Patents

Literature

1679 results about "Material Separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

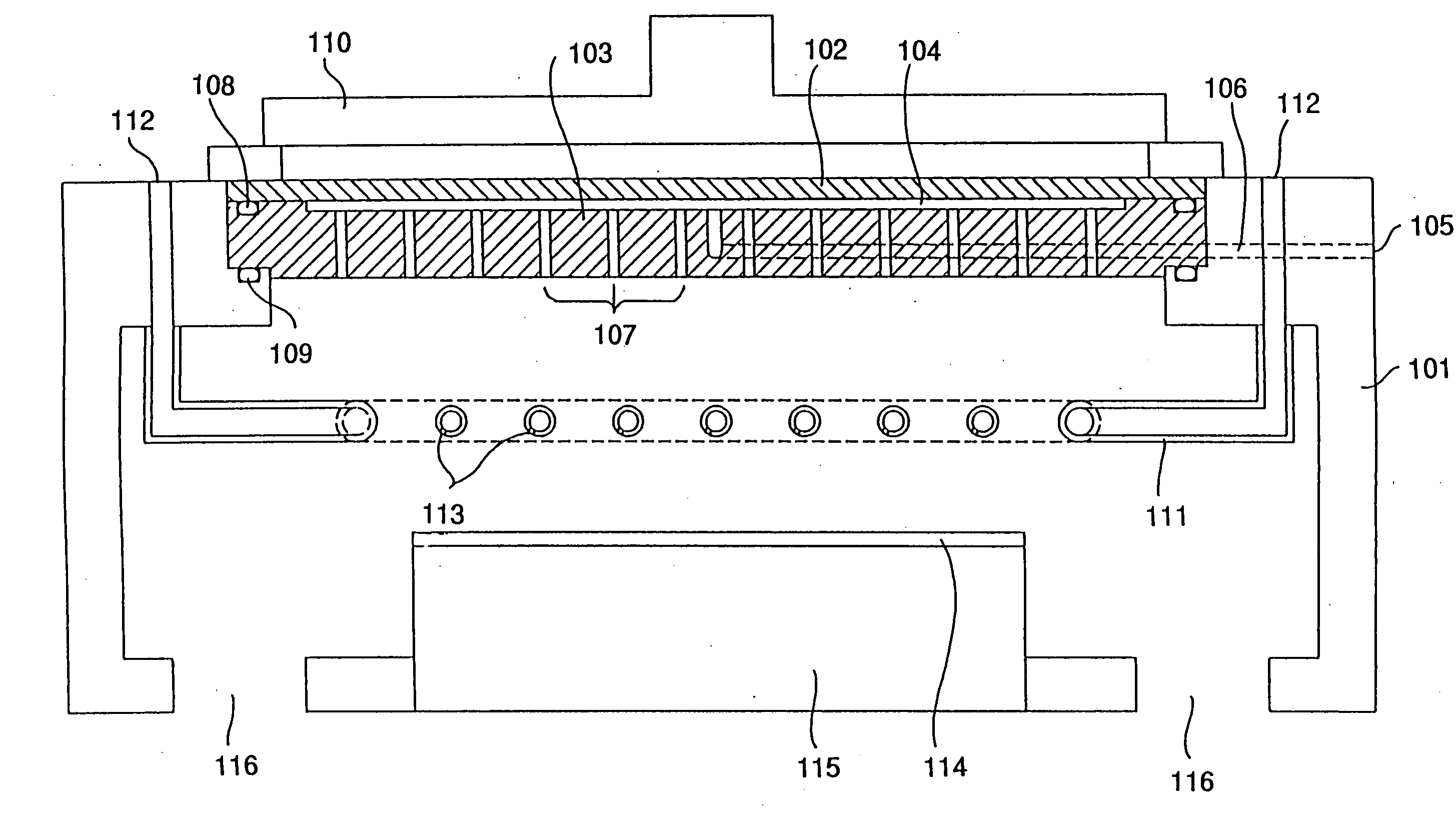

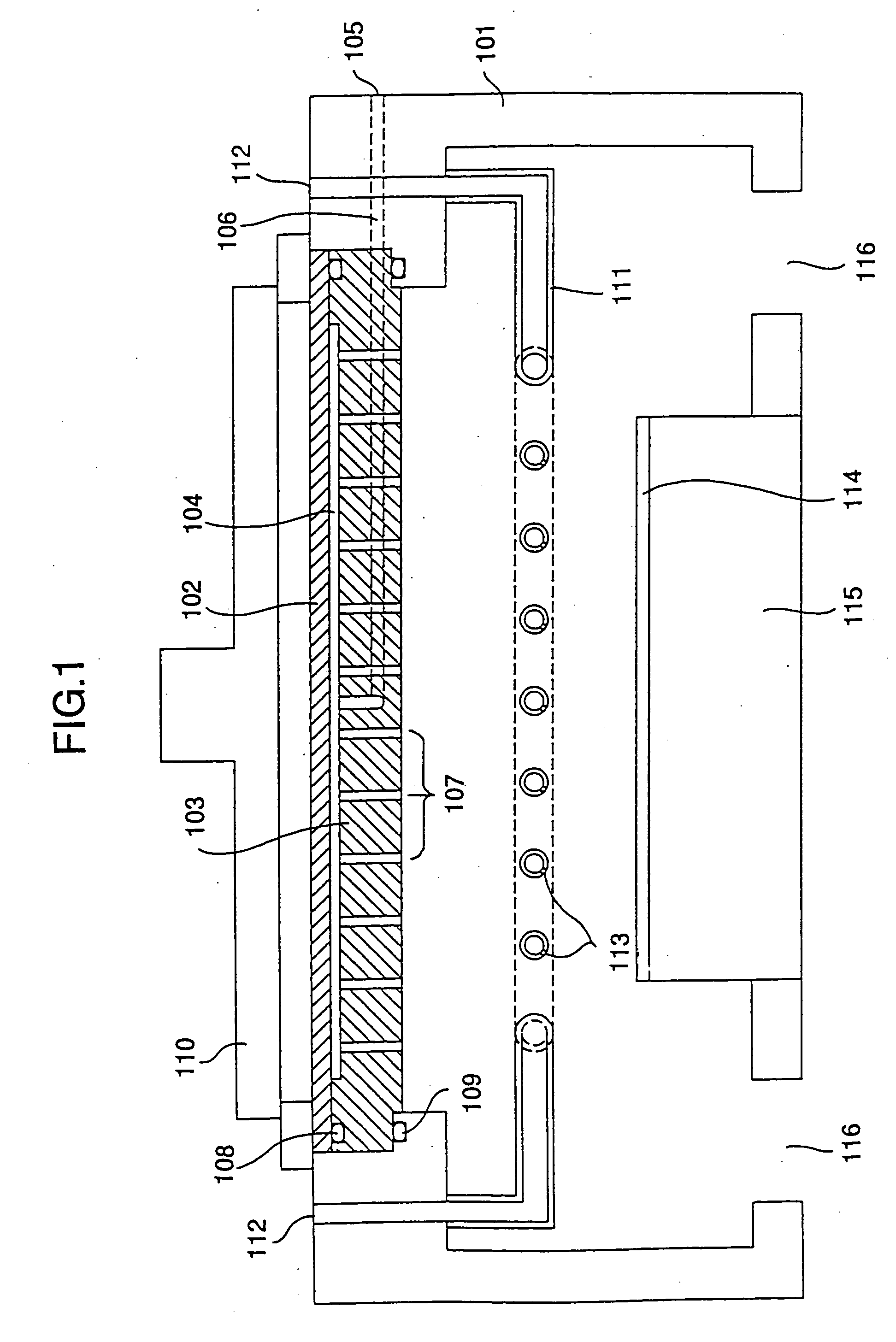

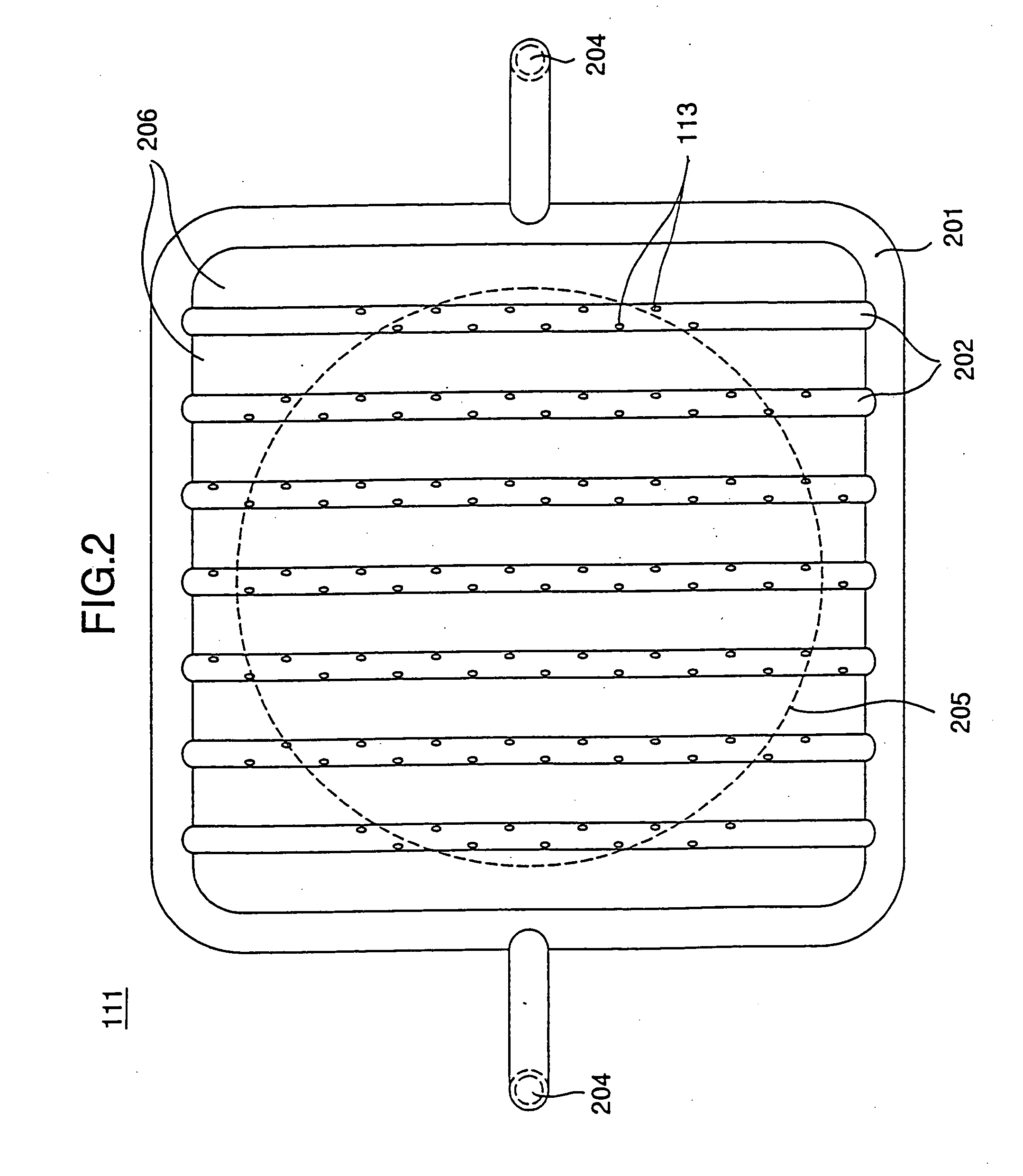

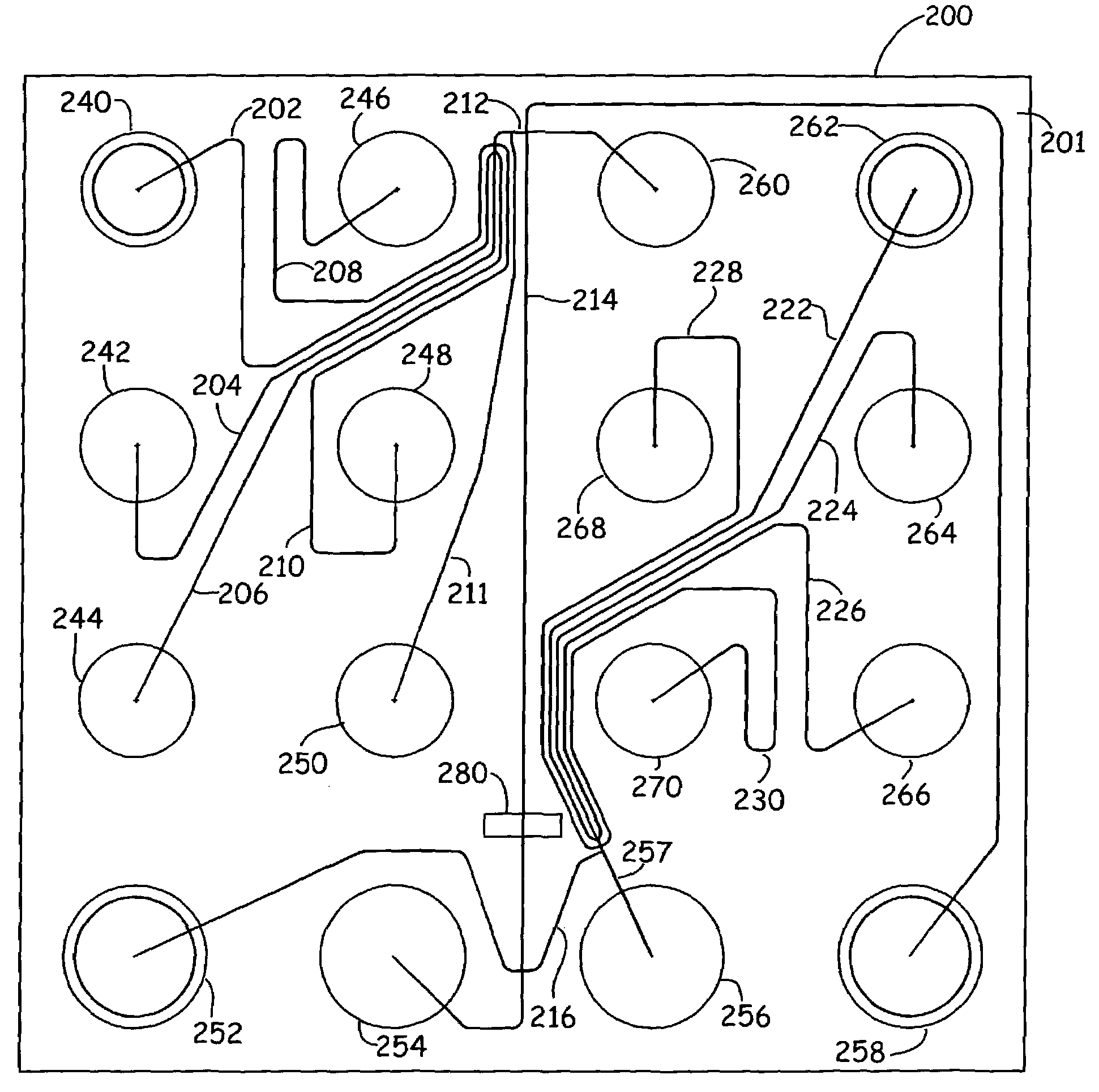

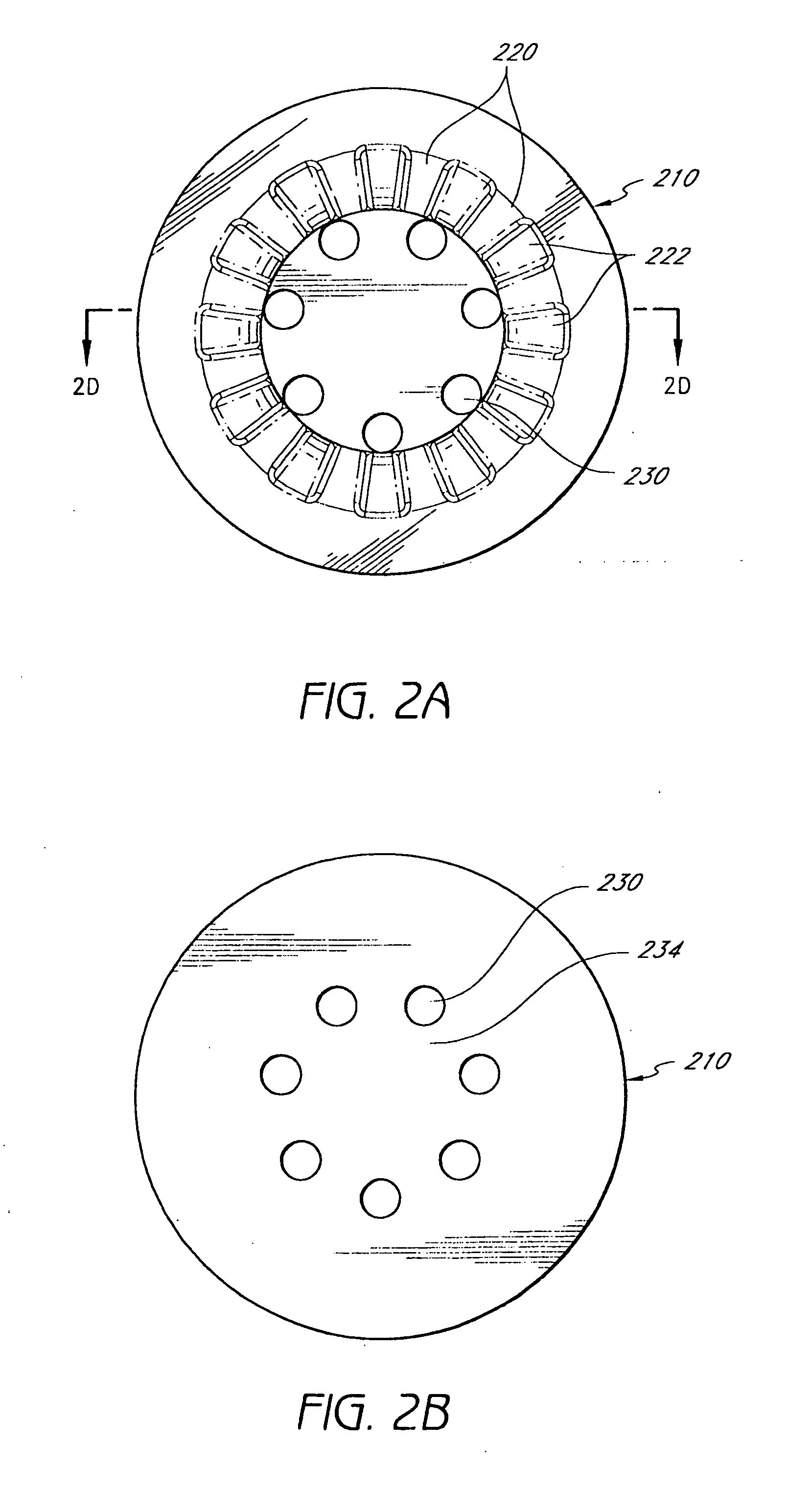

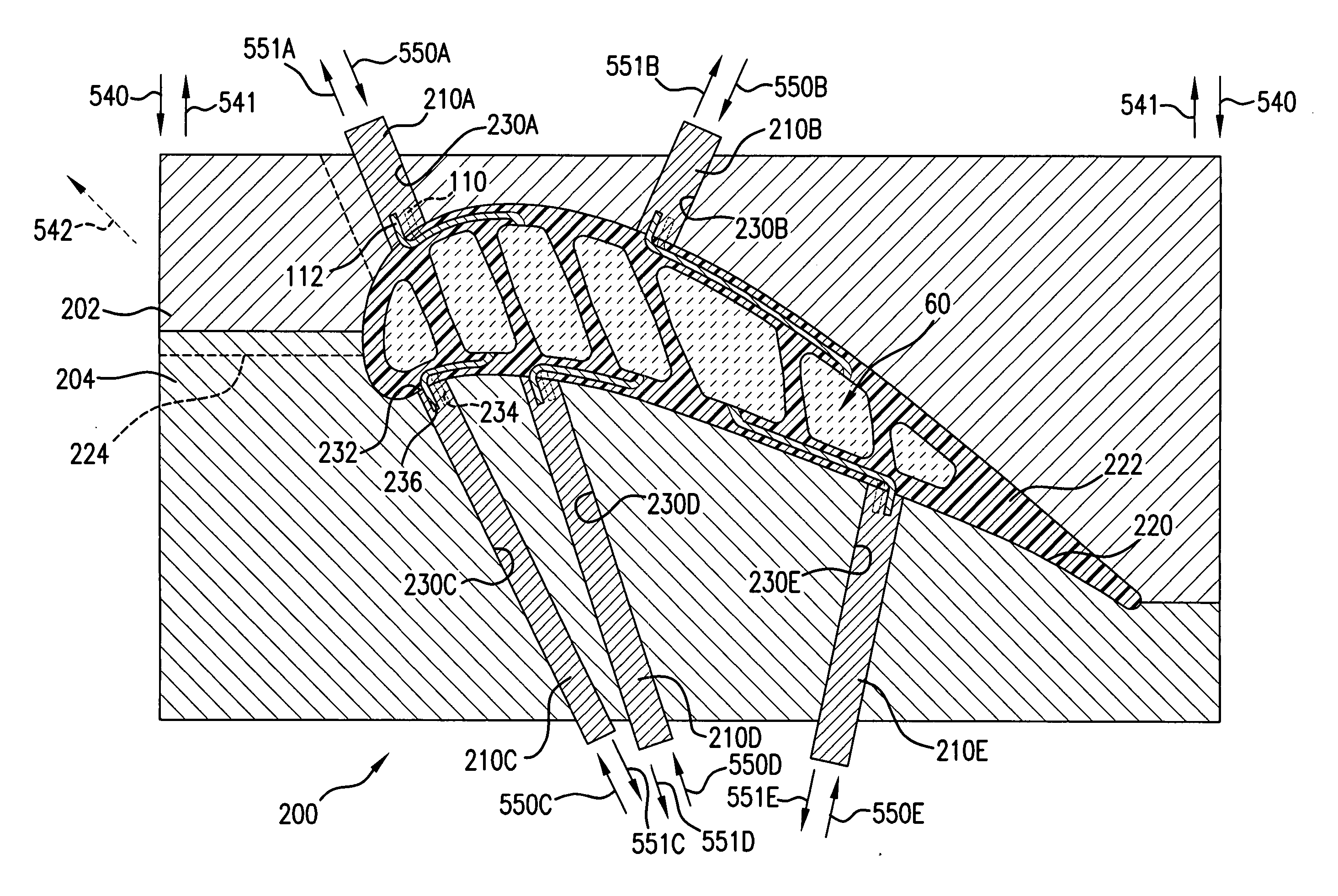

Plasma processing apparatus

InactiveUS20040221809A1Eliminate the problemImprove stabilityElectric discharge tubesSemiconductor/solid-state device manufacturingMicrowaveHigh energy

In a microwave plasma processing apparatus, a metal made lattice-like shower plate 111 is provided between a dielectric material shower plate 103, and a plasma excitation gas mainly an inert gas and a process gas are discharged form different locations. High energy ions can be incident on a surface of the substrate 114 by grounding the lattice-like shower plate. The thickness of each of the dielectric material separation wall 102 and the dielectric material at a microwave introducing part is optimized so as to maximize the plasma excitation efficiency, and, at the same time, the distance between the slot antenna 110 and the dielectric material separation wall 102 and a thickness of the dielectric material shower plate 103 are optimized so as to be capable of supplying a microwave having a large power.

Owner:TOKYO ELECTRON LTD

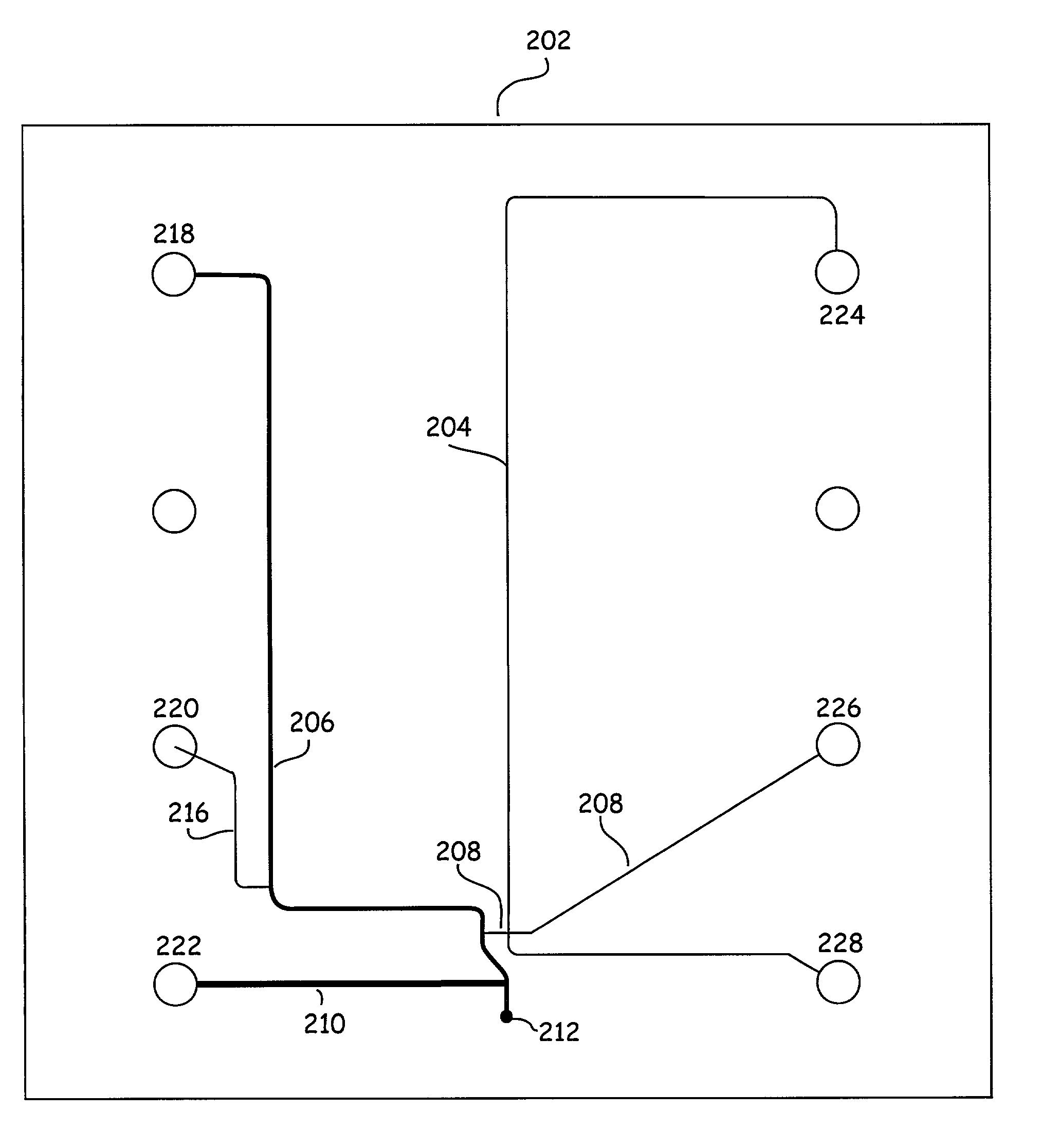

Methods, systems and apparatus for separation and isolation of one or more sample components of a sample biological material

ActiveUS7419784B2Bioreactor/fermenter combinationsBiological substance pretreatmentsElectrophoresisBiological materials

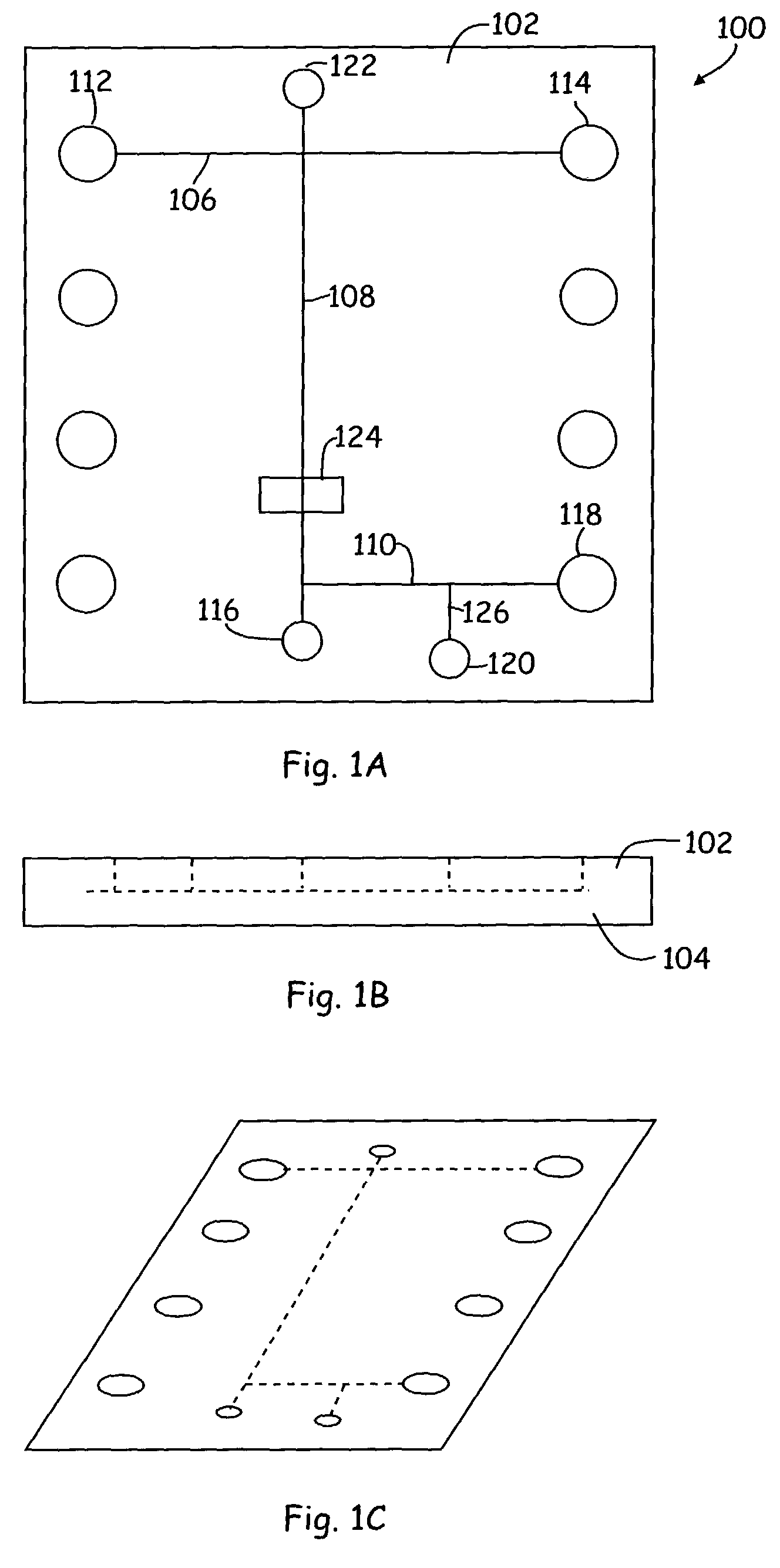

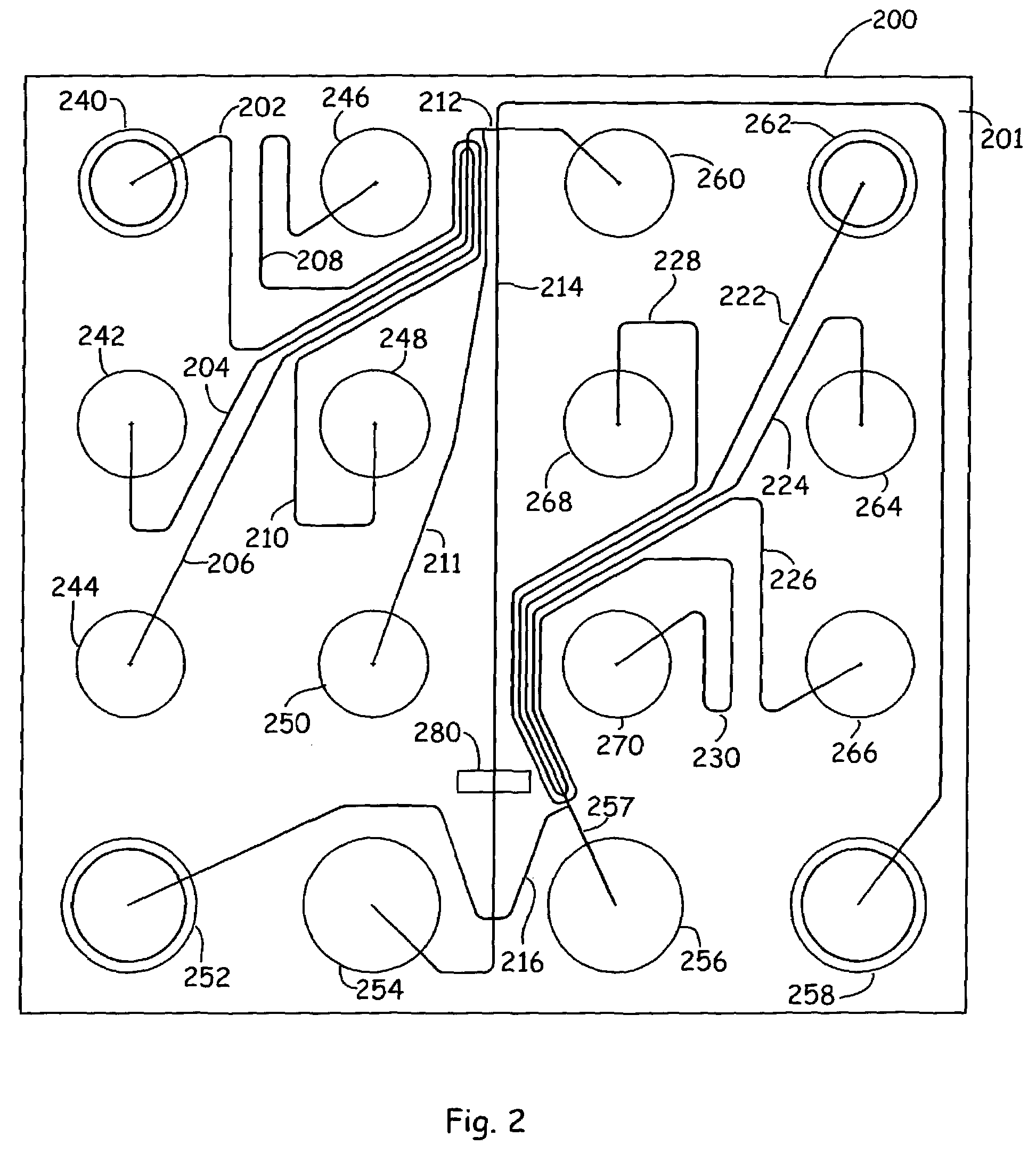

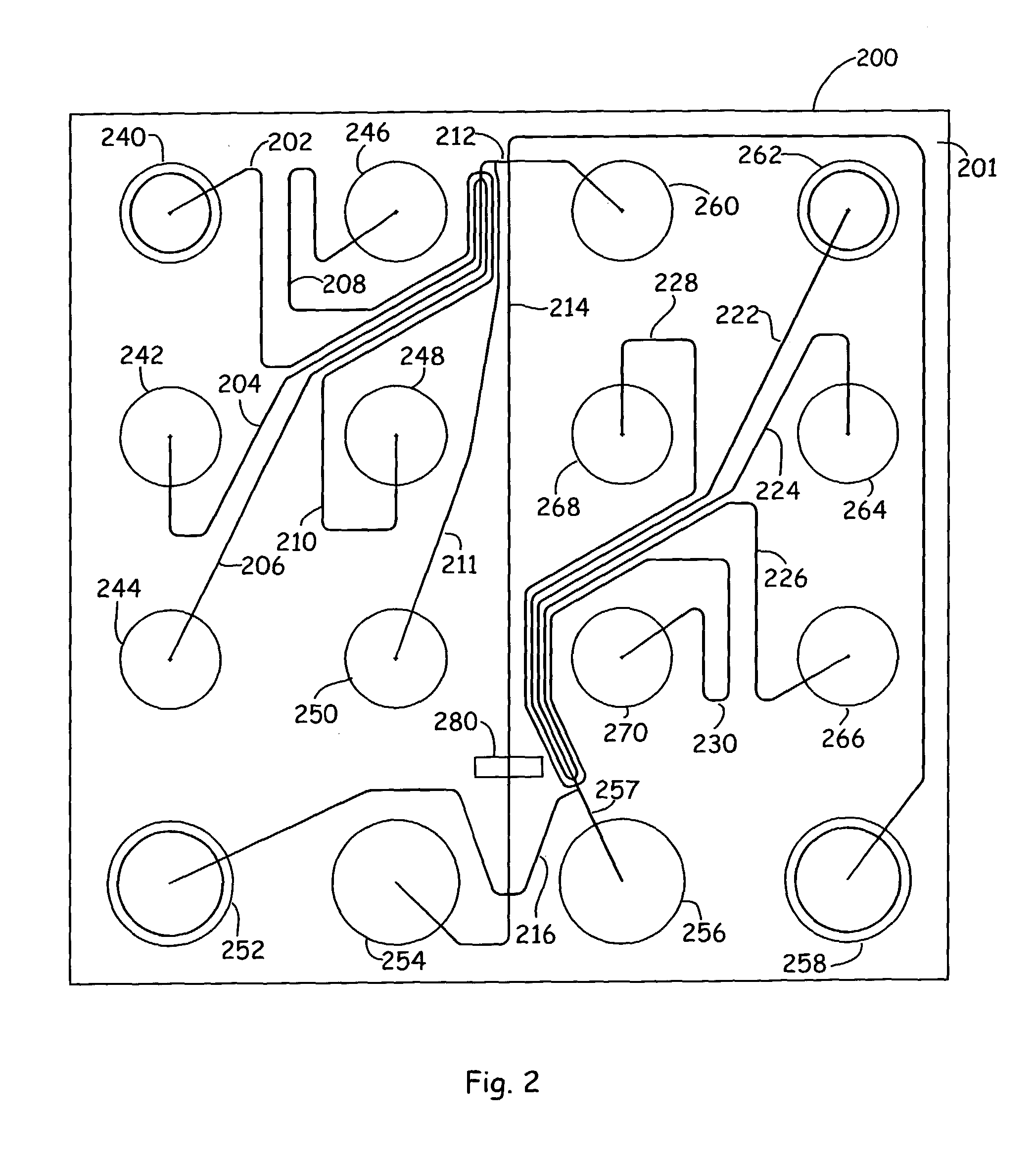

Devices, systems and methods for use in separating sample materials into different sample components and then isolating one or more of the sample components for further processing or analysis are disclosed. Devices employ configurations that optionally allow a sample material to be electrophoretically separated into sample components in a separation matrix within a separation conduit. The sample components may then be detected in a detection zone in the separation conduit, and then selected components shunted to a component collection conduit within the device downstream of the detection zone for further processing or analysis based on information received at the detection zone. Methods of using these devices, and systems that incorporate these devices are also envisioned.

Owner:CAPLIPER LIFE SCI INC

Multi-phase selective mass transfer through a membrane

Disclosed herein are embodiments relating to particular systems comprising a selective transfer membrane that can be utilized in material separation. In certain embodiments, the membrane assembly comprises part of a desalination, distillation, liquid purification, and / or heating and cooling system. Other particular embodiments allow for a high rate of thermal capture by way of the system utilizing a selective transfer membrane. Certain preferred embodiments include a selective transfer membrane comprising an ionomeric polymer that is permeable to high dipole materials.

Owner:TANGREDI PATRICIA

High throughput separations based analysis systems

InactiveUS7169277B2Increase flow resistanceSufficient flow resistanceSludge treatmentFixed microstructural devicesElectrophoresisBulk samples

Devices, systems and methods for use in separating sample materials into different fractions that employ bulk fluid flow for loading of samples followed by electrophoretic separation of the sample material. Devices employ configurations that optionally allow bulk sample loading with some or no displacement of a separation matrix within a separation conduit. Methods of using these devices, and systems that incorporate these devices are also envisioned.

Owner:CAPLIPER LIFE SCI INC

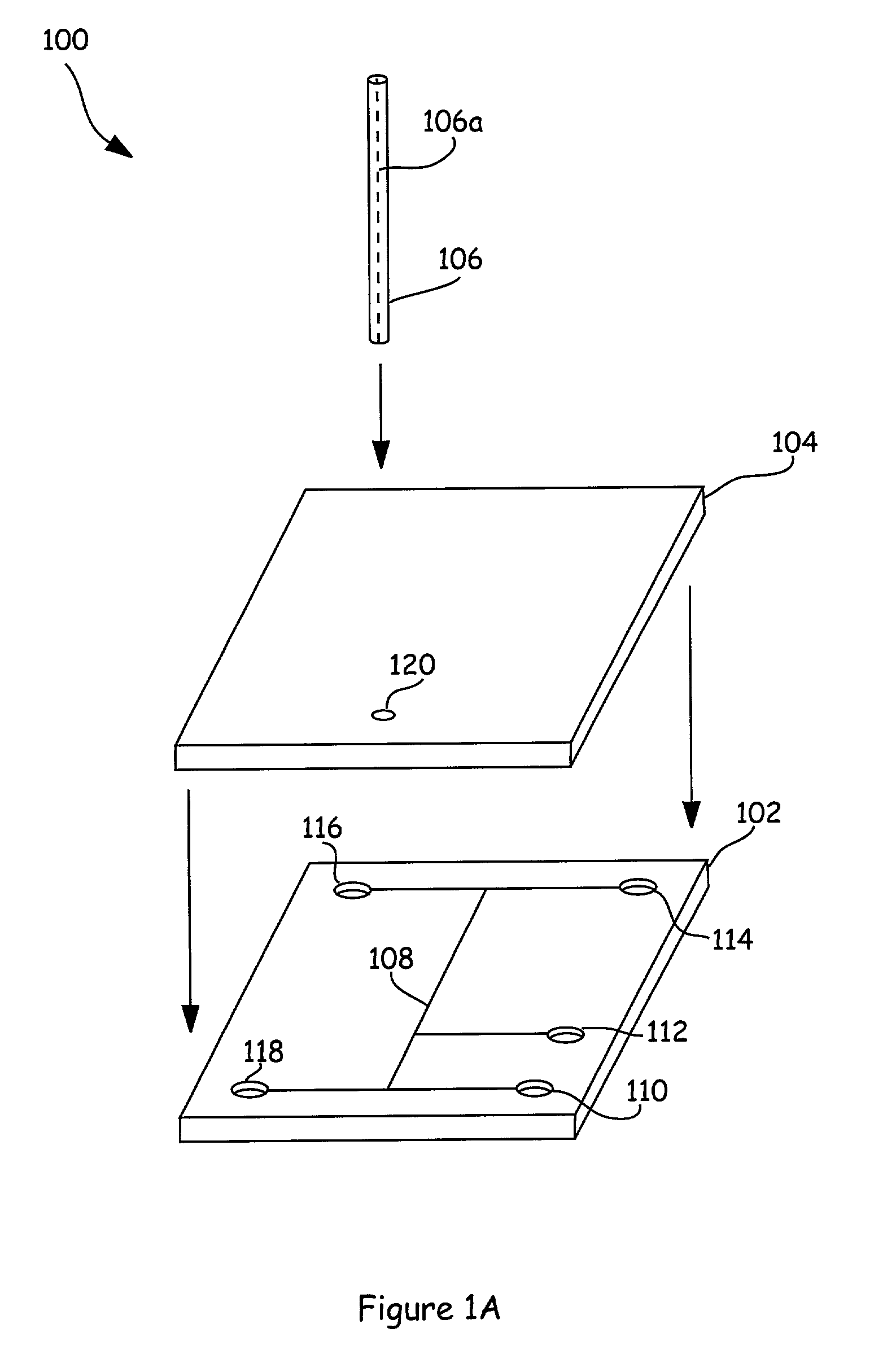

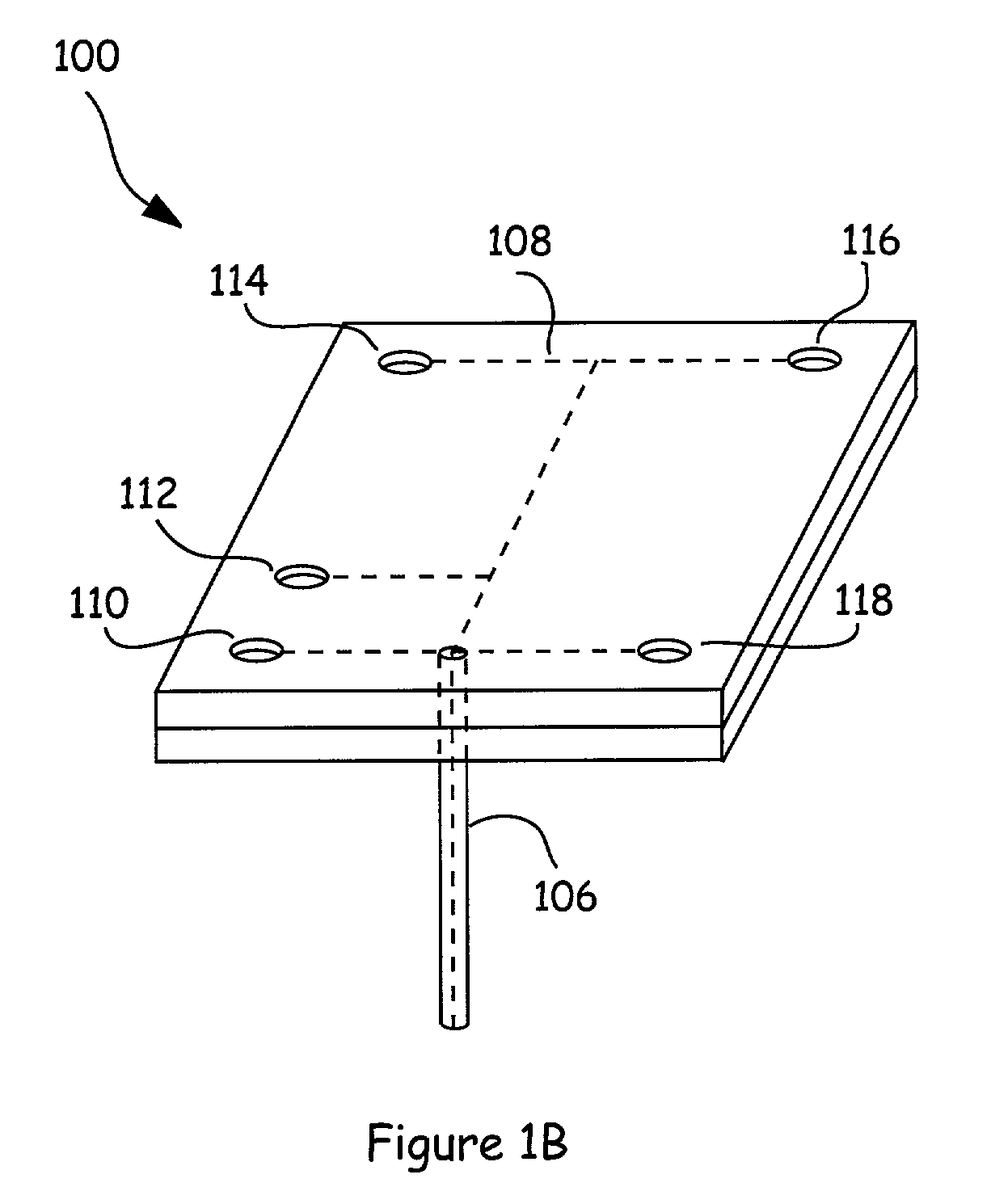

Bubble-free cross-sections for use in solid imaging

ActiveUS20060249884A1Low costHigh resolutionAdditive manufacturing apparatusAuxillary shaping apparatusReciprocating motionImaging equipment

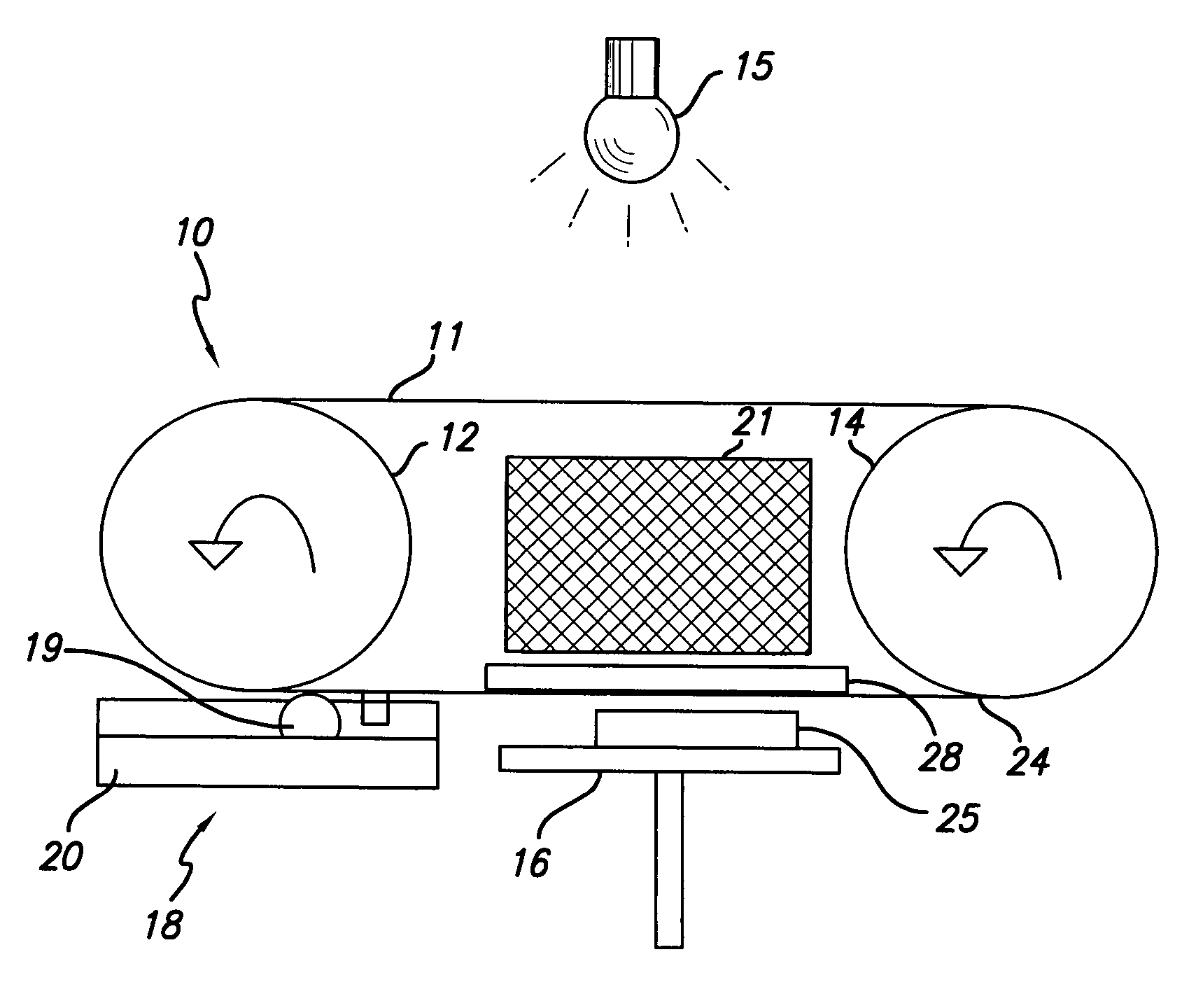

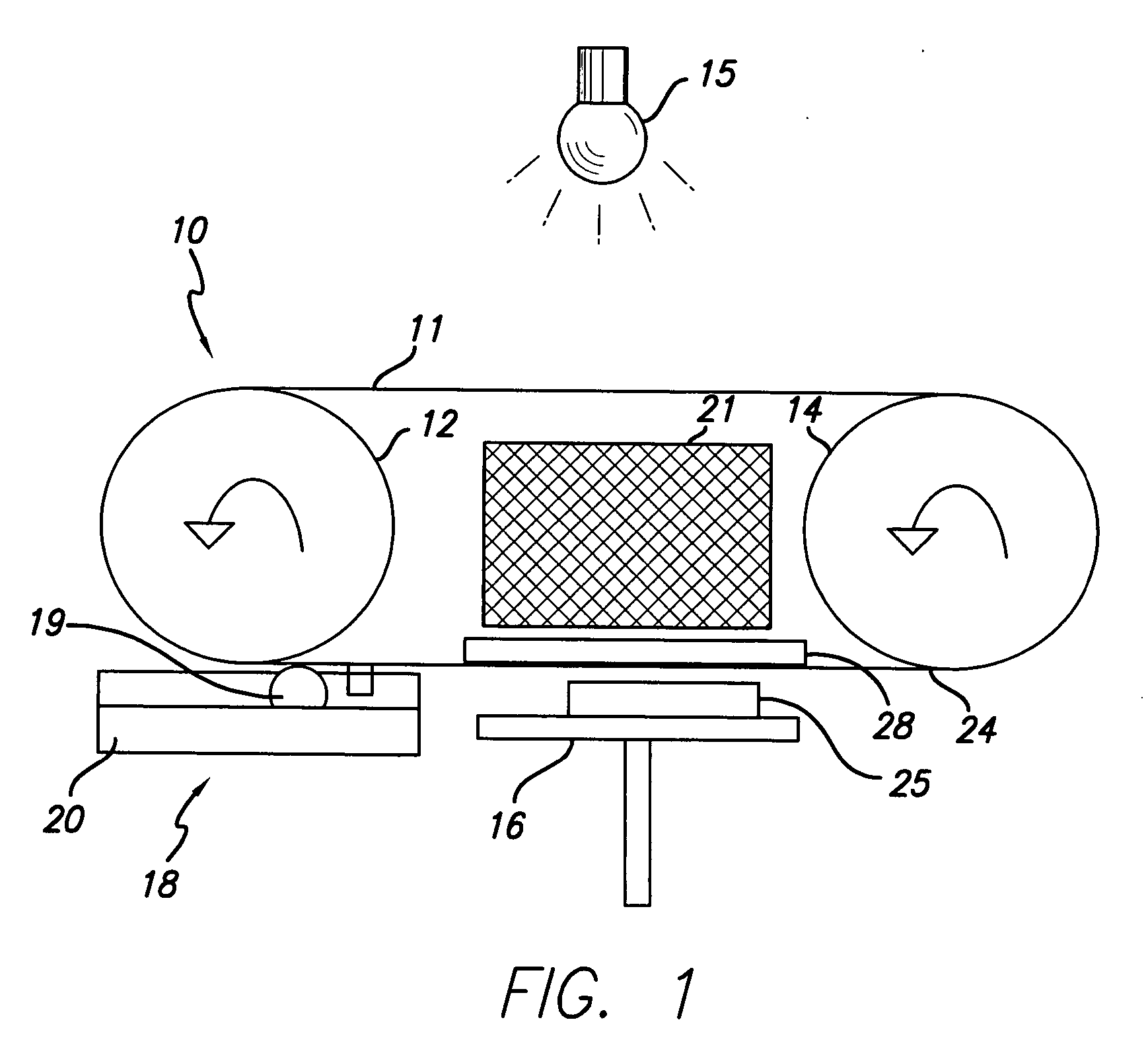

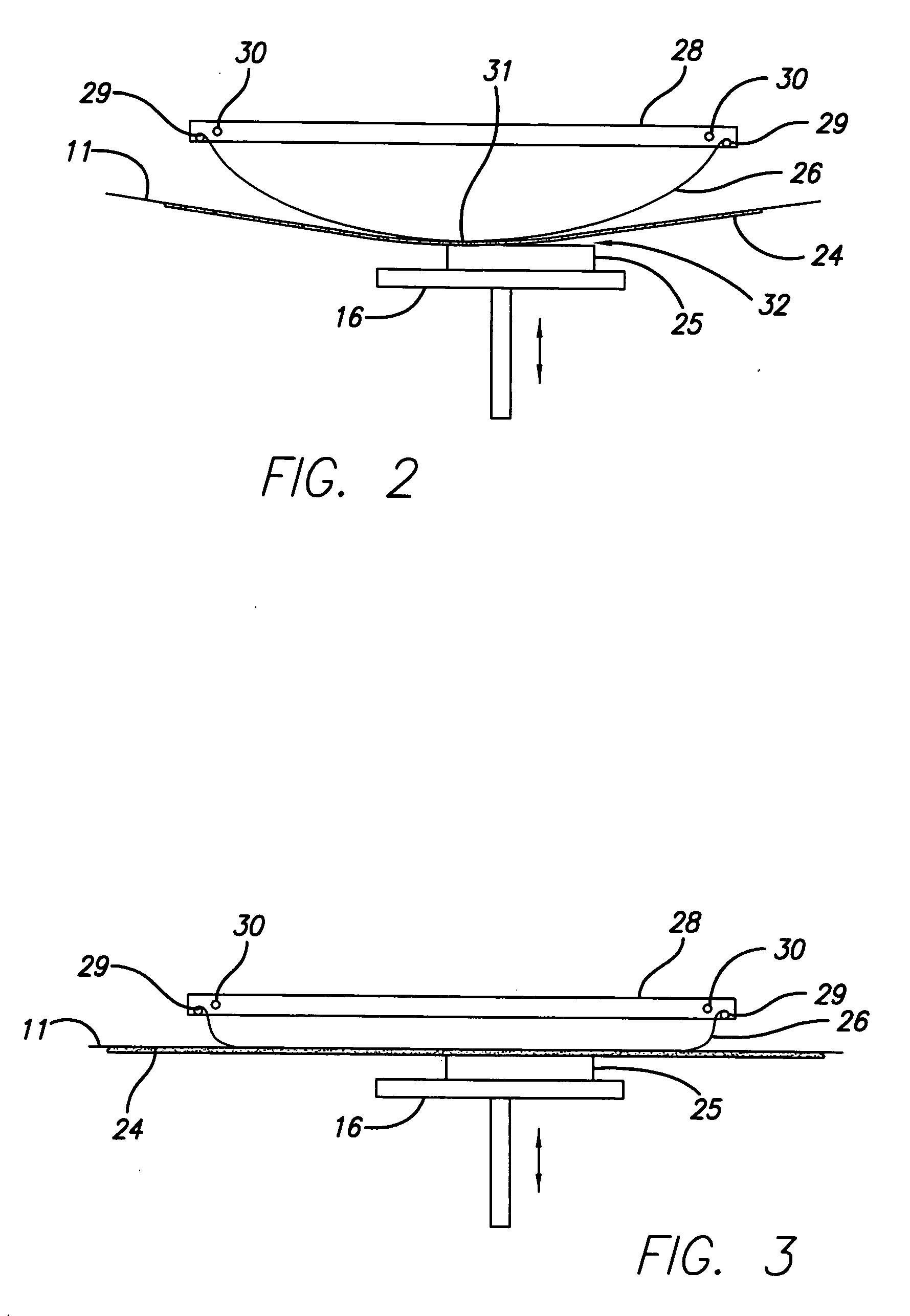

A solid imaging apparatus and method employing build material transfer means effective to transfer solidifiable liquid build material from a first side of a radiation transparent build material carrier to a receiving substrate without entrapping air bubbles in layers of transferred solidifiable liquid build material and to cleanly separate the solidified build material from the radiation transparent build material carrier as each layer is formed during the layerwise building of a three-dimensional object. An expandable membrane forming an arcuate dome and a reciprocatible flexible film are employed to effect transfer of the solidifiable liquid build material.

Owner:3D SYST INC

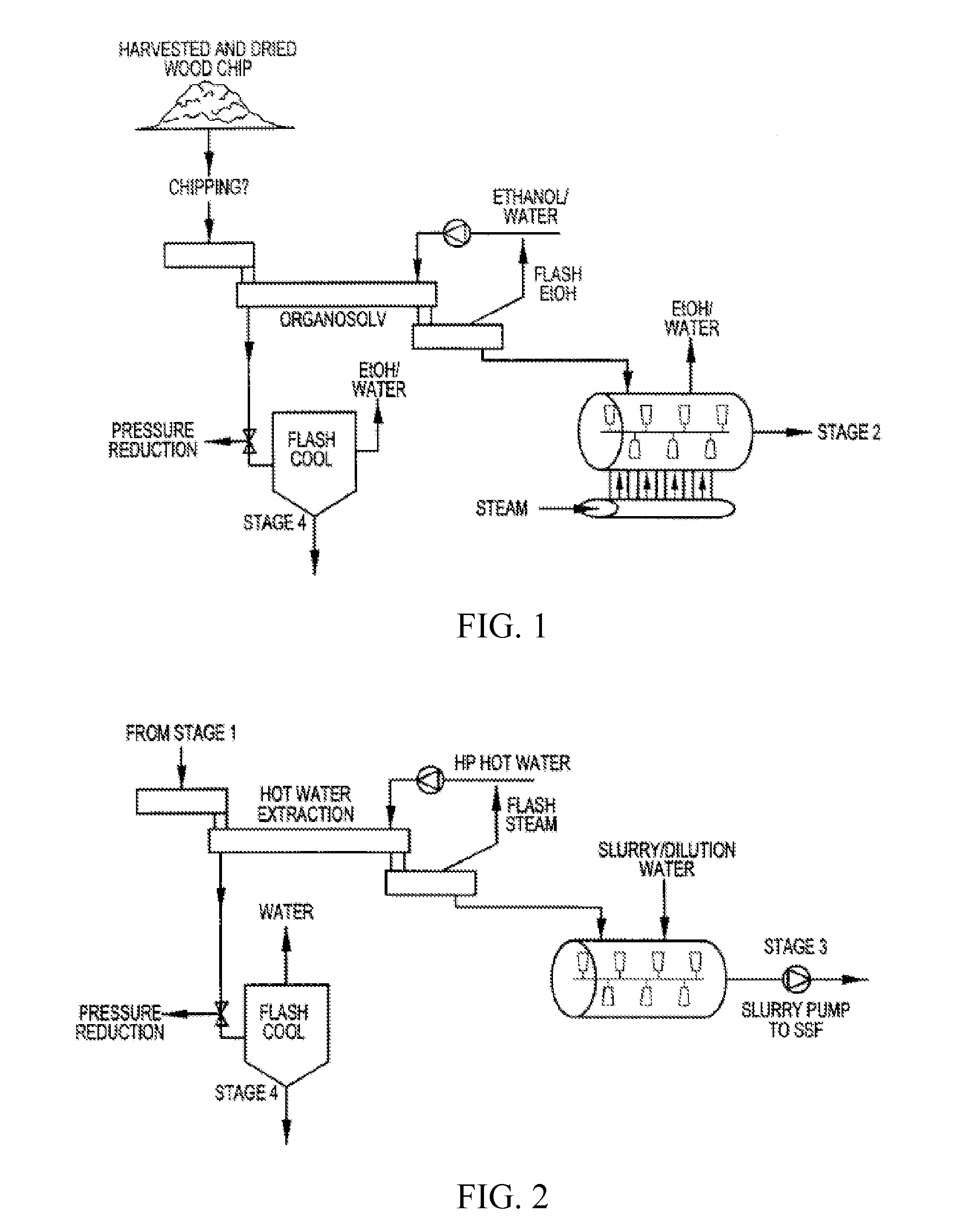

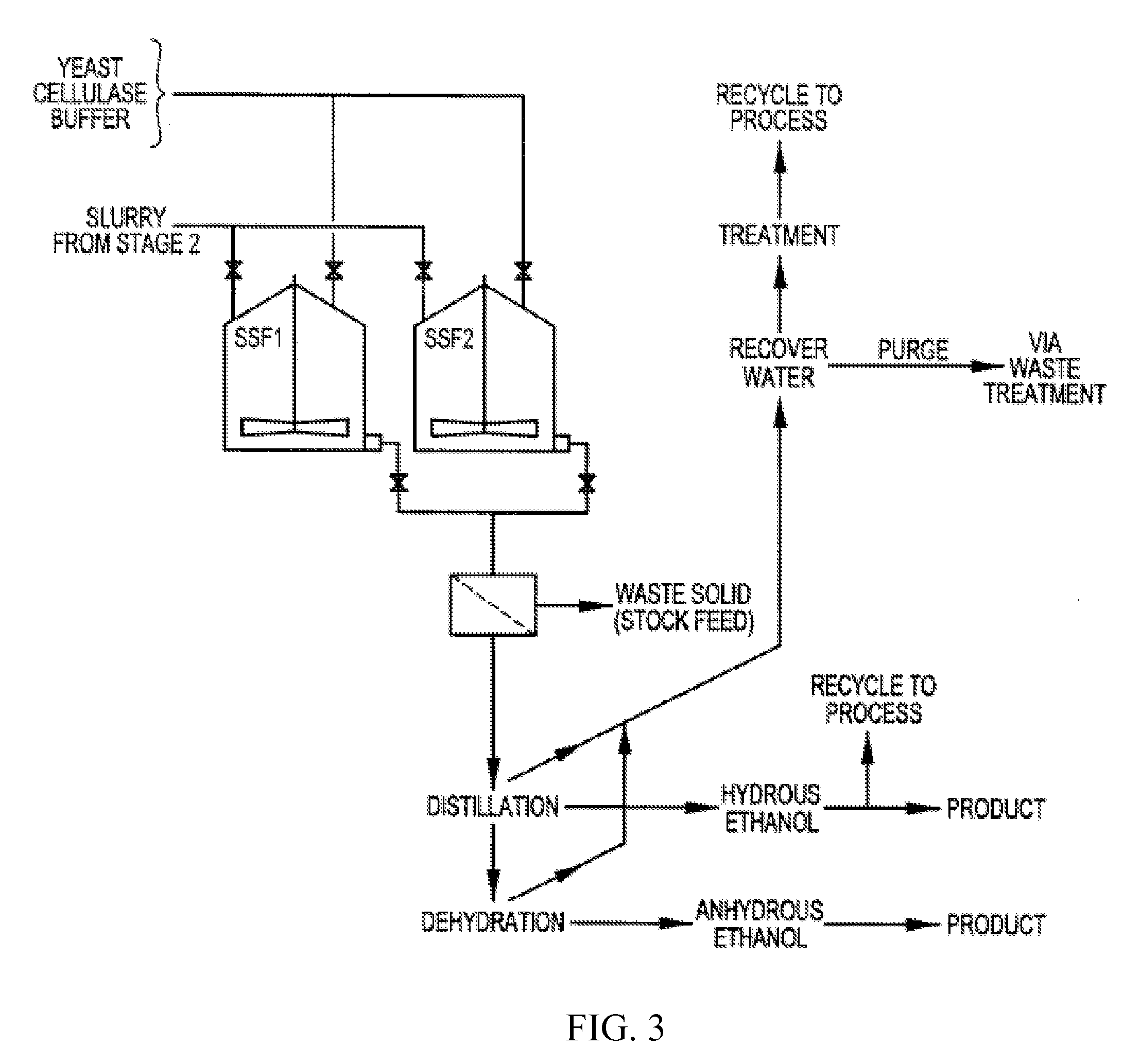

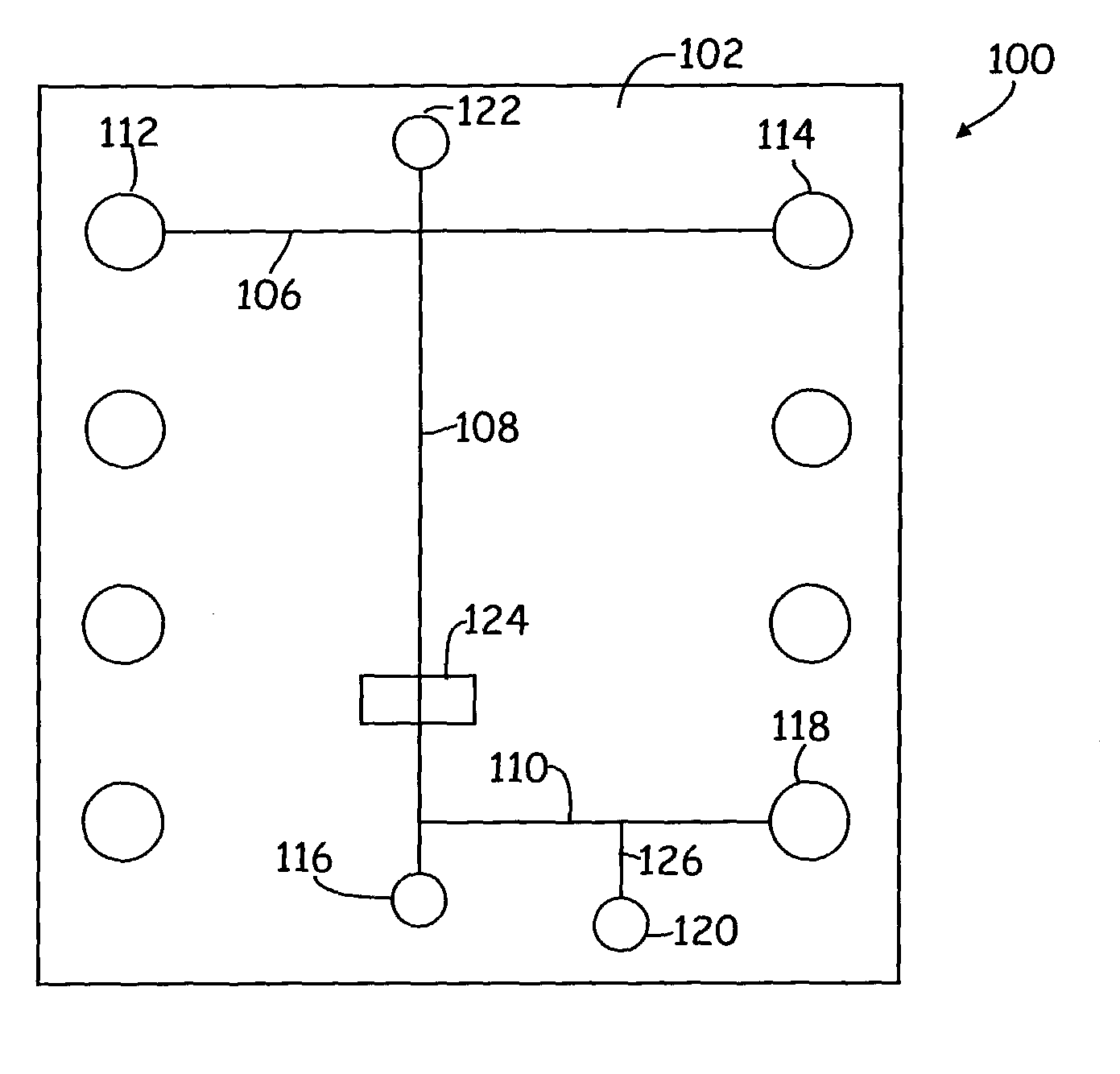

Lignin and other products isolated from plant material, methods for isolation and use, and compositions containing lignin and other plant-derived products

InactiveUS20090062516A1Good for healthImprove responseSugar derivativesOrganic compound preparationFiberElastomer

Lignin polymers having distinctive properties, including a generally high molecular weight and generally homogeneous size distribution, as well as preservation of native reactive side groups, are isolated by solvent extraction of plant materials. Methods for isolation of lignin polymers, and for use of the isolated lignin polymers are disclosed. Compositions containing lignin isolated from plant materials, such as carbon fiber composites, resins, adhesive binders and coatings, polyurethane-based foams, rubbers and elastomers, plastics, films, paints, nutritional supplements, food and beverage additives are disclosed. Xylose and xylose derivatives, furfural, fermentable sugars, cellulose and hemi-cellulose products may be used directly or further processed. The lignin polymers and other plant-derived products disclosed herein may be produced in abundance at low cost, and may be used as substitutes for feedstocks originating from fossil fuel or petrochemical sources in the manufacture of various products.

Owner:VERTICHEM CORP

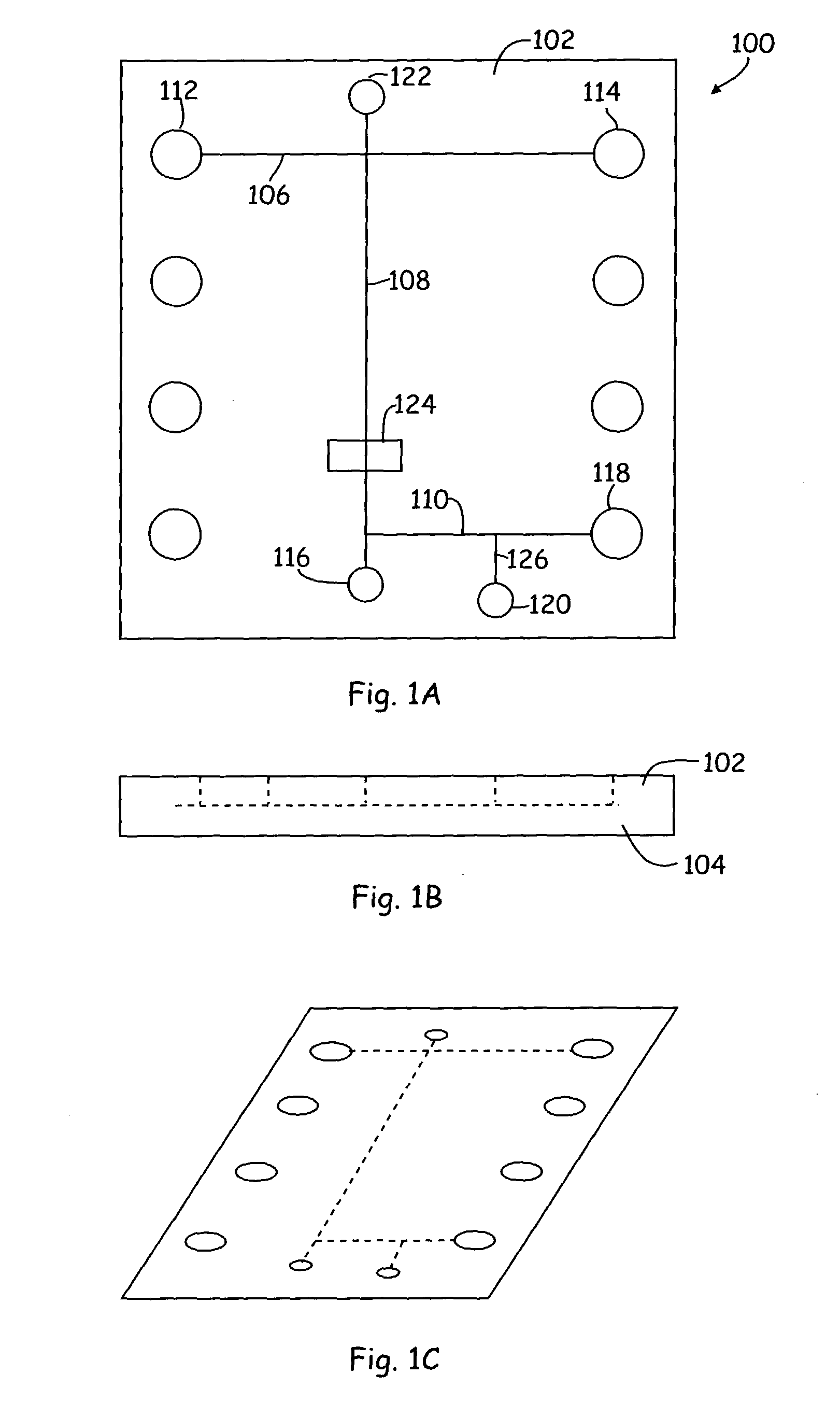

Methods, systems and apparatus for separation and isolation of one or more sample components of a sample biological material

ActiveUS20030215855A1AccuracyAccurate toleranceBioreactor/fermenter combinationsBiological substance pretreatmentsElectrophoresisBiological materials

Devices, systems and methods for use in separating sample materials into different sample components and then isolating one or more of the sample components for further processing or analysis are disclosed. Devices employ configurations that optionally allow a sample material to be electrophoretically separated into sample components in a separation matrix within a separation conduit. The sample components may then be detected in a detection zone in the separation conduit, and then selected components shunted to a component collection conduit within the device downstream of the detection zone for further processing or analysis based on information received at the detection zone. Methods of using these devices, and systems that incorporate these devices are also envisioned.

Owner:CAPLIPER LIFE SCI INC

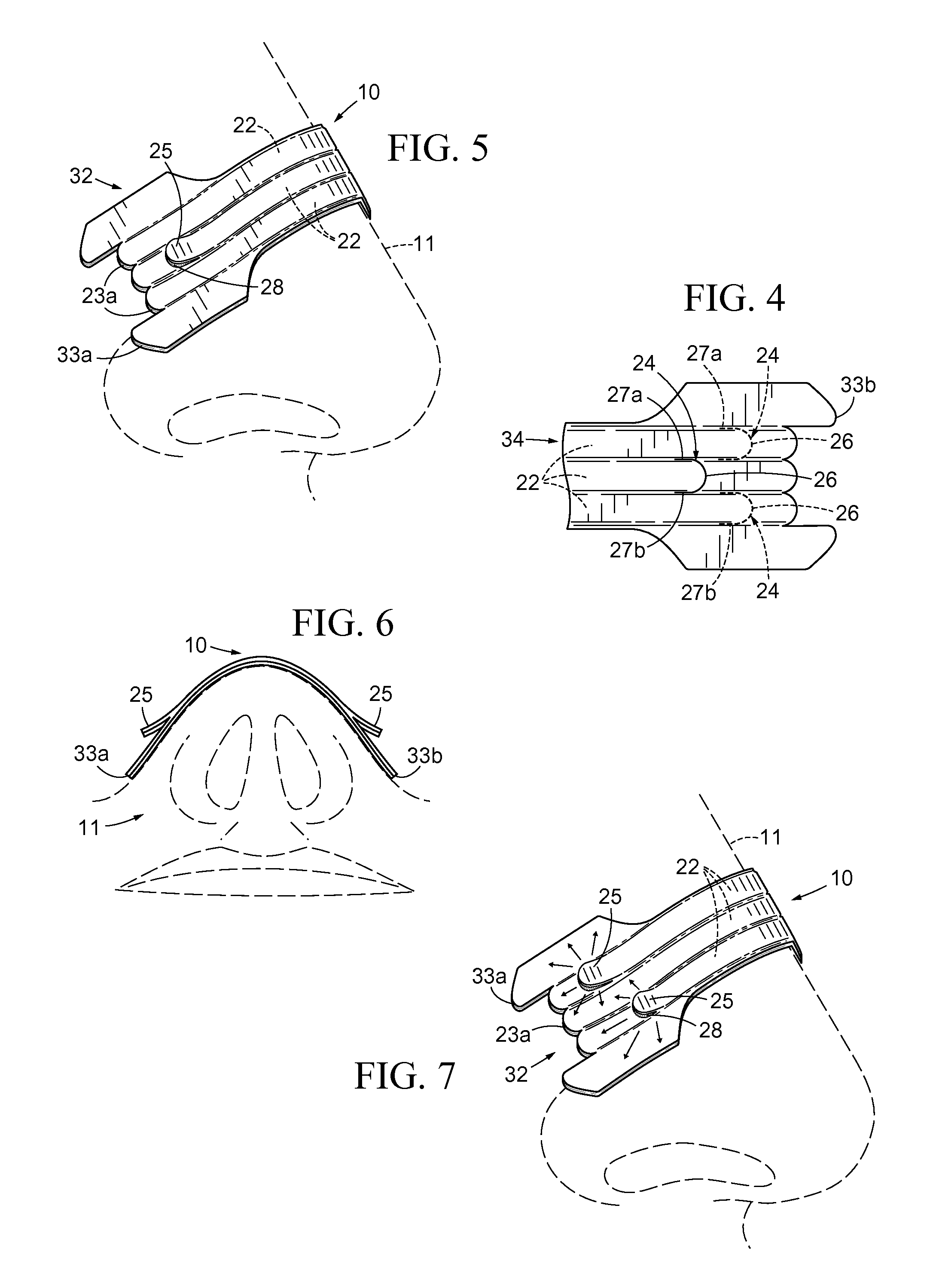

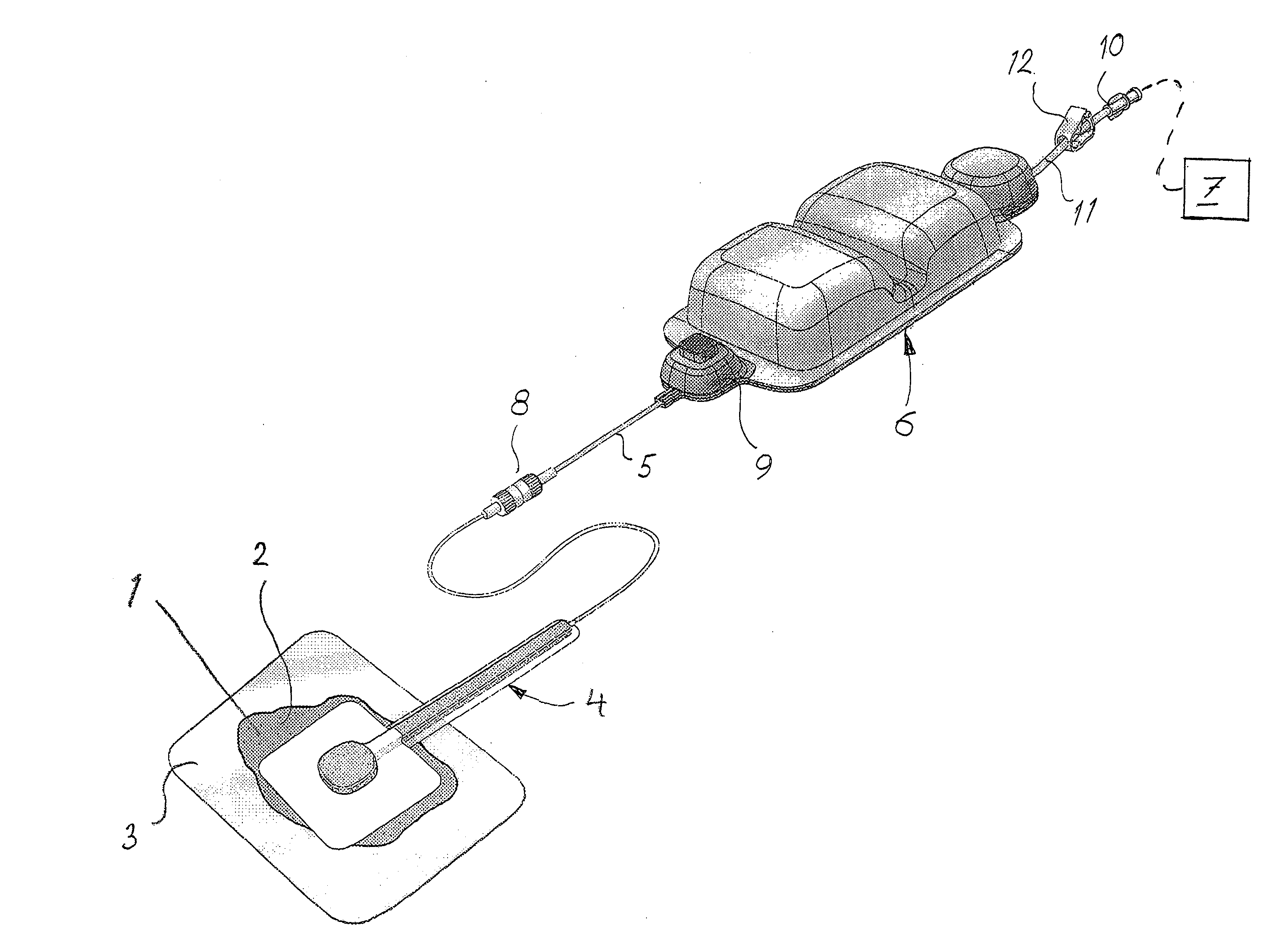

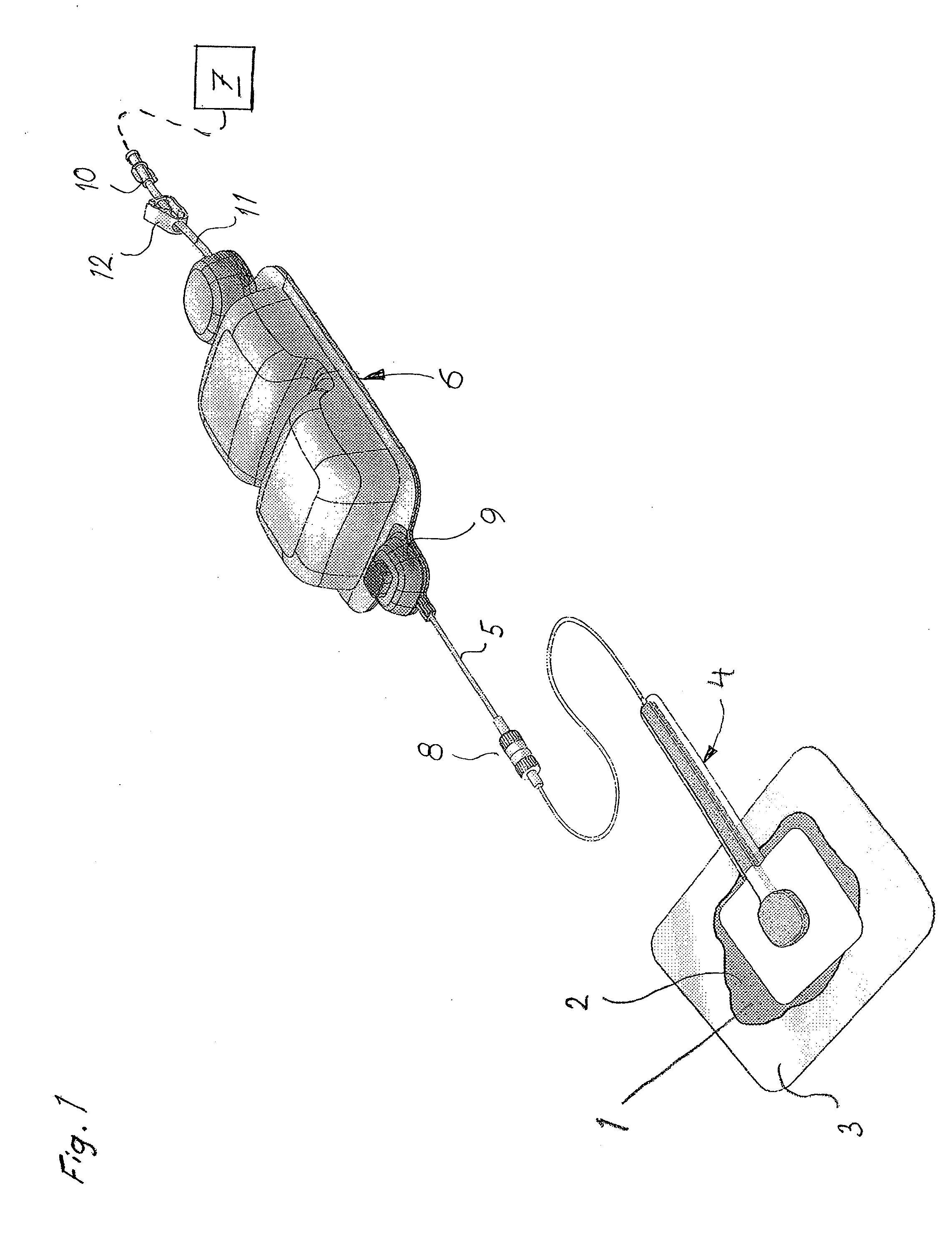

Device for treatment of wound using reduced pressure

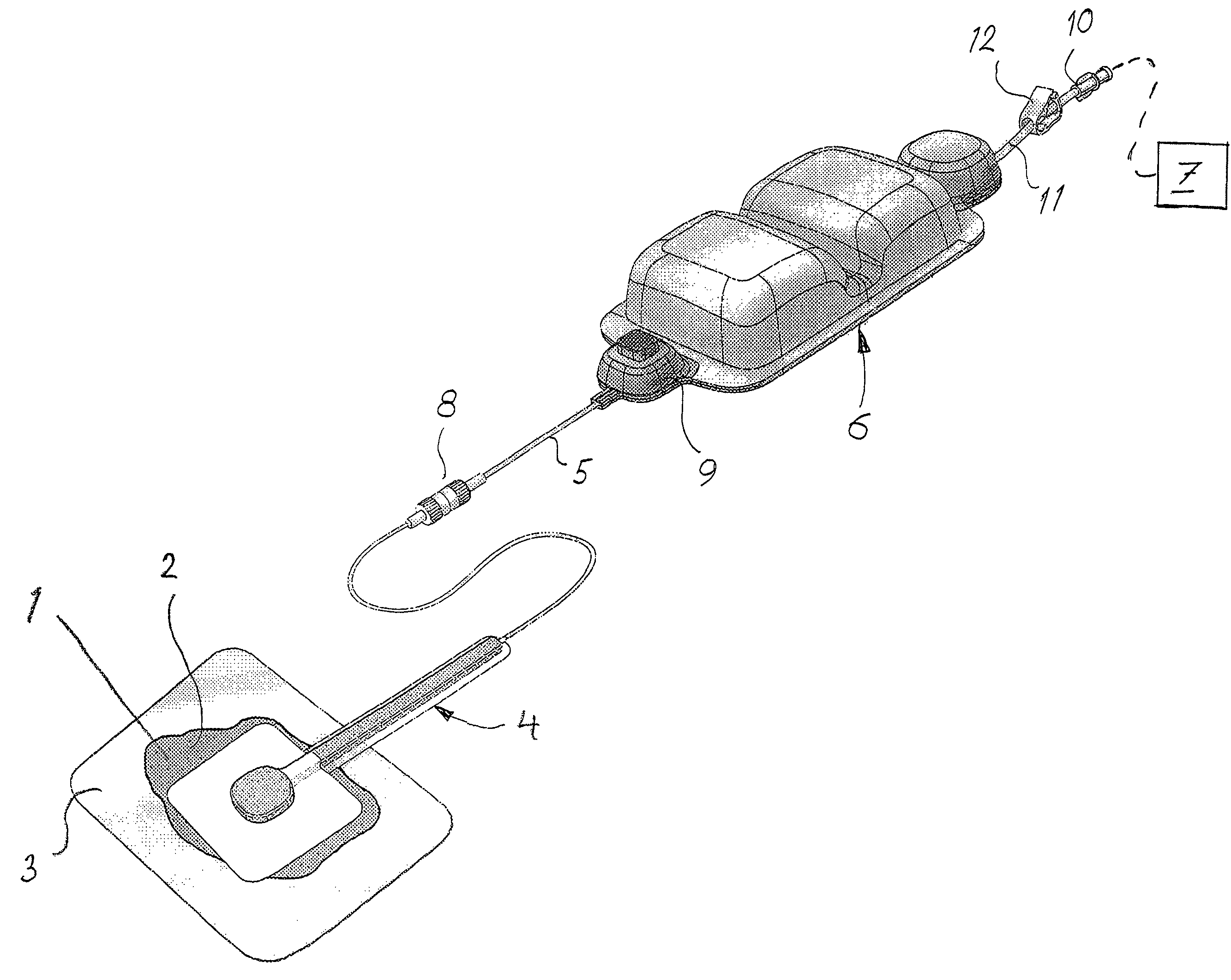

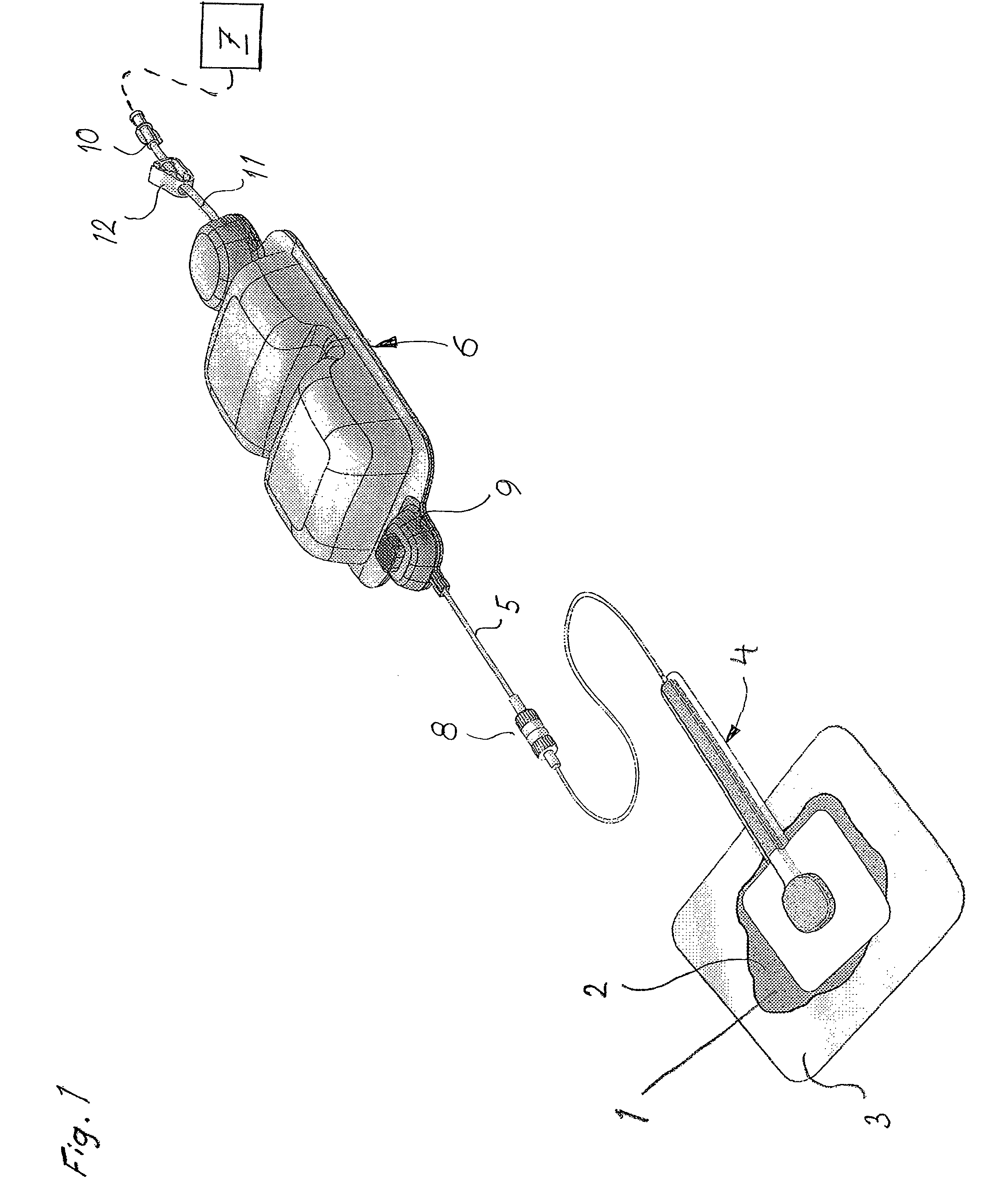

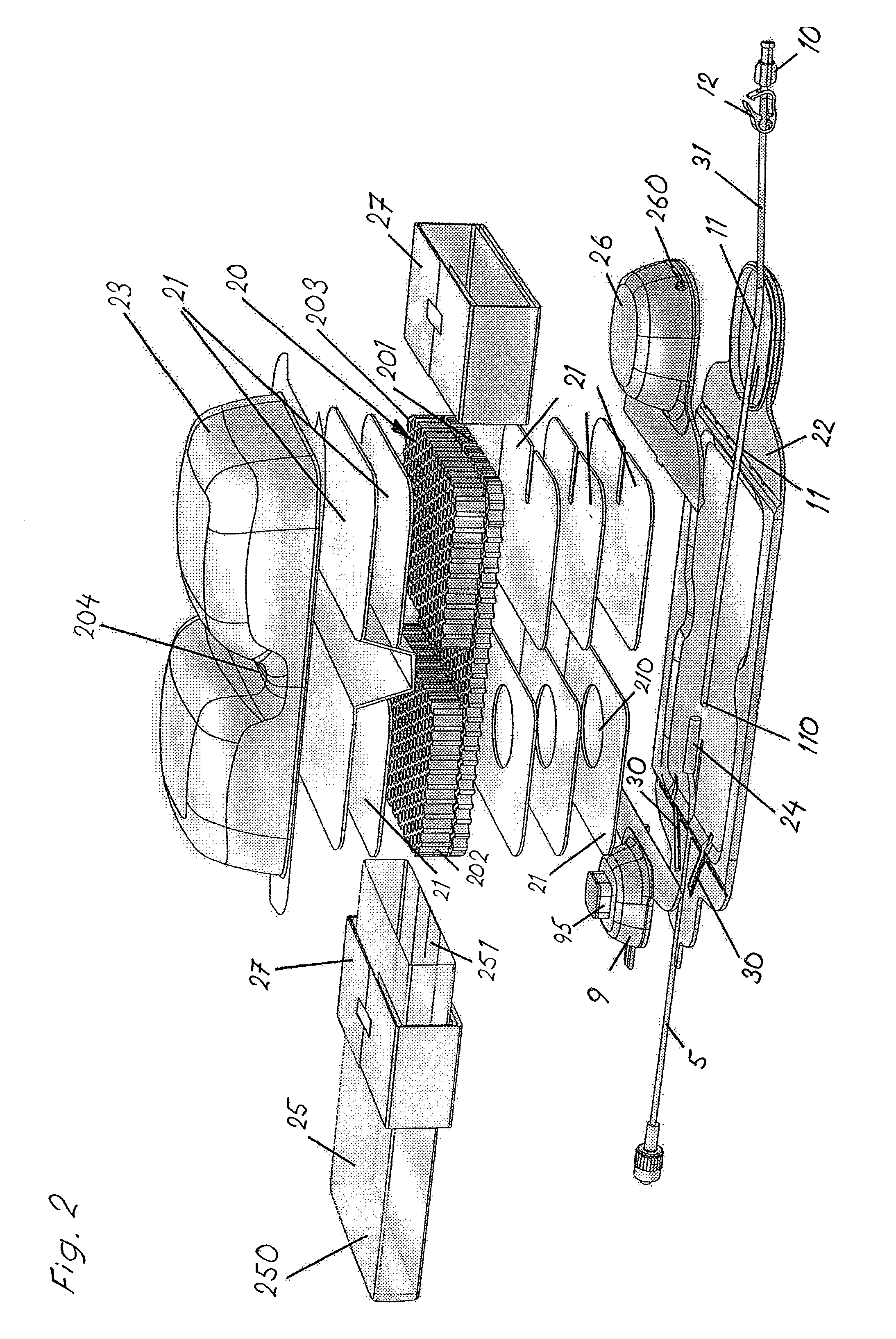

ActiveUS8382731B2Reduce pressureKeep the pressureSurgeryMedical devicesLiquid diffusionCompressible material

Provided is a device for treatment of wounds using reduced pressure, which includes a pump, a gas barrier cover, a first compressible material which expands after compression, and a second material capable of absorbing wound fluids several times its own weight. The first and second materials are arranged inside the cover and form a reservoir connected to the pump. The device also includes an inlet for connecting the reservoir with a wound, a wound pad to be arranged in the wound cavity, and a sealing covering the wound and the wound pad. A third material with high liquid spreading capability is arranged around at least a major part of the first material, and the second material is in the form of at least one layer arranged outside the third material and separated from the first material by the third material.

Owner:MOLNLYCKE HEALTH CARE AB

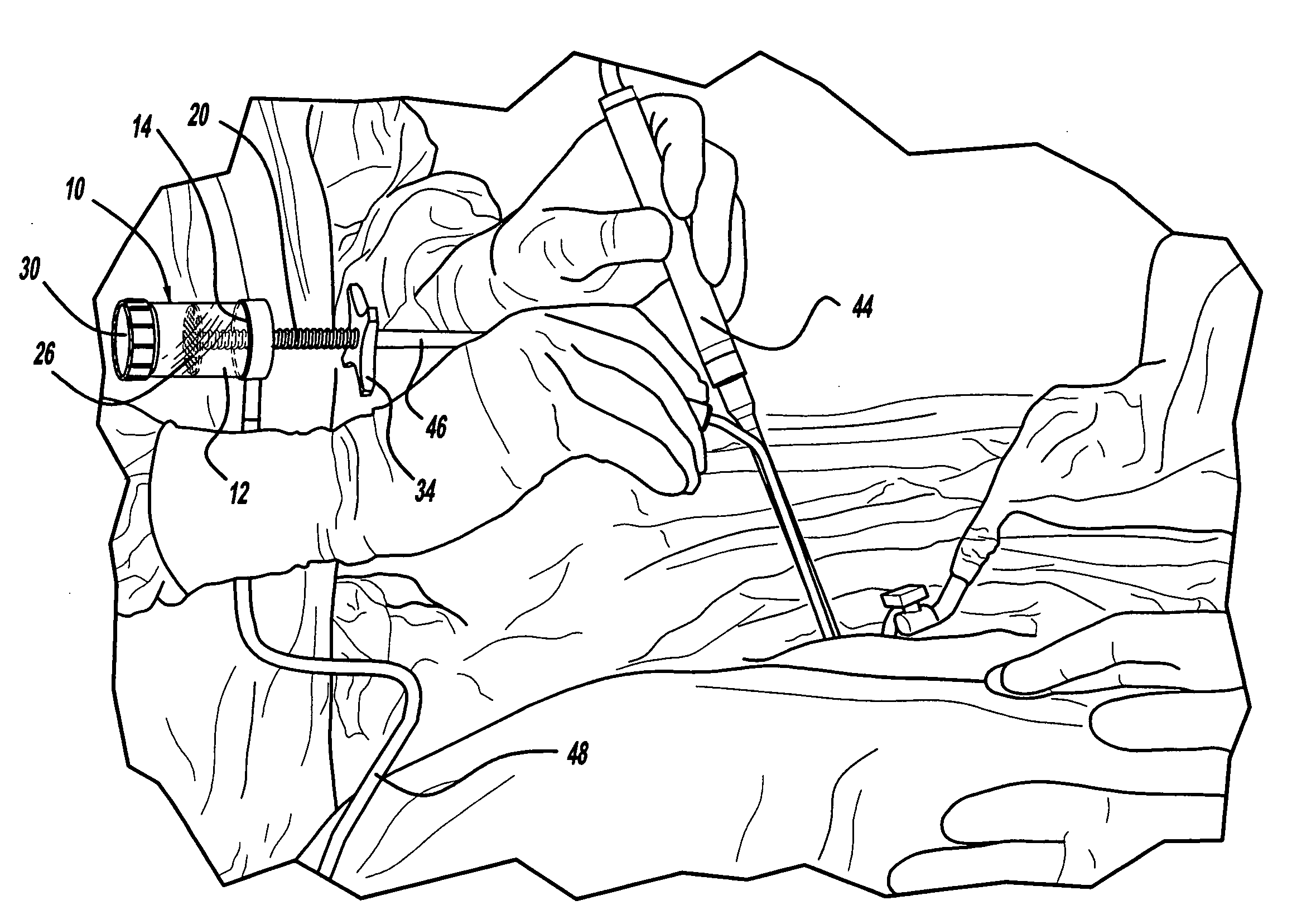

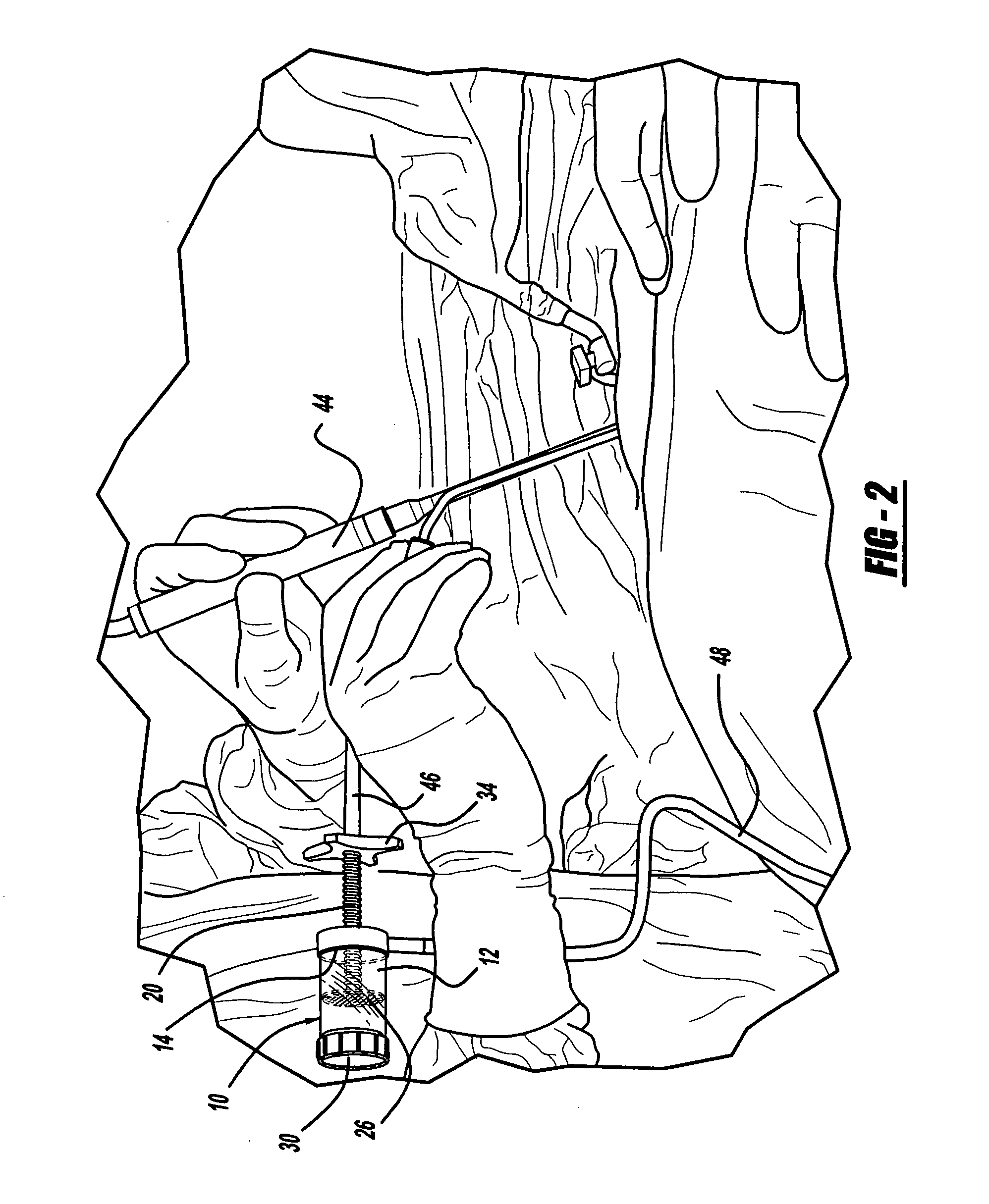

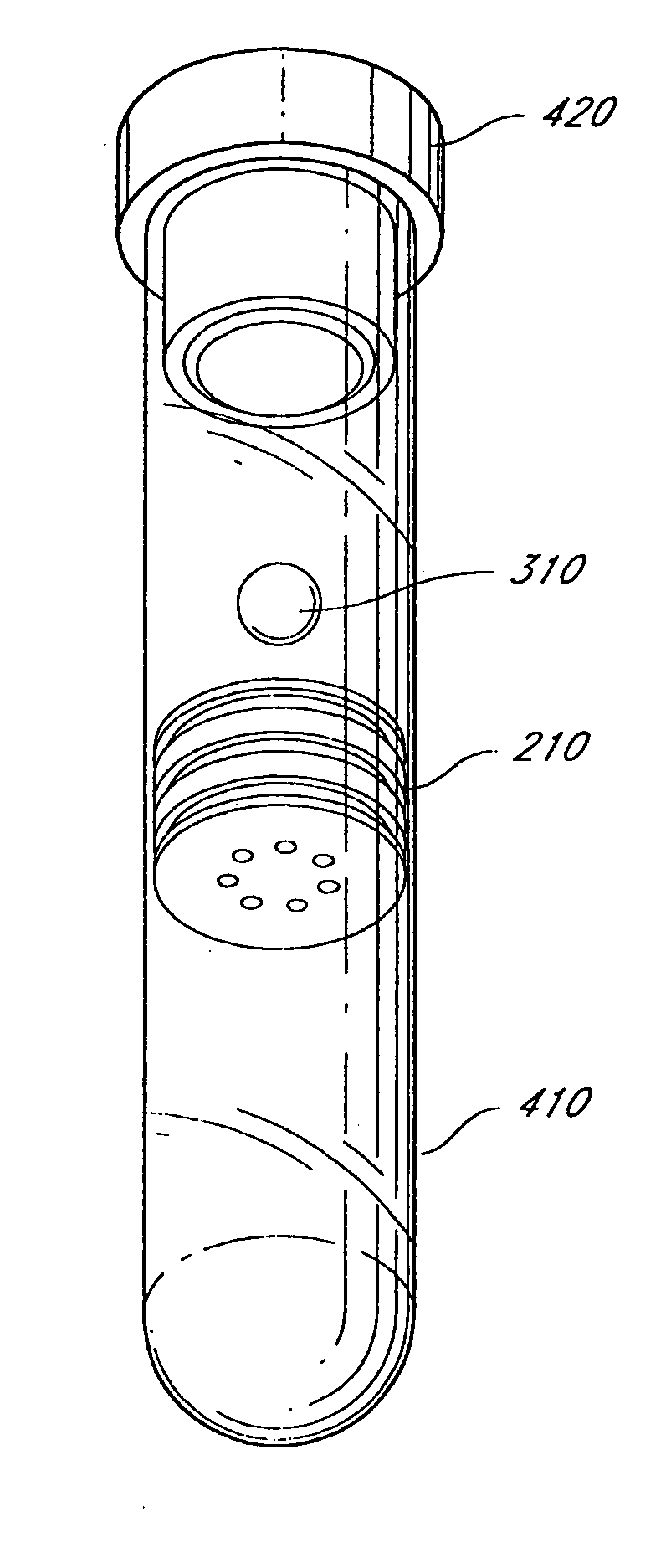

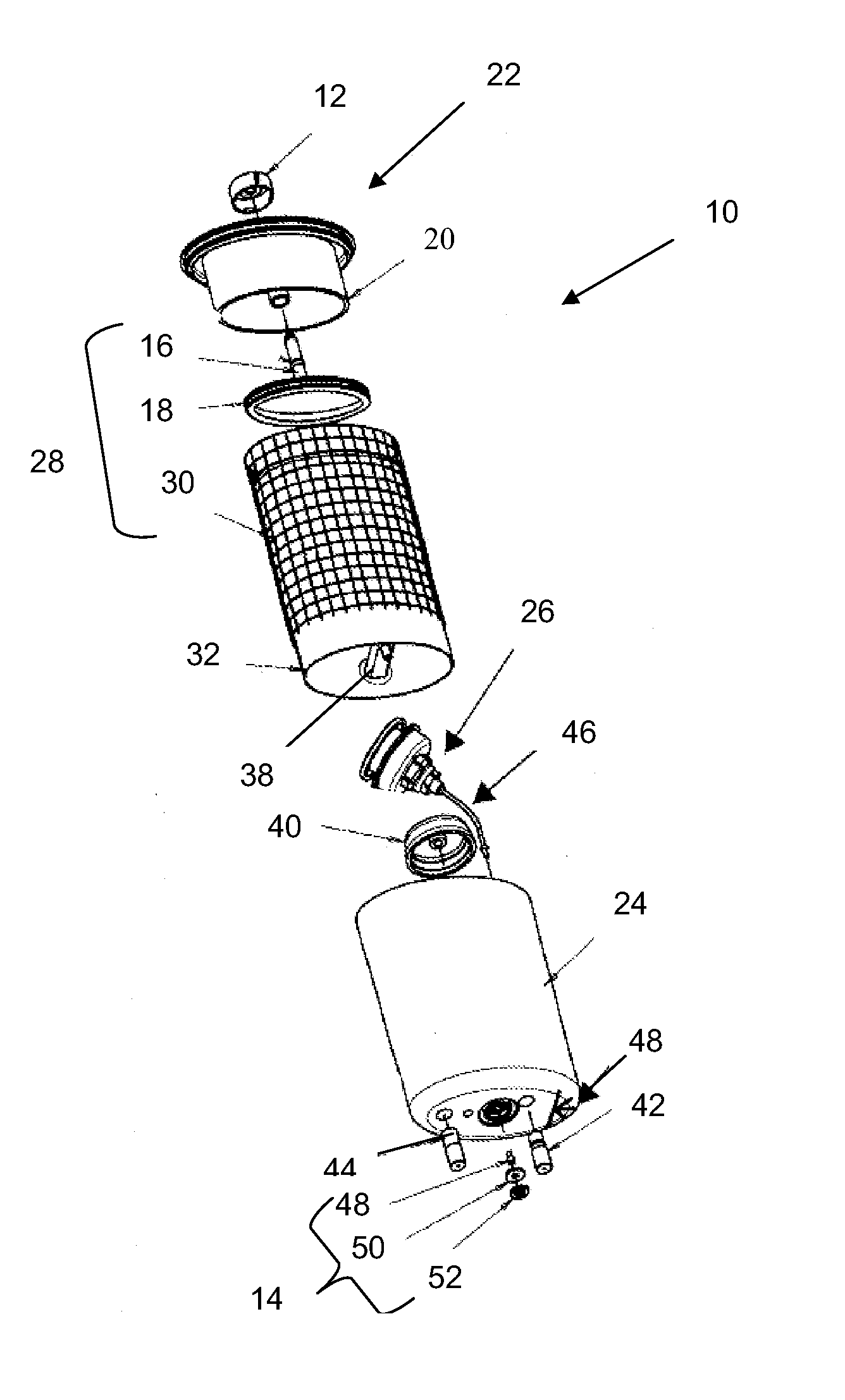

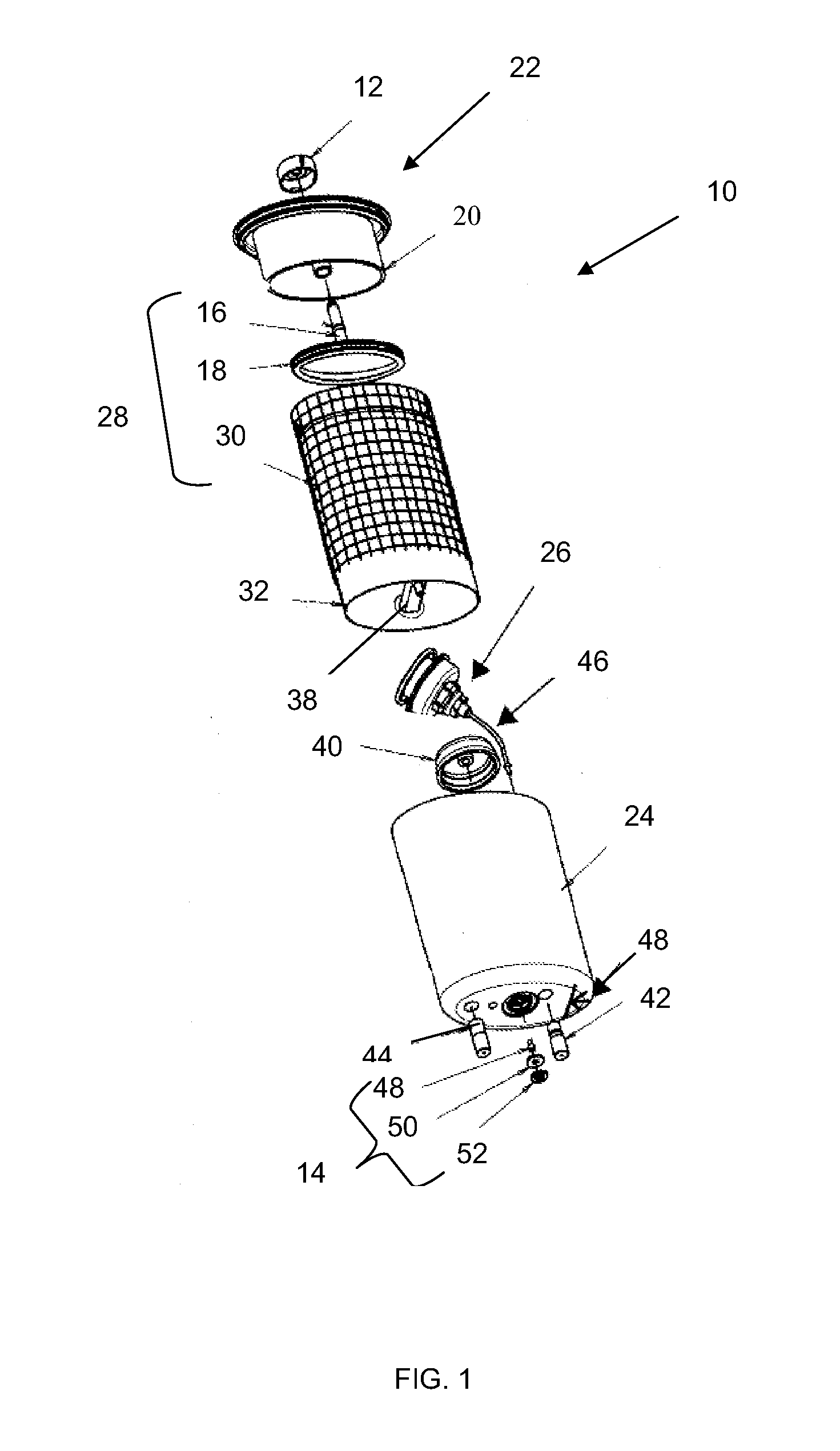

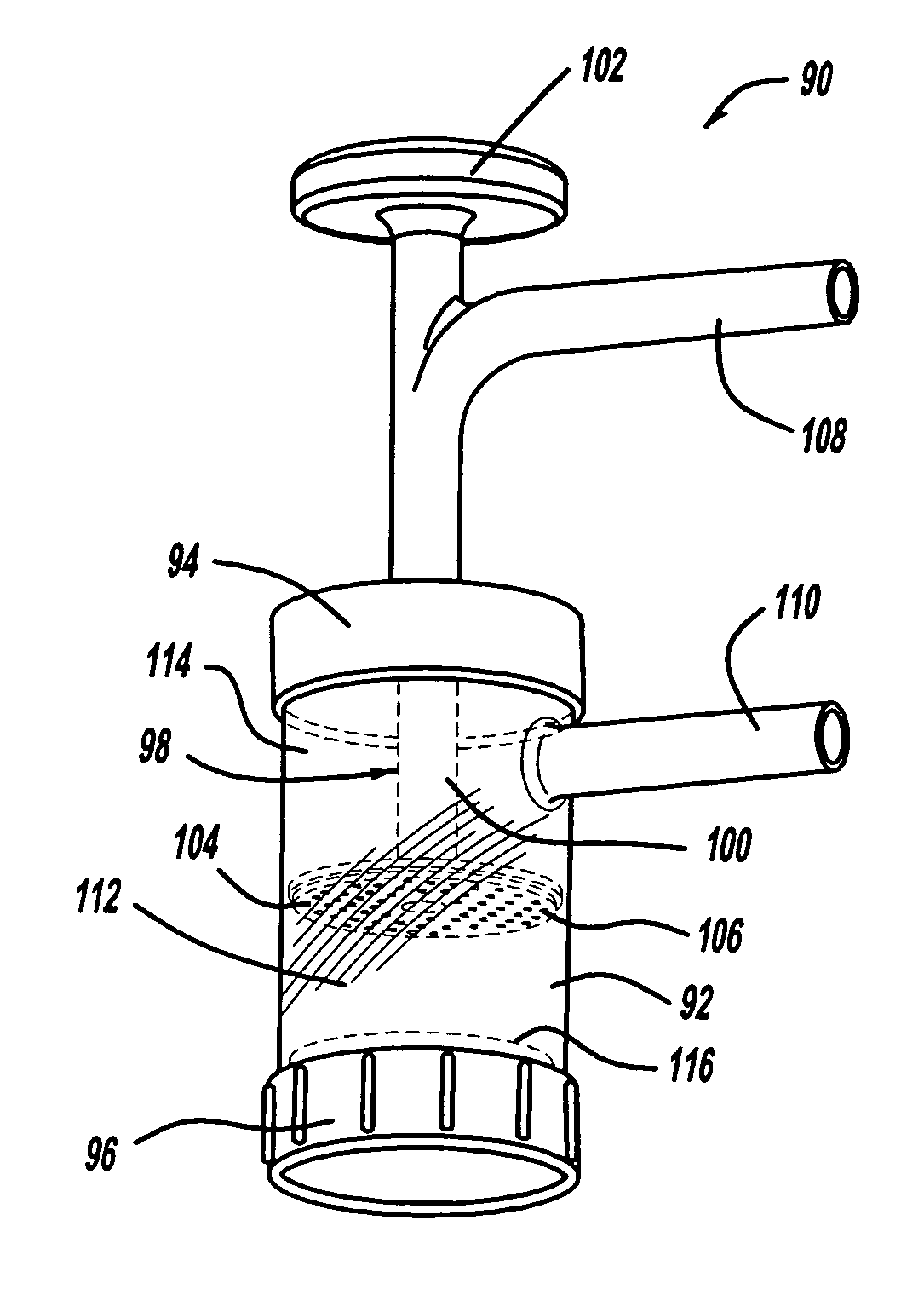

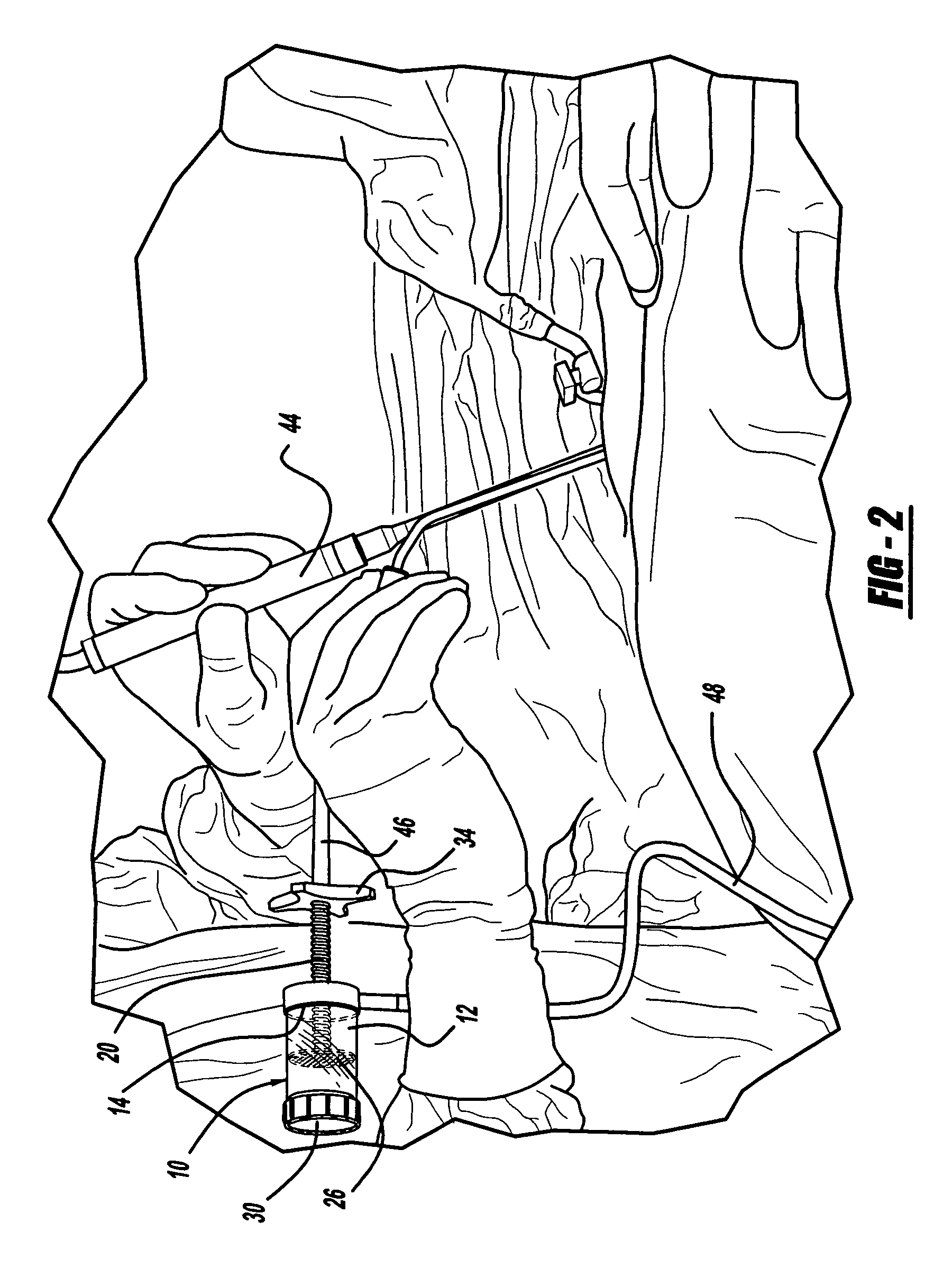

Device for collecting bone material during a surgical procedure

A collection device for collecting bone material during a spinal fusion surgical procedure so that the bone material can later be used as a graft material for the fusion procedure. The device includes a container that collects the bone and other material that is removed from the patient during the surgical procedure through a suction hose. The device includes a plunger having a filter plate sealed to the inside of the container. The plunger is pushed down into the collected material in the container so that blood and other liquids are forced through the plate to be separated from the bone material. A cover at the bottom of the container can be removed to remove the collected bone material.

Owner:THOMPSON MIS

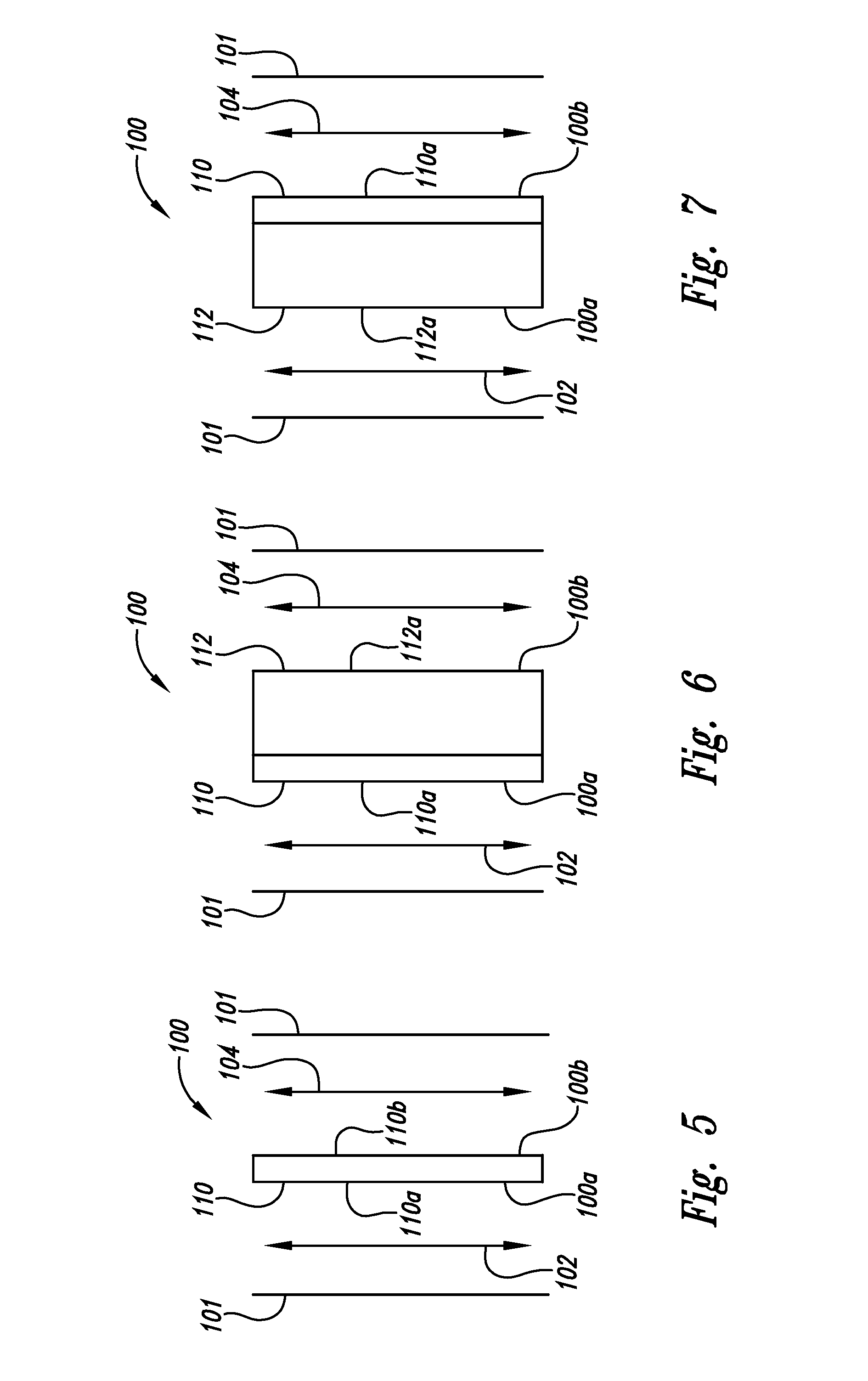

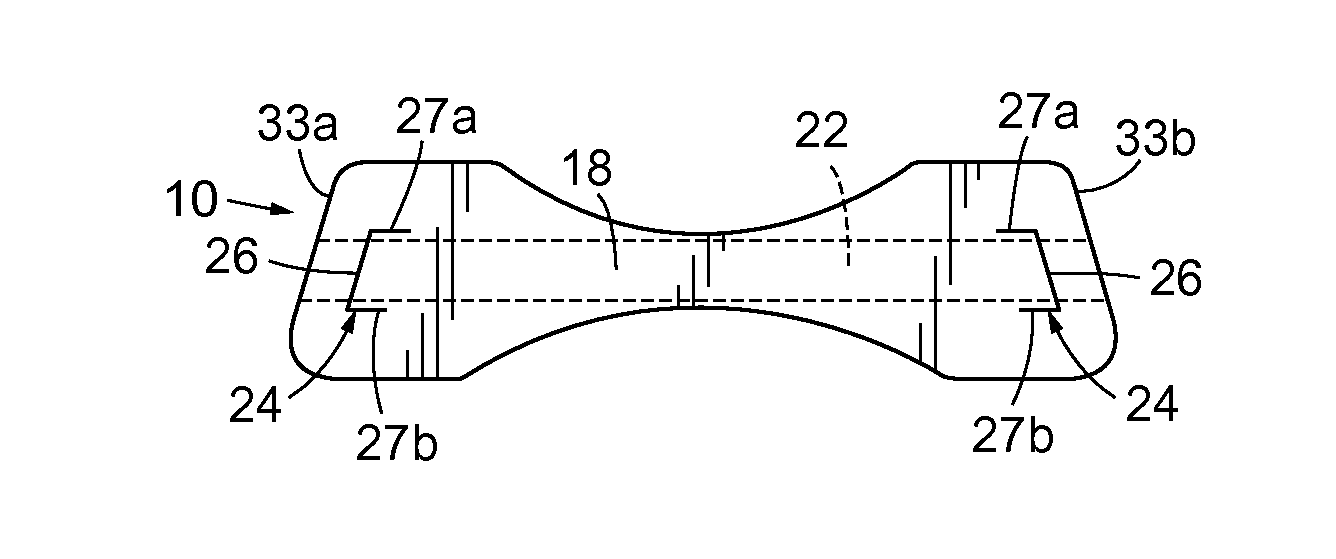

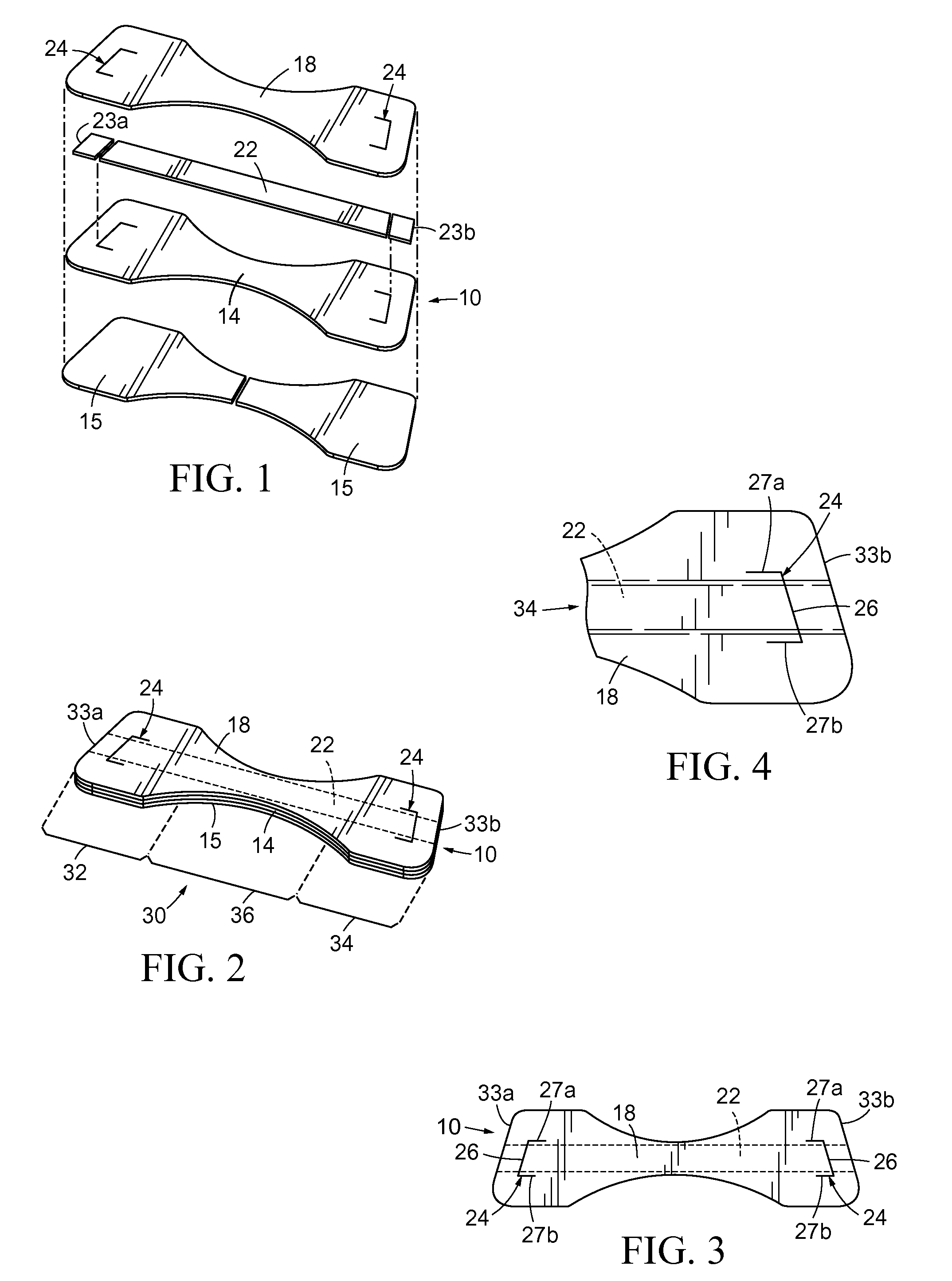

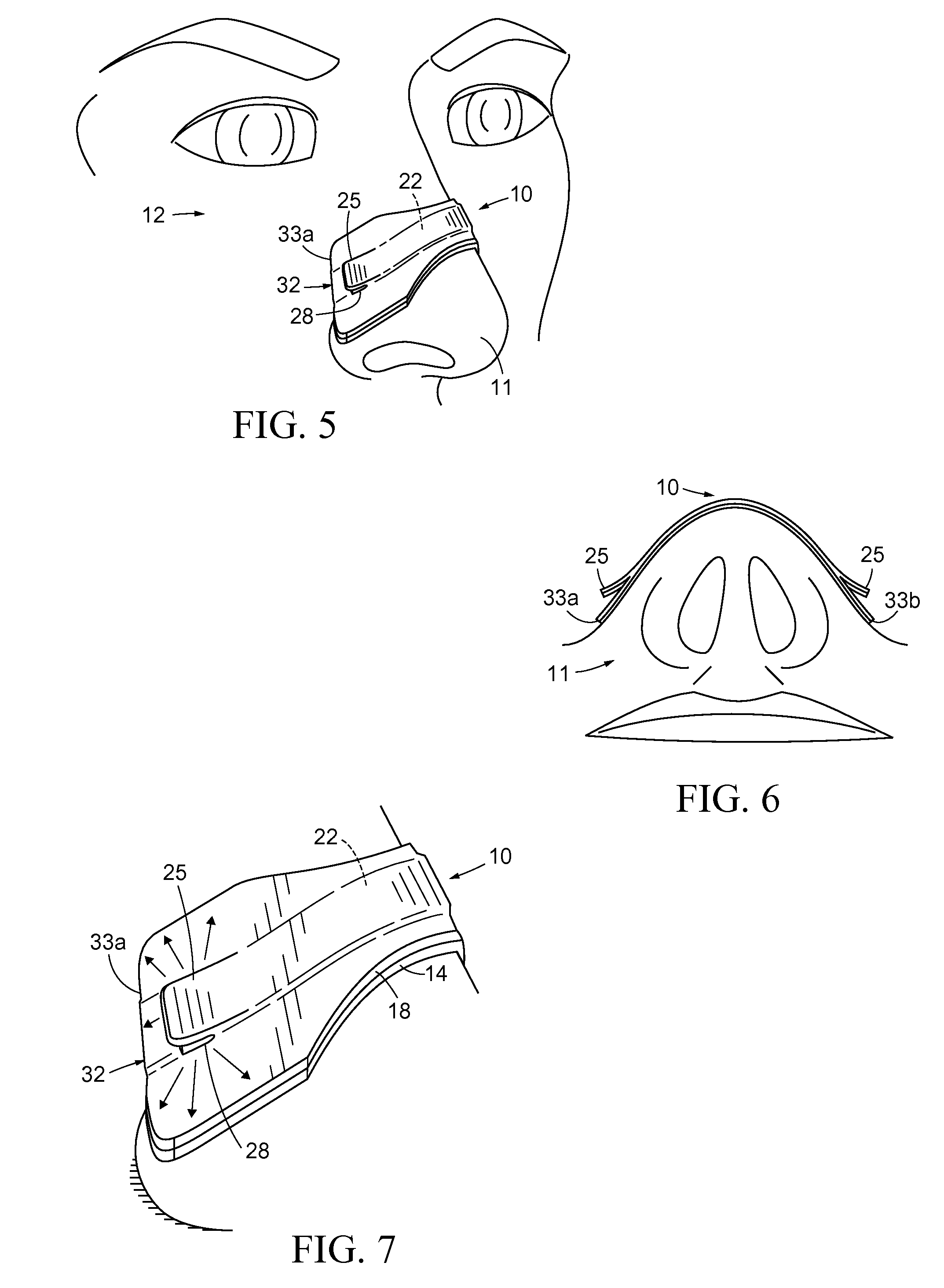

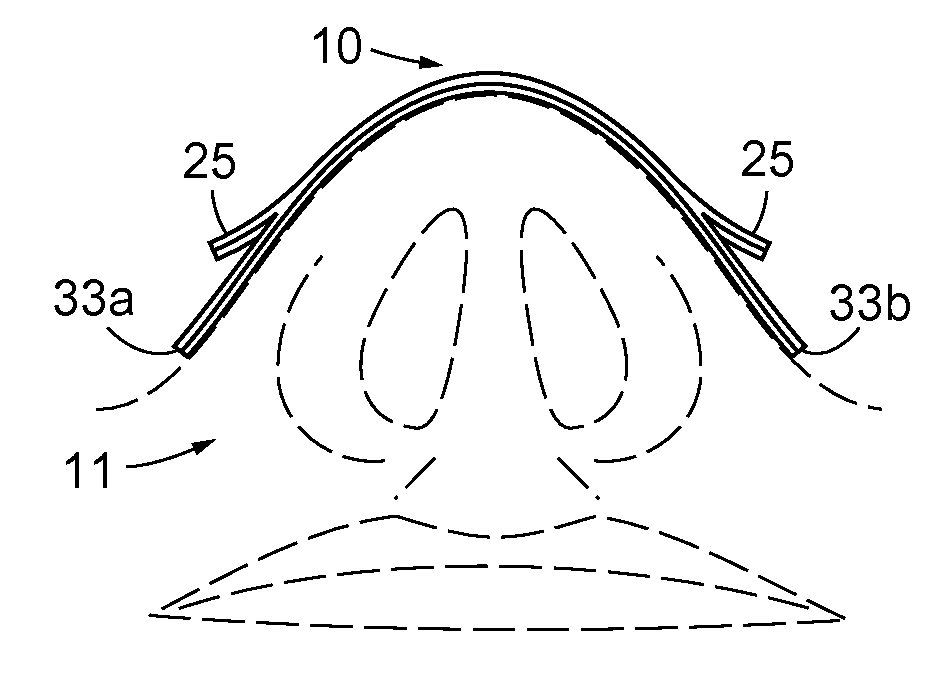

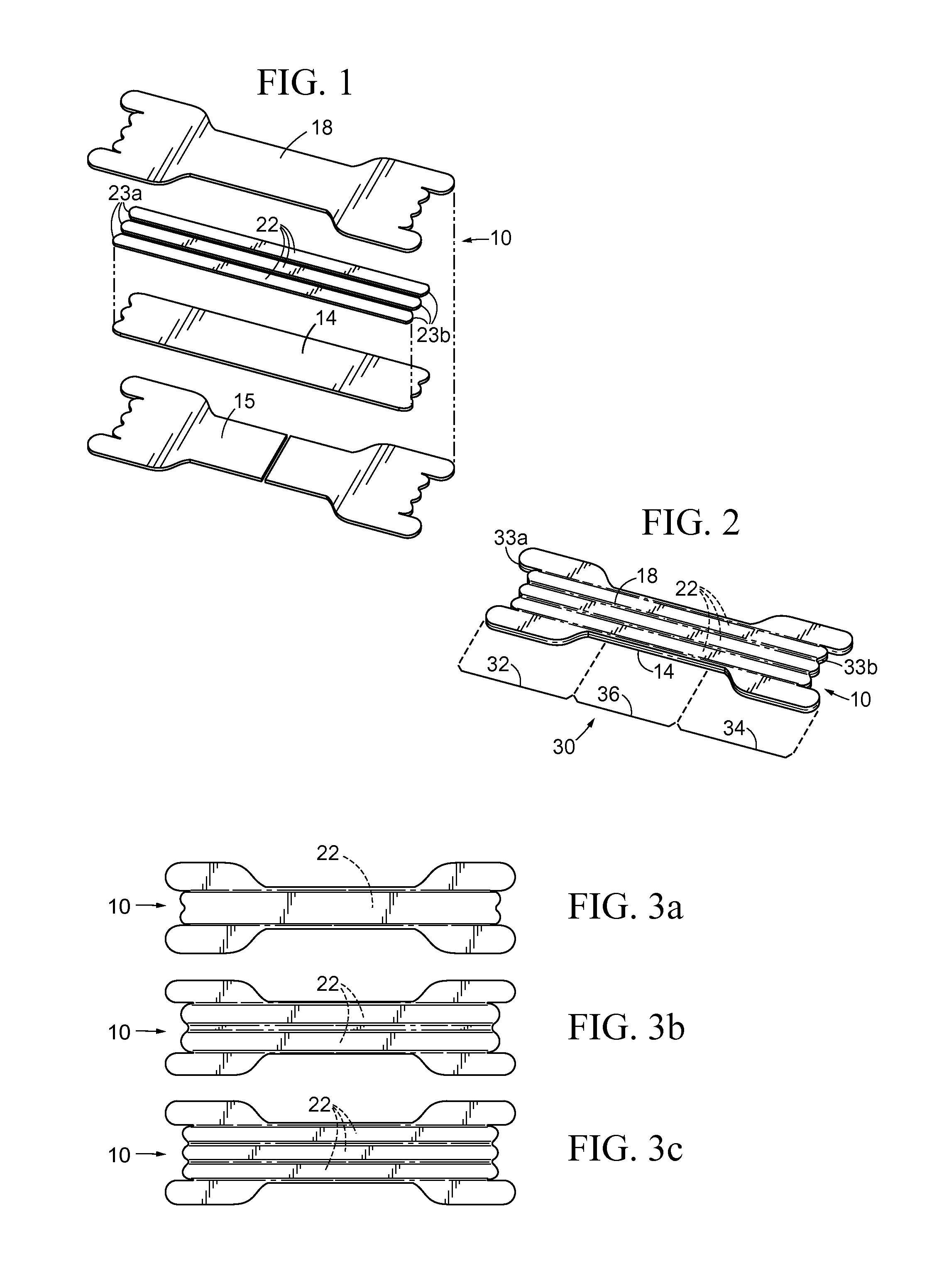

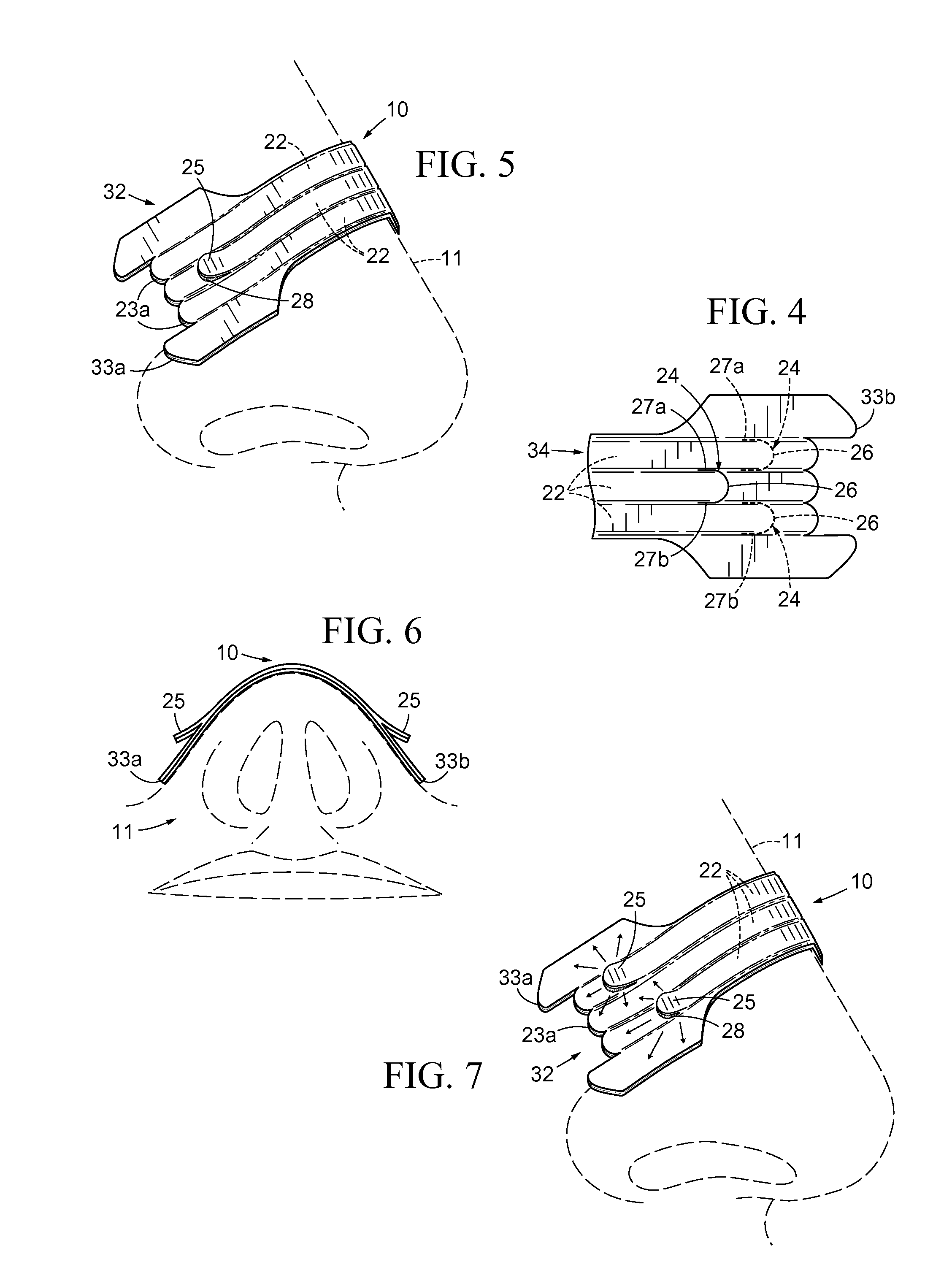

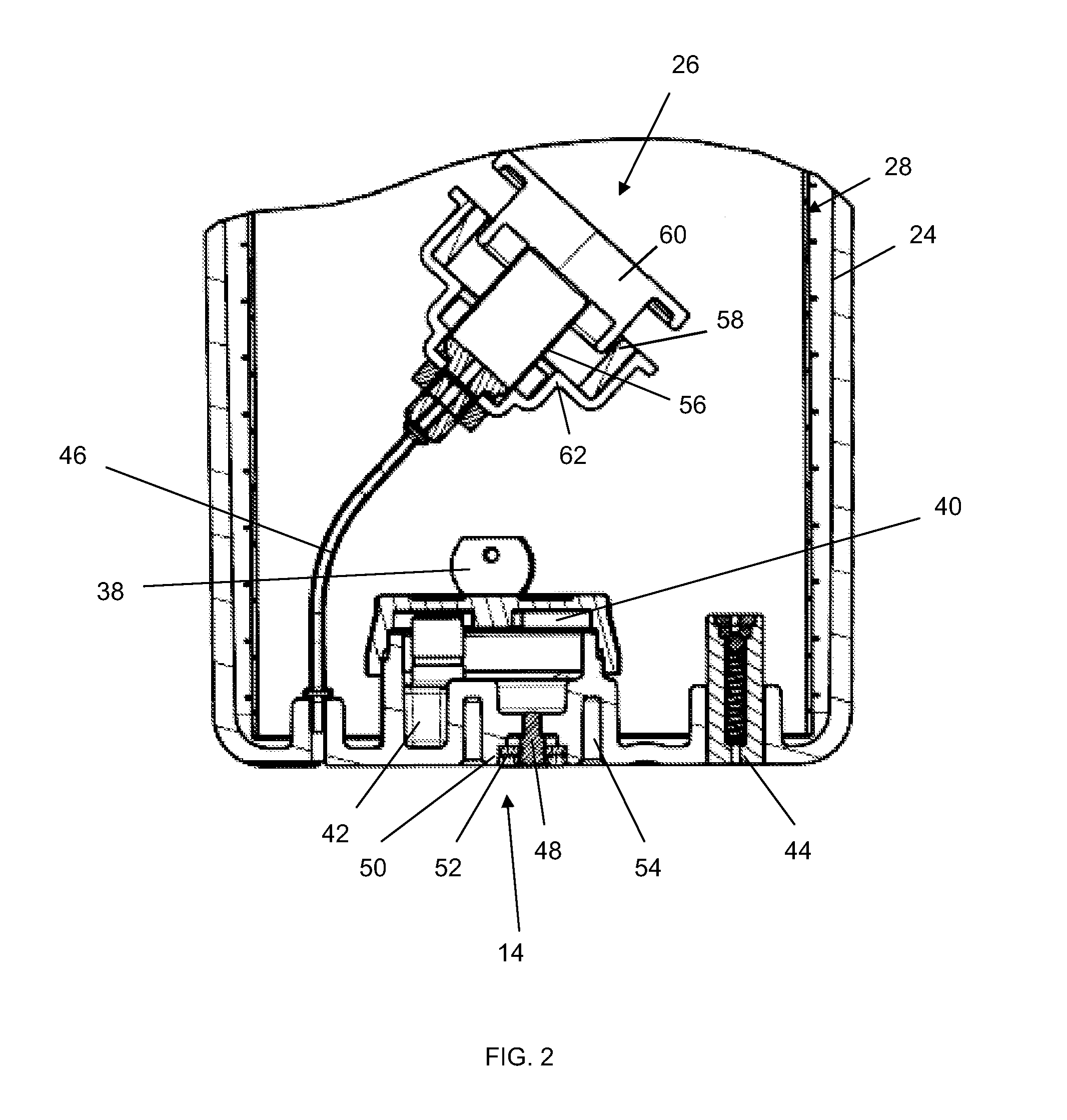

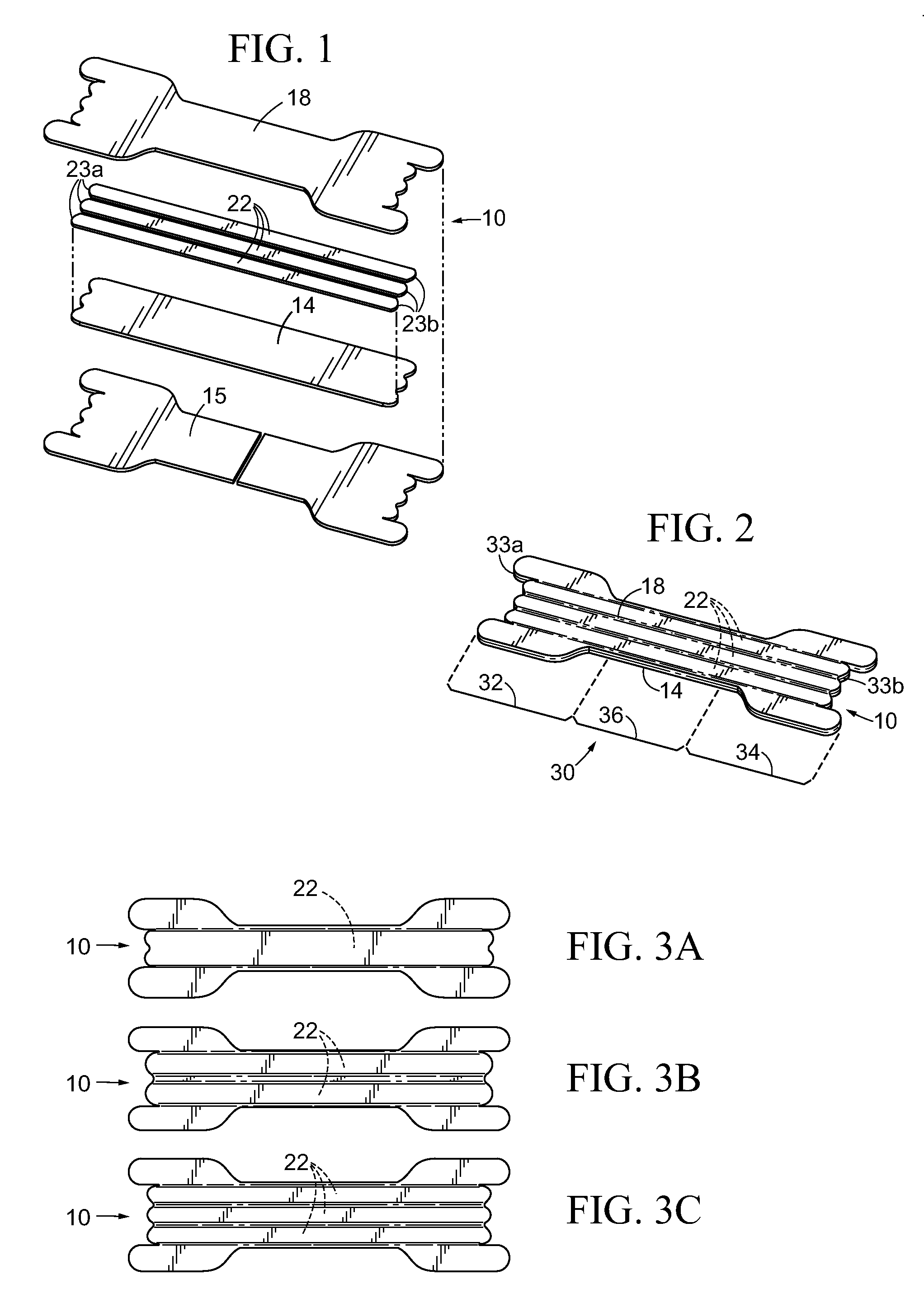

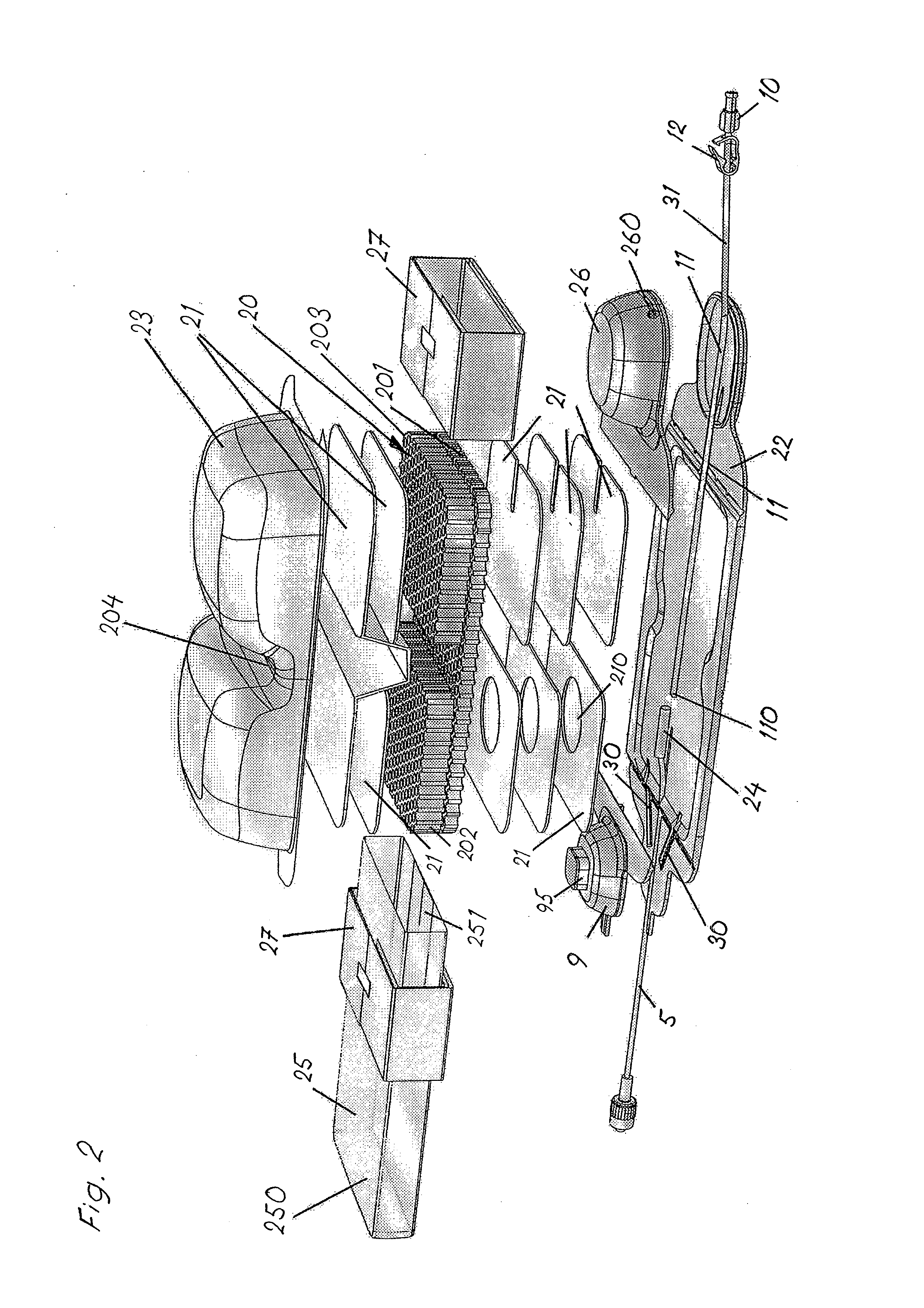

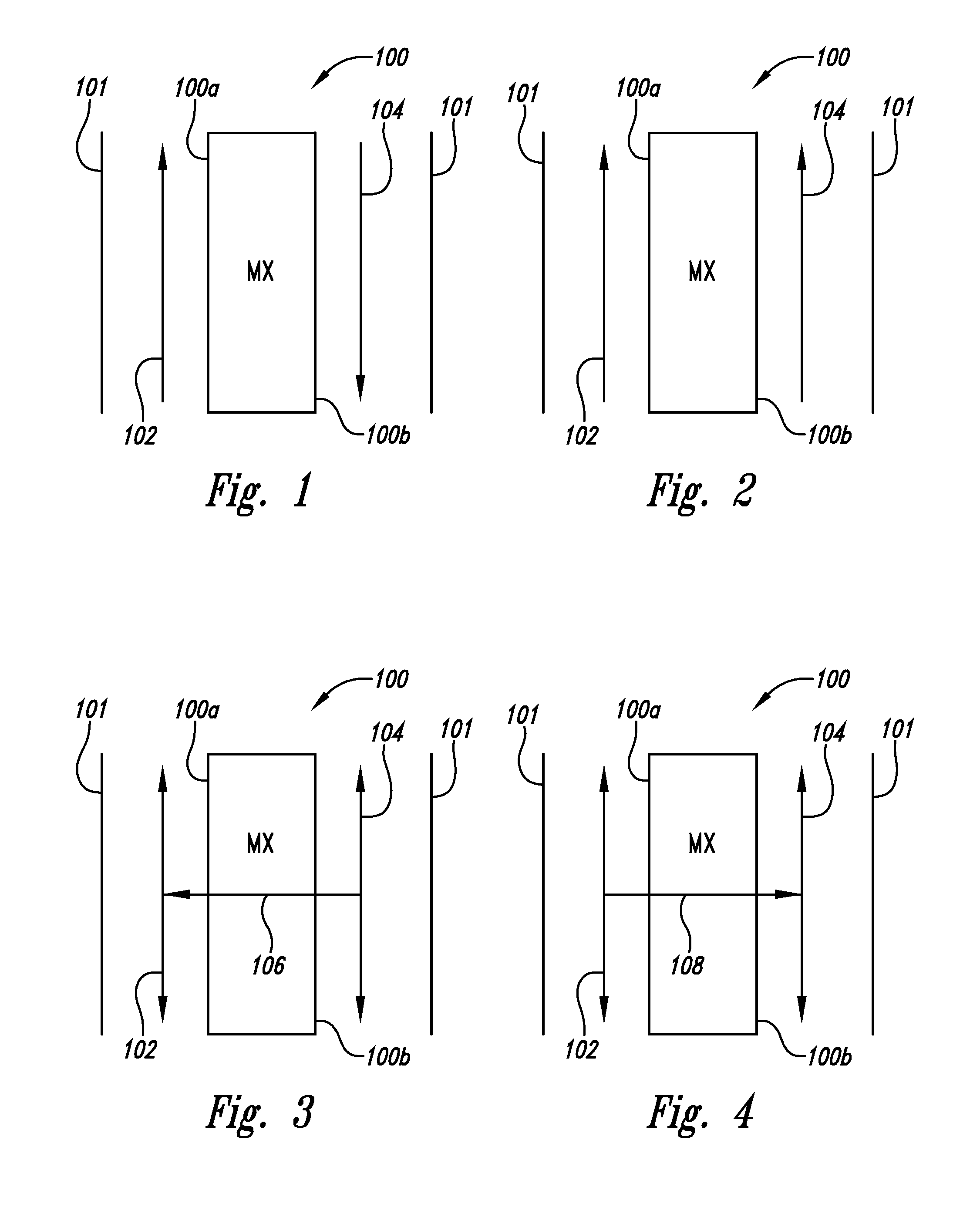

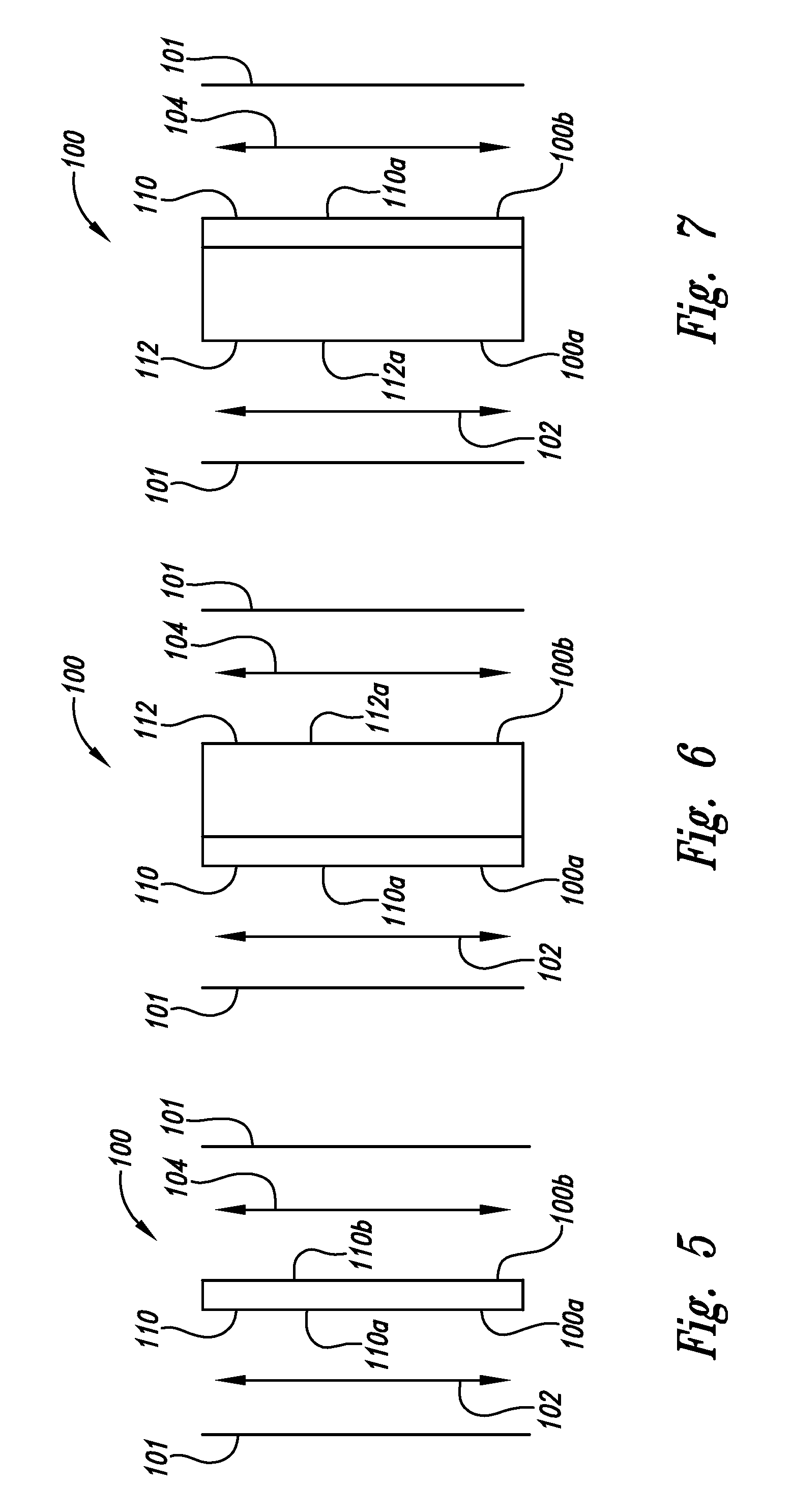

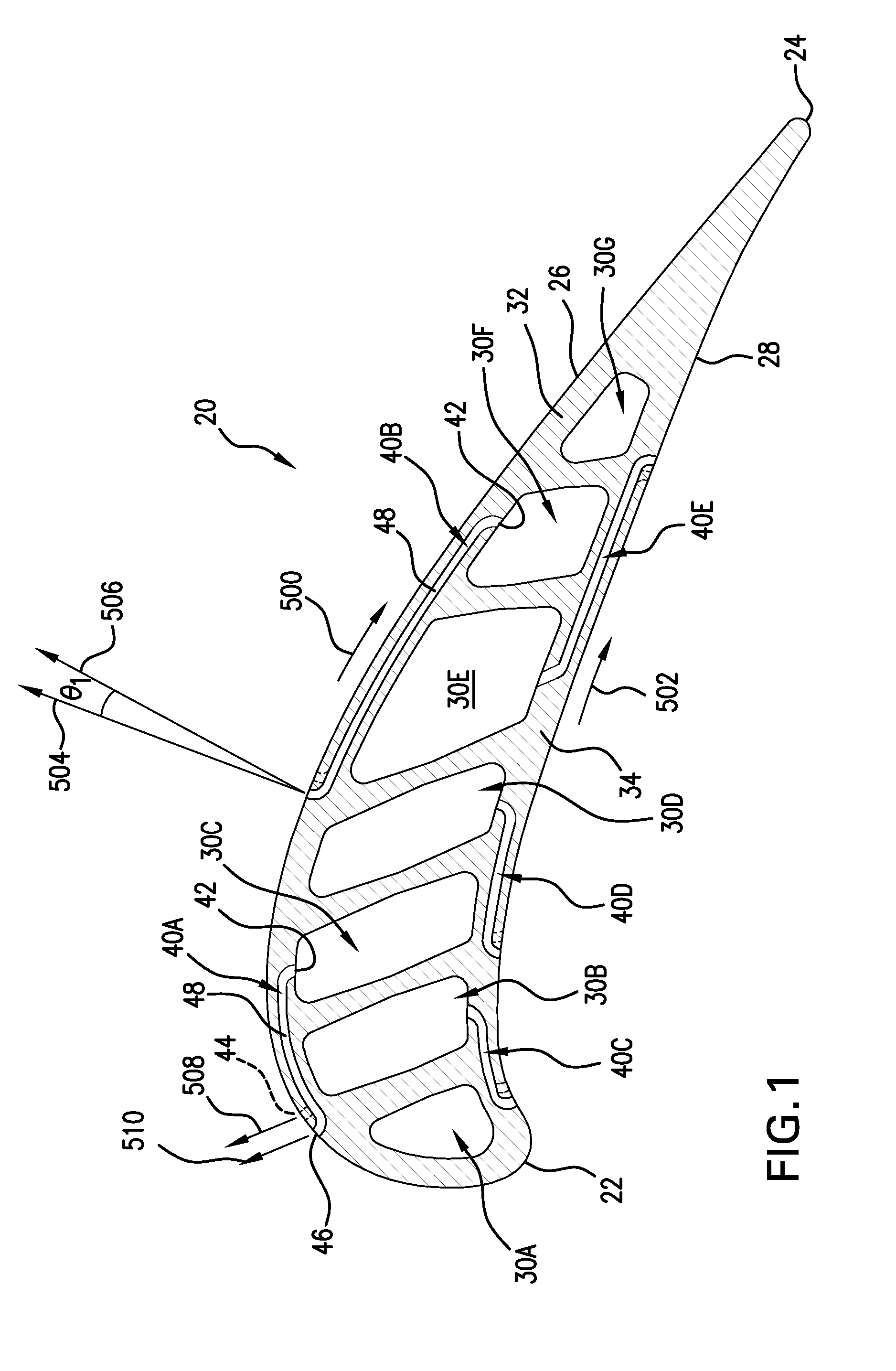

Nasal dilator with means to direct resilient properties

ActiveUS8062329B2Great delaminating tendencyReduce forceRespiratorsBreathing masksNasal passageNasal passages

A nasal dilator comprises a laminate of vertical layers each consisting of one or more members or components. The laminated layers form a unitary, or single body, truss featuring horizontal regions adapted to engage outer wall tissues of first and second nasal passages and to traverse the bridge of a nose therebetween. When in use the dilator acts to stabilize and / or expand the nasal outer wall tissues and prevent said tissues from drawing inward during breathing. The dilator includes means to direct its resilient properties comprising one or more interior or exterior material separations, or discontinuity of shape of material, formed in at least one region of the truss and extending through at least one layer of the dilator. Said material separation or discontinuity of shape may comprise an opening, relief cut, slit or notch, and which may be configured to separate or vertically protrude, in part, from the truss when the dilator is in use on the nose of a wearer. Said separation or vertical protrusion changes the angle of focused delaminating spring biasing forces generated by the resilient layer, transforming said forces, at least in part, from primarily peel forces into primarily shear forces, and further redistributing or imparting said transformed forces to tissue engaging surface areas extending outward and beyond said material separation.

Owner:HORIZON IP TECH LLC

Nasal Dilator With Means To Direct Resilient Properties

InactiveUS20120209313A1Extend and increase tissue engaging surface areaPrevent and more material separation separatingNon-surgical orthopedic devicesNasal passageNasal passages

Owner:CORBETT LAIR INC

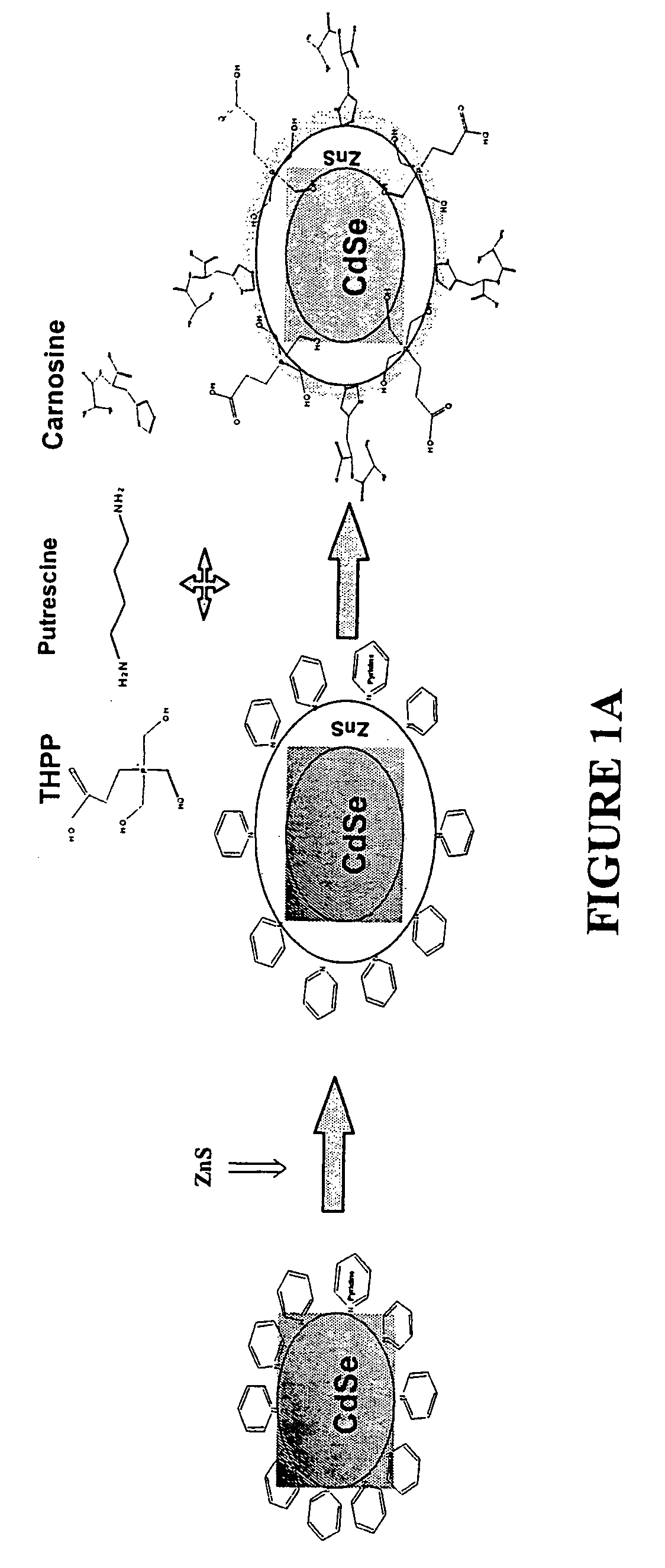

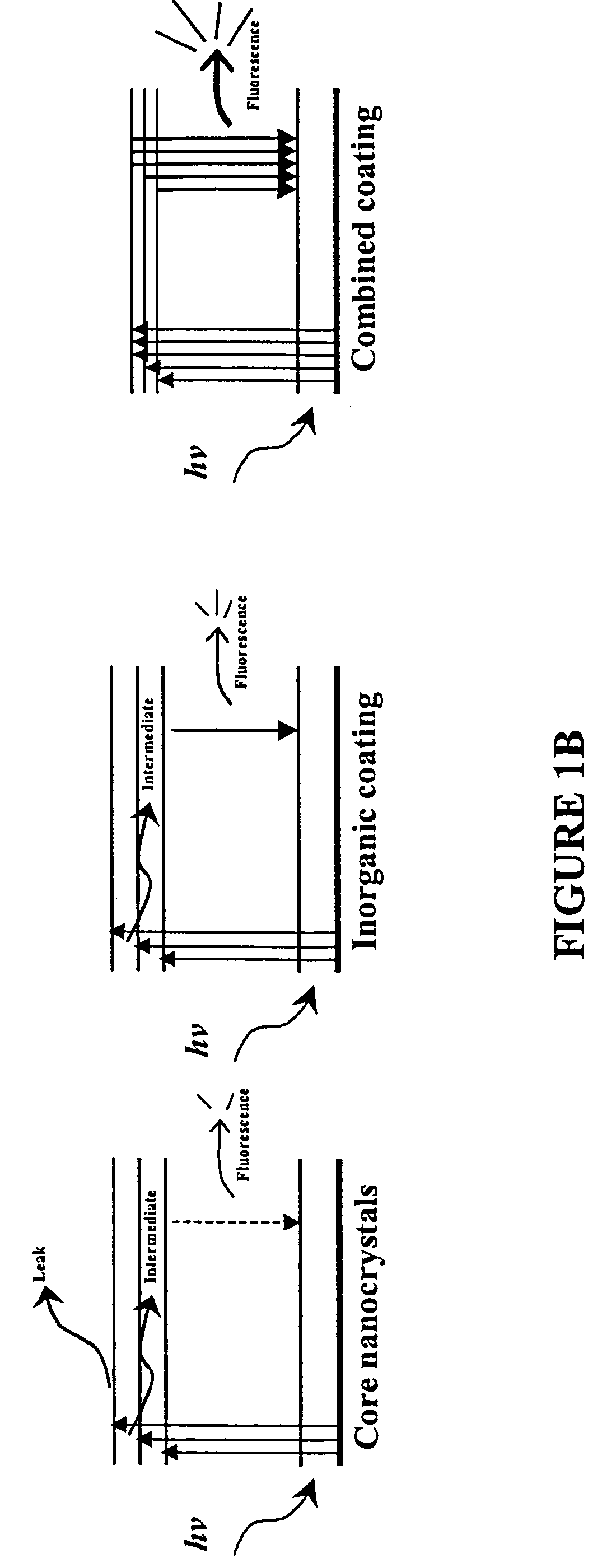

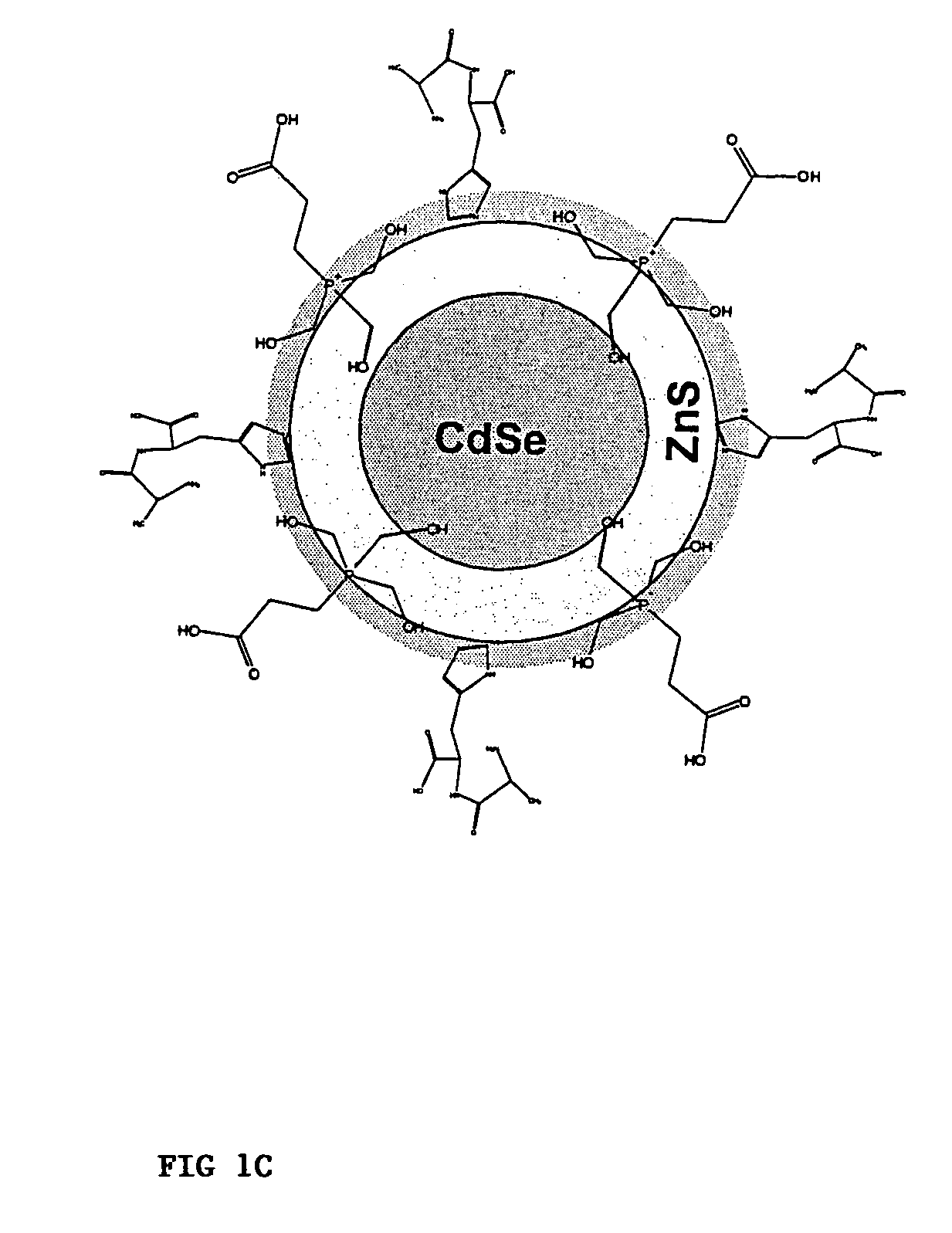

Highly luminescent functionalized semiconductor nanocrystals for biological and physical applications

InactiveUS7214428B2Improve efficiencyImprove solubilitySynthetic resin layered productsCellulosic plastic layered productsCross-linkQuantum yield

The present invention provides for detection apparatus with functionalized fluorescent nanocrystal compositions and methods for making and using these compositions in biological detection applications, material separations, and in the production of biosensors. The compositions are fluorescent nanocrystals coated with at least one coating material comprising ligands with functional groups or moieties with conjugated electrons and moieties for imparting solubility to fluorescent nanocrystals in aqueous solutions. The coating material provides for functionalized fluorescent nanocrystal compositions which are water soluble, chemically stable, and emit light with a high quantum yield and / or luminescence efficiency when excited with light. The coating material may also have chemical compounds or ligands with moieties for bonding to target molecules and cells as well as moieties for cross-linking the coating.

Owner:LIFE TECH CORP

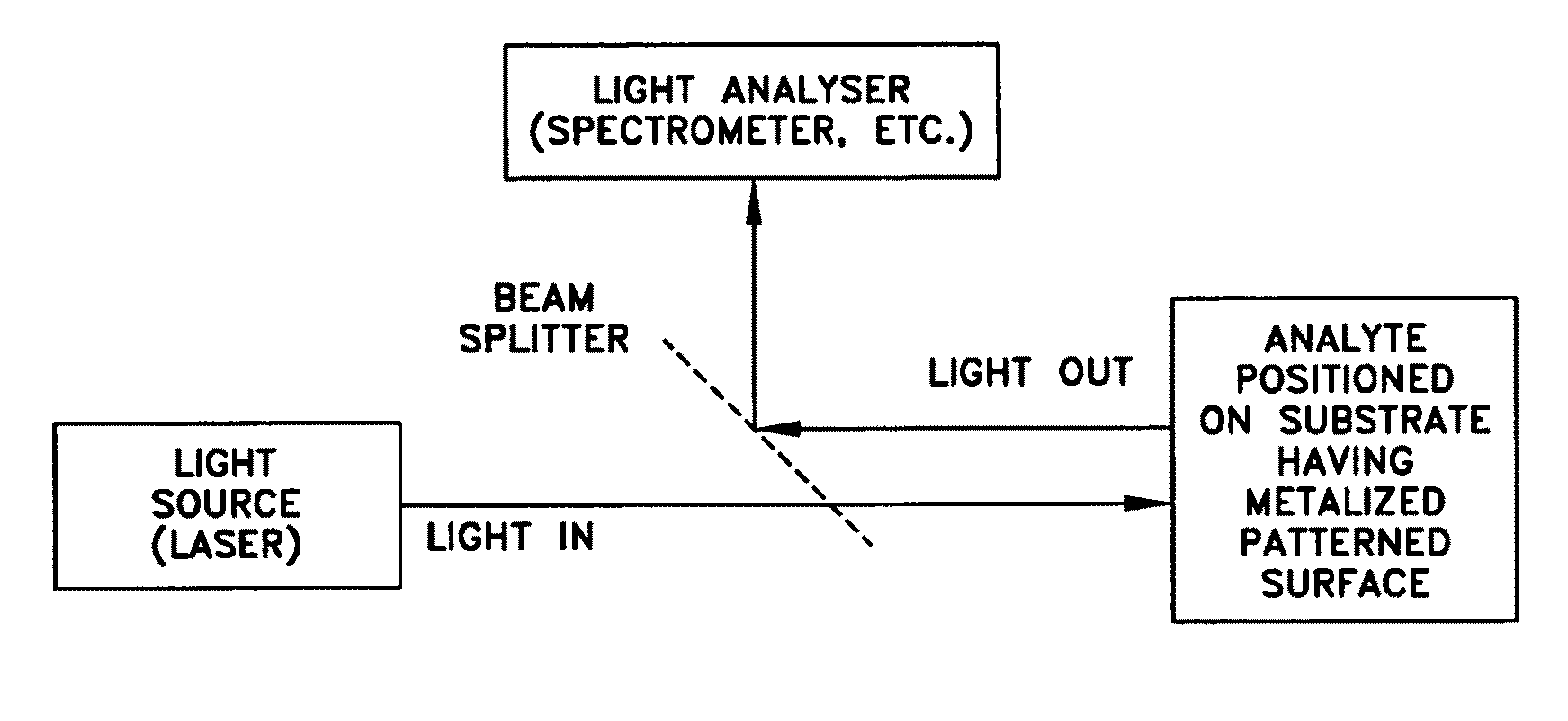

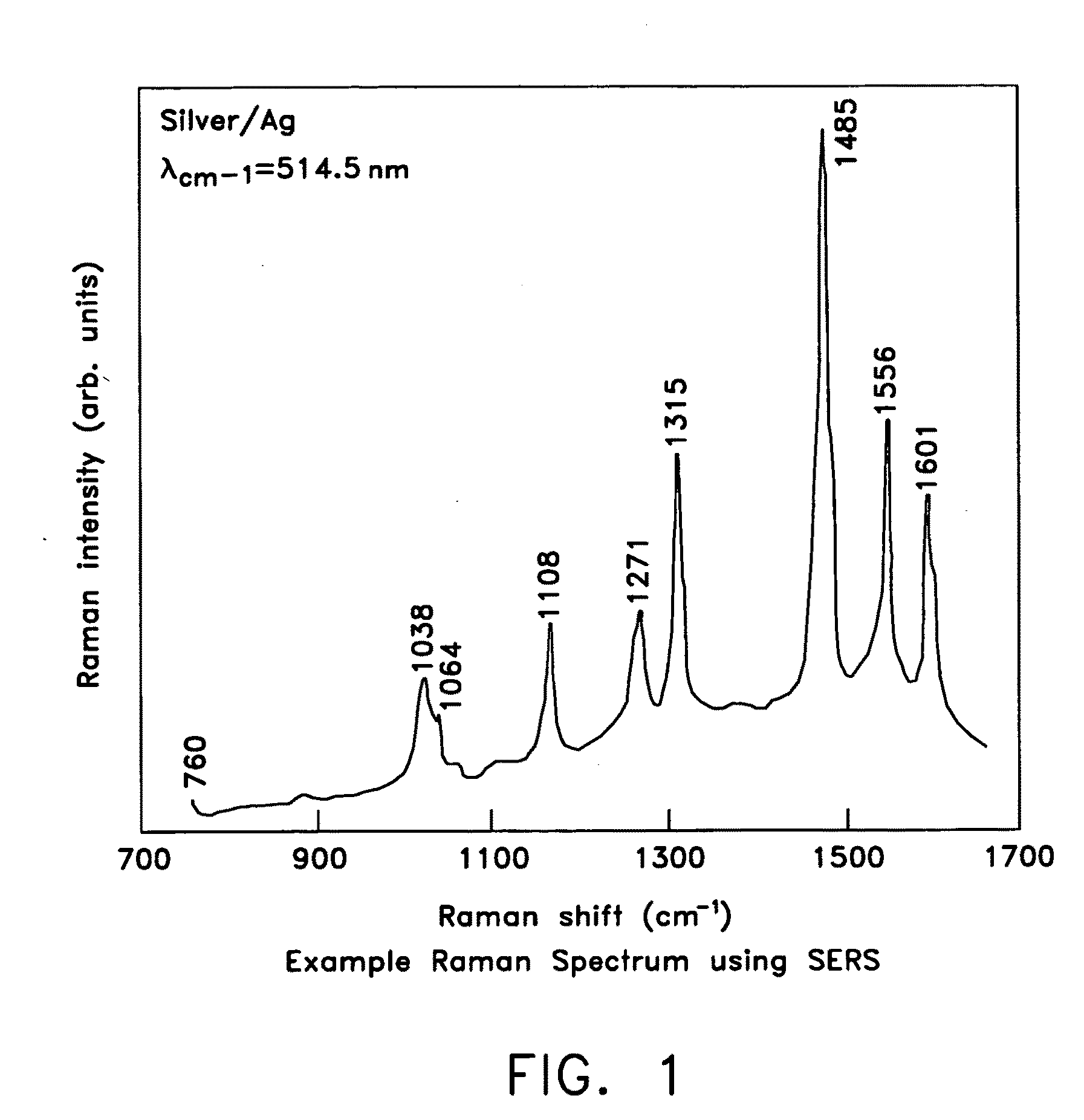

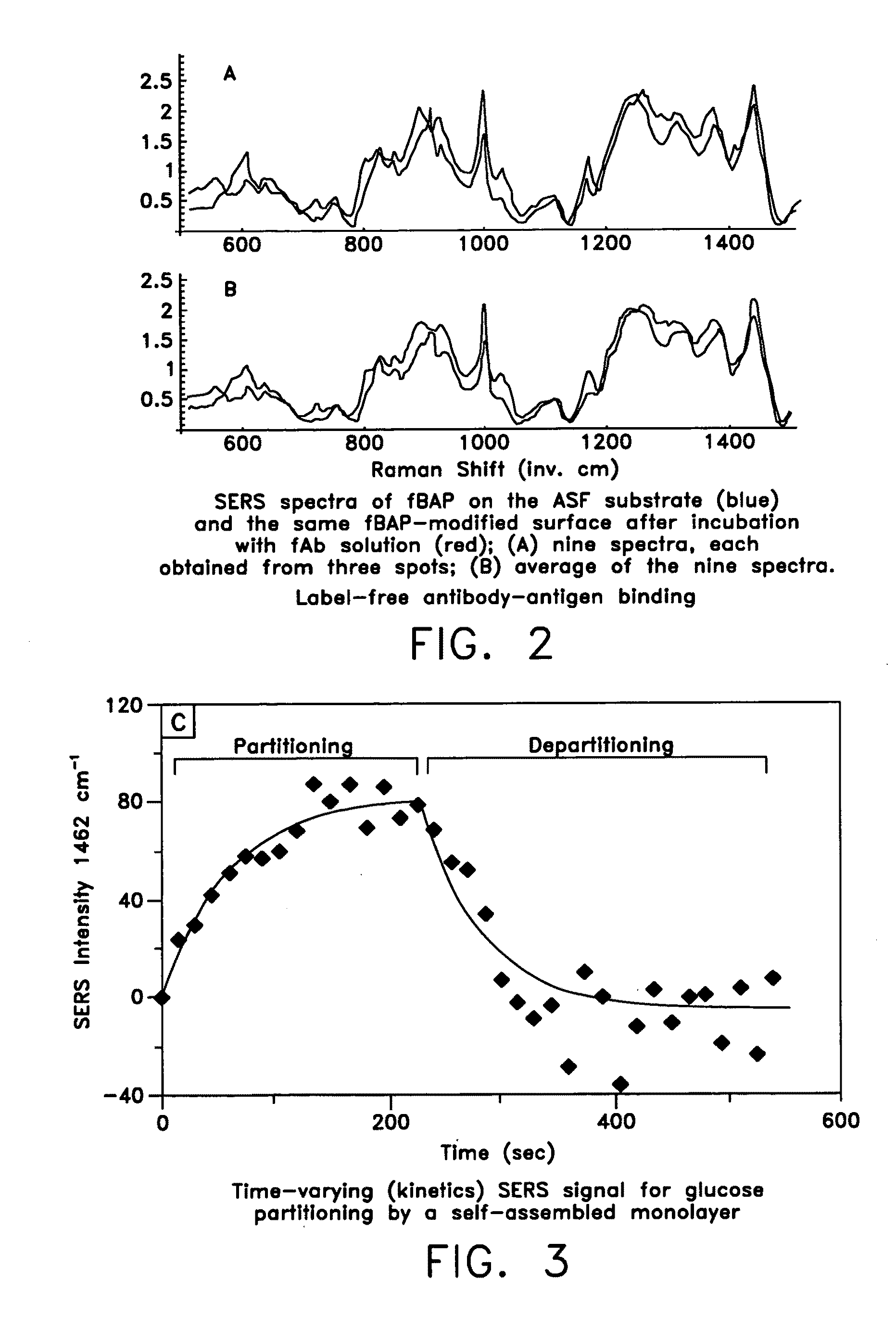

Applications of laser-processed substrate for molecular diagnostics

Owner:EBSTEIN STEVEN M

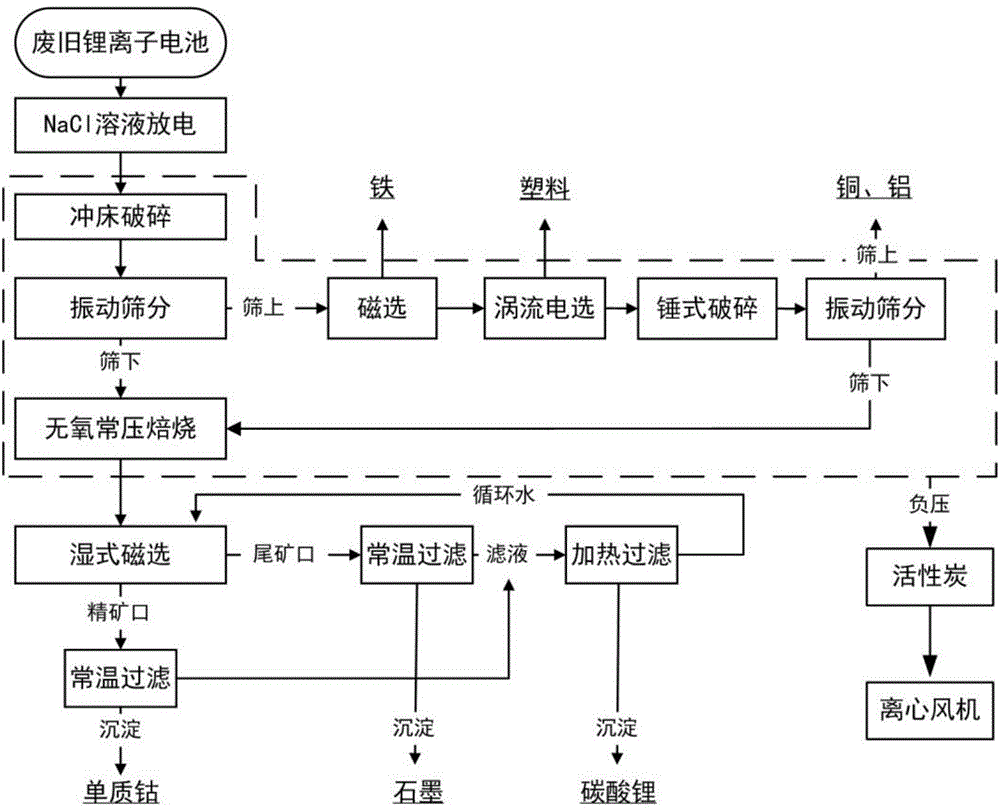

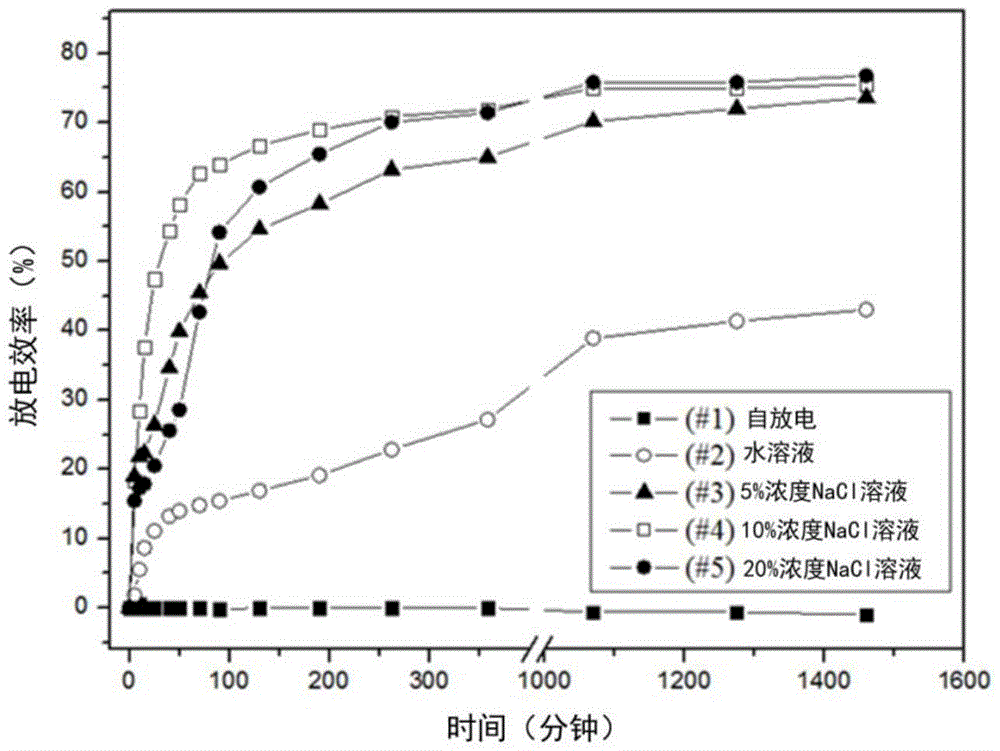

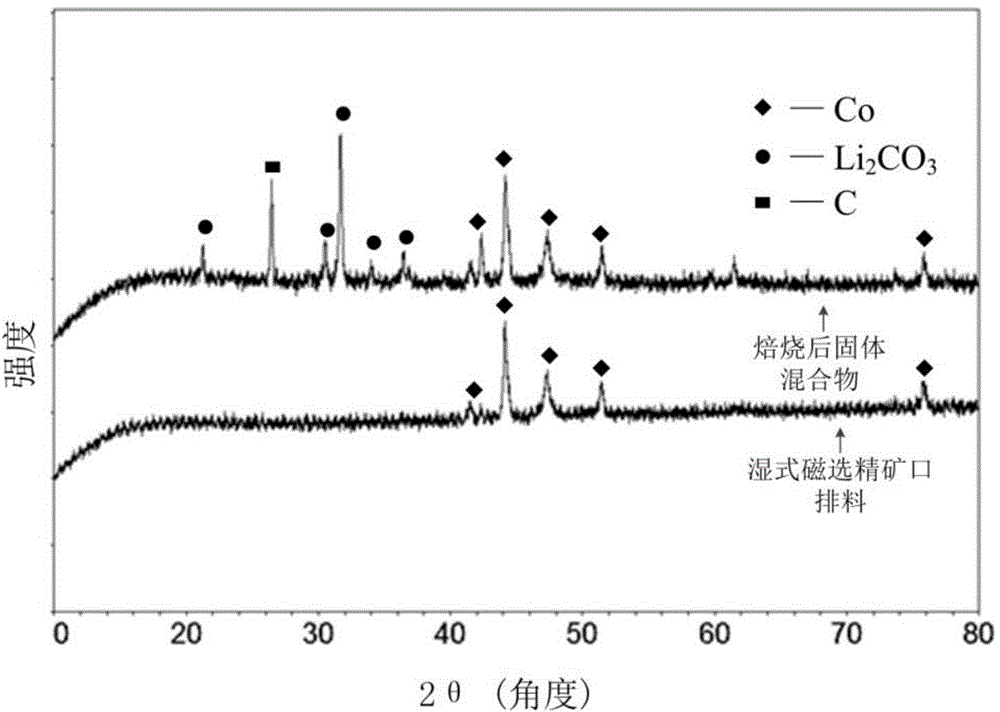

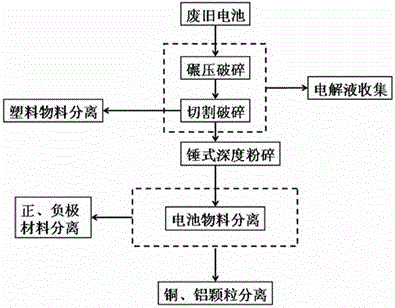

Method for recycling waste lithium cobalt oxide lithium ion battery

ActiveCN104577249AFully resourcedReduce lossesWaste accumulators reclaimingBattery recyclingPunch pressCobalt

The invention relates to a method for recycling waste lithium cobalt oxide lithium ion battery. The method is characterized in that valuable components in the waste lithium ion battery are completely recycled by integrating the processes of crushing by a punch press, magnetic separation, eddy current selection, anaerobic atmospheric roasting, temperature-variable filtering and the like, and products with the relatively high additional values, such as elemental crude cobalt, lithium carbonate, graphite, copper, aluminum, iron, and plastics are obtained. Manners of crushing by a punch press, magnetic separation, eddy current selection and the like are adopted for performing material separation, so that the original physical properties of materials are kept. Meanwhile, positive powder and negative powder of an electrode material are cooperatively treated, the negative graphite material is effectively utilized, the in-situ preparation of a resource can be realized, and the waste lithium ion battery can be relatively completely recycled. The anaerobic atmospheric roasting is adopted, so that the reaction condition is relatively loose, the loss of a graphite material is reduced, the cost is saved, the technological flow is simplified, and the industrial application practice can be facilitated.

Owner:SHANGHAI JIAO TONG UNIV

Valve for facilitating and maintaining separation of fluids and materials

InactiveUS20080164204A1Analysis using chemical indicatorsLaboratory glasswaresCentrifugationVolumetric Mass Density

Some embodiments include a valve positioned within a test tube to maintain a separation between components of liquid with different densities after centrifugation. The valve preferably includes a cylindrically shaped housing with a conical plug configured to nest within the housing. The plug is not in contact with the housing during centrifugation, but comes into position post-centrifugation.

Owner:HATAMIAN MEHDI +2

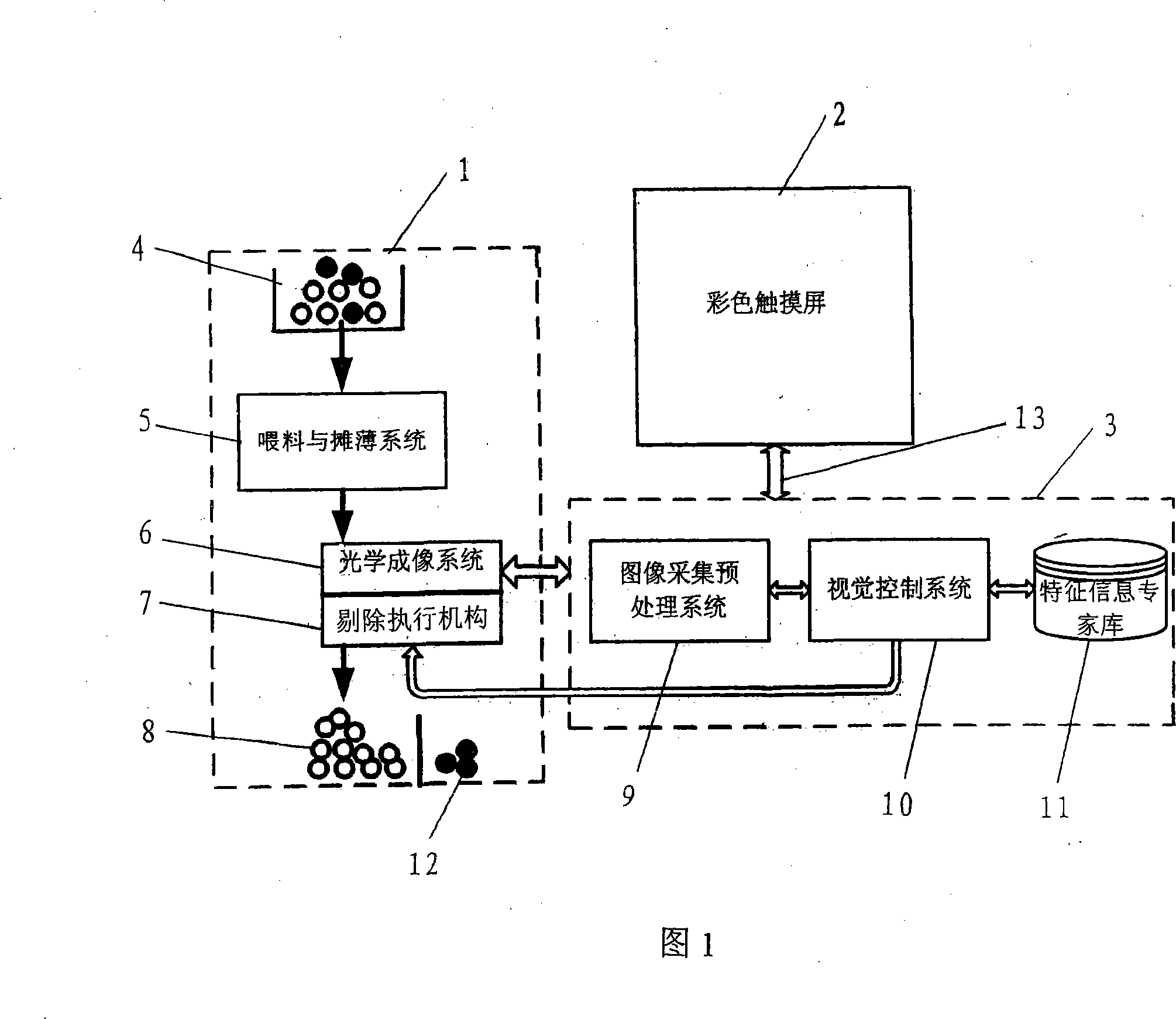

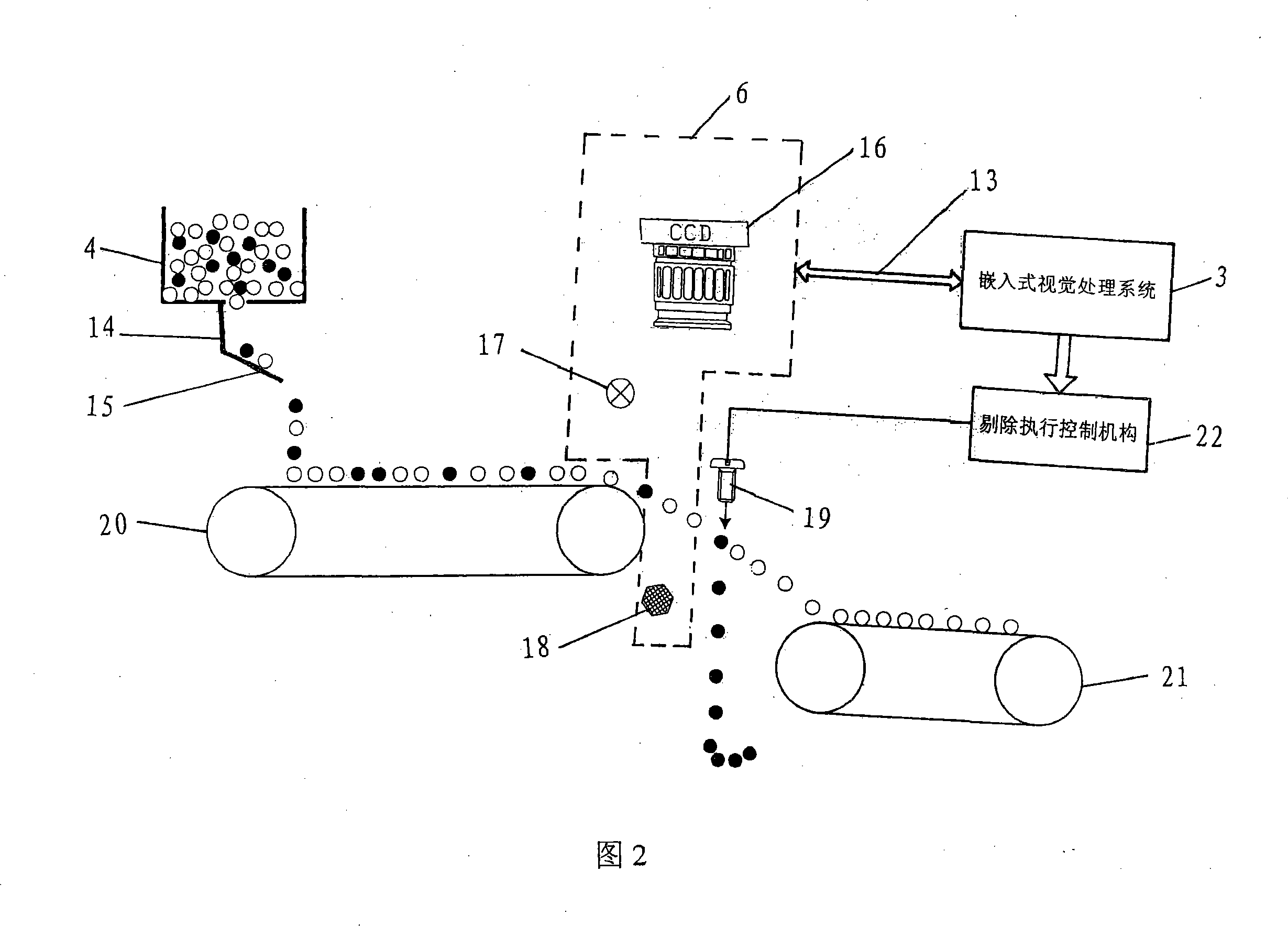

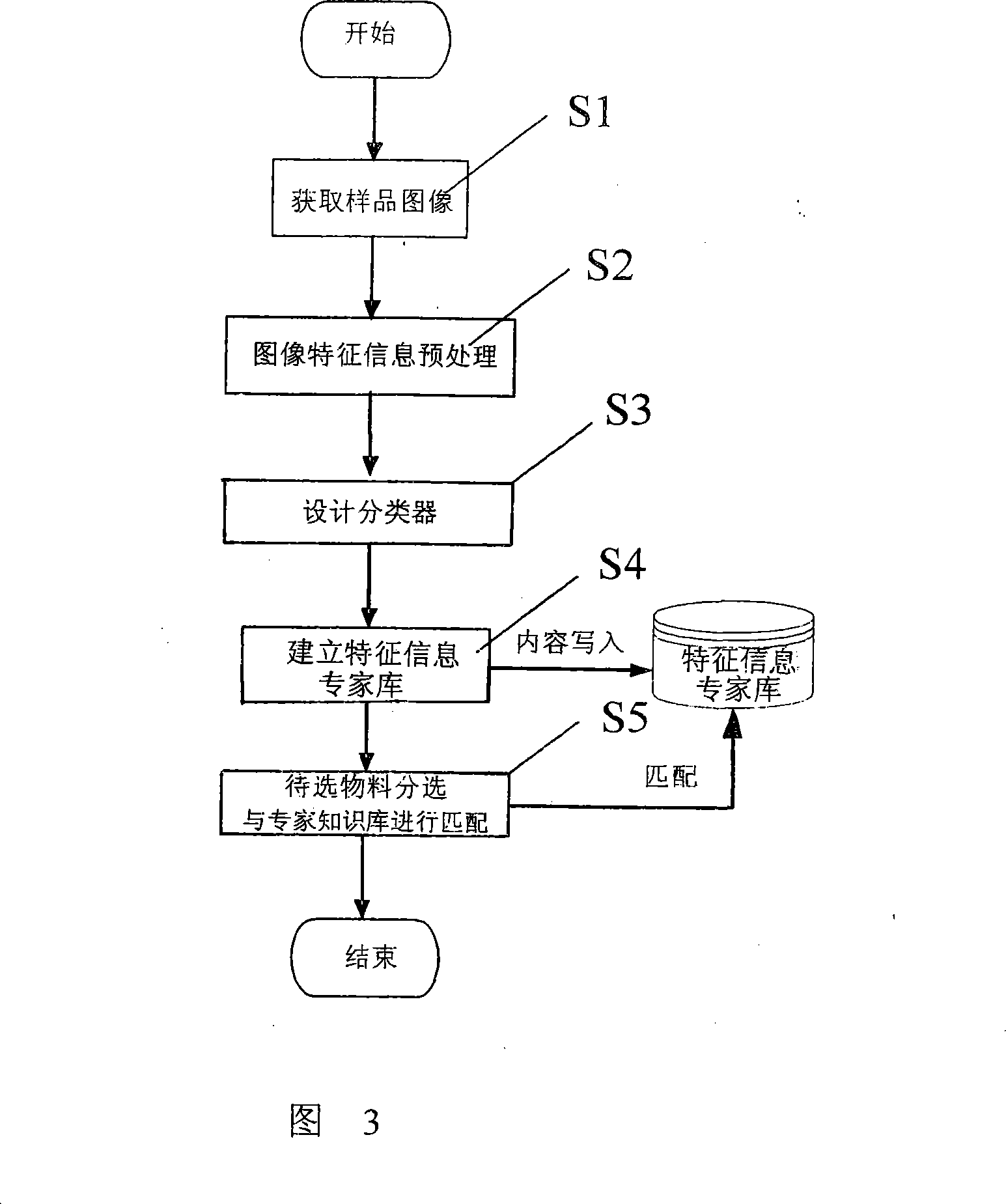

Granular material sorting classifying method based on visual sense recognition

InactiveCN101234381AImprove the efficiency of classification and sortingOvercome accuracyCharacter and pattern recognitionSortingParticulatesVision based

The invention discloses a particulate material separation and classification method based on visual identity. The method comprises obtaining sample images, image feature information preprocessing, designing classifiers, establishing feature information expert database, proposed material separation to match with the feature information expert database and carrying out separation and classification. The separation and classification method overcomes the shortcomings of current poor technical accuracy, low efficiency and being easy to cause the secondary pollution, etc. and the separation and classification method ensures the product quality, realizes fast intelligence and improves the separation and classification effect of particulate materials.

Owner:HUAHE NEW TECH DEV COMPANY RES INST OF PHYSICAL & CHEM ENG OF NUCLEAR IND

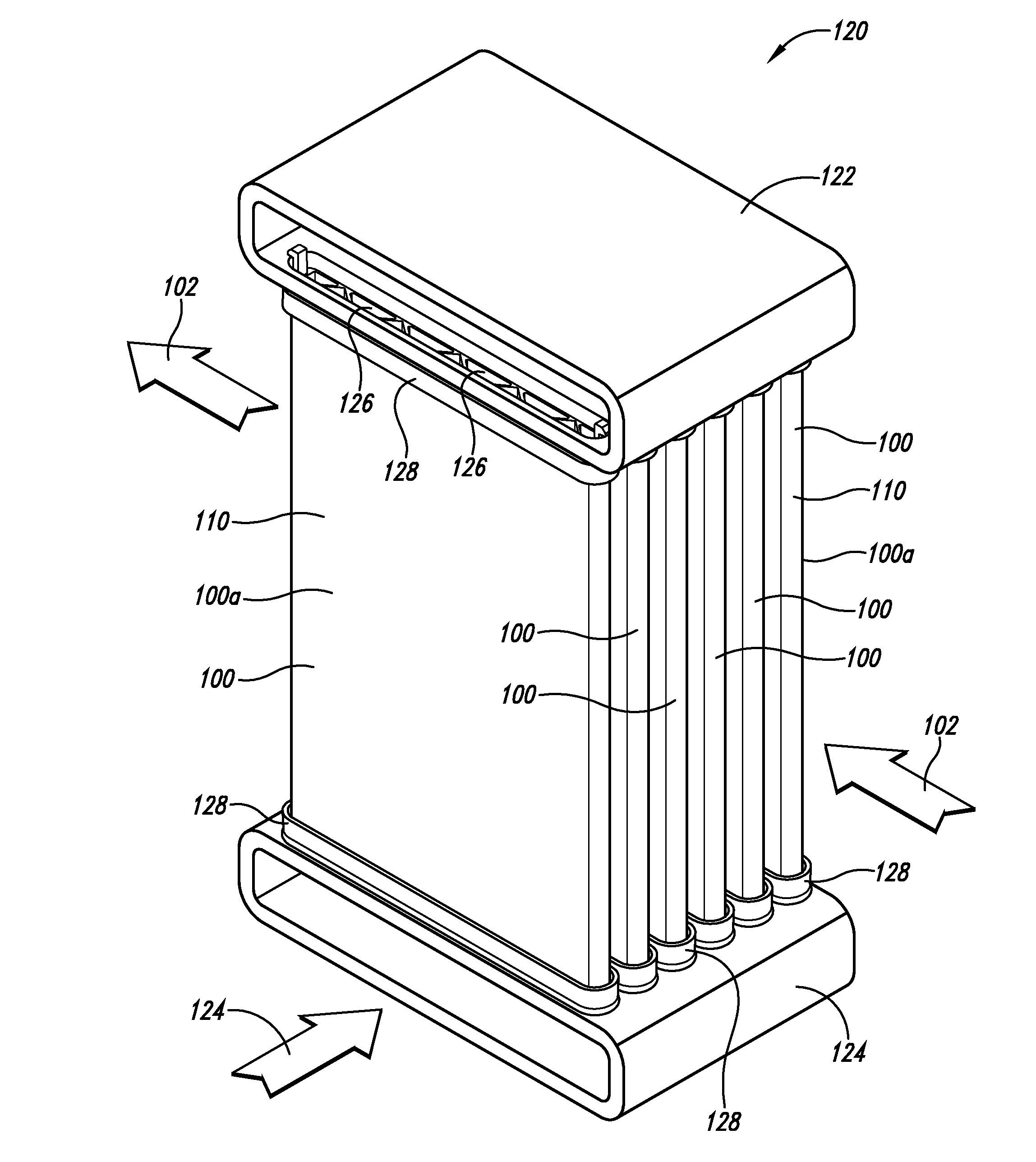

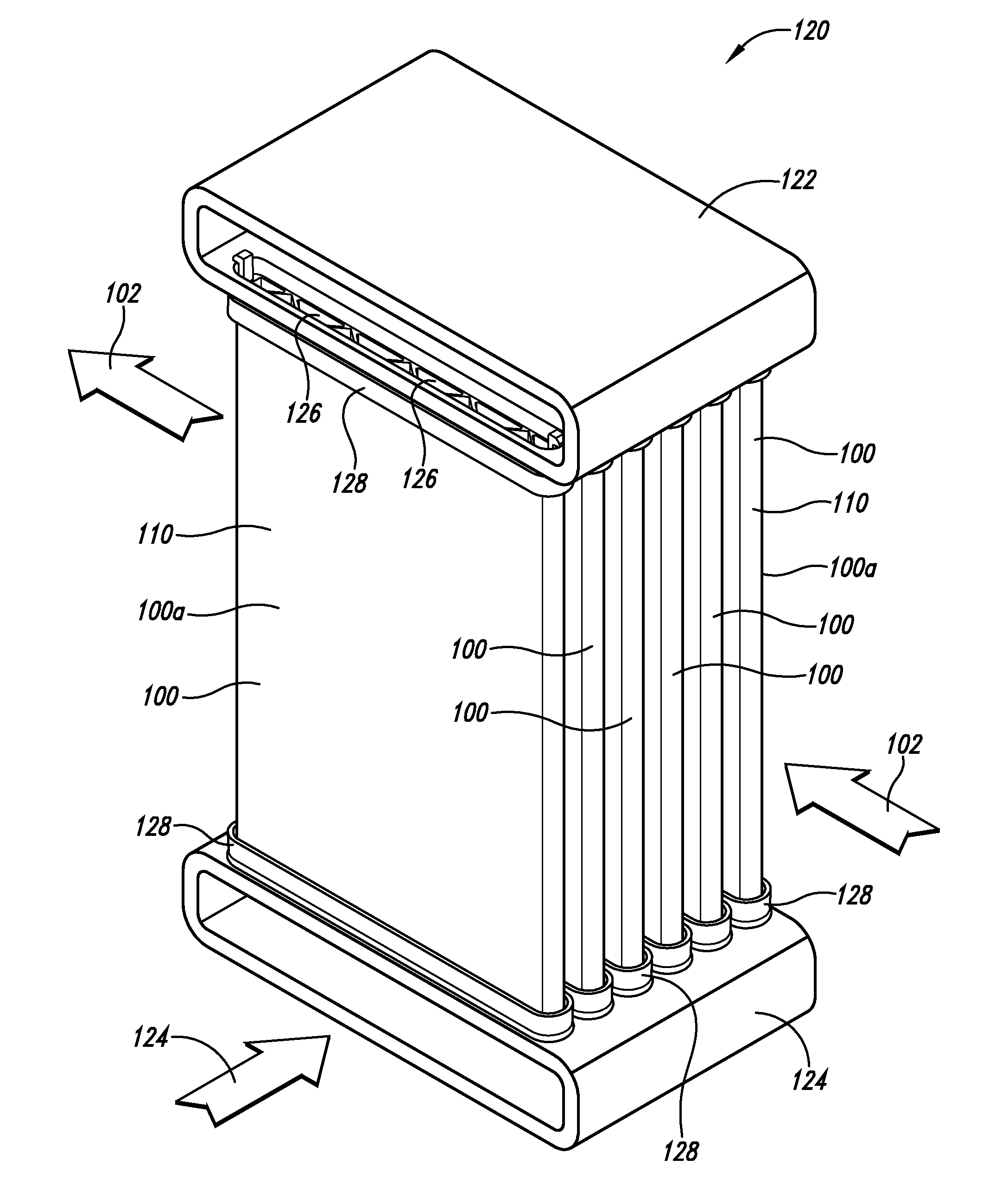

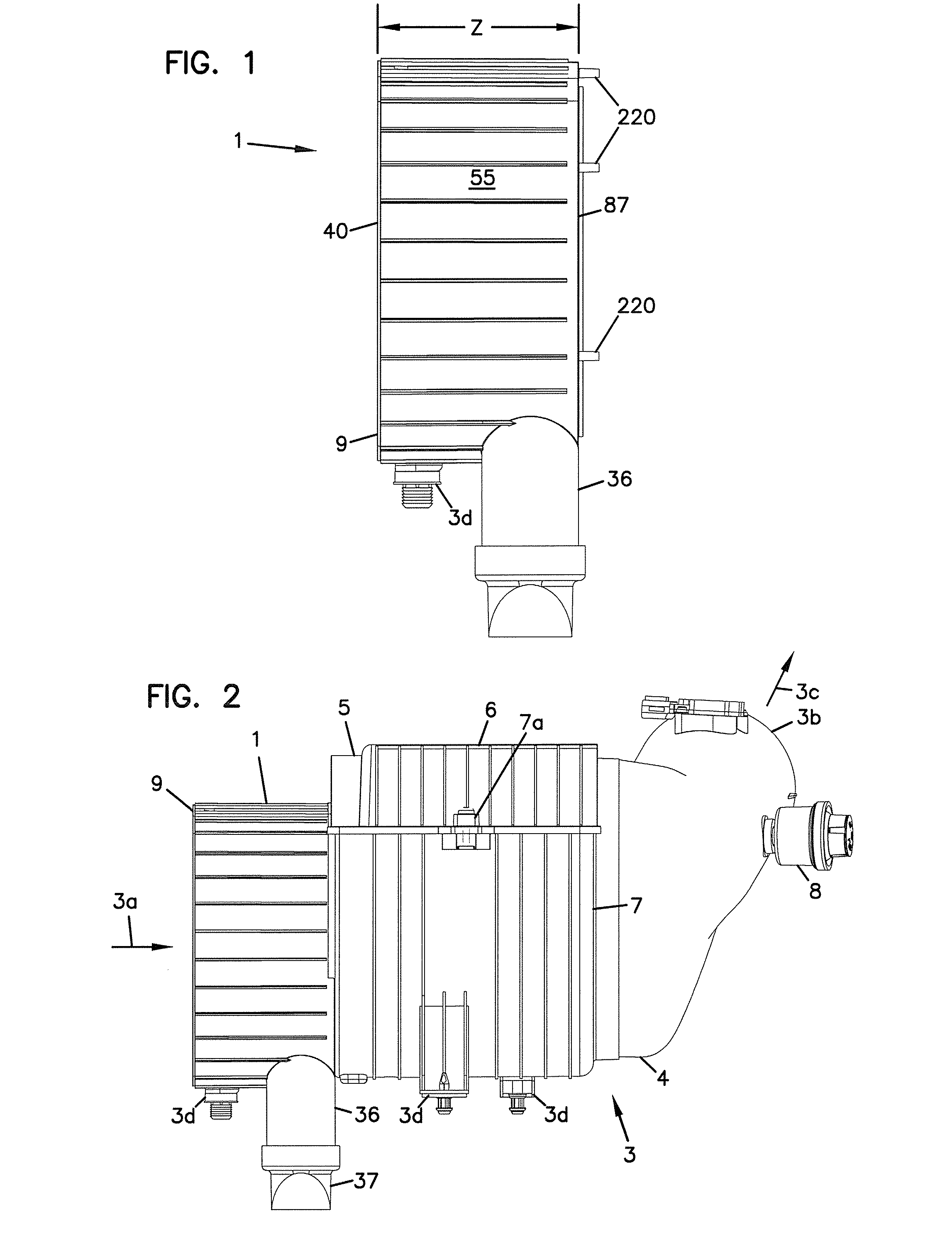

Hydrogen Membrane Separator

ActiveUS20110104021A1Improve hydrophobicityReactant parameters controlLiquid degasification by filtrationHydrogenProduct gas

The present application is directed to a hydrophobic membrane assembly (28) used within a gas-generating apparatus. Hydrogen is separated from the reaction solution by passing through a hydrophobic membrane assembly (28) having a hydrophobic lattice like member (36) disposed within a hydrogen output composite (32) further enhancing the ability of the hydrogen output composite's ability to separate out hydrogen gas and prolonging its useful life.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Nasal Dilator With Means To Direct Resilient Properties

InactiveUS20150250637A1Great delaminating tendencyReduce forceNon-surgical orthopedic devicesNasal passageNasal passages

A nasal dilator comprises a laminate of vertical layers that form a unitary, or single body, truss having horizontal regions adapted to engage outer wall tissues of first and second nasal passages and to traverse the bridge of a nose therebetween. When in use the dilator acts to stabilize and / or expand the nasal outer wall tissues and prevent said tissues from drawing inward during breathing. The dilator includes multiple parallel resilient members or a resilient member having a plurality of component spring fingers extending from a common center. The dilator may further include material separations, or discontinuity of shape of material, formed in at least one region of the truss and extending through at least one layer of the dilator.

Owner:CORBETT LAIR INC

Device for tratment of wound using reduced pressure

ActiveUS20110028920A1Reduce pressureKeep the pressureSurgeryMedical devicesLiquid diffusionCompressible material

A device for treatment of wounds using reduced pressure, comprisinga pump,a gas barrier cover,a first compressible material which expand after compression,a second material capable of absorbing wound fluids several times its own weight.The first and second material are arranged inside the cover and form a reservoir connected to said pump, The device further comprisingan inlet for connecting the reservoir with a wounda wound pad to be arranged in the wound cavity anda sealing covering the wound and said wound pad.A third material with high liquid spreading capability is arranged around at least a major part of the first material, and said second material is in the form of at least one layer arranged outside the third material and separated from the first material by said third material.

Owner:MOLNLYCKE HEALTH CARE AB

Device for collecting bone material during a surgical procedure

A collection device for collecting bone material during a spinal fusion surgical procedure so that the bone material can later be used as a graft material for the fusion procedure. The device includes a container that collects the bone and other material that is removed from the patient during the surgical procedure through a suction hose. The device includes a plunger having a filter plate sealed to the inside of the container. The plunger is pushed down into the collected material in the container so that blood and other liquids are forced through the plate to be separated from the bone material. A cover at the bottom of the container can be removed to remove the collected bone material.

Owner:THOMPSON MIS

Multi-phase selective mass transfer through a membrane

Disclosed herein are embodiments relating to particular systems comprising a selective transfer membrane that can be utilized in material separation. In certain embodiments, the membrane assembly comprises part of a desalination, distillation, liquid purification, and / or heating and cooling system. Other particular embodiments allow for a high rate of thermal capture by way of the system utilizing a selective transfer membrane. Certain preferred embodiments include a selective transfer membrane comprising an ionomeric polymer that is permeable to high dipole materials.

Owner:TANGREDI PATRICIA

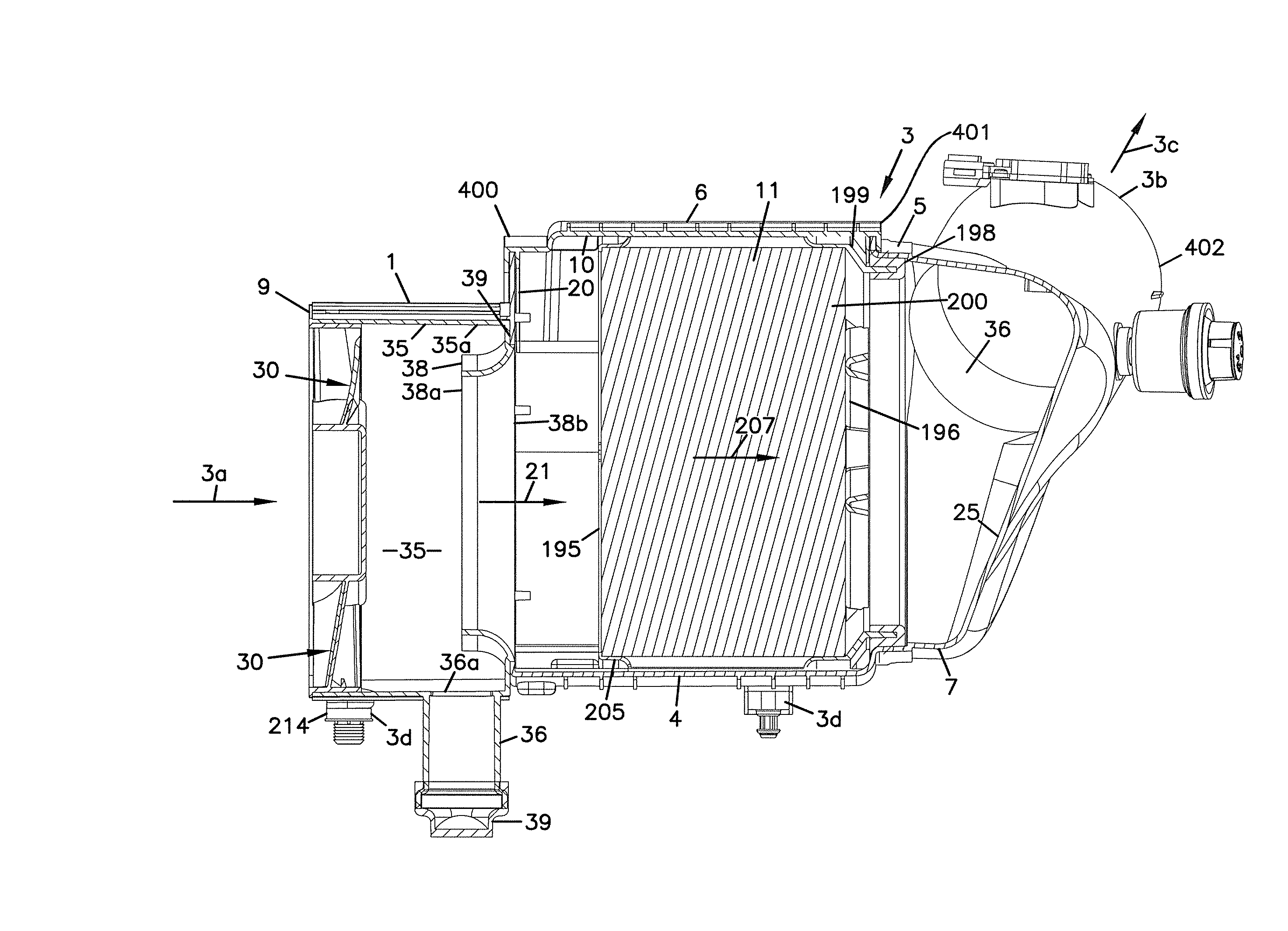

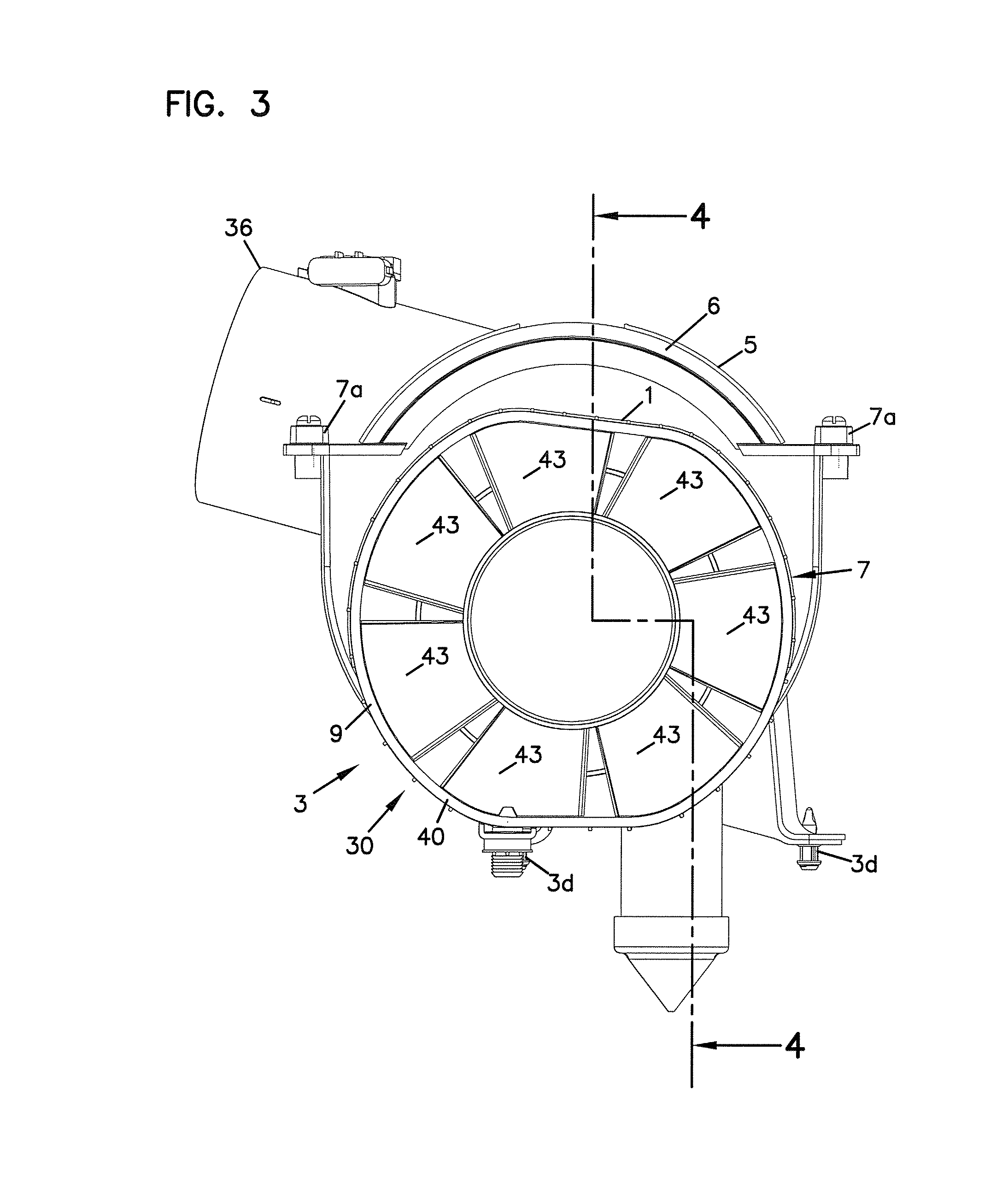

Precleaner arrangement for use in air filtration; method; and, air cleaner using same

ActiveUS20070234903A1Effective levelingLow air flow rateCombination devicesDispersed particle filtrationAir filtrationCyclone

A precleaner arrangement for use in separating a portion of entrained material in air from air entering an air cleaner, is provided. The precleaner arrangement includes a vane structure positioned to direct air into a circular or cyclonic pattern, to facilitate material separation. The vane structure includes one or more adjustable air deflection vanes. Each adjustable air deflection vane is constructed: to have a first position under no air flow or low air flow rate conditions; and, to deflect to import a more open, lower restriction, orientation under increased air flow rates. Preferred precleaner arrangement constructions, assemblies utilizing in the precleaner arrangement and methods are described.

Owner:DONALDSON CO INC

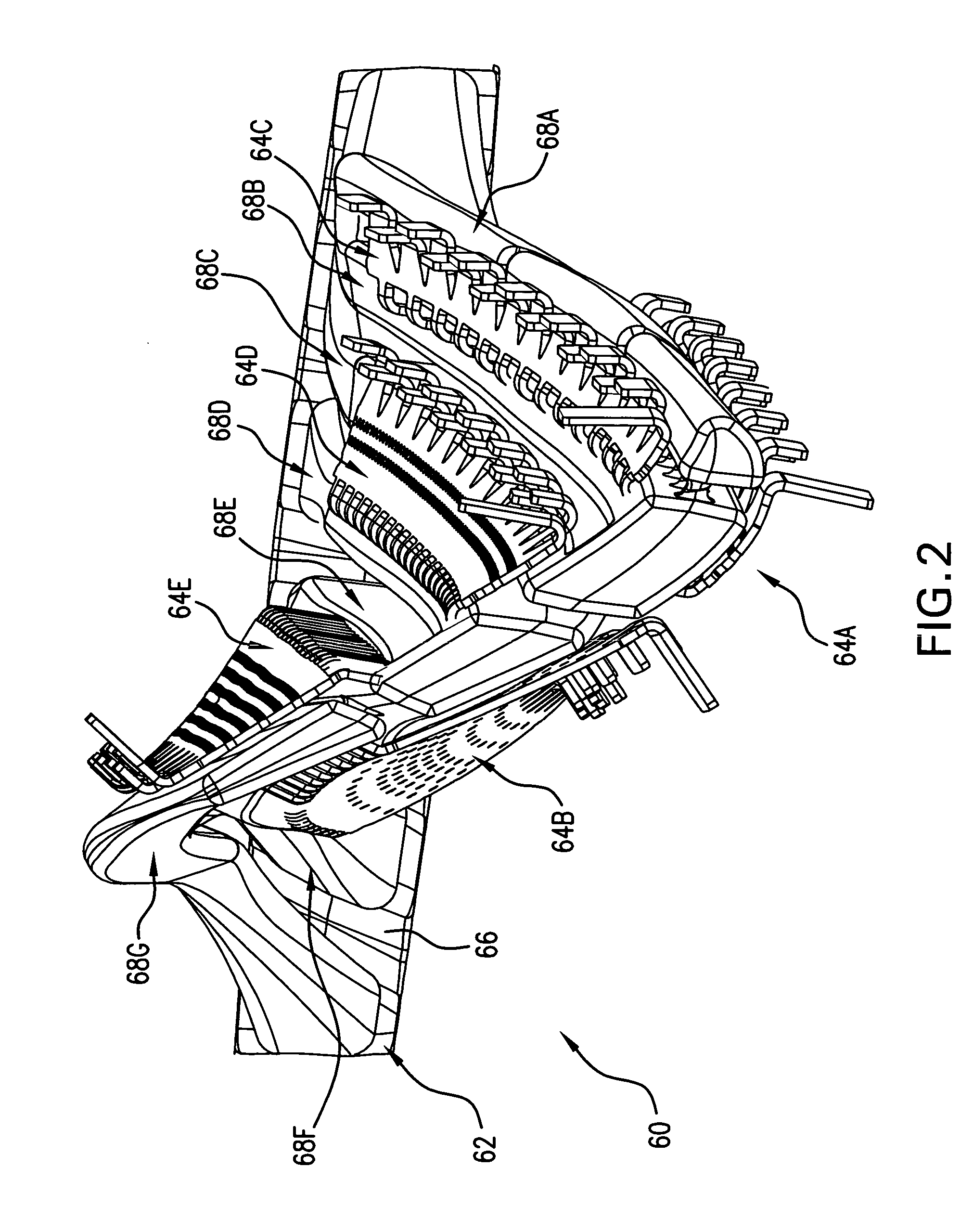

Investment casting pattern manufacture

At least one feed core and at least one wall cooling core are assembled with a number of elements of a die for forming a cooled turbine engine element investment casting pattern. A sacrificial material is molded in the die. The sacrificial material is removed from the die. The removing includes extracting a first of the die elements from a compartment in a second of the die elements before disengaging the second die element from the sacrificial material. The first element includes a compartment receiving an outlet end portion of a first of the wall cooling cores in the assembly and disengages therefrom in the extraction.

Owner:RTX CORP

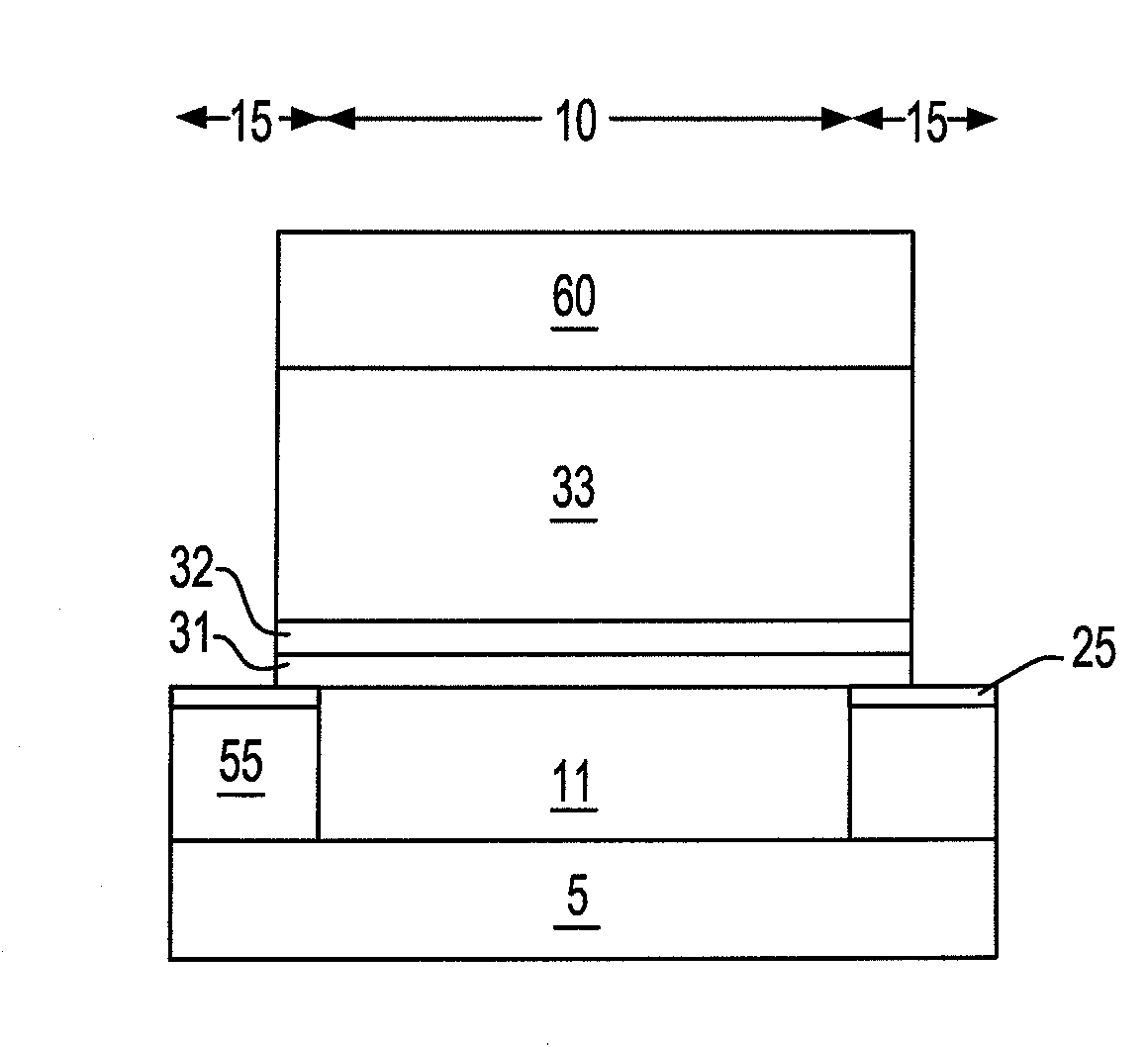

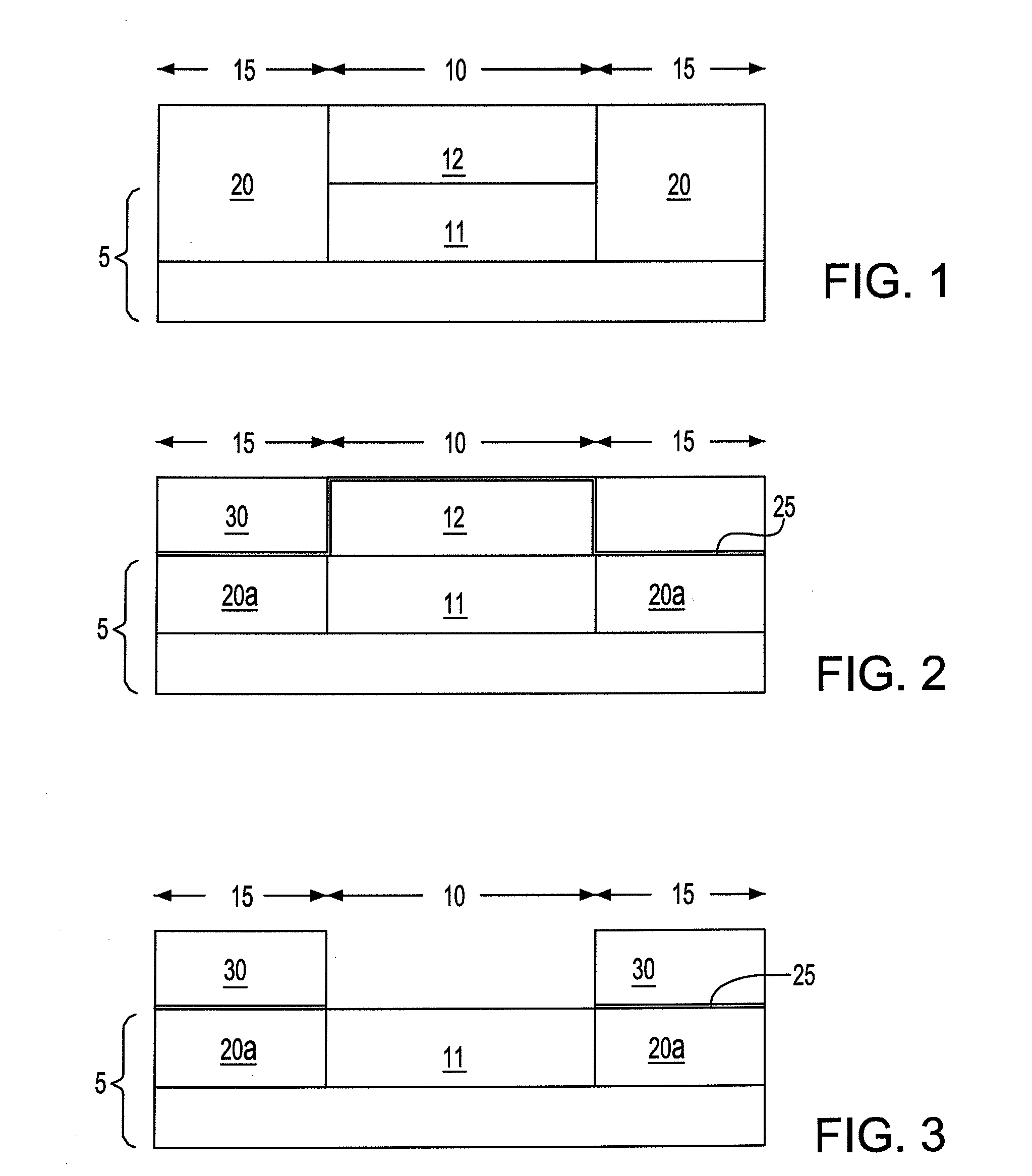

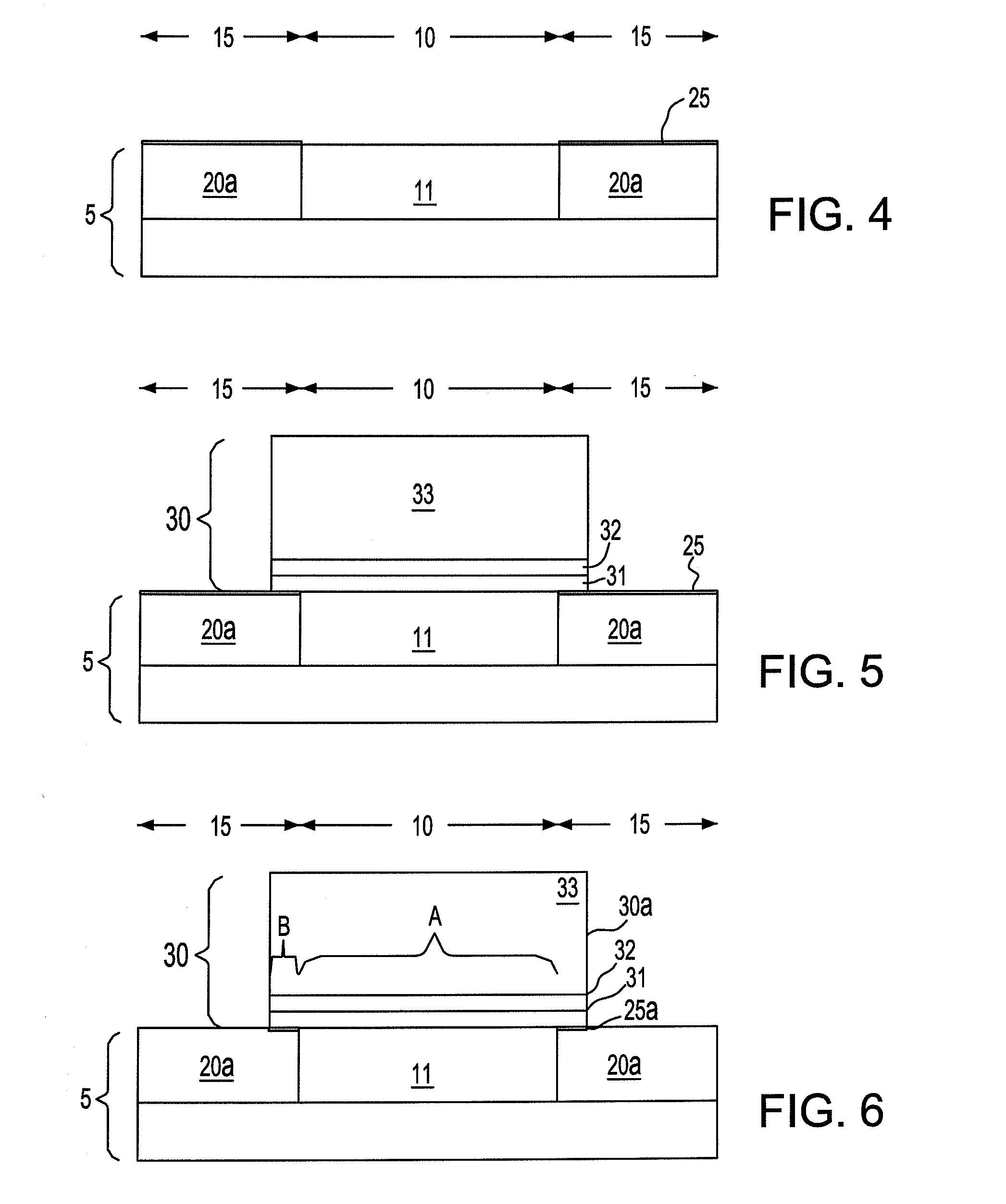

Structure and method to control oxidation in high-k gate structures

In one embodiment, the present invention provides a method of fabricating a semiconducting device that includes providing a substrate including at least one semiconducting region and at least one oxygen source region; forming an oxygen barrier material atop portions of an upper surface of the at least one oxygen region; forming a high-k gate dielectric on the substrate including the at least one semiconducting region, wherein oxygen barrier material separates the high-k gate dielectric from the at least one oxygen source material; and forming a gate conductor atop the high-k gate dielectric.

Owner:IBM CORP

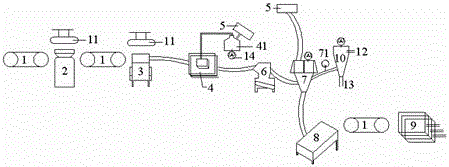

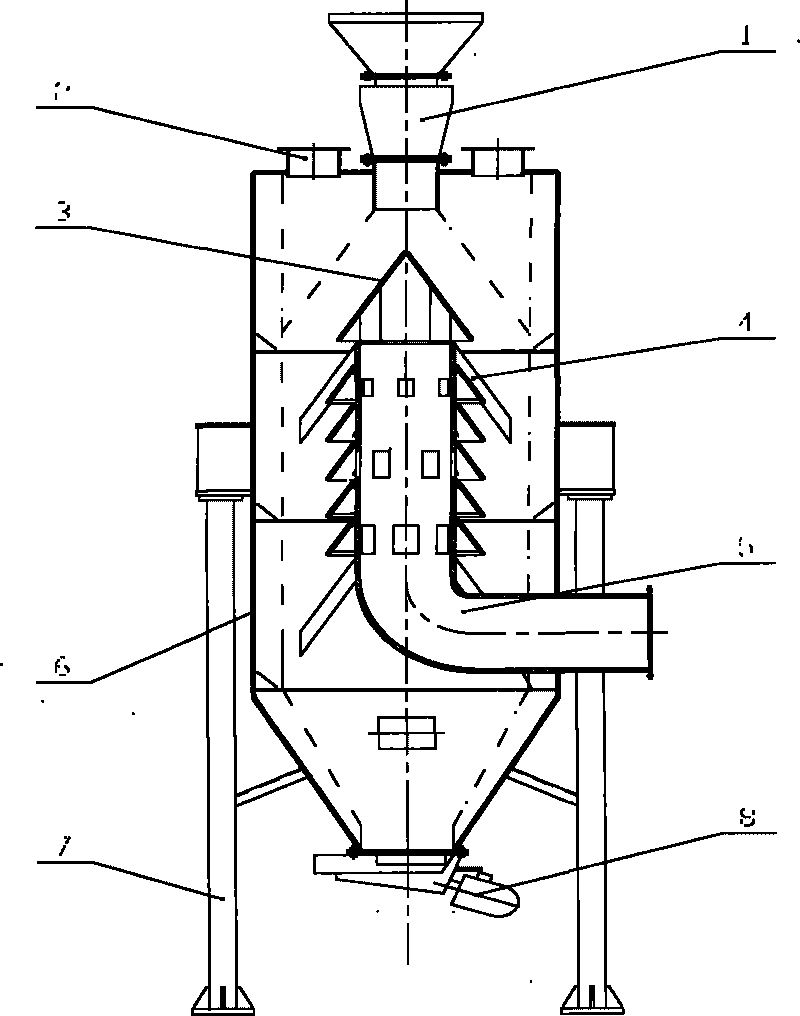

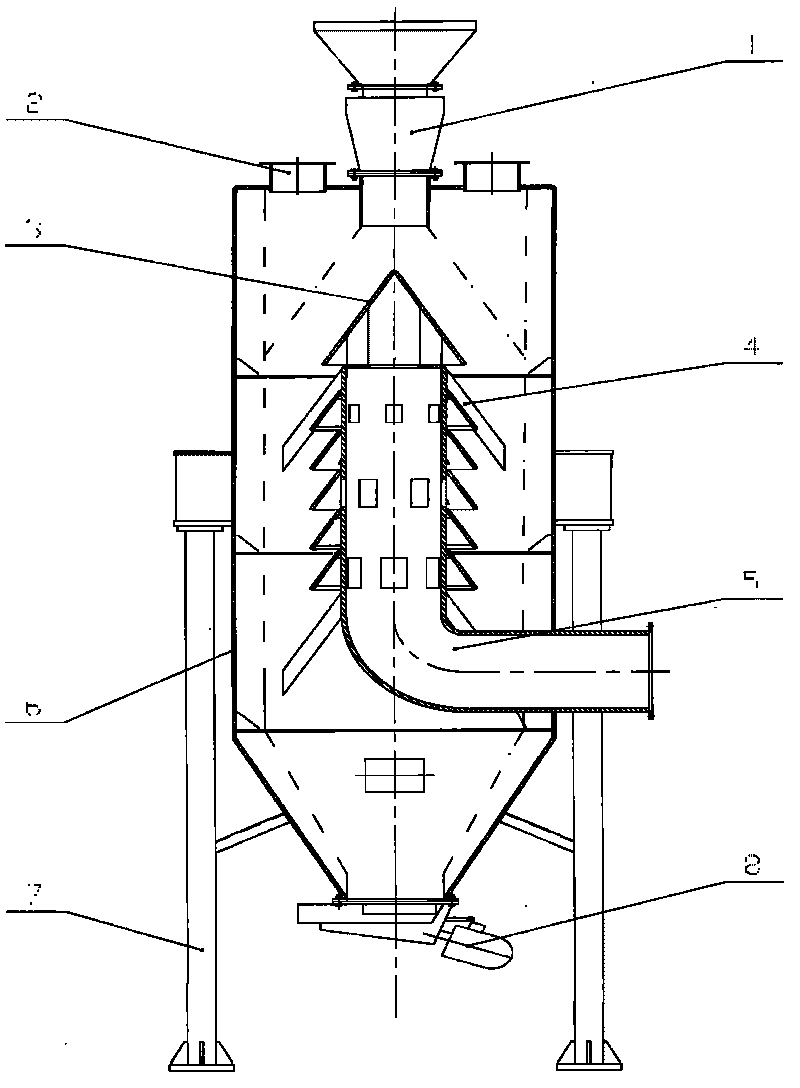

All-component material separation and collection device and method for waste lithium batteries

ActiveCN105826629ARealize separate collectionFully automatedWaste accumulators reclaimingBattery recyclingElectrolytic agentPhysical chemistry

The invention relates to an all-component material separation and collection device and method for waste lithium batteries. The simple dry methods of mechanical smashing, vacuum separation, vibratory screening, specific gravity separation, airflow separation and the like are mainly utilized, and separation and collection of electrode materials, current collector metal, plastic membranes and battery shells in waste lithium batteries are achieved; no chemical reagent is introduced in the separation and collection process, the whole process is automatic, electrolytes, dust and the like are collected and treated at the same time, and the all-component material separation and collection device and method for waste lithium batteries have the advantages that recovery efficiency is high, the environment-friendly and low-carbon effect is achieved, environment protection and energy saving are achieved, and industrialization is easy.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +2

Preparation method for microporous membrane having multi-scale gradient micro-structure surface

ActiveCN103611437APlay the role of inner support reinforcementControllable areaSemi-permeable membranesMicro structureUltrafiltration

The present invention relates to a preparation method for a microporous membrane having a multi-scale gradient micro-structure surface. The method comprises: fixing a screen mesh on the upper surface of a rough flexible substrate, coating a polymer solution layer with a thickness of 50-500 mum on the upper surface of the screen mesh at a constant speed, curing, washing, and carrying out simple mechanical peeling to remove the rough flexible substrate to obtain the microporous membrane having the multi-scale gradient micro-structure surface. According to the present invention, the process of the method is simple, the membrane area can be controlled, continuous production can be achieved, mechanical properties of the membrane are high, and the membrane has super-hydrophobic or super-hydrophilic property, wherein the super-hydrophobic membrane has super-lipophilic property, and the super-hydrophilic membrane has super-oleophobic property under water and has super-hydrophobic property under oil; and the obtained membrane can be adopted to effectively separate various oil and water mixtures including nano-scale oil water emulsions, and can further be used in fields of self-cleaning ultrafiltration / microfiltration membrane sewage treatments, medical sterilization, food turbidity removal, sterilization, material separation, membrane distillation, and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Laser-processed substrate for molecular diagnostics

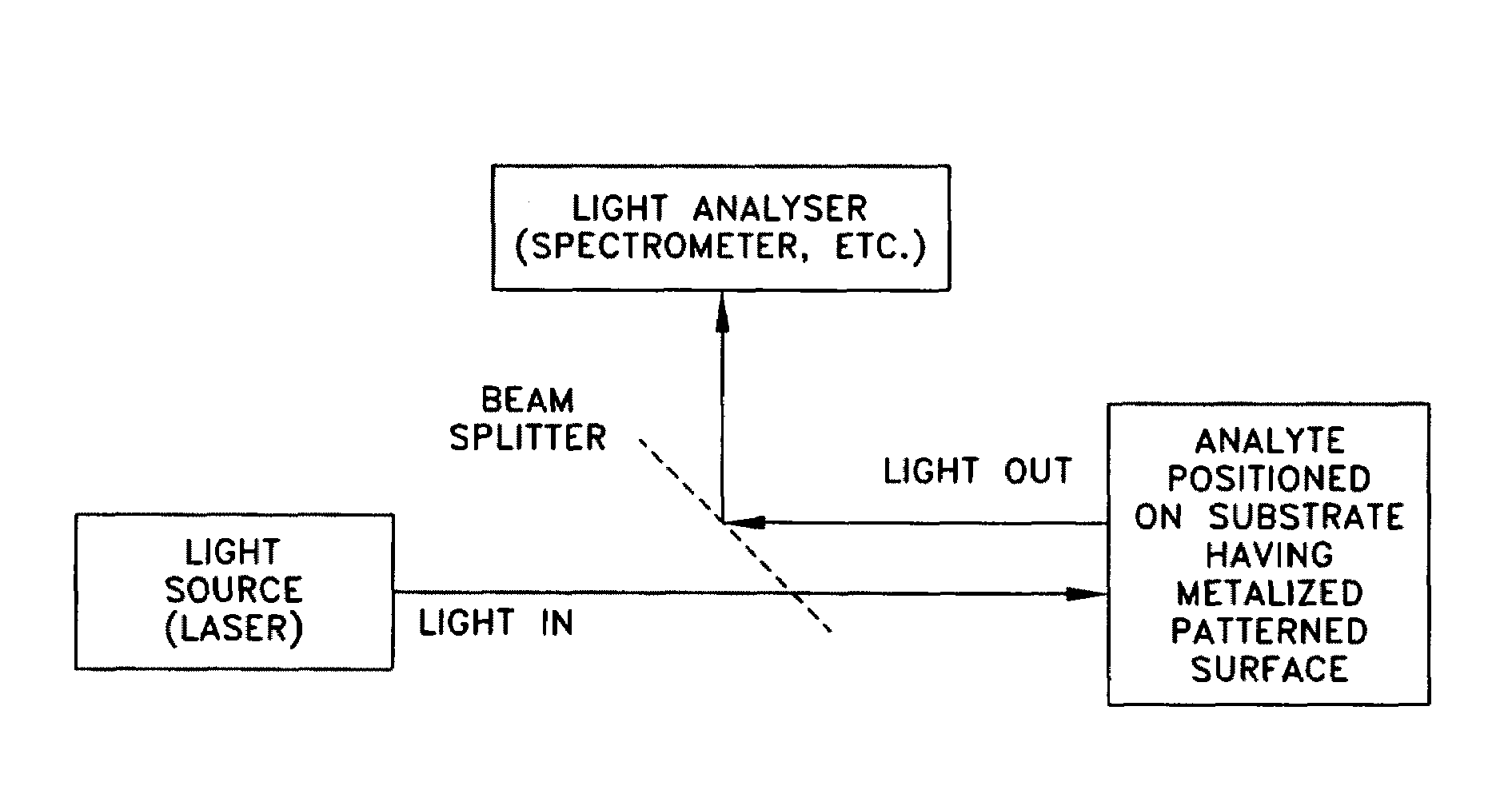

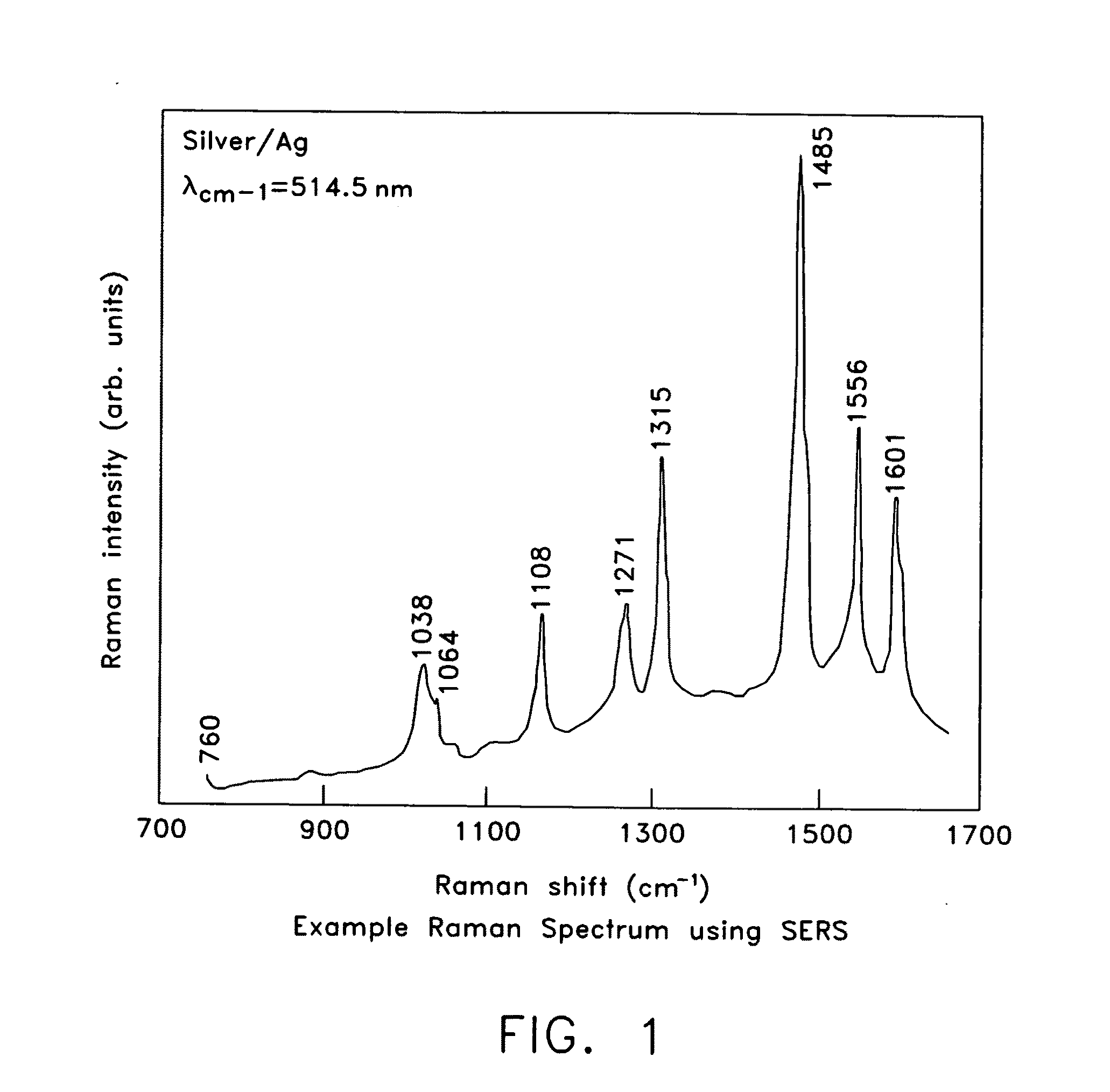

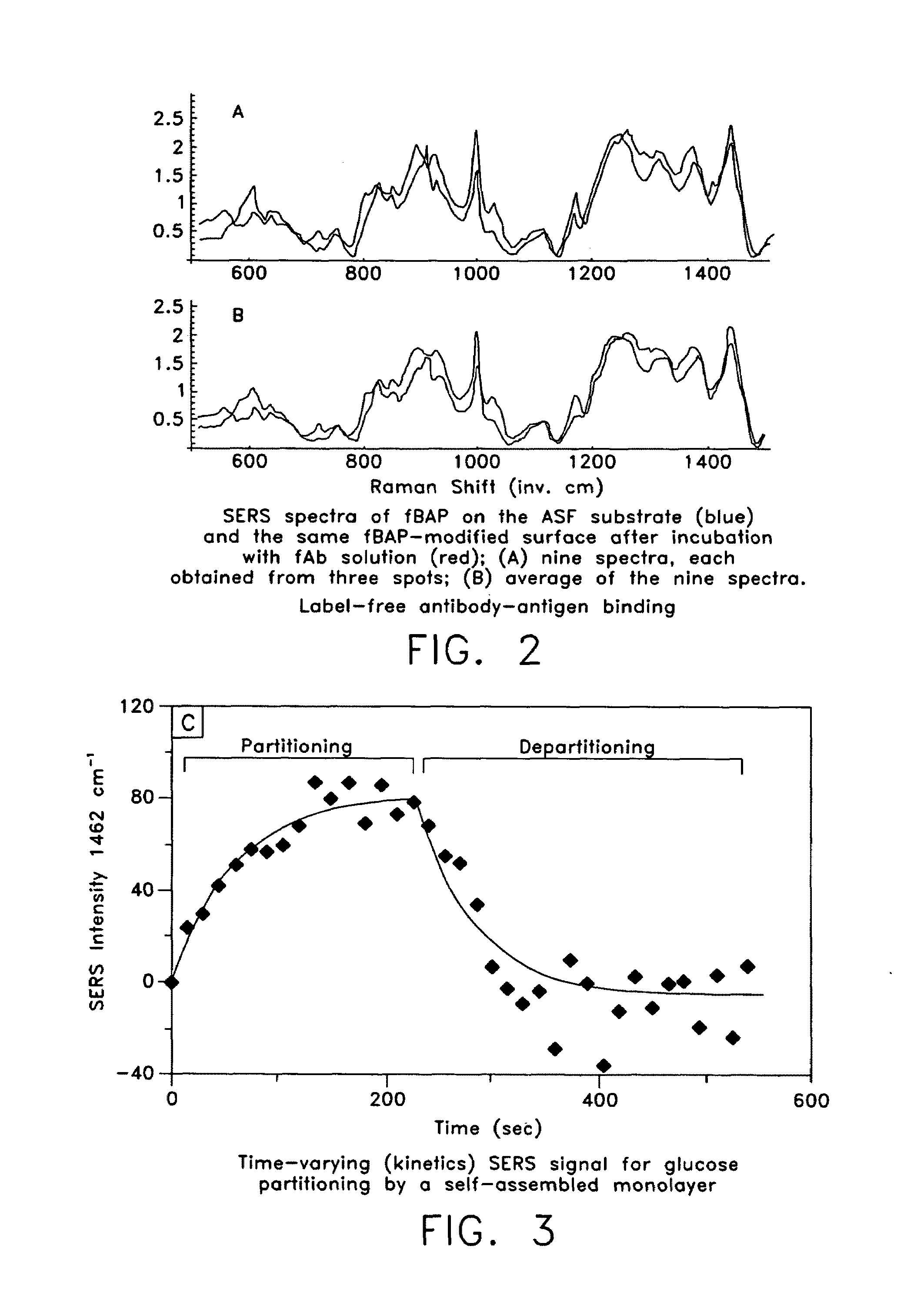

ActiveUS20090279085A1Facilitate SERS analysisMaterial nanotechnologyRadiation pyrometryChemical reactionPhotonics

Surface enhanced Raman Scattering (SERS) and related modalities offer greatly enhanced sensitivity and selectivity for detection of molecular species through the excitation of plasmon modes and their coupling to molecular vibrational modes. One of the chief obstacles to widespread application is the availability of suitable nanostructured materials that exhibit strong enhancement of Raman scattering, are inexpensive to fabricate, and are reproducible. I describe nanostructured surfaces for SERS and other photonic sensing that use semiconductor and metal surfaces fabricated using femtosecond laser processing. A noble metal film (e.g., silver or gold) is evaporated onto the resulting nanostructured surfaces for use as a substrate for SERS. These surfaces are inexpensive to produce and can have their statistical properties precisely tailored by varying the laser processing. Surfaces can be readily micropatterned and both stochastic and self-organized structures can be fabricated. This material has application to a variety of genomic, proteomic, and biosensing applications including label free applications including binding detection. Using this material, monolithic or arrayed substrates can be designed. Substrates for cell culture and microlabs incorporating microfluidics and electrochemical processing can be fabricated as well. Laser processing can be used to form channels in the substrate or a material sandwiched onto it in order to introduce reagents and drive chemical reactions. The substrate can be fabricated so application of an electric potential enables separation of materials by electrophoresis or electro-osmosis.

Owner:EBSTEIN STEVEN M

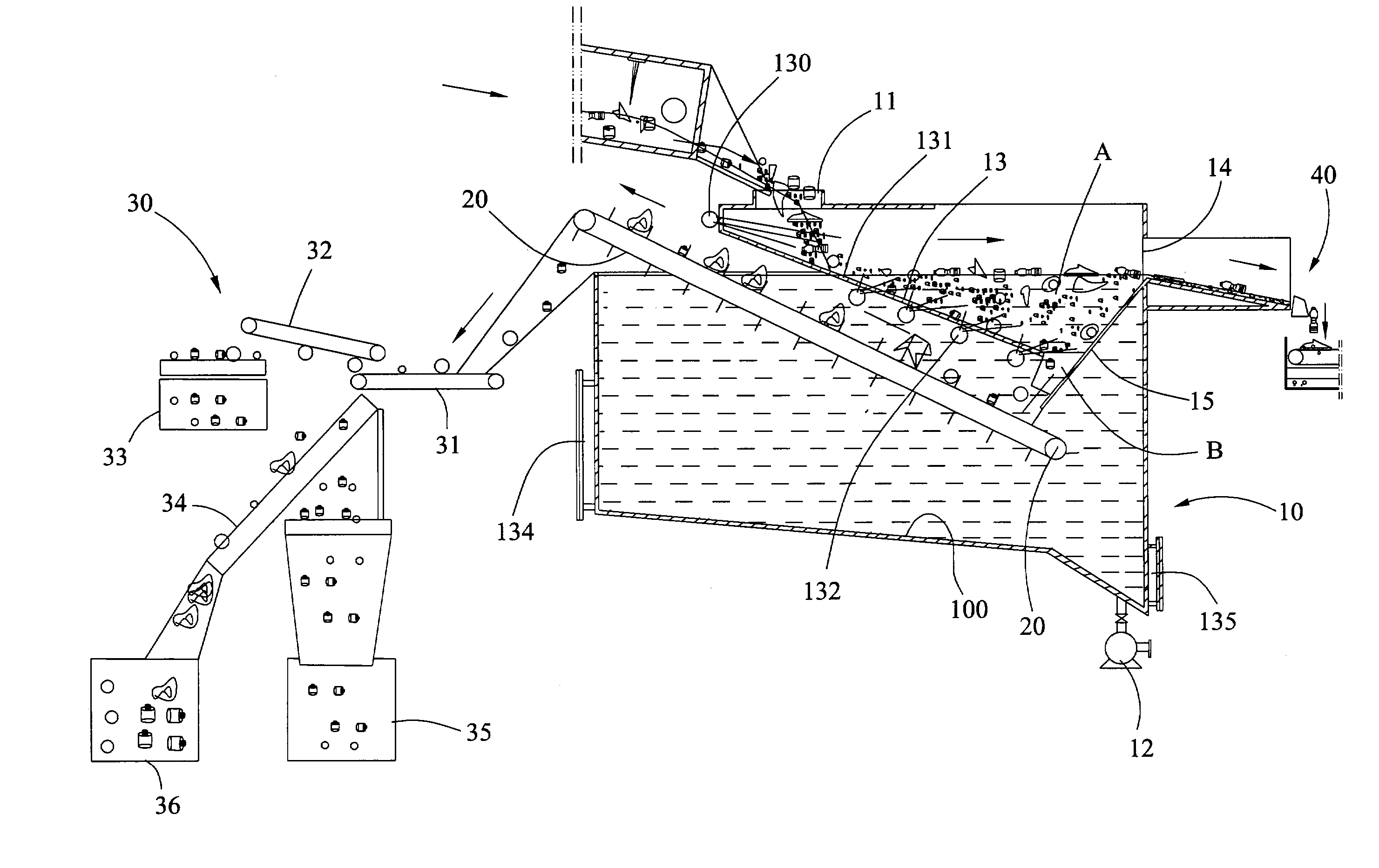

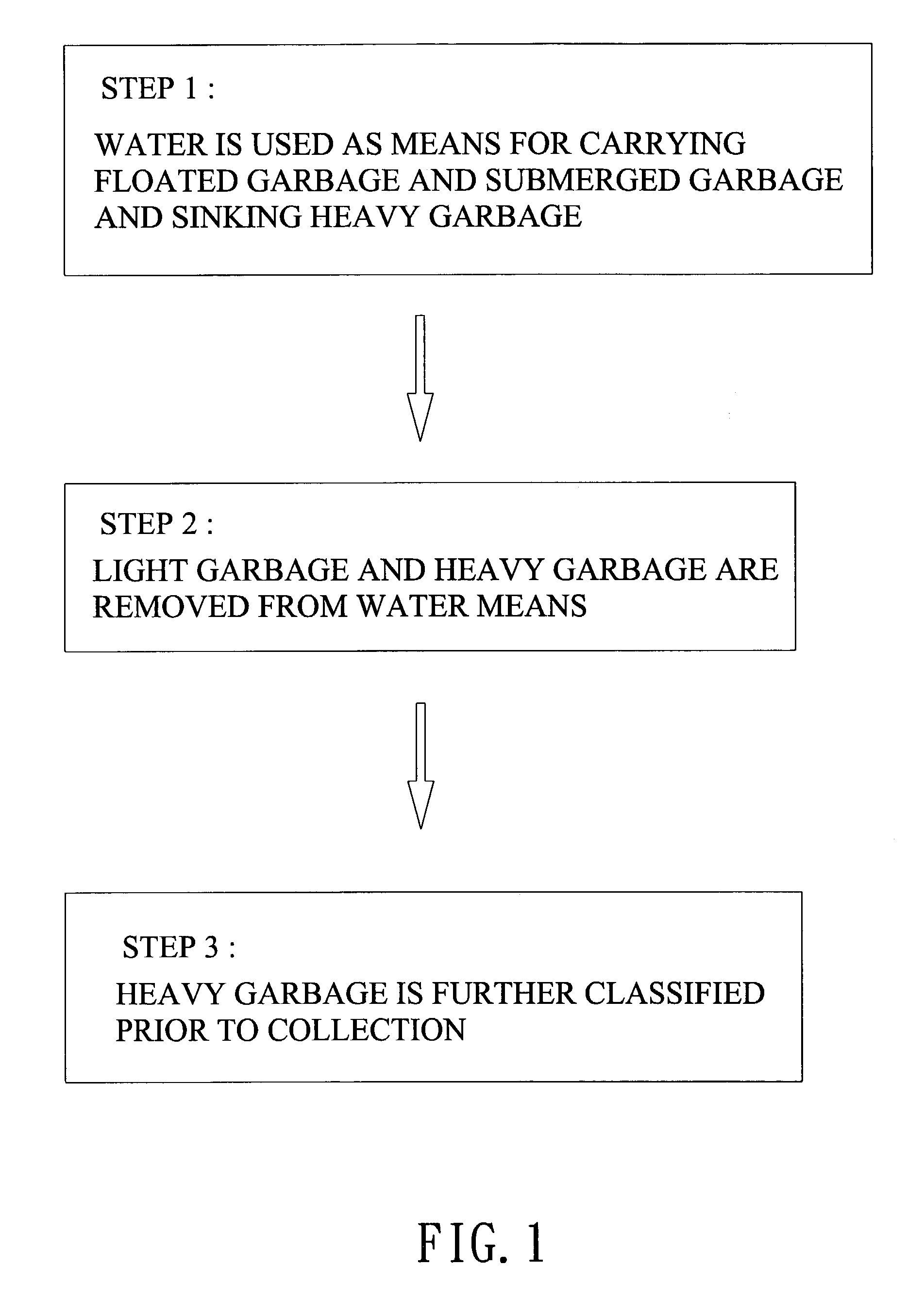

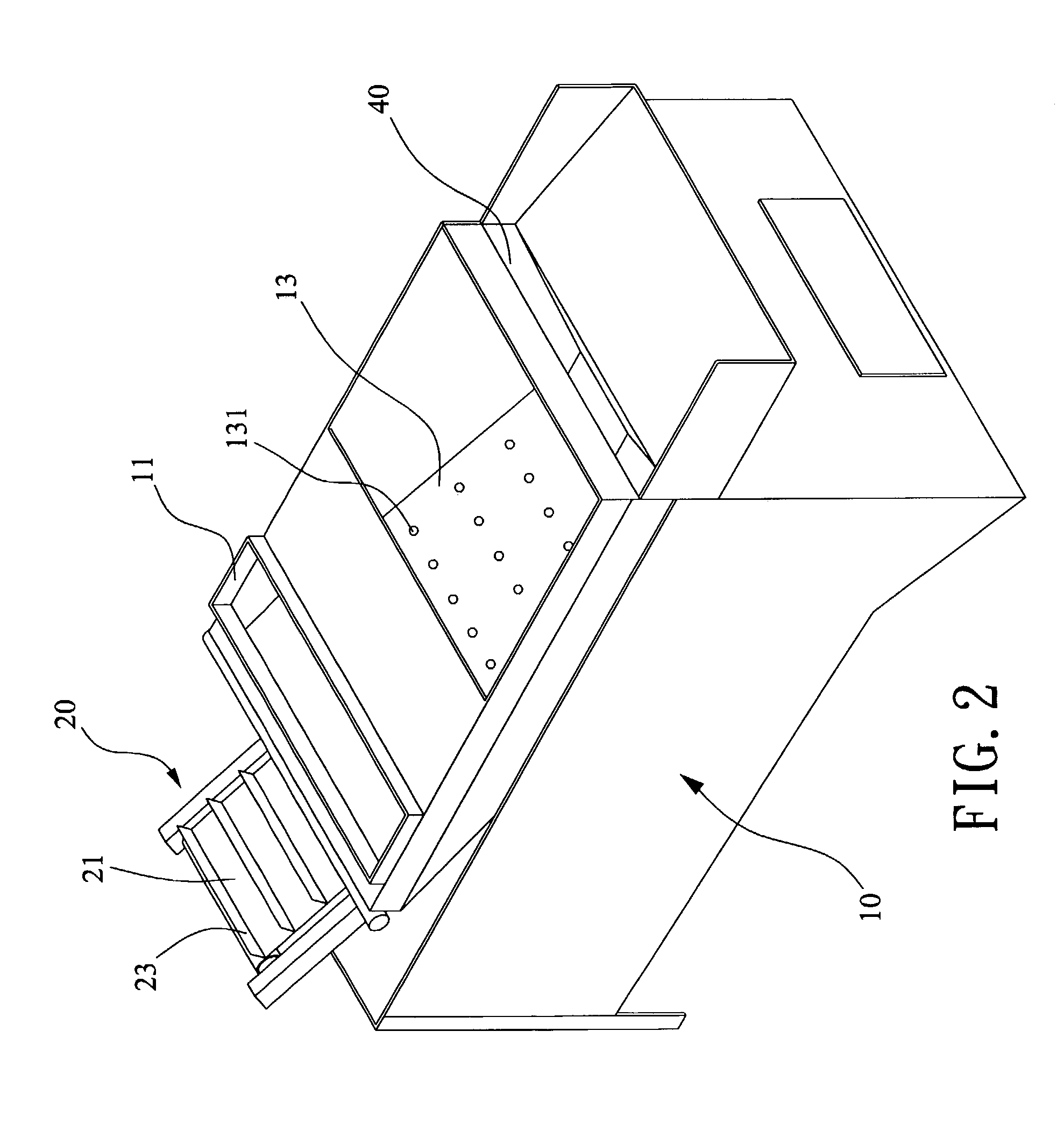

Apparatus and method of separating heavy materials in garbage from light ones and classifying the heavy garbage for collection

InactiveUS7017753B2Prevent leakageEfficient separationPlastic recyclingSeparation devicesLitterEnvironmental engineering

An apparatus and method of separating heavy materials in garbage from light ones is taking advantage of water as a means for carrying floated garbage and submerged garbage and sinking the heavy materials in garbage by considering specific weight, buoyancy, and flow rate of water so as to remove the light materials in garbage and the heavy materials in garbage from the water container at different elevations and then to classify the heavy materials in garbage prior to collection.

Owner:WST INT HLDG

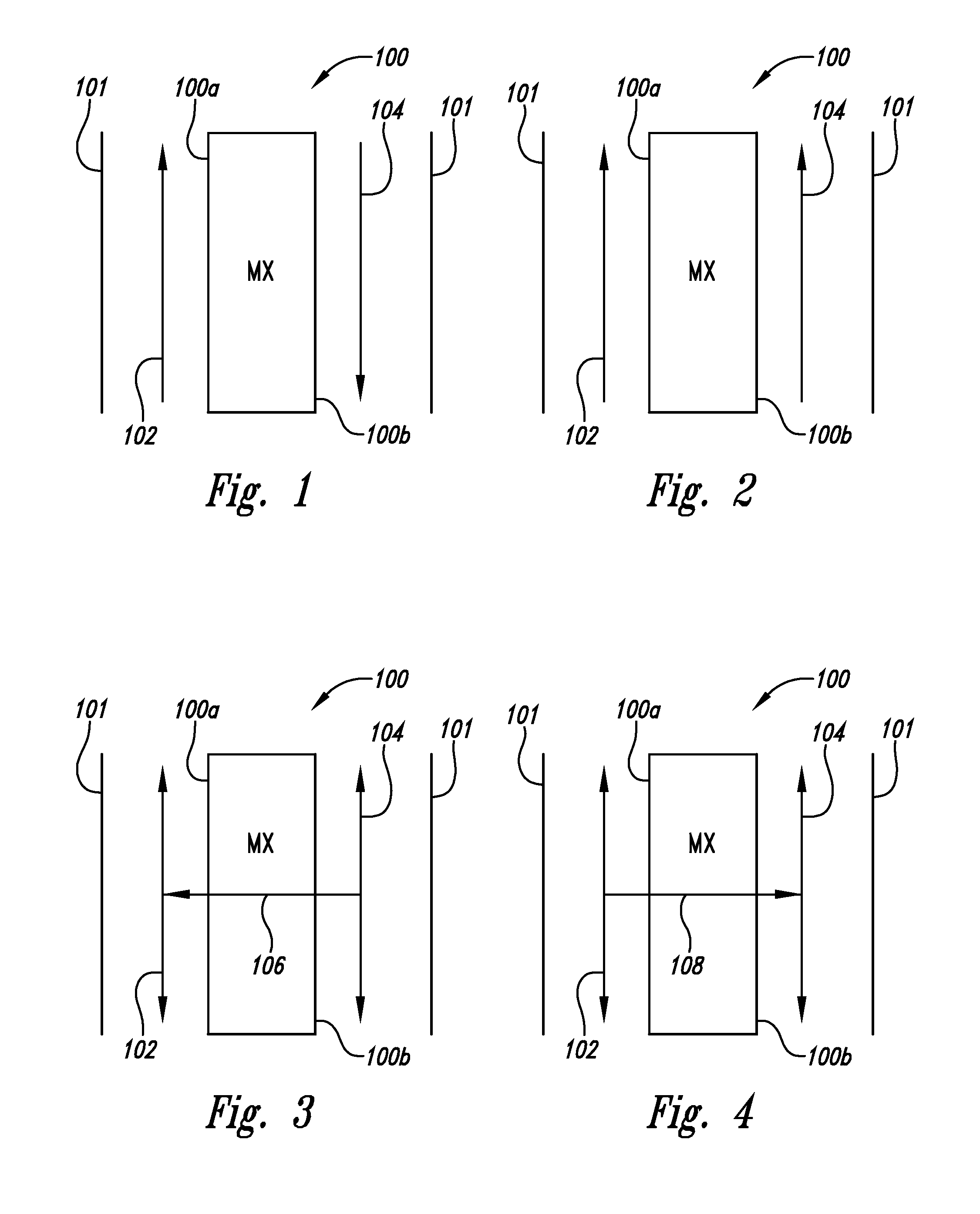

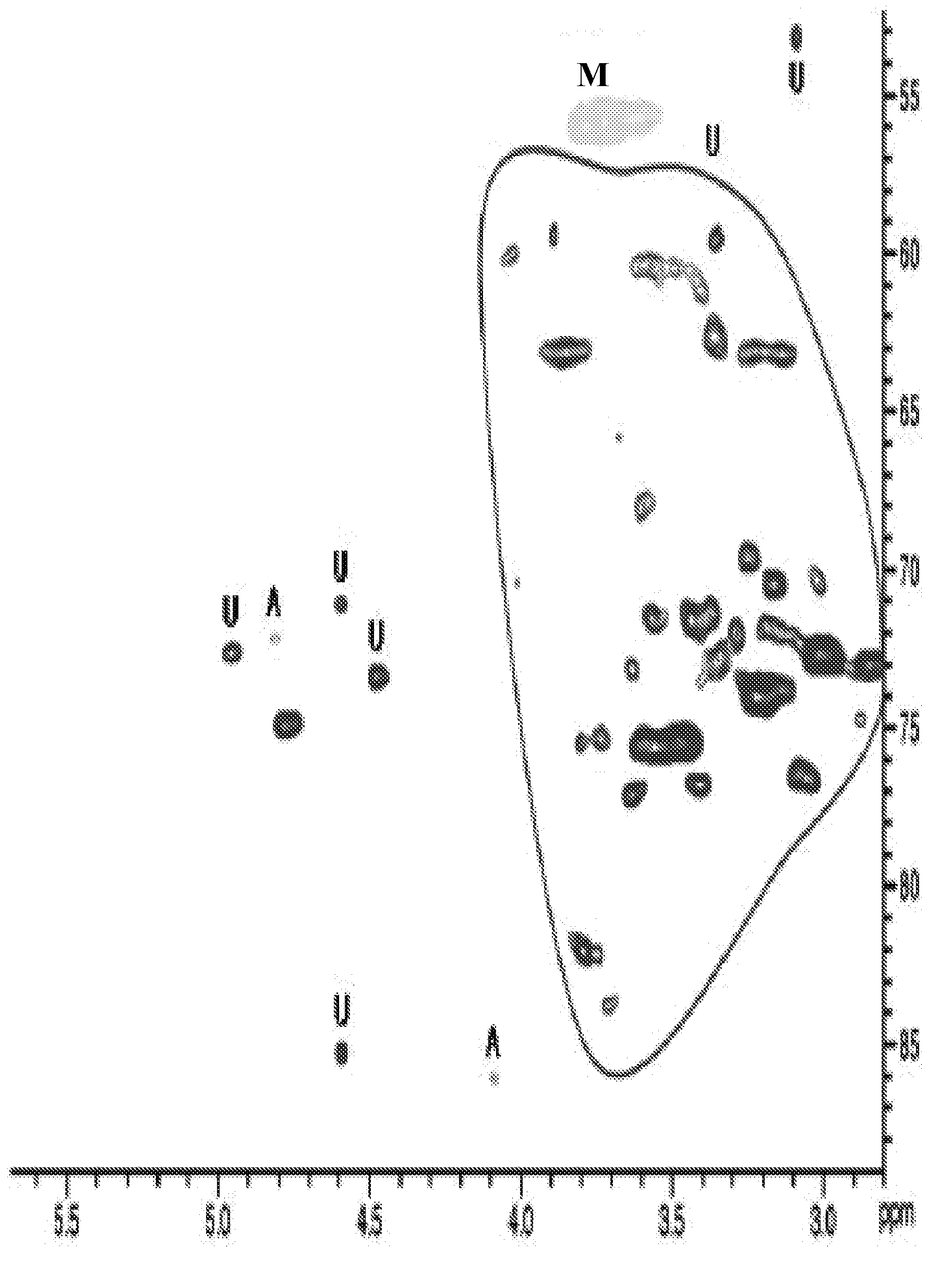

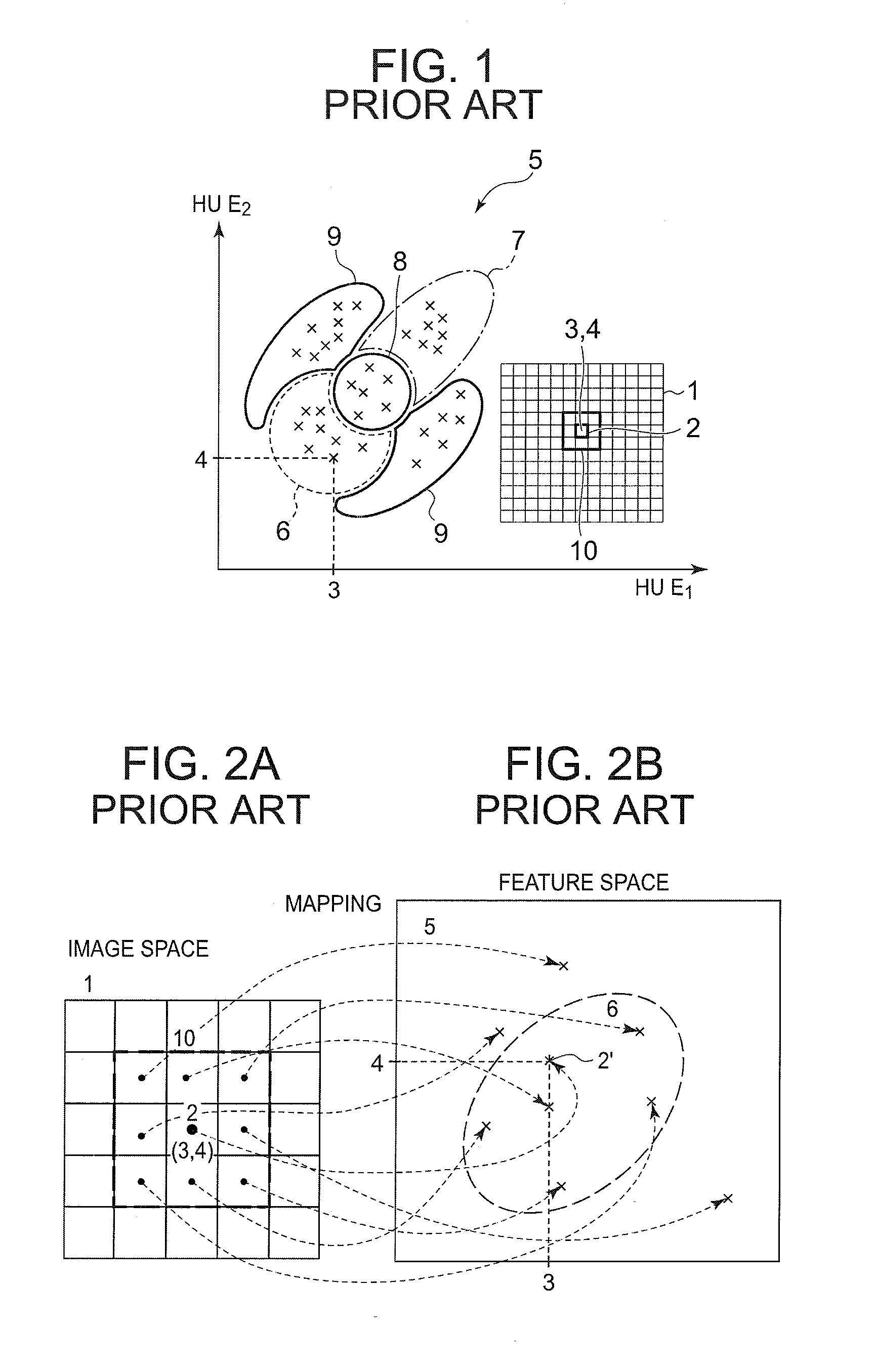

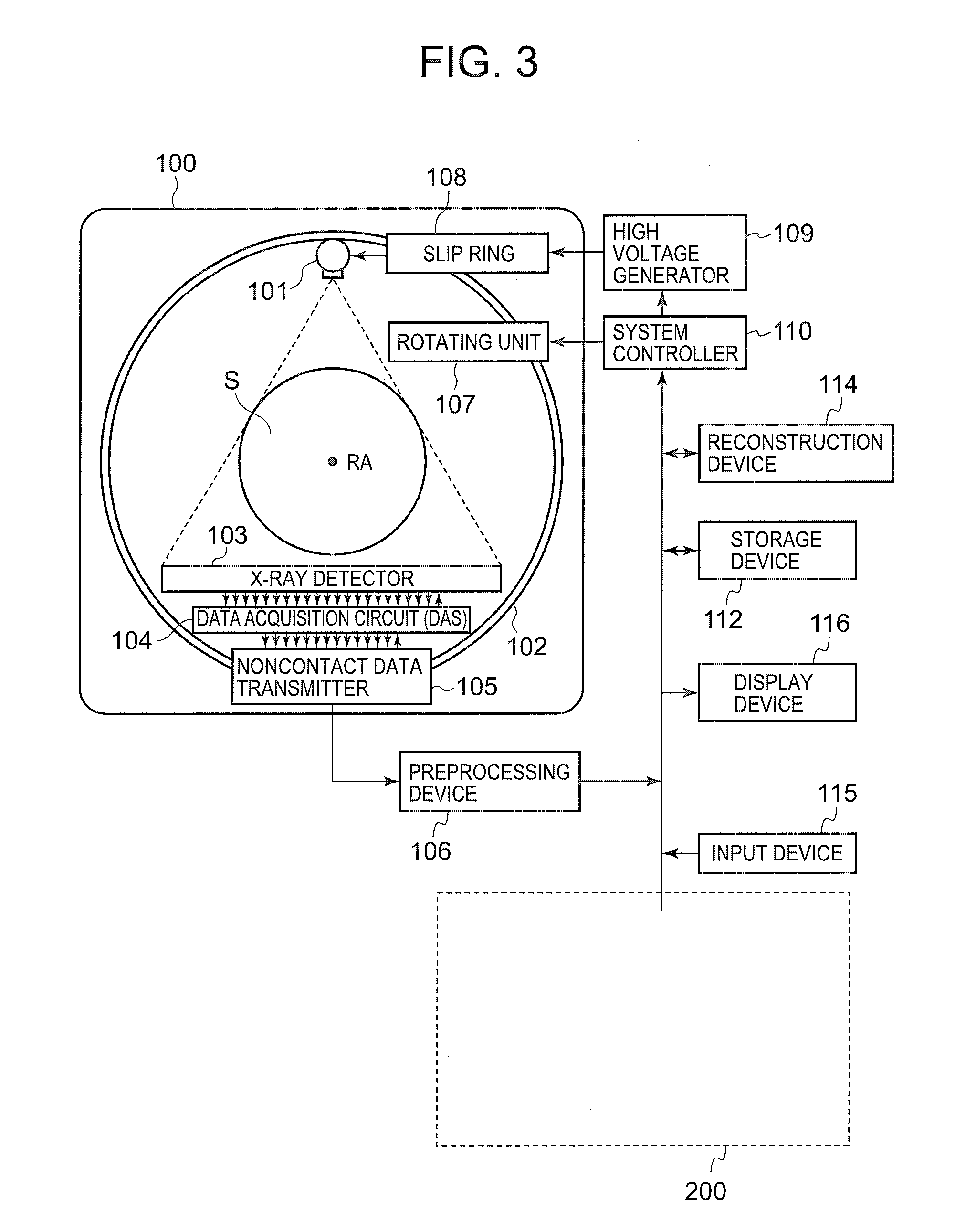

Advanced clustering method for material separation in dual energy ct

ActiveUS20100328313A1Reconstruction from projectionDrawing from basic elementsDecompositionData domain

Three or more materials are advantageously separated from dual energy data by using a material separation technique. To effectively separate material clusters, a density plot is introduced to automatically render cluster separations. Initially, the projection data optionally undergo data-domain dual energy decomposition. Then, the image data is plotted in a vector plot whose axes are the low HU values and the high HU values. For a given data point in the vector plot, a number of data points is counted within in a region of interest surrounding the given data point to generate a density plot where each point now represents a density level surrounding the data point. Thus, clustering of a certain material is visualized by a predetermined color assignment scheme. Furthermore, special image processing methods such as Gaussian decomposition are used to improve the accuracy of material separation. In addition, the HSL color model may be used for better visualization and to bring a new dimension in material separation display.

Owner:TOSHIBA MEDICAL SYST CORP

Incineration treatment method for domestic refuse

ActiveCN101761928AReduce dosageAchieve recyclingCement productionIncinerator apparatusSlagCalcination

The invention provides an incineration treatment method for domestic refuse. The method comprises: having an incinerator arranged between a rotary kiln and a decomposing furnace; introducing tertiary hot air into a wind tower of the incinerator and baking an incinerator body; crushing domestic refuse with the water content less than 20 percent into refuse material 50 to 80 millimeters in particle size and guiding the refuse material into the incinerator body through an electronic control feeder of the incinerator; allowing a material level meter to send a feedback signal to stop adding the refuse material when a refuse material layer is 50 millimeters away from a material separation body; drying the refuse material; burning, decomposing and gasifying organic substances in the refuse material through the tertiary hot air out of a multi-layer air outlet of a central air pipe; ensuring that the temperature in the incinerator body is above 850 DEG C; discharging produced flue gas to the decomposing furnace through a smoke outlet; ensuring that the decomposing furnace reaches a temperature of above 900 DEG C and is in an alkaline atmosphere; and further neutralizing acidic flue gas. Refuse ash-slag is discharged through an electrical vibrating material discharger, sent into the rotary kiln, and is taken as raw material burden for cement production to participate in calcination, so that the aim of treating domestic refuse in a 'harmless, amount-reducing and resource-recovering' way is achieved.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com