Direct current resistance measuring method for electric vehicle battery pack

A DC resistance, electric vehicle technology, applied in the direction of measuring resistance/reactance/impedance, measuring electricity, measuring devices, etc., can solve the problems of increased DC internal resistance detection errors and errors of battery packs, and achieve effective measurement and measurement accuracy. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to facilitate the understanding of those skilled in the art, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments:

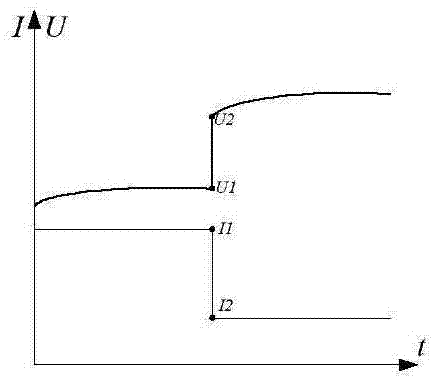

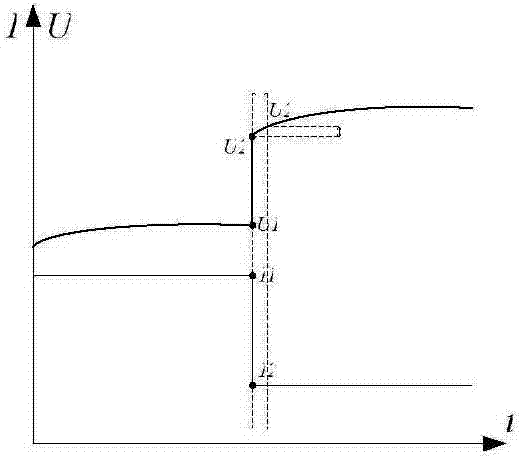

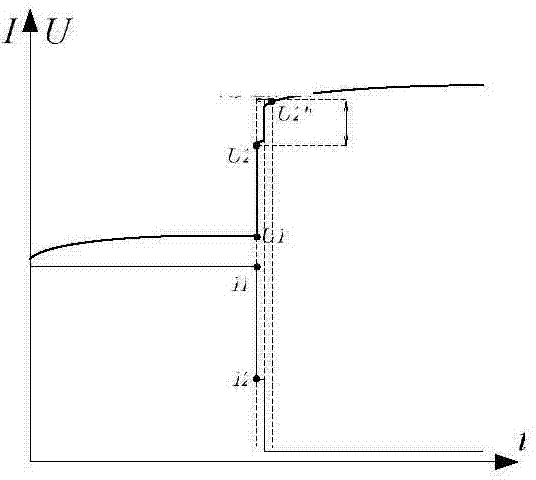

[0024] as attached Figure 4 It is the battery voltage and current waveform of the electric vehicle battery pack working voltage and current asynchronous due to the sampling delay. It can be seen from the figure that the voltage and current of the battery are obviously out of sync. If the traditional method of directly estimating the DC internal resistance of the battery using the voltage and current variation values will be significantly different.

[0025] Considering the sampling delay between the voltage and current of the battery pack, select the time period T of multiple sampling delays as the synchronization judgment period, such as selecting 10 times the synchronization time difference (the synchronization time difference is calculated by the detection cycle and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com