Multi-roller mill backing roller integral gapless repairing method and repairing device thereof

A repairing method and rolling mill technology, which is applied in the field of integral gapless repair of backing rolls of multi-roll mills and its repairing device, can solve problems such as manufacturing errors, uneven gaps, and difficulty in ensuring the quality of backing roll workpieces, and achieve the elimination of internal gap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

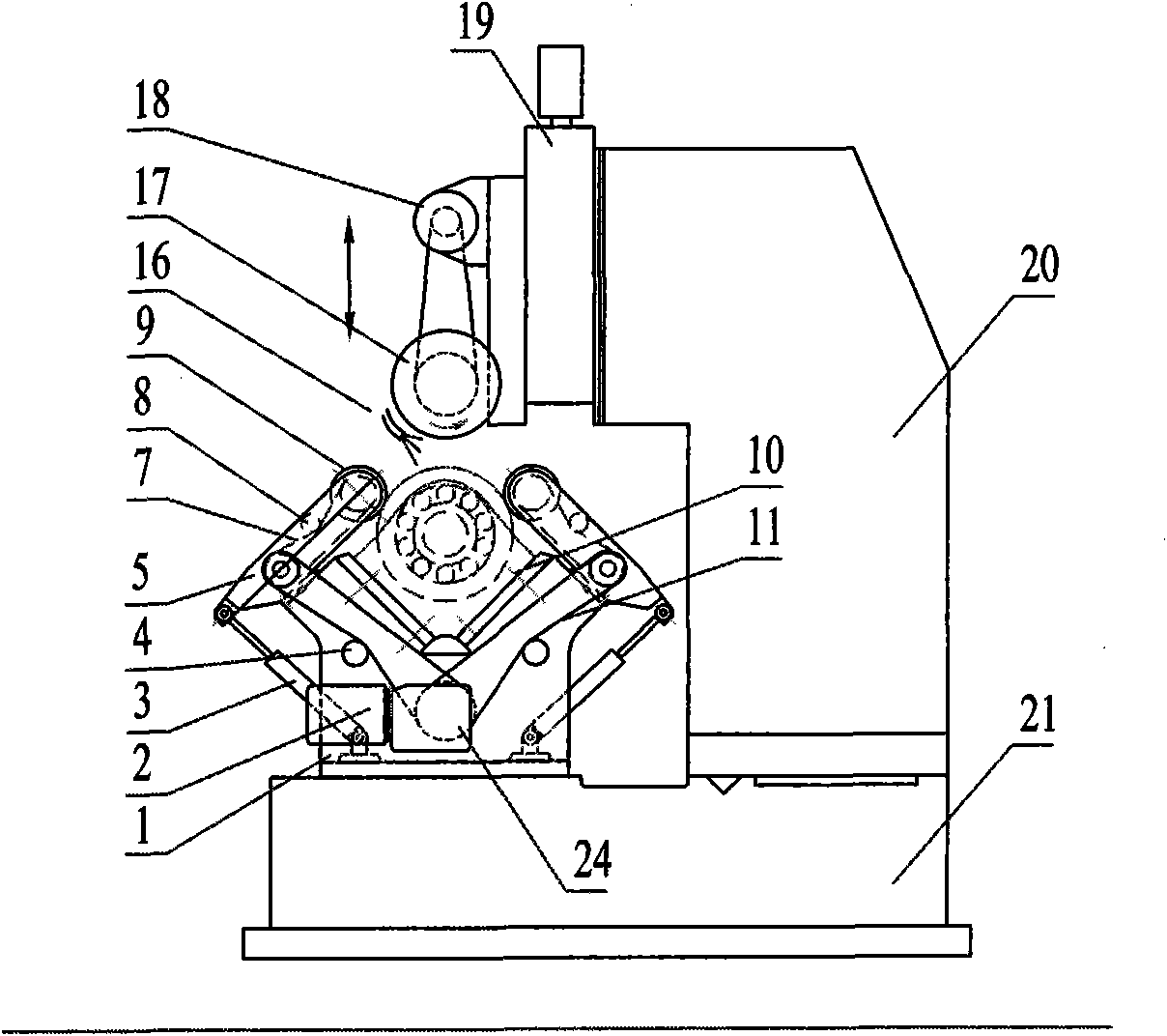

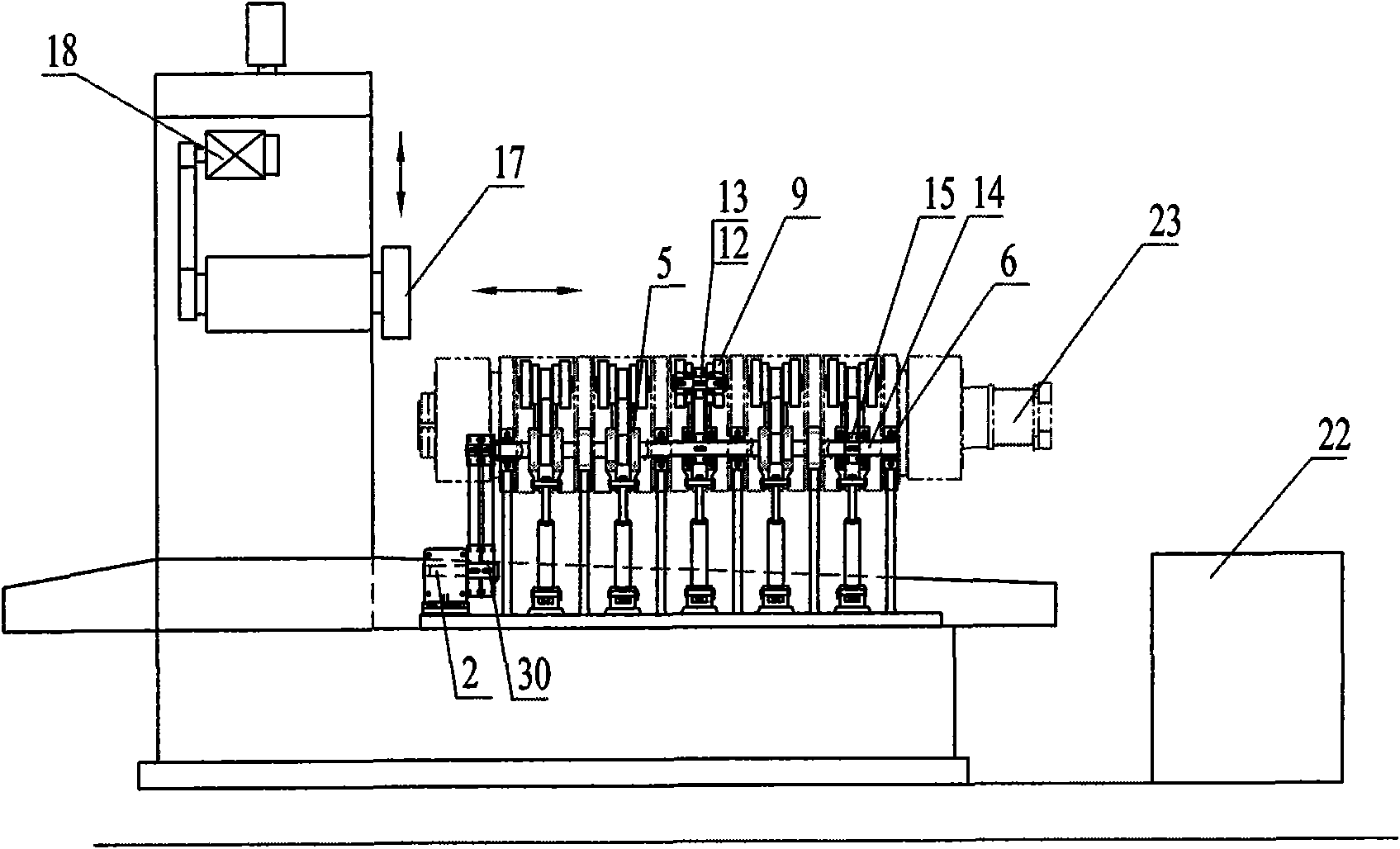

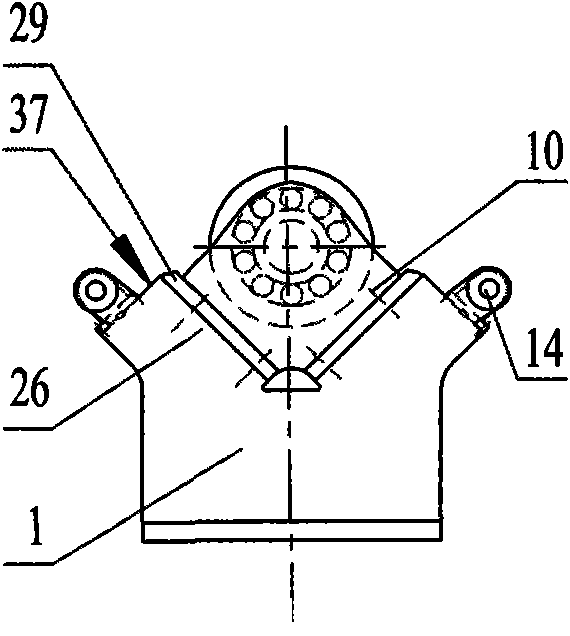

[0038] The method for repairing the backing rolls of a multi-roll mill without gaps as a whole and the specific implementation of the repairing device thereof according to the present invention will be further described below in conjunction with the accompanying drawings.

[0039] see figure 1 and figure 2 , the device for repairing the backing rolls of a multi-roll mill without gaps as a whole according to the present invention includes a mold set on the workbench 21 . in:

[0040] The mold includes a fixed base 1 supporting the backing roll to be ground, on which a pinch roller driving device with a power mechanism and a transmission mechanism and the same number of bearing rollers 27 as the number on the backing roll are installed on the fixed base. Hold-down device on one or both sides of the backing roll to be ground. figure 1 The repair device shown has hold-down devices on both sides of the backing roll to be reconditioned.

[0041] The workbench 21 is a workbench ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com