Turbine-based combined cycle engine super-combustion chamber

A turbine-based combination and combustion chamber technology, applied in the direction of combustion chambers, continuous combustion chambers, combustion methods, etc., can solve the problems of engine performance without in-depth analysis and research on the design method of turbine-based combined cycle engines, and achieve superior lean ignition and lean The effect of oil flameout performance, reasonable design, and reasonable distribution of combustion temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The super combustor of the turbo-based combined cycle engine proposed by the present invention will be described in detail below in conjunction with the accompanying drawings.

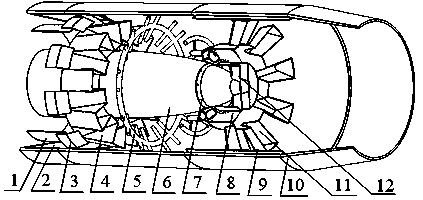

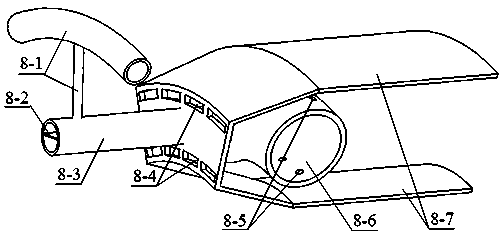

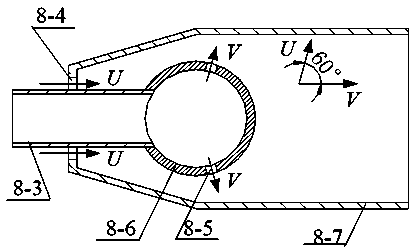

[0030] Such as figure 1 As shown, a kind of turbine-based combined cycle engine super combustor disclosed by the present invention comprises a diverter ring 1, a rear variable area purge valve 2, a guide tongue 3, a square lobe mixer 4, a central cone 6, and is mounted on The oil supply device on the central cone 6, the flame stabilizer, the heat shield 9, and the super combustor barrel 10 cover the outermost layer. The square-lobe mixer 4 adopts lobes with unequal expansion angles up and down, and is separated from the diverter ring 1, and there is a certain axial distance; the guide tongue 3 is fixed in the flow channel, and is placed next to the variable area After the air valve 2, it is directly above the trough of the square lobe mixer 4 in a discrete shape, and its airflow deflection angl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com