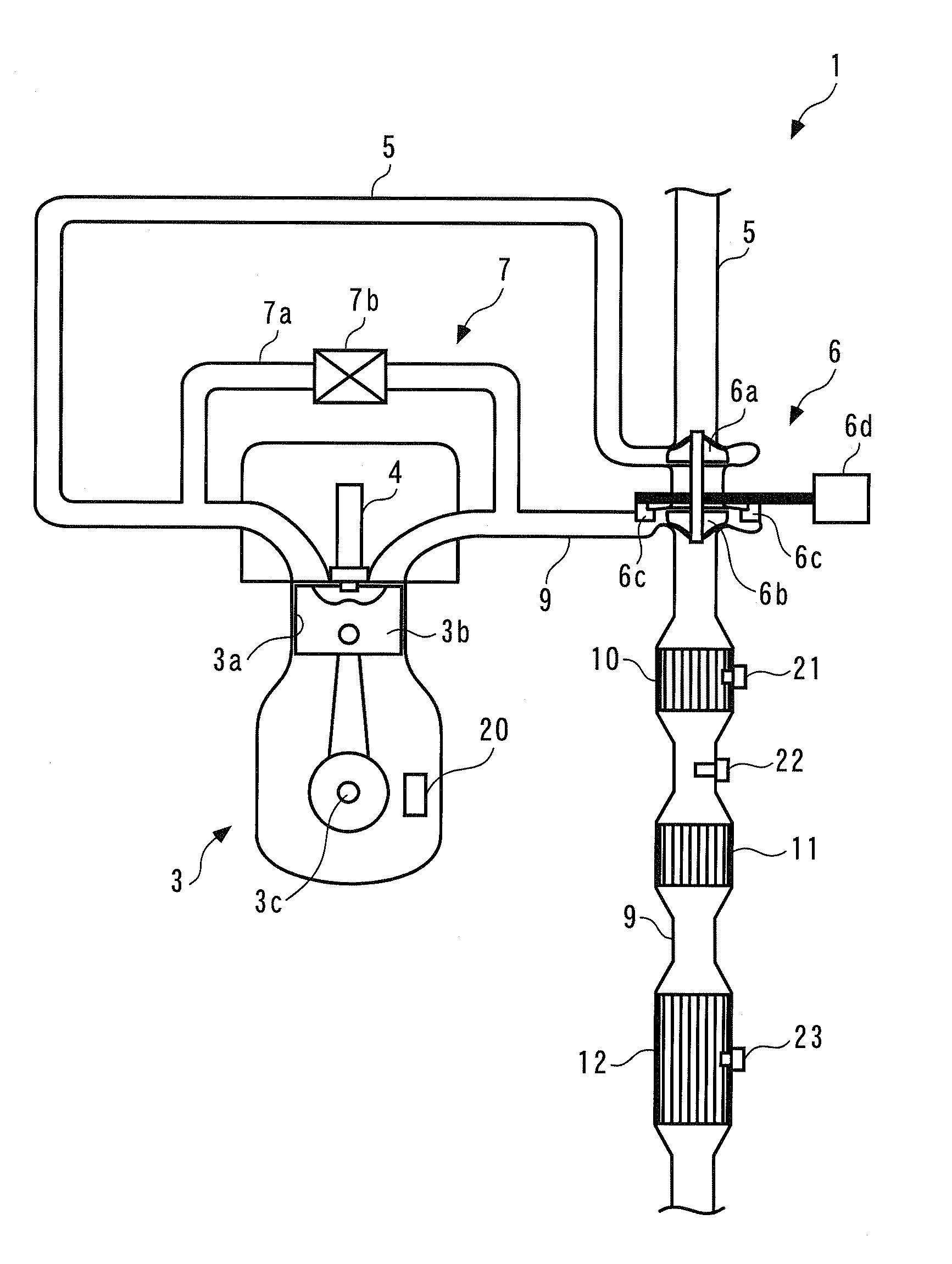

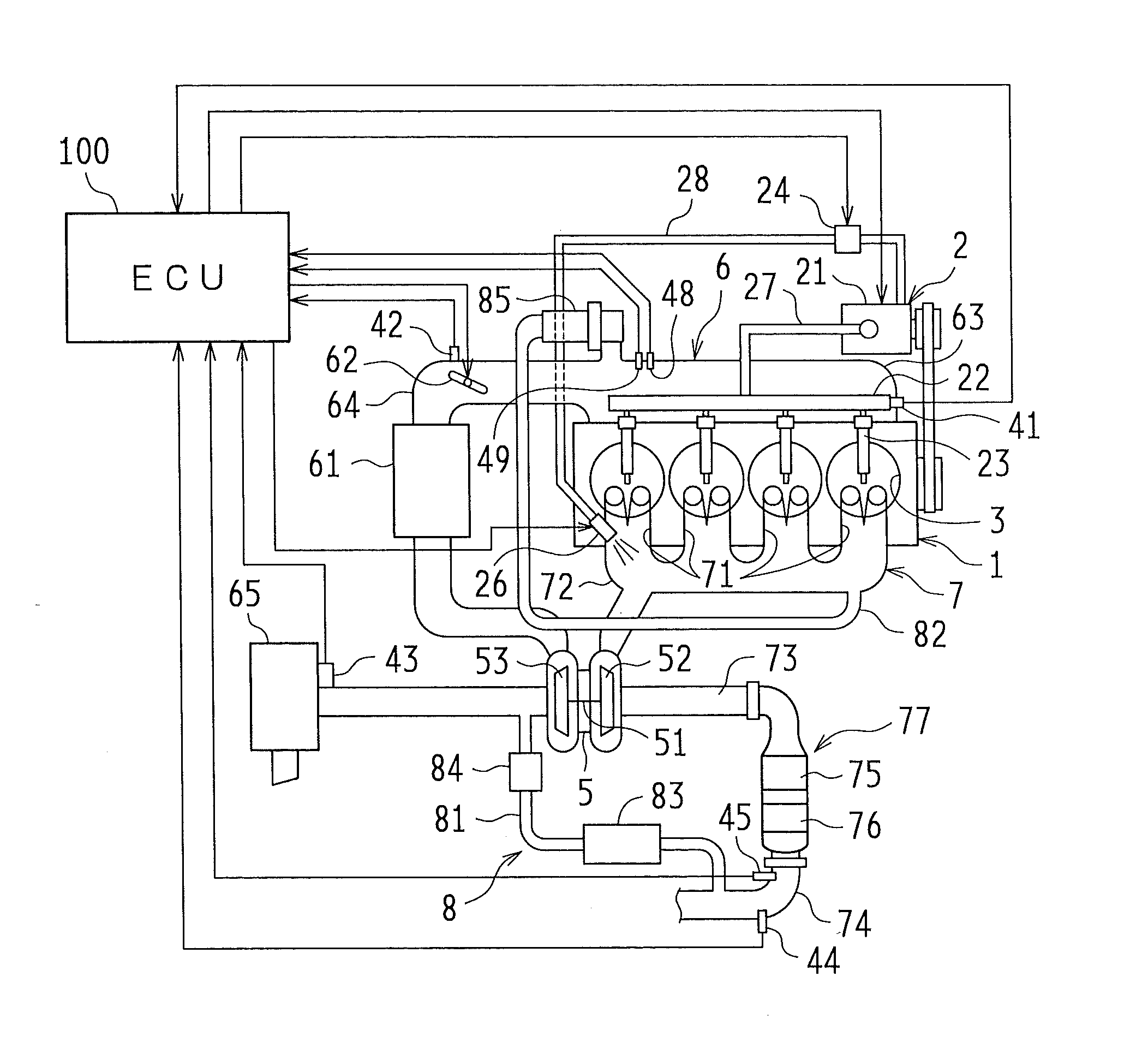

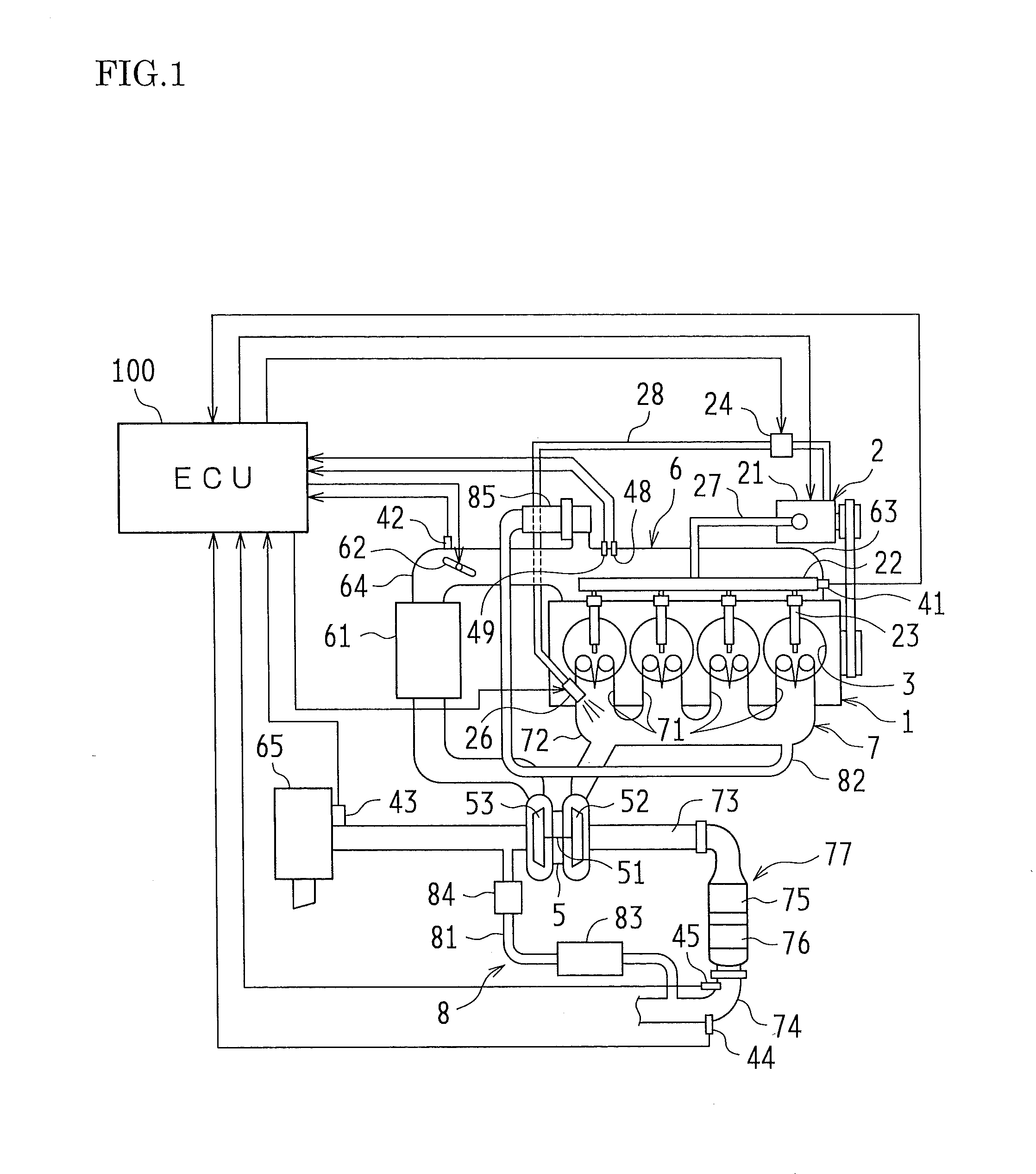

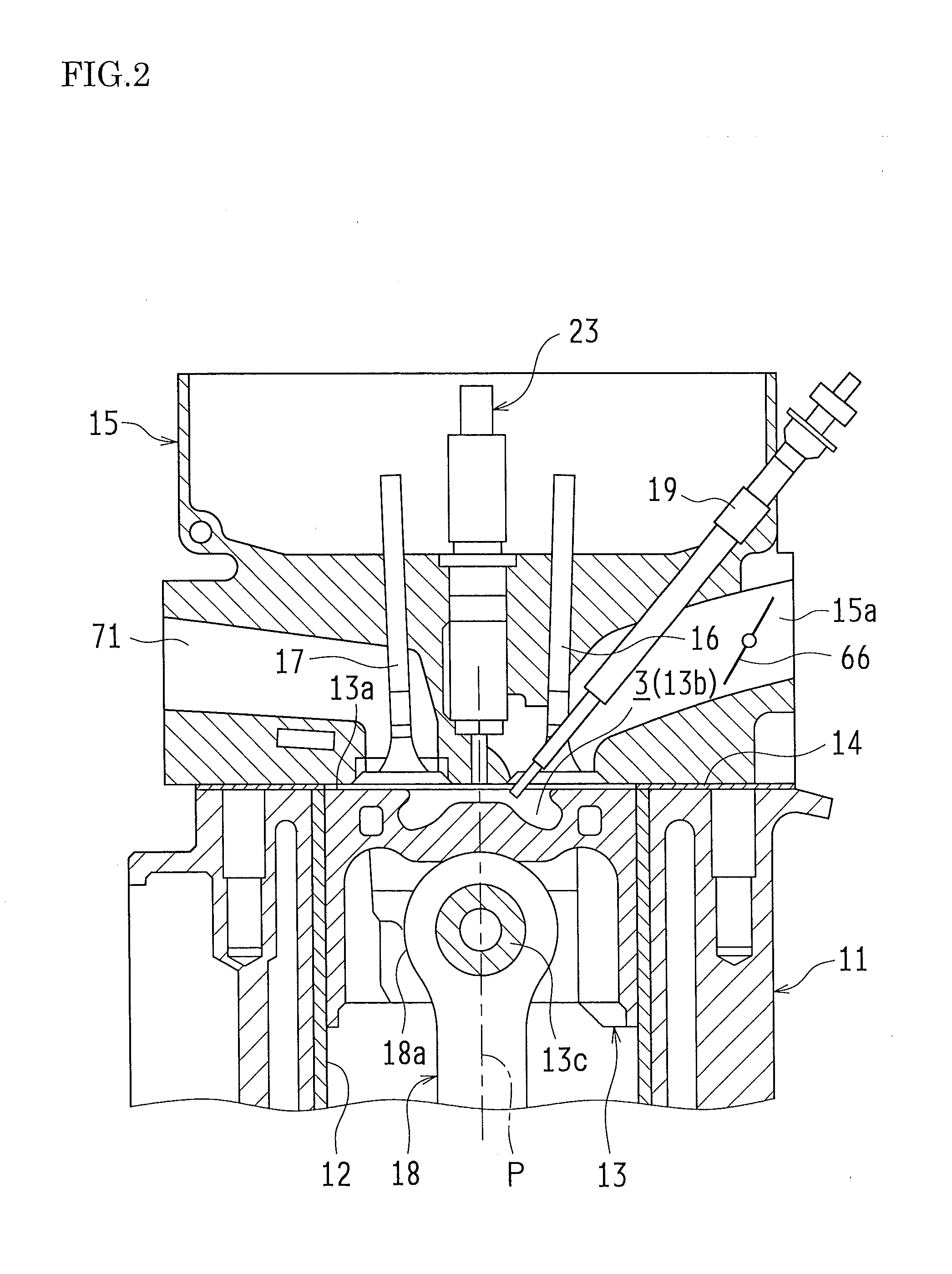

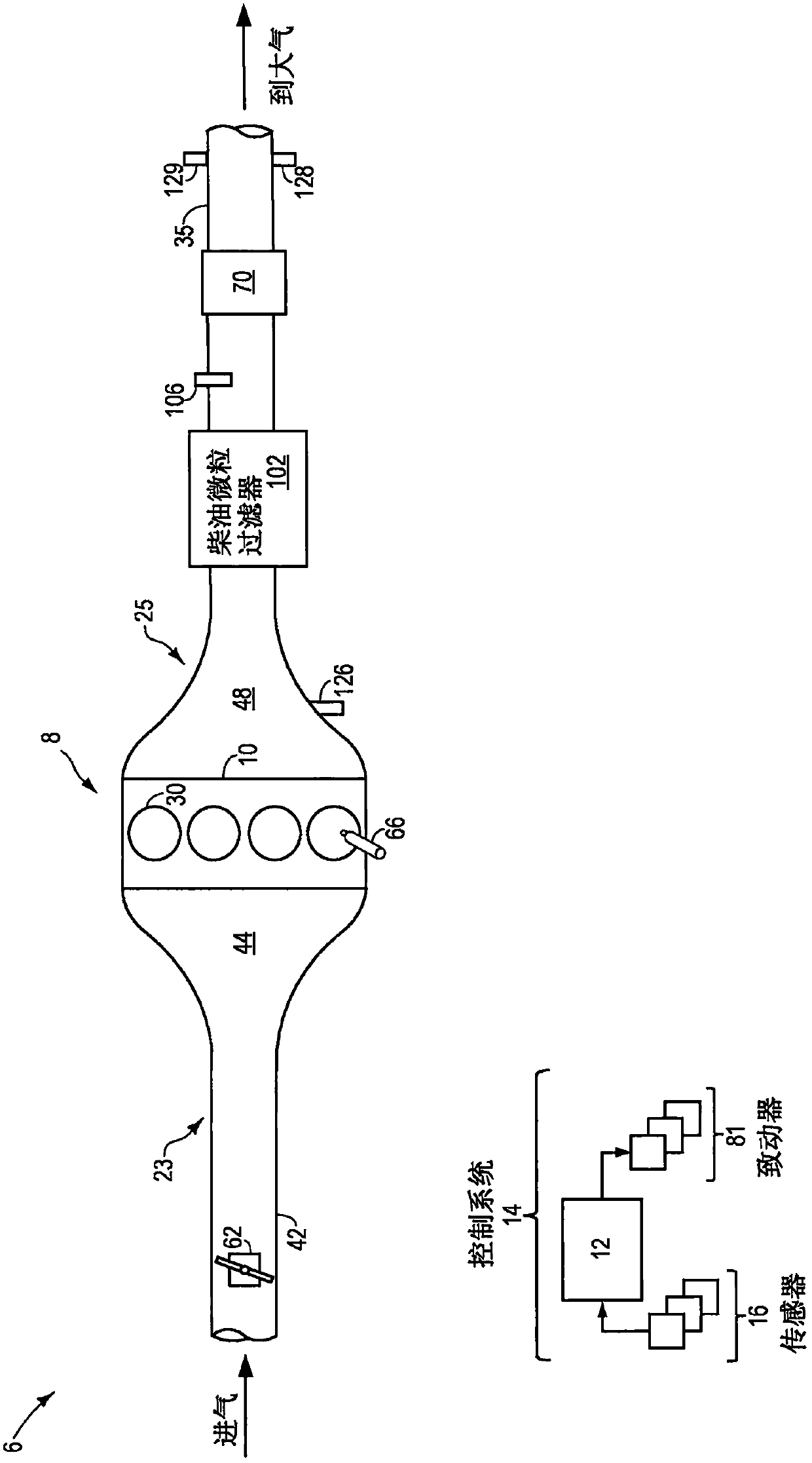

Secondary air supply system and fuel injection amount control apparatus using the same

InactiveUS20050138919A1Improve exhaust emissionsImprove accuracyExhaust apparatusSilencing apparatusDifferential pressureAir pump

A secondary air pipe is connected on the upstream side from catalyst in an exhaust pipe, and a secondary air pump is provided at an upstream portion of the secondary air pipe. An opening / closing valve for opening / closing the secondary air pipe is provided on the downstream side from the secondary air pump. A pressure sensor for detecting pressure within pipe is provided between the secondary air pump and the opening / closing valve. An ECU calculates a secondary airflow rate based upon difference pressure between both secondary air supply pressure which is detected by the pressure sensor when the opening / closing valve is opened under such a condition that the secondary air pump is operated, and also, shutoff pressure which is detected by the pressure sensor when the opening / closing valve is closed.

Owner:DENSO CORP

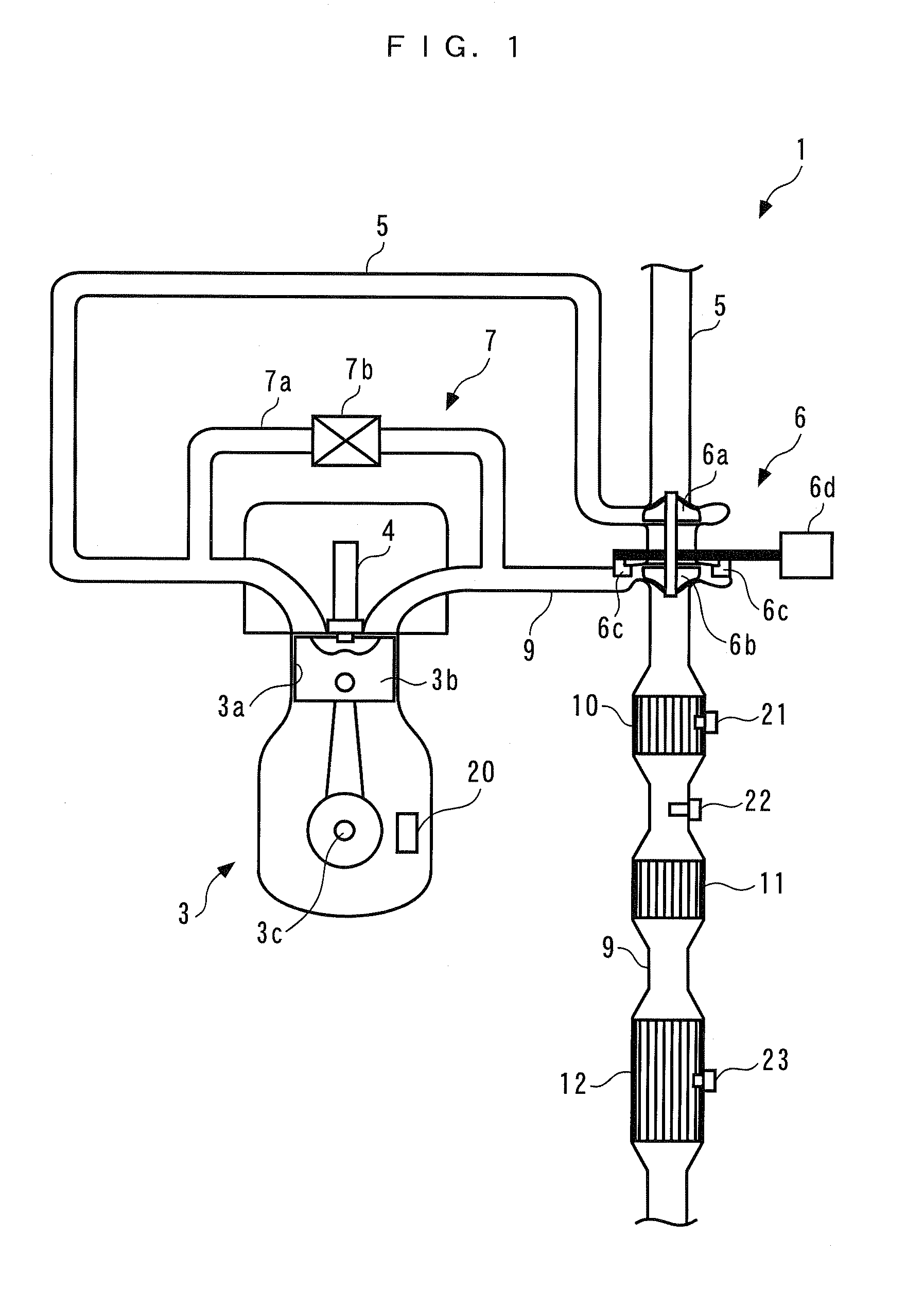

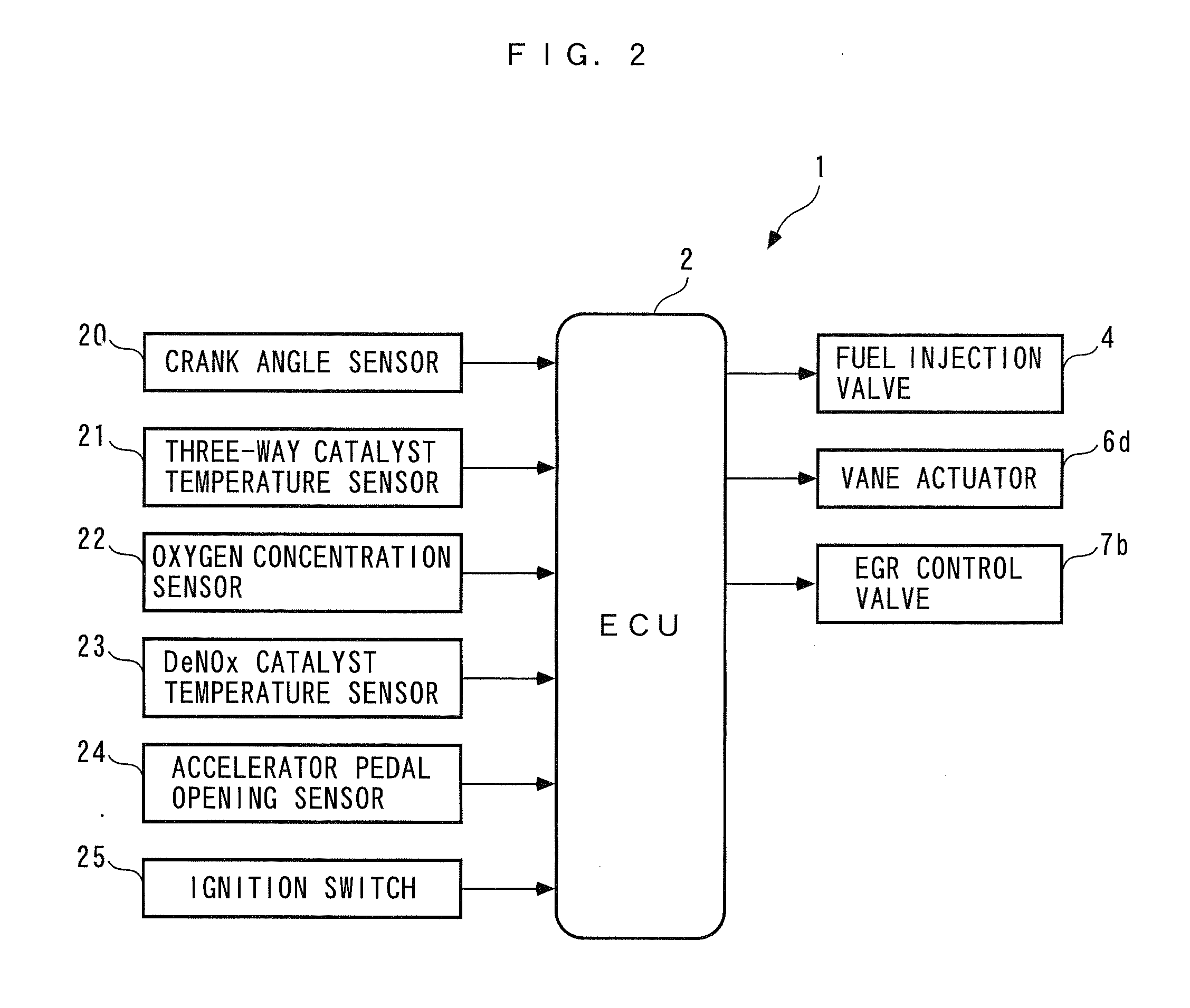

Control system and method for internal combustion engine and engine control unit

InactiveUS20100256894A1Avoid interactionImprove responsivenessAnalogue computers for vehiclesElectrical controlExternal combustion engineControl system

A control system for an internal combustion engine, which is capable of properly controlling both the temperature of an exhaust system and the air-fuel ratio of exhaust gases even when the control range of the air-fuel ratio of a combustion air-fuel mixture is limited, thereby improving the reduction of exhaust emissions. In the control system, a demanded torque-calculating section calculates a demanded torque. A first controller calculates a target equivalent ratio such that a DeNOx catalyst temperature converges to a predetermined target temperature. A second controller calculates three feedback correction values such that an output value from an oxygen concentration sensor converges to a target output value. A third controller calculates a torque fuel injection amount for generating the combustion air-fuel mixture, a post fuel injection amount for supplying unburned fuel to a DeNOx catalyst, etc. based on five values.

Owner:HONDA MOTOR CO LTD

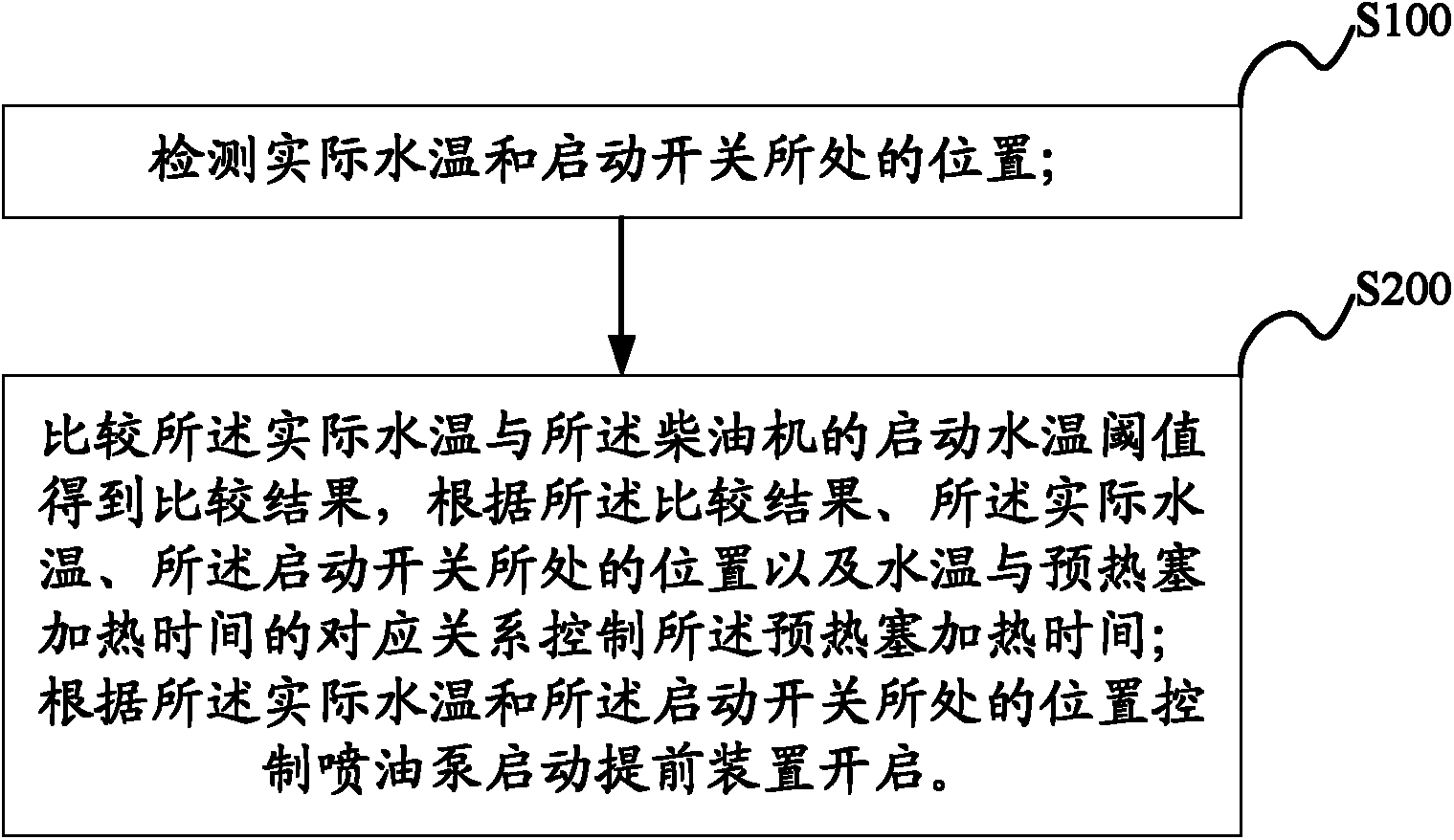

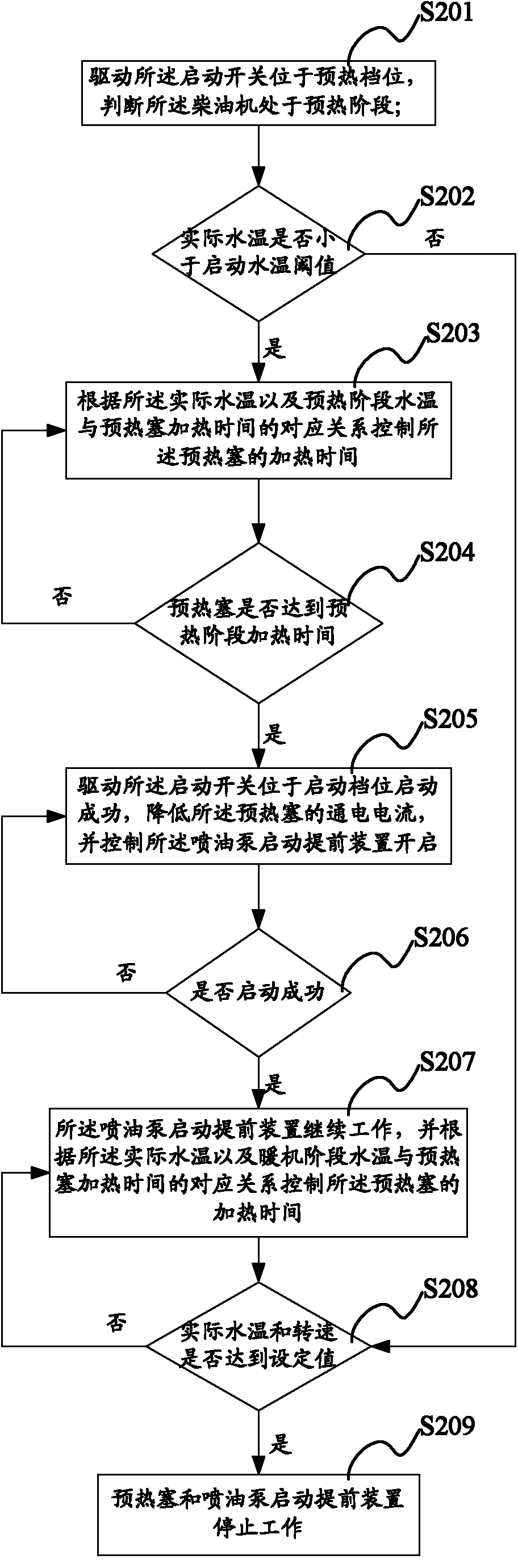

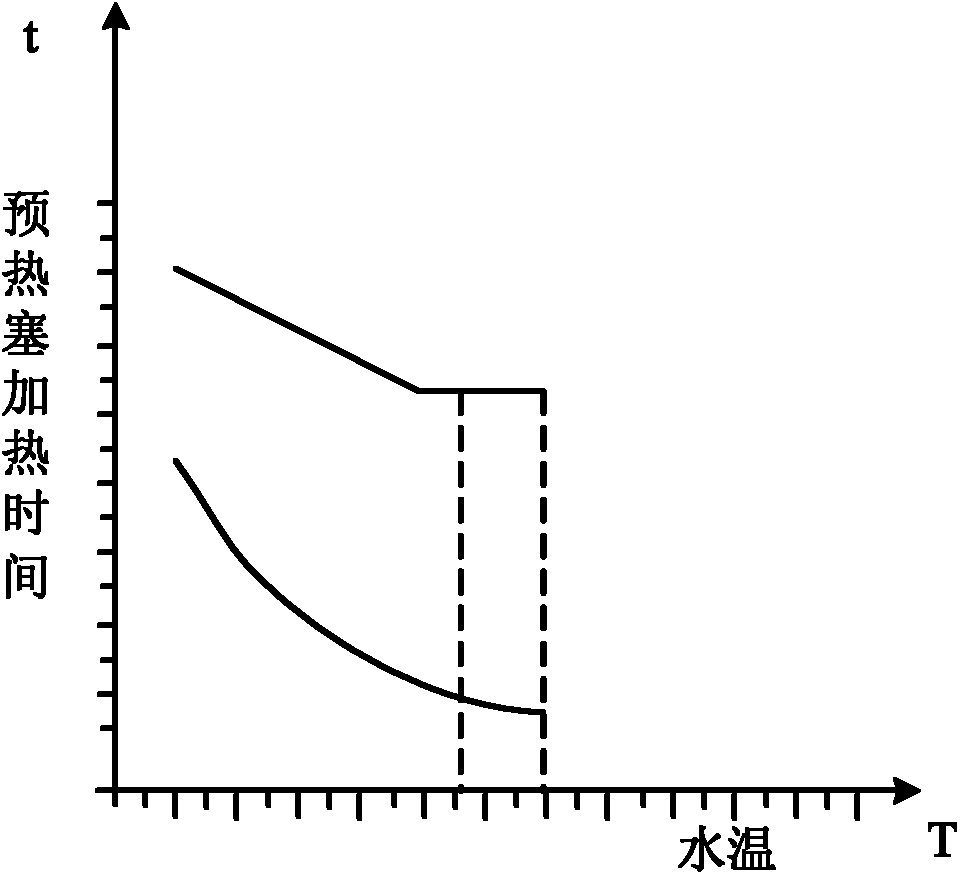

Cold-booting auxiliary device for diesel engine and control method

InactiveCN102493905AImprove cold start performanceIncrease temperatureFuel-injection pumpsMachines/enginesHeating timeGlowplug

An embodiment of this invention discloses a cold-booting auxiliary device for a diesel engine and a control method; because the cold-booting auxiliary method disclosed by this invention adjusts a heating time of a preheating plug according to an actual water temperature, the method disclosed by this invention realizes to adjust the heating time of the preheating plug according to change of an environment temperature and develops heating action at a stating stage and an idling warming-up stage, the temperature of a combustion chamber of an engine is increased, and combustion and tail gas emission of the engine can be improved obviously; simultaneously, an actual temperature and a position of a booting switch are detected so as to control a booting time and a diesel injection quantity of a diesel injection pump advancer, thus, a diesel supply advancing angle of the diesel engine is changed; when a water temperature is low, diesel injection of the diesel engine can be assisted so as to further improve cold-booting performance of the diesel engine; based on an above-mentioned method, the cold-booting auxiliary device disclosed by this invention improves the cold-booting performance of the diesel engine.

Owner:WEICHAI POWER CO LTD

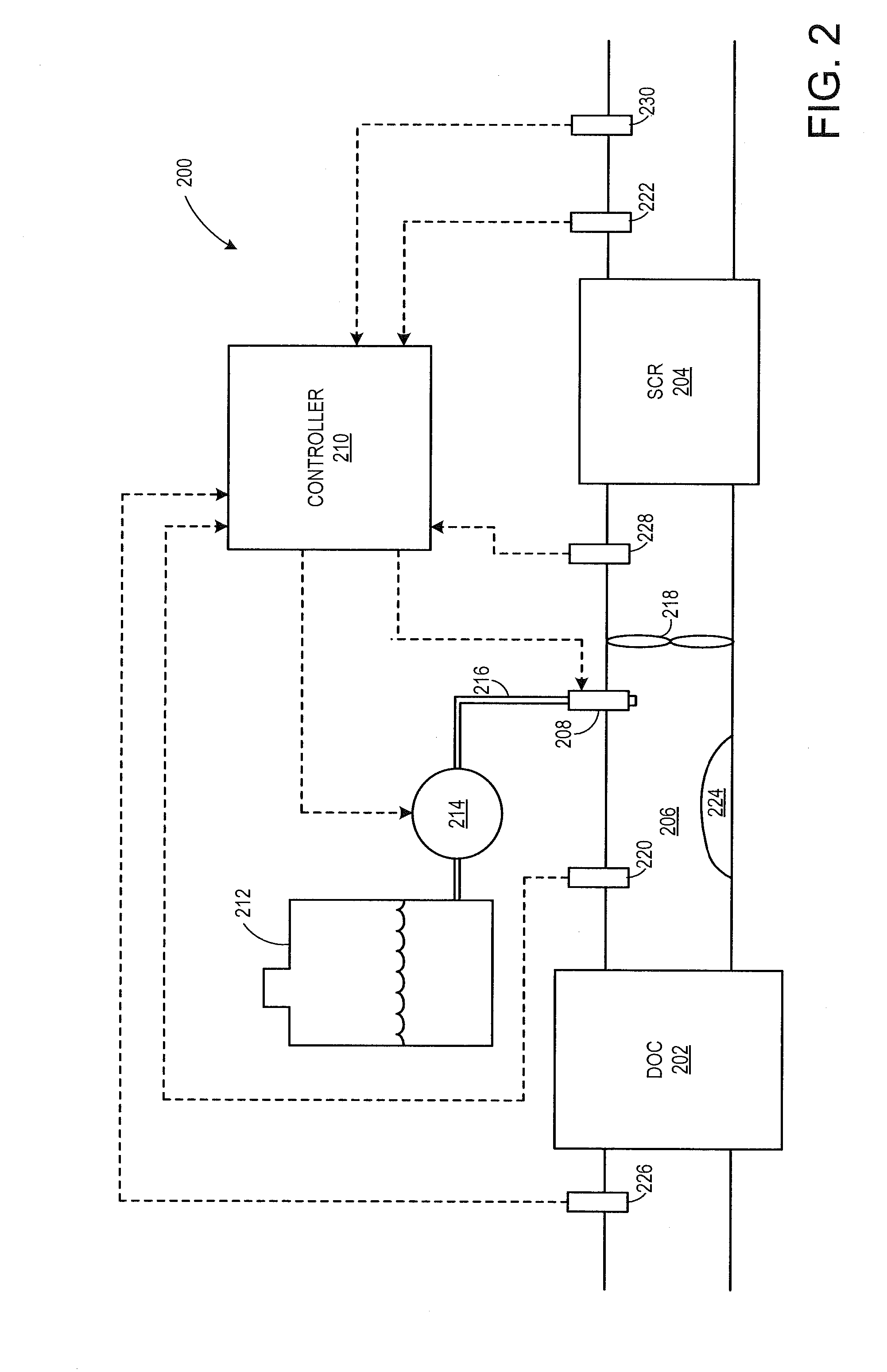

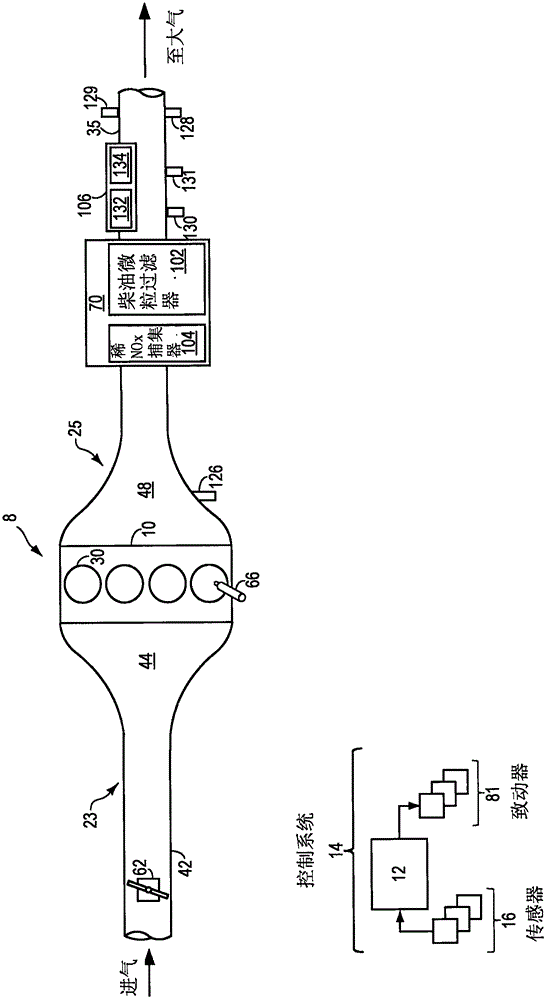

Method and system for reductant injector degradation

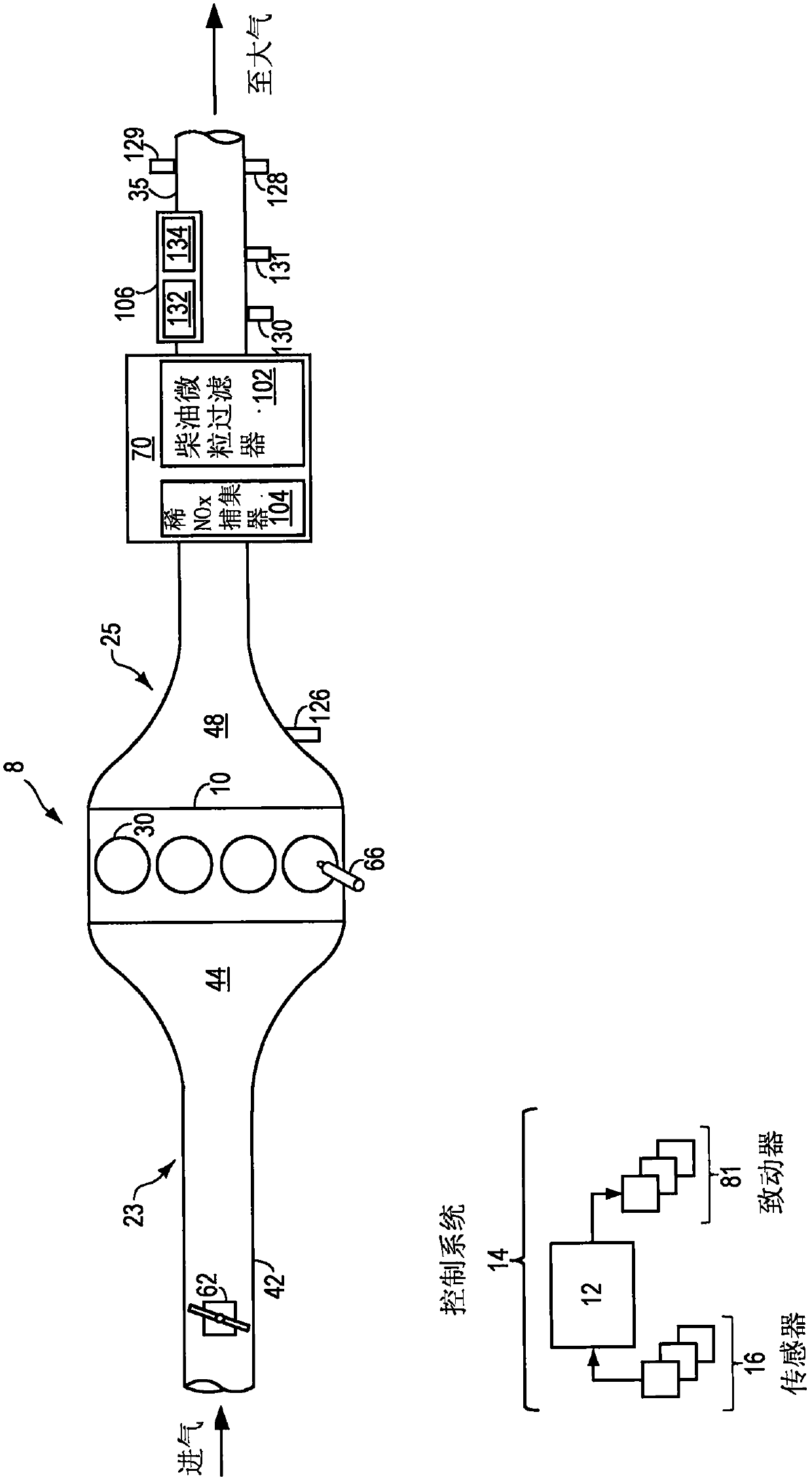

ActiveUS20150128564A1Good for healthNo additional benefitInternal combustion piston enginesExhaust apparatusInjectorAutomotive engineering

Various systems and methods for detecting exhaust reductant injector degradation based on an exhaust NOx sensor are disclosed. In one example, degradation of the reductant injector is indicated when an actual NOx sensor output differs from an expected NOx sensor output by more than a threshold amount under engine off conditions.

Owner:FORD GLOBAL TECH LLC

Ignition delay period estimation apparatus and ignition time control apparatus for internal combustion engine

InactiveUS20130192561A1Improve reliabilityImprove exhaust emissionsElectrical controlInternal combustion piston enginesDelay DurationEquivalence ratio

A period of time from a point in time at which pilot injection is executed until an equivalence ratio in fuel spray, after exceeding a combustible equivalence ratio, falls below the combustible equivalence ratio is calculated as a physical ignition delay period. A chemical ignition delay period is calculated from the temperature and pressure inside a combustion chamber at a point in time at which the equivalence ratio in the fuel spray reached the combustible equivalence ratio. A total ignition delay period is calculated from the above-calculated ignition delay periods. The oxygen concentration and temperature inside the combustion chamber are adjusted such that the total ignition delay period matches a target ignition delay period.

Owner:TOYOTA JIDOSHA KK

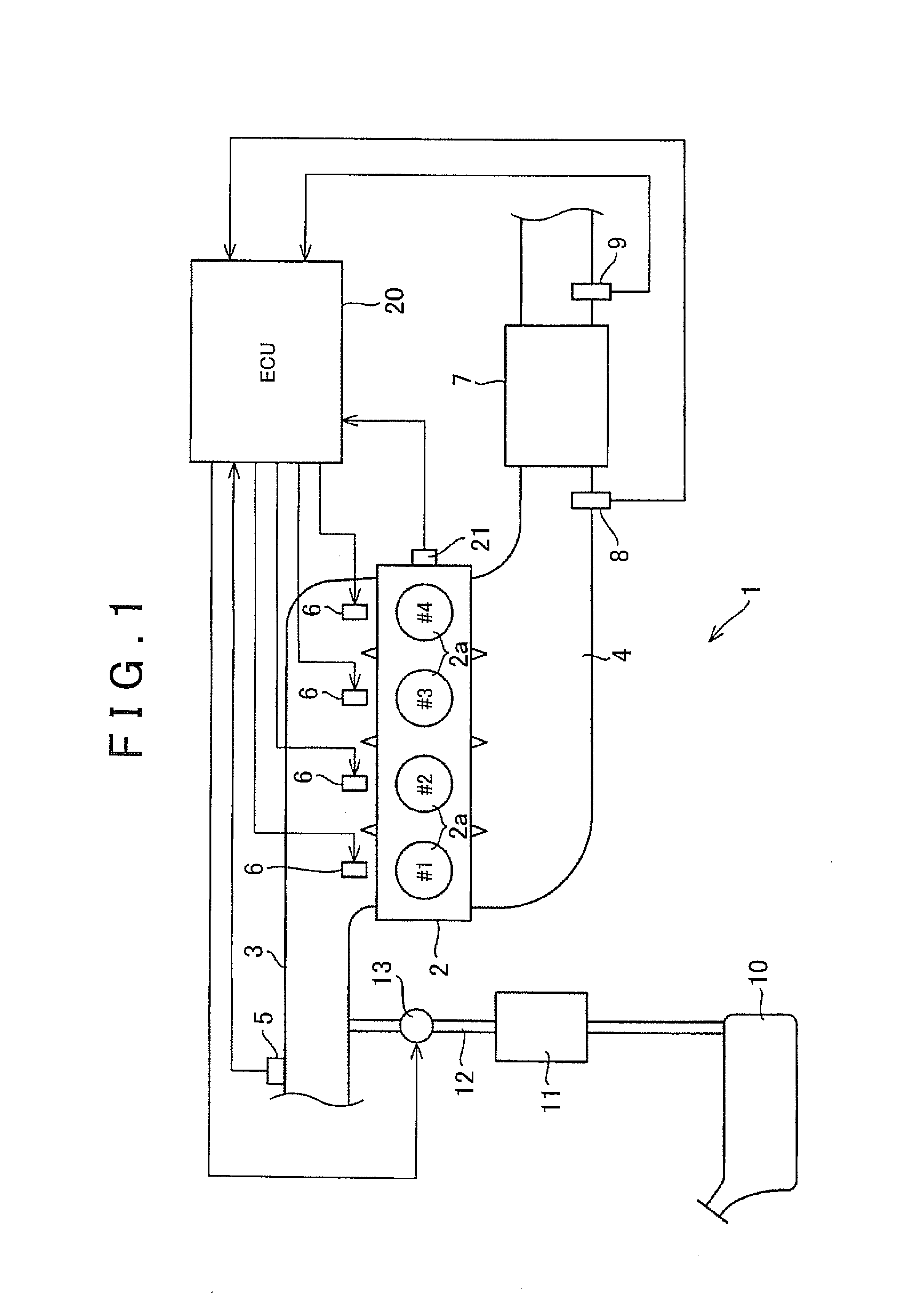

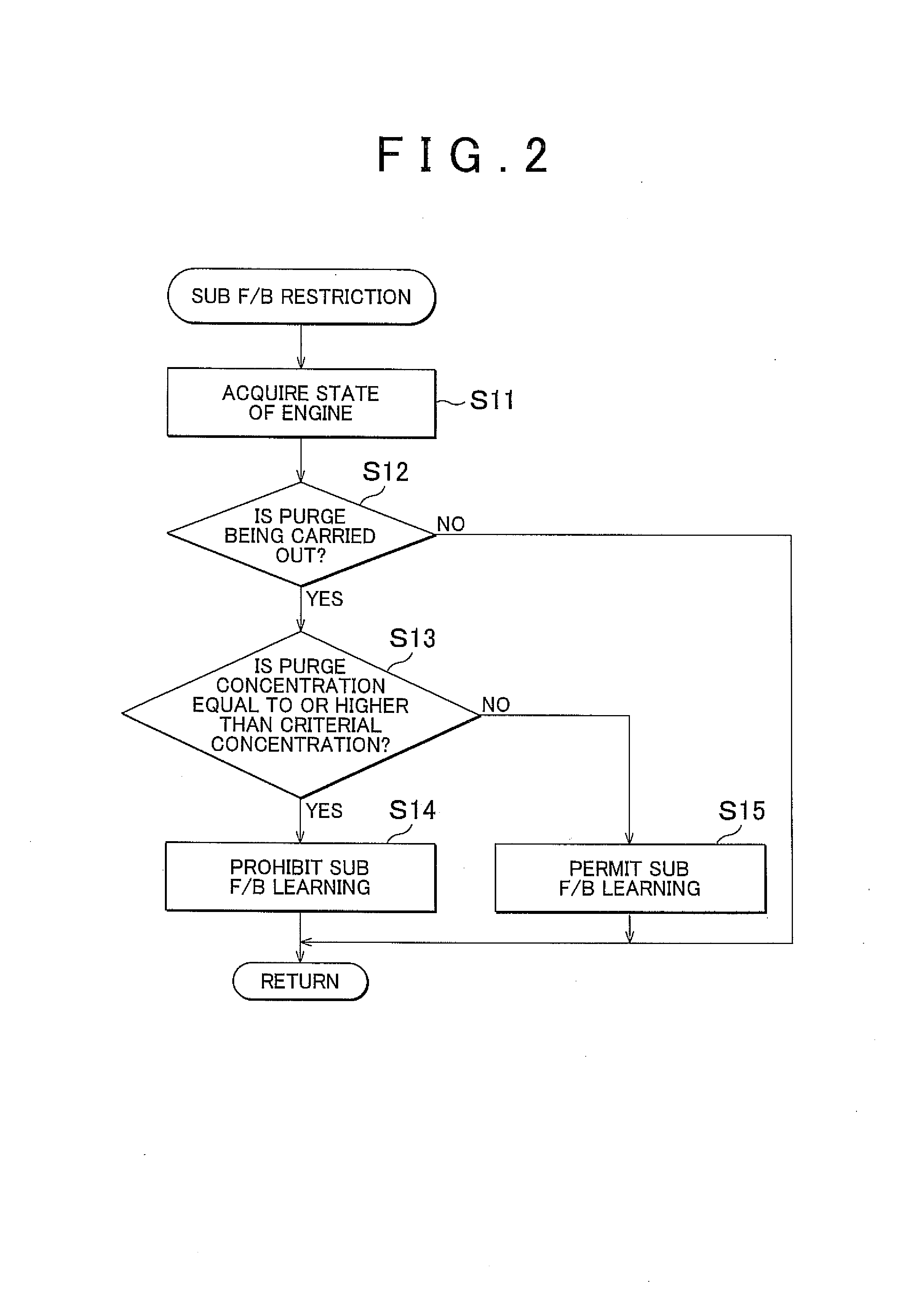

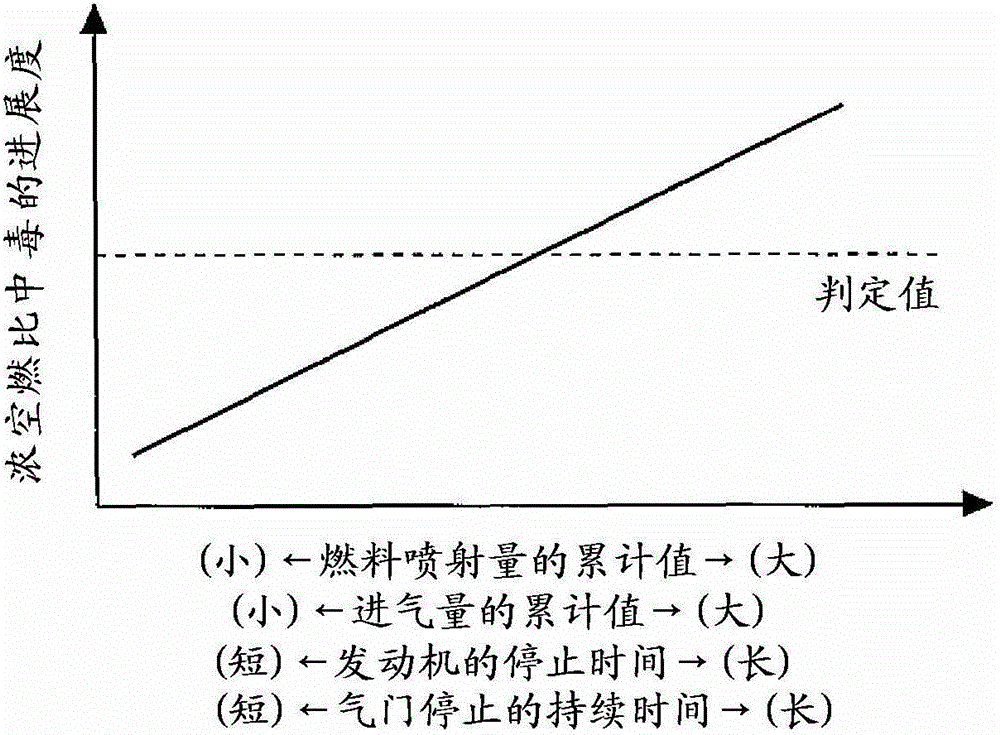

Air-fuel ratio control apparatus for internal combustion engine and control method

InactiveUS20130184972A1Fuel injection amount can be restrainedImprove exhaust emissionsElectrical controlDigital data processing detailsExternal combustion engineFuel supply

An air-fuel ratio control apparatus that is applied to an internal combustion engine having an intake passage to which a canister is connected via an evaporative fuel supply passage, and an exhaust passage that is provided with an exhaust gas purifier, includes a first sensor provided upstream of the exhaust gas purifier, a second sensor provided downstream of the exhaust gas purifier, and a controller that corrects a fuel injection amount through feedback on a basis of the air-fuel ratio acquired by the first sensor, modifies a correction coefficient used for feedback correction on a basis of the air-fuel ratio acquired by the second sensor, and has a storage unit that stores the modified correction coefficient. The controller prohibits the modified correction coefficient from being stored into the storage unit if a concentration of fuel in purge gas is equal to or higher than a predetermined criterial concentration.

Owner:TOYOTA JIDOSHA KK

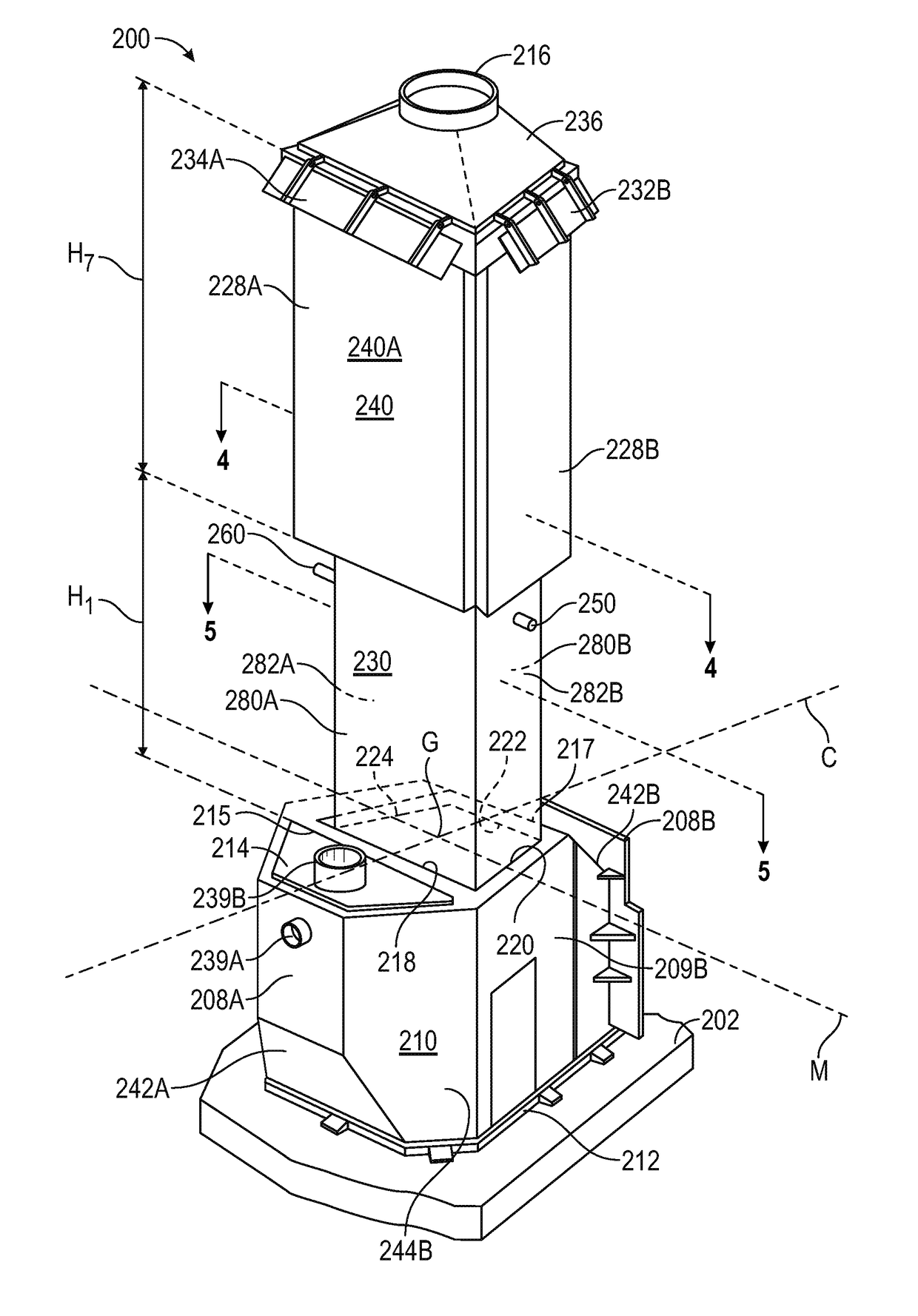

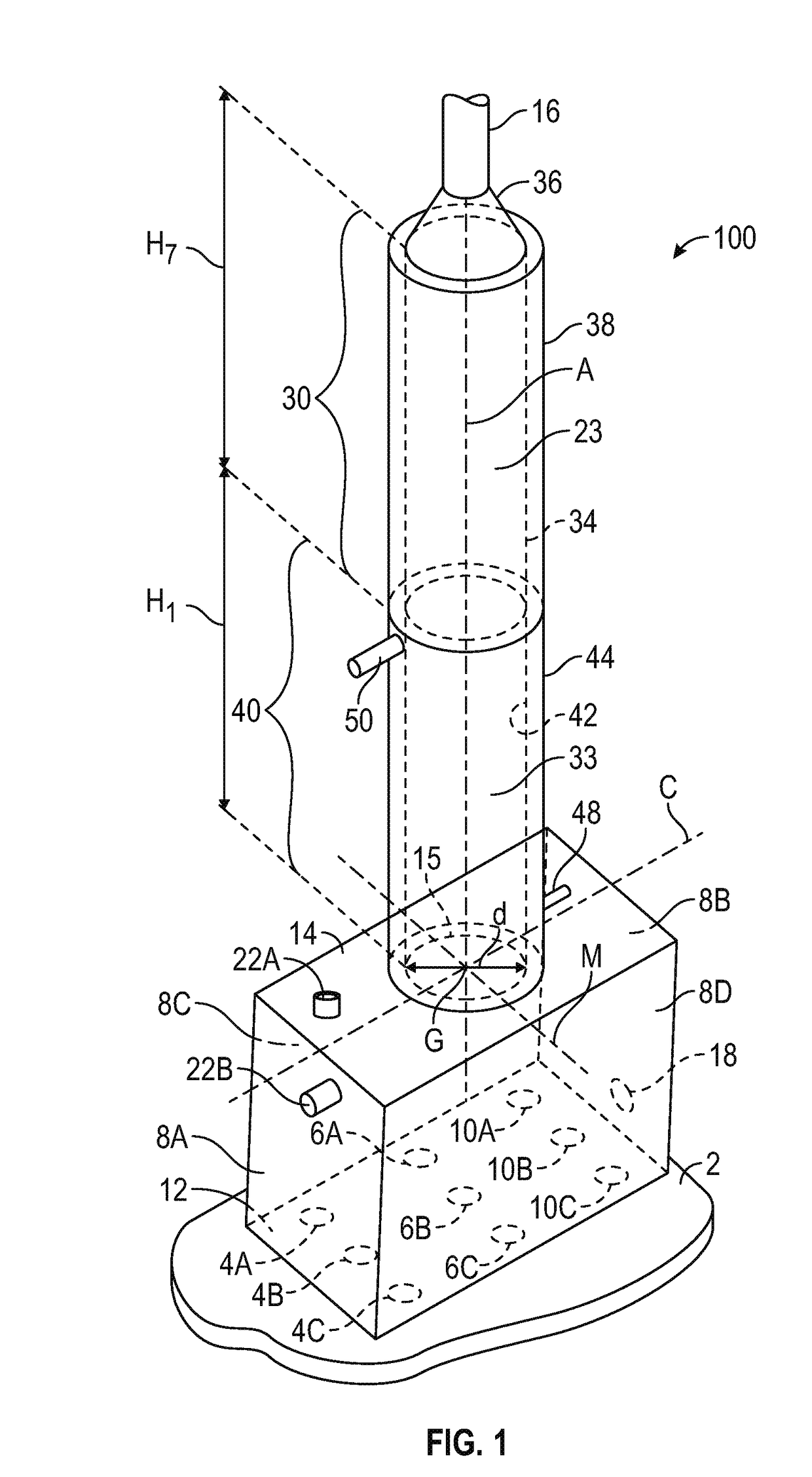

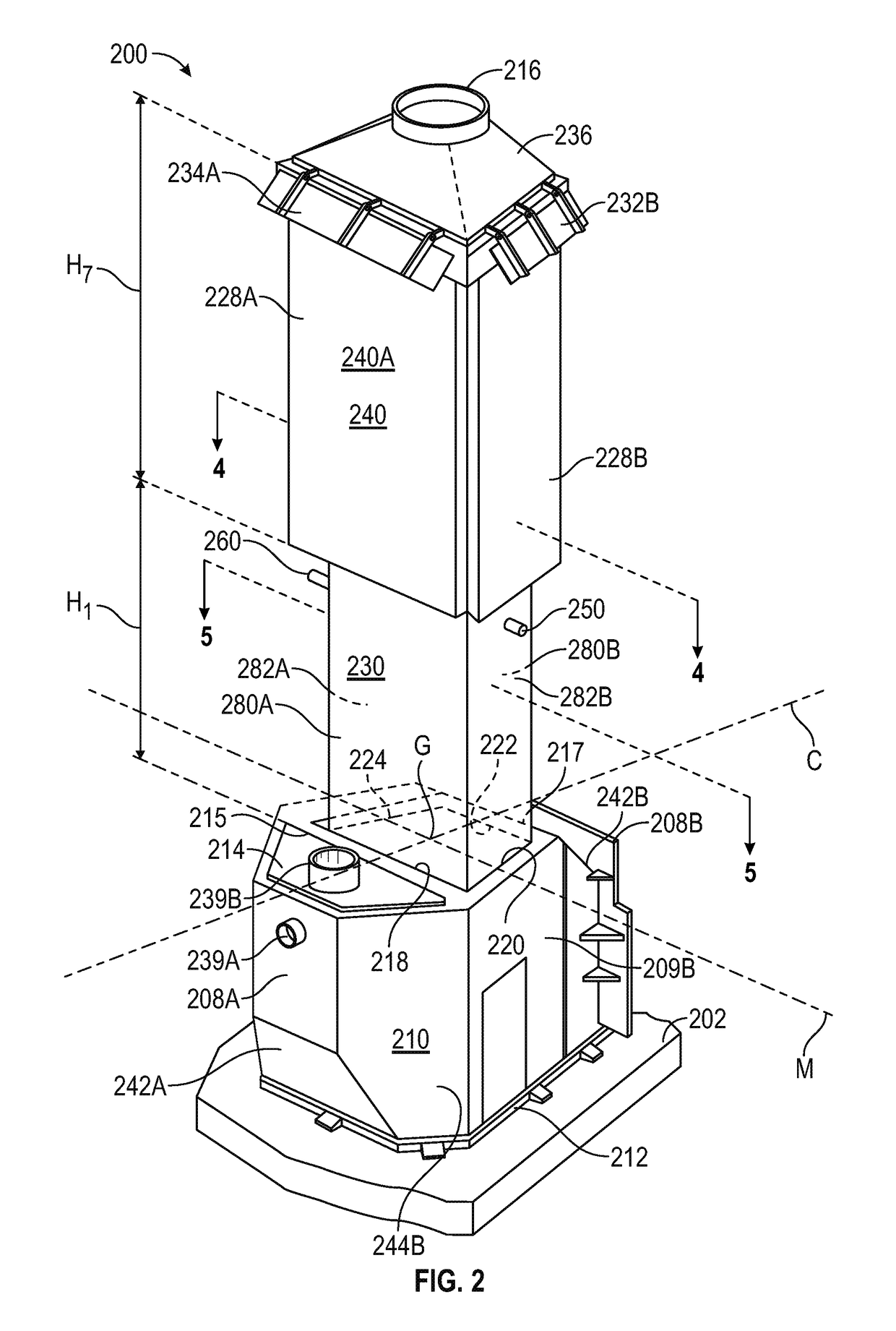

Effective discharge of exhaust from submerged combustion melters and methods

ActiveUS20170369352A1Improve exhaust emissionsMaximize mixingGlass furnace apparatusTank furnacesCombustionExhaust fumes

Submerged combustion methods and systems including a melter equipped with an exhaust passage through the ceiling or the sidewall having an aggregate hydraulic diameter. Submerged combustion burners configured to create turbulent conditions in substantially all of the material being melted, and produce ejected portions of melted material. An exhaust structure including a liquid-cooled exhaust structure defining a liquid-cooled exhaust chamber having a cross-sectional area greater than that of the exhaust stack but less than the melter. The exhaust passage and liquid-cooled exhaust structure configured to maintain temperature and pressure of the exhaust, and exhaust velocity through the exhaust passage and the exhaust structure, at values sufficient to prevent the ejected material portions of melted material from being propelled out of the exhaust structure as solidified material, and maintain any molten materials contacting the first interior surface molten so that it flows down the first interior surface into the melter.

Owner:JOHNS MANVILLE CORP

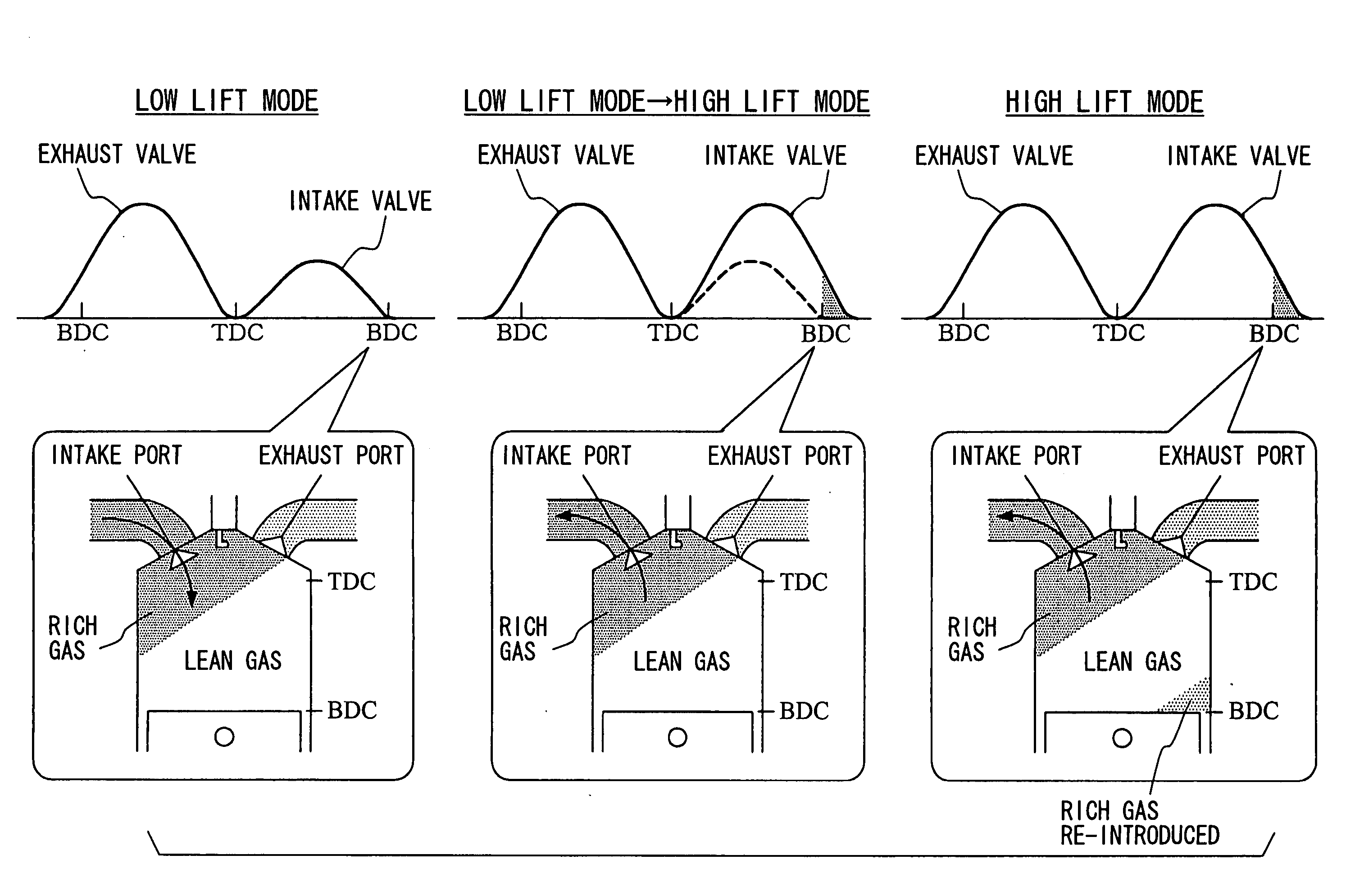

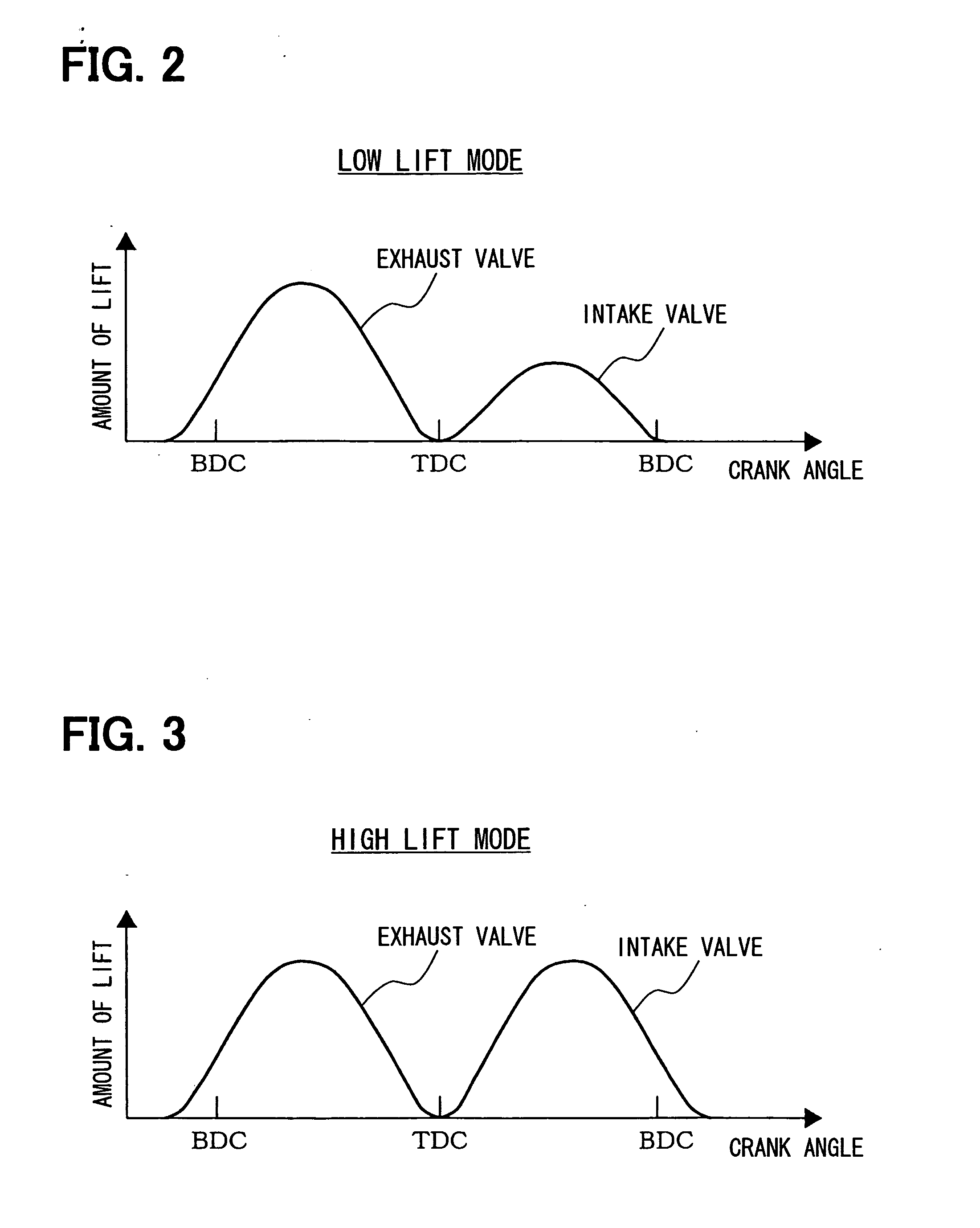

Control apparatus for internal combustion engine

InactiveUS20070056537A1Reduce the amount of solutionIncreased fuel quantityElectrical controlInternal combustion piston enginesVariable valve timingExternal combustion engine

A control apparatus for an internal combustion engine that varies the amount of lift of an intake valve is disclosed. In one embodiment, the control apparatus includes a fuel injection timing correcting device that, when lift of the intake valve is varied, corrects and varies fuel injection termination timing according to the variation of the lift of the intake valve. In another embodiment, an injection quantity correcting device is included that, when lift of the intake valve is varied, corrects and varies an injection quantity. In still another embodiment, a swirl flow generating device is included that generates a swirl flow in the cylinder. In a further embodiment, an intake valve closing timing correcting device is included that, when lift of the intake valve is varied, controls the variable valve timing mechanism so that the valve closing timing of the intake valve remains substantially constant.

Owner:DENSO CORP

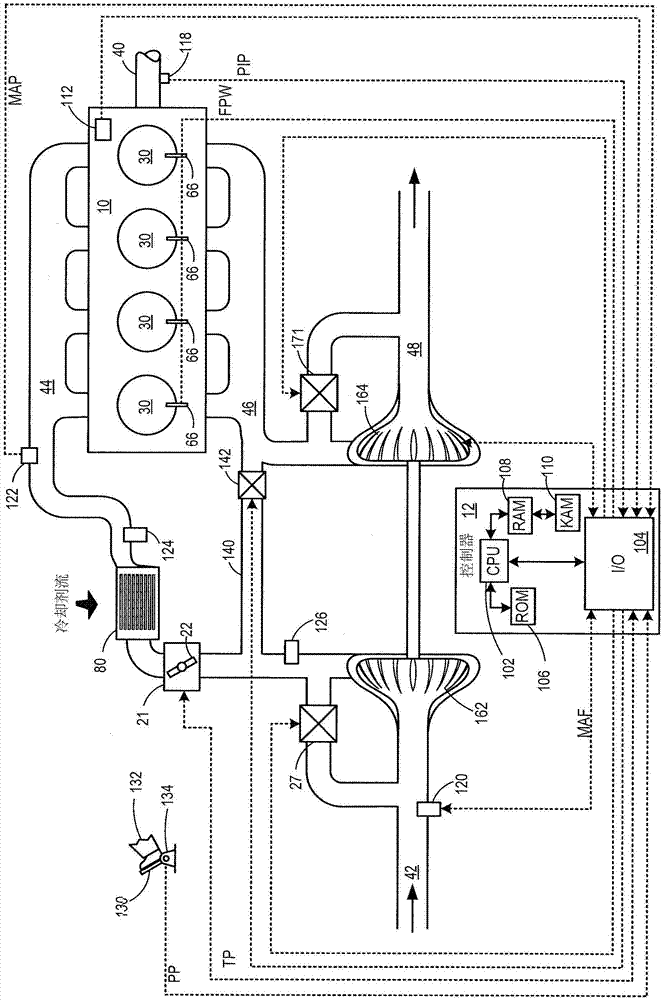

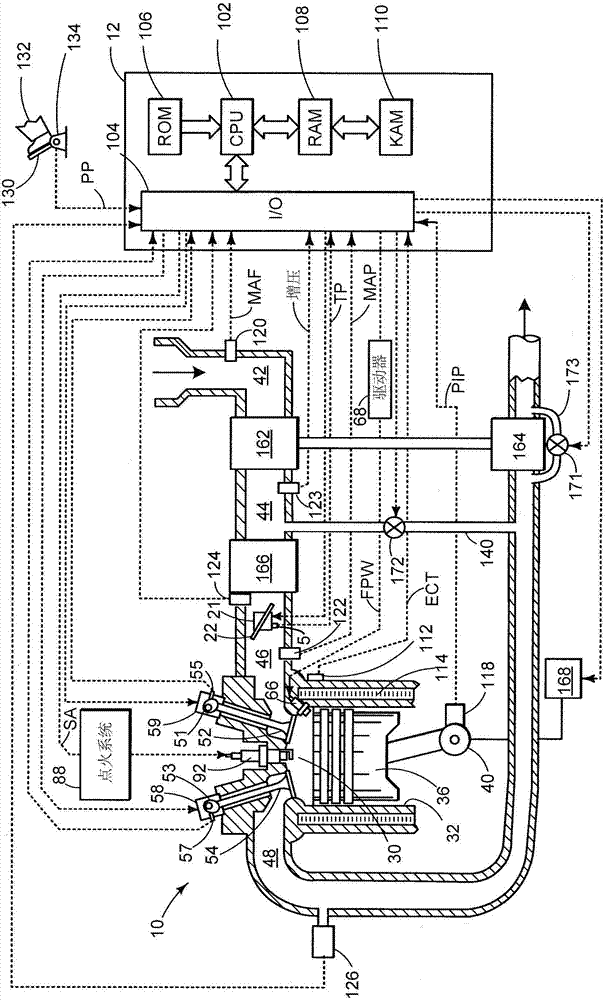

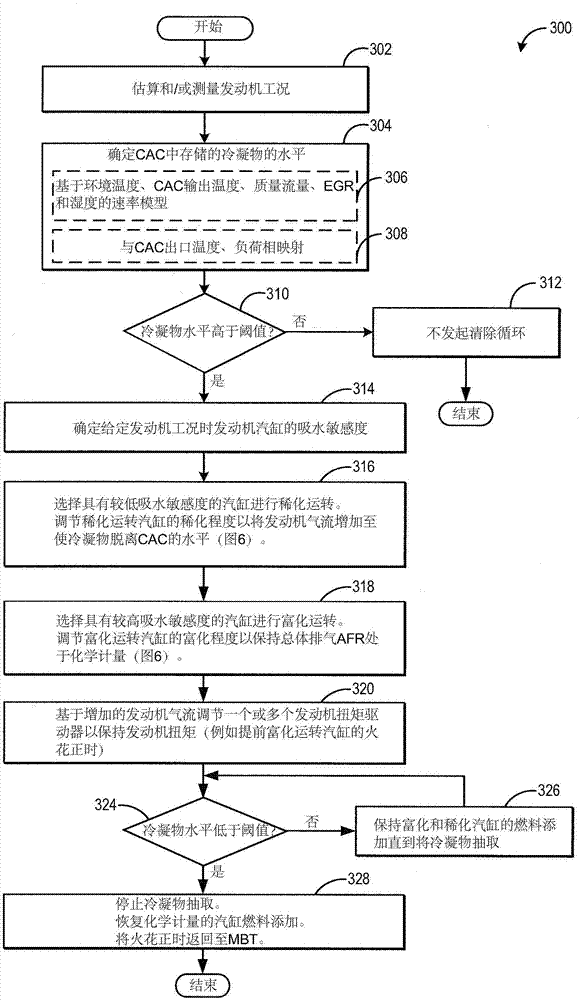

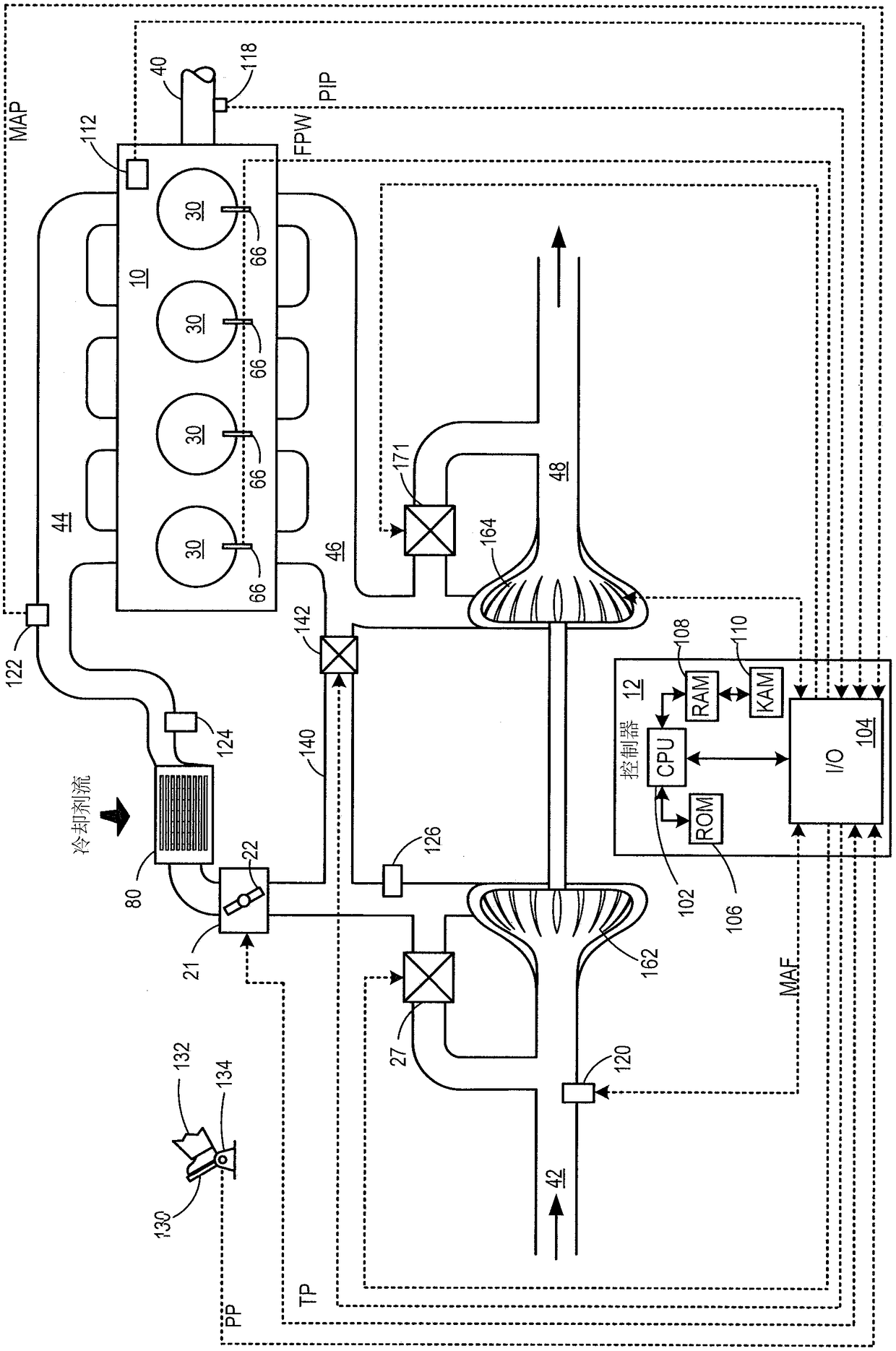

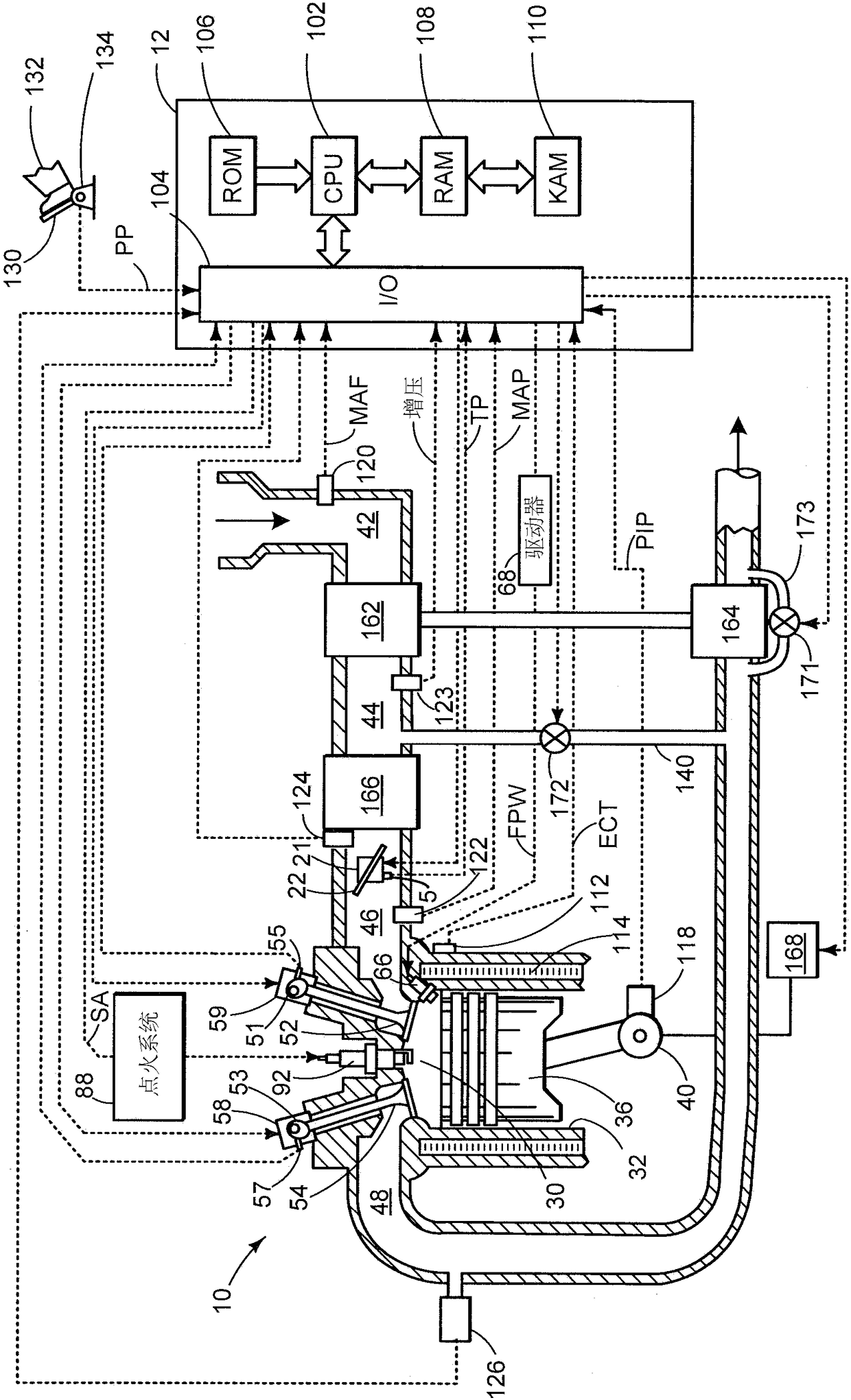

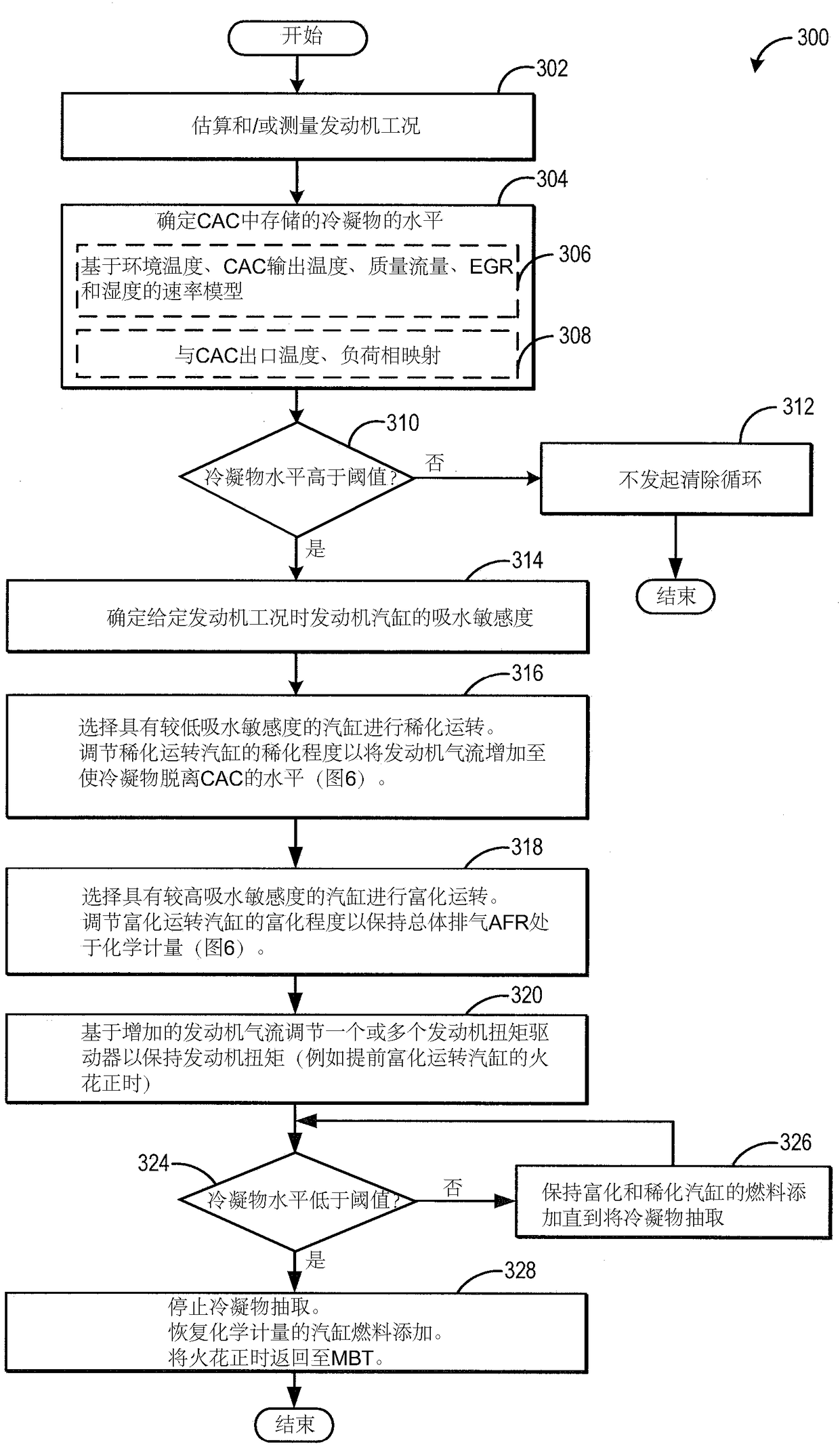

Method for purging condensate from a charge air cooler

InactiveCN104213972AImprove exhaust emissionsIncrease airflow levelsElectrical controlInternal combustion piston enginesThermodynamicsEngineering

Methods and systems are provided for cleaning out condensate stored at a charge air cooler. In response to increased condensate accumulation at a charge air cooler, airflow through the engine is increased to purge the condensate while an engine actuator is adjusted to maintain engine torque. Combustion stability issues of engine cylinders are addressed by adjusting fueling of each cylinder individually during condensate ingestion.

Owner:FORD GLOBAL TECH LLC

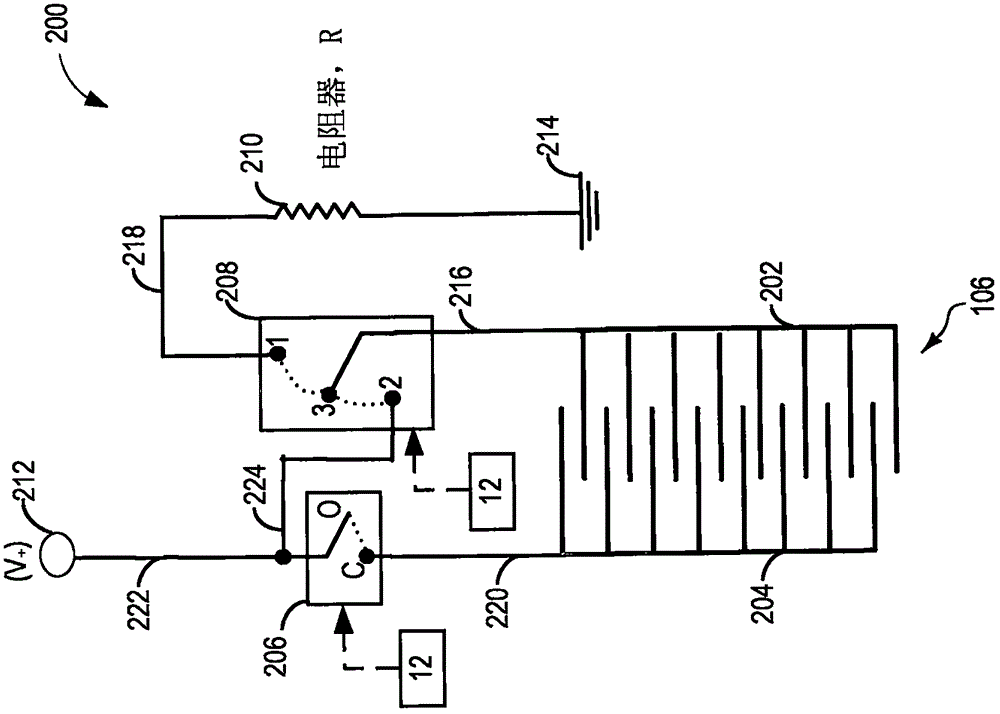

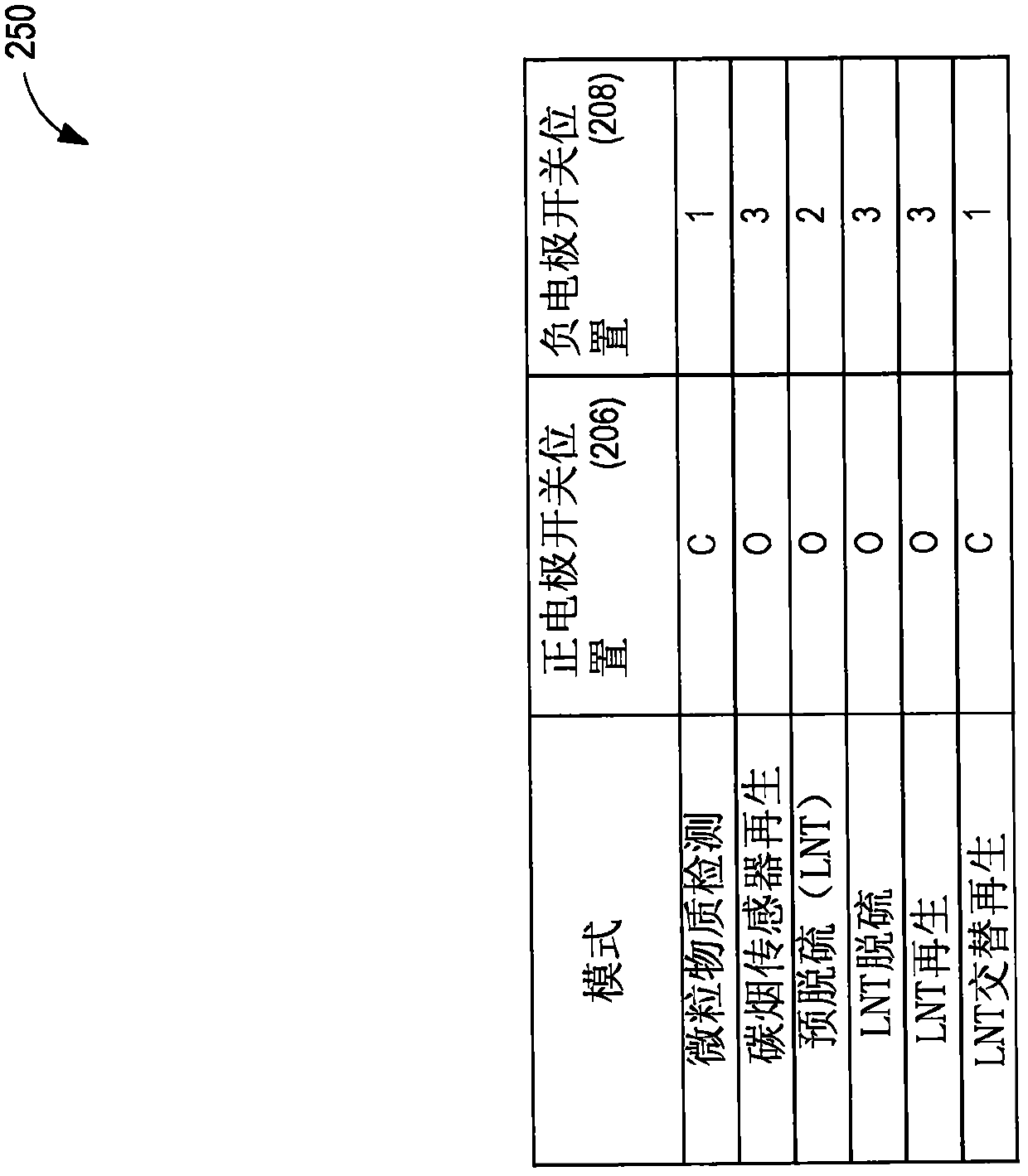

Method And System For Resistive-Type Particulate Matter Sensors

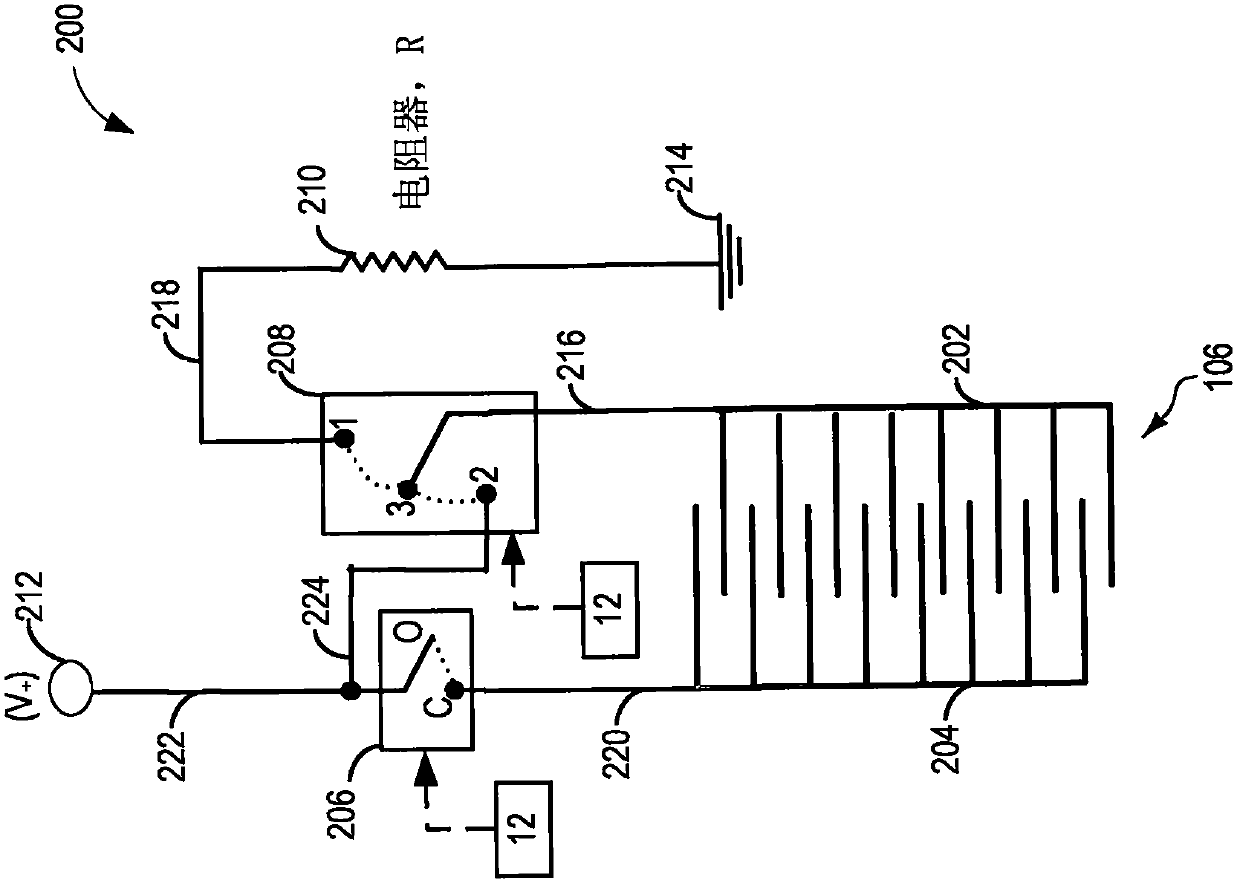

ActiveCN106089382AReduce corrosionHigh precisionElectrical controlInternal combustion piston enginesParticulatesEngineering

Methods and systems are provided for reducing soot sensor electrode degradation in harsh chemical environment introduced as a result of desulfation of a lean NOx trap positioned upstream of the soot sensor. In one example, a method may include in response to the SOx load being higher than the threshold, prior to initiating desulfation of LNT, operating the soot sensor in a pre-desulfation mode where the negative electrode is connected to the positive electrode for a brief duration, while the positive electrode is disconnected from the positive electrode. However during desulfation, when H2S is released as a by-product, both the electrodes may be open, i.e. not connected to the positive electrode or ground, thereby reducing the possibility of sensor degradation.

Owner:FORD GLOBAL TECH LLC

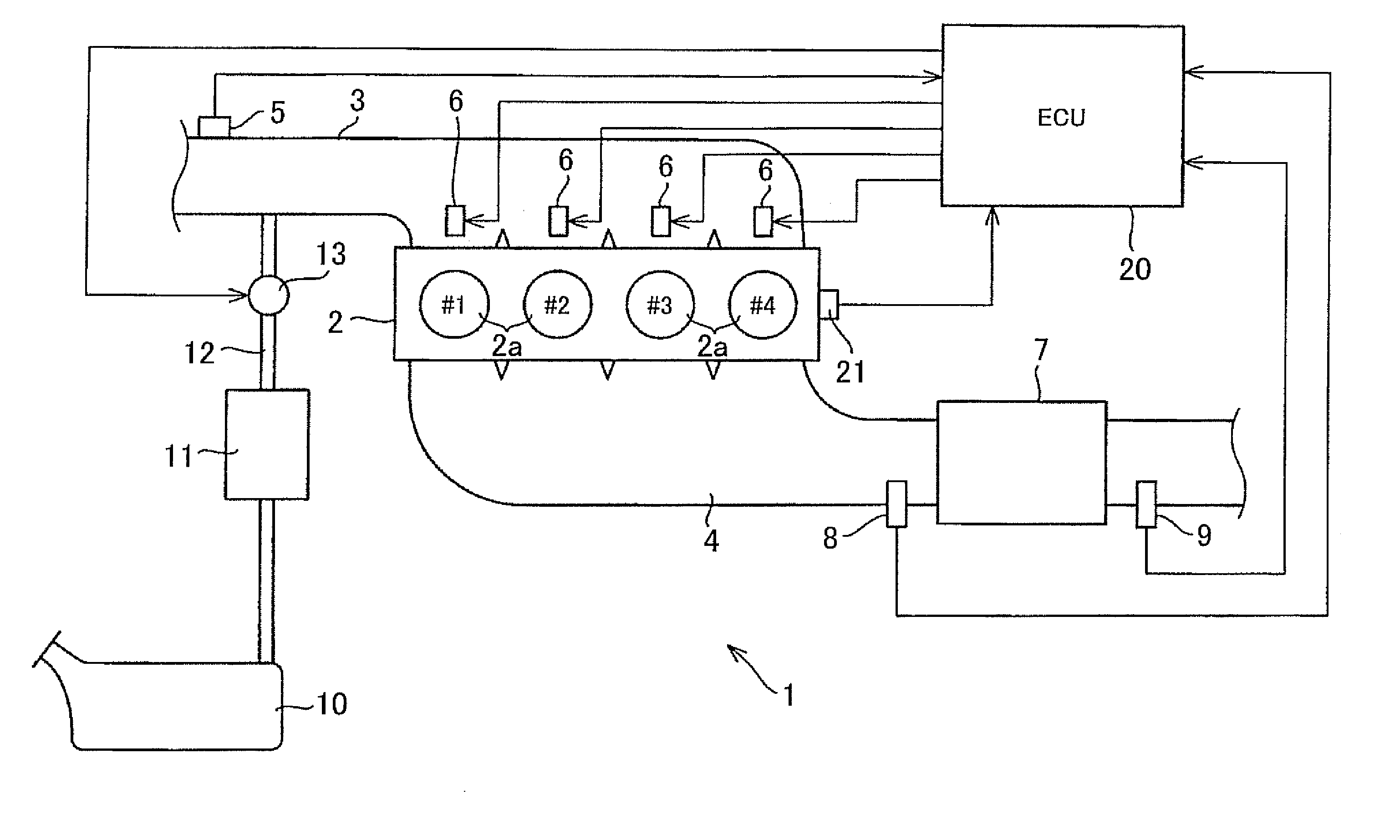

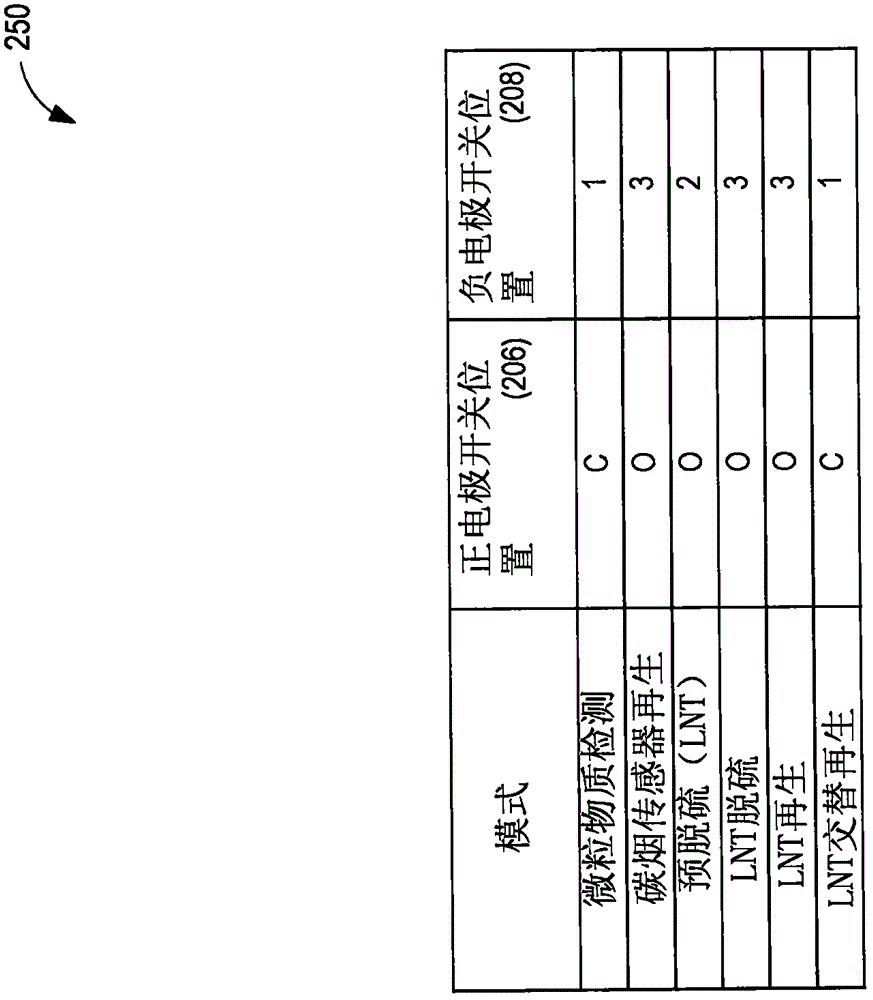

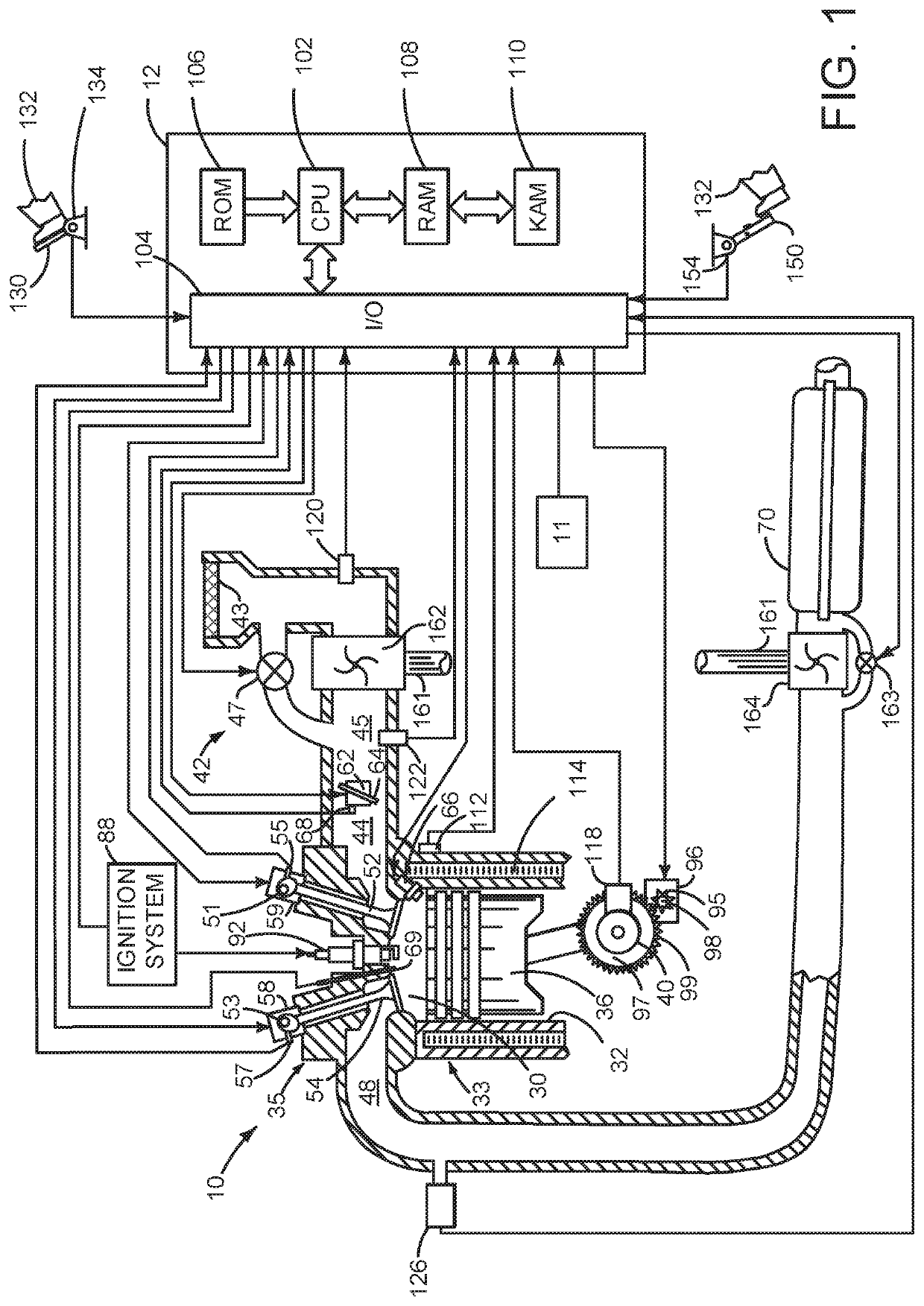

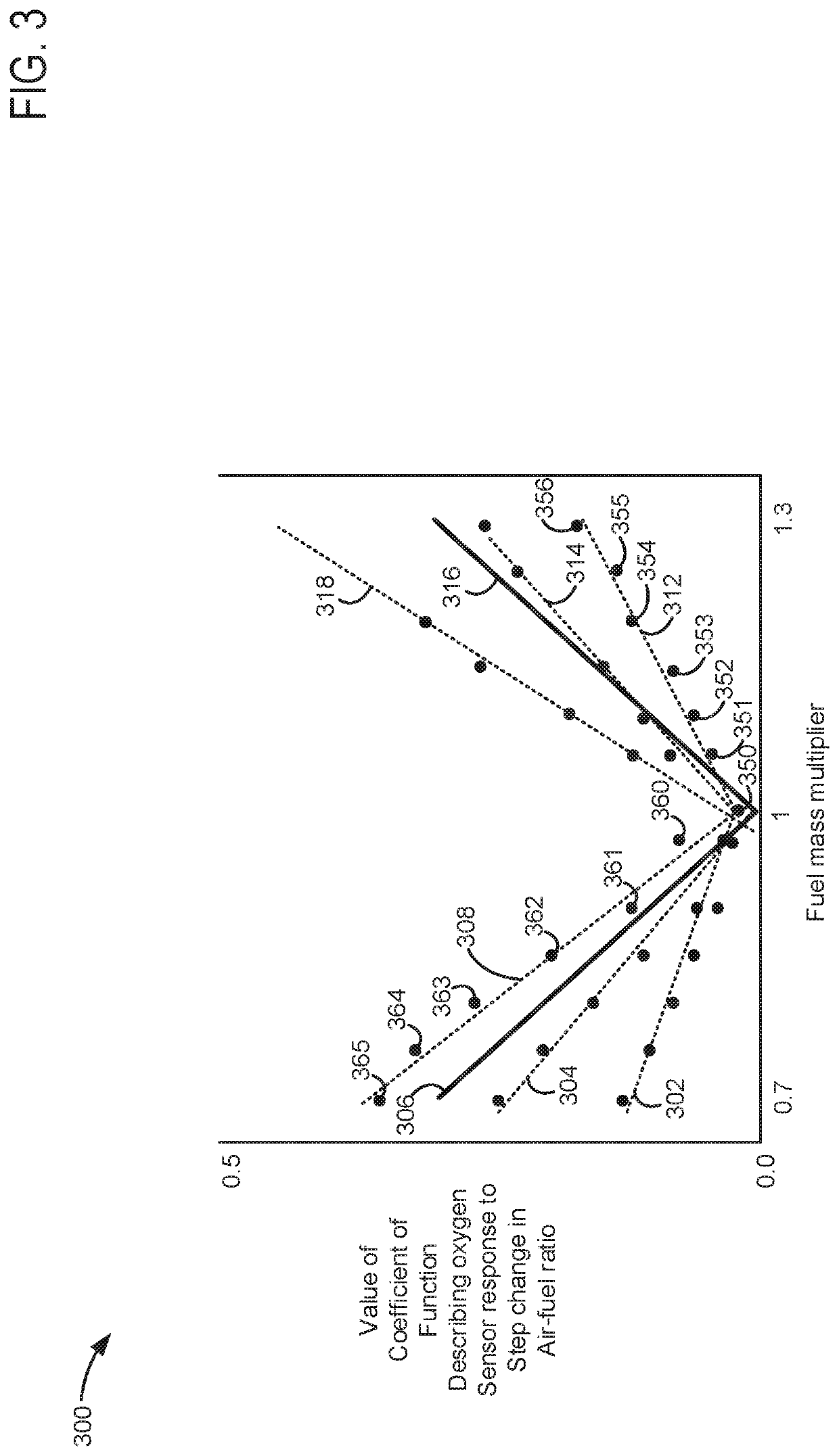

Methods and system for determining engine air-fuel ratio imbalance

ActiveUS20200191082A1Reduced catalytic efficiencyImprove exhaust emissionsElectrical controlInternal combustion piston enginesAutomotive engineeringInjector

Systems and methods for operating an engine that includes an oxygen sensor and one or more fuel injectors for each engine cylinder are described. In one example, lines describing a relationship between a fuel mass multiplier and a coefficient of a function describing output of an oxygen sensor to a step change in fuel mass are a basis for determining air-fuel imbalance of engine cylinders.

Owner:FORD GLOBAL TECH LLC

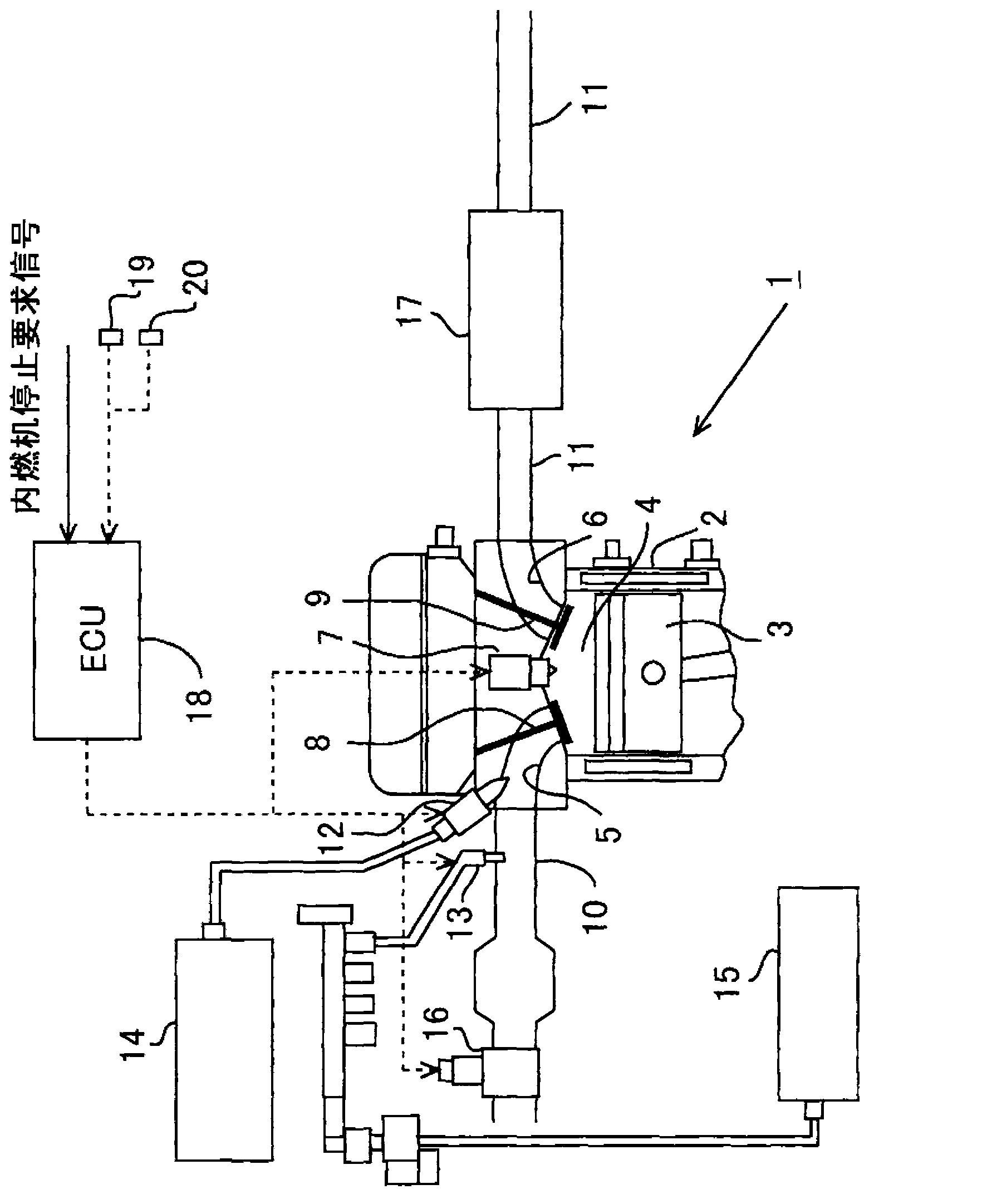

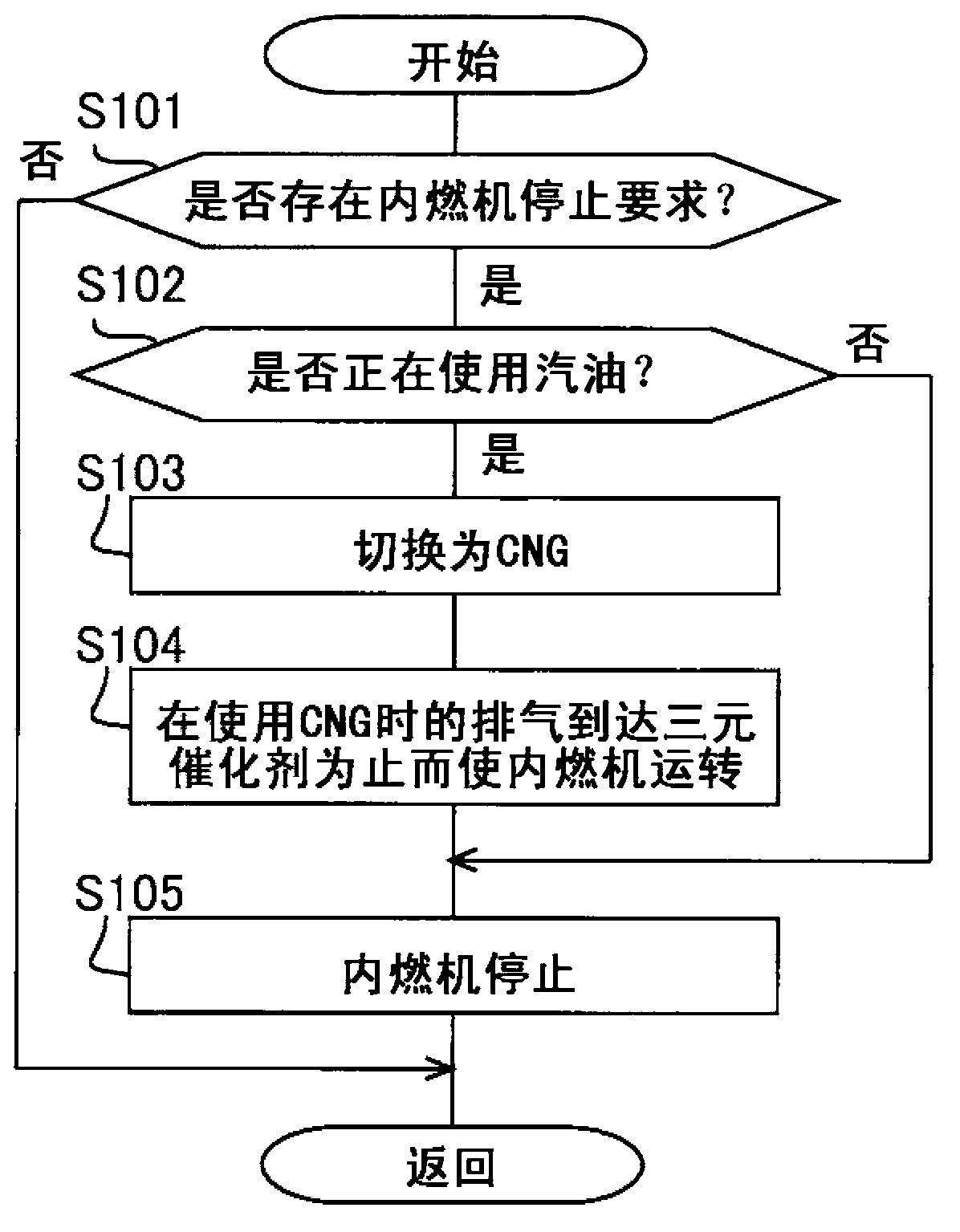

Control device and control method for internal combustion engine

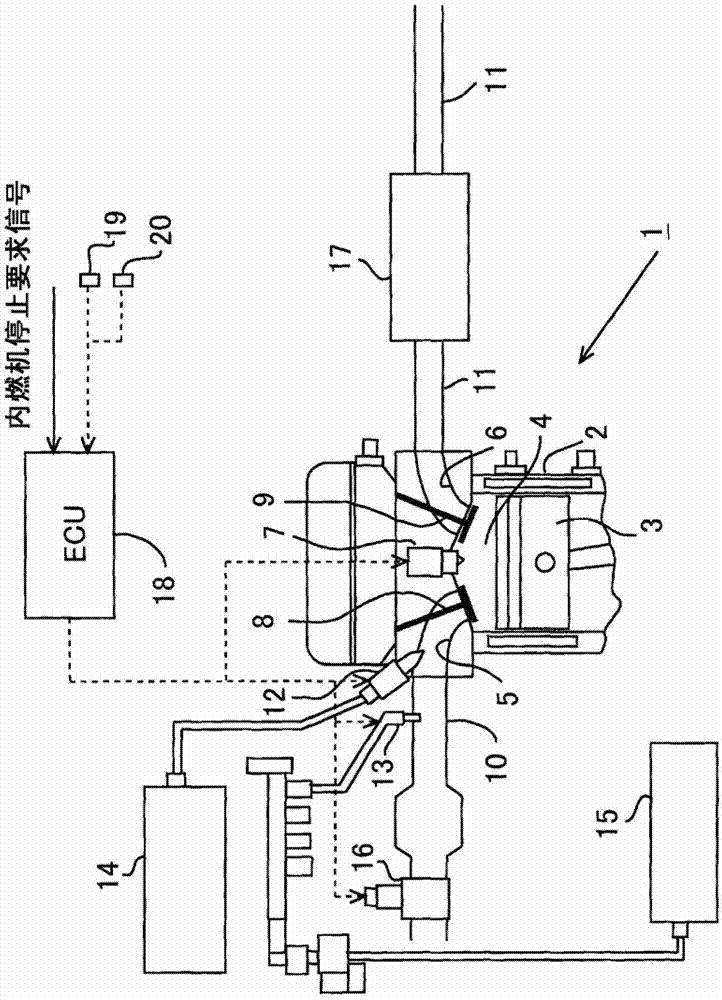

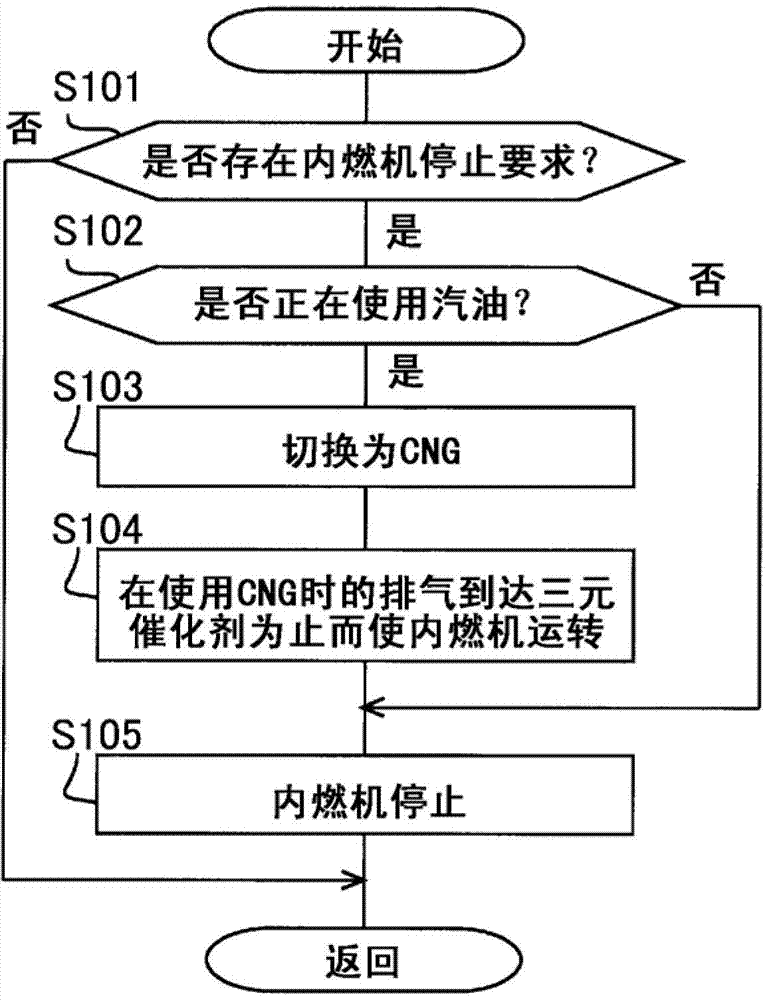

InactiveCN103080508AImprove exhaust emissionsReduce performanceElectrical controlInternal combustion piston enginesMultifuelExternal combustion engine

The invention relates to a control device and a control method for internal combustion engine. The objective of this invention is to provide a technology for improving exhaust emissions at engine startup without reducing the performance of the catalyst at engine startup. This invention is equipped with a catalyst which is provided in the exhaust passage of an internal combustion engine capable of using multiple types of fuels and which adsorbs and purifies the exhaust component discharged from the internal combustion engine. When there is a request to stop the internal combustion engine and, of the multiple fuel types, a first fuel the unburned component of which is easily adsorbed by the catalyst is being used, a switch is made from the first fuel to a second fuel, and running continues until the internal combustion engine stops.

Owner:TOYOTA JIDOSHA KK

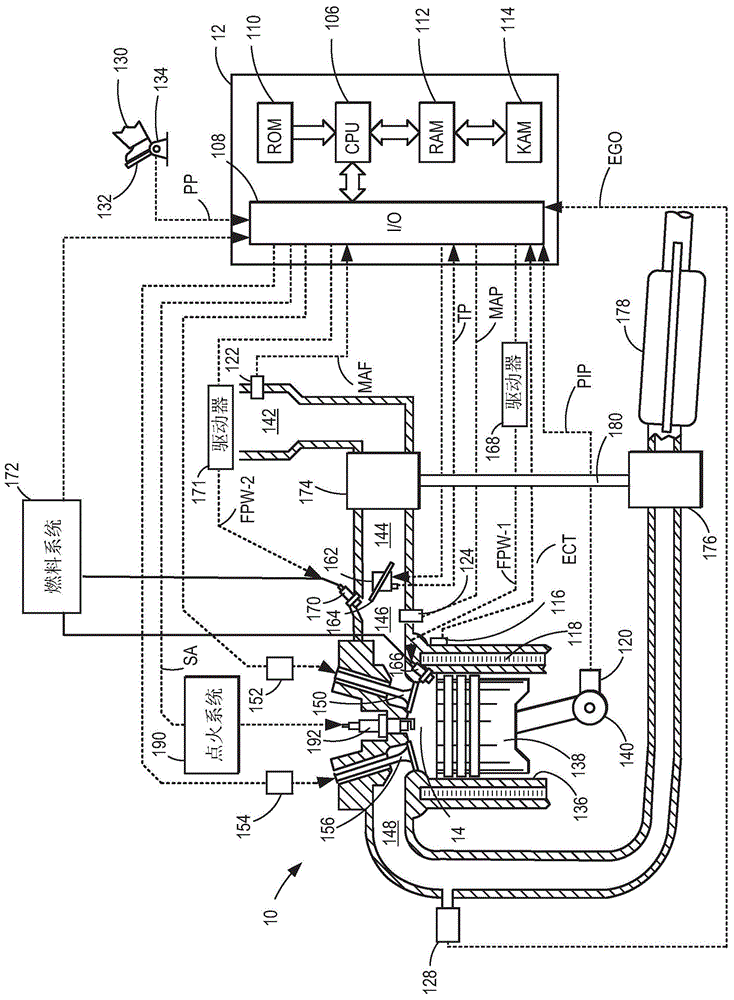

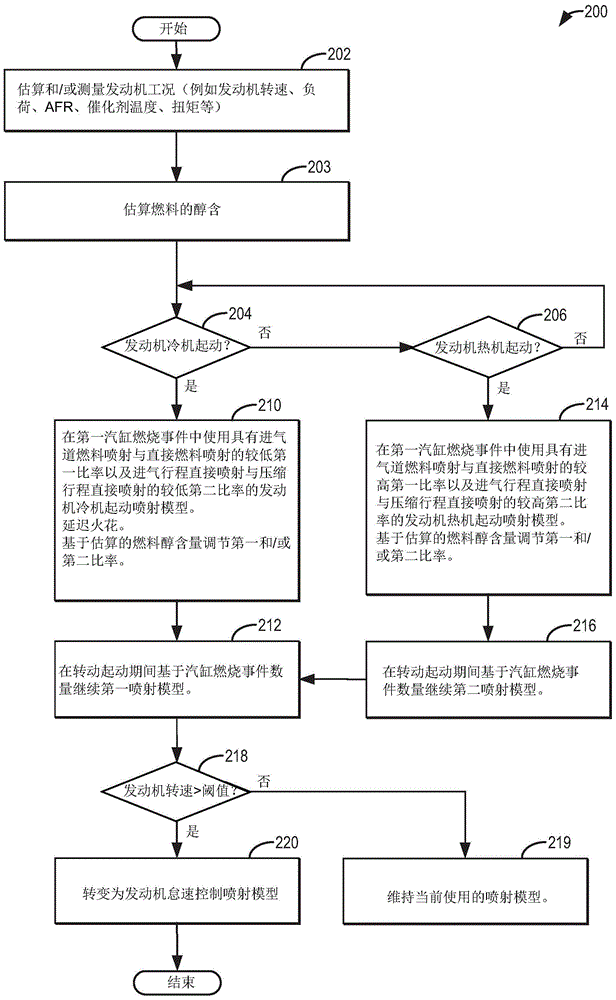

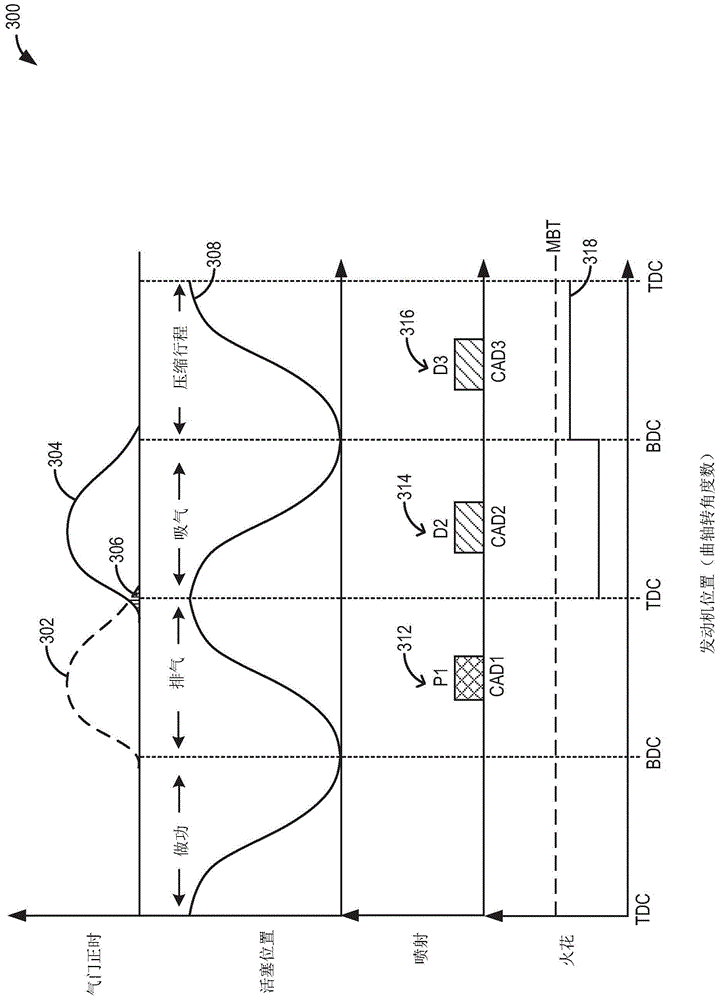

Method and system for engine control

ActiveCN104100396AImprove economyShorten activation timeElectrical controlInternal combustion piston enginesMultiple injectionAlcohol content

Methods and systems are provided for controlling exhaust emissions by adjusting an injection profile for fuel injected into an engine cylinder from a plurality of fuel injectors during engine start and crank. By splitting injection of fuel during start so that a portion of fuel is port injected and a remaining portion is direct injected as one or multiple injections, the soot load of the engine can be reduced and fuel economy can be improved. The injections are adjusted based on the alcohol content of the injected fuel to take advantage of the charge cooling properties of the fuel.

Owner:FORD GLOBAL TECH LLC

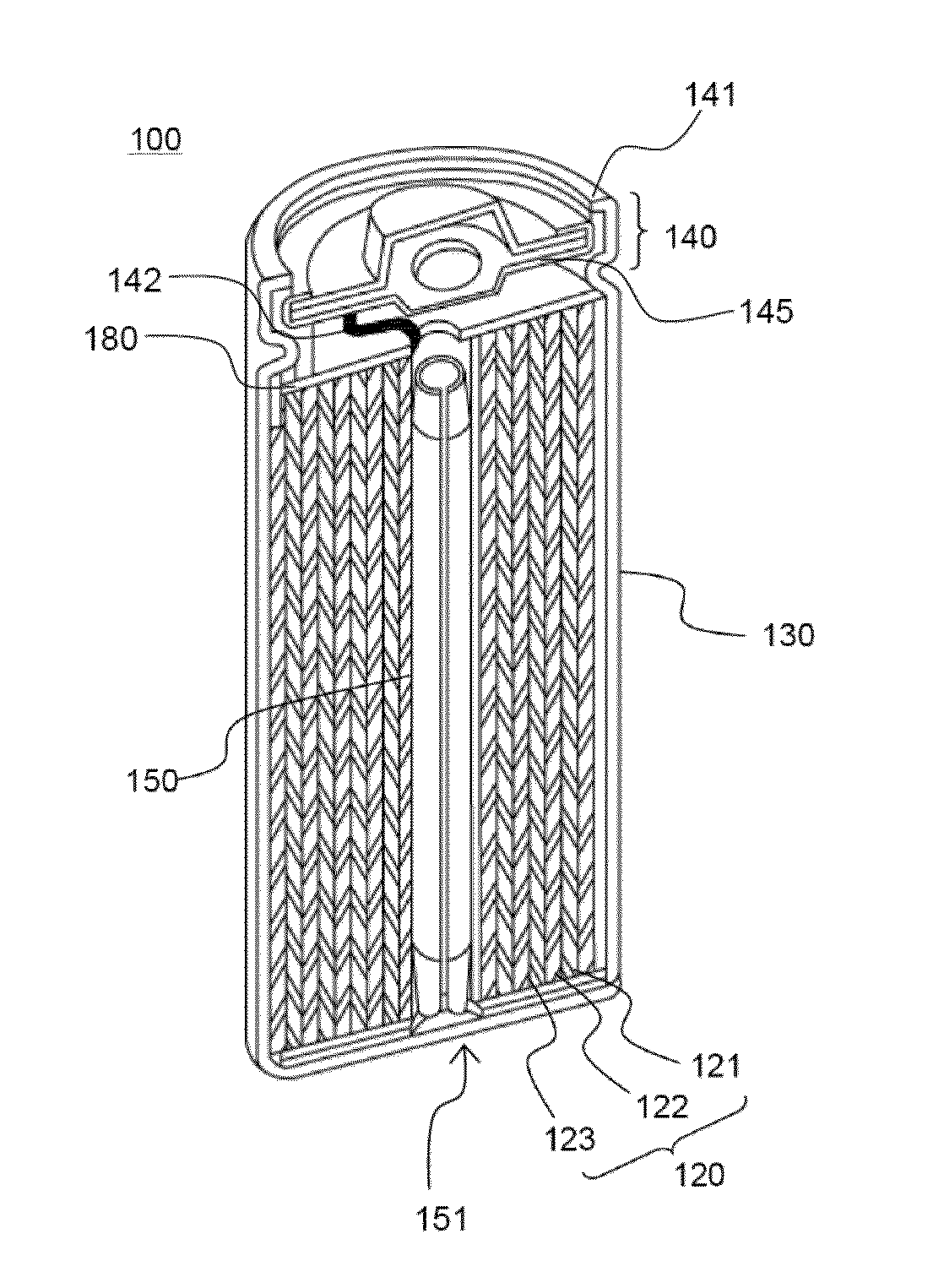

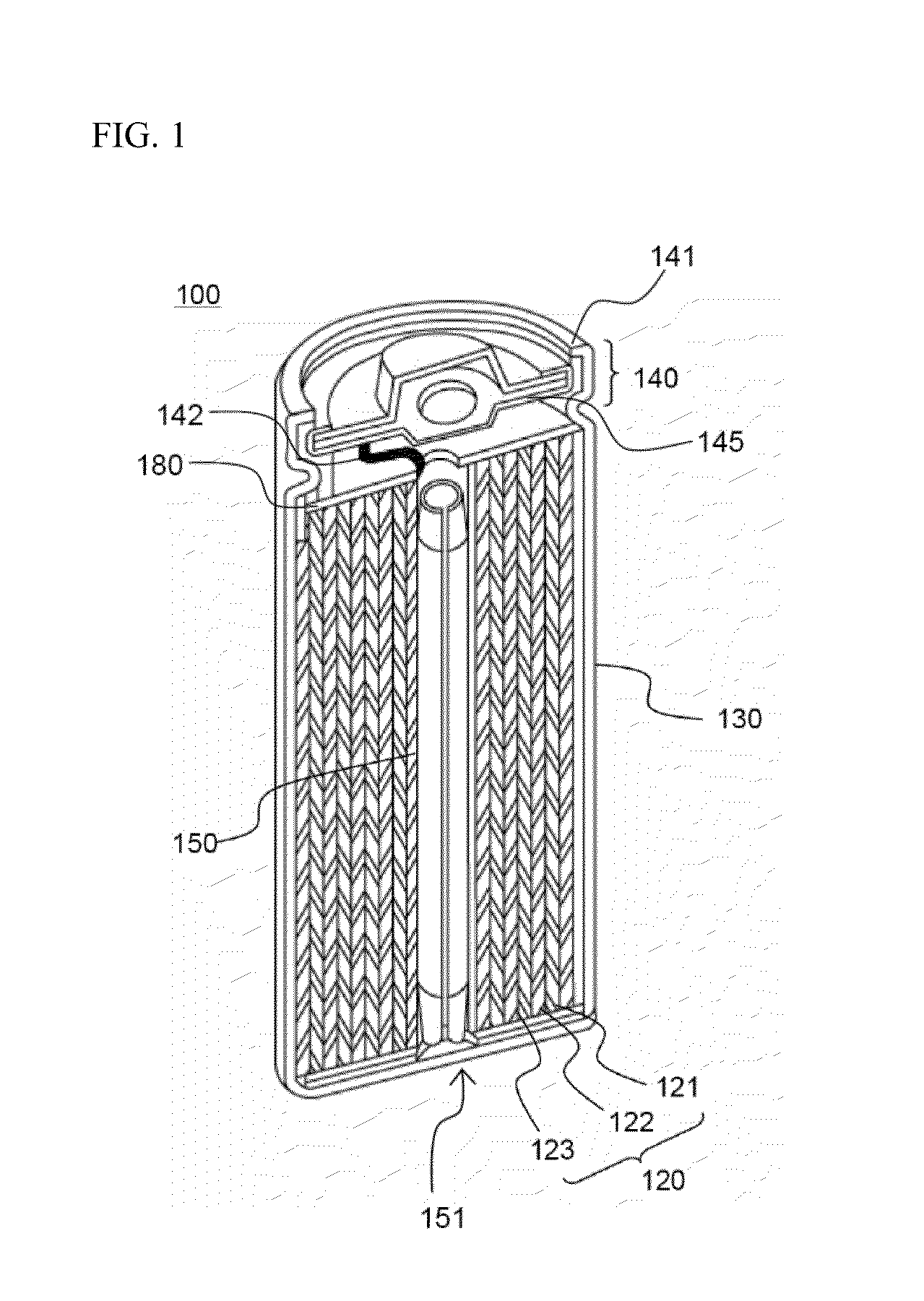

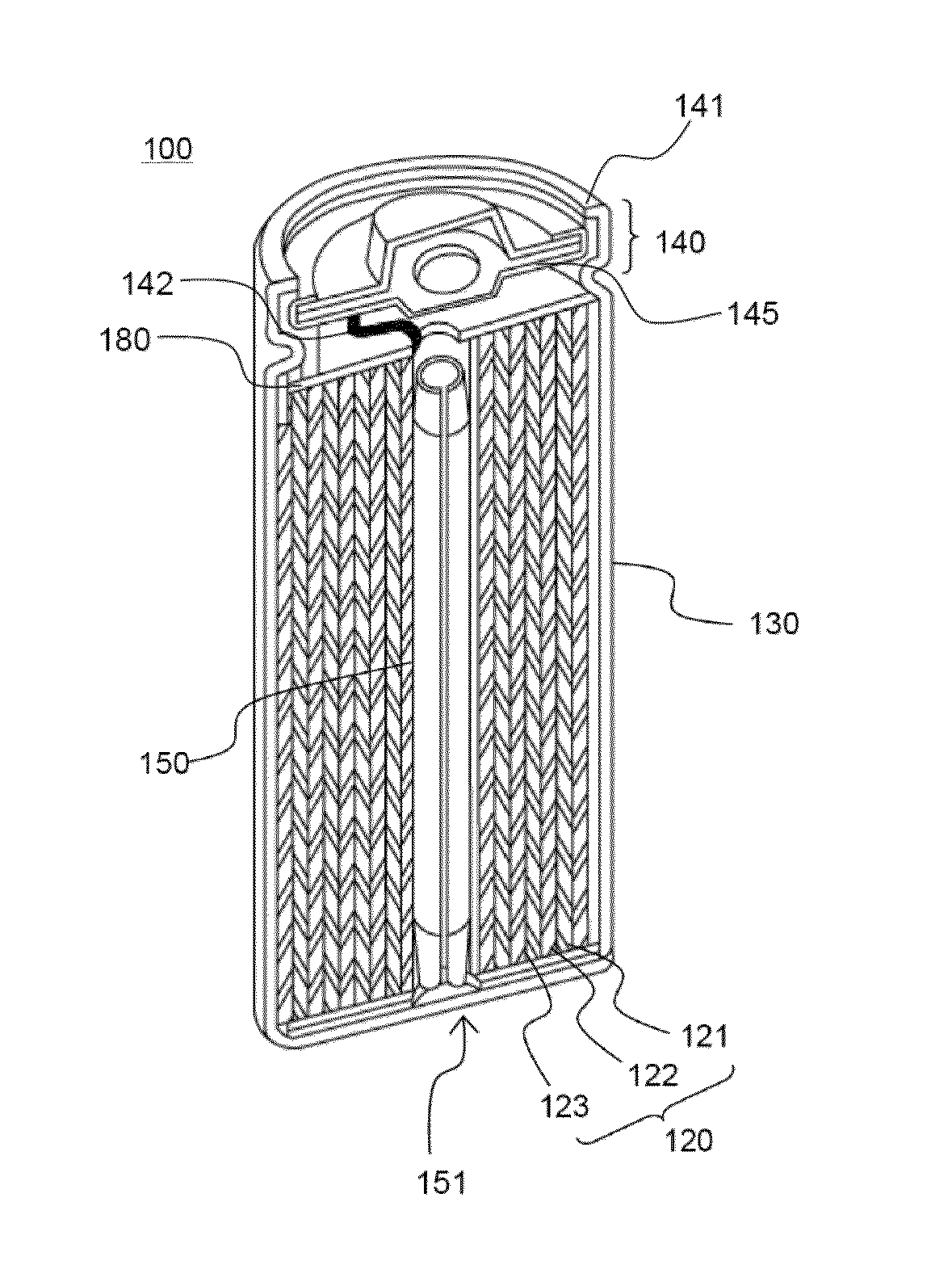

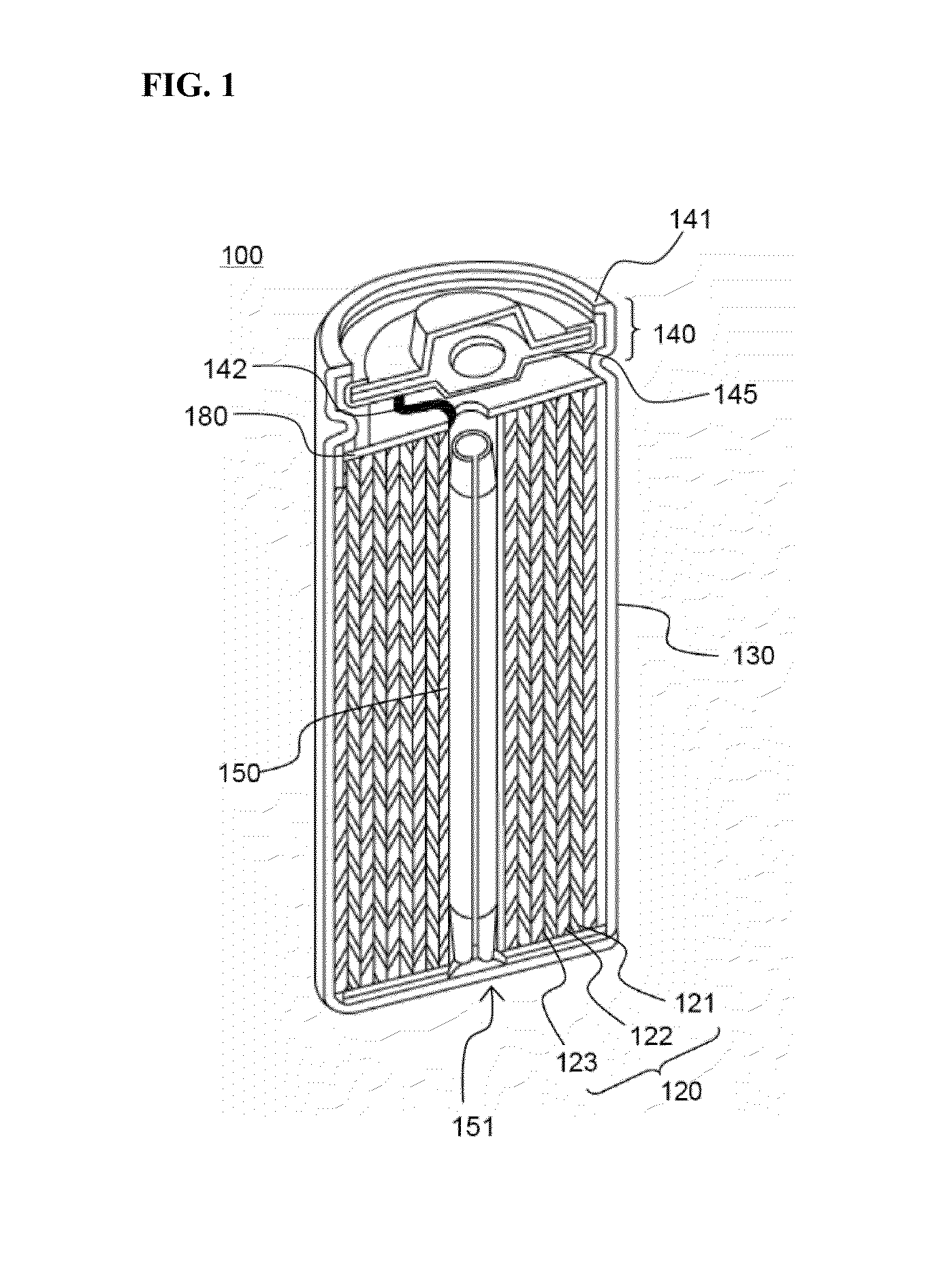

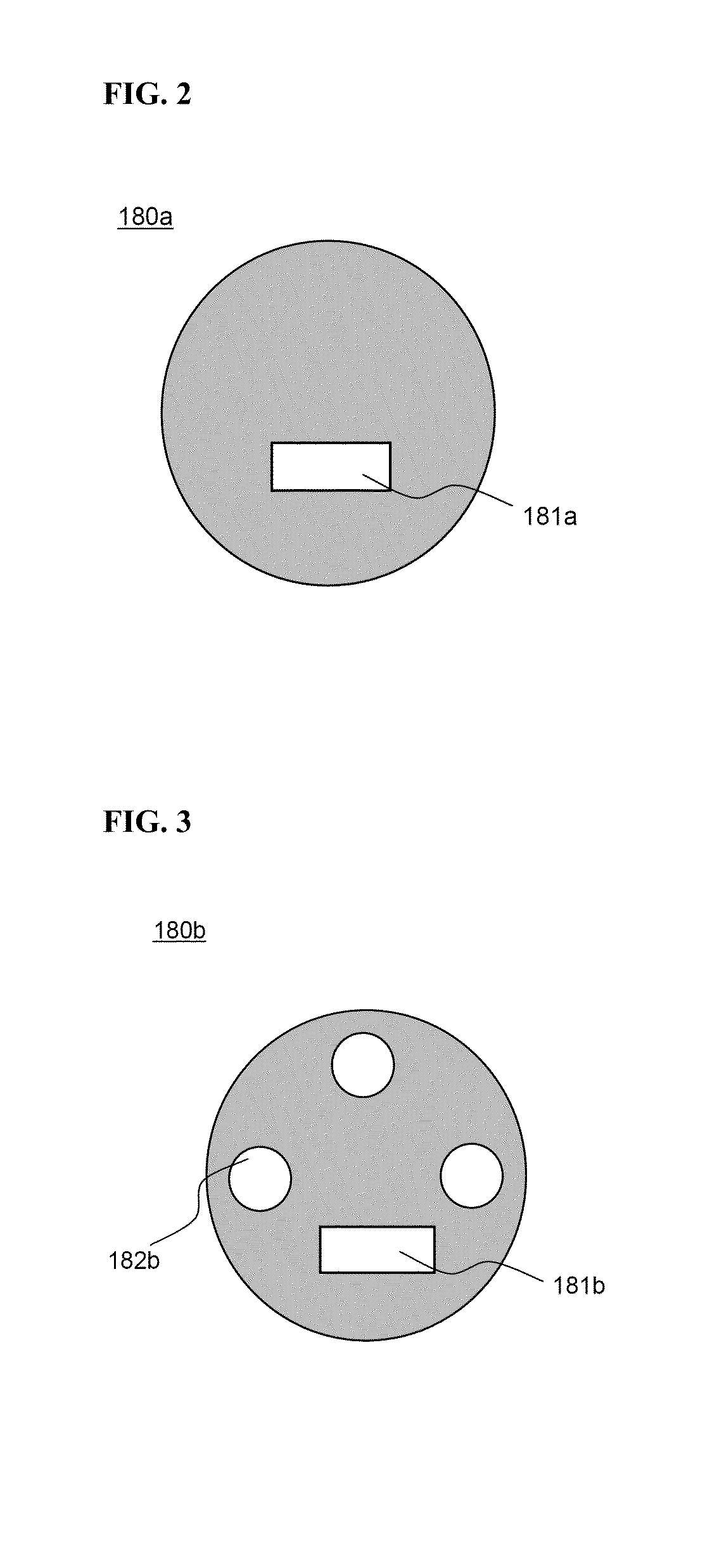

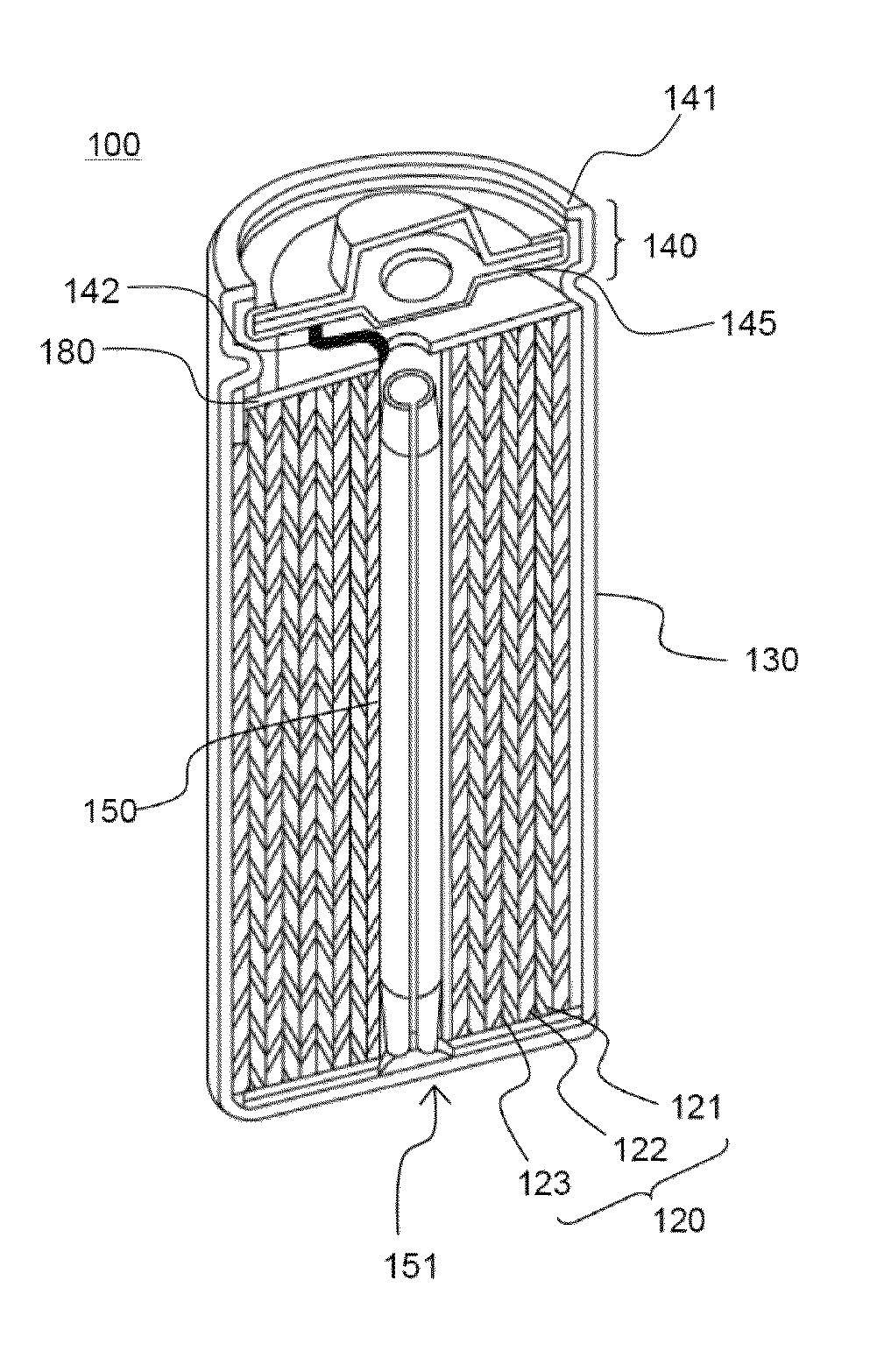

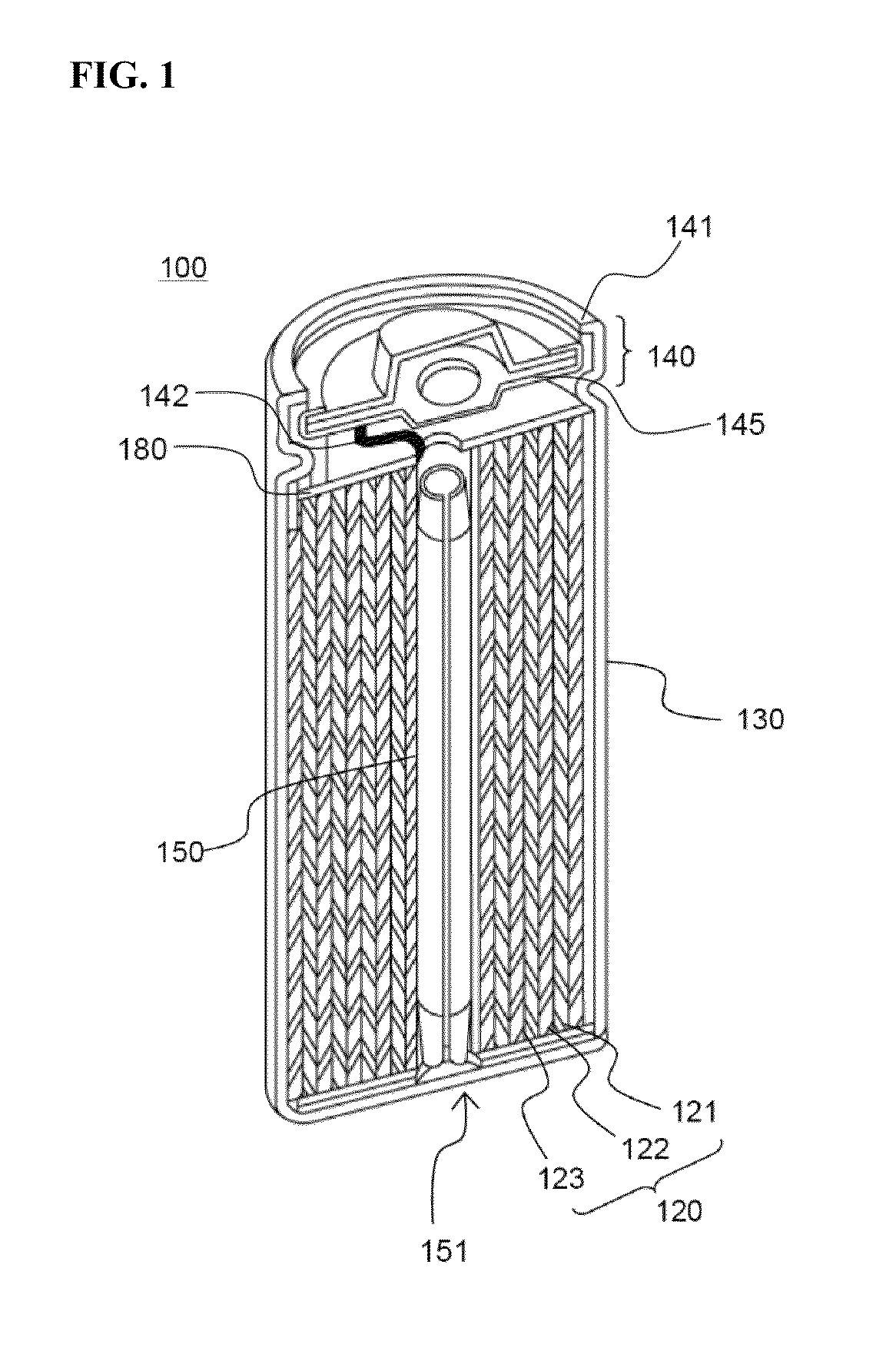

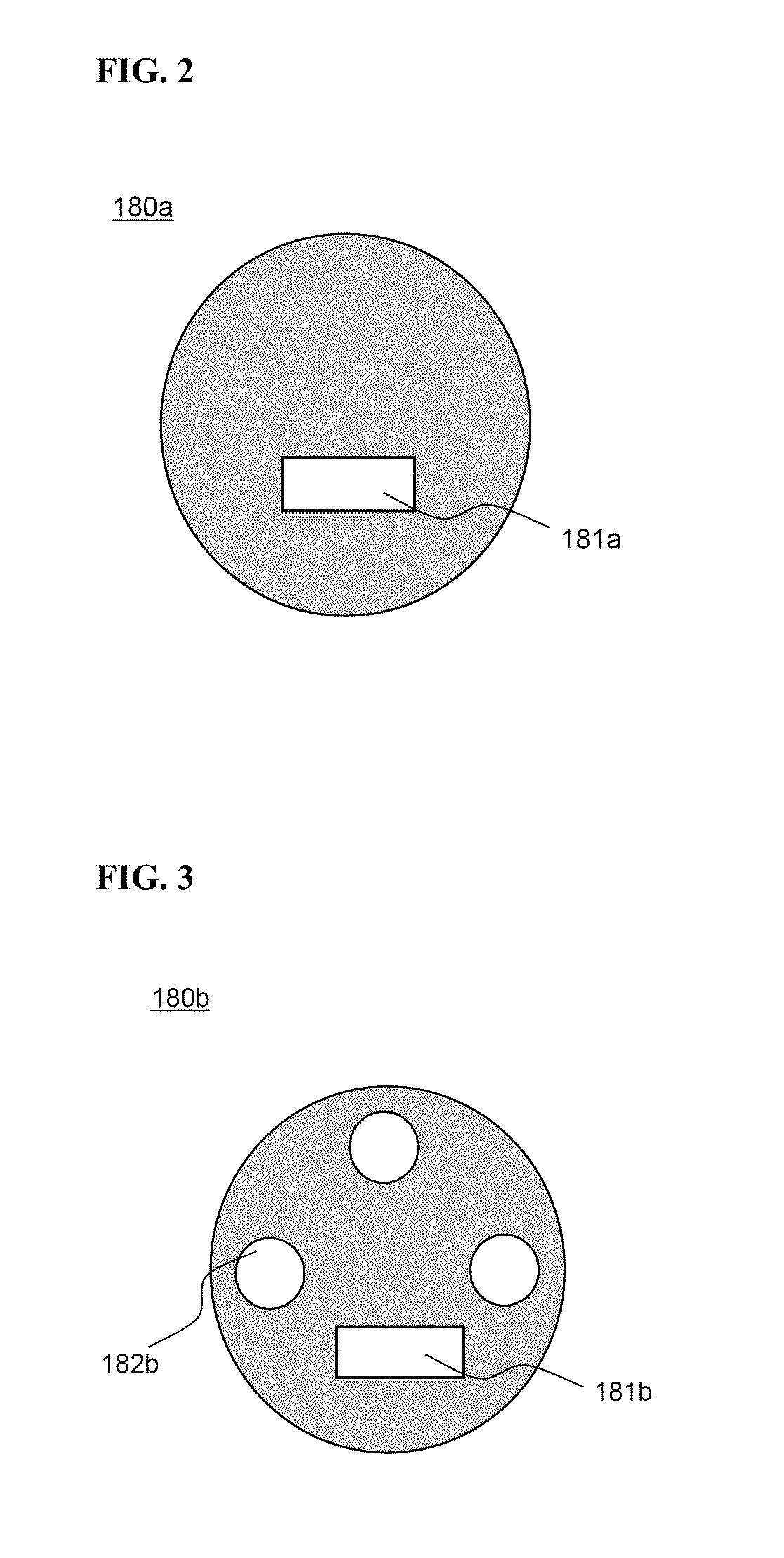

Secondary battery of excellent productivity and safety

ActiveUS20140154543A1Shorten injection timeGood injectabilityFinal product manufactureNegative electrodesFiberProduction rate

Disclosed is a secondary battery having a structure in which a jelly-roll having a cathode / separator / anode structure is mounted in a cylindrical battery case, wherein a plate-shaped insulator mounted on the top of the jelly-roll includes a woven fabric or a knit fabric made of fibers.

Owner:LG ENERGY SOLUTION LTD

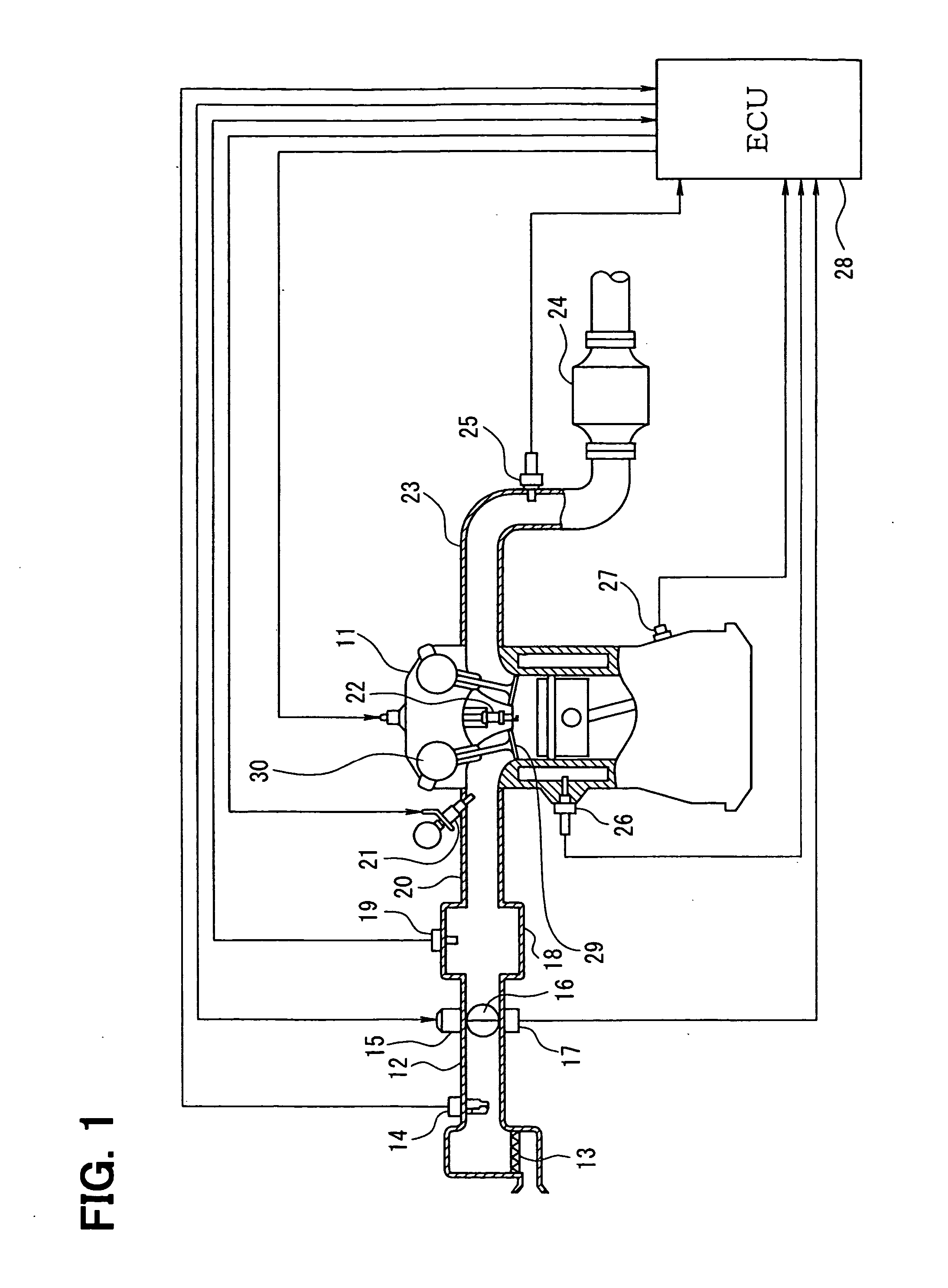

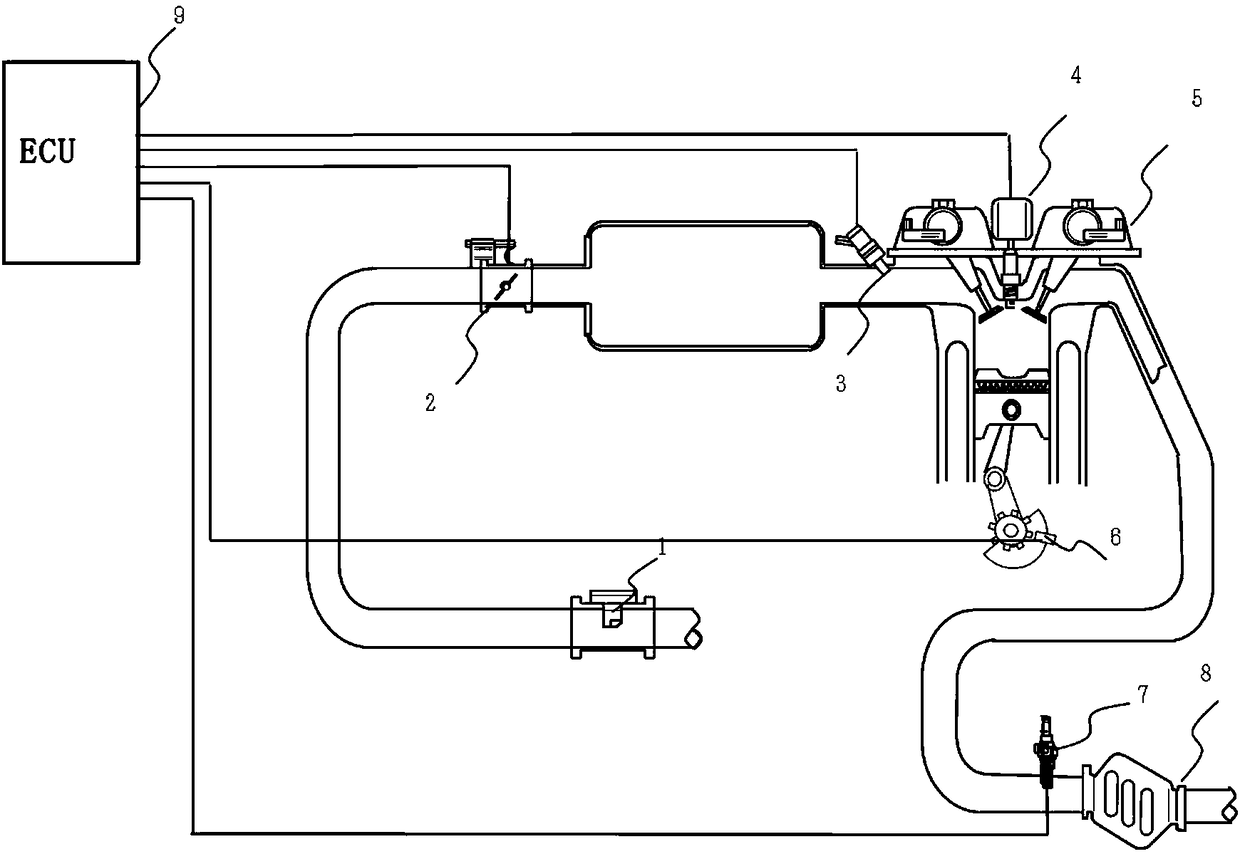

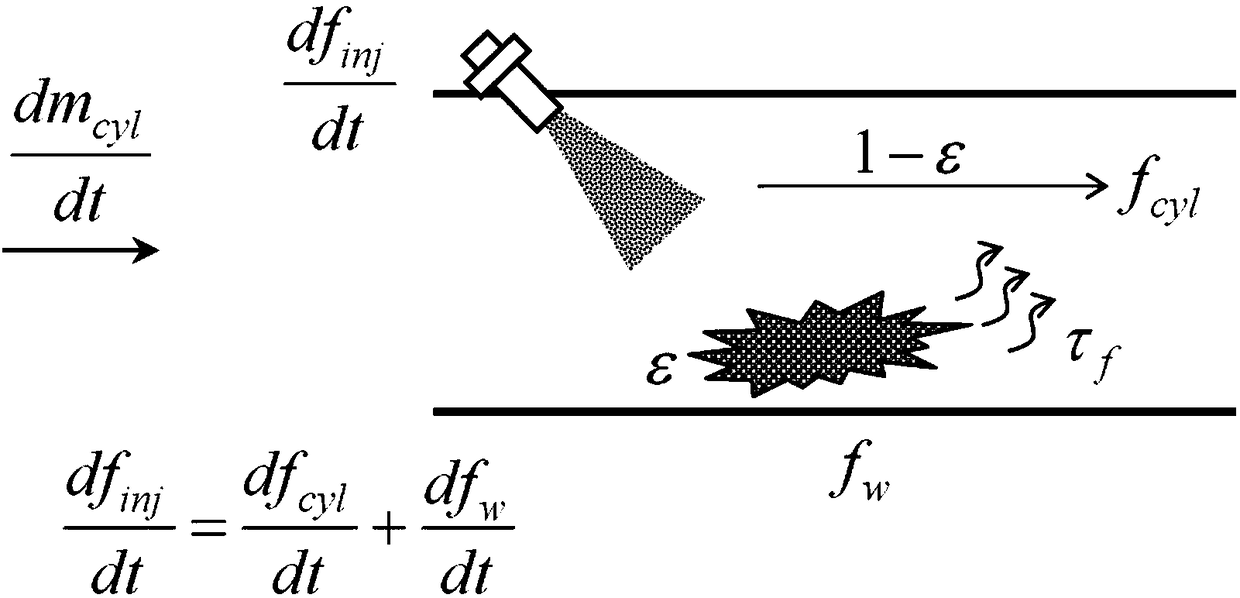

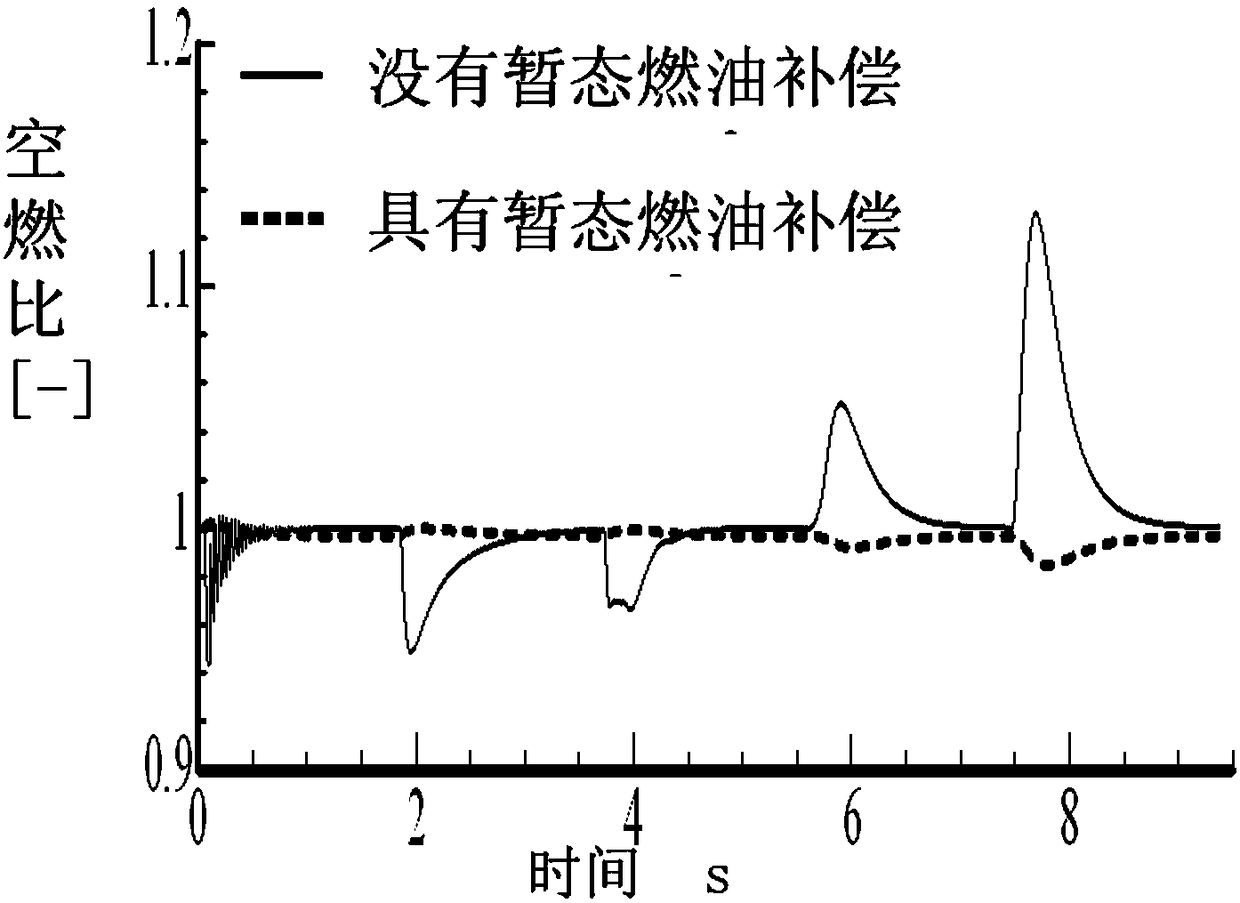

Fuel control device and control method for manifold injection type gasoline engine

ActiveCN109139280AFine-tune delay effectsImprove exhaust emissionsElectrical controlFuel injection apparatusExhaust valveInlet valve

The invention provides a fuel control device and a control method for a manifold injection type gasoline engine. The control device is provided with an internal combustion mechanism, a gas inlet pipeline, a gas exhaust pipeline, a throttle valve, a gas inlet manifold, a gasoline injector, at least one air cylinder, an air-fuel ratio sensor and a controller, wherein the gas inlet pipeline and the gas exhaust pipeline are connected with the internal combustion mechanism; the throttle valve is configured downstream of the gas inlet pipeline; the gas inlet manifold is configured downstream of thethrottle valve; the gasoline injector is used for injecting gasoline into the gas inlet manifold; the at least one air cylinder is provided with a gas inlet valve and a gas exhaust valve; the air-fuelratio sensor is configured downstream of the gas exhaust pipeline; and the controller is used for comparing the actually measured air-fuel ratio data which are measured by the air-fuel ratio sensor with the recorded transient air-fuel ratio data of the working condition which are stored in an ECU (Electronic Control Unit), regulating an air-fuel ratio target value to be a value which fluctuates within a specified amplitude when a comparison result exceeds the specified range, and correcting a fuel compensating parameter in real time according to the waveform of the actually measured air-fuelratio data after regulation. According to the fuel control device and the control method for the manifold injection type gasoline engine, the fuel compensating parameter can be regulated in real time.

Owner:日立安斯泰莫汽车系统(中国)有限公司

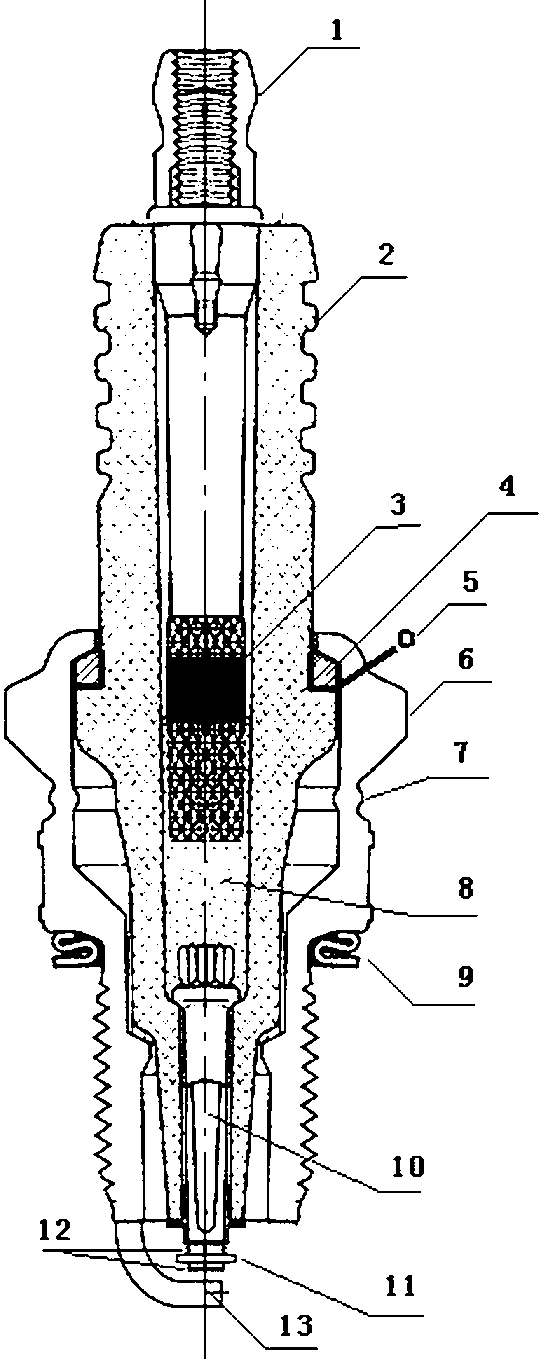

Spark plug sensor

InactiveCN103138162AGuaranteed performanceImprove powerSparking plugsElectrical resistance and conductanceElectrical conductor

The invention relates to a spark plug sensor which comprises a high pressure connection terminal, an insulator, a glass sealant, a central electrode, a grounding electrode, and a shell. The insulator is arranged at the lower end of the high pressure connection terminal. The shell is sleeved outside the insulator. Resistance powder arranged inside the insulator, the glass sealant, and the central electrode are connected and arranged in sequence at the lower end of the high pressure connection terminal. An insulating ceramics is arranged at the lower end of the central electrode, a metal ring conductor is sleeved on the insulating ceramic, and gaps are formed between the insulating ceramic and the grounding electrode which is arranged on the lower portion of the shell. A piezoelectric ceramic is arranged on the insulator, and a piezoelectric ceramic motor is arranged on the piezoelectric ceramic. The structure of a spark plug is changed, the spark plug sensor is realized based on the fact that performance of the spark plug is guaranteed, dynamic performance, startup performance, economic performance, exhaust emission, and environmental-protection performance of an automobile are improved, and the spark plug sensor plays a certain positive role for effective utilization of resources.

Owner:XIAN CHUANGNIER AUTOMOBILE ELECTRONICS TECH

Secondary battery with excellent productivity and safety

ActiveUS20140178725A1Improve productivityImprove securityFinal product manufactureSmall-sized cells cases/jacketsEngineeringCathode

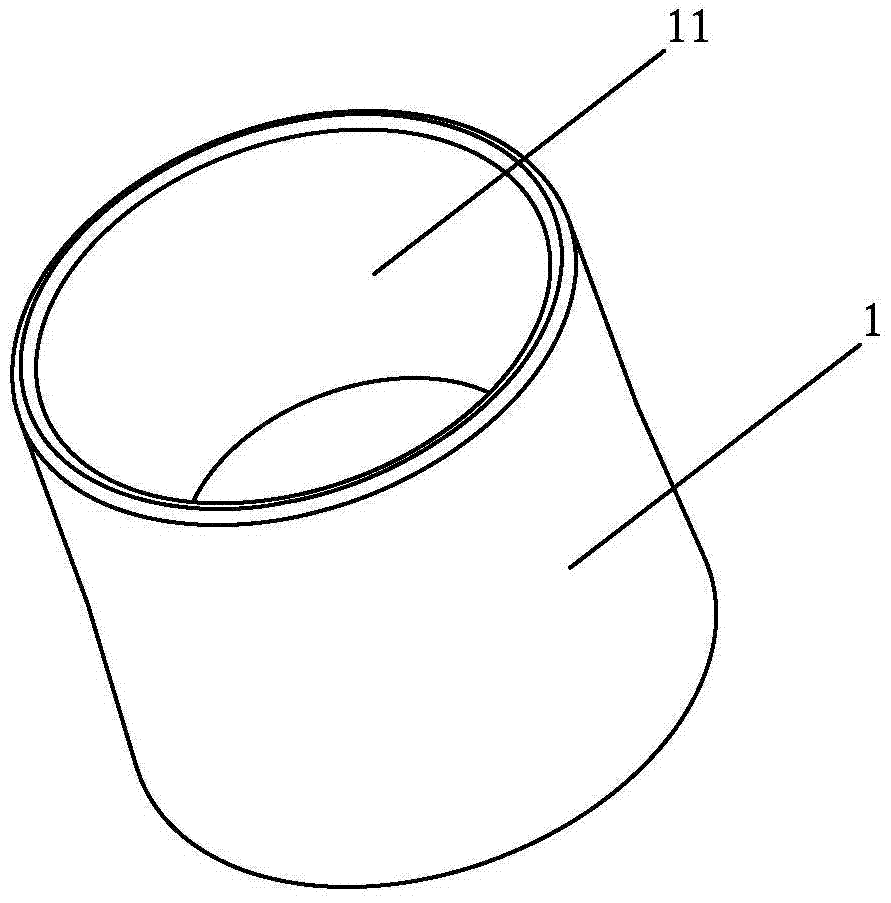

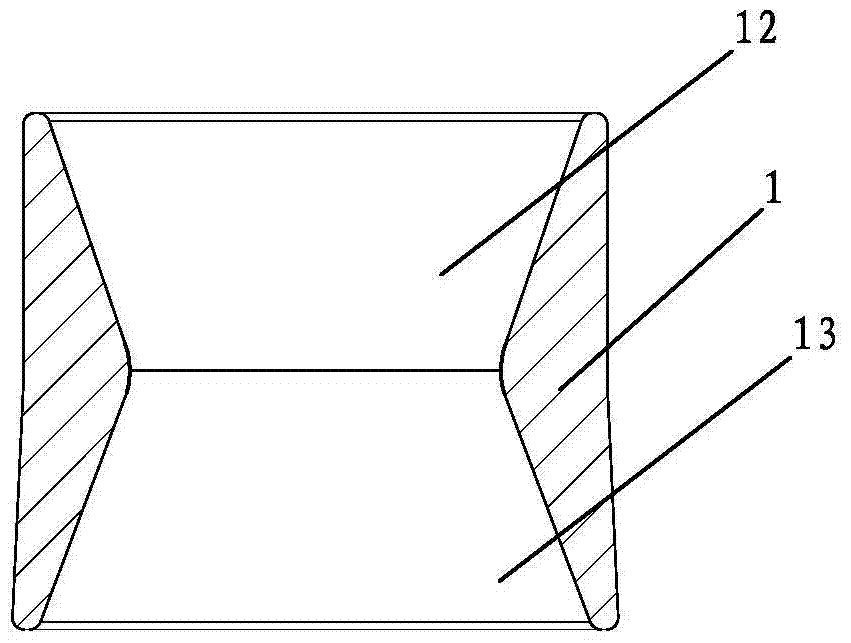

Disclosed is a secondary battery having a structure in which a jelly-roll having a cathode / separator / anode structure is mounted in a cylindrical battery case and a plate-shaped insulator is mounted on top of the jelly-roll, wherein the insulator has a porous structure in which a plurality of fine pores communicate in a longitudinal direction, or in traverse and longitudinal directions.

Owner:LG ENERGY SOLUTION LTD

Secondary battery comprising insulator and reinforcing filler

ActiveUS9236630B2Improve productivityImprove exhaust emissionsFinal product manufactureSmall-sized cells cases/jacketsEngineeringAnode

Disclosed is a secondary battery having a structure in which a jelly-roll having a cathode / separator / anode structure is mounted in a cylindrical battery case and a plate-shaped insulator is mounted on top of the jelly-roll, wherein the insulator has a porous structure in which a plurality of fine pores communicate in a longitudinal direction, or in traverse and longitudinal directions.

Owner:LG ENERGY SOLUTION LTD

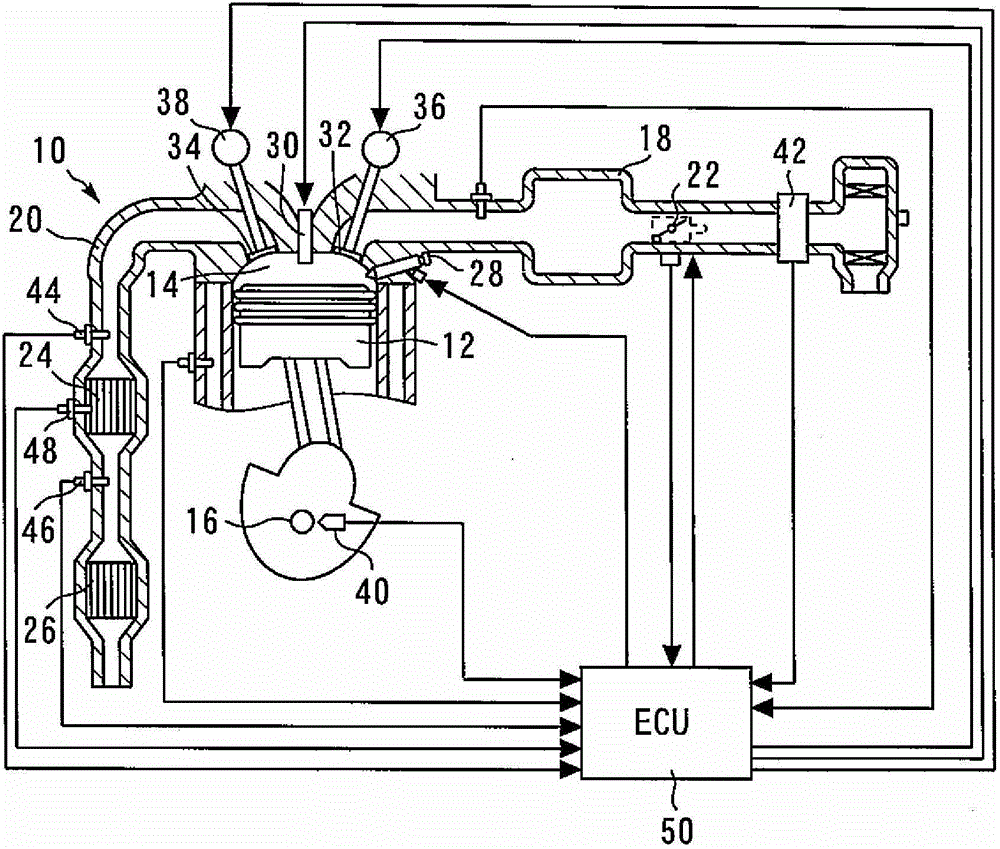

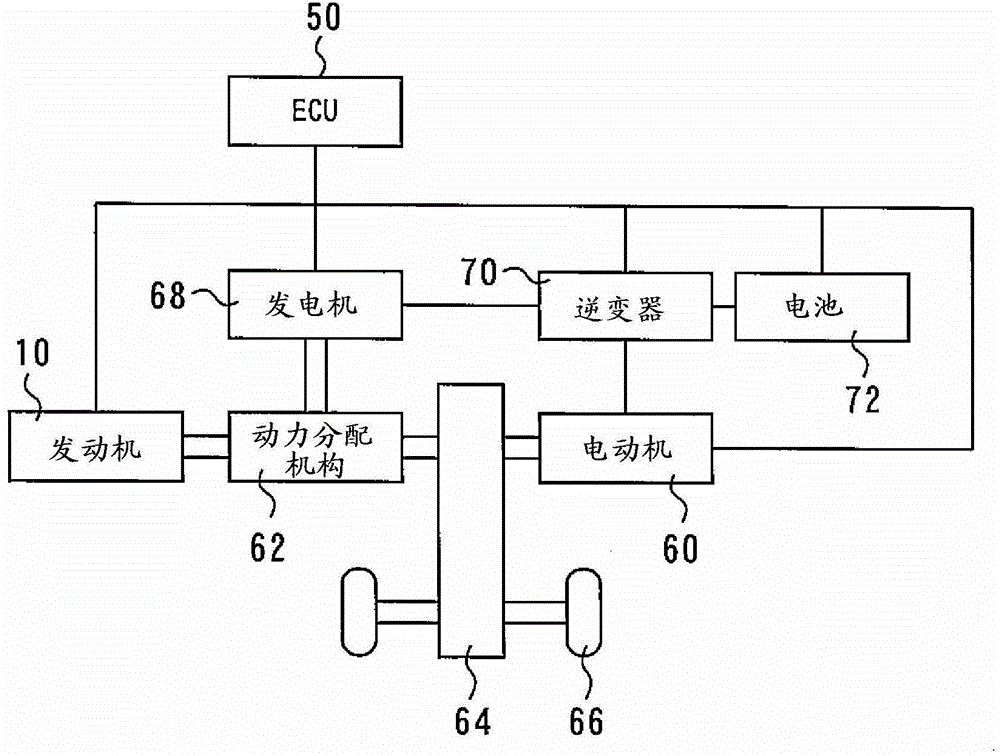

Controls for hybrid vehicles

ActiveCN103025590BInhibit deteriorationImprove exhaust emissionsHybrid vehiclesInternal combustion piston enginesExhaust valveExternal combustion engine

An object of this invention is to prevent rich poisoning of a catalyst utilizing a motor while an internal combustion engine is stopped in a hybrid vehicle. An engine 10 includes variable valve mechanisms 36 and 38 capable of causing an intake valve 32 and an exhaust valve 34 to stop. An ECU 50 estimates poisoning states of catalysts 24 and 26, and executes and prohibits stopping of the valves 32 and 34 based on the poisoning states. When stopping of the valves 32 and 34 is prohibited during a fuel-cut operation, the ECU 50 drives a crankshaft 16 of the engine 10 by means of a motor 60 to idle the engine 10. Thus, even in a hybrid vehicle in which the engine 10 is stopped during a fuel-cut operation, a sufficient amount of oxygen can be rapidly supplied to the catalysts 24 and 26 by utilizing a pumping action of pistons 12, and the catalysts 24 and 26 can be caused to recover from rich poisoning efficiently.

Owner:TOYOTA JIDOSHA KK

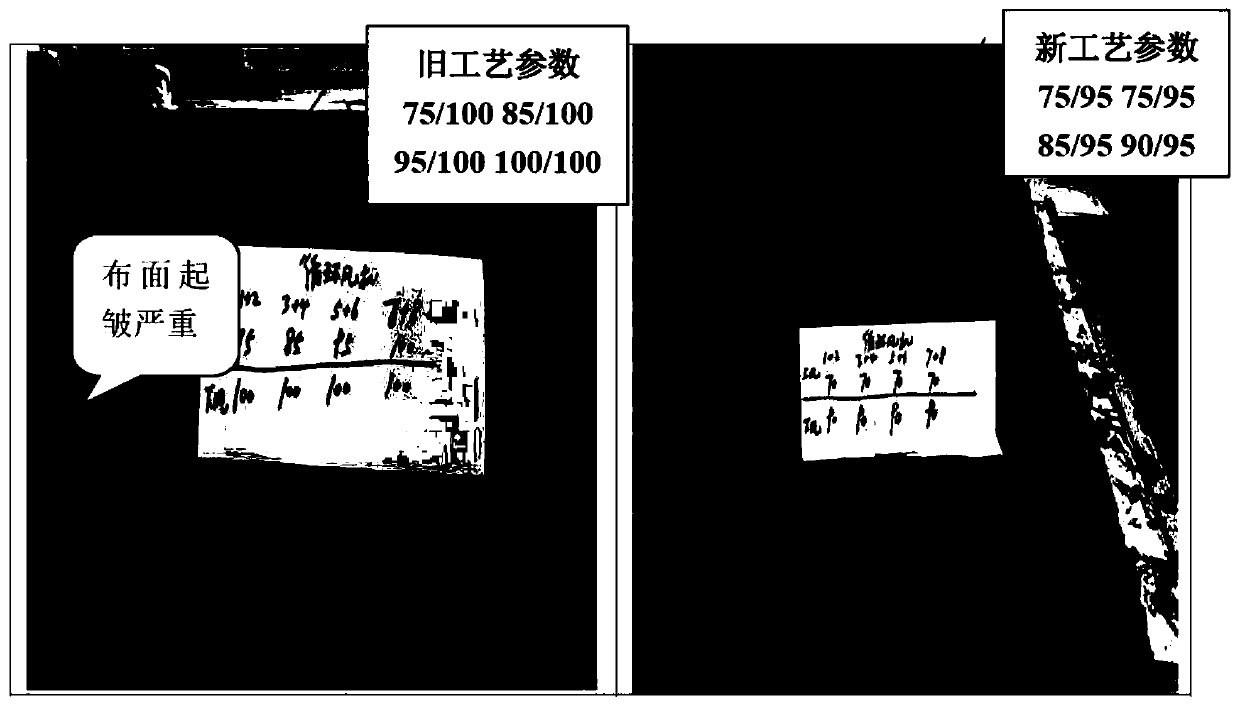

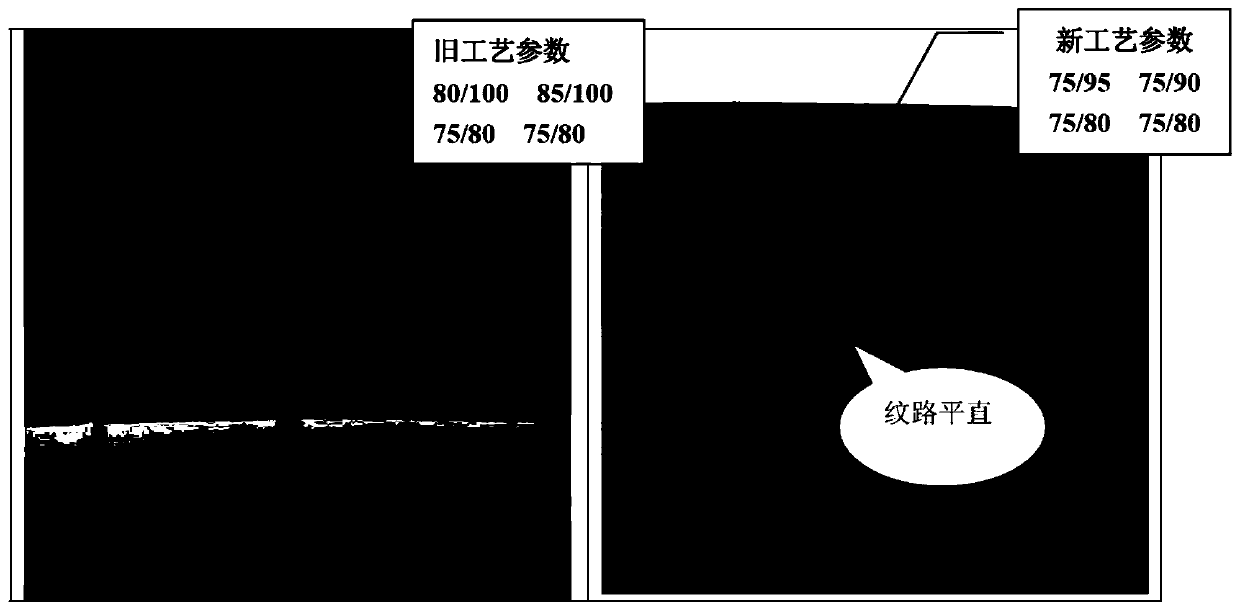

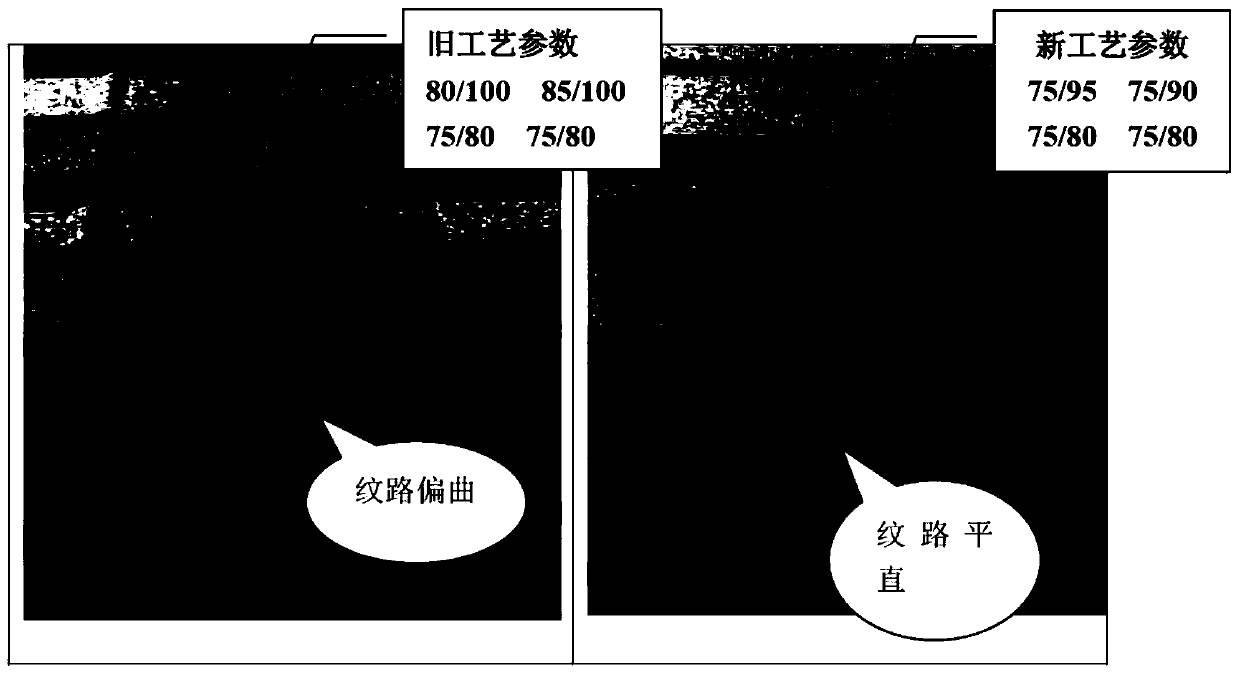

Knitted fabric setting drying method

ActiveCN108149427BImproving the quality of setting and dryingWeakening rangeHeating/cooling textile fabricsYarnAir volume

The invention relates to a setting and drying method of knitted fabric. The method ensures that the air volume of an upper air plate is smaller than that of a lower air plate by controlling the air volume of the upper air plate and the lower air plate, can further ensure that integrally upward air force is formed for the knitted fabric when the knitted fabric passes through the air plates while saving electric energy, and ensure that the knitted fabric is not adhered to the lower air plate, thereby being beneficial to heat transfer and exhaust emission during drying, and can avoid undesirablephenomena, such as snag yarn, and is beneficial to the improvement of setting and drying quality of the knitted fabric; the method respectively controls the air volume of the upper air plate and the lower air plate according to knitted fabric with different gram weight, is further beneficial to energy conservation and environment protection, reasonably reduces the air volume according to the knitted fabric with different gram weight, can reduce the longitudinal range and frequency of the knitted fabric when the knitted fabric passes through a drying oven, is beneficial to the improvement of the tightness of the edge of the knitted fabric and the flatness of the knitted fabric, can further improve cloth cover lines of the knitted fabric, such as yarn dyed fabric, and is beneficial to reducing the problem of weft bow.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Methods of Extracting Condensate from Charge Air Coolers

InactiveCN104213972BImprove exhaust emissionsIncrease airflow levelsElectrical controlNon-fuel substance addition to fuelCombustionEngineering

A method and system for removing condensate stored in a charge air cooler is disclosed. In response to increased condensate buildup in the charge air cooler, airflow through the engine is increased to purge the condensate while adjusting engine drive to maintain engine torque. The problem of combustion stability of the engine cylinders is solved by individually adjusting the fueling of each cylinder during the ingestion of condensate.

Owner:FORD GLOBAL TECH LLC

Device and method for controlling an internal combustion engine

InactiveCN103080508BImprove exhaust emissionsReduce performanceElectrical controlInternal combustion piston enginesInternal combustion engineStart up

The present invention is intended to provide a technique of improving exhaust emissions at the time of starting up of an internal combustion engine, without decreasing the performance of a catalyst at the time of the engine starting up. The present invention is provided with the catalyst that is arranged in an exhaust passage of the internal combustion engine in which a plurality of kinds of fuels are able to be used, and serves to adsorb and remove exhaust gas components discharged from the internal combustion engine, wherein in cases where among the plurality of kinds of fuels, a first fuel is used in which unburnt fuel components thereof are easily adsorbed to the catalyst, at the time when a request is made for stopping the internal combustion engine, said first fuel is changed to a second fuel thereby to operate said internal combustion engine until said internal combustion engine is stopped.

Owner:TOYOTA JIDOSHA KK

Methods and systems for resistive particulate matter sensors

ActiveCN106089382BReduce corrosionHigh precisionElectrical controlInternal combustion piston enginesEnvironmental engineeringSoot

Owner:FORD GLOBAL TECH LLC

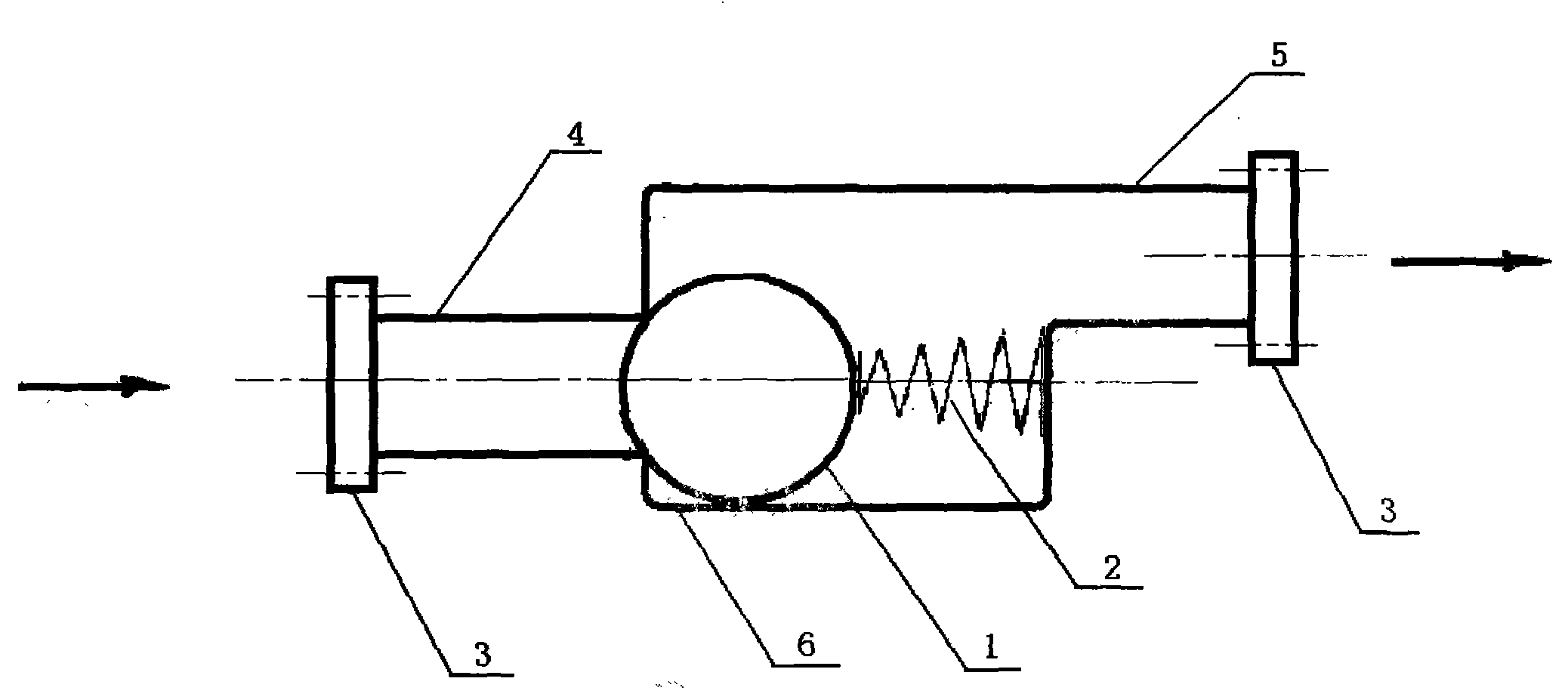

Air check valve device for exhaust pipe of automobile

InactiveCN104279038AHigh technology contentHigh precisionExhaust apparatusSilencing apparatusHigh pressureCheck valve

The invention discloses an air check valve device for an exhaust pipe of an automobile, which is an auxiliary device for the exhaust pipe of the automobile, belongs to the fields of energy conservation and emission reduction of engines, and solves the problem that exhaust does not reach a standard when the automobile runs. A hollow ball and a return spring are arranged in a special metal shell; a flange plate is welded outside the special metal shell; the hollow ball is high in surface smoothness and light in weight and has certain strength, and is made of a stainless steel material; the return spring is a conical pressure spring and can increase the returning directionality of the hollow ball; one end of the return spring is welded to the hollow ball, the other end of the return spring is welded on the inner wall of the shell, and not less than three welding spots are ensured; the hollow ball, the return spring and an air inlet pipe are in the same center line to facilitate the improvement of the returning speed of the hollow ball and the sealing property; the air inlet pipe and an air outlet pipe are the same in pipe diameter and are arranged according to an arrow direction of the shell, so that when the hollow ball is pushed away by high pressure waste gas, the hollow ball cannot block the air outlet pipe, and a sufficient airflow space is reserved above the hollow ball.

Owner:YANTAI NANSHAN UNIV

Method and system for exhaust particulate matter sensing

ActiveCN106499488BImprove the efficiency of regenerative operationReduce needElectrical controlInternal combustion piston enginesEnvironmental engineeringVoltage source

The present application discloses methods and systems for exhaust particulate matter sensing. Methods and systems are provided for sensing particulate matter through a particulate matter (PM) sensor disposed in an exhaust system downstream of a diesel particulate filter (DPF), wherein the PM sensor may include a component coupled to a plurality of voltage sources and A plurality of individual electrode pairs are further coupled to a plurality of measurement devices. In one example, a method may include summing currents generated across multiple electrode pairs to determine a total PM sensor current by determining a sum of currents generated across individual electrode pairs. In this way, the PM sensor can more accurately detect PM in the exhaust gas without being affected by large particles deposited on the electrodes.

Owner:FORD GLOBAL TECH LLC

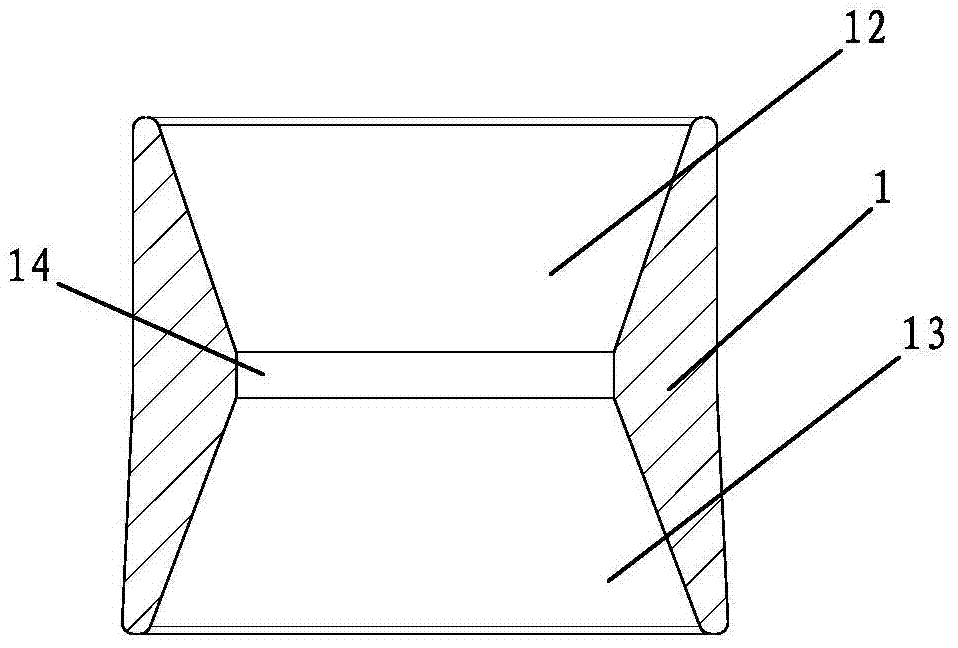

A turbocharger for an exhaust pipe and its installation structure

InactiveCN104712408BSpeed up the flowLarge displacementExhaust apparatusSilencing apparatusCombustion chamberCombustor

The invention discloses an exhaust pipe turbo charger. The exhaust pipe turbo charger is characterized by comprising a turbo charger body, through holes are formed in the turbo charger body, the diameters of the through holes are distributed in the direction of the central axes of the through holes in the mode of being decreased first and then increased, a turbo charger structure is formed when air flows through the through holes, and the circulation speed of the air is increased. The invention further discloses an installation structure of the exhaust pipe turbo charger. The installation structure of the exhaust pipe turbo charger is characterized in that a three-way catalytic converter and a silencer are connected in a butting mode through a connecting pipe with flange plates, and the turbo charger body is arranged in the connecting pipe. According to the exhaust pipe turbo charger and the installation structure thereof, an inertial eddy is formed in the process of engine exhaust, therefore, the effect that the exhaust velocity and the exhaust quantity are improves is achieved, then the air inflow of an engine combustor in a next acting period is improved, accordingly, the combustion efficiency of gasoline is improved, the engine output is promoted, and the exhaust gas emission of the engine is improved.

Owner:张湘杰 +4

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com