Patents

Literature

383results about How to "No skew" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

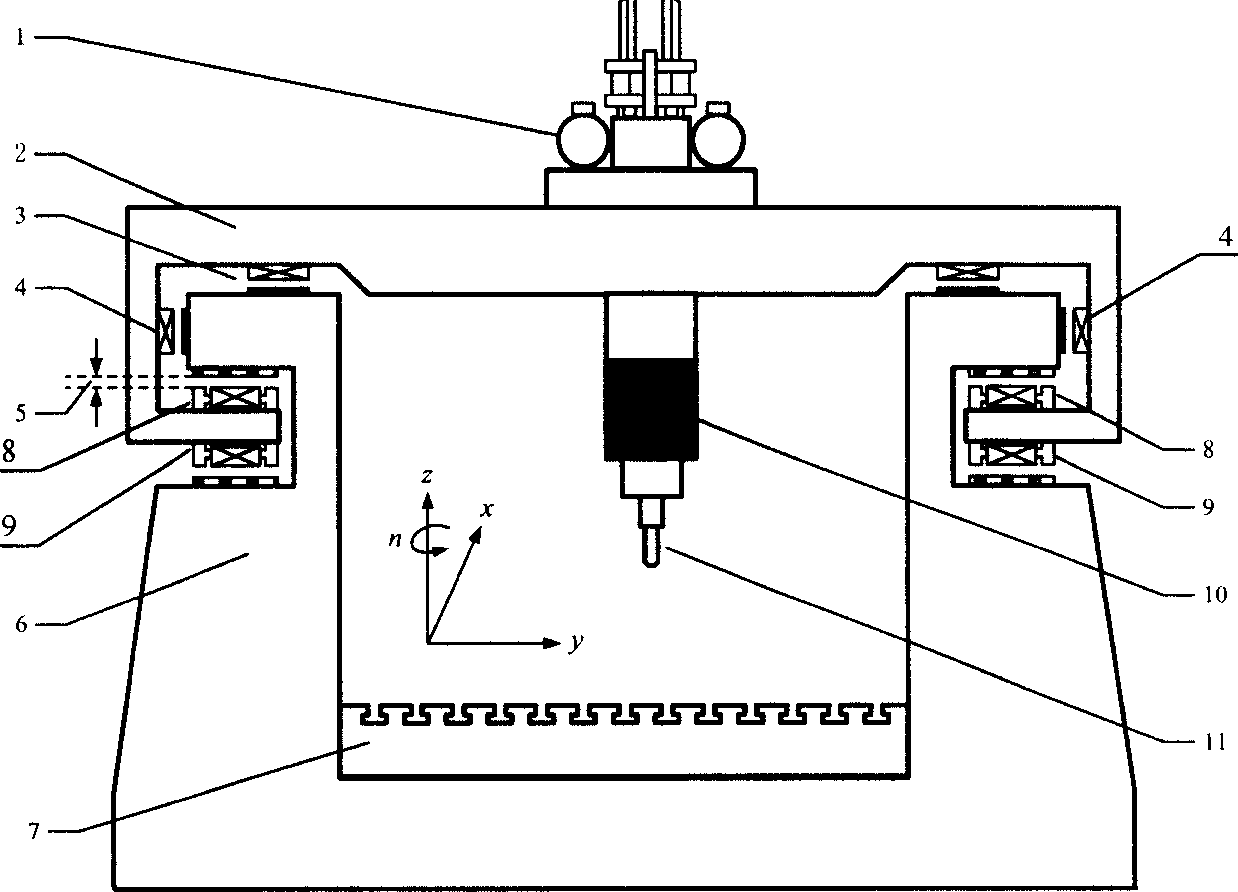

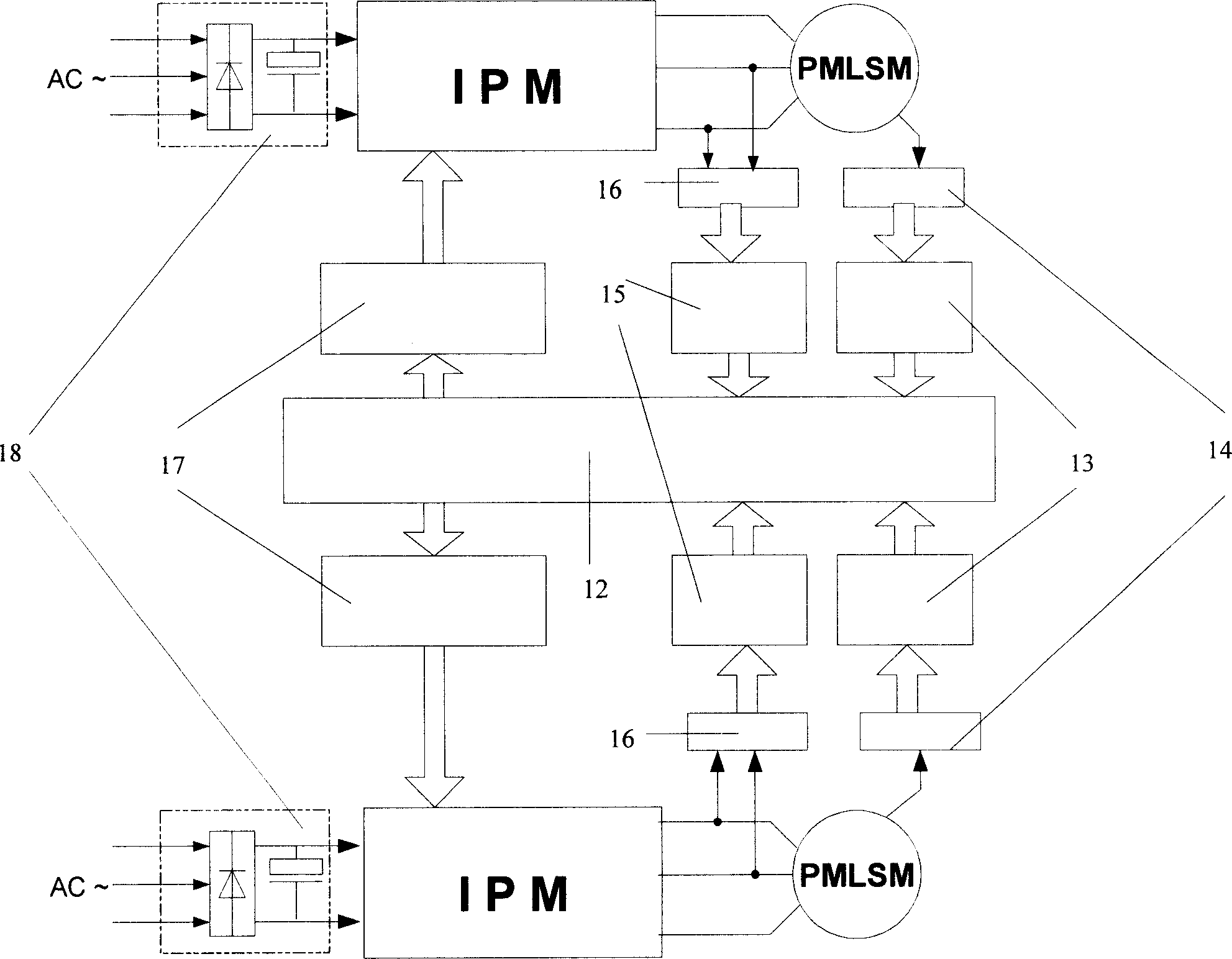

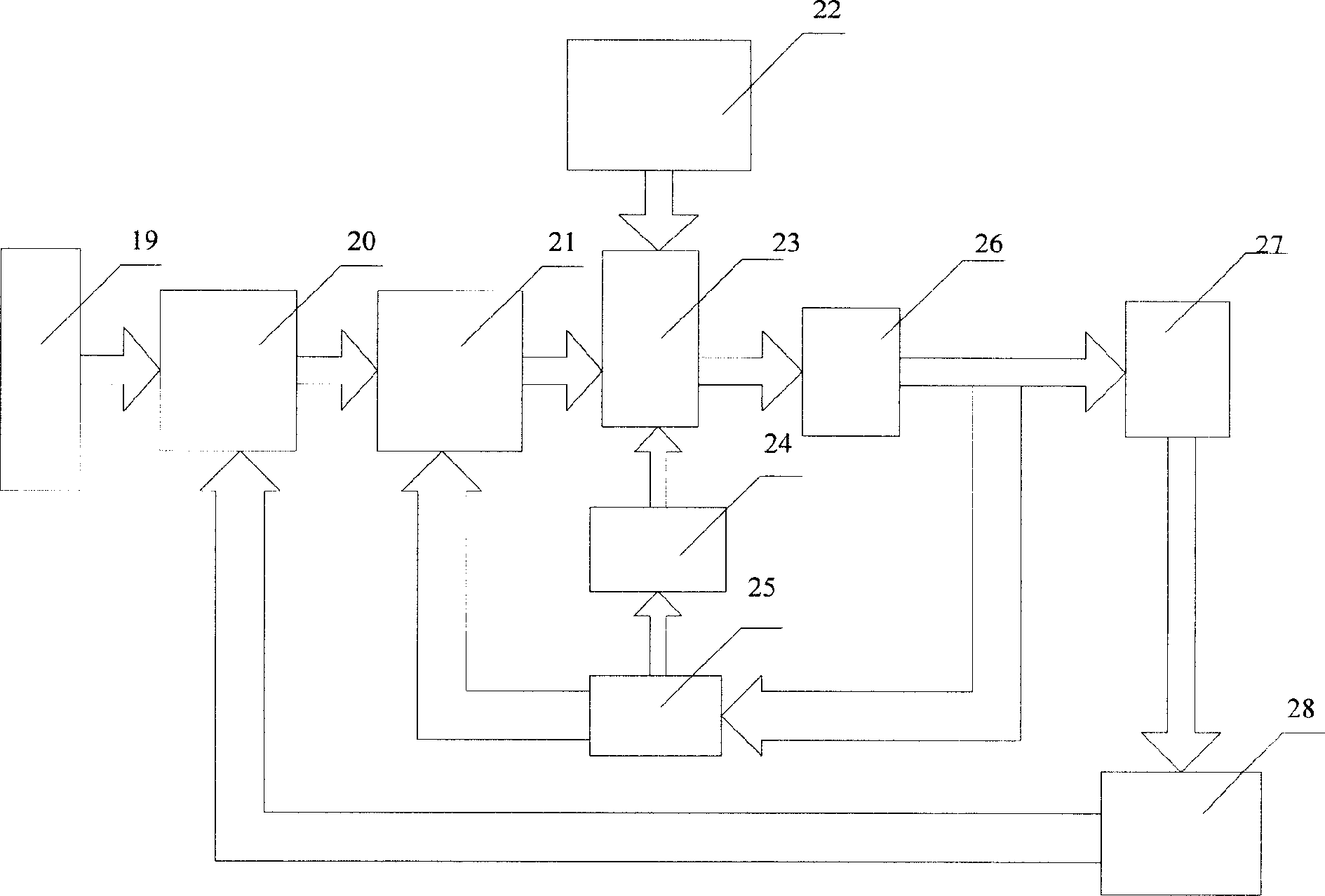

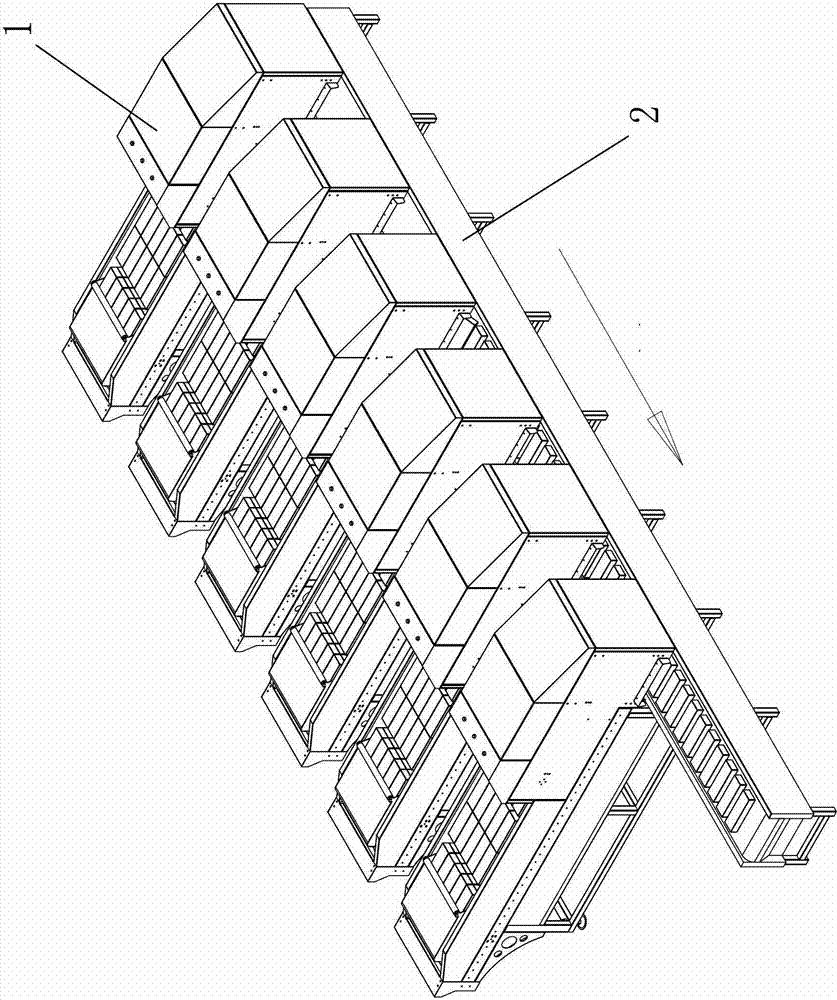

Boring, milling machine primed by straight-line driven portal shaped in zero phase on beam of magnetic suspension

InactiveCN1915587AFast and accurate traceabilityImprove robustnessOther manufacturing equipments/toolsControl using feedbackMotor driveSynchronous control

A movable boring-milling machine is composed of a magnetically suspended transverse beam, a straight-line motor driven gantry, movable machine-tool and control circuit unit including the control circuit for the synchronous drive of dual straight-line motos and the control circuit for controlling the height of transverse beam. Its control method includes the synchronous control to dual straight-line motor by improved master-slave synchronous drive, and controlling the suspended height of said transverse beam.

Owner:SHENYANG POLYTECHNIC UNIV

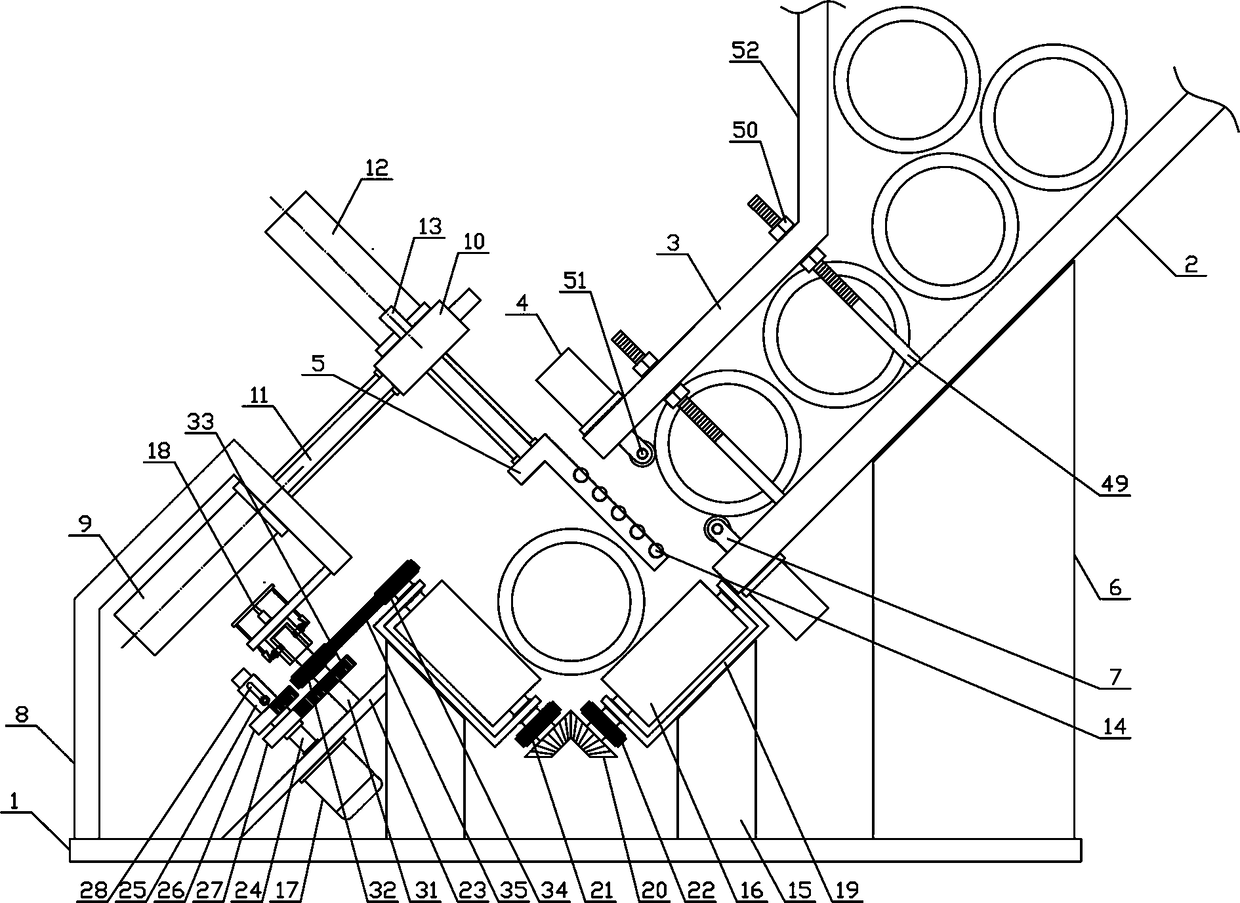

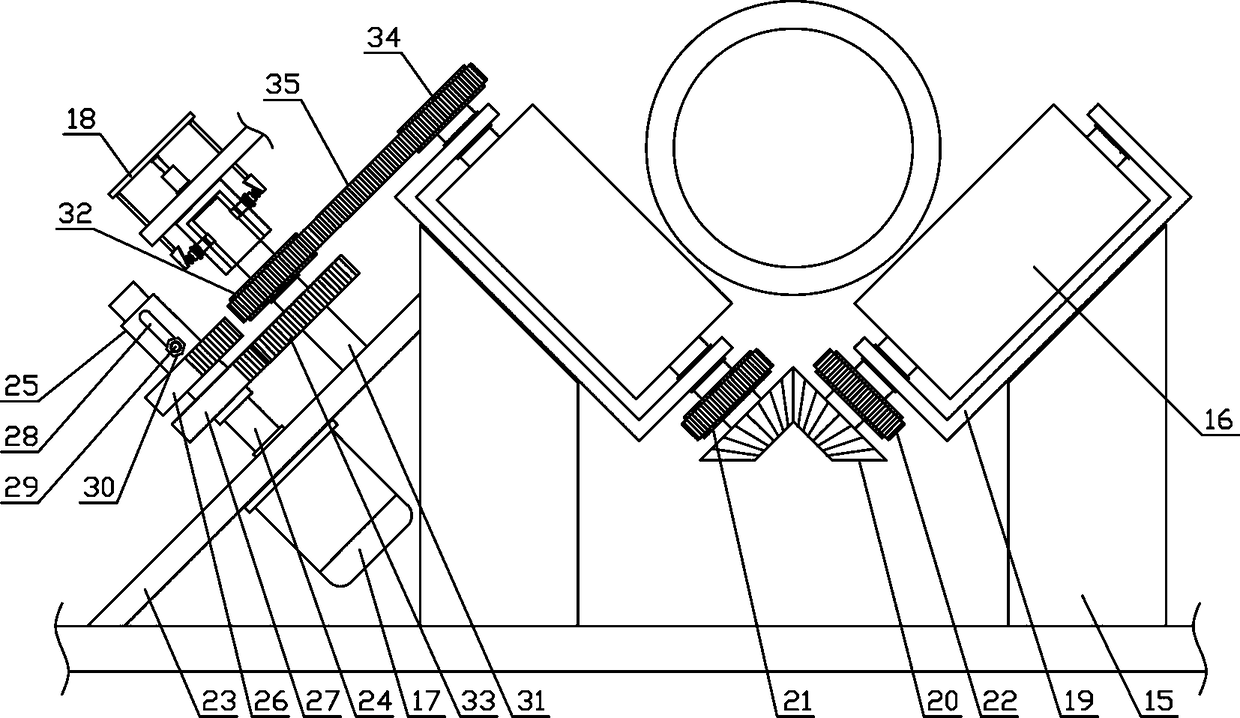

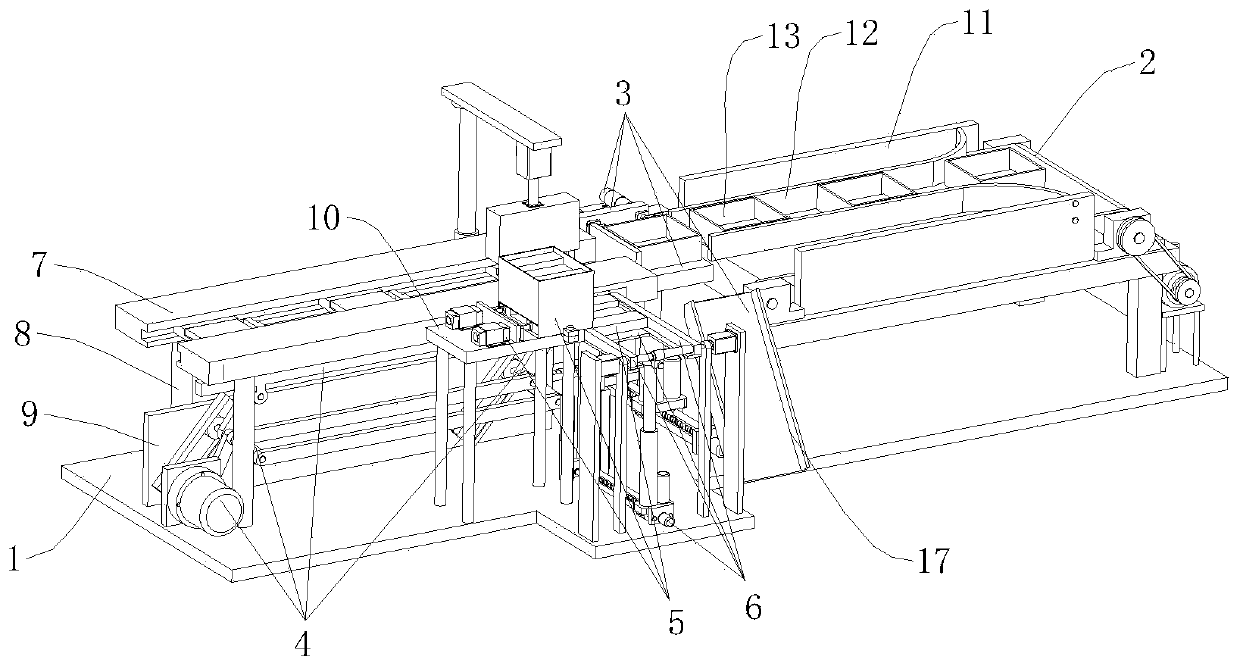

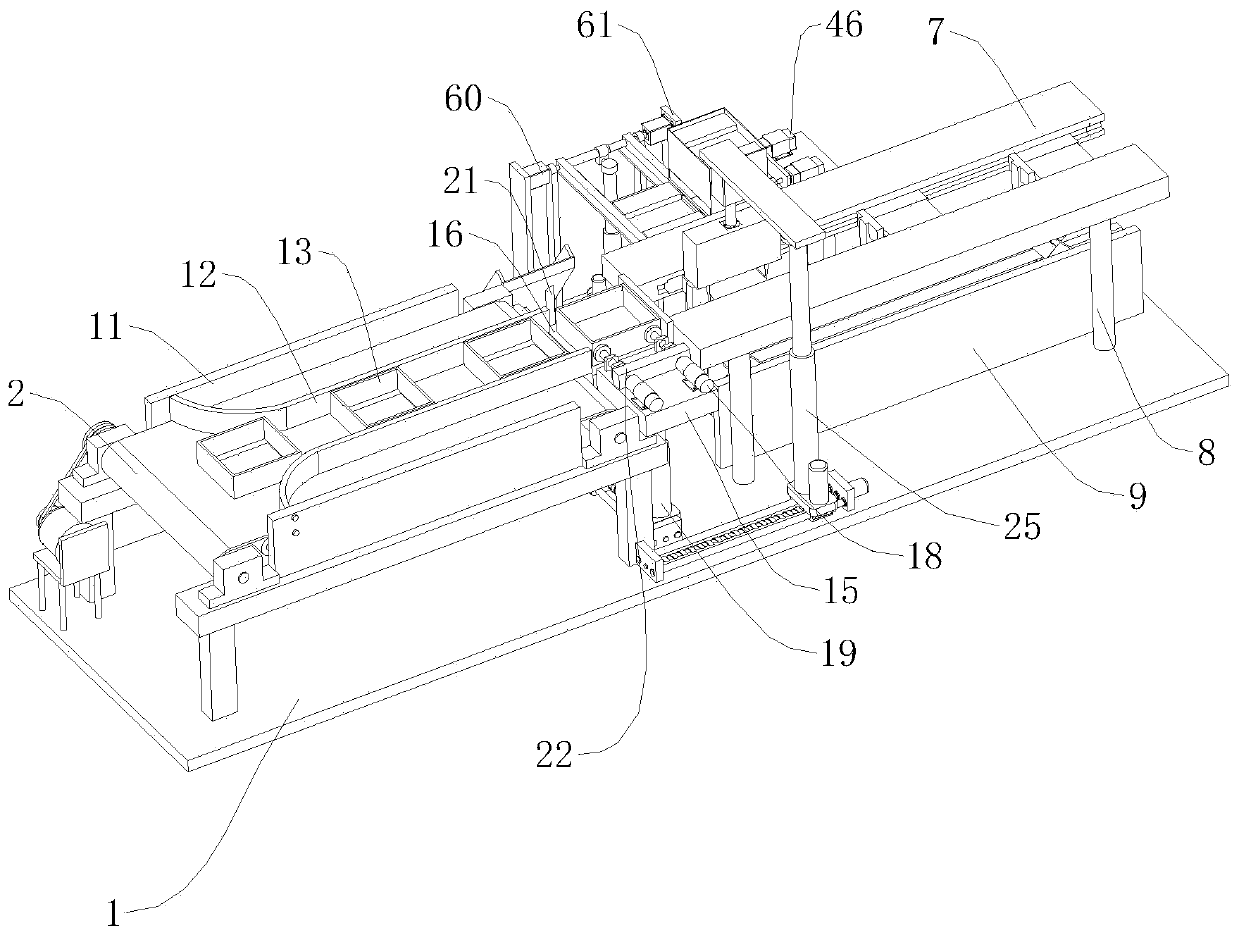

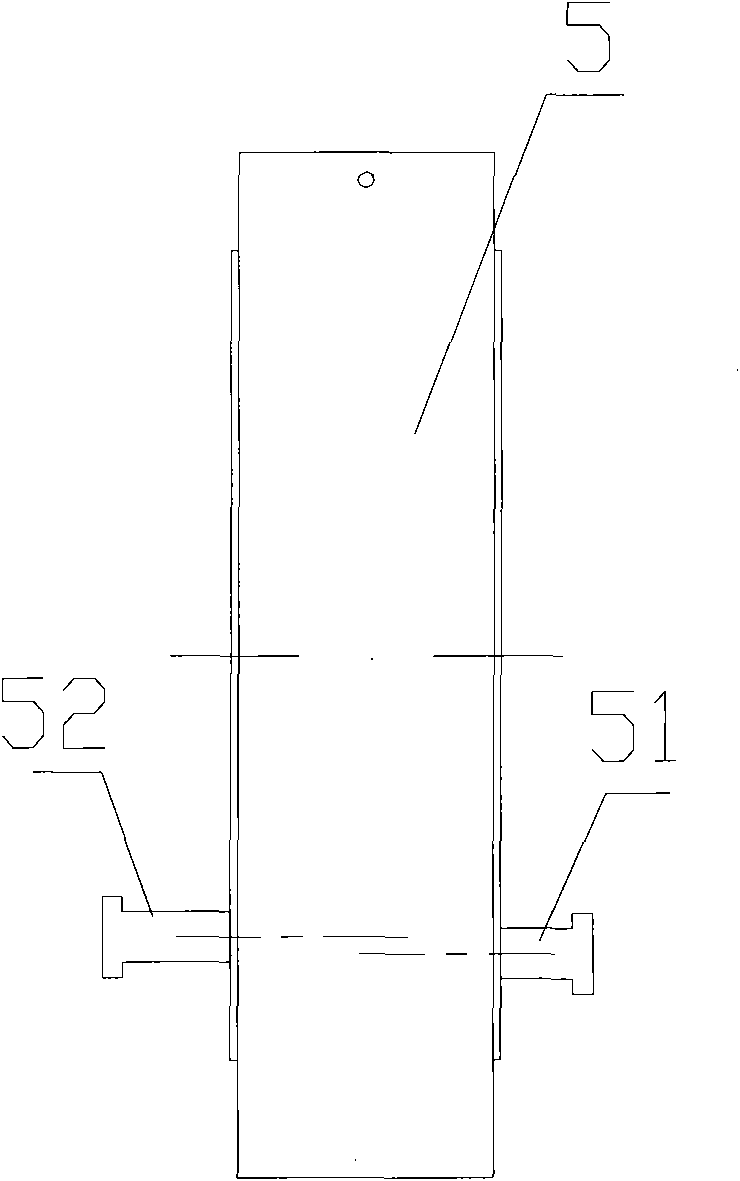

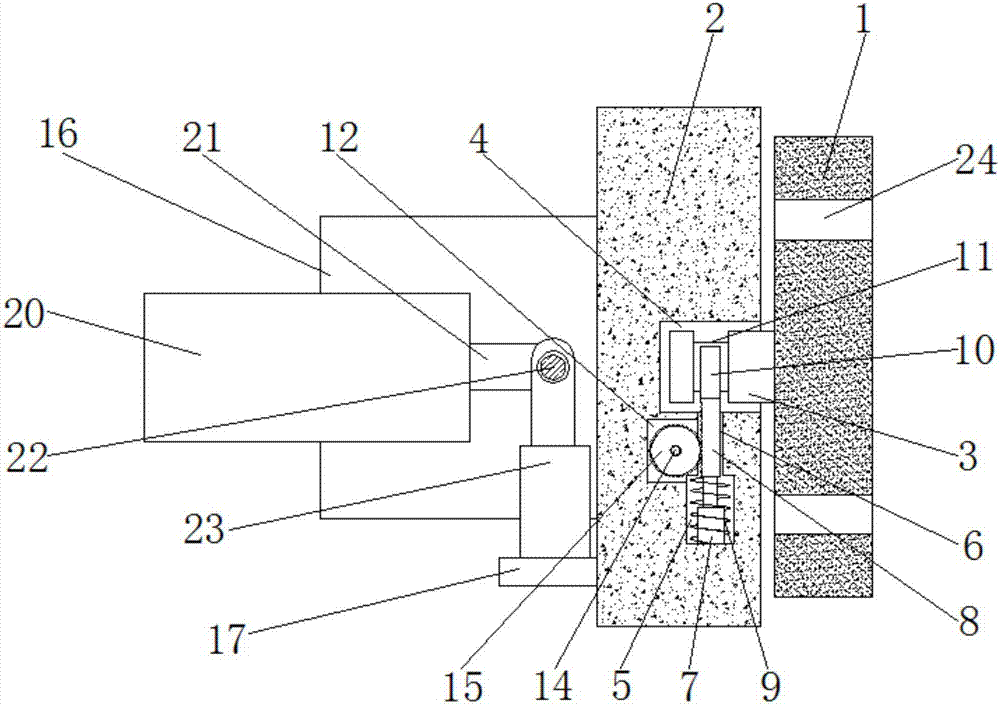

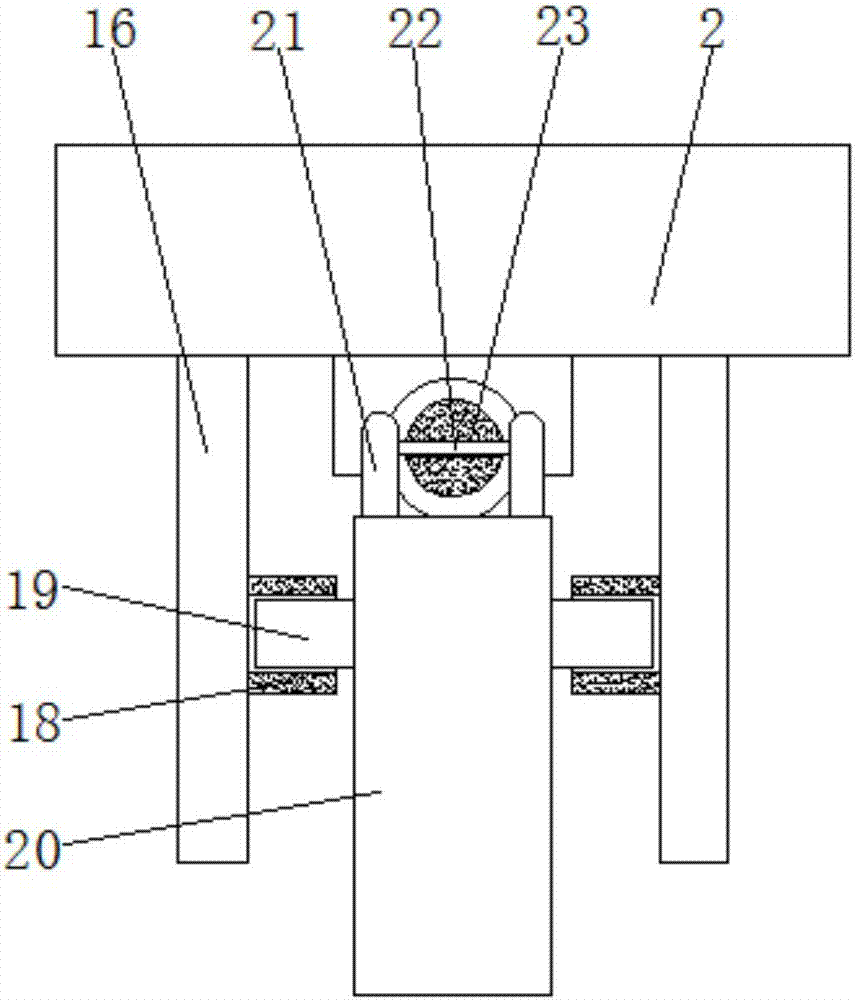

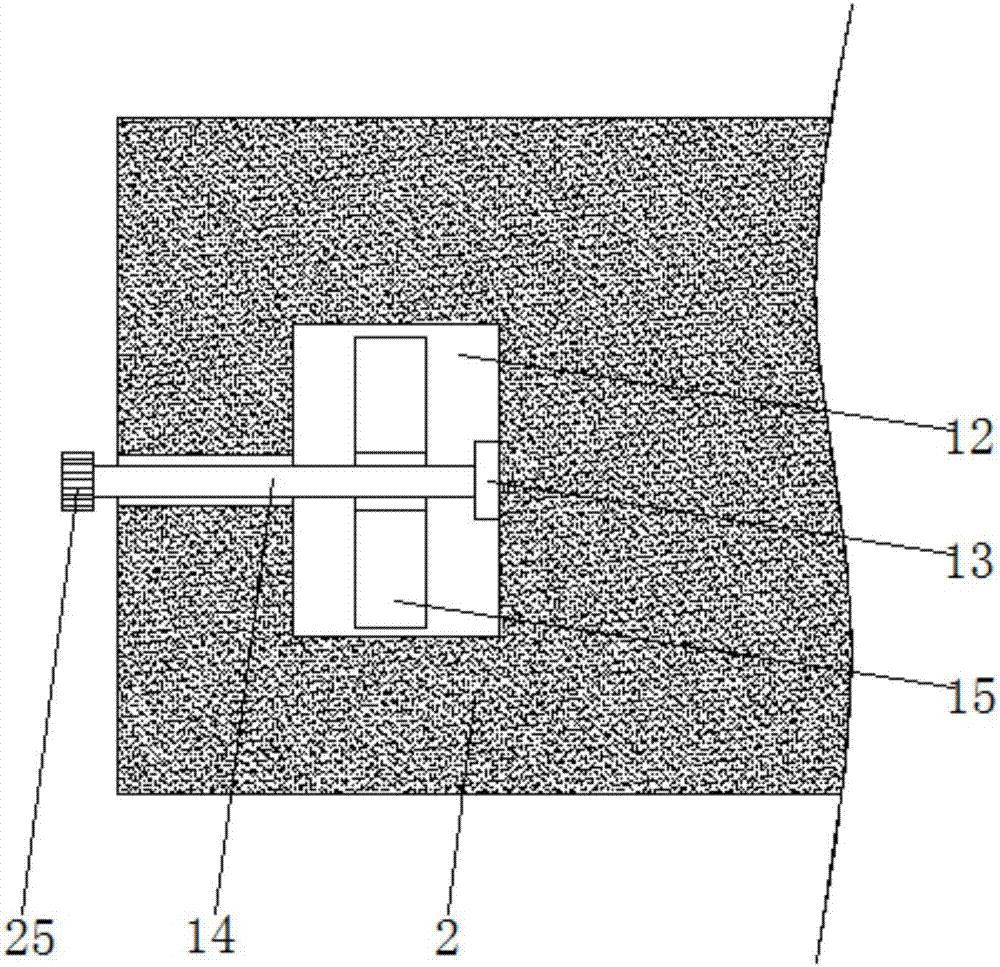

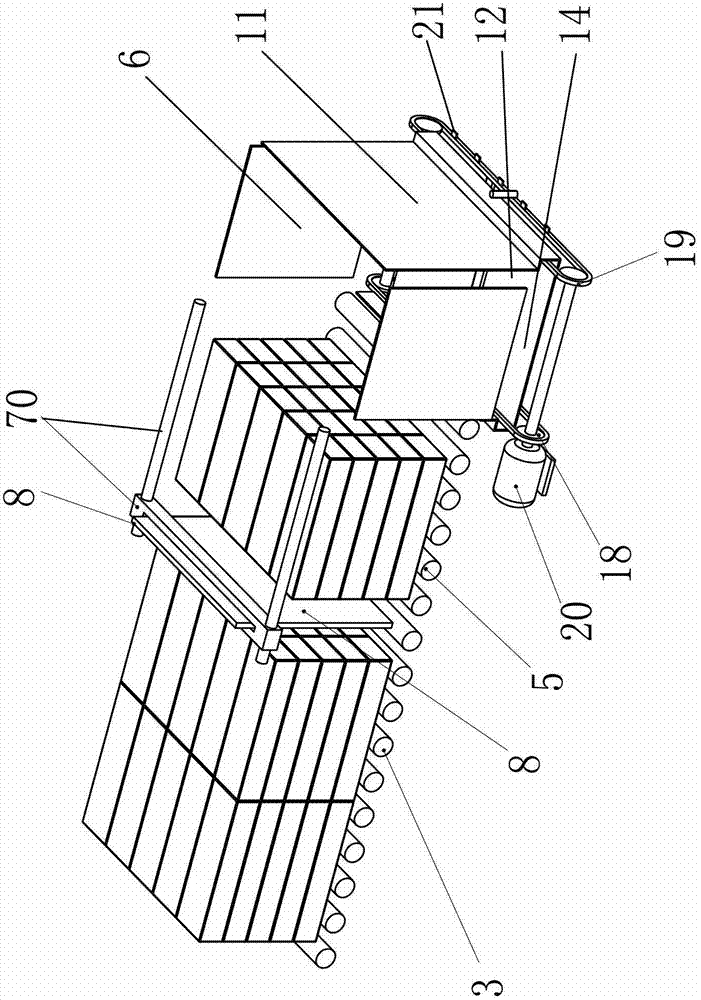

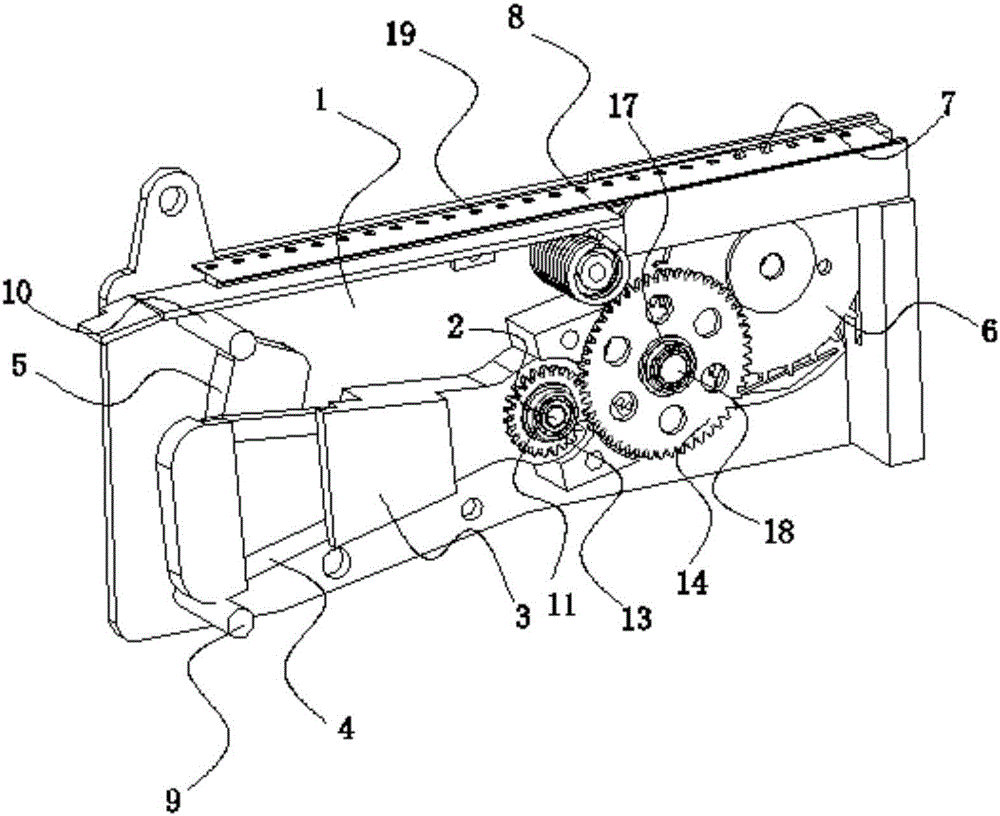

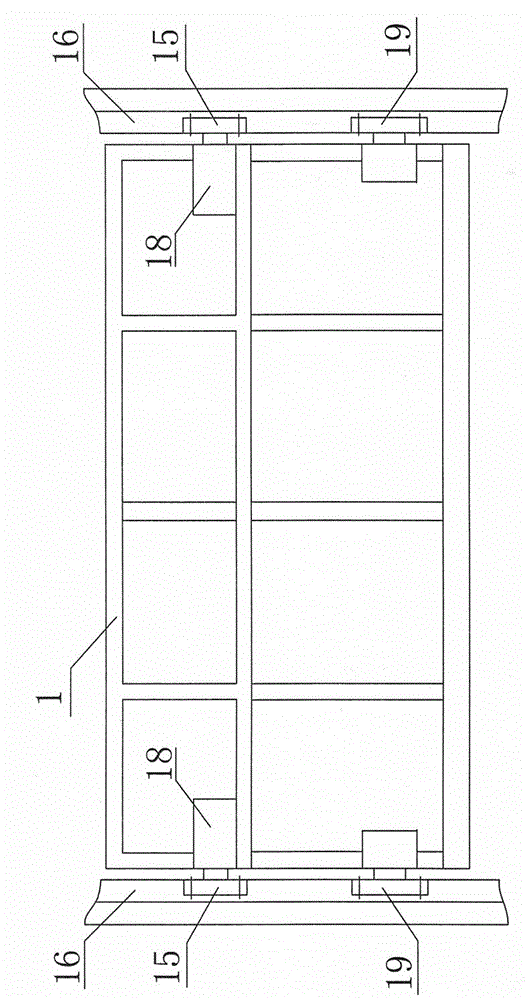

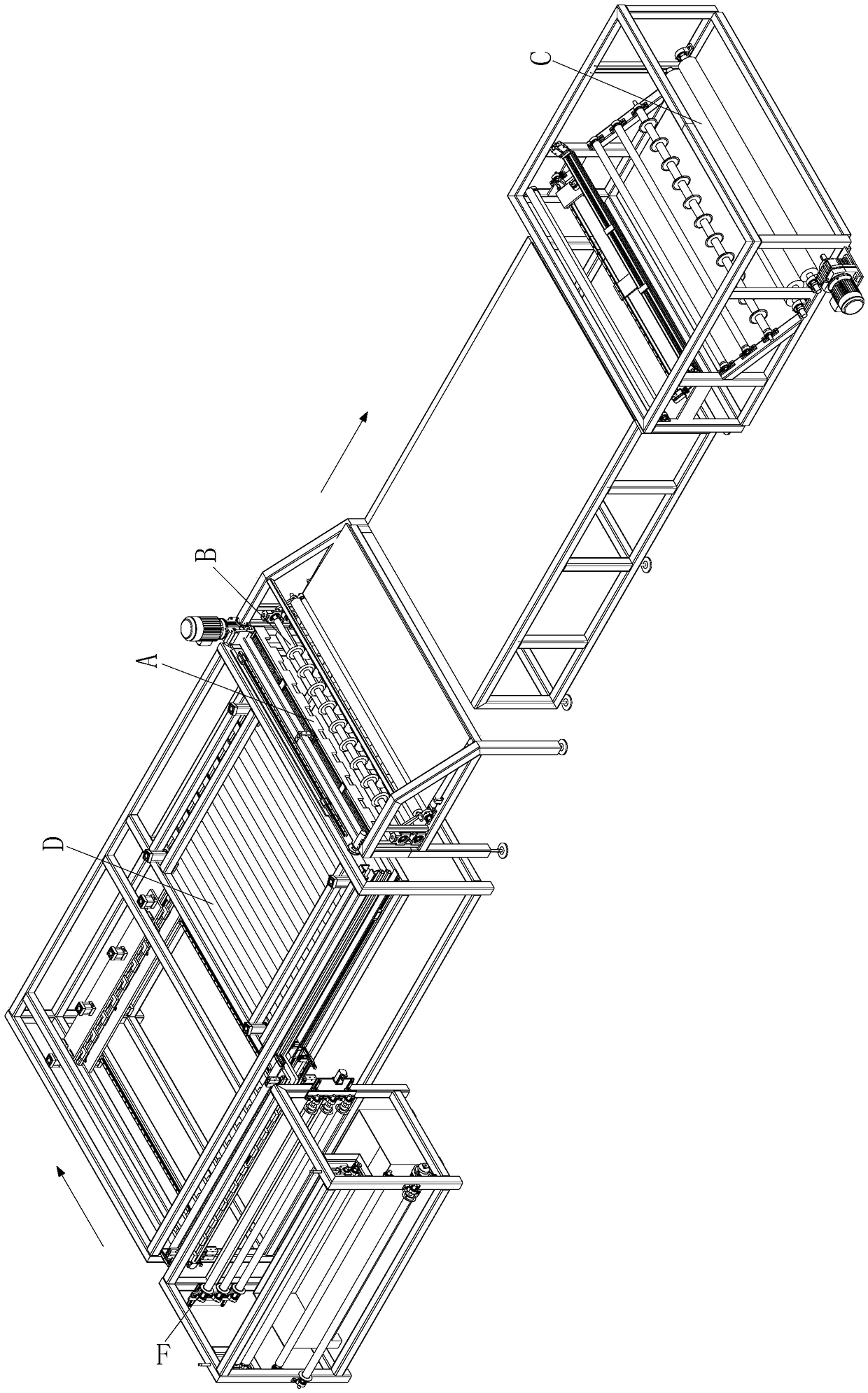

Intermittent pipe loading mechanism

InactiveCN108557448AAffect the normal and stable cuttingReasonable structural designConveyorsPackagingEngineeringMechanical equipment

The invention discloses an intermittent pipe loading mechanism, and belongs to the field of building material processing mechanical equipment. According to the mechanism, a limiting press board is obliquely arranged on the upper side of a pipe guiding oblique board downwards, pipe blanking air cylinders are symmetrically arranged on the lower side of the pipe guiding oblique board and the upper side of the limiting press board obliquely, a lifting bearing board at the output end of a pipe bearing air cylinder is arranged on a pipe bearing guiding rod in a sliding mode, a pipe blanking baffle is fixedly arranged at the output end of a baffle air cylinder on the upper side of the lifting bearing board obliquely, pipe guiding chain wheels of multiple pipe guiding rollers are in transmission connection with each other by adopting translation chains, an adjustment sleeve is arranged on a driving rotating shaft at the output end of a translation motor in a sliding mode, a material guiding rotating shaft is rotatably connected onto a connecting support on one side of the driving rotating shaft, and a damping mechanism is obliquely and fixedly arranged at the upper end of the material guiding rotating shaft. The intermittent pipe loading mechanism is reasonable in structural design, pipes of multiple kinds of dimensions can be subjected to steady blanking one by one and subjected to steady intermittent and accurate translation, so that the requirements of processing use are met.

Owner:桐乡市川泰纺织科技有限公司

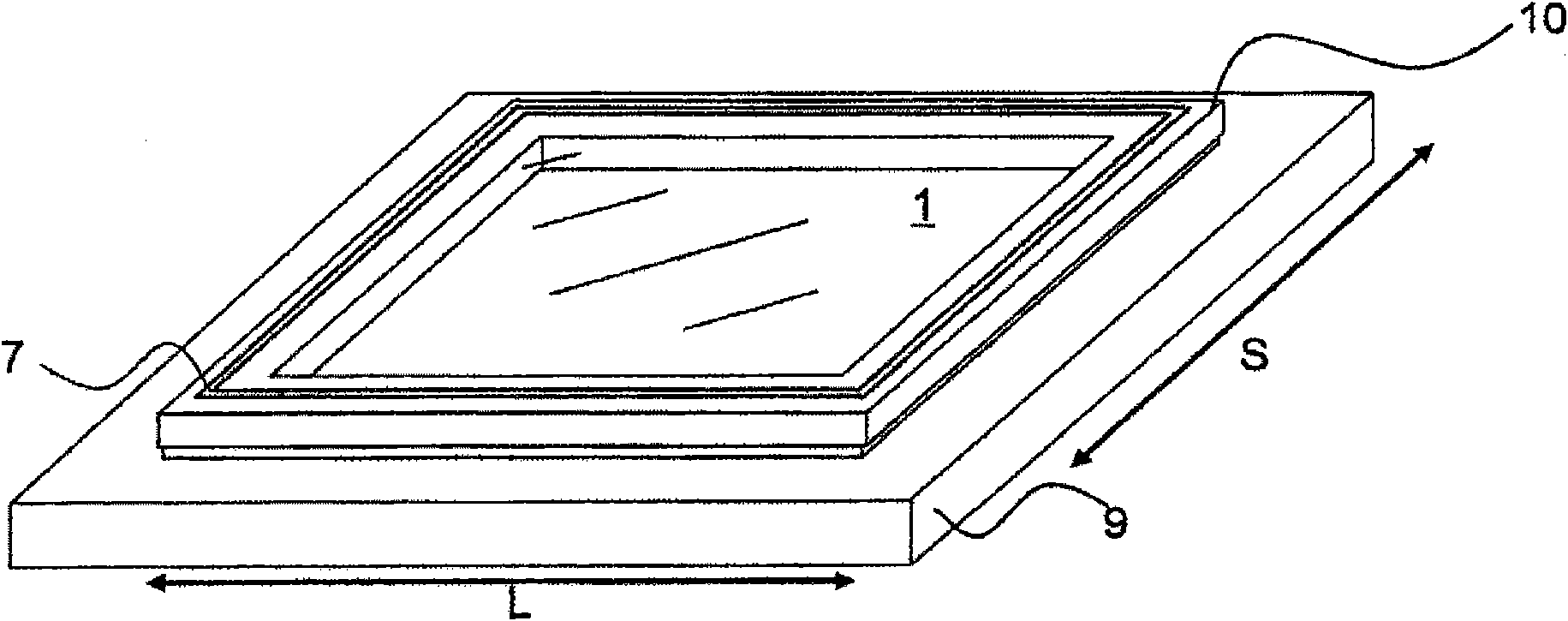

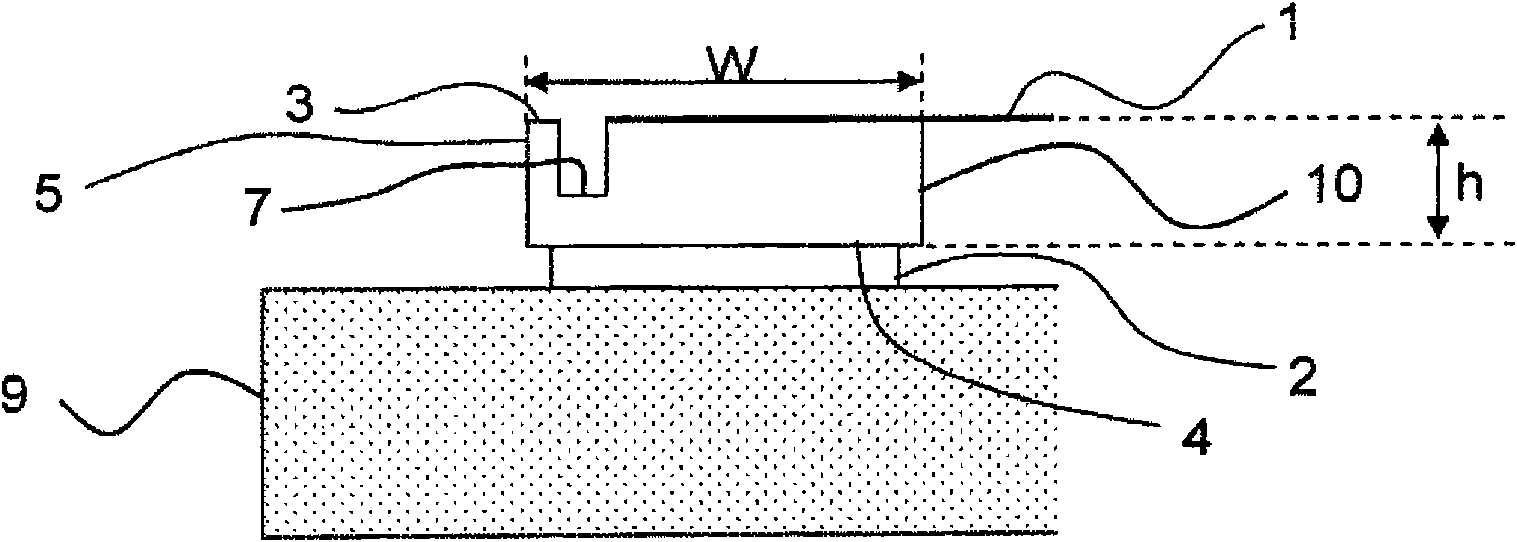

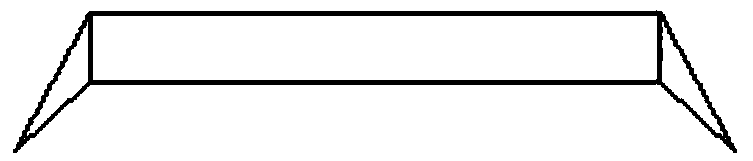

Frame of large pellicle and grasping method of frame

ActiveCN101689018AEasy to take outReliable controlPhotomechanical apparatusOriginals for photomechanical treatmentEdge surfaceAdhesive materials

A frame of large pellicle comprising a polygonal frame having a plurality of sides, a pellicle film bonded to the upper edge surface of the frame, and an adhesive material applied on the lower edge surface of the frame wherein upon grasping the frame of a large-sized pellicle the longest side of which frame is 1m or longer, the frame has protrusions or recesses for grasping on all sides of the frame. The frame is grasped surely by grasping the protrusions or recesses for grasping at at least one position or more on each side of the frame simultaneously, and the pellicle can be taken out easilyfrom a container without causing distortion or flexure when it is stuck on a photomask, or the like.

Owner:ASAHI KASEI KK

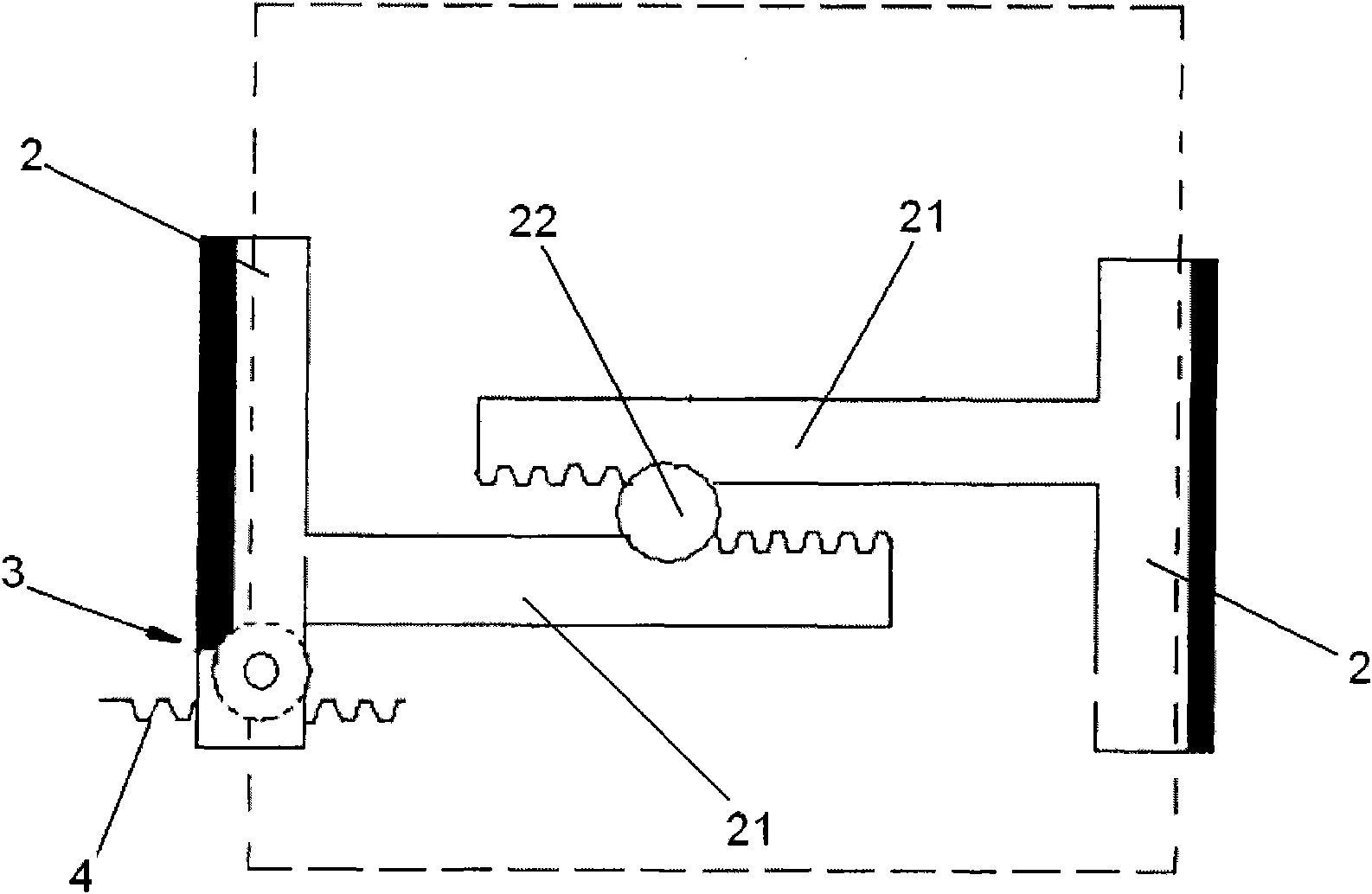

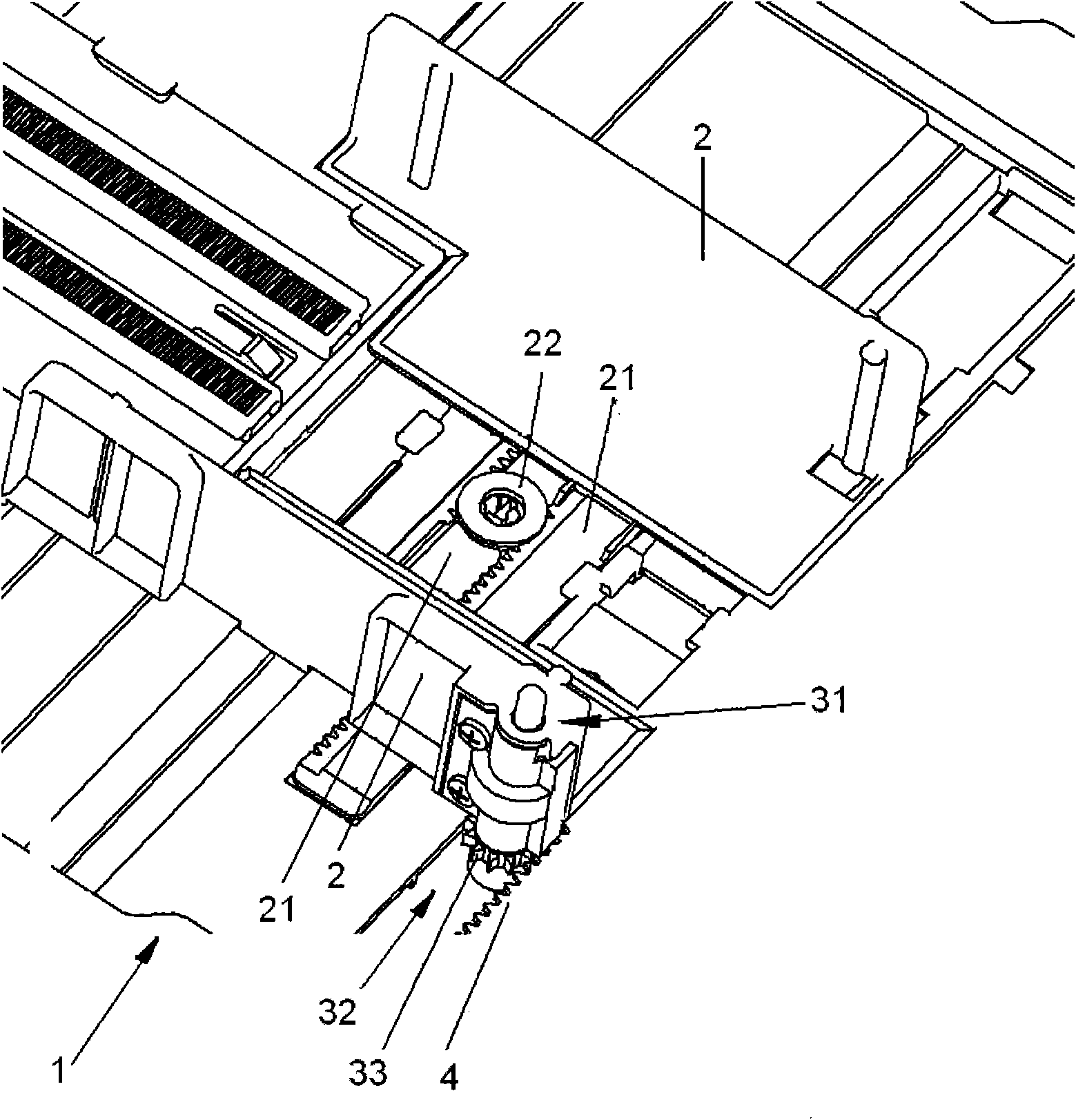

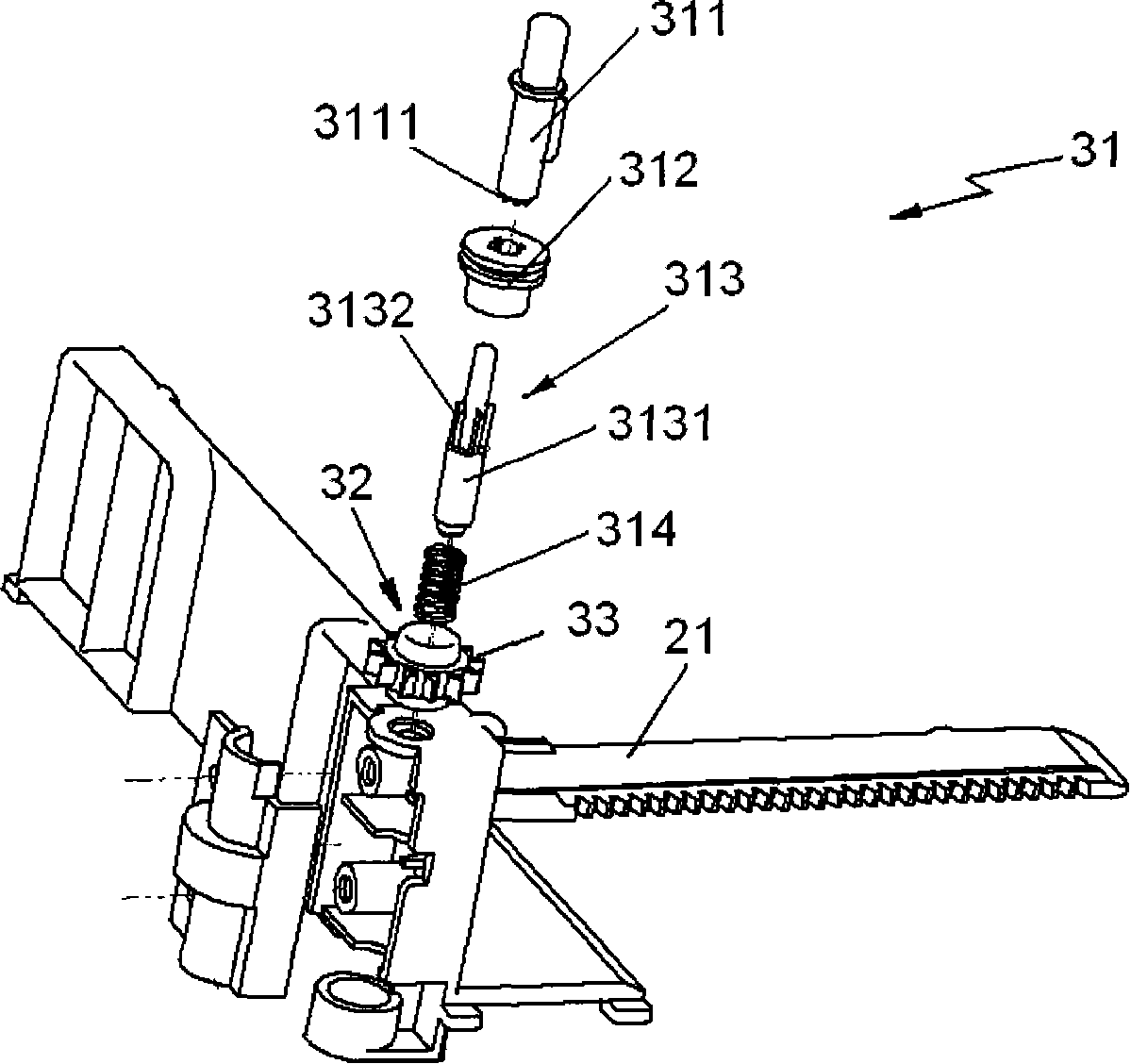

Paper feeder and image forming device using same

Owner:RICOH KK

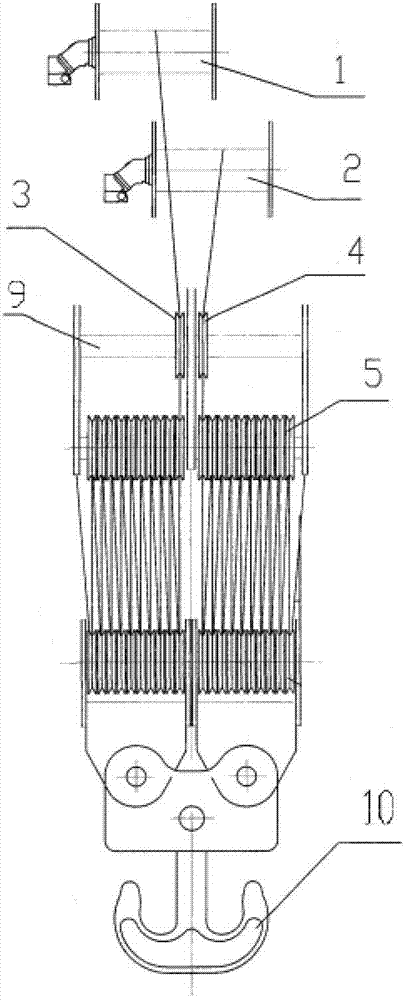

Crane and synchronous control device and method of double winches

ActiveCN102807170AWork synchronizationSynchronous control workWinding mechanismsSynchronous controlControl engineering

The invention discloses a synchronous control device of double winches, wherein a hook is connected with the double winches by a hook component, the synchronous control device comprises an angle signal acquisition part and a controller, wherein the angle signal acquisition part is used for acquiring the gesture angle of a frame of the hook component, the controller outputs a synchronous control signal to a drive mechanism / drive mechanisms of one or both of the double winches according to the gesture angle of the frame of the hook component, so as to control the gesture maintaining level of the frame of the hook component. According to the synchronous control device of the double winches, the frame of the hook component is kept at a horizontal gesture to improve the working stability of the whole machine. On the basis, the invention further provides a synchronous control method of the double winches and a crane applying the synchronous control device.

Owner:XUZHOU HEAVY MASCH CO LTD

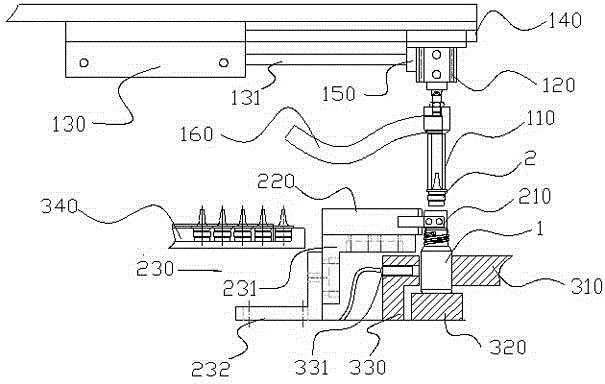

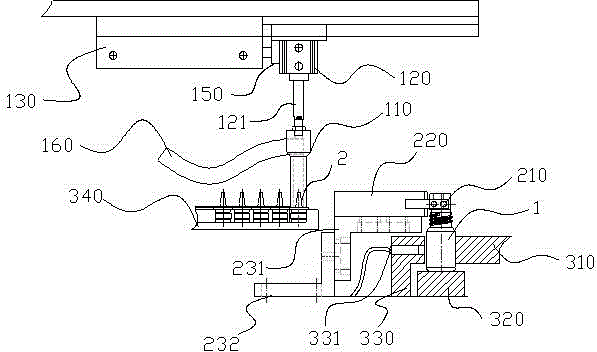

Automatic chip feeding device for printed circuit board welding

InactiveCN109911602ANo skewGuaranteed horizontal stabilityConveyor partsChutesPrinted circuit boardMachining

The invention relates to the field of machining, in particular to an automatic chip feeding device for printed circuit board welding. The automatic chip feeding device comprises a base, and further comprises a feeding mechanism, a clamping mechanism and a material moving mechanism, wherein the feeding mechanism comprises a conveyor and a pushing and separating assembly; the material moving mechanism comprises a driving assembly, a feeding assembly, a pushing assembly and two symmetrically-arranged guide rails, wherein the two guide rails are both arranged right above the base through first supporting rods, the driving assembly is vertically arranged between two workbenches through a first fixing plate, the pushing assembly is horizontally arranged at the end, close to the pushing and separating assembly, of one of the workbenches, and is perpendicular to the workbenches; and the feeding assembly is horizontally arranged at the end, close to the workbenches, of the pushing assembly through a first supporting plate and is perpendicular to the workbenches. The automatic chip feeding device for printed circuit board welding has the advantages that the structure is simple, the use is convenient, the automation degree is high, the fatigue degree of workers is reduced, and the production efficiency is improved.

Owner:夏安祥

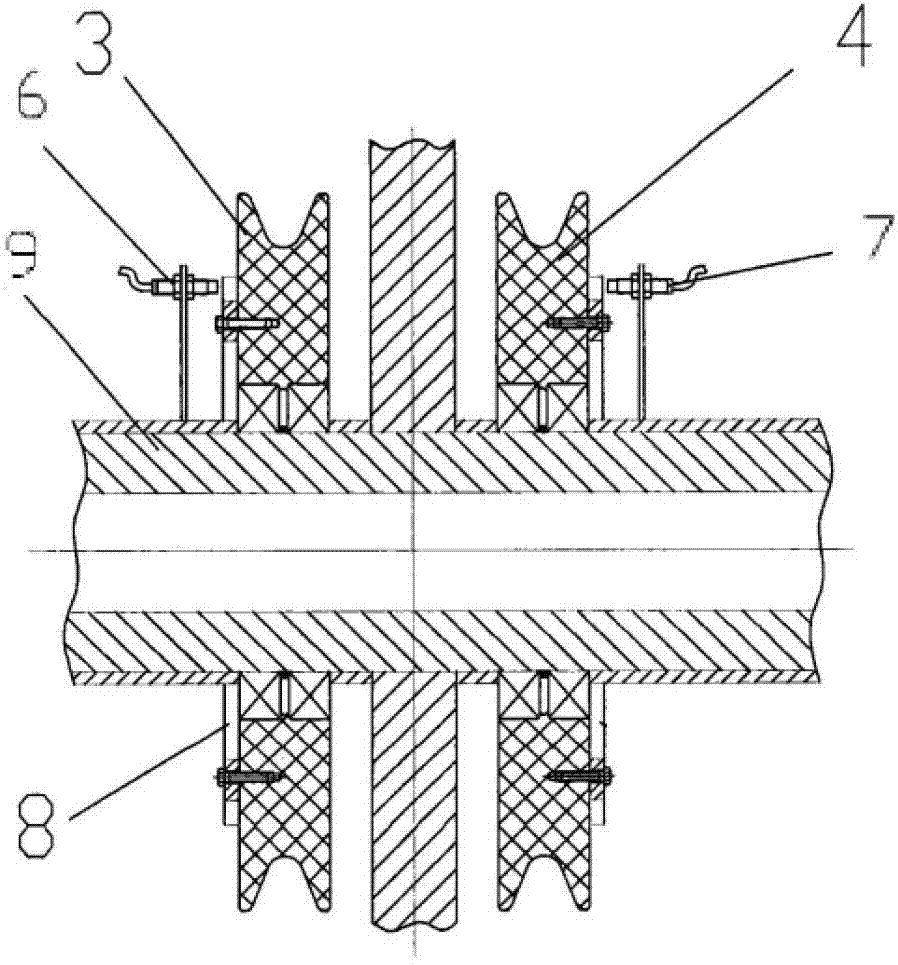

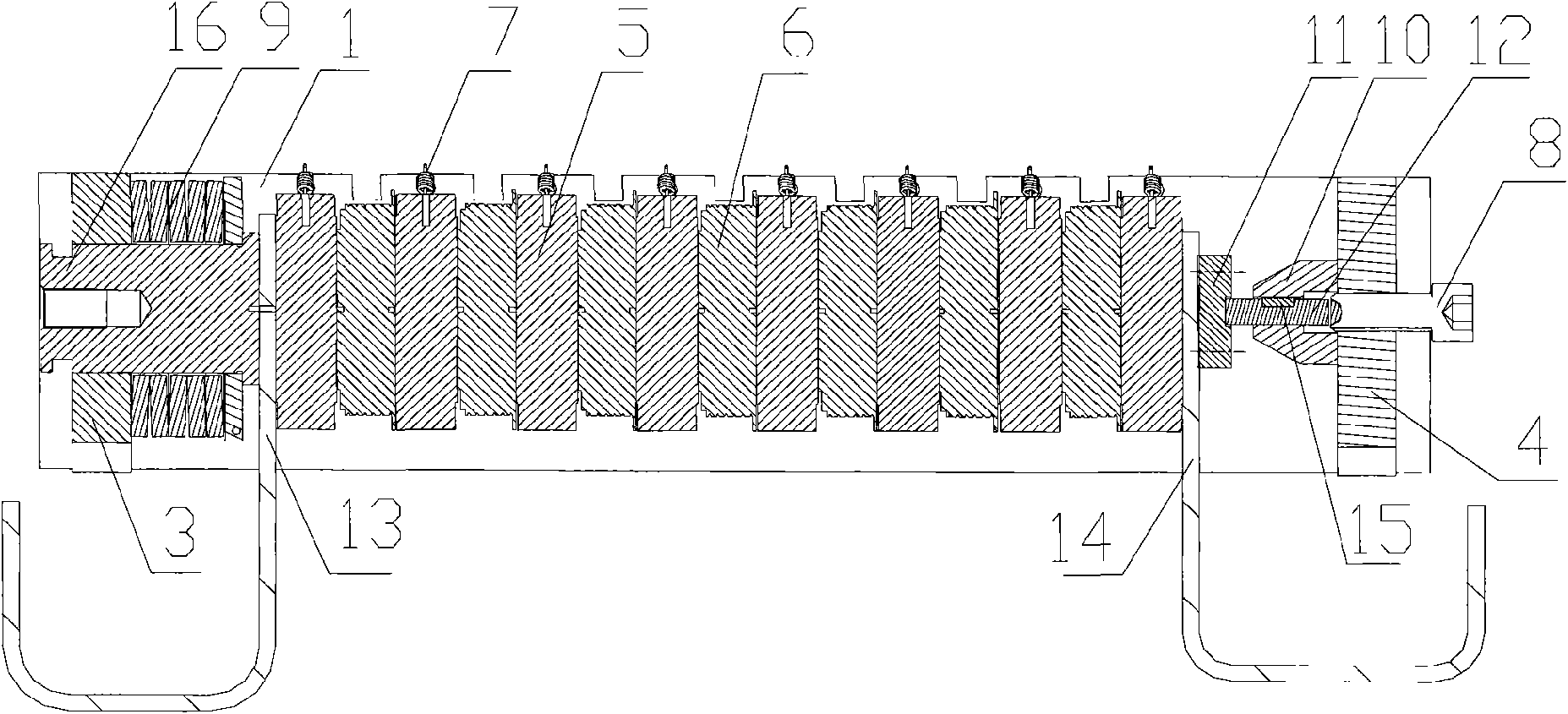

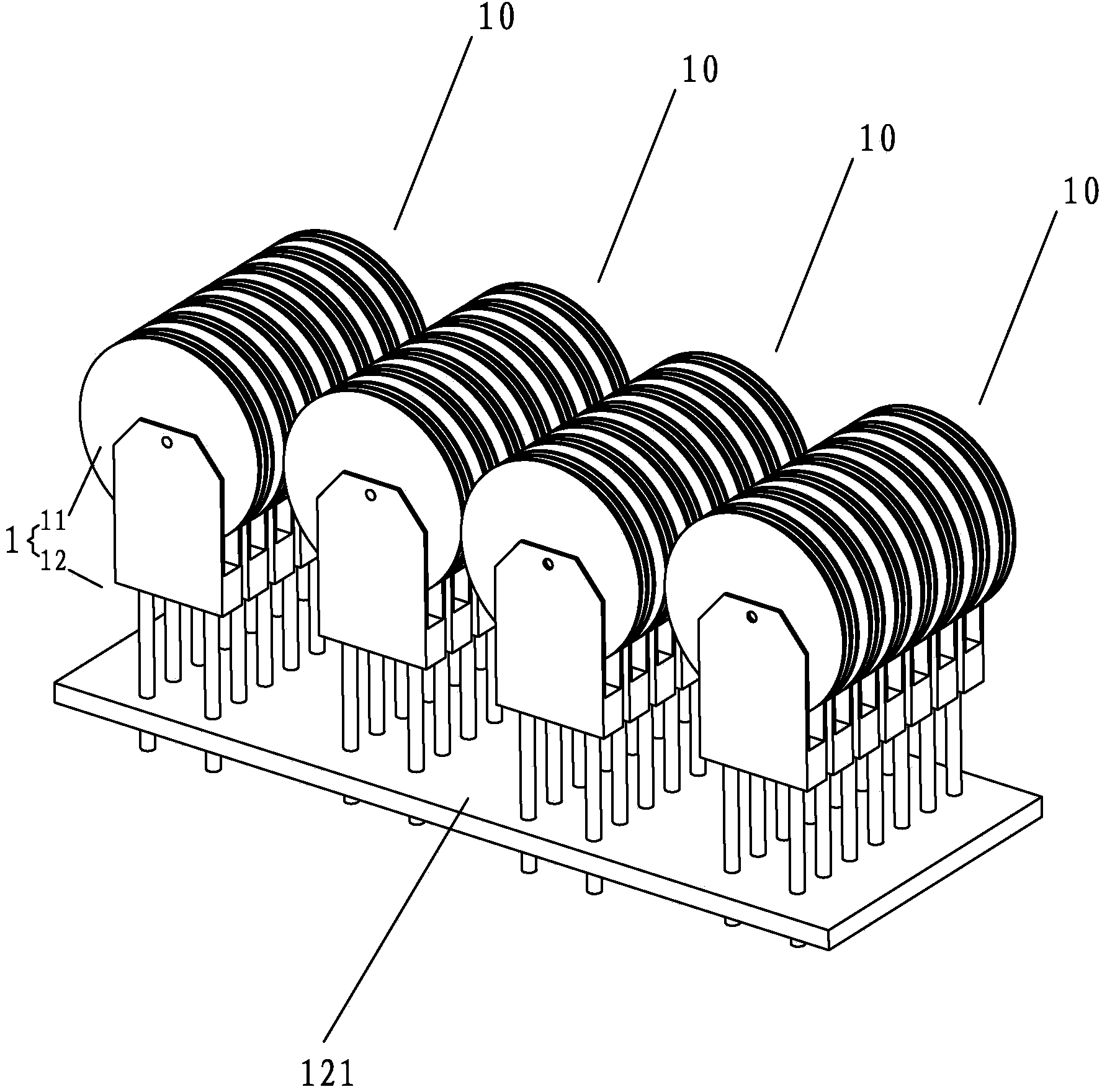

Cascade connected thyristor valve section in jacking connection

ActiveCN101593748AEasy to installEven by forceSemiconductor/solid-state device detailsSolid-state devicesThyratronMechanical stability

The invention discloses a cascade connected thyristor valve section in jacking connection, which comprises a framework, wherein one end of the framework is provided with an elastic clamping device while the other end is provided with a jacking device, a valve bank consisting of thyristors and heat radiators are arranged alternately between the elastic clamping device and the jacking device, the cascade connected thyristor valve section in jacking connection has a horizontal structure, the heat radiators in the horizontal valve section are positioned and hung in the framework through tension springs connected between the heat radiators and valve section fixing plates, and positioning pins aiming at the thyristors are fixed on two lateral surfaces of each heat radiator along the axial direction of the valve section respectively; and the positioning pins make the thyristors and the heat radiators concentric. By adopting the structure, the central connecting lines of the heat radiators and the thyristors are coincided with the central line of the valve section through the positioning pins on the tension springs and the heat radiators in the horizontal cascade connected thyristor valve section in jacking connection, the stress of each thyristor is ensured to be even, and the mechanical stability of the whole valve section is improved.

Owner:XJ ELECTRIC +1

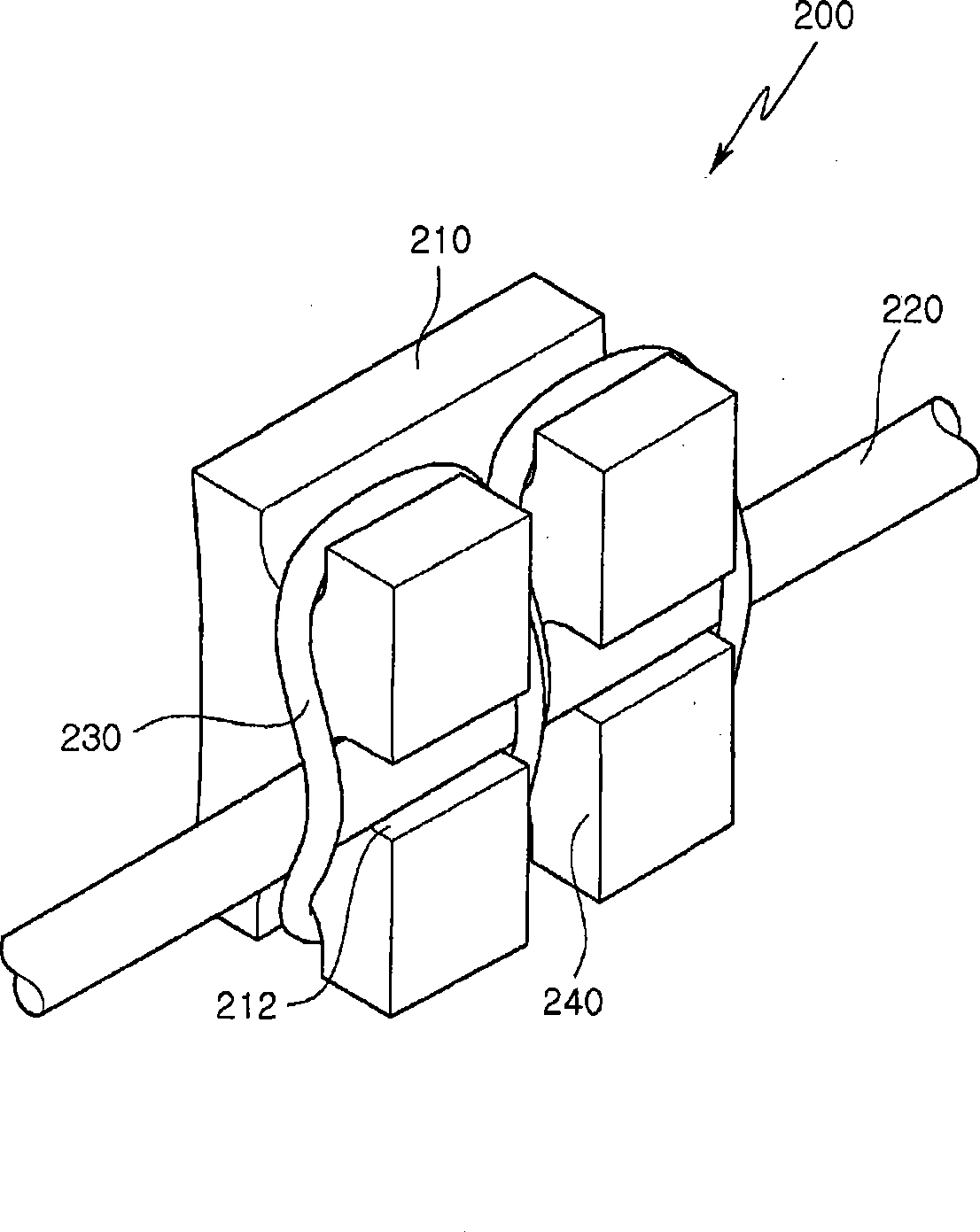

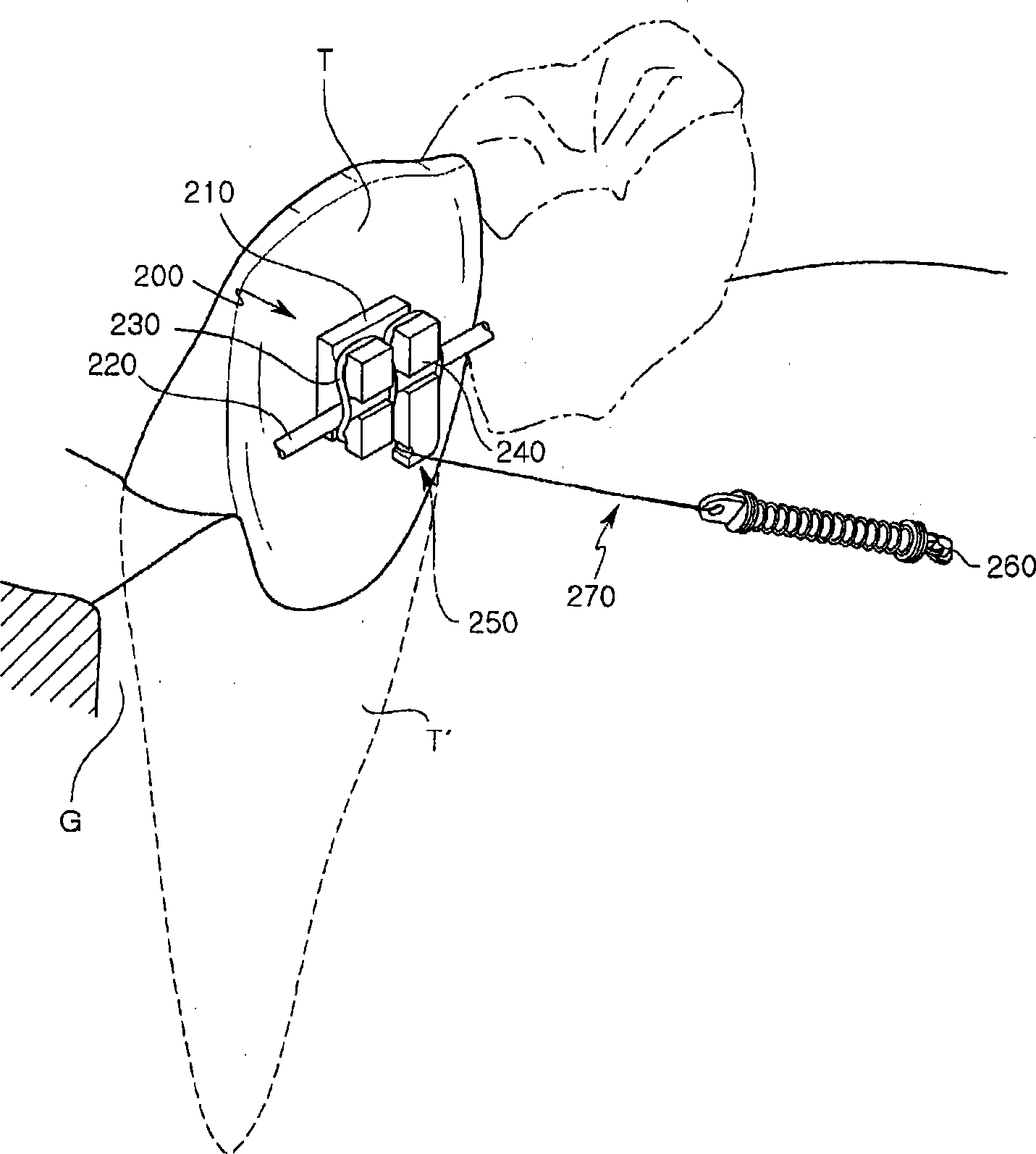

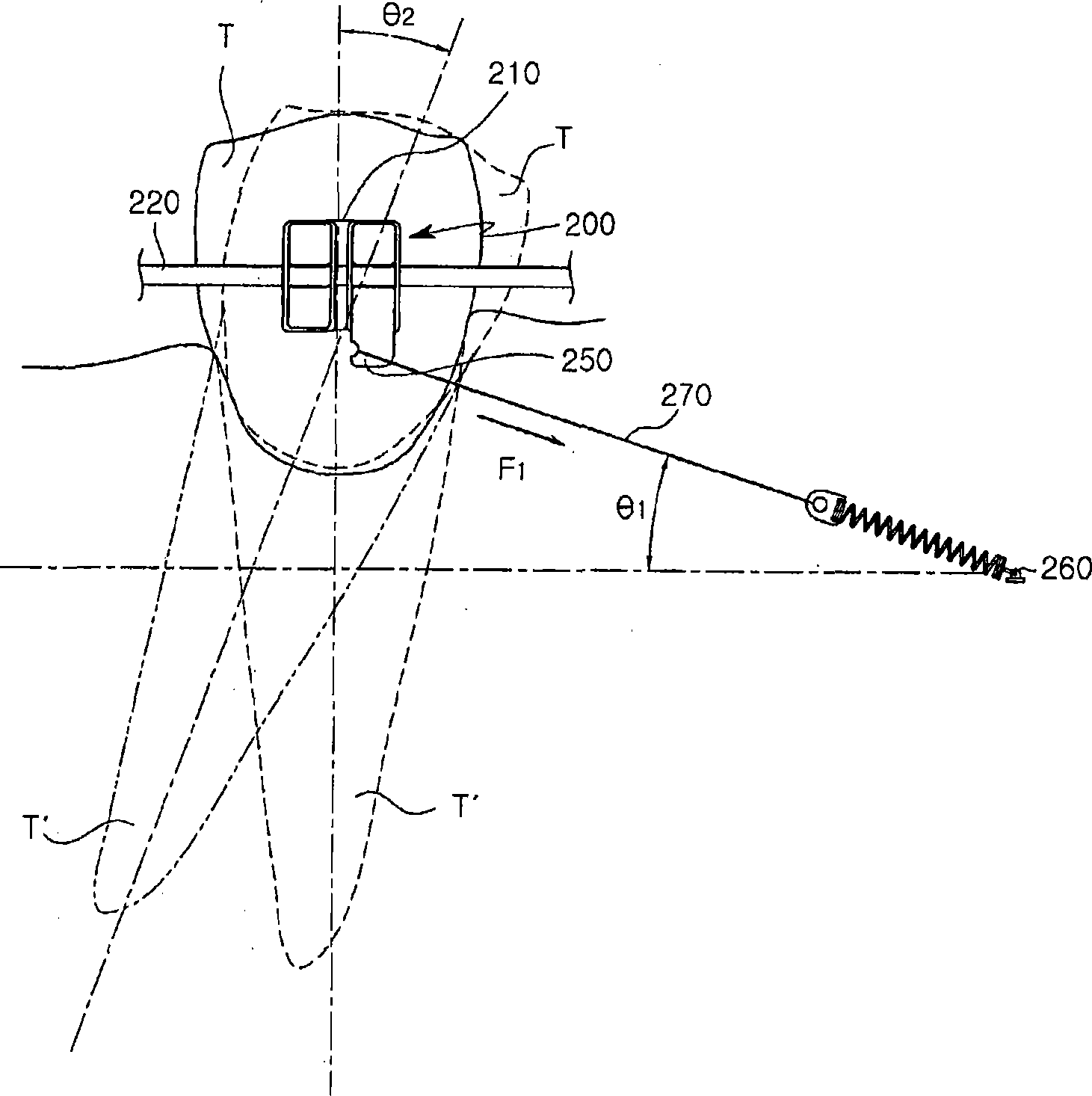

Orthodontic device

InactiveCN101511299AImprove the correction effectNo skewArch wiresDental implantsTraction unitOrthodontics

The present invention relates to an orthodontic device and an orthodontic method that can prevent an orthodontic treatment from being eccentrically performed while aligning straightly tooth. The orthodontic device includes teeth-attachment unit attached to an orthodontic tooth object; and hook member provided in the teeth-attachment unit and having a connection part of traction unit for orthodontic treatment that is located in the vicinity of a center of resistance (C.R) of a tooth. In addition, the orthodontic device includes teeth- attachment unit; and hook member provided in the teeth- attachment unit and having a connection part of traction unit for orthodontic treatment that is located in the vicinity of at least gingiva. According to the invention, since the teeth-attachment unit ofa bracket or a button is substantially horizontal to a traction line of the traction unit connected to the teeth- attachment unit, it is possible to perform the orthodontic treatment effectively without eccentric phenomenon in which the tooth and a dental root are tilted.

Owner:金玉卿

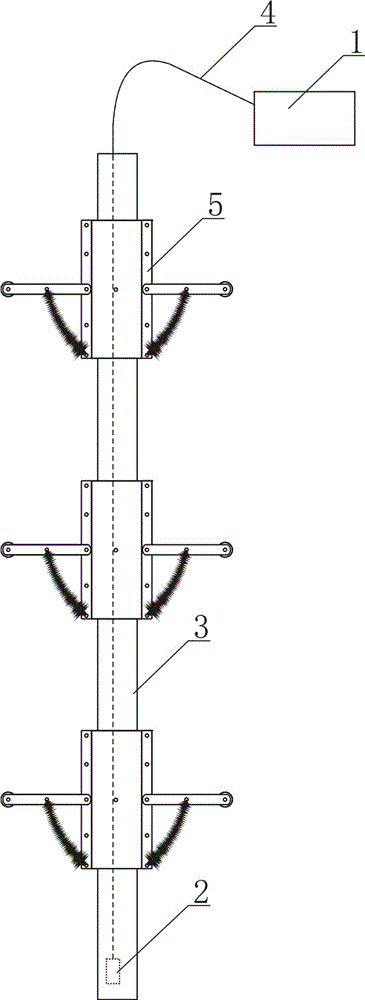

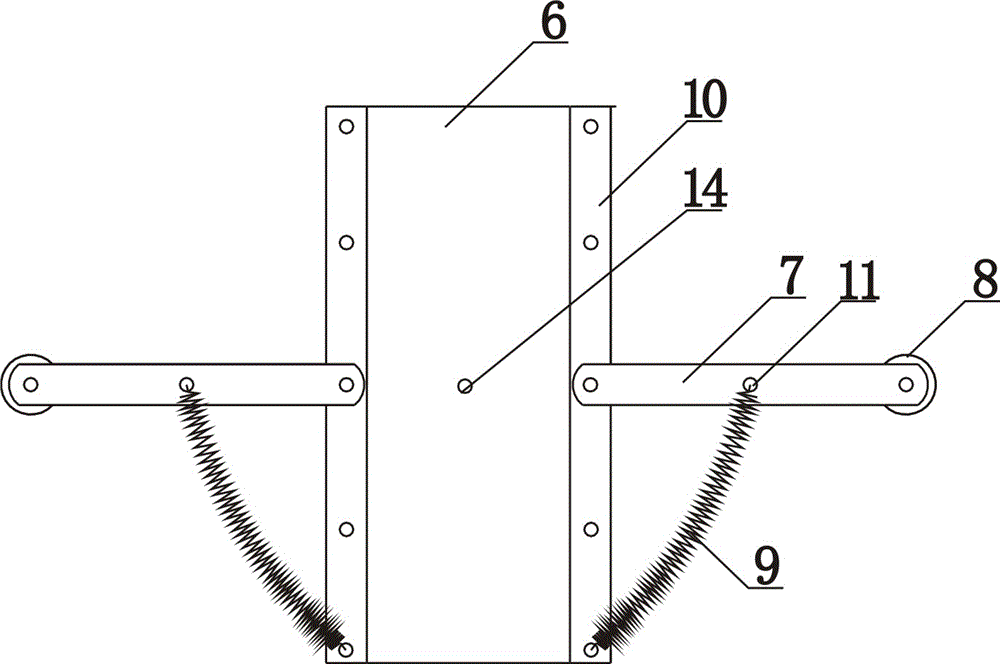

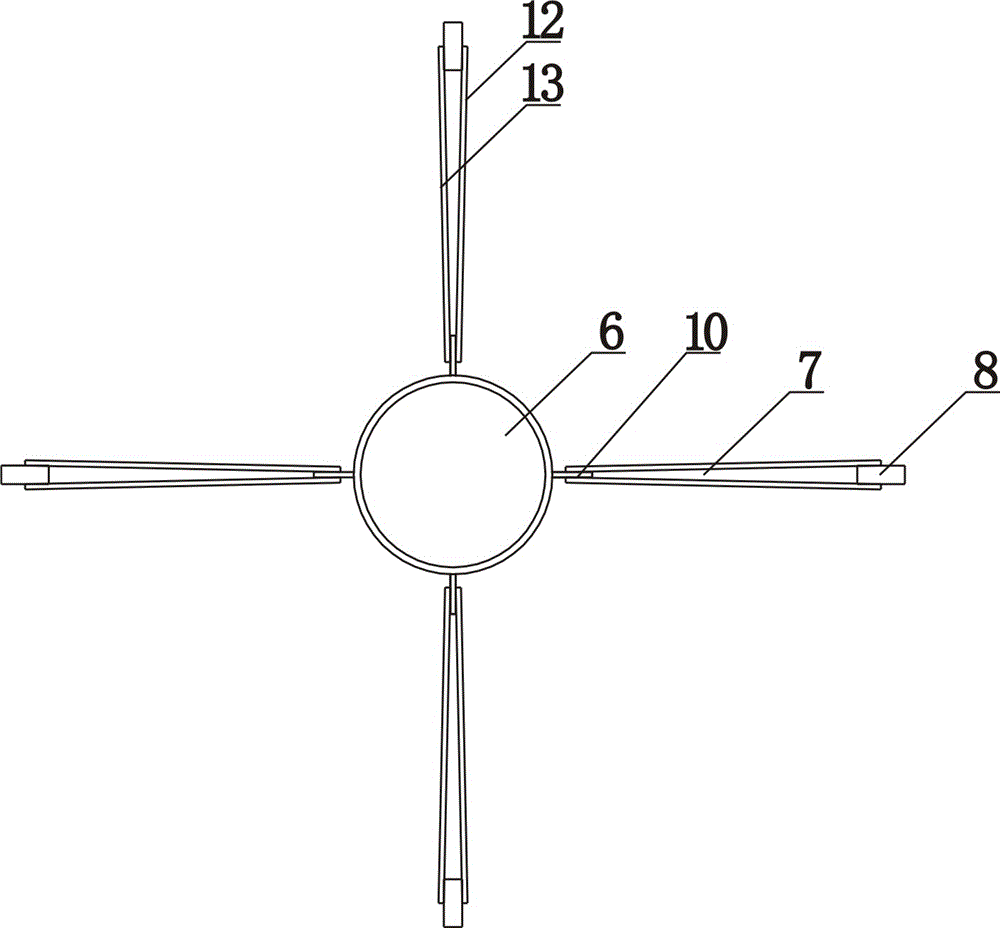

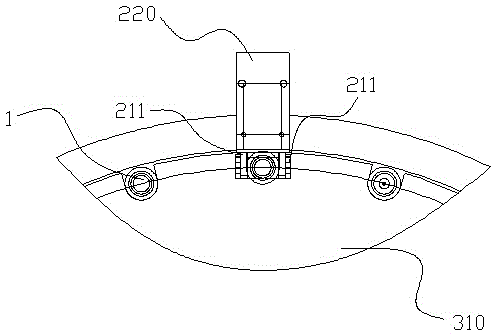

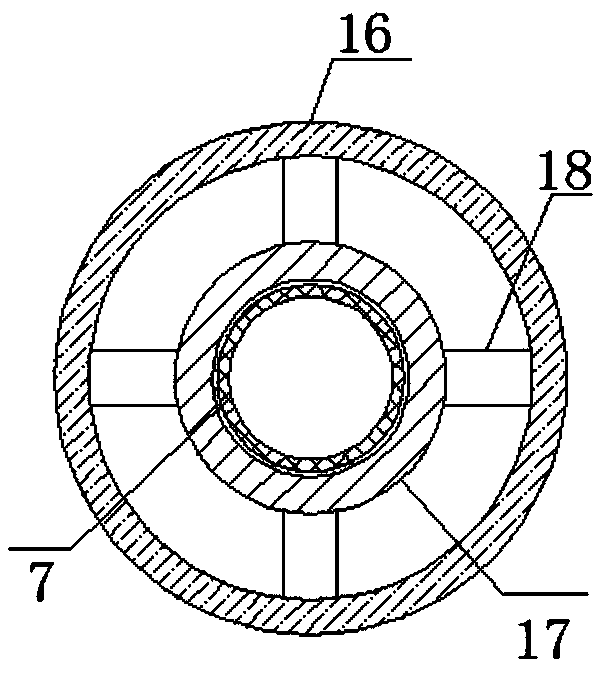

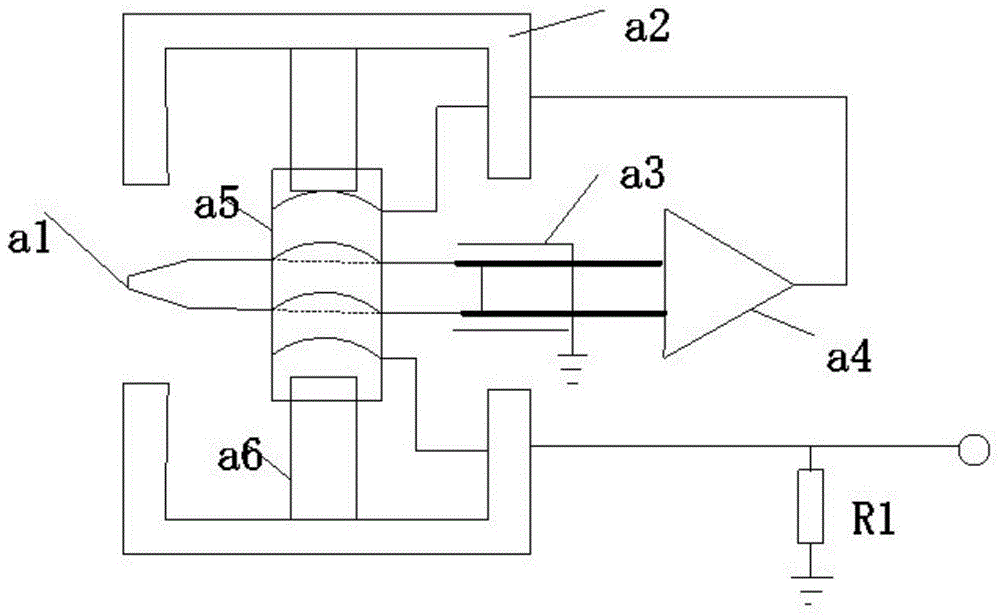

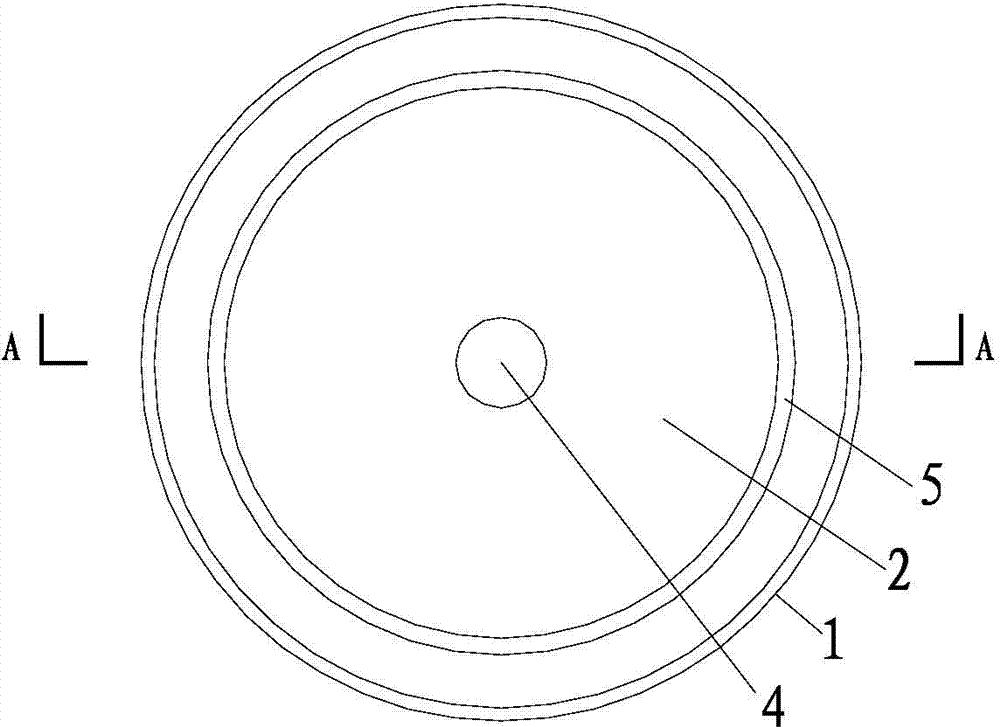

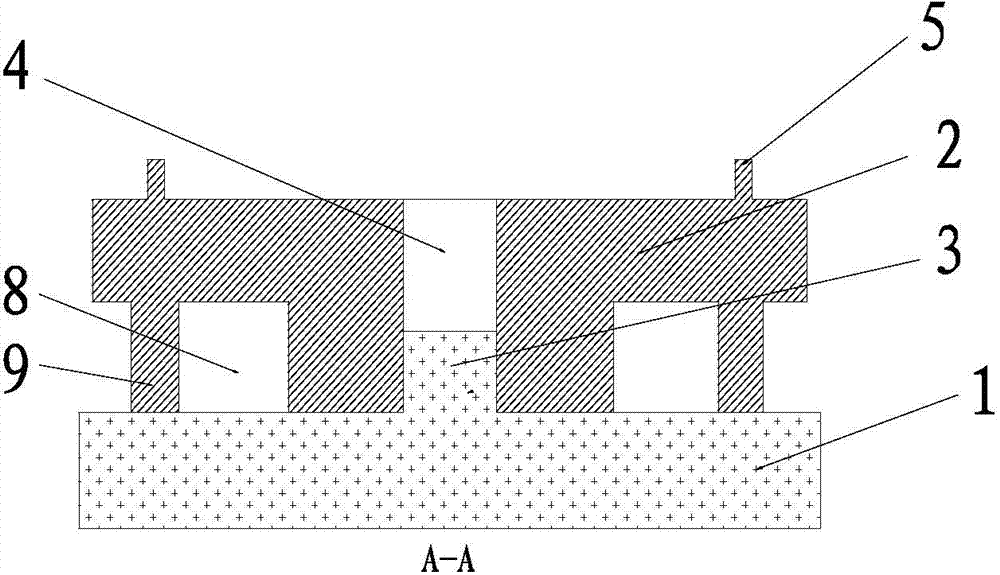

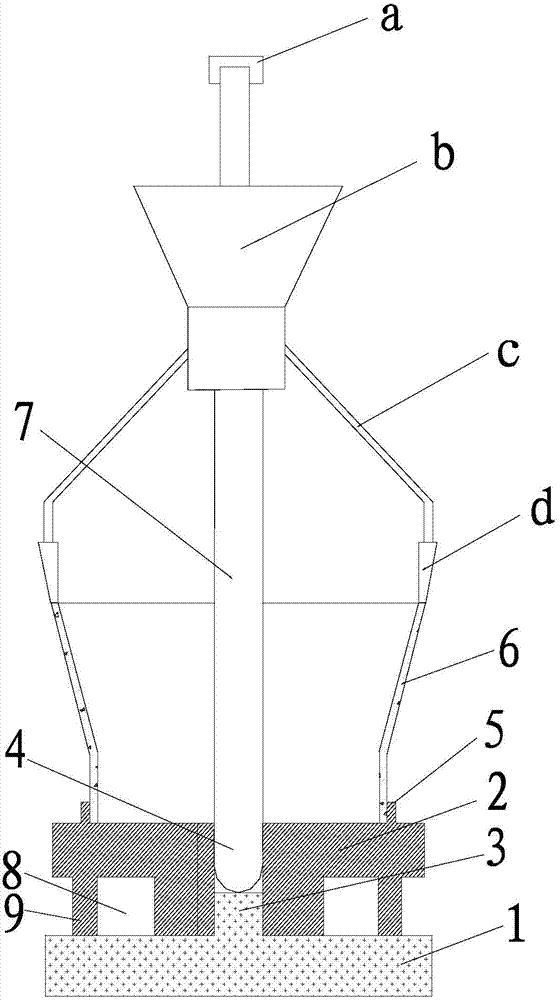

Inclination detection device for tubular pipe and inclinometer tube centring and locating assembly thereof

The invention discloses an inclination detection device for a tubular pipe and an inclinometer tube centring and locating assembly thereof. The inclination detection device for the tubular pipe comprises an inclination detection reading device, an inclination detection probe, the inclinometer tube and a cable used for lifting and pulling the inclination detection probe, and further comprises the inclinometer tube centring and locating assembly, wherein the inclination detection probe slides along a tubular groove in the inclinometer tube through rollers; and the inclination detection probe is connected with the inclination detection reading device through the cable. The inclinometer tube centring and locating assembly is characterized by comprising a locating sleeve, four locating rods, pulleys and springs, wherein the locating sleeve is mounted on the inclinometer tube in a sleeving manner; and the four locating rods are distributed in the circumferential direction of the locating sleeve to form a cross-shaped structure. The inclinometer tube centring and locating assembly guarantees that central positions of the inclinometer tube and the tubular pipe overlap, guarantees that the inclination detection probe does not twist and incline in the horizontal direction inside the inclination detection probe, guarantees that the detection data of the inclination of the tubular pipe is accurate and reliable, and has the characteristics of high measurement accuracy and convenient operation.

Owner:CRCC HARBOR & CHANNEL ENG BUREAU GRP SURVEY & DESIGN INST

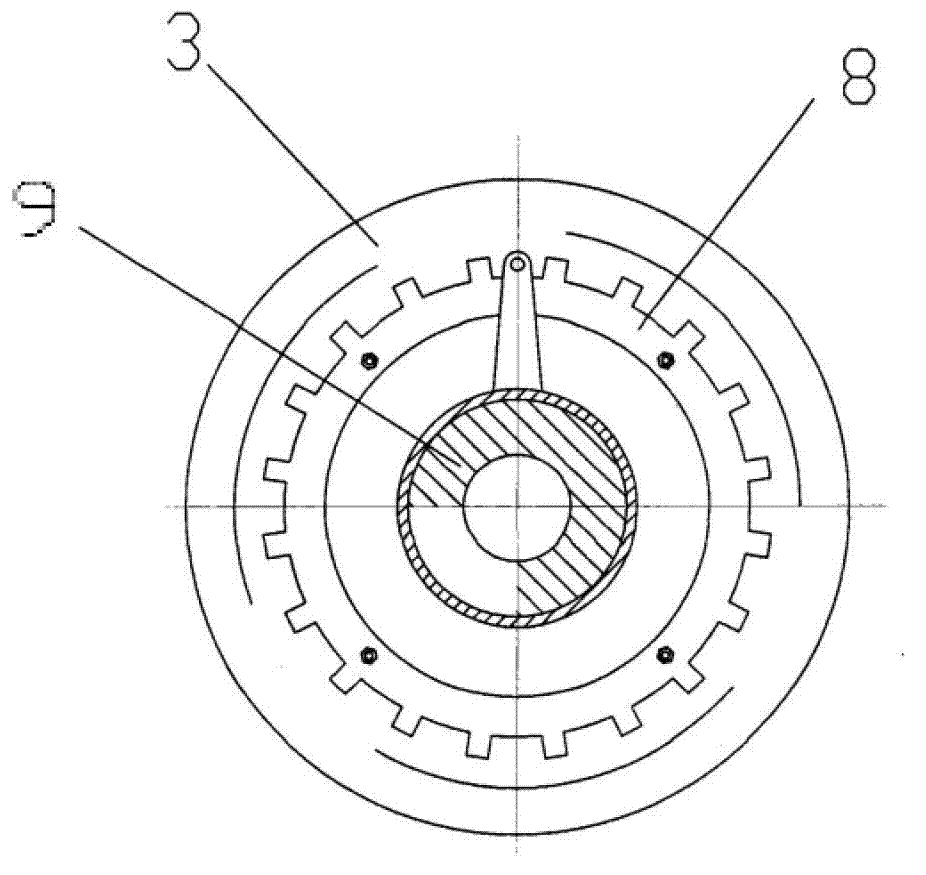

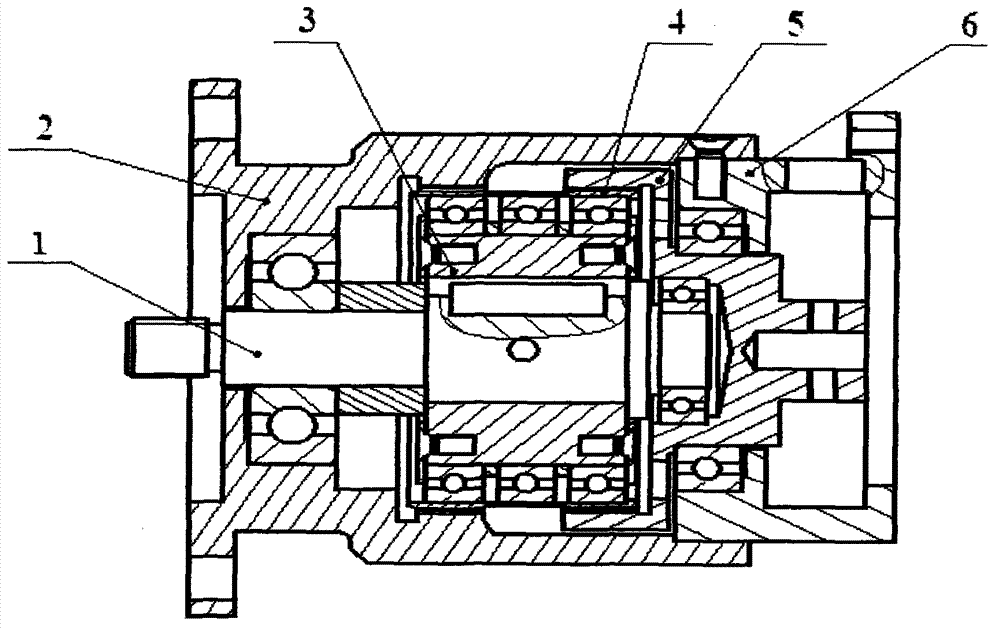

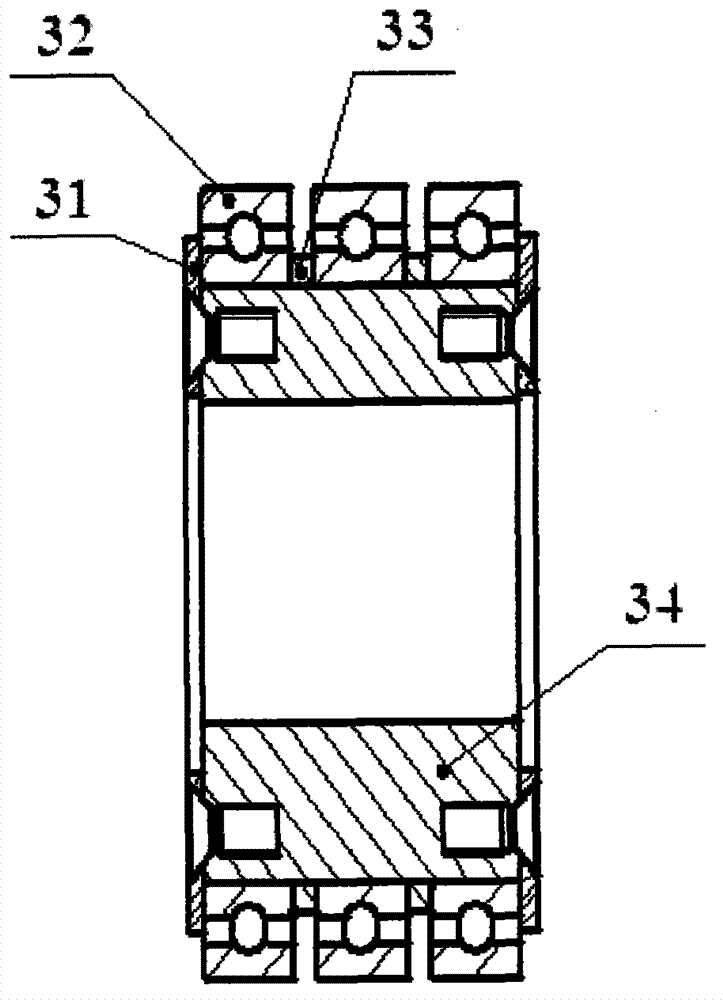

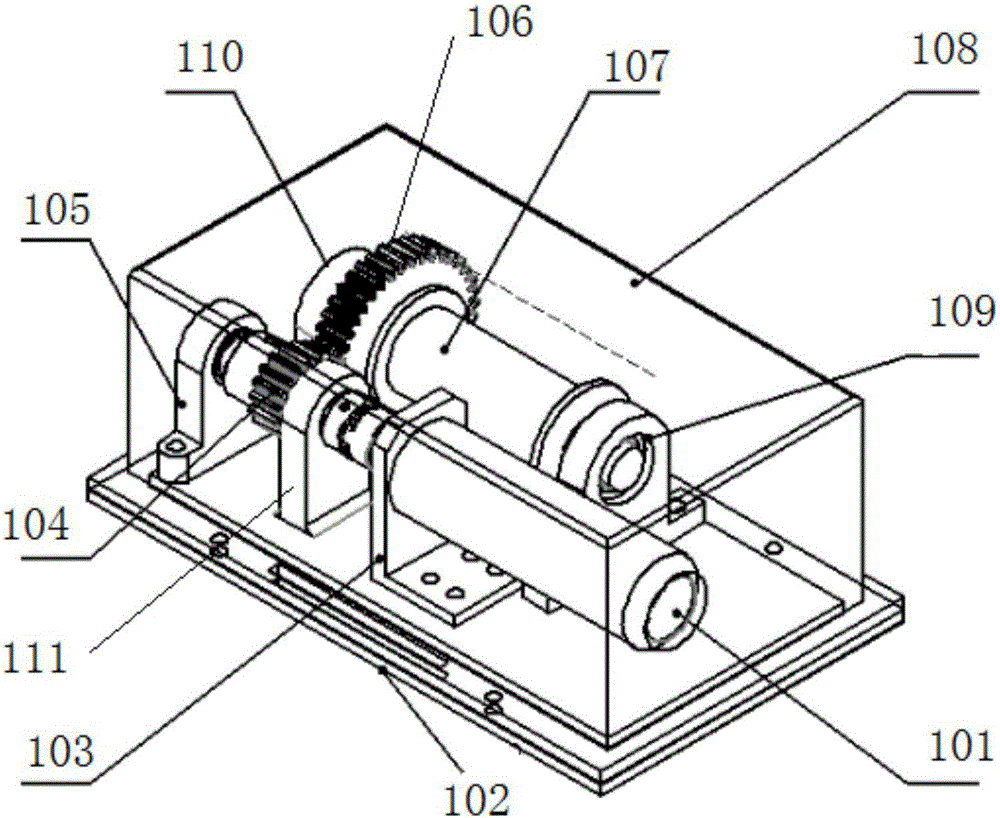

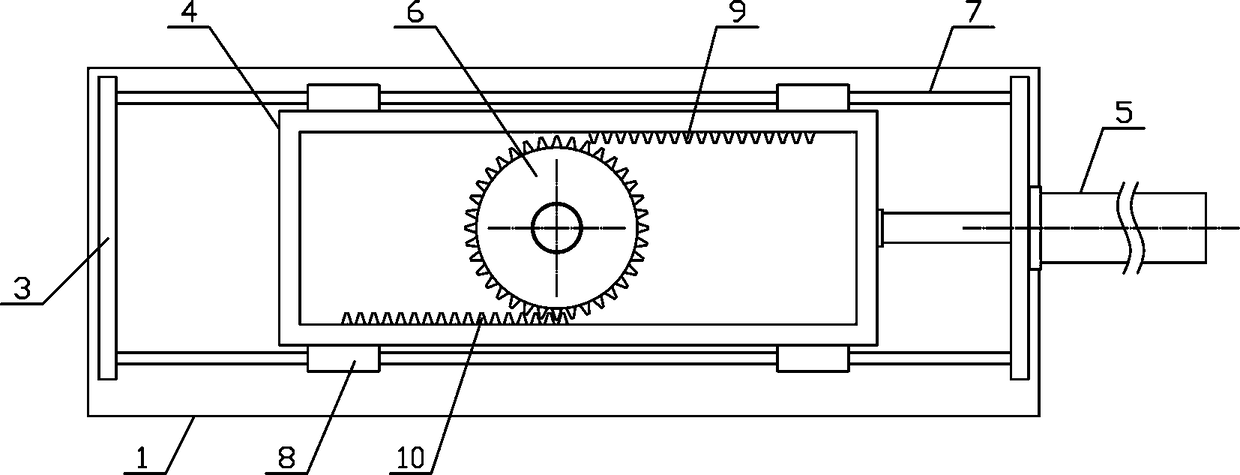

Complex-wave type harmonic drive speed reducer

InactiveCN102927209ACompact structureLarge transmission ratioToothed gearingsGearing detailsEngineeringCam

The invention provides a complex-wave type harmonic drive speed reducer, which comprises a wave generator, a flexible gear, a fixed rigid gear and an output rigid gear, wherein the wave generator is provided with cams, a first flexible bearing and a second flexible bearing; the flexible gear is provided with a first external gear and a second external gear which are respectively arranged at two ends of the flexible gear; a first external gear of the flexible gear is meshed with the fixed rigid gear through the cam via the first flexible bearing, and the second external gear of the flexible gear is meshed with the output rigid gear through the cam via the second flexible bearing. The complex-wave type harmonic drive speed reducer has the advantages of realization of two-stage harmonic-drive speed reduction in the form of complex waves, compact structure, small volume, large transmission ratio, high transmission precision and wide range of application.

Owner:陕西渭河工模具总厂

Automatic inner plug locating and installing mechanism

ActiveCN104058249AGuaranteed stabilityGuaranteed reliabilityClosure using stoppersConveyor partsControl systemEngineering

The invention discloses an automatic inner plug locating and installing mechanism. The automatic inner plug locating and installing mechanism comprises a mechanical hand system, a bottle opening locating system, a transporting system and a control system, wherein the mechanical hand system comprises an inner plug sucking hand, a lifting air cylinder, a transverse moving air cylinder, a guide rail which is arranged on a rack and a sliding block, and the middle upper part of the inner plug sucking hand is provided with a vacuum pipe which is communicated with a vacuum generator; the bottle opening locating system comprises a locating clamping block, a locating air cylinder and a locating and supporting seat which is used for fixing the locating air cylinder; the transporting system comprises a rotating disc which is used for transferring a bottle from a bottle installing station to a plug installing station, a supporting block, a guardrail and an inner plug transporting guide rail; the control system is electrically connected with the mechanical hand system, the bottle opening locating system and the transporting system. According to the automatic inner plug locating and installing mechanism disclosed by the invention, the problem of low working efficiency caused as an inner plug is manually installed by a person is overcome, the automation degree is strong, and the working efficiency can be greatly increased; each system sequentially works, strictness and coordination are realized, the inner plug can be conveniently installed, the stability of the automatic inner plug locating and installing mechanism is ensured from the structure design, and the reliability is strong.

Owner:GUANGZHOU BEAUTY STAR CO LTD

Soil sampler for biological soil enzyme activity determination

InactiveCN109187080ALabor savingImprove sampling efficiencyWithdrawing sample devicesPush outEngineering

The invention discloses a soil sampler for biological soil enzyme activity determination. The soil sampler comprises a handheld rod and a limiting frame; the lower end of the handheld rod is fixedly connected with the limiting frame; a movable sleeve is fixedly connected to the middle of the limiting frame; the lower end of the handheld rod is symmetrically connected with one ends of two telescopic rods; when a motor rotates, a rotating shaft can be driven to rotate, so that a sampling cylinder is driven to move downwards; the sampling cylinder can move downwards better due to the existence ofa spiral blade, so that the sampling can be performed better, the manual sampling is facilitated, and the labor force is reduced; the lower end of the spiral blade and the lower end of the sampling cylinder adopt conical structures, and in the sampling process, the sampling cylinder can enter the soil more easily, so that the sampling efficiency is improved; after the sampling is finished, in theprocess that a scraping plate moves downwards, a soil sample is pushed downwards, so that the soil sample is pushed out; and meanwhile, the inner side wall of the sampling cylinder is scraped by thescraping plate so as to ensure that the next sampling can be very smooth.

Owner:HEFEI HUAGAI BIOTECH CO LTD

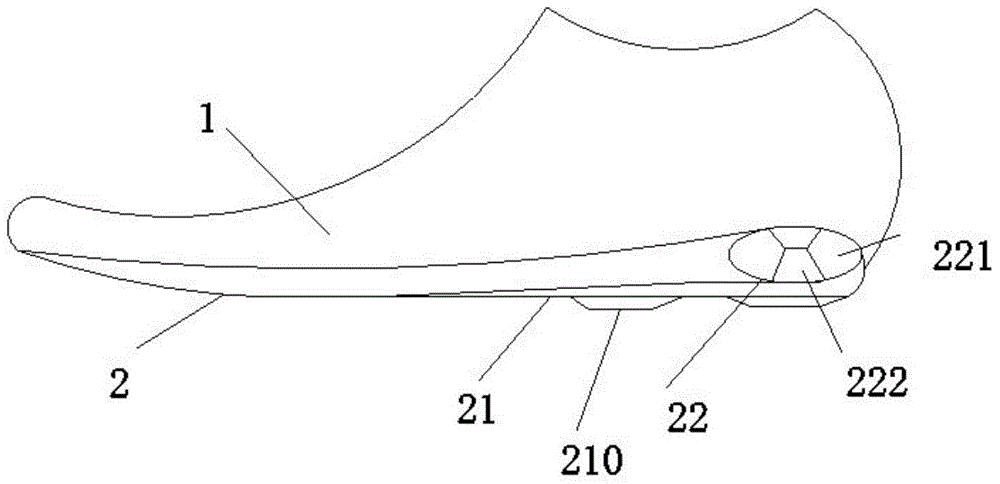

Flexible wearable lower limb assistant exoskeleton suit

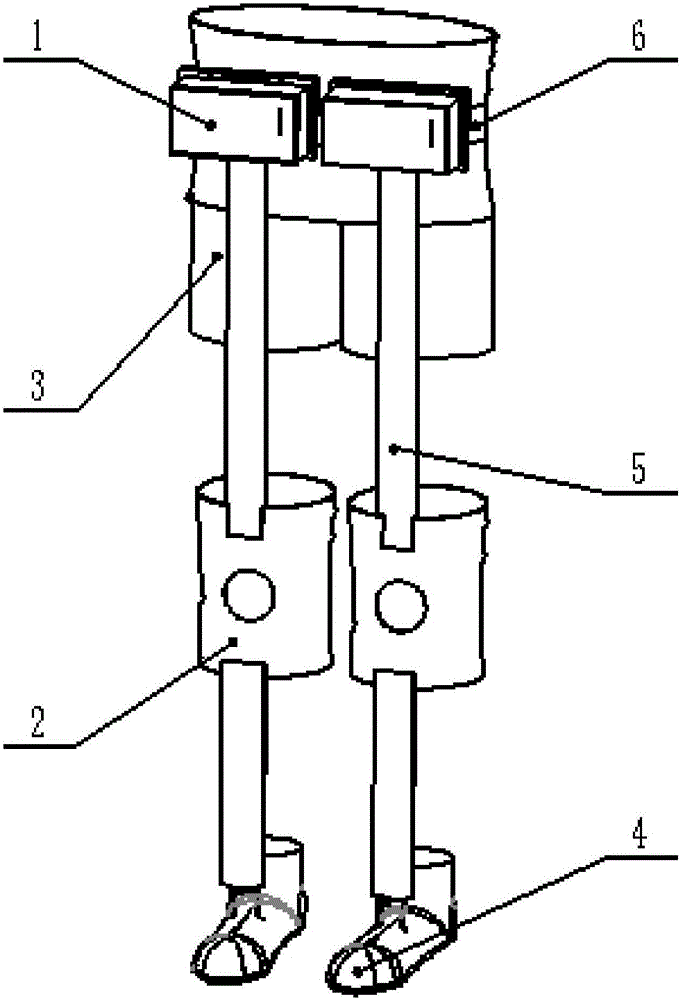

ActiveCN106726359AImprove comfortLose weightProgramme-controlled manipulatorDiagnosticsGyroscopeKnee Joint

The invention provides a flexible wearable lower limb assistant exoskeleton suit. The suit is characterized by comprising high waist short pants, knee caps, shoes, a controller, a traction belt and two drive devices. The left and right hips joints and sacrum position of the high waist short pants are all provided with gyroscope sensors. The waist position of the high waist short pants is fixedly provided with an adjustable belt. The two drive devices are symmetrically installed at the adjustable belt located at front side of the high waist short pants in a left-right mode. Each drive device is connected with the upper end of a traction belt. The lower end of the traction belt penetrates through the kneed caps to be connected with the shores. Each drive device is used for driving the corresponding ankle joint move; the three gyroscope sensors and two drive devices are all connected with the controller; the controller is used for processing the data of three gyroscope sensors and controlling the motion of power elements of the drive devices, the knee caps are located at the knee joints and is provided with a plurality of magic sticker pasting points of different lengths, and the knee caps are also provided with knee dents.

Owner:HEBEI UNIV OF TECH

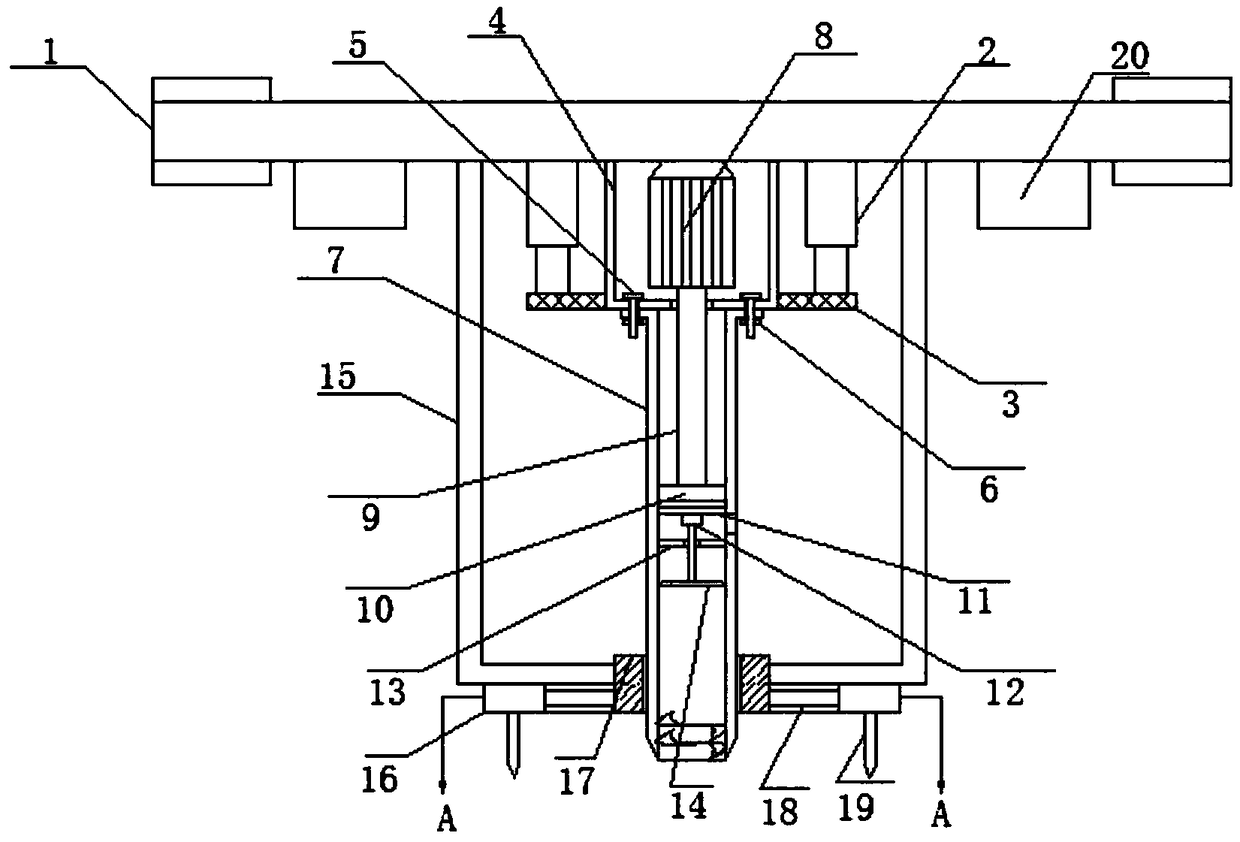

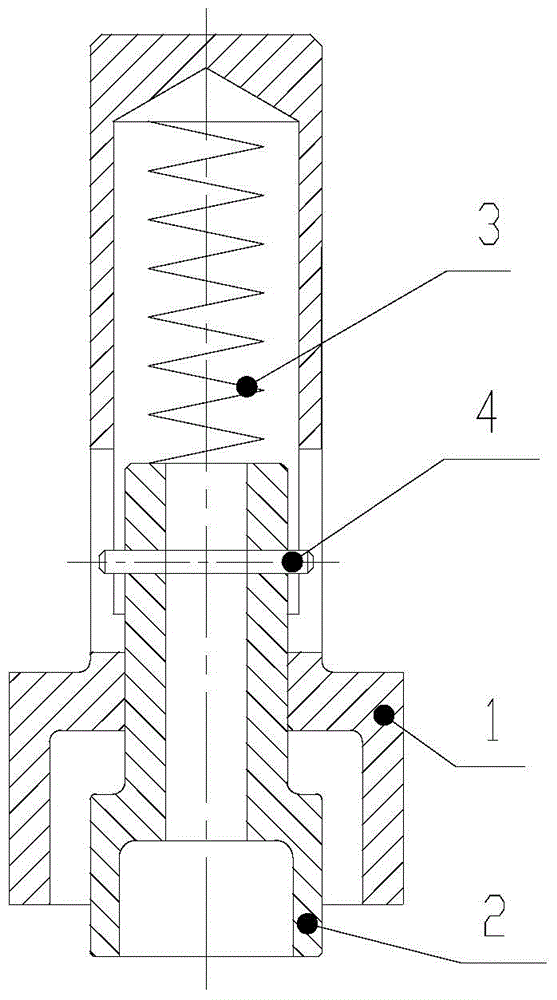

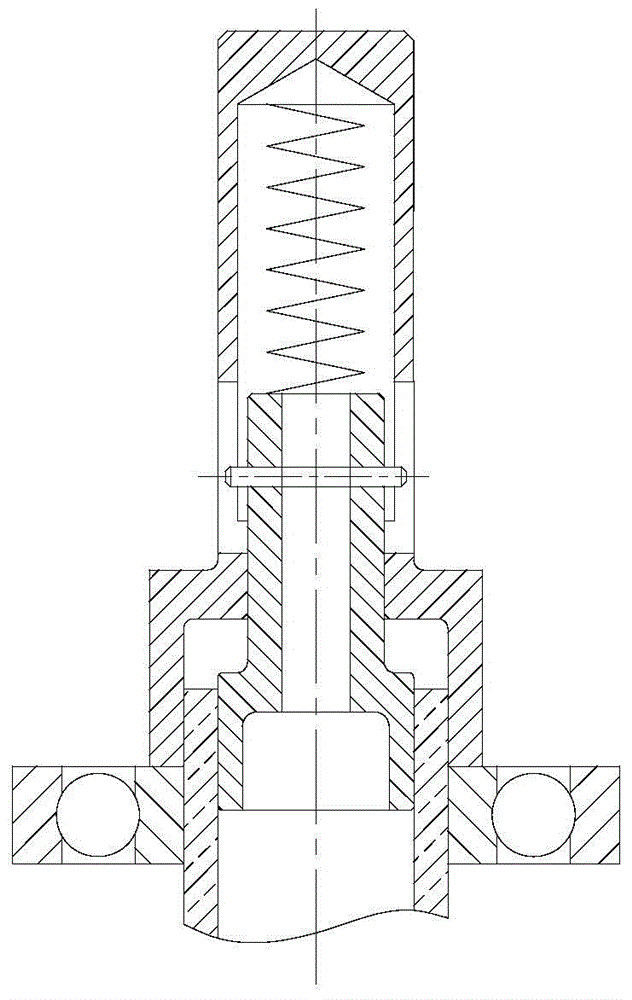

Bearing mounting tool with centering function

InactiveCN104551604ANo skewRealize the centering functionMetal working apparatusEngineeringMechanical engineering

The invention relates to a bearing mounting tool with a centering function; the bearing mounting tool comprises a pressure head (1), a guide shaft (2) and a spring (3); the guide shaft (2) is installed inside the pressure head and is capable of moving axially inside the pressure head (1); the spring (3) is arranged at one end of the guide shaft (2); the other end of the spring (3) is pressed against the internal wall of the pressure head (1); the other end of the guide shaft (2) is capable of being stretched out of the end part of the pressure head (1); the external diameter of the part of the guide shaft (2) stretched out of the pressure head (1) is equal to the internal diameter of the hollow part of a shaft equipped with a bearing; and the internal diameter of the pressure head (1) matches with the external diameter clearance of the shaft to be mounted with the bearing. The centering function during installation is realized; no deflection of the bearing during installation is guaranteed and the requirement without damaging the bearing, the shaft and the bearing seat is satisfied.

Owner:HARBIN DONGAN ENGINE GRP

Security camera convenient in maintenance

ActiveCN107152590AEasy maintenanceThe disassembly process is simple and convenientTelevision system detailsColor television detailsComputer engineering

The invention discloses a security camera convenient in maintenance. The security camera convenient in maintenance comprises a mounting plate and a mounting base; one side surface of the mounting plate is fixedly connected with a round rod; a blind hole is formed in one side surface of the mounting base; the round rod is movably connected into the blind hole; a first cavity is formed in the mounting base; a through groove is formed in the inner wall of the blind hole, and communicates with the first cavity; the bottom of the inner wall of the first cavity is fixedly connected with an extension sleeve; the top of the extension sleeve is fixedly connected with a movable plate; the movable plate is movably connected into the through groove; the surface of the extension sleeve is movably sleeved with a spring; one end of the spring is fixedly connected with the bottom of the inner wall of the first cavity; and the other end of the spring is fixedly connected with the lower surface of the movable plate. Through arrangement of the mounting base, the movable plate, a semicircular clamping block and a gear, the security camera convenient in maintenance solves the problems of difficult manual disassembly and increment of the working danger of workers on climbing tools after traditional cameras are broken down.

Owner:深圳市兆能讯通科技有限公司

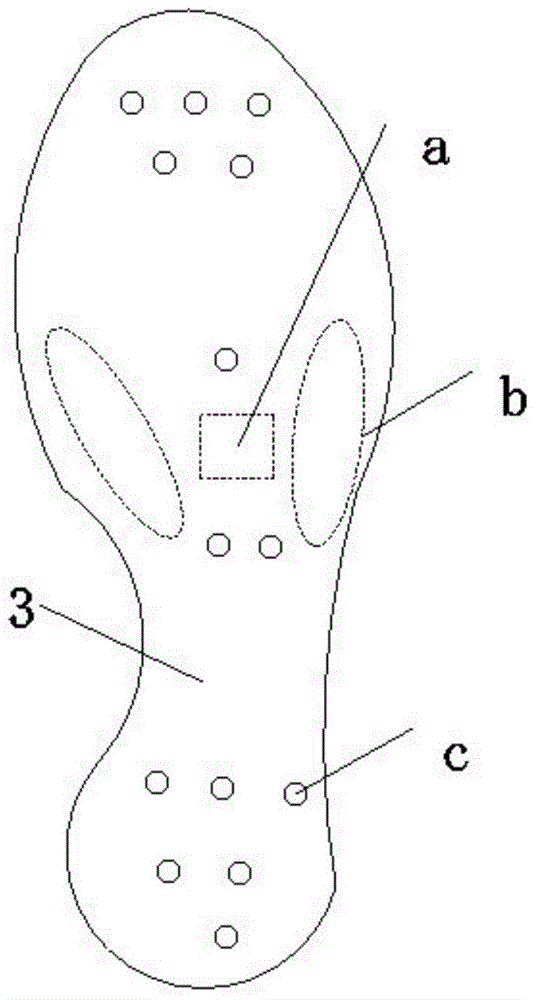

Balance shoes special for the elderly

InactiveCN105266256APlay a role in balancing the bodyEliminate physical hazardsSolesInsolesArches of the footEngineering

The invention provides balance shoes special for the elderly. Each balance shoe comprises an upper, a sole and an insole. The middle portion of the insole is provided with a balance sensor and balance air bags at the location corresponding to the arch of the foot, the balance sensor is connected to the balance air bag, the location of the insole arch is lightly higher than the locations of the heel and the sole of the insole, the middle portion of the insole heel is slightly recessed, the middle portion of the insole sole is slightly uneven, the bottom of the rear-middle portion of a sole is provided with an antiskid bottom layer, a damping device is arranged between the antiskid bottom layer and the sole, the damping device comprises an air bag and a damping column arranged in the air bag, the bottom of the antiskid bottom layer is provided with protruding circular antiskid loops, and the antiskid loop is provided with antiskid lines in the interior. The balance shoes special for the elderly are simple in structure, a balance air bag at one side of each insole can appropriately adjust the height to keep balance when the disposed balance sensor detects that forces on the left and the right are nonuniform, the sensitivity is high, and the damping devices are disposed at the same time, dual balance can be kept.

Owner:XINGTAI POLYTECHNIC COLLEGE

Horizontal type cigarette carton sorting mechanism

A horizontal type cigarette carton sorting mechanism comprises a sorting device and a main conveyor belt. The sorting device comprises a rack, and a conveying rolling way is arranged on the rack. A replenishment tipper hopper is arranged at the front end of the conveying rolling way, and a separation rolling way is connected to the tail end of the conveying rolling way. A sorting bin is arranged at an outlet end of the separation rolling way, and a pusher mechanism for pushing a stack of cigarettes into the sorting bin is arranged above the separation rolling way, and the pusher mechanism comprises a pusher plate, a power device and a guide rail which are capable of moving up and down and moving horizontally. The horizontal type cigarette carton sorting mechanism has the advantages that the drawing speed of cigarette cartons and the speed of the main conveyor belt are homodromous and synchronous by means of arranging the cigarette outlet direction of the cigarette outlet and the main conveyor belt in parallel. Phenomena of rolling, inclination, overlapping and the like of cigarette cartons cannot occur even when the cigarette cartons are drawn rapidly, and not only the sorted orderly and dense cigarette cartons are convenient for subsequent stacking packaging, but also the cigarette carton capacity per unit length of the main conveyor belt is increased; besides, the main conveyor belt is long, accordingly, the capacity is larger, and the efficiency is higher than the prior art.

Owner:中山市平连精机科技有限公司

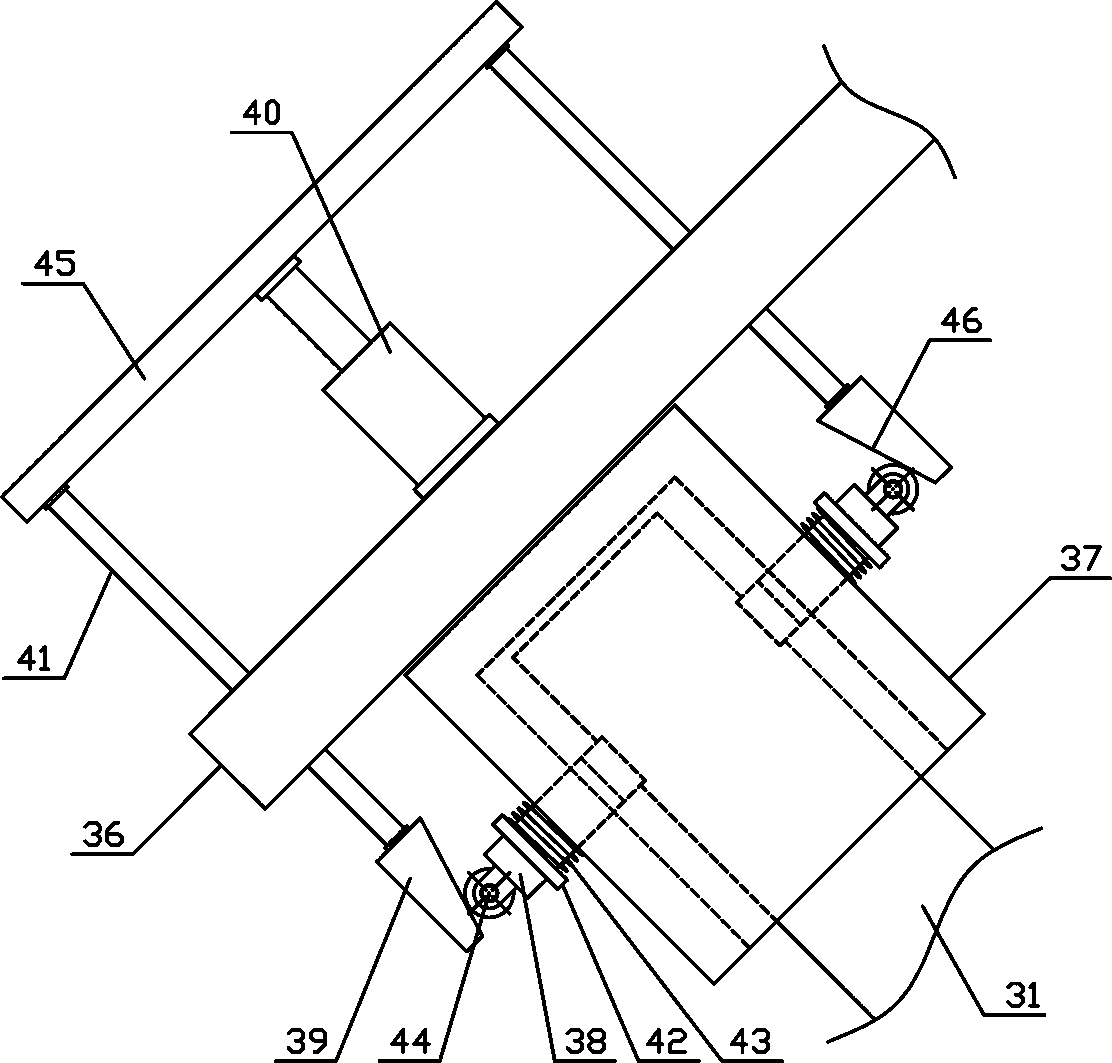

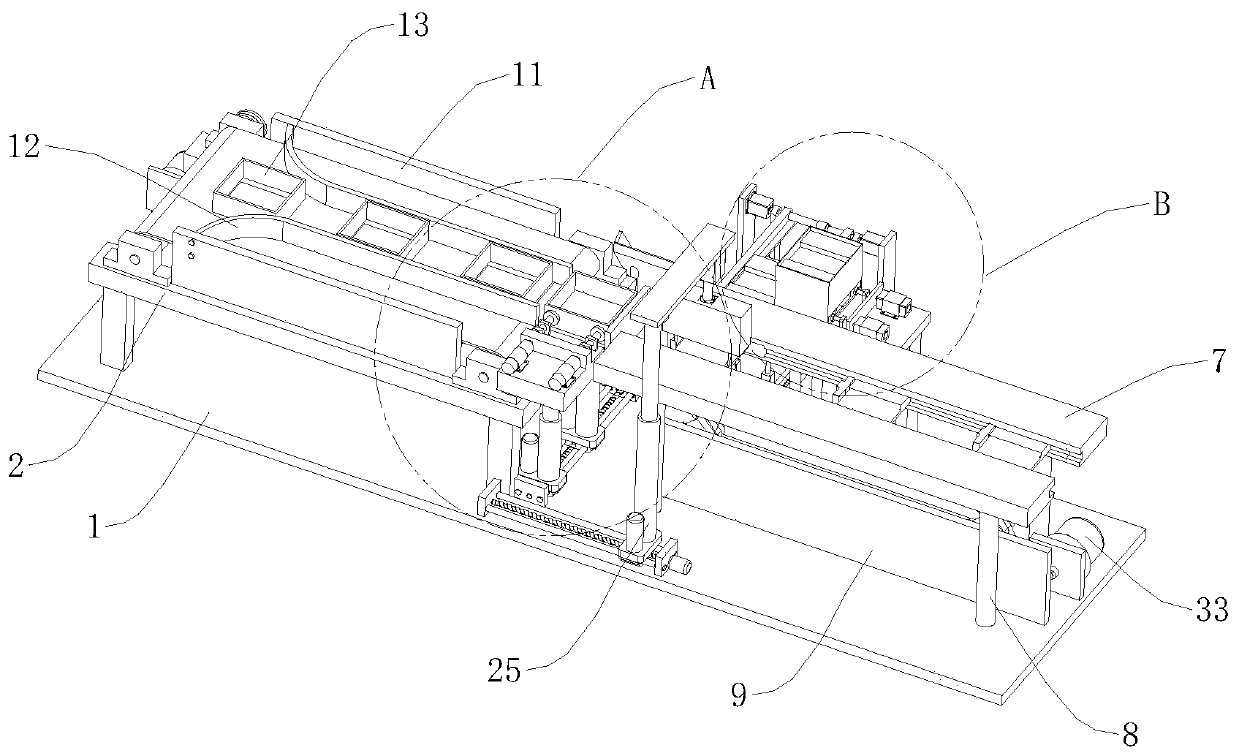

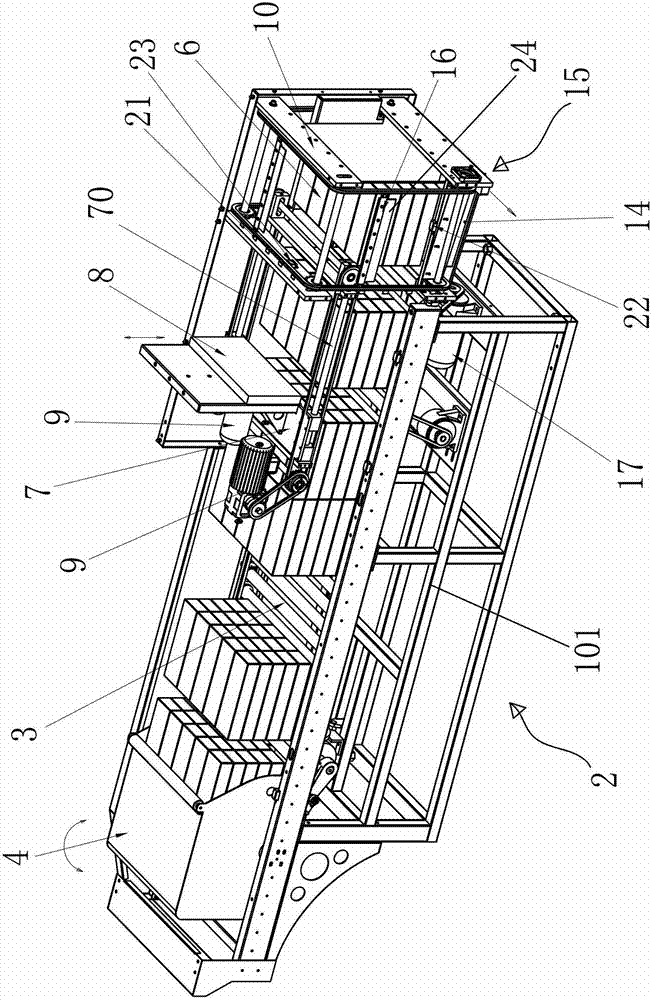

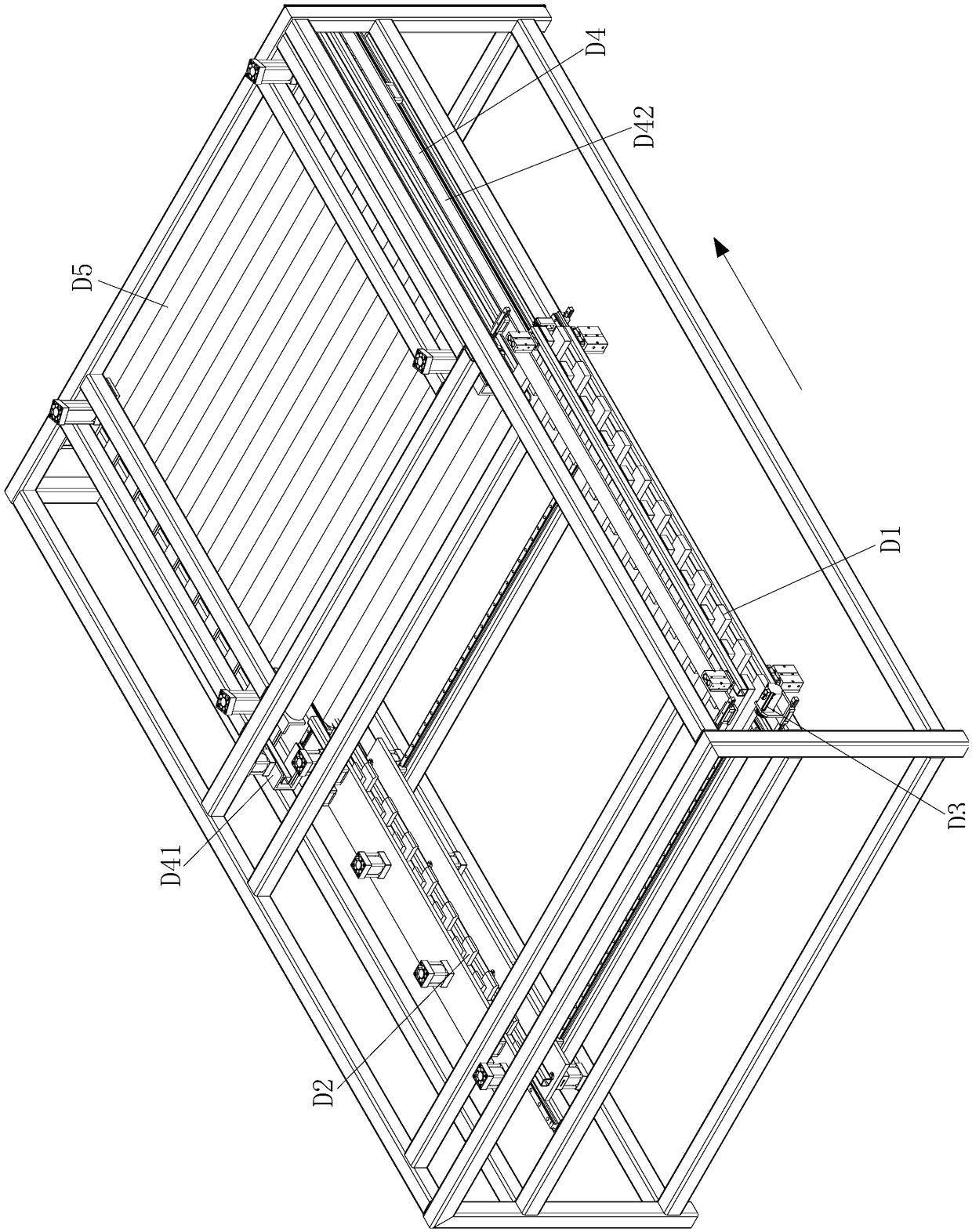

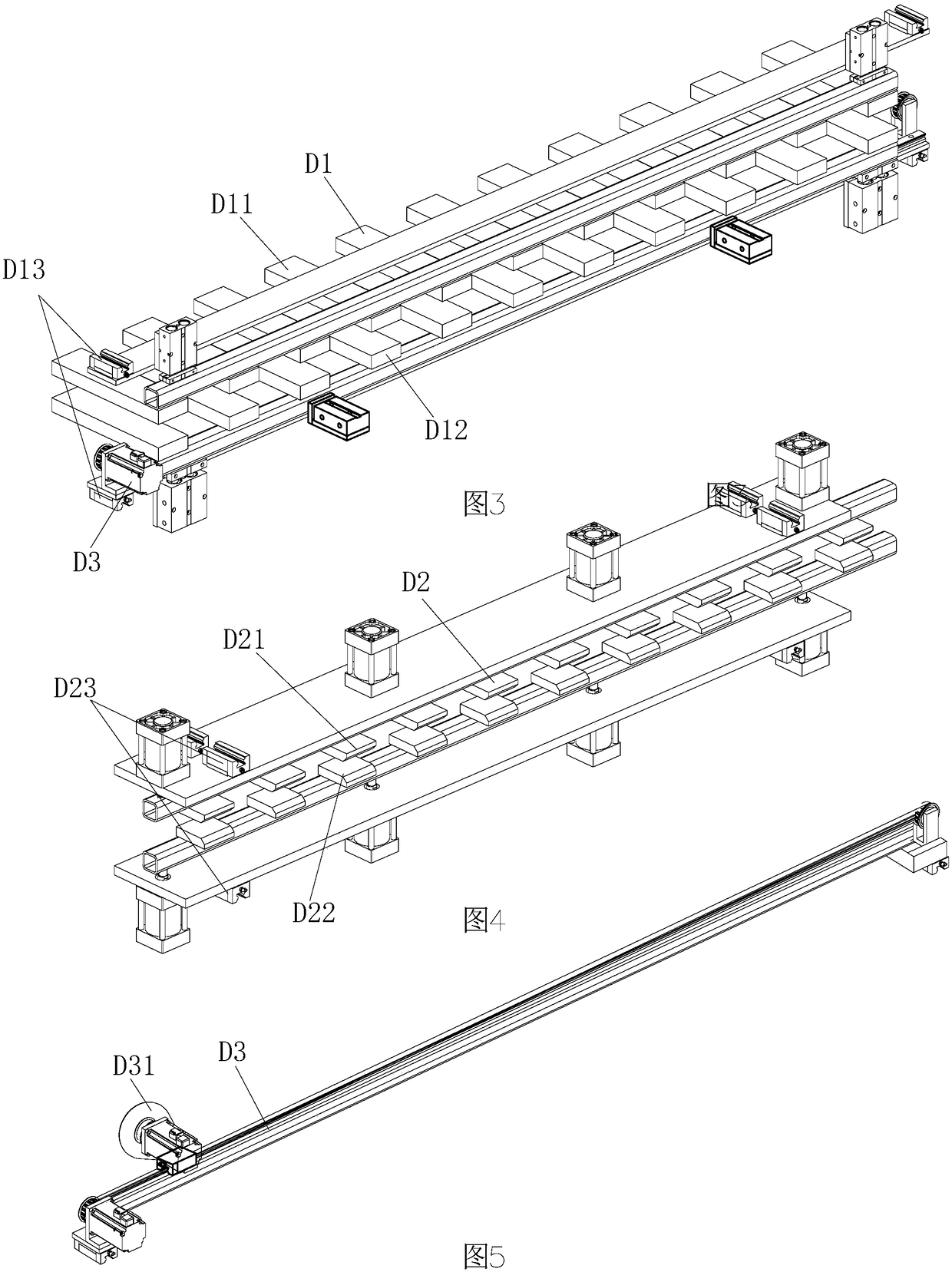

Pipe unloading and translation mechanism

InactiveCN108706285AImprove efficiencyQuality improvementConveyorsConveyor partsElectromagnetic clutchEngineering

The invention discloses a pipe unloading and translation mechanism, and belongs to the field of building material machining mechanical equipment. A reciprocating driving mechanism is vertically fixedon one side of the upper side of a fixed base; a connecting bracket is vertically fixed between the reciprocating driving mechanism and a pushing mechanism; an unloading mechanism is arranged on the upper side of the pushing mechanism; the connecting bracket is horizontally and rotationally connected with an electromagnetic clutch; one end of a one-way clutch on one side of a rotating gear is horizontally arranged in the electromagnetic clutch; a pushing rotating shaft above a pushing bracket is horizontally arranged in the electromagnetic clutch; a damping mechanism is arranged at one end ofthe pushing rotating shaft; pipe pushing support rods are symmetrically arranged on the outer side of a pushing chain; and an unloading mechanism comprises a pipe guide inclined plate, a pipe stop rotating rod, a lower pipe cylinder and a lower pipe baffle plate. The pipe unloading and translation mechanism is reasonable in structural design, can gradually and stably unload pipes, and can flatly shift the pipes as needed efficiently and accurately to meet the machining and use demands.

Owner:桐乡市川泰纺织科技有限公司

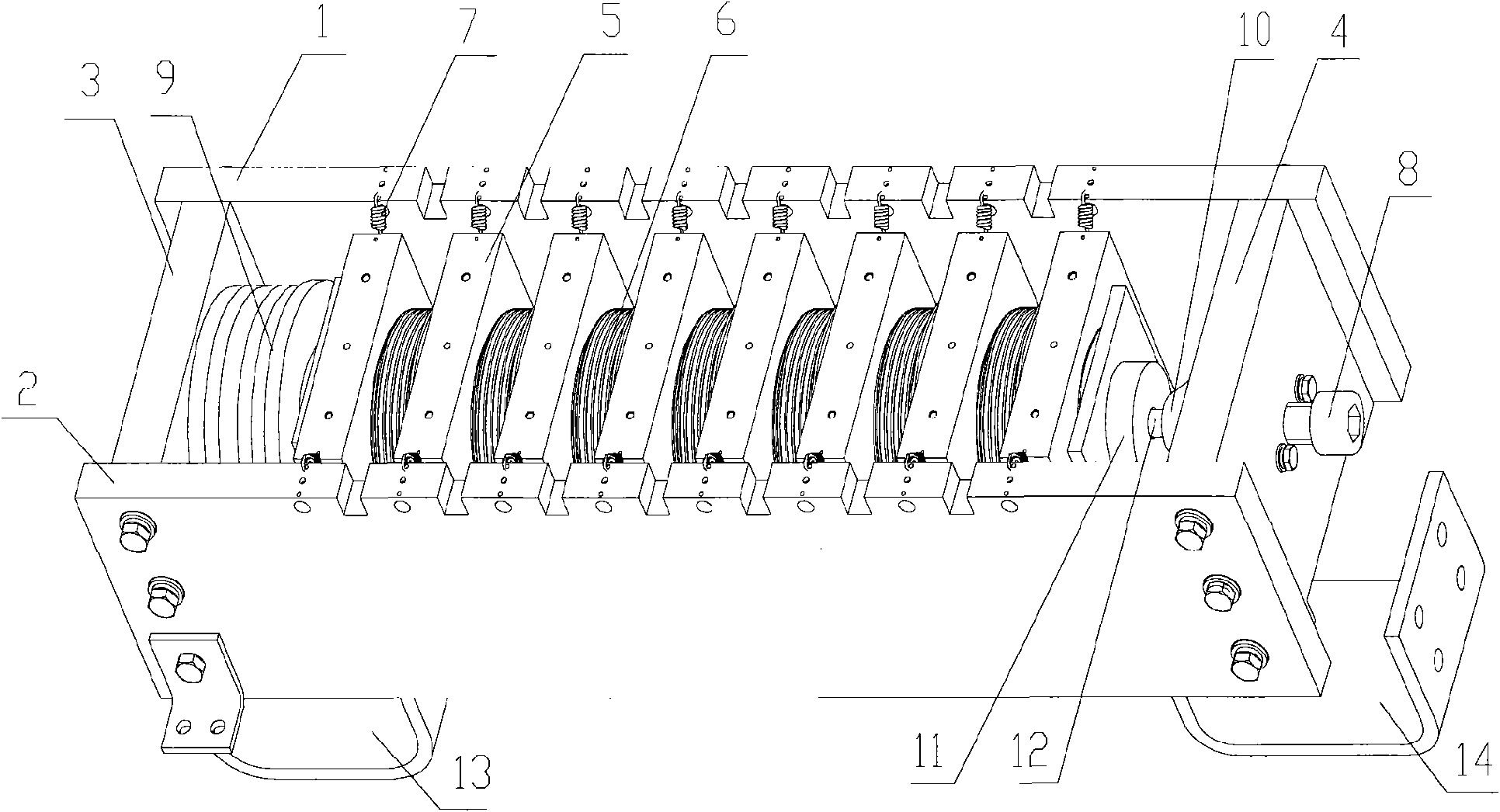

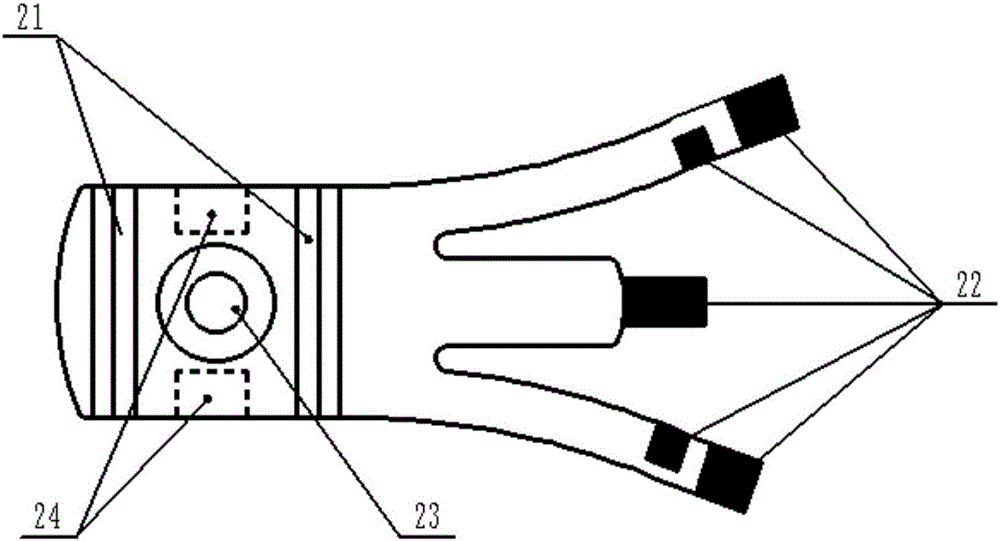

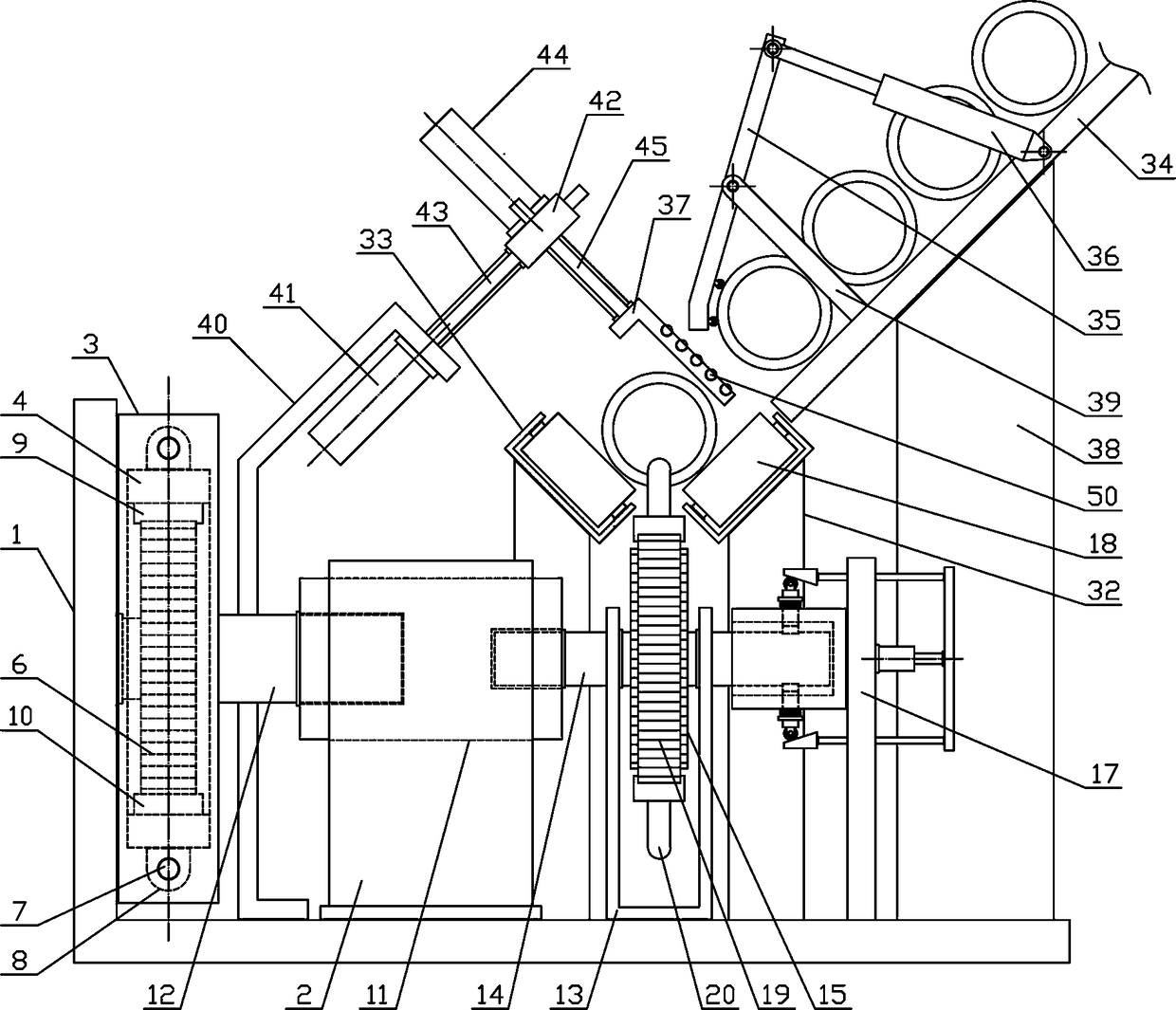

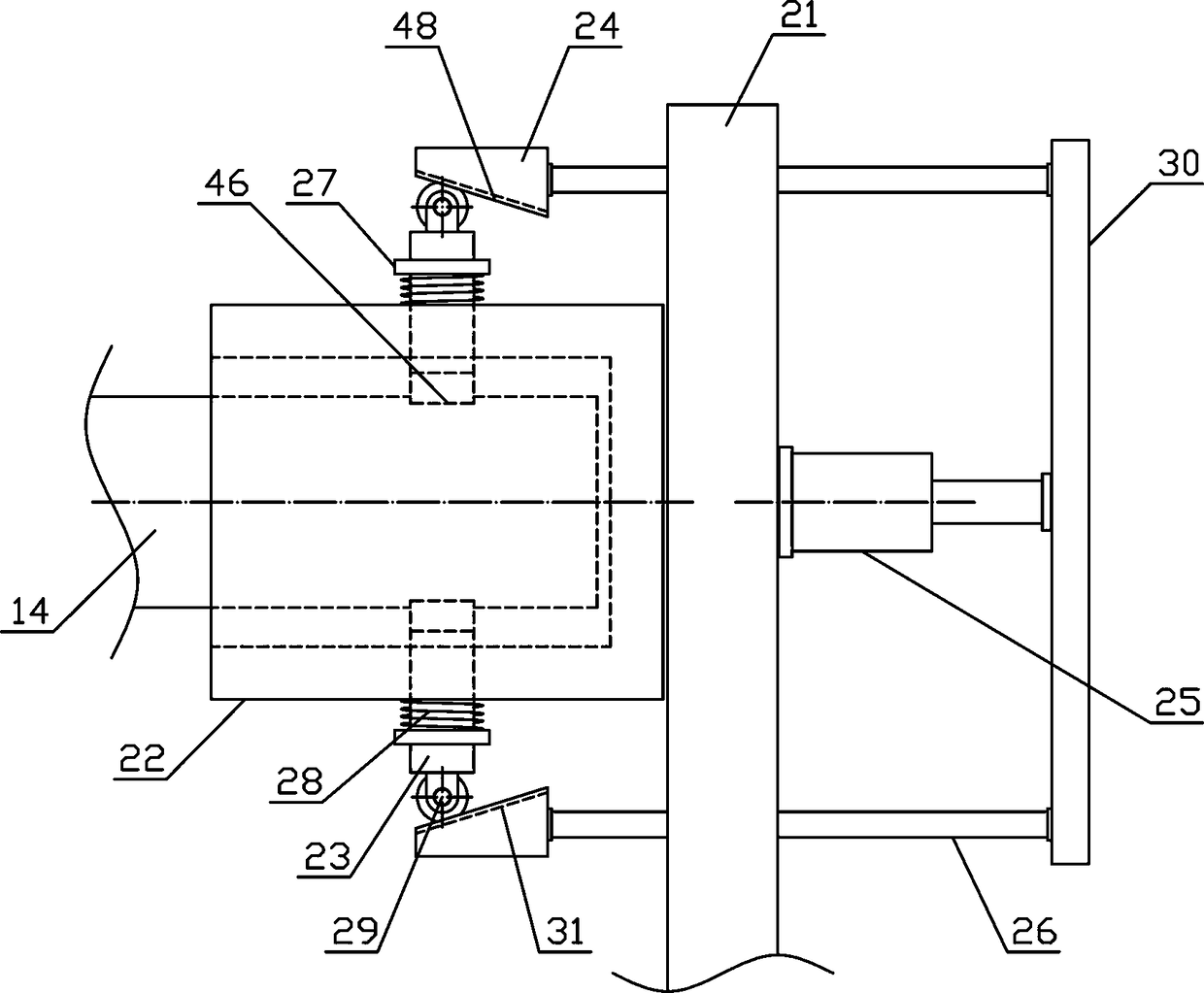

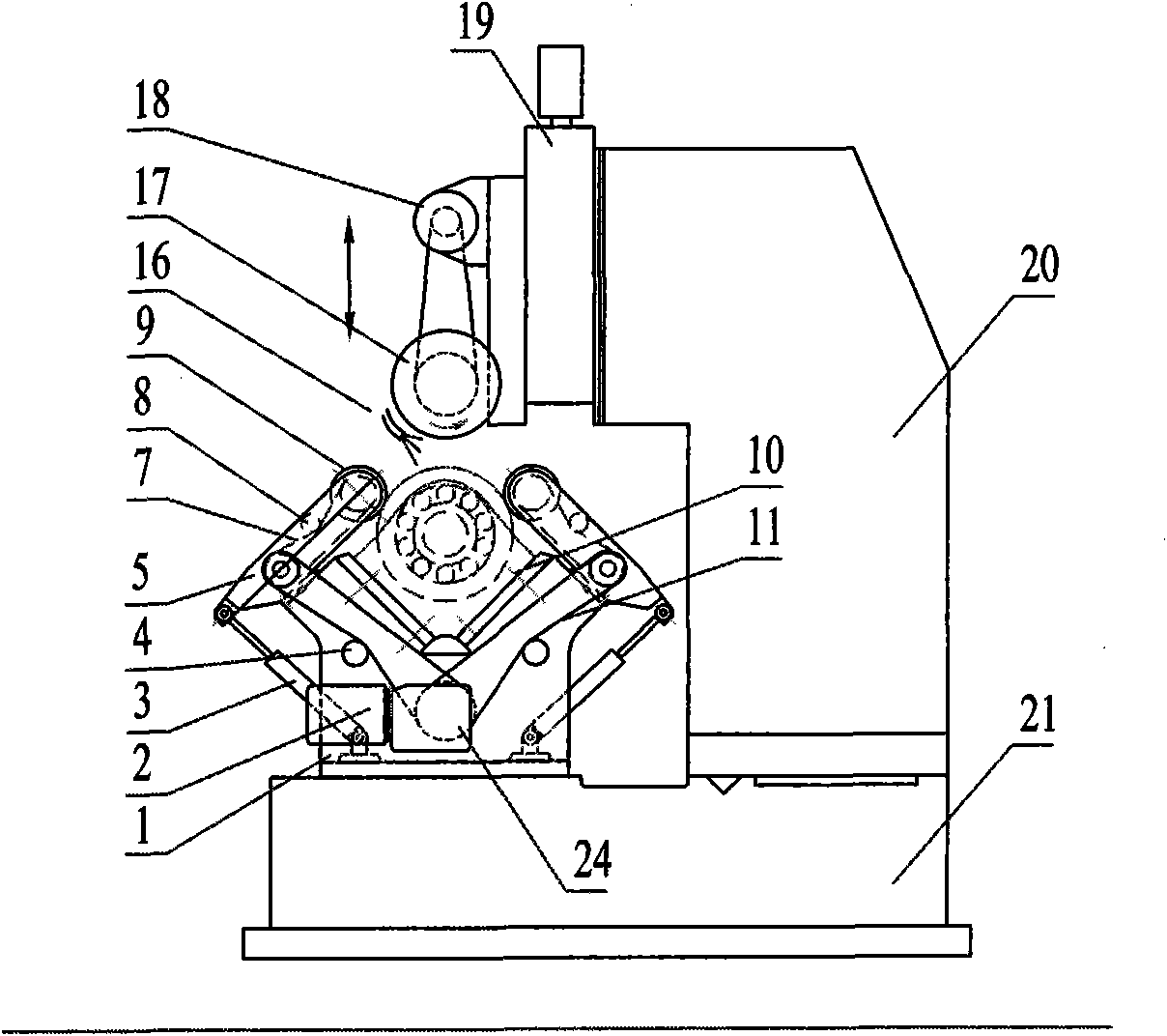

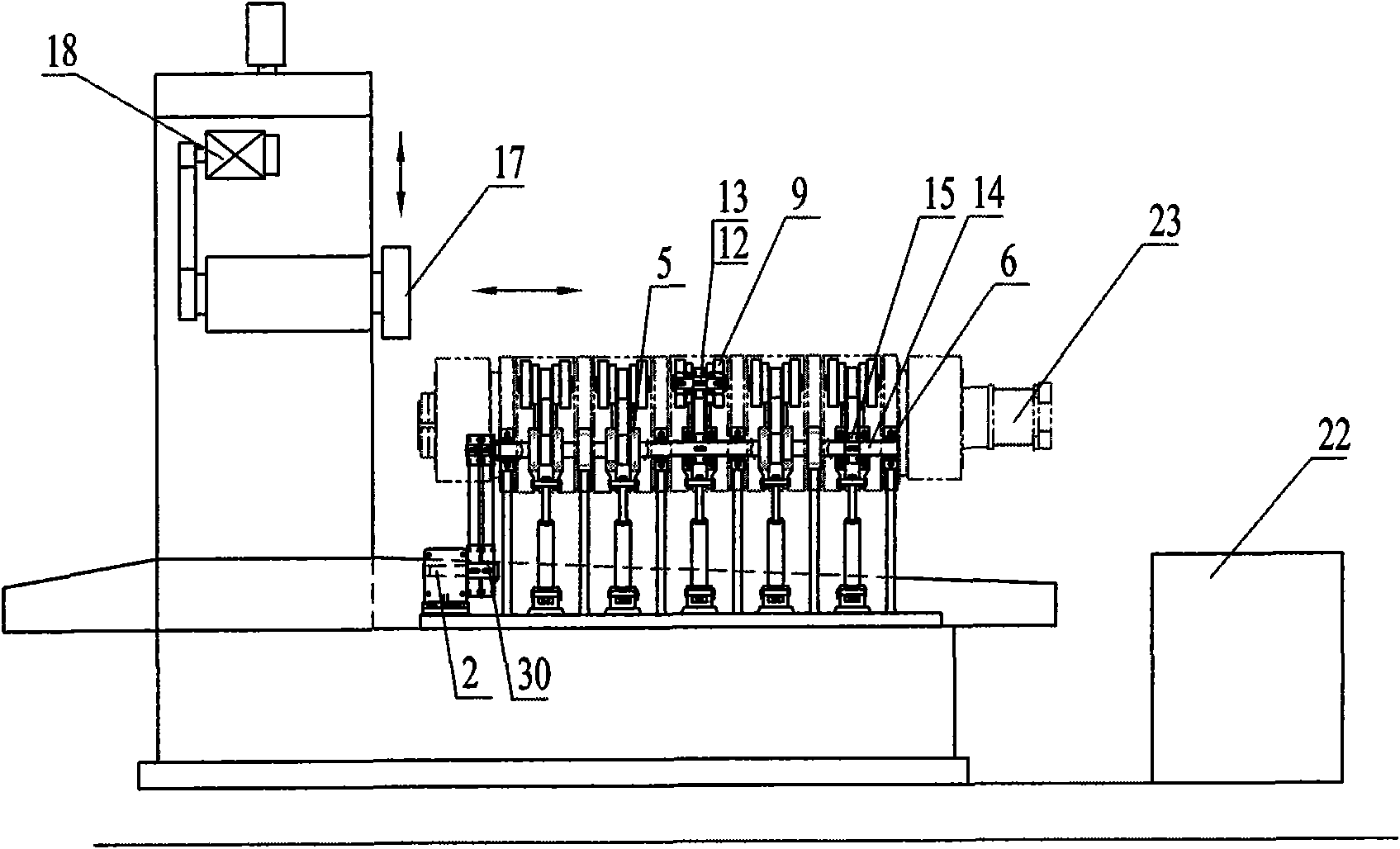

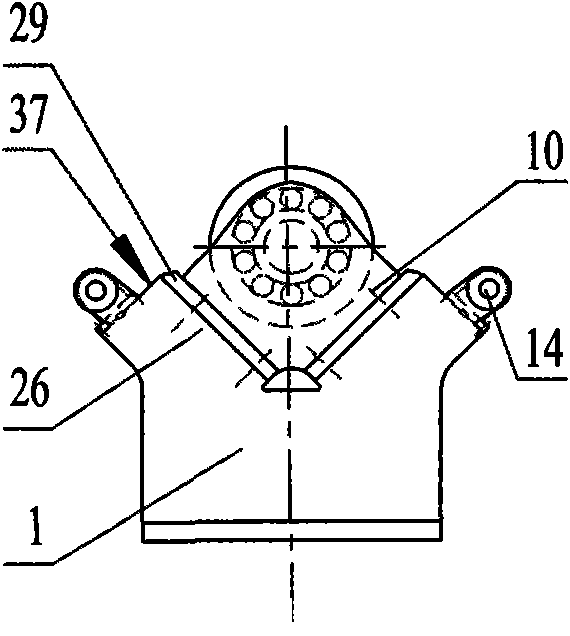

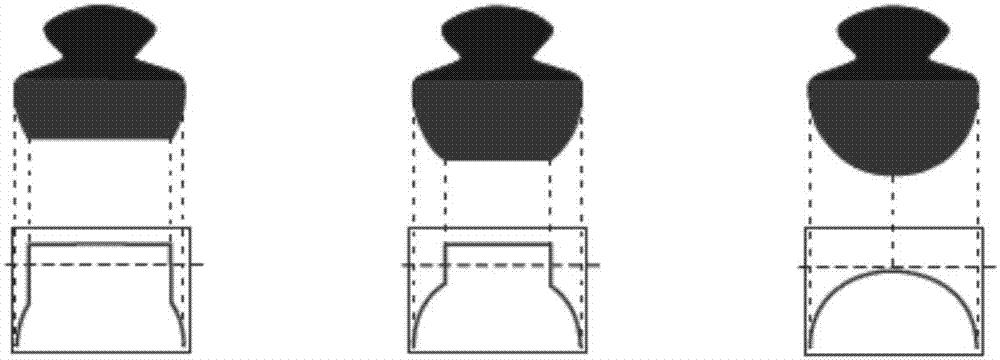

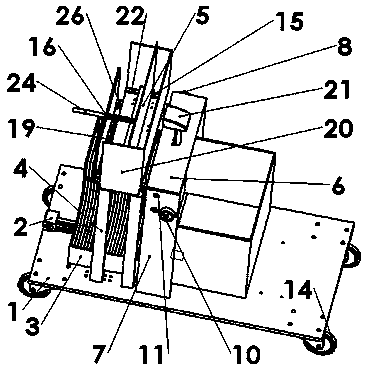

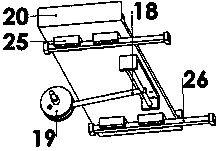

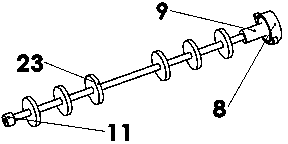

Multi-roller mill backing roller integral gapless repairing method and repairing device thereof

The invention relates to a multi-roller mill backing roller integral repairing method, which includes steps of: selecting, assembling and grinding, wherein bottom surface of a base plate (26) of a backing roller is used as installation standard, the backing roller to be repaired is integrally installed on a grinding processing standard surface of a reconditioning mold. The invention also relates to a multi-roller mill backing roller integral repairing device, which includes a mold arranged on a workbench (21). The mold comprises a fixed base (1) for supporting the backing roller to be repaired, the fixed base is provided with a compaction roller driving device with a power machine and a transmission mechanism and compaction devices which has same number with bearing roller on the backing roller and are arranged at one side or two sides of the backing roller to be repaired, a groove (29) which is adapted with shape of the base plate of the backing roller is arranged at upper end of the fixed base (1), and the groove is in V shape or circular arc shape. The invention can carry out integral gapless grinding for the backing roller to be repaired, realizes integral moulding grinding, and has advantages of simple process, high precision and low cost.

Owner:CERI TECH

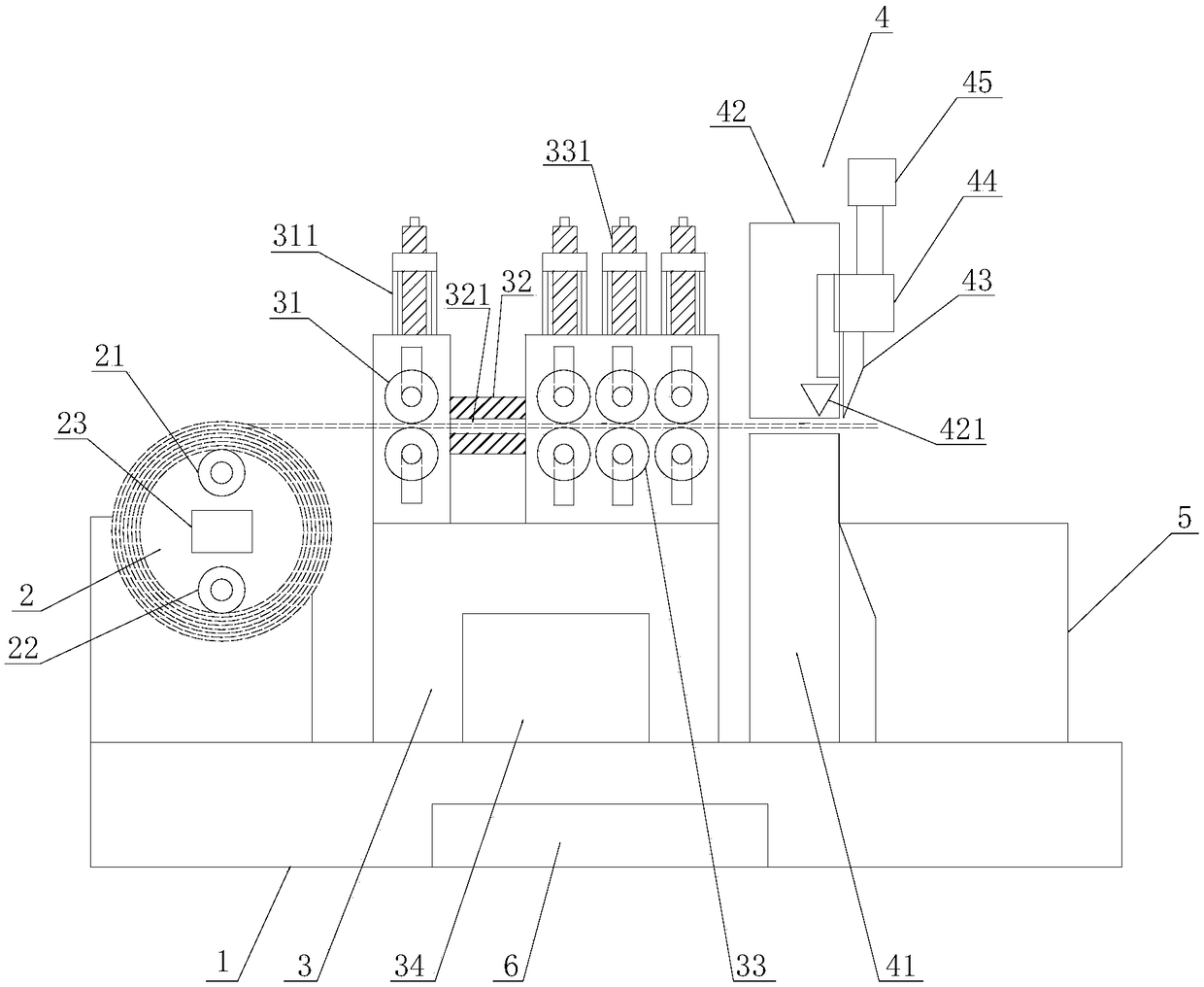

Unreeling and shearing device for bolt machining

PendingCN109014360AGuaranteed stabilityImprove uniformityShearing machinesShearing machine accessoriesEngineeringSurface smoothness

The invention discloses an unreeling and shearing device for bolt machining. The unreeling and shearing device for bolt machining comprises a base, a feed rack, an unreeling mechanism, a shearing mechanism, a collection barrel and a control mechanism. The unreeling mechanism comprises a feeding roller couple, a conveying block and straightening roller couples. The shearing mechanism comprises a shearing workbench, a fixed platform, a cutter, a connecting sliding block and a driving cylinder. The connecting sliding block can be driven by the driving cylinder to vertically slidably mounted on the sidewall of the fixed platform. The cutter is arranged below the connecting sliding block. Through mutual cooperation of the feeding roller couple, the conveying block and the straightening roller couples, a wire rod is ensured not to deflect through a locating through hole in the conveying process. The wire rod is straightened through the straightening roller couples. The surface smoothness andthe size uniformity of the wire rod are improved. Convenience is provided for subsequent machining. The machining quality of bolts is improved. The rejection rate is reduced. The working efficiency is improved. Through mutual cooperation of a meter counter and the cutter, the unreeling and shearing device for bolt machining meets the requirement for machining of bolts with different lengths, is accurate in shearing and increases the material utilization rate.

Owner:HAIYAN HATEHUI MACHINERY HARDWARE

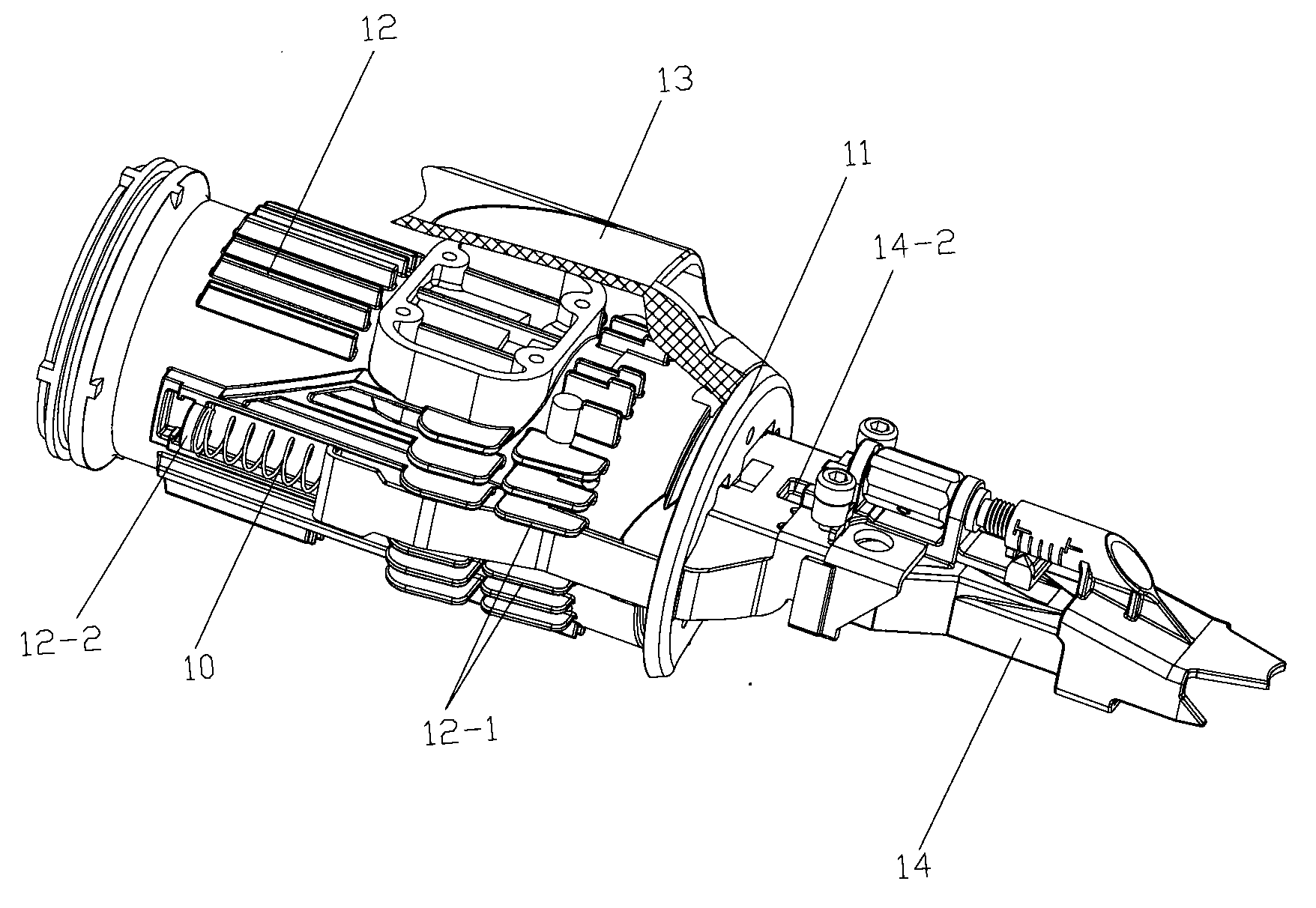

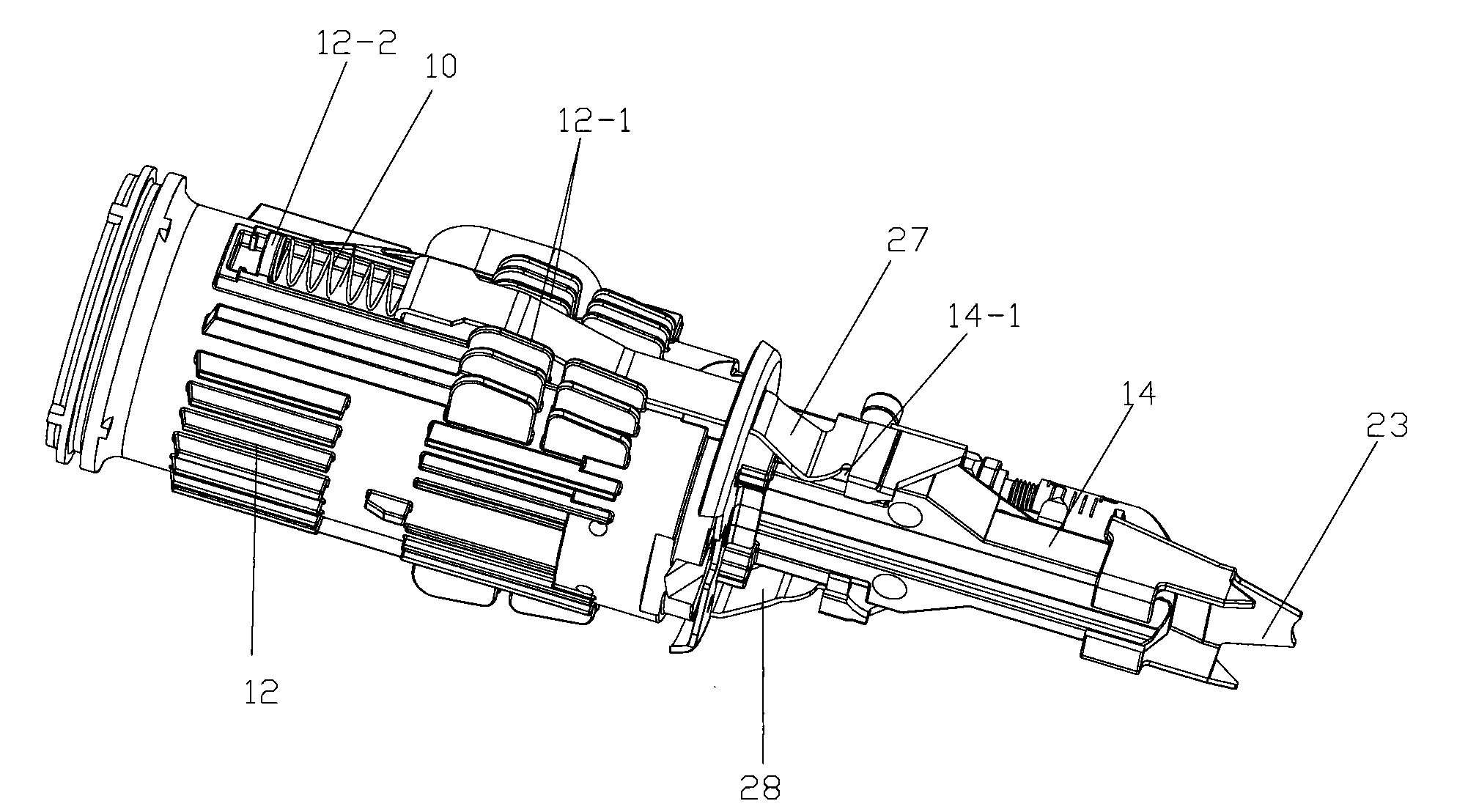

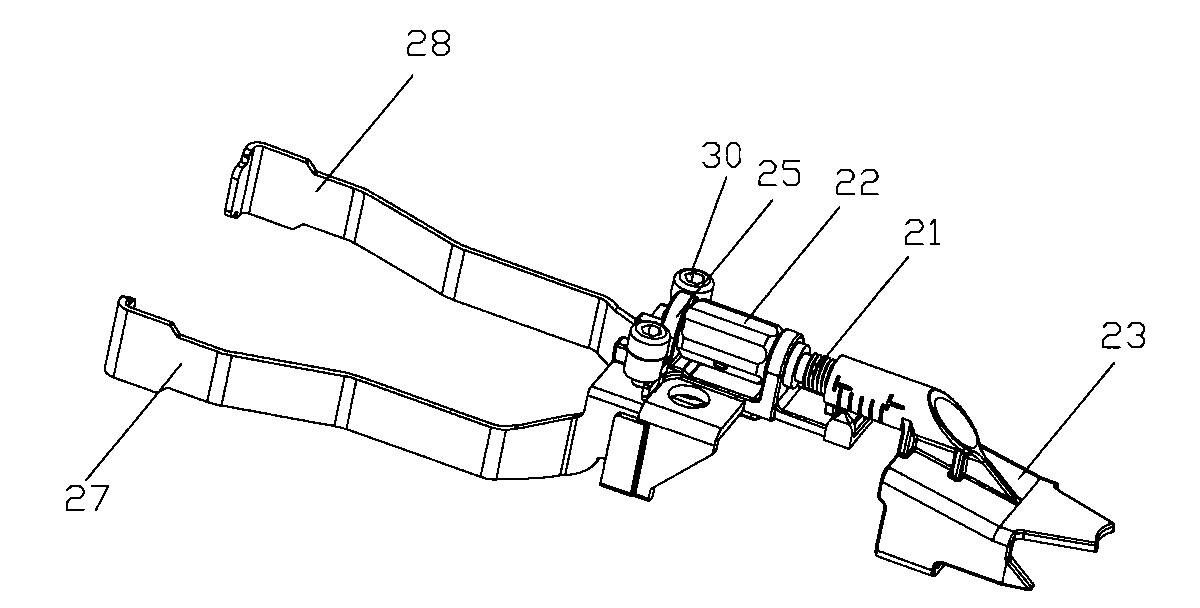

Fuel-powered nail gun

The invention relates to a fuel-powered nail gun and belongs to the technical field of fuel-powered tools. An air cylinder is arranged in the shell of the nail gun; the lower part of the air cylinder is a gun mouth; a vertical sliding rail is arranged in the gun mouth; a striking component striking nails along the vertical sliding rail is arranged at the lower end of a piston in the air cylinder; a limit groove is reserved on the gun mouth; a bunting component capable of moving along the limit groove with respect to the gun mouth is arranged on the gun mouth; guide grooves and flanges are reserved on two sides of the air cylinder respectively; and a left bunting arm and a right bunting arm, which are engaged with the bunting component, are arranged in the guide grooves on two sides respectively. The fuel-powered nail gun is characterized in that a tenon and a mortise which are mutually embedded are reserved at the lower ends of the left and right bunting arms respectively. Because the left and right bunting arms are manufactured respectively, the fuel-powered nail gun has the advantages of simple structure, saved materials and low cost; and because the left and right bunting arms are mutually tenoned and embedded together, the left and right bunting arms are uniformly stressed.

Owner:NANJING TENGYA PRECISE TECH DEV CO LTD

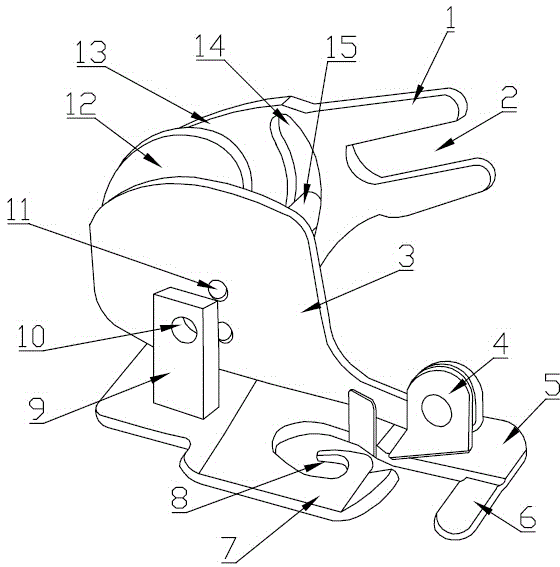

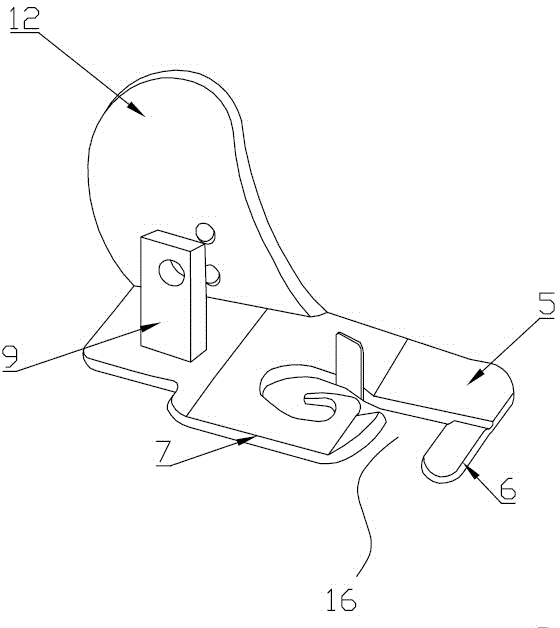

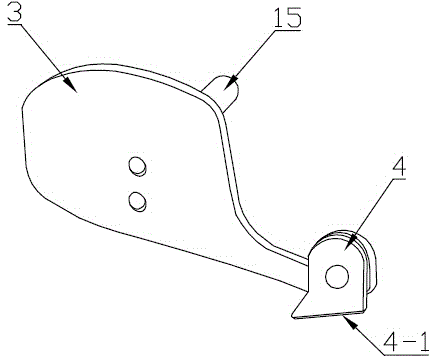

Sewing machine edge cutting presser foot

ActiveCN104088087ARealize the processing effectThe seaming process is neat and convenientPressersEngineeringDeckle

The invention discloses a sewing machine edge cutting presser foot which comprises a presser foot plate, a cutter plate and a swing handle. The presser foot plate comprises a cloth pressing foot, a guide plate and a supporting plate, wherein the supporting plate is perpendicular to the cloth pressing foot and the guide plate. One end of the cloth pressing foot is bent to form a stitch moving groove. One lateral side of the guide plate extends to form a lifting plate. The cutter plate comprises a vertical plate, a cutter and a slide rod, wherein the cutter is installed on the vertical plate, the vertical plate and the supporting plate are fixed through a cylindrical pin, and the cutter is placed above the guide plate. The swing handle comprises a pull handle and a fixed plate. A fork opening is formed in the pull handle. A slide groove corresponding to the slide rod is formed in the fixed plate. The fixed plate is installed on the other side face of the supporting plate through a cylindrical pin. By means of the sewing machine edge cutting presser foot, the deckle edge can be cut while lockstitch is conducted.

Owner:海门华夏时丽网络科技服务有限公司

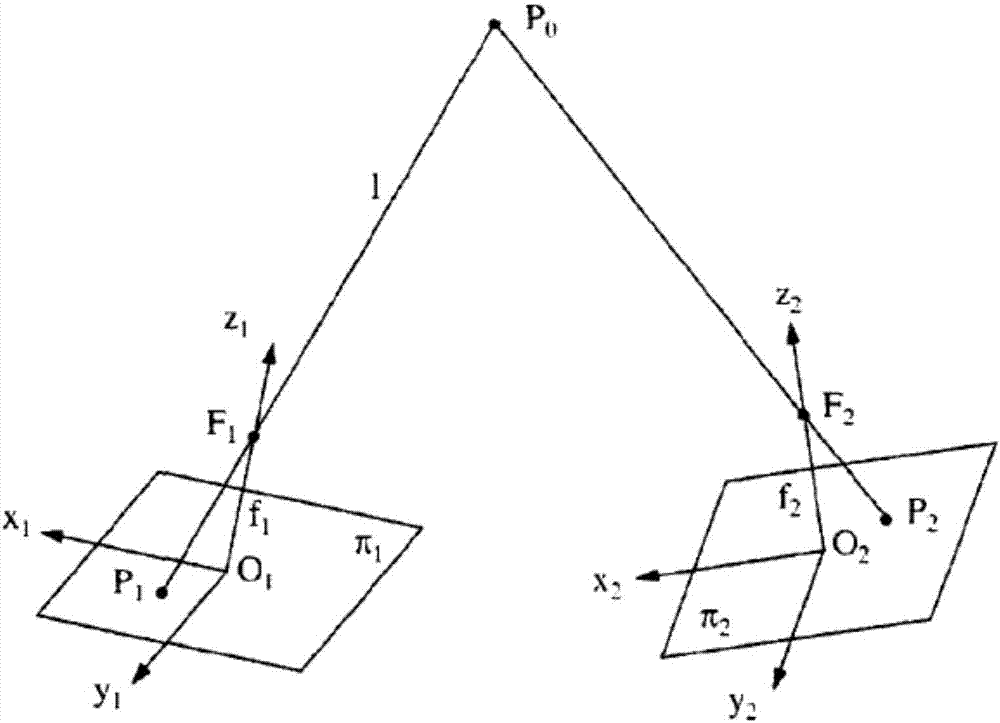

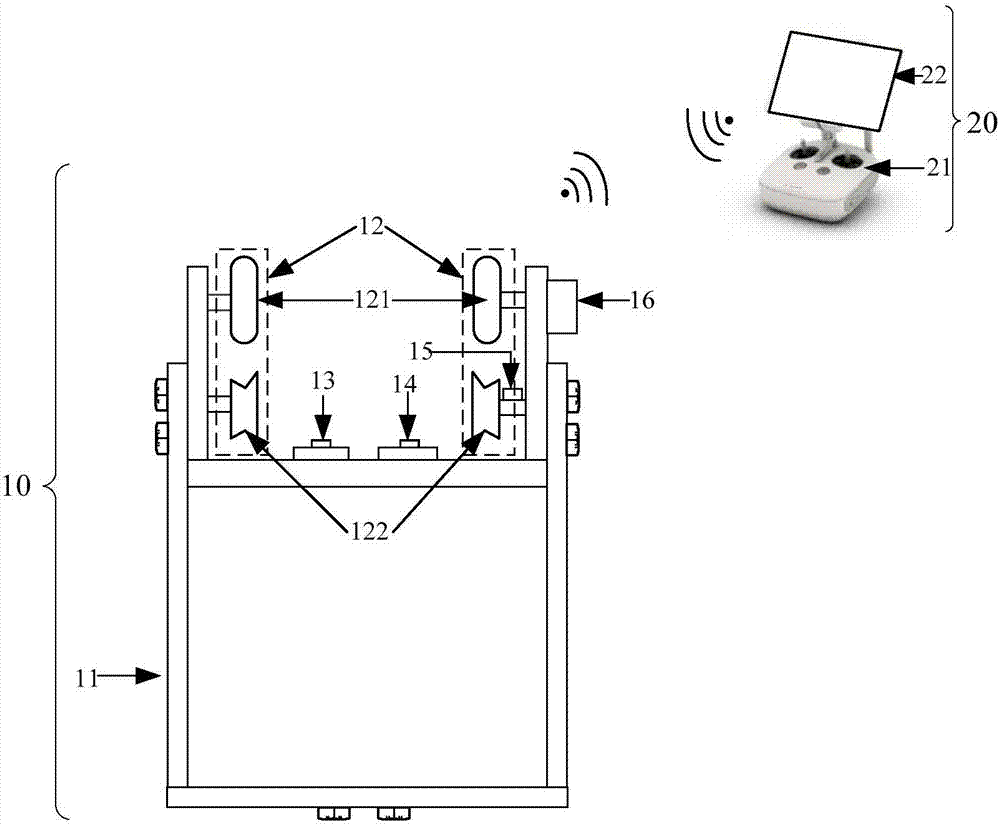

Overhead n-shaped rigidly suspended contact wire abrasion continuous measurement apparatus

PendingCN107388969ARealize continuous measurementSimple structureUsing optical meansContinuous measurementRemote control

The invention provides an overhead n-shaped rigidly suspended contact wire abrasion continuous measurement apparatus. The overhead n-shaped rigidly suspended contact wire abrasion continuous measurement apparatus includes a host computer and a lower computer, wherein the host computer includes a detection vehicle body, a running mechanism on the detection vehicle body, a 2D laser abrasion measurement apparatus, a abrasion morphology image acquisition apparatus, an equidistant synchronous trigger apparatus and a data processing unit, wherein the running mechanism takes a groove of a busbar as a continuous moving track, and is used for going forward, going backward or stopping under control of the host computer; the 2D laser abrasion measurement apparatus is used for measuring the two dimensional space contour data of a contact wire; the abrasion morphology image acquisition apparatus is used for acquiring the image information of the contact wire; the data processing unit is used for calculating abrasion according to the contact wire contour data, synchronously integrating the abrasion and image information and then sending the abrasion and image information to the host computer; the equidistant synchronous trigger apparatus is used for providing an equidistant pulse trigger signal; and the host computer includes a remote control unit and a display which are respectively used for sending a running control command to the lower computer and displaying the abrasion and image information sent from the lower computer.

Owner:RAILWAY INFRASTRUCTURE TESTING RES INST CHINA ACAD OF RAILWAY SCI +2

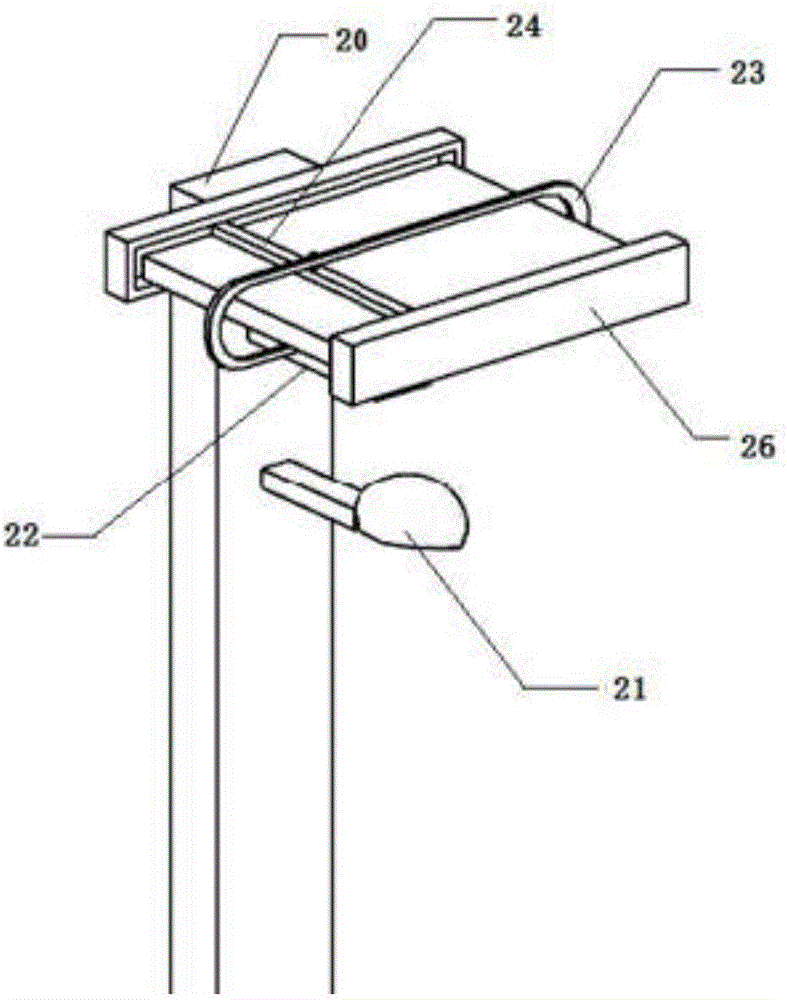

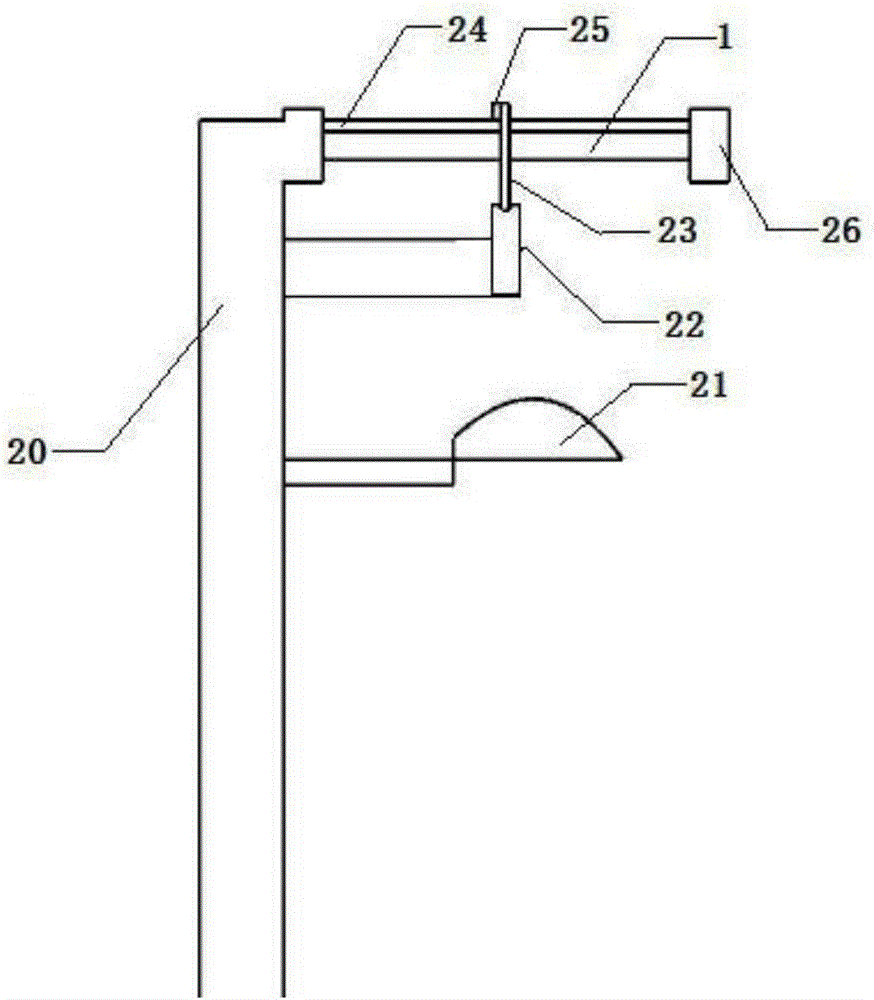

Solar street lamp with cleaning device

InactiveCN106838797ASolve the problem that it is easy to be exposed to wind, sun and rain.Troubleshoot prone to failureMechanical apparatusPhotovoltaicsSolar street lightEngineering

The invention provides a solar street lamp with a cleaning device. The solar street lamp comprises a lamp pole, a street lamp body, a solar battery panel, a power device, a power device frame, a stirring type power device for providing power, a shell, an installation shaft and a stirring wheel, wherein the solar battery panel covers the top of the street lamp body; the power device is fixed on the lamp pole, the street lamp body or the solar battery panel; the power device frame surrounds the solar battery panel; two sides of the solar battery panel are provided with guide rails; the shell and the installation shaft are fixed on the position of the power device; the stirring wheel is driven by the power device for a traction belt to proceed; the stirring wheel is provided with stirring wheel teeth matched with traction belt holes. By use of the solar street lamp, the volume and the cost of a power device are reduced while the cleaning problem of a high altitude solar panel is solved, and therefore, the solar battery panel also can perform a function of a top cover and a lampshade so as to block the lamp body and the power device.

Owner:浙江比弦物联科技有限公司

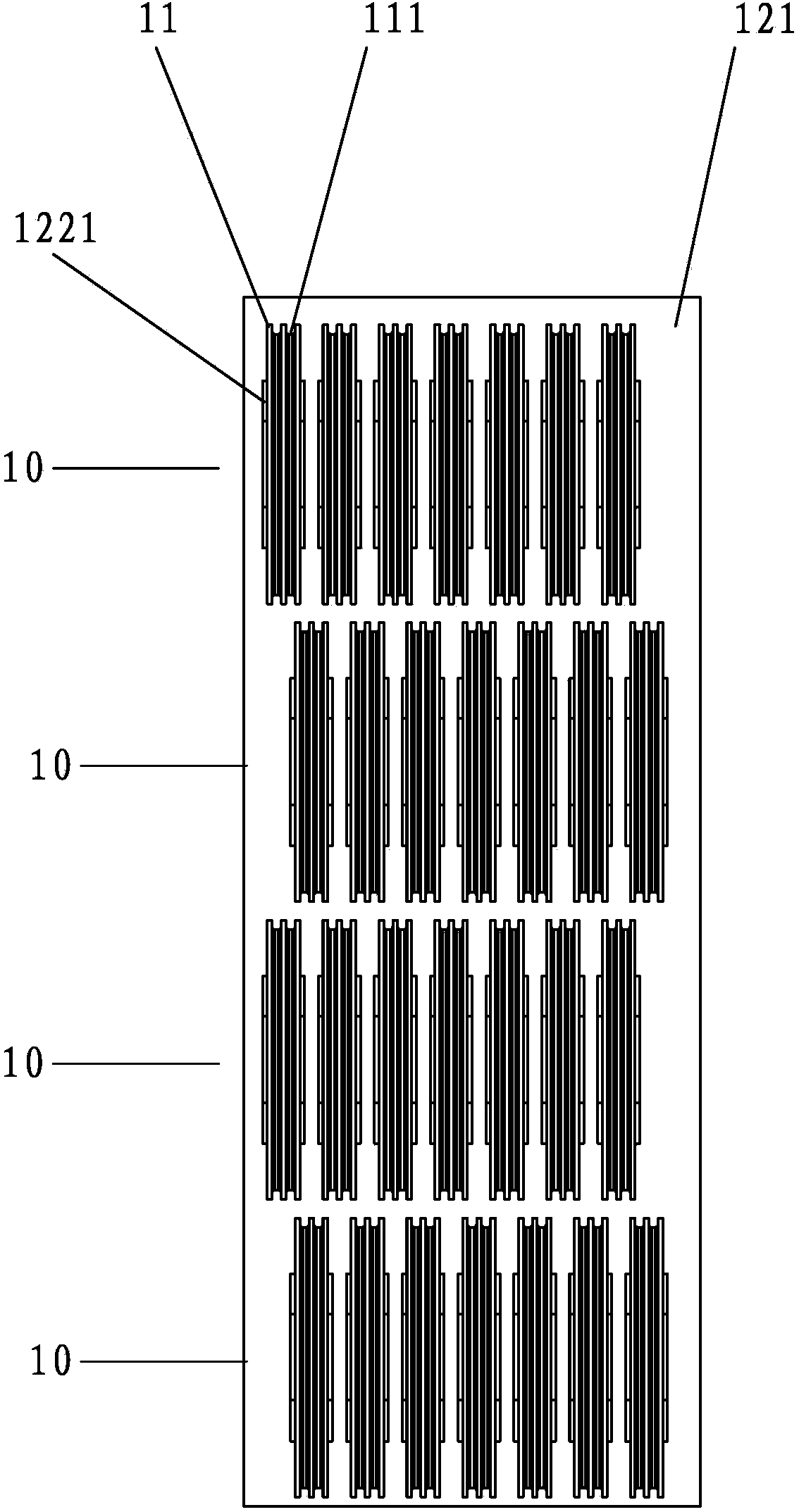

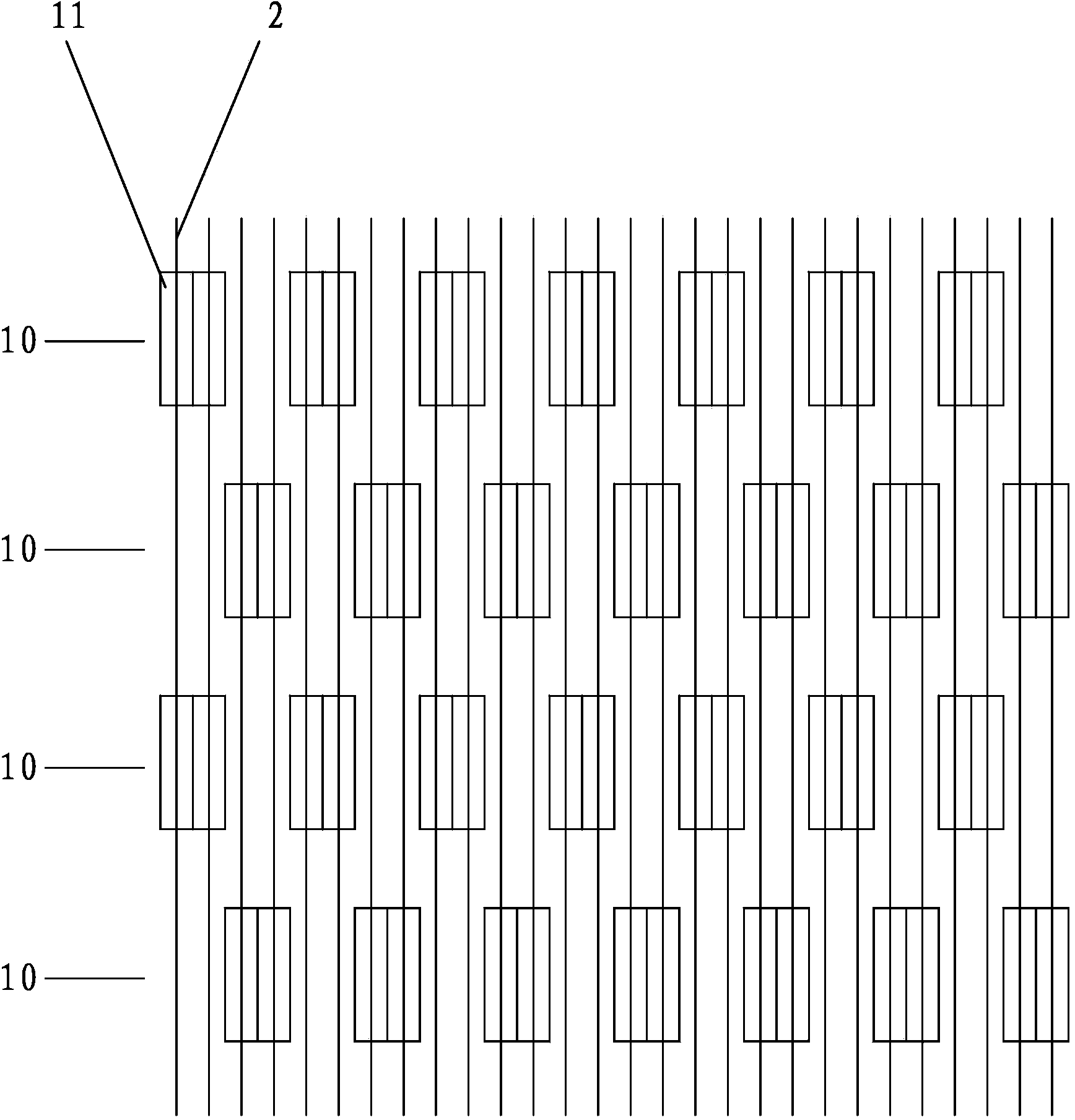

Novel tension adjustment mechanism of multi-wire diamond wire saw

ActiveCN103507176AArrangement rules are reasonableEasy alignmentWorking accessoriesStone-like material working toolsDiamond wire sawEngineering

The invention provides a novel tension adjustment mechanism of a multi-wire diamond wire saw. The novel tension adjustment mechanism comprises a plurality of tension adjustment units, and the tension adjustment units comprise tensioning wheels and tension driving devices. Two wire grooves are evenly formed in each tensioning wheel. Each tension adjustment unit is tabular. The tension adjustment units are arranged in rows, the rows of tension adjustment units are arranged in a staggered mode, tension adjustment units in interval rows are in one-to-one correspondence mutually, and the distances between planes where the adjacent wire grooves are located are equal. Therefore, one or two wire grooves of each tension adjustment unit can be selected and used by people, and the positions of beaded wires can be conveniently adjusted. The tension adjustment units are tabular so as to be conveniently and densely arranged in a regular and reasonable mode, space is saved, and regular beaded wire arrangement and aligning are facilitated. Tension adjustment can be conducted on beaded wires respectively or simultaneously, and therefore the beaded wires are strong in flexibility. The number of the beaded wires can be increased or reduced, beaded wire distribution forms can be changed, and distances between the beaded wires can be adjusted to adapt to all kinds of cutting thicknesses.

Owner:HUAQIAO UNIVERSITY

Wax mold combination positioning device for precision casting of structural part

The invention discloses a wax mold combination positioning device for precision casting of a structural part. The wax mold combination positioning device comprises a base and a rotary positioning device, wherein a raised center shaft is arranged on the upper surface of the base; a center hole communicated with the upper surface and the lower surface of a wall body and used for socketing and positioning a sprue is formed in the middle of the rotary positioning device; the rotary positioning device is arranged on the center shaft by the center hole in a sleeving manner, and rotationally connected with the base around the center shaft; an operating platform used for placing a wax mold is arranged on the upper surface of the rotary positioning device. According to the wax mold combination positioning device, the sprue can be located in the center of the wax mold, and can be vertical, so that a whole mold assembly rotates stably in a housing manufacturing process, the mold assembly and a ceramic sprue cup on the mold assembly cannot be damaged, and a manufactured housing is uniform in thickness and good in performance; the wax mold combination positioning device is labor-saving compared with the traditional combination scheme; the probability of mold assembly damage caused by mold assembly moving and collision in a manual combination process is reduced.

Owner:CHINA HANGFA SOUTH IND CO LTD

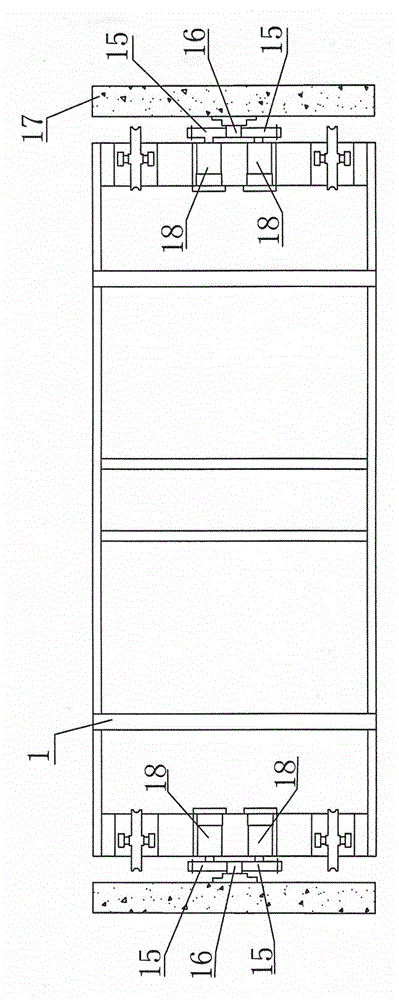

Driving device for lifting platform of stereo garage

The invention provides a driving device for a lifting platform of a stereo garage. The driving device for the lifting platform of the stereo garage comprises four power gears, two vertical double-faced racks and four hydraulic motors, two hydraulic motors are mounted at the left end of a steel truss of the lifting platform, the other two hydraulic motors are mounted at the right end of the steel truss of the lifting platform, the power gears are mounted on the output shafts of the hydraulic motors, the vertical double-faced racks are mounted on the walls of the stereo garage, the faces of the vertical double-faced racks are engaged with the power gears, and driven gears witch are engaged with the vertical double-faced racks are mounted on the steel truss of the lifting platform. According to the driving device for the lifting platform of the stereo garage, the hydraulic motors, the power gears and the driven gears are arranged both at the left end and the right end of the steel truss of the lifting platform, each face of the vertical double-faced racks is engaged with one power gear and one driven gear, therefore, the driving device for the lifting platform of the stereo garage is balanced vertically and is symmetrical laterally, and the lifting platform is table and does not incline or swing in the lifting operation and when a car is parked or picked up. The hydraulic motors, the power gears and the driven gears are all arranged in the lifting platform, the vertical double-faced racks are mounted in the garage, and thus the driving device for the lifting platform of the stereo garage has the advantages that the structure is compact, no additional machine room needs to be built on the ground, and the land surface area is saved.

Owner:JIANGXI ZHONGTIAN INTELLIGENT EQUIP CO LTD

Text sorting machine

The invention discloses a text sorting machine which comprises a collecting device, a paper feeding device, a scanning device, a storing device, a sorting device and a bottom plate. The sorting device is fixed on the bottom plate, the storing device is fixed on the sorting device, the paper feeding device sleeves the storing device, the collecting device is fixed obliquely above the top of the paper feeding device, the scanning device is fixed at the top of the paper feeding device, and the sorting device is located at the bottom of the storing device. By the arrangement, the dumping problem of paper sheets is solved through a slider-crank mechanism; the paper sheets rolled in can be enabled to vertically fall into corresponding case cells through a paper twisting wheel mechanism, and deflection and jamming never occur; sorting of large batches can be realized through a storage box mechanism by the aid of simple concept of sub-areas.

Owner:NANJING UNIV OF SCI & TECH

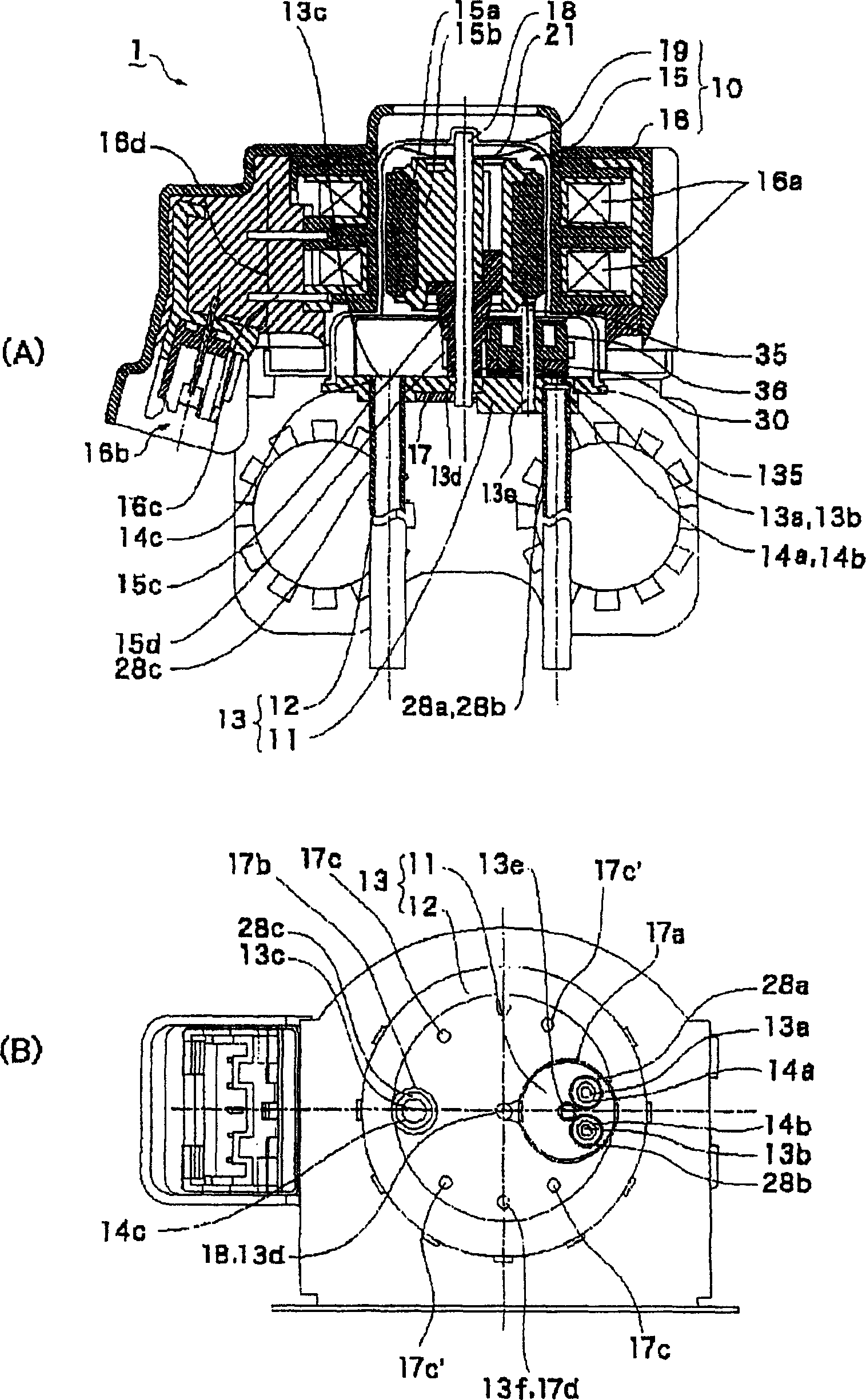

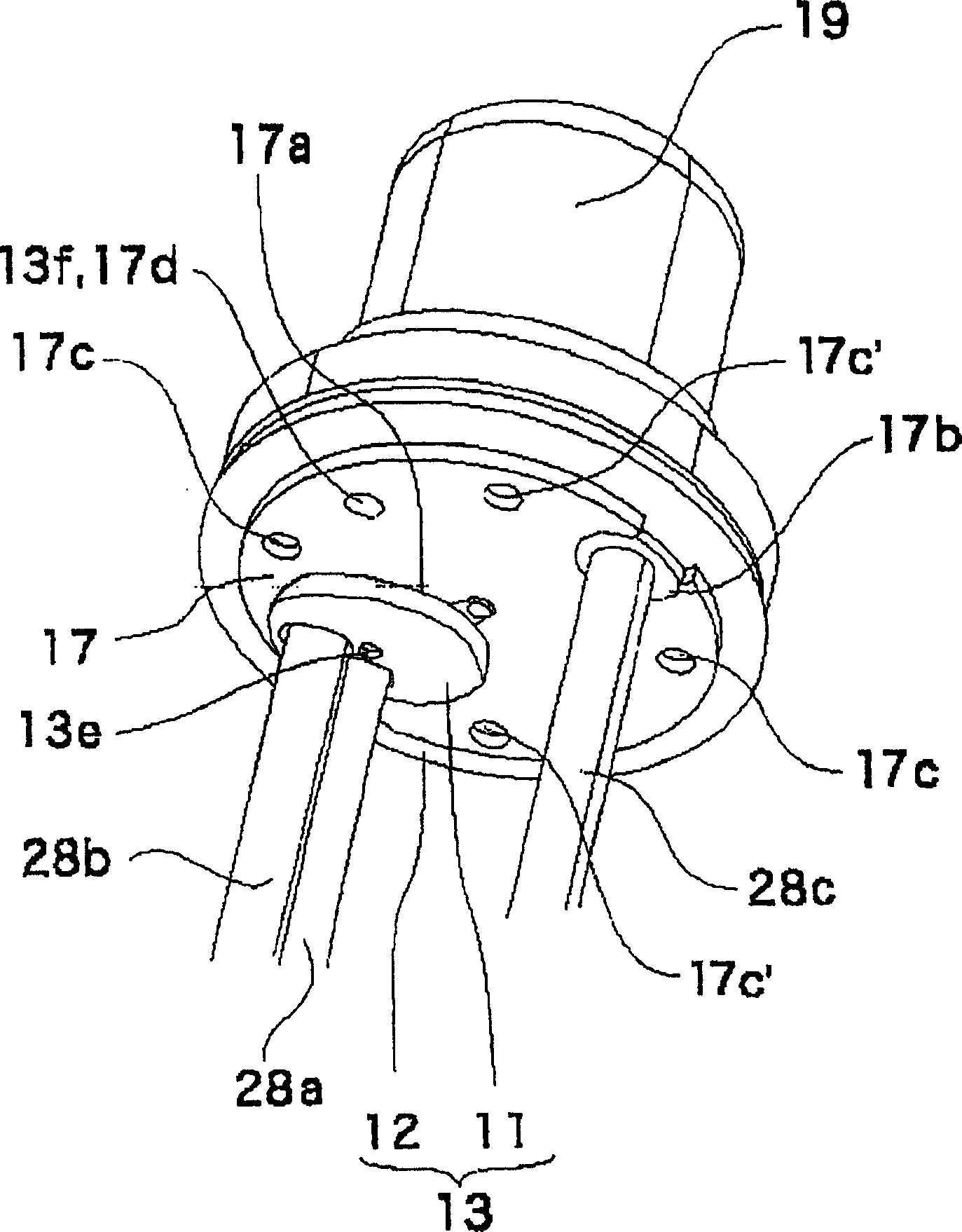

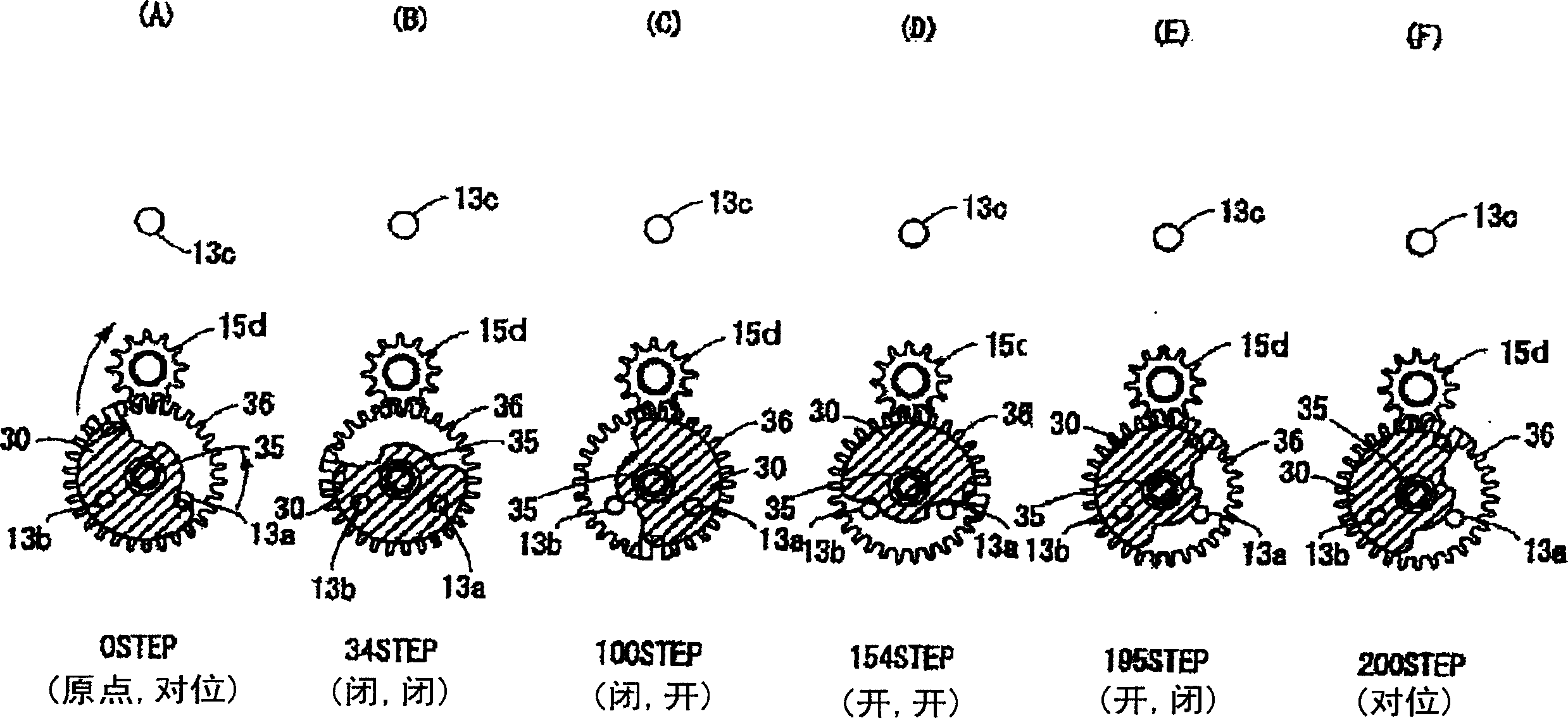

Valve drive device

ActiveCN1752493AHigh precisionNo skewOperating means/releasing devices for valvesMultiple way valvesEngineeringGuide tube

To provide a valve drive device enabling to attach pipe to a part on which a valve element slides without generating deformation and capable of reducing manufacturing cost of a valve seat plate.The valve seat plate 13 of a valve device consists of a first plate structure member 11 constructing a zone where a flow out opening is formed, and a second plate structure member 12 to which the first plate structure member 1 is joined. The second plate structure member 12 is formed by press work, and includes a third plate structure member 17 for preventing deformation with resisting pressure in a sealed space defined by the valve seat plate 13 and a sealed case 19 on a back surface side thereof. The first plate structure member 11 is formed by cutting work of SUS material thicker than the second plate structure member 12.

Owner:SANKYO SEIKI MFG CO LTD

Equipment and process for processing bamboo split roll

InactiveCN109397437ANo disconnectionNo degumming will occurCane mechanical workingGlue gunsEngineeringMechanical engineering

The invention relates to the processing technology of bamboo split rolls, in particular to equipment and a process for processing a bamboo split roll, and specially relates to the processing field ofbamboo split rolls. The equipment comprises a feeding device for conveying and cutting off a bamboo split curtain along a braided wire direction and an axial feeding device for conveying bamboo splitsheets formed by cutting off the bamboo split curtain along the length direction of the bamboo split. The conveying directions of the feeding device and the axial feeding device are mutually perpendicular. The equipment also comprises an adhering device for adhering front and back bamboo split sheets end to end in the length direction of the bamboo split, a slitting device for slitting the bamboosplit curtain formed by adhering the bamboo split sheets in the length direction of the bamboo split curtain and a rolling device for rolling the slit bamboo split long curtains. The feeding device, the axial feeding device, the adhering device, the slitting device and the rolling device are arranged successively. The bamboo split rolls do not shift if being conveyed, split clash during slitting is avoided, distorsion is avoided during rolling, and no gaps are available in the middle of the bamboo split roll.

Owner:ZHEJIANG GUANGXIN BAMBOO BASED MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com