A turbocharger for an exhaust pipe and its installation structure

A technology of eddy current supercharging and installation structure, which is applied in the direction of exhaust device, muffler device, machine/engine, etc. It can solve the problems of reducing gasoline combustion efficiency, output power, gas flow speed, and large airflow resistance, etc., and achieves convenience and speed Effects of installation, faster flow, and improved installation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

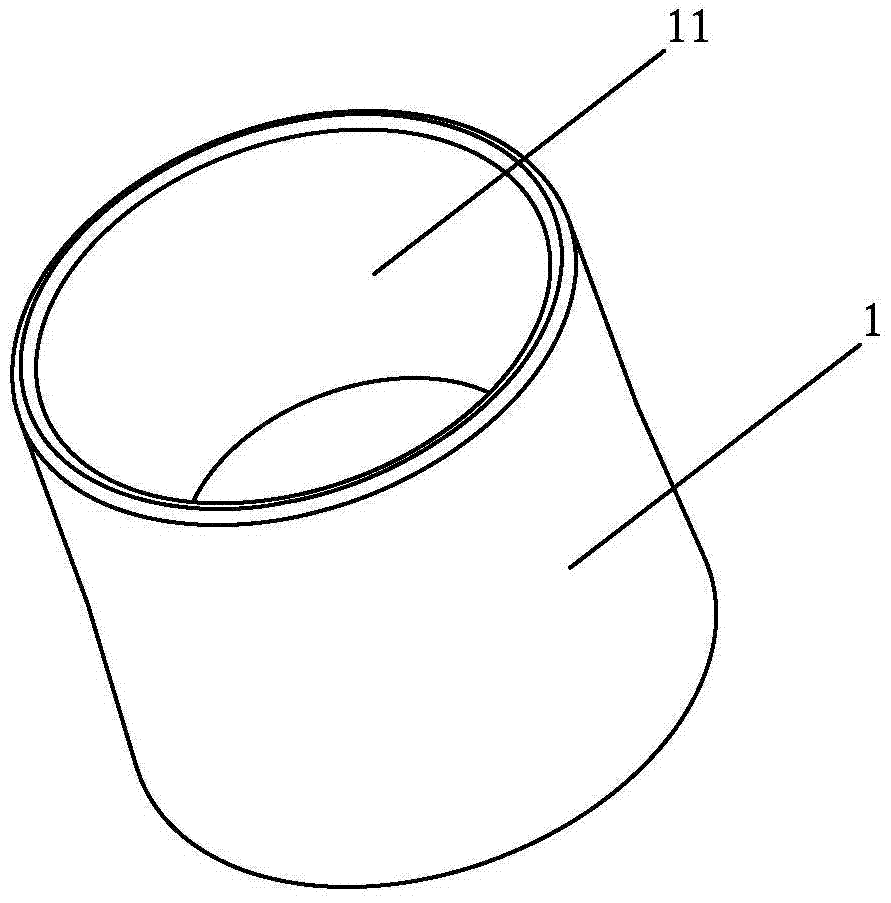

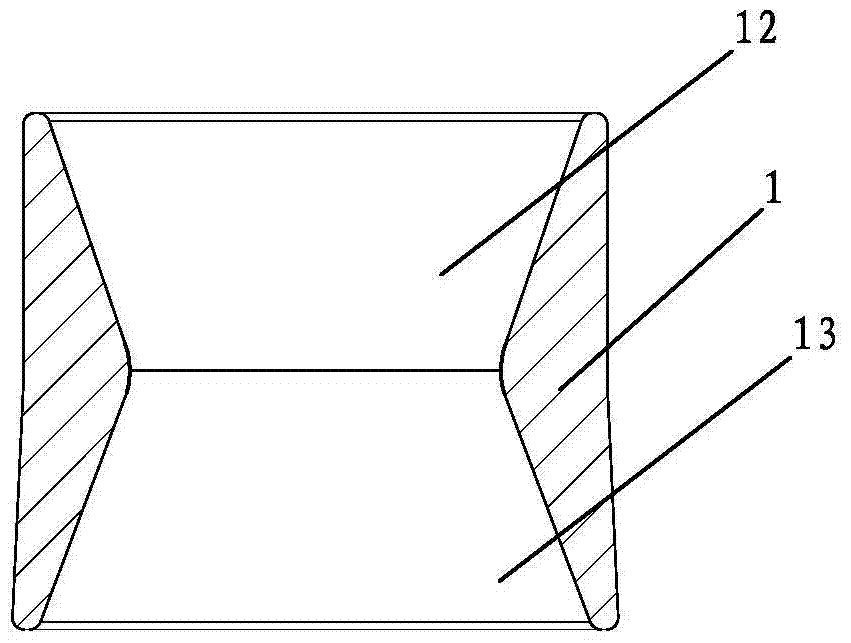

[0028] see figure 1 and figure 2 , the present embodiment relates to an exhaust pipe turbocharger, which is characterized in that it includes a turbocharger body 1, and a through hole 11 is opened on the turbocharger body 1, and the diameter of the through hole 11 is along the The direction of the central axis is distributed from decreasing first and then increasing, and when the gas flows through the through hole 11, a vortex supercharging structure is formed to accelerate the flow velocity of the gas. Specifically, the through hole 11 includes a first tapered hole 12 and a second tapered hole 13 communicating with the first tapered hole 12, and the diameters of the first tapered hole 12 and the second tapered hole 13 are along the The directions of the central axes are gradually distributed from large to small and small to large, respectively. The gas discharged from the combustion chamber flows from the first tapered hole 12 to the second tapered hole 13 or from the seco...

specific Embodiment 2

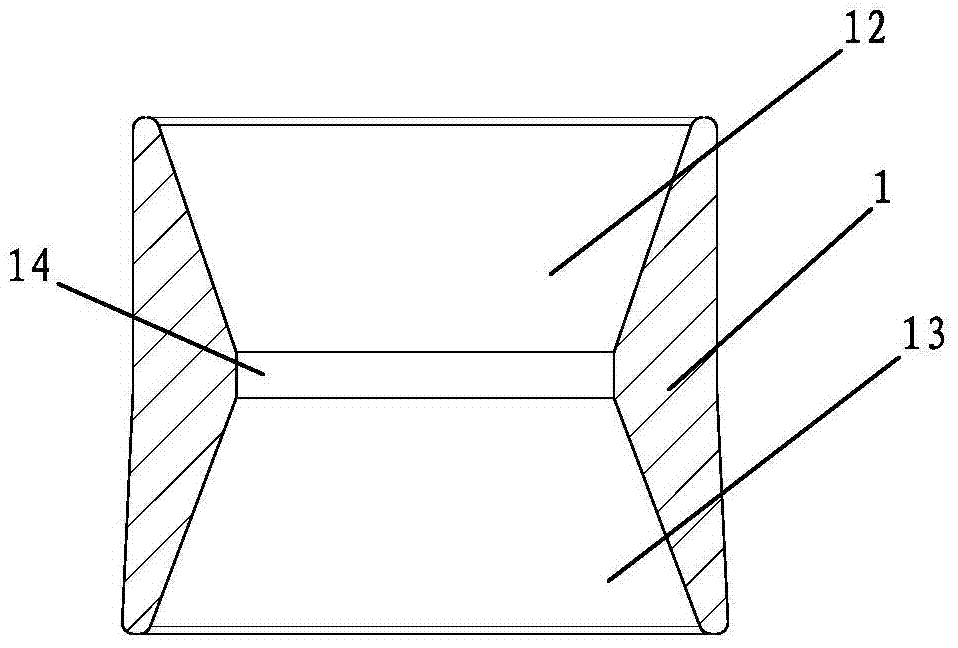

[0034] Such as image 3 As shown, the structure of this embodiment is the same as that of the specific embodiment 1, including a turbocharger body 1, and a through hole 11 is opened on the turbocharger body 1, and the diameter of the through hole 11 is along the direction of its central axis. The direction decreases first and then increases, and when the gas flows through the through hole 11, a vortex supercharging structure is formed to speed up the flow rate of the gas. The difference is: the through hole 11 includes a first tapered hole 12, a straight hole 14 and a second tapered hole 13 connected in sequence, and the diameters of the first tapered hole 12 and the second tapered hole 13 are along the The directions of the central axes are gradually distributed from large to small and small to large, respectively.

specific Embodiment 3

[0035] Such as Figure 4As shown, the structure of this embodiment is the same as that of the specific embodiment 1, including a turbocharger body 1, and a through hole 11 is opened on the turbocharger body 1, and the diameter of the through hole 11 is along the direction of its central axis. The directions are distributed from decreasing first and then increasing, and when the gas flows through the through hole 11, a vortex supercharging structure is formed to speed up the flow velocity of the gas. The difference is: the through hole 11 is a stepped hole, including the first straight hole 111, the second straight hole 112 and the third straight hole 113 connected in sequence, the first straight hole 111 and the third straight hole 113 The diameter is larger than the diameter of the second straight hole 112 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com