City life rubbish fluidized bed gasification combustion processing method

A technology for municipal solid waste and fluidized bed gasification, which is applied in the combustion method, combustion type, and controlled combustion, etc., can solve the problems of high requirements on waste composition and calorific value, unfavorable heavy metal recycling, and complex gasification and melting process. , to solve the problem of high and low temperature acid corrosion, realize the stable combustion of garbage, and inhibit the emission of pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

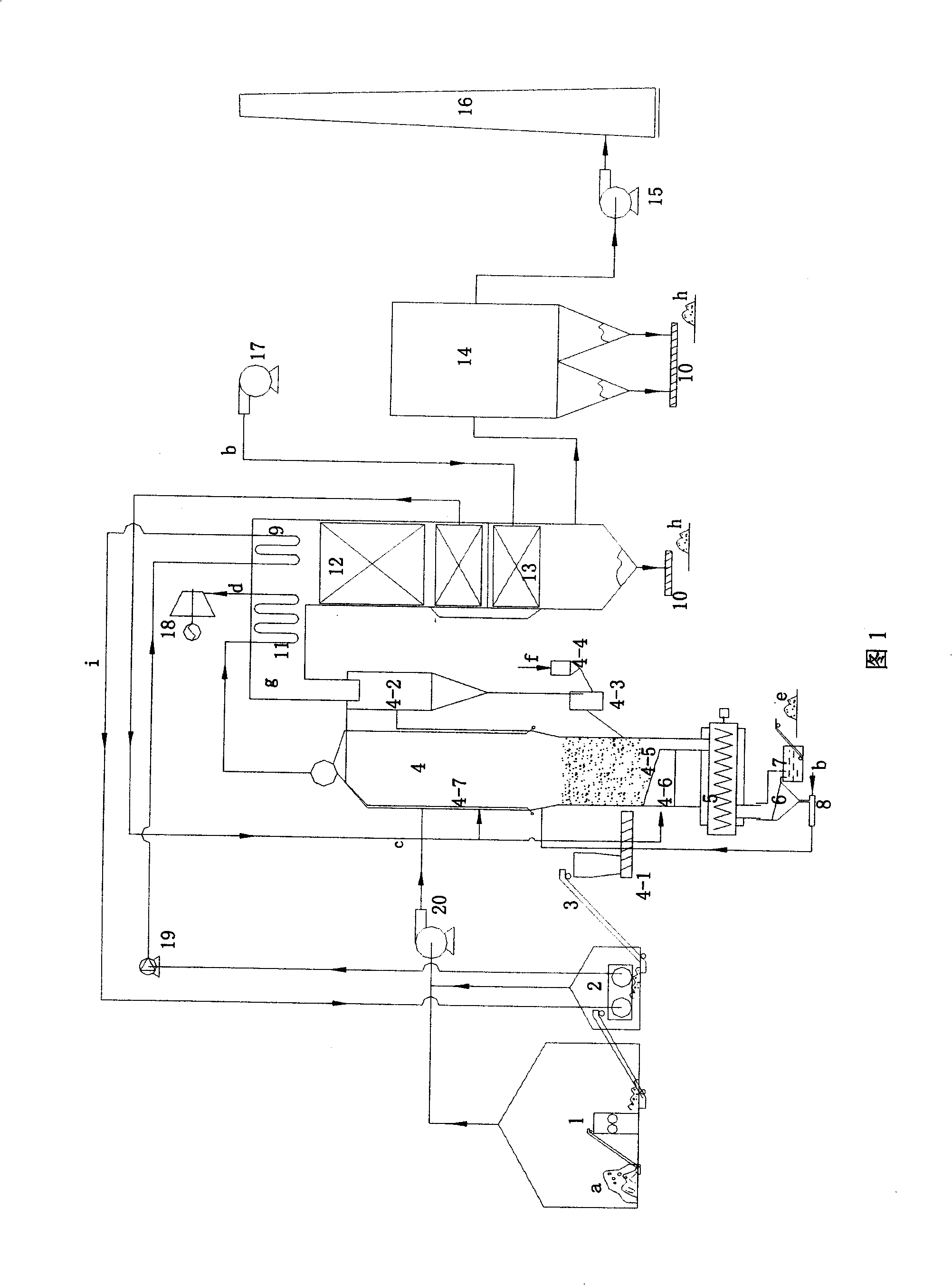

Image

Examples

Embodiment Construction

[0021] specific implementation plan

[0022] The garbage gasification combustion method of the present invention is:

[0023] (1) The fluidized bed incinerator is divided into a gasification zone and a combustion zone. The dense phase zone in the lower part of the furnace is the gasification zone, and the dilute phase zone in the upper part of the furnace is the combustion zone. Garbage is fed into the dense-phase area of the fluidized bed through the feeding port. There is a large amount of inert bed material in the fluidized bed, which can quickly heat up the newly introduced garbage to the gasification reaction temperature. Its heat storage function can also reduce the temperature in the furnace caused by uneven feeding, garbage types and moisture changes. fluctuation.

[0024] (2) Garbage is gasified in a low-temperature gasification zone (600-700°C). In the reducing atmosphere and low temperature of the gasification zone, the oxidation and volatilization of metals are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com