Patents

Literature

115results about How to "Improve spraying accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Robot spraying system and control method thereof

InactiveCN107899814AImprove spraying accuracyReduce teaching workloadSpraying apparatusChain typeEngineering

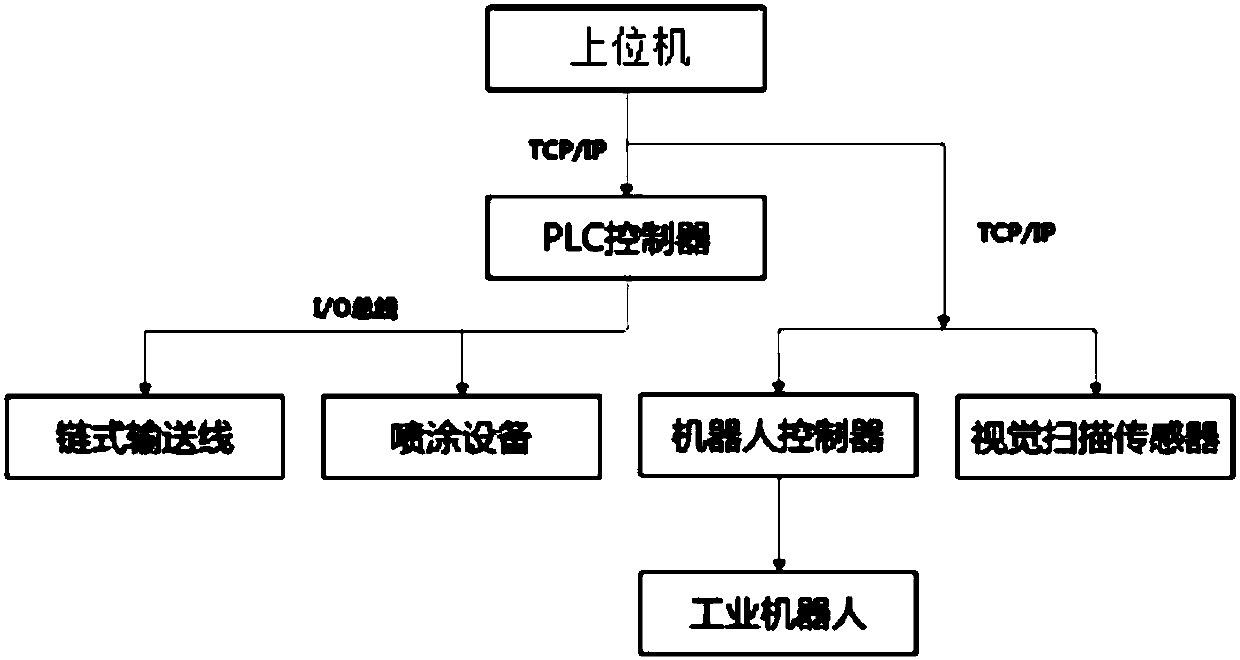

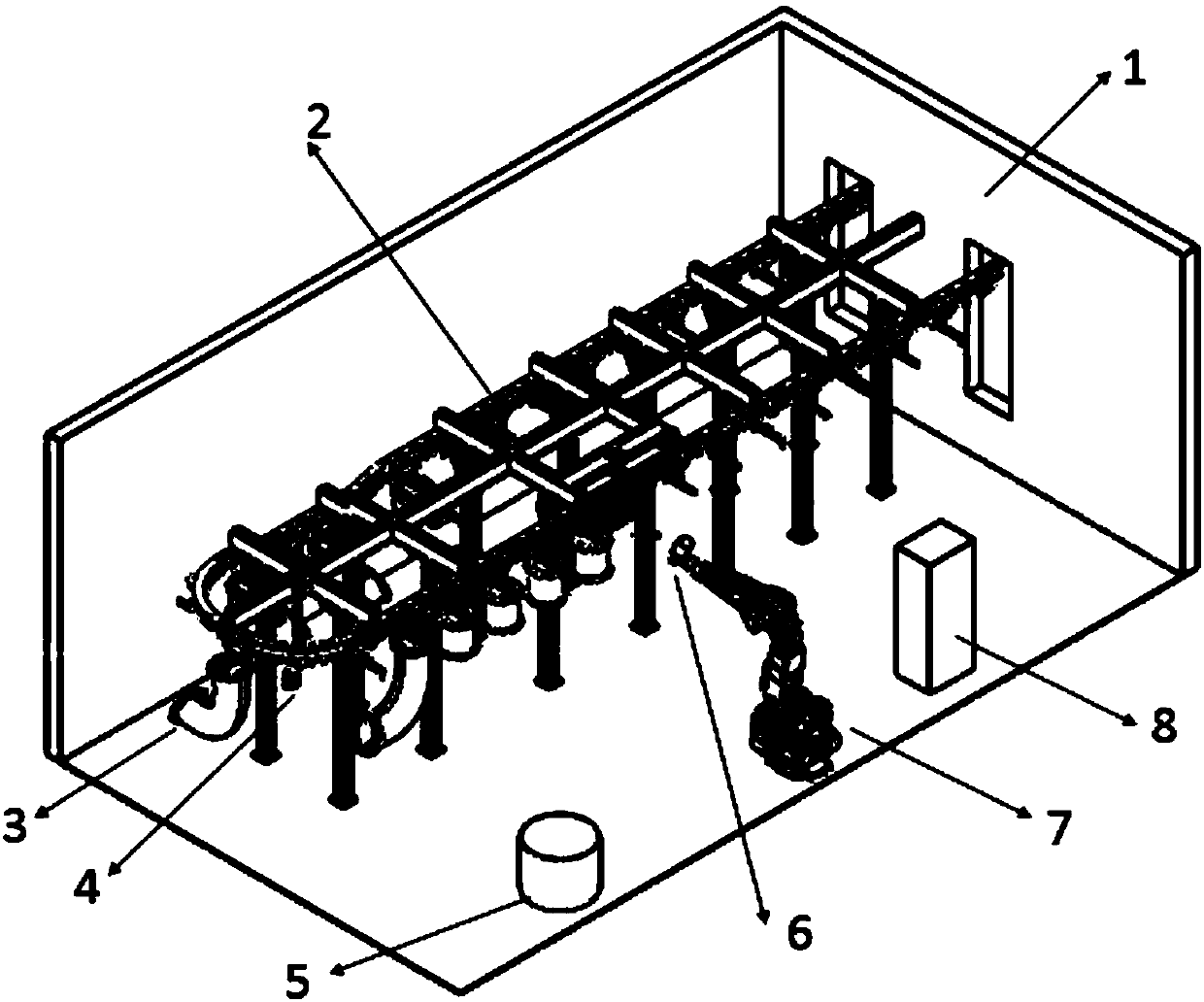

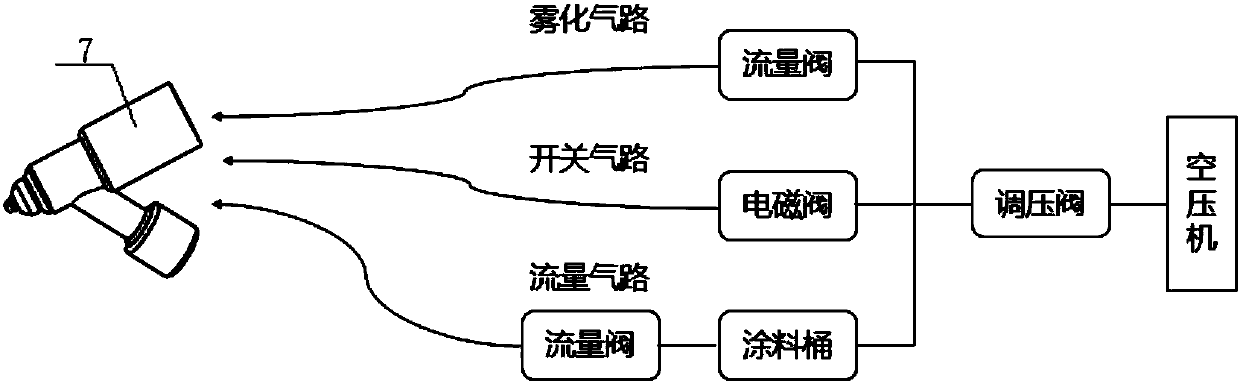

The invention discloses a robot spraying system. The system is provided with a chain type conveying line for conveying a to-be-sprayed workpiece. The chain type conveying line conveys the workpiece tosequentially pass through a vision scanning area and a spraying area. The vision scanning area is provided with a vision sensor used for conducting three-dimensional scanning on the workpiece. The spraying area is provided with an industrial robot. A spray gun is fixed to the end portion of the industrial robot and connected with spraying equipment. The vision sensor outputs signals to an upper computer. The upper computer outputs spraying track signals to a robot controller. The robot controller drives the industrial robot to execute the spraying track. The upper computer outputs the controlsignals to a PLC. The PLC drives the chain type conveying line and the spraying equipment to work. The robot spraying system has the beneficial effects that automatic complex hook face spraying trackplanning can be achieved, and the spraying precision is improved; and the offline programming technology is utilized, the demonstration workload of the robot is reduced to the maximum degree, and productivity can be rapidly achieved.

Owner:WUHU HIT ROBOT TECH RES INST

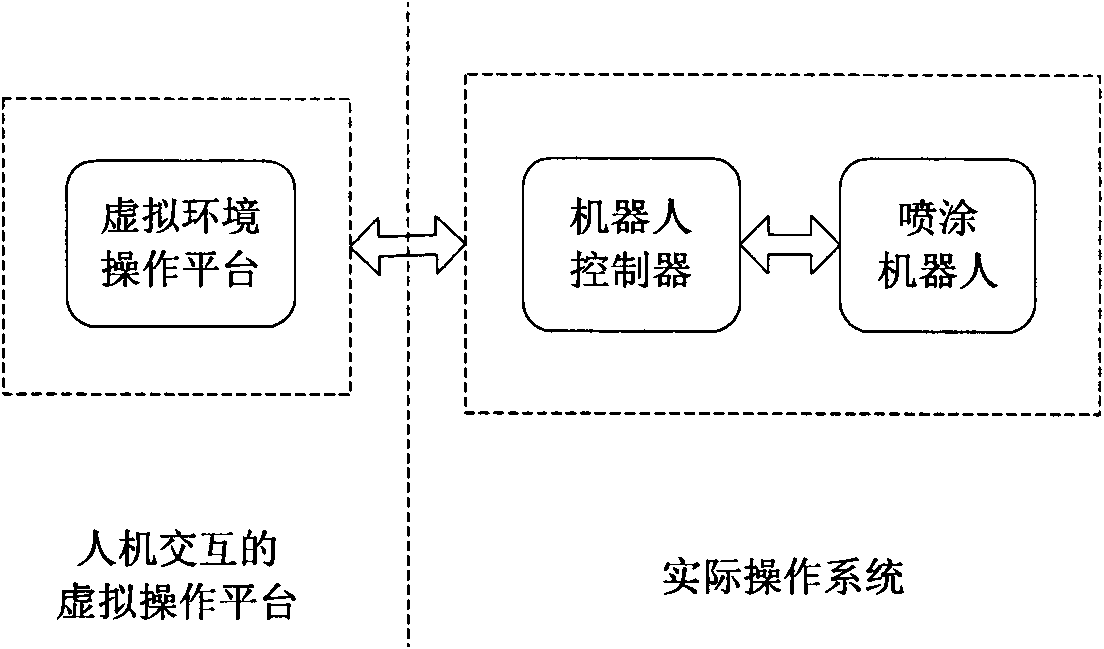

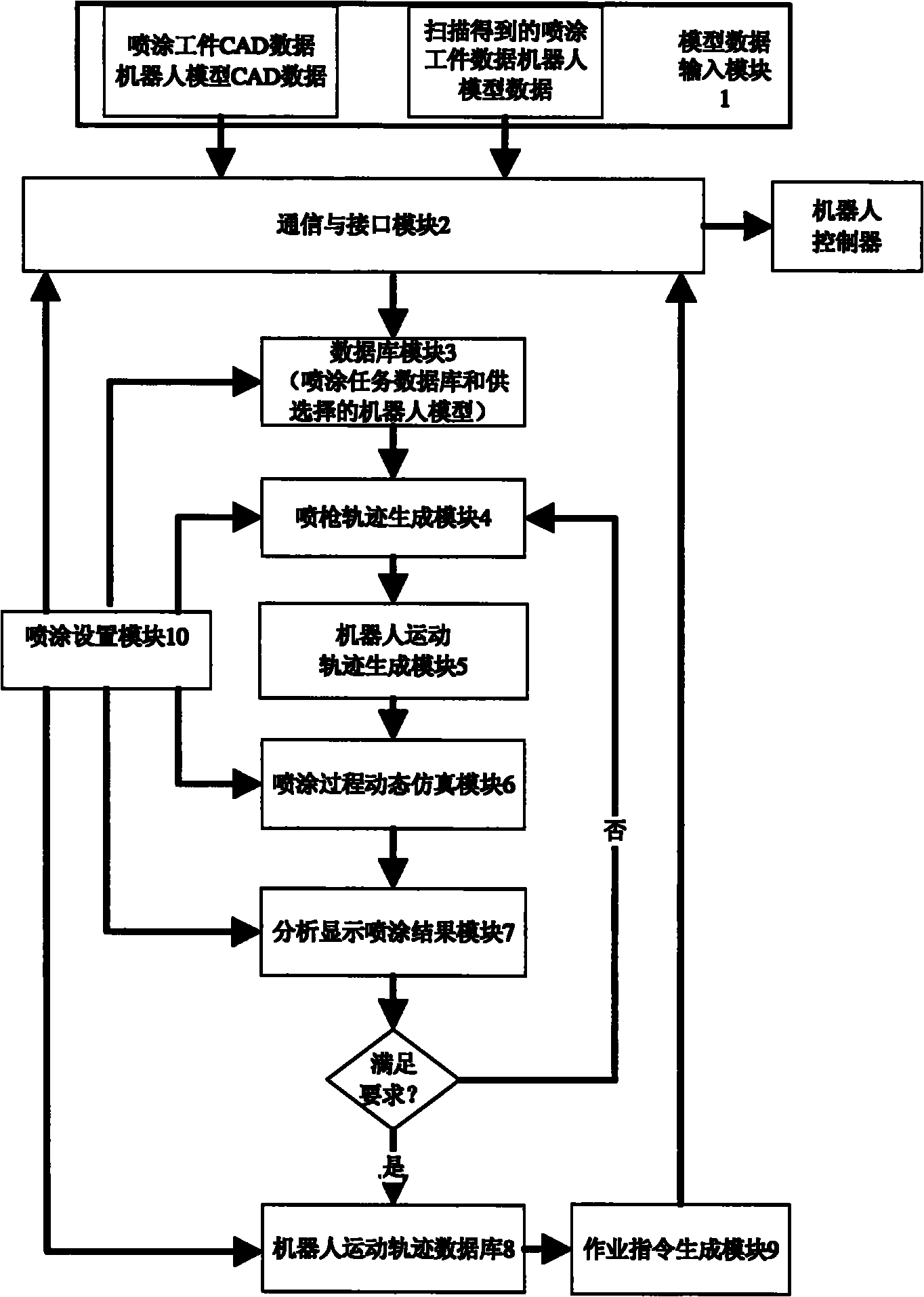

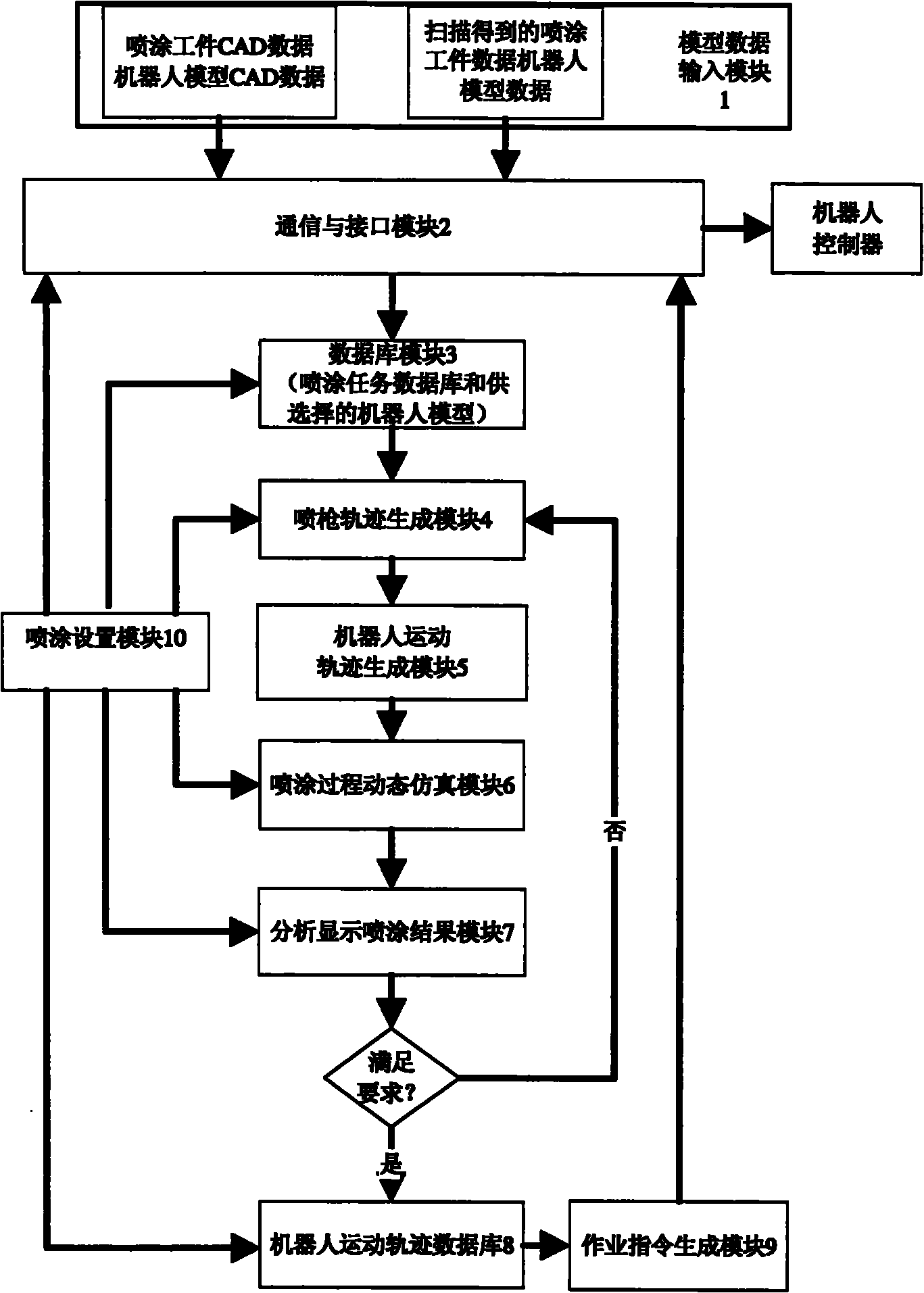

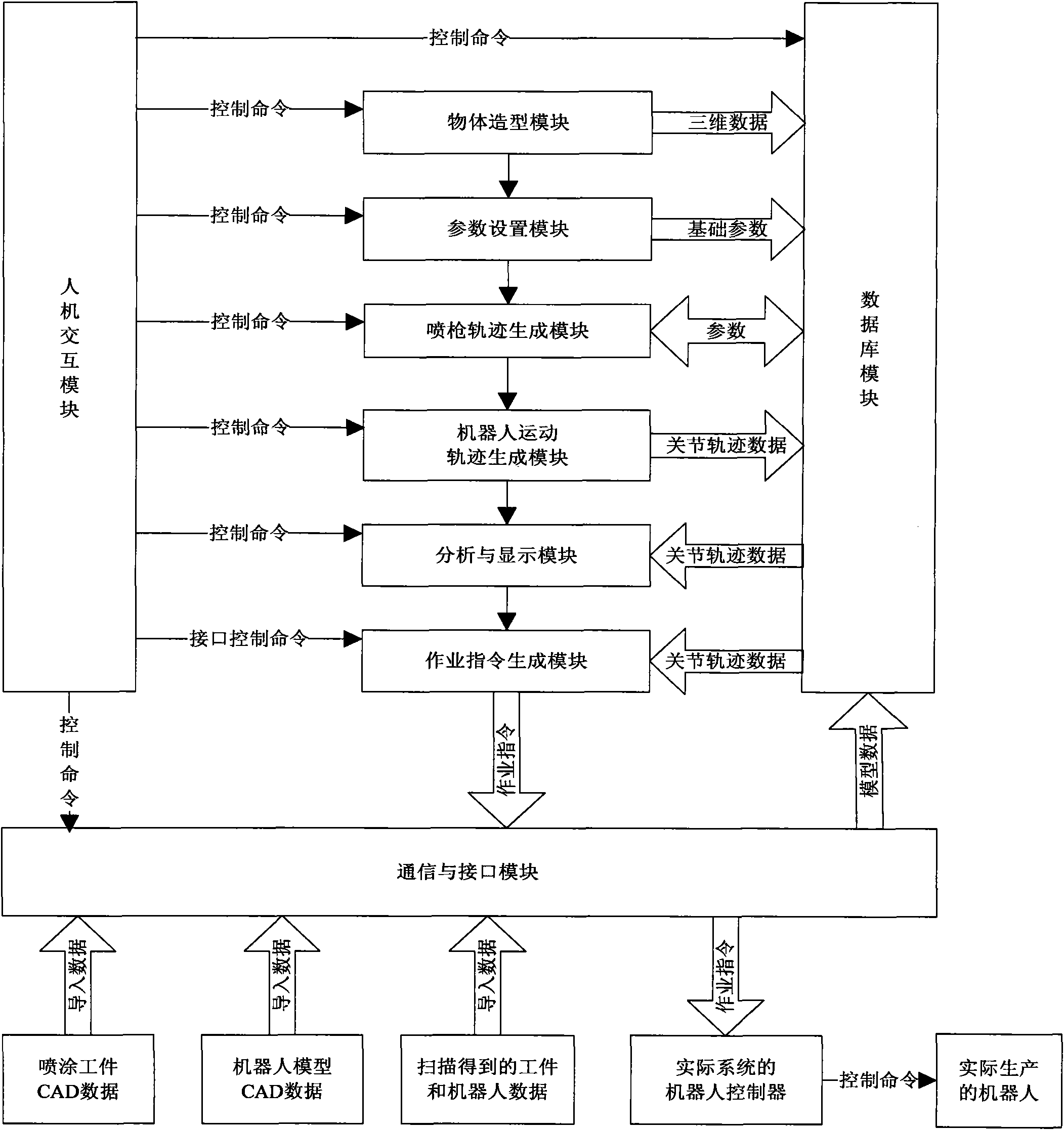

System and method for comprehensively controlling spraying industrial robot based on virtual reality technology

InactiveCN101920233AShorten the development cycleEasy to acceptSpraying apparatusSpecial data processing applicationsControl systemEconomic benefits

The invention comprises a system and a method for comprehensively controlling a spraying industrial robot based on virtual reality technology. The system is characterized by comprising a virtual environment operating platform, a robot controller and a spraying robot, wherein the robot controller is connected with the spraying robot; the virtual environment controller is connected with the robot controller; the system of the invention provides a brand-new man-machine interaction environment, and the preview of an overall spraying process is finished through virtual simulation of the system; a user can observe the overall process of the spraying operation in real time and analyze a spraying effect through virtual operation on the system, so that technical indicators and parameters meeting the spraying effect are selected; and thus the system not only shortens the development period of a robot program but also improves the spraying accuracy, and is a platform with high economic benefit and easy acceptance to the user.

Owner:GUANGDONG UNIV OF TECH

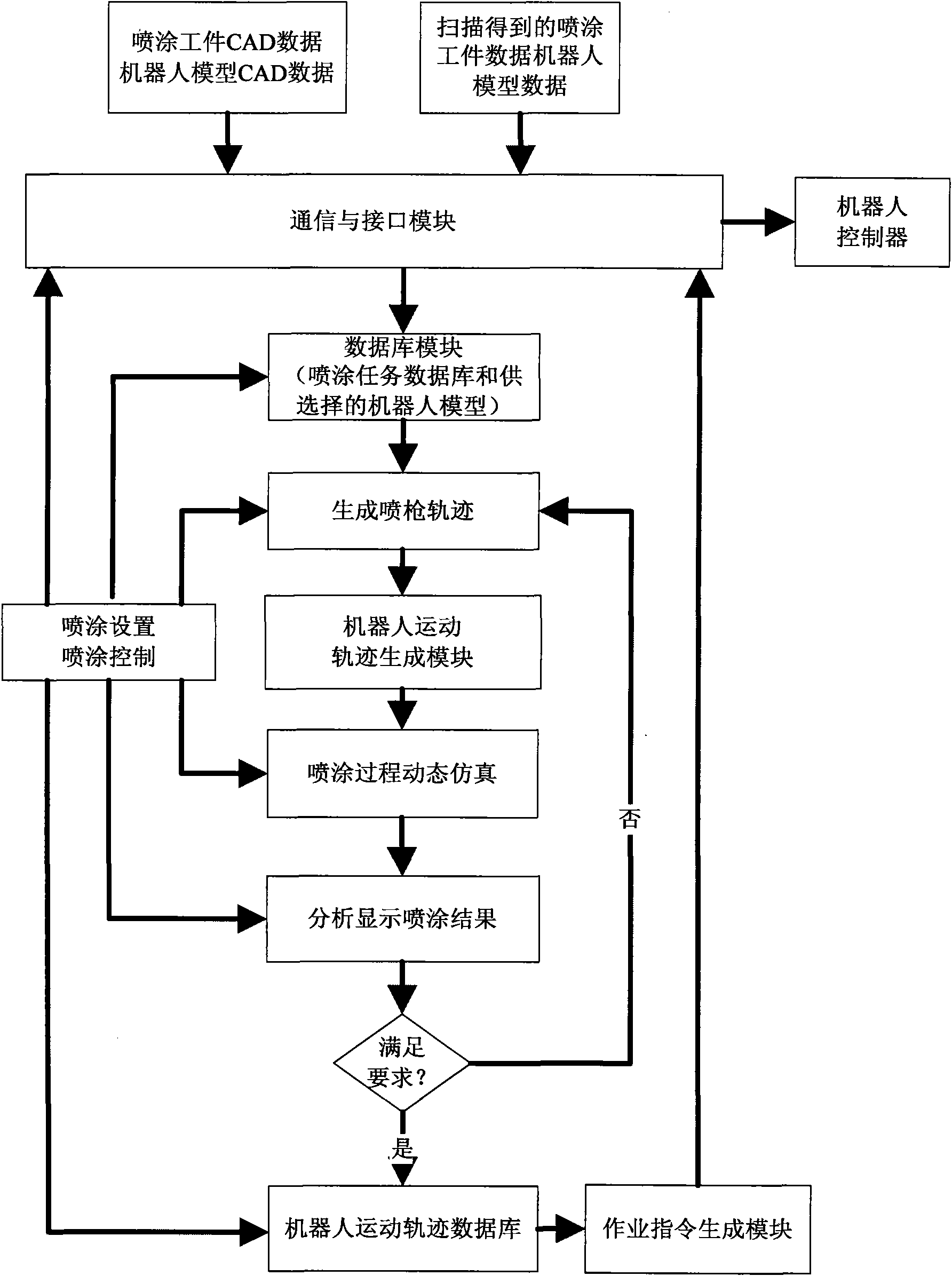

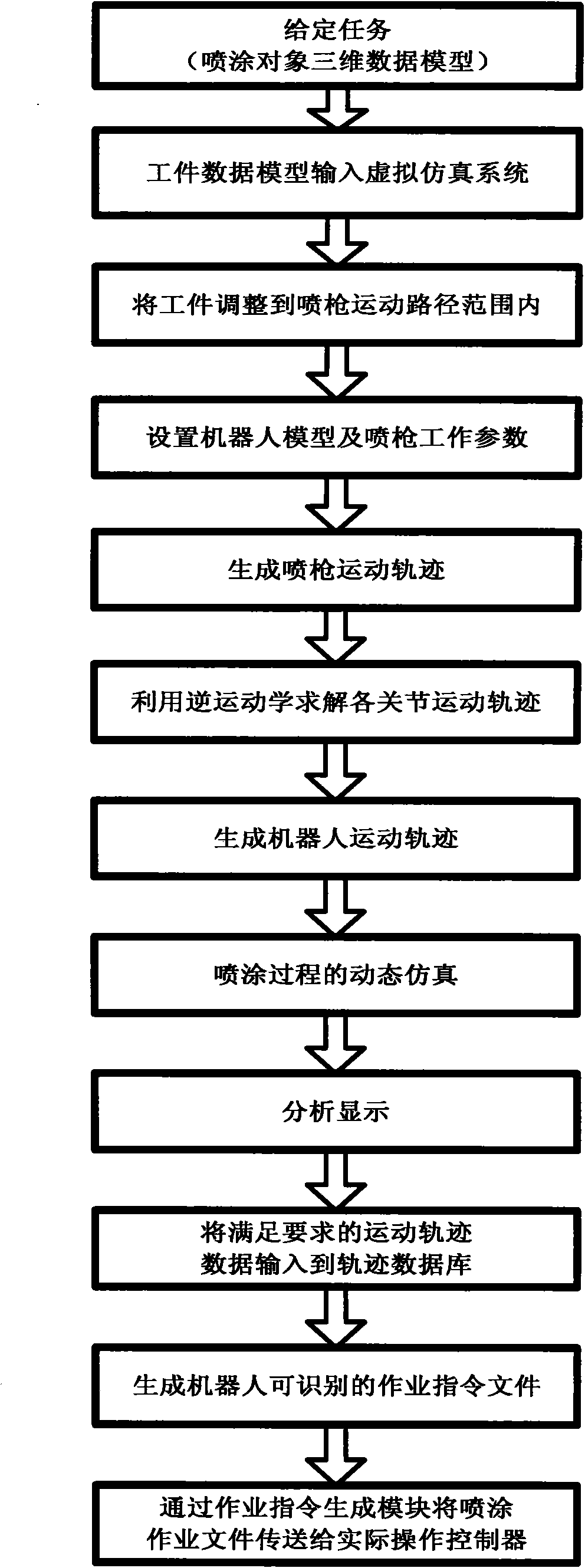

Industrial robot comprehensive control platform and control method thereof

InactiveCN101850552AReduce in-circuit debugging timeDoes not take up working timeManipulatorProduction ratePath generation

The invention relates to an industrial robot comprehensive control platform and a control method thereof. The industrial robot comprehensive control platform comprises an object modeling module, a parameter setting module, a database module, a spray gun path generation module, a robot motion path generation module, a man-machine interaction module, an analysis and display module, an operation command generation module and a communication and interface module. The invention has the advantages that the functions are complete, the commonality is high, the robot program development cycle is shortened, the painting accuracy of the system is improved, the production cost is reduced, the production efficiency is improved, the requirements on the technical capability of operators are reduced, the economic benefit is high and the platform can be easily accepted by users.

Owner:GUANGDONG UNIV OF TECH

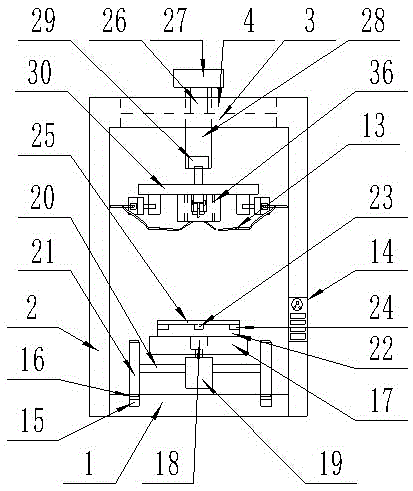

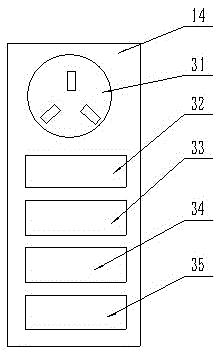

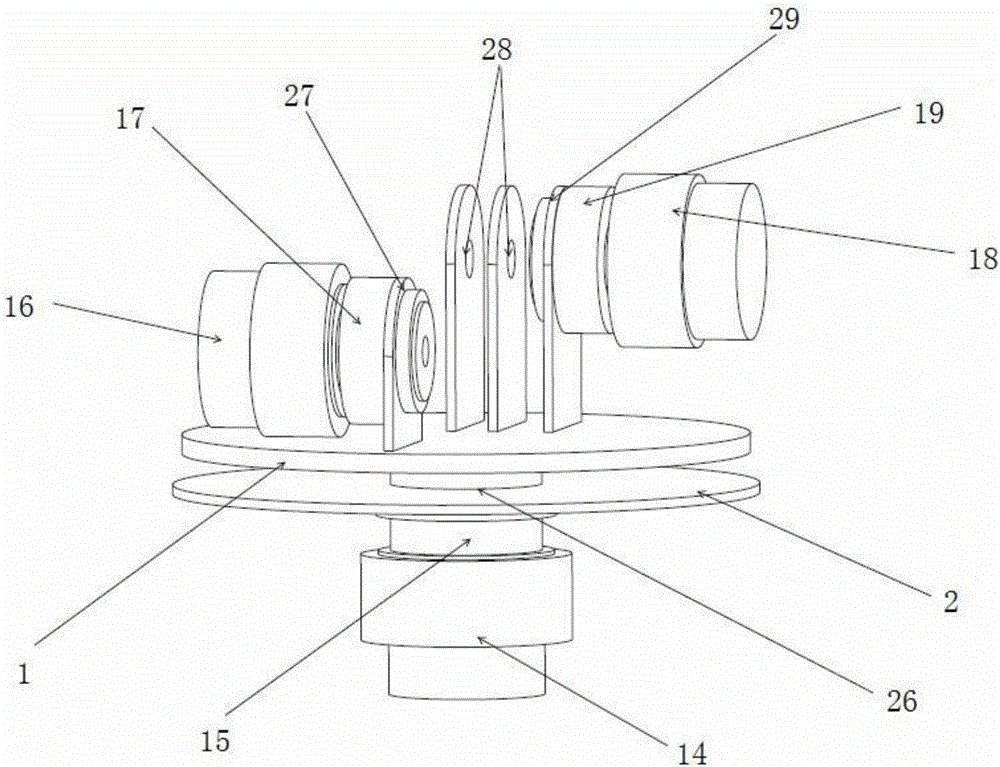

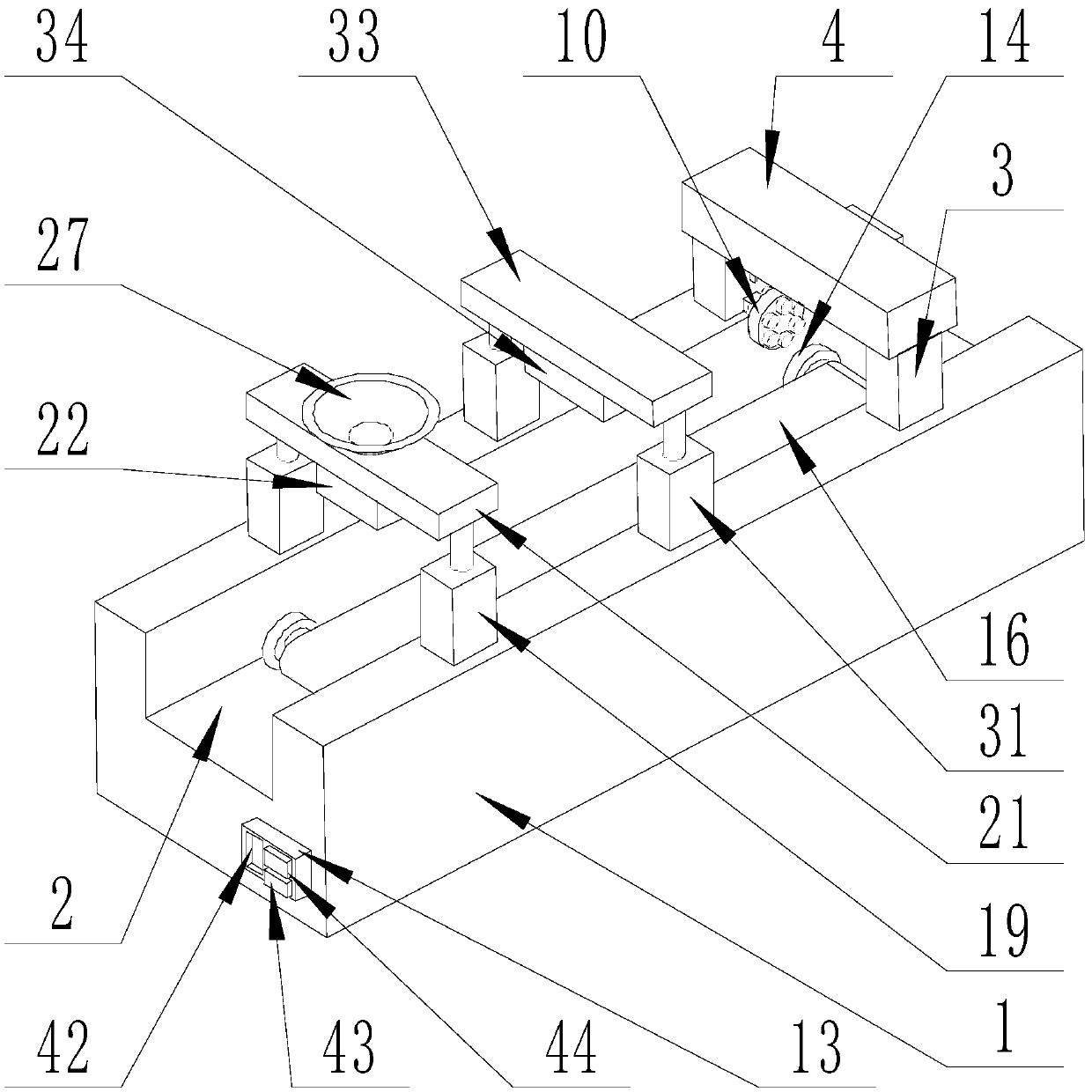

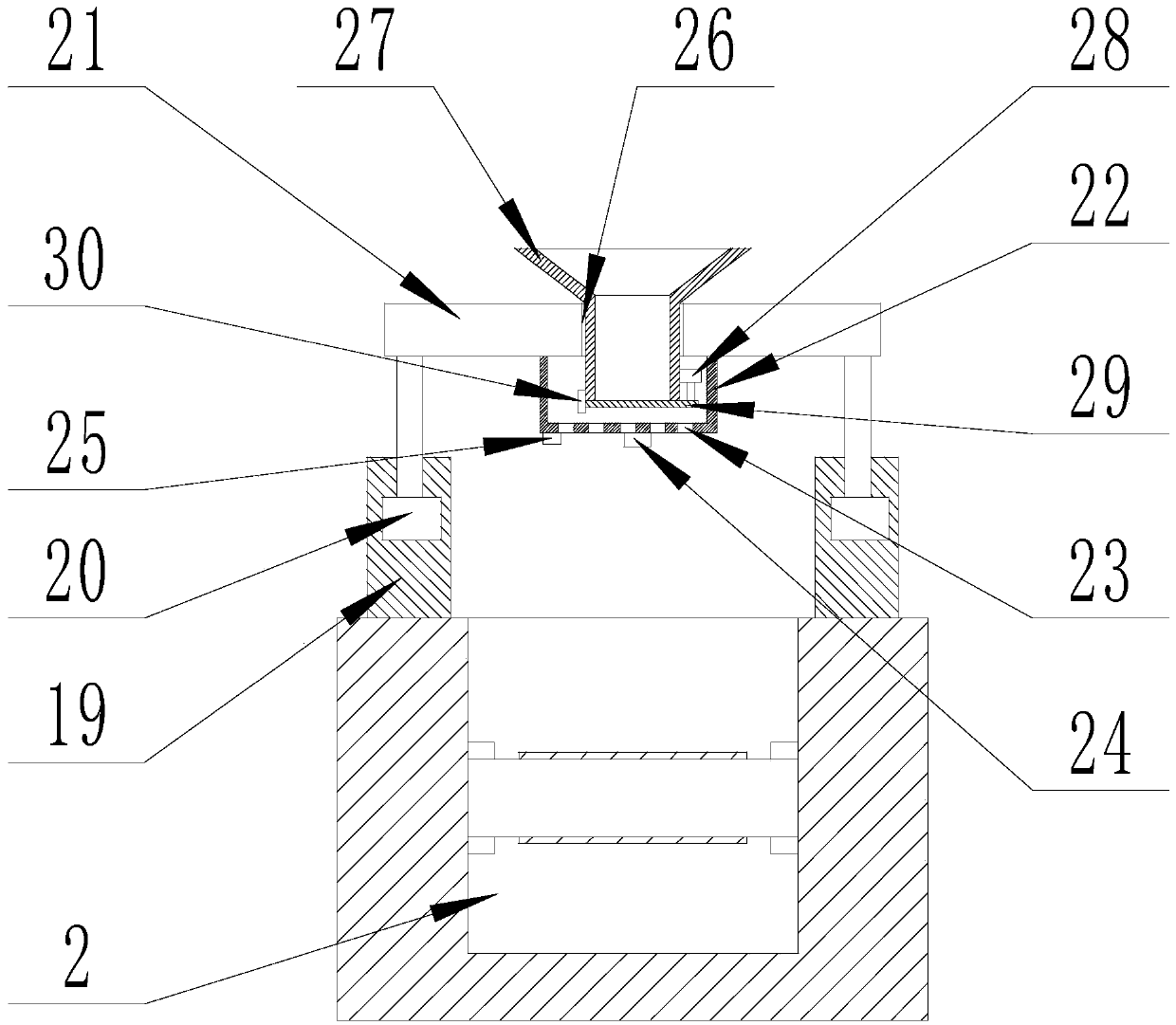

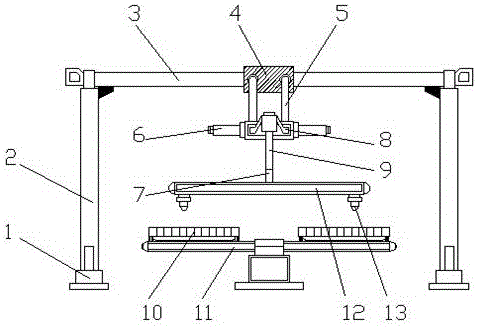

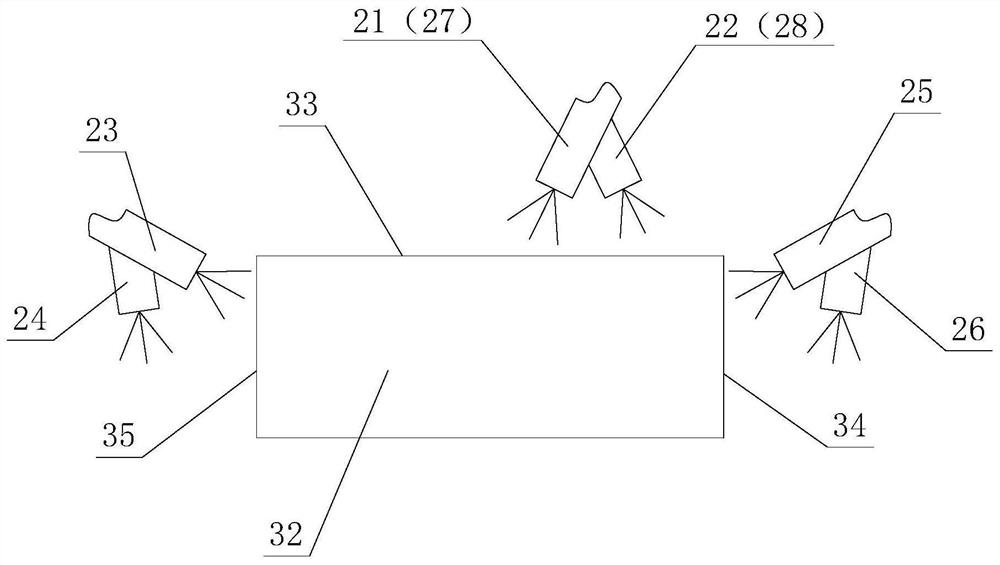

Spraying device

ActiveCN105562265AImprove spraying accuracyReduce manual labor intensitySpraying apparatusEngineeringMechanical engineering

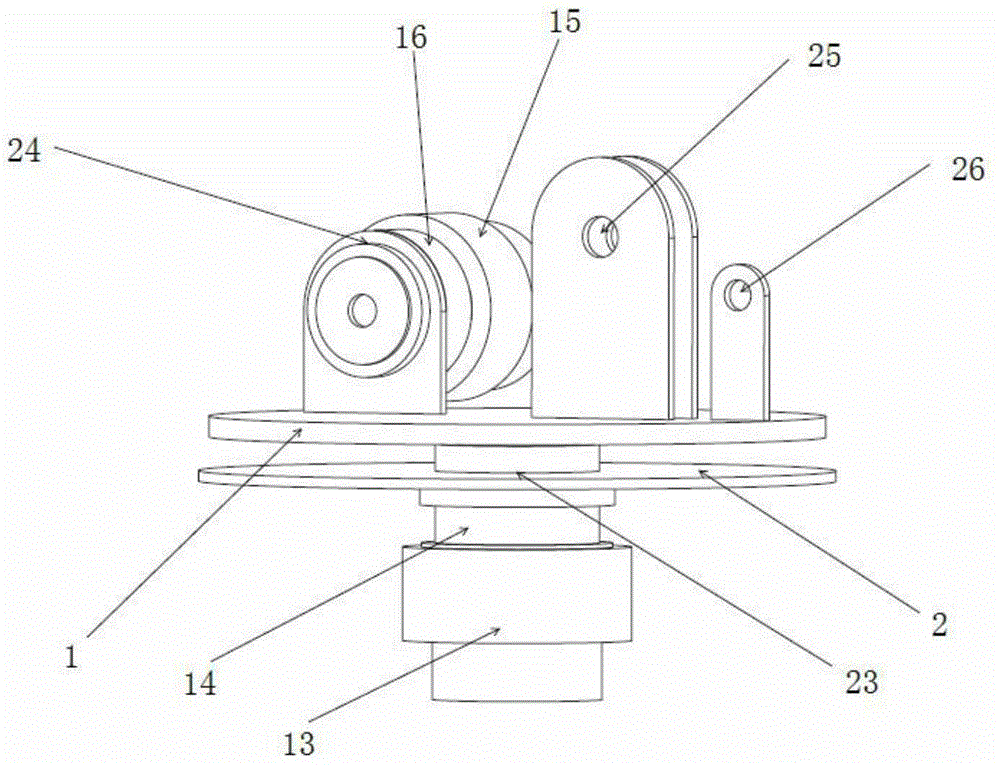

The invention discloses a spraying device. The spraying device comprises a base. The base is fixedly arranged on the ground. The surface of the base is provided with a movable rotating workbench mechanism. An n-shaped support is arranged above the base. The bottom ends of stand columns of the n-shaped support are fixedly arranged on the ground on the two sides of the base. A through groove is formed in the upper surface of a beam of the n-shaped support in the length direction of the beam. The upper surfaces of the portions, on the two sides of the through groove, of the beam are provided with grooves with the same length as the through groove. A transverse sliding mechanism is mounted in the grooves. A lifting-and-rotating mechanism is fixedly mounted at the lower end of the transverse sliding mechanism. A spraying mechanism is fixedly mounted below the lifting-and-rotating mechanism. A controller is arranged on the surface of one of the stand columns of the n-shaped support. The controller is electrically connected with the movable rotating workbench mechanism, the transverse sliding mechanism, the lifting-and-rotating mechanism and the spraying mechanism. The spraying device has the beneficial effects of being simple in structure and high in practicability.

Owner:宣城东海汽车转向部件有限公司

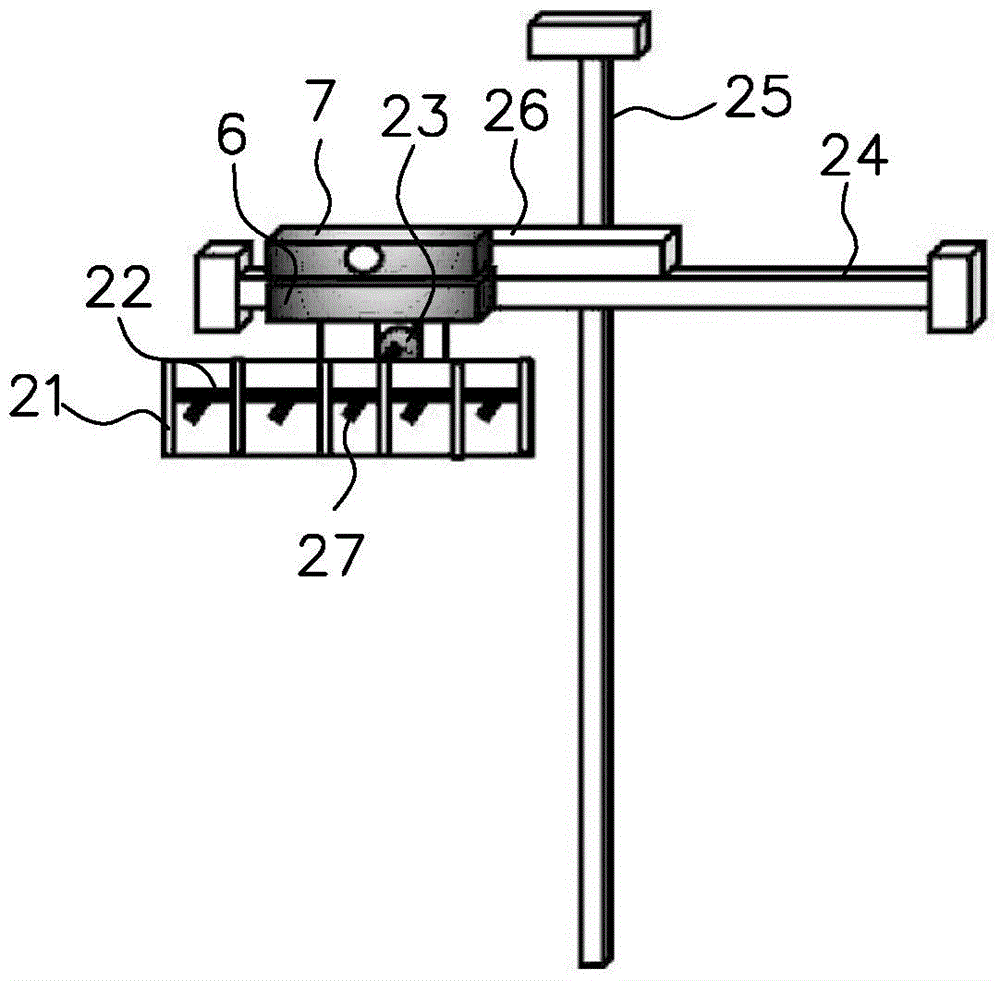

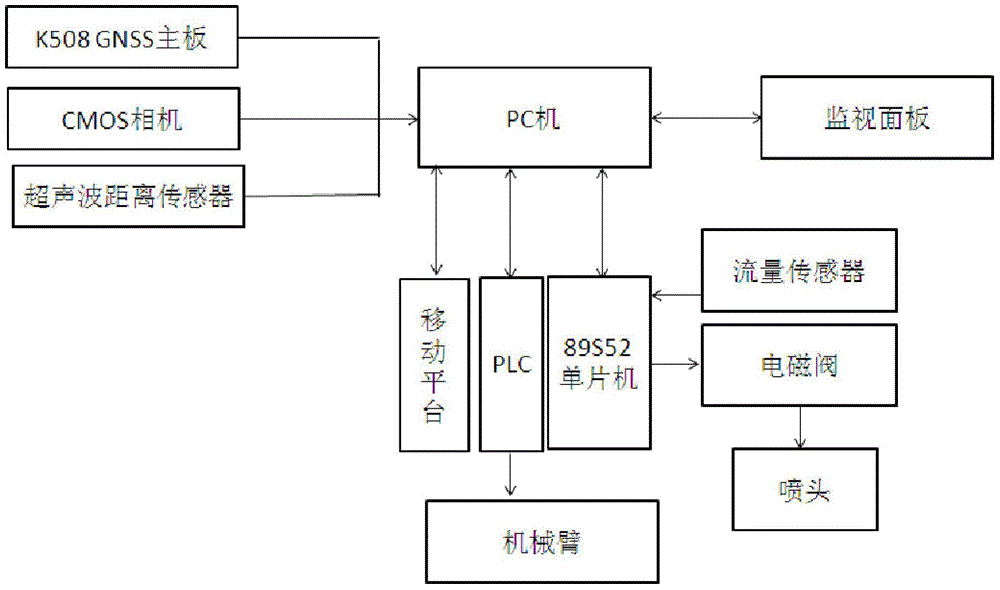

Automatic targeting and spraying system

ActiveCN103999841ARealize all-round image acquisitionFine sprayingPressurised distribution of liquid fertiliserAgriculture gas emission reductionCMOSDistance sensors

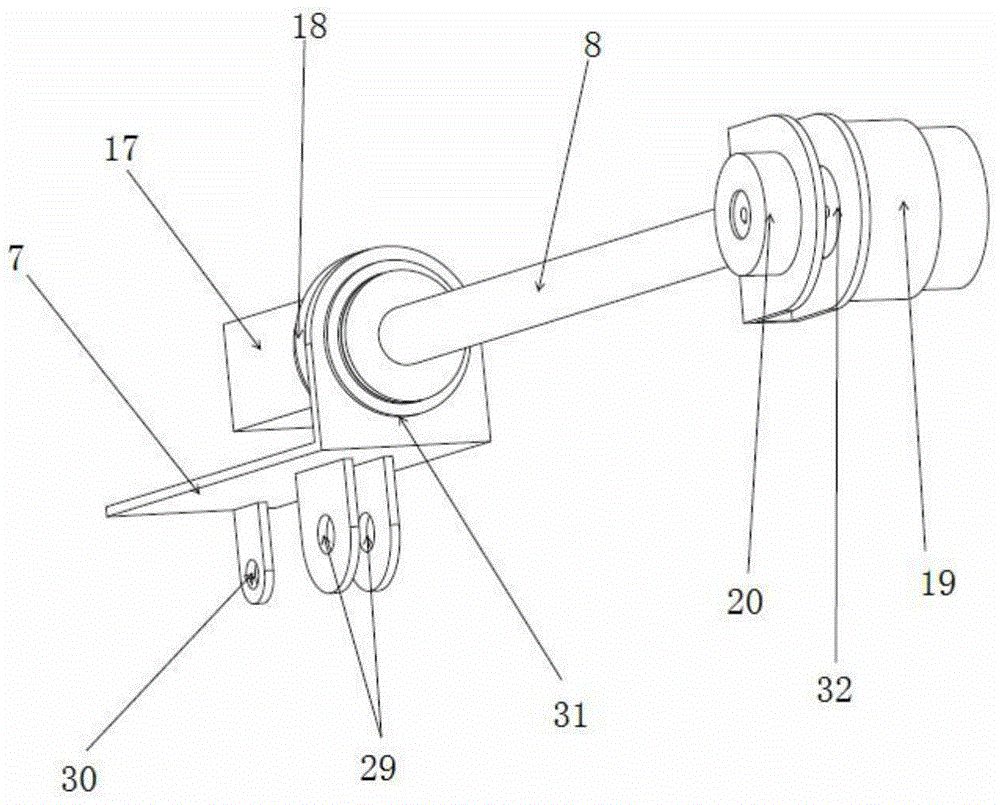

The invention discloses an automatic targeting and spraying system. The automatic targeting and spraying system comprises an all-directional moving platform, an image acquisition device, a spraying device and a control device are mounted on the all-directional moving platform, and the control device is used for receiving and analyzing crop image information outputted by the image acquisition device and controlling operations of the spraying device and the all-directional moving platform; the spraying device comprises a drug container, a liquid outlet pipe, a delivery pump and a mechanical arm, one end of the liquid outlet pipe is communicated with the drug container while the other end of the liquid outlet pipe is connected with a spraying rod, a plurality of nozzles are fixed onto the spraying rod, the delivery pump is mounted on the liquid outlet pipe and used for pumping fertilizer or pesticide from the drug container into the liquid outlet pipe, and the spraying rod is fixed onto the mechanical arm; the image acquisition device comprises a CMOS (complementary metal oxide semiconductor) camera and a distance sensor, the CMOS camera and the distance sensor are fixed onto the mechanical arm. Since the CMOS camera, the distance sensor and the spraying rod are mounted on the mechanical arm, all-directional image acquisition of crops can be completed while pesticide or fertilizer can be sprayed on the crops intensively in all directions, and accordingly pesticide or fertilizer utilization rate is increased.

Owner:ZHEJIANG UNIV

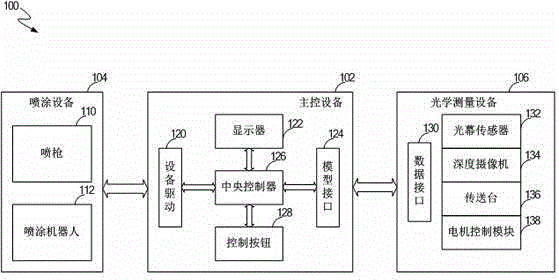

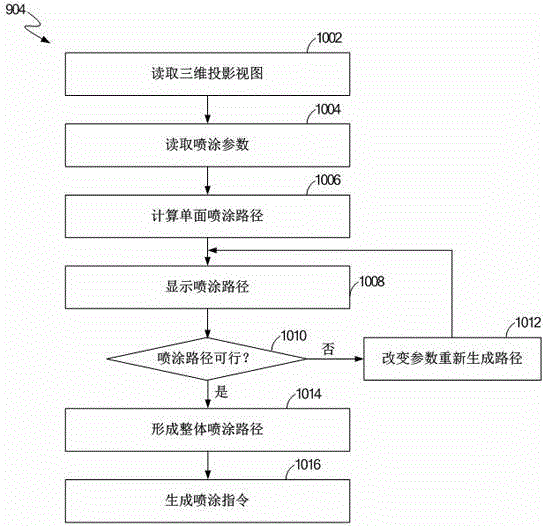

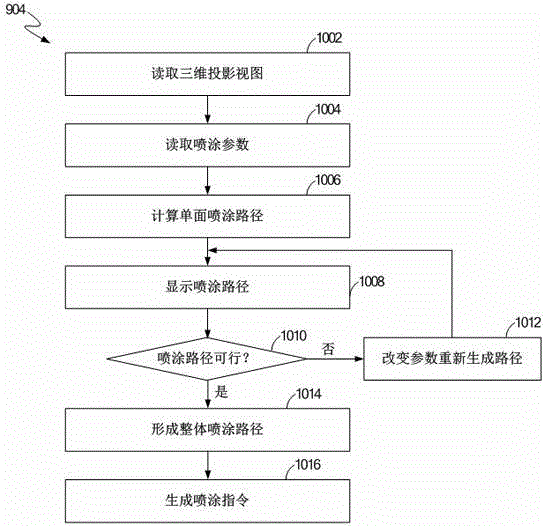

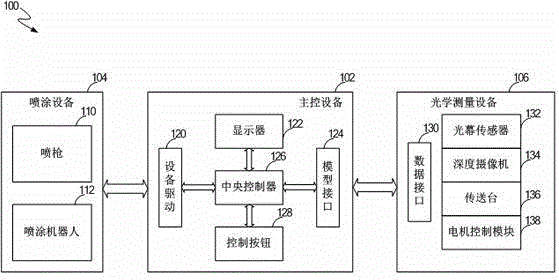

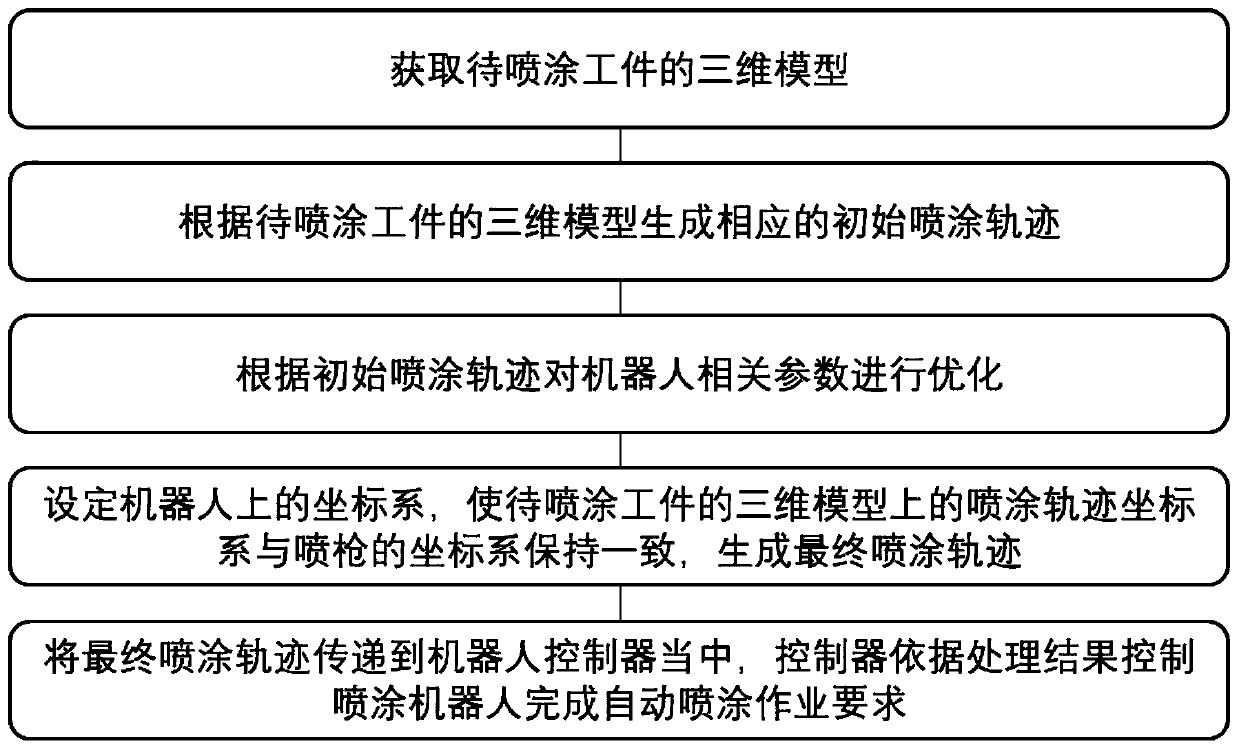

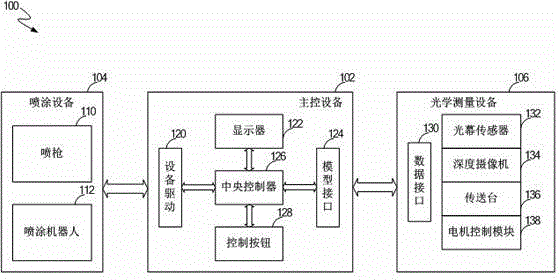

Spraying robot control method based on three-dimensional model recognition

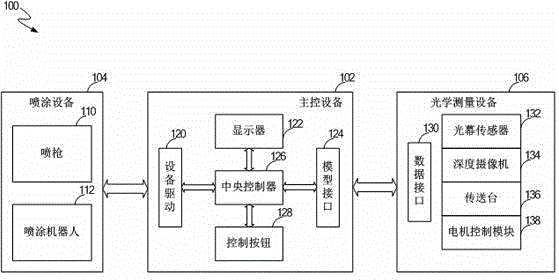

ActiveCN104525420AImprove spraying accuracyReduce human burdenSpraying apparatusThree dimensional modelRobot control

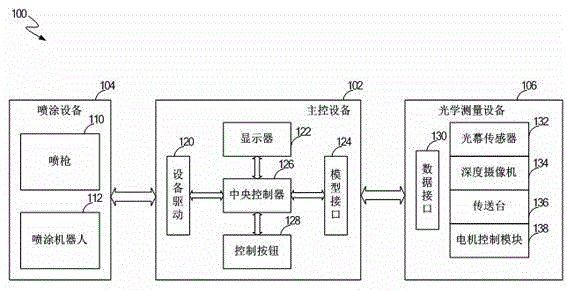

The invention discloses a spraying robot control method based on three-dimensional model recognition. The method comprises the steps that hardware driving parameters are set for a main control device, an optical measuring device and a spraying device; a three-dimensional projection view of a workpiece to be sprayed is read from the optical measuring device; spraying parameters of a spraying robot are read from a memorizer of the main control device; the spraying path of each single face of the workpiece to be sprayed is calculated according to the three-dimensional projection view and the spraying parameters; an integral spraying path is produced according to the spraying paths of the single faces; the spraying track and space condition of a spraying gun are calculated according to the integral spraying path; a spraying instruction is produced according to the spraying track and the space condition of the spraying gun; the spraying instruction is sent to the spraying robot through a data interface to control the spraying robot to spray the workpiece to be sprayed.

Owner:成都思达特电器有限公司

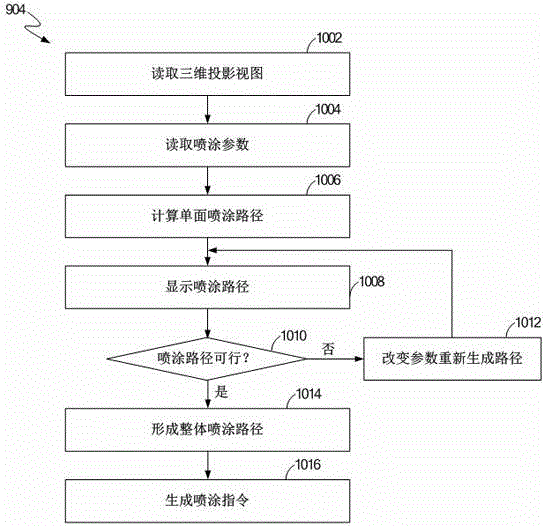

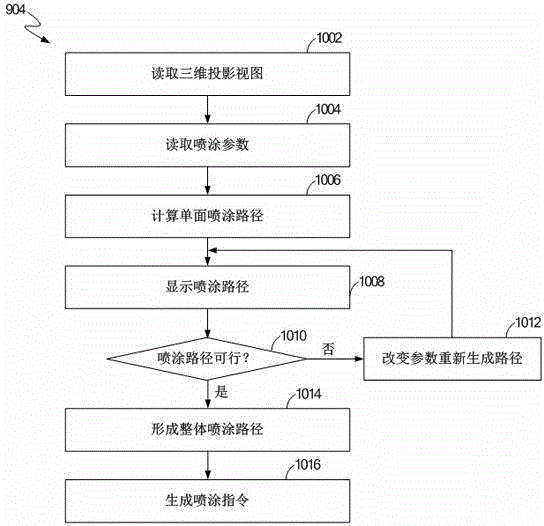

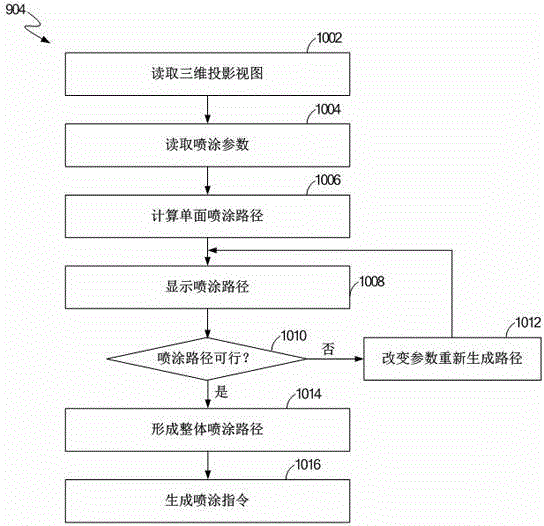

Method for controlling paths of spray robot

ActiveCN104525422ASimple and fast operationImprove spraying accuracySpraying apparatusDisplay deviceComputer science

The invention discloses a method for controlling paths of a spray robot. The method includes the following steps that three-dimensional projection views of a sprayed workpiece are read; spray parameters of the spray robot are read; according to the three-dimensional projection views and the spray parameters, the spray path on each single face of the sprayed workpiece is calculated; the spray path on each single face is displayed on a displayer; user commands are read; according to the user commands, the spray parameters are modified; according to the modified spray parameters, the spray path on each single face of the sprayed workpiece is calculated; according to the spray path on each single face, a whole spray path is generated; spray commands are generated, so that the spray robot is controlled to spray the sprayed workpiece.

Owner:成都思达特电器有限公司

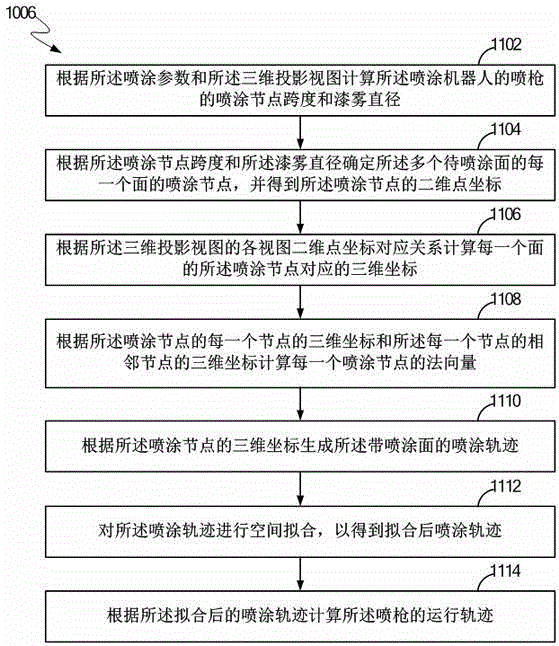

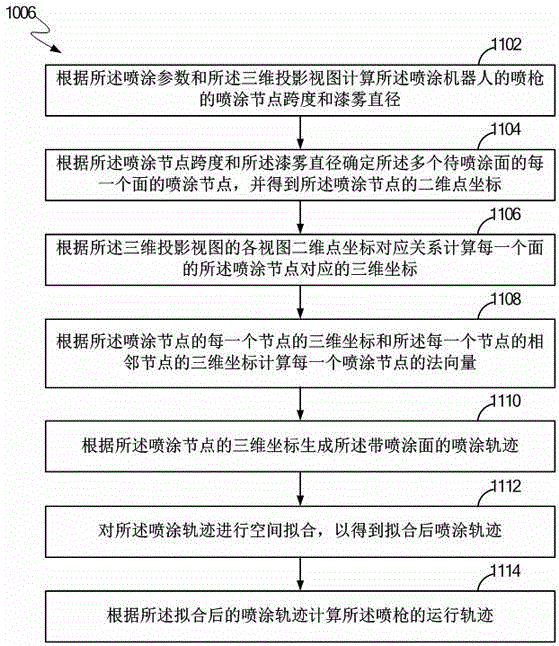

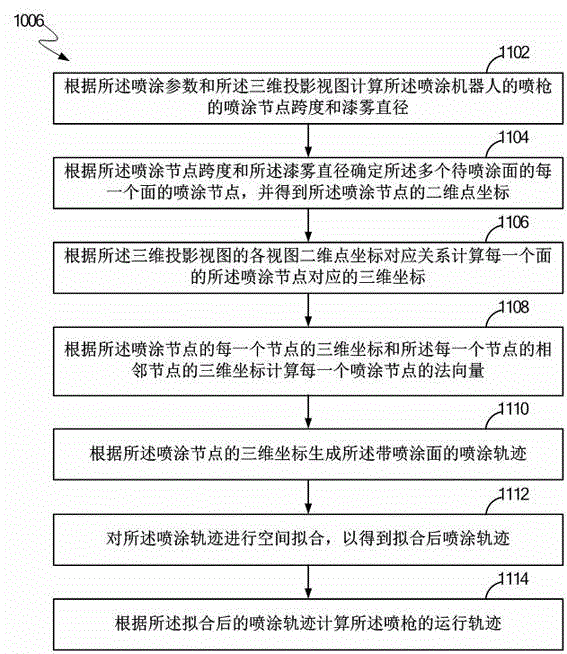

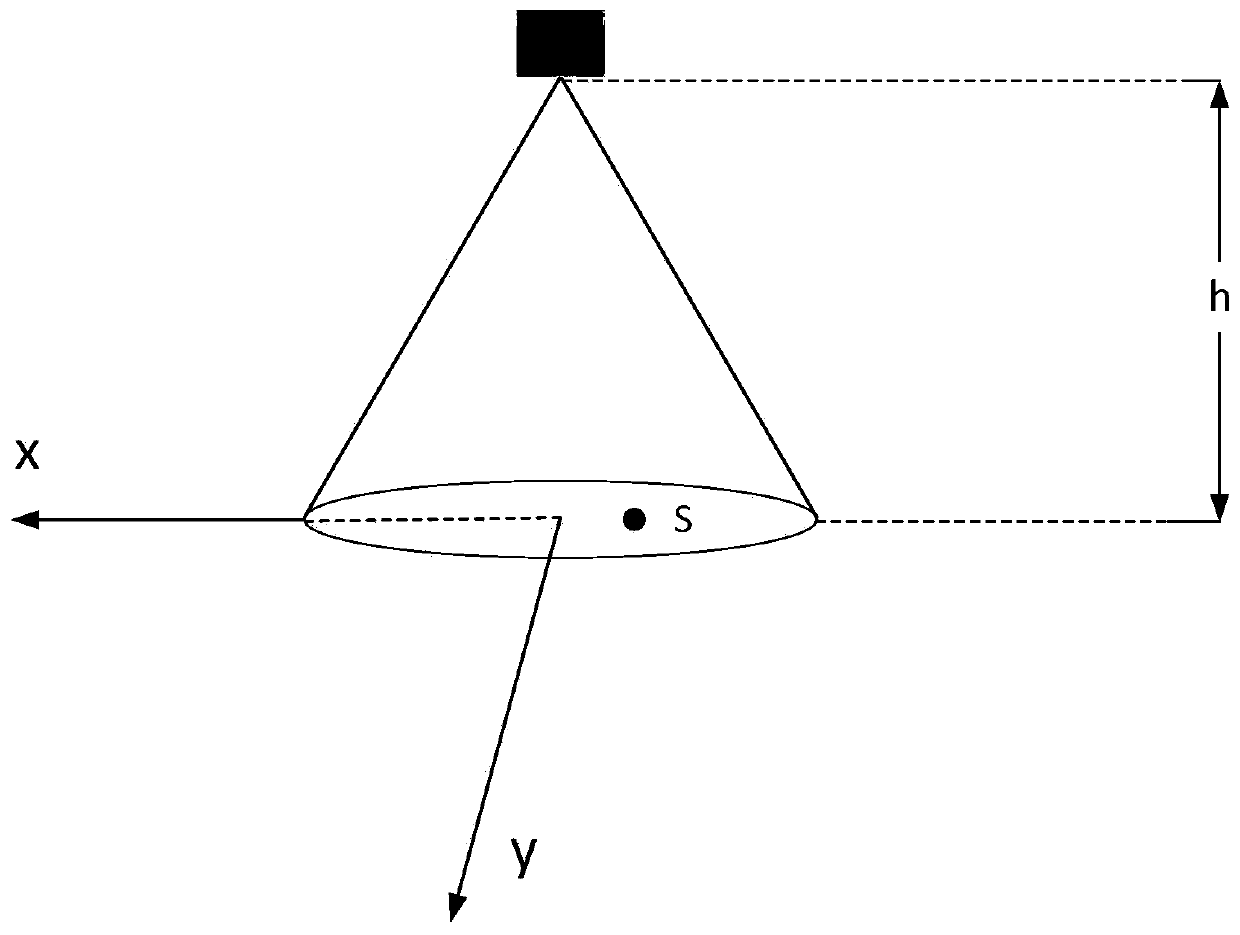

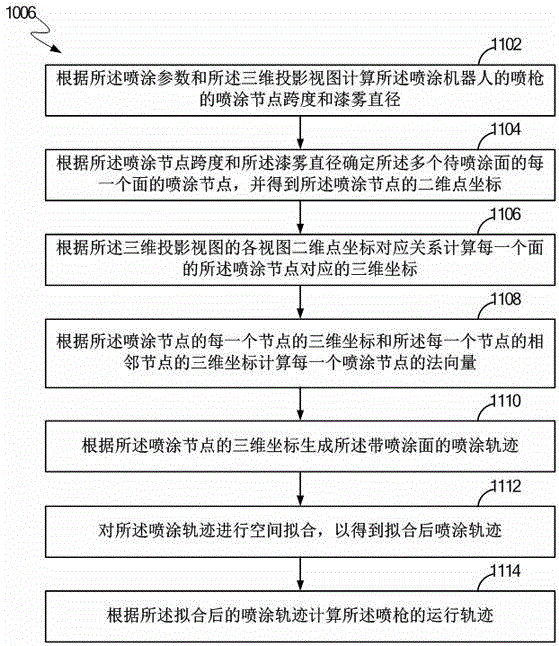

Method for controlling spraying gun of spraying robot

ActiveCN104549850ASimple and fast operationImprove spraying accuracySpraying apparatus3D modellingNODALComputer science

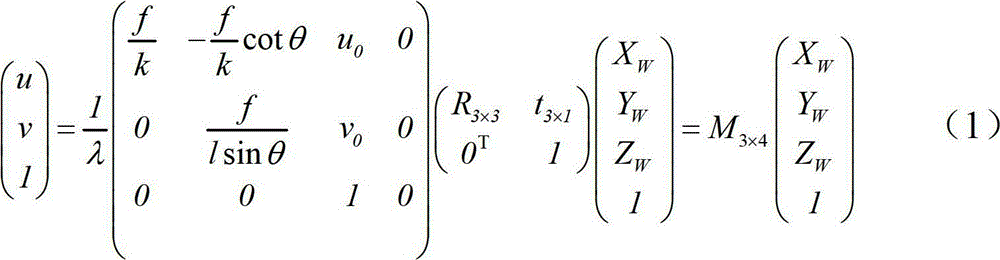

The invention discloses a method for controlling a spraying gun of a spraying robot. The method comprises the steps of determining a plurality of surfaces of a workpiece, to be spayed according to a three-dimensional projection view; determining a spraying joint of each of the plurality of surfaces to be sprayed according to the spraying parameters and the three-dimensional projection view, and obtaining a two-dimensional point coordinate of the spraying joint; calculating a three-dimensional coordinate corresponding to the spraying joint of each surface according to the correspondence relation of the two-dimensional point coordinate of each view of the three-dimensional projection view; calculating a normal vector of each spraying joint according to the three-dimensional coordinate of each of the spraying joints and the three-dimensional coordinate of the joint adjacent to each joint; generating a spraying track of the spraying surface according to the three-dimensional coordinates of the spraying joints; performing spatial fit for the spraying track to obtain the fitted spraying track; calculating the spraying track and the normal vector of the spraying gun by the formula in the specification according to the fit track and the normal vector of the spraying joints.

Owner:成都思达特电器有限公司

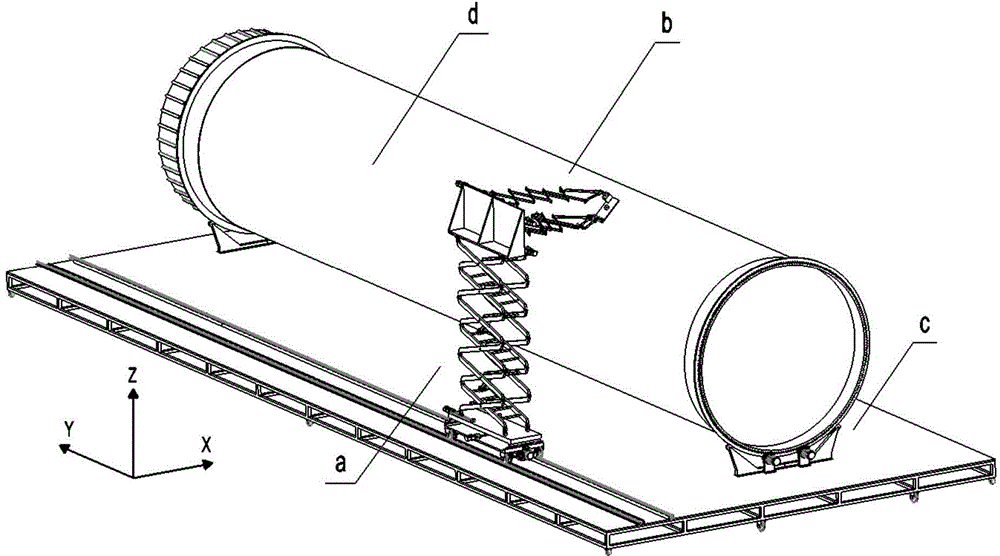

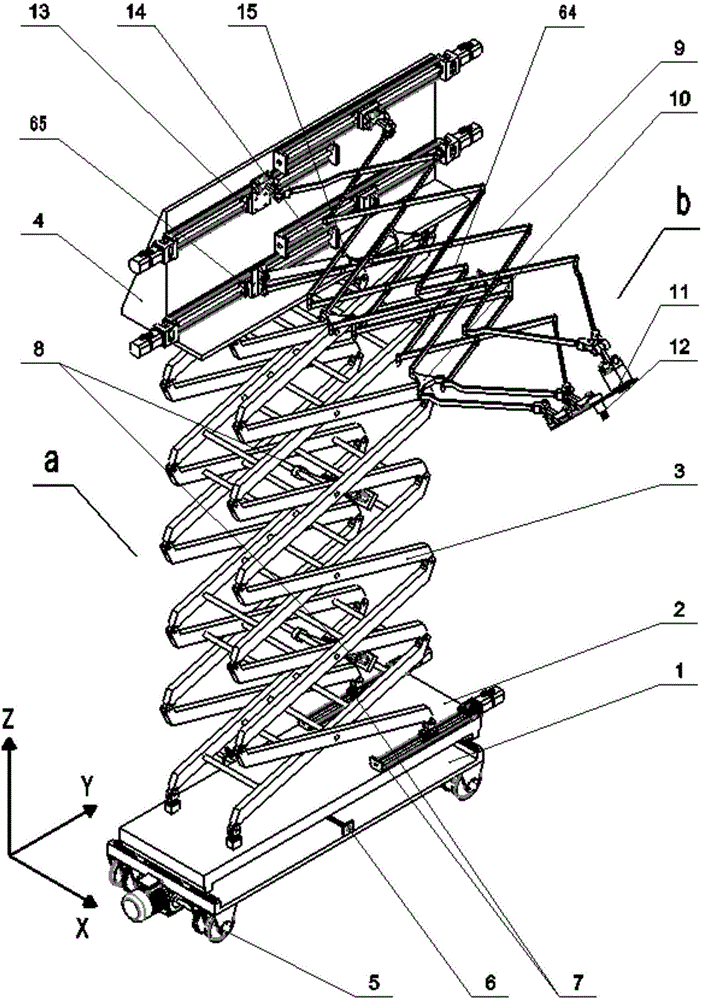

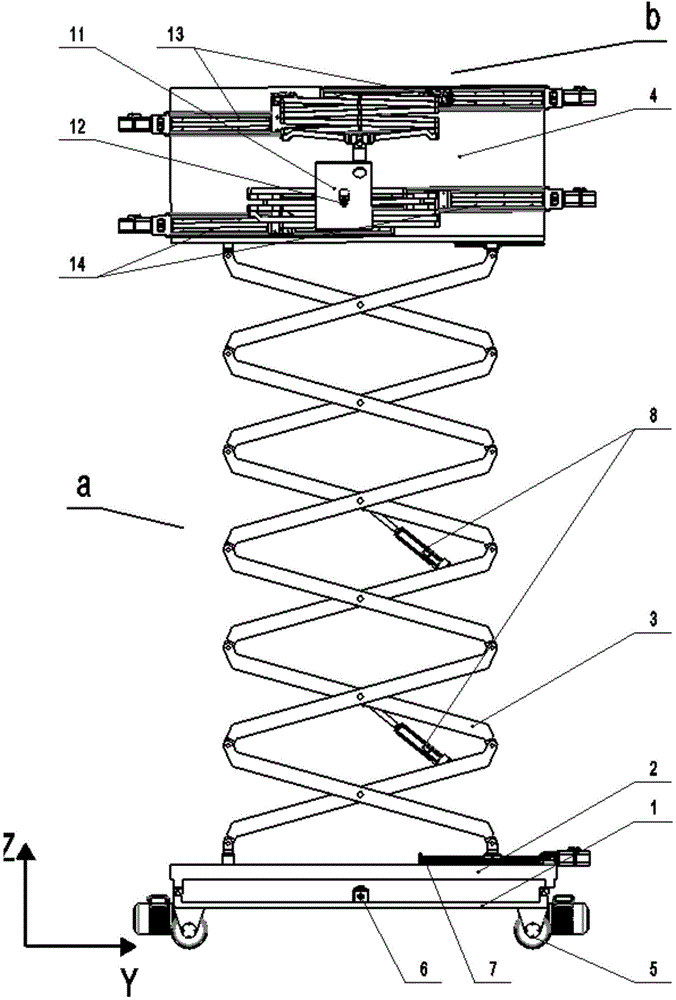

Automatic spraying robot device

ActiveCN104549849AReduce pollutionImprove flexibilitySpraying apparatusControl mannerEconomic benefits

The invention relates to an automatic spraying robot device in the field of automatic coating of an aircraft. The automatic spraying robot device comprises a movable spraying robot consisting of a three-vertical-coordinate-axis movable platform and a spraying execution mechanism, and a barrel supporting autorotation tool, wherein the three-vertical-coordinate-axis movable platform is connected with the spraying execution mechanism in a sliding manner and arranged on a slide rail at one side of a storage box, and the barrel supporting autorotation tool is connected with the storage box in a rotating manner. While the robot moves rapidly along a Y axis, a spray head can form any dihedral angle of 0 to 90 degrees with a YZ plane by adopting the Y axis as an intersection line, so that the spraying in the downward vertical direction, oblique upward direction and horizontal direction can be realized, and the automatic spraying robot device can be adaptive to storage boxes of different diameters and different work conditions, and the flexibility is very high, in addition, the automatic spraying robot can move to an arc end surface, an appropriate distance between the spray head and the arc end surface can be realized, and the vertical uniform automatic spraying can be realized in real time. The automatic spraying robot device is compact in layout, high in flexibility, simple in control way, high in spraying precision, uniform in coating thickness, small in environmental pollution, high in spraying efficiency and good in economic benefit.

Owner:SHANGHAI JIAO TONG UNIV

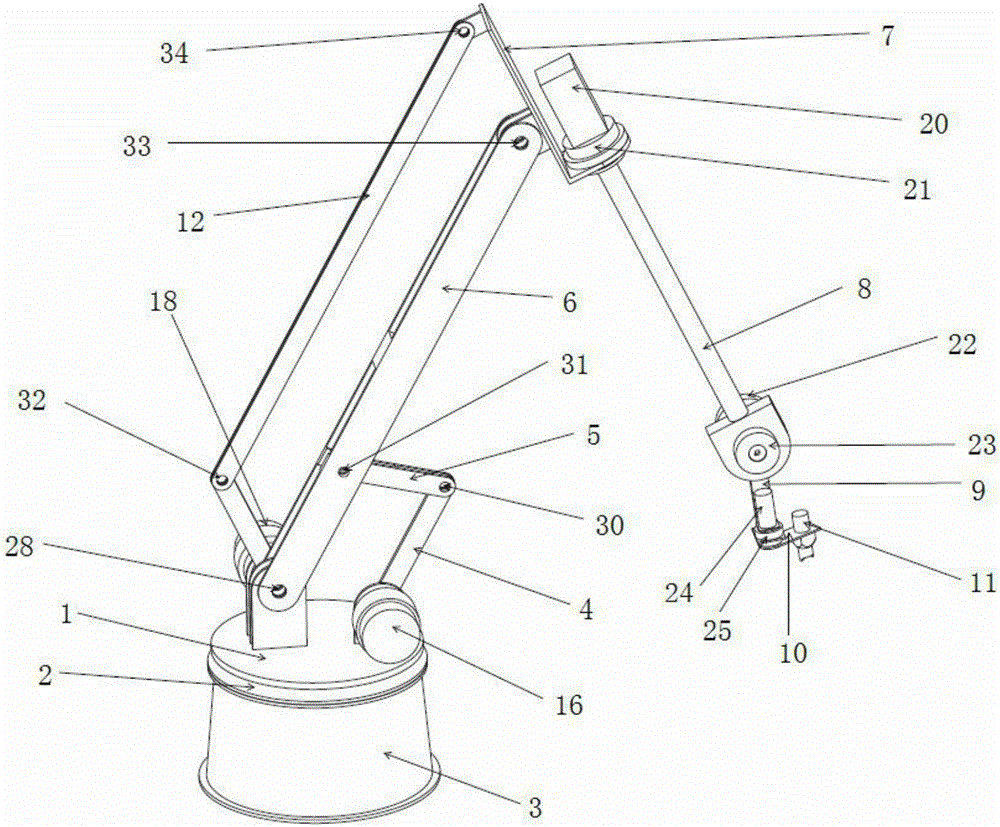

Six-freedom-degree eight-rod series-parallel connection spraying robot

InactiveCN105058381AReduce weightSmall moment of inertiaProgramme-controlled manipulatorSpraying apparatusRobotic armEngineering

The invention provides a six-freedom-degree eight-rod series-parallel connection spraying robot. A first driving rod, a second driving rod and a supporting rod of the spraying robot are connected with a rotating machine frame. A first driving connection rod and a second driving connection rod are connected with the first driving rod and the second driving rod respectively. A moveable arm table is connected with the supporting rod and the second driving connection rod. A rotating arm is connected with the movable arm table. A swing arm is connected with the rotating arm. A spraying head table is connected to the swing arm. A spraying head is connected to the spraying head table. According to the six-freedom-degree eight-rod series-parallel connection spraying robot, a series-parallel connection integrated structure is adopted for replacing a single series connection structure of an existing robot, and rigidity is high; and a parallelogram link mechanism is applied to the six-freedom-degree eight-rod series-parallel connection spraying robot, accurate control can be achieved easily, and the six-freedom-degree eight-rod series-parallel connection spraying robot is suitable for manufacturing various mechanical arms and other engineering machines.

Owner:广西凯纵机械制造有限公司 +1

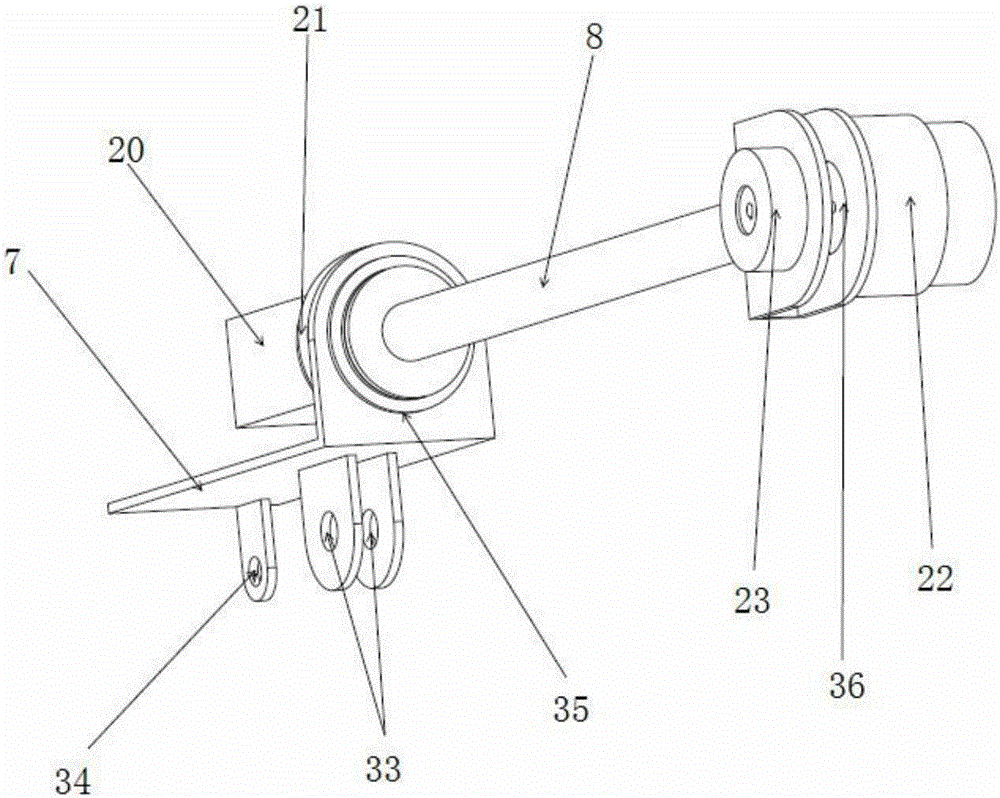

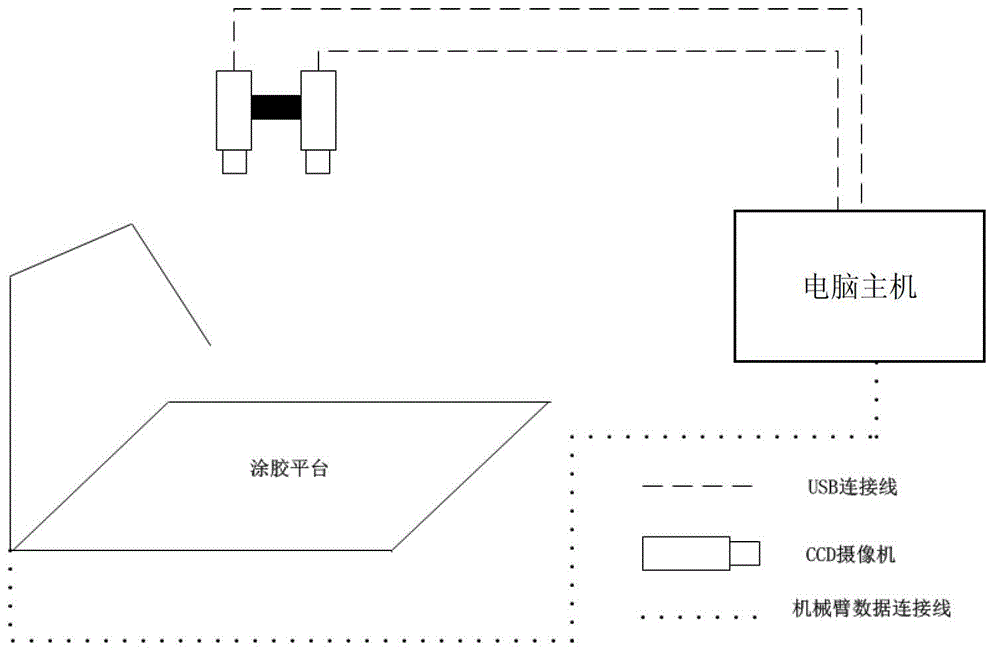

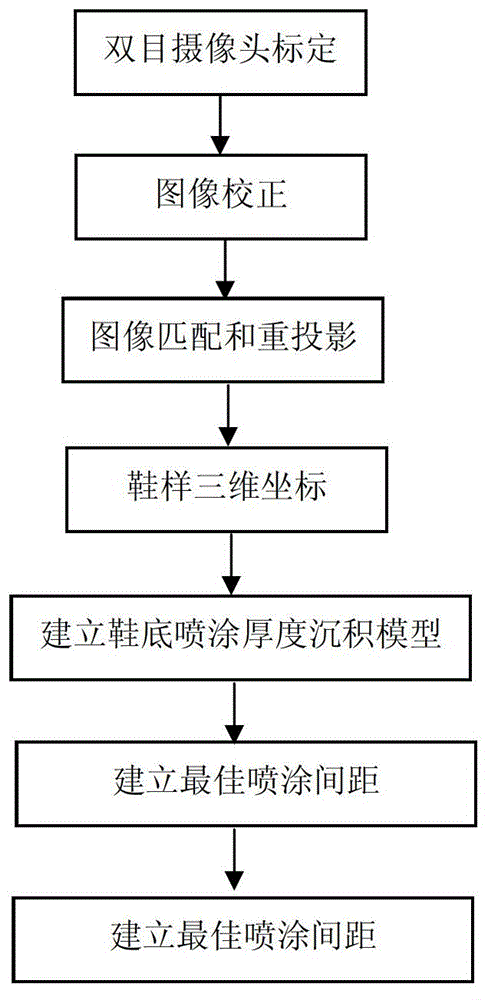

Sole glue spraying thickness control method based on binocular vision

A sole spraying thickness control method based on binocular vision includes the following steps: 1) erecting a binocular camera above a glue spraying platform, and obtaining images of a sole through two camera heads of the binocular camera; 2) performing three-dimensional calibration according to the two camera heads in the step 1), 3) adjusting angles and distance of the camera heads, and outputting calibration images with accurate line alignment; 4) finding identical characteristics in vision fields of the left camera head and the right camera head, outputting a disparity map, calculating a relative geometric position of the camera, and outputting a three-dimensional coordinate of a detection target through a trigonometric survey method; 5) providing a bivariate gaussian distribution model aiming at a discrete point, and building a sole glue spraying thickness sedimentary model; and 6) inputting the obtained three-dimensional coordinate with optimum space to a movement queue of a glue spraying mechanical arm so as to control the mechanical arm to complete a glue spraying process. The sole spraying thickness control method based on the binocular vision improves working efficiency, improves product quality, and solves the problem that traditional manual glue spraying thickness is uneven.

Owner:ZHEJIANG UNIV OF TECH

Spray method for controlling spray robot

InactiveCN104525423ASimple and fast operationImprove spraying accuracySpraying apparatusComputer scienceProjection View

The invention discloses a spray method for controlling a spray robot. The method includes the steps that a sprayed workpiece is optically measured, so that three-dimensional projection views and size information of the sprayed workpiece are acquired; workpiece signals expressing the three-dimensional projection views and the size information are generated; spray parameters related to the spray robot are read; according to the workpiece signals and the spray parameters, spray paths of the spray robot are calculated and spray commands comprising spray path information are generated; according to the spray commands, the spray robot is controlled to conduct spray operation according to the spray paths.

Owner:成都思达特电器有限公司

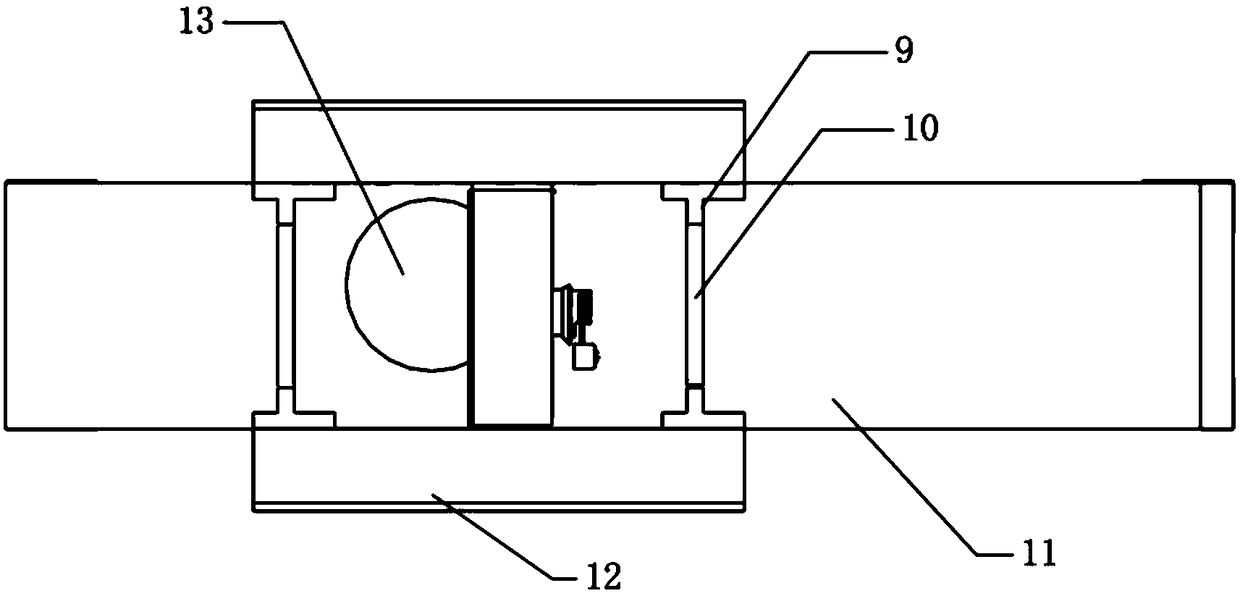

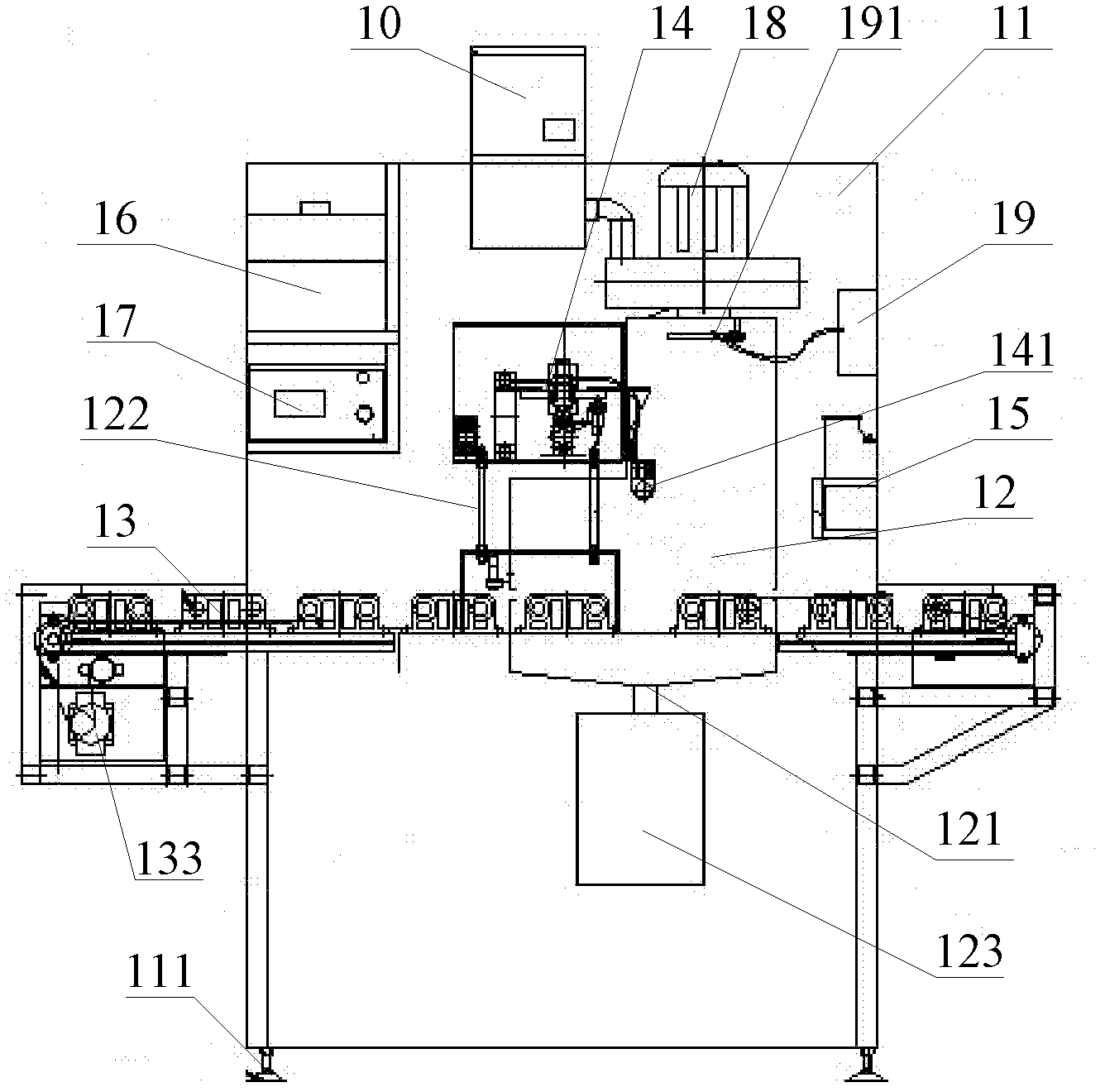

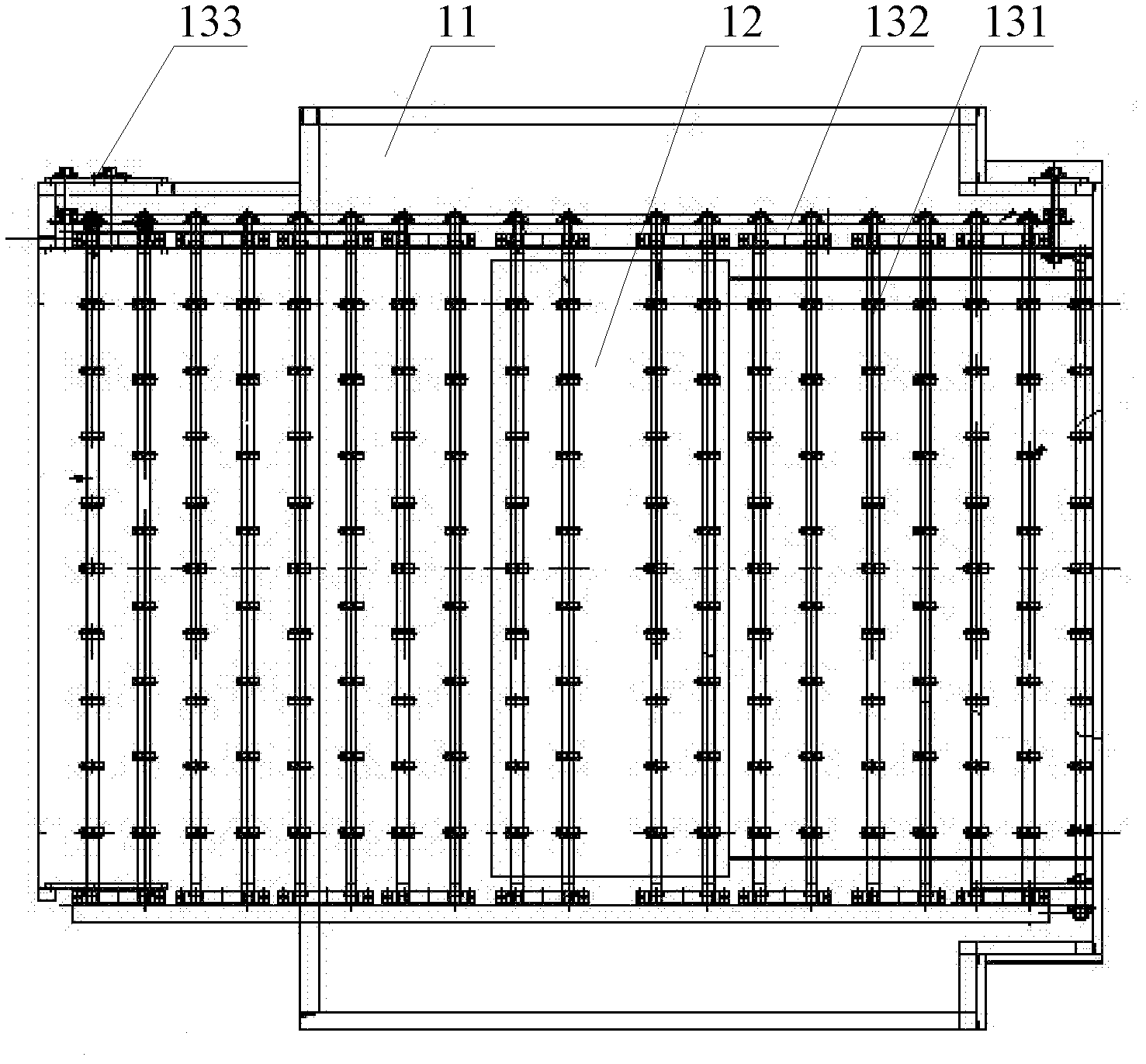

Heating radiator spraying production line

PendingCN110420788ARealize automatic transferStable sprayingPretreated surfacesCoatingsProduction lineDrive shaft

The invention belongs to the technical field of heat radiator electrostatic powder spraying, and particularly relates to a heating radiator spraying production line. The heating radiator spraying production line comprises a suspension chain conveyor, a spraying device and a rotary hanging device. The spraying device comprises spraying guns which are oppositely arranged, the positions of the spraying guns can be adjusted up and down, front and back and left and right, and the spraying device can rotate. The rotary hanging device comprises a rotary hanging base, and a walking support driven by asynchronous walking driving mechanism is slidably arranged on the rotary hanging base. Two oppositely arranged synchronous rocker arms driven by a rotary hanging mechanism are rotationally mounted onthe walking support. Rotary hanging parts are arranged on the synchronous rocker arms. According to the heating radiator spraying production line, spraying can be automatically controlled to replacemanual spraying, and spraying is stable; the production efficiency and the spraying precision can be improved, and automatic workpiece rotary hanging operation is achieved; and manpower is saved, andthe production efficiency is improved.

Owner:临朐浩伟电子设备有限公司

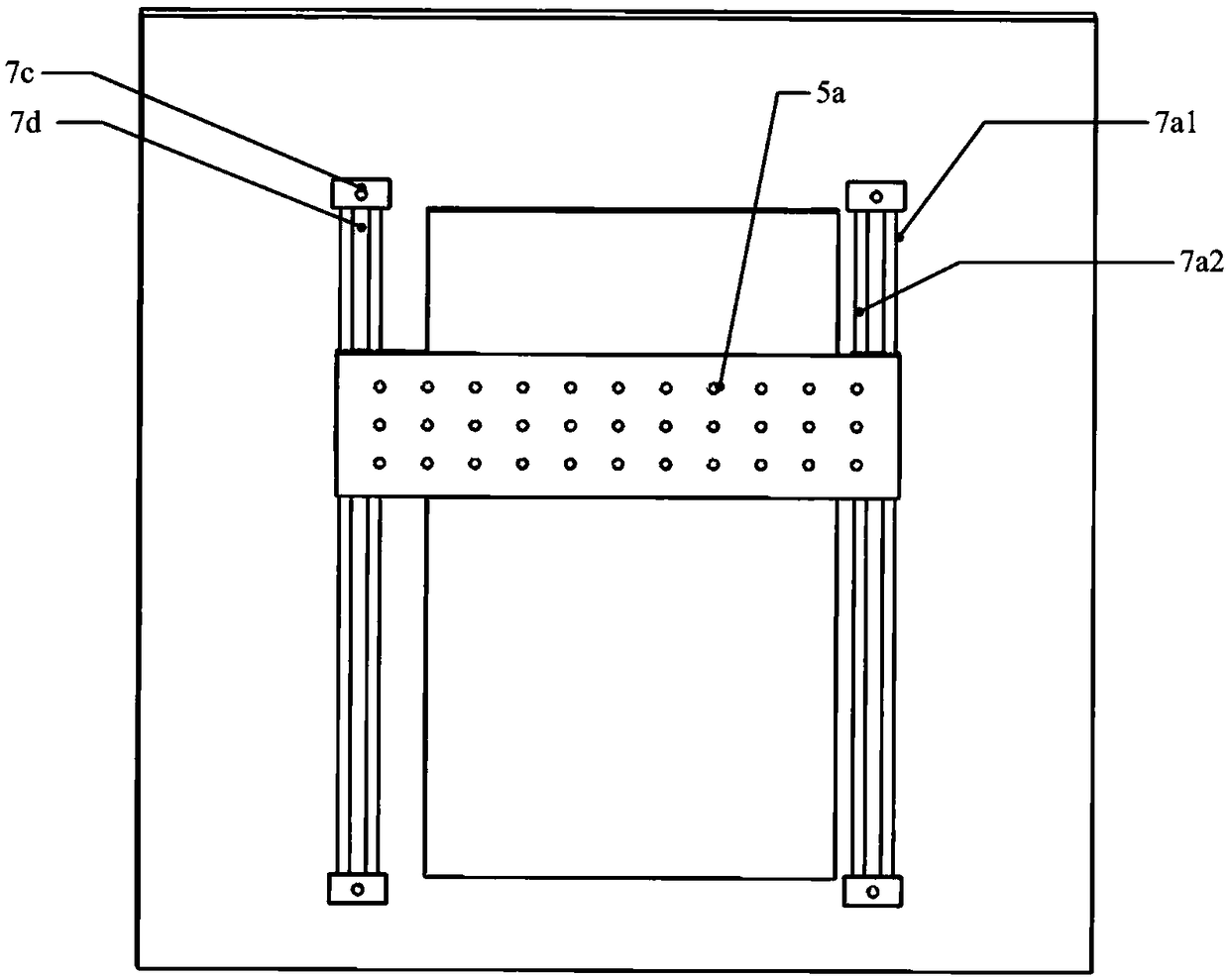

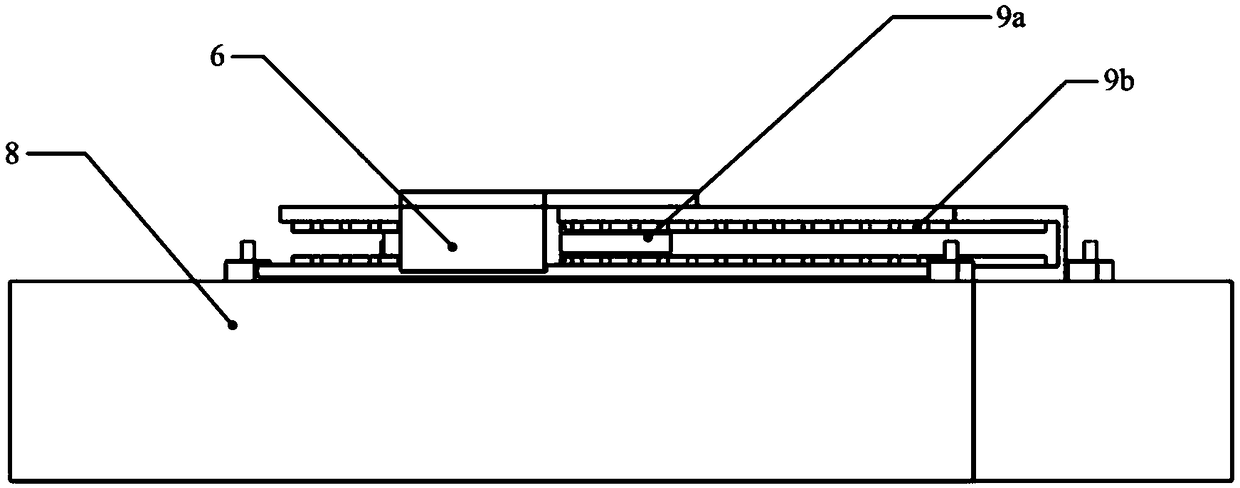

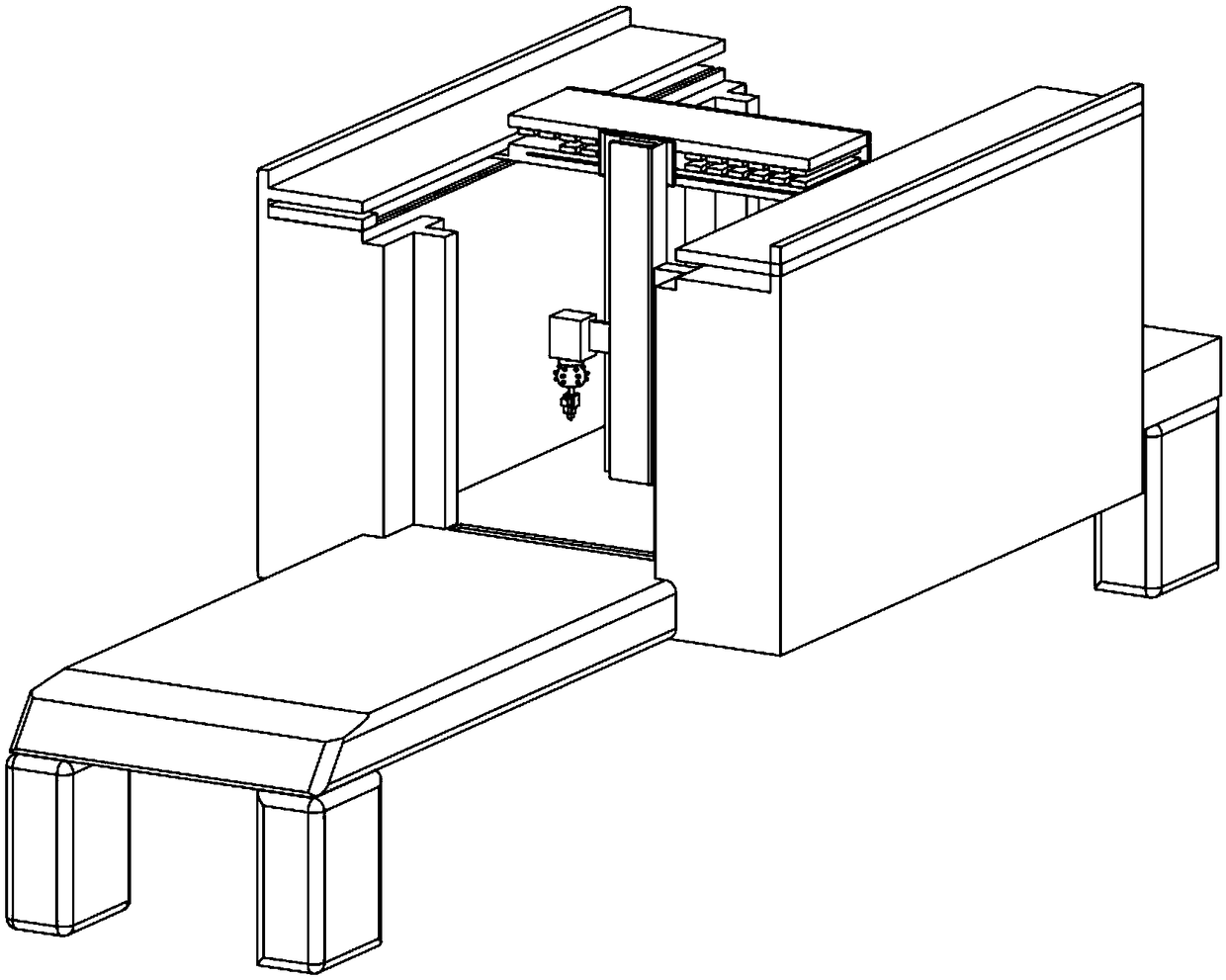

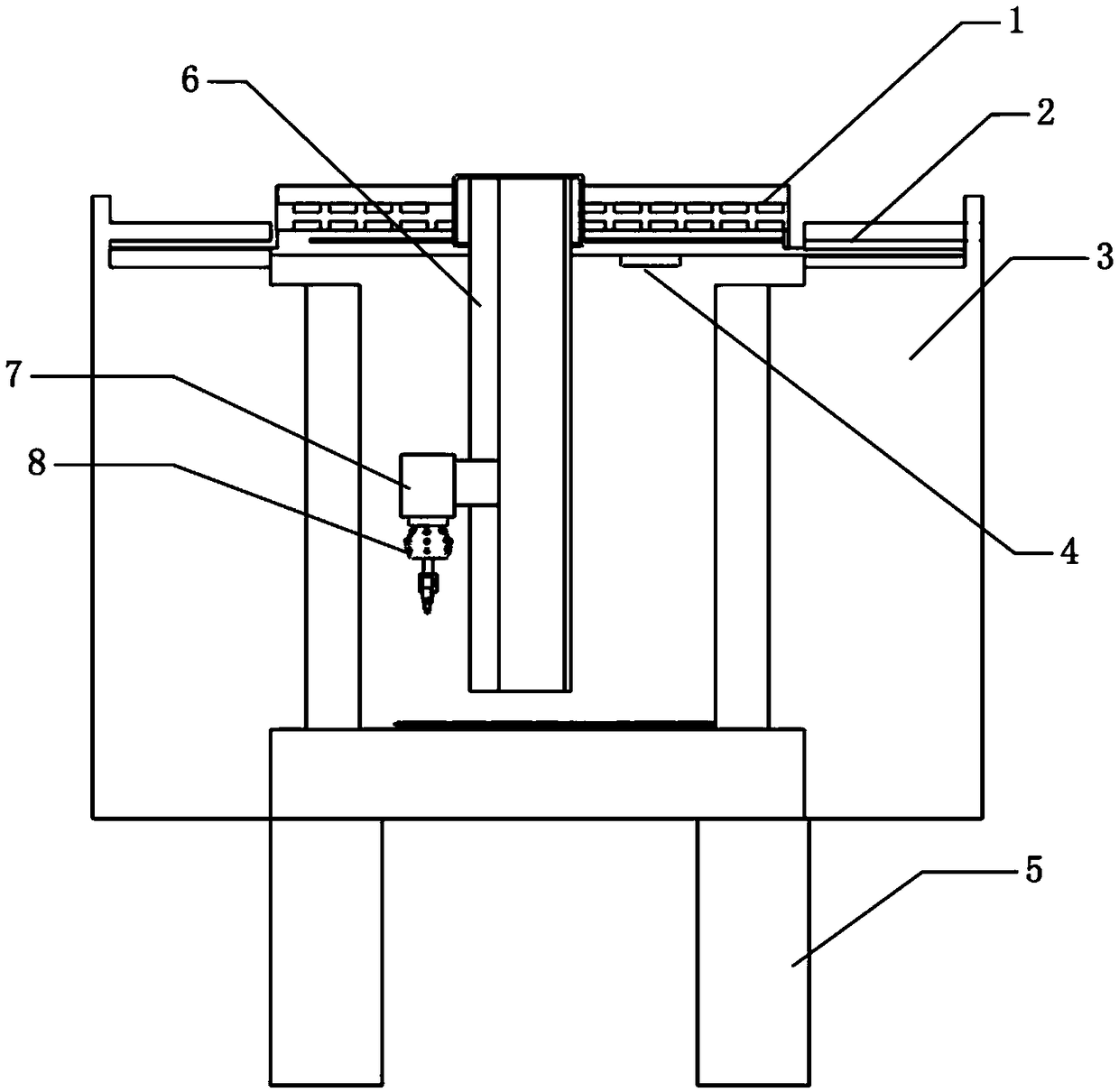

Intelligent circuit board paint spraying equipment based on linear motors

PendingCN109046846AImprove spraying accuracyIncrease productivitySpraying apparatusThree dimensional motionMovement control

The invention provides intelligent circuit board paint spraying equipment based on linear motors, and relates to the technical field of spraying equipment. The equipment mainly comprises a three-dimensional motion mechanism for aligning a nozzle mechanism to a workpiece spraying part on a worktable: an X-axis motion mechanism based on an X linear motor, a Y-axis motion mechanism based on a Y linear motor, and a Z-axis motion mechanism based on a Z linear motor; a mover limiting switch and a position sensor are provided; and a controller receives nozzle position signals to control the three-dimensional motion mechanism and the nozzle mechanism to work. The equipment solves the problems of higher control errors and low spraying precision caused by belt transmission or screw transmission of atraditional three-axis motion control platform in the prior art. An image processing system can be provided for generating spraying areas selected by users, so that the problems of low spraying precision and incapability of intelligently identifying the spraying areas in the prior art are solved. The equipment has the characteristics of high response speed, high control precision and high production efficiency.

Owner:石家庄辐科电子科技有限公司 +2

Spraying equipment based on multi-degree-of-freedom motor

InactiveCN109453928ASolve rough sprayingSolve the dead angle of sprayingSpraying apparatusMotor driveControl system

The invention provides spraying equipment based on a multi-degree-of-freedom motor, and relates to the technical field of spraying equipment. The spraying equipment based on the multi-degree-of-freedom motor mainly comprises a frame body, a three-dimensional movement mechanism, the multi-degree-of-freedom motor, a spray head, a rotary type working table and a control system, wherein the three-dimensional movement mechanism is connected with the multi-degree-of-freedom motor; the multi-degree-of-freedom motor is connected with the spray head; the controller comprises a camera; the three-dimensional movement mechanism drives the multi-degree-of-freedom motor; the multi-degree-of-freedom motor drives the spray head to spray multi-angularly in the space along a workpiece to be sprayed; a workpiece range is determined through image identification; and the angle of the spray head is adjusted according to the surface space radian of the workpiece so as to carry out spraying. The spraying equipment based on the multi-degree-of-freedom motor provided by the invention mainly solves the problems of spraying roughness, the existence of a spraying dead angle, material waste, a poor spraying effect, a big control error, low spraying accuracy and low spraying efficiency in the prior art, and has the characteristics of high spraying accuracy, good quality, high efficiency, saving in materialsand the like.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Intelligent robot spraying method based on spraying system

InactiveCN111530671AReduce dosageOptimize spray speedSpraying apparatusSpray coatingProcess engineering

The invention provides an intelligent robot spraying method based on a spraying system. A machine is adjusted through a spraying process library instead of a machine adjustment process library; for different workpieces to be sprayed, a spraying trajectory program can be automatically identified and generated; and an optimal spraying parameter and an optimal spraying trajectory are selected according to the built spraying process library. Compared with traditional spraying, after applying the method provided by the invention, the spraying quality and the spraying efficiency of workpieces are improved, meanwhile, the dosage of a spraying coating is relatively reduced, and for a determined spraying trajectory, trajectory optimization is carried out on relevant parameters such as the sprayingspeed and the spraying flow of a spraying robot by adopting the spraying uniformity as an optimal object, so that the spraying quality can achieve the best effect.

Owner:FOSHAN UNIVERSITY

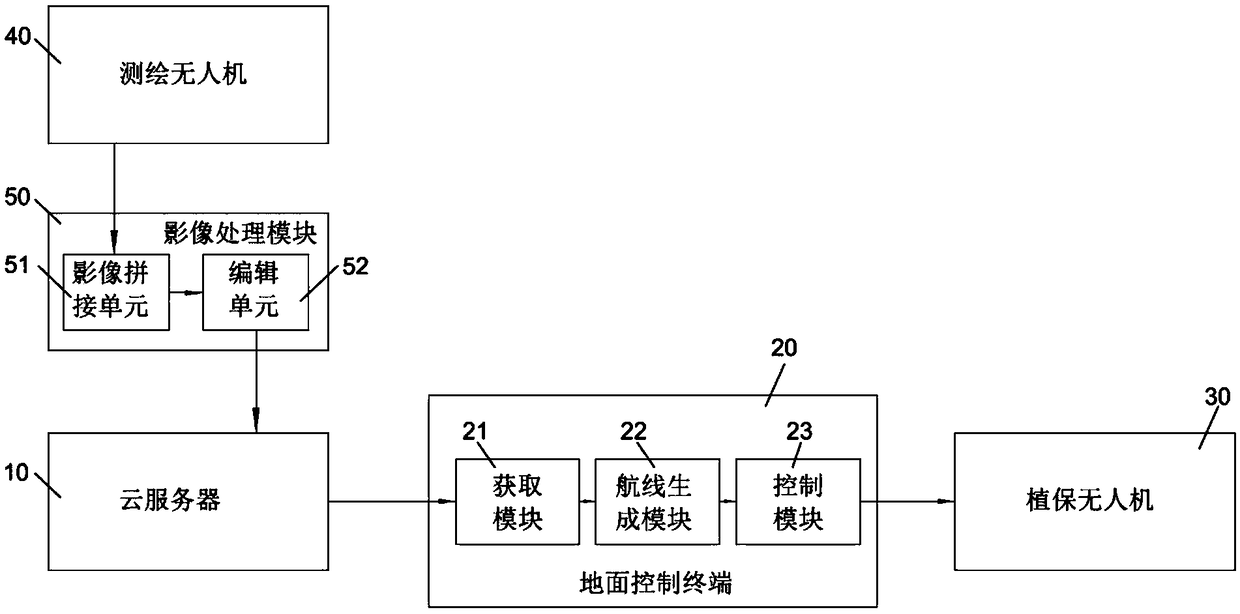

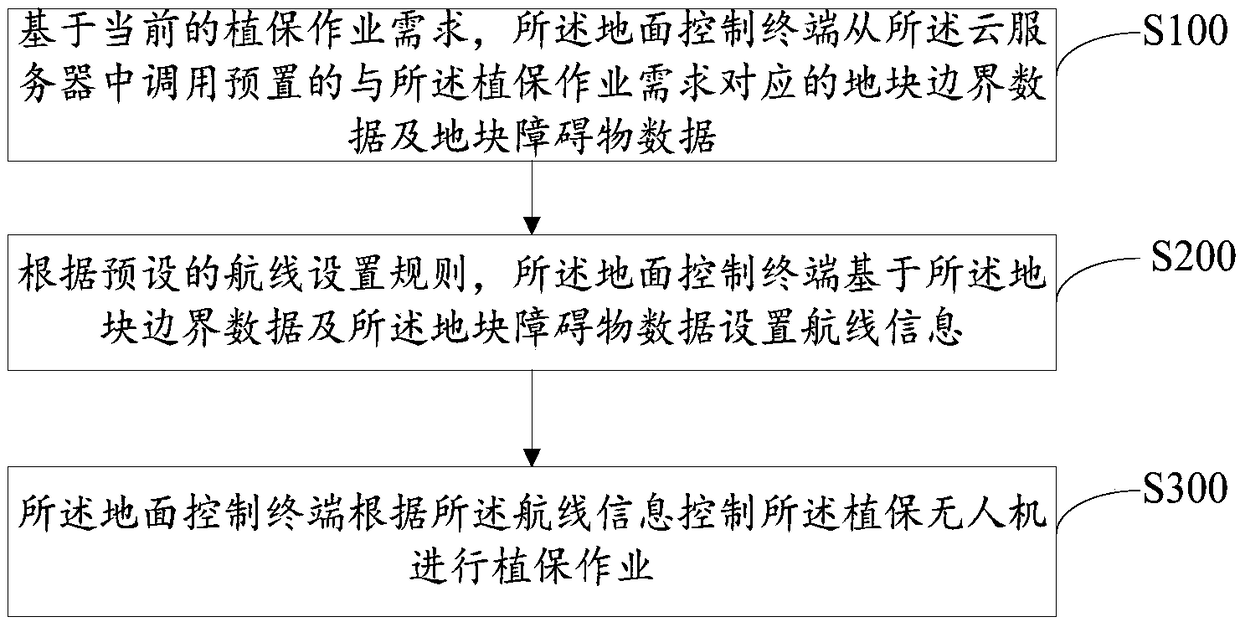

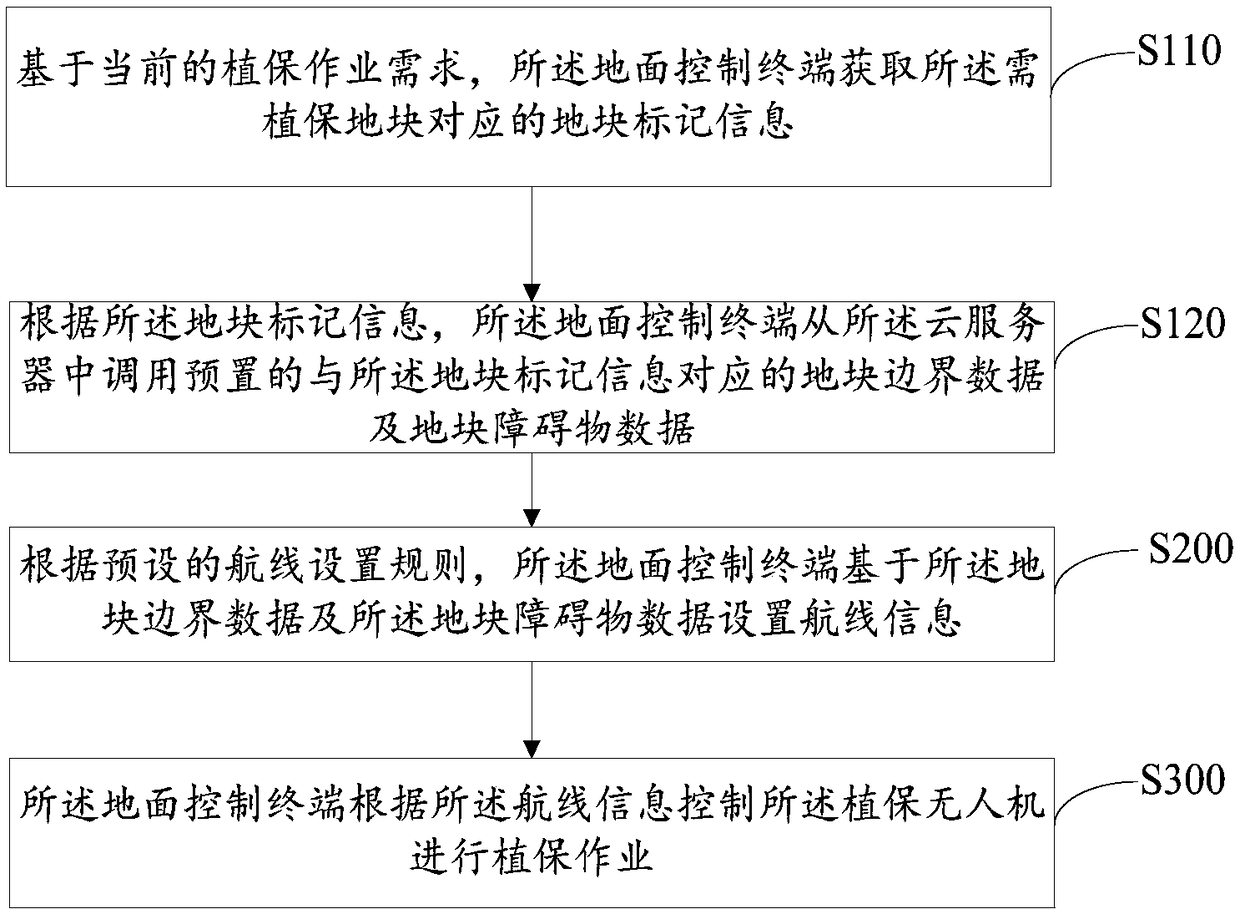

Accurate operation system and method for plant protection unmanned aerial vehicle

PendingCN109343567AAvoid wastingImprove spraying accuracyTotal factory controlPosition/course control in three dimensionsComputer moduleUncrewed vehicle

The invention discloses an accurate operation system for a plant protection unmanned aerial vehicle. The system comprises a cloud server, a ground control terminal and at least one plant protection unmanned aerial vehicle, wherein the cloud server, the ground control terminal and at least one plant protection unmanned aerial vehicle are in communication connection; the ground control terminal comprises an acquisition module, an air line generation module and a control module; according to current plant protection operation requirements, the cloud server sends preset land parcel boundary data and land parcel obstacle data, which correspond to the plant protection operation requirements, to the acquisition module; the acquisition module sends the received land parcel boundary data and land parcel obstacle data to the air line generation module; the air line generation module sets air line information on the basis of the land parcel boundary data and the land parcel obstacle data according to a preset air line setting rule, and sends the air line information to the control module; and the plant protection unmanned aerial vehicle carries out a plant protection operation according to the air line information received by the control module. The invention also discloses an accurate operation method for the plant protection unmanned aerial vehicle. By use of the system and the method,the spraying accuracy of the plant protection operation of the unmanned aerial vehicle can be improved, and the waste of resources, including pesticides, chemical fertilizers and the like, can be avoided.

Owner:SHENZHEN XIANGNONG INNOVATION TECH CO LTD

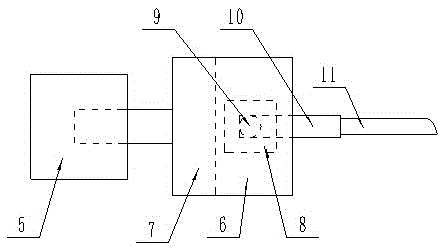

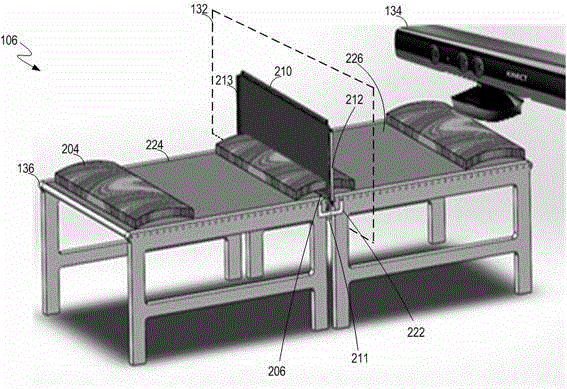

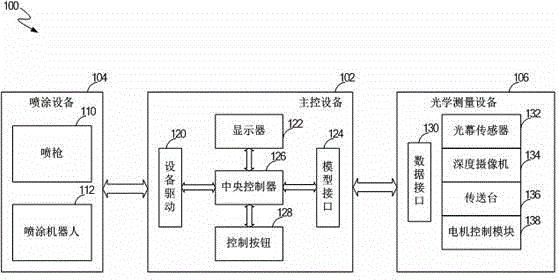

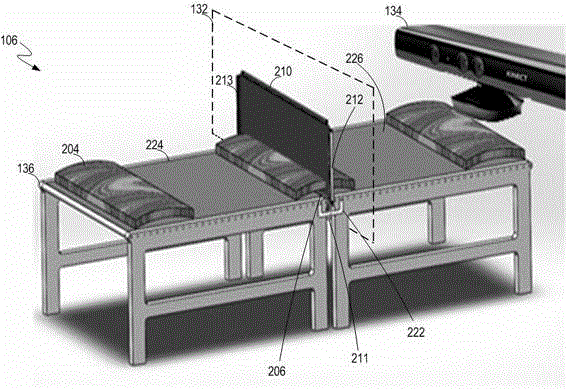

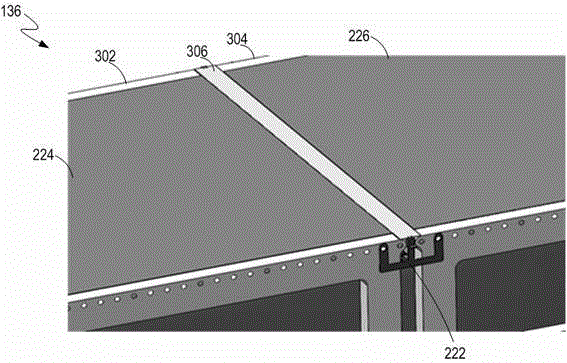

Optical measurement device for setting spraying path of spraying robot

ActiveCN104525424ASimple and fast operationImprove spraying accuracySpraying apparatusOptical detectionOptical measurementsTransmitter

The invention discloses an optical measurement device for setting a spraying path of a spraying robot. The optical measurement device comprises a conveying table, a light curtain sensor, a deep video camera and multiple data interfaces. The conveying table is used for conveying a sprayed workpiece from one end of the conveying table to the other end of the conveying table. The light curtain sensor comprises two groups of light curtain transmitters and receivers, and the two groups of light curtain transmitters and receivers are used for measuring and recording the projection view of the first side of the sprayed workpiece and the projection view of the second side of the sprayed workpiece respectively when the sprayed workpiece is conveyed through the conveying table. The deep video camera is used for measuring and recording the projection view of the third side of the sprayed workpiece according to the distance difference between the sprayed workpiece and the background of the conveying table. The projection view information of the first side, the second side and the third side is transmitted to a main control device through the multiple data interfaces, and the spraying path of the spraying robot is calculated through the main control device according to the projection views.

Owner:成都思达特电器有限公司

Drug advertisement design production line with automatic color changing function

The invention discloses a drug advertisement design production line with the automatic color changing function. The drug advertisement design production line comprises a base. A through groove is formed in the upper surface of the base in the length direction of the base, a conveying mechanism is arranged in the through groove, a drug placing mechanism, a hot-pressing sealing mechanism and a color-changing advertisement spraying device are sequentially arranged on the upper surface of the base in the length direction of the base, and a control cabinet is arranged on the side surface of the base and electrically connected with the conveying mechanism, the drug placing mechanism, the hot-pressing sealing mechanism and the color-changing advertisement spraying device. The drug advertisement design production line has the advantages of being simple in structure and high in practicability.

Owner:赵媛媛

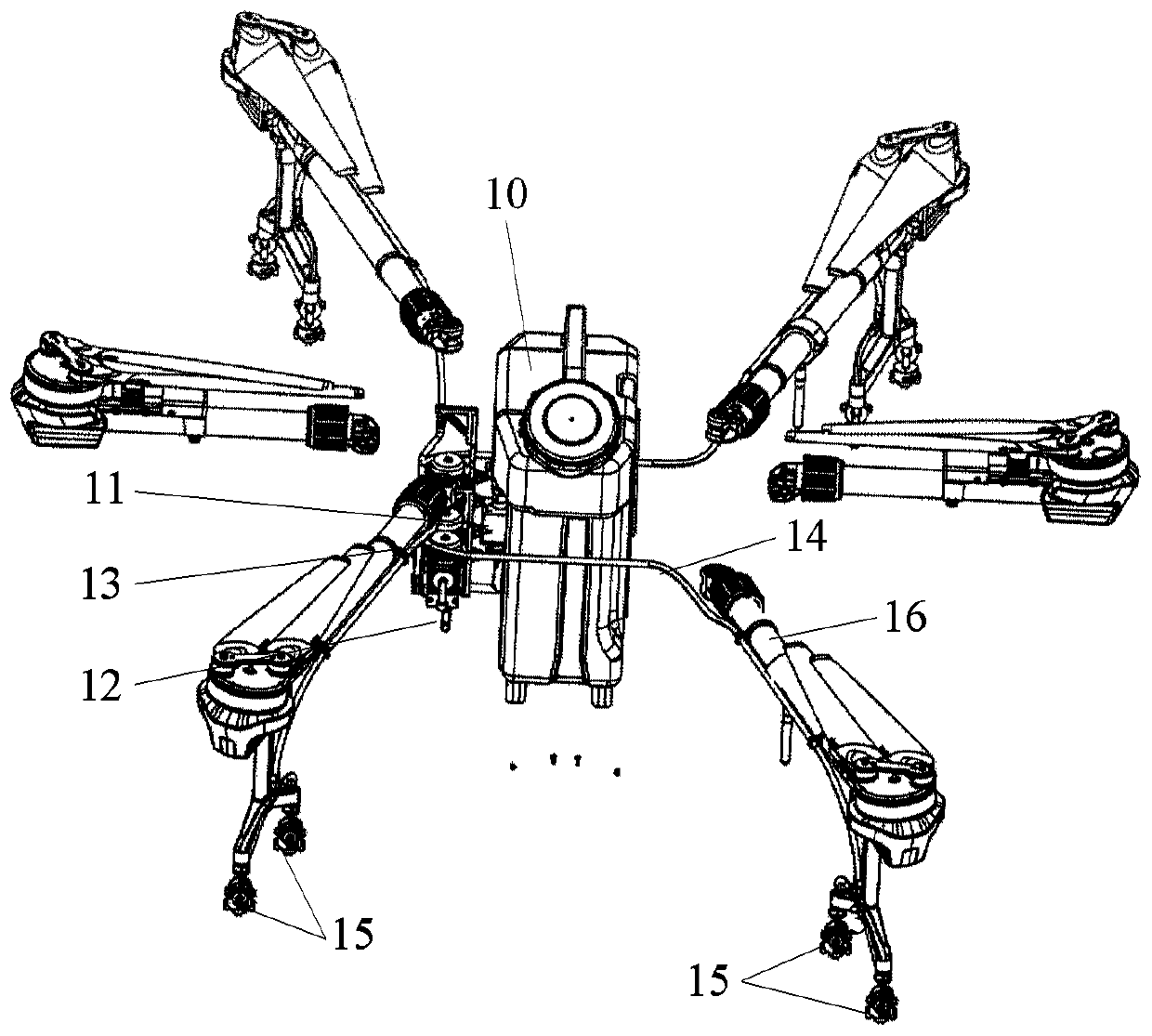

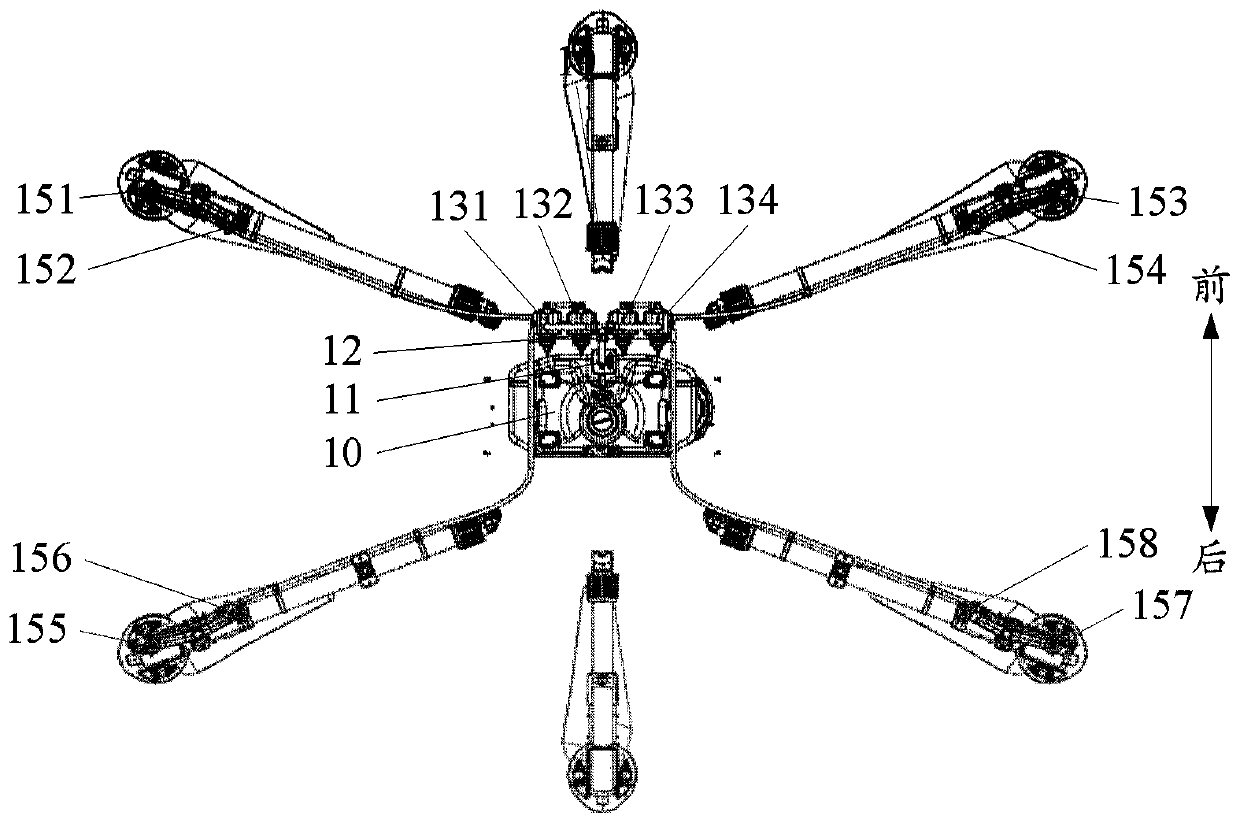

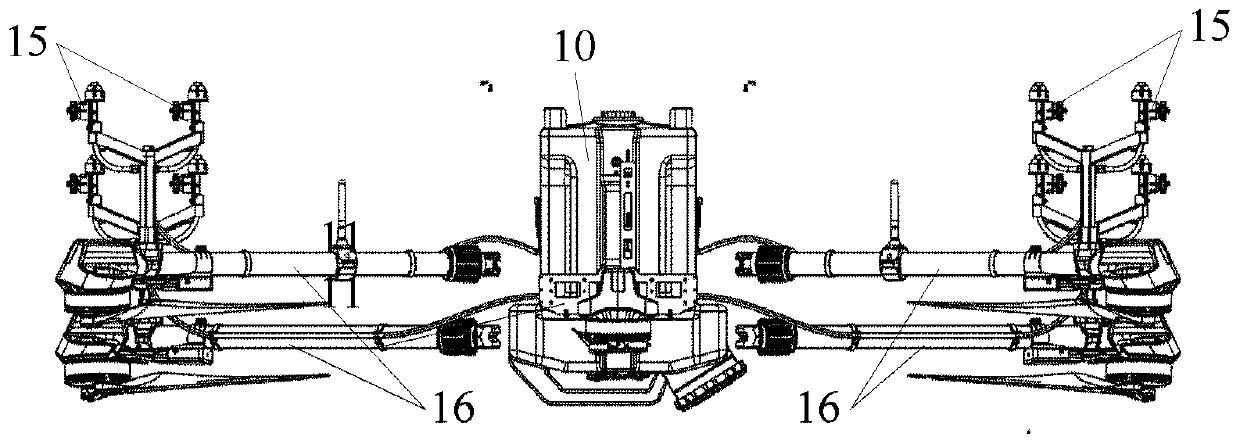

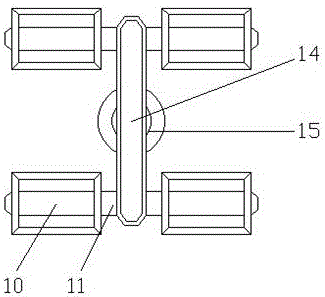

Spraying system and plant protection unmanned aerial vehicle

ActiveCN110876257AIncrease spray flowImprove spraying accuracy and uniformity of sprayingAircraft componentsInsect catchers and killersAutomotive engineeringAgricultural engineering

Provided are a spraying system and a plant protection unmanned aerial vehicle. The plant protection unmanned aerial vehicle comprises a vehicle body, a vehicle head and a plurality of vehicle arms (16) connected with the vehicle body. A spraying system comprises a liquid storage tank (10), a water distributor (12), a water pump (13), a liquid pipe (14) and a spray head (15); a liquid outlet of theliquid storage tank (10) is connected with a plurality of water pumps (13) through a water segregator (12), a water outlet of each water pump (13) is connected with a plurality of spray heads (15) through a liquid pipe (14), and the spray heads (15) connected with the same water pump (13) are all located on the machine arm (16) on the same side or on the same machine arm (16). According to the spraying system, the spraying width and the whole spraying flow can be effectively increased, calibration and adjustment of the spraying flow of the single-side spray head of the spraying system can beachieved, then the spraying precision and the spraying uniformity are improved, and the requirement for precise spraying operation of the plant protection unmanned aerial vehicle is met.

Owner:SZ DJI TECH CO LTD

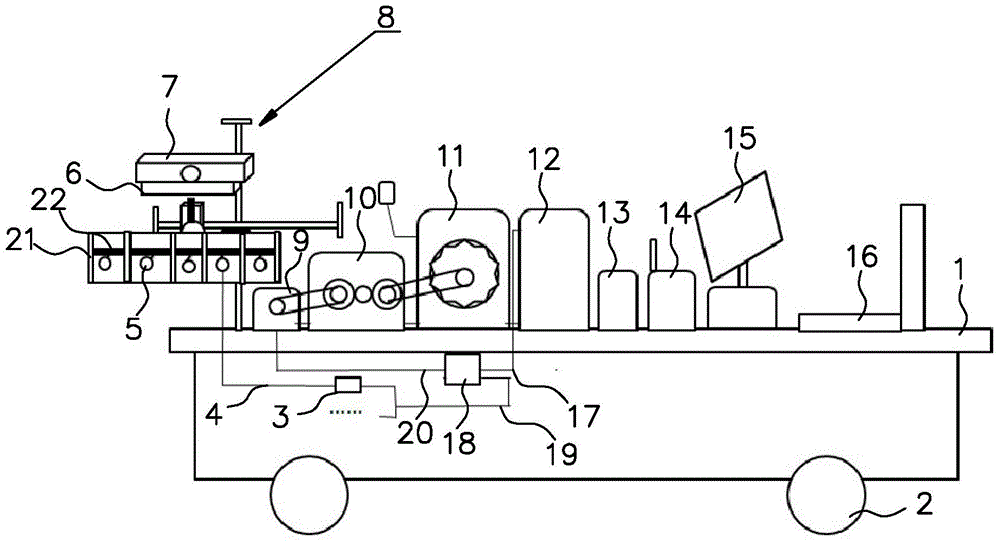

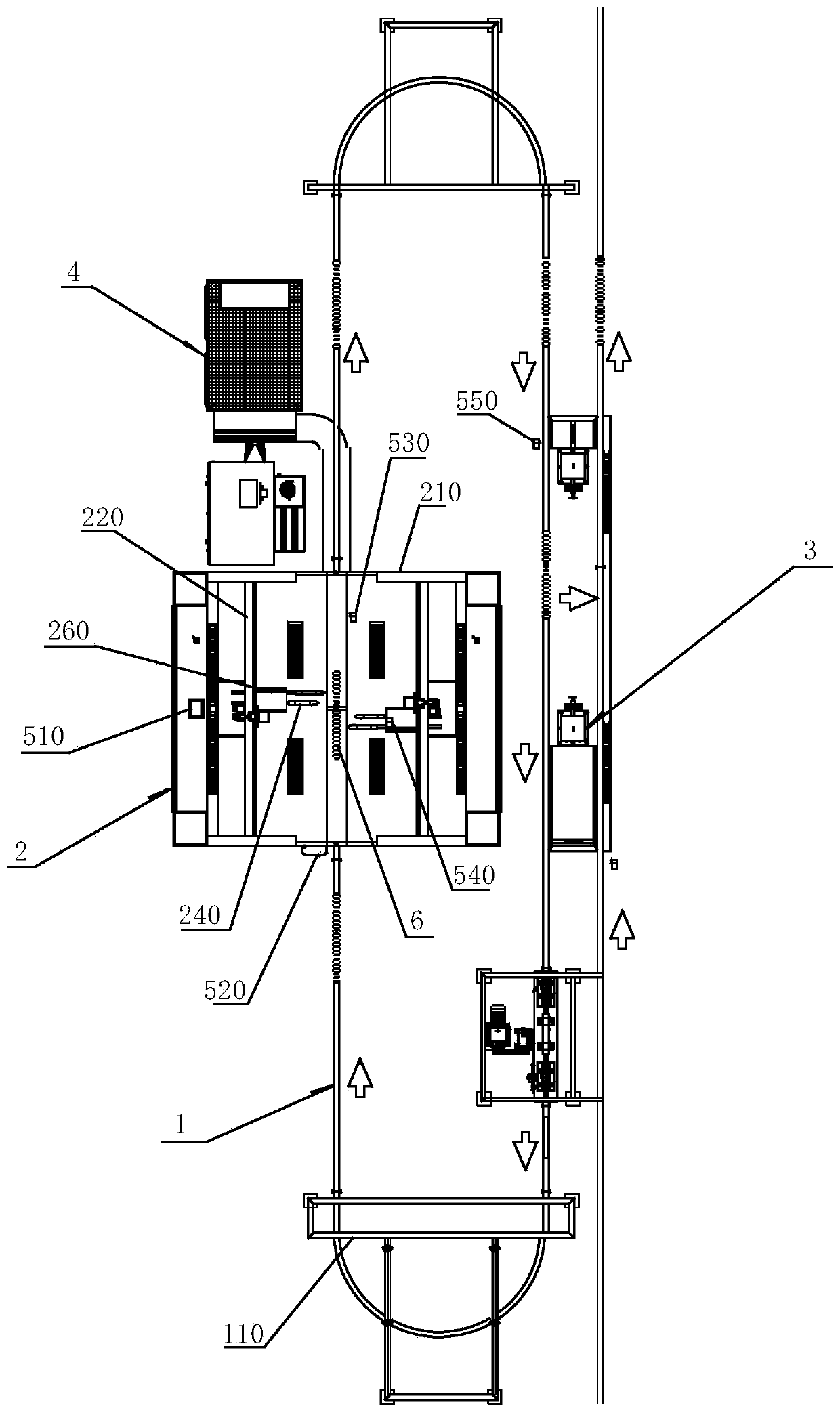

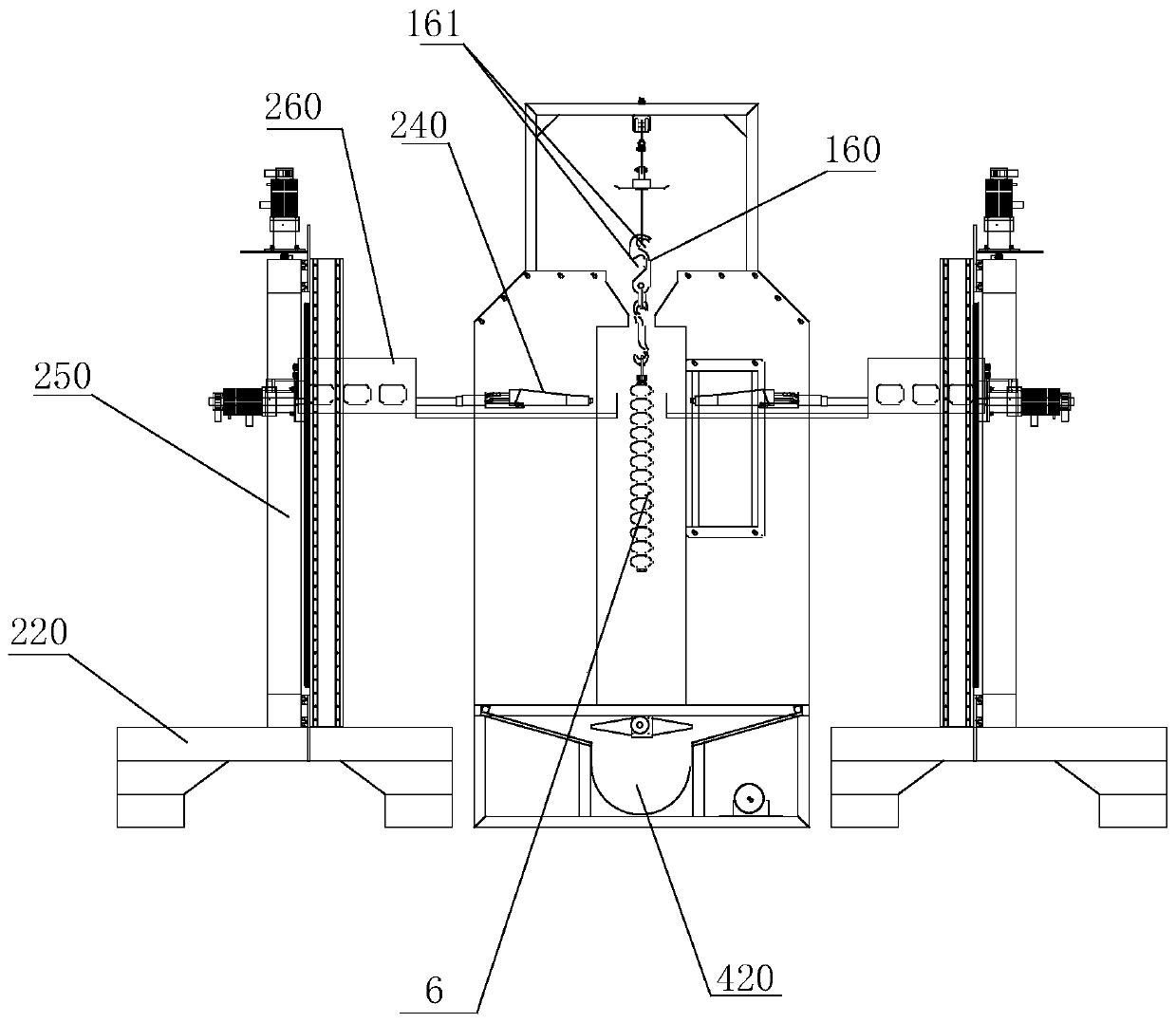

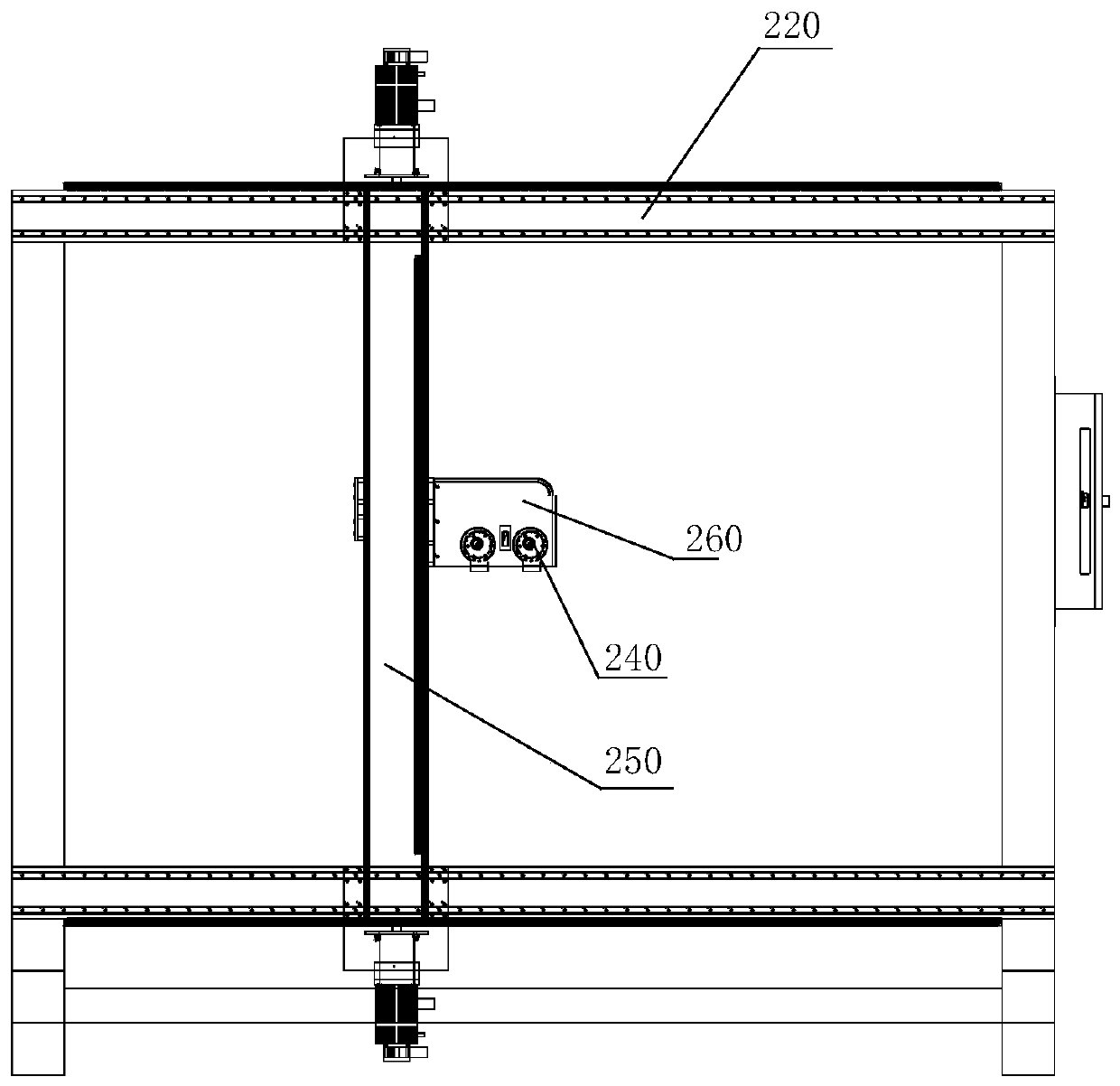

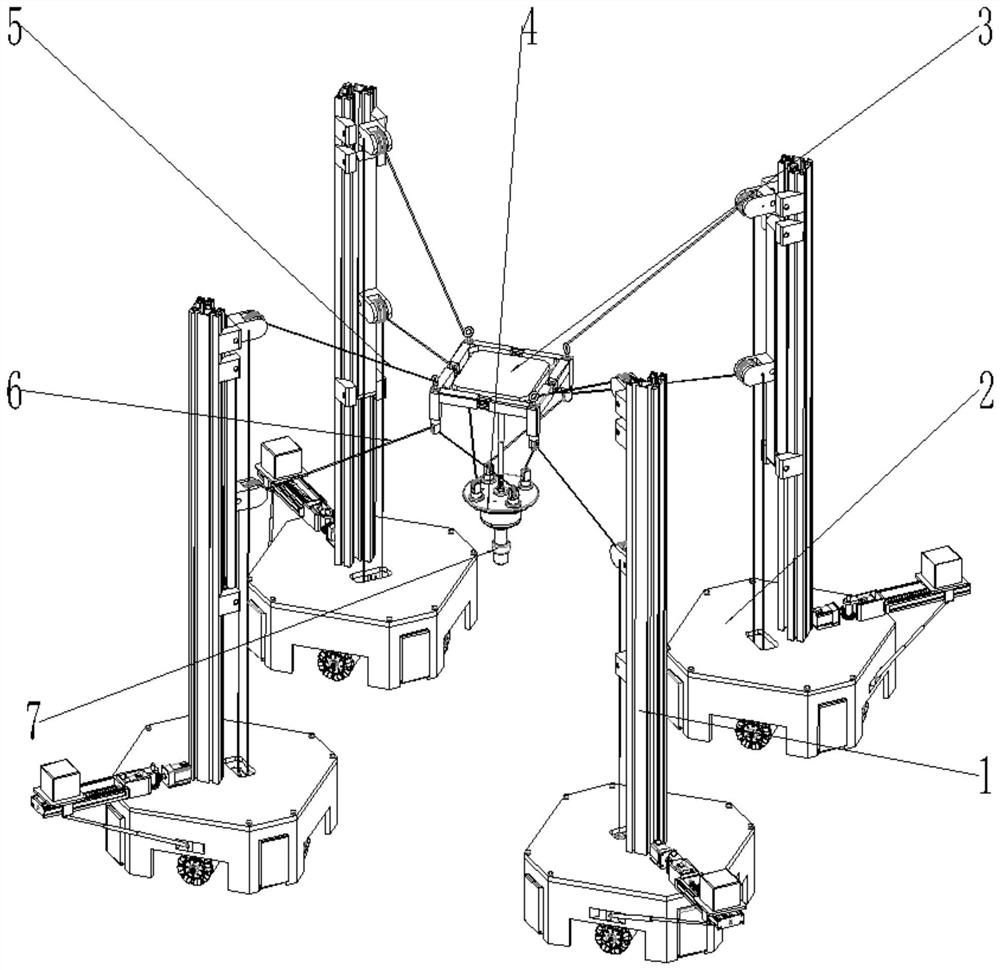

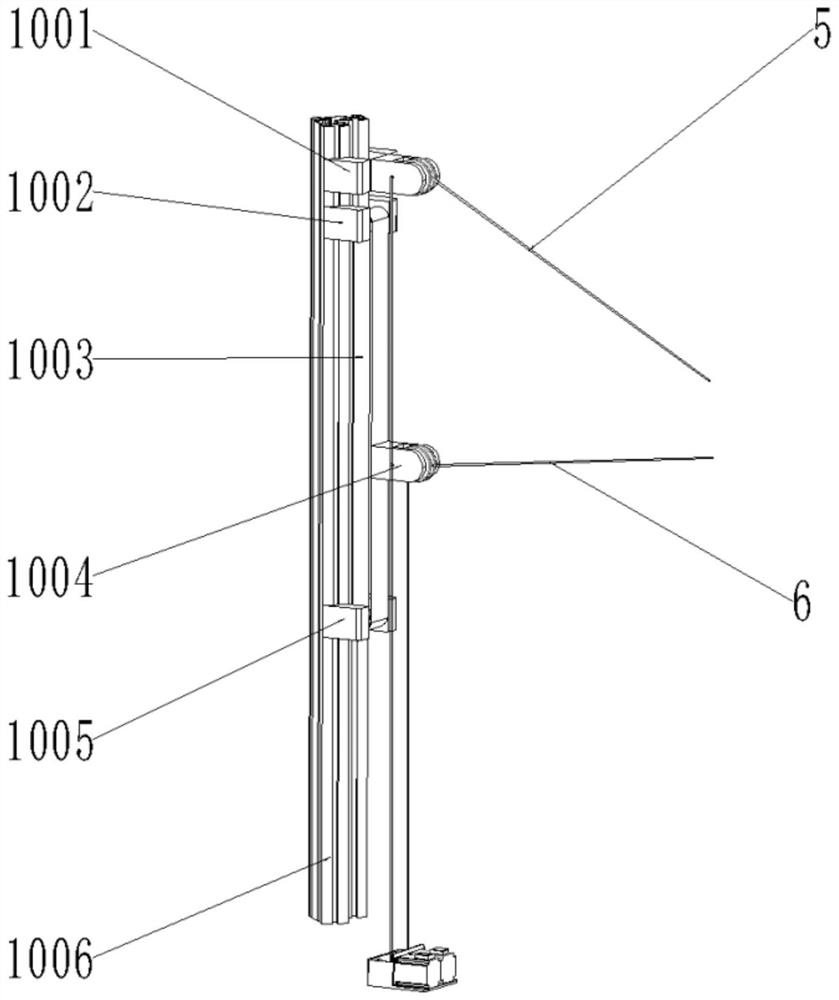

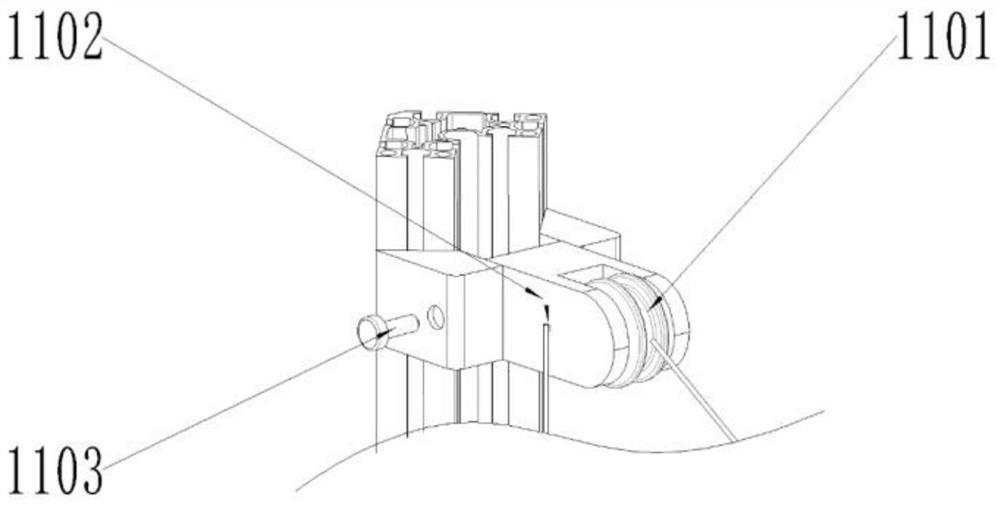

Movable electro-hydraulic composite drive spraying robot with large working space

ActiveCN113171906ALarge working spacePrevent rolloverSpraying apparatusManipulatorBalancing machineControl engineering

The invention discloses a movable electro-hydraulic composite drive spraying robot with a large working space. The movable electro-hydraulic composite drive spraying robot comprises a plurality of movable bases, the movable bases are matched with one another and are used for bearing drive rope adjusting modules, profile struts in the drive rope adjusting modules are respectively fixed on the movable bases, an operation space is defined by the multiple movable bases, a movable adjustable auxiliary motion platform is erected in the operation space, a rotary motion platform is arranged below the adjustable auxiliary motion platform, the adjustable auxiliary motion platform is connected with the rotary motion platform through a hydraulic push rod, a spray gun is installed on the bottom end face of the rotary motion platform, and a balance mechanism and a fixed supporting mechanism which are used for balancing the traction force of a rope and maintaining the balance of the mechanism are further installed on the movable bases. The movable electro-hydraulic composite drive spraying robot is reasonable in structural design, multi-degree-of-freedom movement in a large working space is achieved, meanwhile, interference between a traction rope and a machined workpiece is avoided, and the applicability of equipment is improved.

Owner:HEFEI UNIV OF TECH

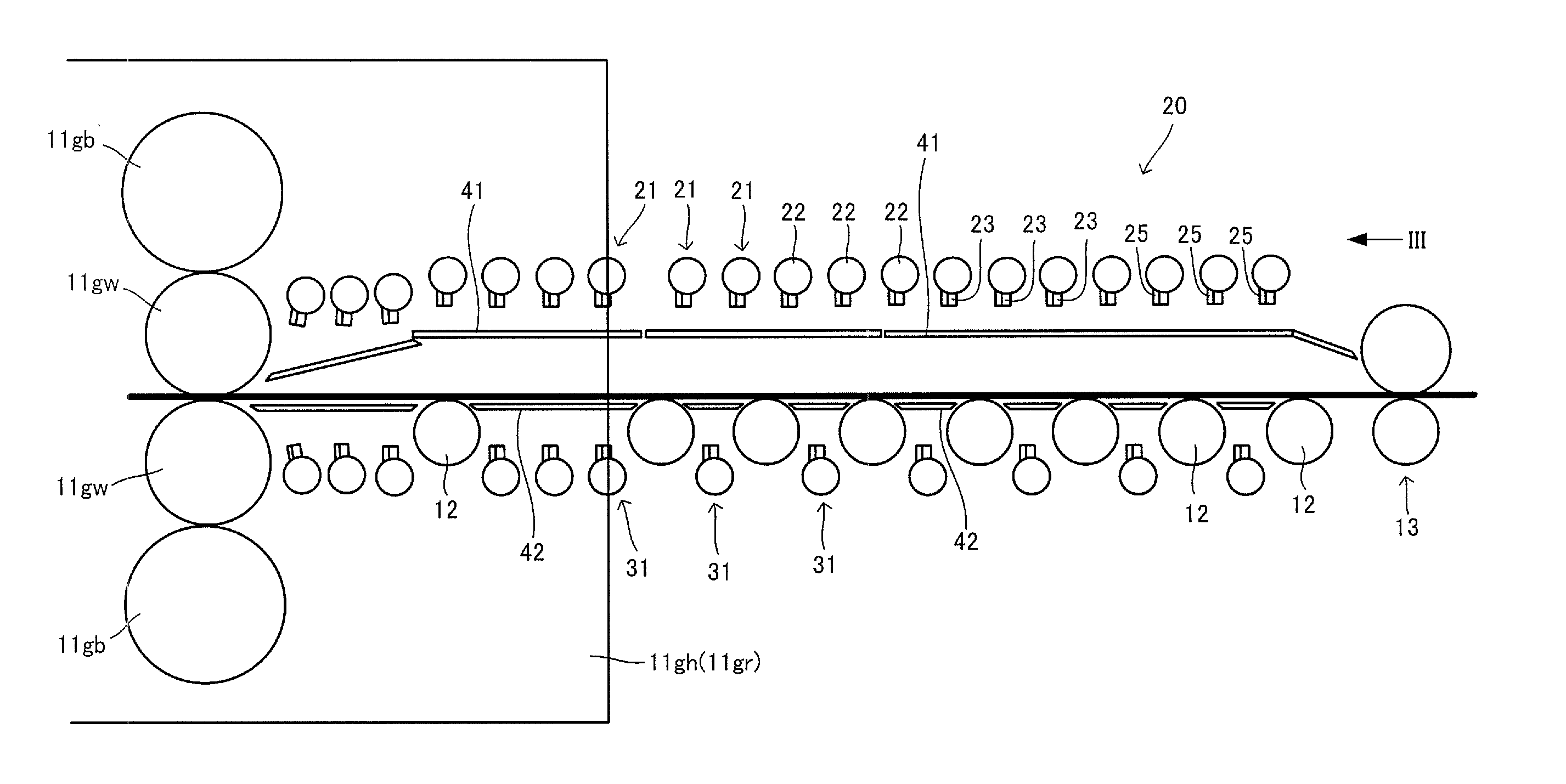

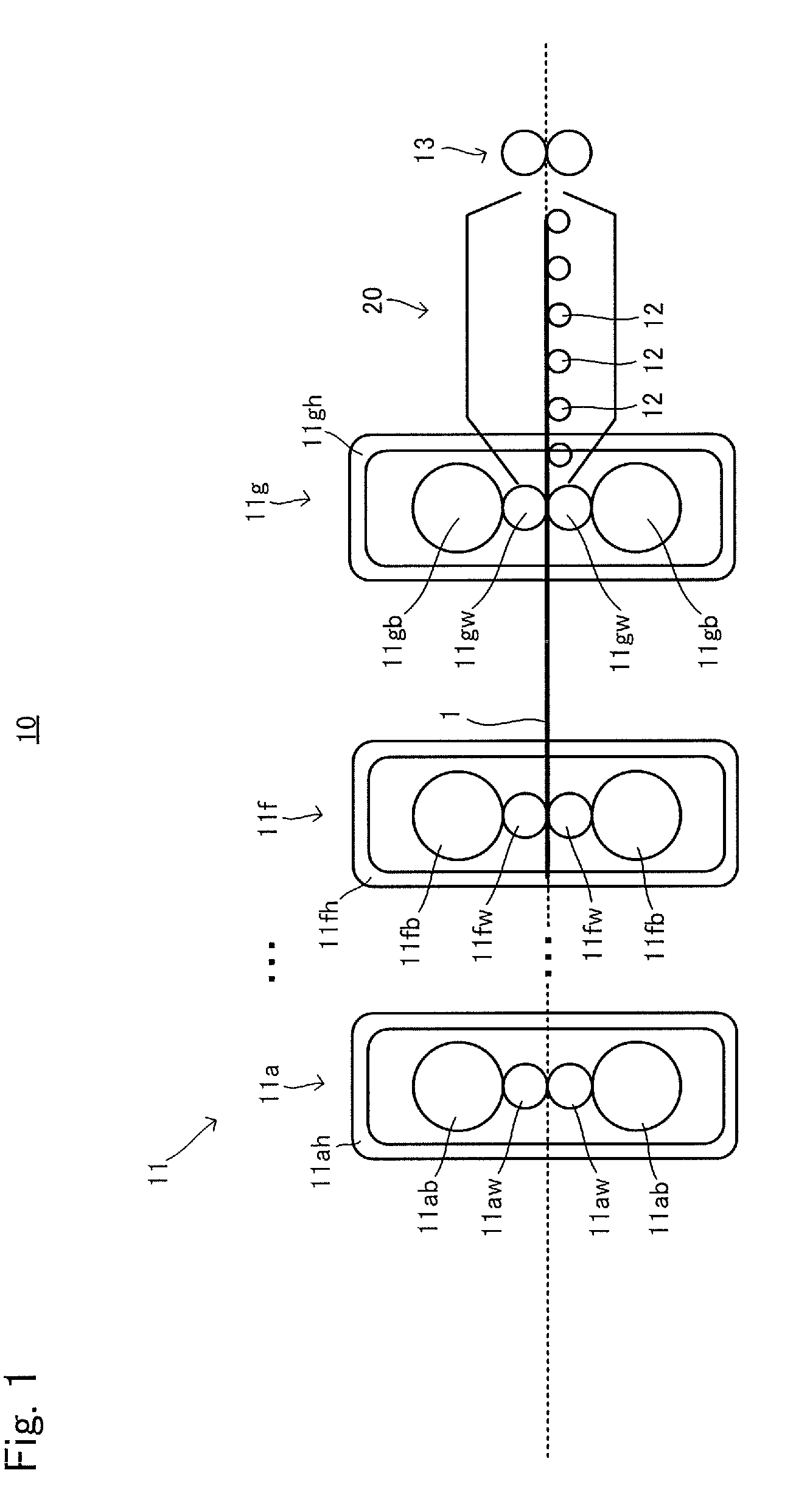

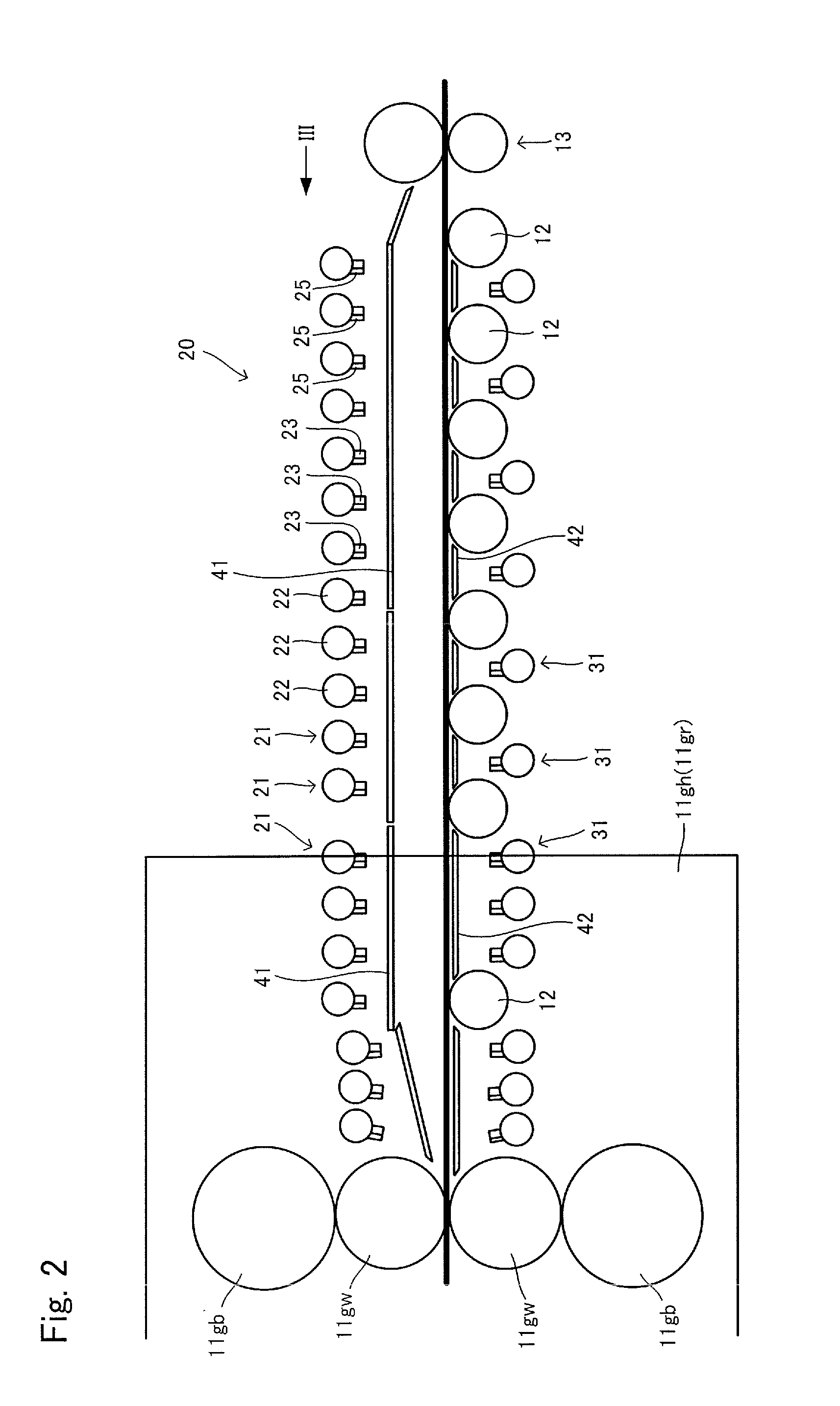

Nozzle header, cooling apparatus, manufacturing apparatus of hot-rolled steel sheet, and method for manufacturing hot-rolled steel sheet

InactiveUS20150224551A1Improve cooling effectAvoid deformationShaping toolsLiquid surface applicatorsManufactured apparatusSpray nozzle

Provided is a nozzle header which sprays pressurized water to a high-temperature object, capable of inhibiting a member provided to spray nozzles from being deformed or damaged by heat at the time of operation, caused by radiation heat from the high-temperature object. The nozzle header for spraying water to a targeted object includes a header which supplies pressurized water, one or more of spray nozzles which spray the pressurized water supplied from the header, and a heat removal structure attached so as to be in contact with at least one of the spray nozzles, wherein the heat removal structure includes a coolant passage through which a cooling medium for cooling the heat removal structure itself and the spray nozzles passes.

Owner:PRIMETALS TECHNOLOGIES JAPAN LTD

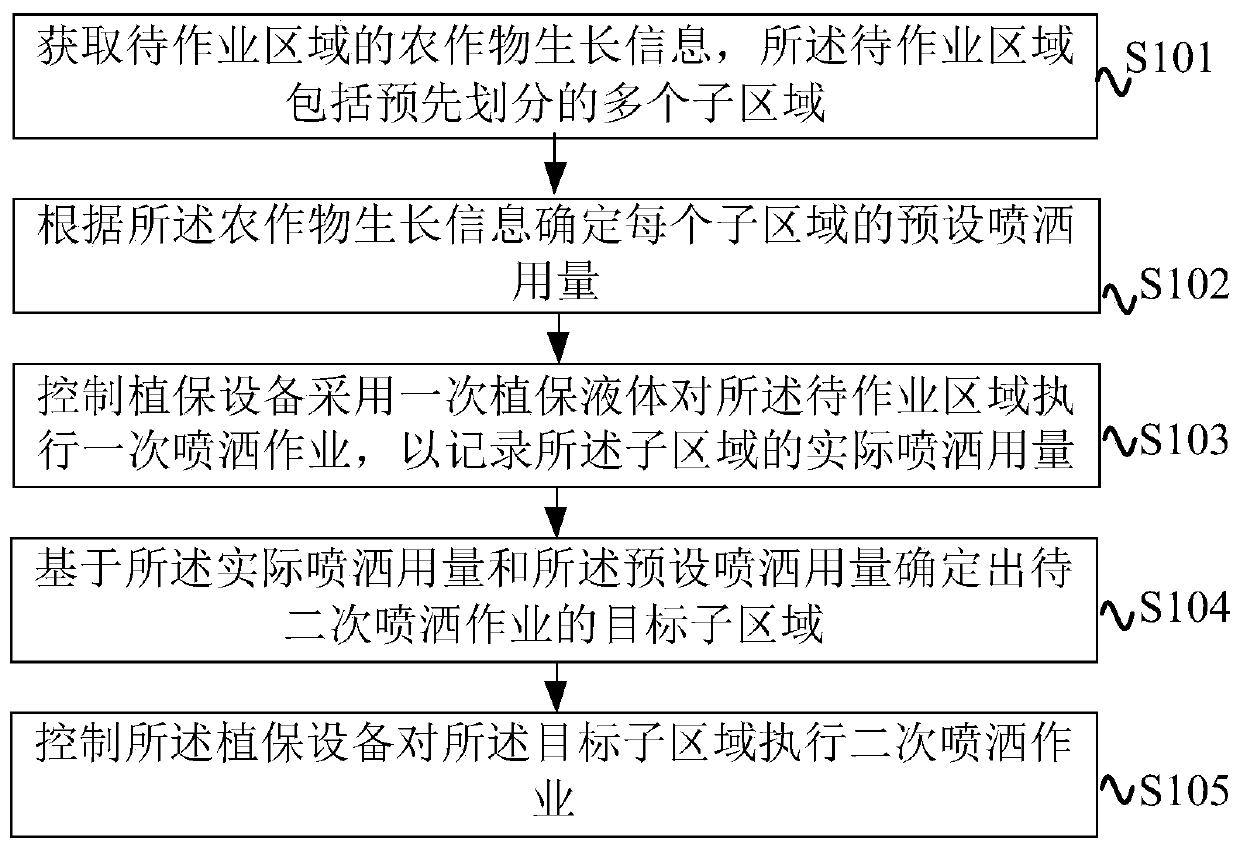

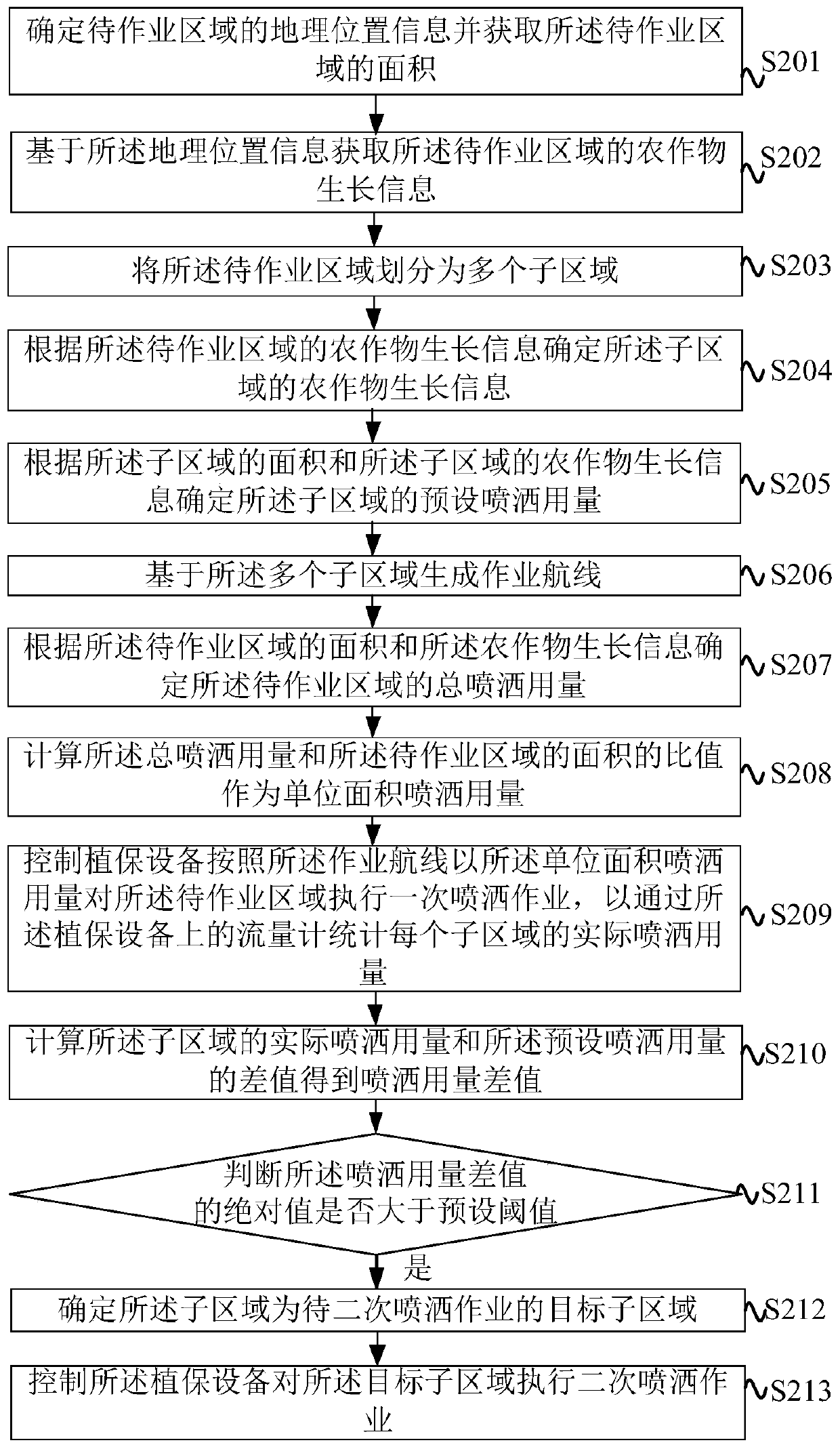

Spraying operation control method and device, ground station and storage medium

ActiveCN110989684AGuaranteed normal growthImprove spraying accuracyPosition/course control in three dimensionsGrowth plantAgricultural science

The embodiment of the invention discloses a spraying operation control method and device, a ground station and a storage medium. The method comprises the steps of obtaining crop growth information ofa to-be-operated region, wherein the to-be-operated region comprises a plurality of pre-divided sub-regions; determining a preset spraying amount of each sub-region according to the crop growth information; controlling plant protection equipment to perform primary spraying operation on the to-be-operated region by adopting a primary plant protection liquid so as to record the actual spraying amount of the sub-regions; determining a target sub-region to be subjected to secondary spraying operation based on the actual spraying amount and a preset spraying amount; and controlling the plant protection equipment to execute secondary spraying operation on the target sub-region. According to the method, the preset spraying amount of each sub-region can be determined according to the condition ofuneven plant growth, whether secondary spraying operation is executed or not can be determined according to the actual spraying amount and the preset spraying amount, the problem that crop growth is affected due to uneven spraying is effectively solved, the spraying accuracy is improved, and the plant protection effect is improved.

Owner:GUANGZHOU XAIRCRAFT TECH CO LTD

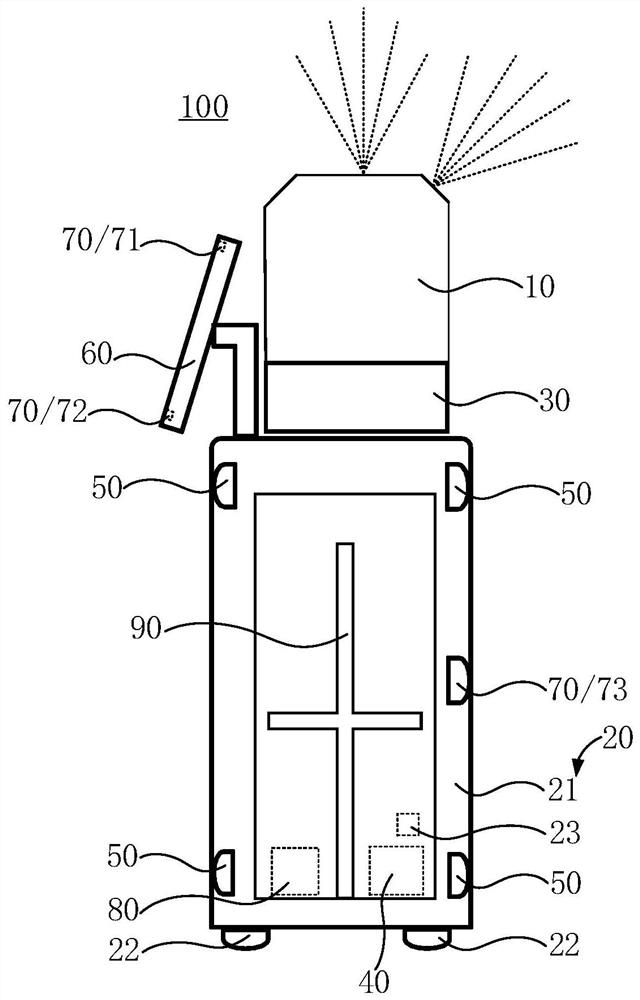

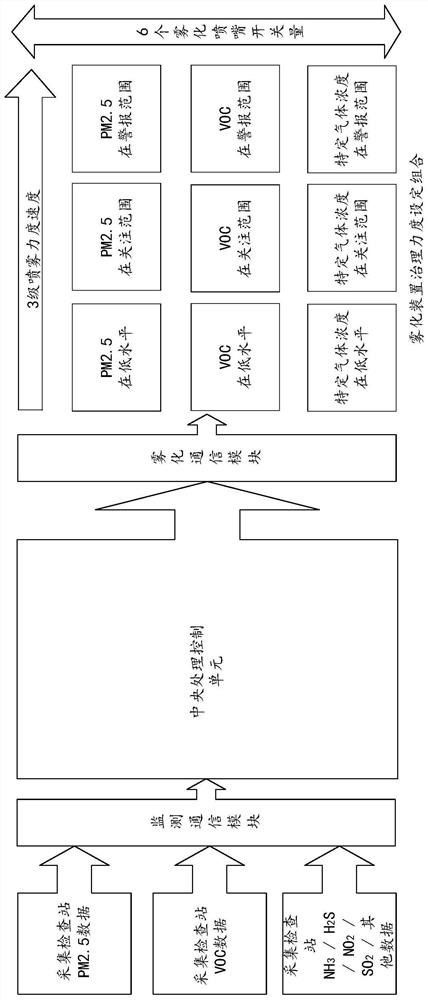

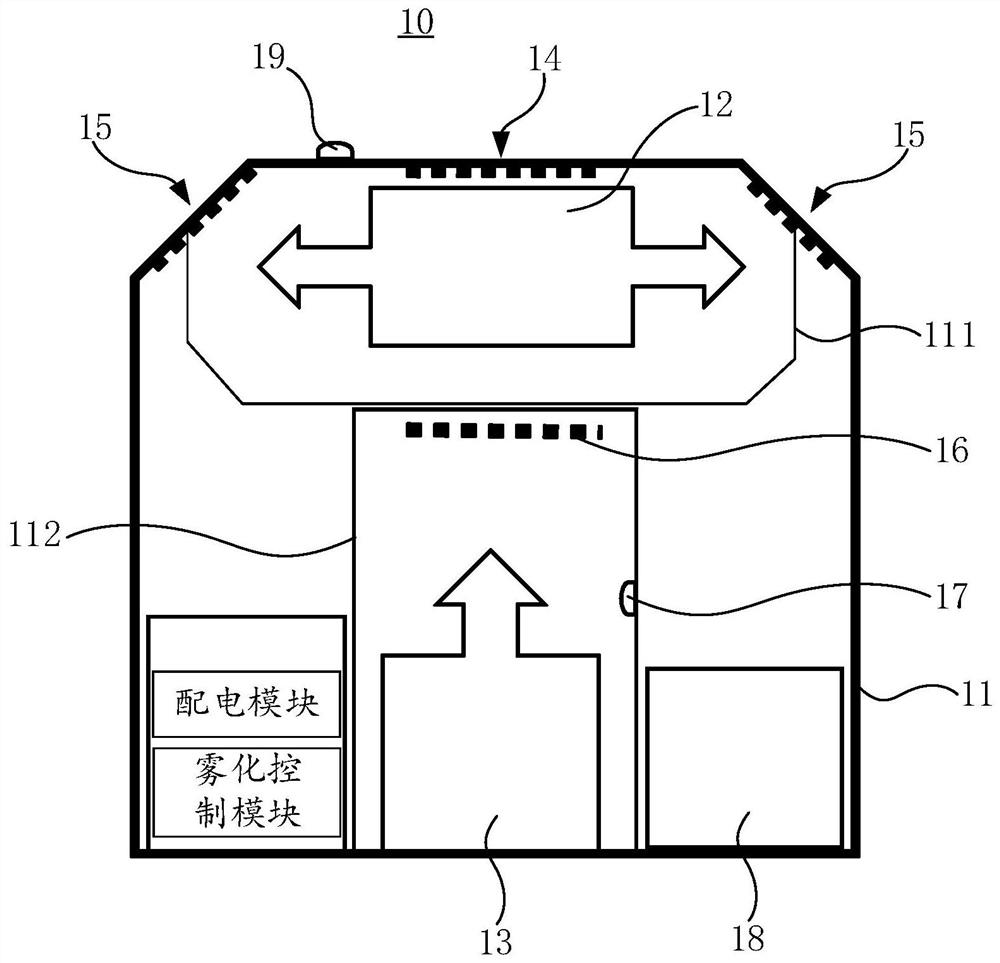

Self movable type indoor air purifying equipment and indoor air purifying method

ActiveCN111678214AImprove spraying accuracyUniform disinfection effectMechanical apparatusSpace heating and ventilation safety systemsAutomotive engineeringIndoor air

Owner:WOOFAA SMART TECH JIANGMEN CO LTD

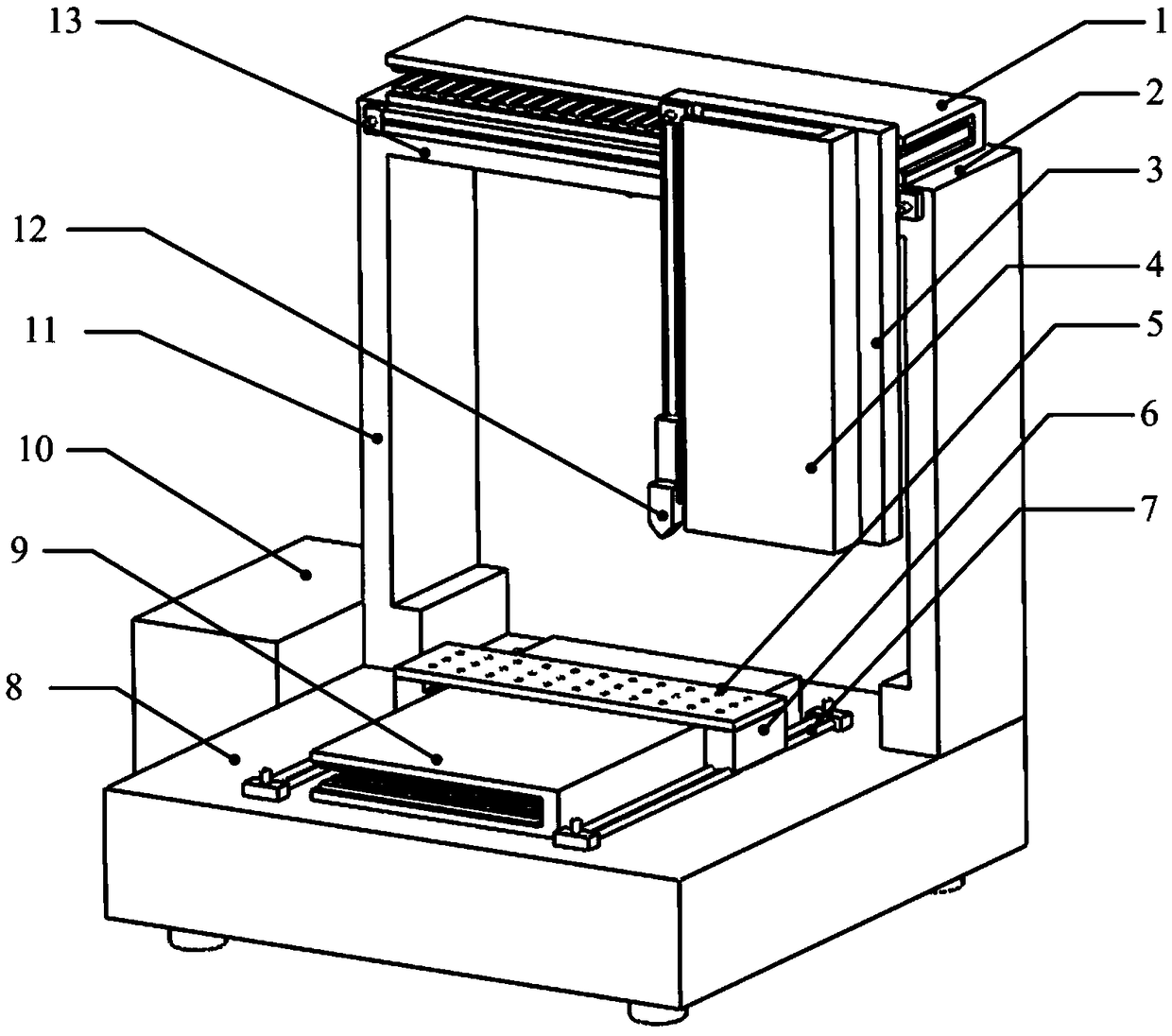

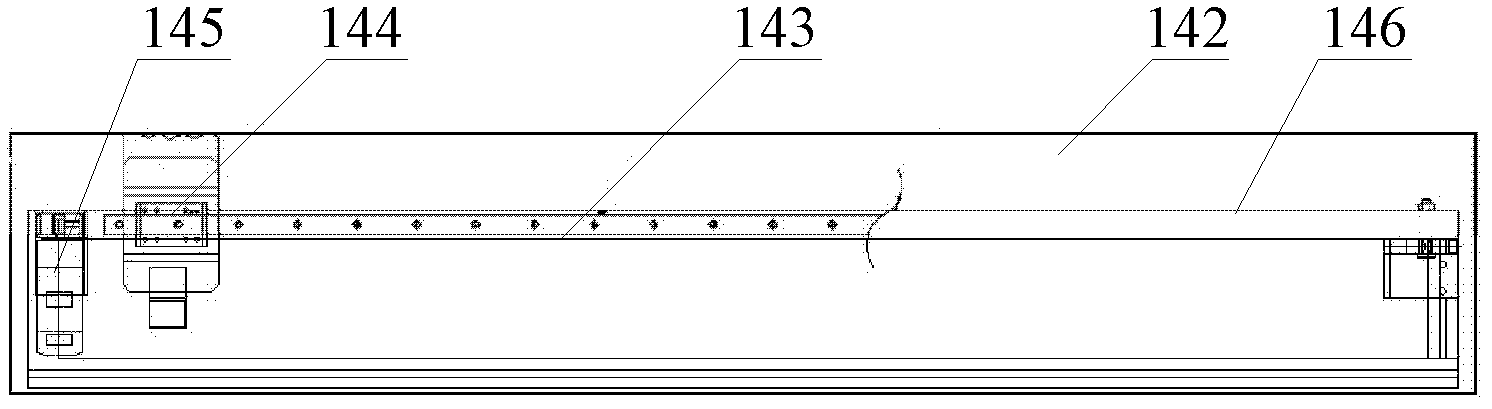

Solution coating machine

ActiveCN103170432AHigh working reliabilityImprove mobile flexibilityLiquid surface applicatorsCoatingsCentrifugationPulp and paper industry

The invention discloses a solution coating machine, an inner casing body is provided at the central section of a frame, a feeding platform passed through the inner casing body is provided at the central section of the frame, a nozzle is provided in the inner casing body, a reciprocating mechanism for driving the movement of the nozzle is connected to the nozzle, the movement direction of the nozzle is perpendicular to the feeding direction of the feeding platform, a waste liquid discharge port is provided at the bottom of the inner casing body, and the waste liquid discharge port is positioned at the lower part of the feeding platform; a reservoir and a transfer pump communicated with the nozzle are provided on the frame, a ultrasonic generrator cooperated with the nozzle is provided on the frame, a centrifugation blower fan used for communicating the inner casing body and an external tail gas processing apparatus is provided in the frame, a negative pressure meter is provided in the frame, a negative pressure meter measurement air tube is provided on the inner casing body, and a control module is connected to the negative pressure meter. The solution coating machine has high toxic solution coating work security and coating efficiency.

Owner:ADVANCED SOLAR POWER HANGZHOU

Multi-joint spraying robot

InactiveCN106111404AAvoid damageIncrease freedomSpraying apparatusProduction rateAgricultural engineering

The invention discloses a multi-joint spraying robot. The multi-joint spraying robot comprises a cross arm, a moving device, a sprayer connecting shaft and a rotary disc. Stand columns are arranged at the left end and right end of the cross arm. The cross arm is fixed to the inner side of the moving device. A third joint is installed on the outer side of a second joint. The third joint is connected with a lifting shaft through a fourth joint. The lower side of the sprayer connecting shaft is connected with sprayers. A connecting plate is arranged at the upper end of the rotary disc. Revolution tables are fixed to the upper end and lower end of the connecting plate, and rotation tables are installed on the outer sides of the revolution tables. The multi-joint spraying robot is provided with multiple joints, the degree of freedom is high, and the spraying robot is suitable for working at any trajectory and angle, high in flexibility, high in spraying precision and high in spraying speed. Through cooperation with the rotary tables, the production rate is greatly increased. By means of free programming, automation work can be completed, operation is easy and convenient, manual operation can be replaced, and harm to human health by paint is reduced.

Owner:WUXI XINGUANG COMP INSTALLATION

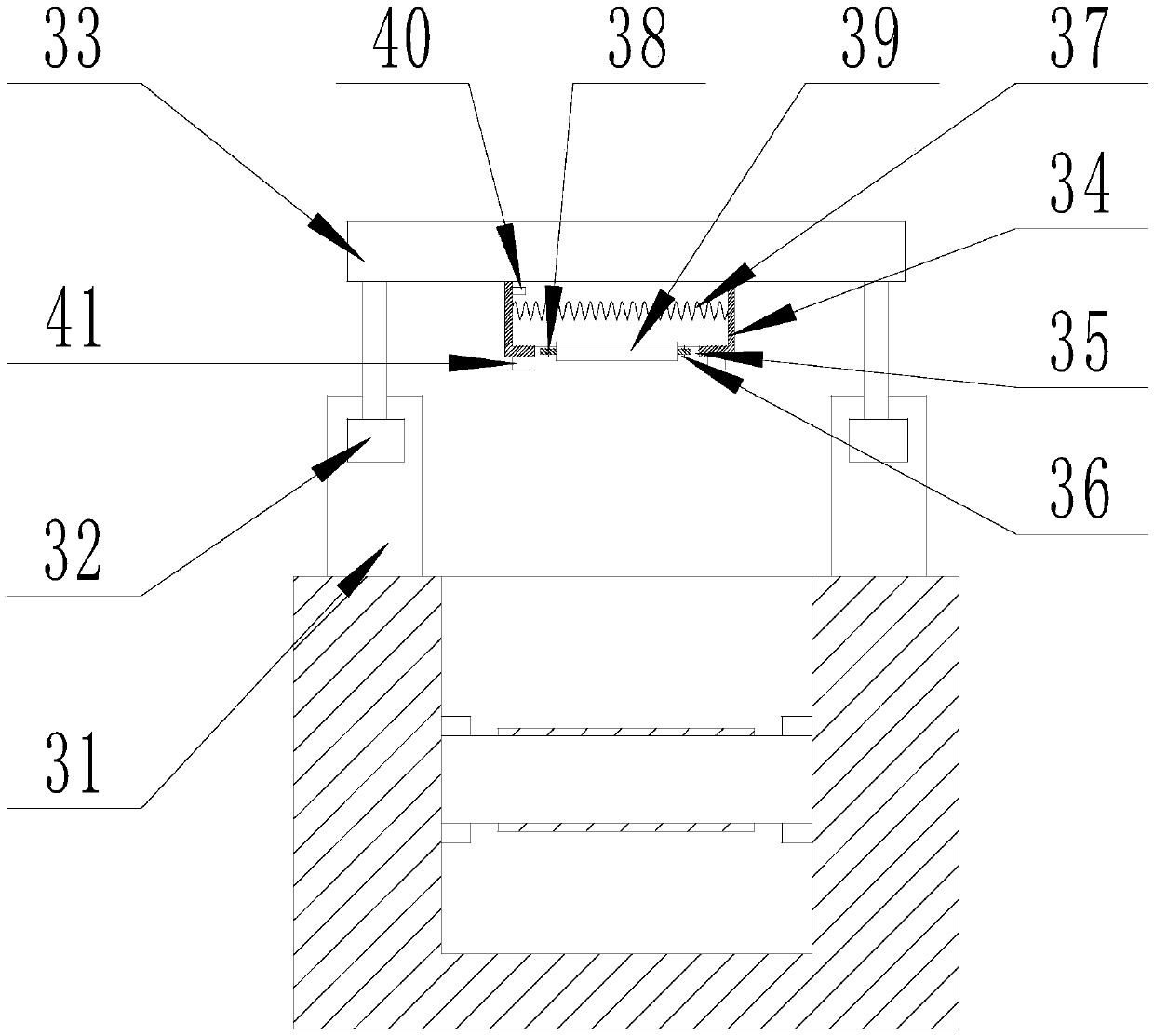

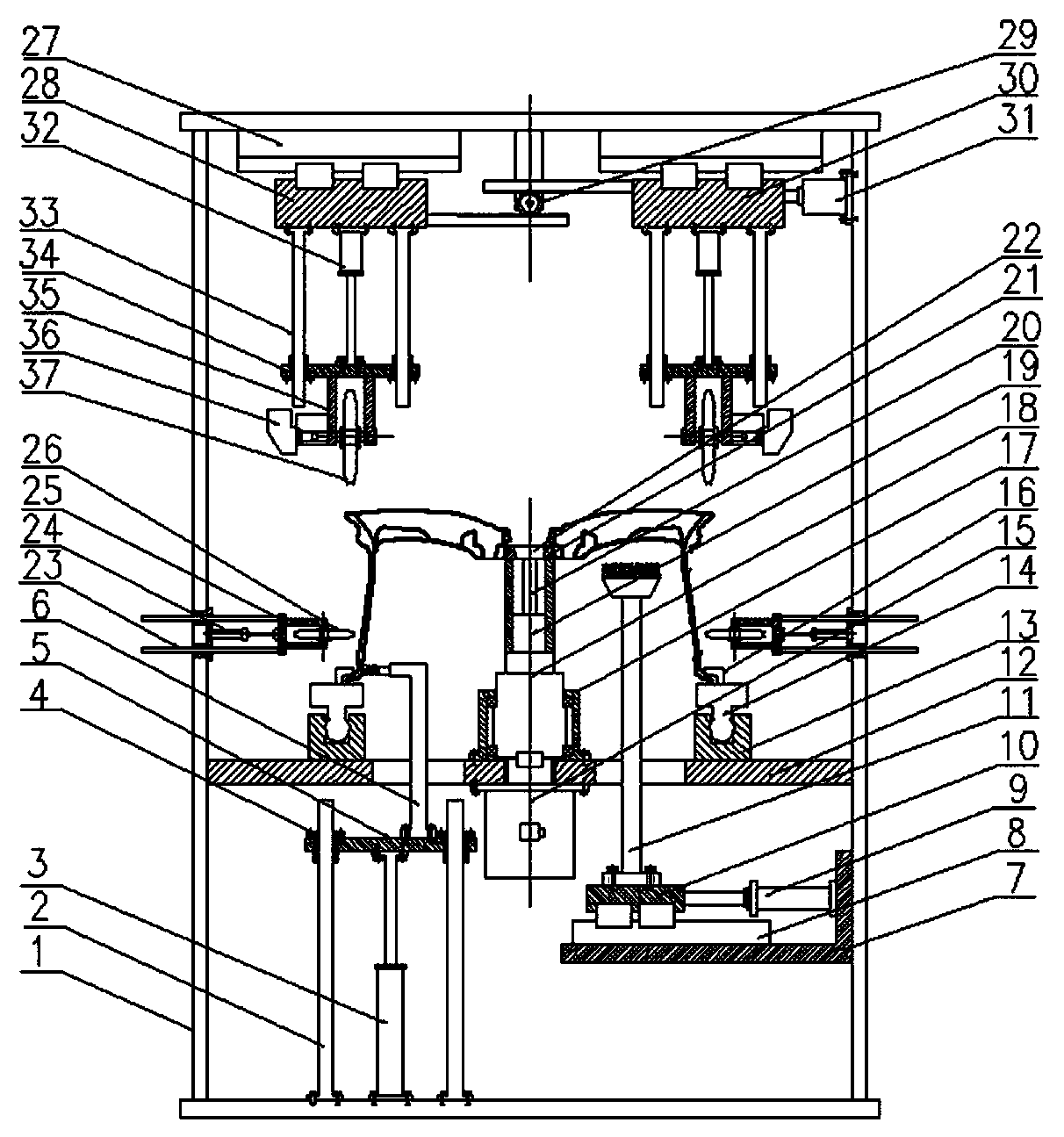

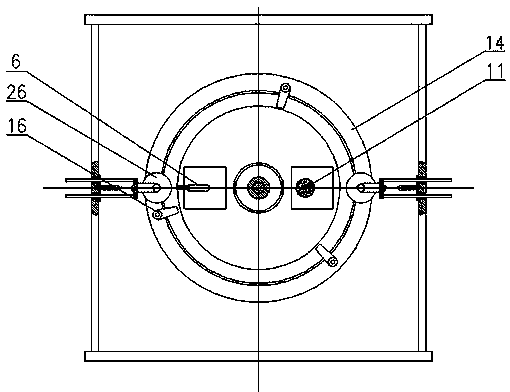

Fixture for wheel spraying strengthening

ActiveCN109225729AAchieve high-precision sprayingEliminate shockSpraying apparatusWheel holding meansPartial systemEngineering

The invention discloses a fixture for wheel spraying strengthening. The fixture is composed of three parts of hub positioning rotary system, a wheel auxiliary system and a hard coating sparying system, wherein the hub positioning rotary system determines the axial direction through an inner side wheel flange, determines the radial direction through a central hole, tightly presses through a rotaryangle cylinder and is driven to rotate by a motor, the wheel auxiliary system can assist wheels to rotate and can offset radial direction impacting force and axial direction impacting force and improve spraying precision, and the hard coating spraying system can achieve the spraying strengthening of wheels with different dimensions by adjusting the position of a spraying tube. Three systems cooperate mutually, operate collaboratively and form the wheel spraying strengthening fixture cooperatively. By means of the fixture, uniform hard coating spraying of inner flanges and back cavities of spokes of the wheels can be completed, the technical difficult problems of nonuniform spraying, poor roundness and the like are effectively solved, high-precision spraying of the hard coatings of the wheels is achieved, and the fixture has the advantages of novel structure, advanced process and high universality.

Owner:CITIC DICASTAL

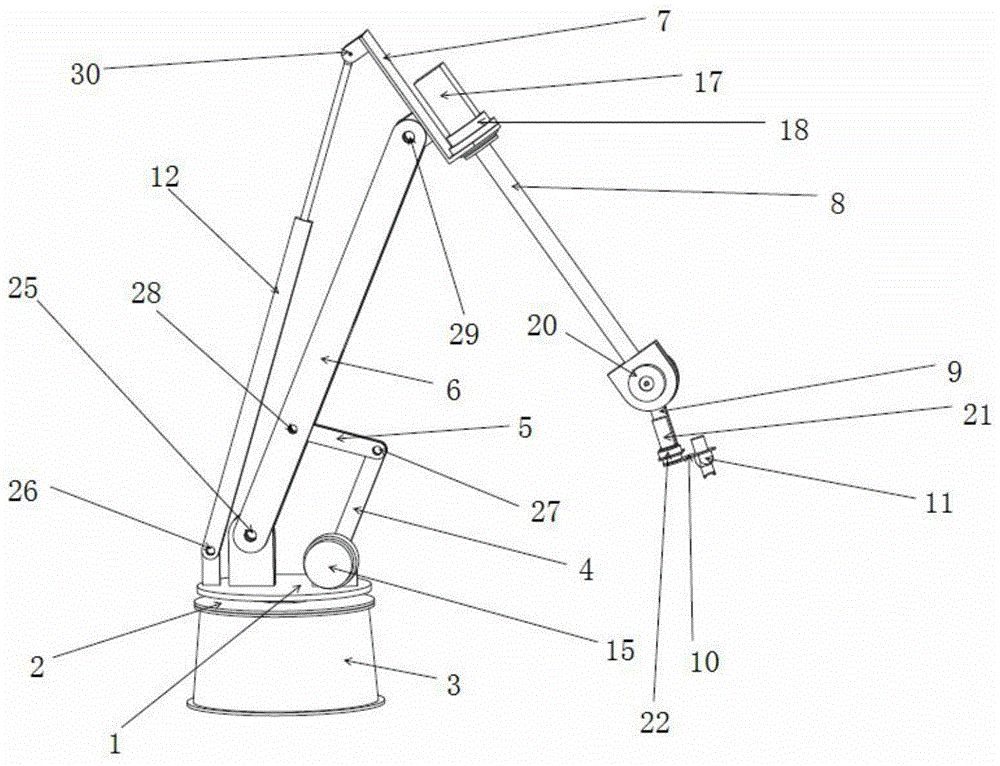

Six-degree-of-freedom seven-rod series-parallel spraying robot

InactiveCN105057148AReduce your weightSmall moment of inertiaSpraying apparatusSix degrees of freedomLinkage concept

The invention provides a six-degree-of-freedom seven-rod series-parallel spraying robot. According to the spraying robot, a driving rod, a linear driver and a support rod are connected with a rotating rack, a driving connecting rod is connected with the driving rod, the other end of the driving connecting rod is connected with the support rod, a movable arm table and the support rod are connected with the linear driver, a rotating arm is connected with the movable arm table, a swing arm is connected with the rotating arm, a sprayer table is connected to the swing arm, and a sprayer is connected to the sprayer table. Single series structure applied by the original robot is replaced by a series-parallel integral structure, so that the rigidity is high. A parallelogram four-linkage mechanism is applied to the six-degree-of-freedom seven-rod series-parallel spraying robot, so that accurate control is easy to realize. The six-degree-of-freedom seven-rod series-parallel spraying robot is suitable for manufacturing various mechanical arms and other engineering machinery.

Owner:GUANGXI UNIV

Method for spraying upper surface and outer side face of workpiece

PendingCN113680555AThe amount of coating remains consistentImprove pass rateSpraying apparatusStructural engineeringManufacturing engineering

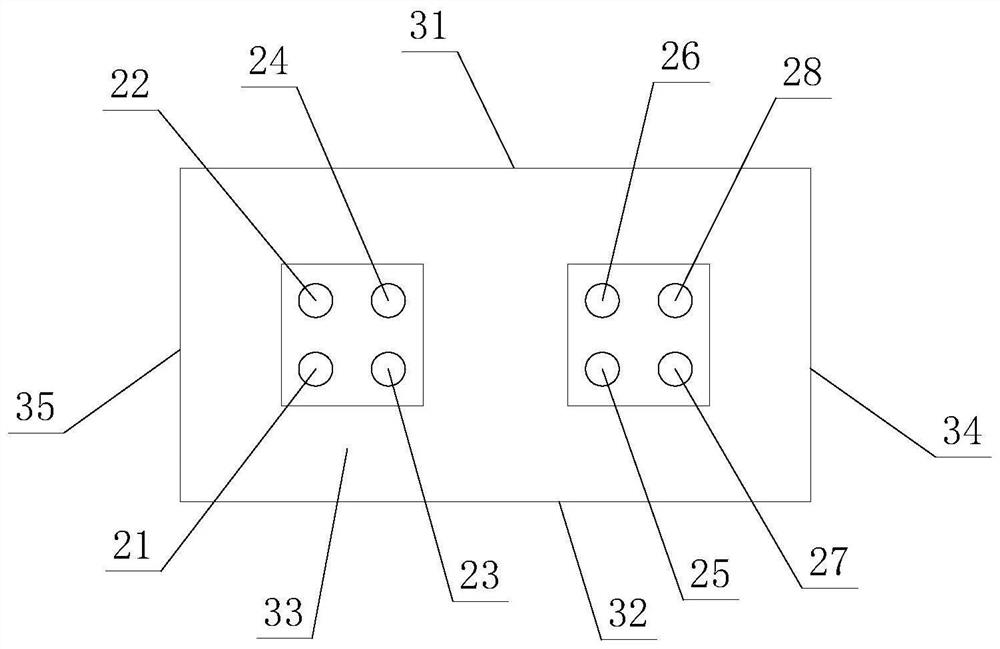

The invention relates to a method for spraying the upper surface and the outer side face of a workpiece. The method comprises the workpiece, a conveying line for conveying the workpiece, a three-dimensional scanning system for scanning the length, the width and the height of the workpiece in the conveying process, a control system for processing scanning information of the three-dimensional scanning system, a first spraying support and a second spraying support, wherein the first spraying support and the second spraying support plan a spraying path through the control system; the first spraying support and the second spraying support transversely slide and vertically move in the workpiece conveying direction under the control of the control system; the first spraying support and the second spraying support are each provided with four spraying guns; and in the one-time conveying process of the workpiece, the four spraying guns of the first spraying support and the four spraying guns of the second spraying support spray the upper side face, the lower side face, the upper surface, the front side face and the rear side face of the workpiece respectively. By means of the method, the spraying efficiency and quality of work can be improved, meanwhile, spraying with the height larger than 5cm of the workpiece can be achieved, and practicability is high.

Owner:广东博硕涂装技术有限公司

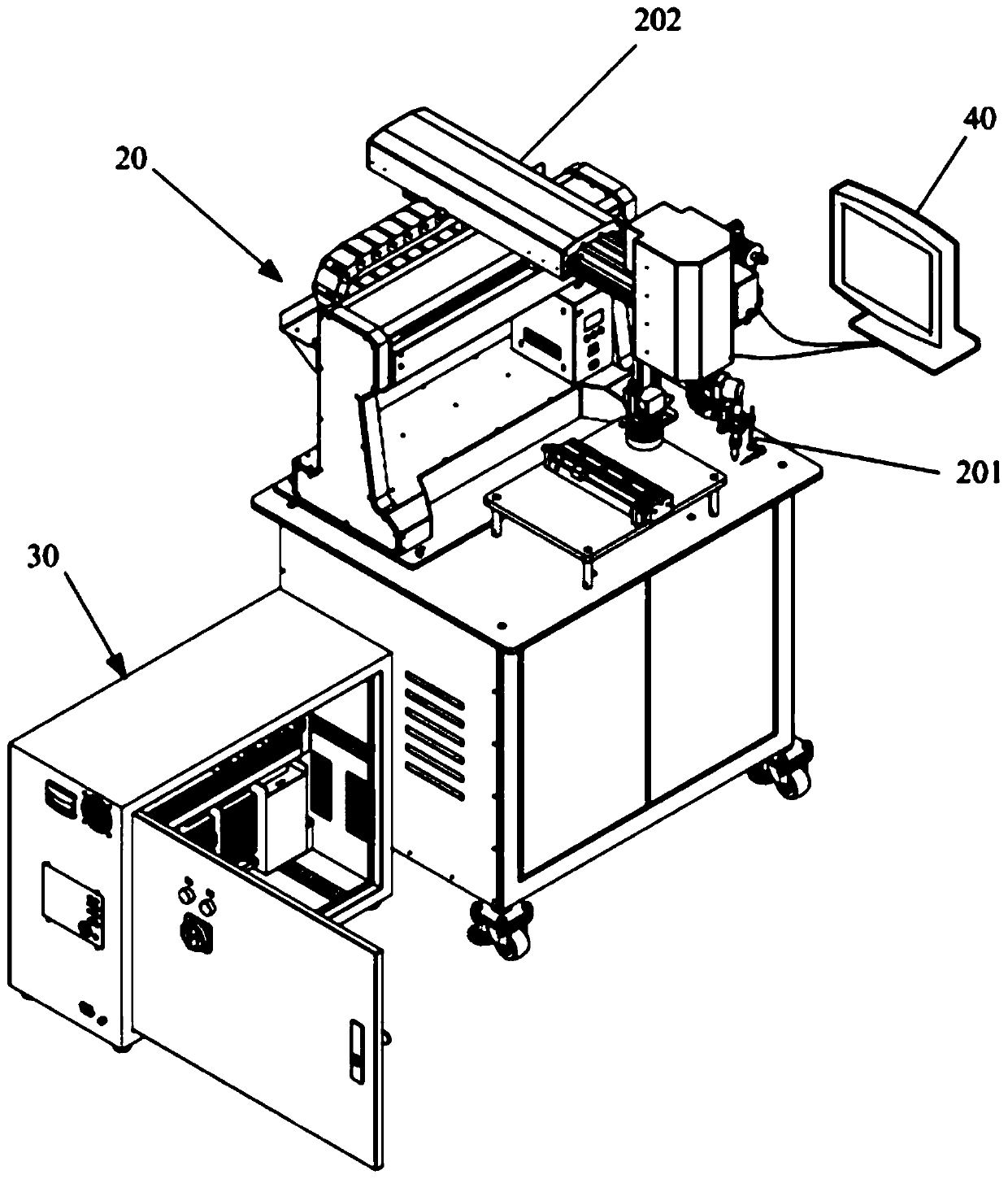

Intelligent robot spraying system

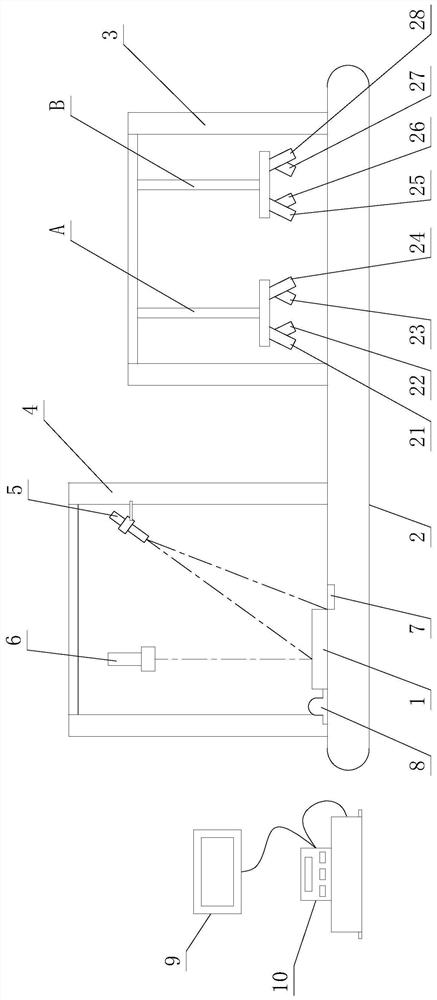

ActiveCN104588243ASimple and fast operationImprove spraying accuracySpraying apparatusOptical measurementsComputer science

The invention discloses an intelligent robot spraying system. The intelligent robot spraying system comprises an optical measurement device, a main control device and a spraying device, wherein the optical measurement device is used for carrying out optical measurement on a sprayed workpiece to obtain a three-dimensional projection view and the size information of the sprayed workpiece and generating workpiece signals representing the three-dimensional projection view and the size information; the main control device is used for receiving the workpiece signals, reading spraying parameters related to a spraying robot, computing a spraying path of the spraying robot according to the workpiece signals and the spraying parameters and generating a spraying order comprising the information of the spraying path; the spraying device is used for carrying out spraying operation according to the spraying order and the spraying path.

Owner:成都思达特电器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com