A centralized plant ash fertilizer production equipment

A production equipment, plant ash technology, applied in the direction of inorganic fertilizers, fertilizer mixtures, potash fertilizers, etc., can solve the problems of production efficiency and cost impact, increase process, high impurity content, etc., to prolong service life, improve firing effect, and separation effect good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

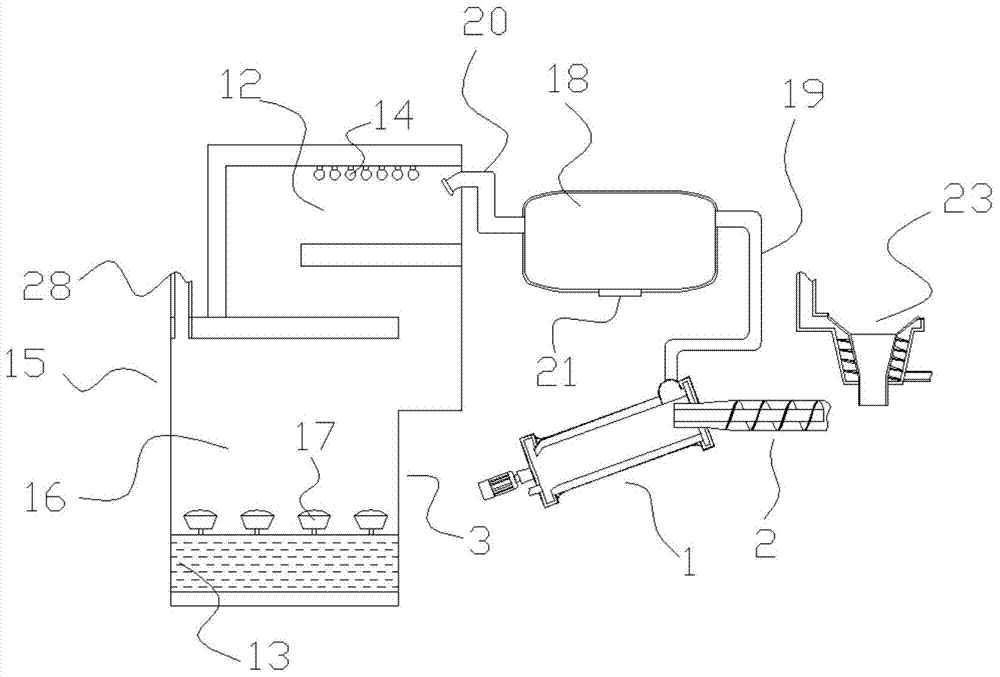

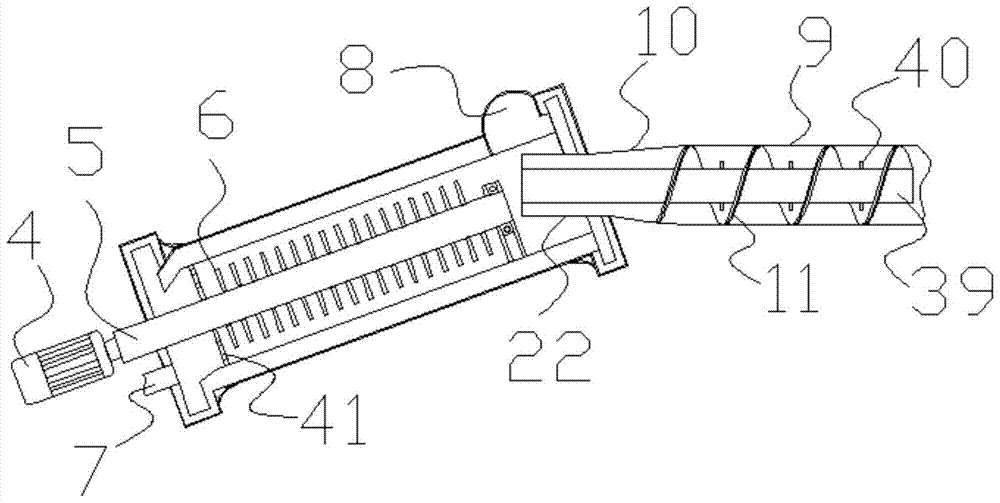

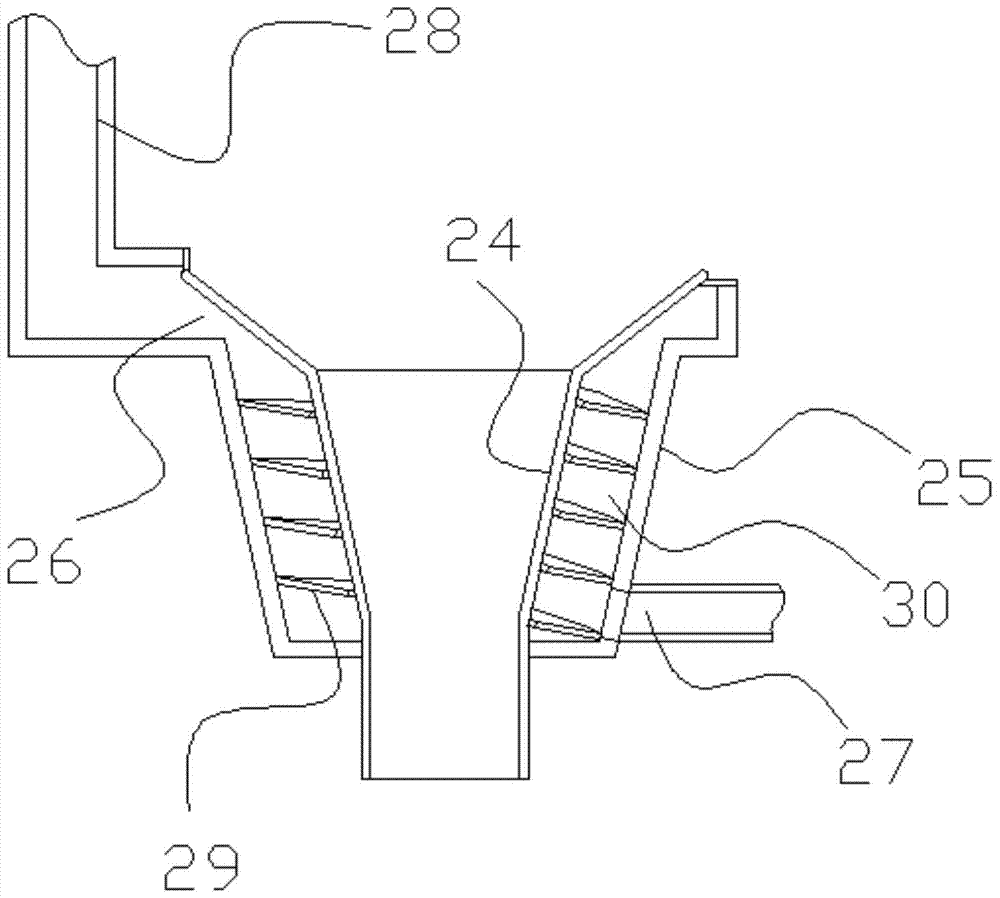

[0026] Embodiment 1: as figure 1 , figure 2 , image 3 In the shown embodiment, a centralized plant ash fertilizer production equipment includes an incineration kiln 1, a feeding device 2, a smoke cleaning device 3, and a material separation net 41: the incineration kiln has an incineration inner cavity, and the incineration kiln is inclined And between 10 to 60 degrees with the horizontal plane, the incineration inner cavity is provided with a transmission main shaft 5 driven by the main motor 4, and a plurality of bulk materials 6 for moving materials are arranged on the transmission main shaft , the incineration kiln is provided with an air inlet 7, a smoke outlet 8, and a feed port; the feeding device includes a feeding cylinder 9 and a compression portion 10, and a feeding auger 11 is provided in the feeding cylinder, The compression part is connected between the feeding cylinder and the feed inlet, the diameter of the compression part gradually decreases from the feed...

Embodiment 2

[0036] Embodiment 2: the basic structure and implementation mode of this embodiment are the same as embodiment 1, and its difference is, as Figure 4 As shown, it also includes a cleaning motor, the transmission main shaft is provided with a main shaft inner cavity 31, and a transmission inner shaft 32 coaxial with the transmission main shaft extends into the main shaft inner cavity, and one end of the transmission inner shaft It is connected with the output shaft of the cleaning motor, and the other end is connected with the bearing of the inner shaft. The cleaning motor can also be arranged in the inner cavity of the main shaft. There are multiple cleaning devices on the transmission main shaft. The cleaning device Including a dirt ball 33, a limit ball 34, a ball receiving spring 35, a slide bar 36, and a slide hole arranged on the wall of the transmission main shaft, the slide bar is slidably matched with the slide hole, and the dirt ball and the limit ball The balls are r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com