Patents

Literature

74results about How to "Easy to change rolls" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

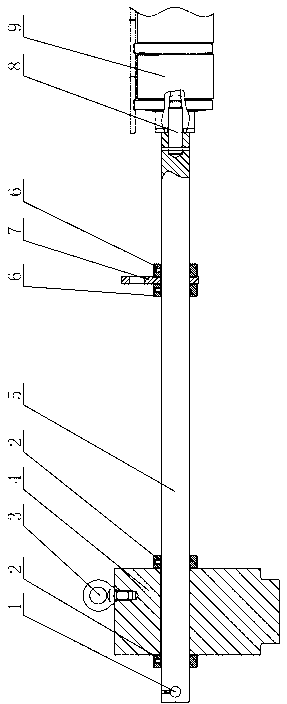

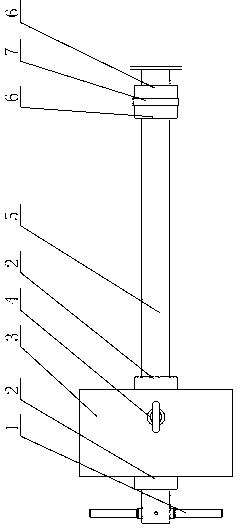

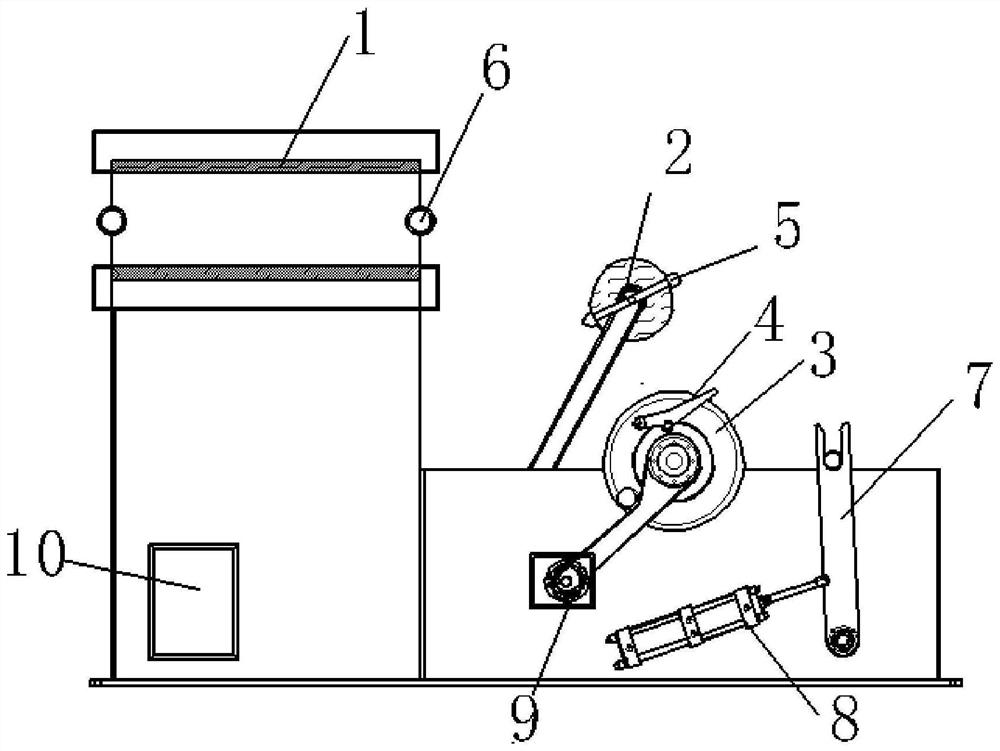

Strip mill of thin film

InactiveCN101347791AEfficient and stable productionEasy to change rollsMetal rolling stand detailsRolling mill drivesAutomatic controlEngineering

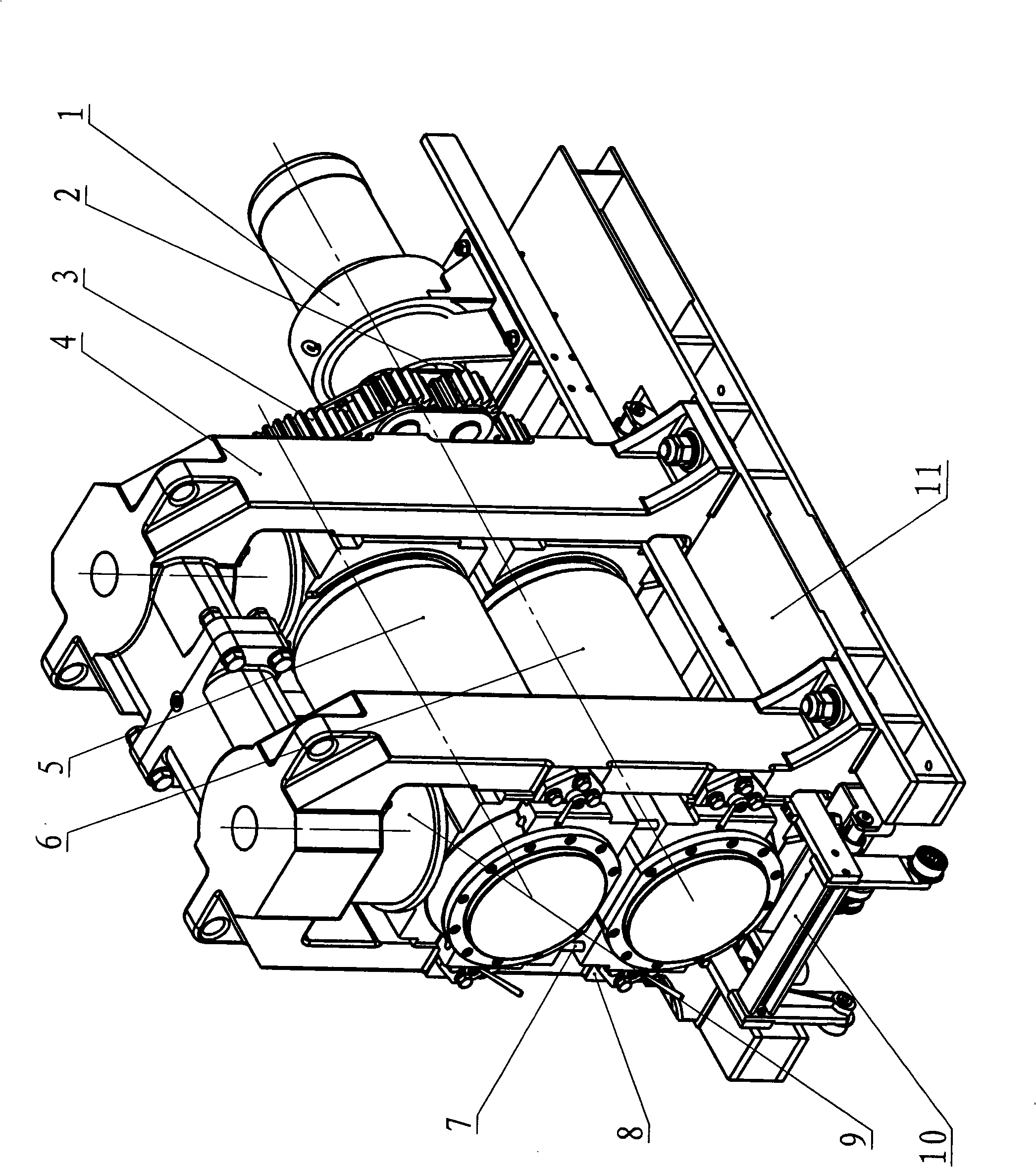

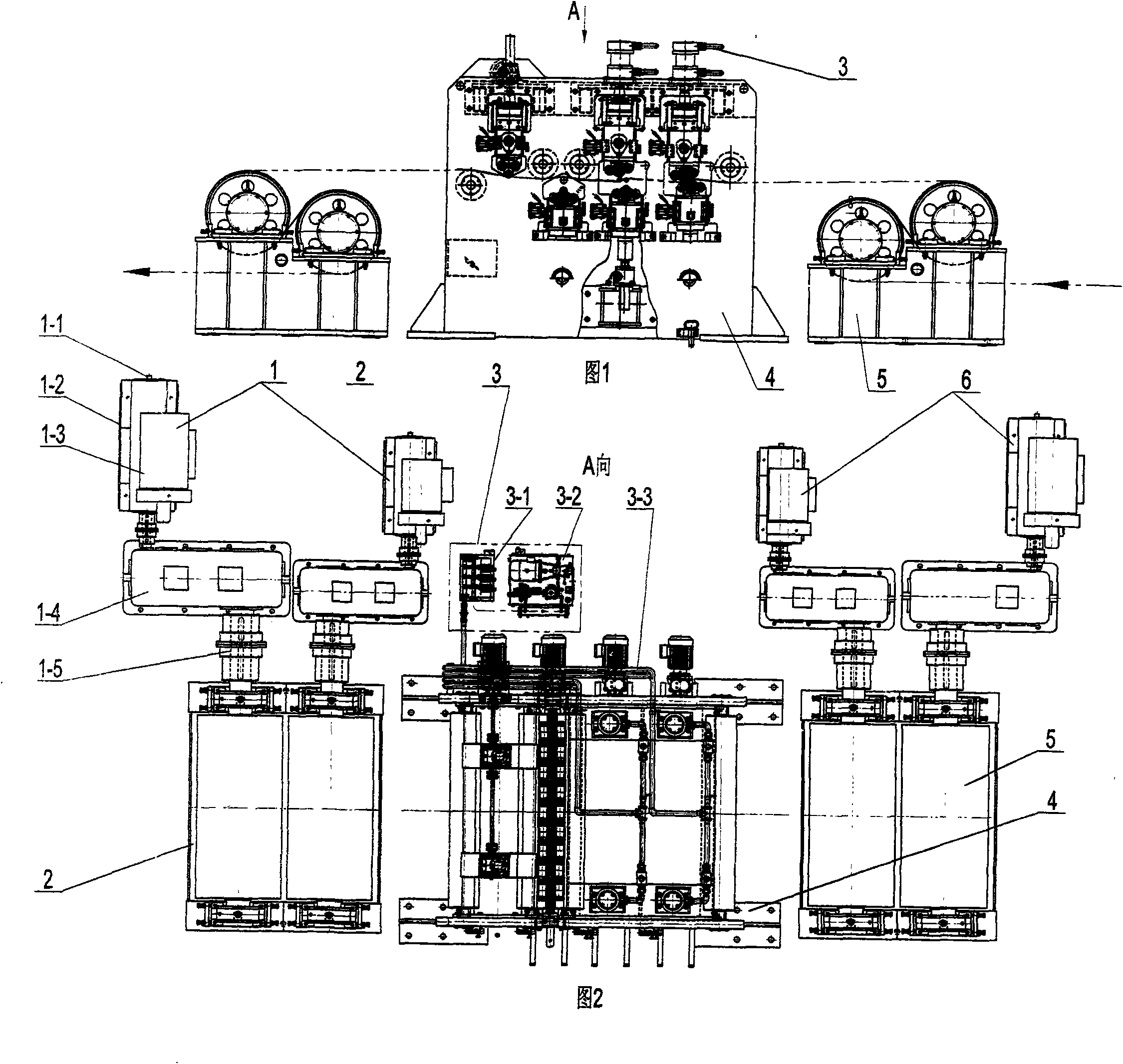

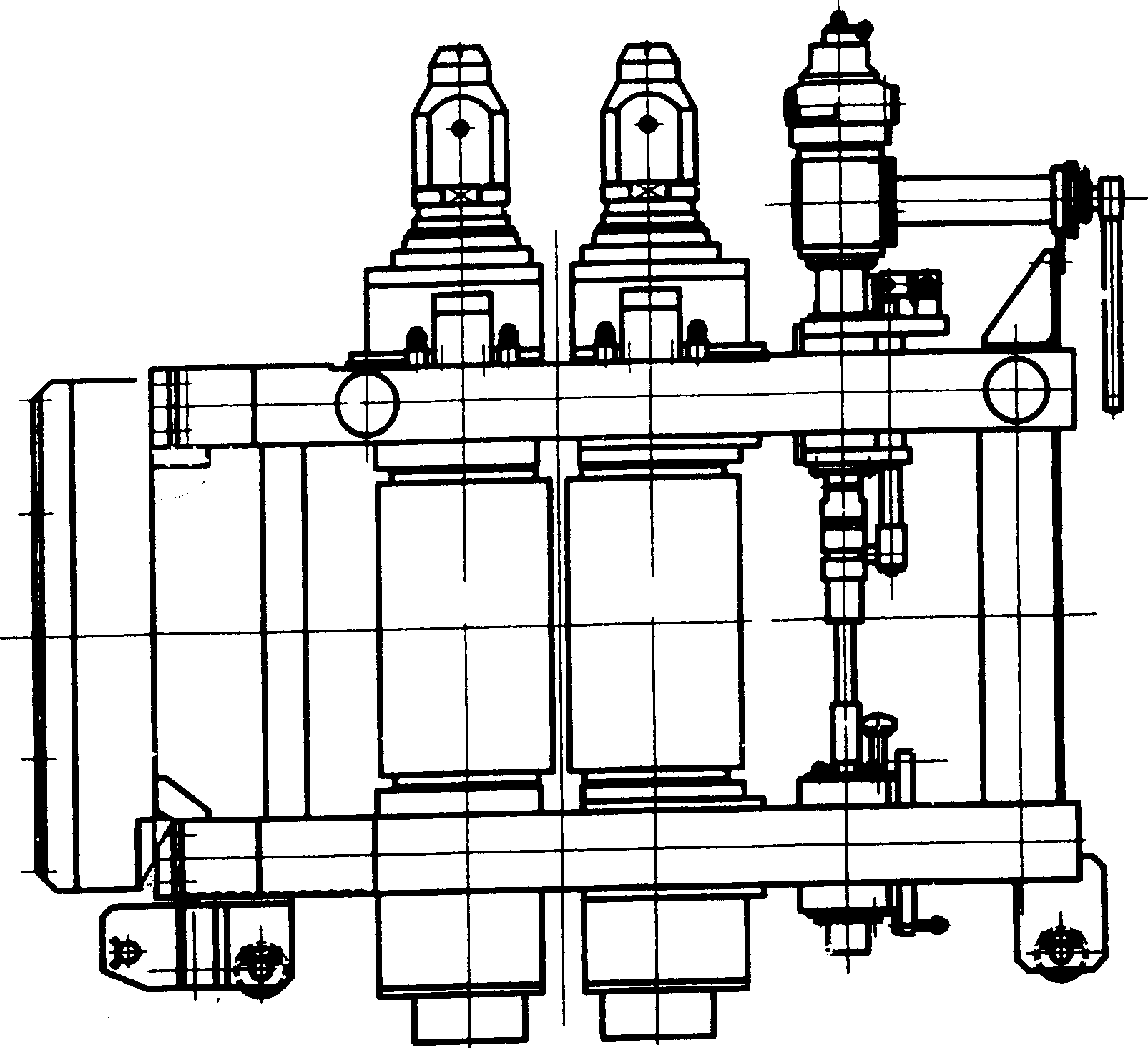

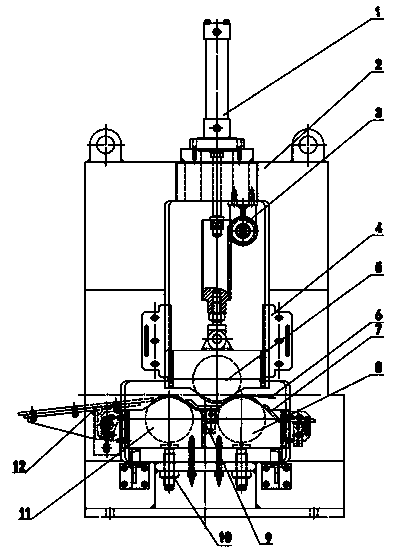

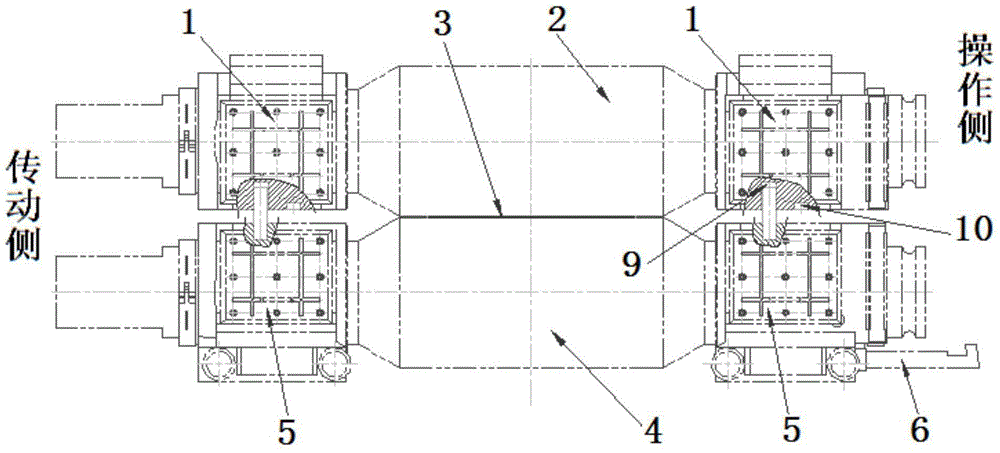

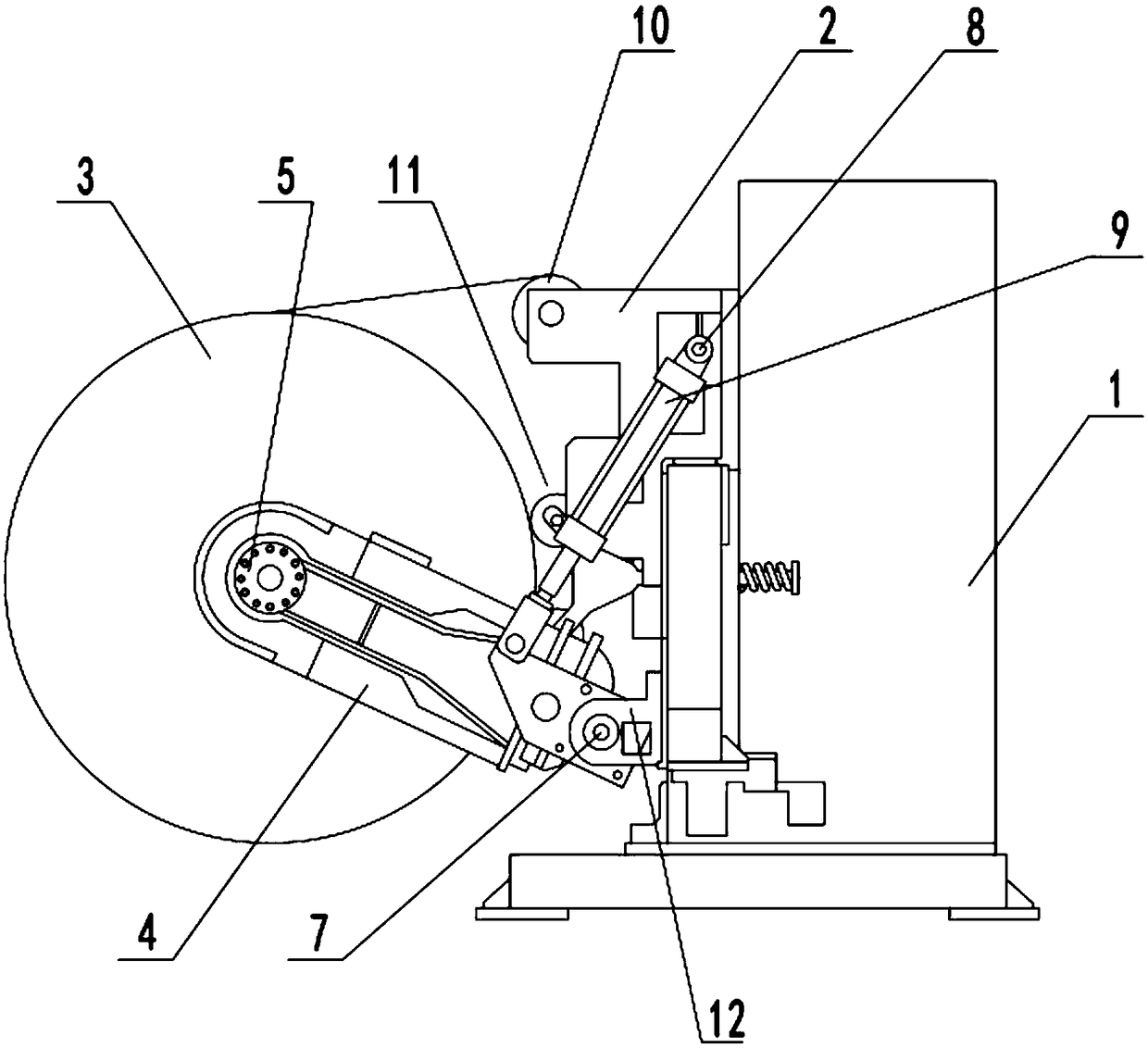

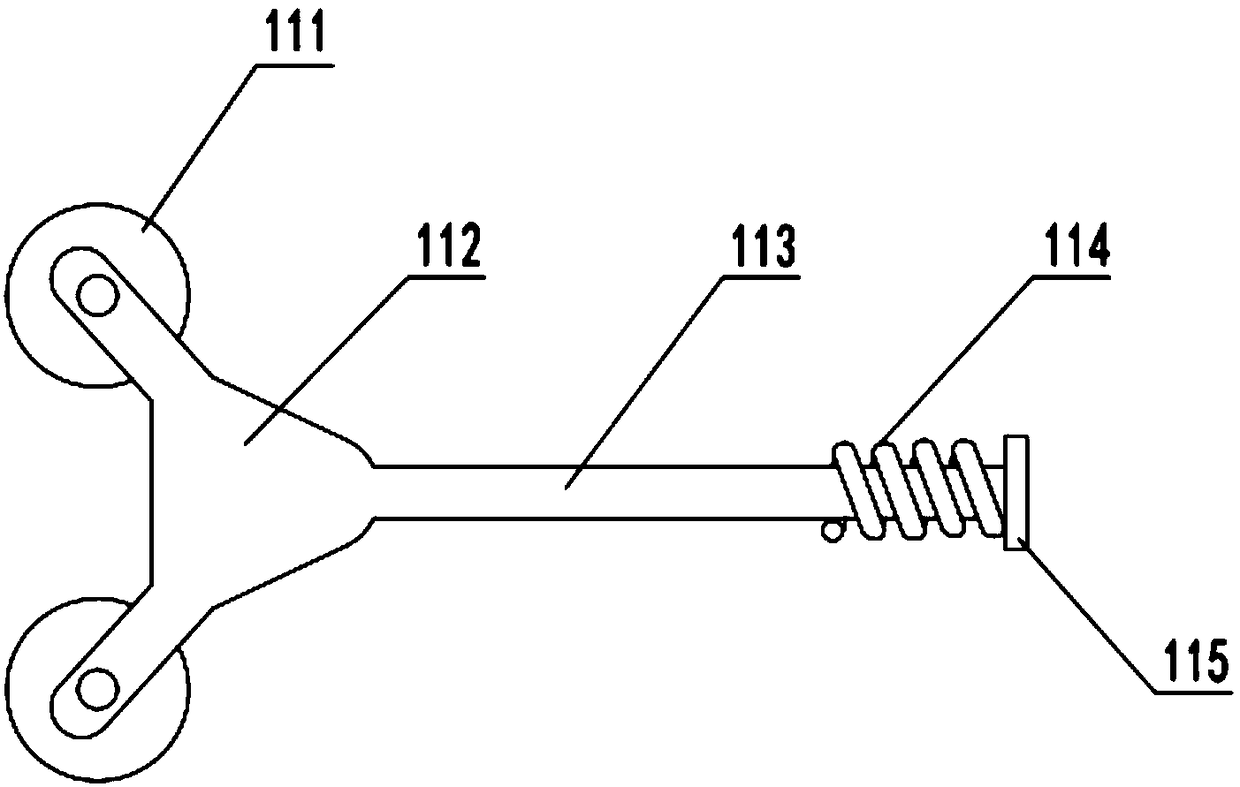

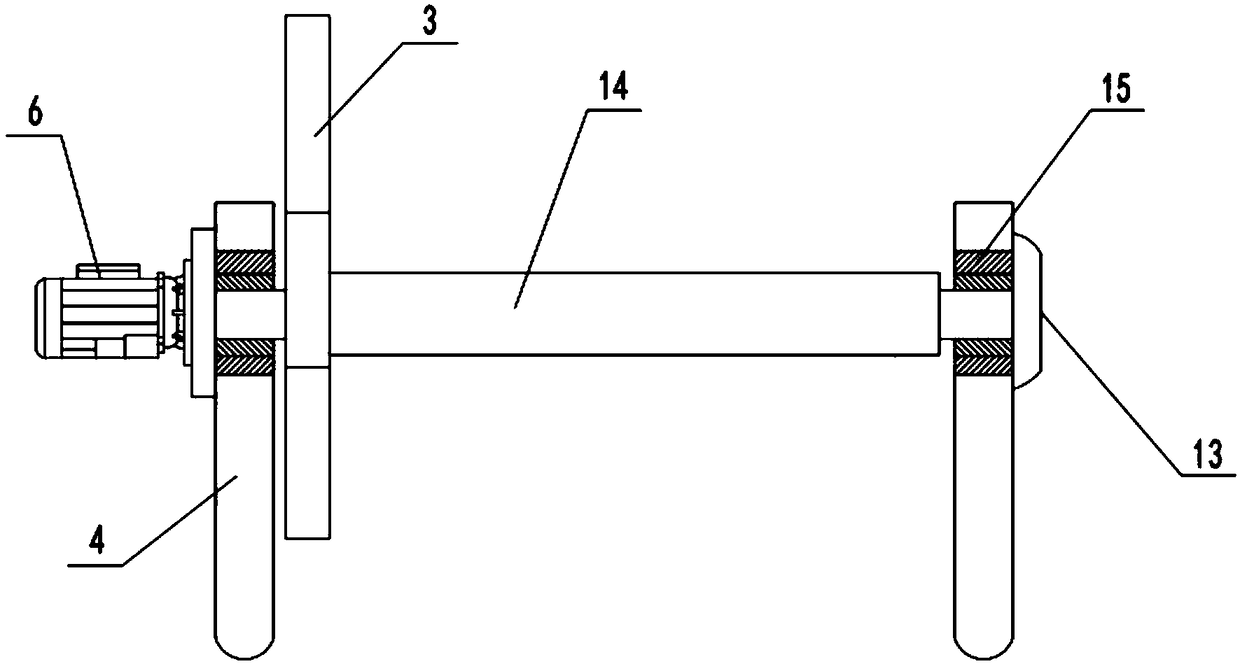

The invention provides a film band and strip rolling mill, consisting of a motor-reducer device, an elastic pin coupling device, a balance symmetric gear transmission device, a front stander device and a rear stander device, a lower roller system device, an upper roller system device, a roller system bearing radial windage eliminating device, a left baffle device of a roller, a right baffle device of the roller, an electro-hydraulic servo press-down device, a roller changing device and a base; the film band and strip rolling mill is characterized in that the size of the roller seam can be automatically controlled by adopting an electro-hydraulic servo control technology, thus stably producing battery electrodes which meet the quality standard without compressing air source from external part; meanwhile, the developed balance symmetric transmission device, the roller system bearing radial windage eliminating device, the roller left baffle device, the roller right baffle device and the roller changing device lead the adjustment and maintenance of the rolling mill to be simple and convenient, The invention is an ideal film band and strip rolling mill which has the advantages of improving the precision of battery electrodes, improving the productivity of the rolling mill and overcoming the shortages of the prior art.

Owner:张清

Cloth winding device capable of facilitating winding drum replacement and dust removal

InactiveCN107381168AEasy to change rollsEasy to remove dustCleaning using toolsCleaning using gasesEngineeringConductor Coil

Owner:梅明会

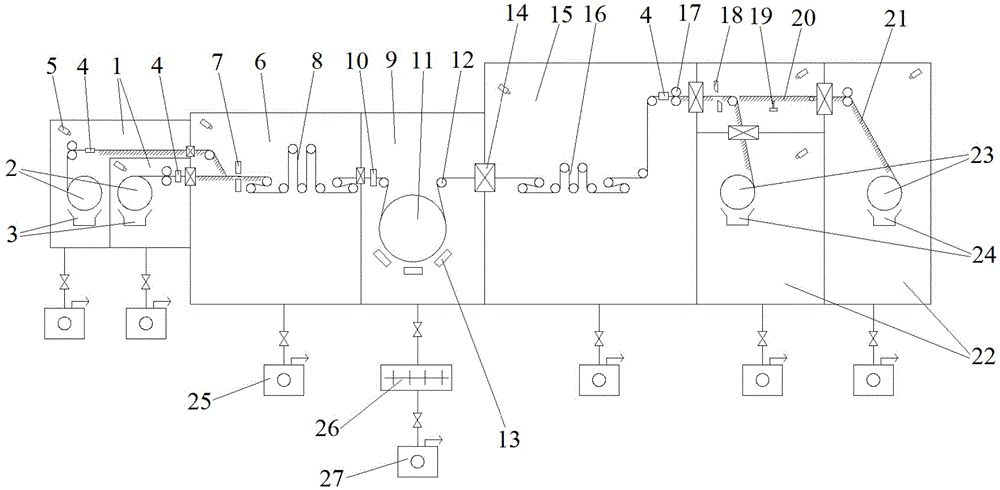

Single-sided continuous winding magnetron sputtering coating automatic production line for flexible substrate

ActiveCN104651792AReduce wasteRealize continuous platingVacuum evaporation coatingSputtering coatingProduction lineMaterials preparation

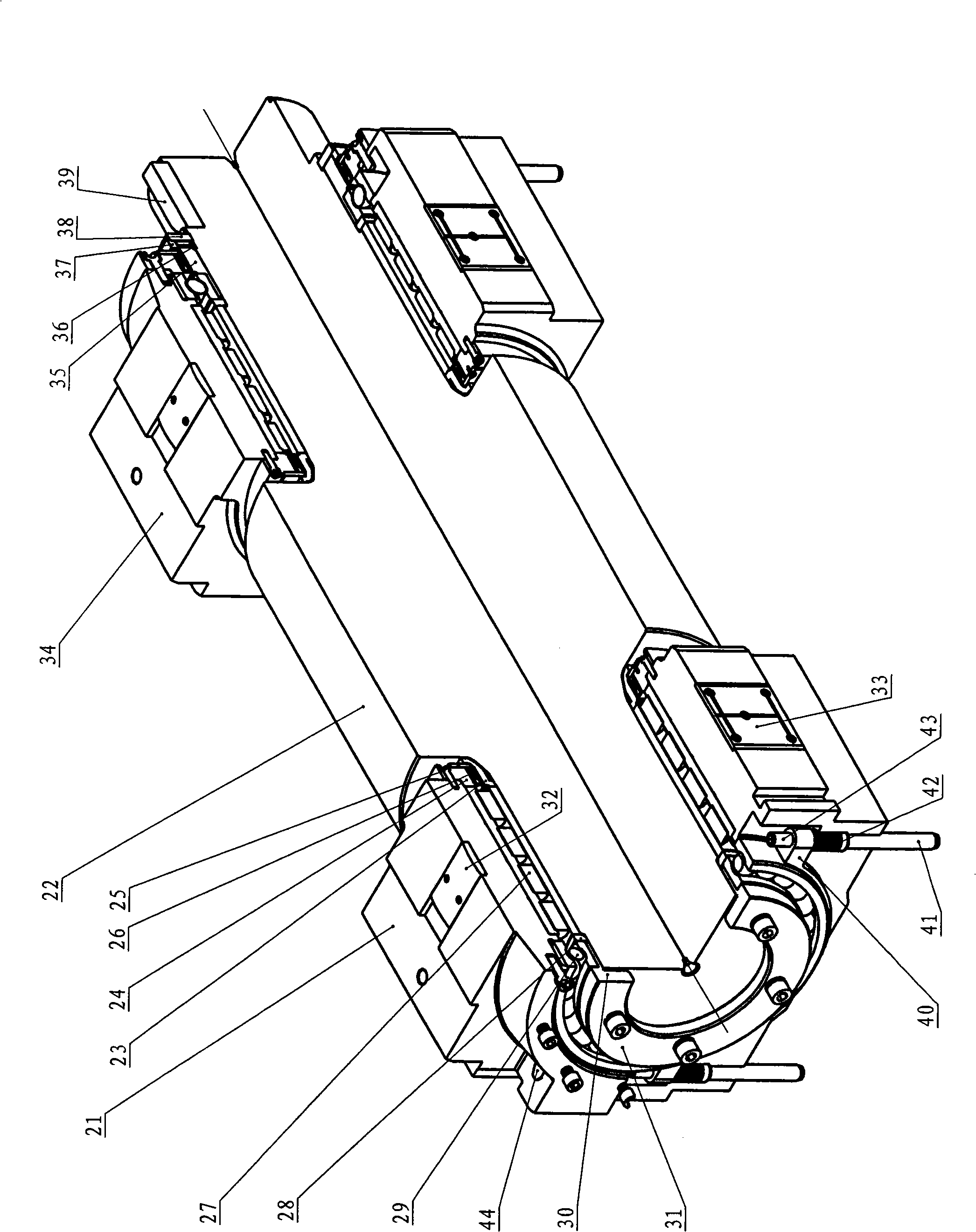

The invention discloses a single-sided continuous winding magnetron sputtering coating automatic production line for a flexible substrate and belongs to the field of coating equipment. The production line comprises an uncoiling room, a rolling room and a coating vacuum room, wherein an unreeling storage room is further arranged between the uncoiling room and the coating vacuum room; a rolling storage room is further arranged between the rolling room and the coating vacuum room; a heat seal mechanism is arranged in front of the unreeling storage mechanism; a cutting mechanism and a substrate steering mechanism are sequentially arranged behind the rolling storage mechanism; one end of a substrate wound on an uncoiling roller is wound on a rolling roller sequentially through the heat seal mechanism, the unreeling storage mechanism, a pre-treatment mechanism, a cold roller, a rolling storage mechanism and the cutting mechanism as well as the substrate steering mechanism. By virtue of material preparation in advance for uncoiling and roller preparation in advance for rolling, multiple substrates are continuously coated by combining the unreeling storage mechanism and the rolling storage mechanism, so that the time for changing rolls and vacuumizing is shortened, and the coating efficiency is greatly improved.

Owner:常州常工院技术转移有限公司

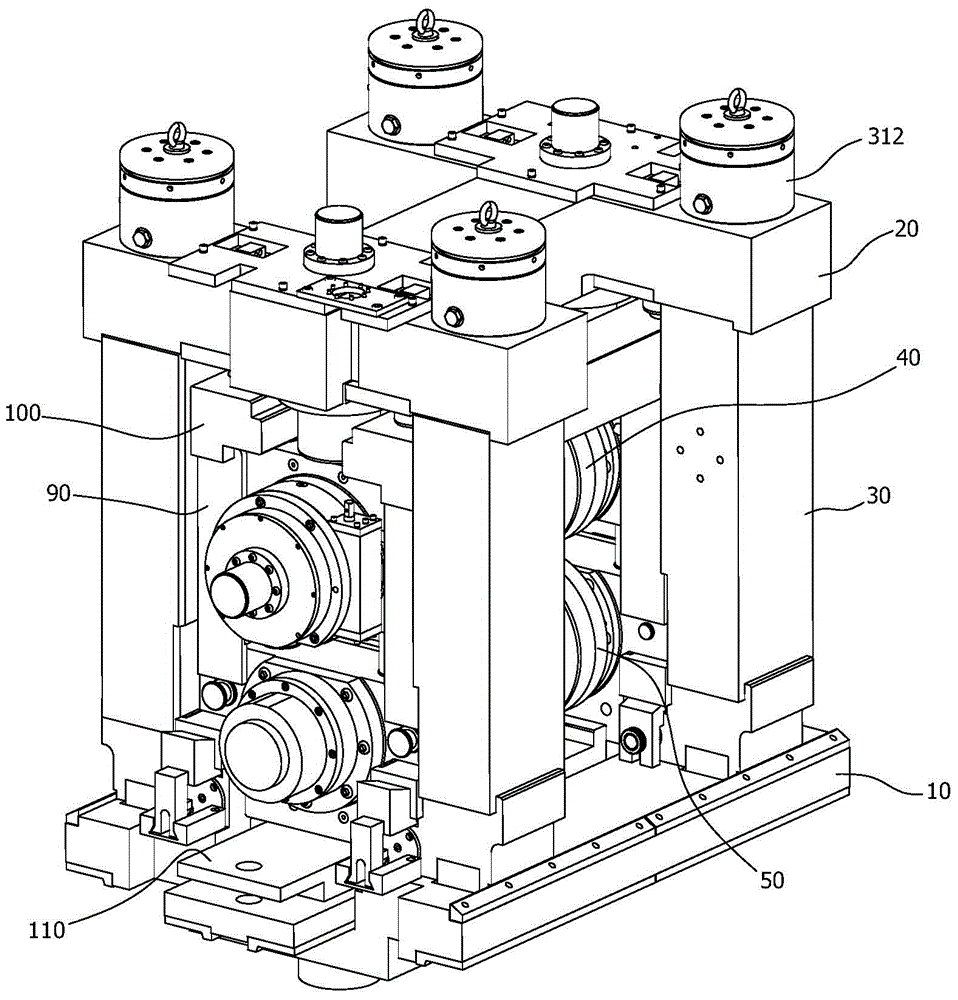

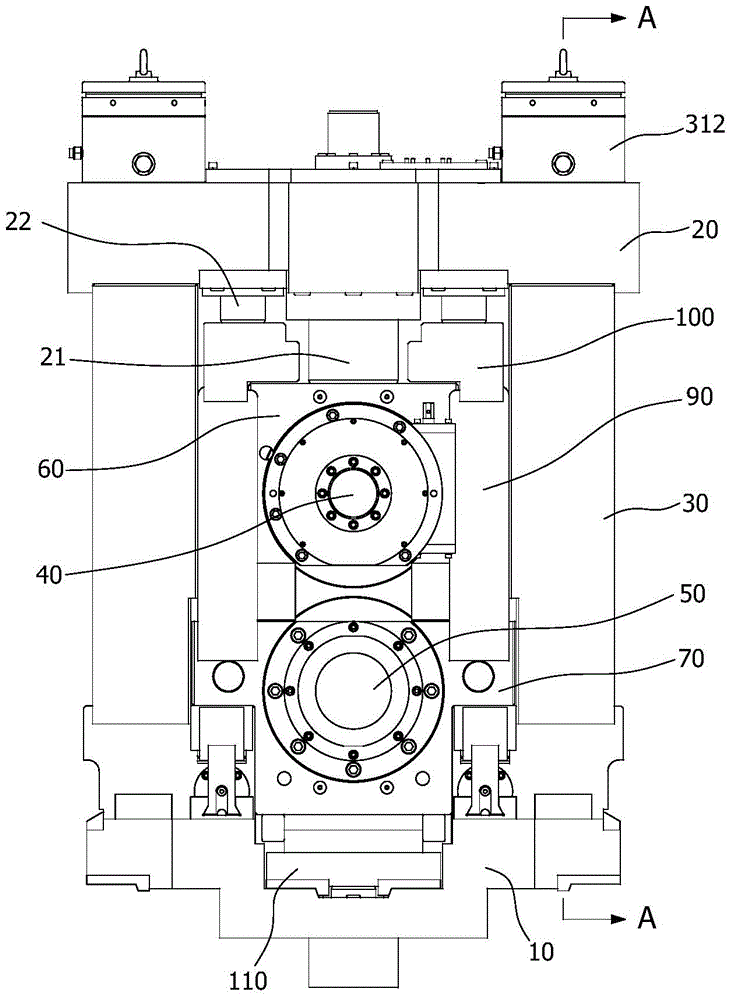

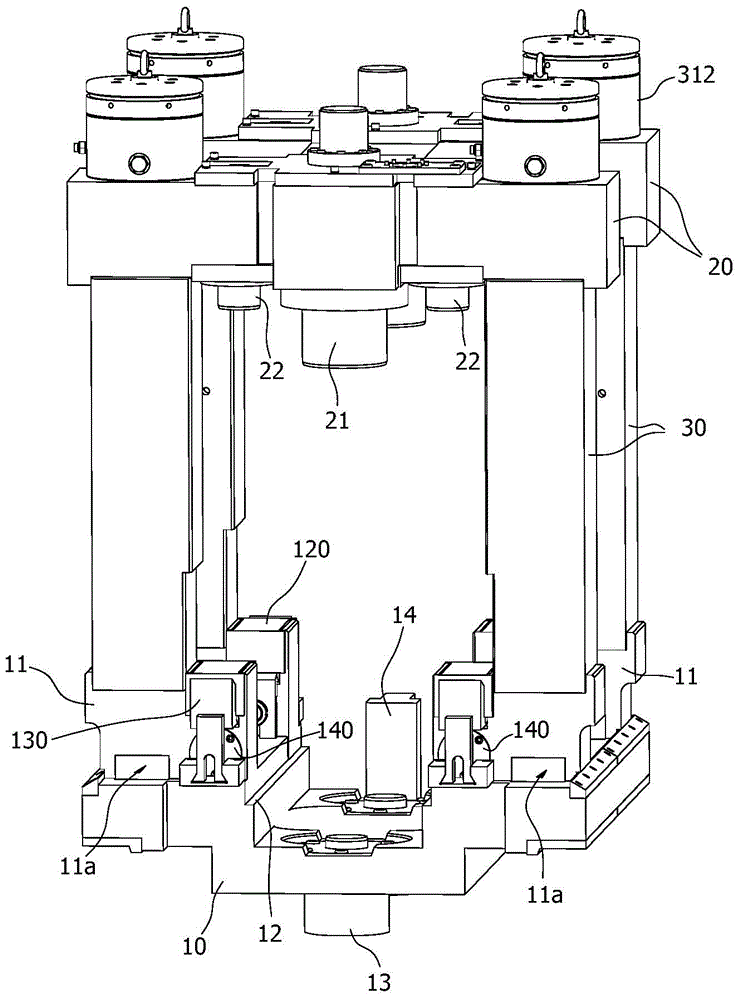

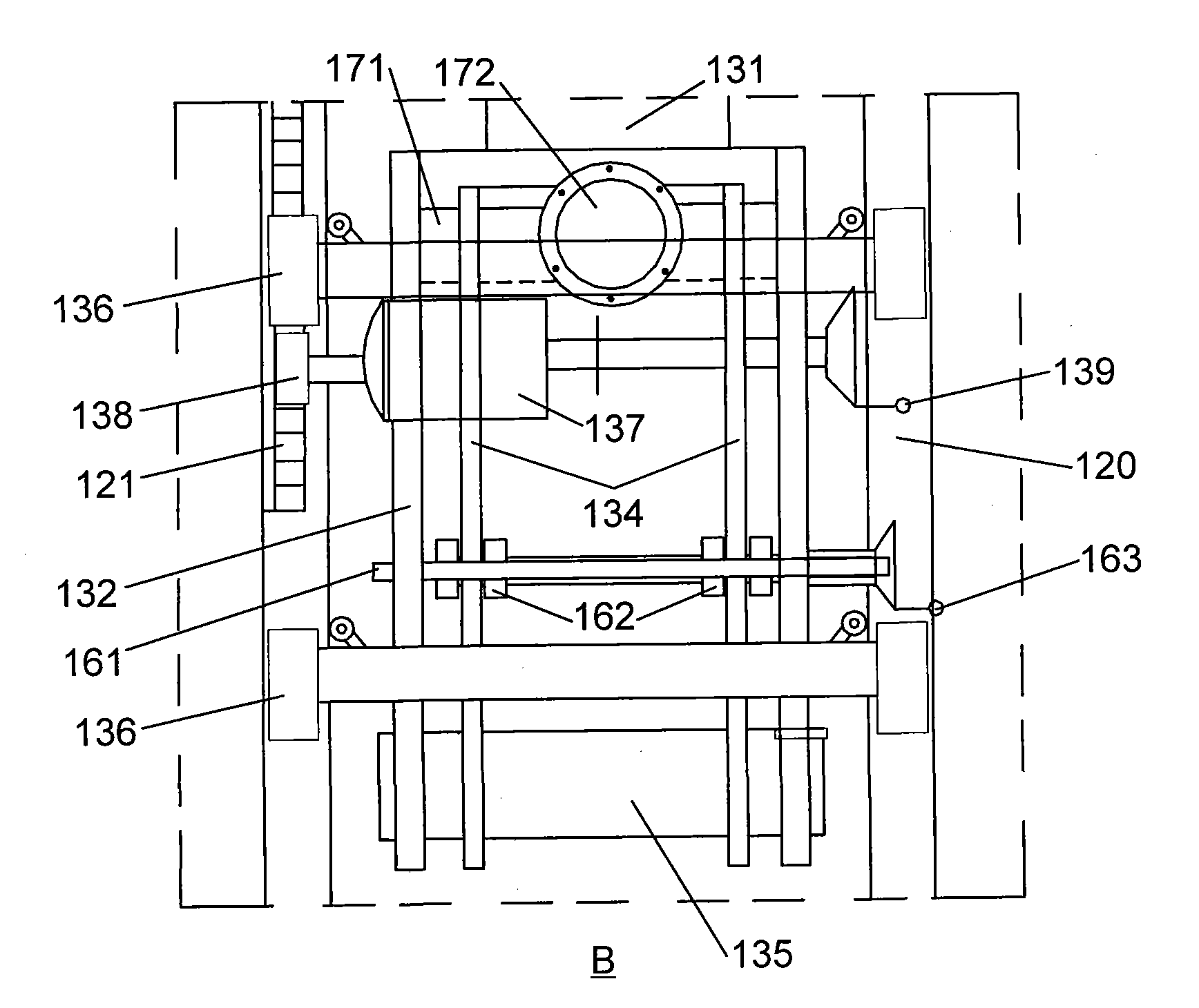

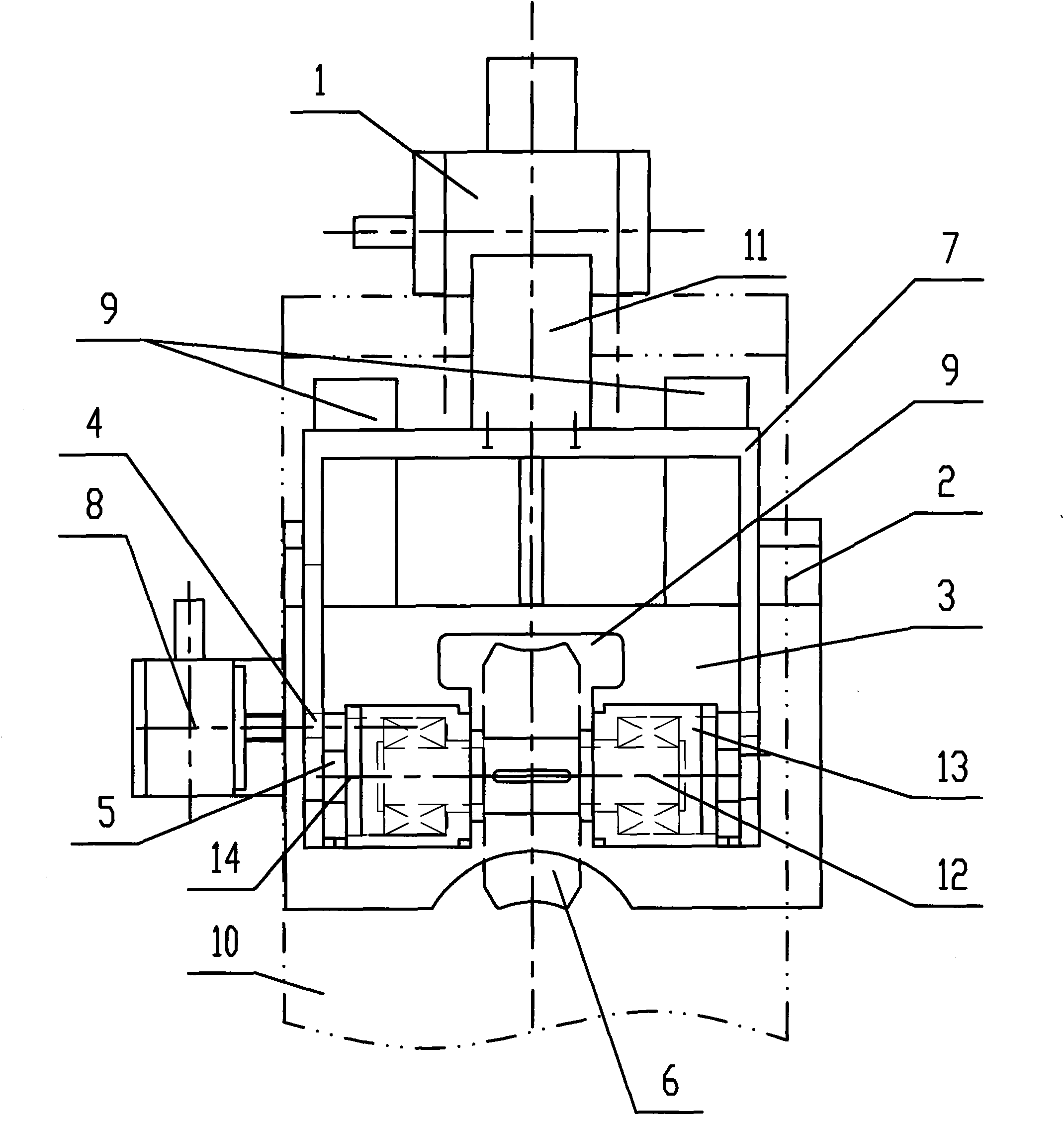

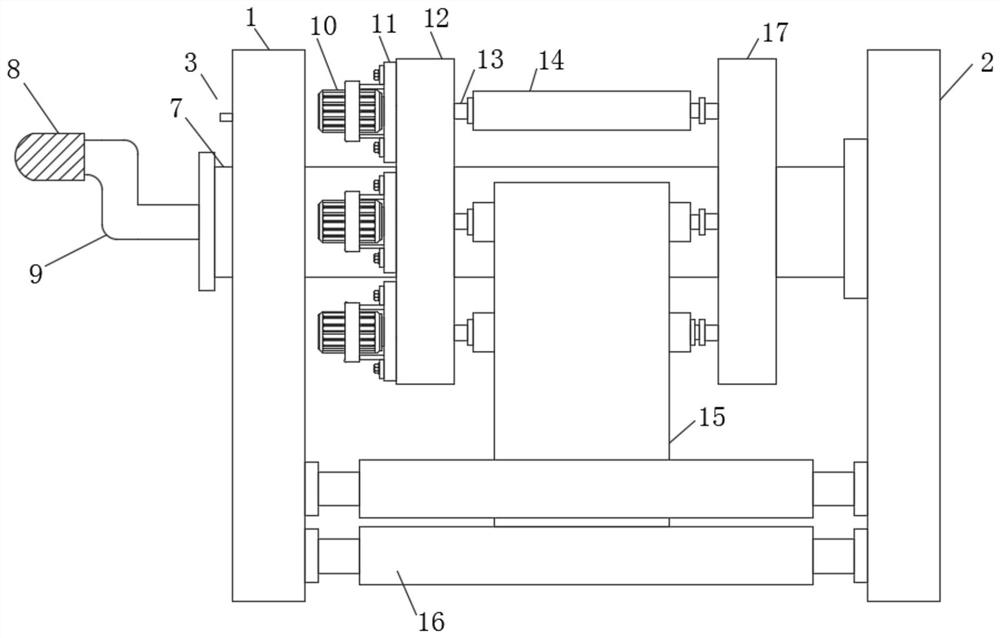

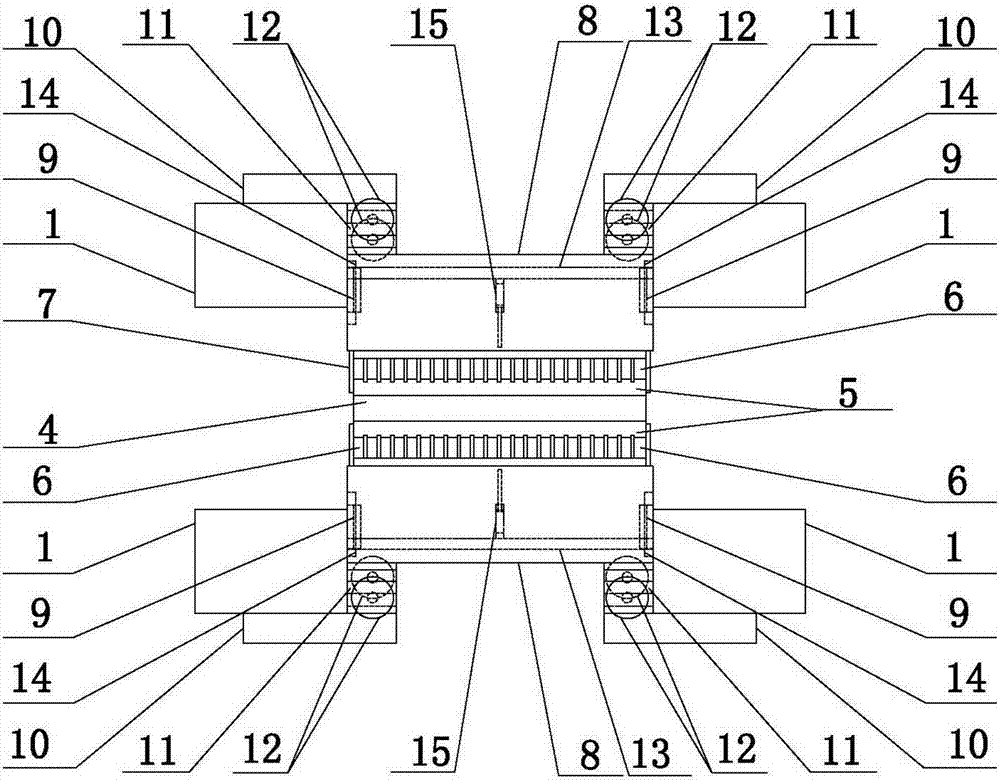

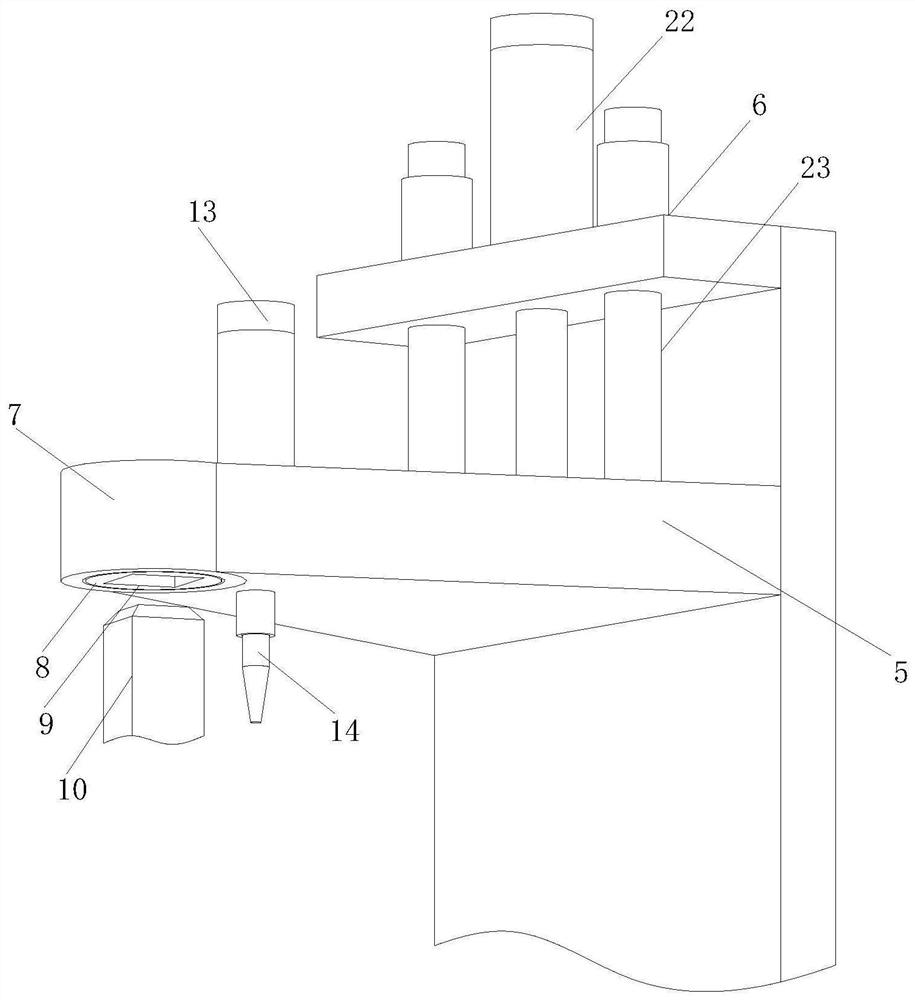

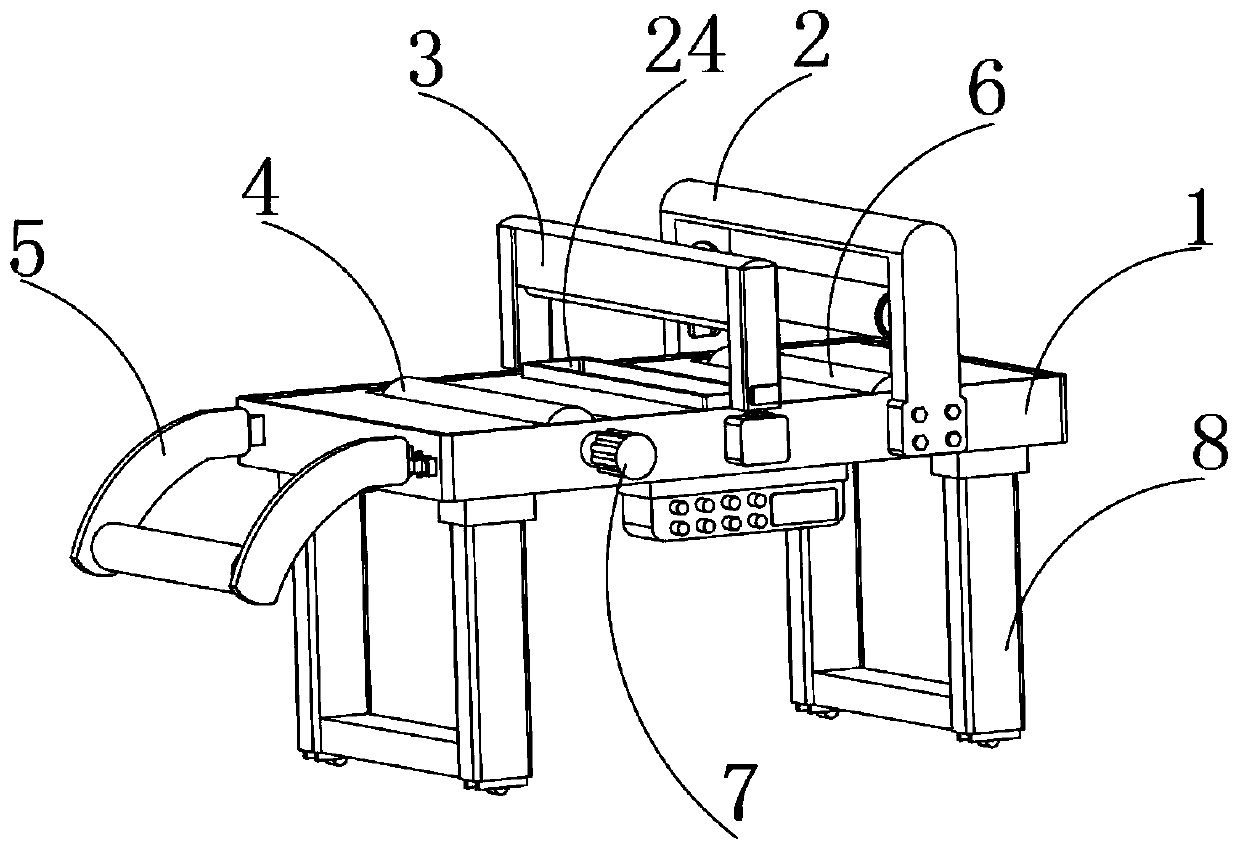

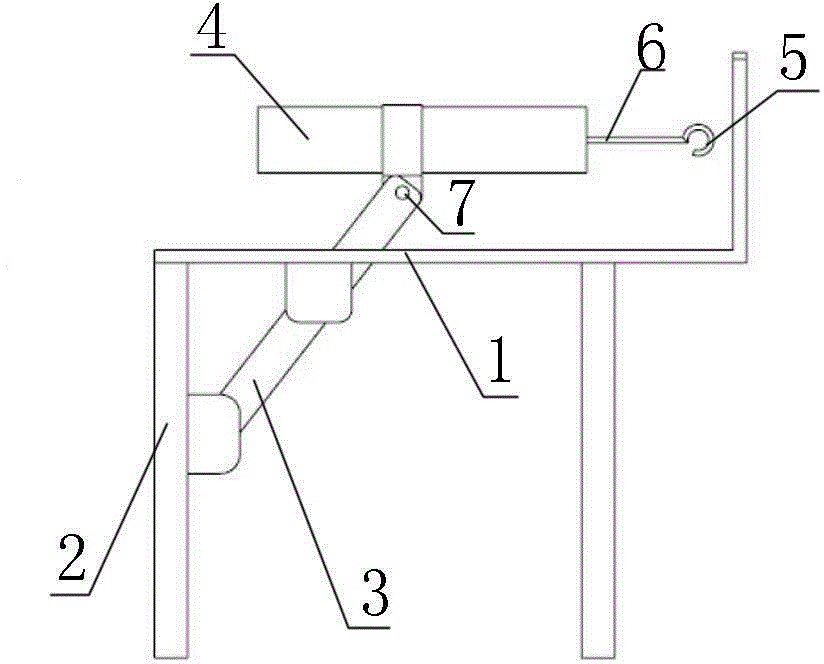

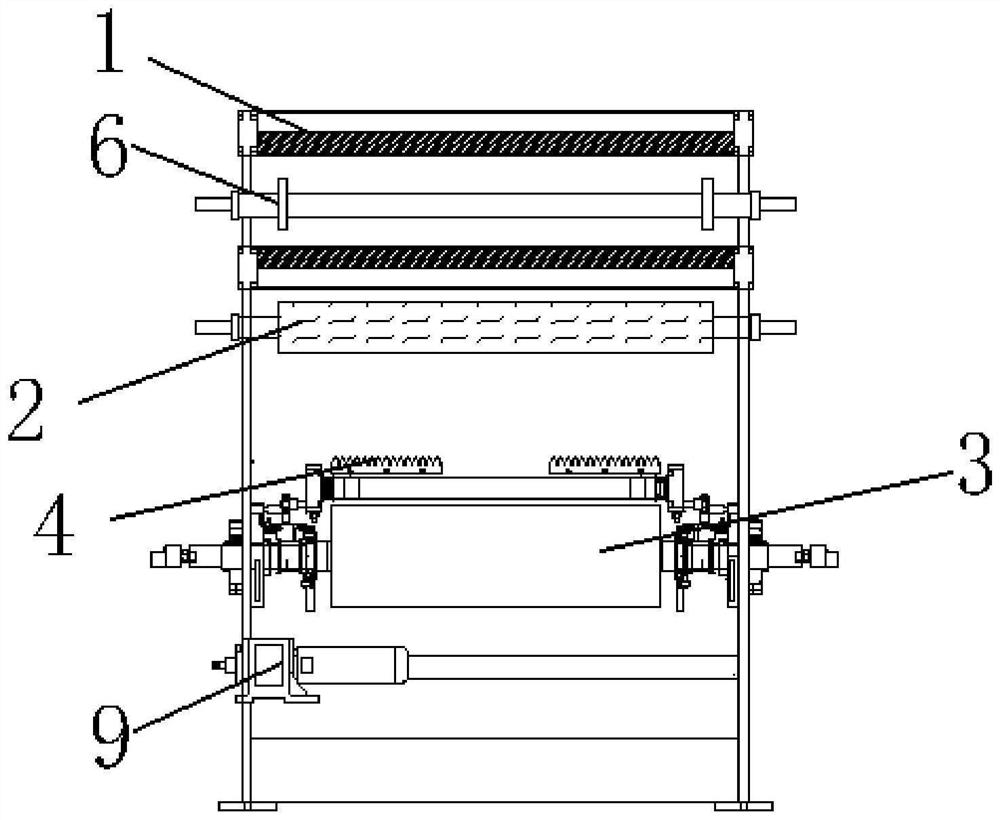

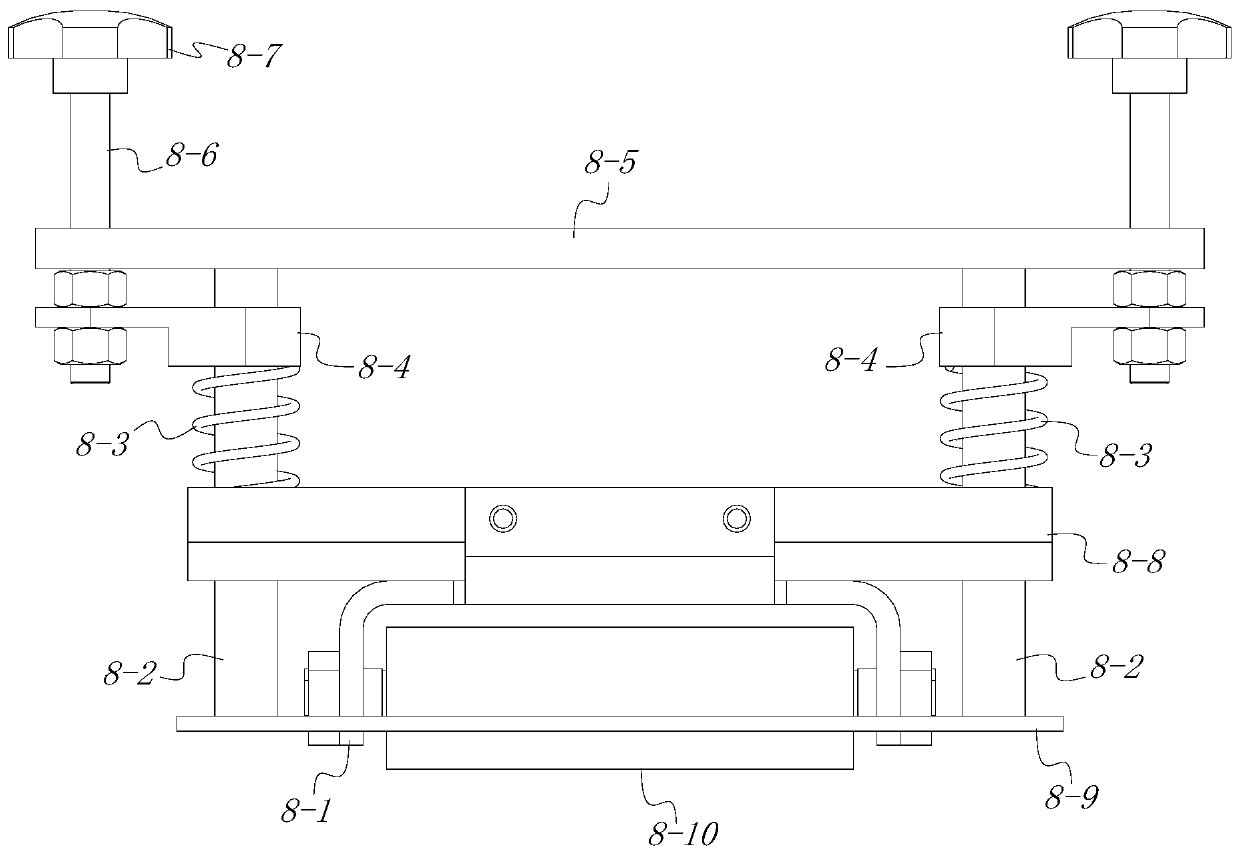

Rolling mill

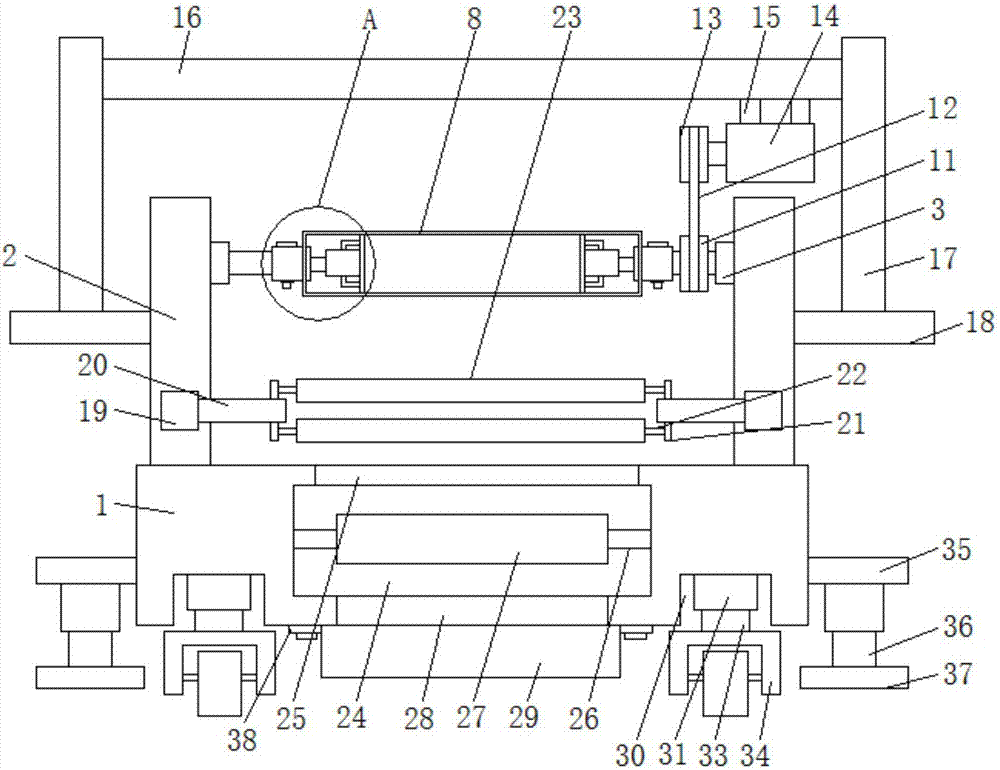

ActiveCN104668290AEasy to pushPromote withdrawalMetal rolling stand detailsMetal rolling arrangementsEngineeringSlide plate

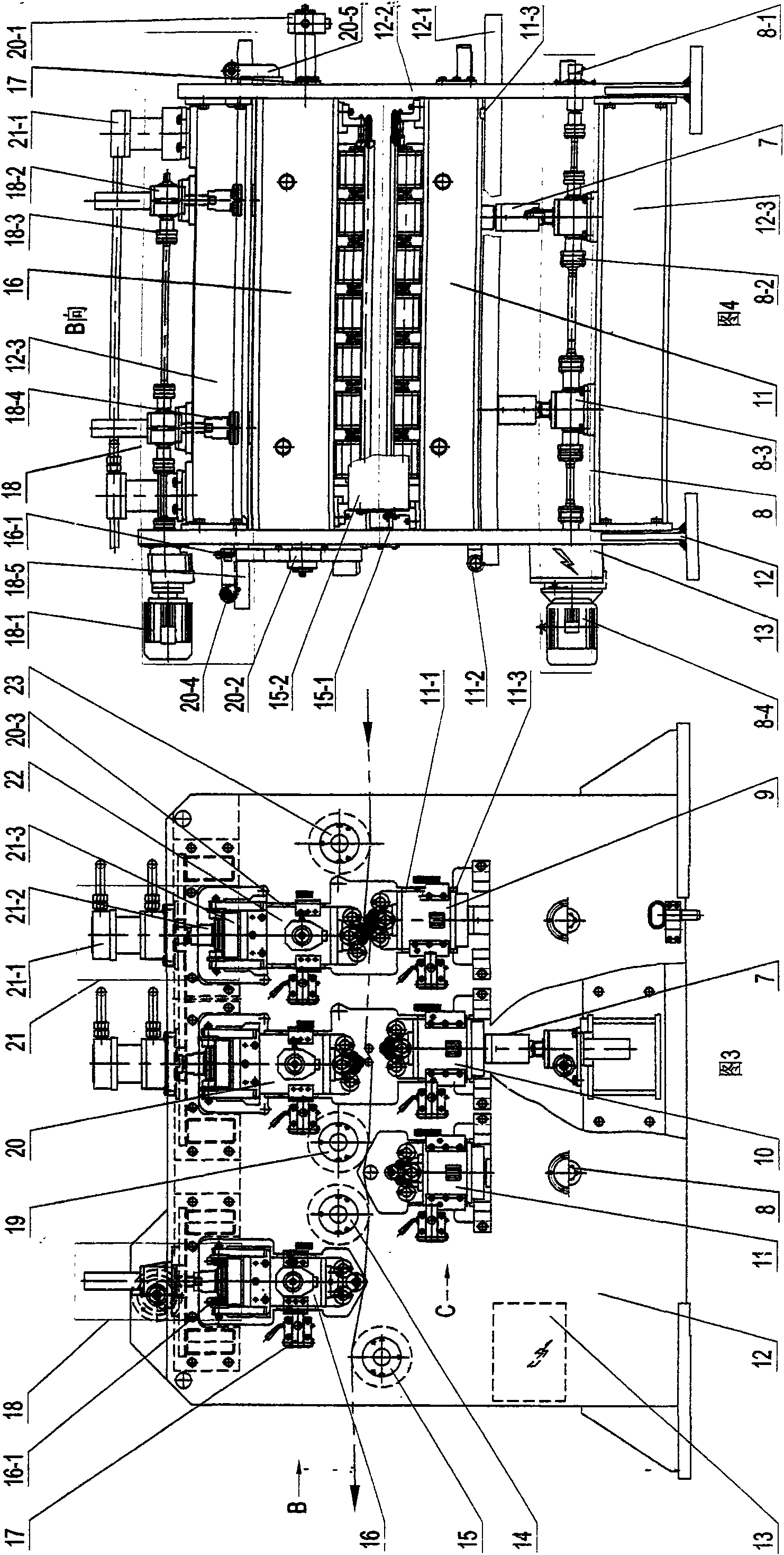

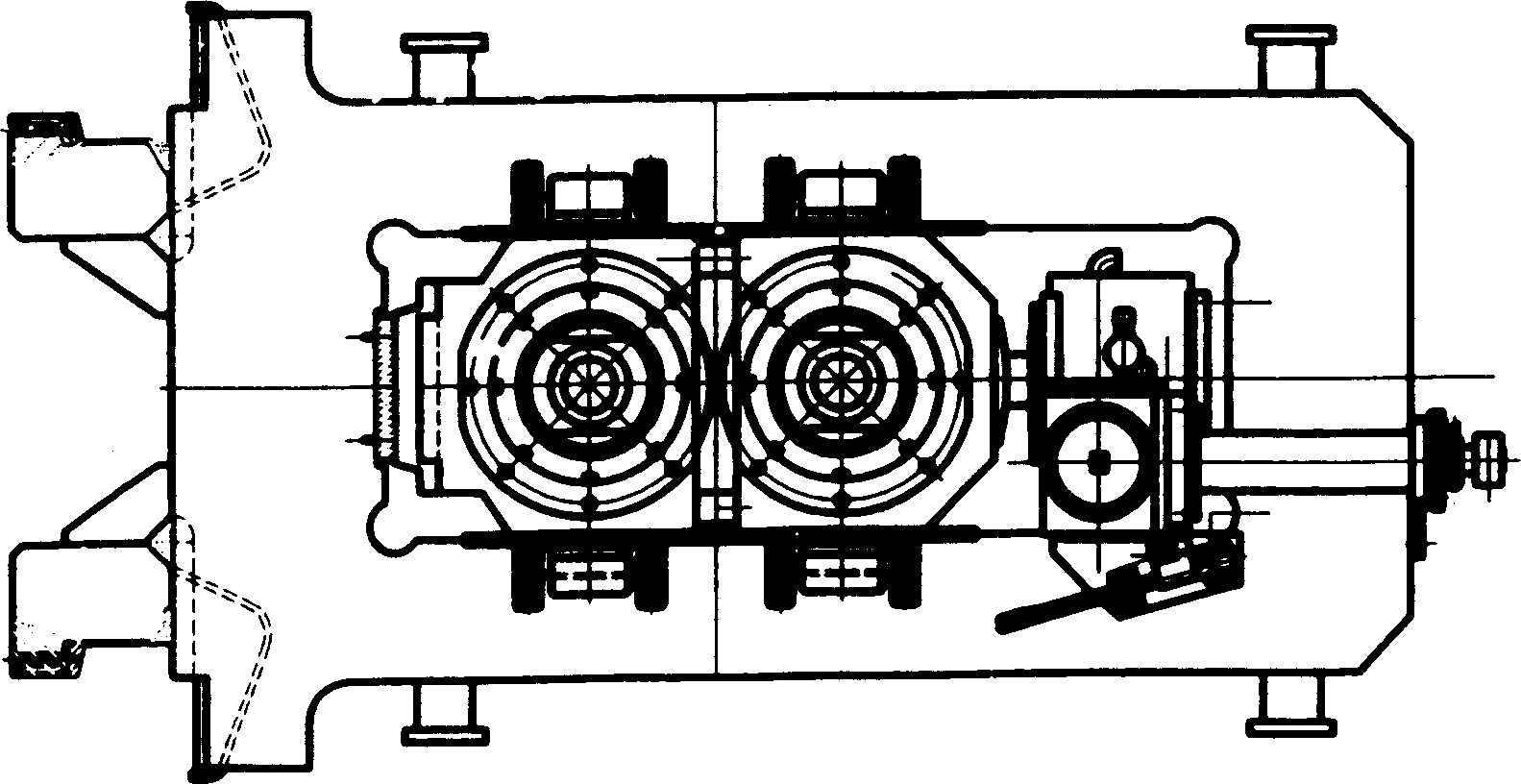

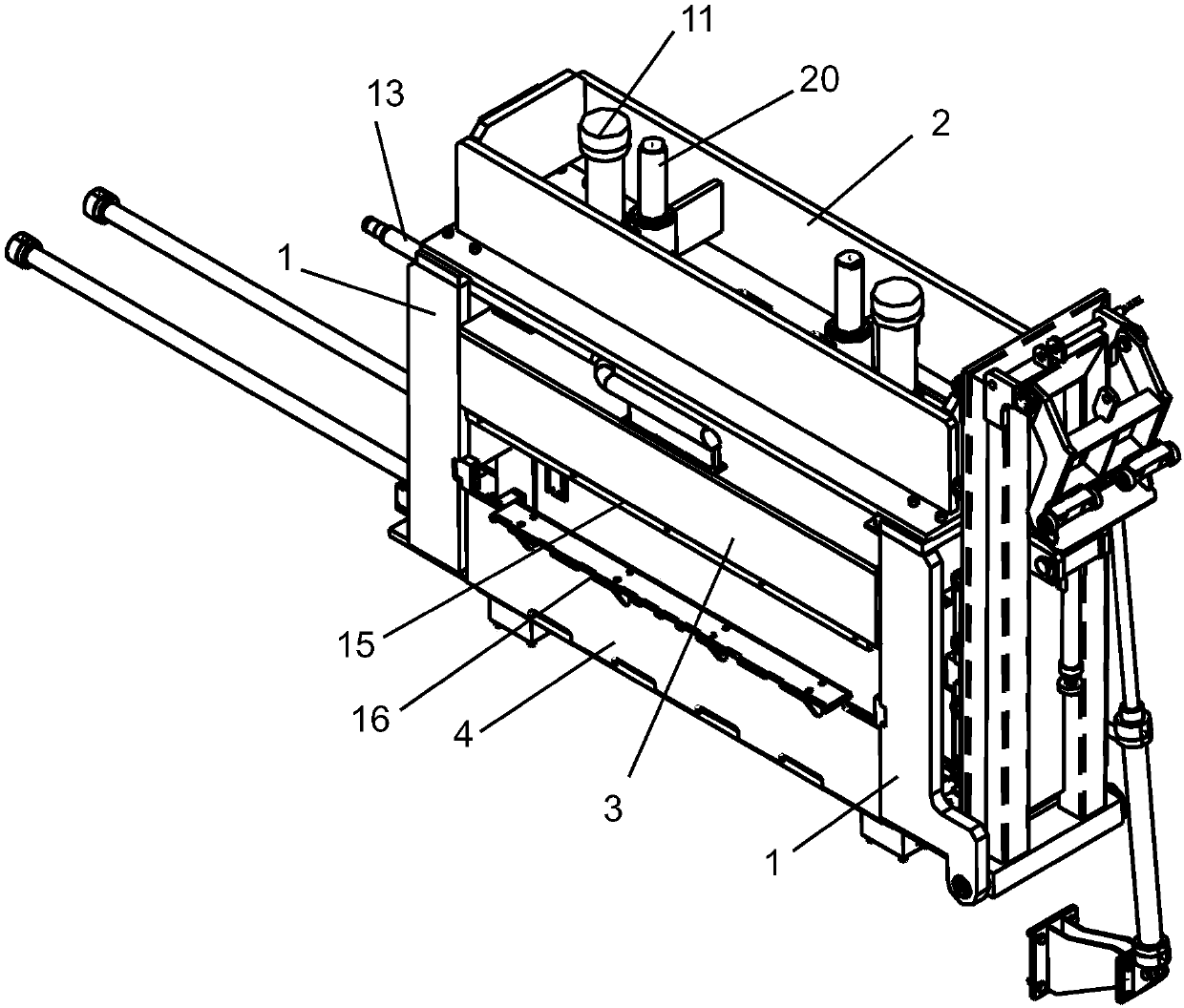

The invention relates to a rolling mill which comprises a rolling mill base, upper cross beams and a rack formed by uprights vertically disposed between the rolling mill base and the upper cross beams. An integral-type roller system comprises an upper roller, a lower roller, an upper bearing seat and a lower bearing seat, the upper bearing seat and the lower bearing seat are used for fixing the upper roller and the lower roller, springs driving the upper bearing seat and the lower bearing seat to separate are arranged between the same, the lower ends of bearing seat uprights are fixedly connected with the lower bearing seat while the upper ends of the same are connected with cross beams, a supporting and height adjusting mechanism is arranged between the lower bearing seat and the rolling mill base, and a pressing-down mechanism for pressing the upper bearing seat down and a locking mechanism used for pressing the cross beams down are arranged on the upper cross beams. The integral-type roller system can be conveniently pushed into or drawn out of the rack by utilizing a sliding plate, so that great convenience in roller changing is realized; the rack does not need to be demounted during roller changing, operating processes are reduced, the rack can be ensured to be adjusted to be in a state required by designing in advance, and the state can be maintained, so that rolling rigidity and accuracy of the rolling mill are guaranteed.

Owner:HEFEI BAISHENG SCI & TECH

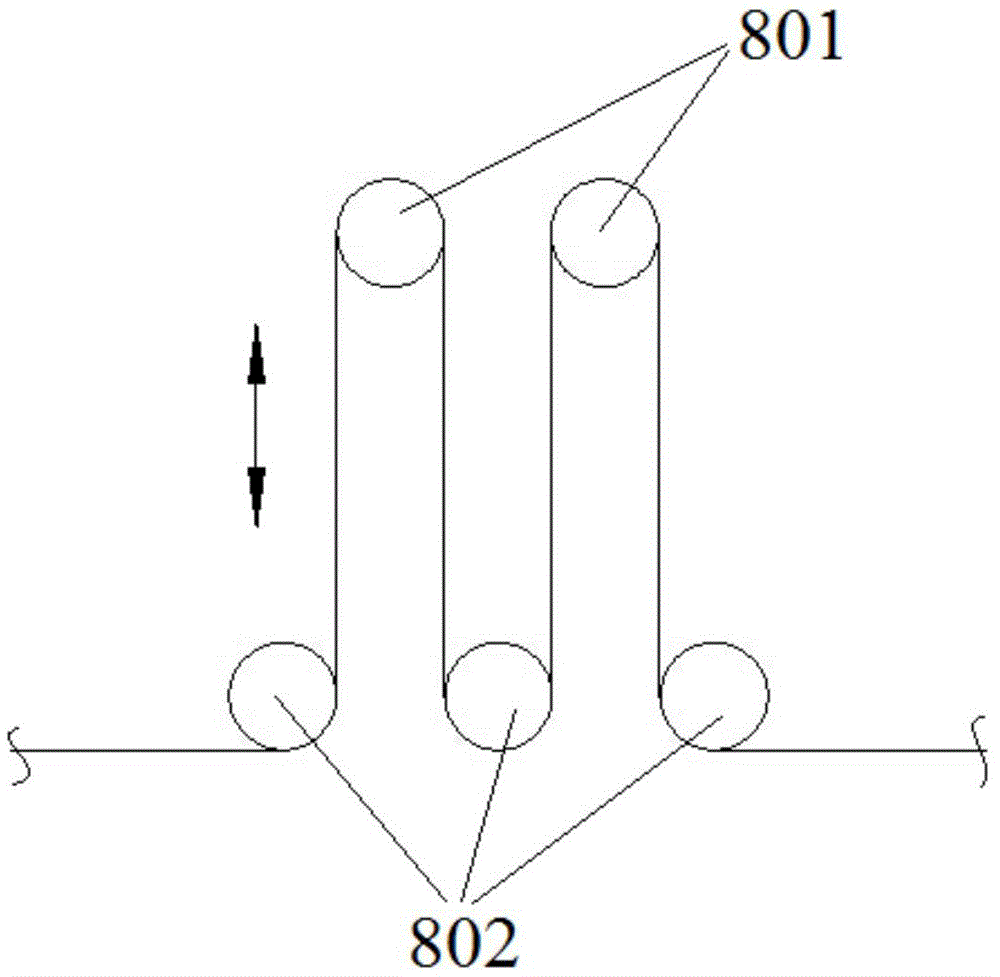

Stretch bending-straightening machine

ActiveCN101767126AOpen quicklyFast rigid couplingMetal rolling stand detailsFlexible work arrangmentsThrust bearingIron industry

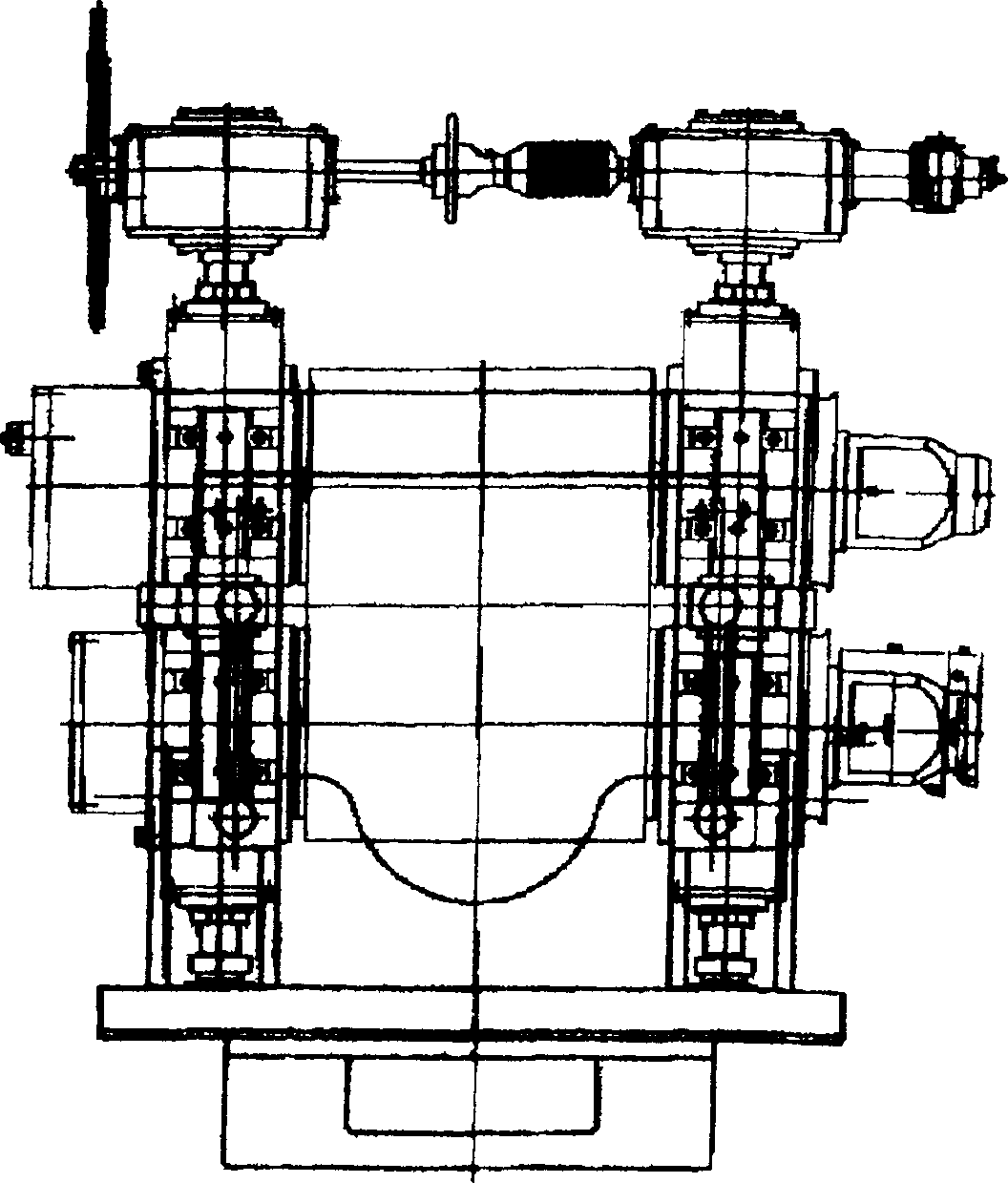

The invention discloses a stretch bending-straightening machine, which is used for continuously straightening a steel strip in the iron industry. The stretch bending-straightening machine consists of an outlet / inlet main drive, a tension device, a hydraulic system and a main body. The main body is additionally provided with a fast open oil cylinder, a support roller, a rotary joint and a limitation stop base, wherein the fast open oil cylinder can be instantaneously and fast opened when a welding gap of the strip steel passes through the main body and can be instantaneously reset to normally work, thereby preventing the surface of a roller and the strip steel from being mutually scrubbed; the support roller changes the installation on a roller box from line contact into face contact, thereby being capable of keeping the precision for long time use and guaranteeing the straightening quality of the strip steel; the rotary joint is in a pretightening type structure which adopts a combined type quill roller thrust bearing with large carrying capability, wherein the rotary joint and a top rod of the stop base are tightly contacted with each other under the function of a spring without impact force caused by axial pulsation when a work roller and a middle roller work, thereby prolonging the service life; and the limitation stop base conveniently changes a single roller on an upper roller box and unscrews screw nails of a lower roller box, so that a plurality of front top rods simultaneously and automatically withdraw from the rotary joint under the function of the spring, thereby being capable of conveniently changing a work roller assembly and a middle roller assembly.

Owner:襄阳博亚精工机器有限公司

Roll changing device for cleaning section of hot dip galvanizing unit

ActiveCN101665896AWith lifting functionWith walking functionHot-dipping/immersion processesEngineeringMechanical engineering

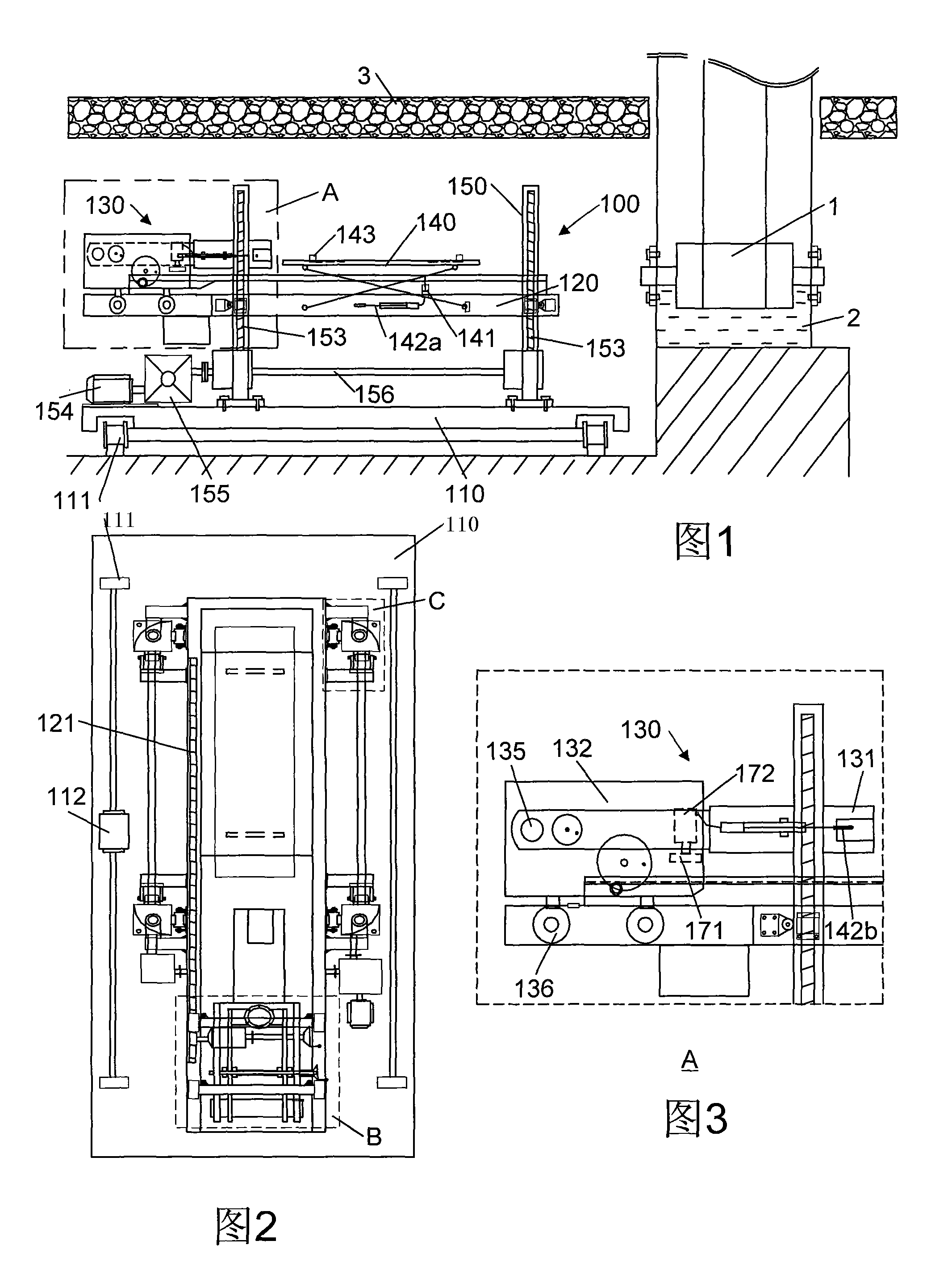

The invention discloses a roll changing device for a cleaning section of a hot dip galvanizing unit. The device comprises a base with walking function, a lifting framework with lifting function, a sliding clamp part for changing a roll and a bracket for supporting the roll, wherein the sliding clamp part is arranged at one end of the upper surface of the lifting framework, and is in sliding connection with the lifting framework. The roll changing device clamps a shaft head of a sink roll through a concave hole of a clinch ear, detaches the roll to the bracket through a sliding trolley, and supports the roll through the bracket. Therefore, the device can realize convenient and quick roll changing, greatly reduce labor intensity and improve operation efficiency, is independent of the influence of a cement platform above, and avoids potential safety hazard.

Owner:BAOSHAN IRON & STEEL CO LTD

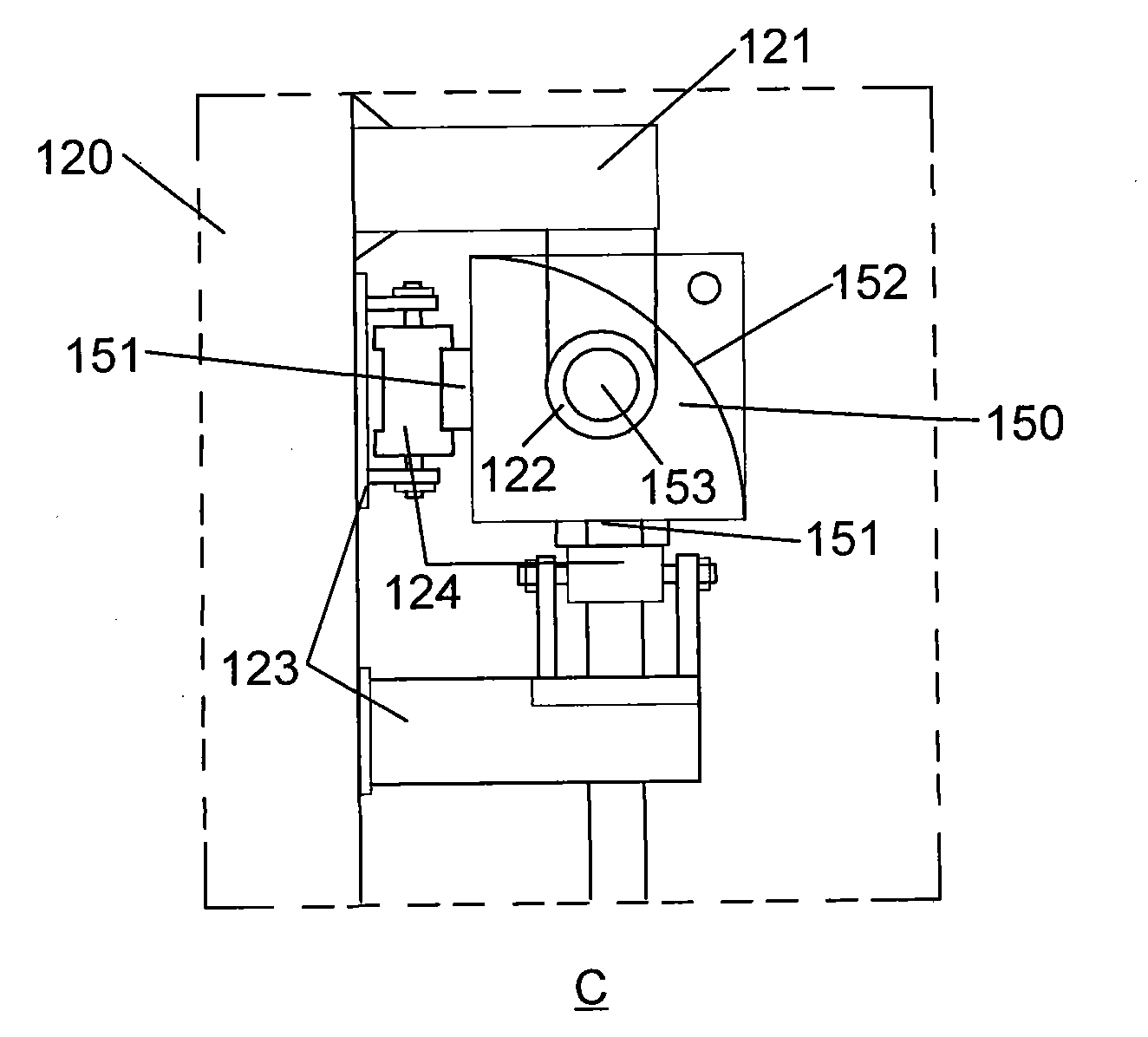

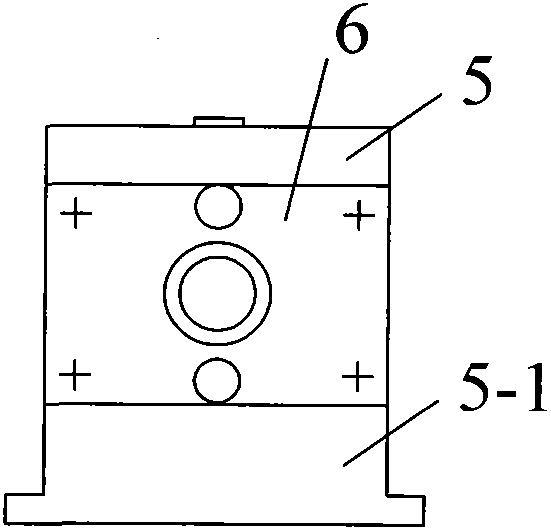

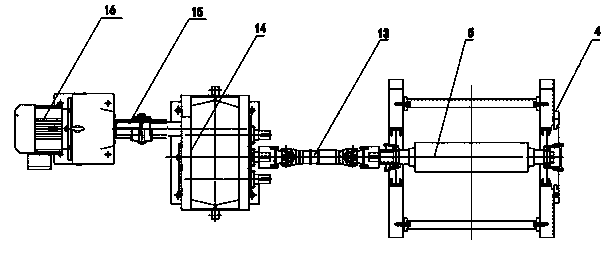

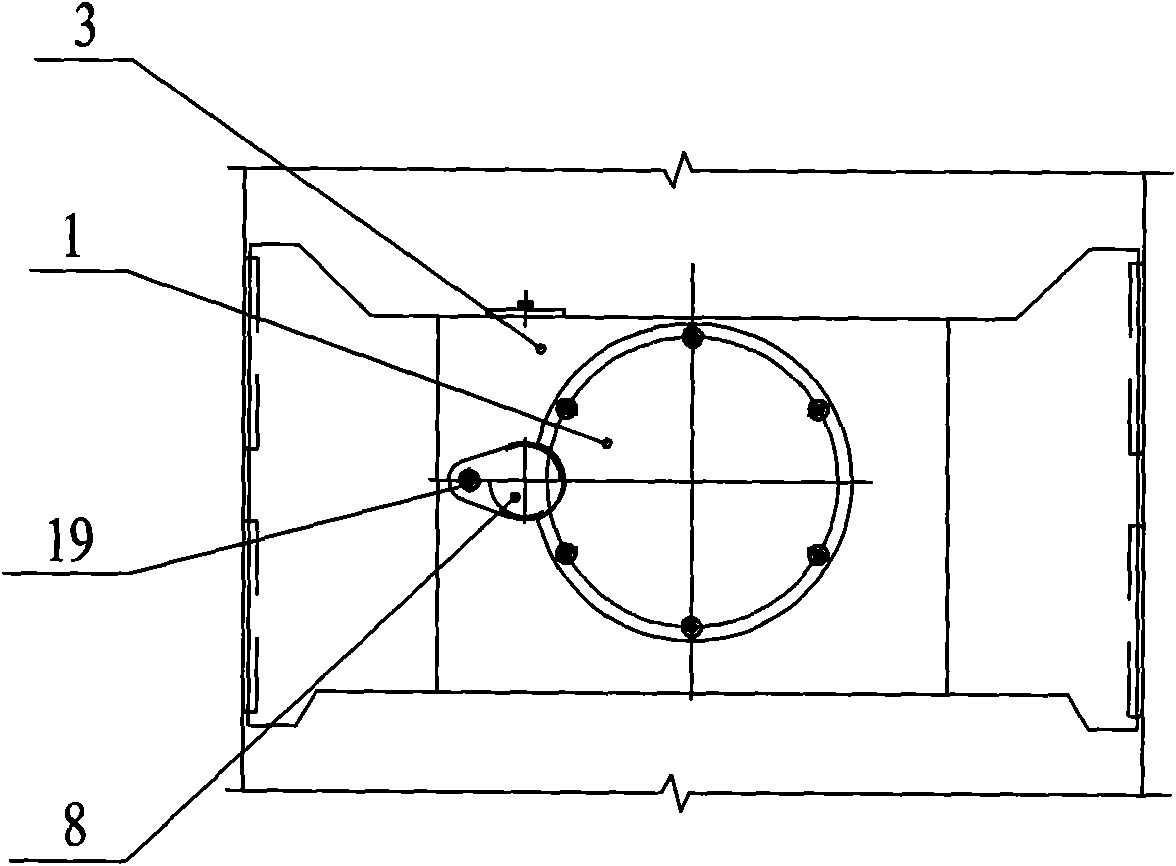

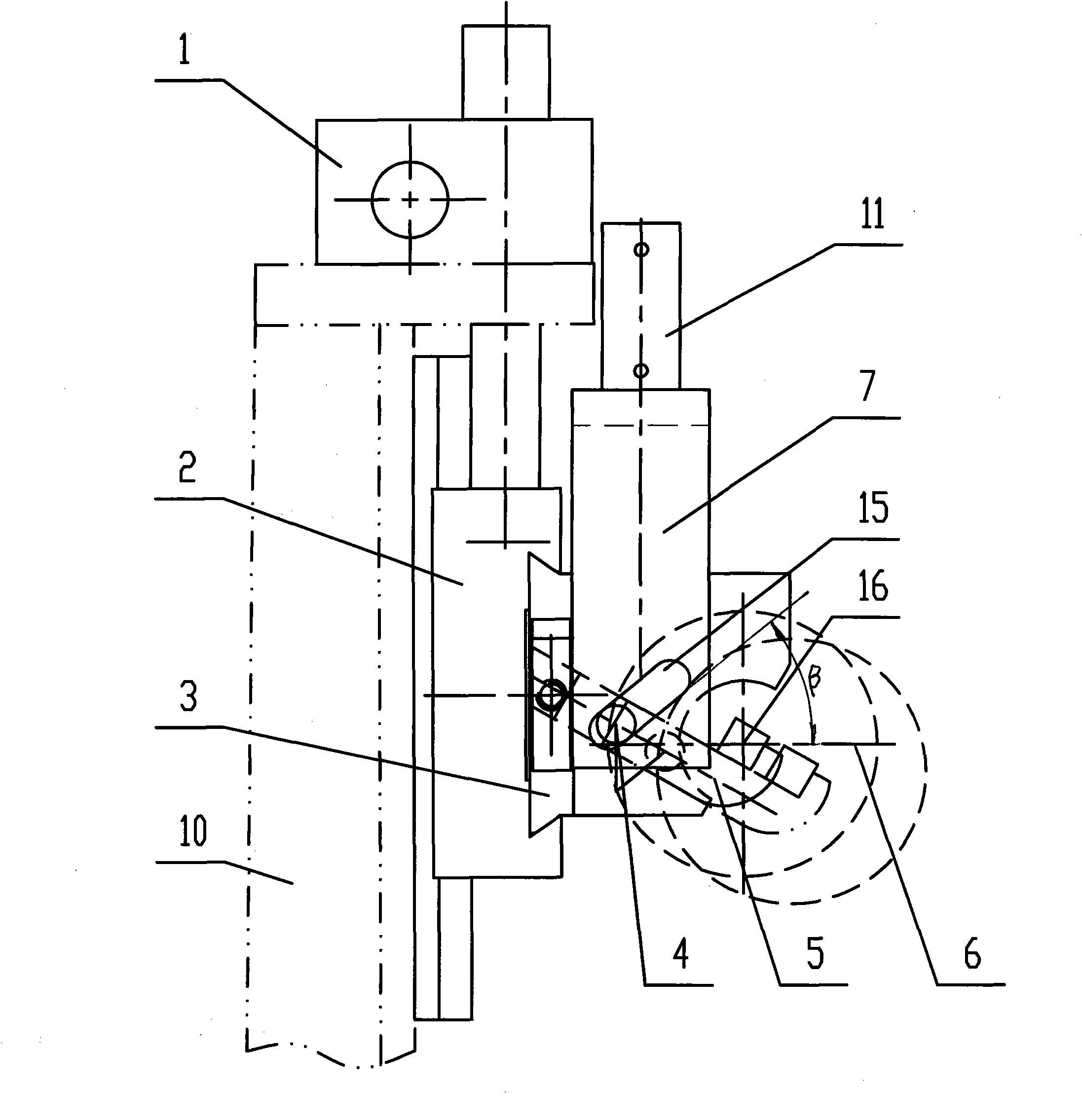

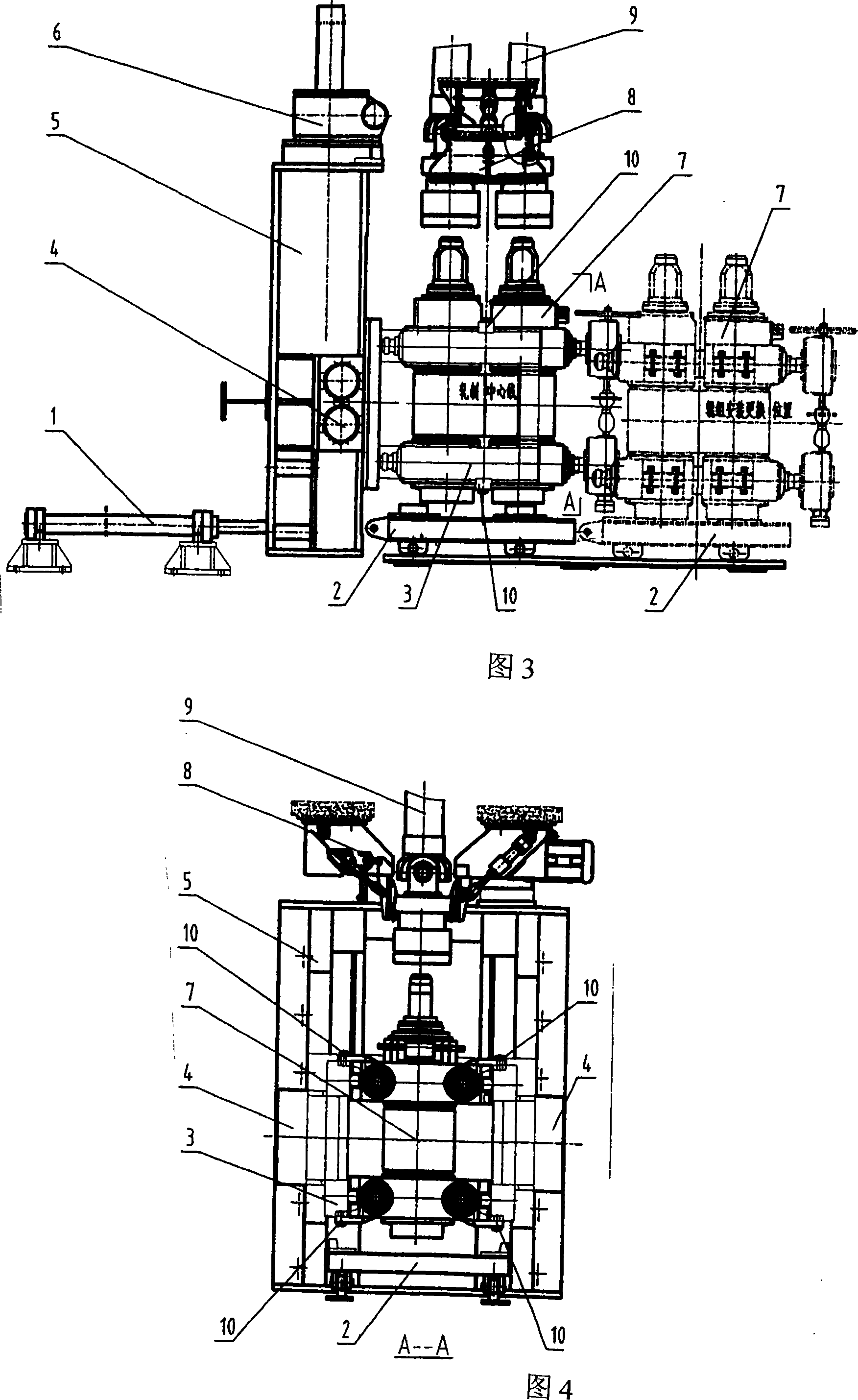

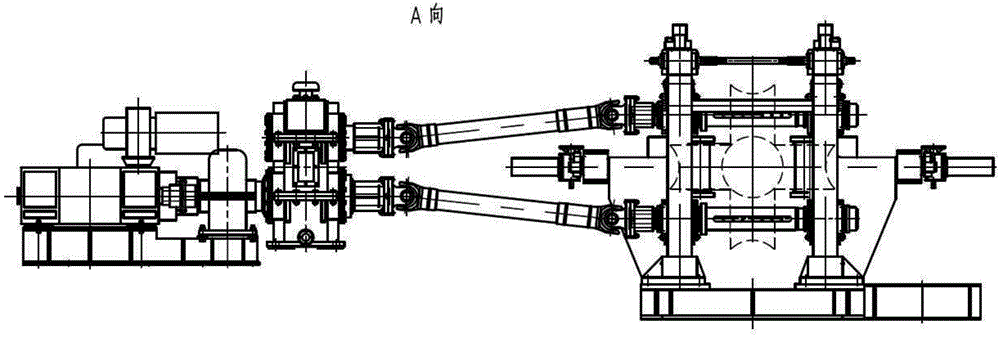

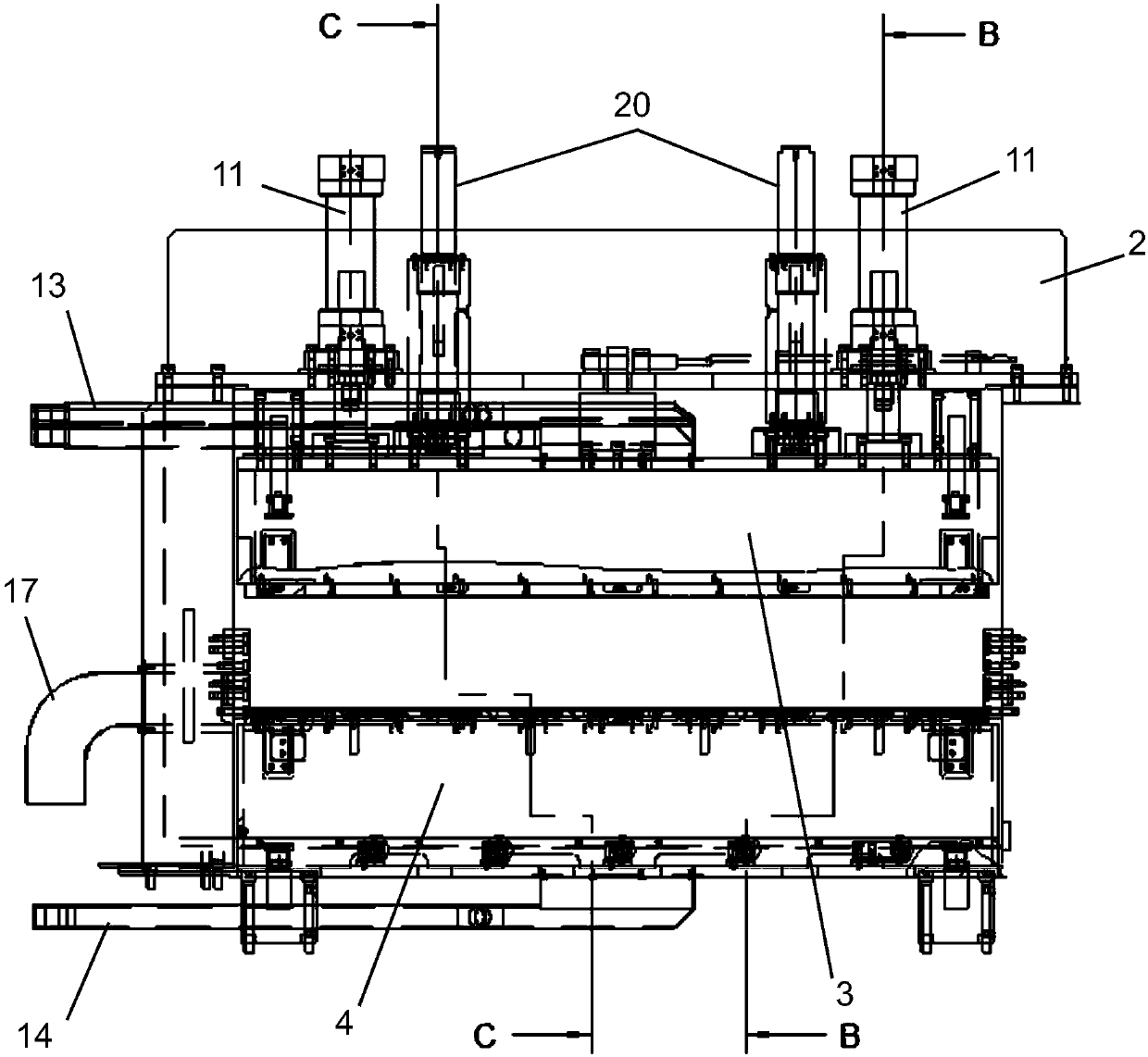

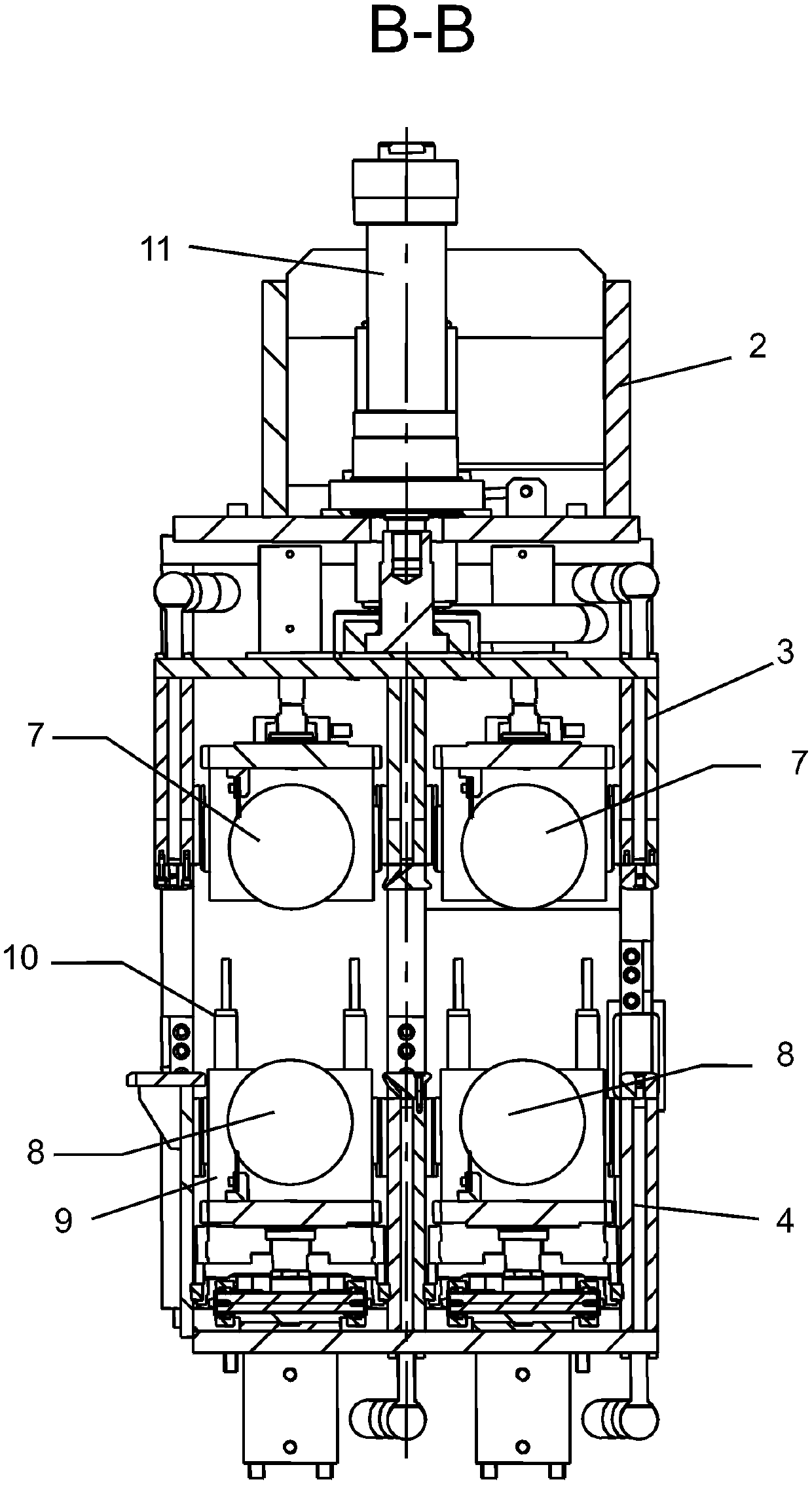

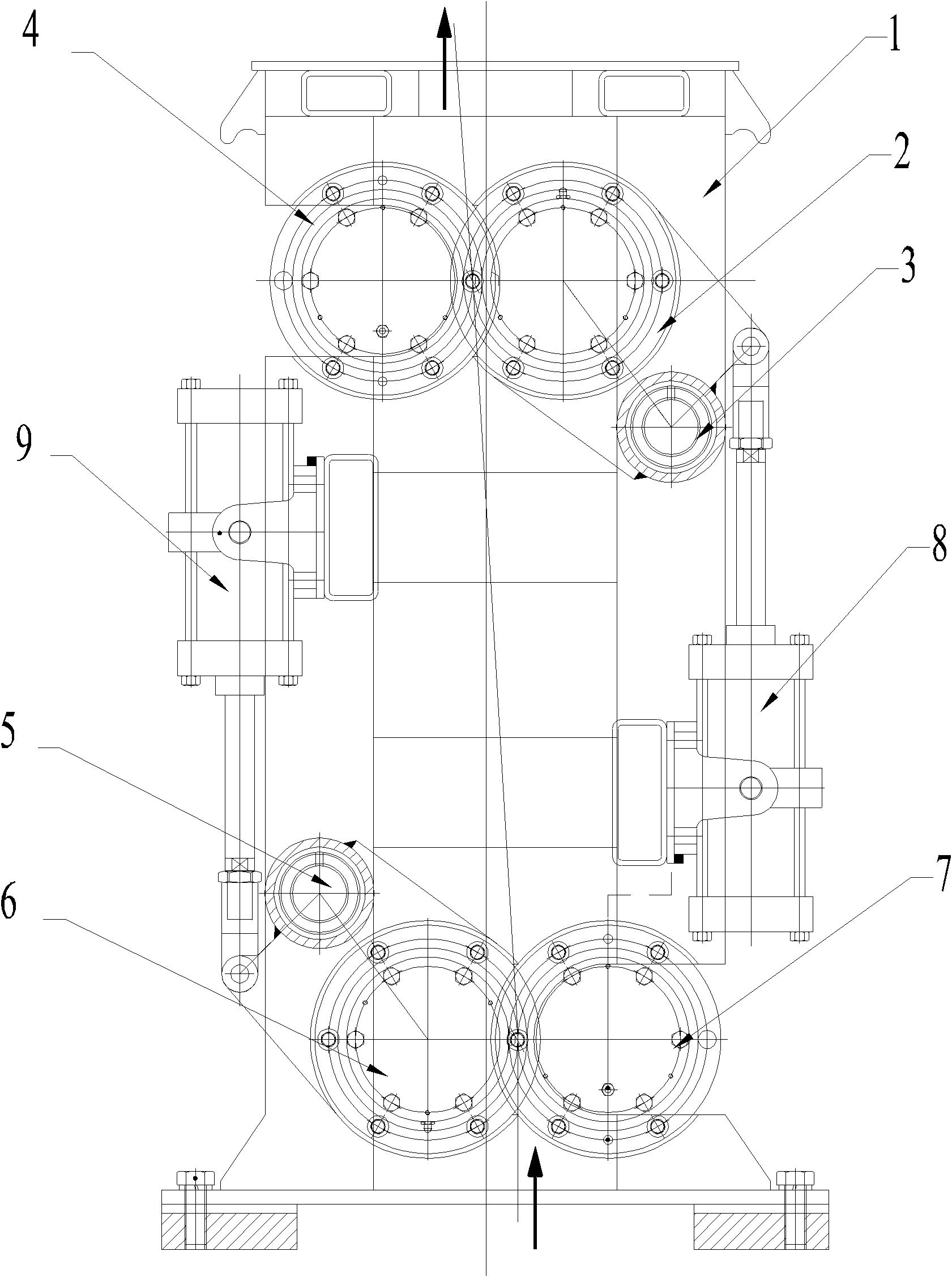

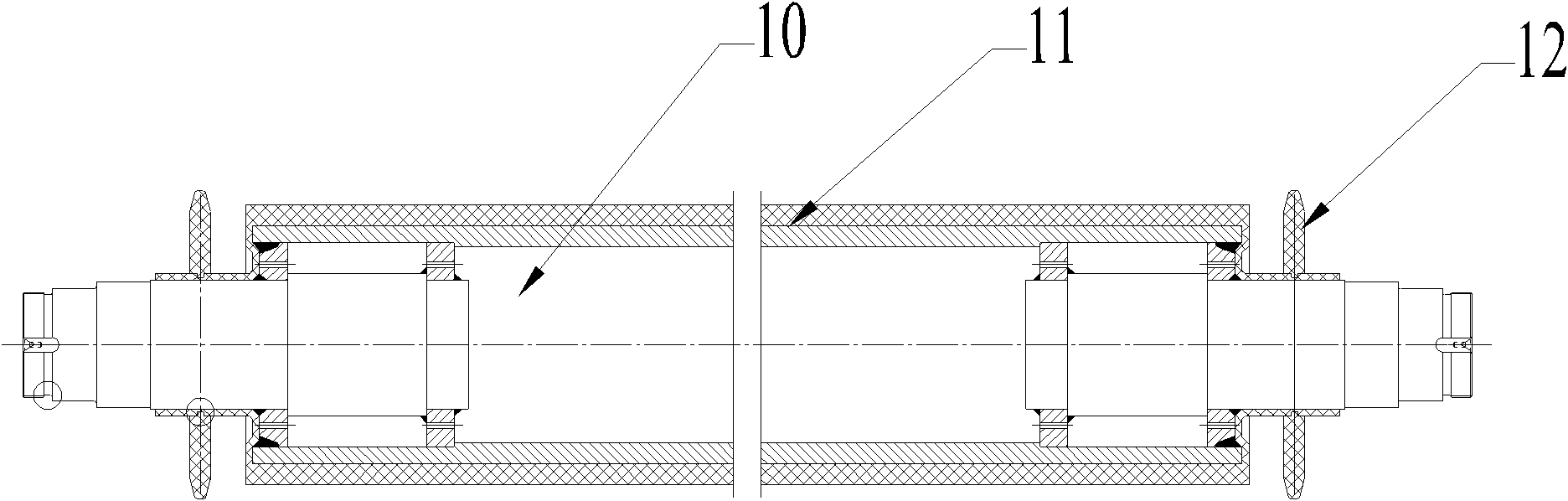

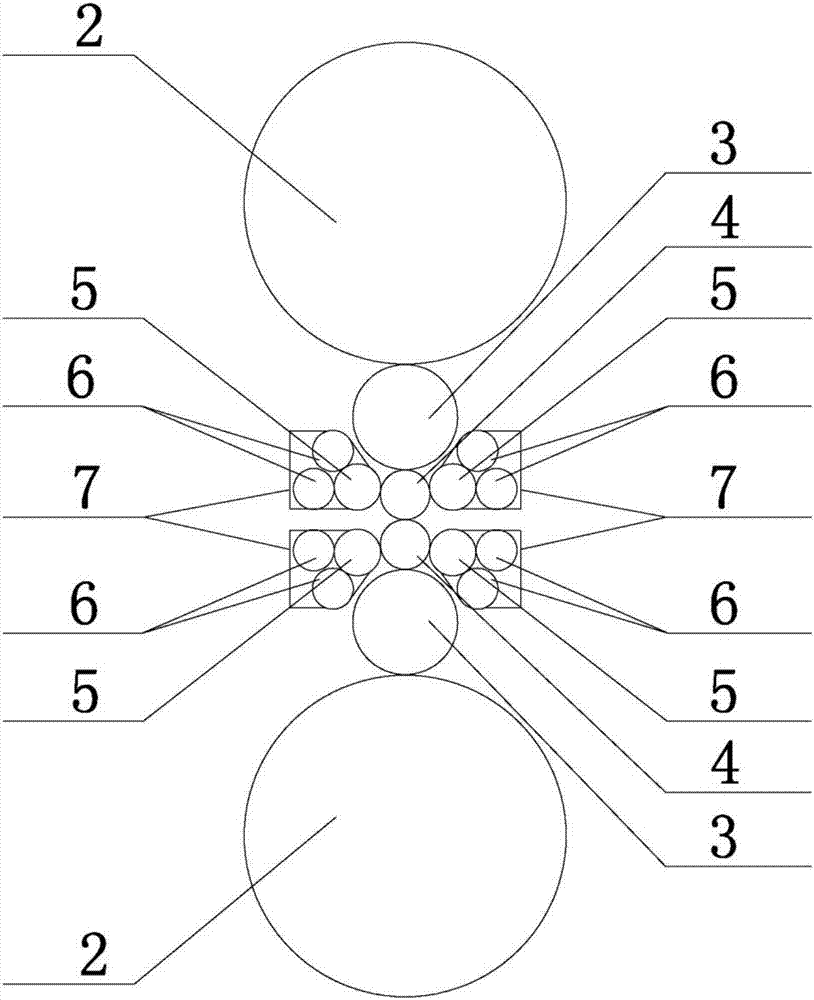

Two roller upright rolling mill

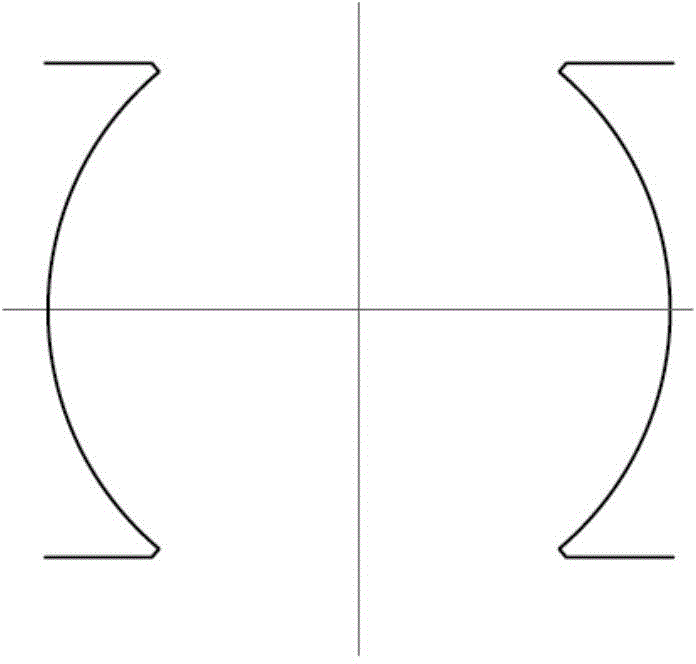

ActiveCN102581011AThe position of the center of the roll gap remains unchangedLess investmentMetal rolling stand detailsMetal rolling arrangementsStrip millRolling mill

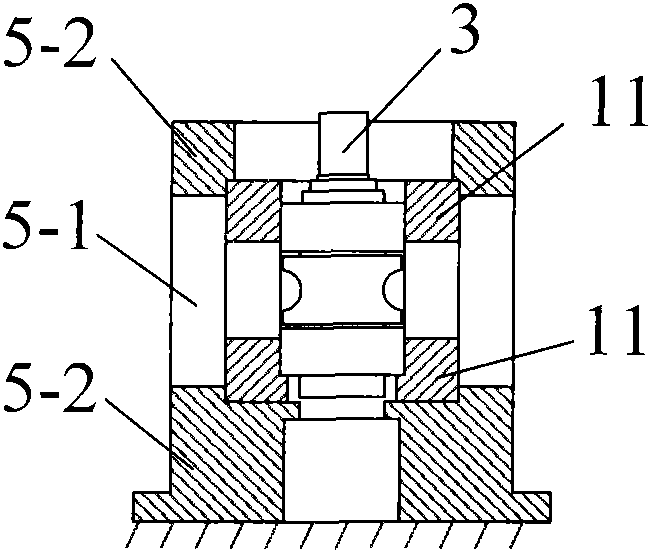

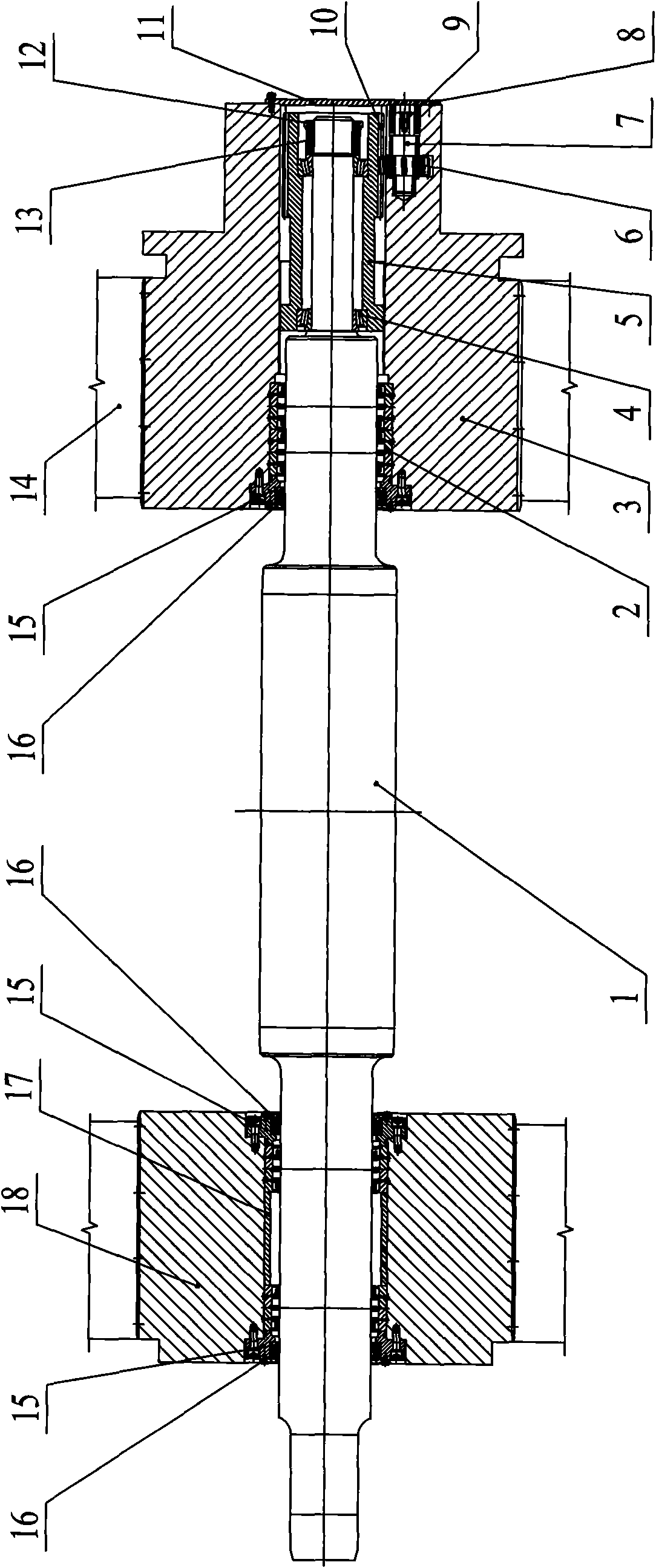

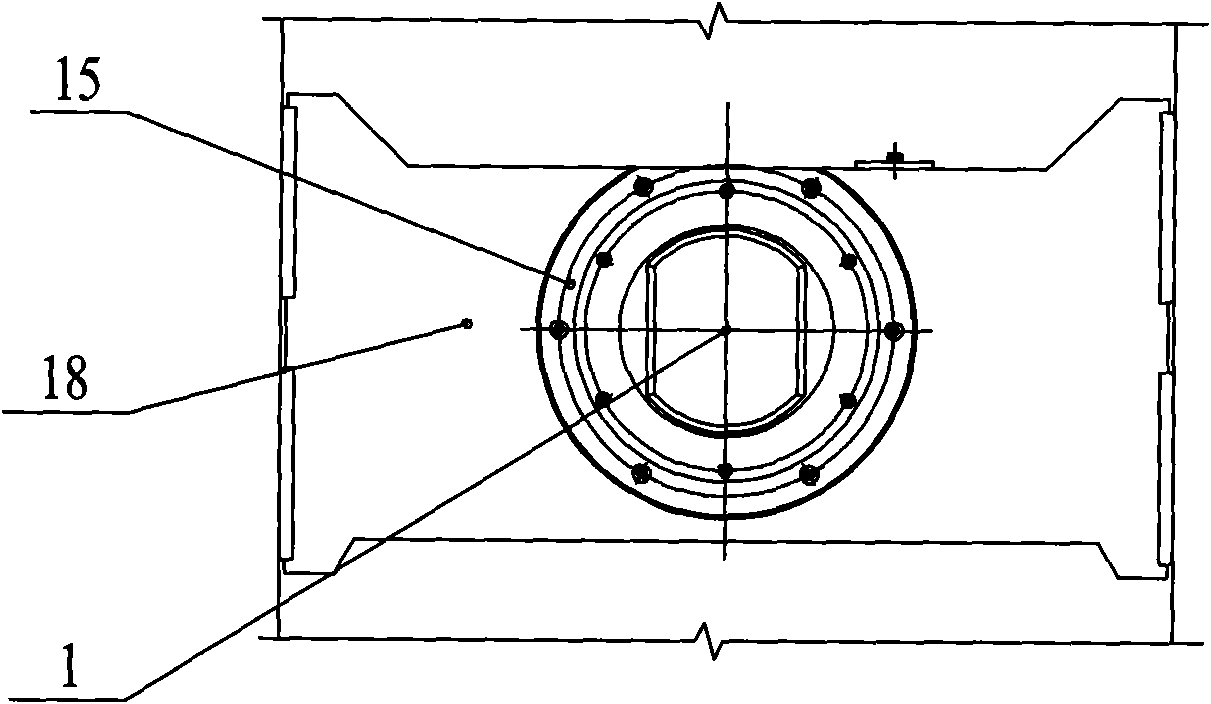

The invention relates to a two roller upright rolling mill, which comprises a rolling mill base, a rolling mill rack, two upright mill rollers (3, 2) and a mill roller clearance regulating mechanism, wherein the two upright mill rollers (3, 2) are arranged inside the rolling mill rack in parallel; the rolling mill base (5) comprises an upright end plate (5-1) and horizontal transverse beams (5-2) which are connected with four angles of the upright end plate (5-1) respectively; the horizontal transverse beams (5-2) are vertical to the upright end plate and extend towards the same direction; the rolling mill base is a floating type rack (11) which is embedded among the four horizontal transverse beams of the rolling mill base; the mill roller clearance regulating mechanism is arranged at the transmission side or the operation side of the rolling mill; and a roller gap centering mechanism is also arranged at the same side with the mill roller clearance regulating mechanism. While the two mill rollers are subjected to clearance regulation, the roller gap between the two mill rollers is centered automatically; the device is simple and convenient to operate and maintain; and the rollers can be exchanged conveniently and rapidly.

Owner:BEIJING JINGCHENG RUIXINCHANGCAI ENG TECH

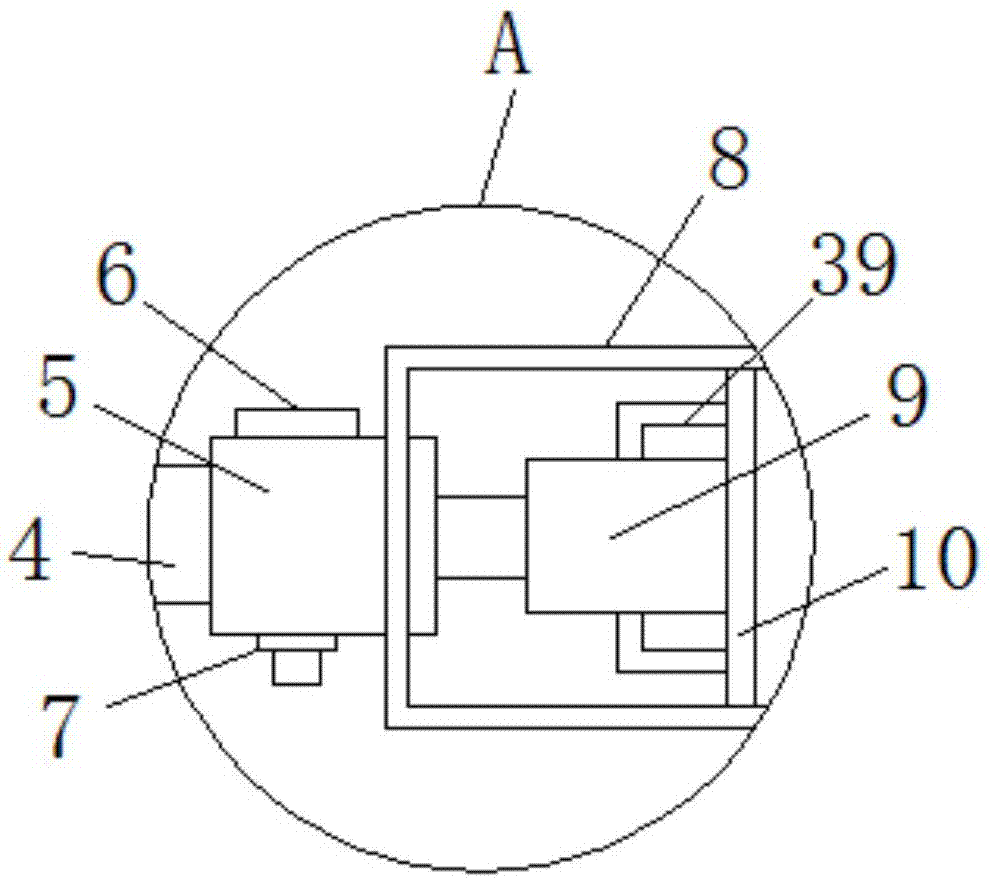

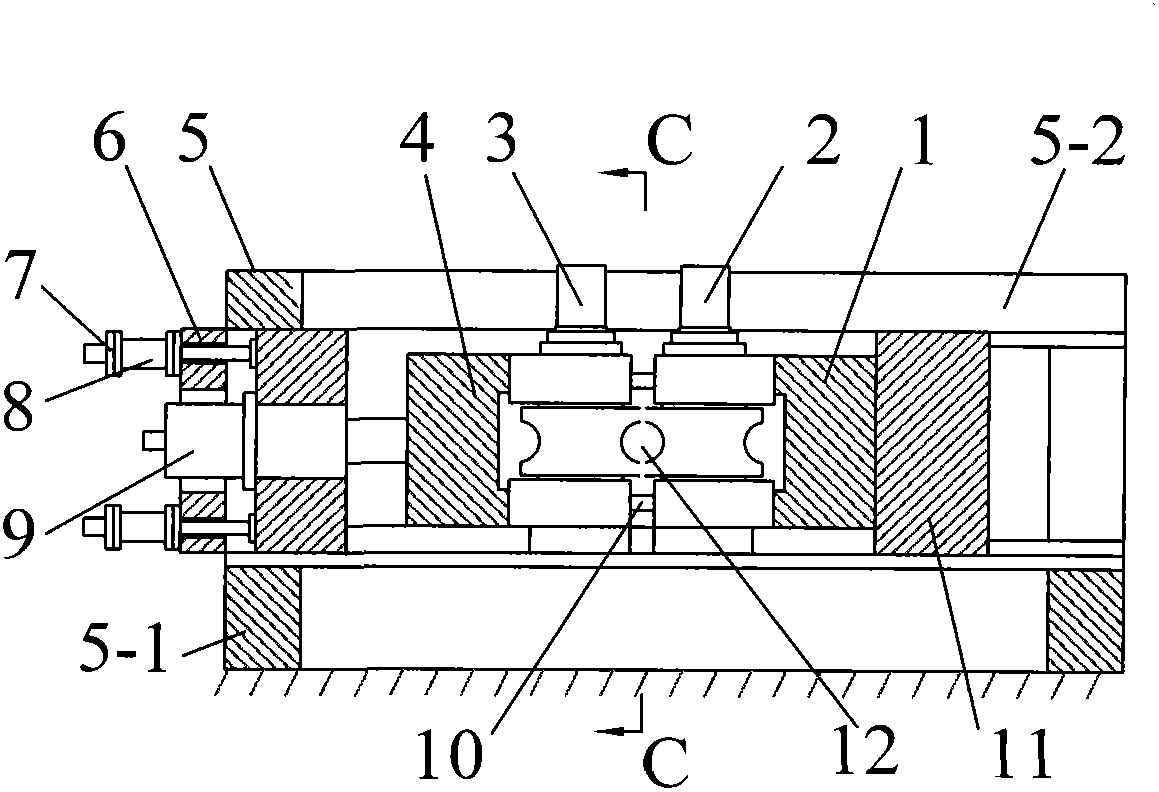

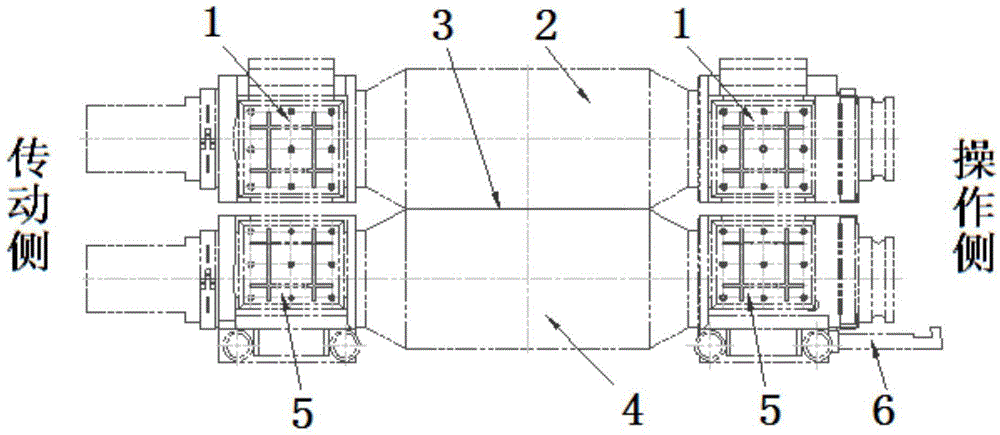

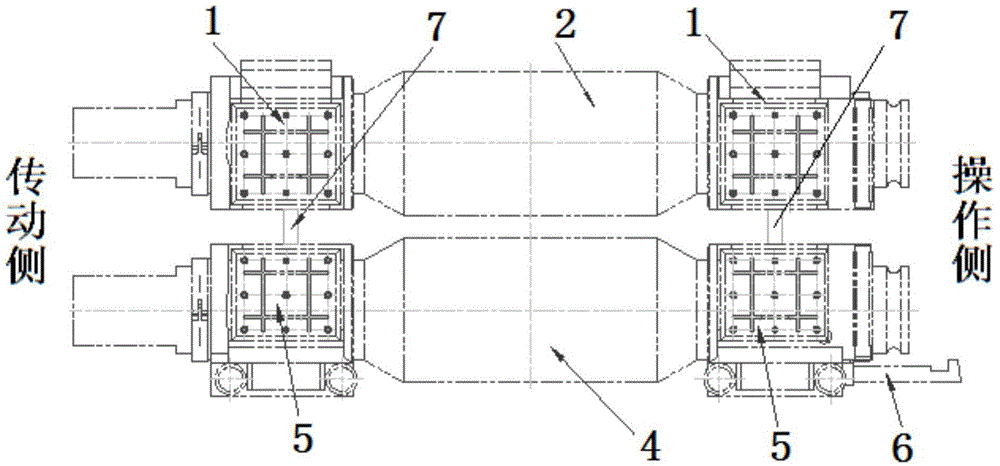

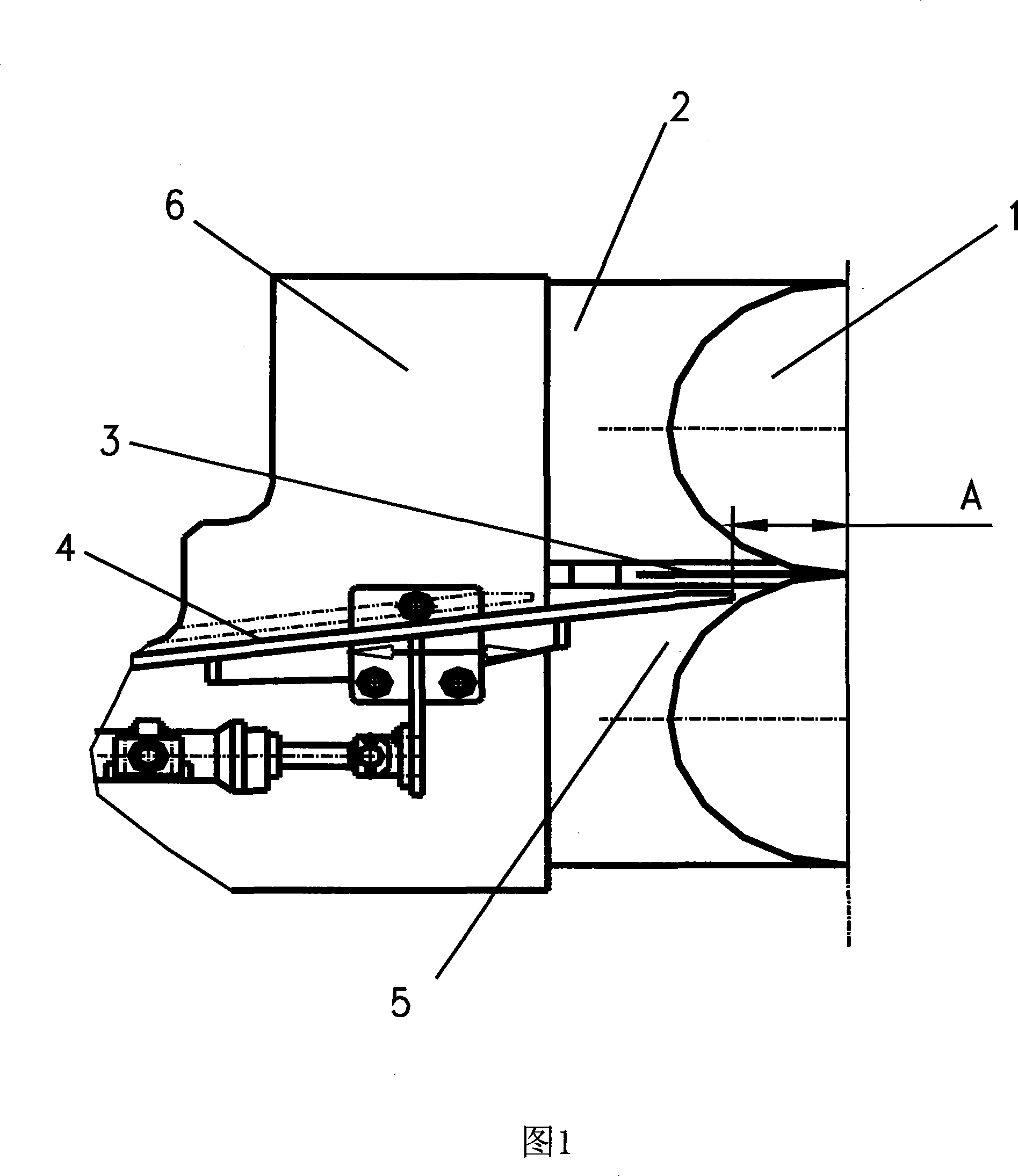

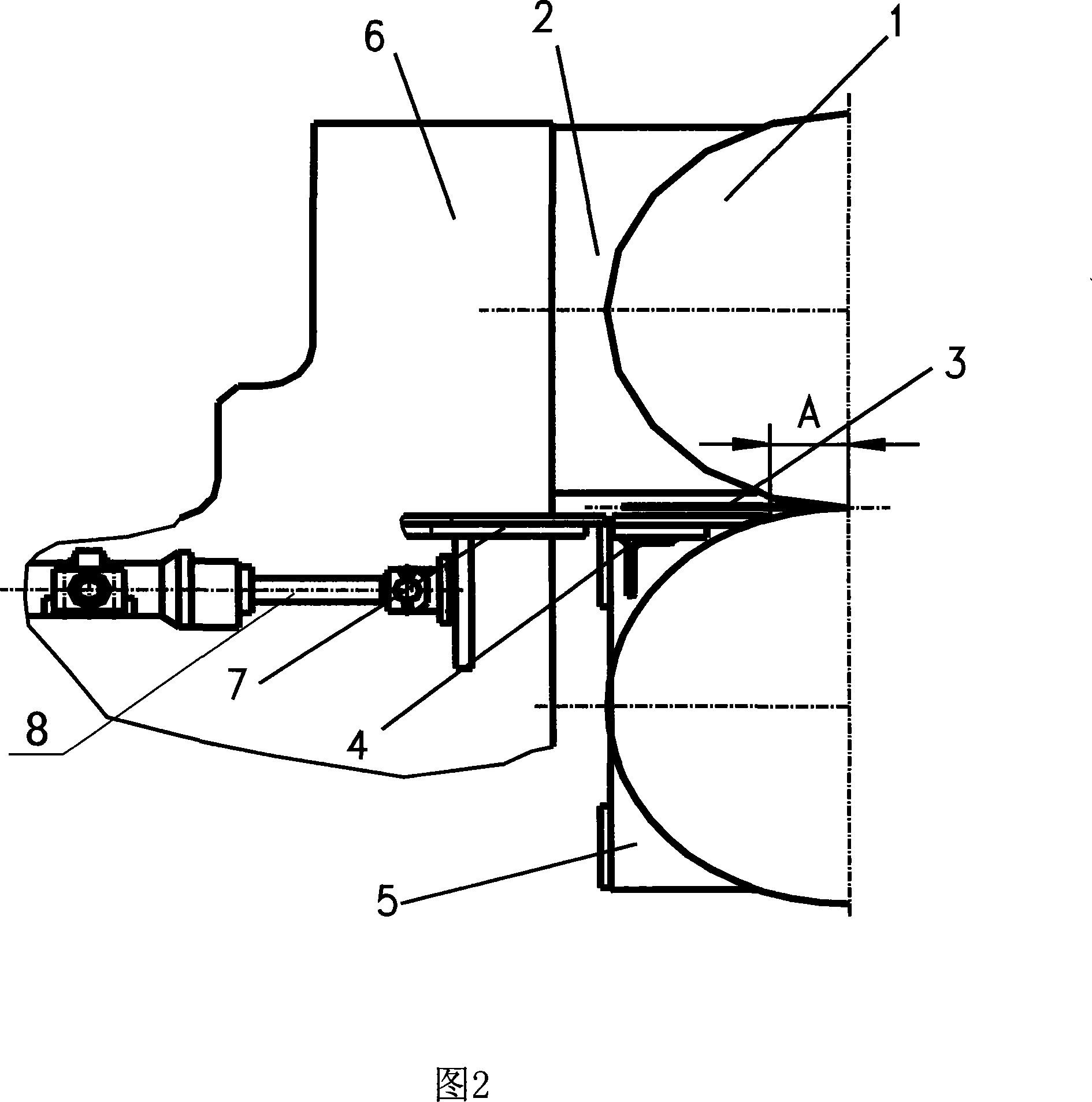

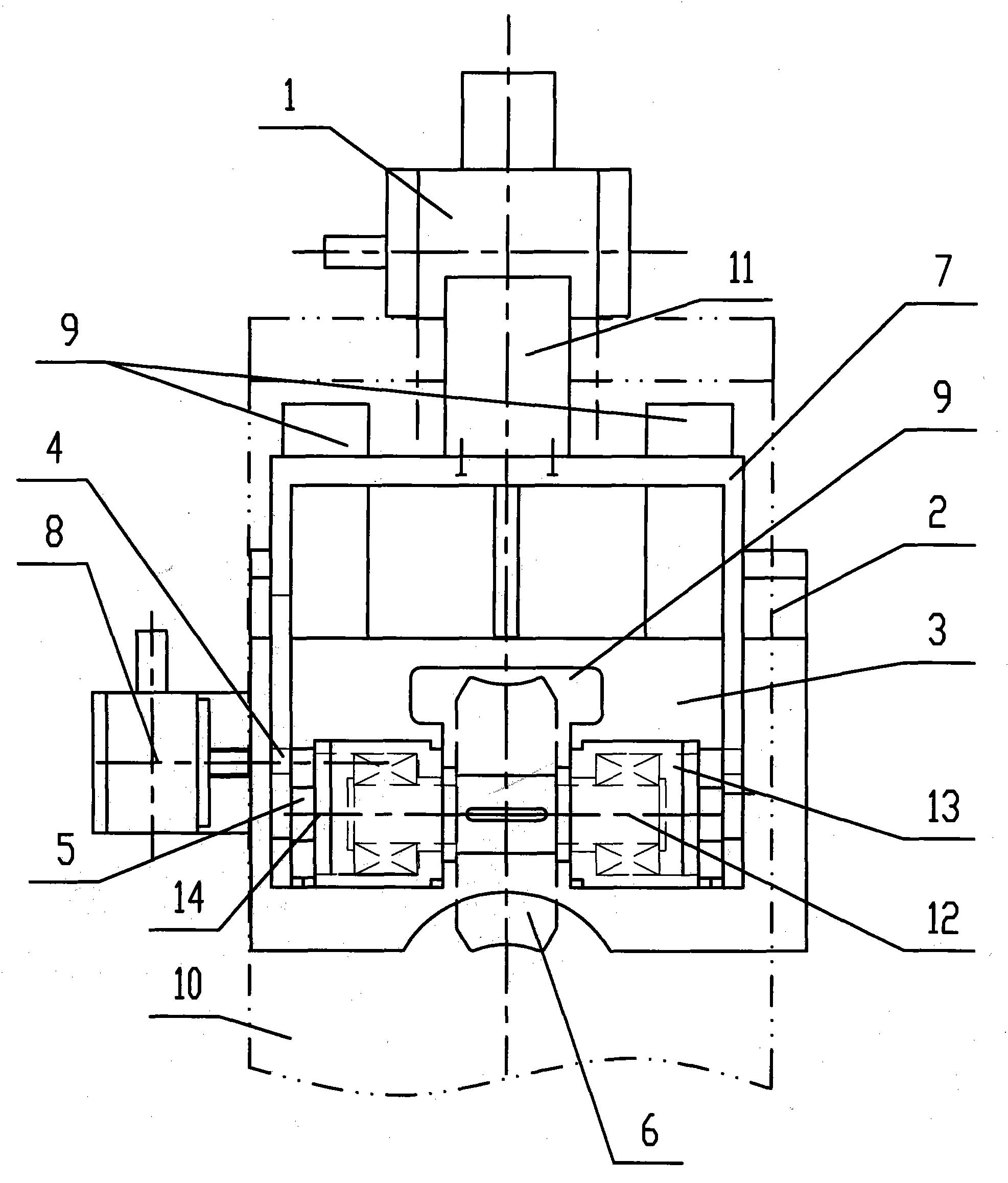

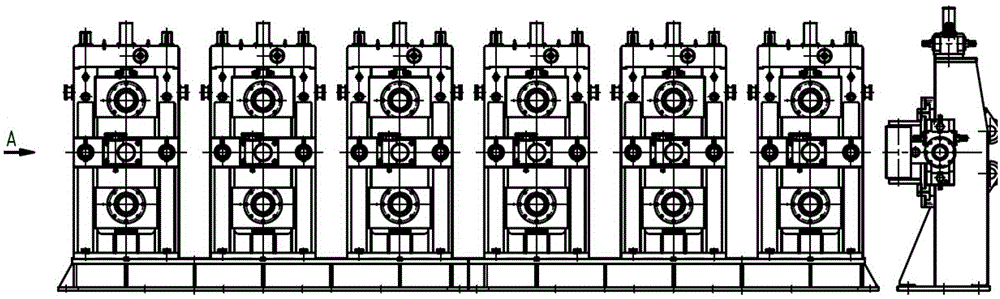

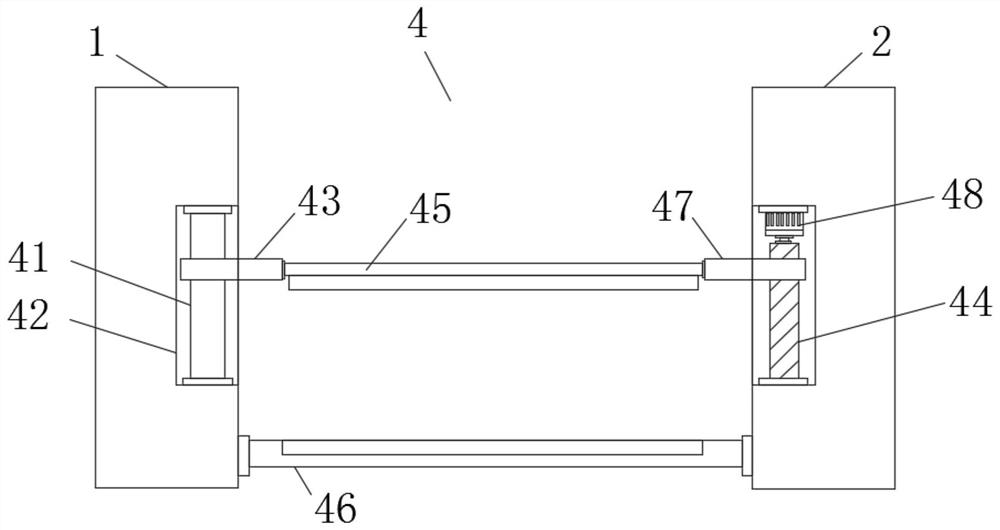

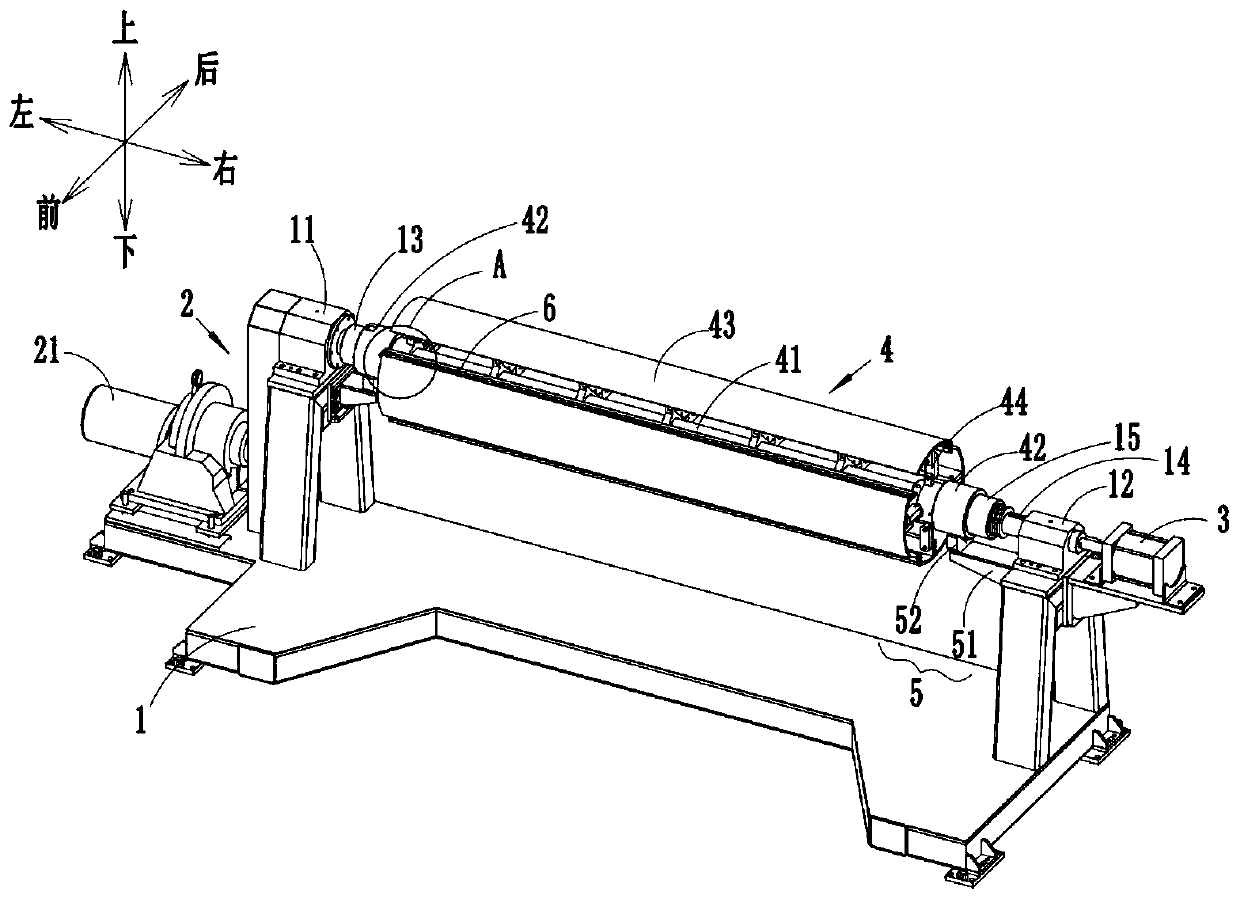

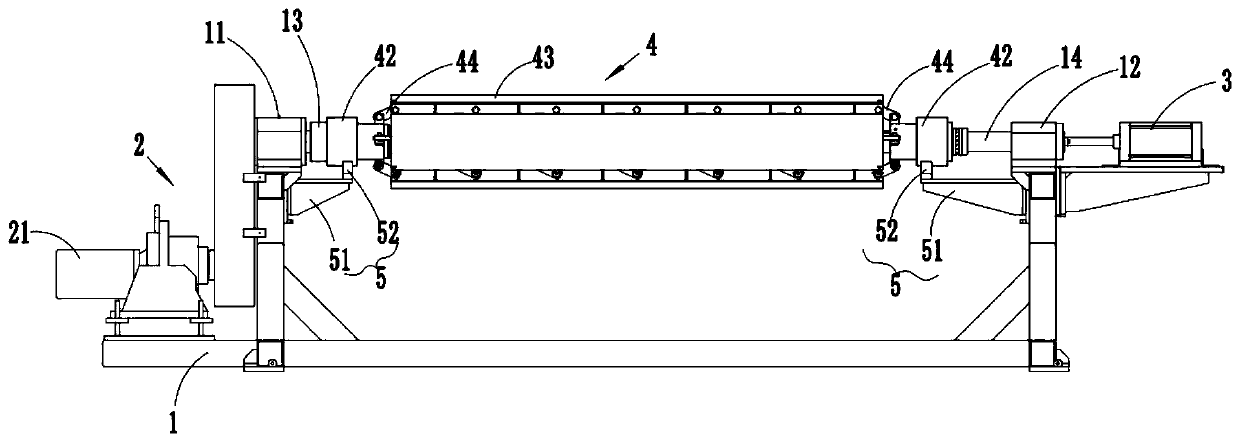

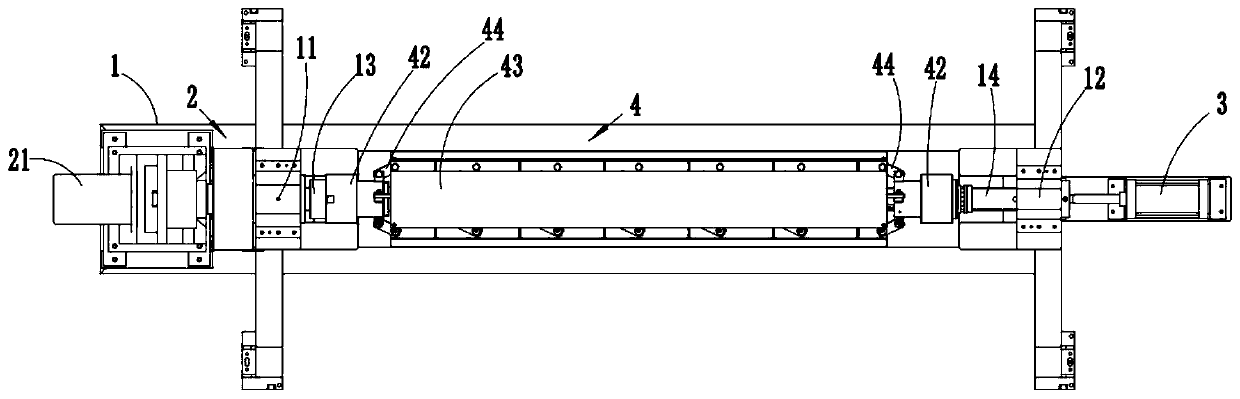

Combined two-roller continuous mill

ActiveCN102581012AReduce length dimensionReduce the length of the out-of-tolerance segmentMetal rolling stand detailsMetal rolling arrangementsEngineeringMechanical engineering

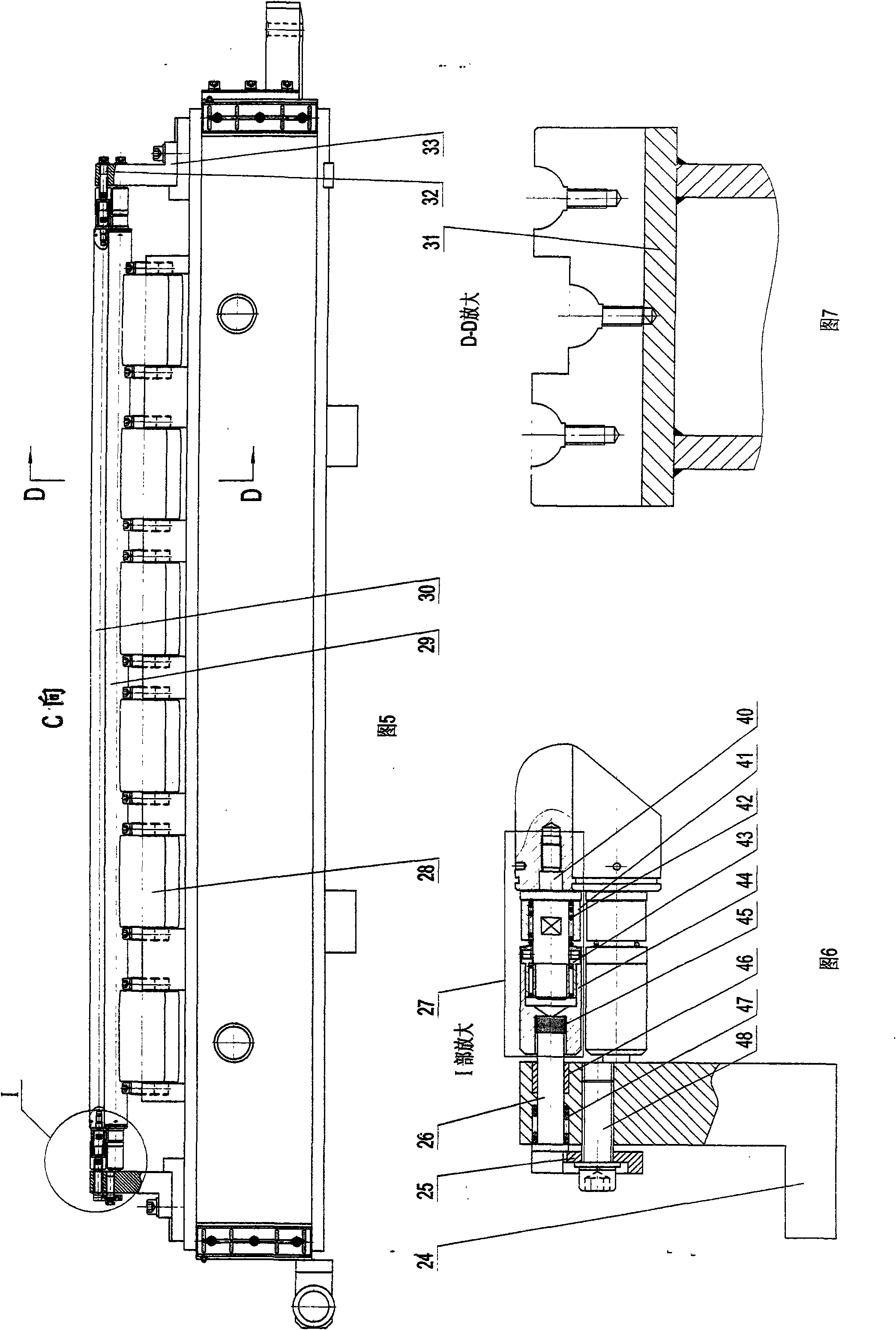

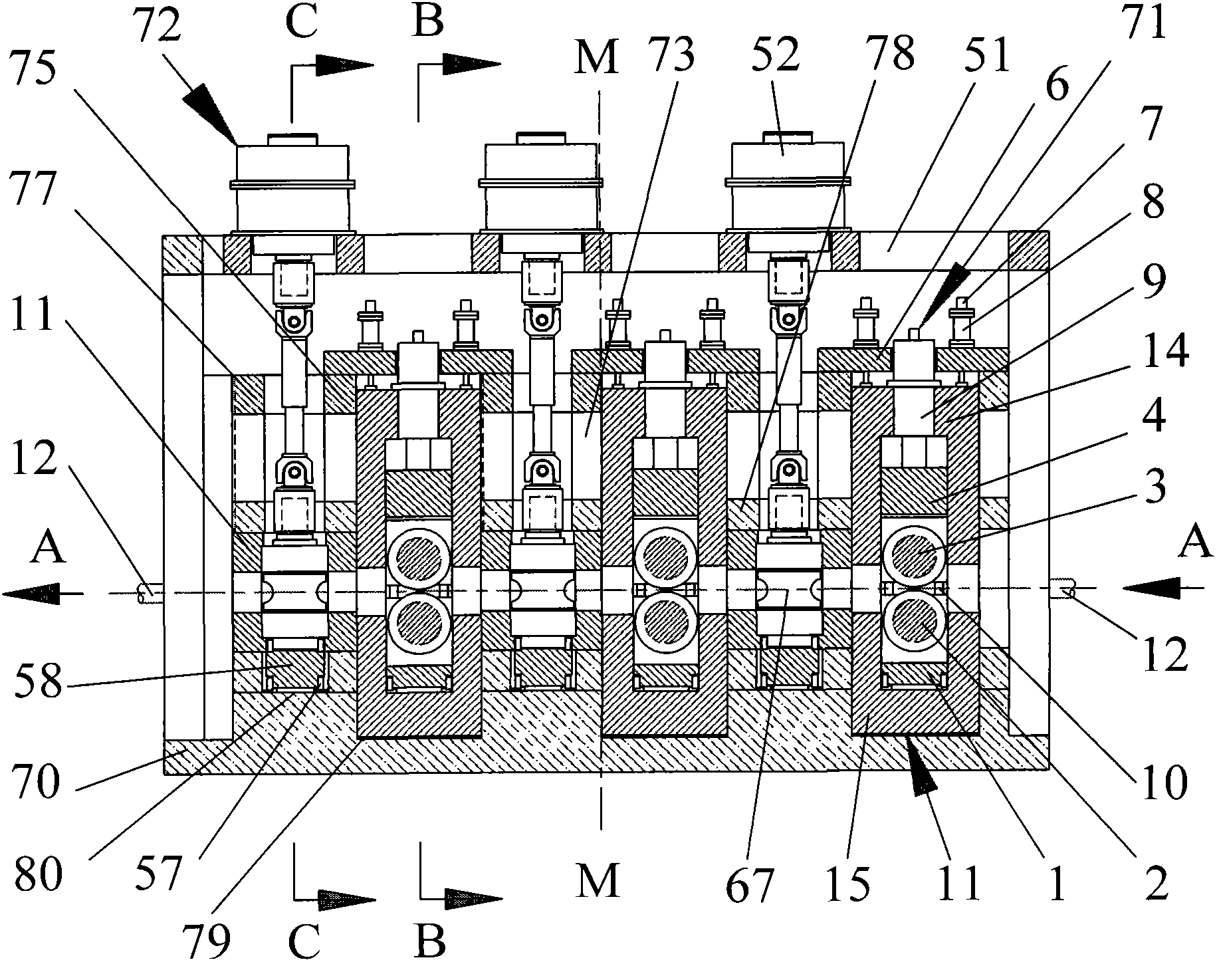

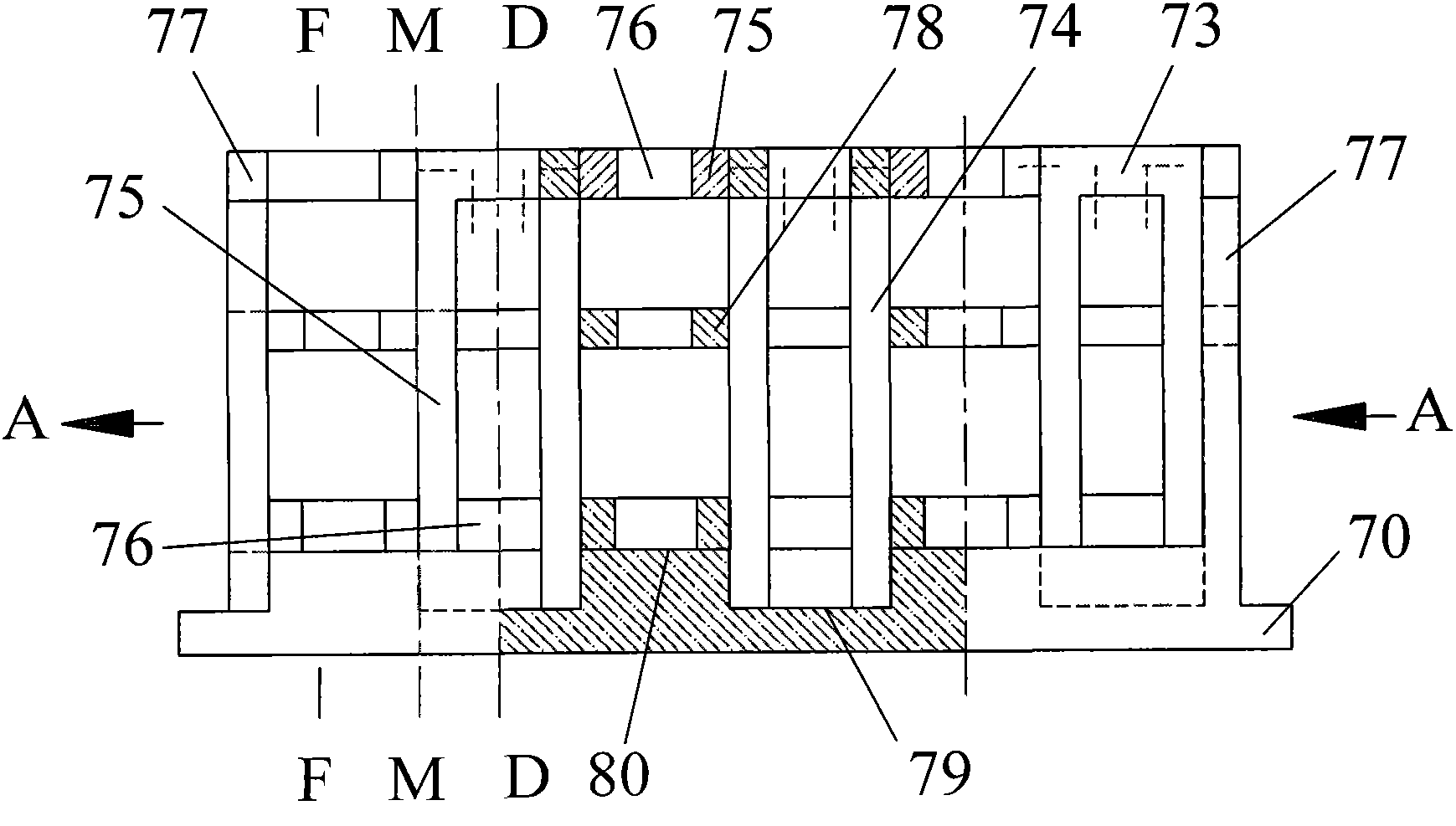

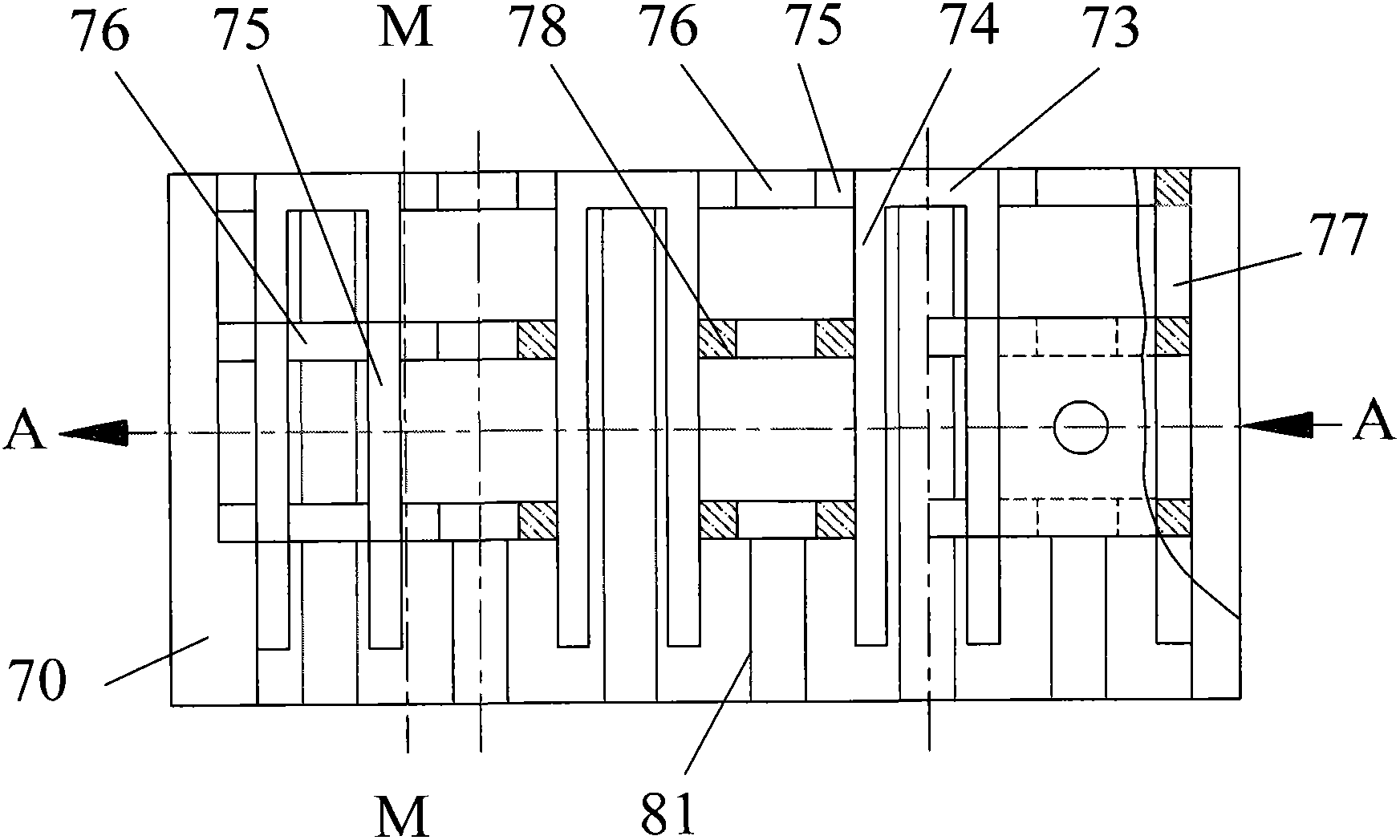

The invention relates to a combined two-roller continuous mill, which comprises at least one horizontal rolling assembly (71), at least one vertical rolling assembly (72) and a roll changing mechanism, wherein rolling assembly frames are alternately and continuously attached along a rolling line (A-A) and are arranged on a base 5 in 90 degrees; each rolling assembly (71) comprises a floating frame (11) which is embedded in the rolling assembly frame; two rollers and a roller bearing seat are arranged in the floating frame; a roller gap adjusting mechanism is arranged on an upper roller bearing seat (4) or on an end plate (14) of the floating frame (11) corresponding to a roller bearing seat(65) at the transmission side; and a roller gap centering mechanism which is arranged on a movable top cover (6) is further added. The rolling assembly frames are compactly arranged in a gapless way, when the gap between two rollers is adjusted by the roller gap adjusting mechanism and the roller gap centering mechanism, the gap between the two rollers is automatically centered; and the continuous mill is high in operating rate.

Owner:BEIJING JINGCHENG RUIXINCHANGCAI ENG TECH

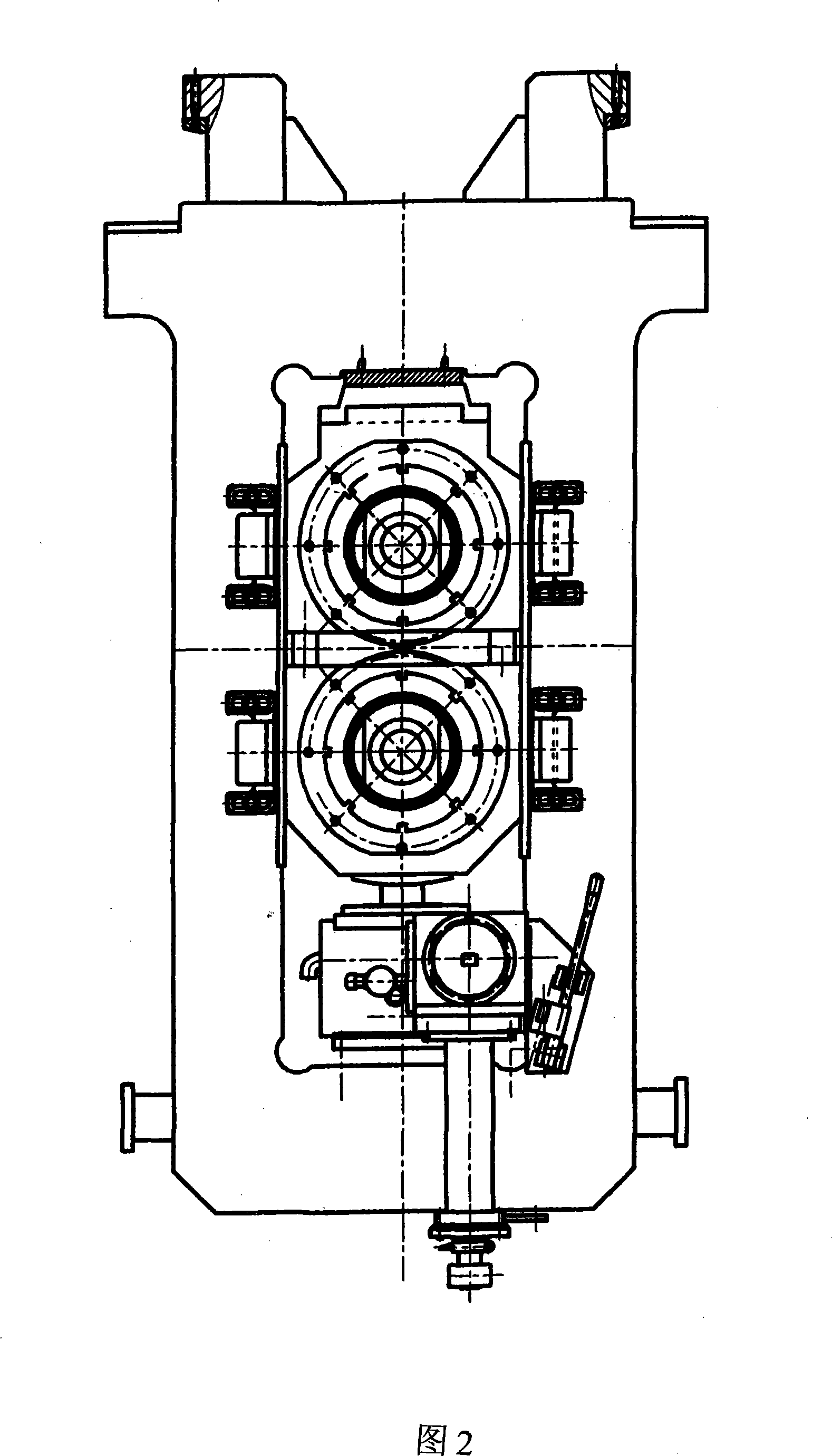

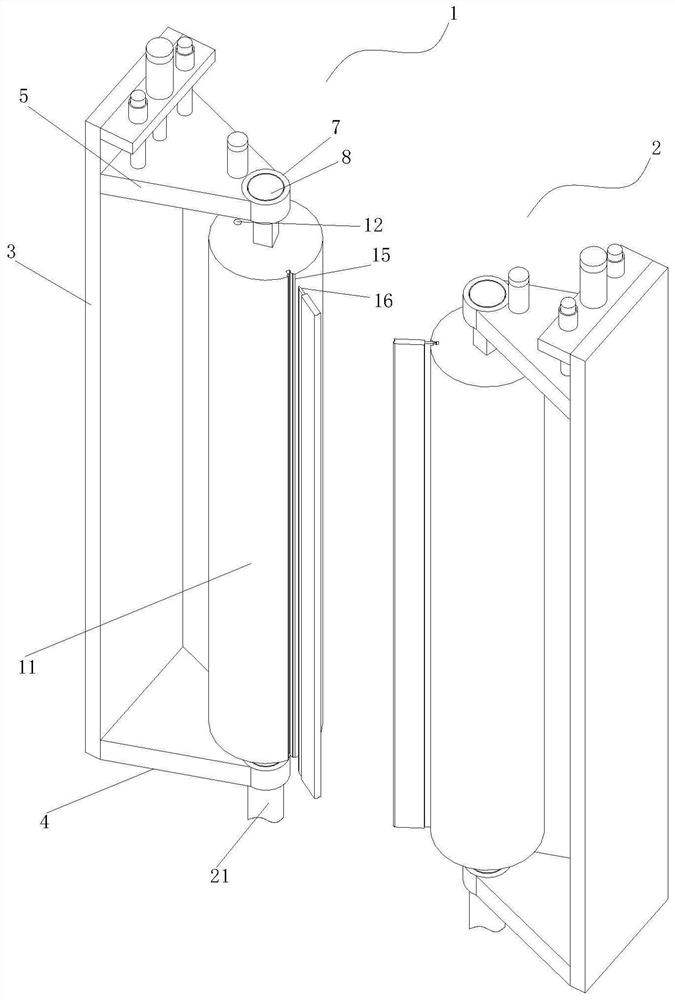

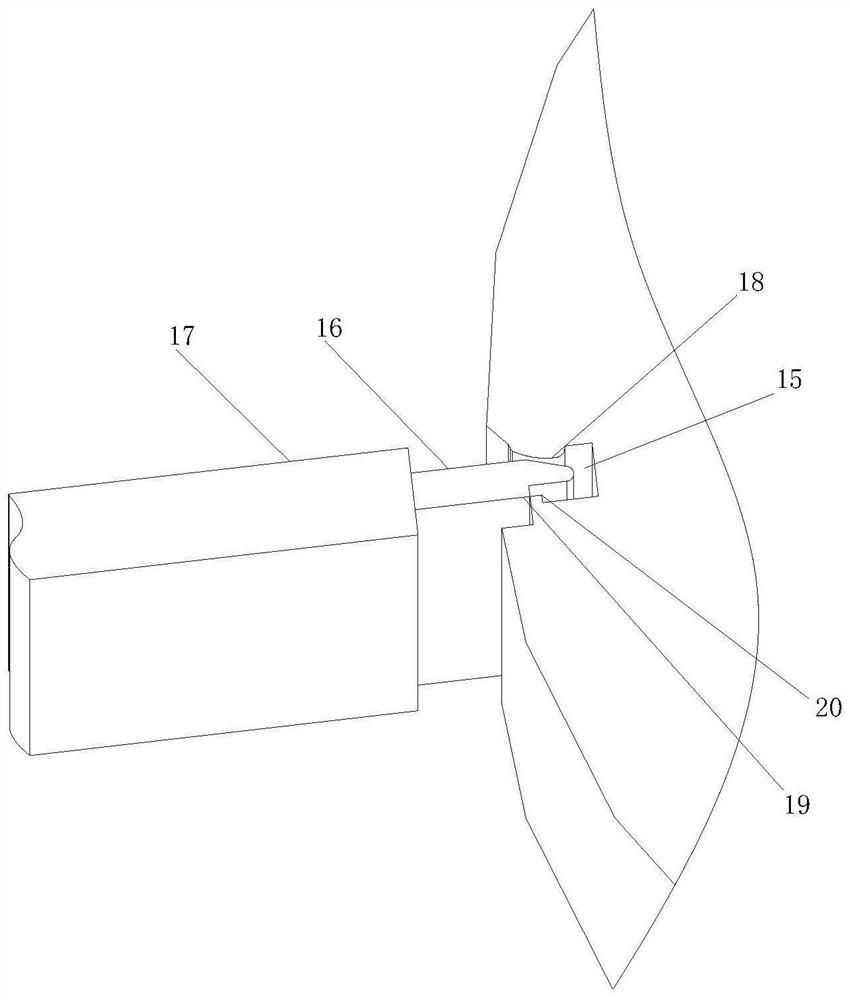

Vertical short stress path rolling mill without frame

InactiveCN1733379ASimple structureReduce weightMetal rolling stand detailsMetal rolling arrangementsLocking mechanismStress path

The disclosed no frame vertical short stress path rolling mill belongs to metallurgical equipment field. The mill comprises roll changing hydrocylinder (1), with rolling mill group (3), roll changer (2), post (4), worm wheel lifting gear (5), U-shaped frame (7), rotation ear (8) and bolt (9). The hydrocylinder runs to pull mill group into U-shaped frame, wherein, the groove rotation locking mechanism (6) composed of rotation ear, bolt, and U-shaped frame fixes the mill group on post with a couple of screw threads, on which the bolt realizes symmetric adjust. This invention cancels frame of mill self and big frame to fix whole mill, which realizes simply structure, light weight, convenience to operate and change, low cost and symmetric adjust.

Owner:UNIV OF SCI & TECH BEIJING

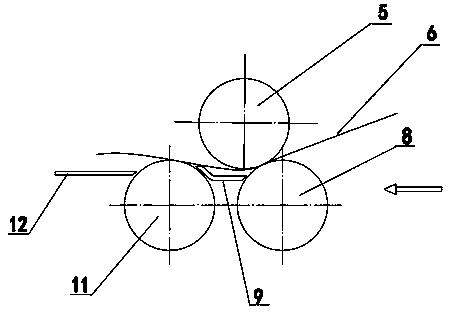

Three-roller strip head forming device with pinching function

ActiveCN104259205ARelative height can be adjusted arbitrarilySmooth wearingMetal-working feeding devicesPositioning devicesStrip steelEngineering

The invention relates to a three-roller strip head forming device with a pinching function. The three-roller strip head forming device comprises a frame, an upper roller, an inlet lower roller, an outlet lower roller, an inlet guide plate, a middle transition guide plate, an outlet guide plate, a lower roller height adjusting mechanism and a transmission device, the upper roller is matched with the inlet lower roller to form a pinching roller set, the upper roller, the inlet lower roller and the outlet lower roller are matched to form a strip head forming roller set, the transmission device rotates forwards or backwards to drive strip steel to a crop shear device or to return to the strip head forming roller set for forming, and the lower roller height adjusting mechanism can adjust the heights of the inlet lower roller and the outlet lower roller, so that the forming requirement of the strip steel with different thicknesses is met. The three-roller strip head forming device has the advantages that the strip steel is conveyed and formed, the device can adapt to the strip steel with different thicknesses, the head of the strip steel obtains the needed bent shape, and a strip can smoothly penetrate the three-roller strip head forming device as the inlet guide plate, the middle guide plate and the outlet guide plate are designed.

Owner:WISDRI ENG & RES INC LTD

Roll changing mechanism for working roll of rolling mill

InactiveCN104858238AQuick roll changeEasy and safe roll changeMetal rolling stand detailsMetal rolling arrangementsWork rollStrip mill

The invention discloses a roll changing mechanism for a working roll of a rolling mill. An upper bearing seat and a lower bearing seat are arranged on an installing seat of a work side and an installing seat of an operating side respectively. The shaft axis of the upper bearing seat and the shaft axis of the lower bearing seat are arranged in parallel. An upper working roll and a lower working roll penetrate through the upper bearing seat and the lower bearing seat respectively. An equal-height hinge pin is fixedly arranged on the upper surface of the lower bearing seat at the working side. A depth hole and a shallow hole are formed in the bottom face of the upper bearing seat at the working side. Another equal-height hinge pin is fixedly arranged on the upper surface of the lower bearing seat at the operating side. A depth hole and a shallow hole are formed in the bottom face of the upper bearing seat at the operating side. According to the structure of the roll changing mechanism for the working roll of the rolling mill, the equal-height hinge pin is included on the upper surface of the lower bearing seat, and two holes with different depths are formed in the bottom of the upper bearing seat correspondingly, the function of adding a height-equal block manually is realized, and fast, convenient and safe roll changing is realized.

Owner:MCC SFRE HEAVY IND EQUIP

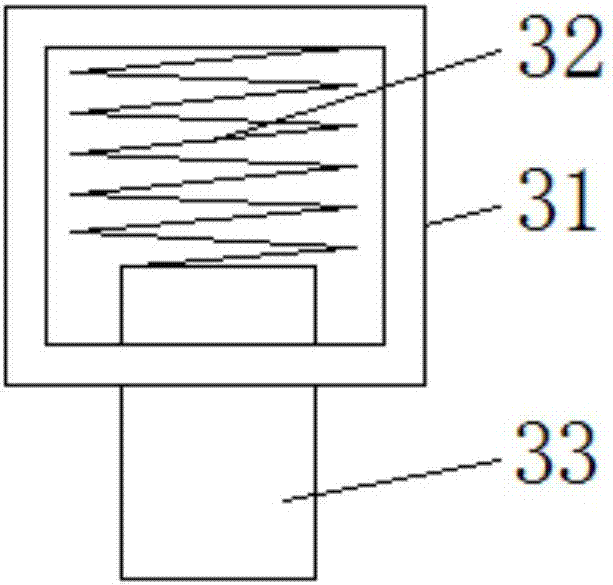

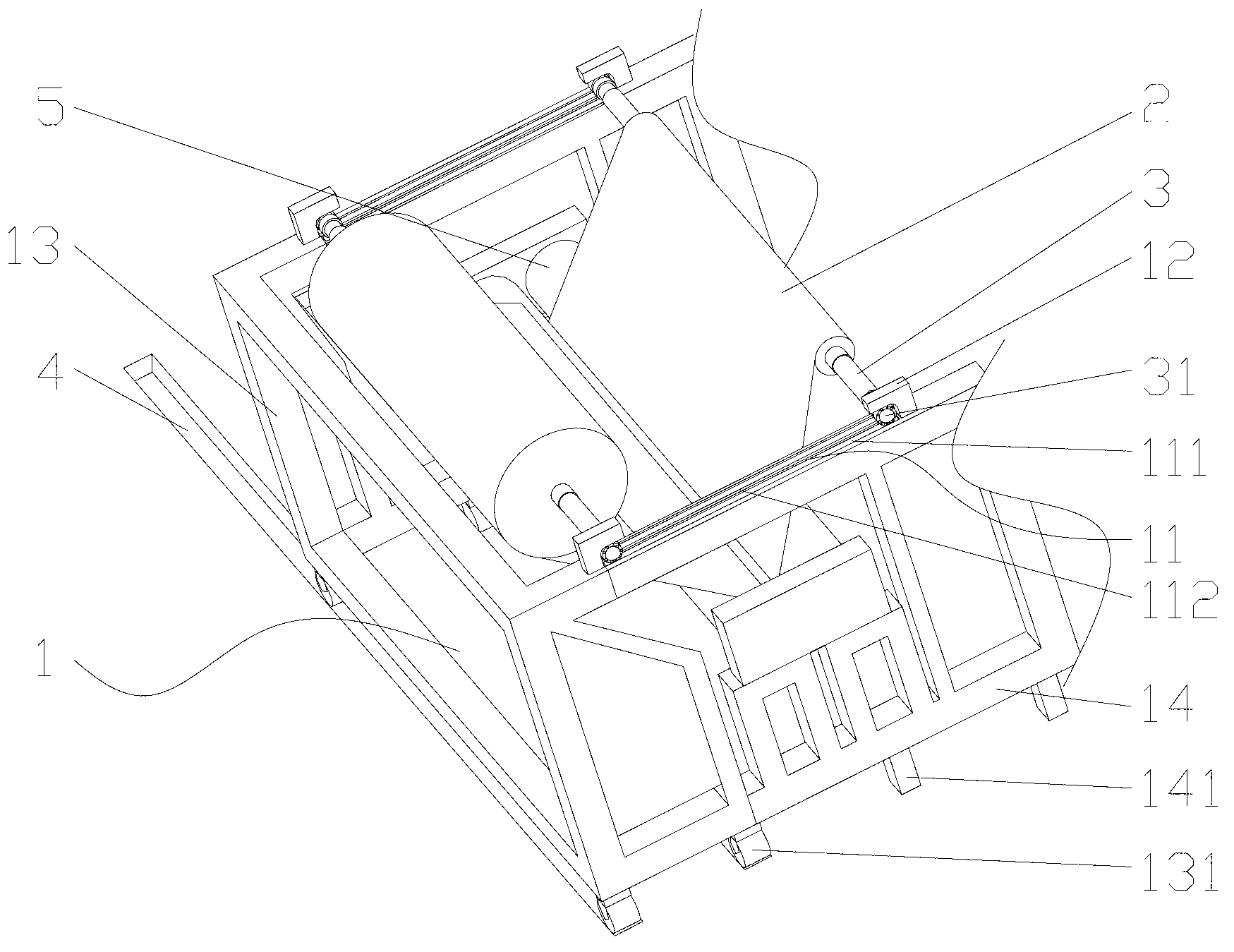

Stroke-adjustable type cloth winding machine

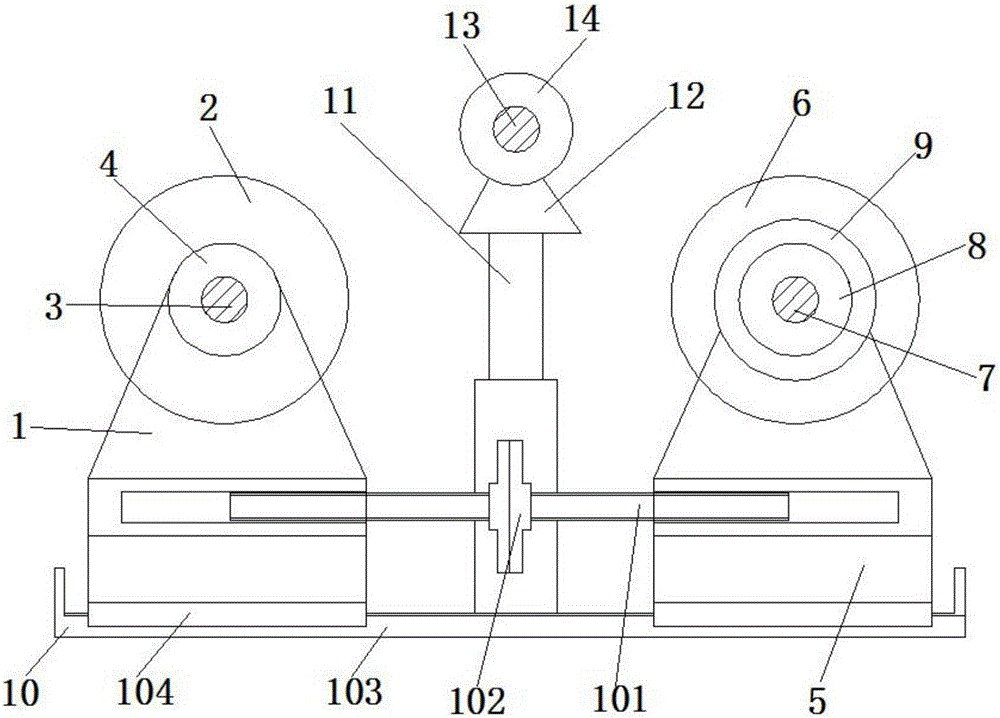

The invention relates to a stroke-adjustable type cloth winding machine. The stroke-adjustable type cloth winding machine comprises a cloth storage support, a cloth storage roller, a cloth storage rotary shaft, a cloth storage bearing, a cloth collection support, a cloth collection roller, a cloth collection rotary shaft, a cloth collection bearing, a driving motor, an adjusting device, a lifting fulcrum bar, a supporting base, a tension shaft and a tension roller. The cloth storage roller is located above the cloth storage support. The cloth storage rotary shaft penetrates through the cloth storage roller. The cloth collection rotary shaft penetrates through the cloth collection roller. The two ends of the cloth collection rotary shaft are connected with the cloth collection bearing and the cloth collection support. The adjusting device is located between the cloth storage support and the cloth collection support. The upper end of the lifting fulcrum bar is connected with the supporting base. The tension roller is mounted on the supporting base through the tension shaft. The cloth roll collection function can be achieved, the tension height is adjustable, different tension forces can be adjusted to meet the requirement according to the cloth of different types, and the application range is wide; and meanwhile the winding stroke is adjustable, and cloth overturning and roll changing can be conducted on cloth with different elastic properties conveniently.

Owner:岳西县桃园服饰有限公司

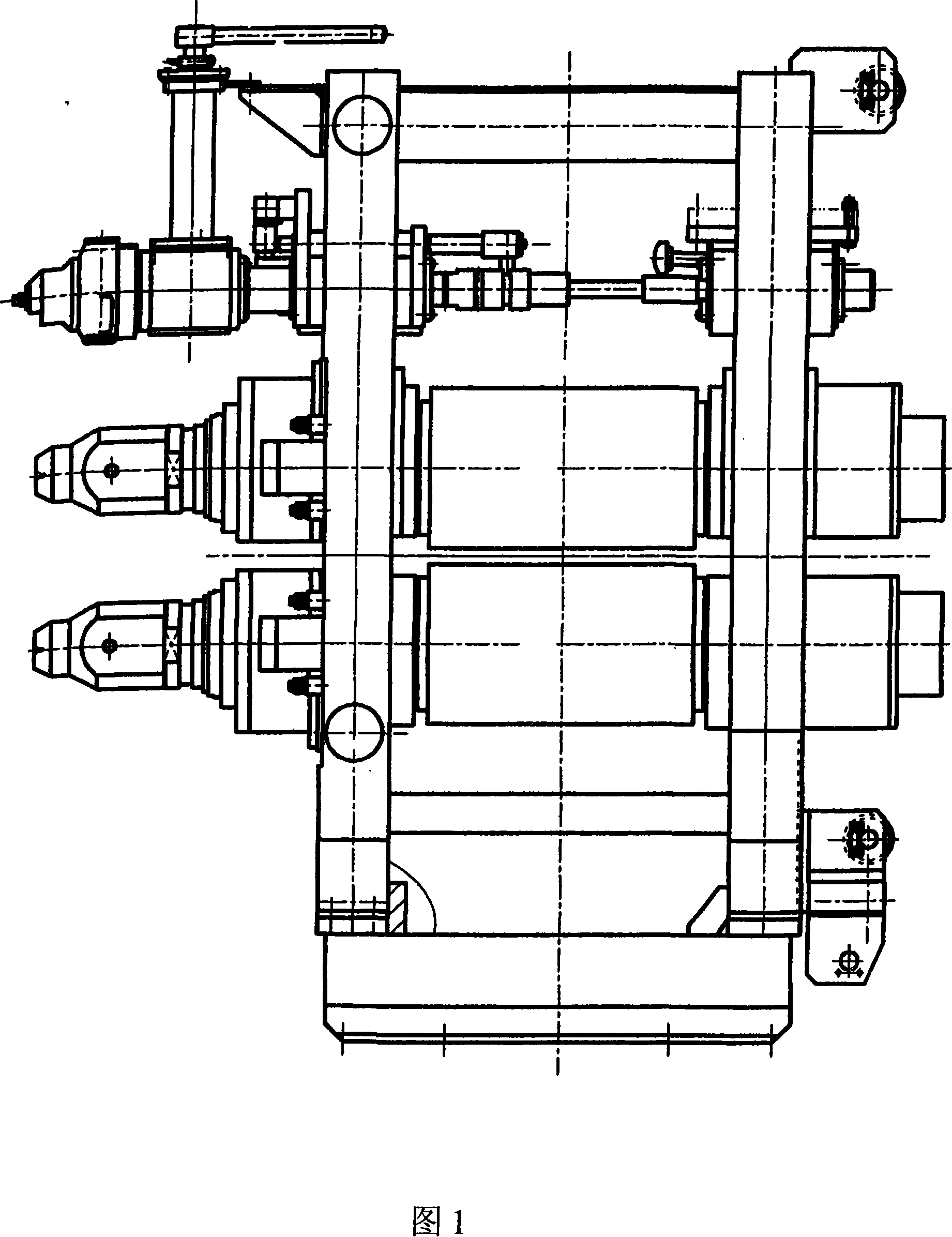

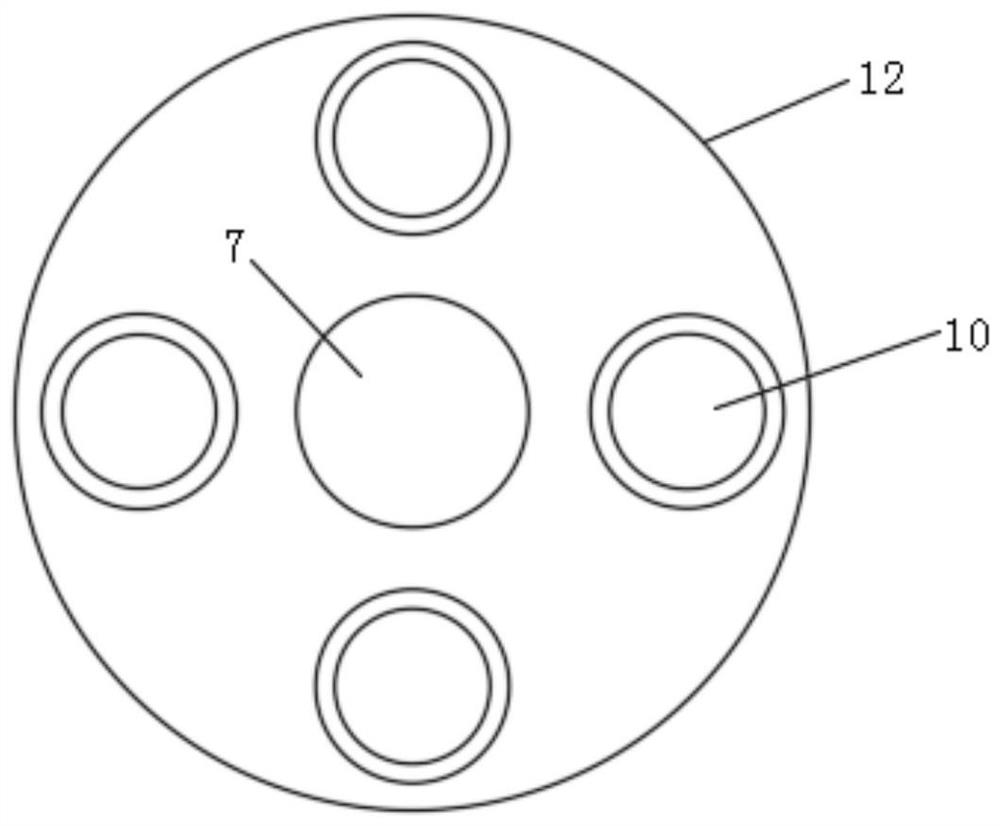

Device for drawing intermediate roll of eighteen-roll cold-rolling mill

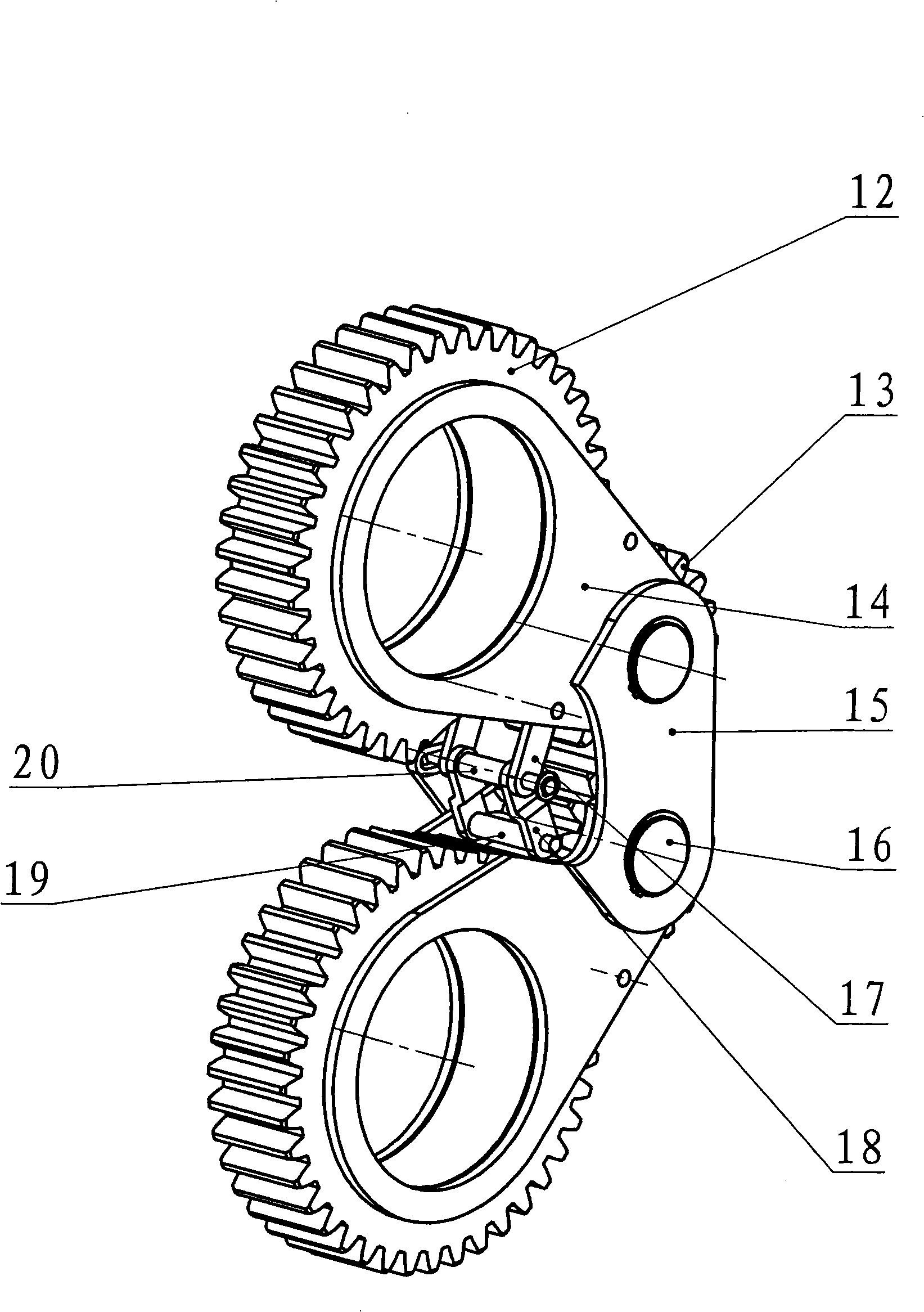

InactiveCN101780473AEasy to replaceSmall footprintMetal rolling stand detailsMetal rolling arrangementsGear wheelEngineering

The invention relates to a device for drawing an intermediate roll of an eighteen-roll cold-rolling mill. The invention adopts a technical scheme that: the operating end and transmission end of the intermediate roll are arranged on an operating-side intermediate roll bearing block and a transmission-side intermediate roll bearing block through an inner ring-free FC bearing respectively; the operating end of the intermediate roll is sleeved and fixed with a helical geared sleeve; the outer sidewall of the inner end of the helical geared sleeve is provided with an outside thread; an internal thread is arranged in the operating-side intermediate roll bearing block and is meshed with the outside thread; the outer sidewall of the outer end of the helical geared sleeve is provided with a driven gear of which one side is provided with a drawing gear meshed with the driven gear; the drawing gear is arranged on the operating-side intermediate roll bearing block through a drawing gear pin shaft, is fixedly connected with the drawing gear pin shaft and can synchronously rotate with the drawing gear pin shaft; and the outer end of the drawing gear pin shaft is provided with a crank hole. The device has the characteristics of greatly simplifying the structure of the drawing device, reducing occupied space of the drawing device and facilitating the replacement of the intermediate roll, along with compact and rational structure, convenient roll replacement and low maintenance cost.

Owner:WUXI WUYE METAL ROLLING

Method convenient for mounting roller mill transition guide plate

InactiveCN101185945ASuperiorEasy to installGuiding/positioning/aligning arrangementsHydraulic cylinderAssistive device/technology

A method that is convenient for installing a rolling mill transitional guide plate relates to the technical field of auxiliary equipment of a cold rolling mill, which is characterized in that according to the design size A, the original movable guide plate is designed into two parts of a fixed guide plate and a movable guide plate, wherein, the fixed guide plate (4) is fixed on a lower bearing base (5) of a pair of working rolls (1), technical requirement parameter A is easy to reach and control, a movable transitional guide plate (7) of the adjacent part is horizontally fixed on a frame work (6) behind the mill, wherein, the frame work behind the mill is fixed on a hydraulic rod (8) of a hydraulic cylinder so as to satisfy the moving requirement of the design. The method can be used for the auxiliary equipment outlet of cold rolling aluminum plate and strip of various cold rolling mills, and can guarantee the technical requirement parameter of the size A when in rolling, thus playing the auxiliary function of the guide plate; the structure is simple, the installation is convenient, not only the performance requirement of the equipment is achieved, but also the installing and maintaining time is saved at the same time.

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

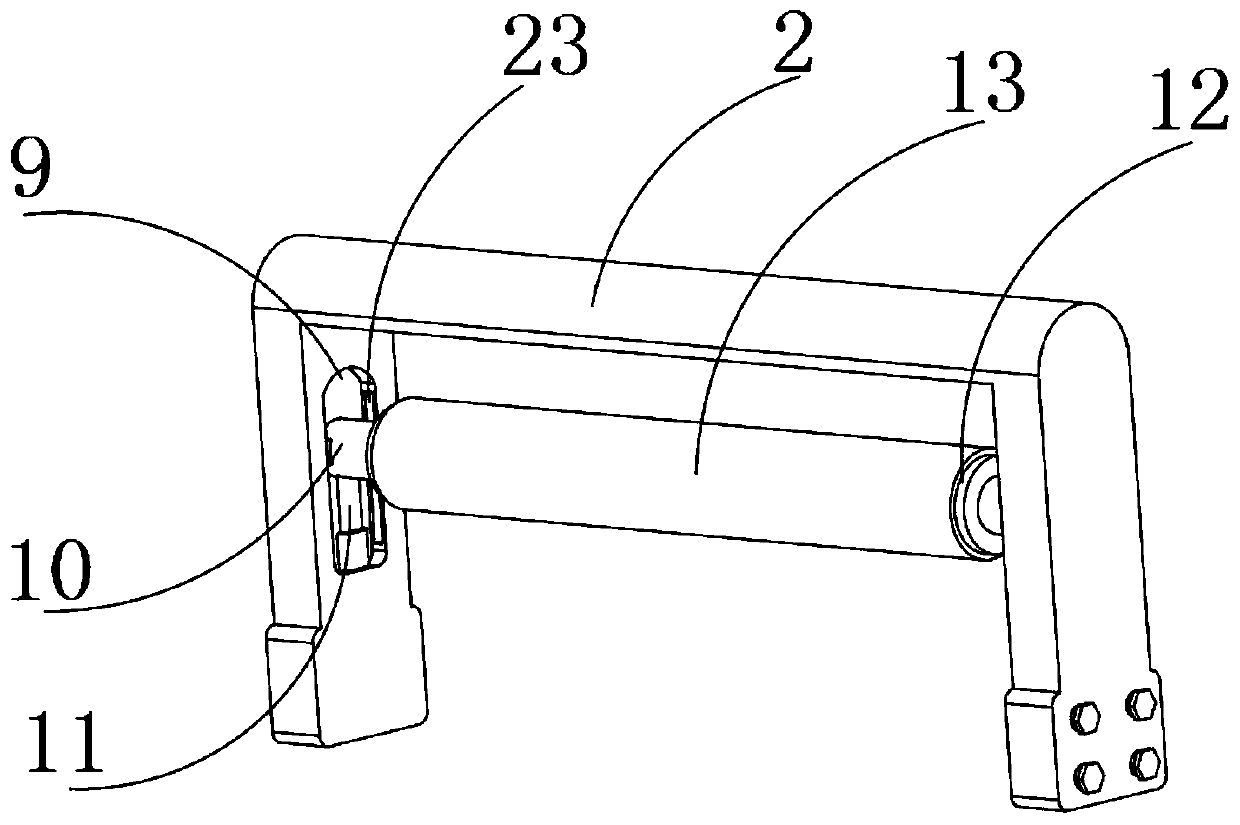

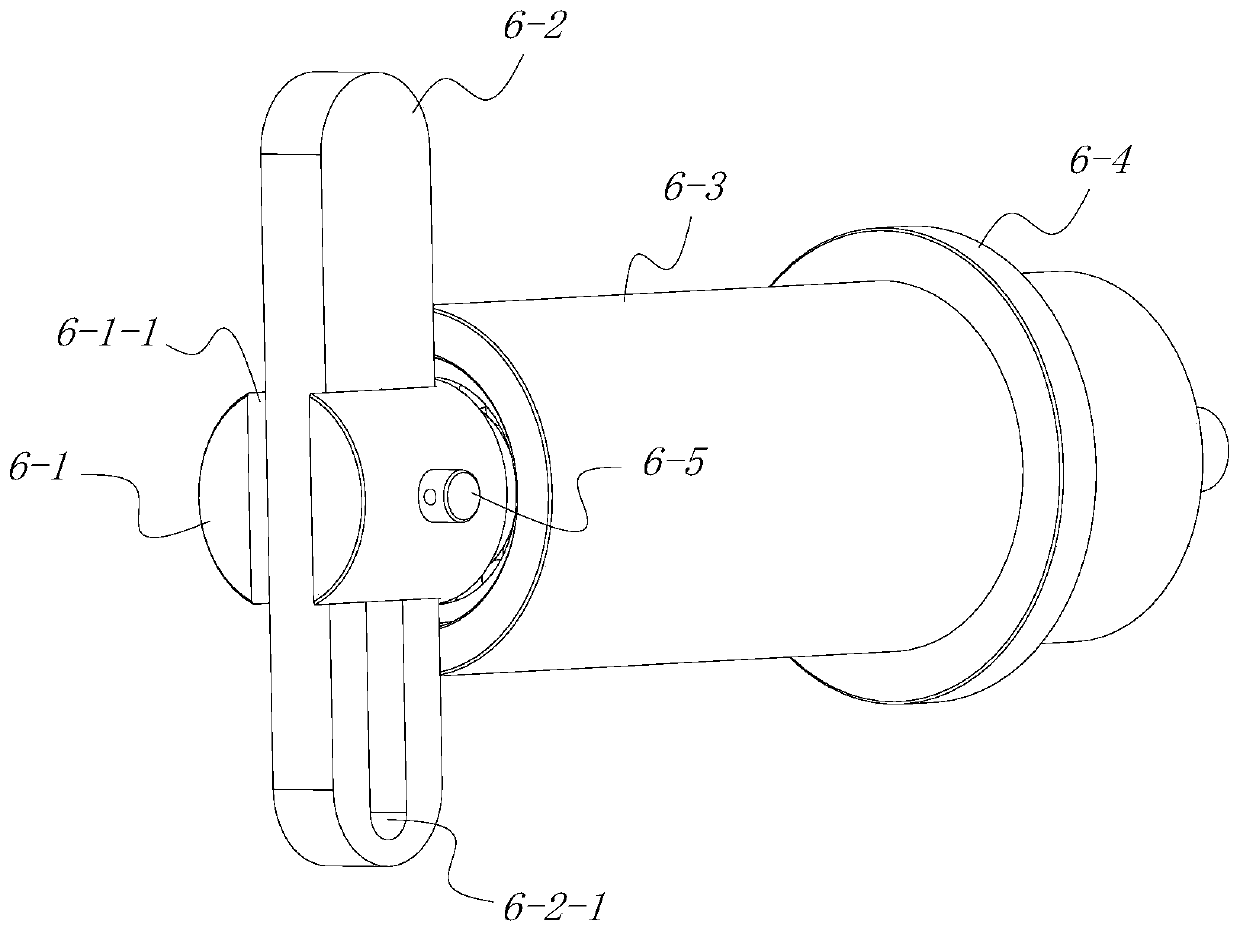

Rapid roller changing device for upper roller on welding and rolling machine

ActiveCN101954380AEasy to installEasy to change rollsMetal rolling stand detailsMetal rolling arrangementsSlide platePulp and paper industry

The invention belongs to an upper roller assembly on a welding and rolling machine, in particular to a rapid roller changing device for the upper roller on the welding and rolling machine. The rapid roller changing device is characterized in that a roller seat sliding laterally is installed on the outer side face of a longitudinal sliding plate, a gantry push frame covers outside both sides and the top of the roller seat, two grooves are symmetrically processed in two side plate faces at the lower part of the push frame, and each groove inclines from the upper part of the outer side to the lower part of the inner side; an upper roller cavity with opening bottom is arranged in the center of the roller seat, and two bearing seats are symmetrically arranged in both end faces of the upper roller cavity, and a roller shaft is installed in the two bearing seats; the upper roller is arranged in the middle of the roller shaft, and an end cover is connected with the outer side of each bearing seat, the end cover side face between the end cover and the push frame is provided with a hook head, and moving mechanisms of two hooks are symmetrically installed on the two hook heads. The invention not only has reasonable design and compact structure, increases installation accuracy and reduces the size of the roller body, but also has the advantages of good rigidity, convenient and fast roller changing, time saving, labor saving, convenient use and the like.

Owner:DALIAN FIELD HEAVY MACHINERY MFG CO LTD

Frameless upright rolling mill with short stress trajectory

InactiveCN101091962AEasy to processReduce weightMetal rolling stand detailsMetal rolling arrangementsFluteEngineering

The invention relates to a frameless vertical short stress rolling mill. The feature is that the flute rotating locking structure is installed on the vertical shaft of the roller group through capping and sliding sleeve to ensure the rolling slot and flute rotating locking structure are on the same rolling line. The roller group keeps stability when adjusting the location of flute rotating locking structure. After installing roller group in U shaped frame, the rotating ear is driven to rotate to make the rotating ear block in the flute of the U shaped frame. Using bolt to fix the rotating ear in the flute of the U shaped frame, and fix the roller group in U shaped frame. The movement of roller locking device relies on piston rod. The advantages of the invention is that it has simple structure and machine work, light weight, convenience to replace roller group and decrease accident and improve produce efficiency.

Owner:UNIV OF SCI & TECH BEIJING +1

Large thick-wall special-shaped pipe cold roll forming method

InactiveCN105583230AQuality improvementWide forming rangeMetal rolling stand detailsMetal rolling arrangementsThick wallEngineering

The invention belongs to the technical field of machine manufacturing, and particularly relates to a large thick-wall special-shaped pipe cold roll forming method. The method comprises the following steps that firstly, at the round pipe selecting stage, a round pipe with the corresponding diameter is selected according to the specification of a needed square pipe or rectangular pipe; secondly, at the rough forming stage, five universal rolling mills are totally arranged, transformation rollers of flat rollers and vertical rollers are adopted for enabling the round pipe to be formed into the needed square pipe or rectangular pipe, wherein the flat rollers and the vertical rollers are symmetric, and the flat rollers are perpendicular to the vertical rollers; thirdly, at the finish forming stage, the square pipe or rectangular pipe formed through rough rolling is subjected to finishing through a sixth flat roller rolling mill, and the square pipe or rectangular pipe can meet various precision requirements; and fourthly, the torsion resistance is adjusted, the square steel pipe or rectangular steel pipe subjected to finishing enters a straightener, the torsion resistance of the square pipe or rectangular pipe is adjusted, the square pipe or rectangular pipe of the needed specification is formed, and accordingly the product quality can be guaranteed.

Owner:TIANJIN TIANZHONG ZHONGZHI TECH ENG CO LTD

Cloth unwinding device for textile

InactiveCN108820969AIncrease contactThere will be no dragging and fallingWebs handlingElectric machineryEngineering

The invention discloses a cloth unwinding device for textile. The cloth unwinding device for the textile comprises an unwinding box, a fixed seat and unwinding seats. The fixed seat is fixedly installed on one side of the unwinding box, a pair of unwinding seats are installed on the fixed seat, a rotating cylinder is arranged between the two unwinding seats, one of the unwinding seats is providedwith a motor through a motor mounting plate, the rotating cylinder is driven to rotate by the motor, and a pressing mechanism capable of maintaining the cloth tightly wound is further installed on thefixed seat. The cloth unwinding device for the textile has the beneficial effects that the pressing mechanism can enable a pressing roller in good contact with the cloth, so that the cloth can be kept in a tight winding state, and the phenomenon of dragging and falling cannot occur; and meanwhile, with the design of an air cylinder, and the coil changing operation can be conveniently carried out.

Owner:绍兴民程纺织科技有限公司

Ultrahigh-strength strip steel surface cleaning device

ActiveCN110052502AReduce sizeShorten the lengthWork cleaning devicesMetal rolling arrangementsHydraulic cylinderSurface cleaning

The invention discloses an ultrahigh-strength strip steel surface cleaning device. The ultrahigh-strength strip steel surface cleaning device mainly comprises a machine body, a squeezing and drying roller assembly, an upper inverted E-shaped frame driving mechanism, an upper squeezing and drying roller box driving mechanism and an air sweeping mechanism. According to the device, frame lifting andpressure adjustment of an squeezing and drying roller are controlled separately, the number of large hydraulic cylinders is reduced from four to two, the hydraulic cylinder used for adjusting the pressure of the squeezing and drying roller can be a small hydraulic cylinder, and follow-up automatic roller changing is possible; and the squeezing-dry pressure adjusting range is widened by adopting the small hydraulic cylinder. The overall device is high in structural rigidity and is suitable for production of high-strength steel. The structure is compact, and the two devices for purging and squeezing are combined into one, so that the requirement for the distance between a roller and a reeling machine is shortened as much as possible by a single-machine reversible rolling mill, and the yieldis improved.

Owner:BAOSHAN IRON & STEEL CO LTD

Vertical double-position wiping machine

InactiveCN102172648AAvoid scratchesScratching the strip effectively solves the problem of preventing the strip from being easily scratchedMetal rolling stand detailsWork treatment devicesProduction lineEngineering

The invention provides a vertical double-position wiping machine, aiming at overcoming the defects that the roller replacing time is long, the roller is easy to scratch and the wiping effect of a horizontal wiping machine is poor. The invention adopts the technical scheme that the wiping machine comprises a rack (1), the rack (1) is provided with a pair of upper wiping rollers and a pair of lower wiping rollers, the upper wiping roller is composed of an upper swing roller (2) and an upper fixed roller (4), the lower wiping roller is composed of a lower swing roller (6) and the lower fixed roller (7), one pair of wiping rollers or two pairs of wiping rollers are caused to operate according to the technological need of a production line to the wiping effect, thus a satisfied wiping effect is achieved and the application is flexible; when the rollers are abraded, one pair of the rollers operate while the other pair of the rollers are replaced, thus one pair of the rollers operate and the pair of the rollers are spare; and the strike direction of plate and strip is not contacted with the surface of the wiping rollers while the wiping rollers are not in operation, thus the plate and strip can not be scratched when the rollers are replaced and the problem that the plate and strip are easy to scratch is effectively solved.

Owner:BEIJING STAR RIVER INTEGRATED EQUIP TECH

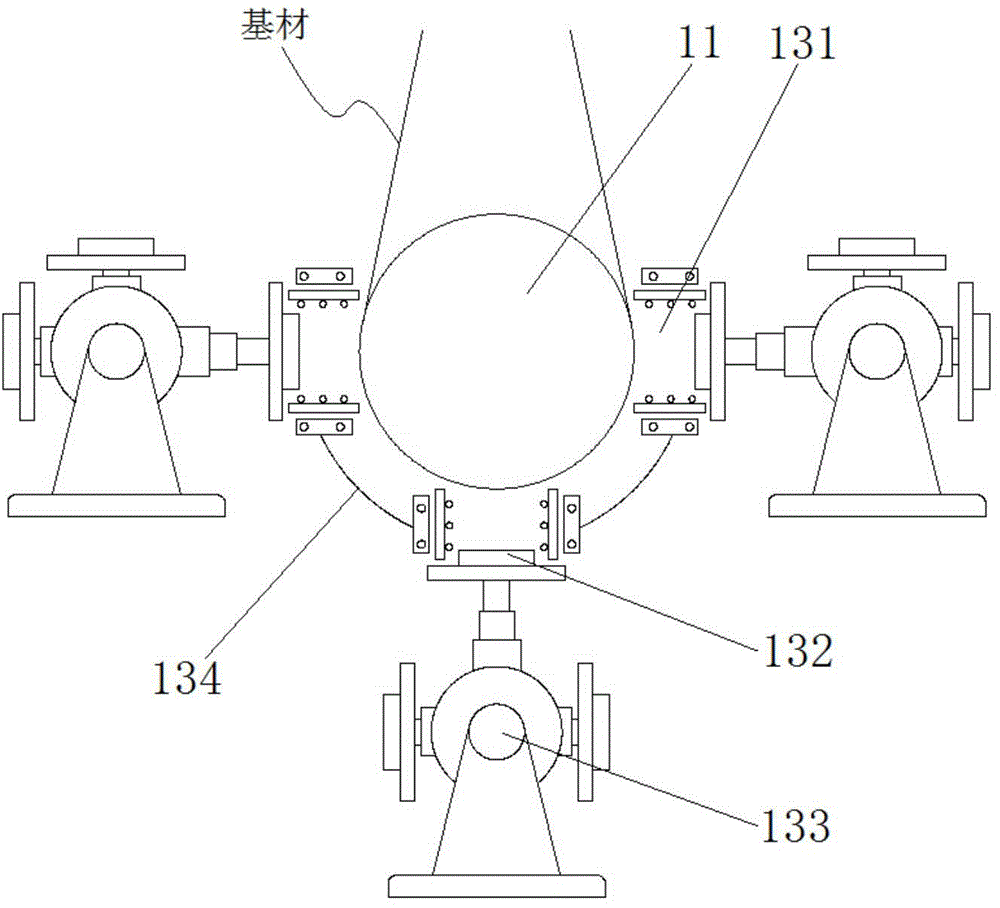

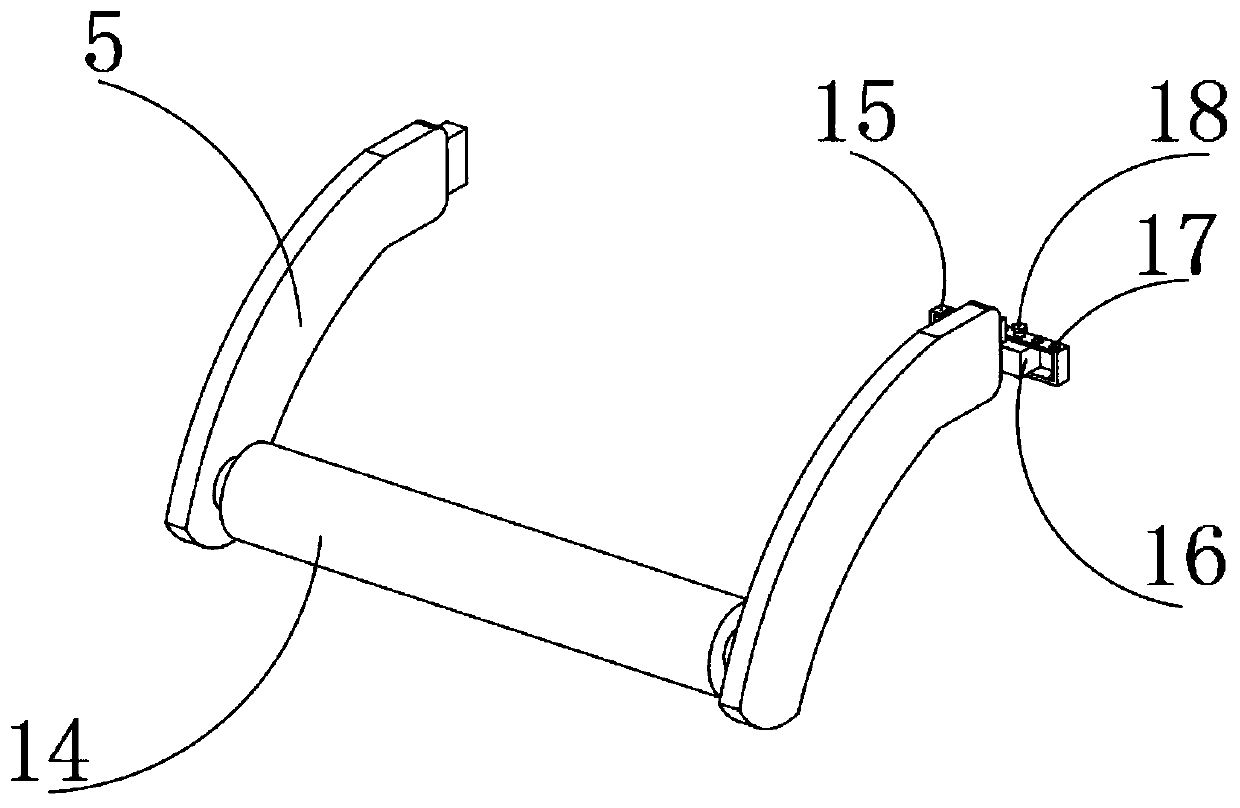

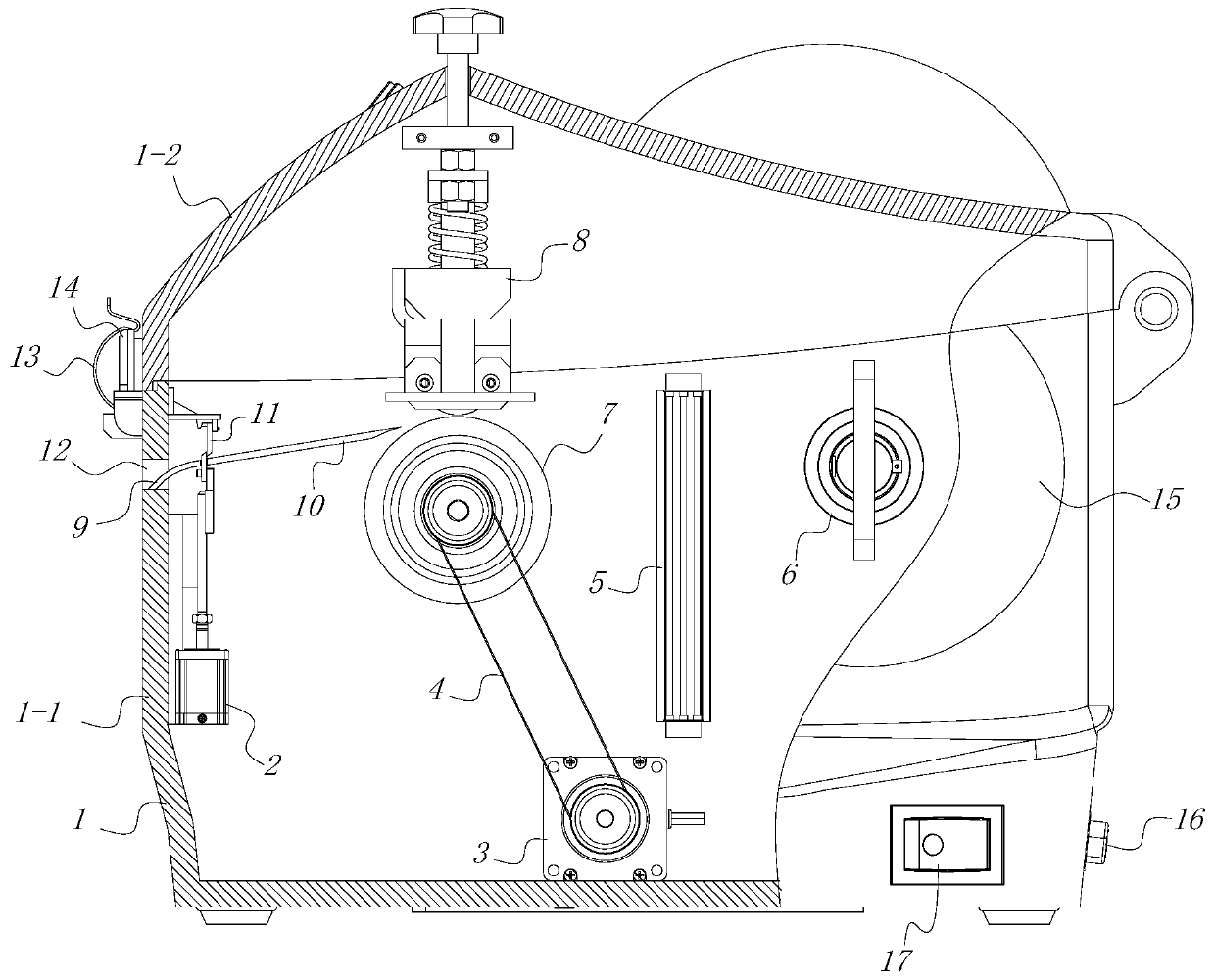

Roll changing device for lithium battery pole piece coating machine

InactiveCN111689270AEasy to change rollsGuaranteed production efficiencyWebs handlingCrankElectric machinery

The invention discloses a roll changing device for a lithium battery pole piece coating machine. The roll changing device comprises a first supporting plate, a second supporting plate and a base material; a rotating rod is arranged between the first supporting plate and the second supporting plate, the rotating rod penetrates through the first supporting plate through a through opening, a limitingmechanism is arranged between the rotating rod and the first supporting plate, one end of the rotating rod is rotationally connected with the second supporting plate, and the other end of the rotating rod is fixedly connected with a crank; the end, away from the rotating rod, of the crank is sleeved with a rubber sleeve; the outer side of the rotating rod is symmetrically sleeved with a first fixing disc and a second fixing disc, the first fixing disc and the second fixing disc are fixedly connected with the rotating rod, and four motors are fixedly connected with the end, away from the second fixing disc, of the first fixing disc through mounting bases; and four winding drums are arranged between the first fixing disc and the second fixing disc. According to the roll changing device, thewinding drums can be rapidly replaced, halt for a long time is not needed, the production efficiency is greatly improved, meanwhile, the winding drums full of base materials can be conveniently replaced, and operation is quite convenient.

Owner:瑞安市本富机电设备有限公司

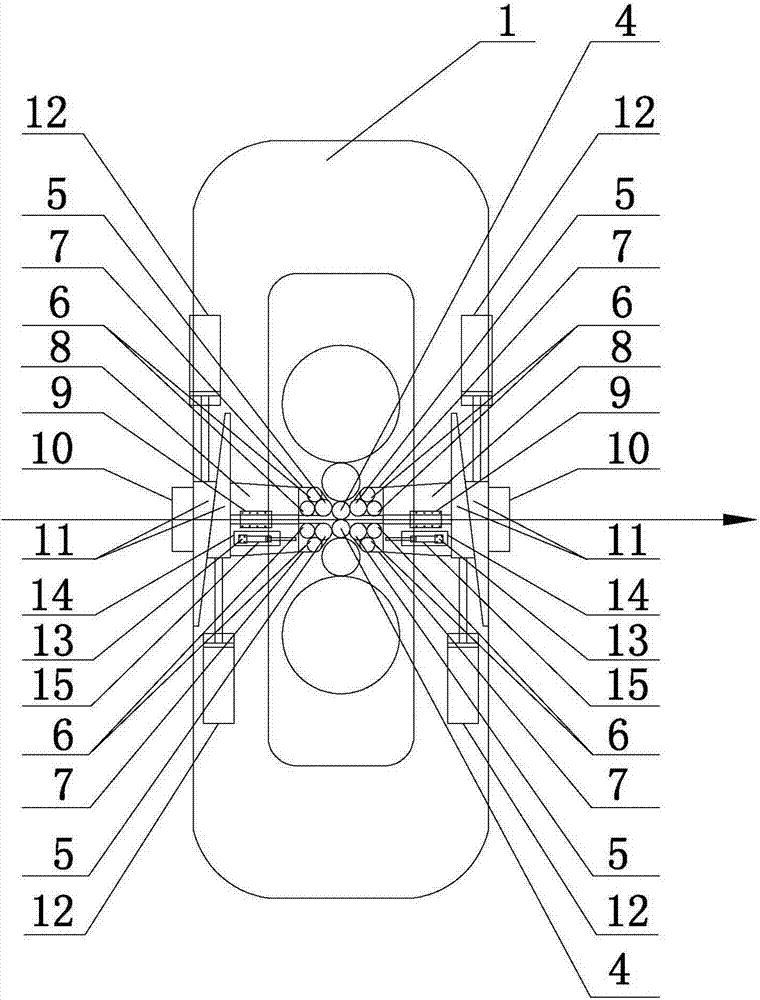

18-roller cold rolling mill lateral supporting device adjustment mechanism and control method

ActiveCN106994465AImprove the state of stressAvoid destructionMetal rolling stand detailsRoll mill control devicesRolling mill

The invention relates to an 18-roller cold rolling mill lateral supporting device adjustment mechanism and a control method. The adjustment mechanism comprises a stand plate, lateral supporting rollers, back lining bearing rollers and lateral supporting frameworks, wherein the lateral supporting rollers and the back lining bearing rollers are mounted in the lateral supporting frameworks; the adjustment mechanism is characterized in that anti-twisting guide plates are arranged on the inlet side and the outlet side of the stand plate and are symmetrically arranged along a rolling line; two lateral supporting frameworks respectively matched with an upper working roller and a lower working roller are mounted at the front ends of the anti-twisting guide plates; guide rails in the horizontal direction and wedge devices in the vertical direction are arranged at positions, which are located on the transmission side and the operation side, on the stand plate; and the anti-twisting guide plates are supported by the guide rails, and are pushed by the wedge devices to slide along the guide rails, so as to drive the lateral supporting frameworks and the lateral supporting rollers to move to the working rollers. The 18-roller cold rolling mill lateral supporting device adjustment mechanism provided by the invention is reasonable in structure, convenient to maintain, quick to operate and simple in control.

Owner:WISDRI ENG & RES INC LTD

PVC (polyvinyl chloride) film transportation device of composite film laminating machine

ActiveCN103231932AEasy to change rollsReduced frequency of roll changesWebs handlingFixed frameElectrical and Electronics engineering

The invention relates to a PVC film transportation device of a composite film laminating machine. The PVC film transportation device of the composite film laminating machine comprises a frame, guide rails are arranged on both sides of the frame separately, and fixing frames are arranged at both ends of each of the guide rails. The PVC film is in a roll, both ends of the PVC film are respectively arranged on a transportation guide roller in a sleeve mode to be formed as a whole with the transportation guide roller, and the PVC film and the transportation guide roller are cradled on a fixed frame of the frame. The portions of both ends of the transportation guide roller, which are connected with the frame, are provided with bearings respectively, and bearing rolling guide grooves are arranged on the guide rails. The bearings roll along the bearing rolling guide grooves or are fixed on the fixed frame. According to the PVC film transportation device of the composite film laminating machine, both ends of the rolled PVC film are respectively arranged on the transportation guide roller in a sleeve mode to be formed as a whole with the transportation guide roller and the PVC film and the transportation guide roller are cradled on the fixed frame of the frame, accordingly the transportation-finished rolled PVC film can be rolled to the guide rails and the portion of the frame on which the guide rails are arranged when the PVC film roll changing is needed, a new rolled PVC film can be replaced on the detachable portion of the frame, and the PVC film roll changing is easy and safe. The bearings which are more than one in number can bear greater gravity, so that the frequency of the PVC film roll changing is reduced to enable finished products to have fewer joints.

Owner:FUJIAN SIJIA ENVIRONMENTAL PROTECTION MATERIAL TECH

Rolling device used for HDPE plate production line

PendingCN110510439AEasy to unload and change rollsOmit structureWebs handlingDrive shaftProduction line

The invention discloses a rolling device used for a HDPE plate production line. The rolling device comprises a rack, a driving mechanism, a jacking mechanism and a rolling assembly. One opposite sideof the rack is provided with a bearing seat, and a shaft support is installed on the other opposite side of the rack. A transmission shaft is rotationally arranged on the bearing seat, a guiding shaftis movably arranged on the shaft support in the transverse direction, and the guiding shaft is coaxially rotationally provided with a jacking head. The driving mechanism is installed on the rack andis in transmission connection with the transmission shaft. The jacking mechanism is installed on the rack and is in transmission connection with the guiding shaft. The rolling assembly is detachably arranged between the transmission shaft and the jacking head and comprises a center shaft, a pair of sliding sleeves arranged on the center shaft in a sliding manner, and multiple expansion plates arranged on the peripheral side of the center shaft in the circumferential direction. The pair of sliding sleeves are located at the two end portions of the center shaft correspondingly, the expansion plates are connected with the pair of sliding sleeves through multiple hinges, and the expansion plates are connected with the center shaft through multiple hinges. One sliding sleeve is connected with the transmission shaft, and the other sliding sleeve is connected with the jacking head.

Owner:SUZHOU JWELL MACHINERY

Novel raw foil machine winding equipment

PendingCN113023426AReasonable designEasy roll changeWebs handlingStructural engineeringElectrical and Electronics engineering

The invention discloses novel raw foil machine winding equipment which comprises a left winding device and a right winding device. The left winding device and the right winding device comprise bottom plates, fixed seats are fixedly connected to the bottoms of the bottom plates, movable seats are fixedly connected to the tops of the bottom plates, and winding rollers are detachably connected between the movable seats and the fixed seats; a clamping groove is axially formed in the circumferential outer wall of each winding roller, the clamping groove in the left winding device is matched with a clamping head on the right side in a clamped mode, the clamping groove in the right winding device is matched with a clamping head on the left side in a clamped mode, the clamping heads are fixedly connected to the tail ends of push plates, and an arc protrusion is arranged on the inner wall of one side of each clamping groove; and a material fracturing step is arranged on the inner wall of the other side of each clamping groove, and a material cutting step is arranged on the side, facing the corresponding material fracturing step, of each clamping head. The novel raw foil machine winding equipment is reasonable in design, the roller replacing operation is simple and convenient, and non-stop continuous winding can be achieved.

Owner:江西铜博科技有限公司

Roll changer of support roll

InactiveCN102814335AEasy to change rollsEasy to operateMetal rolling stand detailsMetal rolling arrangementsFastenerLocking plate

The invention relates to a roll changer of a support roll. The roll changer comprises a shaft, wherein one end of the shaft is connected with a roll through a connector while the other end of the shaft is provided with a balance block; two ends of the balance block are locked through first locking plates; a hanging member is arranged at a fulcrum part in the middle of the shaft; two ends of the hanging member are locked through second locking plates; and a handle is arranged at one side of the balance block and on the shaft through a fastener. According to the invention, through the balance principle, the balance block is arranged on the shaft to balance the two ends of the shaft; and through a method of running, hanging and moving at the fulcrum part, the roll change is realized conveniently; and the roll changer is simple in operation, low in cost and high in efficiency.

Owner:江苏中重智能装备科技有限公司

Grey fabric winding and detection facility

Owner:长兴超特纺织有限公司

Hydraulic roll changing device for rolling mill work roller

InactiveCN104550245ASolve the problem of difficult accessEasy to change rollsMetal rolling stand detailsMetal rolling arrangementsPulp and paper industryRolling mill

The invention discloses a hydraulic roll changing device for a rolling mill work roller. The hydraulic roll changing device for the rolling mill work roller comprises a fixing shelf arranged at the front end of the rolling mill work roller, the outer side wall of the fixing shelf is jointed with a hydraulic support rod, which is arranged obliquely and upwards, the end of the hydraulic support rod is connected with a hydraulic oil cylinder flatly arranged, the hydraulic oil cylinder is connected with the a pull rod provided with a drag hook and hanged to the rolling mill work roller corresponding to the end of the rolling mill work roller; the hydraulic oil cylinder is horizontally located above the fixing shelf and the lower part of the middle thereof is jointed to the end of the hydraulic support rod through a connection end; the hydraulic roll changing device for the rolling mill work roller is simple in structure, convenient and reliable in use, can raise the roll changing efficiency and reduce the use cost.

Owner:浙江富日进精密金属股份有限公司

Winding device for polyimide film production

PendingCN114194886AInhibit sheddingGuaranteed cleanlinessElectrostatic cleaningArticle deliveryPolymer scienceElectric machine

The invention relates to a winding device for polyimide film production. The winding device for polyimide film production comprises an electrostatic dust collection device, a movable winding support and a driving rubber roller. The angle of the movable winding support is adjusted through an air cylinder installed at the bottom, and the driving rubber roller is connected with a motor below through a belt. A rolling shaft is arranged in the electrostatic dust collection device, and an electricity removal roller is arranged below the electrostatic dust collection device. According to the winding device, the electrostatic field can be used for dedusting polyimide, meanwhile, the subsequent rubber rollers eliminate static electricity and flatten the film, and the rotating serrated knife is further arranged on the driving rubber roller so that the film can be cut off conveniently.

Owner:扬州苏伟新材料科技有限公司

Tourniquet machine having function of automatically discharging tourniquets

InactiveCN110013316APlay a positioning roleWith automatic spit functionSurgical furnitureTourniquetsTourniquet timeUv disinfection

The invention relates to a tourniquet machine having the function of automatically discharging tourniquets. The tourniquet machine comprises an outer shell formed through hinging of a lower shell bodyand an upper shell body, wherein a lower cutting knife mechanism and an upper cutting knife corresponding to the lower cutting knife mechanism are arranged in the lower shell body; a front guide plate and a rear guide plate are arranged on both sides of the lower cutting knife mechanism; a discharge opening is formed in the side wall of the head end of the lower shell body; an unreeling mechanismfixedly connected with the side wall is arranged in an inner cavity of the lower shell body; a power roller is arranged between the rear guide plate and the unreeling mechanism, and a pressing rollermechanism tightly propped against the power roller is connected to the inner cavity of the upper shell body; an ultraviolet ray disinfection lamp is arranged in the inner cavity of the outer shell; the tourniquet machine also comprises a rotary driving assembly which can drive the power roller to rotate; and the unreeling mechanism comprises a mandrel fixedly connected with the side wall of the lower shell body, an open slot is formed in the outer end surface of the mandrel, a plug pin is arranged in the open slot in a penetrating manner, a bar-shaped slot is formed in the plug pin, and a pinshaft fixedly connected with the mandrel is arranged in the bar-shaped slot in a penetrating manner. The tourniquet machine disclosed by the invention is simple and reasonable in structural design and good in sterilizing and disinfecting effects, and has the function of automatically discharging the tourniquets.

Owner:TIANJIN HAIMAI MEDICAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com