Ultrahigh-strength strip steel surface cleaning device

A technology of surface cleaning device and strong belt, which is applied in the direction of workpiece cleaning device, workpiece surface treatment equipment, metal rolling, etc., can solve the problems of easy deformation of lining plate, easy breakage of connecting bolts, and failure to meet the requirements of high-strength steel units, and achieve shortening The effect of unit length, reduction of sliding resistance, and assurance of guiding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

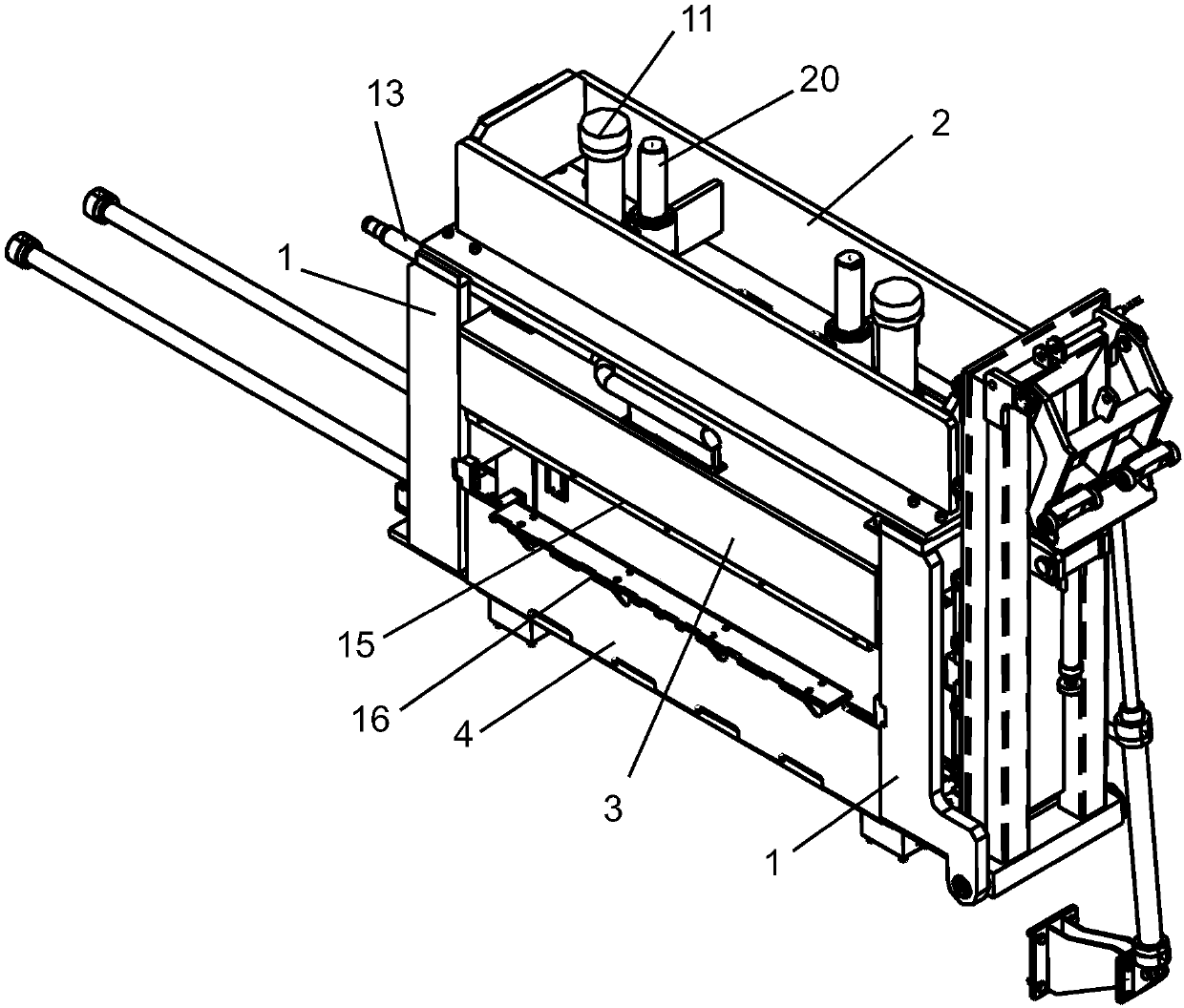

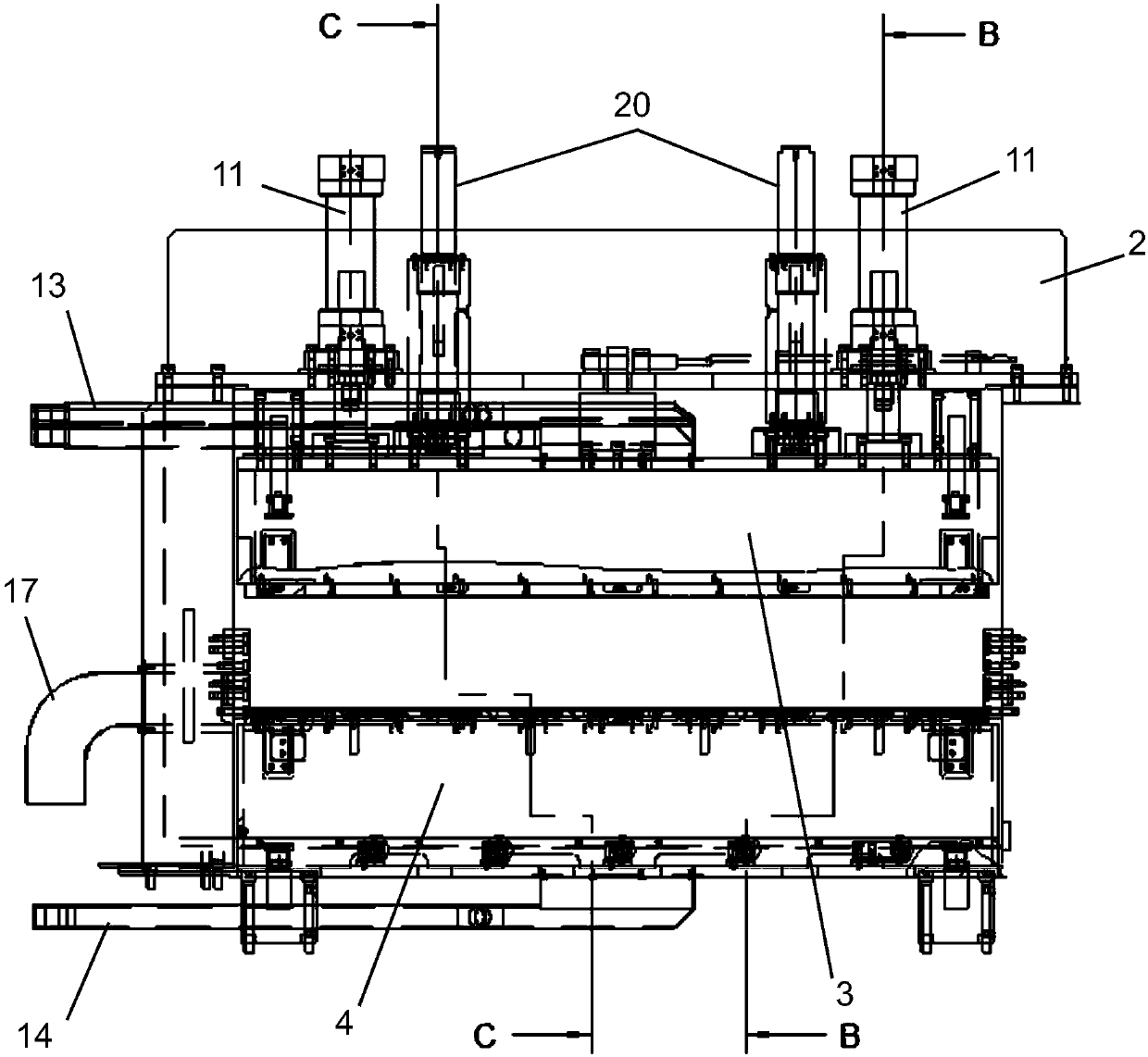

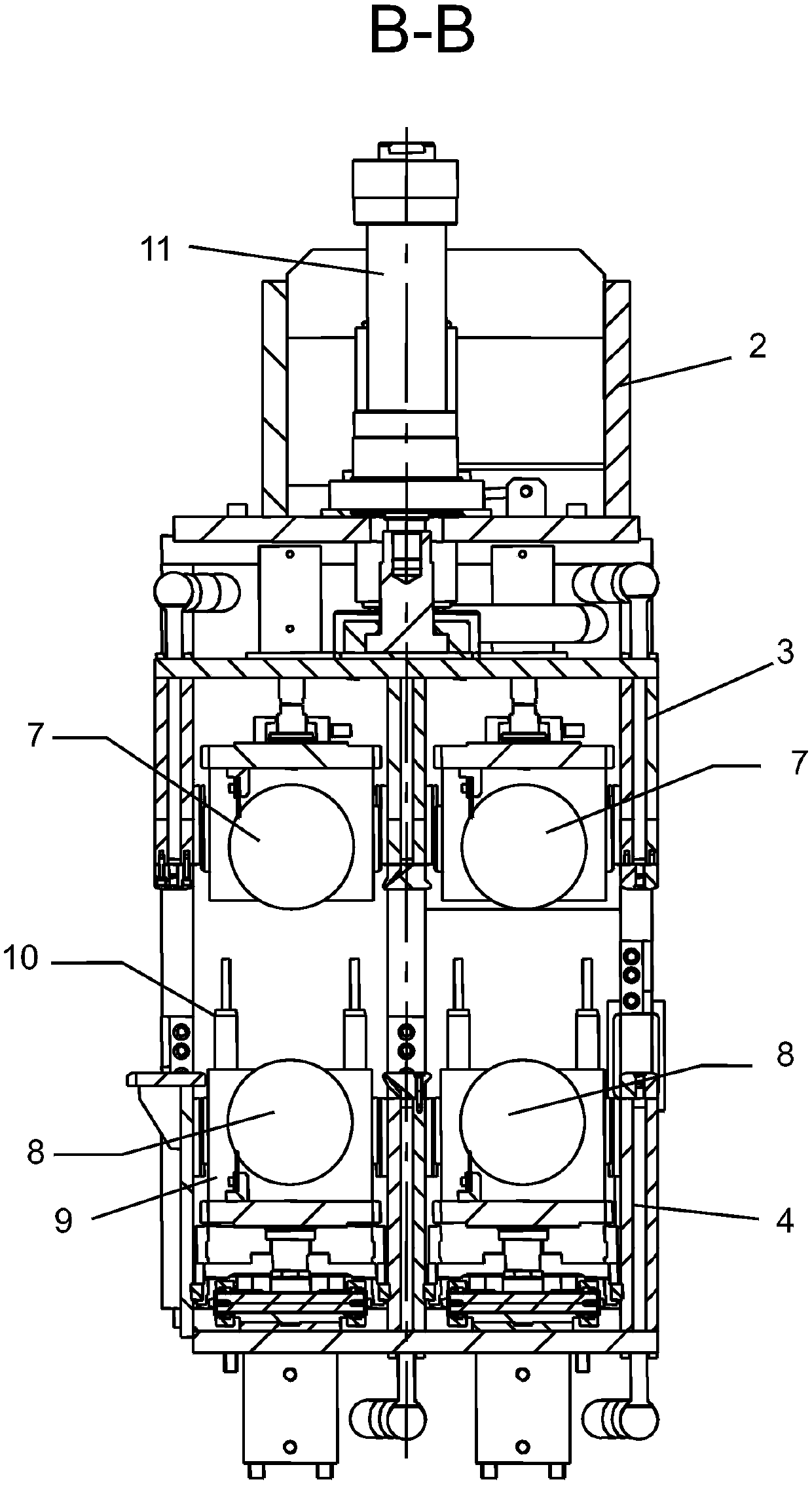

[0022] refer to Figure 1 to Figure 6 As shown, the ultra-high-strength steel strip surface cleaning device of the present invention mainly includes a body, a squeeze roller assembly, an upper inverted E-shaped frame drive mechanism, an upper squeeze roller box drive mechanism and an air sweep mechanism, wherein:

[0023] The machine body includes arches 1 on both sides (ie, the transmission side and the working side), an upper beam frame 2, an upside-down E-shaped frame 3, and a downside-down E-shaped frame 4. Shaped frame 4 is fixedly arranged at the lower end of archways 1 on both sides, and upper inverted E-shaped frame 3 is relatively arranged on the top of inverted E-shaped frame 4 and is positioned at the bottom of upper beam frame 2 .

[0024] The squeezing roller assembly includes two pairs of upper and lower squeezi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com