Patents

Literature

767 results about "Dc resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

DC Resistance of a Conductor. The DC resistance of a conductor or cable is that defined by ohms law. It is a function of many factors including temperature which greatly affects the resistance of a given material.

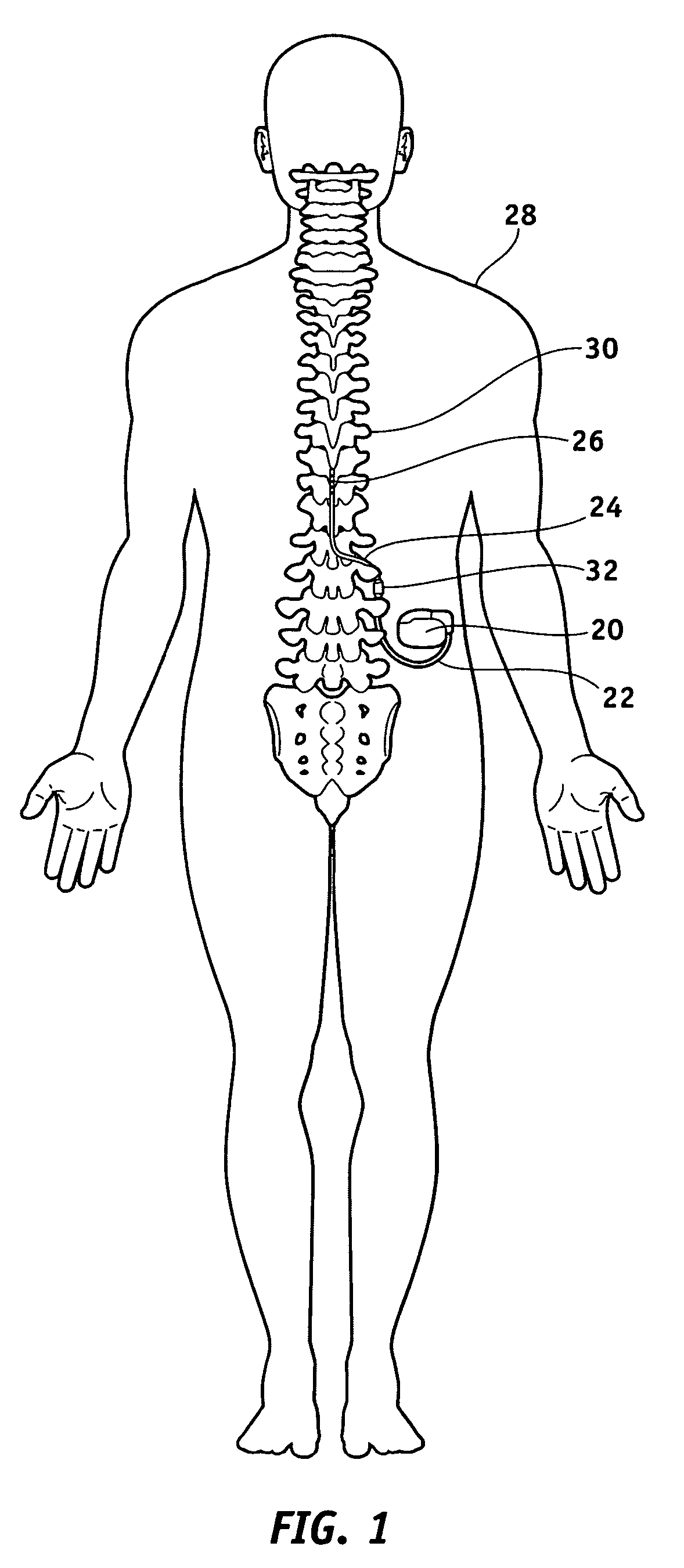

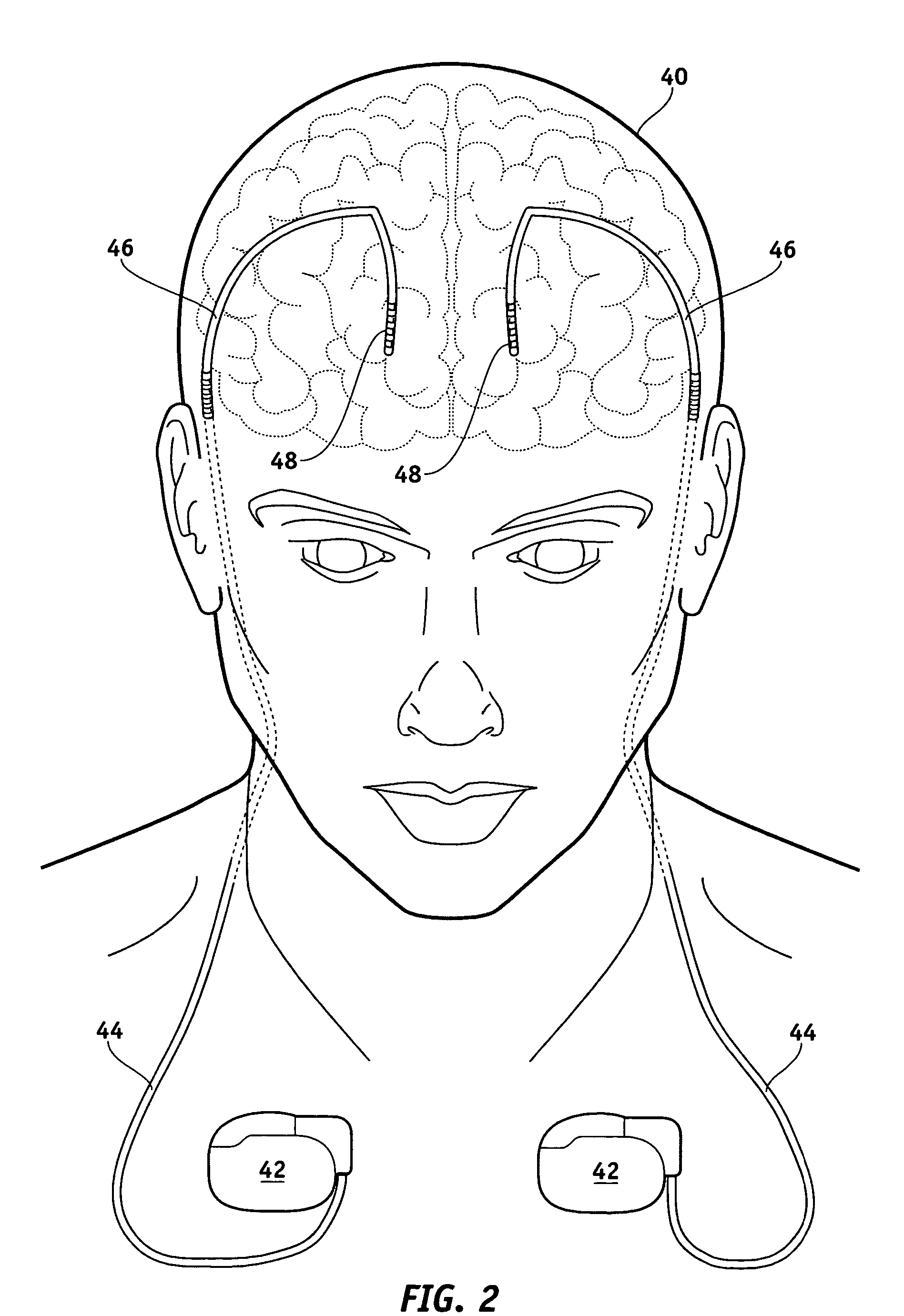

MRI-safe implantable medical device

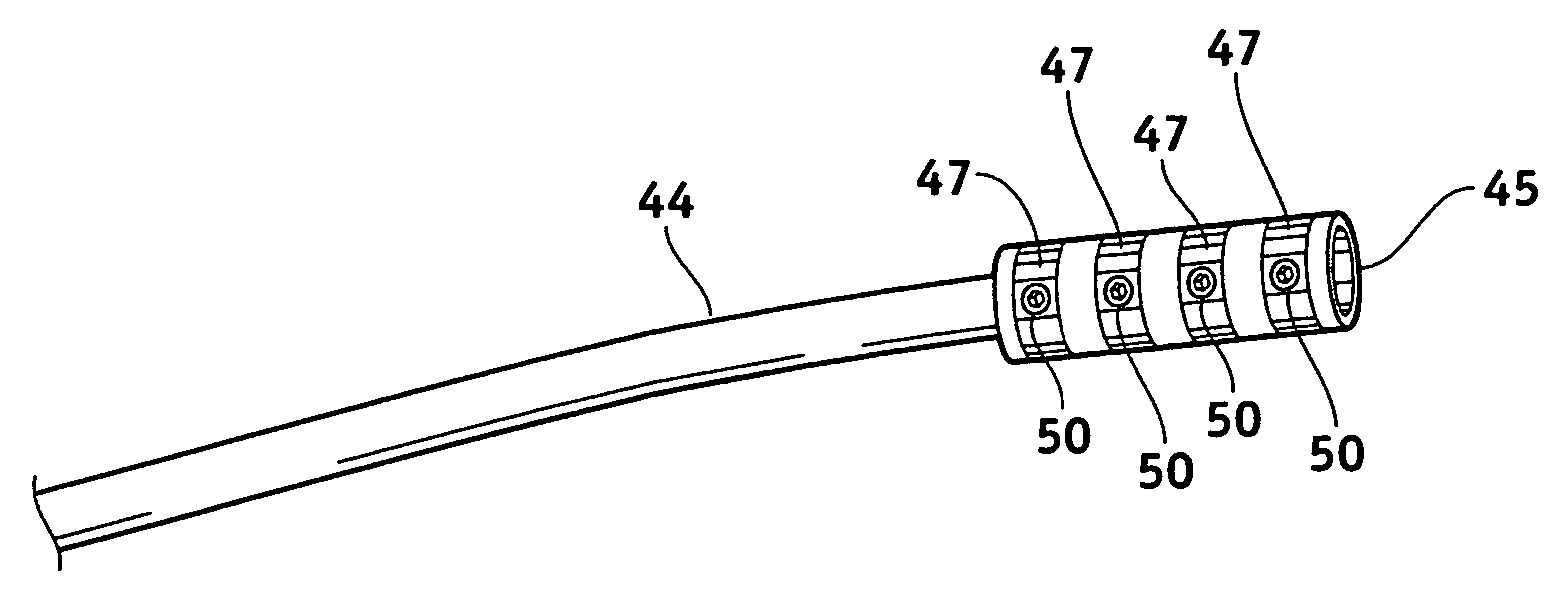

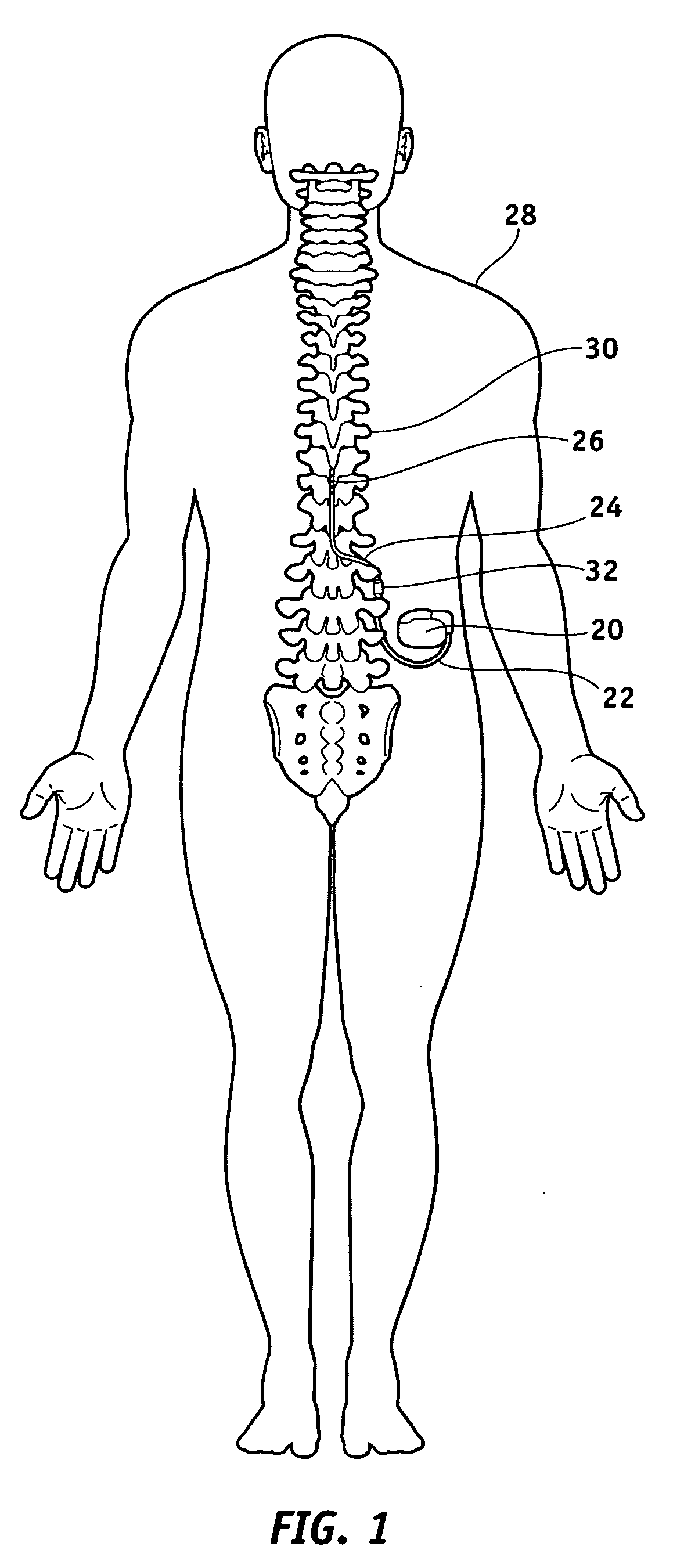

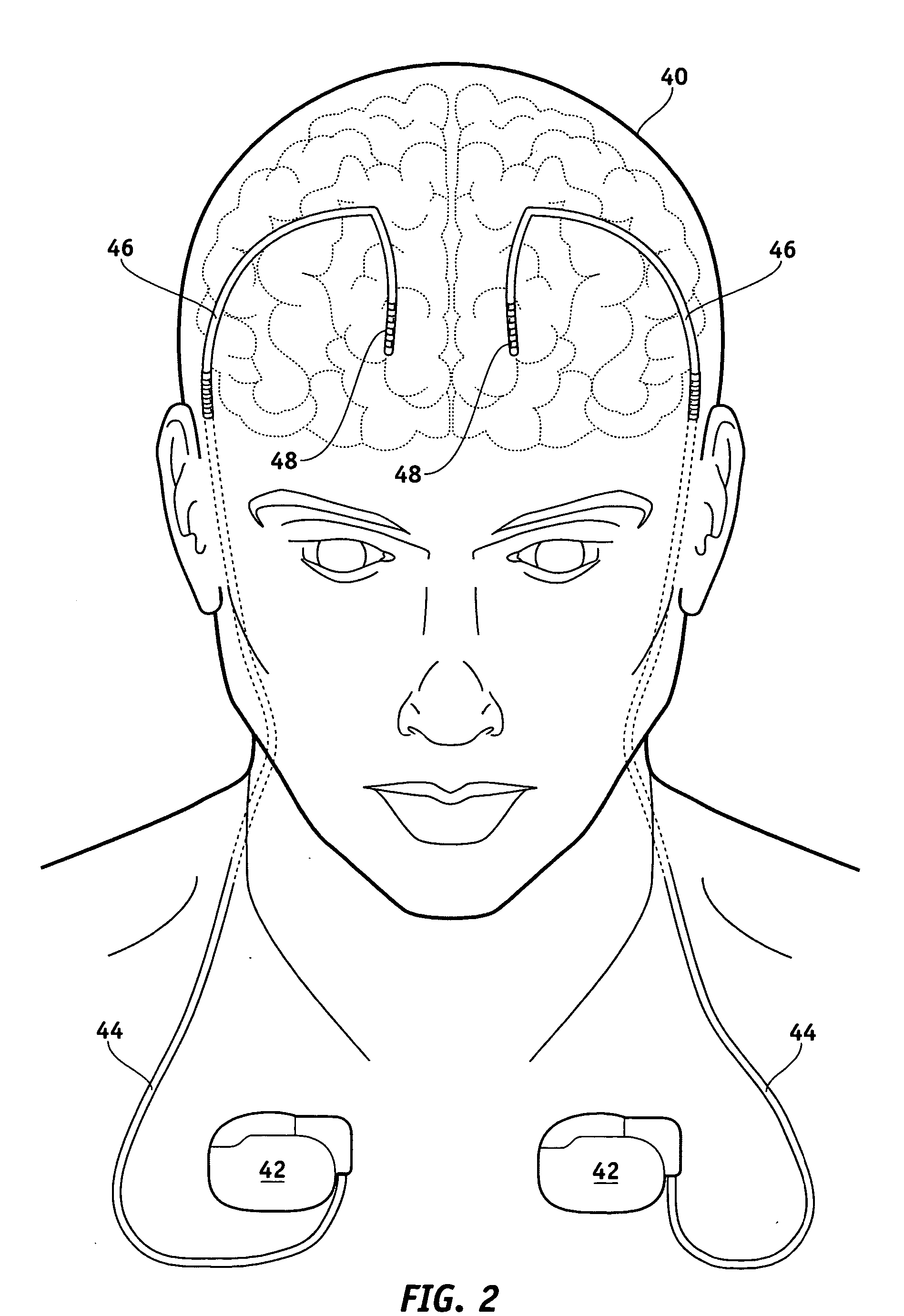

ActiveUS20050222656A1Spinal electrodesHead electrodesElectrical resistance and conductanceElectricity

A medical lead is provided for use in a pulse stimulation system of the type which includes a pulse generator for producing electrical stimulation therapy. The lead comprises an elongate insulating body and at least one electrical conductor within the insulating body. The conductor has a proximal end configured to be electrically coupled to the pulse generator and has a DC resistance in the range of 375-2000 ohms. At least one distal electrode is coupled to the conductor.

Owner:MEDTRONIC INC

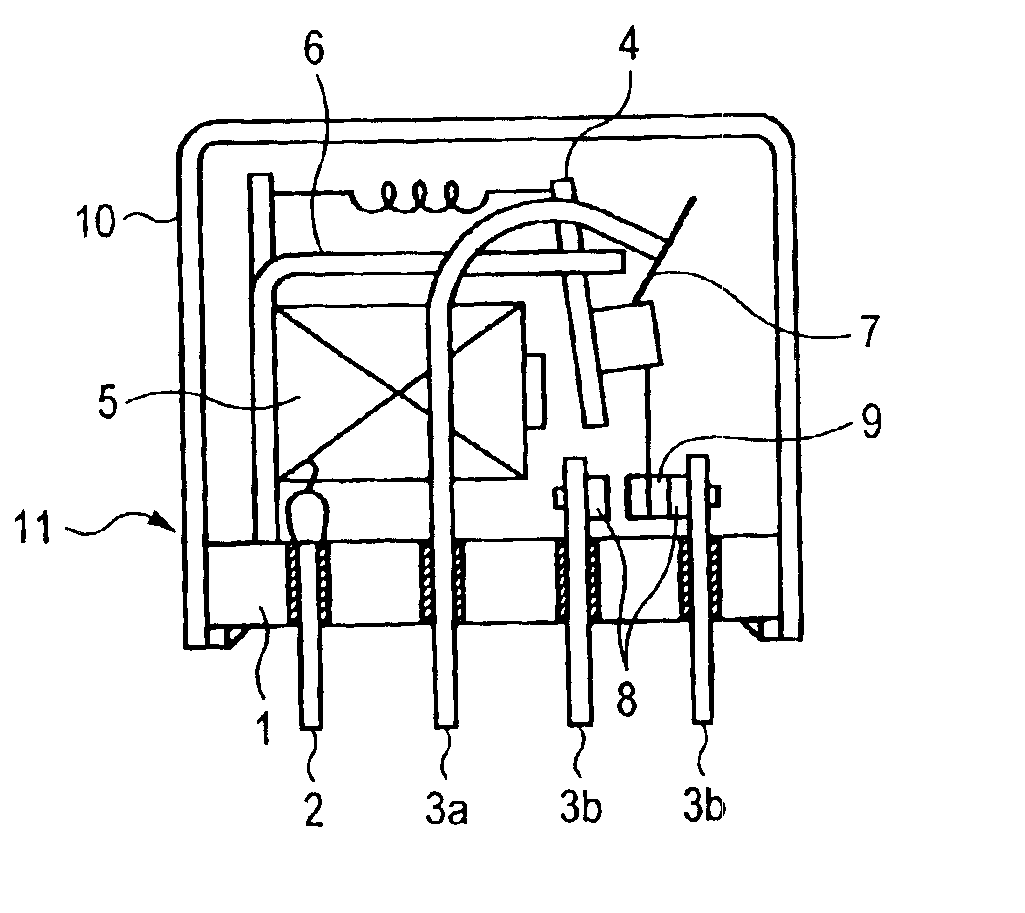

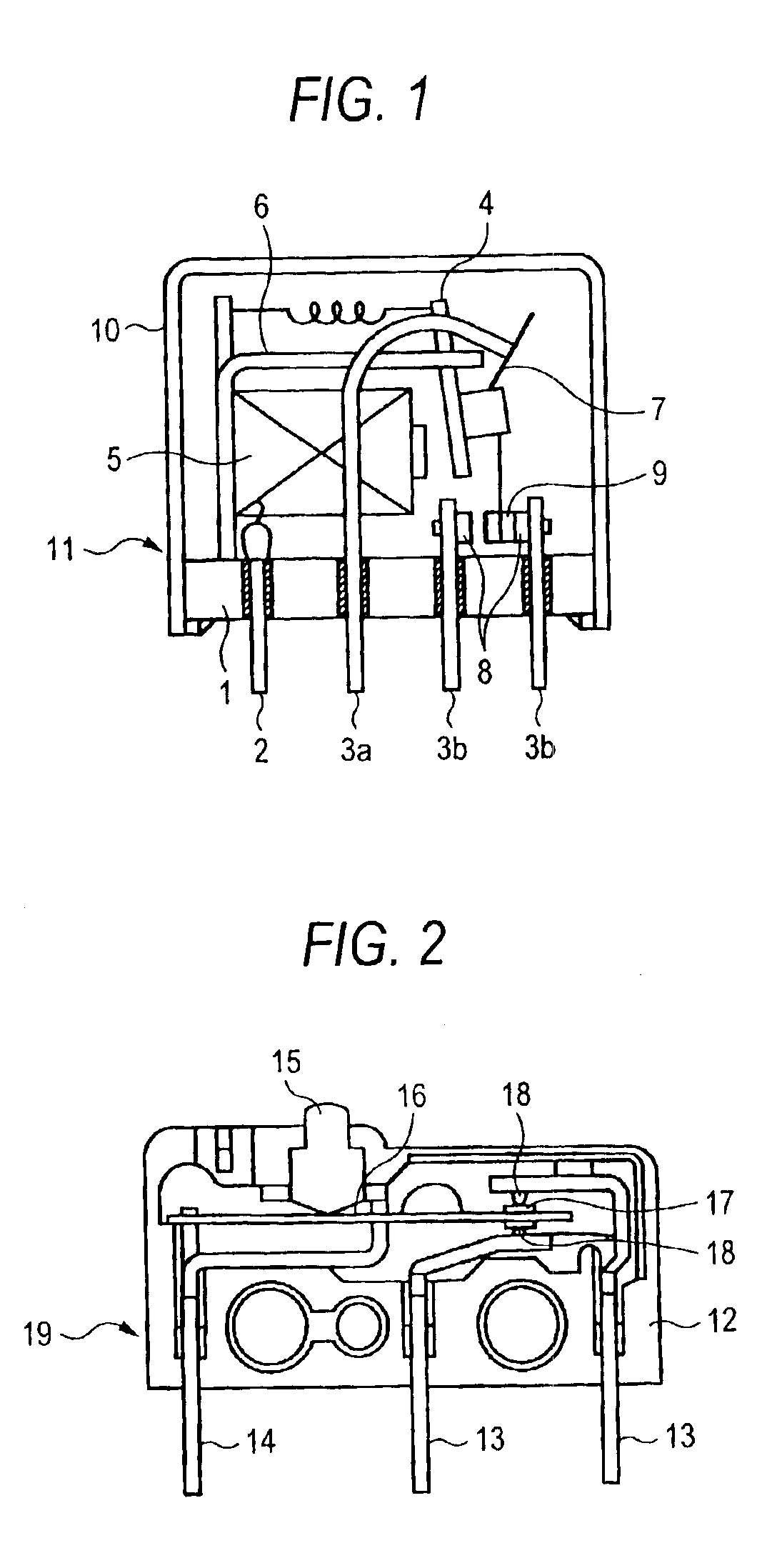

Direct current load breaking contact point constitution and switching mechanism therewith

InactiveUS6934134B2Contact materialsCircuit-breaking switches for excess currentsElectrical resistance and conductanceElectrical polarity

The invention intends to provide a direct current load breaking contact point constitution that can make and break an electrical circuit under both direct current loads of direct current resistance load and direct current inductance load over a long period of time without causing problems such as ① the conduction defect due to the consumption of the contact point, ② the locking due to material transfer from one contact point to the other contact point, ③ the welding between the contact points, and ④ the abnormal arc continuation, and a direct current load breaking switching mechanism such as a relay, a switch and so on that has the contact point constitution. The direct current load breaking contact point constitution according to the invention comprises a movable contact point and a stationary contact point that face each other; wherein the movable contact point is made of AgSnO2In2O3 alloy that contains at least Ag, 8 to 15% by weight in total of metal oxides including SnO2 and In2O3, 6 to 10% by weight of SnO2 and 1 to 5% by weight of In2O3; the stationary contact point is made of AgZnO alloy that contains at least Ag and 7 to 11% by weight of ZnO; and polarity of a movable side is (+) and that of a stationary side is (−).

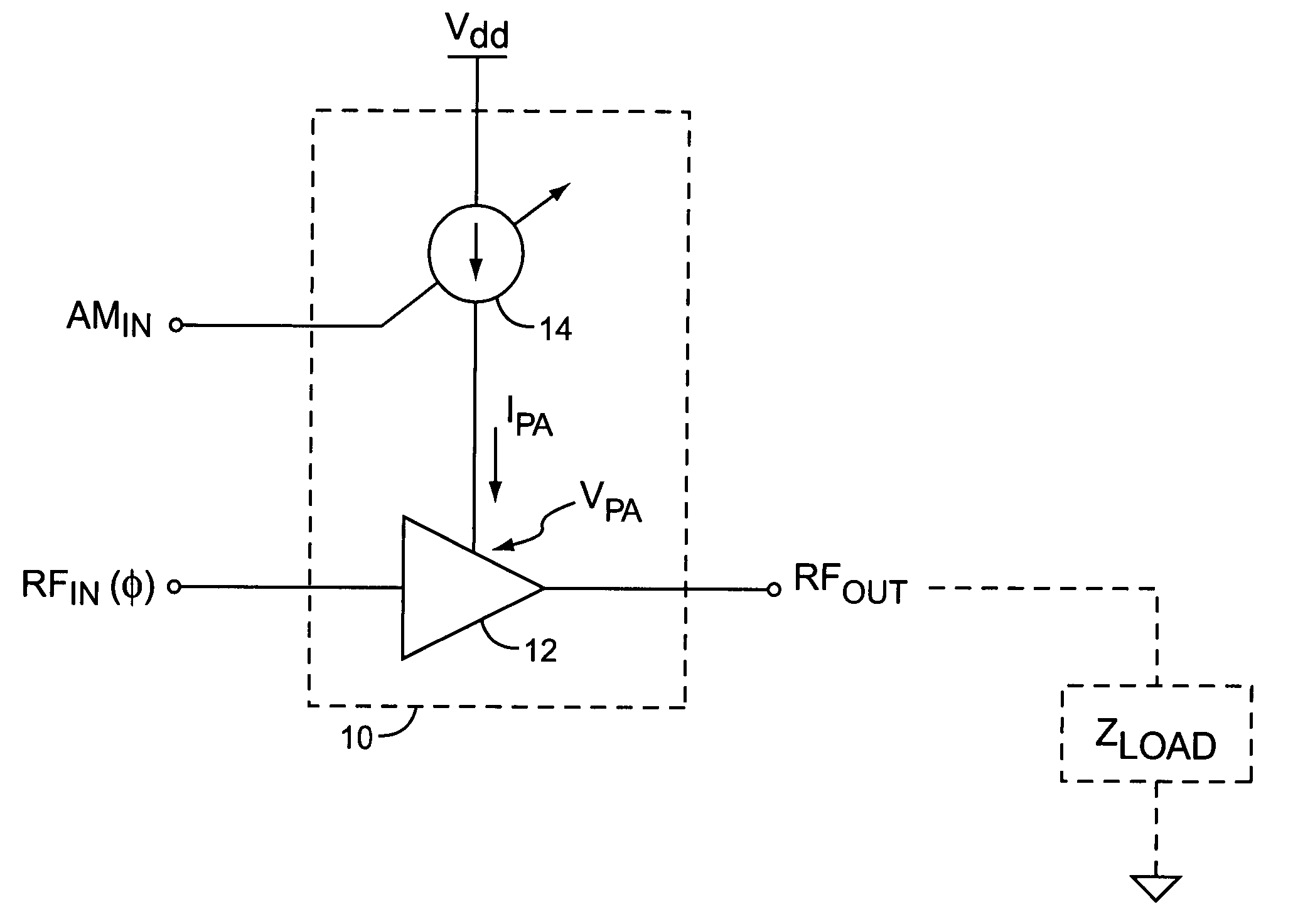

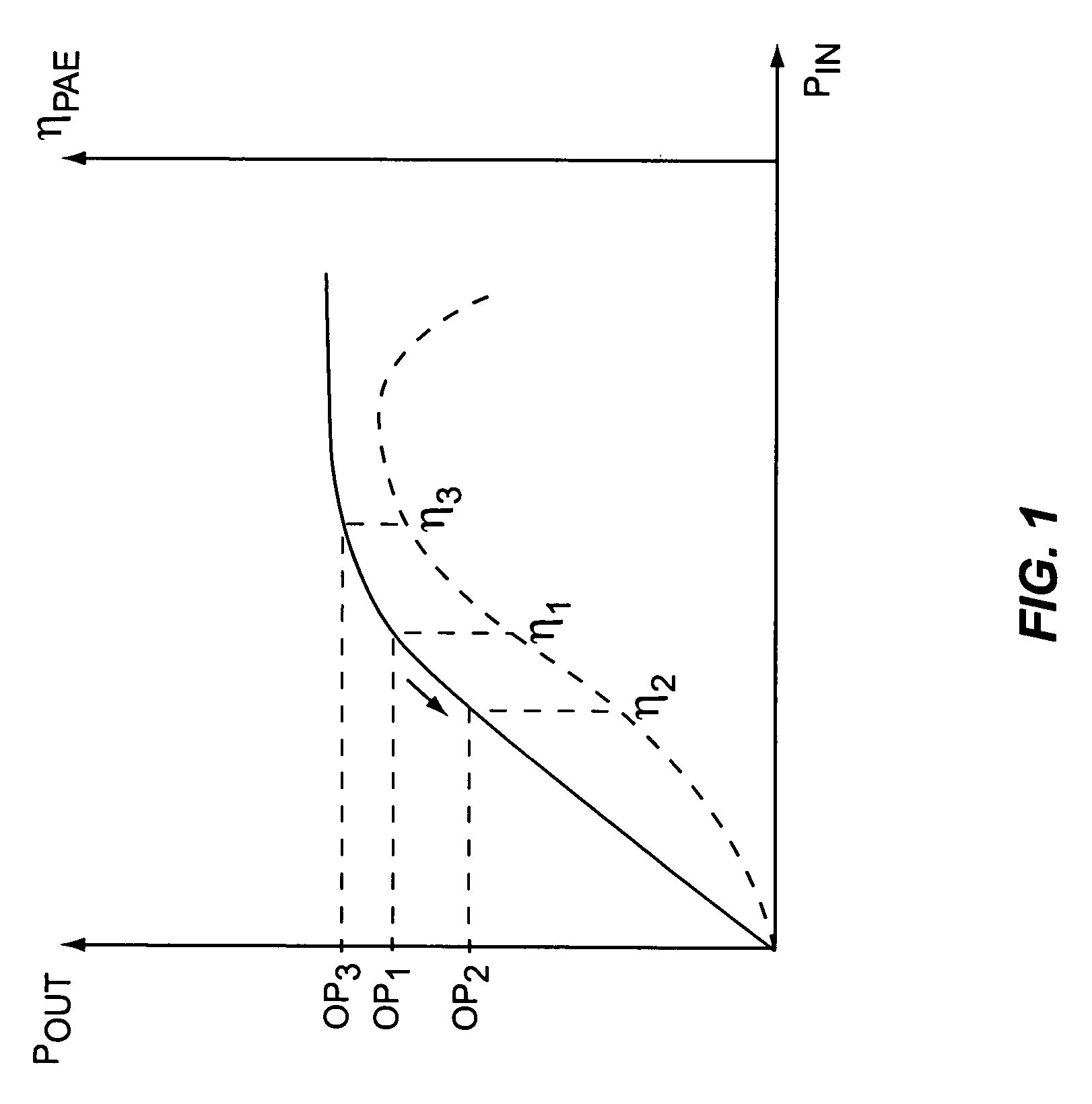

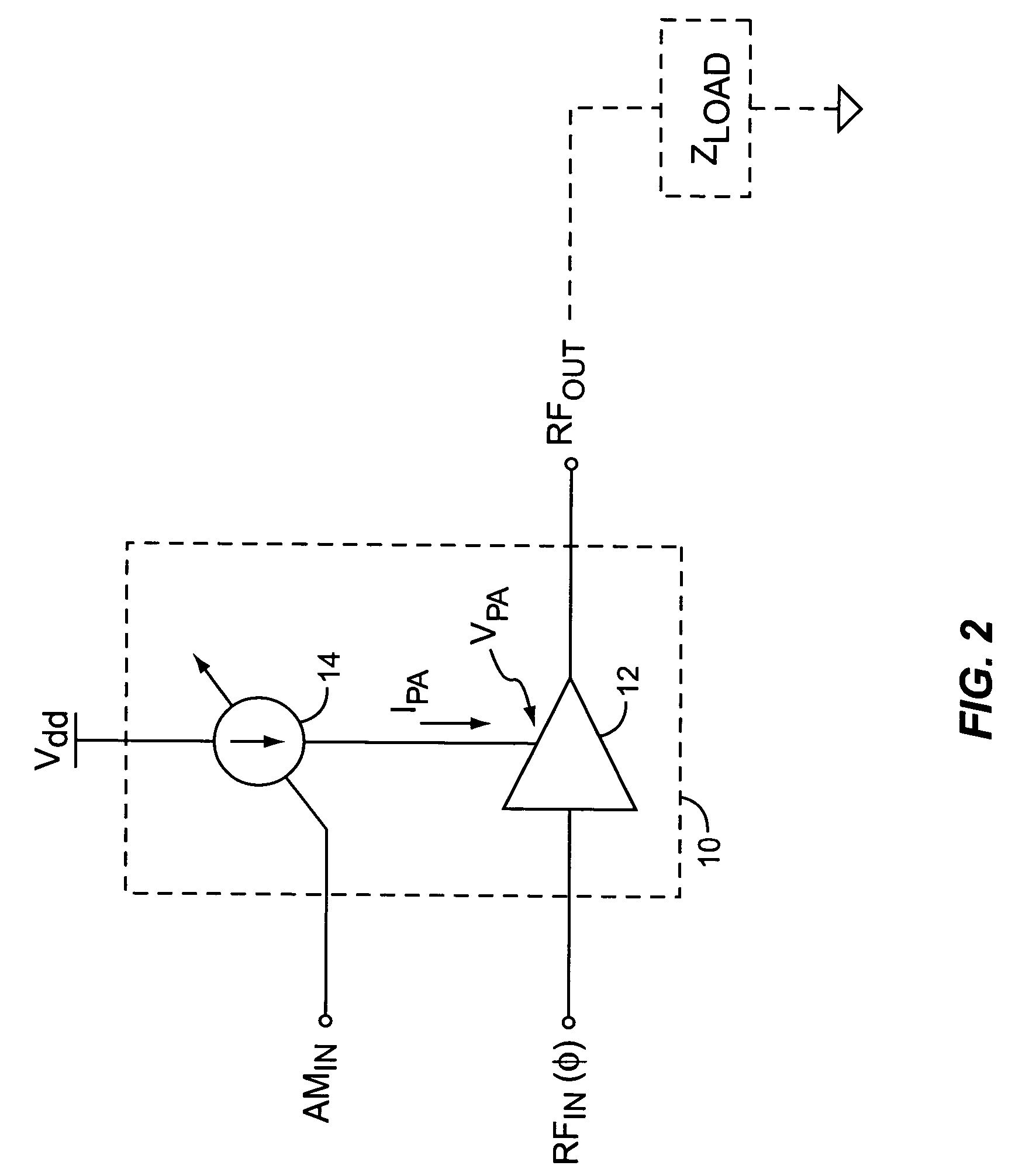

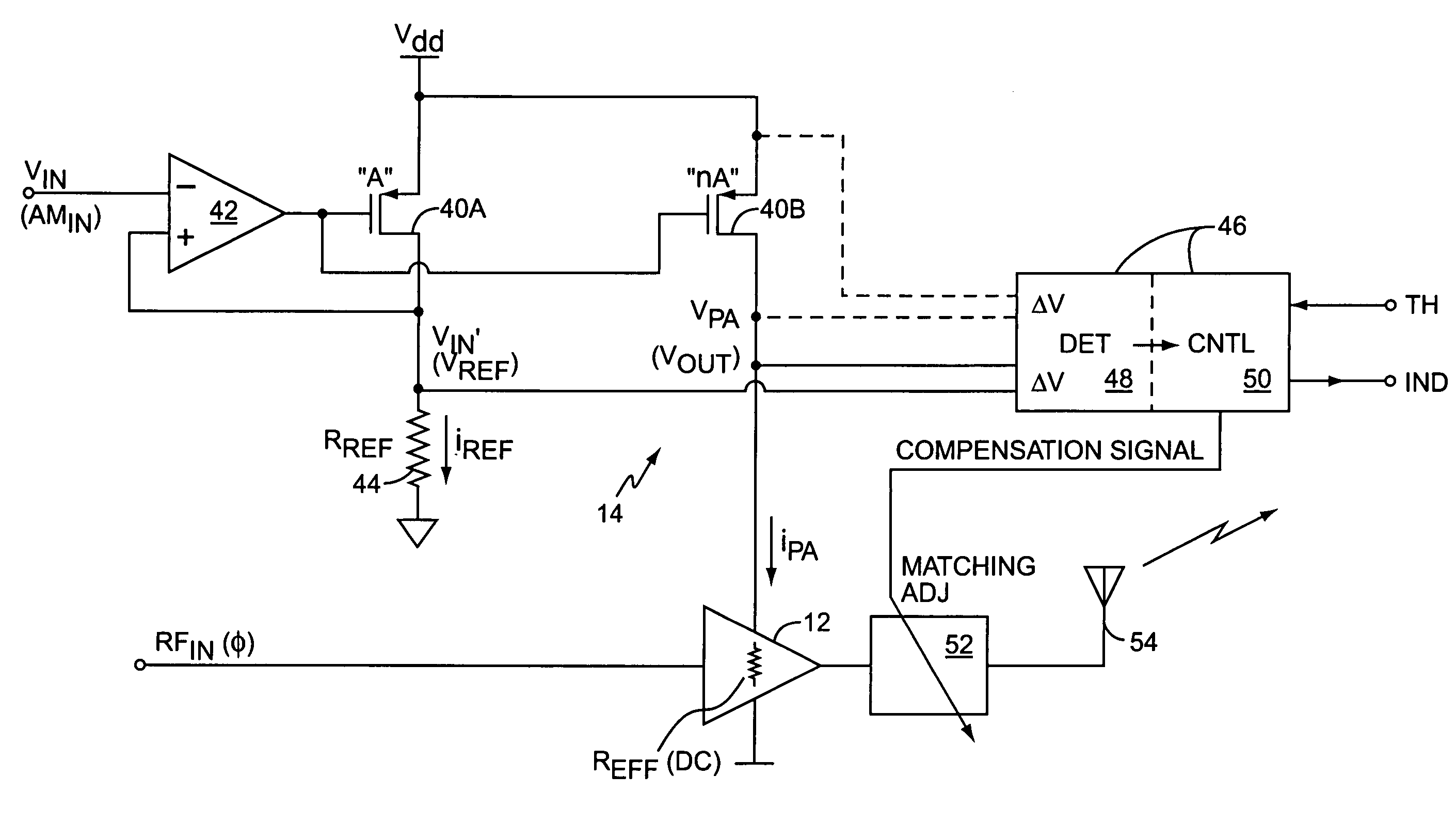

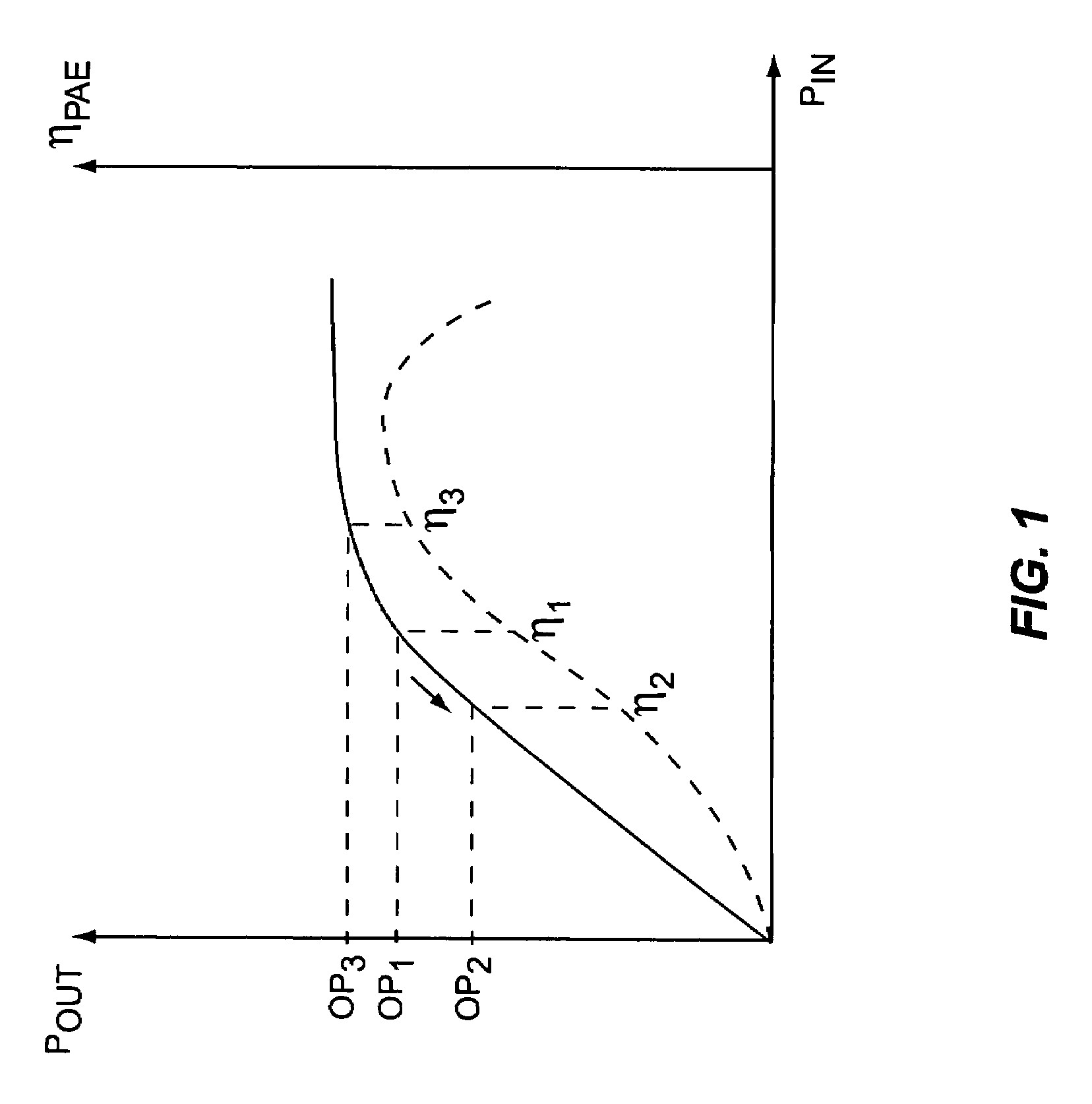

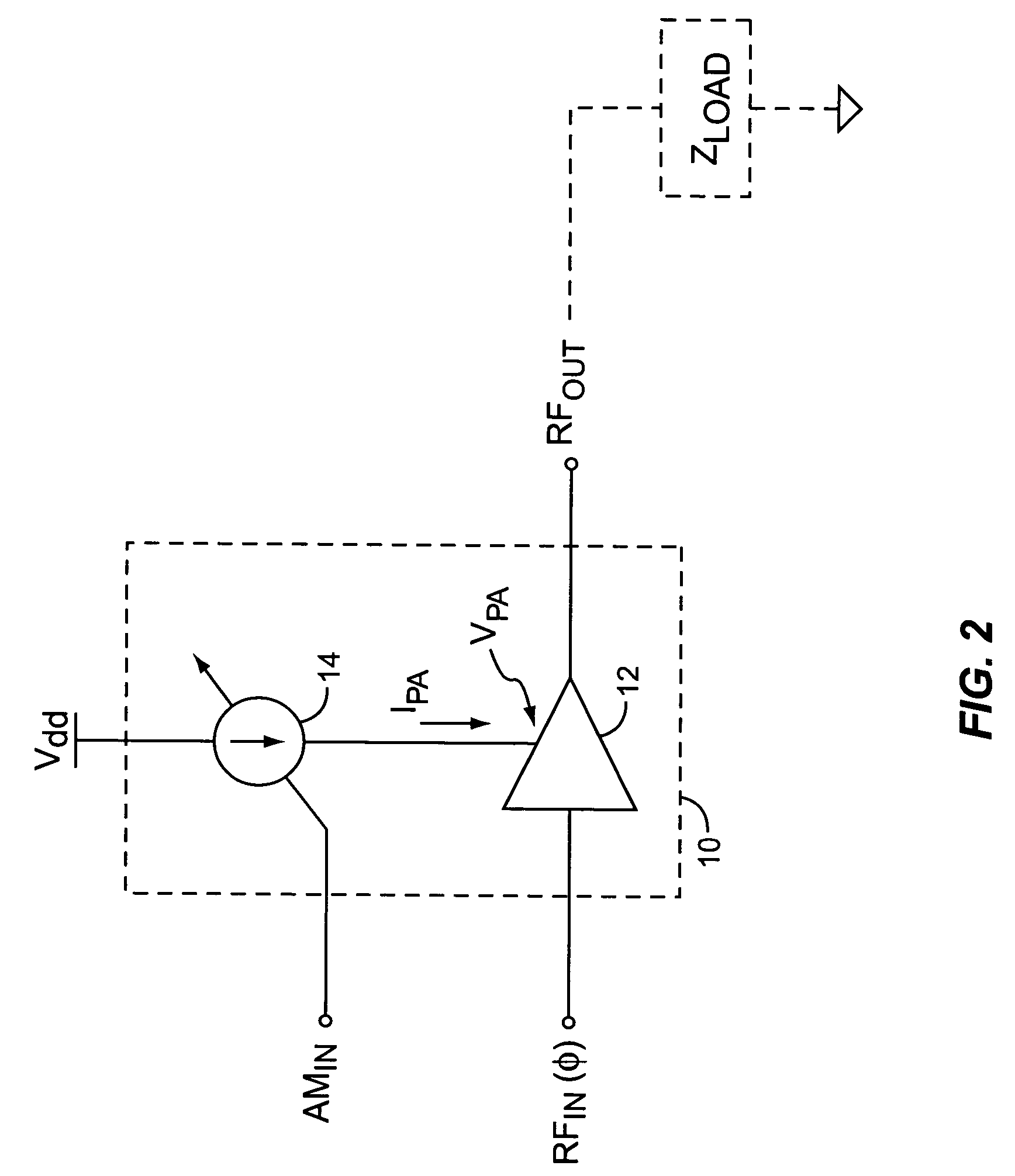

System and method for current-mode amplitude modulation

InactiveUS20050032488A1Efficient and linear amplificationHighly linear envelope modulationSimultaneous amplitude and angle modulationAmplifier modifications to reduce non-linear distortionAntenna impedanceAudio power amplifier

An amplifier circuit includes a power amplifier biased for saturated mode operation, and a controllable current source to provide supply current to the power amplifier. The controllable current source effects desired amplitude modulation of the output signal from the power amplifier by modulating the supply current it provides responsive to an amplitude information signal. In one or more embodiments, the current source includes a circuit that is configured to adjust one or more transmitter operating parameters responsive to detecting changes in the effective DC resistance of the power amplifier. For example, the circuit may generate a compensation signal that reduces the effective DC resistance responsive to detecting that the effective DC resistance has undesirably increased. By way of non-limiting examples, such compensation may be effected by changing a current mirror, an amplifier-to-antenna impedance matching, an amplifier bias or device size, or imposing some form of transmit signal back-off.

Owner:ERICSSON INC

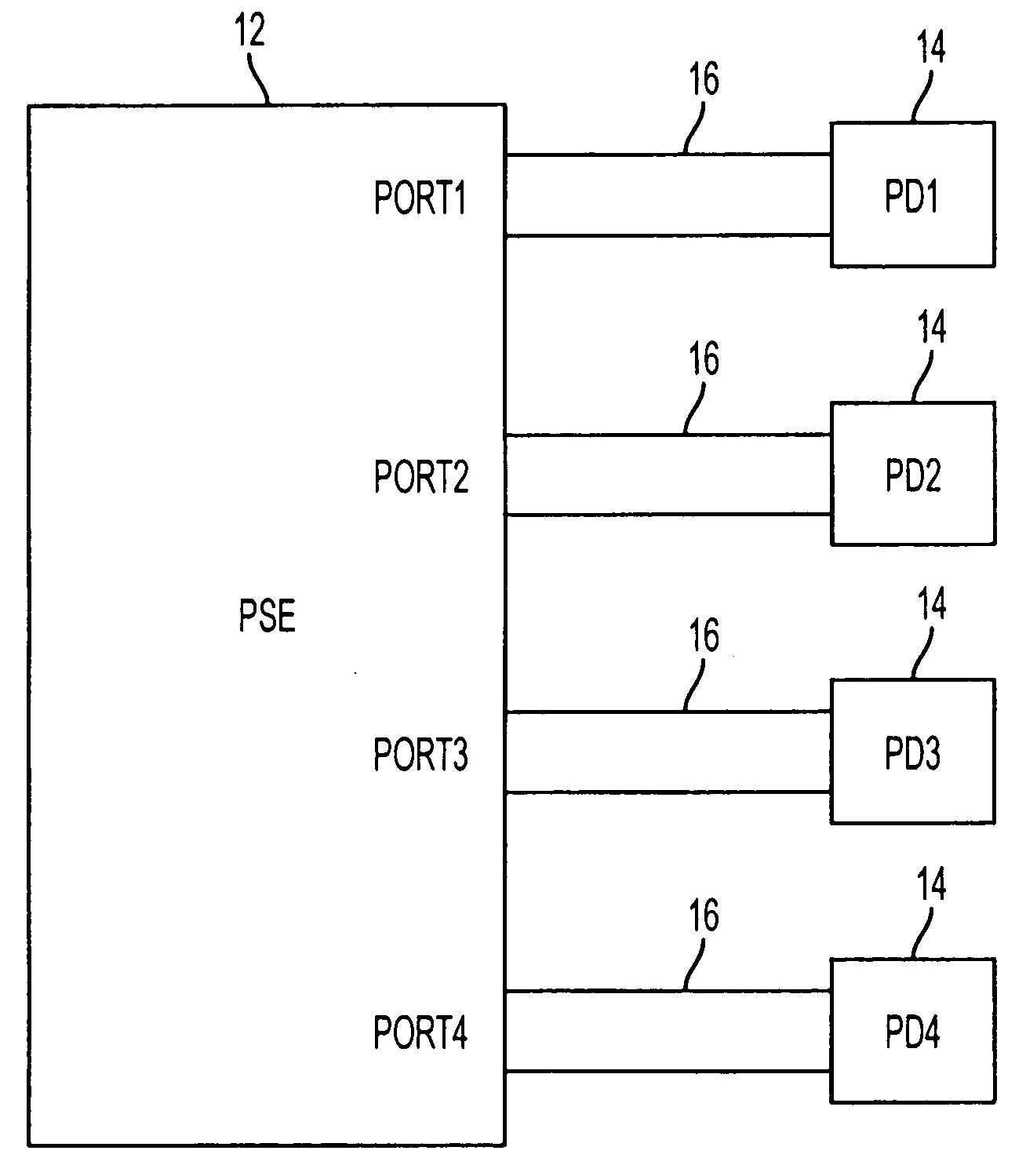

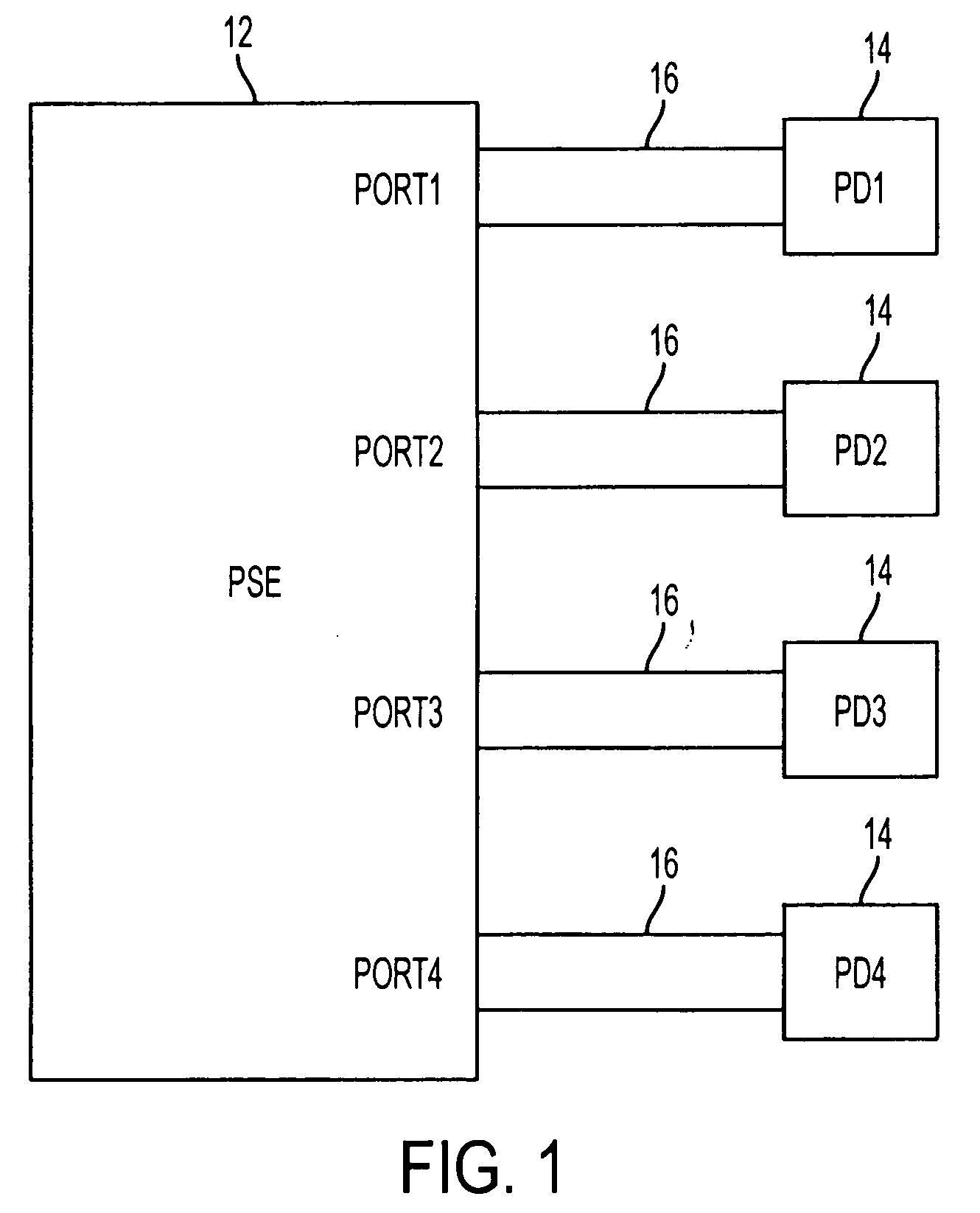

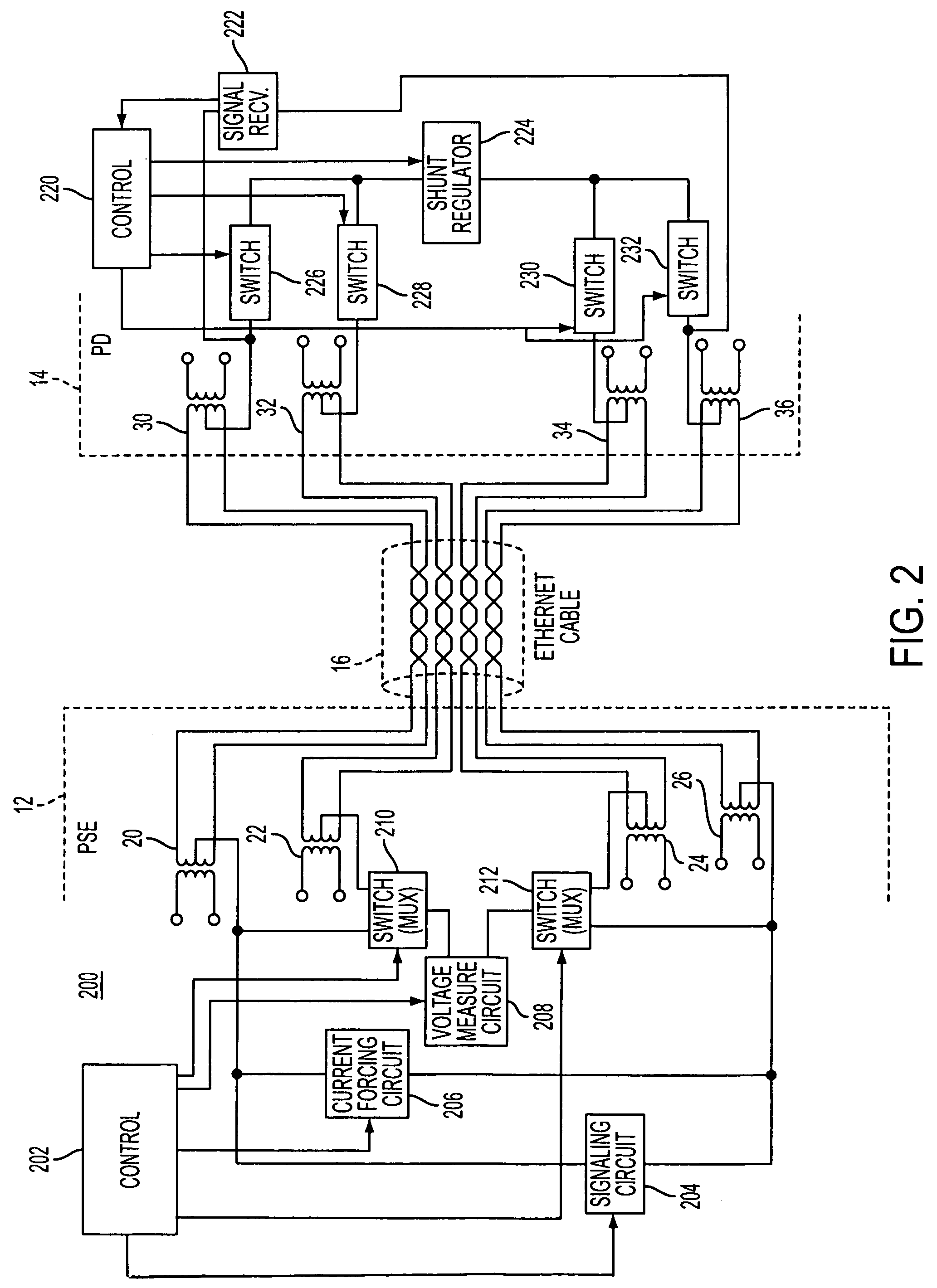

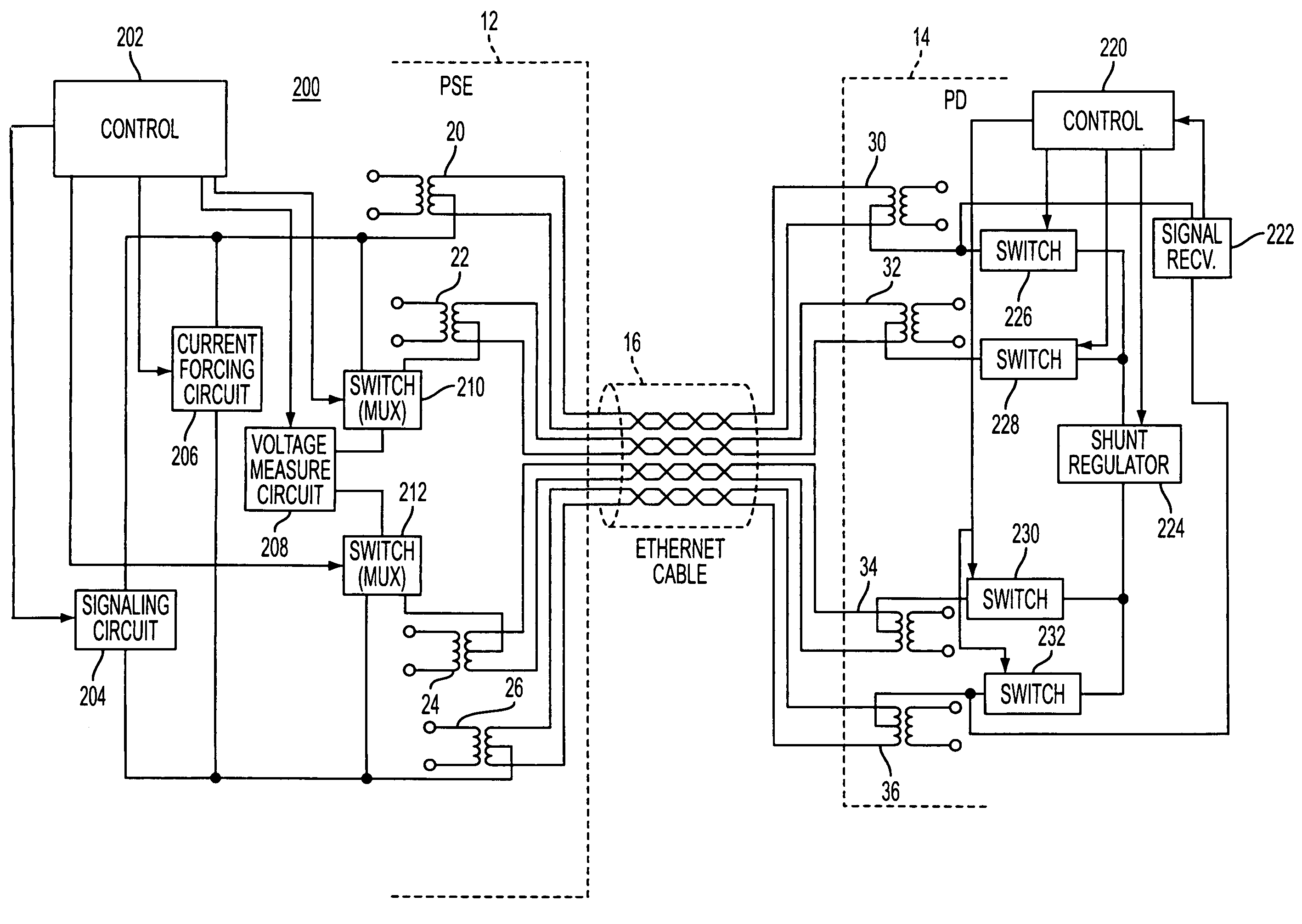

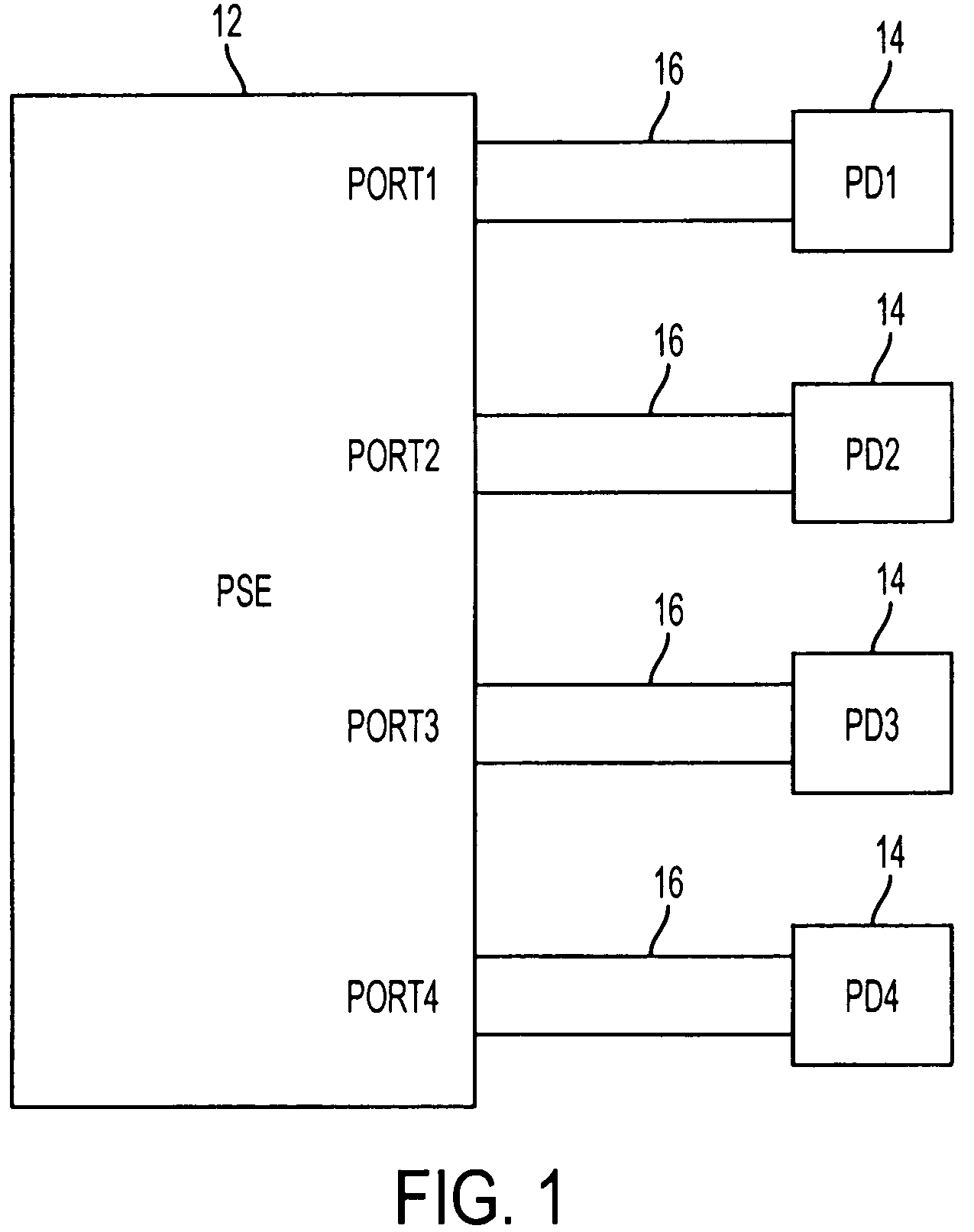

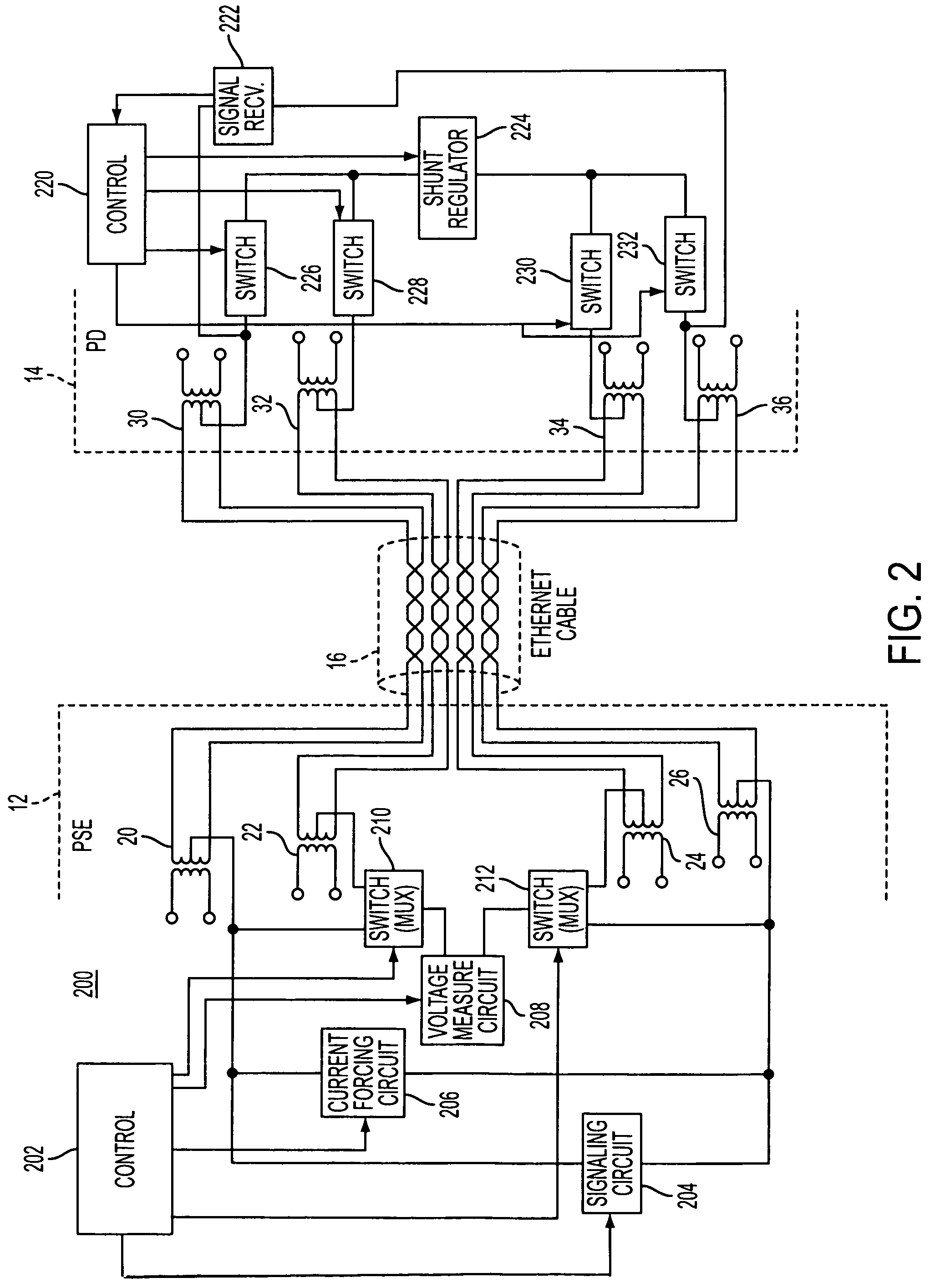

System for providing power over communication cable having mechanism for determining resistance of communication cable

ActiveUS20060164108A1Interconnection arrangementsCurrent/voltage measurementElectricityElectrical resistance and conductance

Novel system and methodology for determining resistance of wires in a communication cable having at least two pairs of wires used for providing power from a power supply device to a powered device. A measuring mechanism may determine DC resistance of the wires before the power supply device applies power to the communication cable.

Owner:ANALOG DEVICES INT UNLTD

MRI-safe implantable medical device

A medical lead is provided for use in a pulse stimulation system of the type which includes a pulse generator for producing electrical stimulation therapy. The lead comprises an elongate insulating body and at least one electrical conductor within the insulating body. The conductor has a proximal end configured to be electrically coupled to the pulse generator and has a DC resistance in the range of 375-2000 ohms. At least one distal electrode is coupled to the conductor.

Owner:MEDTRONIC INC

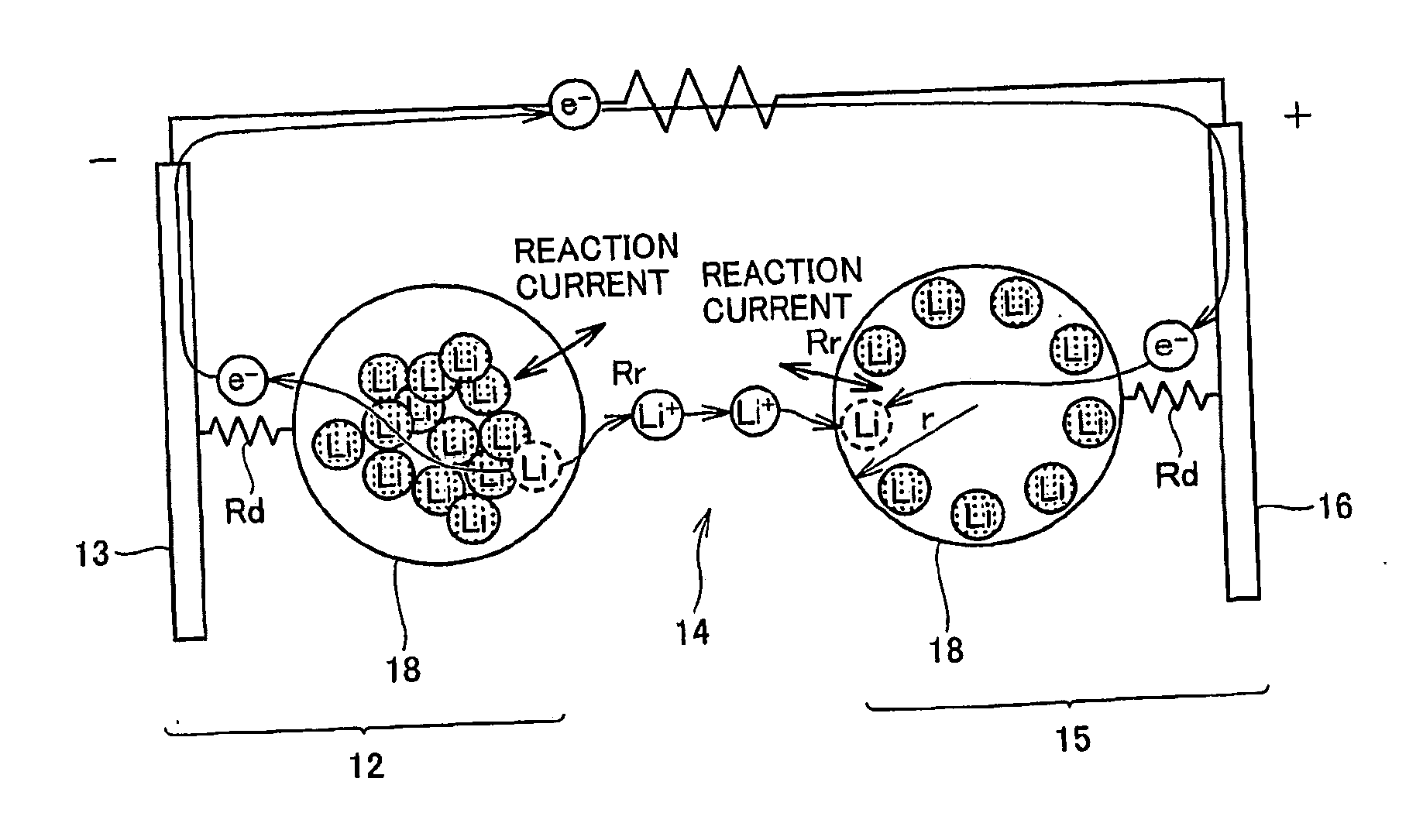

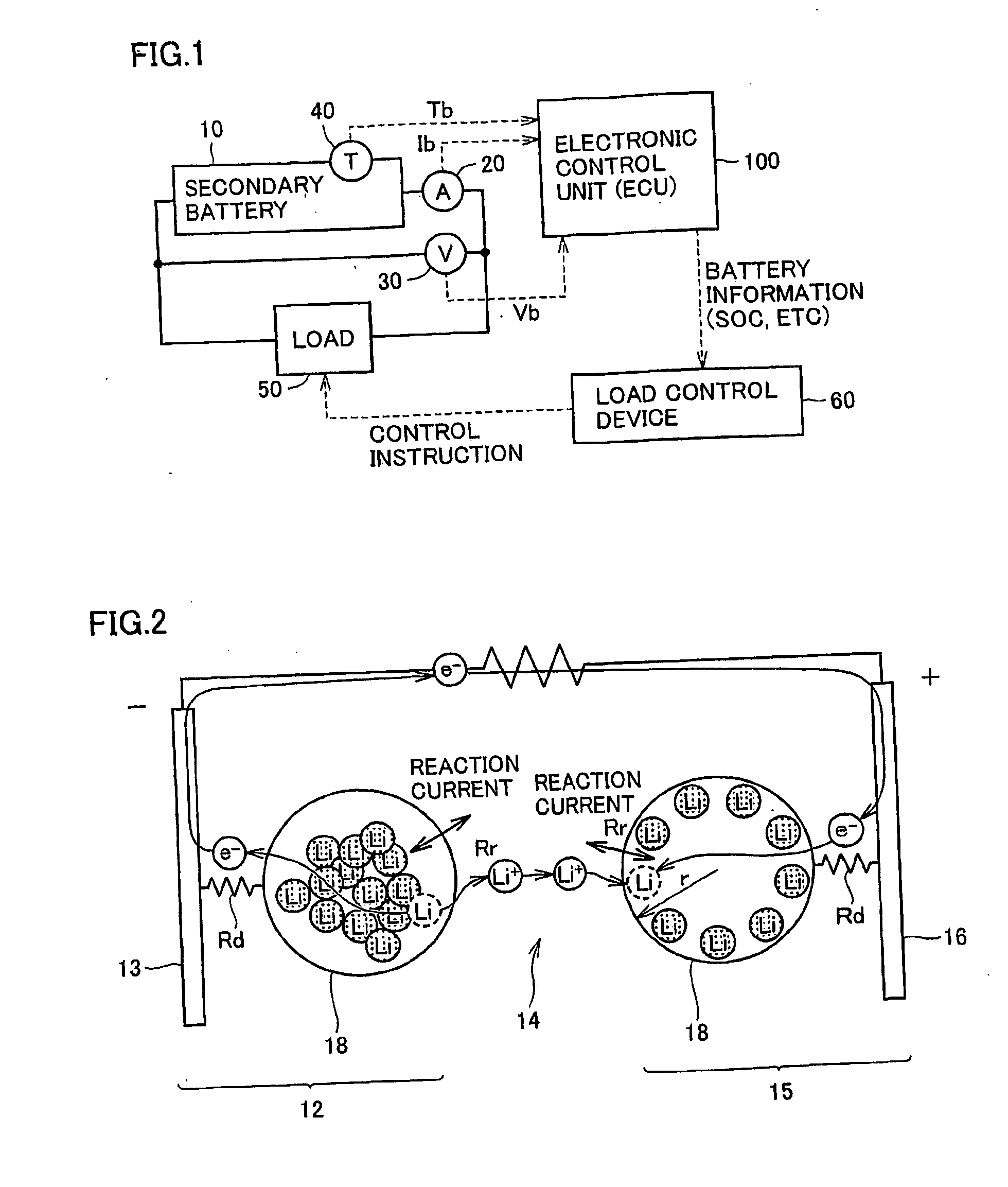

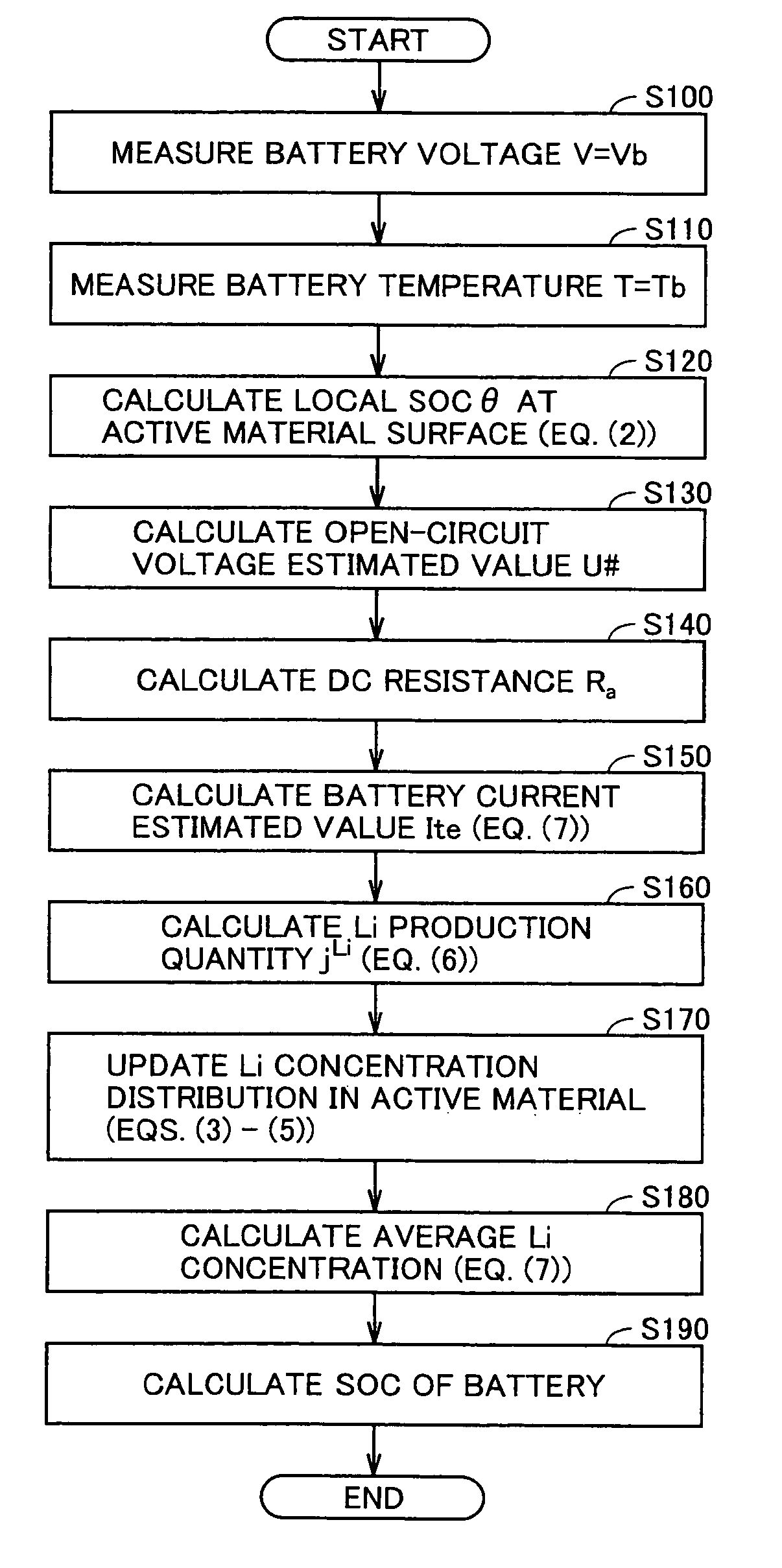

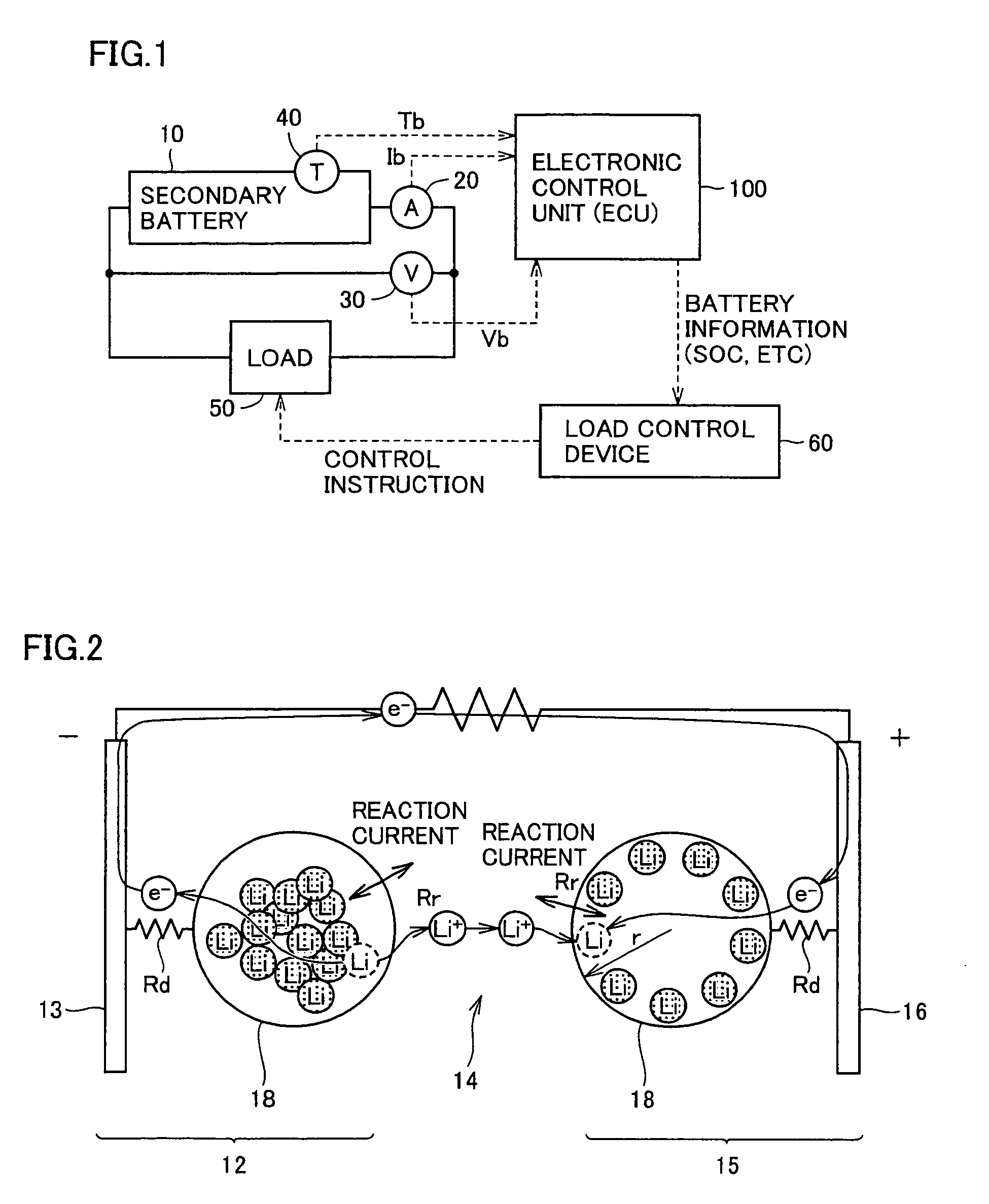

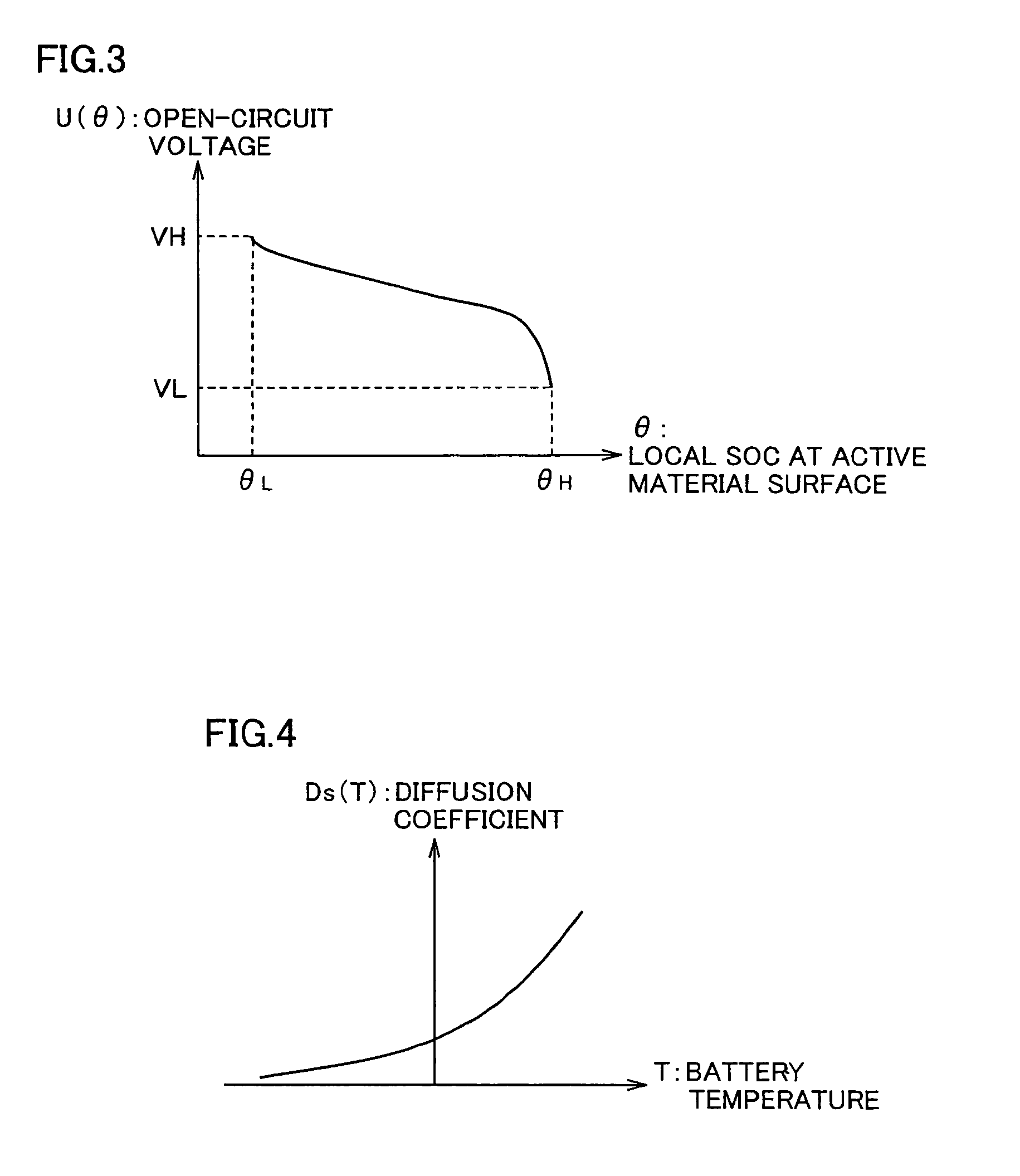

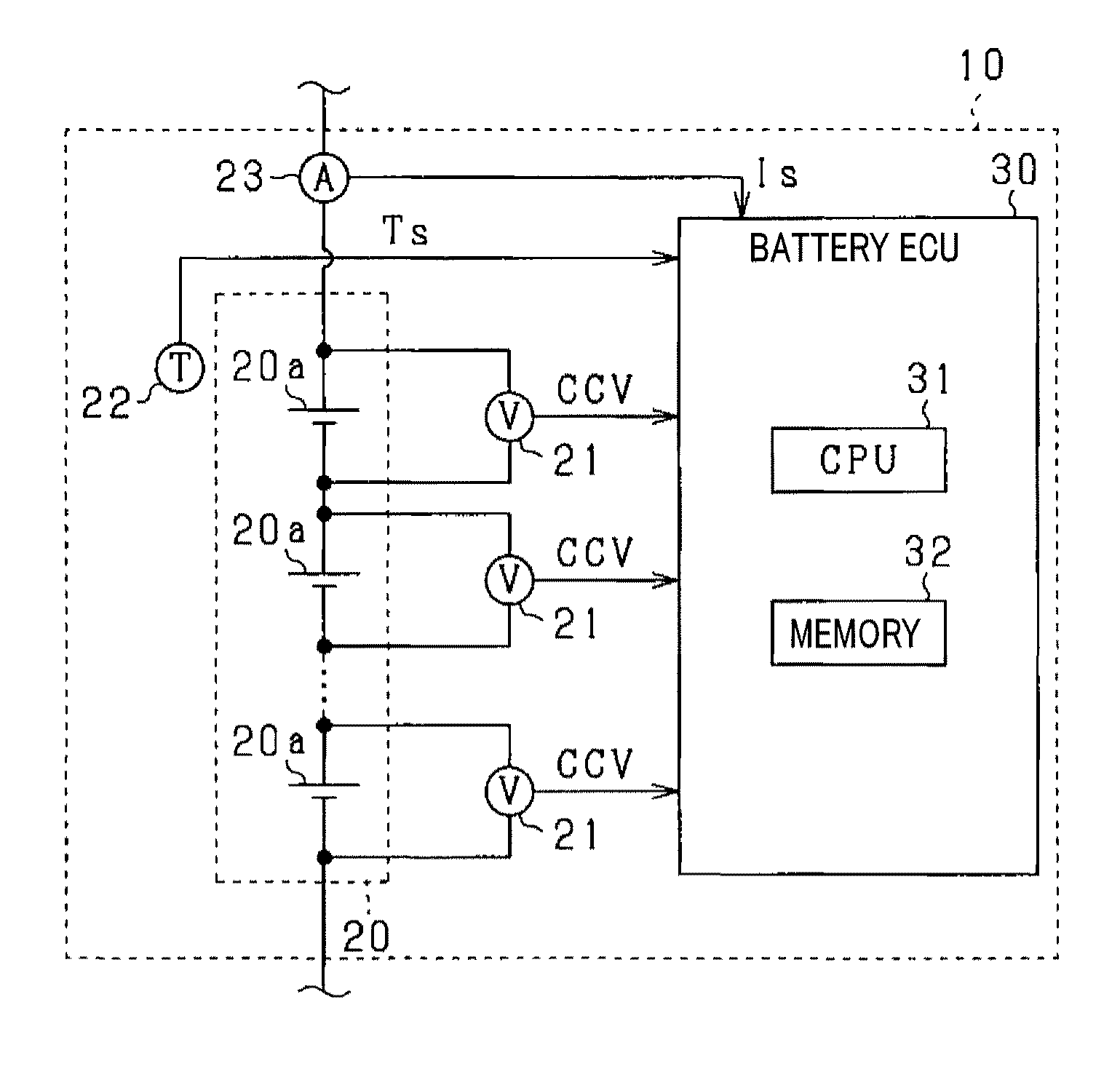

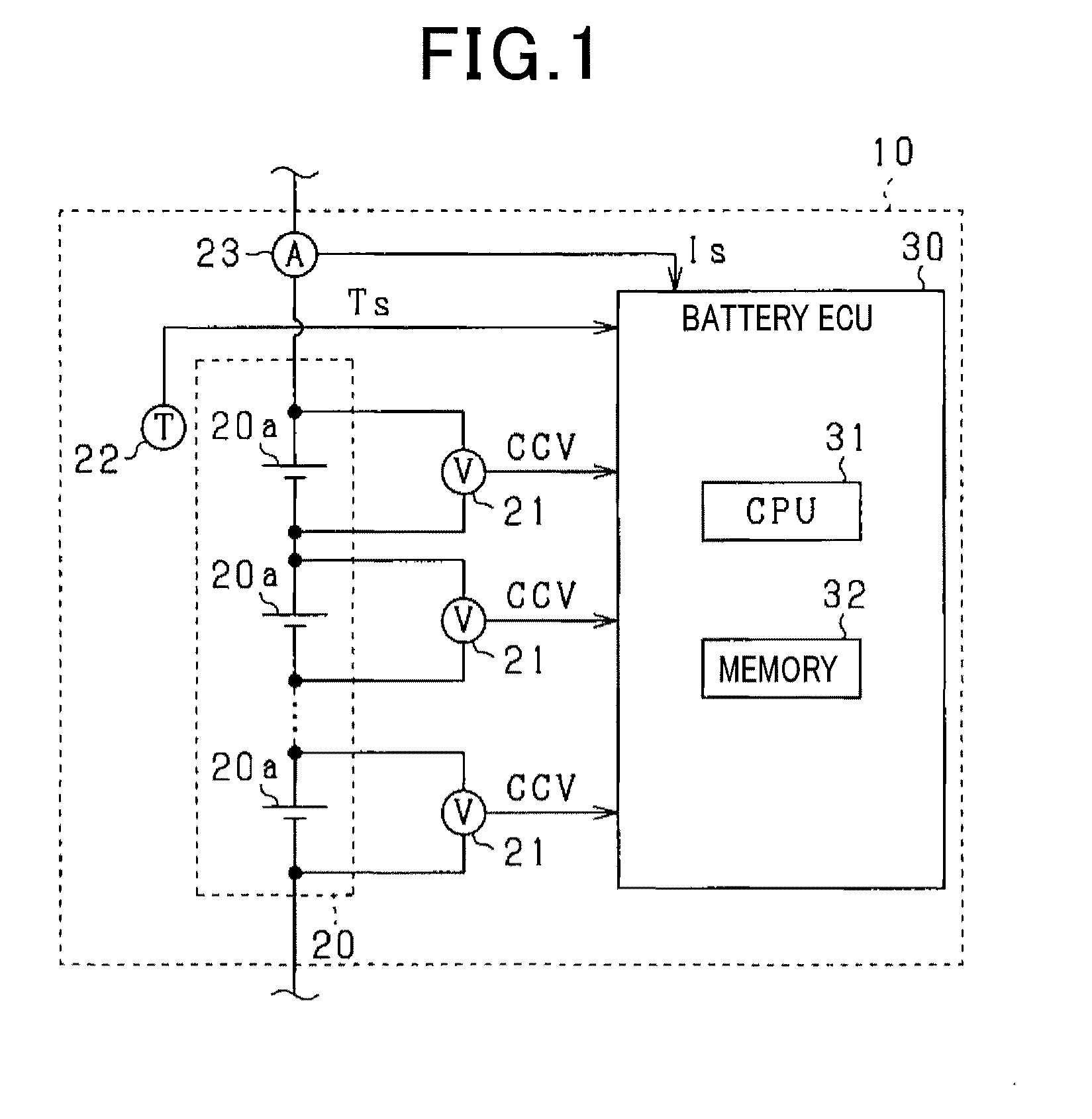

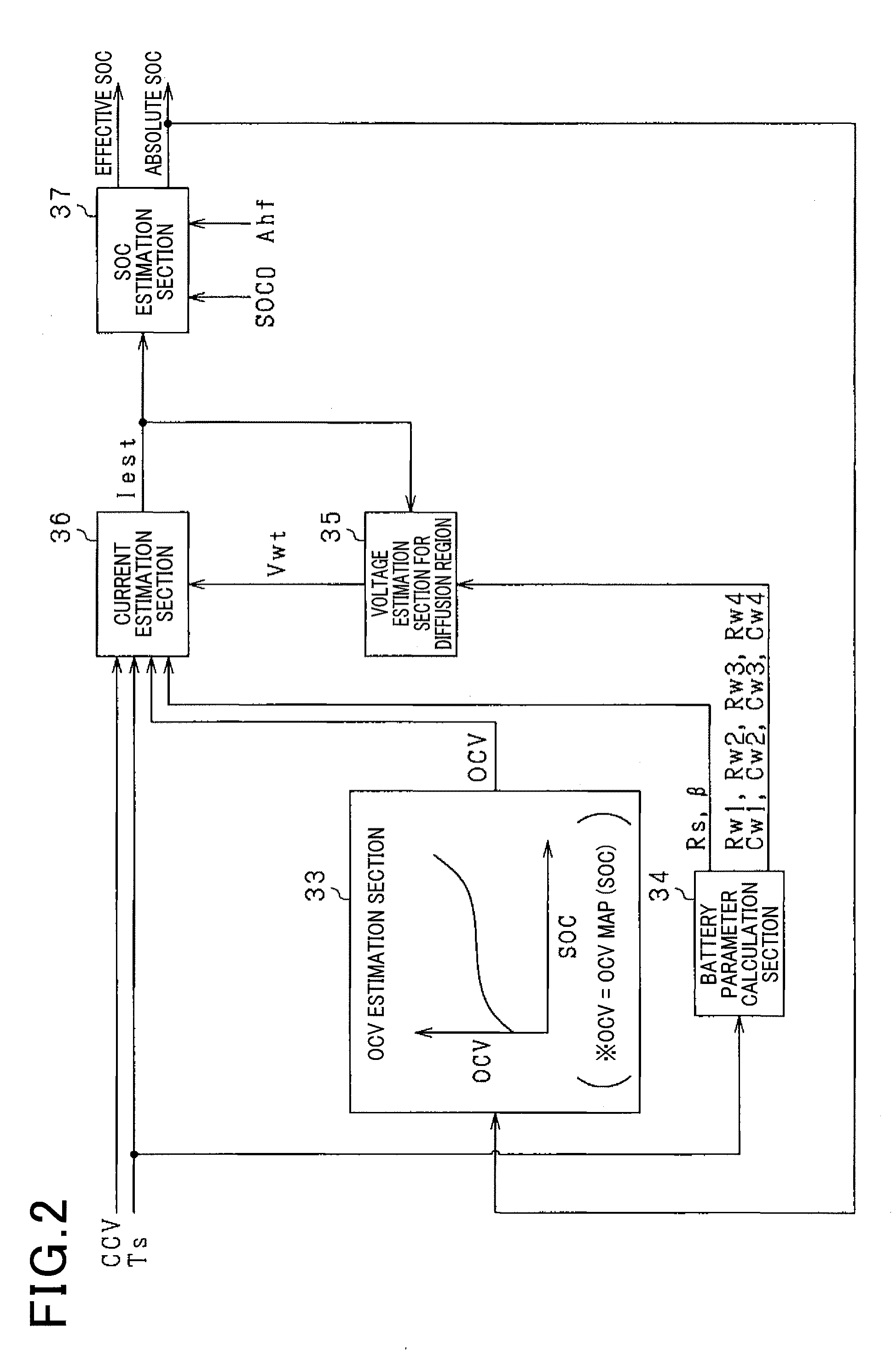

State estimating device of secondary battery

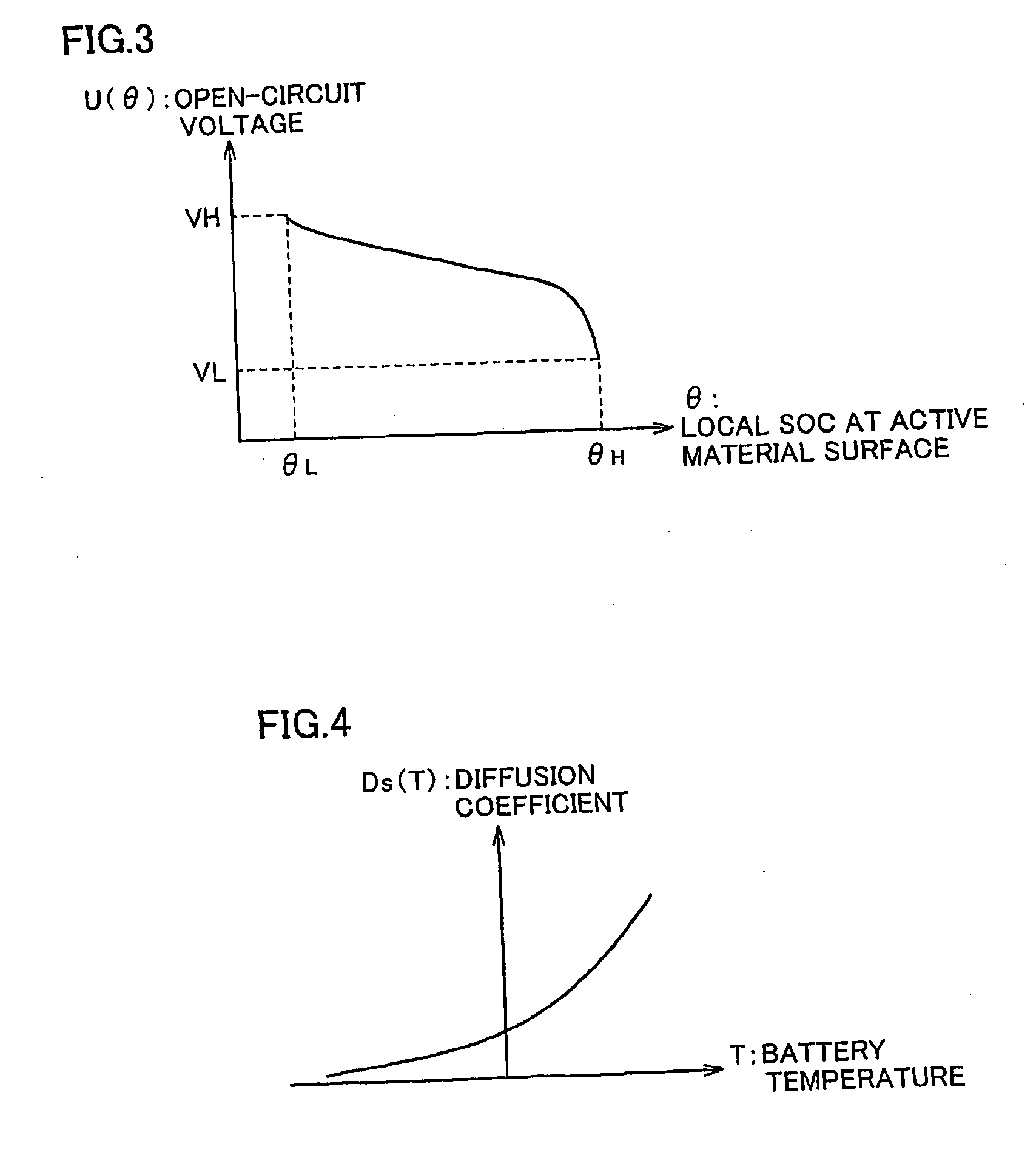

ActiveUS20100153038A1Avoid it happening againAccurate estimateBatteries circuit arrangementsMaterial analysis by electric/magnetic meansDiffusionState parameter

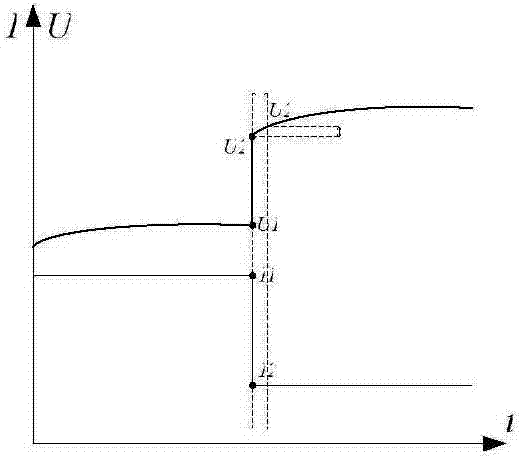

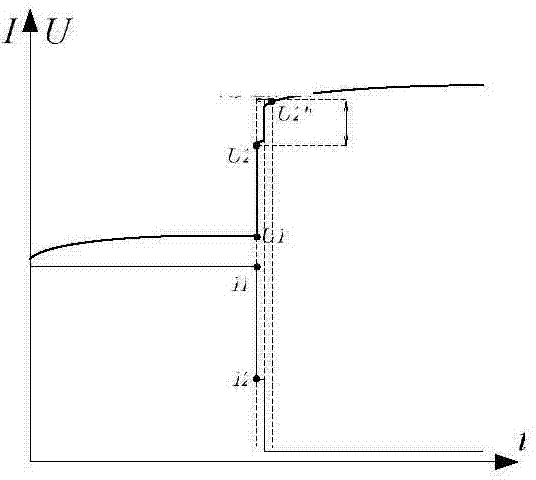

A battery state estimating unit (110) estimates an internal state of a secondary battery according to a battery model equation in every arithmetic cycle, and calculates an SOC based on a result of the estimation. A parameter characteristic map (120) stores a characteristic map based on a result of actual measurement performed in an initial state (in a new state) on a parameter diffusion coefficient (Ds) and a DC resistance (Ra) in the battery model equation. The parameter change rate estimating unit (130) estimates a DC resistance change rate (gr) represented by a ratio of a present DC resistance (Rc) with respect to a new-state parameter value (Ran) by parameter identification based on the battery model equation, using battery data (Tb, Vb and Ib) measured by sensors as well as the new-state parameter value (Ran) of the DC resistance corresponding to the p resent battery state and read from the parameter characteristic map (120).

Owner:TOYOTA CENT RES & DEV LAB INC +1

System and method for current-mode amplitude modulation

InactiveUS7333778B2Efficient and linear amplificationEasy to operateSimultaneous amplitude and angle modulationAmplifier modifications to reduce non-linear distortionAntenna impedanceAudio power amplifier

An amplifier circuit includes a power amplifier biased for saturated mode operation, and a controllable current source to provide supply current to the power amplifier. The controllable current source effects desired amplitude modulation of the output signal from the power amplifier by modulating the supply current it provides responsive to an amplitude information signal. In one or more embodiments, the current source includes a circuit that is configured to adjust one or more transmitter operating parameters responsive to detecting changes in the effective DC resistance of the power amplifier. For example, the circuit may generate a compensation signal that reduces the effective DC resistance responsive to detecting that the effective DC resistance has undesirably increased. By way of non-limiting examples, such compensation may be effected by changing a current mirror, an amplifier-to-antenna impedance matching, an amplifier bias or device size, or imposing some form of transmit signal back-off.

Owner:ERICSSON INC

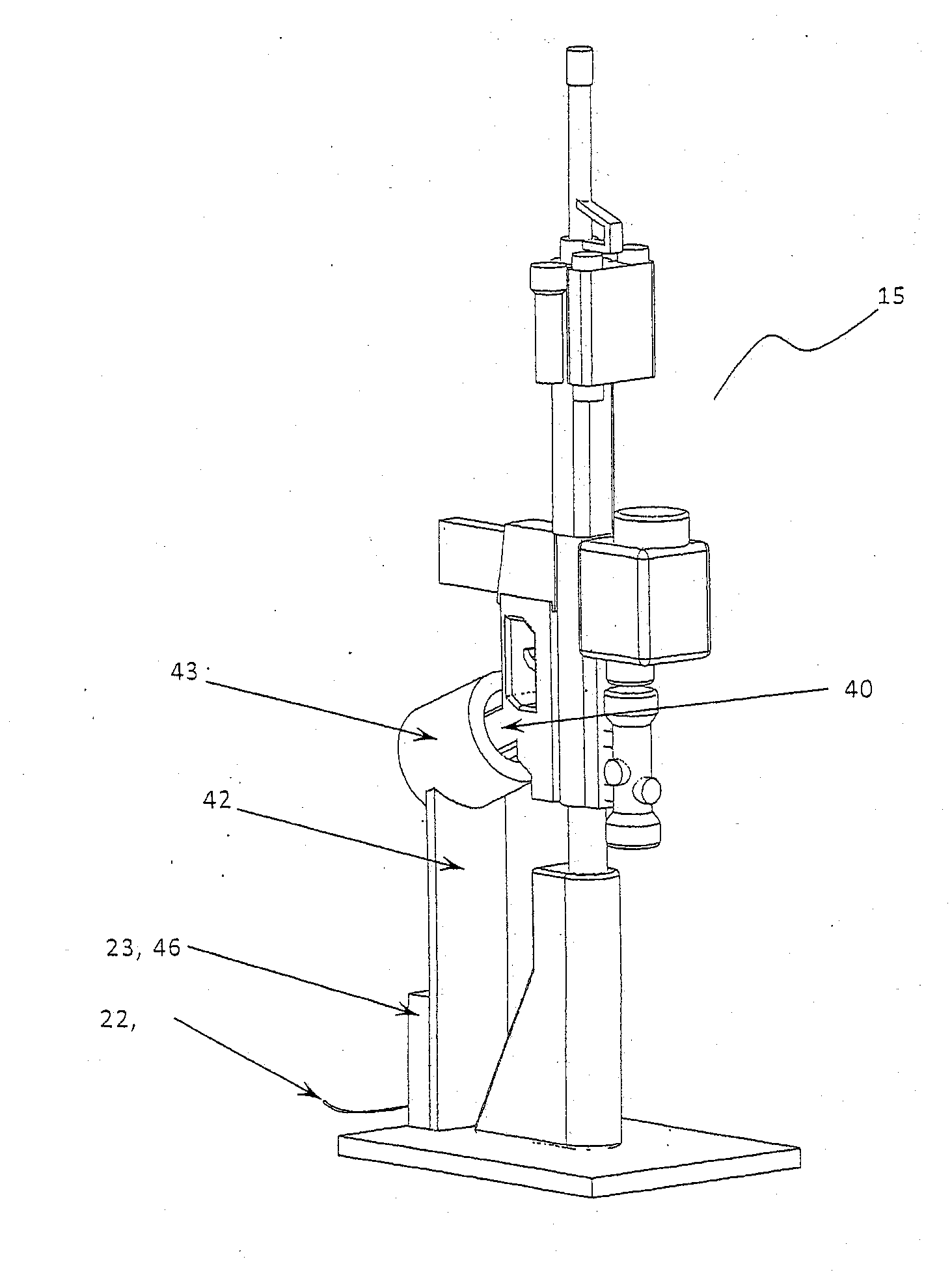

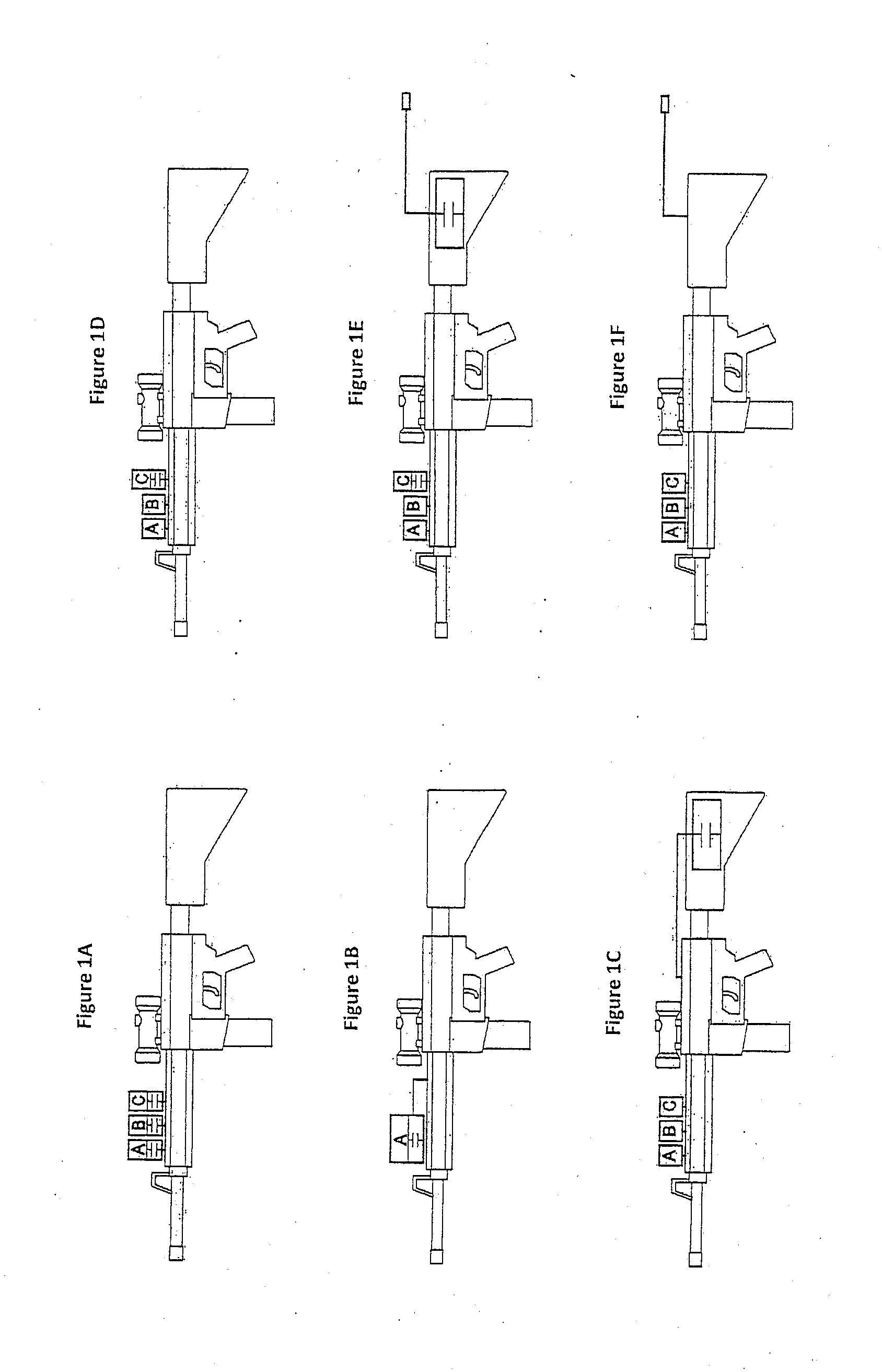

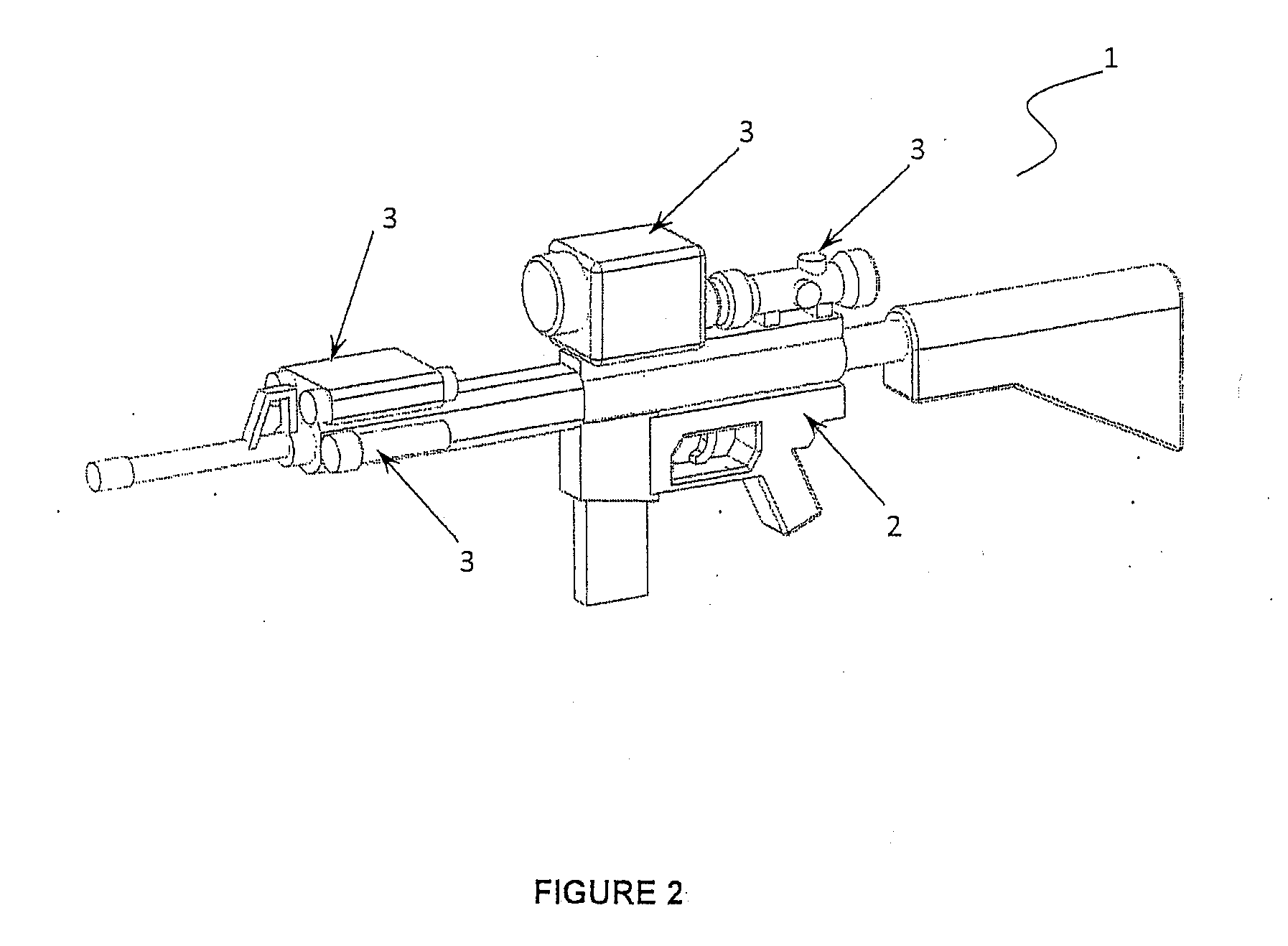

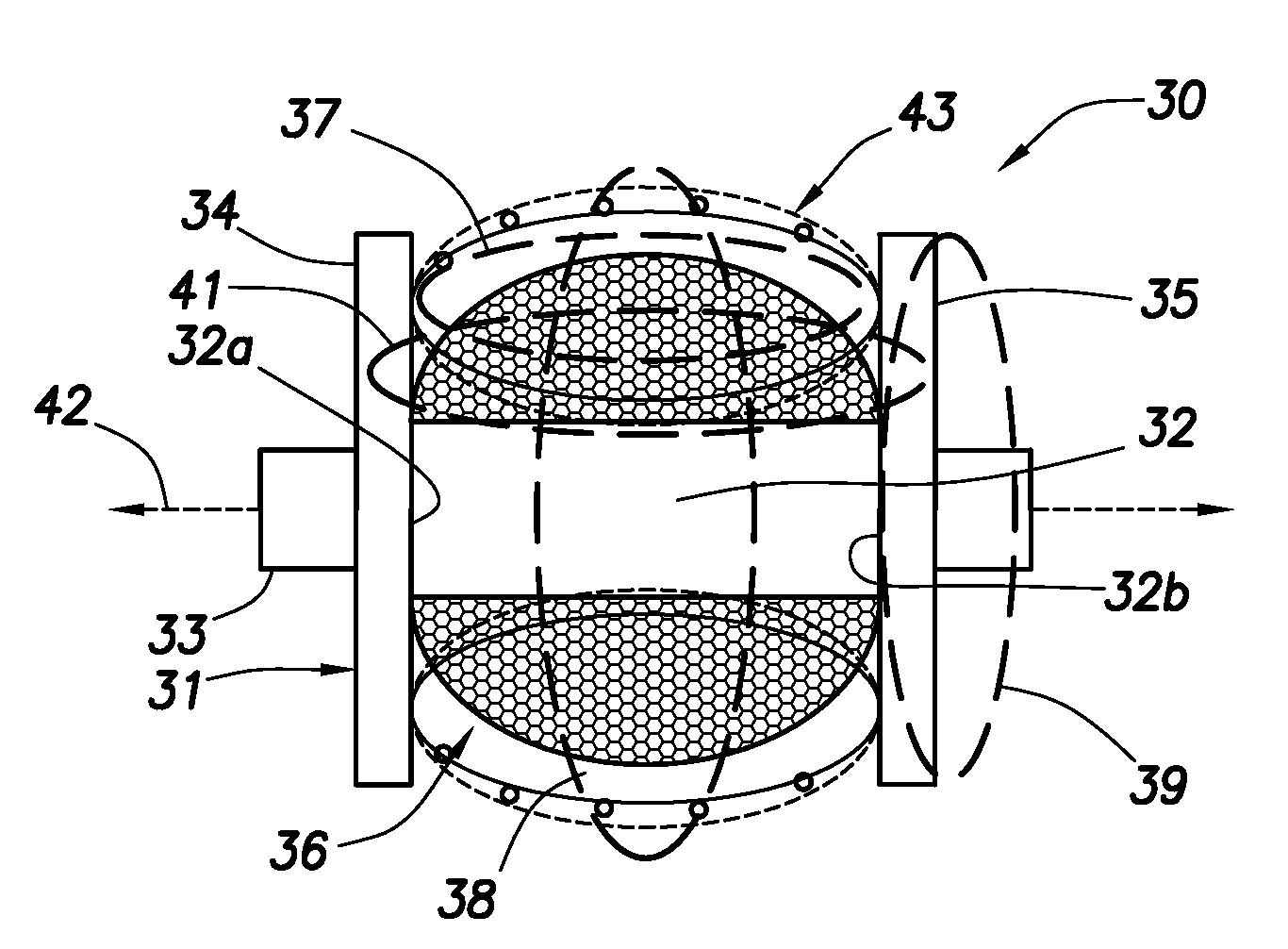

Wireless inductive charging of weapon system energy source

A charging system for the wireless inductive charging of an energy source in a weapon in a weapon system. The charging system includes a first portion of the weapon system, wherein the first portion has a first inductive coil therein, and a female receiver sized for receiving, in a male-female mating engagement, the first portion of the weapon system. The receiver has a second inductive coil positioned to inductively couple with the first inductive coil when the first portion of the weapon system is in the male-female mating engagement with the receiver. The first inductive coil is adapted for electrical connection to a weapon system platform electrical power supply and has a direct current resistance of less than or equal to substantially 0.2 Ohms so as to be adapted to provide charging power having a peak power of at least substantially 10 watts.

Owner:CYNETIC DESIGNS

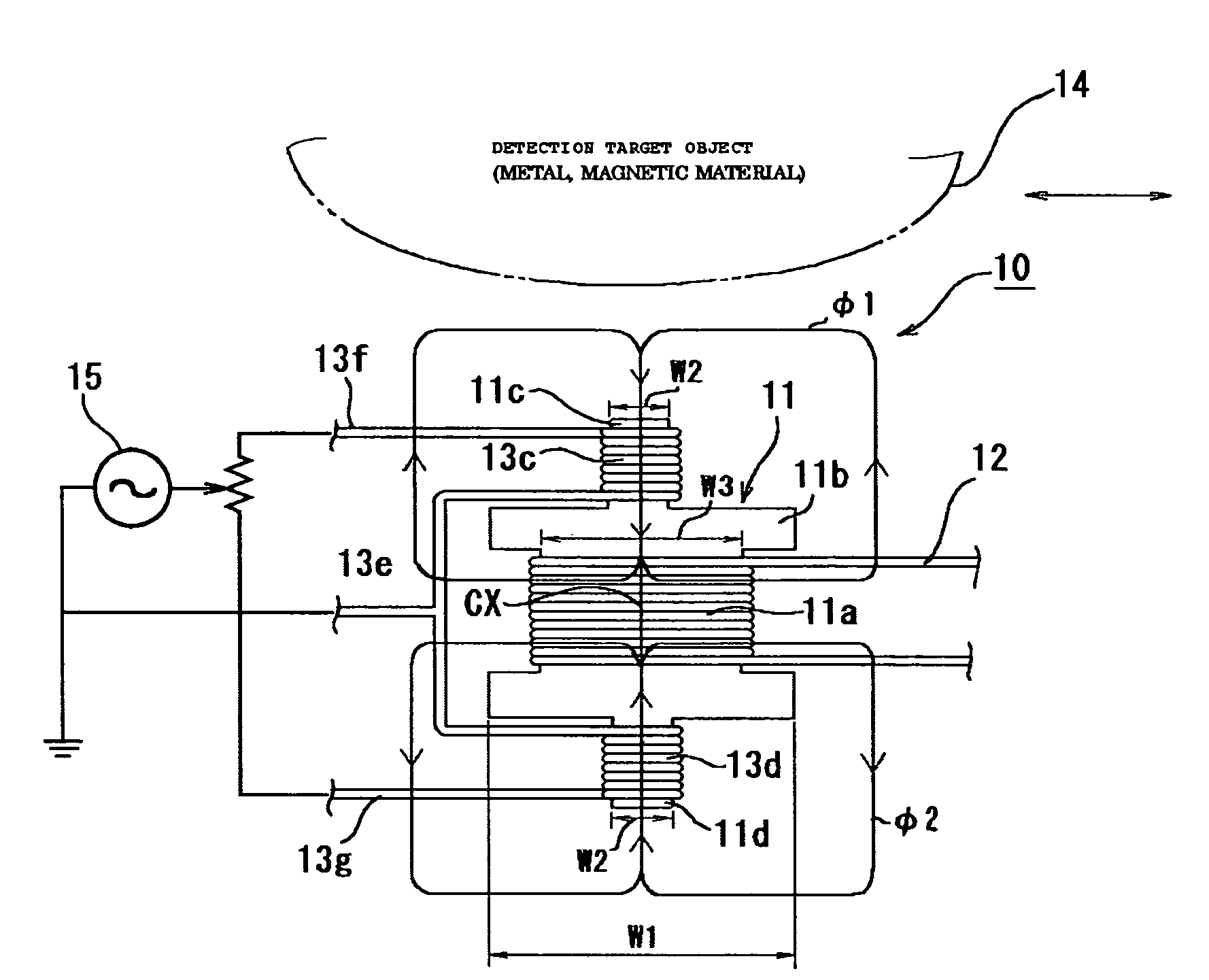

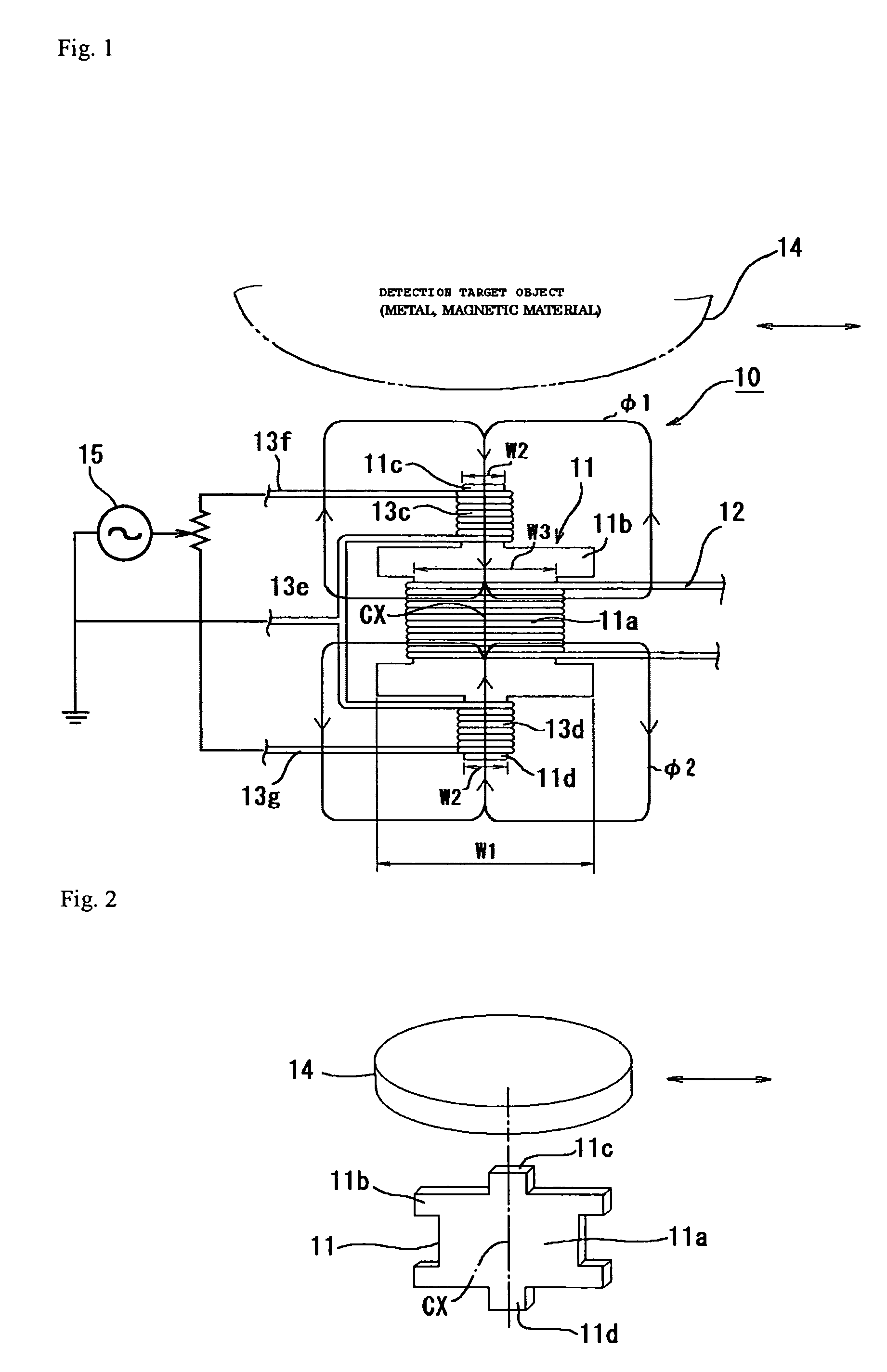

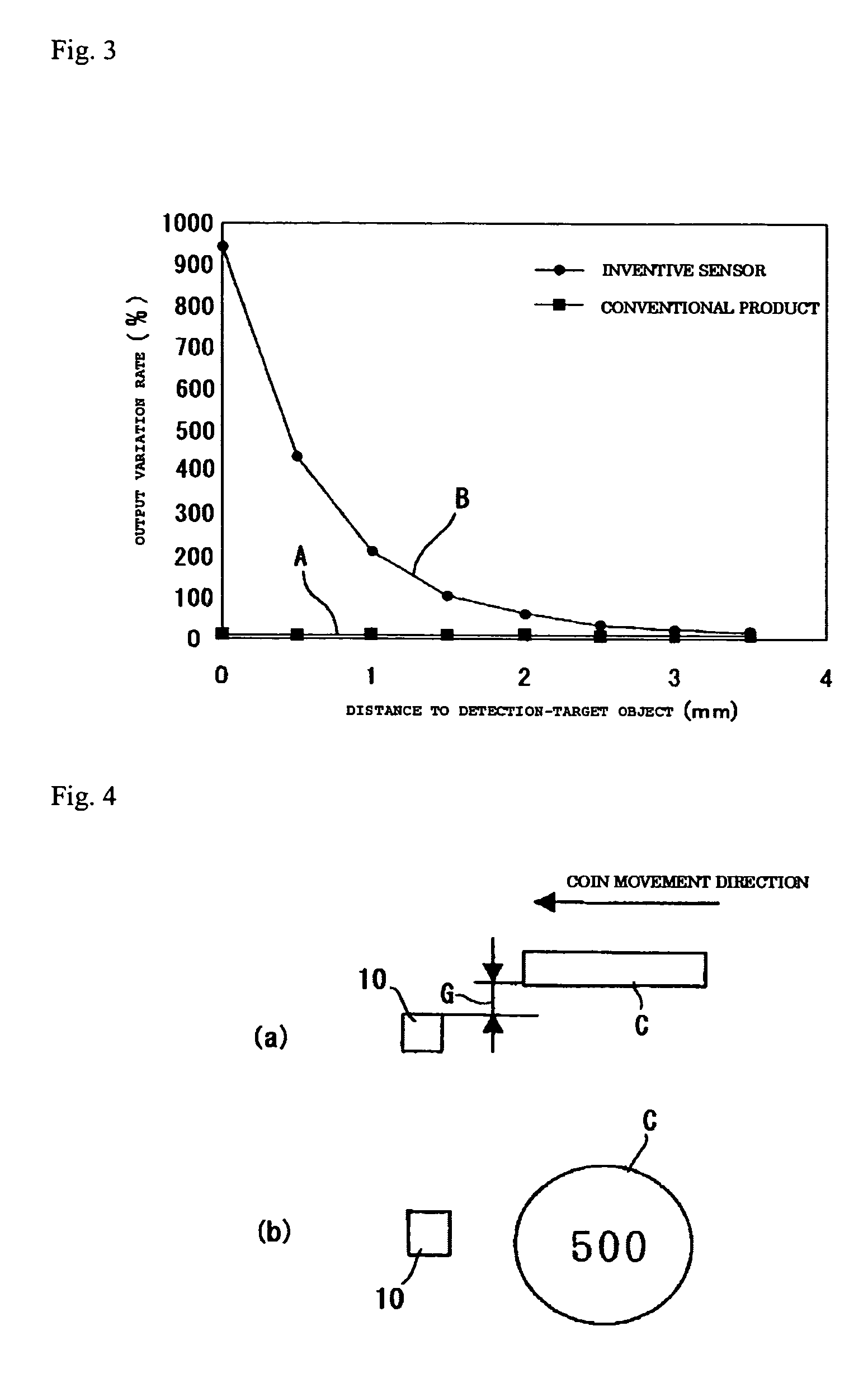

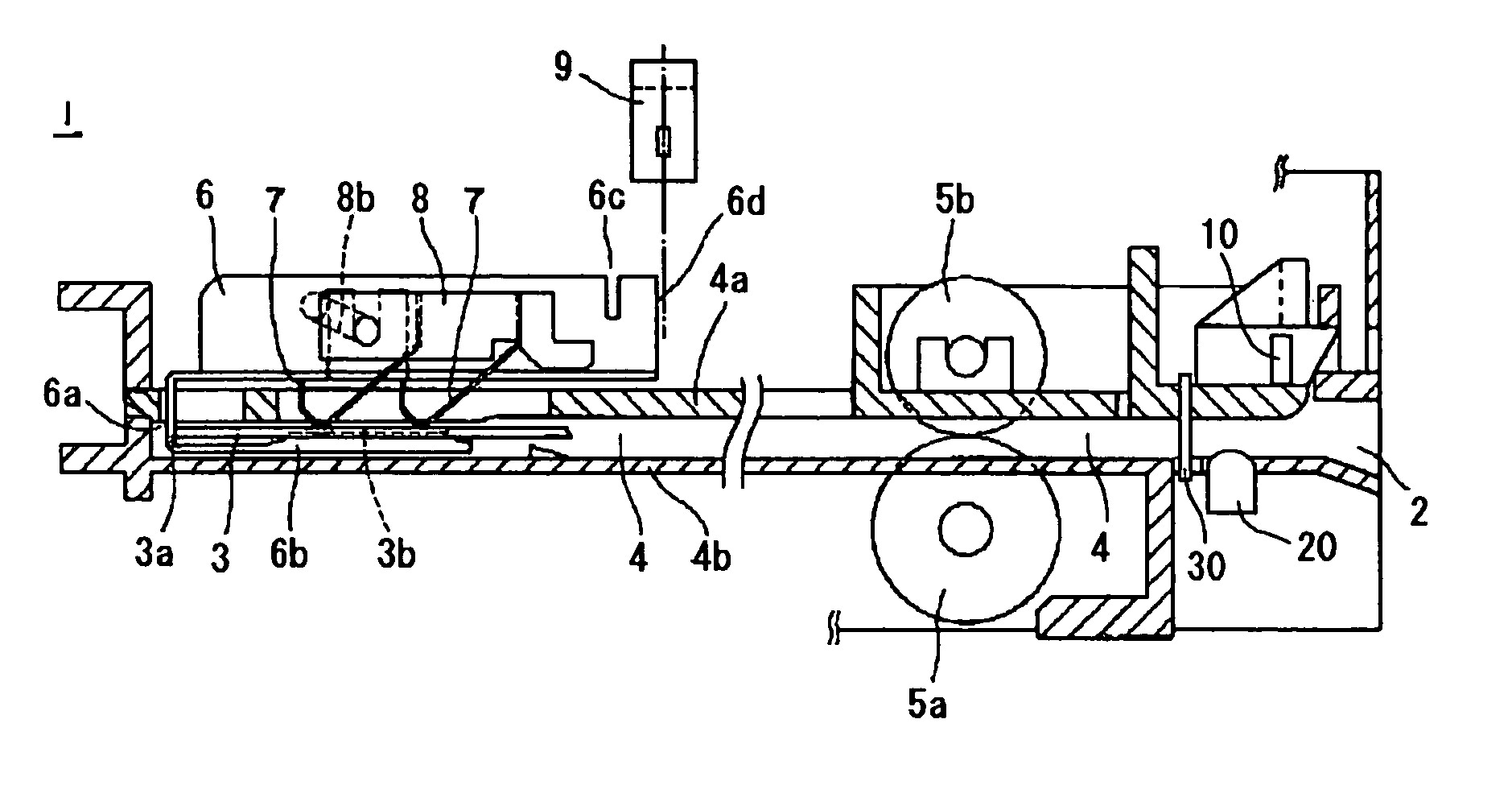

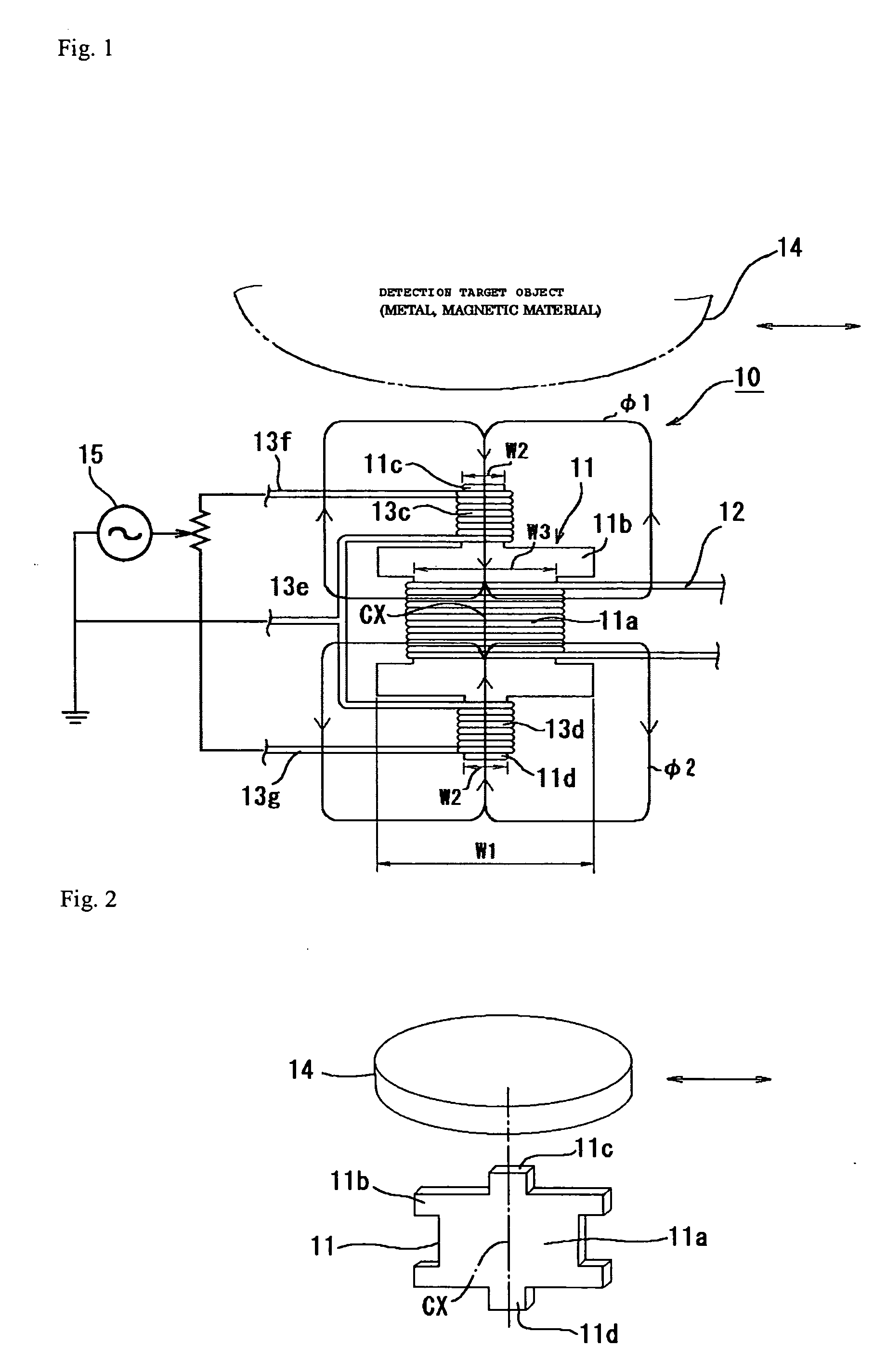

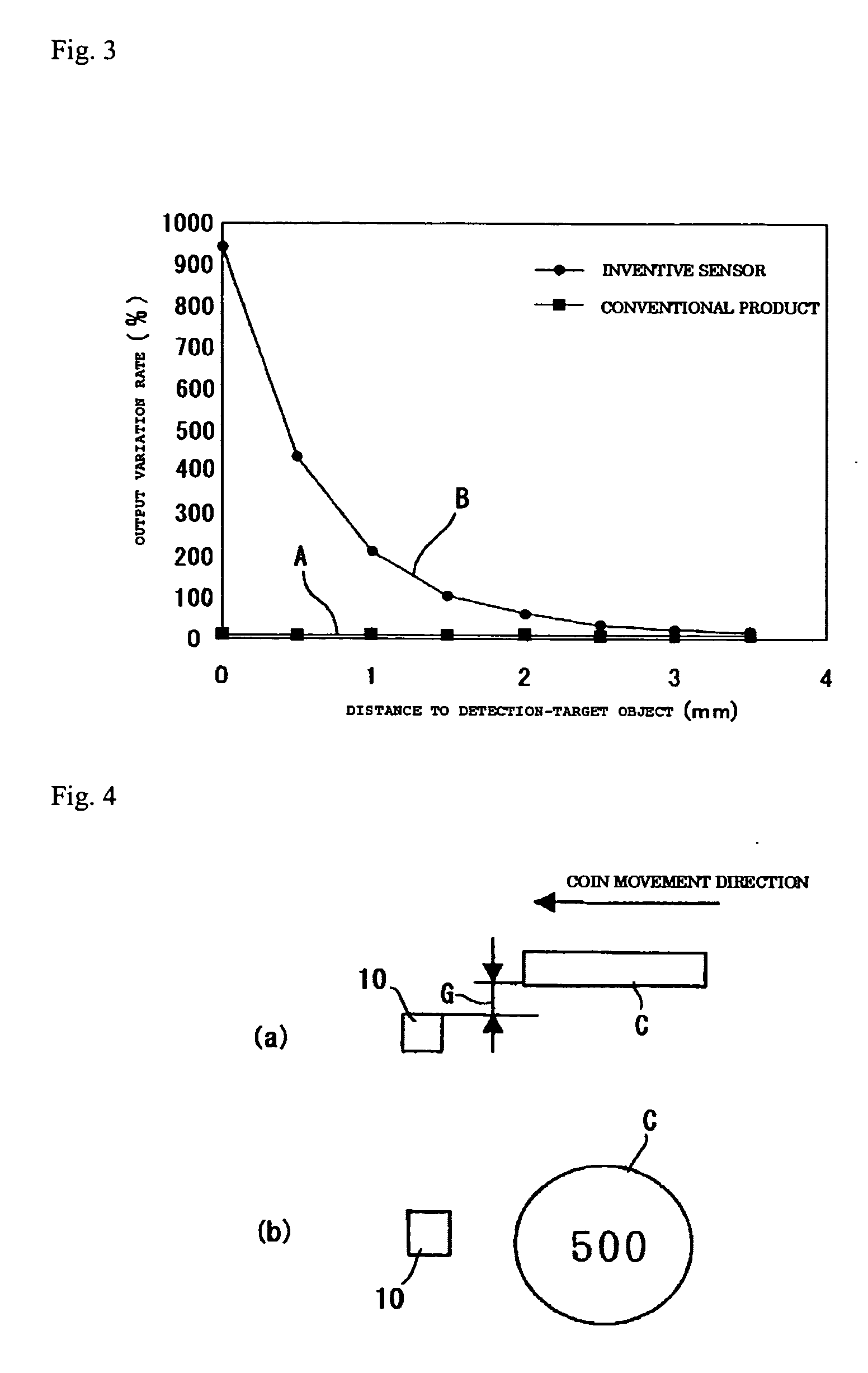

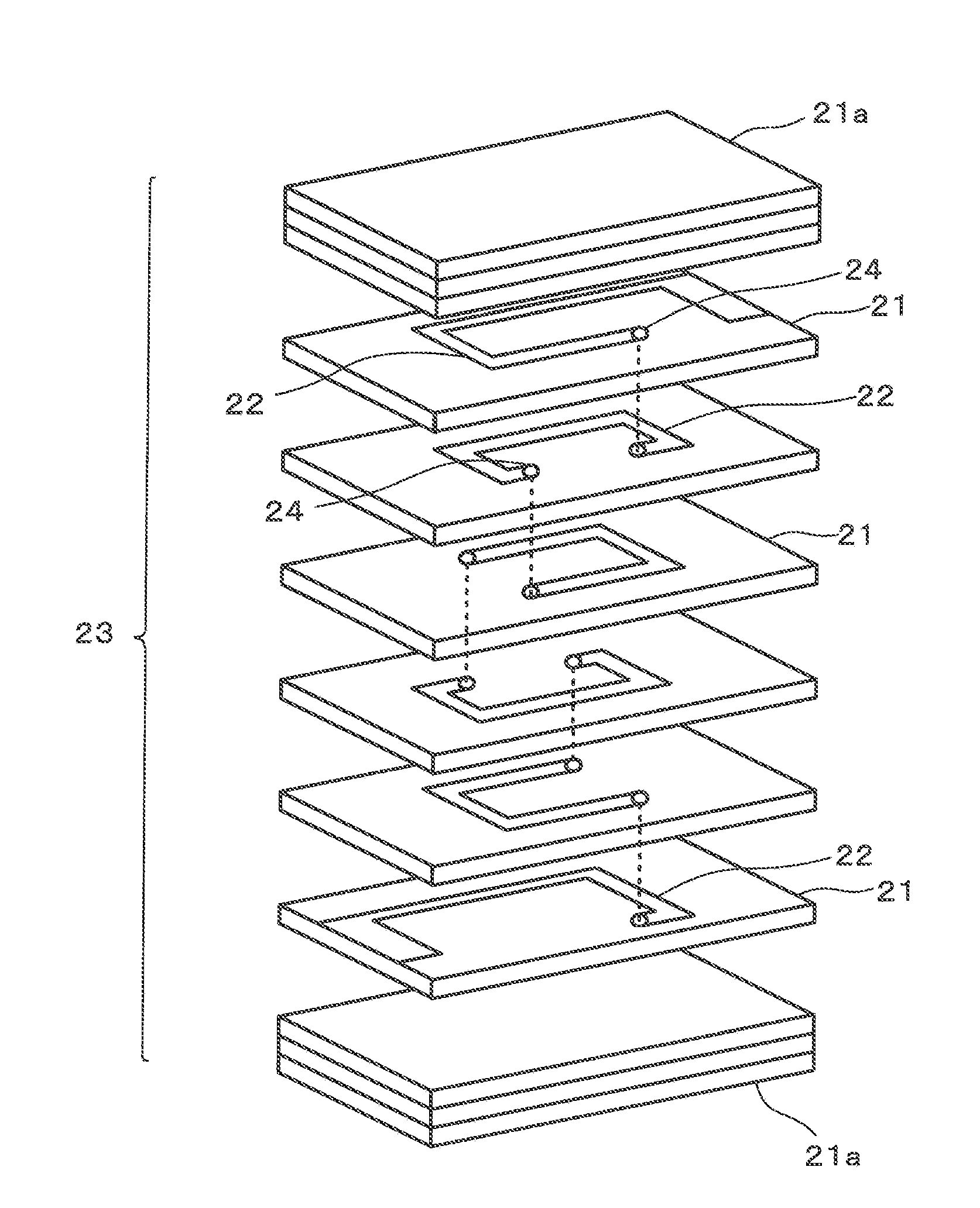

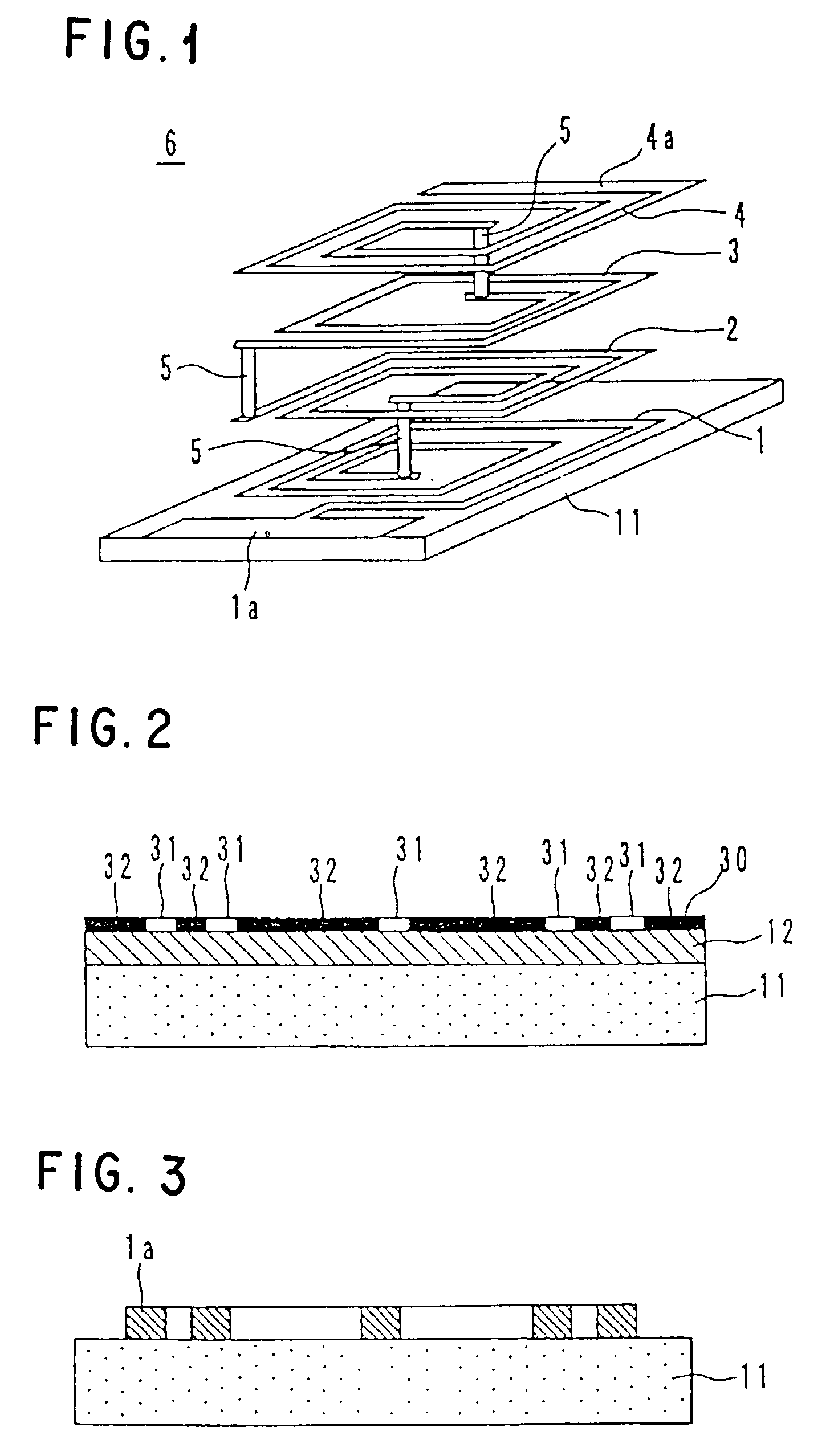

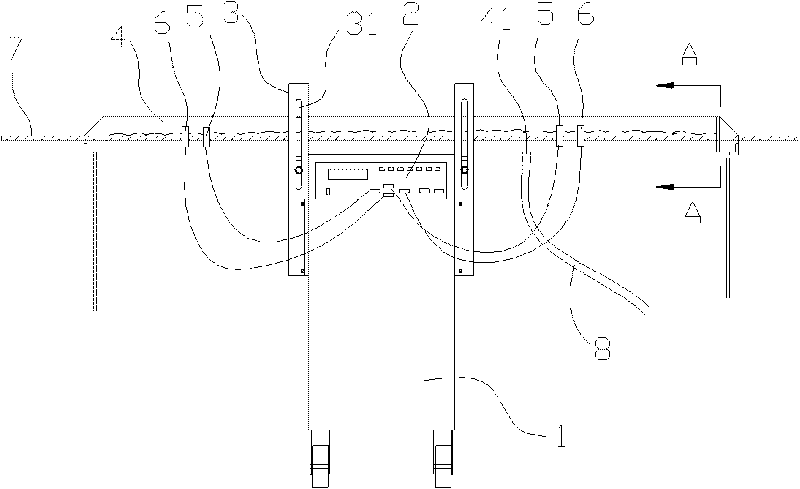

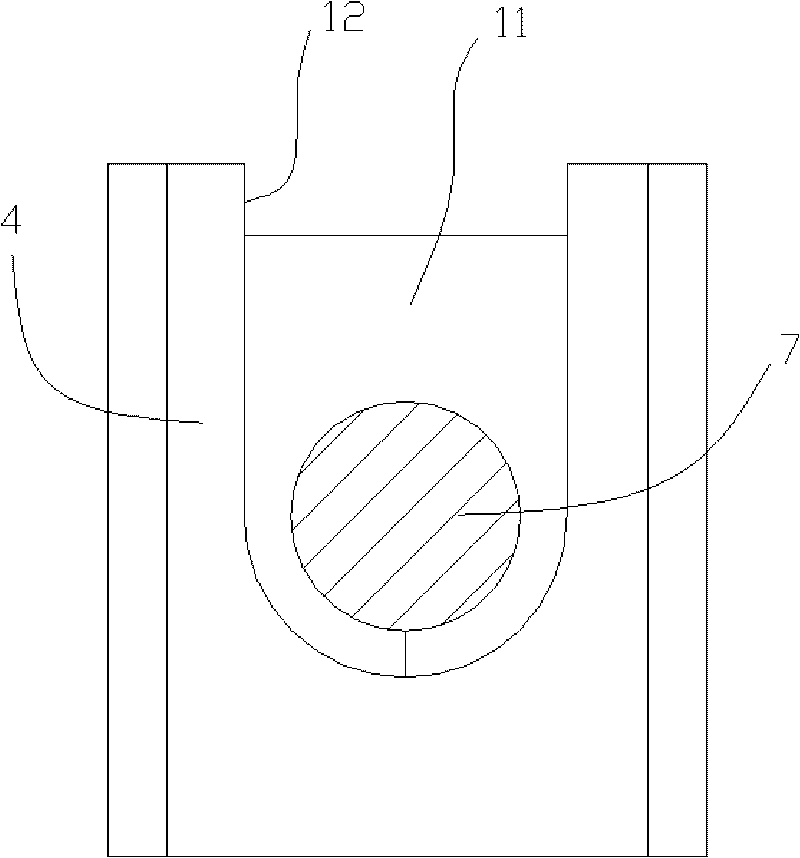

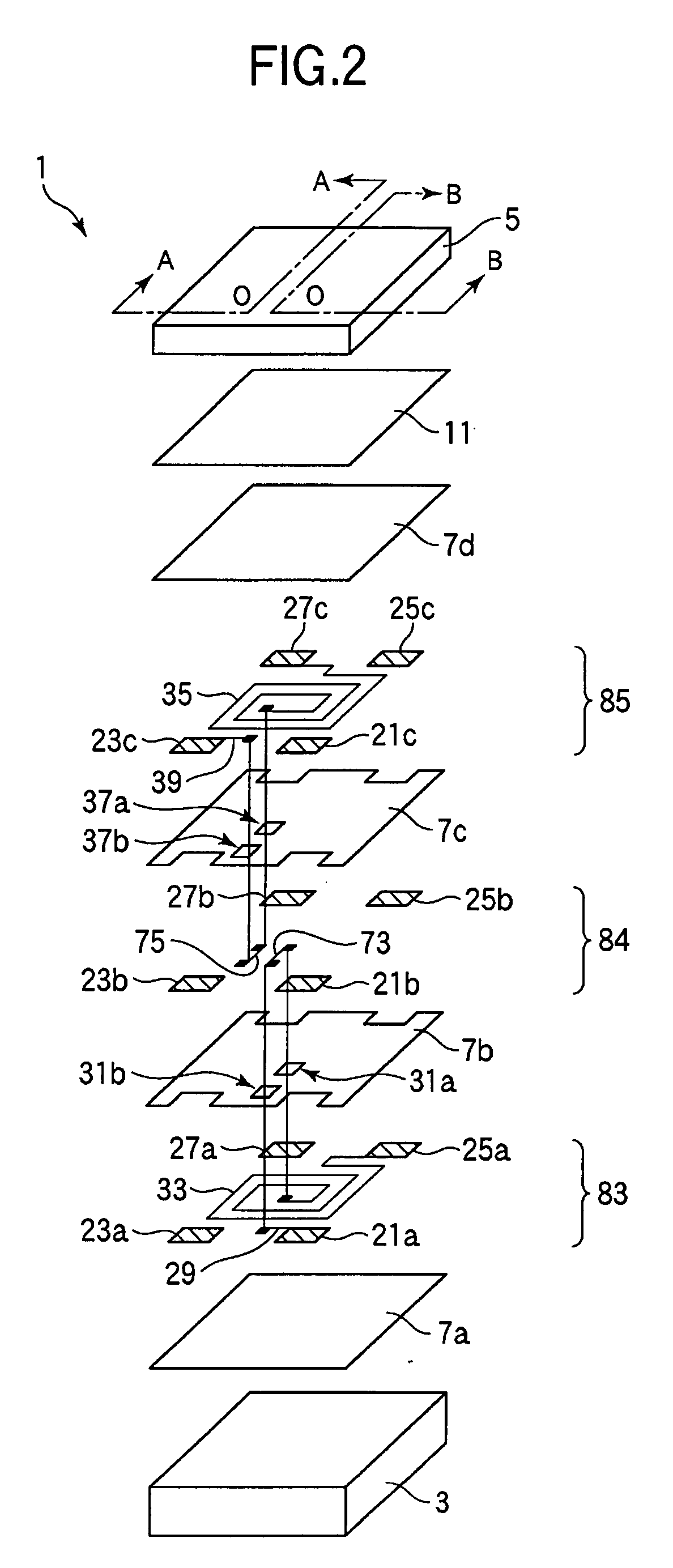

Object sensor and IC card reader with the object sensor

InactiveUS7607580B2Small widthIncrease currentConveying record carriersSensing record carriersElectrical resistance and conductanceCard reader

The present invention provides an object sensor configured such that excitation coils (13c and 13d) and a detection coil (12) are separately disposed, and the detection is performed in accordance with the balance between the excitation coils (13c and 13d) in a pair, a residual variation amount after the impedance due to a DC resistance part and the like has been offset and removed is obtained at high sensitivity with excellent linearity while using a small core body (11), regardless of the impedance including a DC resistance part. Additionally, the object sensor to be used as an inlet sensor is located in an appropriate position on a more upstream side than the read / write position in an insertion direction of the IC card. A contact terminal portion of the IC card is sensed whereby to detect the validity of the card inserted into the apparatus from a card insertion slot. Thereby, steady detection operations can be implemented for the presence or absence of the IC card, notwithstanding environmental temperature variations.The invention further provides an IC card reader configured such that a plurality of inlet sensors for detecting the type of an inserted card is provided in appropriate positions more upstream than the read / write position in a card insertion direction, wherein when an unusable card or the like is inserted, a control operation of closing shutter means can be performed, thereby enabling illegal action with the card to be prevented.

Owner:SANKYO SEIKI MFG CO LTD

System for providing power over communication cable having mechanism for determining resistance of communication cable

ActiveUS7511515B2Interconnection arrangementsCurrent/voltage measurementElectricityElectrical resistance and conductance

Owner:ANALOG DEVICES INT UNLTD

Object sensor and ic card reader with the object sensor

InactiveUS20050218227A1Precise positioningIncrease mutation rateConveying record carriersSensing record carriersElectrical resistance and conductanceCard reader

The present invention provides an object sensor configured such that excitation coils (13c and 13d) and a detection coil (12) are separately disposed, and the detection is performed in accordance with the balance between the excitation coils (13c and 13d) in a pair, a residual variation amount after the impedance due to a DC resistance part and the like has been offset and removed is obtained at high sensitivity with excellent linearity while using a small core body (11), regardless of the impedance including a DC resistance part. Additionally, the object sensor to be used as an inlet sensor is located in an appropriate position on a more upstream side than the read / write position in an insertion direction of the IC card. A contact terminal portion of the IC card is sensed whereby to detect the validity of the card inserted into the apparatus from a card insertion slot. Thereby, steady detection operations can be implemented for the presence or absence of the IC card, notwithstanding environmental temperature variations. The invention further provides an IC card reader configured such that a plurality of inlet sensors for detecting the type of an inserted card is provided in appropriate positions more upstream than the read / write position in a card insertion direction, wherein when an unusable card or the like is inserted, a control operation of closing shutter means can be performed, thereby enabling illegal action with the card to be prevented.

Owner:SANKYO SEIKI MFG CO LTD

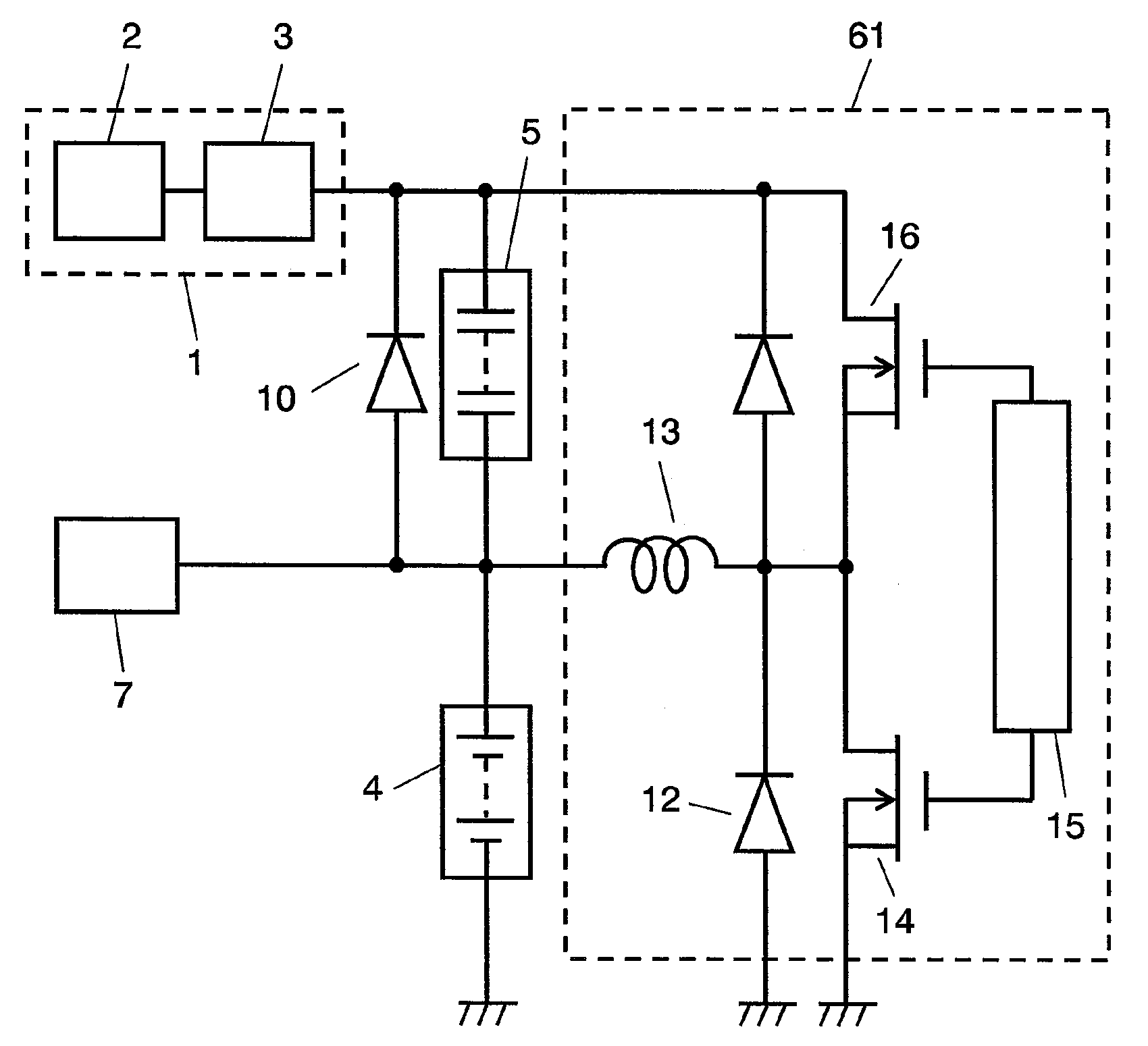

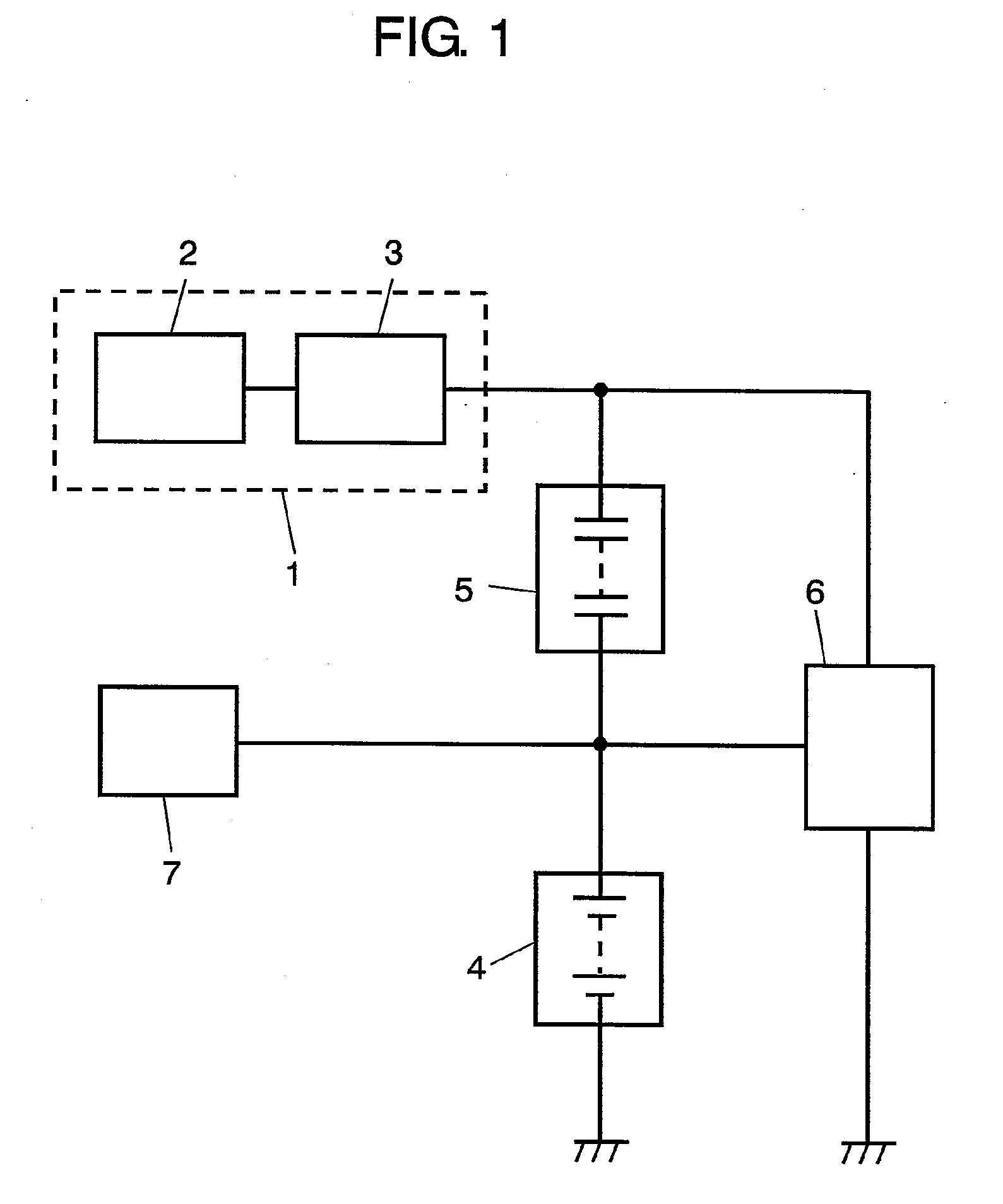

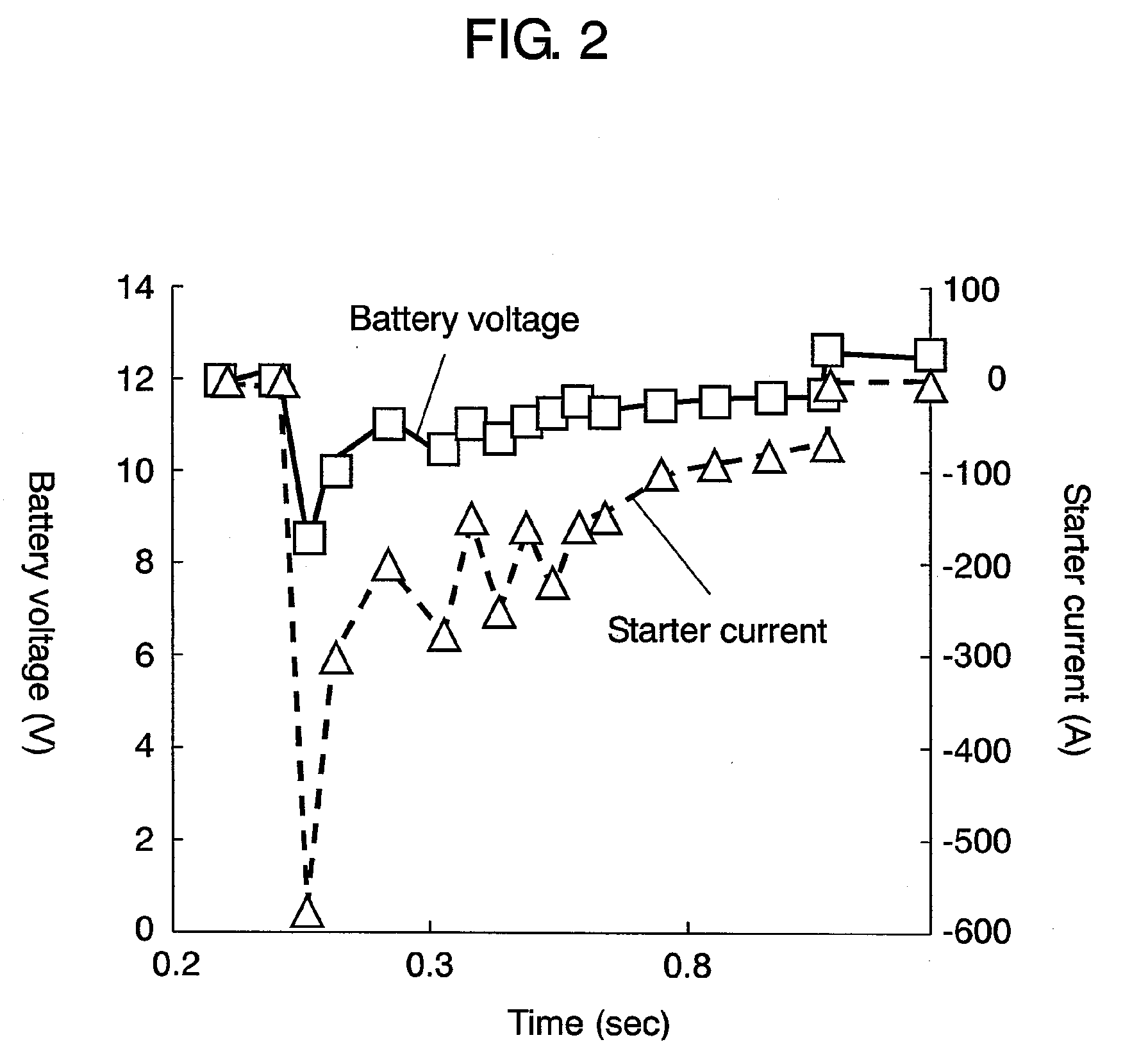

Engine Start Device

InactiveUS20090050092A1Improve startup performanceIncrease torqueBatteries circuit arrangementsMaterial analysis by electric/magnetic meansElectrical resistance and conductanceBattery charge

An engine start device includes a generator, a battery charged by the generator, a starter, an electric double layer capacitor and a DC / DC converter. The electric double layer capacitor is connected between the starter and the battery. The DC / DC converter has an input terminal connected to the battery and the electric double layer capacitor. The DC / DC converter has an output terminal connected to the starter and the electric double layer capacitor. According to voltage of the battery, internal DC resistance of the battery or internal DC resistance of the electric double layer capacitor, the DC / DC converter effects control of charge voltage of the electric double layer capacitor so as to stabilize voltage applied to a starter motor and stabilize the engine start.

Owner:PANASONIC CORP

State estimating device of secondary battery

ActiveUS8108161B2Improve accuracyBatteries circuit arrangementsMaterial analysis by electric/magnetic meansElectrical resistance and conductanceState parameter

A battery state estimating unit estimates an internal state of a secondary battery according to a battery model equation in every arithmetic cycle, and calculates an SOC based on a result of the estimation. A parameter characteristic map stores a characteristic map based on a result of actual measurement performed in an initial state (in a new state) on a parameter diffusion coefficient and a DC resistance in the battery model equation. The parameter change rate estimating unit estimates a DC resistance change rate represented by a ratio of a present DC resistance with respect to a new-state parameter value by parameter identification based on the battery model equation, using battery data measured by sensors as well as the new-state parameter value of the DC resistance corresponding to the present battery state and read from the parameter characteristic map.

Owner:TOYOTA CENT RES & DEV LAB INC +1

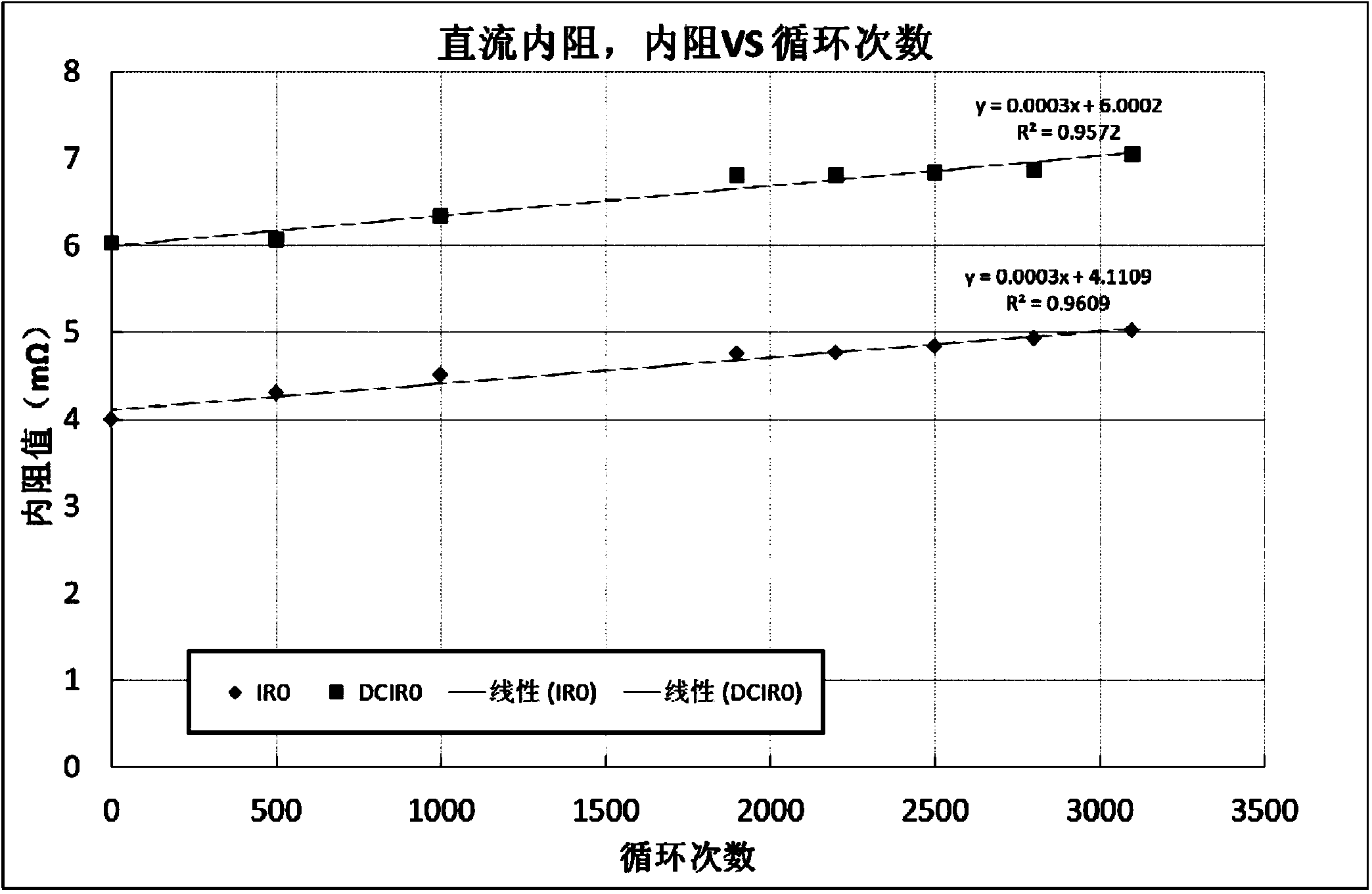

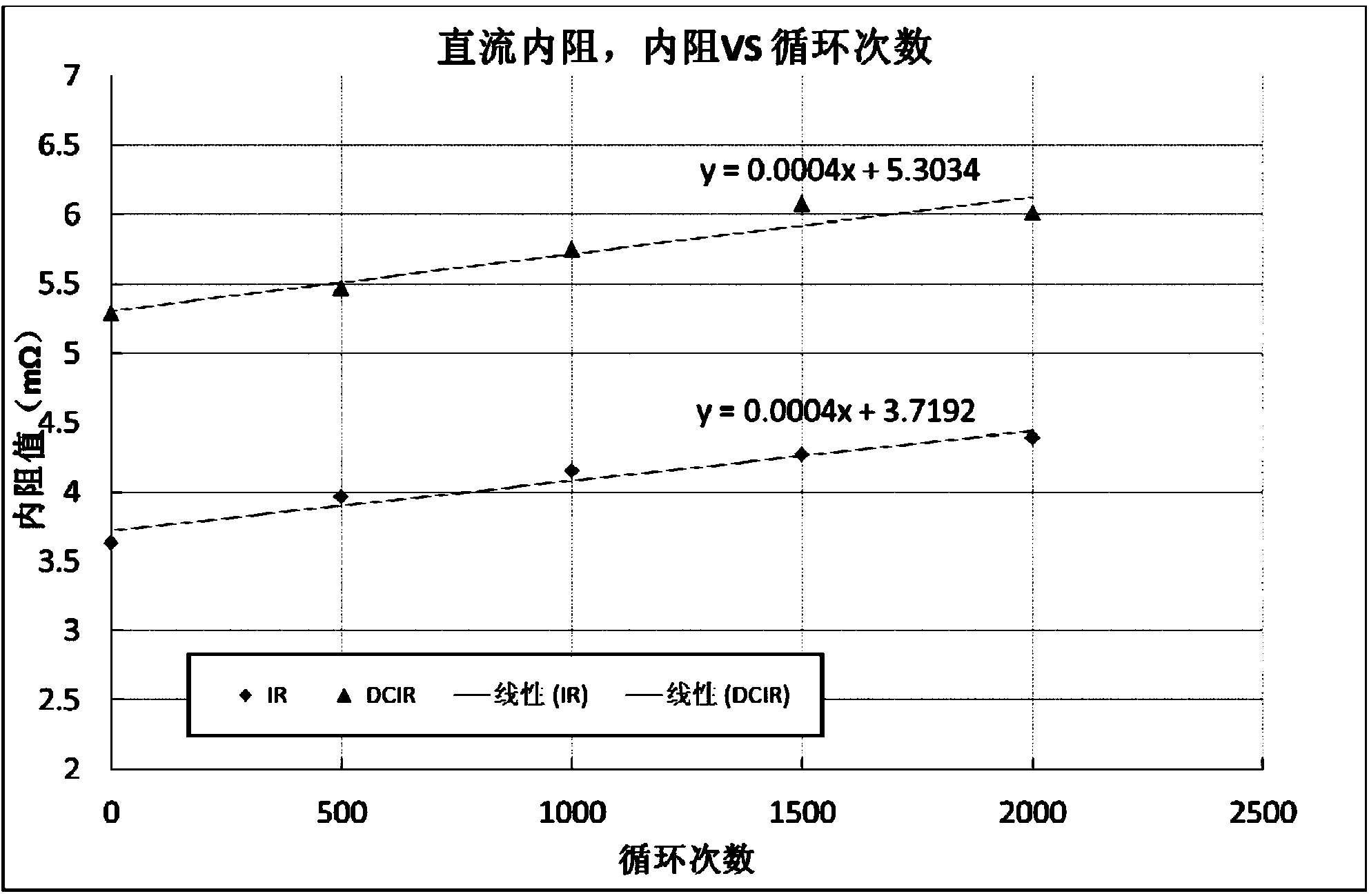

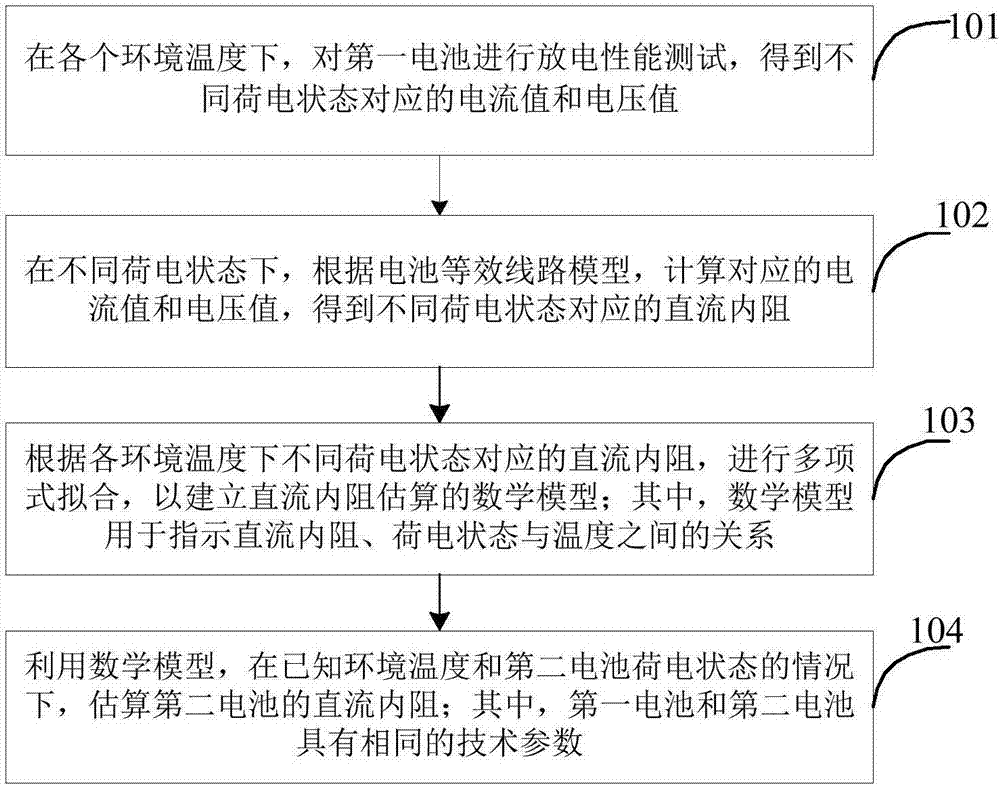

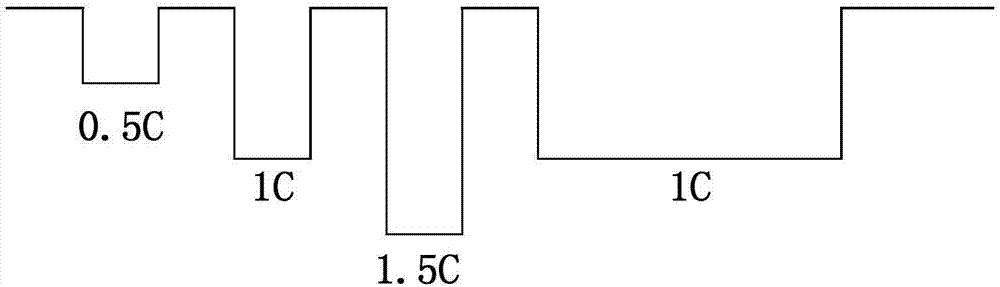

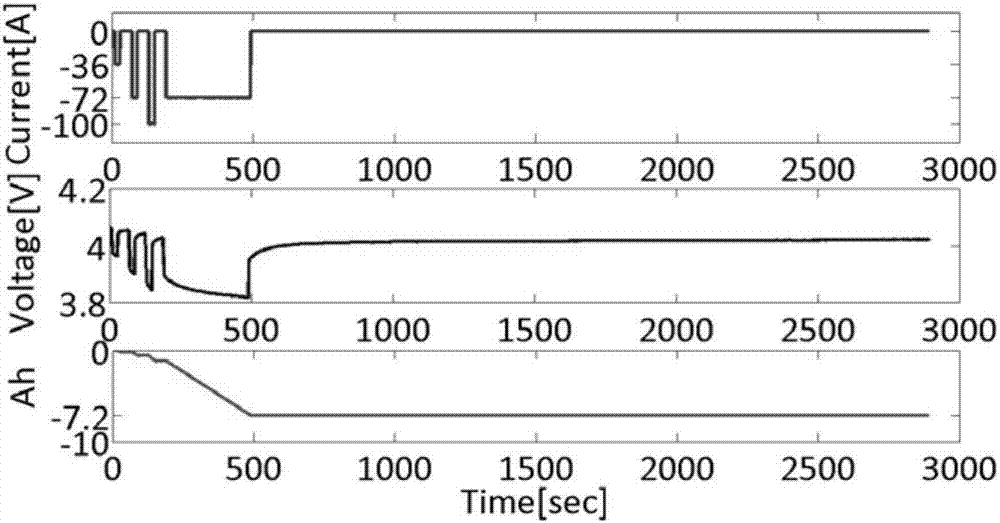

Method for inferring internal DC resistance of lithium ion battery

InactiveCN104330636AAvoid damageSave energyResistance/reactance/impedenceCyclic testInternal resistance

The invention discloses a method for inferring the internal DC resistance of a lithium ion battery. The method comprises the steps of performing cyclic tests on a sampled battery in the environment of a certain temperature and certain humidity, and testing the internal AC resistance IR0 and the internal DC resistance DCIR0 in a certain SOC state every certain cycles, establishing an IR-DCIR linear relation according to the internal AC resistance IR0 and the internal DC resistance DCIR0, when inferring the internal DC resistance of a battery in same model with the sampled battery, measuring the internal AC resistance IR of the battery to be tested at the same frequency according to the SOC state and the temperature and humidity conditions when the internal AC resistance of the sampled batter is measured, comparing the measured internal AC resistance IR with the established IR-DCIR linear relation, and performing ratiometric conversion on the internal AC resistance to obtain the internal DC resistance of the battery. The method for inferring the internal DC resistance of the lithium ion battery is capable of inferring the internal DC resistance according to the linear relation of the internal AC resistance and the internal DC resistance and avoiding the harm of multiple internal DC resistance tests by use of large current discharge to the battery, and also capable of obtaining higher detection speed and accuracy.

Owner:TIANJIN LISHEN BATTERY

DC internal resistance measuring method and device of battery

ActiveCN107045109AImprove accuracyResistance/reactance/impedenceElectrical testingInternal resistanceMathematical model

The invention provides a DC internal resistance measuring method and device of a battery. The method comprises that discharging performance test is carried out on a first battery at different ambient temperatures to obtain current values and voltage values corresponding to different states of charge; the current values and voltage values corresponding to the different states of charge are calculated according to a battery equivalent circuit model to obtain DC internal resistances corresponding to the different states of charge; polynomial fitting is carried out according to the DC internal resistances corresponding to the different states of charge in the ambient temperatures to establish a mathematical DC internal resistance estimation model; the mathematical model indicates relation among the DC internal resistance, state of charge and temperature; and a DC internal resistance of a second battery is estimated via the mathematical model under the condition that the ambient temperature and the state of charge of the second battery are known. Thus, the mathematical DC internal resistance estimation model is established, the DC internal resistance is estimated on the basis of the temperature of the state of charge of the battery, and the estimating accuracy for the DC internal resistance of the battery is improved.

Owner:BEIJING ELECTRIC VEHICLE

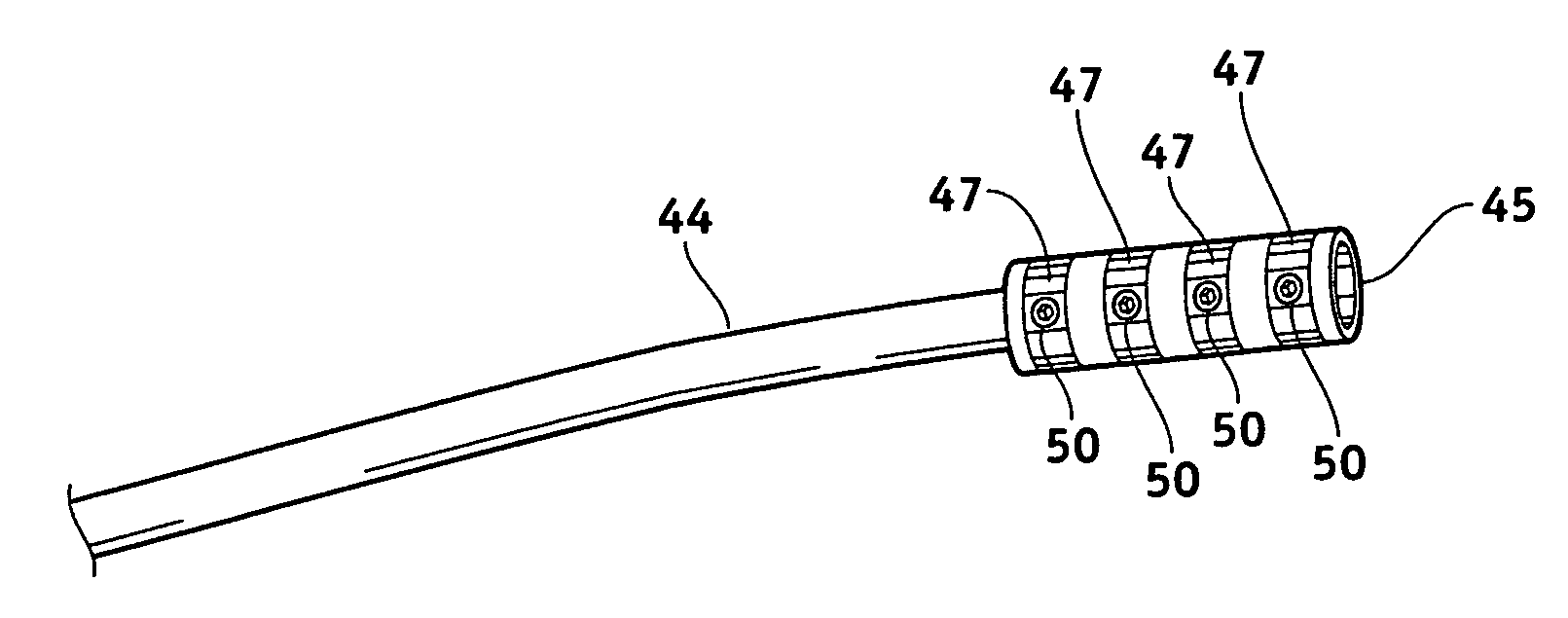

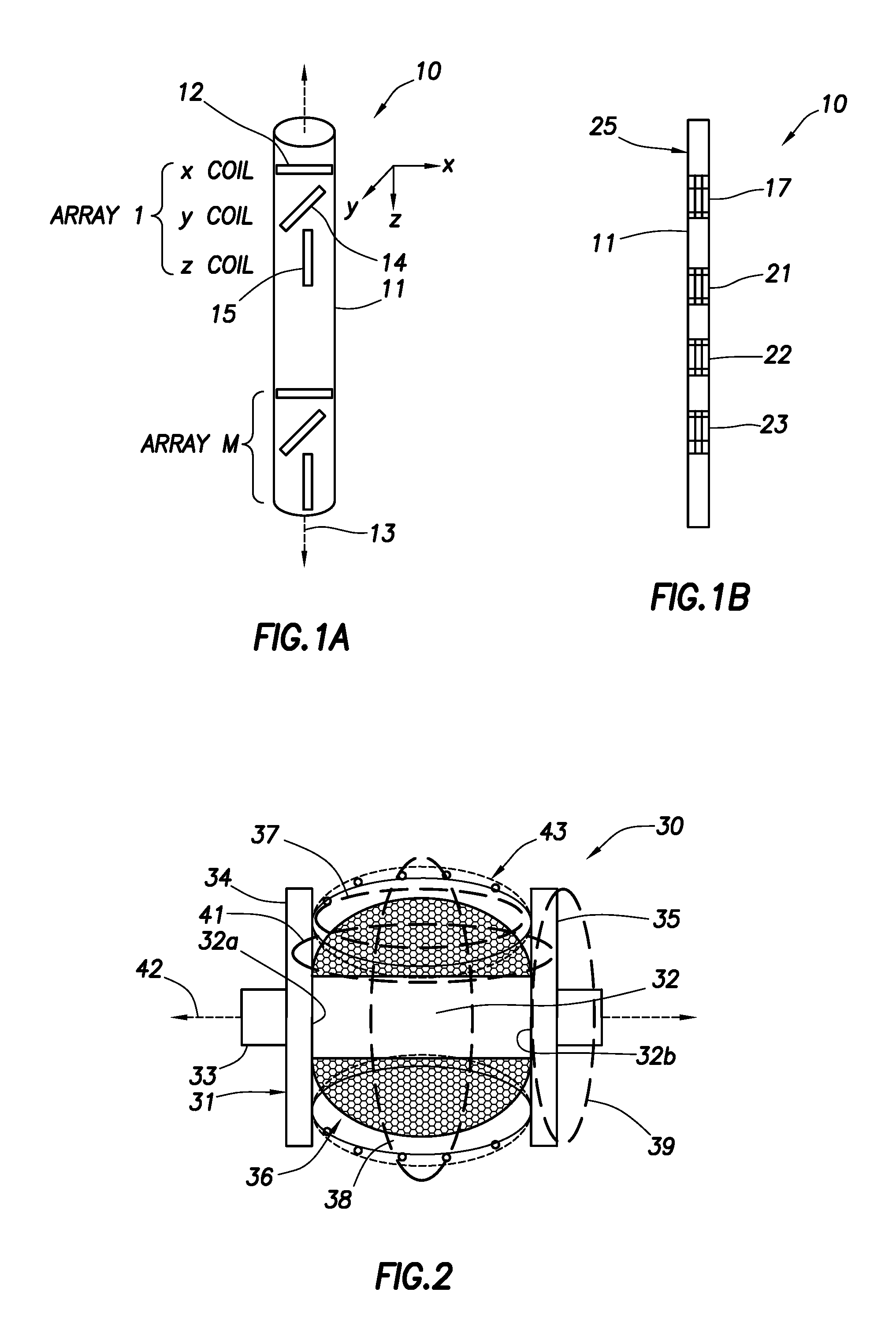

Antennas for Deep Induction Array Tools with Increased Sensitivities

ActiveUS20090160449A1Improved antennaLoop antennas with ferromagnetic coreElectric/magnetic detection for well-loggingBobbinParasitic capacitance

Improved receiver antennas are disclosed for long offset tensor induction army logging tools. The disclosed antennas include a bobbin which accommodates a ferromagnetic core. The outer surface of the bobbin is wrapped around a binding so that winding is thicker or includes more turns towards a center of the bobbin and is thinner or includes less turns towards the outer ends of the bobbin. The result is that the primary winding with a curved or parabolic profile that enhances the effective magnetic permeability and magnetic moment of the antenna. A secondary winding may also be utilized for flux feedback compensation. The elimination of winding turns towards the ends of the magnetic coil result in reduced DC resistance and the reduction in parasitic capacitance of the antennas. The disclosed antennas may be used in x-y-z receiver arrays.

Owner:SCHLUMBERGER TECH CORP

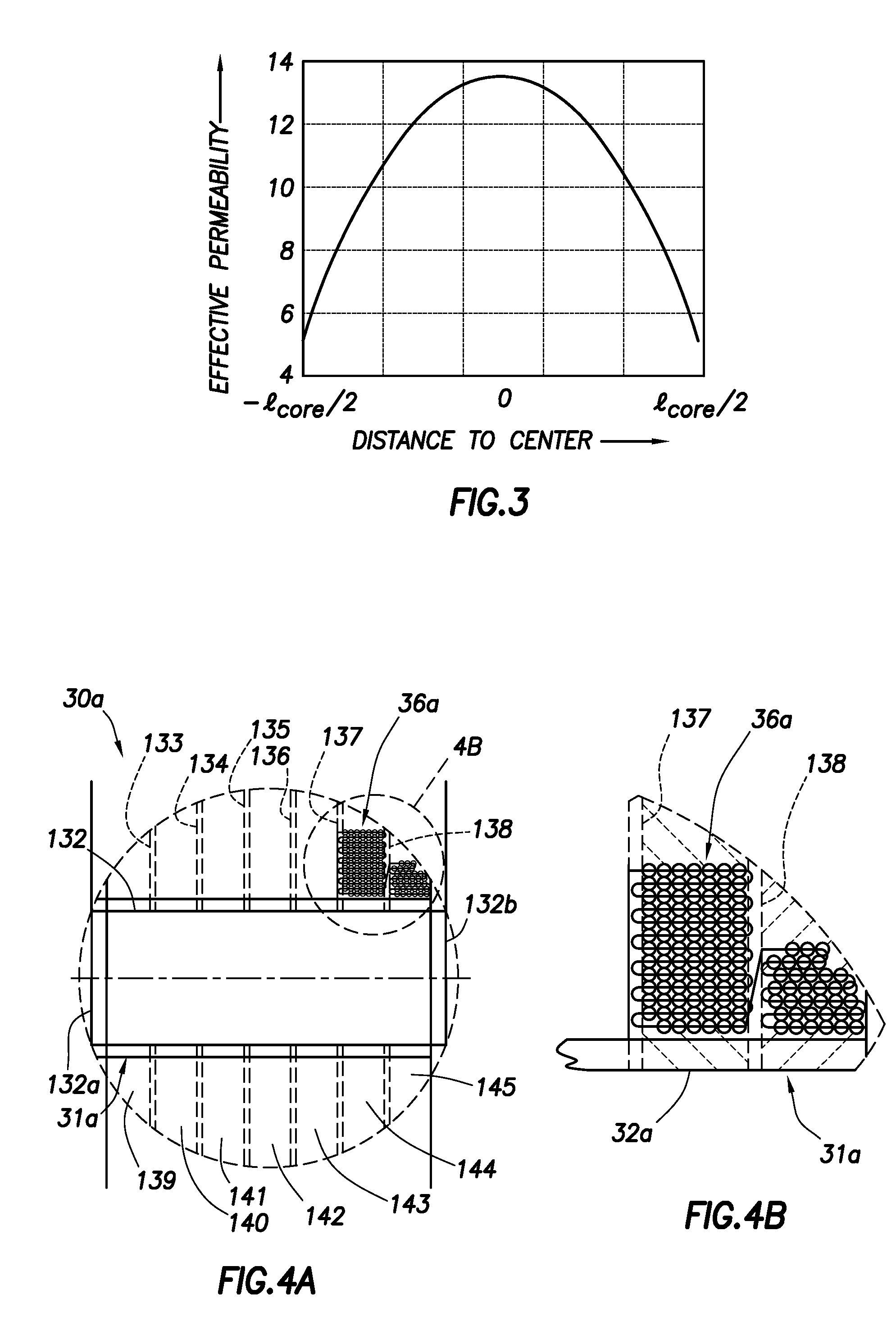

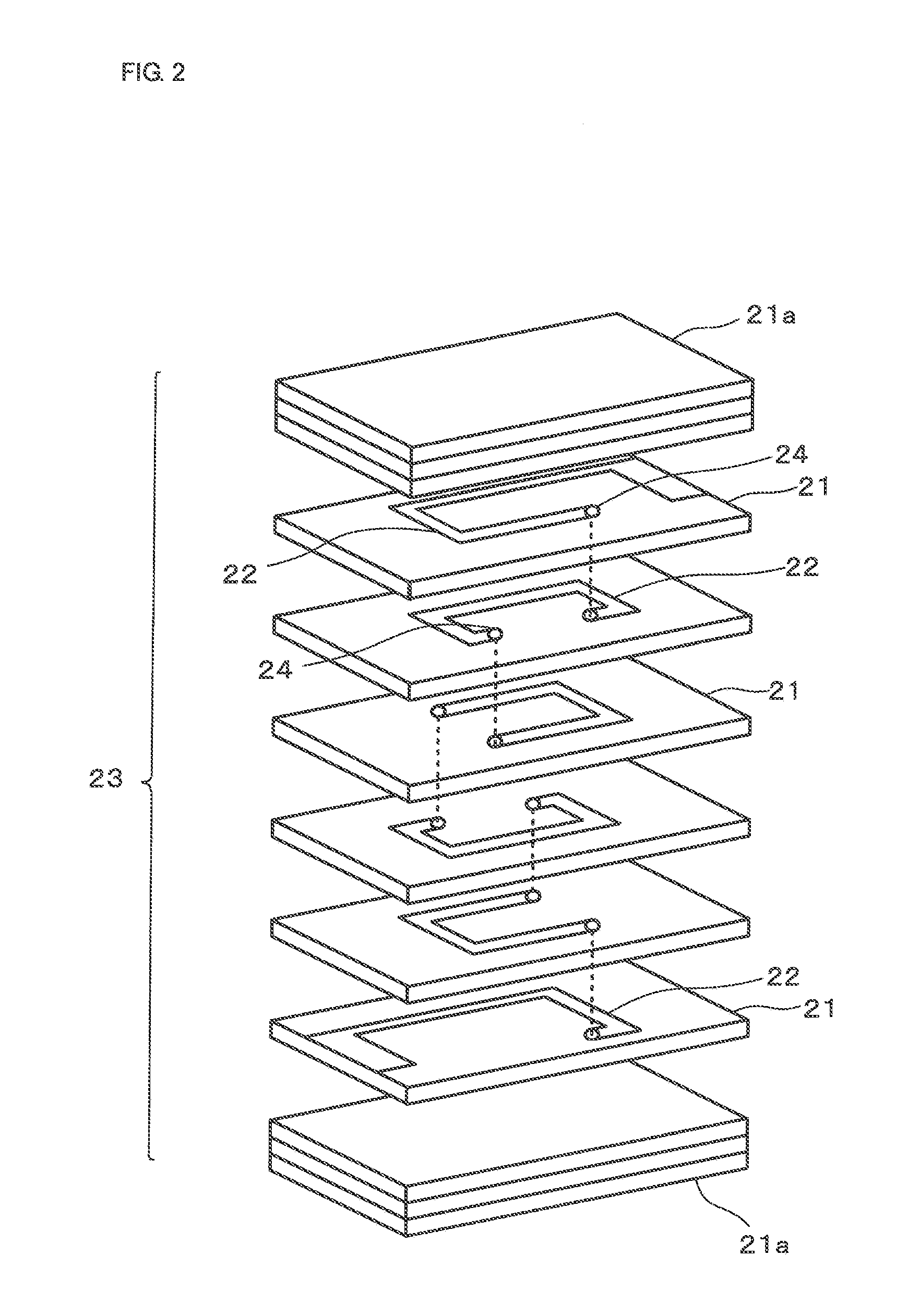

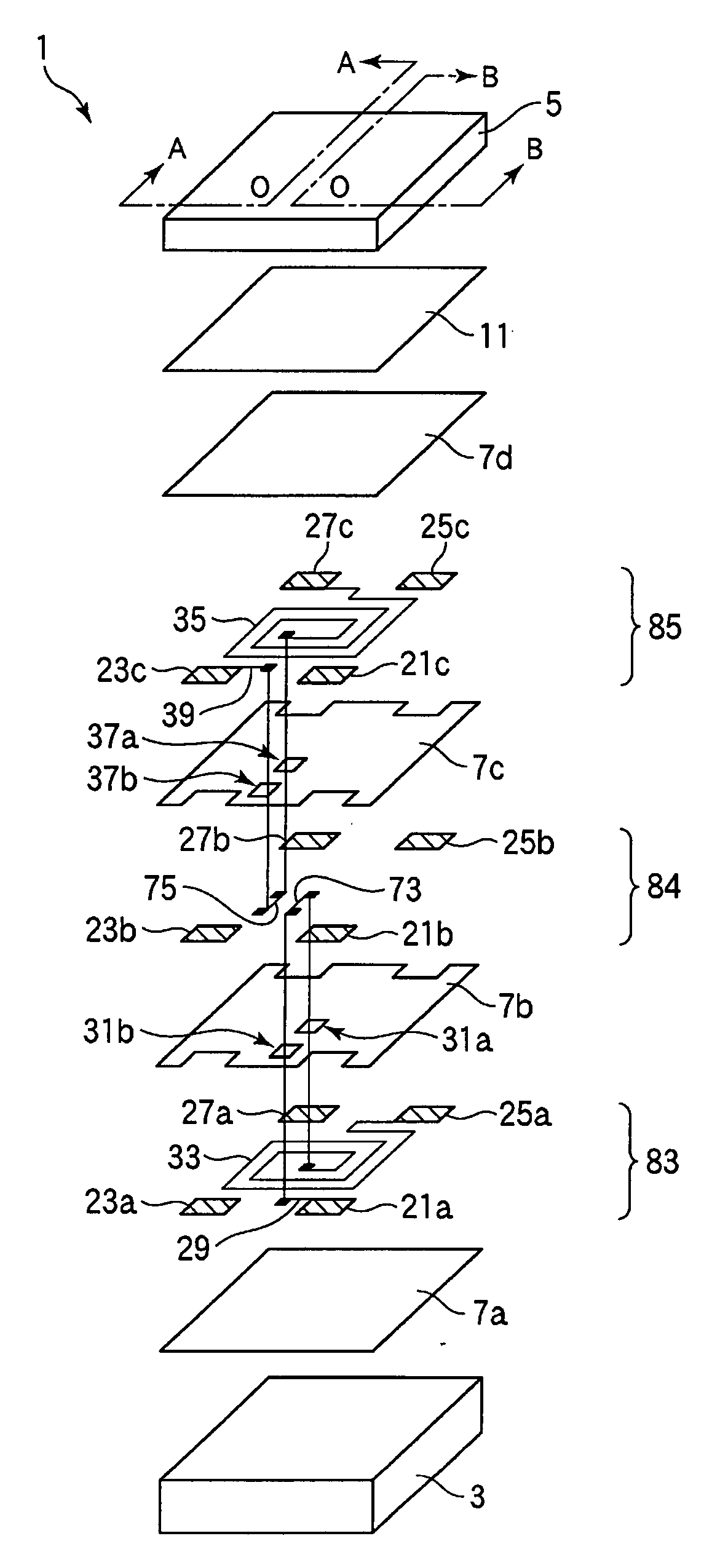

Multilayer coil component and method for manufacturing the same

ActiveUS20100201473A1Ensure the overall effectLow magnetic permeabilityInductance with magnetic coreCoilsElectrical resistance and conductanceElectrical conductor

A highly reliable multilayer coil component is provided without forming voids between magnetic ceramic layers and internal conductor layers. According to the multilayer coil component, an internal stress problem is reduced, the direct current resistance is low, and fracture of internal conductors caused by the surge or the like is not likely to occur. An acidic solution is allowed to permeate a magnetic ceramic element from a side surface thereof through a side gap portion which is a region between side portions of the internal conductors and the side surface of the magnetic ceramic element and to reach interfaces between the internal conductors and a magnetic ceramic located therearound. A pore area ratio of the magnetic ceramic of the side gap portion which is located between the side portions of the internal conductors and the side surface of the magnetic ceramic element is set in the range of 6% to 28%.

Owner:MURATA MFG CO LTD

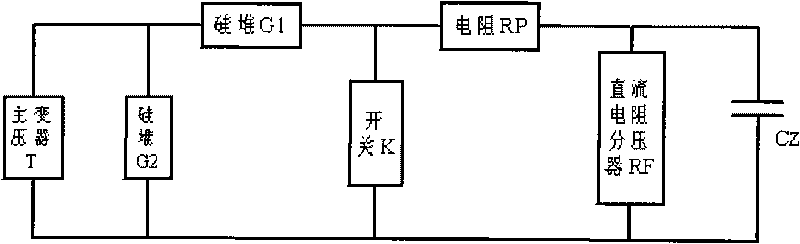

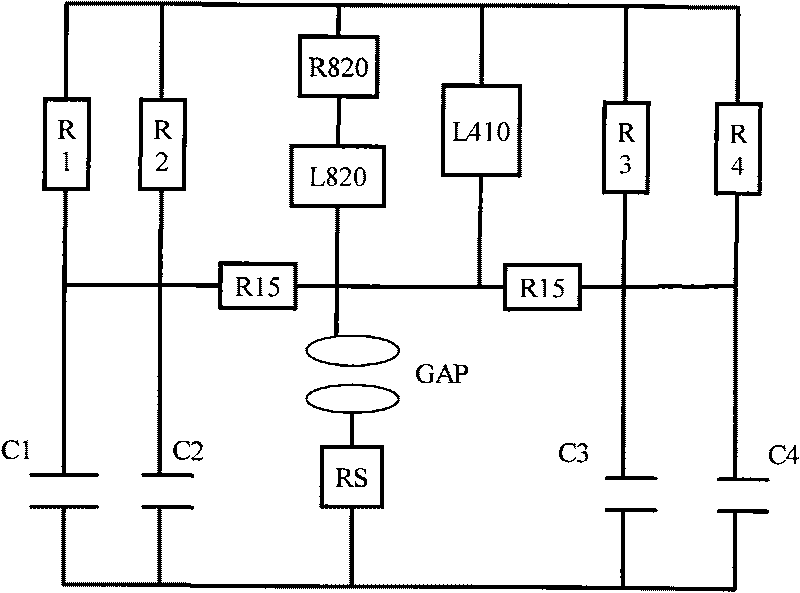

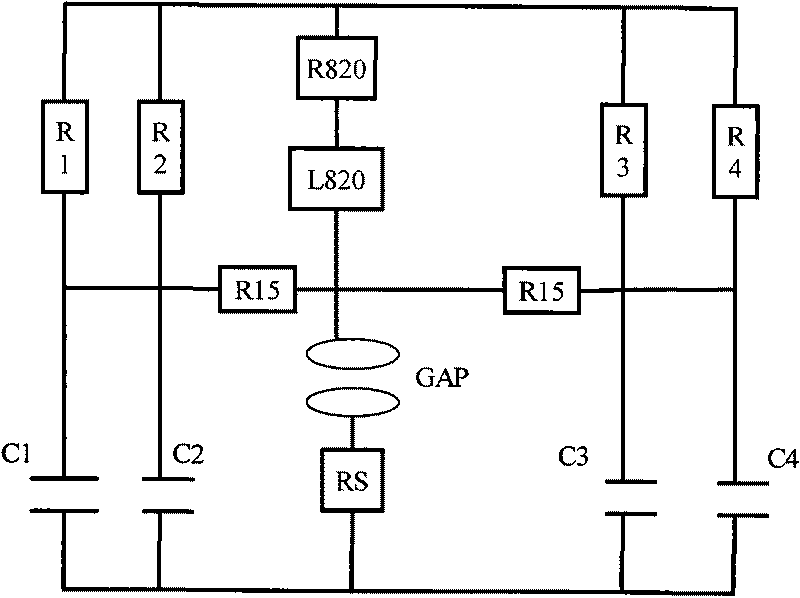

Multi-waveform impulse current generator

A multi-waveform impulse current generator comprises a charge circuit and a discharge circuit. The charge circuit comprises a main transformer T, a high-voltage silicon stack G1, a high-voltage silicon stack G2, a switch K, a charging protection resistor RP, a direct current resistance voltage divider RF and a main capacitor CZ. The discharge circuit comprises the main capacitor CZ, a non-inductive resistor, a wave modulated resistor, a wave modulated inductor, a discharge gap GAP and a tube shunt Rs. The aim of adjusting the waveforms of the impulse current is achieved by adjusting the inductance of the wave modulated inductor and the resistance of the wave modulated resistor in the discharge circuit. The generator can generate the following three different impulse current waves: 1 / 5mu S, 8 / 20 mu S and 4 / 10 mu S, and can realize that one equipment generates 3 waveforms. Compared with the equipment required for generating the standard lightning impulse current wave, switching impulse current wave and steep wave impulse current wave, the generator can save the equipment in bulk, lower the cost, reduce the floor space of the equipment and improve the use ratio of the equipment.

Owner:STATE GRID ELECTRIC POWER RES INST

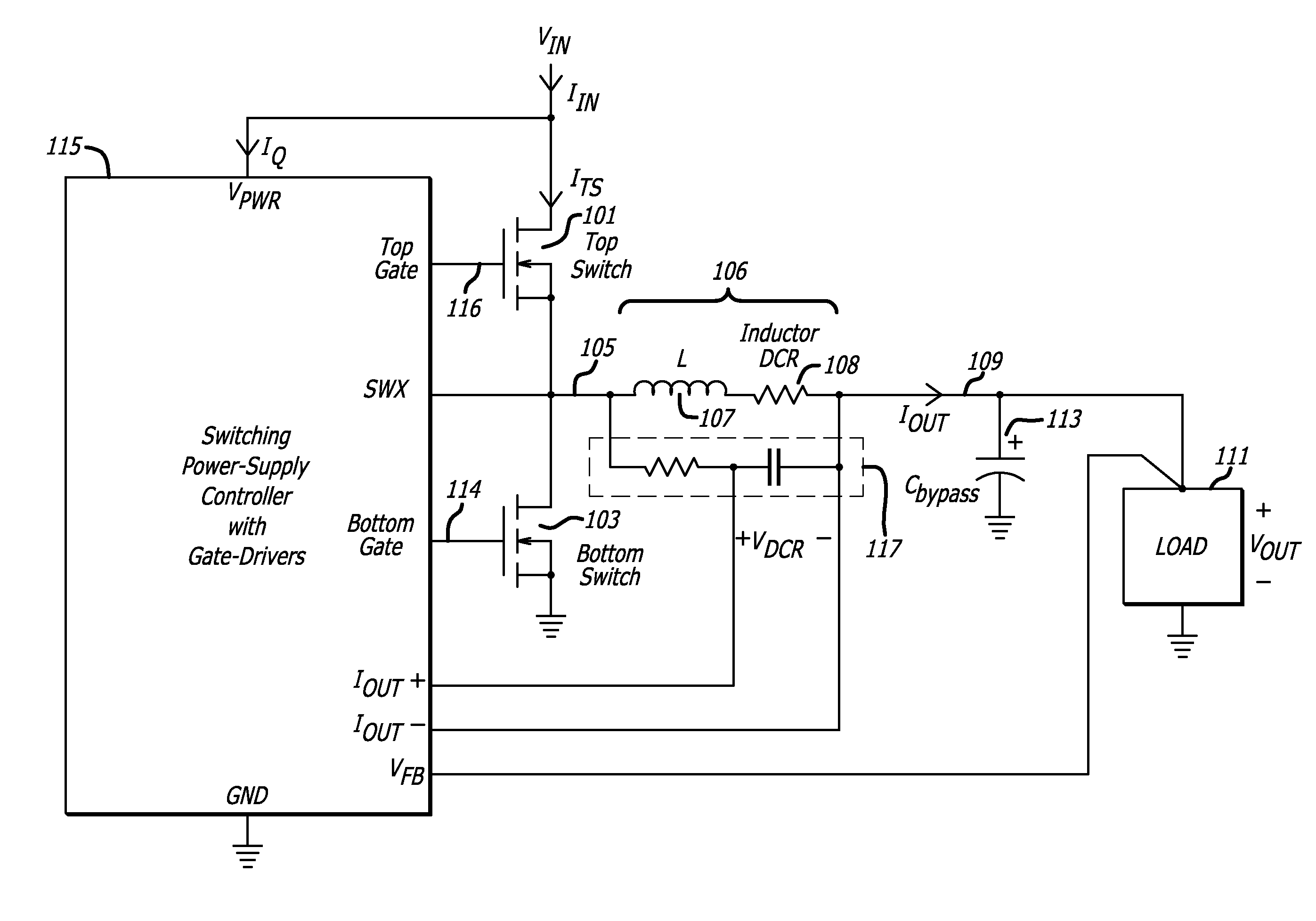

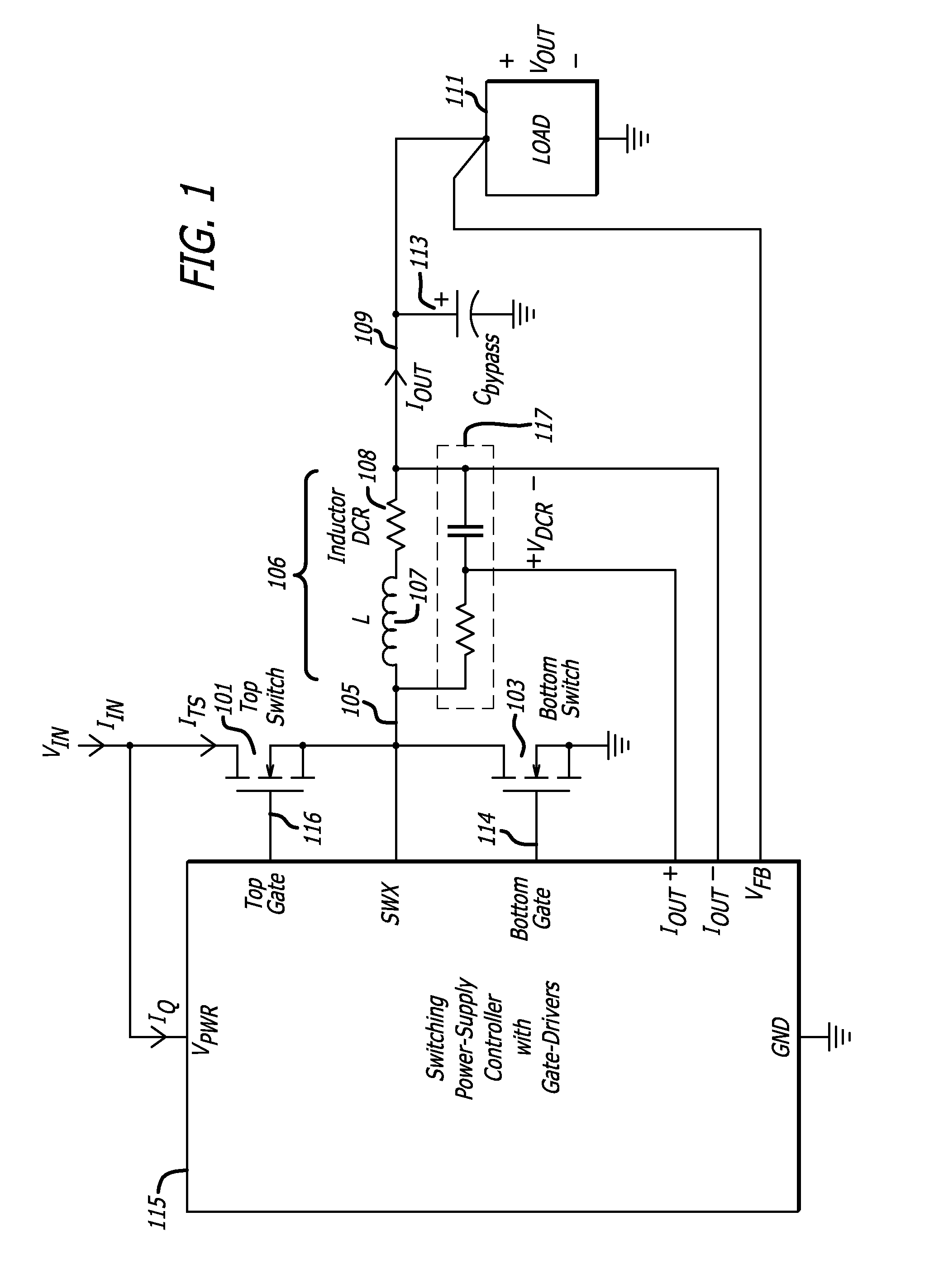

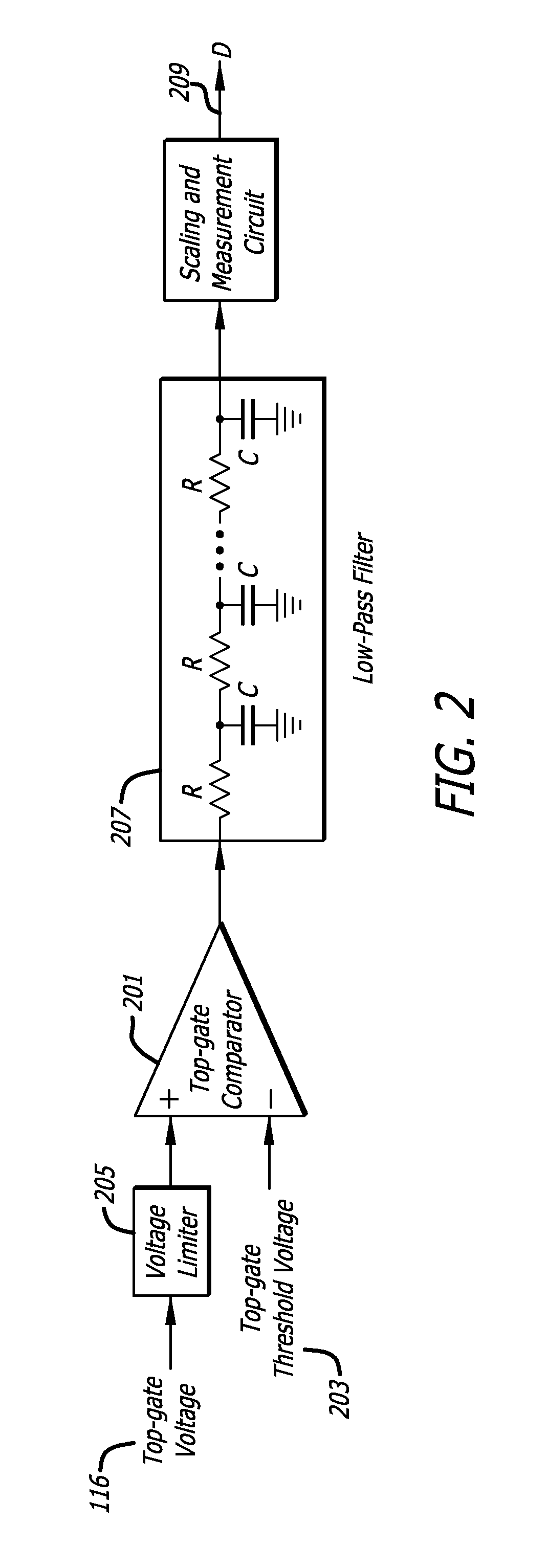

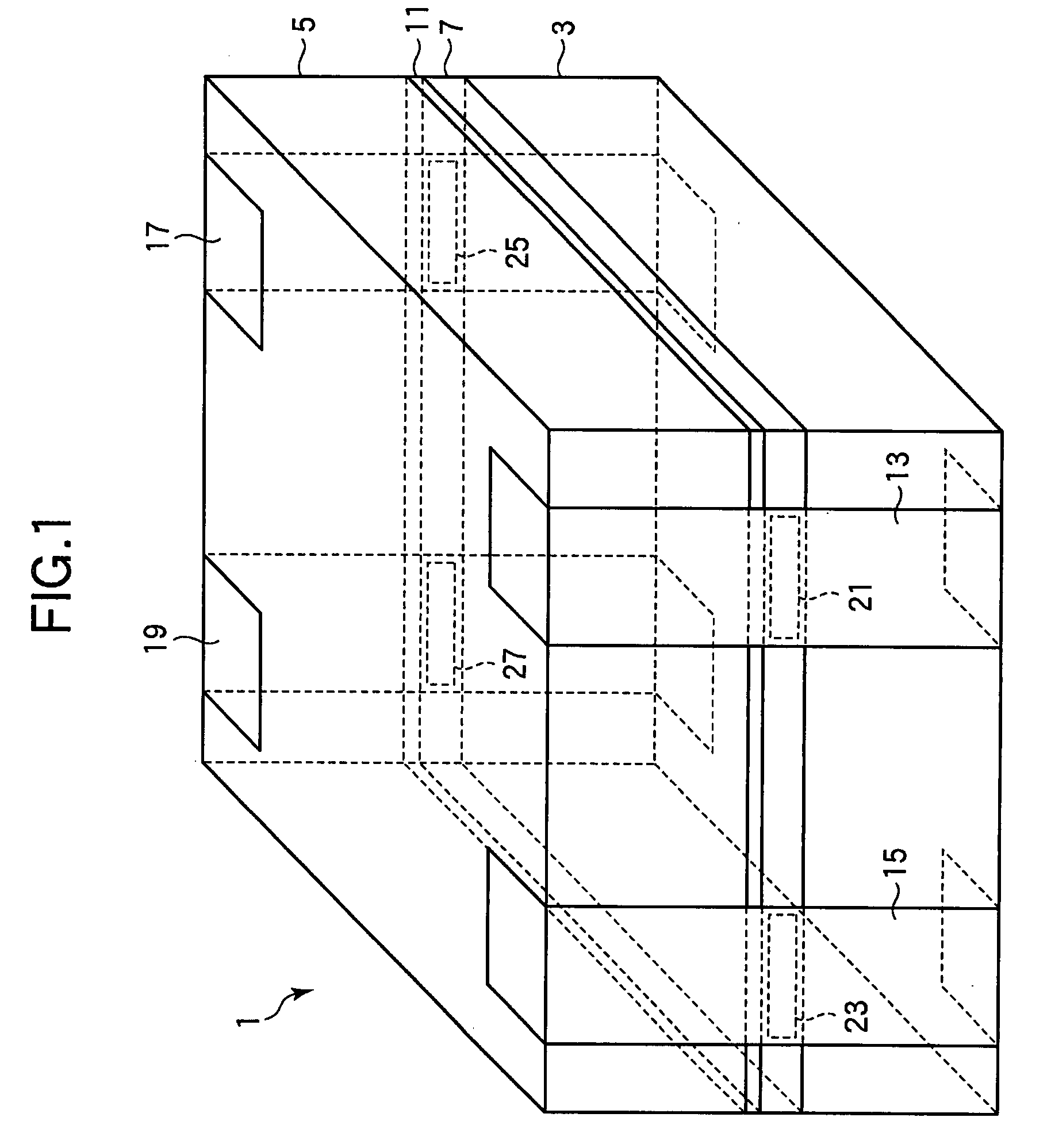

Efficiency measuring circuit for dc-dc converter which calculates internal resistance of switching inductor based on duty cycle

ActiveUS20110156687A1Computationally efficientElectrical measurement instrument detailsDc-dc conversionElectrical resistance and conductanceDc dc converter

An efficiency measuring circuit may measure the efficiency of a DC-DC converter having a switching inductor with an internal DC resistance and a plurality of electronic switches that control current through the inductor. A duty cycle circuit may measure the duty cycle of current flowing through one of the electronic switches. A current sense circuit may measure the current flowing through one of the electronic switches. An inductor voltage sensor circuit may measure the voltage across the inductor. A computation circuit may compute the internal DC resistance of the switching inductor based in part on the duty cycle measured by the duty cycle circuit and the current measured by the current sense circuit. The computation circuit may also compute the efficiency of the DC-DC converter.

Owner:ANALOG DEVICES INT UNLTD

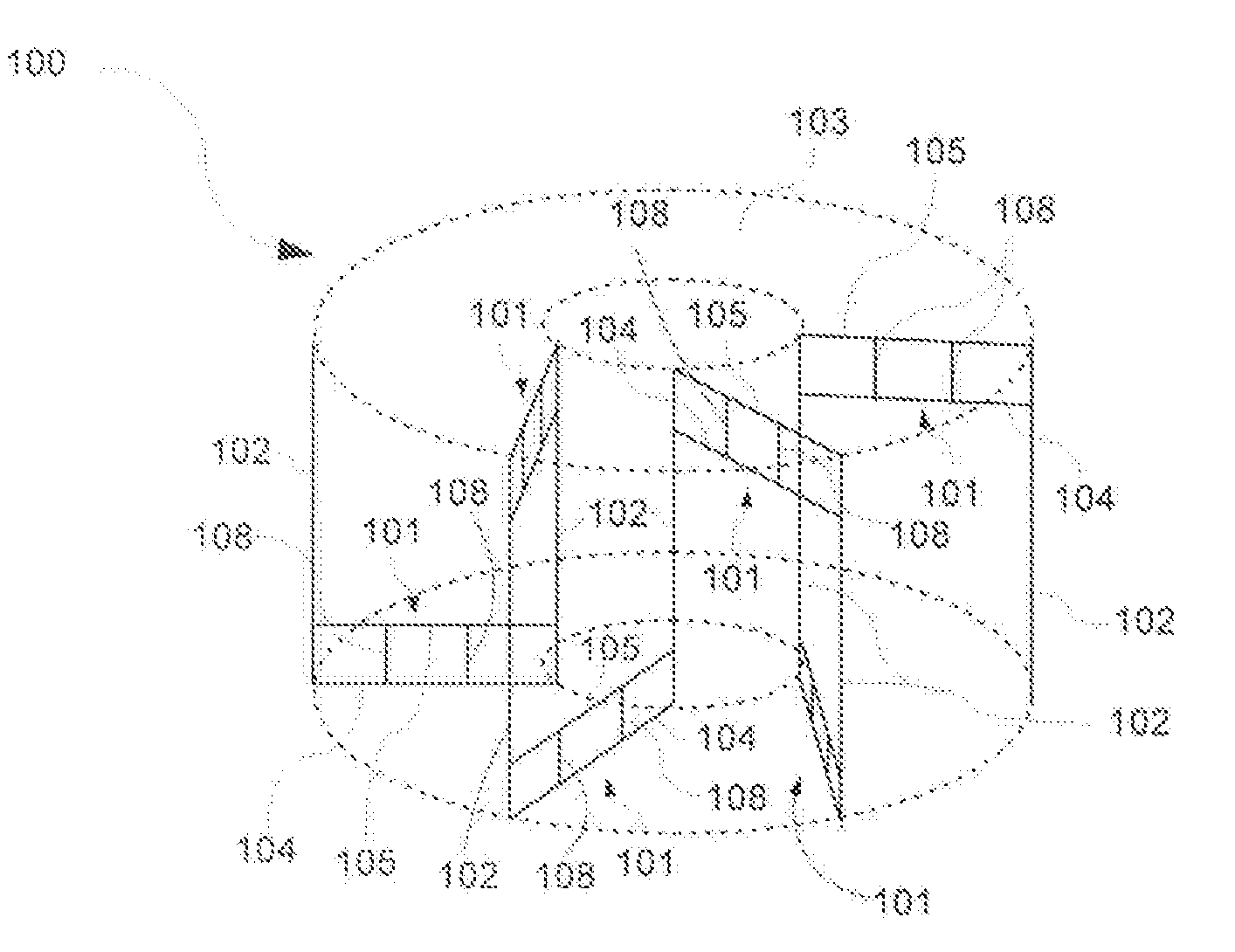

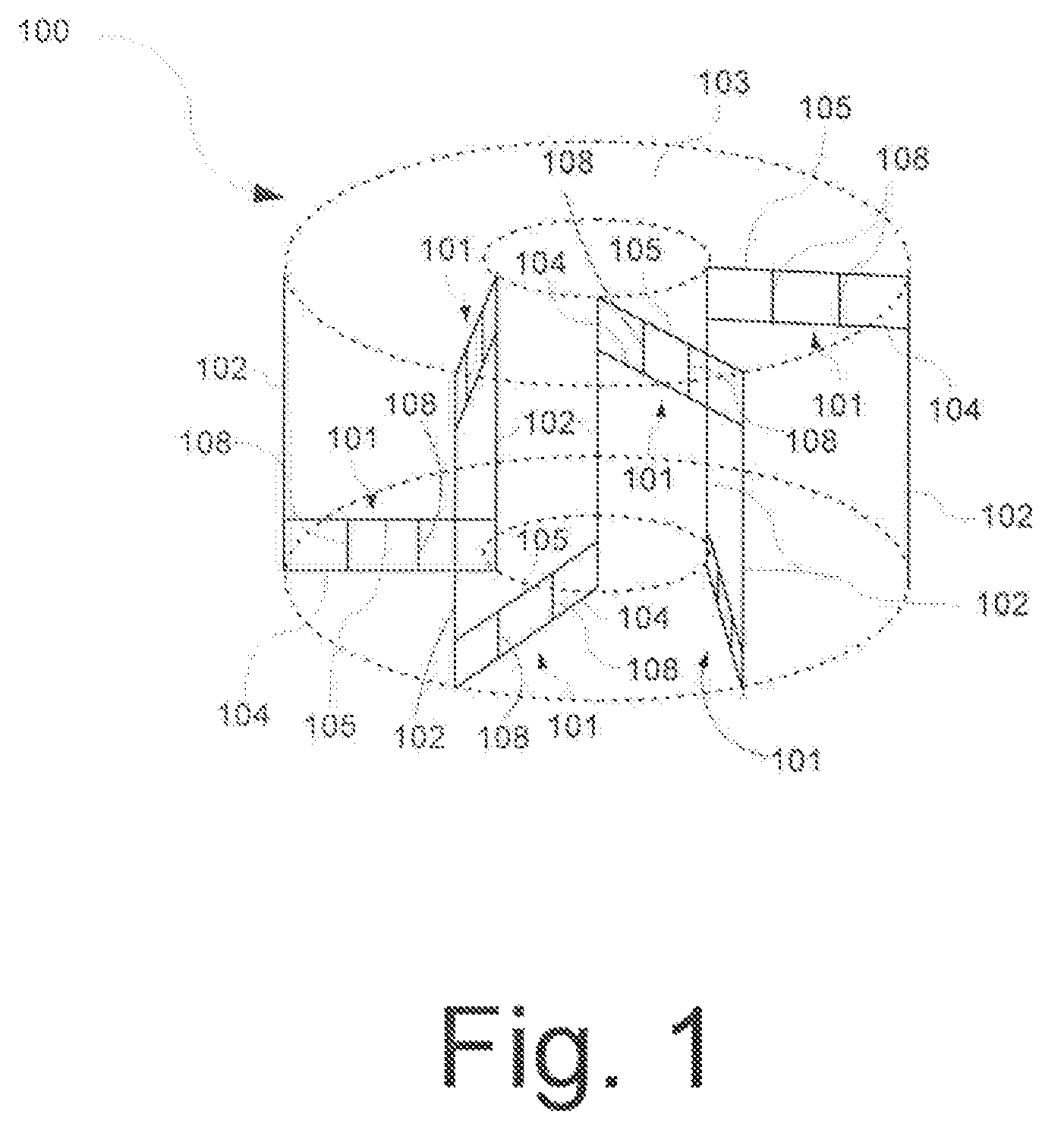

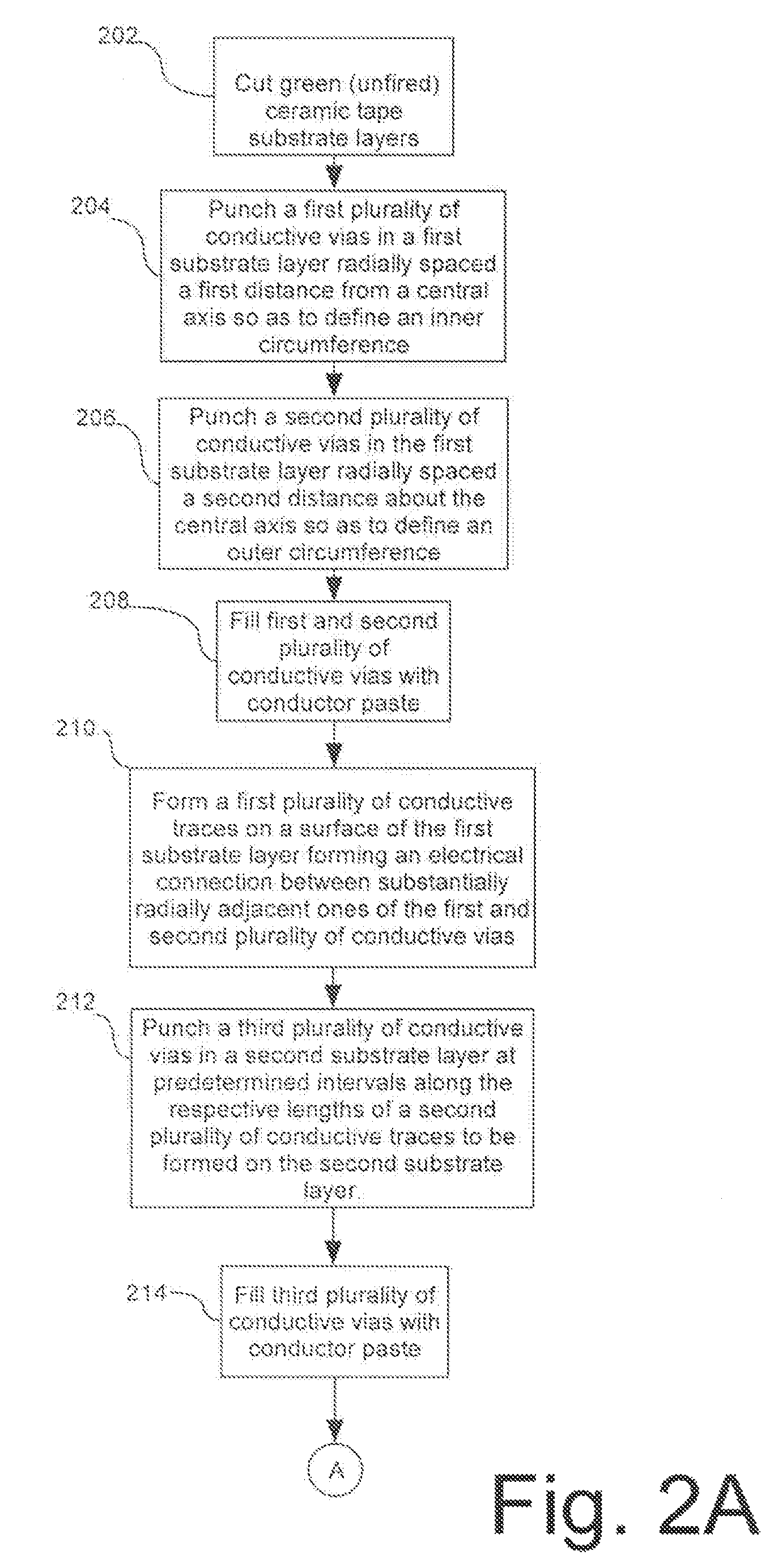

Toroidal inductor design for improved Q

ActiveUS7304558B1Transformers/inductances coils/windings/connectionsElectromagnetsElectrical conductorInductor

A toroidal inductor (100) and method of forming same. The invention is intended to decrease the direct current resistance (DCR) of the toroidal inductor circuit. Thus, an increase in the quality factor (Q) of the circuit is produced. The toroidal inductor includes a coil formed from an elongated conductor extending around a core material and defining a plurality of turns. The elongated conductor is comprised of one or more coil segments. The coil segments are arranged in an alternating pattern of a first type segment (101) and a second type segment (102). Each of the coil segments of the first type includes a plurality of elongated parallel conductors (104, 105) spaced apart and electrically connected by conductive links (108) at predetermined intervals along their respective lengths. The coil segments of the second type are formed of a single conductor defined by a conductive via (302, 304) formed in the substrate.

Owner:HARRIS CORP

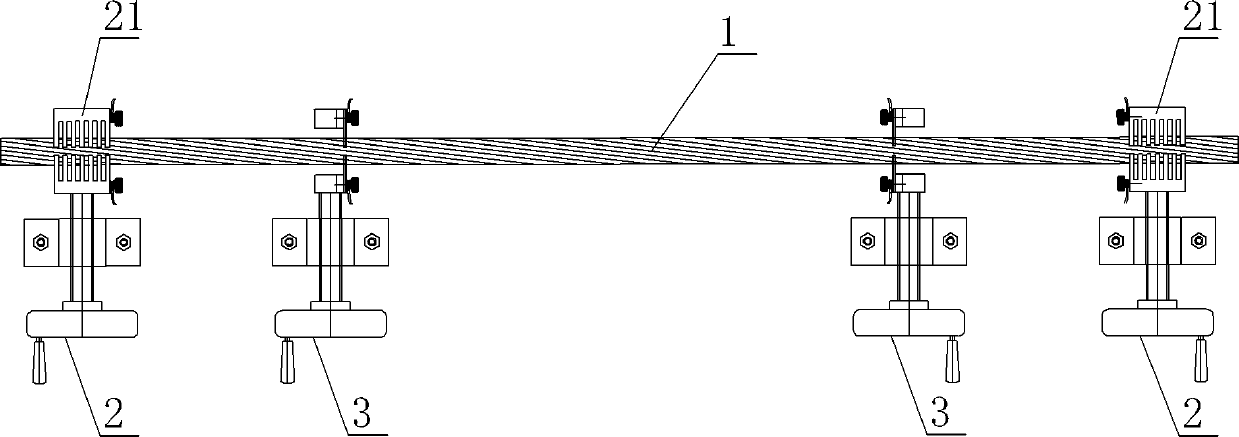

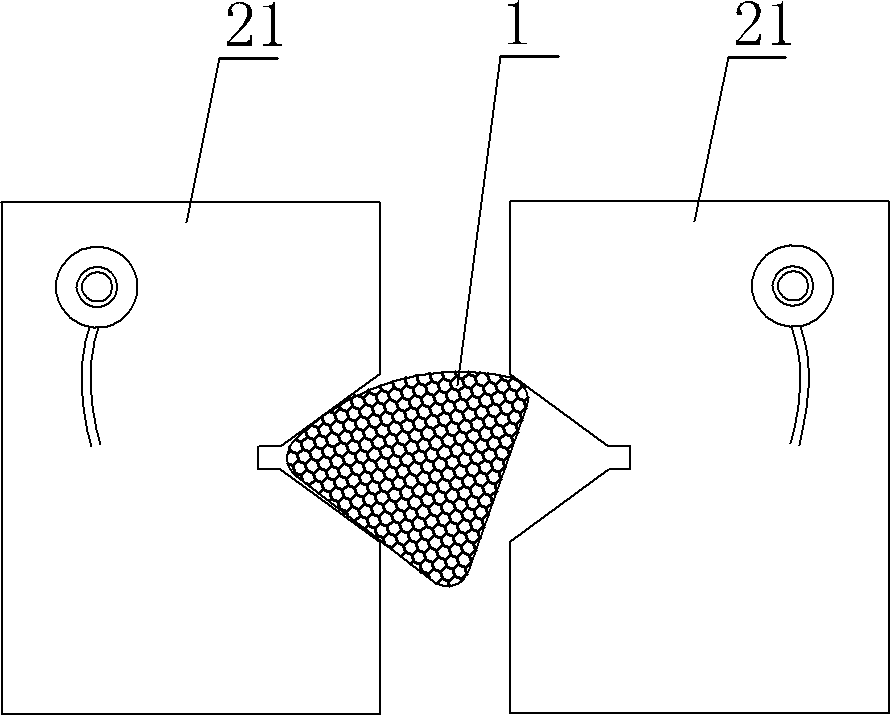

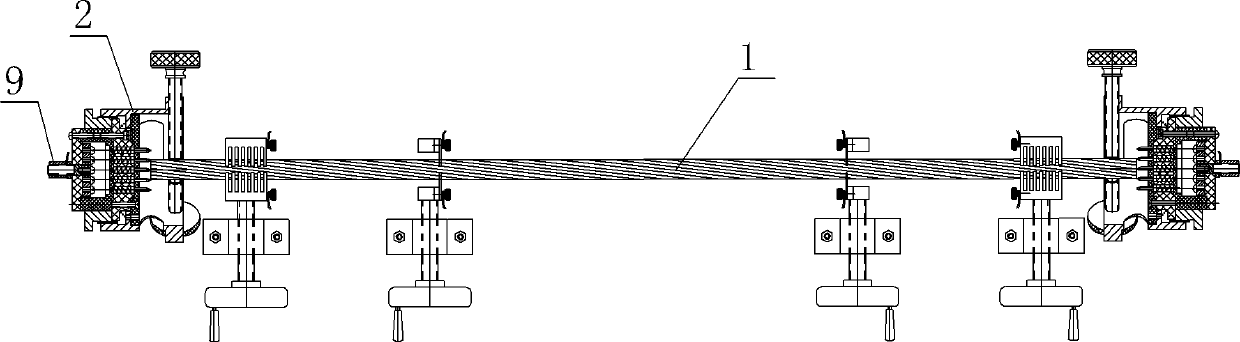

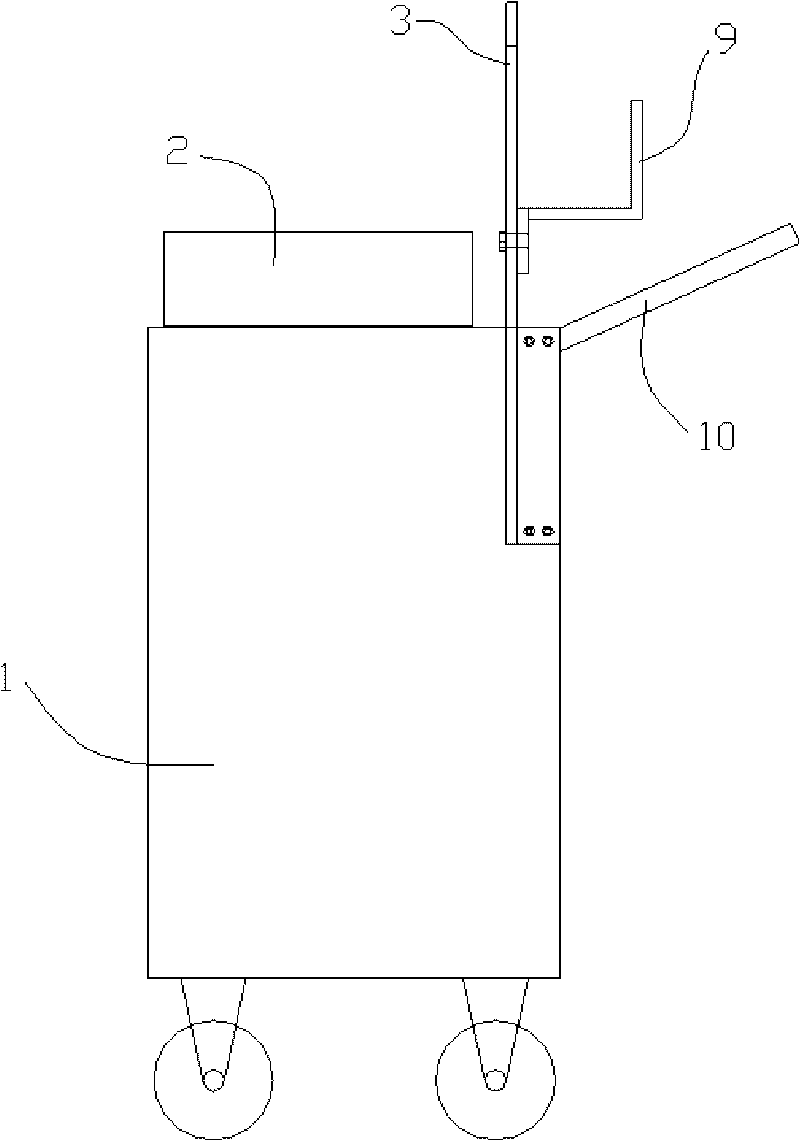

Testing device for direct-current (DC) resistance of cable conductor

ActiveCN102608428AImprove product qualityLow costResistance/reactance/impedenceElectrical resistance and conductanceElectrical conductor

The invention discloses a testing device for the direct-current (DC) resistance of a cable conductor. The testing device comprises two end-face current input fixtures which are respectively arranged at the two ends of the testing device, wherein each end-face current input fixture comprises a hat-shaped base, clamping devices and current importing devices are arranged on the bases, and each current importing device comprises a plurality of current importing terminals arranged at the bottom of the base. With the adoption of the technical scheme, the testing device for the DC resistance of the cable conductor has the advantages that: the DC resistance of the cable conductor is tested by adopting an end-face current input method, a testing current is enabled to directly enter the end faces of the conductor from the end-face current input fixtures through current leads, the current can evenly enter the conductor, and the testing current is truly guaranteed to flow through every monofilament to the maximum, so that the contact resistance between the conductor and the fixtures is reduced, the untruth of tested data on the DC resistance of the conductor is avoided, the quality of cable products is stabilized, and the cable cost is lowered.

Owner:ZHEJIANG CHENGUANG CABLE CO LTD

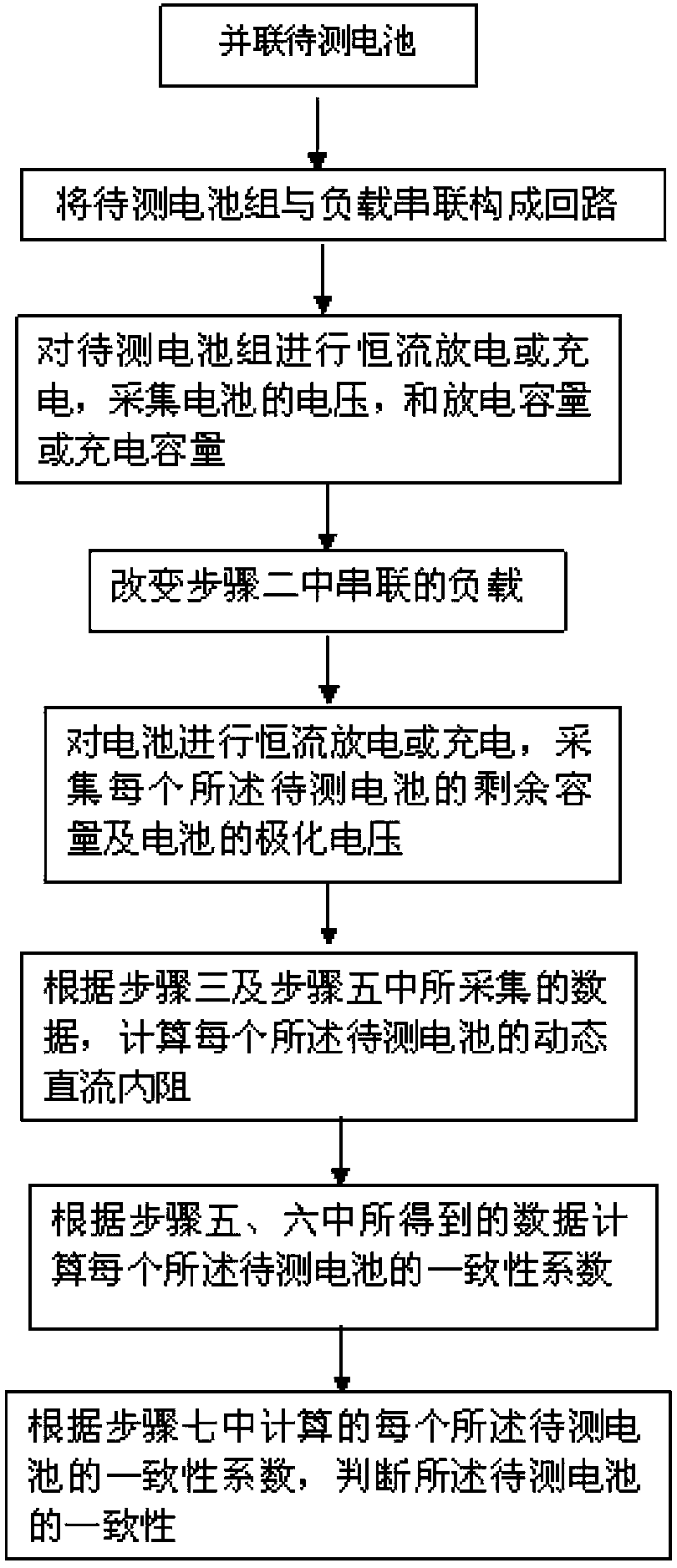

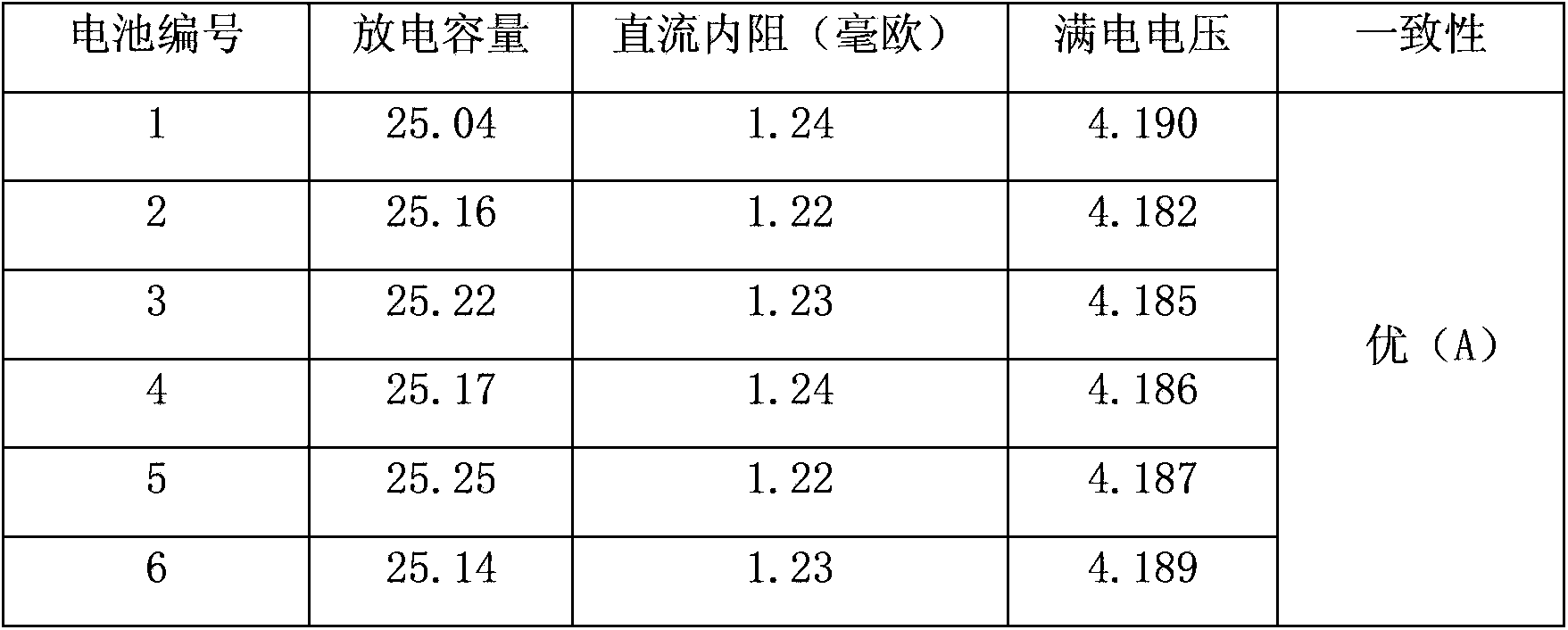

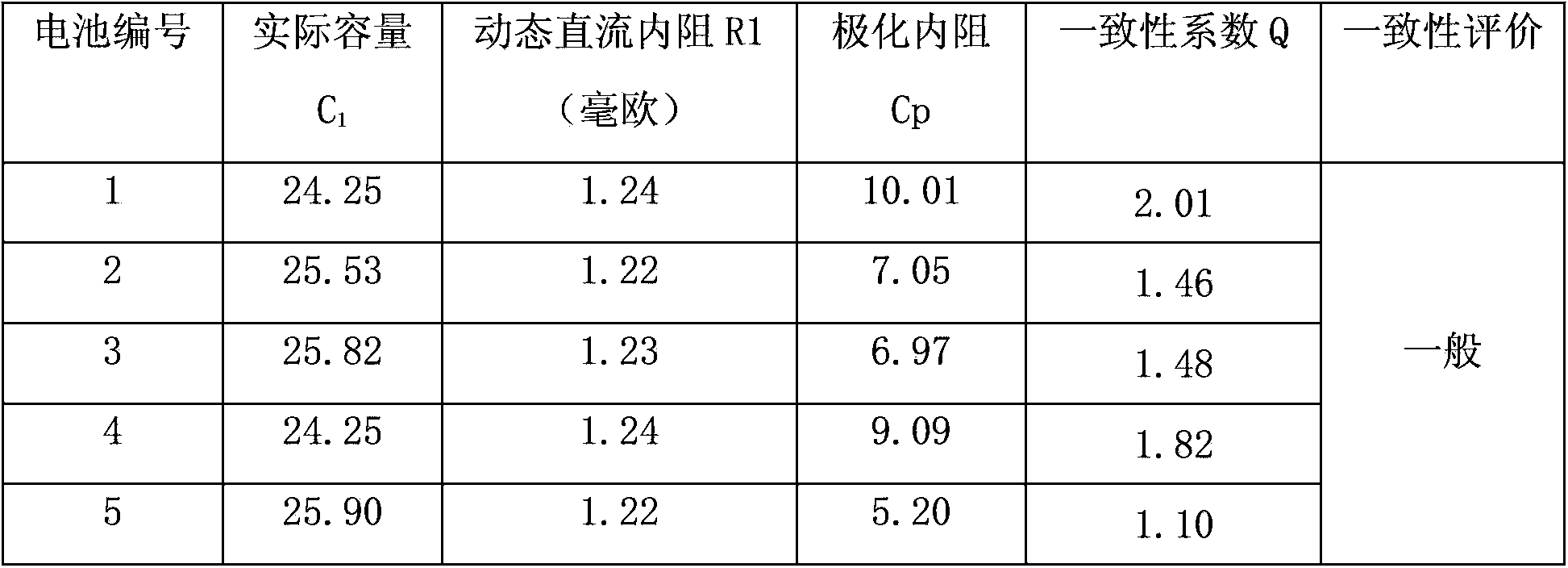

Method for dynamically evaluating battery consistency

ActiveCN104345275AImprove performanceExtended service lifeElectrical testingElectrical batteryEngineering

The invention discloses a method for dynamically evaluating battery consistency. The method comprises steps of (1) carrying out series connection of two batteries to be measured to form a battery group to be measured, (2) carrying out the series connection of the battery group to be measured and a load to form a loop, (3) carrying out constant current discharging or charging on the battery group to be measured and collecting the voltage and discharging capacity or charging capacity of the batteries, (4) changing the load which is in series connection in the step (2), (5) carrying out constant current discharging or charging on the battery group to be measured and collecting the remaining capacity of each battery to be measured and the polarization voltage of the battery, (6) calculating the dynamic DC resistance of each battery to be measured according to the collected data, (7) calculating the consistency coefficient of each battery to be measured according to the above data, and (8) judging the consistency of the batteries to be measured according to the consistency coefficient of each battery to be measured. Through measuring and comparing the data of the batteries in parallel connection in a dynamic environment, the essential difference of a battery group can be directly identified, the group performance of the batteries can be improved, the consistency of the batteries is improved, and the service life of the battery group is prolonged.

Owner:SHANGHAI CENAT NEW ENERGY

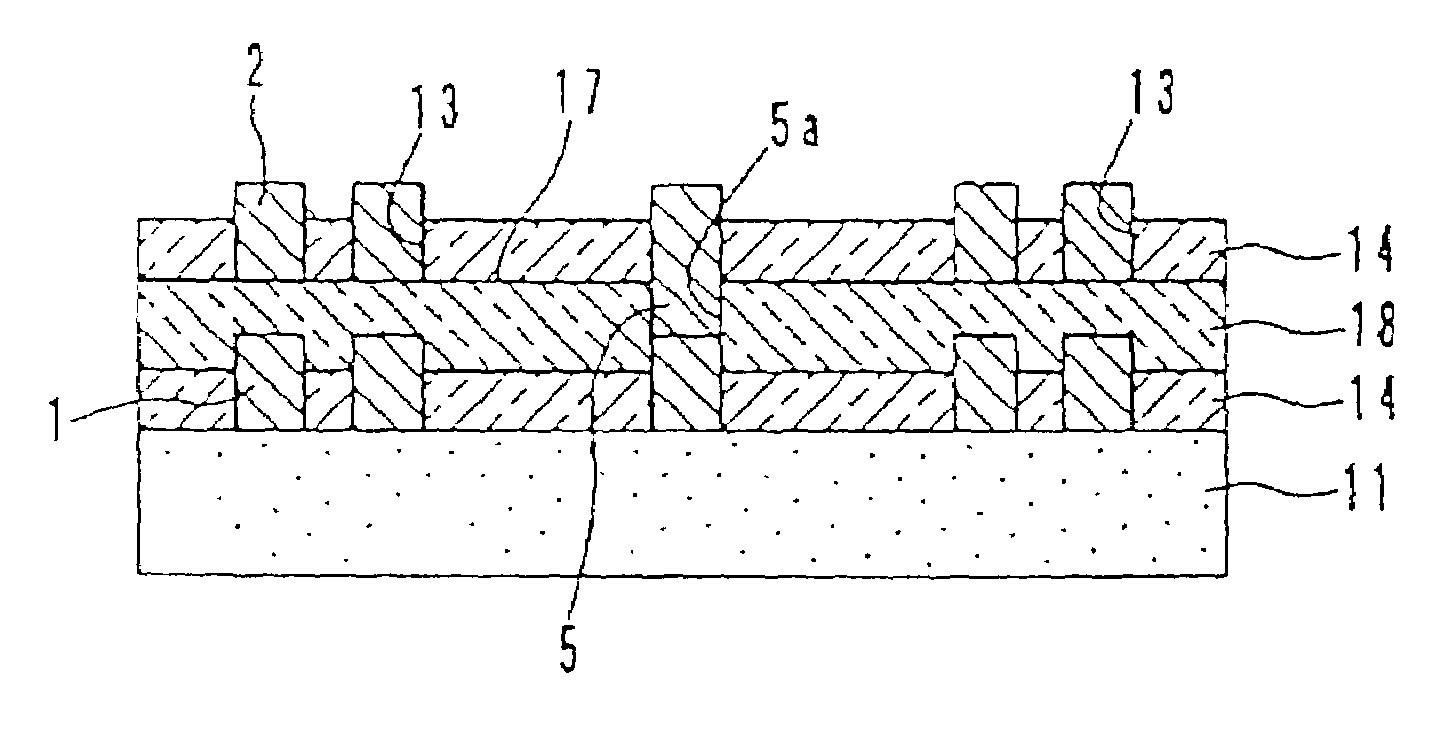

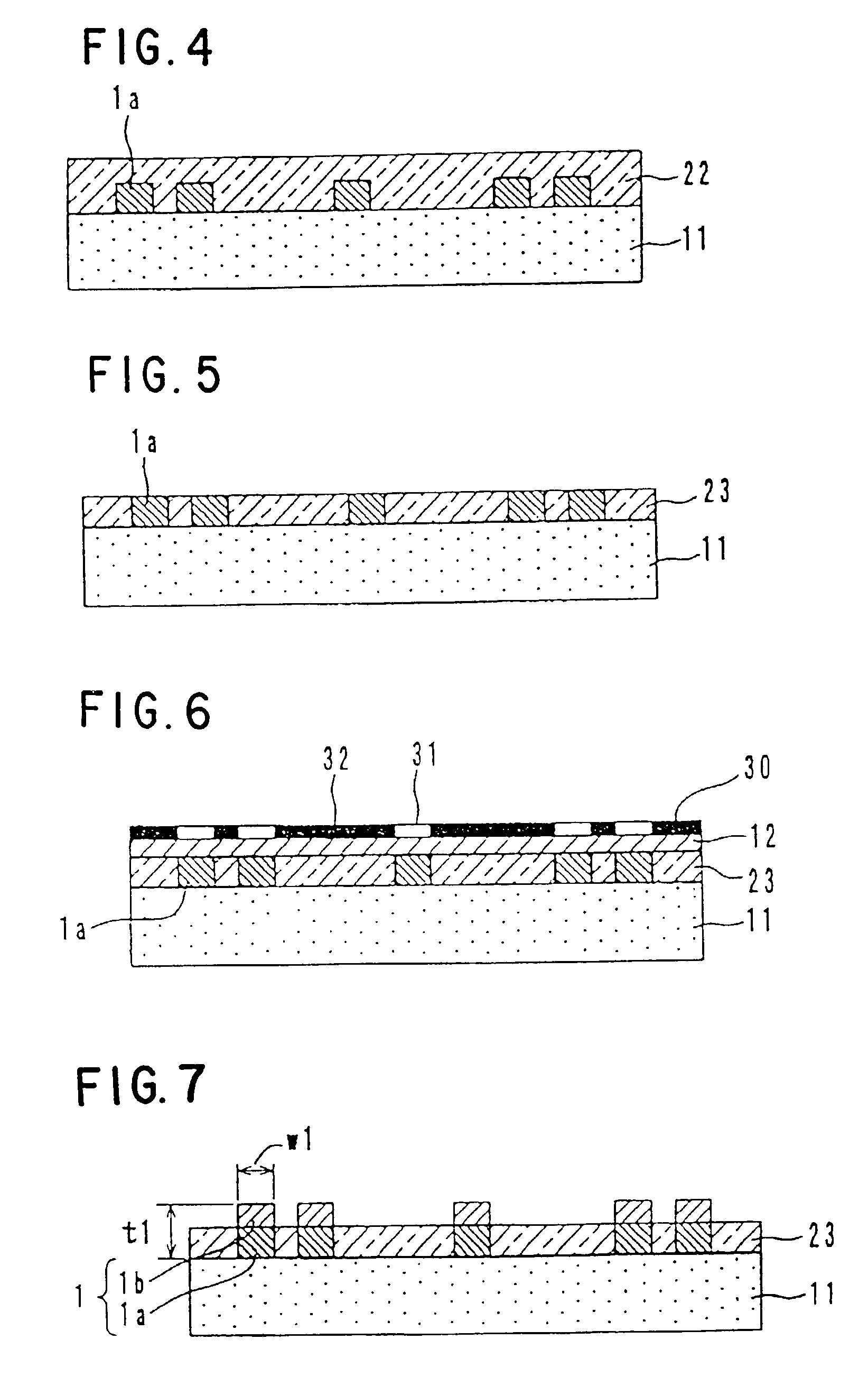

Method of manufacturing an electronic component including an inter-line insulating layer and a conductor pattern

InactiveUS7160770B2Accurate conductor pattern sizeSmall resistance valueSemiconductor/solid-state device detailsSolid-state devicesConductive pasteOptoelectronics

A small size electronic component has a small direct current resistance value of a conductor pattern and minimal dimensional irregularity of a conductor pattern. In order to form such a component, a photosensitive conductive paste applied on a ceramic substrate and is then exposed through a photo mask and developed so as to form a lower conductor pattern layer of a coil conductor pattern. Then an insulating paste is applied on the ceramic substrate so as to cover the lower conductor pattern layer and the insulating paste is removed with a solvent until at least the upper surface of the lower conductor pattern layer is exposed so as to form an inter-line insulating layer. Furthermore, after applying a photosensitive conductive paste as a film, the exposure and development operation is conducted again while using the photo mask so as to form an upper conductor pattern layer on the lower conductor pattern layer.

Owner:MURATA MFG CO LTD

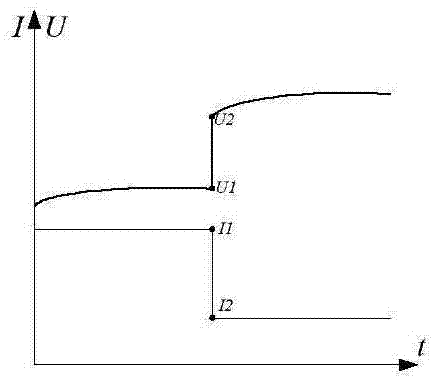

Direct current resistance measuring method for electric vehicle battery pack

ActiveCN102520255AAvoid the problem of increased estimation errorEffective calculationResistance/reactance/impedenceElectrical testingElectrical resistance and conductanceInternal resistance

A direct current resistance measuring method for an electric vehicle battery pack includes the following steps: 1 choosing certain time as a period T, and collecting maximum battery voltage Umax and minimum voltage Umin in the period T; 2 collecting maximum current Imax and minimum current Imin in the period T; and 3 measuring direct current resistance R of the battery pack according to the following formula R=(Umax-Umin) / (Imax-Imin). The direct current resistance measuring method solves problems that battery direct current inner resistance estimation error is added caused by desynchrony of battery voltage sampling and current sampling, achieves effective measuring and calculation of battery direct current inner resistance and is high in measuring and calculation accuracy.

Owner:HUIZHOU EPOWER ELECTRONICS

Battery state estimation apparatus

ActiveUS20160103184A1Improve accuracyHigh precision estimationElectrical testingSpecial data processing applicationsDc resistanceElectrical battery

A battery state estimation apparatus estimates a state of a secondary battery based on a battery model thereof. The battery model includes a DC resistance model, a reaction resistance model, and a diffusion resistance model. The apparatus includes a DC information storage section which stores information on the DC resistance related to temperature of the secondary battery, a reaction information storage section which stores information on the reaction resistance parameter related to the temperature, a diffusion information storage section which stores information on each of the first and second parameters related to the temperature, and a state estimation section which calculates the DC resistance, the reaction resistance parameter, and the first and second parameters from the stored information, by using the temperature as input, and estimates the state of the secondary battery based on the DC resistance, reaction resistance parameter, and first and second parameters.

Owner:DENSO CORP

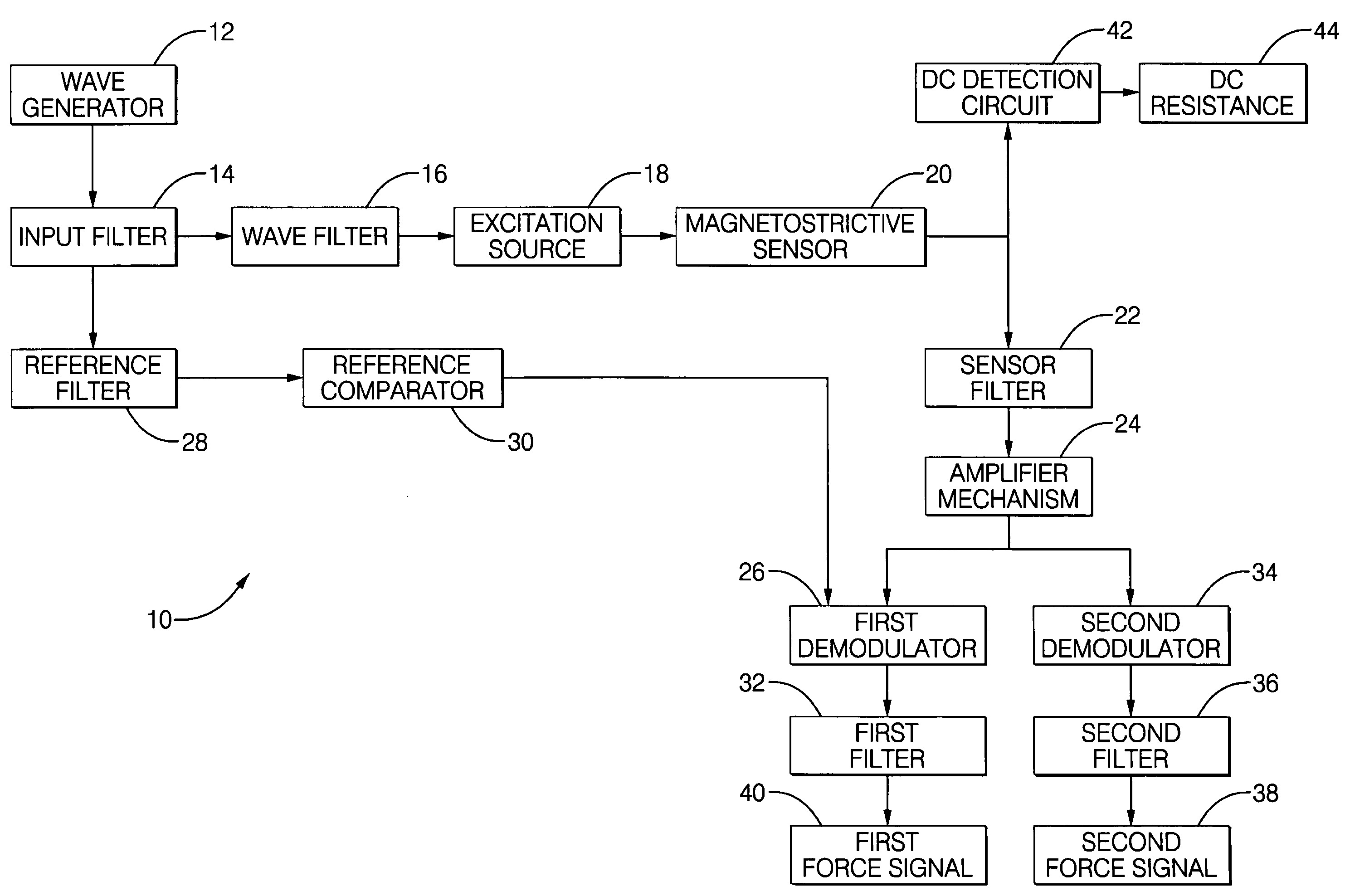

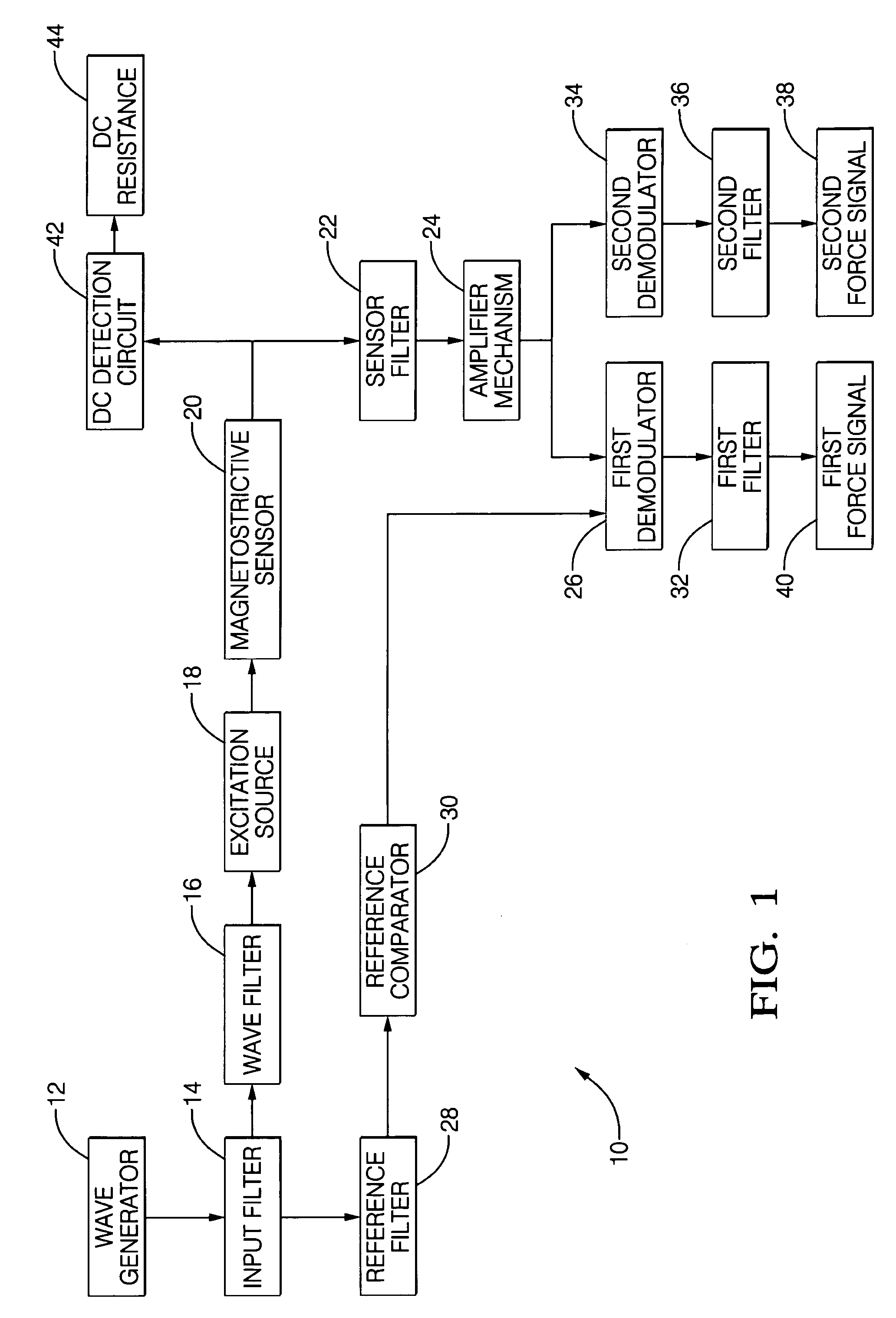

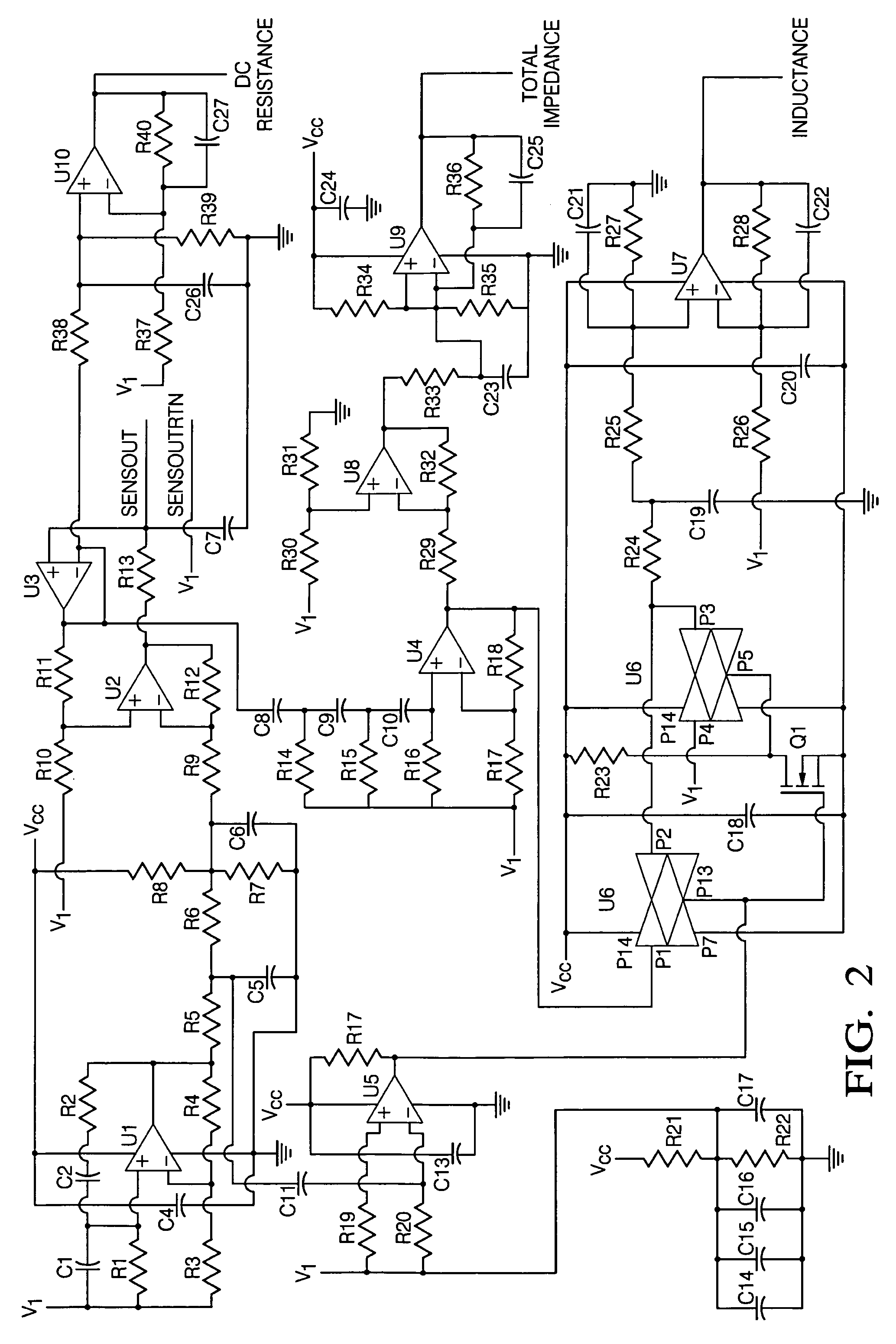

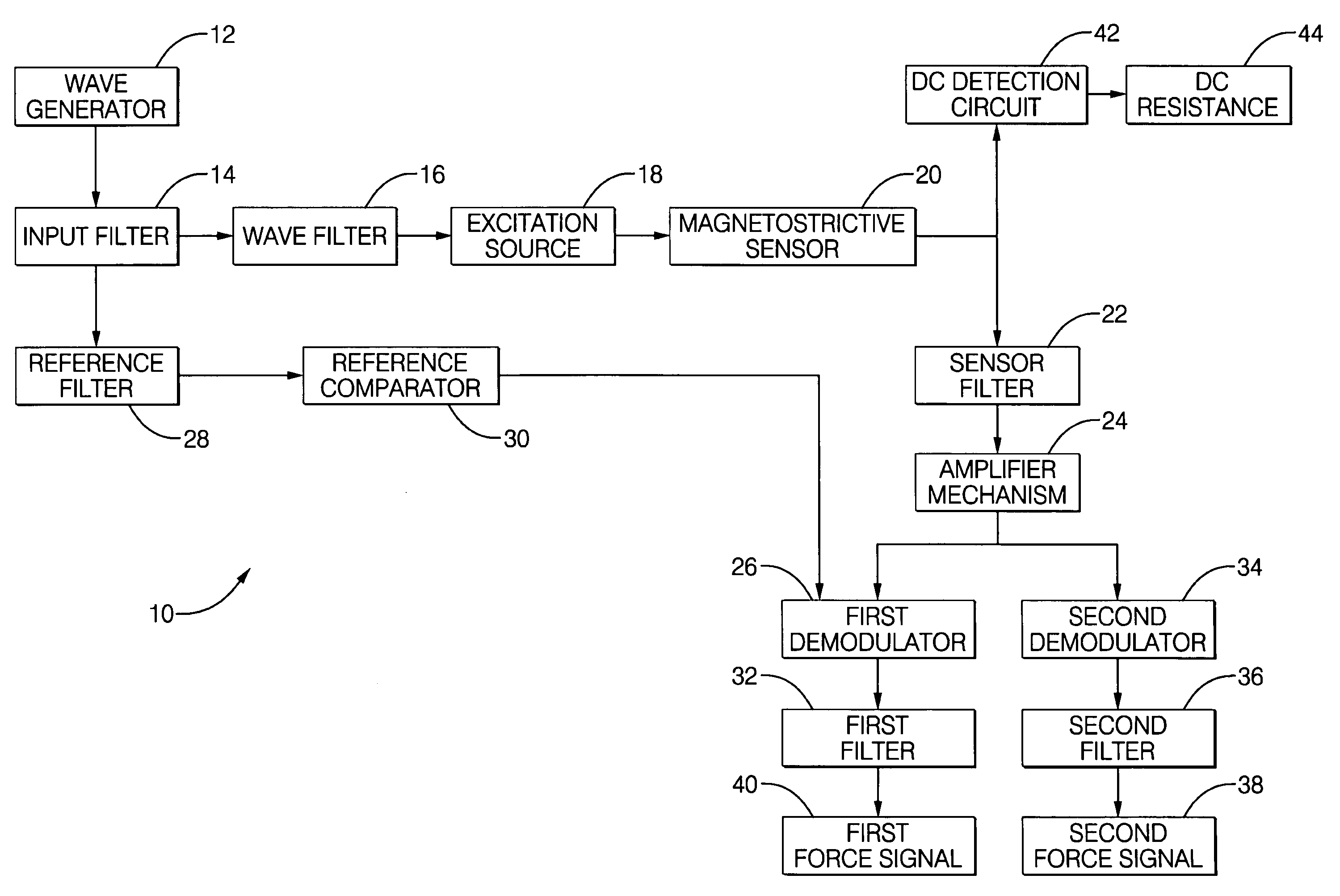

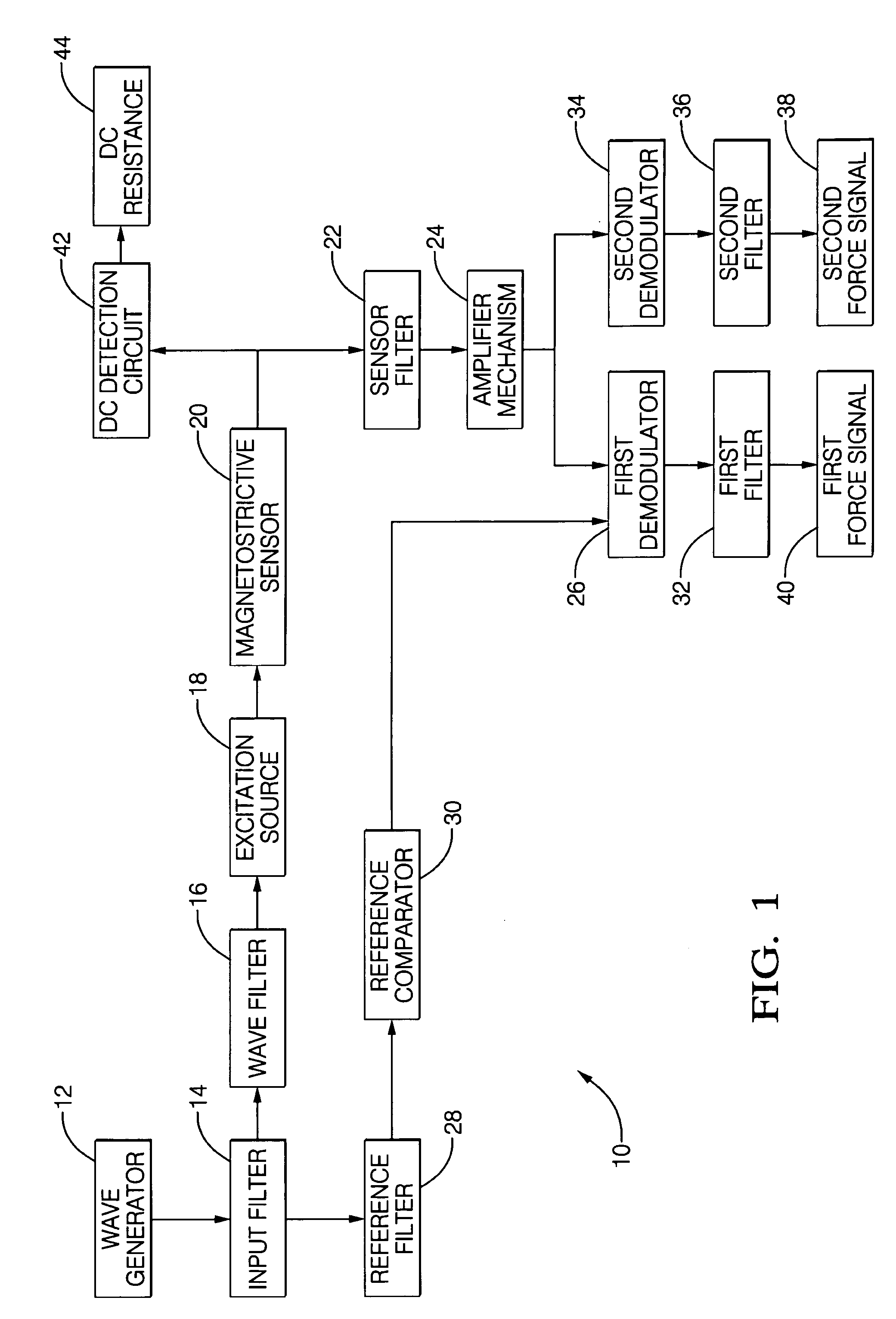

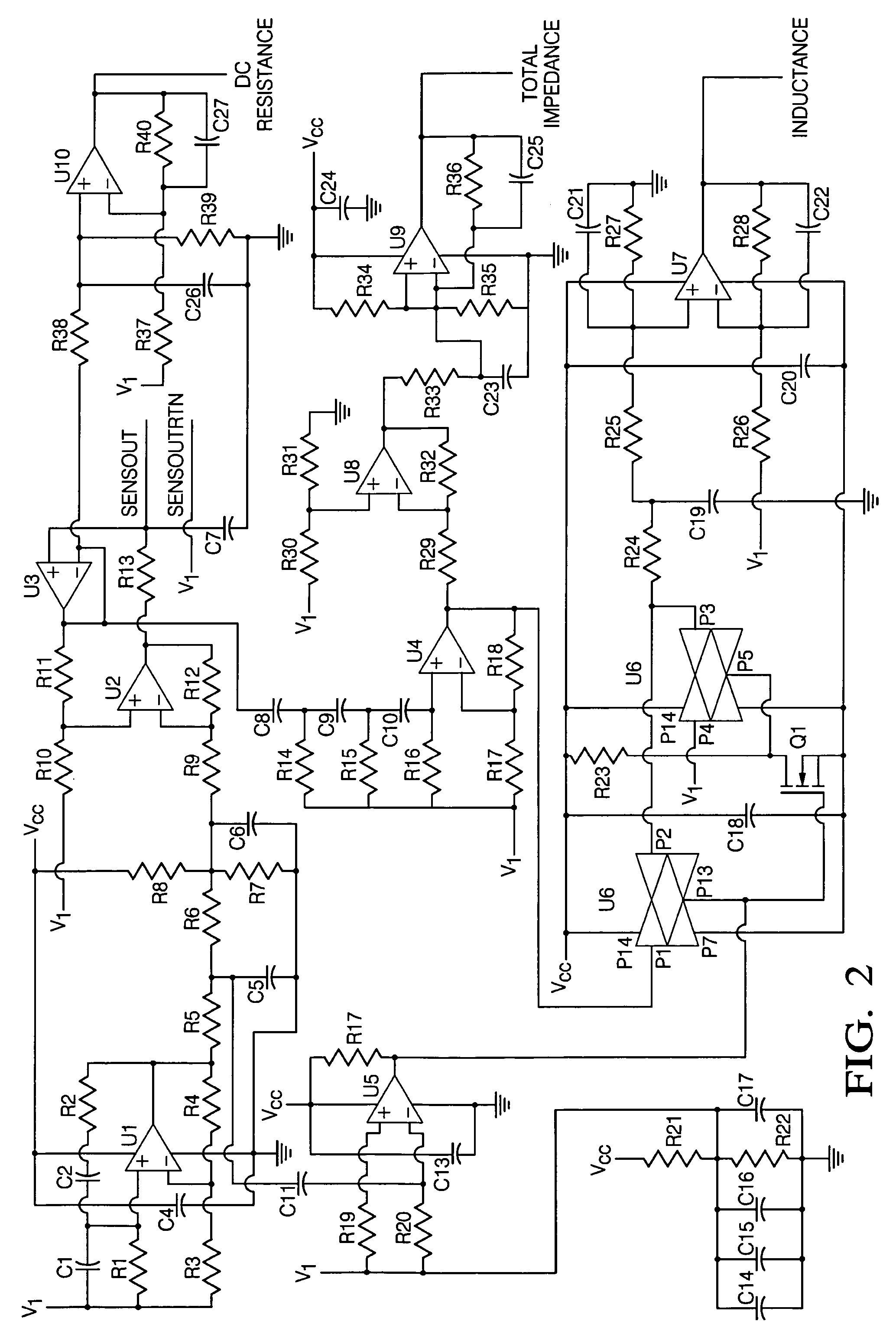

Robust detection of strain with temperature correction

ActiveUS7362096B2High strengthForce measurement by measuring magnetic property varationUsing electrical meansElectrical resistance and conductancePhase shifted

Owner:BWI CO LTD SA

Robust detection of strain with temperature correction

ActiveUS20070096724A1High strengthForce measurementUsing electrical meansElectrical resistance and conductancePhase shifted

An apparatus (10) is set forth for measuring a return signal of a magnetostrictive sensor (20) that detects a force, torque, or pressure. The return signal includes noise, a DC resistance (44), an AC resistance and an inductance and the inductance is shifted ninety degrees from the AC resistance. The apparatus (10) includes a sensor filter (22) to remove the noise from the return signal. A sensor filter (22) shifts the return signal and more specifically, the inductance by an additional angle and the sum of the additional angle and the ninety degrees phase shift is defined as the final detection angle. To detect the inductance at the final detection angle, a wave filter (16) and a reference filter (28) shifts a reference signal by the final detection angle to trigger a first demodulator (26) to detect the inductance at the final detection angle. The inductance detected by the first demodulator (26) varies due to temperature. To remove the temperature from the measured inductance, the apparatus includes a DC detection circuit (42) to detect the DC resistance which is proportional to the temperature across the sensor (20). The DC resistance and the measure inductance are inserted into a correction equation to produce a corrected inductance which is independent of temperature. Instead of inductance, an AC resistance may be used in the equation.

Owner:BWI

Cable conductor DC resistance on-line detection device and method thereof

InactiveCN101706530AImprove accuracyEasy to useResistance/reactance/impedencePotential clampElectrical conductor

The invention relates to a cable conductor DC resistance on-line detection device and a method thereof, aiming at solving the problems of the prior art that detection to a cable conductor needs to cut a section of the cable conductor, which brings inconvenience to operation and causes material waste; the detection is apt to be influenced by air humidity, air temperature and sample temperature and other factors; and the accuracy of detection results is low. The cable conductor DC resistance on-line detection device comprises a resistance tester, a mobile trolley, a potential clamp and a current clamp, wherein the resistance tester is arranged on the mobile trolley; a water tank for containing cables is arranged on the top end of the mobile trolley; the potential clamp and the current clamp are used for clamping cables and connected on the resistance tester through wires. The invention has the advantages of optional movement, convenient use, waster reduction and high detection structure accuracy.

Owner:浙江万马股份有限公司

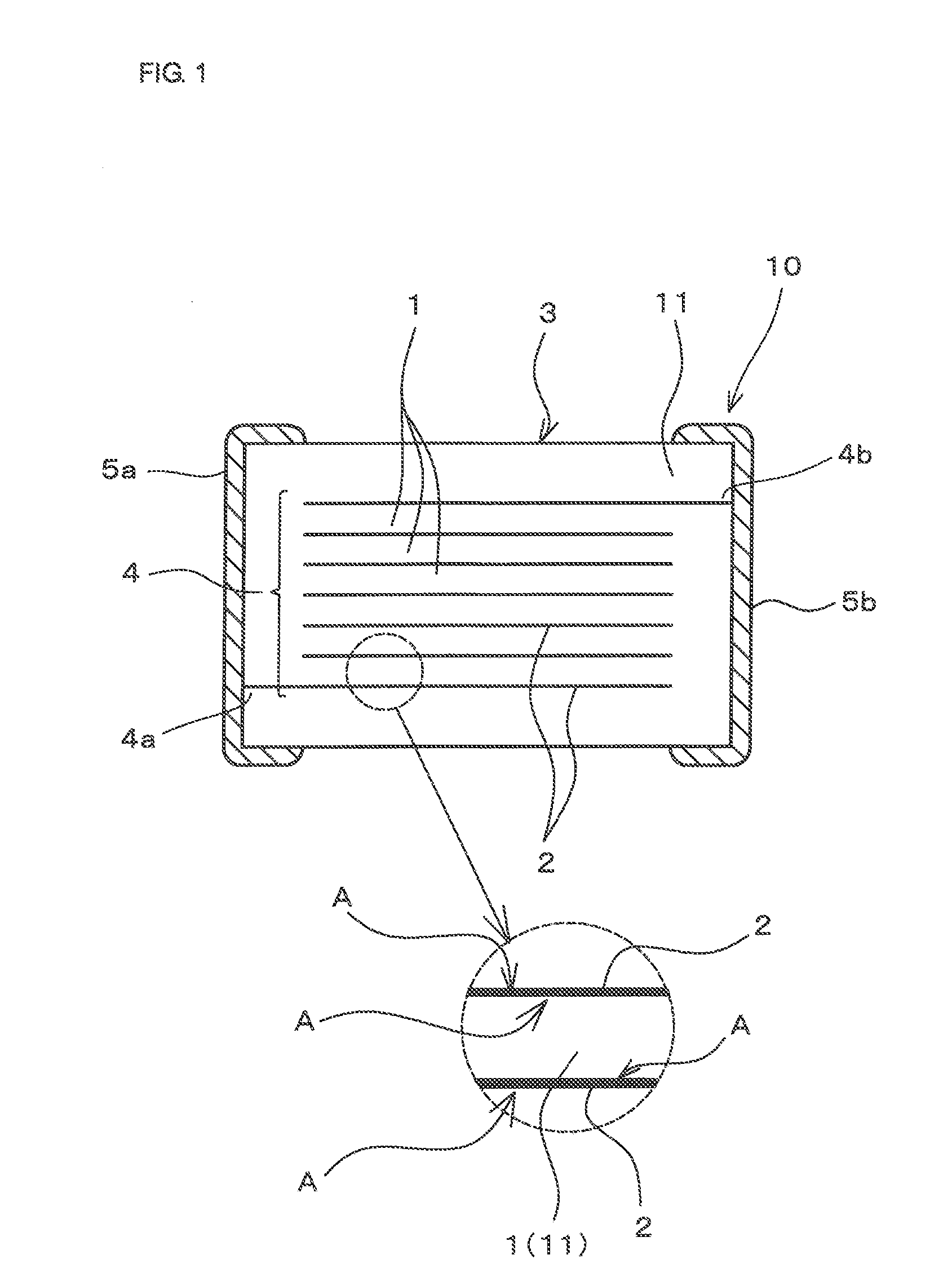

Coil component

ActiveUS20080100409A1Reduce DC resistanceImpedence networksTransformers/inductances coils/windings/connectionsElectrical conductorSurface mounting

The invention relates to surface-mount type coil components having a mounting surface for mounting them on a printed circuit board or hybrid IC (HIC) and provides a low-cost coil component having a low direct-current resistance. A common mode filter includes a bridge conductor layer which has a bridge conductor one end of which is connected to one end of a lead wire and another end of which is connected to an inner circumferential end of a coil conductor and another bridge conductor one end of which is connected to one end of another lead wire and another end of which is connected to an inner circumferential end of another coil conductor, the bridge conductor layer being formed between two coil conductor layers with an insulation film interposed between the bridge conductor layer and each of the coil conductor layers.

Owner:TDK CORPARATION

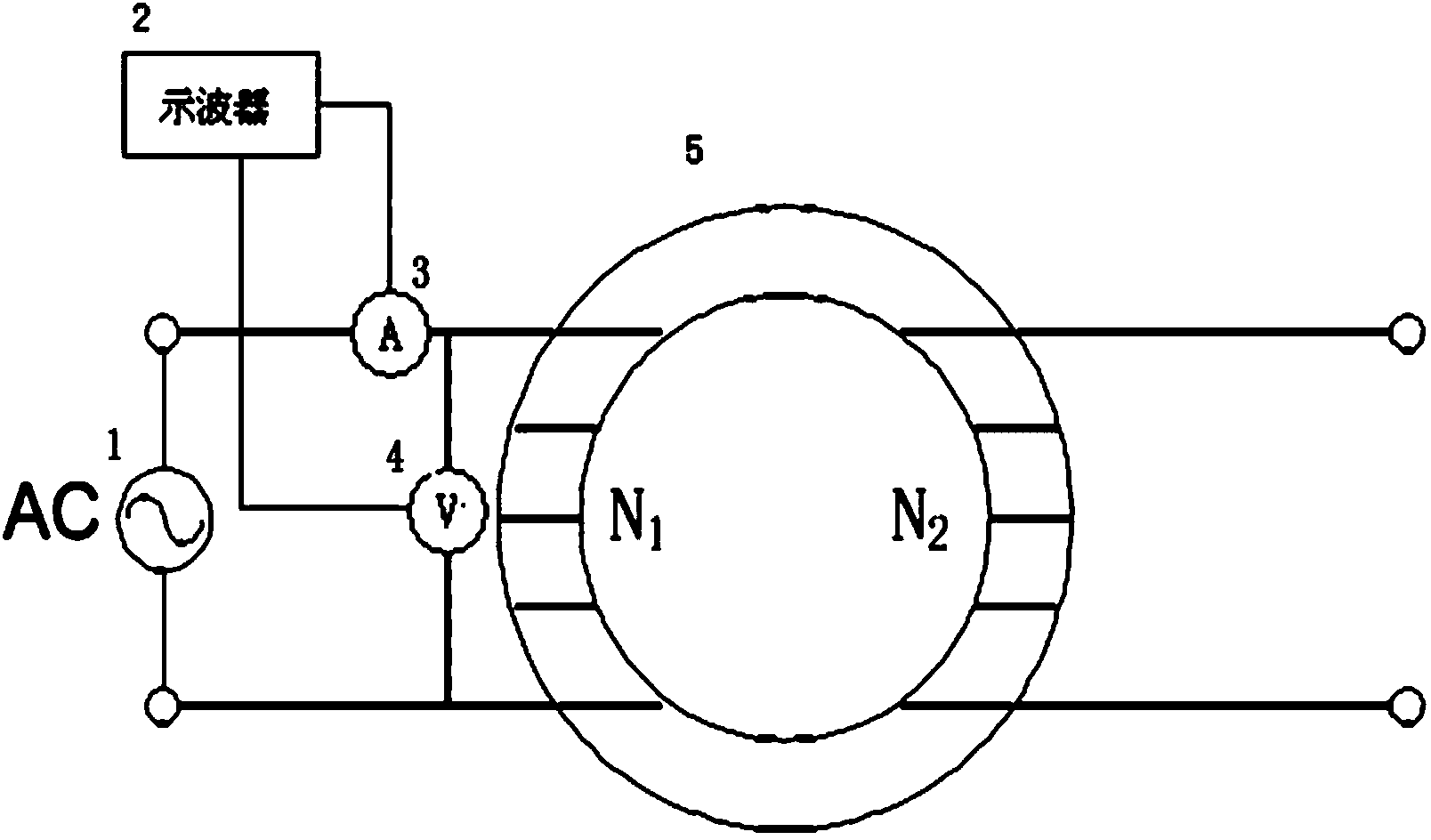

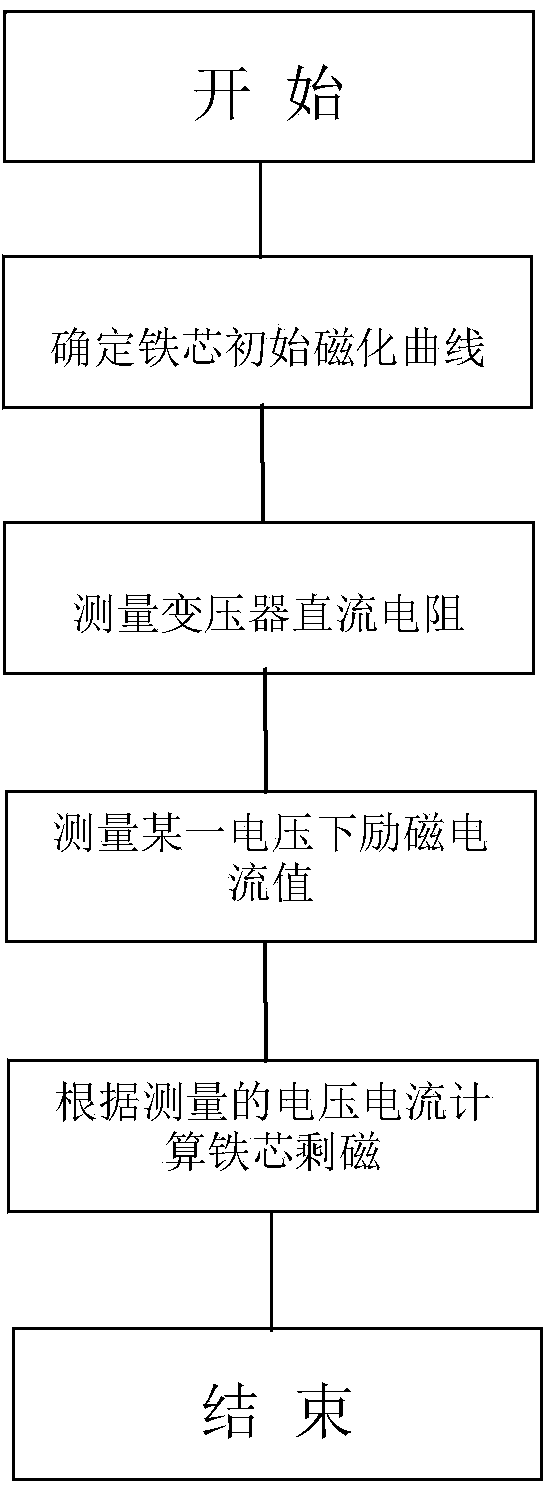

Method for measuring residual magnetic flux density of iron core of transformer

A method for measuring residual magnetic flux density of an iron core of a transformer comprises the following steps that (1) an initial magnetizing curve of the iron core of the transformer is obtained; (2) the direct current resistance of the transformer is measured, wherein high voltage direct current resistance and low voltage direct current resistance are measured respectively; (3) the exciting current of the tested transformer at a certain voltage is measured, the magnetic field intensity H of the iron core is determined and converted according to the exciting current, the magnetic flux intensity B of the iron core at the moment is obtained by searching the initial magnetizing curve; (4) the size of the alternating magnetic flux intensity B1 at the moment is calculated according to an applied voltage effective value, and the residual magnetism Br of the iron core at the moment is obtained simply by subtracting the alternating magnetic flux intensity B1 from the magnetic flux intensity B obtained by using the initial magnetizing curve. The method solves the problem that the residual magnetic flux intensity of the iron core of the transformer cannot be measured, the residual magnetic flux intensity of the iron core is determined by using a mathematic method, the method can be widely applied to the detection of the demagnetizing effect of demagnetizing equipment after demagnetization is carried out by the demagnetizing equipment, and fundamental significance is achieved on the safe and stable operation of the transformer.

Owner:YUN NAN ELECTRIC TEST & RES INST GRP CO LTD ELECTRIC INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com