Patents

Literature

49results about How to "Guaranteed incineration effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

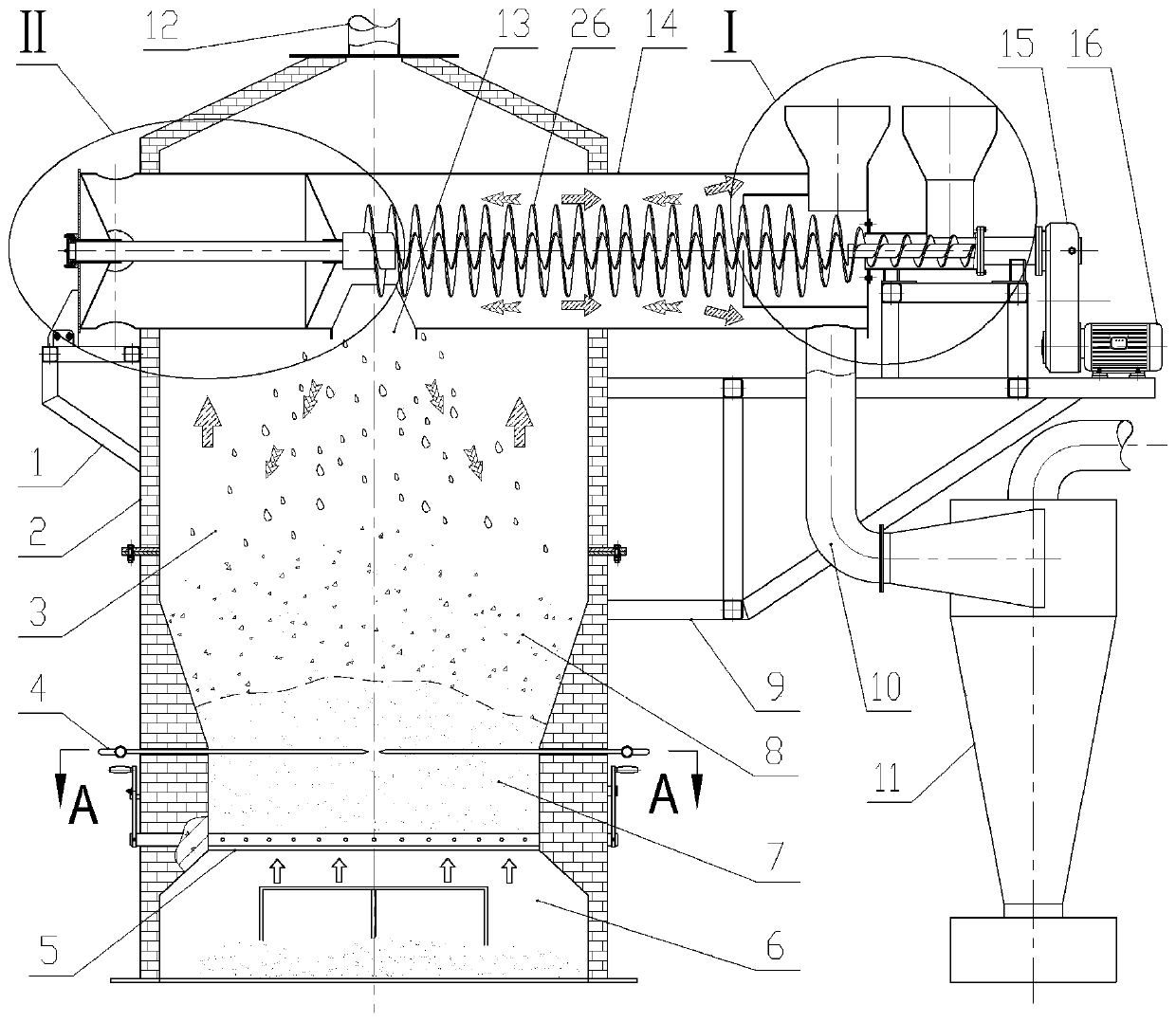

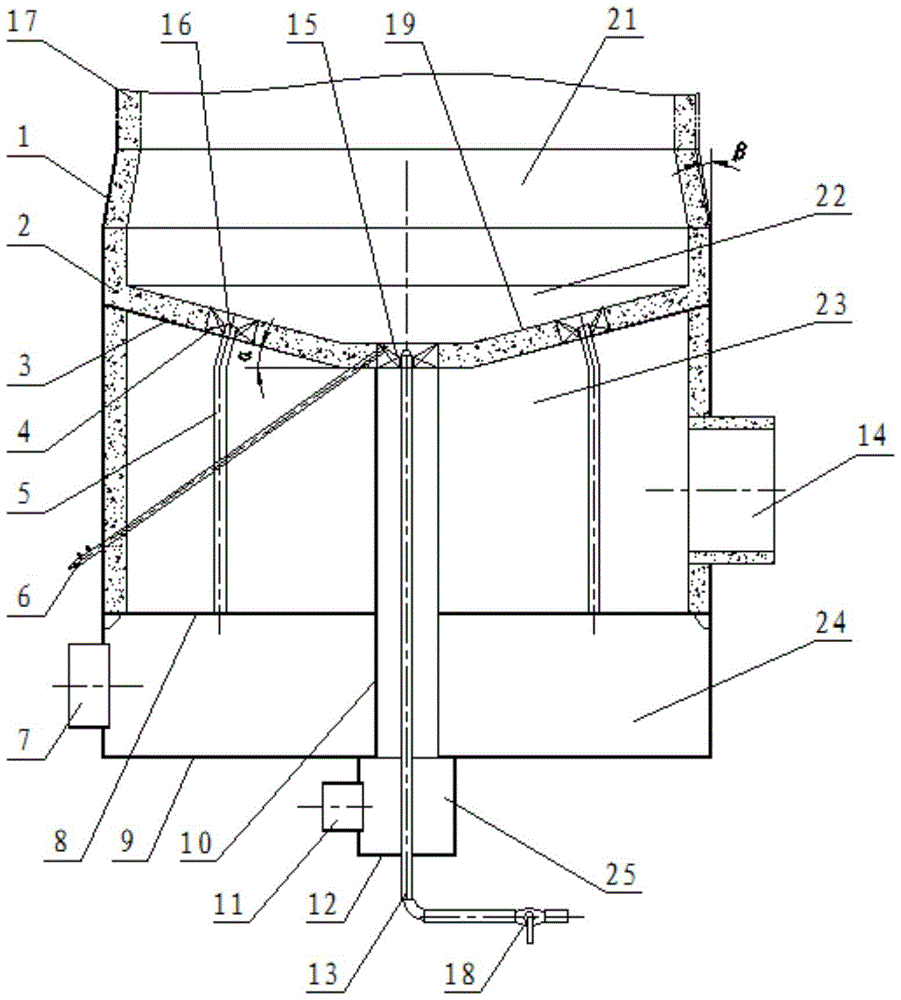

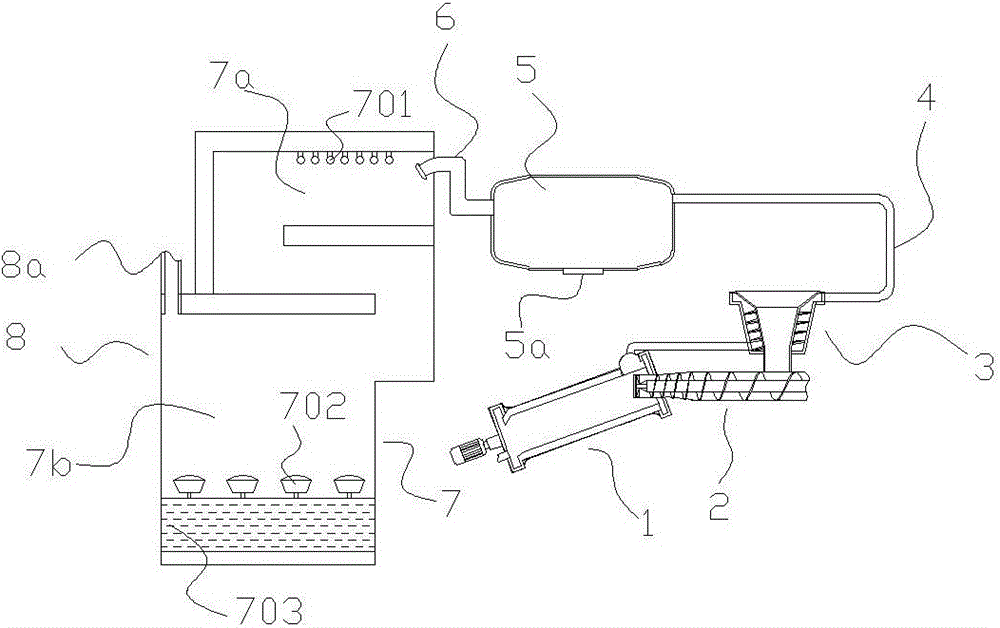

Two-stage garbage incinerator

ActiveCN101922715AGuaranteed incineration effectFully dryInclined grateIncinerator apparatusLoss rateCombustion

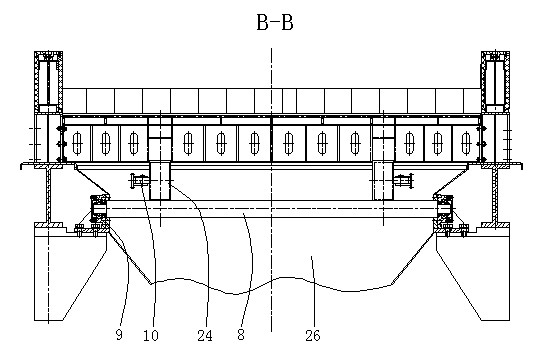

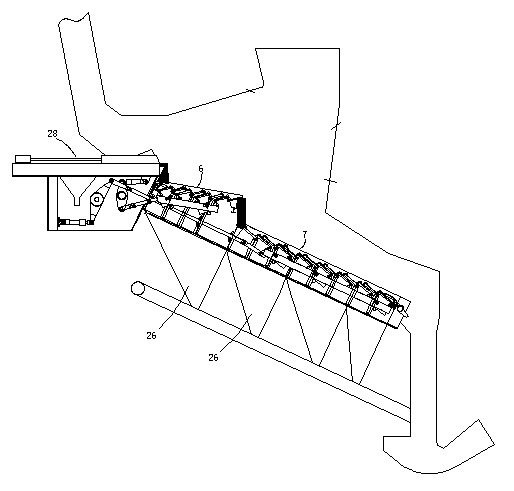

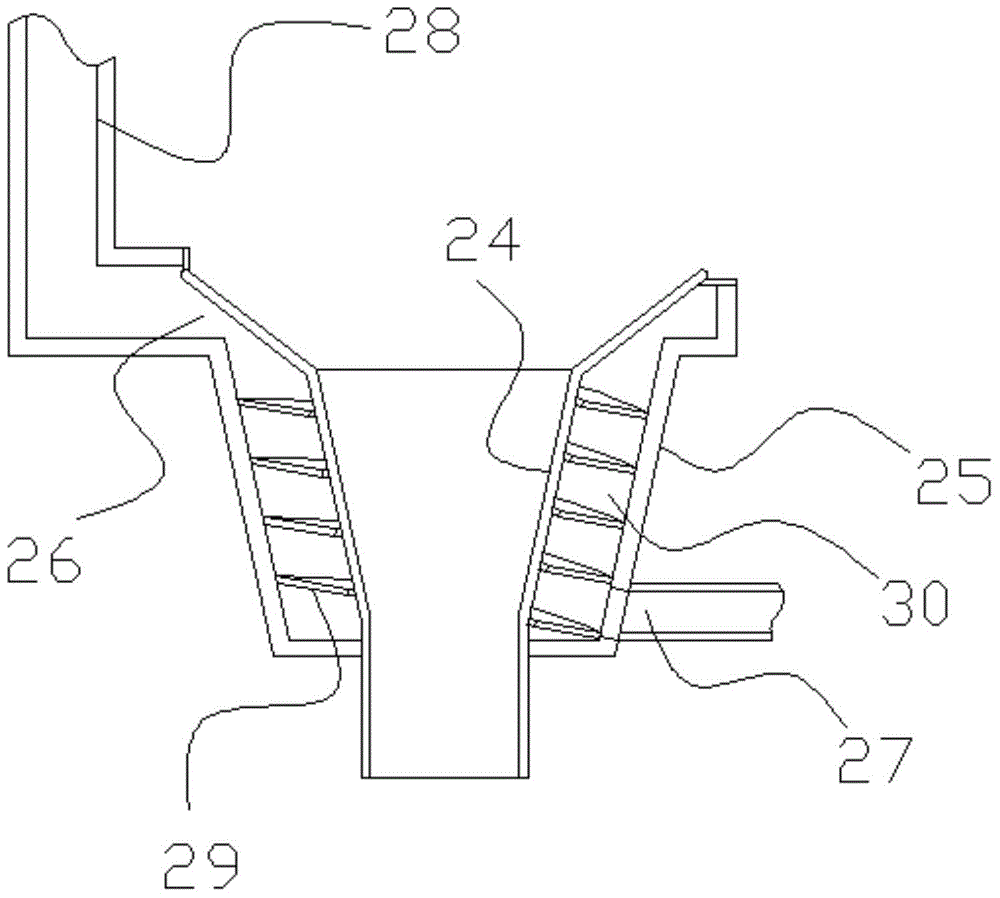

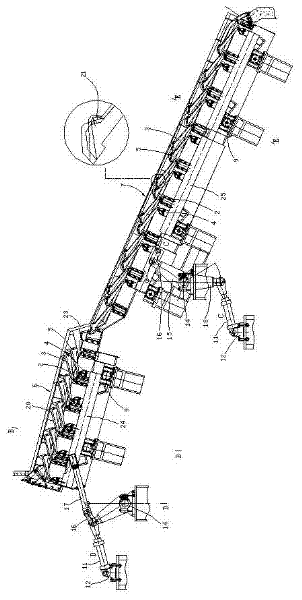

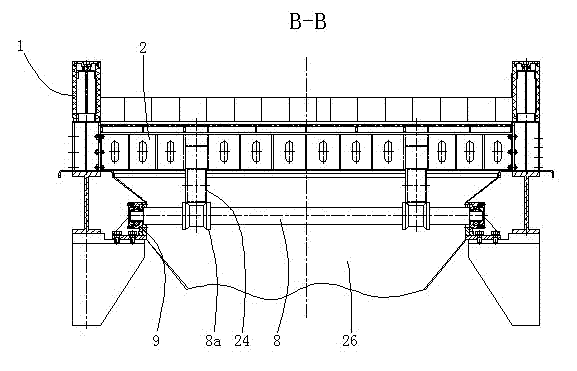

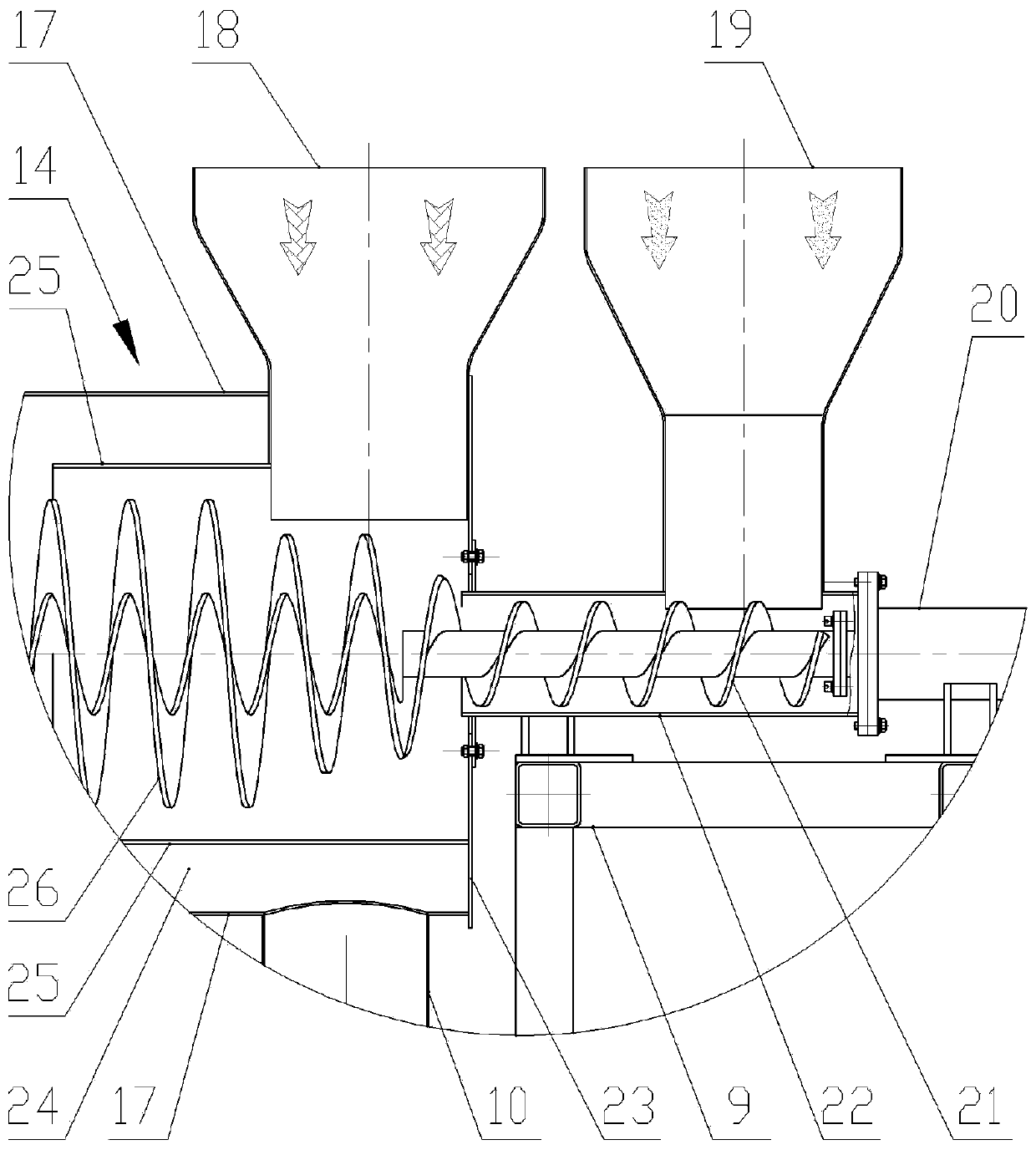

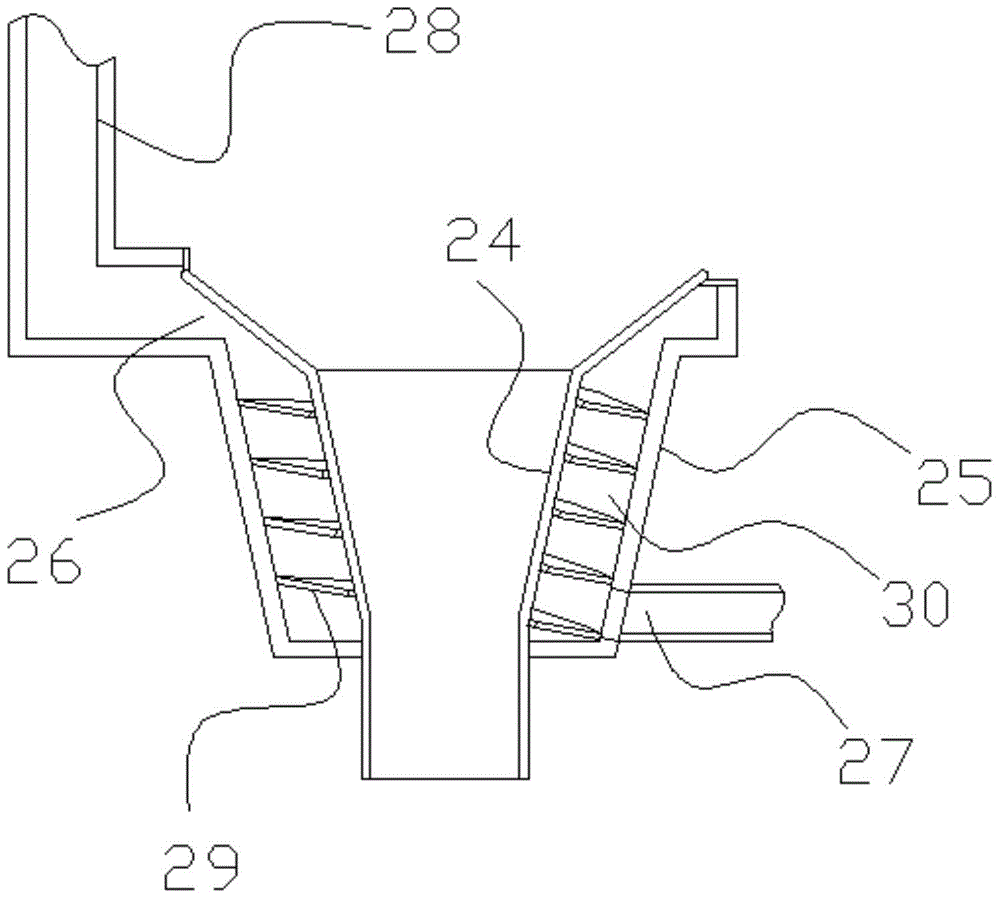

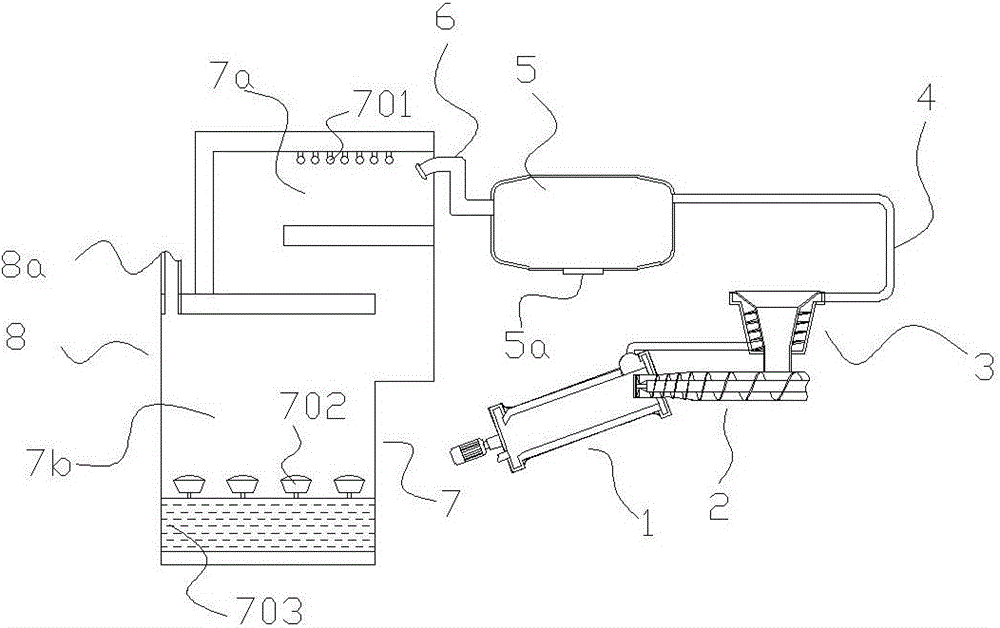

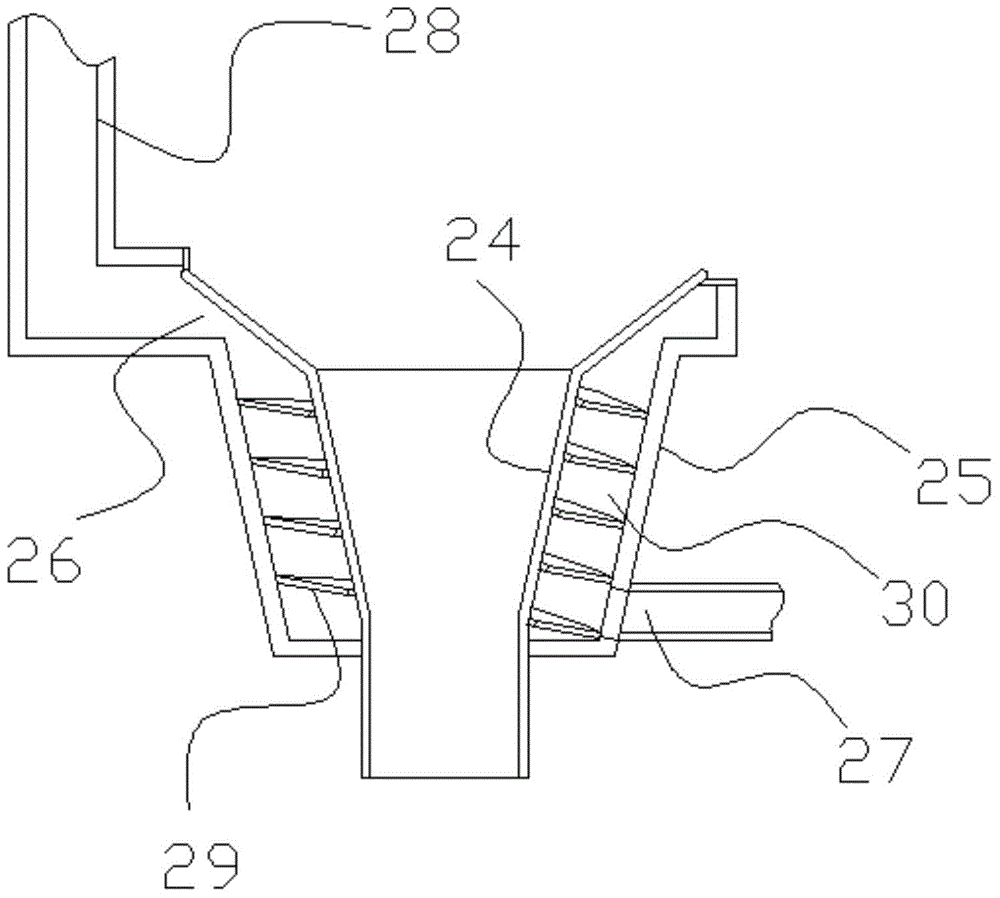

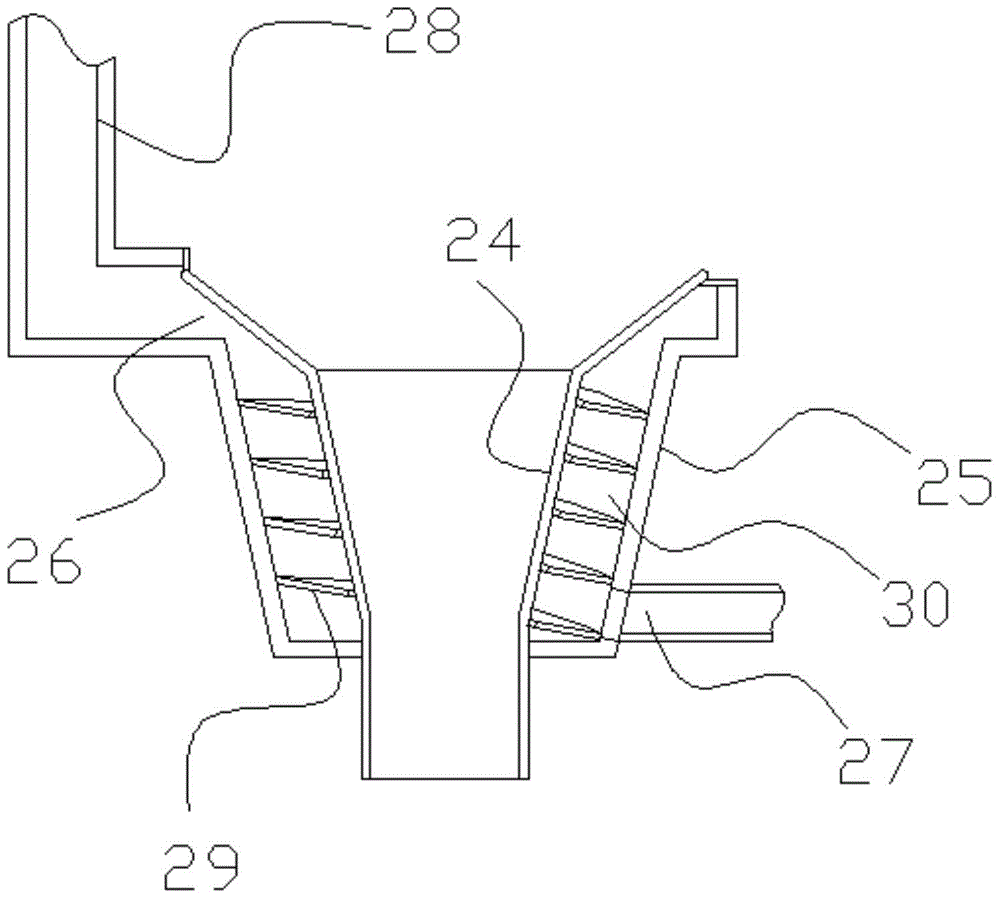

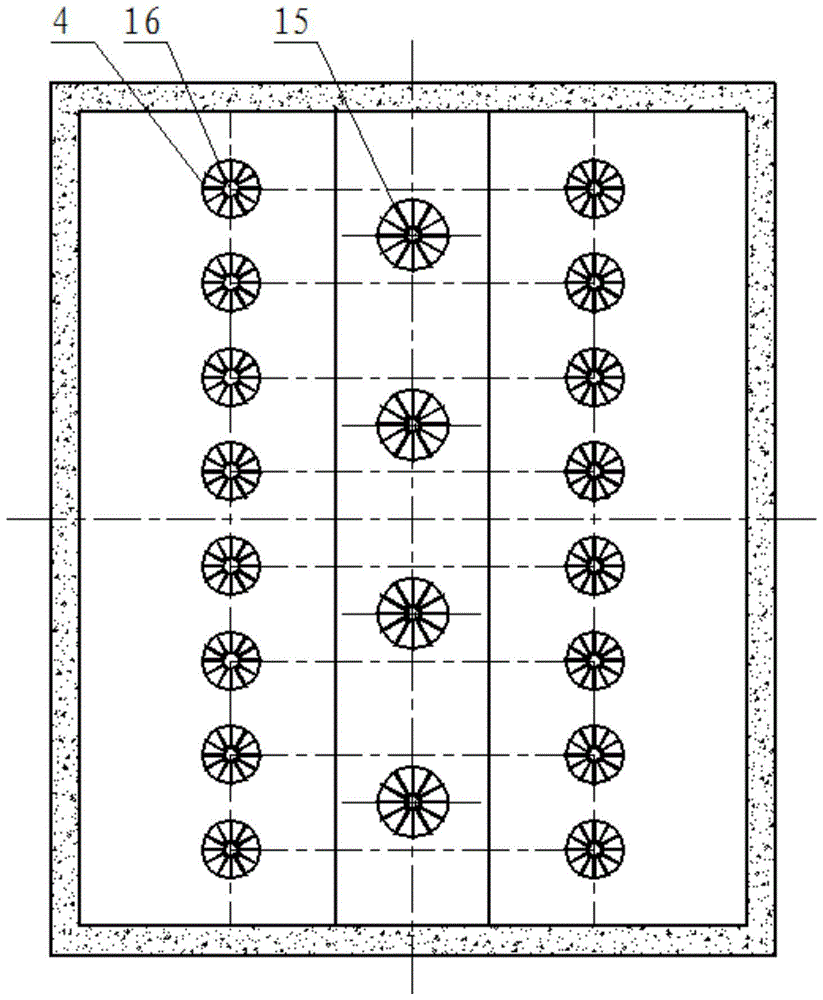

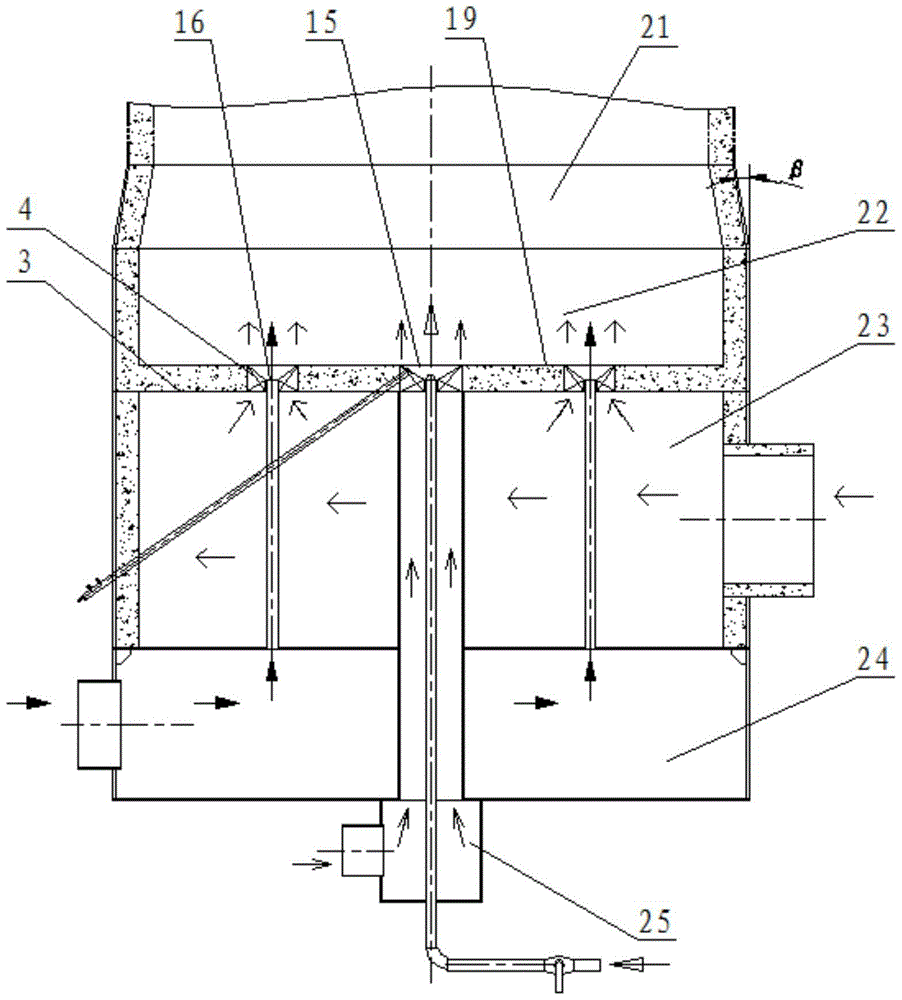

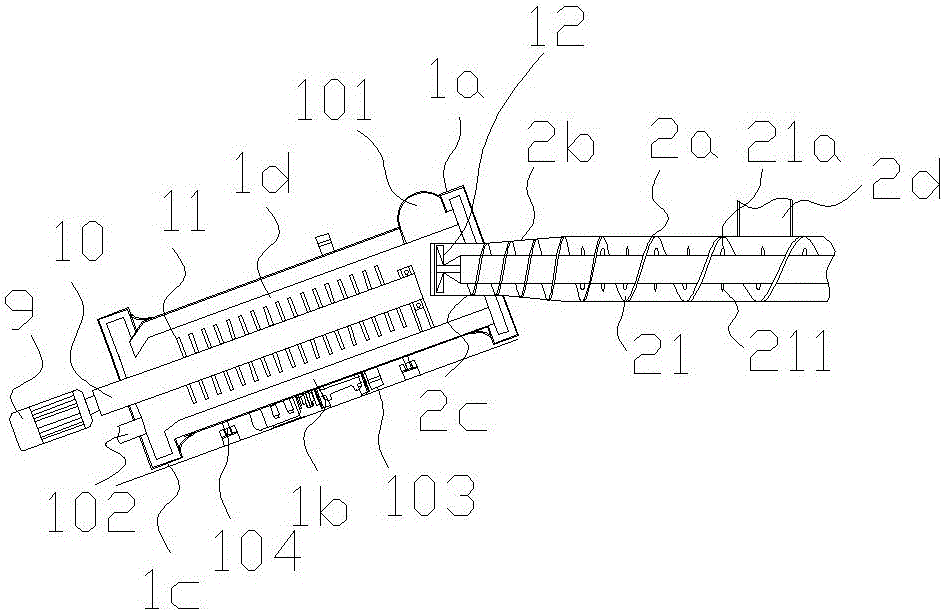

A two-stage garbage incinerator is characterized in that secondary air supply holes are arranged on front and rear arches of a furnace body and an ignition combustion-supporting hole is arranged on the rear arch; a grate in the furnace body is divided into two stages from top to bottom; the upper stage is a forward pushing stage and the lower stage is a backward pushing stage; an independent primary air chamber is arranged below each stage; the heads of the grates on the forward pushing stage face the low point direction of the grates; the heads of the grates on the backward pushing stage face the high point direction of the grates; moving beams of the grates on the same stage are equipped with left and right draw bars arranged side by side; the left and right draw bars are supported by supporting roller devices and are connected with the moving beams to form draw bar frames; and the ends of the draw bar frames are connected with front rocker arm driving mechanisms, lateral rocker arm driving mechanisms or front straight driving mechanisms. The incinerator can realize full drying of the whole garbage material, ensure complete combustion and ensure the garbage incineration effect and hot ignition loss rate. At the same time, the incinerator has less spare parts and spare part specifications, good quick-wear part interchangeability and low manufacture and maintenance costs.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP

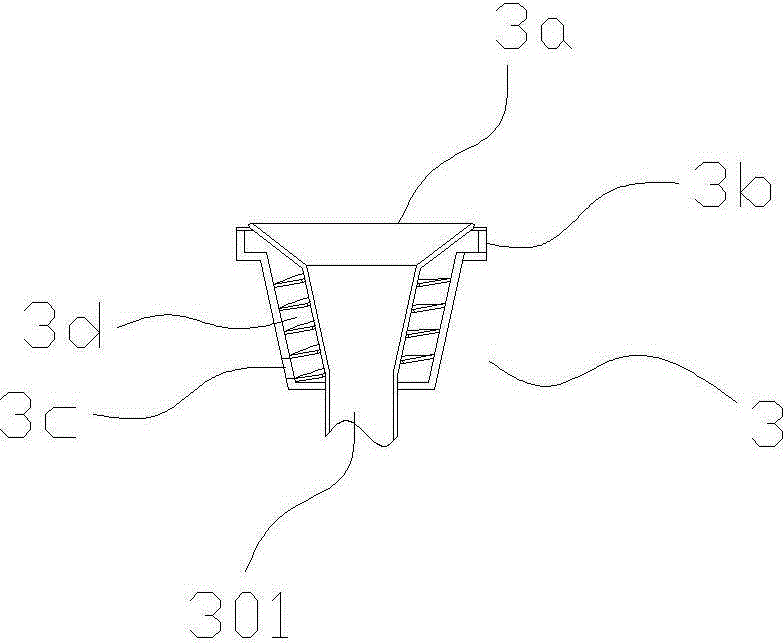

Ash fertilizer firing device

InactiveCN104595913ARealize separation and purificationHas clearedUsing liquid separation agentEnergy inputParticulatesEngineering

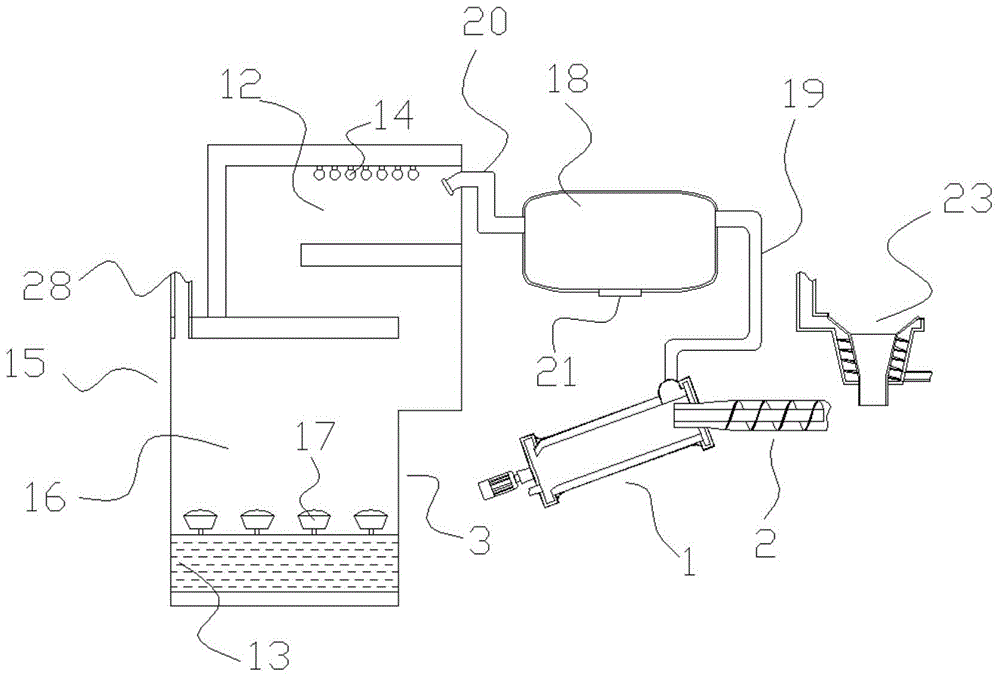

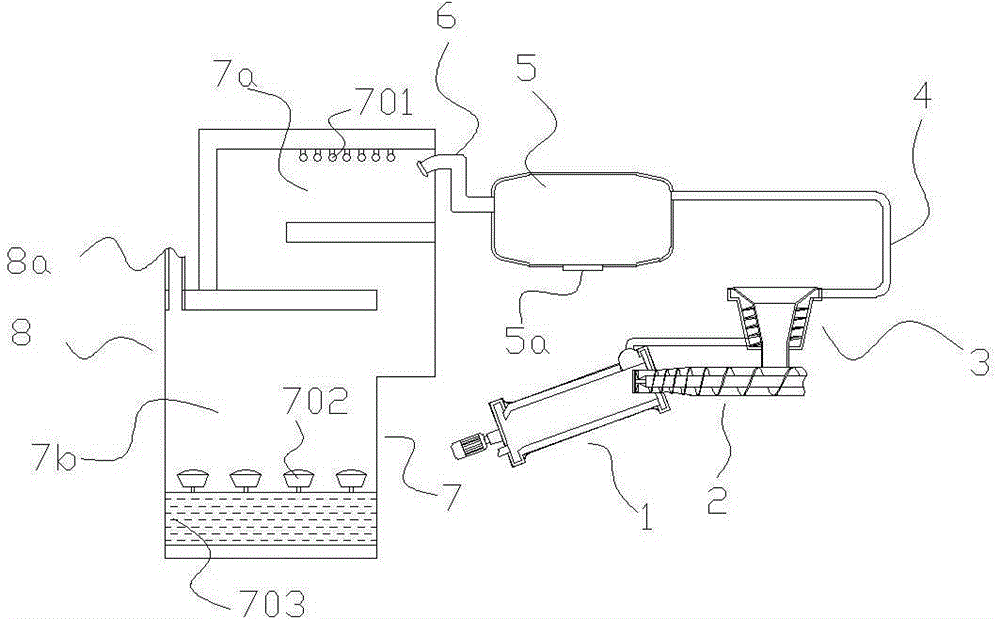

The invention discloses an ash fertilizer firing device which can effectively carry out firing on wheat straw in a concentrating mode, a firing process is stable and efficient, full firing can be guaranteed, prepared ash fertilizer is high in purity, generated smoke can be effectively processed, and smoke pollution can be avoided. The ash fertilizer firing device comprises an incineration kiln, a feeding device and a smoke purifying device. An incineration inner cavity is arranged at the incineration kiln. The incineration kiln is oblique, and the angle between the incineration kiln and the horizontal plane is 10-60 degrees. A transmission shaft driven by a main motor is arranged in the incineration inner cavity. A plurality of material dispersing bodies for stirring materials are arranged on the transmission main shaft. An air inlet, a smoke outlet, a feeding opening and a material clearing opening-closing door are arranged on the incineration kiln. The ash fertilizer firing device has the advantages that separating effect is good, removing of solid particles and dust in smoke can be achieved, raw materials are subjected to drying through smoke waste heat, following firing effect is improved, a preheating structure is arranged, and following incineration can be well and fully guaranteed.

Owner:ZHEJIANG SCI-TECH UNIV

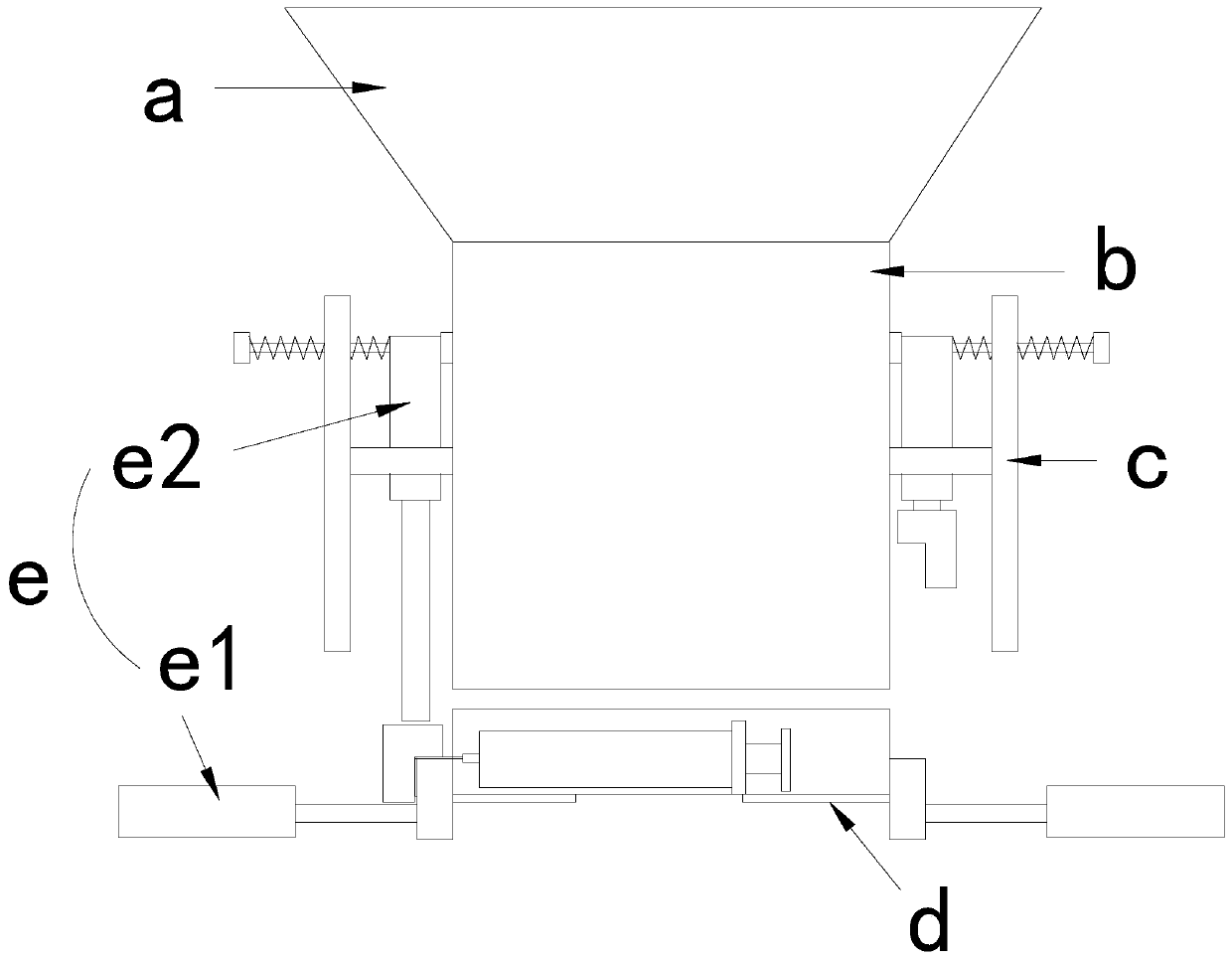

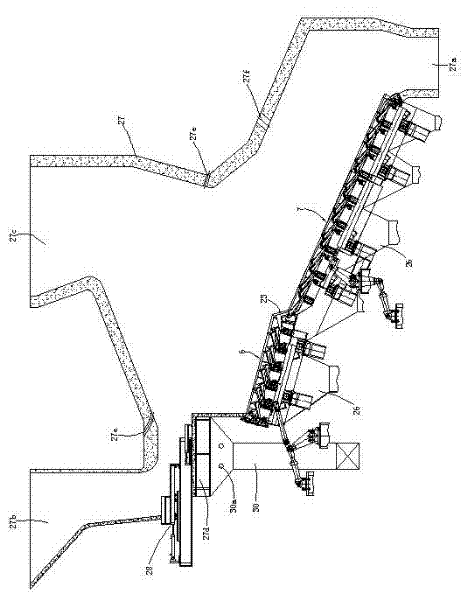

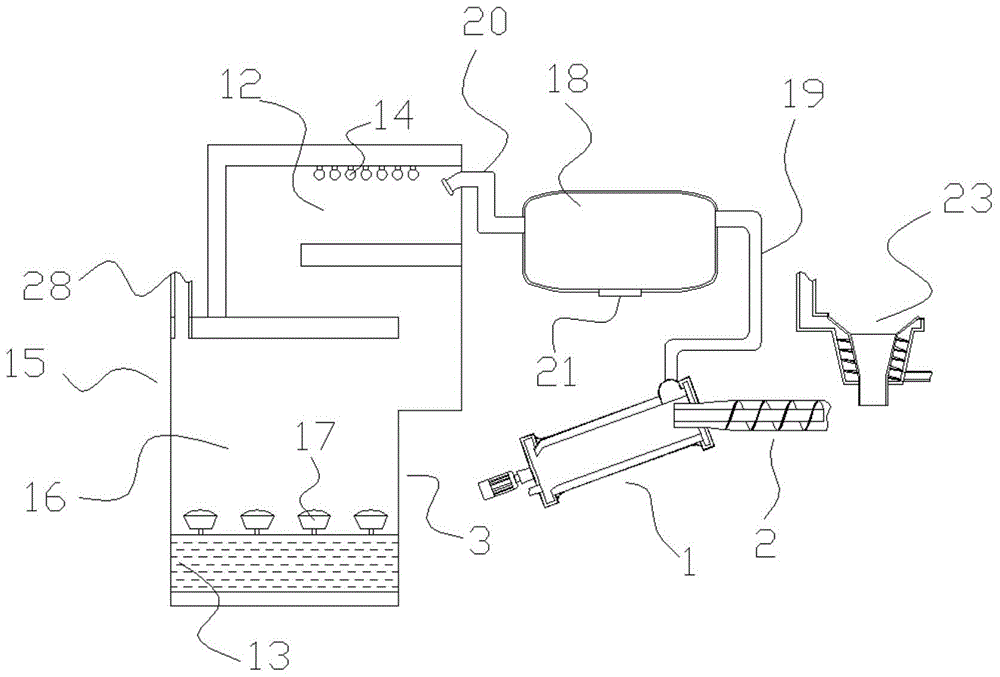

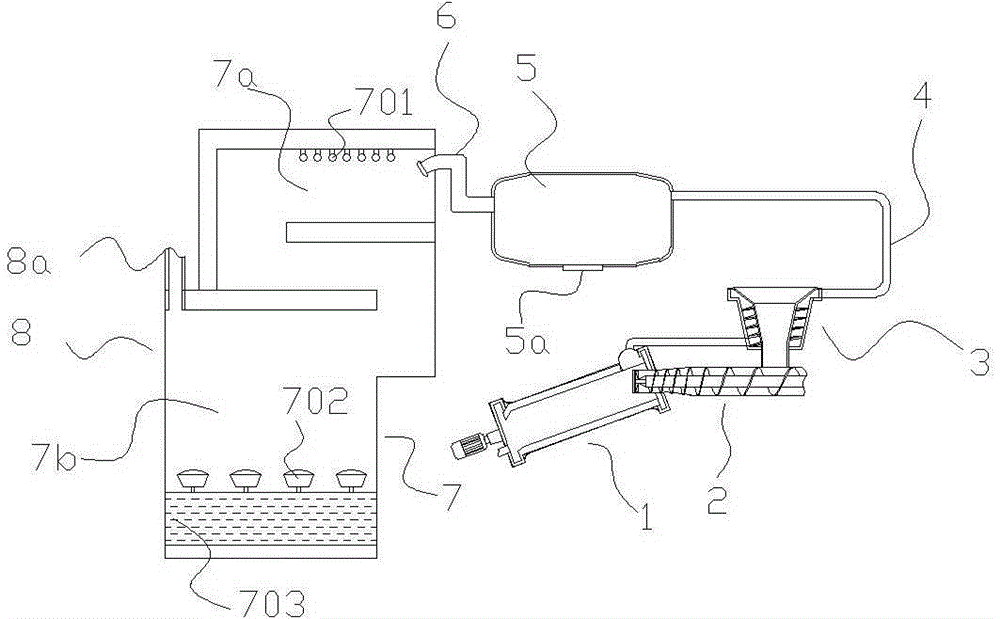

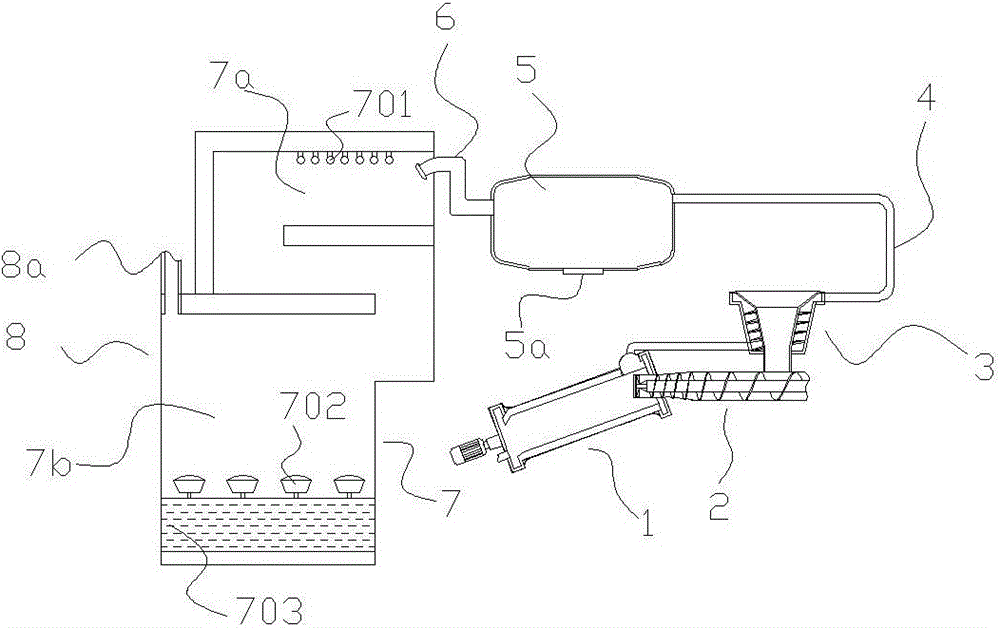

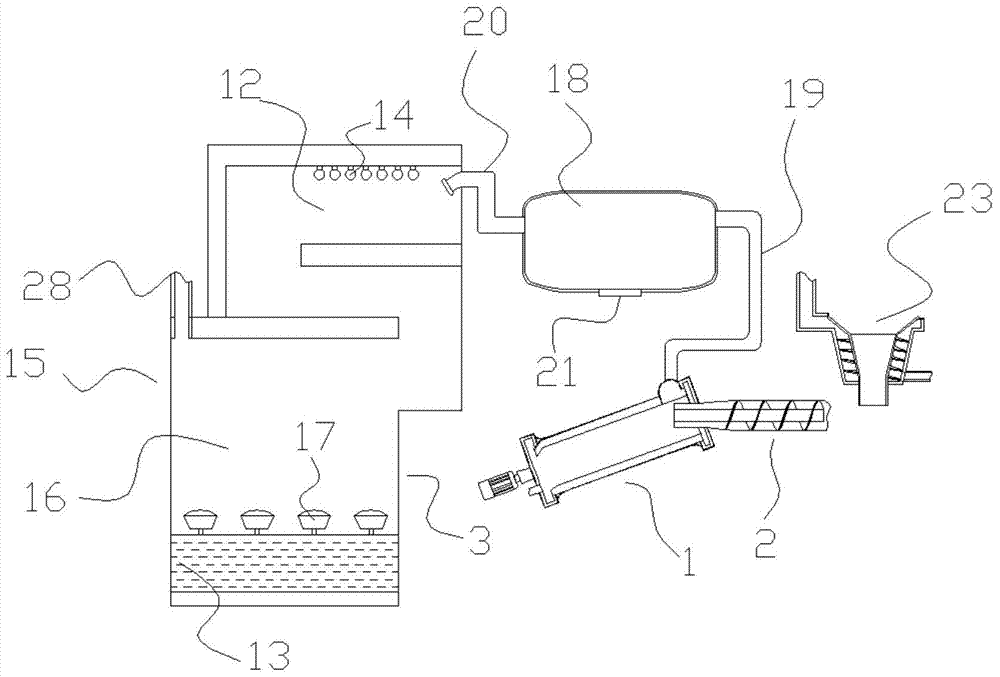

Full-automatic disposal system and method for domestic garbage

InactiveCN108800139AGuaranteed incineration effectHigh degree of reductionIncinerator apparatusCombined combustion mitigationFlue gasMagnetic separator

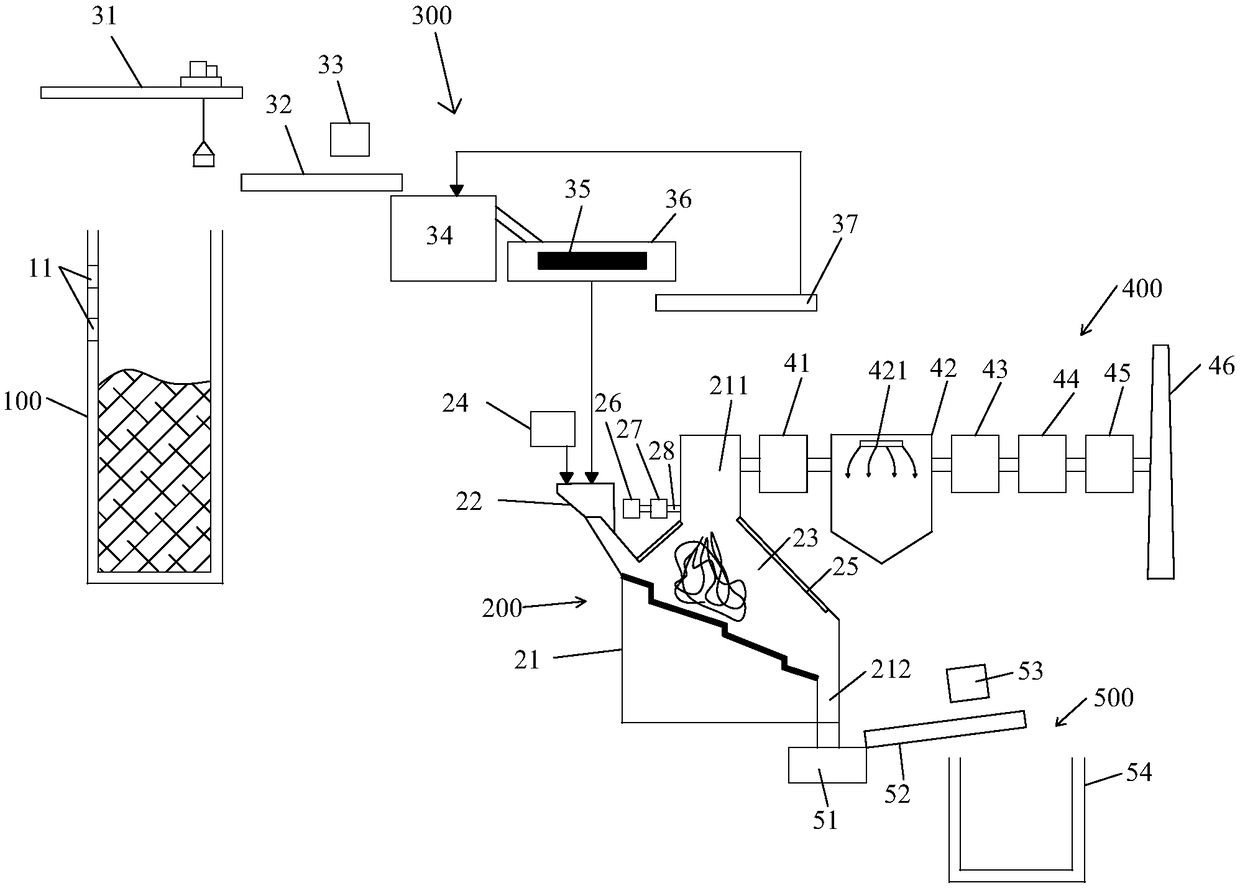

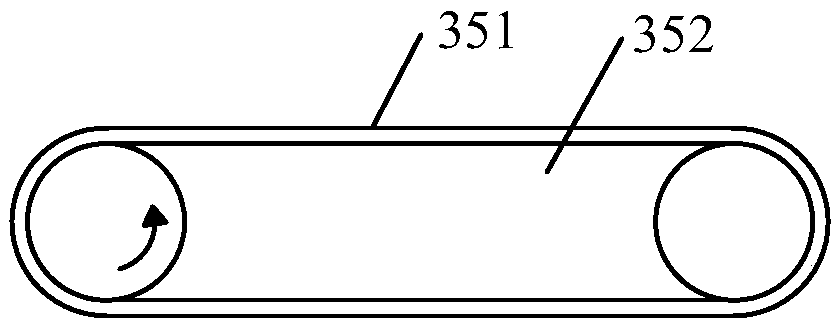

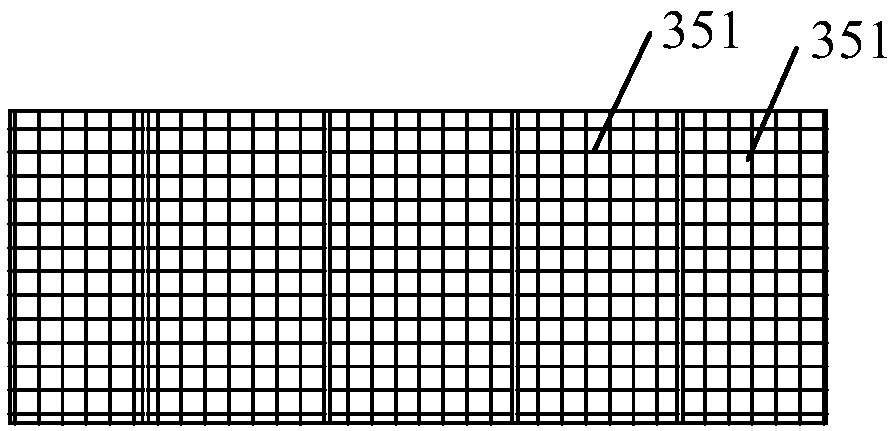

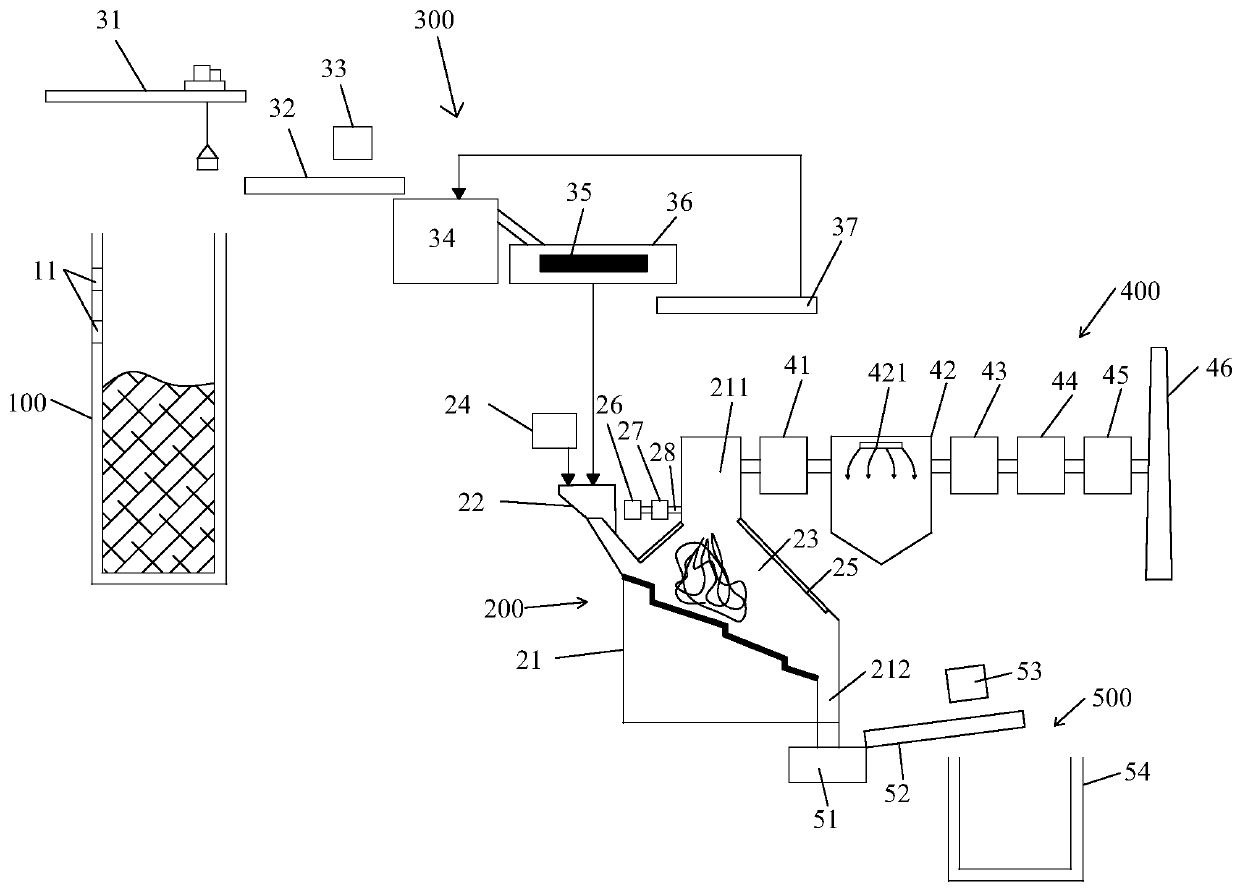

The invention provides a full-automatic disposal system for domestic garbage. The full-automatic disposal system comprises a garbage warehouse, an incinerator, a conveying system, a flue gas treatmentsystem and a slag treatment system. The conveying system comprises a grab bucket crane, a first conveyor belt, a first magnetic separator, a crushing machine, a screening conveyor belt, a second conveyor belt and a third conveyor belt. The screening conveyor belt is separately connected with the crushing machine and the third conveyor belt, and the screening conveyor belt is ring-shaped, includesa plurality of moving grids, and is provided with a cavity accommodating the second conveyor belt in the middle. The conveying direction of the screening conveyor belt is perpendicular to the conveying direction of the second conveyor belt, and the second conveyor belt conveys the domestic garbage filtered by the moving grids in the screening conveyor belt to a feeding hopper of the incinerator.The third conveyor belt returns the domestic garbage conveyed by the screening conveyor belt to the crushing machine. The full-automatic disposal system performs magnetic separation and crushing treatment on the domestic garbage through the conveying system, thereby ensuring the incineration effect of the domestic garbage, effectively improving the degree of reduction, and meeting the present requirements.

Owner:SHAANXI SCI TECH UNIV

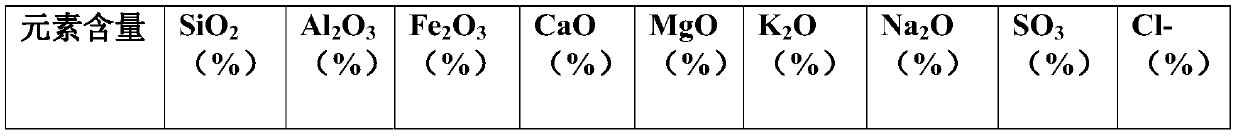

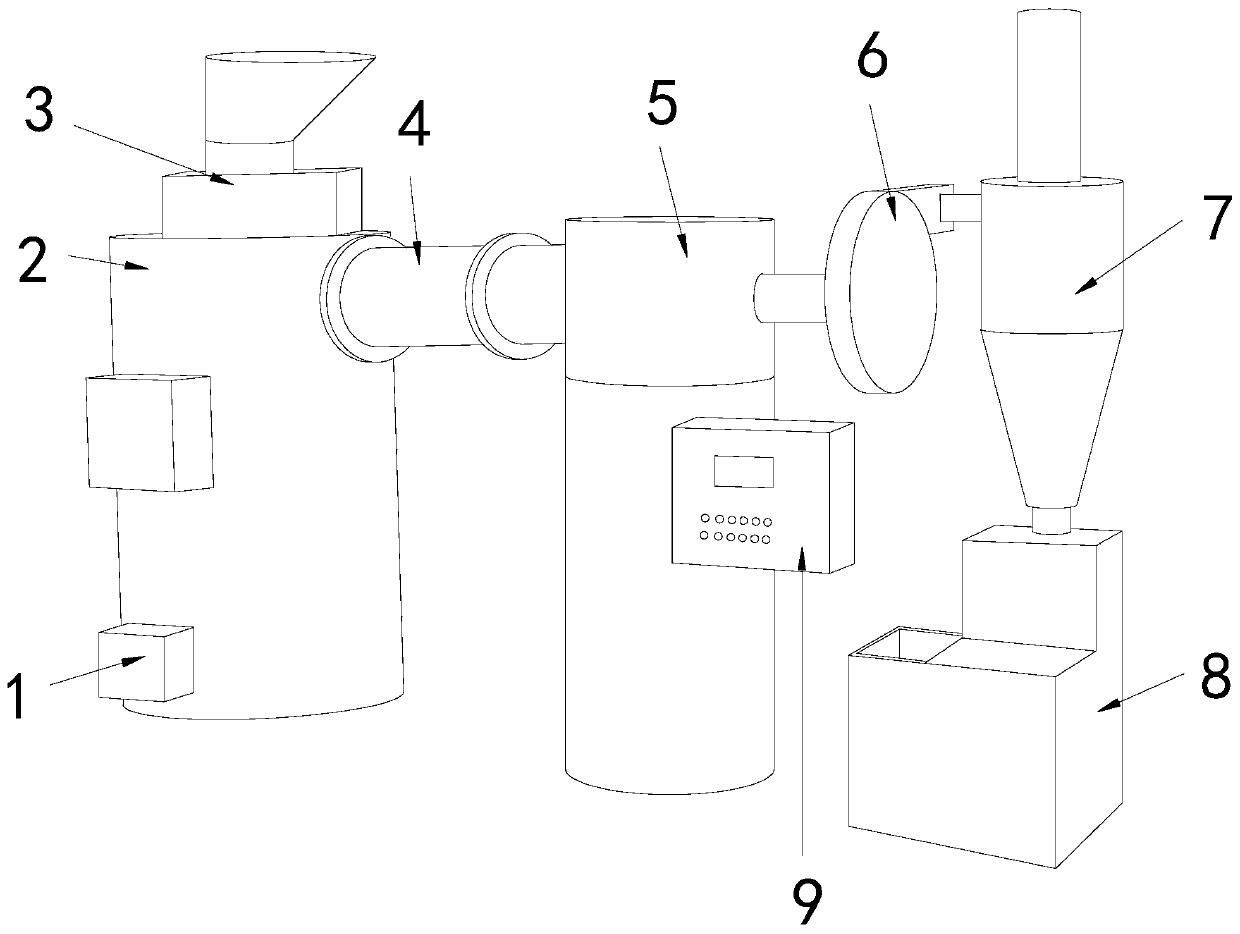

Method for cooperatively treating powder and sludge waste by using cement kiln

ActiveCN110410800AStable incineration temperatureGuaranteed incineration effectCement productionIncinerator apparatusSlagSludge

The invention provides a method for cooperatively treating powder and sludge waste by using a cement kiln. The method comprises the following steps that (1) PTA sludge waste with the water content of55%-65% is pre-treated to obtain PTA sludge mixed waste, wherein the treatment scale is 50-70t / d; (2) waste catalyst powder waste with the water content less than or equal to 5% is pre-treated to obtain two groups of waste catalyst powder waste, wherein the treatment scale is 20-40t / d; (3) the PTA sludge mixed waste and high-metal-content and high-magnetic waste catalyst powder waste are fed intoa feed-end chamber to be incinerated, and then the low-metal-content and low-magnetic waste catalyst powder waste is added into the feed-end chamber to be incinerated; and (4) flue gas generated by incineration is introduced into a kiln tail system, and slag generated by incineration and fly ash generated by incineration waste gas are introduced into a rotary kiln for preparing cement clinker. Themethod can be used for simultaneously treating the PTA sludge waste and waste catalyst powder waste cooperatively to achieve the harmless, minimization, recycling and stabilization treatment on the combustible industrial waste.

Owner:王天陆

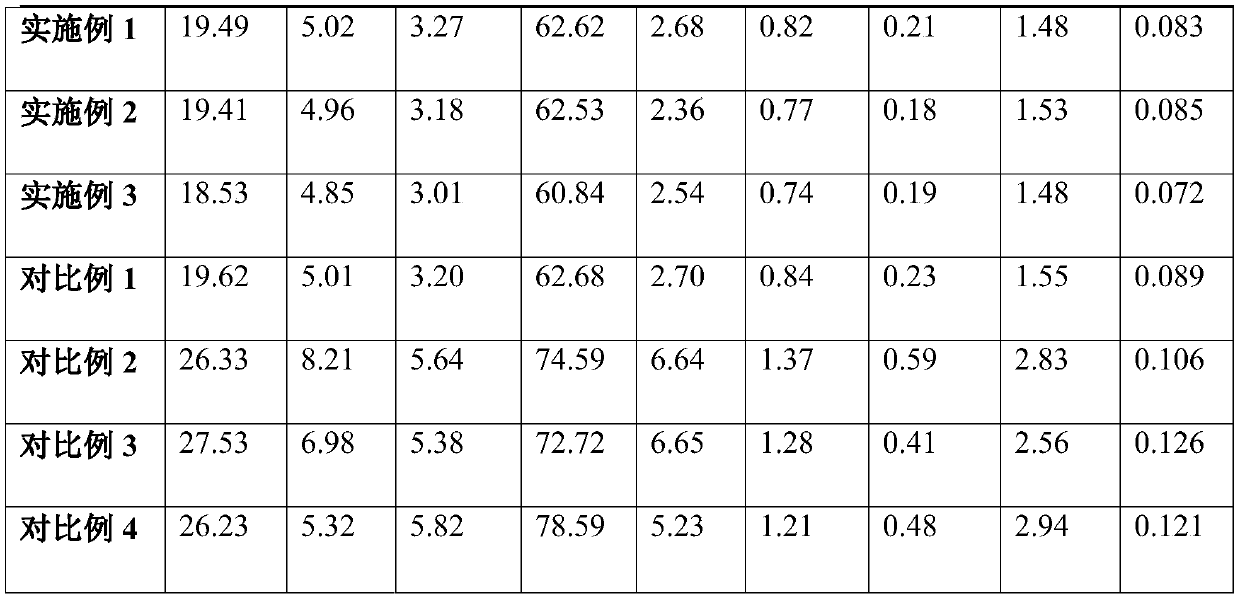

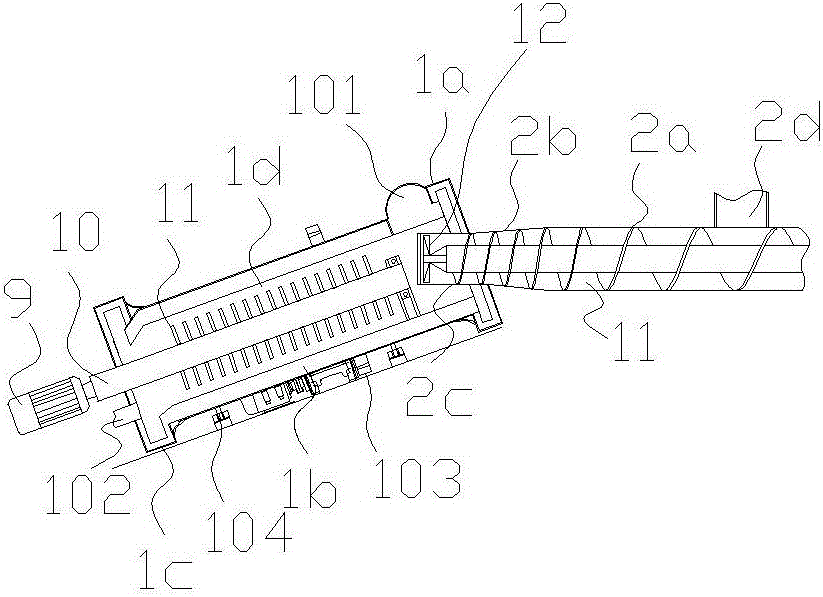

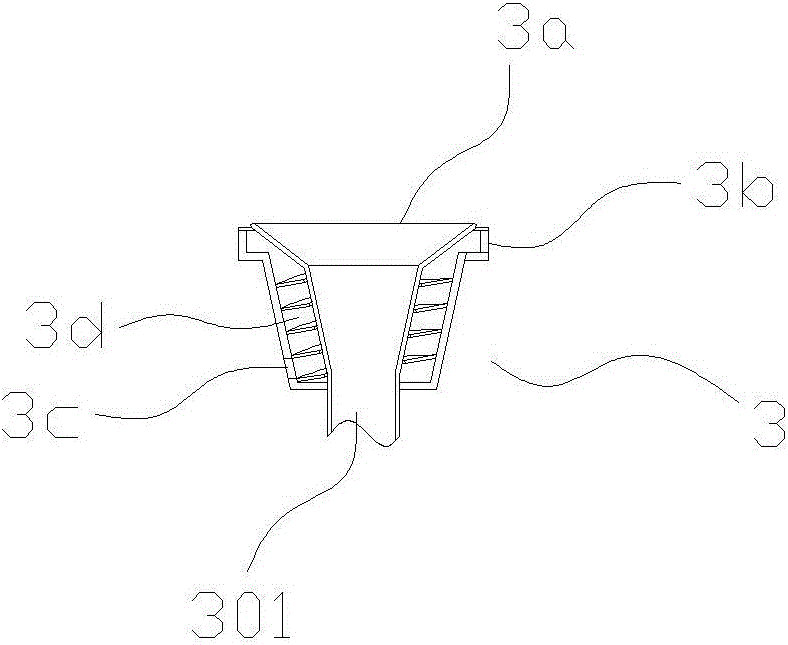

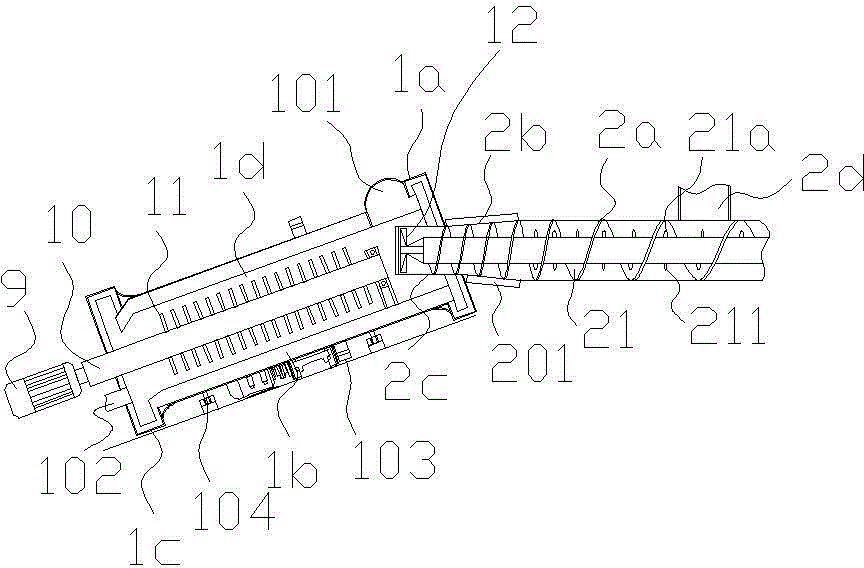

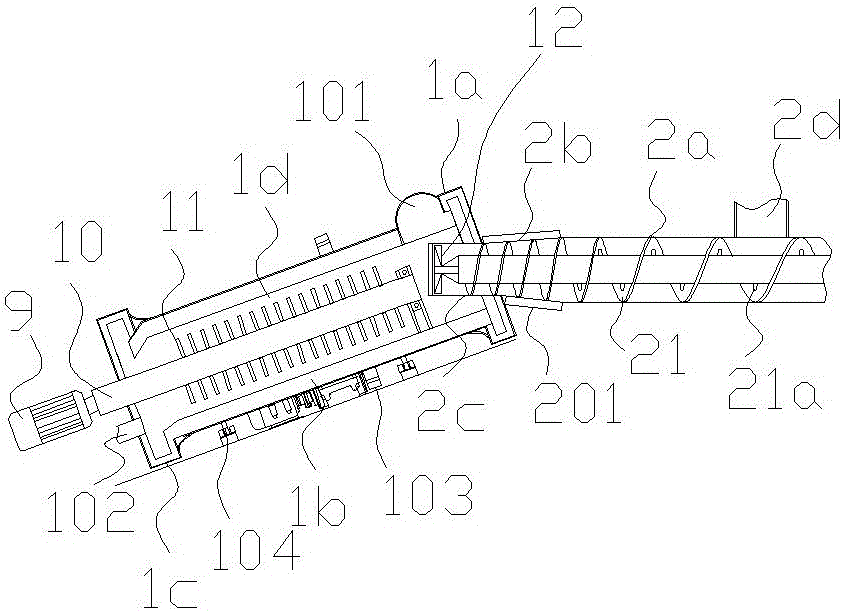

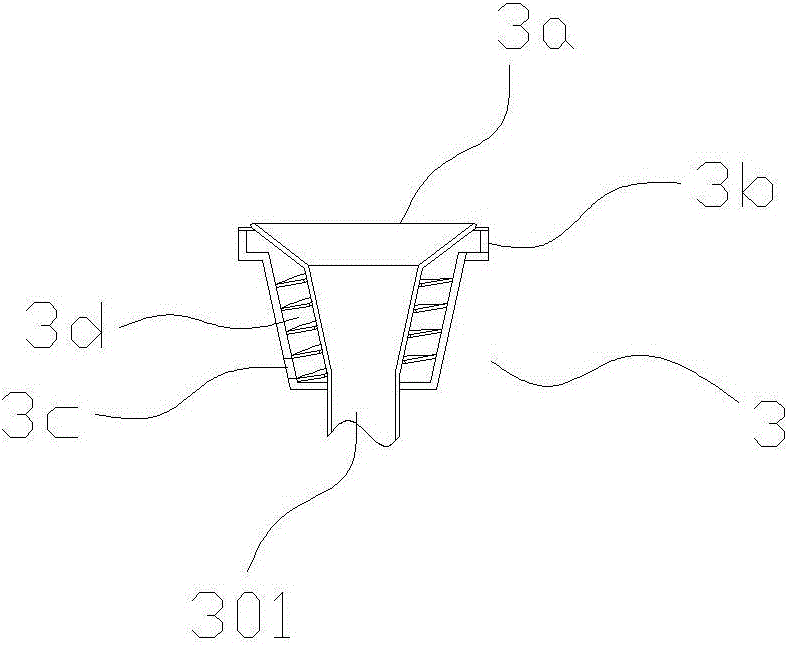

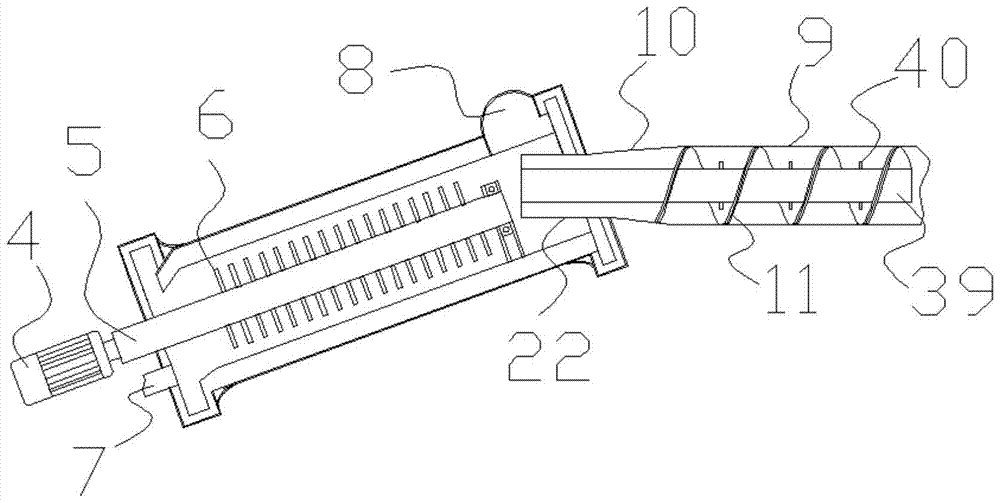

Medical waste crushing and incinerating integrated machine

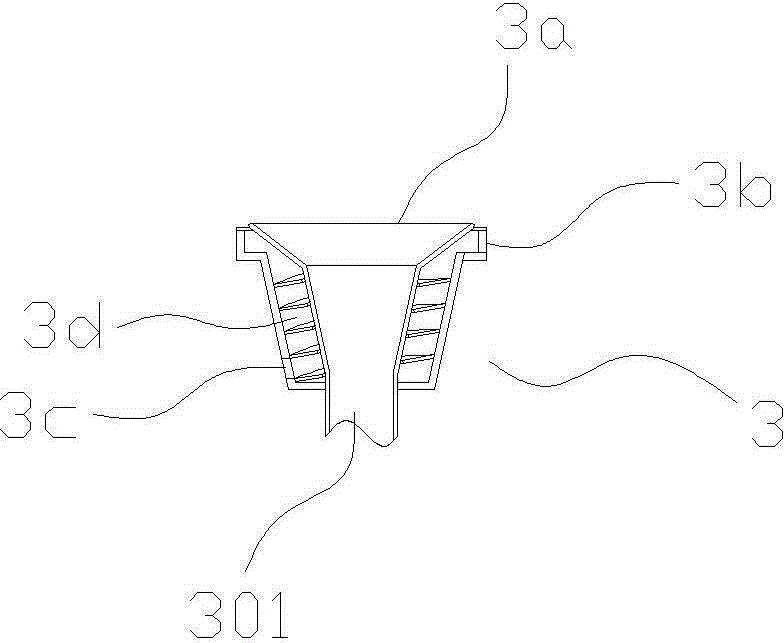

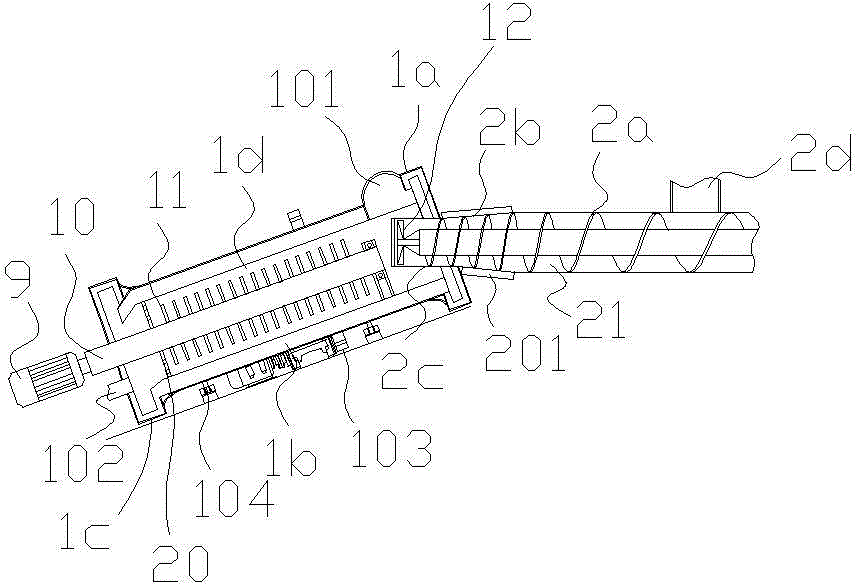

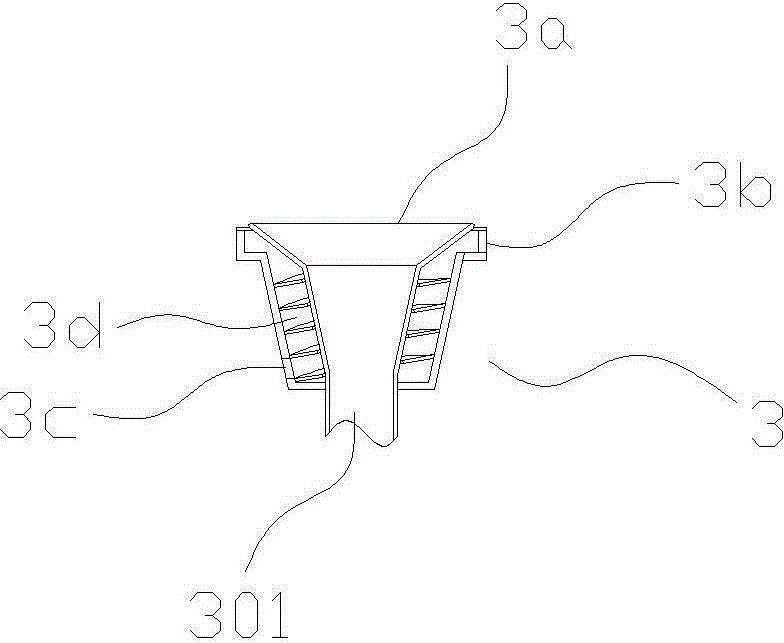

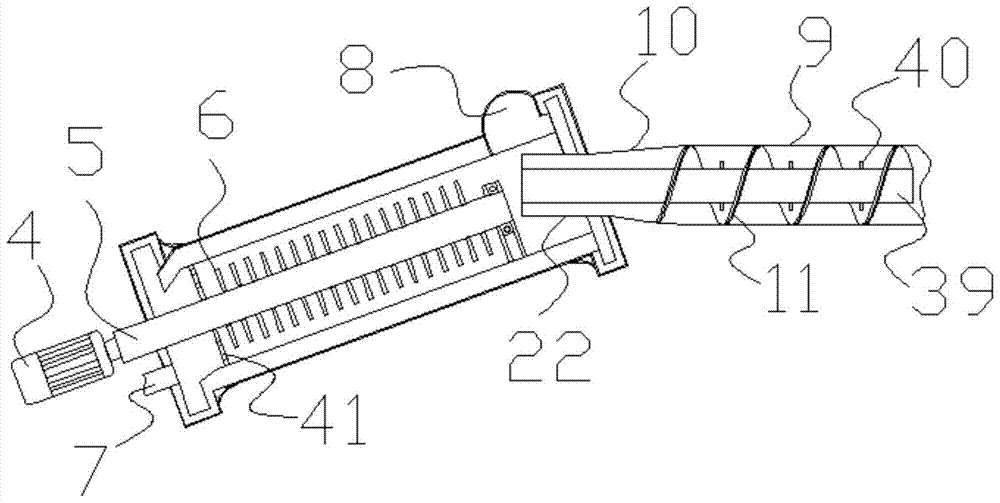

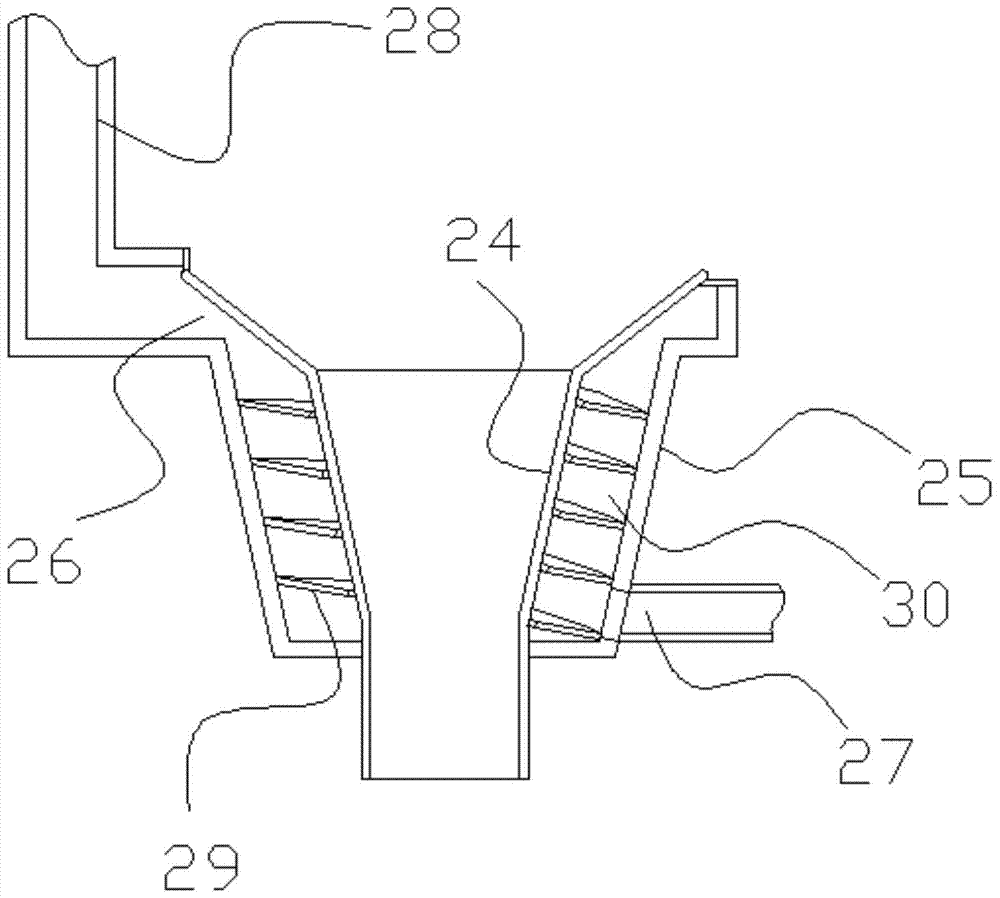

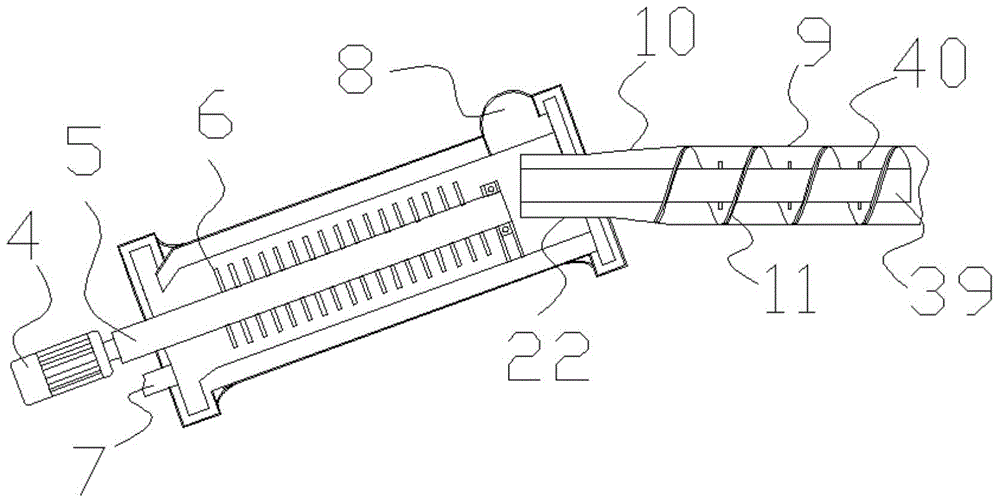

ActiveCN110274233AAvoid blockingGuaranteed incineration effectIncinerator apparatusMedical wasteSpray tower

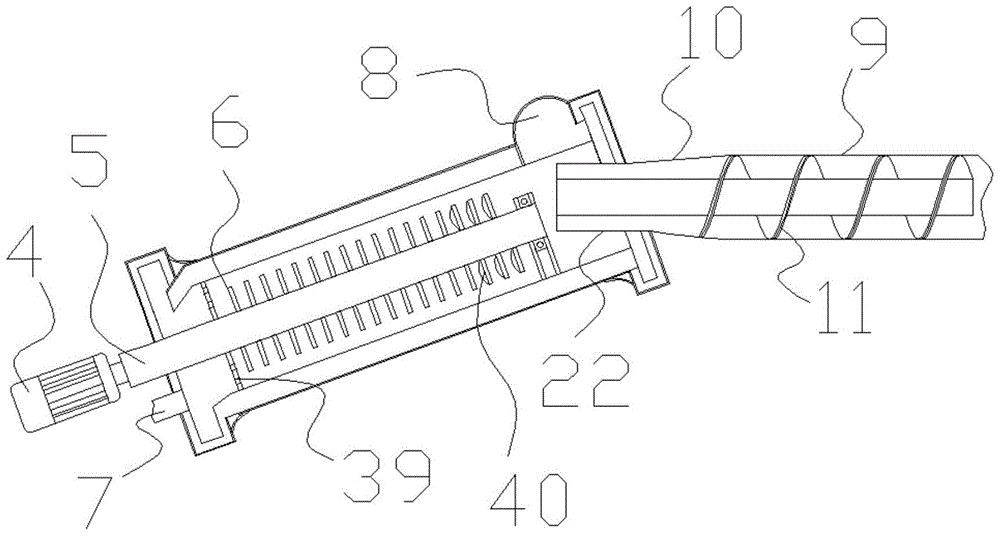

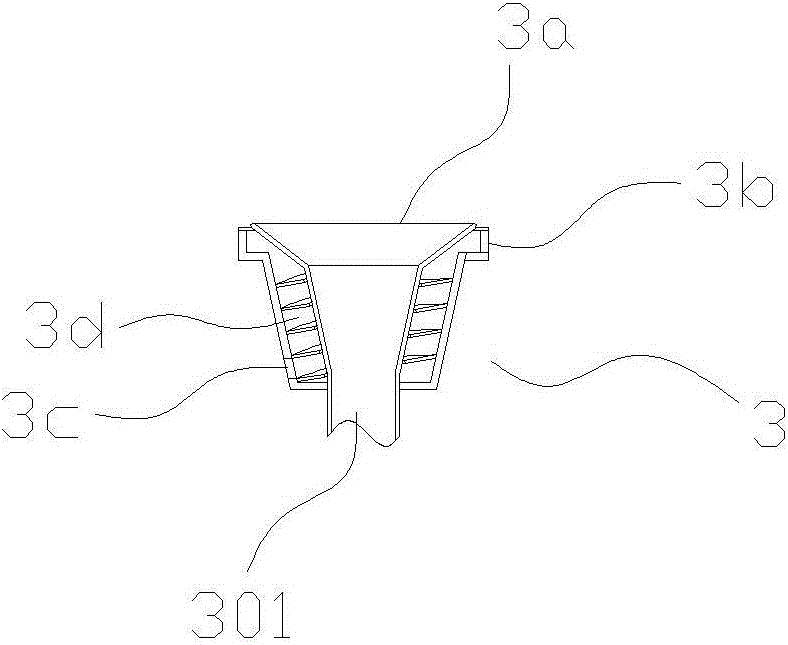

The invention discloses a medical waste crushing and incinerating integrated machine. The medical waste crushing and incinerating integrated machine structurally comprises an ash outlet, an incinerator, a pretreatment device, a pipeline, a spray tower, a fan, a dust remover, a dust-collecting base and a controller; the ash outlet is formed in the side surface of the bottom of the incinerator; the top of the incinerator is connected with the pretreatment device; the side surface of the top of the incinerator communicates with the spray tower through the pipeline; the spray tower is connected with the dust remover arranged on the side surface through the fan; the bottom of the dust remover is welded on the dust-collecting base; the controller is arranged on the side surface of the spray tower; the pretreatment device comprises a feeding hopper, a finisher, a permanent magnet piece, a placing box, a separation device and a shell; and the feeding hopper is connected with the part above the shell. The medical waste crushing and incinerating integrated machine has the following beneficial effects: through the pretreatment device, needle cylinders are finished or orderly fall into the placing box, so that the needle cylinders and needle heads are separated; furthermore, the needle heads are bended by right-angle blocks, so that slip can be avoided when the needle heads are pulled out; and through separation, the phenomenon that a furnace piece is blocked by the needle heads can be avoided and the incineration effect in the incinerator can be guaranteed.

Owner:惠安县锋创商贸有限公司

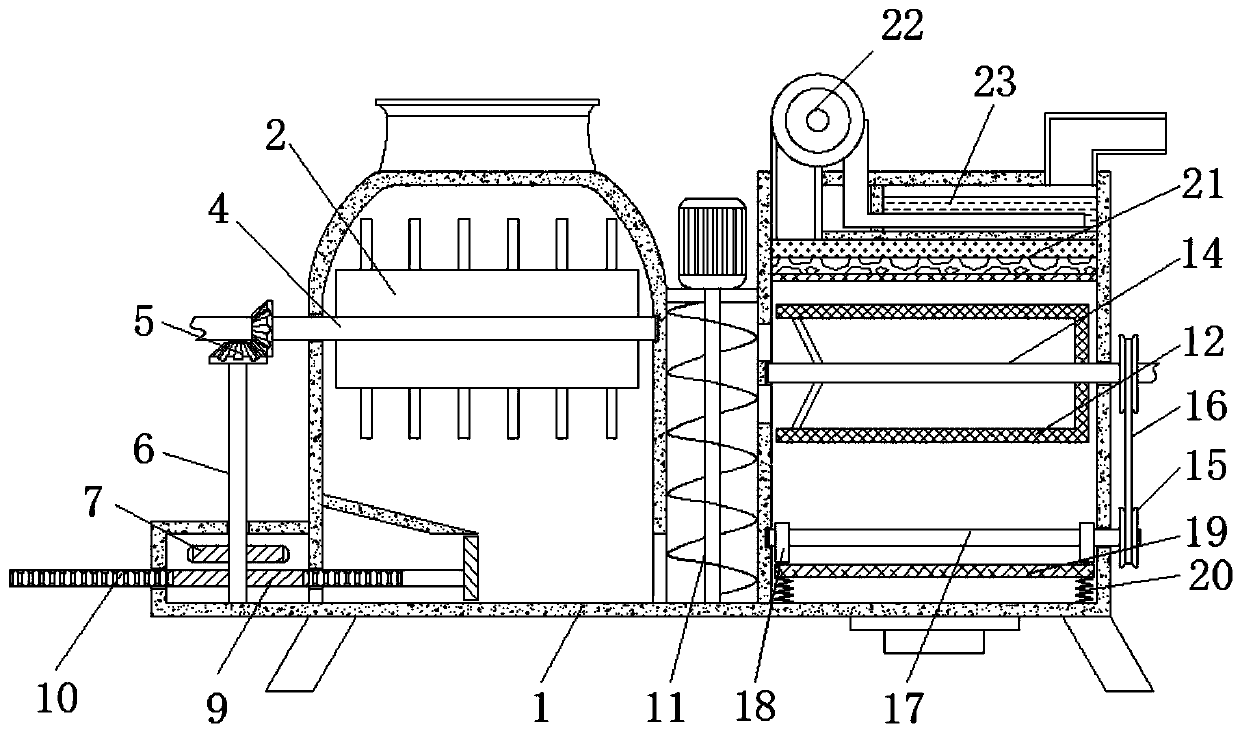

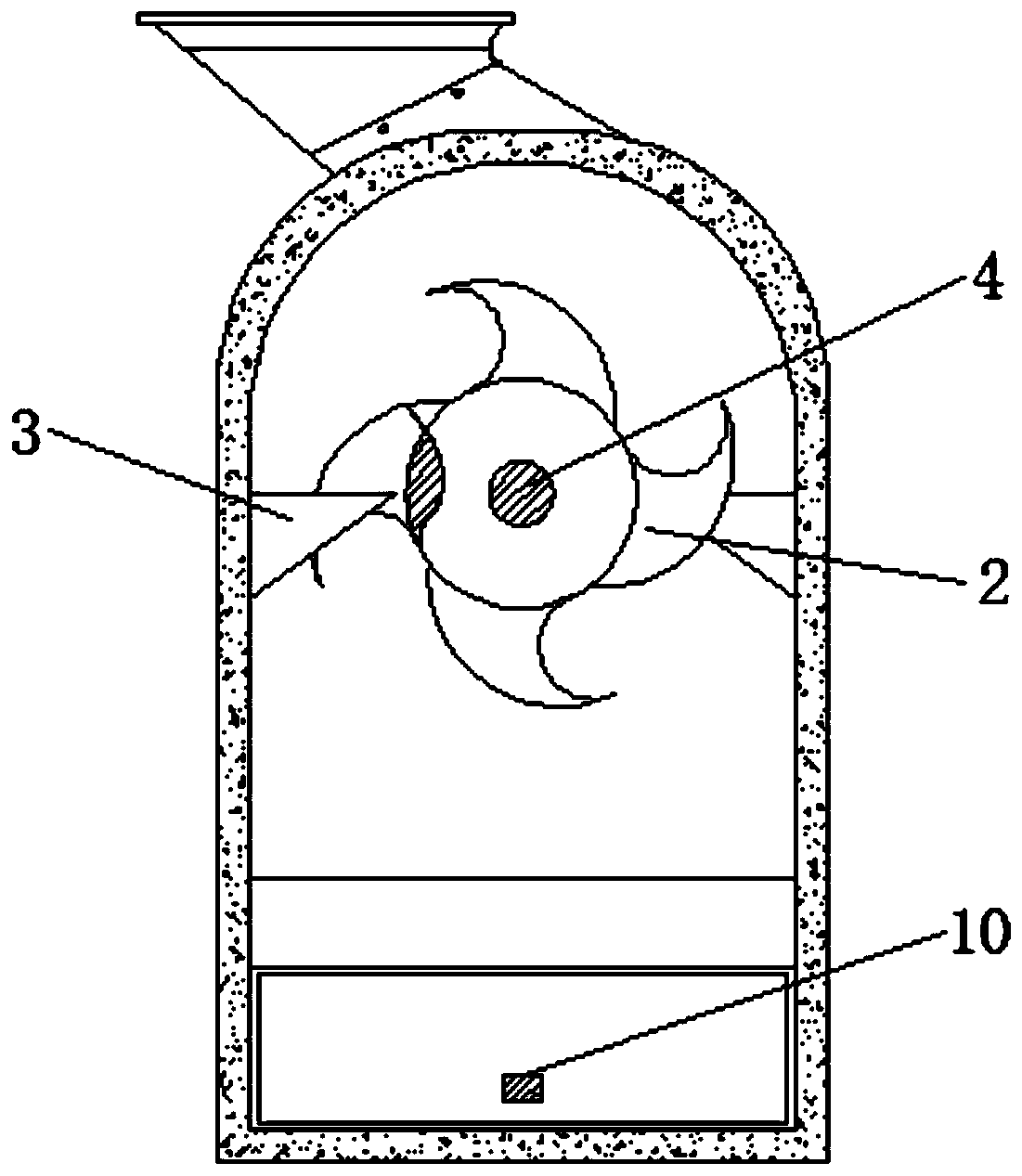

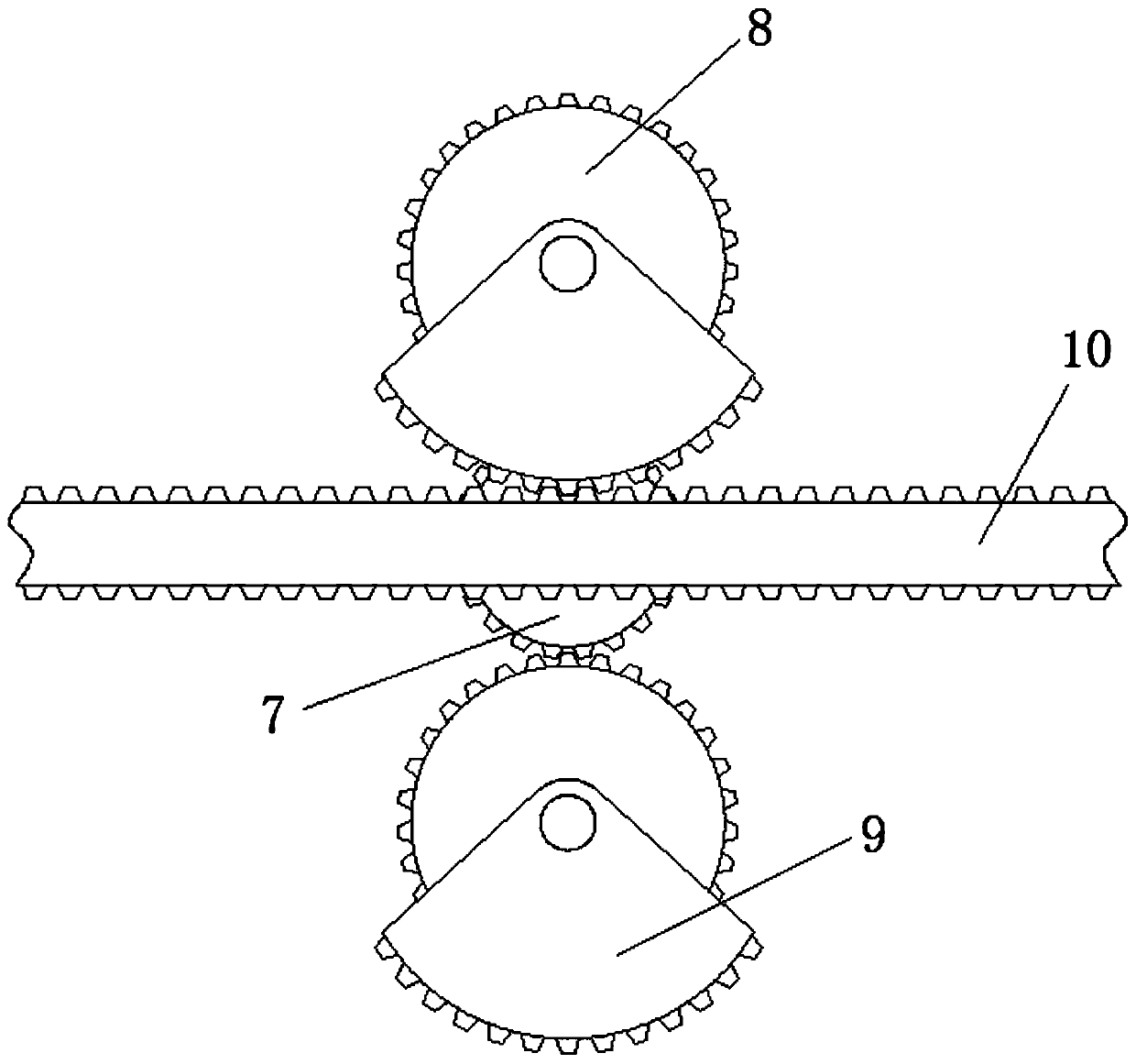

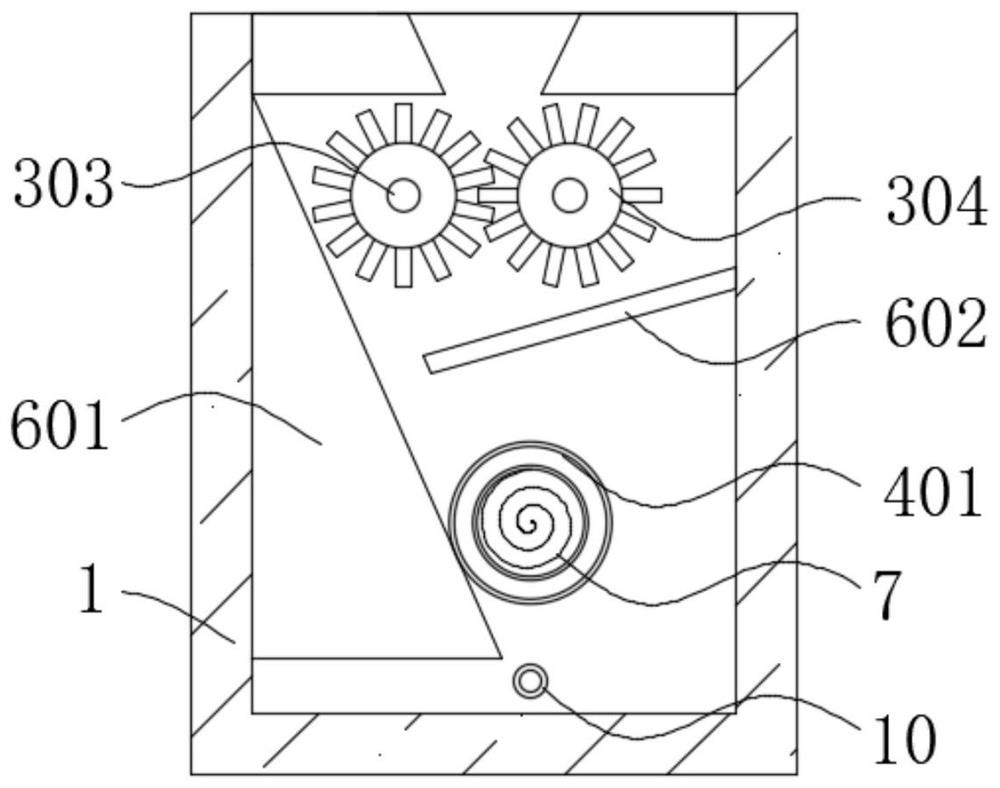

Straw incineration device based on special-shaped gear transmission principle

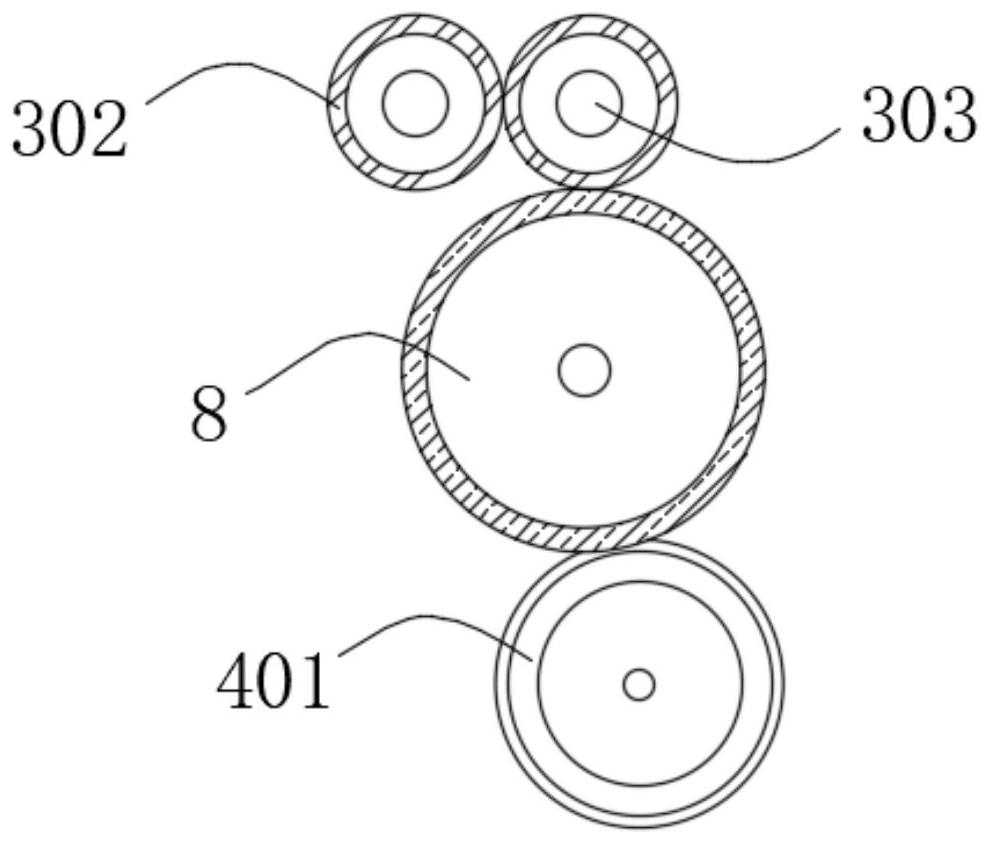

PendingCN111457386AAchieve primary crushingImprove incineration effectIncinerator apparatusSteering wheelGear wheel

The invention relates to the technical field of environmental protection, and discloses a straw incineration device based on a special-shaped gear transmission principle. The straw incineration devicecomprises a frame body, a material guide wheel is movably connected in the frame body, a cutting knife is movably connected to the outside the material guide wheel, a material guide rod is fixedly connected in the material guide wheel, a steering wheel is fixedly connected to the outside of the material guide rod, a connecting rod is fixedly connected to the outside of the steering wheel, a maingear is fixedly connected to the outside of the connecting rod, a connecting gear is connected to the outside of the main gear in an engaged manner, and a sector gear is fixedly connected to the outside of the connecting gear. Through cooperative use of the material guide wheel, the cutting knife, the main gear, the connecting gear, the sector gear and a straight toothed bar, straw is preliminarily crushed, the straw incineration effect is improved, the straight toothed bar pushes the straw so as to guarantee that the straw can smoothly enter an incineration chamber, the straw is prevented from being stuck, and therefore smooth operation of the equipment is guaranteed.

Owner:伍冬秋

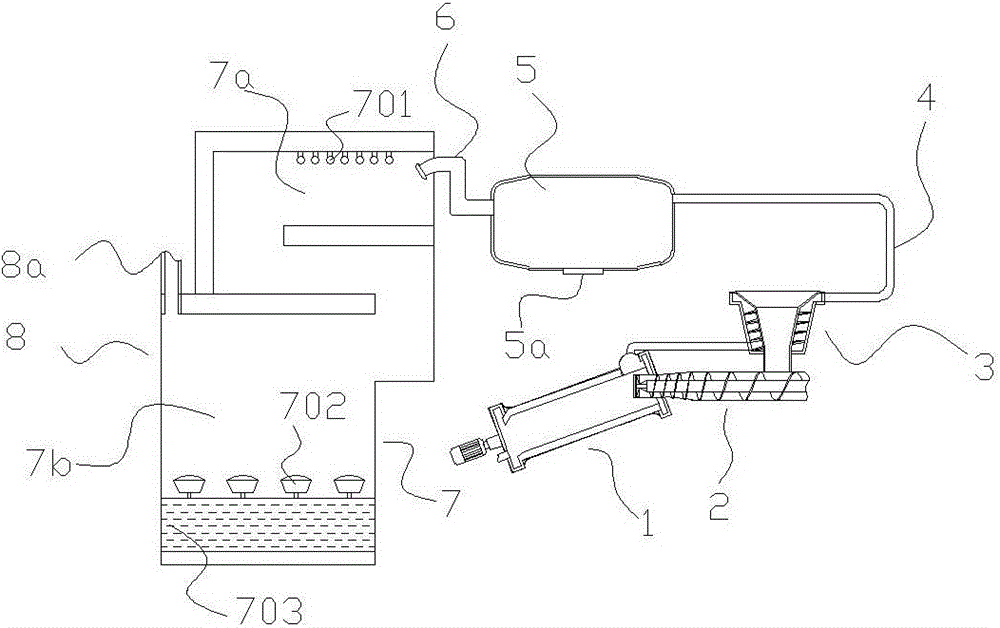

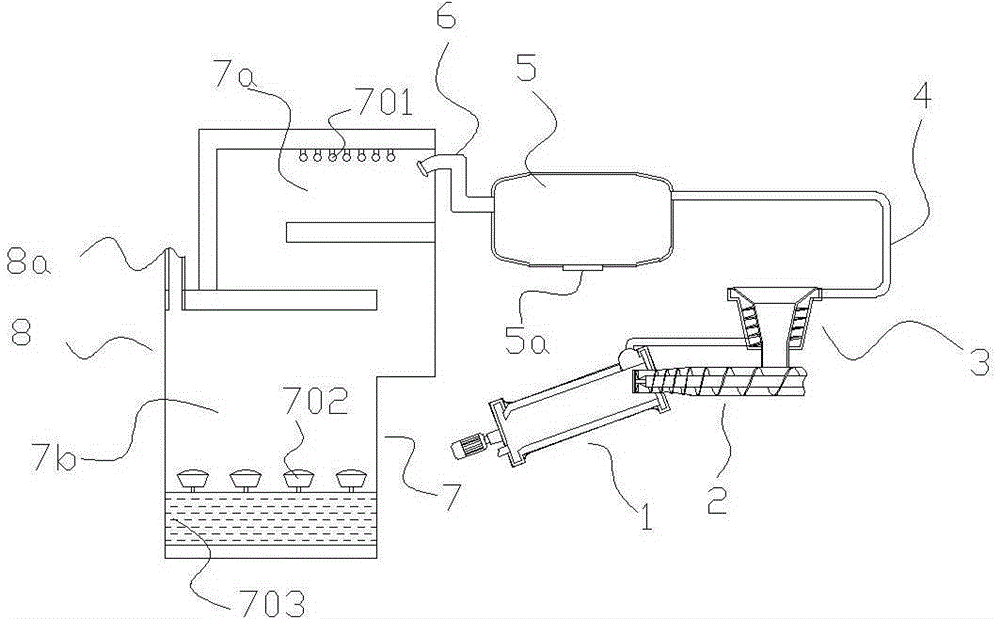

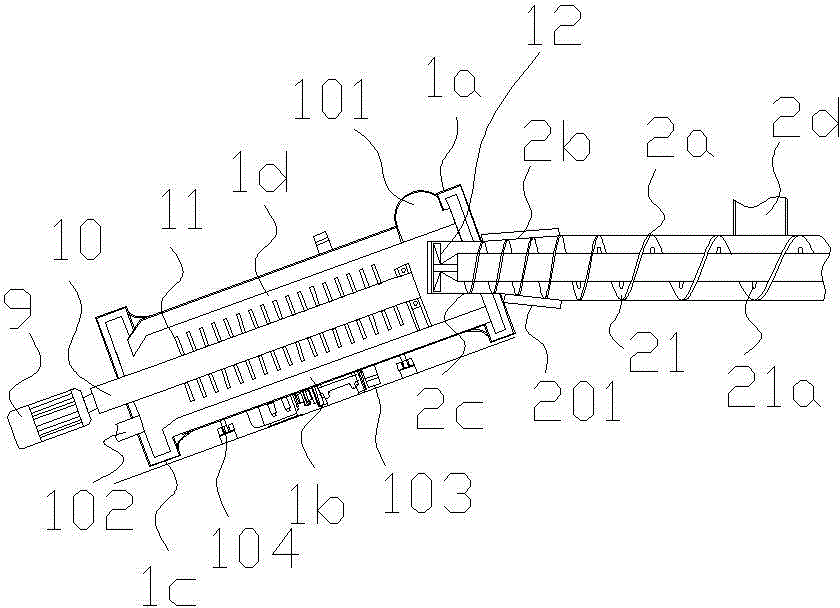

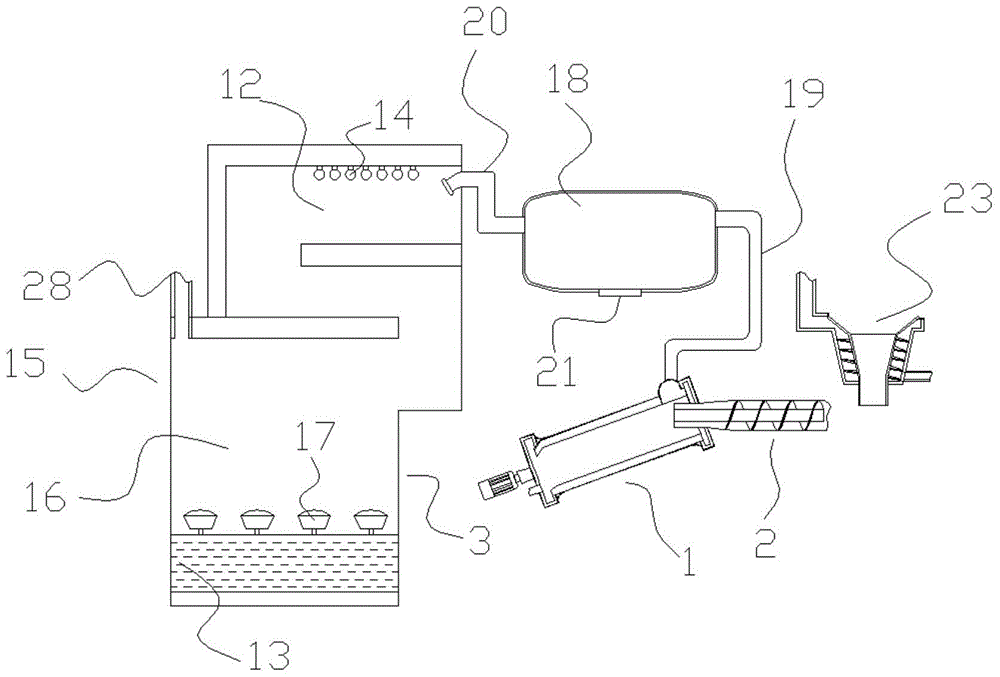

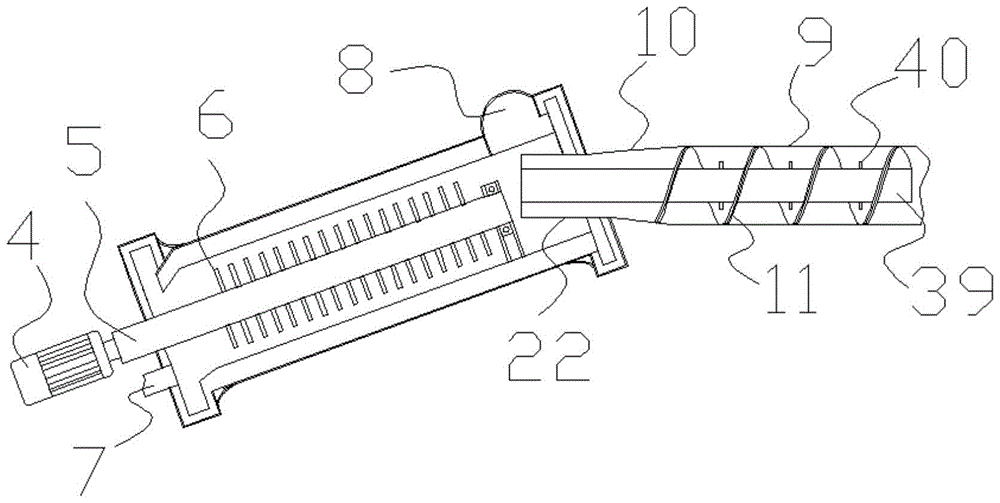

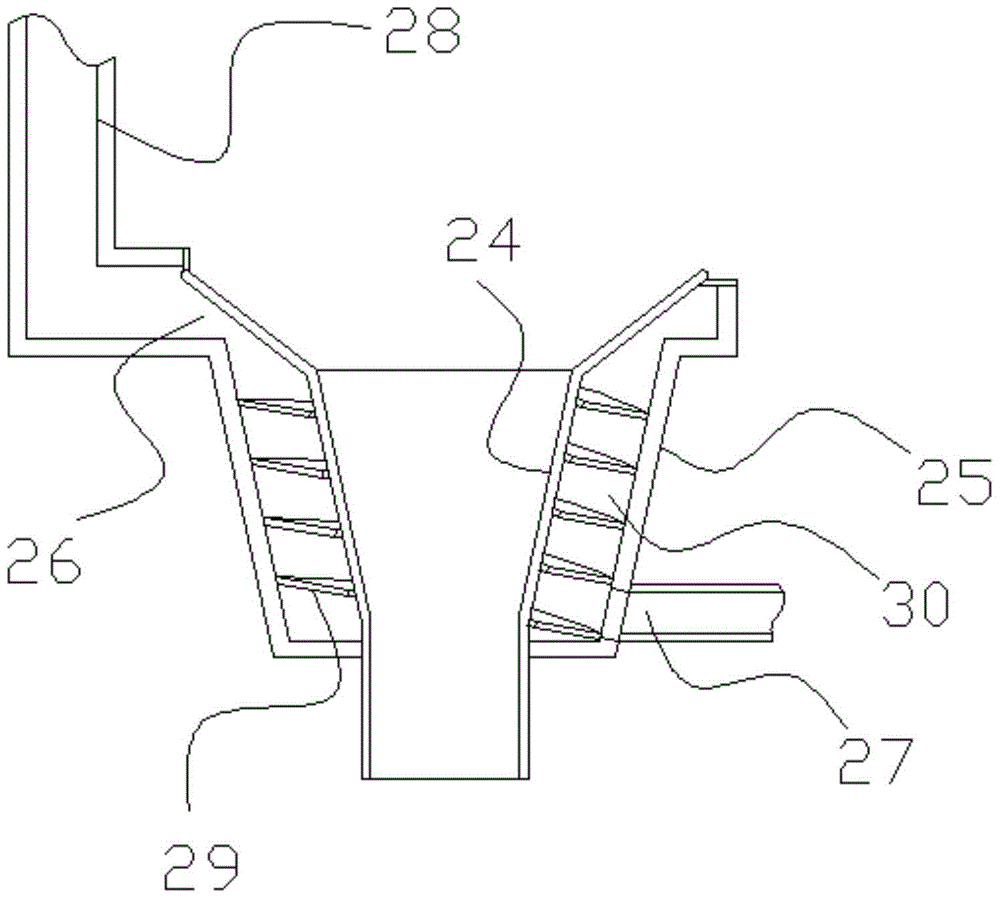

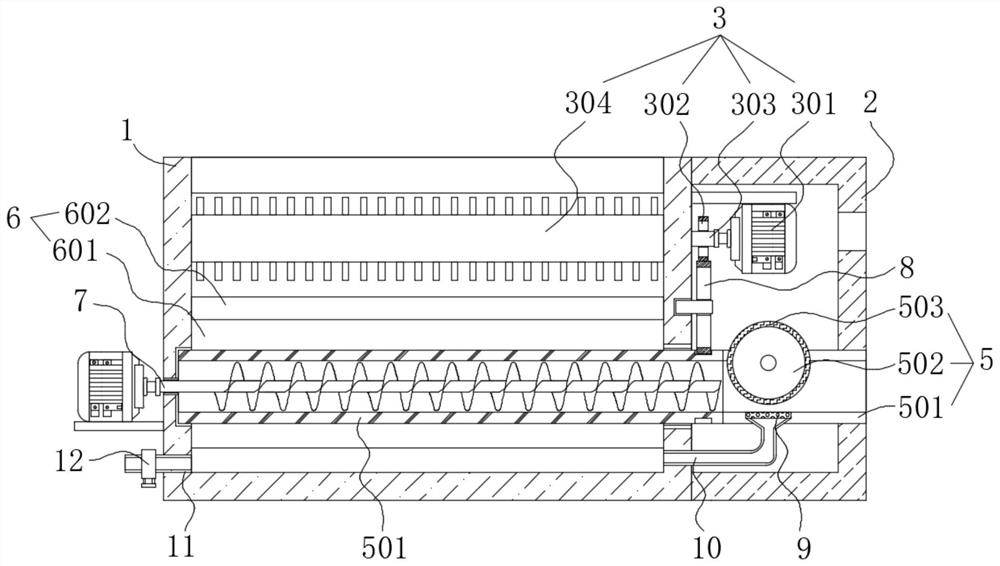

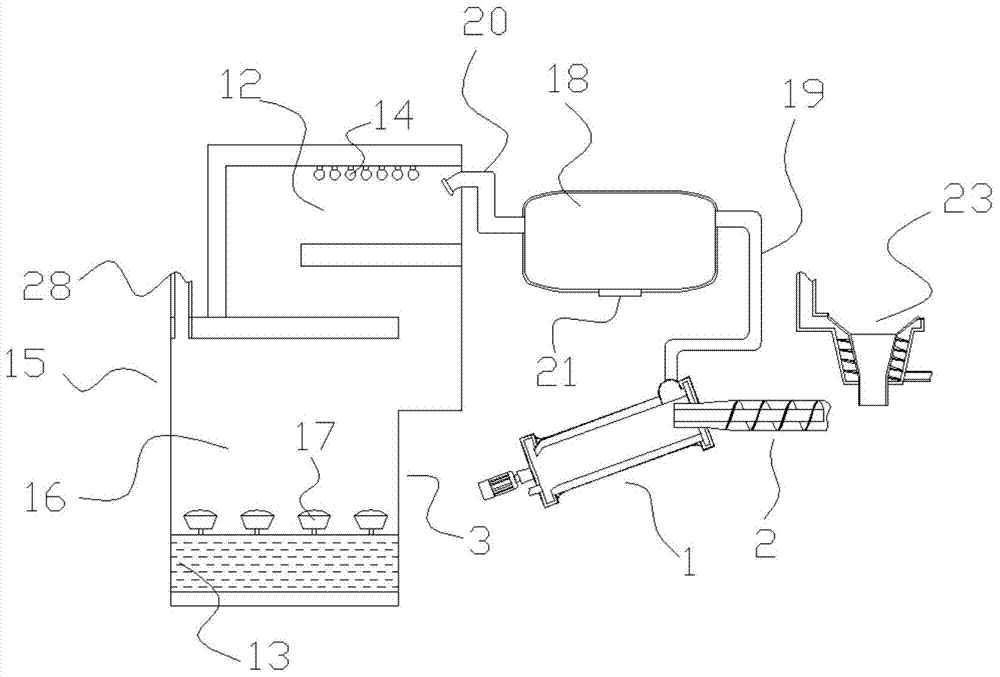

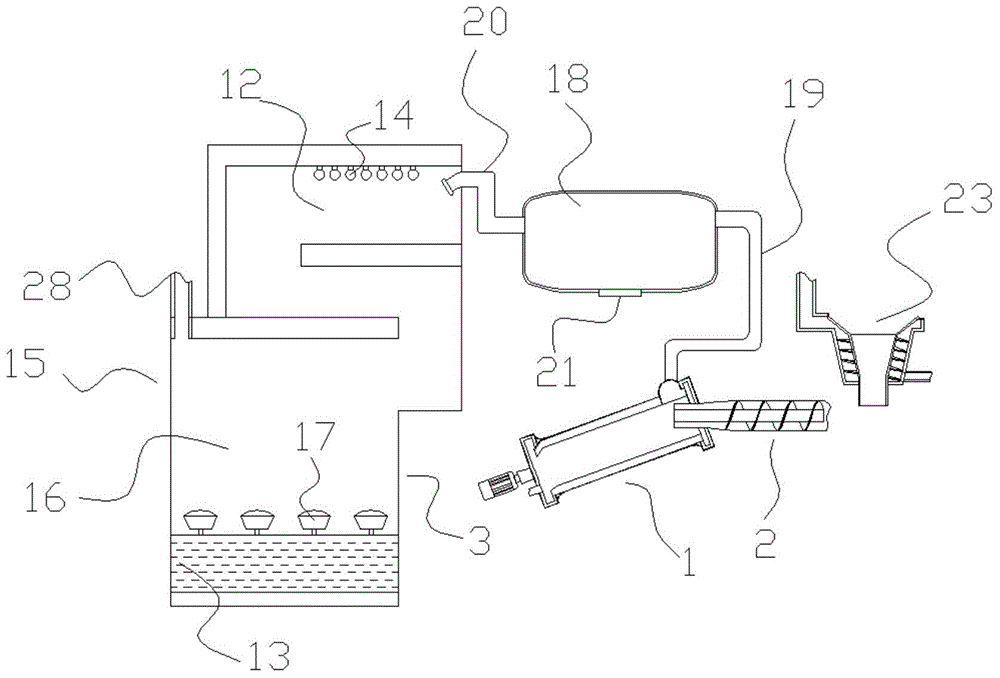

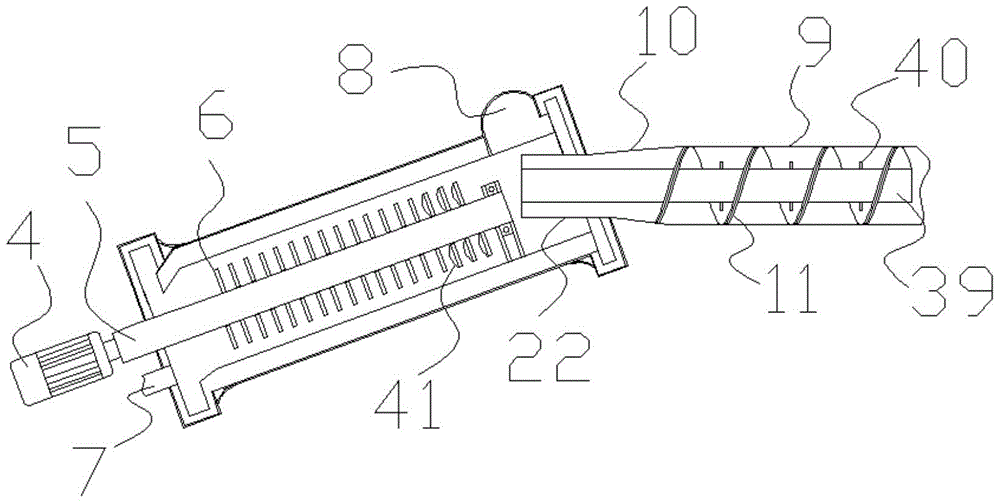

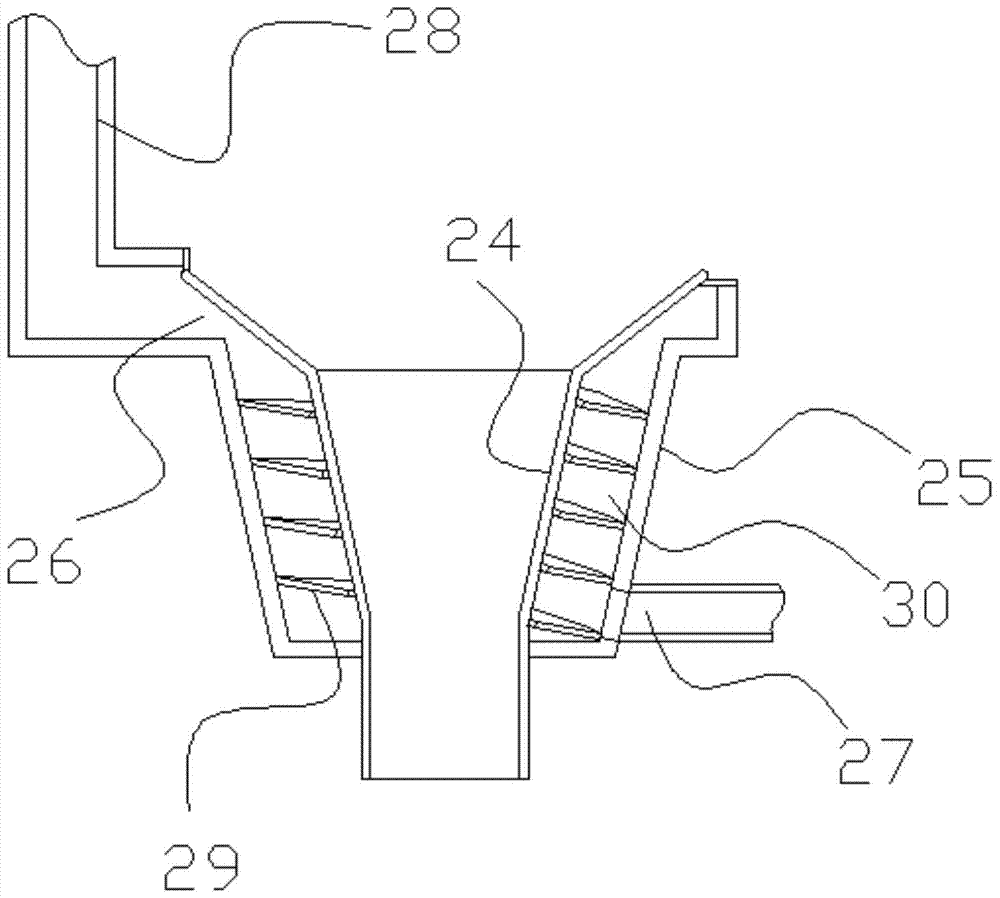

An animal carcass treatment device

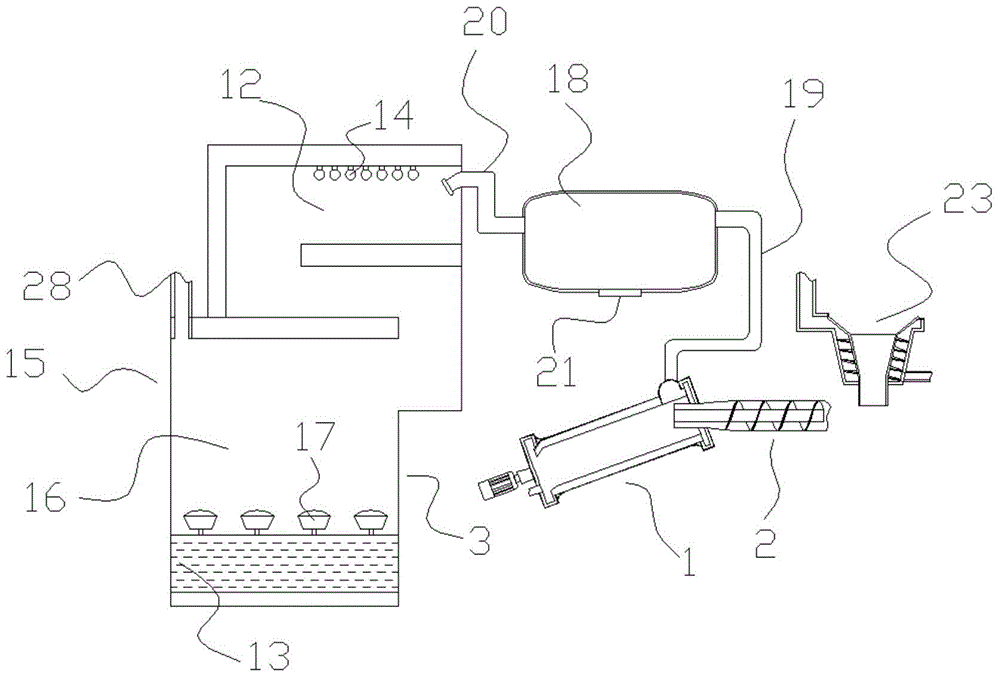

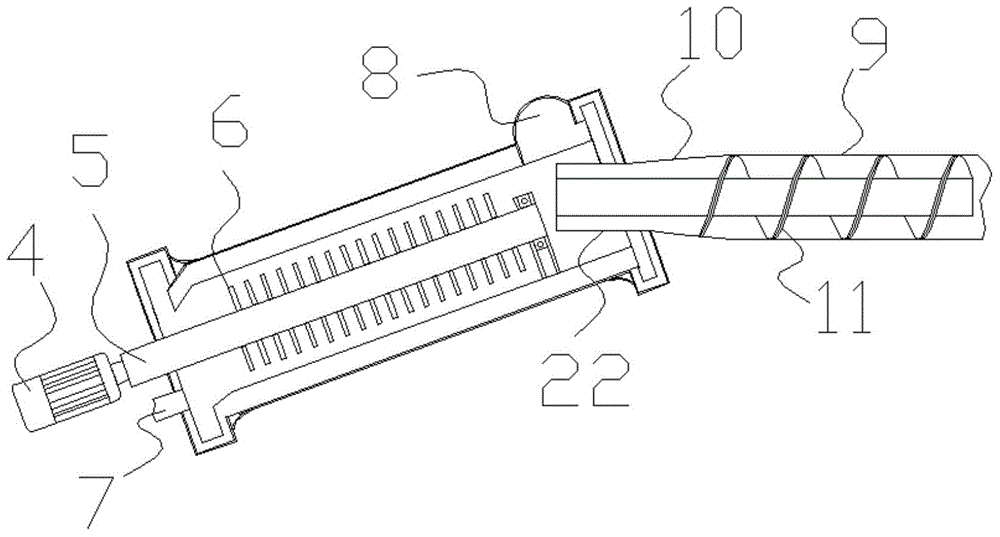

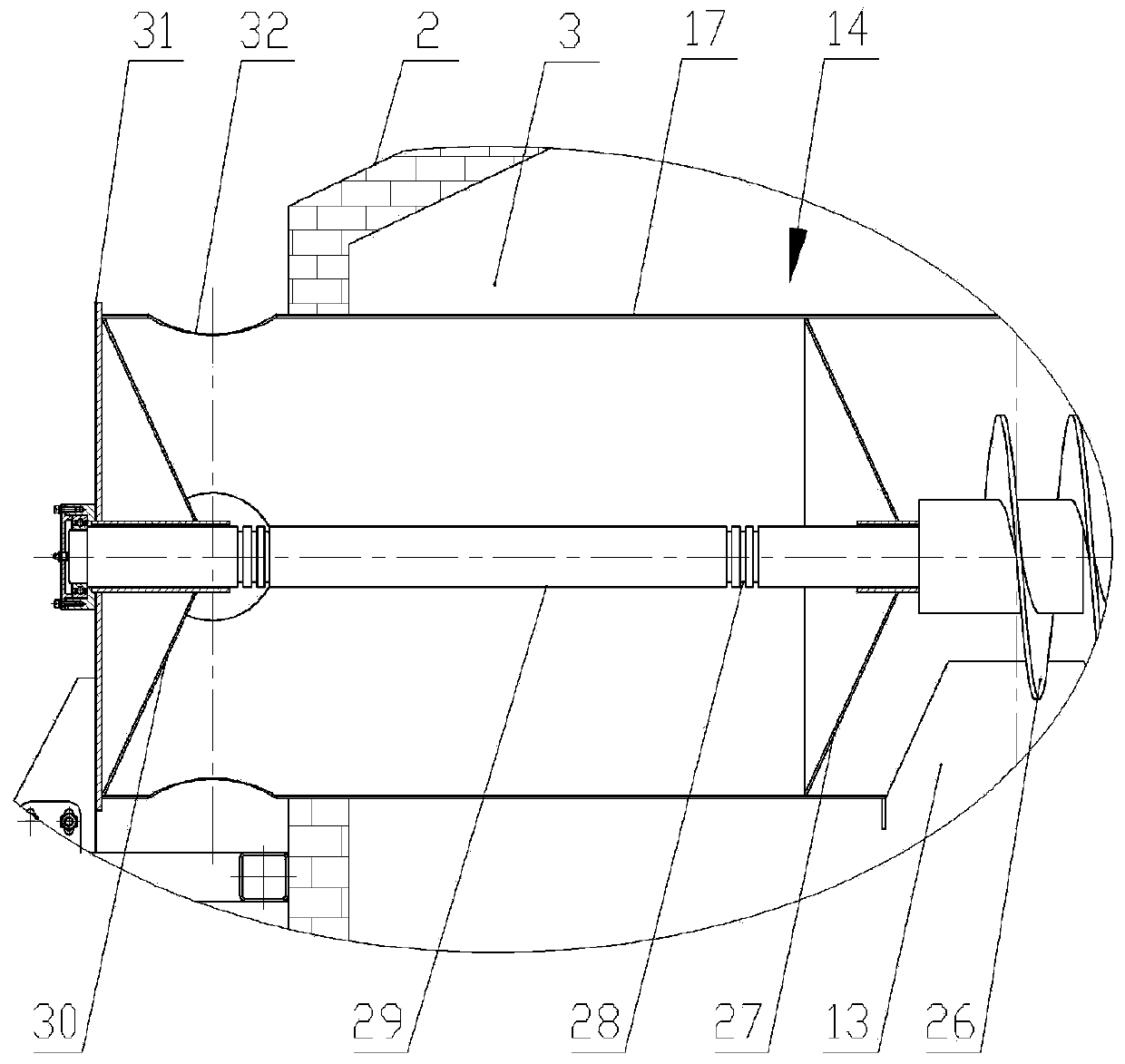

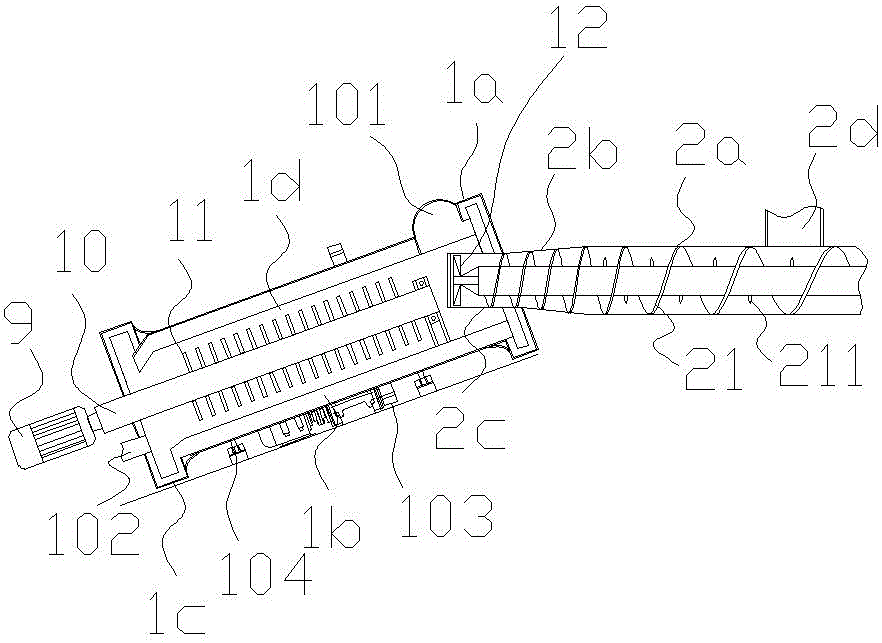

The invention discloses a disposal device for animal carcasses. The disposal device comprises an incinerator, a feeding device for feeding to the incinerator, a smoke purifying device for purifying heat smoke exhausted from the incinerator as well as a preheating device, wherein the incinerator comprises an incinerator body, an incinerator head and an incinerator tail; a driving main shaft driven by a main motor is arranged in an incinerator cavity in the incinerator; a plurality of bulk material bodies for stirring materials are arranged on the driving main shaft; the feeding device comprises a feeding cylinder extending into the incineration cavity from a feed opening; a feeding auger is arranged in the feeding cylinder; the preheating device comprises a preheating hopper and a spiral flue around the preheating hopper; the smoke purifying device comprises a smoke exhausting outer channel and a water falling pool; a plurality of sprinkling heads are arranged at the upper part in the smoke exhausting outer channel. The invention aims at providing the disposal device for the animal carcass; according to the disposal device, the animal carcasses can be effectively and centrally fired; the firing process is stable and efficient; the sufficient incineration can be guaranteed; the smoke gas generated by incineration can be effectively disposed; smoke contamination can be avoided.

Owner:ZHEJIANG SCI-TECH UNIV

Two-stage garbage incinerator

ActiveCN101922715BGuaranteed incineration effectFully dryInclined grateIncinerator apparatusLoss rateCombustion

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP CORP LTD

Livestock and poultry disease carcass process equipment

InactiveCN104654307APerfect removalAchieve clearingCremation furnacesIncinerator apparatusPoultry diseaseProcess equipment

The invention discloses a piece of livestock and poultry disease carcass process equipment. The livestock and poultry disease carcass process equipment comprises an incinerator, a feeding device for feeding materials to the incinerator, a smoke purifying device for purifying hot smoke discharged by the incinerator and a preheating device, wherein the incinerator comprises a furnace body, a furnace head and a furnace tail; a transmission main shaft driven by a main motor is arranged in an incineration chamber in the incinerator; a plurality of material scattering bodies for stirring materials are arranged on the transmission main shaft; the feeding device comprises a feeding tube which extends into the incineration chamber from a feeding hole; a feeding packing auger is arranged in the feeding tube; the preheating device comprises a preheating hopper and a spiral flue around the preheating hopper; the smoke purifying device comprises a smoke discharging outer channel and a fall pool; a plurality of shower heads are arranged in the upper side of the smoke discharging outer channel. The invention aims to provide the livestock and poultry disease carcass process equipment which can burn and process animal carcasses in a concentrated manner, is high and efficient in burning process and full in incineration, can effectively process the generated smoke, and can avoid smoke pollution.

Owner:ZHEJIANG SCI-TECH UNIV

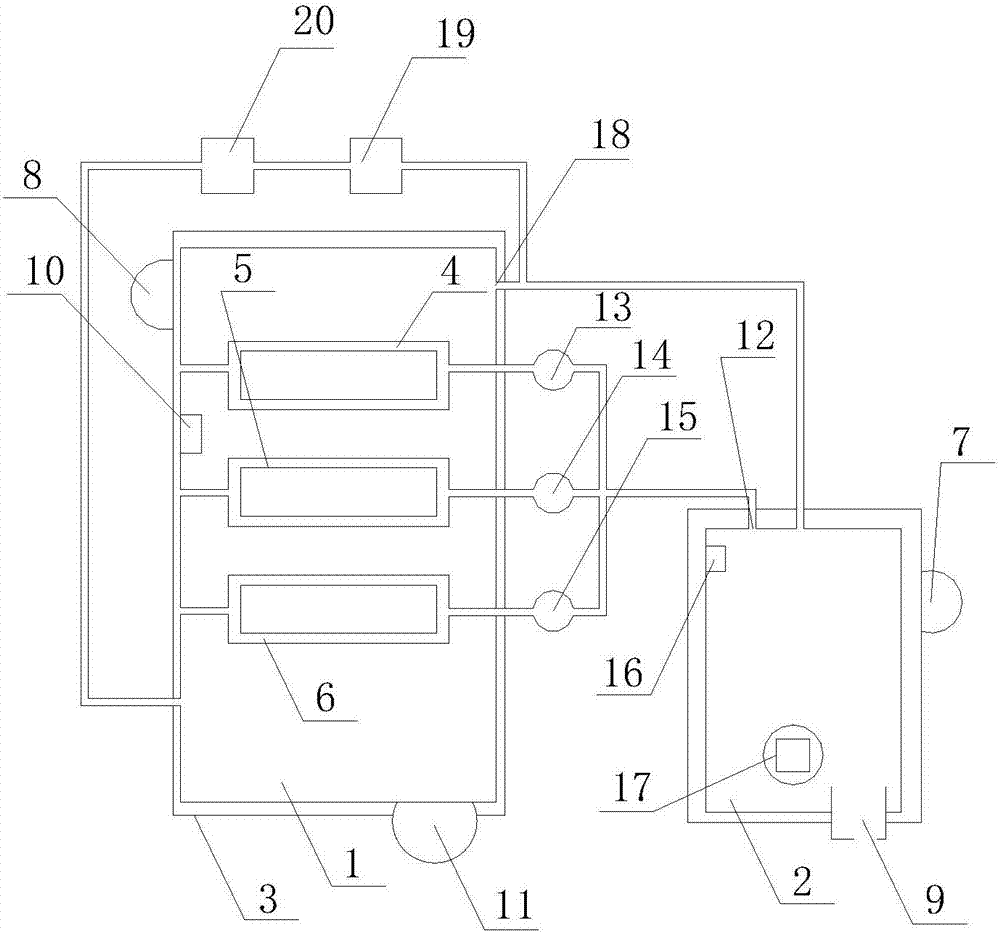

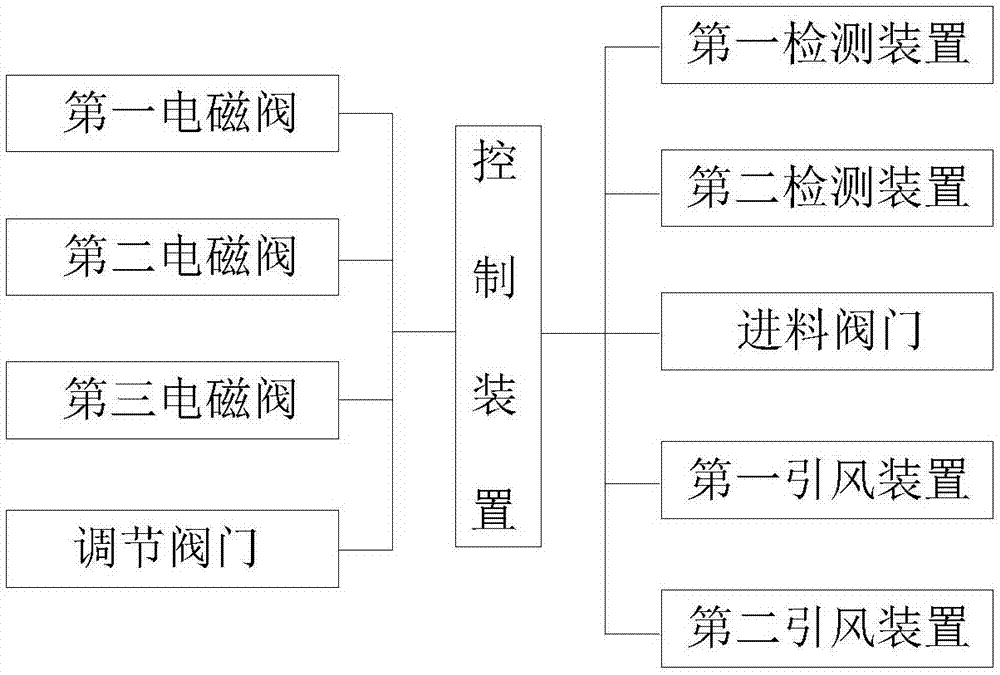

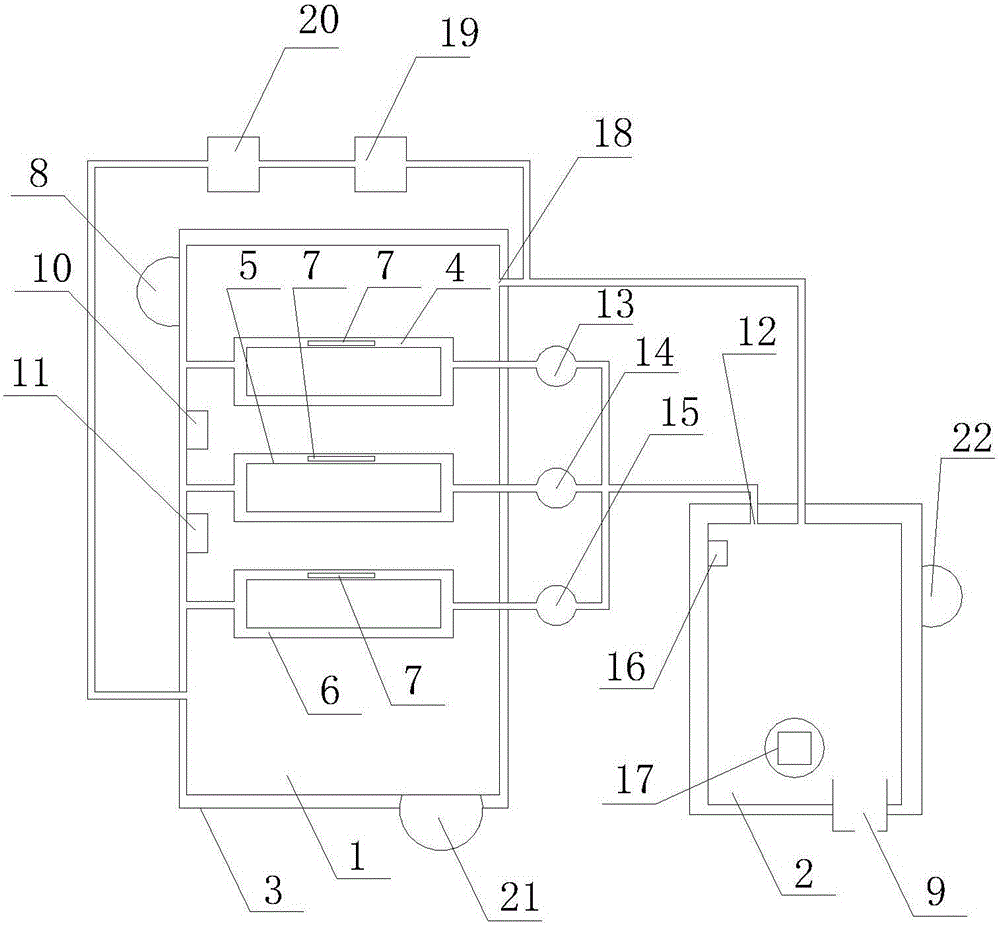

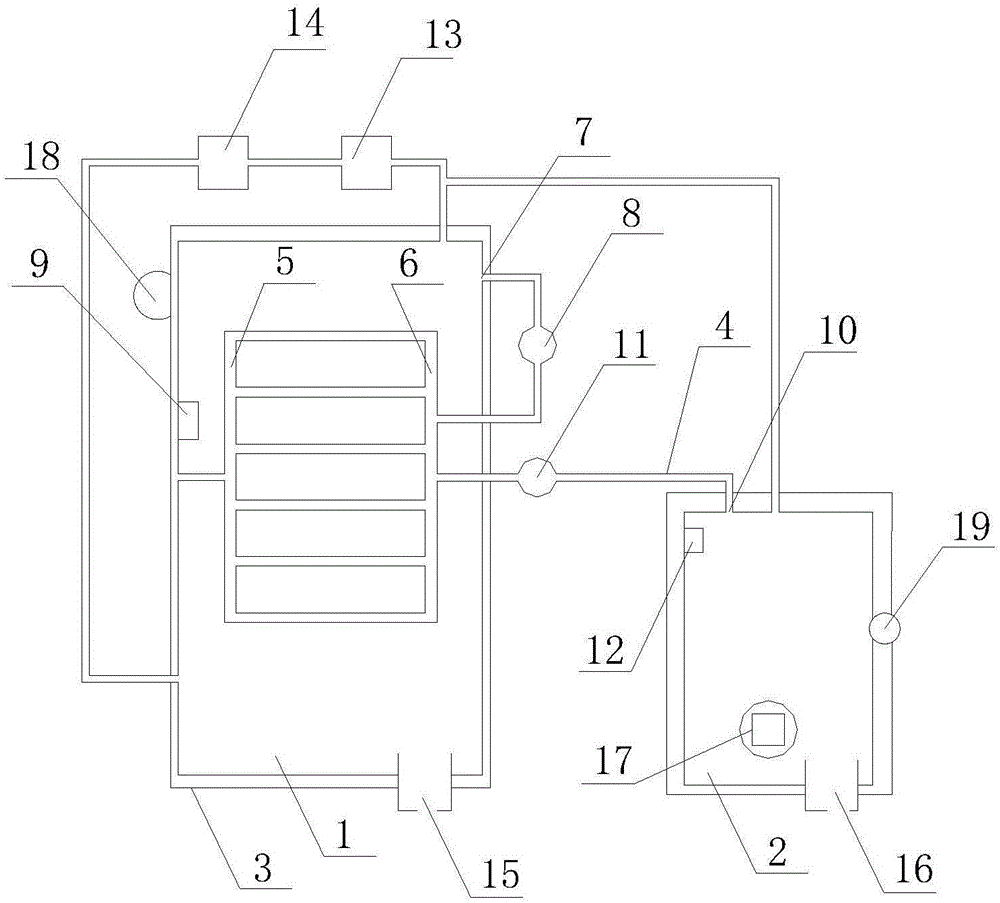

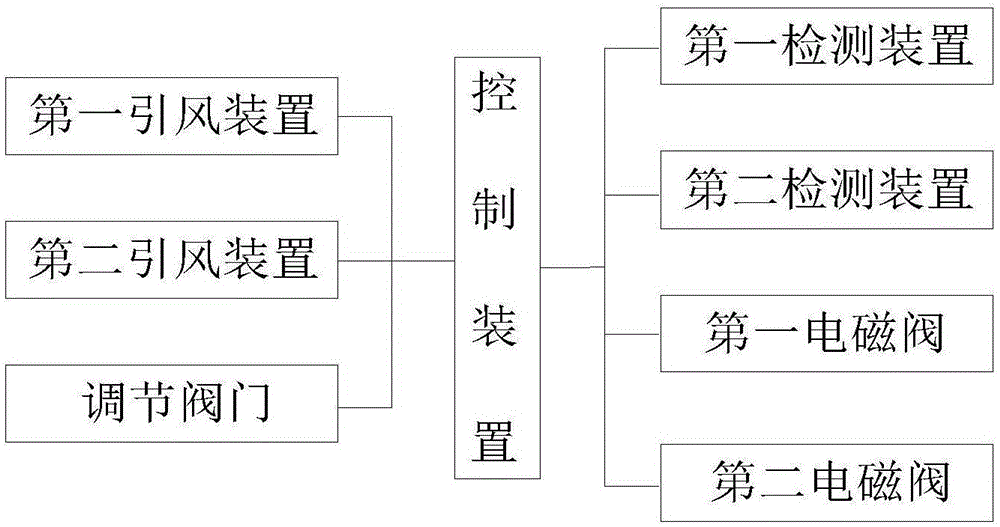

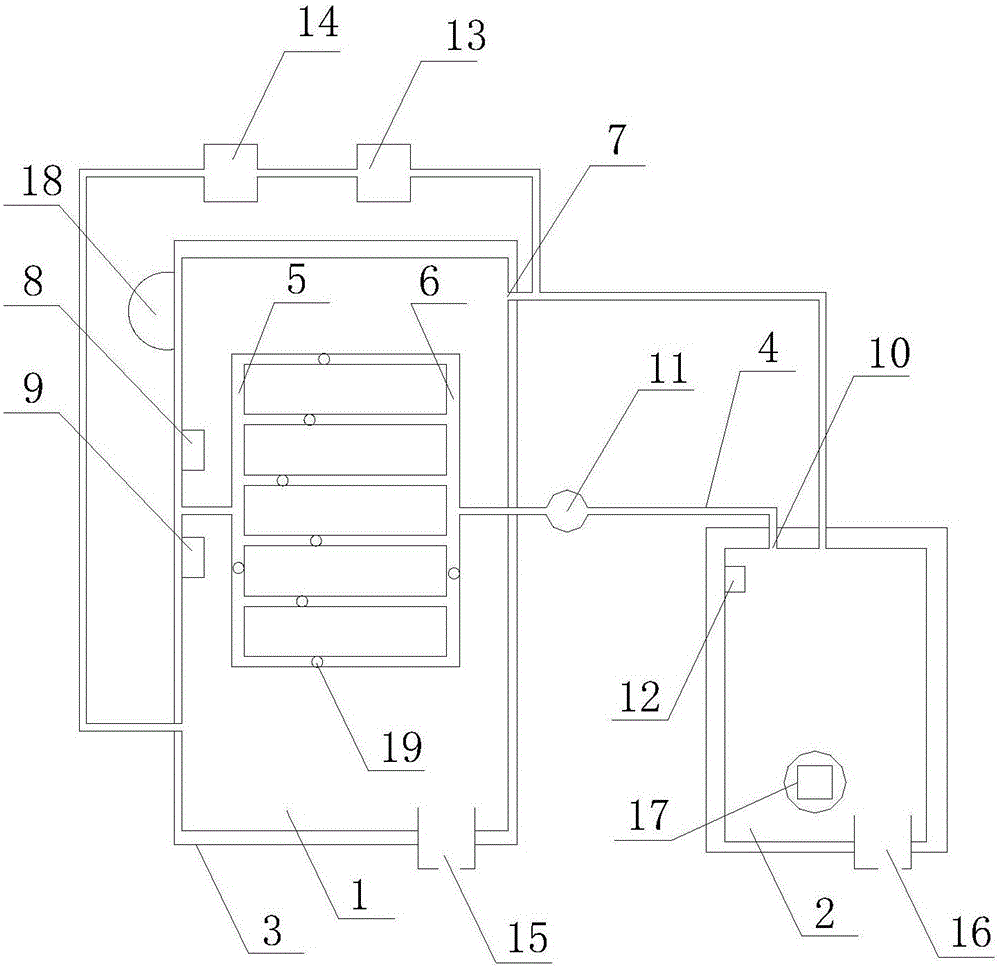

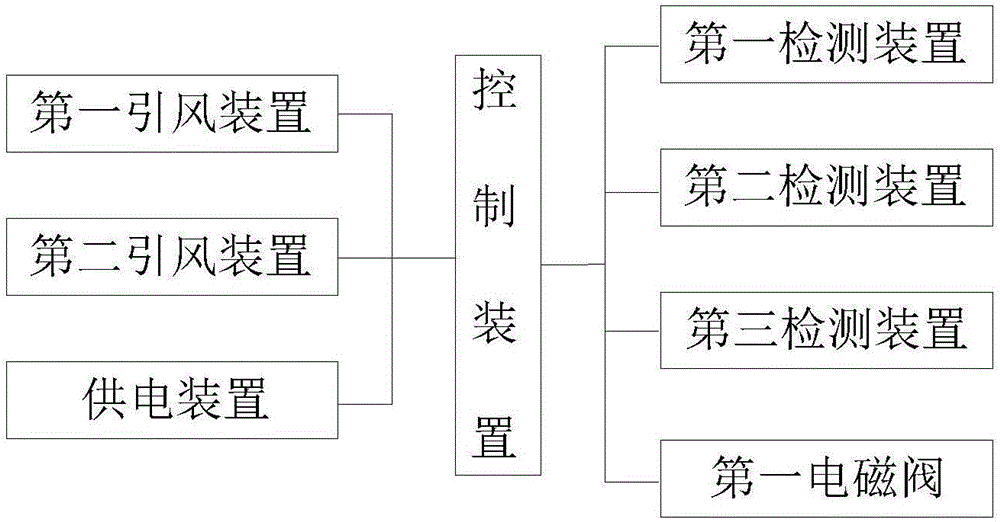

Garbage incinerator circulating gas inlet and automatic falling intelligent control system

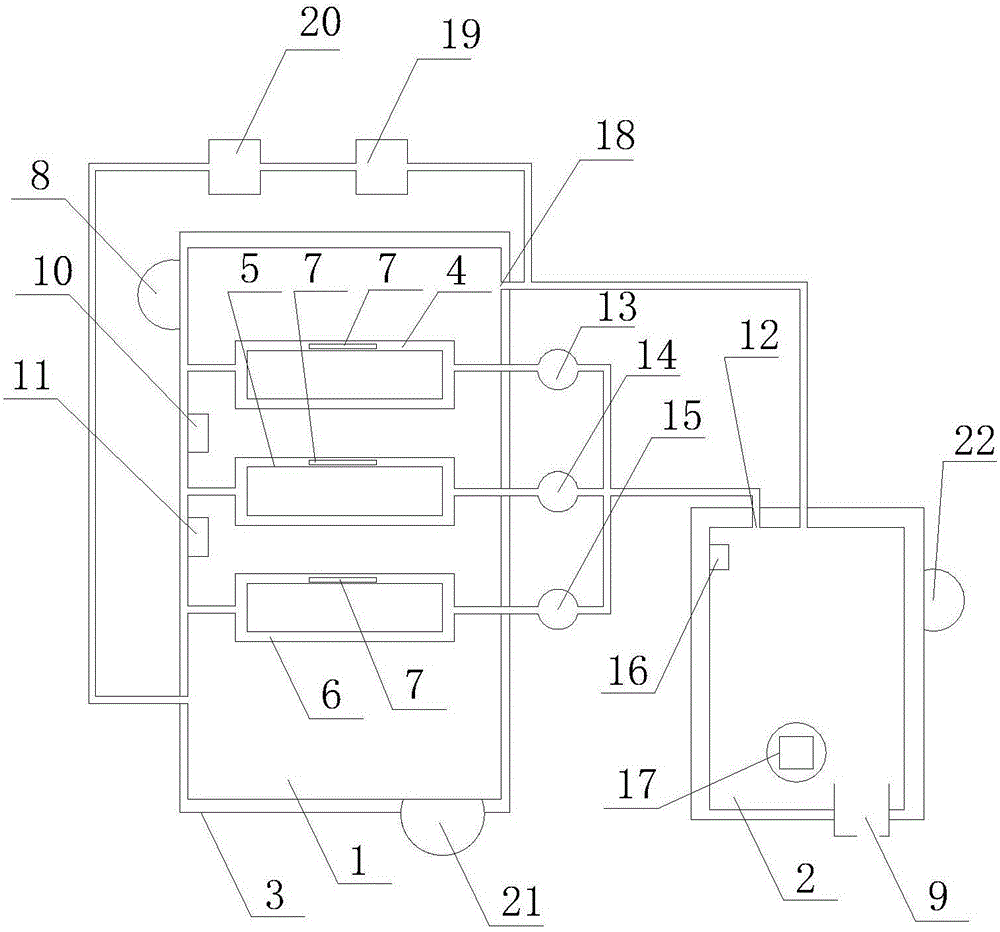

InactiveCN107062260AGood burning conditionBurn completelyIncinerator apparatusSolenoid valveIncineration

The invention discloses a garbage incinerator circulating gas inlet and automatic falling intelligent control system. A first air inducing device is arranged on the outer wall of a shell. A falling opening is formed in the bottom of a first cavity, and an adjusting valve and a speed measuring device are arranged at the falling opening. A first detection device is used for detecting the height value H of the distance between the position, in the first cavity, of a first temperature value and the bottom of the first cavity. A tail gas outlet communicates with a first pipeline loop, a second pipeline loop and a third pipeline loop through pipelines, and the communicating pipelines are provided with a first solenoid valve, a second solenoid valve and a third solenoid valve correspondingly. A second air inducing device is arranged in a second cavity. A second detection device is used for detecting the temperature value T of the tail gas outlet. A control device acquires the detection value H of the first detection device and the detection value T of the second detection device and carries out command control over action of the first air inducing device, the second air inducing device, the first solenoid valve, the second solenoid valve, the third solenoid valve and the adjusting valve according to the magnitude of H and the magnitude of T.

Owner:SINOBIOWAY DINGHE ENVIRONMENTAL PROTECTION CO LTD

Small collaborative incinerator

PendingCN111156522AInhibition of segregationGuaranteed uniformityIncinerator apparatusChimneysCombustionMechanical engineering

The invention relates to a structure of a small collaborative incinerator. The small collaborative incinerator comprises an incinerator body and a feeding system. A small supporting seat and a large supporting seat are arranged on the outer side of the incinerator body, a standby smoke vent is formed in the top, and an incinerator chamber and an ash pit are formed inside. The feeding system comprises an outer cylinder and an auxiliary material barrel and integrally penetrates through the incinerator body, the outer cylinder is provided with a material outlet, a main feeding port and an exhaustpipe, and a material pushing spiral is arranged in the outer cylinder; and the auxiliary material barrel is provided with an auxiliary feeding port, and a material mixing spiral is arranged in the auxiliary material barrel. When the incinerator works, different materials enter the feeding system through the main feeding port and the auxiliary feeding port and stirred evenly and then enter the incinerator chamber through the material outlet to be incinerated; and the incinerator has the advantages that the waste adaptation range is wide, two or more types of waste can be collaboratively treated, and a combustion effect is improved.

Owner:云南净美环保科技有限公司

A plant ash production and collection device

InactiveCN104609922BRealize separation and purificationHas clearedEnergy inputIncinerator apparatusParticulatesStart stop

Owner:ZHEJIANG SCI-TECH UNIV

Inorganic Phosphate Fertilizer Manufacturing Equipment

InactiveCN104654309BPerfect removalAchieve clearingCremation furnacesIncinerator apparatusInorganic phosphateBurn treatment

The invention discloses an inorganic phosphate fertilizer manufacturing device. The inorganic phosphate fertilizer manufacturing device comprises an incinerator, a feeding device for feeding materials to the incinerator, a smoke purification device for purifying hot smoke exhausted by the incinerator and a preheating device, wherein the incinerator comprises a furnace body, a furnace head and a furnace tail, a transmission main shaft driven by a main motor is arranged in an incineration cavity in the incinerator, and the transmission main shaft is provided with multiple bulk cargo bodies which are used for stirring the materials; the feeding device comprises a feeding tube stretching from a feed inlet into the incineration cavity, and a feeding auger is arranged in the feeding tube; the preheating device comprises a preheating hopper and a spiral flue surrounding the preheating hopper; the smoke purification device comprises an outer smoke discharging channel and a water falling pool, and multiple sprinkler heads are arranged on the upper side in the outer smoke discharging channel. According to the inorganic phosphate fertilizer manufacturing device provided by the invention, burning treatment can be effectively carried out on animal carcasses, the burning process is stable and efficient, full incineration is ensured, the generated smoke can be effectively treated, and smoke dust pollution can be prevented.

Owner:ZHEJIANG SCI-TECH UNIV

Kitchen garbage disposal system

The invention discloses a kitchen garbage disposal system. The kitchen garbage disposal system comprises an incinerator, a feeding device, a smoke purifying device and a preheating device, wherein the feeding device feeds materials to the incinerator; the smoke purifying device is used for purifying hot smoke discharged from the incinerator; the incinerator comprises an incinerator body, an incinerator head and an incinerator tail; a transmission spindle which is driven by a main motor is arranged in an incineration cavity in the incinerator; a plurality of material scattering bodies which are used for shifting the materials are arranged on the transmission spindle; the feeding device comprises a feeding barrel which extends into the incineration cavity from a feeding opening; a feeding auger is arranged in the feeding barrel; the preheating device comprises a preheating hopper and a spiral flue surrounding the preheating hopper; the smoke purifying device comprises a smoke discharging outer channel and a pond; and a plurality of shower heads are arranged on the upper portion of the inside of the smoke discharging outer channel. By the kitchen garbage disposal system, dead animals can be incinerated effectively in a centralized manner, an incinerating process is stable and efficient, sufficient incineration can be guaranteed, generated smoke can be treated effectively, and smoke pollution can be avoided.

Owner:ZHEJIANG SCI-TECH UNIV

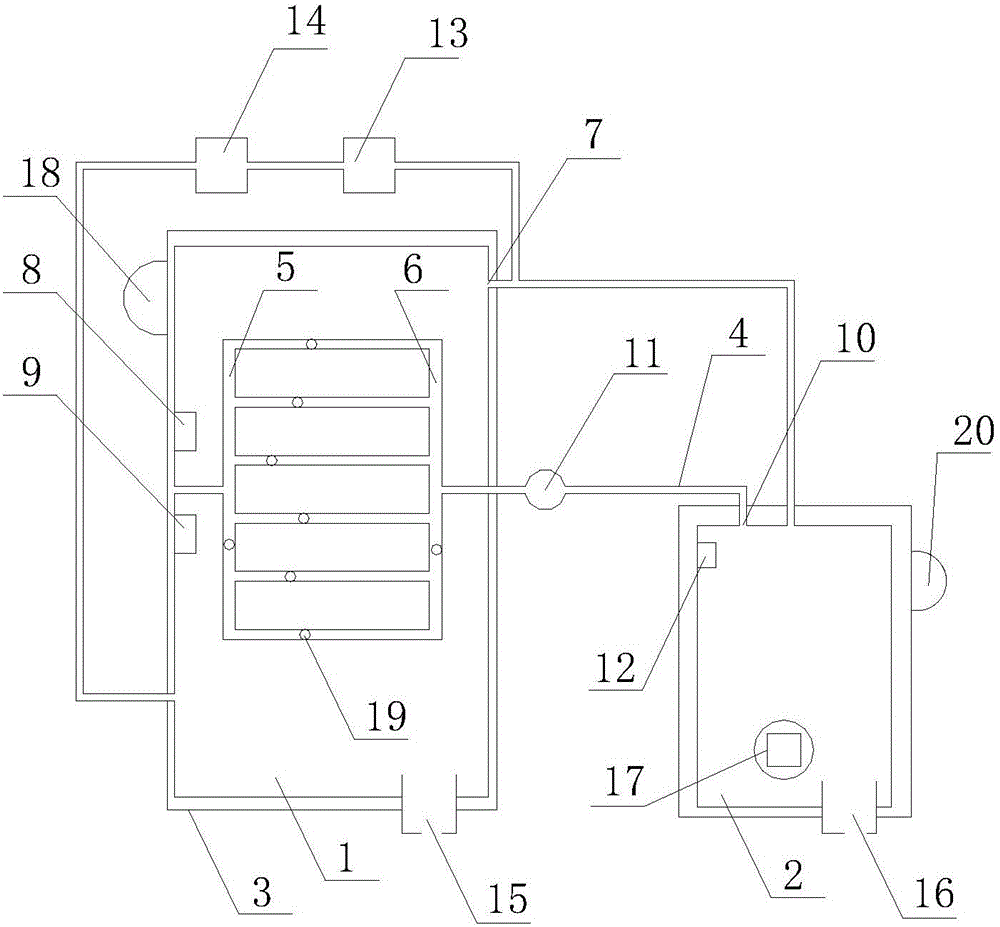

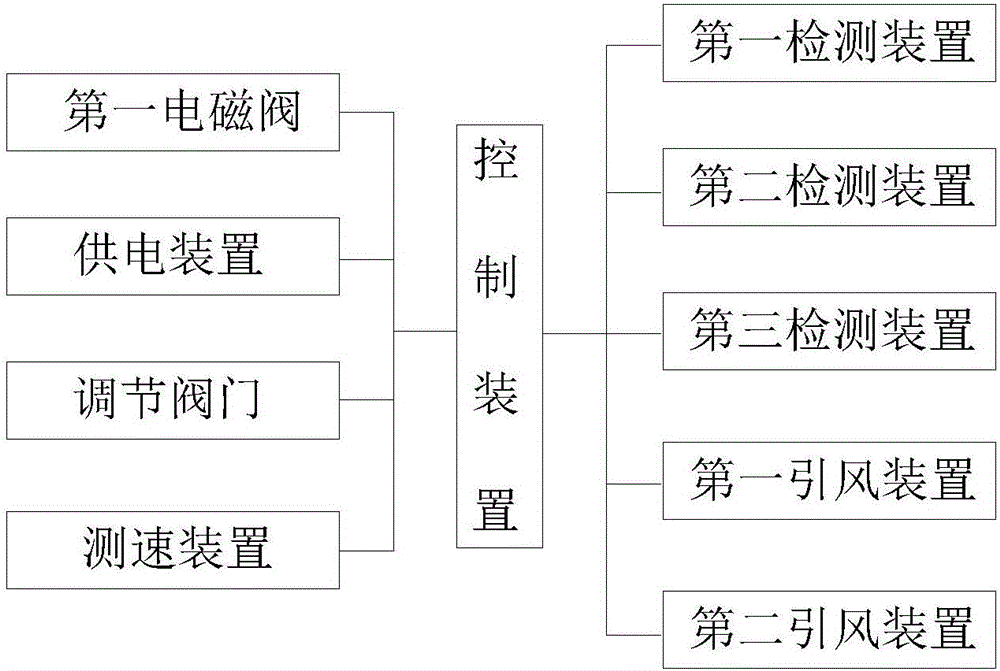

Efficient circular air inlet and automatic blanking control system of garbage incinerator

InactiveCN106838925AImprove incineration effectGuaranteed incineration effectIncinerator apparatusExhaust gasEngineering

The invention discloses an efficient circular air inlet and automatic blanking control system of a garbage incinerator. A first air inducing device is arranged on the outer wall of a shell body. A power supplying device is connected with a heating device. A blanking opening is formed in the bottom of a first cavity. An adjusting valve is arranged at the blanking opening. A first detecting device is used for detecting the temperature value of a first position. A second detecting device is used for detecting the temperature value of a second position. A third detecting device is used for detecting the temperature value of a tail gas outlet. The control device detects the temperature value T01 of the first position in the first cavity through the first detecting device, detects temperature value T02 of the second position in the first cavity through the second detecting device, calculates a difference value T0 of the T01 and the T02, obtains the temperature value T at the tail gas outlet through the third detecting device and controls the motions of the first air inducing device, a second air inducing device, a first electromagnetic valve, a second electromagnetic valve, a third electromagnetic valve, the power supplying device and the adjusting valve with commands according to T and T0.

Owner:SINOBIOWAY DINGHE ENVIRONMENTAL PROTECTION CO LTD

A device for incinerating crop straw

InactiveCN104566406BRealize separation and purificationHas clearedIncinerator apparatusParticulatesFlue gas

The invention discloses an incinerator for crop straws, and aims to provide an incinerator capable of effectively and intensively burning wheat straws, effectively treating flue gas and preventing smoke contamination caused by flue gas pollution, wherein a stable and efficient burning process can be ensured, the sufficient burning can be guaranteed and the purity of an ash fertilizer is high. The incinerator comprises an incineration kiln, a feeding device and a smoke purifying device, wherein the incineration kiln comprises an inner incineration cavity, the incineration kiln is inclined, an angle of 10-60 degrees is formed between the horizontal plane and the incineration kin, and the inner incineration kiln is provided with a driving spindle driven by a main motor; the driving main motor is provided with a plurality of material scattering bodies used for poking materials, and the incineration kiln is provided with an air inlet, a smoke outlet, a feeding hole and a purging opening and closing door. The incinerator provided by the invention has the beneficial effects of good separation effect, and solid particulate matters and powder in flue gas can be cleaned up; furthermore, raw materials can be dried by the waste heat of the flue gas, therefore the successive burning effect can be improved; in addition, the incinerator is provided with a preheating structure, and the subsequent incineration can be ensured more sufficiently.

Owner:ZHEJIANG SCI-TECH UNIV

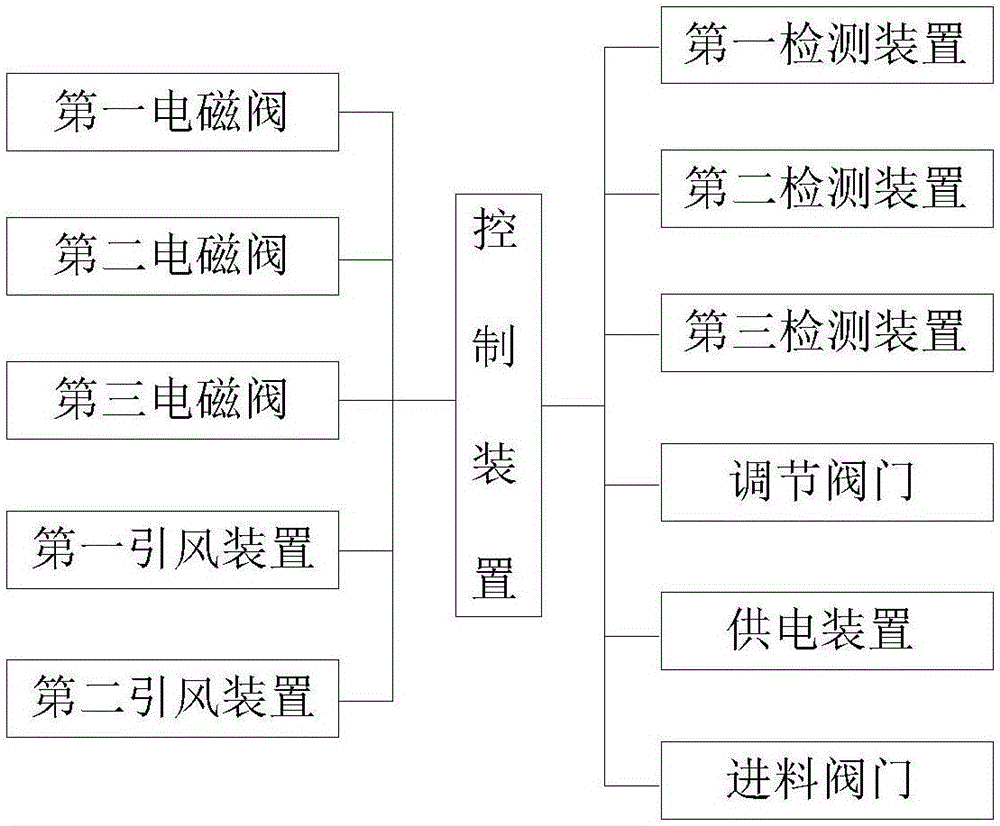

Garbage incinerator efficient circulation controlling system

The invention discloses a garbage incinerator efficient circulation controlling system. A first air inducing device is arranged on the outer wall of a shell body. Heating devices are arranged in a first pipeline loop, a second pipeline loop and a third pipeline loop correspondingly. A power supply device is connected with the heating devices. An adjusting valve is arranged in the position of a blanking opening. A first detection device and a second detection device are arranged in a first cavity. A first solenoid valve, a second solenoid valve and a third solenoid valve are arranged on a fourth pipeline, a fifth pipeline and a sixth pipeline correspondingly. A second air inducing device is arranged in a second cavity. A feeding valve is arranged in the position of a feeding inlet. A third detection device is arranged in a second cavity. A controlling device obtains the detected values of the first detection device and the second detection device and calculates the differential value T0. The controlling device obtains the detected value T of the third detection device and controls the first air inducing device, the second air inducing device, the first solenoid valve, the second solenoid valve, the third solenoid valve, the power supply device, the adjusting valve and the feeding valve to operate with instructions according to the size of T and T0.

Owner:SINOBIOWAY DINGHE ENVIRONMENTAL PROTECTION CO LTD

Municipal waste treatment device with water source separation function

PendingCN114749239AImprove processing efficiencyEfficient separationGrain treatmentsPressesWater sourceEnvironmental engineering

The invention relates to municipal waste treatment equipment, in particular to a municipal waste treatment device with a water source separation function. Comprising a first box body, a second box body, a crushing assembly, a solid-liquid separation assembly, a discharging assembly, a material guiding assembly and an auger, the first box body is adjacent to the second box body, the crushing assembly, the material guide assembly and the solid-liquid separation assembly are sequentially installed in the first box body from top to bottom, a drainage pipe is arranged at the bottom of the first box body, and the auger is installed in the solid-liquid separation assembly; the auger is connected with the discharging assembly, the discharging assembly is installed in the second box body, one end of the water guide pipe is connected with the discharging assembly, and the other end of the water guide pipe is communicated with the interior of the first box body. According to the garbage treatment device, water sources attached to garbage can be efficiently separated, the later incineration effect is guaranteed, and the garbage treatment efficiency is improved.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Garbage incinerator gas circulating control system based on temperature detection

InactiveCN106813248AIncrease temperatureGuaranteed incineration effectIncinerator apparatusExhaust gasGas pipeline

The invention discloses a garbage incinerator gas circulating control system based on temperature detection. The system comprises a first cavity, a second cavity, a shell, a first detection device, a second detection device and a control device; a first air induction device is arranged on the outer wall of the shell, a first tail gas outlet is communicated with a second pipeline through a first tail gas pipeline, a first electromagnetic valve is arranged on the first tail gas pipeline, the first detection device is used for detecting the temperature value T of the first position in the first cavity, a second tail gas outlet is communicated with a second pipeline through a second tail gas pipeline, a second electromagnetic valve is arranged on the second tail gas pipeline, a second air induction device is arranged in the second cavity, and the second detection device is used for detecting the temperature value T0 on a tail gas outlet; the control device obtains the detection value T of the first detection device and the detection value T0 of the second detection device and controls the first air induction device, the second air induction device, the first electromagnetic valve and the second electromagnetic valve to act according to size instructions of T and T0.

Owner:SINOBIOWAY DINGHE ENVIRONMENTAL PROTECTION CO LTD

A centralized plant ash fertilizer production equipment

InactiveCN104557192BRealize separation and purificationHas clearedEnergy inputPotassium fertilisersParticulatesWood ash

The invention discloses a plant ash fertilizer centralized production equipment, aiming to provide a kind of equipment which can effectively carry out concentrated burning treatment on wheat straw, the burning process is stable and efficient, can ensure sufficient burning, the ash fertilizer produced has high purity, and can reduce the production of wheat straw. The flue gas is effectively treated to avoid the equipment that causes smoke pollution. It includes an incineration kiln, a feeding device, and a smoke-cleaning device: the incineration kiln has an incineration cavity, the incineration kiln is inclined and is 10 to 60 degrees from the horizontal plane, and the incineration cavity is equipped with a main The transmission shaft driven by the motor, the transmission shaft is provided with a plurality of bulk materials for moving materials, and the incineration kiln is provided with an air inlet, a smoke outlet, a material inlet, and a material cleaning opening and closing Door. The beneficial effects of the invention are: excellent separation effect; removal of solid particles and dust in flue gas; use of waste heat of flue gas to dry raw materials to improve subsequent firing effect; with preheating structure, better and more Fully guarantee the subsequent incineration.

Owner:ZHEJIANG SCI-TECH UNIV

Incinerator for crop straws

InactiveCN104566406ARealize separation and purificationHas clearedIncinerator apparatusParticulatesMaterial scattering

The invention discloses an incinerator for crop straws, and aims to provide an incinerator capable of effectively and intensively burning wheat straws, effectively treating flue gas and preventing smoke contamination caused by flue gas pollution, wherein a stable and efficient burning process can be ensured, the sufficient burning can be guaranteed and the purity of an ash fertilizer is high. The incinerator comprises an incineration kiln, a feeding device and a smoke purifying device, wherein the incineration kiln comprises an inner incineration cavity, the incineration kiln is inclined, an angle of 10-60 degrees is formed between the horizontal plane and the incineration kin, and the inner incineration kiln is provided with a driving spindle driven by a main motor; the driving main motor is provided with a plurality of material scattering bodies used for poking materials, and the incineration kiln is provided with an air inlet, a smoke outlet, a feeding hole and a purging opening and closing door. The incinerator provided by the invention has the beneficial effects of good separation effect, and solid particulate matters and powder in flue gas can be cleaned up; furthermore, raw materials can be dried by the waste heat of the flue gas, therefore the successive burning effect can be improved; in addition, the incinerator is provided with a preheating structure, and the subsequent incineration can be ensured more sufficiently.

Owner:ZHEJIANG SCI-TECH UNIV

A kind of inorganic potassium fertilizer manufacturing device

InactiveCN104613479BRealize separation and purificationHas clearedEnergy inputIncinerator apparatusParticulatesBurn treatment

The invention discloses an inorganic potash fertilizer manufacturing device assembly and is aimed at providing the device assembly which can effectively conduct a centralized burning treatment on wheat straw while achieving a stable and high efficiency burning process with guaranteed sufficient burning. Moreover, the device assembly is capable of manufacturing high purity ash fertilizer, conducting an effective treatment on flue gas generated, and avoiding flue dust pollution. The inorganic potash fertilizer manufacturing device assembly comprises a burning kiln, a feeding device and a flue gas purifying device, wherein the burning kiln is provided with a burning cavity; the burning kiln inclines and an angle of 10-60 degree is formed between the burning kiln and a horizontal plane; the inner burning cavity is internally provided with a transmission main shaft driven by a main motor; the transmission main shaft is provided with multiple material scattering objects used for stirring materials; the burning kiln is provided with an air inlet, a flue gas outlet portion, a material feeding port and an opening-closing door for scrap cleaning. The inorganic potash fertilizer manufacturing device assembly has the advantages that the separating effect is excellent; solid particles and dust in the flue gas can be eliminated; raw materials are subjected to drying by the adoption of residual heat of the flue gas so that a subsequent burning effect can be improved; a preheating structure is arranged so that subsequent burning can be guaranteed better and more sufficiently.

Owner:ZHEJIANG SCI-TECH UNIV

Bone incinerating equipment

InactiveCN104676594APerfect removalAchieve clearingCremation furnacesIncinerator apparatusDead bodyEngineering

The invention discloses bone incinerating equipment comprising an incinerator, a feeder, a smoke purifier and a preheater. The feeder is used for feeding materials into the incinerator. The smoke purifier is used for purifying hot smoke discharged by the incinerator. The incinerator comprises a body, a head and a tail; an incinerating chamber in the body is provided with a transmission spindle driven by a main motor; the transmission spindle is provided with a plurality of scattering members used for stirring the materials. The feeder comprises a feed cylinder extending into the incinerating chamber from a feed opening. A feed screw is disposed within the feed cylinder. The preheater comprises a preheating hopper and a spiral flue surrounding the preheating hopper. The smoke purifier comprises a discharge outer duct and a water receiver; a plurality of sprinklers are arranged in the upper portion of the inside of the discharge outer duct. The bone incinerating equipment has the advantages that animal corpses can be effectively centrally incinerated, the incinerating process is stable and efficient, sufficient incineration is guaranteed, produced smoke can be effectively treated, and smoke pollution can be avoided.

Owner:ZHEJIANG SCI-TECH UNIV

an exhaust gas burner

ActiveCN105240862BReduce the number of openingsReduce areaIncinerator apparatusCombustorCombustion chamber

An exhaust gas burner, which is installed at the lower part or the head of the incinerator, and a plurality of burner nozzles are arranged inside, and each burner nozzle is equipped with an independent ignition gun, a fuel pipeline rising pipe and a valve. To the bottom, there are outlet contraction section, combustion chamber, waste gas collection cabin, mixing air collection cabin, and combustion air collection cabin; the exhaust gas burner is connected with the incinerator body through the exit contraction section, and the waste gas collection cabin, The mixing air collection cabin and the combustion-supporting air collection cabin are all equipped with independent inlets, and each collection cabin is connected to the corresponding outlet on the distribution mixing plate through the corresponding riser pipe to form independent exhaust flow channels, mixing air flow channels, Combustion-supporting air flow channel; the fuel pipeline rising pipe of each burner burner is coaxially arranged with the combustion-supporting air rising pipe, and the outlet is arranged at the combustion-supporting air outlet. The exhaust gas burner proposed by the invention has high integration degree, compact and reliable structure, sufficient incineration, high thermal efficiency and convenient operation.

Owner:LUOYANG MINGYUAN PETROCHEM IND TECH +1

A fully automatic domestic waste treatment system and method

InactiveCN108800139BGuaranteed incineration effectHigh degree of reductionIncinerator apparatusCombined combustion mitigationFlue gasMagnetic separator

The invention provides a full-automatic disposal system for domestic garbage. The full-automatic disposal system comprises a garbage warehouse, an incinerator, a conveying system, a flue gas treatmentsystem and a slag treatment system. The conveying system comprises a grab bucket crane, a first conveyor belt, a first magnetic separator, a crushing machine, a screening conveyor belt, a second conveyor belt and a third conveyor belt. The screening conveyor belt is separately connected with the crushing machine and the third conveyor belt, and the screening conveyor belt is ring-shaped, includesa plurality of moving grids, and is provided with a cavity accommodating the second conveyor belt in the middle. The conveying direction of the screening conveyor belt is perpendicular to the conveying direction of the second conveyor belt, and the second conveyor belt conveys the domestic garbage filtered by the moving grids in the screening conveyor belt to a feeding hopper of the incinerator.The third conveyor belt returns the domestic garbage conveyed by the screening conveyor belt to the crushing machine. The full-automatic disposal system performs magnetic separation and crushing treatment on the domestic garbage through the conveying system, thereby ensuring the incineration effect of the domestic garbage, effectively improving the degree of reduction, and meeting the present requirements.

Owner:SHAANXI SCI TECH UNIV

Livestock and poultry disease meat carcasses processing equipment

InactiveCN104654307BPerfect removalAchieve clearingCremation furnacesIncinerator apparatusIncineration

The invention discloses a piece of livestock and poultry disease carcass process equipment. The livestock and poultry disease carcass process equipment comprises an incinerator, a feeding device for feeding materials to the incinerator, a smoke purifying device for purifying hot smoke discharged by the incinerator and a preheating device, wherein the incinerator comprises a furnace body, a furnace head and a furnace tail; a transmission main shaft driven by a main motor is arranged in an incineration chamber in the incinerator; a plurality of material scattering bodies for stirring materials are arranged on the transmission main shaft; the feeding device comprises a feeding tube which extends into the incineration chamber from a feeding hole; a feeding packing auger is arranged in the feeding tube; the preheating device comprises a preheating hopper and a spiral flue around the preheating hopper; the smoke purifying device comprises a smoke discharging outer channel and a fall pool; a plurality of shower heads are arranged in the upper side of the smoke discharging outer channel. The invention aims to provide the livestock and poultry disease carcass process equipment which can burn and process animal carcasses in a concentrated manner, is high and efficient in burning process and full in incineration, can effectively process the generated smoke, and can avoid smoke pollution.

Owner:ZHEJIANG SCI-TECH UNIV

Gas circulation automatic control system of garbage incinerator

InactiveCN106678825AIncrease temperatureGuaranteed incineration effectIncinerator apparatusAutomatic controlControl system

The invention discloses a gas circulation automatic control system of a garbage incinerator. A first air inducing device is arranged on the outer wall of a shell; a power supply device is connected with a heating device and starts or stops supplying power to the heating device according to instructions of a control device; a first detecting device is used for detecting the height value between the position to which the first temperature corresponds and the bottom of a first cavity, and a second detecting device is used for detecting the height value between the position to which the second temperature corresponds and the bottom of the first cavity; a first electromagnetic valve is arranged on a tail gas pipeline; a second air inducing device is arranged inside a second cavity; a third detecting device is used for detecting the temperature value T at a tail gas outlet; and the control device obtains the detection value of the first detecting device and the detection value of the second detecting device to work out the difference value H, and the control device obtains the detected temperature value T at the tail gas outlet through the third detecting device, and controls the first air inducing device, the second air inducing device, the first electromagnetic valve and the power supply device to act through instructions according to the difference value H and the temperature value T.

Owner:SINOBIOWAY DINGHE ENVIRONMENTAL PROTECTION CO LTD

Automated control system for cyclical air inlet and cyclical charging of garbage incinerator

InactiveCN106705071AIncrease temperatureBurn completelyIncinerator apparatusElectricityControl system

The invention discloses an automated control system for cyclical air inlet and cyclical charging of a garbage incinerator. A first draught device is arranged on the outer wall of a housing; a first detecting device is used for detecting a height value H01 between a position corresponding to a first temperature and the bottom of a first cavity; a second detecting device is used for detecting a height value H02 between a position corresponding to a second temperature and the bottom of the first cavity; a first electromagnetic valve is arranged on a tail gas pipeline; a second draught device is arranged in a second cavity; a third detecting device is used for detecting the temperature value T at an exit of the tail gas; a feed opening is formed in the second cavity; an adjusting valve and a speed measuring device are arranged at the feed opening; a control device is used for obtaining the detected value H01 of the first detecting device and the detected value H02 of the second detecting device, and the difference value H of the H01 and the H02 is calculated; and the control device is used for obtaining the detected value T of the third detecting device, and according to the difference value H and the detected value T, controlling the first draught device, the second draught device, the first electromagnetic valve, an electricity supply device and the adjusting valve to move by an instruction.

Owner:SINOBIOWAY DINGHE ENVIRONMENTAL PROTECTION CO LTD

An inorganic agricultural fertilizer production device

InactiveCN104591809BRealize separation and purificationHas clearedEnergy inputIncinerator apparatusParticulatesAgricultural engineering

The invention discloses an inorganic agricultural fertilizer production device, and aims to provide a method that can effectively carry out centralized burning treatment of wheat straw, the burning process is stable and efficient, can ensure sufficient burning, the ash fertilizer produced is high in purity, and can The flue gas can be effectively treated to avoid the device that causes smoke and dust pollution. It includes an incineration kiln, a feeding device, and a smoke cleaning device: the incineration kiln has an incineration inner cavity, the incineration kiln is inclined and is 10 to 60 degrees from the horizontal plane, and the incineration inner cavity is provided with a main A drive spindle driven by a motor, the drive spindle is provided with a plurality of bulk material bodies for dislodging the material, and the incineration kiln is provided with an air inlet, a smoke outlet, a feeding port, and a material cleaning opening and closing Door. The beneficial effects of the invention are as follows: the separation effect is excellent; the solid particles and dust in the flue gas can be removed; the waste heat of the flue gas is used to dry the raw materials, and the subsequent firing effect is improved; Adequate assurance of subsequent incineration.

Owner:ZHEJIANG SCI-TECH UNIV

A kind of bone china raw material preparation device

InactiveCN104676593BPerfect removalAchieve clearingCremation furnacesIncinerator apparatusPollutionBone china

The invention discloses production equipment of bone china materials. The production equipment comprises an incinerator, a feeder, a smoke purifier and a preheater; the feeder is used for feeding materials into the incinerator, and the smoke purifier is used for purifying hot smoke discharged by the incinerator; the incinerator comprises a body, a head and a tail, and an incinerating chamber in the body is provided with a transmission spindle driven by a main motor; the transmission spindle is provided with scattering members used for stirring materials; the feeder comprises a feed cylinder extending into the incinerating chamber from a feed opening; a feed screw is disposed within the feed cylinder; the preheater comprises a preheating hopper and a spiral flue surrounding the preheating hopper; the smoke purifier comprises a discharge outer duct and a water receiver; a plurality of sprinklers are arranged in the upper portion of the inside of the discharge outer duct. The production equipment has the advantages that animal corpses can be effectively centrally incinerated, the incinerating process is stable and efficient, sufficient incineration is guaranteed, the produced smoke can be effectively treated, and smoke pollution can be avoided.

Owner:ZHEJIANG SCI-TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com