Patents

Literature

212 results about "Centring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Centring, centre, centering, or center is a type of falsework: the temporary structure upon which the stones of an arch or vault are laid during construction. Until the keystone is inserted an arch has no strength and needs the centring to keep the voussoirs in their correct relative positions. A simple centring without a truss is called a common centring. A cross piece connecting centring frames is called a lag or bolst.

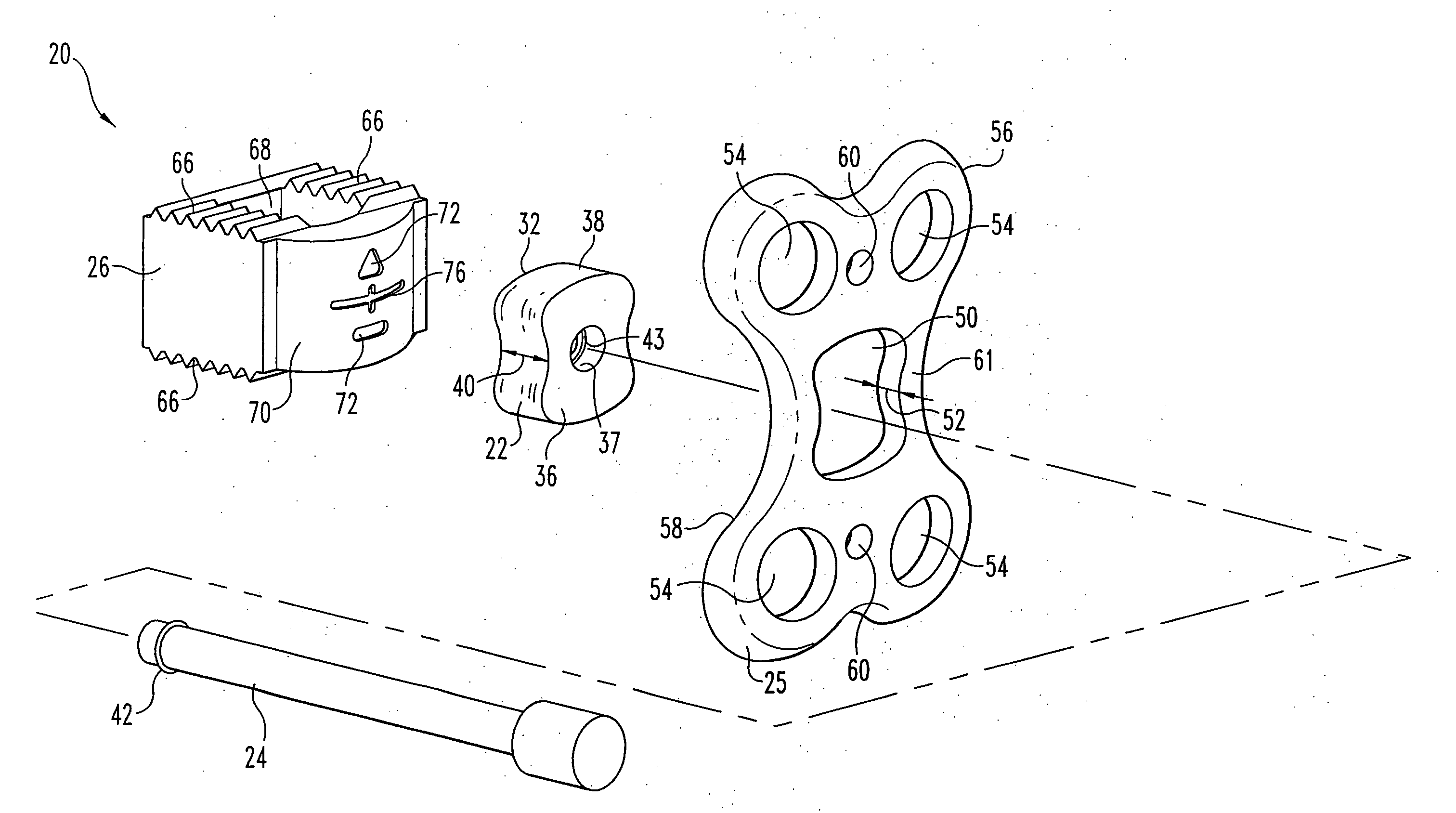

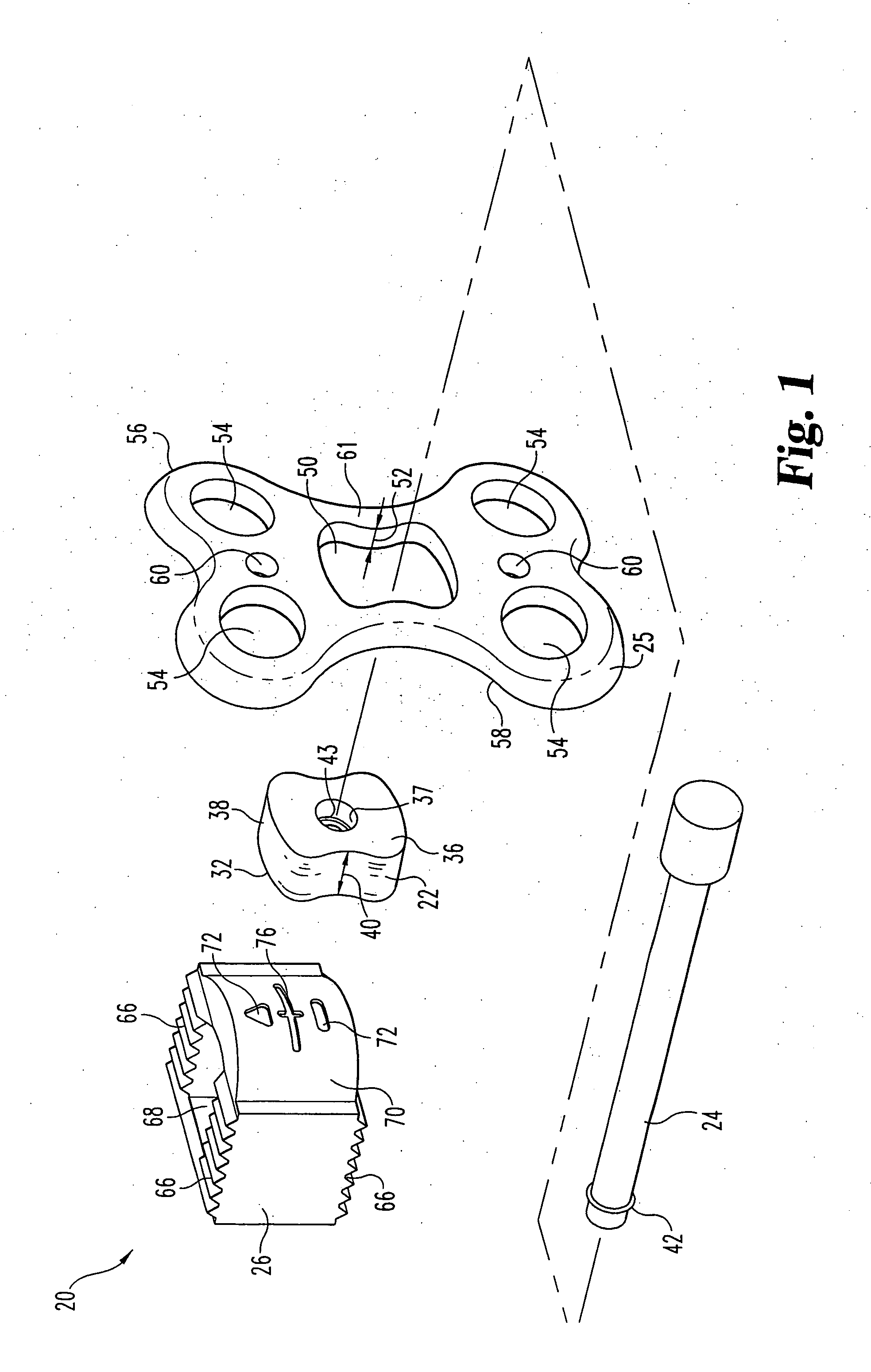

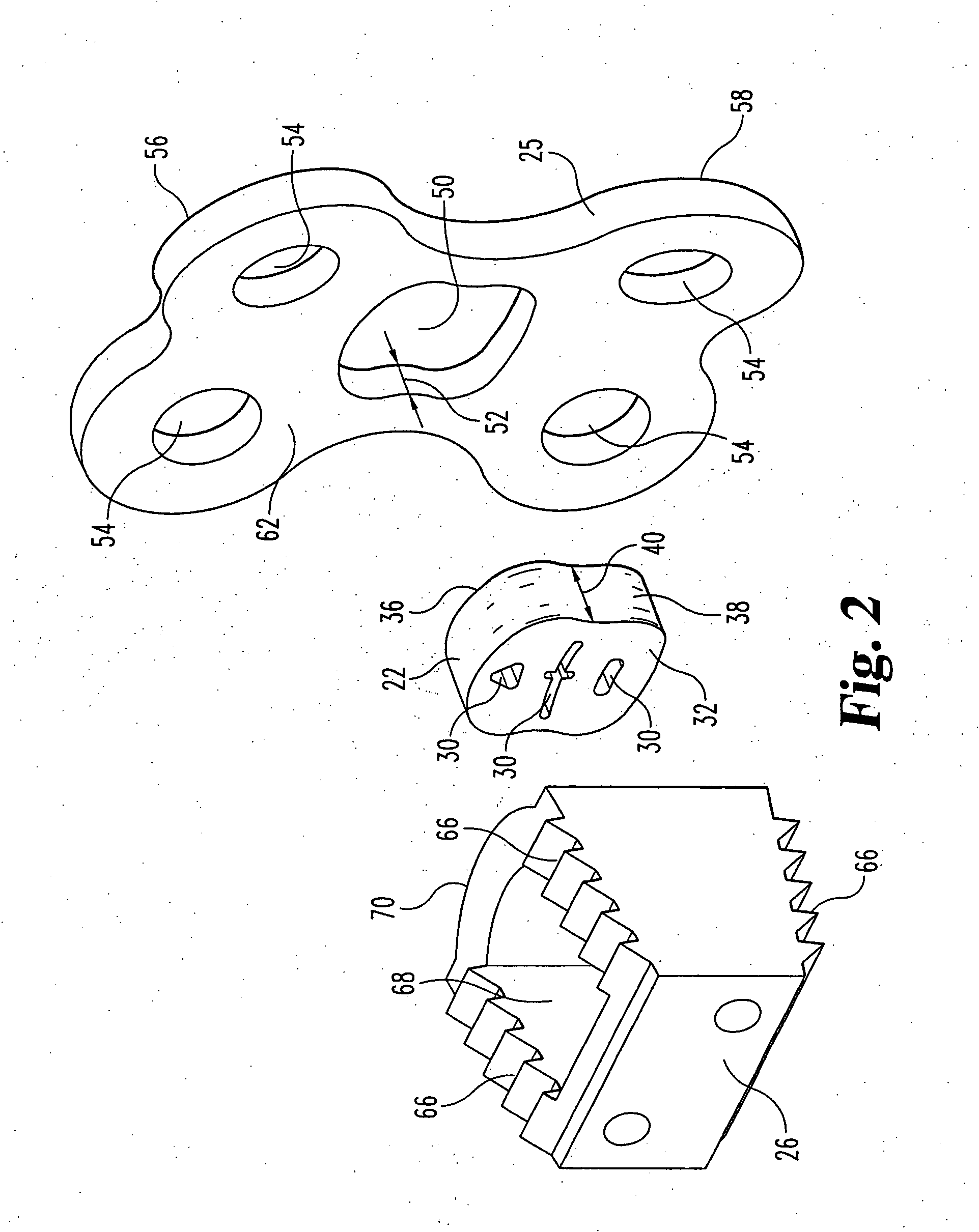

Orthopedic support locating or centering feature and method

ActiveUS20070270965A1Stabilize spineDistributes forceInternal osteosythesisJoint implantsIntervertebral spaceCentring

Spinal plate positioning system including a spinal plate, centering member and implant, is used to position and center a spinal plate over an implant in an intervertebral space. Implant may include a centering feature which may engage a surface of centering member or spinal plate to aid in placement of spinal plate.

Owner:WARSAW ORTHOPEDIC INC

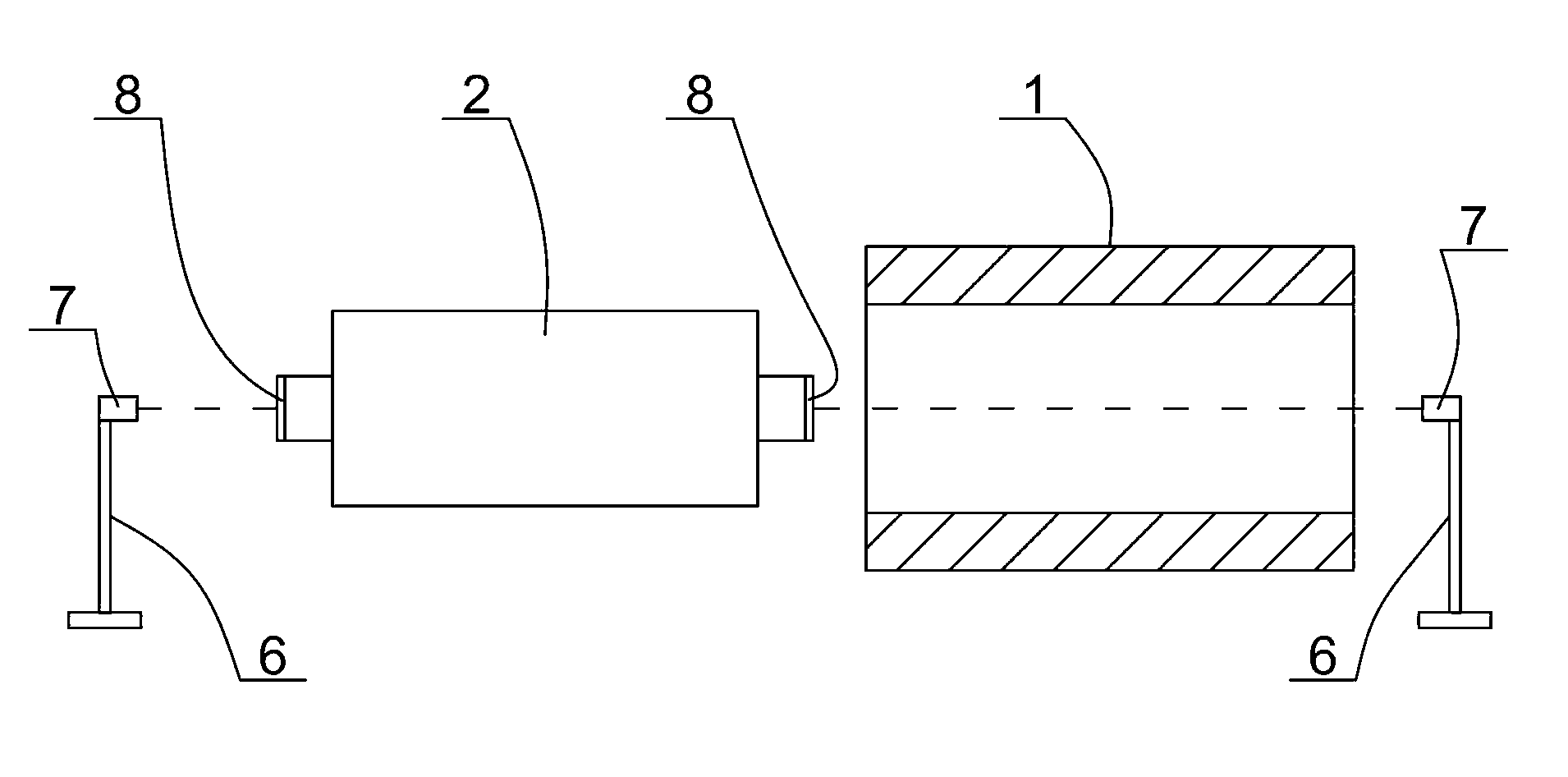

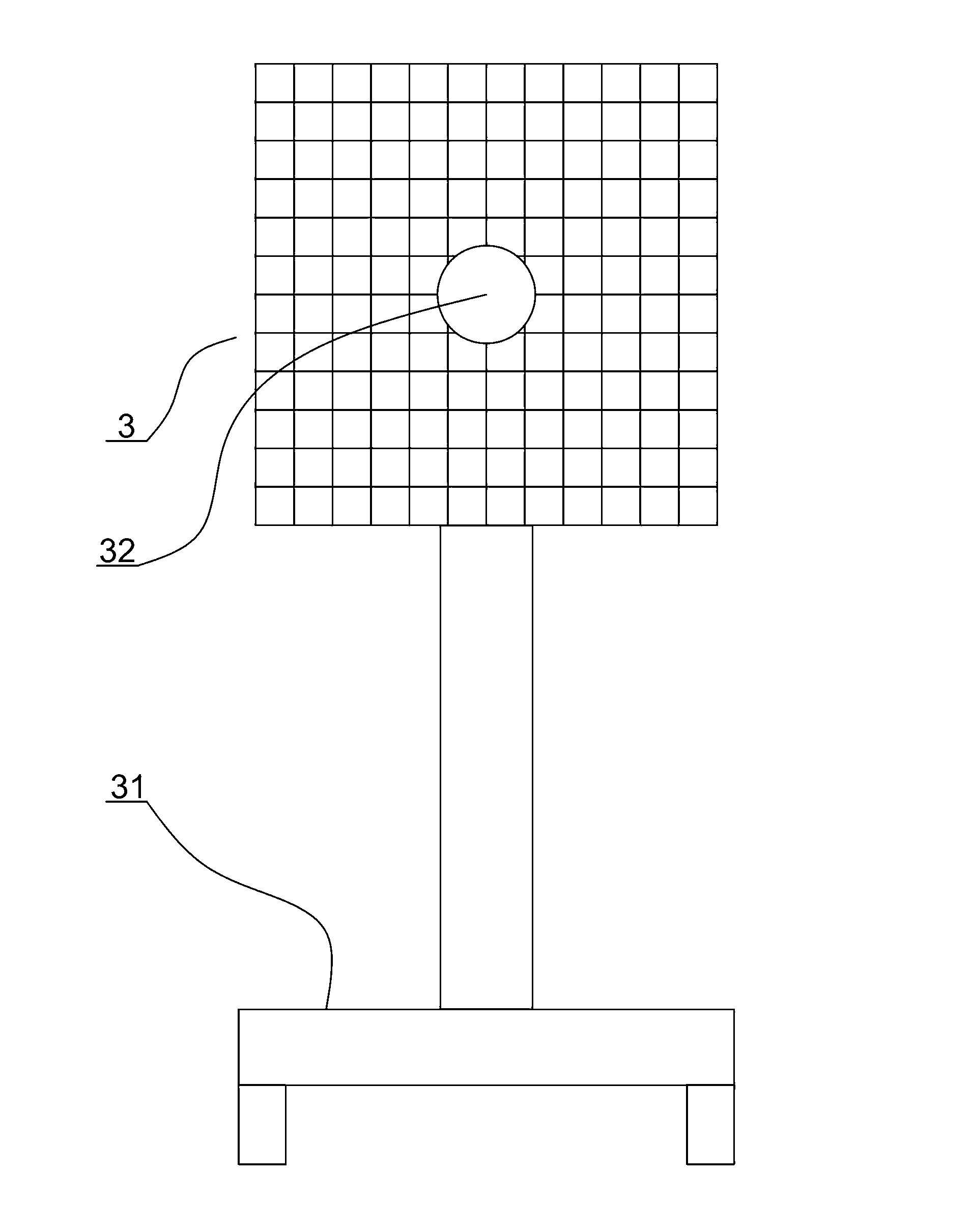

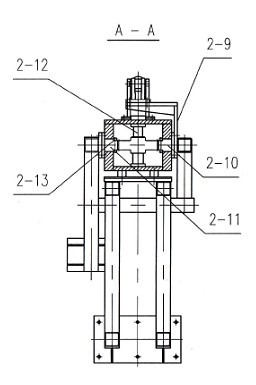

Centring method in process of mounting generator rotor in threading mode

ActiveCN103296845AImprove coordinationLower requirementUsing optical meansCentering/balancing rotorsLaser transmitterEngineering

The invention discloses a centring method in the process of mounting a generator in a threading mode. The centring method comprises the steps of arranging a laser emitter on each side of the rotor, enabling the two laser emitters to be opposite to each other, adjusting the positions of the laser emitters to enable the laser beams emitted by the laser emitters to be located on the central line of a stator, arranging centring target boards at the two ends of the rotor correspondingly, arranging a circular centring ring at the position corresponding to the rotor central line, and keeping the imaging points of the laser beams on the centring target boards to be in the circular centring ring when the rotor is mounted in the threading mode. Therefore, the rotor is kept to be coaxial with the stator, and friction and collision are avoided. By means of the centring method in the process of mounting the generator in the threading mode, the coaxiality of the rotor and the stator can be observed and confirmed rapidly and conveniently, on-site coordination and command can be conducted conveniently when the rotor is mounted, and the rotor is guaranteed not to rub or collide with the stator in the whole mounting process.

Owner:NINGBO FUSHIDA ELECTRIC ENG

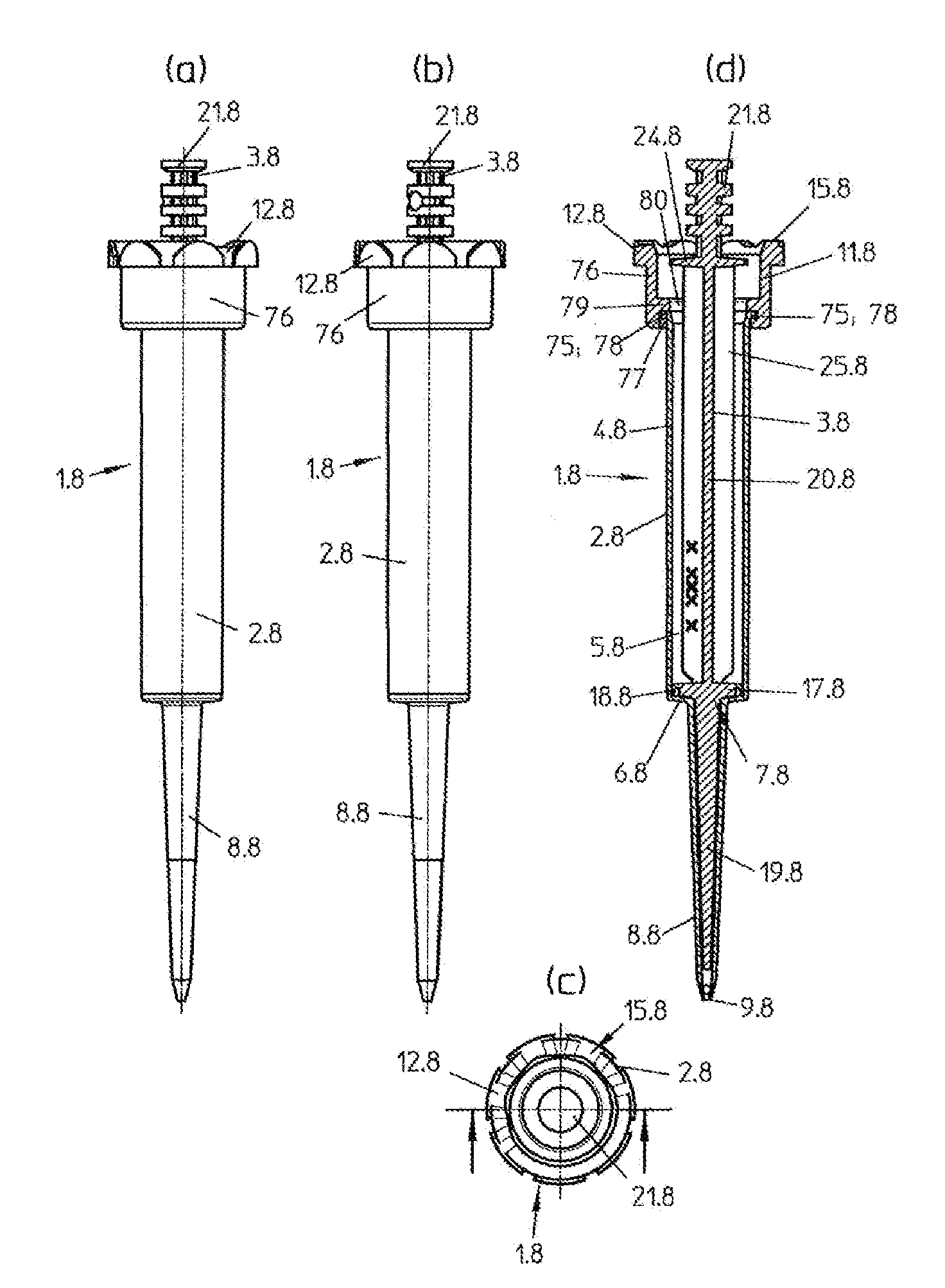

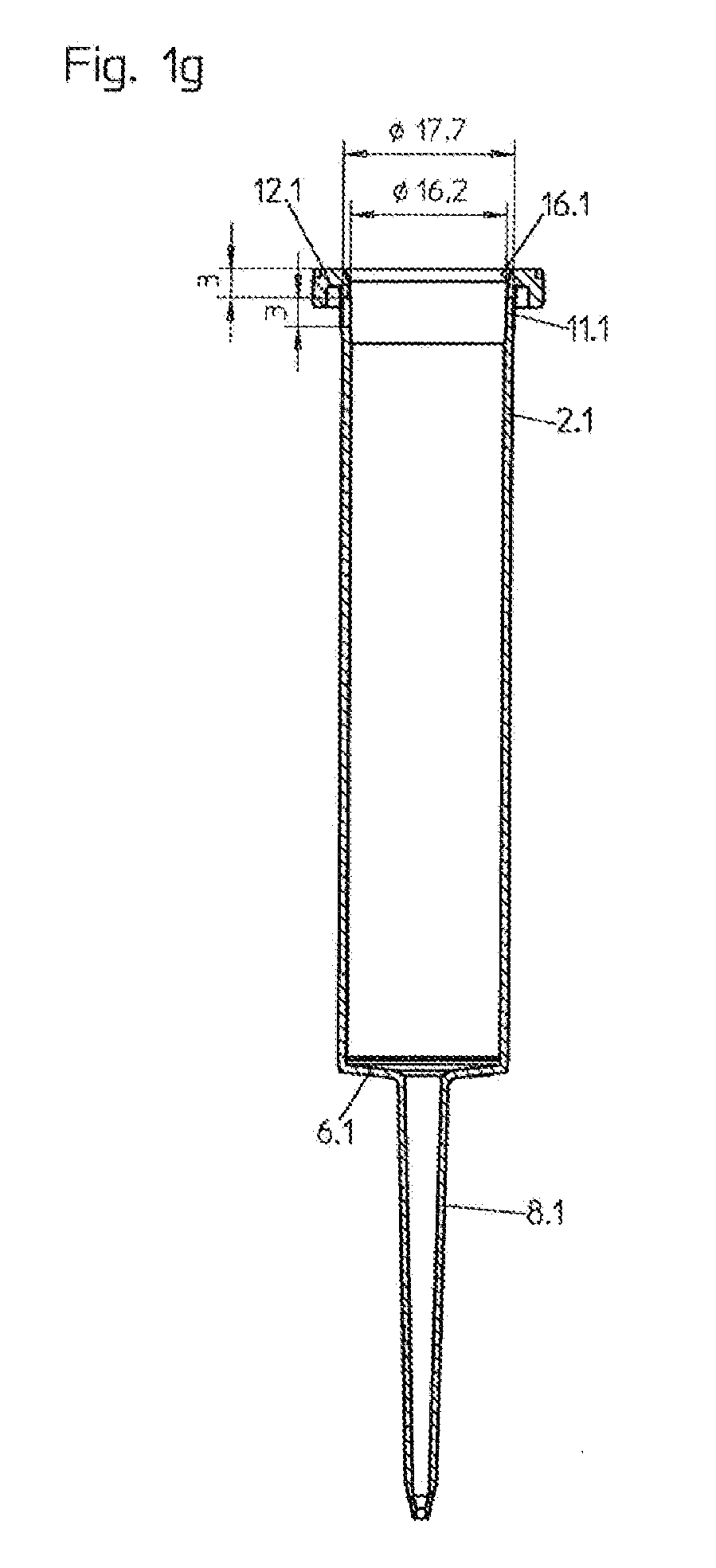

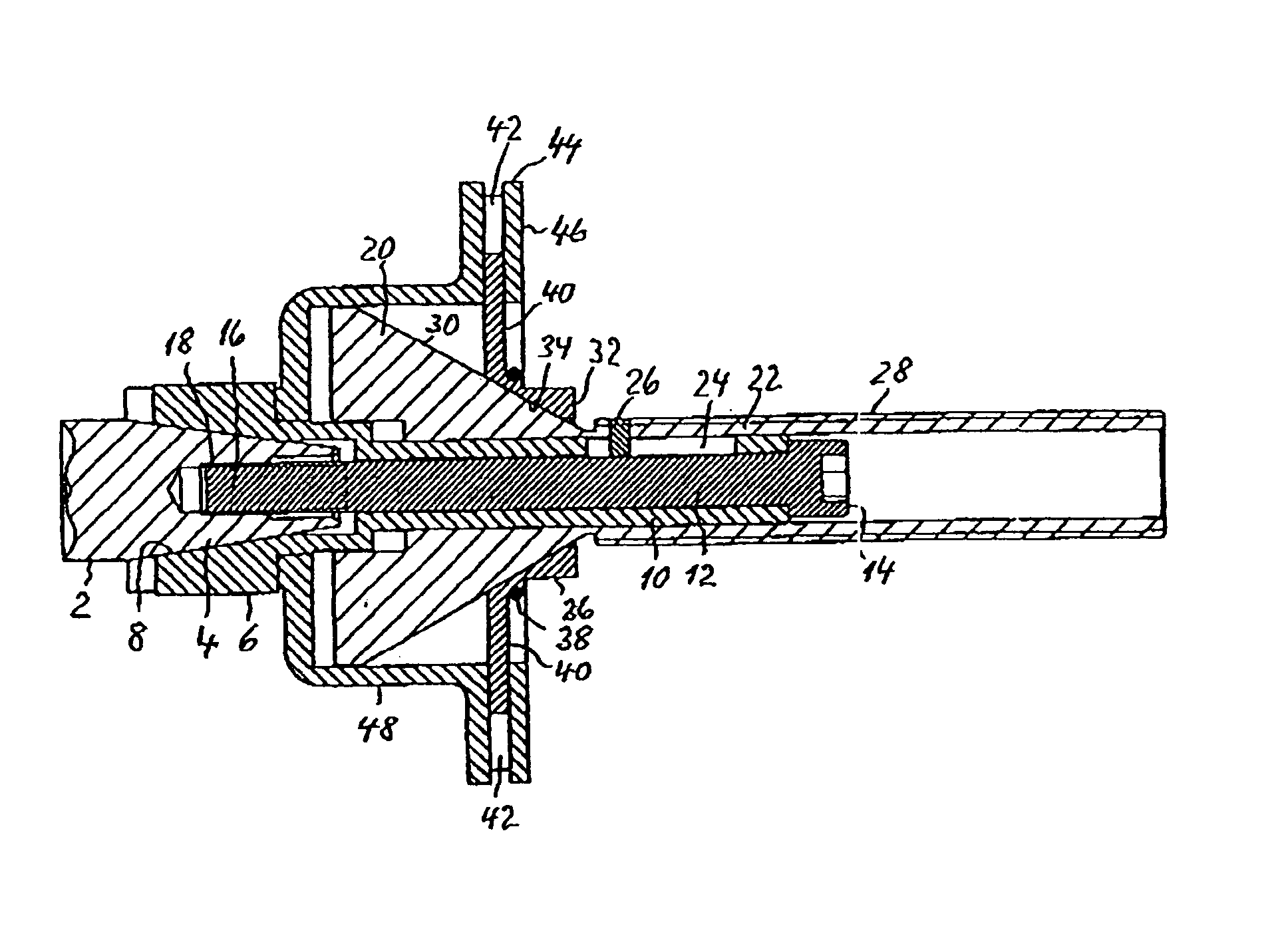

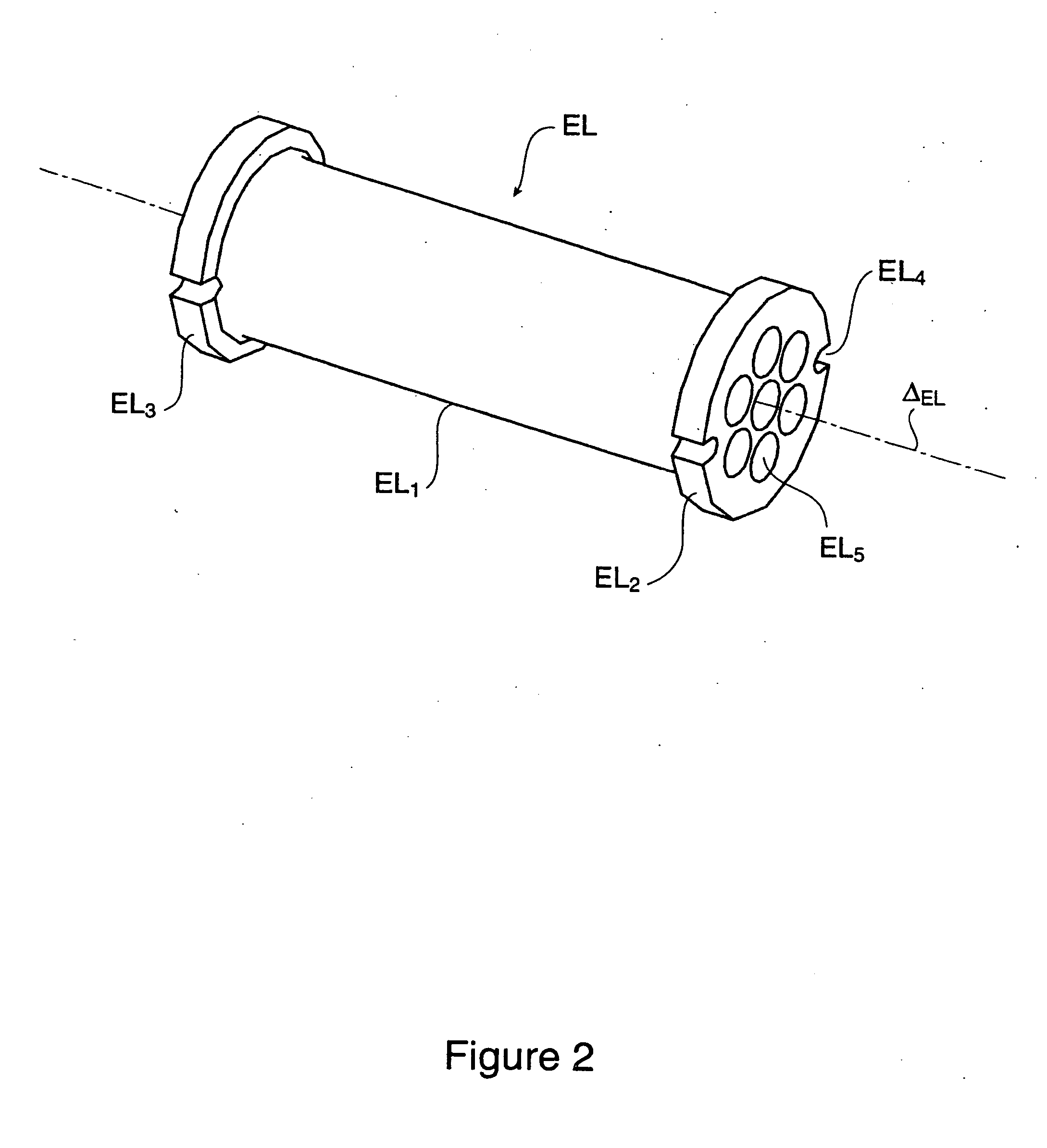

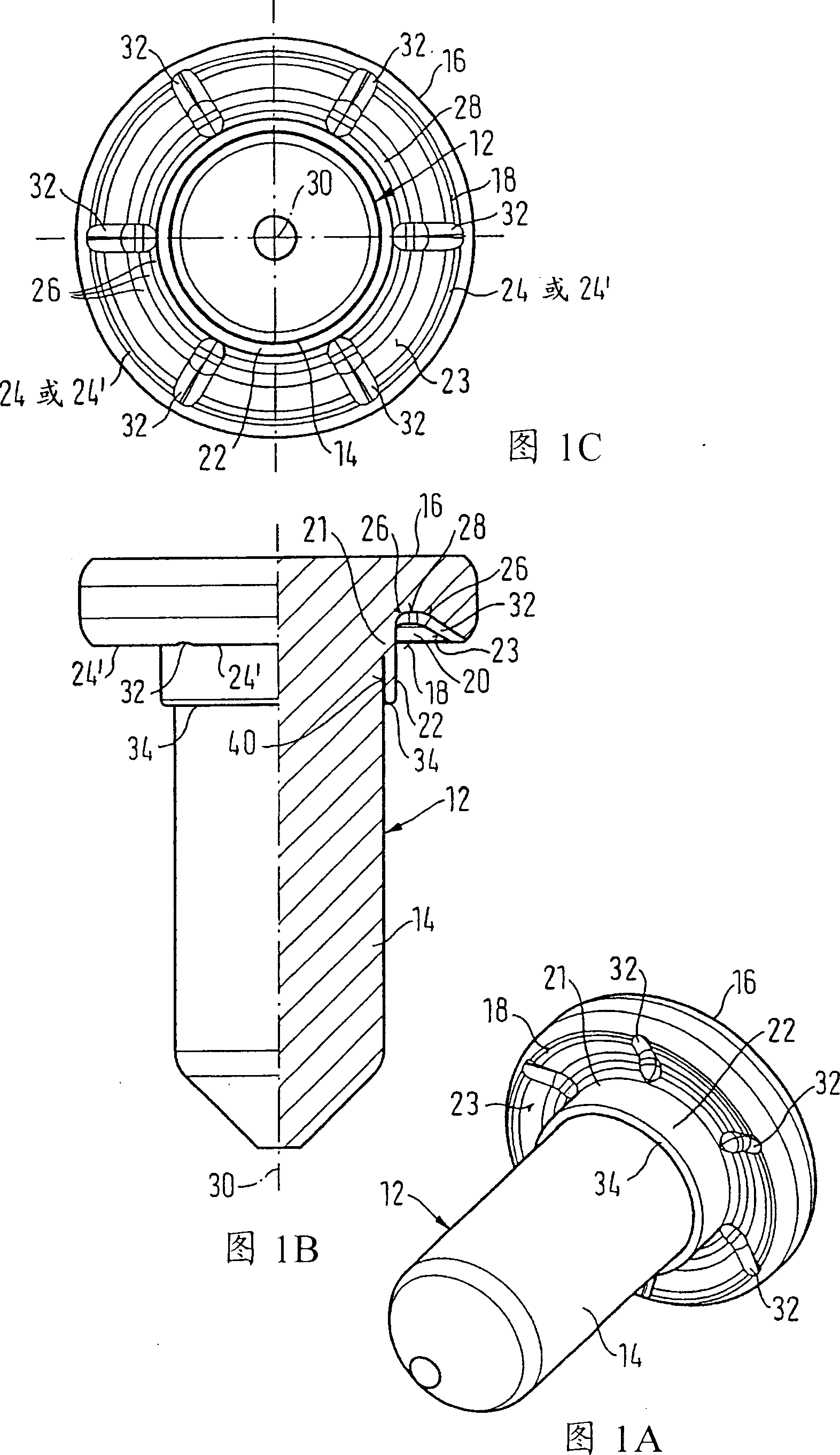

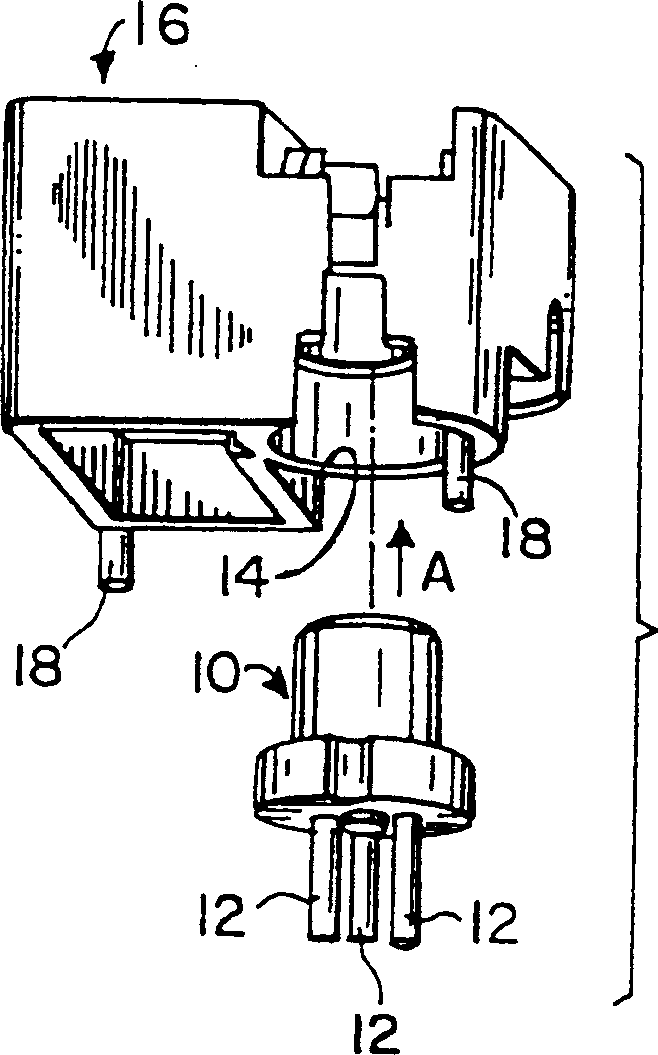

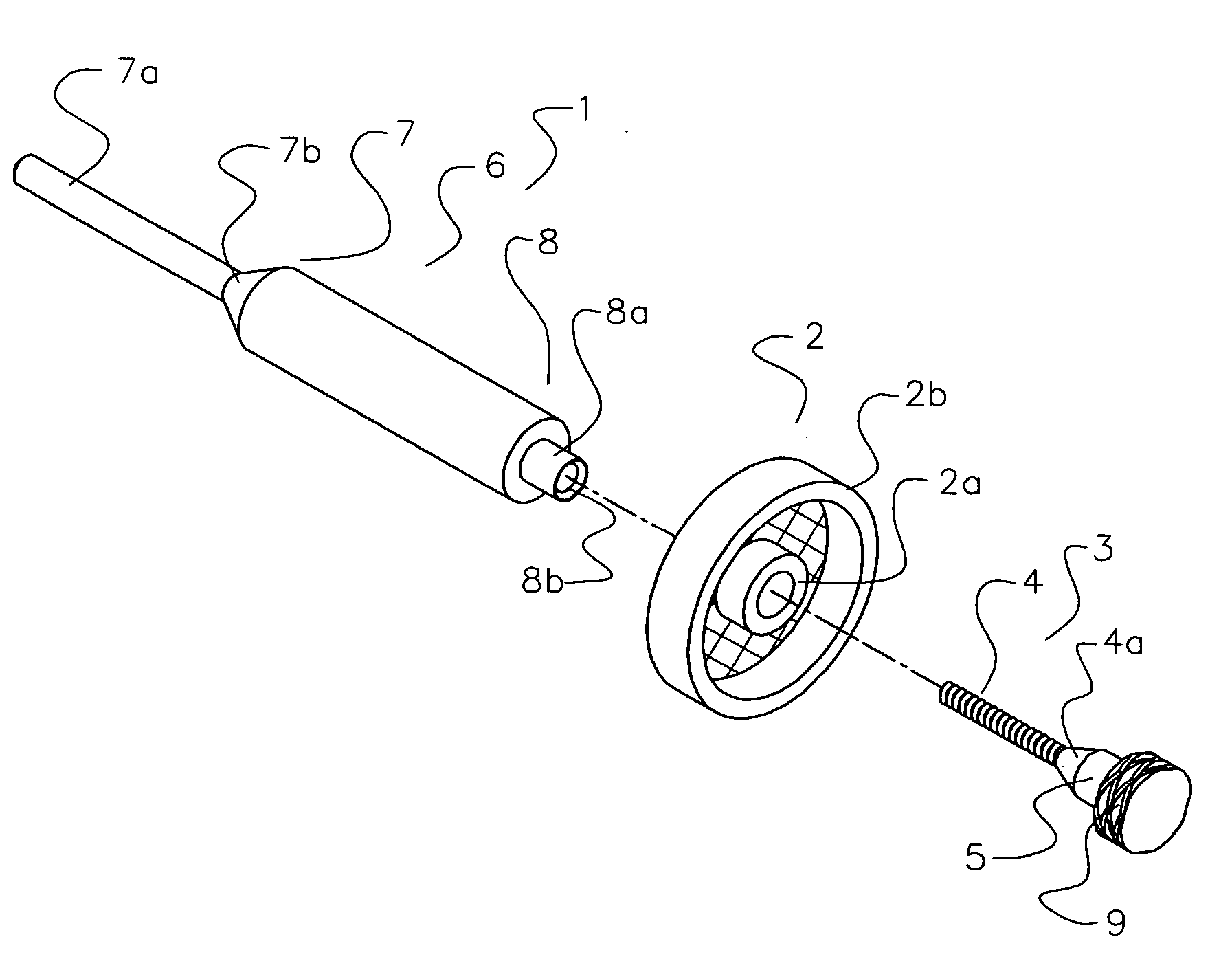

Syringe, syringe family and metering device

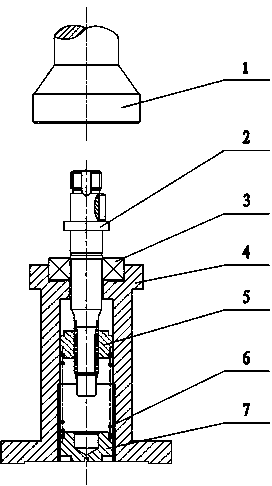

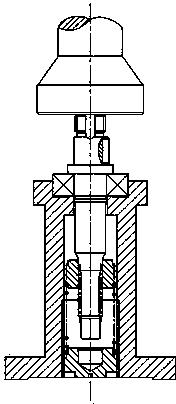

ActiveUS20110088493A1High measurement accuracyWithdrawing sample devicesBurettes/pipettesCouplingCentring

Syringe for use with a metering device comprising a centring element with an axial through-passage in a receiver for a syringe cylinder and an axially displaceable piston receiver for a syringe piston, comprisingsyringe cylindersyringe piston,the syringe cylinder comprising an outlet at the bottom,centring flange at the top on the external periphery for inserting into the receiver,cylindrical piston movement area connected to the outlet, with a first internal diameter, in which the syringe piston is sealingly guided, andat least at a distance of at least 3 mm from the upper end of the syringe cylinder a centring region for inserting the centring element, which has a second internal diameter, which exceeds the first internal diameter and is at least 16.2 mm,the syringe piston at the upper end has a coupling piece for inserting into the piston receiver.

Owner:EPPENDORF SE

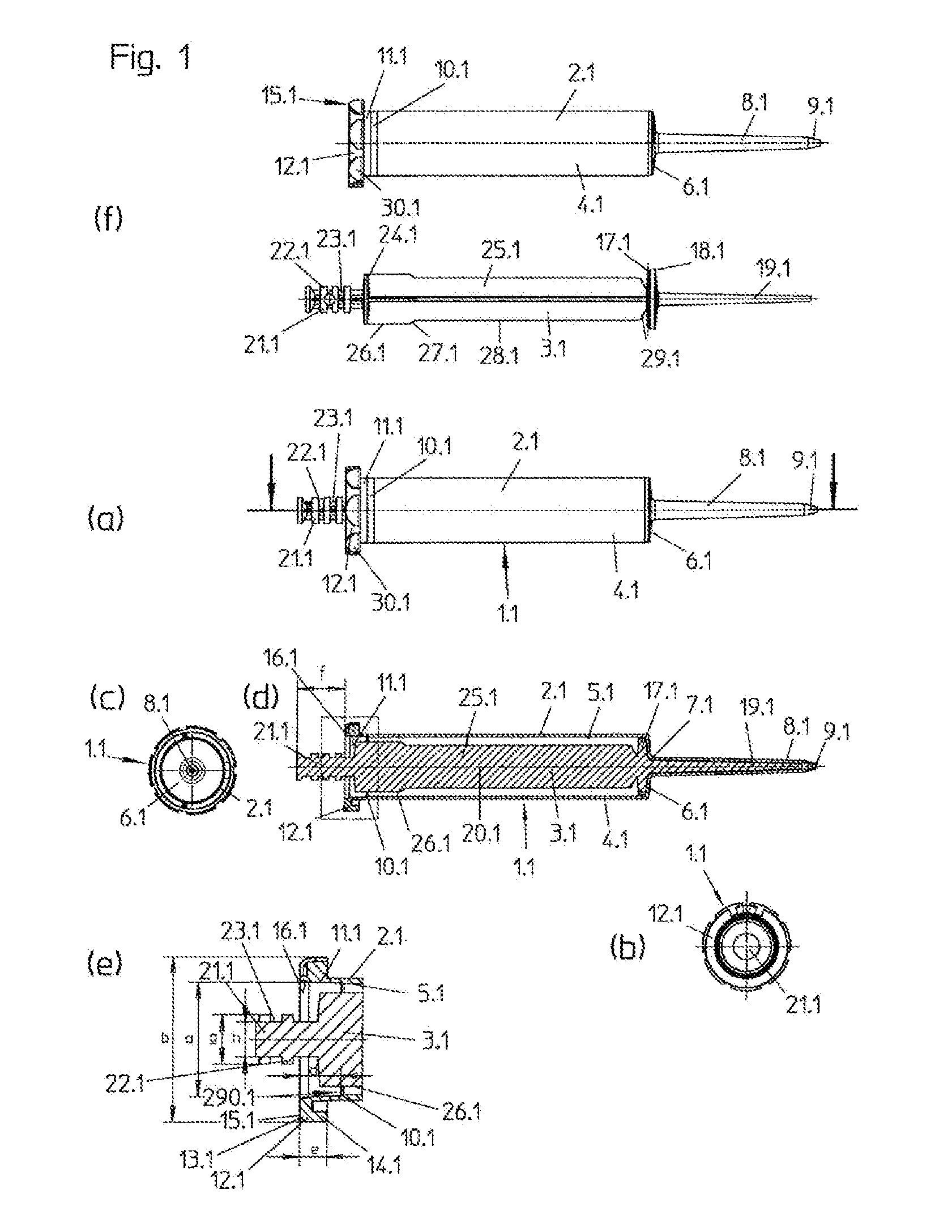

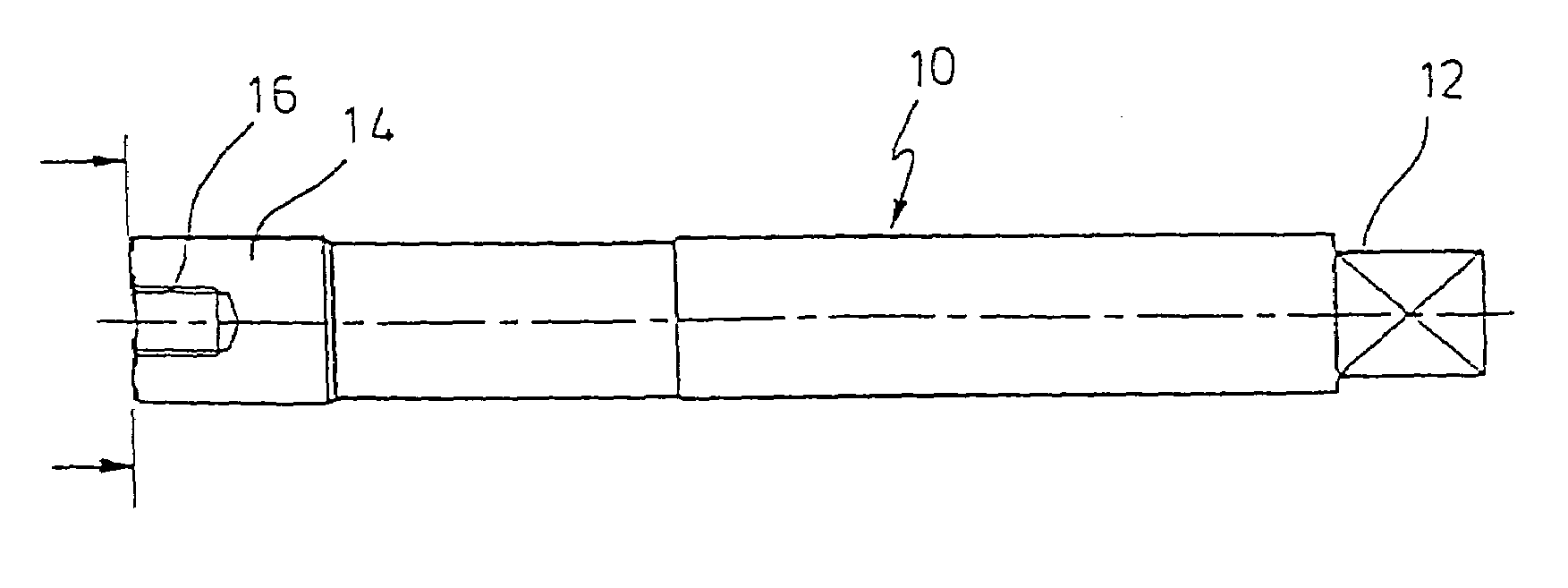

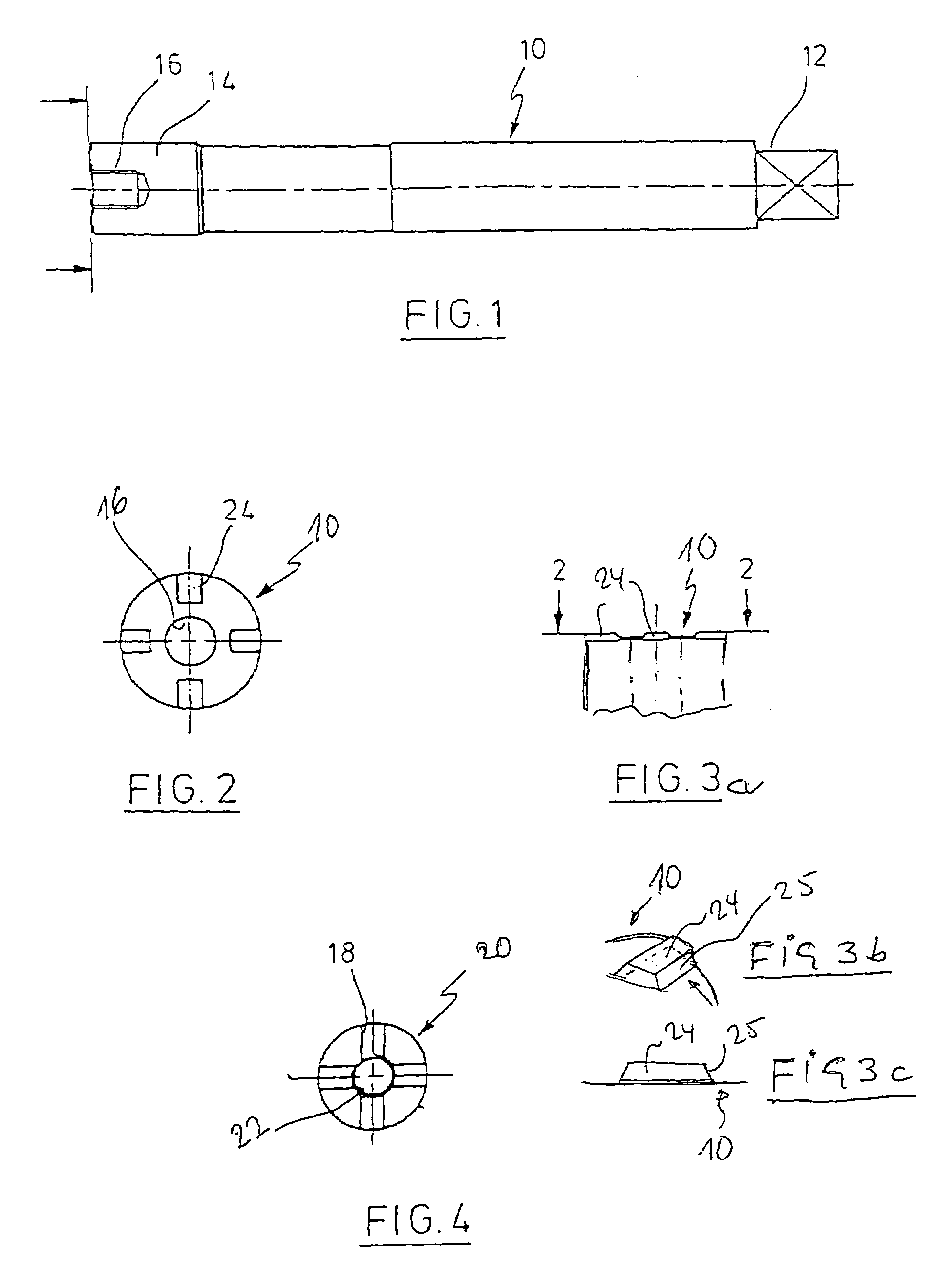

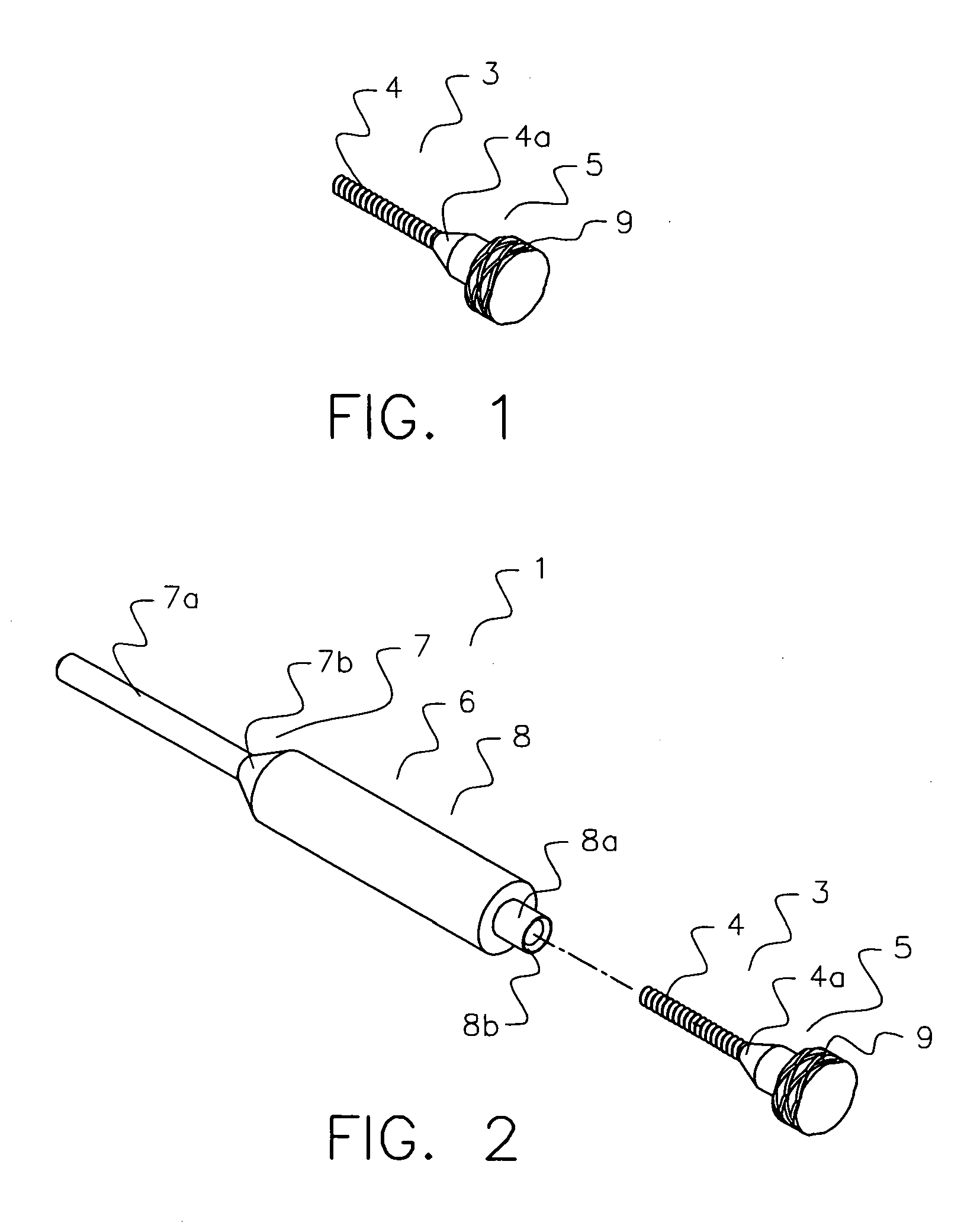

Thread former or tap

Cold thread forming tap or screw tap with a shaft, said shaft having a chuck portion at the one end and a forming or cutting profile portion on the other end, the forming or cutting profile portion being realised as a separate profile element and being fixable centrically and secured against rotation on the shaft by means of a fixing device, characterised in that the profile element has a small axial length and on the outside a lead-in or starting tap cone, respectively, that juts and / or indentations are formed at the end of the shaft and on that side of the profile element facing the shaft, which interlock in a positively fitting manner, that an automatic centring of the profile element takes place on the shaft when the profile element is put onto the shaft.

Owner:FETTE

Self-centering fixture

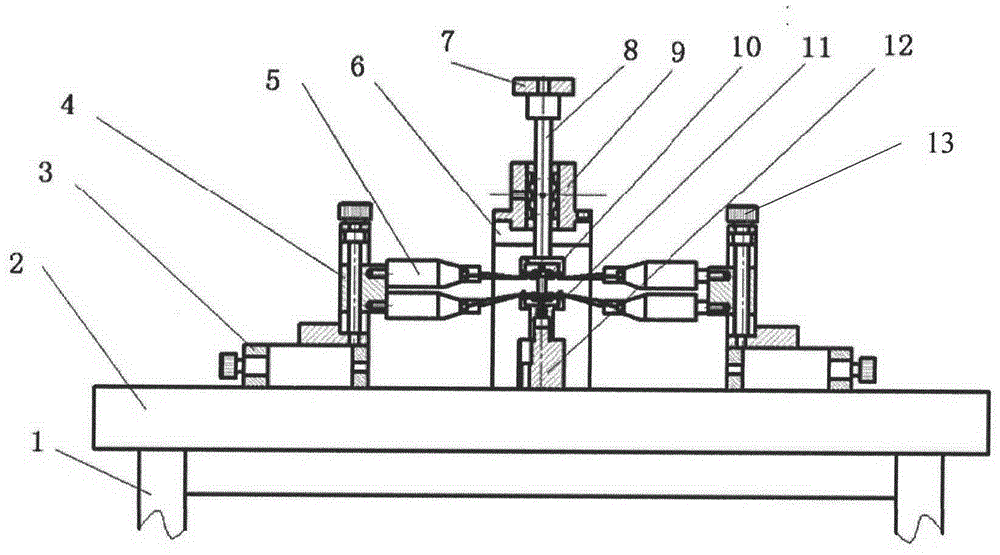

InactiveCN102357826AEasy loading and unloadingGuaranteed concentricityPositioning apparatusMetal-working holdersExpansion jointCentring

The invention discloses a self-centering fixture which comprises a mandrel and an expansion sleeve, wherein the mandrel is mounted on a machine tool through a flange; the expansion sleeve is sleeved on the outer circumference of the mandrel and can move axially; multiple expansion joints are arranged on the outer wall of the expansion sleeve; the outer wall of the mandrel and the inner wall of the expansion sleeve are matched conical surfaces; the mandrel is provided with an adjusting nut for driving the expansion sleeve to move along the mandrel; a pull rod and a stop ring are arranged between the mandrel and the expansion sleeve to pull the expanded sleeve to a shrinkage end; and through the expansion and shrinkage of the expansion joints, the outer diameter is controlled to increase / reduce so as to position / dismantle a workpiece. The fixture has a simple structure, is convenient to use and can realize self centering; and moreover, the processing accuracy of the workpiece is improved, the concentricity and verticality between the processed surface and an inner hole of the workpiece can be ensured, and the fixture deserves popularization and application in the fields realizing positioning and clamping by use of the inner hole of the workpiece.

Owner:JIANGSU FULIHUA GENERAL EQUIP

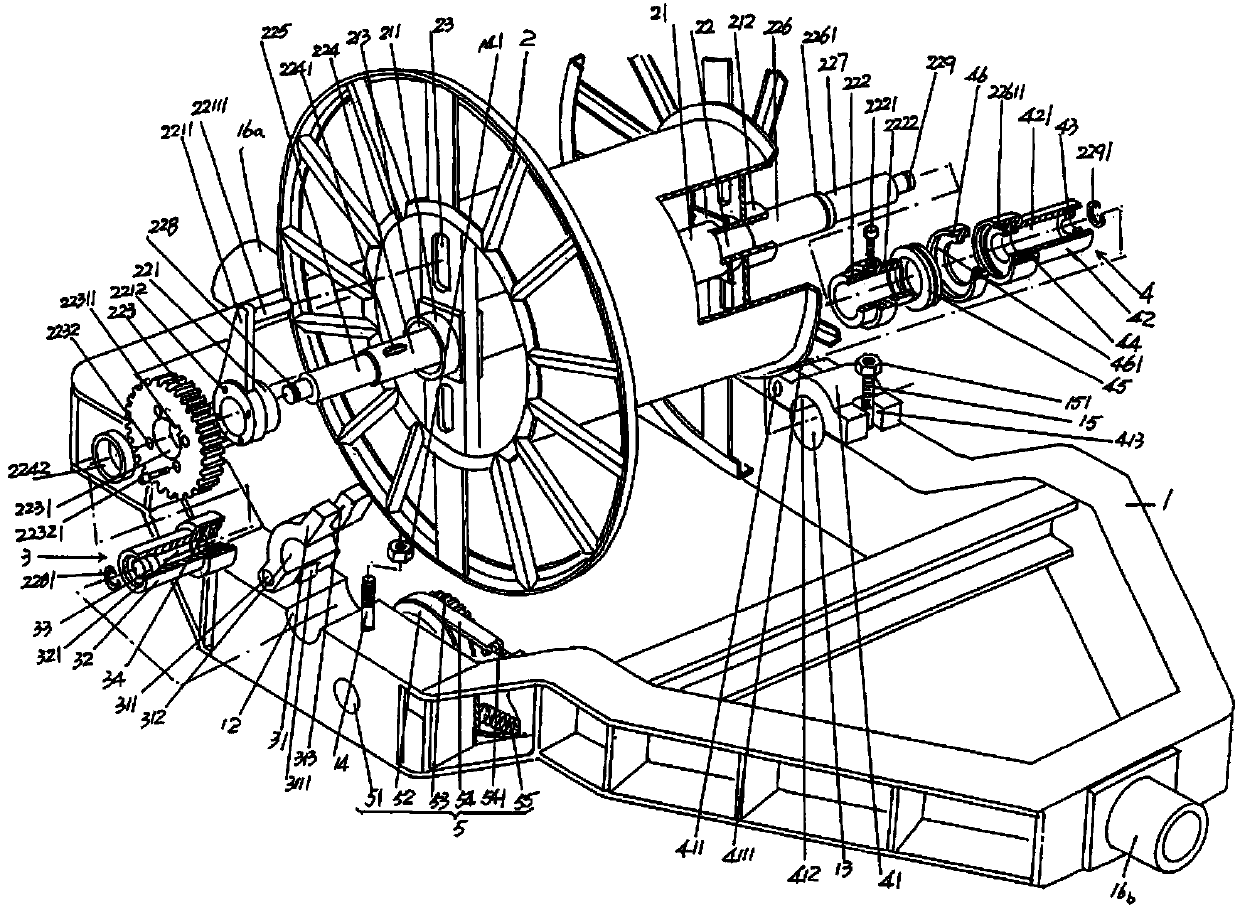

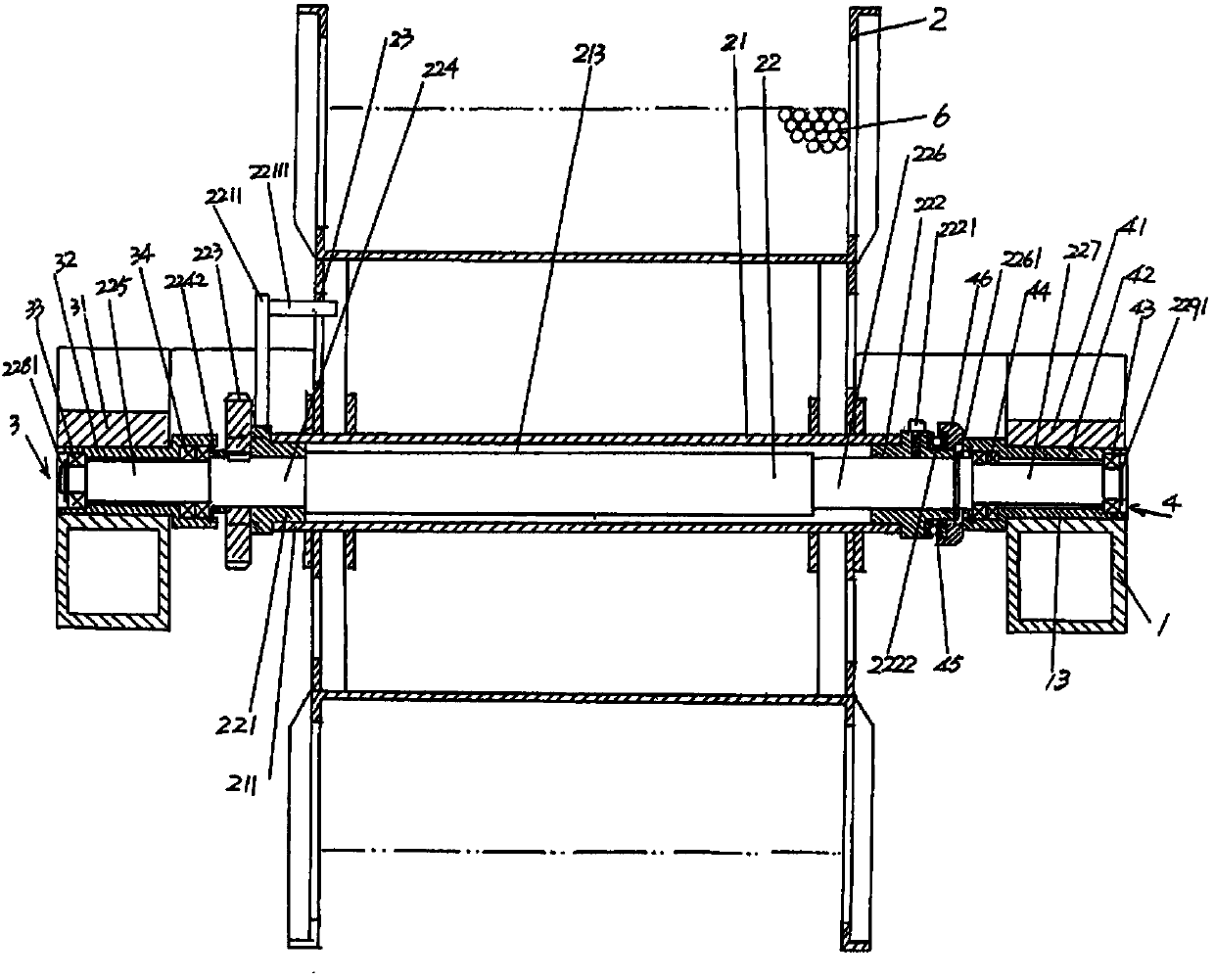

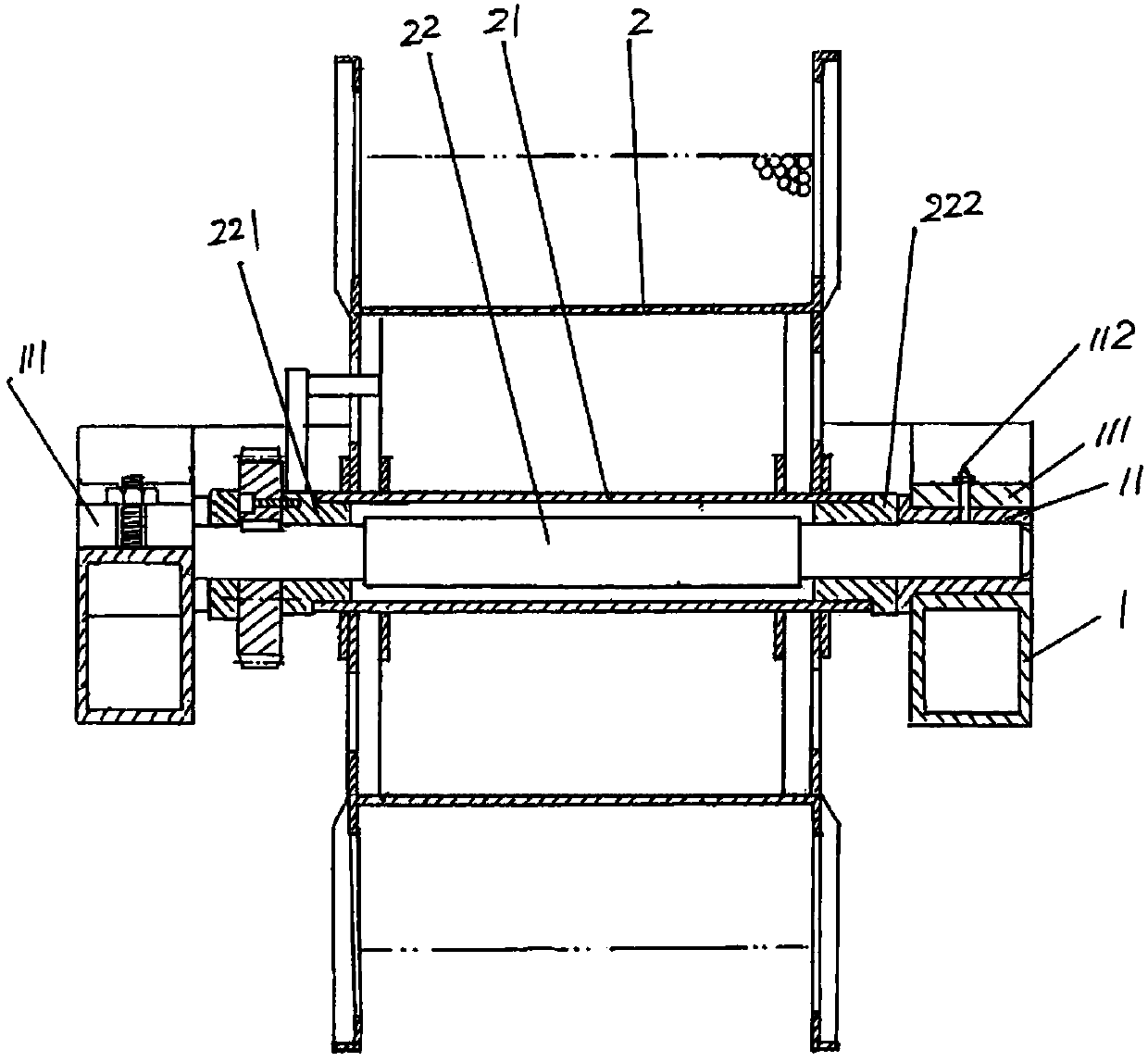

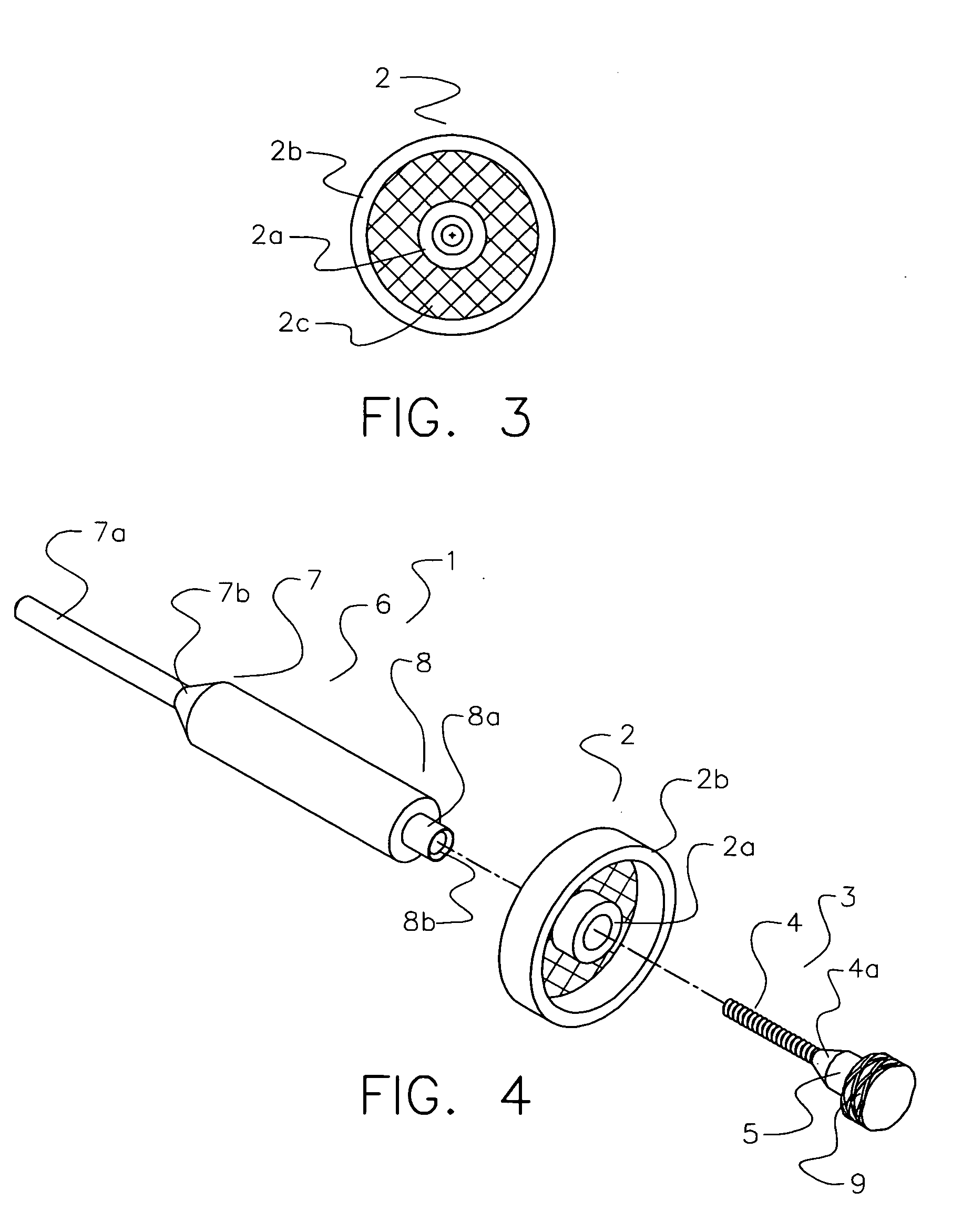

Cradle and pay-off reel structure of cable-former stranding cage device

The invention discloses a cradle and pay-off reel structure of a cable-former stranding cage device and belongs to the technical field of electric wire and cable processing facilities. The cradle and pay-off reel structure of the cable-former stranding cage device comprises a cradle and a pay-off reel. The center of the pay-off reel is provided with a pay-off reel center shaft sleeve; one end of the pay-off reel center shaft sleeve forms an outer centring sleeve matching end; the other end of the pay-off reel center shaft sleeve forms an inner centring sleeve matching end; a pay-off reel center shaft outer centring sleeve is provided with a damping arm; the damping arm is fixedly provided with a deflector rod; a pay-off reel center shaft is fixedly provided with a damping gear. The cradle and pay-off reel structure of the cable-former stranding cage device is characterized in that one side of the cradle is provided with a pay-off reel center shaft outer pivotal bearing mechanism; the other side of the cradle is provided with a pay-off reel center shaft inner pivotal bearing mechanism; one end of the pay-off reel center shaft is supported to the pay-off reel center shaft outer pivotal bearing mechanism; the other end of the pay-off reel center shaft is supported to the pay-off reel center shaft inner pivotal bearing mechanism; one side of the cradle is provided with a damping gear regulating mechanism; the damping gear is matched with the damping gear regulating mechanism. The cost of spare parts is reduced, the working strength is reduced, the cabling efficiency is improved, and the tension of a lead released from the pay-off reel is ensured.

Owner:CHANGSHU CABLE WORKS

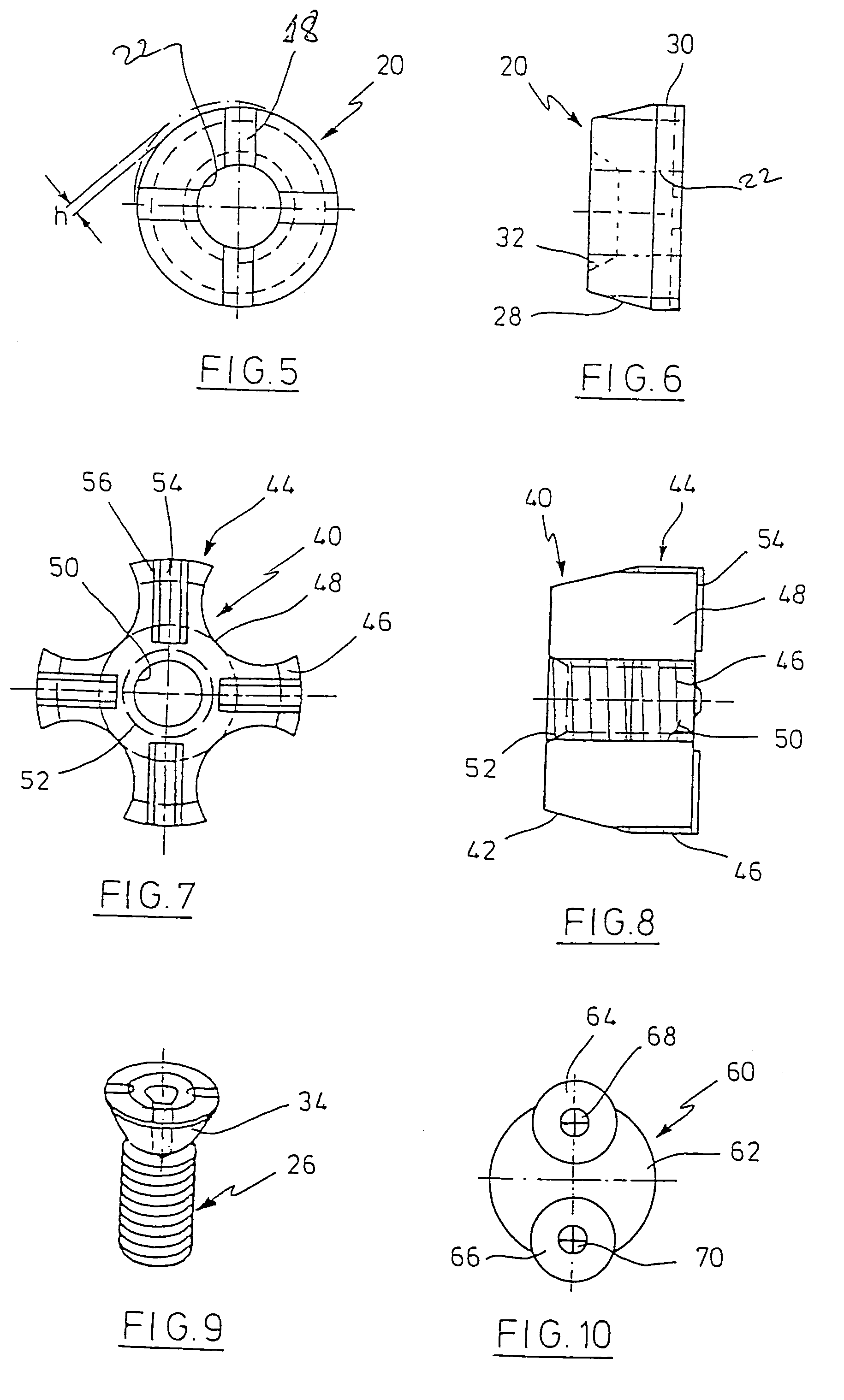

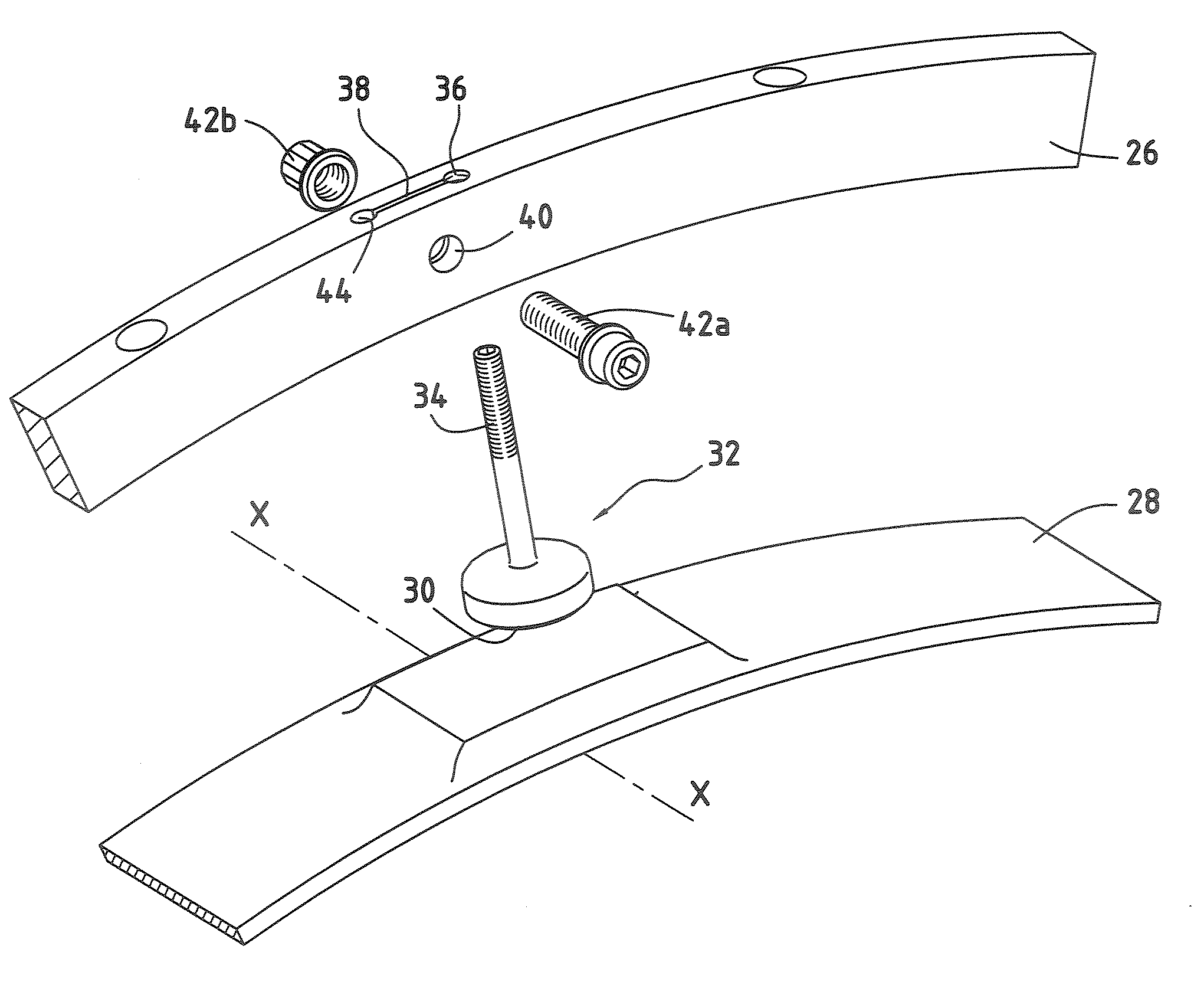

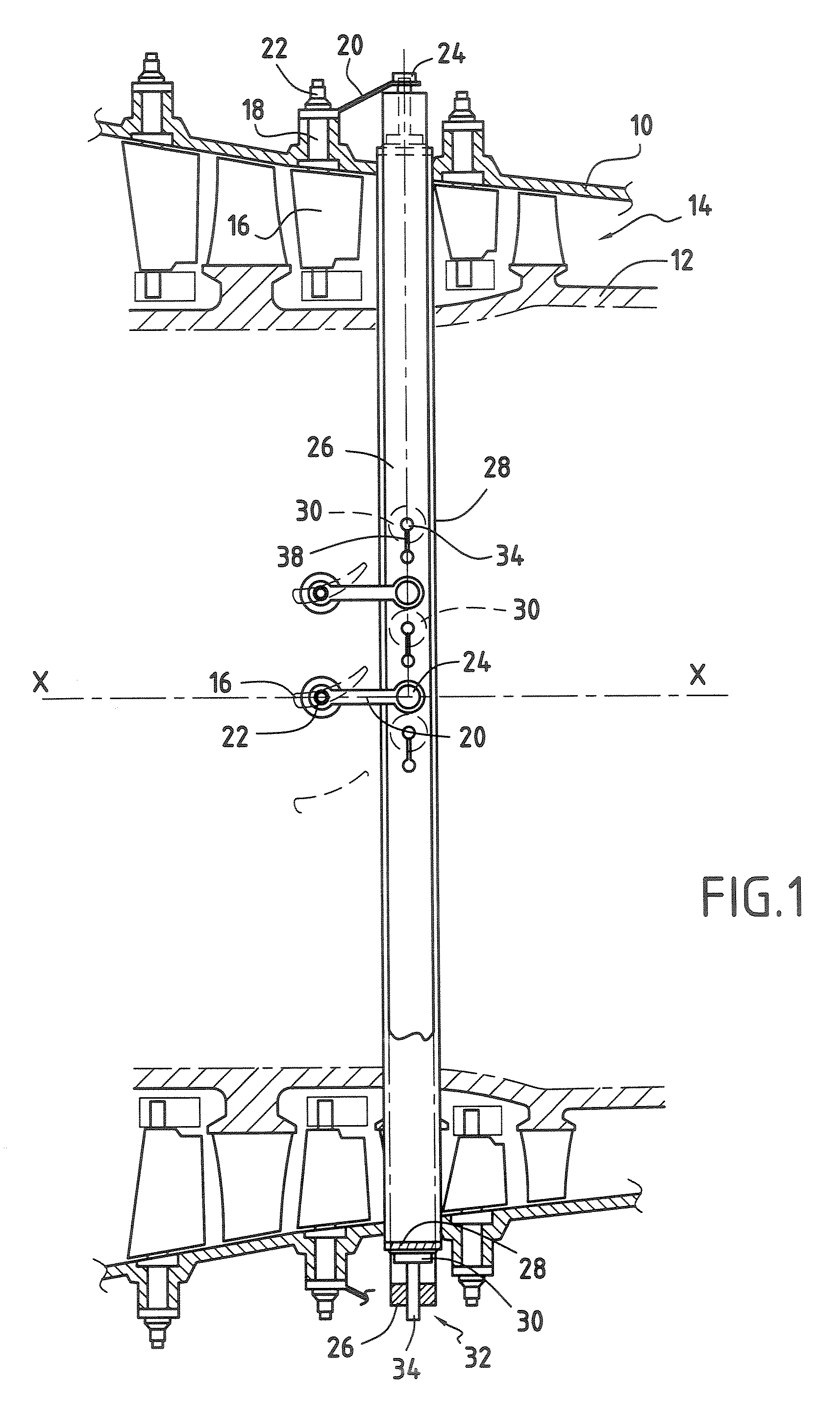

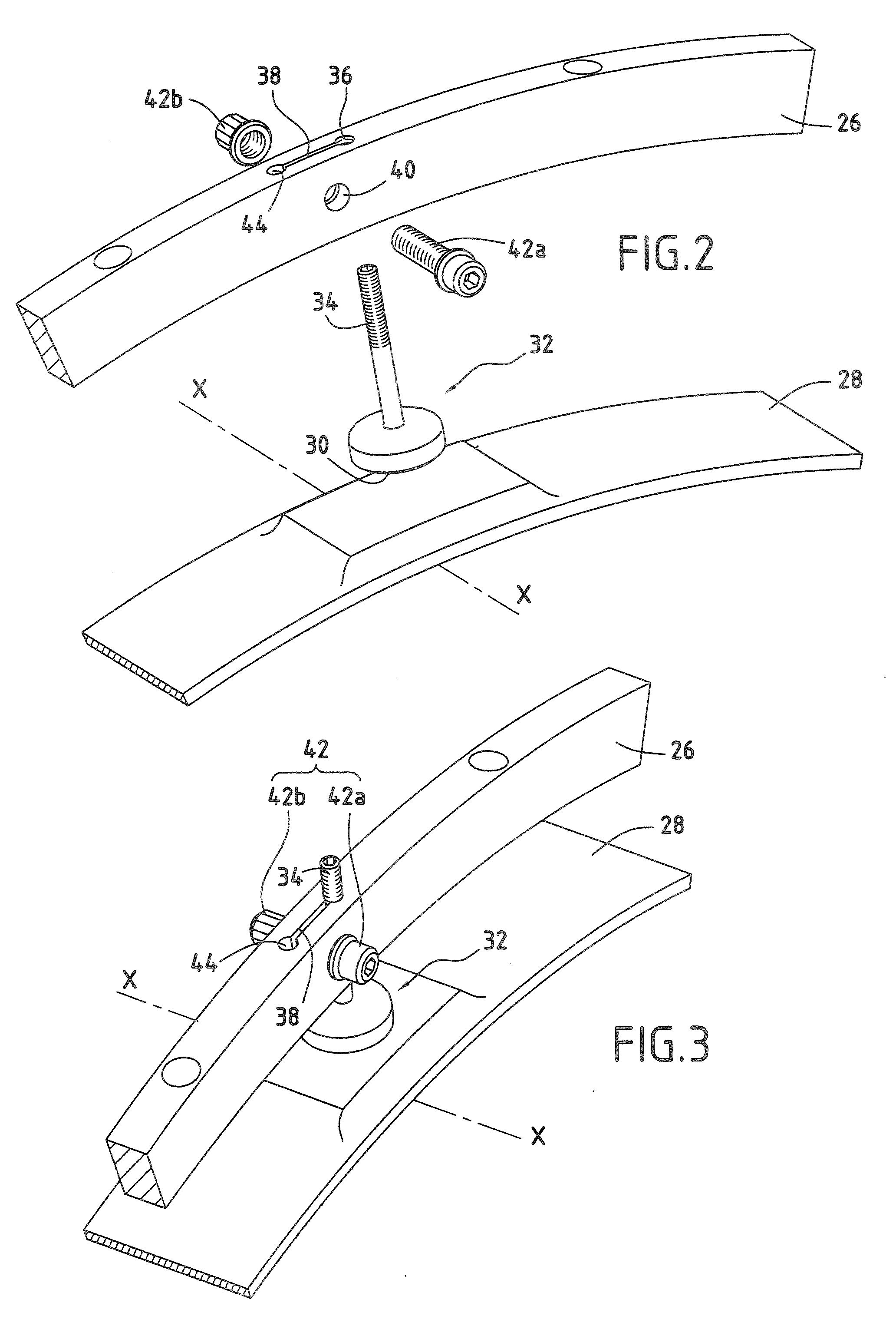

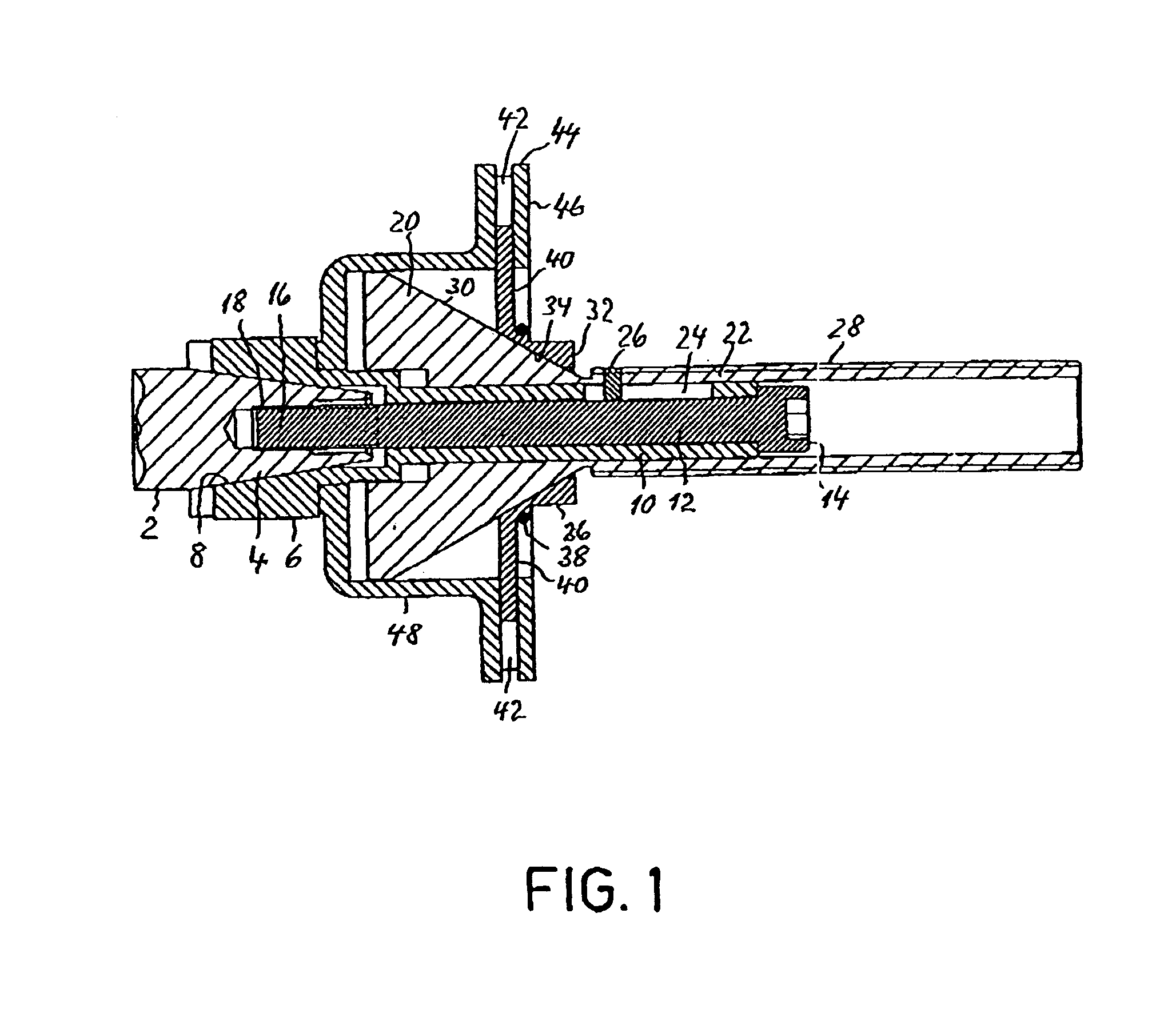

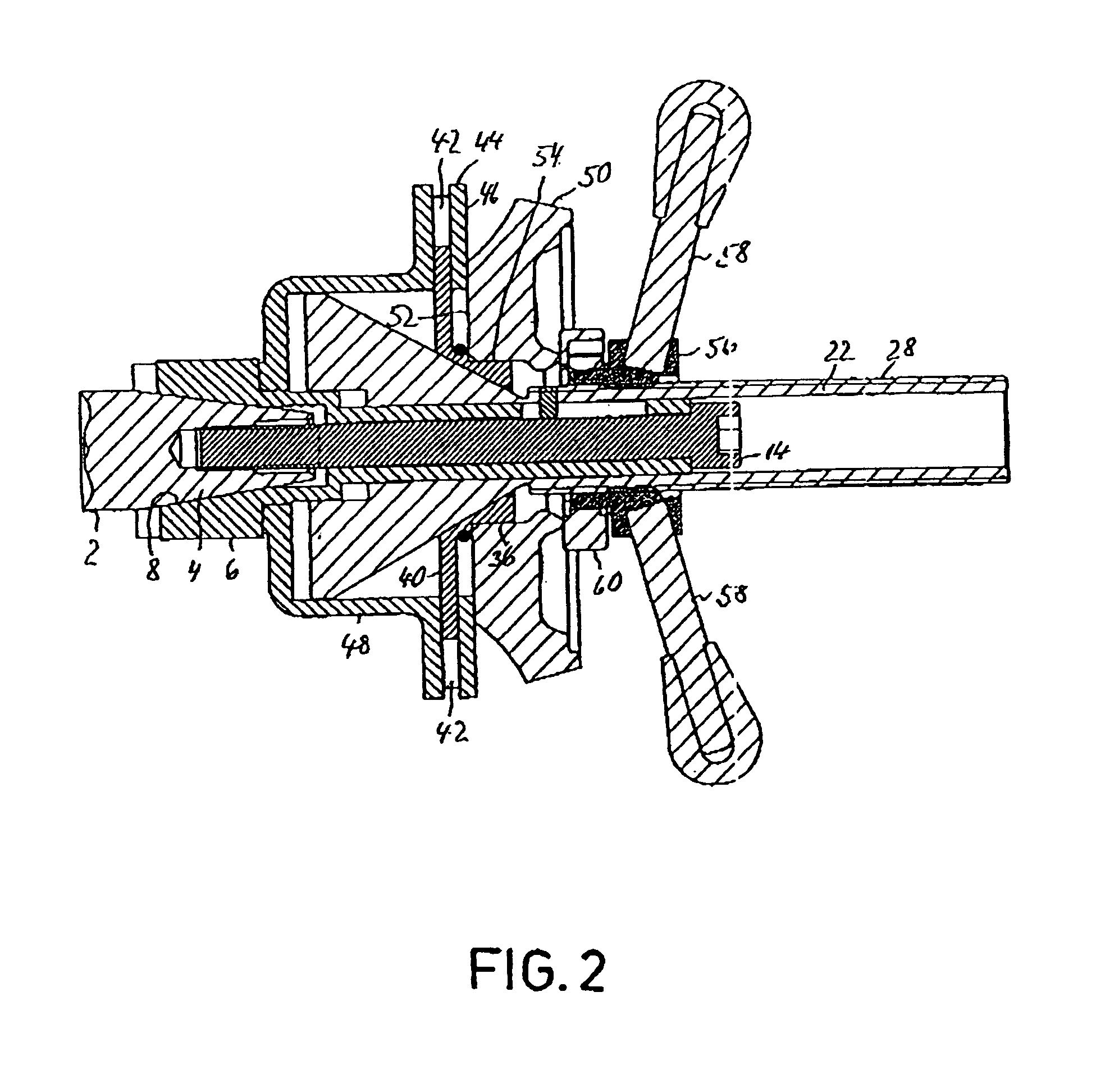

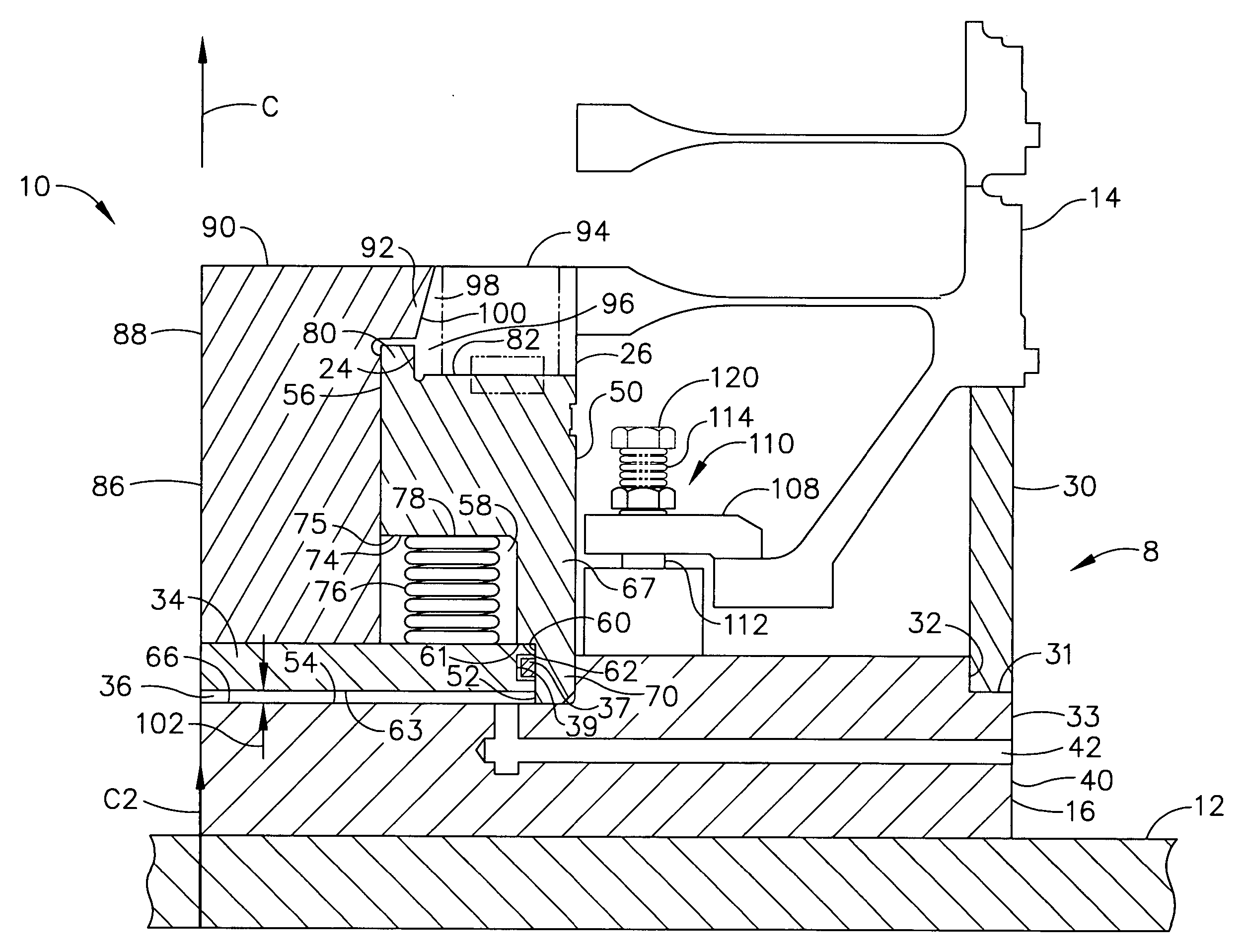

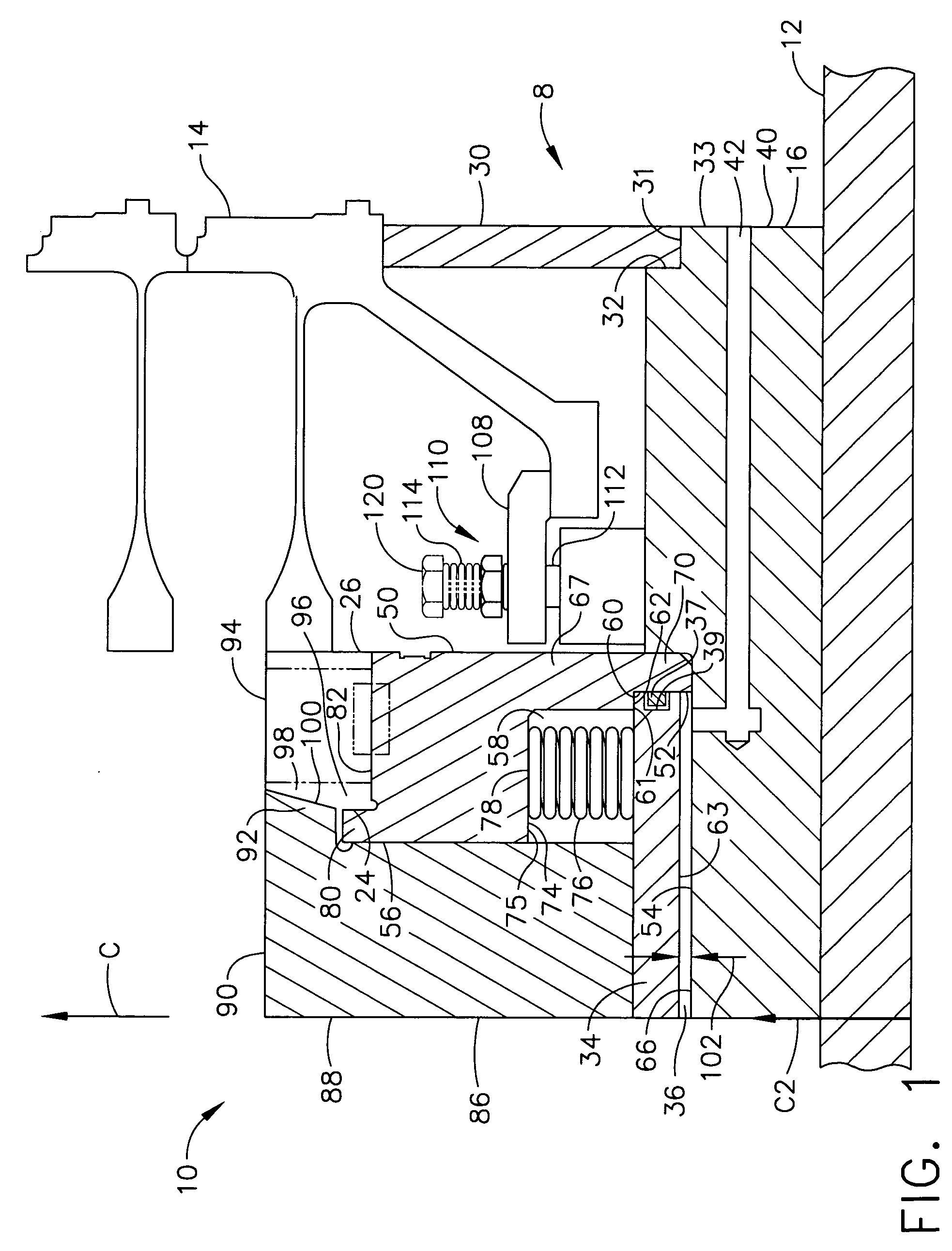

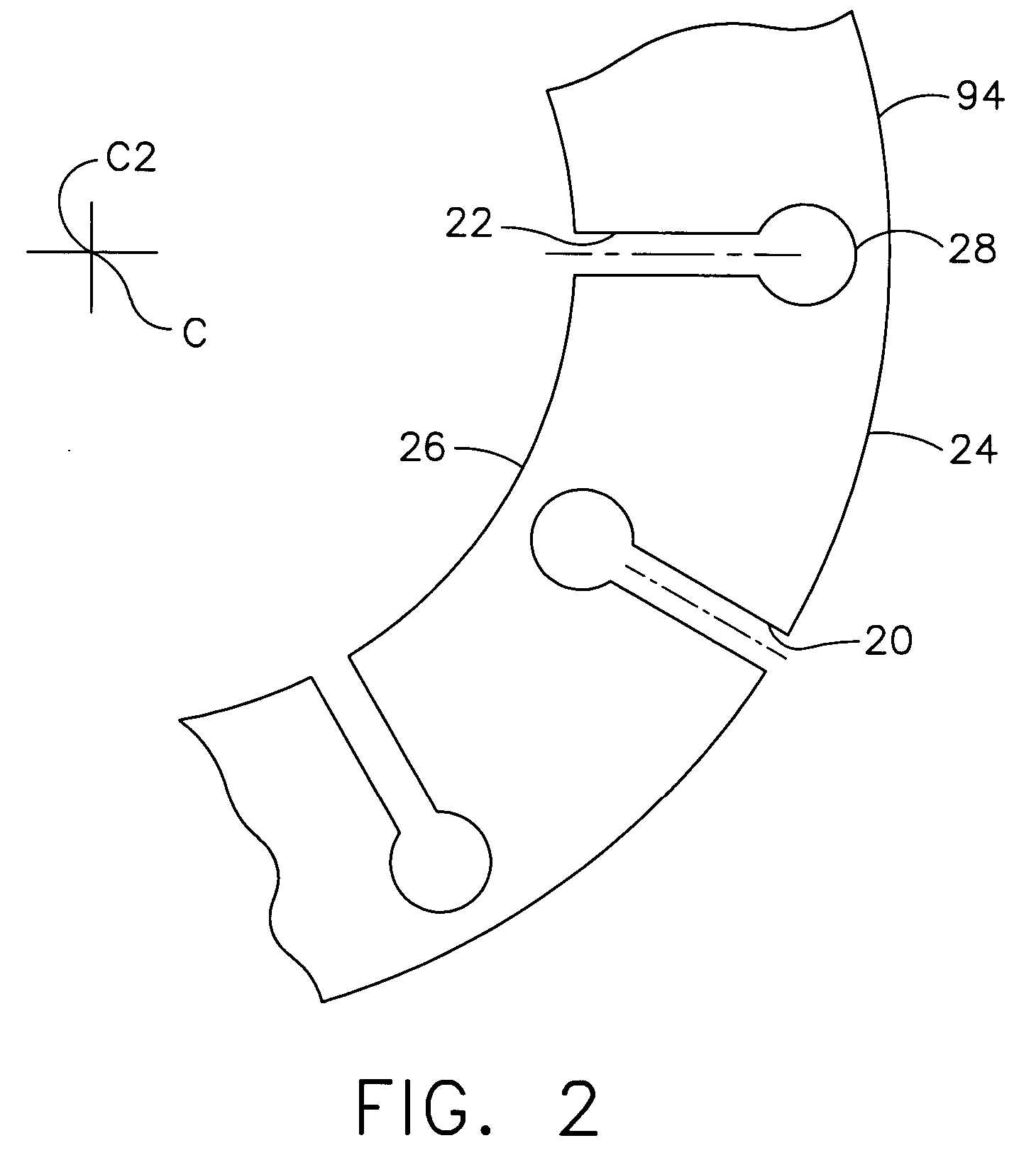

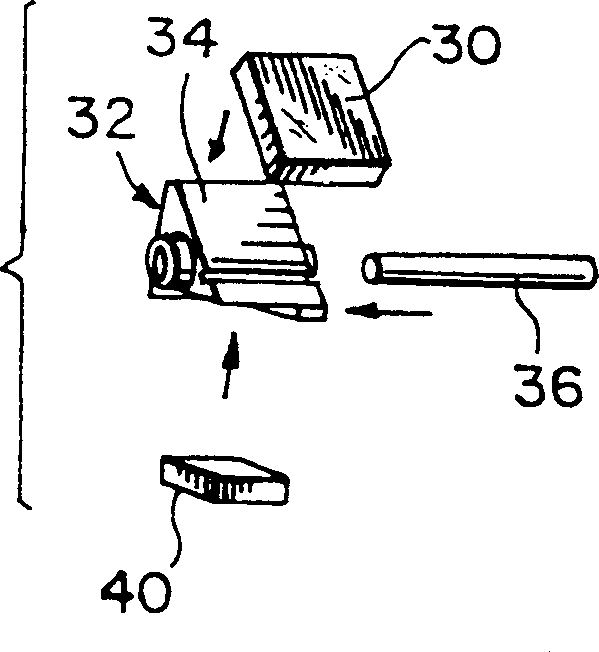

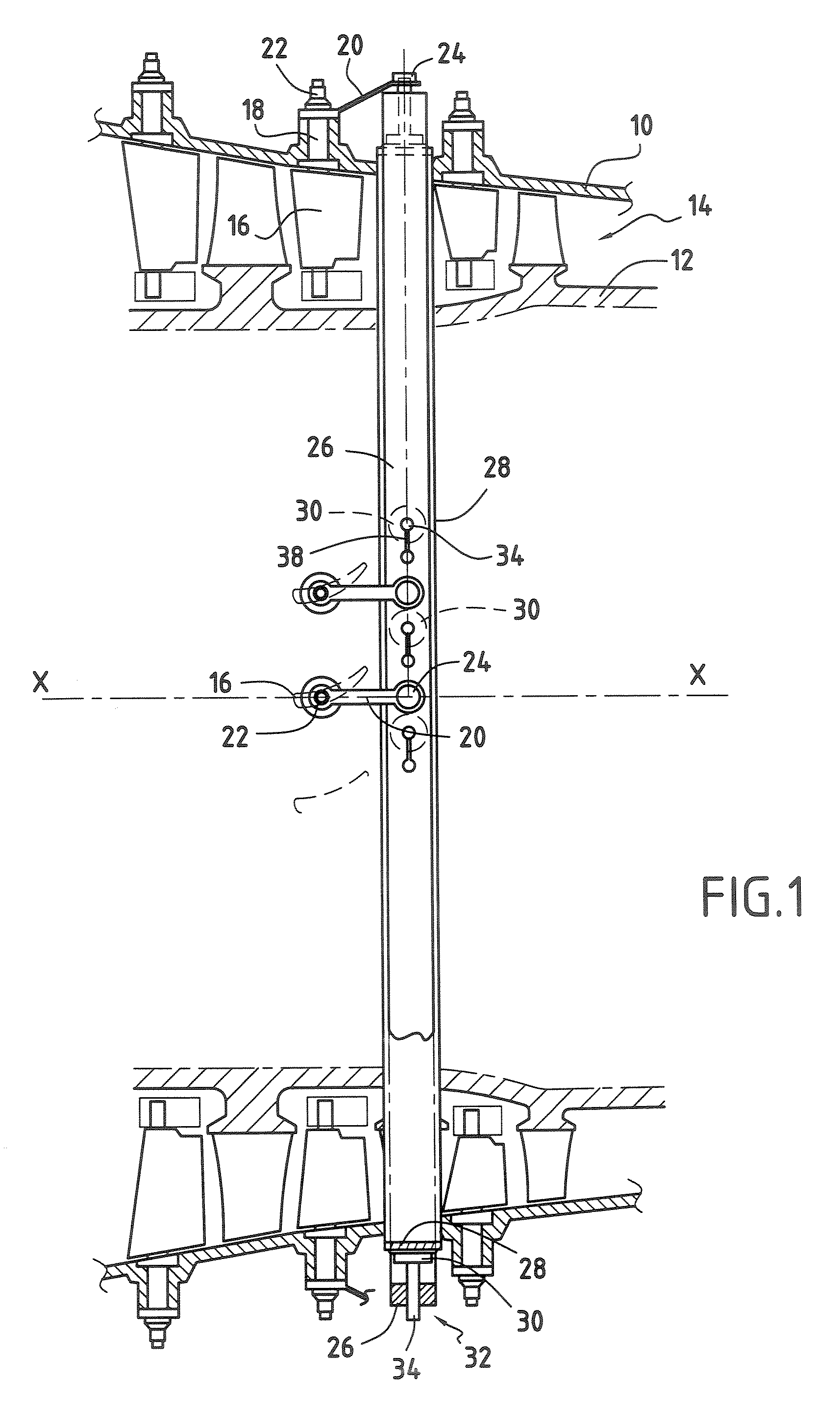

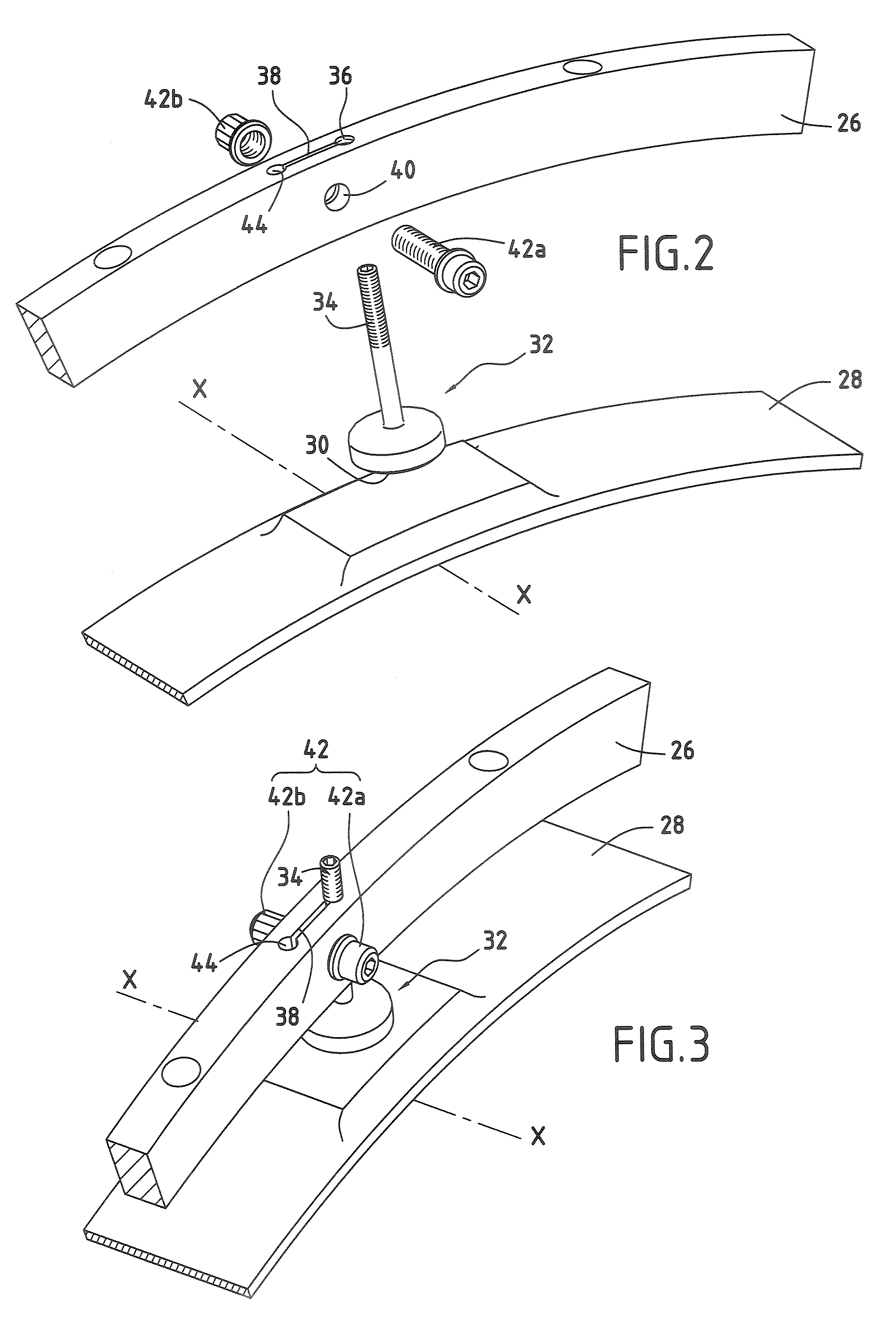

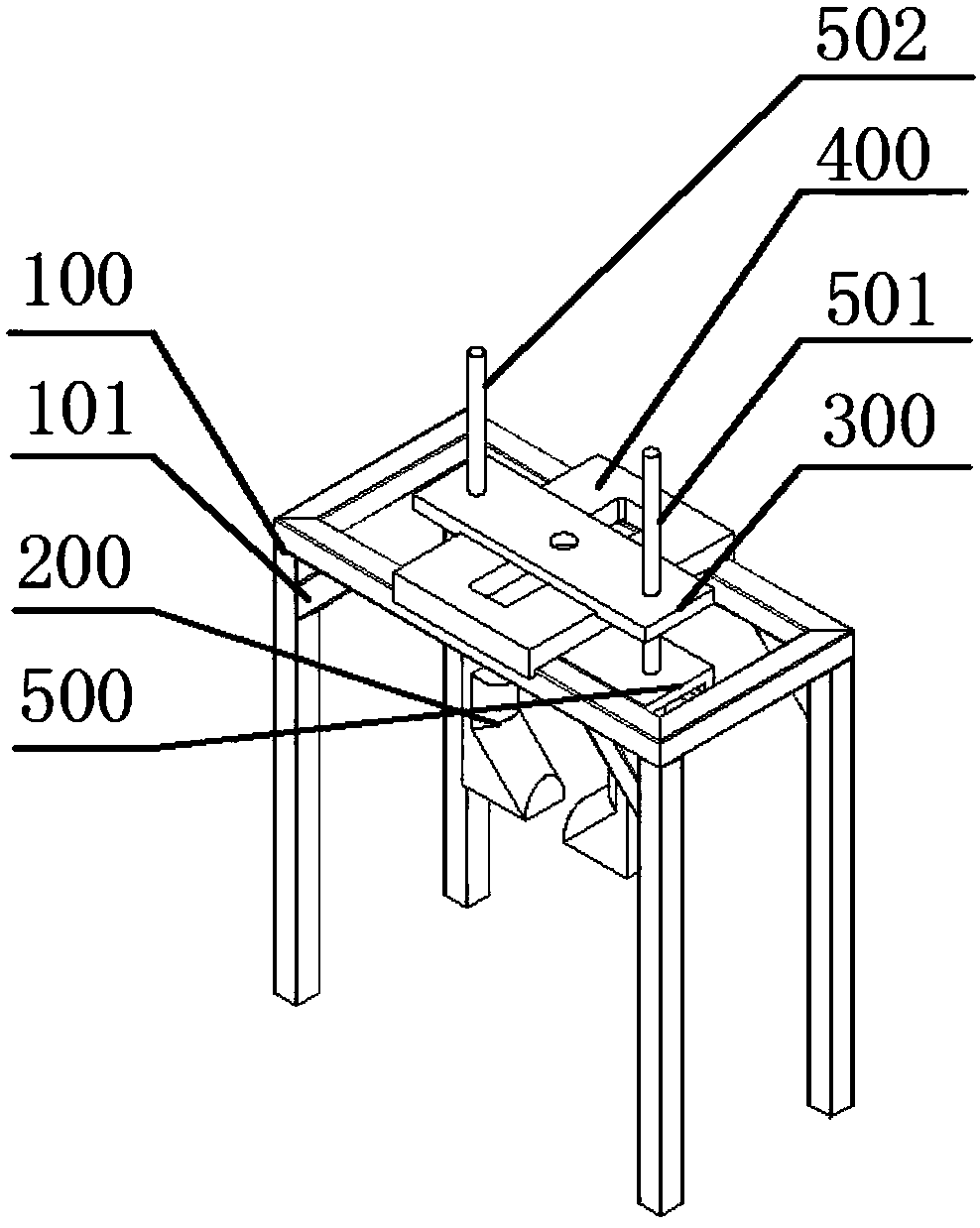

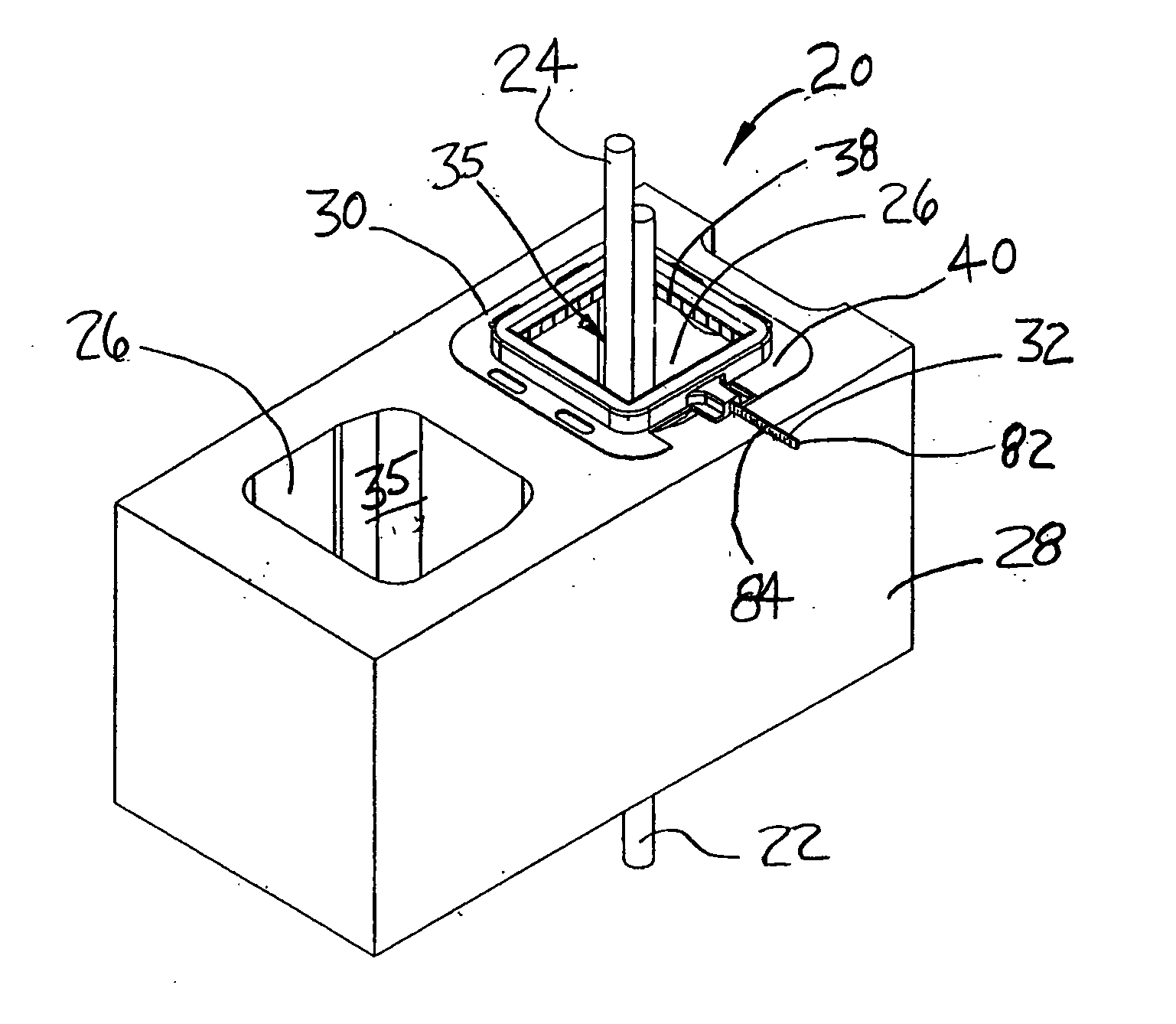

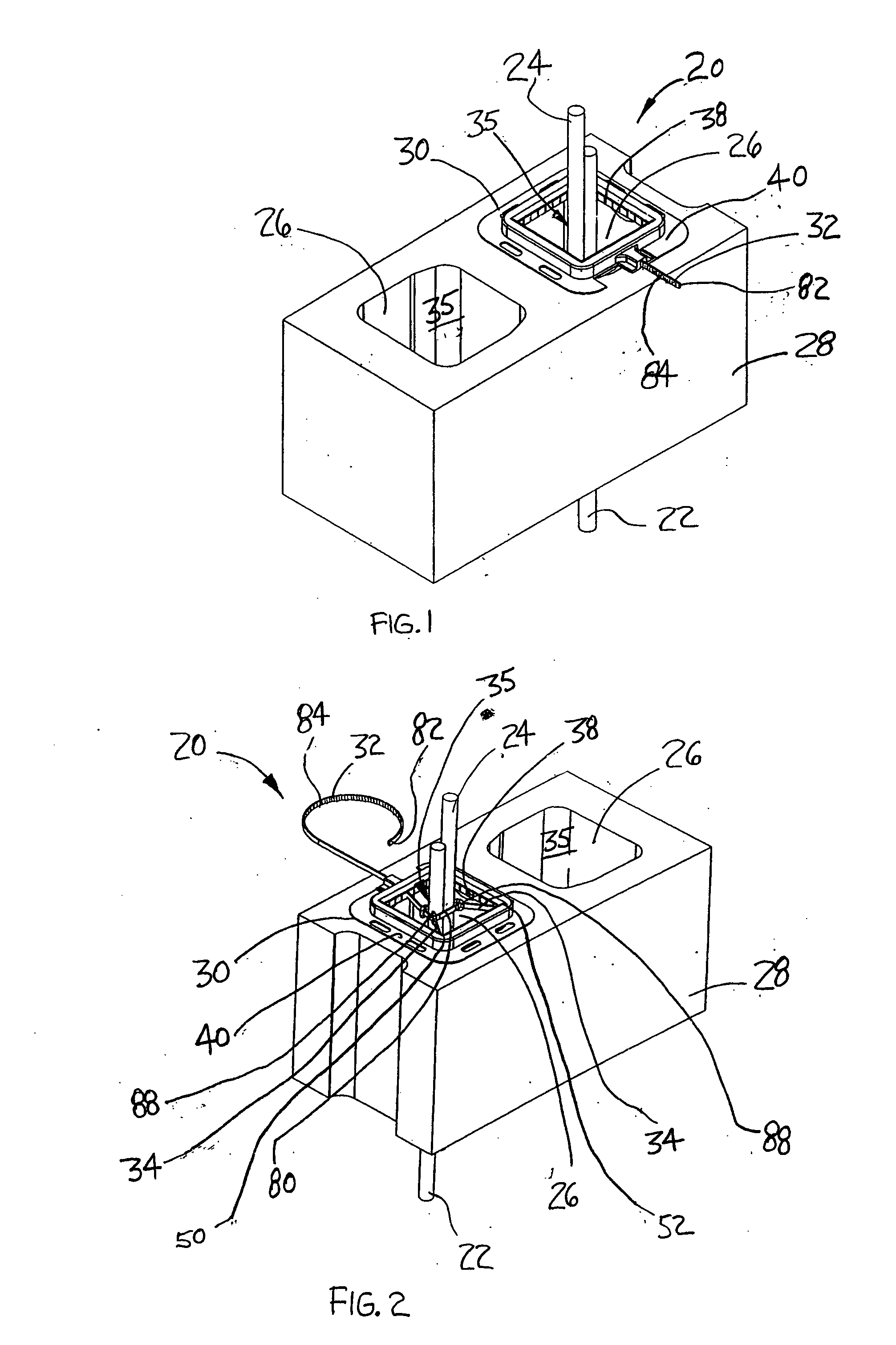

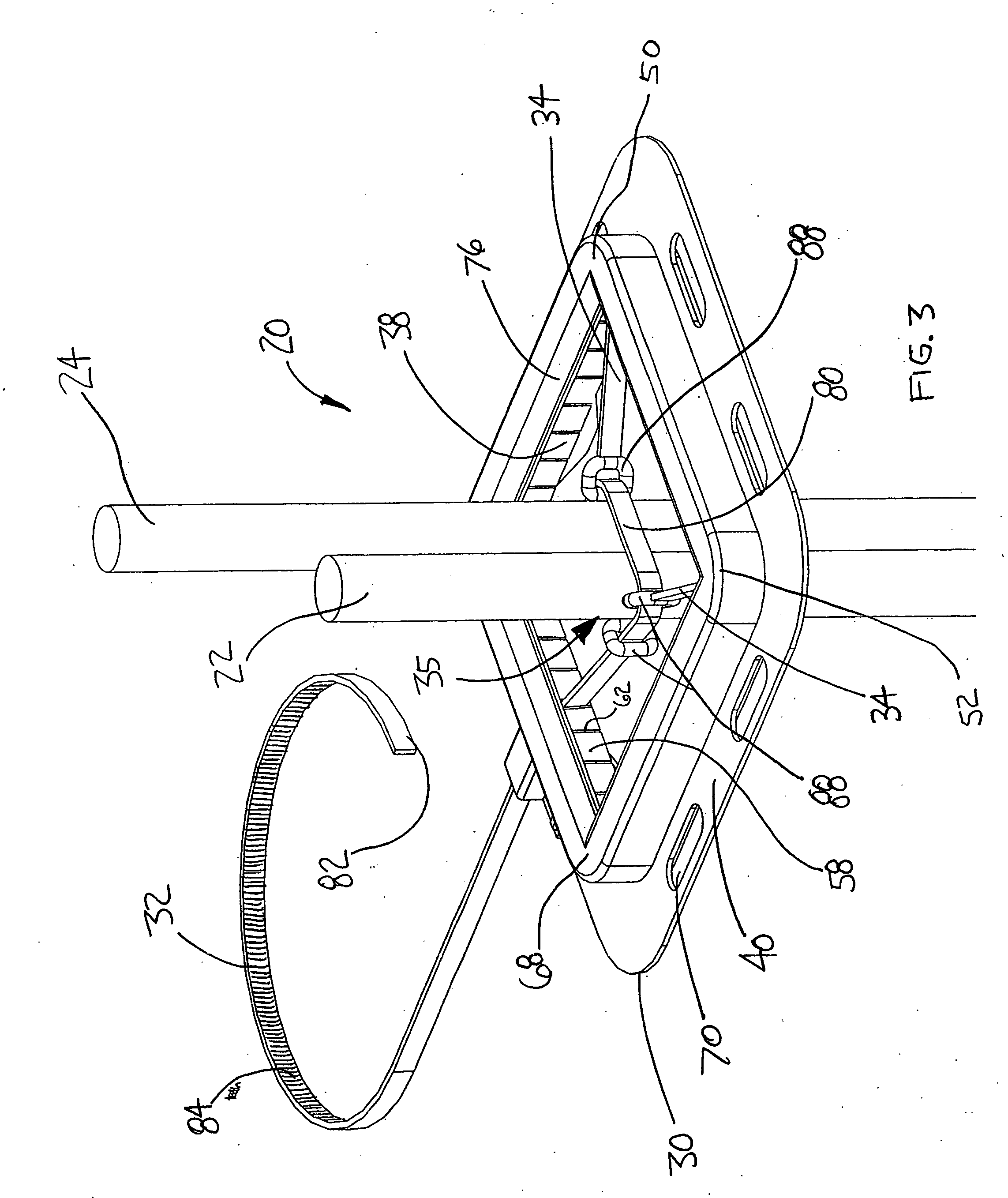

Device for adjusting the centring of a turbo-engine pivoting vane control synchronization ring

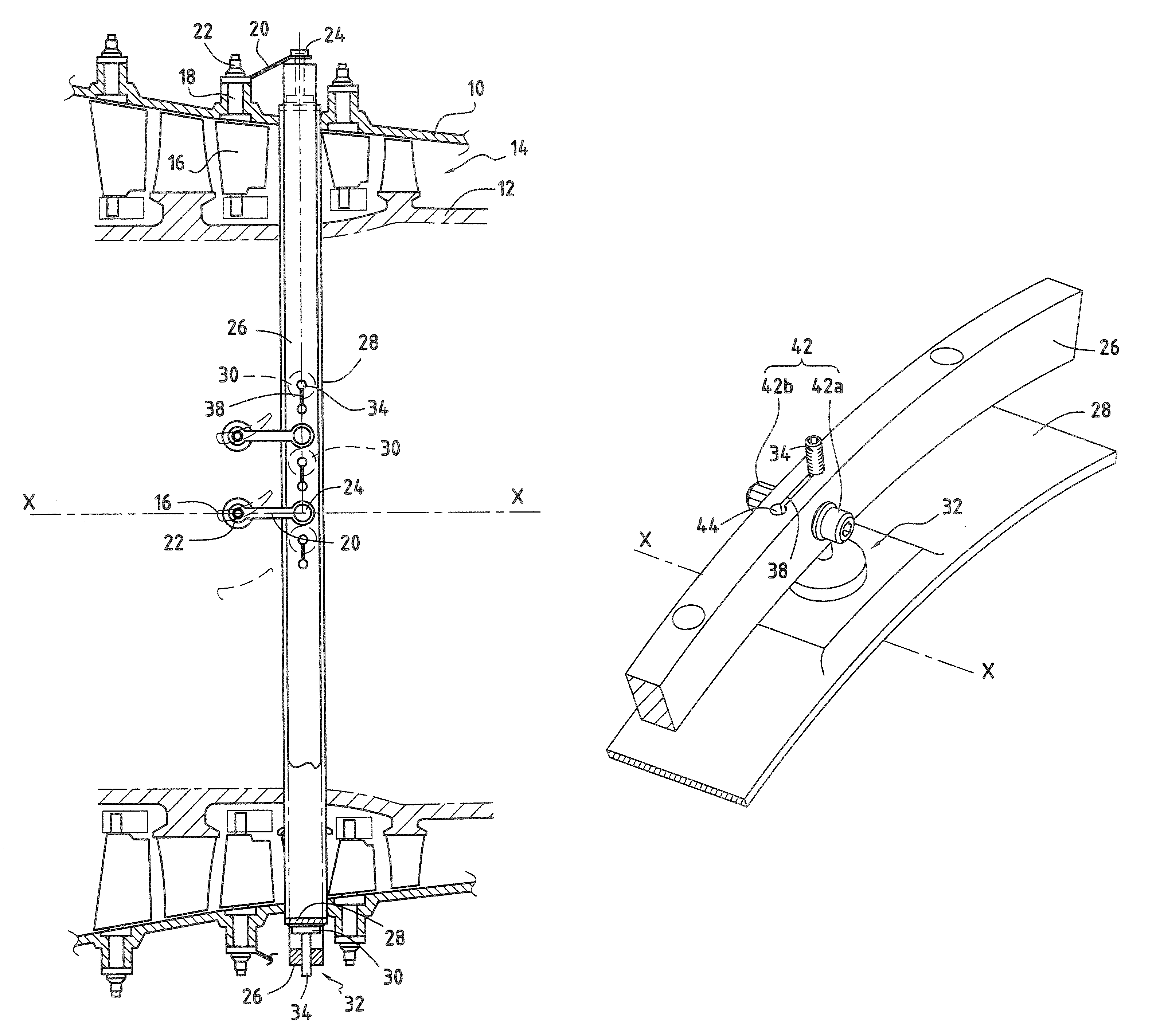

ActiveUS20070183889A1Simple designMitigate such drawbackEngine manufactureWind motor controlEngineeringTurbine

The invention relates to a device for adjusting the centring of a turbo-engine pivoting vane control ring, comprising a control ring (26) centred on a longitudinal axis (X-X) of the turbo-engine and provided with a plurality of tapped holes (36) running in a radial direction and a plurality of pad holders (32), each comprising a threaded rod (34) screwed into one of the ring's tapped holes (36), each pad holder (32) holding, at an inner end, a pad (30) intended to come into contact with a cylindrical shell (28), coaxial with the ring. The control ring (26) comprises, in addition, a plurality of slots (38) running in a tangential direction, each slot (38) communicating with one of the ring's tapped holes (36) The device comprises means (40, 42a, 42b) of pinching, in a longitudinal direction, each of the slots (38) in such a way as to lock the pad holders (32) in position.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

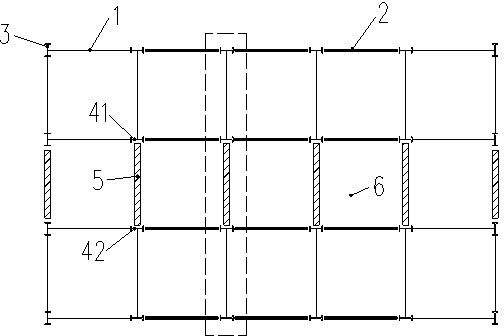

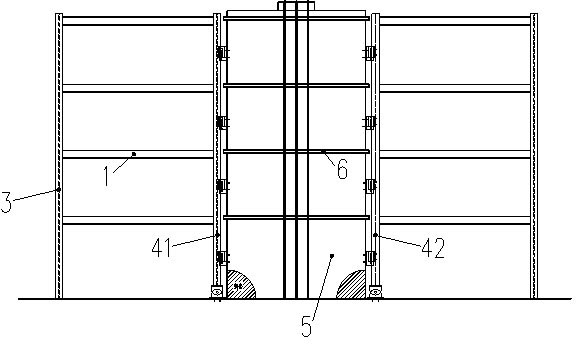

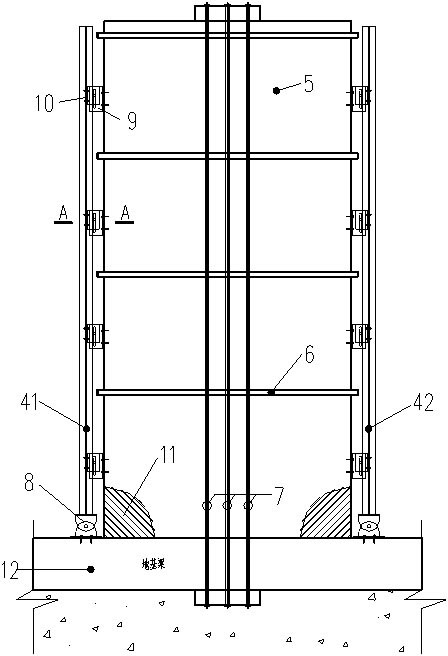

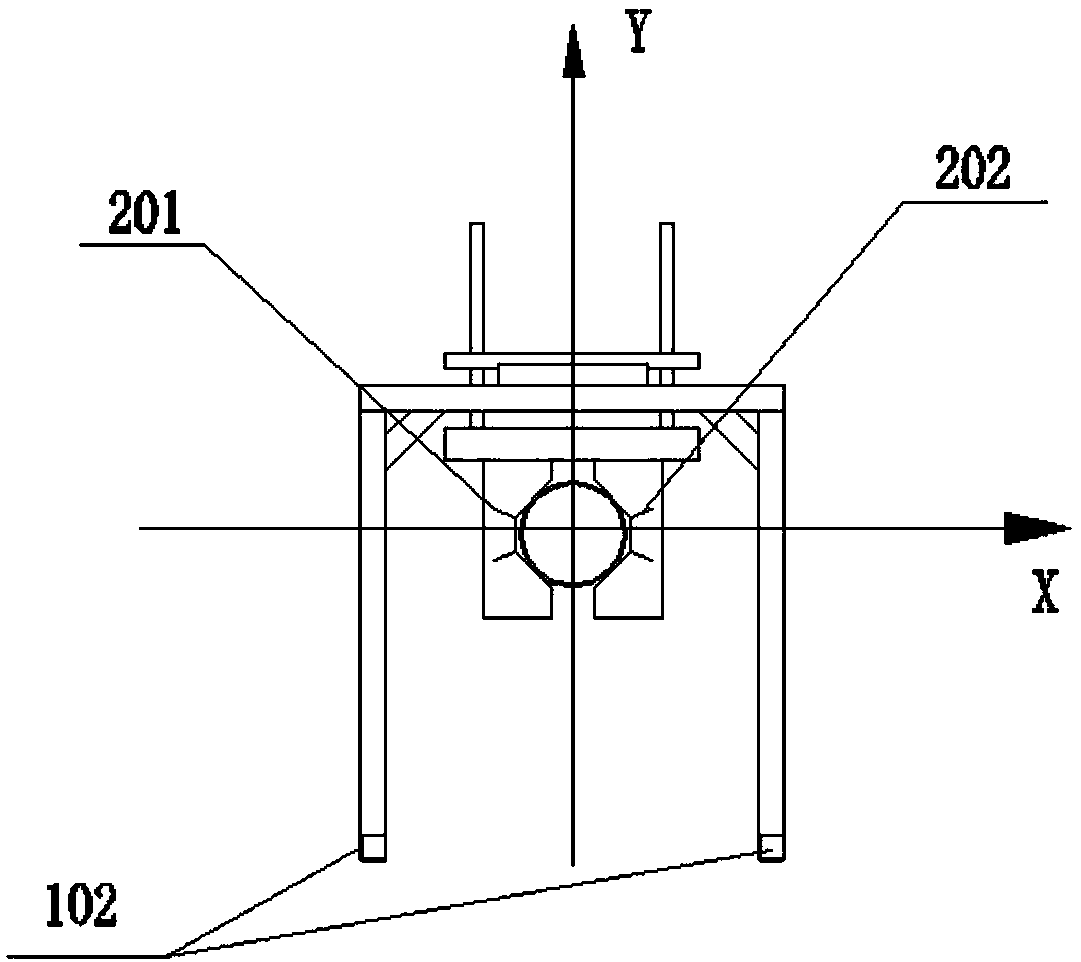

Swinging type self-centering steel frame and concrete shear wall anti-seismic system

The invention provides a swinging type self-centering steel frame and concrete shear wall anti-seismic system, which comprises a first steel column (41), a second steel column (42), a concrete wall (5) and friction parts. The first steel column (41) and the second steel column (42) are oppositely arranged in parallel, the concrete wall (5) is located between the first steel column (41) and the second steel column (42), the friction parts comprise a first friction part and a second friction part, and the structure of the first friction part is identical to that of the second friction part; and the first steel column (41) is connected with the concrete wall (5) via the first friction part, the second steel column (42) is connected with the concrete wall (5) via the second friction part, the concrete wall (5) is connected with a foundation beam (12) via a vertical prestress wire (7), a floor is fixedly connected with the concrete wall (5), and the first steel column (41) and the second steel column (42) are respectively hinged to the foundation beam (12) via hinging devices (8). Damage of a total steel frame structure can be reduced when in earthquake by the aid of the swinging type self-centering steel frame and concrete shear wall anti-seismic system, and an anti-seismic performance is improved.

Owner:SOUTHEAST UNIV

Clamping mechanism

InactiveUS20040141821A1Effectively and simply clampEffectively and simply and simultaneously positionDrilling/boring measurement devicesThread cutting feeding devicesClassical mechanicsEngineering

The drilling of a hole through at least two structural components in alignment with a predrilled hole or marked location in one of the structural components is facilitated by a clamping mechanism that has a bail with two legs. One leg carries a first clamping section with a guide channel for a centering pin or a drill bit. When the centering pin has served its purpose it is removed from the guide channel which then guides the drill bit. The other leg carries a second clamping section opposite the first clamping section. The second clamping section has a pressure bushing drivable by a clamping drive for clamping the second structural component against the first structural component for drilling a hole through all structural components including through a predrilled hole or for simultaneously drilling all structural components at the marked location. The pressure bushing has a hollow free end forming a cavity.

Owner:AIRBUS OPERATIONS GMBH

Quick-clamping device with hub centering ring for securing a vehicle wheel on the shaft of wheel-balancing machines

InactiveUS20060055125A1Avoid disadvantagesEasy to fixSleeve/socket jointsStatic/dynamic balance measurementBalancing machineEngineering

Quick-clamping device with a hub centering ring secures a vehicle wheel rim on the shaft of a wheel-balancing machine. Securely attached to the shaft is a flange to facilitate a friction fit placement on the rim. For centering, a conical assembly is provided, including an inner bore to be slid onto the shaft of the balancing machine, as well as an outer centering surface for engaging the centering hole of the rim. Conical assembly includes a cone, from the apex of which a tubular element extends, and which is mounted with its inner wall axially displaceable on the shaft or an extension of it, and a clamping element for tightening the rim against the flange abuts its outer wall. Advantageously, until reaching the centering and clamping position by using the clamping element, quick-clamping device ensures no forces must be overcome. This provides ease of use of the quick-clamping device.

Owner:WARKOTSCH HORST

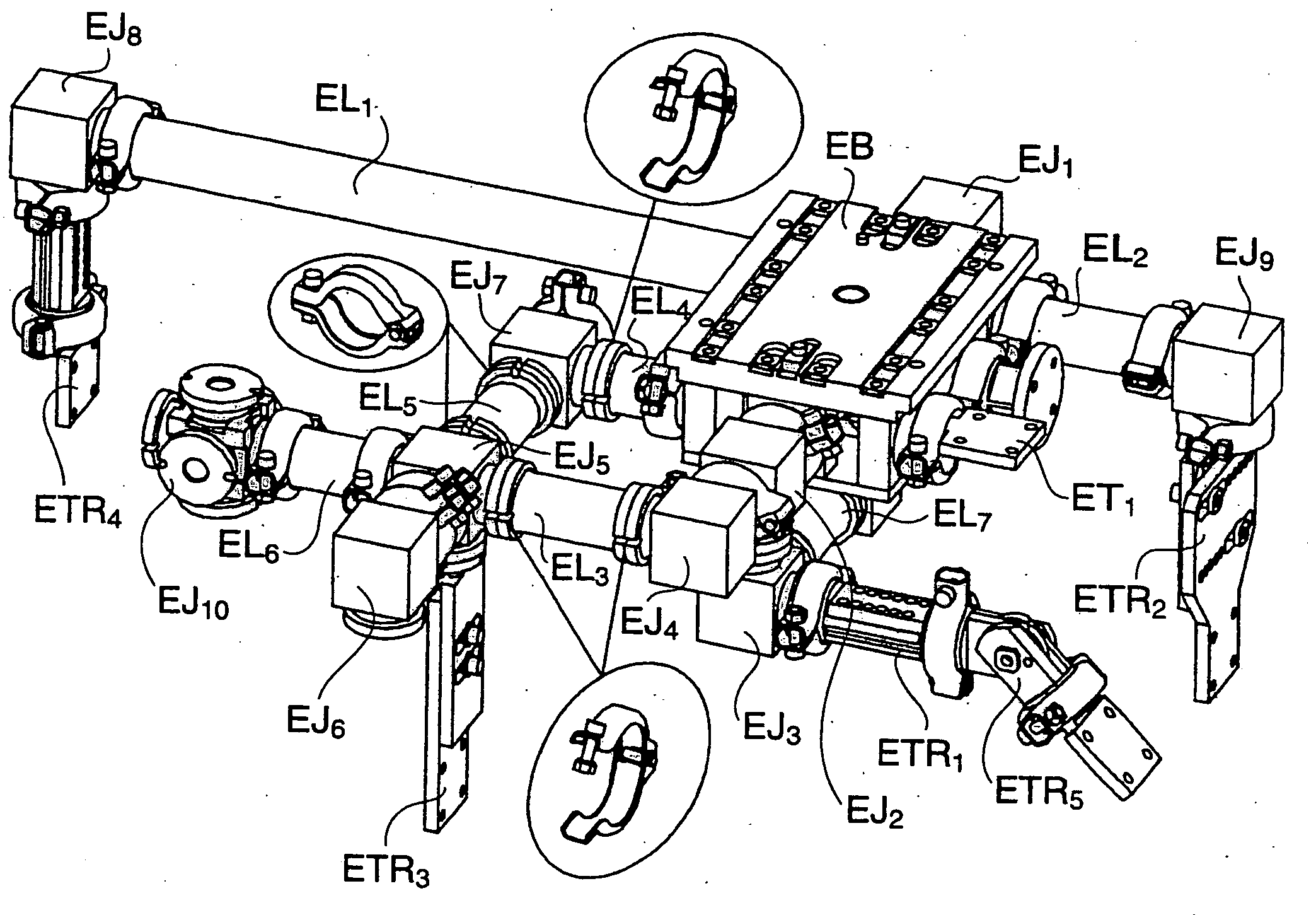

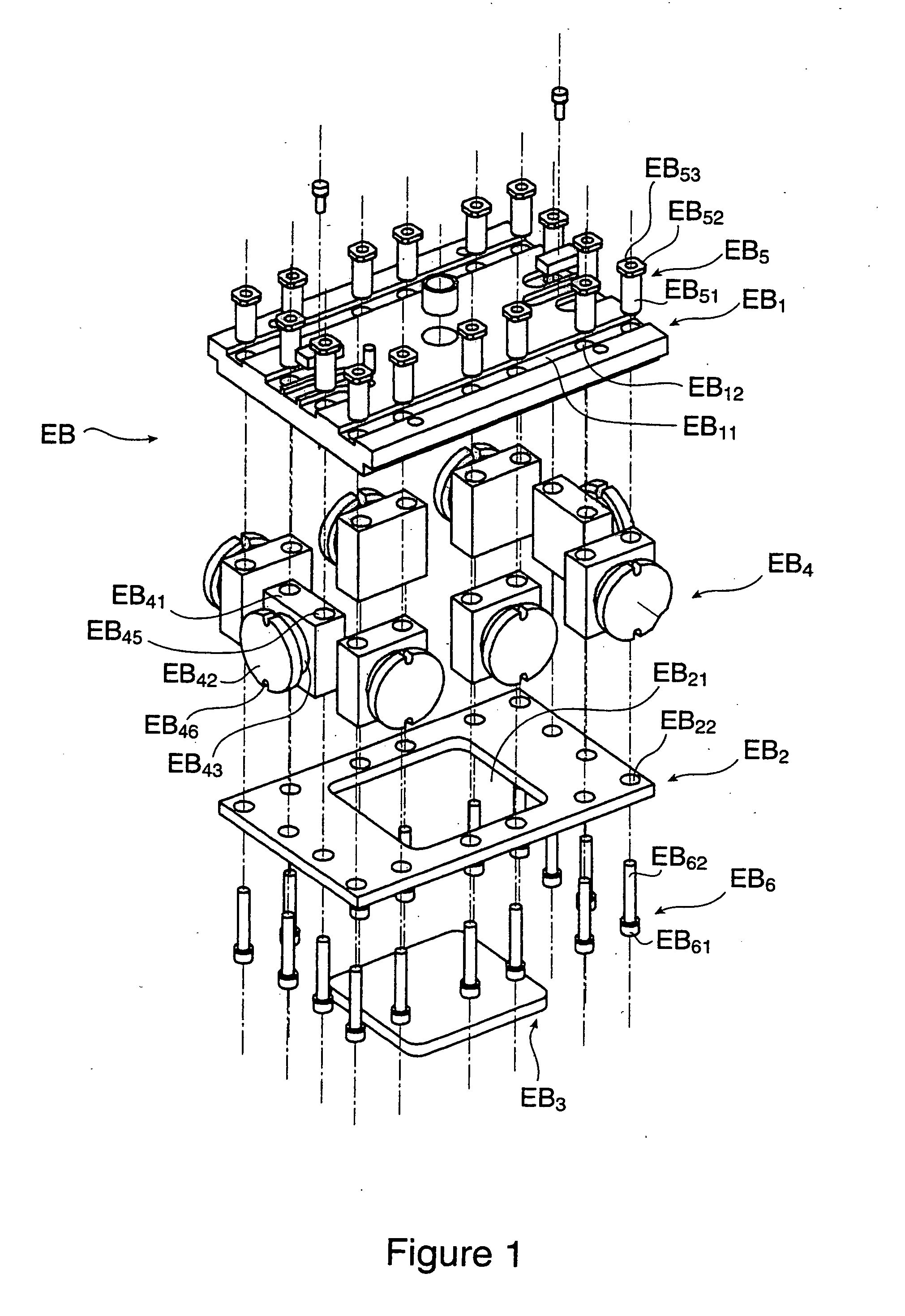

Device for the assembly of standard elements intended for the creation of precision mechanical structures

A device for the assembly of at least two standard elements (EB) of a precision mechanical structure by means of a linking element, where the first standard element includes a reference surface, while the second standard element includes a bearing surface which has to be positioned with precision in an orthonormal coordinate system associated with the aforementioned reference surface, given that the connection between the linking element and at least one of said standard elements (EB) includes: two contact faces provided on said linking element and said standard element (EB) respectively, a clamp composed of two half collars, held together by tightening means, and presenting shapes which interlock with the corresponding shapes of said linking element and of said standard element (EB) in such a way that the clamping of the two half collars causes the application and the centring of the two aforementioned contact faces against each other.

Owner:DELAWARE CAPITAL FORMATION INC

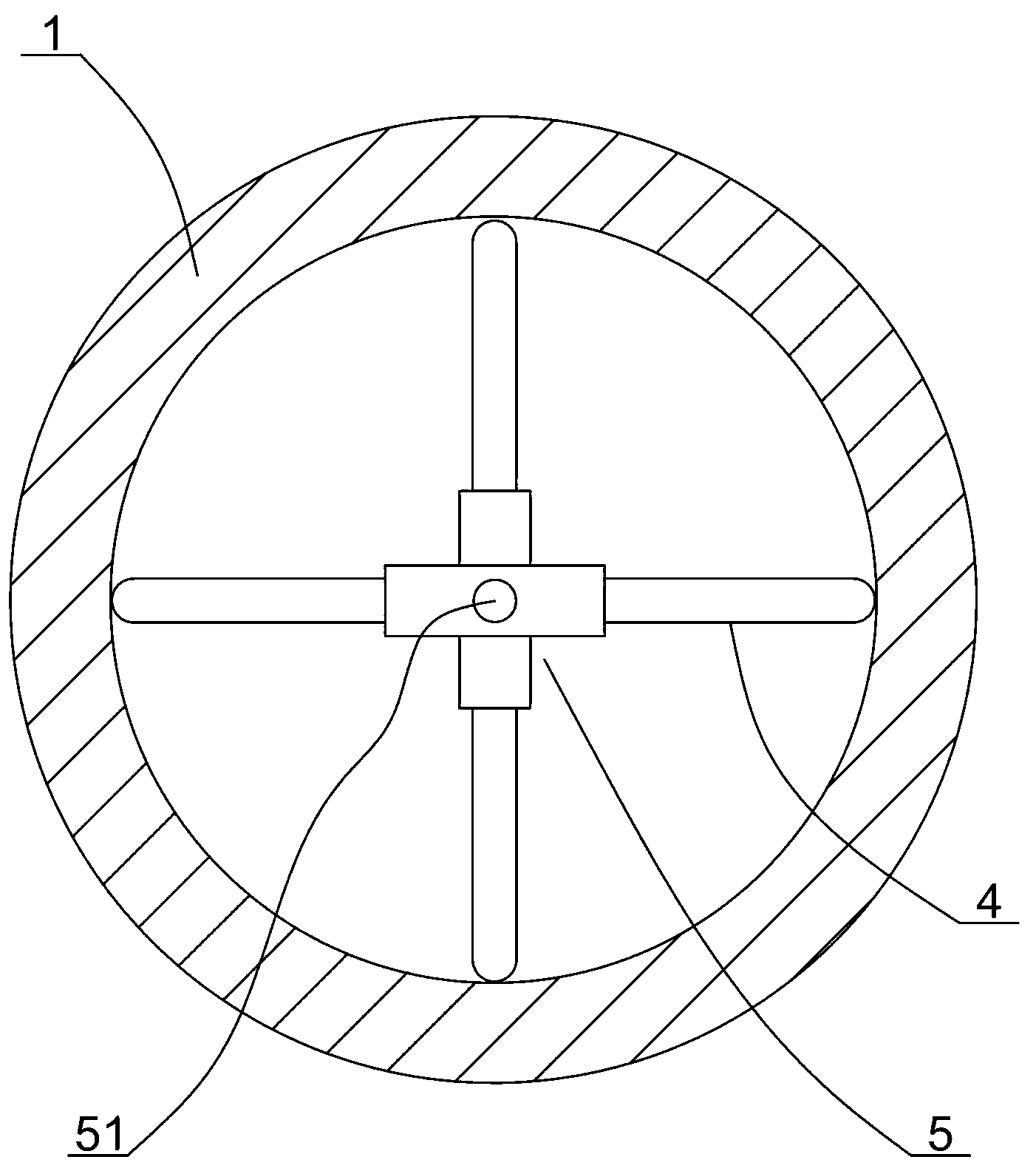

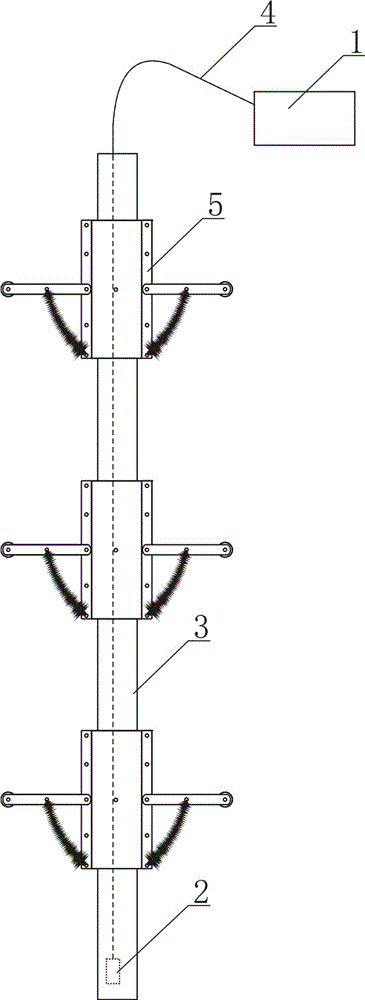

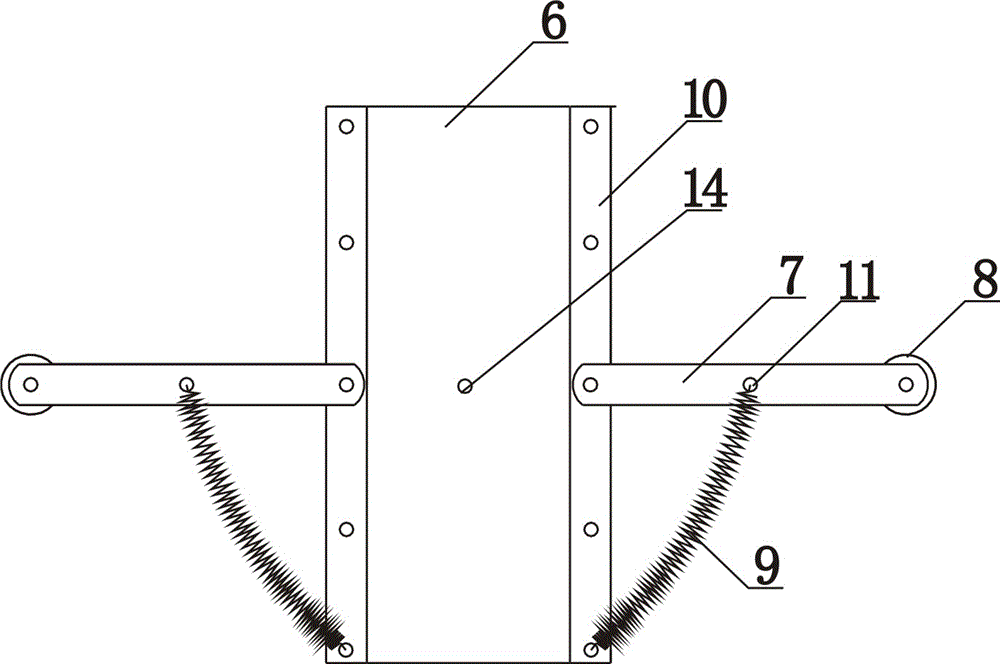

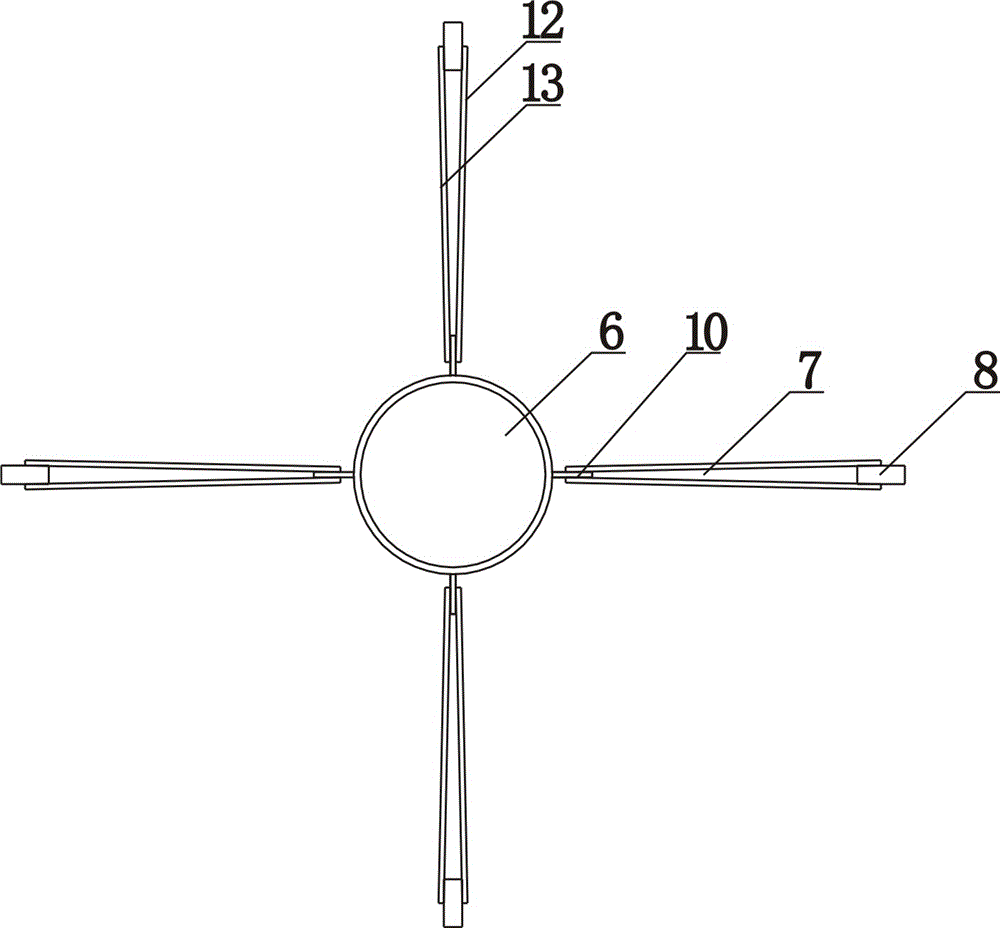

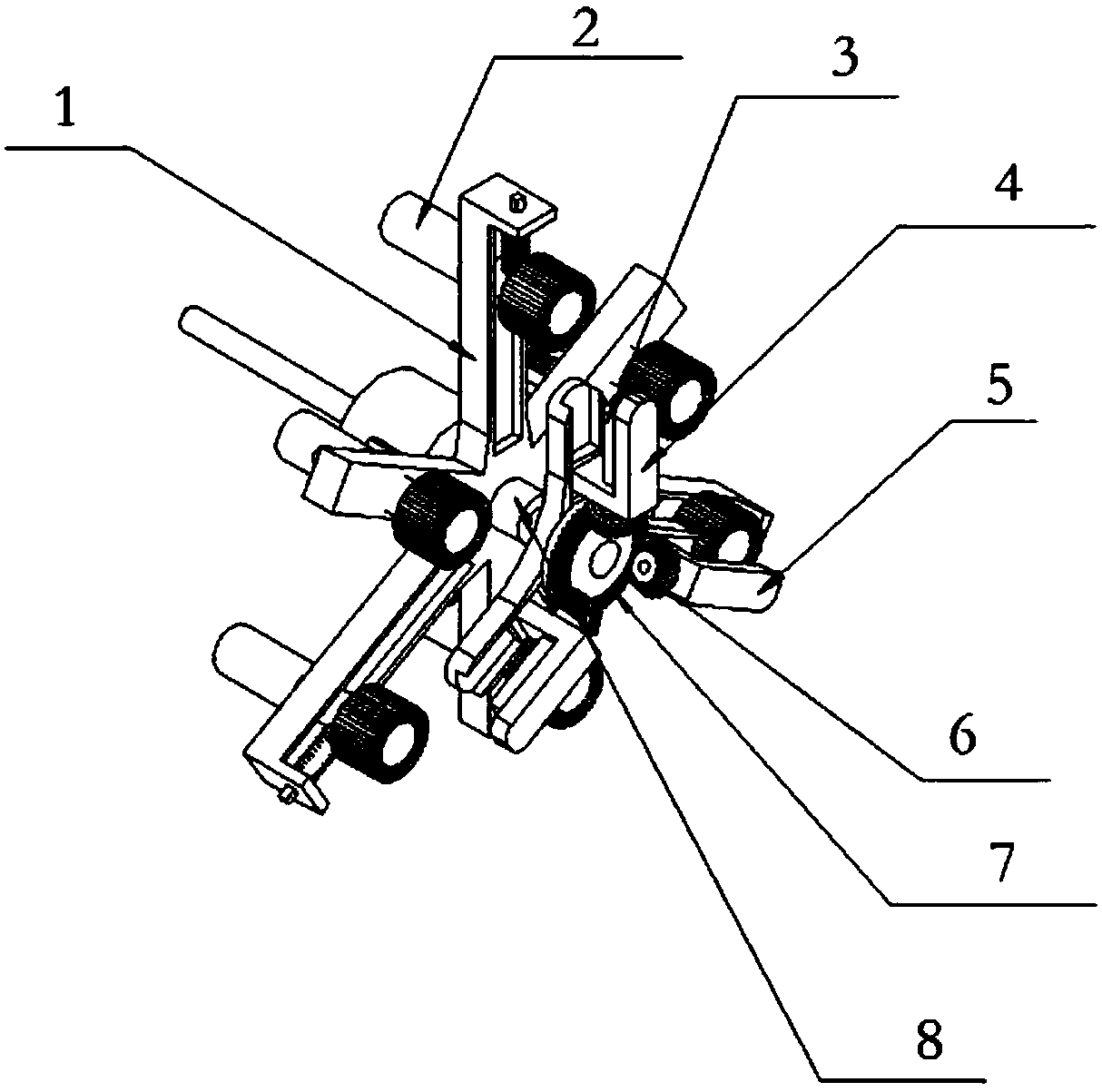

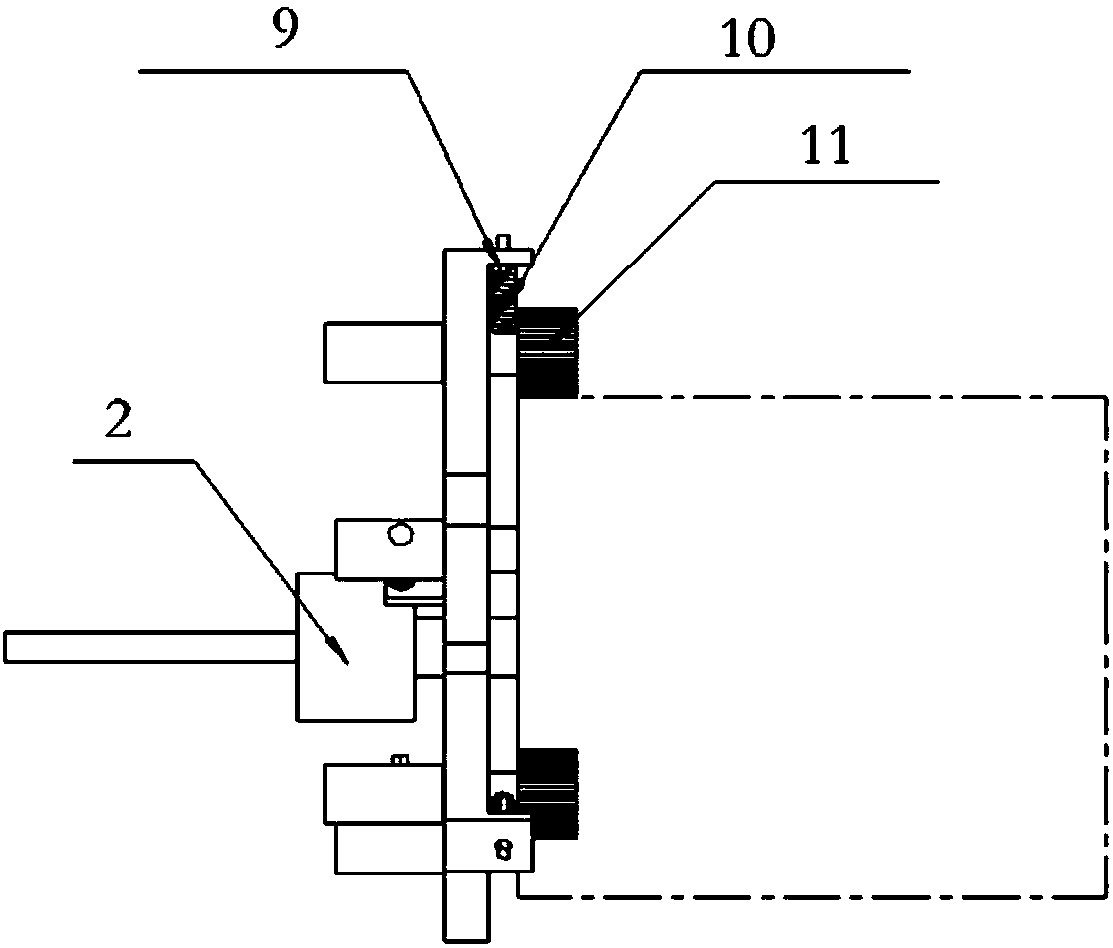

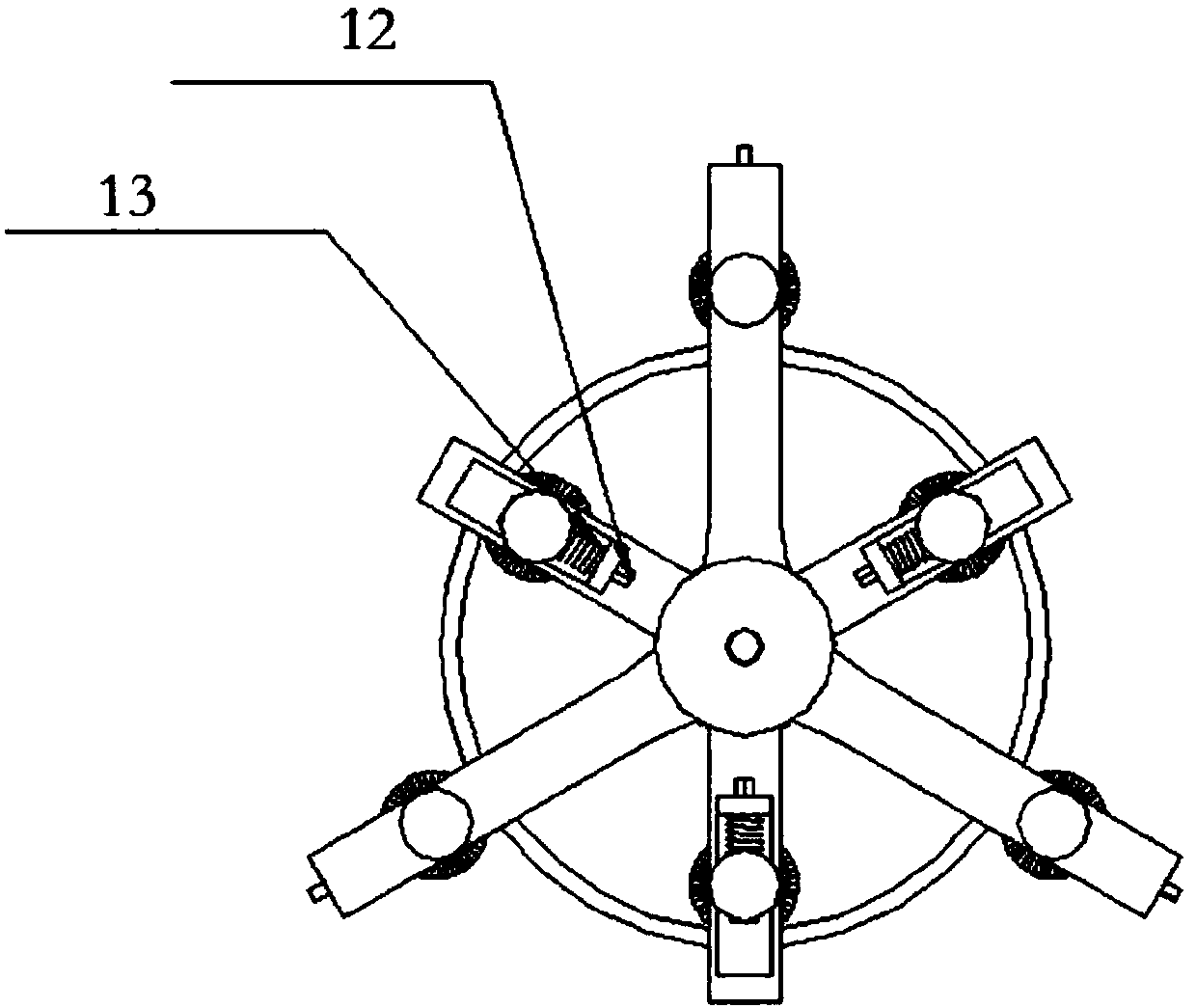

Inclination detection device for tubular pipe and inclinometer tube centring and locating assembly thereof

The invention discloses an inclination detection device for a tubular pipe and an inclinometer tube centring and locating assembly thereof. The inclination detection device for the tubular pipe comprises an inclination detection reading device, an inclination detection probe, the inclinometer tube and a cable used for lifting and pulling the inclination detection probe, and further comprises the inclinometer tube centring and locating assembly, wherein the inclination detection probe slides along a tubular groove in the inclinometer tube through rollers; and the inclination detection probe is connected with the inclination detection reading device through the cable. The inclinometer tube centring and locating assembly is characterized by comprising a locating sleeve, four locating rods, pulleys and springs, wherein the locating sleeve is mounted on the inclinometer tube in a sleeving manner; and the four locating rods are distributed in the circumferential direction of the locating sleeve to form a cross-shaped structure. The inclinometer tube centring and locating assembly guarantees that central positions of the inclinometer tube and the tubular pipe overlap, guarantees that the inclination detection probe does not twist and incline in the horizontal direction inside the inclination detection probe, guarantees that the detection data of the inclination of the tubular pipe is accurate and reliable, and has the characteristics of high measurement accuracy and convenient operation.

Owner:CRCC HARBOR & CHANNEL ENG BUREAU GRP SURVEY & DESIGN INST

Device and method for machining end part of pipe fitting, and application

InactiveCN107900806ASimple structureEasy clampingRevolution surface grinding machinesCleaning using toolsPipe fittingInsertion stent

The invention discloses a device and a method for machining the end part of a pipe fitting, and an application. The device comprises a self-centering component and an internal adjustment component or / and an external adjustment component which are distributed separately along the same axis, wherein each of the internal adjustment component and the external adjustment component comprises a pluralityof adjustable supports which are uniformly distributed along the axis and rotary elements arranged on the supports; and with the automatic alignment of the self-centering component in the pipe fitting, the rotary elements of the internal adjustment component are outwards extensible in the radial direction of the adjustable supports, and the rotary elements of the external adjustment component areinwards extensible in the radial direction of the adjustable supports until the inner pipe wall or / and the outer pipe wall of the pipe fitting are clamped separately. The device disclosed by the invention is simple in structure and convenient to clamp, and the pipe fitting does not need to be moved during machining.

Owner:山东豪迈重工有限公司

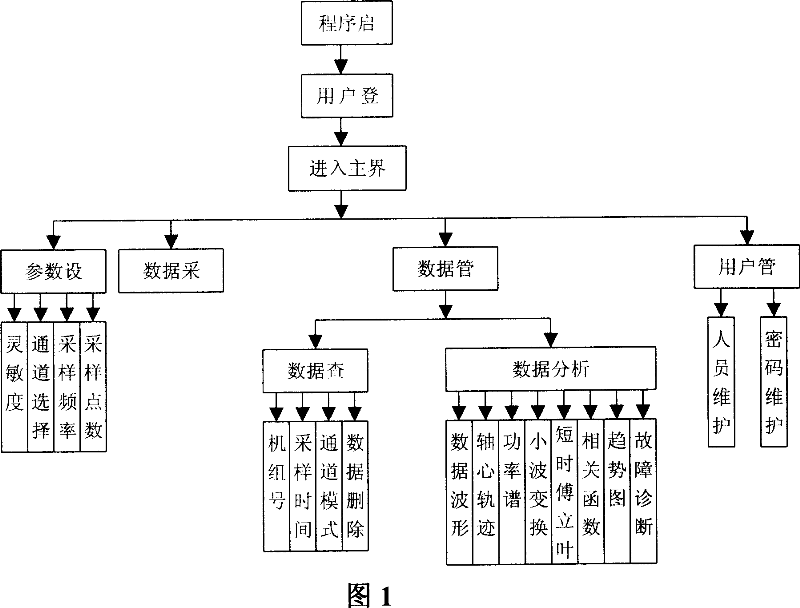

Vibration monitoring and failure diagnosis system of gas turbine

InactiveCN101038231AObvious superiorityNoticeable speed changeVibration testingFrequency spectrumFourier transform on finite groups

The present invention relates to an oscillation monitoring and fault diagnosis system of a combustion turbine. The characteristics are: the oscillation signals of the combustion turbine generator group can be measured, and the oscillation and the corresponding analyzing results can be displayed in a dynamic mode, and the waveform, peak-peak value, frequency spectrum can also be displayed; the rotor axes trace and the time frequency analyzing including a small wave transforming, a short-time Fourier transforming, the corresponding functions and the tendency chart of each testing point can be displayed in a dynamic mode to the displacement signals; firstly, the familiar faults of the rotor system such as the unbalance, the colliding and friction and un-centring are judged, at the same time, alarming function is provided; the normal or un-normal of the moving of the shaft can be seen form the displayed dynamic trace and the short-time Fourier transforming of the combustion turbine at the starting and stop moment can displays the change of the rotating speed and the frequency doubling; the small wave analyzing method can decompose the main components of the signals to observe the main oscillation signals and high-frequency overlapped signals and some transilient signals of the running combustion turbine.

Owner:PETROCHINA CO LTD

Machining fixture for centering and holding workpiece

A centering and holding fixture includes a base, a piston disposed within a piston chamber at least partially located within the base, and a radially flexible ring connected to the piston by force transmission apparatus operable to contract and expand the radially flexible ring by upward and downward motions respectively of the piston. The flexible ring may be slotted and may include alternating inwardly and outwardly extending radial slots extending axially through the flexible ring and extending radially inwardly and radially outwardly from radially outer and inner surfaces of the flexible ring respectively to axial stress relief holes extending axially through the flexible ring. The apparatus may further be operable to contract the radially flexible ring when the piston chamber is pressurized and to expand it when the piston chamber is depressurized. Spring loaded clamps mounted to the base may be used to secure a workpiece to the holding fixture.

Owner:GENERAL ELECTRIC CO

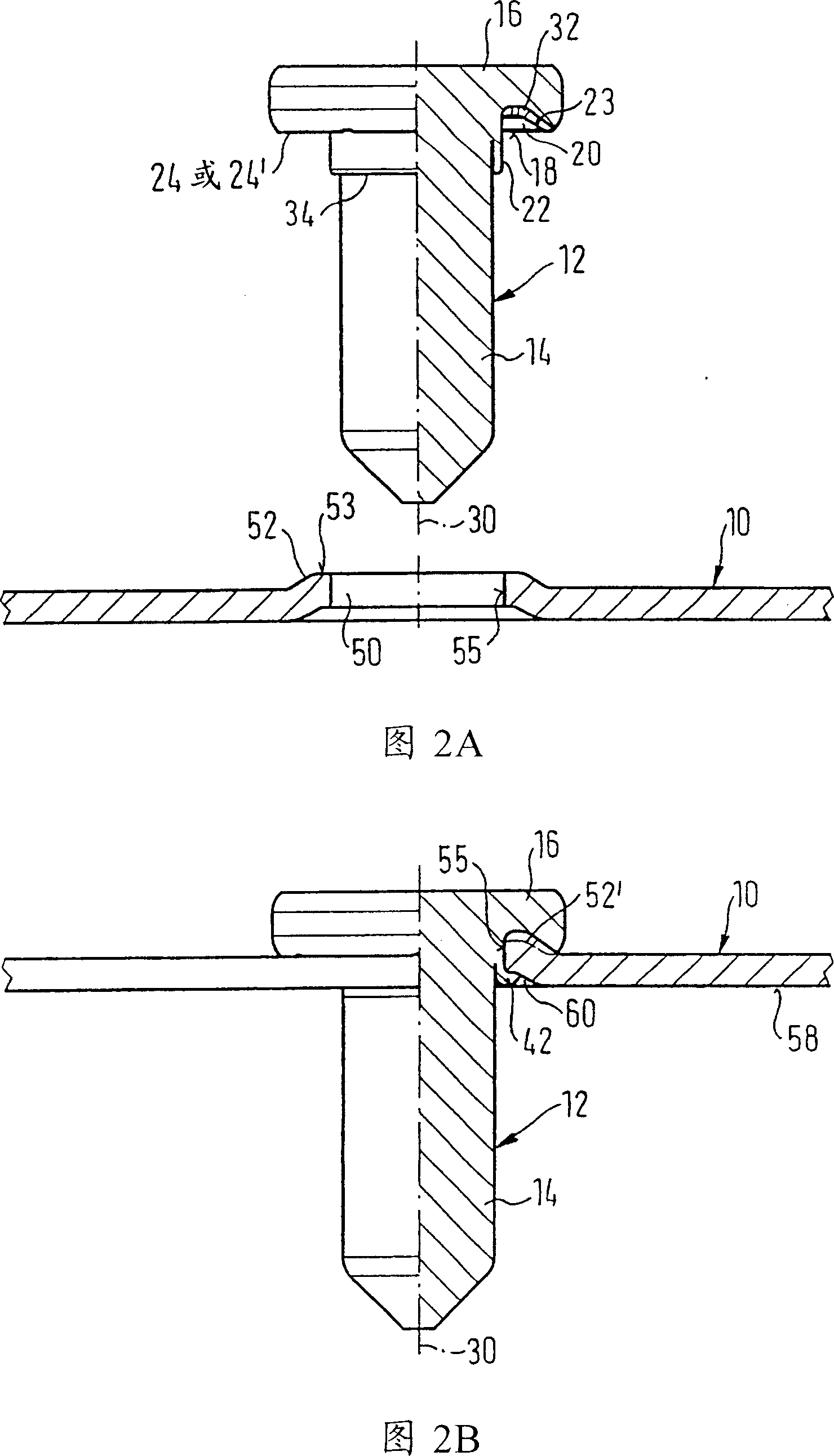

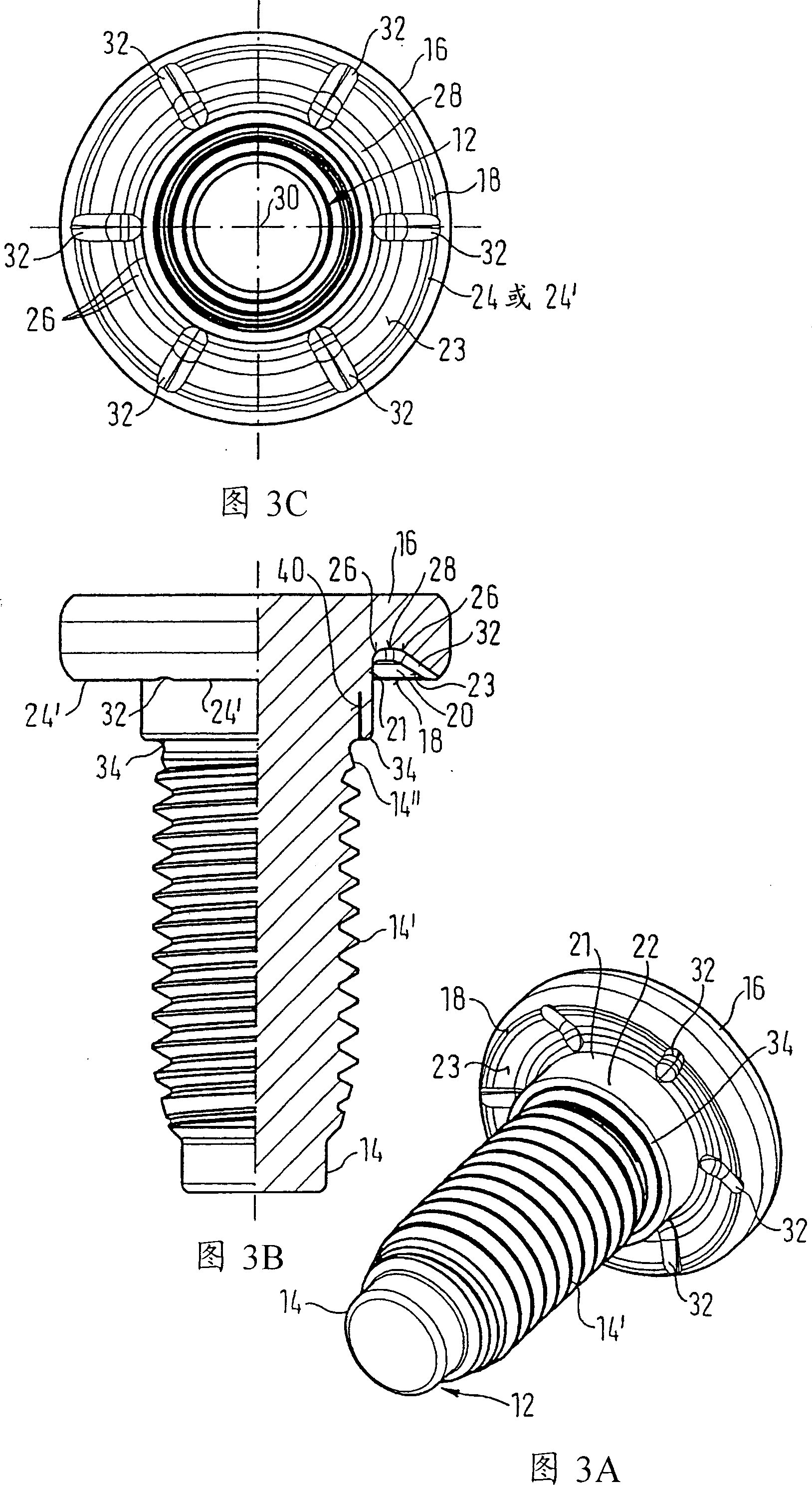

Connecting element, part assembly and method for forming the part assembly

ActiveCN101086270AWith pure centering functionPrevent rotationScrewsSheet joiningMetal sheetEngineering

The invention discloses an element which can be connected on the metal sheet component through riveting, particularly the element in the form of centering bolt. It consists of bar part and head part, among them the side facing metal sheet component of the head part is machined with circular groove or at least near-circular groove, the circular groove is apposed into the circular column section of head part in the radial inner side, and the circular column section is apposed into the bar part and the pipe-type riveting section, the riveting part circulates the bar part in the zone which head part in, the circular groove is located in the circular contact face which is arranged at the outer side of circular groove radically, and the circular groove is apposed on the circular contact face at the radial outer side through the at least near conical wall, it is characterized by: the conical wall of circular groove and / or the circular bottom which is alternative on the circular groove are equipped with at least one local groove, preferentially several local groove particularly the local grooves distributed uniformly. The invention also discloses a piece unit which includes said elements and metal sheet component. It also discloses a method machining the piece unit.

Owner:PROFIL VERBINDUNGSTECHN

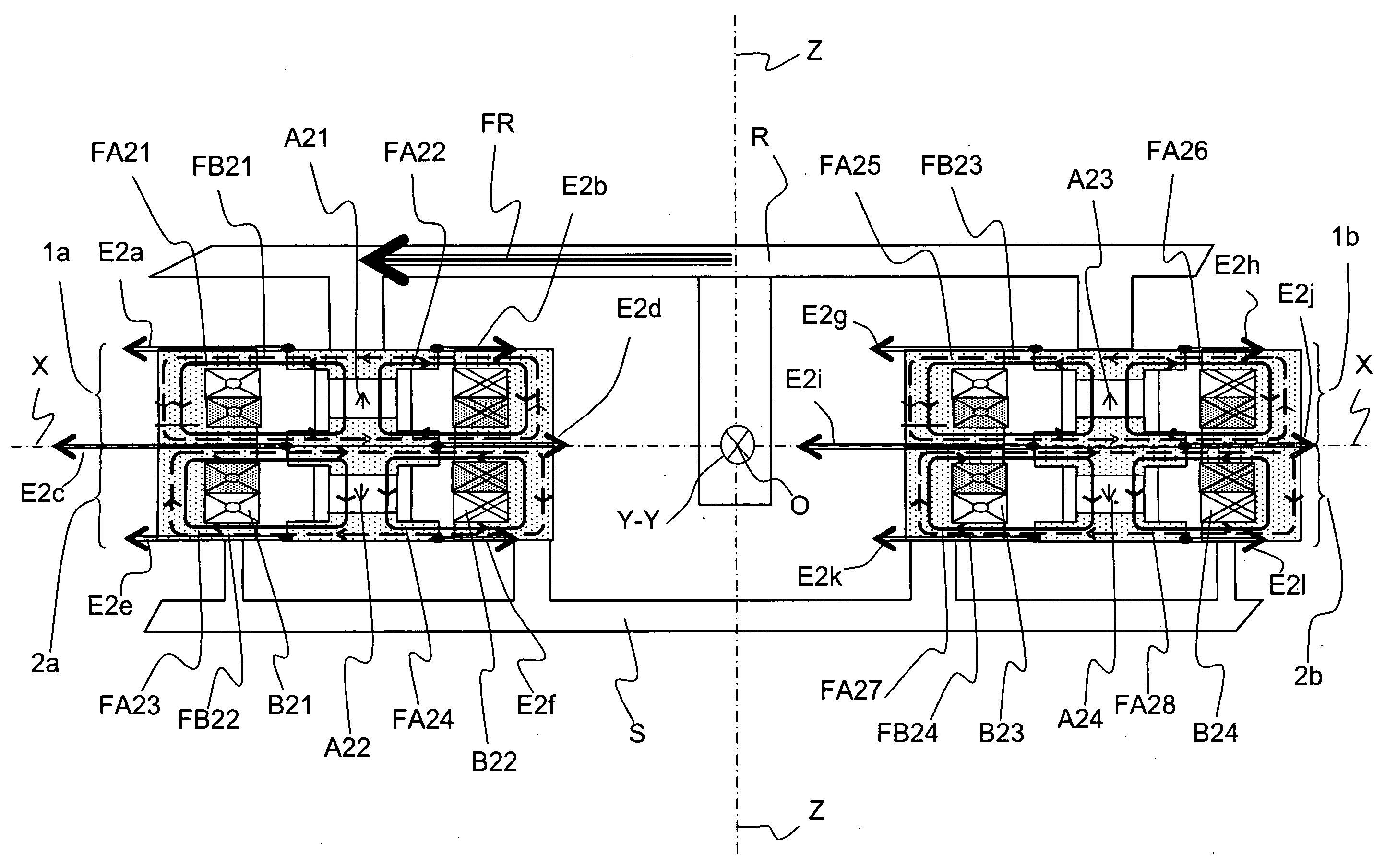

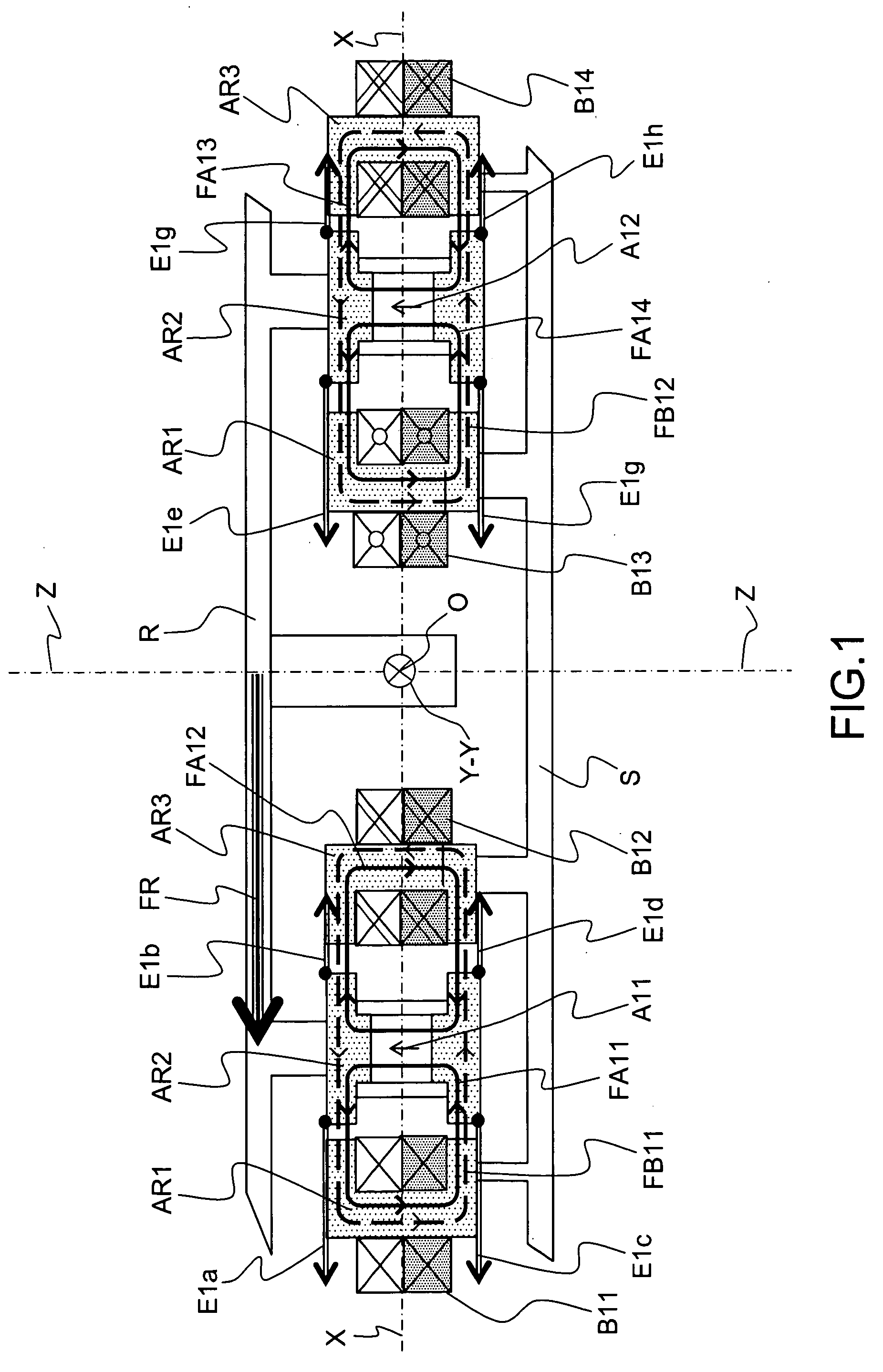

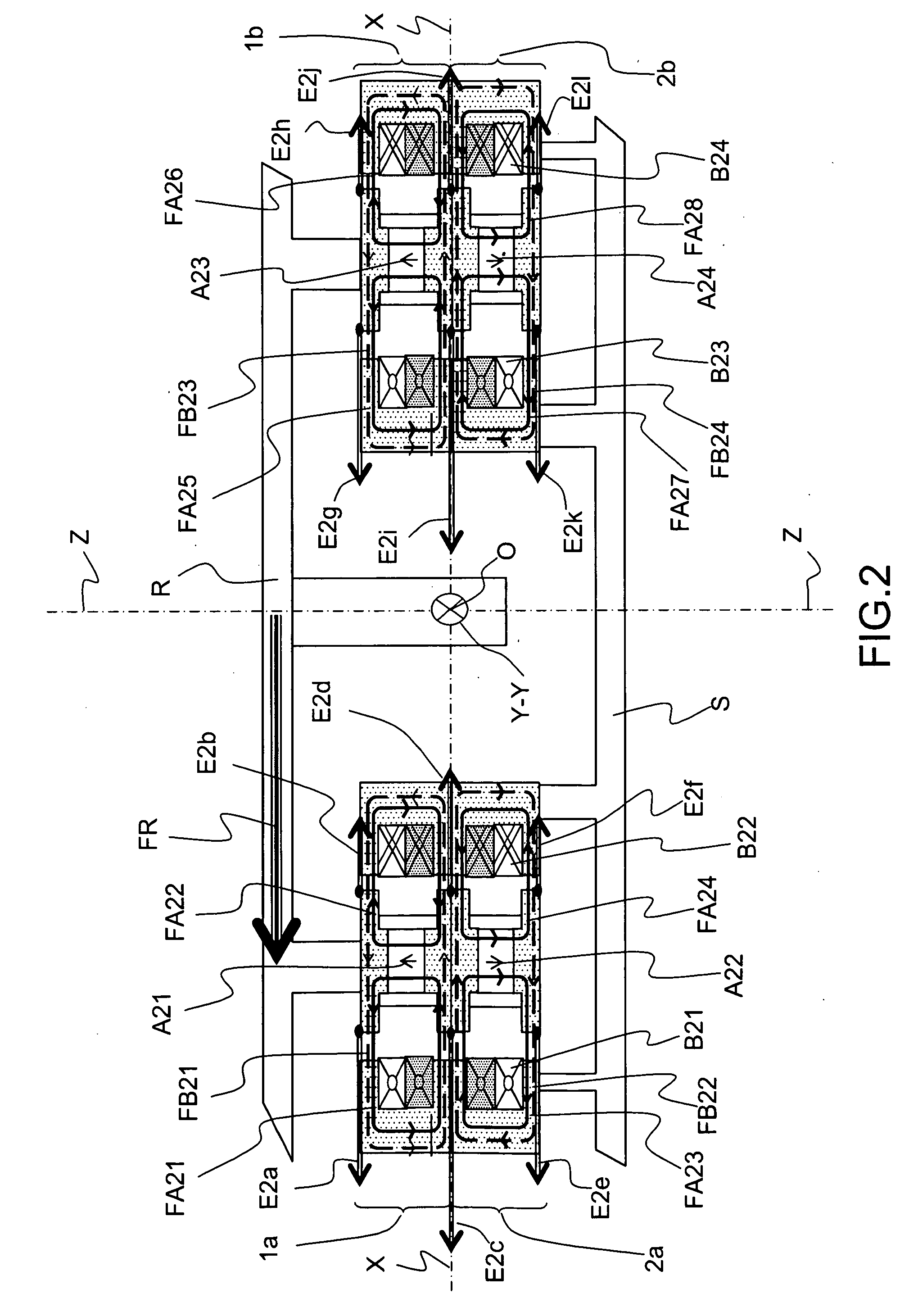

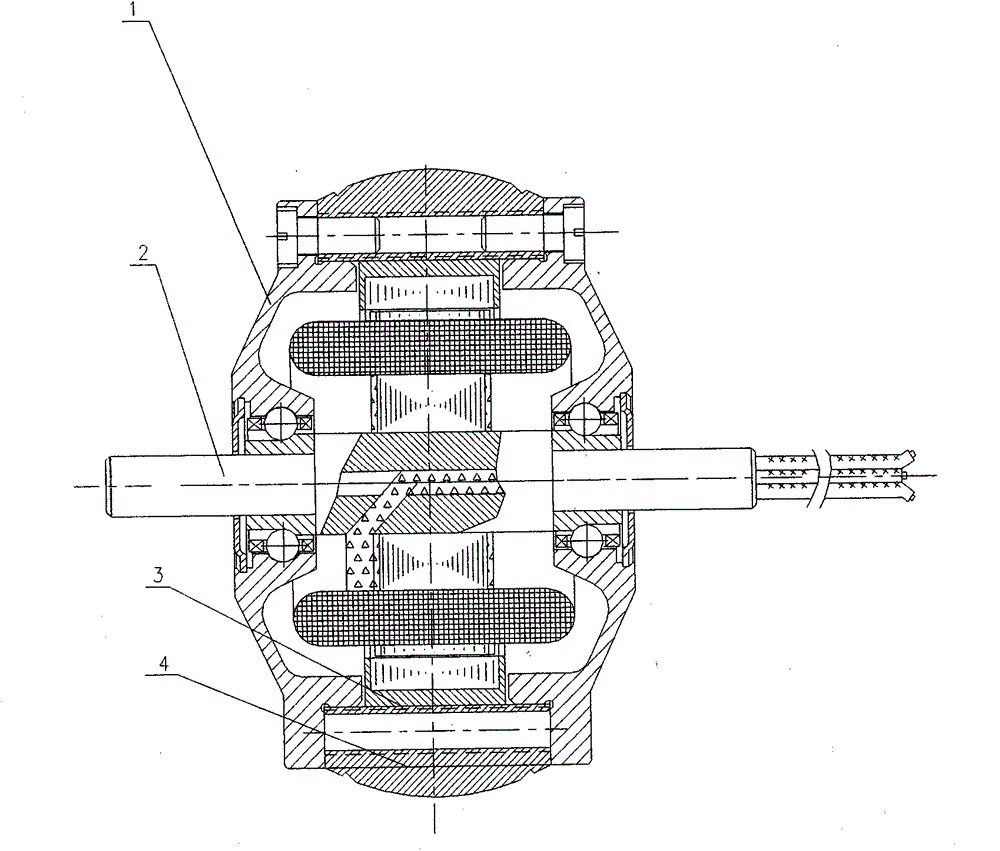

Dual-stage centring magnetic bearing

The present invention relates to a magnetic centring structure, and more particularly a structure of a centring magnetic bearing intended notably for space applications. The solution proposed in the present patent is suited to the centerers used on gyroscopic wheels and actuators. The main originality of the invention is the proposal of a dual-stage magnetic bearing structure. According to the implementation chosen, this invention presents the significant advantage of an improvement in terms of radial bulk.

Owner:THALES SA

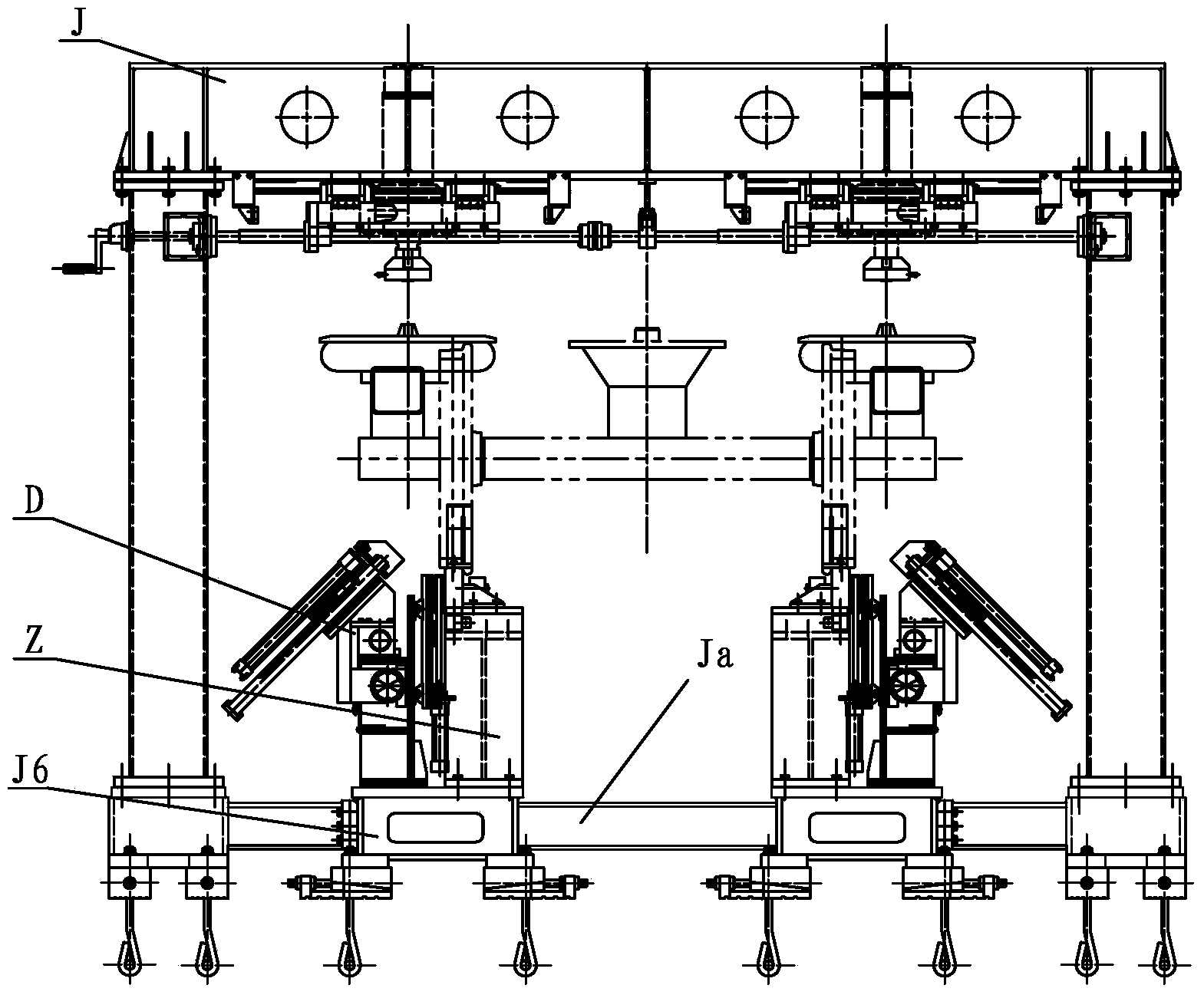

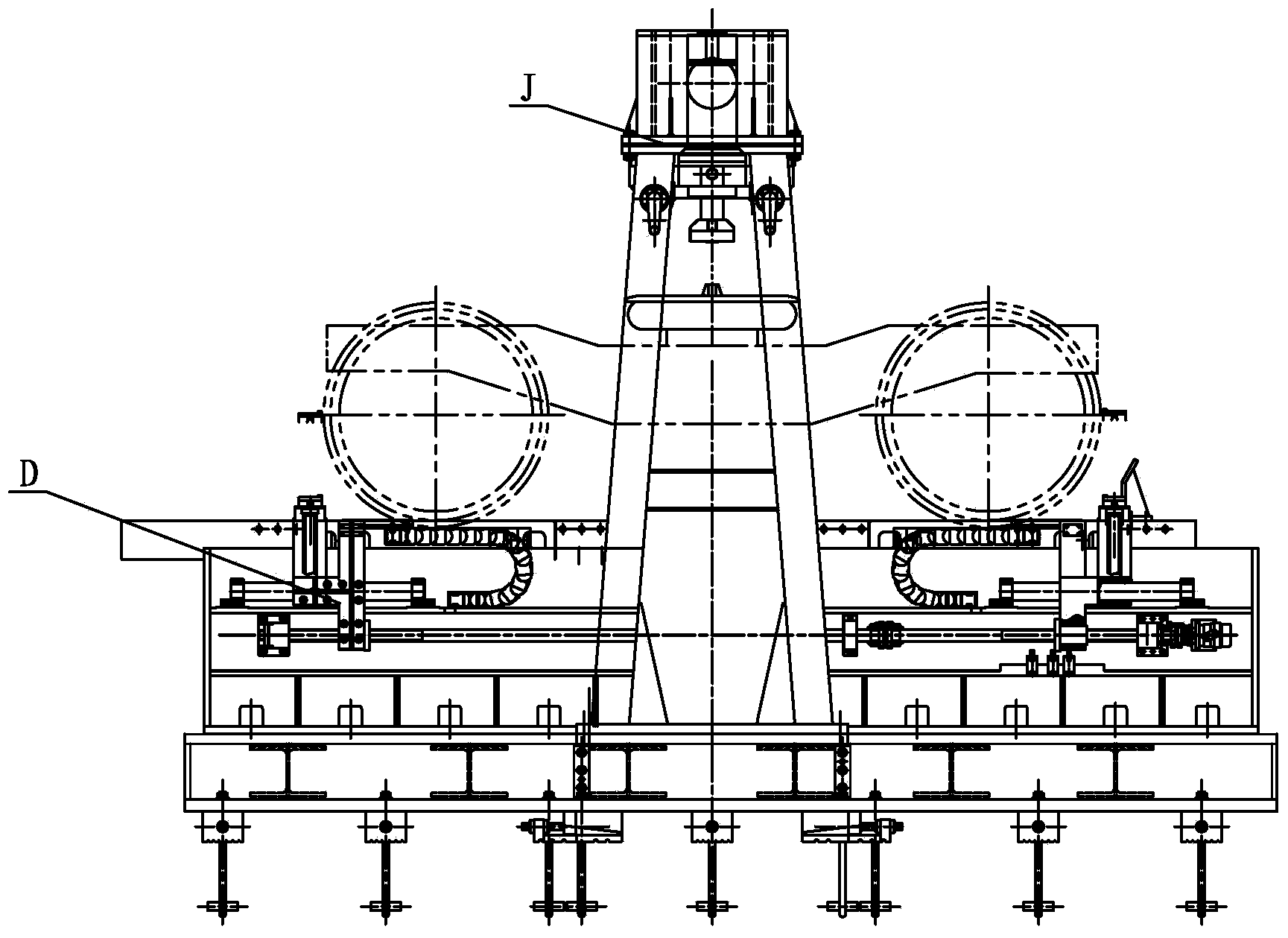

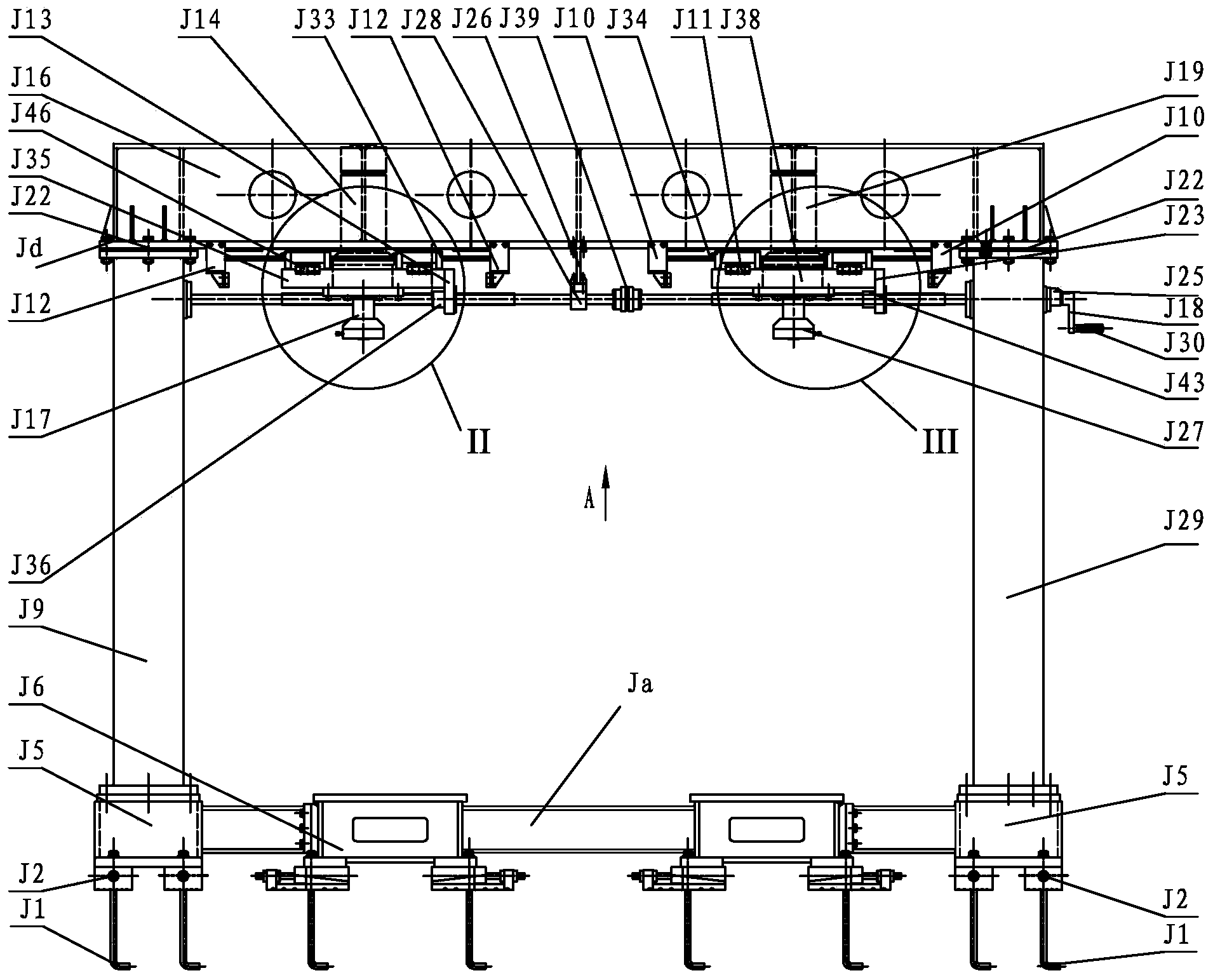

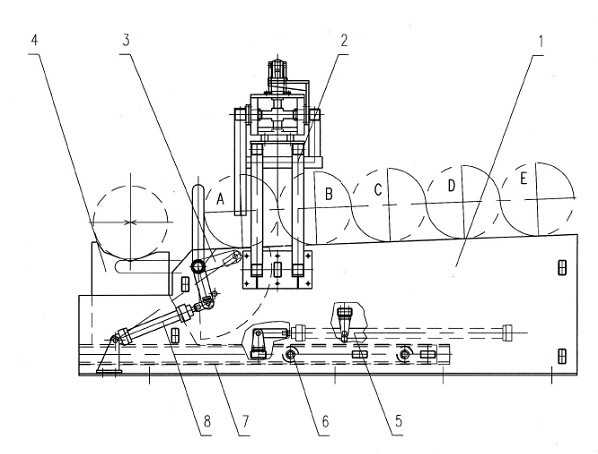

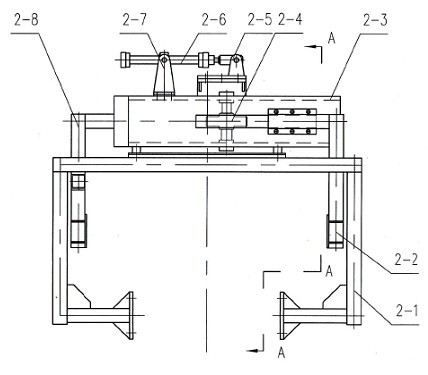

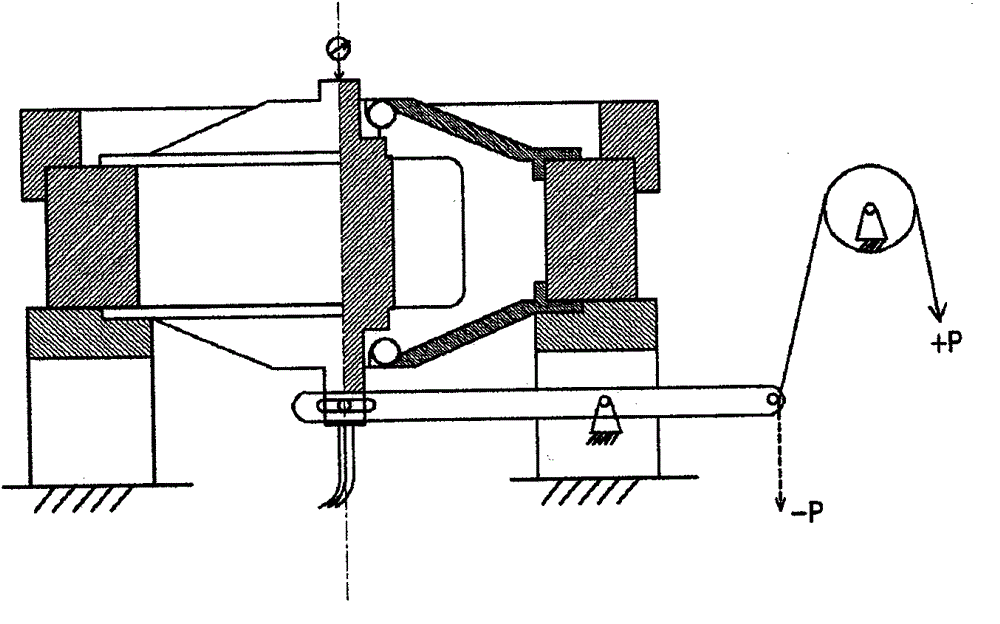

Railway vehicle bogie static load comprehensive detection system

The invention discloses a railway vehicle bogie static load comprehensive detection system, and belongs to the technical field of railway vehicle manufacturing safety. The railway vehicle bogie static load comprehensive detection system solves the problems that an existing detection system cannot be applied to railway bogies in different types and in different specifications and cannot carry out calibration on multiple kinds of performance of the bogie. The railway vehicle bogie static load comprehensive detection system comprises a loading device, a weighing device and a centring device, the weighing device and the centring device are arranged on a main bed body of a foundation platform of the loading device, and the weighing device is arranged inside the centring device. The loading device comprises the foundation platform, a left transmission mechanism, a right transmission mechanism and a portal frame. The foundation platform, the left stand column, the right stand column and a cross beam form a sealed framework. A guiding rail, a first weighing rail, a connecting rail, a second weighing rail and a transition rail of the weighing device are arranged from front to back in sequence, the left centring component of the centring device and the right centring component of the centring device are arranged symmetrically in a left-right mode, and an inclined cylinder motion system of the left centring component and an inclined cylinder motion system of the right centring component are arranged side by side. The railway vehicle bogie static load comprehensive detection system is used for a railway vehicle bogie static load test.

Owner:GRAND NEW POWER

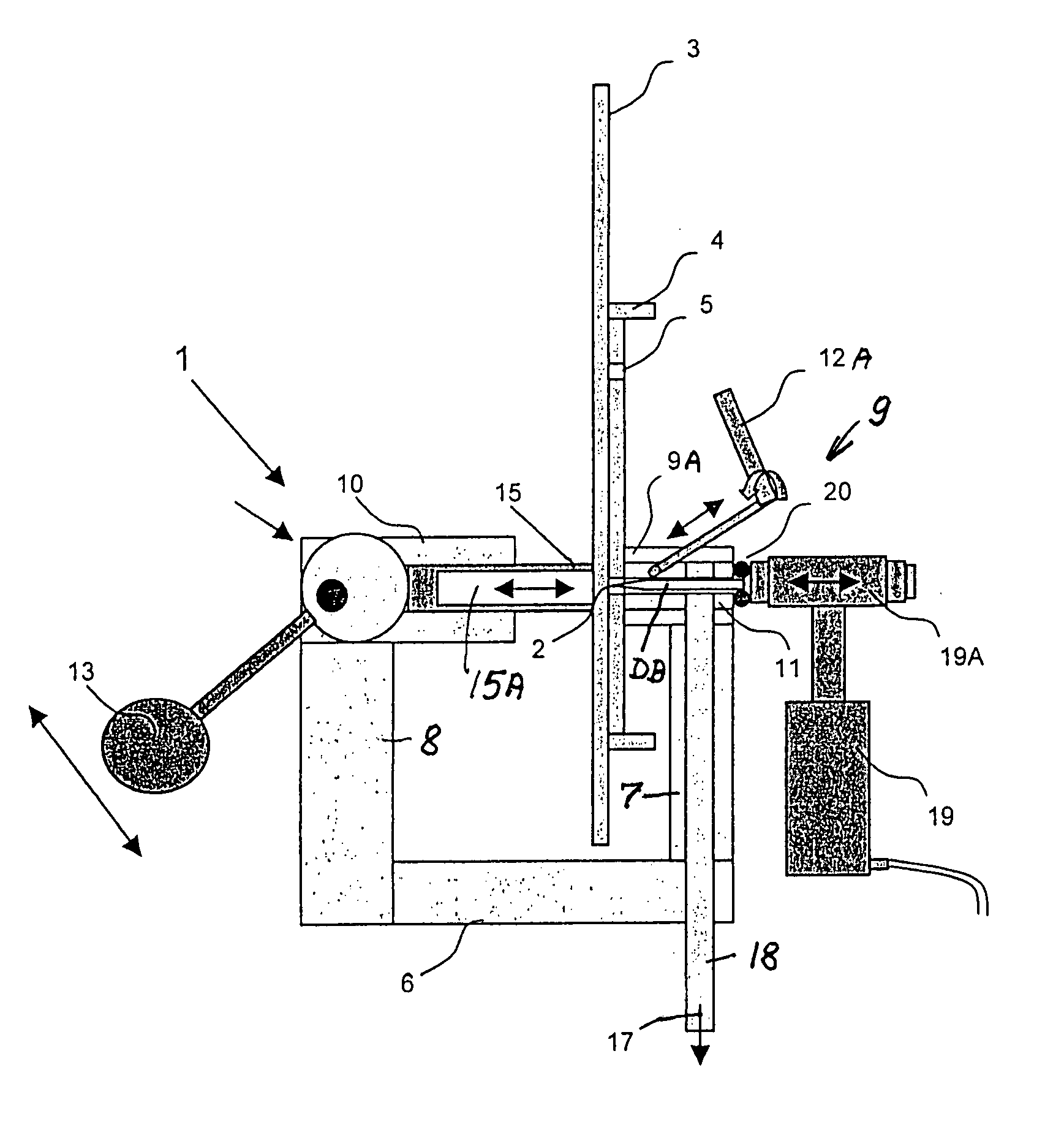

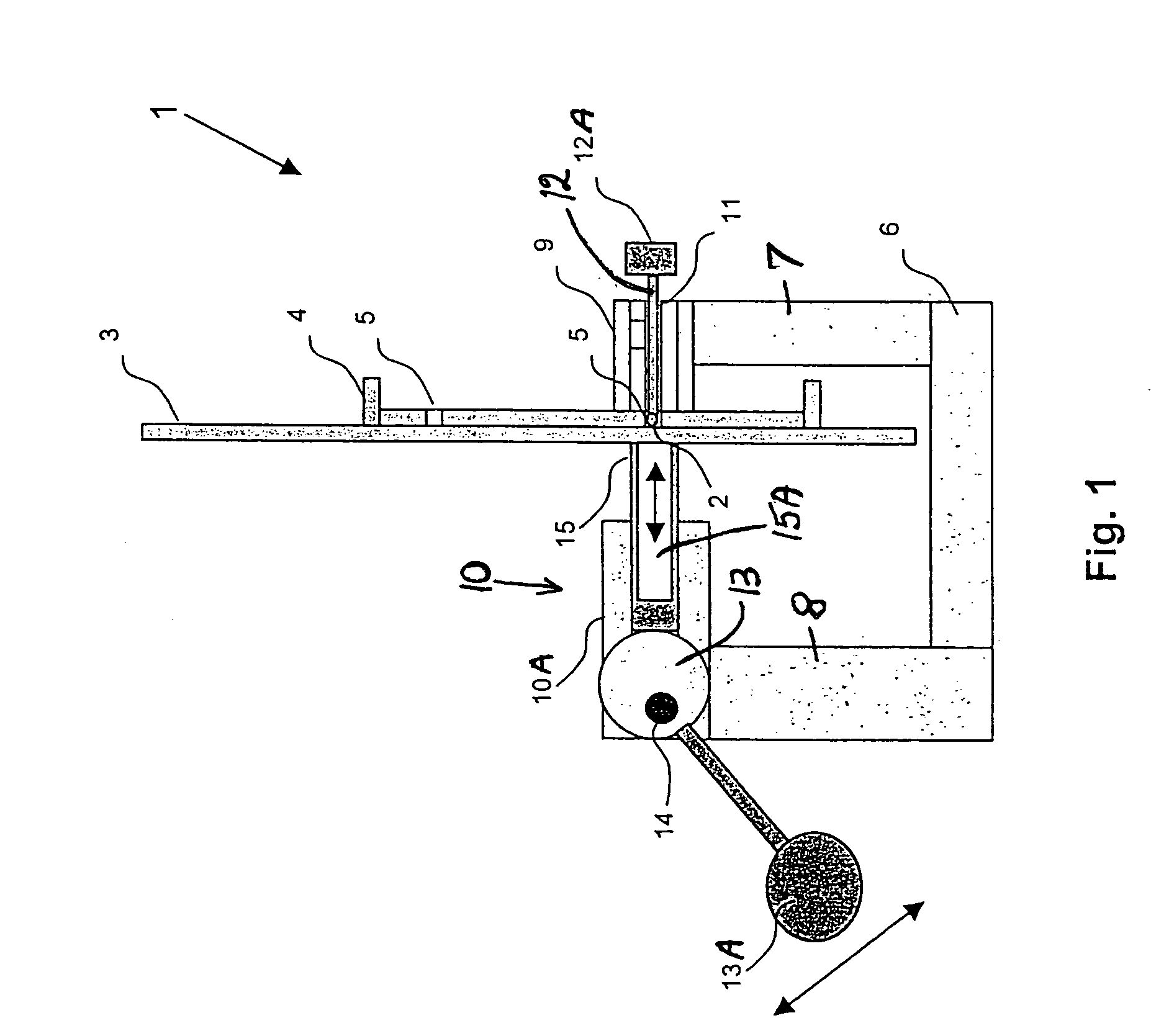

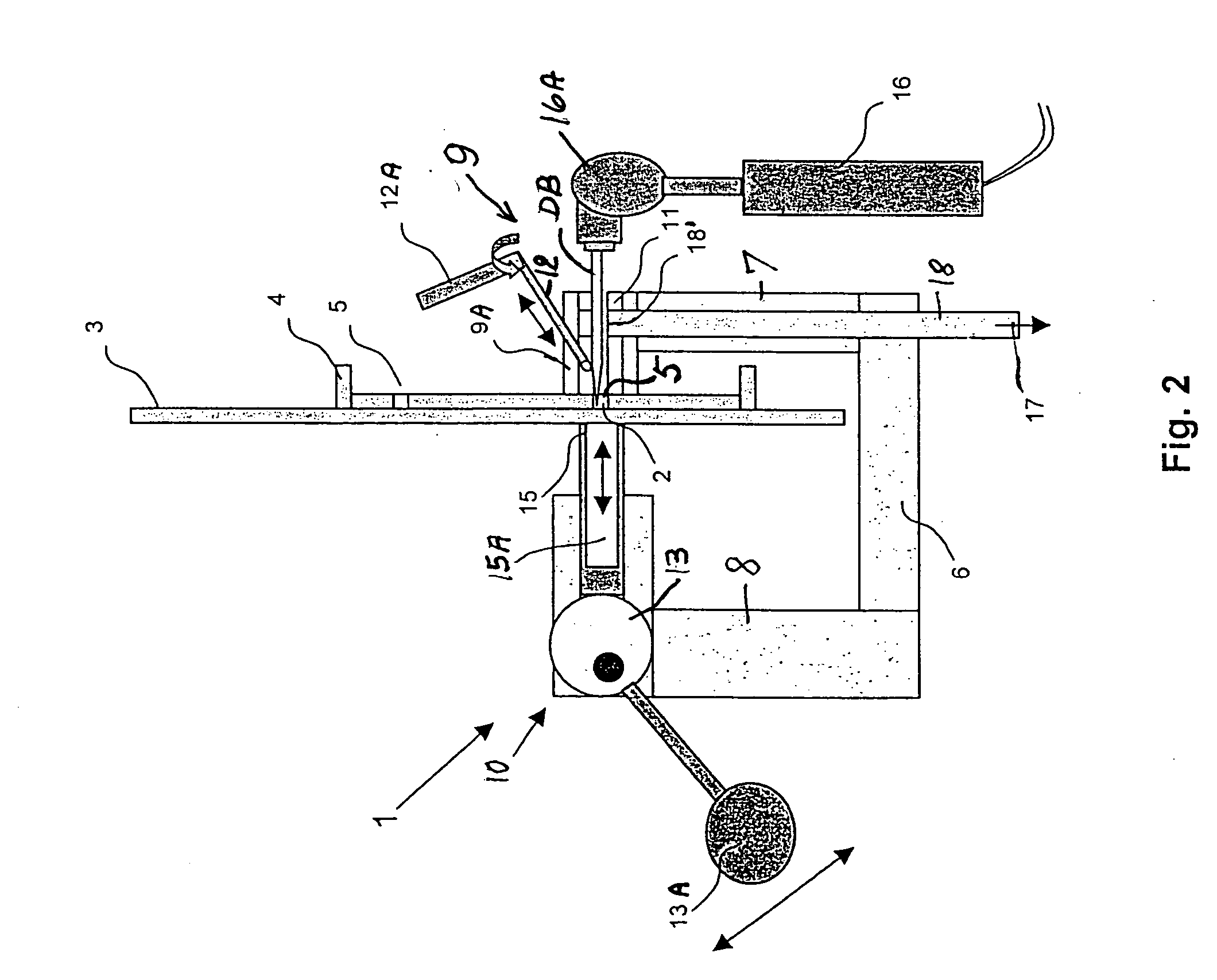

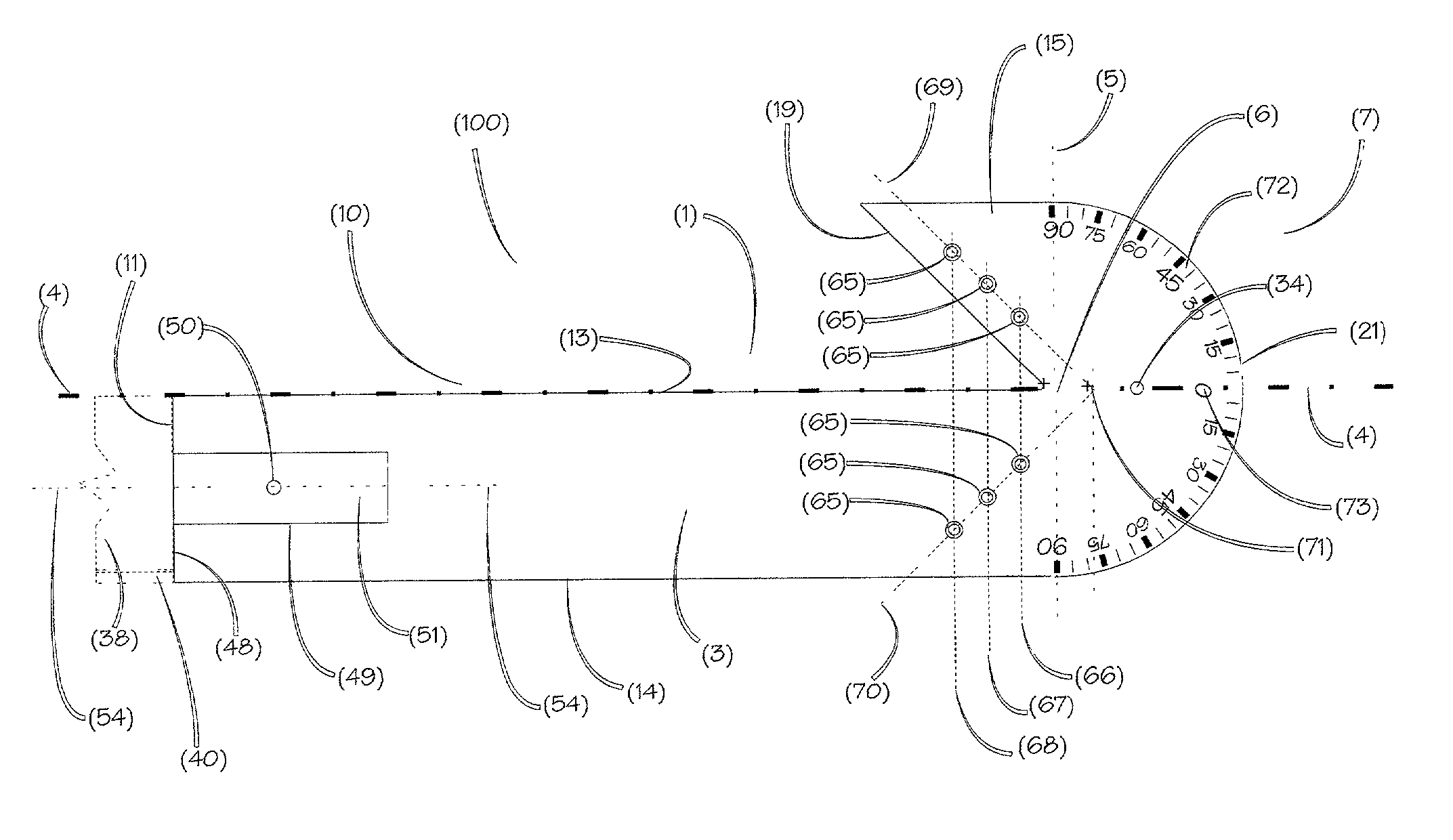

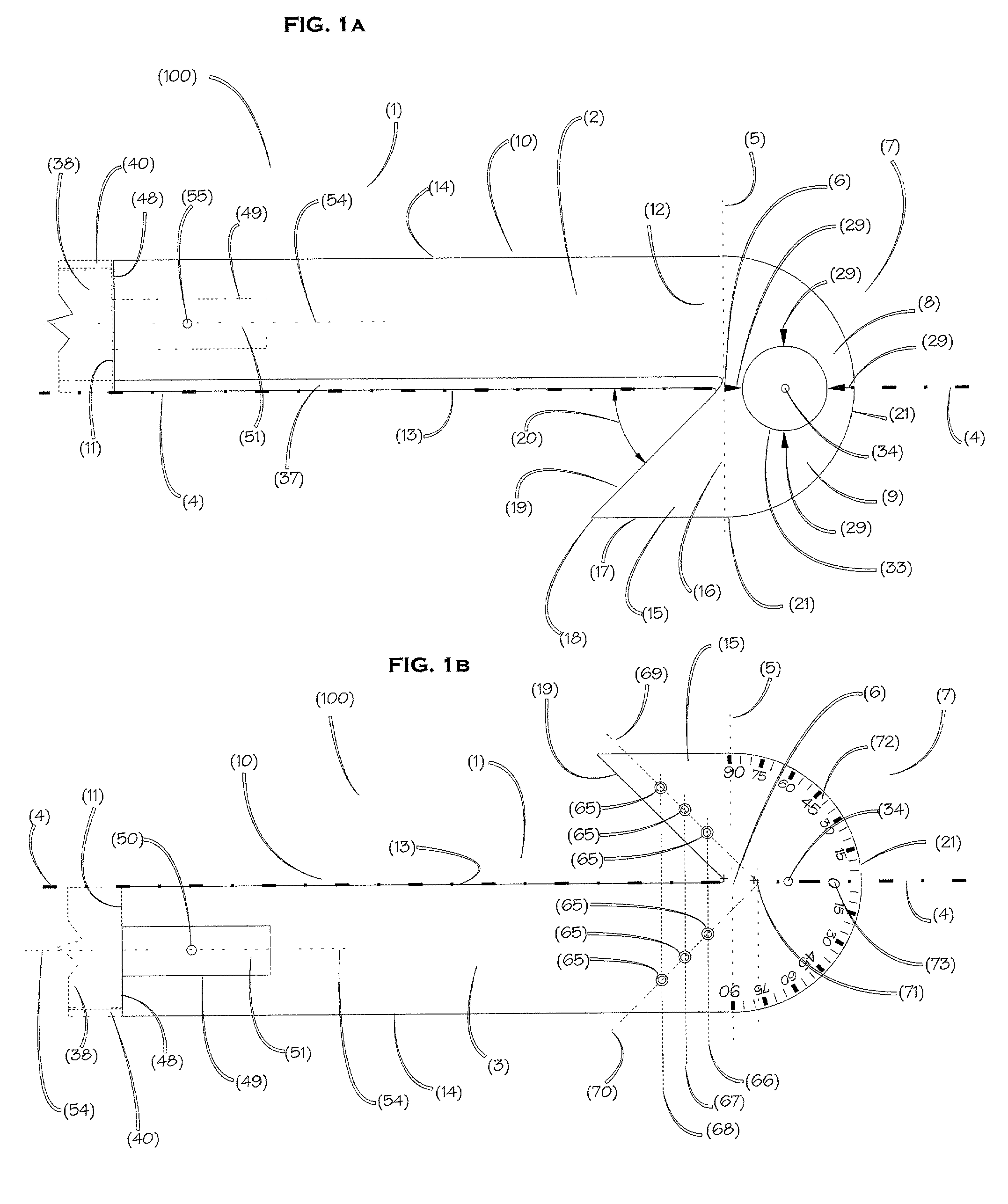

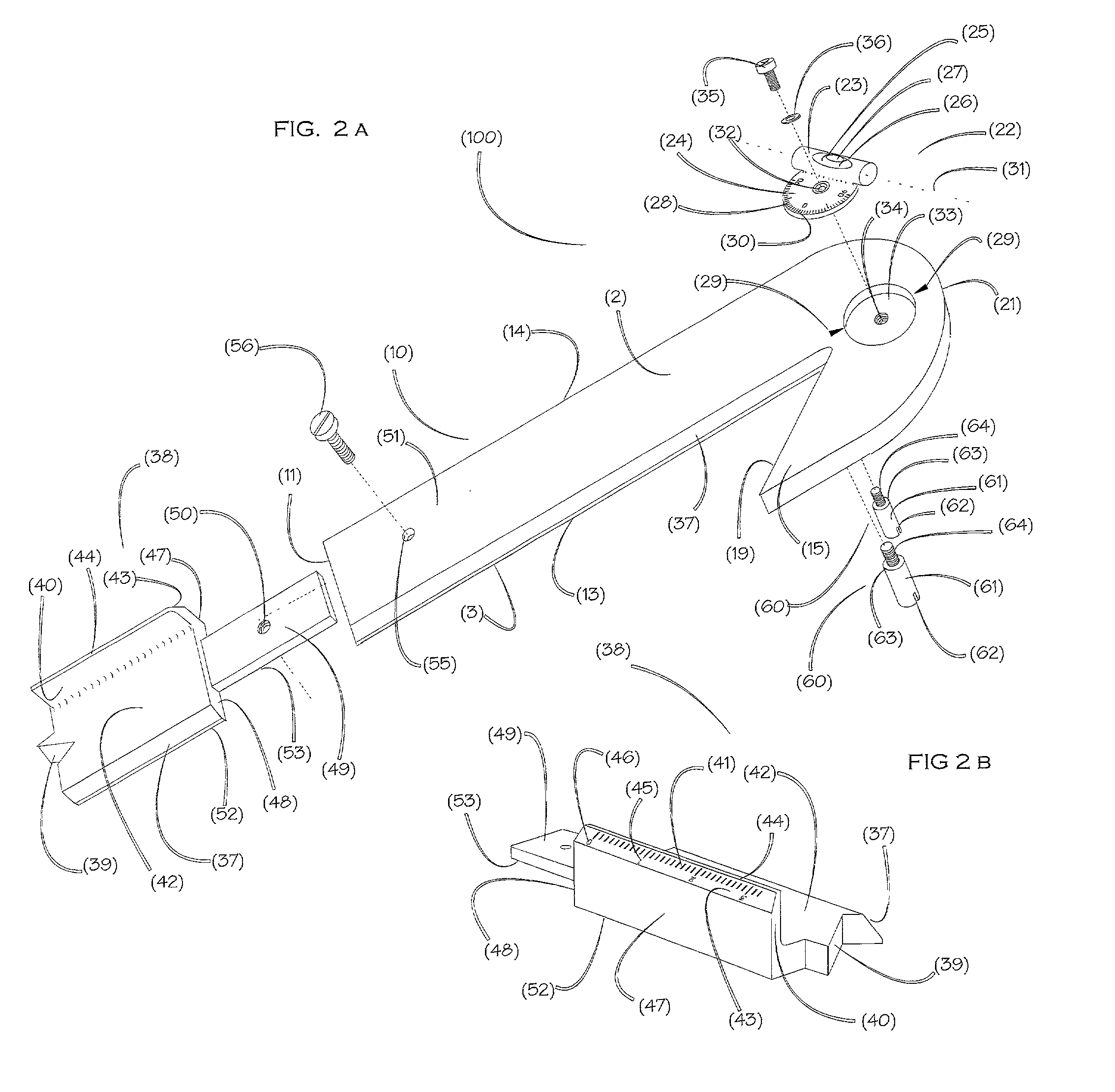

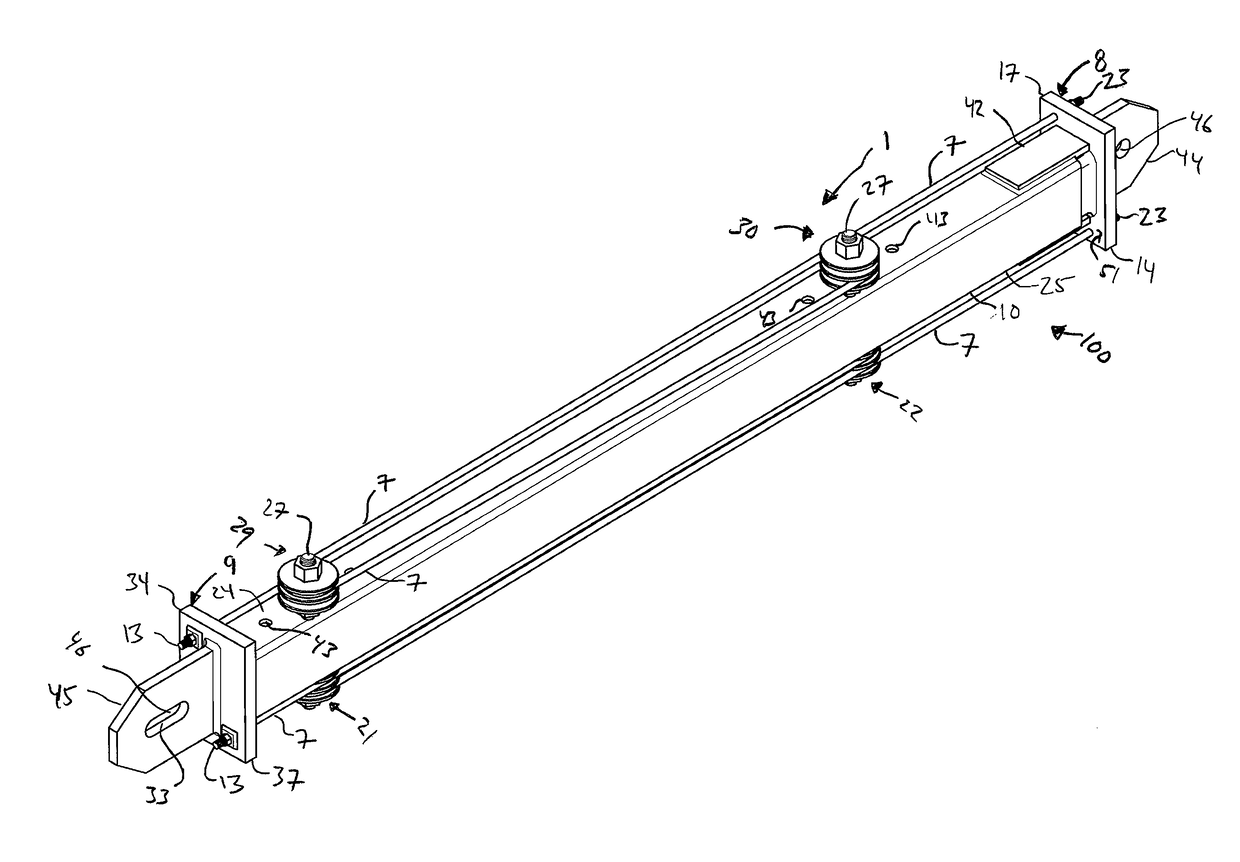

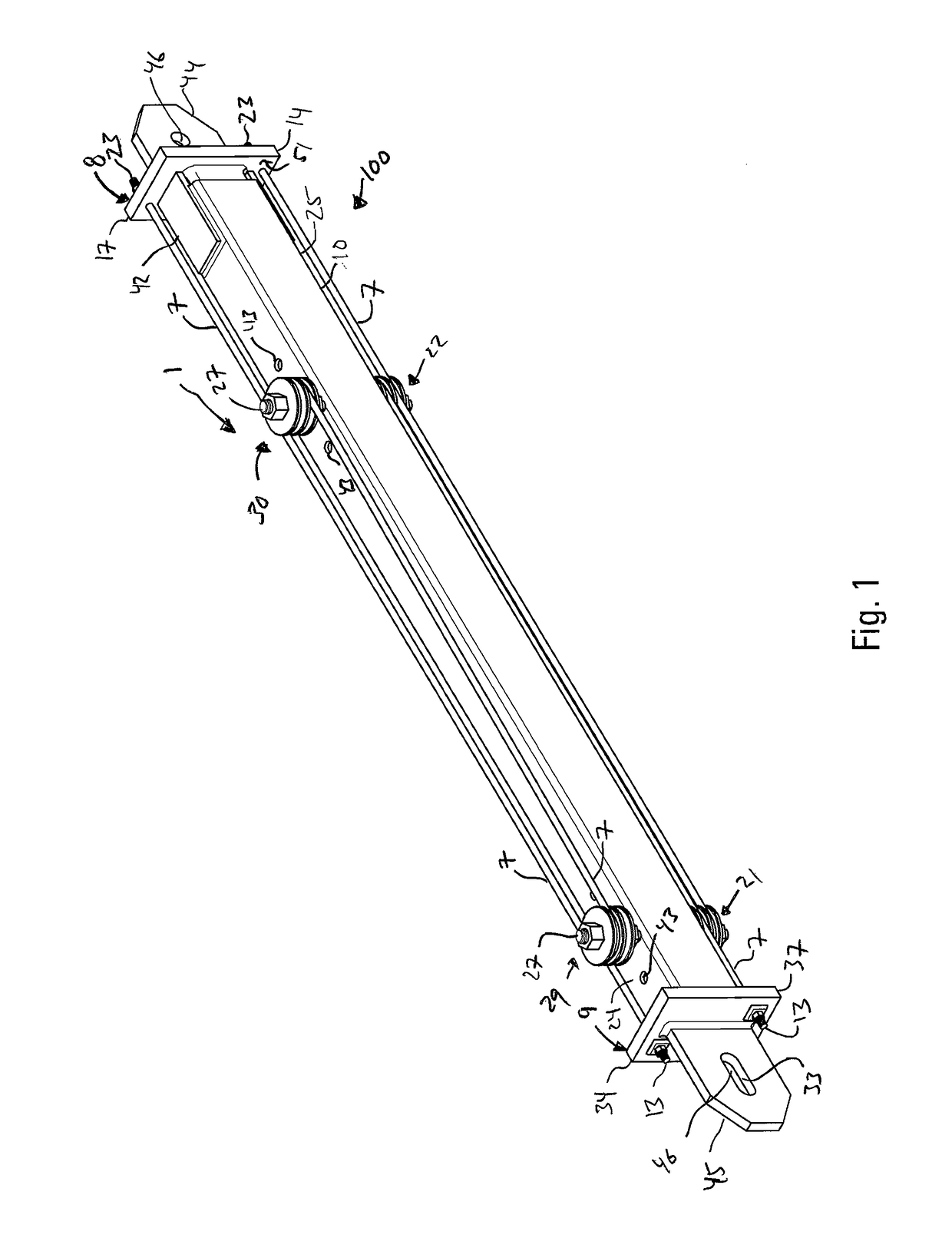

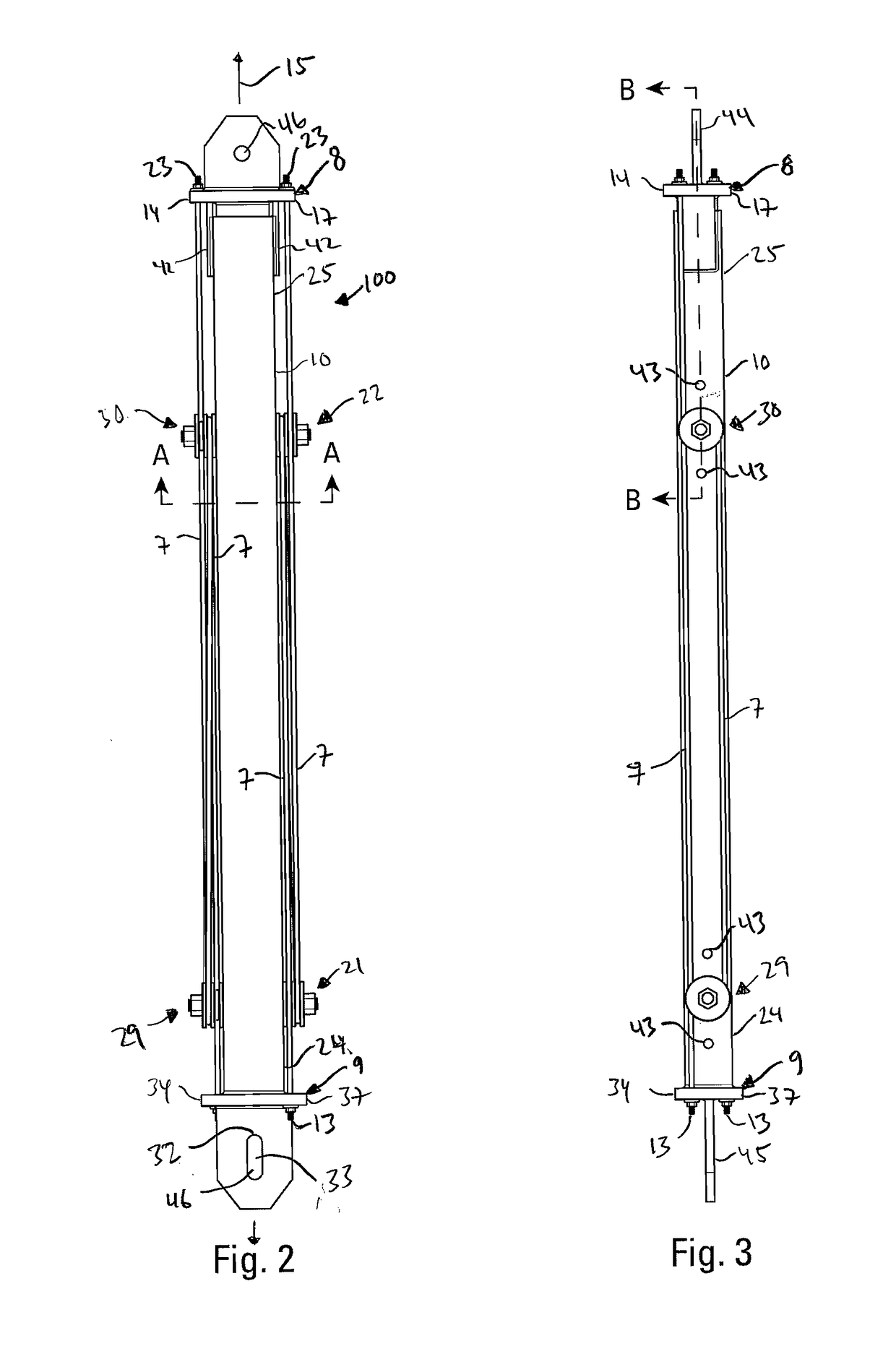

Pipe fitters lay out tool

A simplified light weight squaring tool used by pipe fitters in conjunction with templates or pipe fitters tables for laying out pipe intersect angles and geometry as required for cutting and joining pipe of various sizes at various angles. A rugged tool intended primarily for on sight use, comprises a self centering straight edge arranged for guiding and scribing of lines on flat surfaces, curved surfaces or across the diameter of a pipe face, an integral adjustable protractor level, allowing for fast and accurate perpendicular and angular orientation of the straight edge when used in the vertical plane and a self aligning extension arranged for expanding the capacity of the squaring tool and transcribing angular lines from the face of pipe sections onto the circumference or outside diameter of pipe parallel to longitudinal centerline of the pipe as required for layout

Owner:KNEIPP MATT C

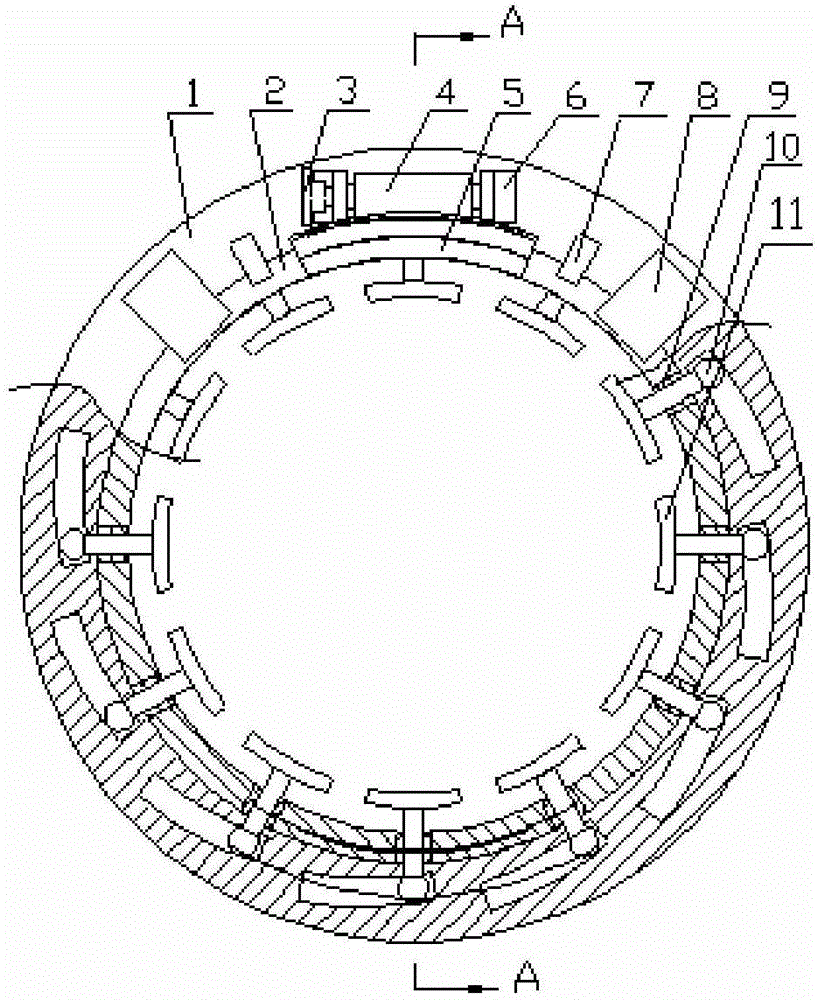

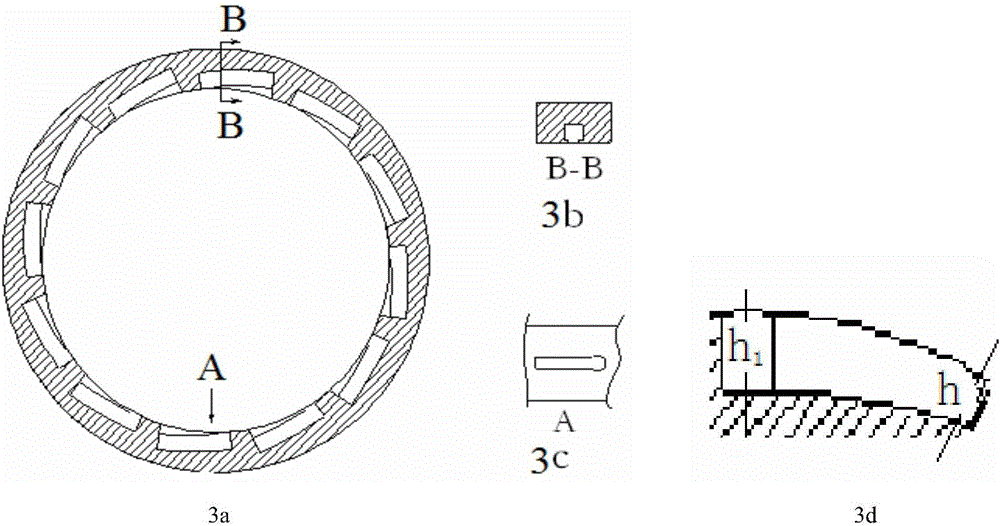

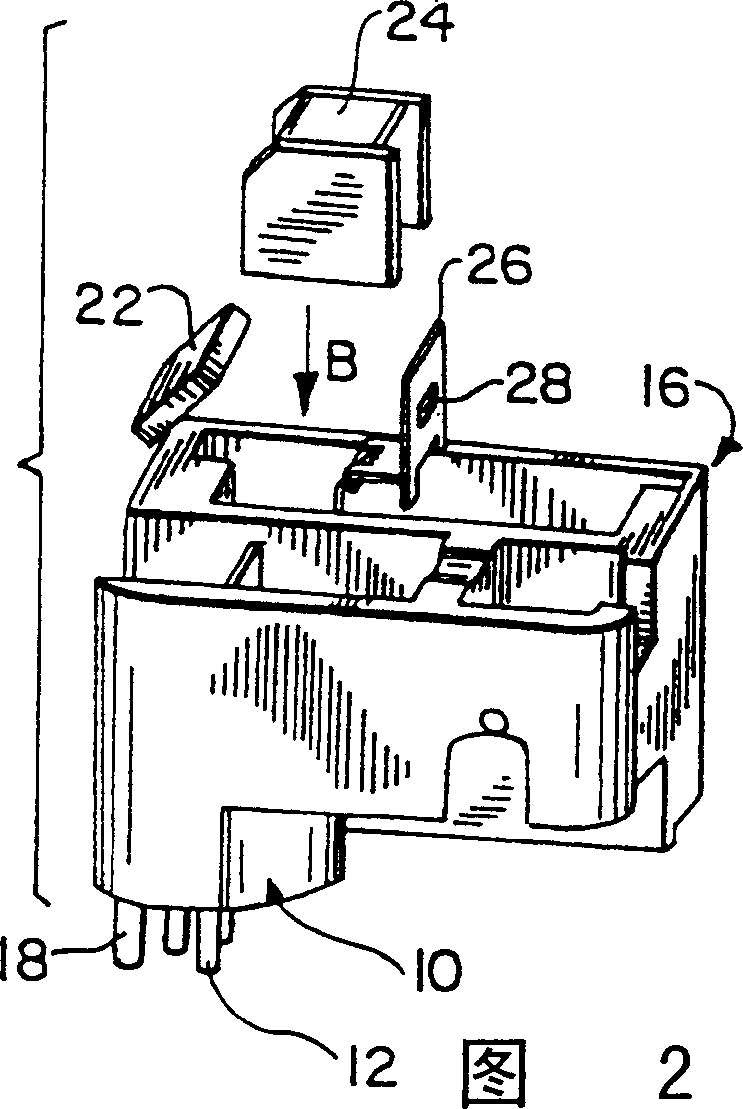

Automatic centring and clamping mechanism

ActiveCN106272160ARealize clampingRealize alignmentWelding/cutting auxillary devicesWork holdersEngineeringCentring

The invention discloses an automatic centring and clamping mechanism. An outer ring body is arranged on the surface of the outer circumference of an inner ring body in a sleeving manner, and the outer ring body and the inner ring body are in clearance fit. The ball head ends of telescopic shafts in a plurality of telescopic bodies penetrate guide holes in the circumference of the inner ring body and then are mounted in sliding grooves located in the inner circle surface of the outer ring body. A worm gear body is fixed to the end face of the inner ring body. A worm is fixed to the end face of the outer ring body through a bearing pedestal and engaged with the worm gear body, and therefore the outer ring body and the inner ring body generate relative rotation. The number of the guide holes in the surface of the outer circumference of the inner ring body, the number of the sliding grooves in the surface of the inner circumference of the outer ring body and the number of the telescopic shafts are the same. According to the automatic centring and clamping mechanism, in the clamping process, all clamping blocks stretch out and retract back at the same time through telescopic bolts, and the clamping blocks are rounded at the same time in the clamping process; and in the whole implementation process, no machine tool is needed, operation is easy and convenient, efficiency is high, and the high application and popularization value is achieved.

Owner:XIAN AEROSPACEMOTOR MACHINE FACTORY

Sleeve mounting mechanism

The invention relates to a sleeve mounting mechanism used during the production process of plates. The sleeve mounting mechanism is characterized by mainly comprising a sleeve collection rack, a sleeve centring device, a shift fork and a moving frame; the sleeve centring device, the shift fork and the moving frame are connected to the sleeve collection rack; the moving frame is in transmission connection with a moving frame driving oil cylinder; the shift fork is in transmission connection with a shift fork driving oil cylinder; the sleeve centring device is fixed on the sleeve collection rack; and the shift fork is connected to the sleeve collection rack through a slide bearing I and a slide bearing II. The sleeve mounting mechanism has complete functions, integrates the functions of sleeve centring and sleeve mounting, can realize automation in sleeve mounting, is provided with the sleeve centring device to ensure that a sleeve is mounted correctly on a winding drum, has high degree of mechanization, accomplishes all the operations of centring, conveying and transportation of sleeves without manual assistance, and is simple in structure and easy in maintenance and overhaul.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Small scanning module with magnetic centring scanning mirror

InactiveCN1393822AReduce volumeLower assembly costsSensing by electromagnetic radiationOptical elementsRest positionLaser light

A non-retroreflective compact scan module in an electro-optical reader includes a laser light source, a photosensor and an electromagnetic coil mounted at one surface of a printed circuit board. The laser emits a laser beam perpendicular to the board, and is redirected to an oscillatable scan mirror which is magnetically centered to a rest position when the coil is de-energized. Electrical circuitry is mounted at an opposite surface of the board.

Owner:SYMBOL TECH INC

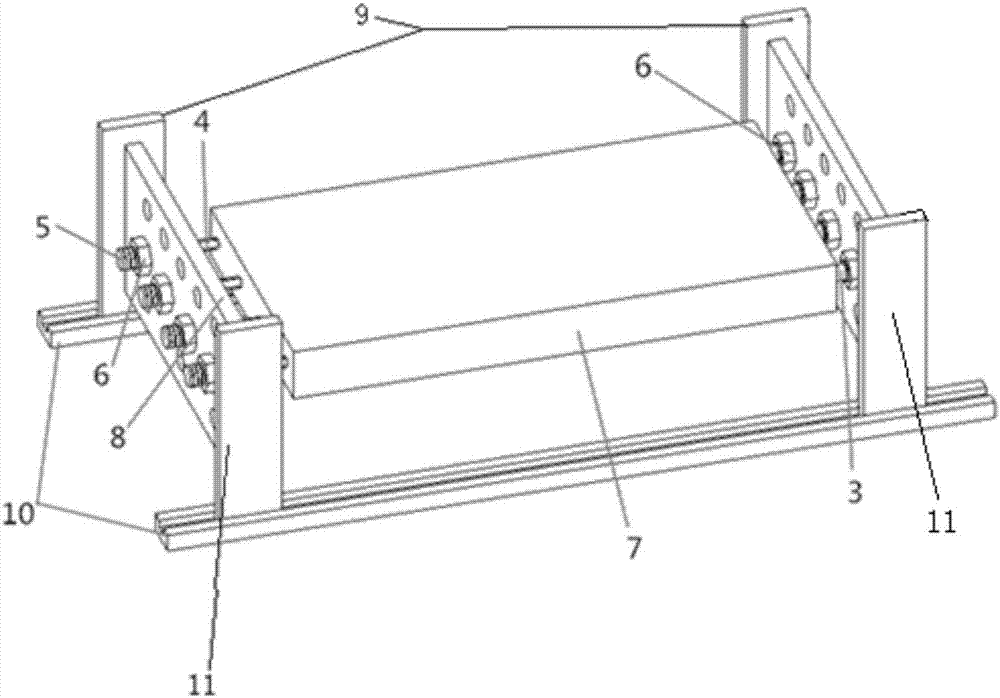

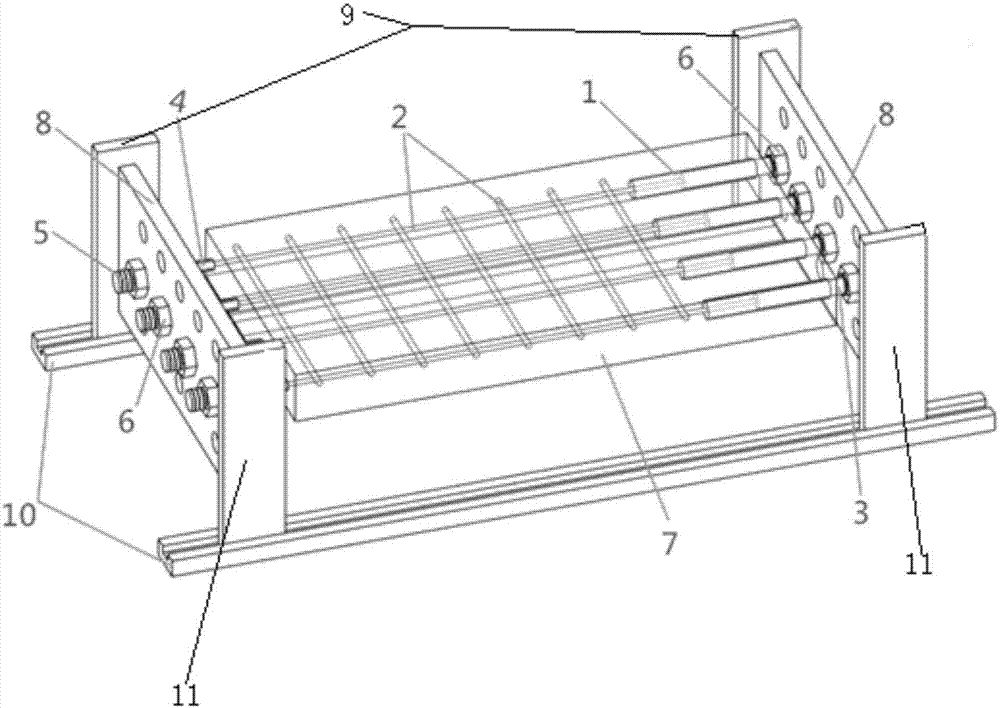

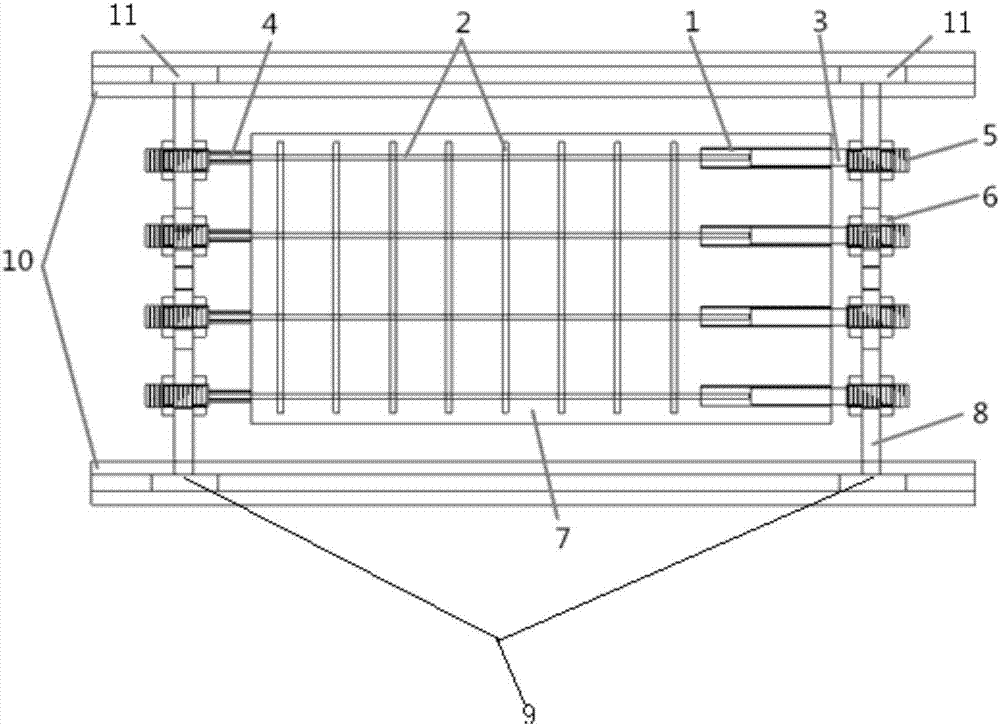

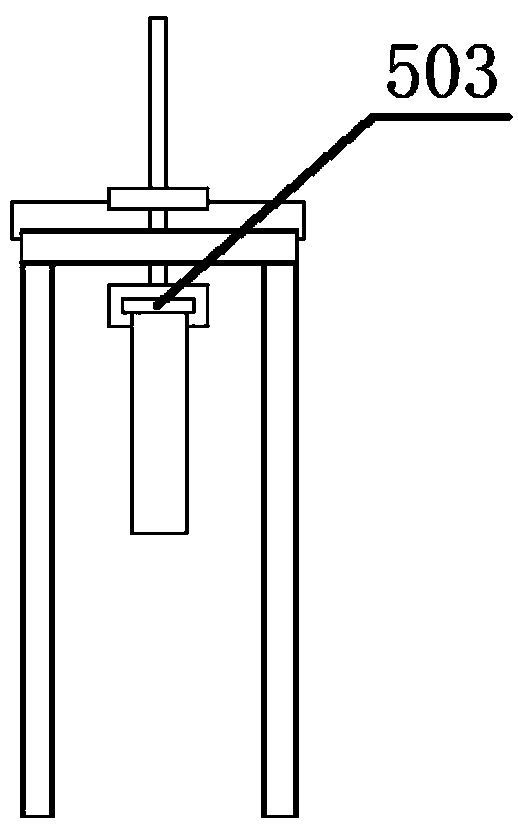

Precise centring die device for prefabricated concrete structure grouting sleeve

InactiveCN106965299AImprove versatilityMeet the positioning needsMould auxillary partsSteel frameEngineering

The invention discloses a precise centring die device for a prefabricated concrete structure grouting sleeve. The precise centring die comprises a slideway, two sets of steel frames, a sleeve positioning shaft roller, a protruding bar positioning shaft roller and fixing nuts. The two sets of steel frames are oppositely arranged on the prefabricated part production line slideway in a parallel manner. Each steel frame set comprises two side steel plates and a cross steel plate, wherein the cross steel plate is arranged between the two side steel plates, and the cross steel plate is provided with a plurality of rows of small holes. One end of the sleeve positioning shaft roller penetrates the small holes of the cross steel plate of one steel frame set and is fixed to the corresponding cross steel plate through the corresponding fixing nut, and the other end of the sleeve positioning shaft roller extends into the grouting sleeve. One end of the protruding bar positioning shaft roller penetrates the small hole of the cross plate of the other steel frame set and is fixed to the corresponding cross steel plate through the corresponding fixing nut, and the other end of the protruding bar positioning shaft roller is in a tubular shape and is inserted into a protruding bar. The precise centring die device can ensure centring of the prefabricated concrete unit sleeve and the protruding bar in a high-precision manner, the site construction difficulty is lowered, and the connection quality of the prefabricated concrete structure grouting sleeve is practically guaranteed.

Owner:SHENYANG JIANZHU UNIVERSITY

Centering mandrel for turning wheels

InactiveUS20050110224A1Easy and efficient to manufactureReduce manufacturing costSleeve/socket jointsExpansion mandrelsEngineeringHand tool

Owner:LAUNIUS WILLIAM E JR

High precision gyro motor bearing loading method

ActiveCN103148818AImprove displacement measurement accuracyHigh loading accuracyMeasurement devicesAir bearingDifferential measurement

The invention relates to a high precision gyro motor bearing loading method. The loading can be achieved by using of a gyro motor loading device, and the gyro motor loading device consists of a machine frame, a platform surface, a horizontal guide rail system, a lifting guide rail system, two displacement sensors, an air bearing support, weights, an air shaft, a bearing centering sleeve and a bearing centering base. The centring can be achieved through a shaft at one end of the gyro motor, and the positioning can be achieved on an outer ring of a bearing, weights are placed in a weight plate, and required loads (namely, preloads) are added on an outer ring of a bearing at the other end through the air bearing. Then the size between two sets of bearing outer ring shaft shoulders is measured with a method of differential measurement through a displacement sensor 1 and a displacement sensor 2 which are calibrated. The height size of an outer rotor of the gyro motor is matched according to the measured size, and the post-installed preload of the gyro motor is guaranteed. The loading precision is greatly improved, errors caused by that the loading force does not pass through the center line of the motor bearing are eliminated, and the displacement measurement accuracy is improved.

Owner:BEIJING INST OF CONTROL ENG

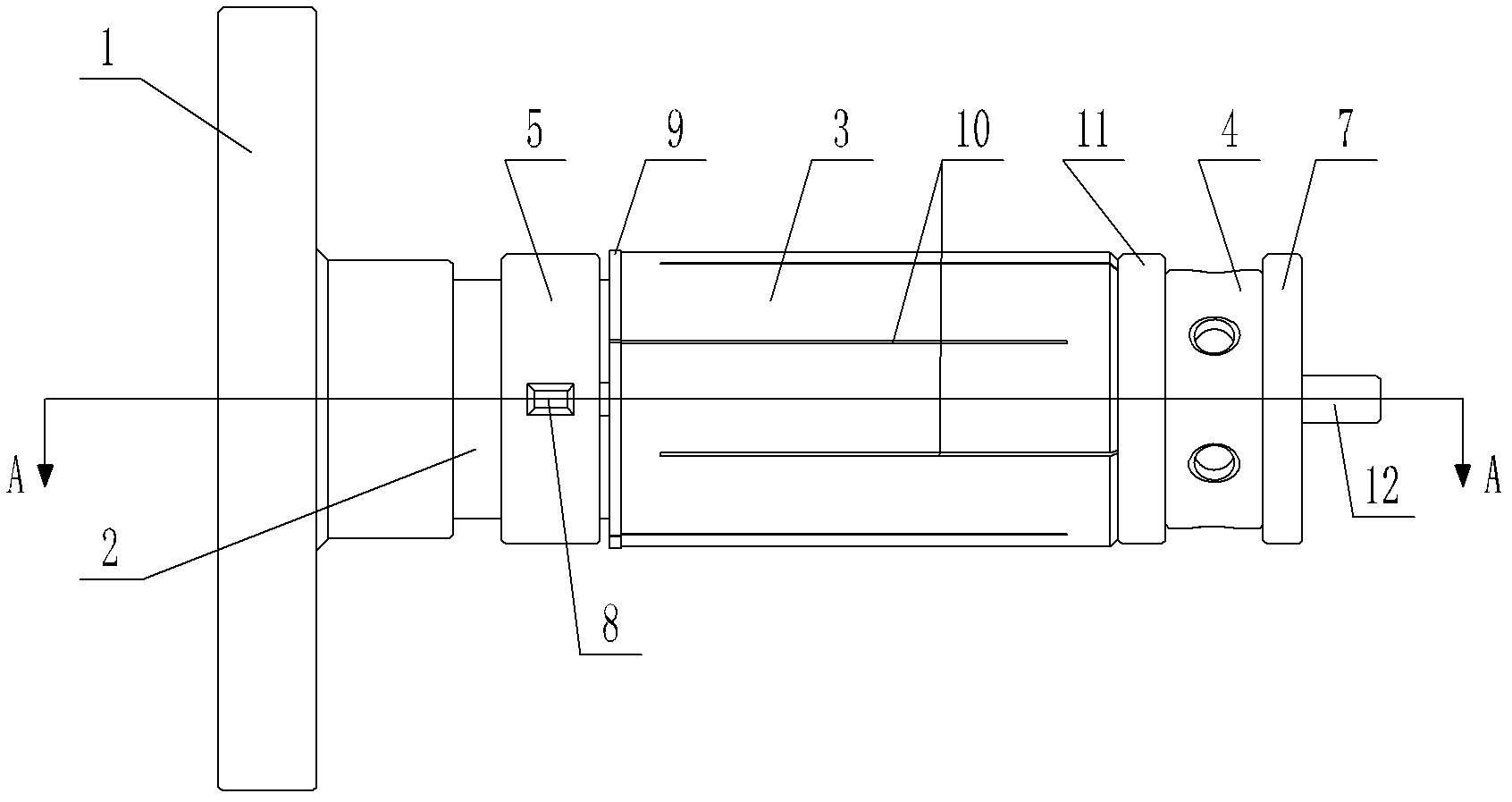

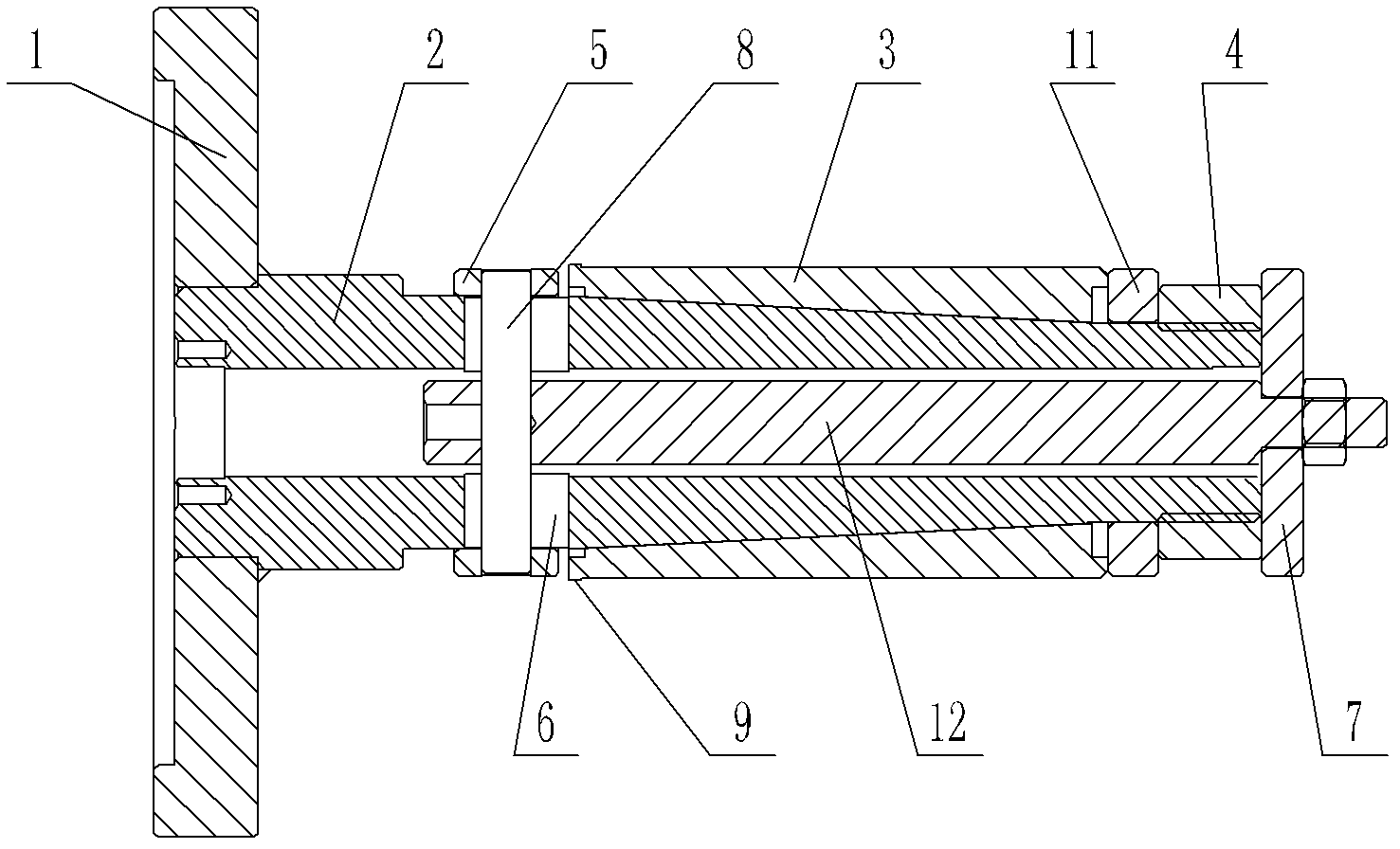

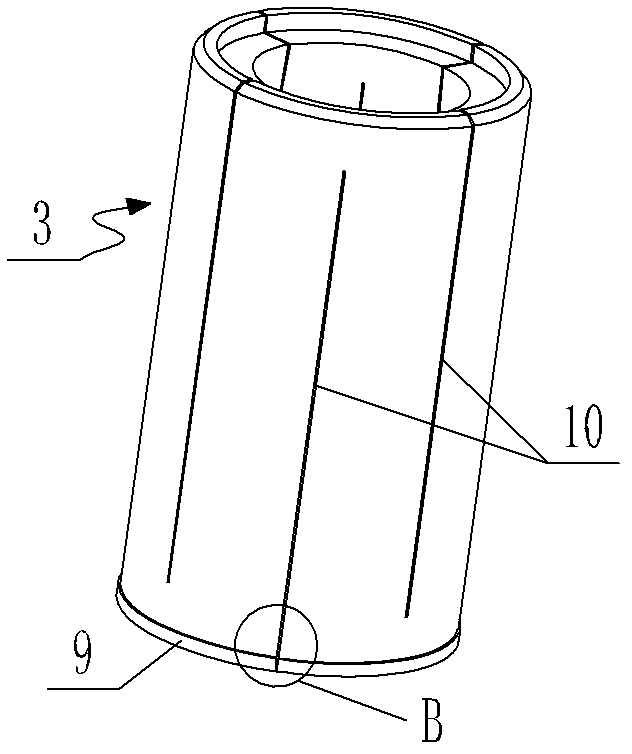

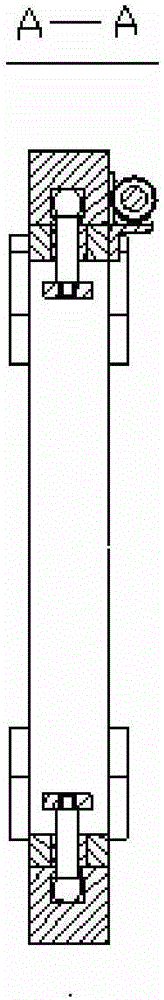

Floating centring-type installation device for shaft parts

The invention discloses a floating centring-type installation device for shaft parts. According to the floating centring-type installation device for shaft parts, an adjusting plug screw is installed on the lower portion of a location seat; a spring is installed in the location seat and located on the upper portion of the adjusting plug screw; a floating slide sleeve is installed on the upper portion of the spring; the excircle of the floating slide sleeve is installed by being in centring slide fit with the inner cavity of the location seat; a bearing is coaxially installed in the upper location hole of the location seat; a shaft is installed in the inner hole of the bearing; the spline portion of the lower portion of the shaft is superposed with the inner hole of the floating slide sleeve; the shaft is coaxial with the location seat. According to the floating centring-type installation device for shaft parts disclosed by the invention, when the shaft and the bearing are installed, the centring and guide of the shaft and the bearing are always kept from workpiece placement to press-fitting completion, thus ensuring smooth and difficulty-blocked press-fitting process, no scratches on a matching surface and assembly quality, reducing a product fault rate, avoiding impact and wear on press-fitting equipment, prolonging the service duration of the equipment, decreasing the cost, meeting the assembly needs of shafts with various length specifications in a certain range, avoiding machining and use for a plurality of location fixtures, decreasing production cost, and increasing working efficiency.

Owner:DALIAN HYDRAULIC COMPONENT

Device for adjusting the centring of a turbo-engine pivoting vane control synchronization ring

ActiveUS7677866B2Simple designMitigate such drawbackEngine manufactureWind motor controlEngineeringCentring

The invention relates to a device for adjusting the centring of a turbo-engine pivoting vane control ring, comprising a control ring (26) centred on a longitudinal axis (X-X) of the turbo-engine and provided with a plurality of tapped holes (36) running in a radial direction and a plurality of pad holders (32), each comprising a threaded rod (34) screwed into one of the ring's tapped holes (36), each pad holder (32) holding, at an inner end, a pad (30) intended to come into contact with a cylindrical shell (28), coaxial with the ring. The control ring (26) comprises, in addition, a plurality of slots (38) running in a tangential direction, each slot (38) communicating with one of the ring's tapped holes (36) The device comprises means (40, 42a, 42b) of pinching, in a longitudinal direction, each of the slots (38) in such a way as to lock the pad holders (32) in position.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Pipeline centring method

ActiveCN108247280AAchieve alignmentQuick alignmentWelding/cutting auxillary devicesAuxillary welding devicesEngineeringCentring

The invention discloses a pipeline centring method. The pipeline centring method comprises the steps that centring devices are jointed; initial values are set; the coordinates on a first pipeline aredetermined; the axis equation of the first pipeline is determined; the coordinates on a second pipeline are guided out; displacement is determined; and centring is carried out according to the displacement. Meanwhile, the centring devices with clamping mechanisms are adopted. The centring method is provided, the centring devices which are provided with the clamping mechanisms and can move in the Xdirection, the Y direction and the Z direction are adopted, the coordinates of the first pipeline are adopted as the datum, the second pipeline is adjusted through the displacement, and therefore fast, effective and convenient pipeline centring is achieved.

Owner:BEIHUA UNIV

Self-centering braced frame for seismic resistance in buildings

An elongated tension-only or centering brace for a structural frame is provided where the brace is anchored at a first attachment point and to a second attachment point that is removed from the first attachment point. The elongated tension-only brace has one or more elastic restoring force elements that have effective lengths greater than the length of the tension only brace between the attachment points.

Owner:SIMPSON STRONG TIE

Device for tying and centering reinforcing bar

A device for tying and centering reinforcing bars within a cell of a concrete block. A housing adapted to be positioned adjacent the cell contains a tie, which extends from the housing. The tie includes a loop, a free end, at least one centering portion that engages the housing at one end and the loop at an opposite end, and teeth. The at least once centering portion is adapted to position the loop substantially within the center of the cell when the loop is closed around the reinforcing bars. When the free end is pulled, the loop is closed and substantially centered within the cell. Either the housing or the loop itself include a ratchet portion having teeth, which engage the teeth of the tie and hold the loop in a closed position after the free end of the tie is pulled.

Owner:POLYLOK

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com