Patents

Literature

7428results about How to "Reduce manual labor intensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stainless steel cleaning agent

InactiveCN101135056AImprove cleaning efficiencySimple cleaning processPhosphoric acidCleansing Agents

The stainless steel detergent for washing stainless steel product is prepared with acids, basic salts, surfactant, assistant, stabilizer and water, and through stirring and reaction at normal temperature. Specifically, it consists of sodium carbonate, sodium tripolyphosphate, tartaric acid, citric acid, hydrofluoric acid, nitric acid, phosphoric aicd, JFC, OP-10, triethanolamine, urotropin, trisodium phosphate, acetic acid, alcohol and water in certain weight proportion. It has the features of simple preparation process, environment friendship, high cleaning efficiency, low cleaning cost, etc.

Owner:吴铭鑫

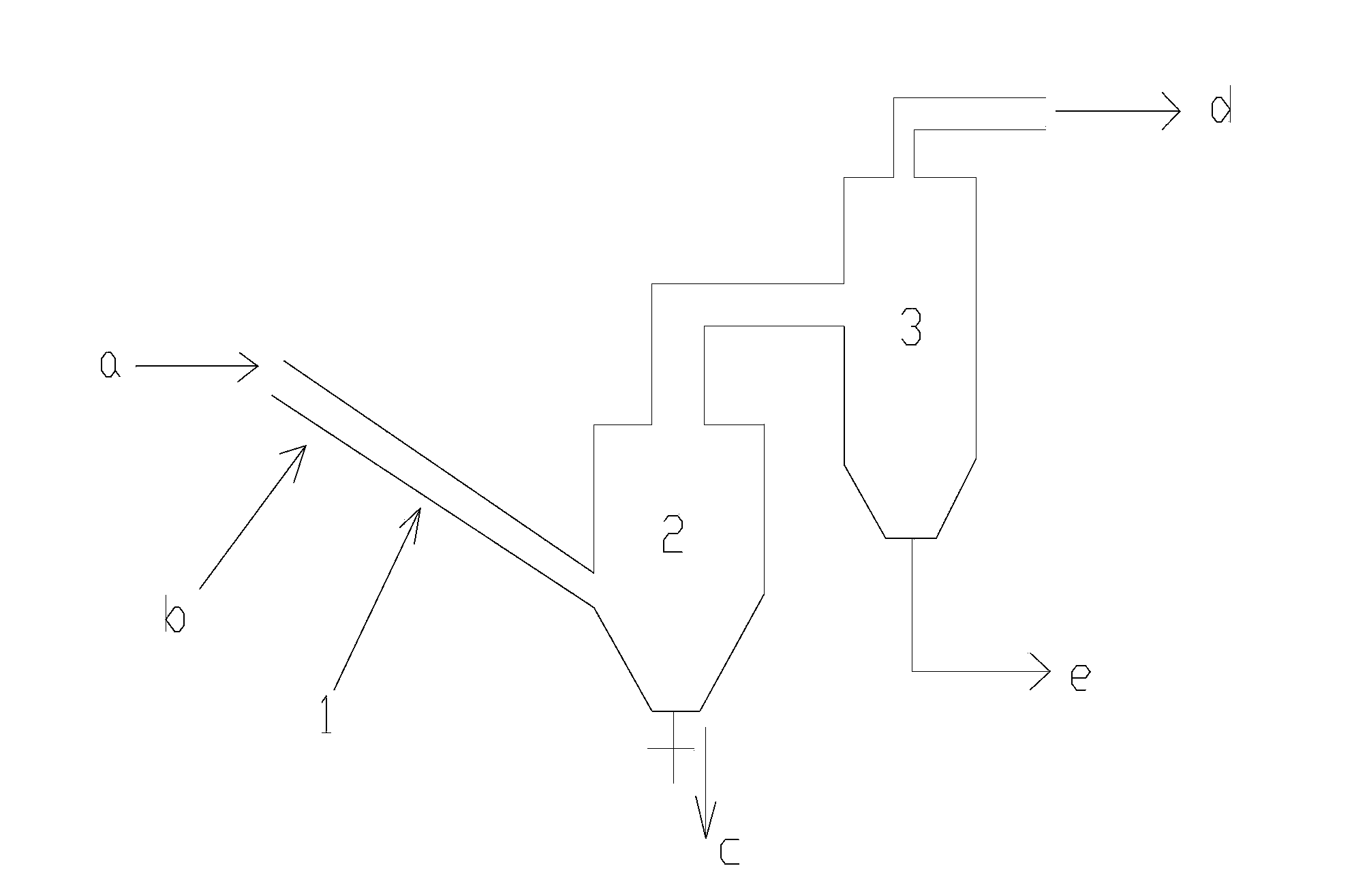

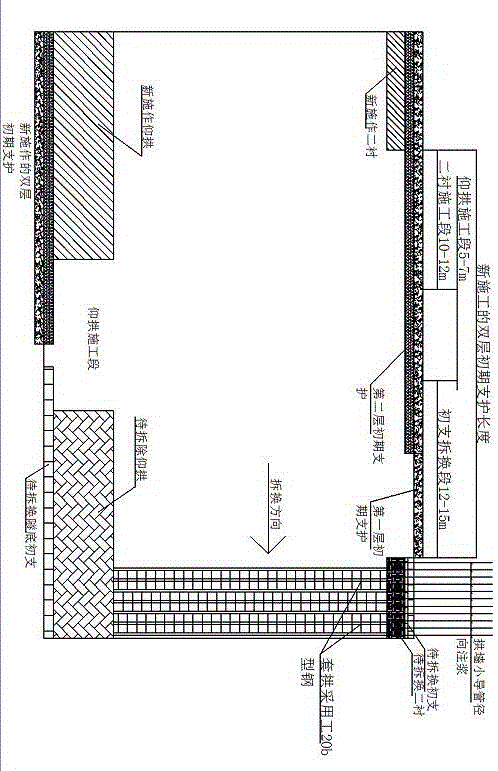

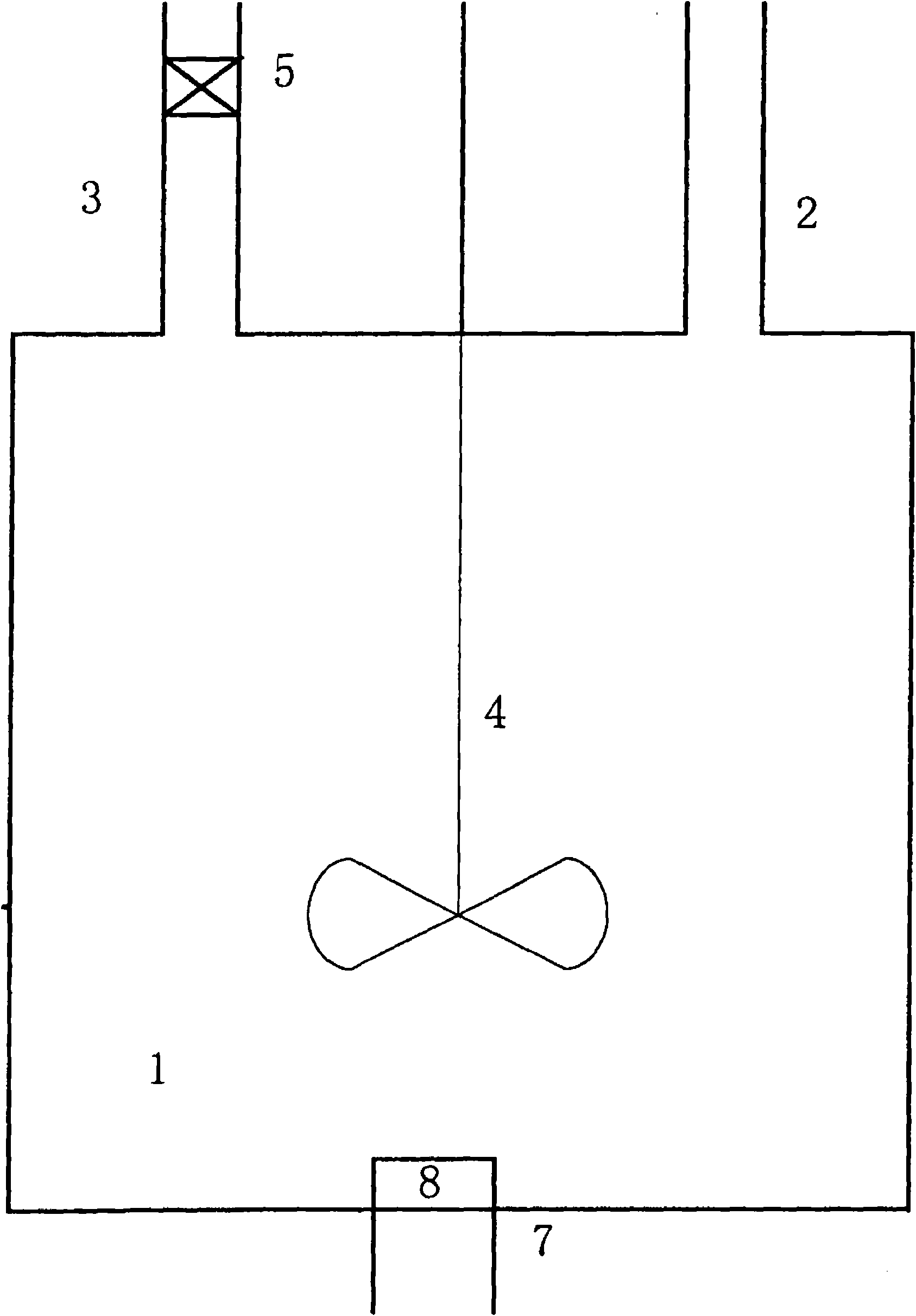

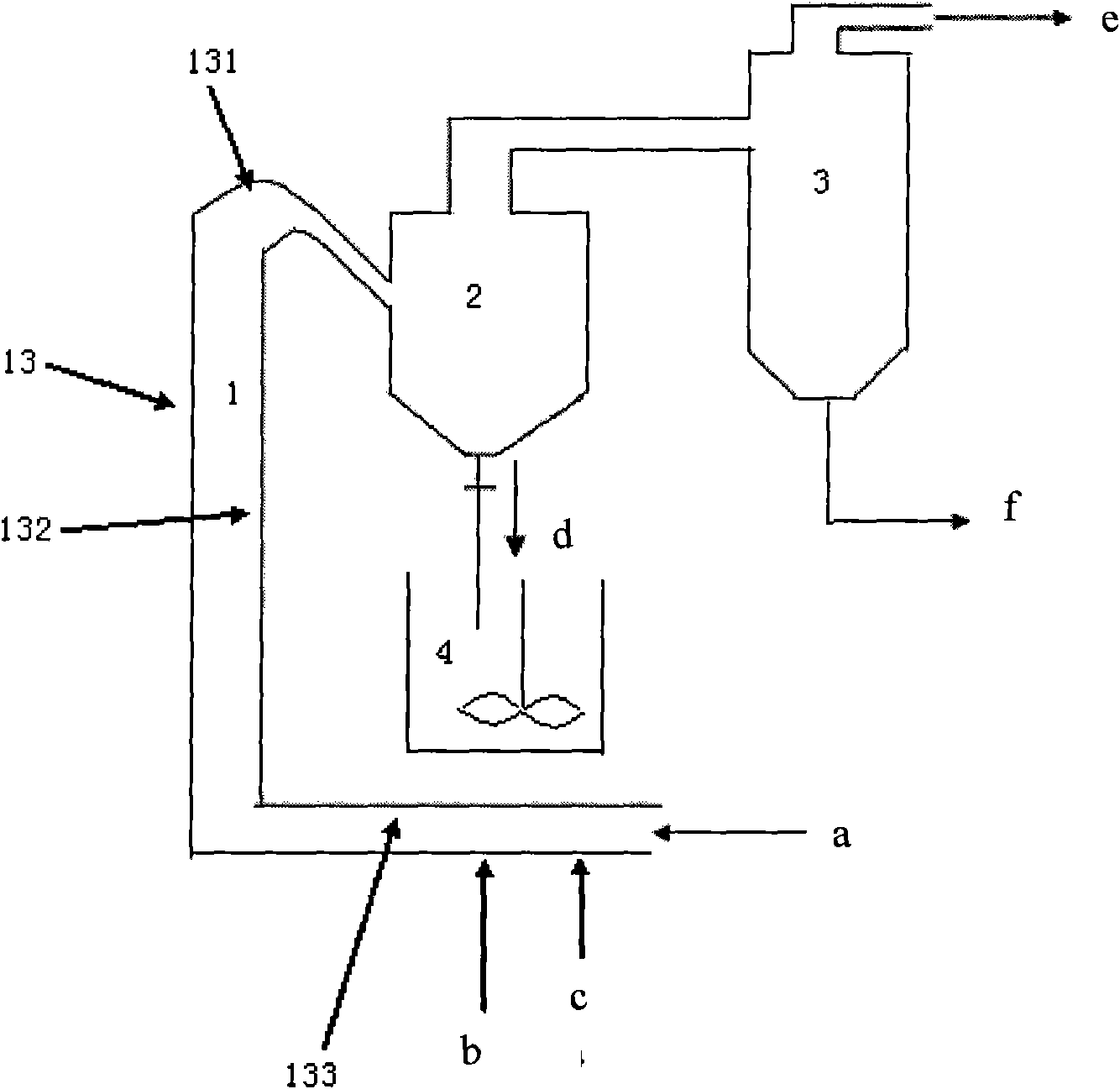

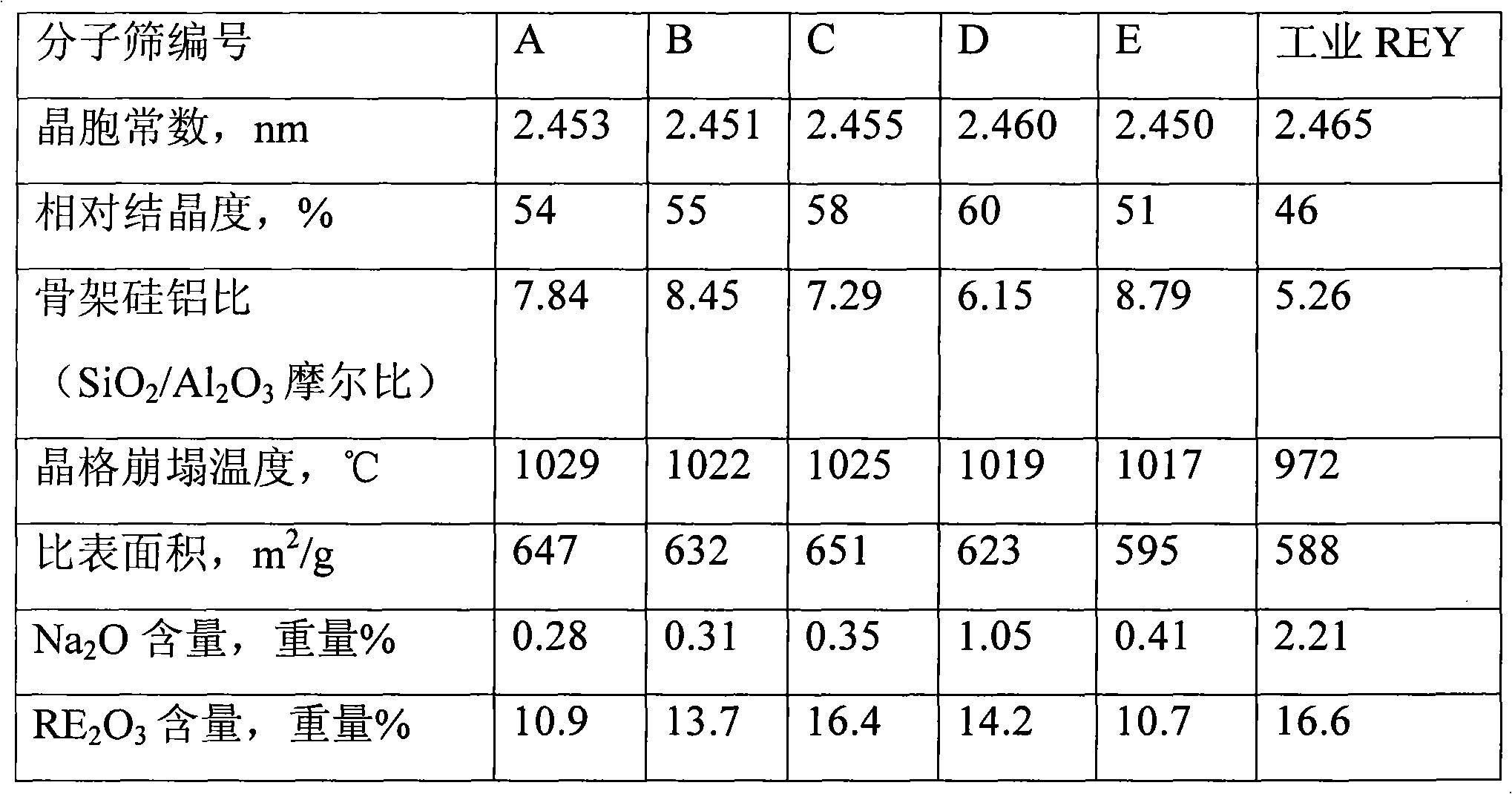

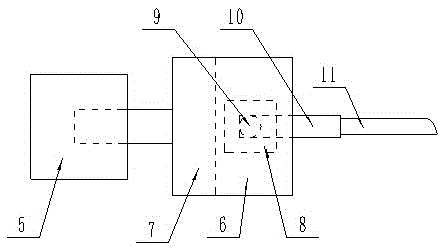

Method for preparing molecular sieve

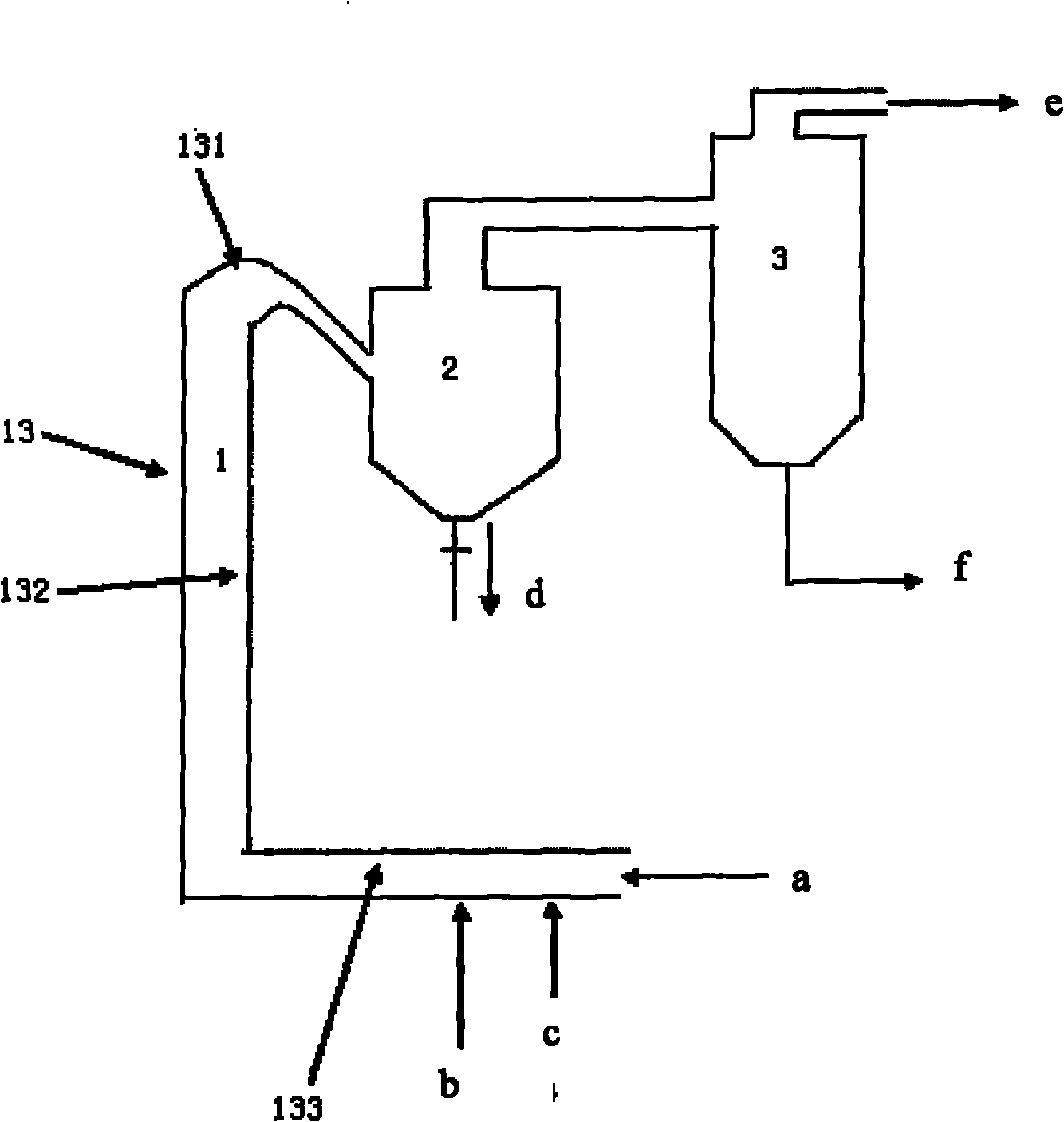

ActiveCN103787352AFull residence timeFull contact timeCrystalline aluminosilicate zeolitesMolecular sieveGas phase

The invention relates to a method for preparing a molecular sieve, which comprises the following steps: the molecular sieve is introduced in a gas phase ultra-stable reactor, the gas phase ultra-stable reactor is capable of moving the molecular sieve from the molecular sieve inlet of the gas phase ultra-stable reactor to the molecular sieve outlet of the gas phase ultra-stable reactor under the condition that carrying gas is not used for conveying, and the molecular sieve and gas-phase silicon tetrachloride are contacted for reacting in the gas phase ultra-stable reactor. The conveying of the molecular sieve does not require inertia carrying gas, the technology flow is simplified, carrying gas amount is saved, and the consumption of silicon tetrachloride can be greatly reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

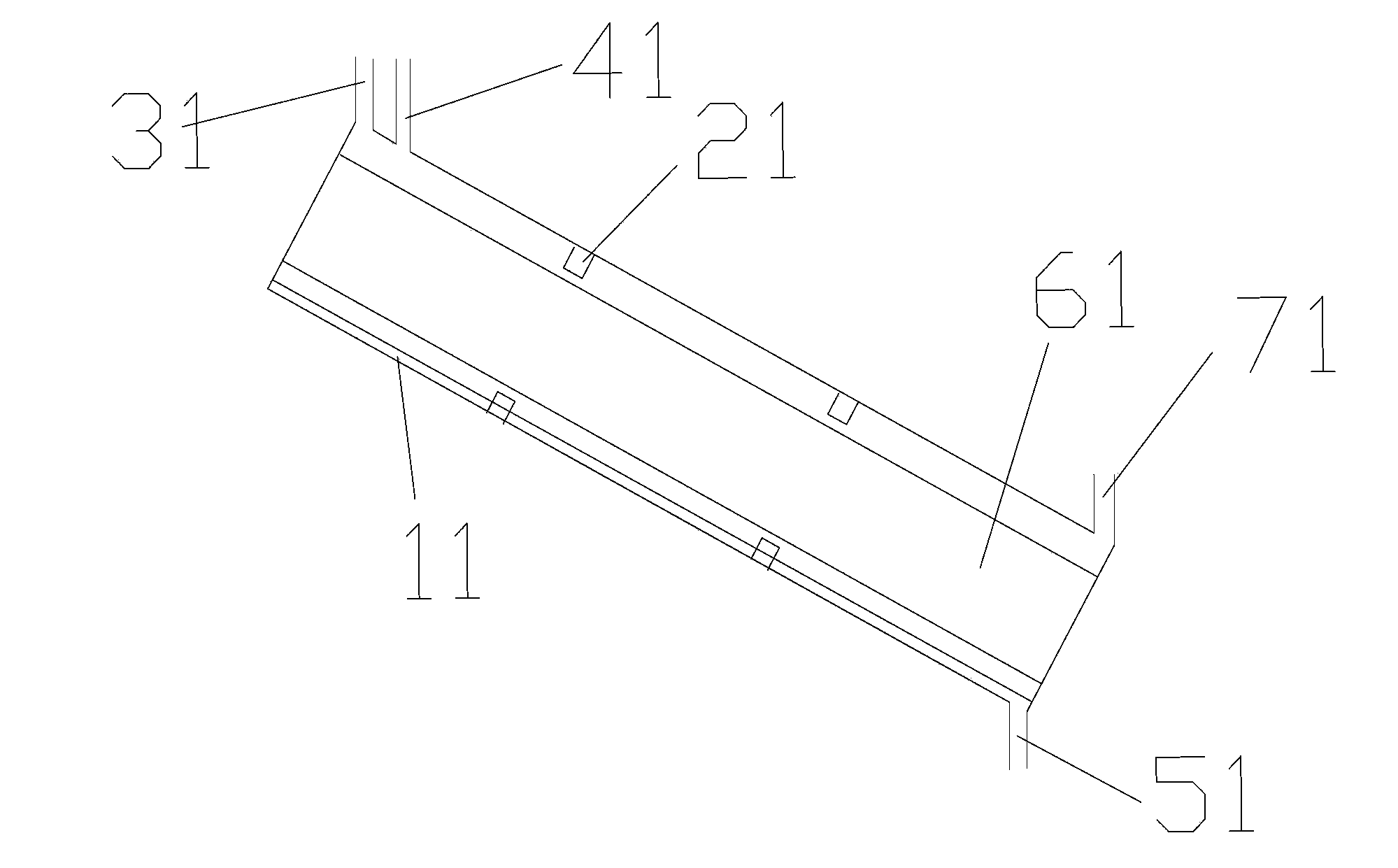

Method for preparing high silicon molecular sieve

ActiveCN102050459AAdequate contact responseContinuous contact reactionFaujasite aluminosilicate zeoliteMolecular-sieve compoundsMolecular sieveGas phase

The invention relates to a method for preparing a high silicon molecular sieve. The method comprises the following steps: circulating a molecular sieve along with inert carrier air under the carrying of inert carrier air flow and contacting the molecular sieve with gas-phase SiCl4 in a flowing sate, wherein the contact time of the molecular sieve and the gas-phase SiCl4 is from 10 seconds to 100 minutes. By using the method for preparing the high silicon molecular sieve in the invention, the continuous contact reaction of the molecular sieve and the SiCl4 can be achieved, and the contact time of the molecular sieve and the SiCl4 can be controlled through controlling the flow speed of the carrier air and the length of a tubular reactor, thus the contact reaction of the molecular sieve and the SiCl4 can be fully carried out in the tubular reactor.

Owner:CHINA PETROLEUM & CHEM CORP

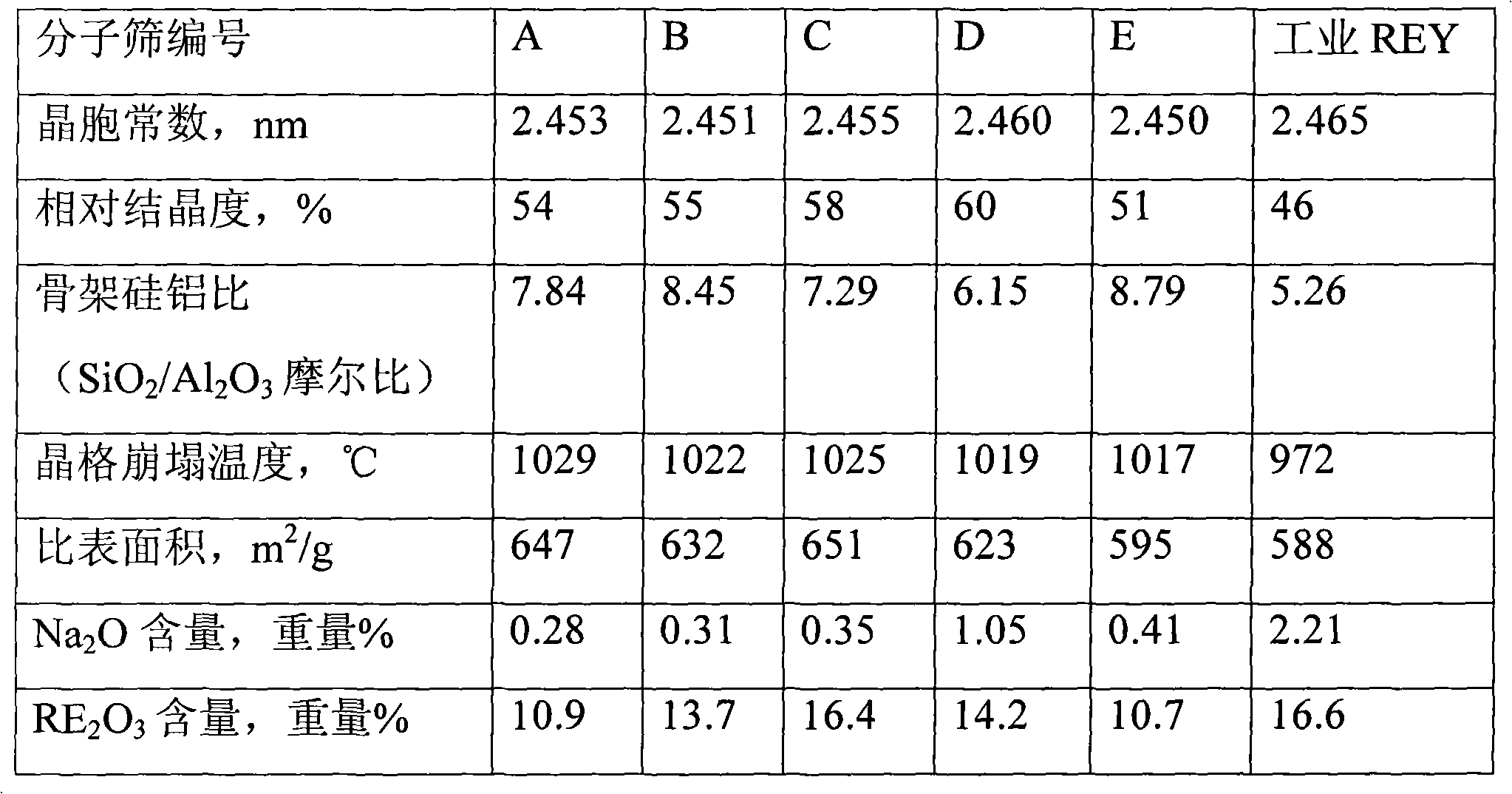

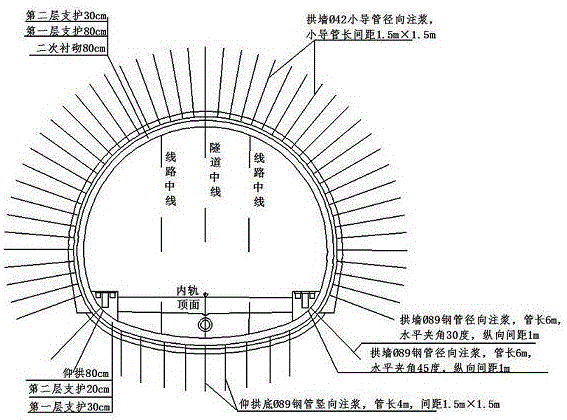

Construction method for soft rock deformation tunnel lining support dismantling-replacing arch

InactiveCN105781571AGuaranteed carrying capacityGuaranteed integrityUnderground chambersTunnel liningEngineeringLarge deformation

The invention provides a construction method for a soft rock deformation tunnel lining support dismantling-replacing arch. One-time whole section integral dismantling and replacing of a lining support is achieved. The construction method has the advantages that before dismantling and replacing, a lining which loses bearing capacity is subjected to grouting reinforcement treatment first, then a temporary cover arch is additionally arranged outside for reinforcement, and afterwards, the lining support is dismantled step by step, so that potential safety hazards caused by dismantling or removing of a temporary platform frame are avoided, and some security risks are avoided effectively. According to the construction method, the construction difficult problem of soft rock large deformation occurs during construction of a tunnel in special and complex geology is solved. Through the created novel construction method, the construction difficult problem of second lining cracking deformation needing remediation due to weak surrounding rock large deformation is solved. Through the construction method, safe, fast and economic treatment and remediation of the lining support and arch replacing construction are achieved, and the tunnel structure stability and construction safety are ensured effectively.

Owner:CCCC SECOND HIGHWAY ENG CO LTD

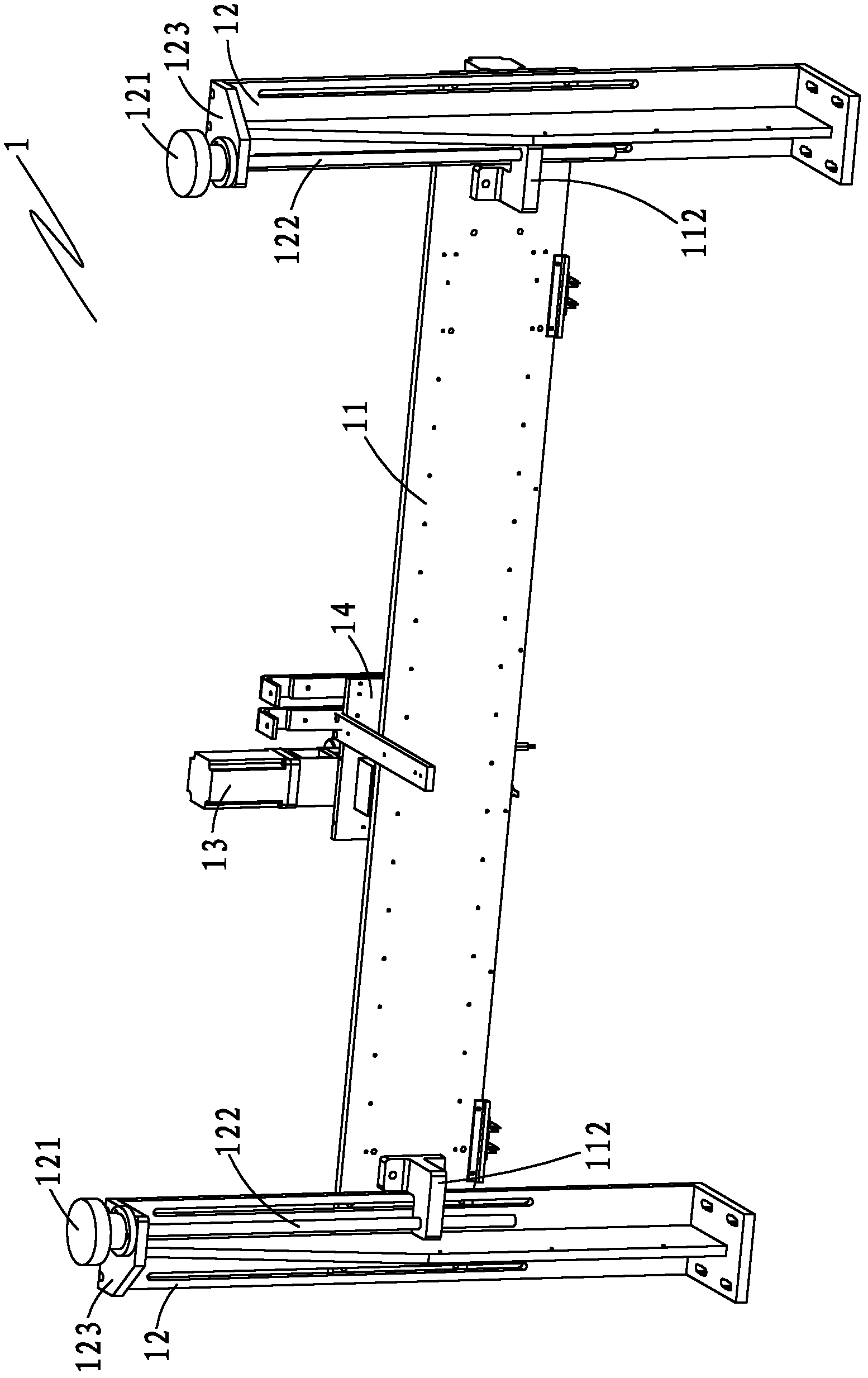

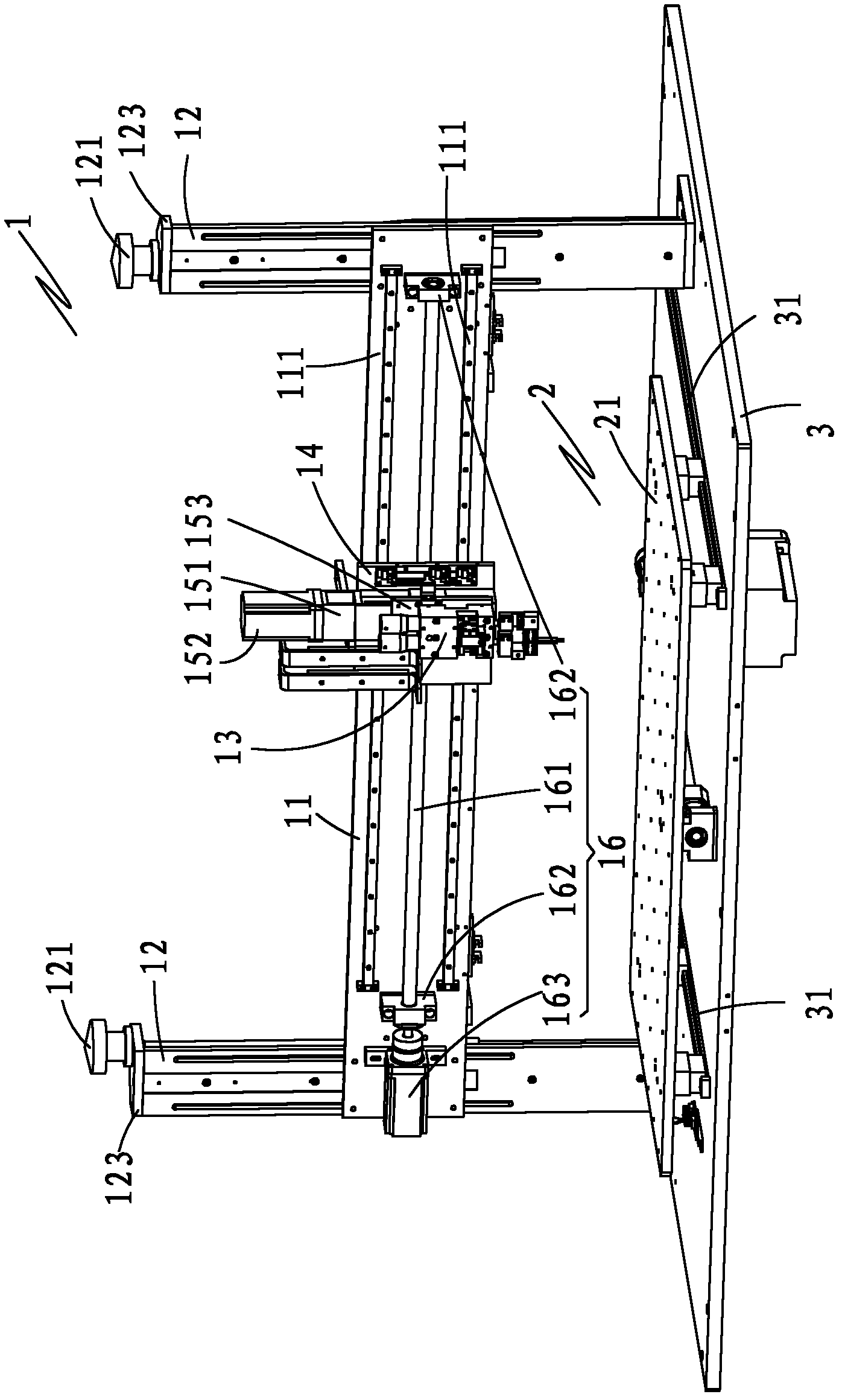

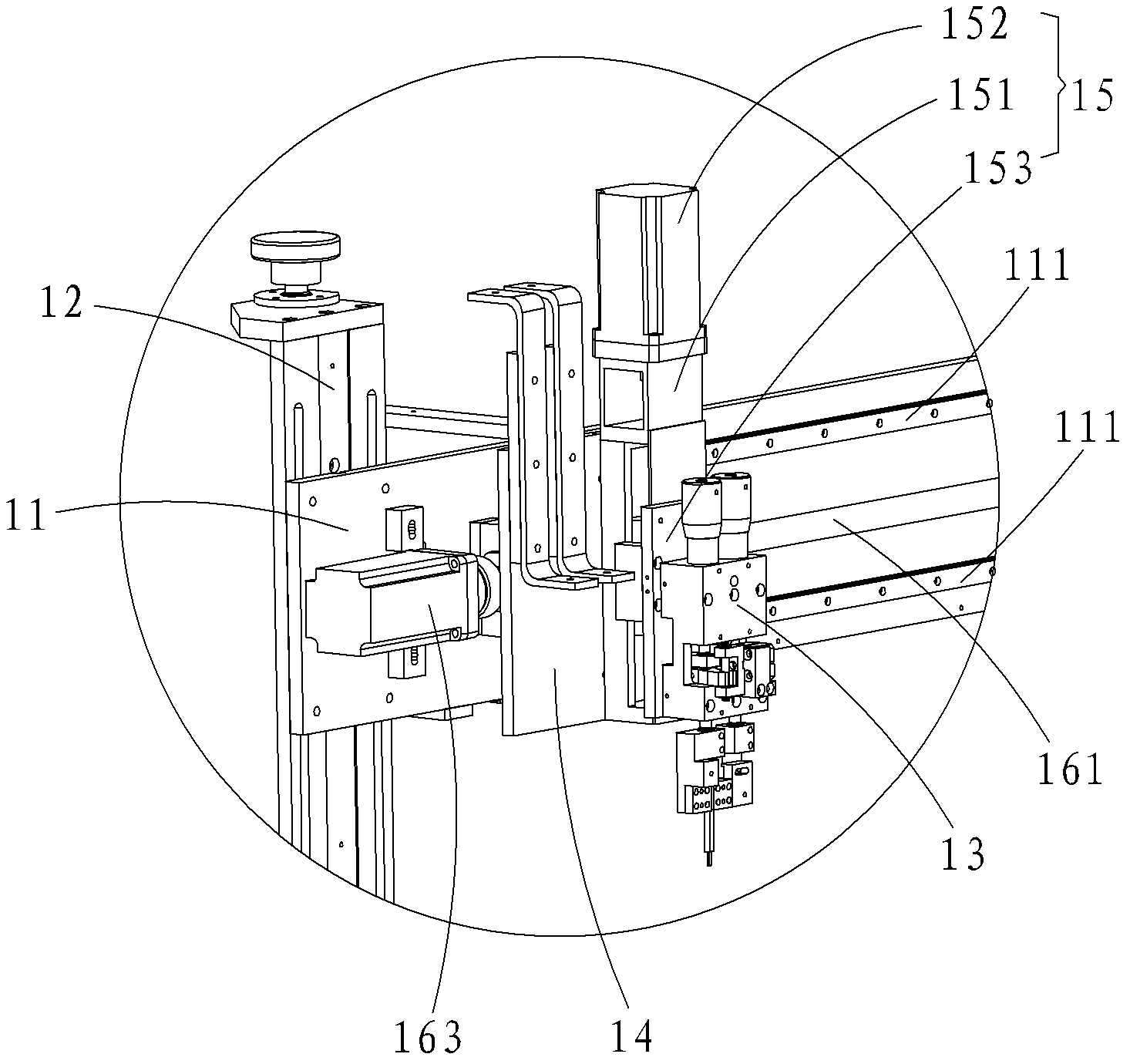

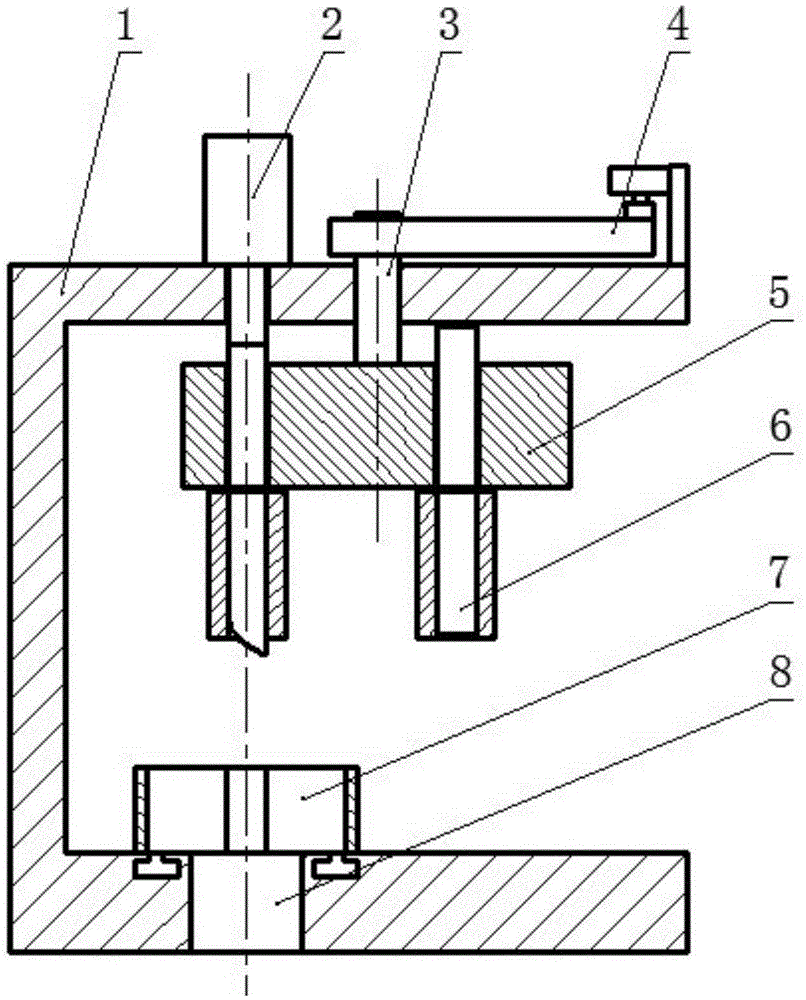

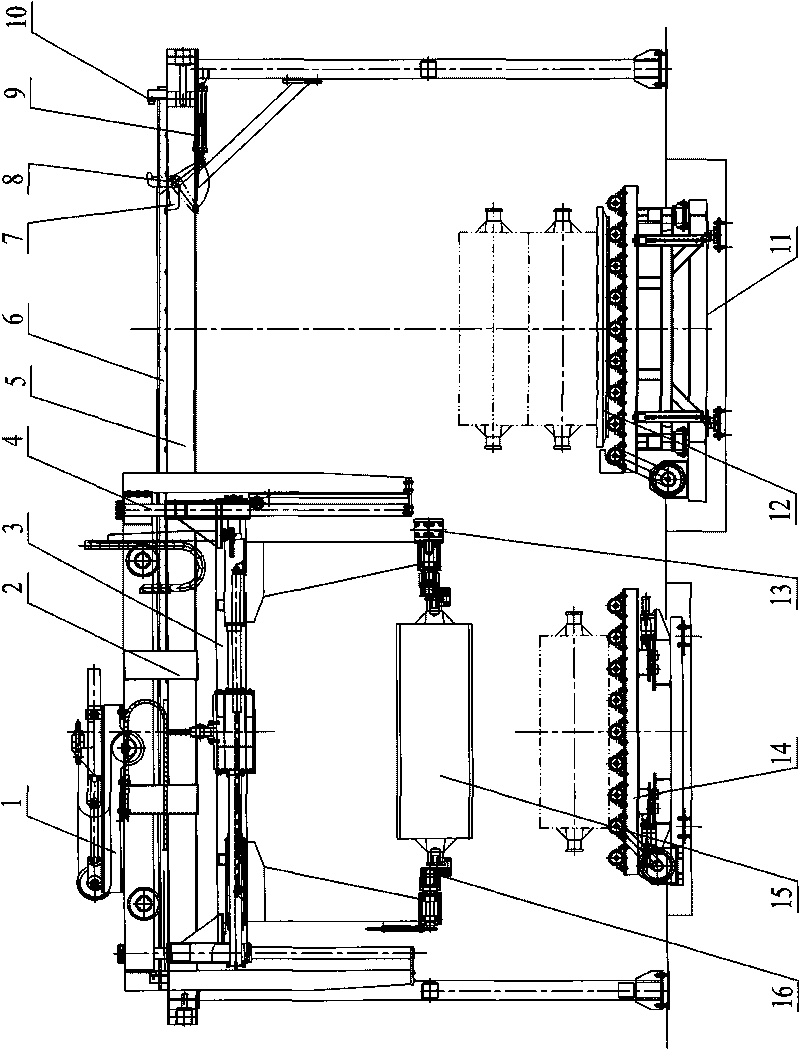

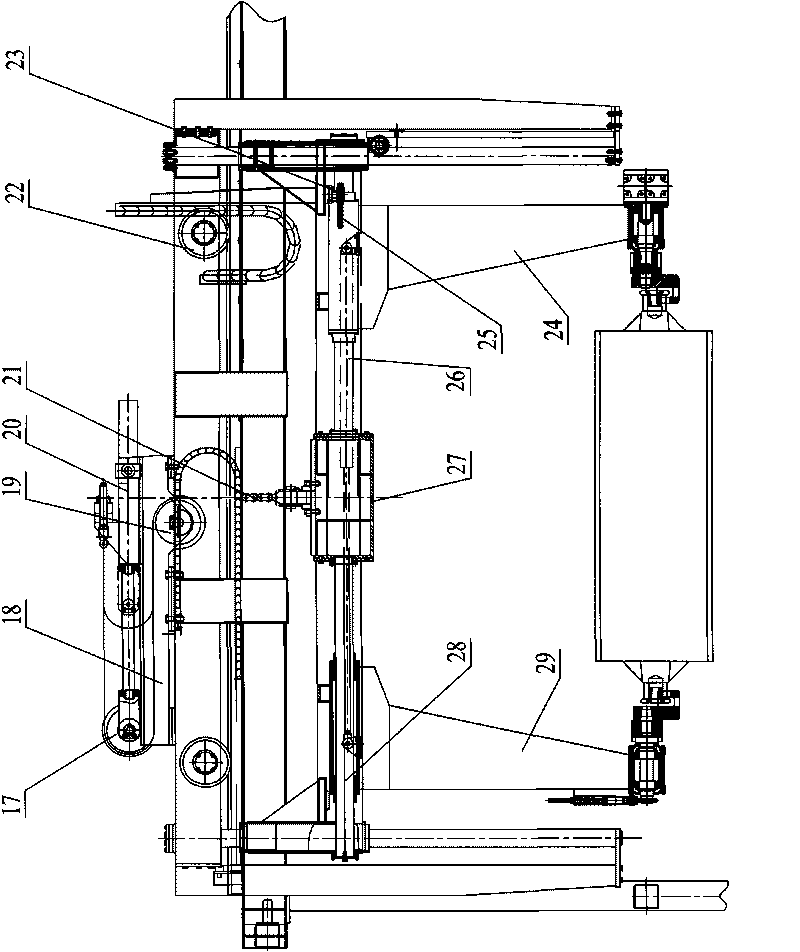

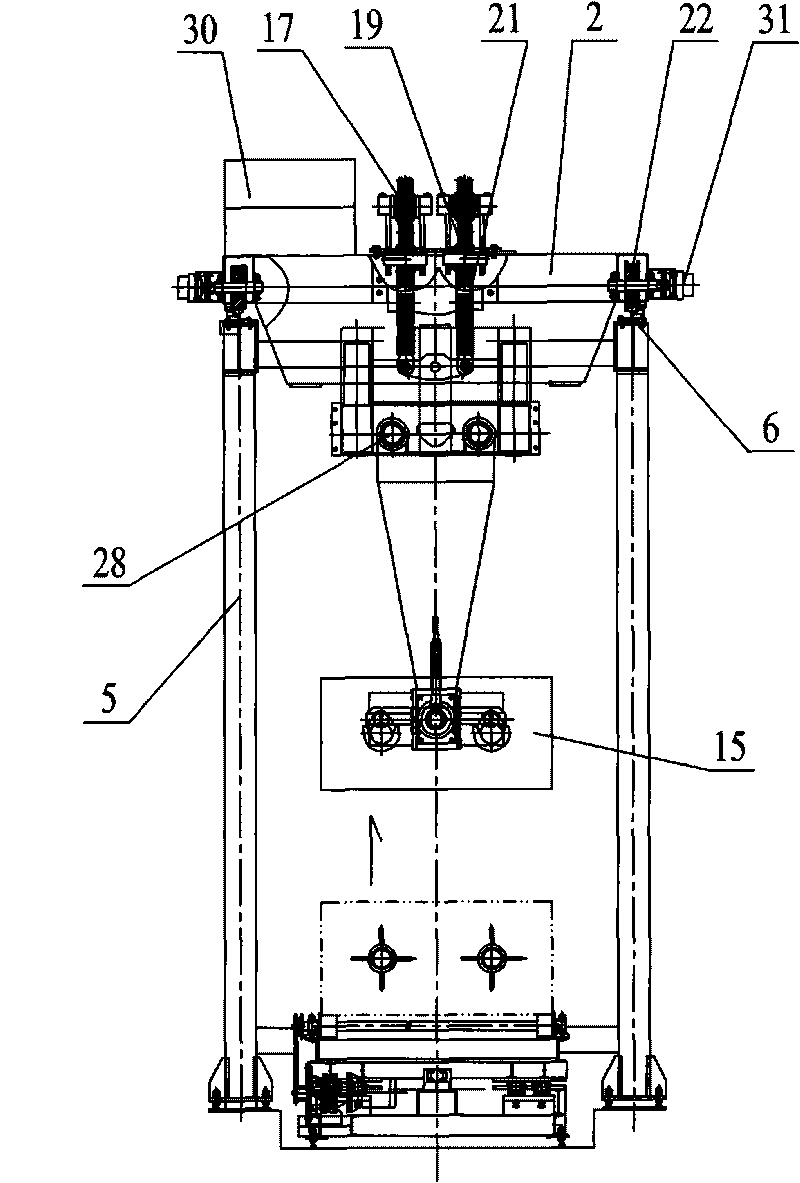

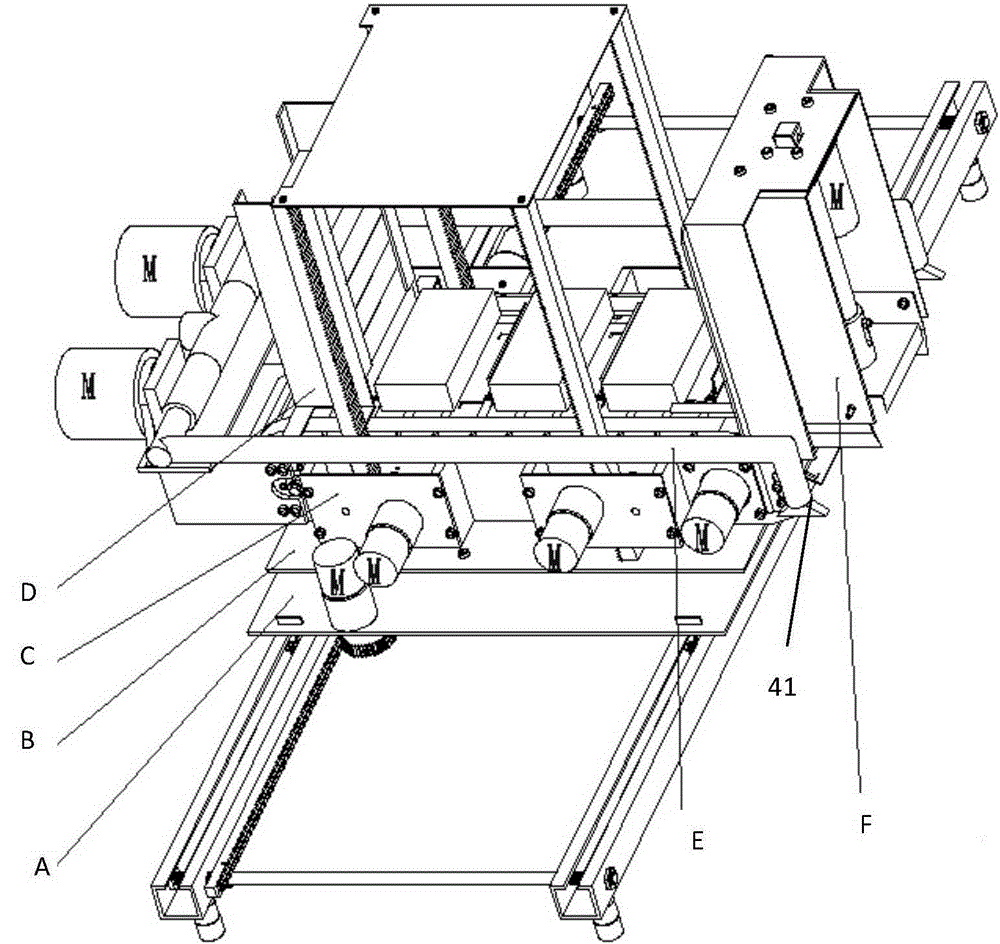

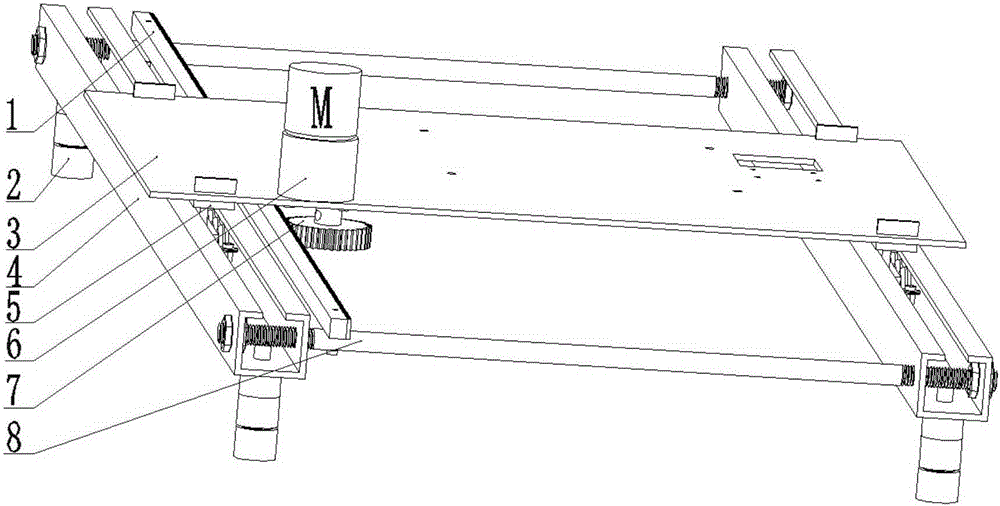

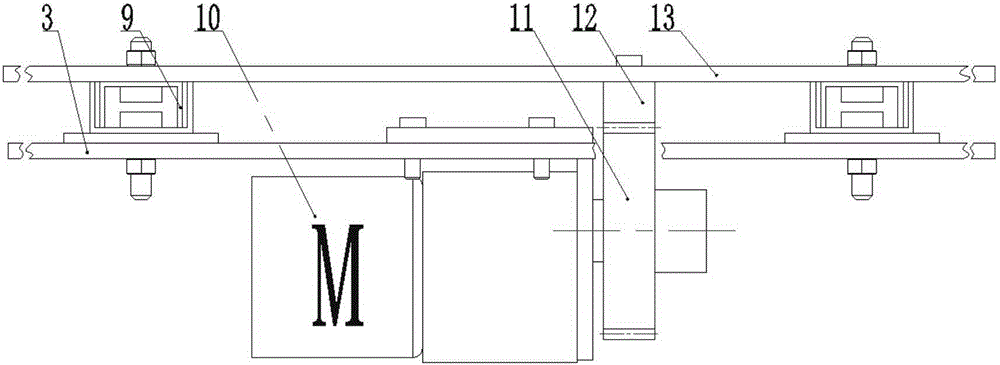

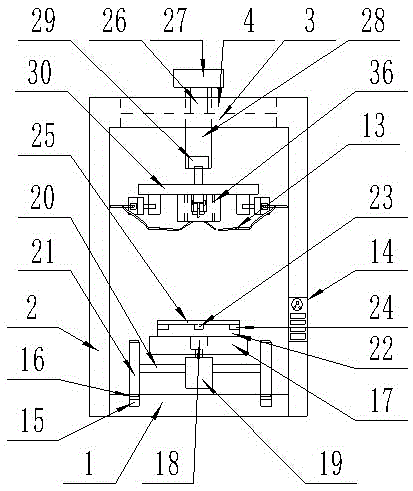

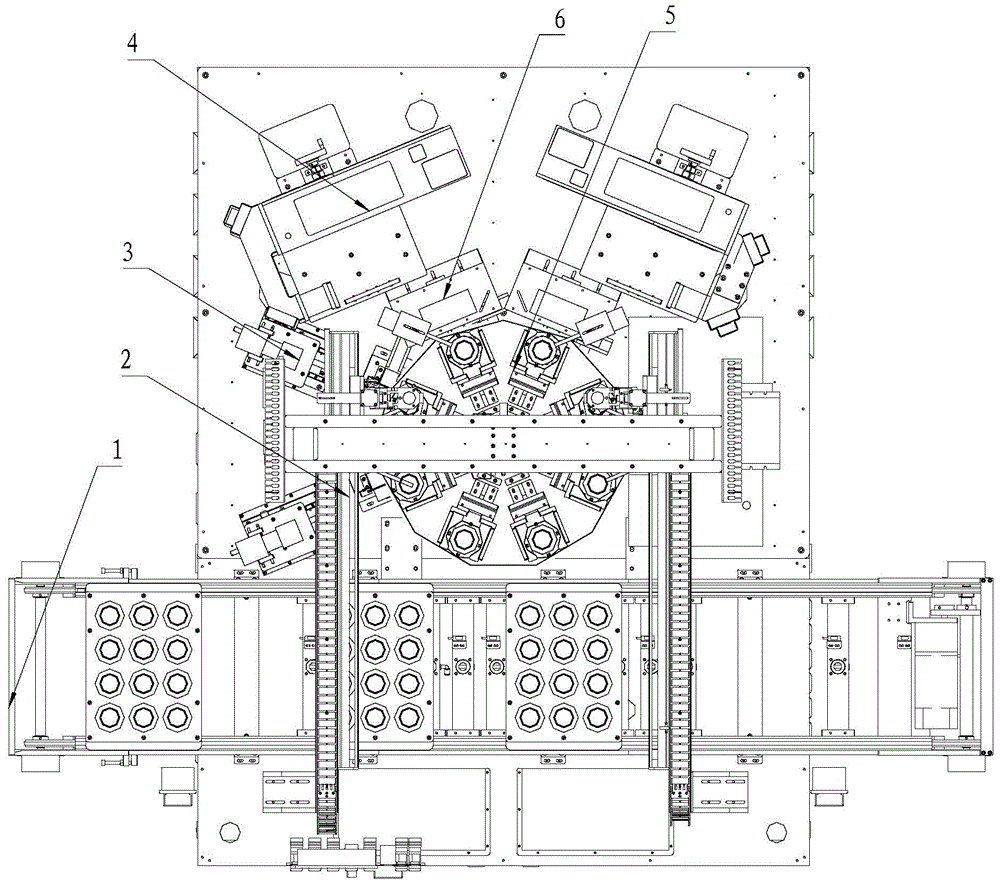

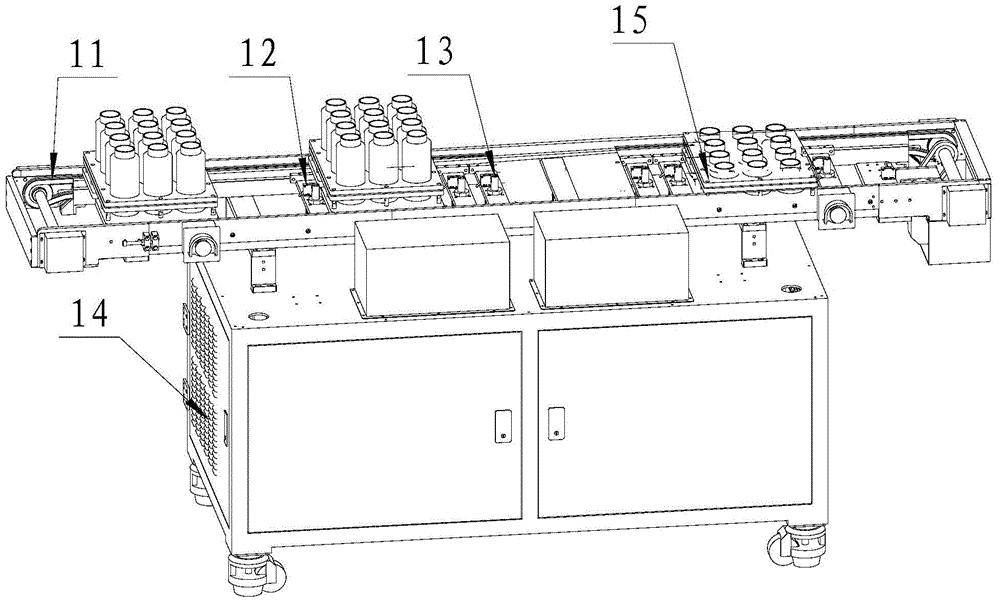

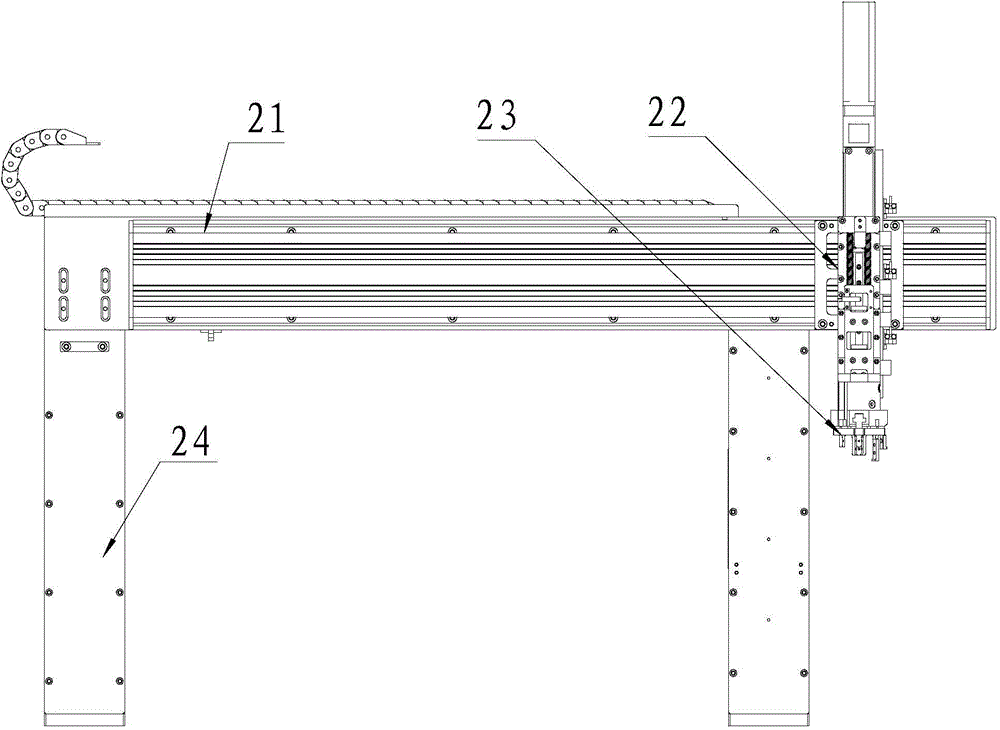

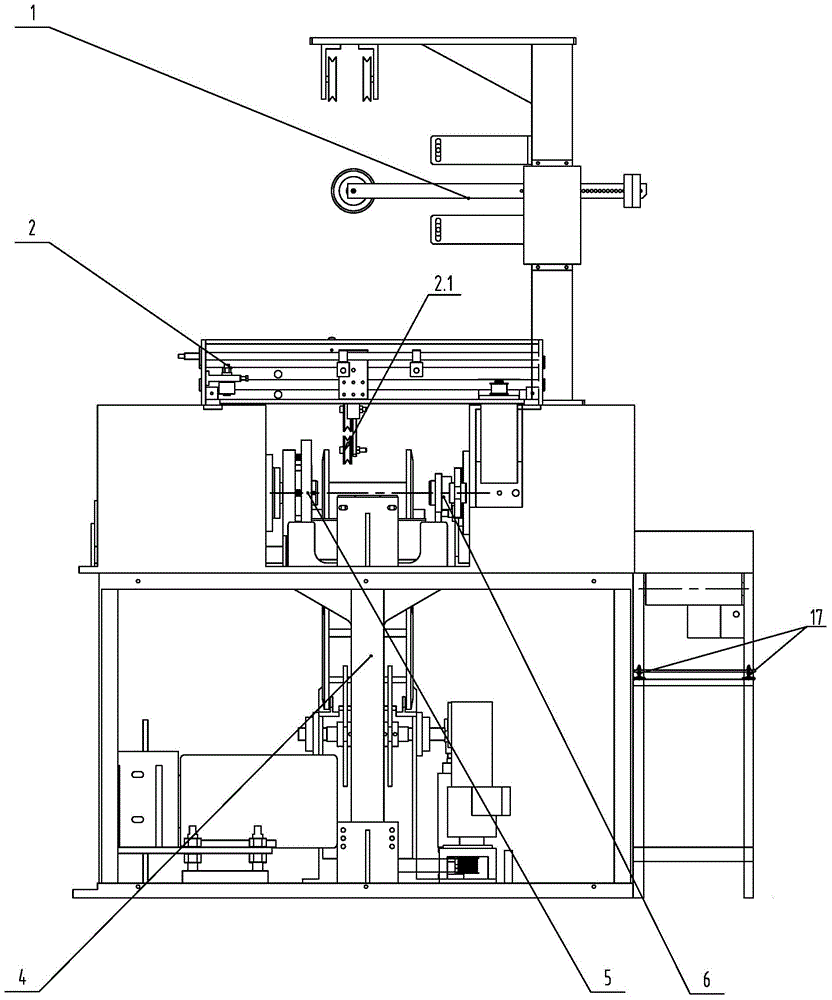

Gantry-type automatic spot welding system for battery pack

ActiveCN102554437AIncrease the number of installations andReduce manual labor intensityResistance welding apparatusProgrammable logic controllerMechanical engineering

The invention provides a gantry-type automatic spot welding system for a battery pack, which comprises a spot welding device and a spot welding jig fixing device which are vertically arranged and are connected with a PLC (programmable logic controller) of the system. The spot welding device comprises a beam, a group of opposite vertical columns in parallel, a spot welding mechanism, an X-axis sliding table, a Y-axis movement mechanism and an X-axis movement mechanism, wherein the vertical columns are used for adjusting the height of the beam, the X-axis sliding table is used for fixing the spot welding mechanism, the Y-axis movement mechanism enables the spot welding mechanism to transversely move, and the X-axis movement mechanism enables the X-axis sliding table to transversely move. The spot welding jig fixing device comprises a spot welding jig platen and a clamping mechanism for clamping a spot welding jig, wherein the clamping mechanism is arranged on the spot welding jig platen and is perpendicular to the spot welding mechanism. By the aid of a gantry-type structure, clamping is performed once, cells are numerous, spot welding parameters are controllable, and the system is fast in running speed, high in spot welding efficiency, highly adaptable to the cells, accurate in positioning and fine in spot welding quality.

Owner:FUJIAN NEBULA ELECTRONICS CO LTD

Method for preparing catalytic cracking catalyst

ActiveCN102049315AAdequate contact responseContinuous contact reactionCatalytic crackingMolecular sieve catalystsMolecular sieveContact time

The invention relates to a method for preparing a catalytic cracking catalyst. The method comprises the following steps: a molecular sieve flows along with inert carrier gas under the condition of being carried by the inert carrier gas flow, and is in contact with gas phase SiCl4 under the flow state; the contact time between the molecular sieve and the gas phase SiCl4 is 10 seconds to 100 minutes; and then the molecular sieve in contact with the gas phase SiCl4 is mixed with a binding agent, clay and water for pulping and pelleting to obtain the catalytic cracking catalyst. The provided preparation method for the catalytic cracking catalyst can realize the continuous contact reaction between the molecular sieve and the gas phase SiCl4 and can control the contact time between the molecular sieve and the gas phase SiCl4 by controlling the flow velocity of the carrier gas and the length of the tubular reactor, so that the contact reaction between the molecular sieve and the gas phase SiCl4 can be fully carried out in the tubular reactor.

Owner:CHINA PETROLEUM & CHEM CORP +1

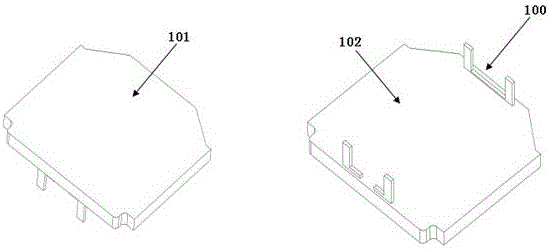

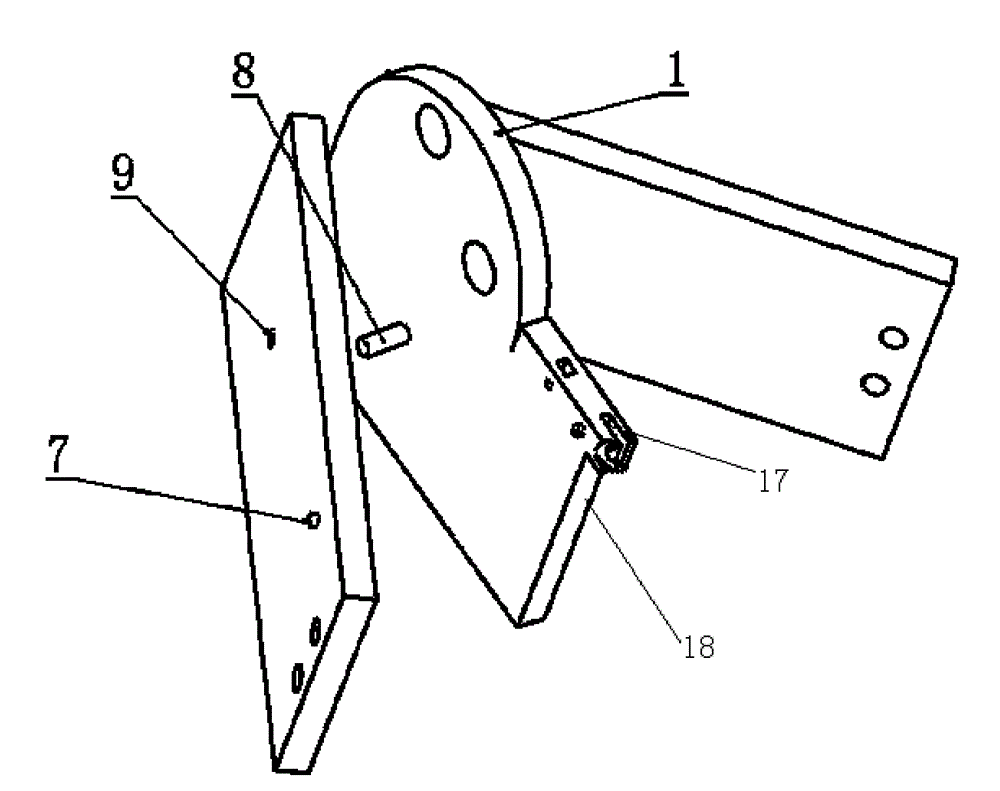

Multifunctional wiring-duct machining device and machining method thereof

InactiveCN105251878APerfect shapeConsistent processing shapeShaping toolsPerforating toolsEngineeringMachining

The invention relates to a multifunctional wiring-duct machining device and a machining method thereof. The machining device comprises a C-shaped base, an upper die rotary plate, a plurality of upper dies, a downward pressing device and a lower die. The upper die rotary plate is rotationally mounted at the upper end of the inner side of the C-shaped base, and the upper dies are mounted at the lower end of the upper die rotary plate in the radial direction. The downward pressing device is vertically mounted on the top of the C-shaped base and located on one side of the radial direction of the rotary plate. The lower die is fixedly mounted in the position, below the downward pressing device, of the upper end of the bottom of the C-shaped base. According to the multifunctional wiring-duct machining device and the machining method thereof, the problem that dies are frequently replaced during wiring-duct machining is solved; after integration, operation is convenient, batch machining can be achieved, work hours are shortened, and the manual labor intensity is relieved; in addition, after program control is added, automatic machining can be achieved, and the automation degree is increased.

Owner:TIANJIN RES INST OF ELECTRIC SCI

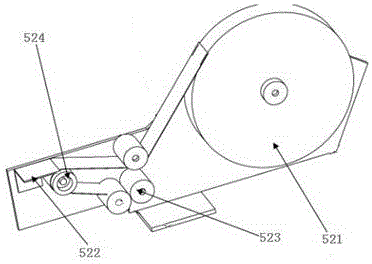

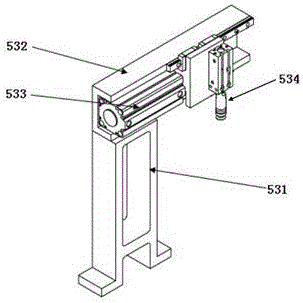

Automatic backlight component detecting, labeling and film sticking production line and method

InactiveCN105819050AImprove output efficiencyReduce output processLabelling machinesProduction lineEngineering

The invention provides an automatic backlight component detecting, labeling and film sticking production line which is automatically controlled by a software driving system. The automatic backlight component detecting, labeling and film sticking production line comprises a workbench arranged horizontally. A conveying mechanism, an energization detecting platform, a rotating disk, a feeding device, a position detecting camera, a film sticking device, a film pressing device, a labeling device, a bubble detecting camera and a discharging device are installed on the workbench, wherein the film sticking device is used for sticking a thin film on a backlight component. At least seven positioning stations are arranged on the rotating disk in the circumferential direction, and the feeding device, the position detecting camera, the film sticking device, the film pressing device, the labeling device, the bubble detecting camera and the discharging device are sequentially arranged on the rotating disk in the circumferential direction in a surrounded mode and are in one-to-one correspondence with the seven positioning stations. According to the automatic backlight component detecting, labeling and film sticking production line, the output efficiency of the backlight component is greatly improved, the manual labor intensity is relieved, and the output processes of the backlight component are simplified. The invention further provides an automatic backlight component detecting, labeling and film sticking method.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

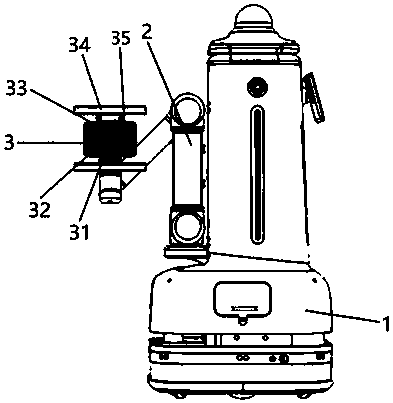

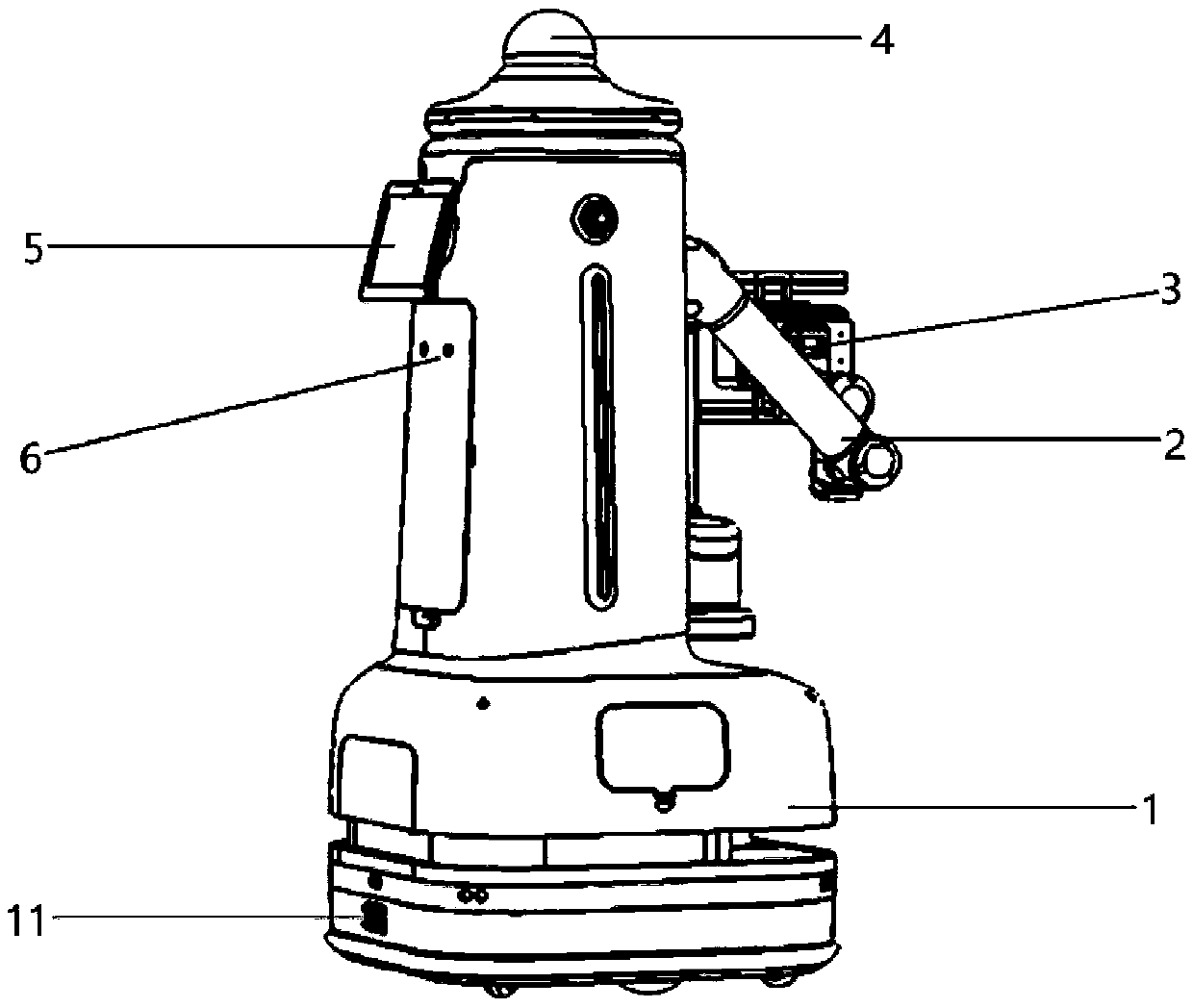

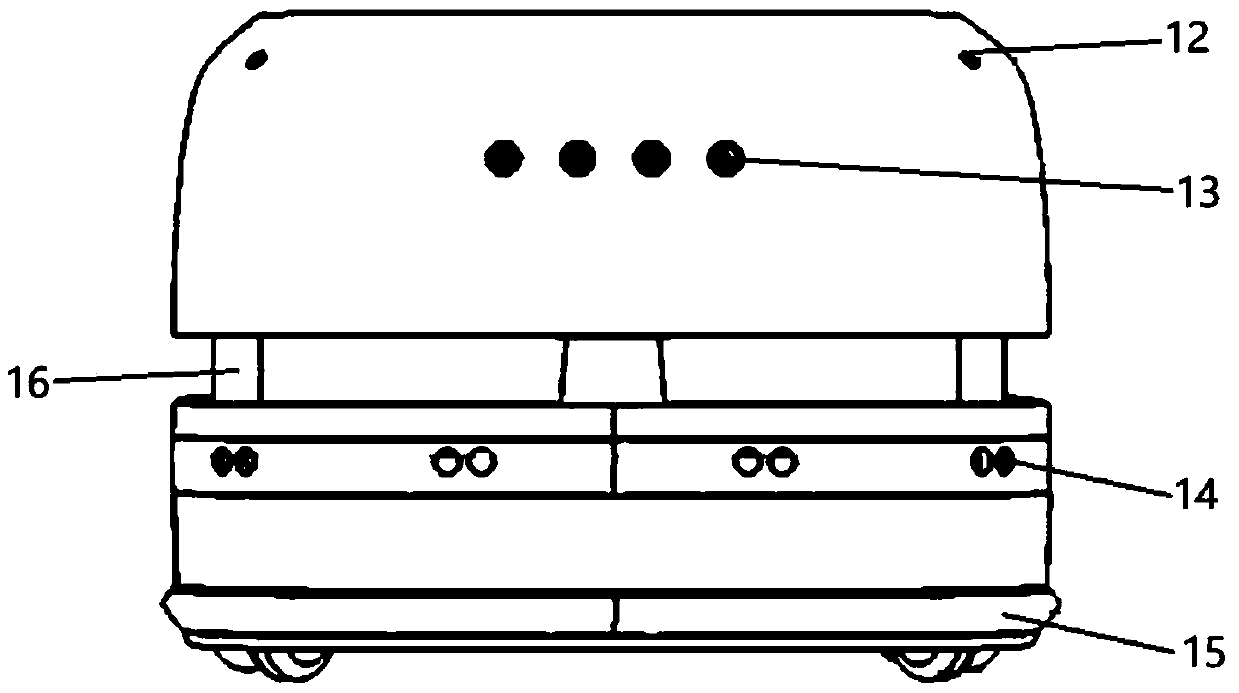

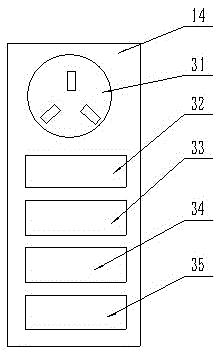

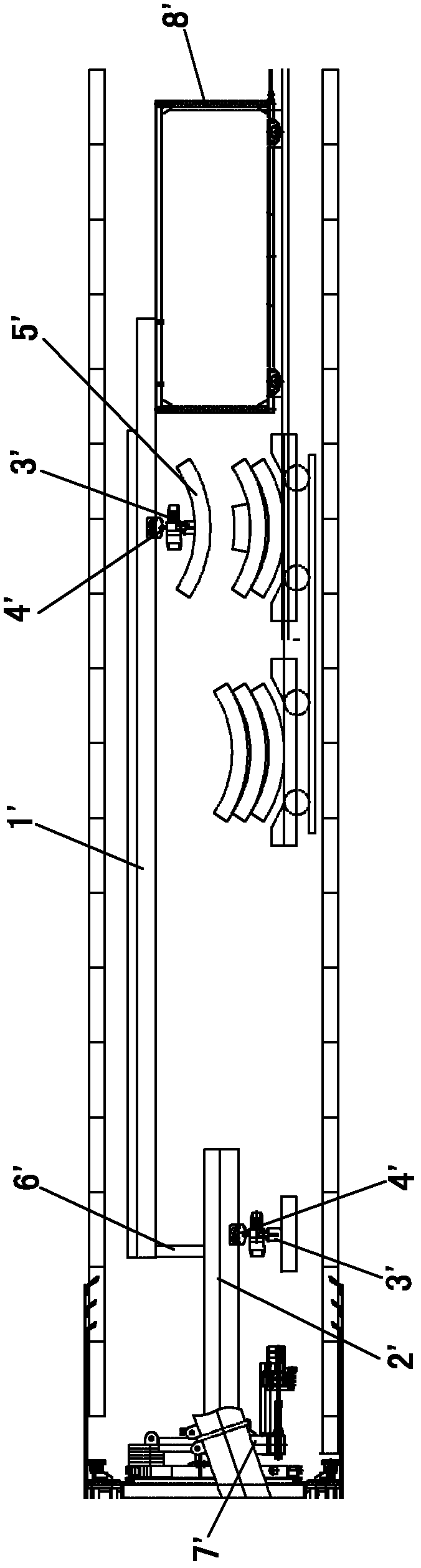

Machine room inspection system and working method thereof

ActiveCN109531533AAccurate collectionReduce manual labor intensityProgramme-controlled manipulatorEngineeringWorking set

The invention relates to a machine room inspection system and a working method thereof. The inspection system comprises a movable robot and a mechanical arm, a movable robot, an information shooting part (31), a positioning detection part (32) and a control part, wherein the movable robot comprises a mechanical arm (2); the information shooting part (31) is arranged on the mechanical arm (2) terminal and is used for shooting the state attribute information of the equipment to be detected in the machine room; the positioning detection part (32) is arranged at the tail end of the mechanical arm(2) and is used for detecting the orientation information of the information shooting part (31) and the target to be shot; and the control part is used for moving the robot to the equipment to be detected according to the pre-planned route, according to the detection information provided by the positioning detection part (32), and the information shooting part is enabled to arrive at a proper shooting position for shooting by controlling the movement of the mechanical arm. According to the inspection system, equipment in the machine room can be intelligently inspected, and the inspection efficiency is improved; after the robot arrives at the equipment to be detected, the information shooting part is positioned to a proper shooting pose through the movement of the mechanical arm, so that the information acquisition is more accurate.

Owner:JD DIGITS HAIYI INFORMATION TECHNOLOGY CO LTD

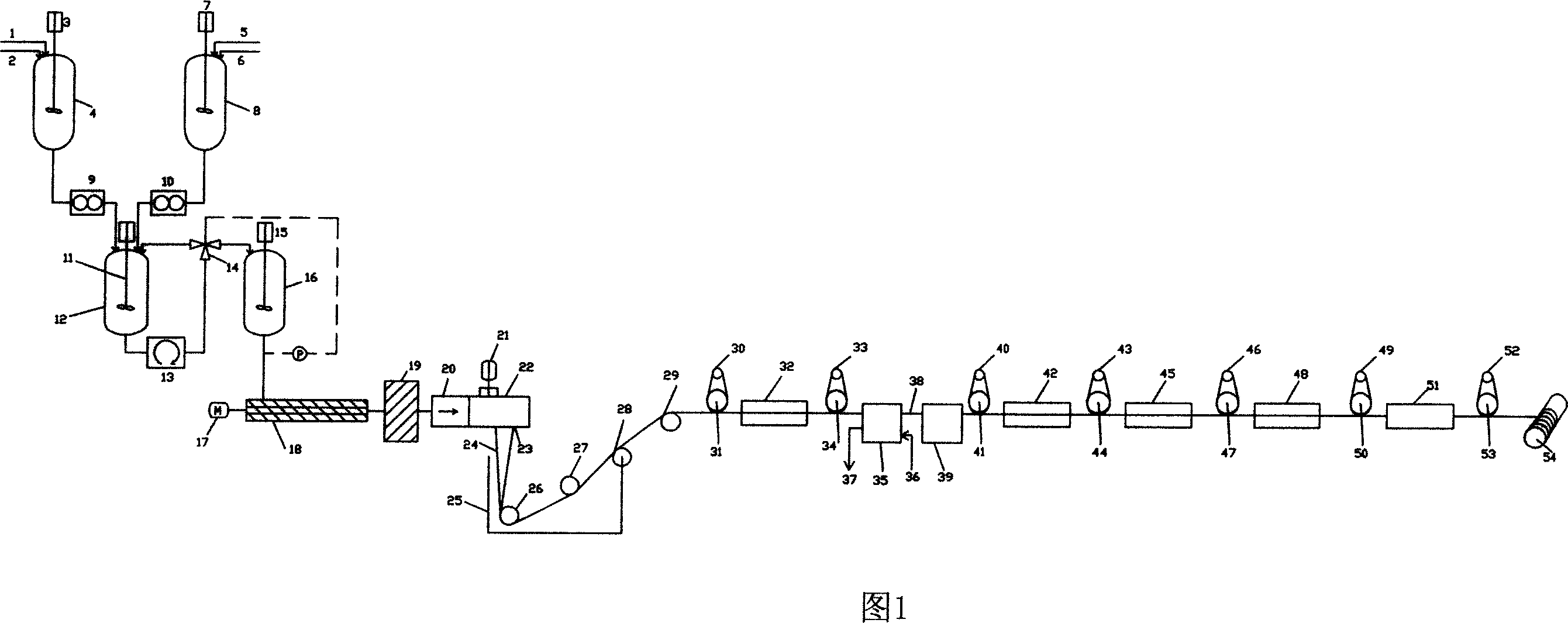

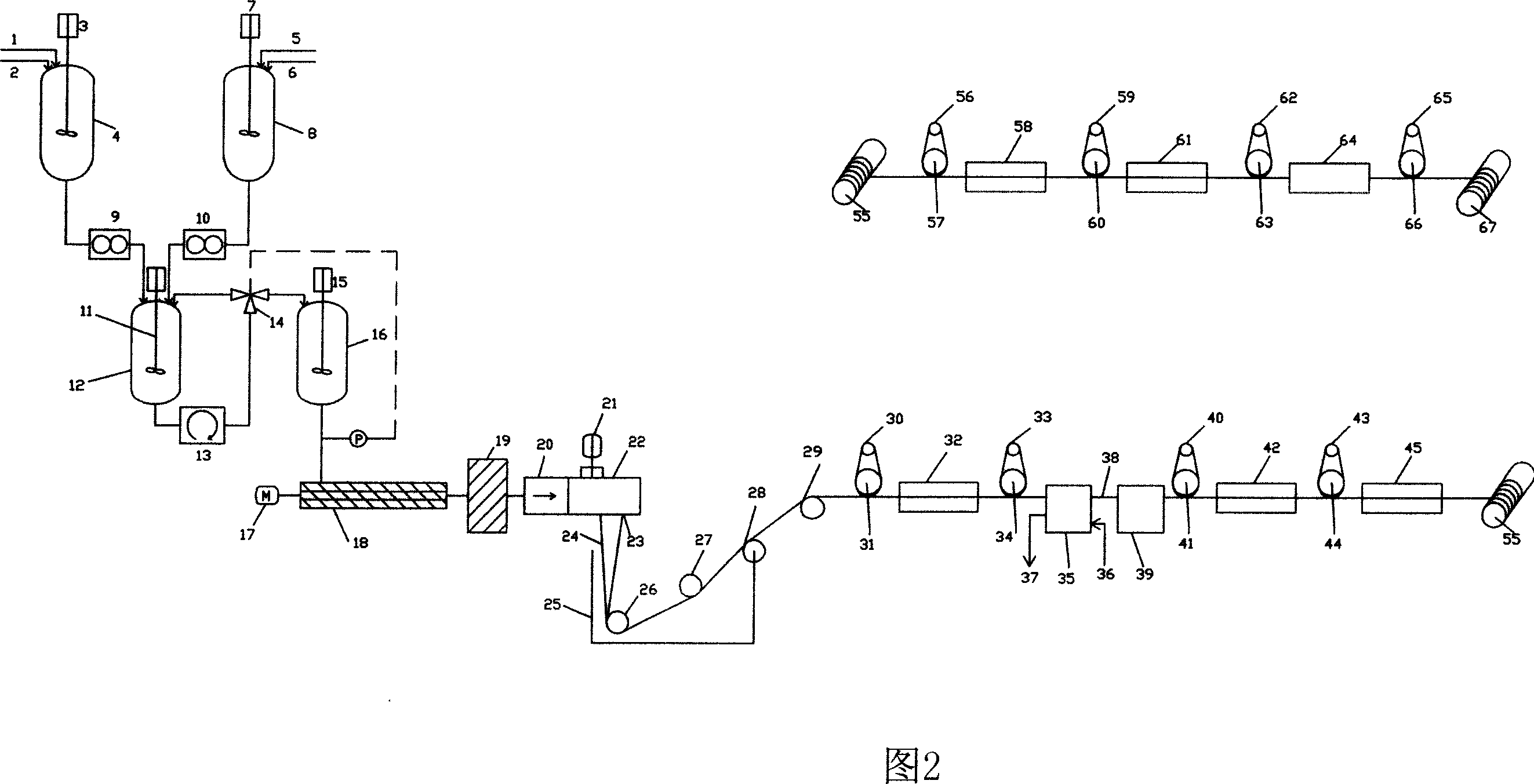

Super high molecular weight polyethylene gel method for continuous producing direct spinning fine denier filament

InactiveCN1995496AUniform and stable qualityGuaranteed accurate feedingWet spinning methodsMonocomponent polyolefin artificial filamentFiberState of art

The invention relates to a manufacturing method for continuous direct spinning fine denier yarn by uhmwpe jelly method, belonging to the spinning area and solving the problem that the single yarn or yarn beam generated by prior technology is on the high side and bad uniformity so that the difficulty for stability of manufacturing and quality of subsequent product is enhanced and the applicable range is limited. The method is provided with reasonable and compact process flow, stable process control, skillful operation and improving the quality and uniformity of product. By the method continuous stable spinning in line is realized in process parameters and the production efficiency is improved. The labor cost and intensity are lessened. Because there is less turnover link in the middle of process it is favor of decreasing producing consumption and uncontrollable factors. Under the stable running, uhmwpe fine denier yarn or yarn beam with even and stable quality, and good performance is provided.

Owner:SINOTEX INVESTMENT & DEV CO LTD

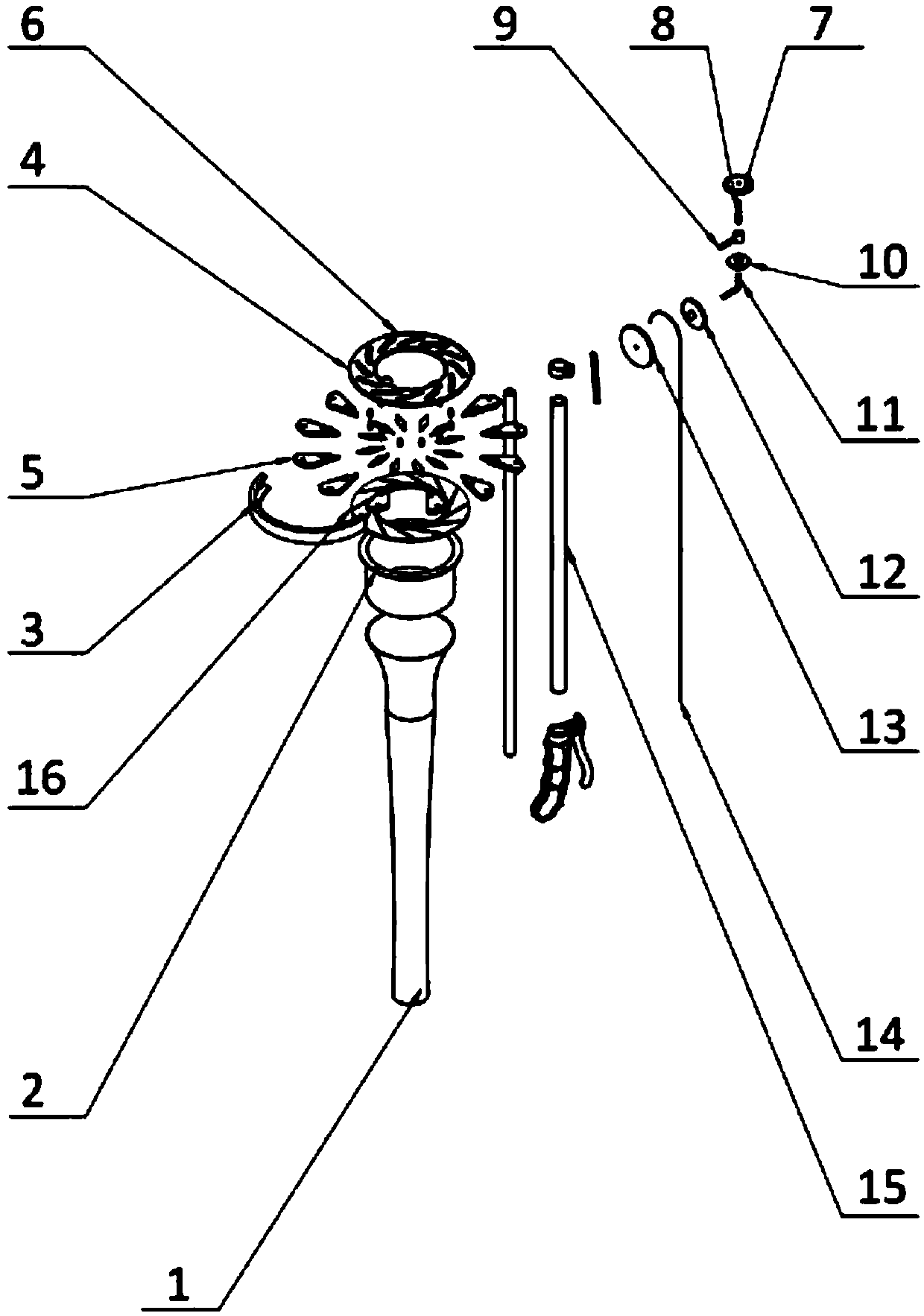

Magic expansible broom

The invention discloses a magic expansible broom, which comprises a support seat. An operating rod is mounted on the support seat. A step and a groove are arranged at the front end of the support seat, a support rod is disposed in the groove, two front support boards are movably mounted on the support rod, hinge ends of the support boards are respectively inset into the step, the other end of one front support board and the other end of the other front board are hinged to rear support boards respectively, and the other end of one rear support board and the other end of the other rear support board are respectively hinged to the rear end of the support seat. A locking block is mounted on the support seat at an opening of the groove. Elastic rods are hinged to front two sides of the support seat respectively, and one end of one elastic rod and one end of the other elastic rod are hinged to the inner side of one front support board and the inner side of the other front support board respectively. A three-way limit switch mounting hole is reserved on the support seat behind the groove, and a limit switch is mounted in the three-way limit switch mounting hole and used for fixation and for limiting the distances from the support seat to the front support boards and the rear support boards. The lower end of each of the front support boards and the rear support boards is provided with bristles. The magic expansible broom can be used for cleaning garbage and pushing garbage, so that cleaning efficacy is improved greatly. The magic expansible broom is suitable for large-scale production, production efficiency is high, bamboo and wood resources are economized, and the ecological environment is protected.

Owner:陆永成

Magic expansible broom

InactiveCN102535375BSave resourcesReasonable structural designRoad cleaningBristleEcological environment

The invention discloses a magic expansible broom, which comprises a support seat. An operating rod is mounted on the support seat. A step and a groove are arranged at the front end of the support seat, a support rod is disposed in the groove, two front support boards are movably mounted on the support rod, hinge ends of the support boards are respectively inset into the step, the other end of one front support board and the other end of the other front board are hinged to rear support boards respectively, and the other end of one rear support board and the other end of the other rear support board are respectively hinged to the rear end of the support seat. A locking block is mounted on the support seat at an opening of the groove. Elastic rods are hinged to front two sides of the support seat respectively, and one end of one elastic rod and one end of the other elastic rod are hinged to the inner side of one front support board and the inner side of the other front support board respectively. A three-way limit switch mounting hole is reserved on the support seat behind the groove, and a limit switch is mounted in the three-way limit switch mounting hole and used for fixation and for limiting the distances from the support seat to the front support boards and the rear support boards. The lower end of each of the front support boards and the rear support boards is provided with bristles. The magic expansible broom can be used for cleaning garbage and pushing garbage, so that cleaning efficacy is improved greatly. The magic expansible broom is suitable for large-scale production, production efficiency is high, bamboo and wood resources are economized, and the ecological environment is protected.

Owner:陆永成

Large drawing and overturning molding box closer

ActiveCN101758166AIncrease production capacityImprove machining accuracyMould loosening devicesProduction lineVehicle frame

The invention belongs to the technical field of casting, relating to a large drawing and overturning molding box closer. A lead rail is mounted on a fixed framework on which a mobile frame is placed and slides horizontally; a limiting baffle is mounted on the right side of the fixed framework for limiting the sliding position of the mobile frame; a hydraulic lifting mechanism is mounted on the mobile frame and is connected with a hydraulic extensible mechanism and can lift and drop the hydraulic extensible mechanism. A mechanical hand is mounted on the hydraulic extensible mechanism for supporting and releasing the molding flask. A rotary motor is mounted on the mechanical hand to control the rotation of the mechanical hand. The invention is controlled by the all-hydraulic system and has good work coordination, safety and reliability and high precision of functional actions such as drawing, overturning and mould closing. The invention has the advantages of greatly simplified operation sequences and high degree of automation, thereby lightening the labor intensity and enhancing the mechanic production capacity and the machining accuracy of casting production line.

Owner:WUXI XINAN FOUNDARY MACHINERY

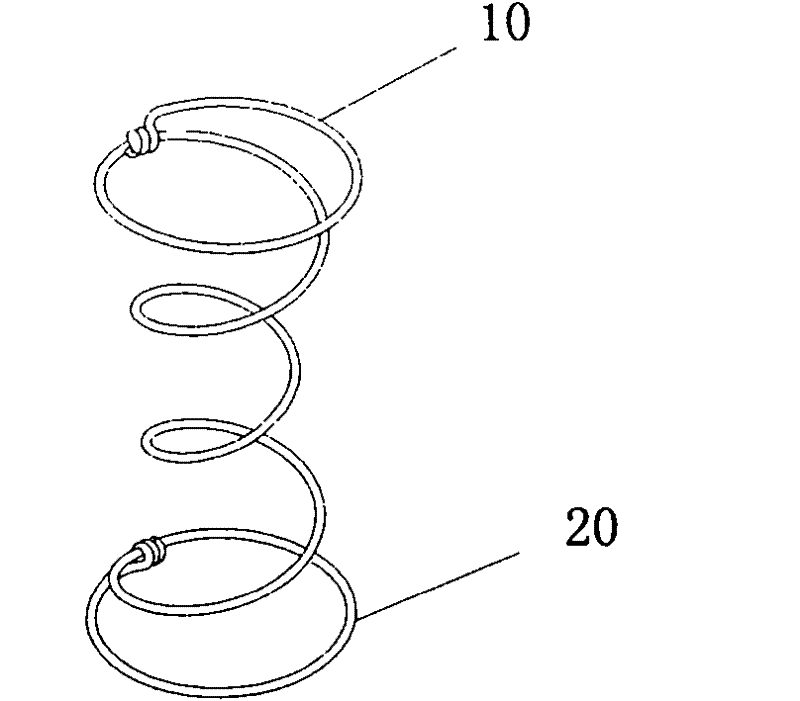

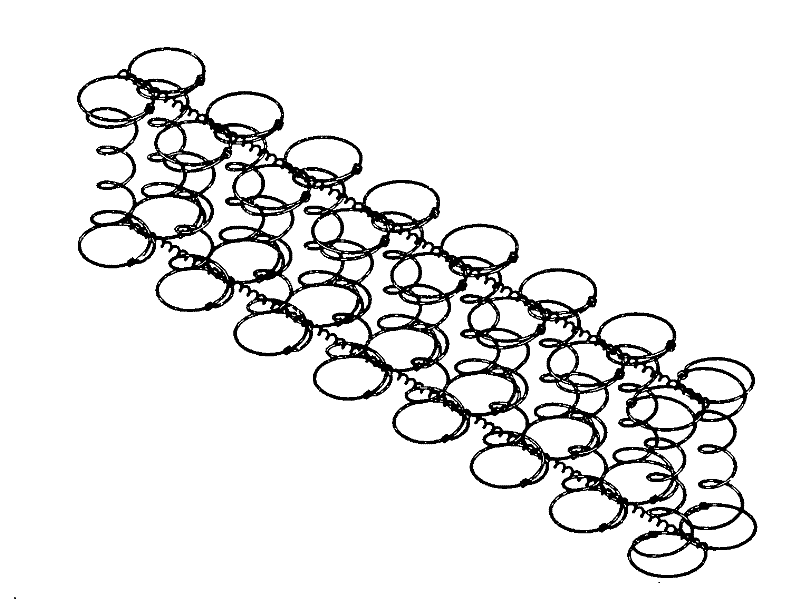

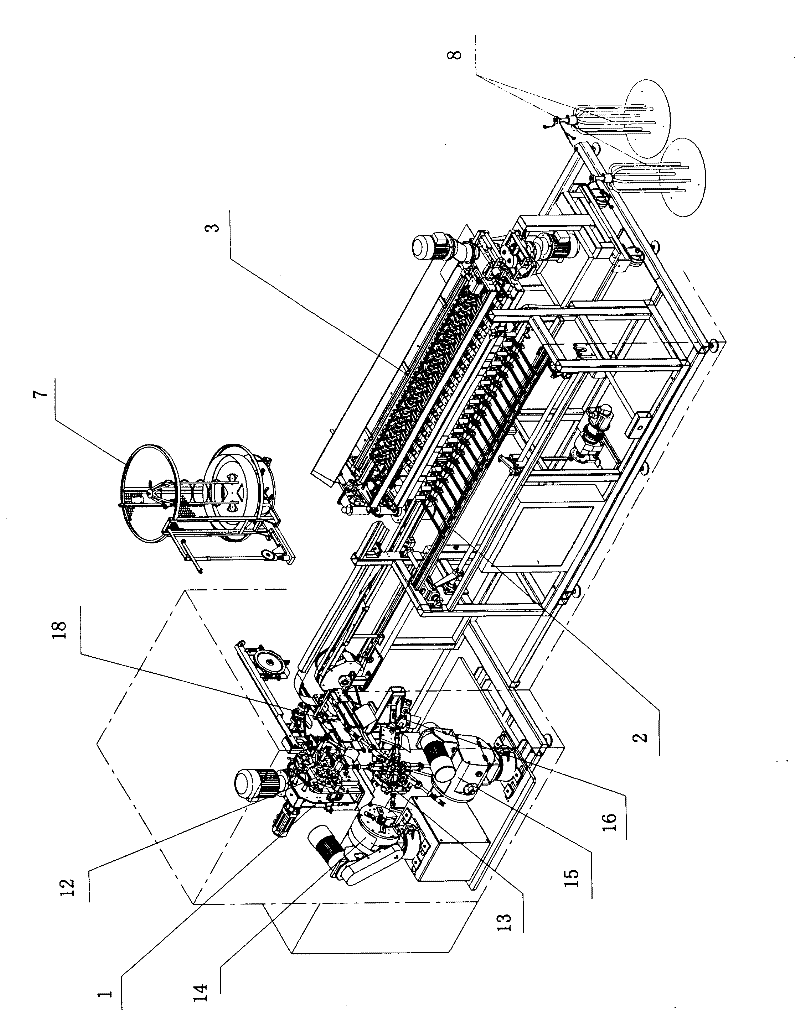

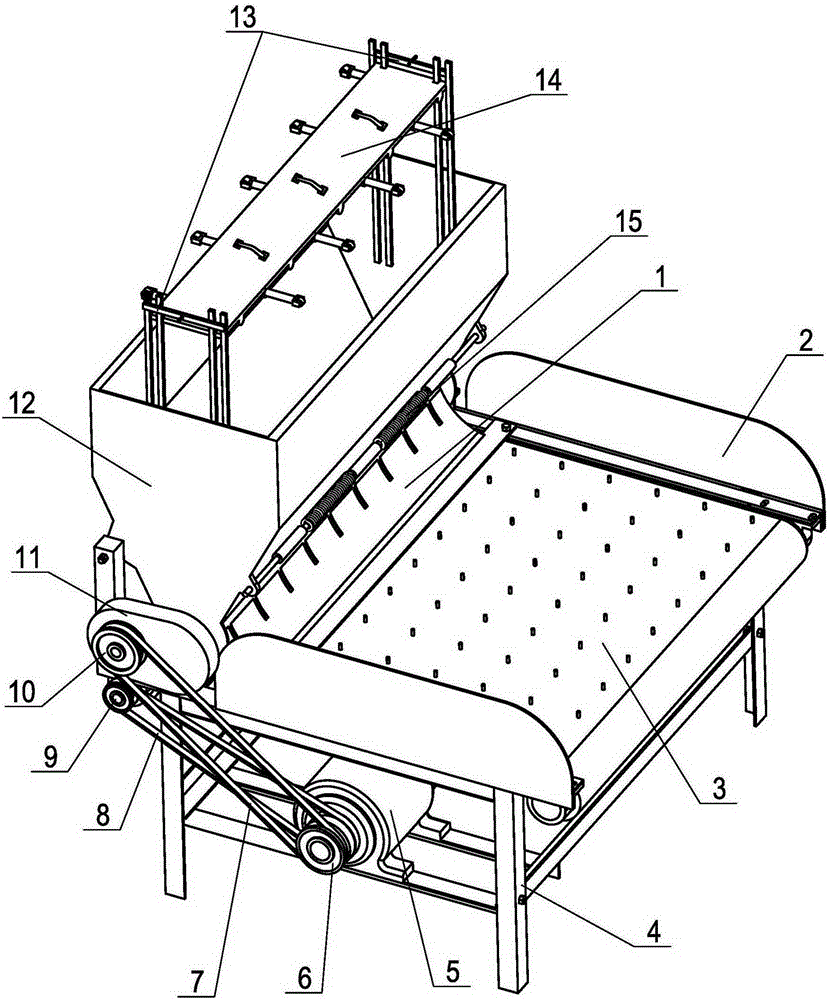

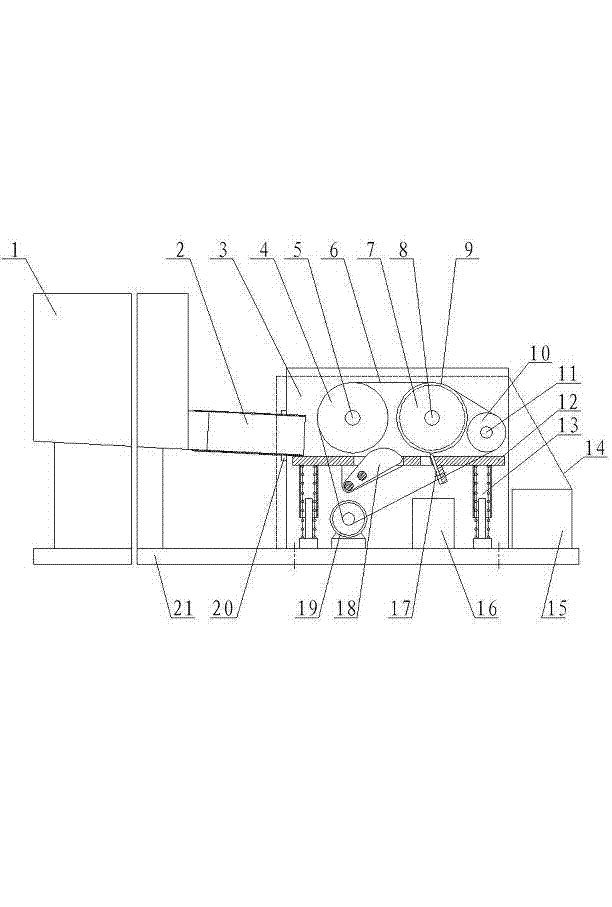

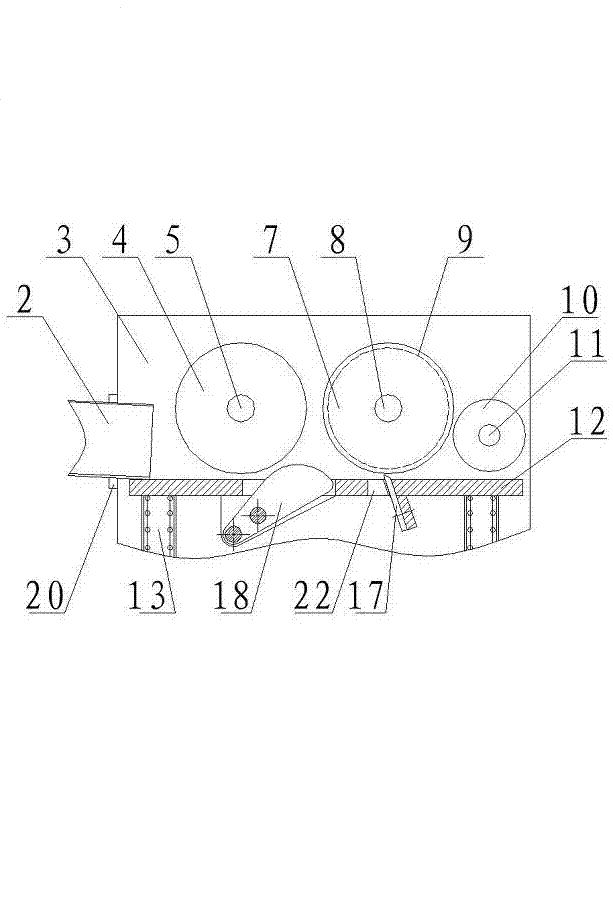

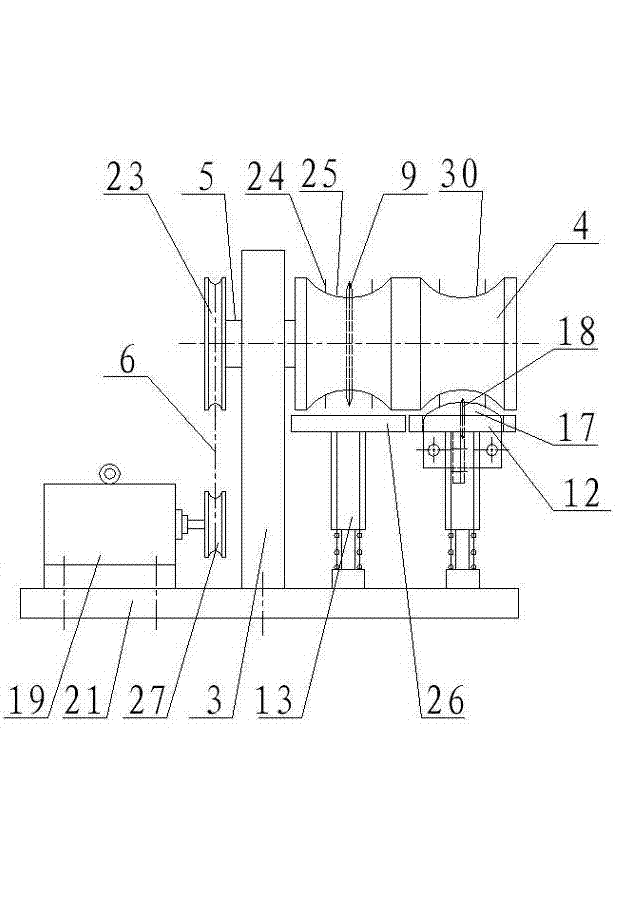

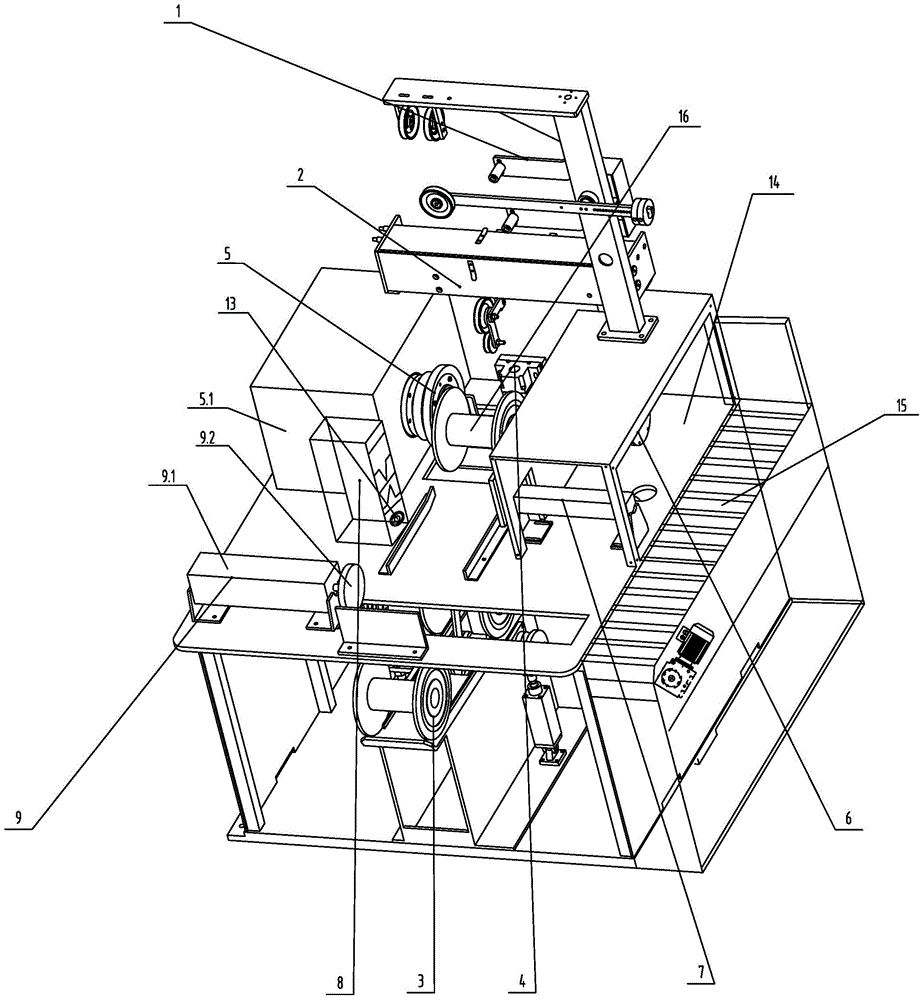

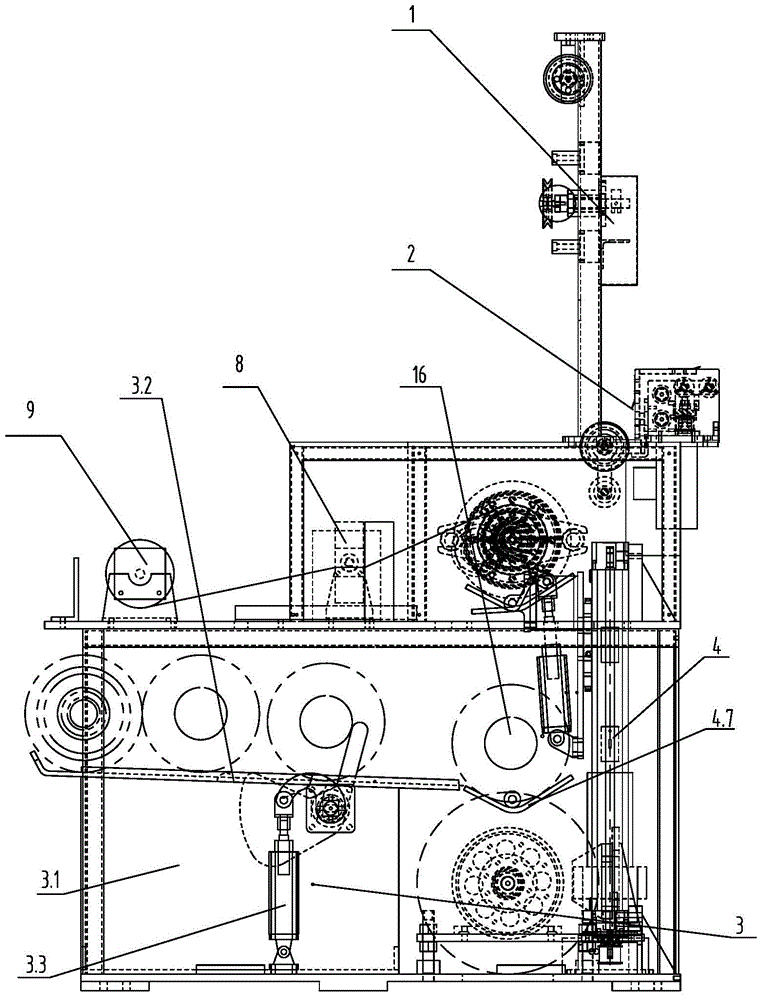

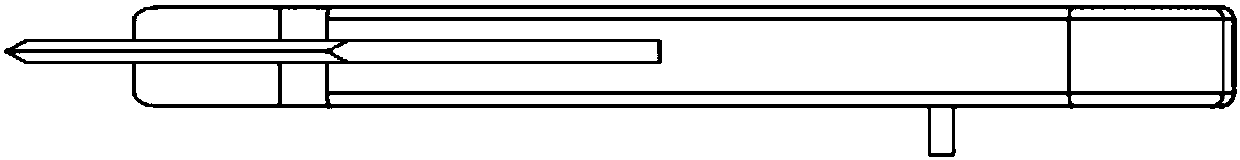

Method and device for producing spring bed core full-automatically

ActiveCN101780511BIncrease productivityShorten production timeConveyorsMetal-working apparatusProduction lineSynchronous control

The invention mainly discloses a method and device for producing spring bed core full-automatically; an automatic transmitter with simple and easy operation is used for connecting a spring coiling machine and a spring stringing machine integrally; under synchronous control, three machines coordinate the motion so as to realize full automatic production line from steel wire to bed core. The springcoiling machine equidistantly and horizontally outputs springs through a step conveying mechanism; the springs horizontally output adjust the turnover component of the automatic transmitter to be upright state and positioned into groups equidistantly by positioning components; the springs are pushed into the spring stringing machine from a conveying belt by means of the pushing component of the automatic transmitter to realize spring string. A full automatic production line is formed, and the steel wire as raw material is automatically made into the spring bed core, thereby greatly improving the production efficiency, shortening the production time in unit, reducing the labor intensity, and forming great economic benefit in enterprises; moreover, the obtained product has high quality and low defective rate, and the equipment failure rate is low.

Owner:SHAOXING HUAJIAN MATTRESS MACHINERY

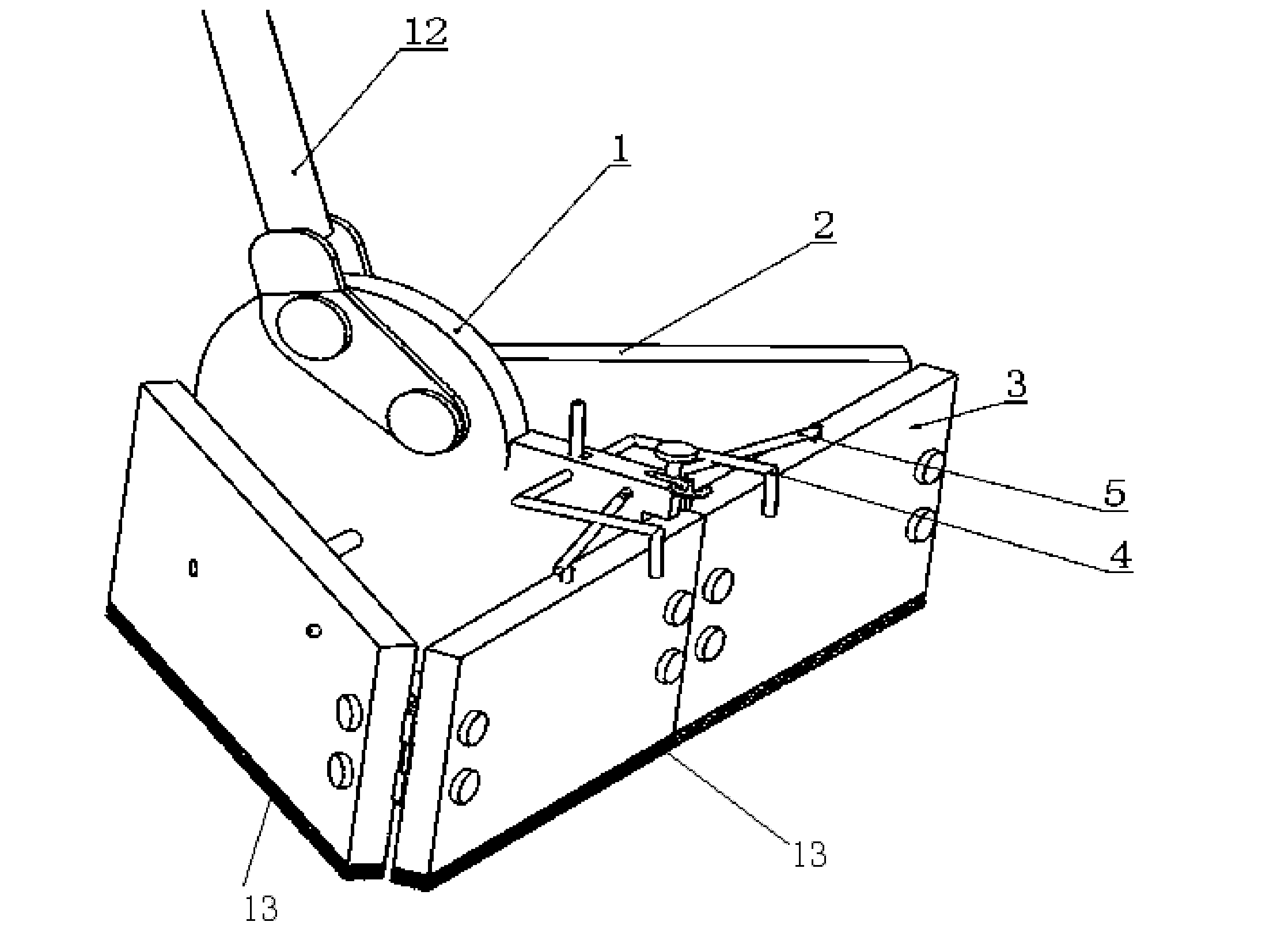

Automatic bundle splitting and lay-feeding device and control method thereof

ActiveCN105171863ARealize automatic beam separation and pavingEasy to handleCane mechanical workingButt jointEconomic benefits

Disclosed is an automatic bundle splitting and lay-feeding device. According to the device, a motor is installed below a machine frame and connected with a feeding transmission mechanism and a conveying part which are installed above the machine frame, and side baffles are installed at the two sides of the conveying part; a hopper is installed on the machine frame, a pressing plate guiding part is arranged on the upper portion of the interior of the hopper, and a pressing mechanism is arranged on the pressing plate guiding part; a feeding roller part is installed on the machine frame, part of composing mechanisms are arranged in the hopper, and an upper movable scraper blade part is installed on the hopper and attached to a lower fixed scraper blade installed on the machine frame; the feeding roller part is in butt joint with the lower fixed scraper blade to achieve bundle splitting separation of straw, straw finally falls on the conveying part and is conveyed to a straw braiding machine through a conveyer belt provided with conveying spike teeth, and then automatic bundle splitting separation and lay-feeding of straw are achieved. The working efficiency of the straw braiding machine is effectively improved, labor intensity is relieved, processing and recycling of straw are facilitated, and greater economic benefits are created.

Owner:HUNAN AGRICULTURAL UNIV

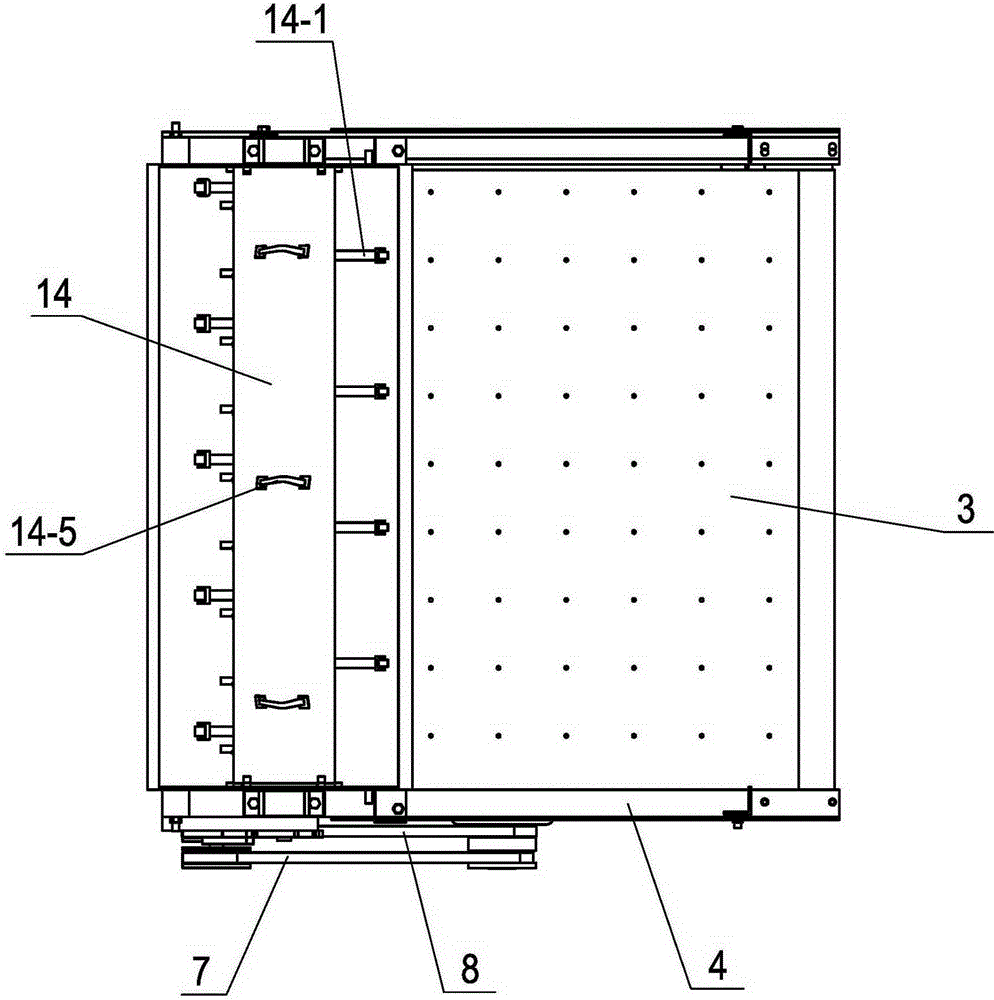

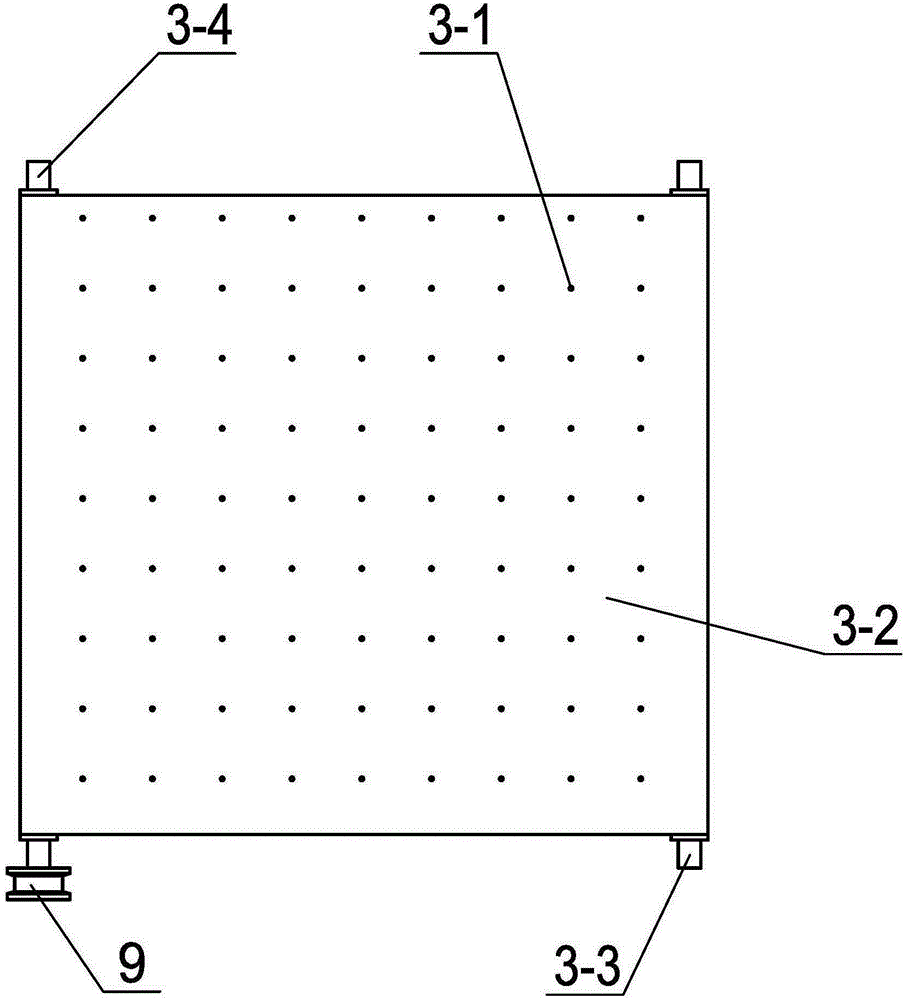

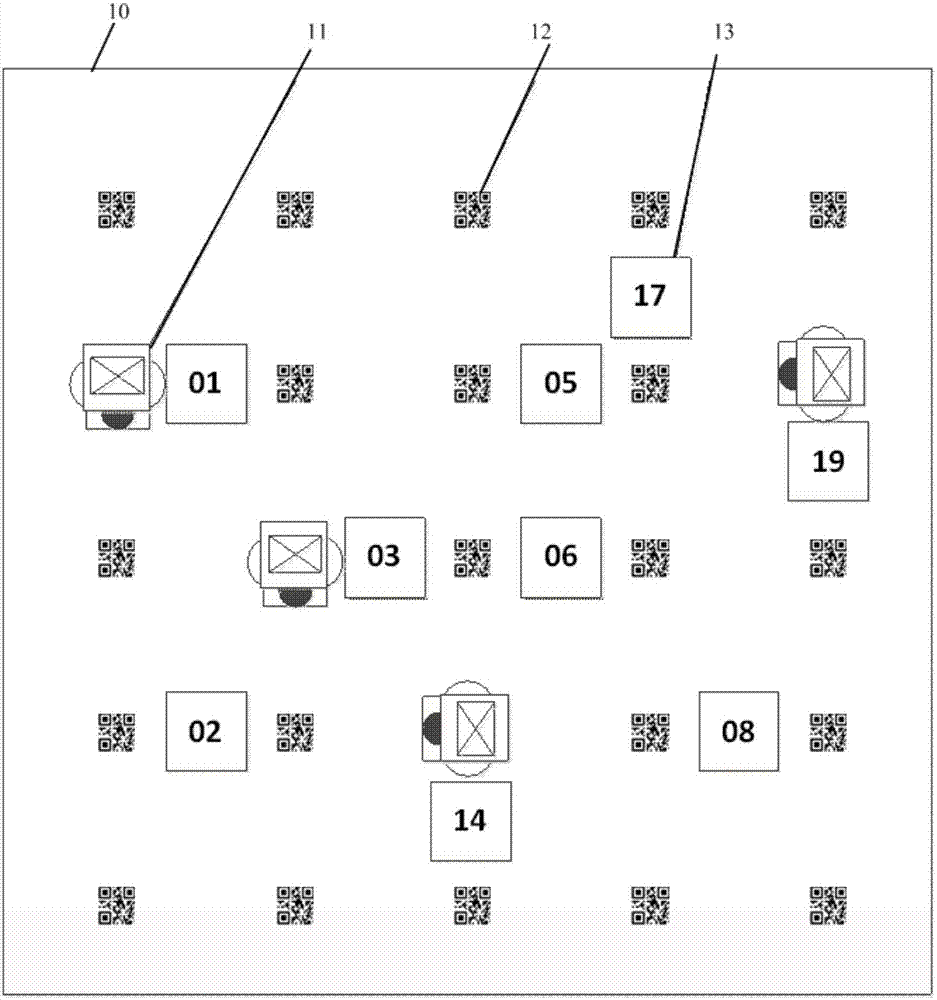

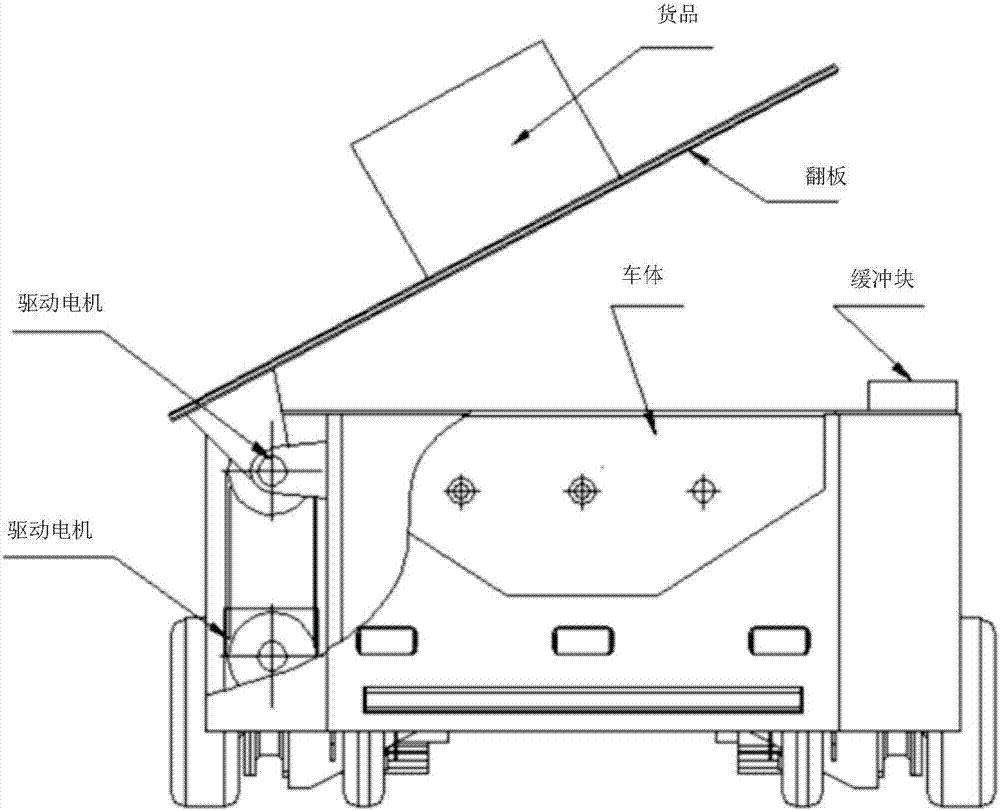

Parcel sorting AGV system

PendingCN107458828AImprove automated sorting efficiencyImprove flexible operationSortingMechanical conveyorsAlgorithmComputer engineering

The embodiment of the invention provides a parcel sorting AGV system. The system comprises a sorting platform, a plurality of two-dimensional code positioning coordinates, at least one sorting AGV and a plurality of sorting grids, wherein the two-dimensional code positioning coordinates are fixed to the sorting platform, the sorting AGVs operate on the sorting platform, positioning is carried out through the two-dimensional code positioning coordinates, each sorting grid is bound with a corresponding two-dimensional code positioning coordinate, and therefore parcels can be sorted to the corresponding sorting grids. The technical scheme of the system has the beneficial effects that the parcels can be automatically sorted through the dispatching and simultaneous operation of the multiple sorting AGVs, a novel sorting operation mode is provided, the automation degree is high, the automatic sorting efficiency of a warehouse can be effectively improved, the manual work is replaced by the AGVs, the labor intensity can be reduced, the accuracy rate can be increased, and the flexible operation of the warehouse can be improved

Owner:BEIJING WUZI UNIVERSITY

Automatic detector for welding line of storage tank bottom plate based on wireless transmission

ActiveCN105158337ARealize non-destructive testingAchieve horizontal movementAnalysing solids using sonic/ultrasonic/infrasonic wavesWireless transmissionComputer module

The invention relates to an automatic detector for a welding line of a storage tank bottom plate based on wireless transmission. The automatic detector comprises a machine body, a synchronous positioning and map construction module, a wireless data communication module and a control mechanism, wherein front wheels capable of controlling steering are mounted on the two sides of the machine body; driving rear wheels are mounted on the two sides of the rack; a bottom plate is arranged at the front end of the machine body in a manner of stretching frontwards; a lossless detection mechanism is mounted on the bottom plate; the lossless detection mechanism is provided with two air coupling ultrasonic probes with adjustable positions; the two air coupling ultrasonic probes are obliquely arranged in a V shape; a laser welding line tracking device is arranged between the two probes; an infrared camera and an infrared sensor are mounted at the top of the machine body; the control mechanism is connected with the front wheels and the driving rear wheels respectively; and the synchronous positioning and map construction module, the wireless data communication module, the laser welding line tracking device, the infrared camera and the infrared sensor are connected with the control mechanism respectively. With the adoption of the automatic detector, intelligent detection and evaluation of the welding line of the bottom plate are realized, and the manual detection cost is greatly reduced.

Owner:桐乡金橙云智科技有限公司

Automatic wall-building machine

ActiveCN105178616AEffective positioningImprove parallelismBuilding material handlingBrickEngineering

The invention discloses an automatic wall-building machine, characterized by comprising a longitudinal movement mechanism (A), a transverse movement mechanism (B), a vertical lifting mechanism (C), a brick conveying mechanism (D), a mortar spraying mechanism (E), and a brick discharging mechanism (F). The longitudinal movement mechanism (A) comprises two guide rails (4) which are parallel. A first bottom plate (3) is slidably fitted on the two guide rails (4). The transverse movement mechanism (B) comprises a second bottom plate (13) which is mounted on the first bottom plate (3) through a moving slide rail (9). A horizontal movement direction of the moving slide rail (9) is parallel to that of the first bottom plate (3). The vertical lifting mechanism (C) is arranged on the second bottom plate (13). The brick conveying mechanism (D), the mortar spraying mechanism (E) and the brick discharging mechanism (F) are arranged on the vertical lifting mechanism (C). The brick conveying mechanism (D) is used for conveying bricks. A conveying exit of the brick conveying mechanism (D) is located opposing a discharge exit of the brick discharging mechanism (F). A mortar spout of the mortar spraying mechanism (E) exactly faces the discharge exit of the brick discharging mechanism (F).

Owner:山东岱圣建设有限公司

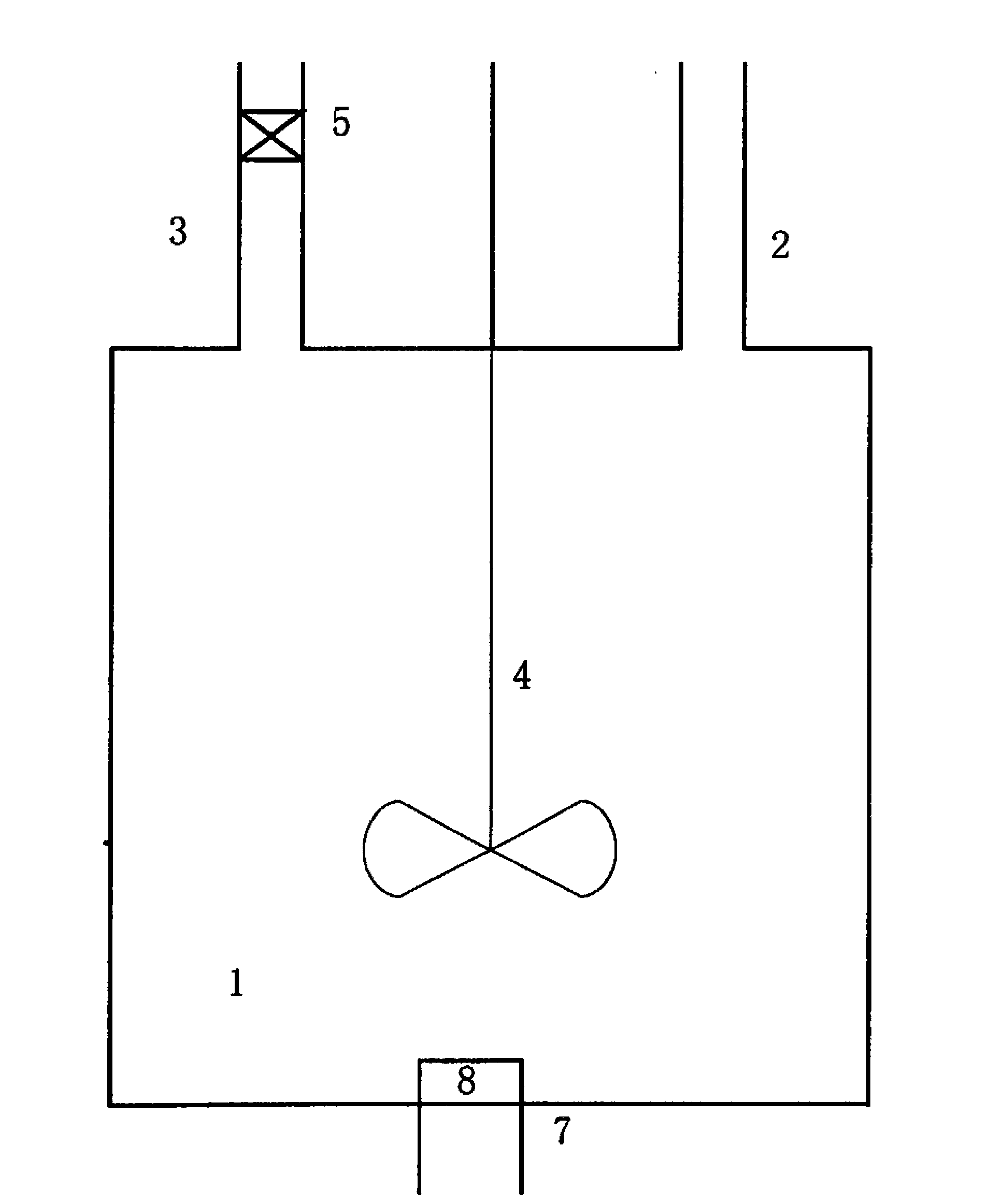

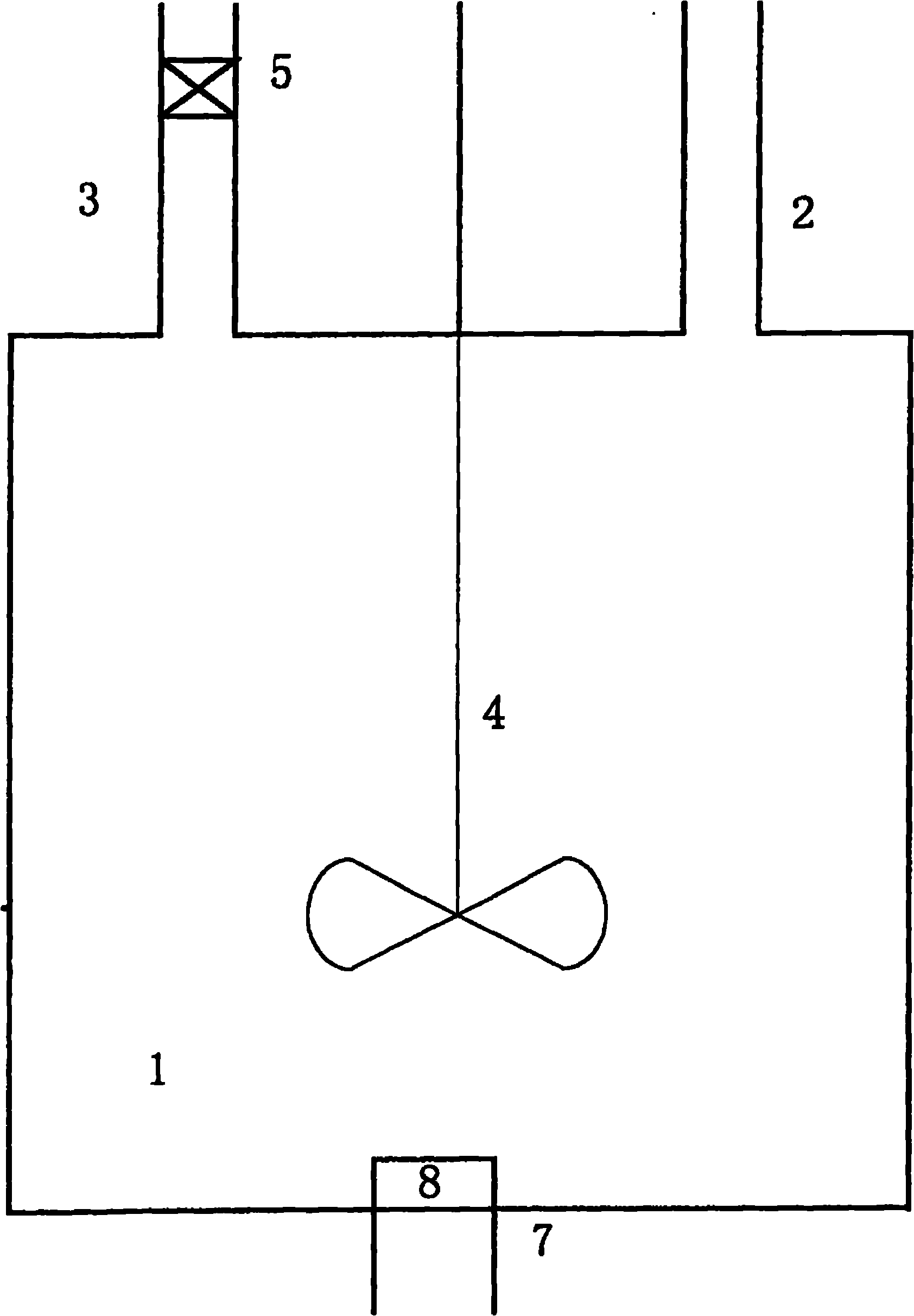

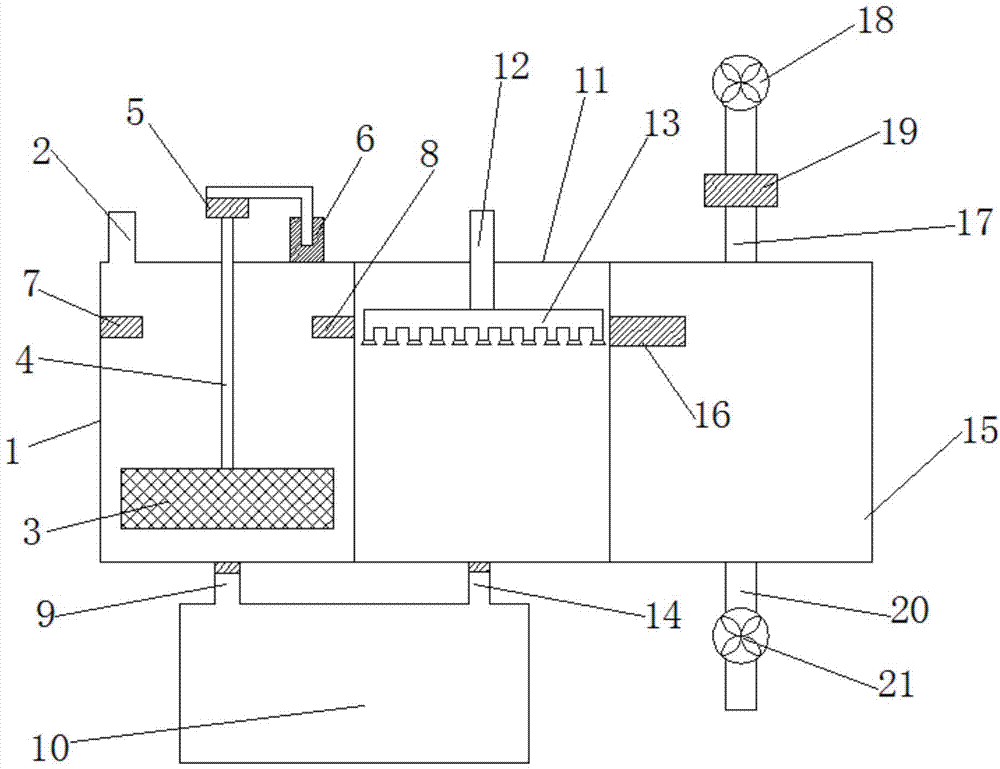

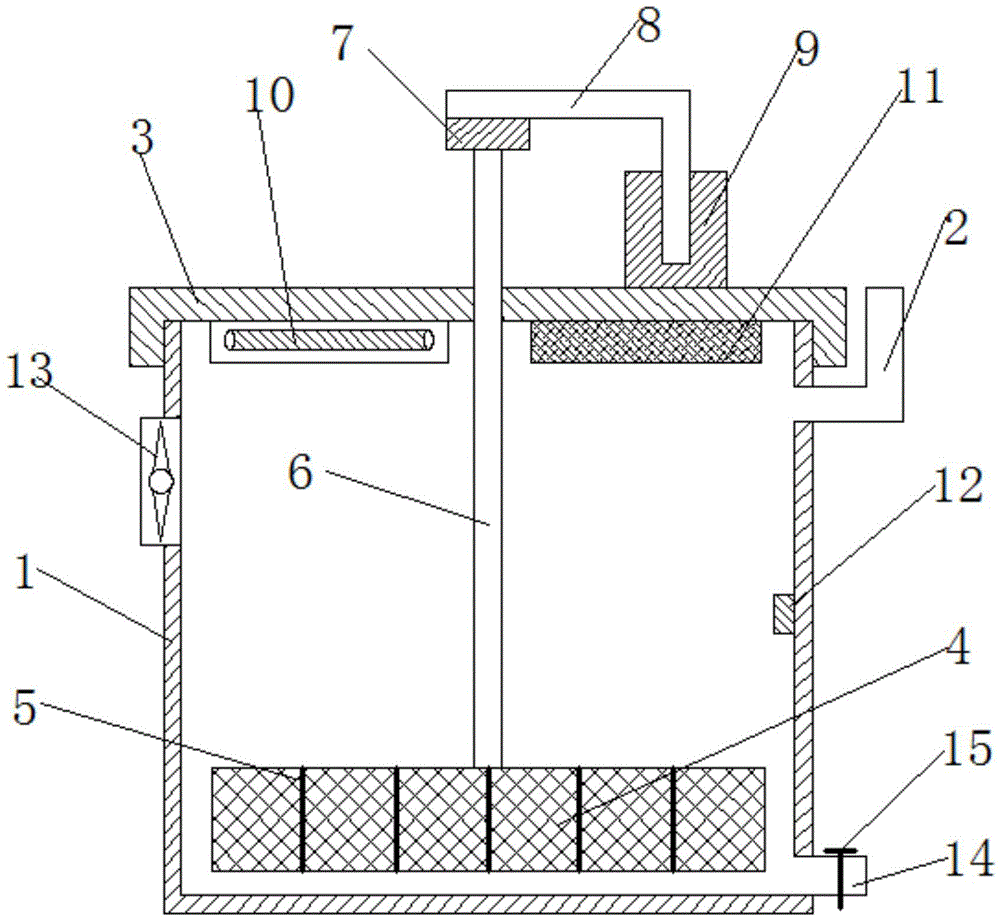

Efficient medical instrument disinfection and cleaning device

InactiveCN104840984AFully disinfectedImprove work efficiencyLavatory sanitoryHeatDisinfectantEngineering

The invention discloses an efficient medical instrument disinfection and cleaning device, which comprises a disinfection device, a cleaning device and a storage device, wherein a disinfectant inlet is formed in the upper part of the left side of the disinfection device; an instrument placement frame is arranged on the inner lower side of the disinfection device; a vertical rod is connected to the upper side of the instrument placement frame; a rotating motor is connected to the top end of the vertical rod, and is connected with a lifting device through a connecting rod; a heating probe is arranged on the upper inner wall of the left side of the disinfection device; an ultrasonic probe is arranged on the upper inner wall of the right side of the disinfection device. According to the efficient medical instrument disinfection and cleaning device, a medical instrument can be completely disinfected, cleaned, dried and stored; the lifting device can be rotated to spin-dry and drain the medical instrument after disinfection, so that the working efficiency of the device is greatly improved; waste liquor produced during working can be collected by a waste liquor tank, so that secondary pollution is reduced; in addition, a good hot air drying effect is achieved, so that the working efficiency of the device is further improved.

Owner:苏州福利恒电子科技有限公司

Spraying device

ActiveCN105562265AImprove spraying accuracyReduce manual labor intensitySpraying apparatusEngineeringMechanical engineering

The invention discloses a spraying device. The spraying device comprises a base. The base is fixedly arranged on the ground. The surface of the base is provided with a movable rotating workbench mechanism. An n-shaped support is arranged above the base. The bottom ends of stand columns of the n-shaped support are fixedly arranged on the ground on the two sides of the base. A through groove is formed in the upper surface of a beam of the n-shaped support in the length direction of the beam. The upper surfaces of the portions, on the two sides of the through groove, of the beam are provided with grooves with the same length as the through groove. A transverse sliding mechanism is mounted in the grooves. A lifting-and-rotating mechanism is fixedly mounted at the lower end of the transverse sliding mechanism. A spraying mechanism is fixedly mounted below the lifting-and-rotating mechanism. A controller is arranged on the surface of one of the stand columns of the n-shaped support. The controller is electrically connected with the movable rotating workbench mechanism, the transverse sliding mechanism, the lifting-and-rotating mechanism and the spraying mechanism. The spraying device has the beneficial effects of being simple in structure and high in practicability.

Owner:宣城东海汽车转向部件有限公司

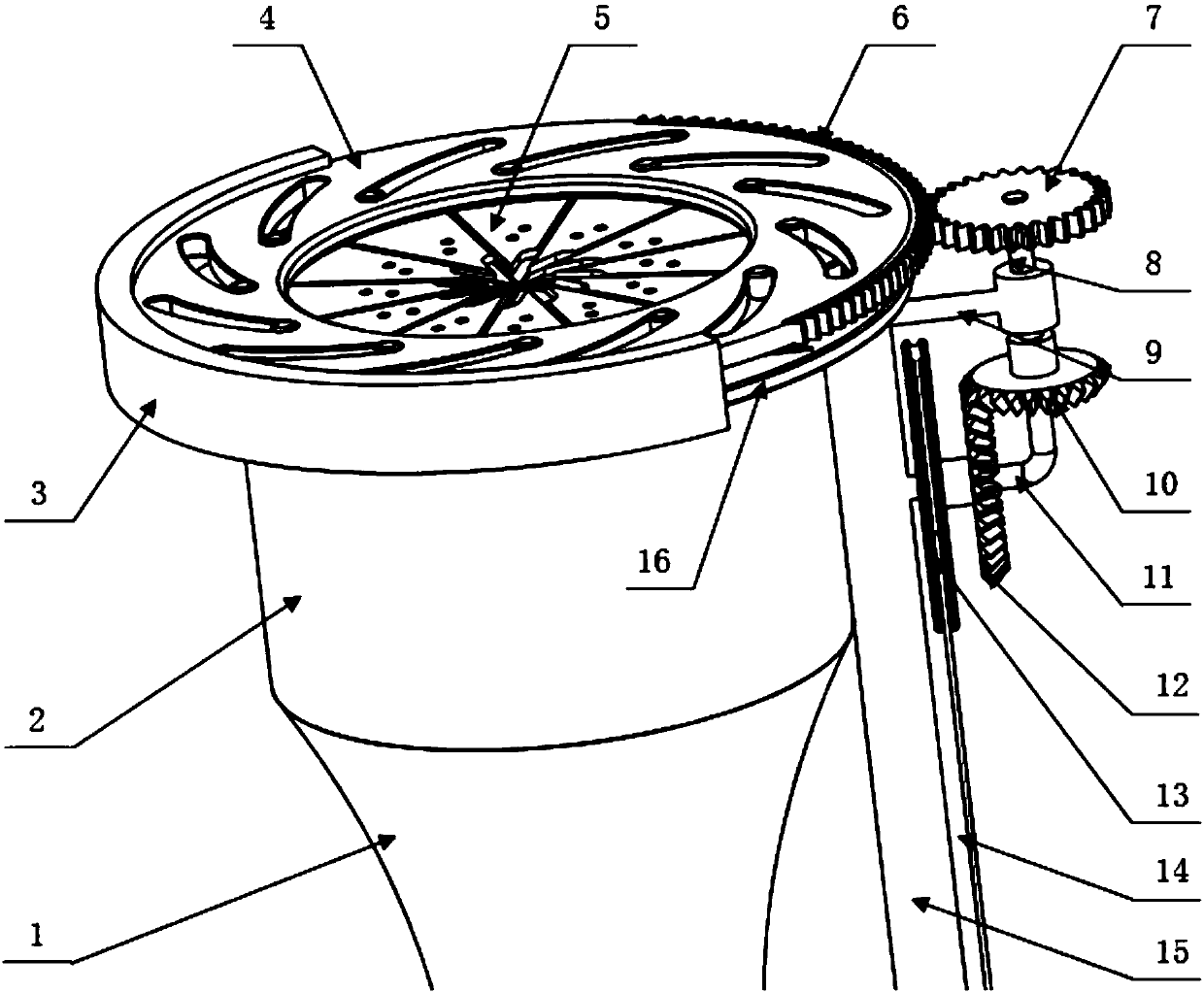

Eel and loach slaughtering machine

InactiveCN103168819ASolve the problemSolve the problem of missed killingPoultry/fish slaughtering/stunningAquatic productBack cutting

The invention relates to an eel and loach slaughtering machine which belongs to the field of an aquatic product processing machine. The eel and loach slaughtering machine is formed by a rack, a feeding barrel and a slaughtering device, wherein the feeding barrel is mounted at the one end of the rack and the slaughtering device is arranged at the other end of the rack; the feeding barrel and the slaughtering device are movably connected through a feeding hose and a hose clamp; and the slaughtering device is provided with a protection cover. The eel and loach slaughtering machine disclosed by the invention adopts a feeding roller to randomly grasp and convey eel and loach, the slaughtering speed is high, the slaughtering requirements on eel and loach with different sizes can be met, and the frequent problems that some eel and loach are not correctly slaughtered or are not slaughtered when an existing slaughtering machine is used for slaughtering eel and loach with different sizes are solved. When the eel and loach slaughtering machine disclosed by the invention is used for slaughtering eel and loach, eel and loach do not need to be classified according to specifications and sizes in advance, so that the labor intensity of workers is reduced and the working efficiency is improved; and eel and loach can be slaughtered from abdomens or from backs through the selection connection between the feeding hose and a back cutting supporting plate and between the feeding hose and an abdomen cutting supporting plate, and furthermore, the requirements on deep processing of eel and loach can be met.

Owner:李平

Medical apparatus cleaning and disinfecting device

The invention discloses a medical apparatus cleaning and disinfecting device, which comprises a main cleaning machine body, an upper cover and an apparatus placement rack, wherein a liquid inlet pipe is arranged above the right side of the main cleaning machine body; the upper cover board is arranged on the upper side of the main cleaning machine body; the apparatus placement rack is arranged on the lower side inside the main cleaning machine body; a partition plate is arranged on the apparatus placement rack; a rotating shaft is vertically arranged at the center of the apparatus placement rack; and the top end of the rotating shaft penetrates through the upper cover board and is connected with a rotary motor. According to the medical apparatus cleaning and disinfecting device disclosed by the invention, a medical apparatus can be fully disinfected, sterilized, cleaned and dried; draining of the apparatus is realized by adjusting the height of the apparatus placement rack; the apparatus can be spun by the rotary device in a rotating manner, and can be dried by a heating device at a high temperature; air convection in the device can be increased by a draught fan; and the drying effect and efficiency are improved.

Owner:苏州福利恒电子科技有限公司

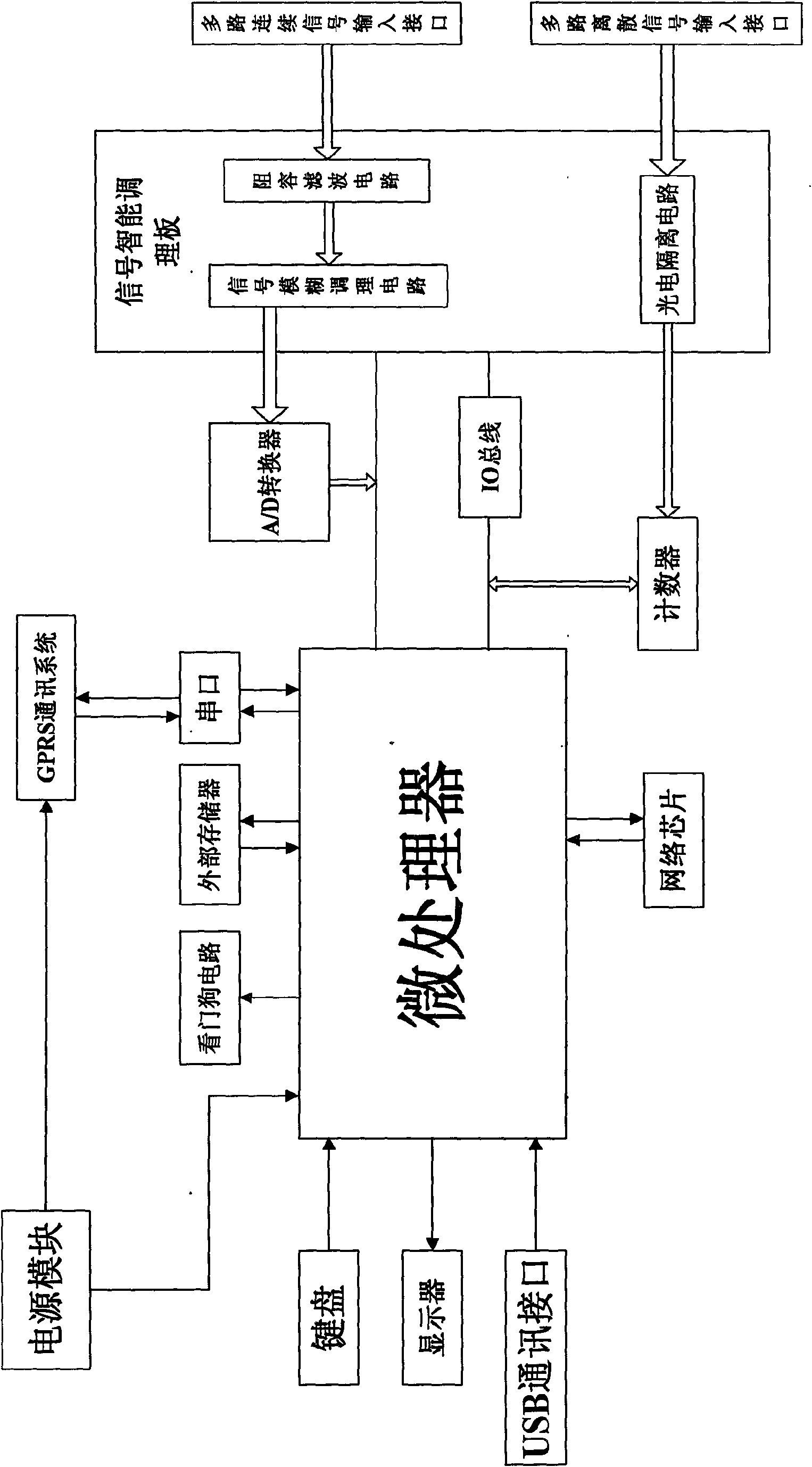

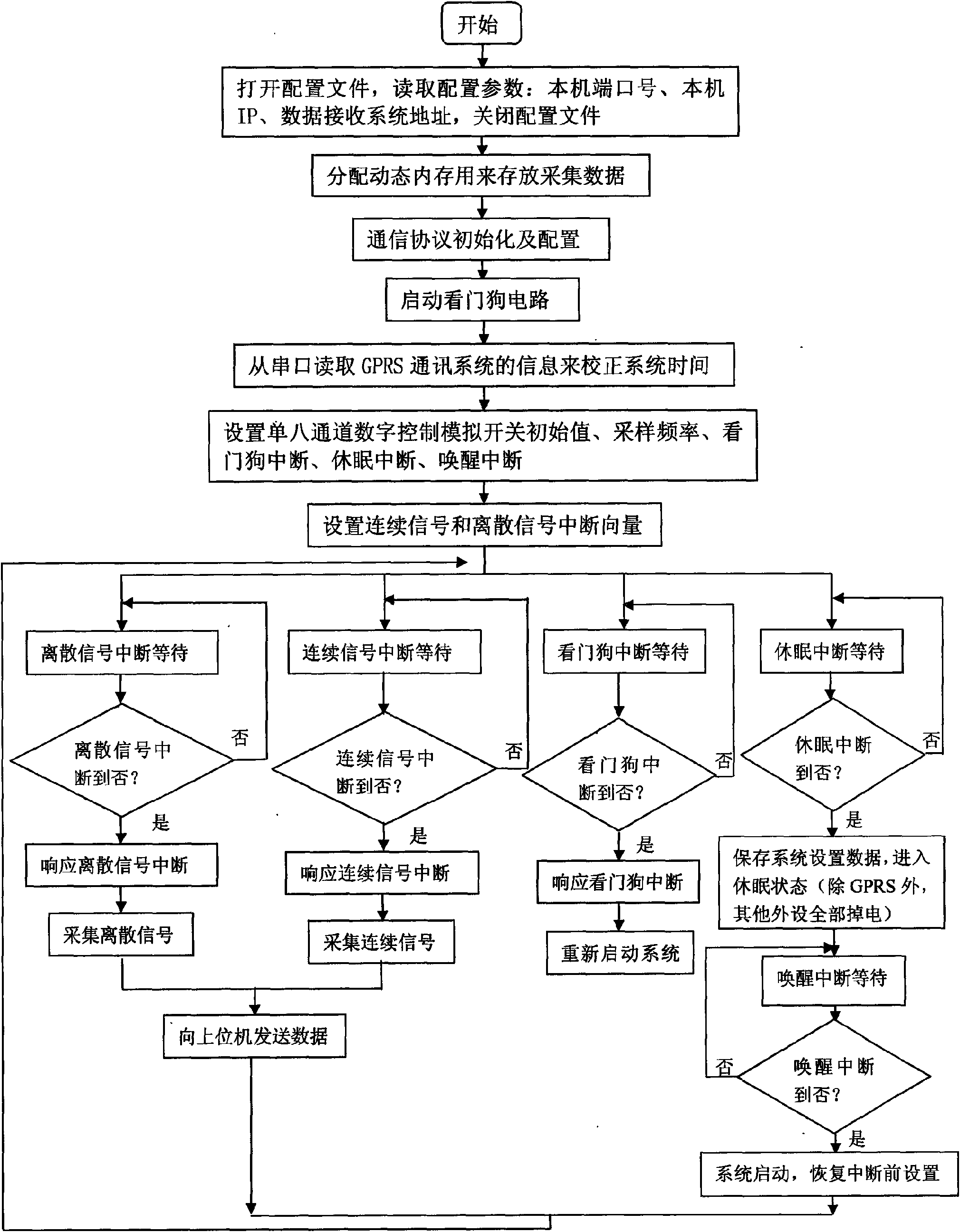

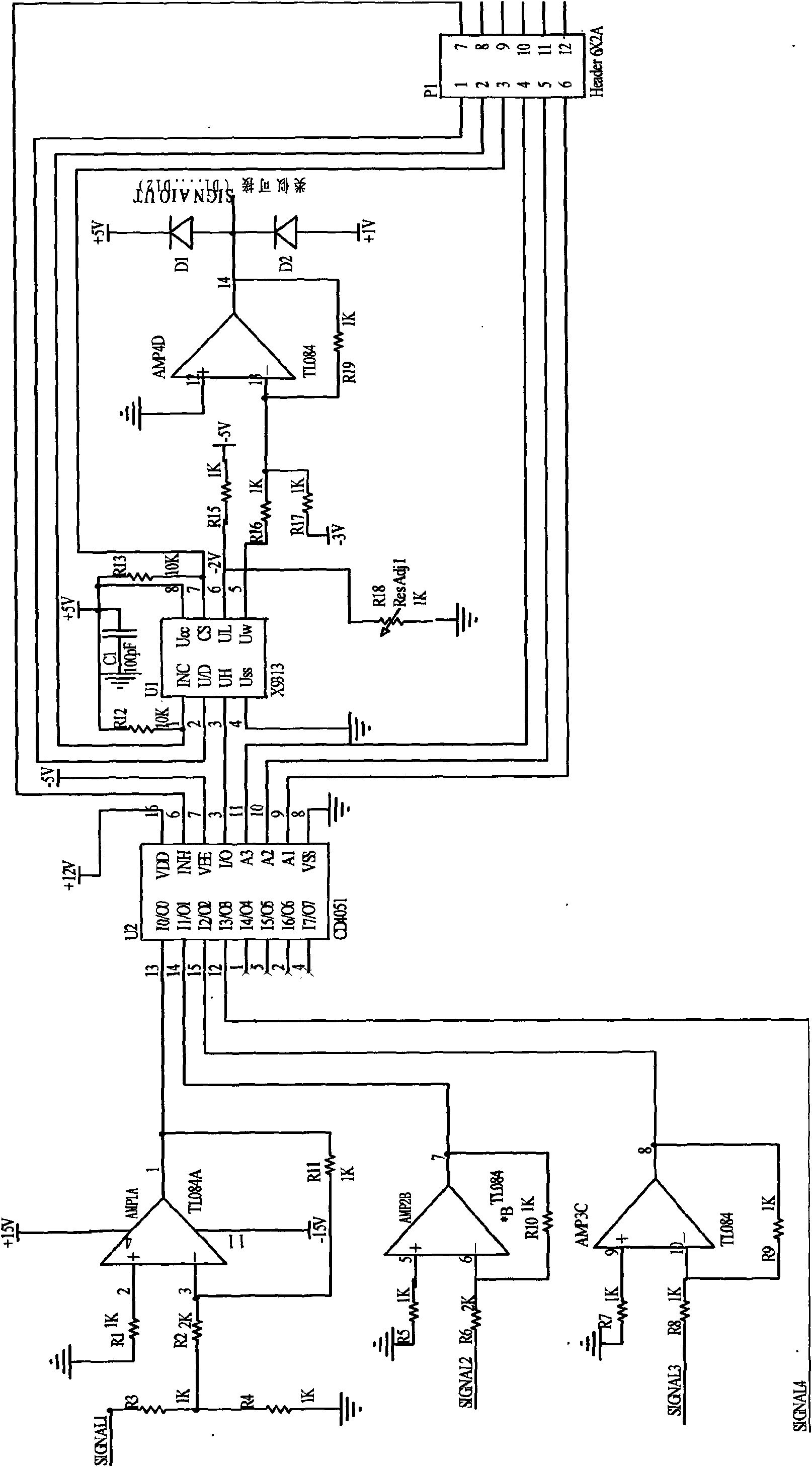

Universal data acquisition unit and data acquisition method thereof

InactiveCN101661276AImprove performanceReduce power consumptionProgramme controlComputer controlData acquisitionContinuous signal

The invention relates to a universal data acquisition unit and a data acquisition method thereof, belonging to the technical field of data acquisition; the universal data acquisition unit comprises amicroprocessor; a multi-path discrete signal input interface is connected with the input end of a counter by a photoelectric isolating circuit, and a multi-path continuous signal input interface is connected with the input end of an A / D converter, and a microprocessor is connected with the input ends of the A / D converter and the counter. The data acquisition method comprises that: system initialization is carried out; continuous and discrete signal interrupt vector is set; interrupt latency is carried out, if the discrete signal is interrupted, the discrete signal is acquired; if the continuous signal is interrupted, the continuous signal is acquired; if a watchdog is interrupted, a system is restarted; if hibernation is interrupted, system setting data is stored, and then a hibernation state is carried out; and then, interrupt latency awaken operation is carried out, if awakening is interrupted, the system is started, and the setting is restored before interruption; if the continuoussignal and the discrete signal are acquired, interrupt latency is continuously carried out after data is transmitted to an upper computer; if not, interrupt latency is carried out directly.

Owner:NORTHEASTERN UNIV

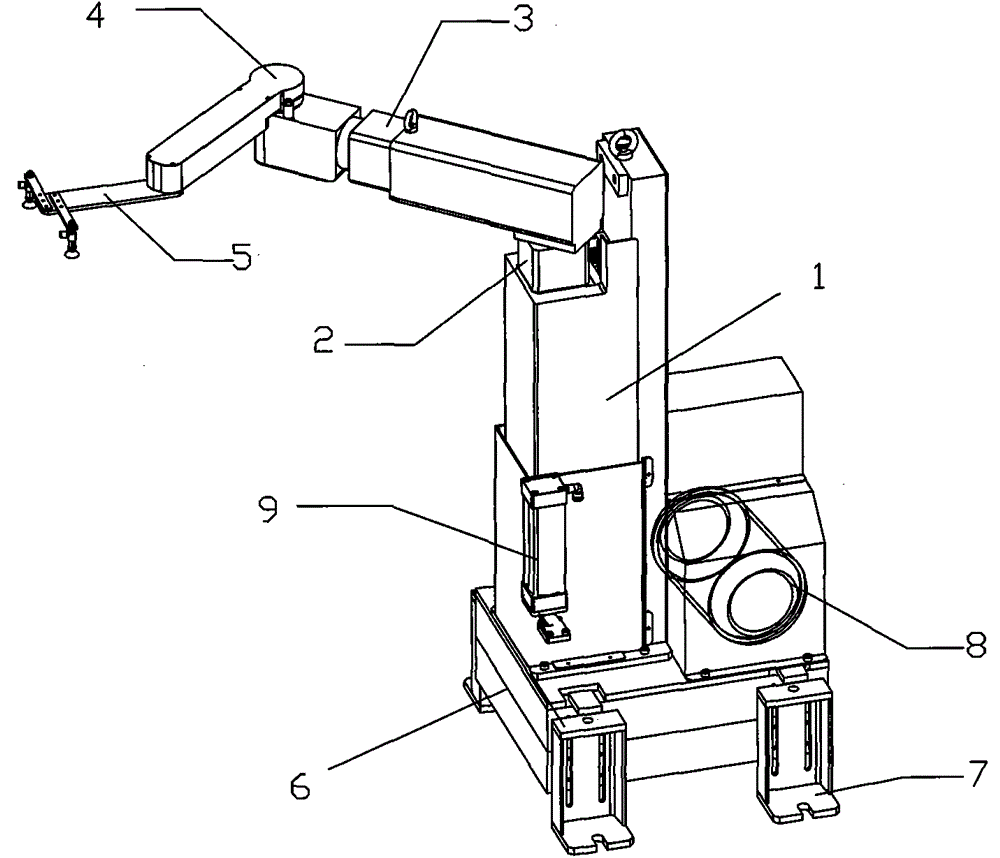

Multi-shaft horizontal joint intelligent robot

ActiveCN103978478AImprove operational efficiencyImprove work tempoProgramme-controlled manipulatorWorking environmentElectric machinery

The invention discloses a multi-shaft horizontal joint intelligent robot. The multi-shaft horizontal joint intelligent robot comprises an intelligent control mechanical hand, wherein the intelligent control mechanical hand is formed by a control device, an executing mechanism, a driving device and a base; the executing device comprises one shaft which is used for controlling vertical motion and three shafts which are used for controlling horizontal motion; a vertical moving function of a workpiece is realized in a way that the workpiece is driven to move on a sliding rail under the transmission of a screw rod by a first shaft; a speed reducing ratio is increased through a planetary gear reducer under the driving of a second shaft absolute value servo motor, and thus a horizontal 180-degree arm oscillating motion is realized as the mechanical hand is driven by a second shaft; a horizontal 360-degree arm oscillating motion is realized by a third shaft under the driving of a third shaft absolute value servo motor through the planetary speed reducer; a vertical 180-degree mechanical arm overturning motion is realized by a fourth shaft under the driving of a fourth shaft absolute value servo motor through a harmonic speed reducer. The multi-shaft horizontal joint intelligent robot disclosed by the invention has the advantages that the operation is simple and safe, horizontal and vertical moving ranges are larger, the locating is accurate, and the grabbing weight is large; a complicated carrying motion can be realized by simulating a person under a severe working environment.

Owner:HUIZHOU SUNNEMER AUTOMATION EQUIP CO LTD

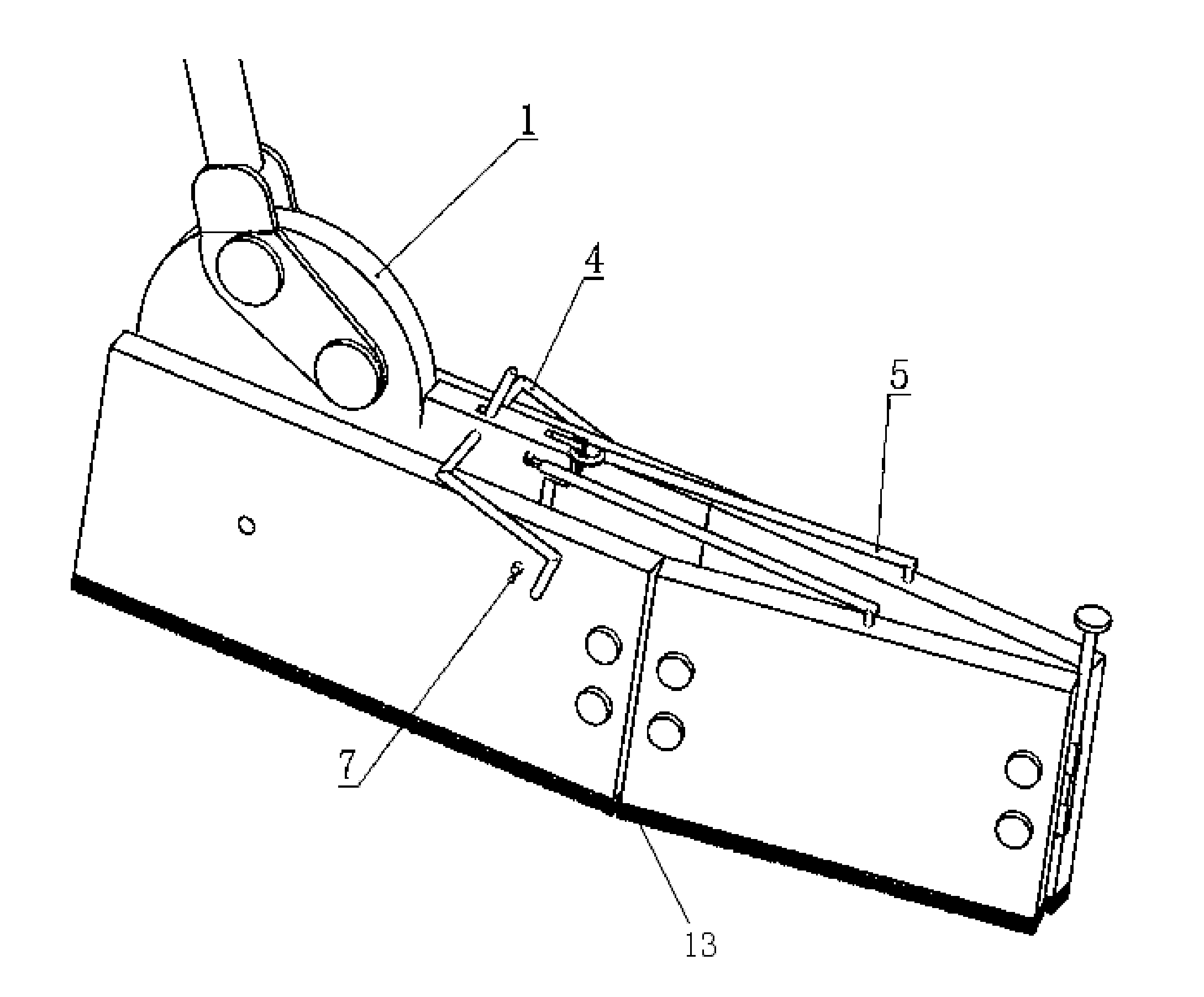

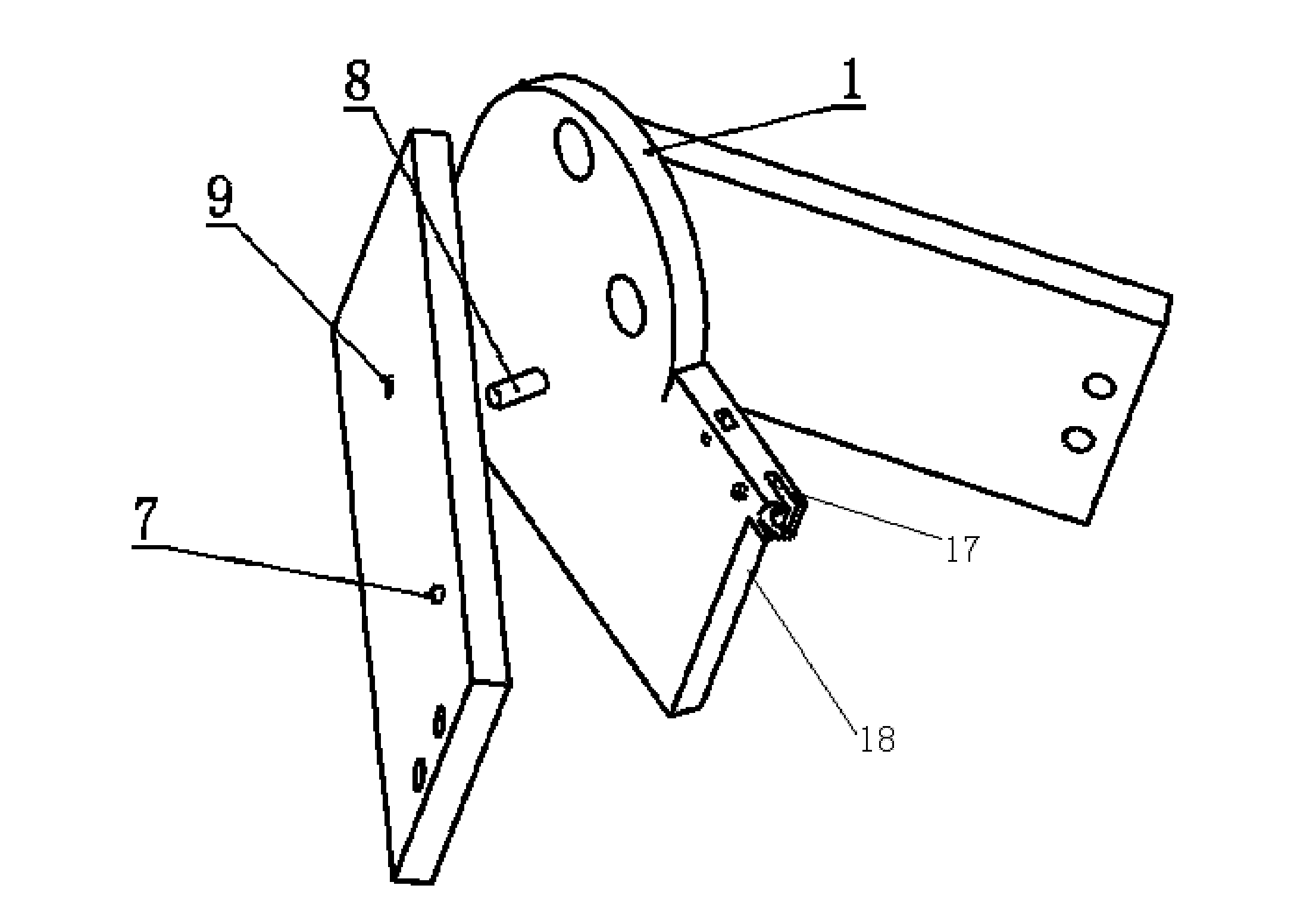

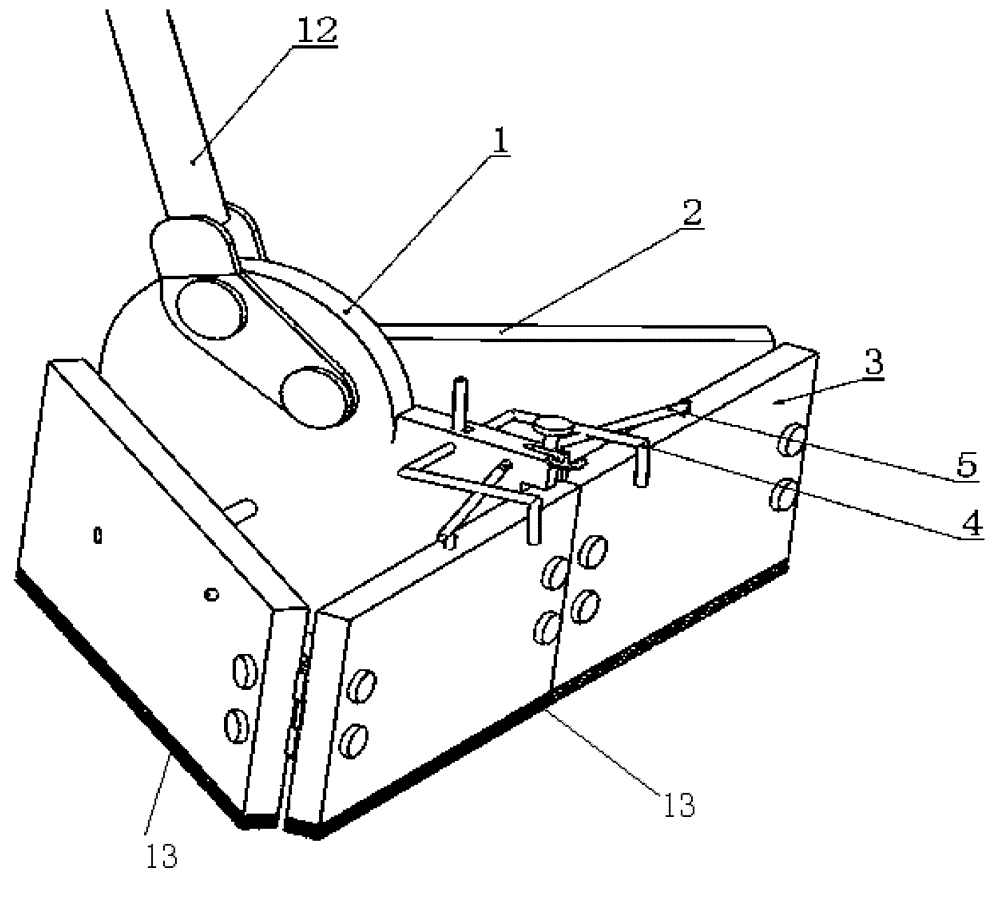

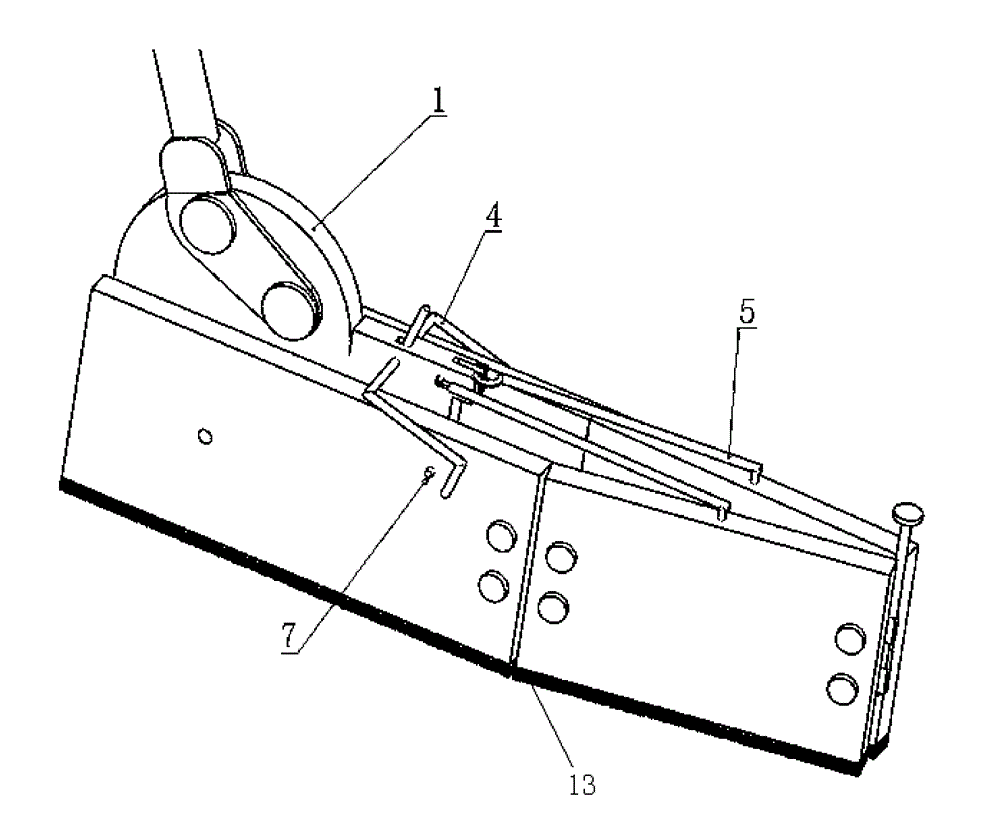

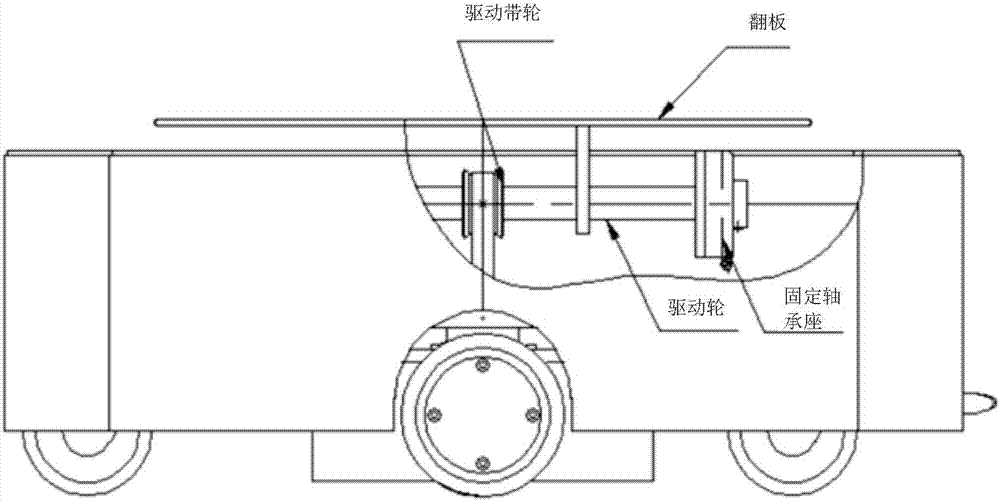

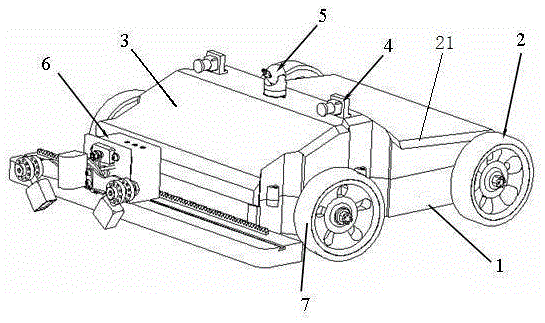

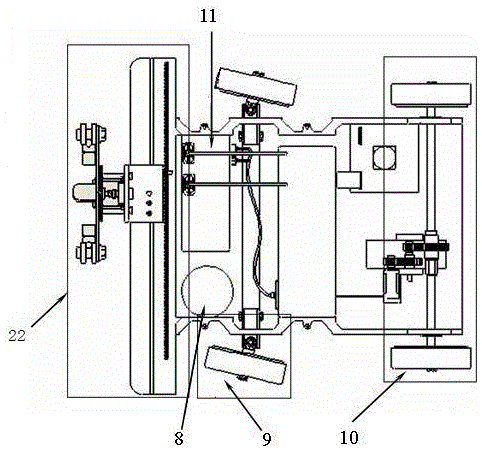

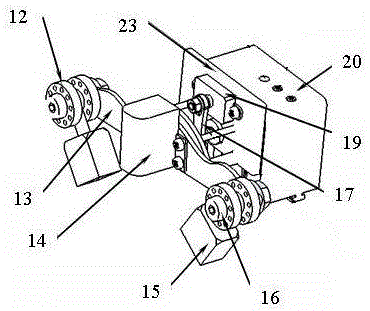

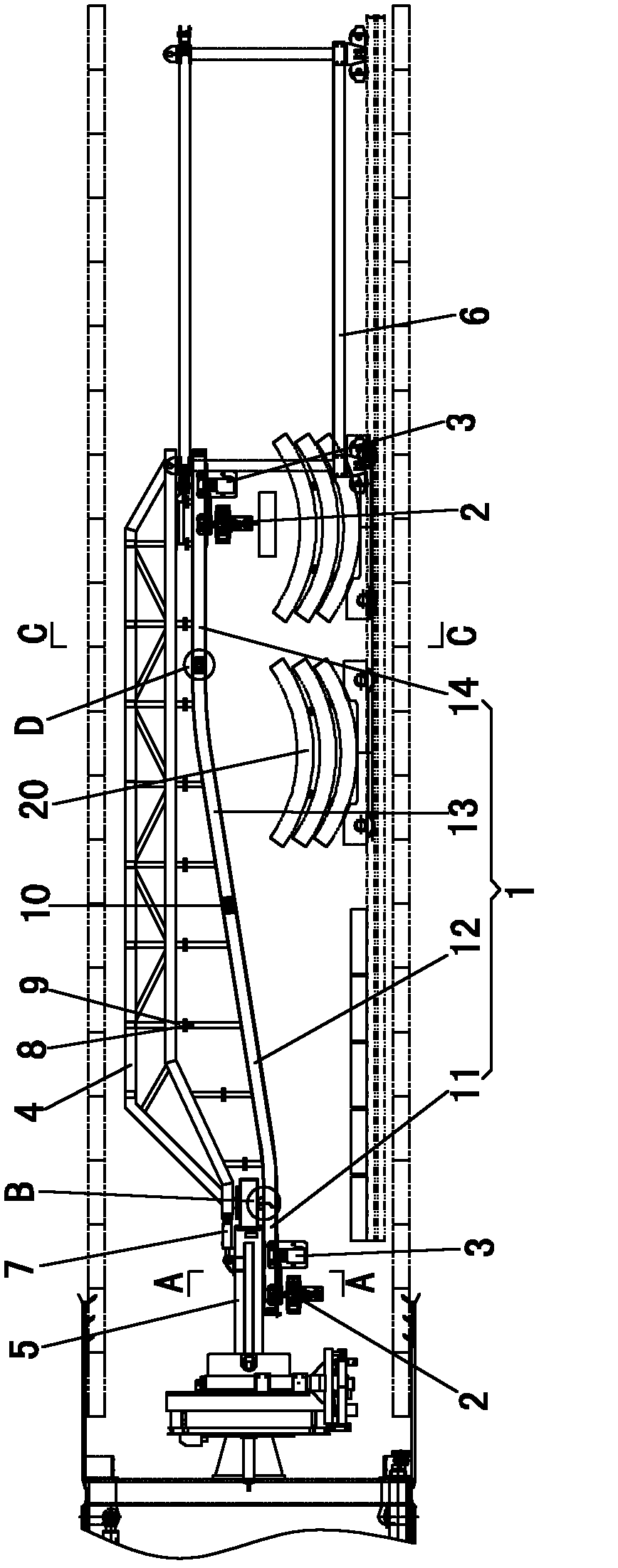

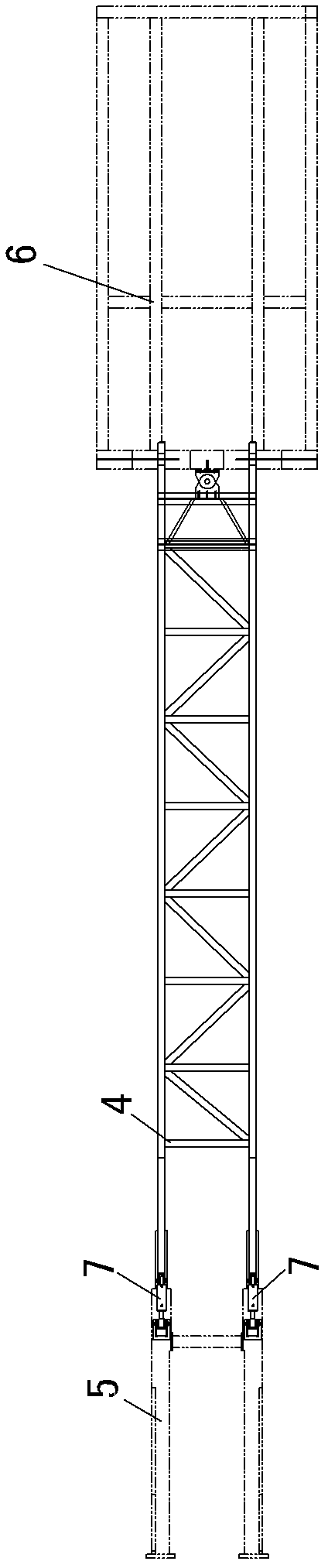

Tube segment shipping and trolley towing integrated device of shield machine

InactiveCN102381635AImprove transportation efficiencyReduce manual labor intensityUnderground chambersTrolley cranesShield machineEngineering

The invention relates to a tube segment shipping and trolley towing integrated device of a shield machine, belonging to the technical field of tunneling equipment. The integrated device comprises a two-track beam, a pair of electric hoists mounted under the two-track beam, a travelling trolley towing the electric hoists to travel and a connecting frame; the connecting frame is mounted on the two-track beam; the two-track beam is mounted between a traveling beam of a tube segment assembling machine and a first-section trolley of a back affiliated system; the front-station working end and the back-station working end of the two-track beam are horizontal beams, and a middle part of the two-track beam is an tilted beam; the front end of the two-track beam is lower than the back end of the two-track beam; the connecting frame is a truss structure; the left side and the right side of the connecting frame are respectively connected with the two beams of the two-track beam; the front end of the connecting frame is movably connected with the traveling beam of the tube segment assembling machine; and the back end of the connecting frame is connected with the first-section trolley of the back affiliated system through a pin shaft. The tube segment shipping and trolley towing integrated device of the shield machine provided by the invention has a simple structure, the bearing strength is enhanced under the premise of not increasing the weight, the shipping efficiency is high, the labor intensity for workers is lowered, and the cost and the failure rate of equipment are lowered.

Owner:BEIJING SANY HEAVY MASCH CO LTD

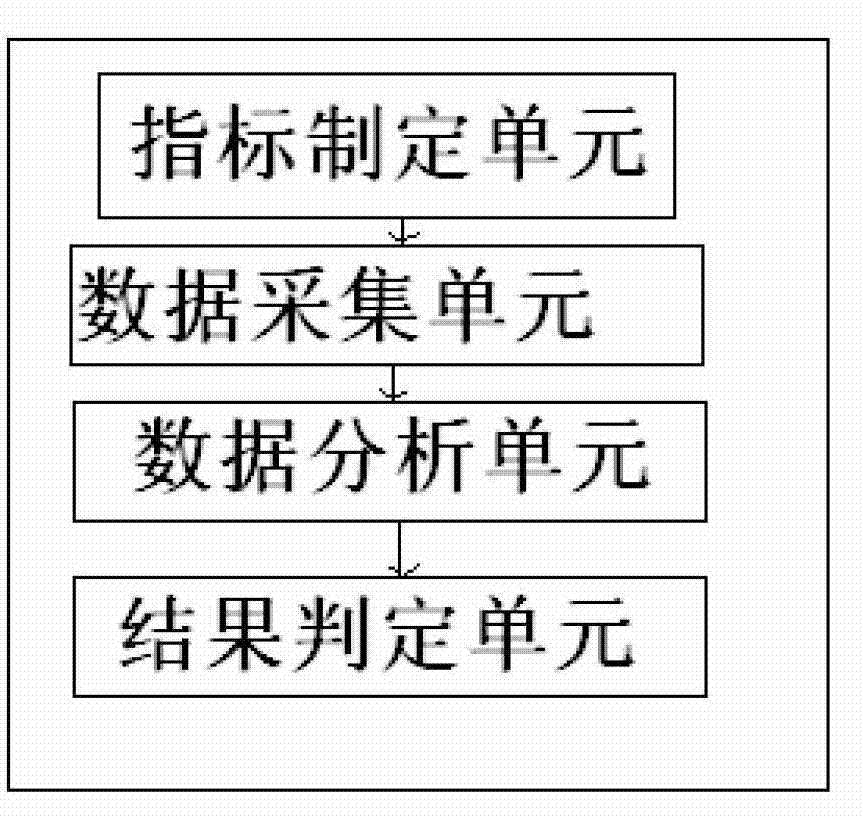

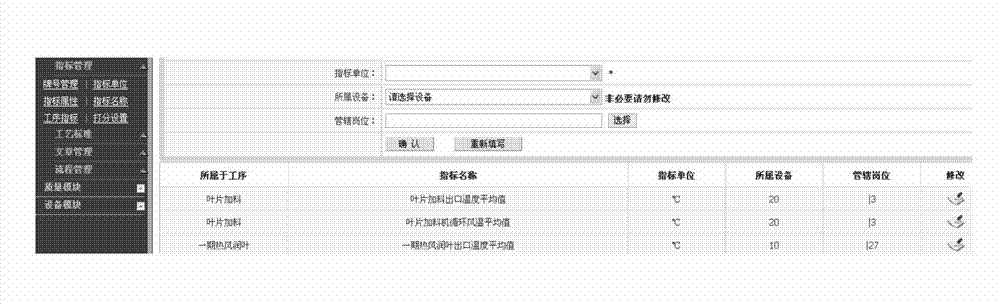

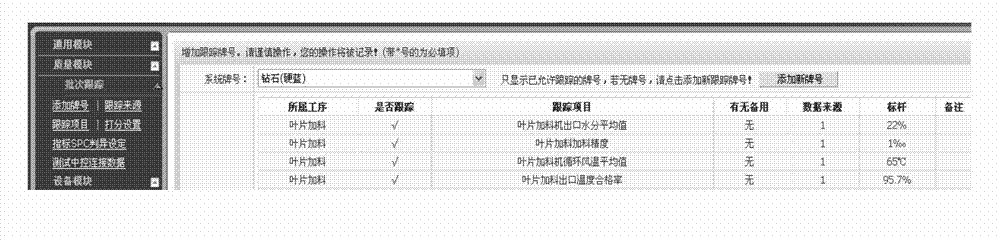

Quality monitoring system and method of tobacco primary process

ActiveCN102885392AGuaranteed processing effectEasy to operateTobacco preparationAutoanalysisControl data

The invention relates to a quality monitoring system and a method of a tobacco primary process. The quality monitoring system of the tobacco primary process comprises an index formulating unit, a data collection unit, a data analysis unit and a result determination unit; the collected data is modeled and analyzed on the basis of a tobacco primary process center control data system, so that the indexes according with current tobacco requirements, device processing capacity and processing direction are obtained, and the indexes are subjected to SPC (statistical process control) tracking determination. According to the technical scheme, the technical problem that a tobacco primary process parameter in the prior art cannot objectively reflect an actual production condition is effectively avoided. The quality monitoring method and the system are capable of monitoring and automatically analyzing the tobacco primary process.

Owner:ZHANGJIAKOU CIGARETTE FACTORY

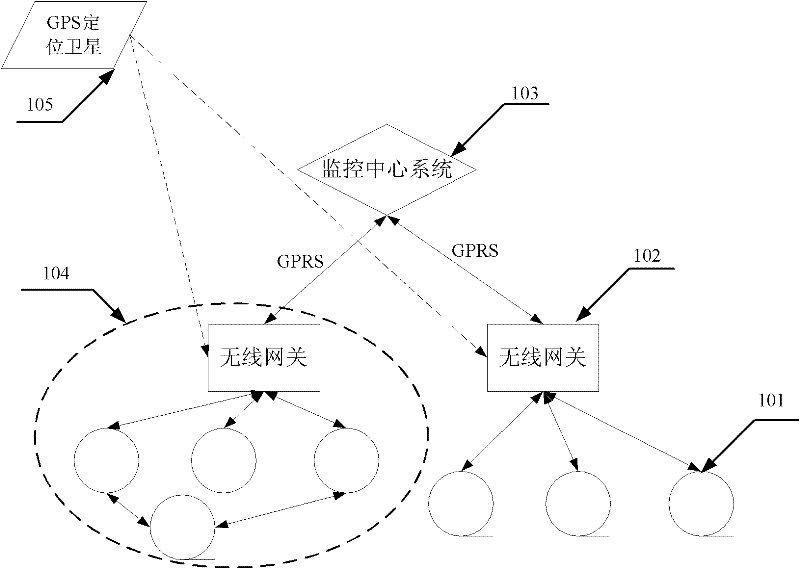

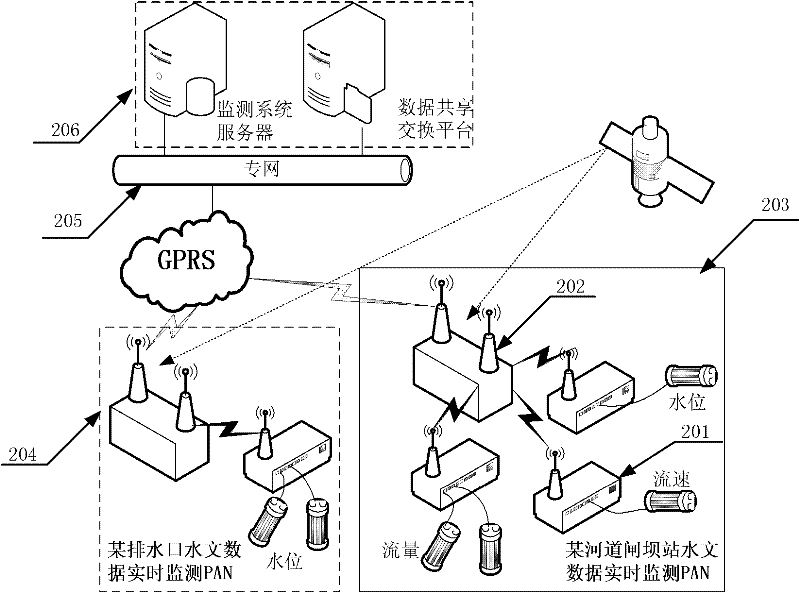

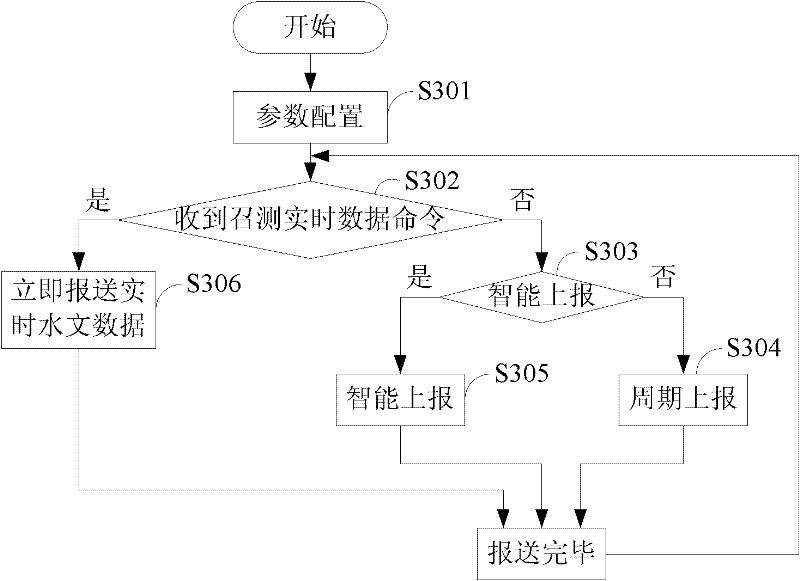

Hydrologic data monitoring system

InactiveCN102540993AImprove efficiencyReduce manual labor intensityTotal factory controlProgramme total factory controlData monitoringLow complexity

The invention discloses a hydrologic data monitoring system, which comprises a monitoring center system, one or more wireless gateways, one or more wireless hydrologic data acquisition terminals and one or more sensors for measuring hydrologic data, wherein each wireless hydrologic data acquisition terminal is connected with the one or more sensors, and used for receiving the hydrologic data from the sensor which is connected with the wireless hydrologic data acquisition terminal, converting the hydrologic data and then sending the hydrologic data to each wireless gateway; and each wireless gateway is used for receiving the hydrologic data from the one or more wireless hydrologic data acquisition terminals in a coverage range of the wireless gateway, aggregating the hydrologic data and then sending the hydrologic data to the monitoring center system. By adoption of the hydrologic data monitoring system, low-cost and low-complexity sensor data acquisition, transmission and monitoring associated with hydrologic monitoring can be realized.

Owner:BEIJING LOIT TECH

Device and method for using laser technology to mark feeding bottle

The invention relates to the laser processing technology field and discloses a device and a method for using the laser technology to mark the feeding bottle. The device for using the laser technology to mark the feeding bottle comprises an automatic material feeding mechanism, a material receiving-taking mechanism, a laser marking mechanism and a rotary disc mechanism; the automatic material feeding mechanism is provided with a product to be processed and the product to be processed is delivered to a material taking-receiving position of the material taking-receiving mechanism, and the automatic material feeding mechanism is also used for delivering processed products; the taking-receiving material mechanism takes product to be processed and puts the product to be processed on the rotary disc mechanism; the processed product on the rotary disc mechanism is taken away and is put back on the automatic material feeding mechanism; the rotary disc mechanism clamps the product to be processed and drives the product to be processed to rotate to a position corresponding to the position of a laser marking mechanism; and the laser marking mechanism performs laser marking on the product to be processed. The device and method can perform laser calibration on the glass bottle, the structure is simple, the function is reliable and easy to implement, and the automation is realized.

Owner:HANS LASER TECH IND GRP CO LTD

Steel wire rod take-up device

ActiveCN104944214ARealize automatic loadingHigh degree of automationFilament handlingAutomationWire rod

The invention discloses a steel wire rod take-up device which comprises a rack and a wire arranging assembly. An automatic wire clamping and wheel discharging assembly used for clamping a spool and a spool ejecting assembly are arranged on one side below the wire arranging assembly, wherein the automatic wire clamping and wheel discharging assembly and the spool ejecting assembly are fixed to the rack respectively, an automatic disc feeding and discharging assembly located between the automatic wire clamping and wheel discharging assembly and the spool ejecting assembly is arranged below a wire arranging wheel set, a wire pushing and locating assembly and an automatic fusing assembly are oppositely arranged on one side of the automatic wire clamping and wheel discharging assembly and one side of the spool ejecting assembly, the distance between the wire pushing and locating assembly and the automatic fusing assembly is larger than the axis length of the spool, a steel wire locating clamp is arranged on the automatic fusing assembly, and the signal input end of the wire arranging assembly, the signal input end of the automatic wire clamping and wheel discharging assembly, the signal input end of the spool ejecting assembly, the signal input end of the automatic disc feeding and discharging assembly, the signal input end of the wire pushing and locating assembly and the signal input end of the automatic fusing assembly are all connected with the signal output end of a PLC. The steel wire rod take-up device is high in automation degree, high in production efficiency, low in manual labor intensity, and suitable for being widely applied to cable devices.

Owner:湖北三江航天江北机械工程有限公司

Fruit picking device

The invention discloses a fruit picking device. The fruit picking device comprises a telescopic supporting rod, wherein a pipe sleeve is arranged on the top end of the supporting rod; a containing netis arranged at a lower end opening of the pipe sleeve; a blade annular cutting mechanism is arranged in an upper end opening of the pipe sleeve; the supporting rod is provided with a mechanism whichis used for driving the blade annular cutting mechanism to open and close through a gear transmission mechanism so as to realize blade engaged cutting. According to the fruit picking device disclosedby the invention, the cam driving blade annular cutting mechanism adopted by the invention is used as a tool for cutting stems of fruits, so that the characteristic of labor saving is obtained, and the accuracy and the reliability that the fruits fall into a net after cutting can also be increased; a mode of using a big pipe to sleeve a small pipe is adopted, and a seat pipe clamp is used as a locking device, so that length stretching is realized, and risk of manual operation is greatly reduced; a multi-blade cutting mode is adopted, so that the cutting efficiency can be increased; by adoptingthe containing net which is smaller in inner diameter and has certain elasticity, cut fruits can be buffered, the fruits are prevented from being damaged due to direct falling, and meanwhile, the manual labor strength is reduced.

Owner:GUANGDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com