Patents

Literature

3405 results about "Material transfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

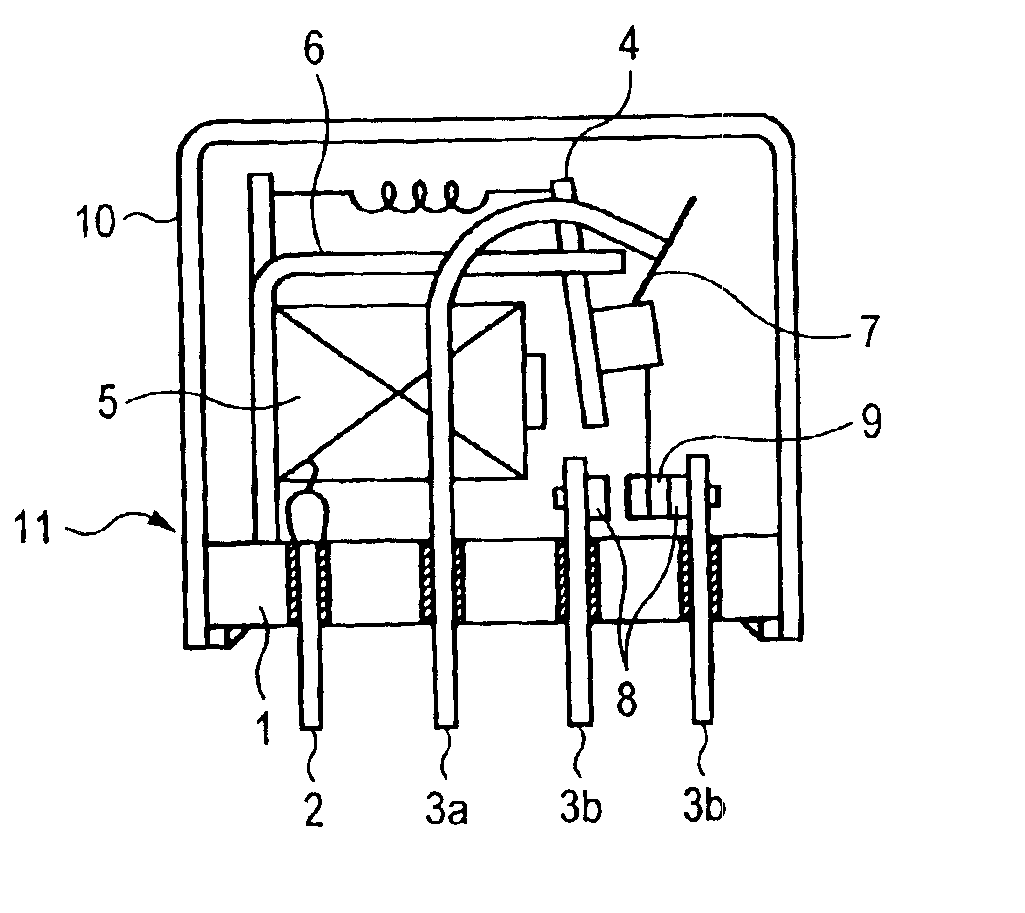

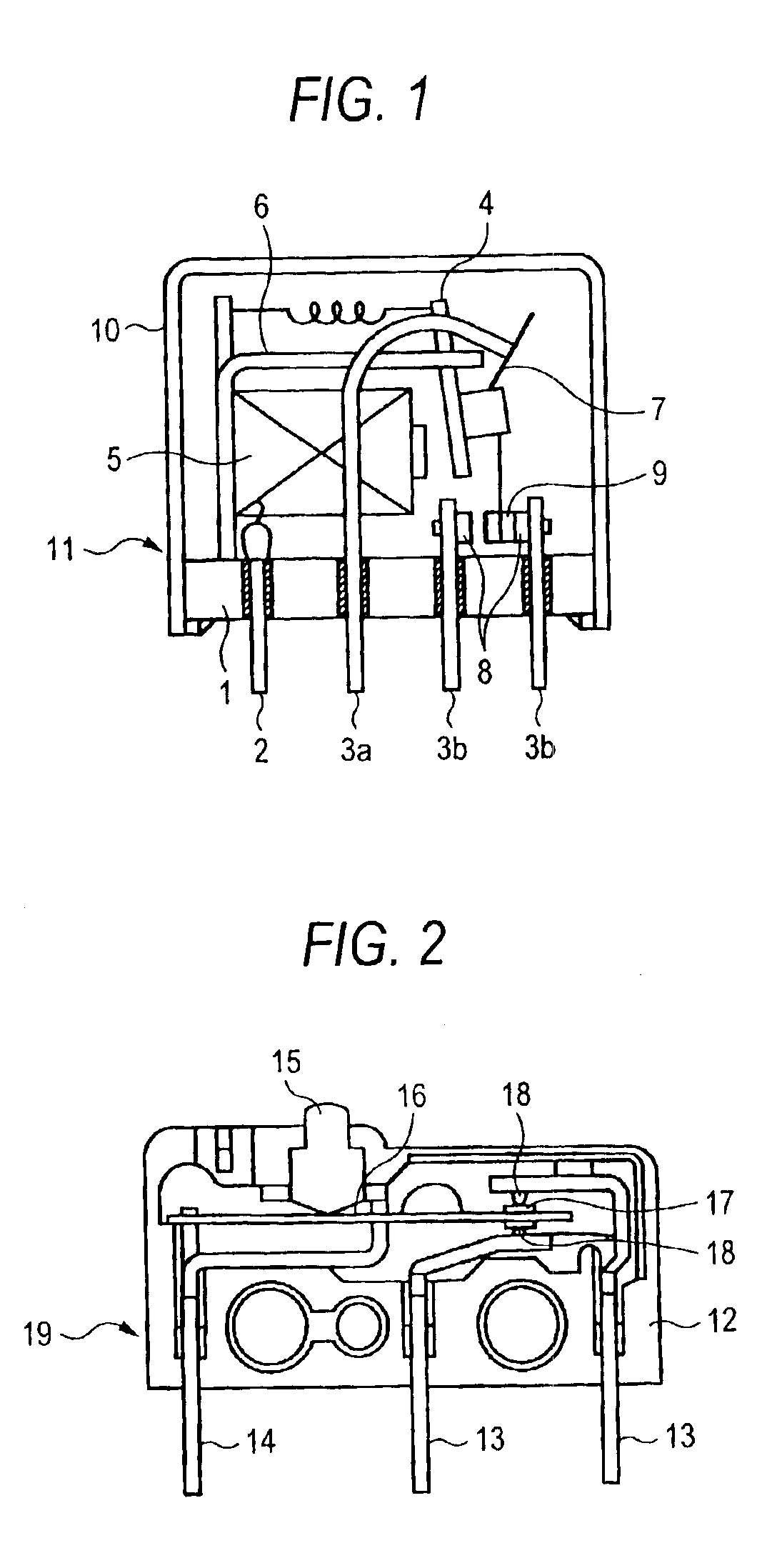

Direct current load breaking contact point constitution and switching mechanism therewith

InactiveUS6934134B2Contact materialsCircuit-breaking switches for excess currentsElectrical resistance and conductanceElectrical polarity

The invention intends to provide a direct current load breaking contact point constitution that can make and break an electrical circuit under both direct current loads of direct current resistance load and direct current inductance load over a long period of time without causing problems such as ① the conduction defect due to the consumption of the contact point, ② the locking due to material transfer from one contact point to the other contact point, ③ the welding between the contact points, and ④ the abnormal arc continuation, and a direct current load breaking switching mechanism such as a relay, a switch and so on that has the contact point constitution. The direct current load breaking contact point constitution according to the invention comprises a movable contact point and a stationary contact point that face each other; wherein the movable contact point is made of AgSnO2In2O3 alloy that contains at least Ag, 8 to 15% by weight in total of metal oxides including SnO2 and In2O3, 6 to 10% by weight of SnO2 and 1 to 5% by weight of In2O3; the stationary contact point is made of AgZnO alloy that contains at least Ag and 7 to 11% by weight of ZnO; and polarity of a movable side is (+) and that of a stationary side is (−).

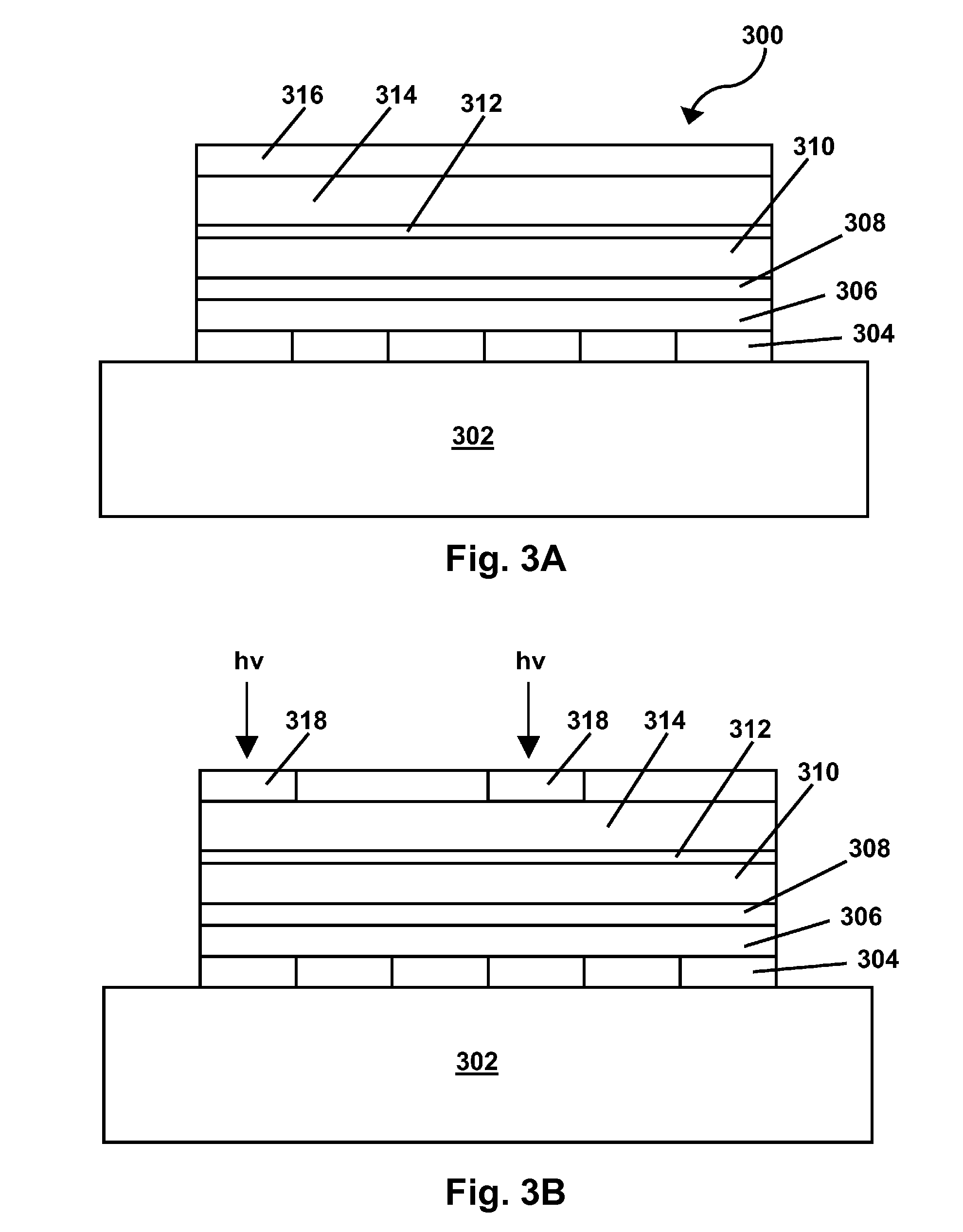

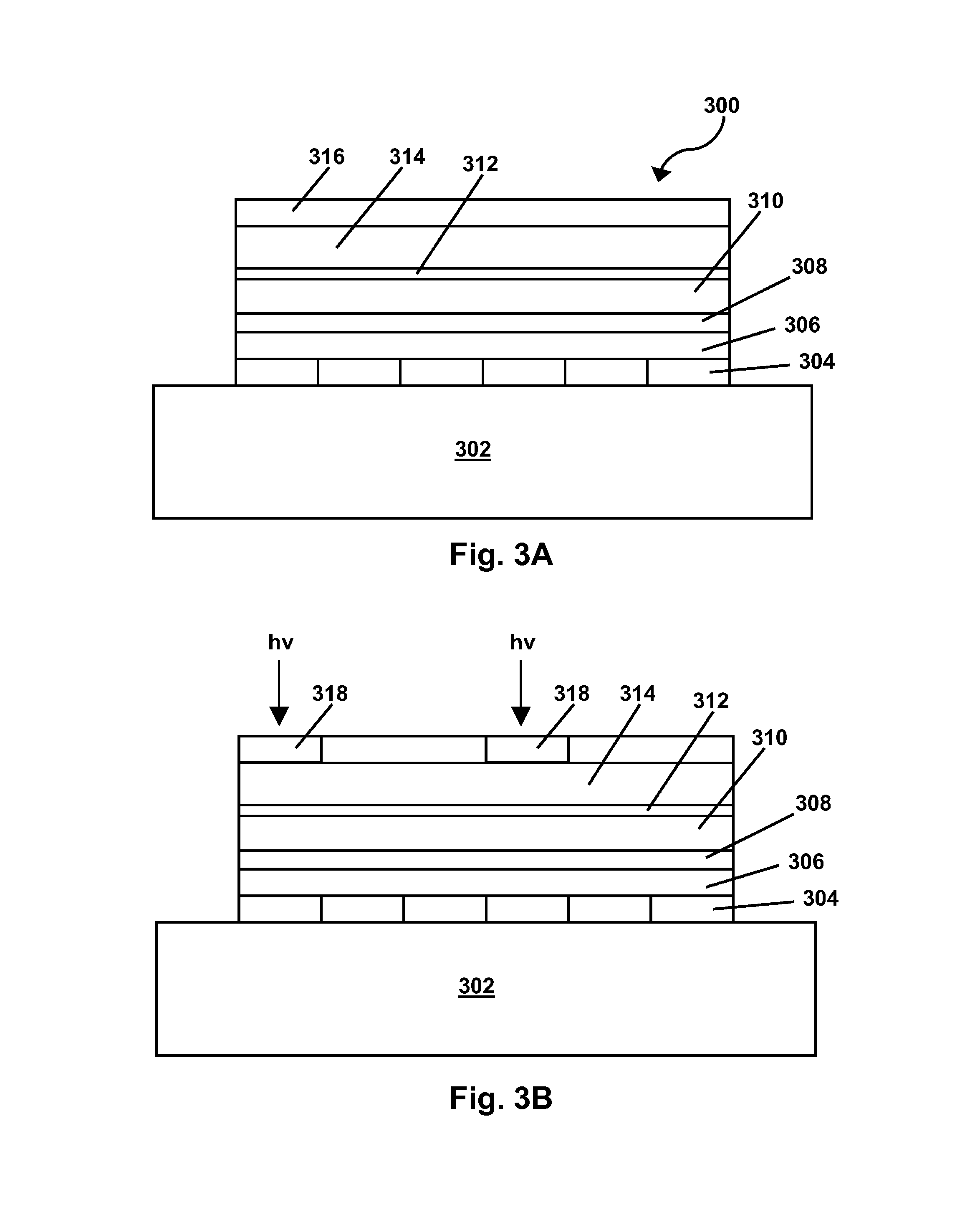

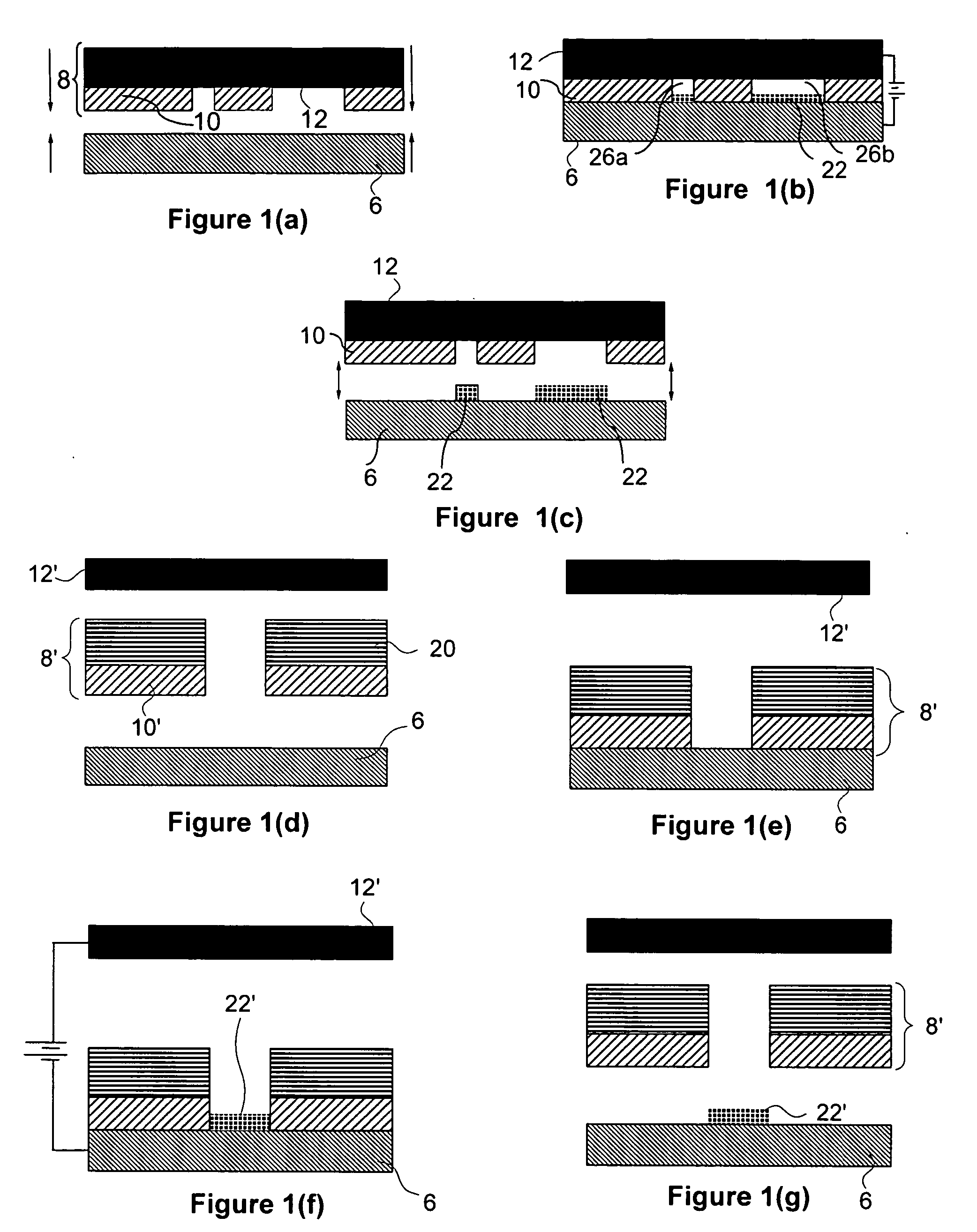

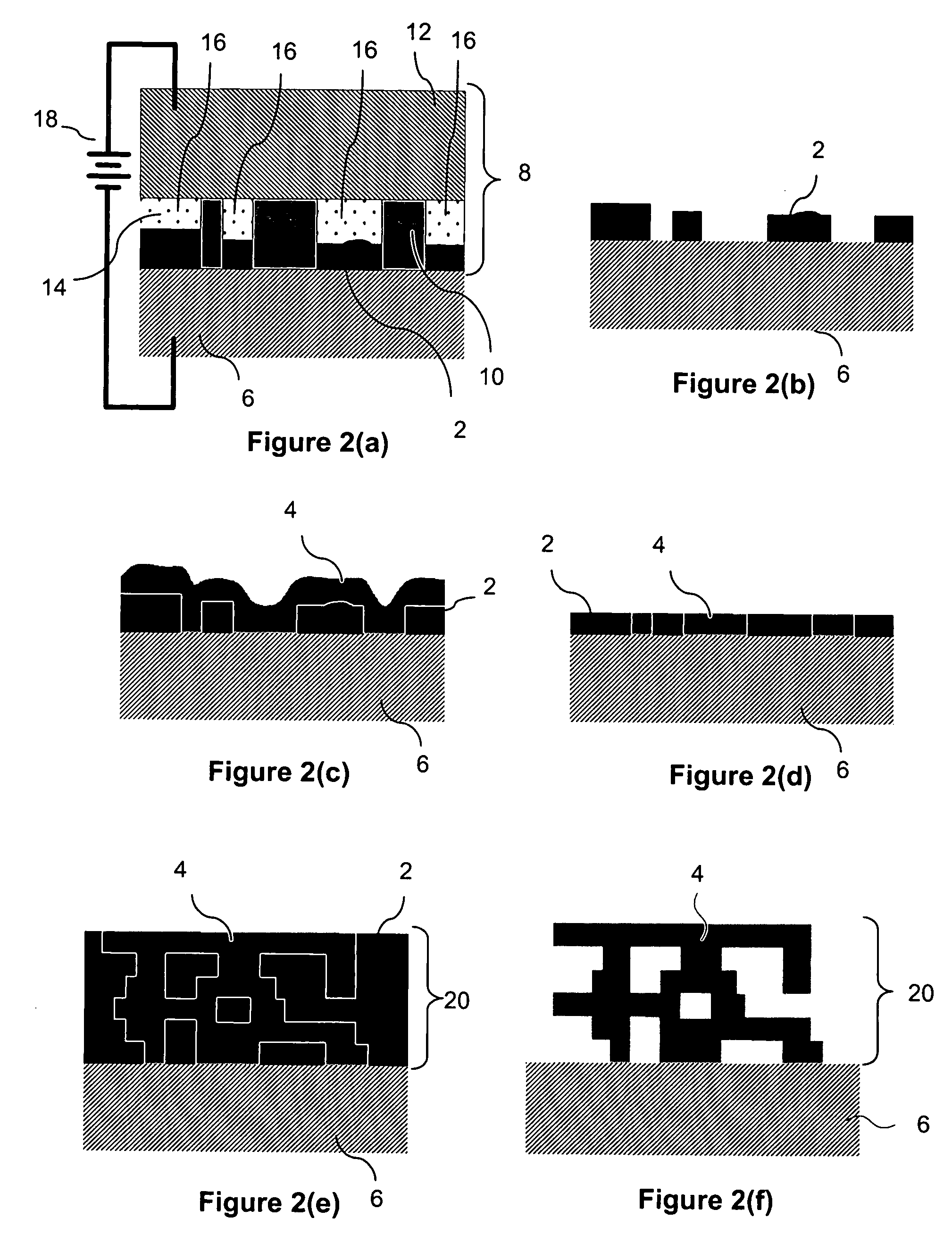

Processes for the production of electro-optic displays, and color filters for use therein

ActiveUS20090004442A1Decorative surface effectsPhotomechanical apparatusRadiative transferEngineering

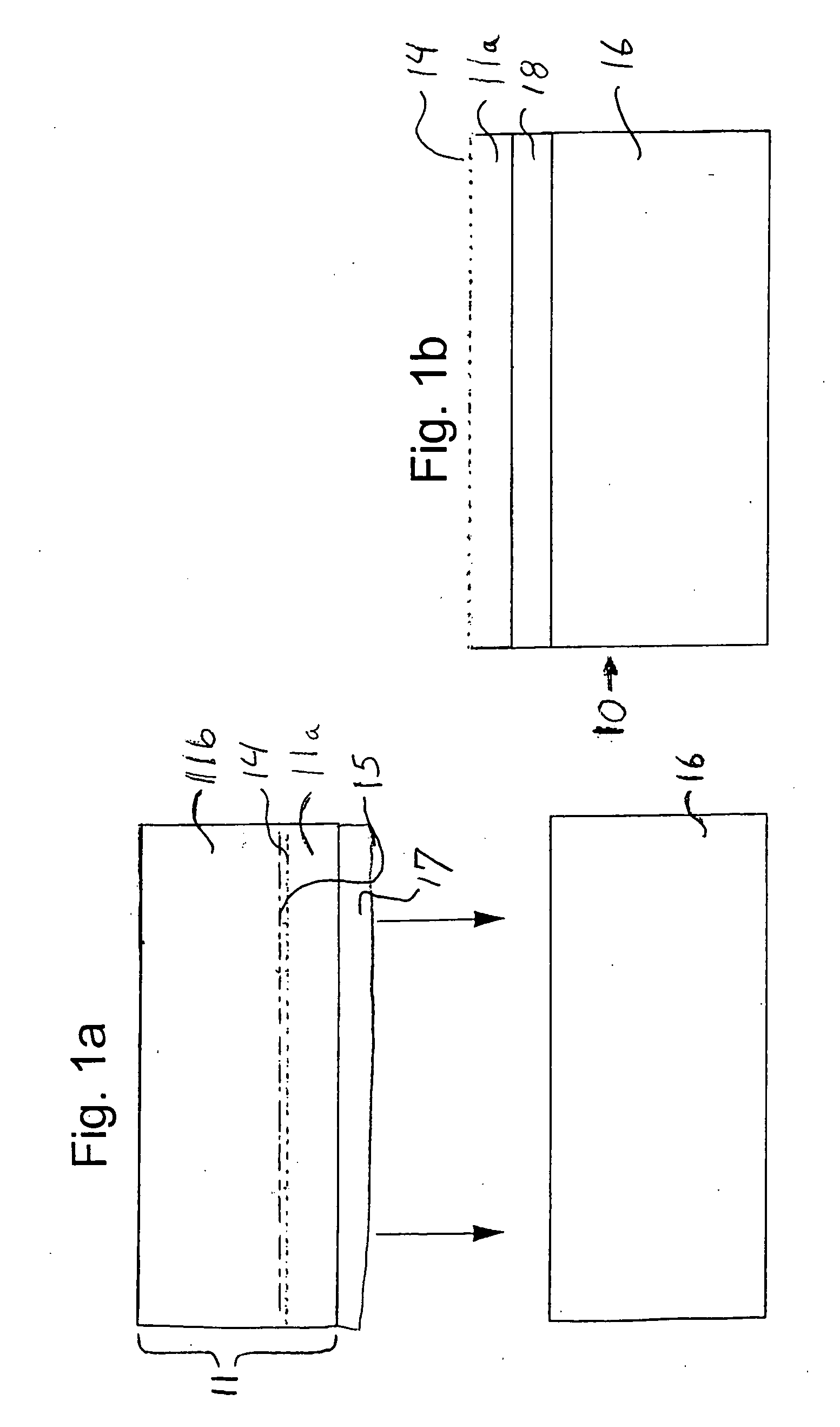

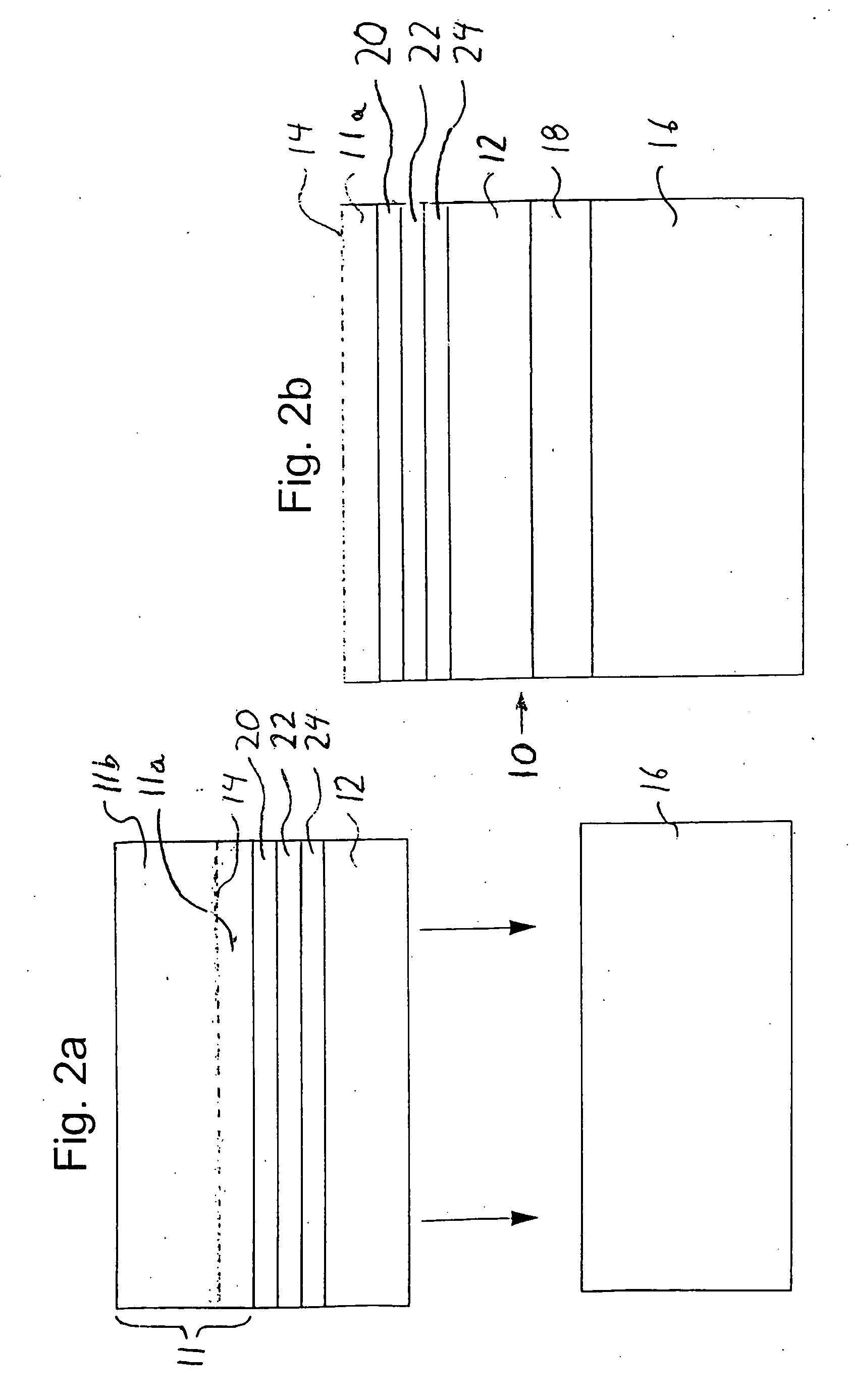

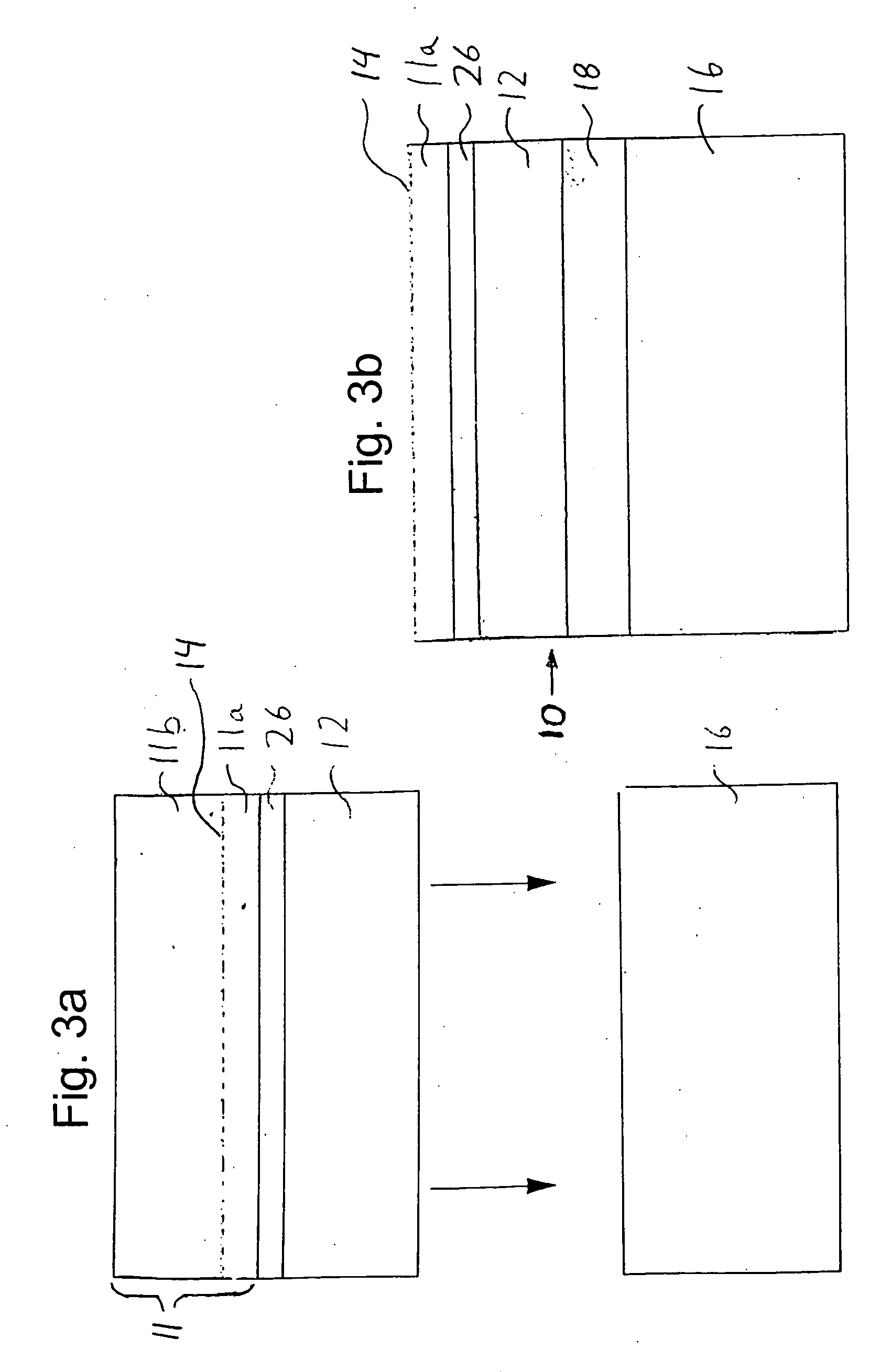

Processes are provided for depositing multiple color filter materials on a substrate to form color filters. In a first process, the surface characteristic of a substrate is modified by radiation so that a flowable form of a first color filter material will be deposited on a first area, and converted to a non-flowable form. A second color filter material can then be deposited on a second area of the substrate. In a second process, first and second color filter materials are deposited on separate donor sheets and transferred by radiation to separate areas of the substrate. A third process uses flexographic printing to transfer the first and second color filter materials to the substrate.

Owner:E INK CORPORATION

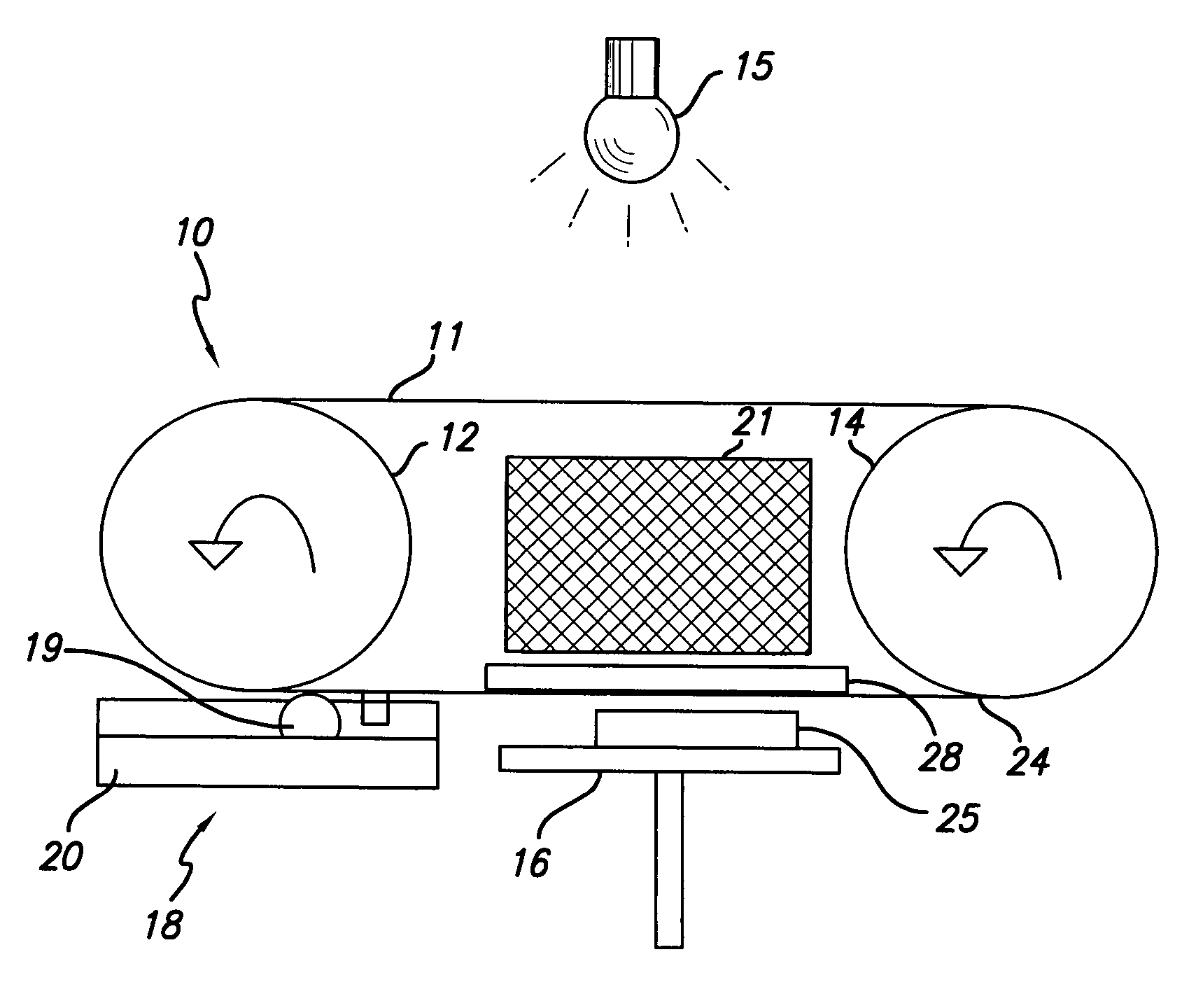

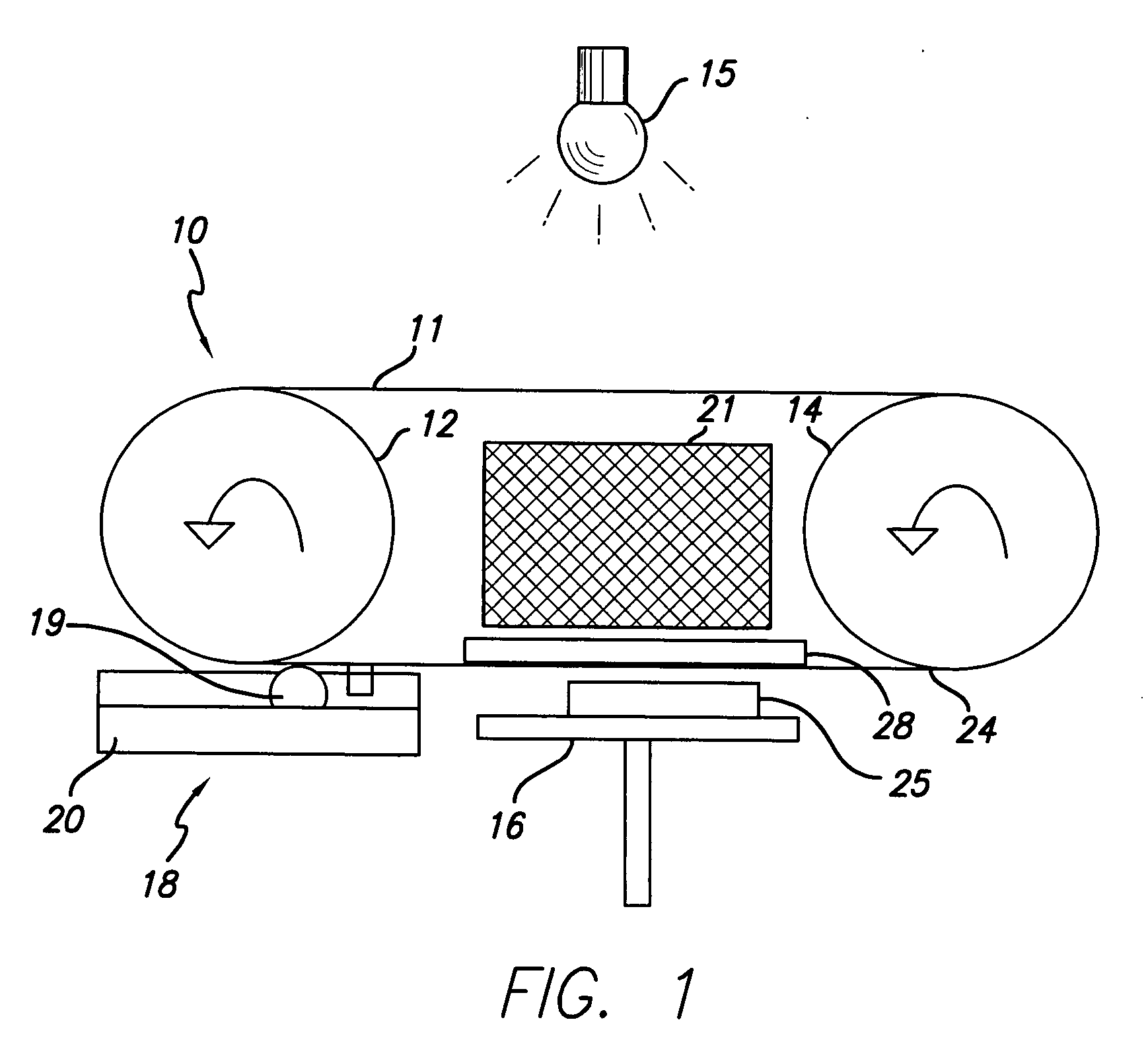

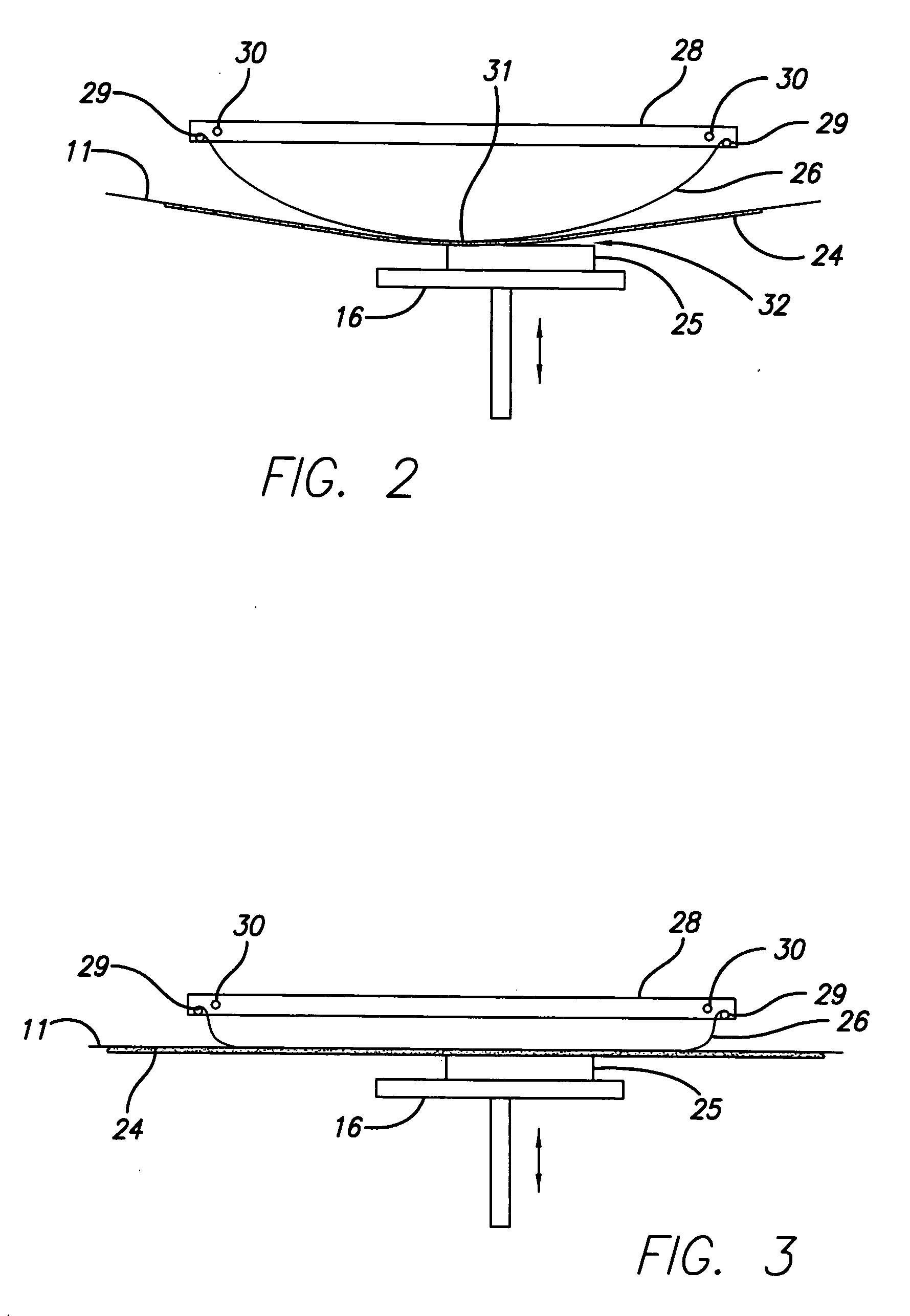

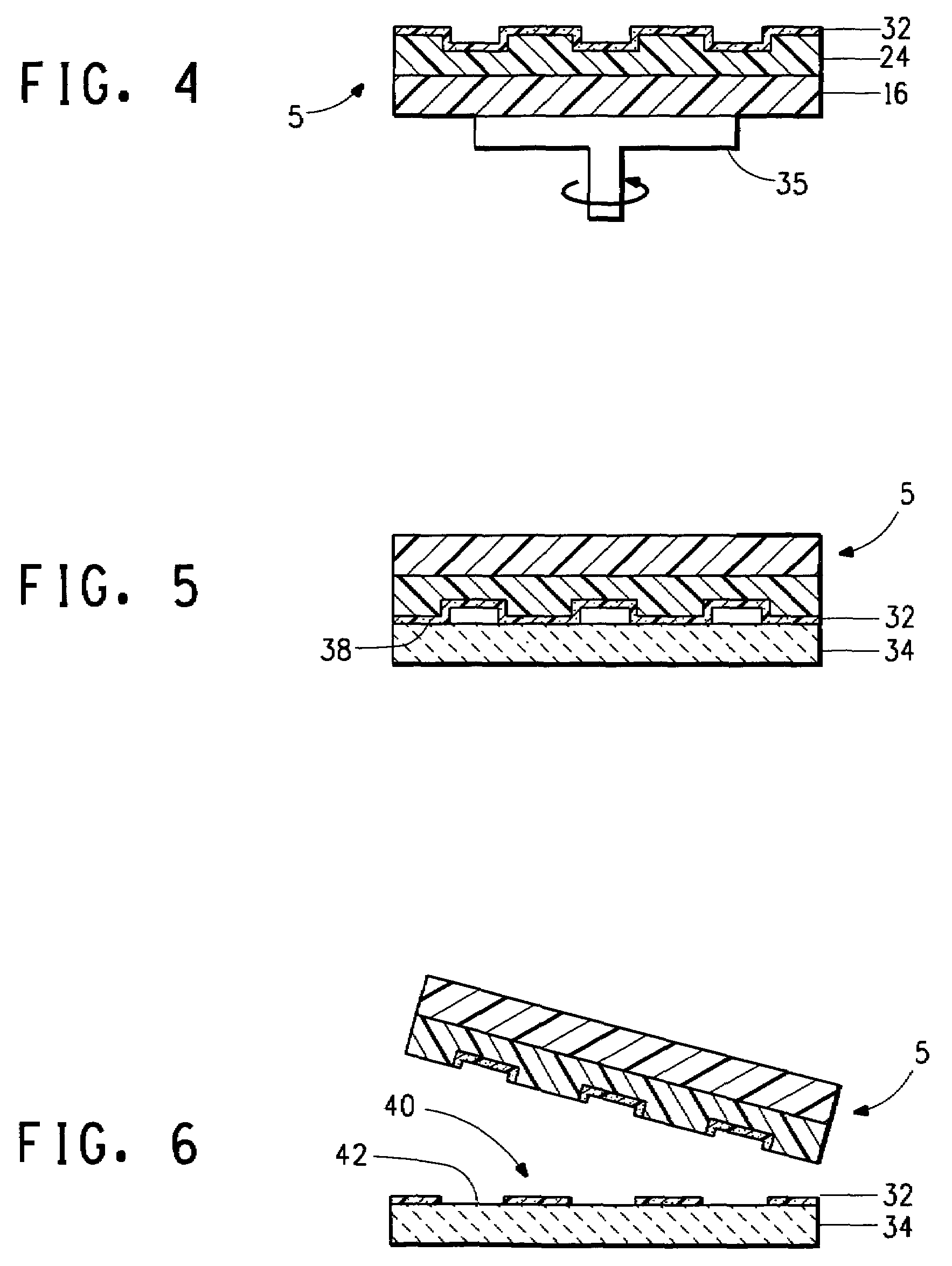

Bubble-free cross-sections for use in solid imaging

ActiveUS20060249884A1Low costHigh resolutionAdditive manufacturing apparatusAuxillary shaping apparatusReciprocating motionImaging equipment

A solid imaging apparatus and method employing build material transfer means effective to transfer solidifiable liquid build material from a first side of a radiation transparent build material carrier to a receiving substrate without entrapping air bubbles in layers of transferred solidifiable liquid build material and to cleanly separate the solidified build material from the radiation transparent build material carrier as each layer is formed during the layerwise building of a three-dimensional object. An expandable membrane forming an arcuate dome and a reciprocatible flexible film are employed to effect transfer of the solidifiable liquid build material.

Owner:3D SYST INC

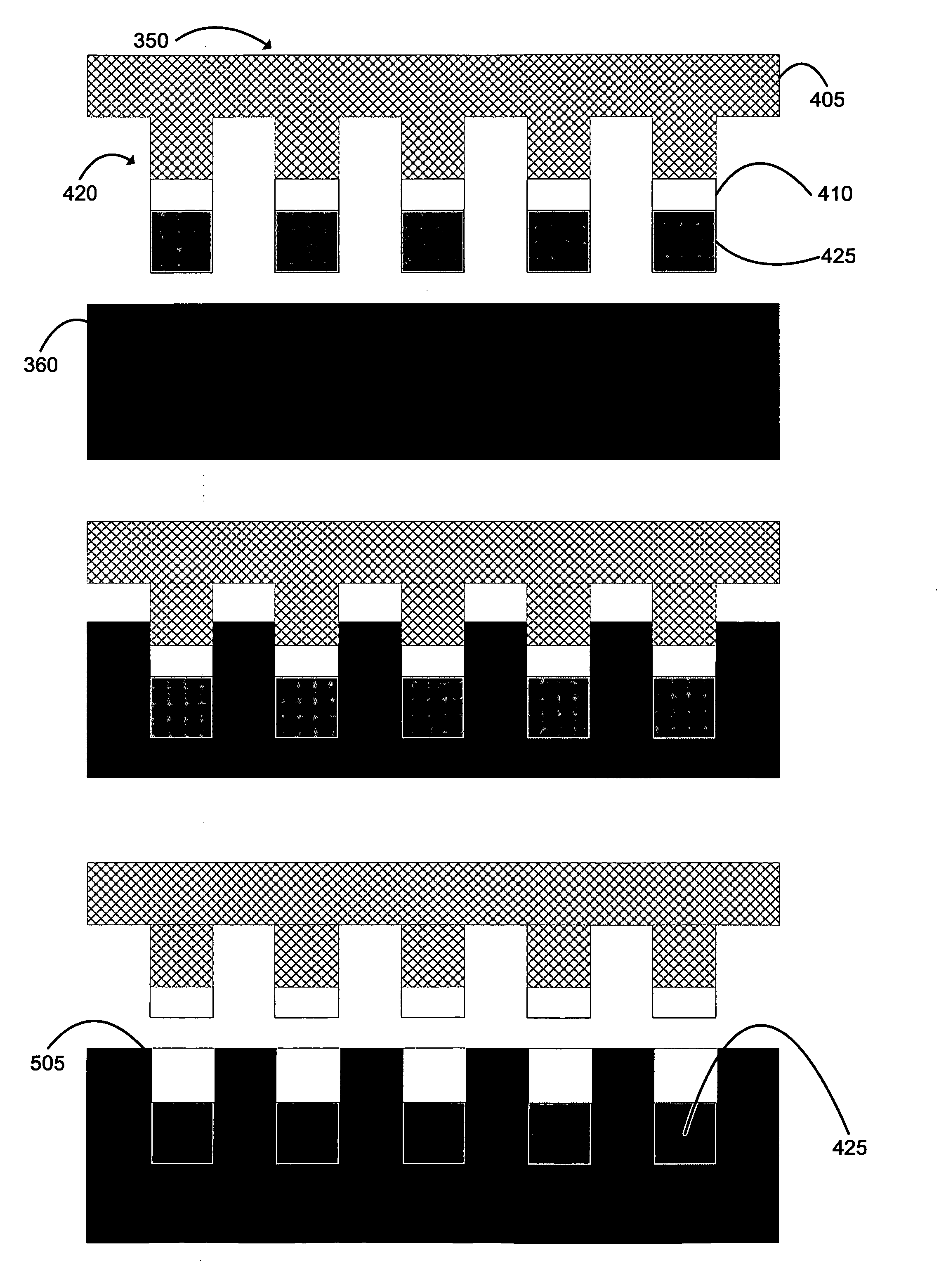

Processes for the production of electro-optic displays, and color filters for use therein

ActiveUS9199441B2Lamination ancillary operationsLayered product treatmentRadiative transferEngineering

Processes are provided for depositing multiple color filter materials on a substrate to form color filters. In a first process, the surface characteristic of a substrate is modified by radiation so that a flowable form of a first color filter material will be deposited on a first area, and converted to a non-flowable form. A second color filter material can then be deposited on a second area of the substrate. In a second process, first and second color filter materials are deposited on separate donor sheets and transferred by radiation to separate areas of the substrate. A third process uses flexographic printing to transfer the first and second color filter materials to the substrate.

Owner:E INK CORPORATION

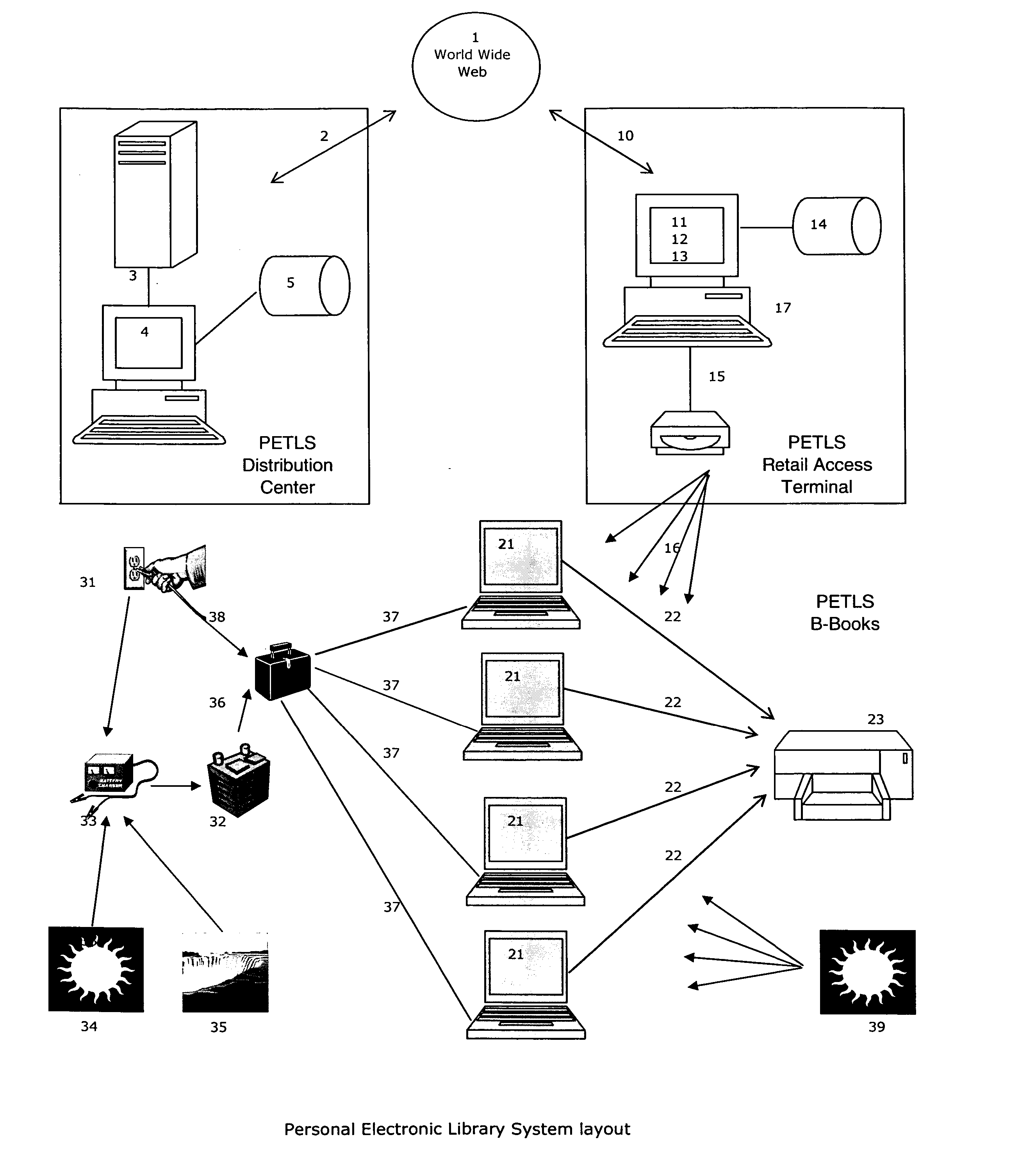

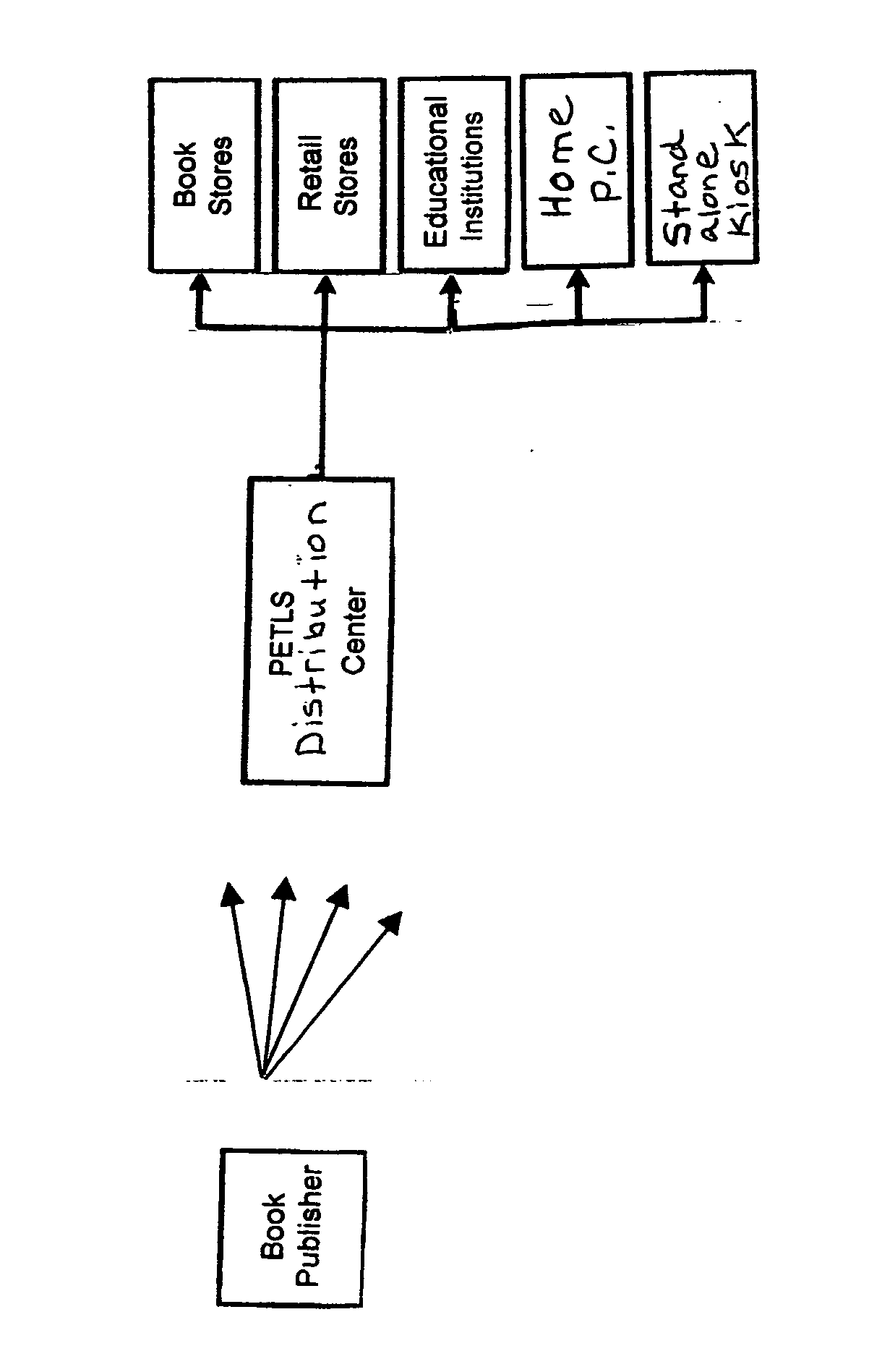

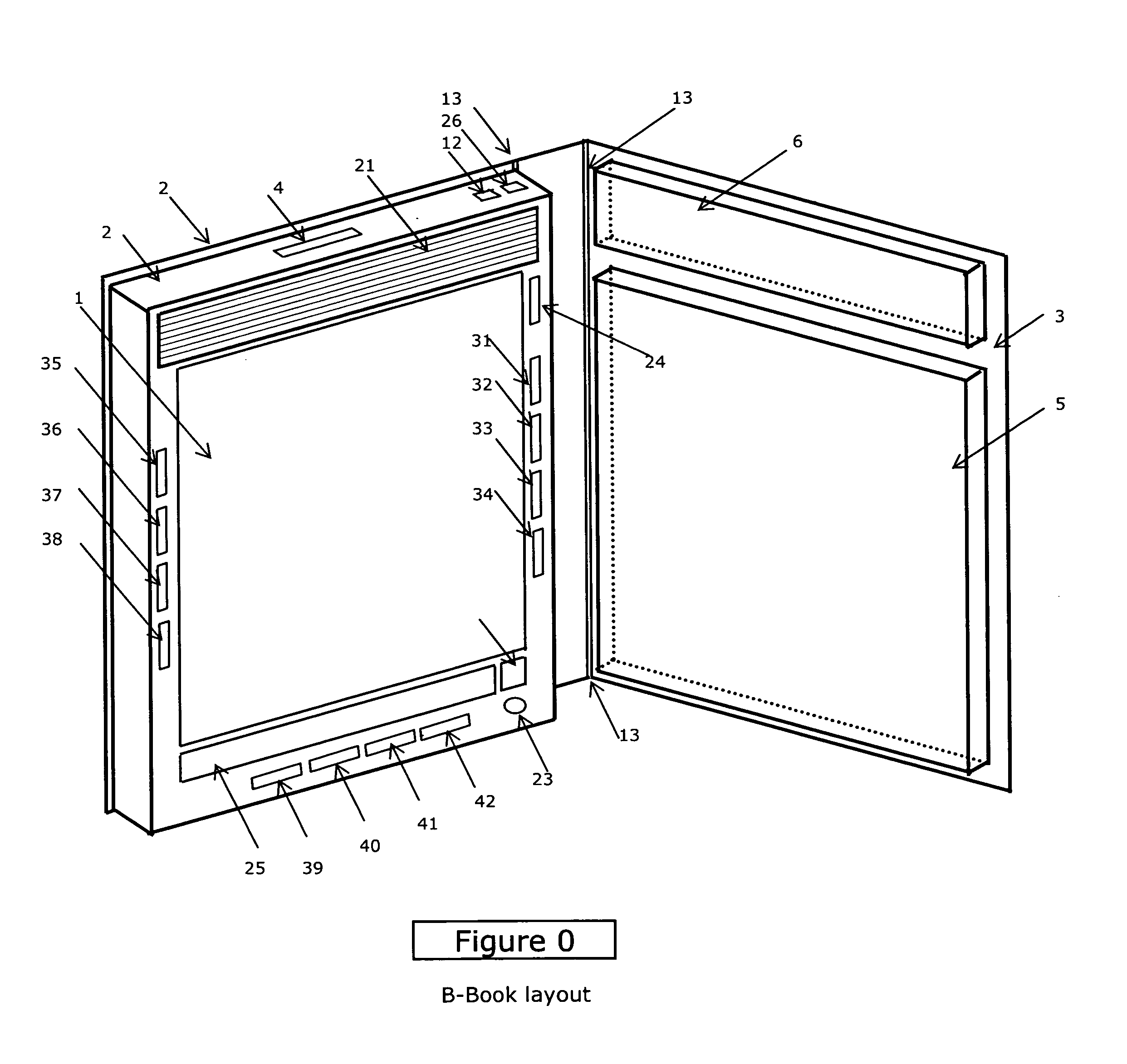

Personal electronic text library system patent

The Personal Electronic Text Library System [PETLS] invention is a means for the collection, storage and distribution of text book and / or printed material in electronic format protected against unauthorized duplication according to the proprietary PETLS Protection Standard. Said protection applies to text book and / or printed material in electronic format originating from a plurality of sources of said material transferred into PETLS, the storage of said material within PETLS, the transfer of copies of said material to portable physical media through a plurality of points of access and the display of said material from said portable physical media on dedicated PETLS display devices, the B-Books. Text book and / or printed material in electronic format stored on the portable PETLS Electronic Storage Media being protected against unauthorized duplication can be purchased and / or shared and / or lent and / or traded and / or donated between any and / or all individuals and / or users of the B-Book dedicated display devices.

Owner:WOOD BERYL

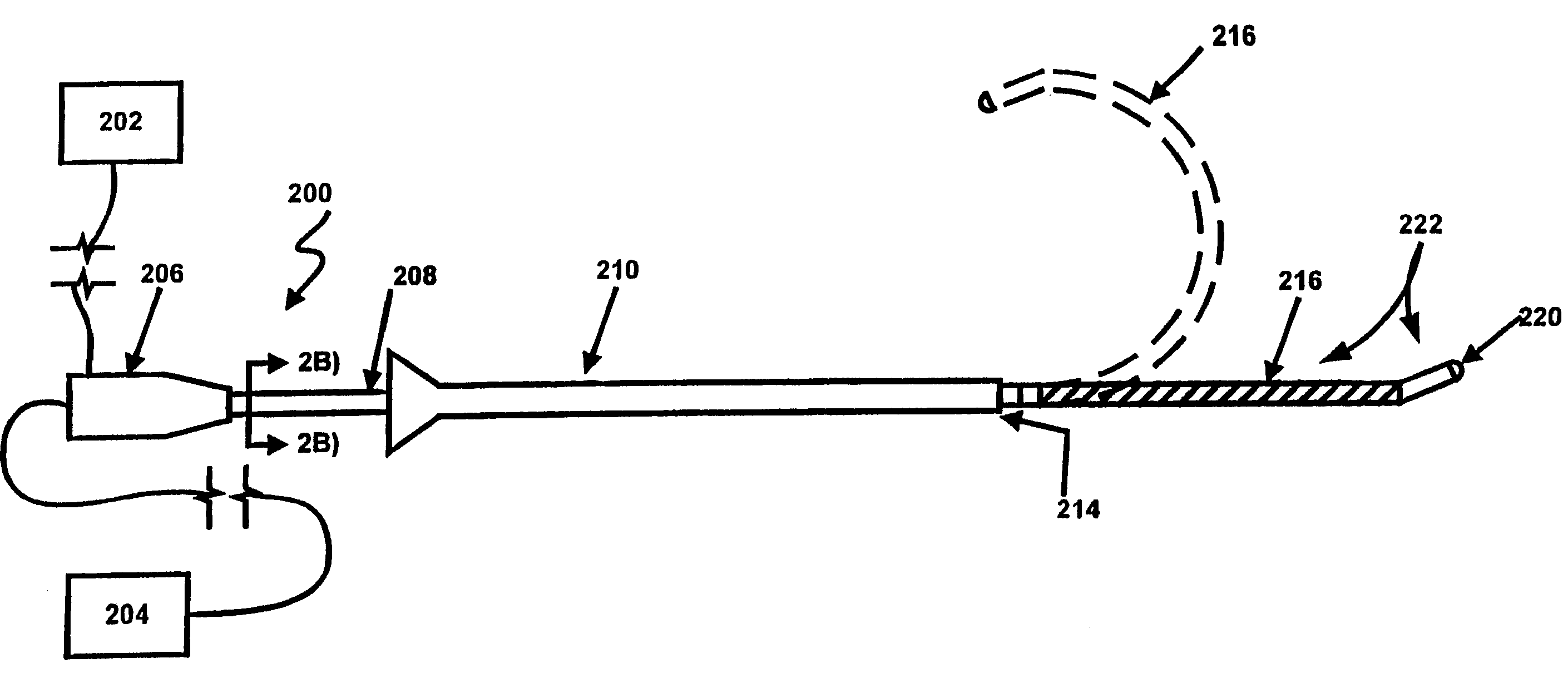

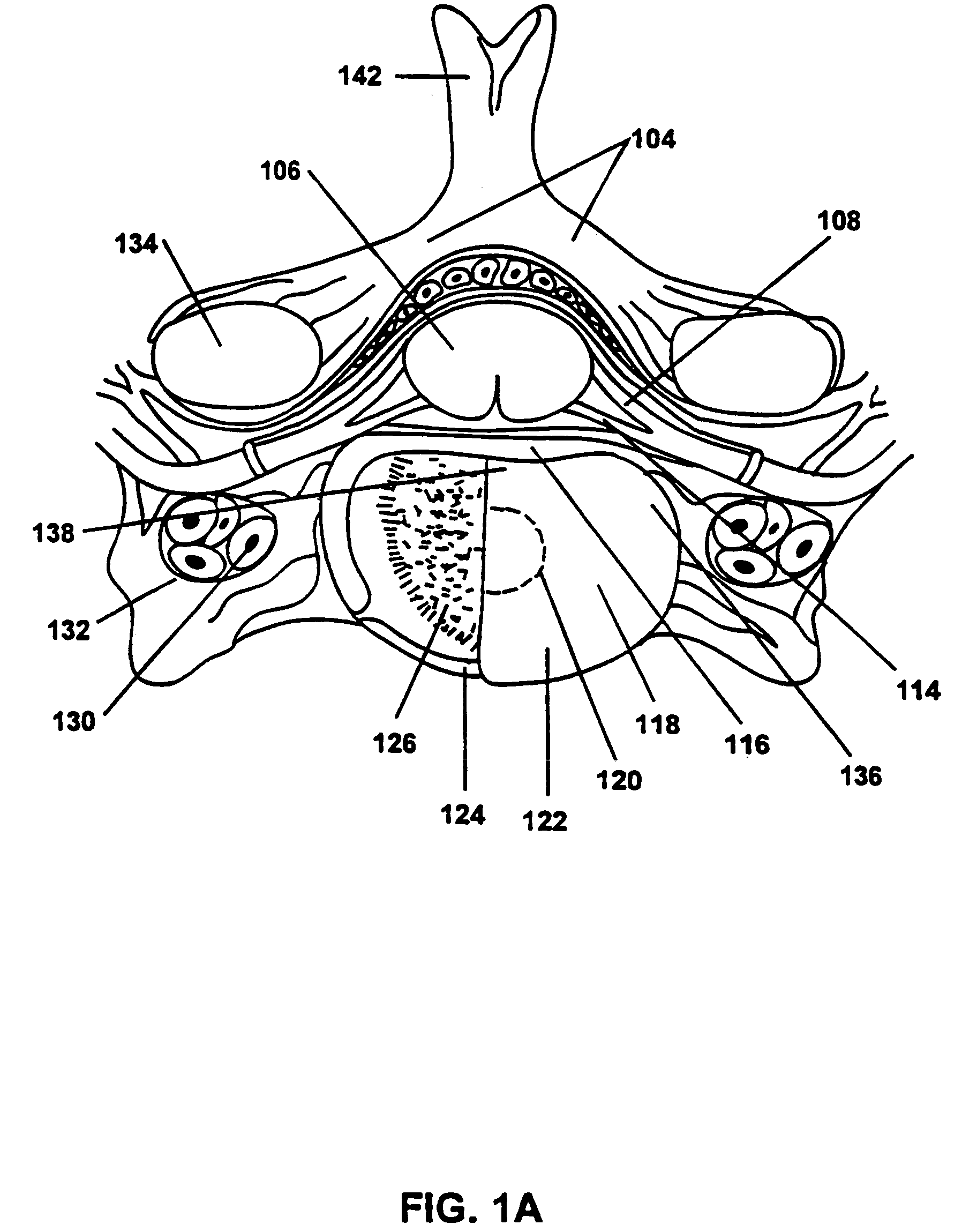

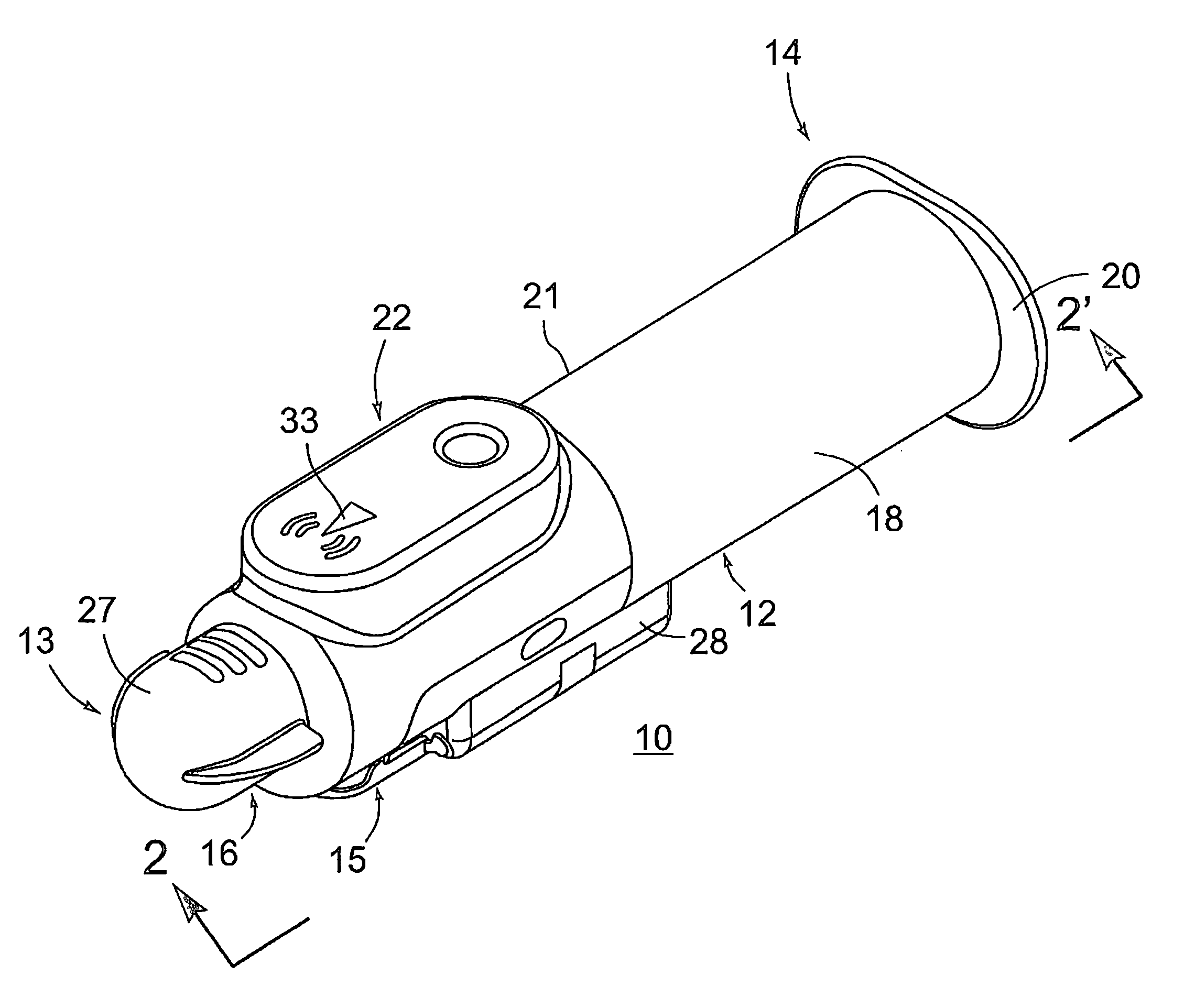

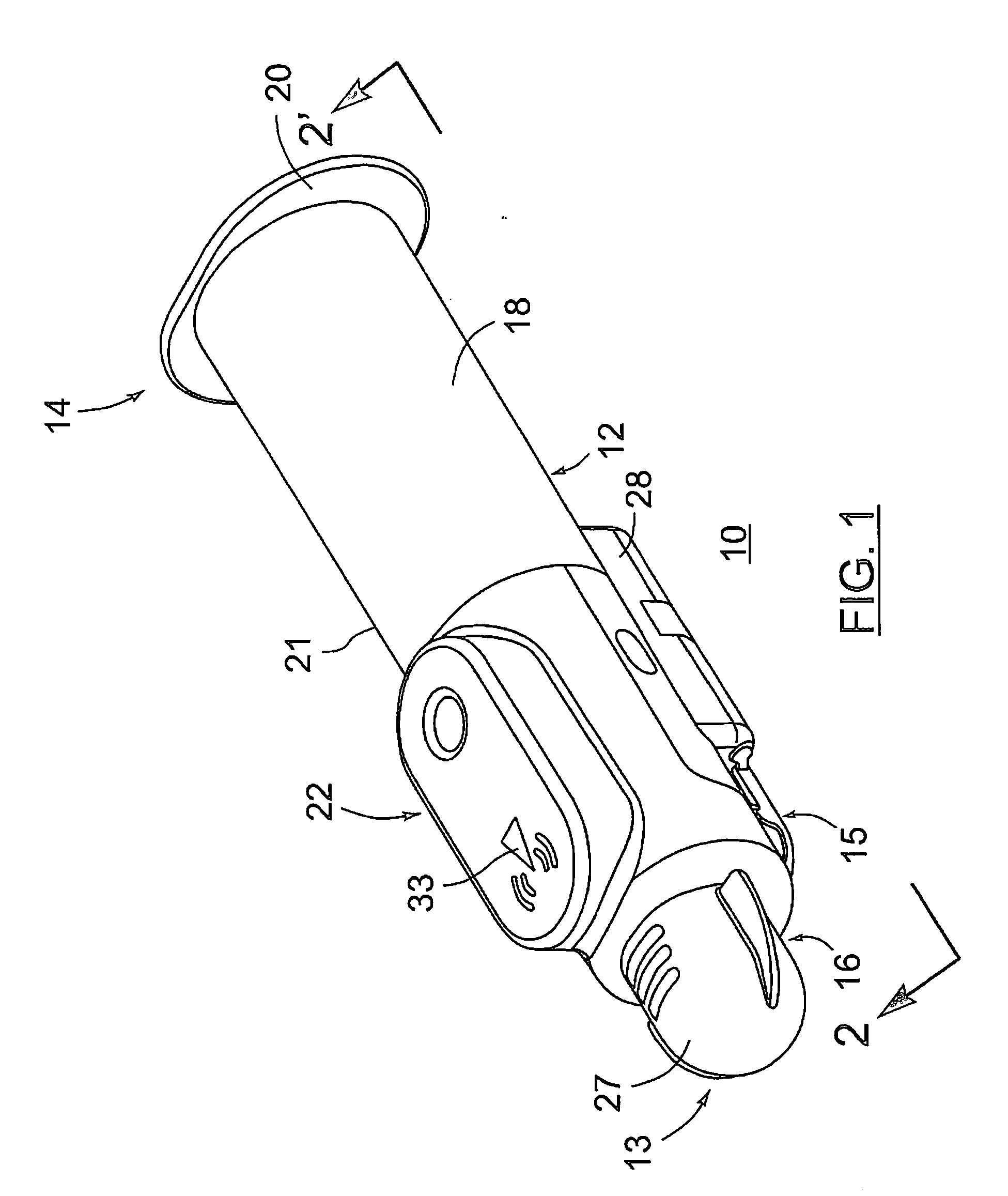

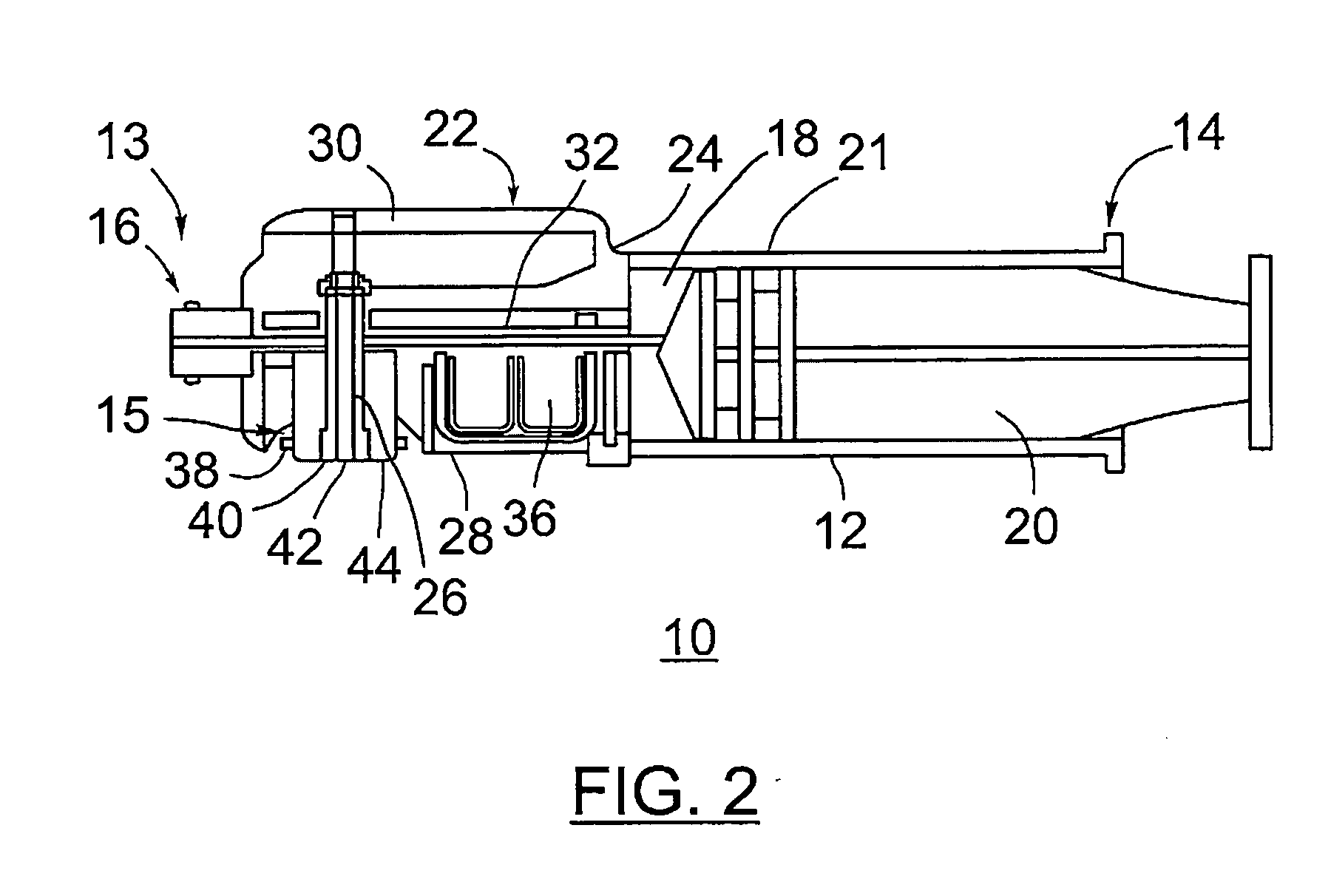

Catheter for delivery of energy to a surgical site

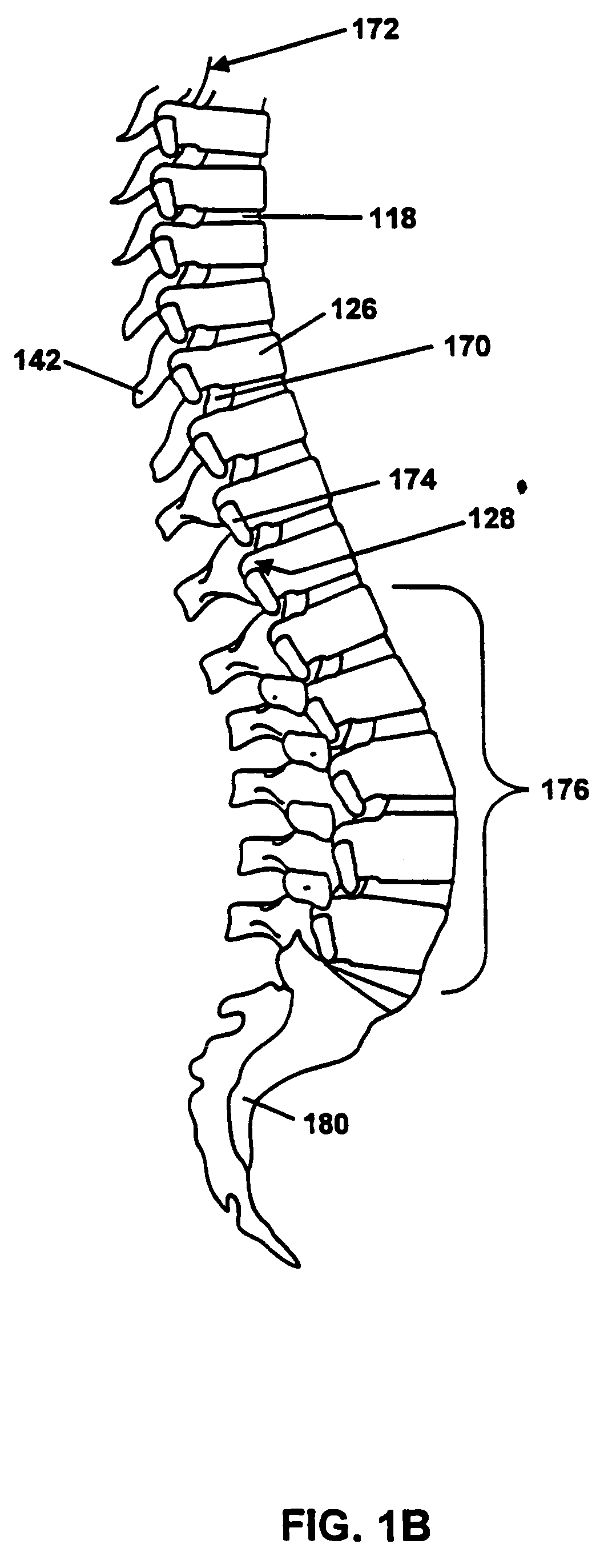

InactiveUS7309336B2Minimally invasiveEliminate redundancyElectrotherapyCannulasThermal energyIntervertebral disc

A catheter for delivering energy to a surgical site is disclosed. The catheter includes at a proximal end a handle and at a distal end a probe. The catheter includes at least one energy delivery device and an activation element. The at least one energy delivery device is located at the distal end of the catheter to deliver energy to portions of the surgical site. The activation element is located at the distal end of the catheter, to transition the probe from a linear to a multi-dimensional shape, within the surgical site. Methods for deploying the probe from the linear to multi-dimensional shape are disclosed.In another embodiment of the invention the catheter includes a heating element fabricated on a substrate by photo-etching to deliver thermal energy to portions of the surgical site. In another embodiment of the invention the catheter includes an energy delivery element, a tip and a blade. The energy delivery element is located at the distal end of the catheter to deliver energy to portions of the intervertebral disc. The blade is positioned within a first lumen of the tip and is extensible beyond the tip, to cut selected portions within the intervertebral disc. In another embodiment of the invention a catheter includes both energy and material transfer elements and an interface on the handle thereof. The interface couples the energy delivery element and the material transfer element to external devices for energy and material transfer to and from the intervertebral disc.

Owner:NEUROTHERM

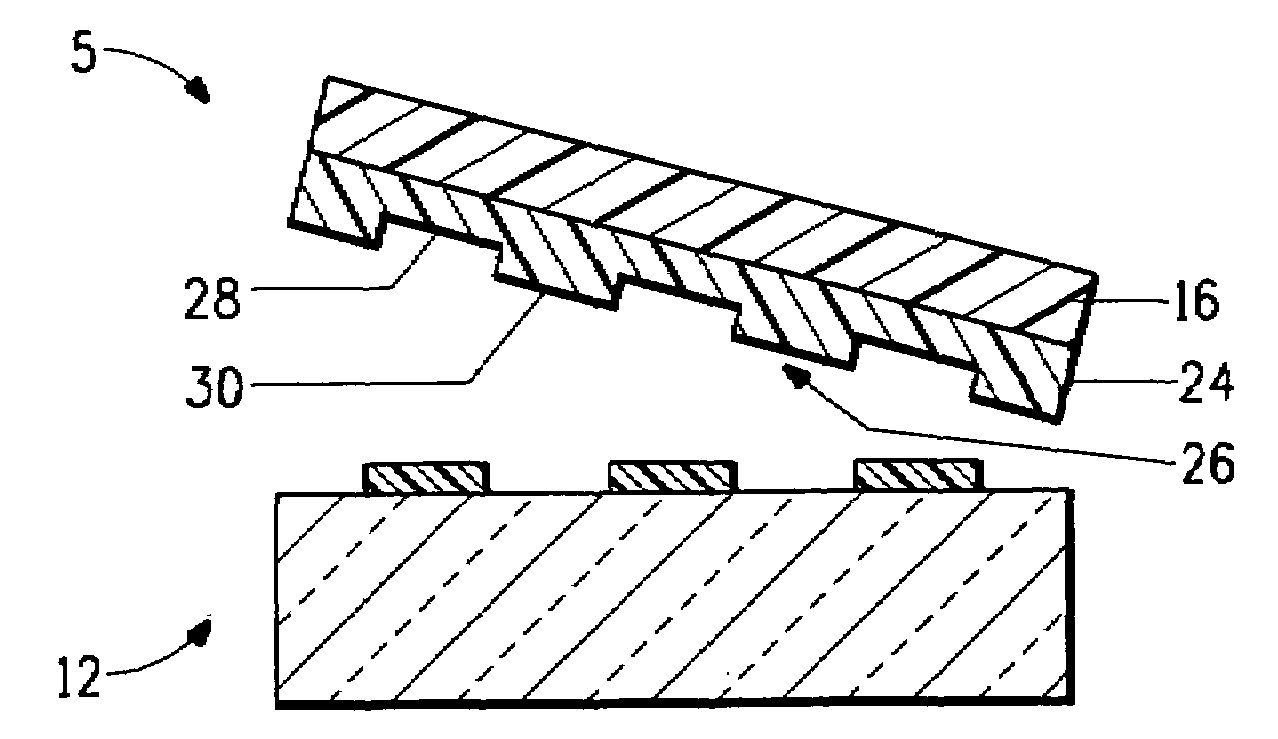

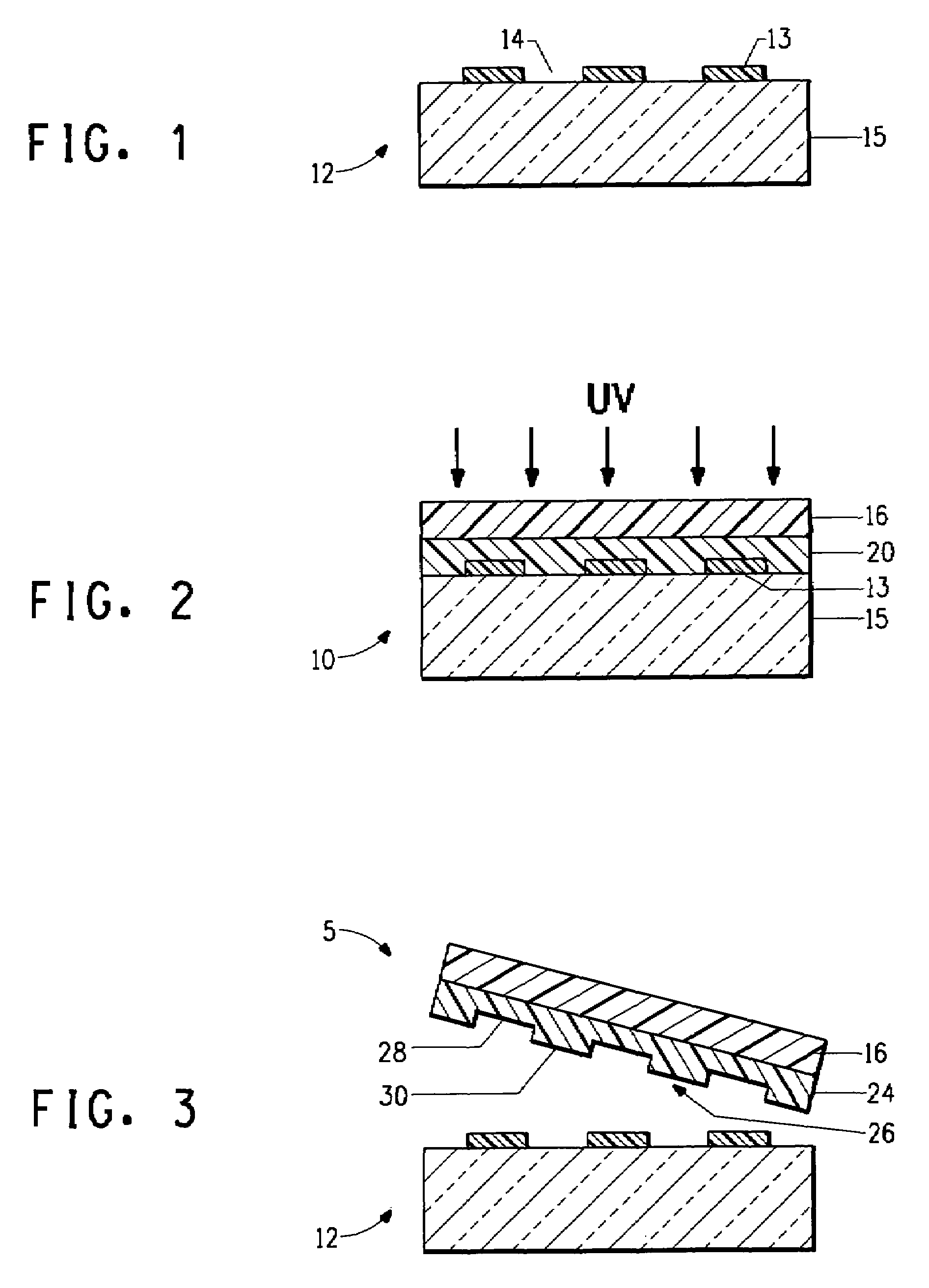

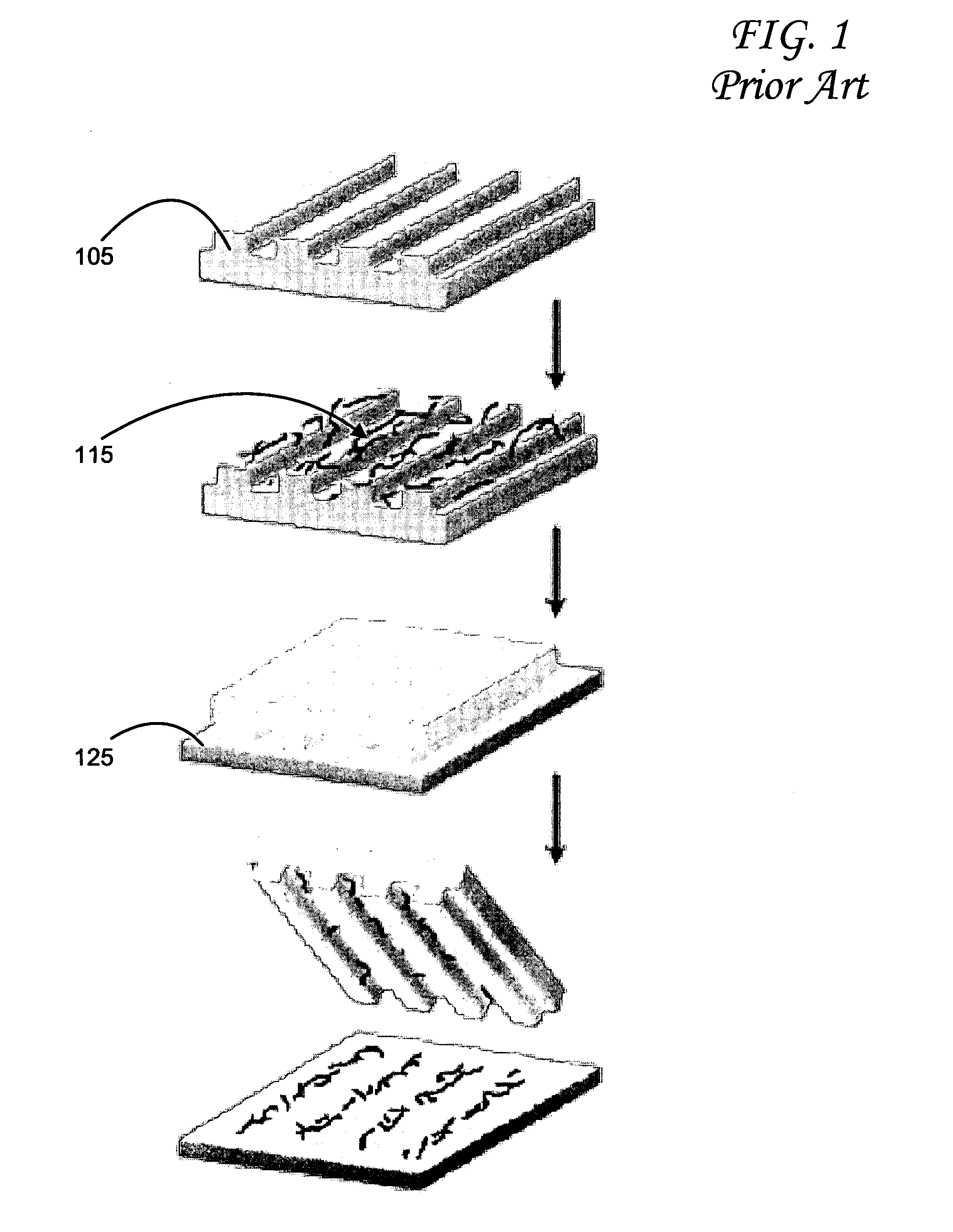

Method to form a pattern of functional material on a substrate

InactiveUS20080047930A1Excellent conductive silver pattern formationEliminates possibility of shortingDecorative surface effectsNanoinformaticsOptoelectronicsMaterial transfer

The invention provides a method to form a pattern of a functional material on a substrate for use in electronic devices and components. The method uses a stamp having a relief structure to transfer a mask material to a substrate and form a pattern of open area on the substrate. The functional material is applied to the substrate in at least the open area. The mask material is removed from the substrate, forming the pattern of functional material on the substrate. The method is suitable for the fabrication of microcircuitry for electronic devices and components.

Owner:EI DU PONT DE NEMOURS & CO

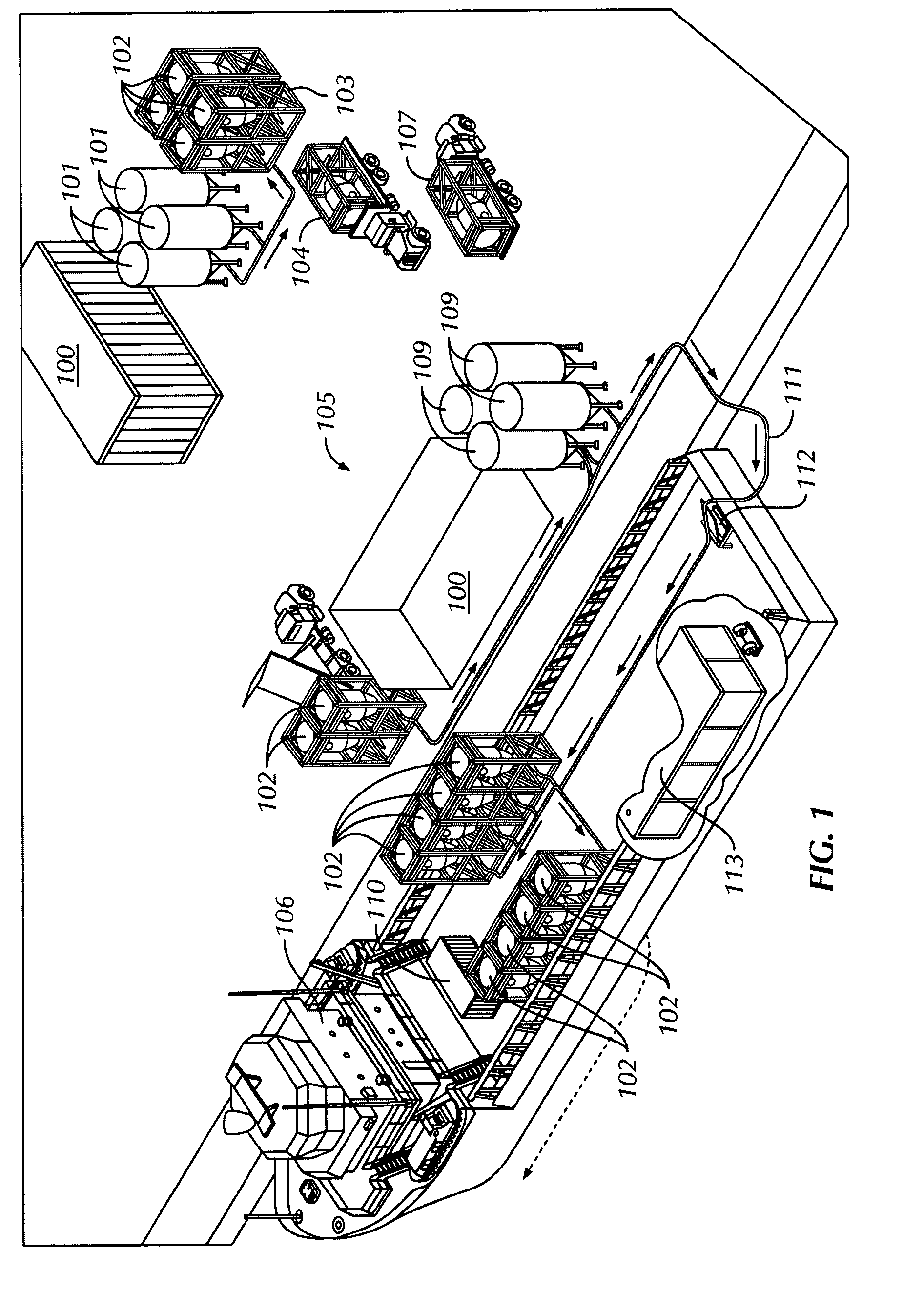

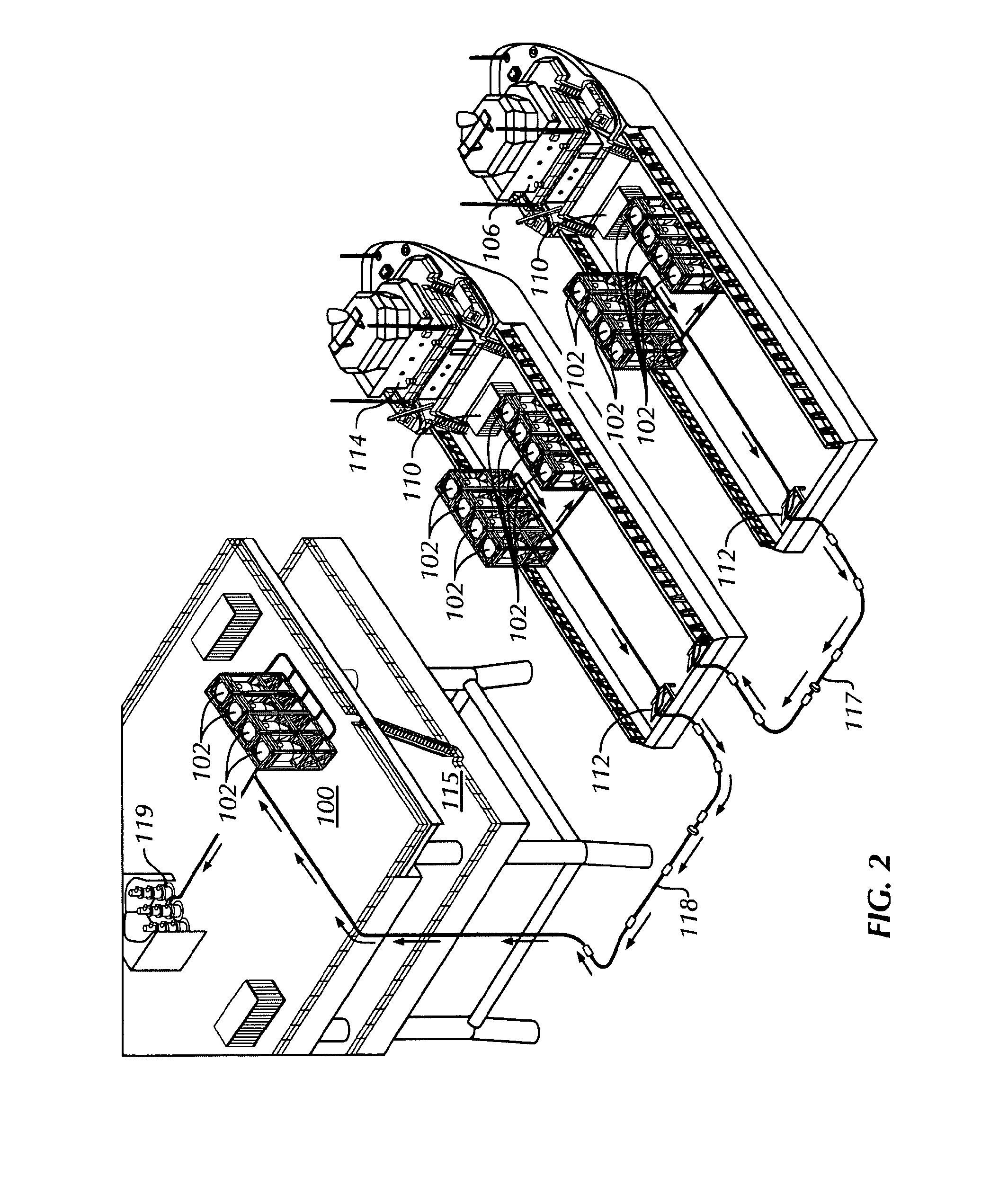

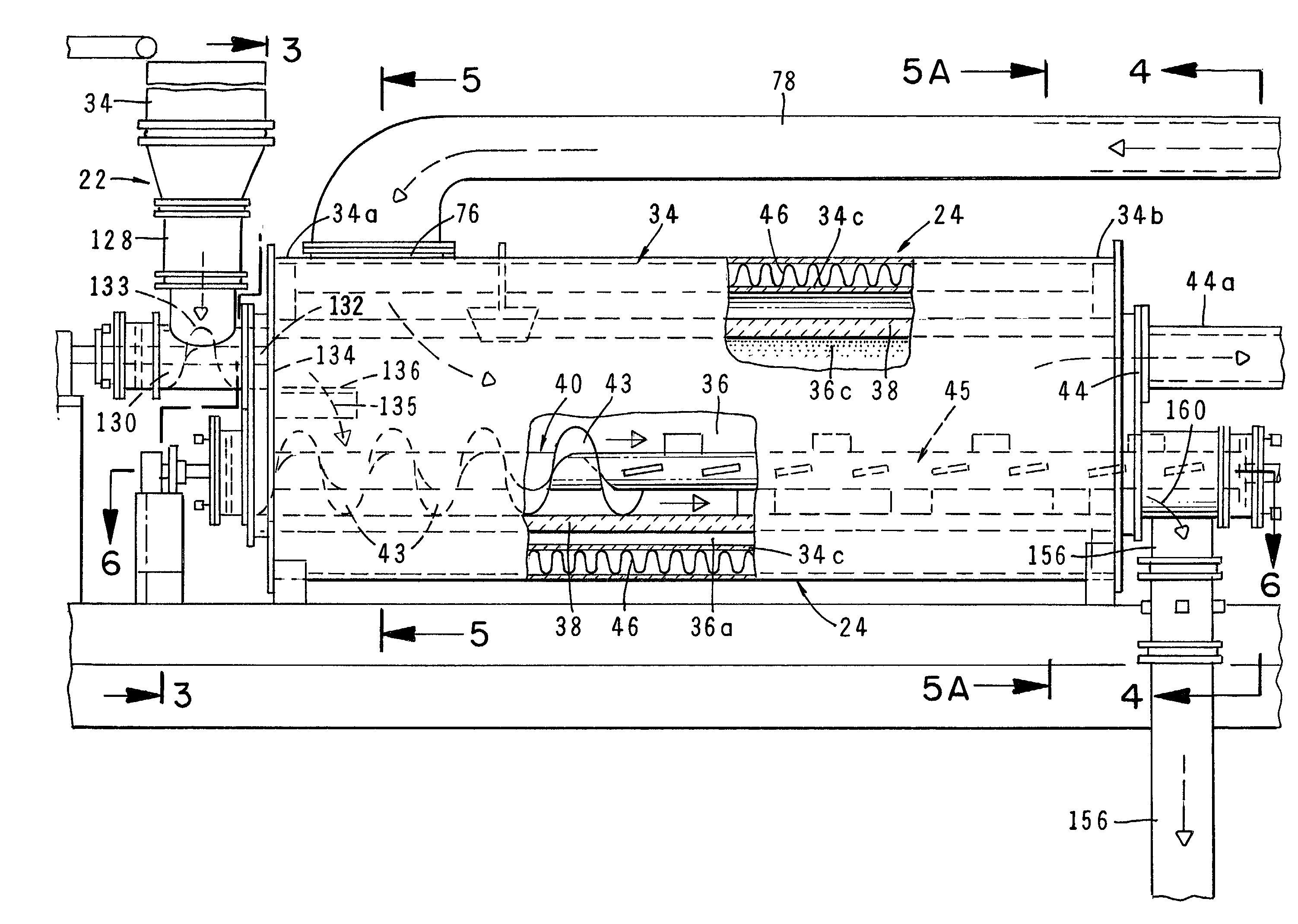

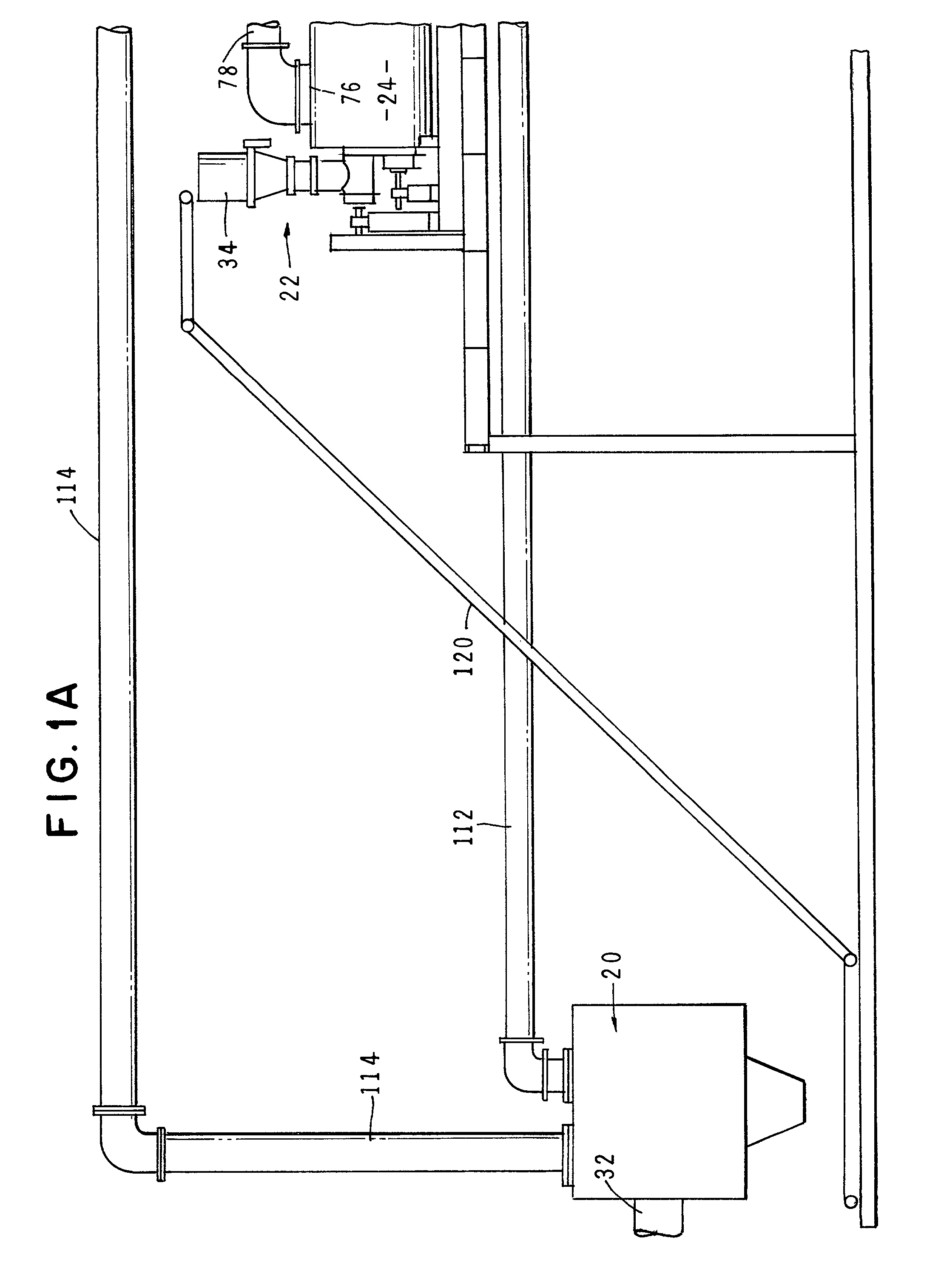

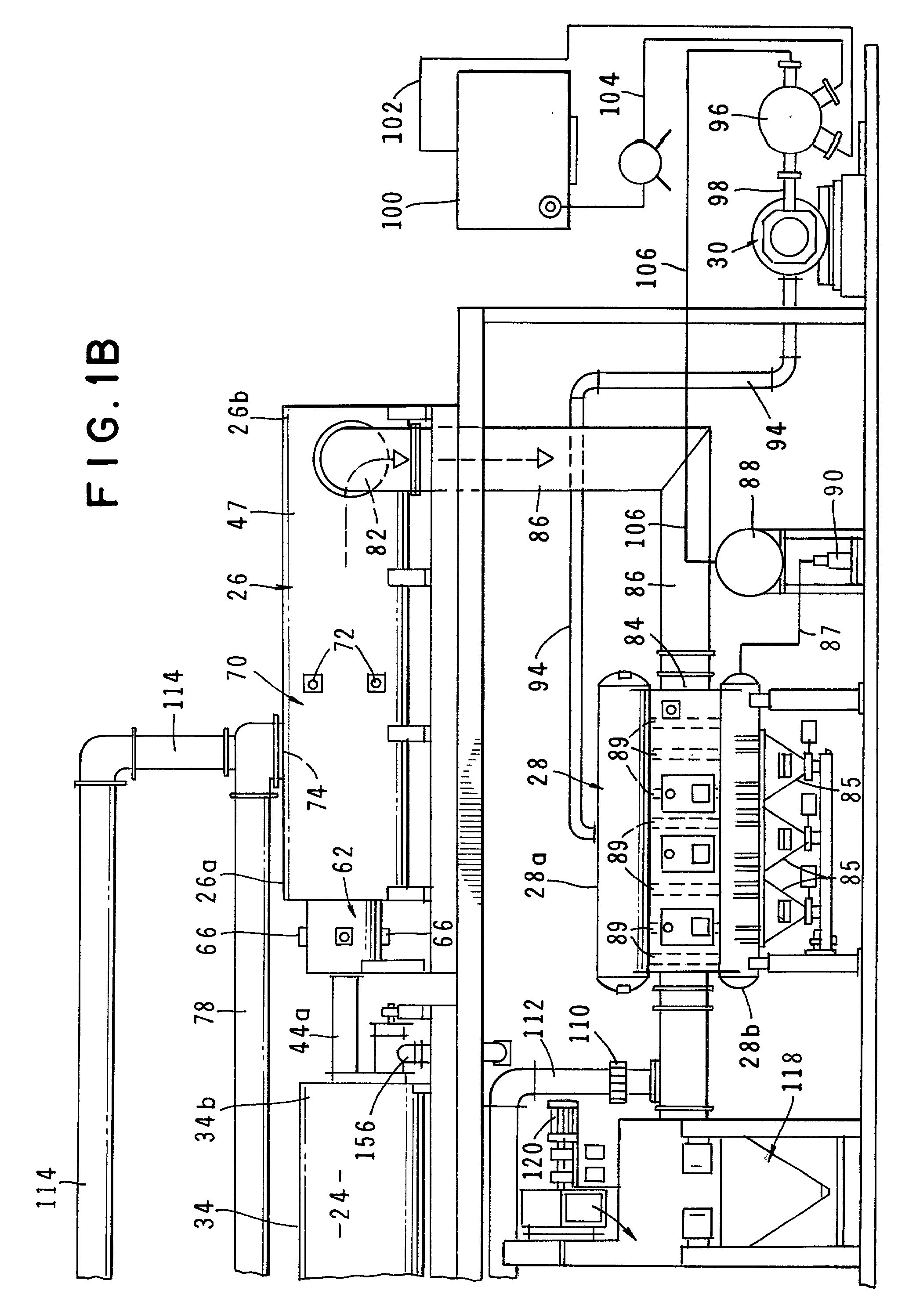

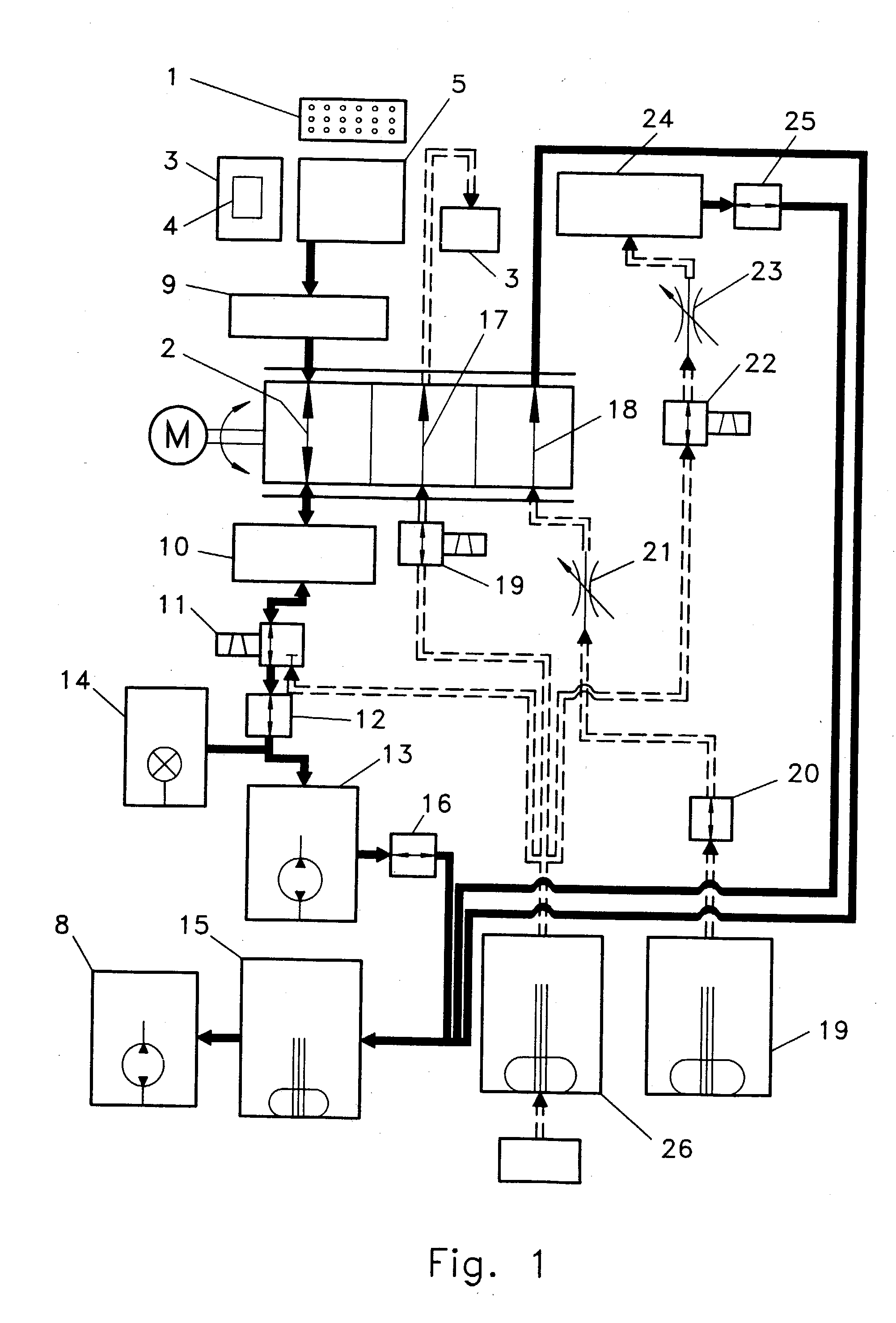

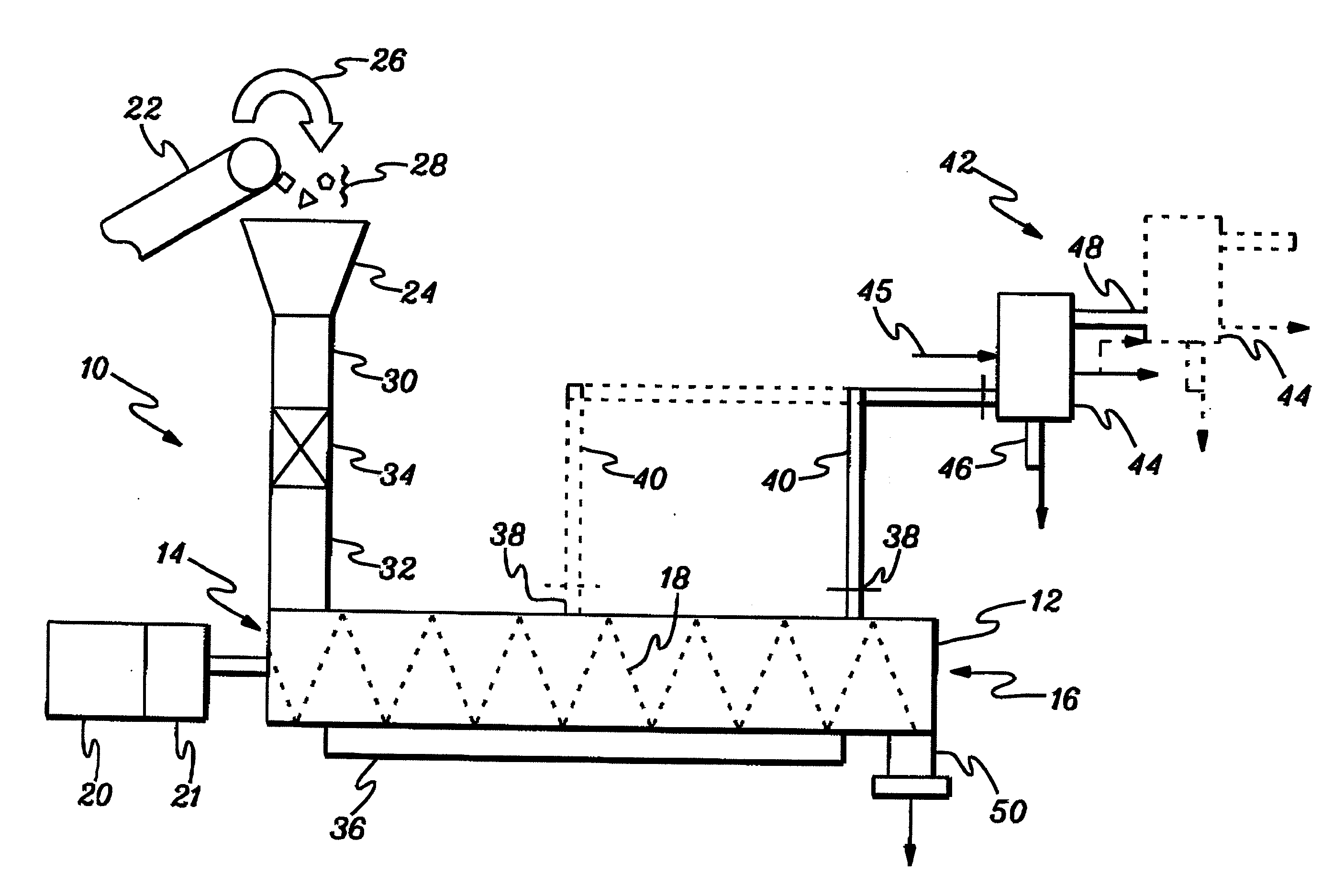

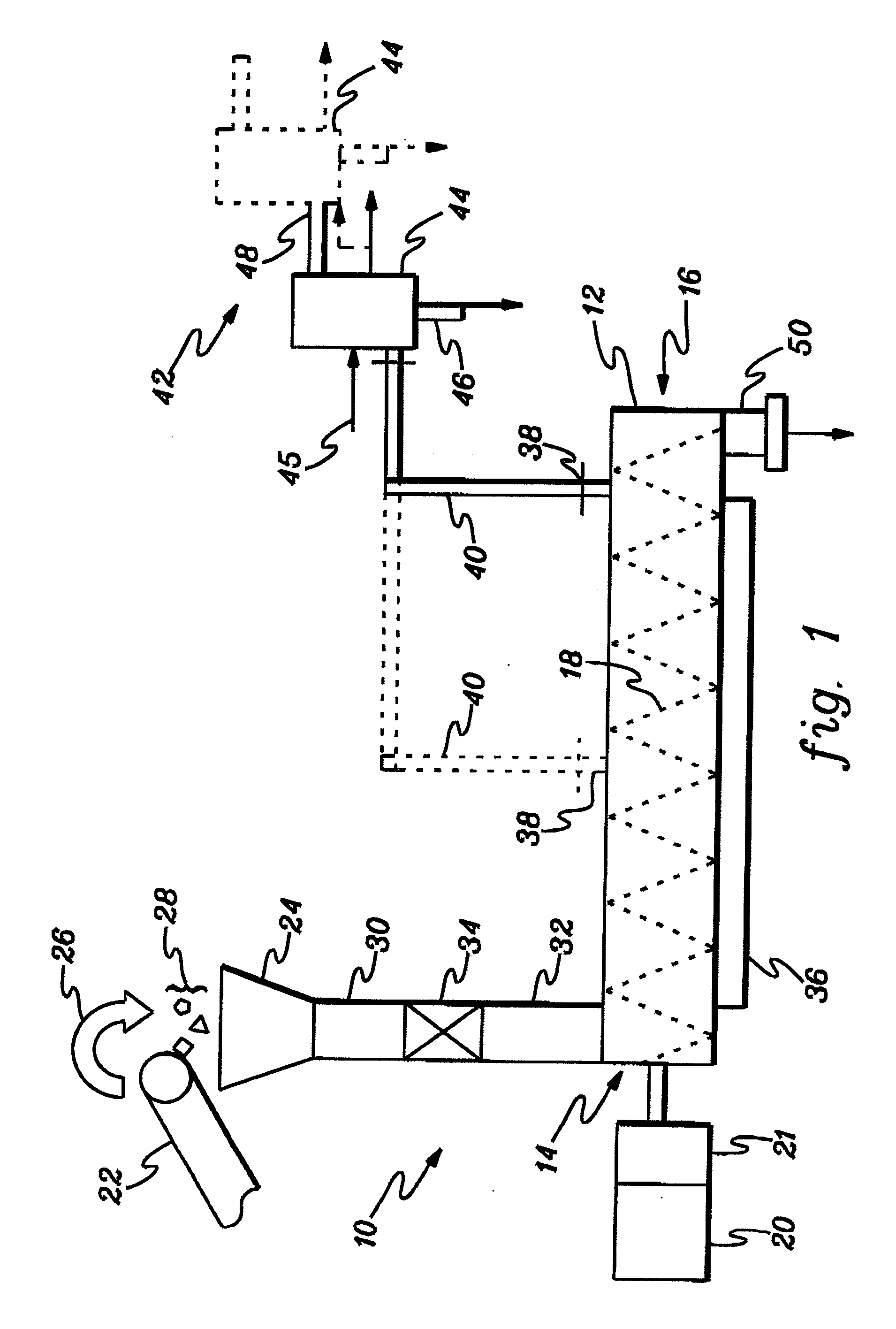

Method and apparatus for treatment of waste

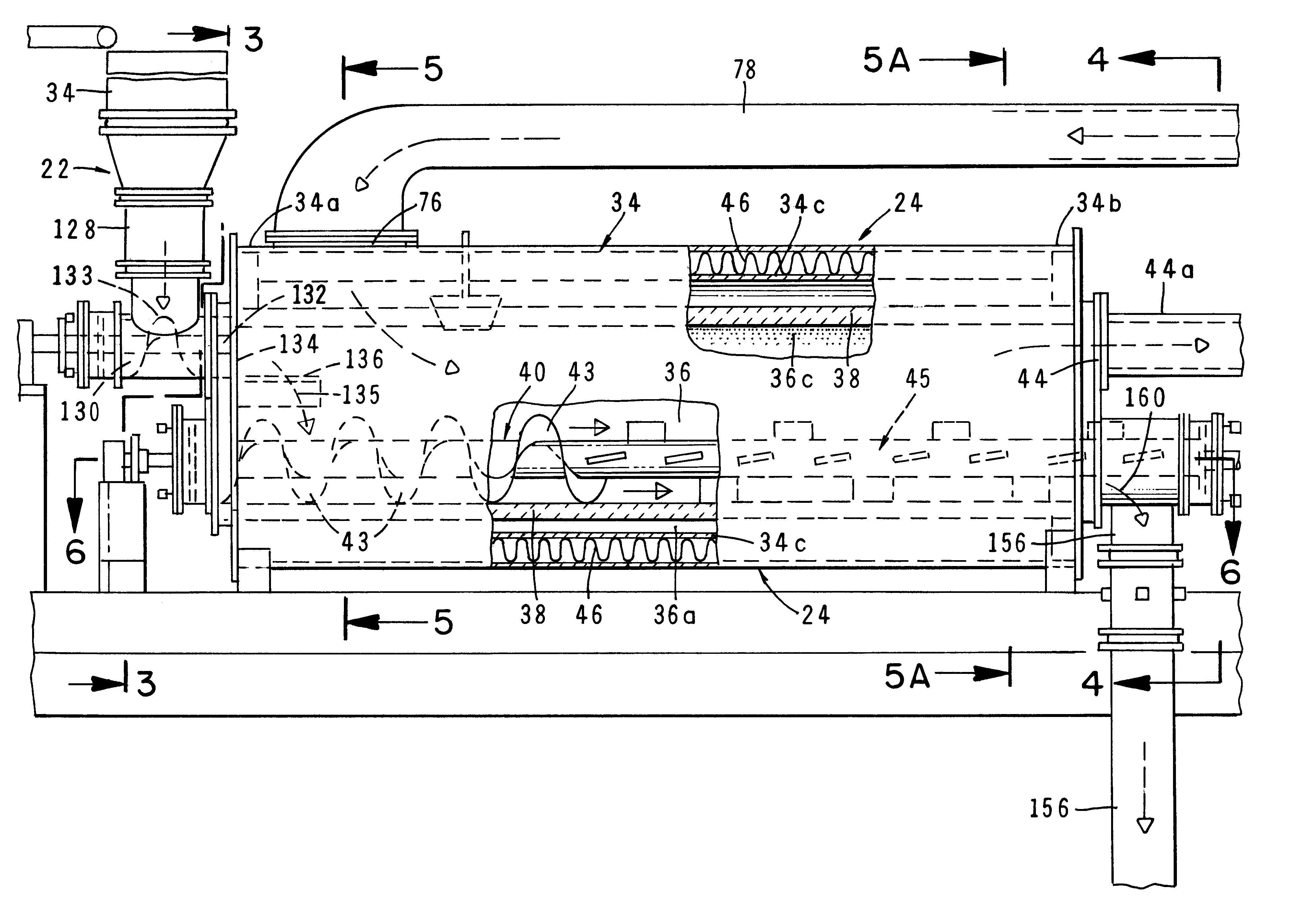

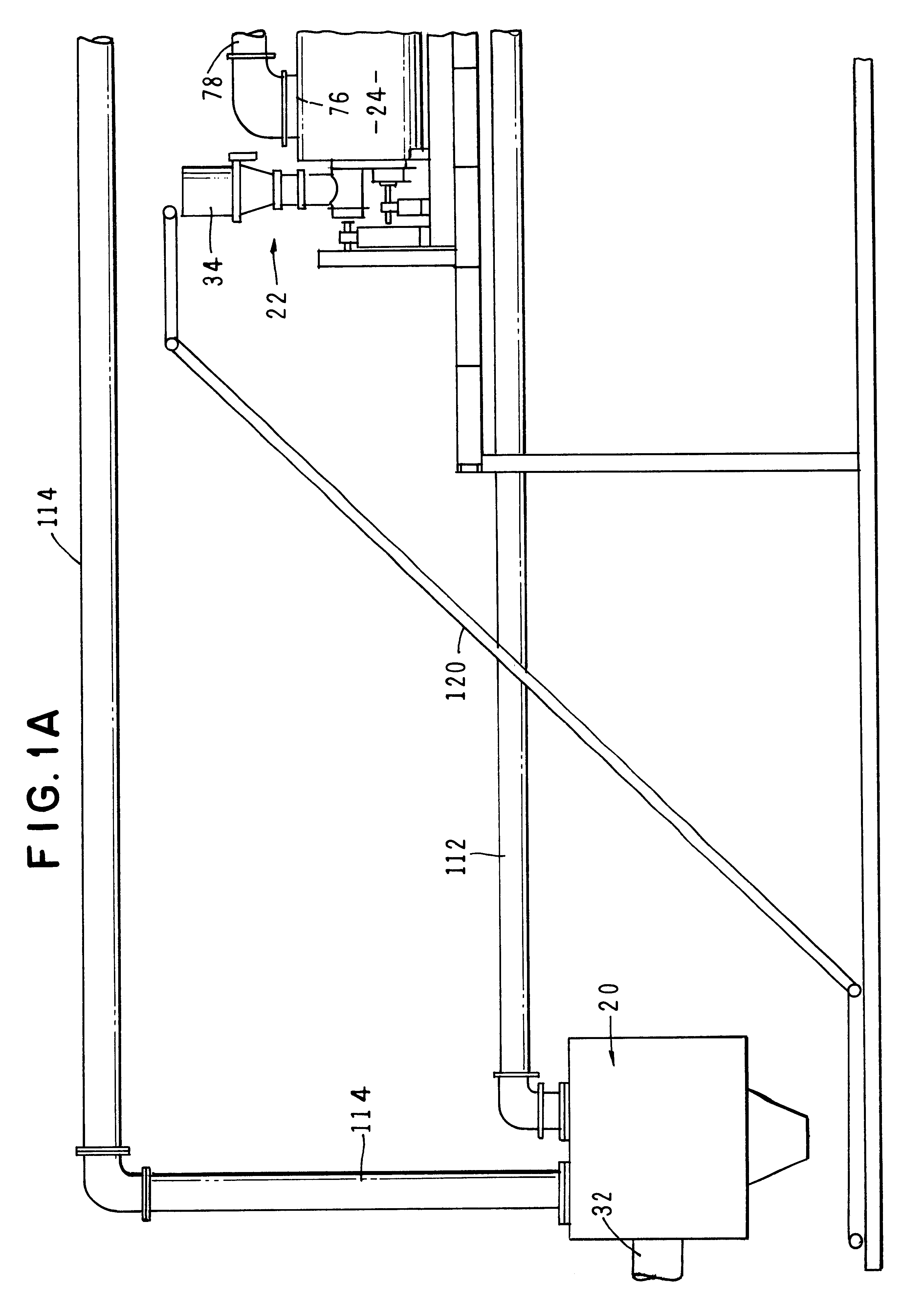

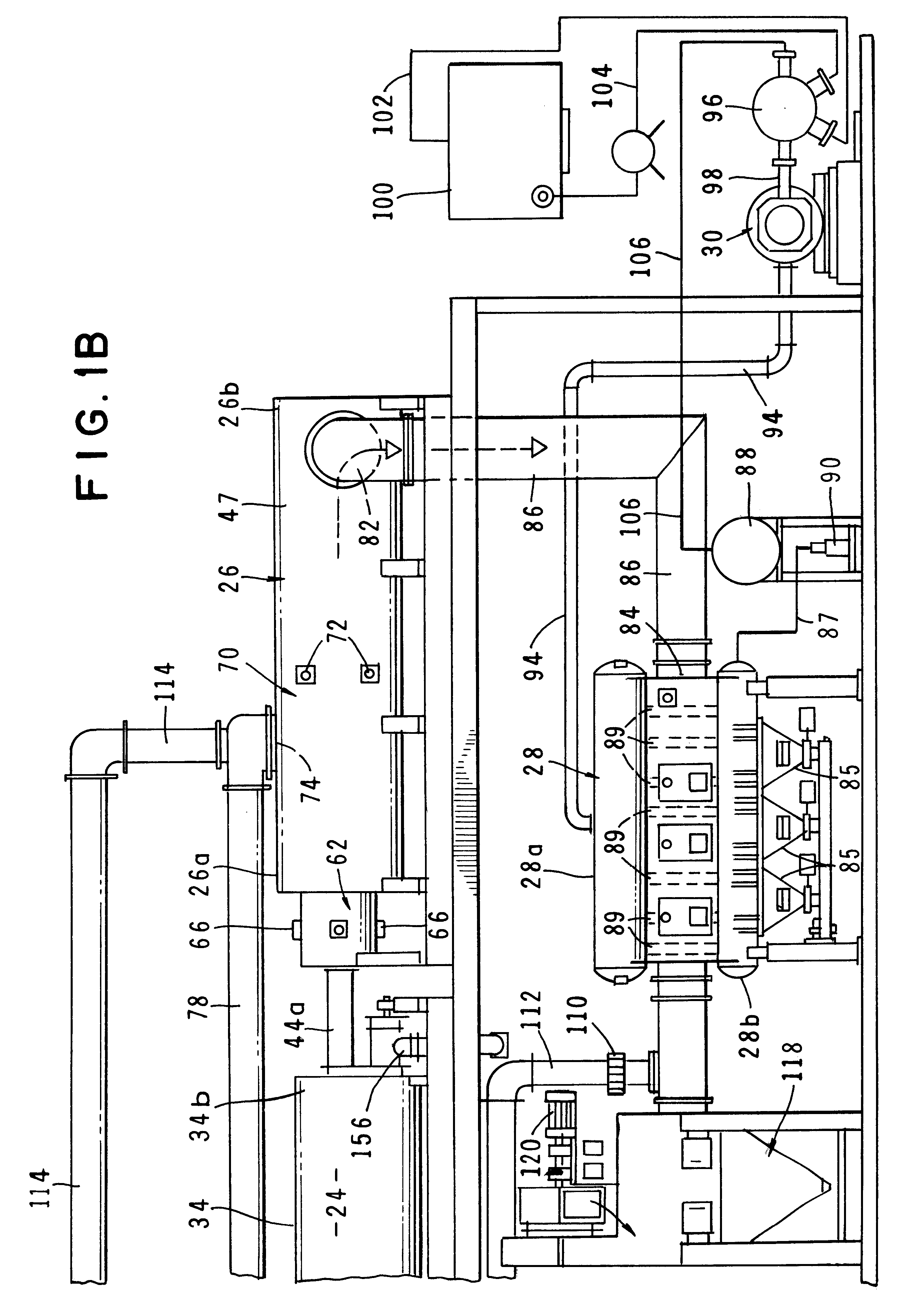

InactiveUS6619214B2Efficient and reliable in operationEasy maintenanceSolid fuel combustionIncinerator apparatusEngineeringTransfer mechanism

An apparatus for treating waste material that comprises four major cooperating subsystems, namely a pyrolytic converter, a two-stage thermal oxidizer, a steam generator and a steam turbine driven by steam generated by the steam generator. In operation, the pyrolytic converter is uniquely heated without any flame impinging on the reactor component and the waste material to be pyrolyzed is transported through the reaction chamber of the pyrolytic converter by a pair of longitudinally extending, side-by-side material transfer mechanisms. Each of the transfer mechanisms includes a first screw conveyor section made up of a plurality of helical flights for conveying the heavier waste and a second paddle conveyor section interconnected with the first section for conveying the partially pyrolyzed waste, the second section comprising a plurality of paddle flights. Once operating, the apparatus is substantially self-sustaining and requires a minimum use of outside energy sources for pyrolyzing the waste materials.

Owner:APS IP HLDG

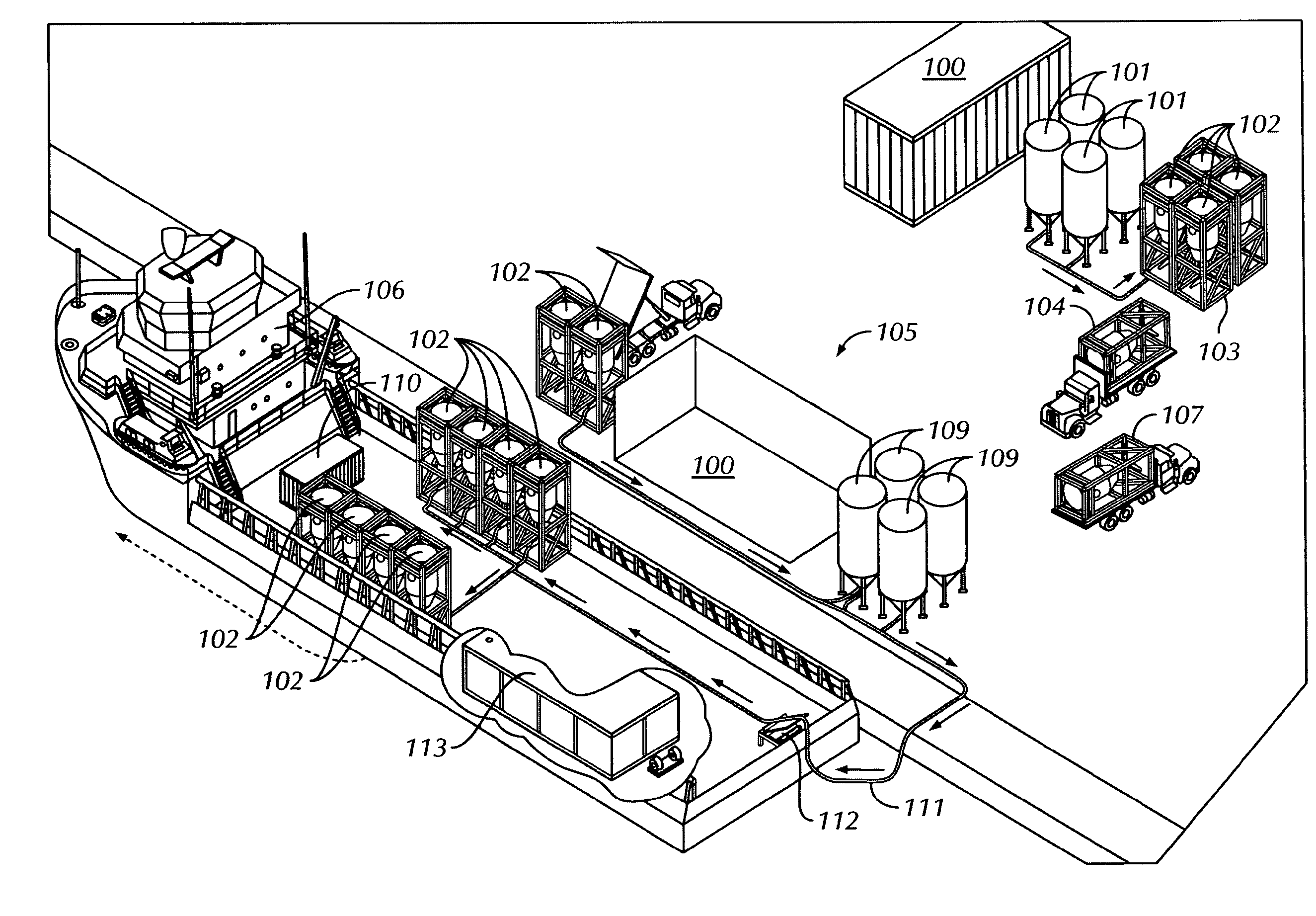

System and method for proppant transfer

A method of transferring proppant materials, wherein the method includes providing a first pressurized container (102) containing proppant materials on a first vessel (106). The method also includes connecting the first pressurized container (102) on the first vessel (106) to a second container (102) on a second vessel (114) and transferring pneumatically, proppant materials from the first pressurized container (102) on the first vessel (106) to the second container (102) on the second vessel (114). Also, a method of transferring proppant materials, the method including removing a wellbore fluid comprising excess proppant materials from a well, and screening the excess proppant materials from the wellbore fluid. The method also includes transferring the excess proppant materials to a first pressurized container (102) and transferring pneumatically, the excess proppant materials from the first pressurized container to a second pressurized container.

Owner:SHCLUMBERGER NORGE AS

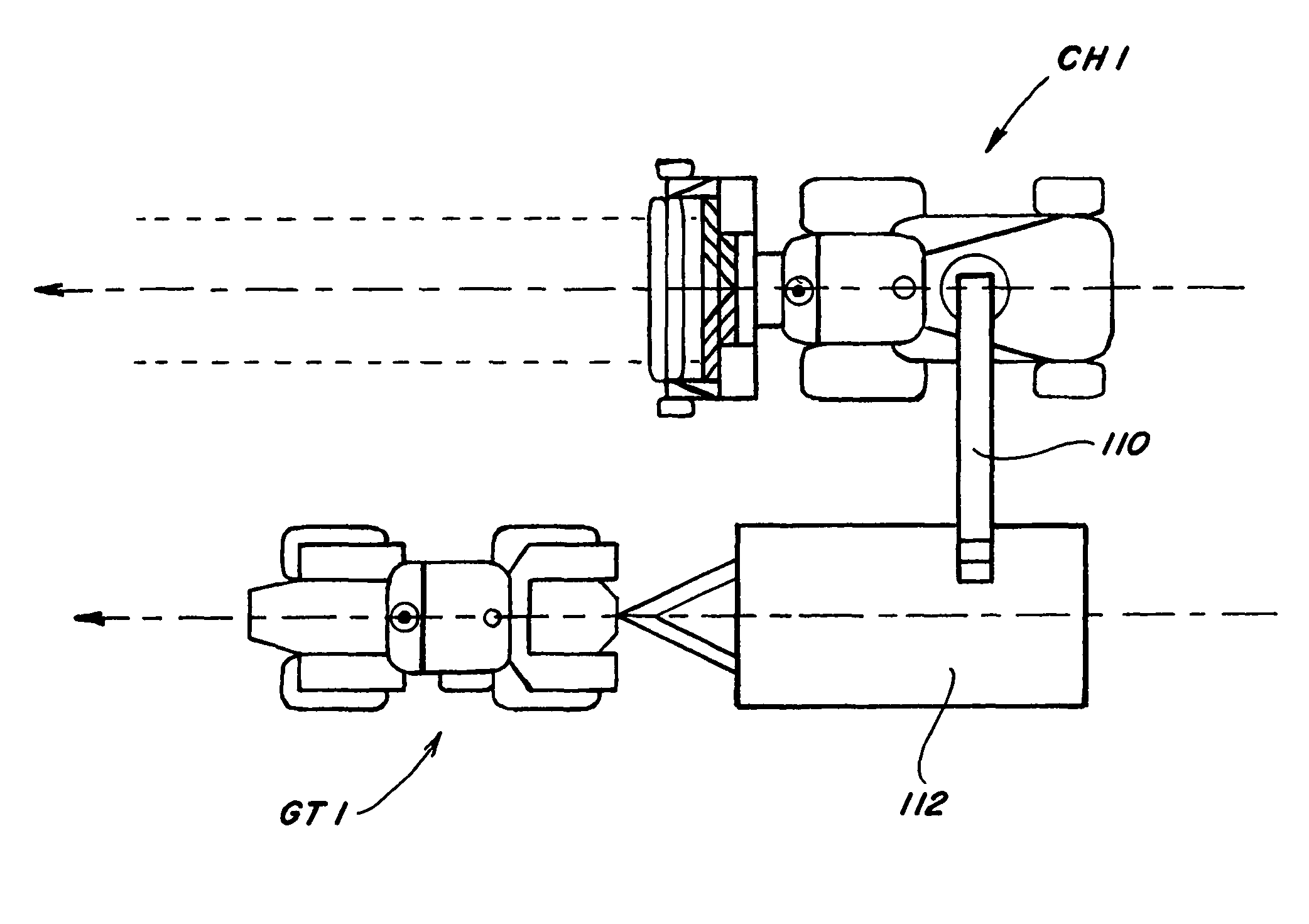

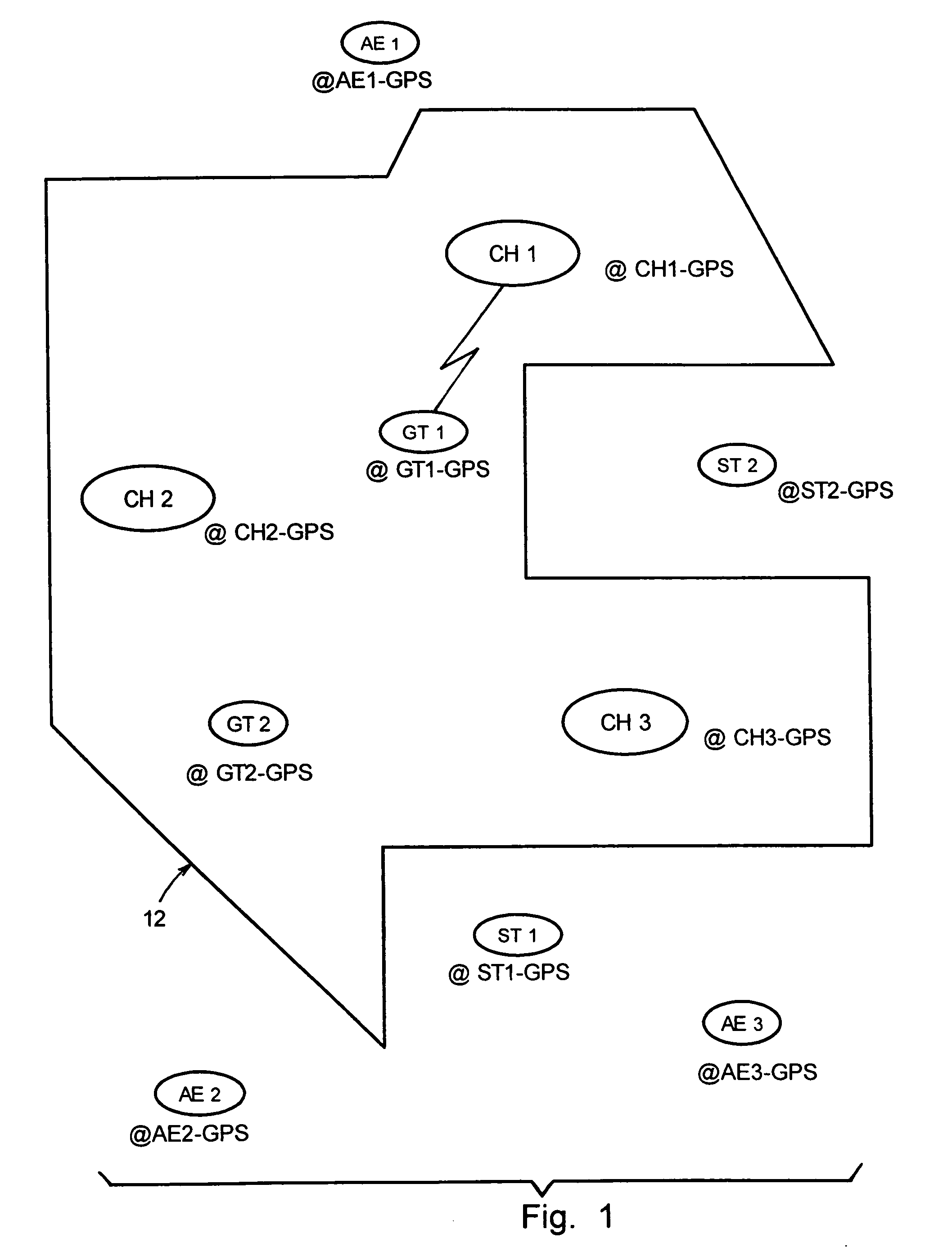

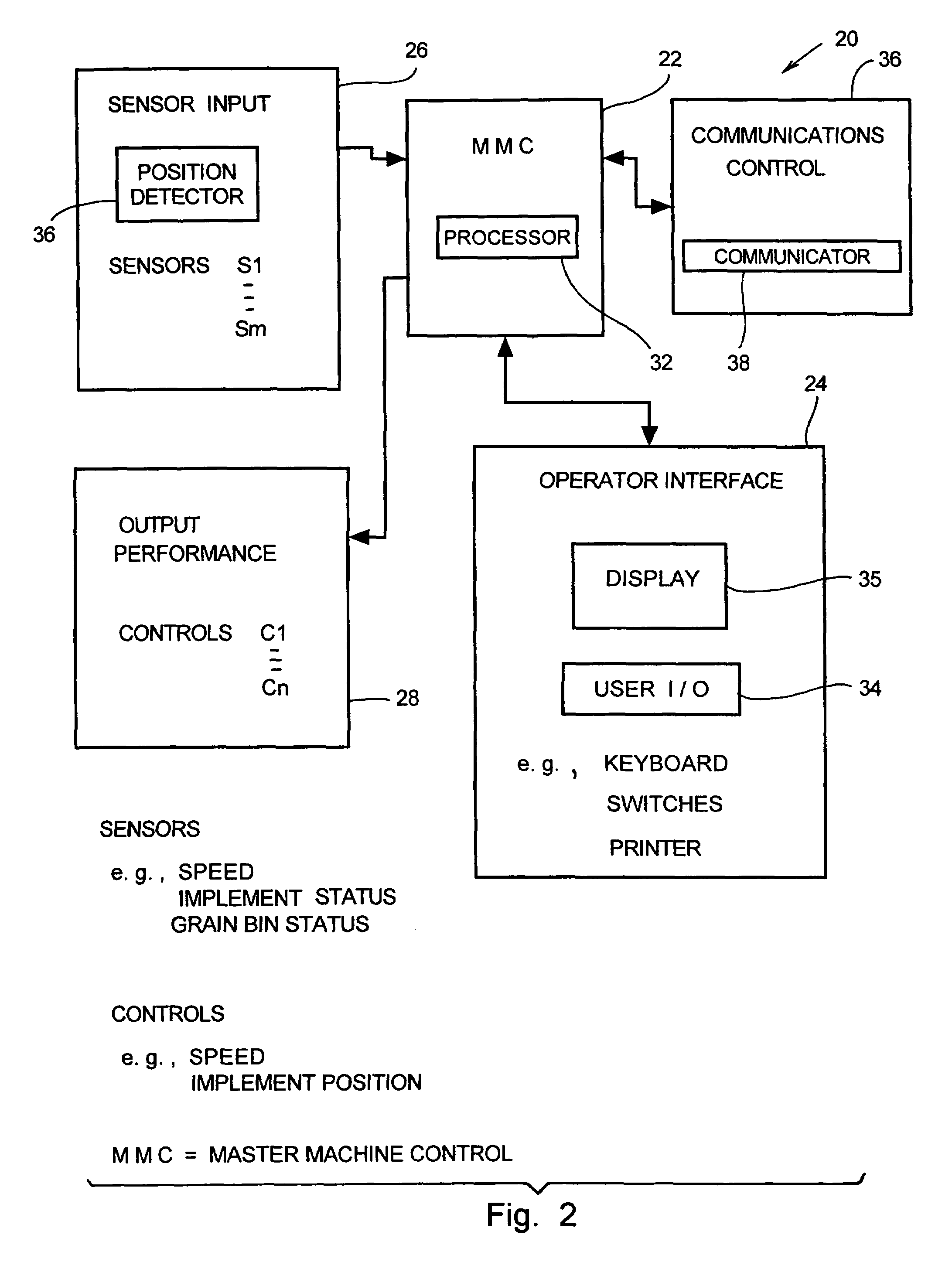

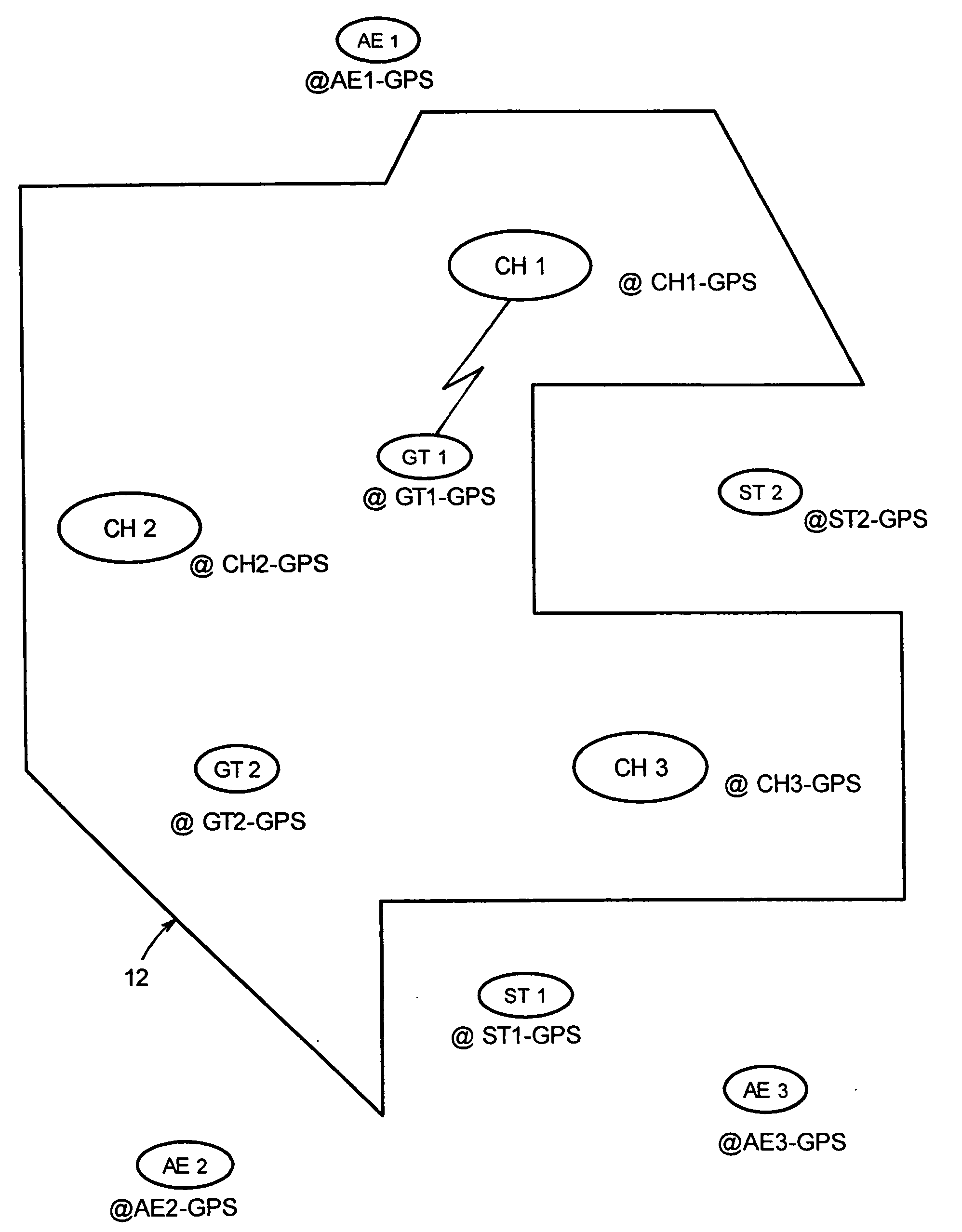

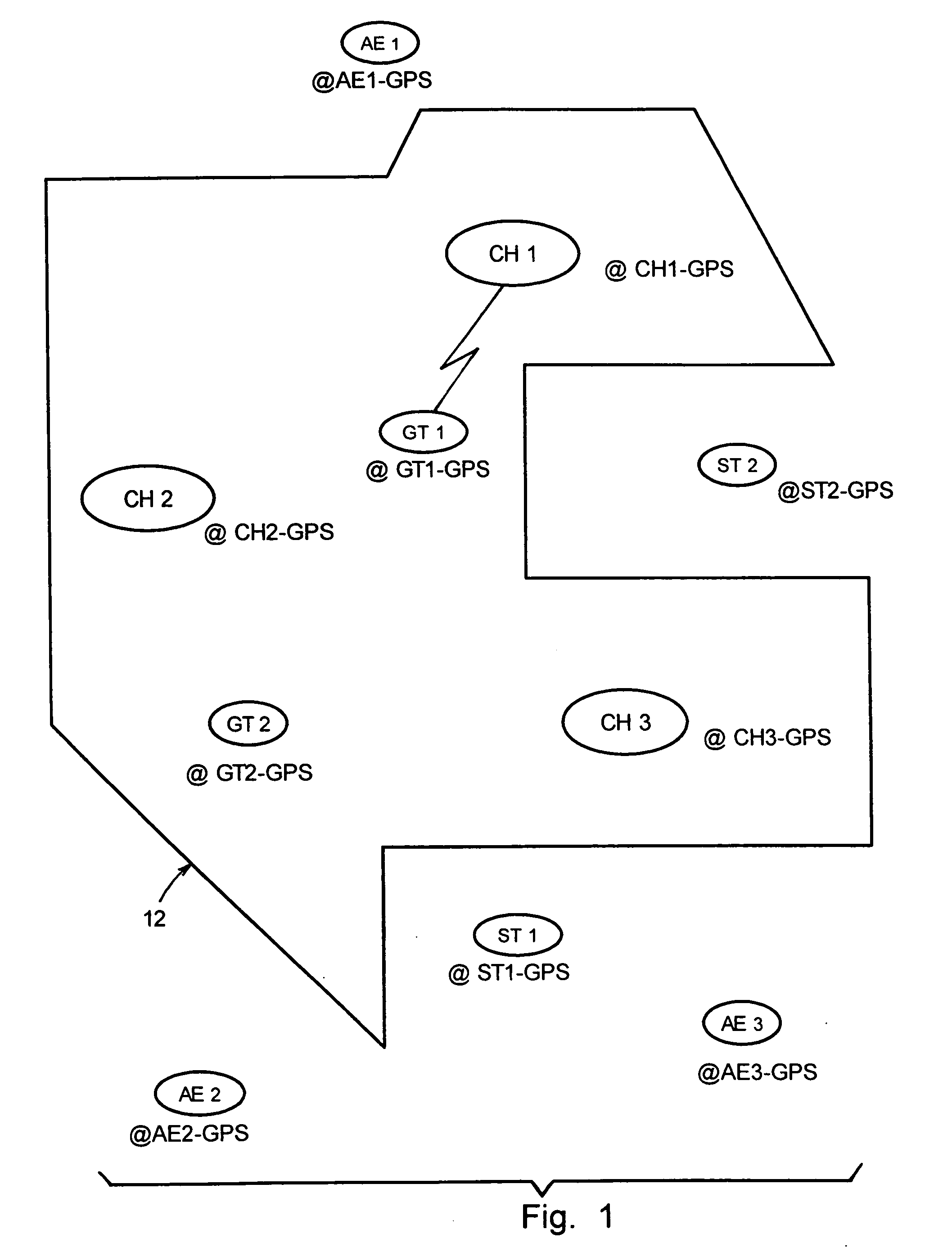

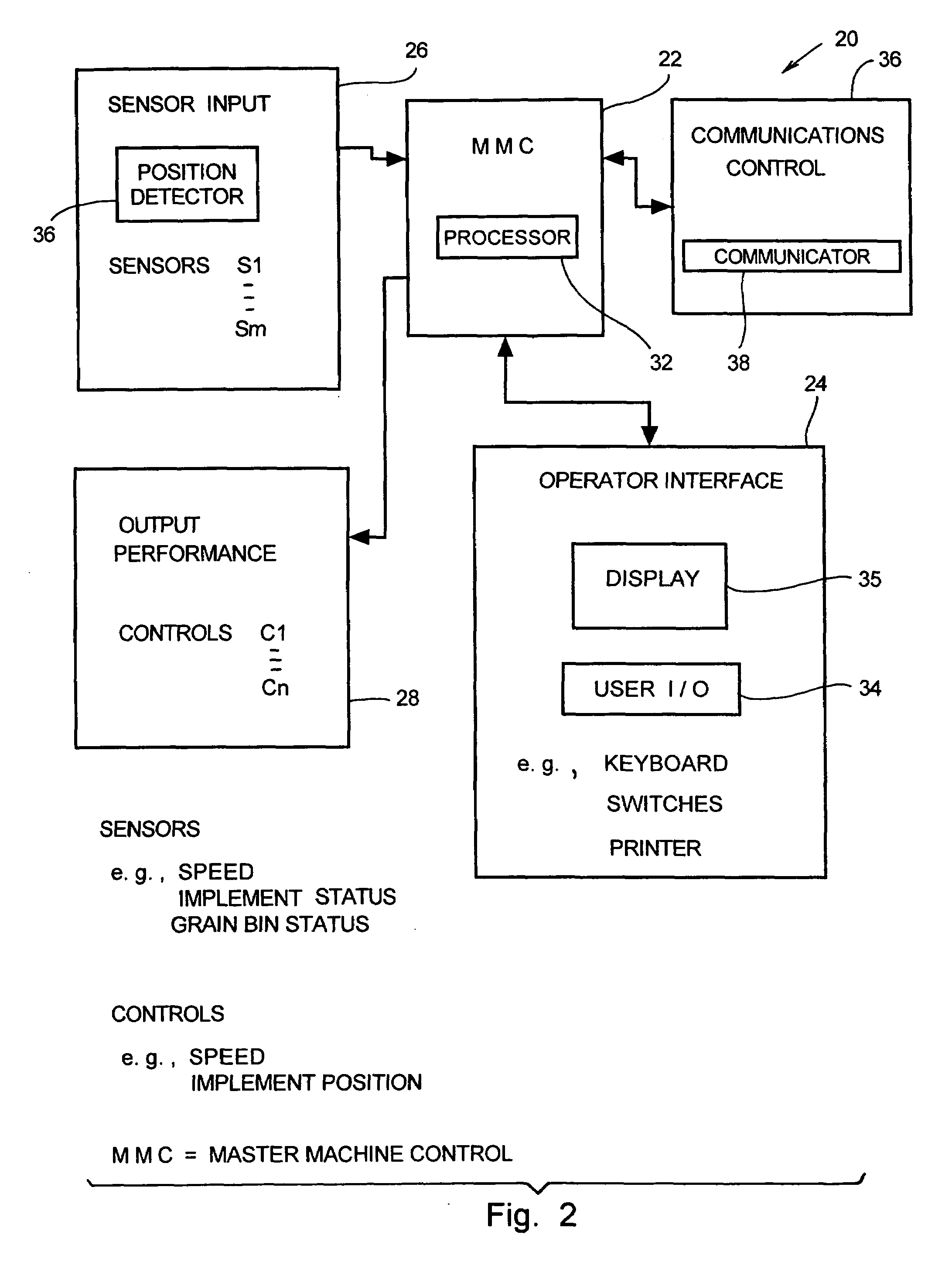

System and method employing short range communications for interactively coordinating unloading operations between a harvester and a grain transport

ActiveUS8145393B2Effectively and advantageously communicateWide of informationAnalogue computers for vehiclesGrain huskingTelecommunications linkOperational system

A system, and method of use thereof, that employs short distance communications signals, thereby limiting and localizing the dissemination area for such signals, for interactively coordinating crop material transfer operations between a harvester and a grain transport, including the automated conduct of an unloading operation, including commencement of the actual unloading of the grain through continuation of such unloading to termination of such unloading, which system and method of the present invention employs operating systems in the harvester and grain transport that so operate to become electronically linked to one another to thereafter operate in unison with one another to effect and control the conduct of the crop material transfer operation between the harvester and grain transport, with each of such operating systems having associated therewith a short range communications system for the transmission and receipt at close range of electronic data signals, such operating systems, when appropriately electronically linked to one another, being operable in conjunction with one another to exchange information, to maintain a communications link therebetween, and to automatedly coordinate and effect various activities of the harvester and grain transport as a crop material transfer operation is effected and proceeds.

Owner:BLUE LEAF I P INC

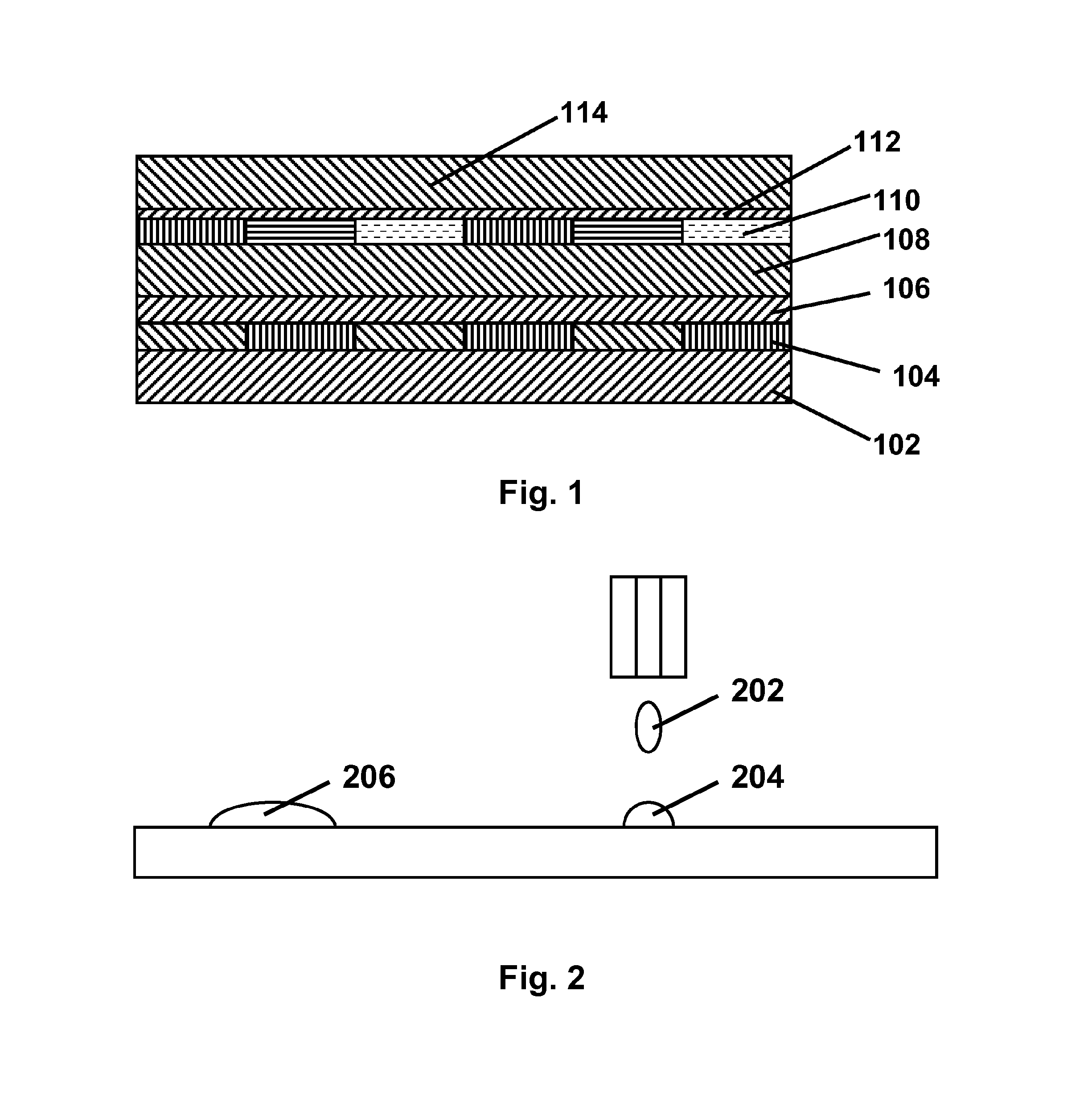

Method for transferring thin film layer material to a flexible substrate using a hydrogen ion splitting technique

InactiveUS20040224482A1Semiconductor/solid-state device manufacturingPiezoelectric/electrostrictive/magnetostrictive devicesSemiconductor materialsDevice material

A method for making thin film functional material and thin film single crystal semiconductor devices having a flexible substrate is provided. In one alternative, a film layer of thin film functional material is grown on a large diameter growth substrate. One or more protective layer may be deposited on the surface of the growth substrate before the thin film functional material is deposited. Hydrogen is implanted to a selected depth within the growth substrate [or within a protective layer] to form a hydrogen ion layer. The growth substrate and associated layers are bonded to a second substrate. The layers are split along the hydrogen ion implant and the portion of the growth substrate and associated layers, which is on the side of the ion layer away from the second substrate, is removed. In another alternative, an implanted single crystal semiconductor substrate material is bonded to a flexible substrate. The substrate is split and a thin film of the single crystal semiconductor material remains bonded to the flexible substrate.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

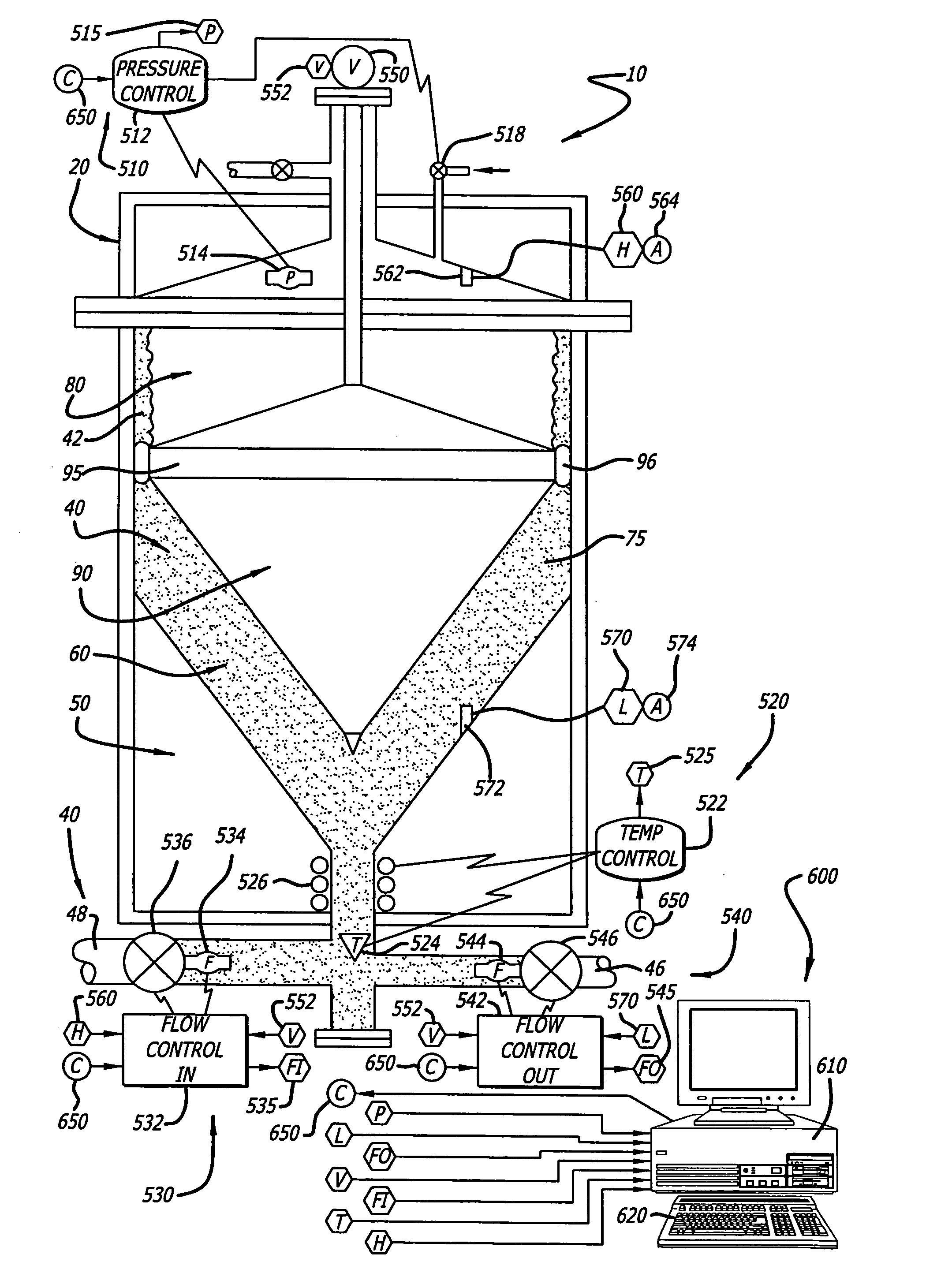

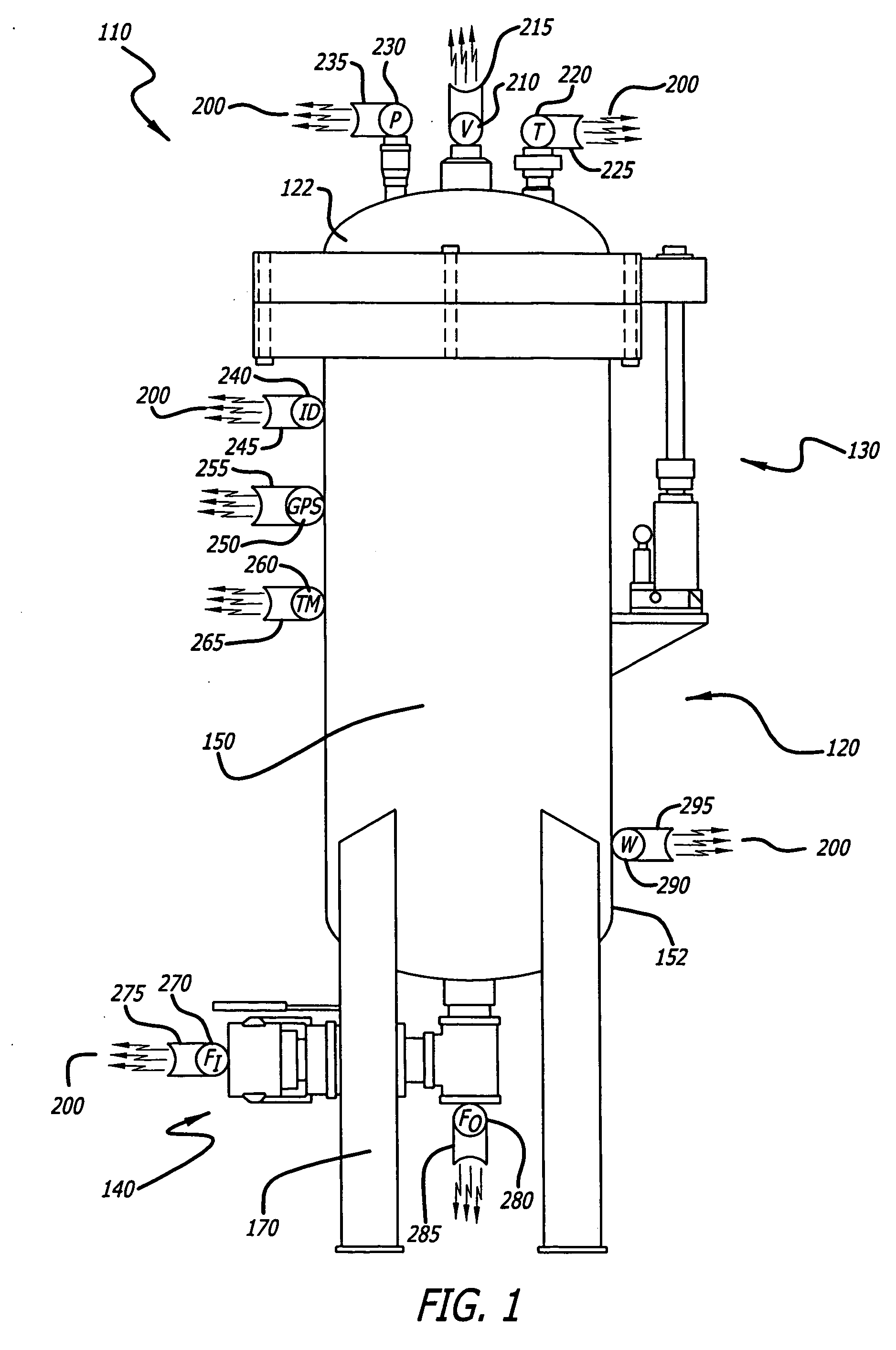

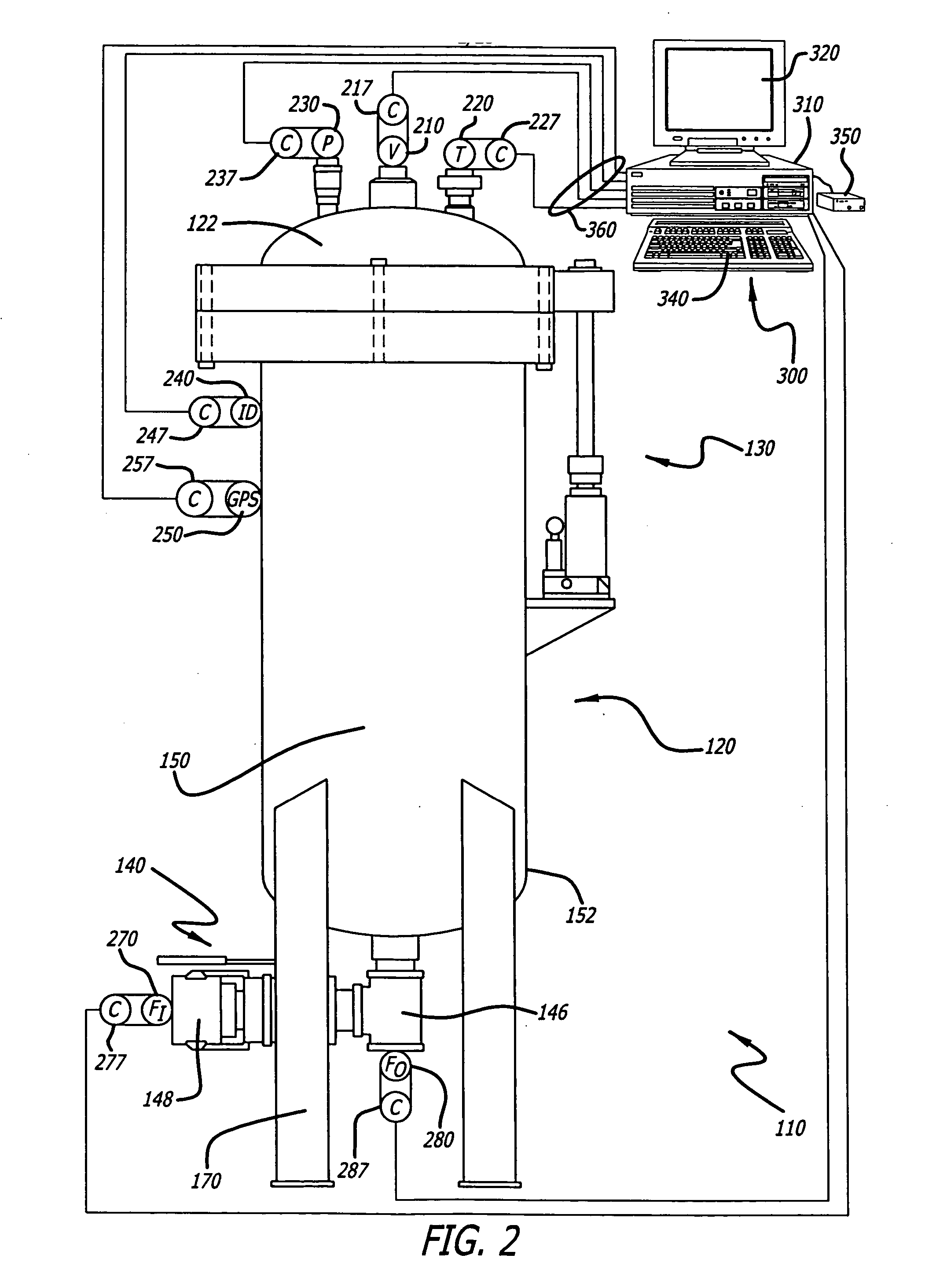

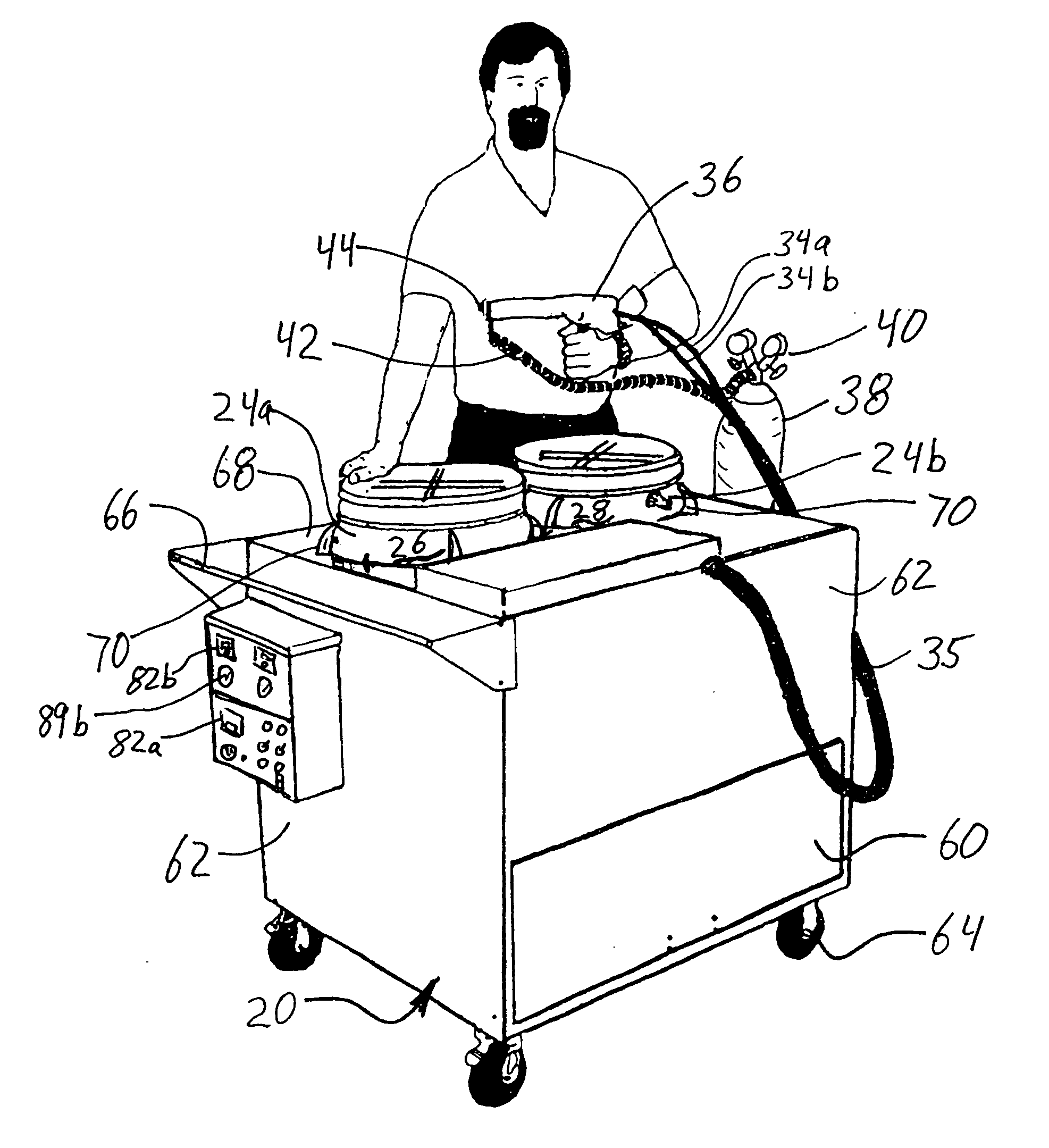

Integrated material transfer and dispensing system

ActiveUS20070090132A1Increase fluid velocityWide operating temperature rangeLiquid flow controllersLiquid transferring devicesStream flowMaterial transfer

An integrated material transfer and dispensing system for storing, transferring and dispensing materials, such as fluids, and liquids, for example, liquid applied sound deadener (LASD). The system includes at least one vessel having a force transfer device. Each vessel may be removably enclosed in cabinet to form an automated station. Each vessel may be configured with a data logger, cleanout port, a sample valve at least one sight window and an access port for introducing a compound such as a biocide. Each vessel may be configured with instruments including sensors for measuring process variables, such as material volume, level, temperature, pressure and flow. The system may further include a metering device system and a robotic material dispenser system without a pump interface. The robotic system may further include a computer control system connected to flow and pressure sensors. The system may directly feed an applicator without an intervening pump.

Owner:CH & I TECH INC

System and method employing short range communications for interactively coordinating unloading operations between a harvester and a grain transport

ActiveUS20100070145A1Effectively and advantageously communicateSpread widelyAnalogue computers for trafficMowersOperational systemTelecommunications link

A system, and method of use thereof, that employs short distance communications signals, thereby limiting and localizing the dissemination area for such signals, for interactively coordinating crop material transfer operations between a harvester and a grain transport, including the automated conduct of an unloading operation, including commencement of the actual unloading of the grain through continuation of such unloading to termination of such unloading, which system and method of the present invention employs operating systems in the harvester and grain transport that so operate to become electronically linked to one another to thereafter operate in unison with one another to effect and control the conduct of the crop material transfer operation between the harvester and grain transport, with each of such operating systems having associated therewith a short range communications system for the transmission and receipt at close range of electronic data signals, such operating systems, when appropriately electronically linked to one another, being operable in conjunction with one another to exchange information, to maintain a communications link therebetween, and to automatedly coordinate and effect various activities of the harvester and grain transport as a crop material transfer operation is effected and proceeds.

Owner:BLUE LEAF I P INC

Method and apparatus for treatment of waste

InactiveUS20020195031A1Efficient and reliable in operationEasy maintenanceSolid fuel combustionIncinerator apparatusEngineeringTransfer mechanism

An apparatus for treating waste material that comprises four major cooperating subsystems, namely a pyrolytic converter, a two-stage thermal oxidizer, a steam generator and a steam turbine driven by steam generated by the steam generator. In operation, the pyrolytic converter is uniquely heated without any flame impinging on the reactor component and the waste material to be pyrolyzed is transported through the reaction chamber of the pyrolytic converter by a pair of longitudinally extending, side-by-side material transfer mechanisms. Each of the transfer mechanisms includes a first screw conveyor section made up of a plurality of helical flights for conveying the heavier waste and a second paddle conveyor section interconnected with the first section for conveying the partially pyrolyzed waste, the second section comprising a plurality of paddle flights. Once operating, the apparatus is substantially self-sustaining and requires a minimum use of outside energy sources for pyrolyzing the waste materials.

Owner:APS IP HLDG

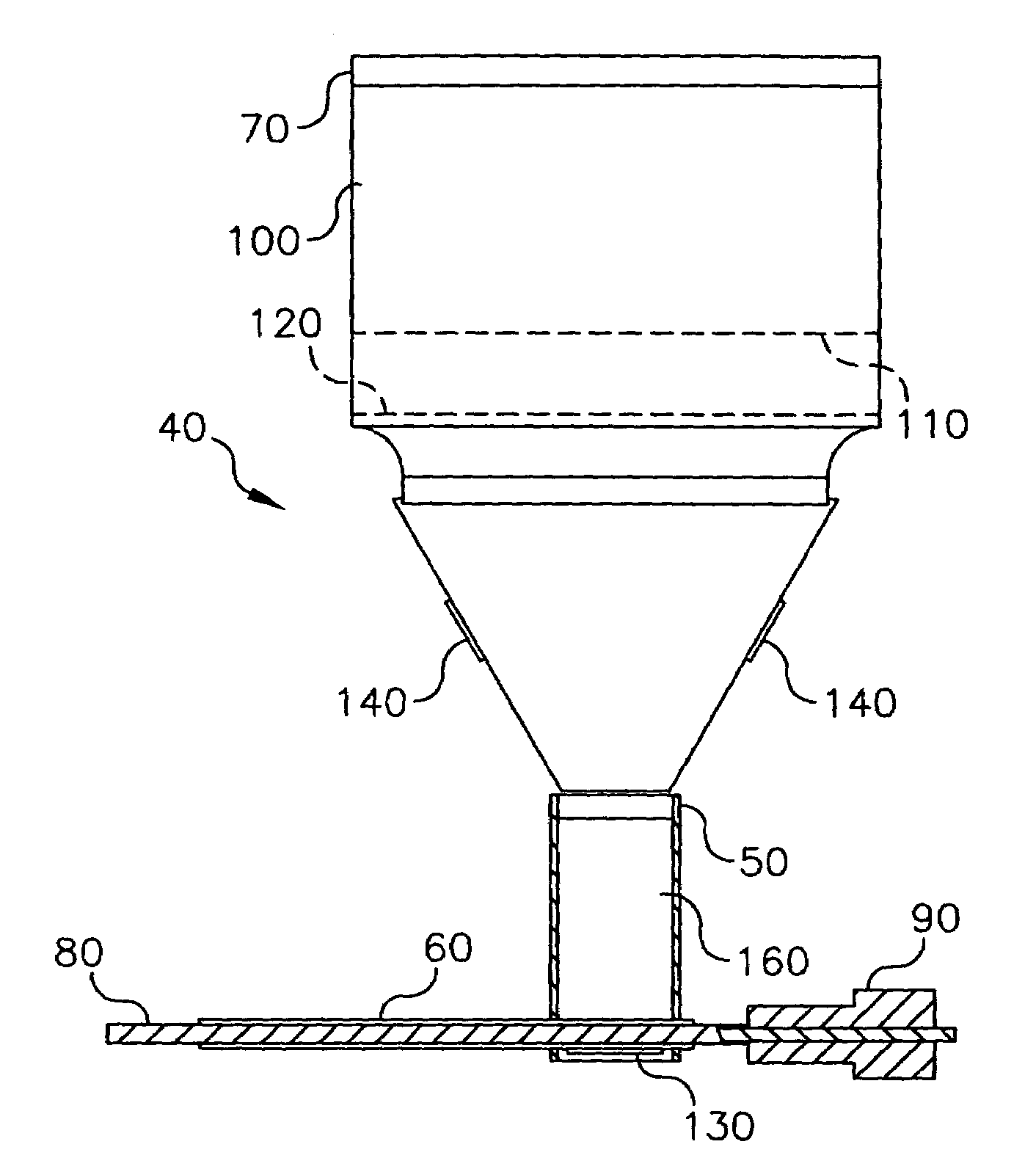

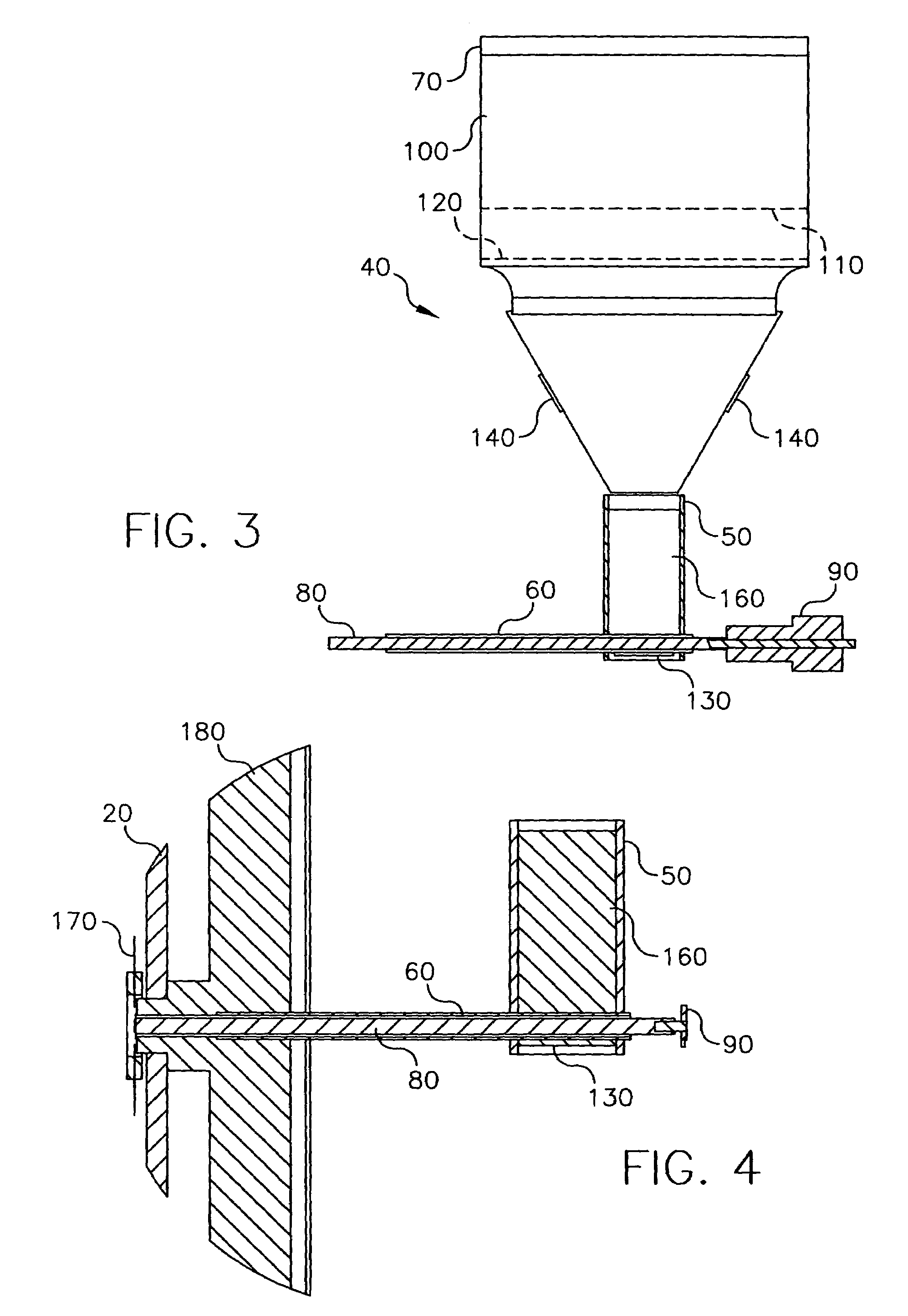

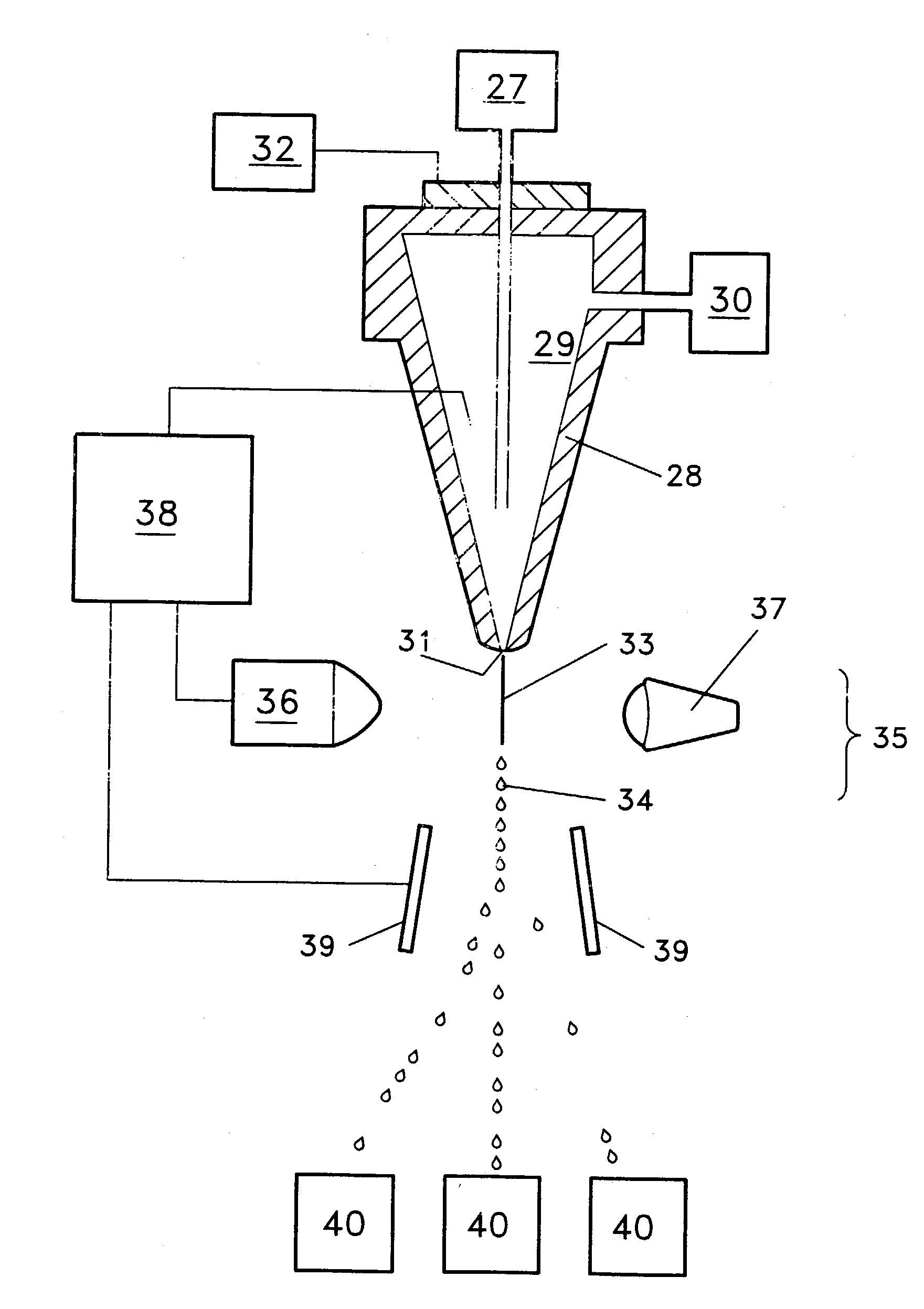

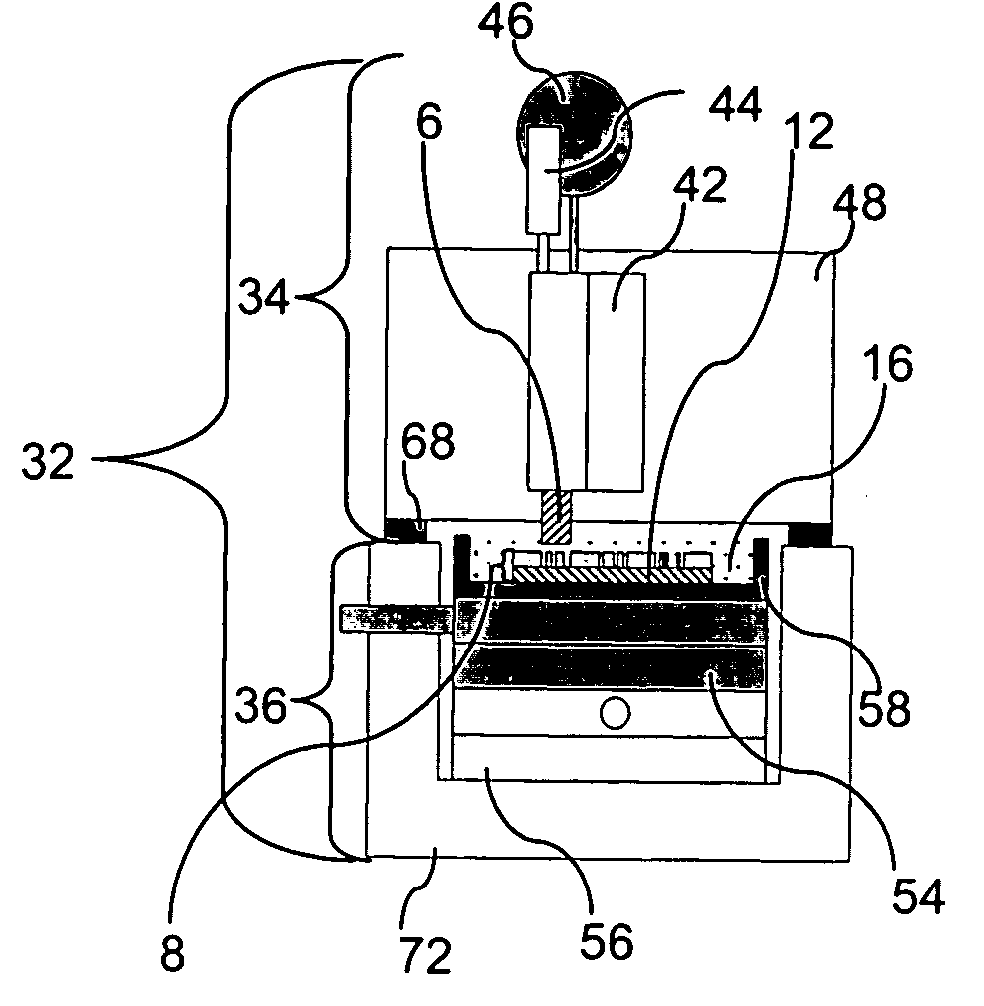

Delivering organic powder to a vaporization zone

ActiveUS7288285B2Reduce riskStable rateVacuum evaporation coatingSputtering coatingVaporizationMaterial transfer

A method for vaporizing organic materials and condensing them onto a surface to form a layer, comprising: providing a quantity of organic material in a powdered form in a first container; fluidizing the organic material in the first container and transferring such fluidized material to an auger structure; and rotating at least a portion of the auger structure to transfer fluidized powder from the first container along a feeding path to a vaporization zone where such powder is vaporized and delivered to the substrate to form the layer.

Owner:GLOBAL OLED TECH

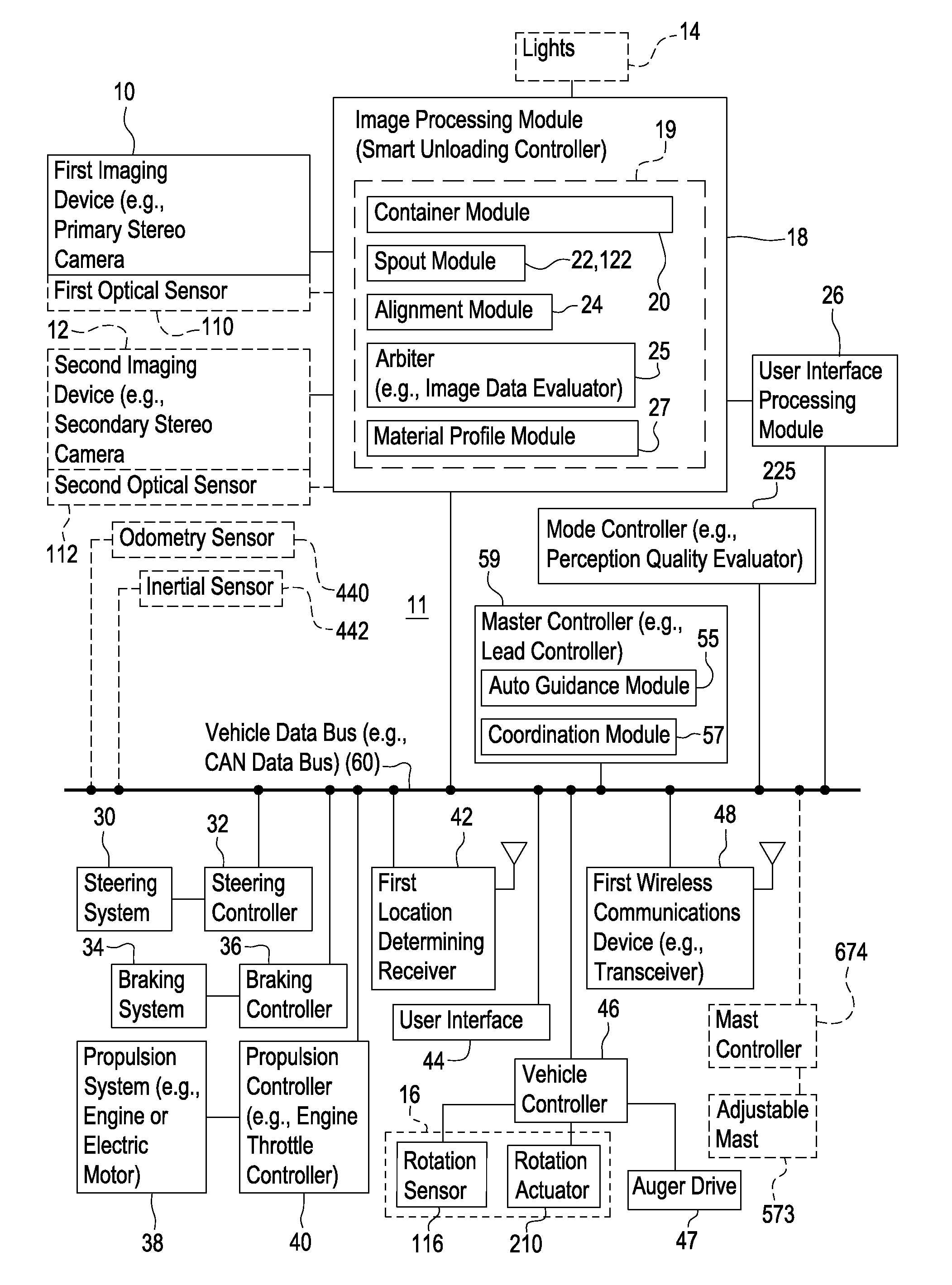

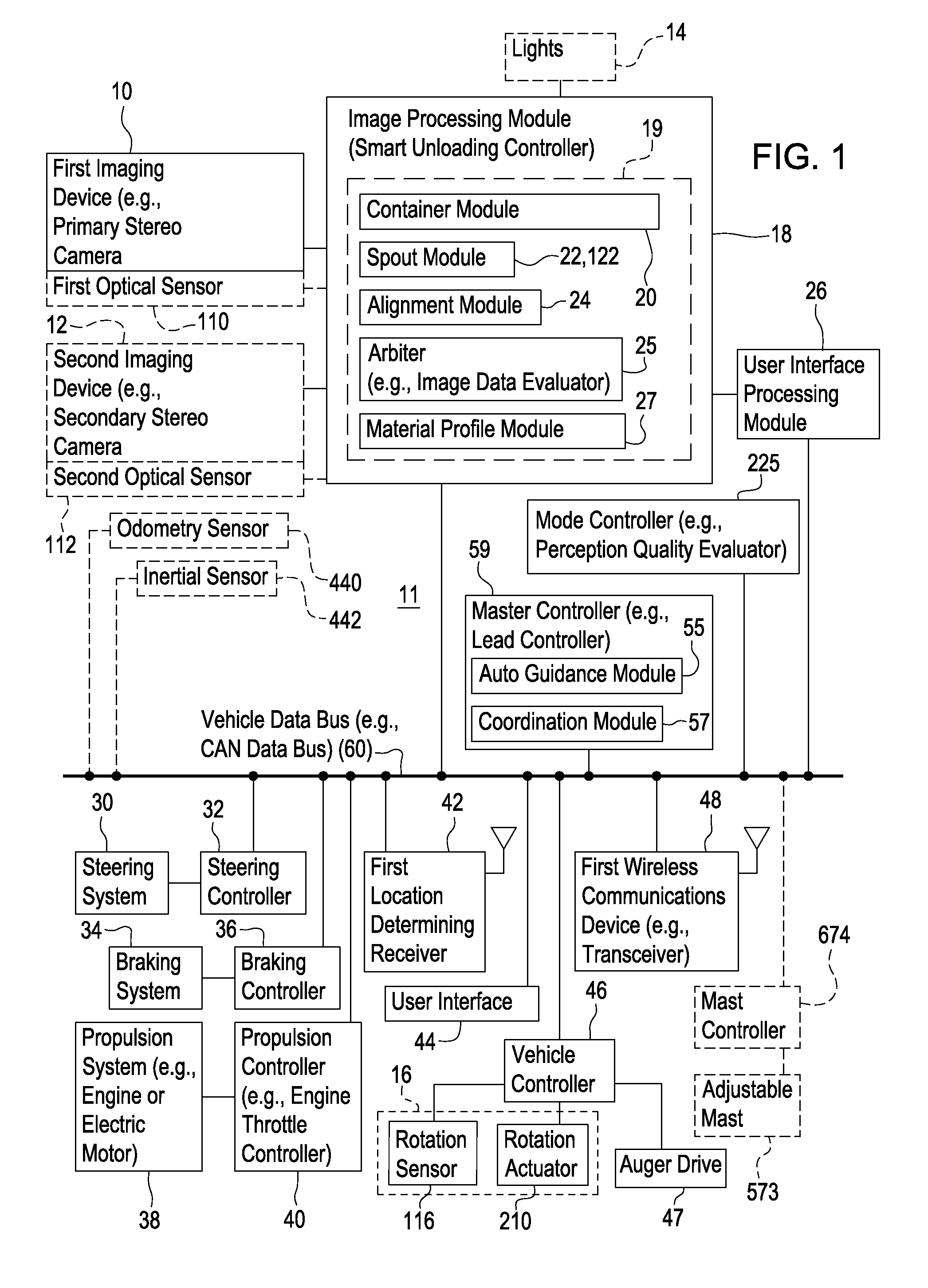

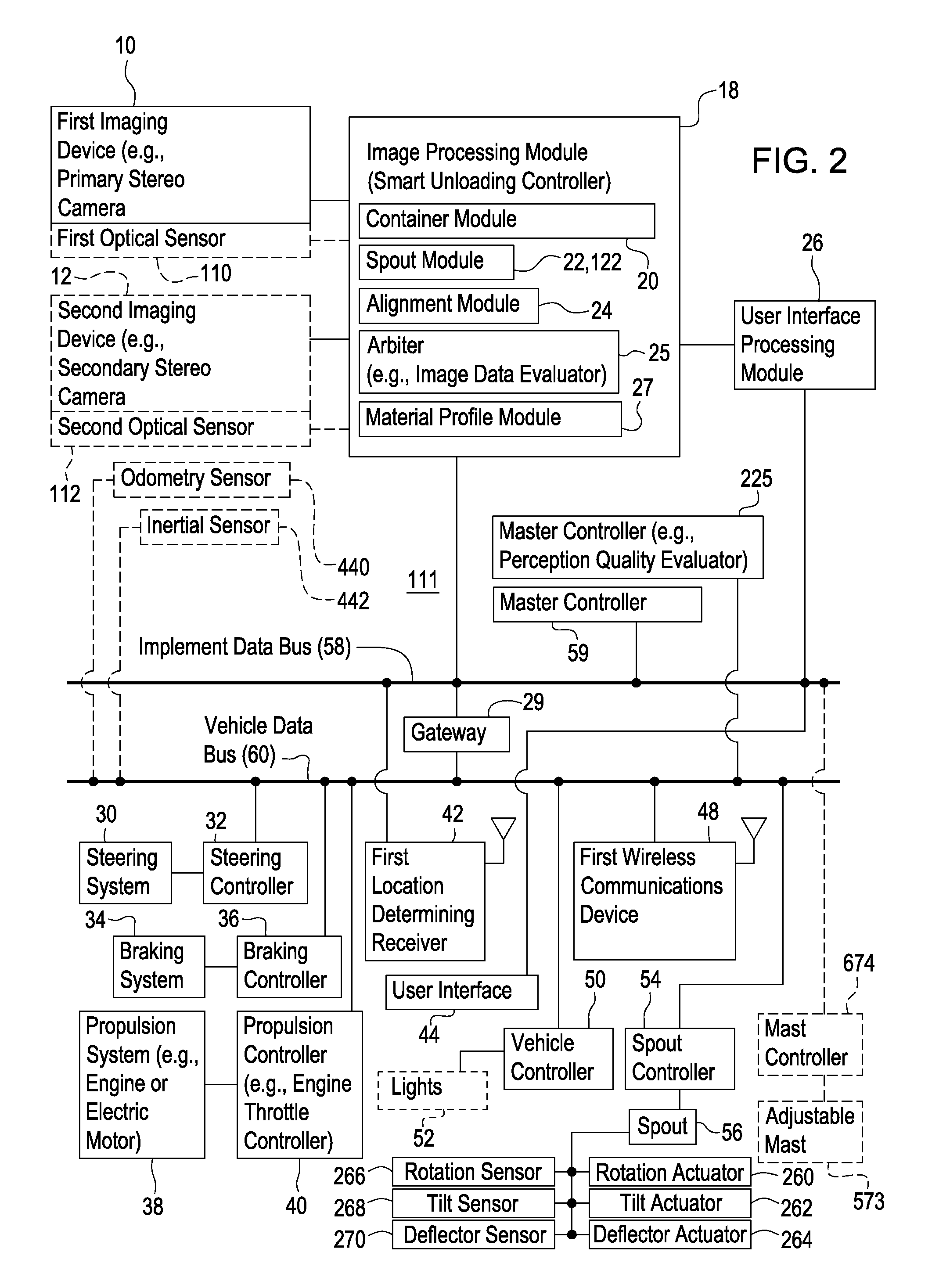

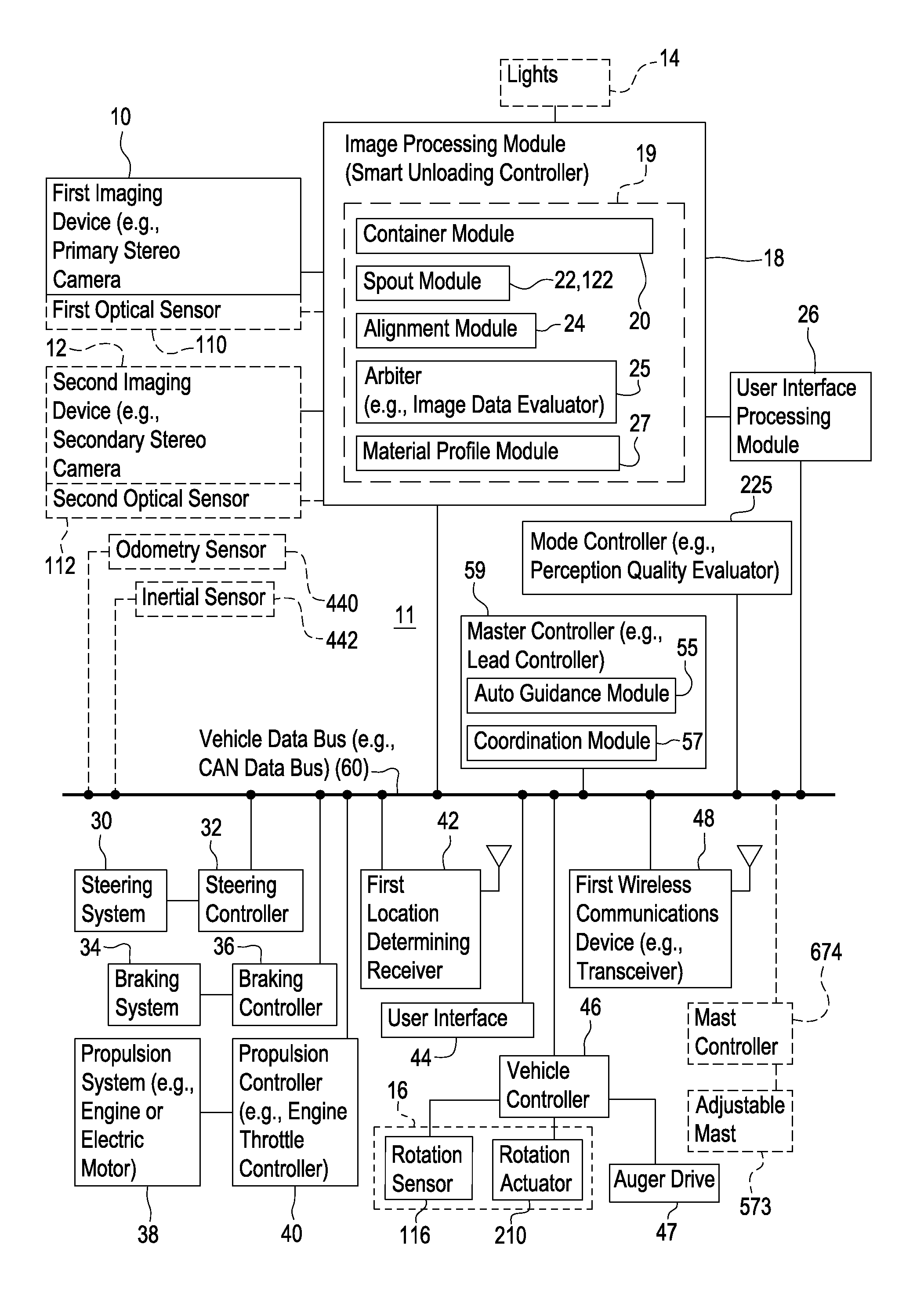

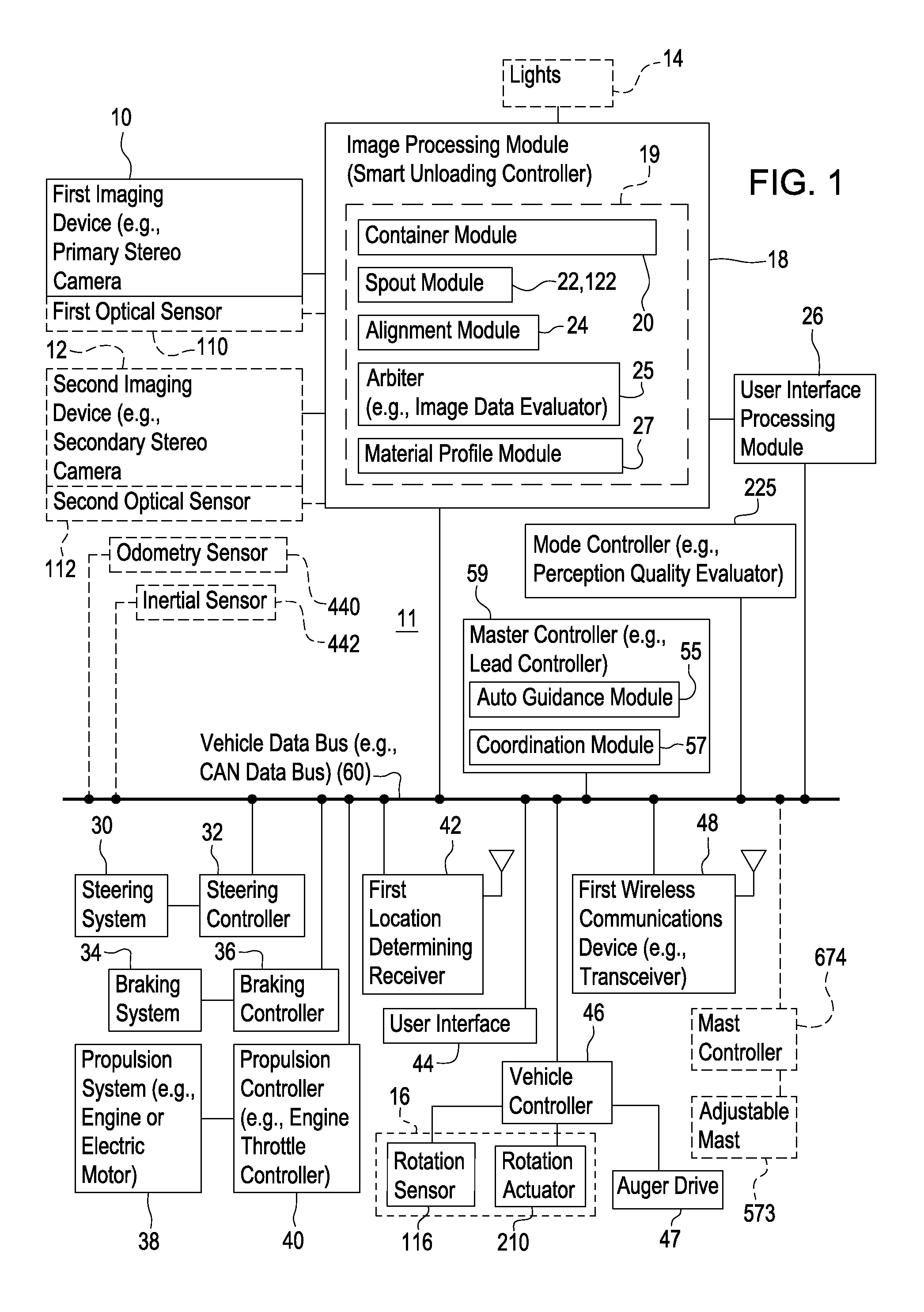

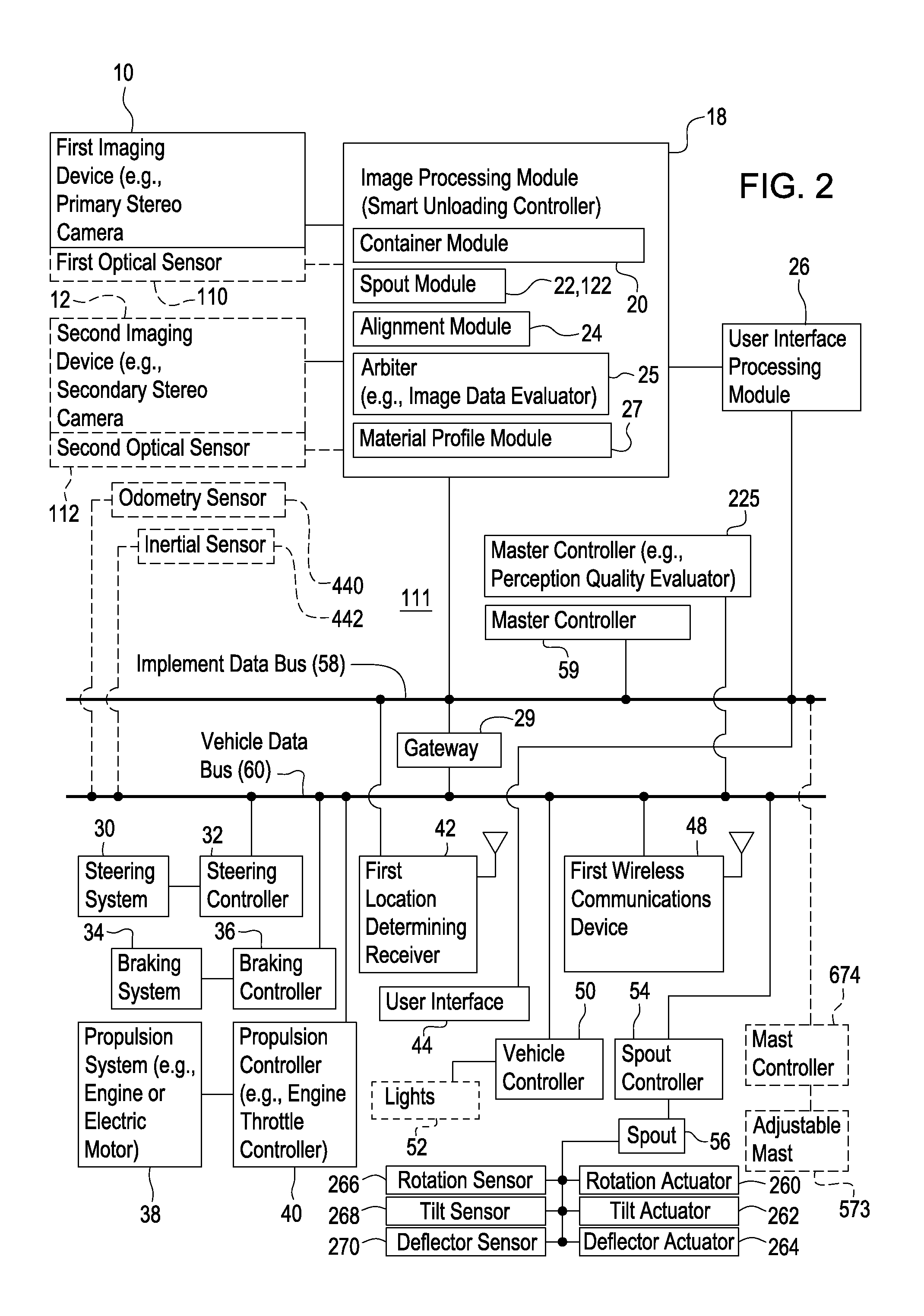

Method and stereo vision system for facilitating the unloading of agricultural material from a vehicle

ActiveUS8868304B2Easy transferHelp positioningDigital data processing detailsMowersAutomatic controlImaging processing

A mode controller determines whether to use an automated control mode of the spout or operator-directed manual control mode of the spout, based on a first operational status of a first location determining receiver associated with the propelling vehicle, a second operational status of a second location determining receiver associated with the harvesting vehicle, a third operational status of the imaging device or devices. In the automated control mode, an image processing module is adapted to facilitate the determination of the relative position of the spout and the storage portion and to generate command data place the storage portion and spout in relative cooperative alignment for transferring of material into the storage portion.

Owner:DEERE & CO

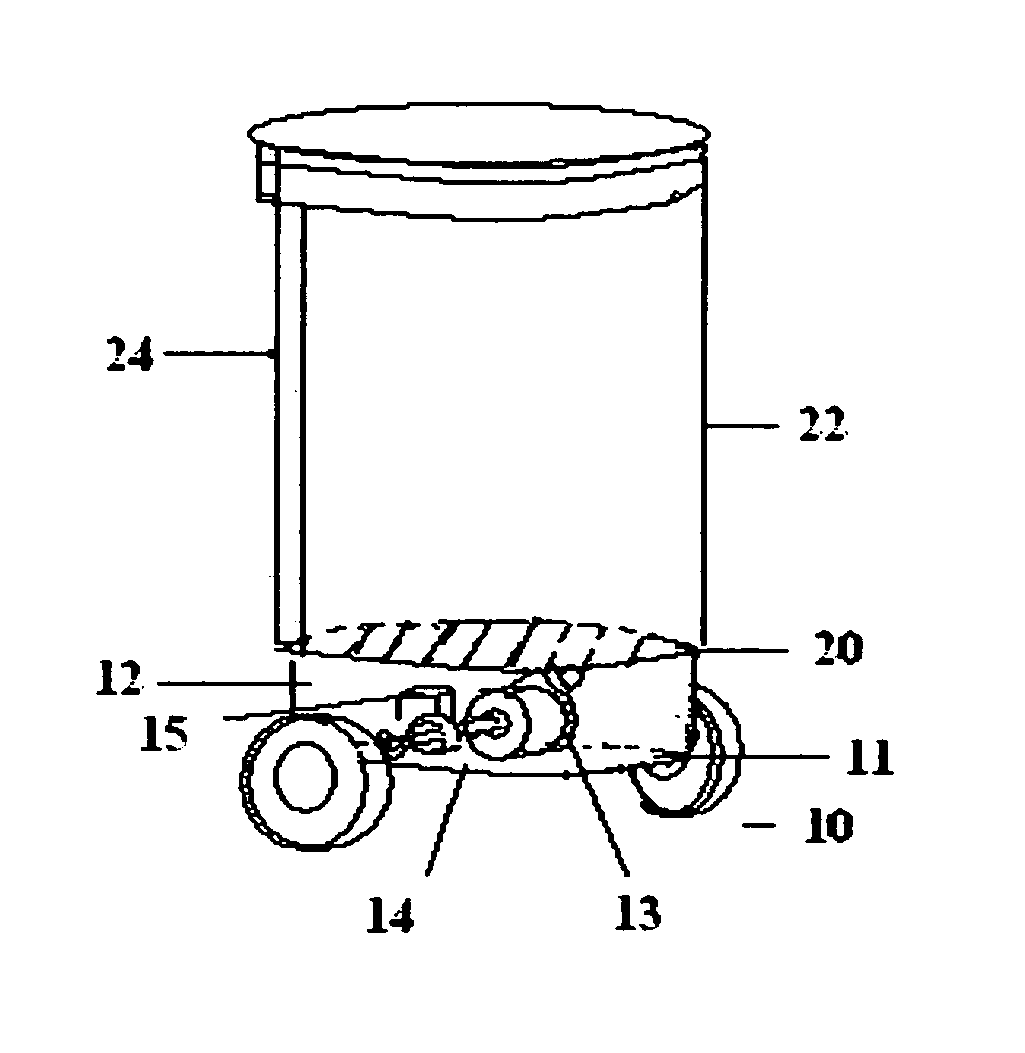

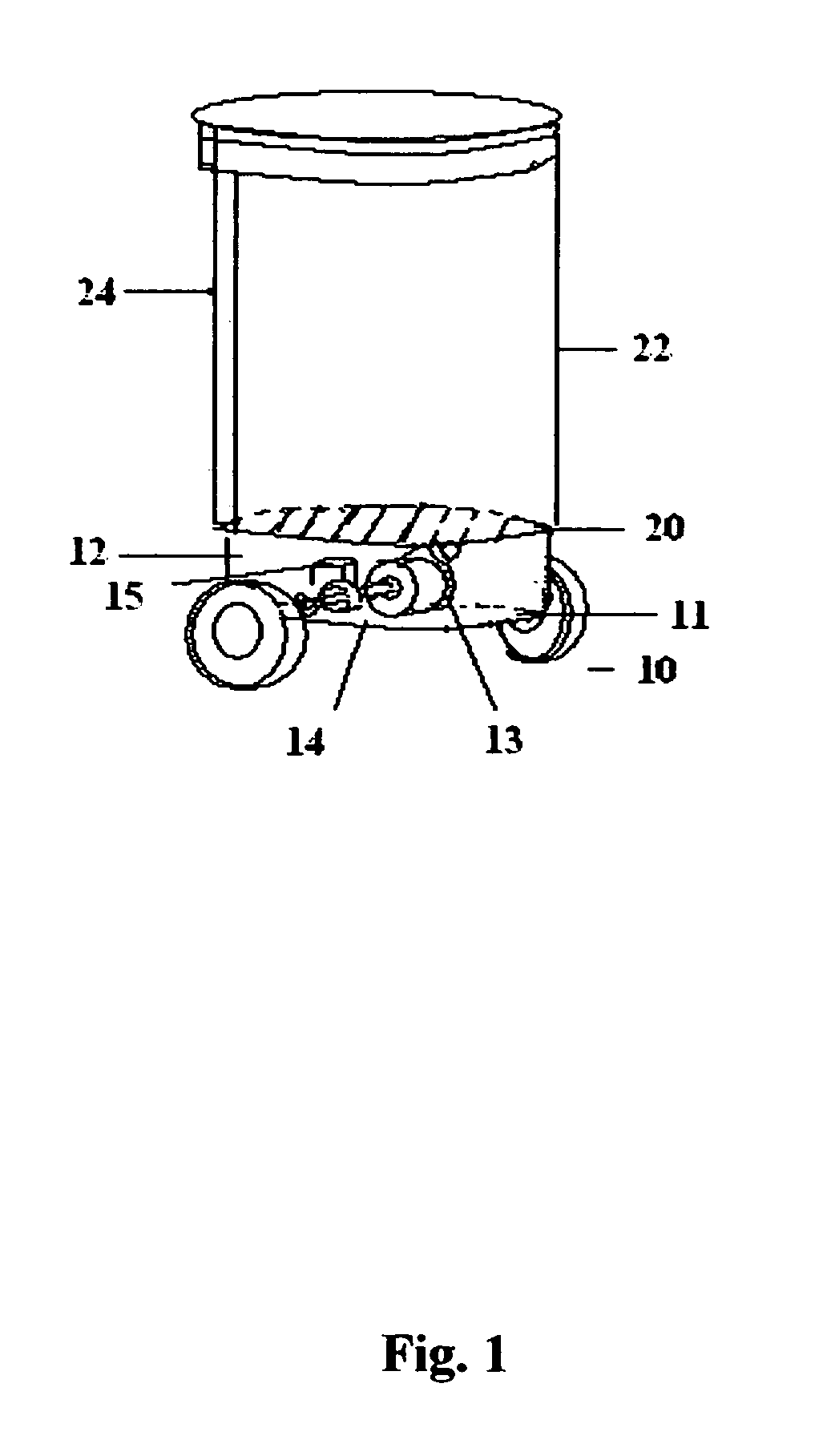

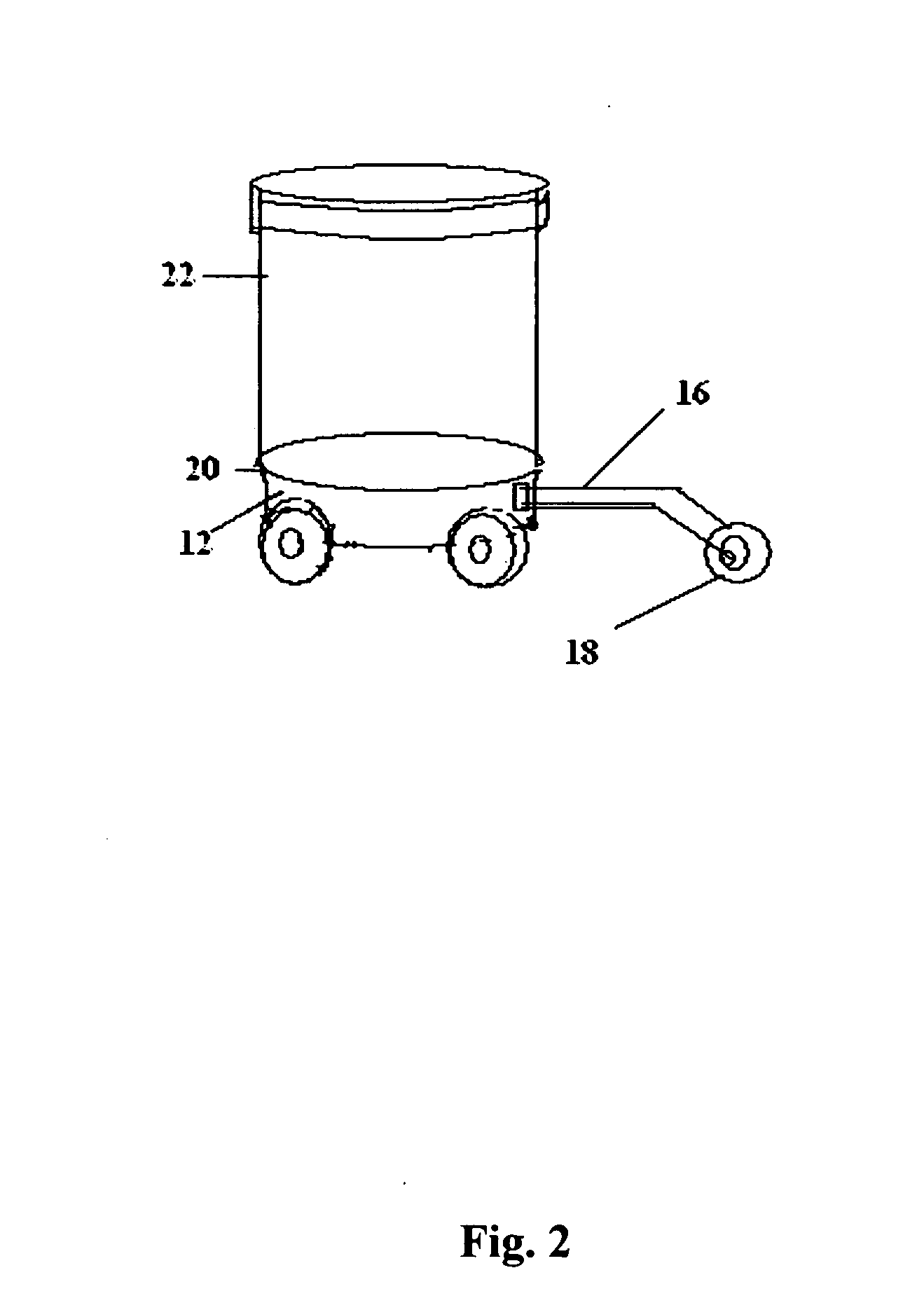

Motorized garbage can and automatic lid opener

A remote controlled motorized garbage can that is capable of transferring material to the intended designation, in conjunction, an automatic lid opener apparatus to facilitate in the dispersing of material and the lid comprising a lock and sensor mechanism to prevent personal, financial and other such information readily accessible for unlawful inclinations. To transfer the container by a remote control, rather than manual exertion, provides an efficient, convenient and permits accessibility, in consideration, to almost all individuals of physical ability.

Owner:WILSON KRISTIE LYNN

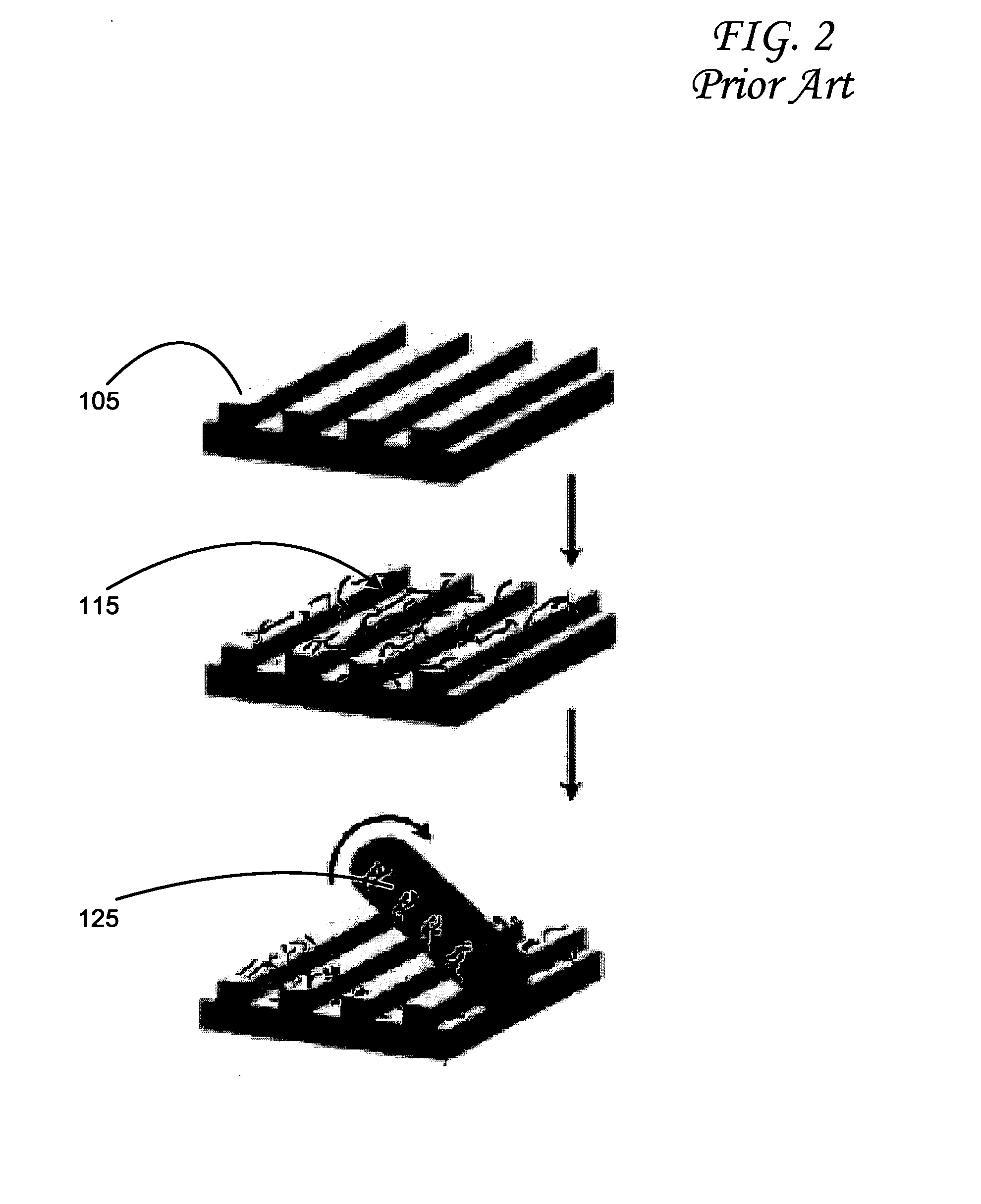

Systems and methods for nanomaterial transfer

Systems and methods of nanomaterial transfer are described. A method of nanomaterial transfer involving fabricating a template and synthesizing nanomaterials on the template. Subsequently, the nanomaterials are transferred to a substrate by pressing the template onto the substrate. In some embodiments, the step of transferring the nanomaterials involves pressing the template onto the substrate such that the nanomaterials are embedded below a surface layer of the substrate. In some embodiments, the temperature of the plurality of nanomaterials is raised to assist the transfer of the nanomaterials to the substrate.

Owner:GEORGIA TECH RES CORP

Rapid multi-material sample input system

InactiveUS20030211009A1Rapid introductionBroadening fluid stream widthAnalysis using chemical indicatorsSamplingMulti materialProcess engineering

Material transfer technology that apportions discrete amounts of material (1) and introduces the apportioned material into a selectably engaged flow path (17) to provide a plurality of separate materials within a continuous fluid stream that can be delivered to numerous material differentiation technologies (3) for analysis.

Owner:CYTOMATION +1

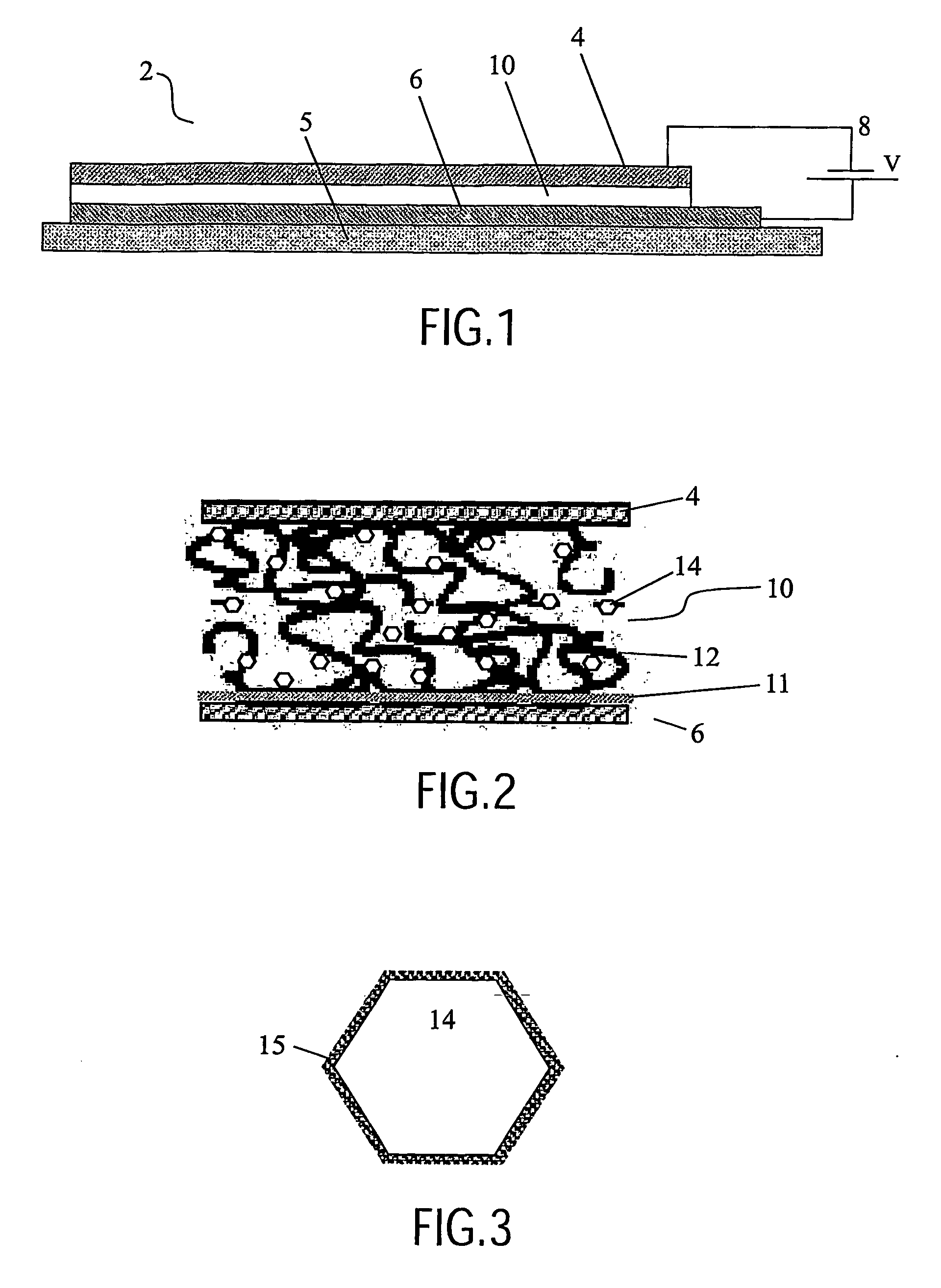

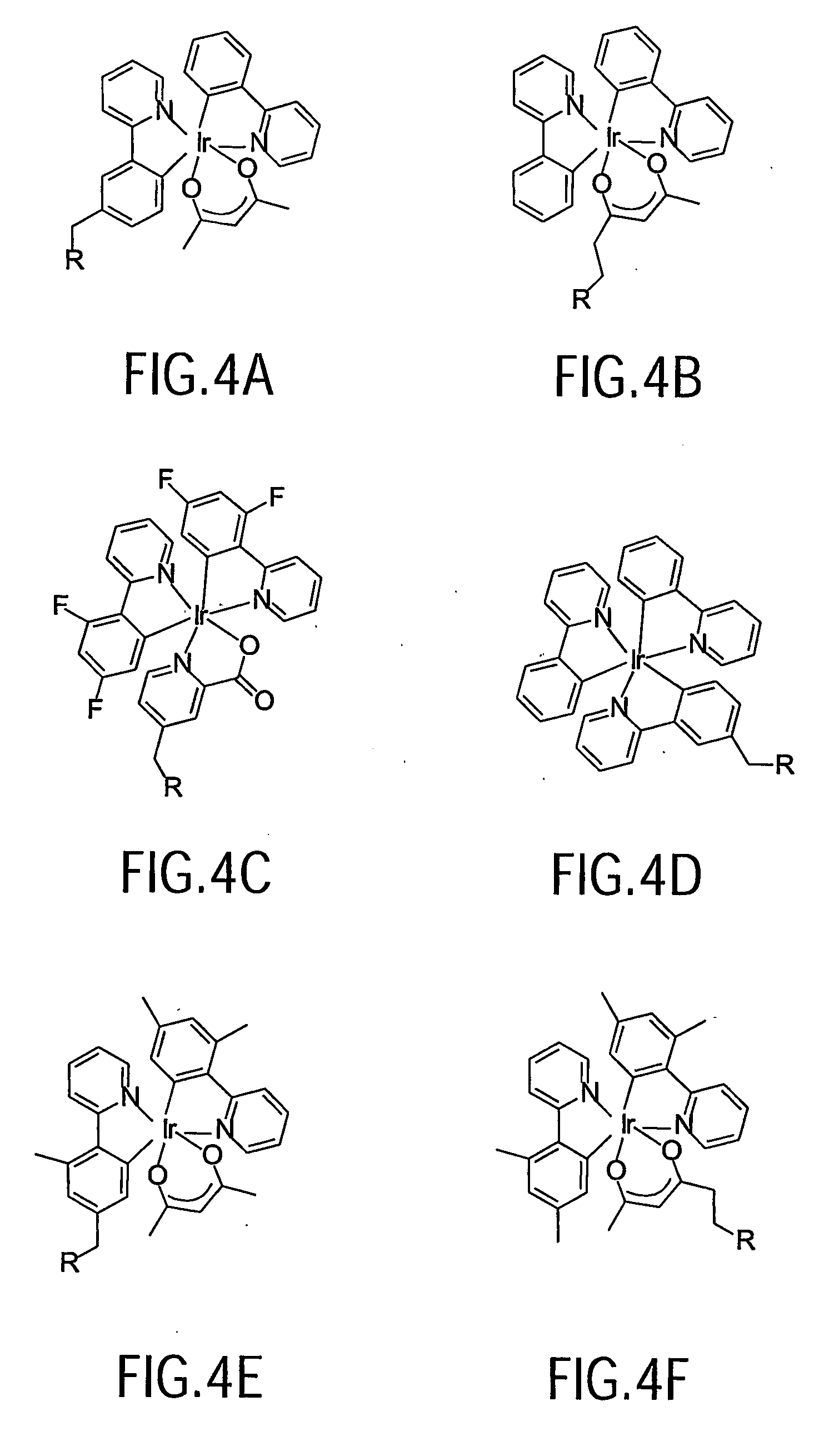

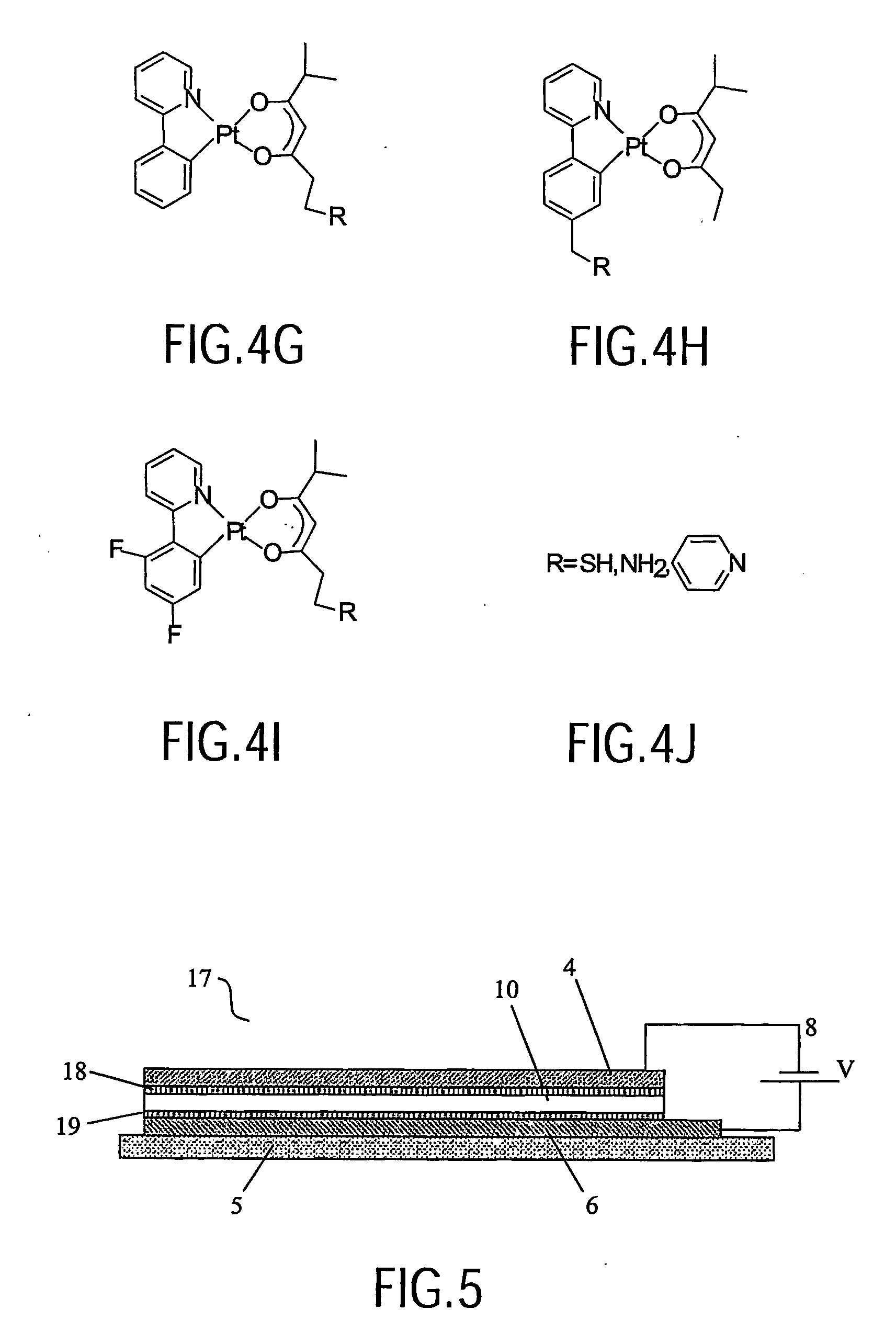

Electroluminescent device

InactiveUS20070077594A1Improve performanceImprove power efficiencyMaterial nanotechnologyPreparing sample for investigationQuantum dotLight emitting device

The invention relates to a matrix of electroluminescent organic material having quantum dots embedded therein. Electrodes provide electrons and holes to the matrix forming excitons to be transferred to the quantum dots. The invention provides transfer molecules on the quantum dots facilitating the transfer of excitons from the electroluminescent organic material to the quantum dots, by first transferring them to the transfer molecules. The transfer molecules are chosen to make a transfer rate of excitons from the organic material to the transfer molecules larger than a decay rate of excitons in the organic material. More specifically, the organic matrix forms a light emitting layer in a light emitting device (LED). Also, the electroluminescent organic material is preferably an electroluminescent polymer.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Methods for electrochemically fabricating structures using adhered masks, incorporating dielectric sheets, and/or seed layers that are partially removed via planarization

InactiveUS20050032375A1Additive manufacturing apparatusLiquid surface applicatorsAdemetionineMaterial transfer

Embodiments of the present invention provide mesoscale or microscale three-dimensional structures (e.g. components, device, and the like). Embodiments relate to one or more of (1) the formation of such structures which incorporate sheets of dielectric material and / or wherein seed layer material used to allow electrodeposition over dielectric material is removed via planarization operations; (2) the formation of such structures wherein masks used for at least some selective patterning operations are obtained through transfer plating of masking material to a surface of a substrate or previously formed layer, and / or (3) the formation of such structures wherein masks used for forming at least portions of some layers are patterned on the build surface directly from data representing the mask configuration, e.g. in some embodiments mask patterning is achieved by selectively dispensing material via a computer controlled inkjet nozzle or array or via a computer controlled extrusion device.

Owner:MICROFAB

Material dispenser with a control valve

A syringe comprising a chamber and material transfer portion with a cavity in communication with an inlet portion and an outlet portion. The inlet portion includes an inlet valve means for controlling material flow therethrough, and the material transfer portion includes a control valve operable between a first position to control the inflow of material from the inlet portion to the material container portion, and a second position to control the flow of material from the chamber to the outlet portion, and the outlet portion includes a releasable lock means for allowing discharge the material through the outlet portion.

Owner:VASOGEN IRELAND LTD

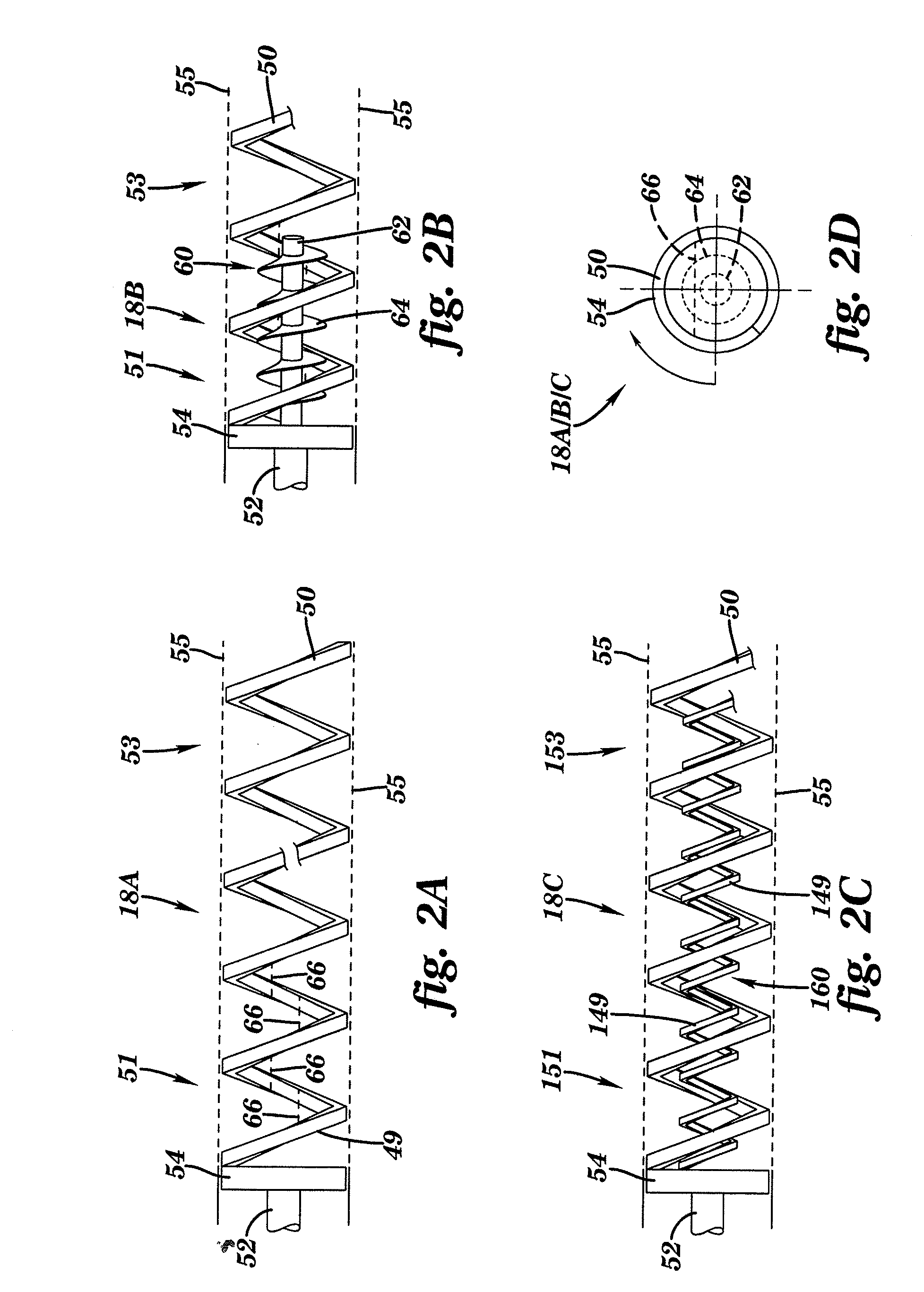

Methods and apparatus for pyrolyzing material

InactiveUS20080128259A1Direct heating destructive distillationIndirect and direct heating destructive distillationHydrogenProcess engineering

Methods and systems for substantially continuously treating comminuted material containing carbon and hydrogen, for example, used tires, are provided. The methods include the steps of introducing the tire material to an elongated chamber, transferring the tire material through the elongated chamber, heating the tire material to a temperature sufficient to pyrolyze the material to produce a gaseous stream; discharging the gaseous stream from the chamber, and cooling at least some of the gaseous stream to liquefy components of the stream. The transfer may be effected by a flexible, center-less screw conveyor to minimize material buildup in the vessel. The cooling of the gaseous stream may be practiced by reverse condensation. One or more re-usable fuel streams are provided by aspects of the invention.

Owner:KOSTEK STANISLAW

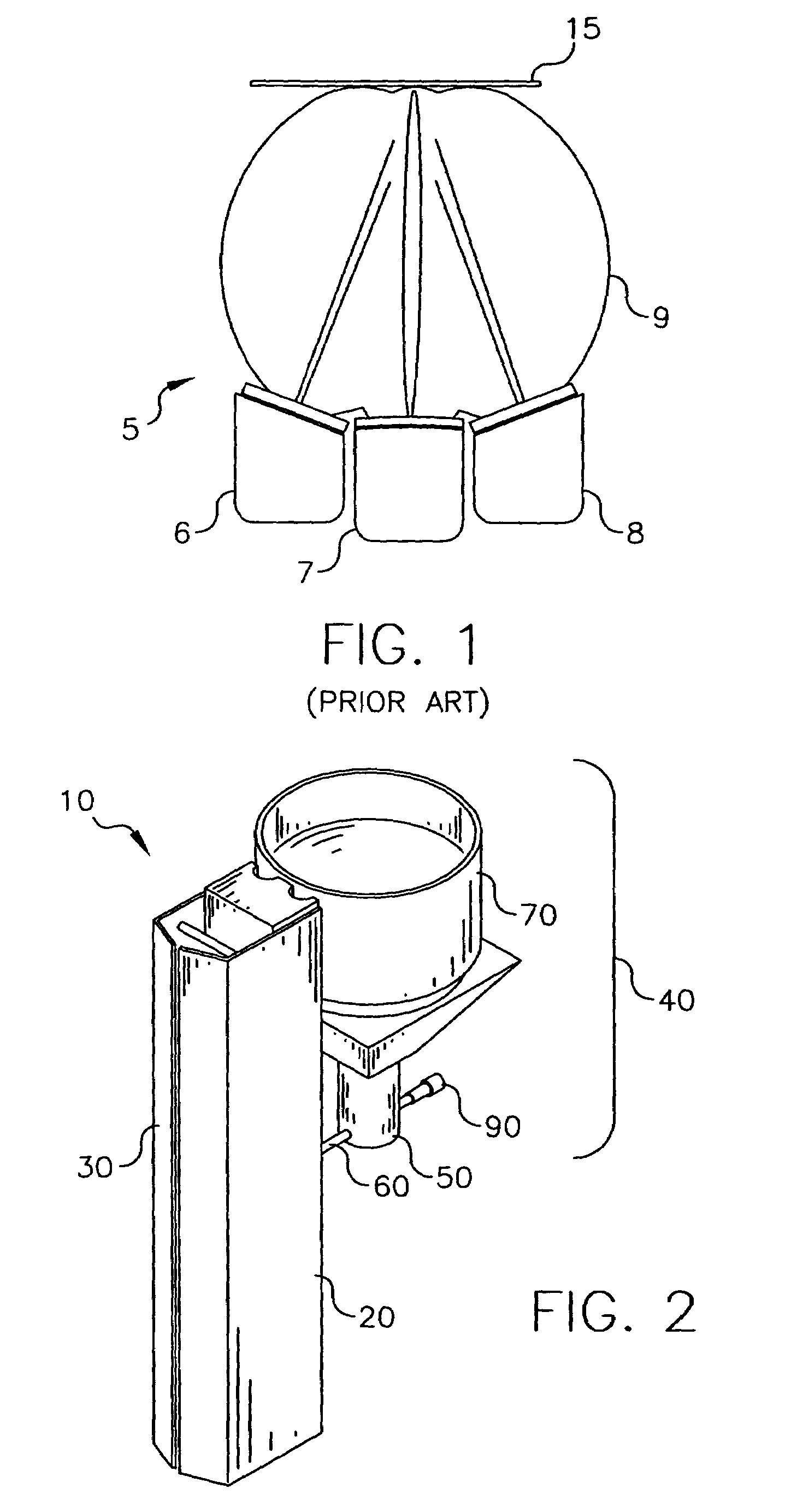

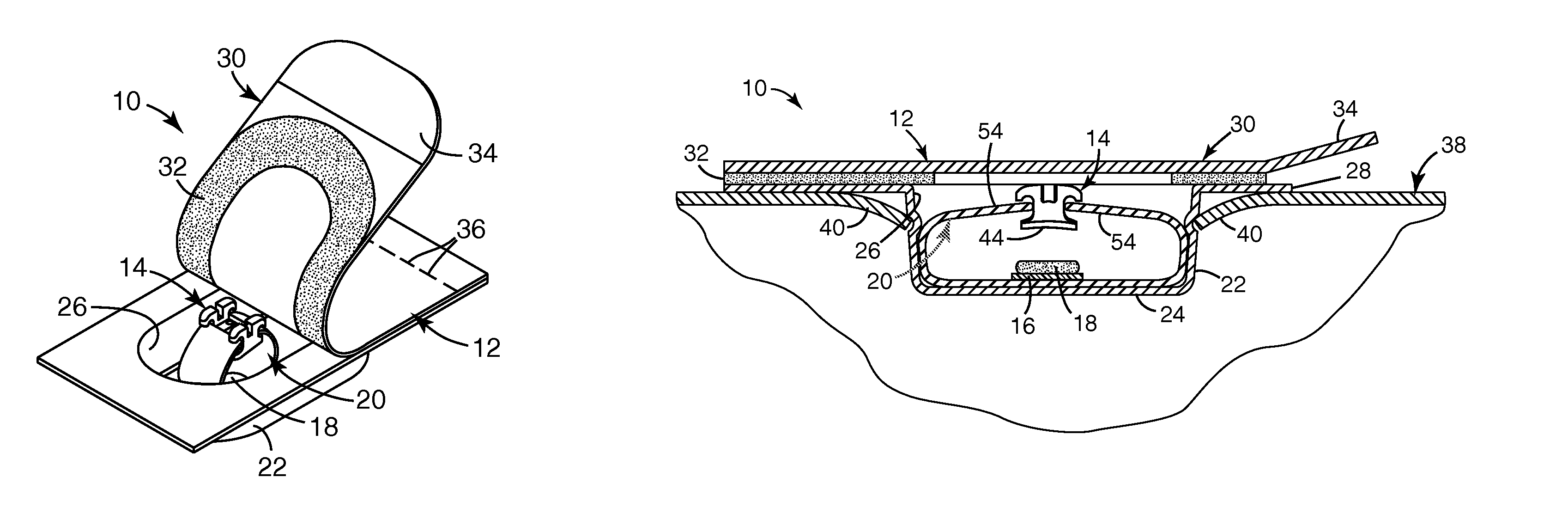

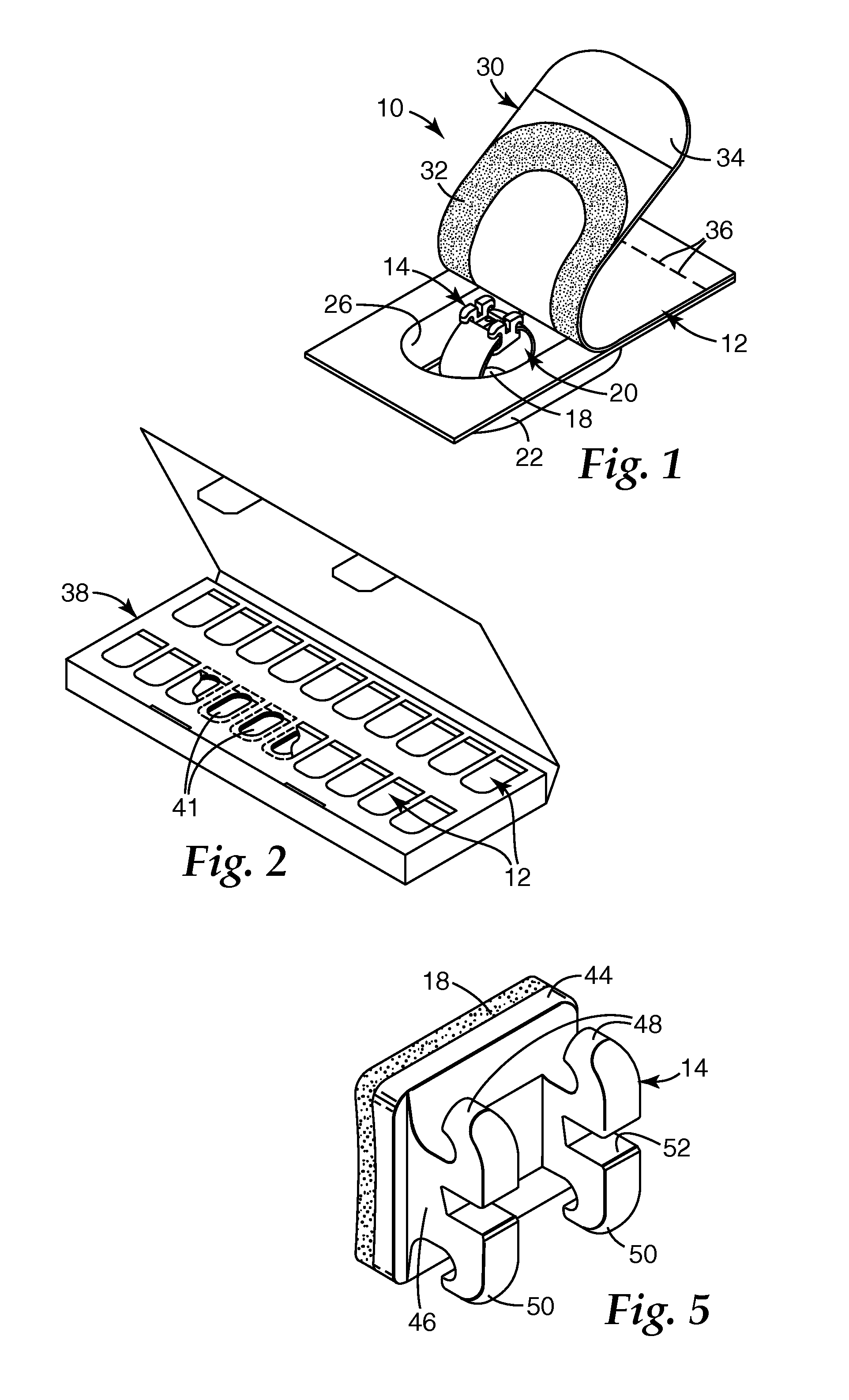

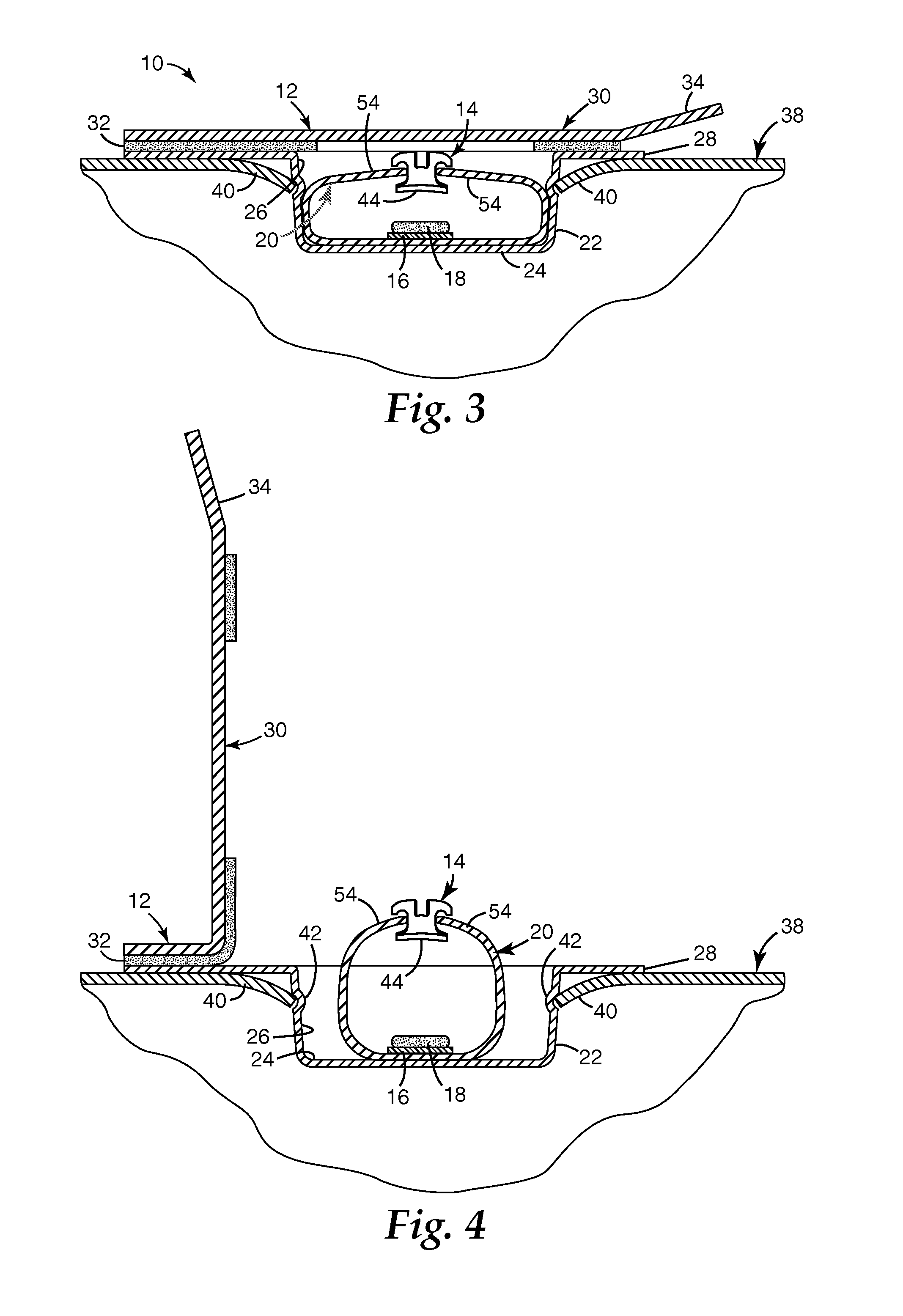

Packaged orthodontic appliance with user-applied adhesive

InactiveUS7841464B2Low viscosityTrend downBracketsDispensing apparatusEngineeringOrthodontic Adhesives

Owner:3M INNOVATIVE PROPERTIES CO

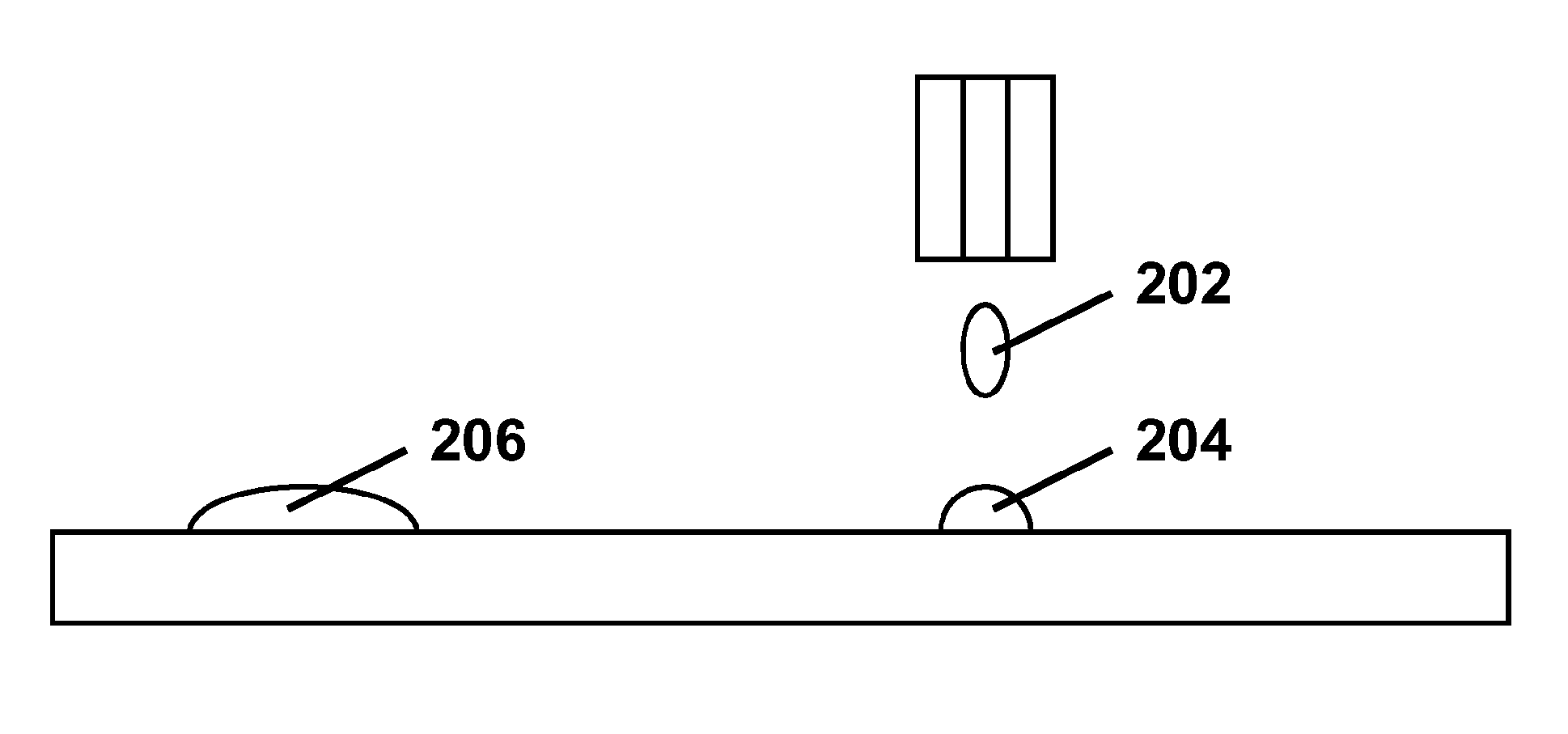

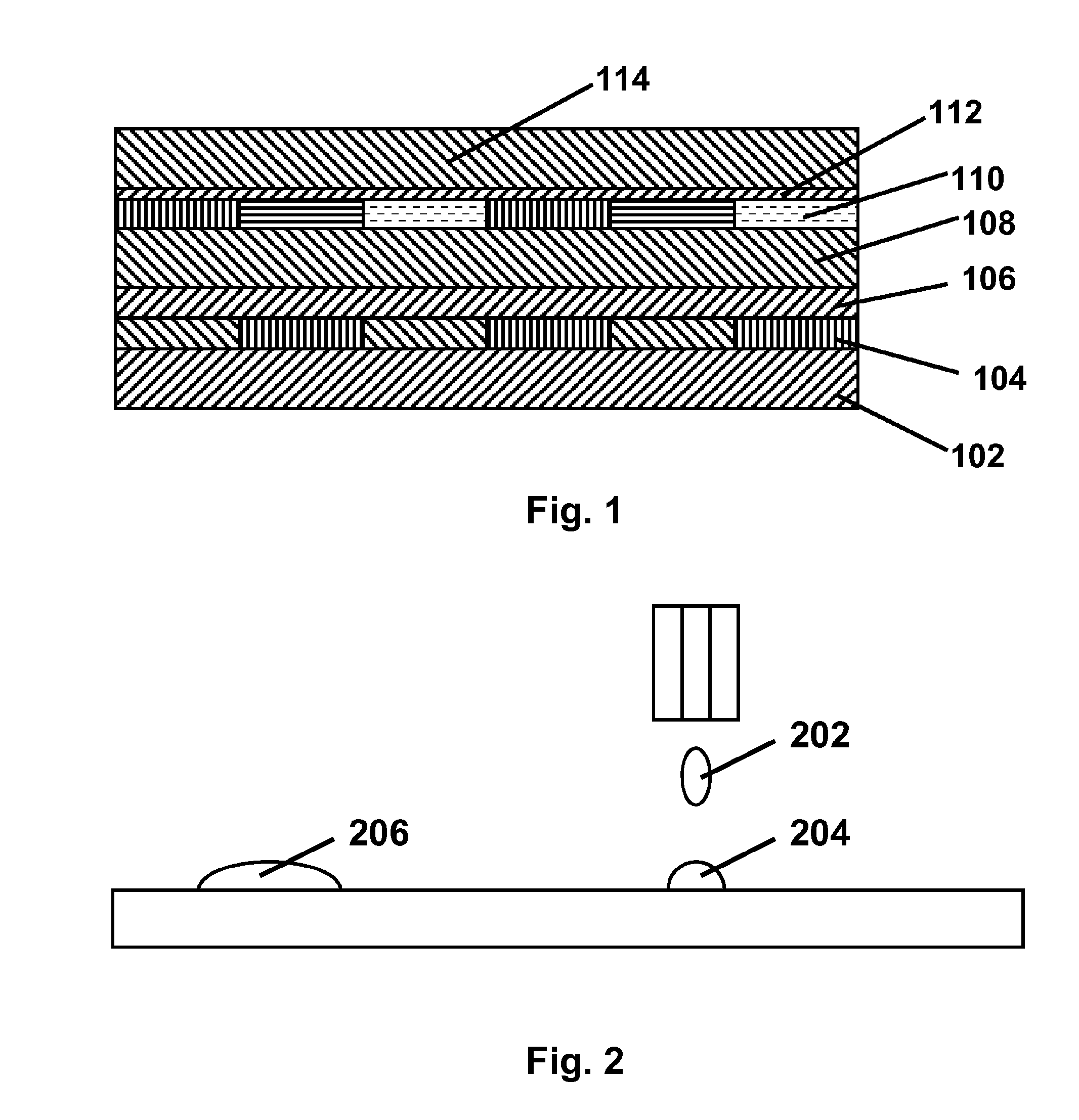

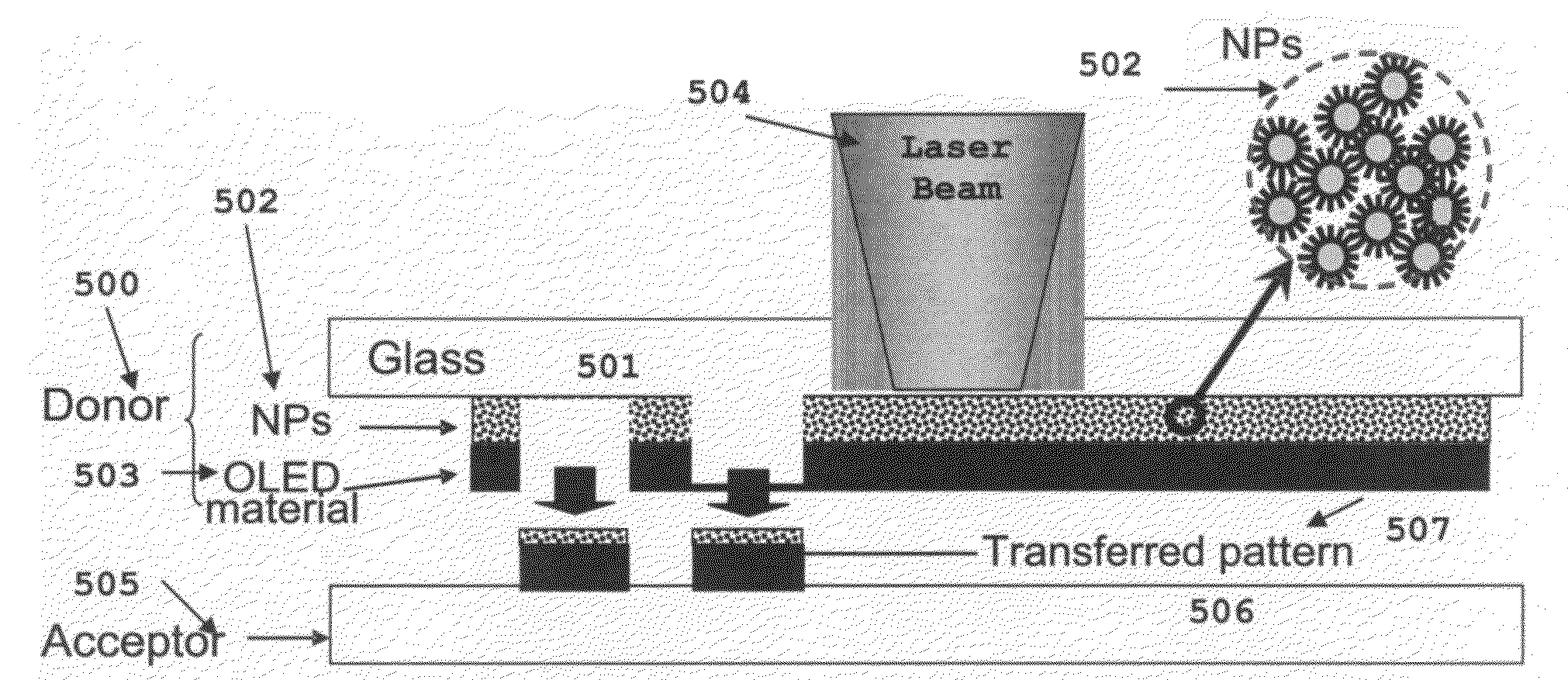

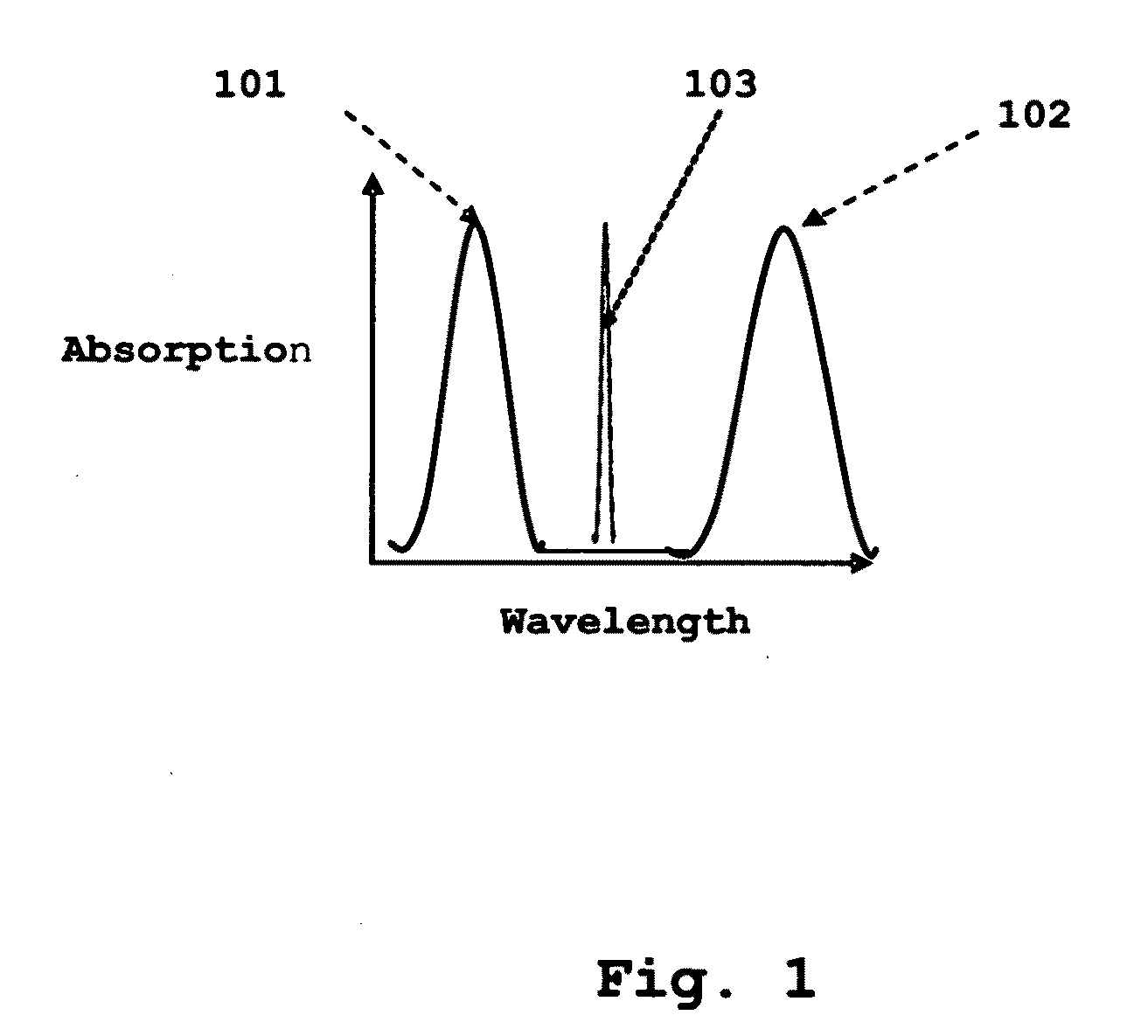

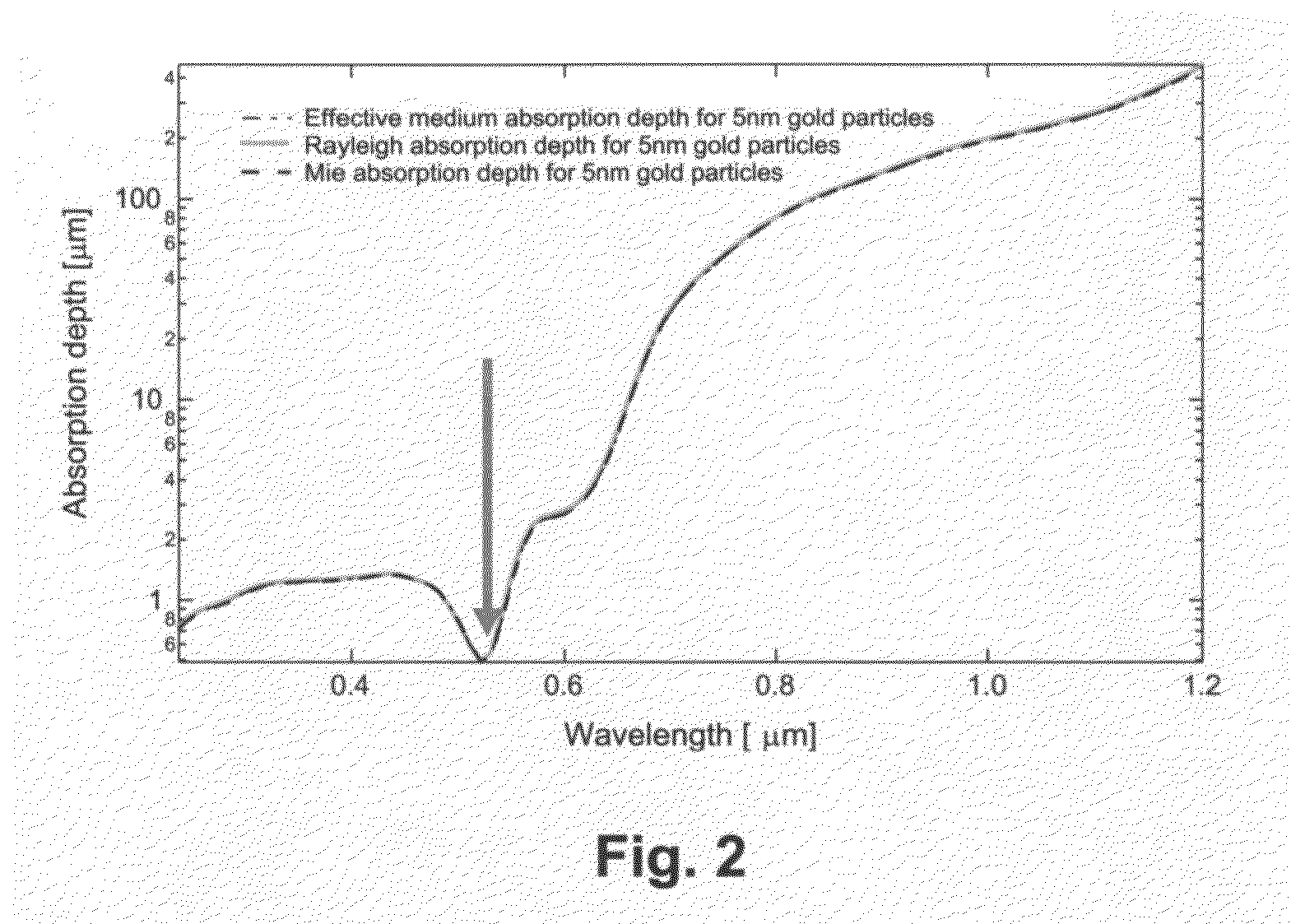

Nanomaterial facilitated laser transfer

InactiveUS20090130427A1Facilitate deposition/removalLayered productsTransfer patterningNanoparticleSelf-assembled monolayer

The invention relates to the deposition or transfer of material using a laser induced forward transfer process. More specifically, the invention relates to the transfer of material using a laser induced forward transfer process wherein the transfer process is facilitated or enabled by nanomaterials. Nanomaterials in the form of nanoparticles or nanofilms may be employed, optionally including a surface coating or self-assembled monolayer surface coating, making use of properties of the nanomaterials that allow the laser induced forward transfer process to be practiced at irradiation energies and temperatures lower than commonly used. The technique may be well suited for depositing organic layers.

Owner:RGT UNIV OF CALIFORNIA +1

Method and stereo vision system for facilitating the unloading of agricultural material from a vehicle

ActiveUS20130211658A1Easy transferFacilitate determination of relative positionDigital data processing detailsMowersImaging processingAutomatic control

A mode controller determines whether to use an automated control mode of the spout or operator-directed manual control mode of the spout, based on a first operational status of a first location determining receiver associated with the propelling vehicle, a second operational status of a second location determining receiver associated with the harvesting vehicle, a third operational status of the imaging device or devices. In the automated control mode, an image processing module is adapted to facilitate the determination of the relative position of the spout and the storage portion and to generate command data place the storage portion and spout in relative cooperative alignment for transferring of material into the storage portion.

Owner:DEERE & CO

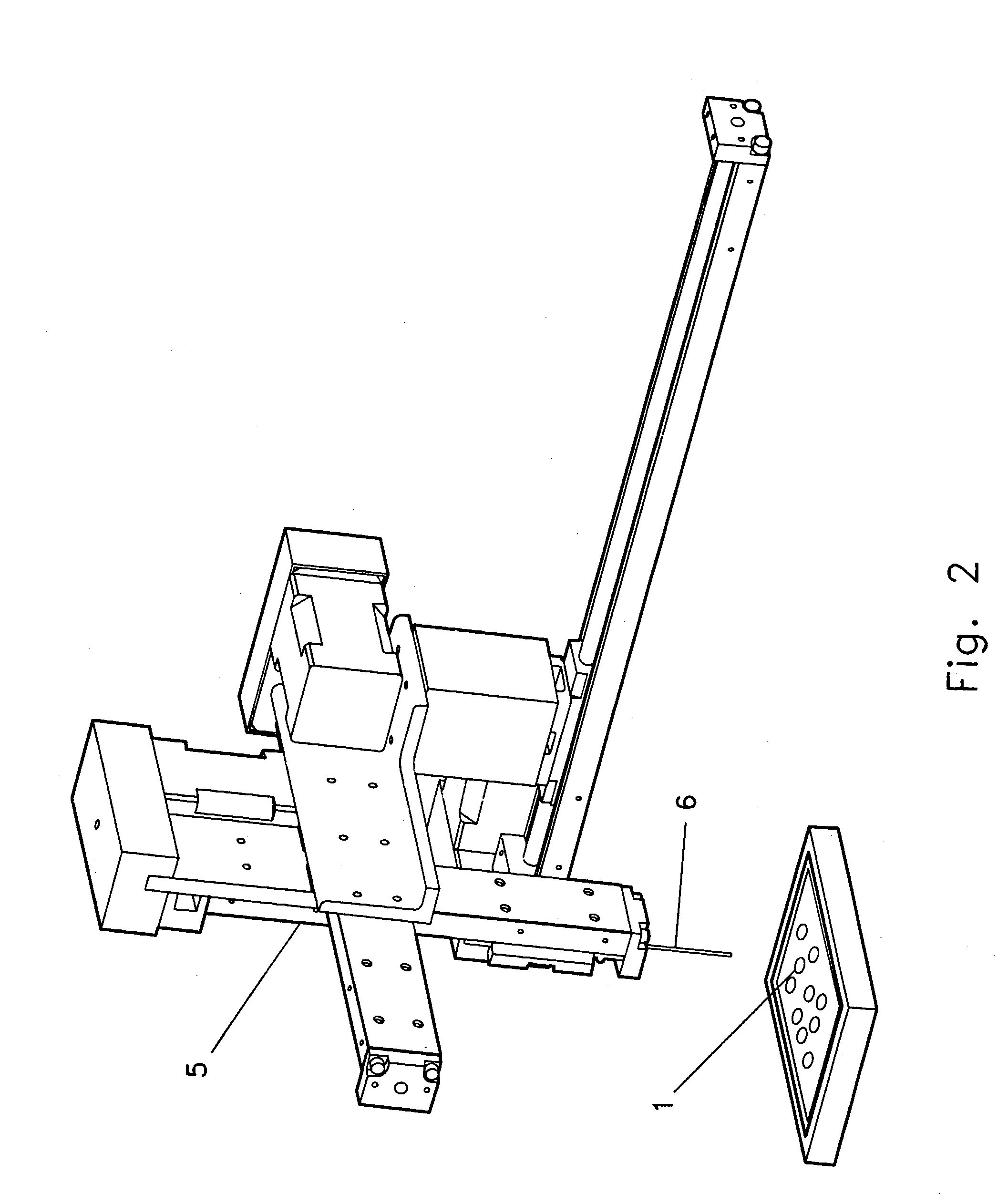

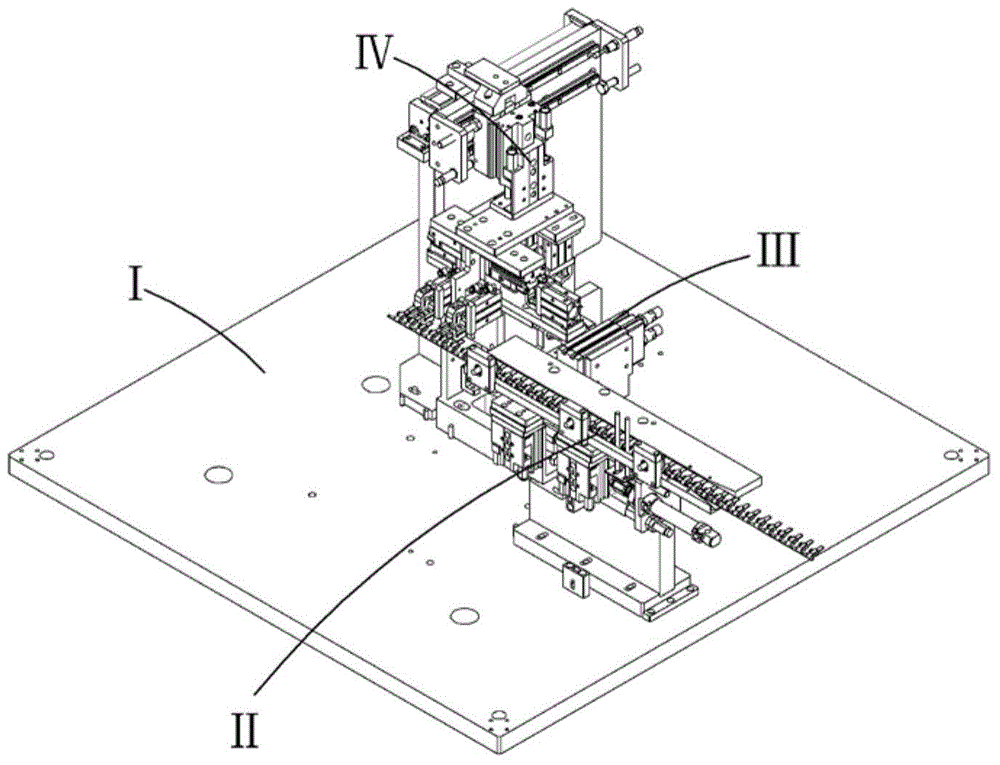

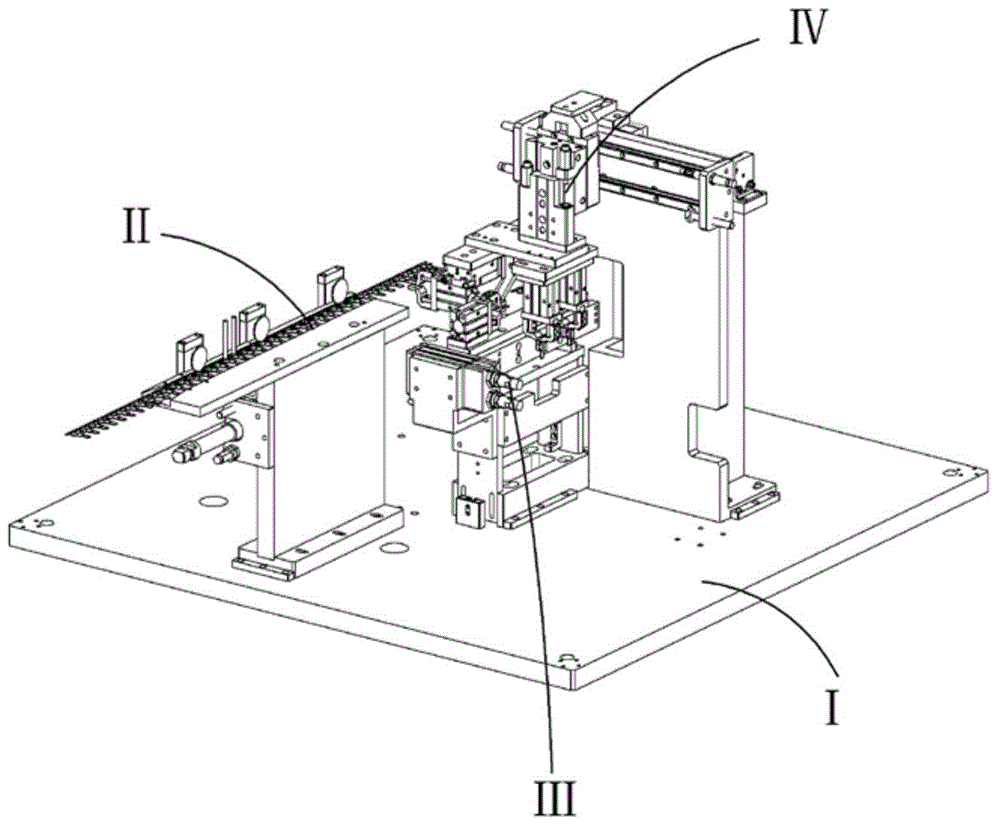

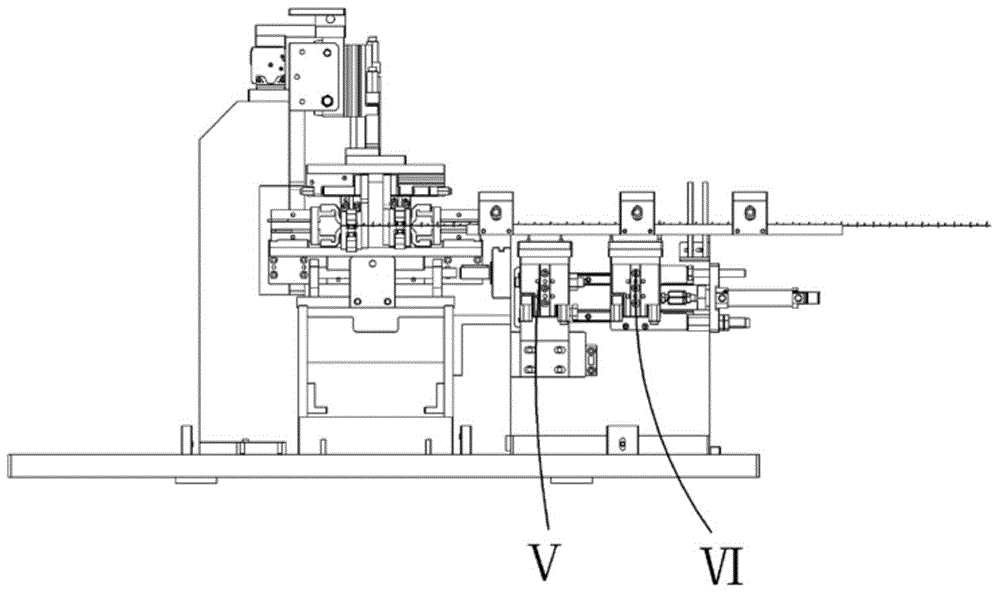

Automatic feeding mechanism

ActiveCN104444289ANo overtravelReduce labor intensityControl devices for conveyorsEngineeringUltimate tensile strength

The invention relates to an automatic feeding mechanism. A feeding mechanism, a material overturning mechanism and a material transferring mechanism are mounted on a large base plate; the feeding mechanism can realize reciprocating feeding and material supply; the material overturning mechanism can be used for clamping a product, and the product rotates by 90 degrees under the driving of a rotating cylinder; the material transferring mechanism can be used for fetching a material from a material belt of the feeding mechanism and transferring the product onto the material overturning mechanism, and after the product is overturned by 90 degrees, the material transferring mechanism can be used for receiving the material and transferring the product to other mechanisms for making preparations for the next step. Under cooperation with the feeding mechanism, the material overturning mechanism and the material transferring mechanism, the product is conveyed to a standard position, so that the work efficiency is high, the feeding position is accurate and the labor intensity of workers is reduced.

Owner:BOZHON PRECISION IND TECH CO LTD

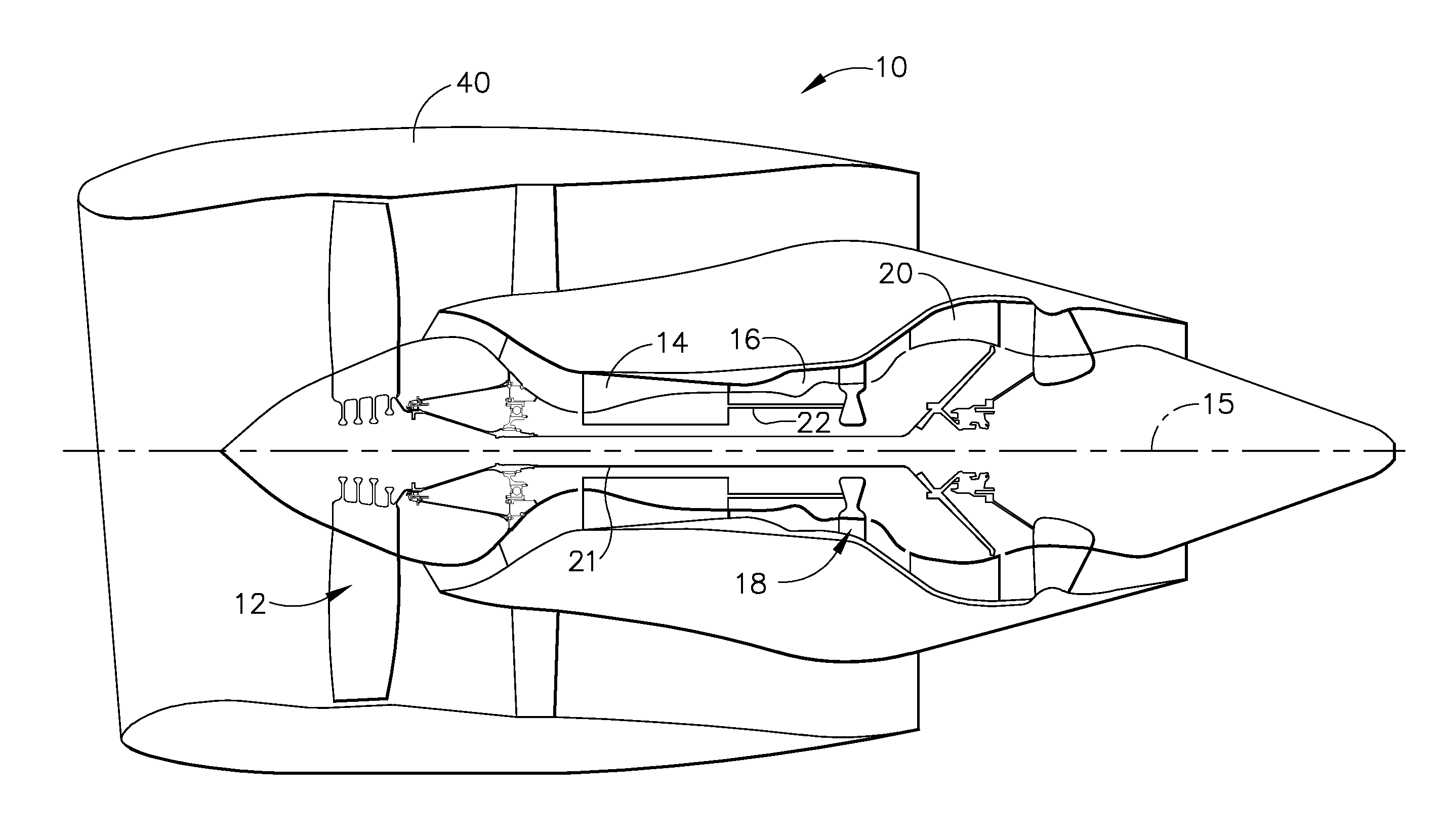

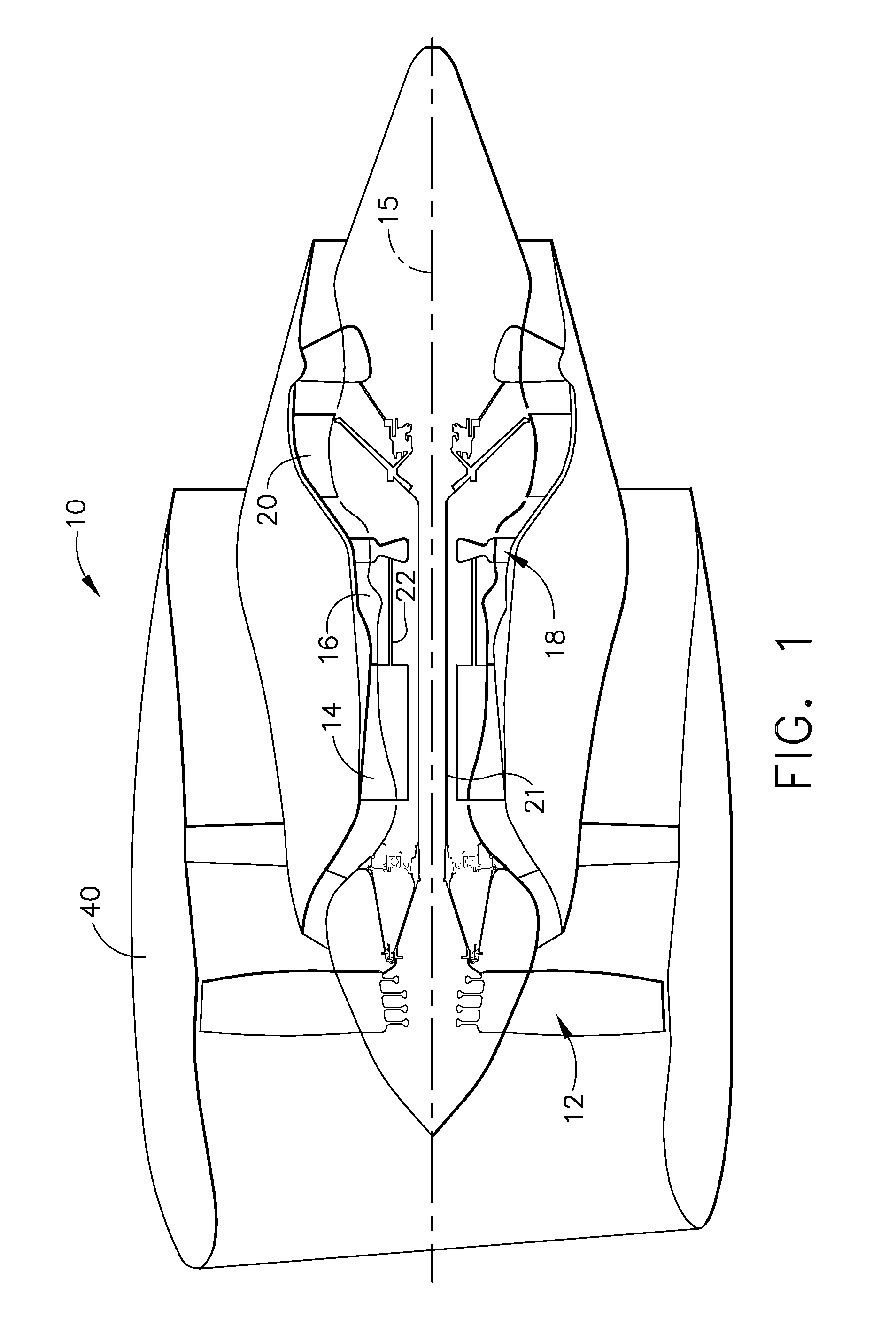

Composite an containment case and method of fabricating the same

A method of fabricating a fan containment case for a gas turbine engine is provided. The method includes forming a core layer material, wrapping the core layer material about a cylindrically-shaped take-up spool, and transferring the core layer material to a cylindrically-shaped mandrel by wrapping a plurality of layers of the core layer material about the mandrel such that the mandrel is circumscribed by the layers and such that a size and a cylindrical shape of the fan containment case are defined by the layers of core layer material.

Owner:GENERAL ELECTRIC CO

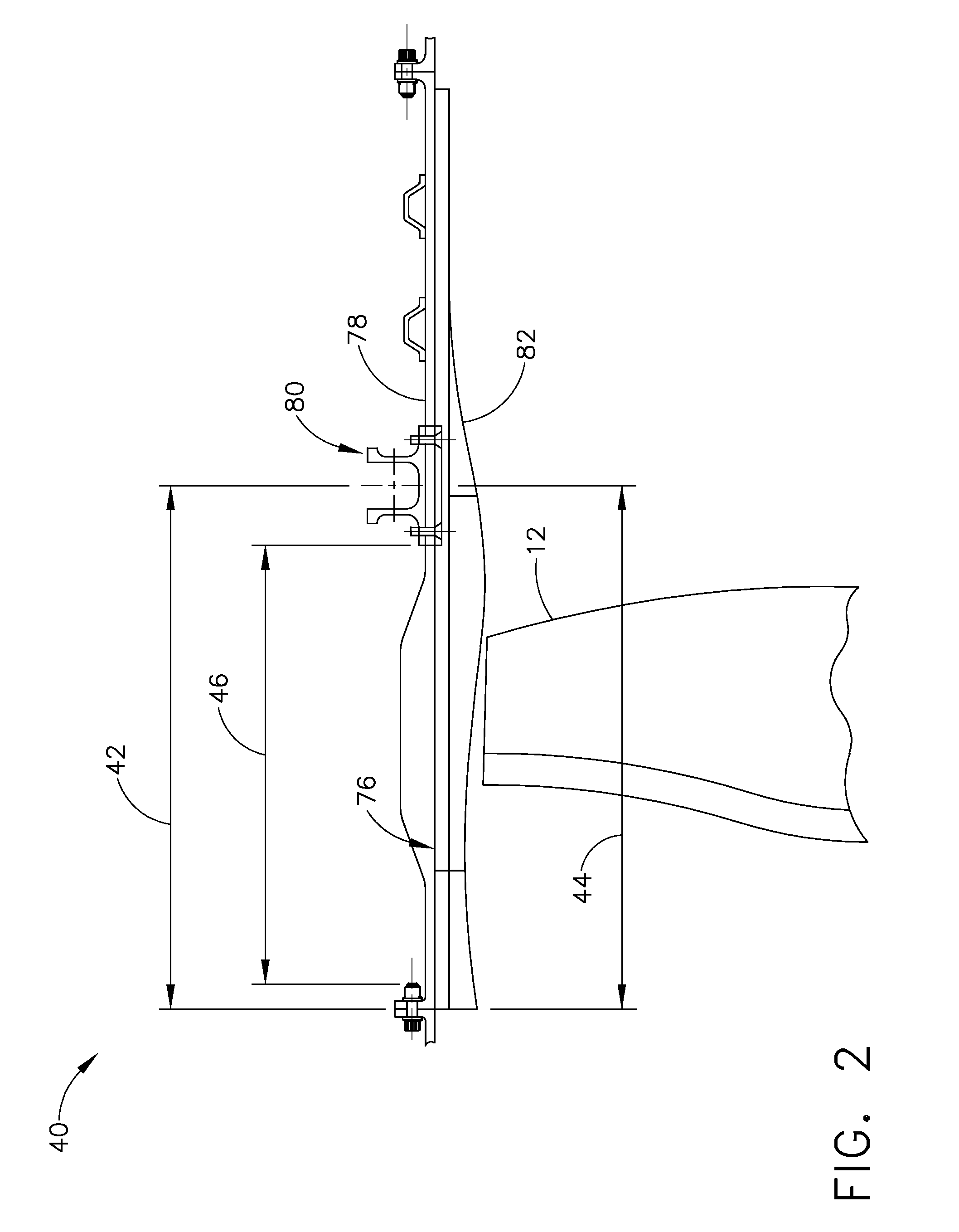

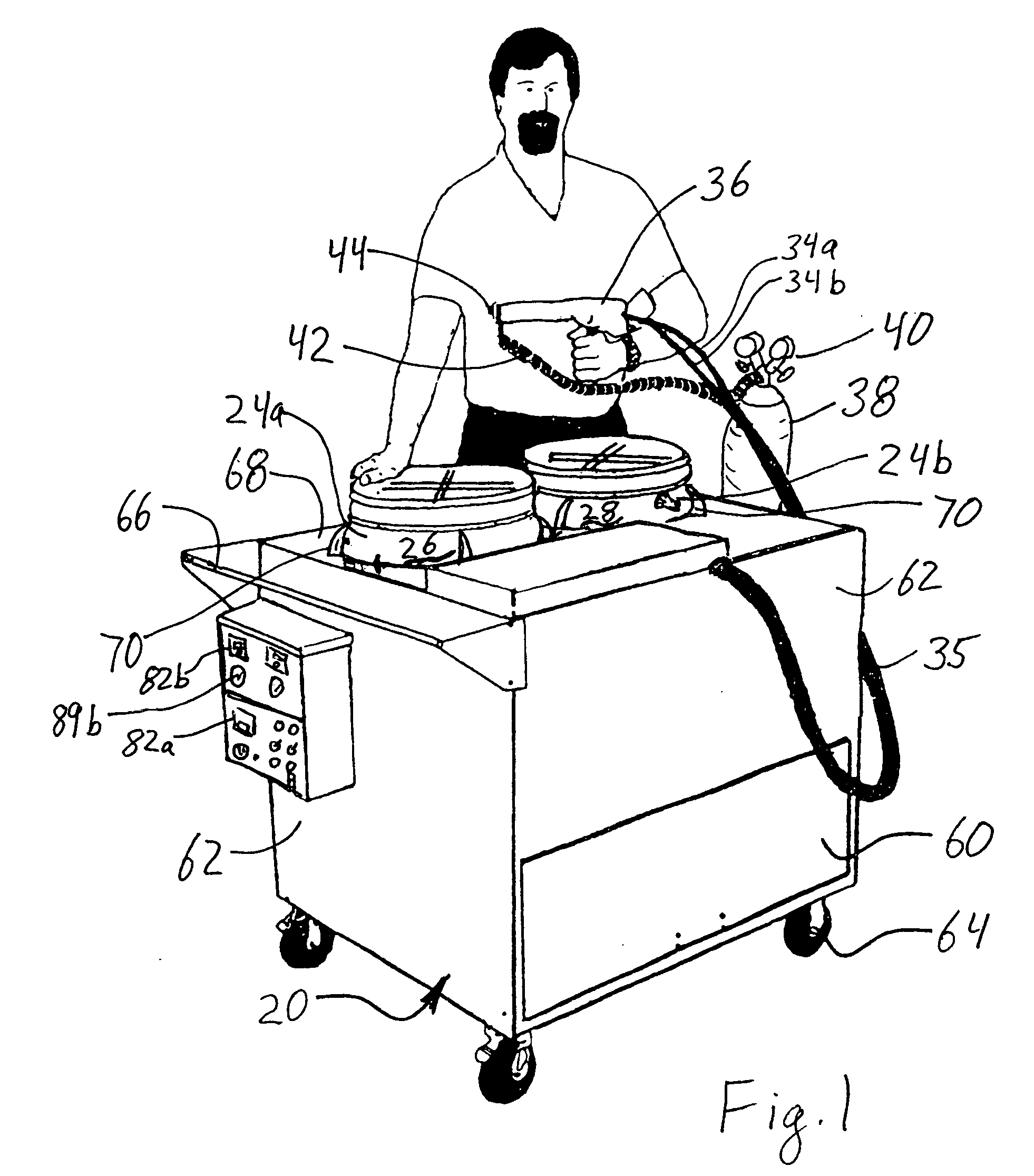

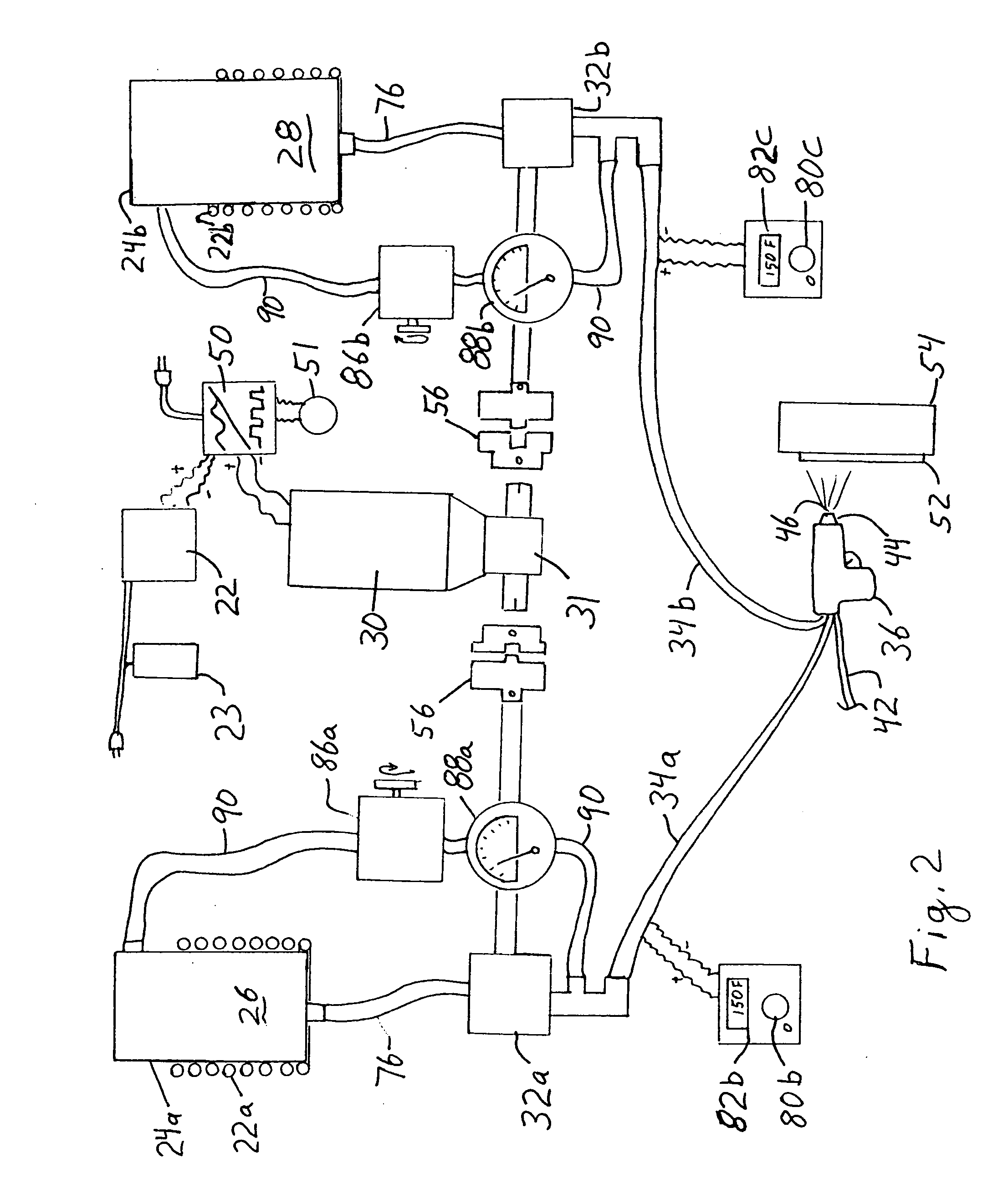

Portable spray system

InactiveUS20070045289A1Improve transmission efficiencyReduced Power RequirementsLiquid spraying apparatusHeating element materialsMotor driveEngineering

A portable cart is provided for spraying viscous coating material. The cart holds a resin container and an activator container, each of which is separately heated by conduction. Material transfer lines run from the containers to a spray gun, and the lines are heated. A gas tank and pressure regulator provide compressed gas to the spray gun for spraying the coating material. The spray gun is a positive displacement gun. A direct current, double stack, low-ramp motor drives two material transfer pumps to force the resin and activator through the lines to the spray gun. The two pumps are each driven through a separate helicoidal gear box. A single 110 volt AC input provides the power for the entire cart.

Owner:KOTT JOHN +1

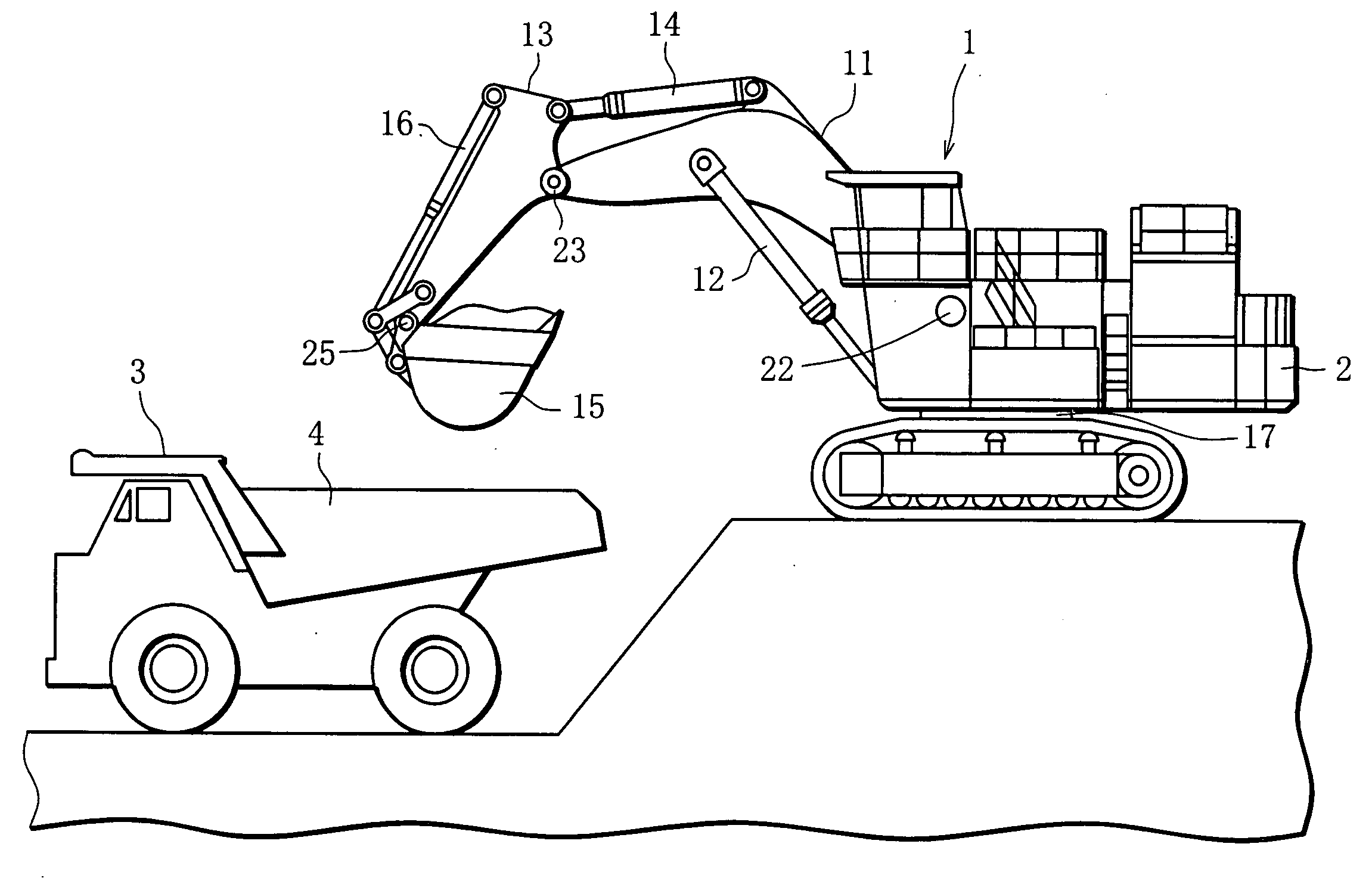

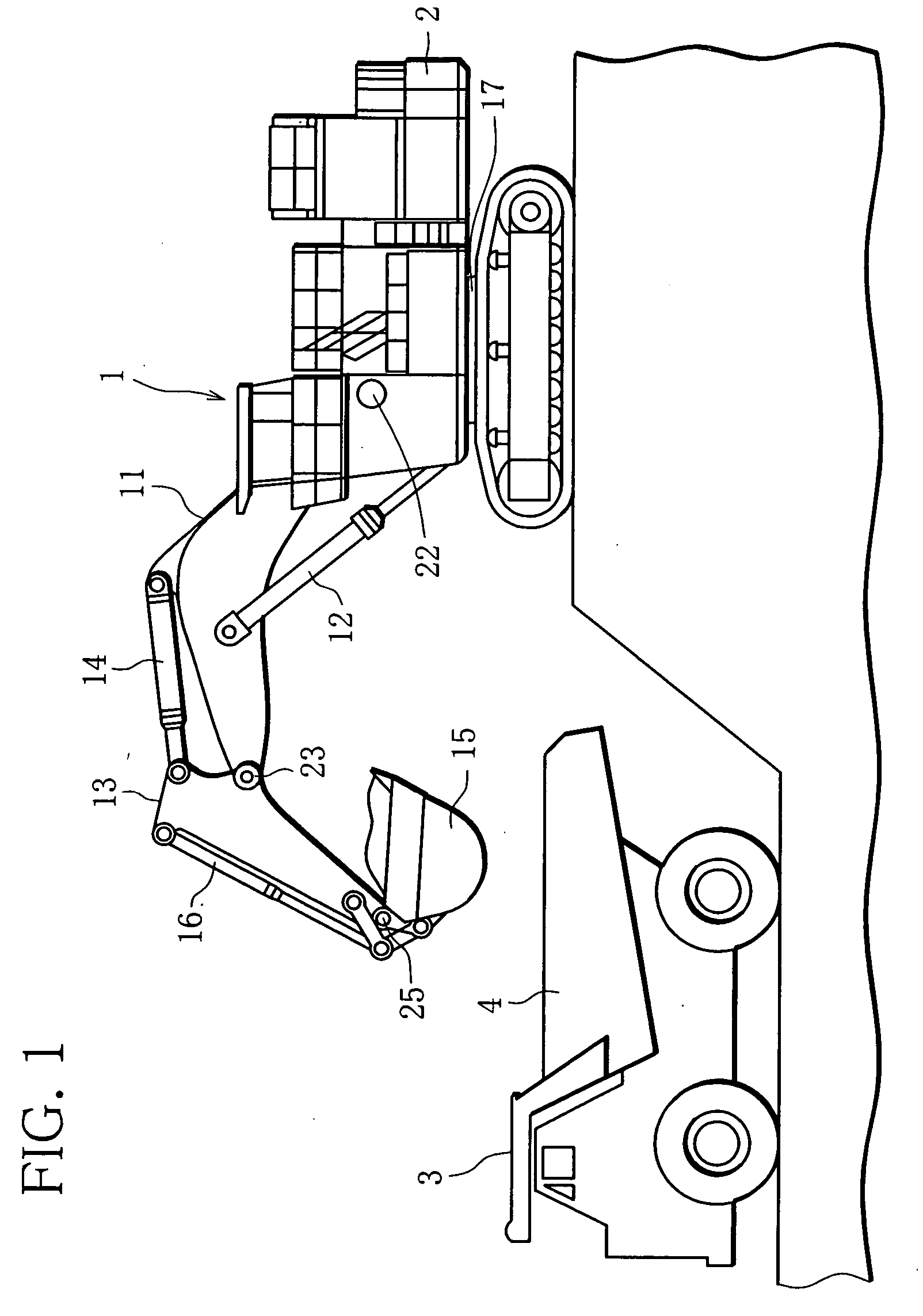

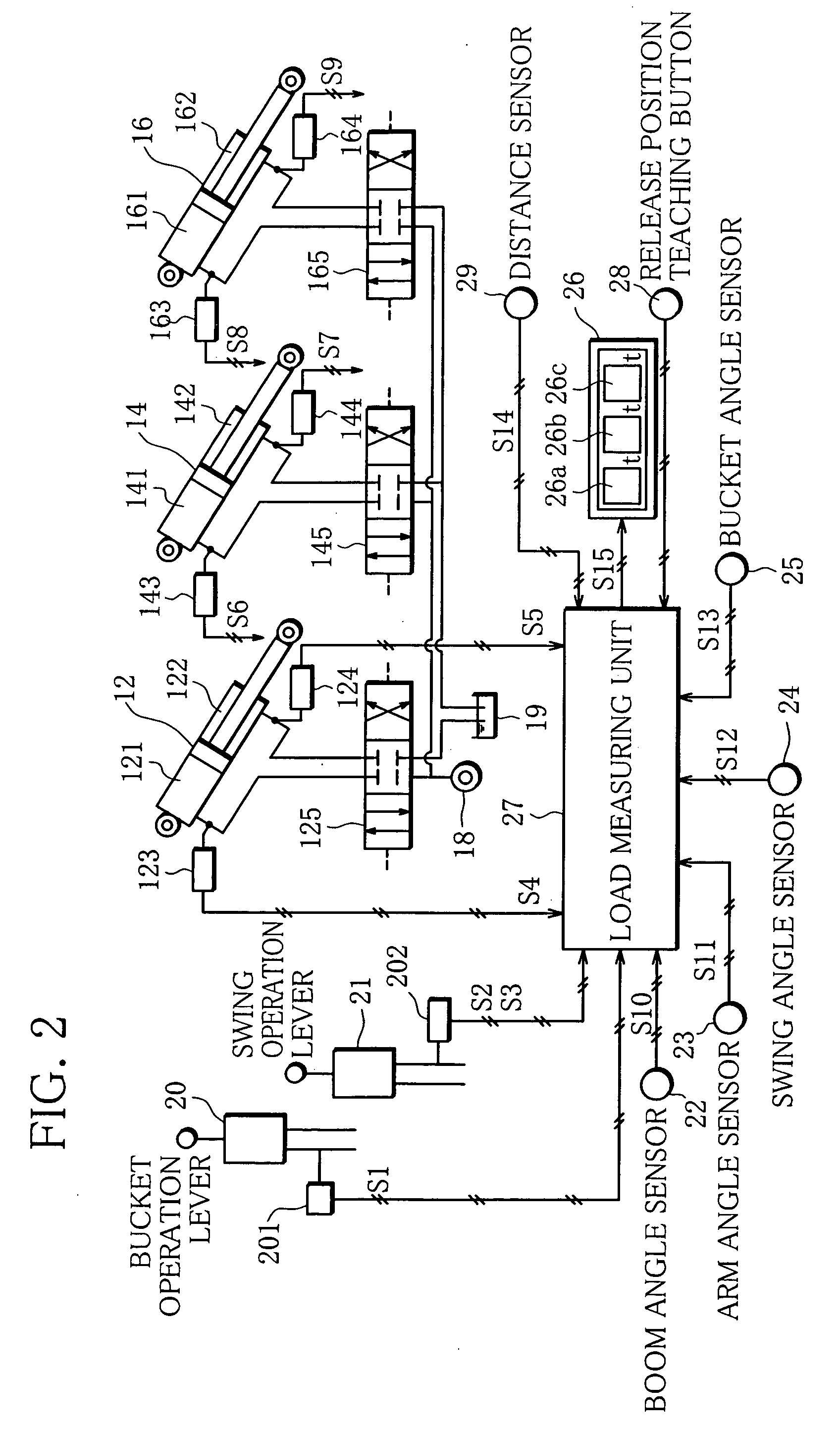

Hydraulic shovel work amount detection apparatus, work amount detection method, work amount detection result display apparatus

InactiveUS20050000703A1Precise managementIncrease weightAnalogue computers for trafficSoil-shifting machines/dredgersExcavatorMaterial transfer

During transfer of a material by a hydraulic excavator, load computing means periodically computes the weight of the material in a bucket of the excavator. Average value computing means computes an average value of weights of the material including a currently computed weight and a predetermined number of weights computed prior to the currently computed weight (M6), and standard deviation computing means computes, based on the average value, a standard deviation of the weights of the material (M7). True load value determining means selects a minimum standard deviation from among the standard deviations computed by the standard deviation computing means from the start of the transfer of the material to a different location until the end of the transfer of same, and judges the average value based on which the minimum standard deviation was computed, to be a true value of the weight of the material (M10, M11).

Owner:NIHON KENKI CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com