Robot spraying system and control method thereof

A control method and robot technology, applied in the direction of injection devices, etc., can solve the problems of high labor intensity, time-consuming, increased production costs, etc., to achieve offline and automation, improve system flexibility, and quickly realize the effect of productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

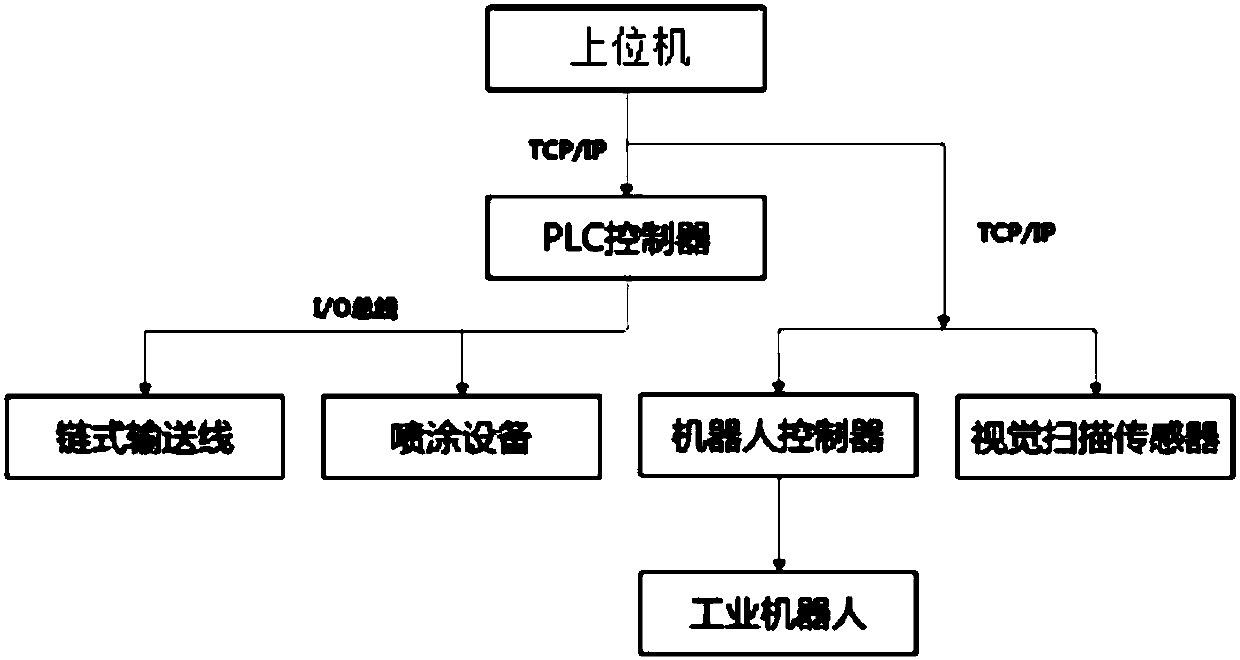

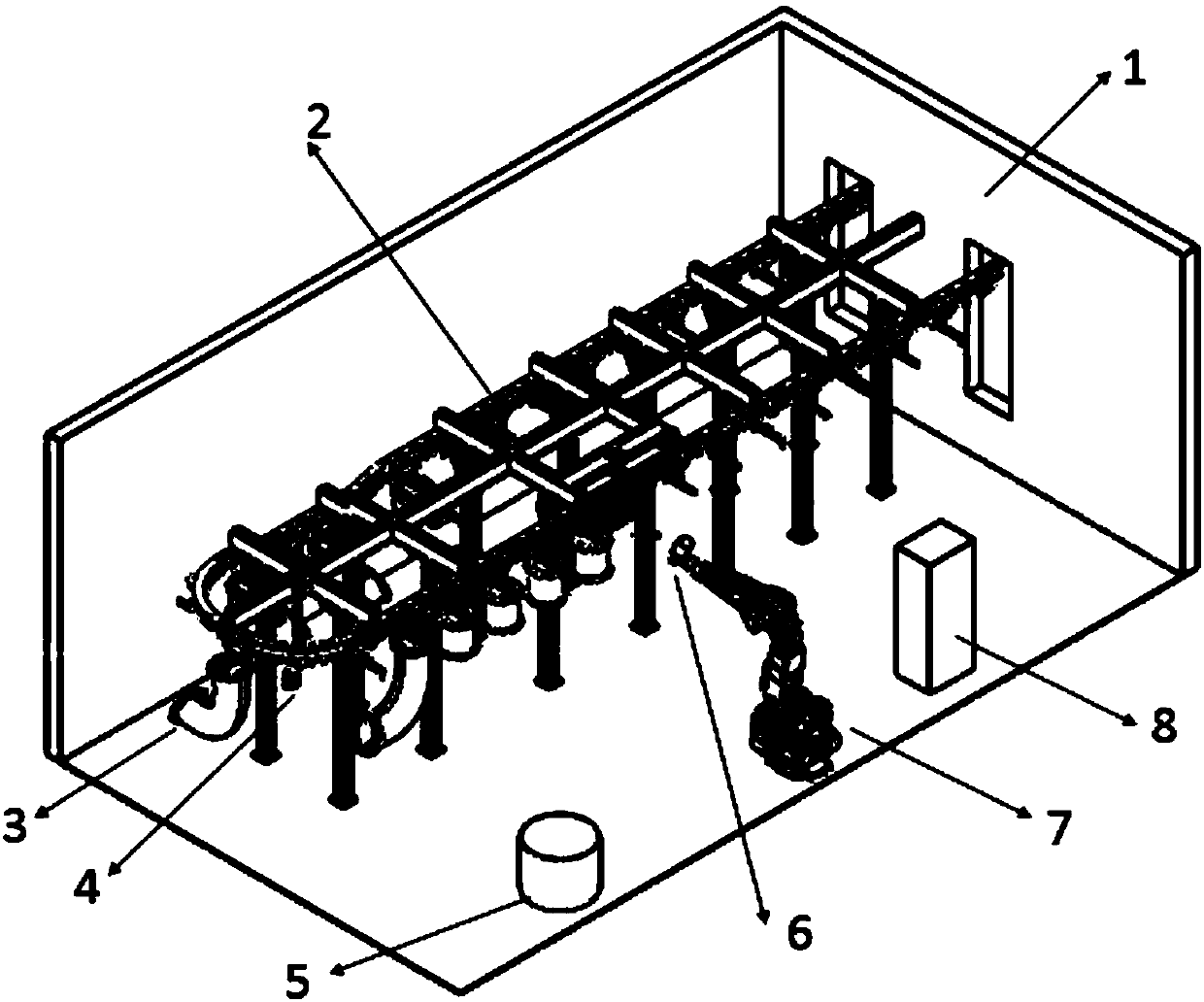

[0047] The robot spraying system is set in the spraying room 1, such as figure 1 , 2 As shown, the system is equipped with a chain conveyor line 2 for transporting the workpiece 3 to be sprayed. The chain conveyor line 2 is used as the conveying carrier of the workpiece 3 in the system. It adopts a hanging method to carry the sprayed workpiece 3 into the spraying area. After visual scanning and robot After spraying, the workpiece 3 is carried away from the spraying area to complete the spraying process.

[0048] The visual scanning area is equipped with a visual sensor 4 for three-dimensional scanning of the workpiece 3. The visual sensor 4 scans the workpiece 3 through line structured light to obtain the point cloud of the workpiece 3, and transmits the feature point information to the host computer 8 through Ethernet.

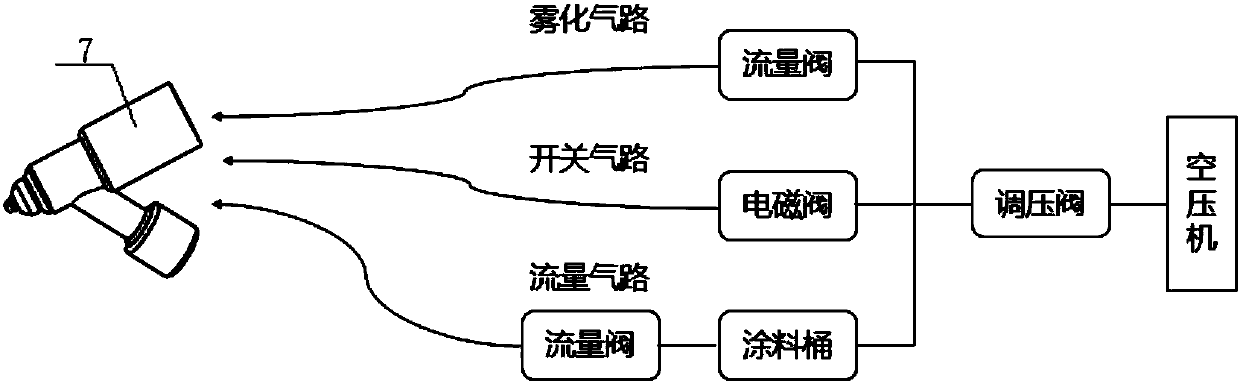

[0049] An industrial robot 7 is installed in the spraying area. The industrial robot 7 is the actuator of the system, and a spray gun 6 is installed at its ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com