Oil tank straight seam welding machine

A straight seam welding, straight seam technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as reduced production efficiency and poor product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

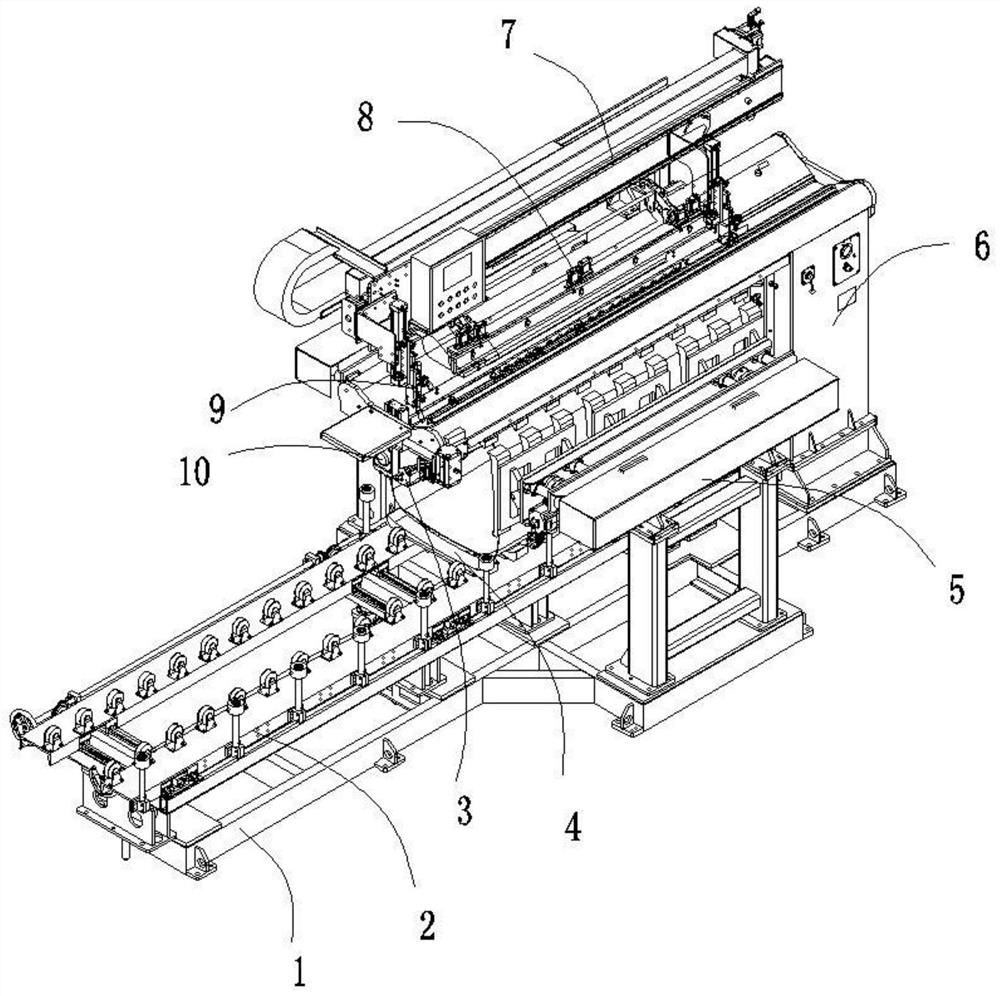

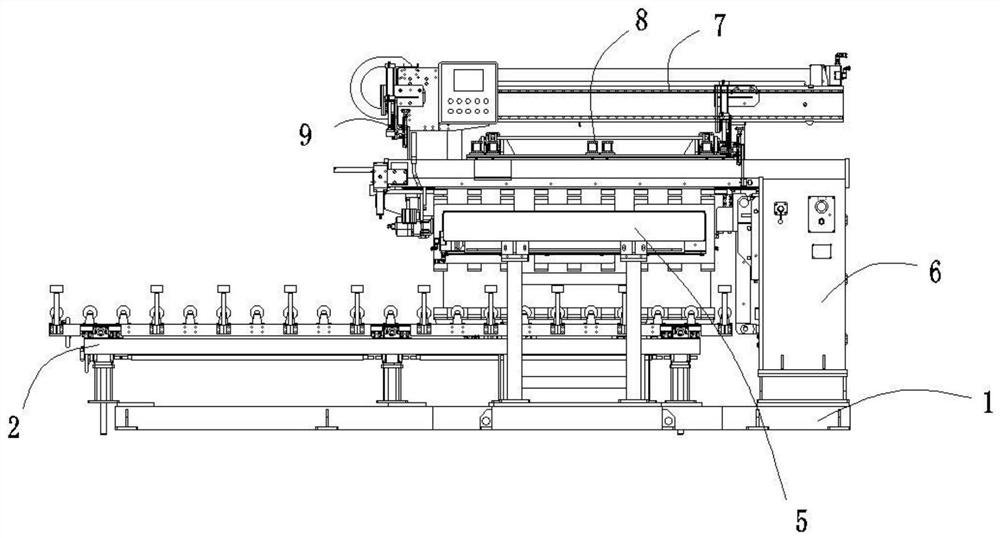

[0043] Such as Figures 1 to 17 As shown, this embodiment provides a fuel tank straight seam welding machine, including a base 1, an automatic loading and unloading mechanism 2 arranged on the base 1 for conveying workpieces, and a straight seam welding machine arranged at one end of the automatic loading and unloading mechanism 2 The main body, the welding main body includes a mandrel 10 and a welding assembly 9 that is arranged on the mandrel 10 and can move along the axis of the mandrel 10. The pressing mechanism of the piano key type pressed on the mandrel 10 is characterized in that: the automatic loading and unloading mechanism 2 extends into the main body of the straight seam welding and is located below the mandrel 10, and the automatic loading and unloading mechanism 2 includes extending into the straight seam welding body. The lower jacking mechanism 4 for lifting and lowering the workpiece under the part of the seam welding main body. The front and rear sides of the...

Embodiment 2

[0046] This embodiment is further optimized on the basis of embodiment 1, specifically:

[0047] The composite pneumatic centering assembly 8 includes a centering knife assembly and a lifting drive mechanism that drives the centering knife assembly to lift, and the centering knife assembly includes a vertically arranged centering knife mounting plate 8-2, a The horizontal horizontal plate on the top of the mounting plate 8-2, the centering knife 1 8-4 and the centering knife 2 8-3 arranged in front of the centering knife installation plate 8-2, and the horizontal horizontal plate is provided with two groups respectively Drive centering knife one 8-4 and centering knife two 8-3 lifting centering knife cylinder one 8-7 and centering knife cylinder two 8-6.

[0048] The lifting driving mechanism includes two cylinder connecting rod driving mechanisms symmetrically arranged on the main body of the straight seam welding, and each of the cylinder connecting rod driving mechanisms in...

Embodiment 3

[0053] This embodiment is further optimized on the basis of embodiment 1, specifically:

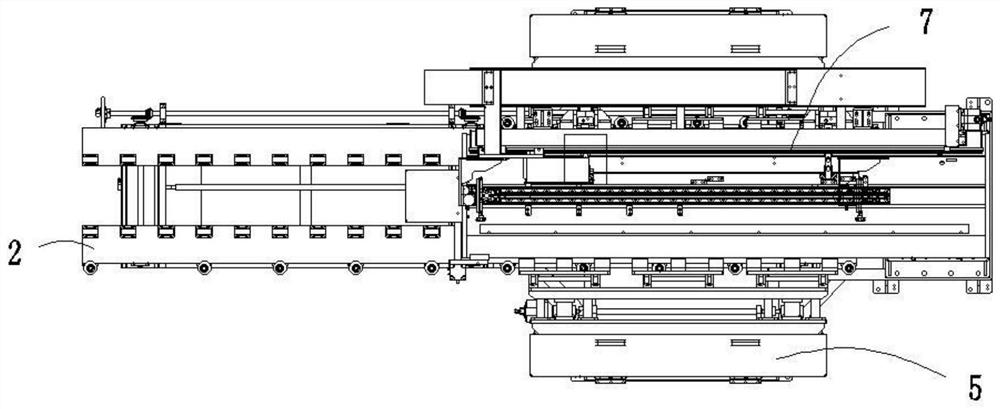

[0054] The side pushing mechanism 5 includes a mounting base B5-1 connected to the base 1, the top of the mounting base B5-1 is provided with a movable mounting plate C5-4, and the mounting plate C5-4 passes through the mounting hinge 5-5. A plurality of vertically arranged profiling plates 5-3 that cooperate with the workpiece are installed, and the top of the mounting base B5-1 is provided with a worm turbine lifting mechanism 5-6 that drives the horizontal reciprocating motion of the mounting plate C5-4. The top of the mounting base B5-1 is also provided with a guide rod 5-2 that prevents the mounting plate C5-4 from rotating.

[0055] The lower jacking mechanism 4 includes a support platform 4-1 and a profile plate A horizontally arranged above the support platform 4-1 for supporting the workpiece

[0056] 4-2, a mounting base C4-4 connected to the base 1 is provided under the suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com