Method for measuring residual magnetic flux density of iron core of transformer

A magnetic induction intensity, transformer core technology, applied in the direction of magnetic performance measurement, etc., can solve the problem of difficulty in measuring the residual magnetic induction intensity of the iron core, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

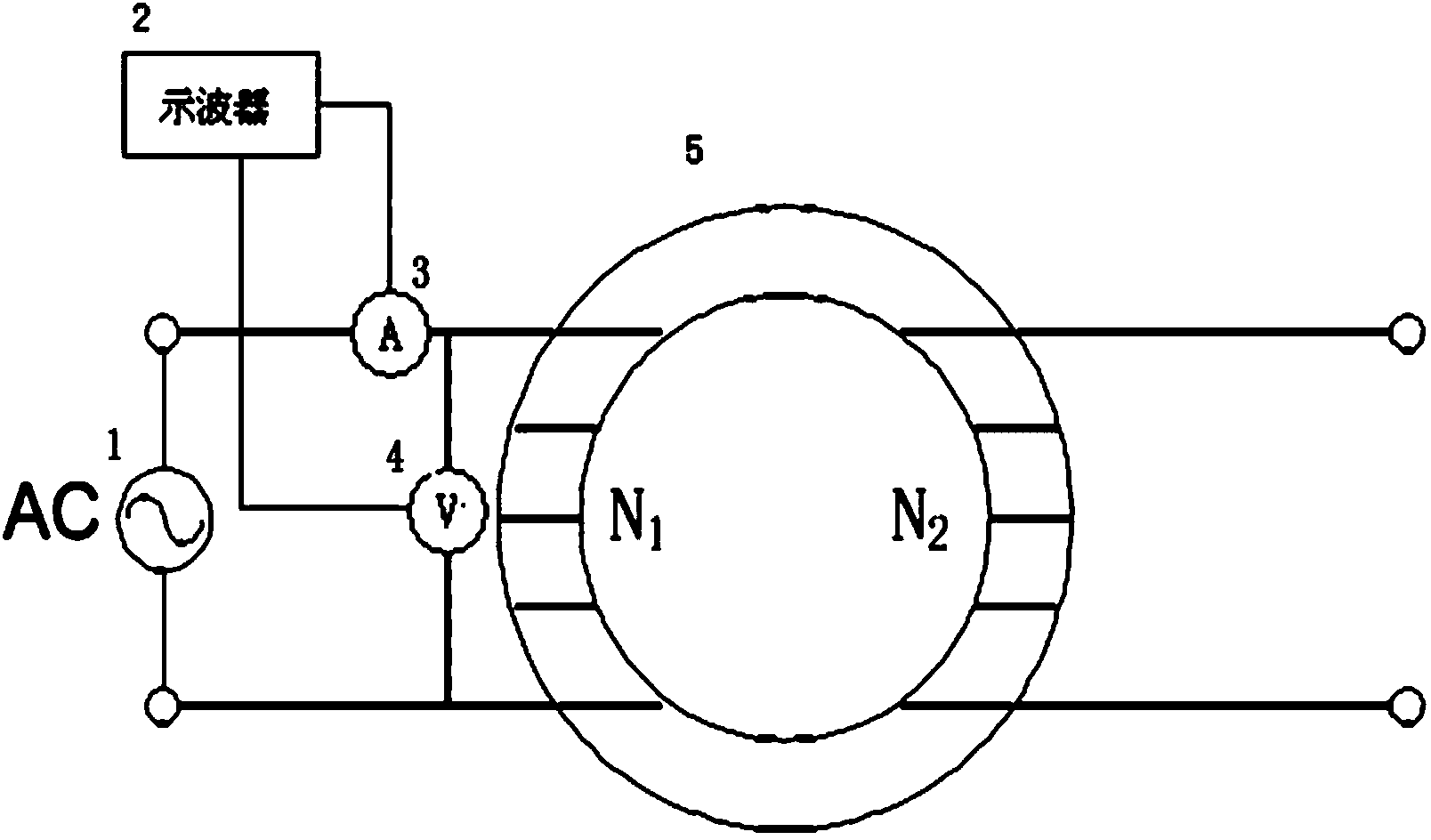

[0028] The problem to be solved by the present invention is achieved through the following technical solutions.

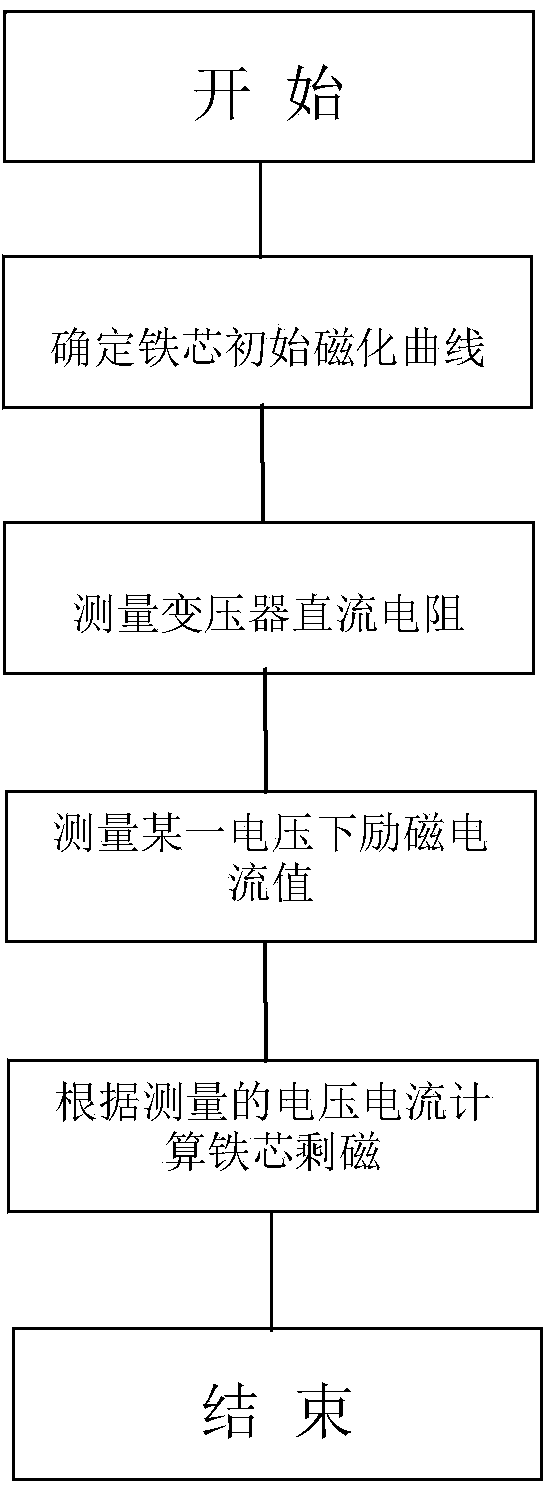

[0029] Implementation steps of the present invention are as follows:

[0030] The first step is to obtain the initial magnetization curve of the transformer core, which can be obtained from the core manufacturer or the transformer manufacturer;

[0031] The second step is to measure the DC resistance of the transformer, and measure the DC resistance of high voltage and low voltage respectively;

[0032] The third step is to measure the excitation current under a certain voltage of the transformer under test, determine the conversion of the magnetic field strength H of the iron core according to the excitation current, and obtain the magnetic induction intensity B of the iron core at this time by searching the initial magnetization curve;

[0033] The fourth step is to calculate the alternating magnetic induction intensity B at this time according to the effective ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com