Patents

Literature

7098results about How to "Improve combustion efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

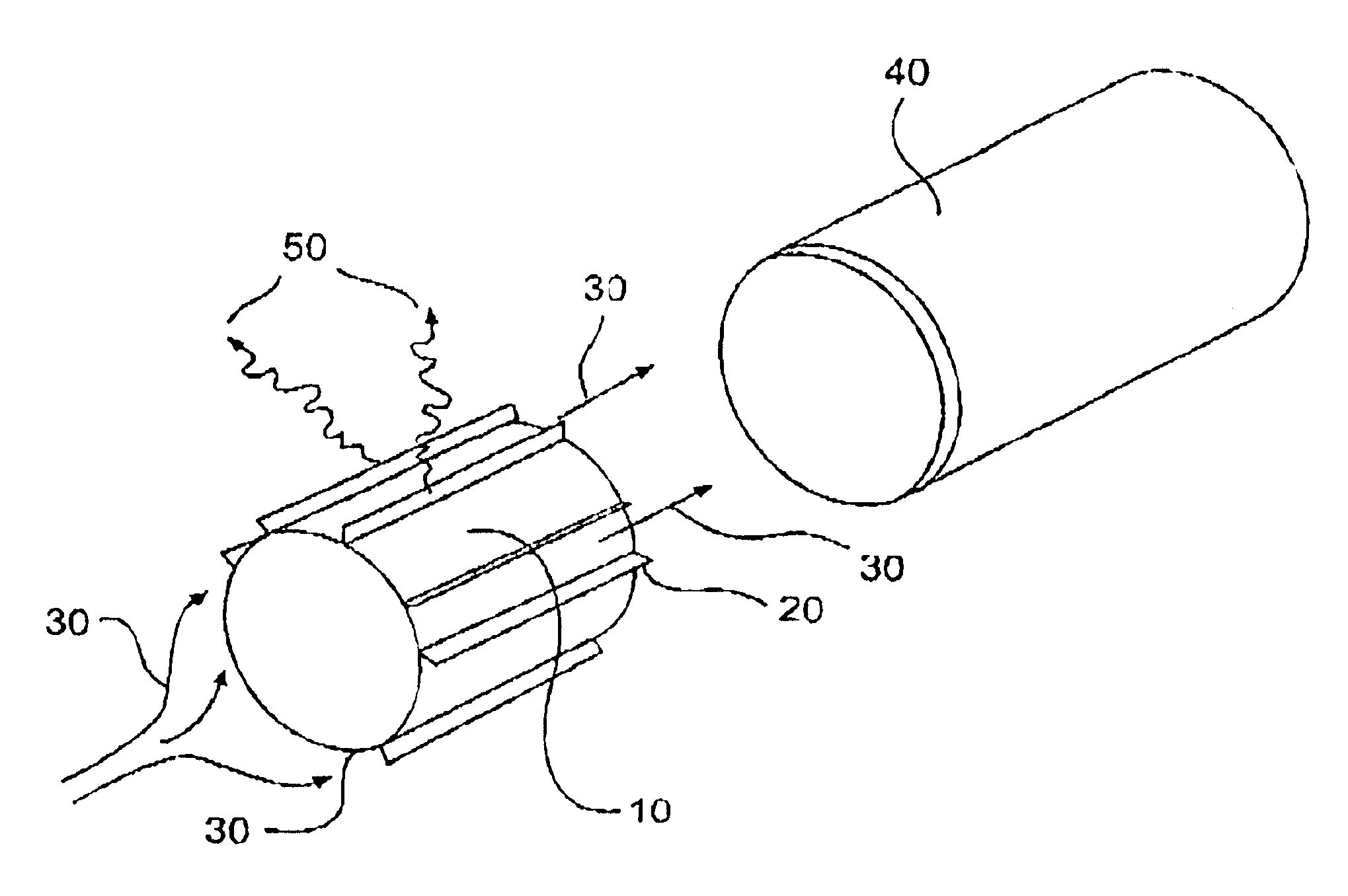

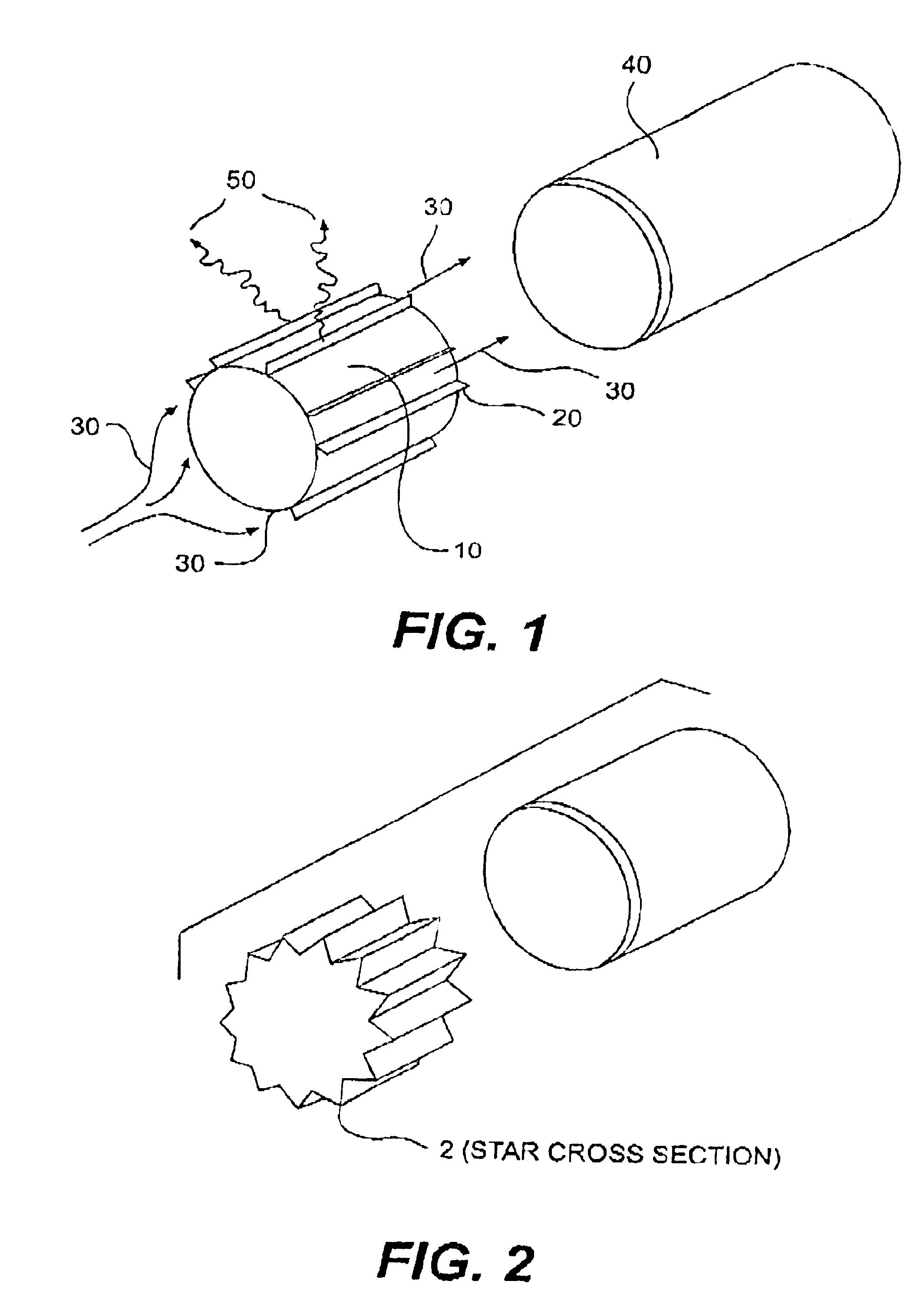

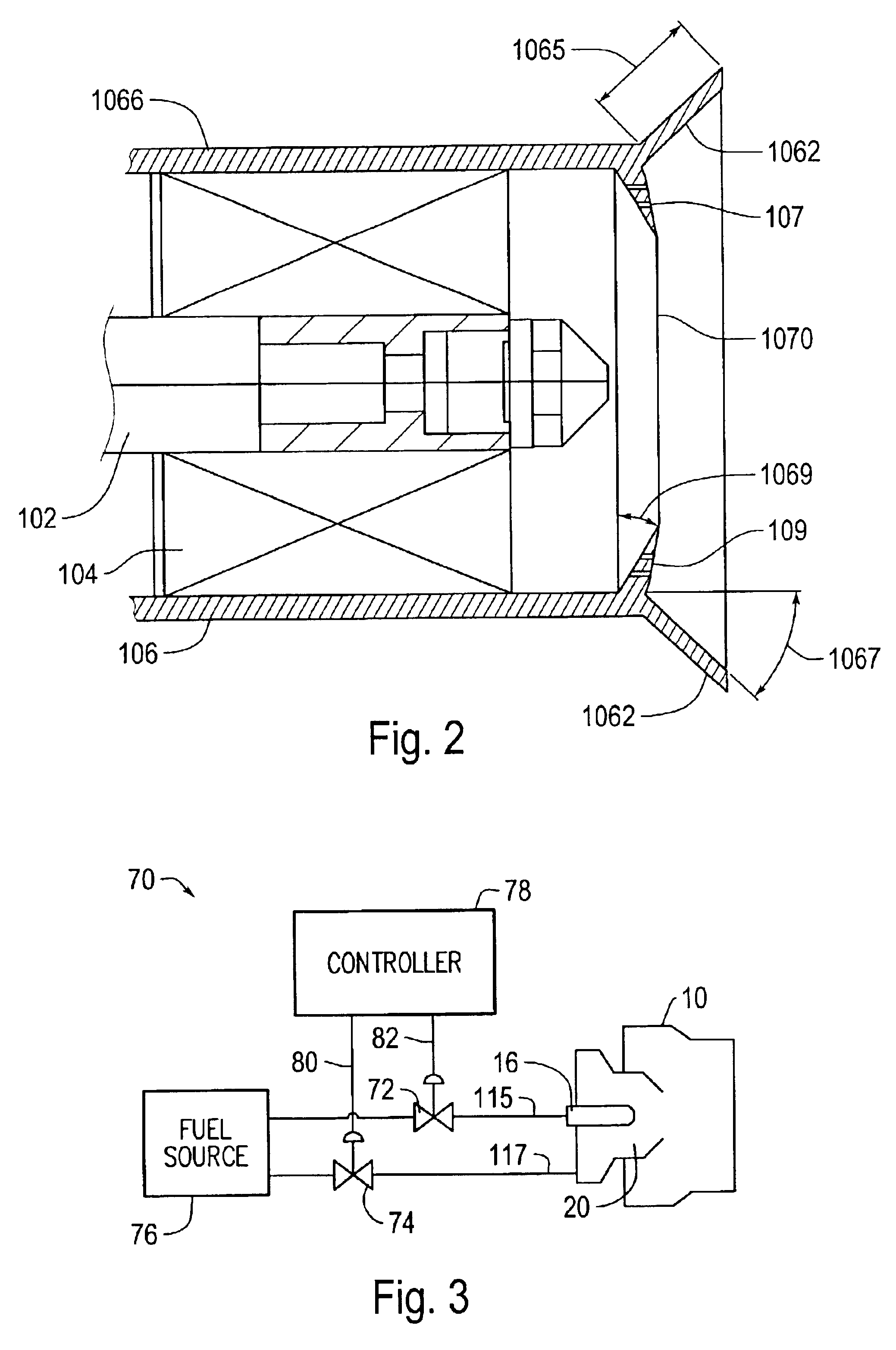

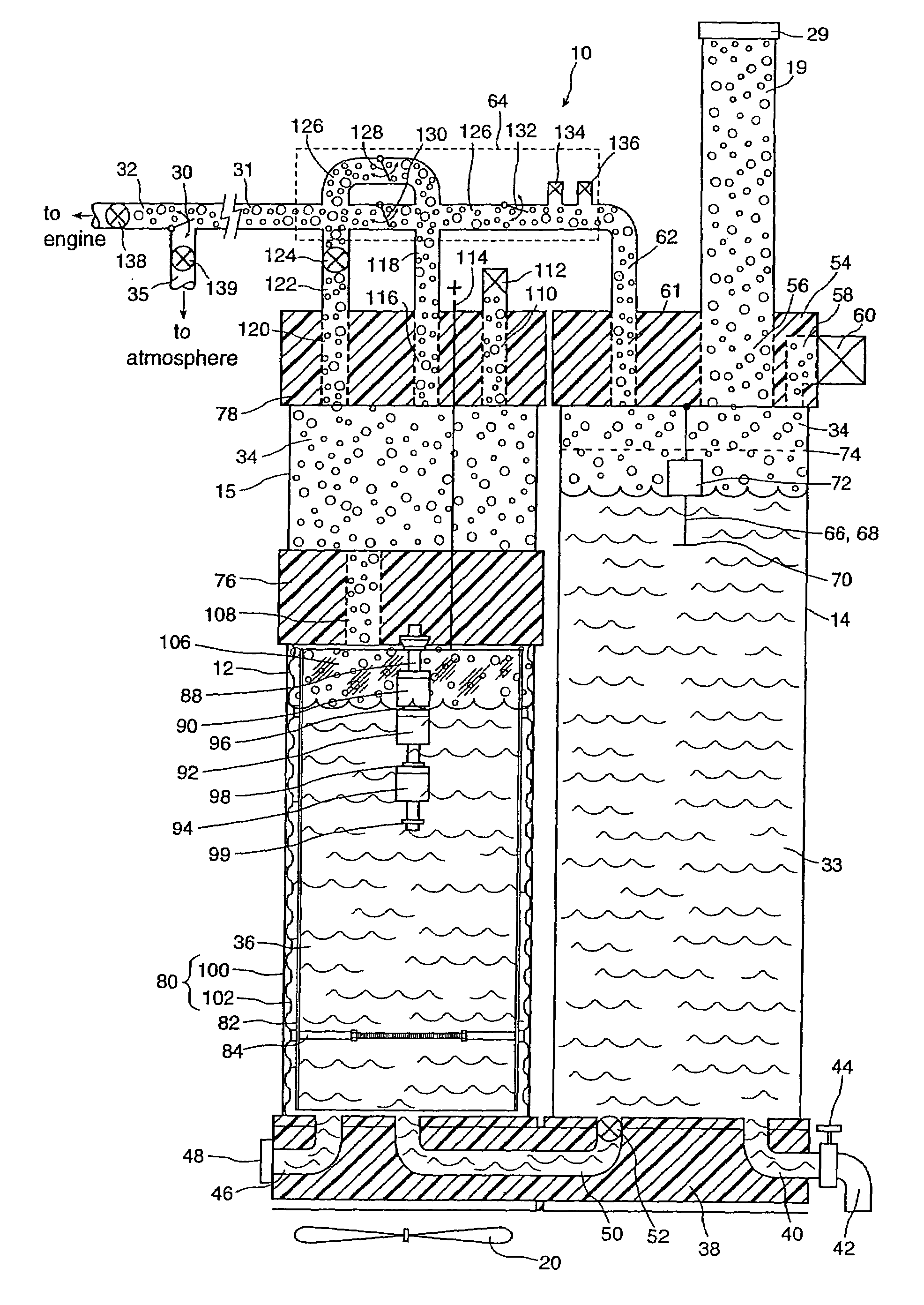

Method and apparatus to increase combustion efficiency and to reduce exhaust gas pollutants from combustion of a fuel

InactiveUS6851413B1Improve combustion efficiencyFacilitate fuel combustionBurnersLiquid fuel feeder/distributionCombustorExhaust fumes

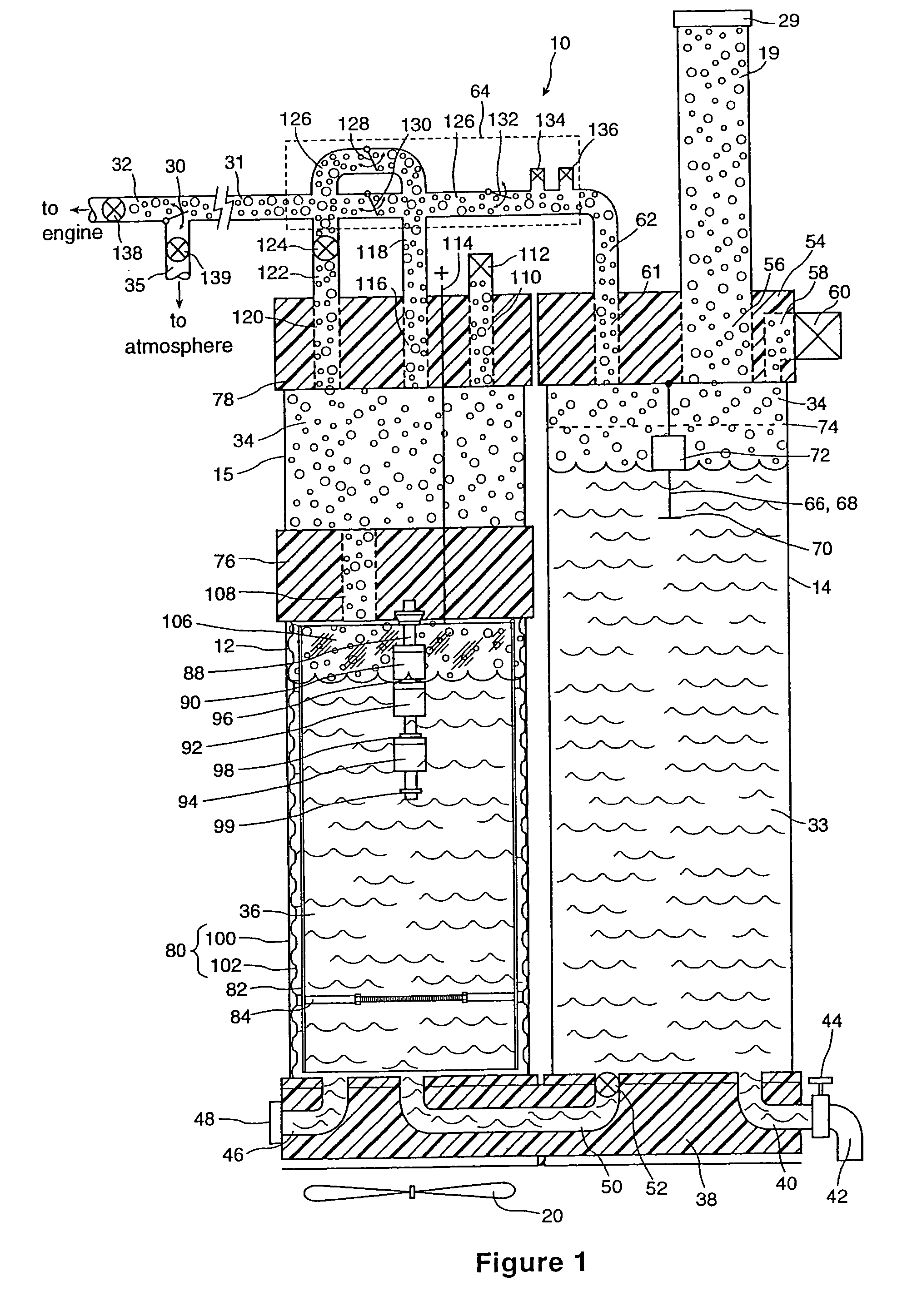

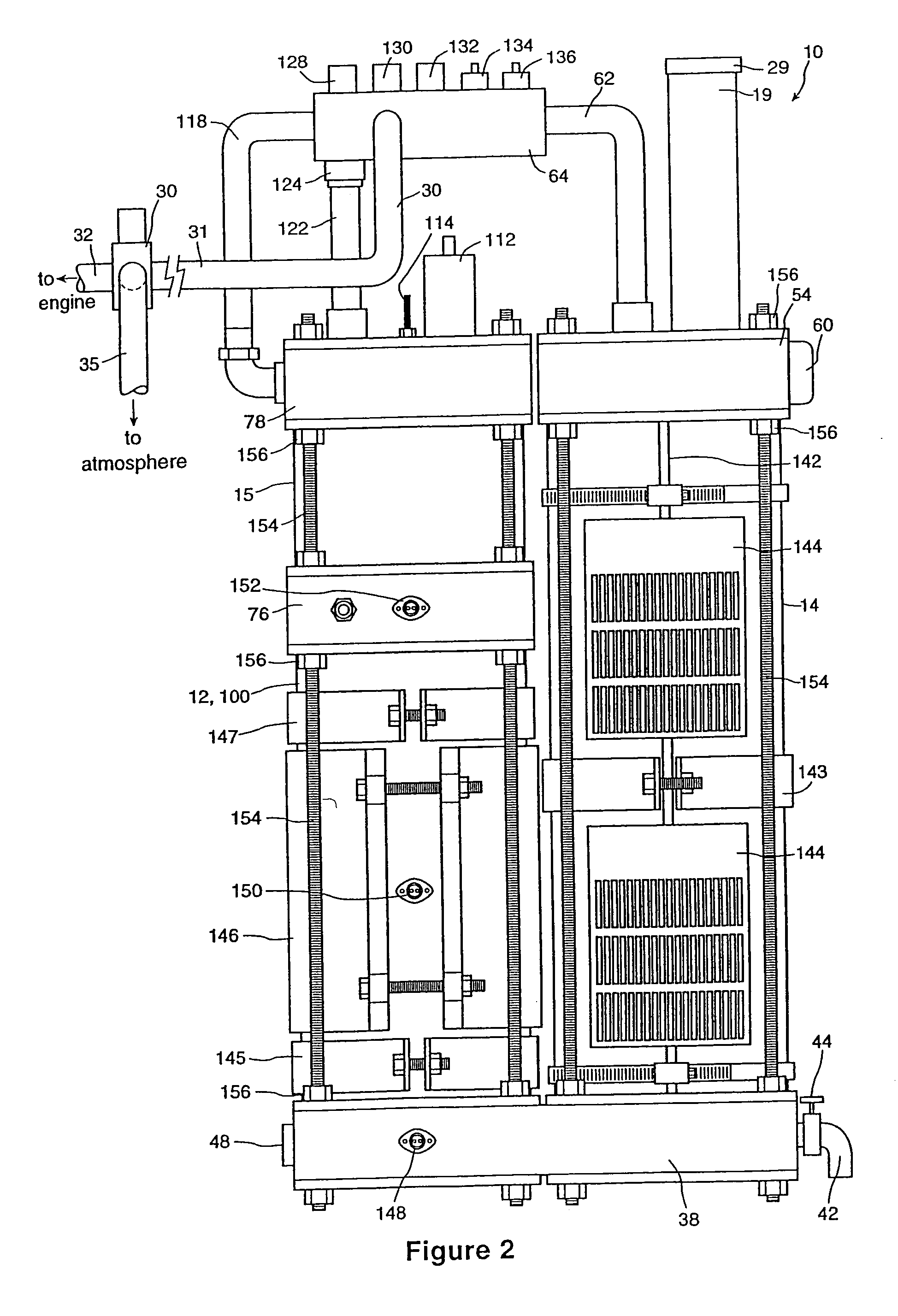

A method and apparatus is disclosed for increasing combustion efficiency in internal combustion engines and external combustors resulting in increased fuel economy and reduced exhaust pollutants. The same principles and apparatus of the invention are used in the exhaust stream to further reduce pollutants.

Owner:RONNELL

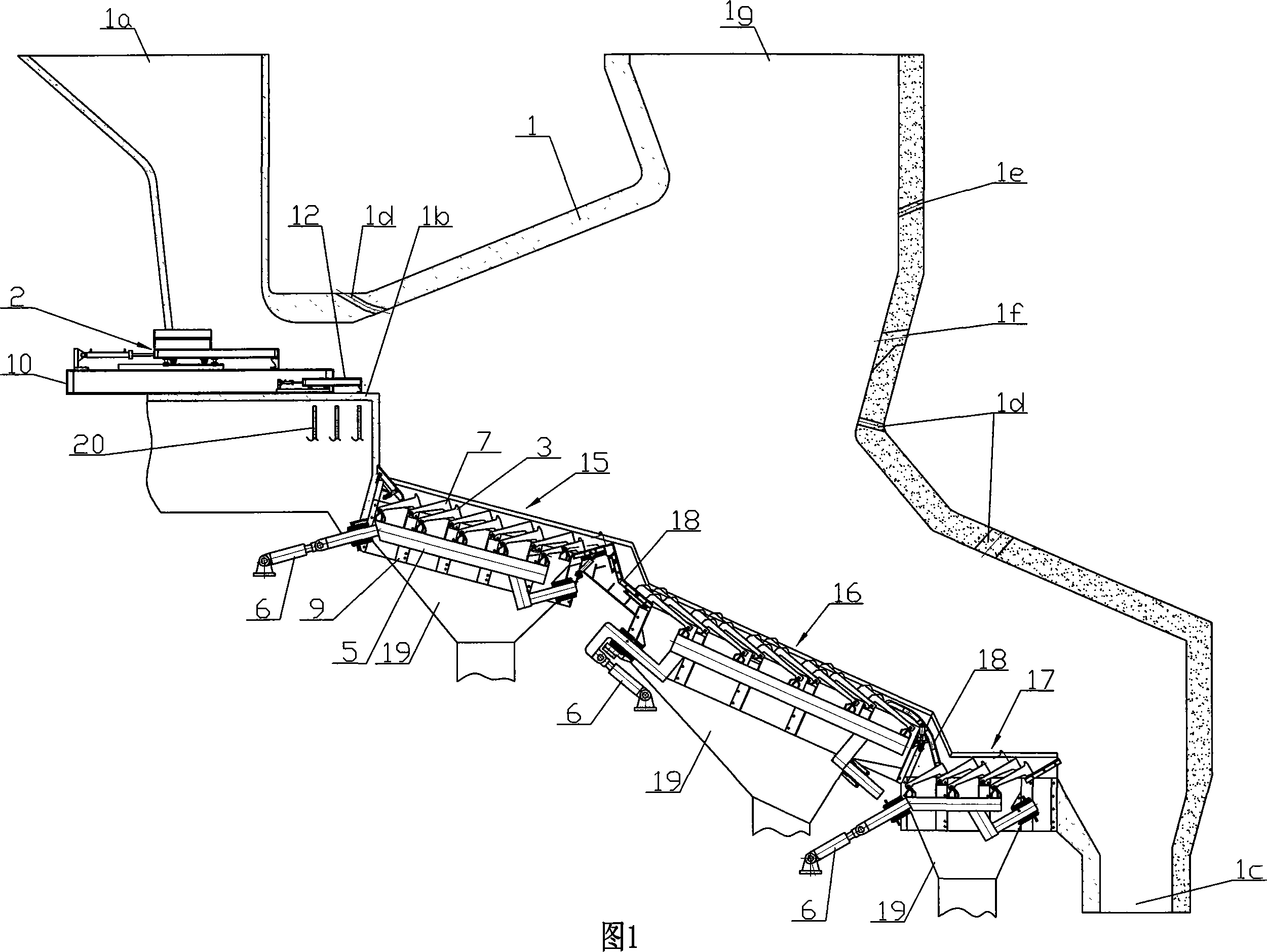

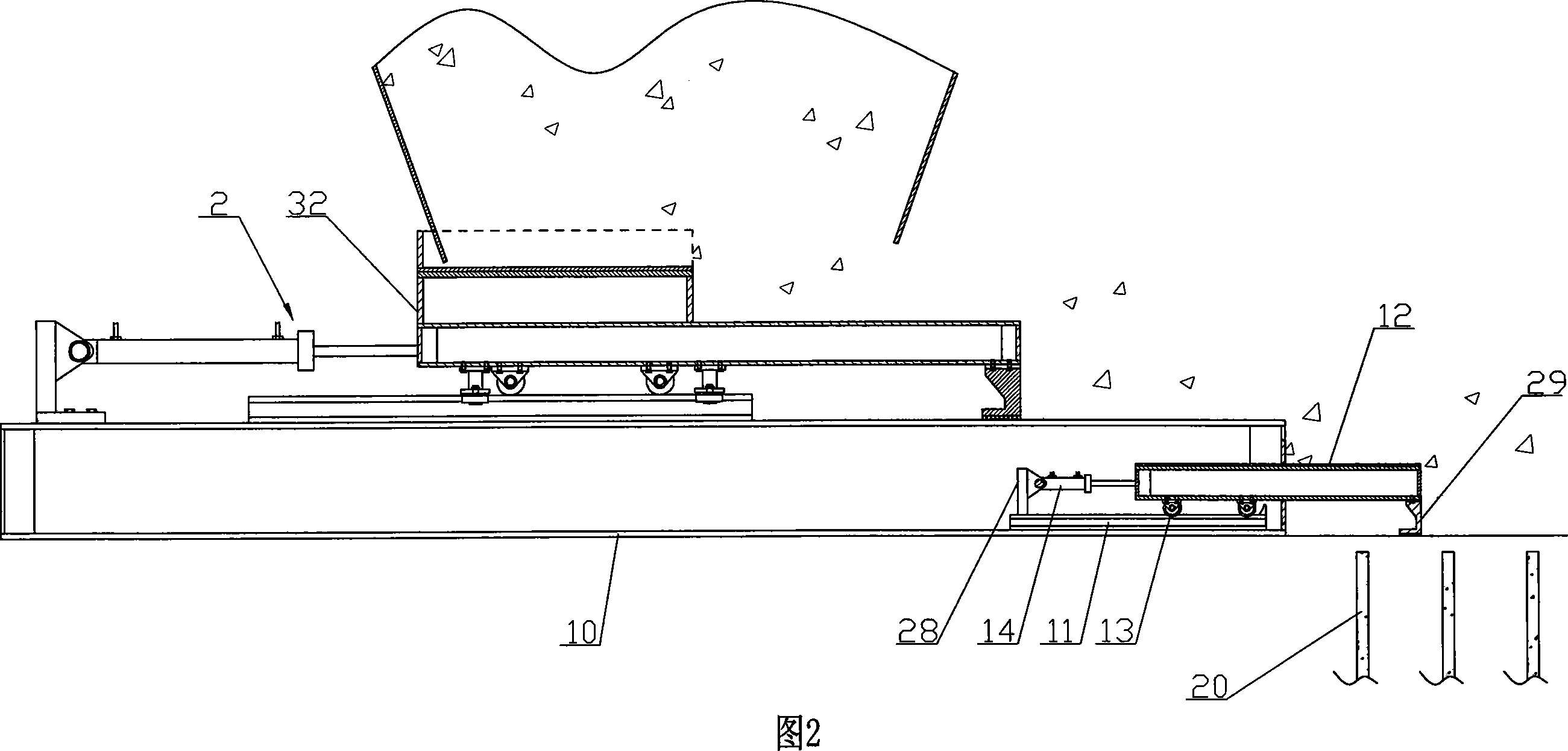

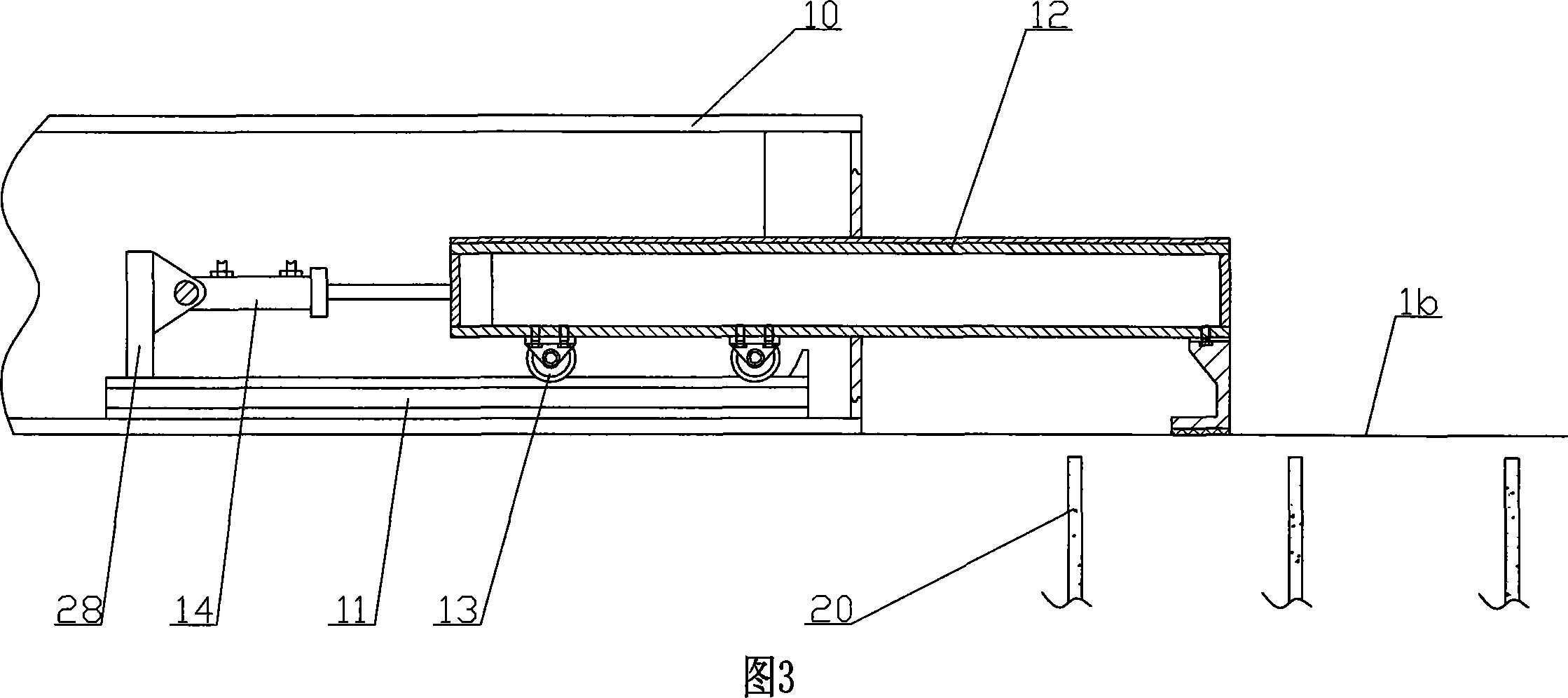

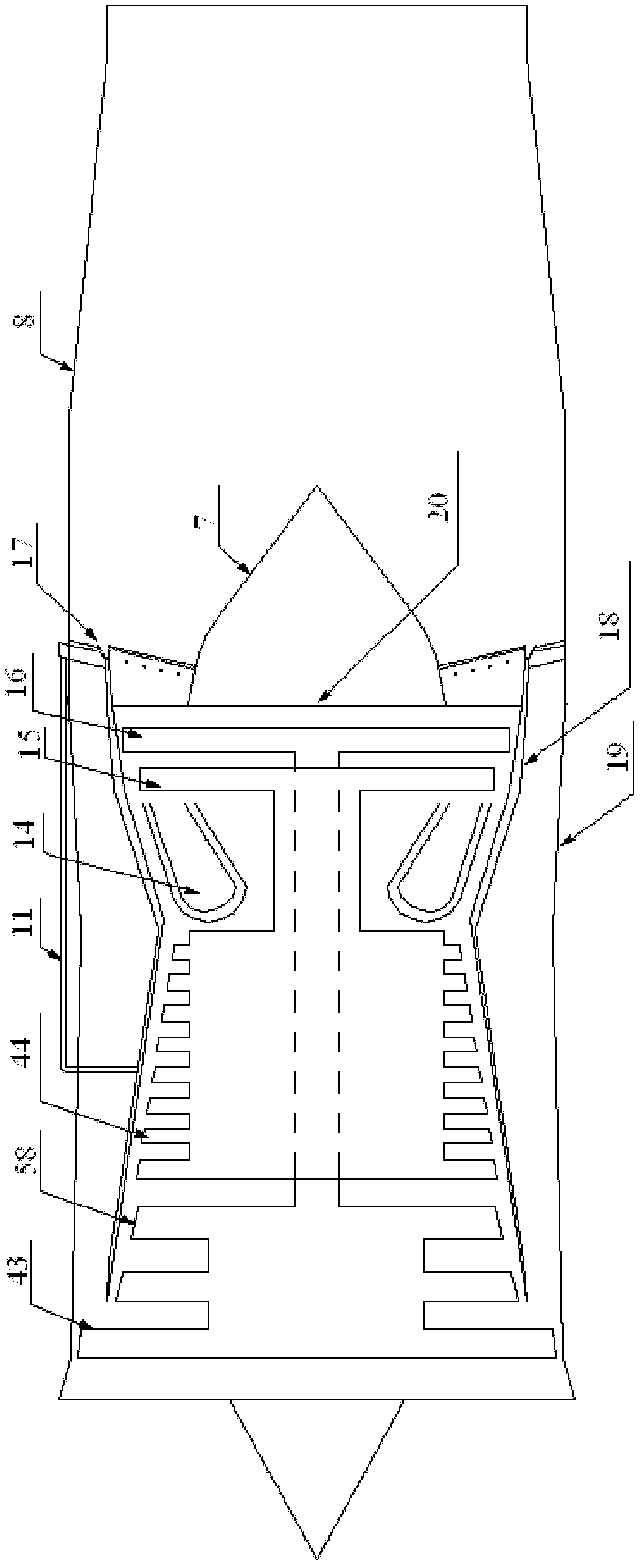

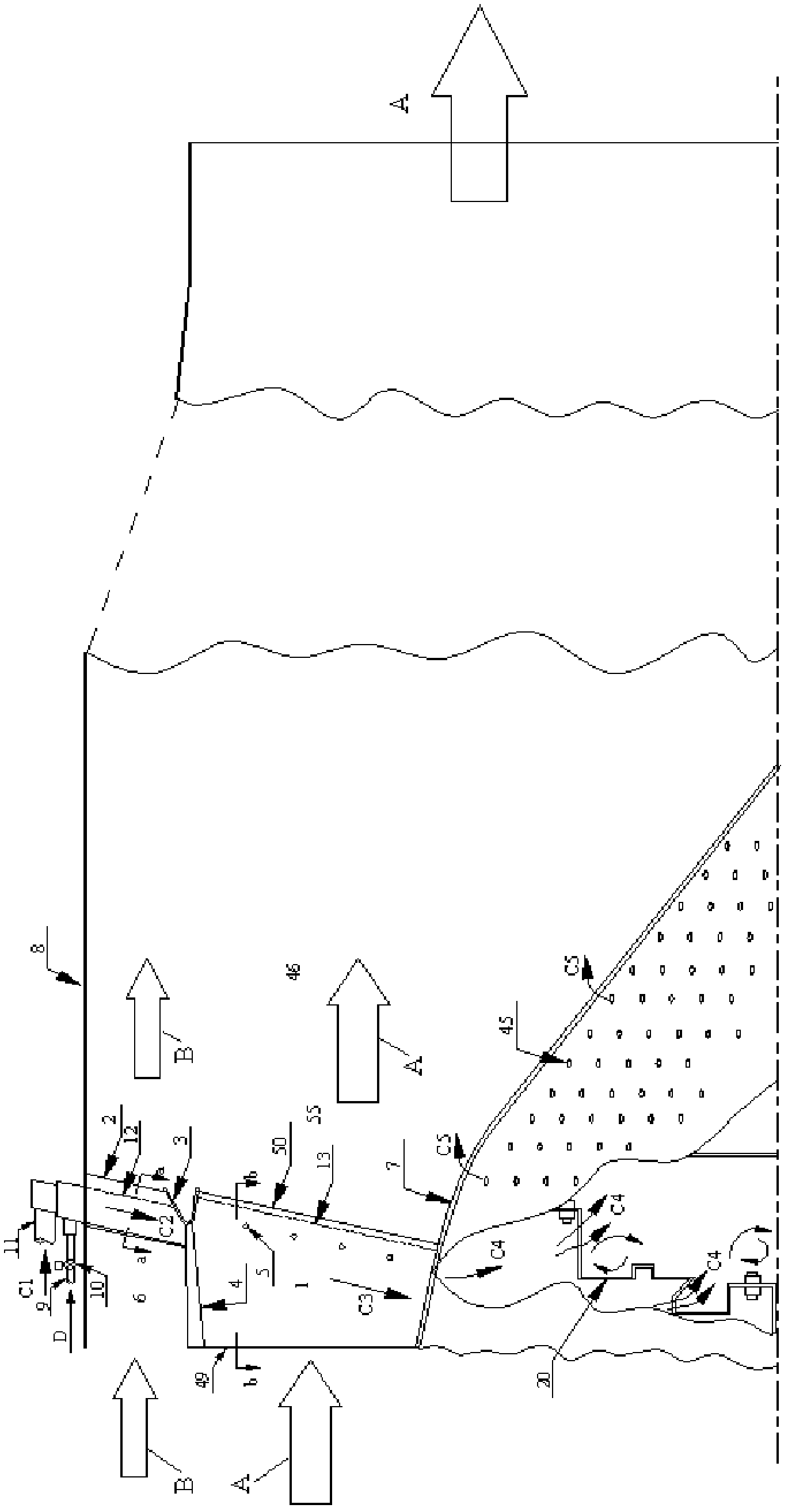

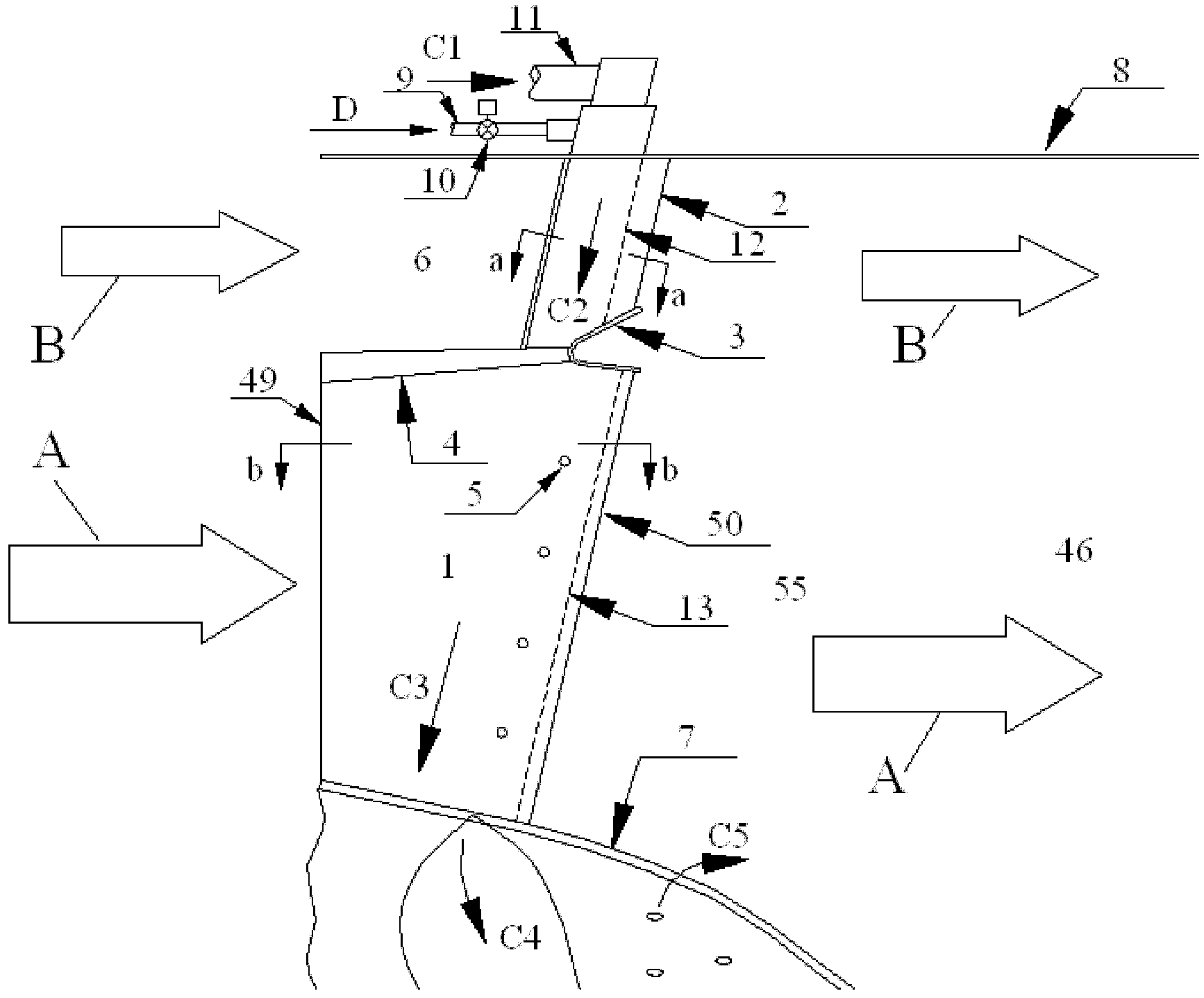

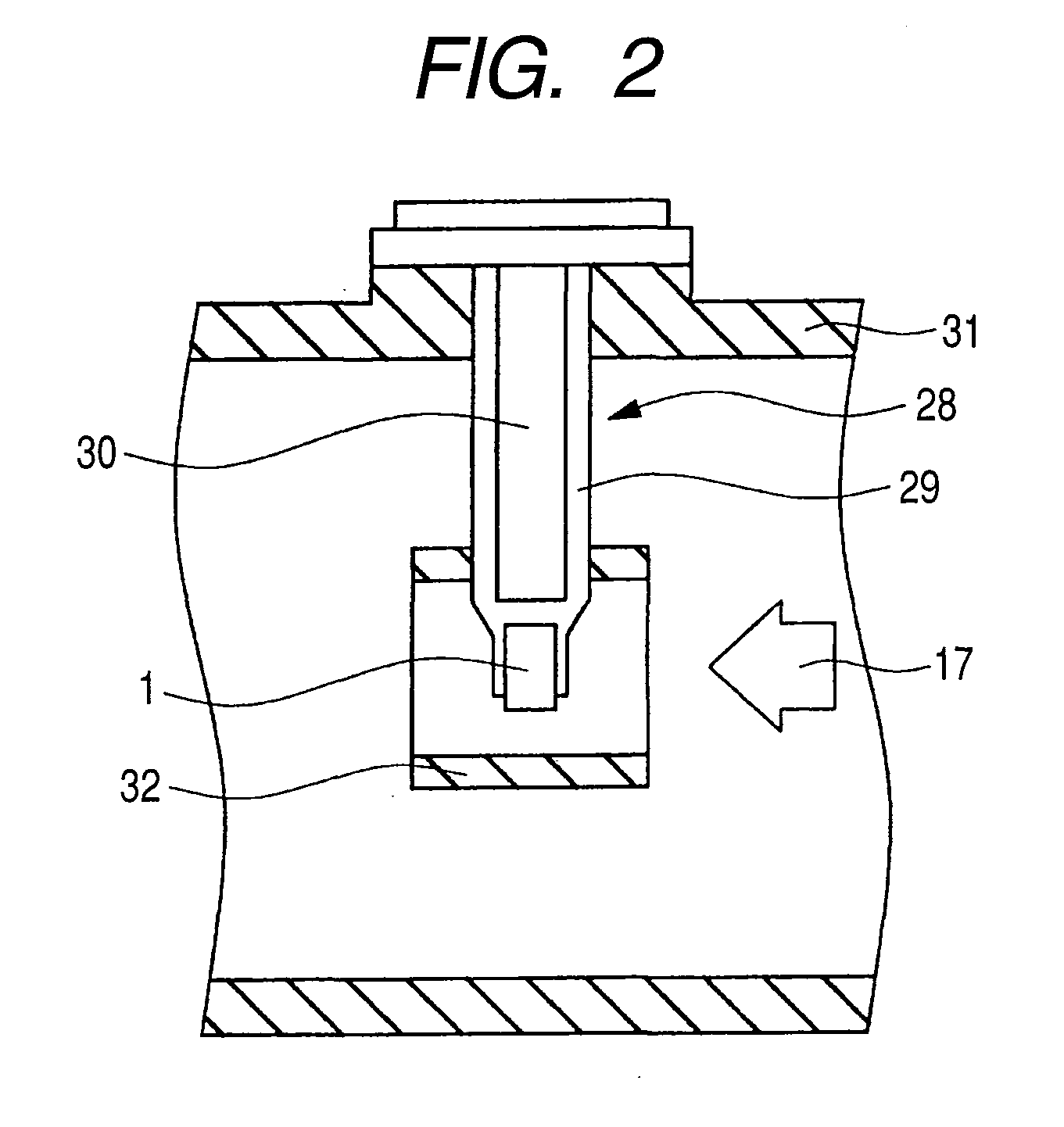

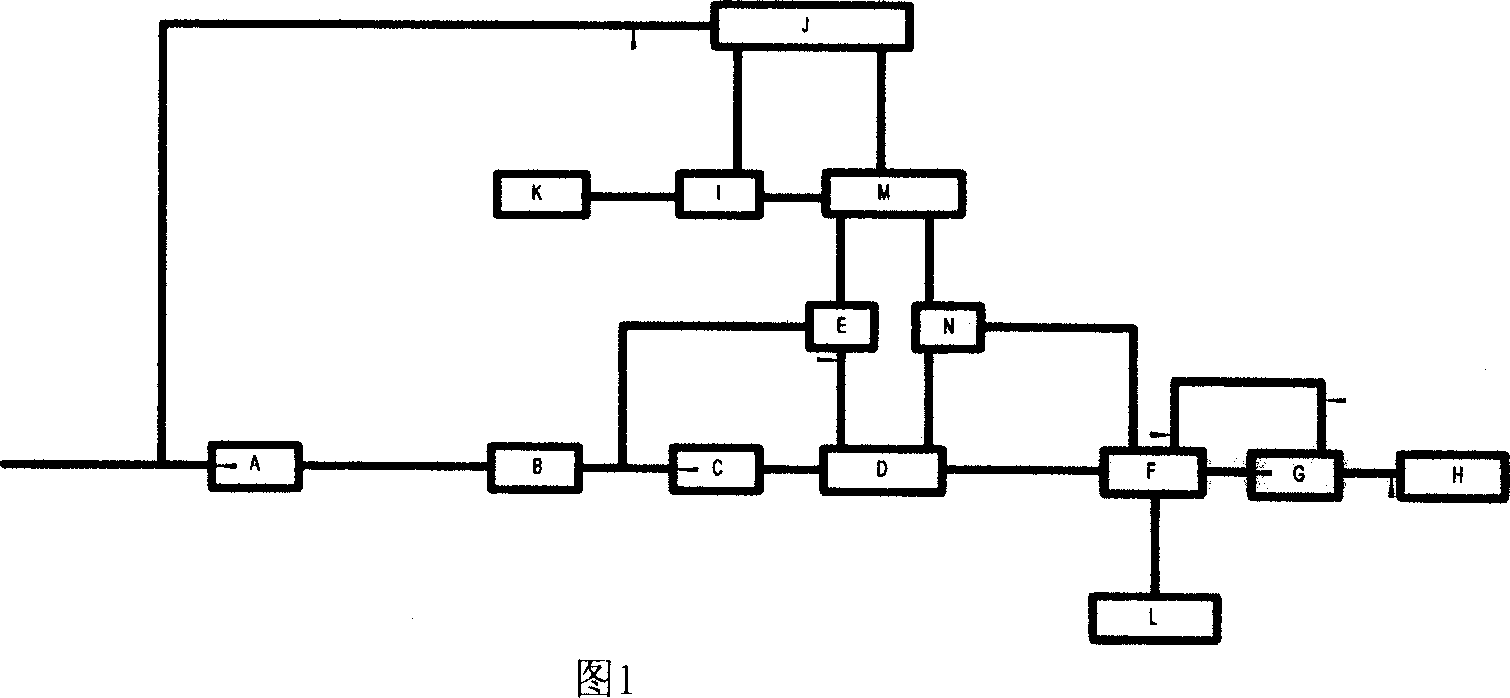

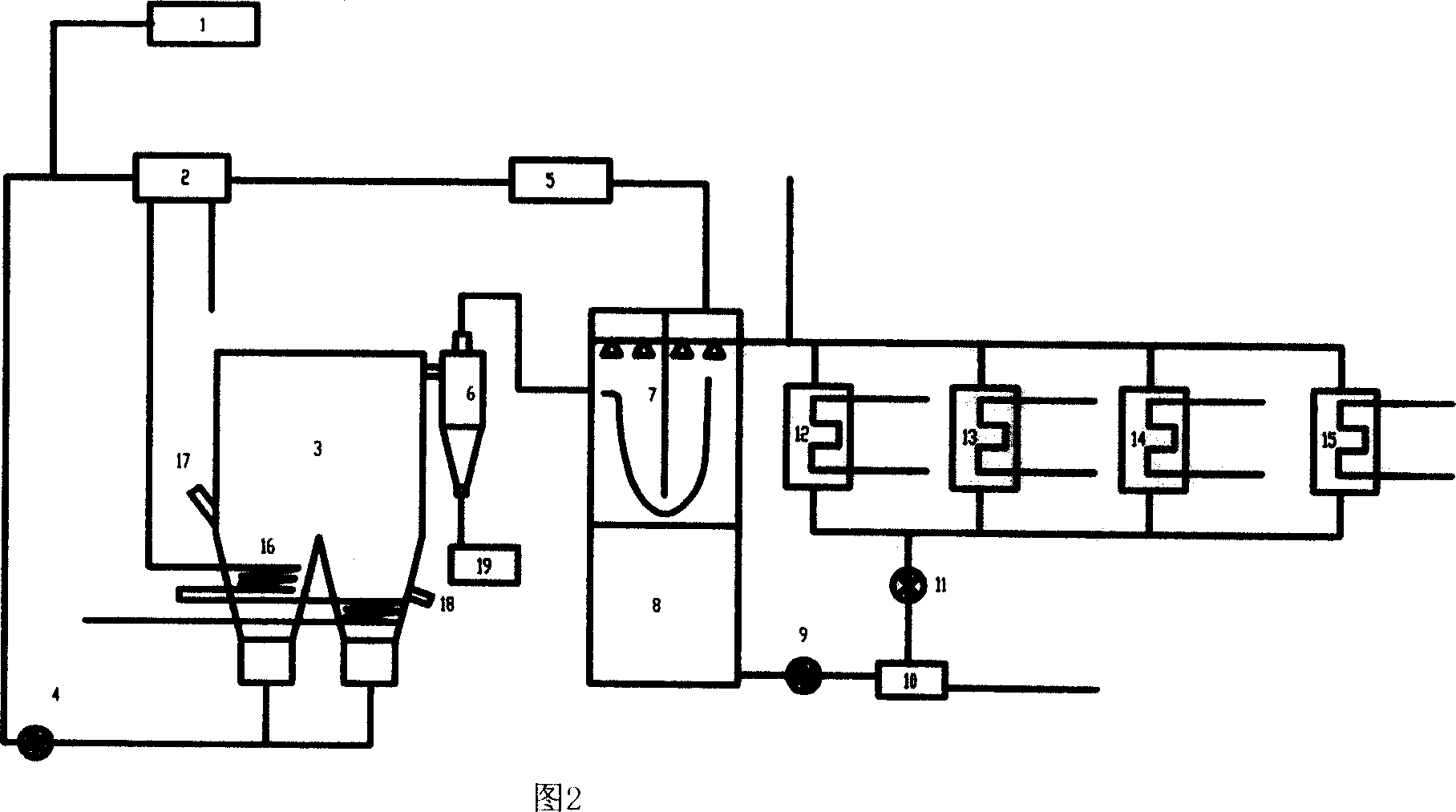

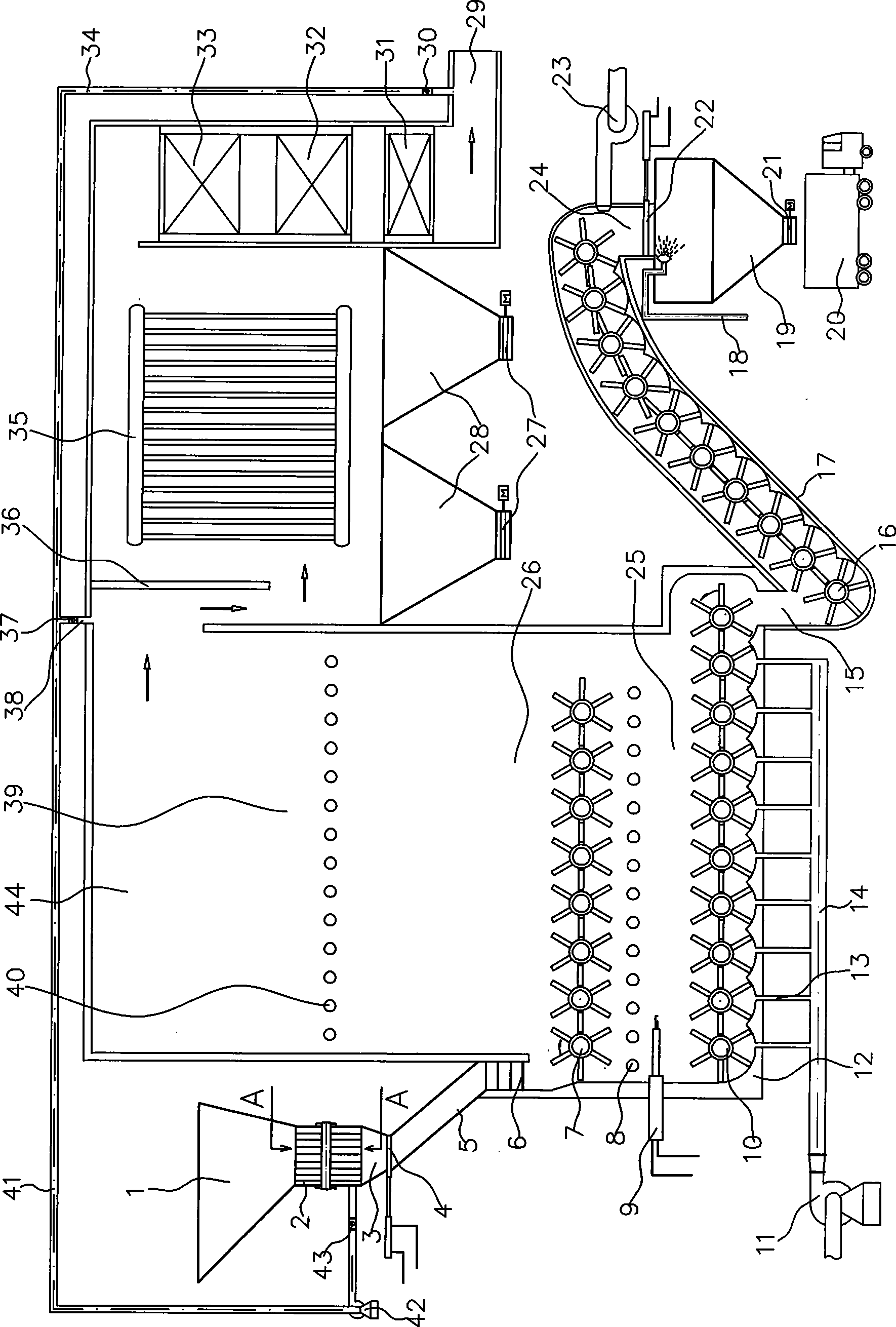

Multiple row sectional drive combined type domestic garbage incinerator

The invention relates to multi-column sectional drive combined type domestic incinerator. It is set three fire-grates that drying section, burning section, and firing section. The middle fire grate is connected between them. There is altitude fall between them that the drying section is the highest point; the firing one is the lowest point. The primary air chamber is respectively set under them. The incinerator fire grate system of the invention has independent drive mechanism, air supply system, and air chamber for each section which is convenient for controlling technical parameter that traveling speed, air quantity, air temperature, air pressure etc to realize full drying and burning for whole garbage layer.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP

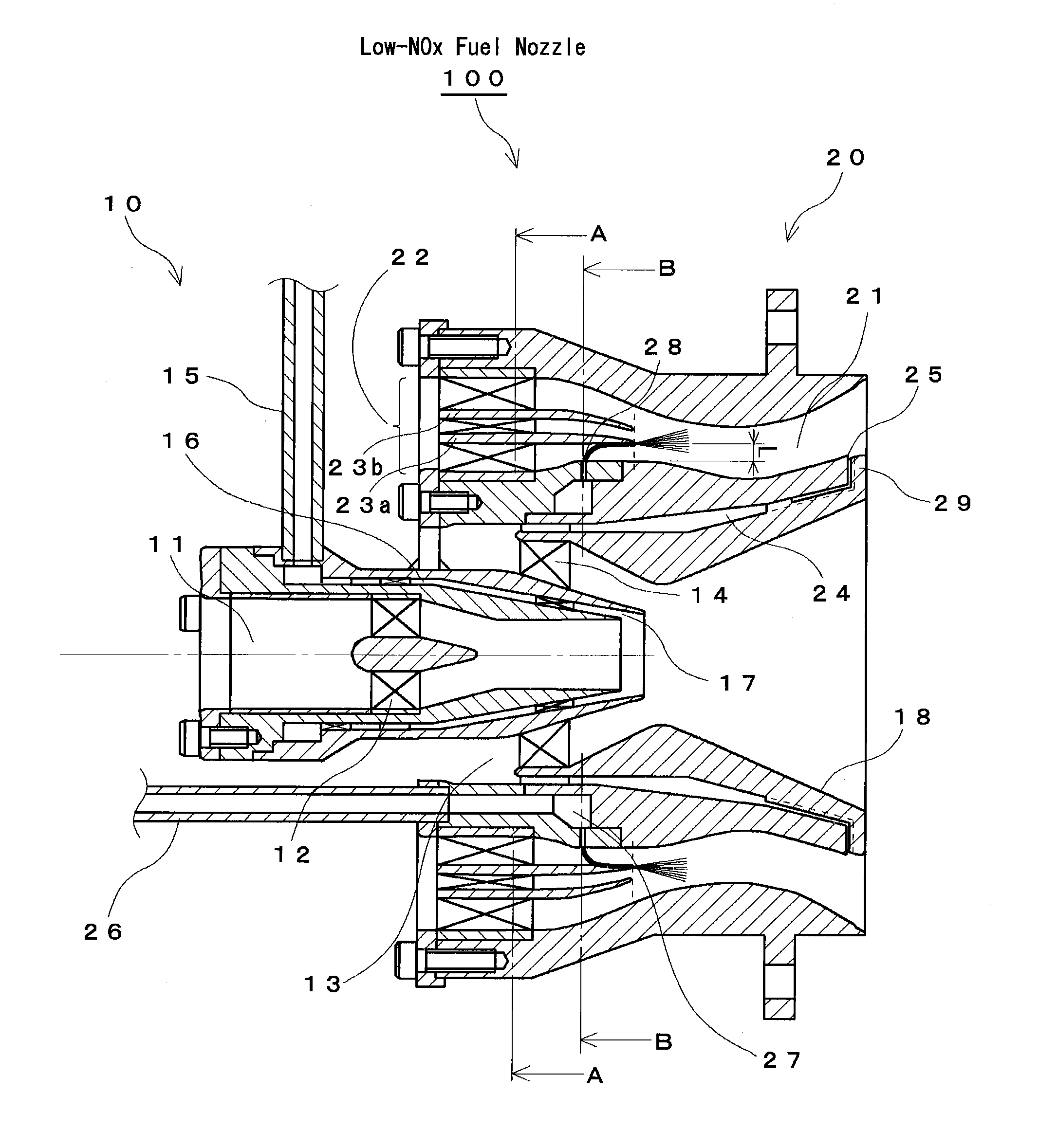

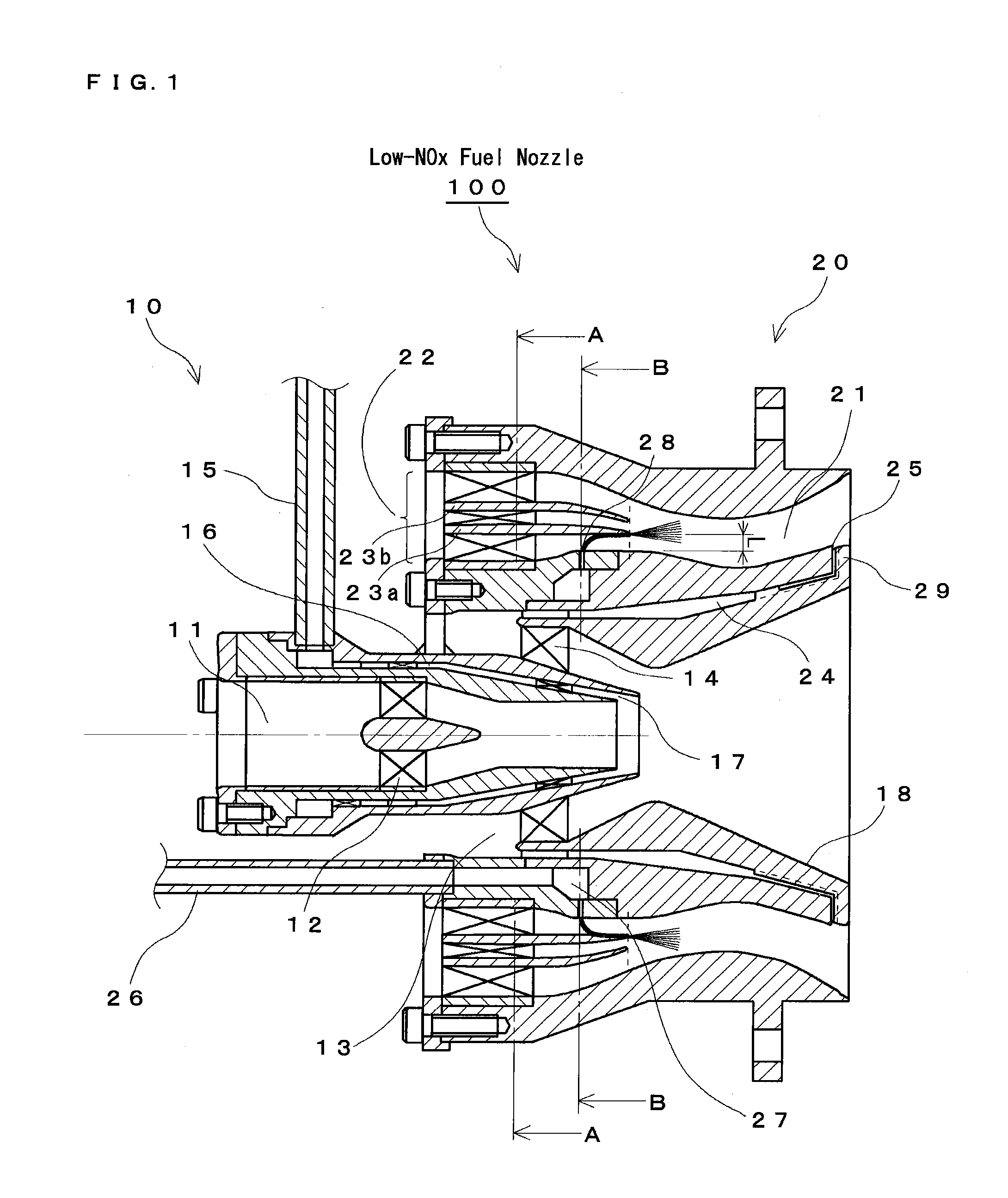

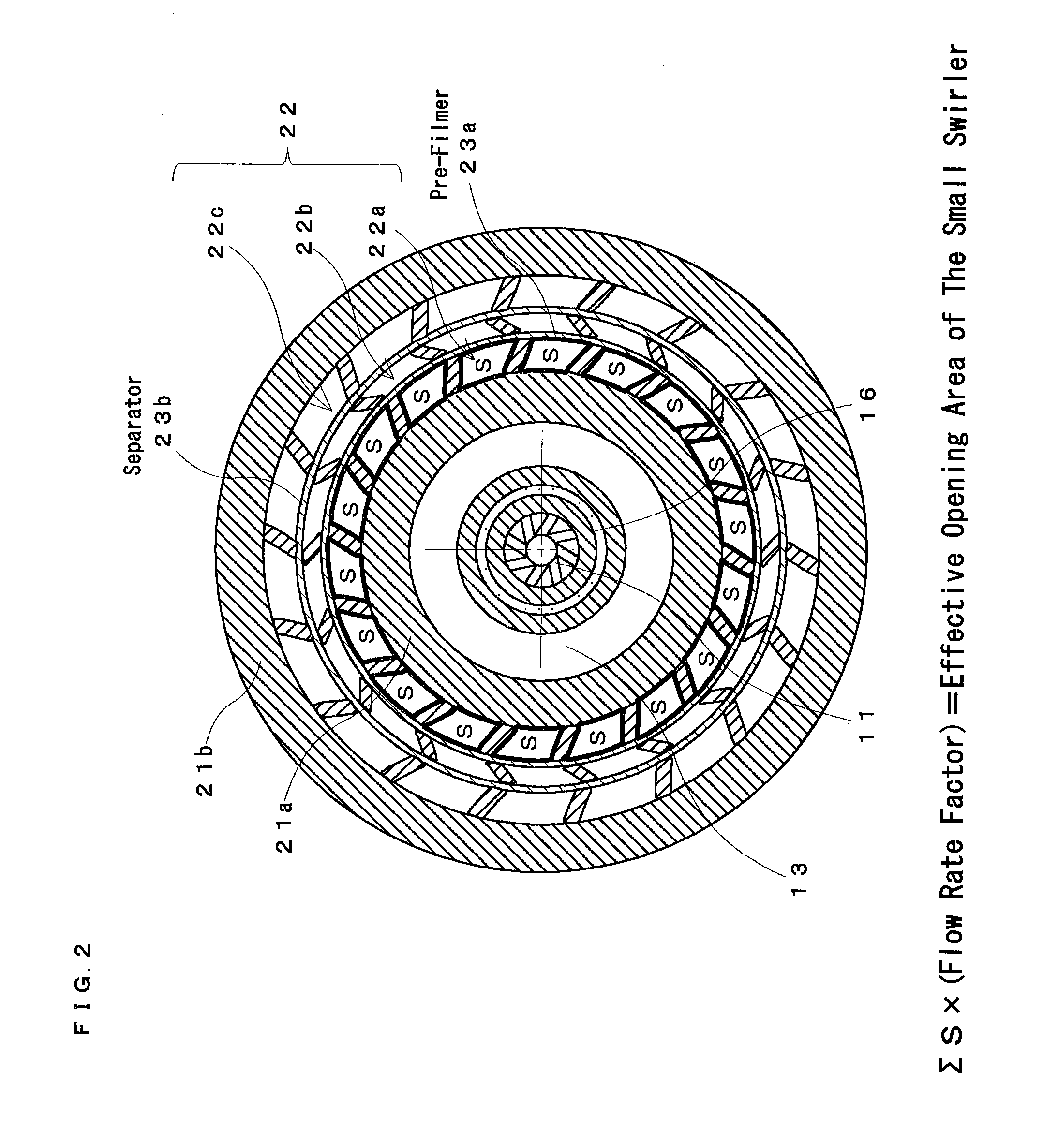

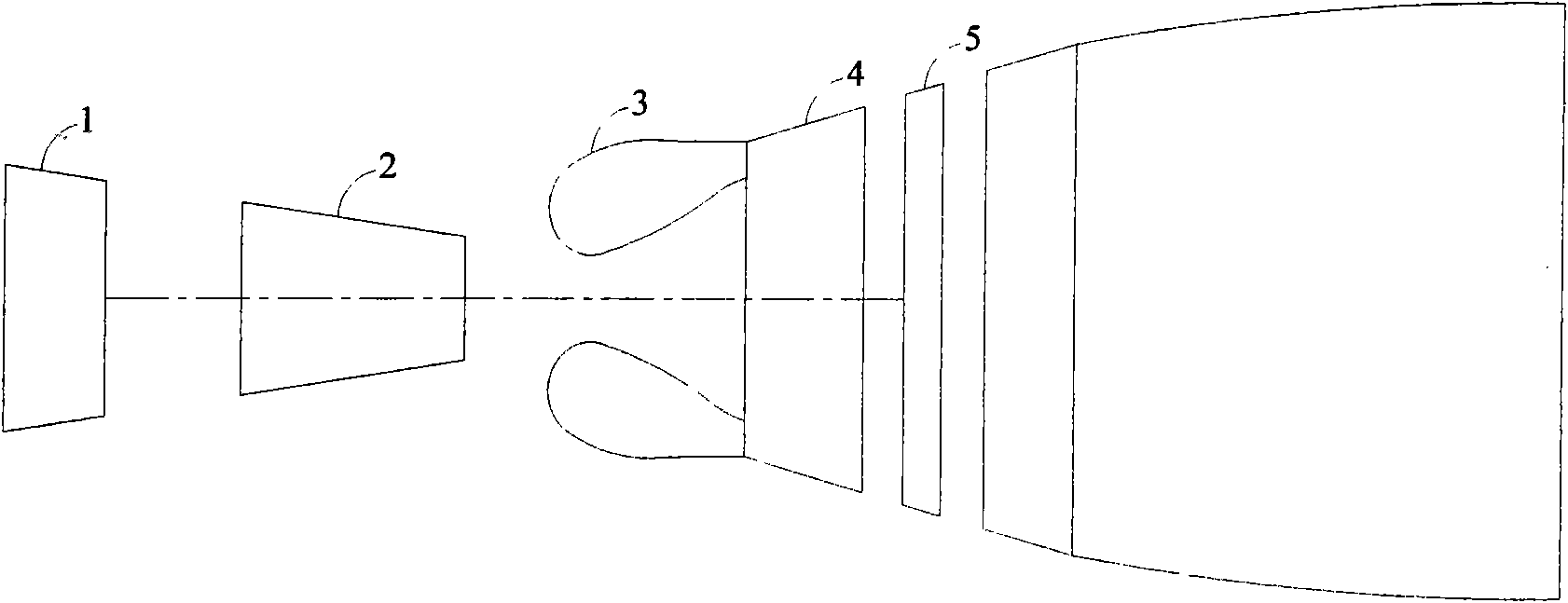

Staging fuel nozzle

ActiveUS20100308135A1Reduce amount of NOx generateHigh degree of atomizationBurnersTurbine/propulsion fuel supply systemsEngineeringFuel injection

A main swirler of a triple annular configuration that is partitioned by a pre-filmer and a separator is installed in an inlet port of a main air flow channel. The vicinity of the inner wall of the main air flow channel provided with a main fuel injection port is bulged radially outward from the innermost surface (innermost surface of a small swirler) of a main swirler. Further, a distance from the main fuel injection port and the pre-filmer is set such that an effective opening area between the pre-filmer and “the inner wall of the main air flow channel provided with the main fuel injection port” is equal to an effective opening area of the small swirler. The swirling directions of the swirlers of the main swirler are “clockwise”-“counter-clockwise”-“clockwise” respectively along the radial outward direction when the swirling direction of the innermost swirler is taken as “clockwise”.

Owner:JAPAN AEROSPACE EXPLORATION AGENCY

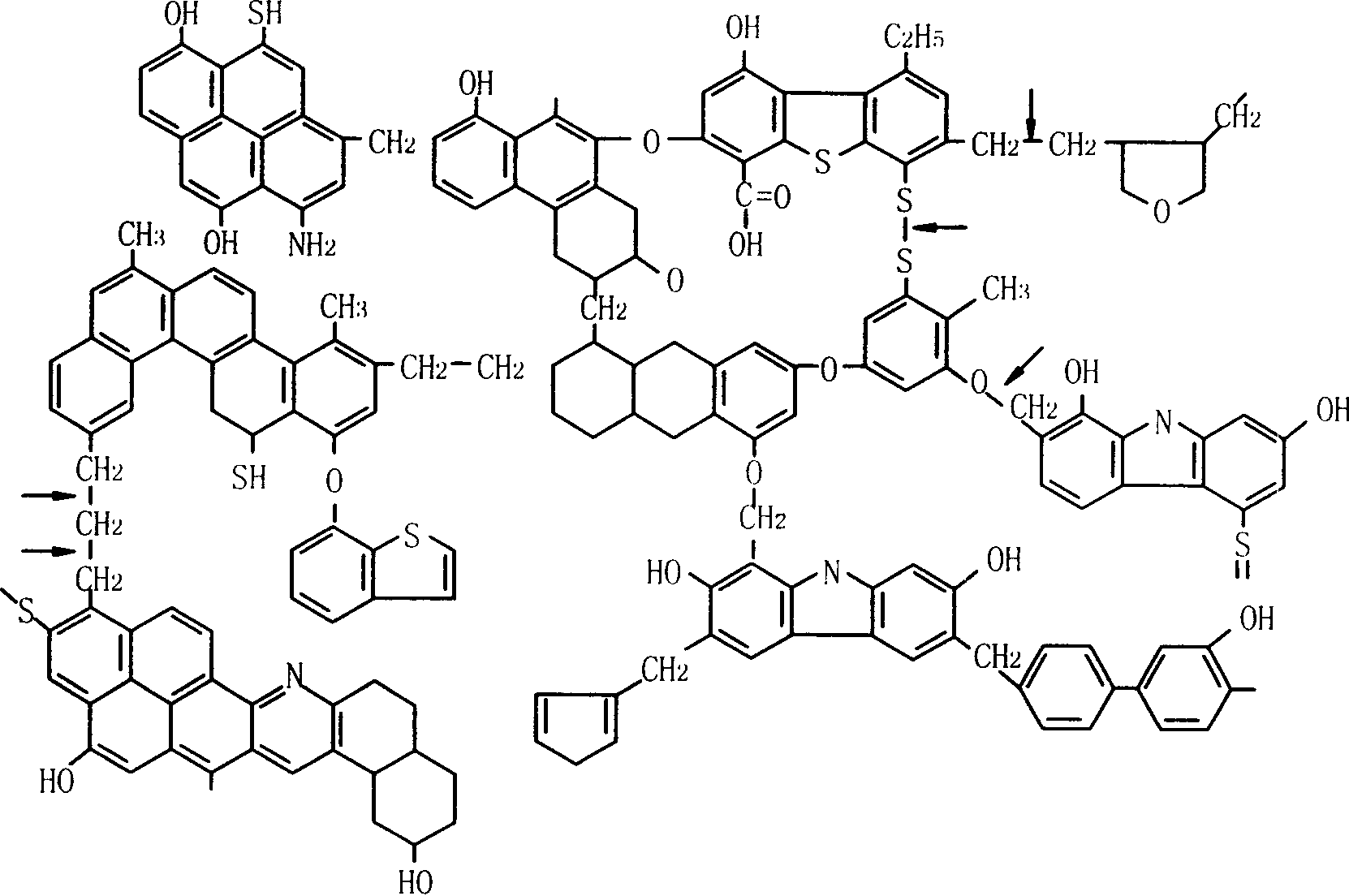

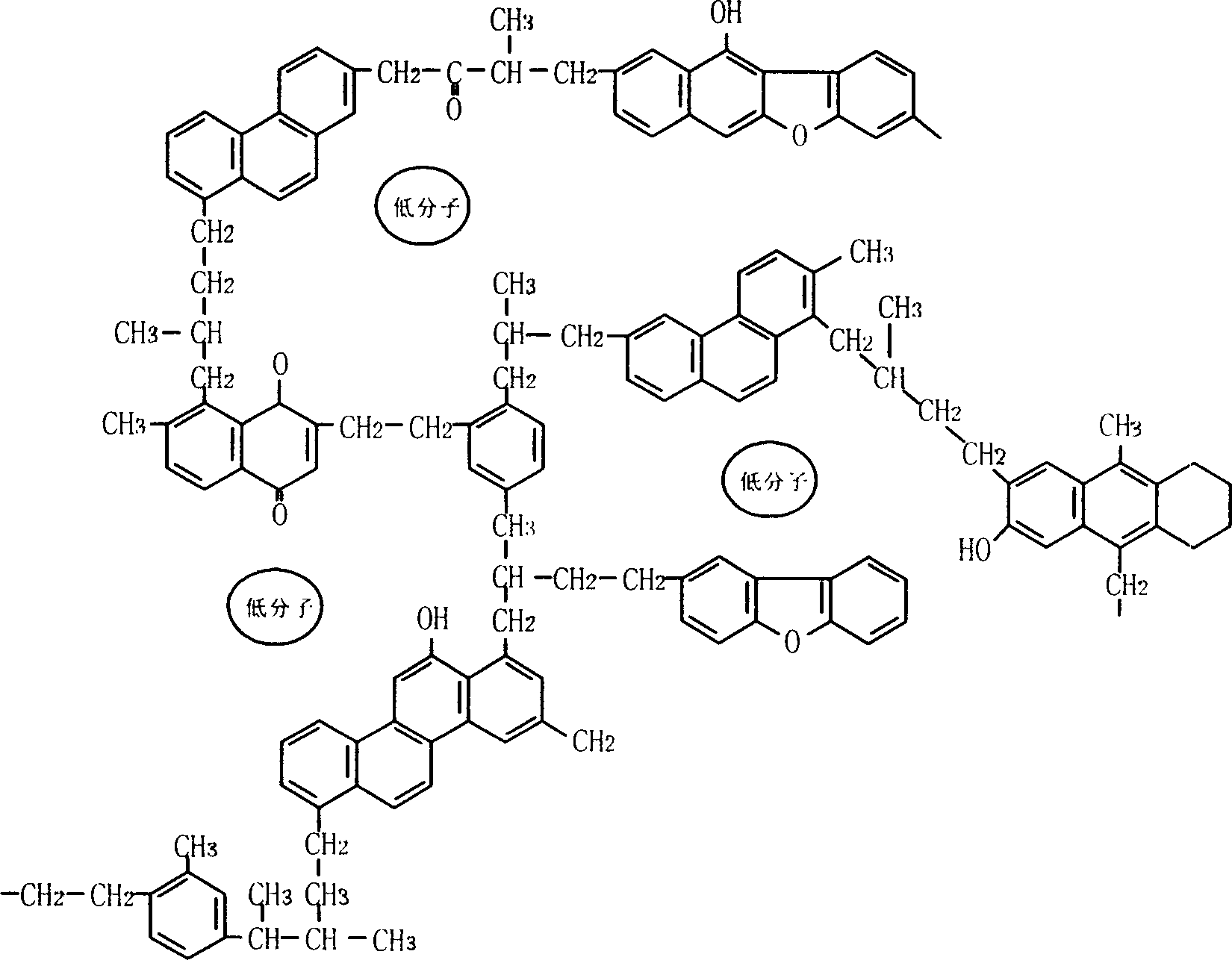

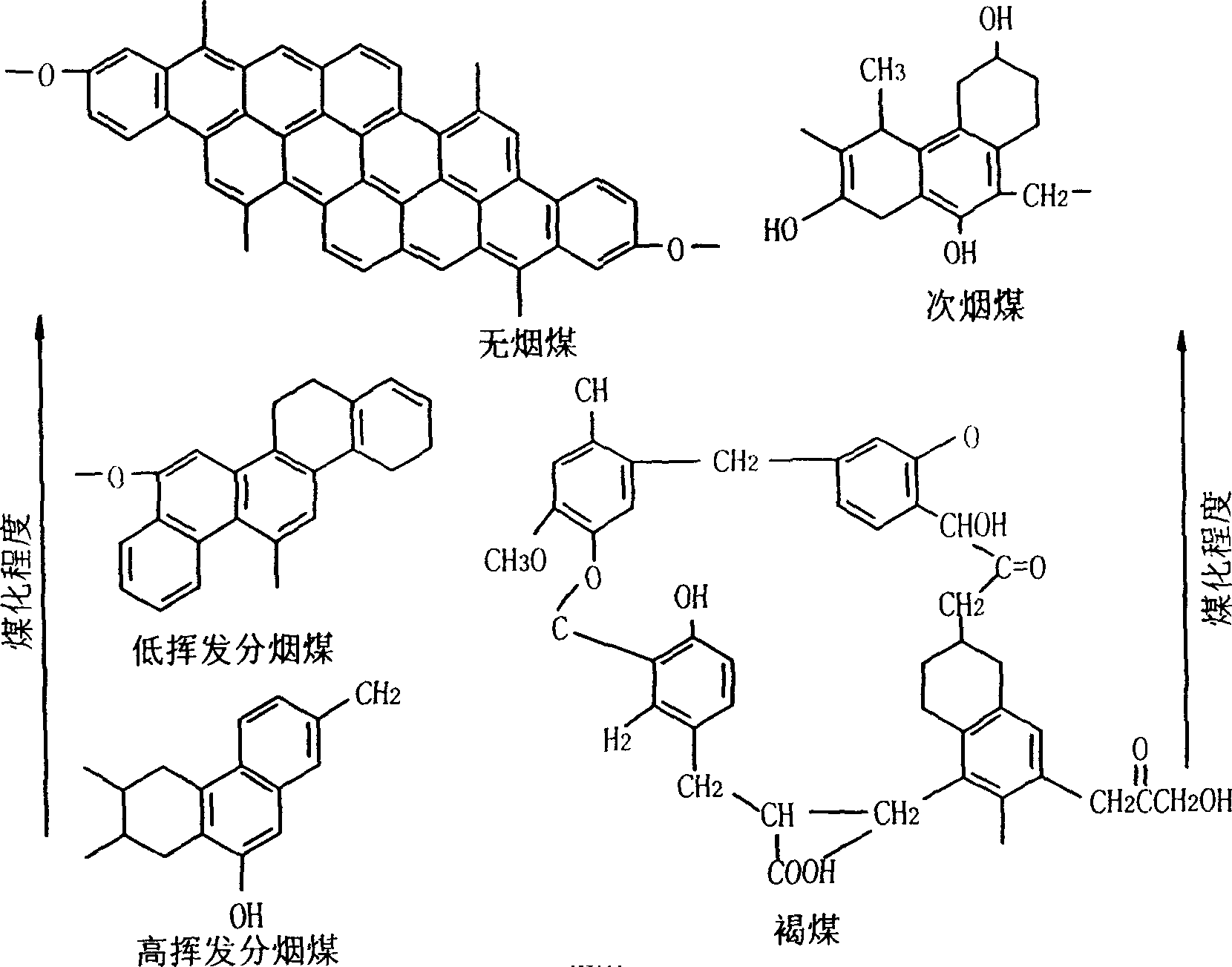

Catalytic combustion adjuvant for coal

A catalytic combustion improver of coal for increasing combustion efficiency and decreasing the exhaust of SO2, CO and NOx is composed of the primary raw materials chosen from 17 salts of organic acid, including acetate, oxalate, succinate, etc, the organic compound prepared by reaction between 17 organic acids and ore, metal, metallic oxide, or compound, chloride, etc, and the secondary raw materials chosen from high-caloricity agent, surface coating agent, solvent, assistant, emulsifying disperser, sulfur fixating agent and filler.

Owner:尹小林

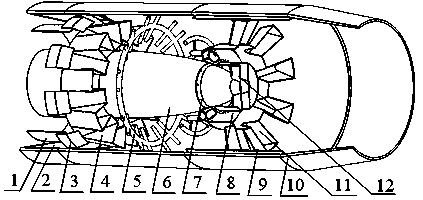

Afterburner integrated with stabilizer and worm wheel rear rectification support plate

InactiveCN102538010ASolve the technical problems of ablationImprove reliabilityContinuous combustion chamberEfficient propulsion technologiesCombustion chamberFuel oil

The invention discloses an afterburner integrated with a stabilizer and a worm wheel rear rectification support plate. A combustion part in the afterburner is integrated with a worm wheel rear load-bearing framework; the worm wheel rear rectification support plate is integrated with an inner culvert flame stabilizer, and cooling air is fed; a fuel oil supply pipe and a fuel oil nozzle are arranged in the rectification support plate; main fuel oil is transversely sprayed out from two sides of the support plate; and duty fuel oil is sprayed out from a groove on the rear surface of the stabilizer to form a duty flame. A pneumatic appearance of an outer culvert flame stabilizer is designed as a V-shaped bluff body, and the cooling air is fed into the outer culvert flame stabilizer; a fuel oil pipeline is arranged in the outer culvert flame stabilizer; the main fuel oil is transversely sprayed by a baffle plate nozzle; and the duty fuel oil is sprayed out from a groove on the rear surface of the outer culvert flame stabilizer. An annular flame stabilizer is arranged between the inner culvert flame stabilizer and the outer culvert flame stabilizer, so that functions of the stabilizer and a flame coupler are realized in a circumferential direction. The internal parts of the afterburner are integrated, so that the part utilization efficiency is improved, and the engine thrust-weight ratio is increased.

Owner:BEIHANG UNIV

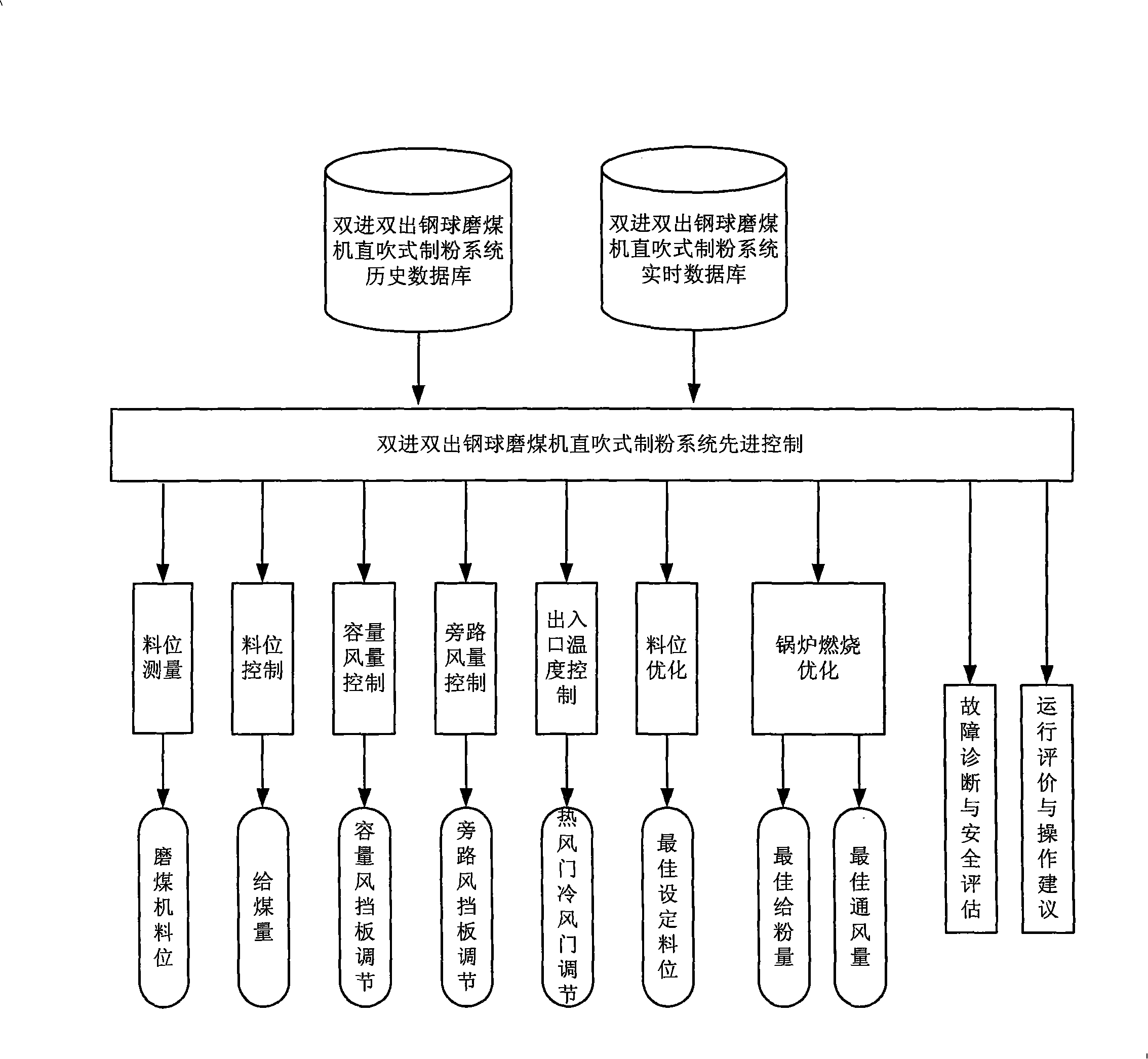

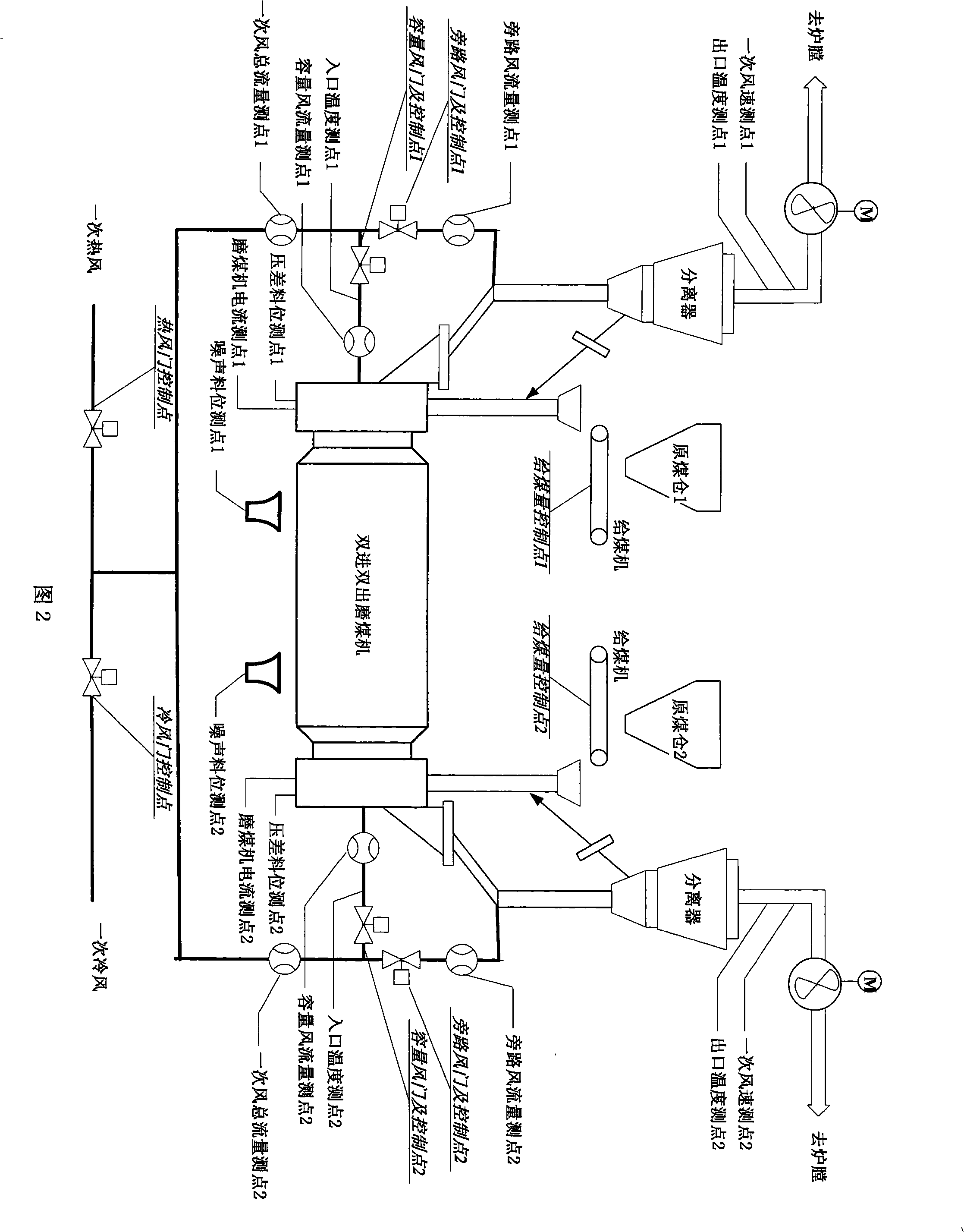

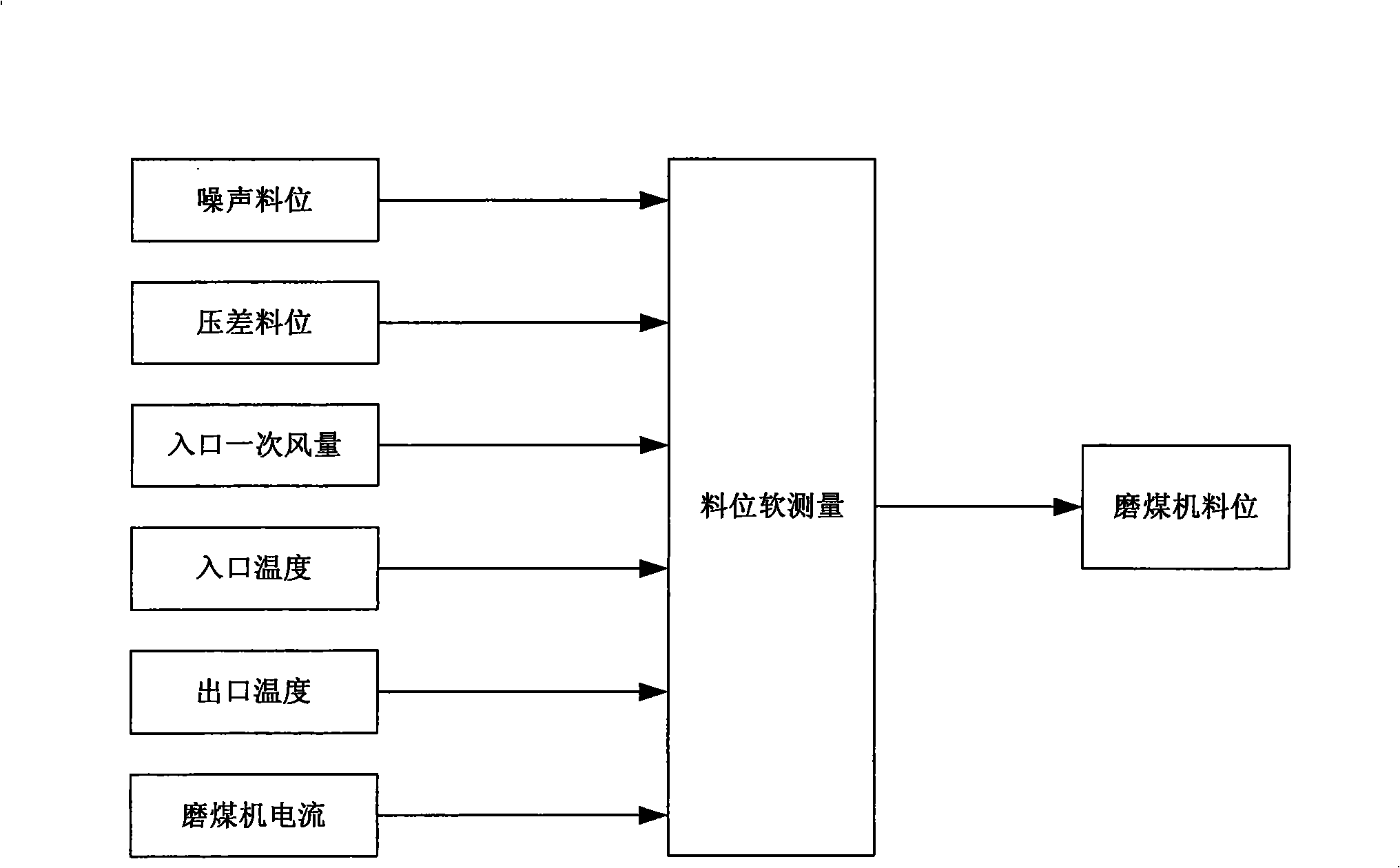

Double-inlet double-outlet steel ball coal mill straight blowing type milling system optimized control method

ActiveCN101334666AImprove combustion efficiencyGuaranteed uniformityGrain treatmentsProgramme total factory controlTemperature controlCombustion

The invention discloses an optimum dual-inlet and dual-outlet steel ball coal grinding machine direct-blow type powder-preparation control method. The method obtains the material position of the coal grinding machine after carrying out soft-measurement processing by collecting the noise material position of the coal grinding machine, the material position of pressure difference, the current of the coal grinding machine, one-time air quantity, one-time opening of the hot wind door and the cold wind door of an inlet, inlet temperature and outlet temperature; the control comprises material position control, air quantity capacity control, bypass air quantity control and the temperature control of the inlet and the outlet; the material position is optimized and the best material position of the coal grinding machine is searched online so as to ensure the combustion safety of the boiler and coal powder supply quantity when the load of the boiler is adjusted. The boiler combustion is optimized: according to the boiler technology, the load and the running working conditions, the powder supply quantity and the ventilation quantity of each coal grinding machine are optimized and the combustion efficiency of the boiler is improved. Malfunction diagnosis, running evaluation and analysis are carried out to the system and reasonable suggestions are provided so as to ensure the system to run continuously, stably, safely and economically; the optimum dual-inlet and dual-outlet steel ball coal grinding machine direct-blow type powder-preparation control method is widely applied to the dual-inlet and dual-outlet steel ball coal grinding machine direct-blow type powder-preparation system or industrial similar systems in other industries.

Owner:西安蓝海机械仪表成套有限责任公司

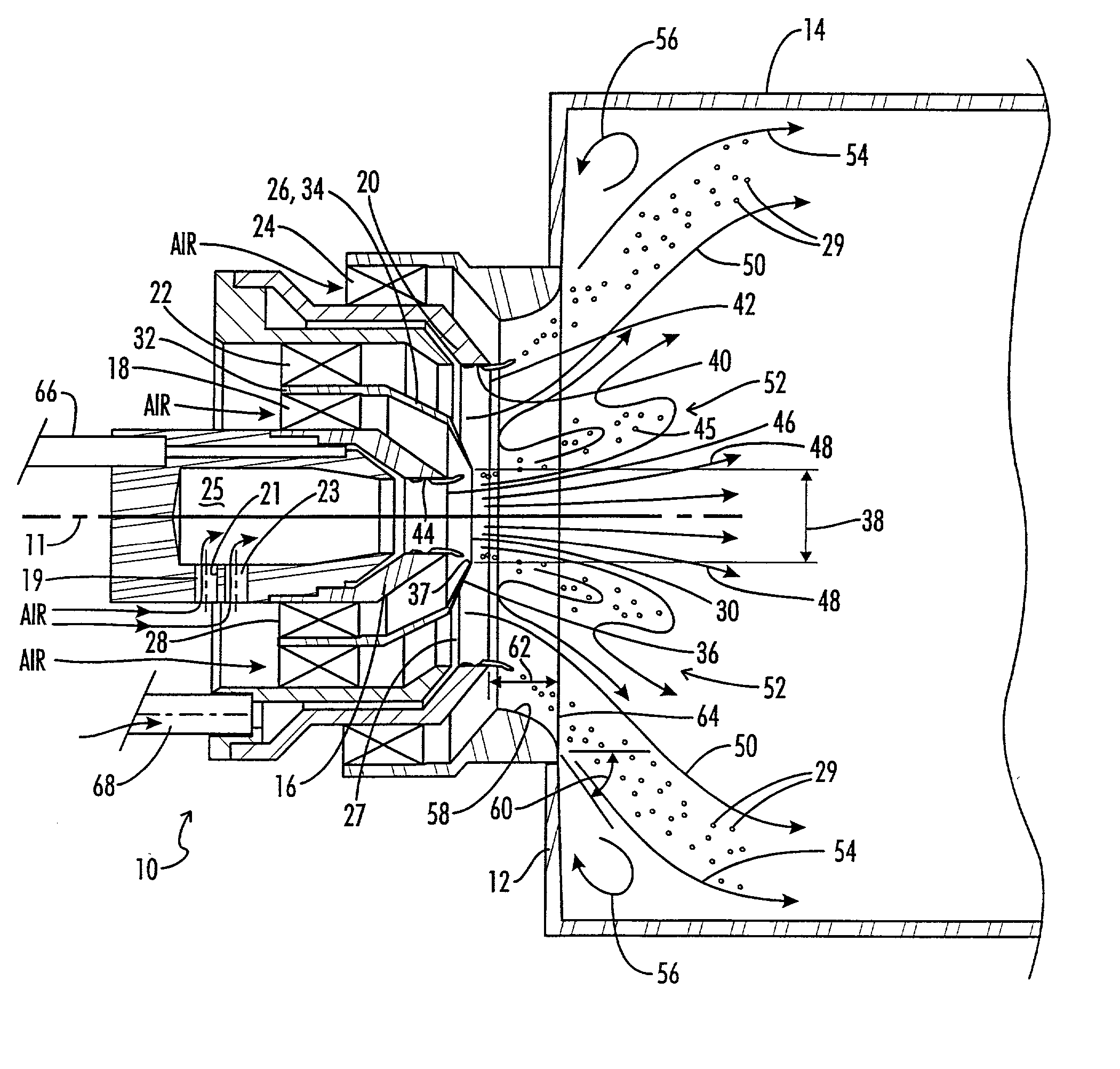

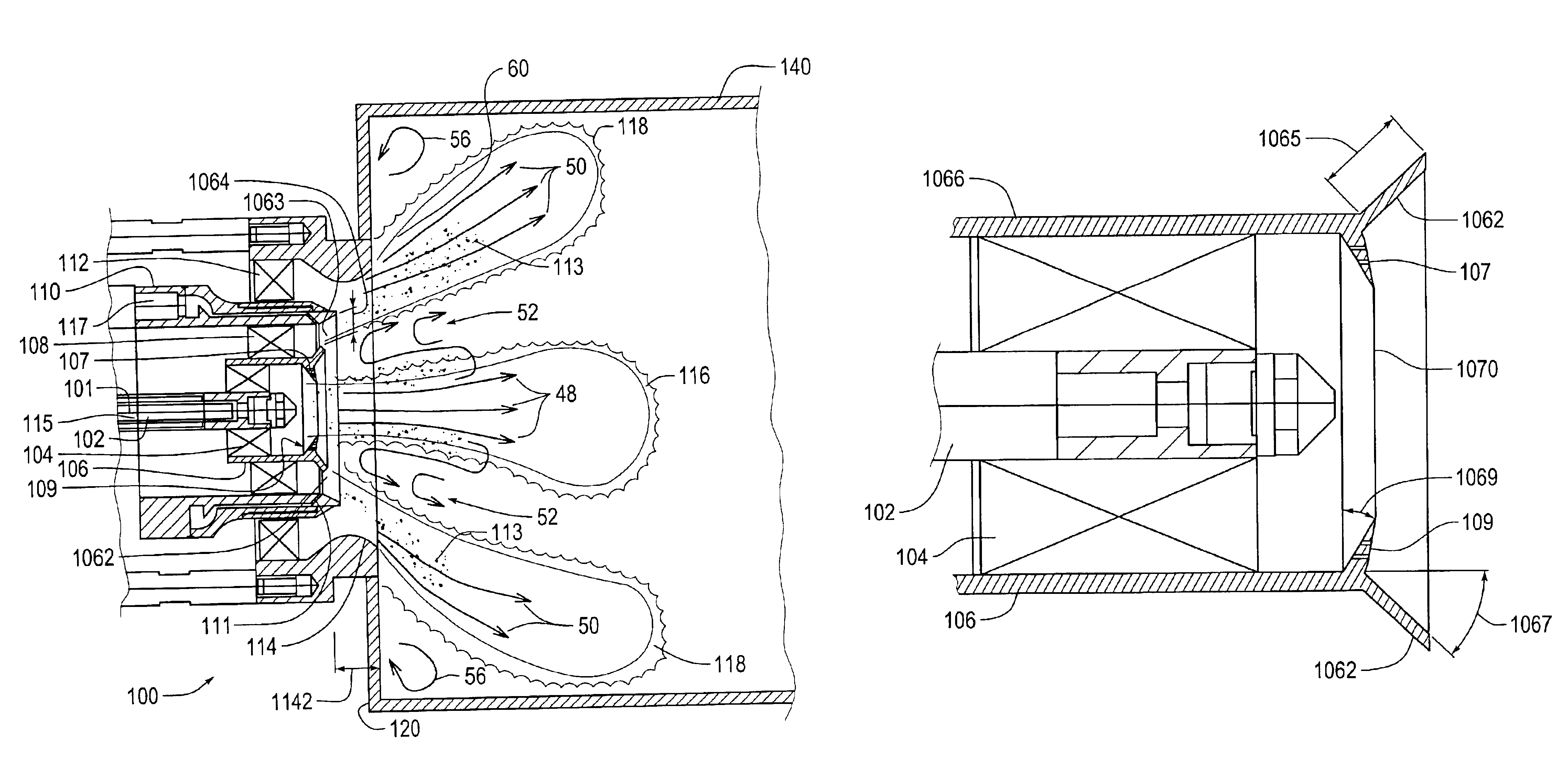

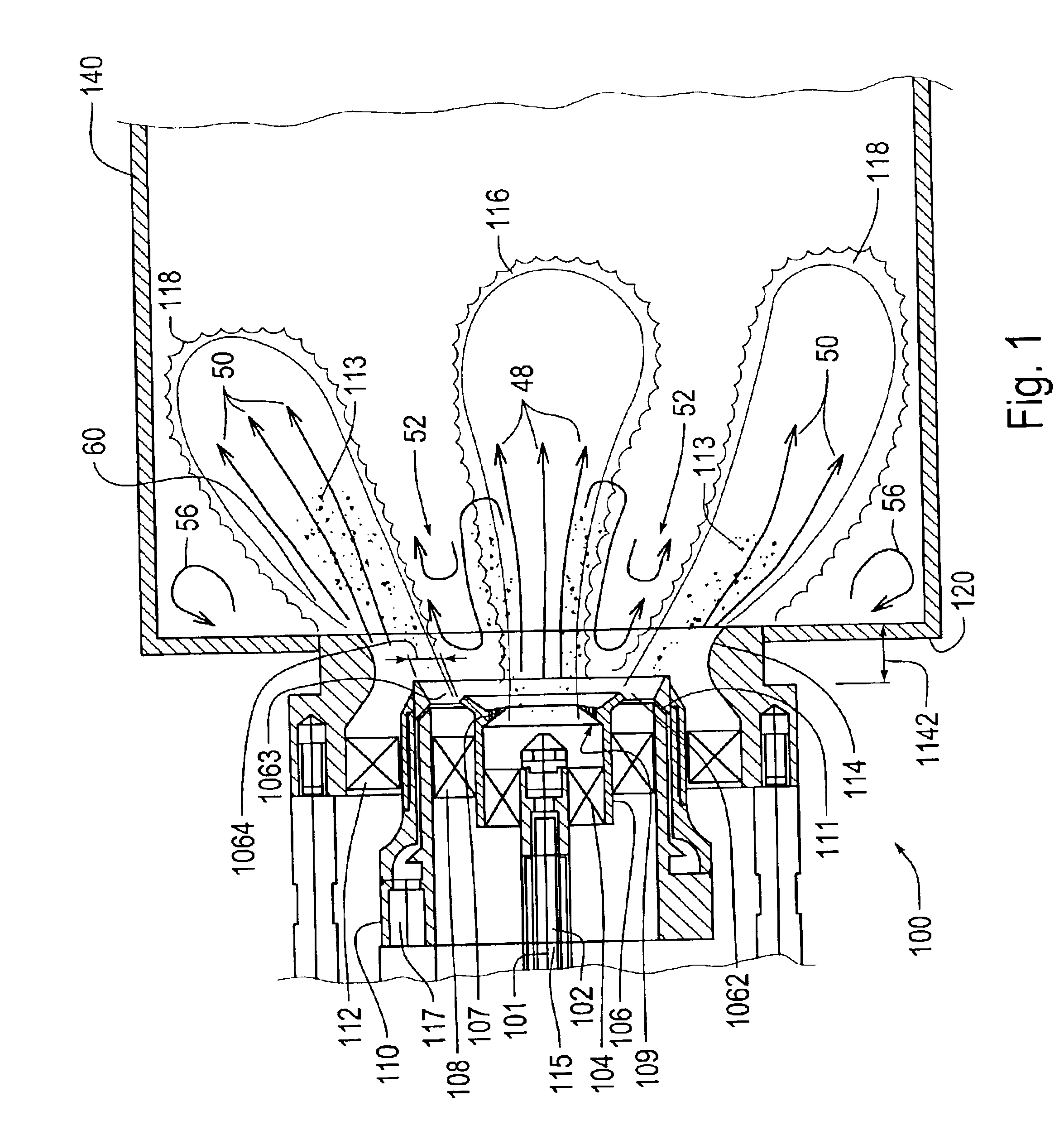

Fuel injector with bifurcated recirculation zone

InactiveUS20020011064A1Low pollutant emissionReduce nitrogen oxide emissionsBurnersTurbine/propulsion fuel supply systemsProcess engineeringNitrous oxide

A gas turbine fuel injection system of the lean direct injector type designed to reduce nitrous oxide (NOx) emissions is provided. The configuration includes a pilot fuel injector for injecting a pilot fuel stream, and a pilot swirler for providing a swirling pilot air stream to atomize and entrain the pilot fuel stream. A main airblast fuel injector is located concentrically about the pilot fuel injector, for injecting a main fuel stream concentrically about the pilot fuel stream. Inner and outer main swirlers provide a swirling main air stream to atomize and entrain the main fuel stream. An air splitter is located between the pilot swirler and the main swirler. The air splitter is so arranged and constructed as to divide the pilot air stream exiting the pilot swirler and the air splitter, from the main air stream exiting the inner main swirler, whereby a bifurcated recirculation zone is created.

Owner:CROCKER DAVID S +2

Fuel additive composition and method for treatment of middle distillate fuels and gasoline

InactiveUS6923838B2Increase and improvement of performanceIncrease and improvement of and lubricityLiquid carbonaceous fuelsFuel additivesVegetable oilAntioxidant

A fuel additive for middle distillate fuels is a mixture of at least one methyl, ethyl, propyl or butyl ester of a vegetable oil or a C16-C18 fatty acid, at least one alkyl ether of propylene glycol, a surfactant, and an antioxidant. A fuel additive for gasoline is a mixture of ligroin or toluene / xylene, at least one alkyl ether of propylene glycol, a surfactant, and tertiary amyl methyl ether.

Owner:ADVANCED COMBUSTION TECH

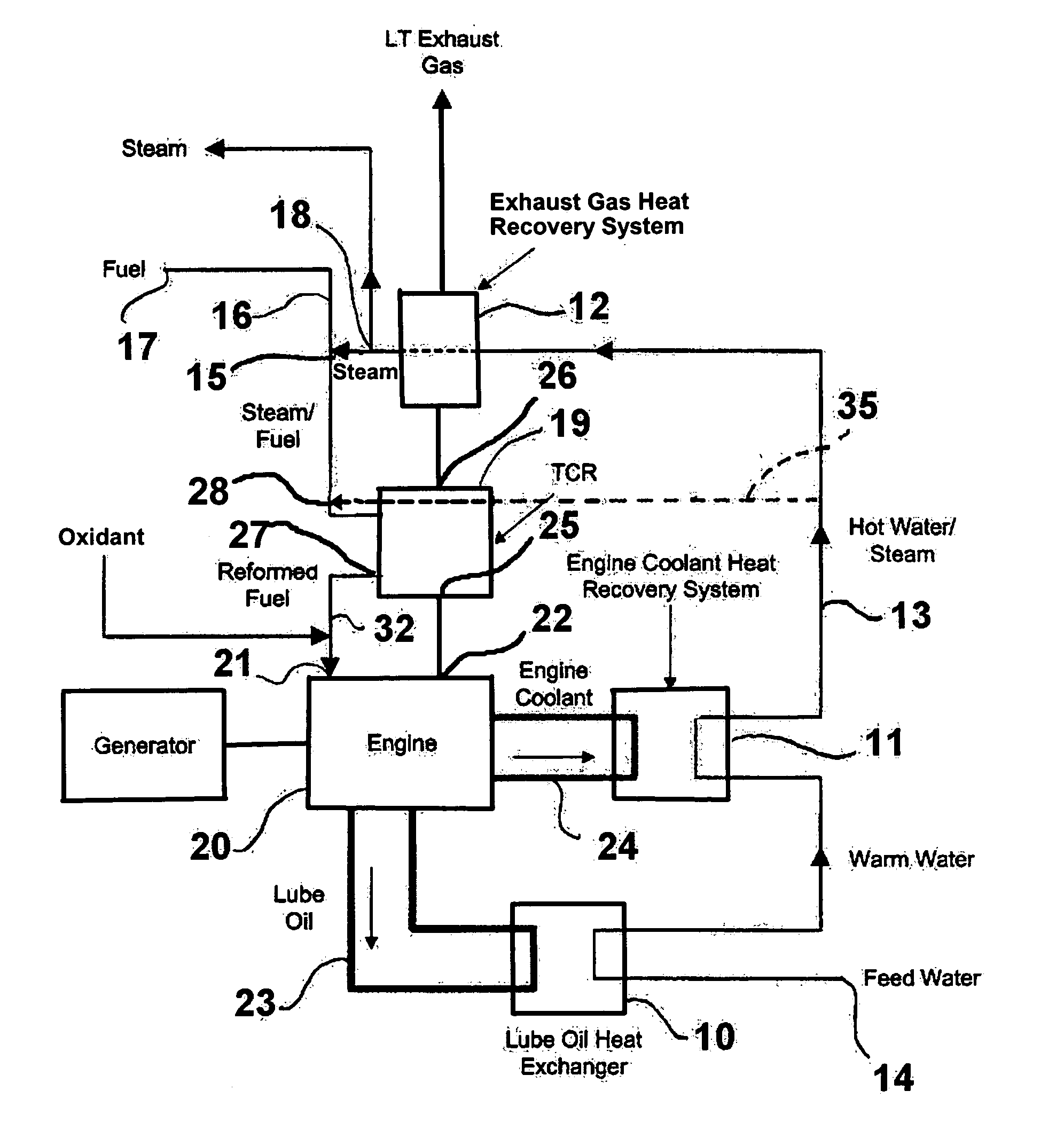

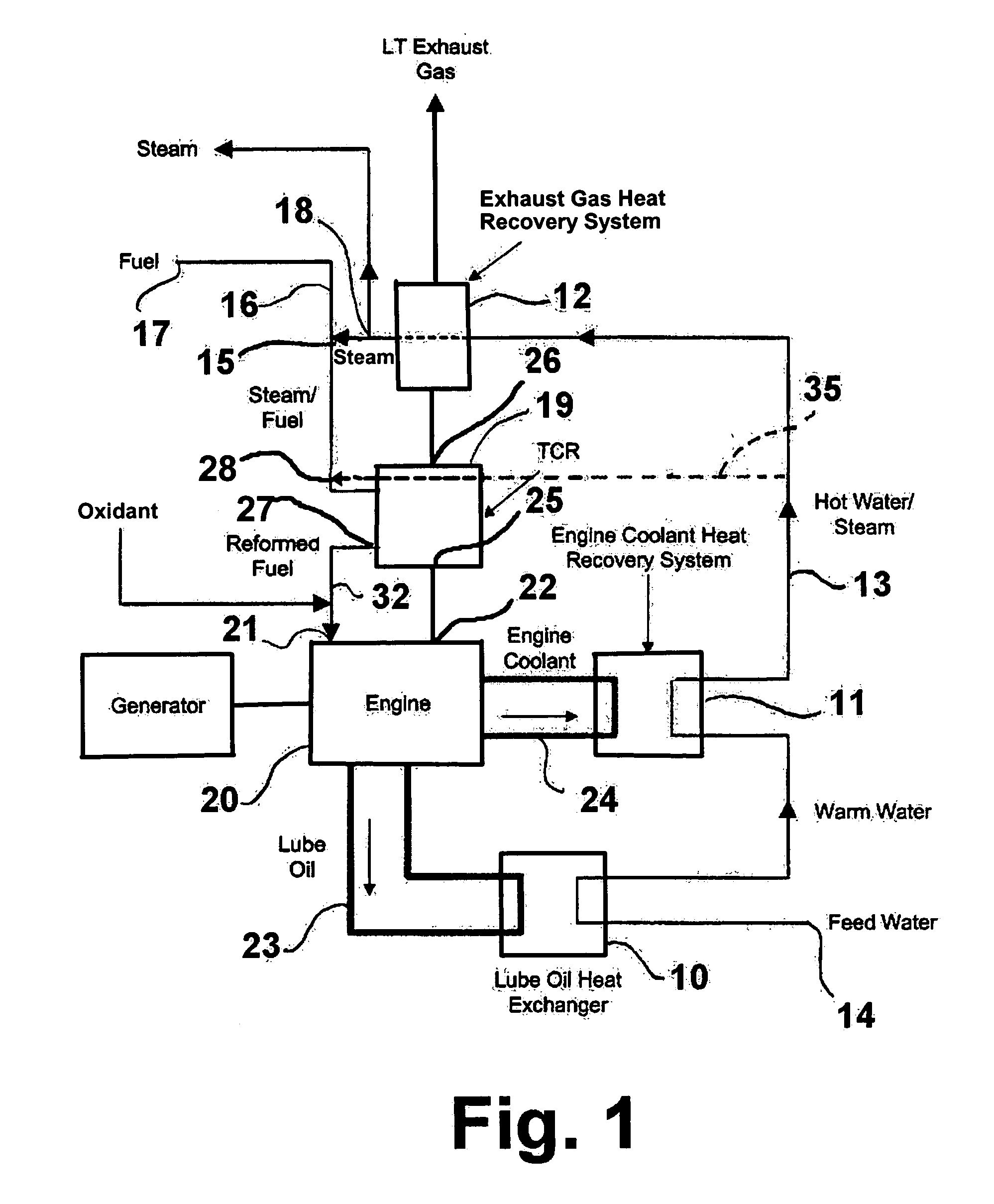

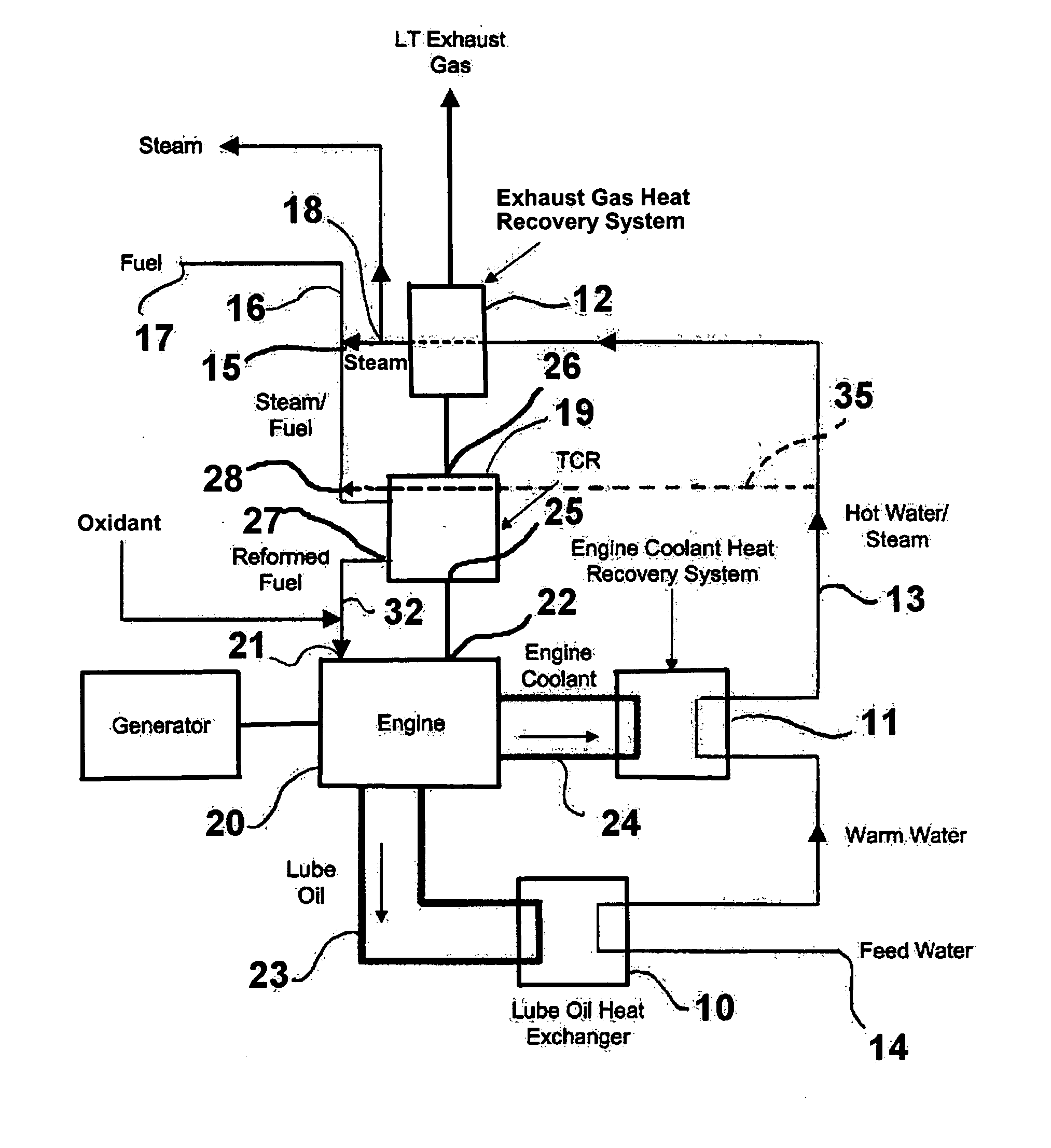

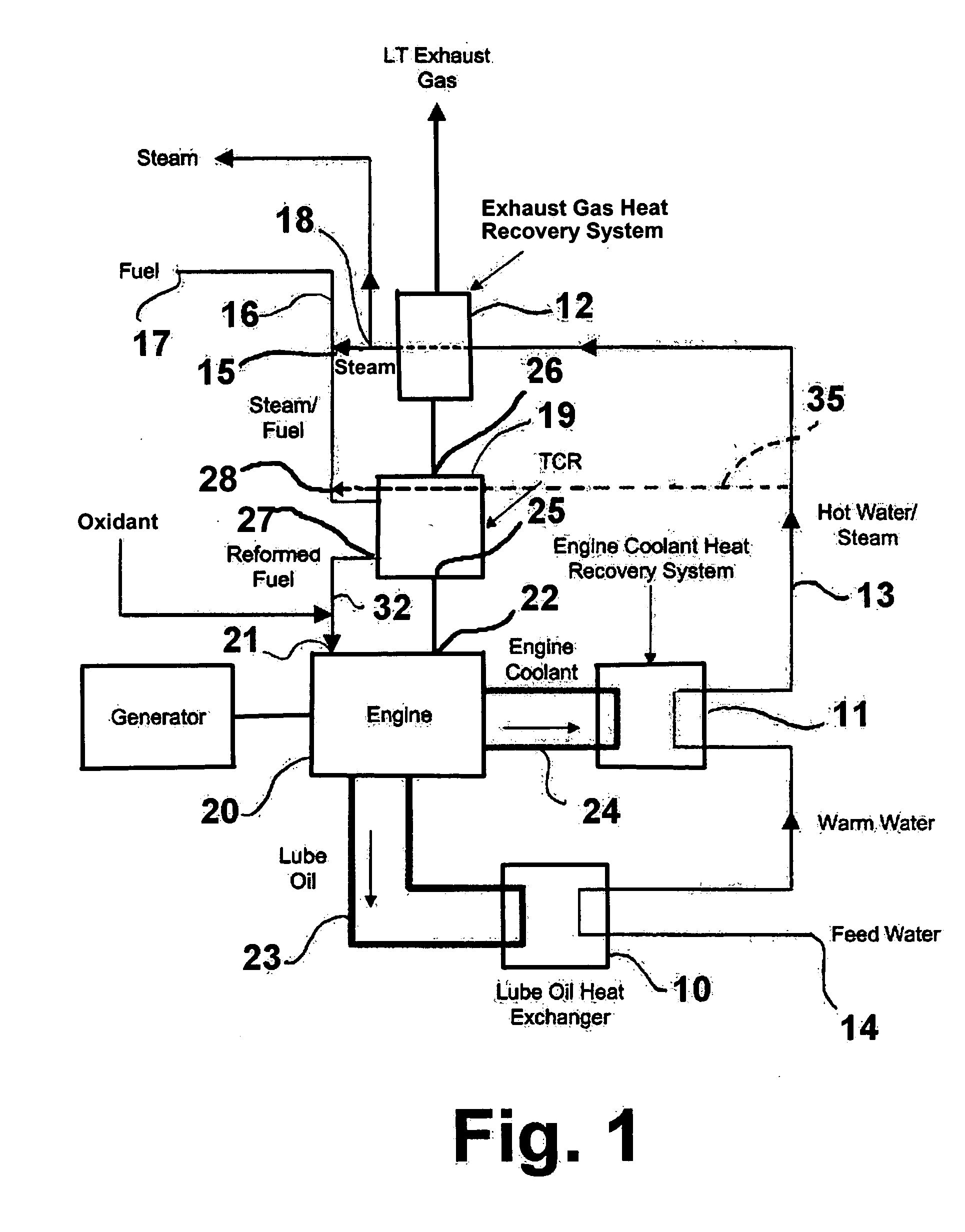

Advanced high efficiency, ultra-low emission, thermochemically recuperated reciprocating internal combustion engine

ActiveUS7210467B2Emission reductionImprove efficiencyInternal combustion piston enginesExhaust apparatusExternal combustion engineEngineering

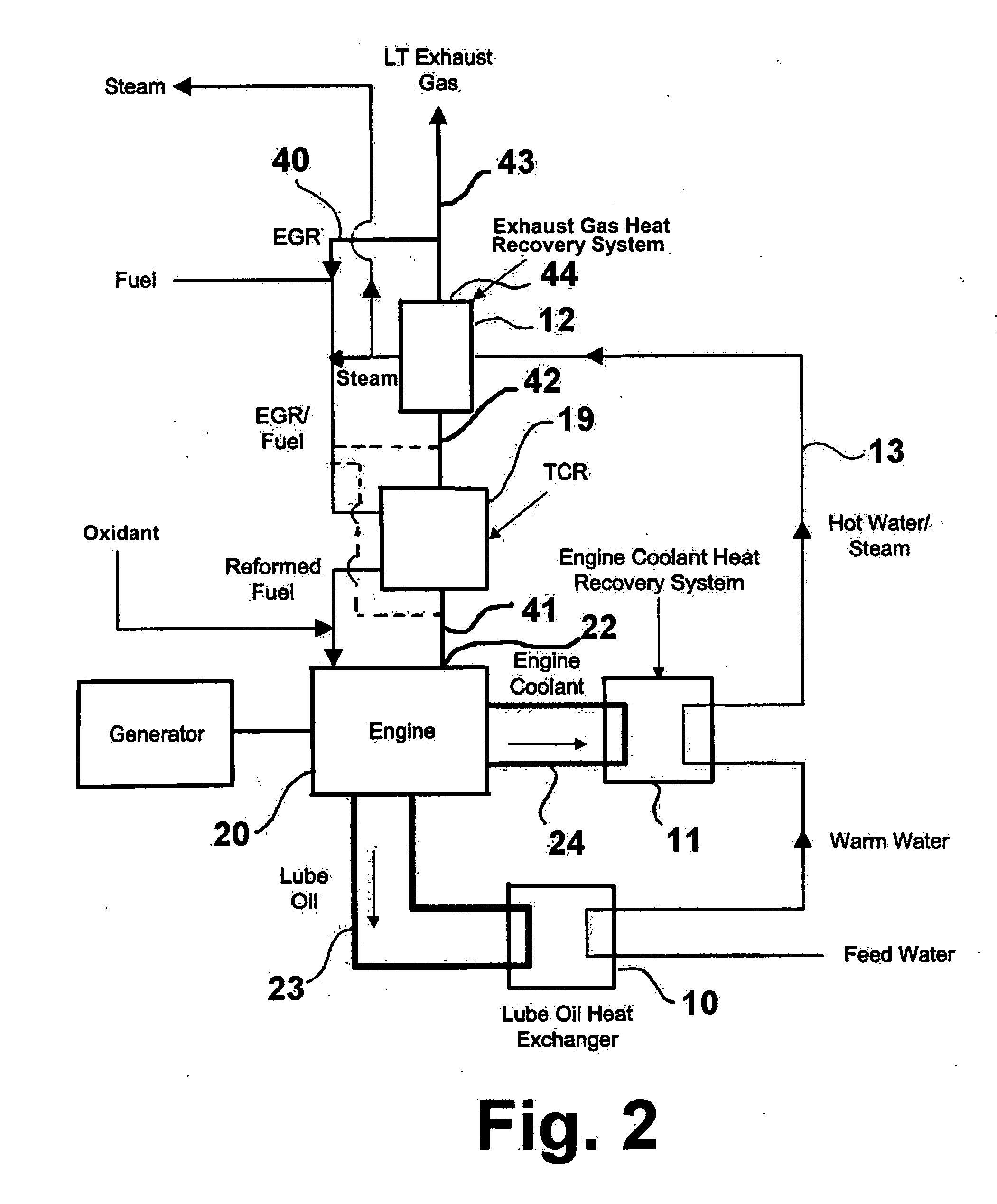

An apparatus including a reciprocating internal combustion engine and a thermochemical recuperator in which a fuel is reformed. The thermochemical recuperator is heated by exhaust gases from the reciprocating internal combustion engine and steam for the reforming process is produced by passing feed water through an engine lubricating oil heat exchanger, an engine cooling system heat recovery system and an exhaust gas heat recovery system arranged in series.

Owner:GAS TECH INST

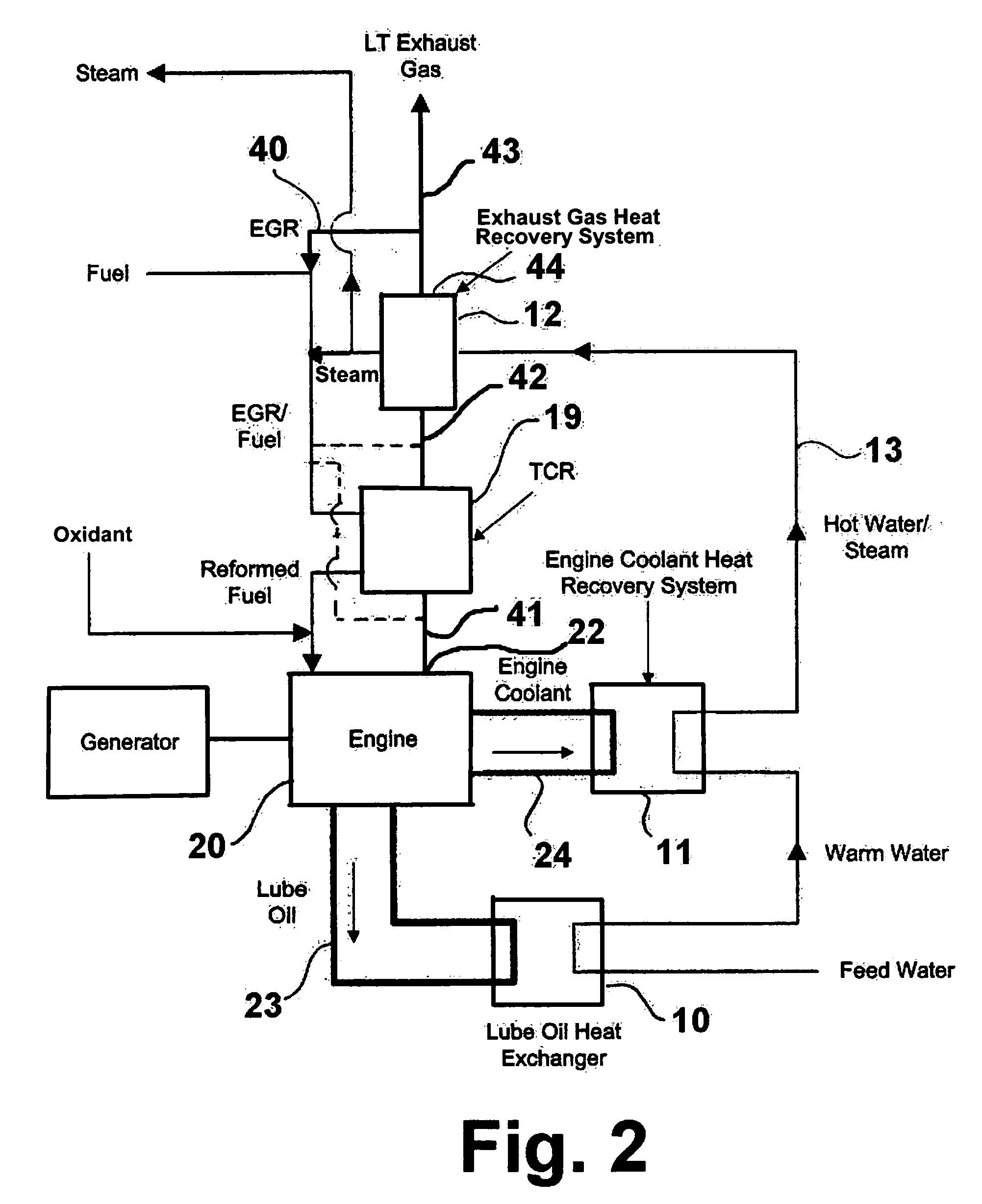

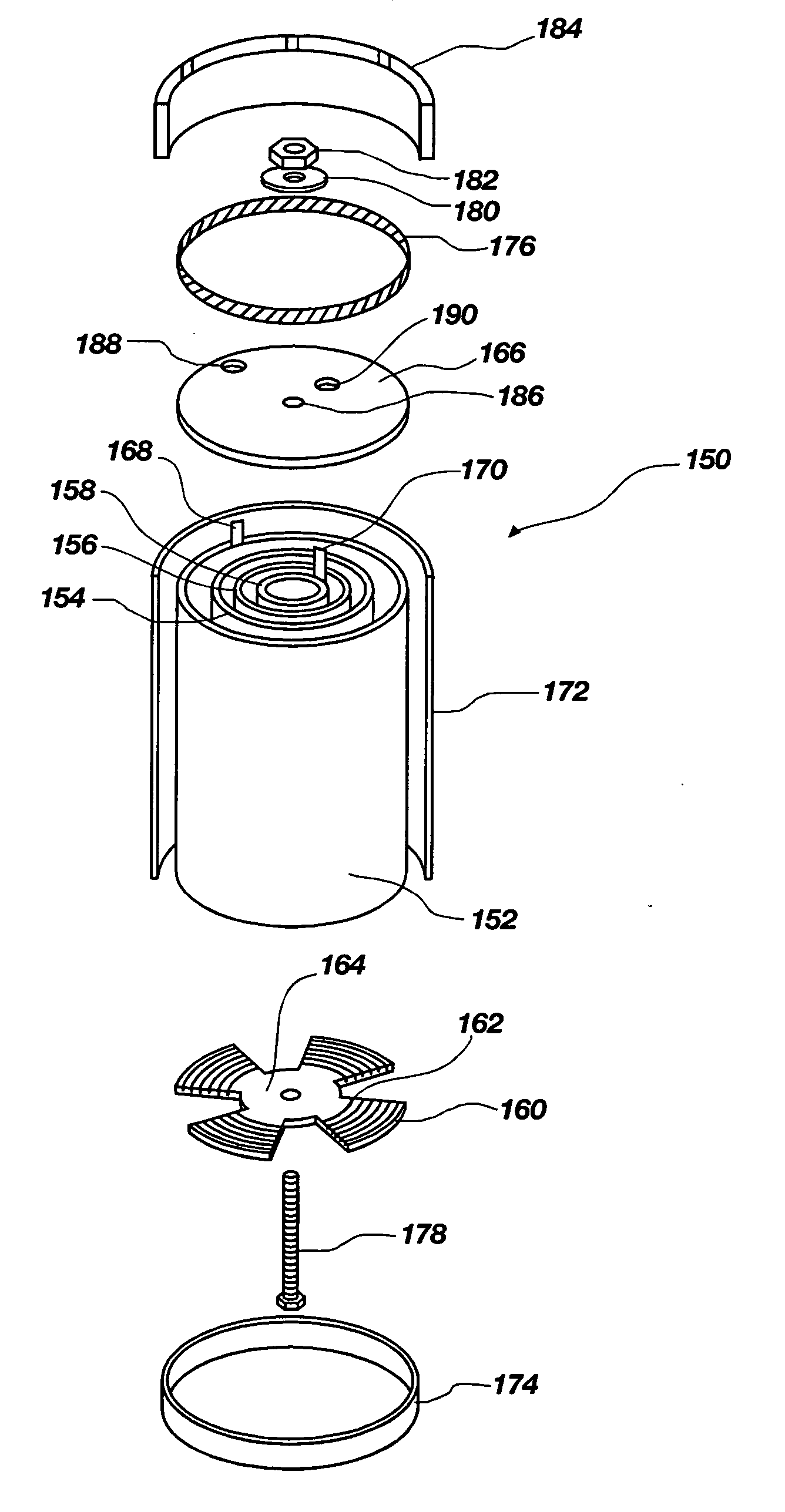

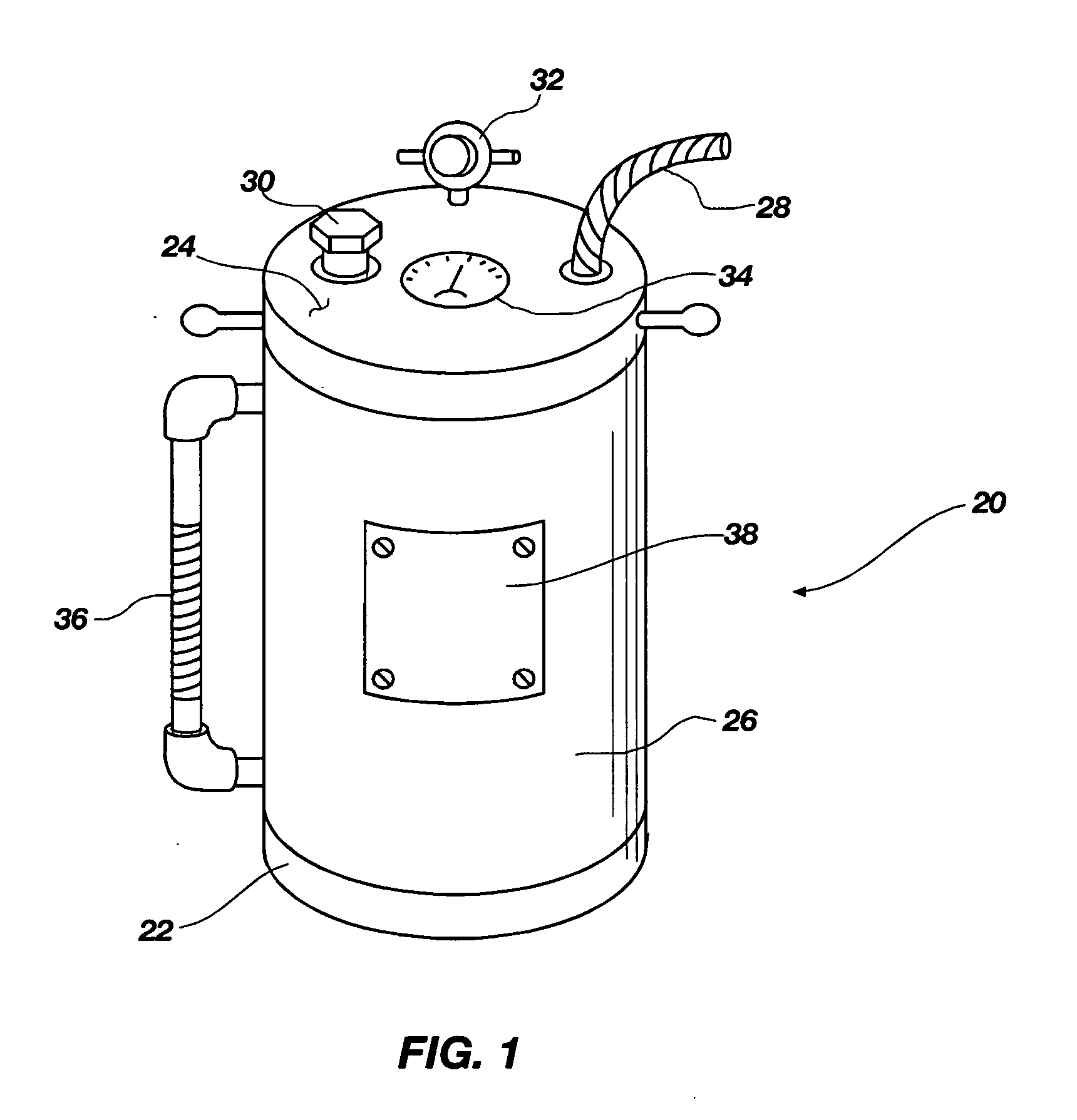

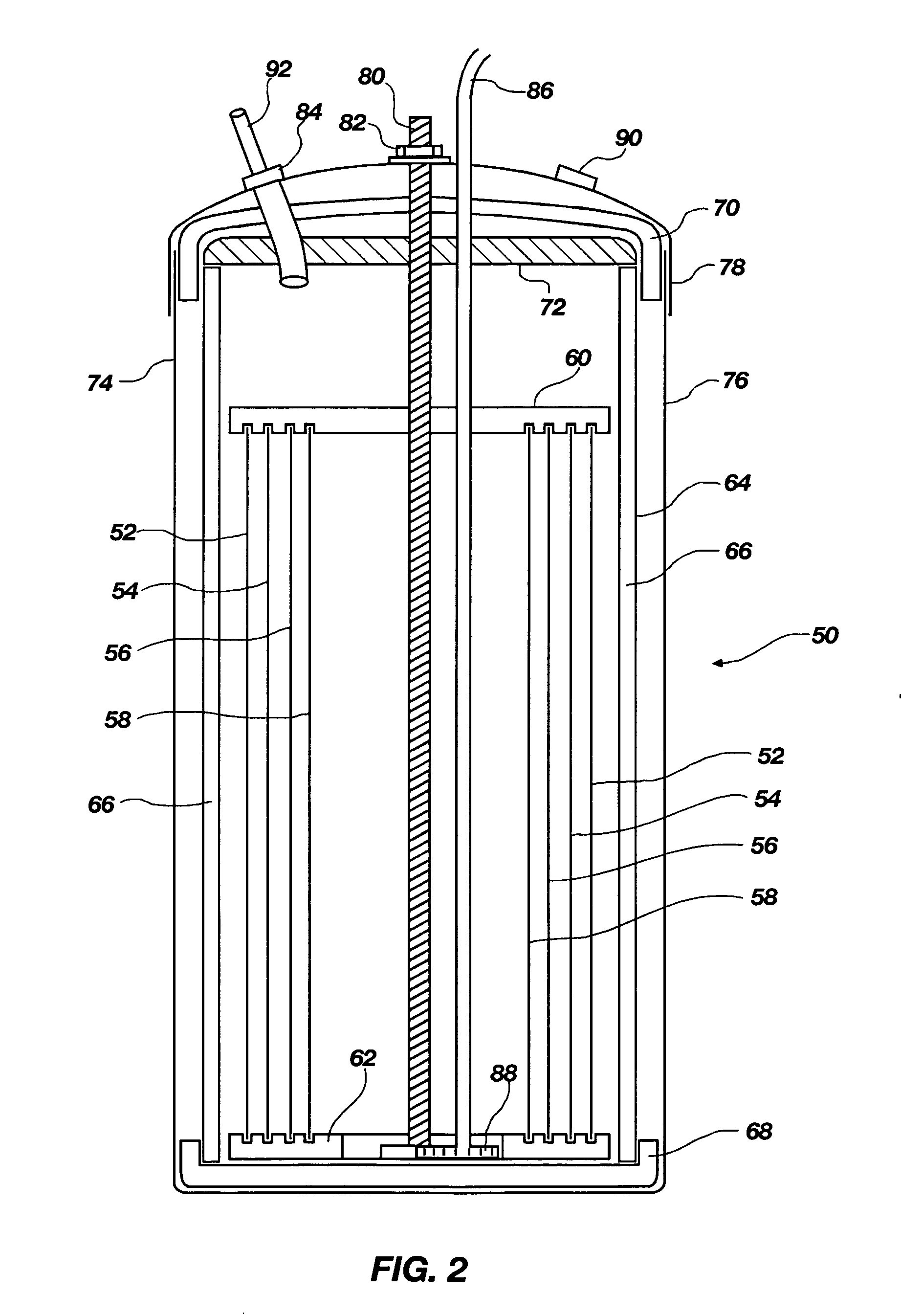

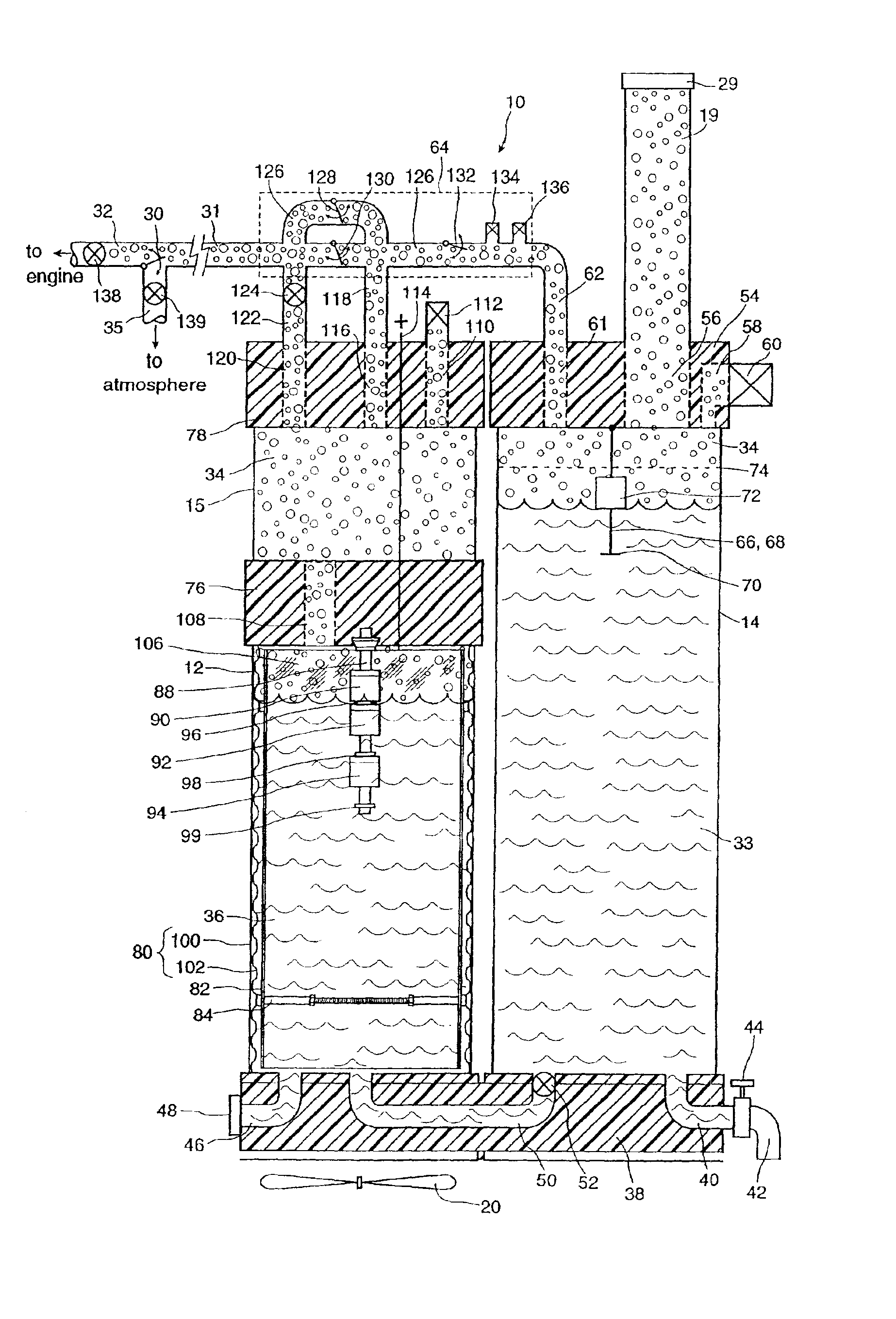

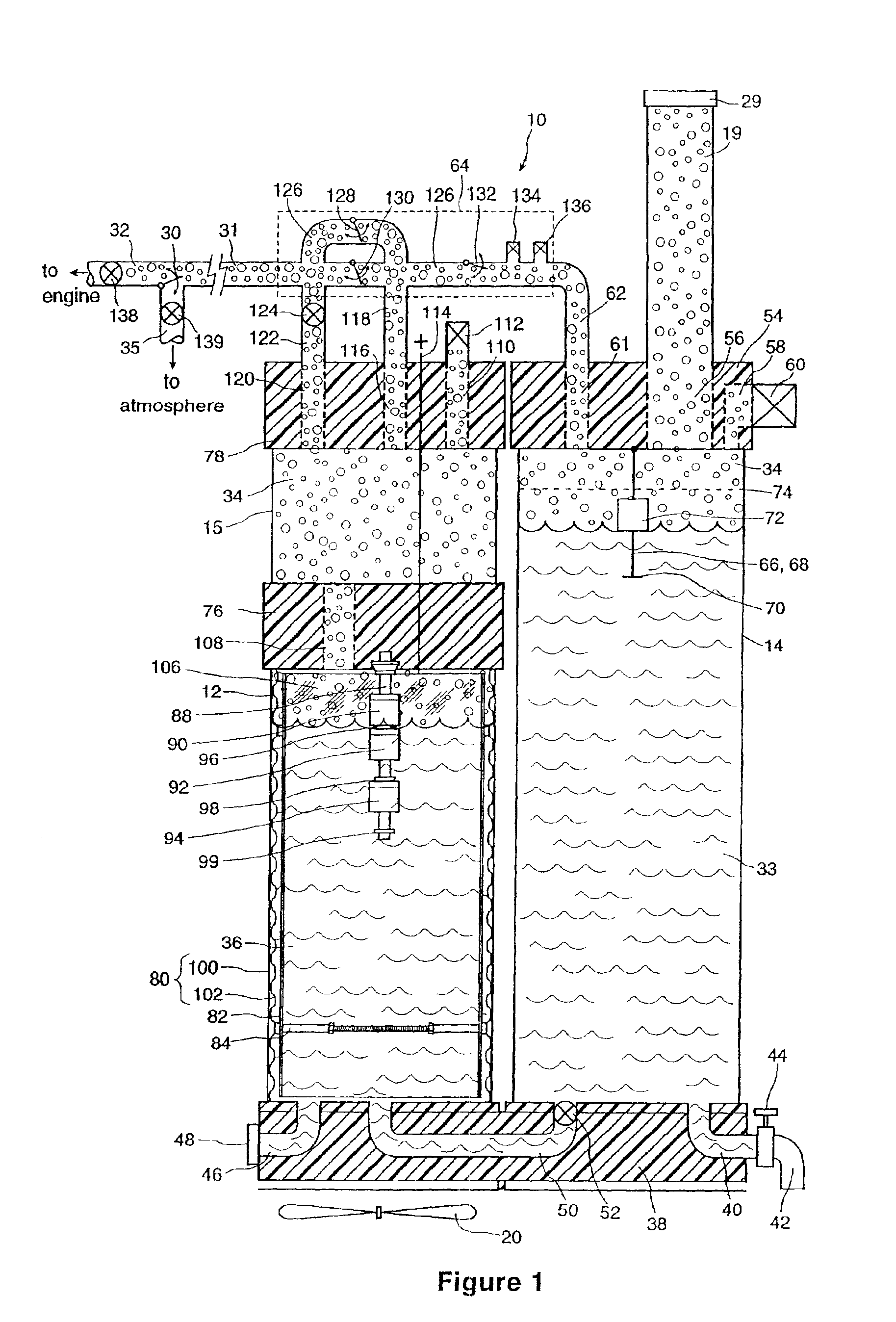

Fuel system for internal combustion engine

InactiveUS20050217991A1Increase flow rateReduces and eliminates contaminantCellsElectrolysisExternal combustion engine

A fuel system is provided for generating hydrogen and oxygen for use in an internal combustion engine to improve combustion efficiency, horsepower, and torque and to decrease emissions. The fuel system has at least one electrolysis cell for generating hydrogen and oxygen by electrolysis of an aqueous solution, a power source for providing electrical power to the electrolysis cell, and a heating and cooling system for maintaining the temperature of the electrolysis cell in a desired range to obtain the desired quantities of hydrogen and oxygen for operation of the internal combustion engine. The invention also includes an electrode array of a plurality of spaced apart electrodes for use in this fuel system and a nonconductive support connected to each of the electrodes to hold the electrodes in place, while leaving adequate room around the electrodes to allow free flow of the aqueous solution between the electrodes. High purity electrolyte and substantially non-reactive electrodes result in improved electrolysis.

Owner:HYDROGEN INNNOVATIONS

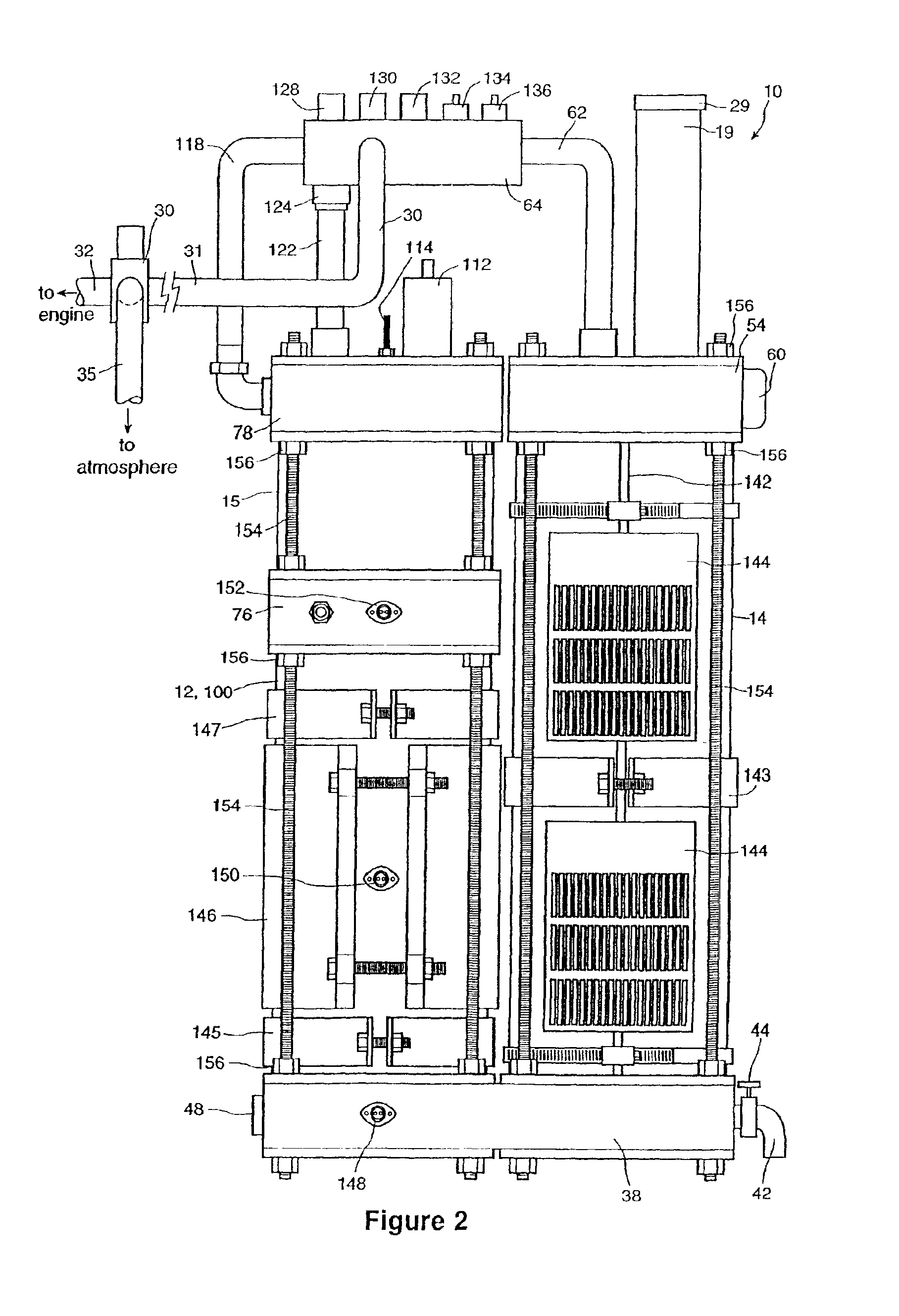

Advanced high efficiency, ultra-low emission, thermochemically recuperated reciprocating internal combustion engine

ActiveUS20050279333A1Improve engine efficiencyIncreases engine combustion efficiencyInternal combustion piston enginesExhaust apparatusEngineeringRecuperator

An apparatus including a reciprocating internal combustion engine and a thermochemical recuperator in which a fuel is reformed. The thermochemical recuperator is heated by exhaust gases from the reciprocating internal combustion engine and steam for the reforming process is produced by passing feed water through an engine lubricating oil heat exchanger, an engine cooling system heat recovery system and an exhaust gas heat recovery system arranged in series.

Owner:GAS TECH INST

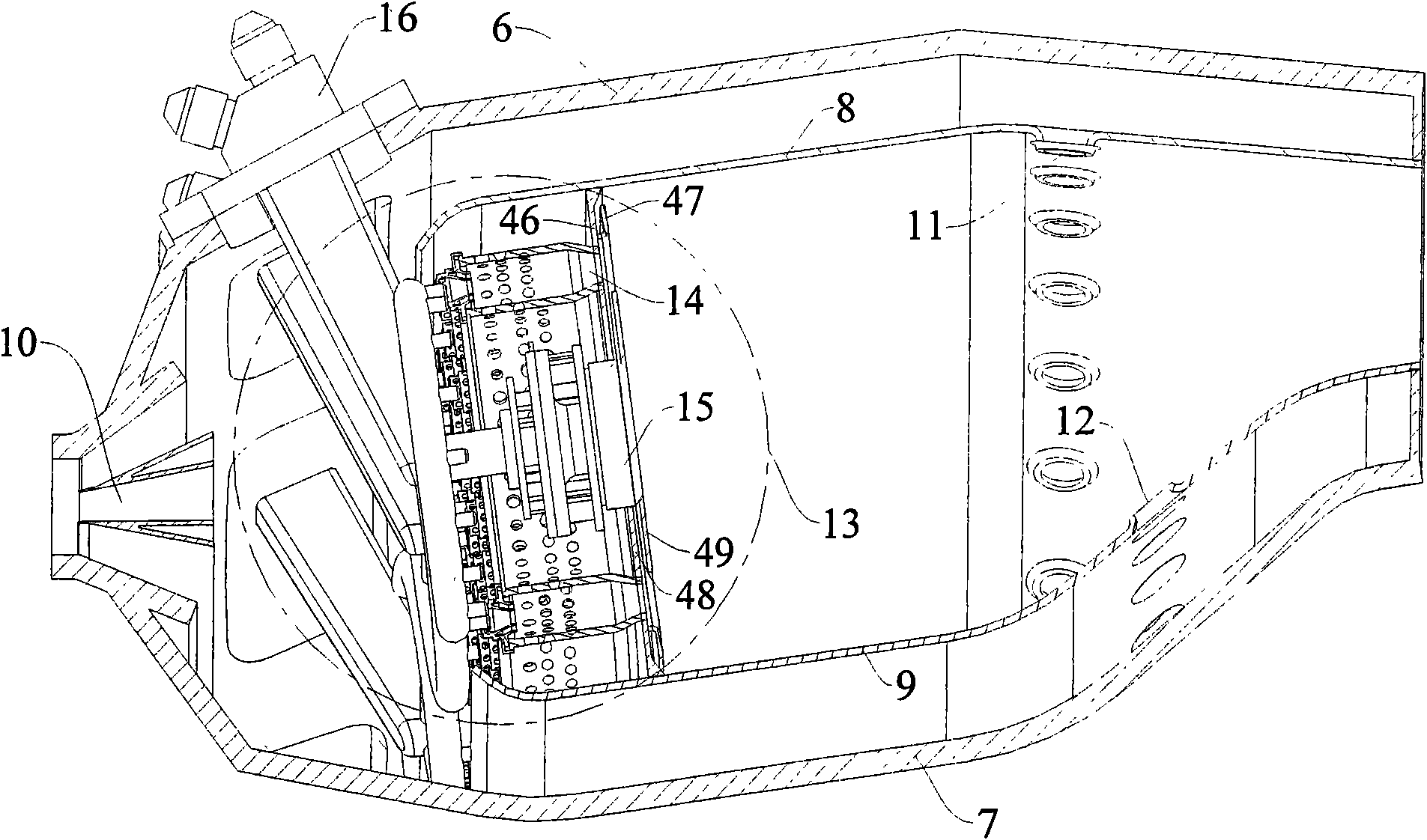

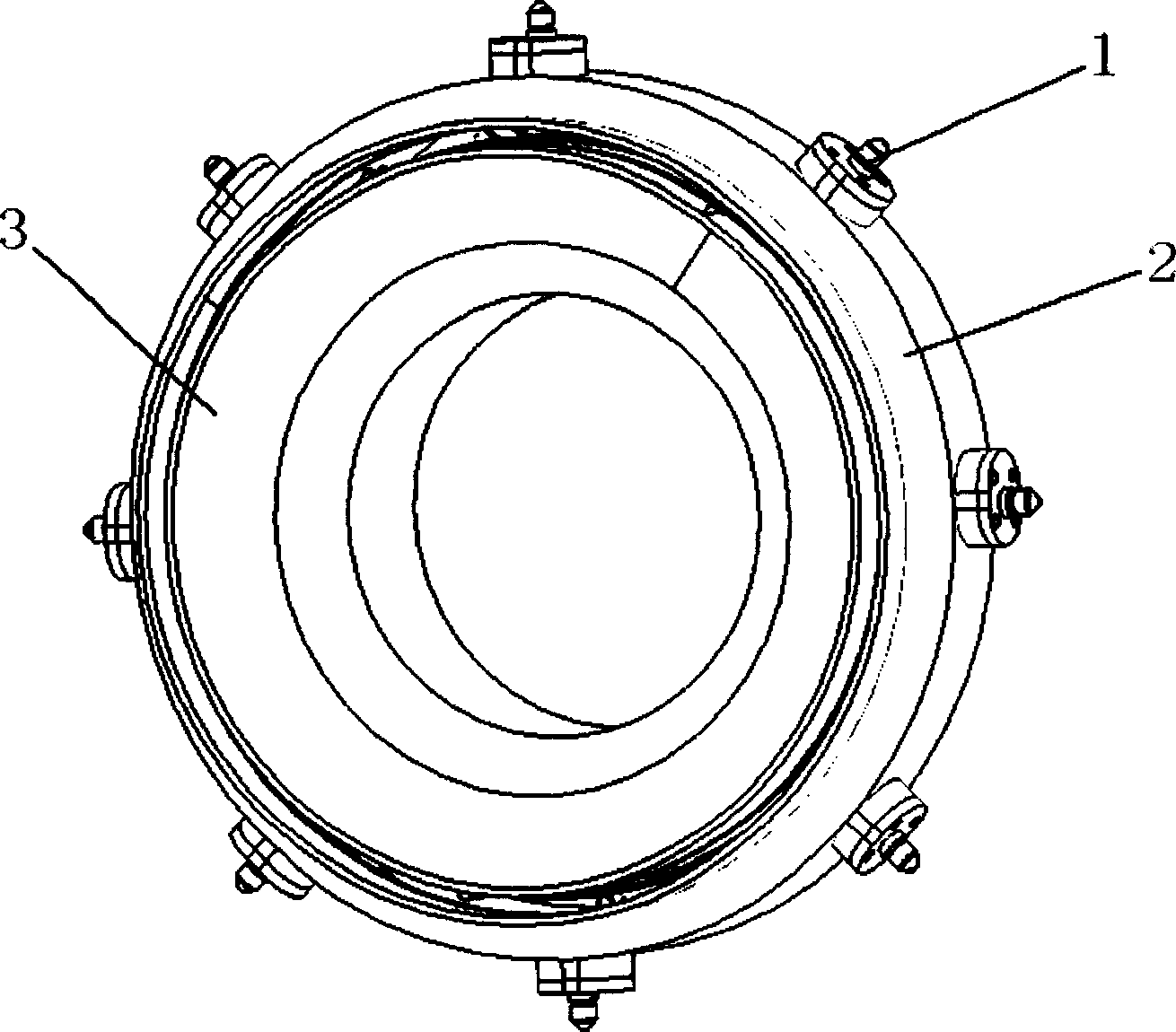

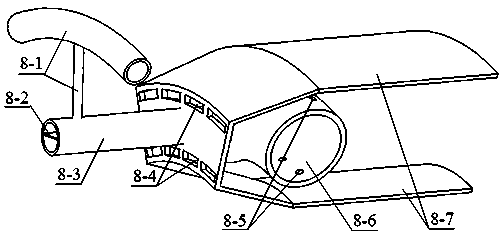

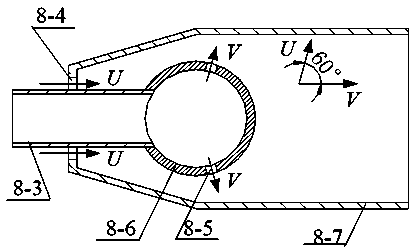

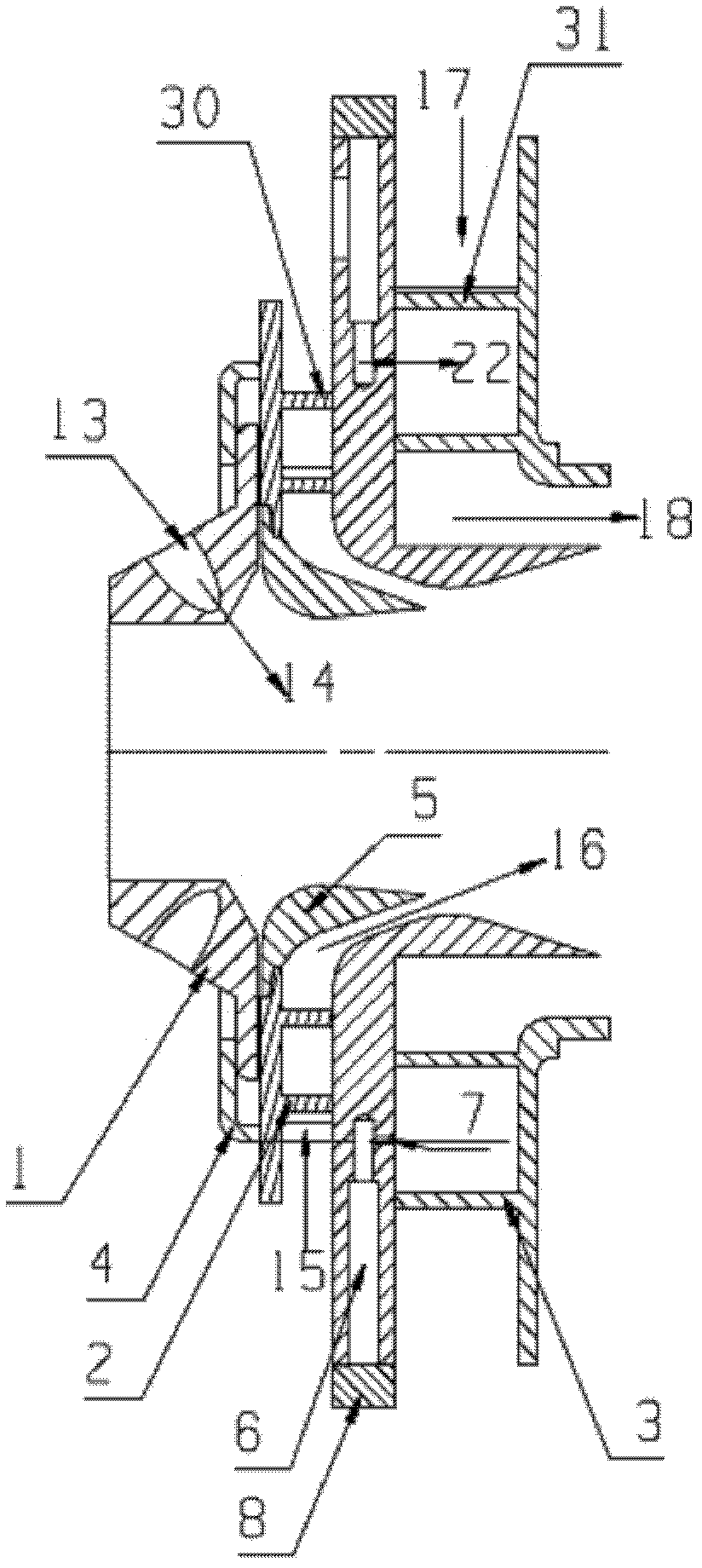

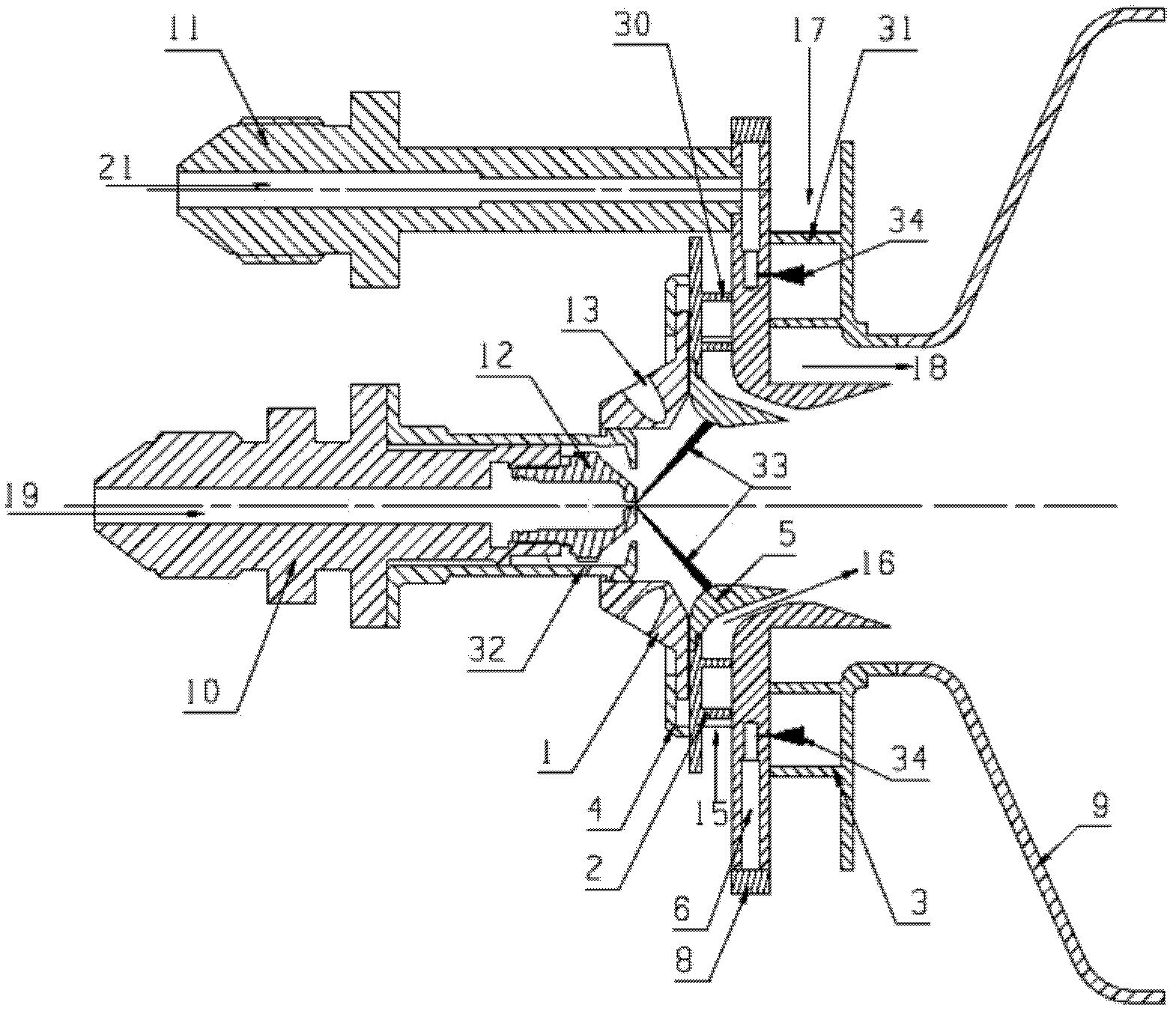

Low-pollution combustion chamber provided with premixing and pre-evaporating ring pipe

ActiveCN101788157AReduce pollutionFast evaporation blendingContinuous combustion chamberCombustion chamberCombustible gas

The invention relates to a low-pollution combustion chamber provided with a premixing and pre-evaporating ring pipe, which adopts a single-ring cavity structure and consists of a combustion chamber outer casing, a combustion chamber inner casing, an outer flame tube, an inner flame tube and a combustion chamber head part, wherein air used for combustion completely enters into the flame tubes from the combustion chamber head part; the scheme of fractional combustion can be adopted, and pre-combustion stage and a main-combustion stage are divided; the main-combustion stage comprises the premixing and pre-evaporating ring pipe, a main-combustion stage nozzle and a main-combustion stage swirler; fuel oil is evaporated and mixed inside the premixing and pre-evaporating ring pipe and then enters into the flame tubes after forming even mixed combustible gas, belonging to premixed combustion; a fuel nozzle is used for supplying the fuel oil for the pre-combustion stage and the main-combustion stage; the stable working range of the combustion chamber is mainly controlled by the pre-combustion stage, so that the stable combustion can be ensured to be carried out in the combustion chamber within wider working range, and a stable ignition source can be provided for the main-combustion stage; the pollution emission is mainly controlled by the main-combustion stage, and the equivalent weight ration of the premixed gas of the main-combustion stage can be controlled within the low-pollution combustion range, so that the pollution emission of the whole combustion chamber cam be ensured to be greatly reduced. The premixing and pre-evaporating structure has small size, simple structure and modularized characteristic, can reduce the pollution emission of the combustion chamber of an aircraft engine, and ensures good combustion stability.

Owner:BEIHANG UNIV

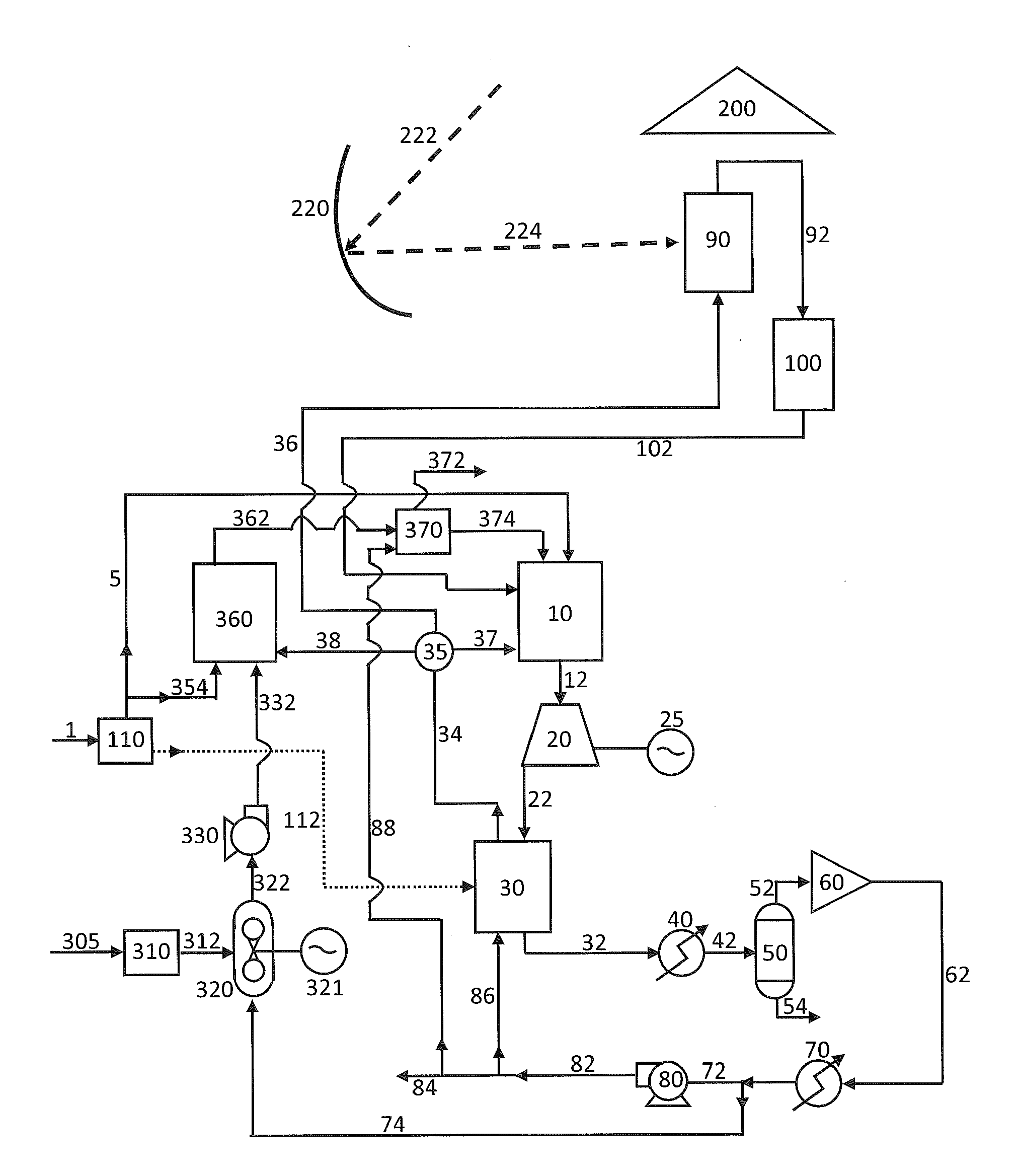

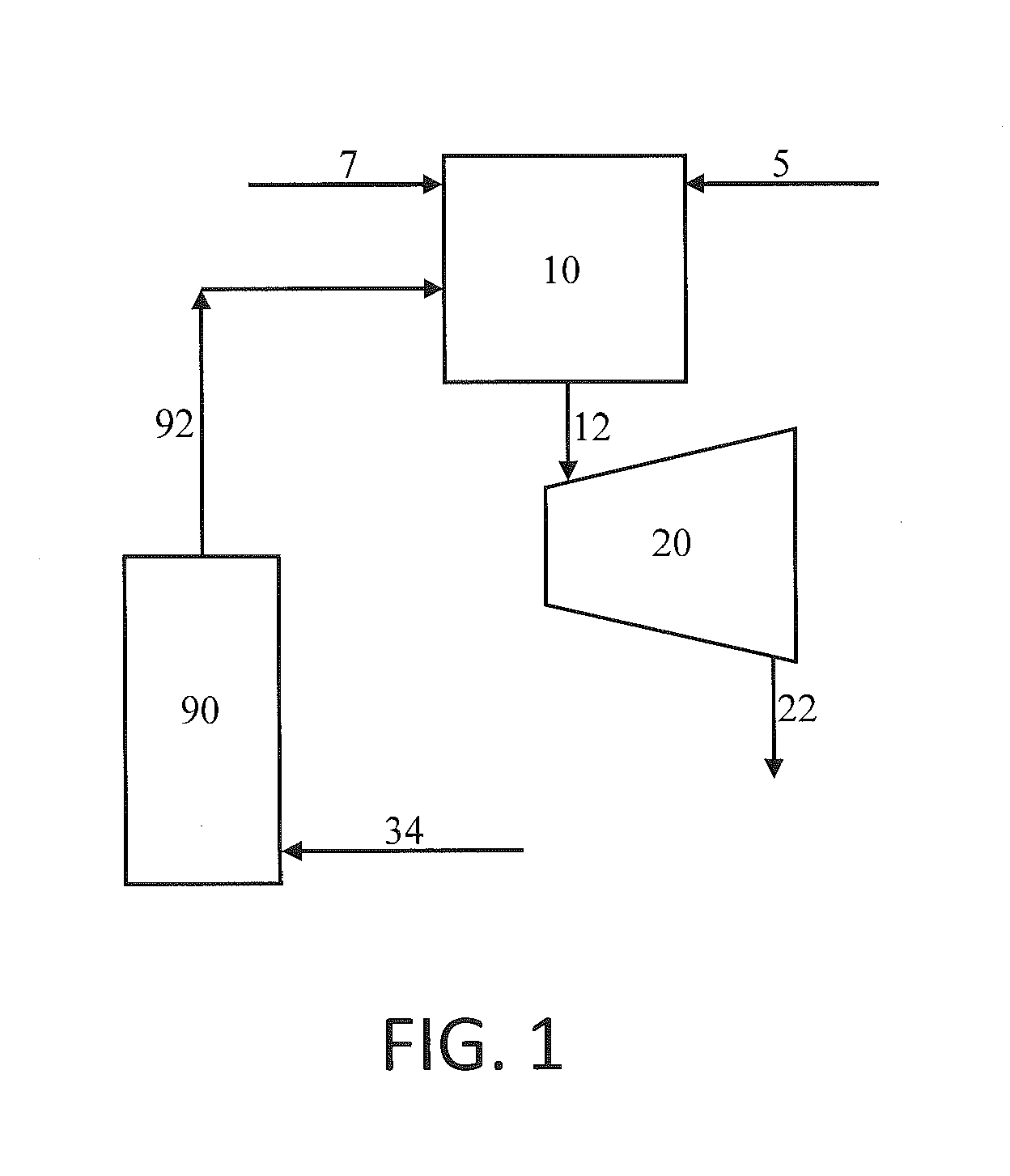

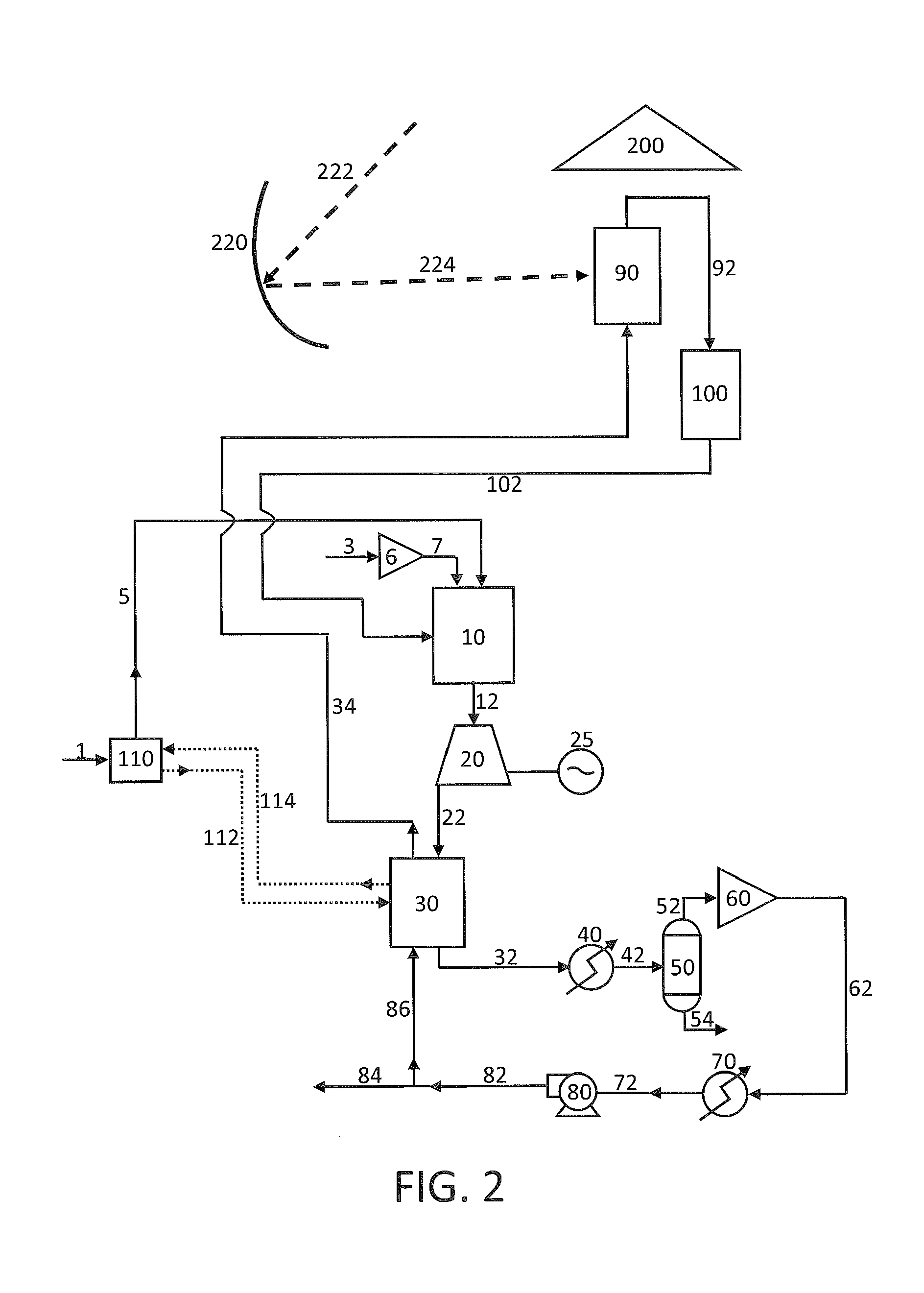

Hybrid fossil fuel and solar heated supercritical carbon dioxide power generating system and method

InactiveUS20130118145A1Improve efficiencyLow calorific valueSolar heating energyFrom solar energyCombustion systemWorking fluid

The present disclosure provides an integrated power generating system and method that combines combustion power generation with solar heating. Specifically, a closed cycle combustion system utilizing a carbon dioxide working fluid can be increased in efficiency by passing at least a portion of a carbon dioxide working fluid through a solar heater prior to passage through a combustor.

Owner:8 RIVERS CAPTTAL LLC

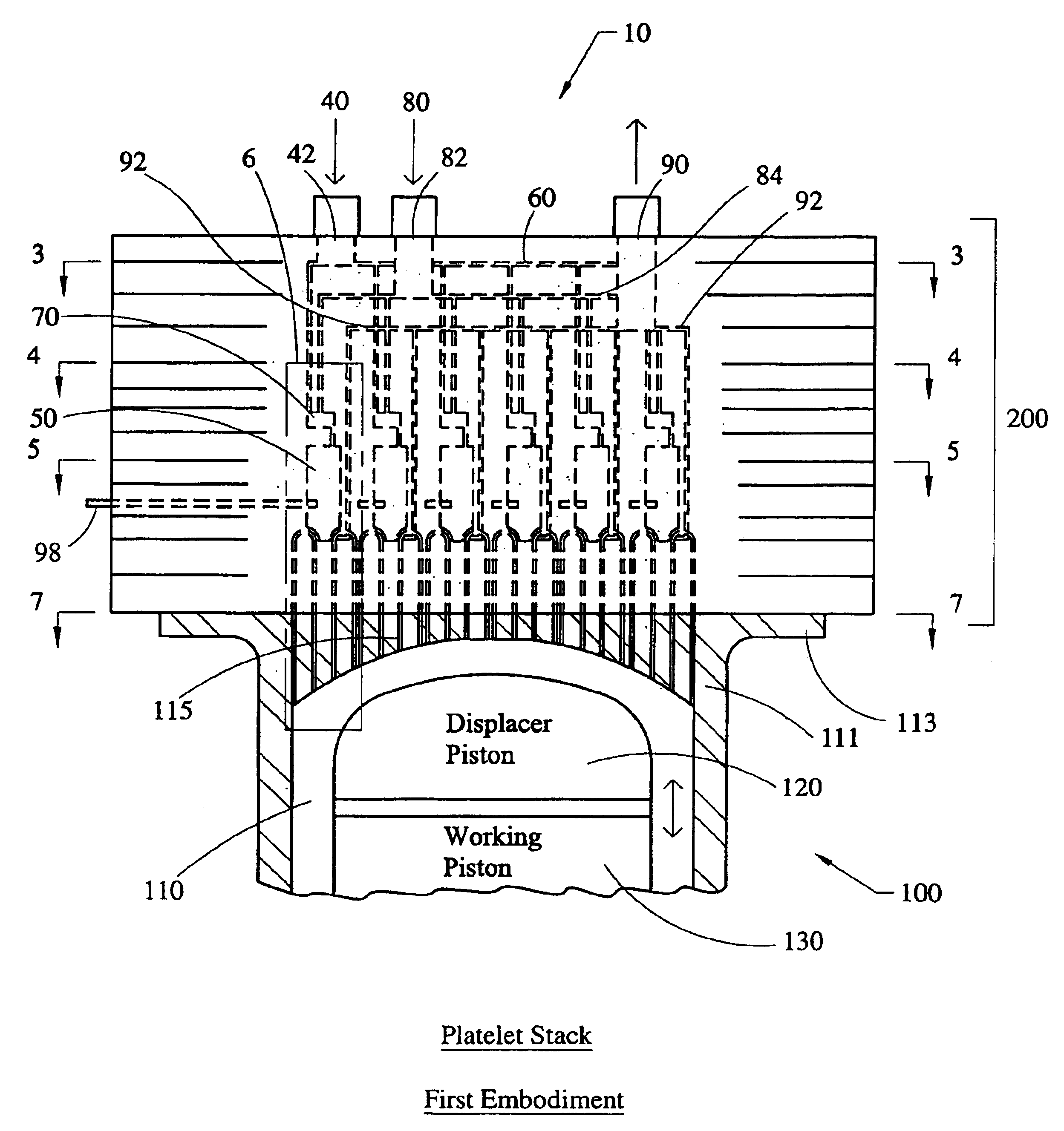

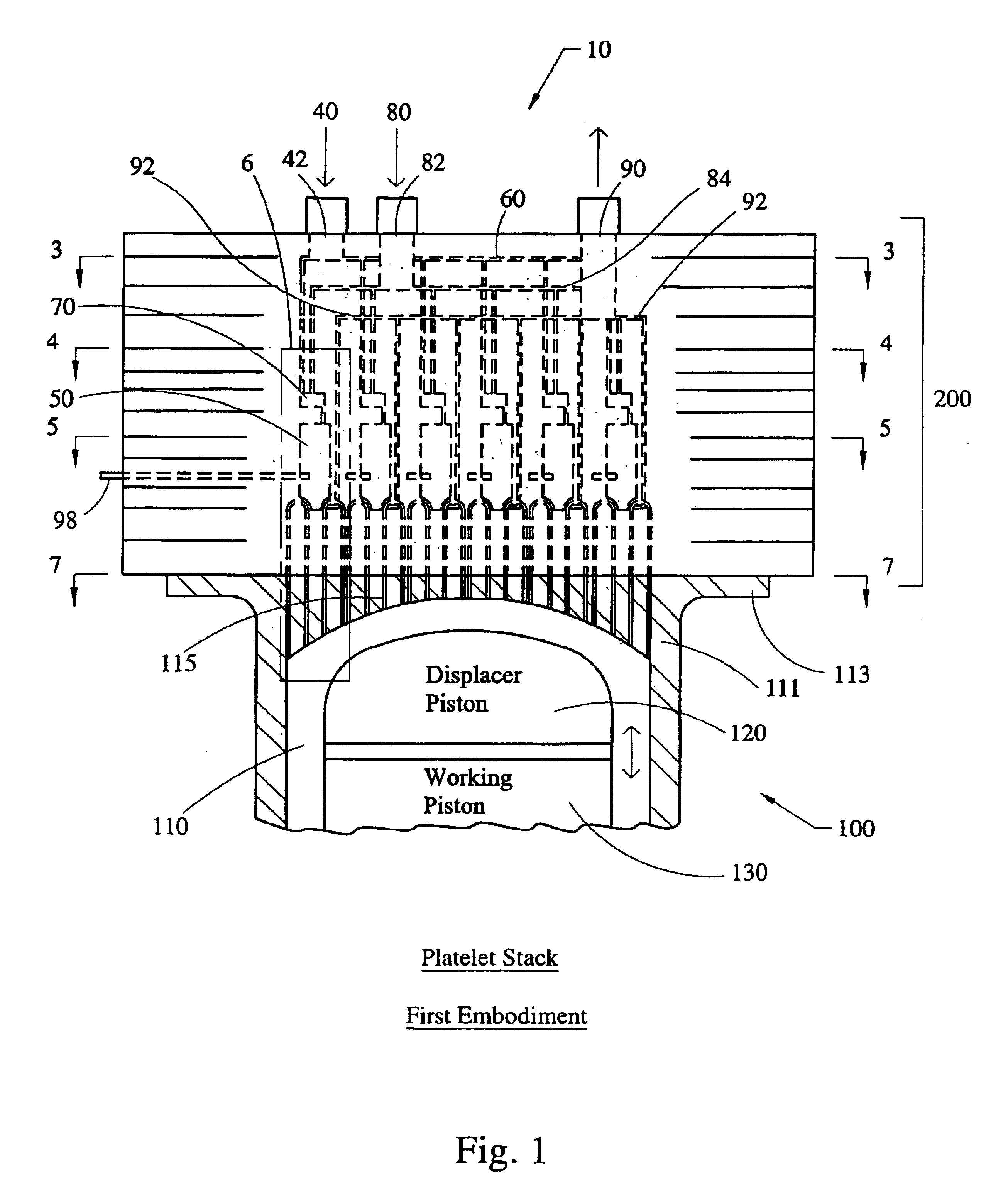

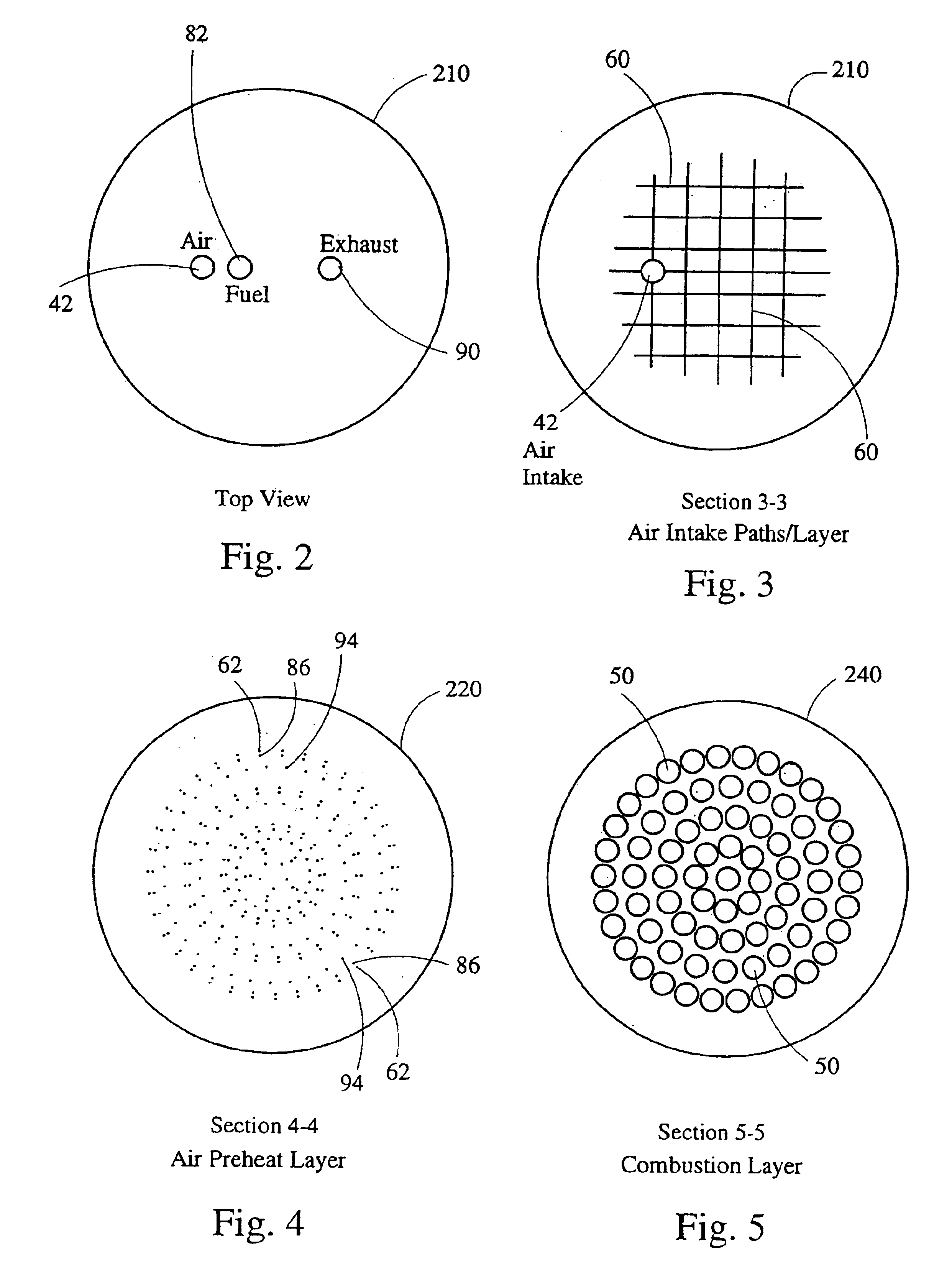

Stirling engine having platelet heat exchanging elements

InactiveUS6931848B2Guaranteed uptimeEfficient heat transferSolar heating energySolar heat devicesEngineeringStaged combustion

The present invention provides heat exchanging elements for use in Stirling engines. According to the present invention, the heat exchanging elements are made from muliple platelets that are stacked and joined together. The use of platelets to make heat exchanging elements permits Stirling engines to run more effiecient because the heat transfer and combustion processes are improved. In one embodiment, multi-stage combustion can be introduced with platlets, along with the flexibility to use different types of fuels. In another embodiment, a single component constructed from platelets can provide the heat transfer rquirements betweeen the combustion gas / working gas, working gas in the regenerator and the working gas / coolant fluid of a Stirling engine. In another embodiment, the platelet heat exchanging element can recieve solar energy to heat the Stirling engine's working gas. Also, this invention provides a heat exchanging method that allows for multiple fluids to flow in opposing or same direction.

Owner:DISENCO +1

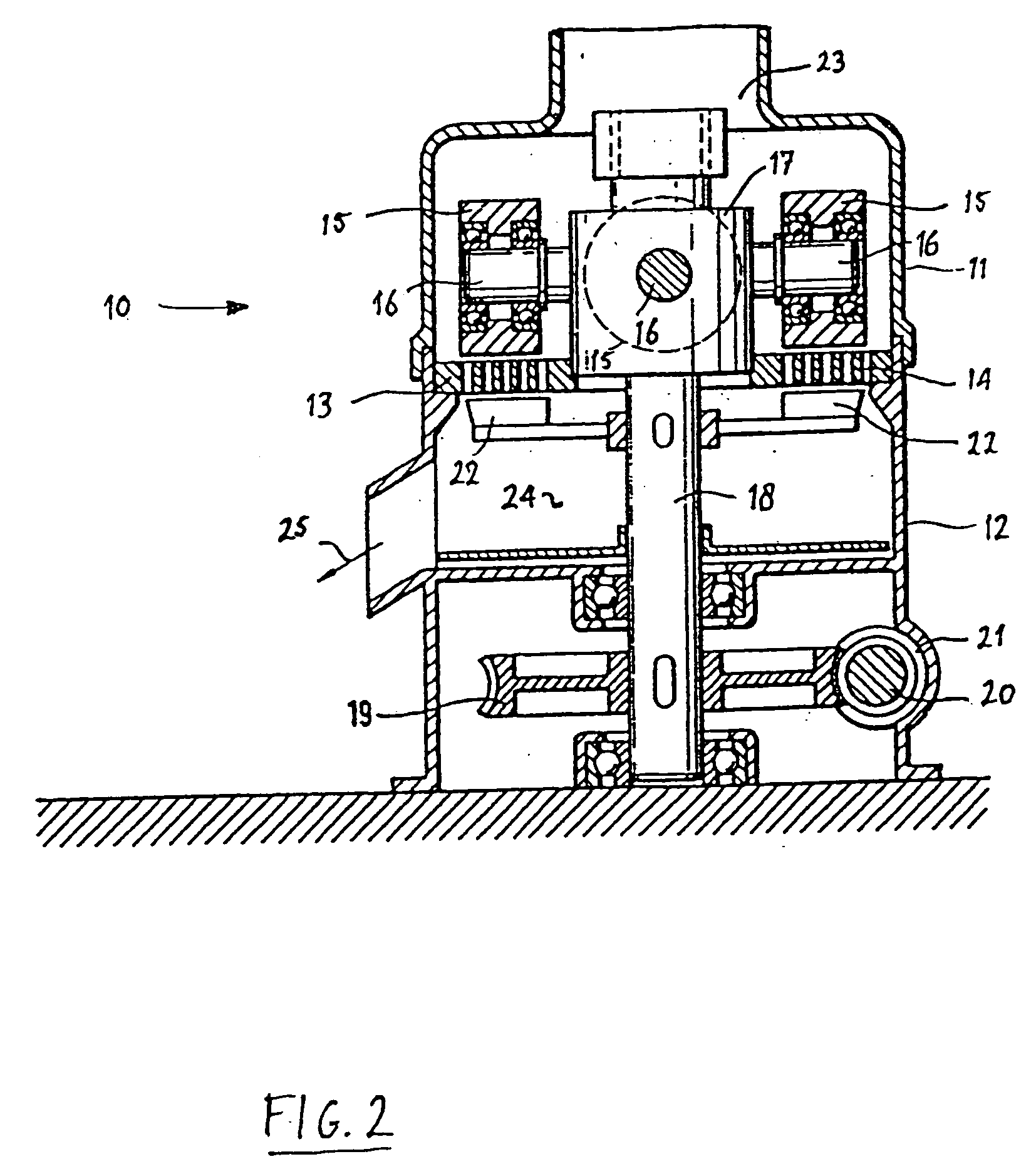

Electrolysis cell and internal combustion engine kit comprising the same

InactiveUS6896789B2Improve combustion efficiencyRealized benefitsCellsPhotography auxillary processesElectrolysisCombustion

A system for producing one or more gases for enhancing combustion in an internal combustion engine, the engine having an intake, the system comprising: an electrolysis cell, for generating one or more combustion enhancing gases under pressure; a gas conduit, for connecting the electrolysis cell to the internal combustion engine; and a flow regulator, operatively connected between the electrolysis cell and the intake of the engine, for regulating a flow of the combustion enhancing gases to the engine.

Owner:CANADIAN HYDROGEN ENERGY CO LTD

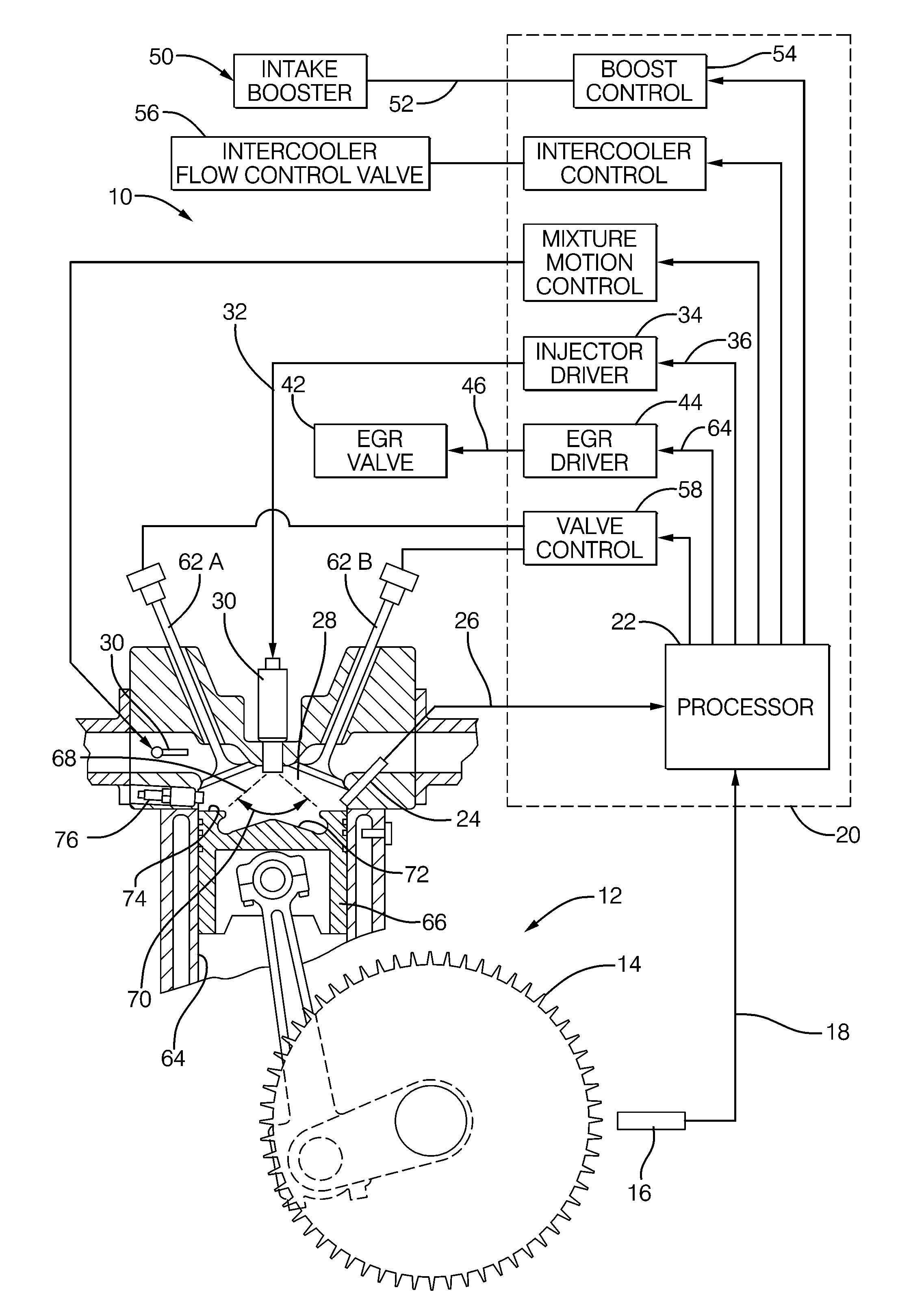

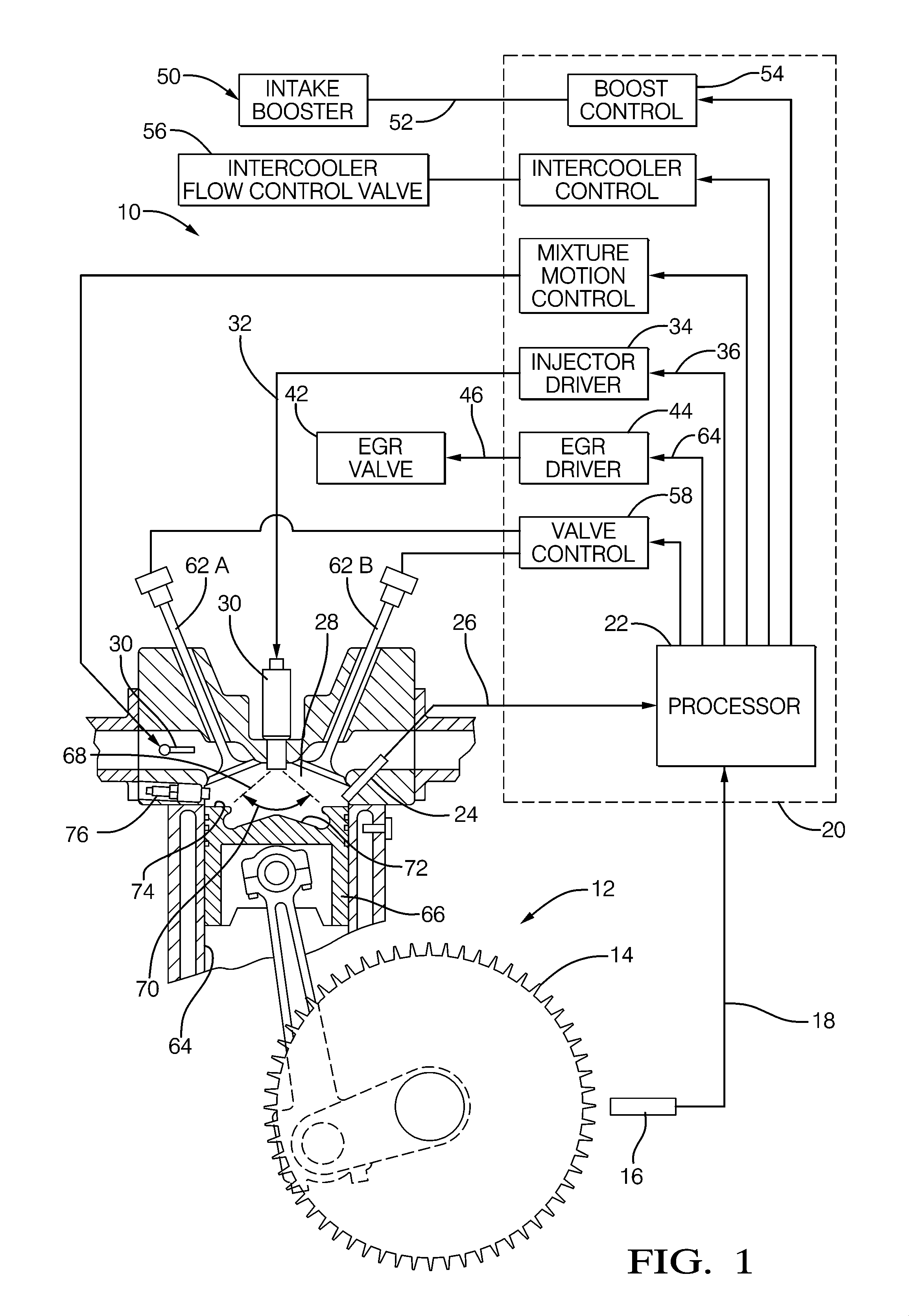

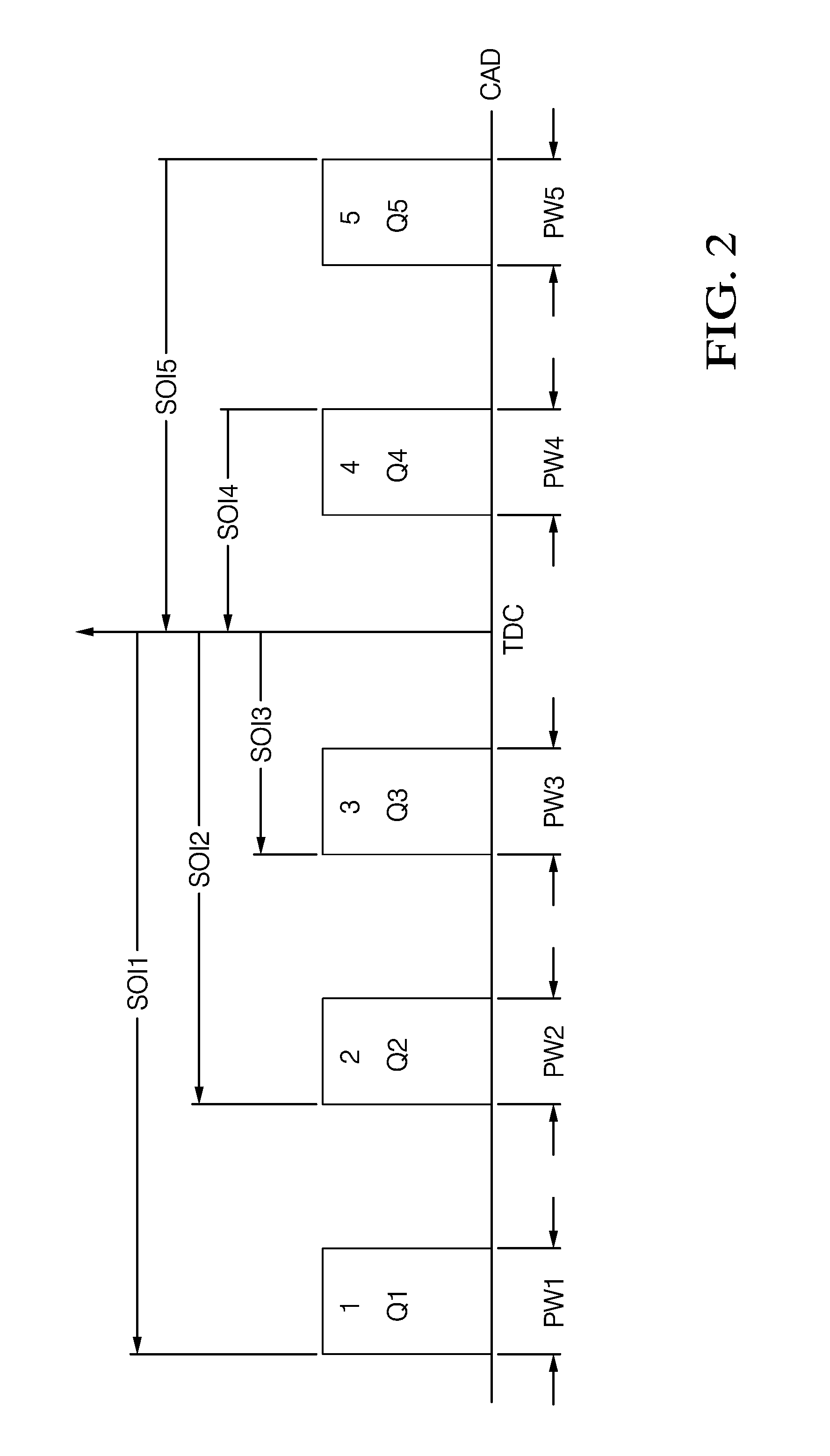

High-Efficiency Internal Combustion Engine and Method for Operating Employing Full-Time Low-Temperature Partially-Premixed Compression Ignition with Low Emissions

InactiveUS20130213349A1Improve efficiencyIncrease relative volatilityElectrical controlInternal combustion piston enginesLow noiseGasoline

An engine system and a method of controlling a combustion process in an internal combustion engine are disclosed. The combustion process is based on compression ignition of a stratified air-fuel mixture using a high octane fuel such as gasoline. Multiple fuel injections may be used in a given combustion cycle. Fuel injection timing, EGR, exhaust rebreathing, late intake valve closing, and intake boost are controlled to enable autoignition over essentially the entire speed and load operating range of the engine, while providing reduced emissions, low noise, and low fuel consumption.

Owner:DELPHI TECH IP LTD

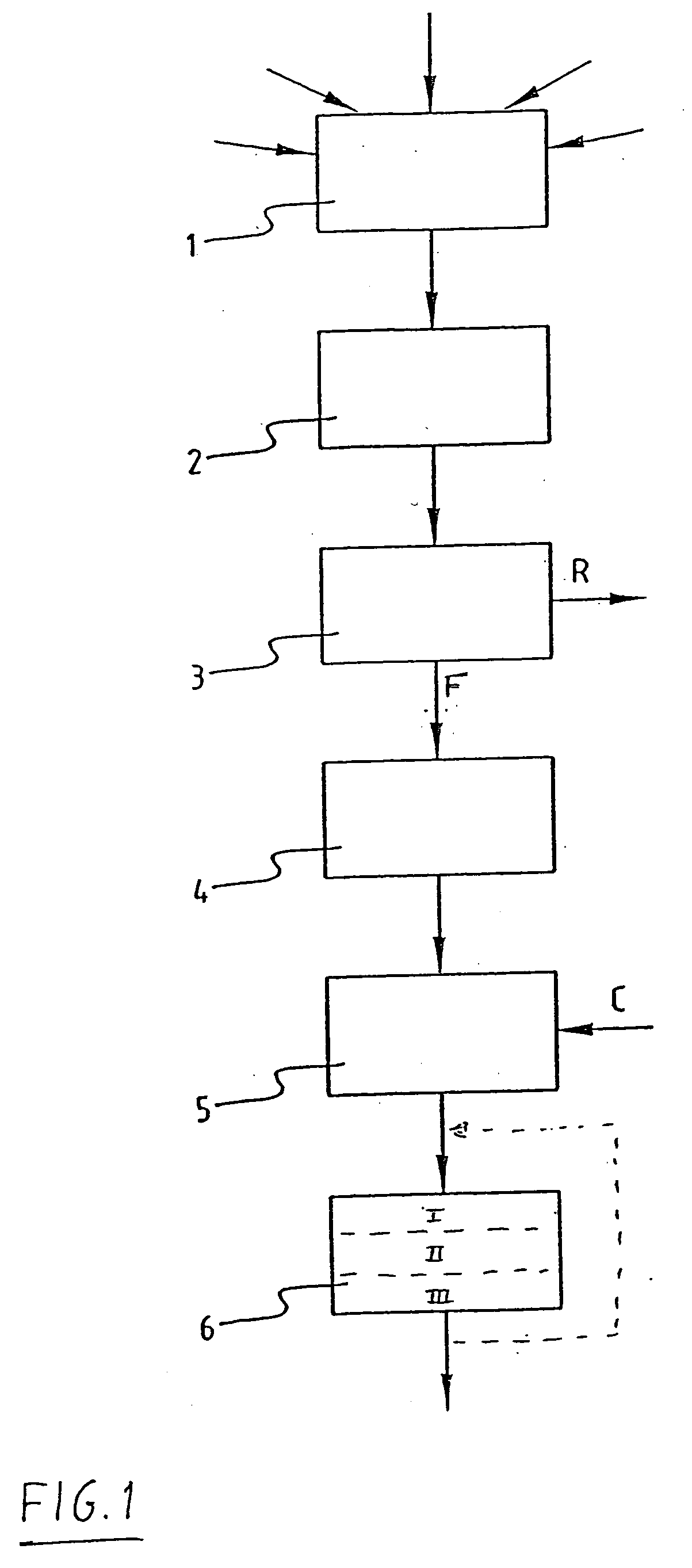

Method and installation for conversion into fuel of organic material originating for instance from domestic waste

InactiveUS20060123697A1Solution value is not highReduce outputBiofuelsSolid fuelsEnvironmental engineeringEngineering

A method is provided for converting organic material from domestic refuse into fuel for use in a pulverized coal power plant, comprising of mixing the organic material with at least one flammable material while adding binder, and pressing the mixture to form hard, relatively brittle agglomerates. Further provided is an installation for converting organic material from domestic refuse into fuel, comprising a device for mixing the organic material with at least one flammable material while adding binder, and device for pressing the mixture to form hard, relatively brittle agglomerates.

Owner:NEDCOAL PATENT IO

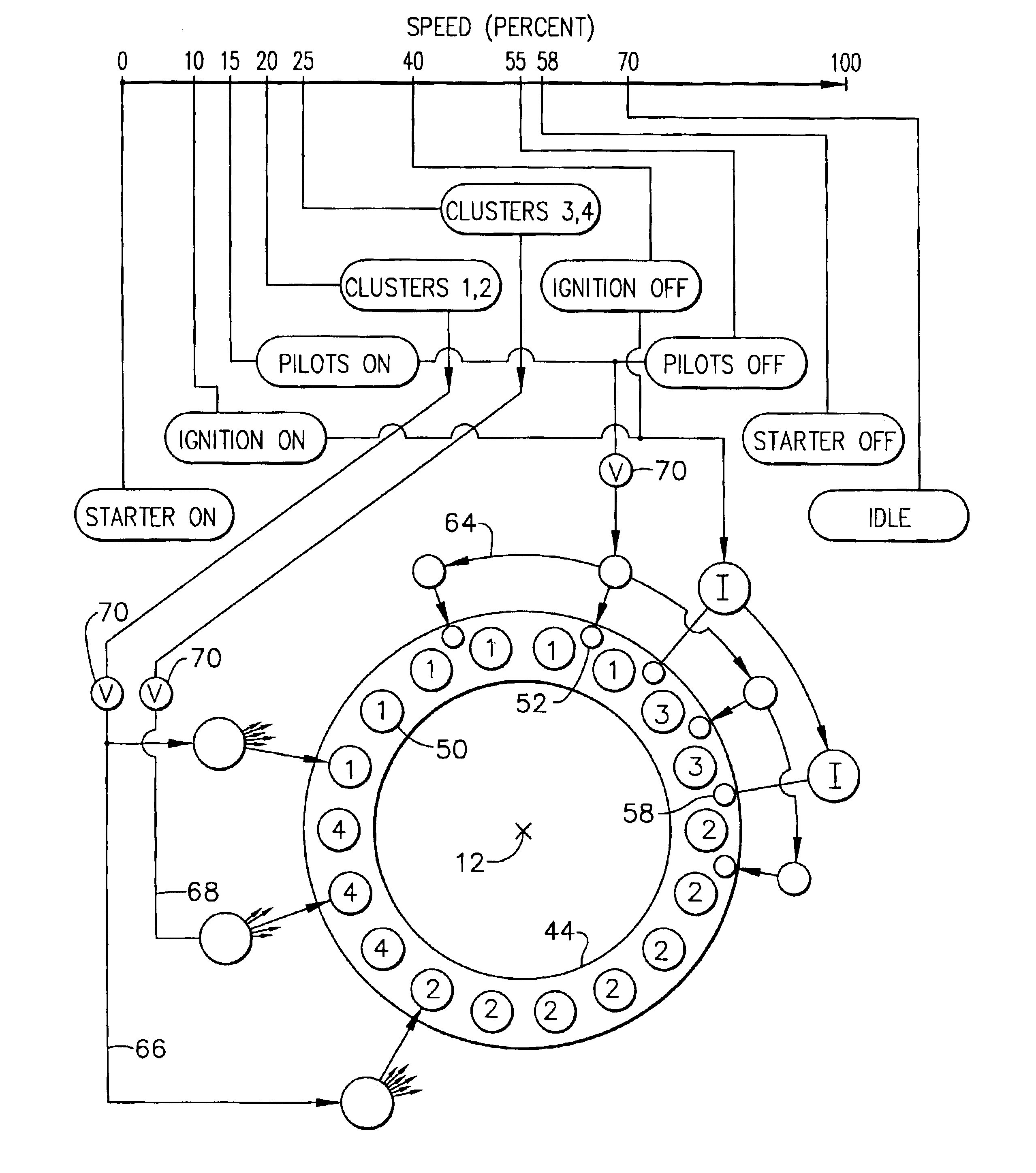

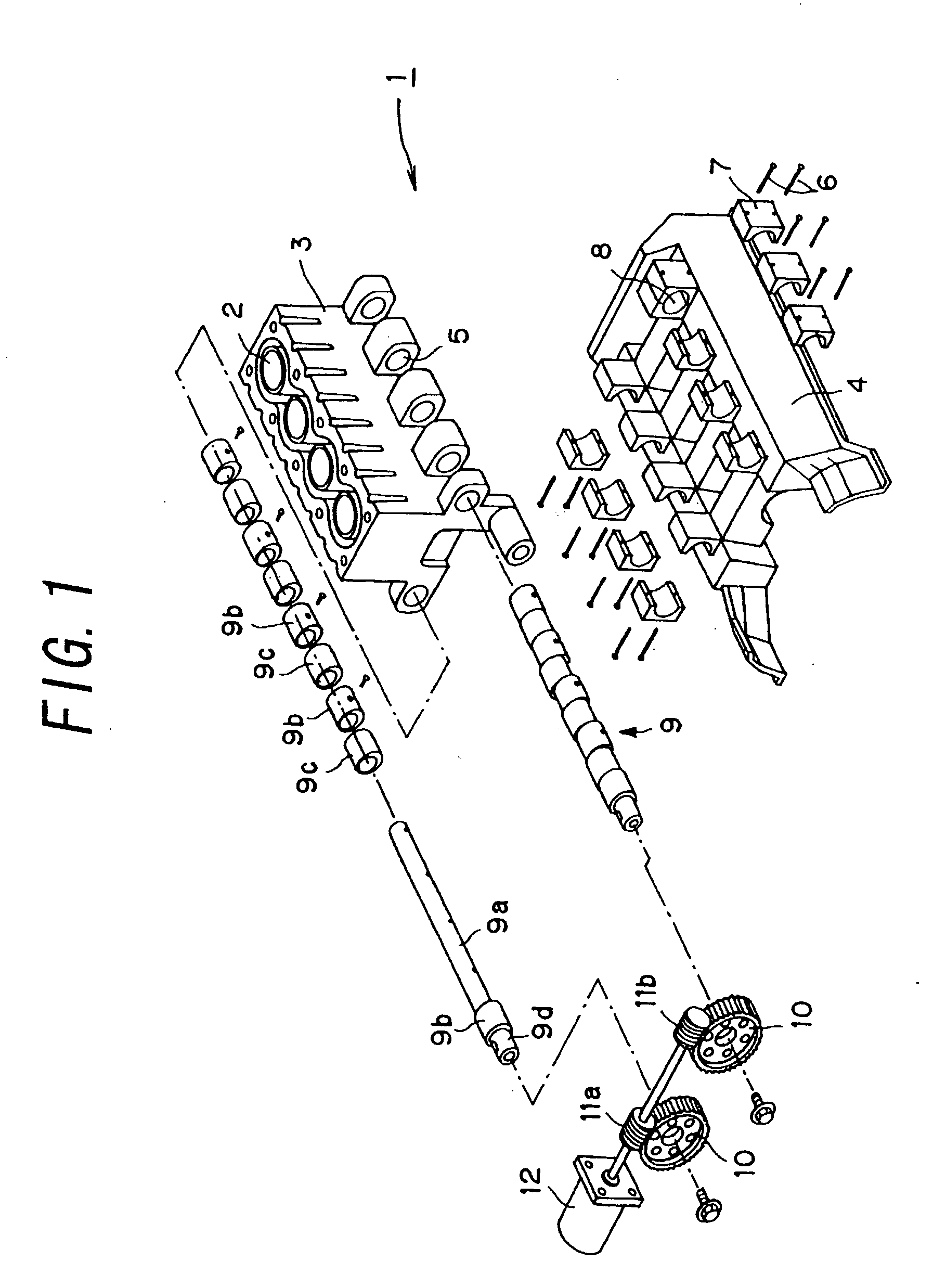

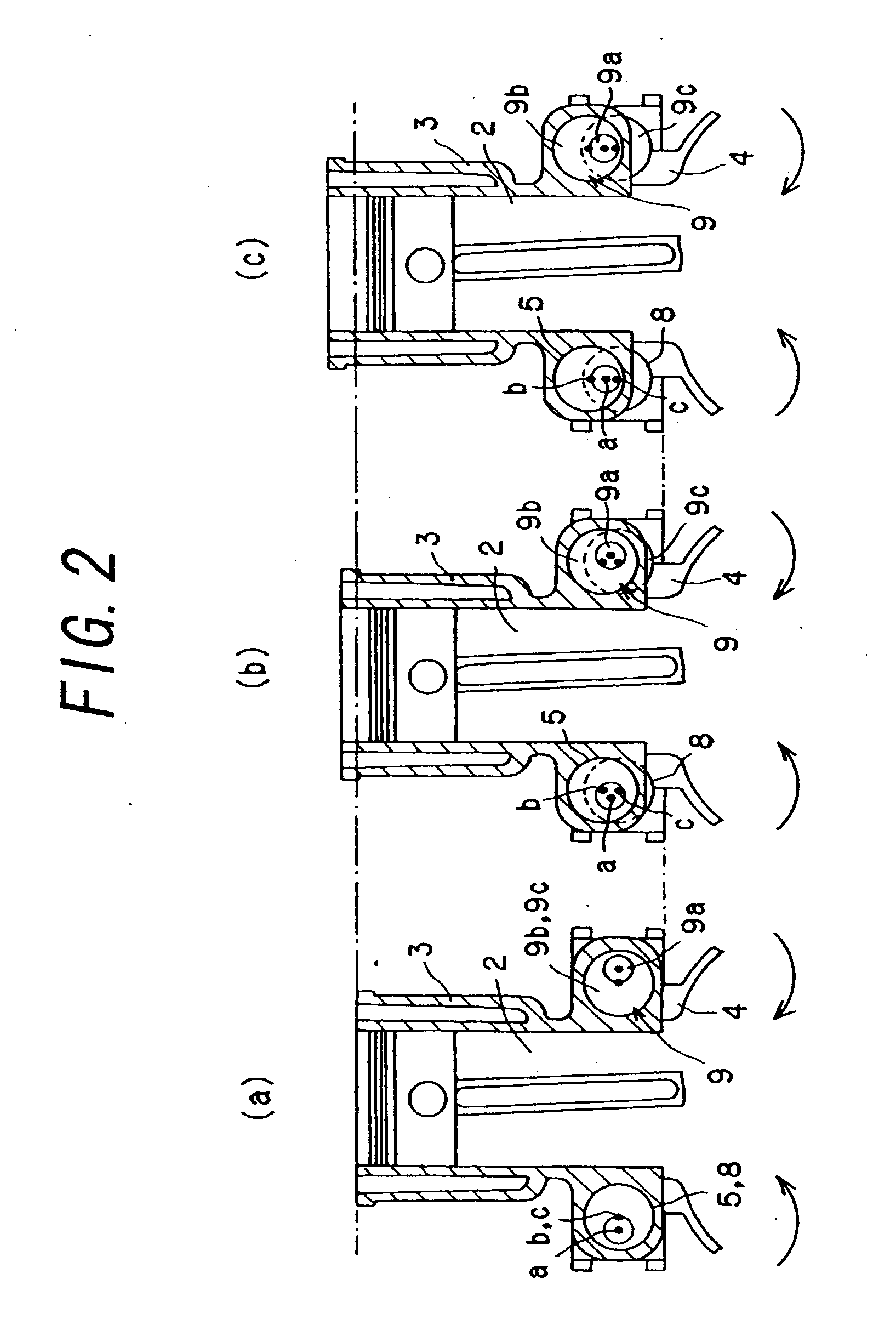

Sector staging combustor

InactiveUS6968699B2Improve combustion efficiencyLower ratioBurnersContinuous combustion chamberCombustorCombustion chamber

A combustor includes outer and inner liners joined together by a dome to define a combustion chamber. A row of air swirlers is mounted in the dome and includes corresponding main fuel injectors for producing corresponding fuel and air mixtures. Pilot fuel injectors fewer in number than the main injectors are mounted in the dome between corresponding ones of the swirlers. Staged fuel injection from the pilot and main injectors is used for starting the combustor during operation.

Owner:GENERAL ELECTRIC CO

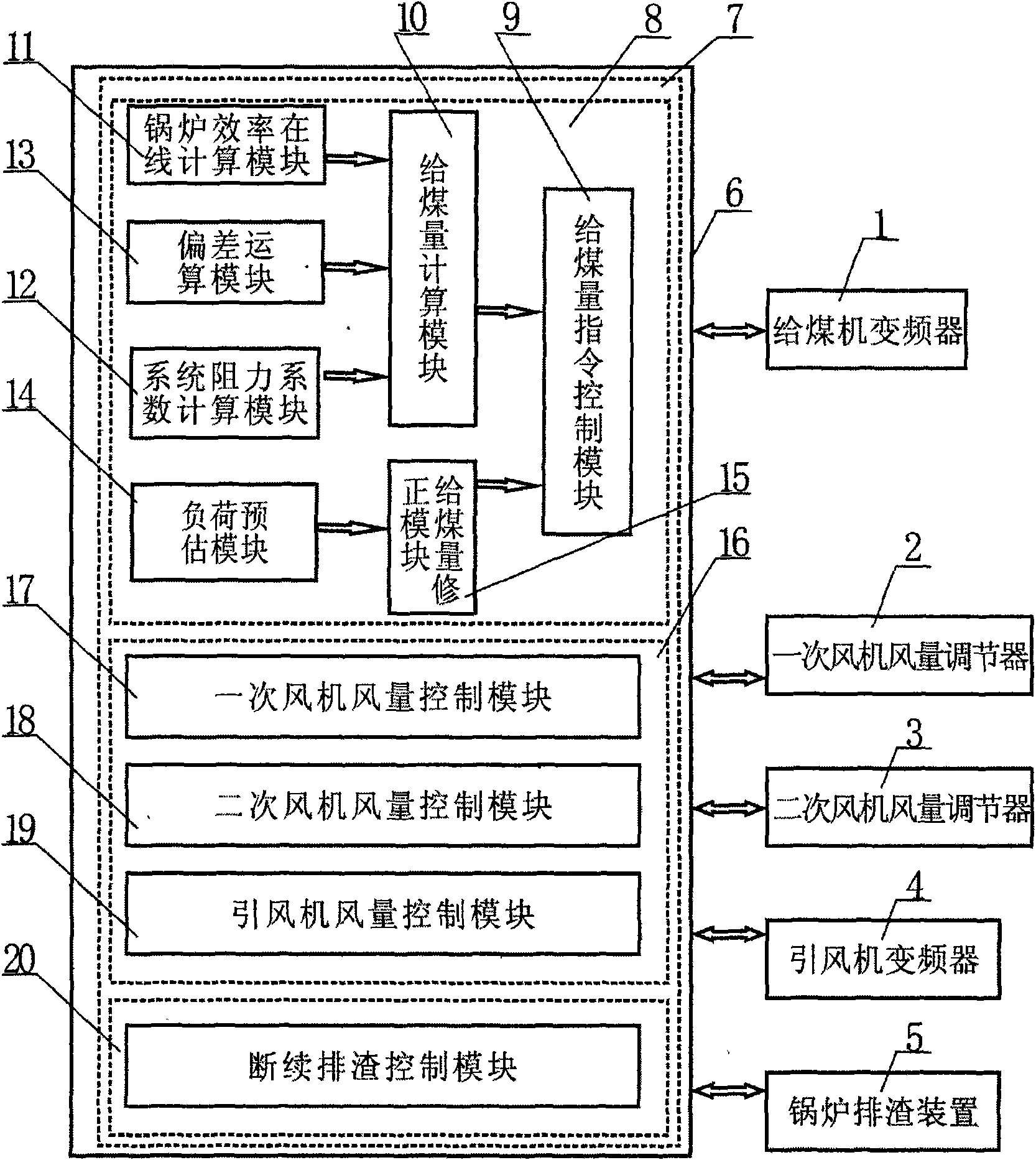

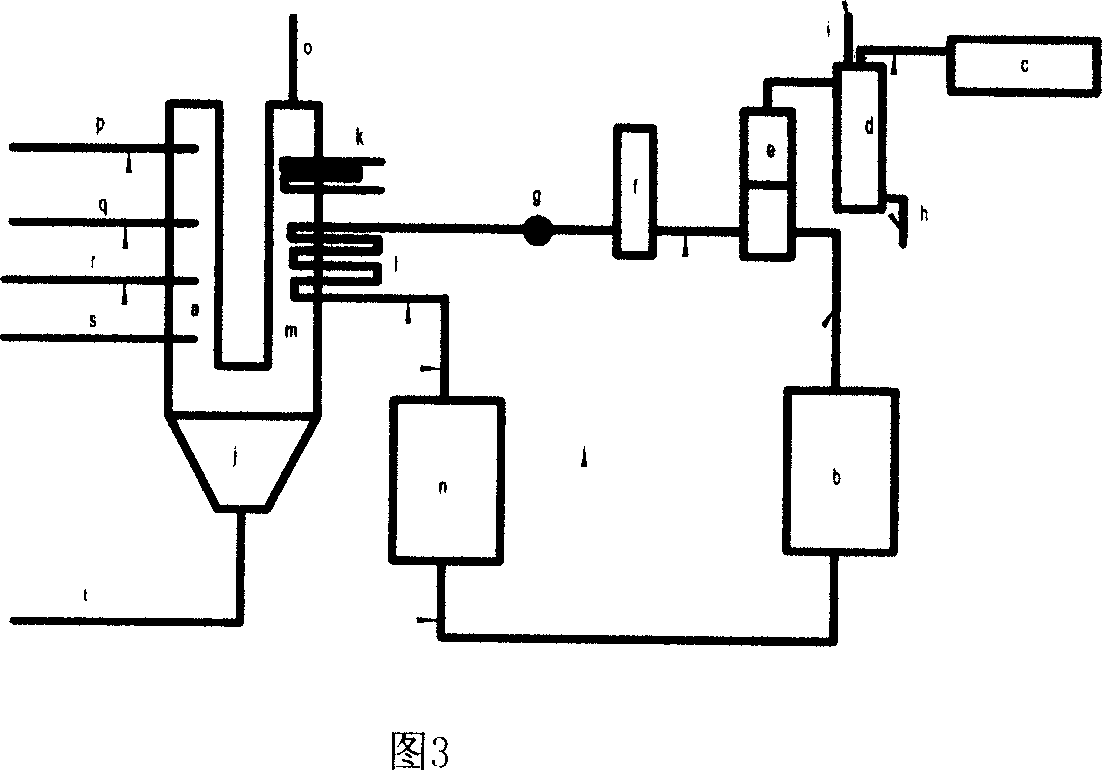

Automatic boiler combustion control system of circulating fluid bed

ActiveCN101551103AAdvanced and reasonable designImprove combustion efficiencyFluidized bed combustionProgramme control in sequence/logic controllersSteam pressureAir volume

The invention discloses an automatic boiler combustion control system of a circulating fluid bed, which is applied to machine sets for coal-fired power generation, heat supply or combined heat and power generation. The system comprises hardware and control program software, wherein the control program software comprises a fuel control part, an air volume control part and a deslagging control part, and the control program software can automatically and timely control the input quantity of boiler fuel, the oxygen content in the boiler and the boiler deslagging device. The combustion control system is applicable to all sorts of complicated operating conditions, has consistently correct and reliable reaction, advanced and reasonable algorithm design as well as good control effect, is safe and effective, has the capabilities of improving boiler combustion condition, increasing boiler combustion efficiency and reducing unburned carbon in flue dust, leads main steam pressure control to be stable, enhances the capability of tracking the change in load of the boiler and greatly improves the running safety performance, leads main steam temperature control precision to be effectively improved, avoids temperature excursion of an overheater, reduces the danger of steam turbine water slug caused by low-temperature steam, and improves the thermal efficiency and automation control degree of the steam turbine.

Owner:DONGGUAN TEXWINCA HLDG

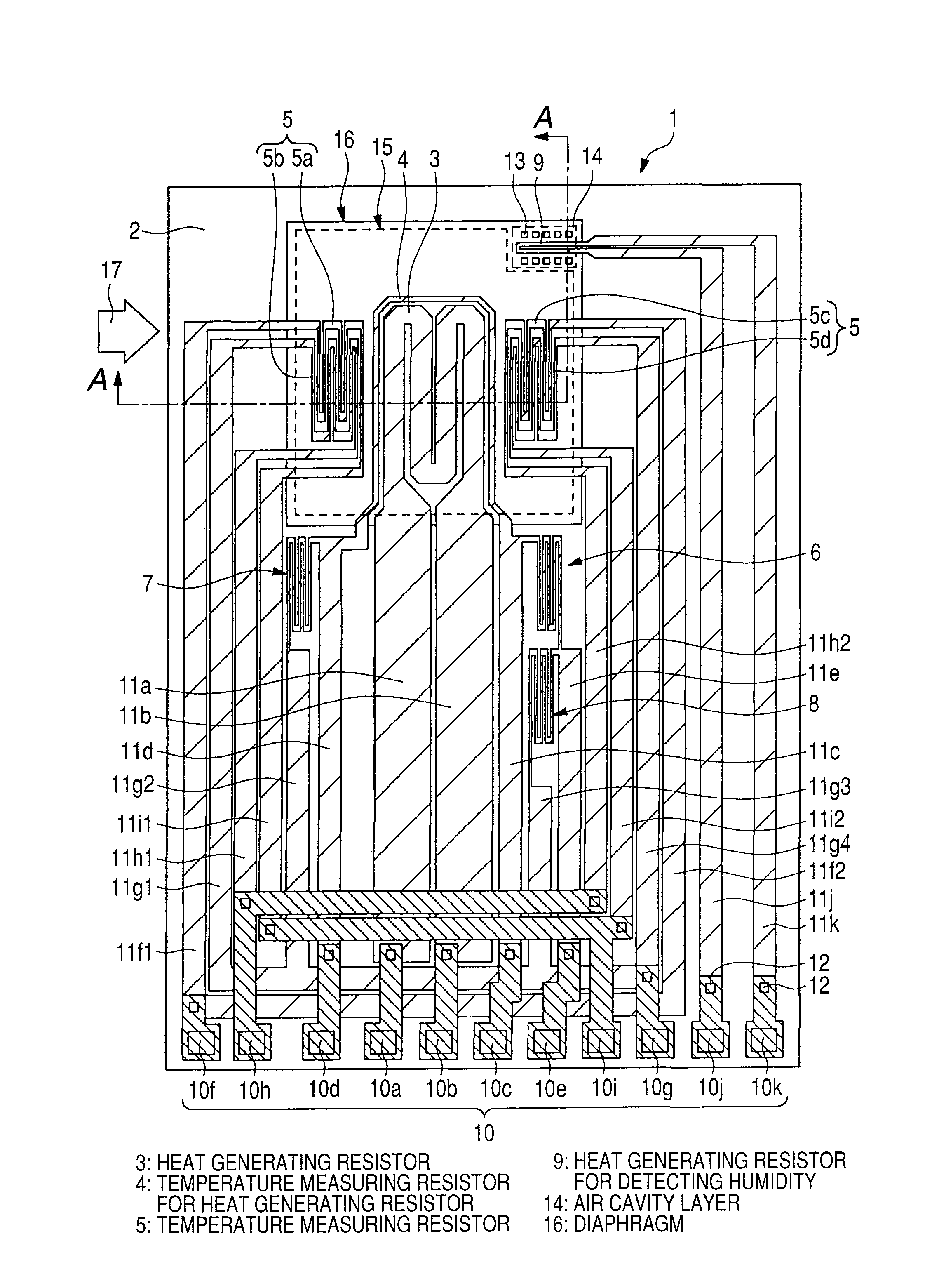

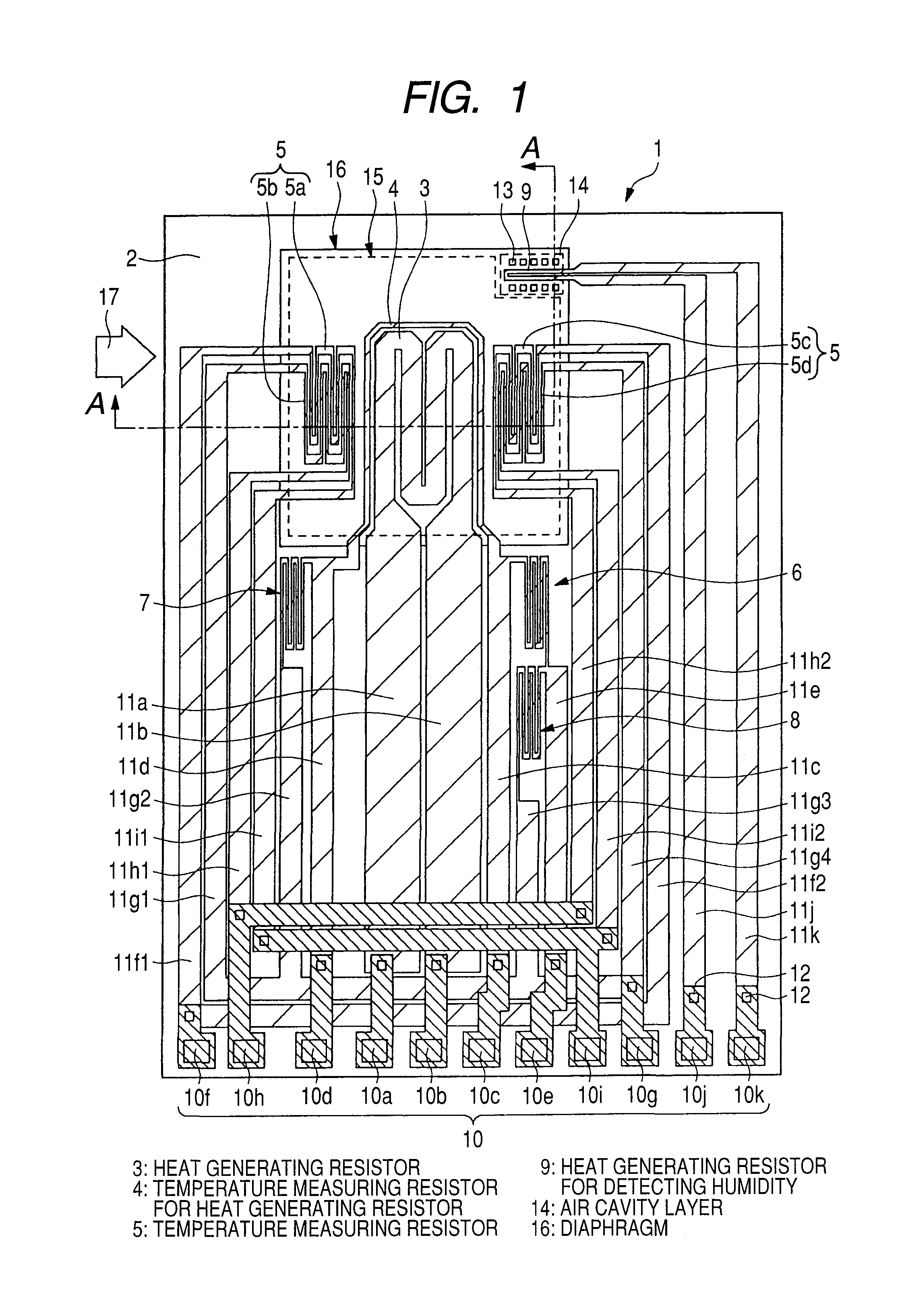

Thermal Type Fluid Flow Sensor and Fabricating Method

ActiveUS20110107832A1Improve accuracyAccurate humidityWave amplification devicesVolume/mass flow by thermal effectsEngineeringAir cavity

A thermal type fluid flow sensor includes an air flow detecting portion and a temperature detecting portion formed above the same substrate, capable of correcting a humidity, and having a high measuring accuracy at a low cost, and a heat generating resistor, a temperature measuring resistor for the heat detecting resistor, a temperature measuring resistor for detecting an air flow, and a heat generating resistor for detecting a humidity are arranged in a diaphragm formed above a semiconductor substrate, an air cavity layer, and a protecting film above the air cavity layer are formed above the heat generating resistor for detecting the humidity, and the protecting film is provided with plural holes reaching the air cavity layer.

Owner:HITACHI ASTEMO LTD

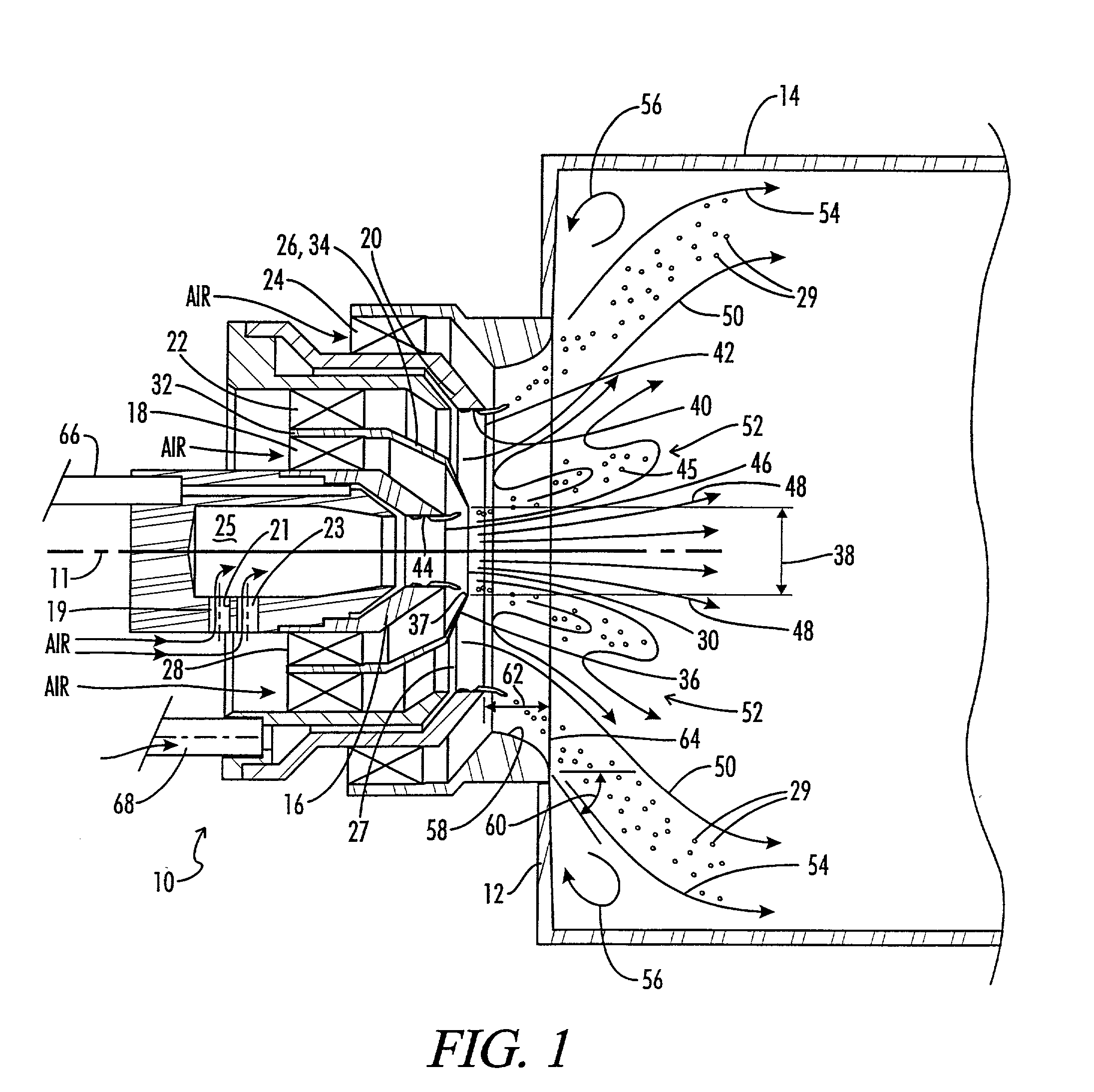

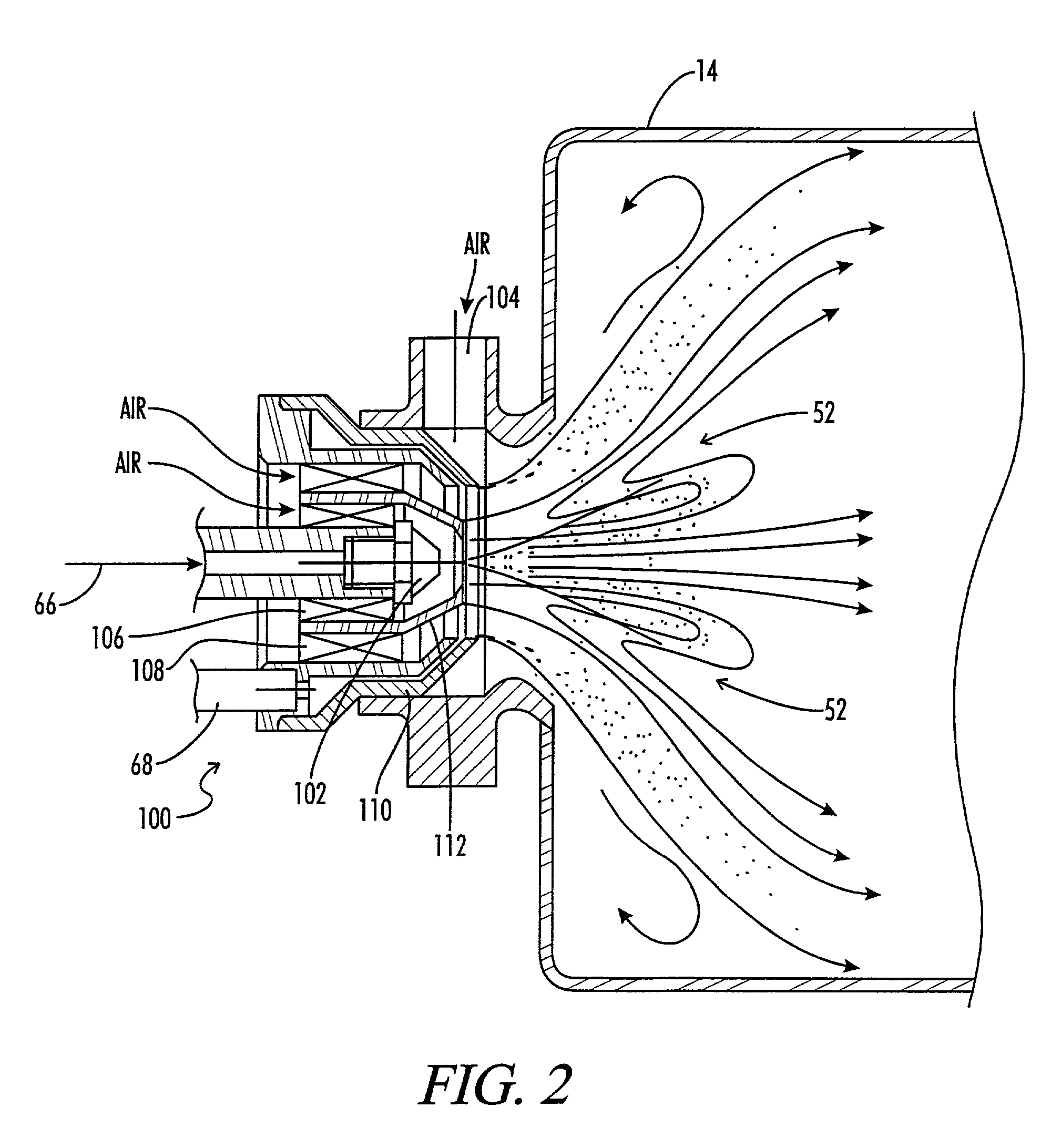

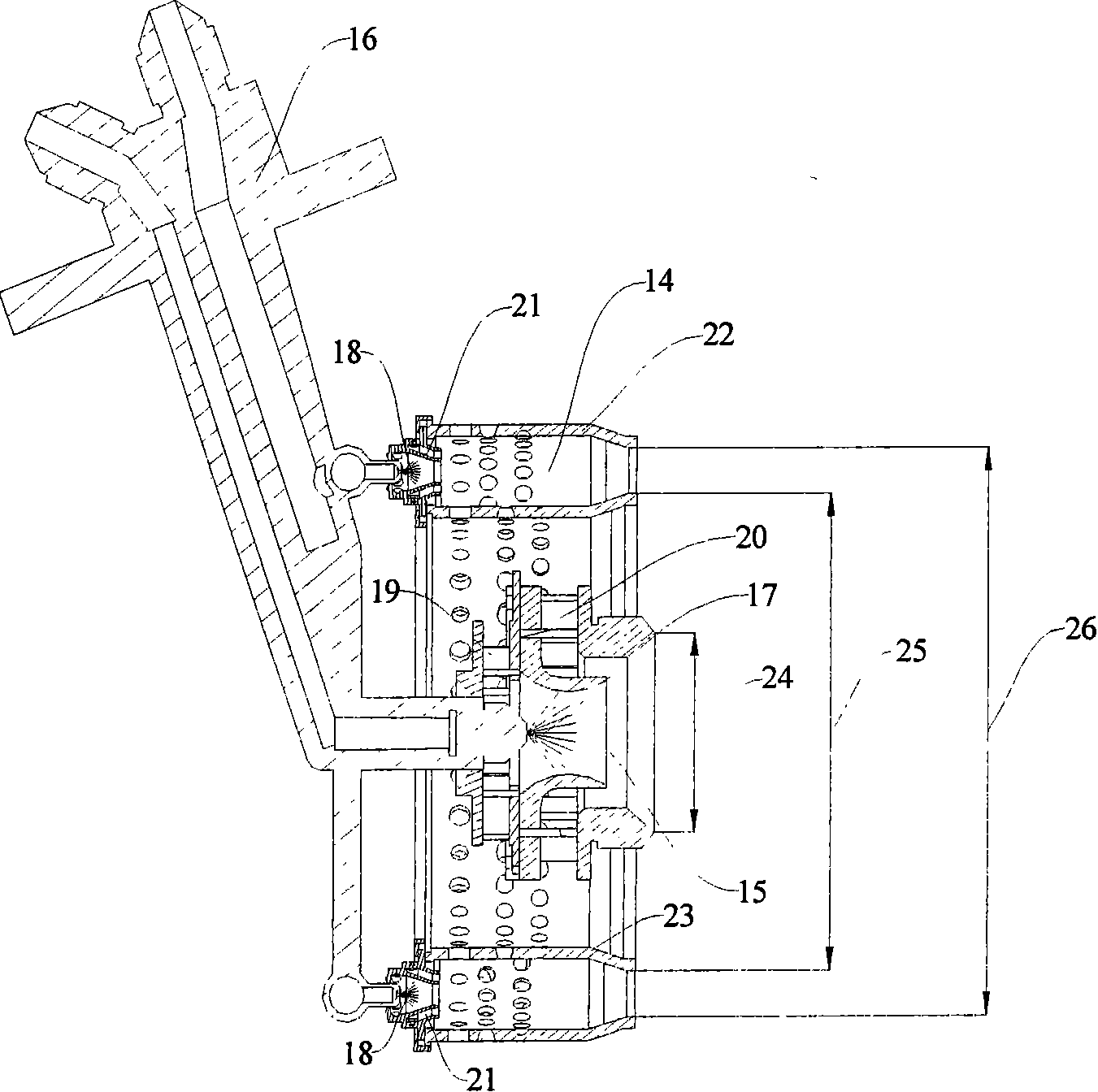

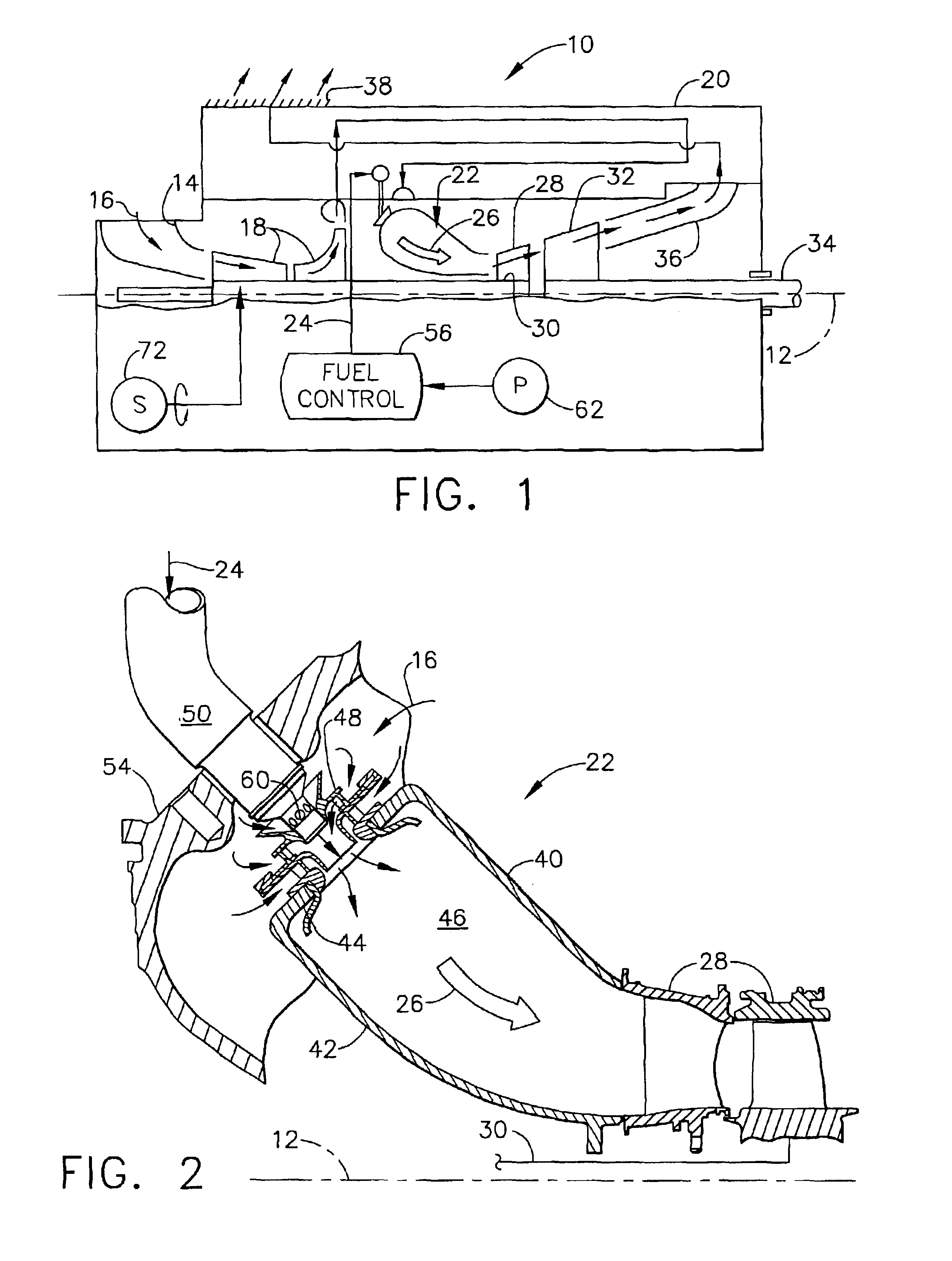

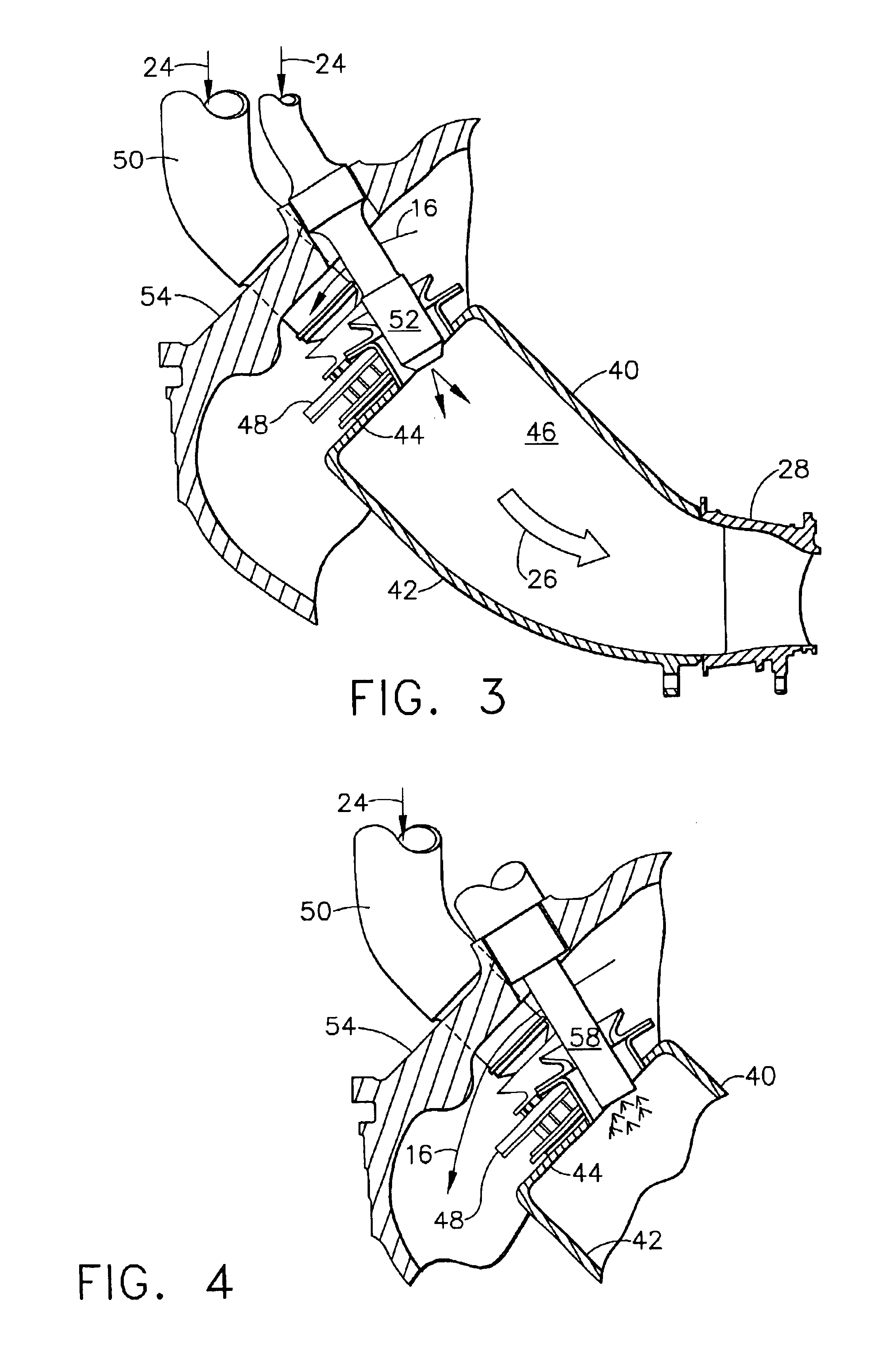

Piloted airblast lean direct fuel injector with modified air splitter

ActiveUS6986255B2Improve combustion efficiencyEmission reductionBurnersContinuous combustion chamberCombustion instabilityInjector

A fuel injector system that reduces and / or eliminates combustion instability. The fuel injector system includes a pilot fuel injector, a pilot swirler that swirls air past the pilot fuel injector, a main airblast fuel injector having an aft end, inner and outer main swirlers that swirl air past the main airblast fuel injector, and an air splitter located between the pilot swirler and the inner main swirler. The air splitter includes at least one aft end cone angled radially outboard and axially positioned downstream of the main airblast fuel injector aft end. The air splitter divides a pilot air stream exiting the pilot swirler from an inner main air stream exiting the inner main swirler to create a bifurcated recirculation zone.

Owner:ROLLS ROYCE PLC

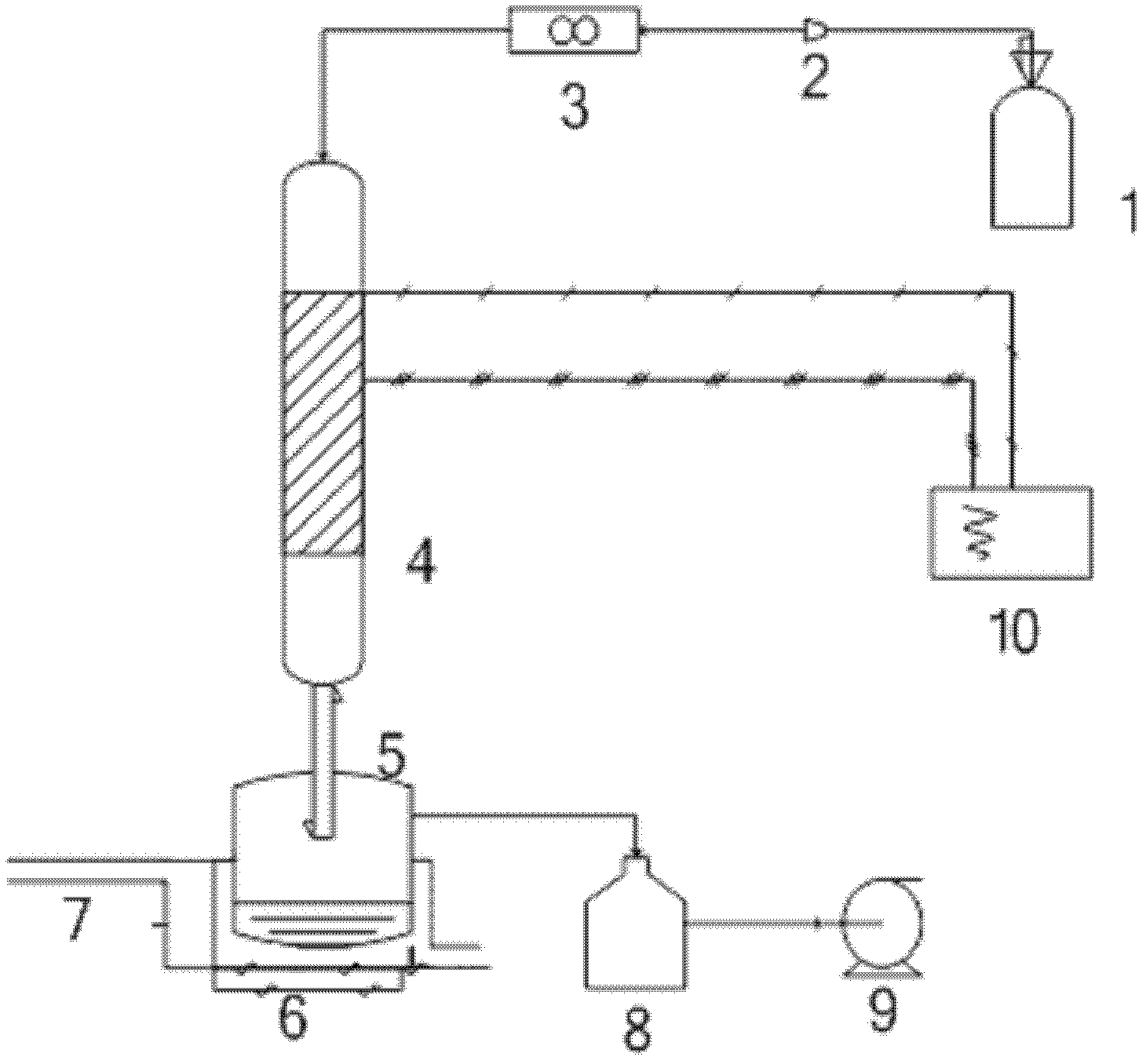

Method for coating micro/nano-metal powder by chemical vapor deposition

ActiveCN102581274ALow ignition temperatureShorter ignition delay timeChemical vapor deposition coatingThermal chemical vapor depositionIgnition delay

The invention discloses a method for coating micro / nano-metal powder by chemical vapor deposition, including: decomposing difluorocarbene precursor gas via a cracking pipe to generate difluorocarbene free radicals; contacting the generated difluorocarbene free radicals with micro / nano-metal powder, and due to polymerization between difluorocarbene free radicals, a compact polytetrafluoroethylene coating film is generated on the surface of micro / nano-metal powder. In allusion to disadvantages and defects of the application of micro / nano-metal powder in energy-containing materials, polytetrafluoroethylene is polymerized on the surface of metal powder by chemical vapor deposition in order to coat micro / nano-metal powder. In the invention, the ignition temperature of metal powder is effectively decreased, the ignition delay time is shortened, and the combustion speed of metal powder is improved; the surface of metal powder coated with polytetrafluoroethylene is highly hydrophobic, so that reactive metal powder can be effectively prevented from absorption of moisture and oxidation.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Electrolysis cell and internal combustion engine kit comprising the same

InactiveUS7143722B2Improve combustion efficiencyRealized benefitsCellsNon-fuel substance addition to fuelElectrolysisCombustion

A system for producing one or more gases for enhancing combustion in an internal combustion engine, the engine having an intake, the system comprising: an electrolysis cell, for generating one or more combustion enhancing gases under pressure; a gas conduit, for connecting the electrolysis cell to the internal combustion engine; and a flow regulator, operatively connected between the electrolysis cell and the intake of the engine, for regulating a flow of the combustion enhancing gases to the engine.

Owner:CANADIAN HYDROGEN ENERGY CO LTD

Sludge drying and incinerating treatment process

InactiveCN1931753AAvoid pollutionAvoid harmSludge treatment by oxidationByproduct vaporizationChemical compositionSludge

The present invention relates to environmental protection engineering technology, and is especially sludge drying and incinerating treatment process. The present invention has effective utilization of heat energy, no exhaust of harmful gas and bad smell, no exhaust of dangerous clinker, simple structure and high burning efficiency of the sludge incinerating system, no need of auxiliary fuel and other advantages.

Owner:BEIJING CHINA SCI GENERAL ENERGY & ENVIRONMENT CO LTD

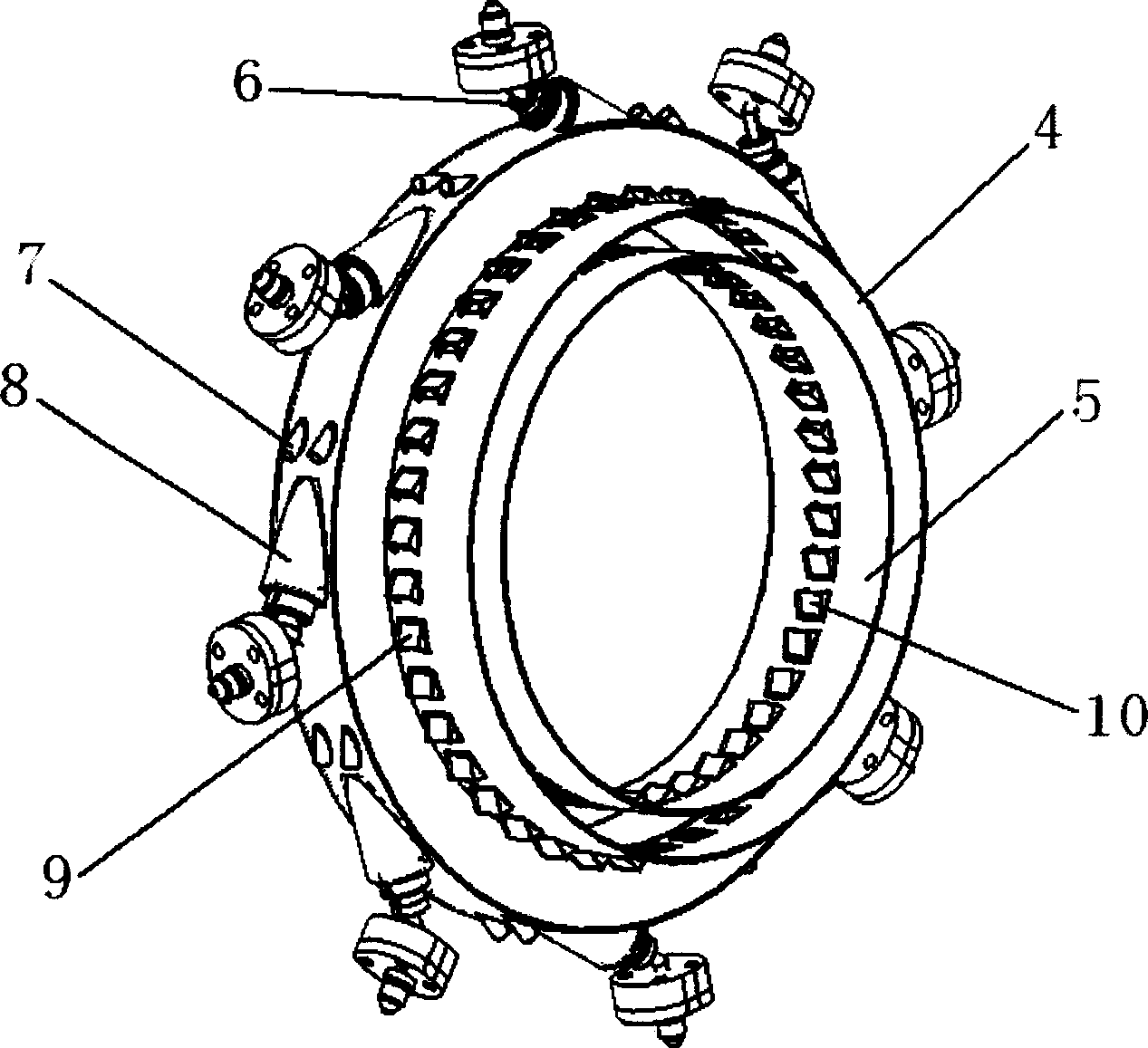

Tangential standing vortex burning chamber

InactiveCN1858498AReduce aerodynamic lossesReduce complexityContinuous combustion chamberCombustion chamberCombustor

The tangential standing vortex burning chamber in annular flame tube structure consists of inner and outer boxes and inner and outer flame tubes separately inside the inner and the outer boxes. The outer flame tube has one circumferential head including oil nozzle and flame stabilizing tube, and one main burning hole in the downstream of the head, and the central line of the head and the main burning hole is in some angle to the circumference tangent. The inner and outer flame tubes have inner and outer mixing holes separately in front of their combustors to ensure the excellent outlet temperature distribution, and inclined cooling holes in the walls and inclined to the main burning holes. The present invention has raised liquid atomizing combustion efficiency, reduced combustor outlet temperature distribution coefficient and expanded stable operation range of combustor.

Owner:BEIHANG UNIV

Turbine-based combined cycle engine super-combustion chamber

InactiveCN104019465ASatisfy Advancement RequirementsSolve key technical difficultiesContinuous combustion chamberRamjetGroove width

The invention discloses turbine-based combined cycle engine super-combustion chamber. Key parts of the super-combustion chamber comprise a shunt ring, a rear area-variable deflation valve, a flow guide tongue piece, a square lobe mixer, a first area fuel ejector, a center cone, a second area fuel injection ring, an evaporation tube flame stabilizer, a heat-isolating screen, a super-combustion chamber cylinder, an outer extending groove-width-variable radial flame stabilizer and an inner extending radial flame stabilizer. An internal flow field of the super-combustion chamber is reasonably distributed, the phenomenon of backflow from a punching duct to a turbofan duct can not occur, flow separation can not occur in the square lobe mixer, and the evaporation tube flame stabilizer can achieve soft ignition of the super-combustion chamber. The whole super-combustion chamber is high in mixing efficiency, little in cold flow resistance, high in combustion efficiency, reasonable in temperature distribution, and capable of meeting use requirements in a whole flight envelope of the super-combustion chamber in each work state and the requirement for boost of an turbofan ramjet.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

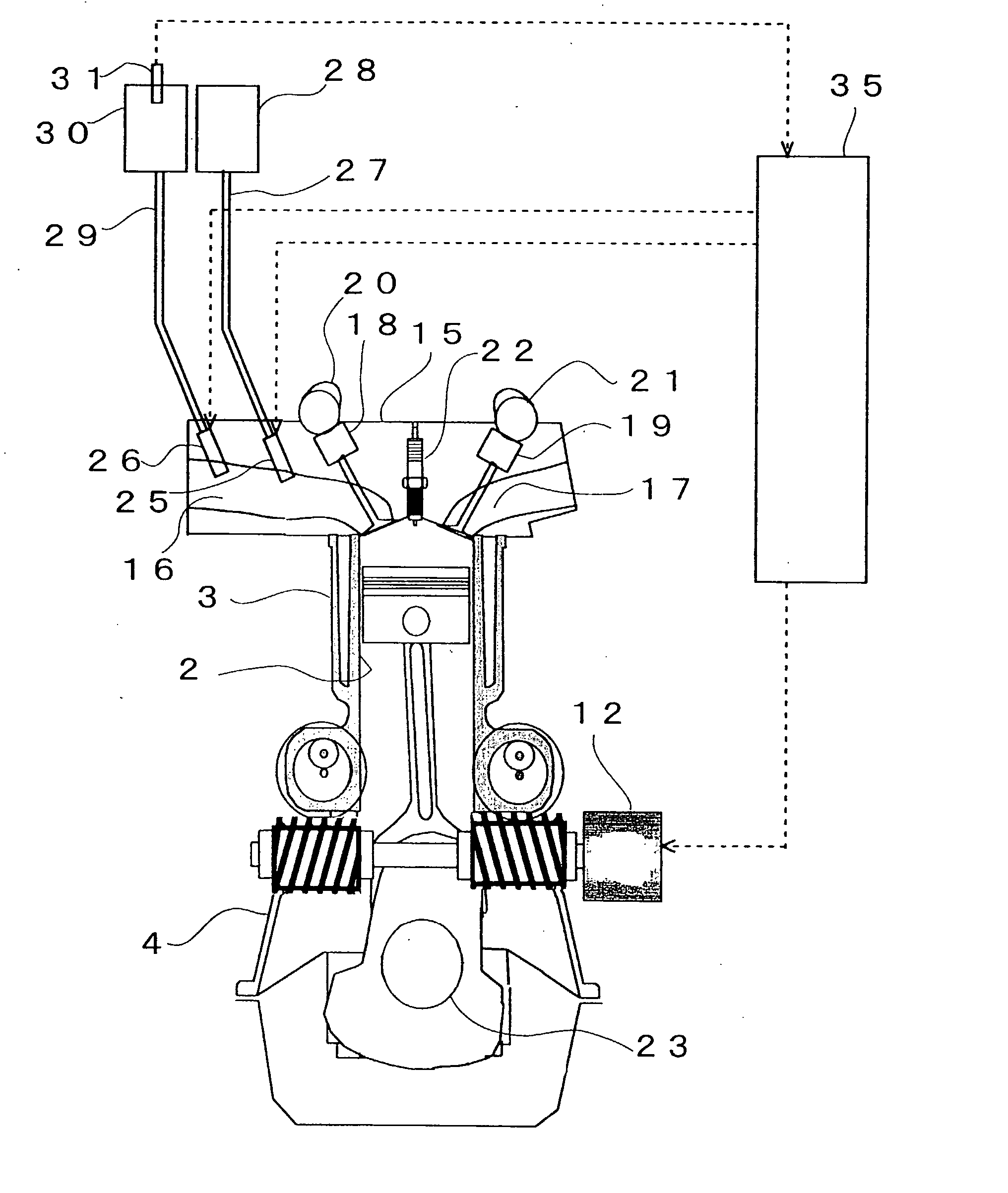

Variable Compression Ratio Internal Combustion Engine

InactiveUS20080022982A1Improve engine performanceImprove combustion efficiencyElectrical controlInternal combustion piston enginesCombustionFuel injection

The invention is directed to a variable compression ratio internal combustion engine in which the compression ratio of the engine can be varied and multiple types of fuels having different combustion velocities are used. The invention provides a technology for achieving excellent engine performance for respective types of fuels. In the variable compression ratio internal combustion engine in which the compression ratio can be varied and multiple types of fuels having different combustion velocities are injected through multiple fuel injection valves, maps from which a target compression ratio of the internal combustion engine is read out are switched in accordance with the fuel used, thereby suppressing knocking or other disadvantages.

Owner:TOYOTA JIDOSHA KK

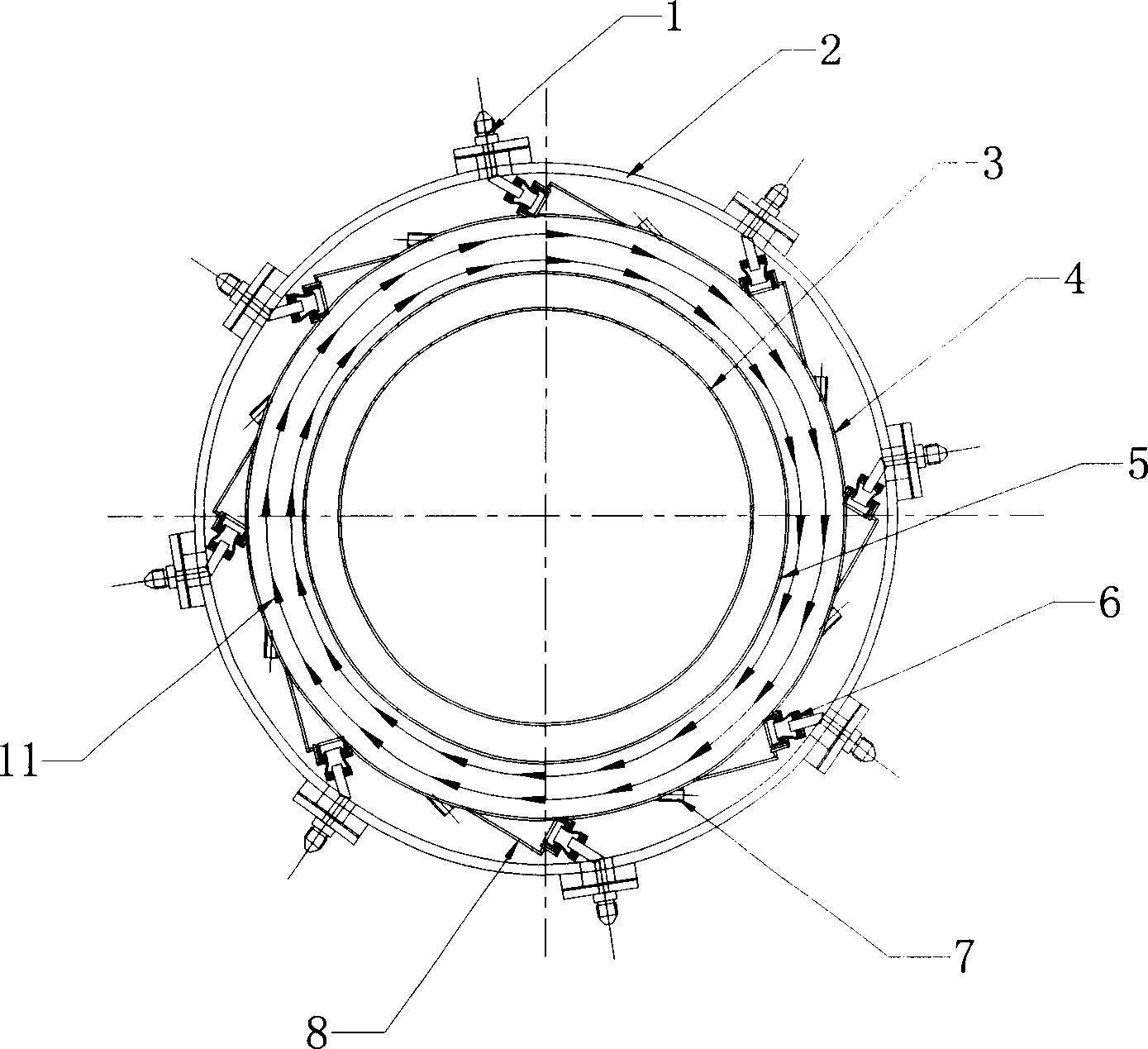

Low-pollution combustion chamber adopting fuel-grading and three-stage cyclone air inlet

ActiveCN103256633AEvenly distributedInhibition formationContinuous combustion chamberCycloneCombustion chamber

The invention discloses a low-pollution combustion chamber adopting fuel-grading and three-stage cyclone air inlet. The low-pollution combustion chamber comprises an on-duty oil supply nozzle, a primary-combustion oil supply nozzle, three-stage cyclones and a flame tube. Fuel is respectively provided for the on-duty oil supply nozzle and the primary-combustion oil supply nozzle in two ways, and the three-stage coaxial cyclones supply air to the head of a combustion chamber. The two stages of cyclones on the inner side of the combustion chamber refer to an oblique-cutting hole cyclone and a radial cyclone, cyclone of the two-stage cyclones are in opposite directions. A centrifugal atomizing nozzle is arranged at the center of the oblique-cutting hole cyclone, and the second-stage cyclone on the inner side are combined and matched with a center on-duty nozzle. The cyclone on the outside of the combustion chamber is a radial cyclone with cyclone direction opposite to that of a second-stage cyclone. Primary combustion fuel enters a cyclone blade channel from small holes of a front wall surface of a third-stage cyclones by way of multipoint direct injection and is accelerated to be crushed and atomized in a cyclone channel to be mixed with the air, and forms premixed or partly premixed fuel-air mixture at an exit of the tertiary swirling influx to enter a primary combustion zone to be combusted. The low-pollution combustion chamber is applicable to aircraft engine combustion chambers or industry fuel turbine combustion chambers.

Owner:中科航空动力(株洲)装备制造研究院有限公司

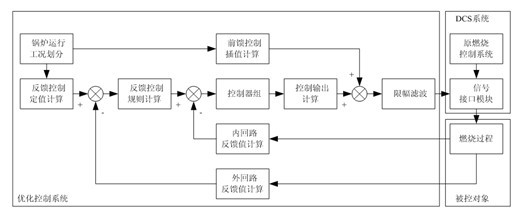

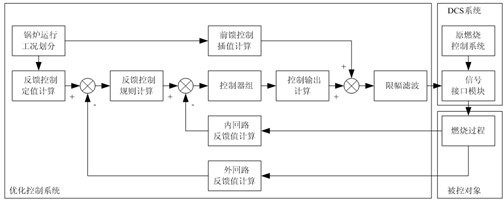

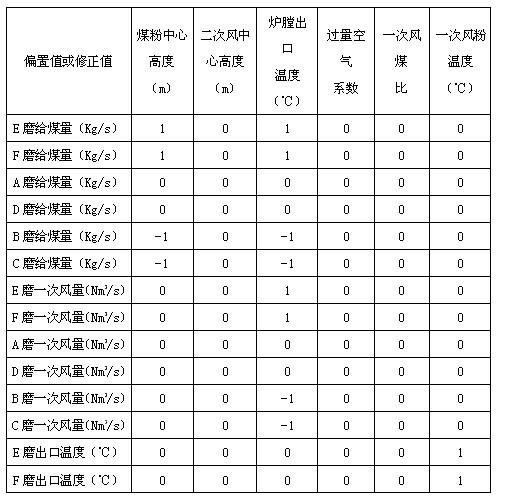

Combustion feedforward and feedback composite optimization controlling method for pulverized coal fired boiler

InactiveCN102425807AImprove combustion efficiencyEmission reductionCombustion regulationCombustorComposite optimization

The invention discloses a combustion feedforward and feedback composite optimization controlling method for a pulverized coal fired boiler. The method is used for realizing dynamic accurate proportioning of wind and coal under a full working condition and in the full combustion process. According to the technical scheme, the method comprises the following steps of: determining feedforward signals according to combustion adjusting experiment data or operation personnel experience, determining feedback signals according to the thermodynamic properties and laws of the boiler, and automatically and accurately adjusting the coal quantity proportion of each burner, the primary air quantity proportion of each coal mill, the outlet temperature of each coal mill and the secondary air quantity and burning-out air quantity proportion of each burner under different working conditions to keep the burning efficiency and the NOX discharge of the boiler in an optimal state. By the method, the advantage of coexistence of a plurality of independent adjusting means of the large pulverized coal fired boiler and the advantages of high dynamic response speed of feedforward control and high static precision of feedback correction control are fully exerted, the pulverized coal fired boiler is close to the optimal state under various working conditions, the burning efficiency of the boiler is improved, and the discharge of NOX is reduced.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

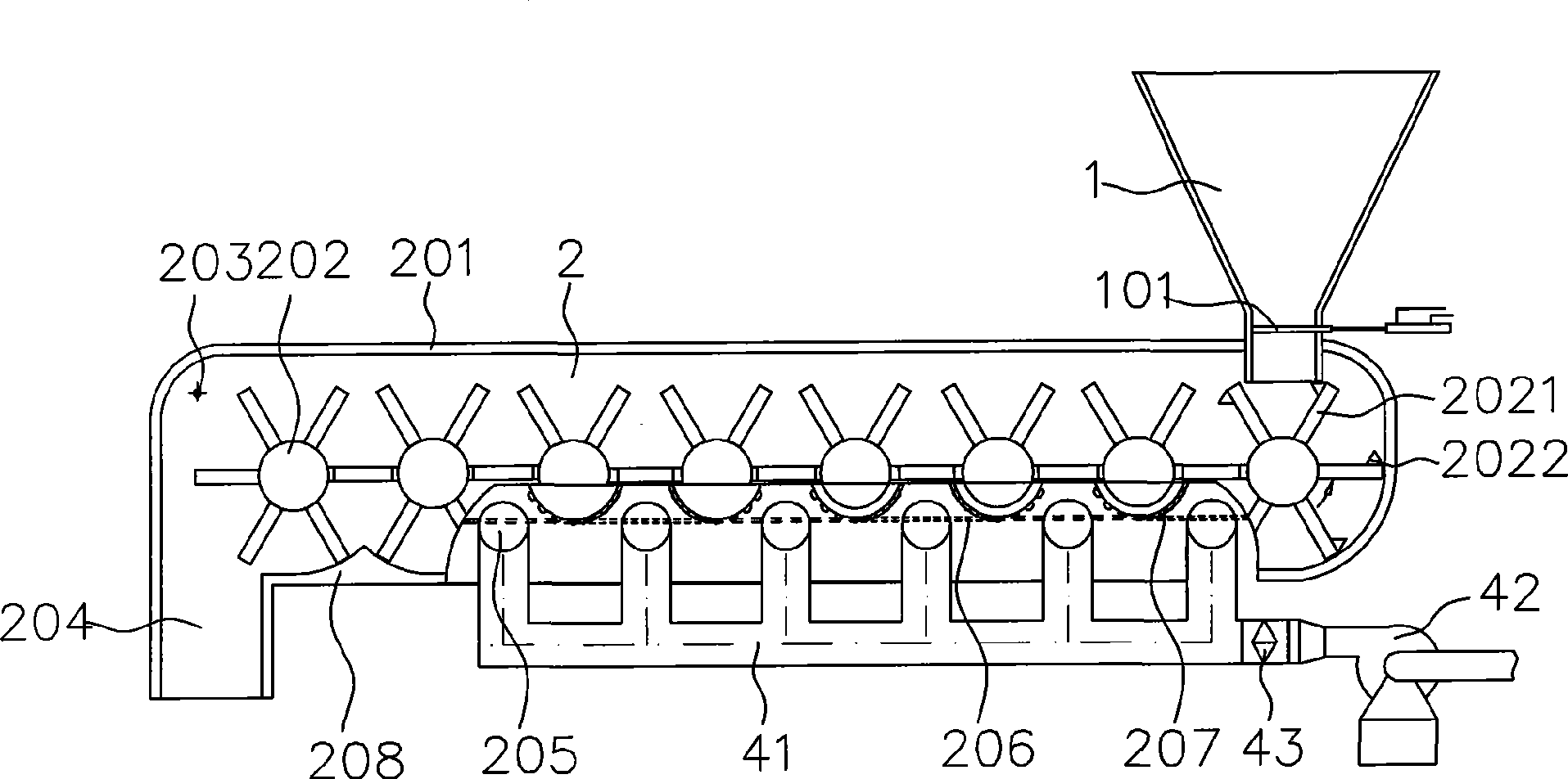

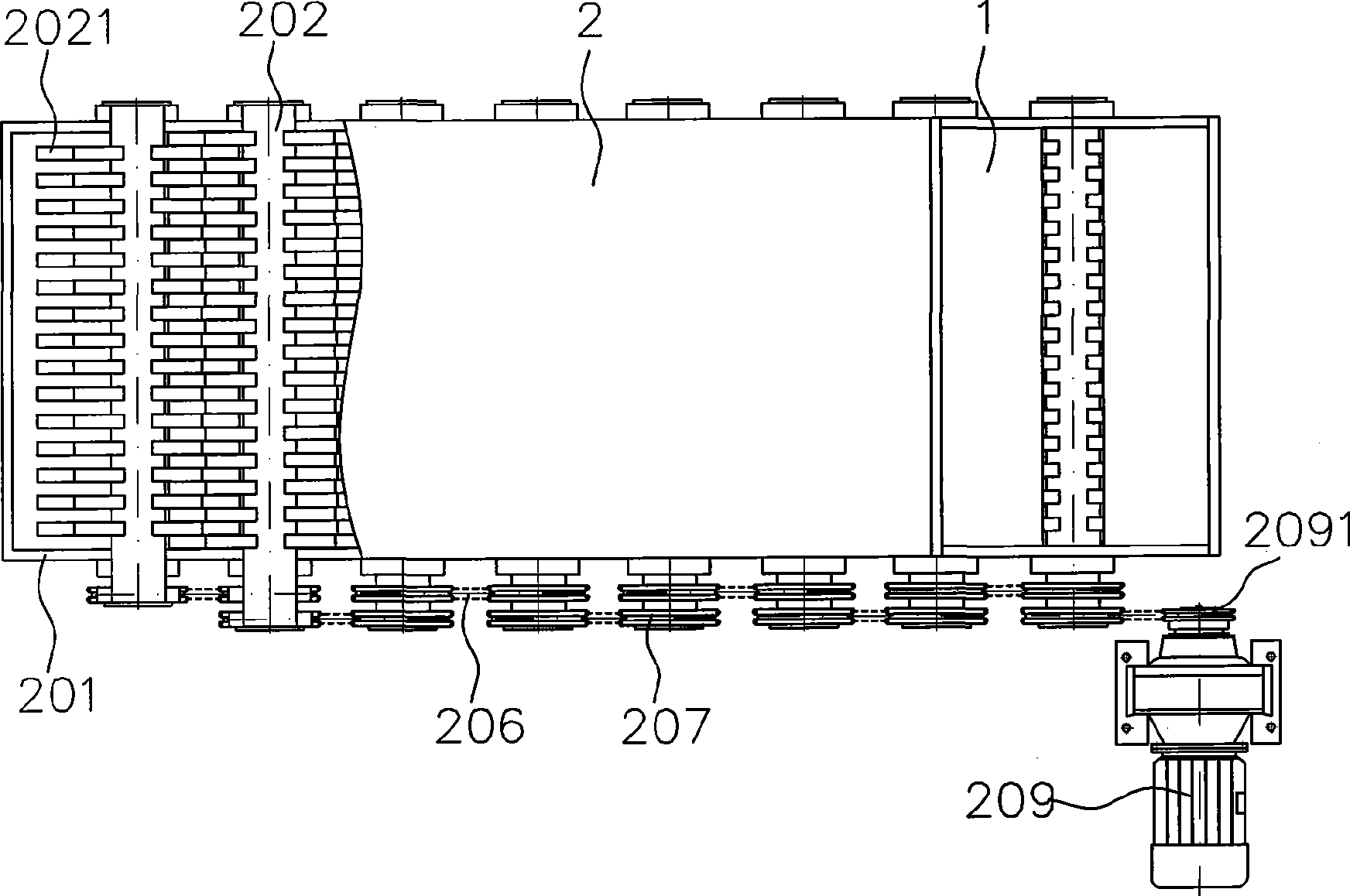

Efficient burning furnace with rotary fluidization grate

InactiveCN101532667ATurn overWith self-cleaning functionRevolving grateRocking grateCombustion systemFlue gas

The invention relates to an efficient burning furnace with a rotary fluidization grate. The burning furnace with the rotary fluidization grate consists of a feeding system, a burning system and a slagging system; moreover, a waste heat boiler and a flue gas treatment system are connected with the burning furnace to form a complete garbage burning and generating system. The feeding system consists of a feeding hopper, a pre-drying conveying device, an aggregate bin, a chute and a charge distributor. The feeding hopper is a receiving opening for feeding garbage into the burning furnace and is arranged in a garbage storage pit close to one side of the burning furnace. An outlet of the feeding hopper is connected with an inlet of the pre-drying conveying device. A material level switch is arranged in the feeding hopper, and gives an alarm to prompt an operator to feed materials when the material level is lower than a set value so as to ensure that the hopper is not empty. The outlet of the hopper can be selectively provided with a feeding device. The burning furnace has the advantages of high burning speed, high burning efficiency, high slag burning degree, easy control, lower energy consumption, low pollution, low cost and investment conservation, and is applicable to domestic garbage with low thermal value and high moisture; and the garbage does not need to be pretreated.

Owner:新乡锅炉制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com