Patents

Literature

873 results about "Strip mill" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

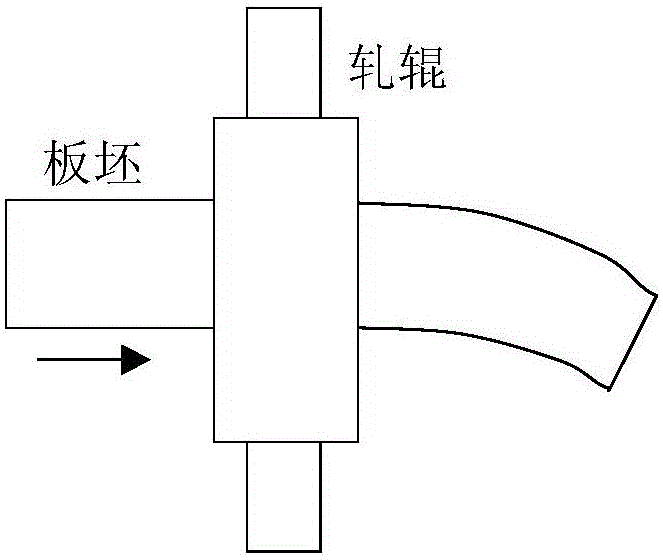

The strip mill was a major innovation in steelmaking, with the first being erected at Ashland, Kentucky in 1923. This provided a continuous process, cutting out the need to pass the plates over the rolls and to double them, as in a pack mill. At the end the strip was cut with a guillotine shear or rolled into a coil. Early (hot rolling) strip mills did not produce strip suitable for tinplate, but in 1929 cold rolling began to be used to reduce the gauge further. The first strip mill in the United Kingdom was opened at Ebbw Vale in 1938 with an annual output of 200,000 tons.

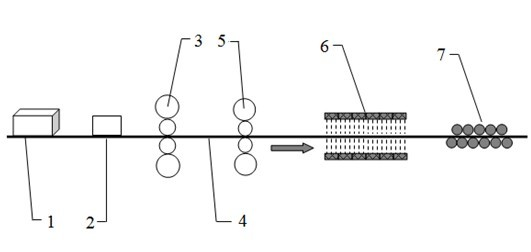

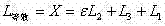

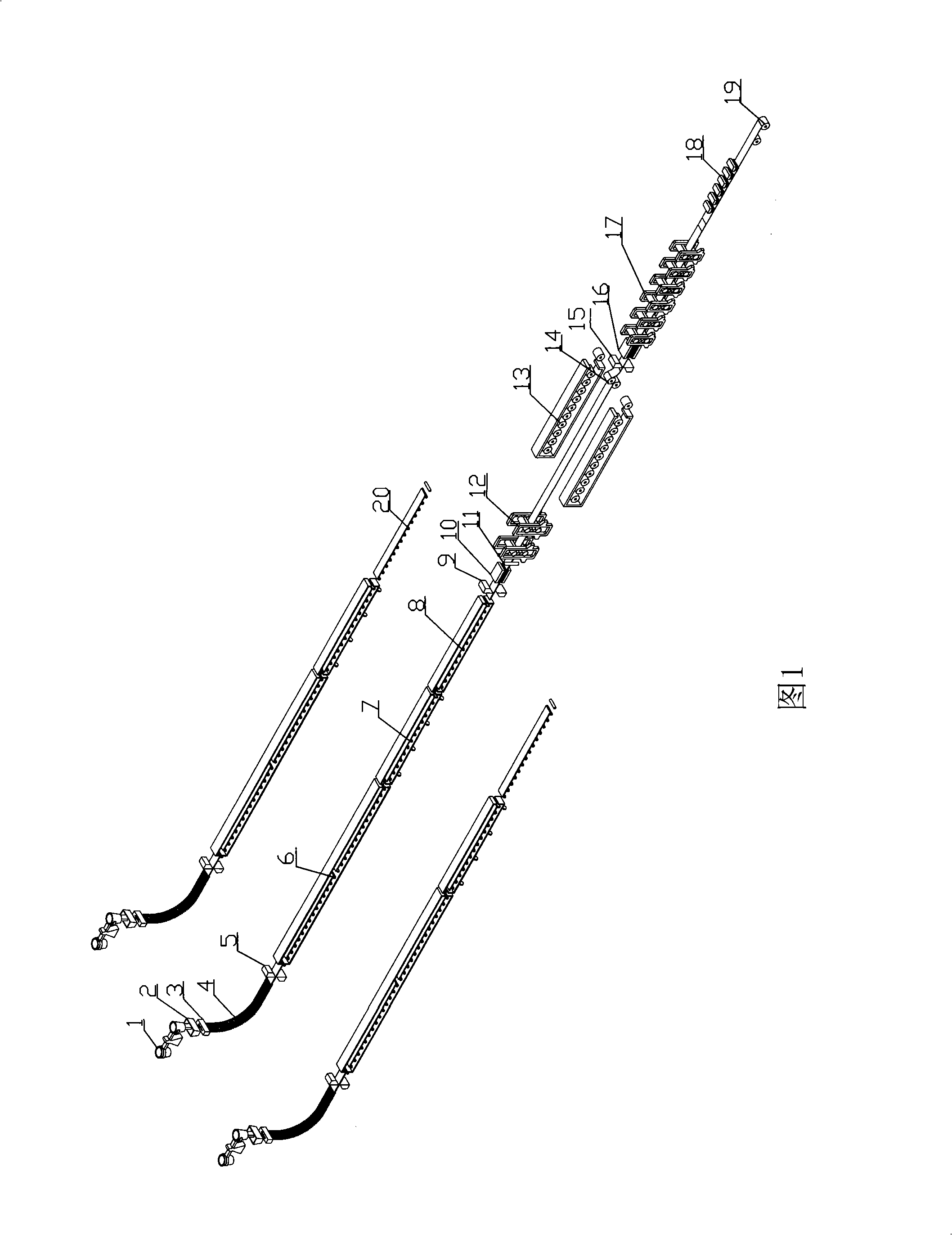

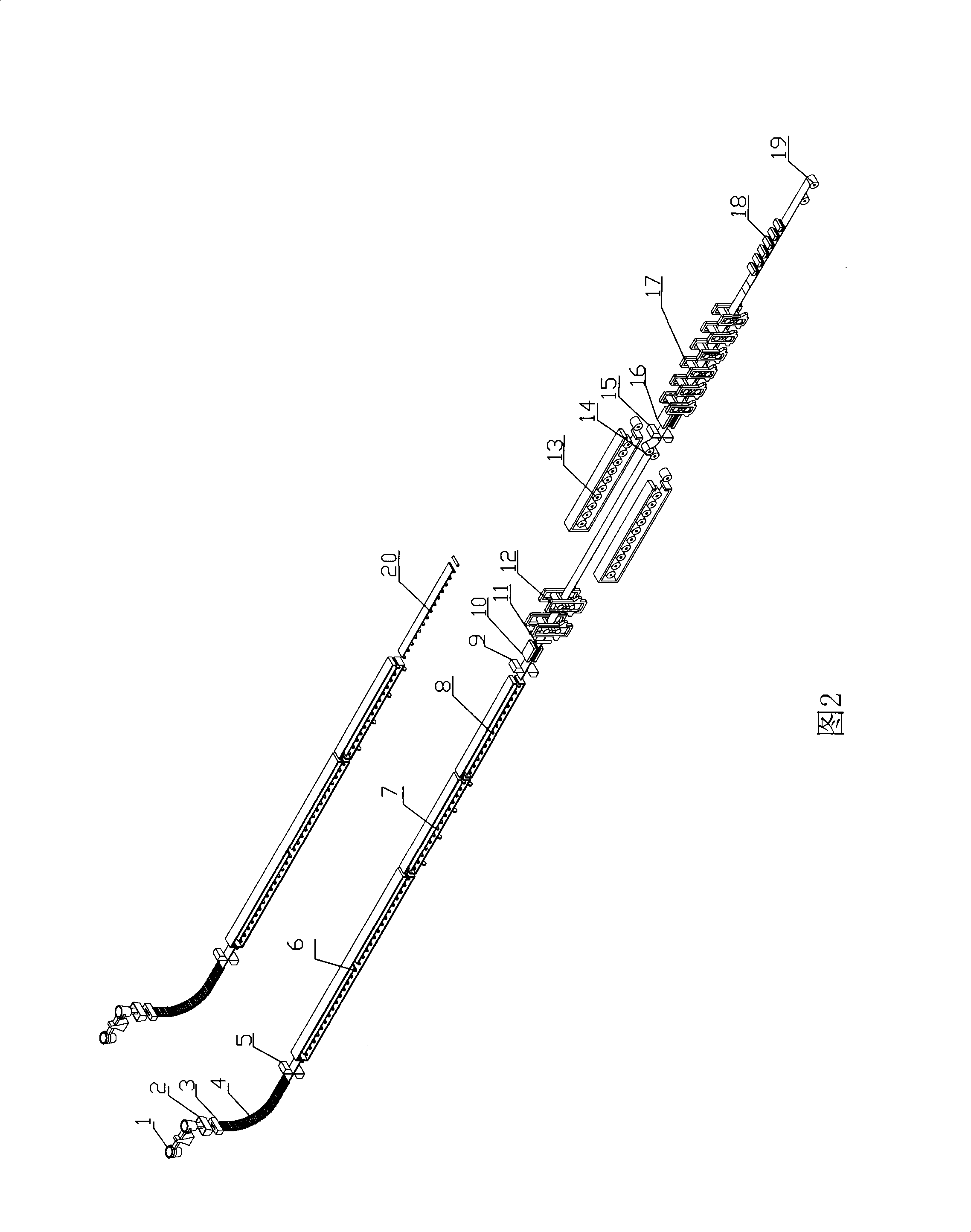

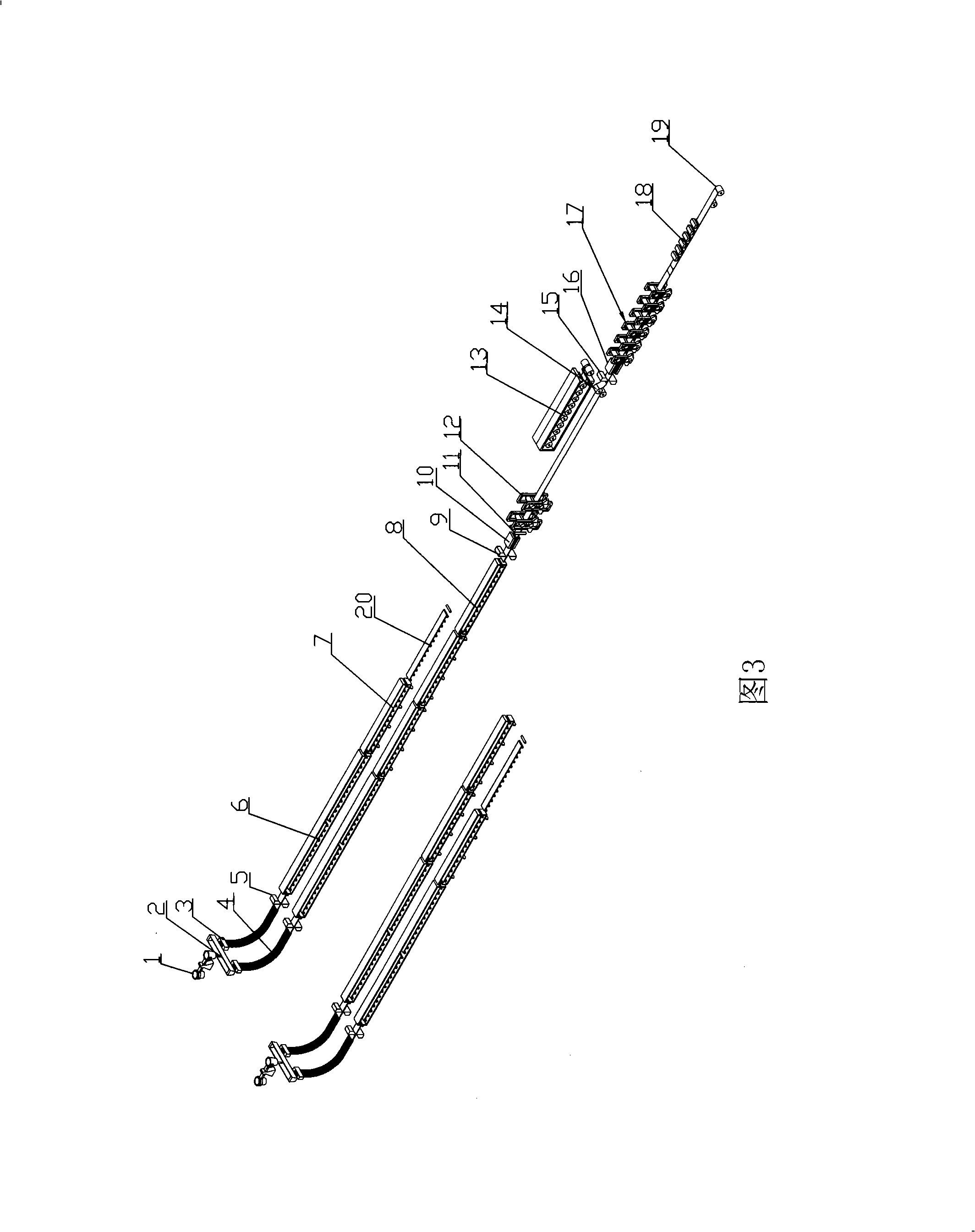

Method of sheet billet continuously casting and rolling to produce thin strip steel coil

ActiveCN101108394AShort production processSave construction investmentMetal rolling arrangementsProduction lineStrip mill

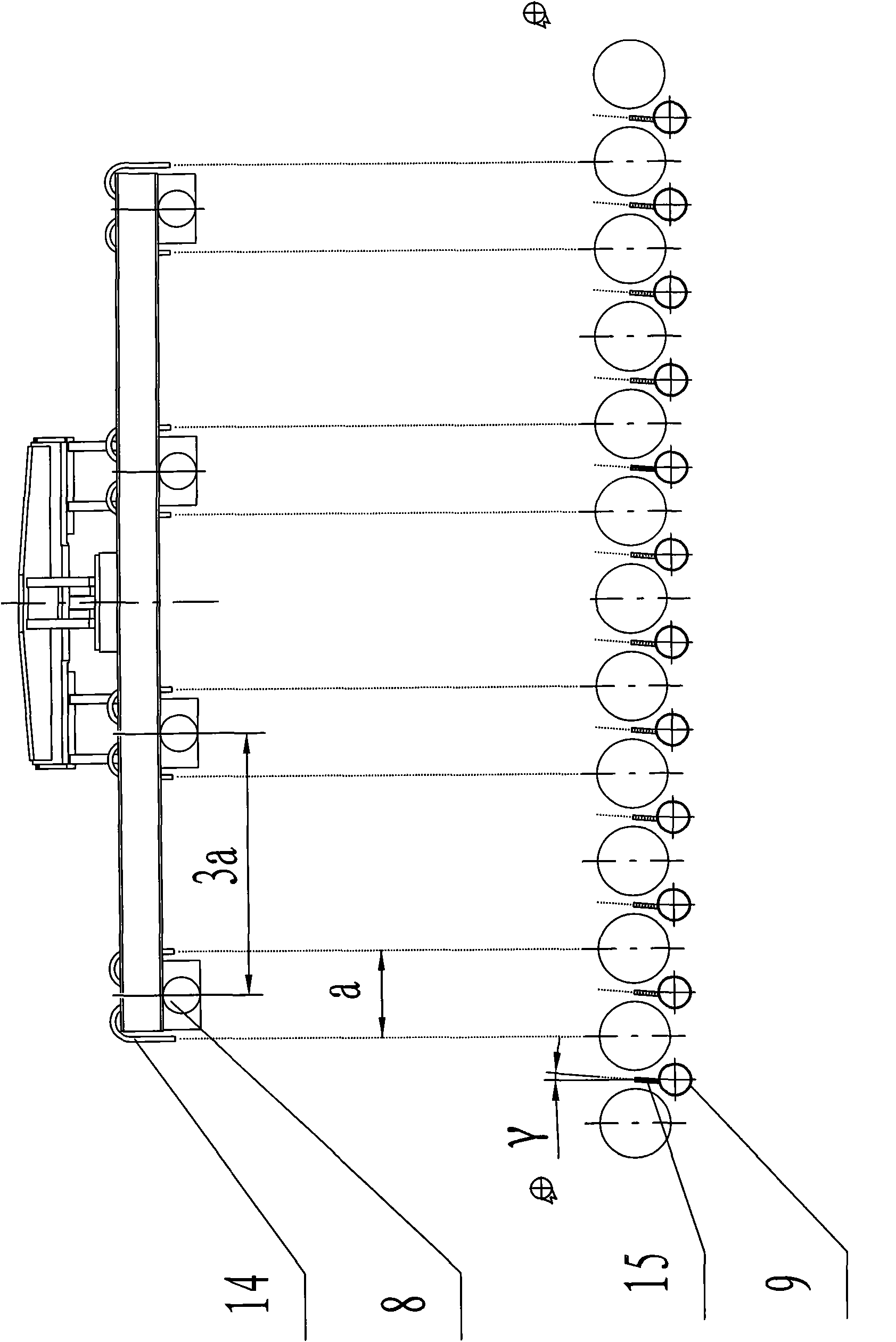

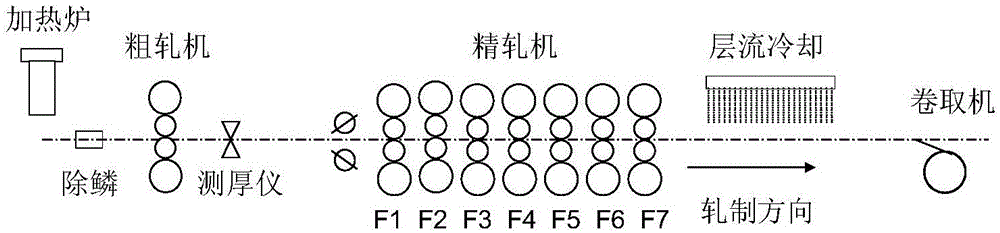

A method of using thin plate adobe continuous casting and rolling to producing thin band steel coil is provided, which belongs to rolling metal at once after continuous casting, in particular relating to thin standard band steel production method. The invention is characterized in that: a conticaster, a swing shear, a roller-hearth type heating furnace, a scale breaker, a vertical miller, 7 mill groups, laminar flow cooling device and reeling machine are connected to a CSP produce line, the produce line adopts reasonable temperature system, rolling equipment, rolling way and combining with cooling after rolling, the molten steel after continuous casting is a casting adobe of 50 to 70mm thick and 900 to 1300 wide, after cutting, heating, scale breaking, proceed continuous rolling to form a thin band of 1.2 to 1.5mm thick and 900 to 1300 wide, then after cooling to reel steel coil. The production flow is short, the equipment is few, the investment is less and the running expense is low; The technics and equipment is reasonable and high efficient, double locomotive and double flow casting, heating by two furnaces, seven rolling machines roll continuously, the production is smooth and saves energy with high production efficiency; the product performance is even and stable, the board shape is regular with high accuracy and good surface quality.

Owner:MAANSHAN IRON & STEEL CO LTD

Method for mounting large-sized rolling mills

InactiveCN101275400AReduce loosenessAvoid damageFoundation engineeringBuilding material handlingStrip millMechanical equipment

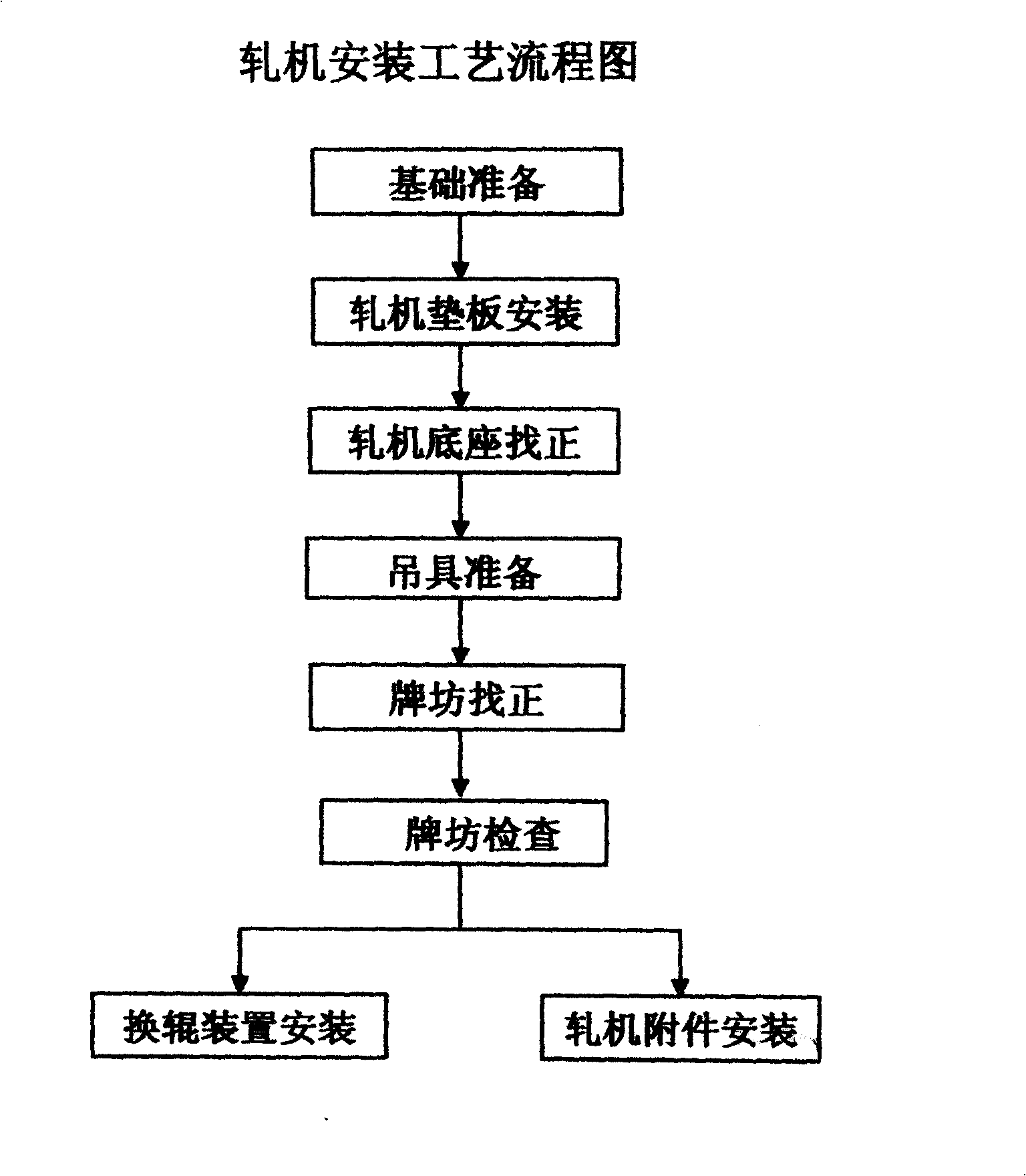

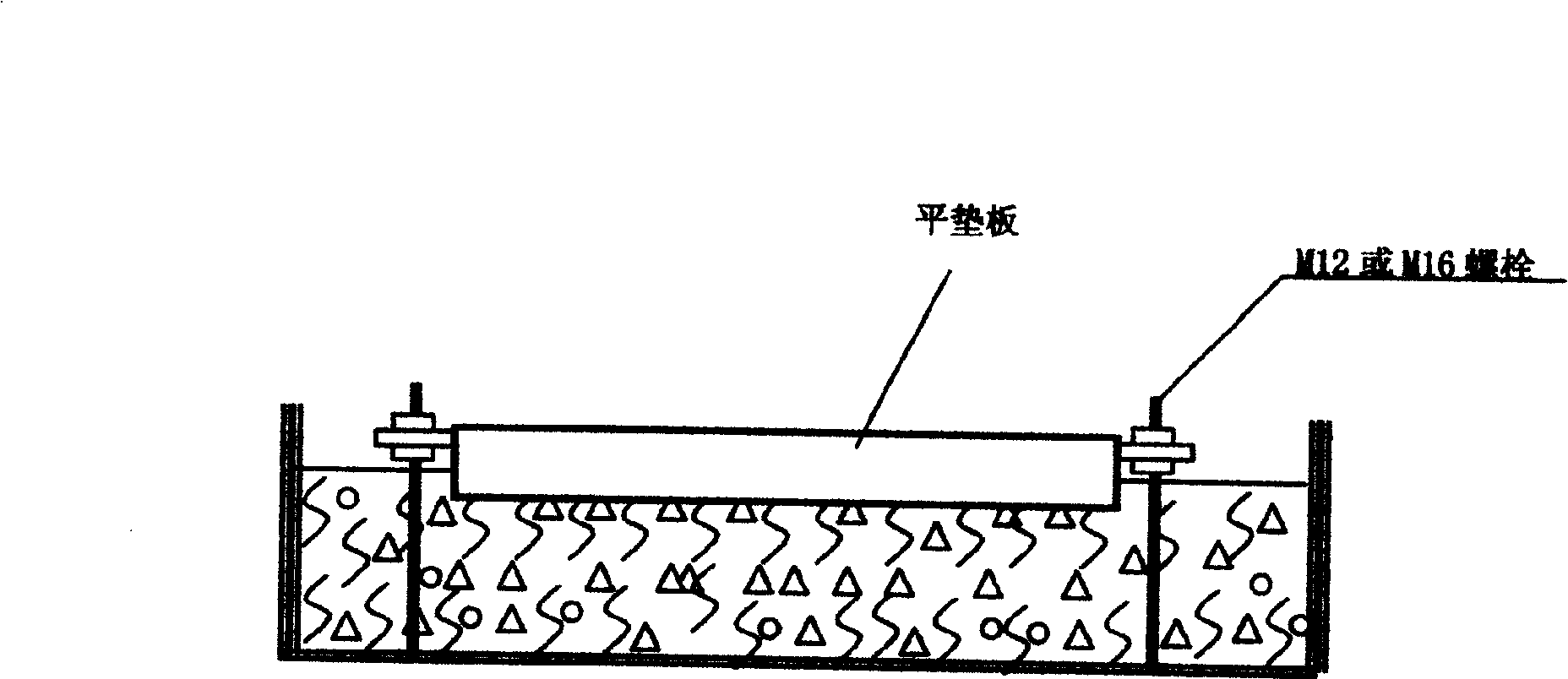

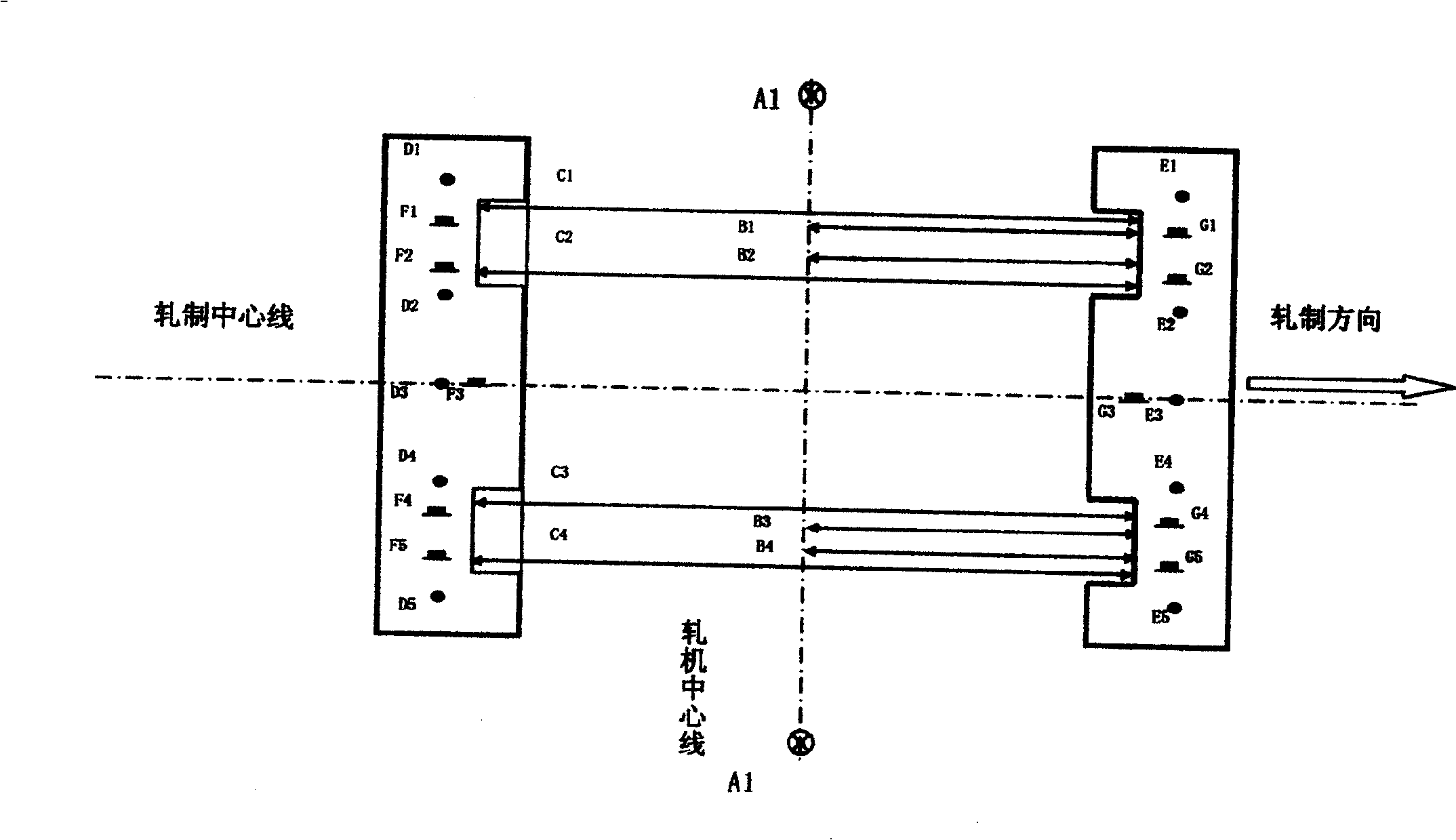

The invention relates to an installation of metallurgy industry rolling mills, pinch pass mill, burnishing machines and the like large-scale mechanical equipment, especially to an installation method of a large-scale rolling mill, which is characterized in that the installation of a large-scale rolling mill is realized by the process steps of base preparation, rolling mills bearing plate installation, rolling mills motherboard transverse alignment, sling preparation, memorial archway transverse alignment, memorial archway check-up, roll-changer installation and rolling mill accessory installation. The invention satisfies all requirement of different construction sites, effectively resolves hanging difficult problem, saves work efficiency about 6-7 times, ensures installation quality, uses hydraulic bolt stretchers to avoid bolt up force moment from macrolesion bolt, and adopts small fastening force moment to allow rolling mills subbase to become flexible. Work difference bands are used to control the roll changing transmission device central line and the rolling mill central line to ensure installation quality. According to combination of calculation and on-site practicality, the invention not only can be used for rolling mills installation, but also can spread in mechanical equipment installation with common advising signification.

Owner:ANGANG CONSTR CONSORTIUM

High-speed steel composite roller and casting method thereof

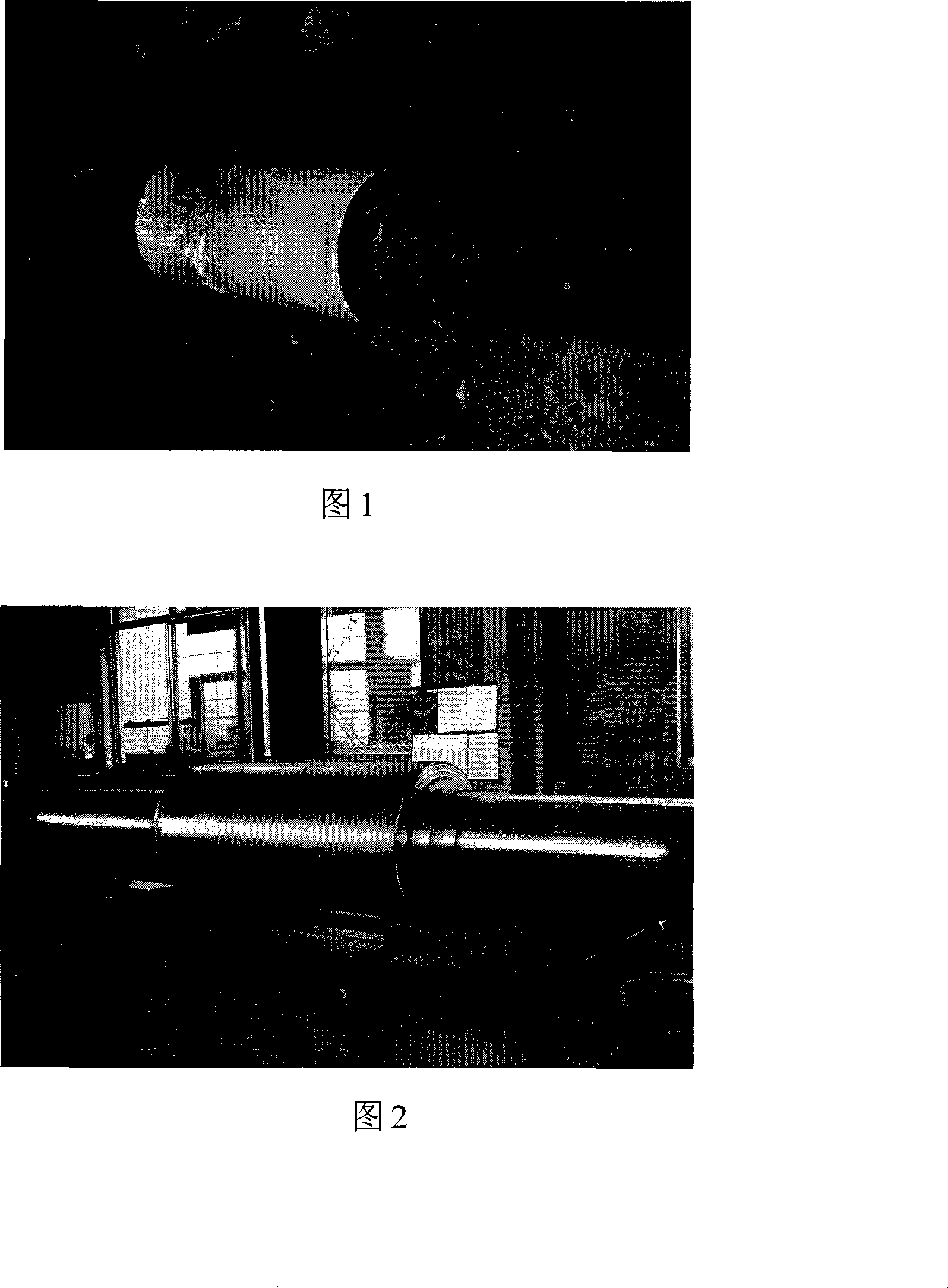

The invention belongs to the field of steel rolling manufacture, specifically is a high-speed steel composite roll for strip mill in steel rolling industry and casting method thereof. The outer layer of the composite roll is made of high-speed steel, the middle layer is made of ductile cast iron base iron or graphite semisteel, the core is made of ductile cast iron. The invention employs centrifugal compound foundry technique, the roll is moulded by three times of casting. Constant centrifugal rotating speed is kept in centrifuge, the metal material of the outer layer and the middle layer are mould cast, and then the metal of the roll core is statically cast to form the final product. Compared with former dual-layer or other three-layer composite high-speed steel rolling rolls, the three layers of metal of the high-speed steel composite roll of the invention are well combined and have high strength; the optimal selection of the material of the middle layer improves the strength of the bonding layer, the carbide affecting the binding performance in the middle layer is reduced, the spreading of alloy element in the outer layer high-speed steel to the core, which affects the core material performance, is also effectively avoided by the middle layer, cracking and dropping off of the working layer in hot processing and rolling process are prevented as well.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

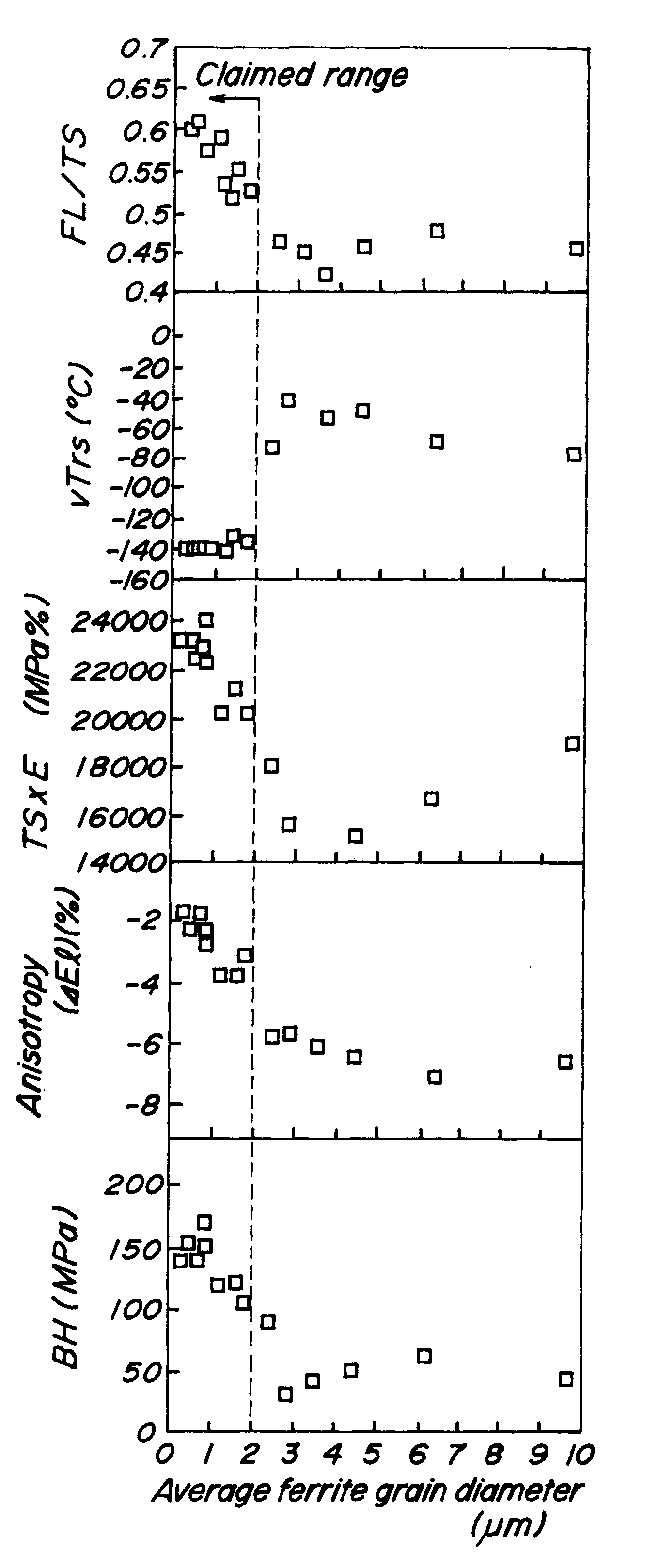

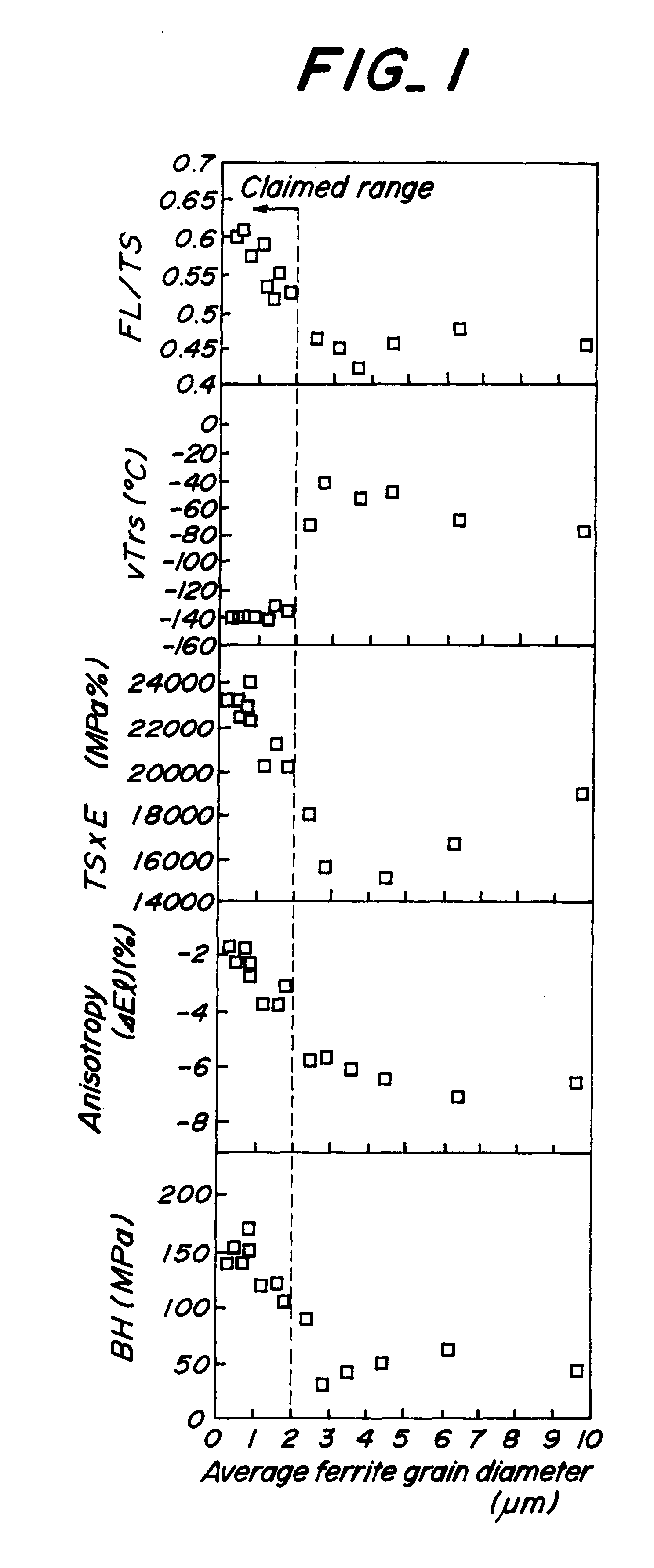

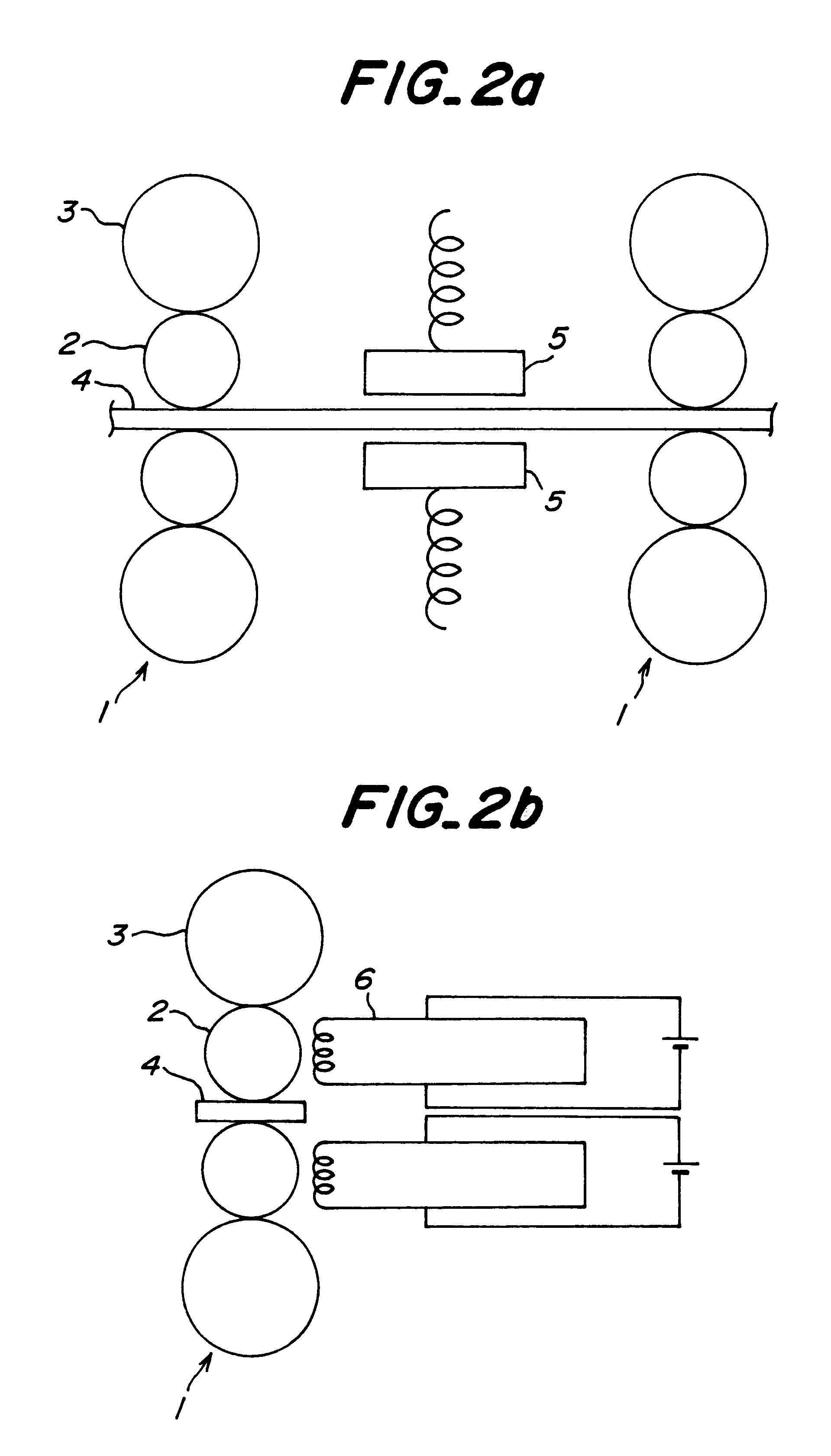

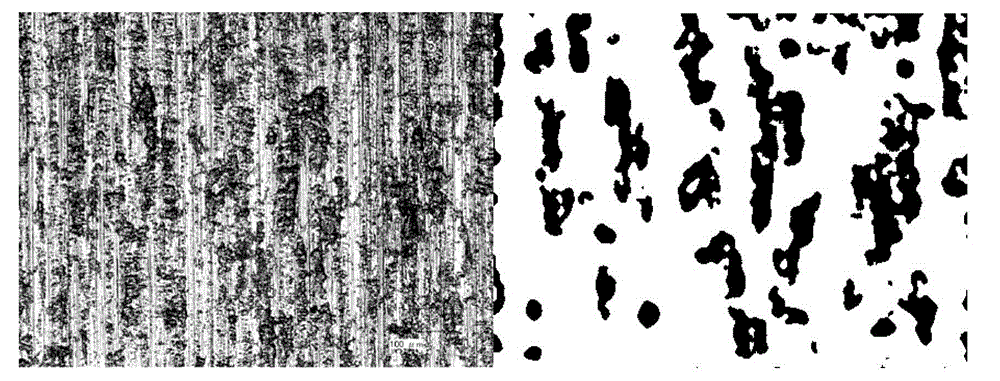

Hot rolled steel plate to be processed having hyper fine particles, method of manufacturing the same, and method of manufacturing cold rolled steel plate

A hot rolled steel sheet with improved formability and producing method therefor, which can be easily produced with general hot strip mills, having less anisotropy of mechanical properties and final ferrite grain diameter of less than 2 mum that could not be achieved by the prior art. The hot rolled steel sheet comprises a ferrite phase as a primary phase, and has an average ferrite grain diameter of less than 2 mum, with the ferrite grains having an aspect ratio of less than 1.5. The hot rolled steel sheet is obtained by carried out a reduction process under a dynamic recrystallization conditions through reduction passes of not less than 5 stands in the hot finish rolling.

Owner:KAWASAKI STEEL CORP

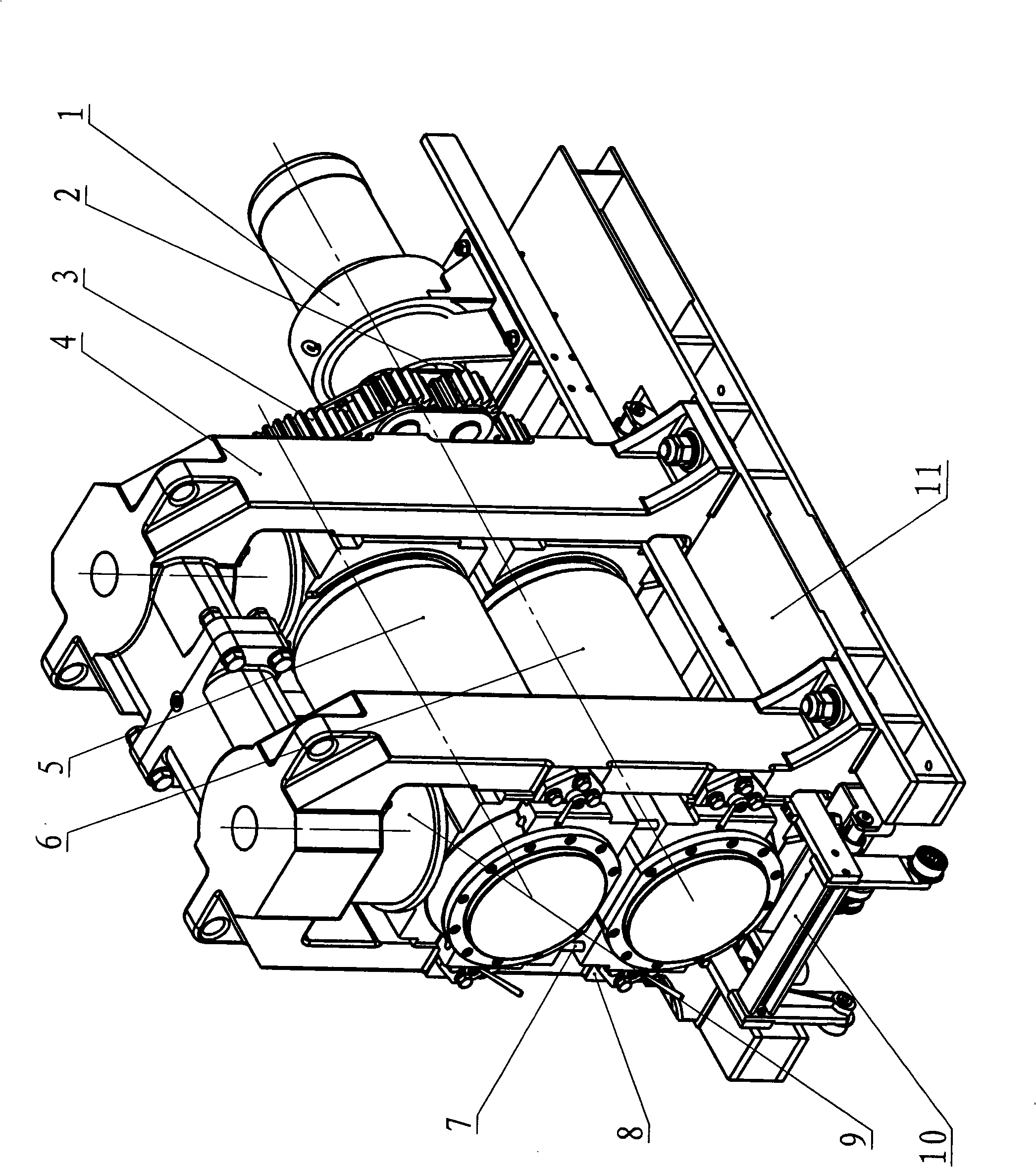

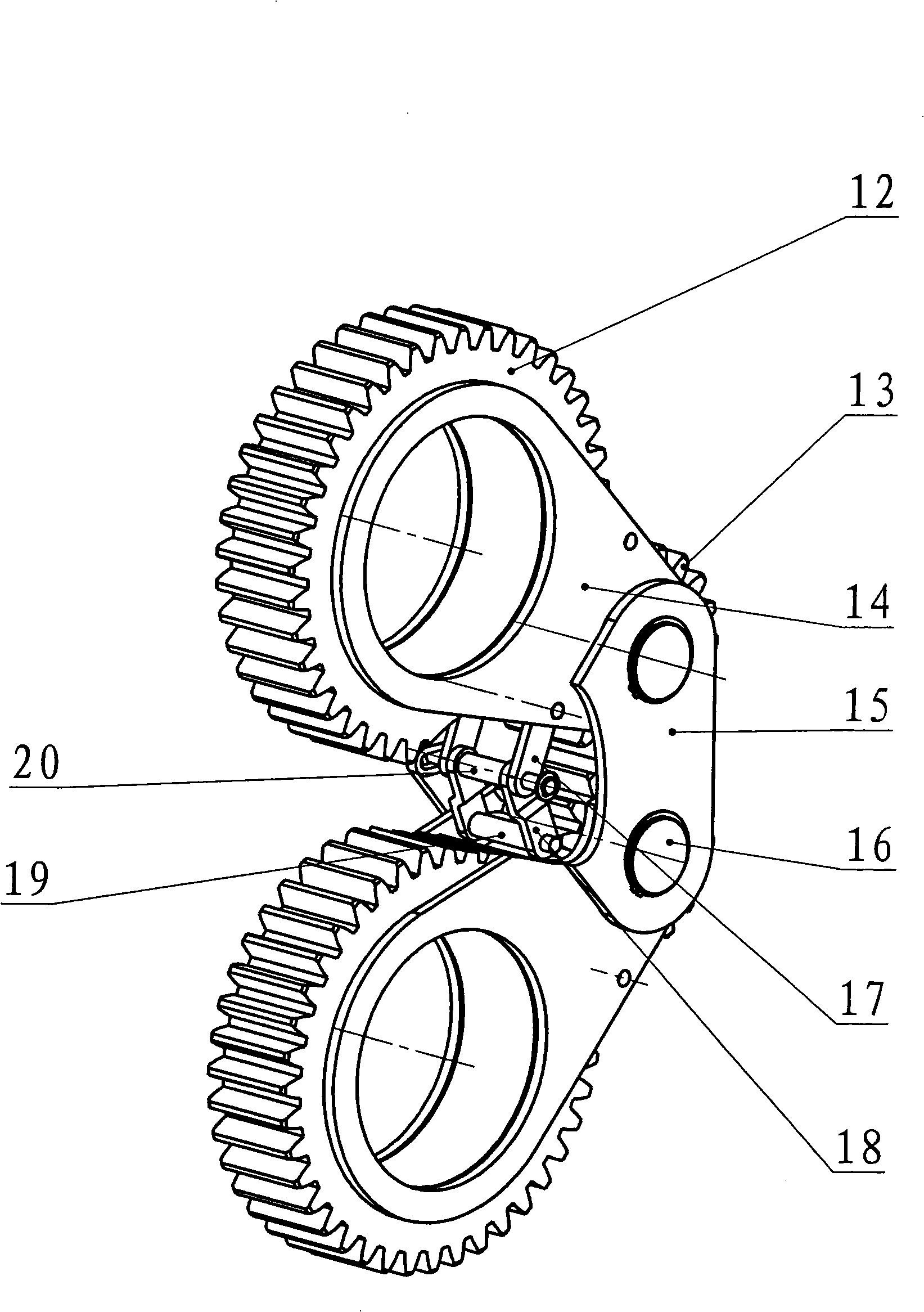

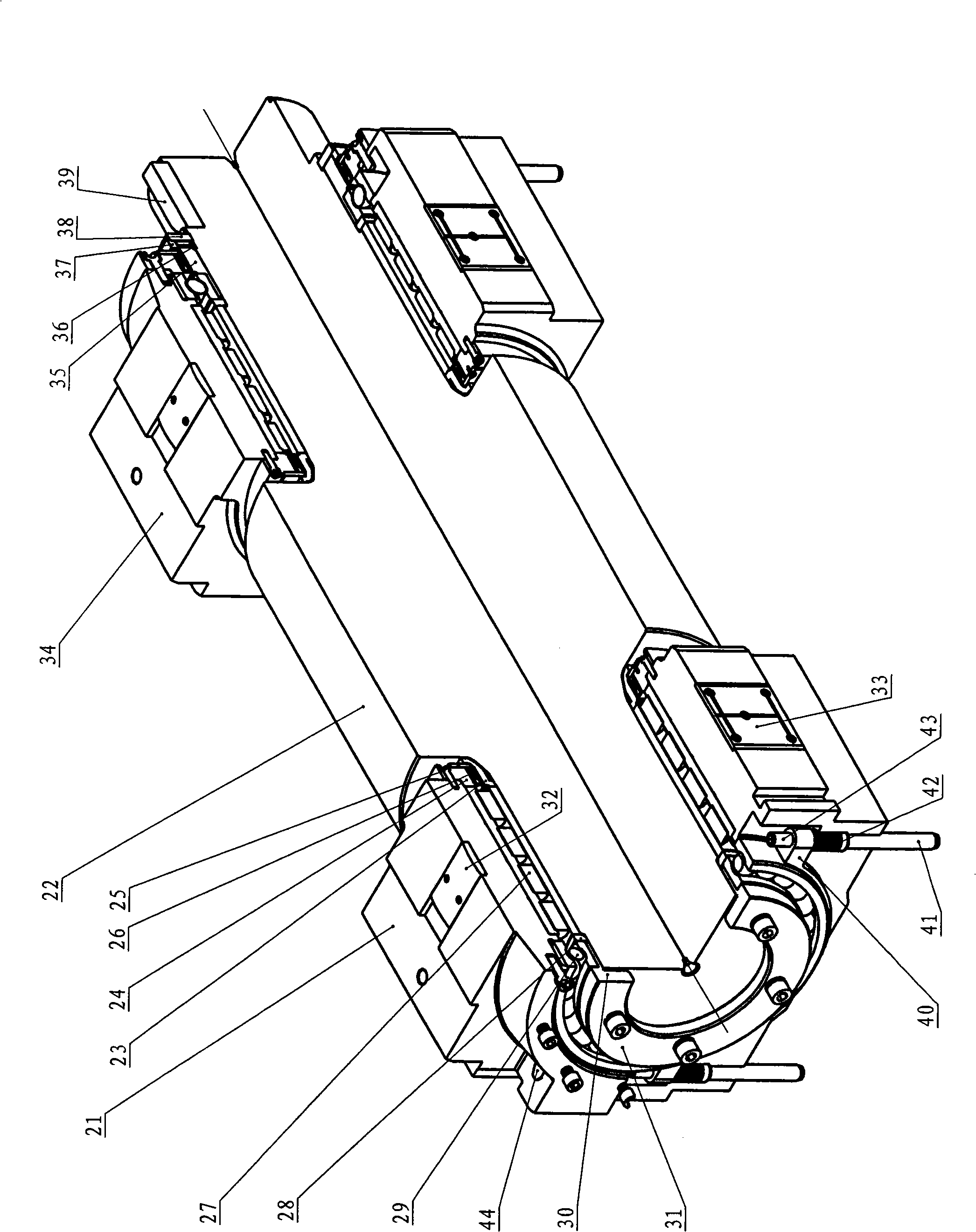

Strip mill of thin film

InactiveCN101347791AEfficient and stable productionEasy to change rollsMetal rolling stand detailsRolling mill drivesAutomatic controlEngineering

The invention provides a film band and strip rolling mill, consisting of a motor-reducer device, an elastic pin coupling device, a balance symmetric gear transmission device, a front stander device and a rear stander device, a lower roller system device, an upper roller system device, a roller system bearing radial windage eliminating device, a left baffle device of a roller, a right baffle device of the roller, an electro-hydraulic servo press-down device, a roller changing device and a base; the film band and strip rolling mill is characterized in that the size of the roller seam can be automatically controlled by adopting an electro-hydraulic servo control technology, thus stably producing battery electrodes which meet the quality standard without compressing air source from external part; meanwhile, the developed balance symmetric transmission device, the roller system bearing radial windage eliminating device, the roller left baffle device, the roller right baffle device and the roller changing device lead the adjustment and maintenance of the rolling mill to be simple and convenient, The invention is an ideal film band and strip rolling mill which has the advantages of improving the precision of battery electrodes, improving the productivity of the rolling mill and overcoming the shortages of the prior art.

Owner:张清

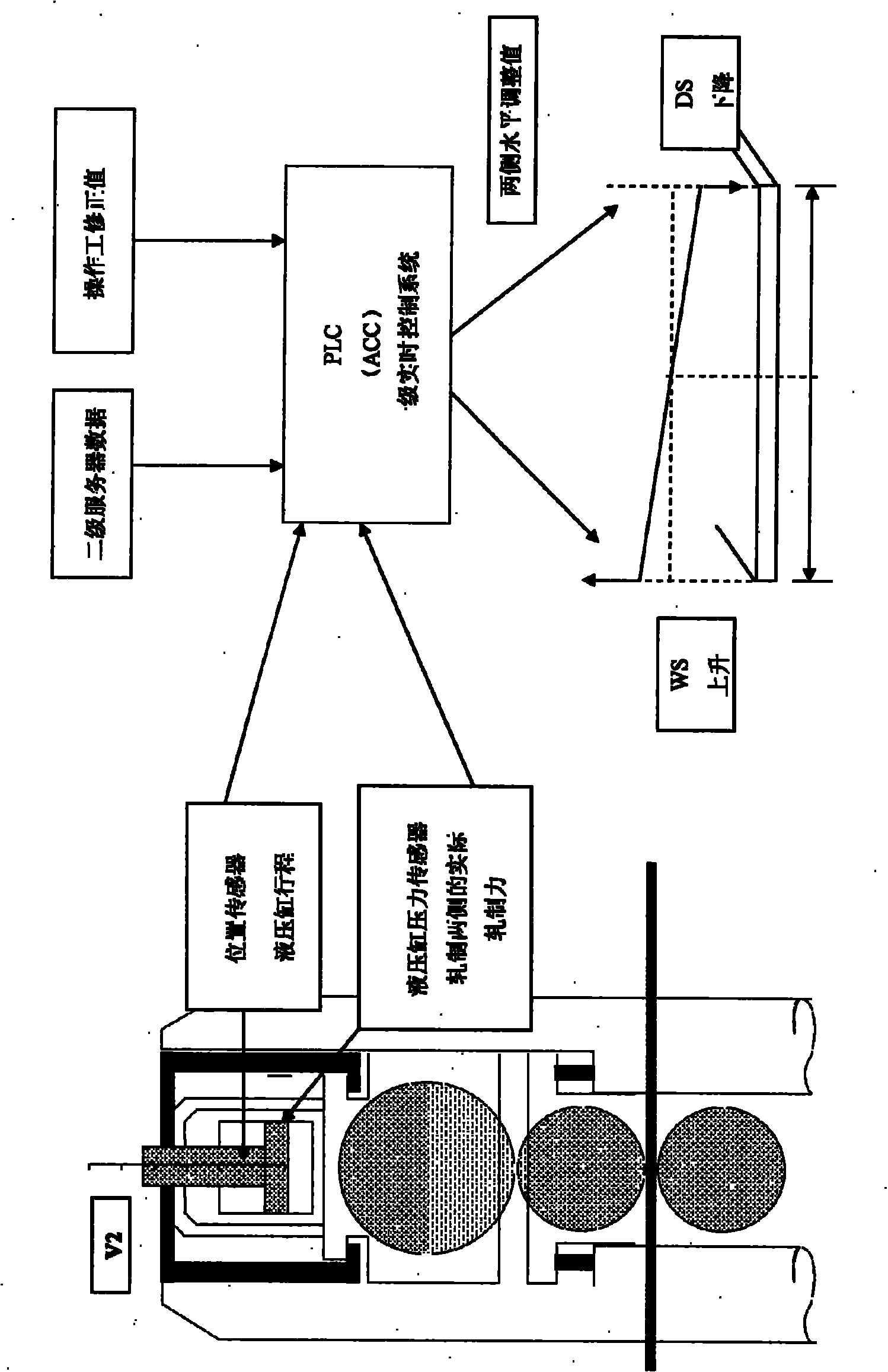

Automatic control method for camber and wedge of hot rolled strip roughing mill

ActiveCN101934292AOptimal control methodEasy to implementRoll mill control devicesMetal rolling arrangementsAutomatic controlStrip mill

The invention provides an automatic control method for a camber and a wedge of a hot rolled strip roughing mill, which is realized by adding an auxiliary control module in a hot rolled strip roughing mill control system. The automatic control method takes the actual values of rolling forces on two sides of an in-situ roughing mill, the actual calculated values of a gap between rolls and bounce parameters on two sides of a rack as inputs to be accurately calculated, and finally realizes the correction to the camber and the wedge through regulating the gap between rolls on one side or two sides of the rolling mill. By applying the control method, the extremely accurate control over the camber and the wedge can be realized without adding a camber shape detection device with blanks, and the control effect of the control method can be further assured if the camber shape detection device is equipped in situ.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

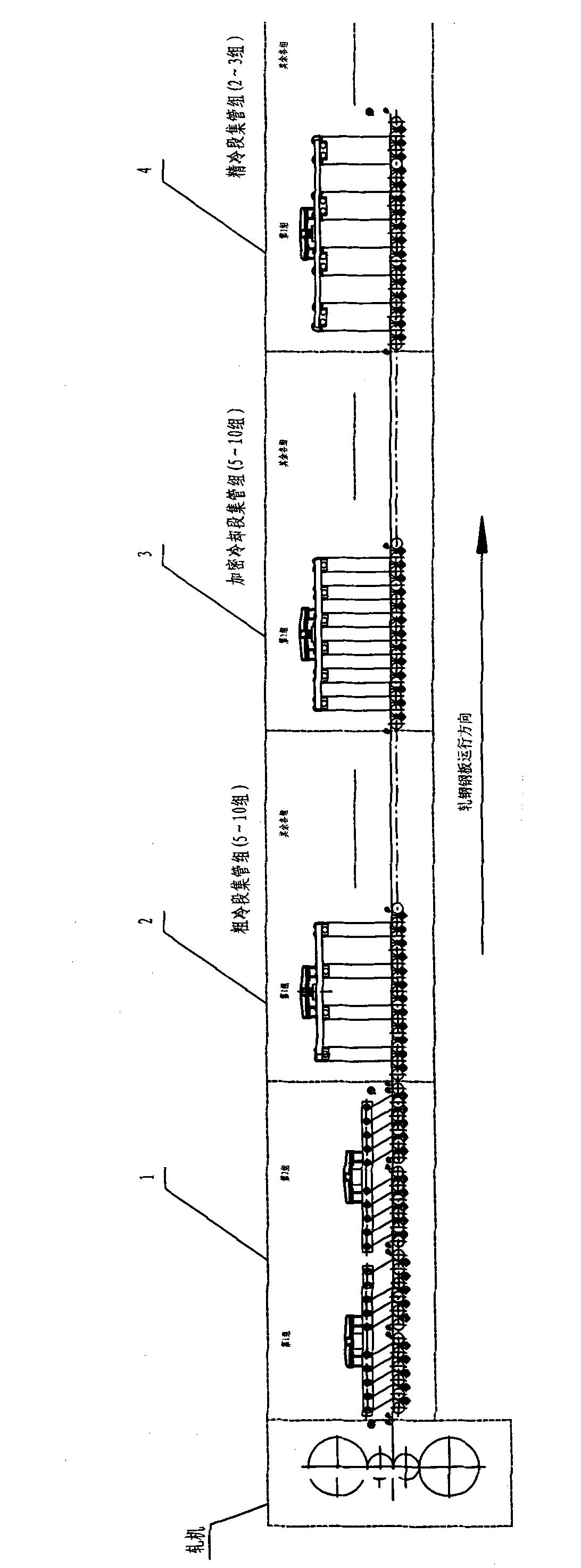

After-rolling cooling system for hot rolled steel strip production line

ActiveCN101890437AReasonable speedReasonable precisionWork treatment devicesMetal rolling arrangementsSprayerVolumetric Mass Density

The invention relates to an after-rolling cooling system for a hot rolled steel strip production line. A cooling device is provided with collecting pipes which have different densities and are arranged on a rolling line along the rolling operation direction of a steel plate sequentially. The after-rolling cooling system is characterized in that: a super fast cooling region and a laminar cooling region are arranged at the back of a rolling mill; the super fast cooling region has a dense pipe flow structure and is provided with two groups; the upper and lower collecting pipes are correspondingly arranged above and below each roller and are connected with high-pressure water pipes; the nozzle of each collecting pipe has an inclined injection-type gap structure; the number of the collecting pipe groups in the roughly cooling section of the laminar cooling region is 5 to 10; the number of the collecting pipe groups in the densely cooling section of the laminar cooling region is 5 to 10; the number of the collecting pipe groups in the finely cooling section of the laminar cooling region is 2 to 3; the lower collecting pipes in the laminar cooling section adopt sprayer nozzles which are formed in the gap of each roller way and are connected with normal-pressure water supply pipelines; sweeping devices are arranged in front of and at the back of each group of collecting pipes of the system; and side blowing devices are arranged on two sides of each roller way and are used for removing residual water on the surface of the steel plate. Cooling intensity is adjusted according to different parameters of products and rolling mills, so the requirement that the steel strip is quickly cooled from a temperature range of 800 to 1,000 DEG C after rolling to a temperature range of 200 to 750 DEG C can be met.

Owner:NORTHEASTERN UNIV +2

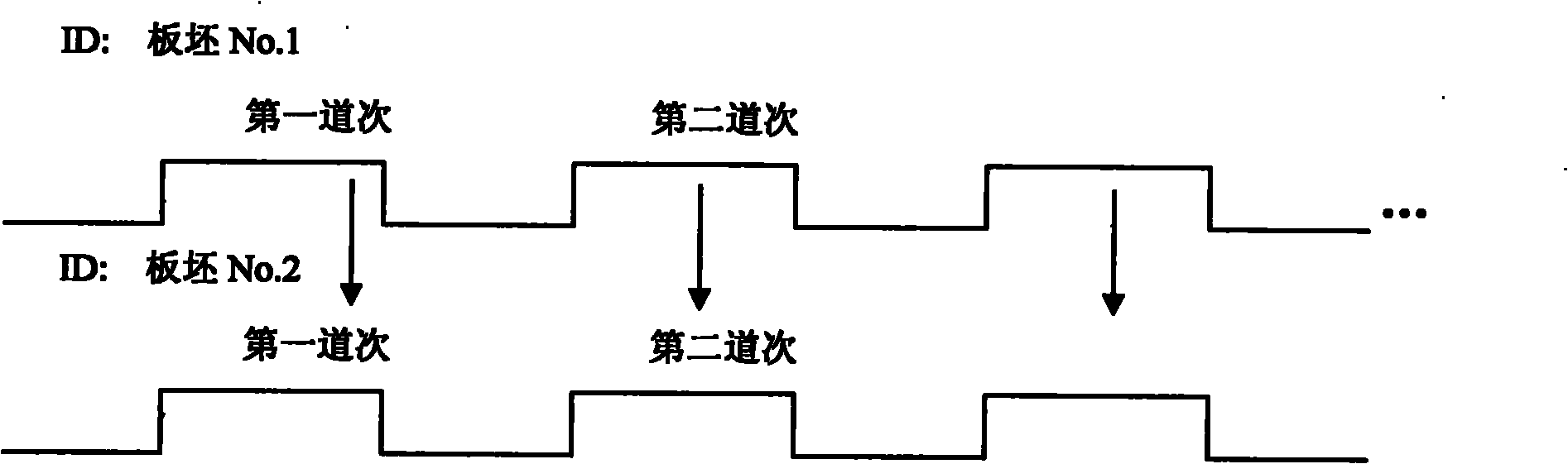

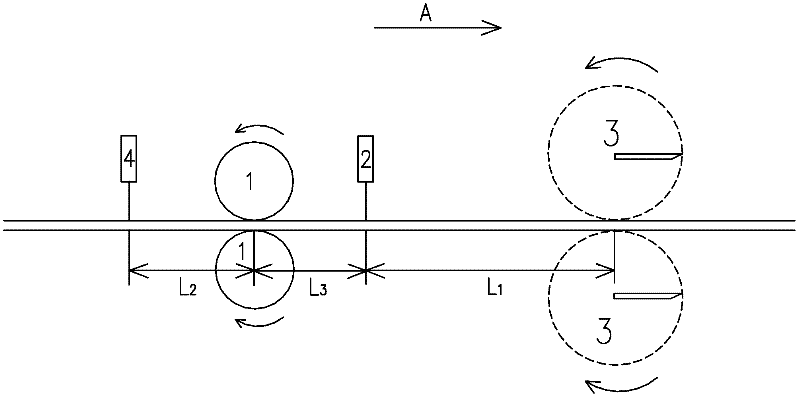

Control method for improving rolling pace of roughing mill

ActiveCN103372572AImprove rolling rhythmImprove equipment utilizationRoll mill control devicesMetal rolling arrangementsStrip millEngineering

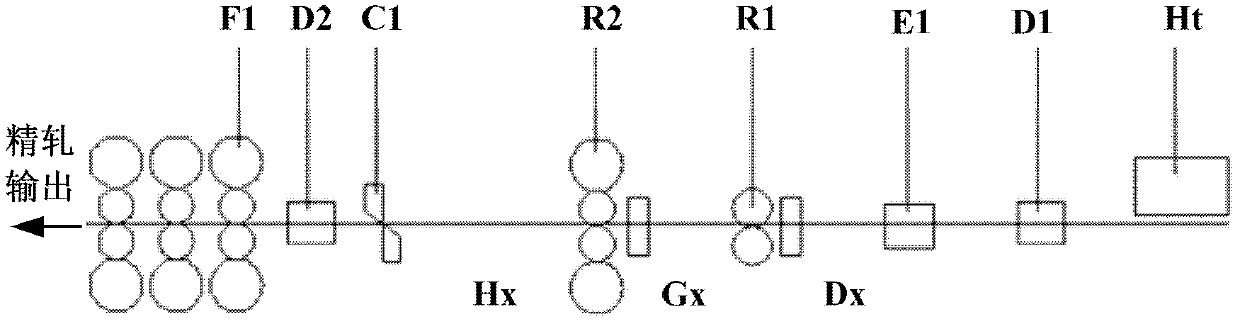

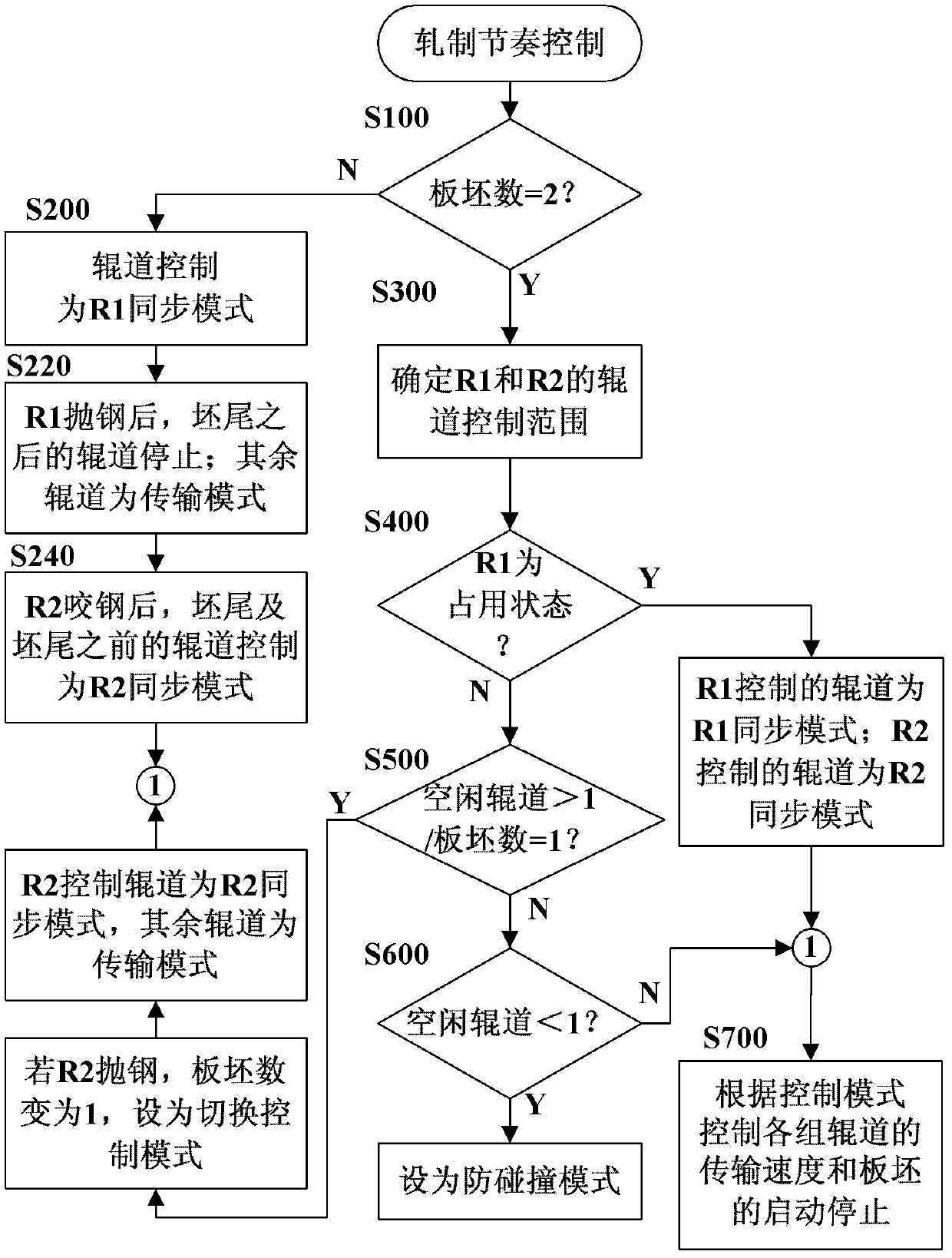

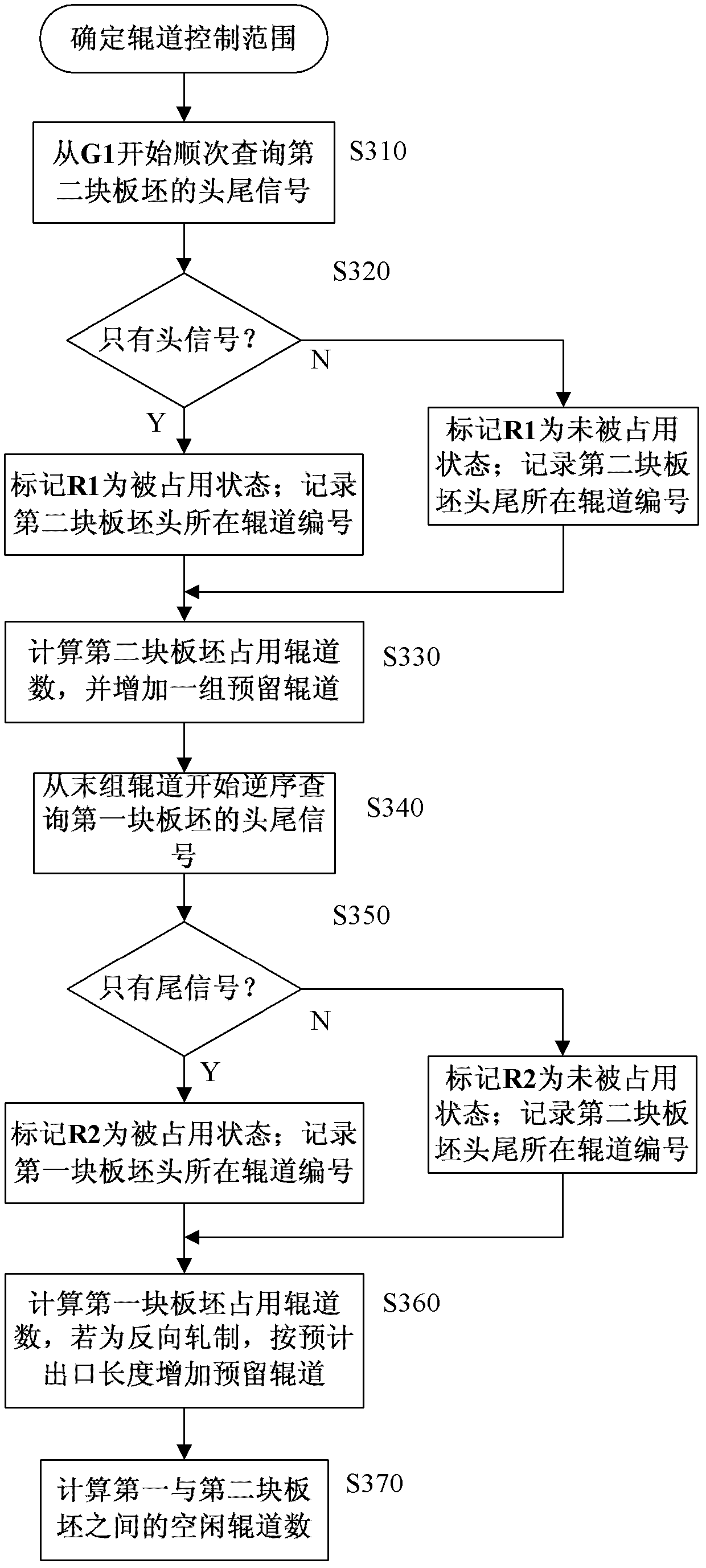

The invention discloses a control method for improving rolling pace of a roughing mill and relates to a control device or method which is specially applicable to a metal rolling mill or machined products of the metal rolling mill. Plate blank head and plate blank tail detection devices are arranged on all groups of roller beds; according to detected plate blank head and plate blank tail signals, plate blank collision prevention conditions are set, and the occupancy state of a rack and the number of the idle roller beds are determined; according to the occupancy state of the rack and the number of the idle roller beds, control modes of the groups of roller beds are set; according to the plate blank collision prevention conditions and the control modes of the groups of roller beds, transmission speeds of the groups of roller beds are controlled respectively, and starting and stopping of a second plate blank are controlled to minimize the distance between a first plate blank and the second plate blank, so that the transmission time interval between the two plate blanks is minimized. By the aid of the method, the distance between the two adjacent machined plate blanks can be greatly shortened, so that the front and back rack production is closely connected, and the rolling pace of the rolling mill and the device utilization rate can be greatly improved.

Owner:BAOSHAN IRON & STEEL CO LTD

Process for producing thin gauge pipeline steel by using double-stand medium and heavy plate mill

ActiveCN102671941AGuaranteed Dynamic RecrystallizationImprove lateral performanceTemperature control deviceWork treatment devicesMetallurgyLaminar cooling

The invention discloses a process for producing thin gauge pipeline steel by using a double-stand medium and heavy plate mill. A plate blank with the thickness of 180 mm is used for producing the thin gauge pipeline steel with the thickness less than 10 mm. On the basis that the performance of a rolled piece meets requirements, the thin gauge pipeline steel with a good plate shape can be obtained by controlling the tapping temperature of the plate blank, the rough rolling broadening pass pressing rate, the longitudinal rolling pass pressing rate after rough rolling broadening pass, the rough rolling finishing temperature, the thickness of a middle blank, the finish rolling ending pass pressing rate, the finish rolling finishing temperature, the roller gap inclination and sled function in the rolling process, a high pressure water descaling system, the water entry temperature, the re-reddening temperature, and the head and tail shielding and straightening process of a laminar cooling system. The deformation rate is reduced, and the economic benefit is increased.

Owner:NANJING IRON & STEEL CO LTD

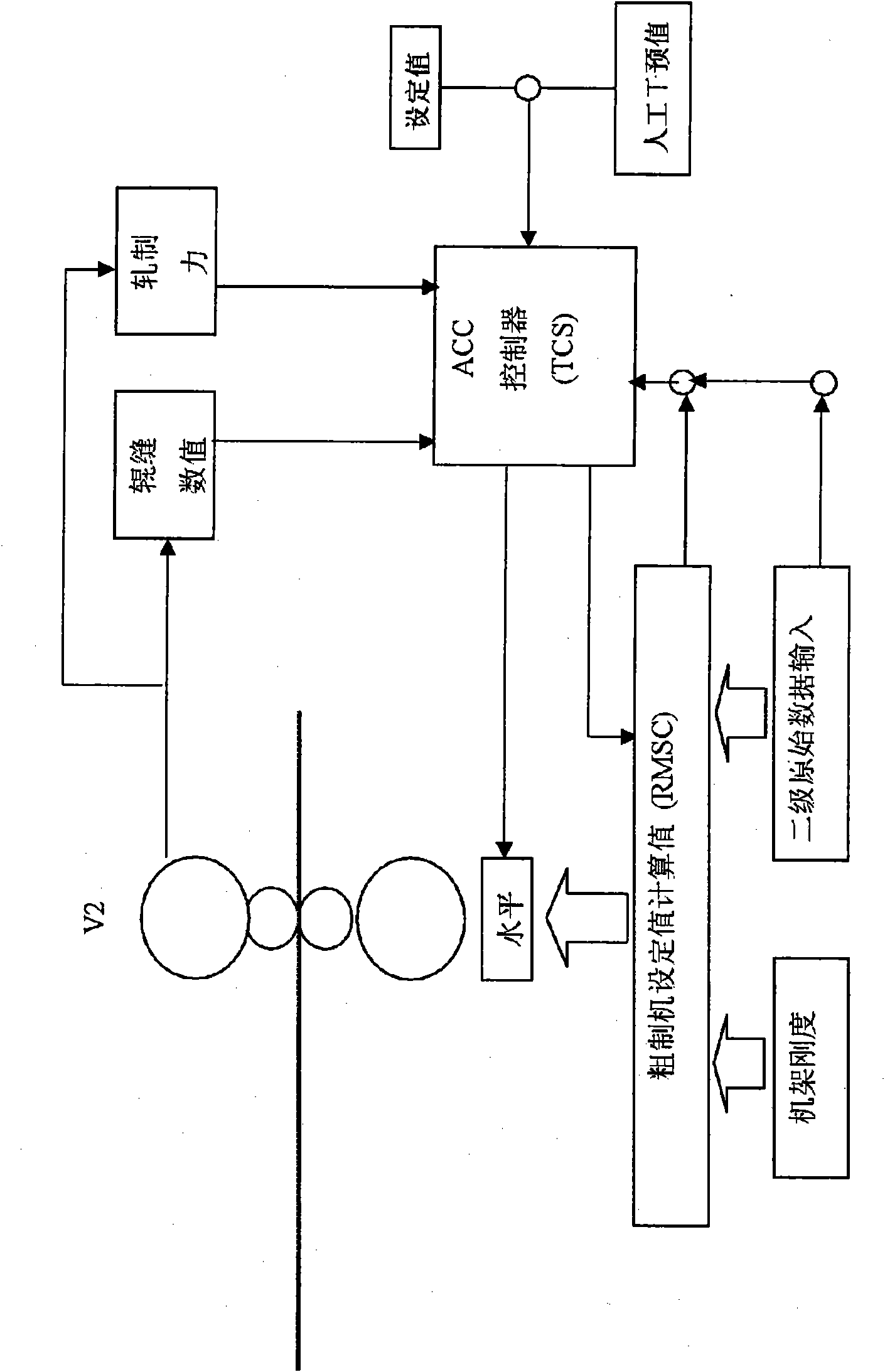

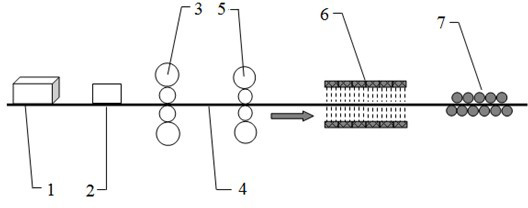

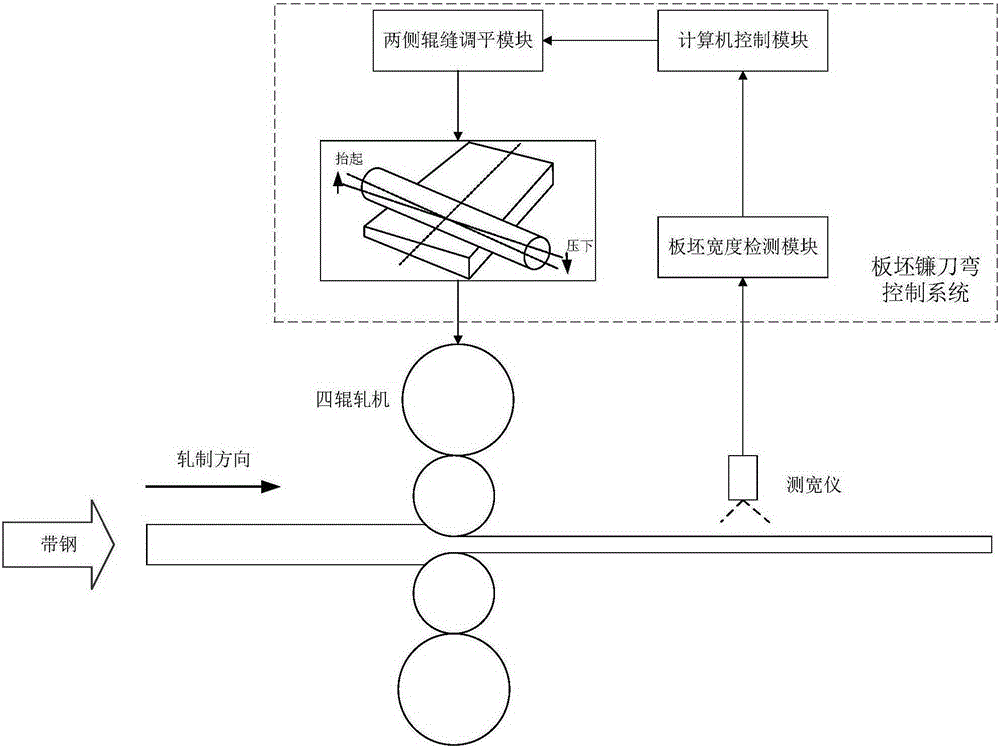

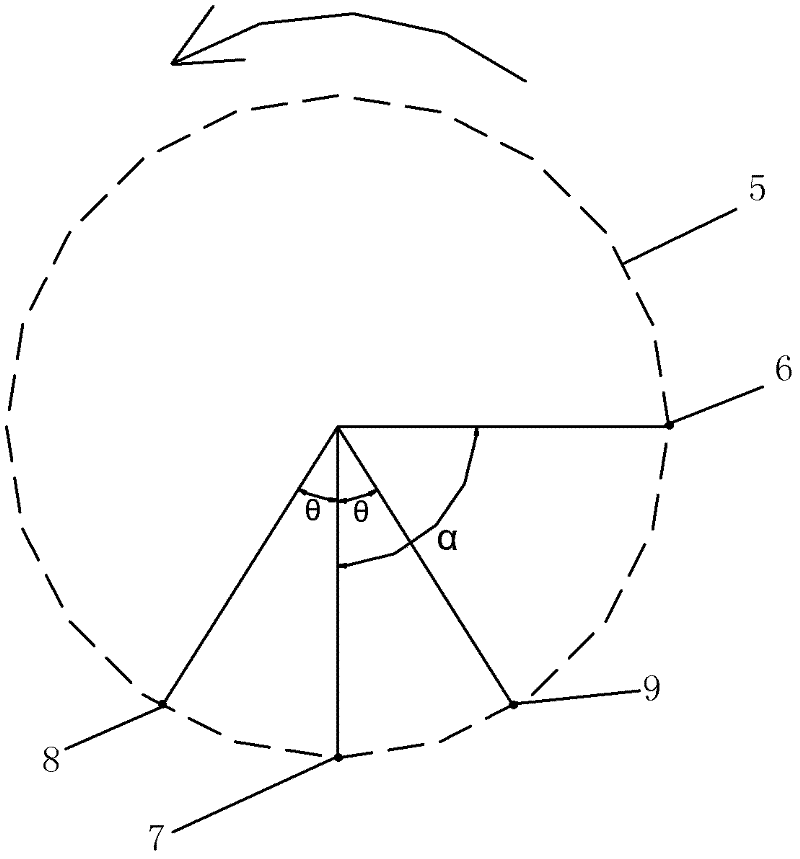

Slab sickle bending control system and method used for roughing mill

InactiveCN105234189AIncreased level of controlInhibition defectRoll force/gap control deviceAutomatic controlStrip mill

The invention discloses a slab sickle bending control system and a slag sickle bending control method used for a roughing mill, and belongs to the field of mechanical automatic control. The control system comprises a slab width detecting module, two side roller beam leveling modules, a computer control module and a storage unit. The slag width detecting module is used for processing centre line offset data detected by a width detector and sending the processed centre line offset data to the computer control module; the computer control module is used for calculating a leveling value of each gate by collecting a set value of slag and practically measured value data, and sending the leveling value to the two side roller beam leveling modules; and the two side roller beam leveling modules are used for regulating two side roller beams of the roughing mill according to the leveling value, and controlling the slab sickle bending. The control system is applicable on the roughing mill, capable of calculating the leveling value of each gate more accurately, and capable of effectively controlling slag sickle bending and guaranteeing stability of finishing rolling unit production, thereby relieving steel scrap caused by off-tracking, shifting and the like, increasing yield and bringing direct economic benefits for enterprises.

Owner:BEIJING SHOUGANG AUTOMATION INFORMATION TECH

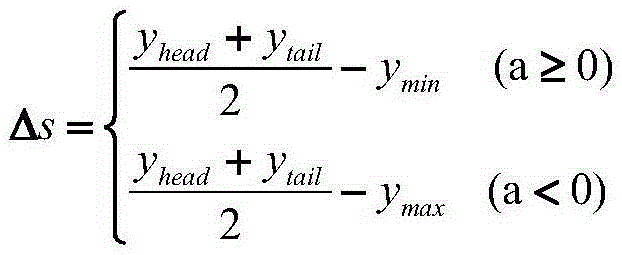

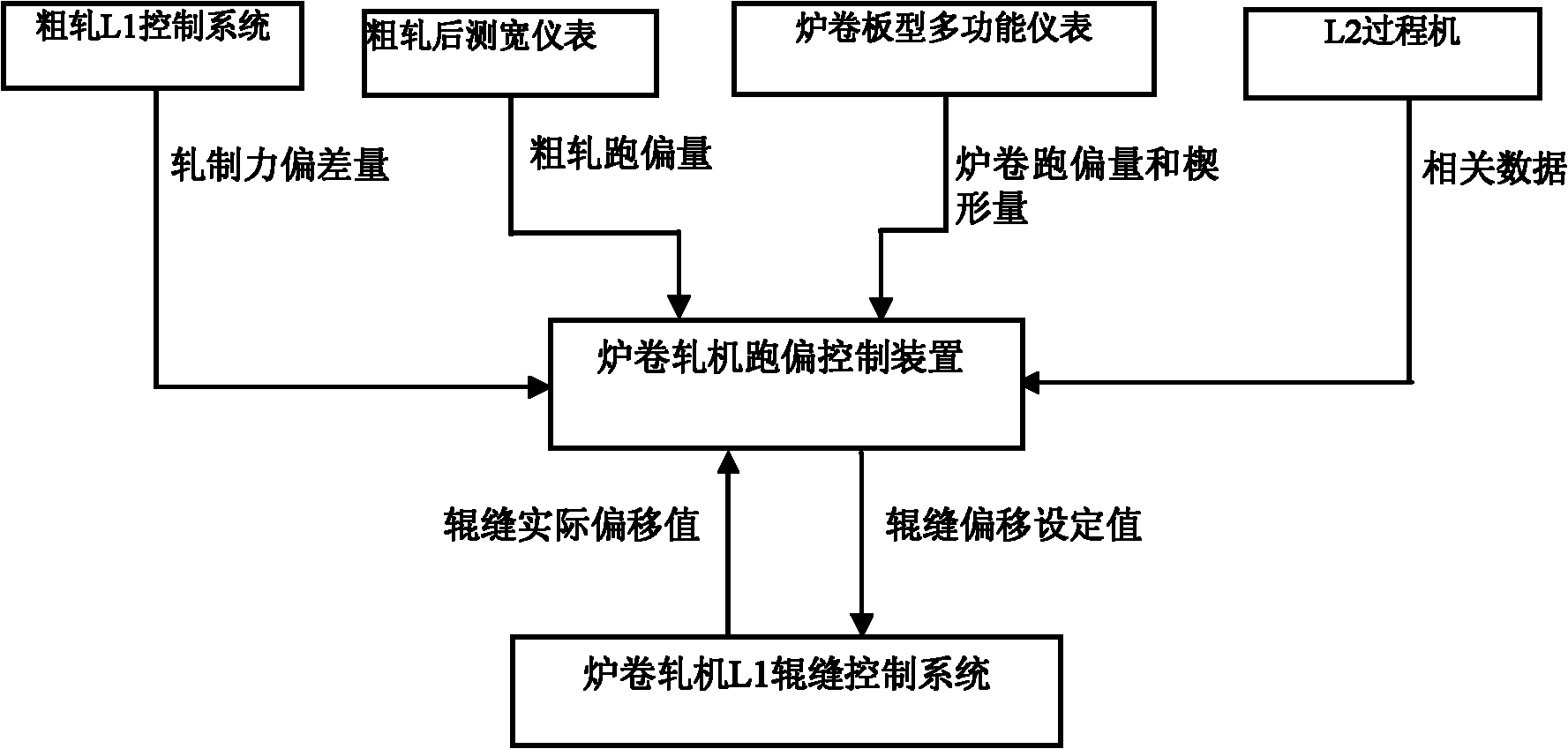

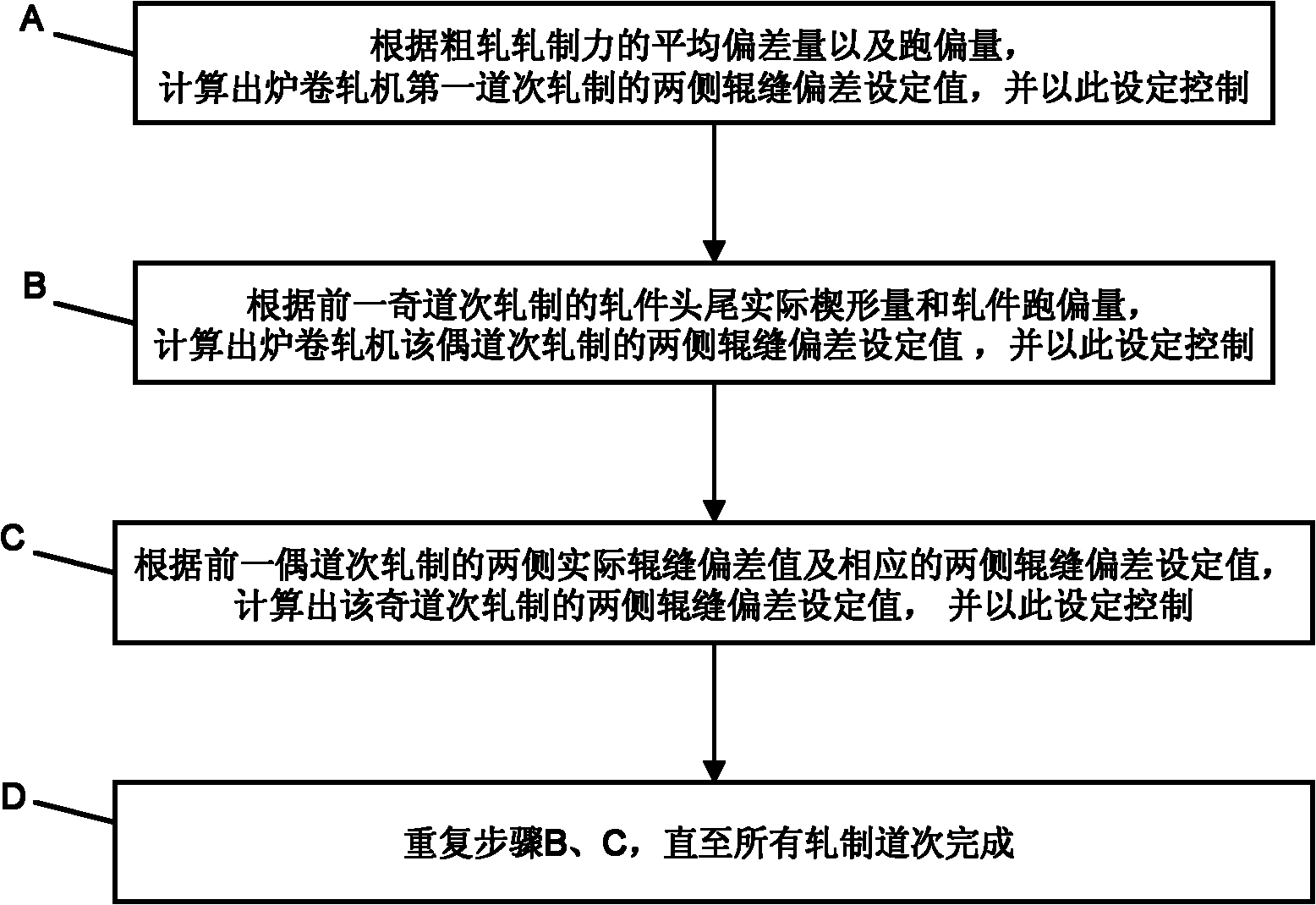

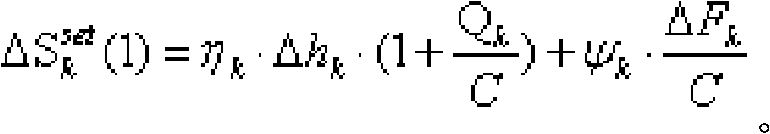

Steckel mill rolled piece head-and-tail deviation control method

InactiveCN102641903AImprove rolling stabilityPrevent set controlRare end control deviceRoll force/gap control deviceStrip millStrip steel

The invention discloses a steckel mill rolled piece head-and-tail deviation control method which comprises the following steps that: based on existing equipment configuration, different modes are distinguished by integrating the rolling information of a steckel mill according to the rolled piece deviation and rough rolling force in the final step of rough rolling, then the deviation controlled by roll gaps on both sides of the steckel mill is determined, and roll gap setting control for preventing deviation is carried out. Through the method, the hand-and-tail deviation of strip steel can be reduced, shut-down accidents caused by the deviation of strip steel can be prevented, and the rolling stability of the steckel mill can be improved.

Owner:BAOSHAN IRON & STEEL CO LTD

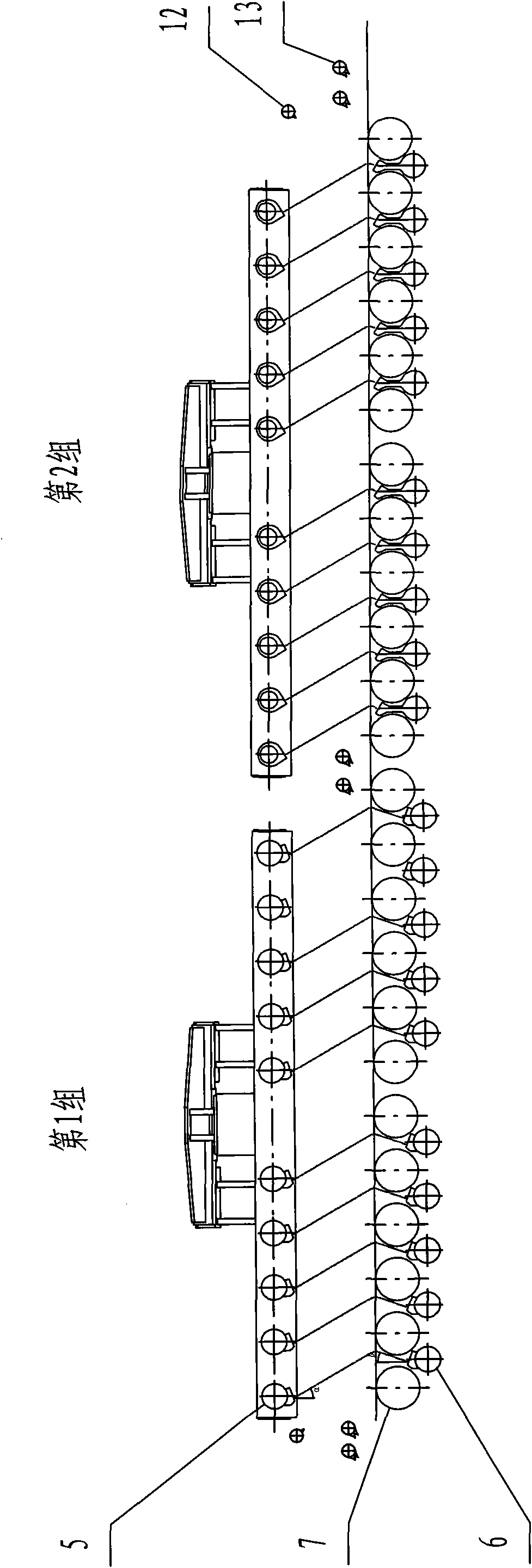

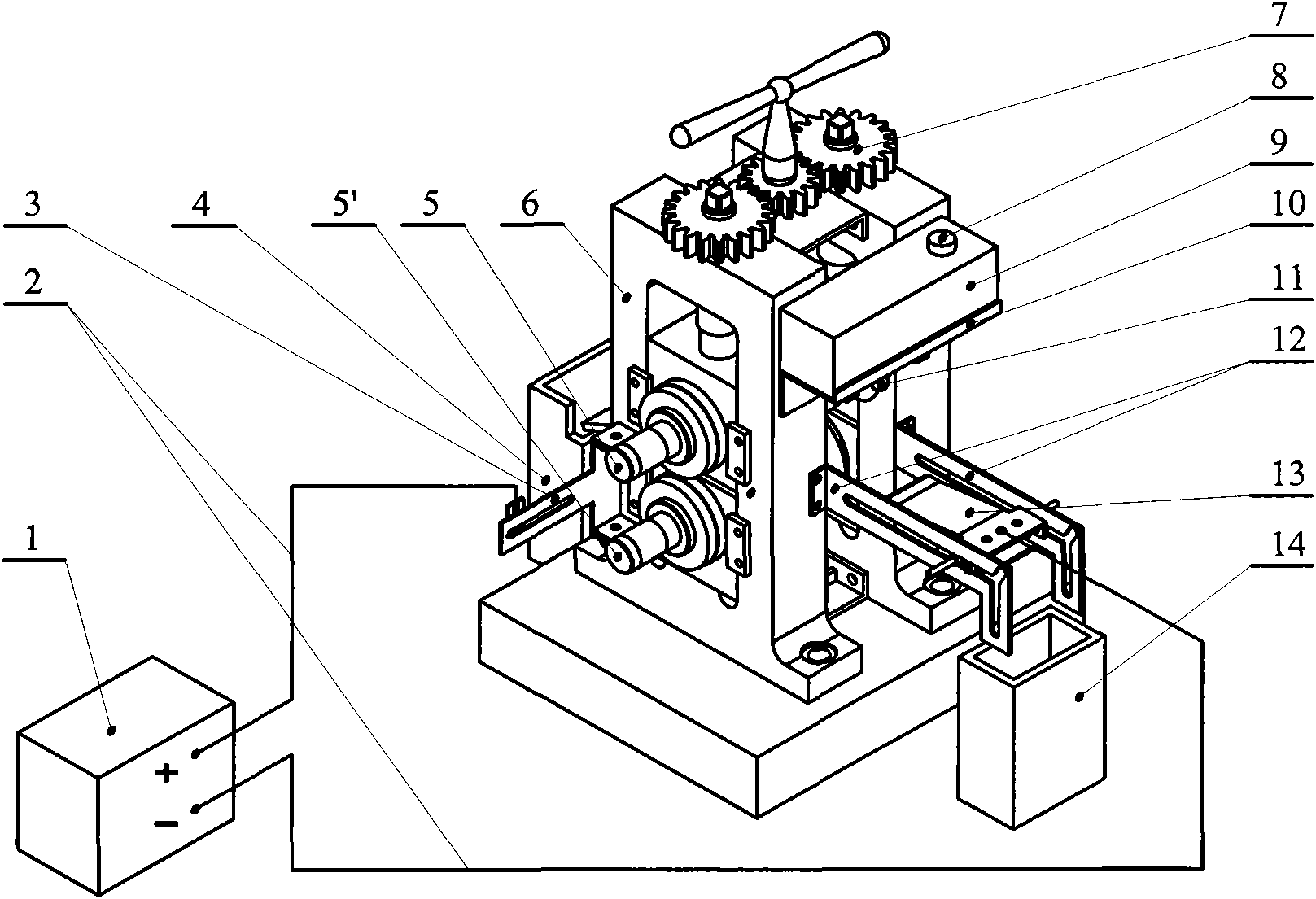

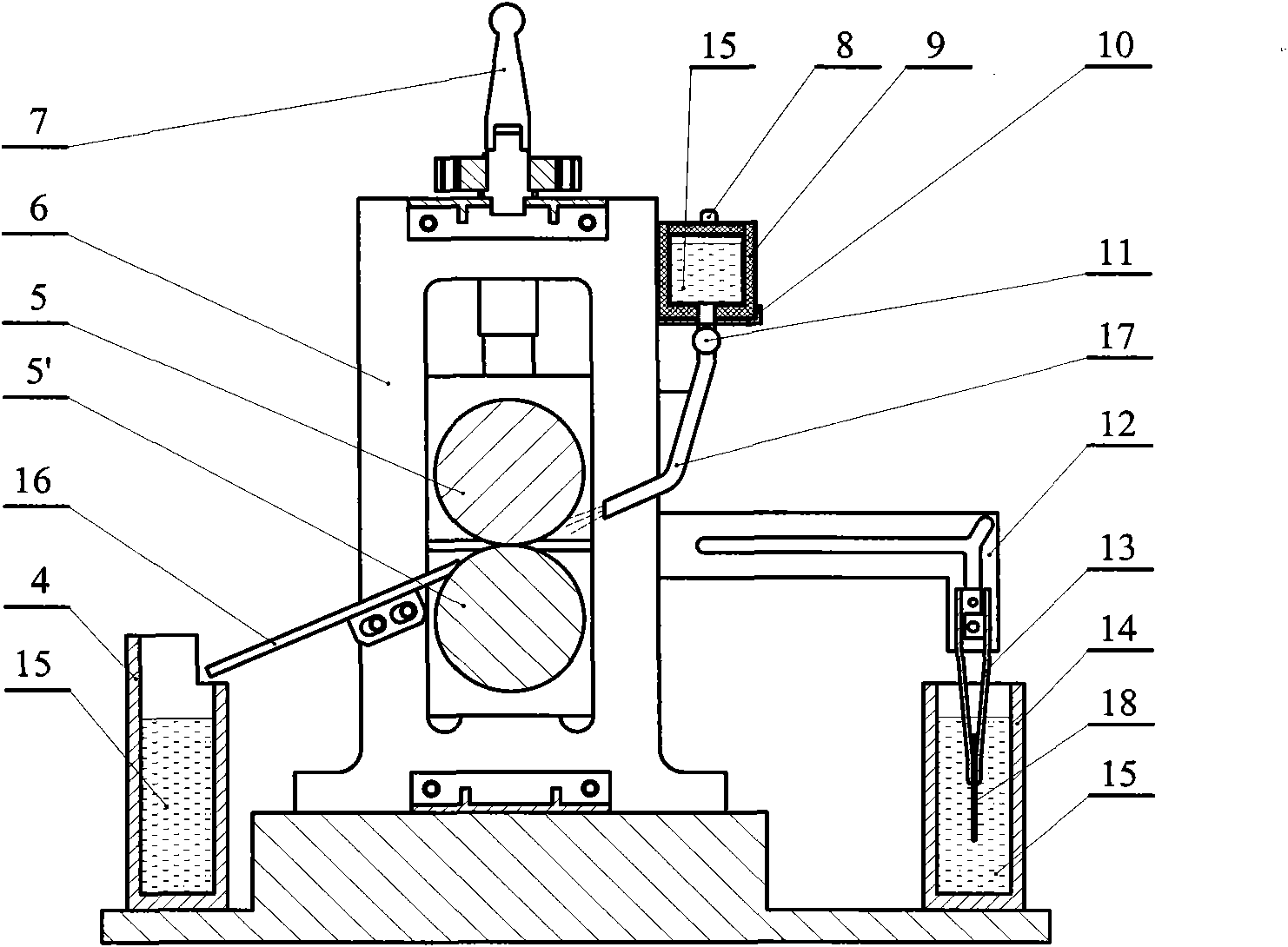

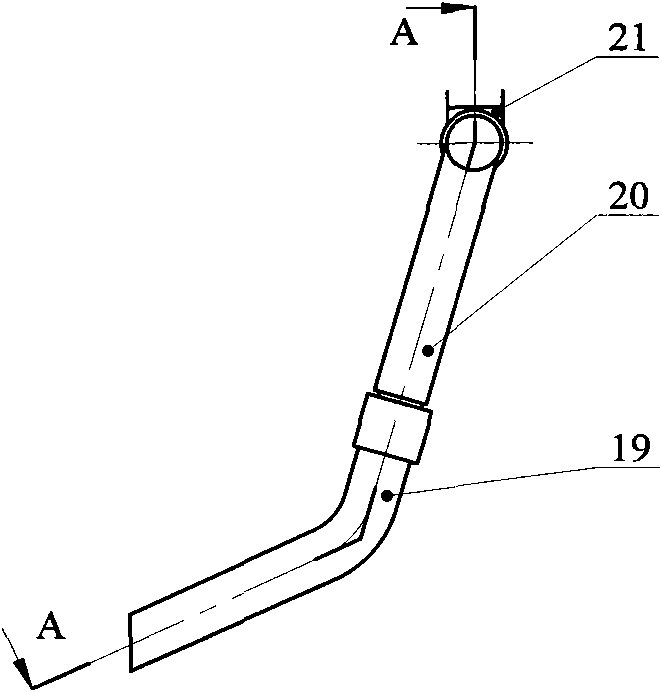

Electro-plastic two-roll mill of low-temperature liquid nitrogen cooling medium

InactiveCN102059250AReduce deformation resistanceImprove plastic deformation abilityMetal rolling stand detailsWork treatment devicesLiquid nitrogen containerStrip mill

The invention discloses an electro-plastic two-roll mill of a low-temperature liquid nitrogen cooling medium. A rack (6) at the entrance of the two-roll mill is provided with two dragging tracks (12 and 12'); a track groove between the two dragging tracks (12 and 12') is internally provided with a feeding clamp (13); a cooling tank (14) is arranged below the rear ends of the two dragging tracks (12 and 12'); the rack (6) at the entrance of the two-roll mill is provided with a delivery guide (16); a collecting tank (4) is arranged below the delivery guide (16); a liquid nitrogen container (9) is arranged on a bracket (10) for fixing the rack (6); the negative electrode of an impulse power source (1) is connected with the upper plywood of the feeding clamp (13) by a cable (2), and the positive electrode of the impulse power source (1) is connected with a roll electrode (3) by the cable (2). In the rolling process by using the electro-plastic two-roll mill, the low-temperature liquid nitrogen is automatically sprayed on a rolled piece deformation zone; and the rolled piece is in the low temperature environment of minus 160 to minus 70 DEG C before the process of rolling processing, in the process of rolling plastic deformation, and after the process of rolling processing. Hard pulse current vertical to the deformation direction is imported into the rolled piece deformation zone between an upper roller and a lower roller, and the electro-plastic effect is used to reduce the deformation resistance of the rolled piece and improve plastic deformation capacity of the rolled piece, thus obtaining the rolled piece product with serious plastic deformation.

Owner:YANSHAN UNIV

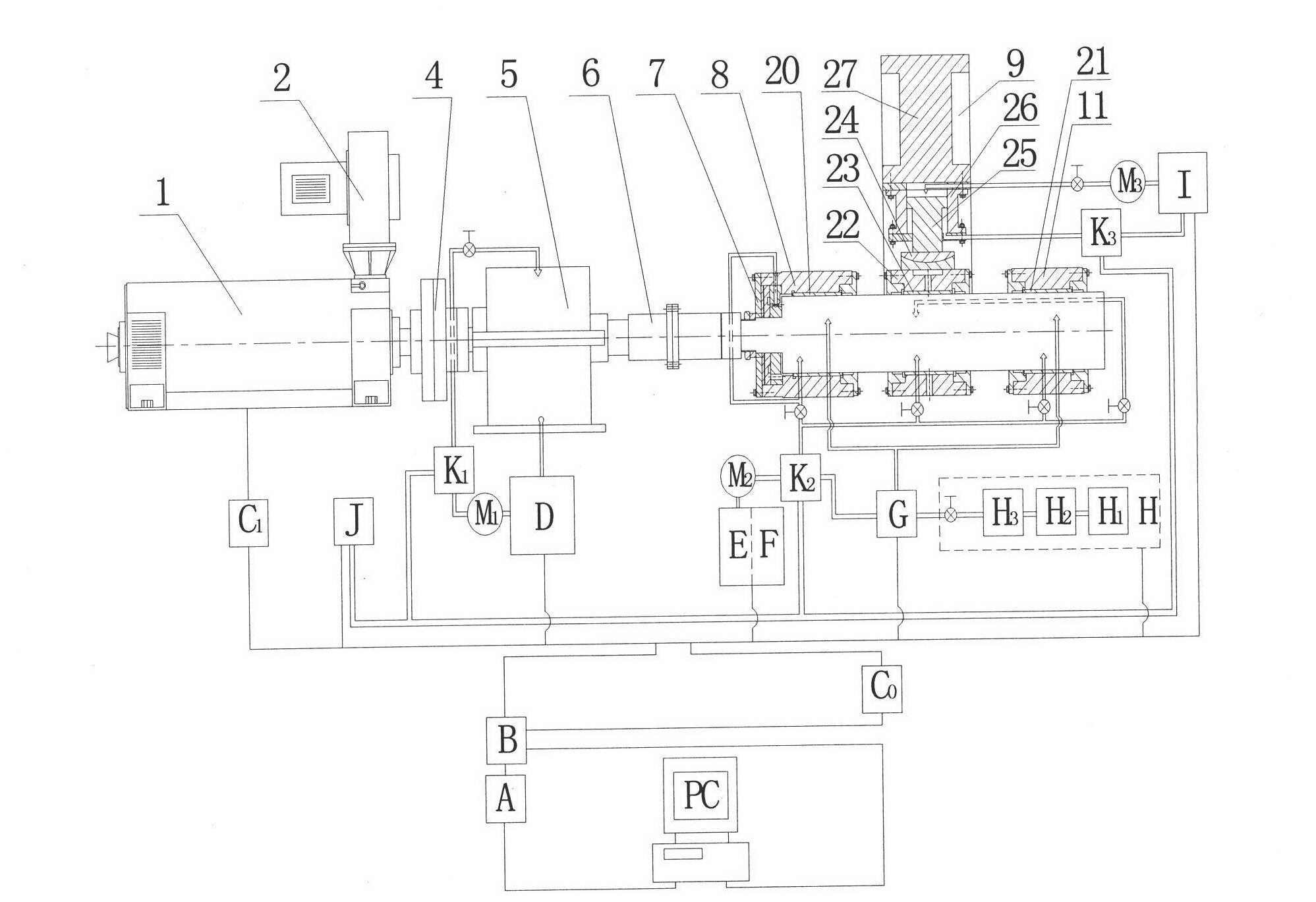

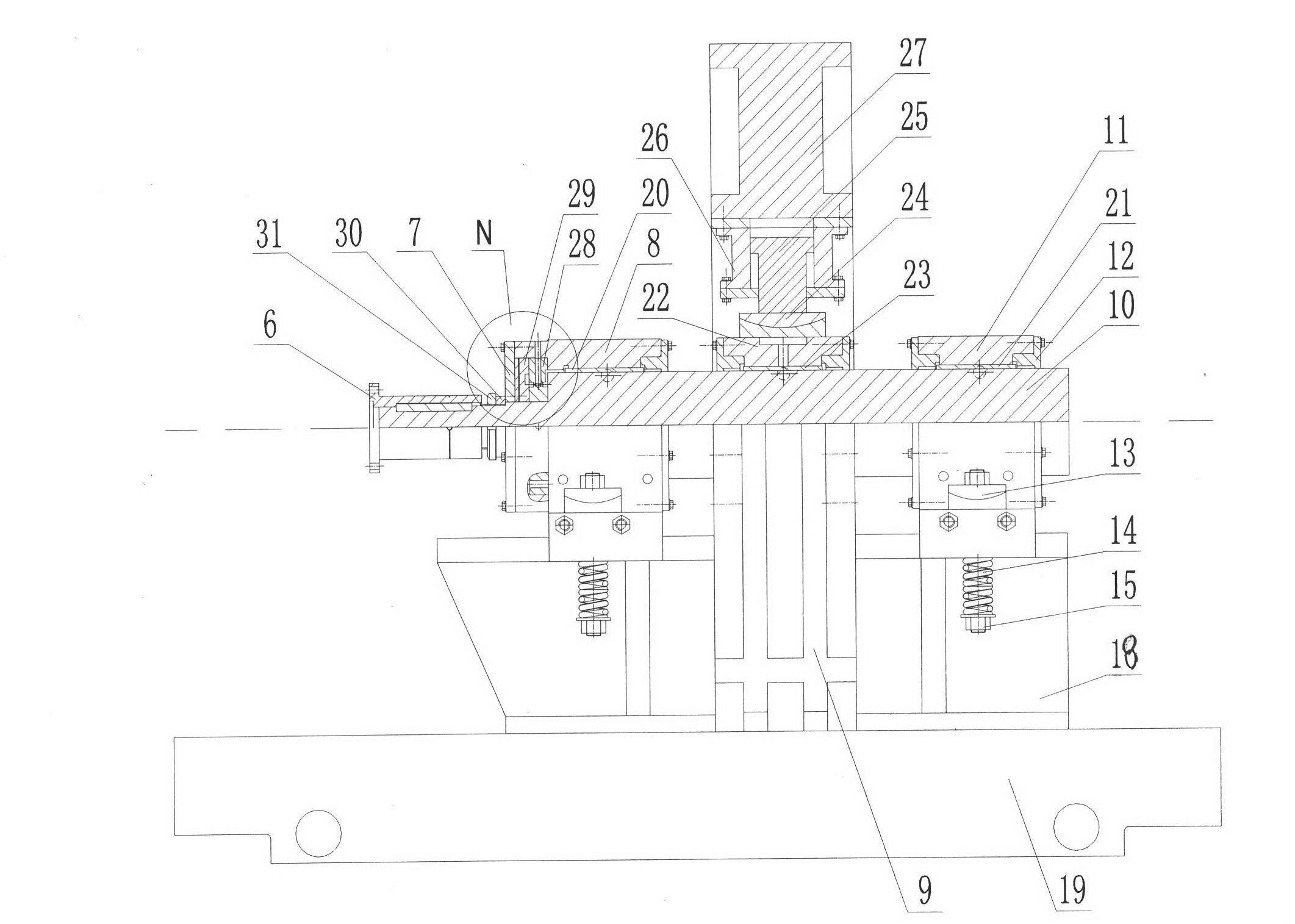

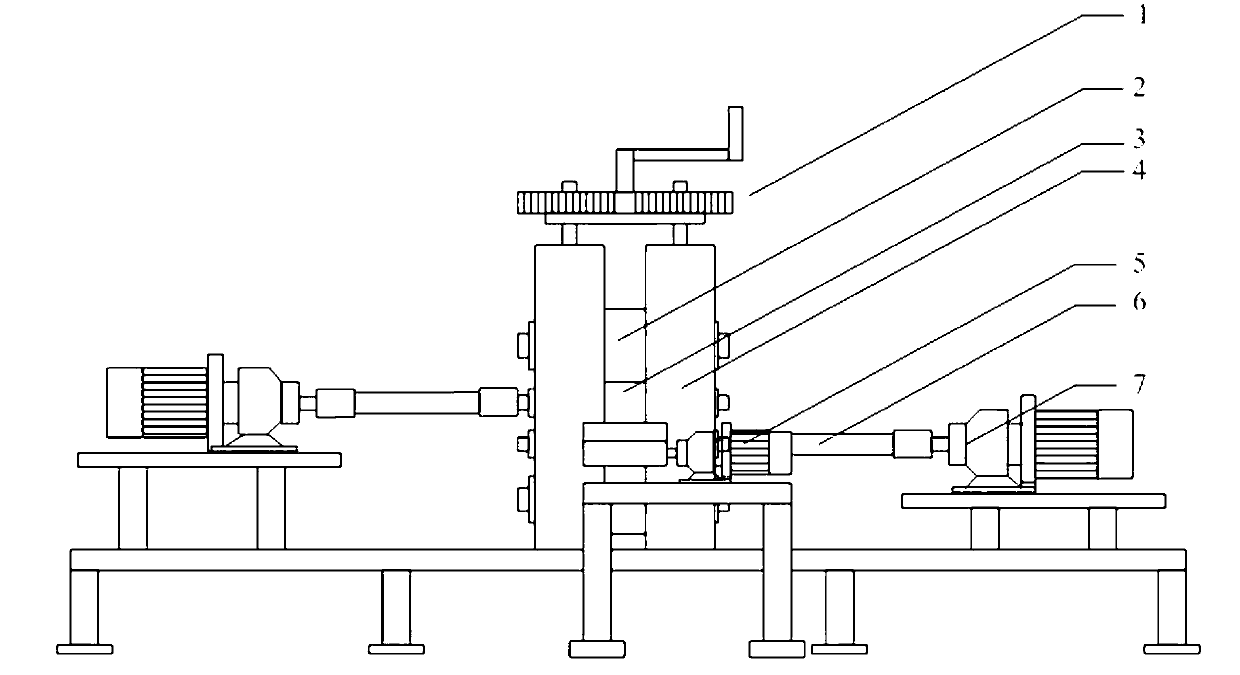

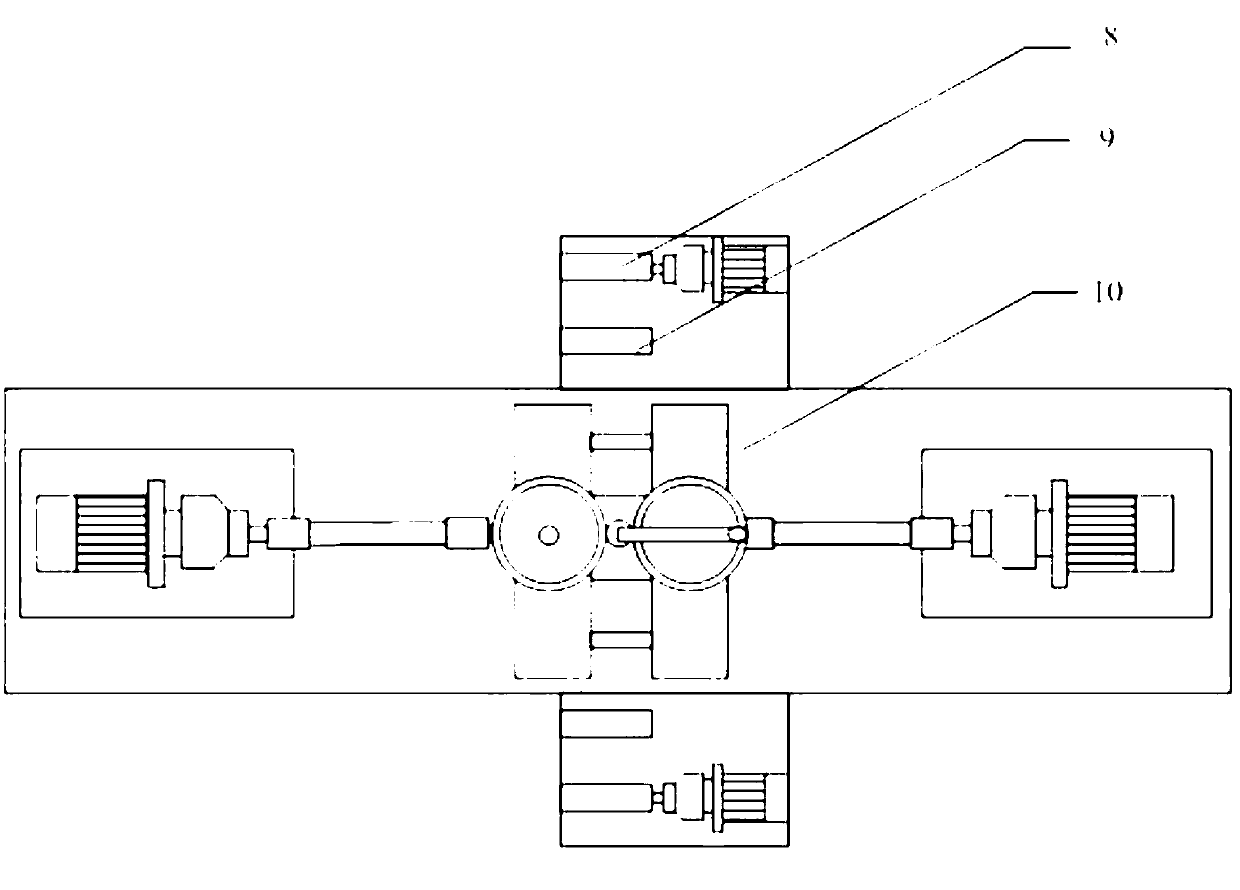

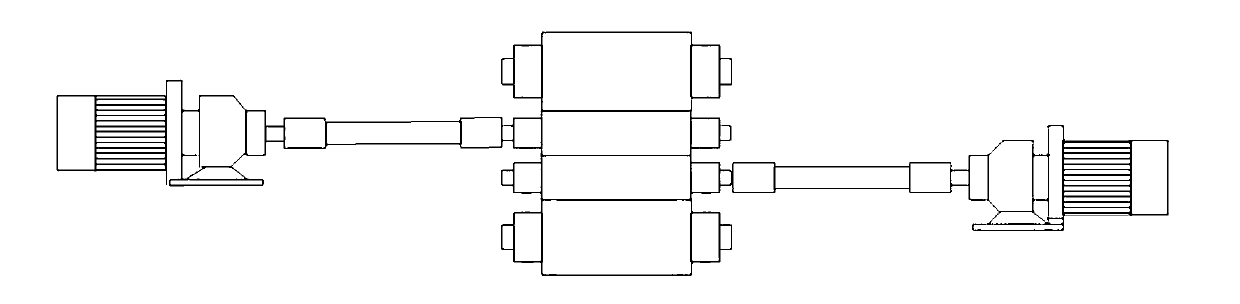

Rolling mill oil film bearing comprehensive test bench

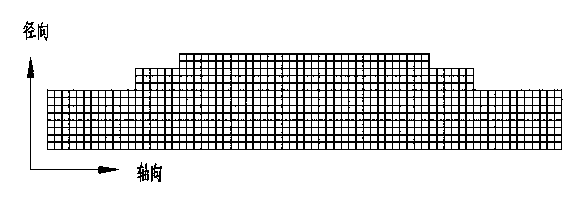

The invention discloses a comprehensive test-bed for an oil film bearing of a rolling mill, belonging to the technical field of testing equipment of oil film bearings of rolling mills. The comprehensive test-bed is characterized by comprising a mechanical system, a motor driving system, a hydraulic loading system, a lubricating system, an air pressure control system, an electric control system and a computer data acquisition system which are combined to form an integral and uniform operation; flow sensors, temperature sensors, pressure sensors and displacement sensors mounted on the bearing and all pipelines are connected to the computer data acquisition system through a PLC (Programmable Logic Controller); and the electric control system is connected with and controls the motor driving system, the hydraulic loading system, the lubricating system and the air pressure control system. The invention realizes integration of an electromechanical hydropneumatic integral system by setting rotation speed of a motor shaft and the dynamically controlling rolling conditions of the hydraulic load and testing performance of the oil film bearing of the rolling mill by the data acquisition system. The system has the advantages of compact structure and convenience for operation, and is suitable for the fields of various teaching and scientific research.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

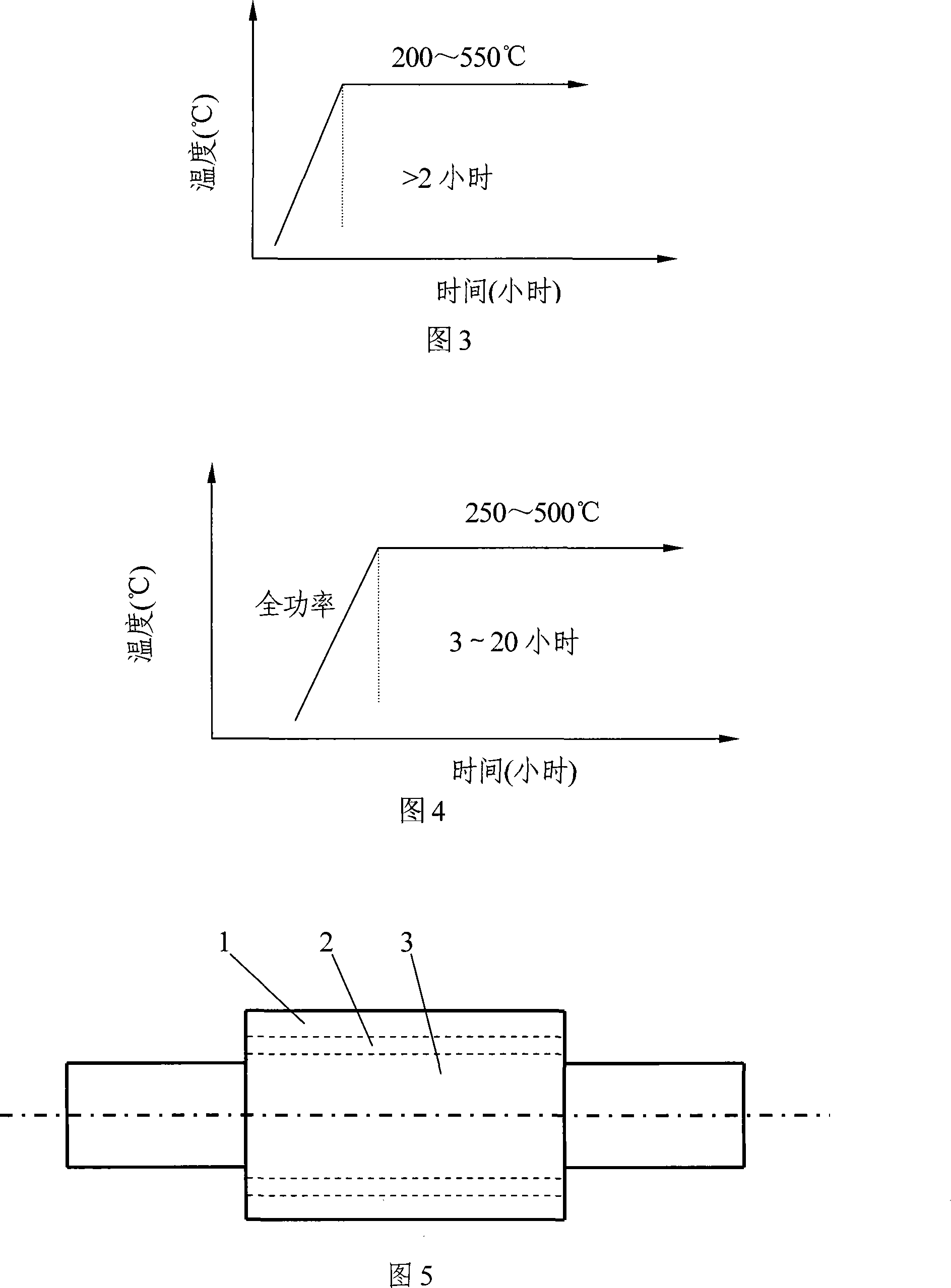

Post-forging heat treatment process for 45Cr4NiMoV alloy steel large back-up rolls of rolling mills

InactiveCN102417965AAvoid white spotsFurnace typesHeat treatment process controlHeat treatingCrystallite

The invention belongs to the technical field of large forging heat treatment processes, and mainly relates to a post-forging heat treatment process for 45Cr4NiMoV alloy steel large back-up rolls of rolling mills. A forged back-up roll is cooled to 400 DEG C to 500 DEG C by the air and put into a furnace, and the material temperature in the heat treatment furnace is not lower than 600 DEG C; a high-temperature normalizing plus low-temperature normalizing plus spheroidizing annealing plus high-temperature tempering process is adopted, and air cooling is carried out. The adopted post-forging heat treatment process disclosed by the invention is characterized in that: crystalline grains are thinned; the structure is regulated, so that the network structure is removed; the carbon segregation ofthe upper part of the large steel ingot is considerable, temperature higher than Ac1 is kept for a long time, consequently, part of carbide is remelted, the remaining unmelted carbide is spheroidized, and a granular pearlite structure is obtained during cooling; consequently, the structure toughness is high, and structure preparation is done for the next step of heat treatment; and fish eyes are prevented.

Owner:洛阳中创重型机械有限公司

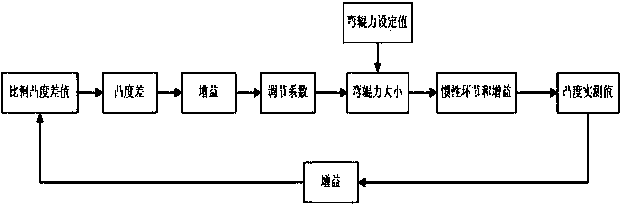

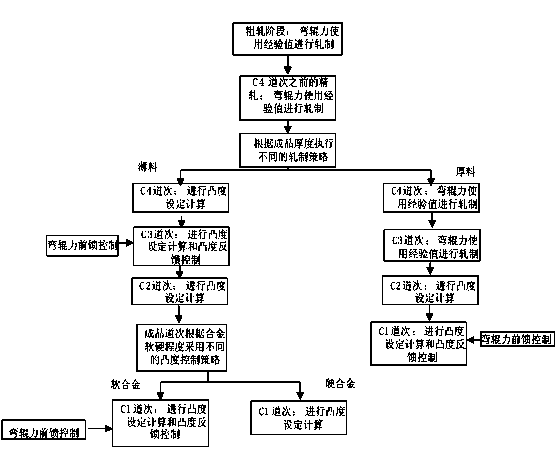

Method for controlling convexity of single-rack double-coiler aluminum hot mill

ActiveCN103433295AImproved crown setting accuracyHighlight substantive featuresProfile control deviceAutomatic controlStrip mill

The invention relates to a method for controlling convexity of a single-rack double-coiler aluminum hot mill. A convexity control strategy of the single-rack double-coiler aluminum hot mill is made according to the characteristics of the mill and field rolling experience; a convexity presetting model, a thermal expansion calculation model and convexity feed-forward and feedback control systems, which are suitable for a single rack, are established; excellent full-automatic control on convexity and flatness of an aluminium sheet strip in the rolling process of the mill is implemented; a corresponding convexity control strategy is made according to the alloy characteristics of the strip; roll bending force set values and head convexity guarantee values in a cooling spray mode in two rolling stages of rough rolling and finish rolling are given by the convexity presetting model and the thermal expansion model; feed-forward compensation on a roll bending force is carried out in the finishing pass so as to reduce influence of fluctuation of a rolling force on convexity; in the last third pass or the final pass in which convexity measurement is carried out, closed-loop control on the roll bending force is carried out according to the alloy characteristic condition so as to ensure full-length convexity and the sheet shape; and after rolling is finished, self-learning of the roll bending force and a cooling spray model is carried out so as to improve accuracy of the presetting model.

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

Continuous casting blank hot charging and hot conveying process for preventing surface crack of steel plate

InactiveCN102059331AAvoid Surface Crack DefectsMake full use of waste heatMetallic materialsMaterials processing

The invention relates to a continuous casting blank hot charging and hot conveying process for preventing a surface crack of a steel plate under the condition of raising temperature of continuous casting blank hot charging, belonging to the technical field of metal material processing. The process comprises the following steps of: cutting a continuous casting blank on a cutting roller way, then introducing the cut continuous casting blank into a conveying roller way located between a continuous casting machine and a rolling mill, and spraying water and cooling the continuous casting blank quickly; reducing the temperature of the surface of the continuous casting blank to about 600 DEG C; controlling the cooling rate of the surface of the continuous casting blank to be 20-50 DEG C / s; controlling the cooling time of the surface of the continuous casting blank to be 15-60s; and cooling the continuous casting blank, and then introducing the cooled continuous casting blank to a heating furnace within 15min and heating. The process has the advantages that the temperature inside the continuous casting blank is ensured to be higher than 800 DEG C under the condition of ensuring the surface temperature of the continuous casting blank introduced into the heating furnace to be lower than 600 DEG C, therefore, the surface crack defect of the rolled steel plate is prevented, the waste heat of the continuous casting blank can be fully utilized, and the favorable energy saving effect is achieved.

Owner:SHOUGANG CORPORATION

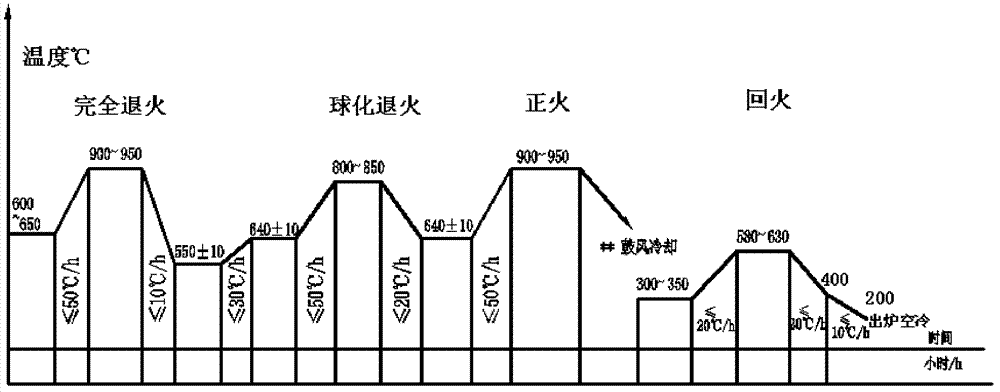

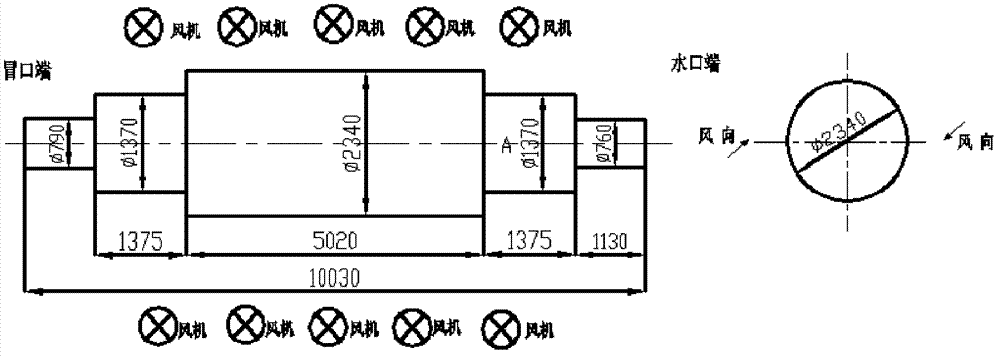

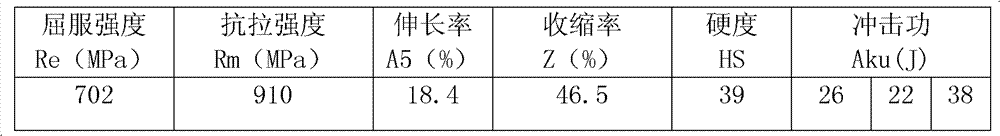

Heat treatment method after forging for forged steel bearing roller used for large heavy plate mill

ActiveCN103088199AEasy to shapeMeet the hardnessFurnace typesHeat treatment furnacesStrip millHardness

The present invention discloses a heat treatment method after forging for forged steel bearing roller used for large heavy plate mill, which is used for heat treatment after forging of supporting rollers used for a rolling mill with a plate width of above 2500 mm. The method comprises the following steps of: first, fully annealing; second, spheroidizing annealing; third, normalizing; and fourth, tempering. The operation method of once heat treatment after forging is used for supporting rollers used for the rolling mill with the plate width of above 2500 mm, so that the roll neck stiffness and other mechanical properties of the workpiece meet technical requirements through a manner of normalizing blast cooling. A preheat treatment process is reduced, the production cycle is shortened, and the production cost is reduced. The large plate supporting roller after heat treatment after forging can acquire pearlitic structure and sorbite structure with good mechanical properties, so that the hardness of the roll neck is up to 30-40 HS. The mechanical properties meet the technical requirements. The structure preparation for subsequent heat treatment is made.

Owner:SHANGHAI ELECTRIC SHMP CASTING & FORGING CO LTD +1

Thermal treatment process for quick cutting steel composite roll

ActiveCN101403032AReduce distortionReduce crackingFurnace typesHeat treatment furnacesThree stageStrip mill

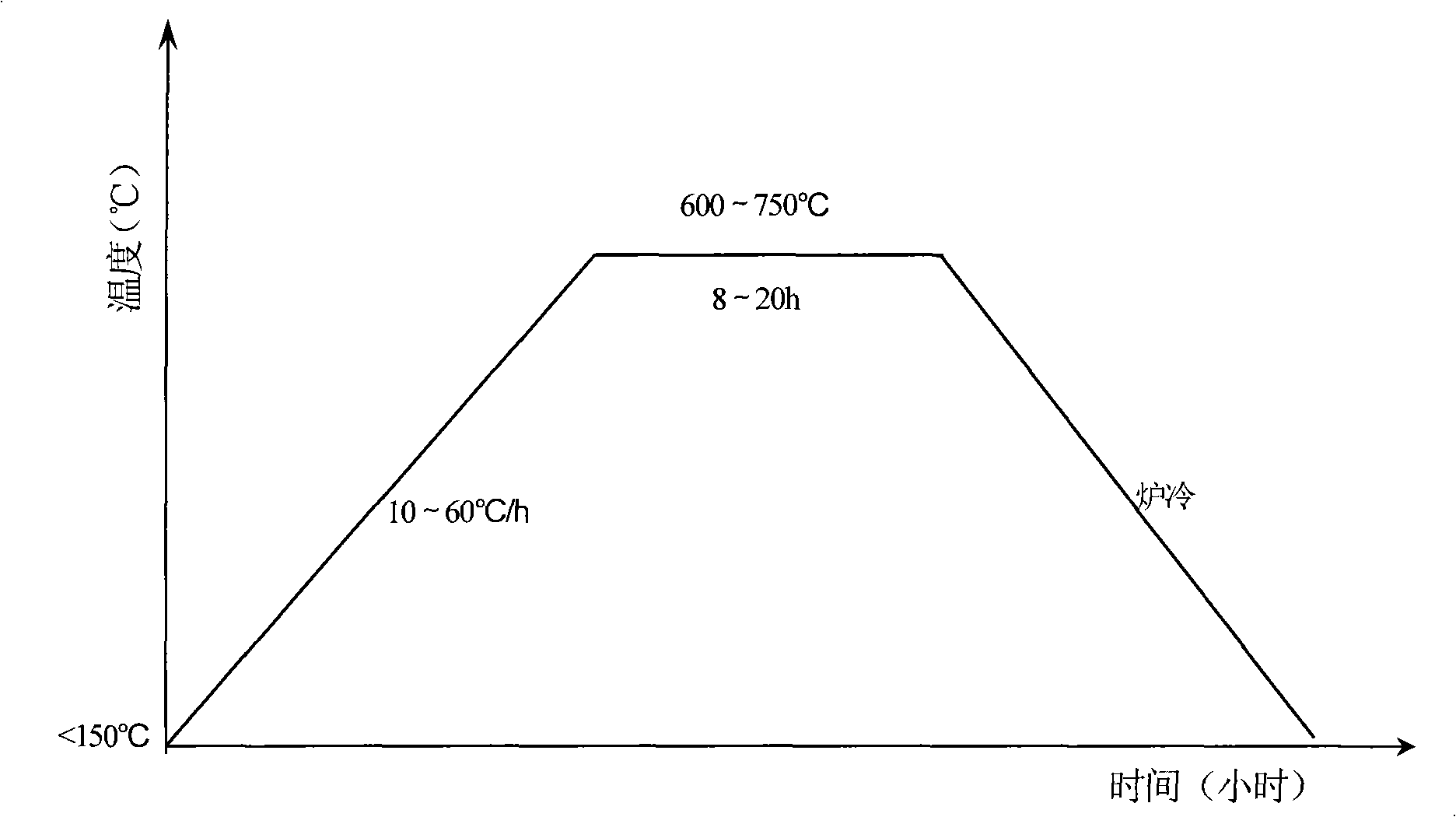

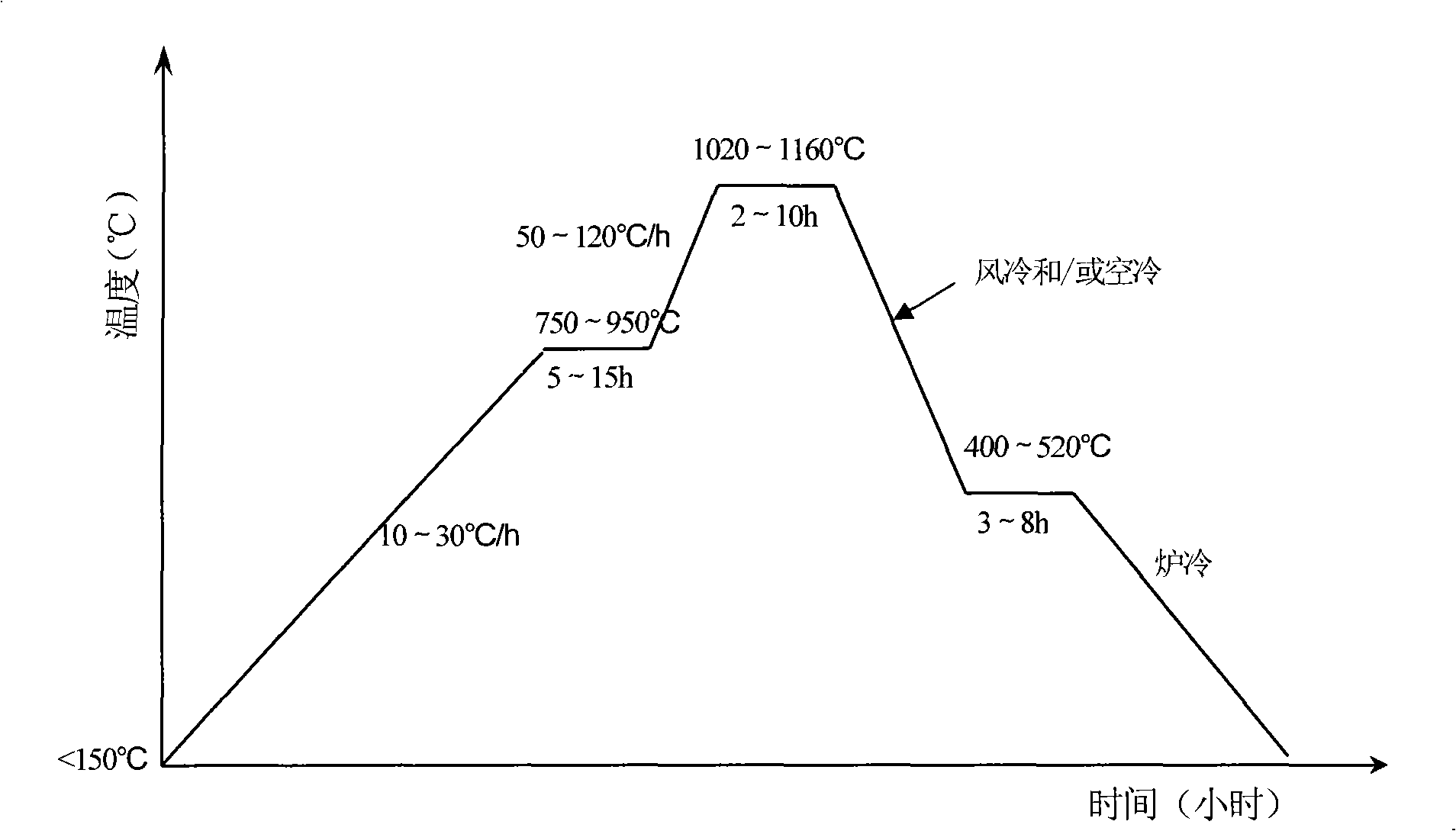

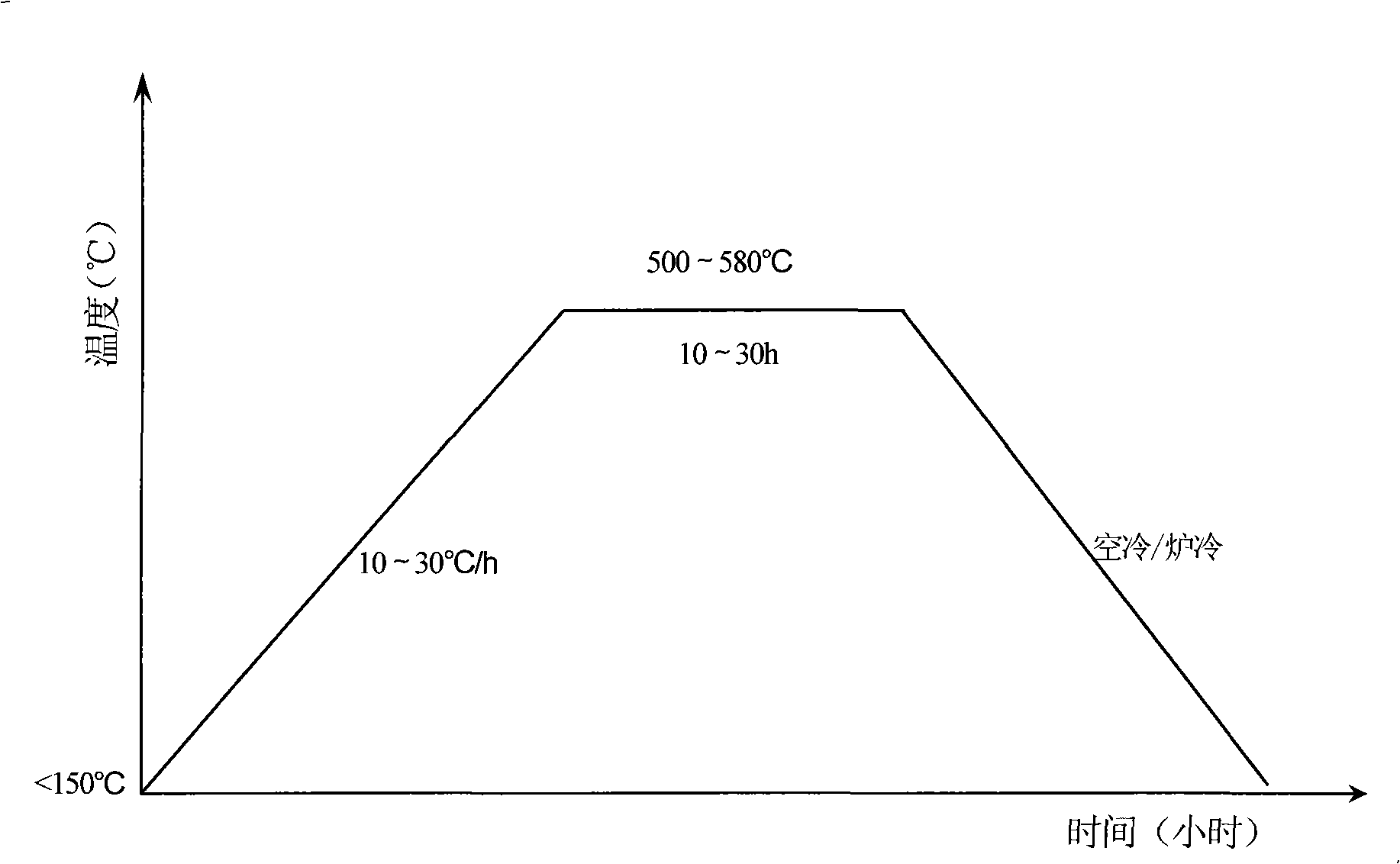

The invention belongs to the rolled steel manufacturing field, in particular to a heat treatment technology of high-speed steel composite roll, which is applied in a strip rolling mill of the rolling steel industry. The heat treatment technology is divided into three stages of annealing, quenching and tempering and is applicable to the high-speed steel composite roll, wherein, the heating speed of the annealing is 10 to 60 DEG C / h, the heating temperature of the annealing is 600 to 750 DEG C, the temperature-holding time is 8 to 20h and the annealing cooling adopt furnace cooling. The invention is characterized by low annealing hardness, being beneficial to cutting and processing, high hardness of the high-speed steel roll, good uniformity of hardness, little radial hardness after quenching and tempering and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Production method of environment-friendly high-surface quality and pickling-free beamsteel

ActiveCN101906584AAvoid breakingSpeed up coolingTemperature control deviceMetal rolling arrangementsSteelmakingChemical composition

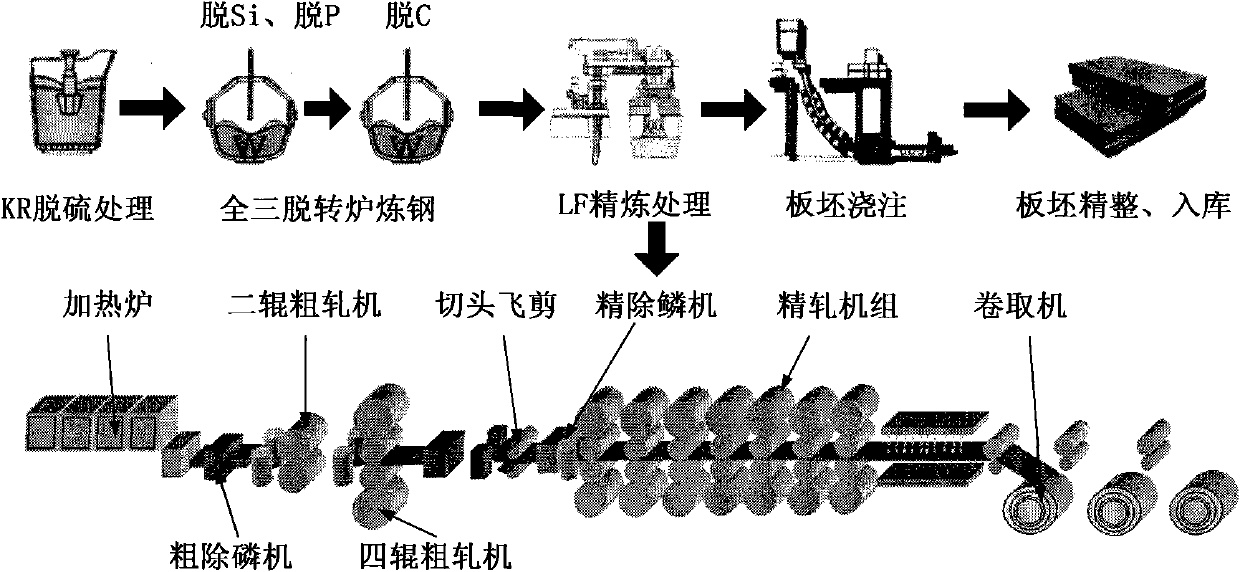

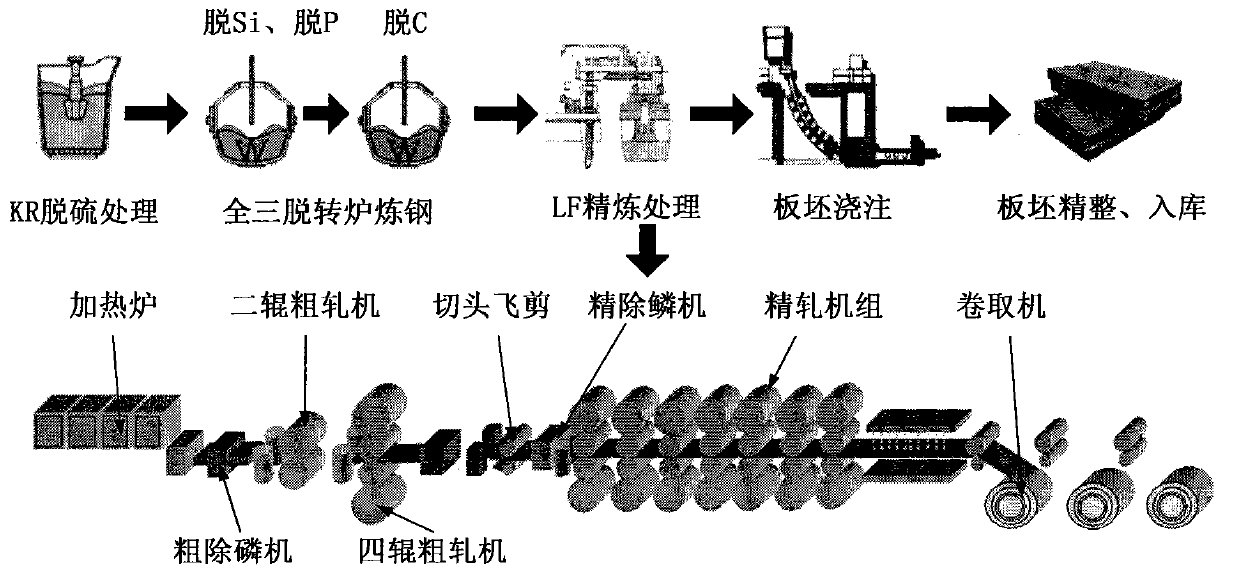

The invention provides a production method of environment-friendly high-surface quality and pickling-free beamsteel, belonging to the technical field of steel rolling and comprising the following steps: continuously casting molten iron after KR desulfuration treatment, complete pretreatment convertor steelmaking and LF furnace refining treatment; crimping a plate blank after reheating, roughing, finish rolling and laminar cooling; and finally obtaining the beamsteel satisfying the production requirement. Therefore, on the basis of meeting the beamsteel performance, by optimizing the chemical components of the beamsteel, heating cycle, rolling technology and the like and controlling the structure of surface scale of the beamsteel, the high-surface quality and pickling-free beamsteel can be produced. A 2250mm hot continuous rolling broad strip mill is used to produce pickling-free 510L and 610L steel plates for automobile beams, wherein the width of the steel plate is 1100-2100mm and the thickness thereof is 1.6-14.0mm. By controlling the chemical components and melting and rolling key process parameters, the high-surface quality and pickling-free steel plate for the automobile beam can be produced, which meets the production requirement.

Owner:SHOUGANG CORPORATION +1

Method for controlling automatic equidistant steel tapping of heating furnace

InactiveCN101701287AEasy to controlReduce pile of steelHeat treatment process controlStrip millHeating furnace

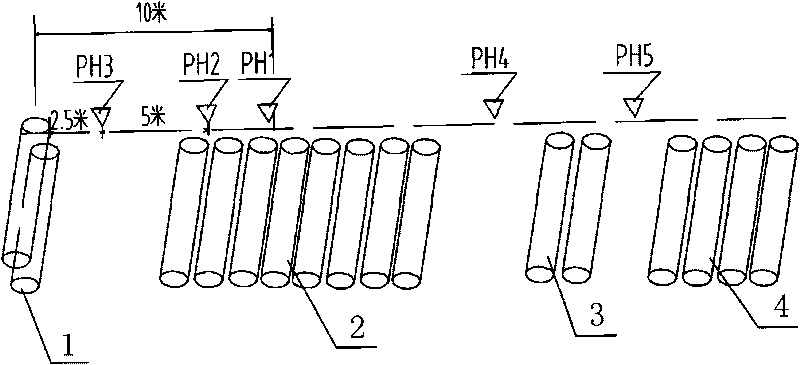

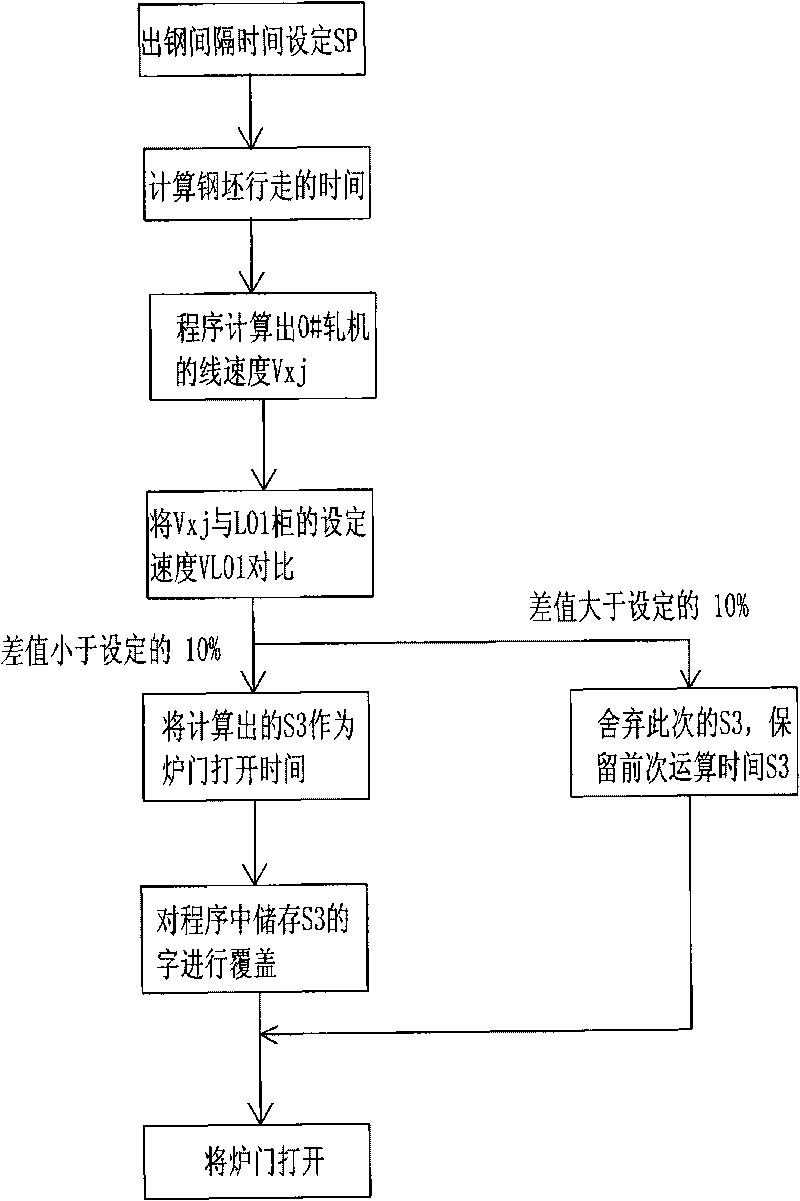

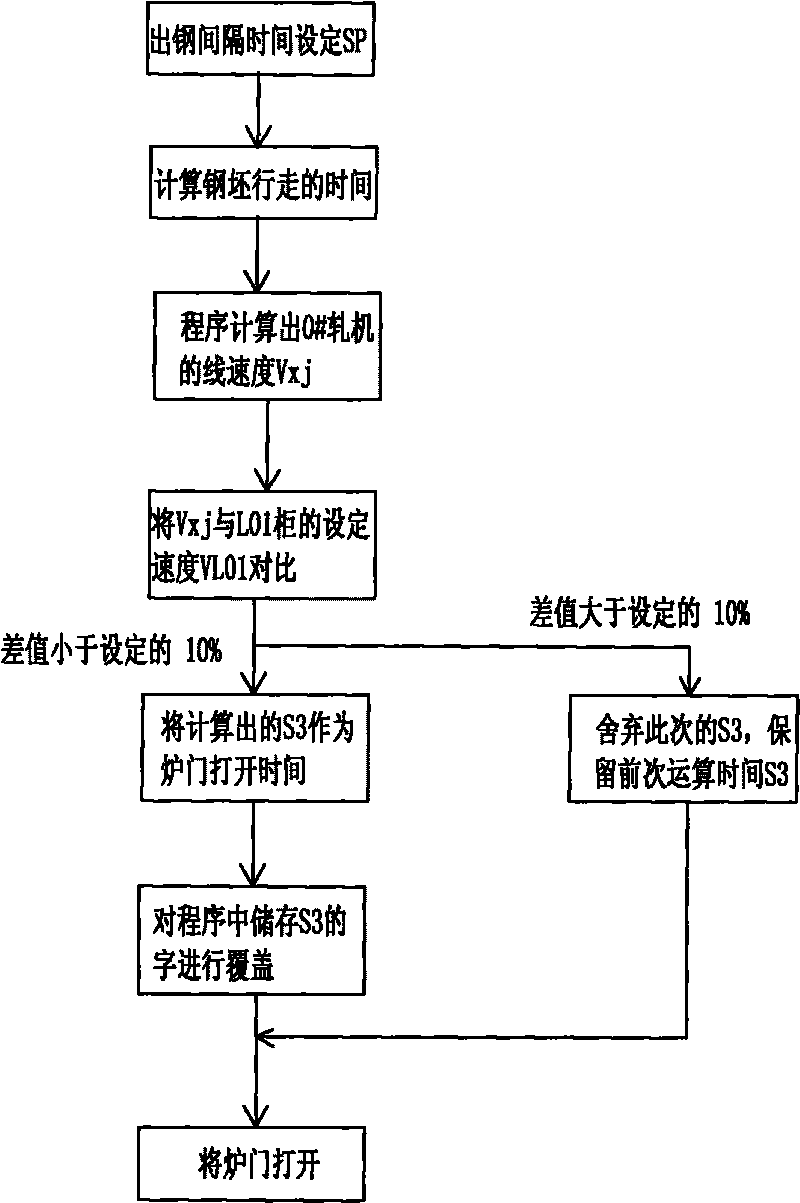

The invention relates to a method for controlling automatic equidistant steel tapping of a heating furnace, comprising the following steps of: setting steel tapping intervals; obtaining the time that billet is conveyed to the outlet of a heat insulating roller bed according to the distance from the head of the billet in the heating furnace to a hot metal detector at the outlet of the heat insulating roller bed and the speed of the roller bed; calculating the line speed of the billet in a 0# rolling mill; calculating the time that the tail of the billet is separated from the hot metal detector at the outlet of the heat insulating roller bed and enters the 0# rolling mill; calculating the time S3 when the furnace door of the heating furnace is opened; comparing the speed of the billet in the rolling in actual production with the linear speed of the billet in the 0# rolling mill, wherein if the difference is smaller than or equal to 10% of the linear speed of the billet in the 0# rolling mill, S3 is used as the time that the furnace door is opened, and if the difference is greater than 10% of the linear speed of the billet in the 0# rolling mill, the time S3of opening the furnace door calculated previously is retained. The invention can avoid repeat steel heaping and reduce delay of machine halt, thereby the dimensional accuracy of the product is improved, and the hour yield of roll line production is improved greatly.

Owner:NANJING IRON & STEEL CO LTD

Control method for flying shear tail-shearing of rod wire

InactiveCN102513355ASolve the problem that the tail clipping cannot be completed normallyLow costMetal rolling arrangementsProduction lineStrip mill

The invention relates to a control method for flying shear tail-shearing of rod wire. Specifically, when over compact arrangement of an upstream rolling mill (1) and the flying shear results in an over short distance from a first hot metal detector (2) to a shearing central line of the flying shear which does not allow normally shearing tail, a second hot metal detector (4) is additionally arranged in front of the upstream rolling mill (1); and the tail-shearing control, when the distance from the rod wire flying shear to the first hot metal detector (2) is over short, is realized by combining precise shear blade position control, precise shear tail length control, conversion of equivalent distance from the second hot metal detector (4) to the flying shear center line, actual measurement and compensation of elongation rate of the upstream rolling mill (1). The invention solves the problem that the tail-shearing project is not normally finished because of over compact arrangement of the upstream rolling mill (1) and the flying shear and over short distance from the first hot metal detector (2) and the flying shear in the rod wire production wire; and the tail-shearing is steady and reliable according to the actual application result.

Owner:WISDRI WUHAN AUTOMATION

Control method of rolling deflection of hot-rolled strip steel

ActiveCN106475424AImprove rolling stabilityImprove shape qualityRoll force/gap control deviceStrip millEngineering

The invention relates to a control method of rolling deflection of hot-rolled strip steel. The control method comprises the following steps that horizontal thickness distribution of an intermediate billet is measured in a real-time manner at a rough rolling outlet; and the wedge compensation of a finishing roller gap is calculated according to the horizontal thickness measured data of the roughly rolled intermediate billet, and the rolling reductions of two sides of finishing mills are reasonably set. Steel scraps generated due to rolling deflection are decreased, and the hot rolling stability and the strip shape quality of a strip steel product are improved. The problem that since the roughly rolled intermediate billet is wedged, the finish rolling deflection of the strip steel is caused is solved.

Owner:BAOSTEEL ZHANJIANG IRON & STEEL CO LTD +1

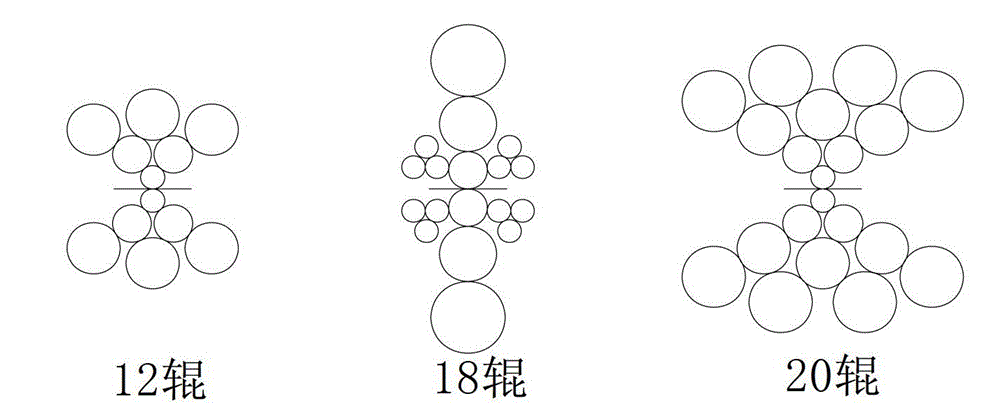

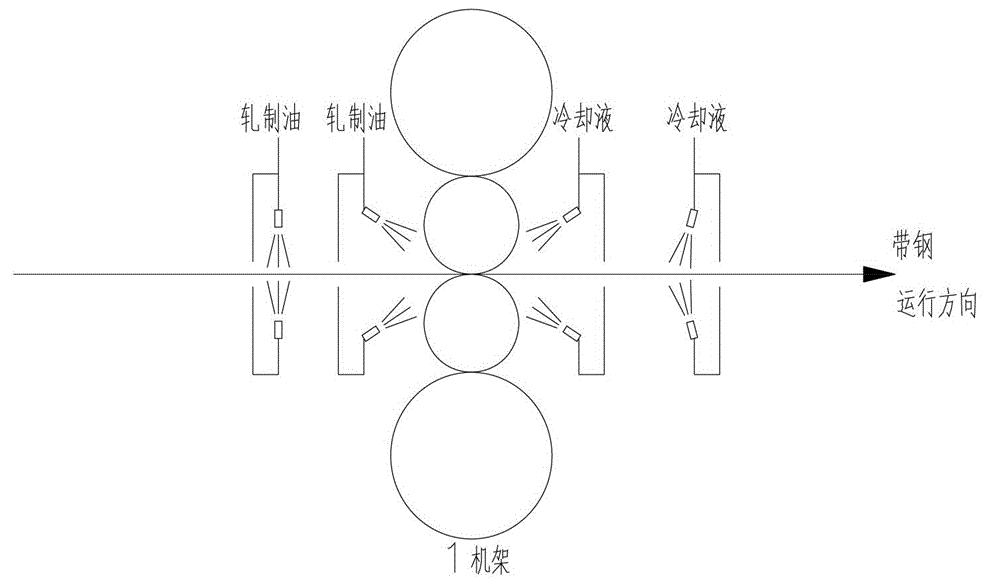

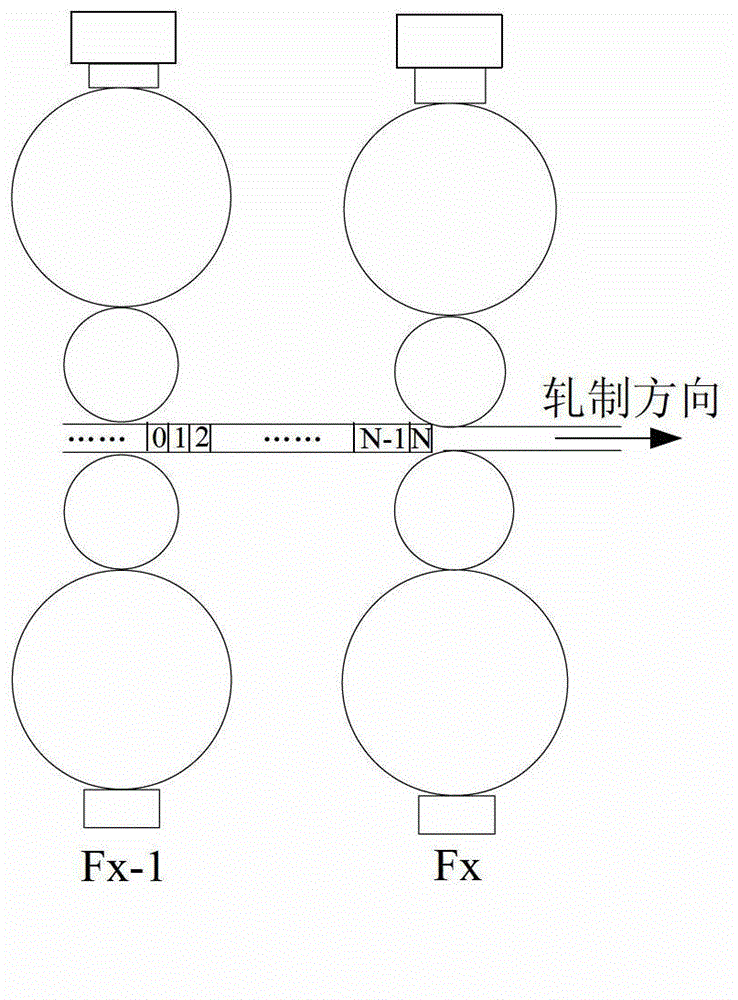

Lubricating method for rolling of stainless steel products on tandem cold rolling mill

The invention provides a lubricating method for rolling of stainless steel products on a tandem cold rolling mill, which is a method for rolling stainless steel plates with low surface defects on the tandem cold rolling mill comprising machine frames with the number of N. The method is characterized in that emulsified liquid is used for rolling, lubricating and cooling on the second machine frame to the N-1th machine frame of a tandem cold rolling mill group, and pure rolling oil is used for lubricating the surface of band steel before the band steel enters the rolling mill and / or inlet roll gap areas between rollers of the machine frames and the band steel on the first and Nth machine frames of the tandem cold rolling mill. At the same time, cooling liquid is used for cooling the rollers and the band steel on the first and Nth machine frames, and at this time, the cooling liquid does not come into contact with the pure rolling oil on the machine frames, i.e., the lubrication by the pure rolling oil is not interfered. The number N of the machine frames of the tandem cold rolling mill is 4 to 6, and the number of the rollers of each machine frame is 4 to 6. The lubricating method for rolling of stainless steel products on the tandem cold rolling mill, provided by the invention, is a novel method for producing the stainless steel products with low surface defects on the tandem cold rolling mill. Through the adoption of the rolling method and a system thereof, the requirements for high-quality surfaces can be met at low costs.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for producing pure titanium strip through cold rolling

The invention discloses a method for producing a pure titanium strip through cold rolling, comprising the steps of pickling, cold-rolling, degreasing and annealing hot-rolled titanium strips. The method is characterized by adopting a 1500mm 6-high reversing cold rolling mill to cold-roll the pickled hot-rolled titanium strips. The cold rolling method comprises the following steps: sending the pickled hot-rolled titanium strips to the 1500mm 6-high reversing cold rolling mill to be rolled in first rolling length, annealing the titanium strips rolled in first length; and resending the annealed titanium strips to the 1500mm 6-high reversing cold rolling mill to be rolled in second rolling length. Large-coil heavy titanium strips with thickness of 0.3-0.8mm can be obtained on the conventional 6-high reversing cold rolling mill unit through two rolling lengths; therefore, the method is simple in procedures, low in cost and easy to realize rolling and can meet the requirement of production without improving the rolling mill.

Owner:SHANDONG IRON & STEEL CO LTD +1

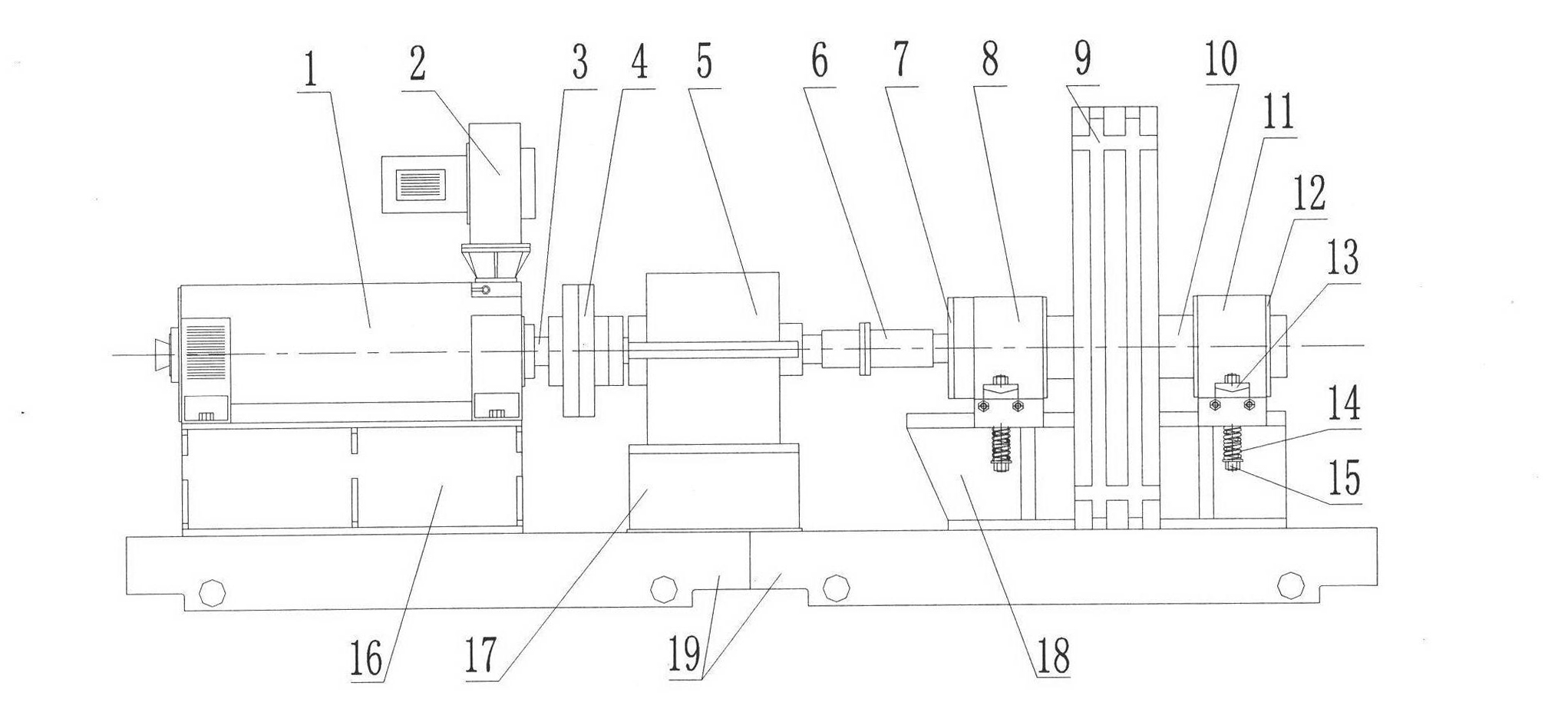

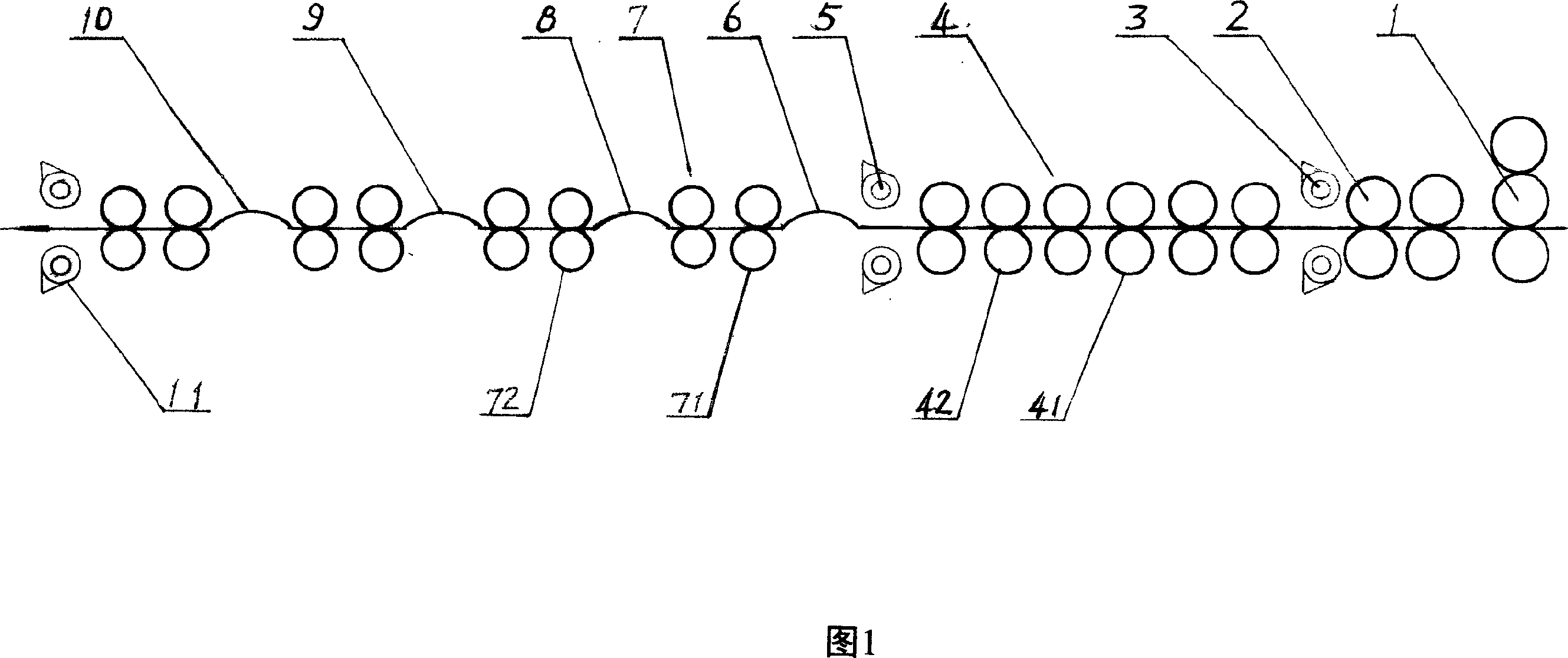

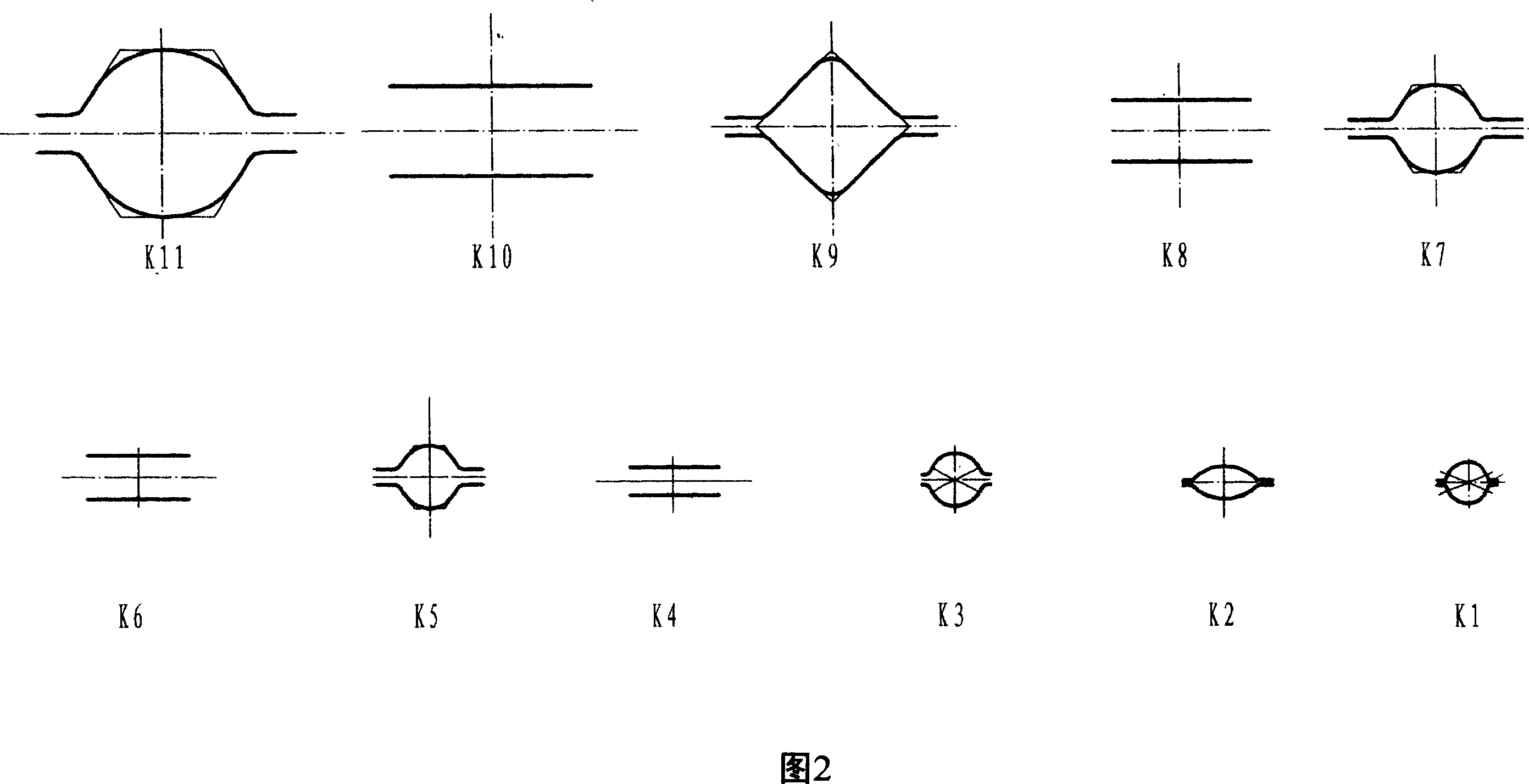

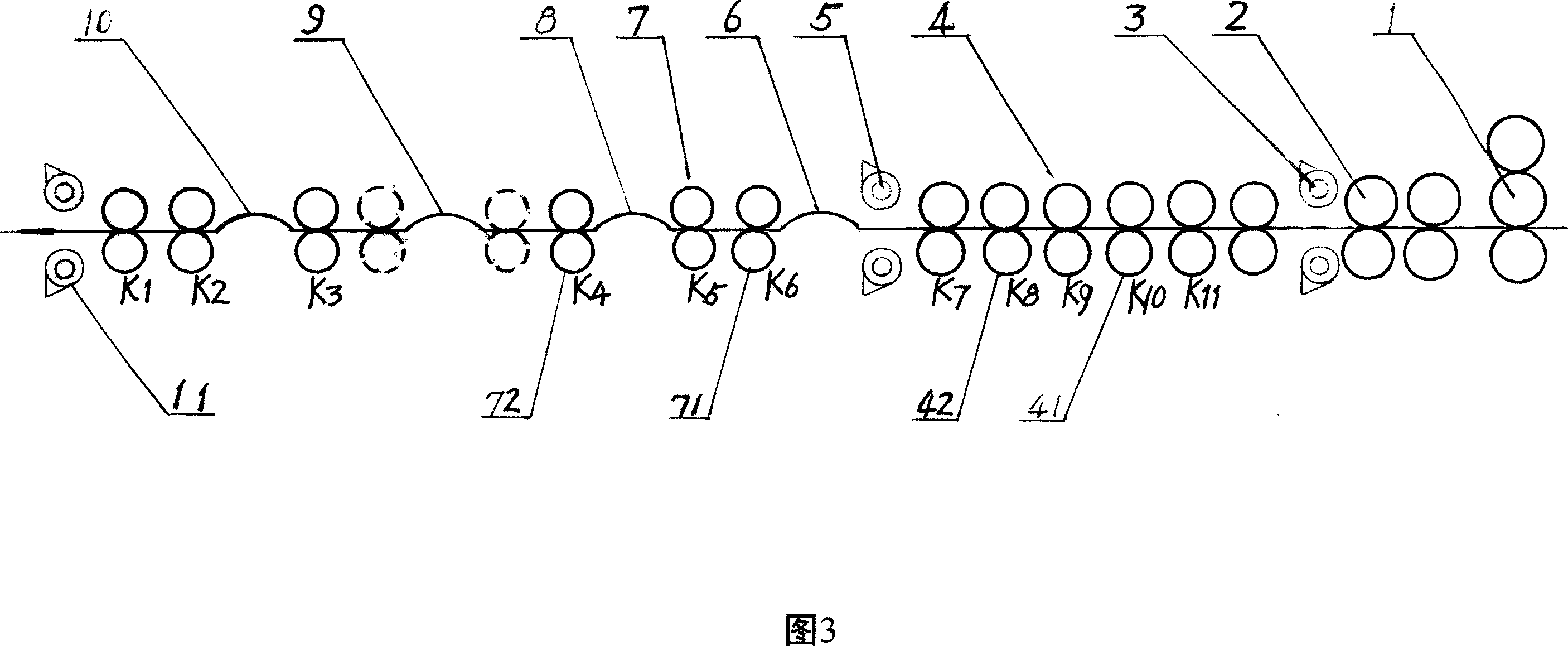

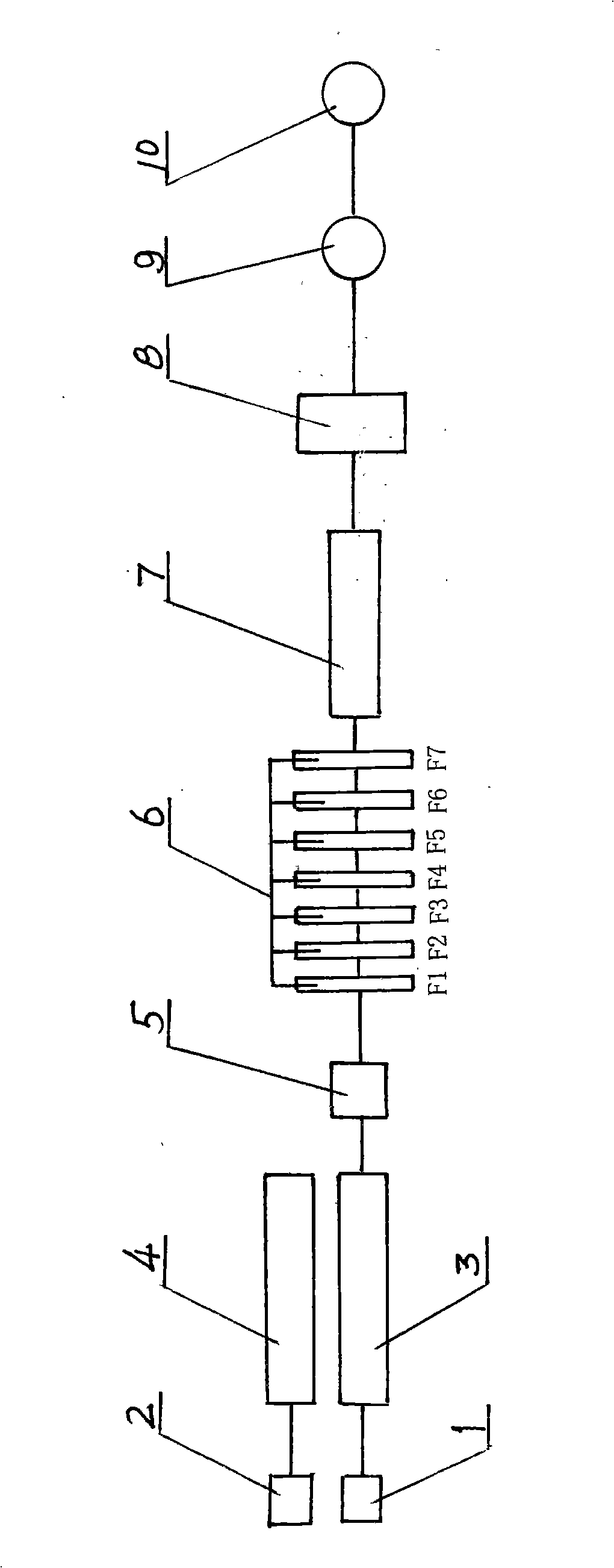

Non-groove rolling technology of horizontal mill

ActiveCN101007315AReduce rolling accidentsReduce intermediate rolling wasteRollsMetal rolling arrangementsStrip millRound bar

The invention discloses a slotless rolling art for all-horizontal rolling mill which rolls round bar and screw-thread steel on semi-continuous rolling process online. It arranges junior mill 2, crop flying shear 3, junior mills group 4, crop and crop end flying shear 5, loop 6 or 8 or 9 or 10, finishing mills group 7 and times ruler flying shear 11 after blooming mill 1 consecutively; installs plain-barreled roll 41 or 42 and 71 or 72 on the third or fifth rolling mill frames of junior mills group 4 and the first and third rolling mill frames of finishing mills group 7, the plain-barreled rolls need not be processed hole-type groove, the rolling pressure is decreased significantly. The plain-barreled rolling mills does not have wrong rollers in whole rolling process, does not generate ears, decreases central waste rollers, saves changing roller time, increases rolling mill efficiency. The plain-barreled roll slotless rolling art not only can be used in flat alternative continuous rolling process line, but has a bright prospect in development and application of all-horizontal rolling mill process line.

Owner:湖南华菱涟源钢铁有限公司

Method for rolling ultra-thin metal strap

InactiveCN102989766AFacilitate online changesReduced roll preparation timeMetal rolling arrangementsAutotransformerThin metal

The invention belongs to the technical field of rolling and particularly relates to a method for rolling an ultra-thin metal strap. The method comprises the steps of starting a system power supply of a multifunctional rolling machine, and starting a main motor fan; rocking a pressing handle clockwise to lift a roller gap; twining a raw strap material round a roller on one side, wherein the outgoing end is twined round the other roller for 2-3 circles after passing through a tension roller on the side, the working roller gap and two tension rollers on the outer side; starting a tension motor, building up the tension force, giving a tension value of a rolled piece through adjustment of the voltage value of an auto-transformer; rocking the pressing handle counterclockwise to close the roller gap; setting the speed ratio of the upper roller and the lower roller on a human-computer interface; starting a main transmission motor to start positive roller gap rolling, zero roller gap rolling and negative roller gap rolling processes; and repeating rolling till the outlet thickness of the rolled piece meets requirements. According to the method, a plurality of procedures of positive roller gap and negative roller gap rolling are adopted, in coordination with high-tension asynchronous rolling, the rolled piece with the thickness of the submicron level can be thinned continuously.

Owner:NORTHEASTERN UNIV

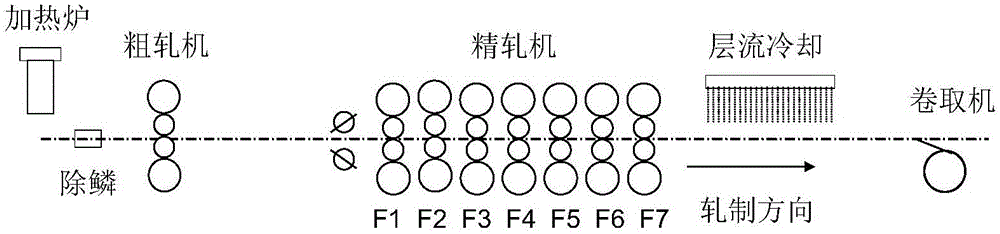

Method for producing variational format/constant format ultra-thin hot-rolled strip steel by using semi-headless technique

InactiveCN101293259AHigh elongationNormal structureRoll force/gap control deviceTemperature control deviceStrip millStrip steel

The invention discloses a method for producing ultra-thin hot rolling strip steel with variable / constant specification by adopting a semi-endless technology; qualified molten steel after refining is sent to a first continuous caster and a second continuous caster to be cast into a flat blank; the semi-endless flat blank cast by the first continuous caster enters a first roller-hearth type soaking furnace for being heated at the temperature of 1050-1150 DEG C, which is sent to a high pressure water descaler at a rolling mill area for the removal of iron scale on the surface of the flat blank and is rolled into the ultra-thin hot rolling strip steel with the thickness being 0.8-1.8mm and the width being 1229-1265mm by F1-F7 rolling mills of a fine continuous rolling mill group; the hot rolling strip steel within the final rolling temperature rang of 860 DEG C to 880 DEG C enters a laminar flow cooler for cooling and is quickly cut by a high-speed flying shear according to the weight of each steel coil; the cut strip steel is alternately coiled by a first coiling machine or a second coiling machine into a finished coil with three or four variable / constant specifications. The ultra-thin hot rolling strip steel produced by the method can expand the products of the strip steel, stabilize rolling condition, lower abrasion of rollers, reduce the times of band penetration and whipping, decrease the loss of waste head and crop end of the products and enhance the yield of the products and productivity.

Owner:湖南华菱涟源钢铁有限公司

Process for manufacturing hot rolled steel strips by using compaction type continuous casting and rolling technique

InactiveCN101293257AEasy to produceIncrease production capacityFurnace typesHeat treatment process controlProduction lineStrip mill

The invention discloses a compact continuous casting and tandem rolling method for producing hot rolling strip steel, including the following steps: 1) liquid molten steel passes through a long nozzle from a ladle to be cast to a pouring box, flows through a submerged nozzle from the pouring box to be cast in a crystallizer of a continuous caster and is continuously cooled in the continuous caster to form a casting blank; 2) a shearing machine is used for cutting a flat blank into certain size; 3) the flat blank enters a tunnel roller hearth heating furnace for heating; 4) the continuous caster is provided with a plurality of casting flows, one of which is in collineation with a rolling mill, the casting blank of other flows passes through a swinging section and is converged with the casting blank of the collinear flow and then is descaled by high pressure water; 5) the casting blank carries out rough rolling into an intermediate blank by a roughing mill group; 6) the intermediate blank is coiled and decoiled by a hot coiling box; 7) the head and the tail of the decoiled intermediate blank are cut and descaling by high pressure water is carried out to the decoiled intermediate blank; 8) the intermediate blank carries out finish rolling into a steel strip with standard thickness; 9) the steel strip is coiled into a finished steel coil by laminar flow cooling. The method is characterized by stable production technique, shorter production line, low equipment investment and high utilization rate of energy in the whole production process, etc.

Owner:BAOSHAN IRON & STEEL CO LTD

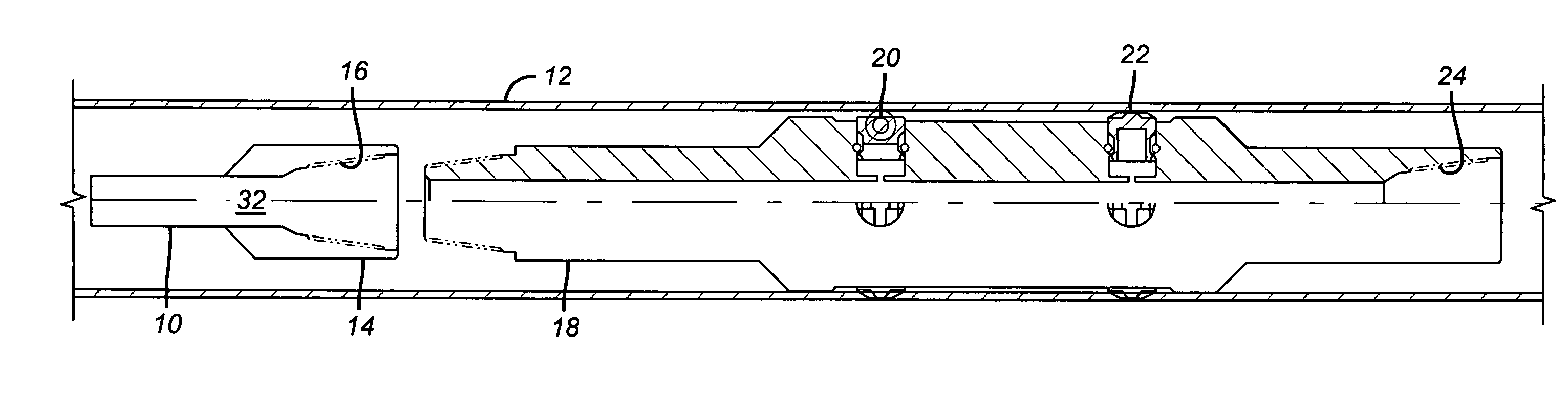

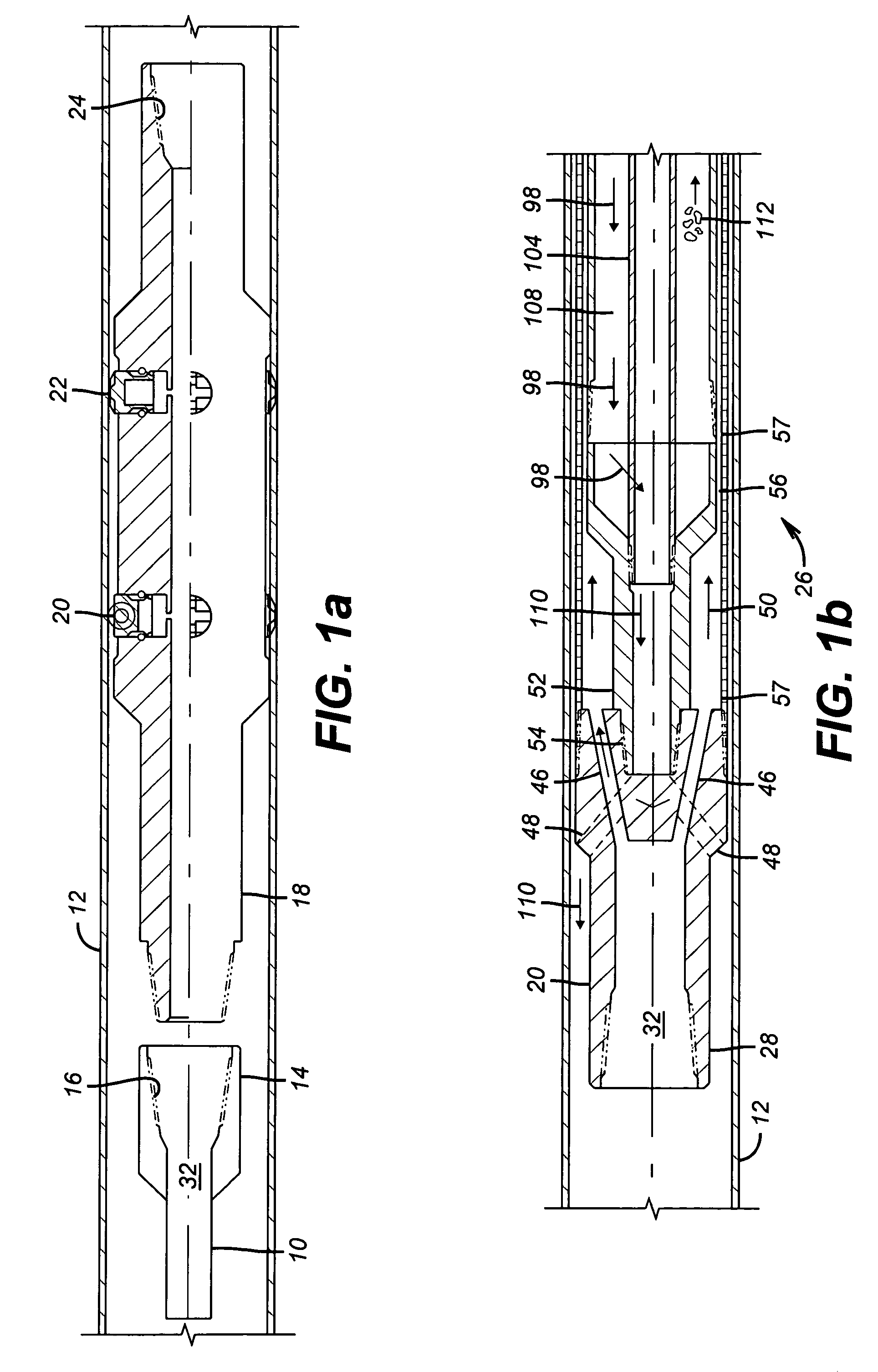

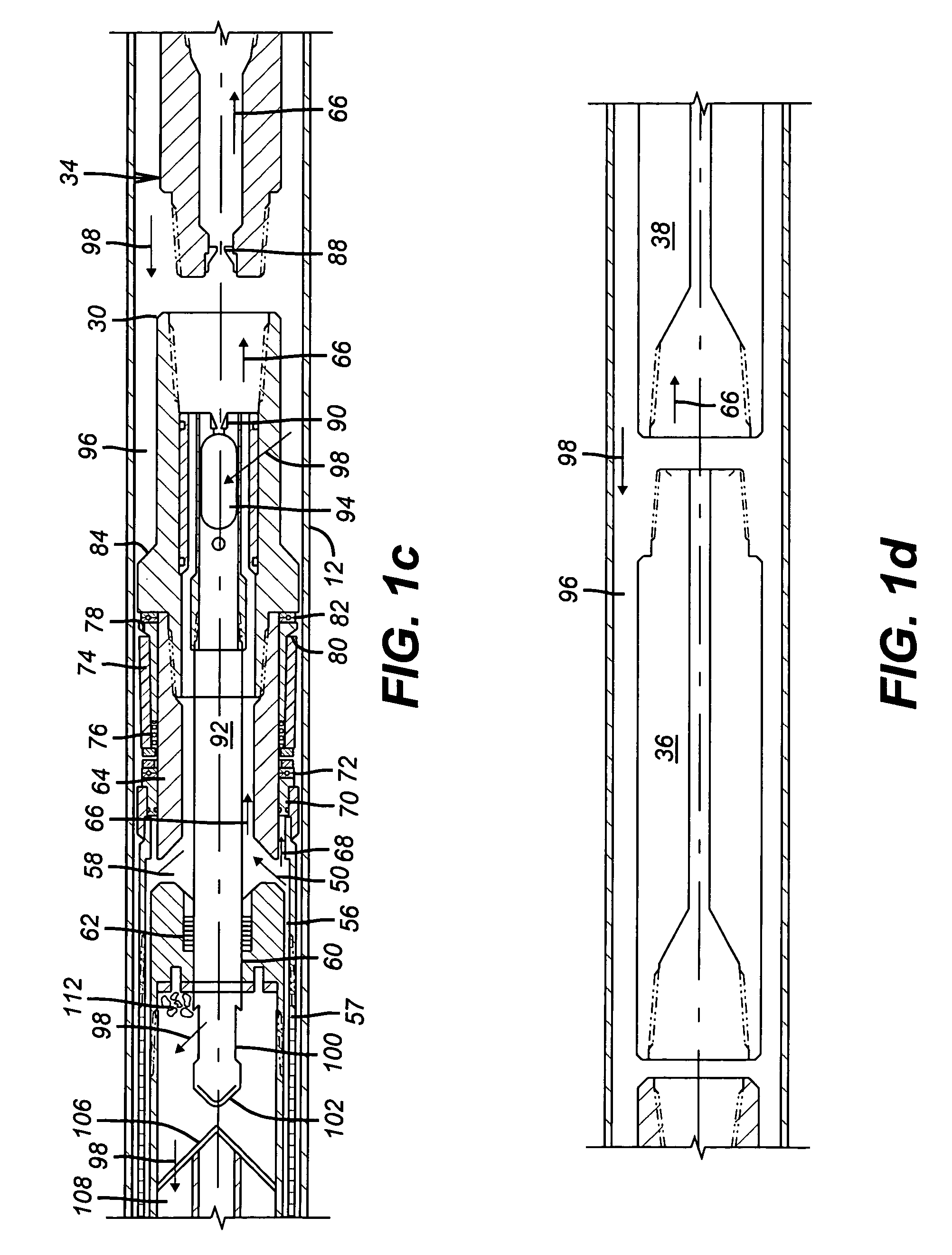

Coiled tubing conveyed milling

Milling in casing that is over 4½ inches is done with coiled tubing that is anchored against torque reaction. An improved debris catcher is part of the bottom hole assembly to capture cuttings from the milling. A thruster can be used to maintain weight on the mill during the milling. The coiled tubing supports a mud motor to drive the mill. Return fluid is separated from the cuttings and returned to the surface.

Owner:BAKER HUGHES INC

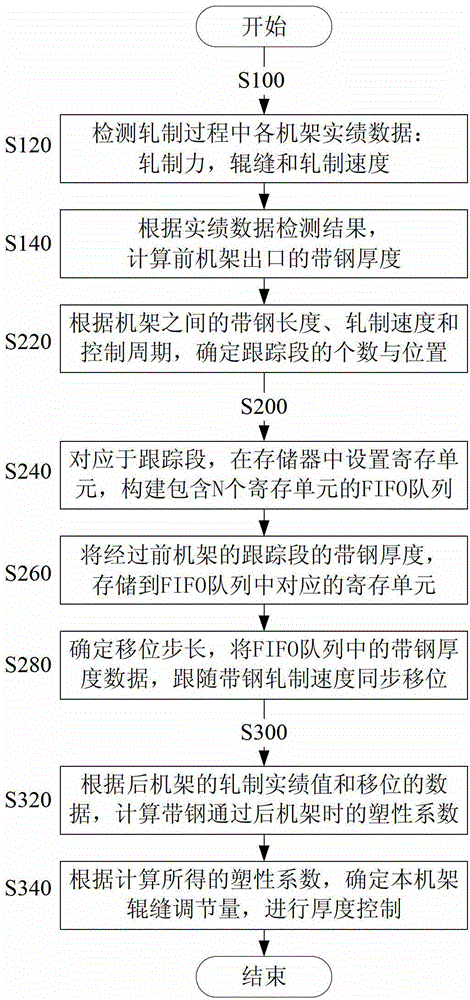

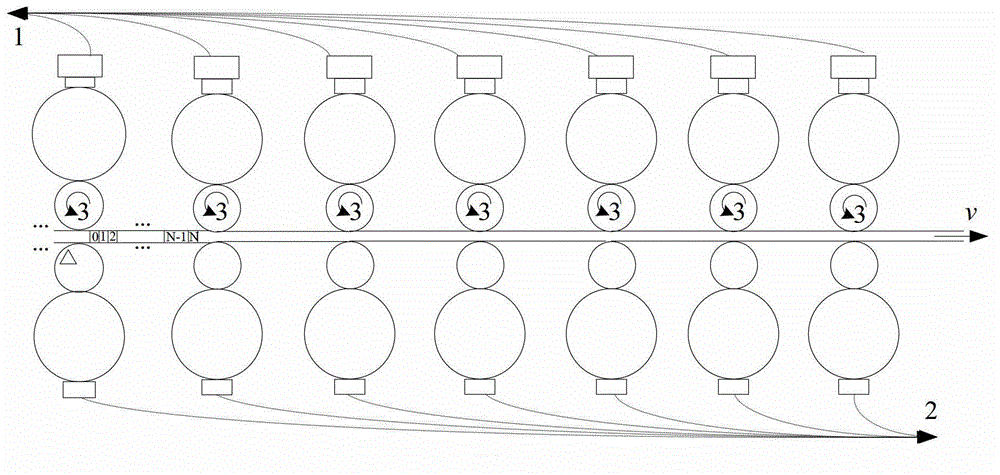

Hot-rolling and finish-rolling strip steel thickness control method

ActiveCN103934278AAccurately obtain the plasticity coefficientImprove thickness control accuracyRoll mill control devicesMetal rolling arrangementsProduction lineStrip mill

The invention provides a hot-rolling and finish-rolling strip steel thickness control method which is especially suitable for metal rolling mills or control devices for machining products, and particularly relates to a method for controlling the thickness of hot-rolling and finish-rolling strip steel through computer programs. According to the detection value of rolling actual performance value of a machine frame, the thickness of strip steel at the outlet of the machine frame is calculated; the moment the calculated strip steel thickness data reaching the machine frame is tracked and combined with the rolling actual performance value data, the plasticity coefficient of the strip steel passing through the machine frame is calculated in real time; according to the plasticity coefficient, which is obtained through real-time calculation, of the strip steel, the roll gap adjustment amount of the machine frame is determined, and feed-forward control is carried out on the thickness of the strip steel in real time. The control method can accurately obtain the plasticity coefficients of different sections of the strip steel, the plasticity coefficients are shown in roll gap adjustment amount of the different sections so as to be adaptive to hardness changes of the strip steel, control precision of the thickness of a finish rolling area is improved, a software programming control method is adopted, hardware investment is not needed, and the method is widely applied to new production lines and production line renovation projects.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com