Patents

Literature

397results about "Wheel holding means" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

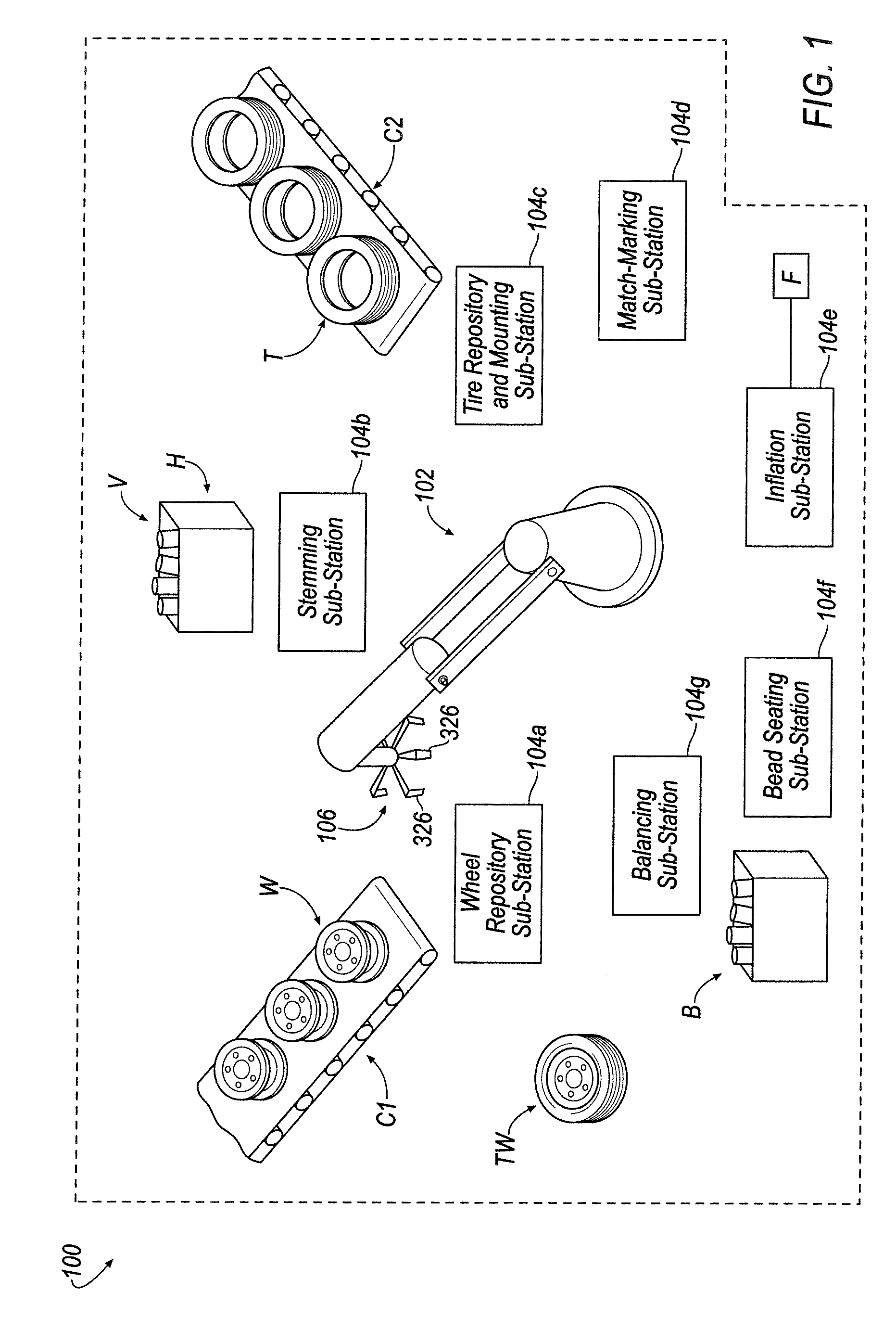

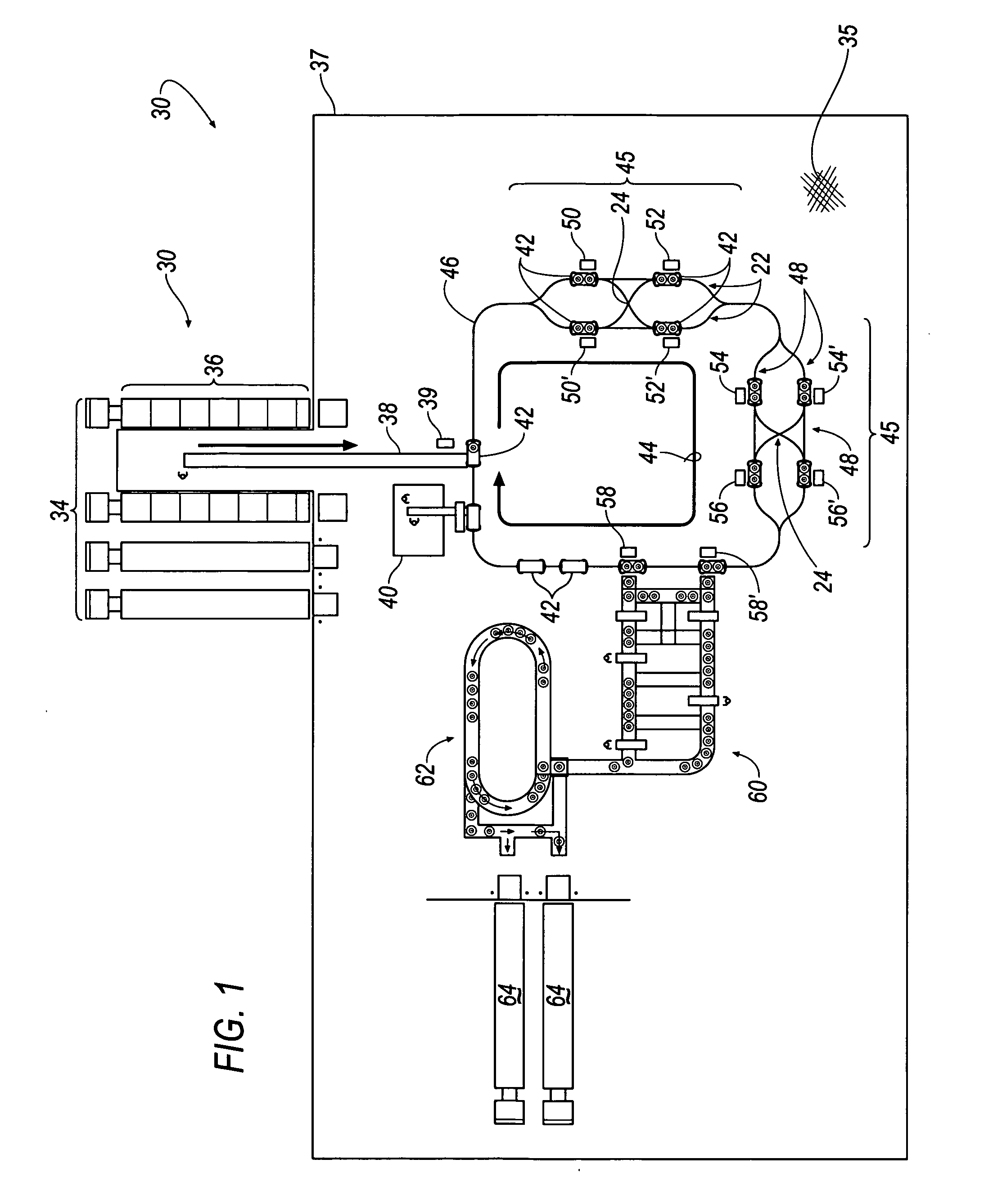

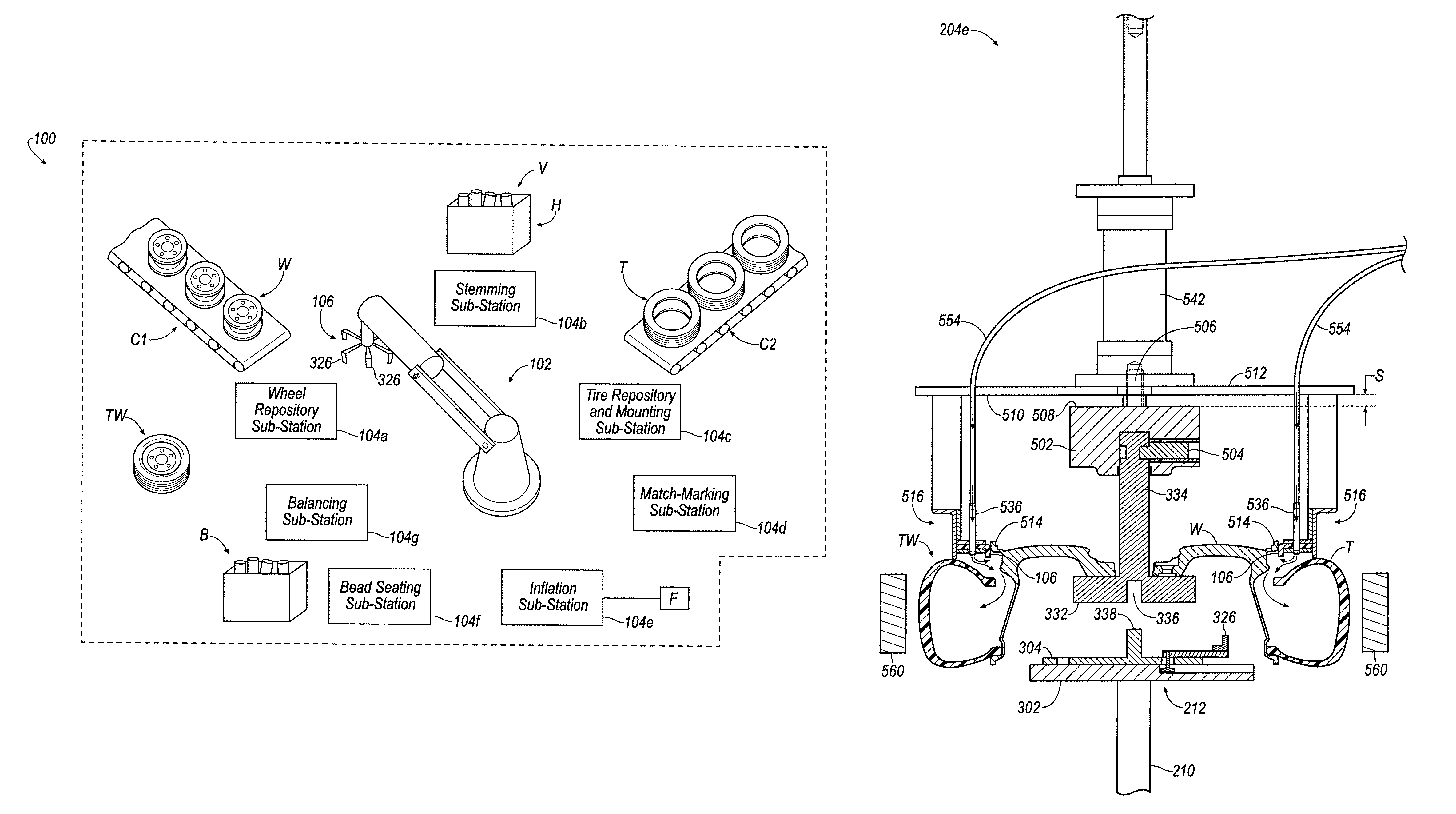

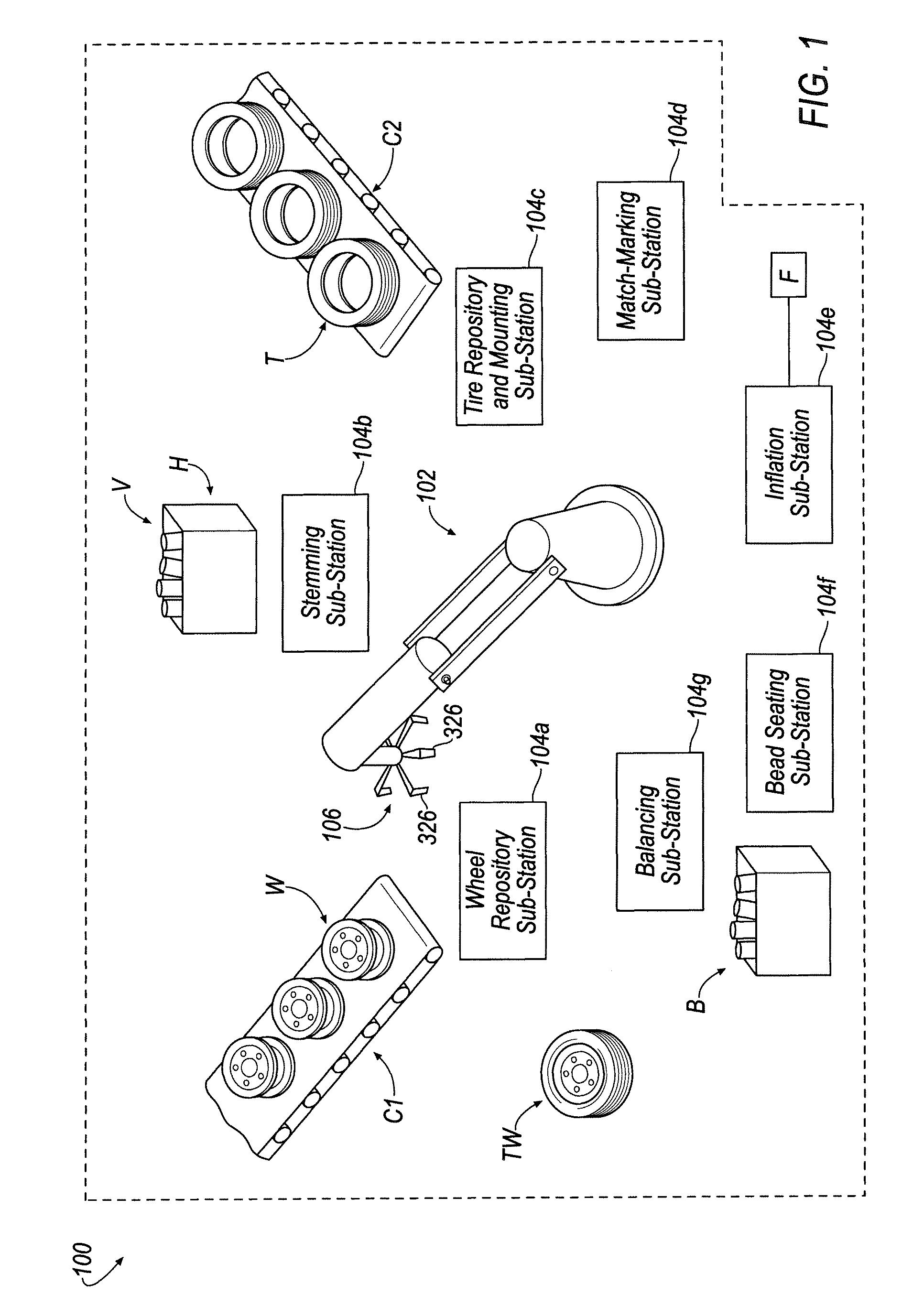

System and Method for Assembling a Tire and a Wheel

An apparatus for assembling a tire and a wheel is disclosed. The apparatus includes a single-cell workstation including a device that retains a wheel, and a plurality of sub-stations. The device moves the wheel to each of the plurality of sub-stations, without releasing the wheel, to assemble a tire-wheel assembly. A method is also disclosed.

Owner:ANDROID INDS OF MICHIGAN

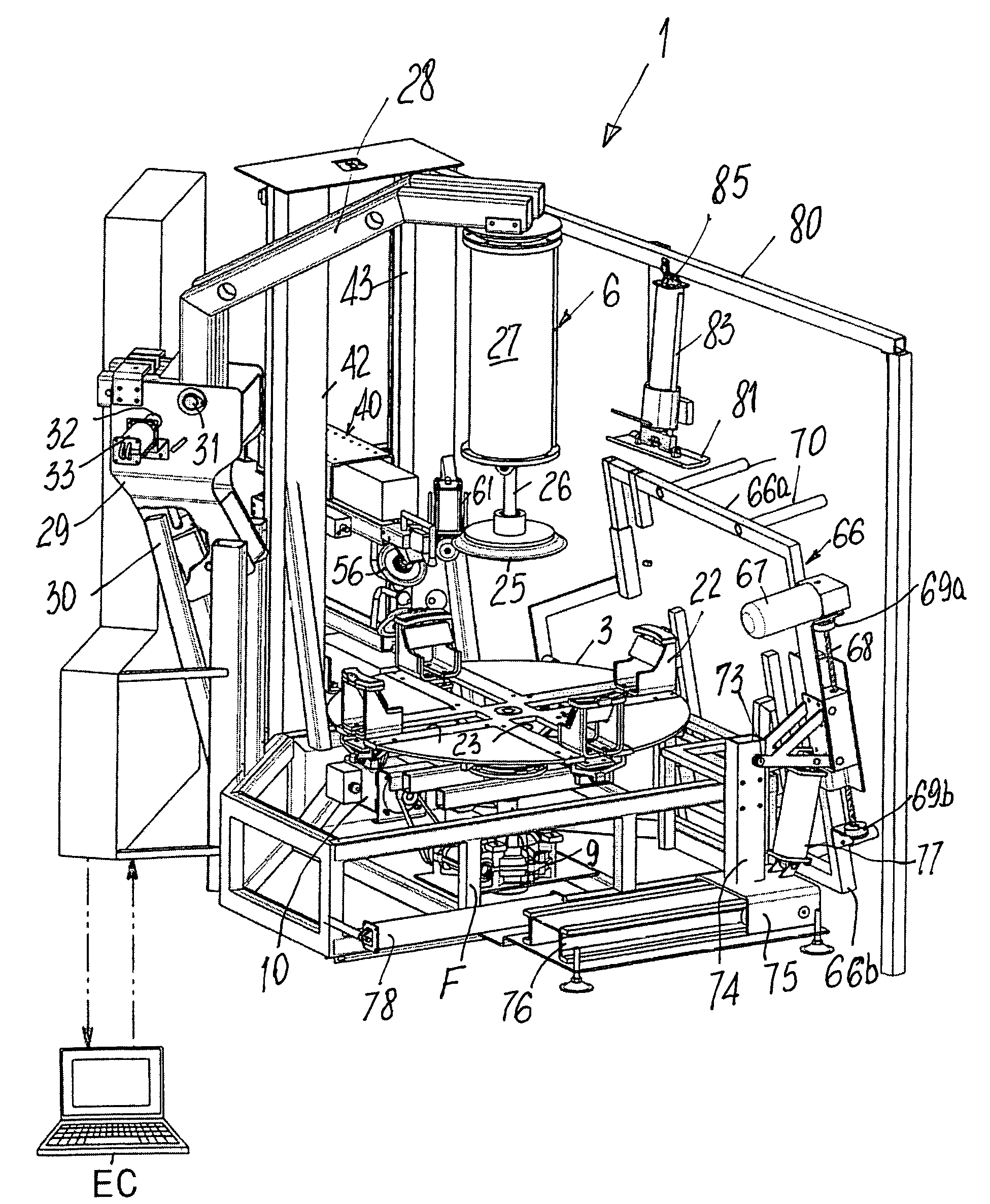

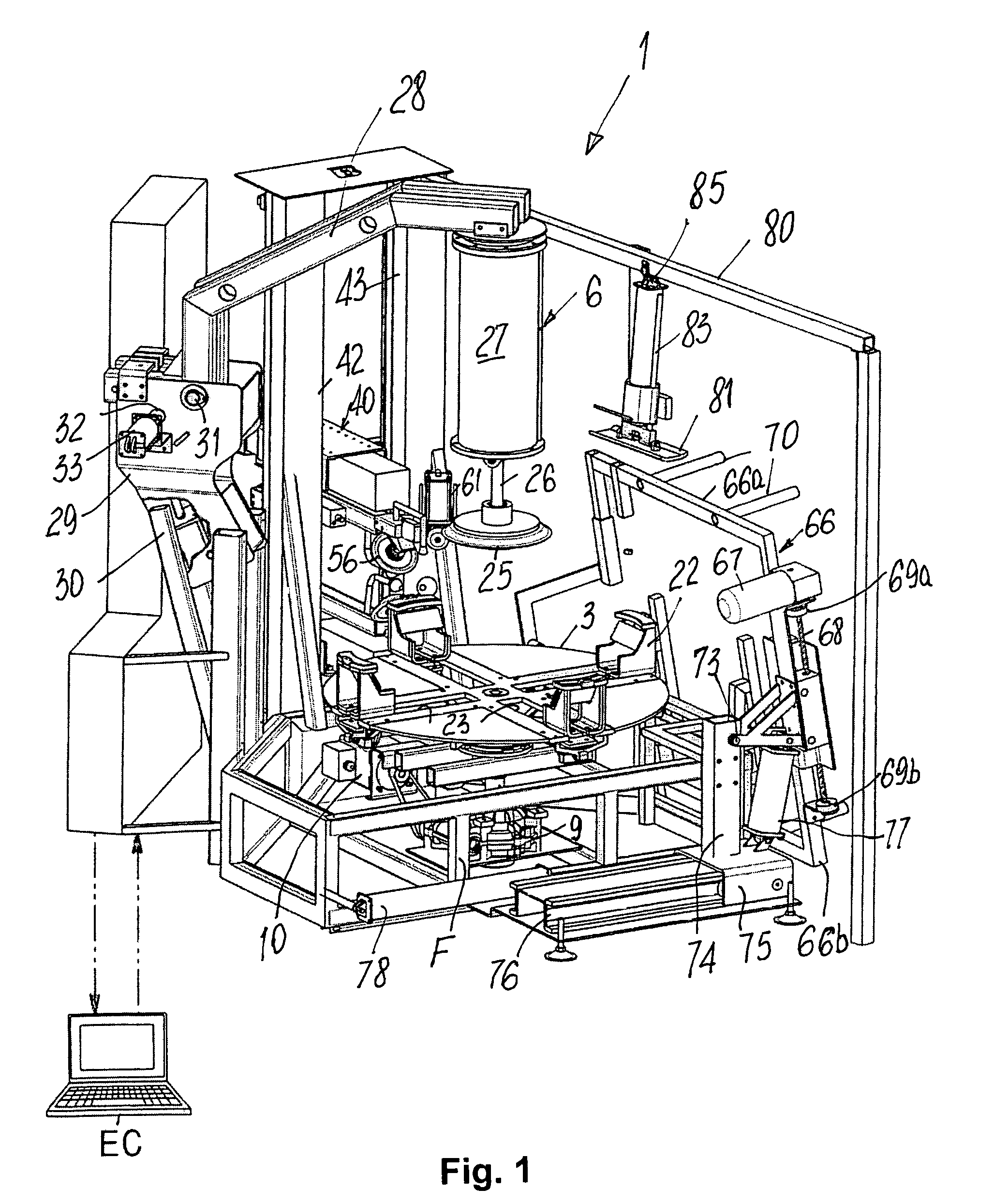

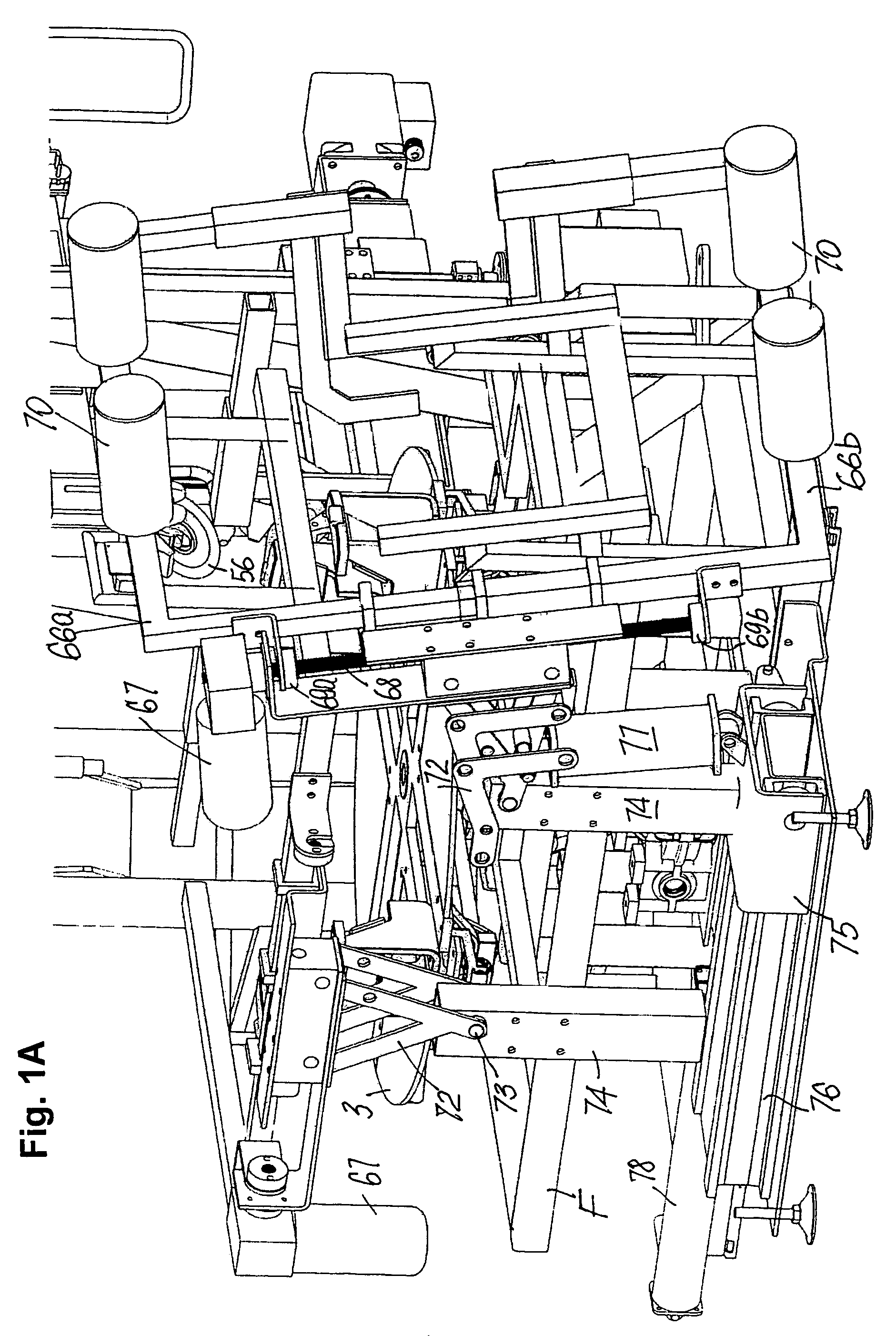

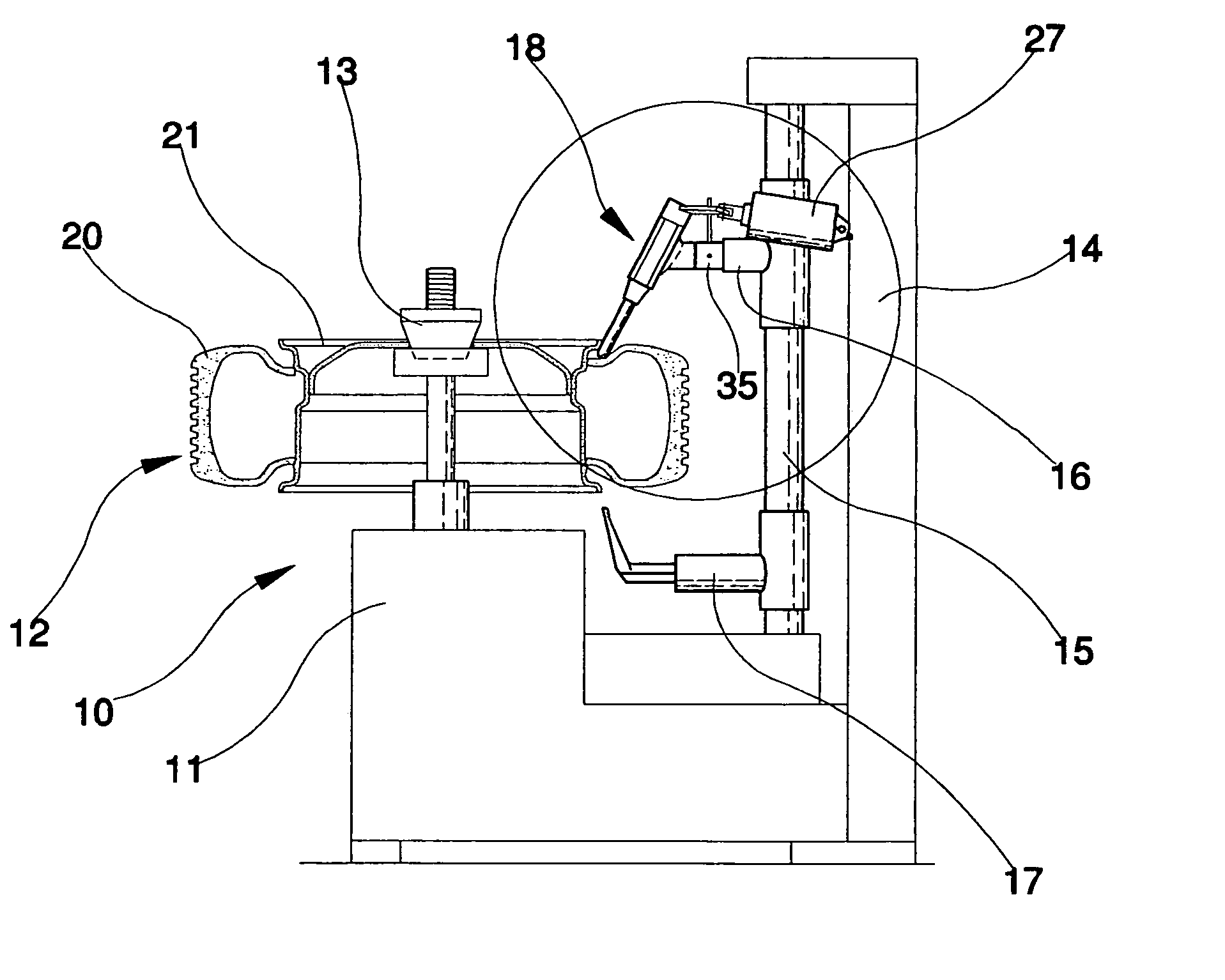

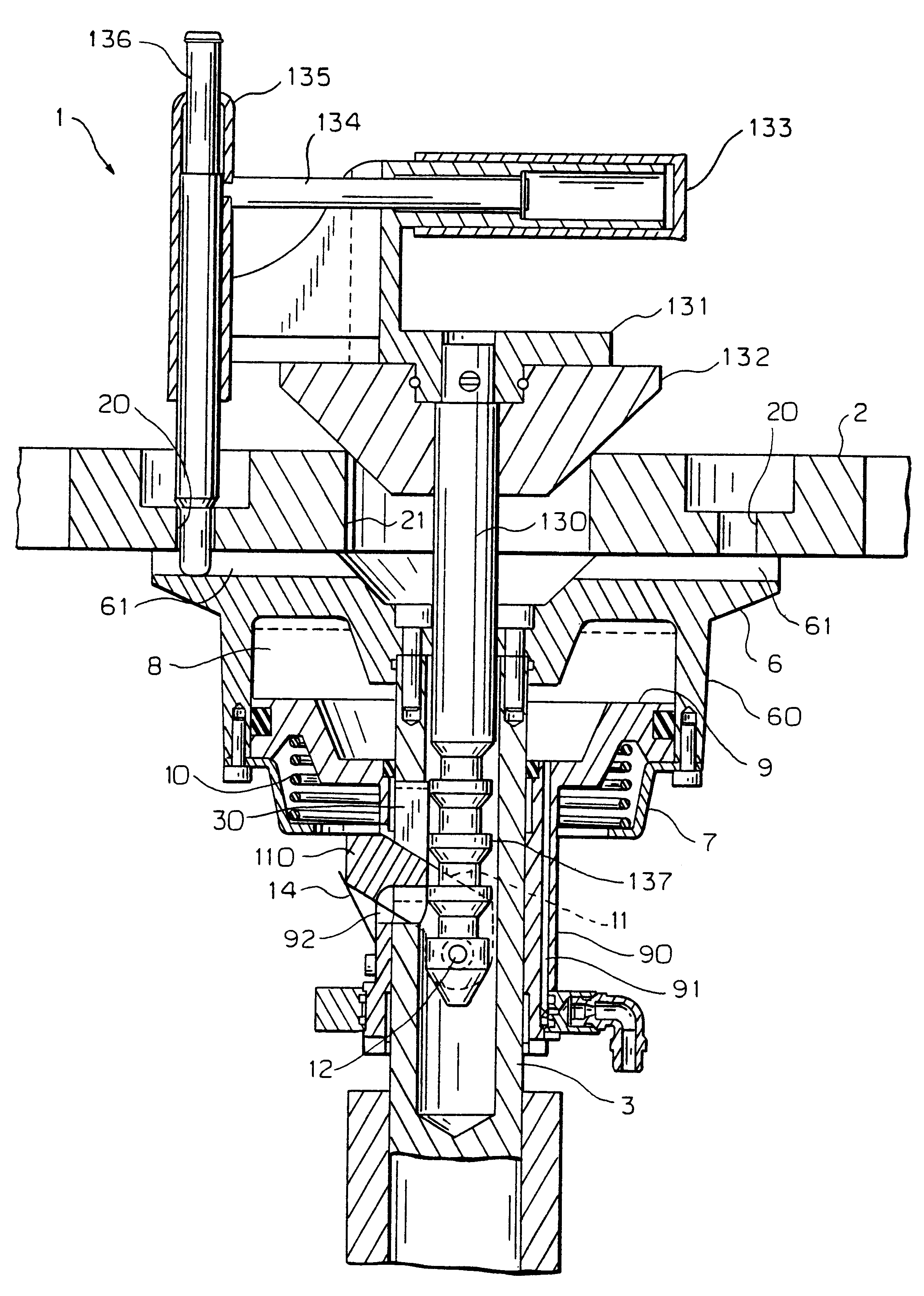

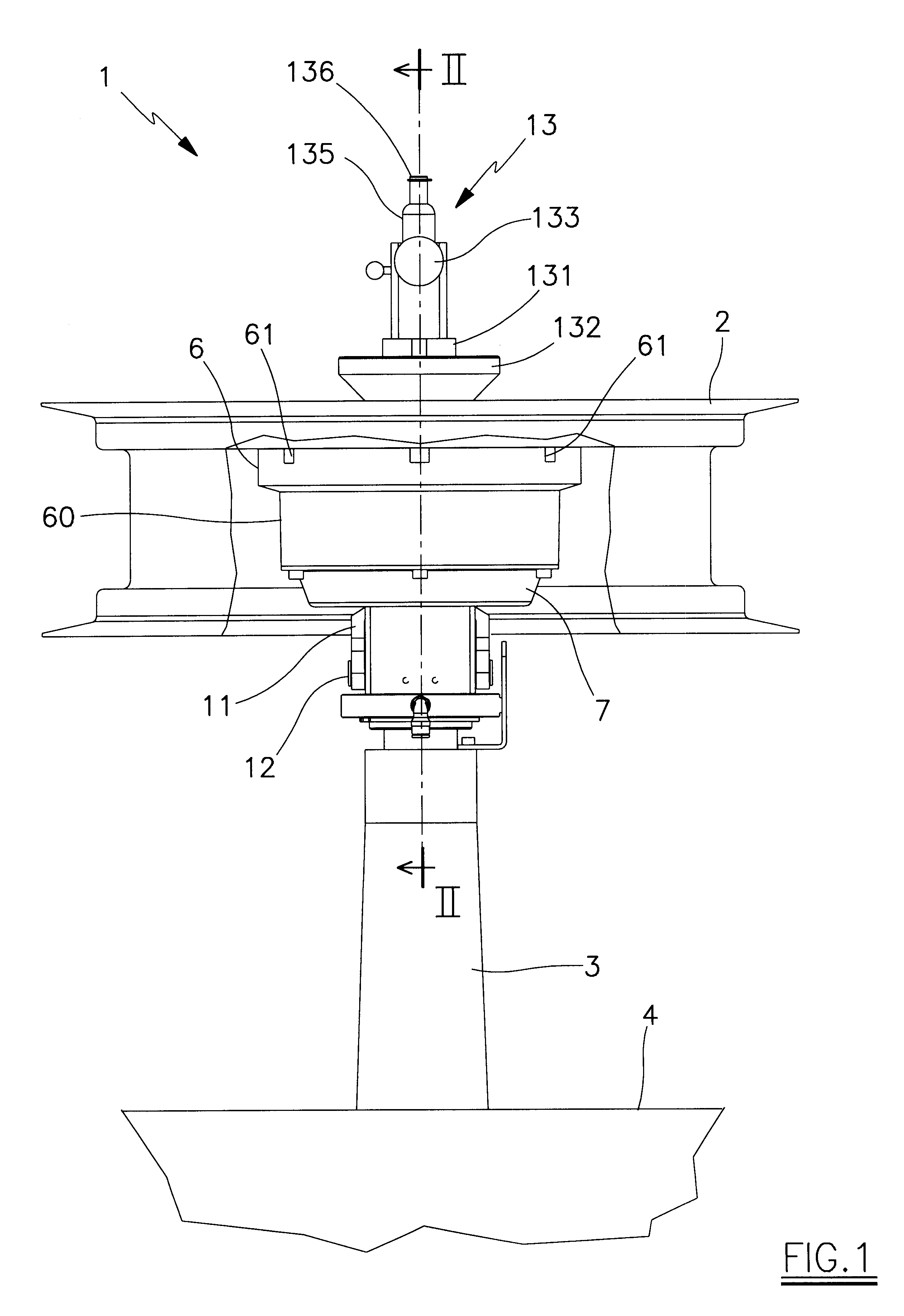

Apparatus for servicing a tired wheel

ActiveUS7089987B2Easy to controlEasy to operateStatic/dynamic balance measurementTyresMotor driveEngineering

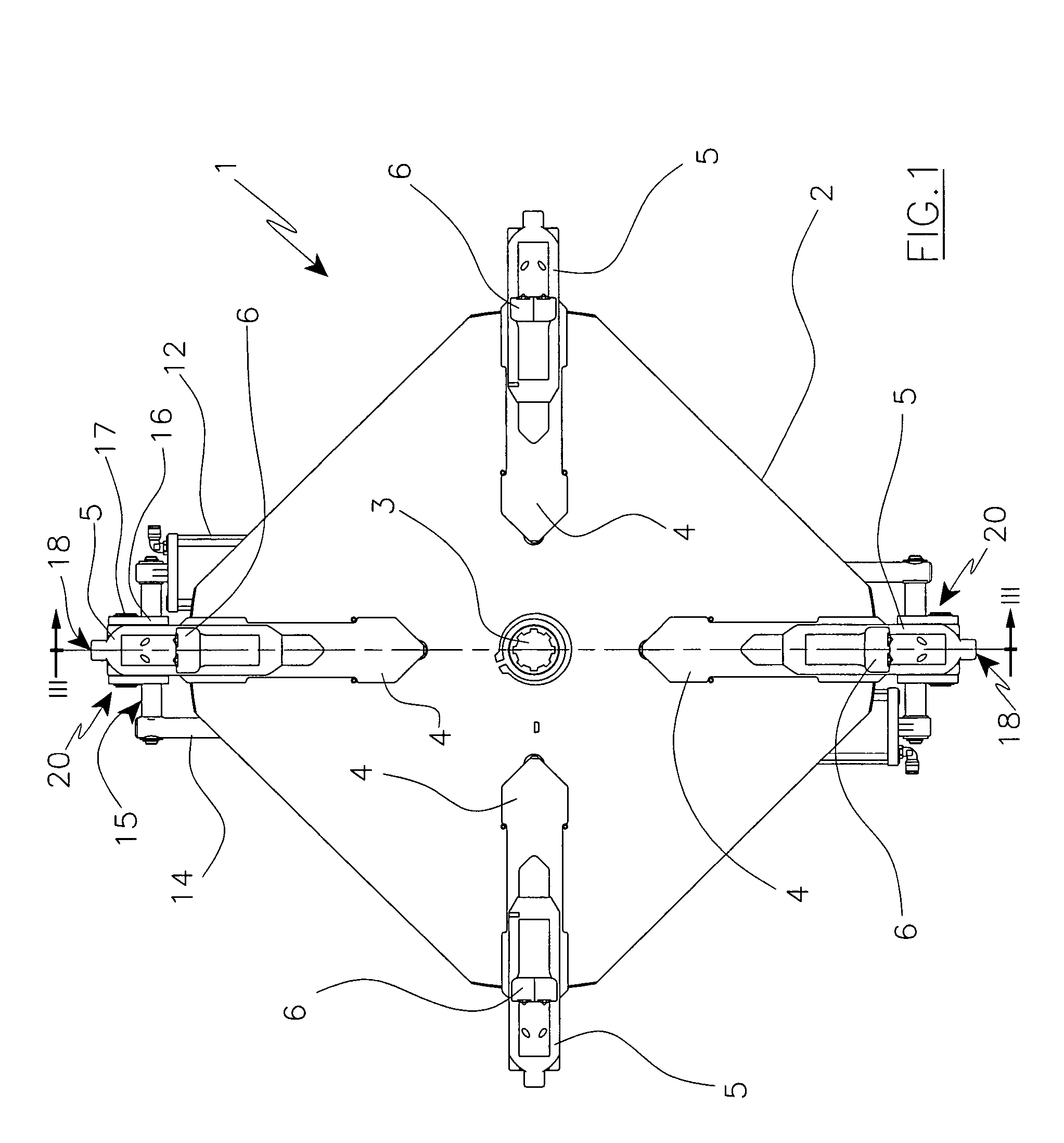

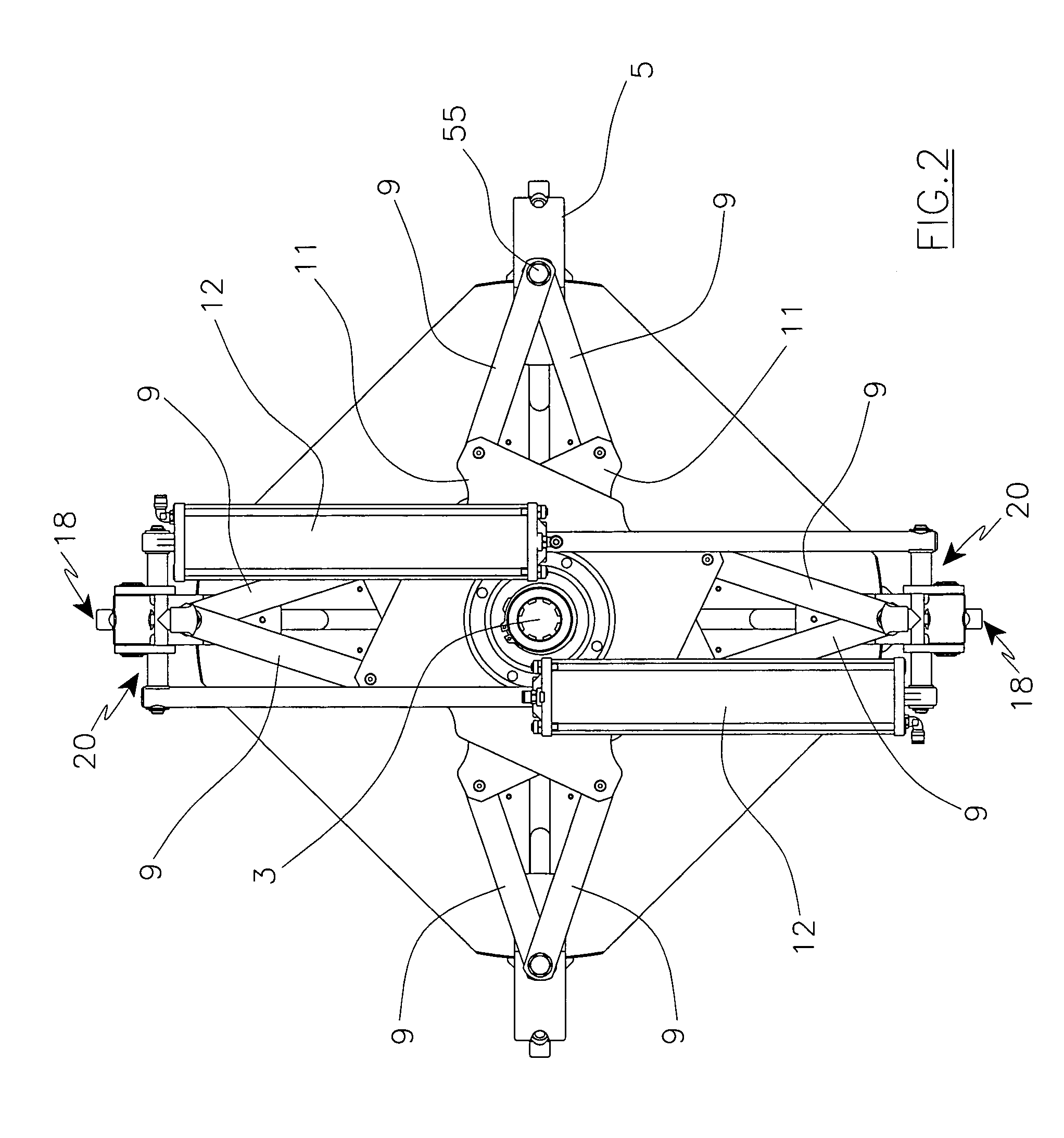

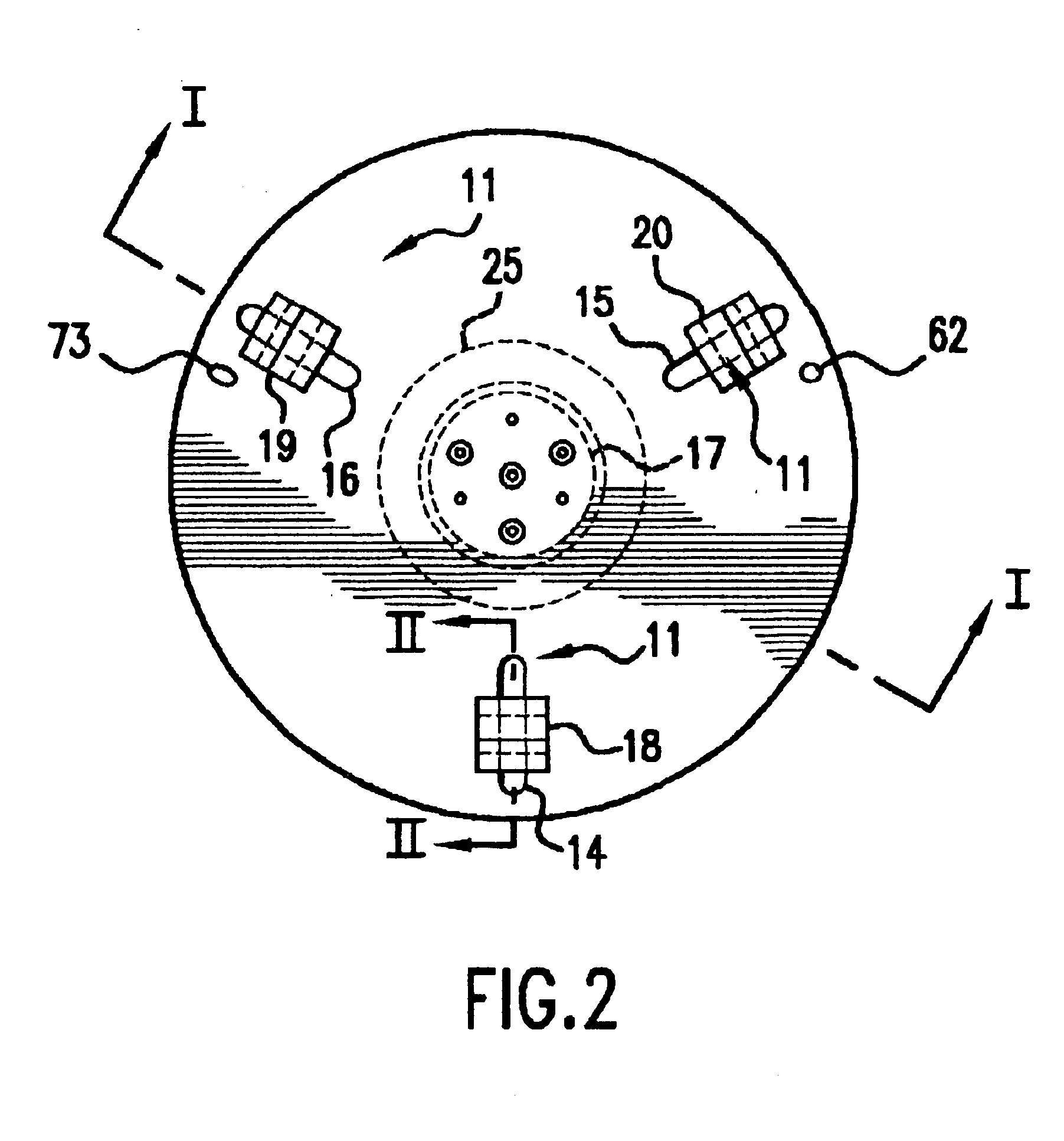

An apparatus for servicing a tired wheel for motor vehicles, which comprises a tire assembling-disassembling machine provided with a rotatable motor-driven support (3) for supporting a wheel to be handled, sensor means (4, 5) for controlling both the position of, and the load on, the rotatable support (3), urging locking means (6) designed to act on the middle portion of the wheel-rim to make the wheel rigid in rotation with the rotatable support (3), detecting means (7, 7a, 7b) designed to measure the size of the wheel-rim, and program control means (EC).

Owner:BUTLER ENG & MARKETING

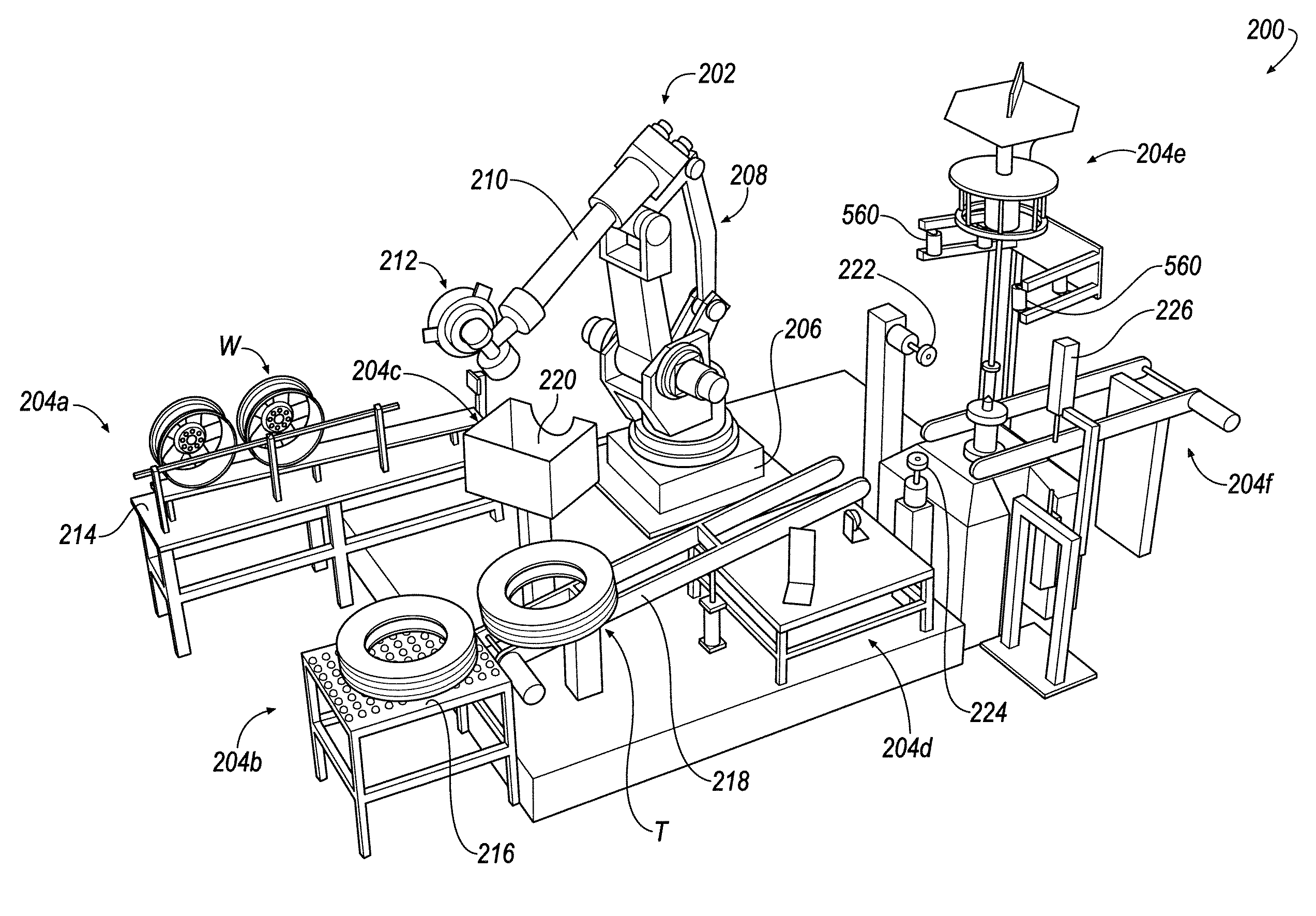

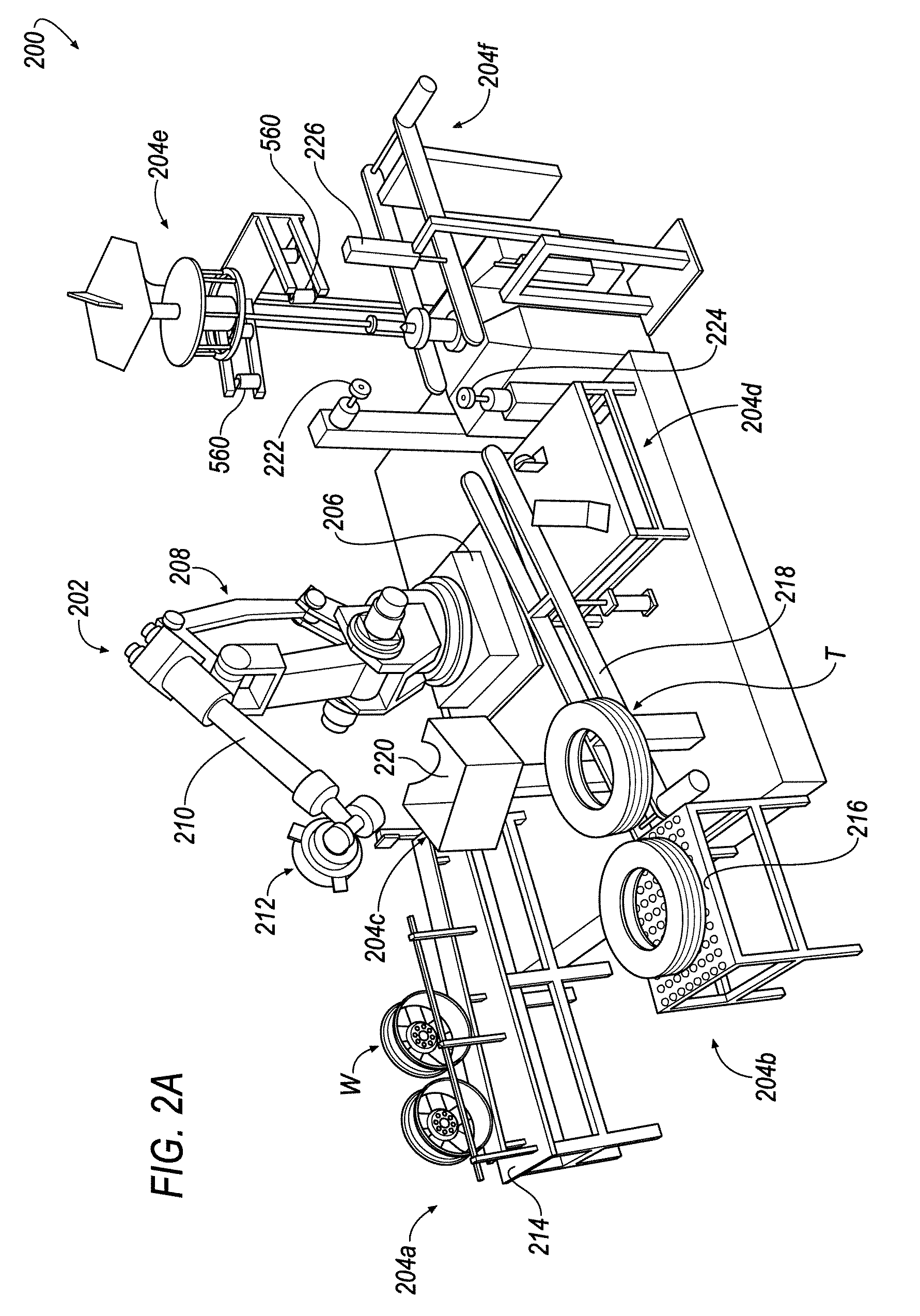

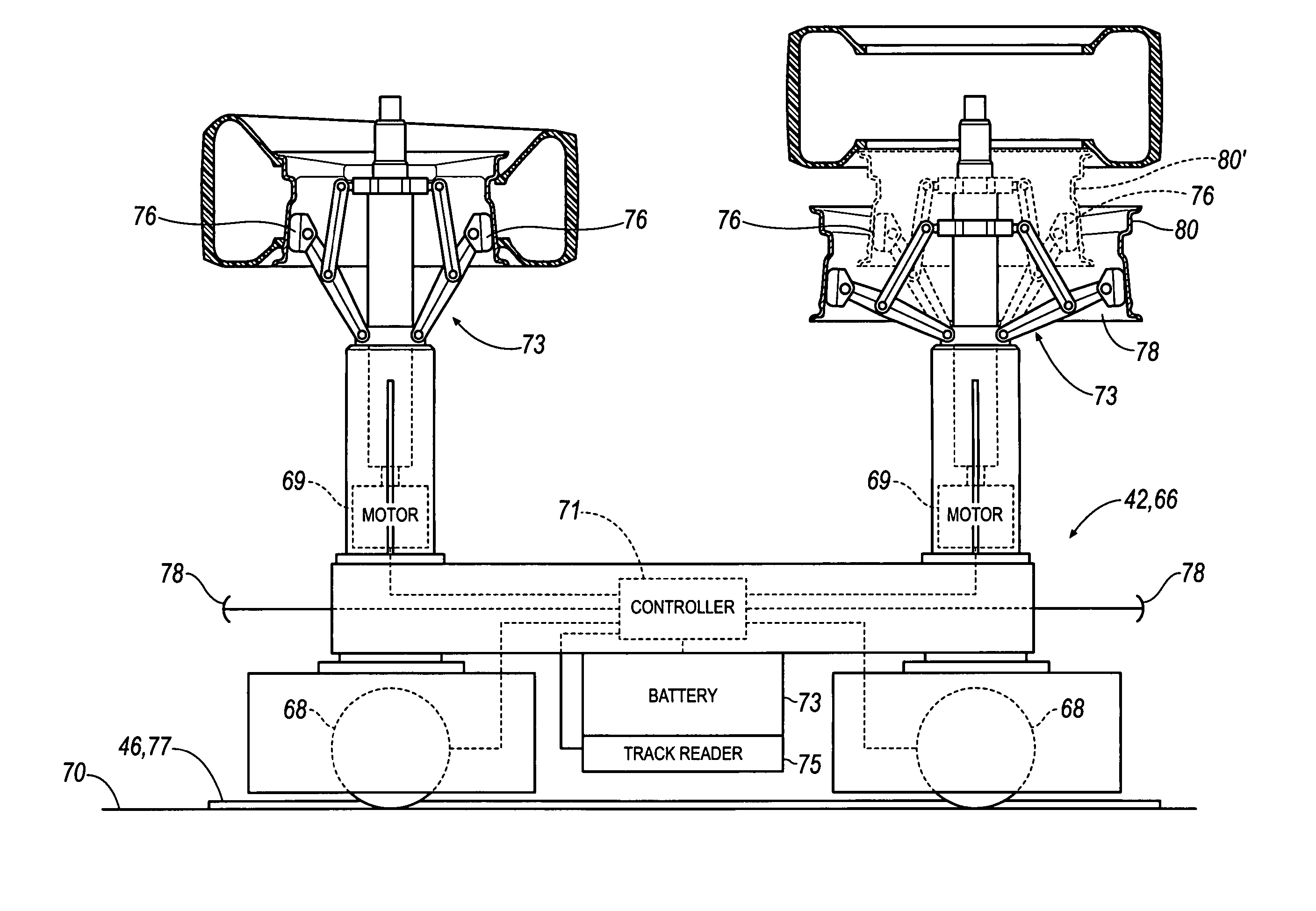

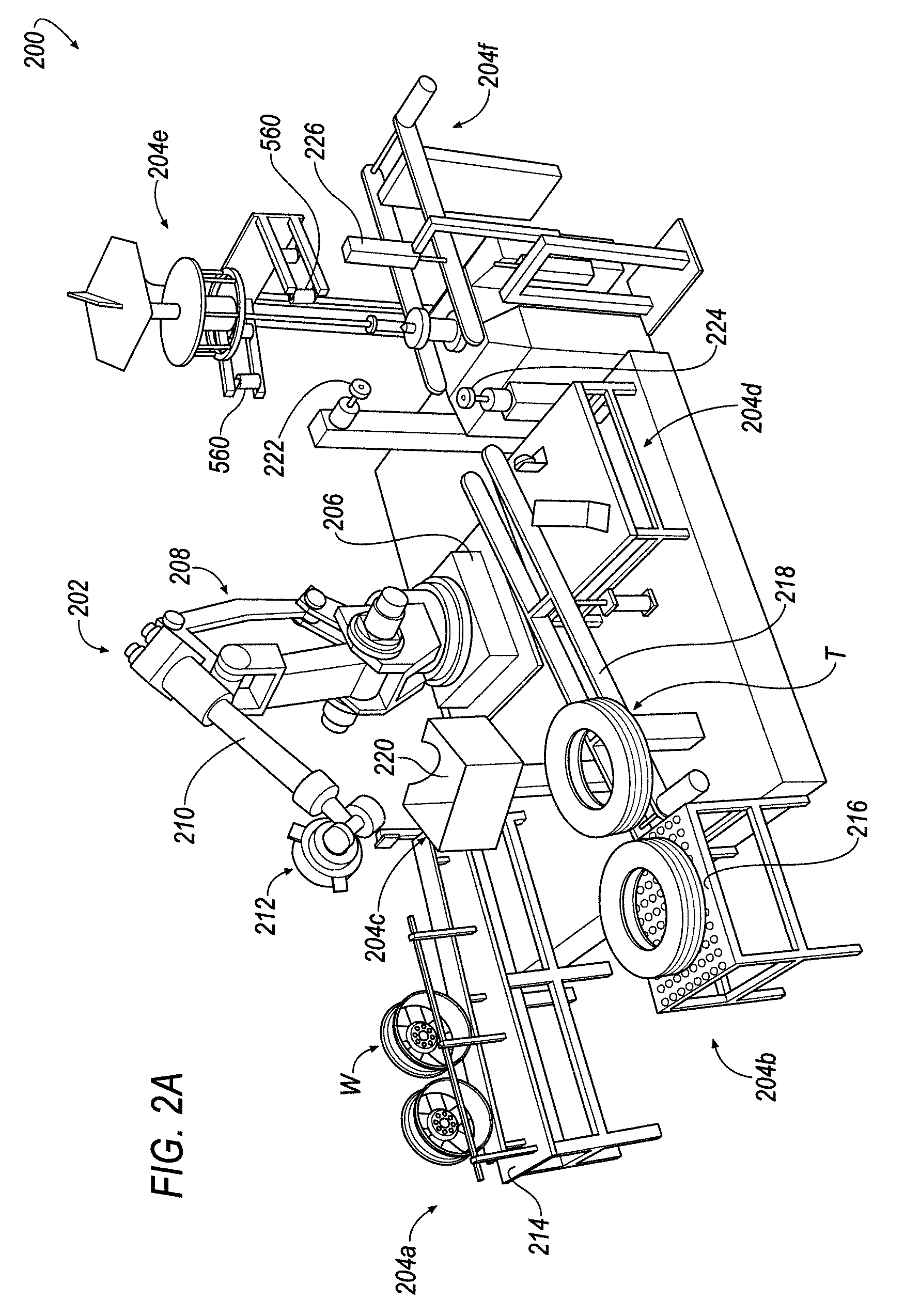

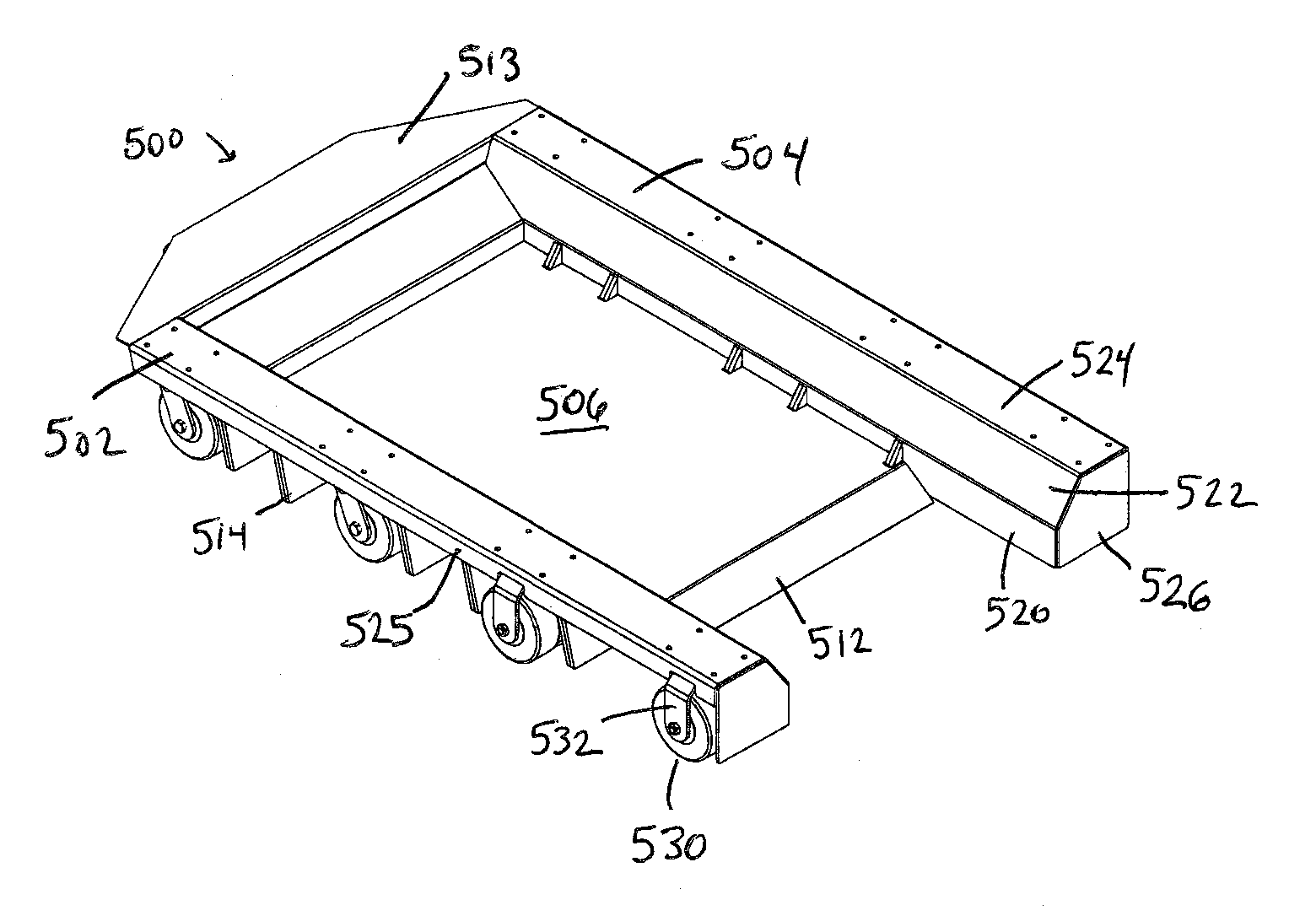

System for transporting and manipulating tires and wheels

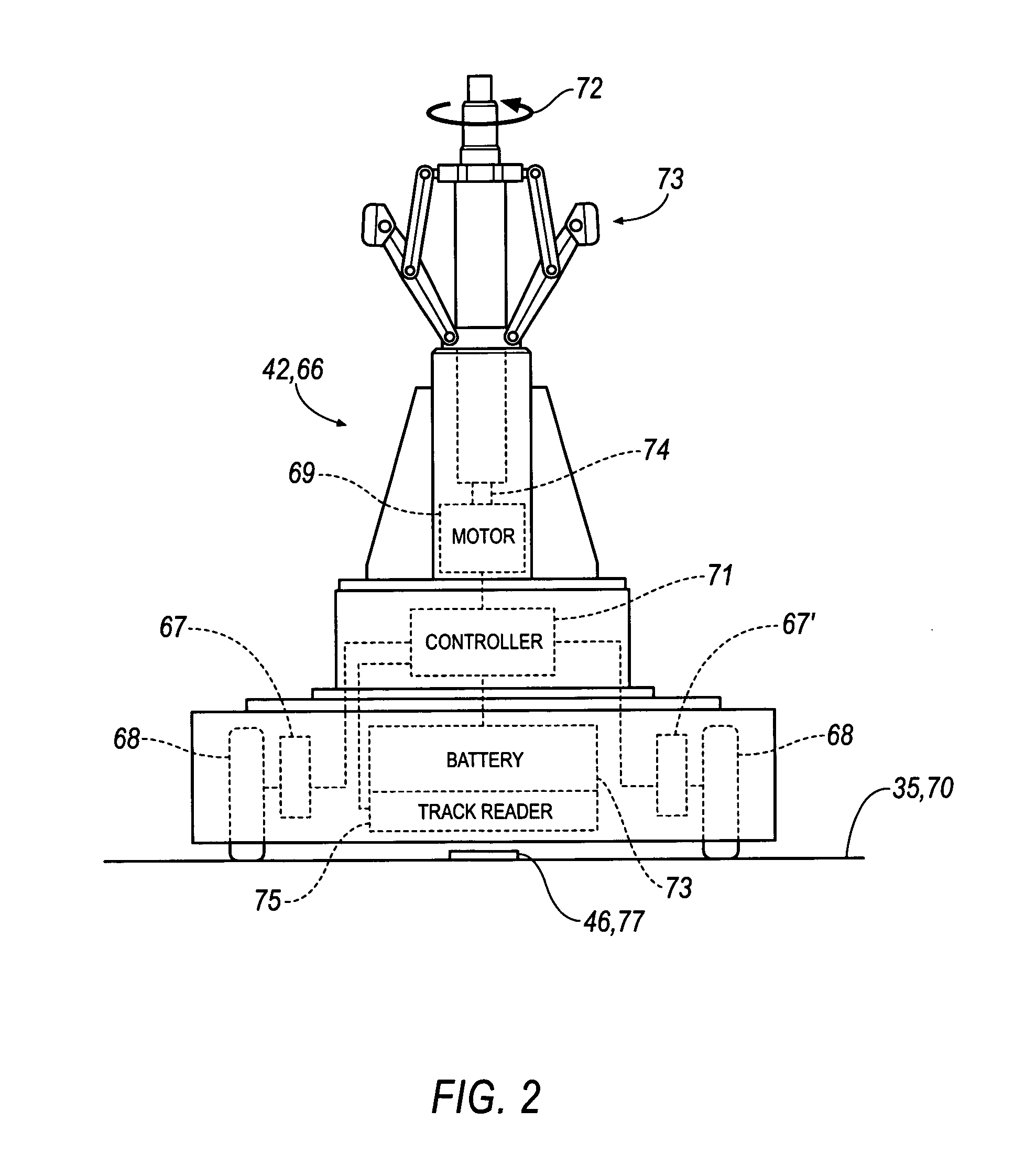

A factory layout including a track circuit, one or more wheeled carts for traversing the track circuit and a tire / wheel assembly carried by the wheeled cart. One or more work stations can be positioned at locations along the track circuit. Various wheeled cart embodiments are disclosed and various work station configurations are disclosed.

Owner:ANDROID INDS OF MICHIGAN

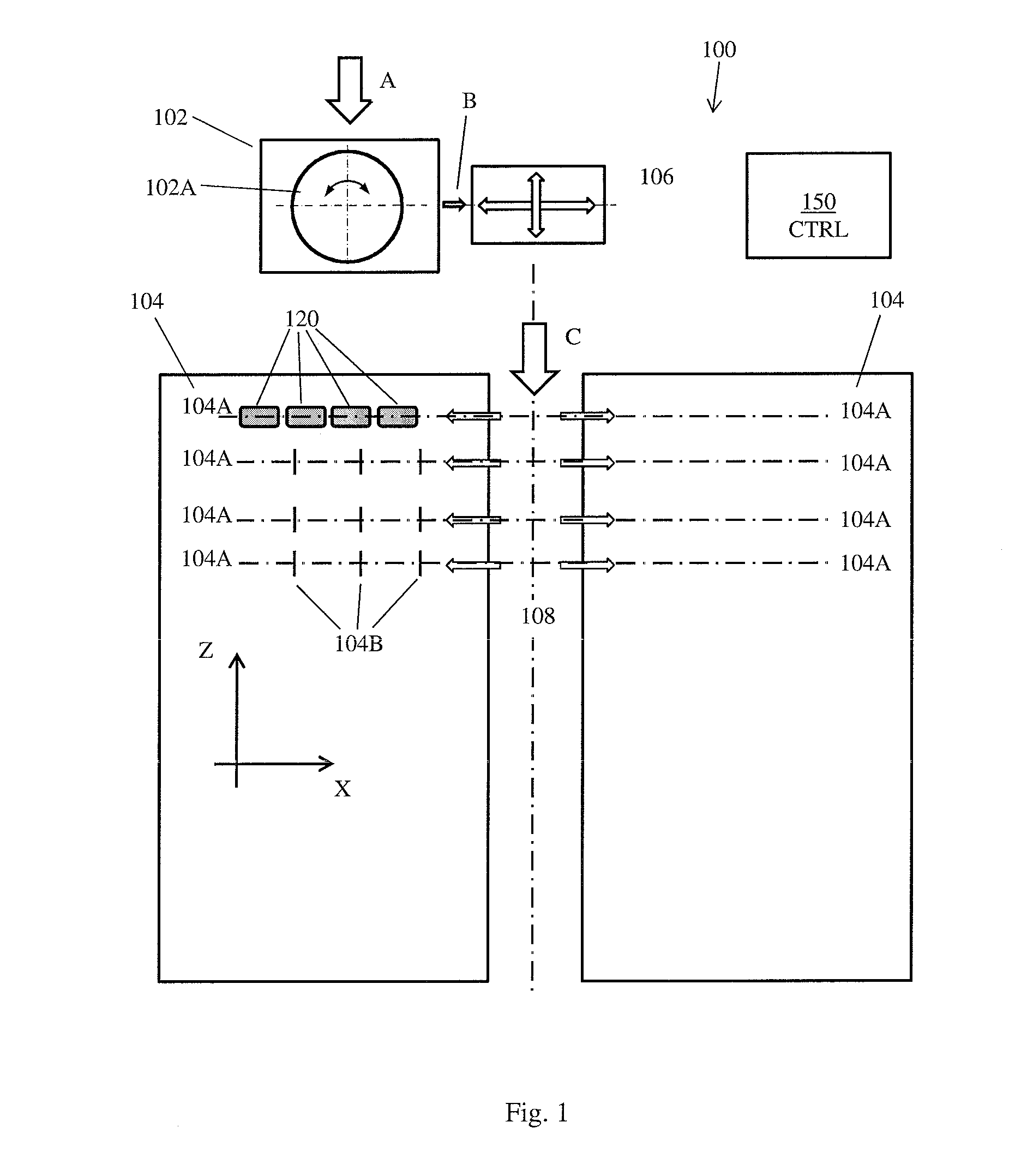

System and method for tracking guiding lines by an autonomous vehicle

An autonomous transporting tool is adapted to travel along a guiding line. The tool comprises two transporting elements. Each of the transporting elements comprise autonomous propulsion means, a control system and an optical system. The optical system comprises two cameras and two lighting units. The system is adapted to identify the location of the image of a guiding line within a received image of the floor and to provide steering commands adapted to steer the transporting tool so that the image of the guiding line is located substantially in the center of the received image.

Owner:UNITRONICS AUTOMATED SOLUTIONS

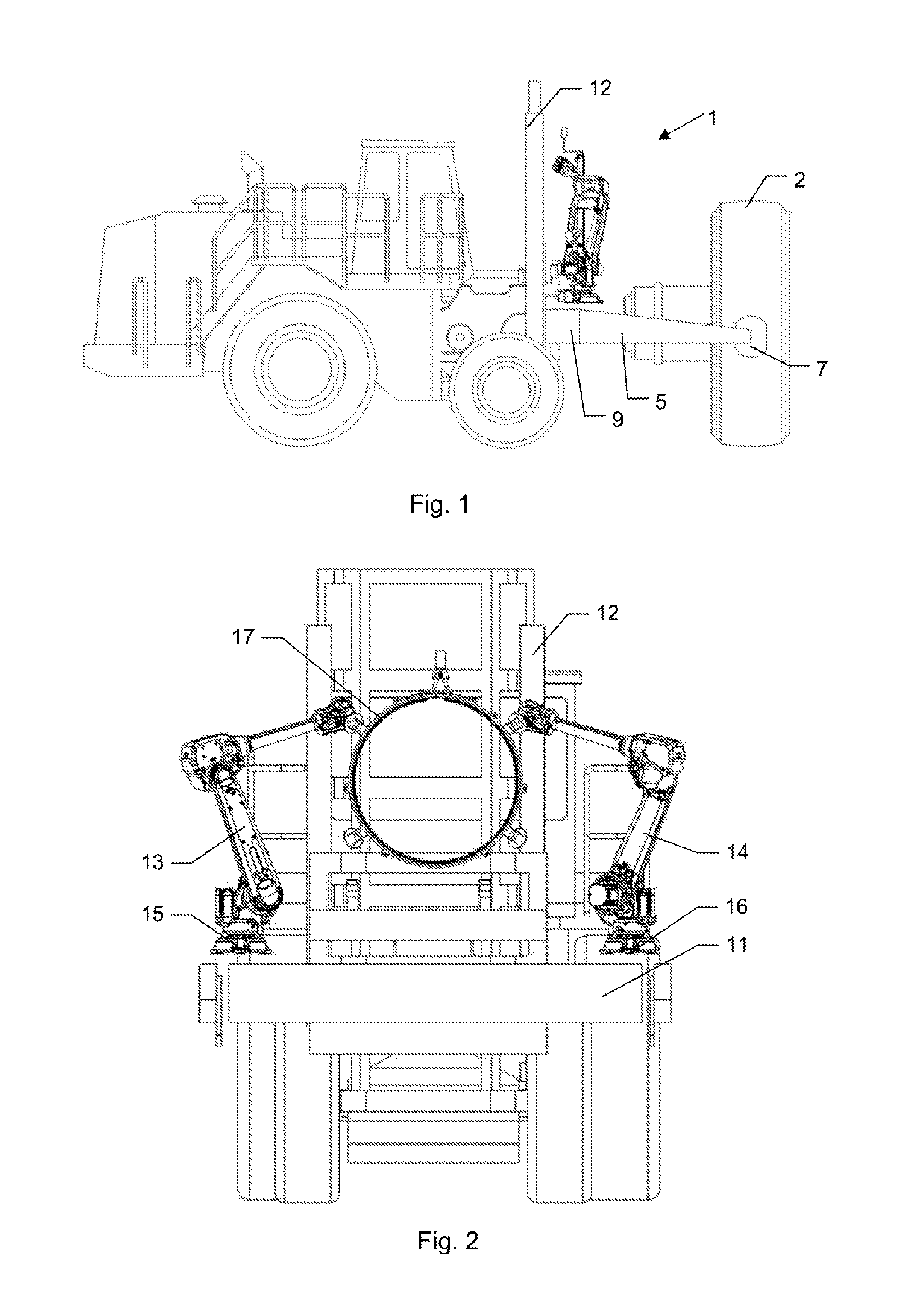

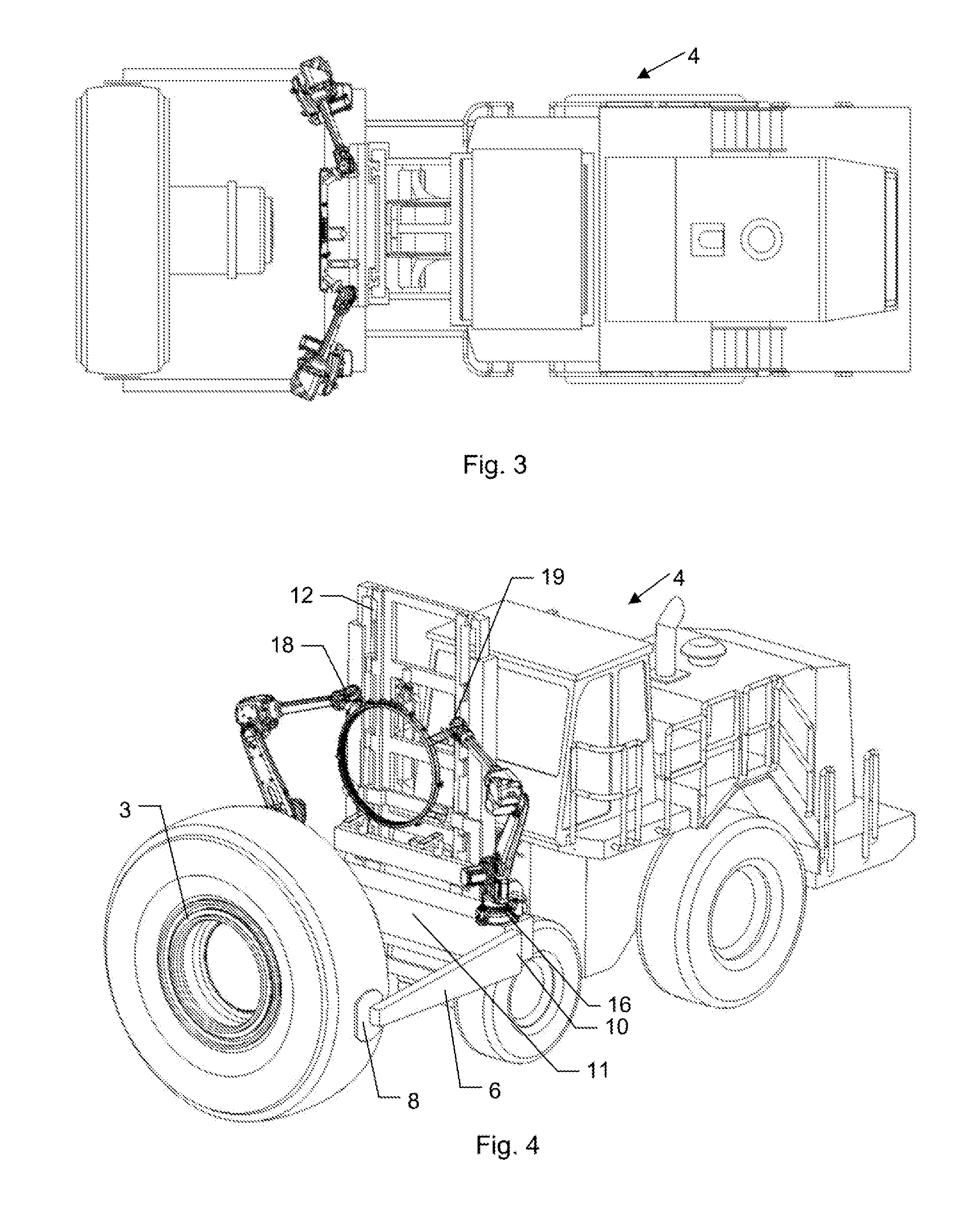

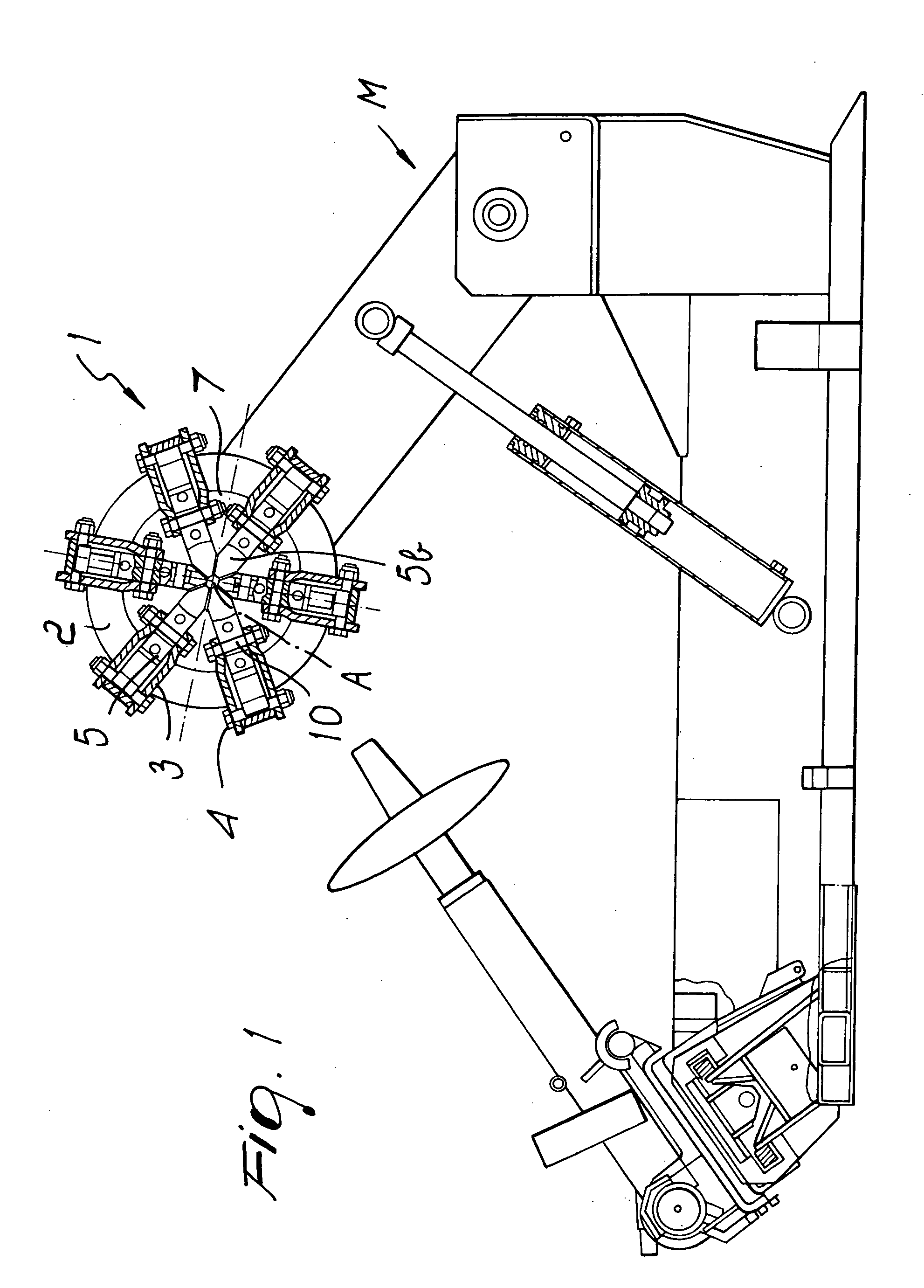

Robotic tyre changing apparatus and associated hardware and methods

InactiveUS20160152102A1Stablise against twistingTyresStatic/dynamic balance measurementRoboticsEngineering

A tyre changing apparatus 1, for use with tyres on large haul trucks employed in mining operations. The apparatus includes a tyre handler. The grab unit of the tyre handler can provide a stable work platform from which robots may execute tasks. Hence, a first robot is disposed adjacent to the proximal end of arm and a second robot is disposed adjacent to the proximal end of the second arm. This apparatus may be utilised by the robots so as to spread the gap in a lock ring to assist when removing and installing the lock ring. An o-ring installation device may be utilized by the robots when installing an o-ring.

Owner:MACHINERY AUTOMATION & ROBOTICS

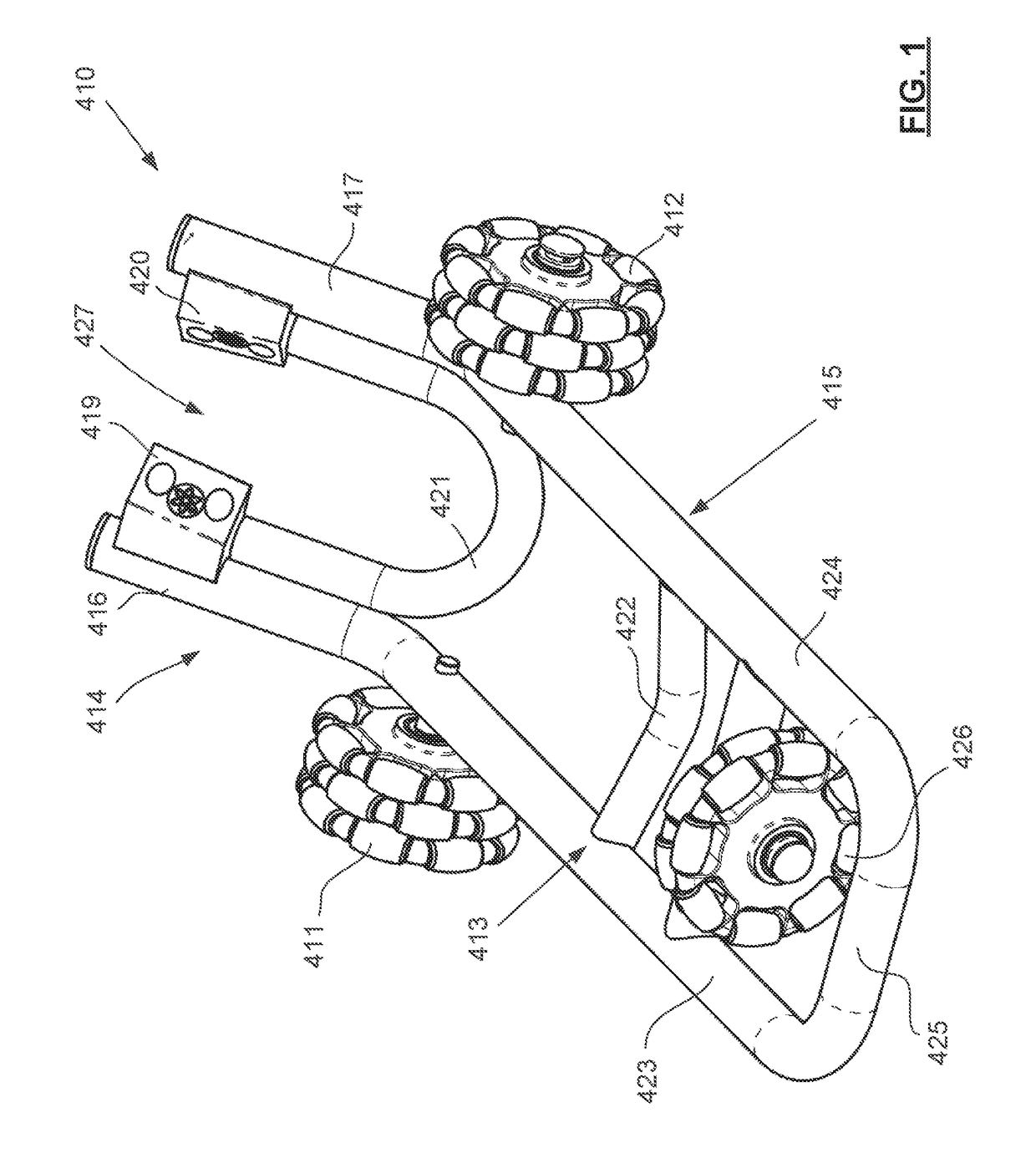

Dual Mode End Effector

A dual mode end effector is disclosed. The dual mode end effector includes a bridge member having a first end and a second end, wherein the bridge member includes a first substantially axial flange extending from the first and, wherein the bridge member includes a second substantially axial flange extending from the second end; a tire / wheel gripping assembly connected to the bridge member, wherein the tire / wheel gripping assembly includes a pair of substantially axial members, a substantially radial support member, and a pair of radially-projecting engaging assemblies, wherein the pair of substantially axial members are movably-supported upon the substantially radial support member, wherein a first end of the substantially radial support member is connected to the first substantially axial flange of the bridge member, wherein the a second end of the substantially radial support member is connected to the second substantially axial flange of the bridge member, wherein a first radially-projecting engaging assembly of the pair of radially-projecting engaging assemblies is connected to an inner radial surface of a first substantially axial member of the pair of substantially axial members, wherein a second radially-projecting engaging assembly of the pair of radially-projecting engaging assemblies is connected to an inner radial surface of a second substantially axial member of the pair of substantially axial members.

Owner:ANDROID INDS OF MICHIGAN

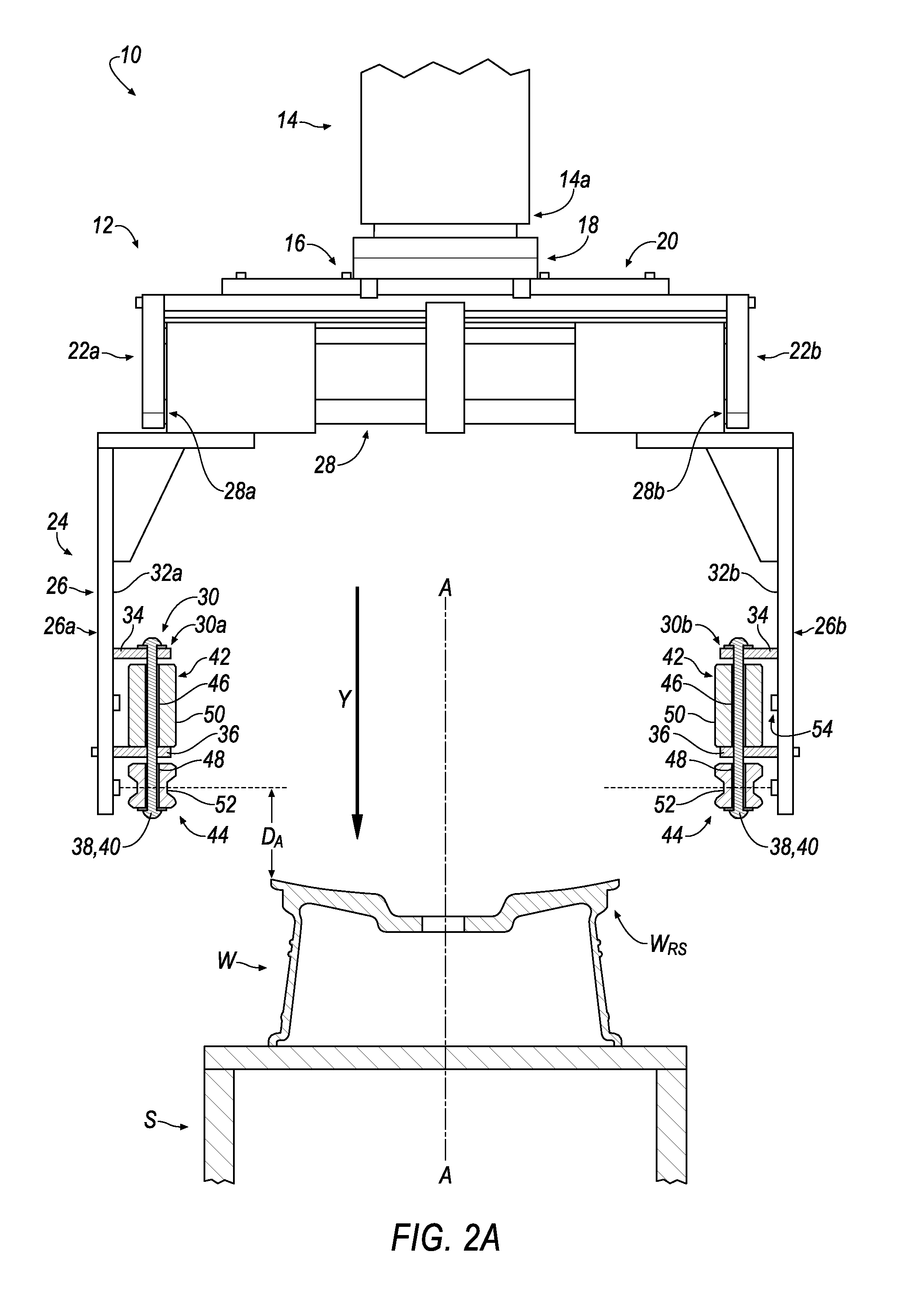

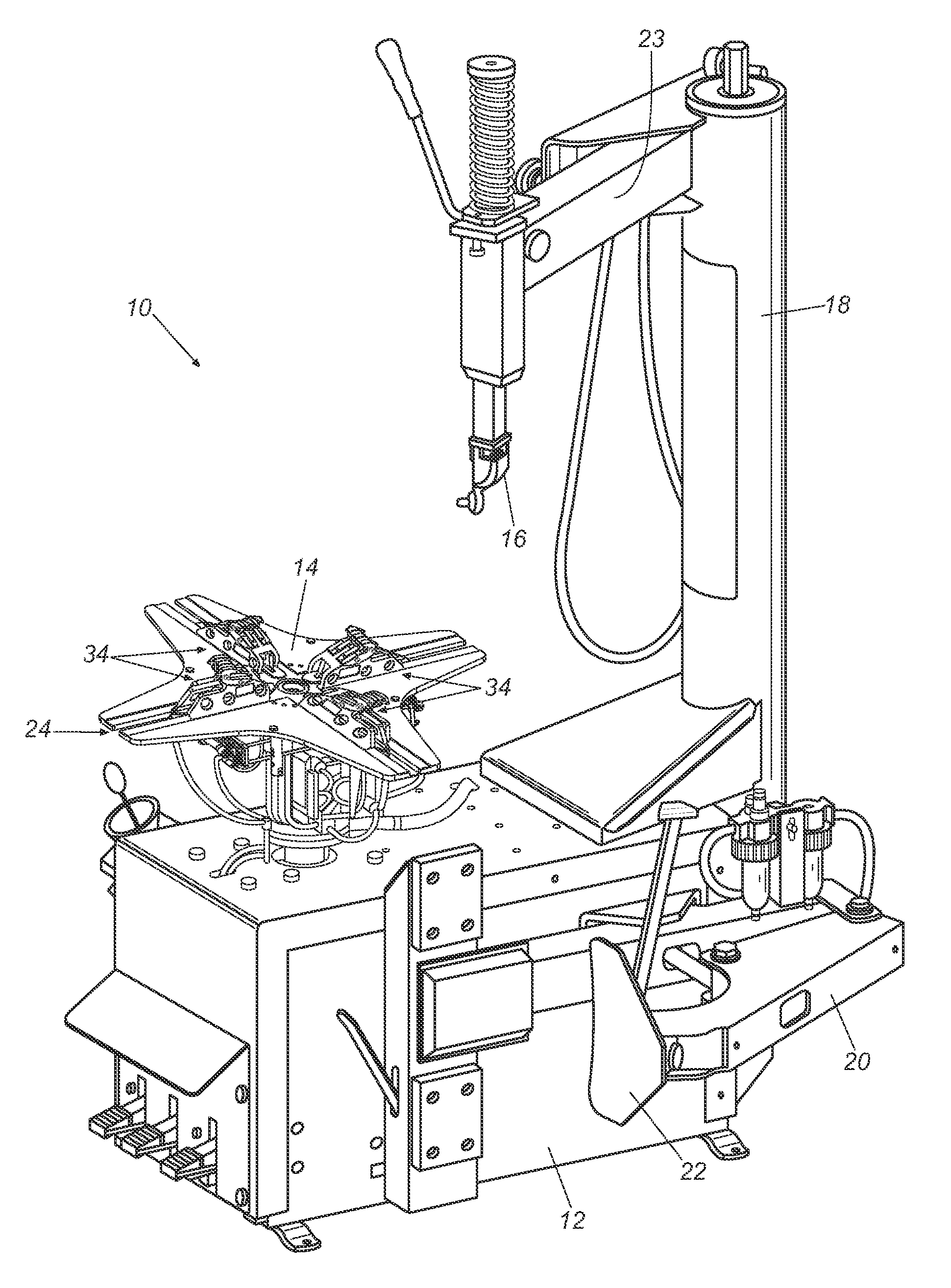

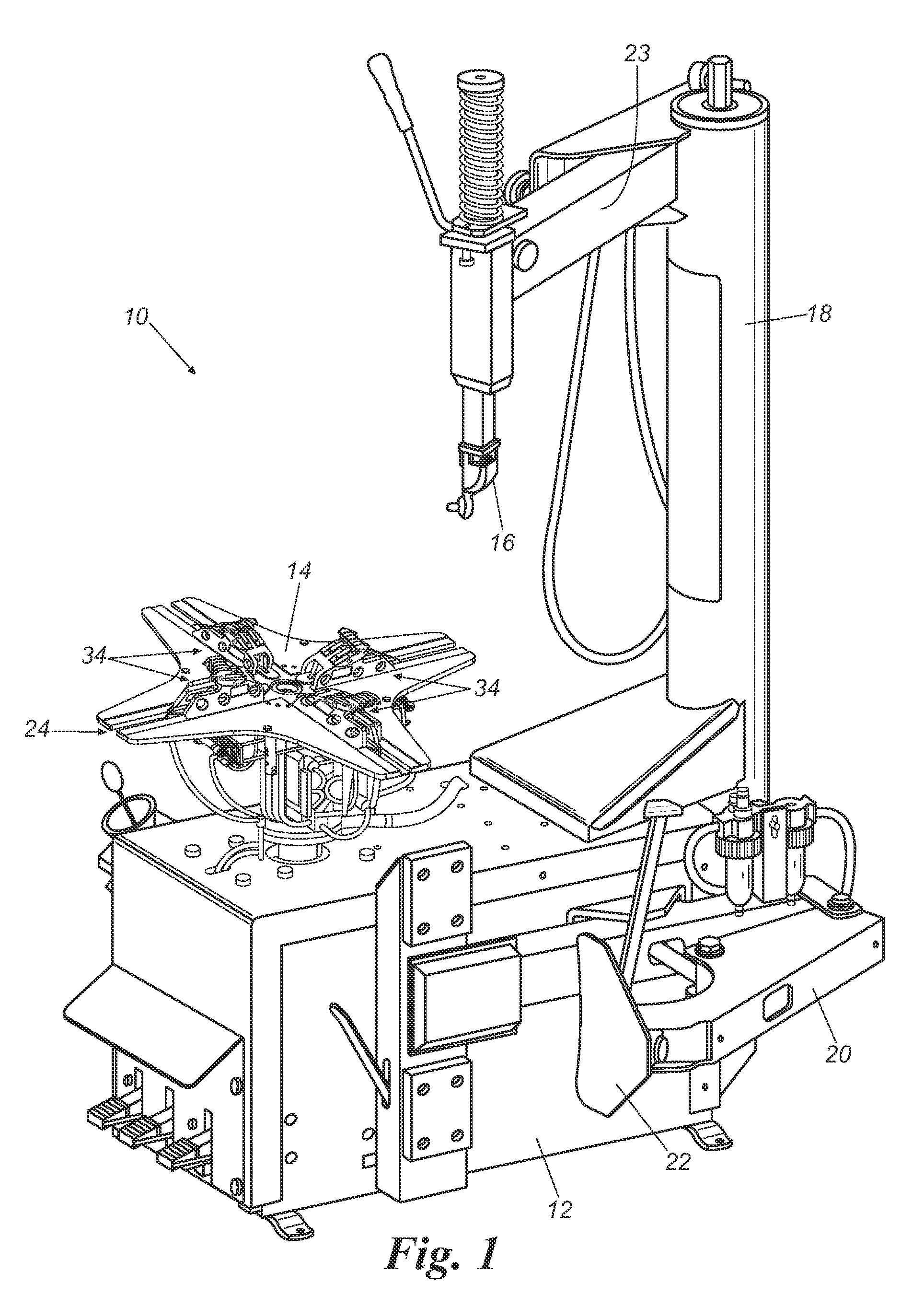

Workcell for tire and wheel assembly including a tire inflating sub-station that utilizes a flexible flip seal

An apparatus for assembling a tire and a wheel is disclosed. The apparatus includes a single-cell workstation including a device that retains a wheel, and a plurality of sub-stations. The device moves the wheel to each of the plurality of sub-stations, without releasing the wheel, to assemble a tire-wheel assembly. A method is also disclosed.

Owner:ANDROID INDS OF MICHIGAN

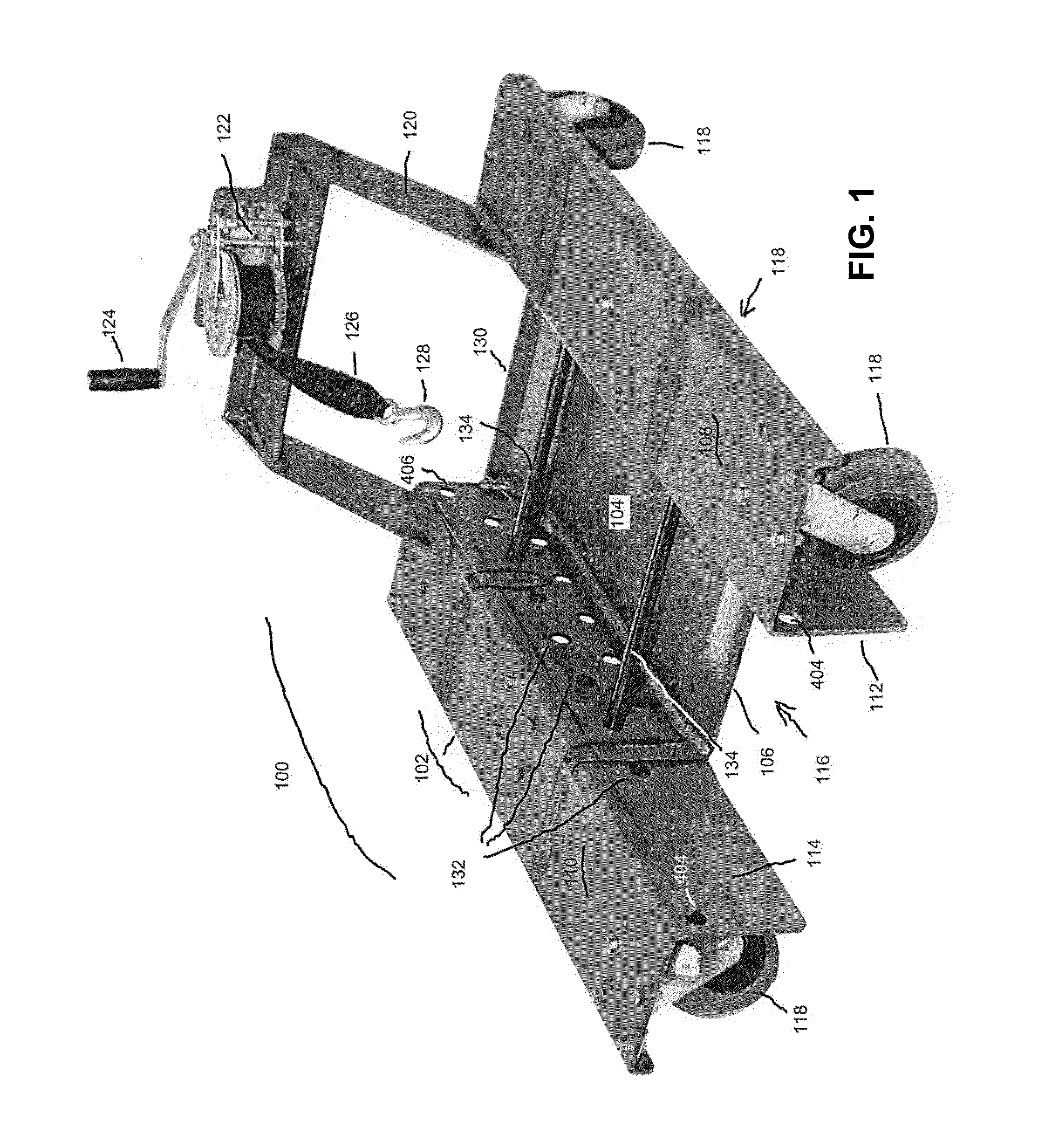

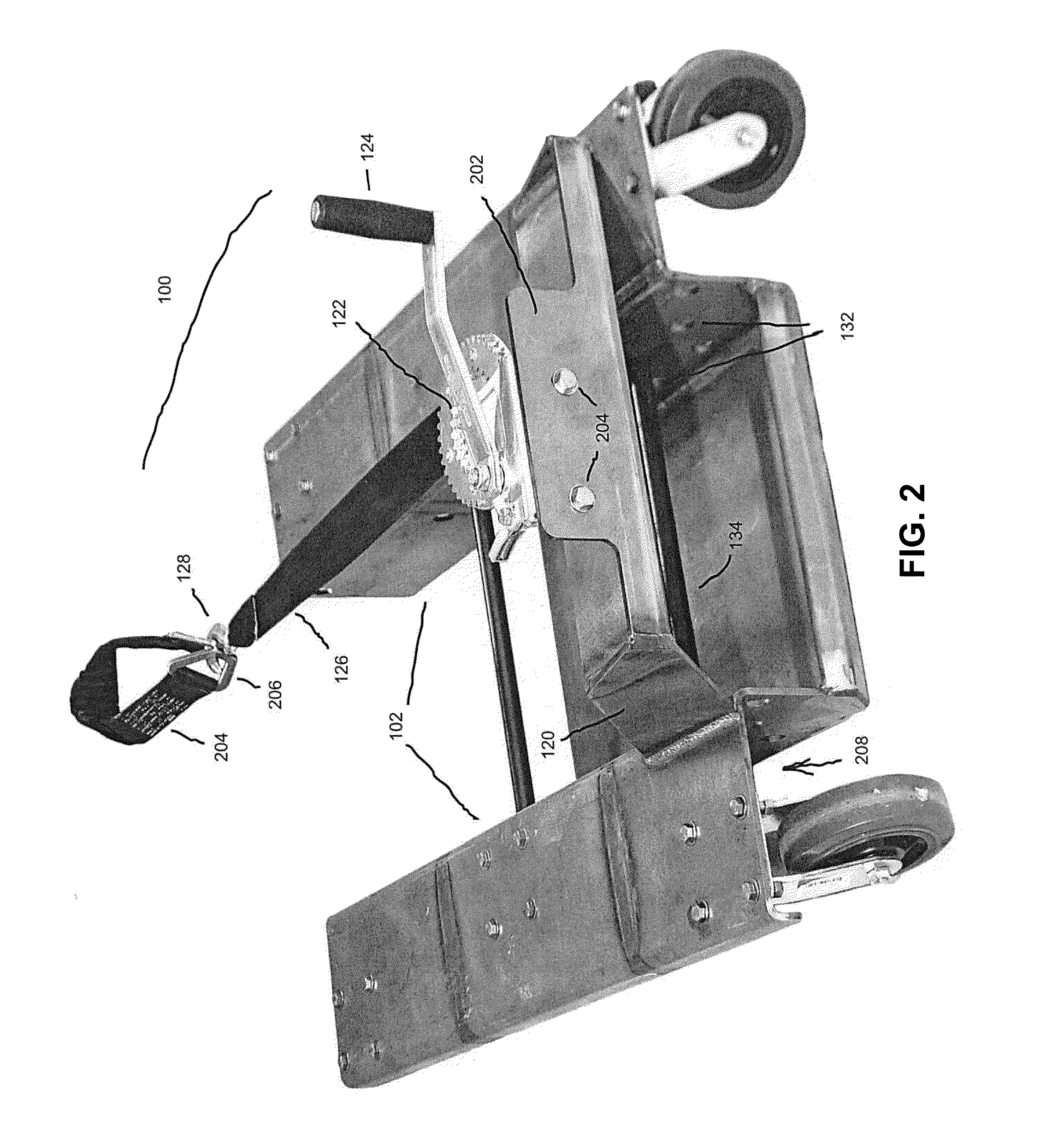

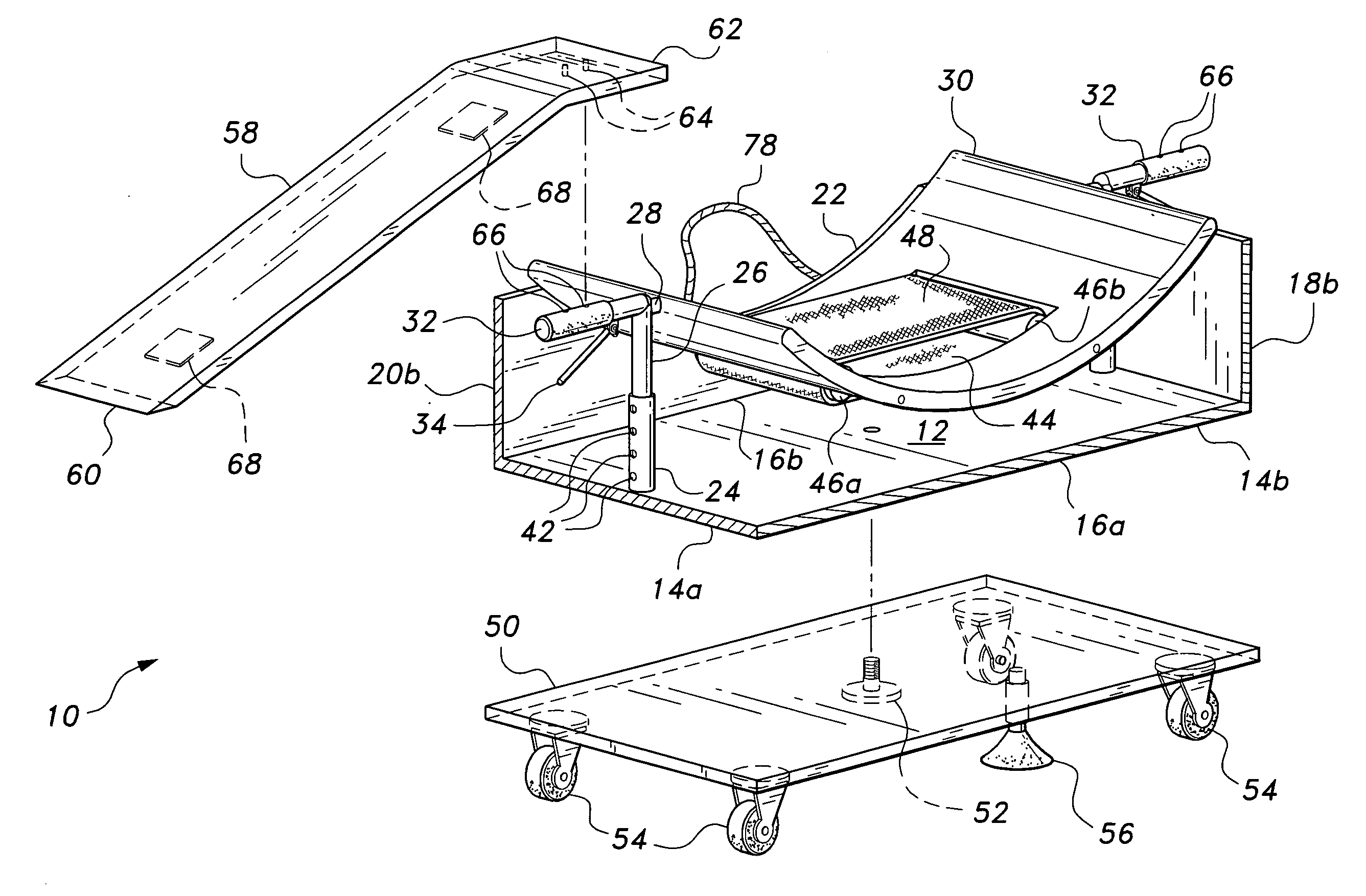

Aircraft dolly

InactiveUS20150259077A1Easily coupled beneathEasy to moveStatic/dynamic balance measurementTyresAircraft landingWinch

A dolly for placement beneath a landing gear of an aircraft that enables transport of the aircraft without rolling the tire of the aircraft. The dolly includes a platform for a tire to rest on and a channel for positioning the tire. The dolly includes a winch for translating the dolly and aircraft tire relative to each other such that the landing gear is brought to rest on the platform, and one or more stops for securing the aircraft landing gear with respect to the dolly. Once positioned, the dolly can be used while transporting the aircraft, either by hand pushing, a hand towbar, a motorized tug with a towbar, or other mode. The dolly is useful for moving aircraft in tight spaces and is also useful for transporting aircraft with damaged landing gear or flat tires.

Owner:WEST METRO AVIATION

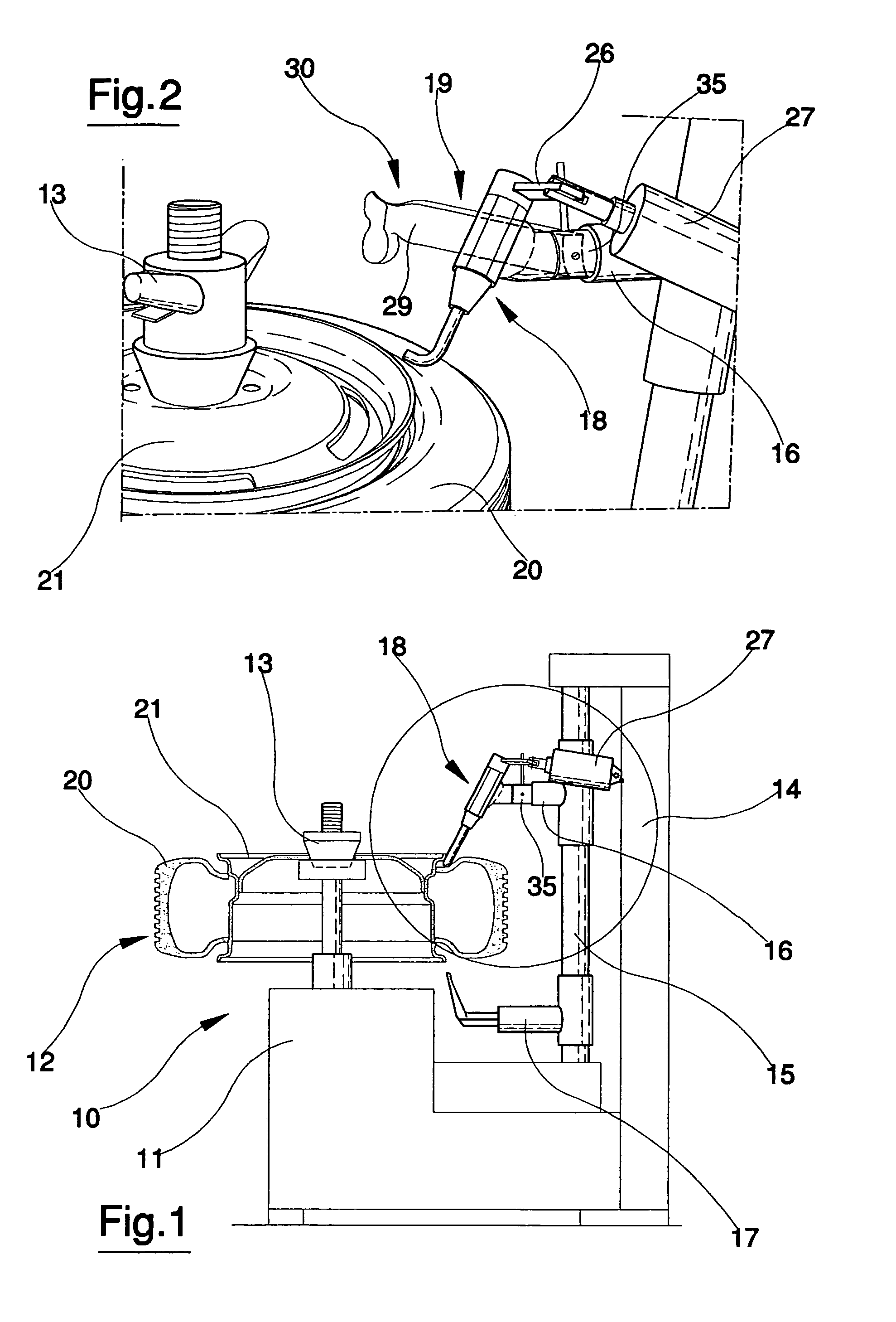

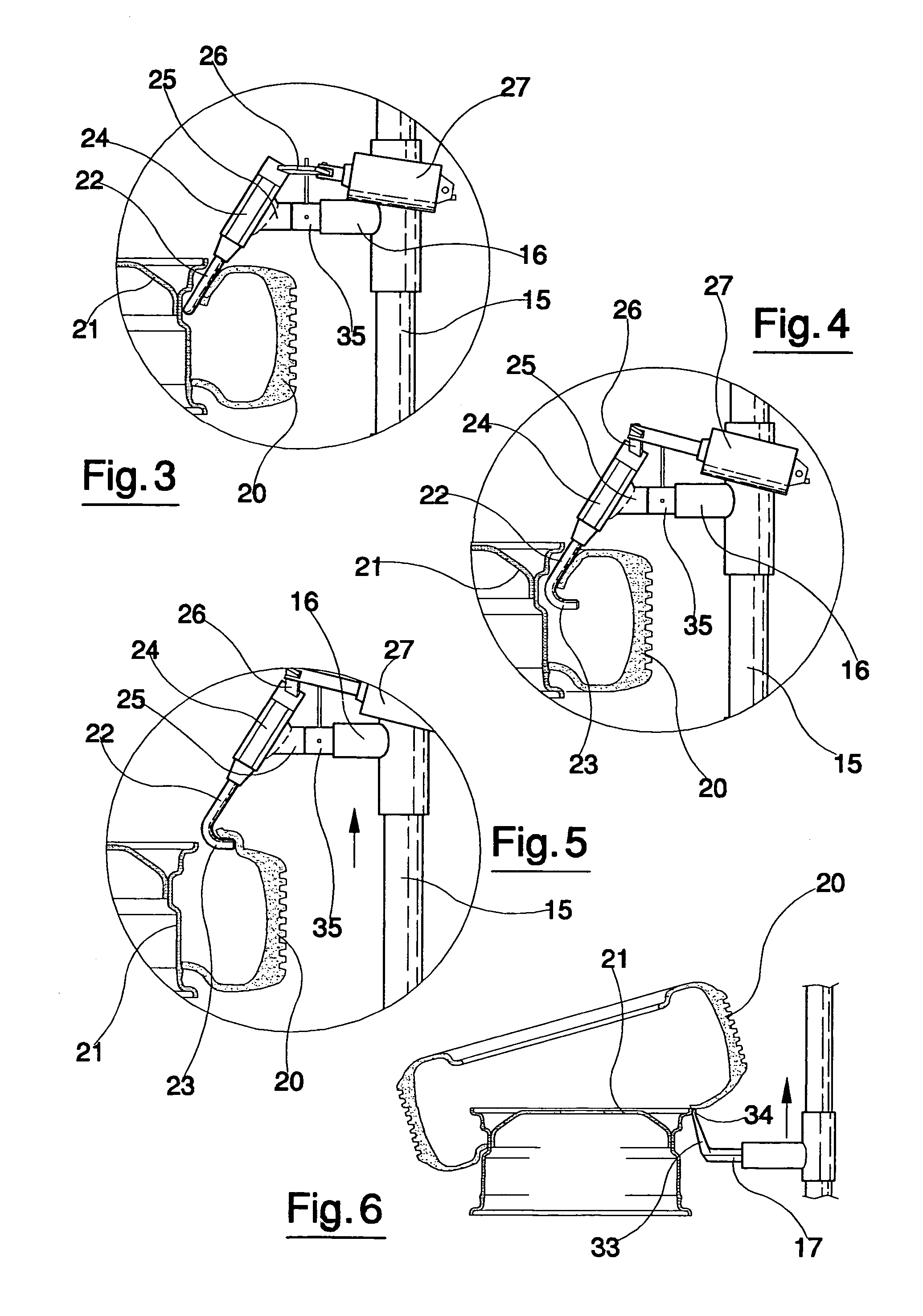

Device for mounting and dismounting tires of wheels positioned on a wheel support of a tire changing machine

Owner:SNAP ON EQUIP

Wheel rim locking device for tire removal machines

Owner:NEXION SPA

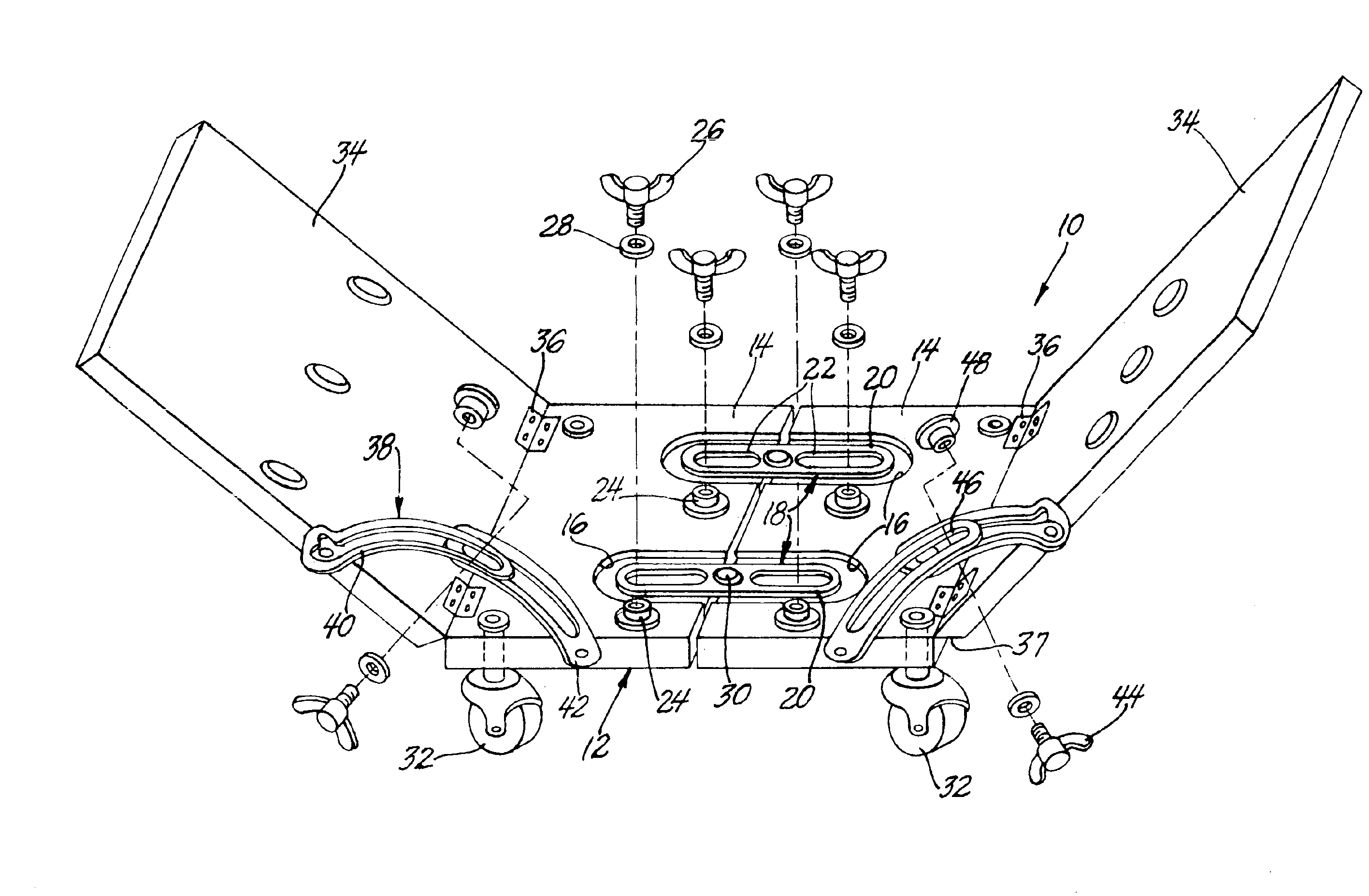

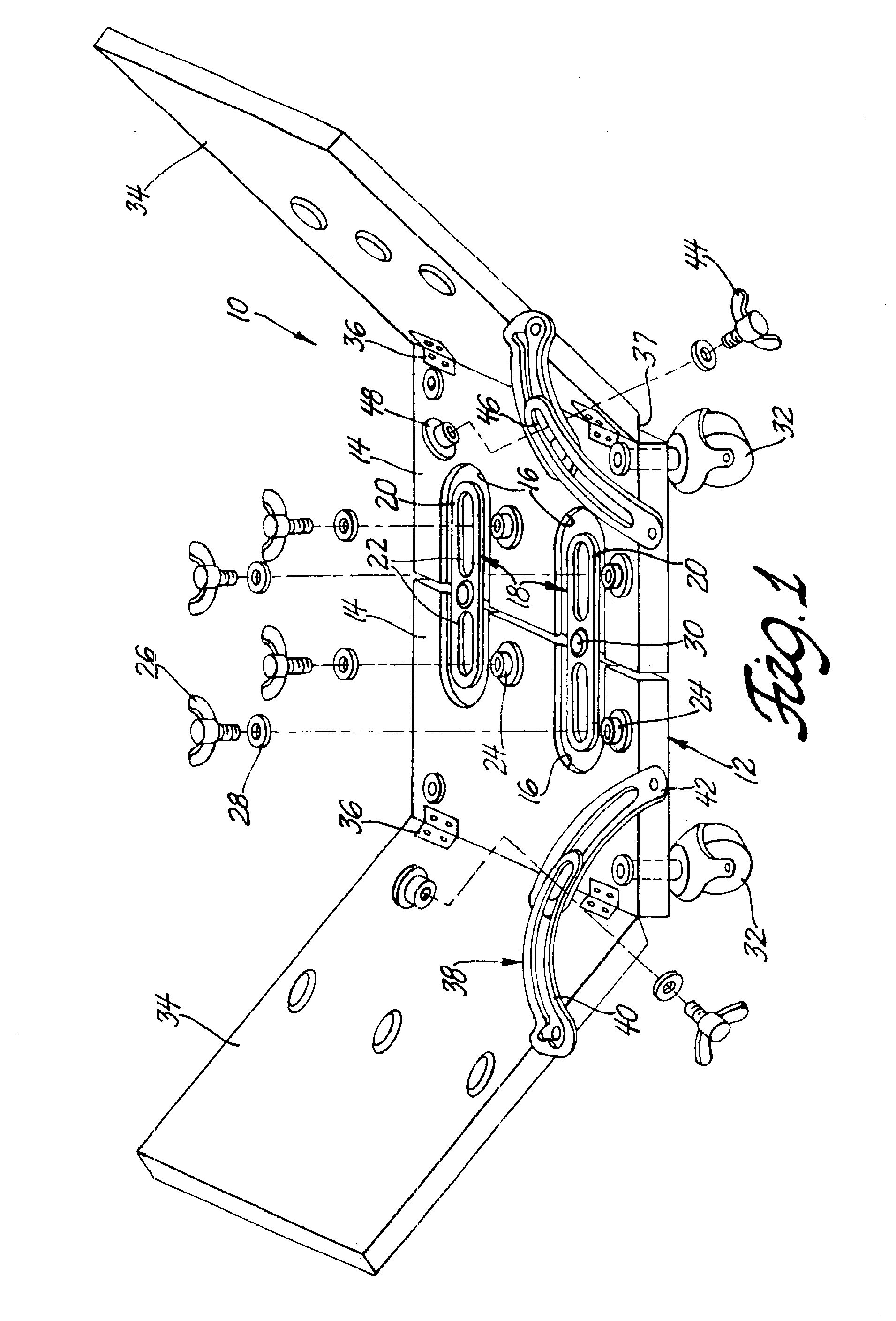

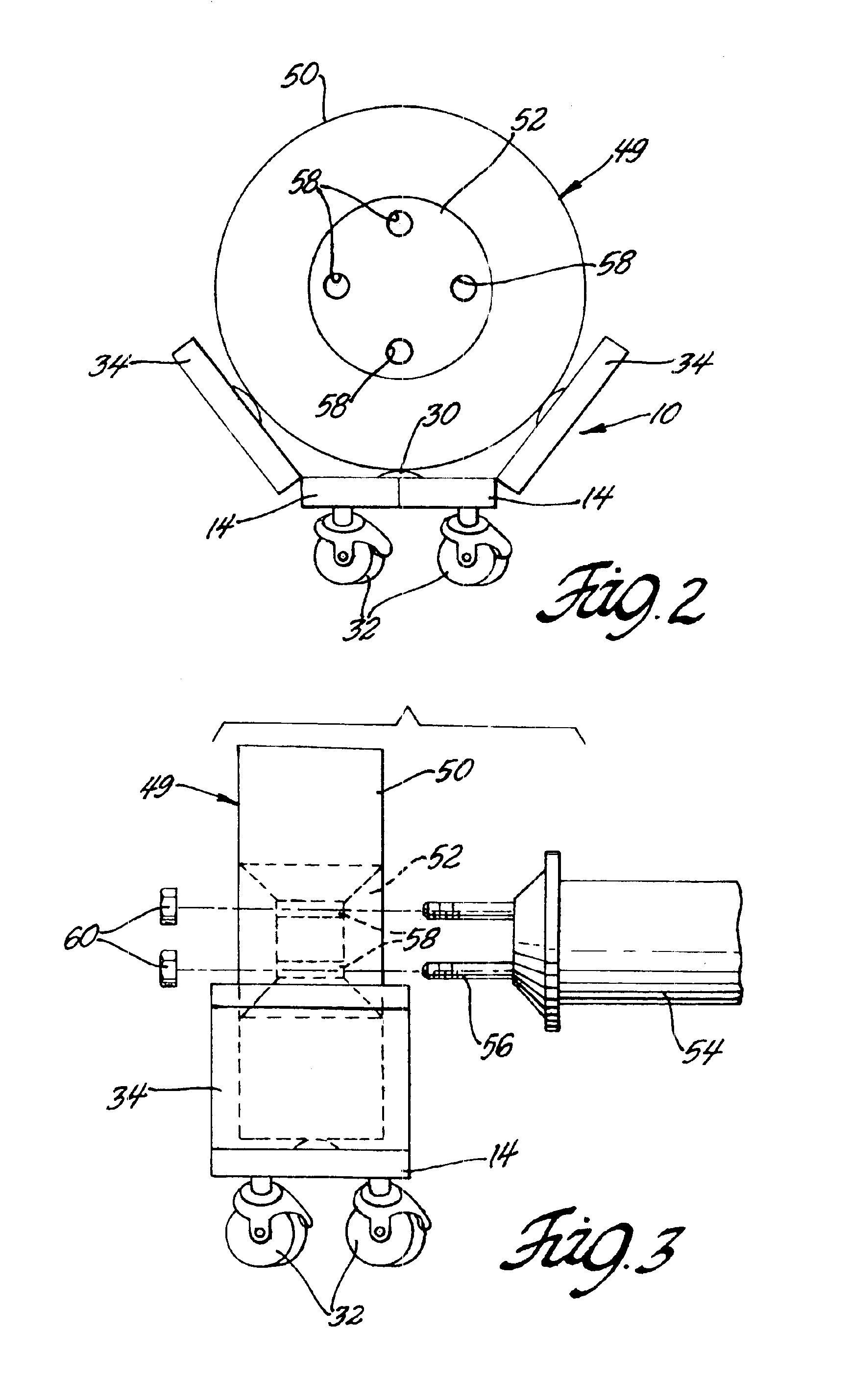

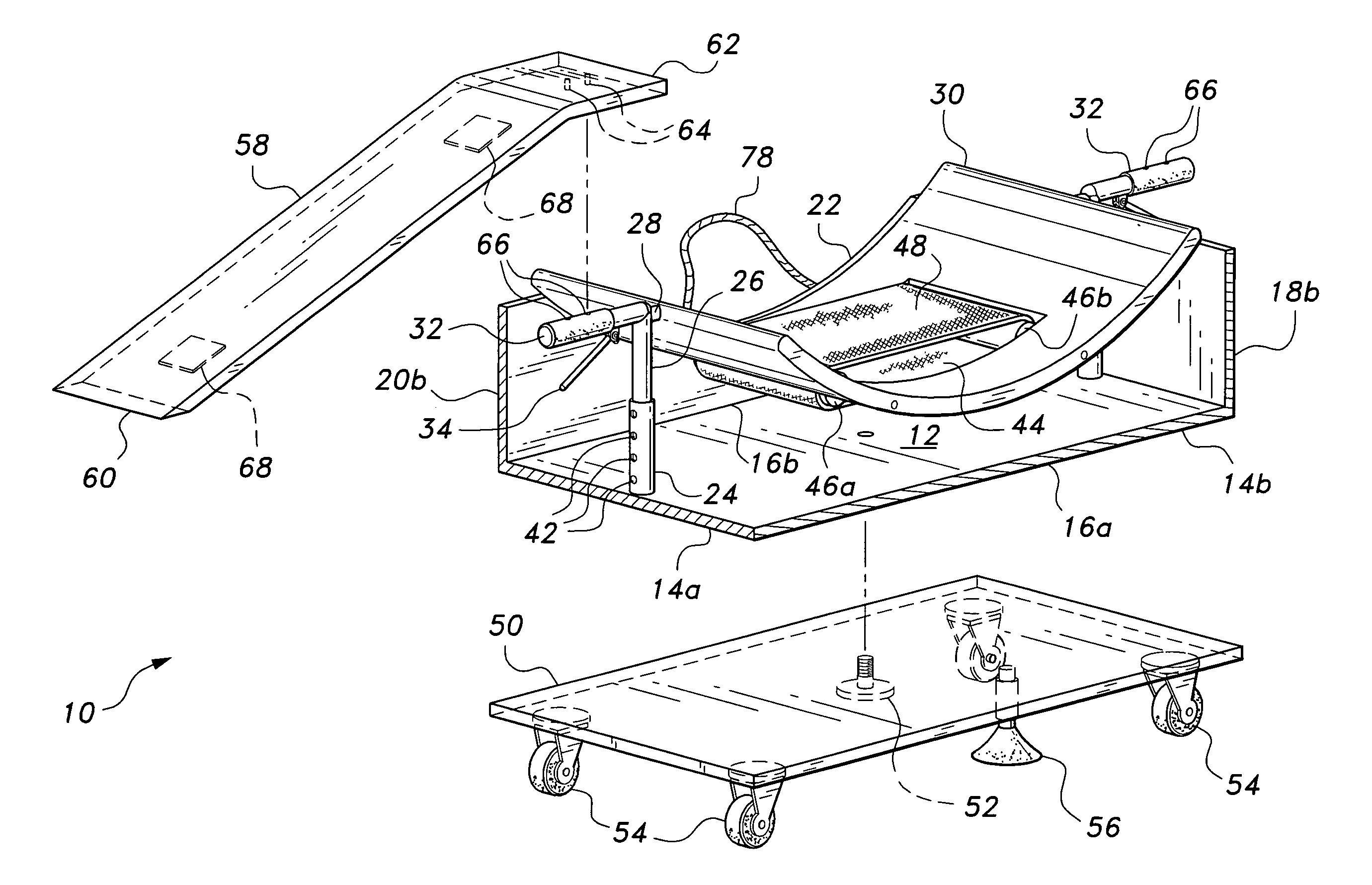

Foldable tire dolly

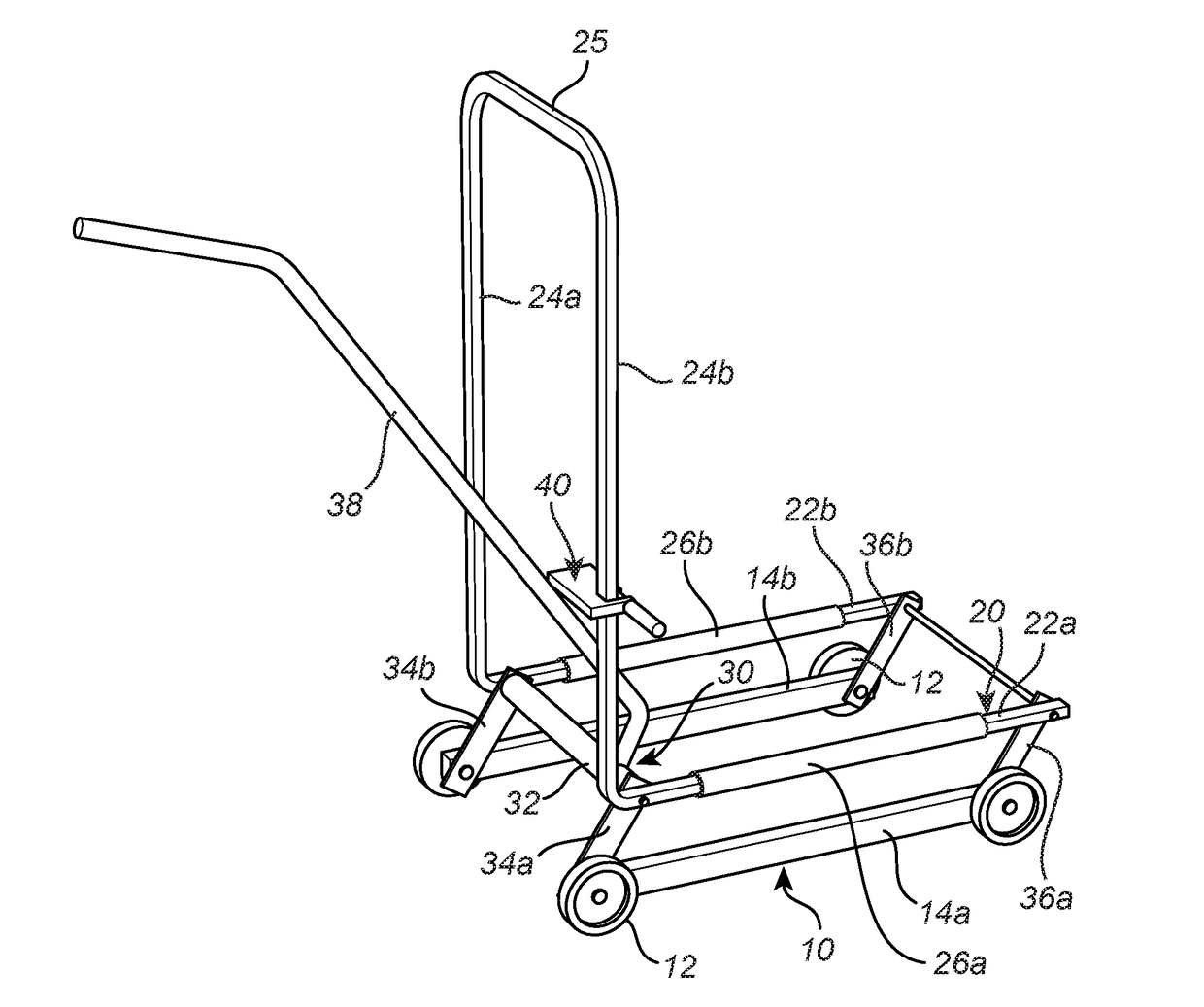

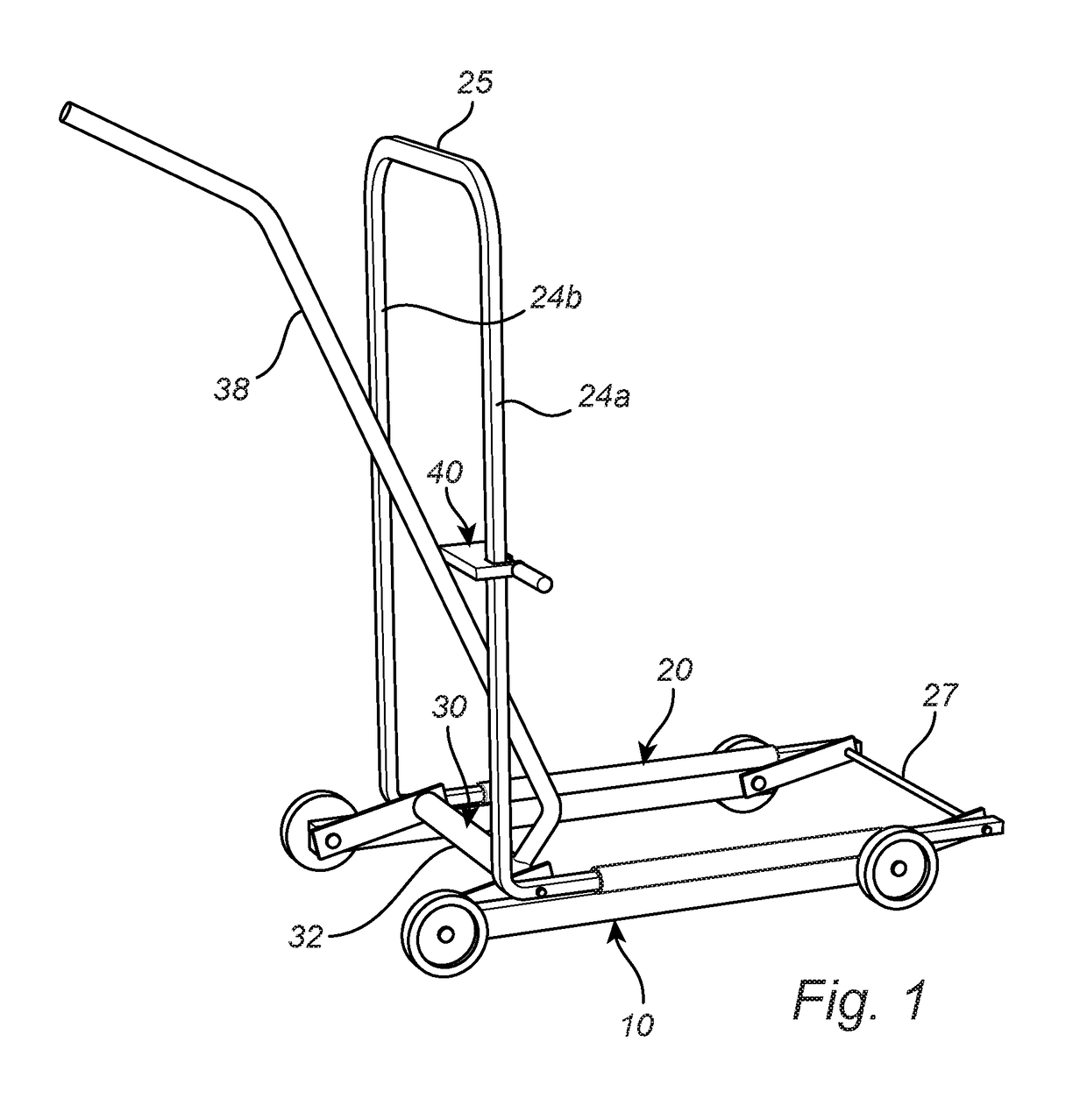

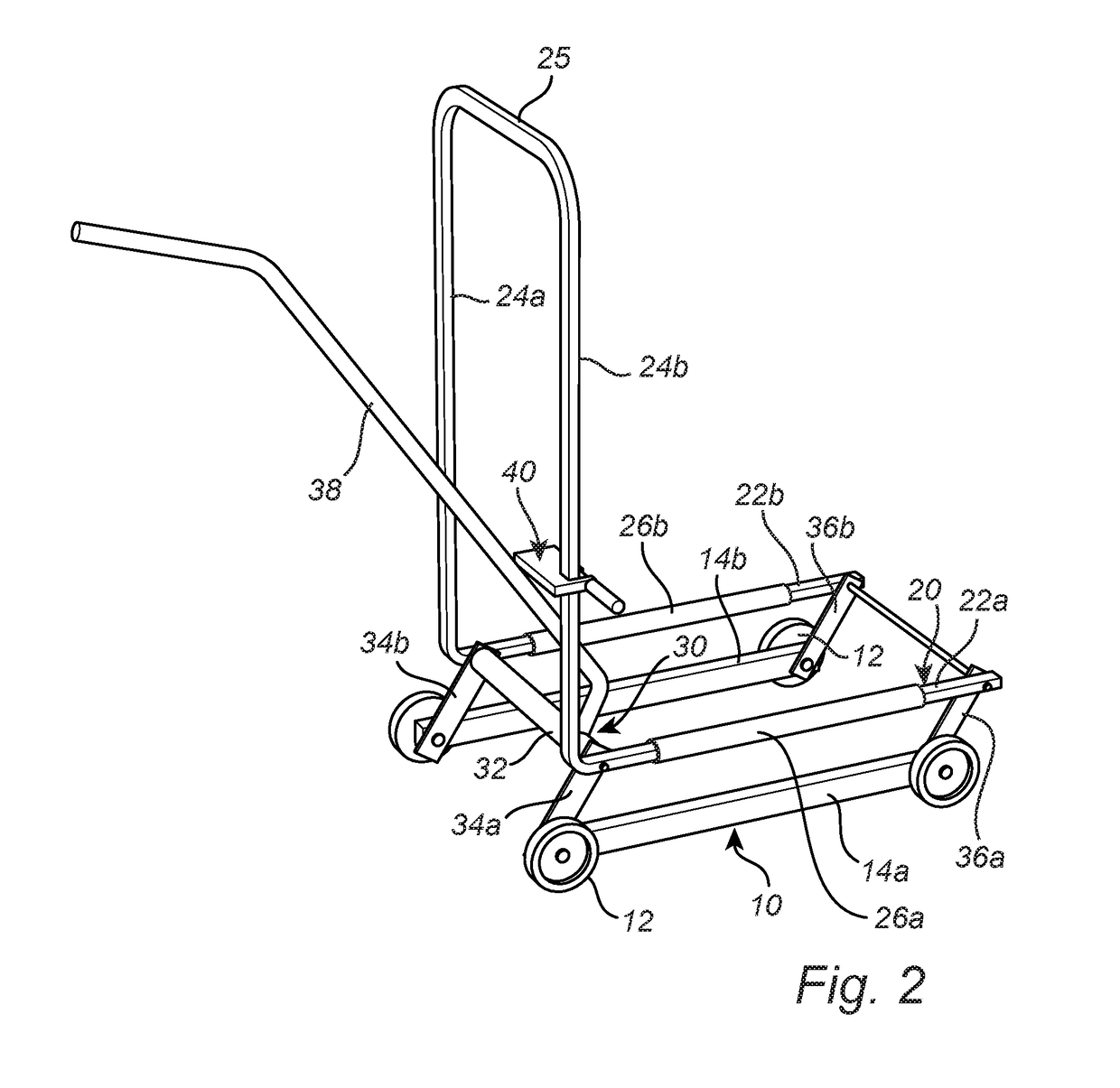

InactiveUS6863488B2Good for scrollingExcessive movementTyresStatic/dynamic balance measurementEngineeringCaster

A foldable dolly for moving and positioning a vehicle tire assembly is formed with a rectangular base member mounted on a plurality of casters. Two wings are hinged to opposite ends of the rectangular member and have adjustable positioning members having one end attached to the base member and the other end attached to one of the wings. A plurality of bearings at least one bearing being mounted on each wing and one on the rectangular base member allow rotation of the tire assembly on the dolly and easy withdrawal of the dolly when the tire is mounted on a vehicle.

Owner:THE SEC OF THE ARMY

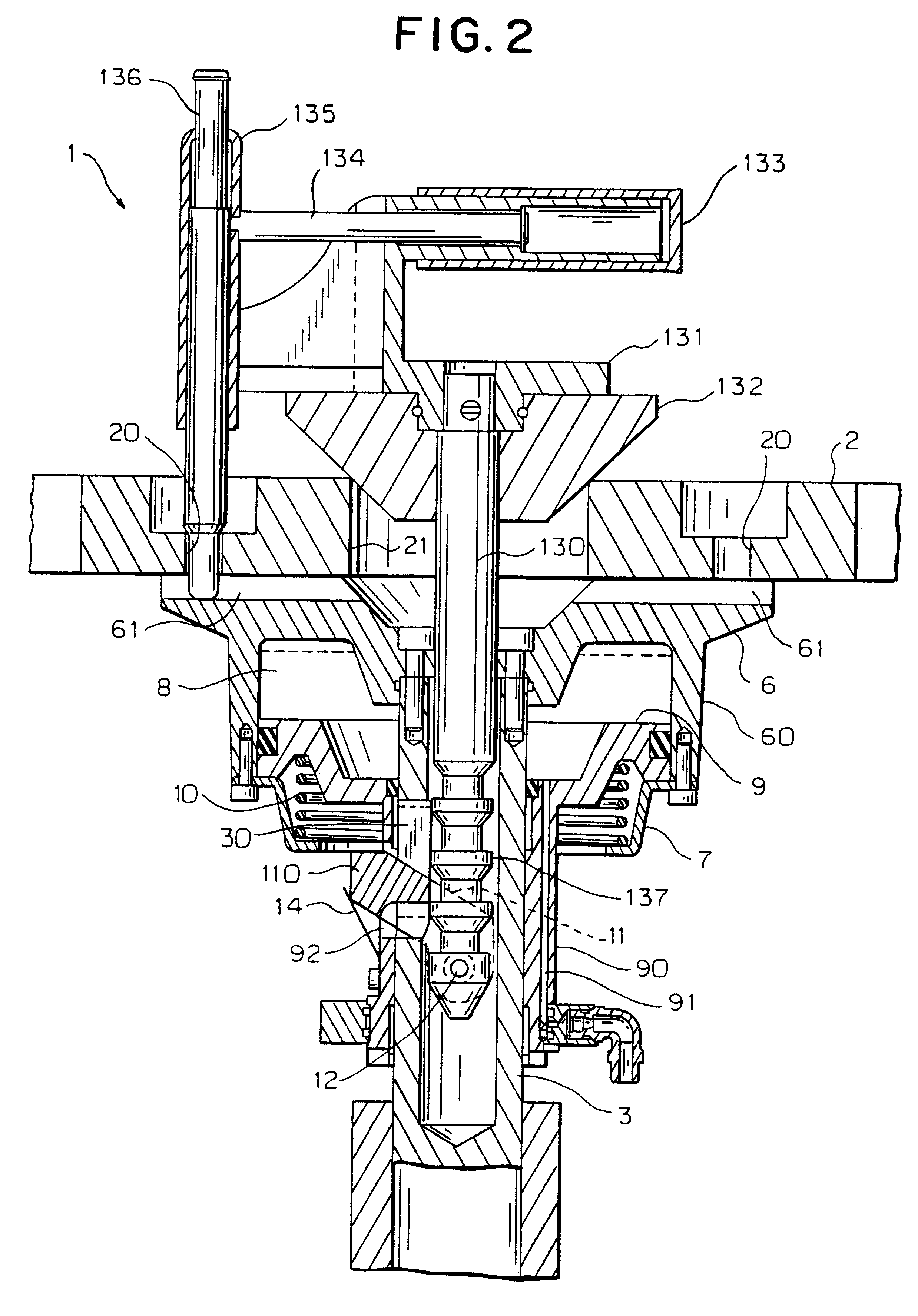

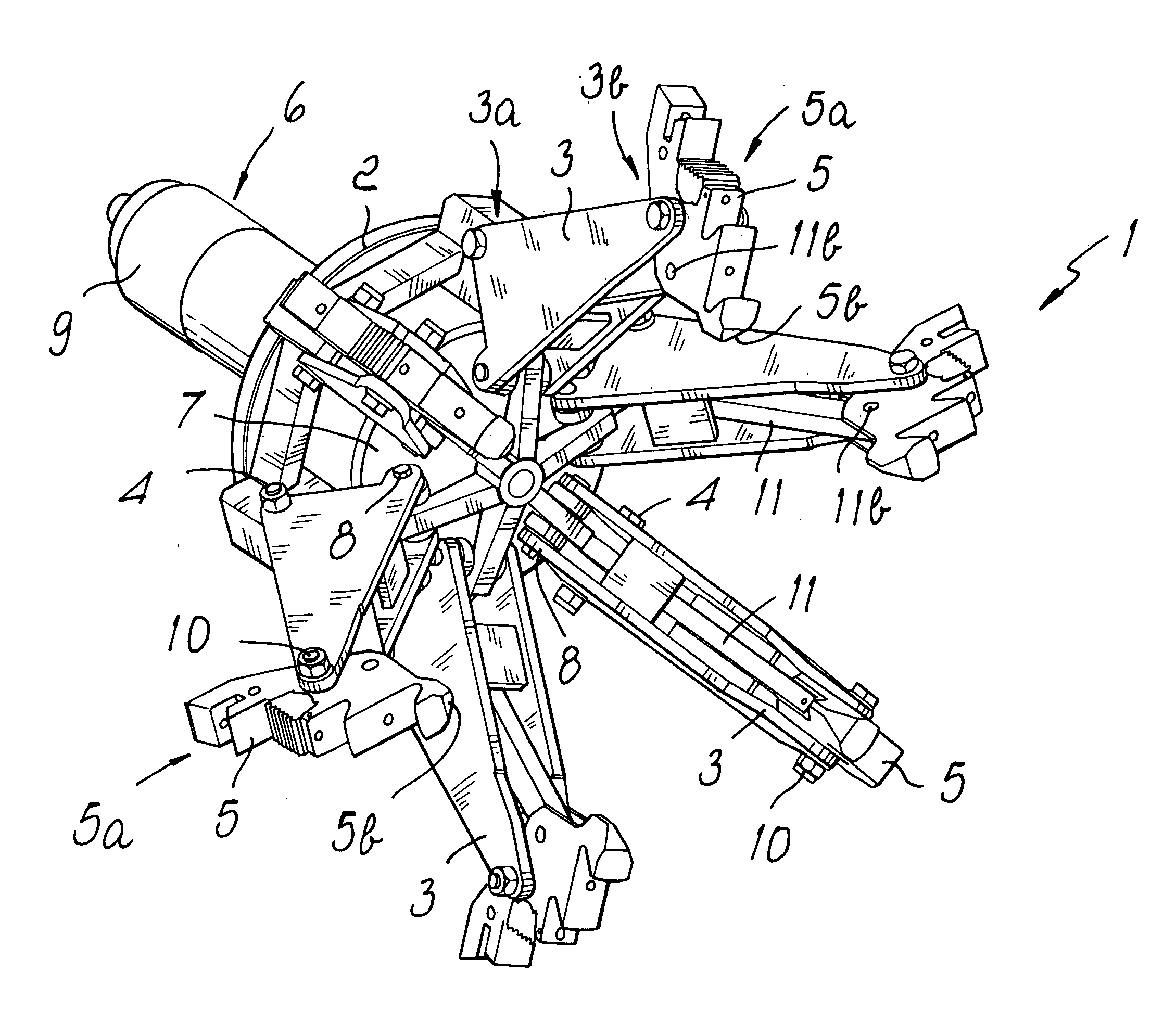

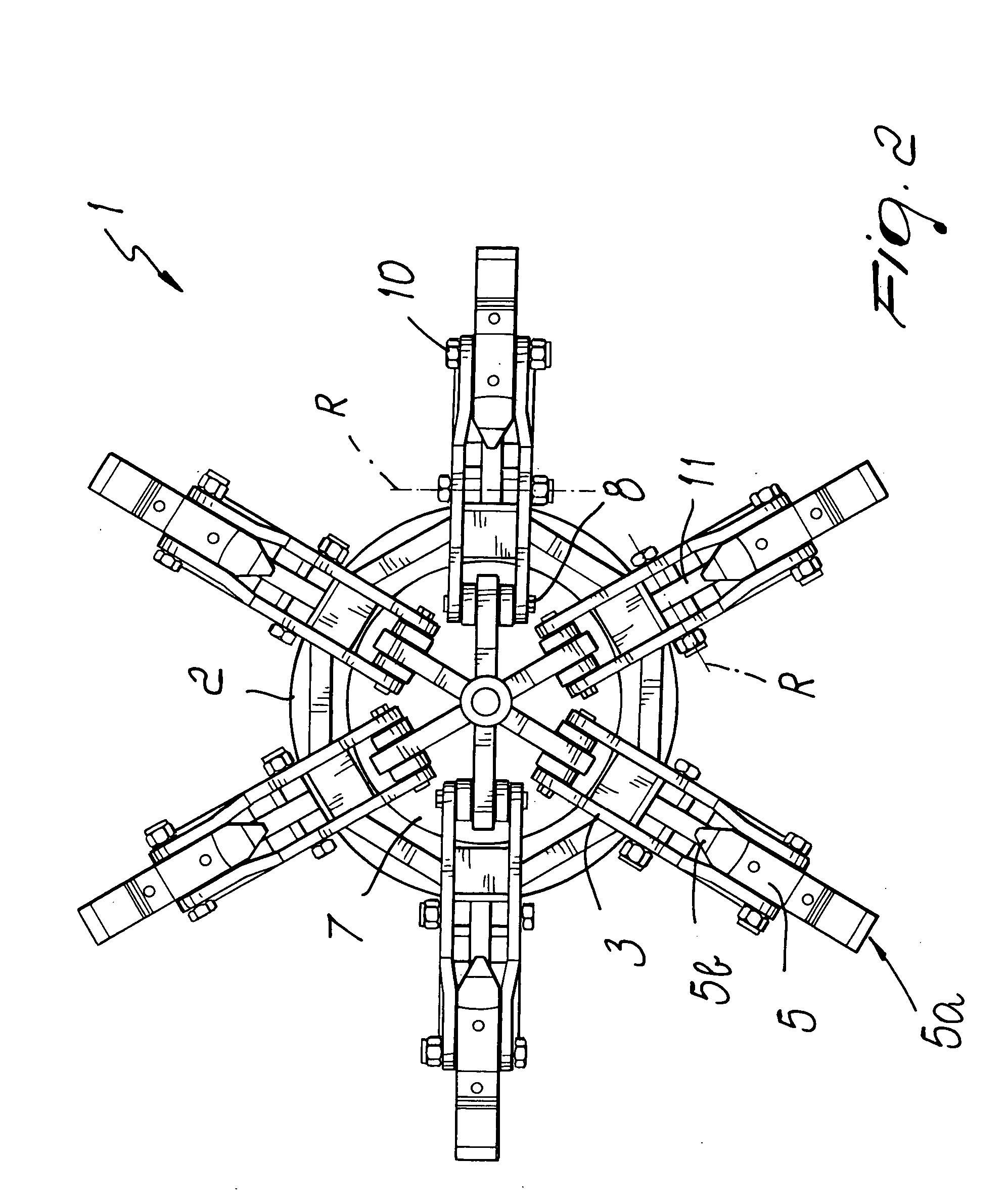

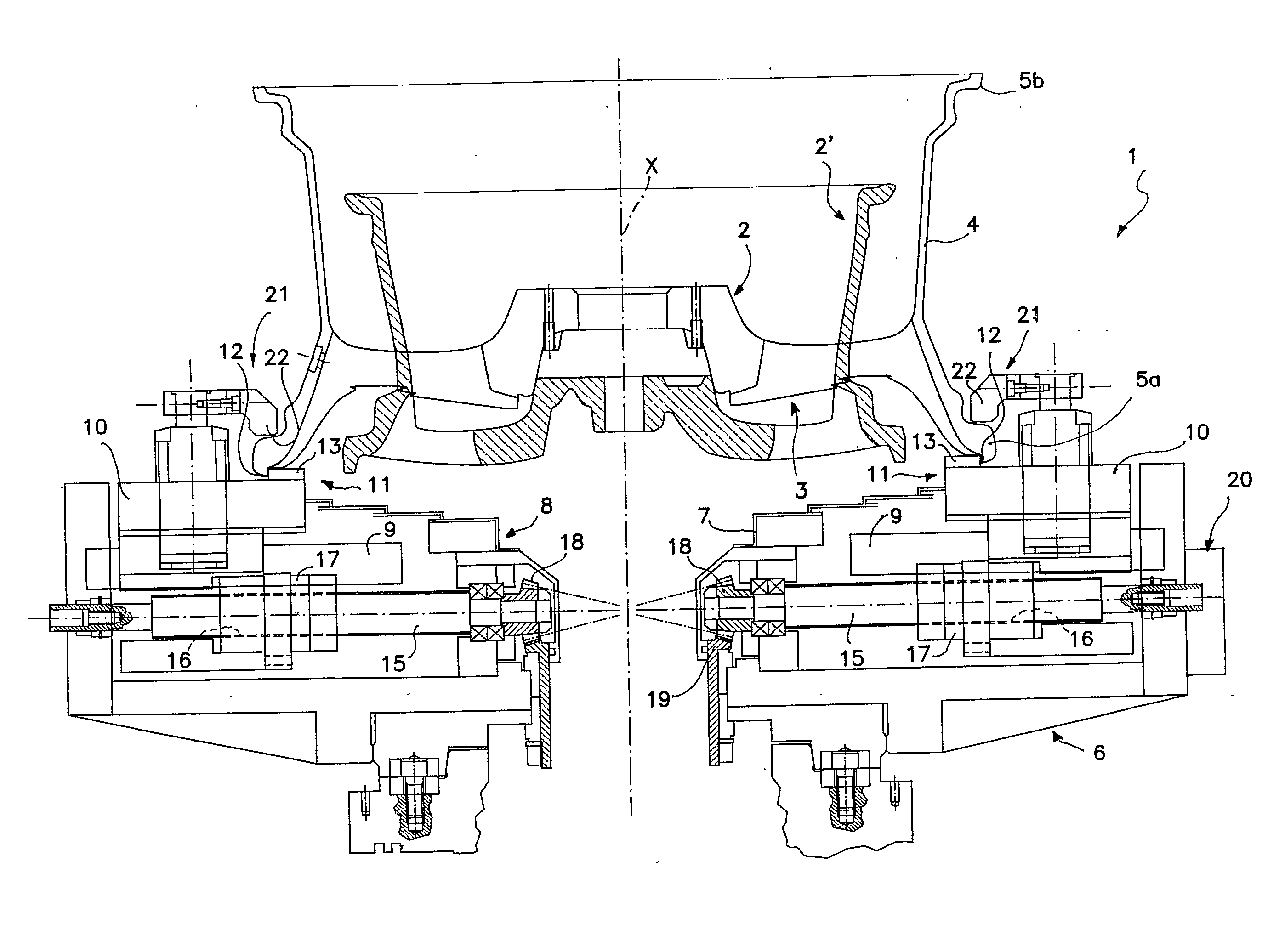

Spindle for fastening rims of vehicle wheels on repair shop machines

ActiveUS20050199349A1Stable and mannerEasy to provideSleeve/socket jointsStatic/dynamic balance measurementRepair shopEngineering

A spindle for fastening rims of vehicle wheels on repair shop machines, which comprises a frame that can be associated rotationally about a working axis with a repair shop machine, six or more movable arms that are associated with the frame, are distributed around the working axis and can rotate about respective rotation axes that lie on a plane that is substantially perpendicular to the working axis, and claws for gripping the rim of a vehicle wheel, which are associated with the arms and on which it is possible to fit the internal cylindrical portion of the rim.

Owner:SICAM SRL

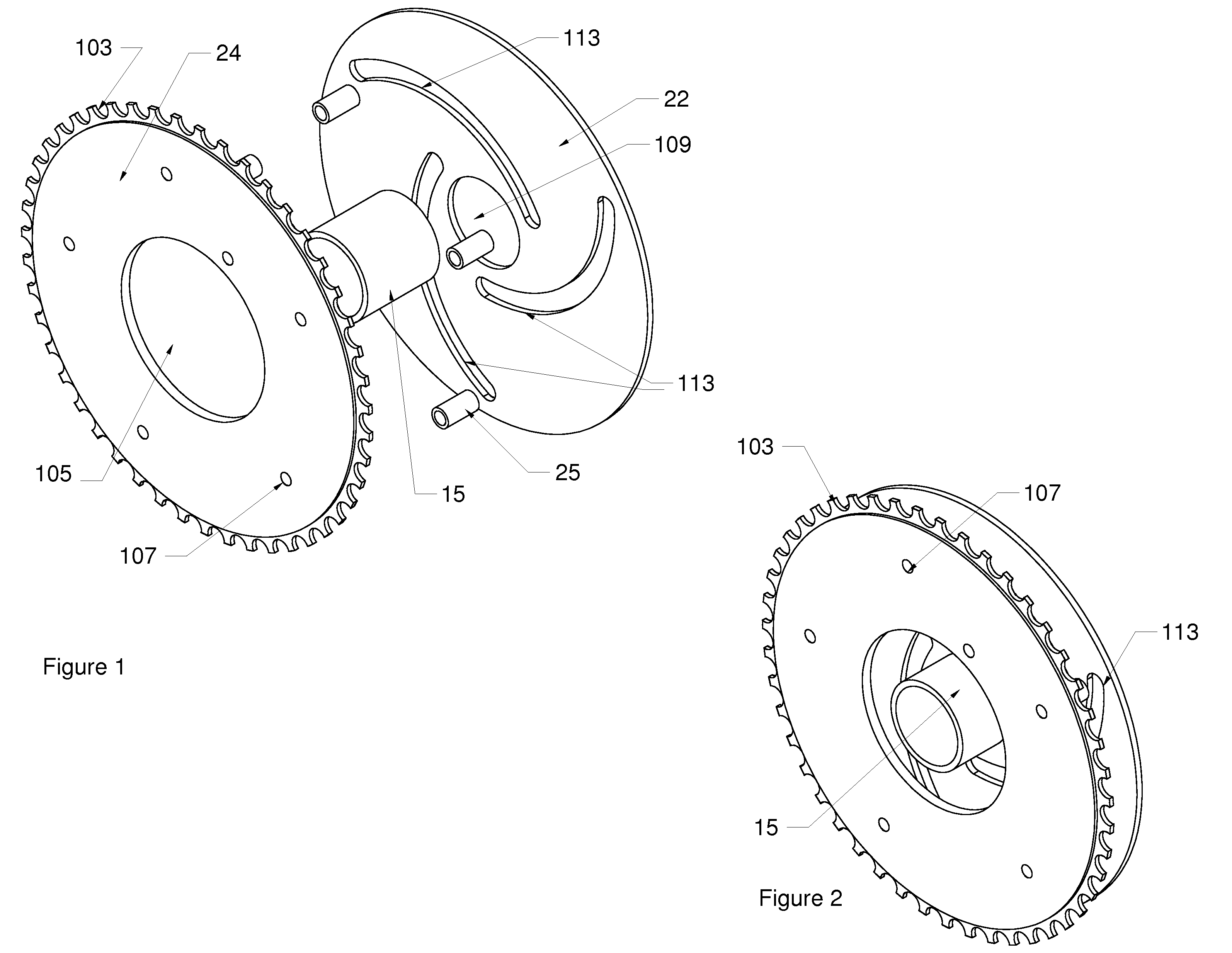

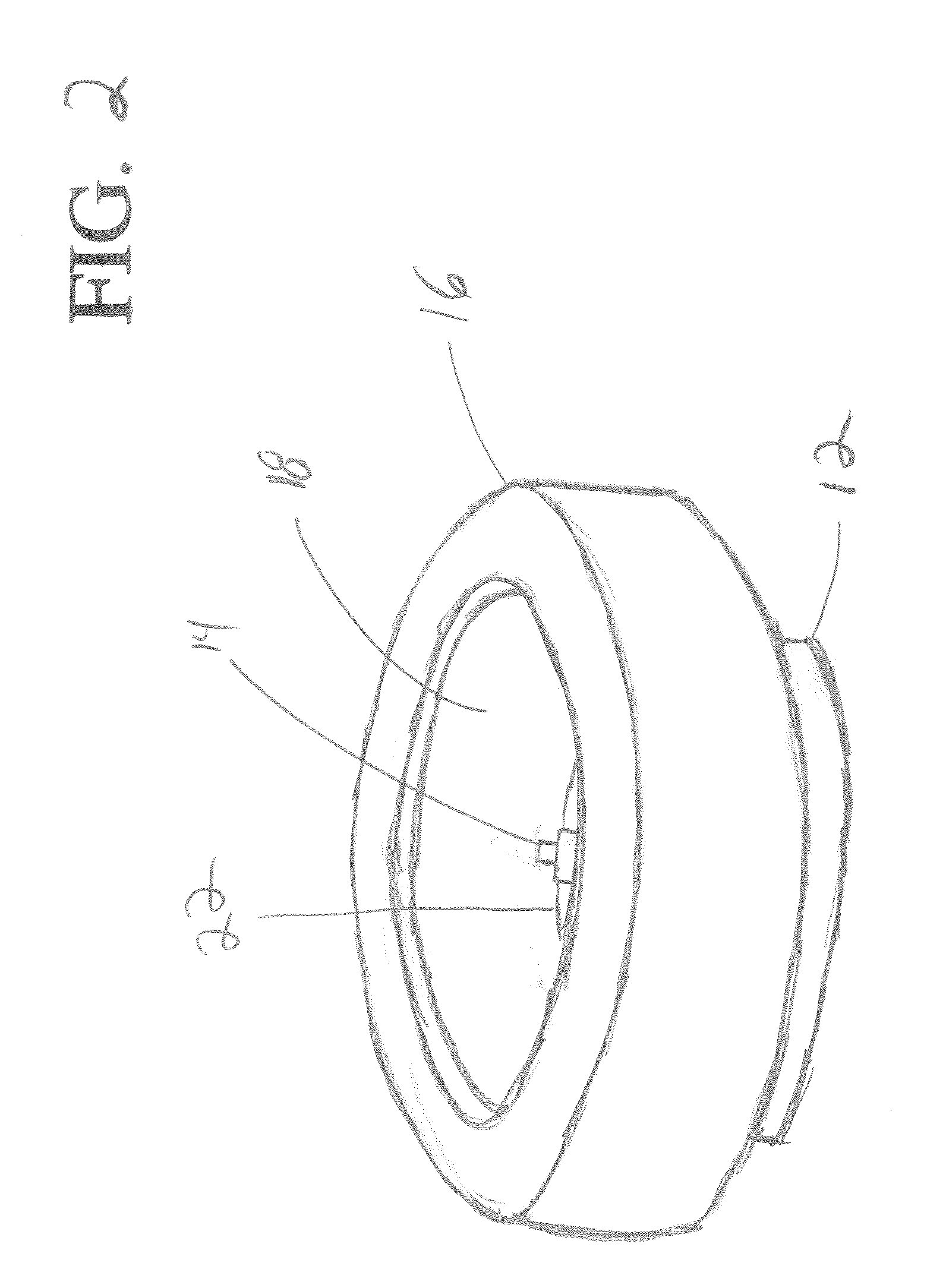

Self-centering unit

Self-centering unit for tire removal machines, comprising a plate provided with a series of angularly equidistant radial slots, in each of which a clamping jaw is received and slides to grip the edge of a wheel rim, said clamping jaws being linked together in such a manner as to be always equidistant from the axis of said plate, at least one clamping jaw being associated with actuator means causing it to translate in a radial direction by means of a positioner device arranged to vary the working position of said clamping jaws relative to the actuator means, without modifying their travel stroke.

Owner:NEXION SPA

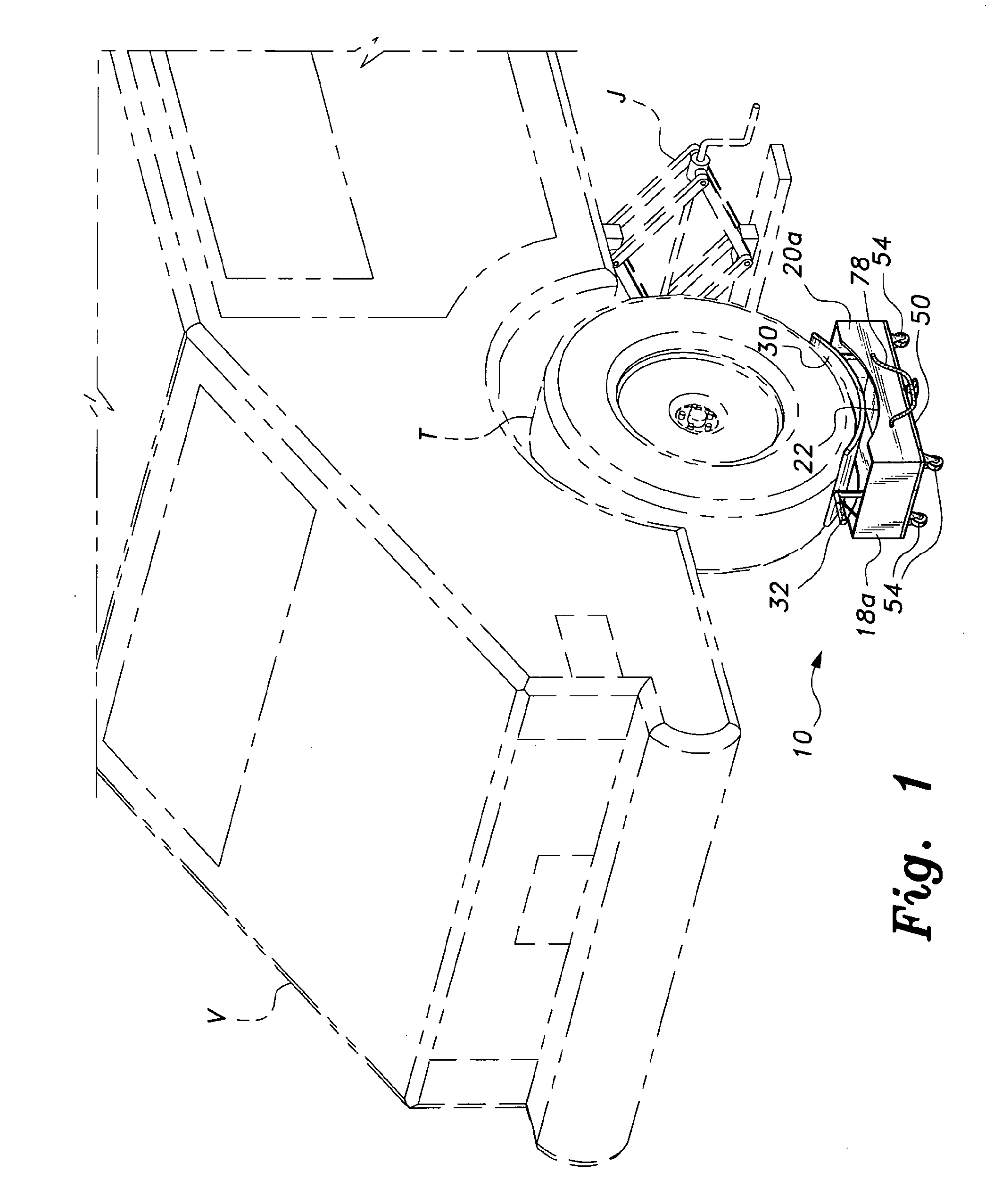

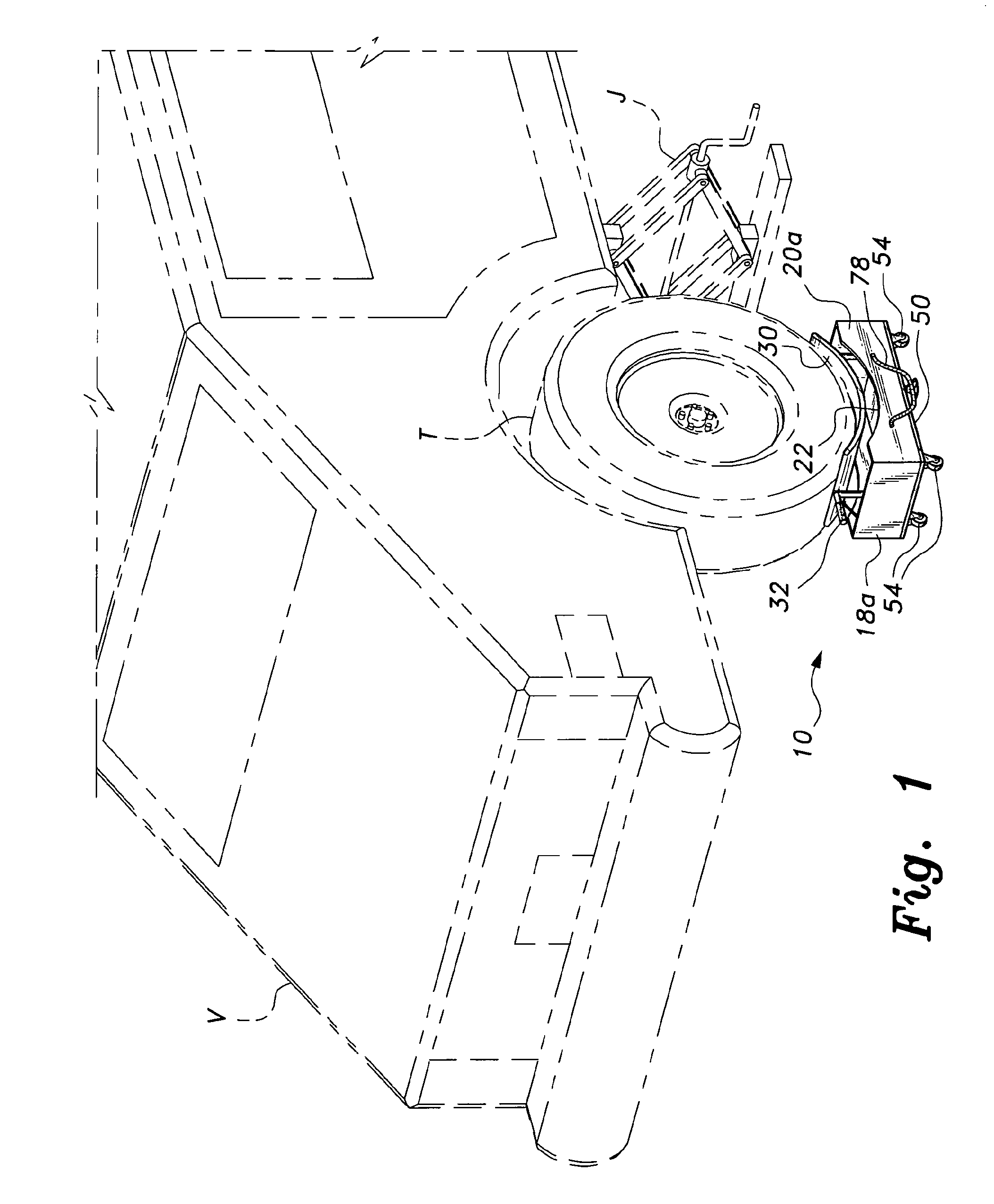

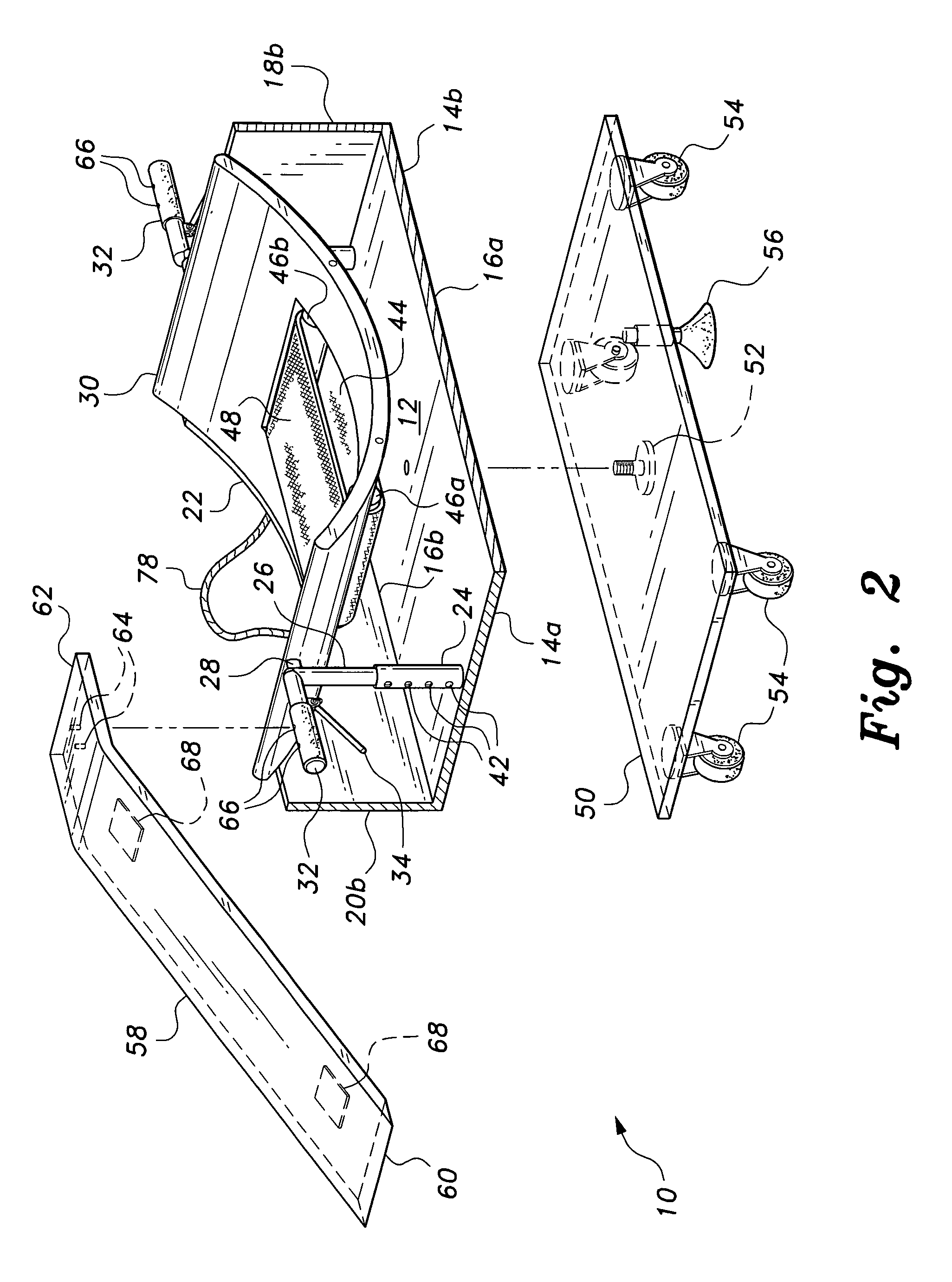

Tire-handling device

InactiveUS20100092270A1Easy to carryClearance can be providedStatic/dynamic balance measurementTyresMobile vehicleMotorized vehicle

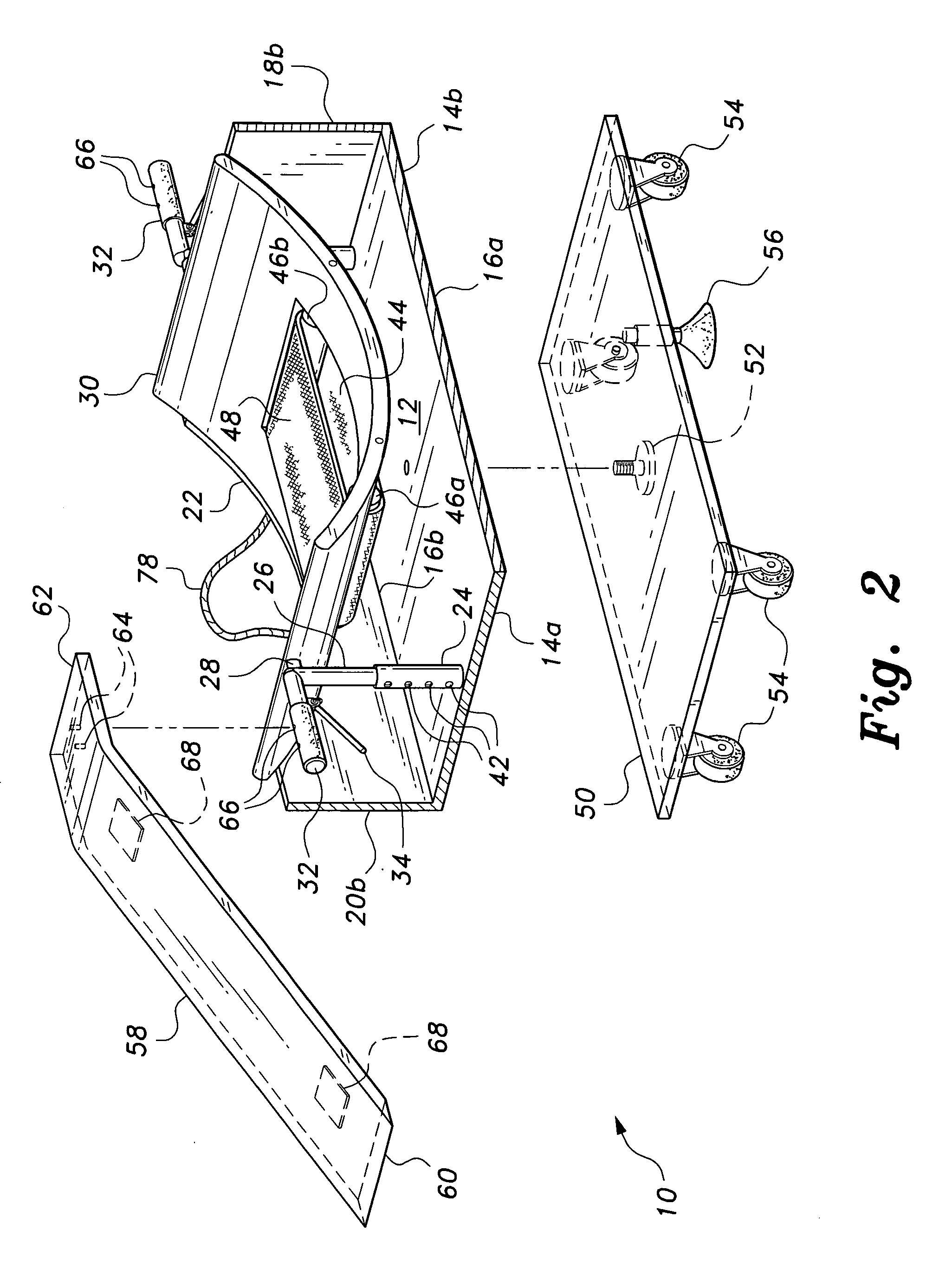

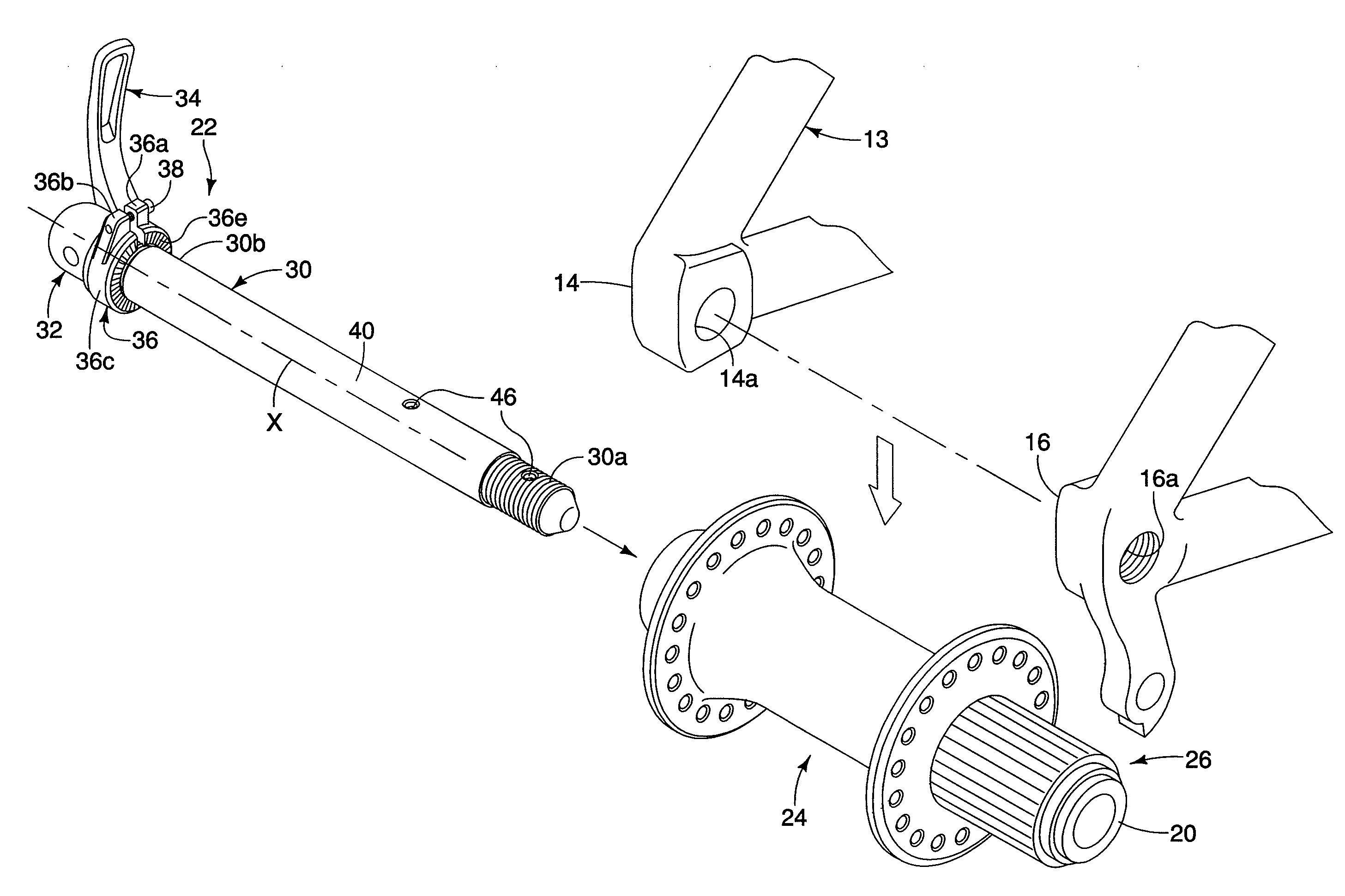

The tire-handling device (10) is a compact, lightweight tool for carriage within a motor vehicle trunk or storage compartment to facilitate handling of a tire (T) during a tire change or similar operation. The device includes a tire support cradle (30) supported by opposed vertically adjustable handles (32). The handles (32) and cradle (30) therebetween may be adjusted to position the cradle (30) beneath a tire (T) on a raised axle during a tire change, or for aligning a fresh tire with the wheel mounting studs of the wheel hub. Two mutually opposed tire support belt rollers are disposed within the cradle (30). A tire support belt extends between the rollers, allowing a tire (T) resting thereon to be rotated for alignment with the mounting studs of the vehicle wheel hub.

Owner:ADAMS SKY A

Vertical tire changing device

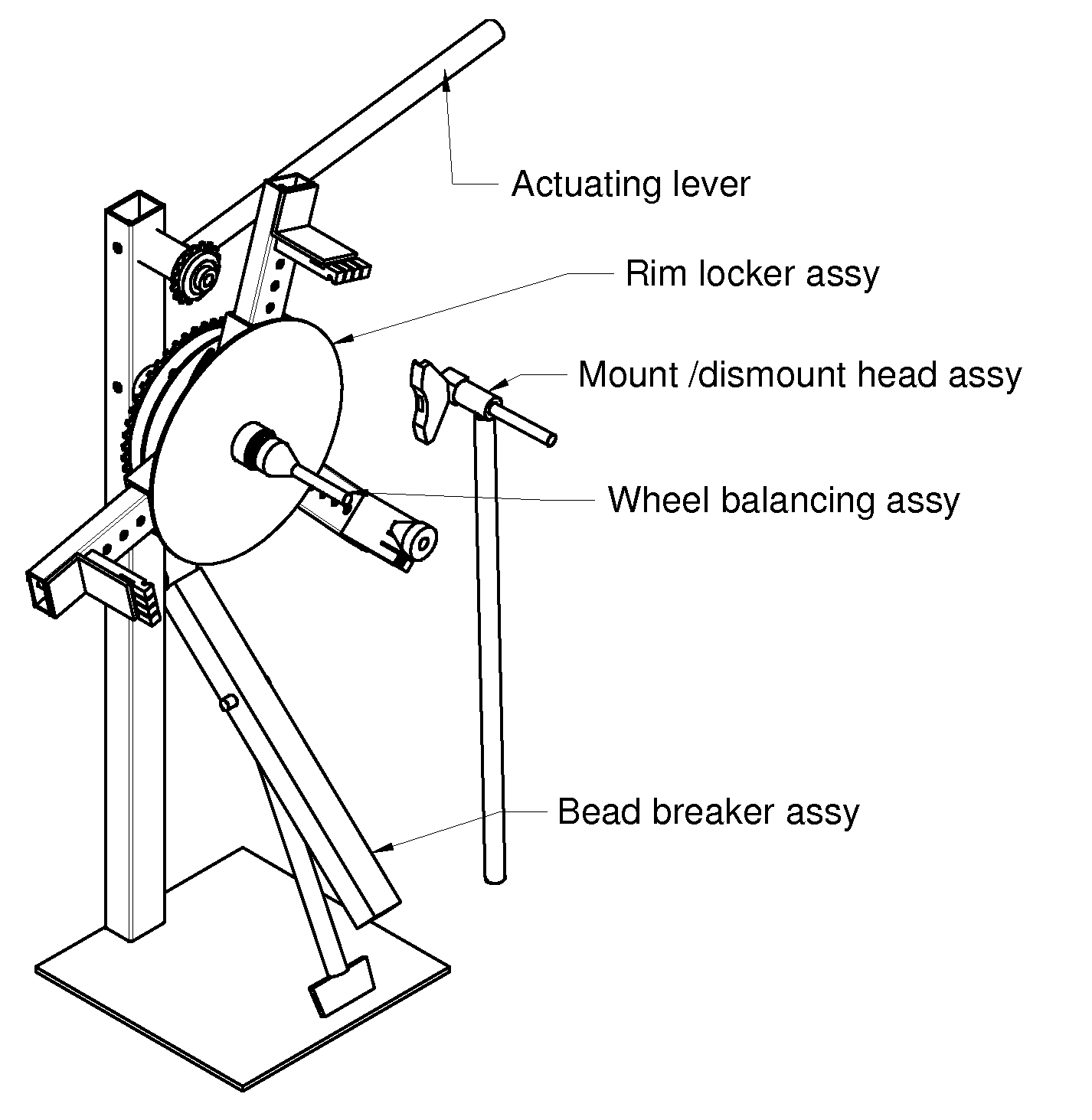

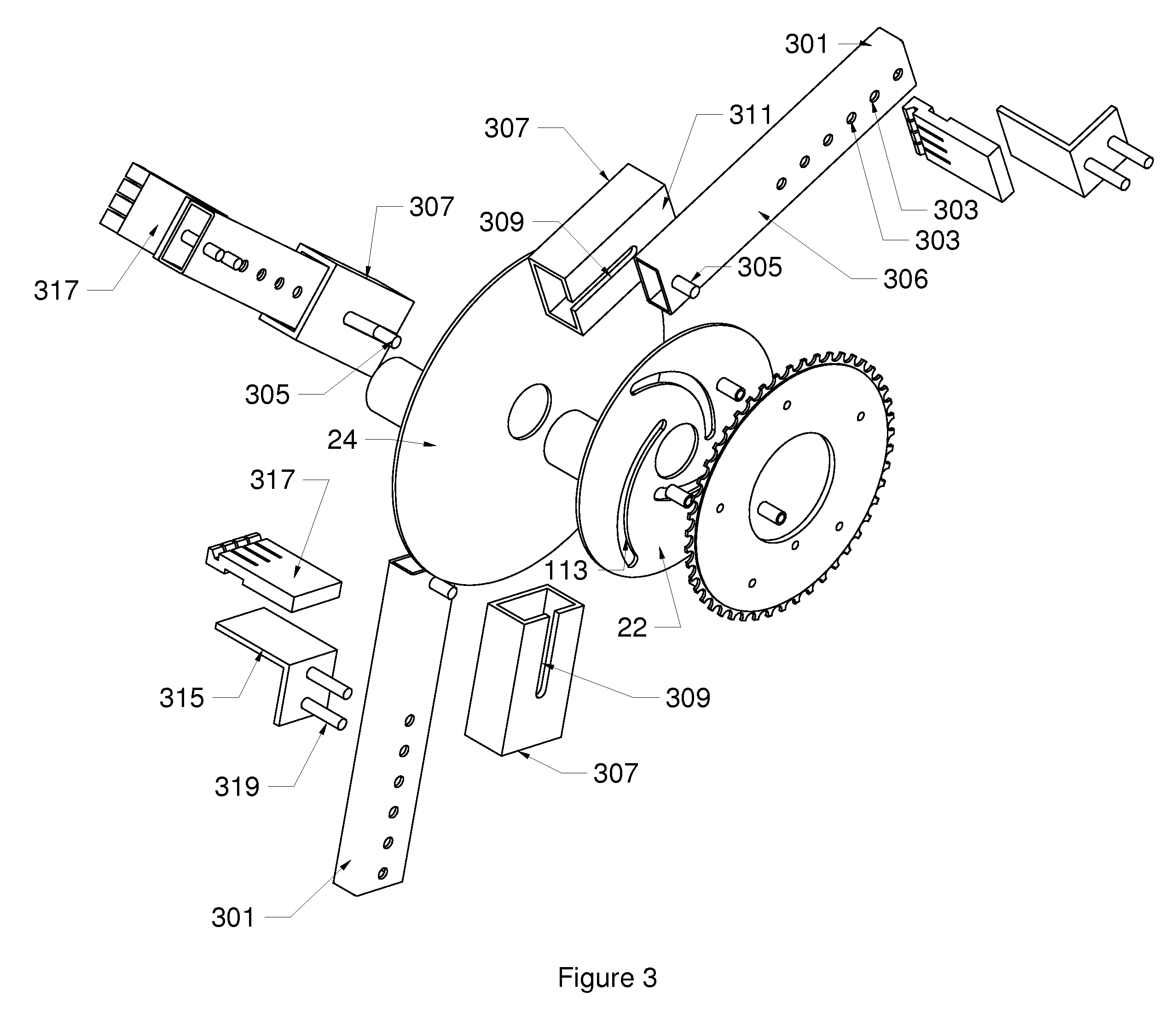

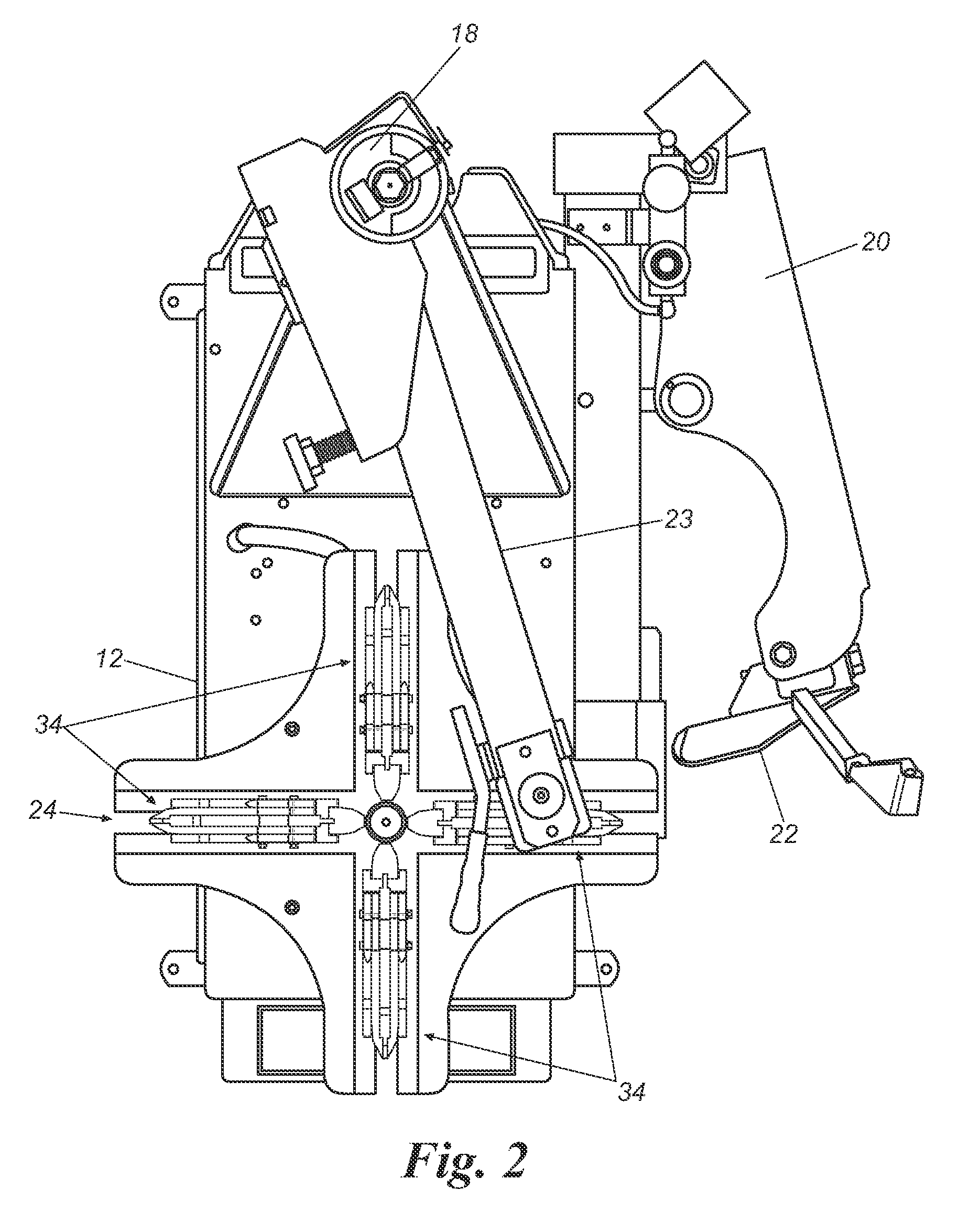

A tire changing apparatus to remove a tire from a wheel may include a substantially vertical stand for supporting a wheel balancing assembly and the vertical stand supporting a rim locker assembly which is operated by a arm. The rim locker assembly may include an adjustable arm extending device to adjust to different size rims, and the arm extending device may include a base member. The base member may include a spiral slot, and the base member may be driven by a drive gear. The drive gear may be driven by a opposing drive gear, and the opposing drive gear may be connected to a rotating arm.

Owner:ROUSSEL PHILIPPE PIERRE

Tire-handling device

InactiveUS7988402B2Easy to carryClearance can be providedTyresStatic/dynamic balance measurementAutomotive engineeringSupport belt

The tire-handling device (10) is a compact, lightweight tool for carriage within a motor vehicle trunk or storage compartment to facilitate handling of a tire (T) during a tire change or similar operation. The device includes a tire support cradle (30) supported by opposed vertically adjustable handles (32). The handles (32) and cradle (30) therebetween may be adjusted to position the cradle (30) beneath a tire (T) on a raised axle during a tire change, or for aligning a fresh tire with the wheel mounting studs of the wheel hub. Two mutually opposed tire support belt rollers are disposed within the cradle (30). A tire support belt extends between the rollers, allowing a tire (T) resting thereon to be rotated for alignment with the mounting studs of the vehicle wheel hub.

Owner:ADAMS SKY A

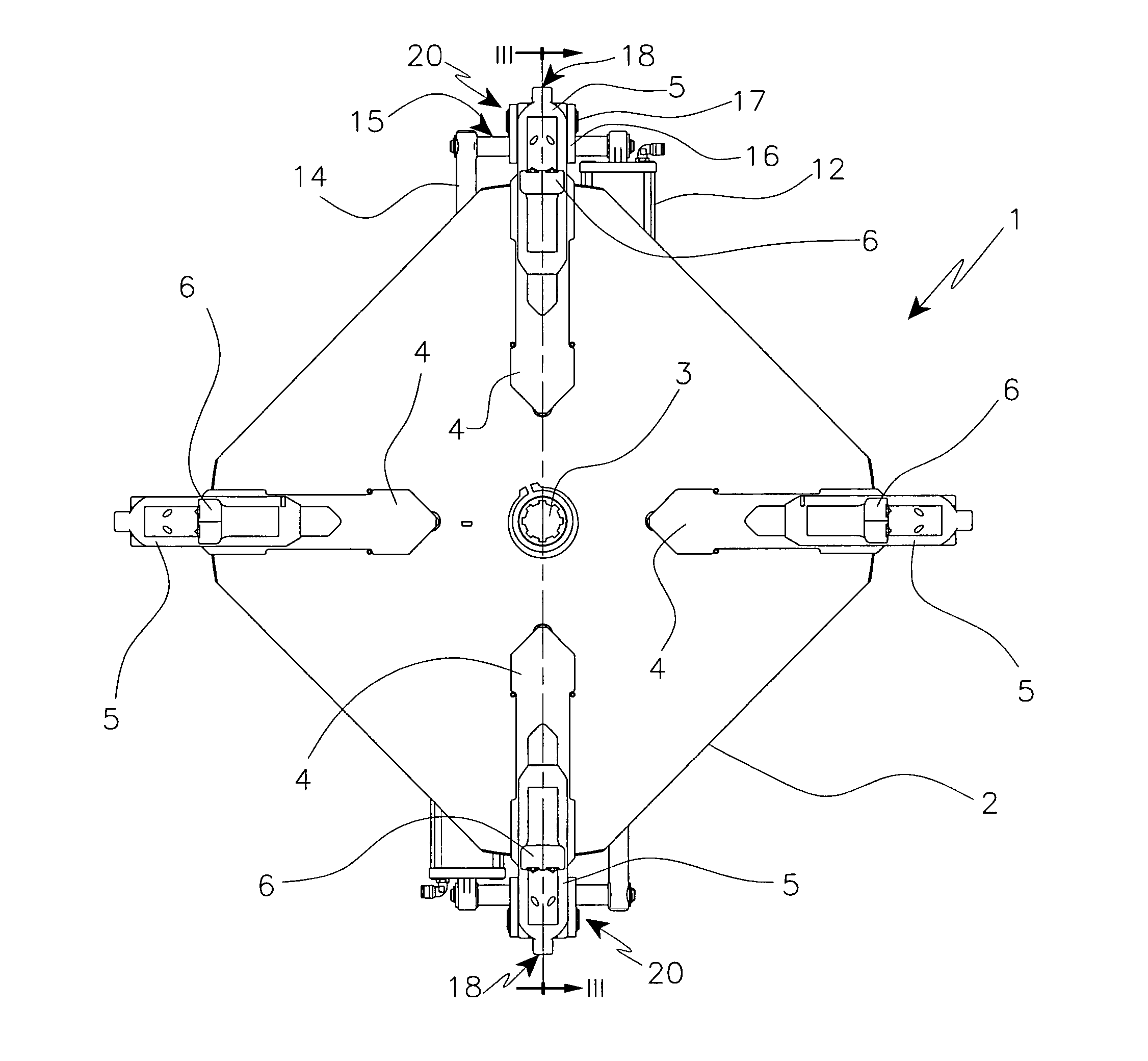

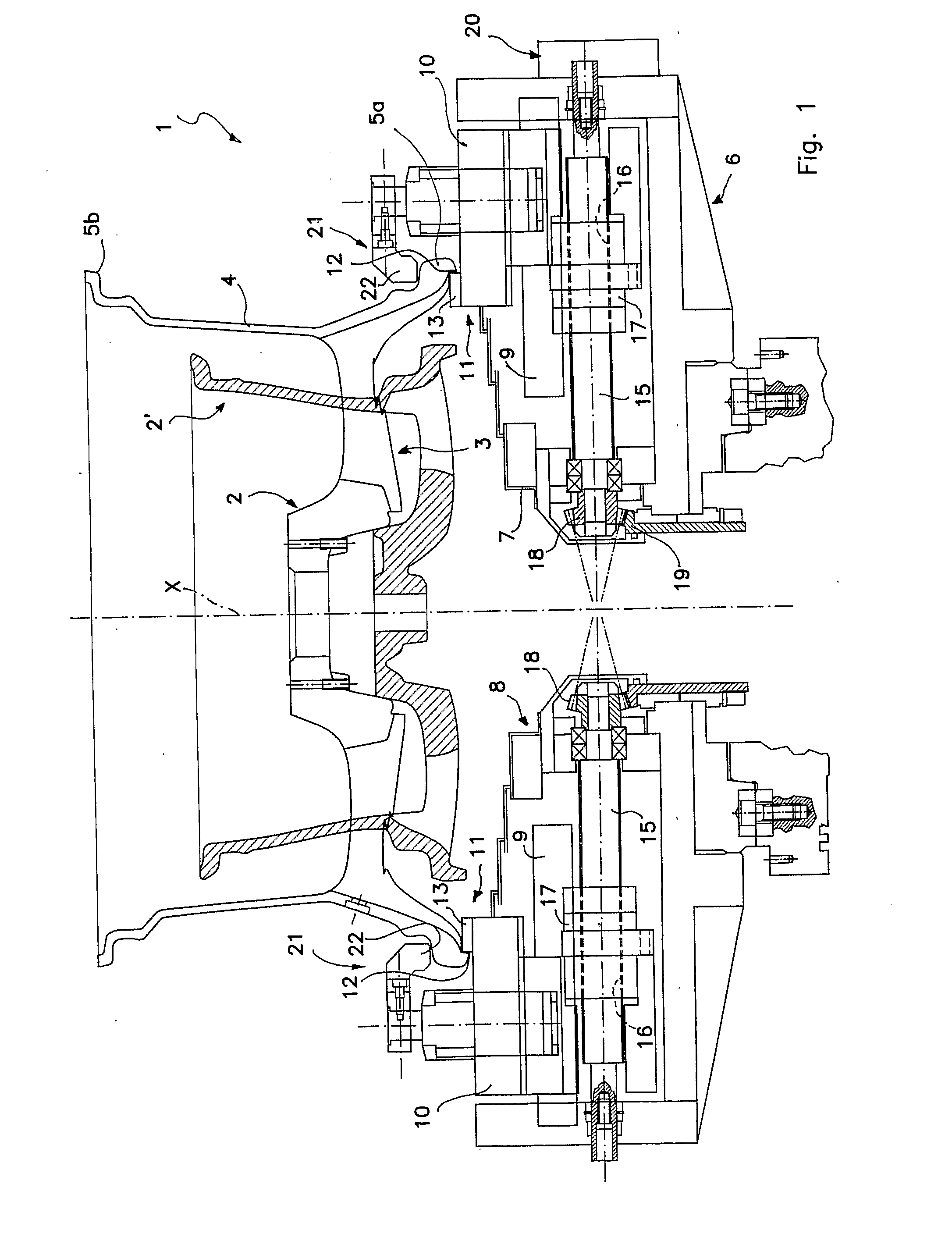

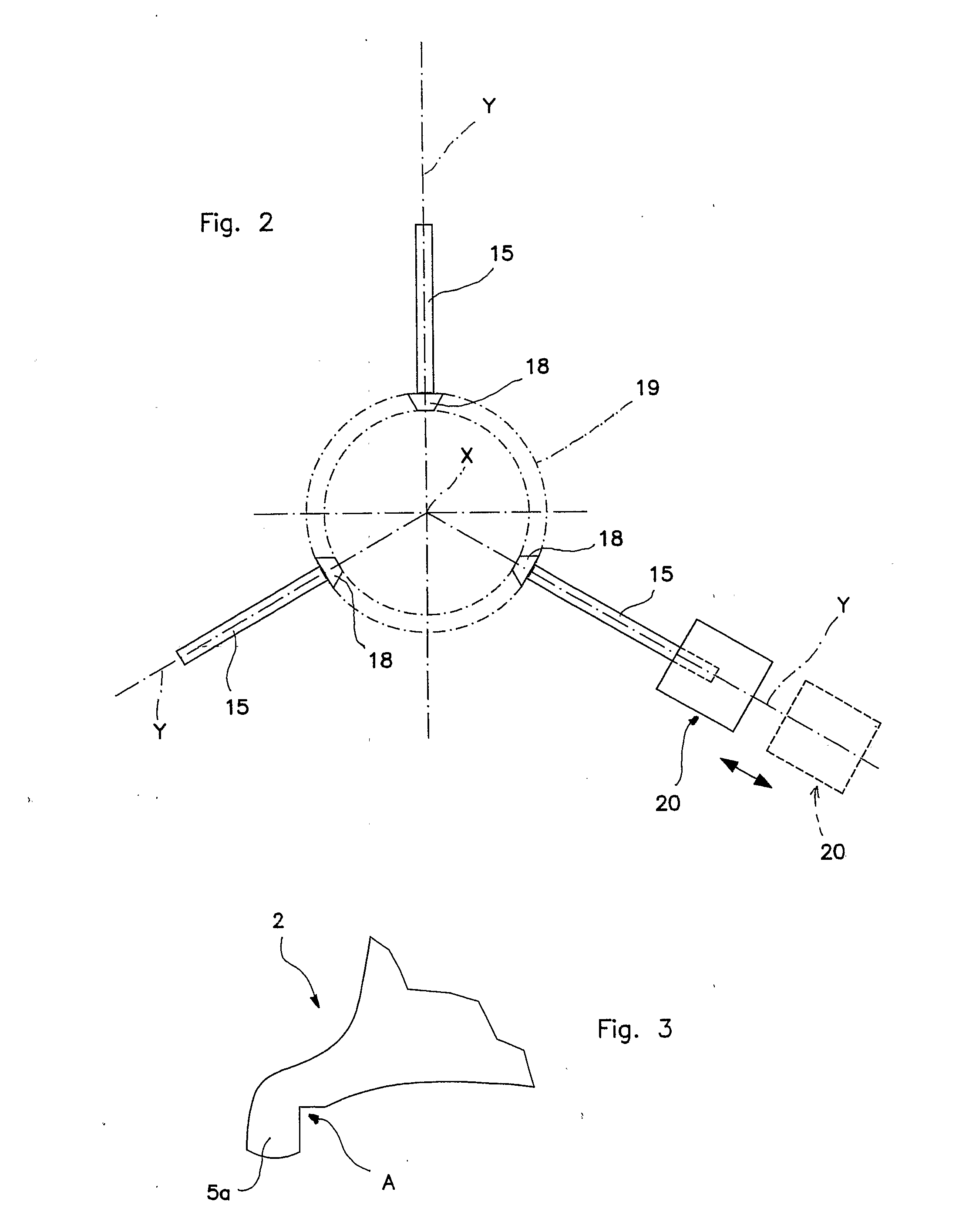

Device for Clamping in Centered Position Parts to be Subjected to Machining and Machine

InactiveUS20070221337A1Overcomes shortcomingStatic/dynamic balance measurementTyresEngineeringMotion transfer

A device is described for clamping parts in a centered position which are to be machined, including a device for centring the part on a worktable including at least three centering elements with a regular angular spacing. Each centering element is displaceable along a predetermined radial direction (Y), and there are actuating devices associated with each respective centering element for operational actuation thereof in the translational movement along the corresponding radial direction (Y). Each actuating device, for each centring element, includes a an actuating element capable of being driven in a rotational motion and a first motion transmission device capable of converting the rotational motion of the actuating element into translational motion of the corresponding centering element along the corresponding radial direction (Y), and a second motion transmission device between the actuating elements capable of synchronously transmitting the rotational motion of one of the actuating elements to the other actuating elements so as to impart a synchronized translational movement of the centering elements along the respective radial translation directions (Y).

Owner:MAUS SPA

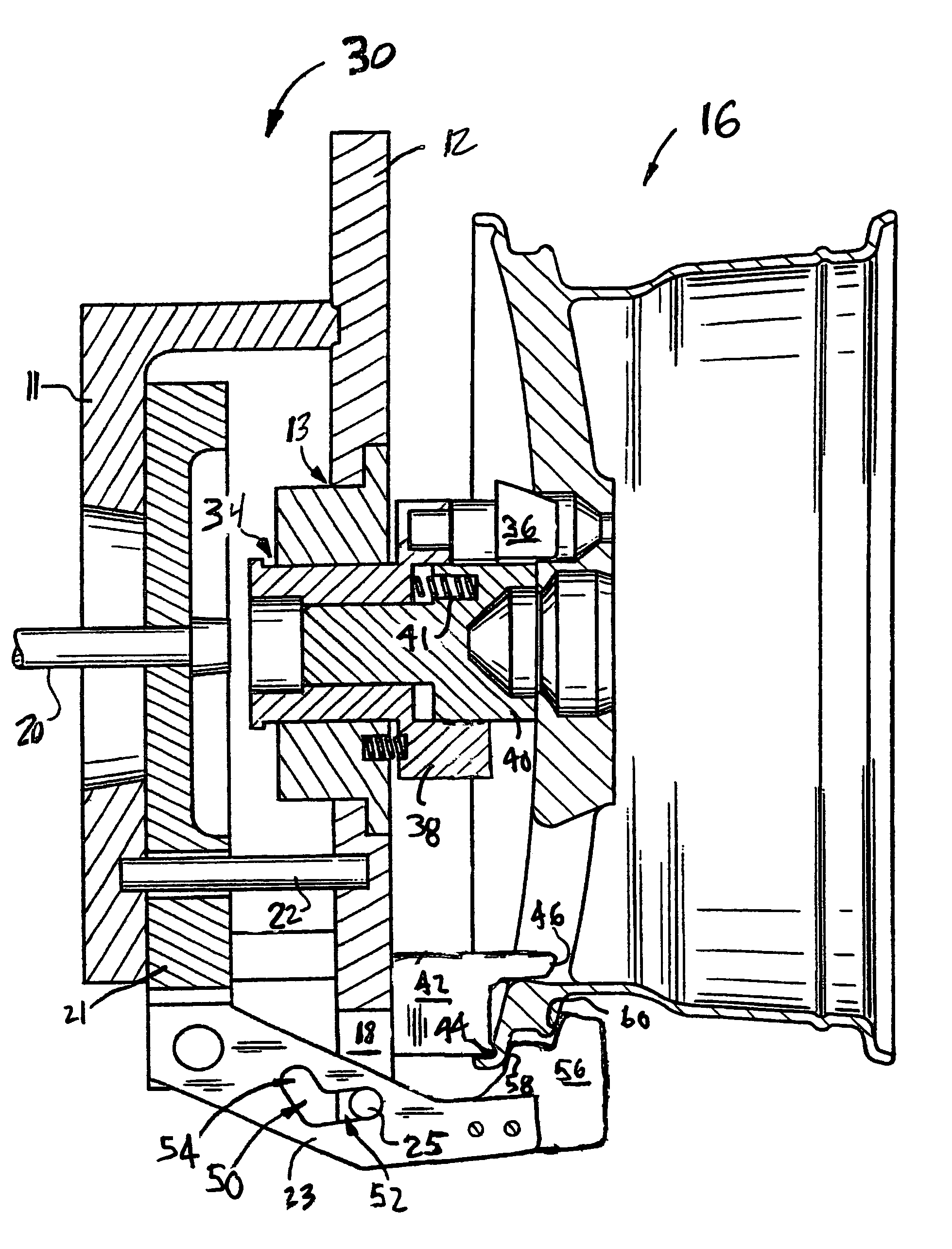

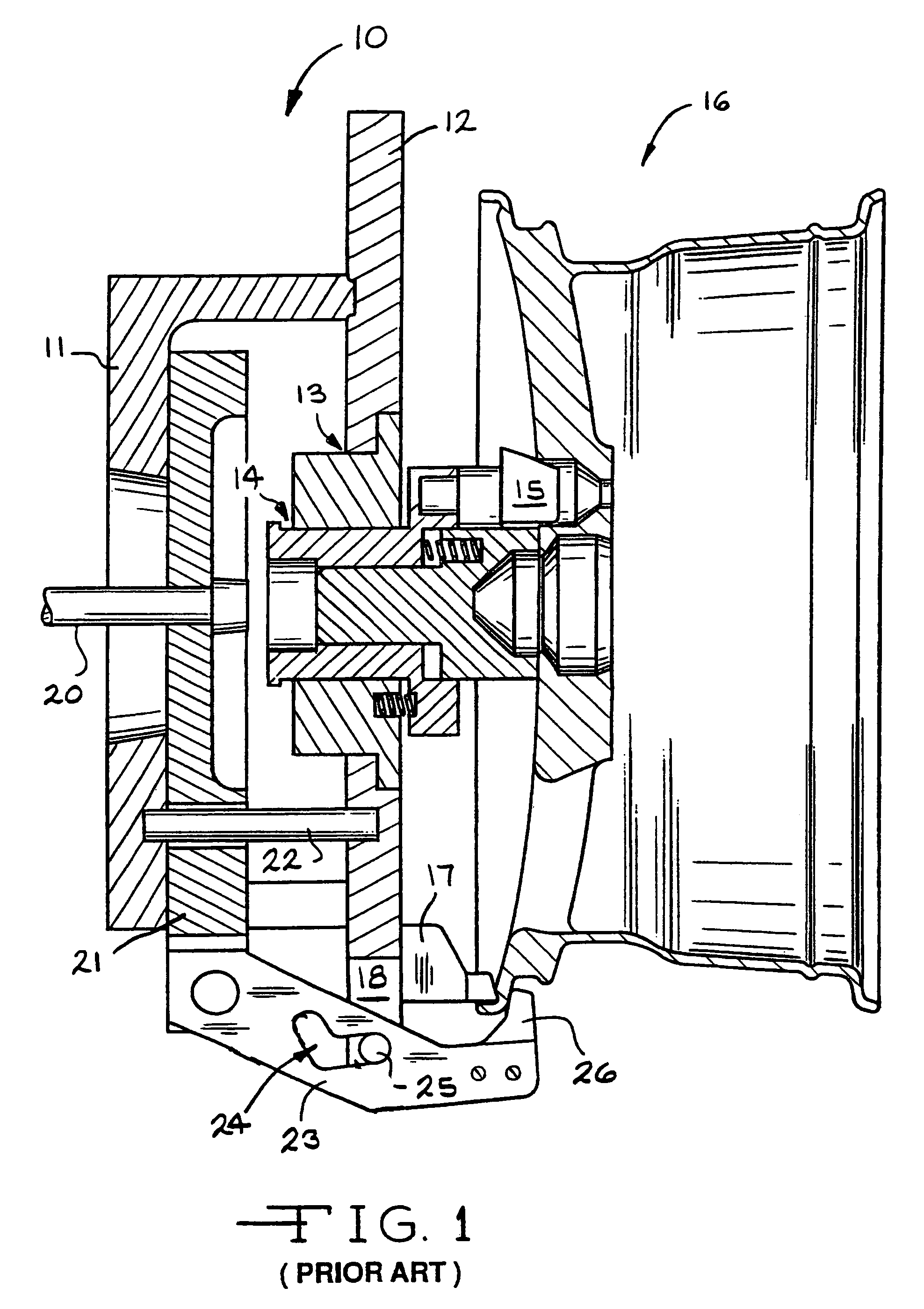

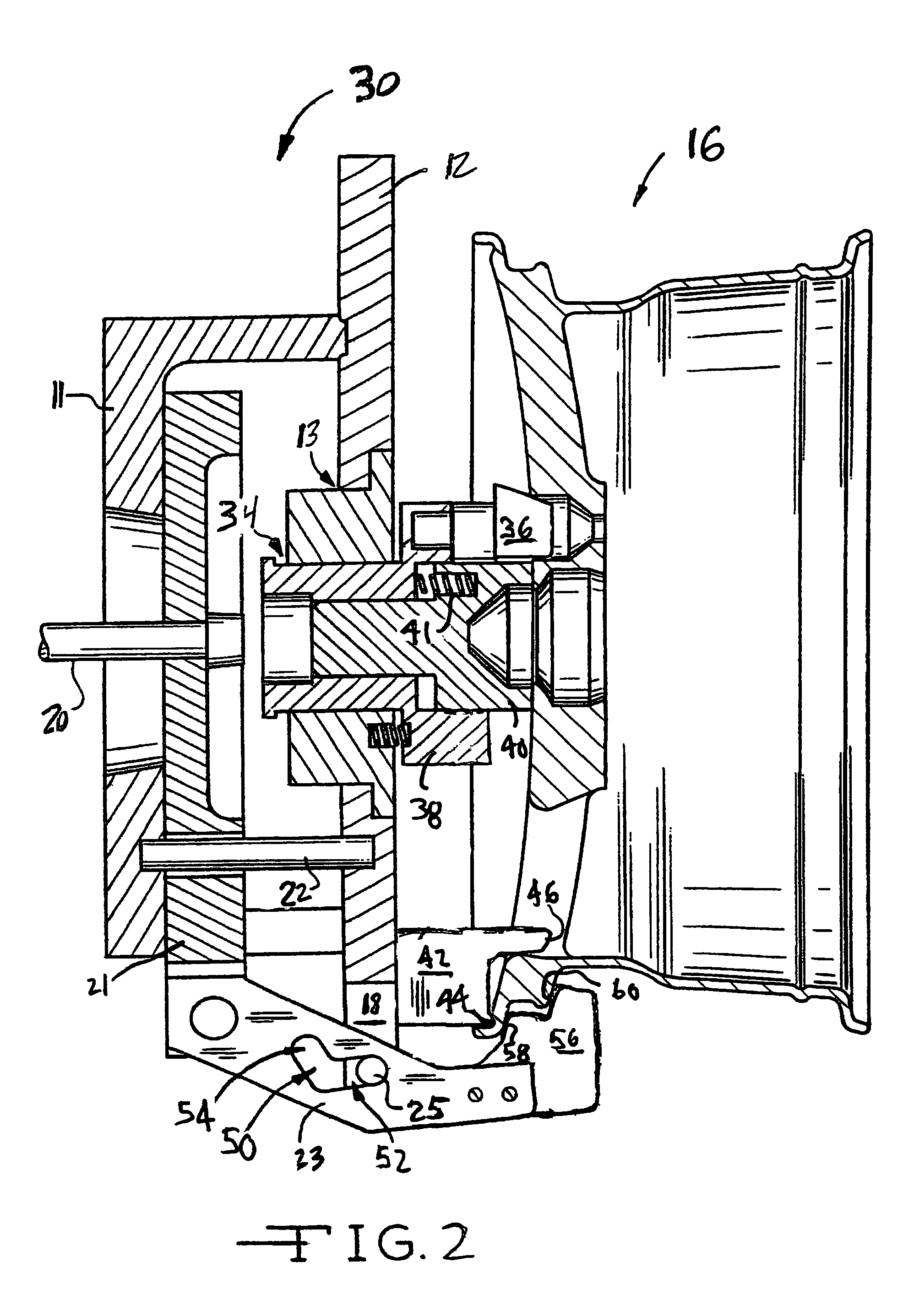

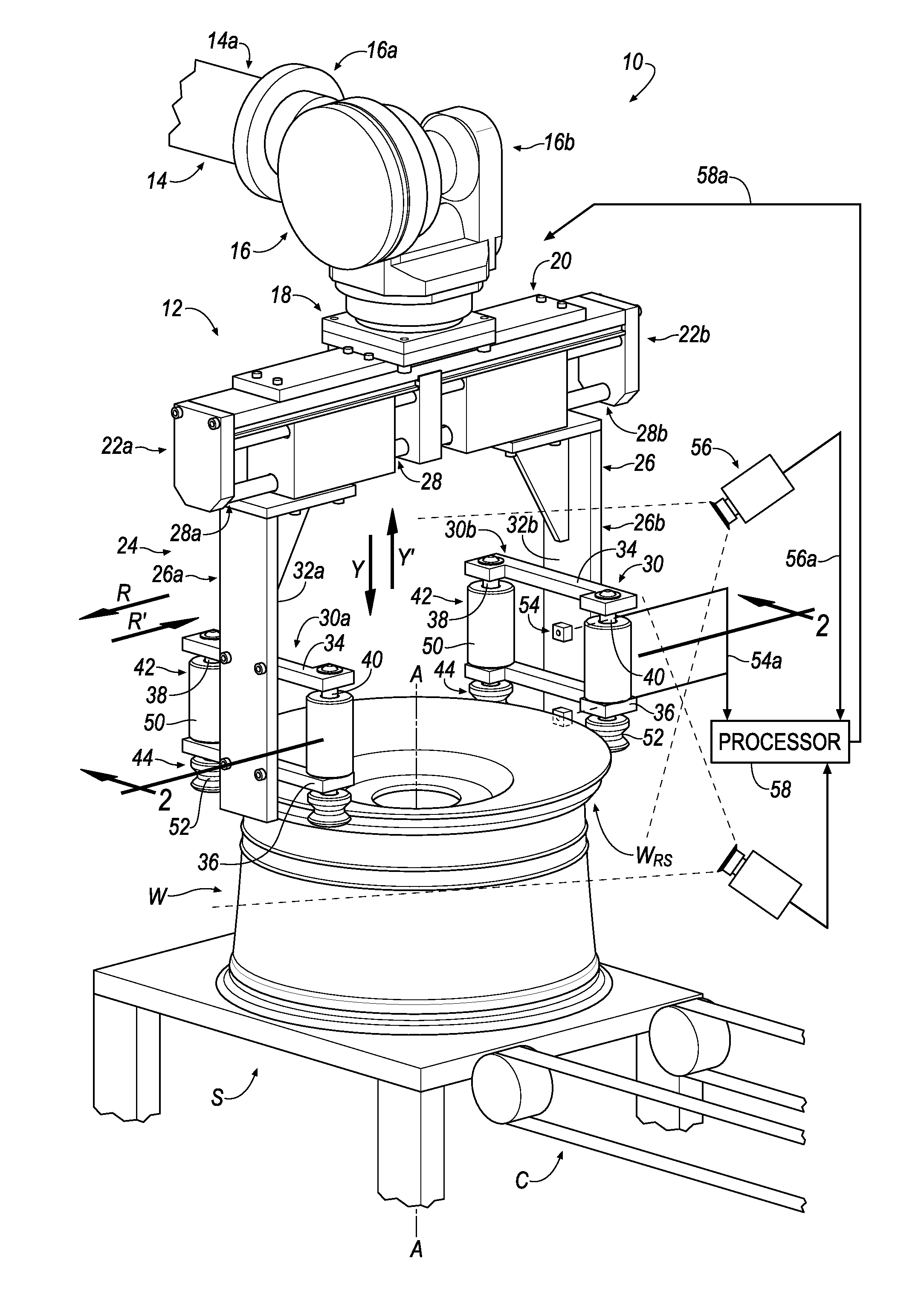

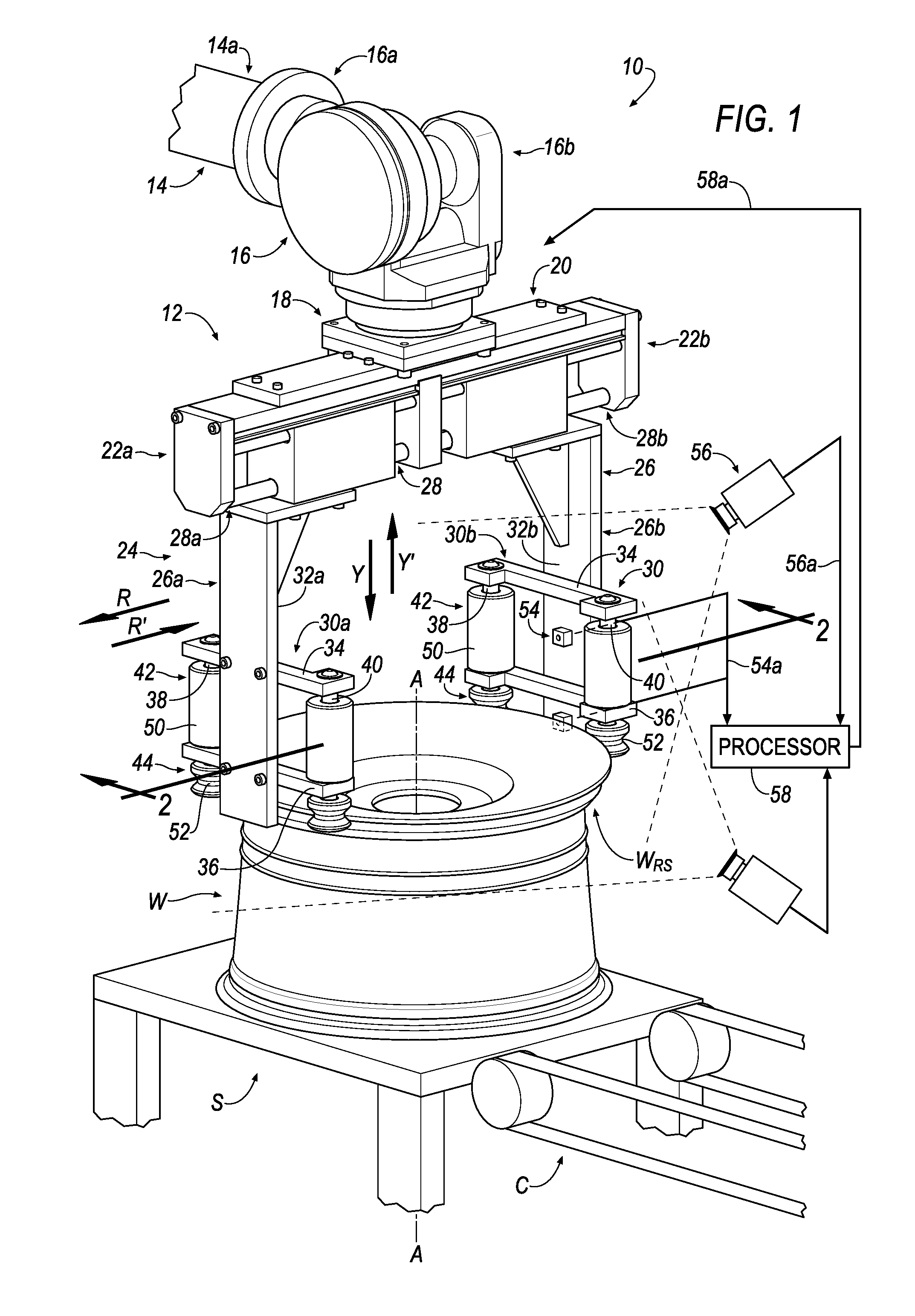

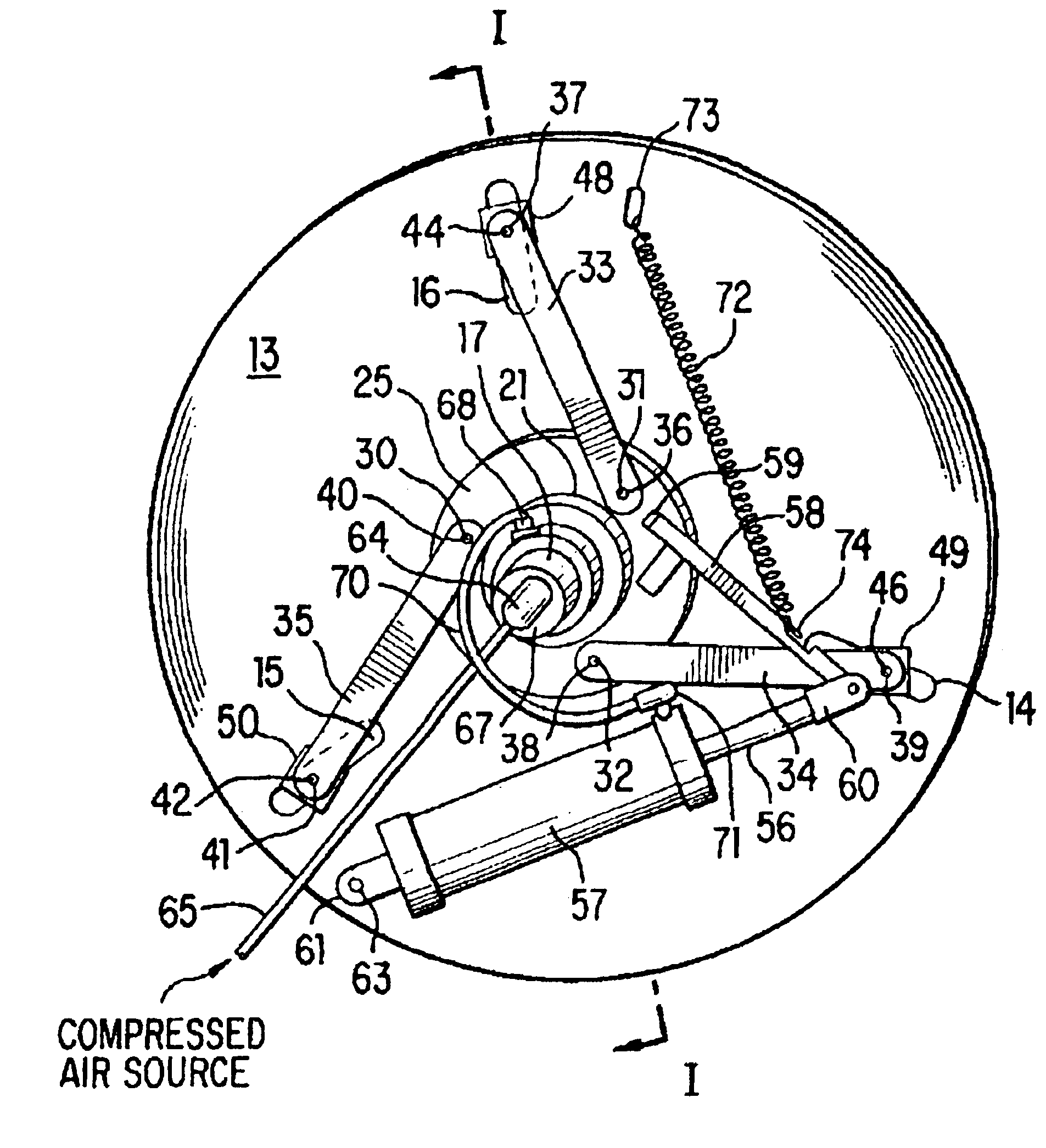

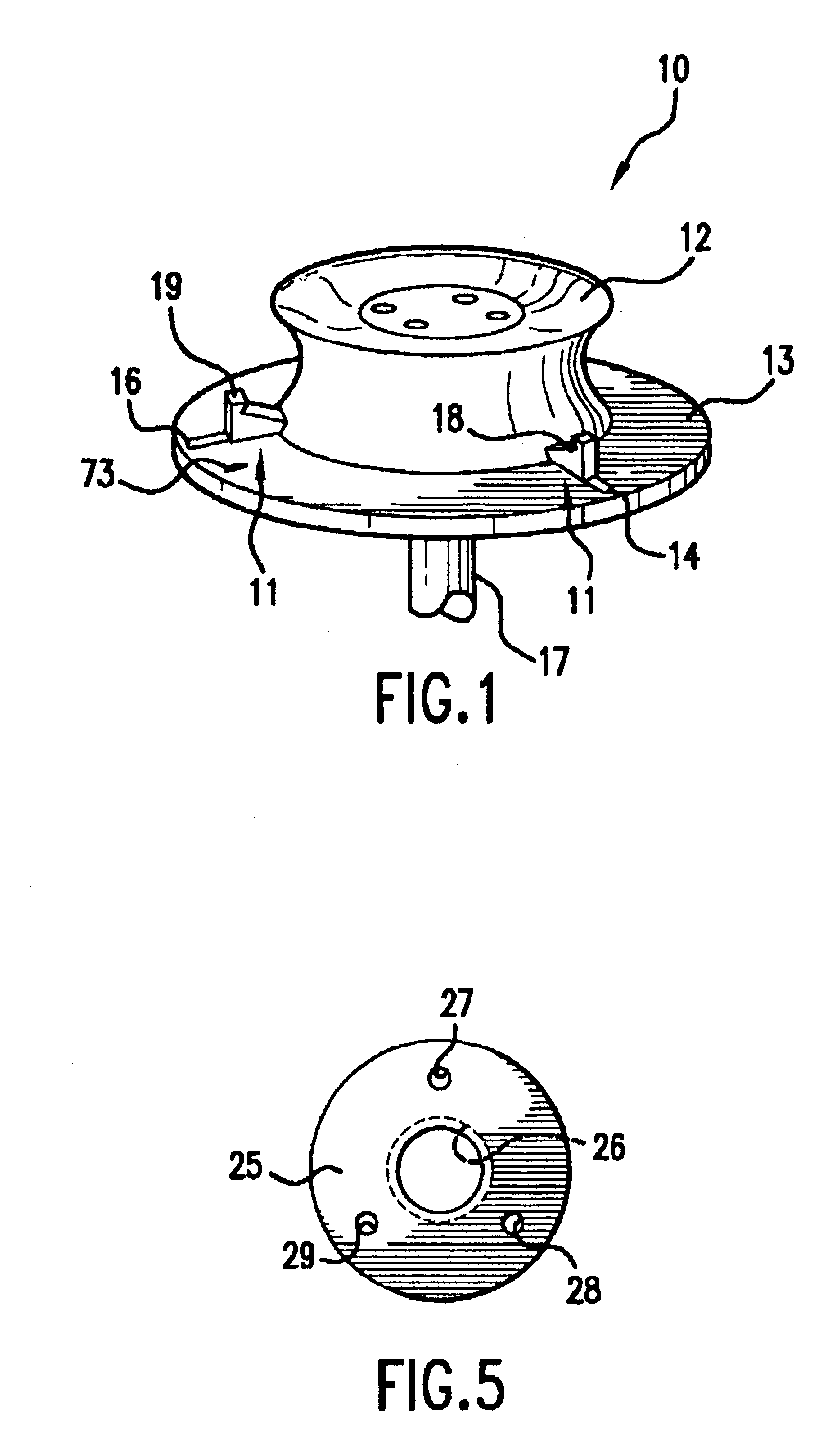

Powered turntable with universal, self-adjusting chuck for holding auto wheels and the like for polishing

InactiveUS6916026B2Easy to manufactureSave effortStatic/dynamic balance measurementChucksEngineeringMotorized vehicle

A new and improved powered rotating turntable with a universal, self-adjusting chuck for holding auto wheels and the like for polishing, which includes a pneumatically-adjusted, self-centering metal chuck for gripping and holding specialty wheel rims of motor vehicles for polishing. The chuck is self-adjusting, self-centering and is able to handle any diameter of wheel. With the self-adjusting, self-centering capability, this chuck eliminates the need to set up a new jig for gripping and holding a wheel rim each time a series of rims having a different diameter or style from the last series of wheel rims previously chucked-up and polished, thereby greatly improving the efficiency of the entire wheel polishing operation in terms of both time and cost of operation.

Owner:MEZA ARTURO

Wheel lifting device

ActiveUS20180319212A1Increase heightEnhanced wheel liftingSupporting partsWheel mounting apparatusEngineeringMechanical engineering

Owner:KOMPOSITPRODR VIKMANSHYTTAN

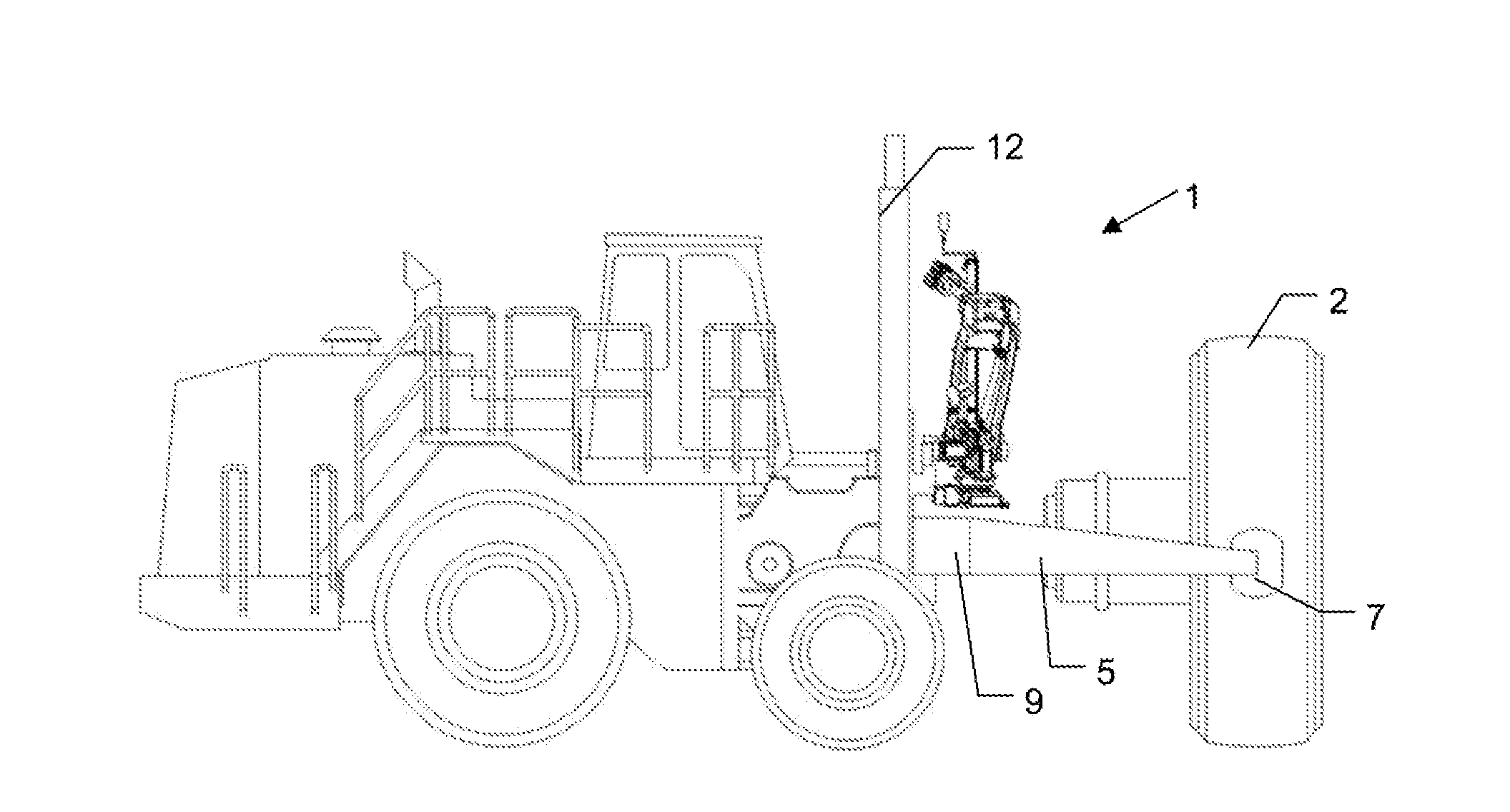

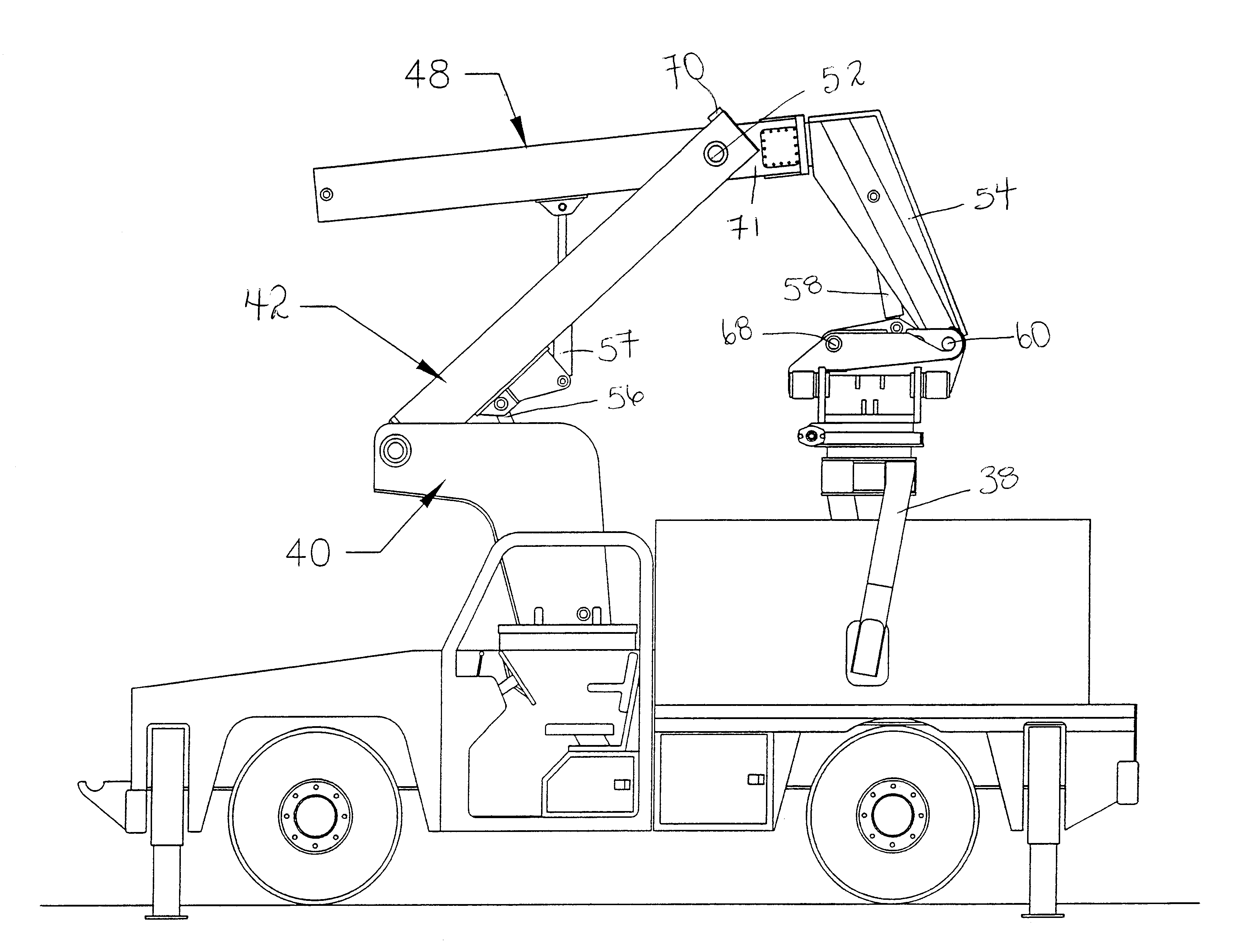

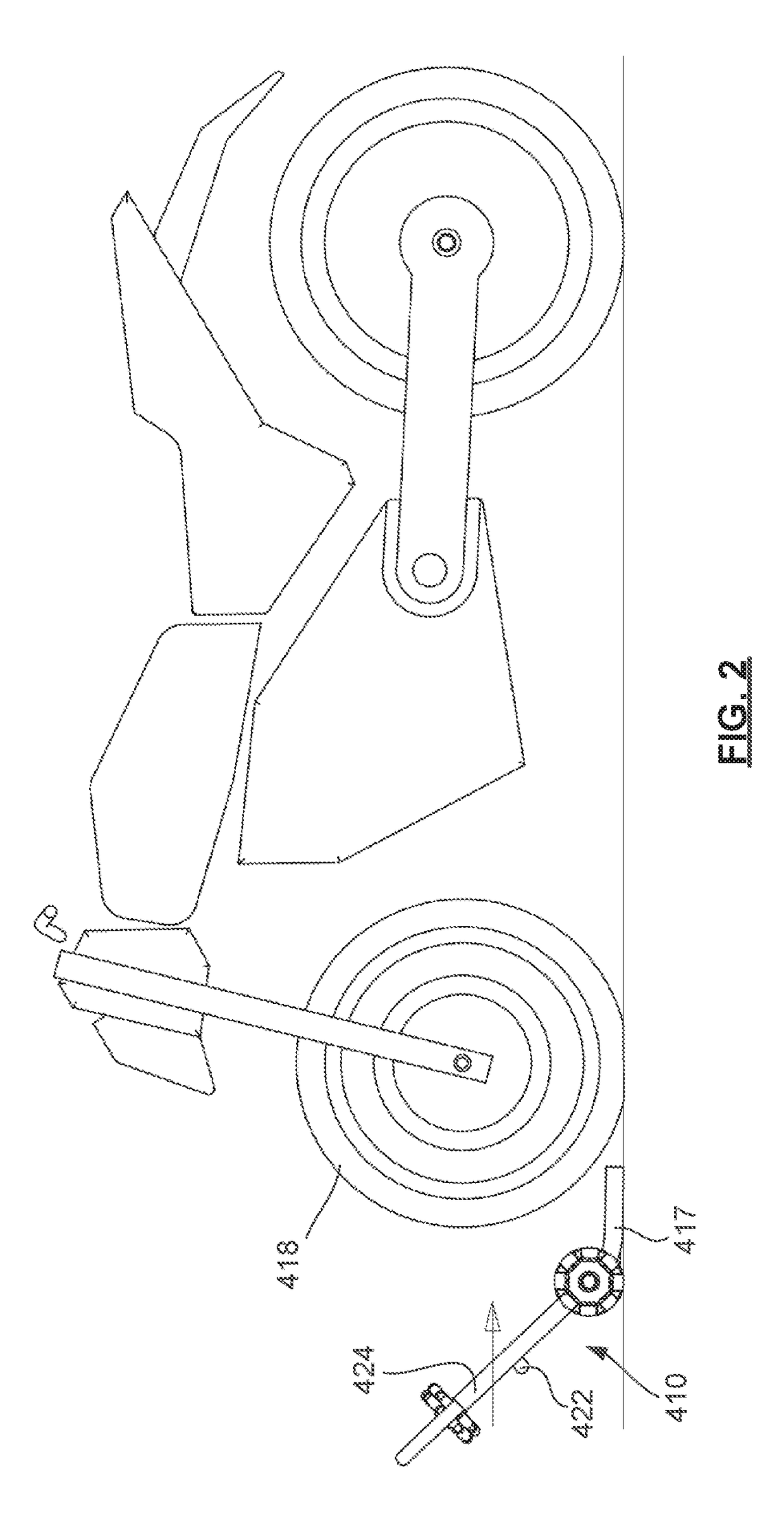

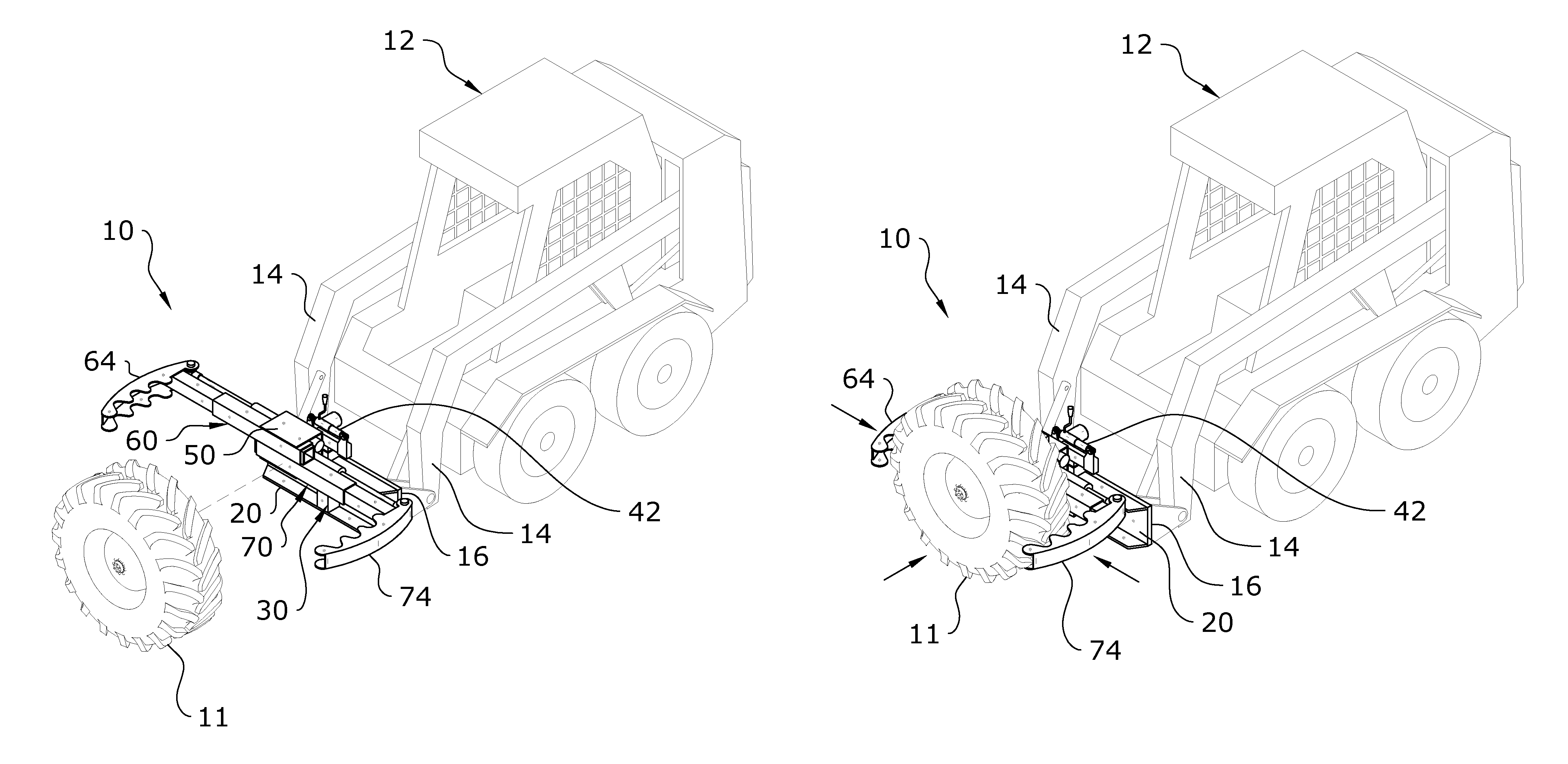

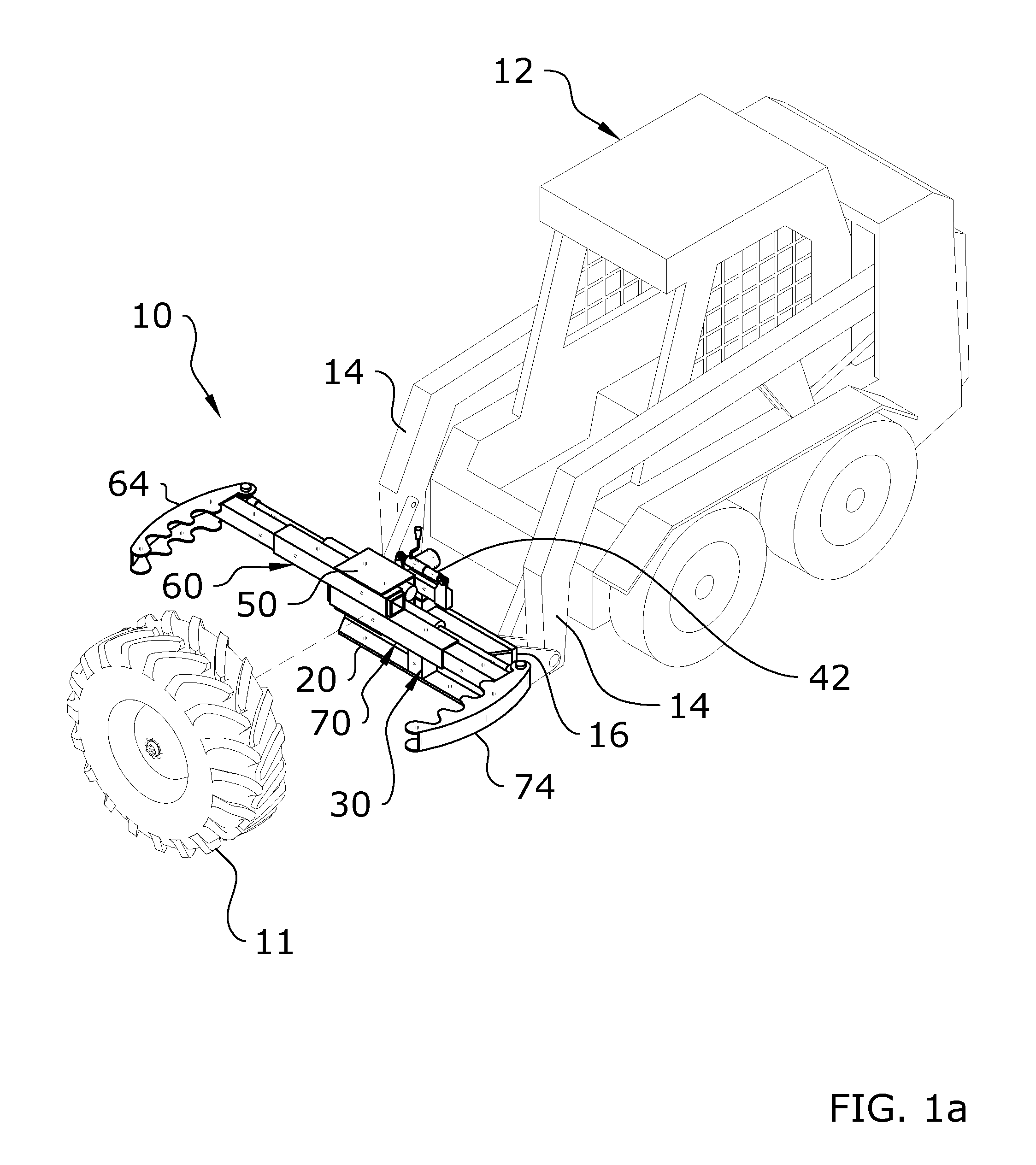

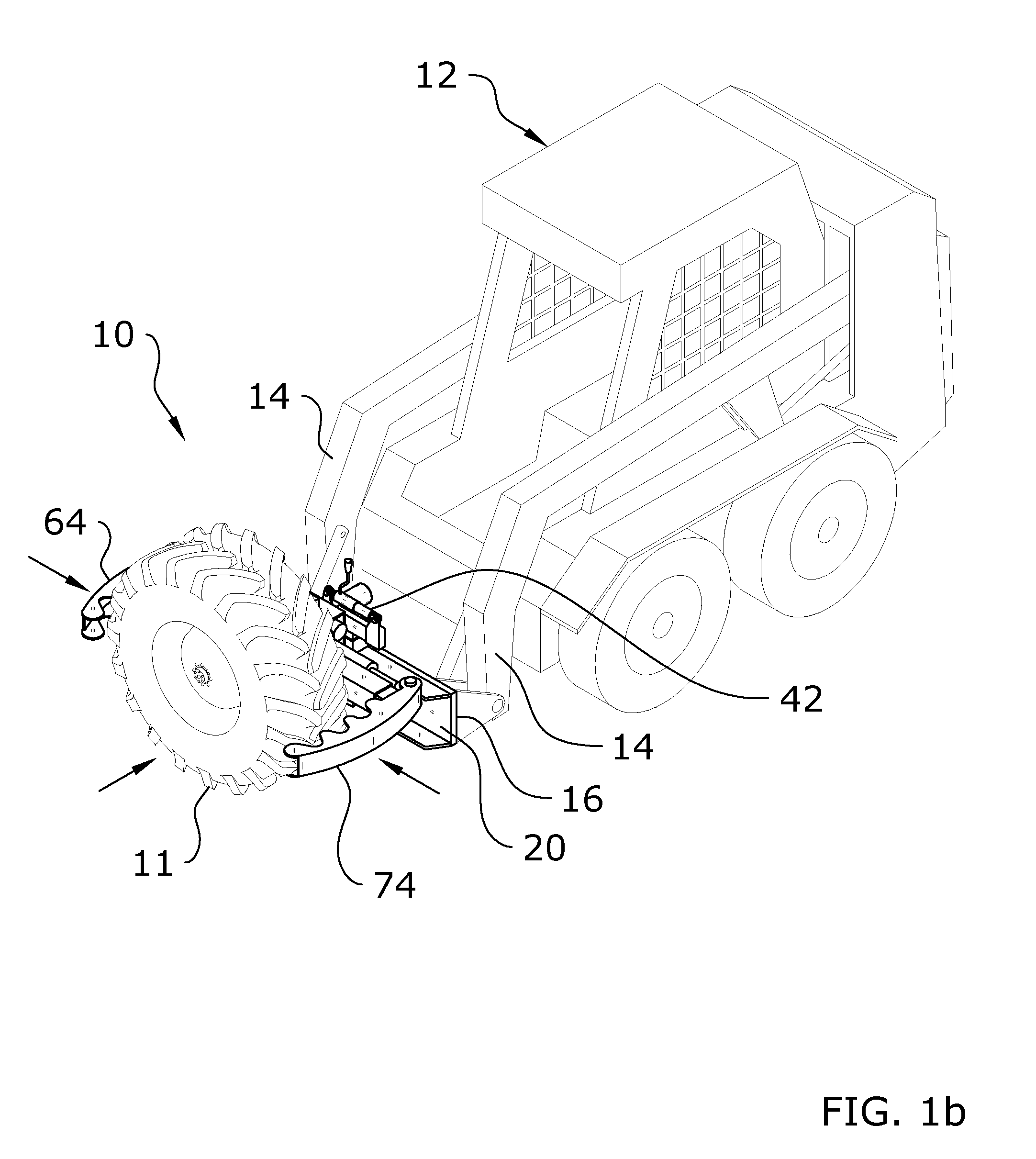

Tire manipulator for mine service vehicles

A tire manipulator for mine service vehicles has a mast for mounting on a vehicle, a telescopic boom connected to said mast and wheel handling equipment connected to said telescopic boom. A first boom may connect said mast to a moveable boom, the moveable boom being connected to said telescopic boom.

Owner:SMITH BARRY

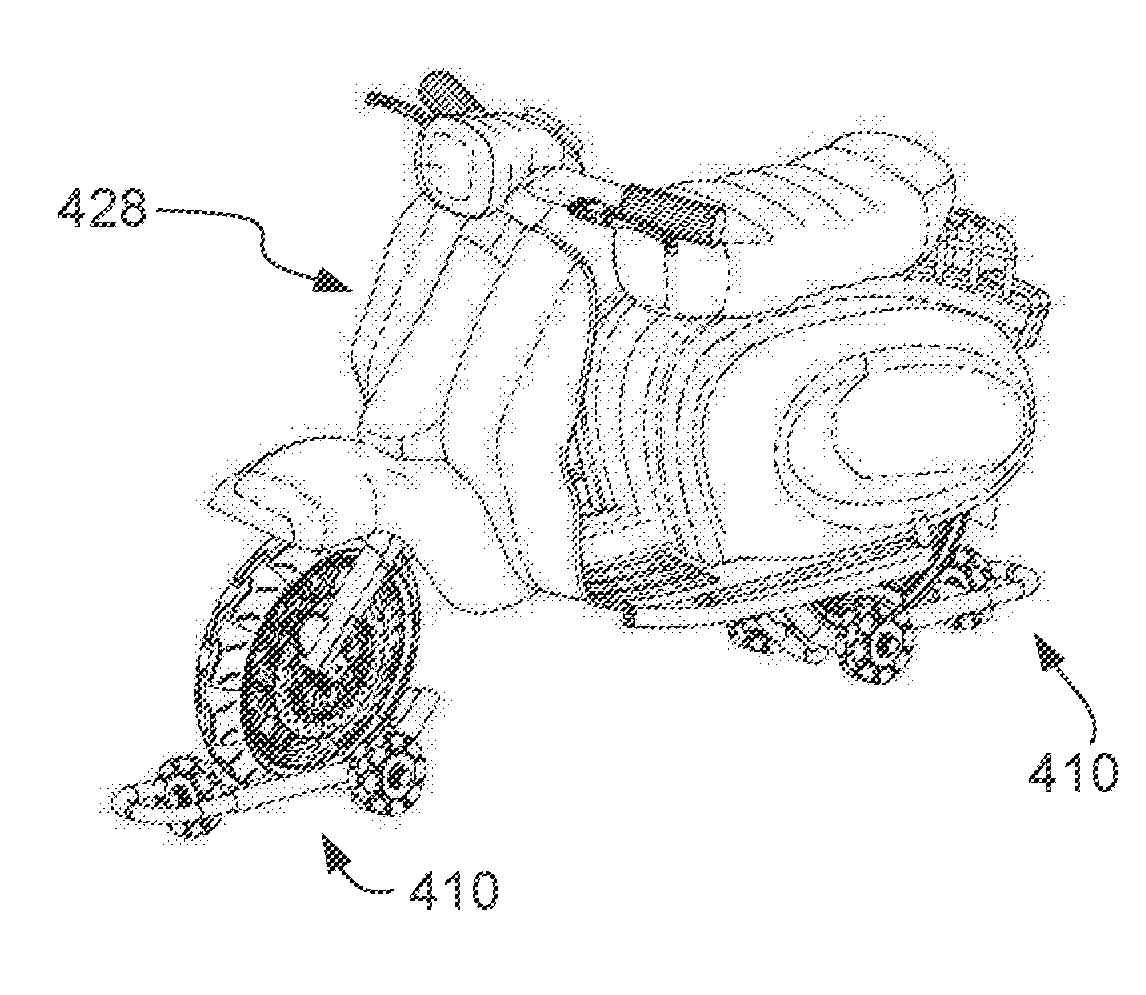

Improved apparatus for maneuvering parked motorcycles and motor scooters

Owner:BLACK MC PTY LTD

Lamintated clamp for a tire changer

Owner:HENNESSY IND

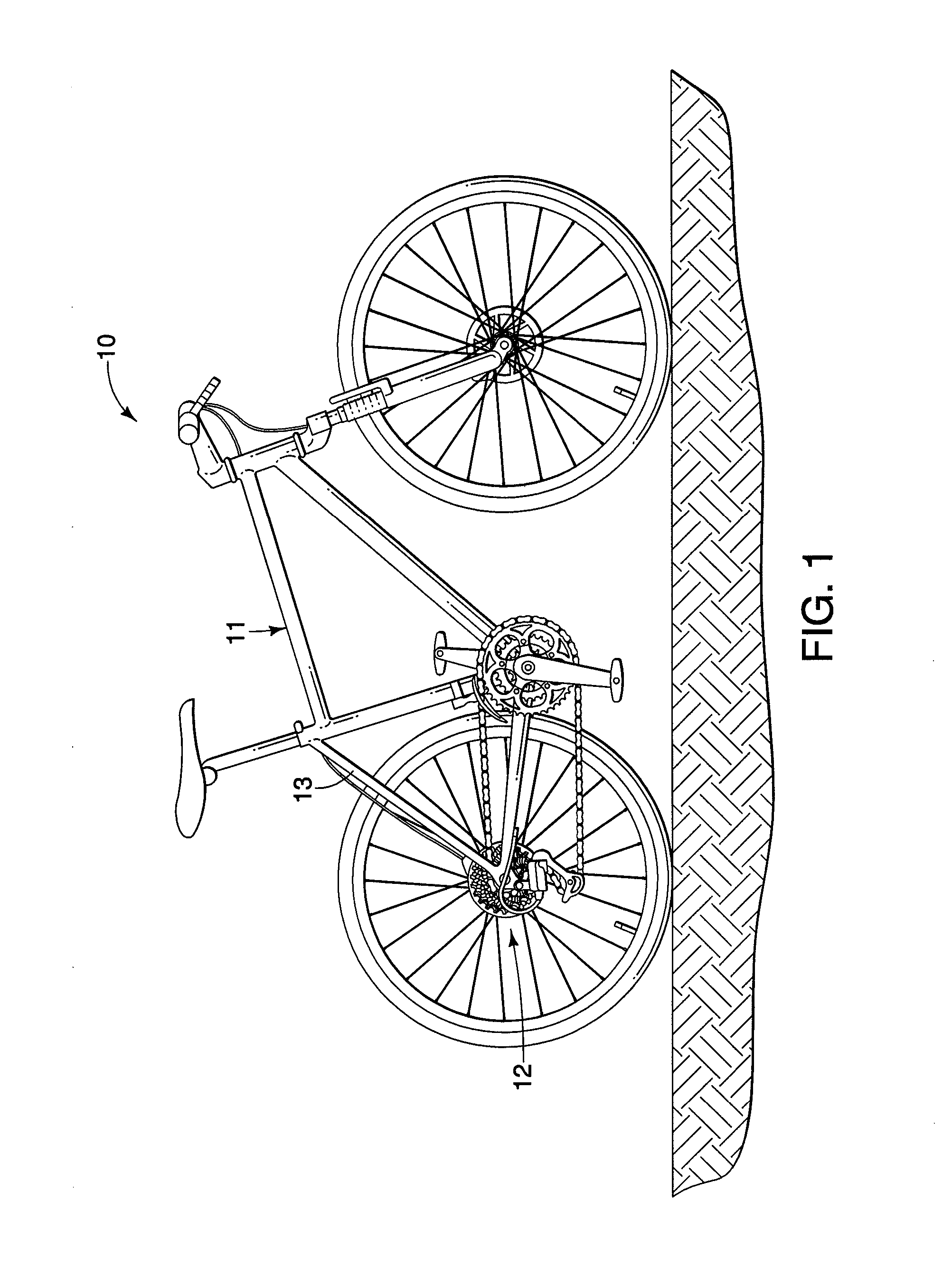

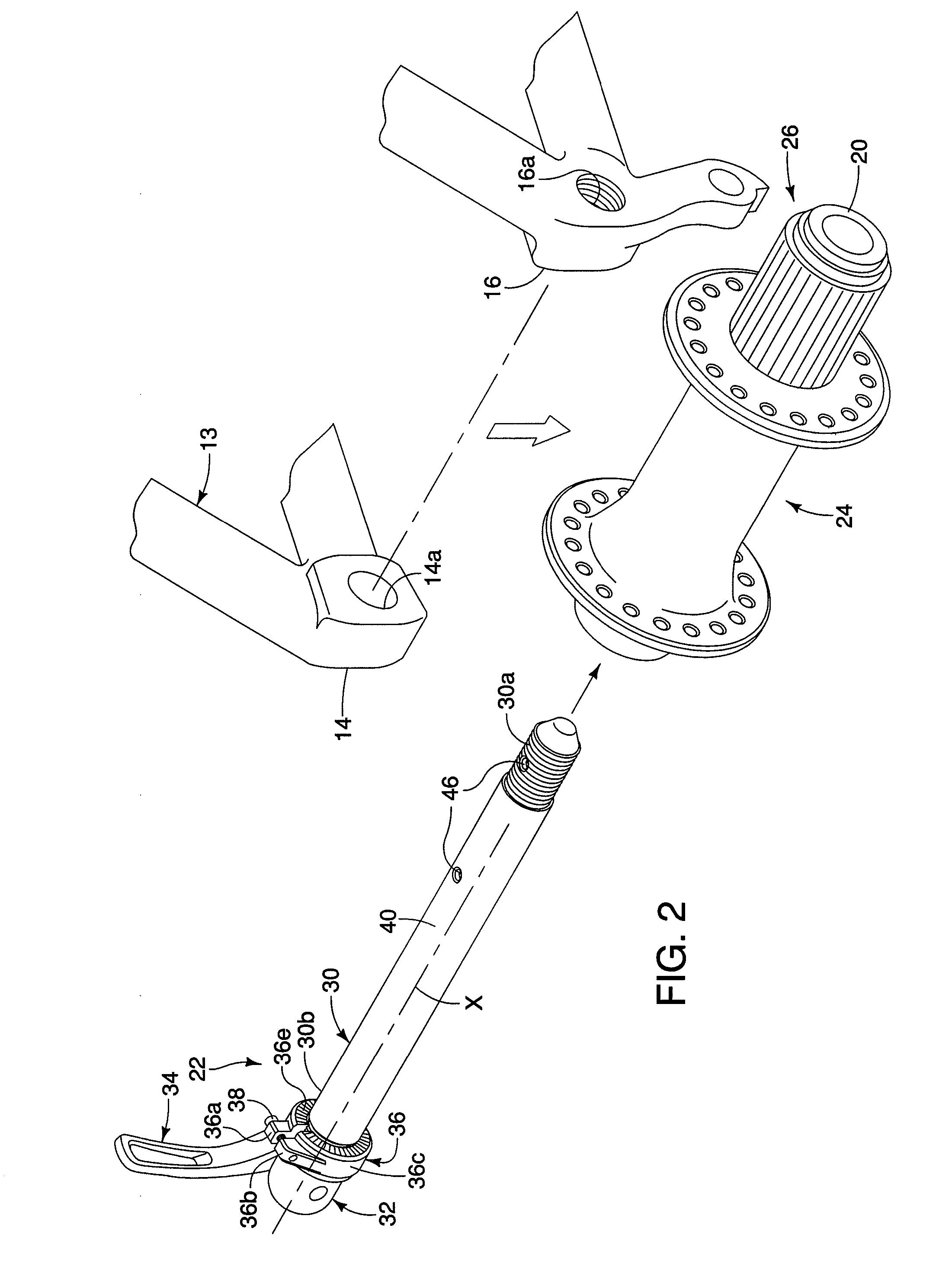

Bicycle wheel securing structure

Owner:SHIMANO INC

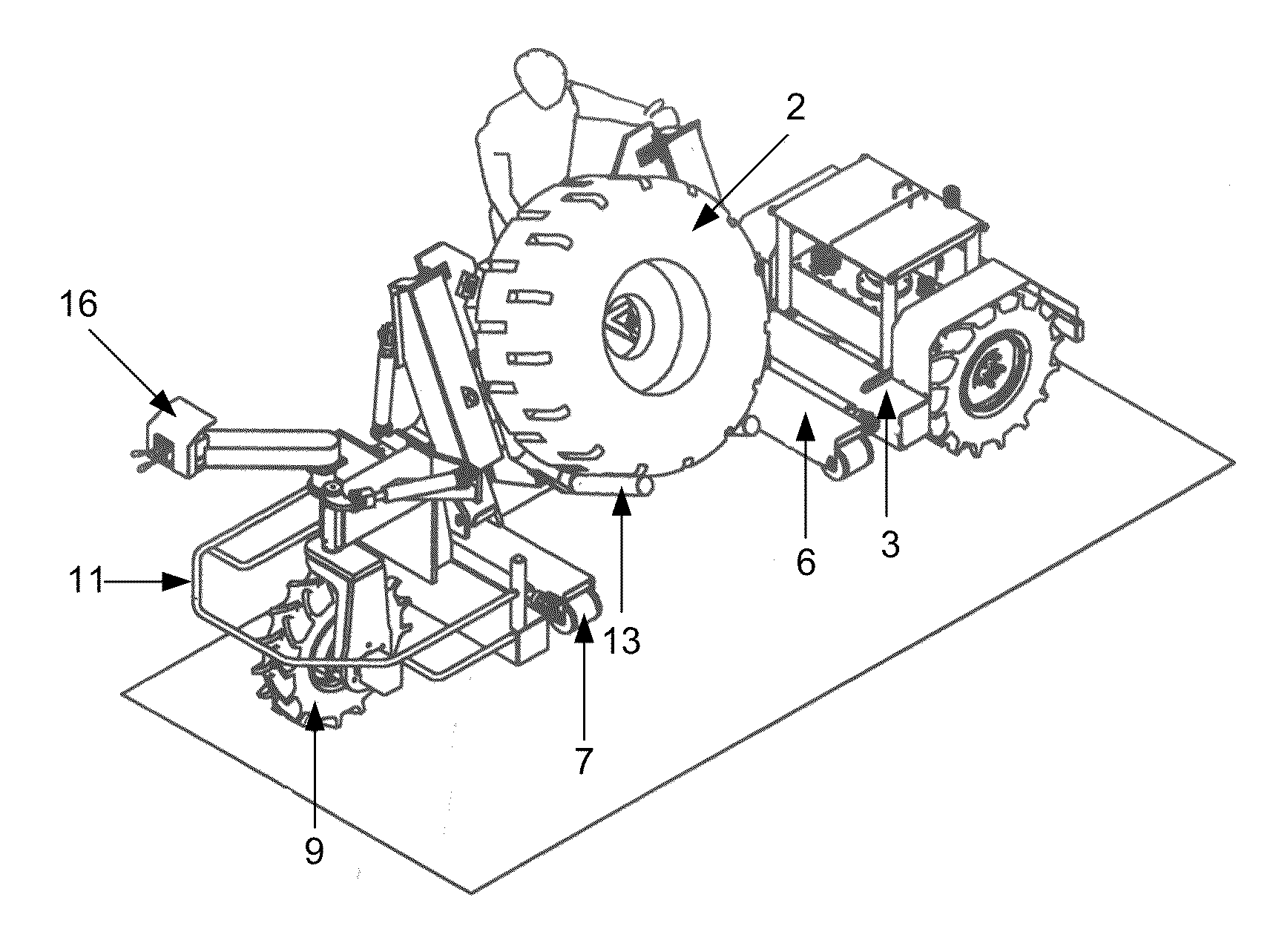

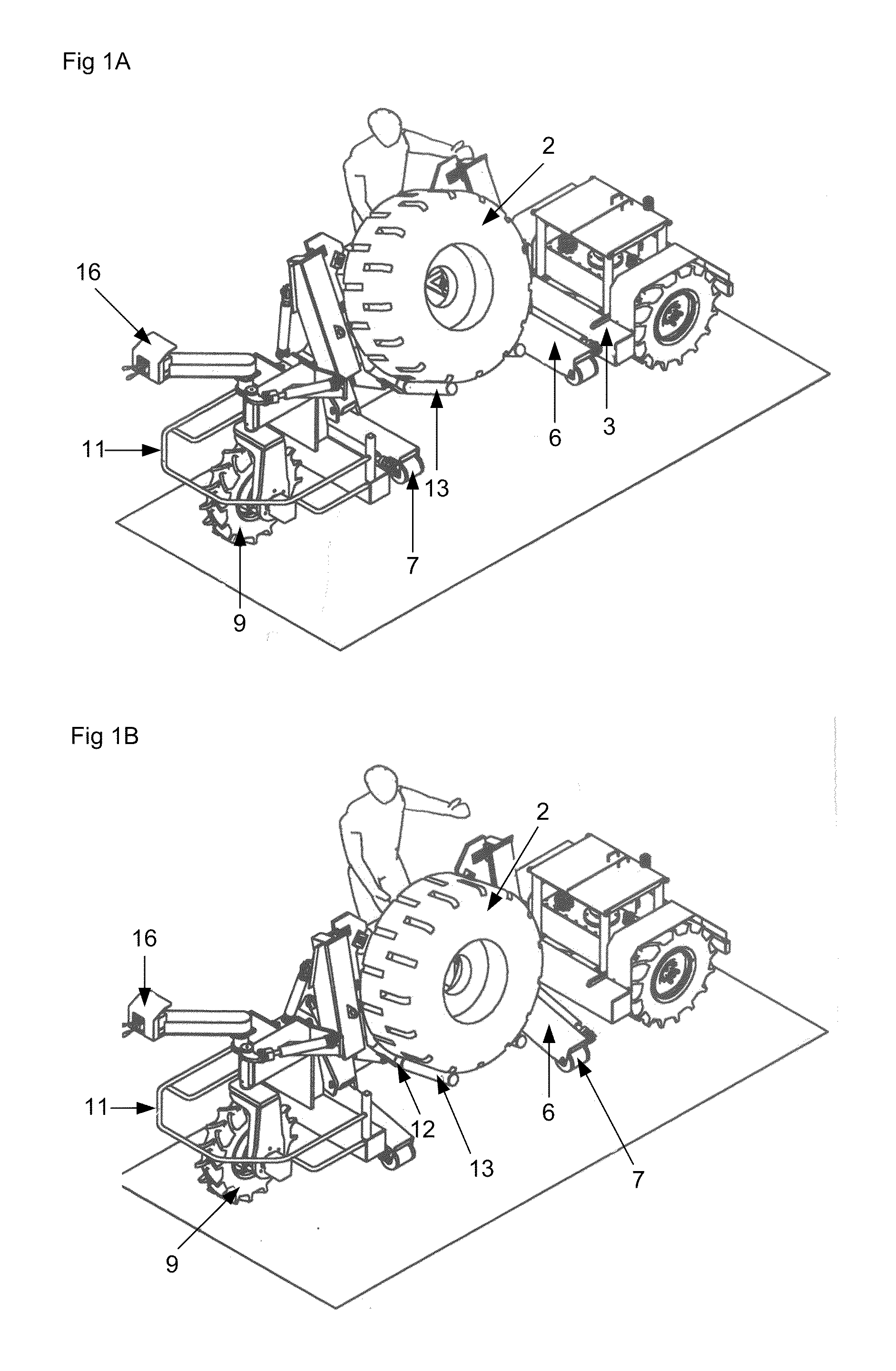

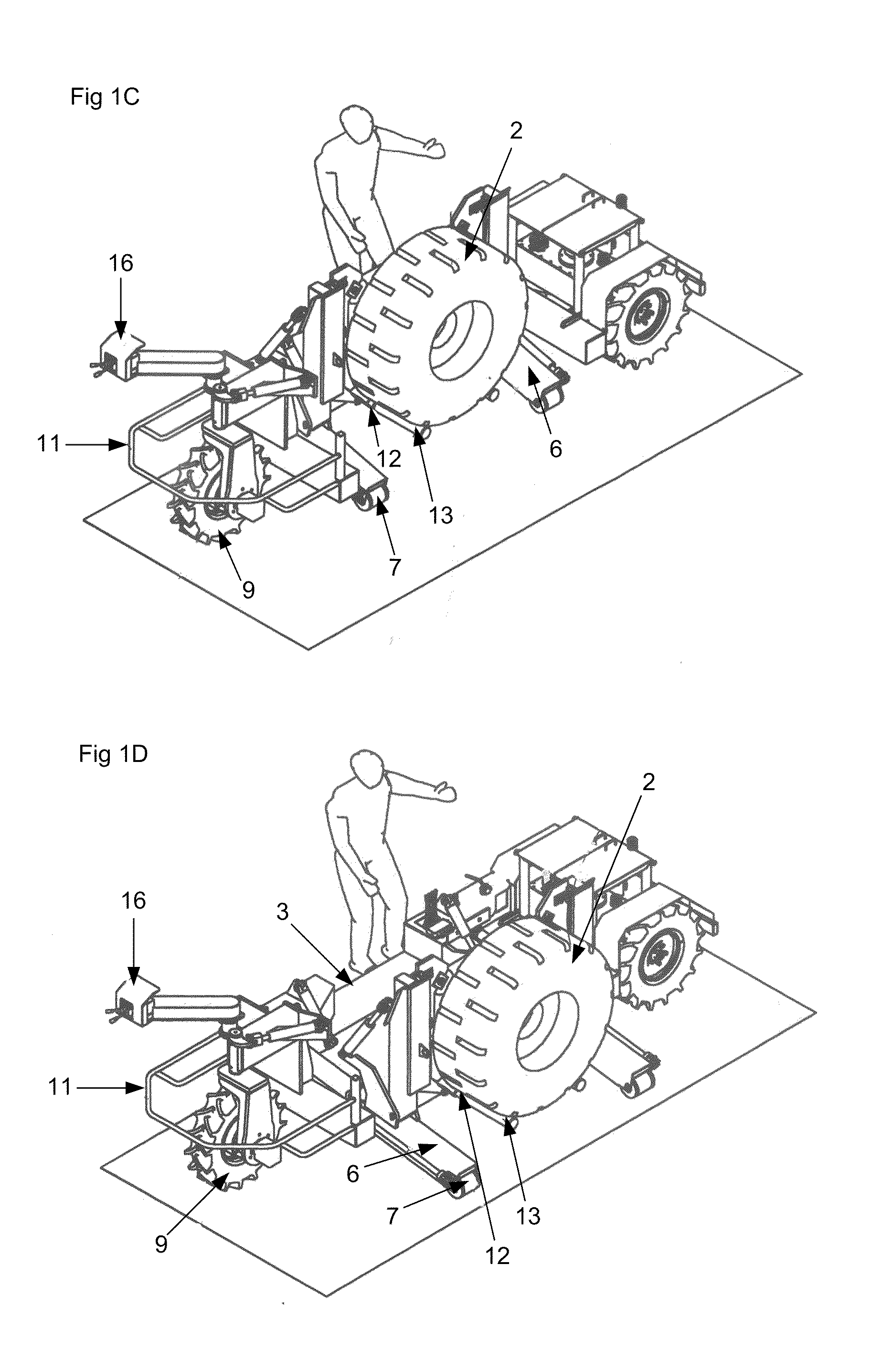

Handling device and method

InactiveUS20110197416A1Static/dynamic balance measurementOther workshop equipmentConfined spaceEngineering

An apparatus (1) for transporting an article (2). The apparatus (1) includes a frame (3) and an article support (4) operatively coupled to the frame (3). The article support (4) is movable relative to the frame (3) such that the apparatus (1) provides a first configuration for retaining the article (2) and a second configuration for receiving or unloading the article (2). The apparatus (1) includes a plurality of wheels (9) for movement over a substrate surface, and, a stabilising means (6) to engage the substrate surface and stabilise the frame (3) when the apparatus (1) is in the extended position. In use, the apparatus (1) may be used to support a wheel, tyre or other vehicular component (2) during installation, for example, in a confined space such as a mine.

Owner:JUSTOY PTY LTD

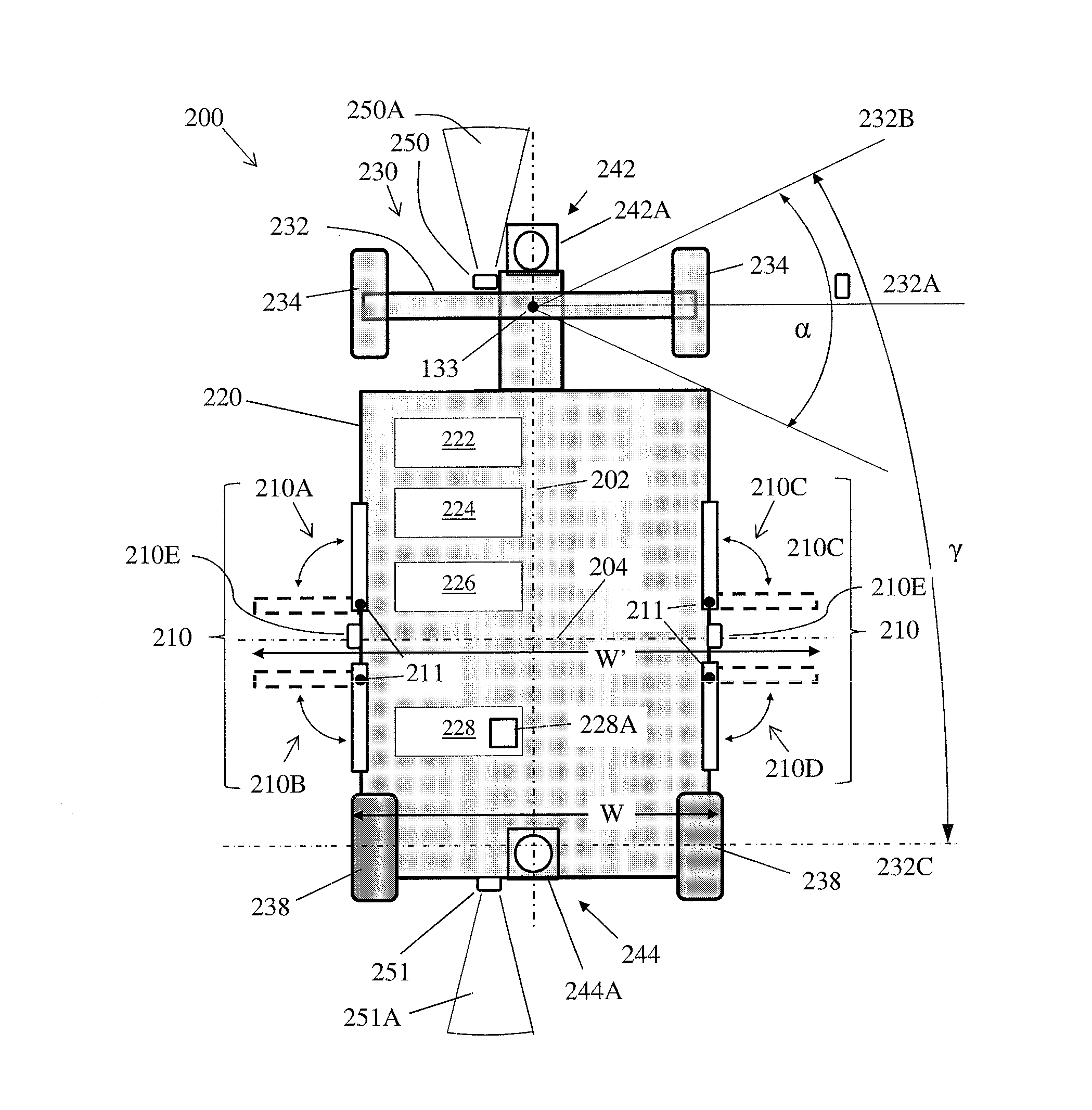

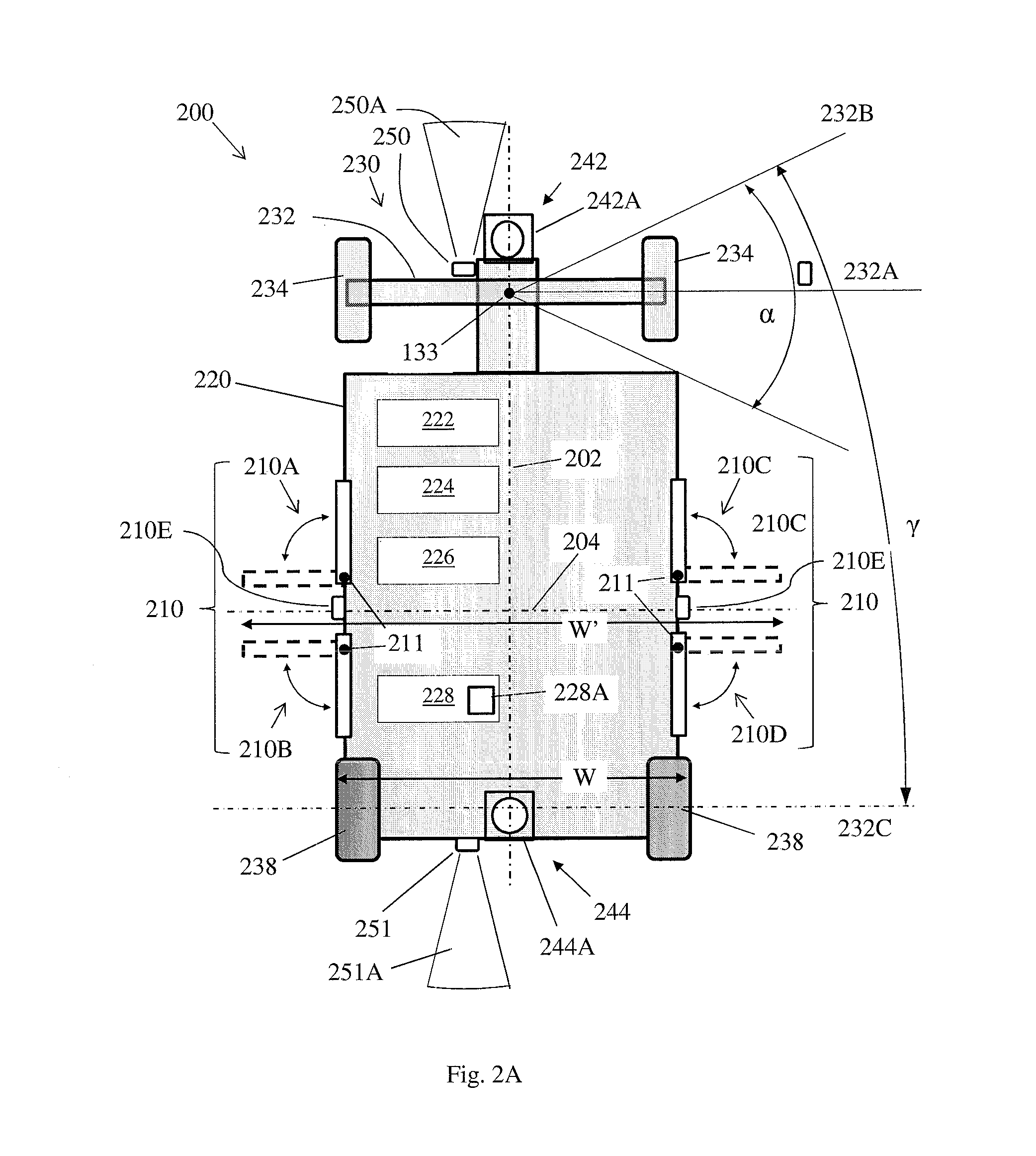

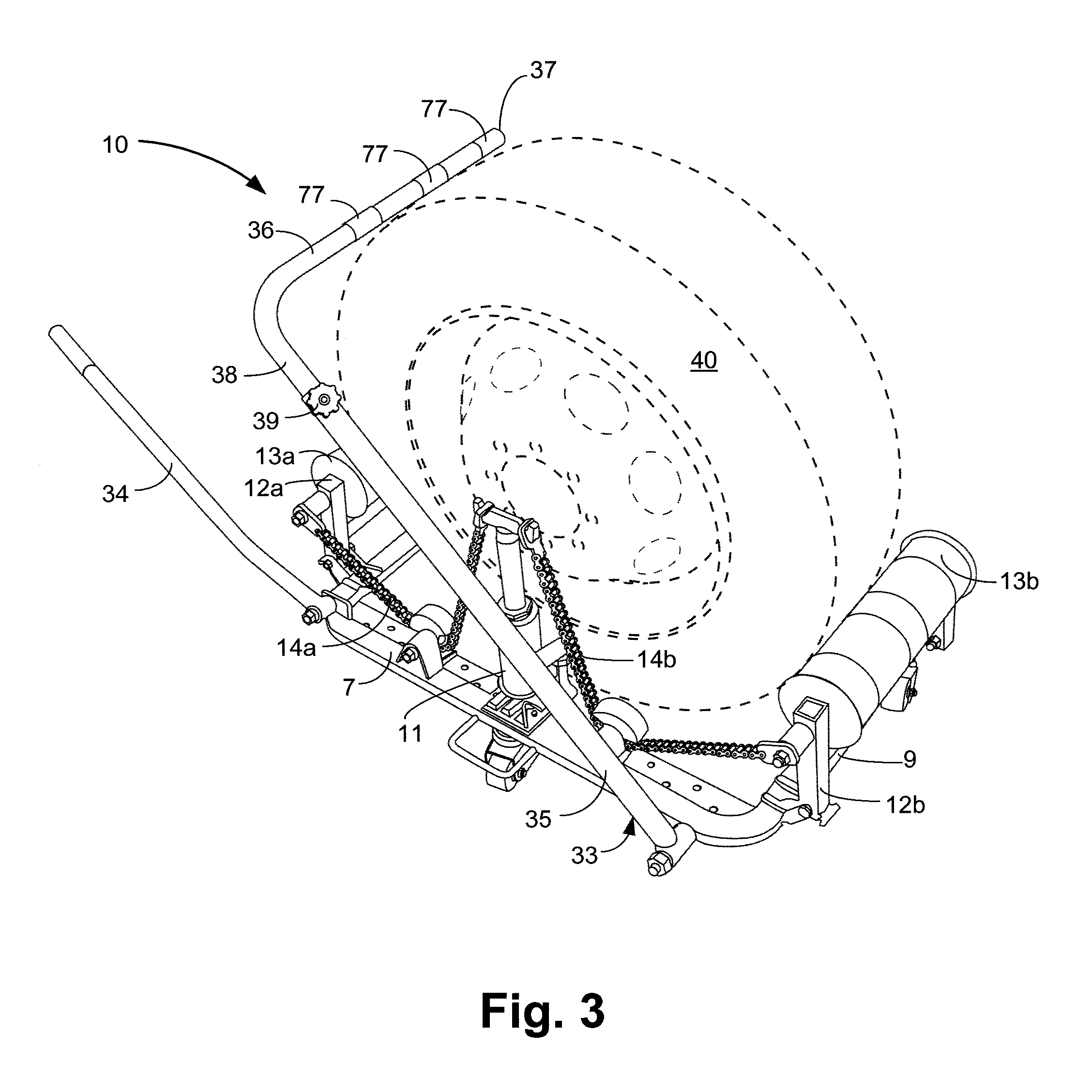

Tire Manipulation System

A tire manipulation system for efficiently manipulating the position of a tire. The tire manipulation system generally includes a mounting device for removable attachment to a tractor, a telescoping main support structure attached to the mounting device, a main actuator connected to the main support structure, a pivot axle rotatably connected to the main support structure, a support frame connected to the pivot axle, and a pair of telescoping supports each having an actuator and a gripping member for engaging a tire to be manipulated. The gripping members first engage the perimeter of a tire to be manipulated and then using the loader system of the tractor the user is able to manipulate the attitude of the tire.

Owner:JOGGER IND LLC

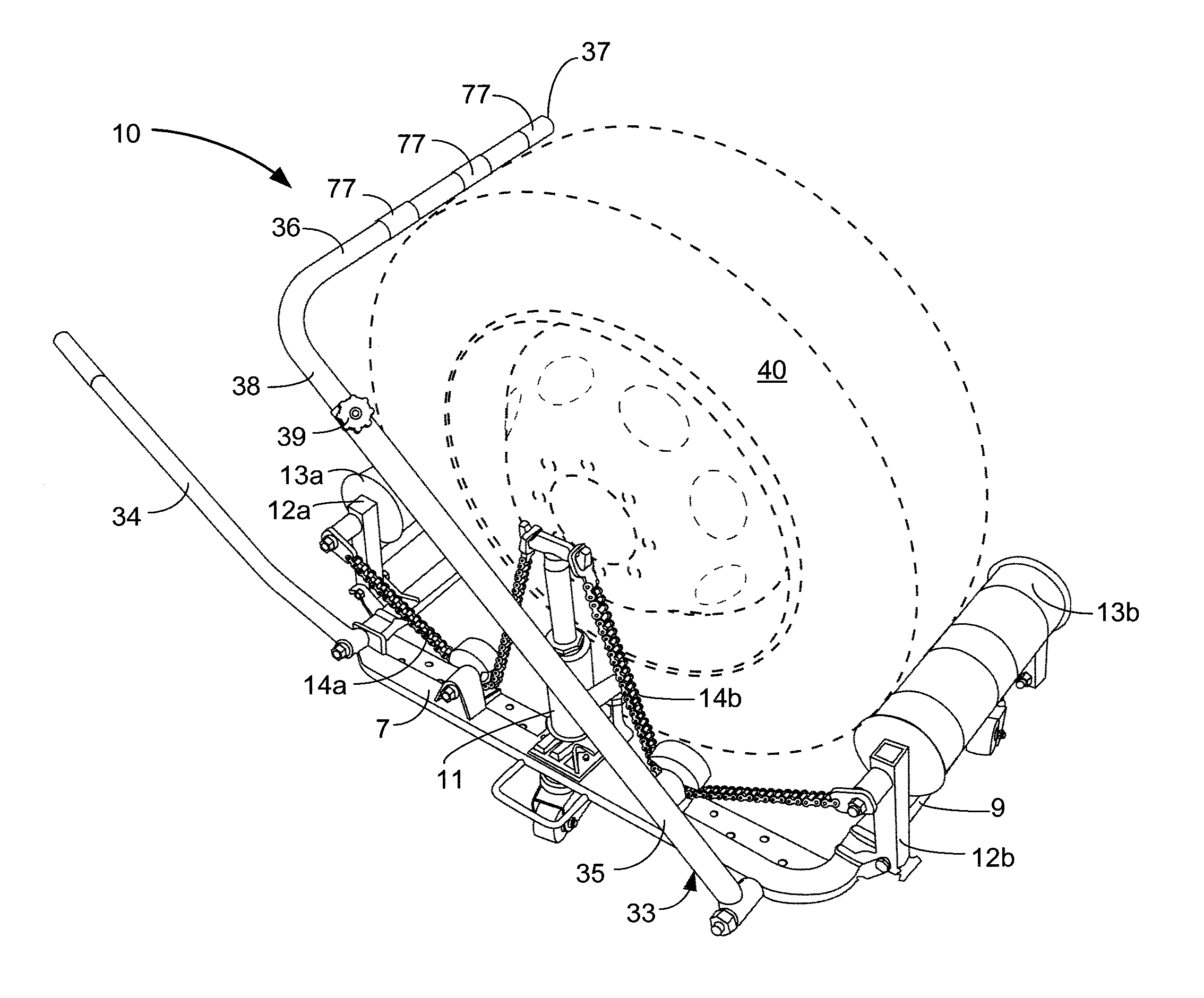

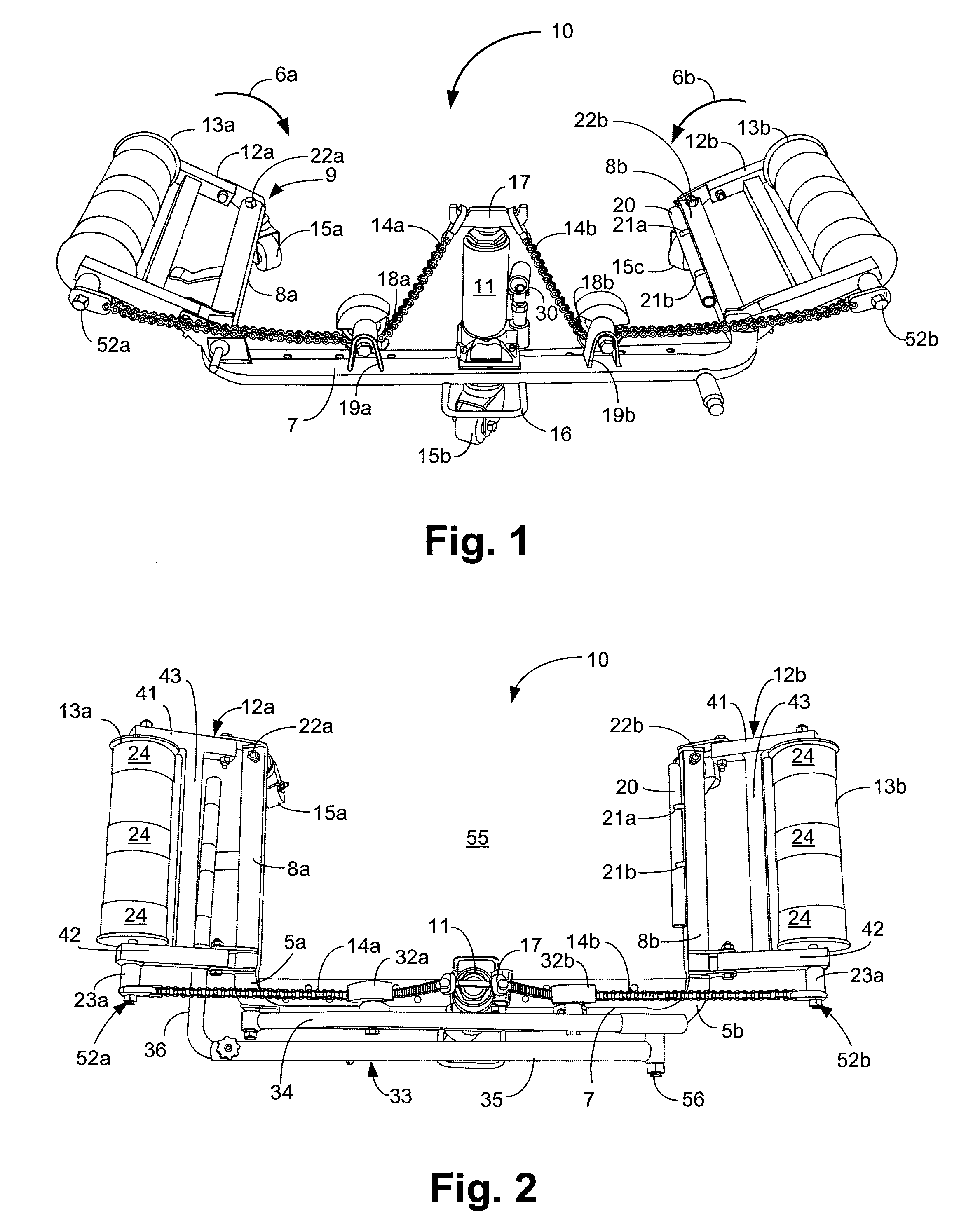

Wheel Lift and Transport Device

A device for lifting, supporting and moving large vehicle wheels allows a single person to install and remove wheels. The device has a U-shaped frame with two opposed straight sides connected by a jack side of the frame. Lift arms rotatably affixed to the opposed straight sides have rotatable rollers that contact the vehicle wheel. The lift arms are connected to a jack via chains that translate vertical motion from the jack to raise the lift arms, and thus raise the vehicle wheel. The rollers allow a user to rotate the vehicle wheel to position it for reinstallation onto the vehicle. A stabilizer bar rotatably affixed to the frame contacts the vehicle lift to stabilize the wheel during use of the device.

Owner:VISION GLOBAL TECH

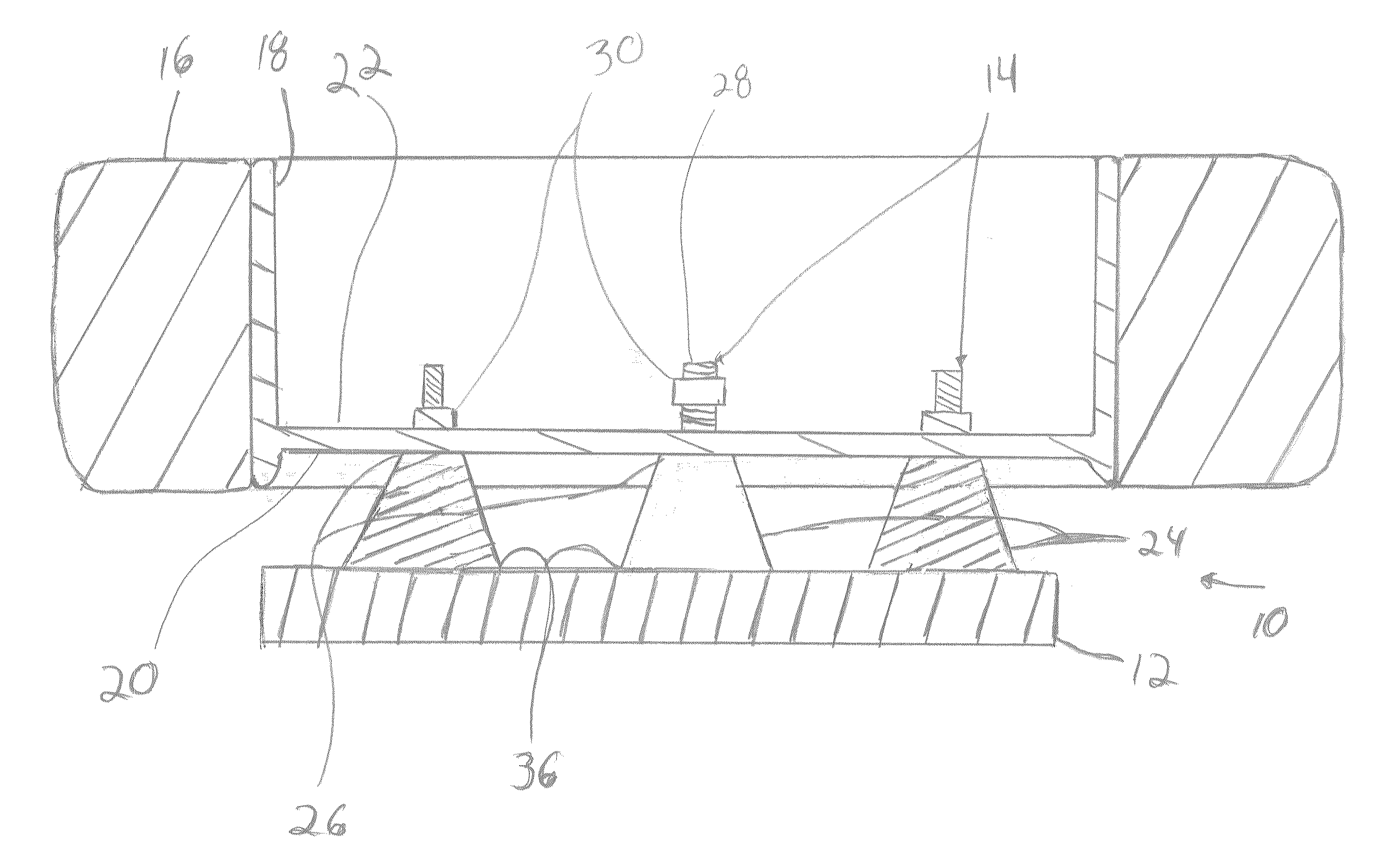

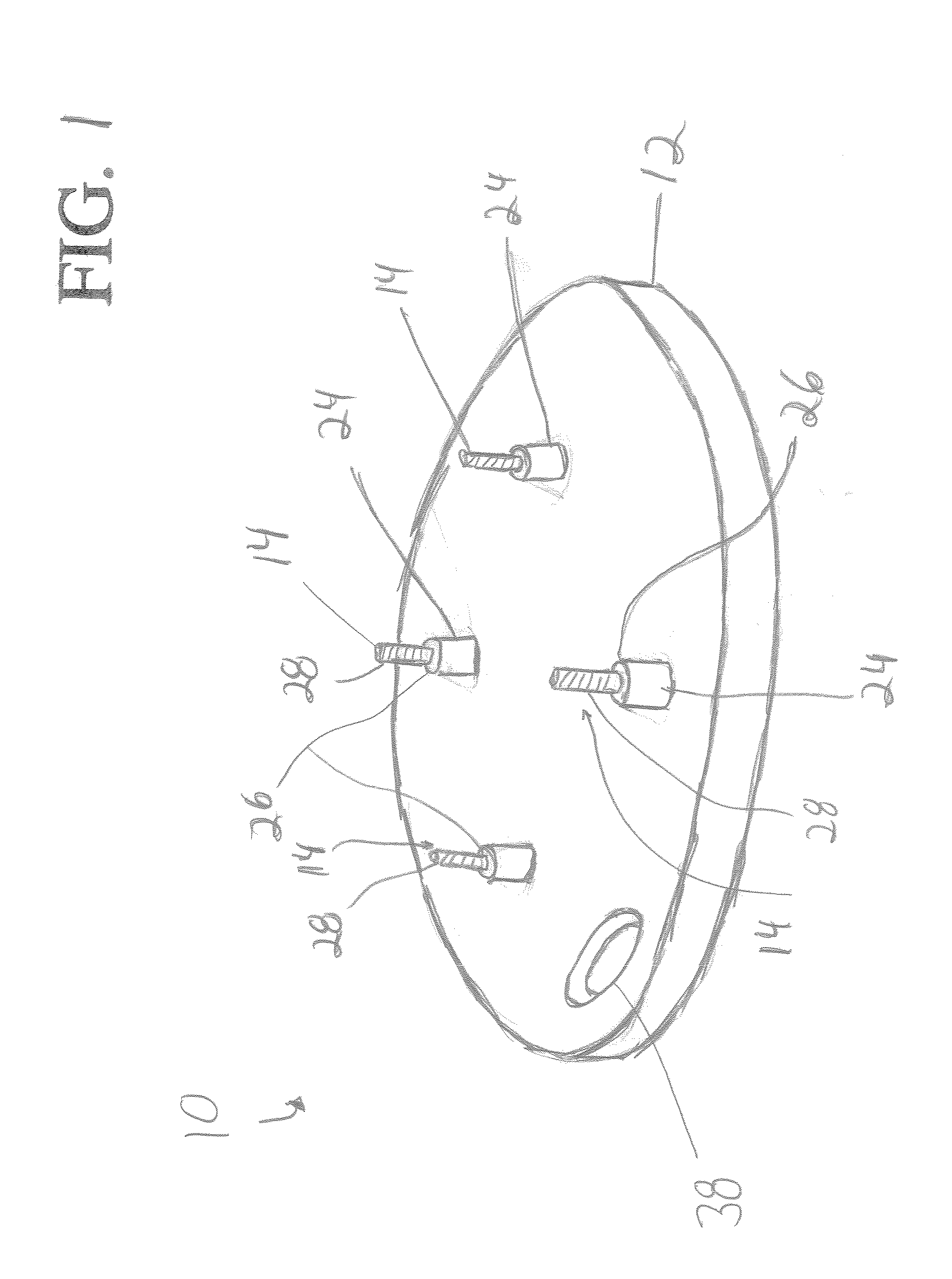

Tire Removal Aid For Large Tires To Minimize / Eliminate Scuffing Of The Wheel

ActiveUS20080185106A1Assist in removingHigh surfaceStatic/dynamic balance measurementTyresEngineeringShaft collar

An apparatus for protecting the exterior or polished surface of wheels as tires are removed and placed on the wheel. The apparatus includes a substantially flat base having a plurality of stanchions extending out from the base. Each stanchion has a collar positioned adjacent to the base that includes a diameter greater than the stanchion. The stanchions are sized to fit through the bolt holes of the wheel in order to generally align each stanchion with one of those holes. Each collar is sized to be preferably slightly larger than the average bolt, or lug, hole on the wheel. Additionally, each collar is sized to cover substantially the same area as the lug nut or nut that normally attaches the wheels to the vehicle upon which they are used.

Owner:MELZO INNOVATIONS

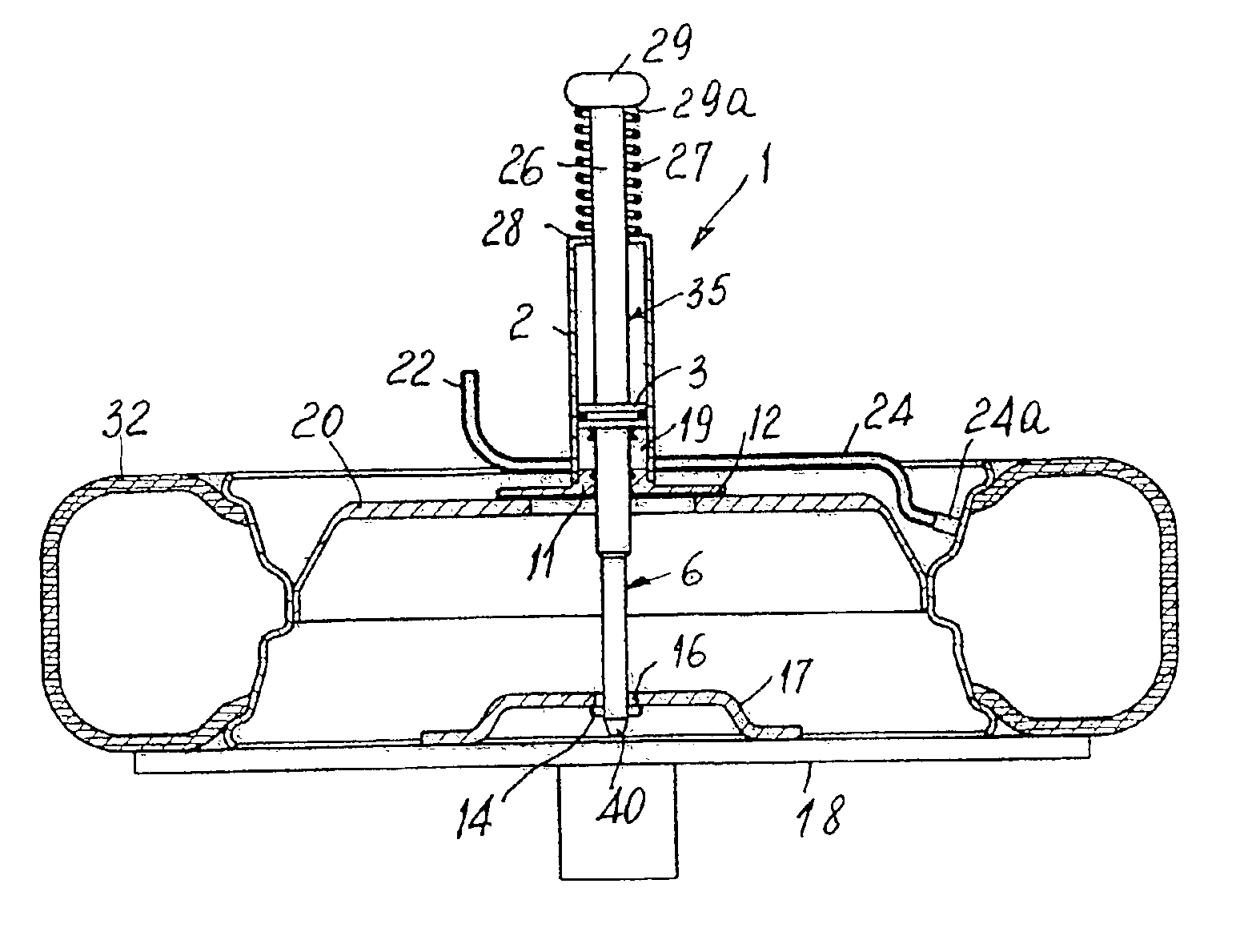

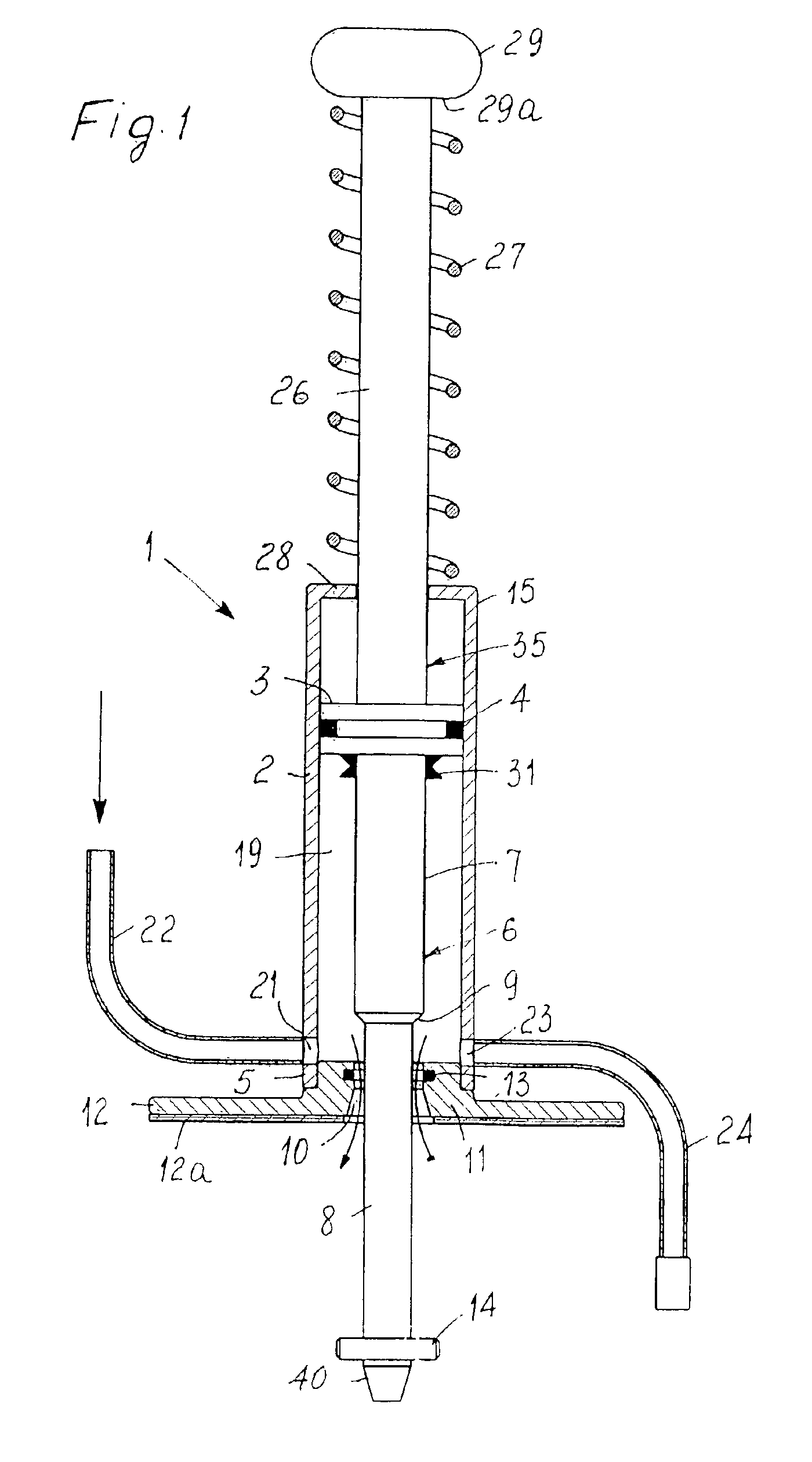

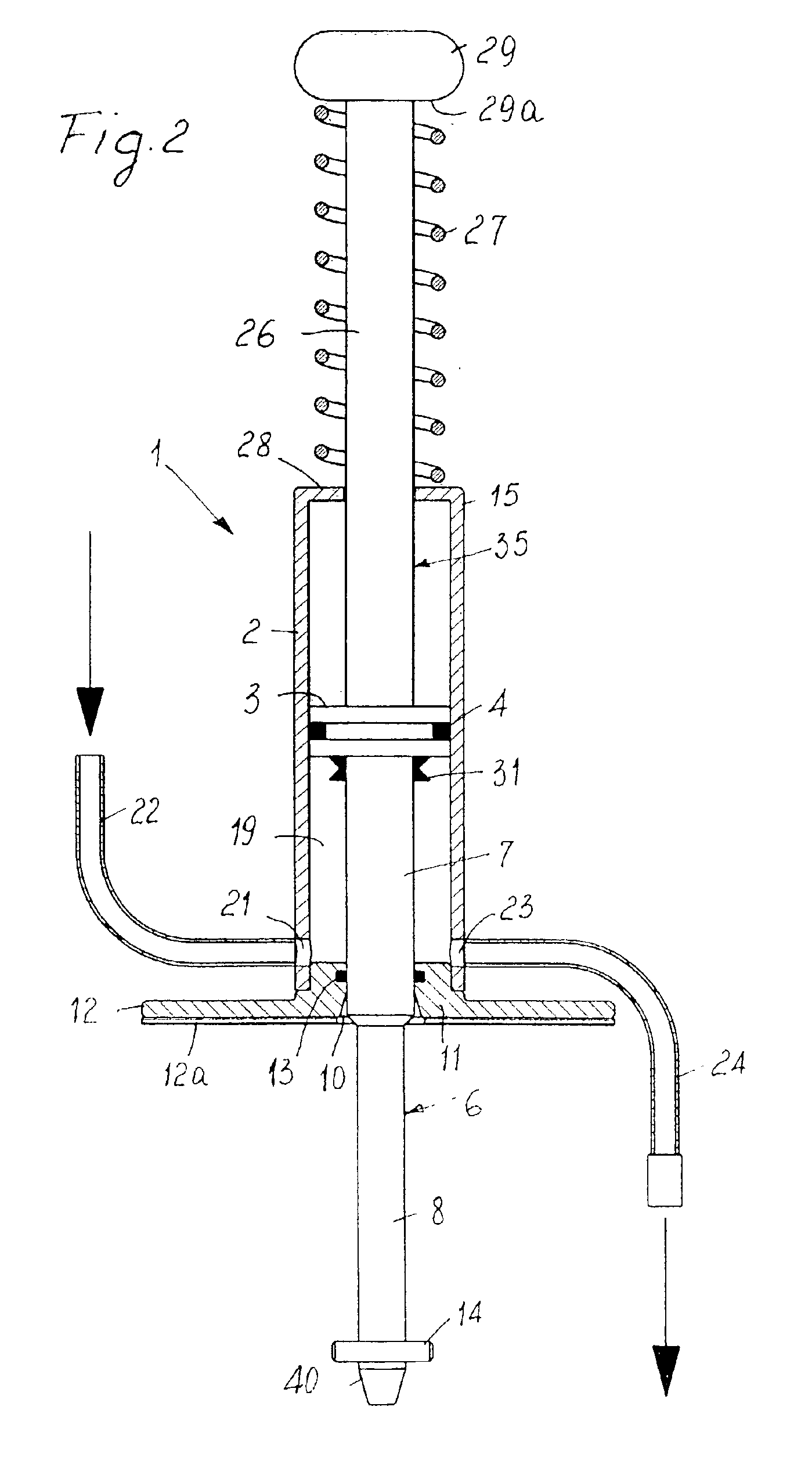

Safety device for pressurizing an envelope at risk of bursting

InactiveUS6923200B2Easy to operateCompetitive production costCheck valvesStatic/dynamic balance measurementEngineeringMechanical engineering

A safety device for inflating an envelope at risk of bursting comprising: a tubular body, a piston element slidably and sealably mounted within at least one inner portion of the tubular body; at least one piston rod integral with the piston element and extending so as to protrude from a first end of the tubular body; an annular bottom member, located in the tubular body or at the first end of the tubular body and suitable for slidably guiding the piston rod and for closing the tubular body whereby delimiting an annular space together with the tubular body and with the piston; removable anchoring device suitable for acting at a protruding end of piston rod and for constraining the piston rod to a support; at least one inlet opening and at least one outlet opening formed in the tubular body at the annular space, in operation said inlet opening being suitable for being connected to a pressurize fluid source and the outlet opening being designed to be connected to the envelope to be pressurized; and a yielding retainer for holding in position the said piston element, so that in case of bursting, the unit formed by the tubular body and the annular bottom member can be moved longitudinally following a bursting impact with respect to the piston element in contrast with the yielding retainer.

Owner:BUTLER ENG & MARKETING

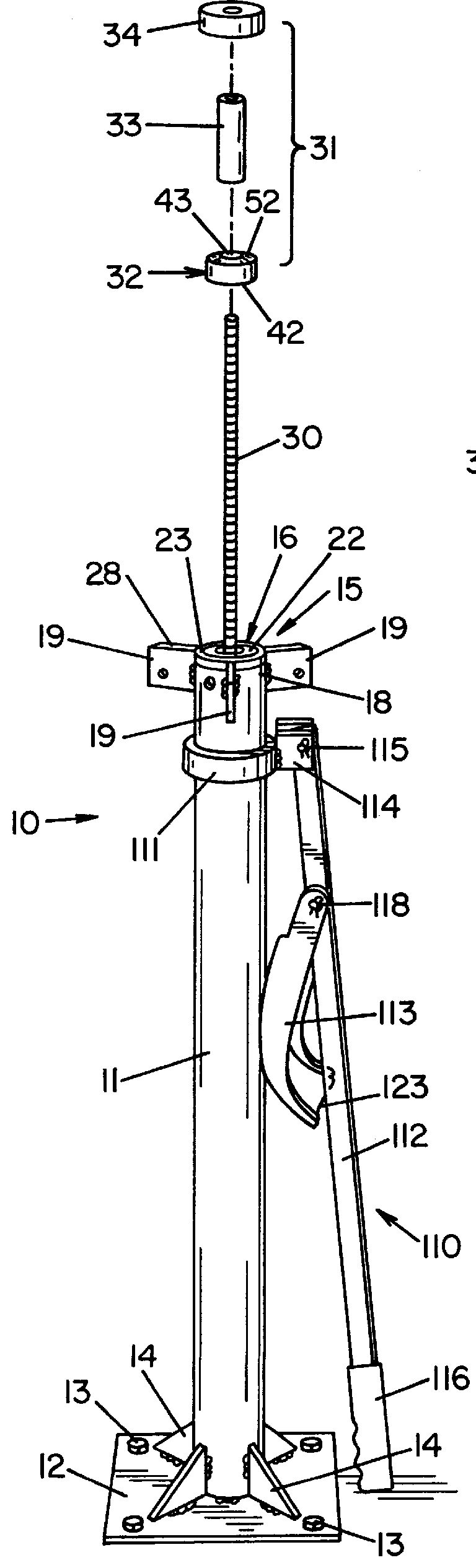

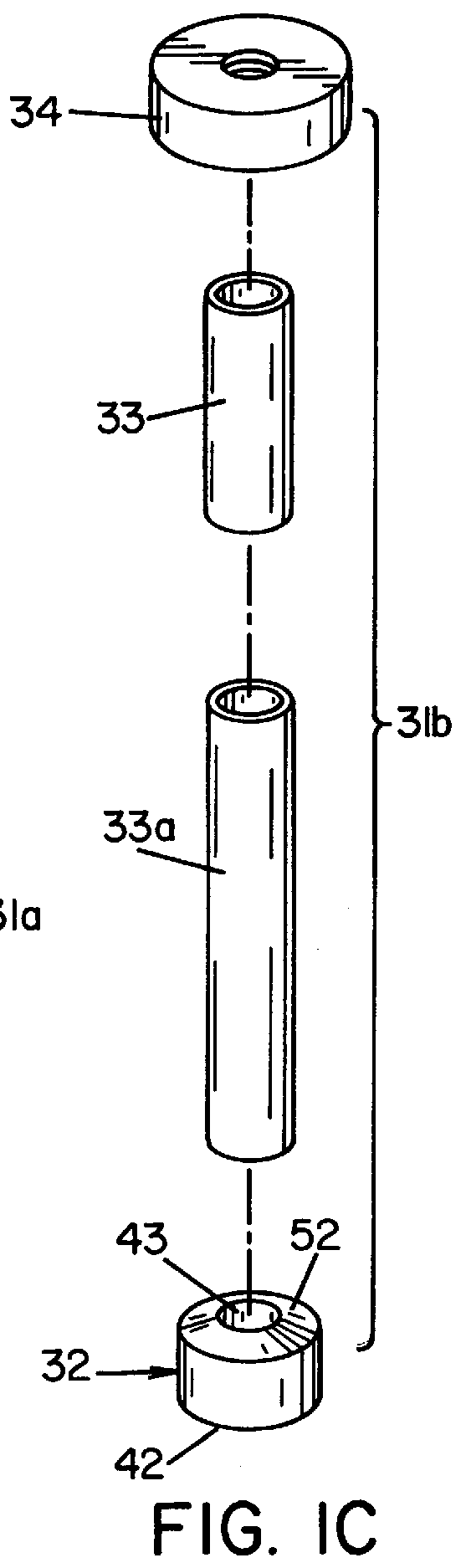

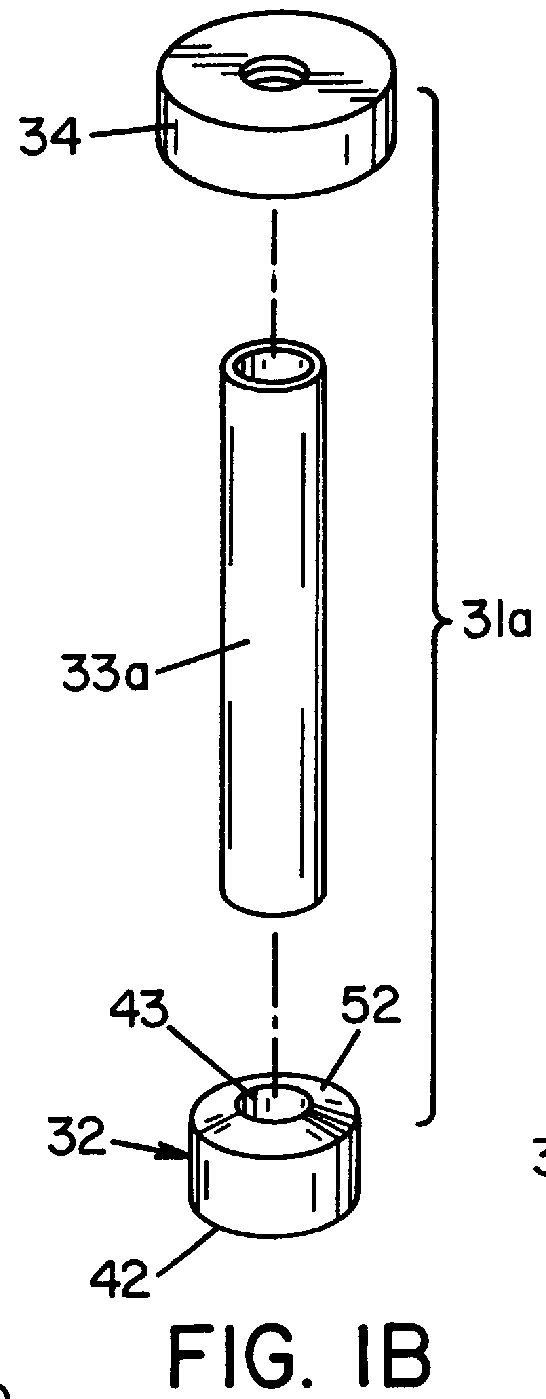

Center post tire changing apparatus

A center post tire changing apparatus for mounting or demounting a tire from a wheel includes an elongated support post having a wheel support assembly disposed on one end of the support post and a center post connected to and extending upwardly from the wheel support assembly and in coaxial alignment with the support post. A wheel securing assembly is disposed upon the center post, wherein the wheel is securely mounted on the center post between the wheel support assembly and the wheel securing assembly. A bead beaker is preferably permanently secured to the support post and is noted to be continuously adjustable thereon.

Owner:SUMMIT TOOL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com