Patents

Literature

733 results about "Direct combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Direct combustion is the most common way of converting biomass to energy - both heat and electricity- and worldwide it already provides over 90% of the energy generated from biomass. Direct combustion of solid biomass fuel is well understood, relatively straightforward, commercially available, and can be regarded as a proven technology.

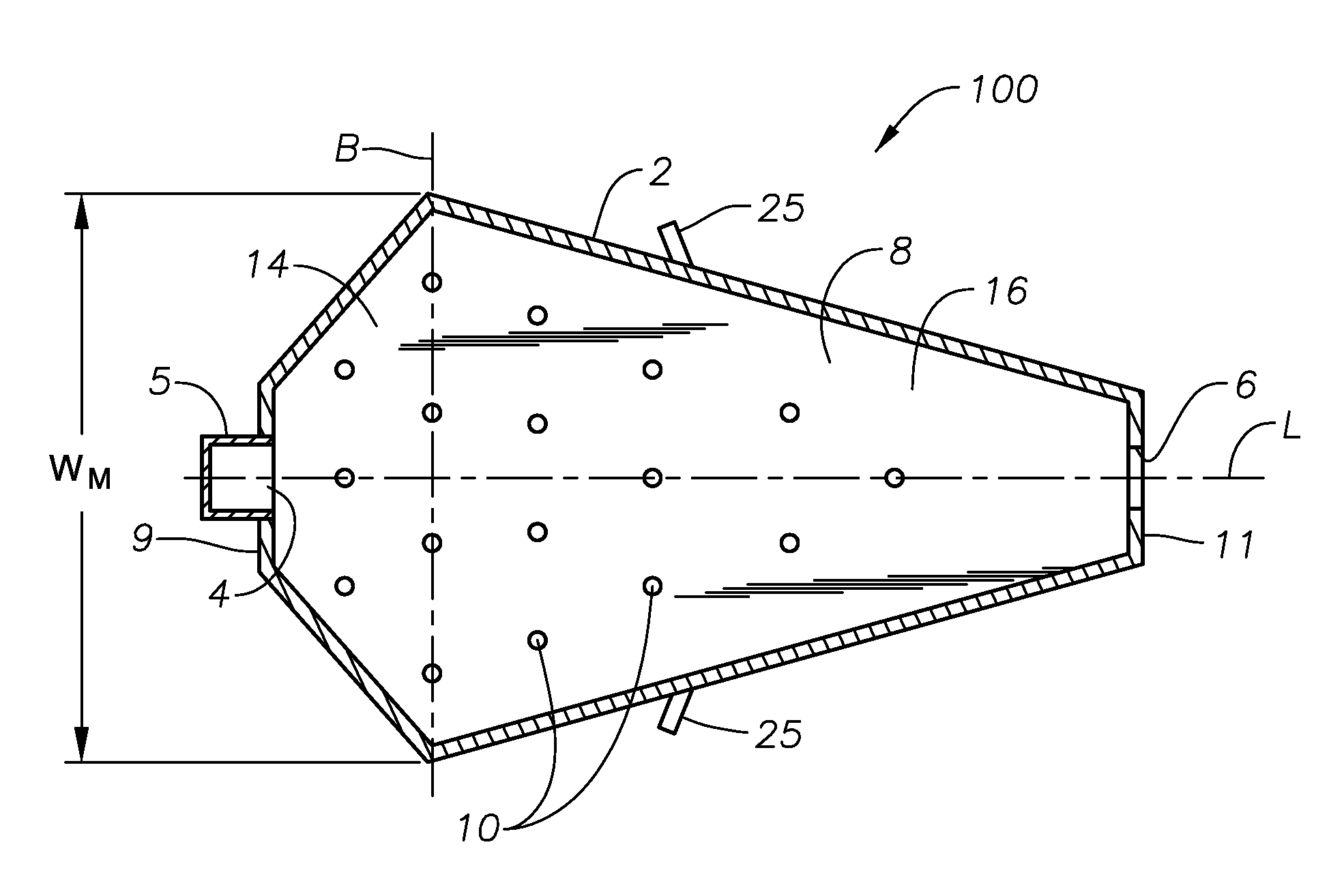

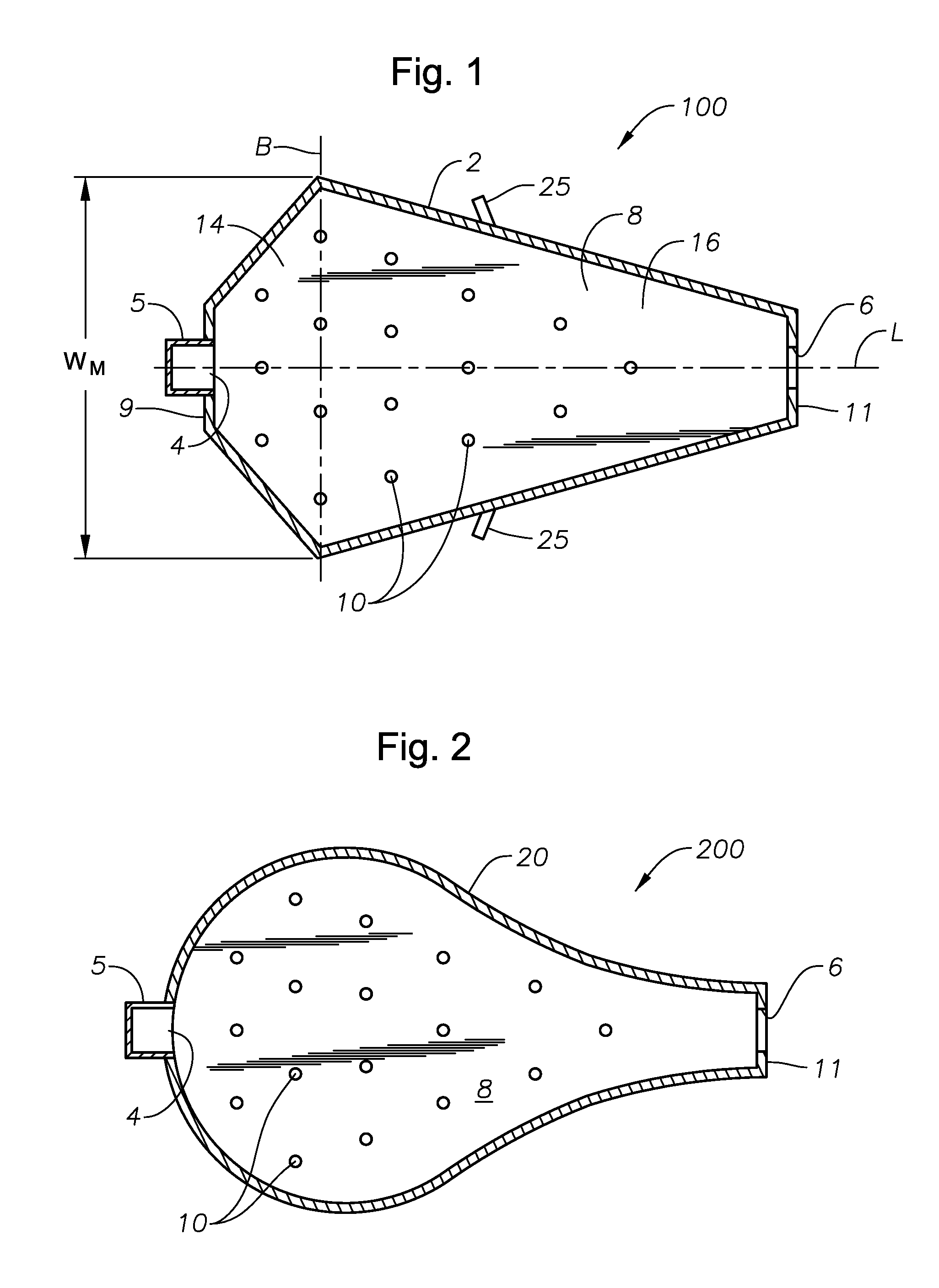

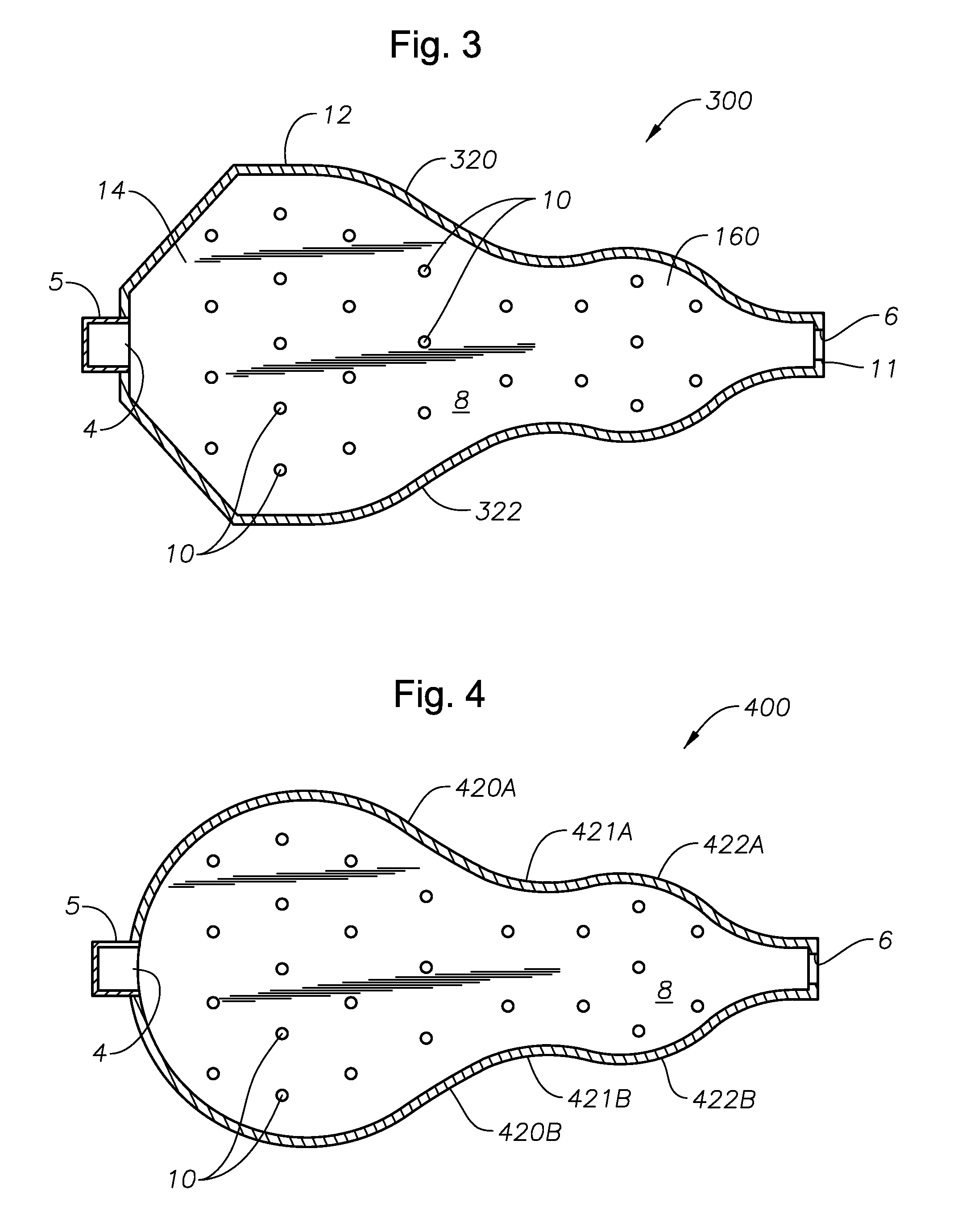

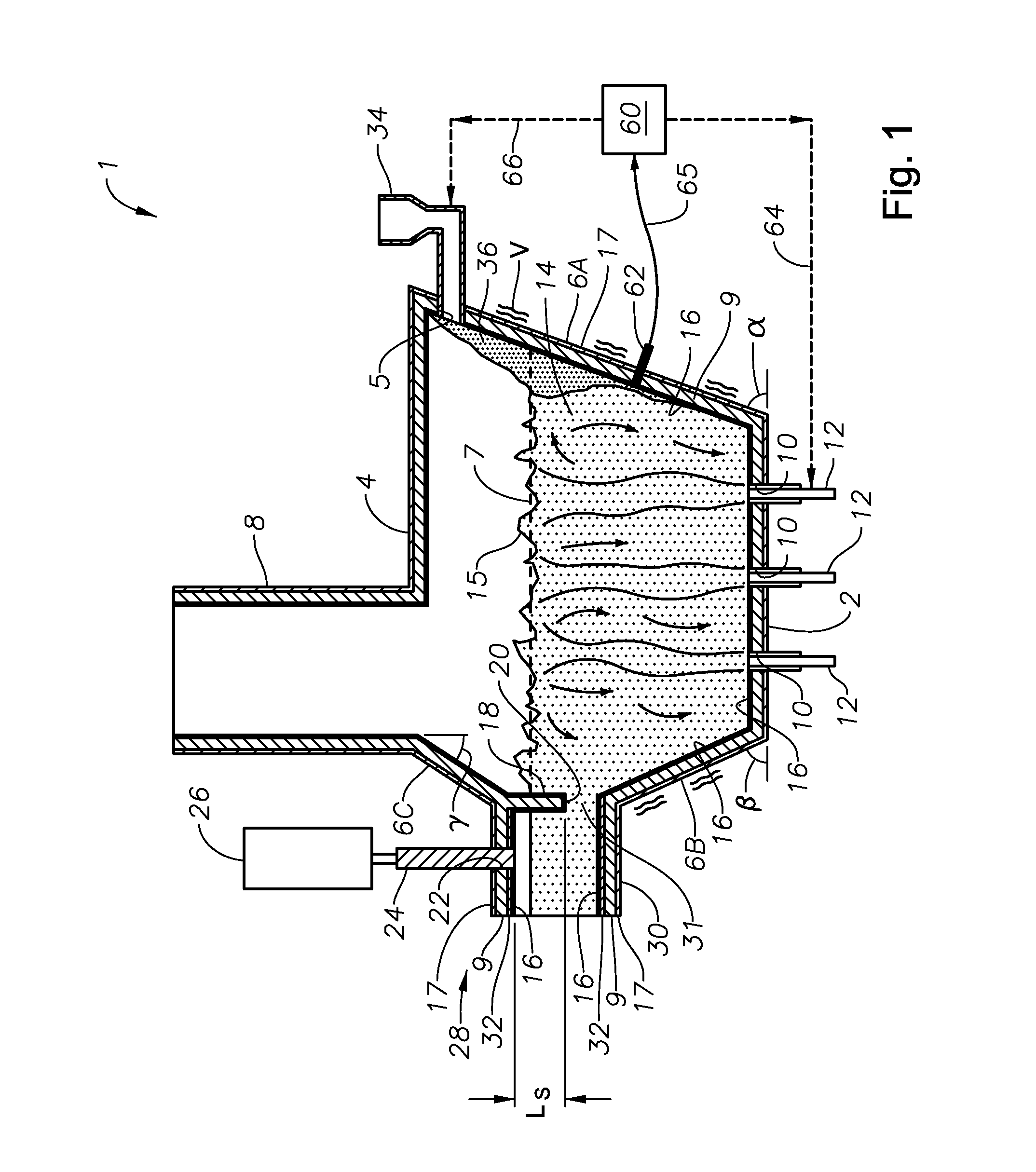

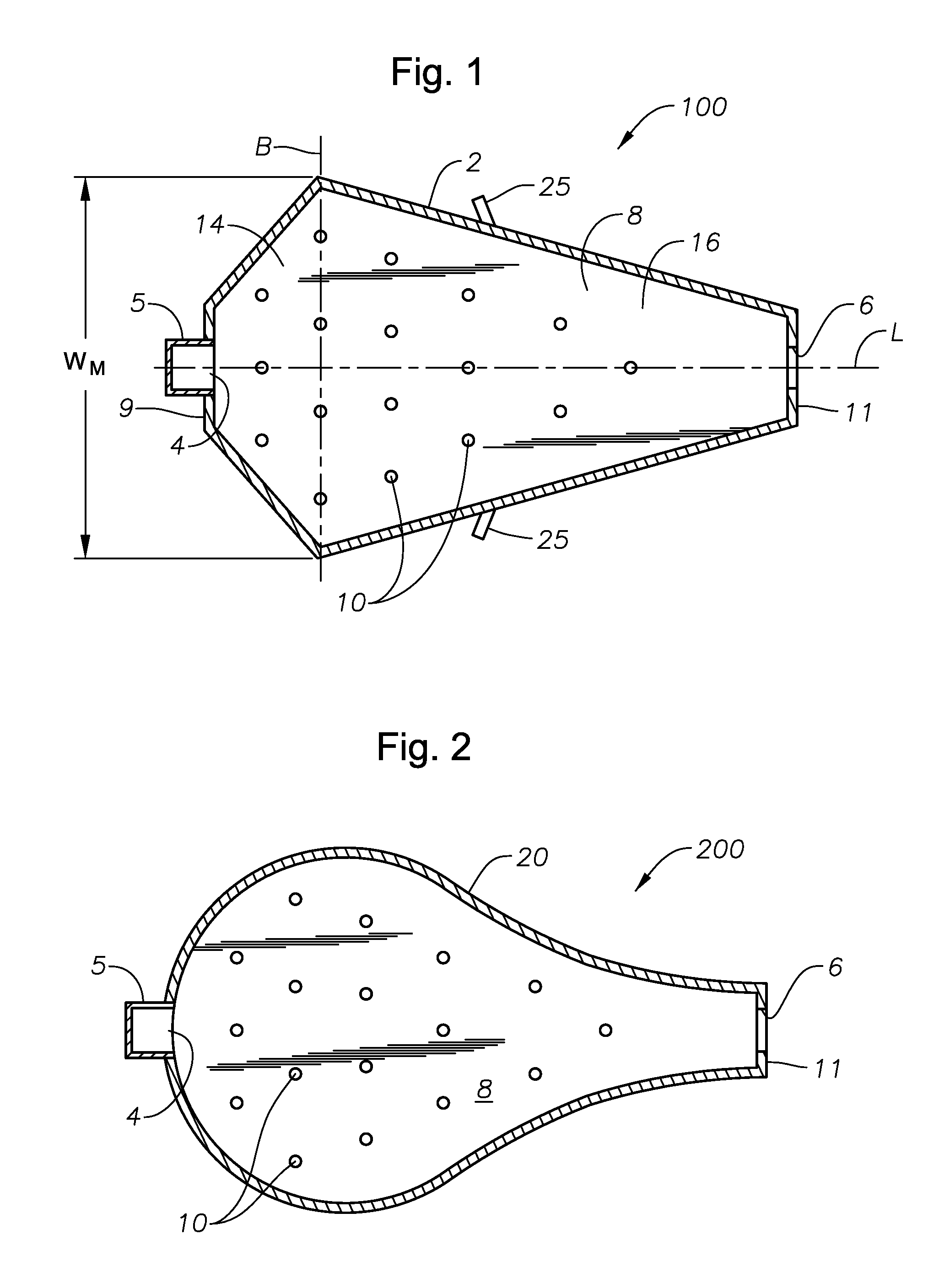

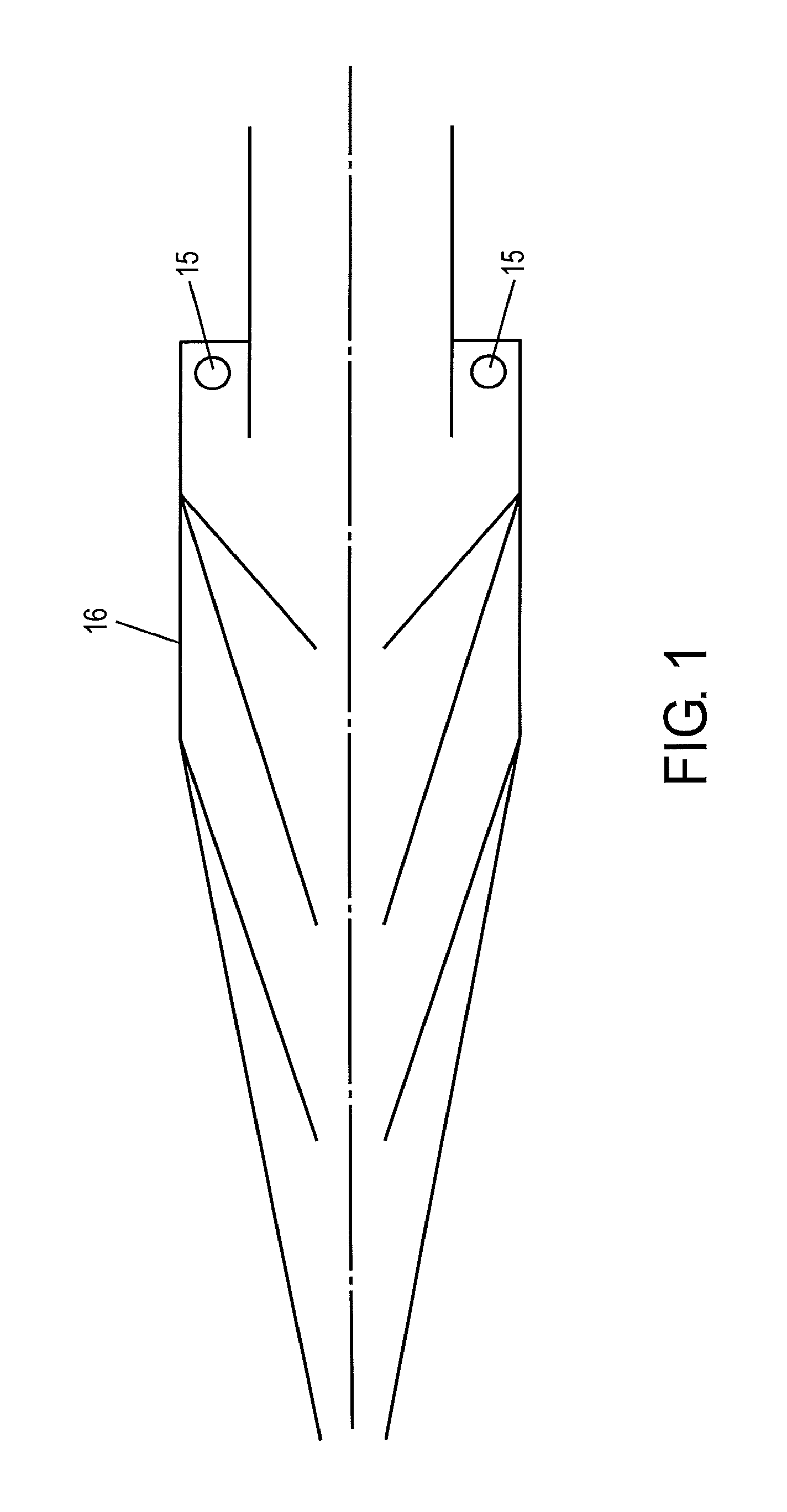

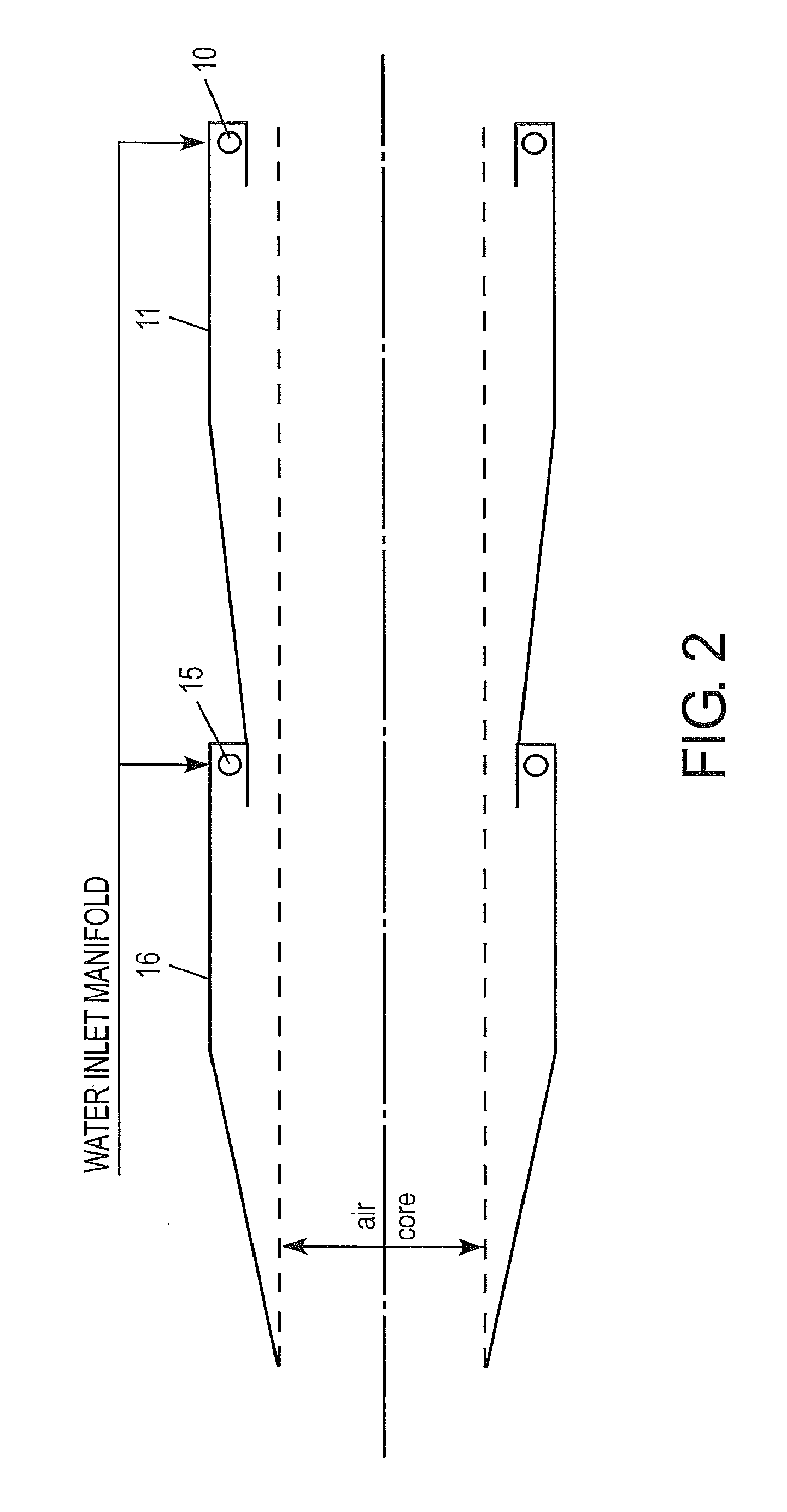

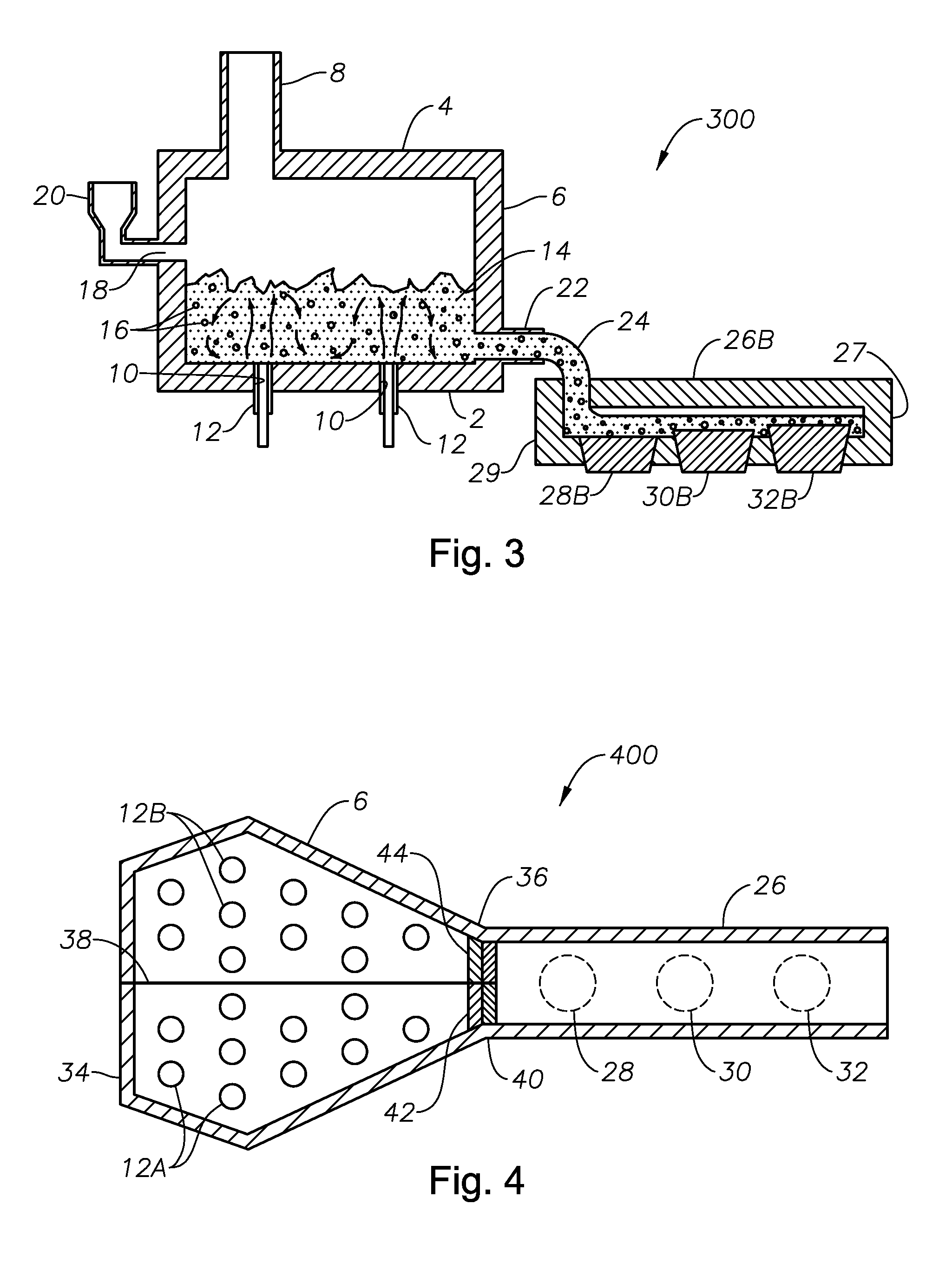

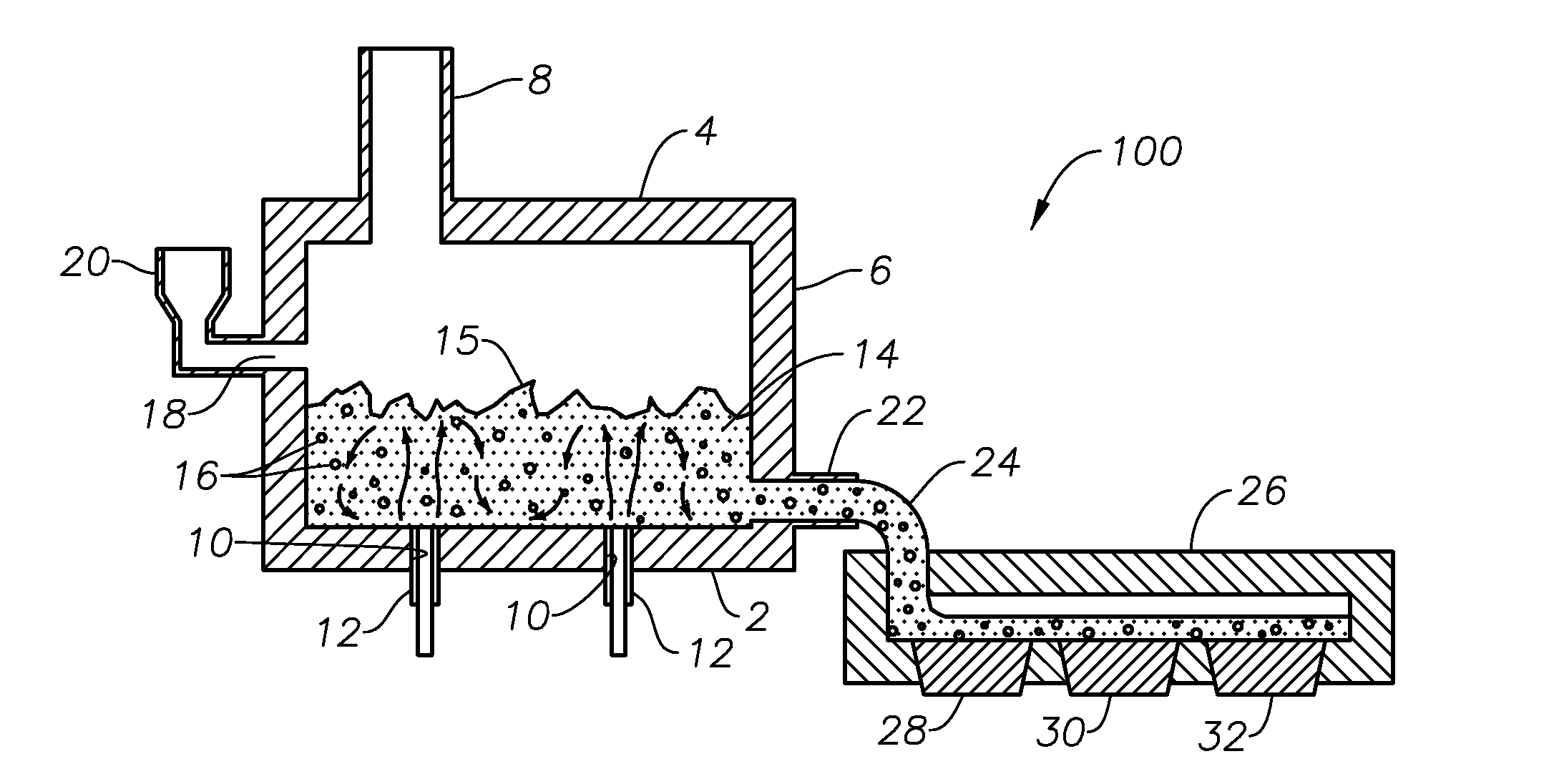

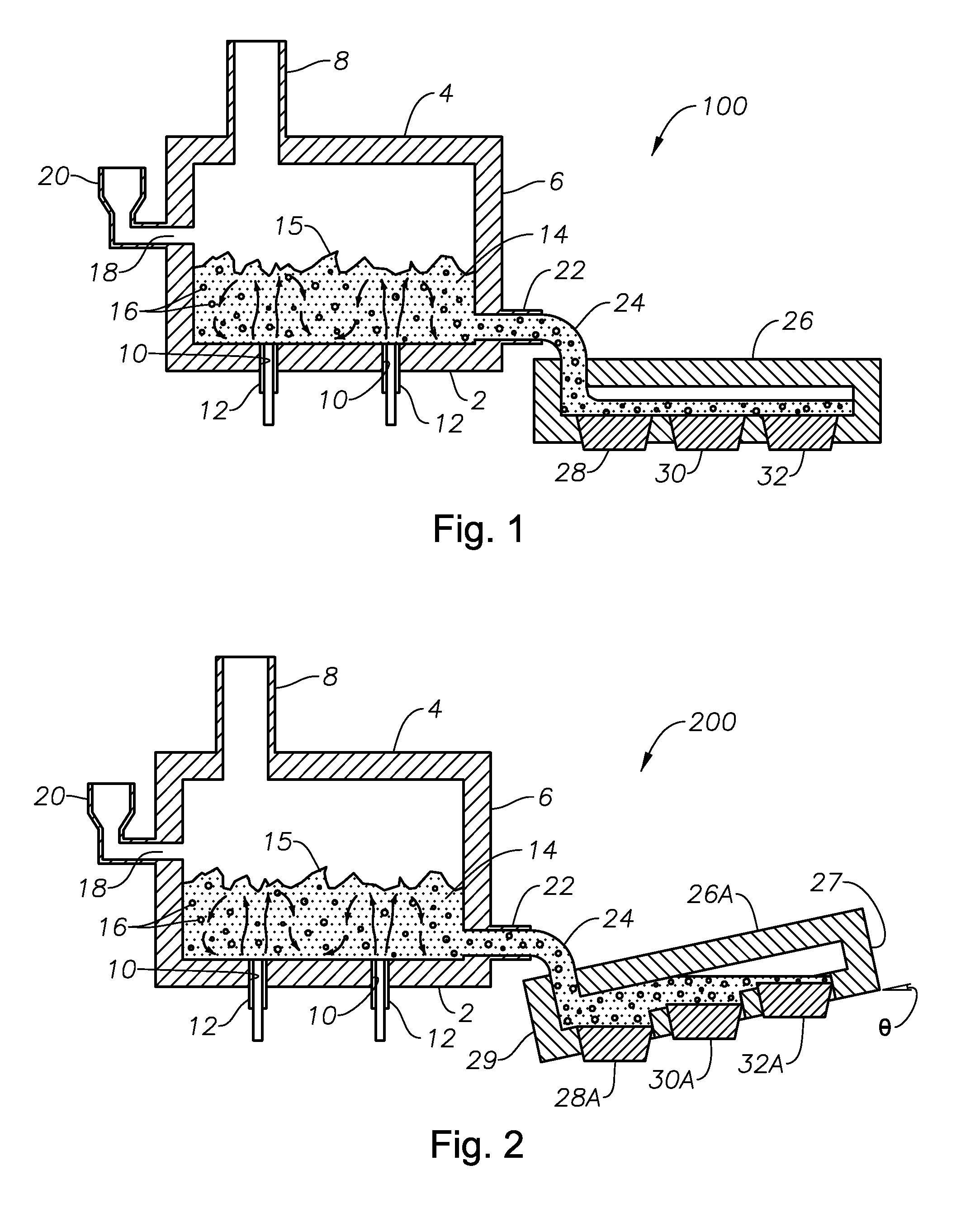

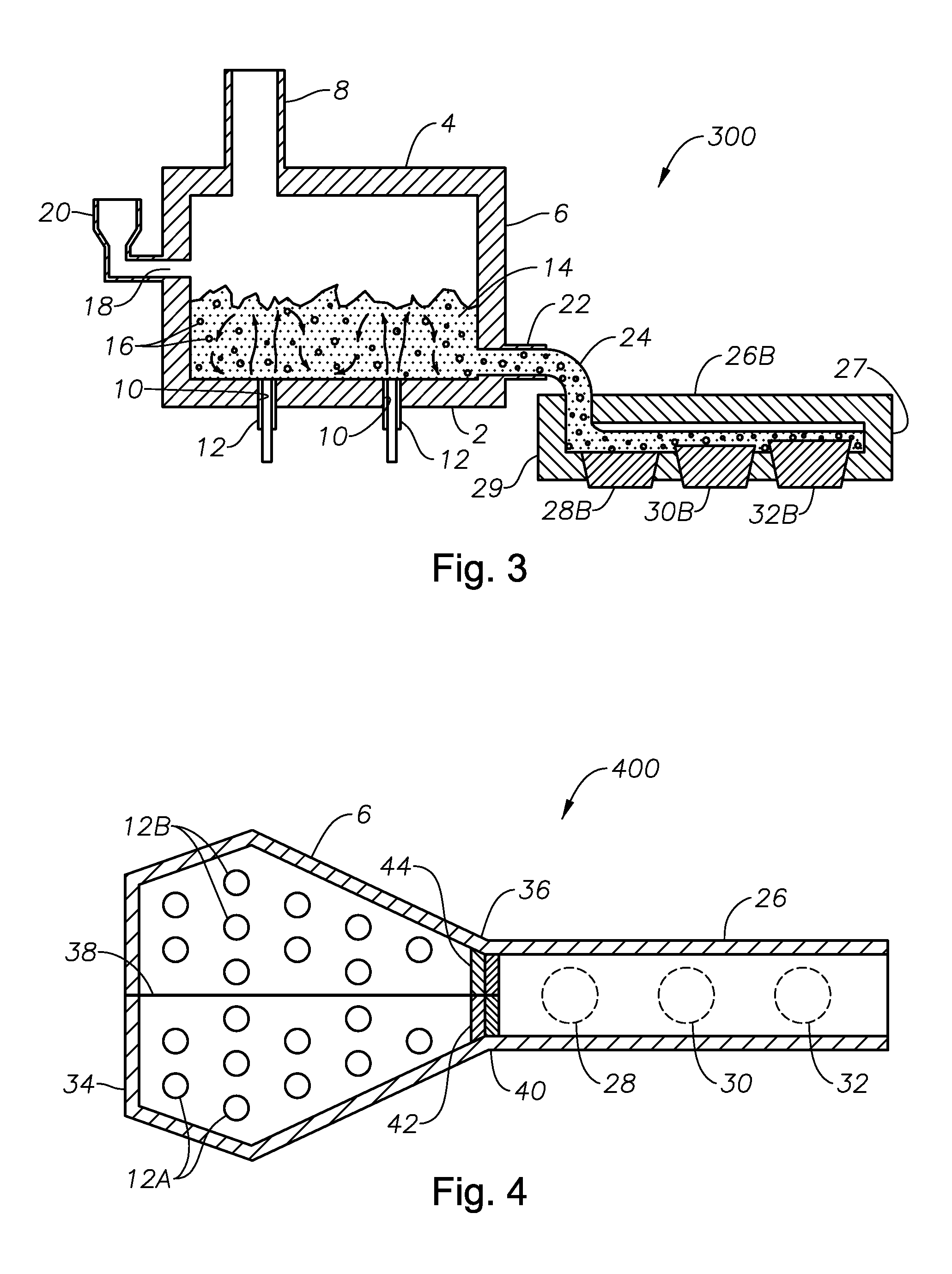

Panel-cooled submerged combustion melter geometry and methods of making molten glass

ActiveUS20110308280A1Reduce dead flow (stagnant) regionSmall sizePulsating combustionTank furnacesCombustorDirect combustion

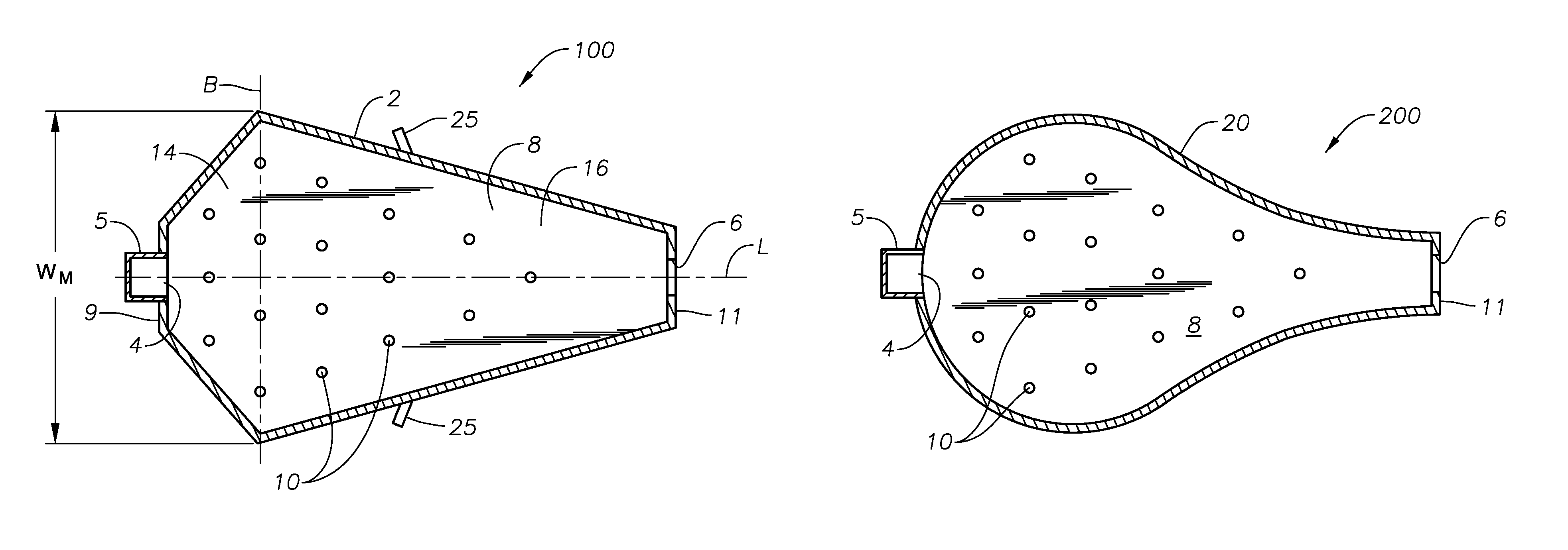

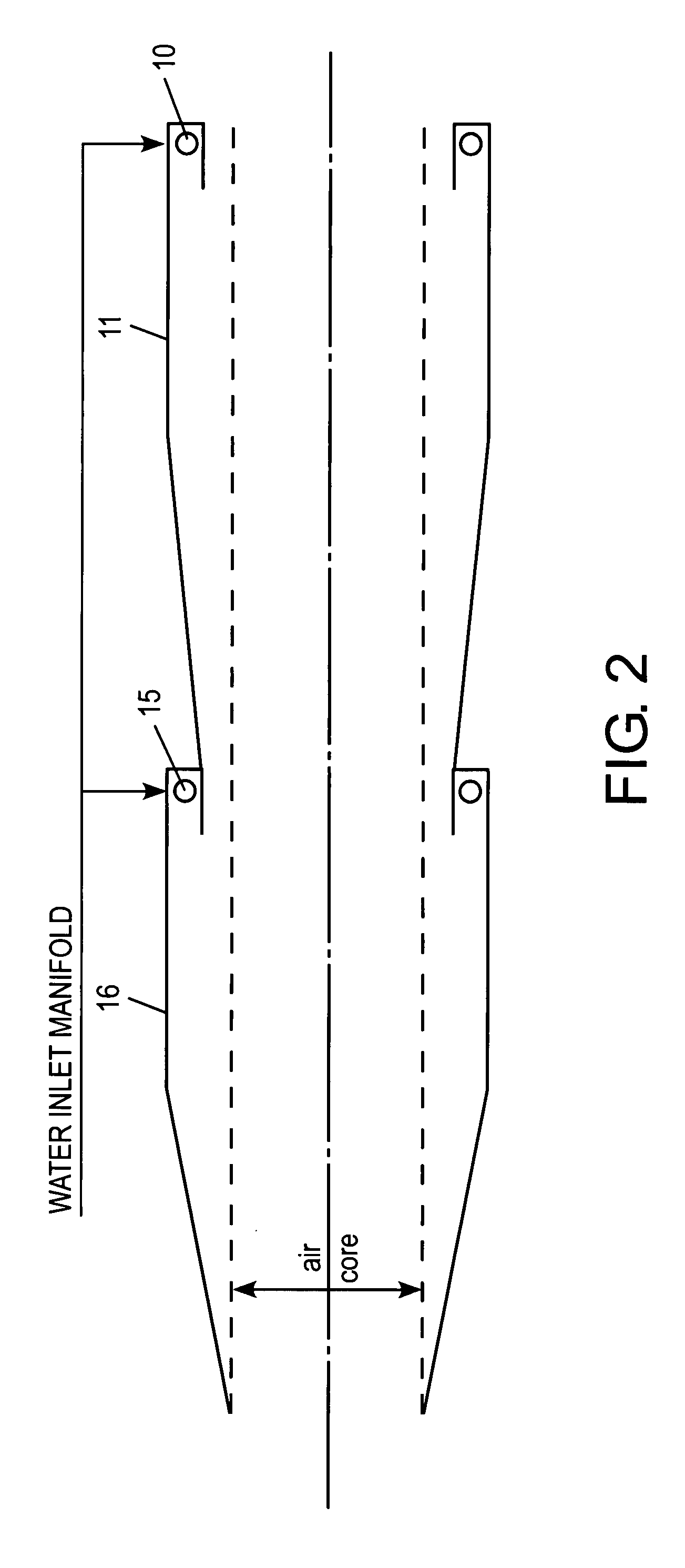

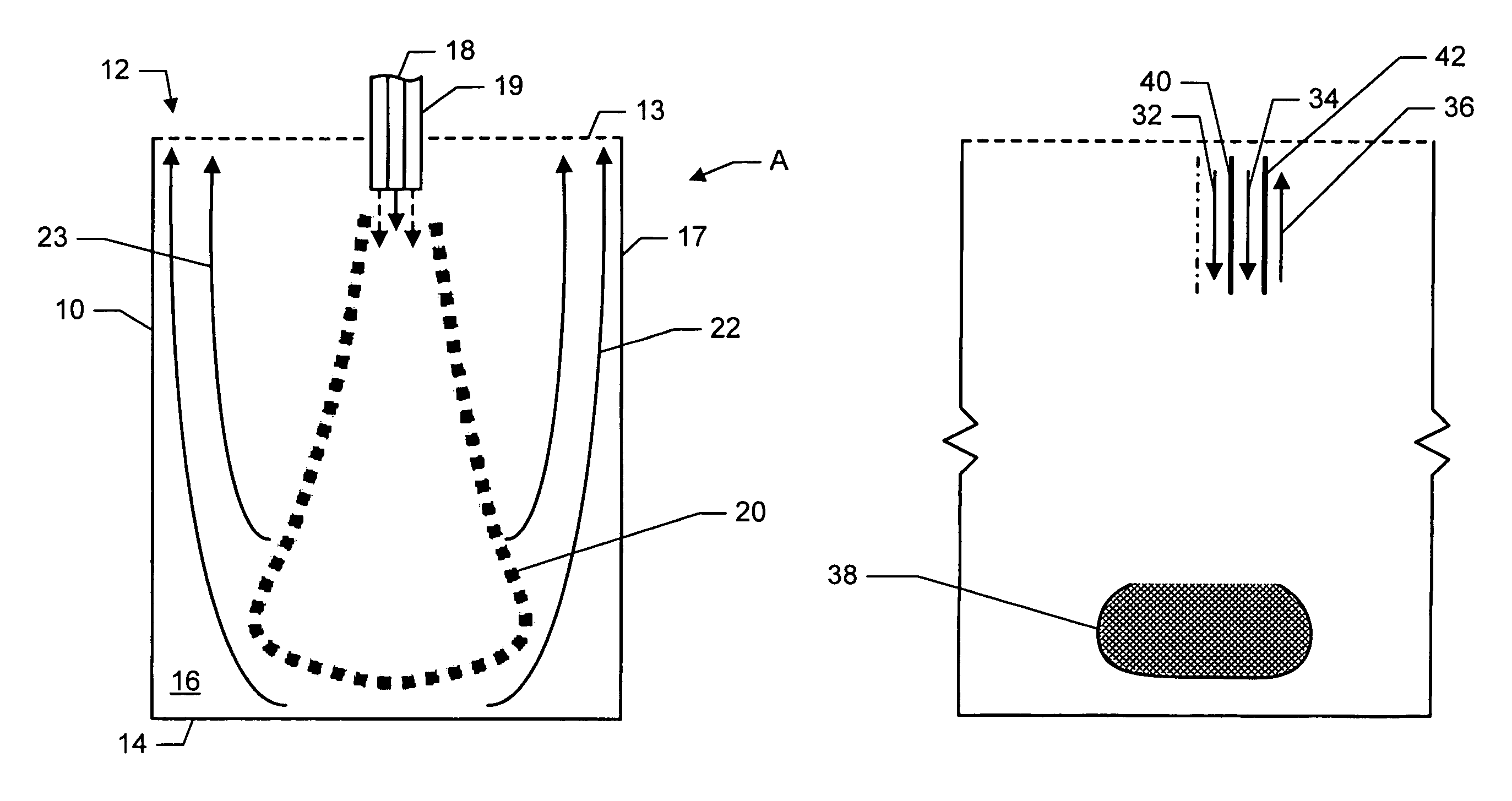

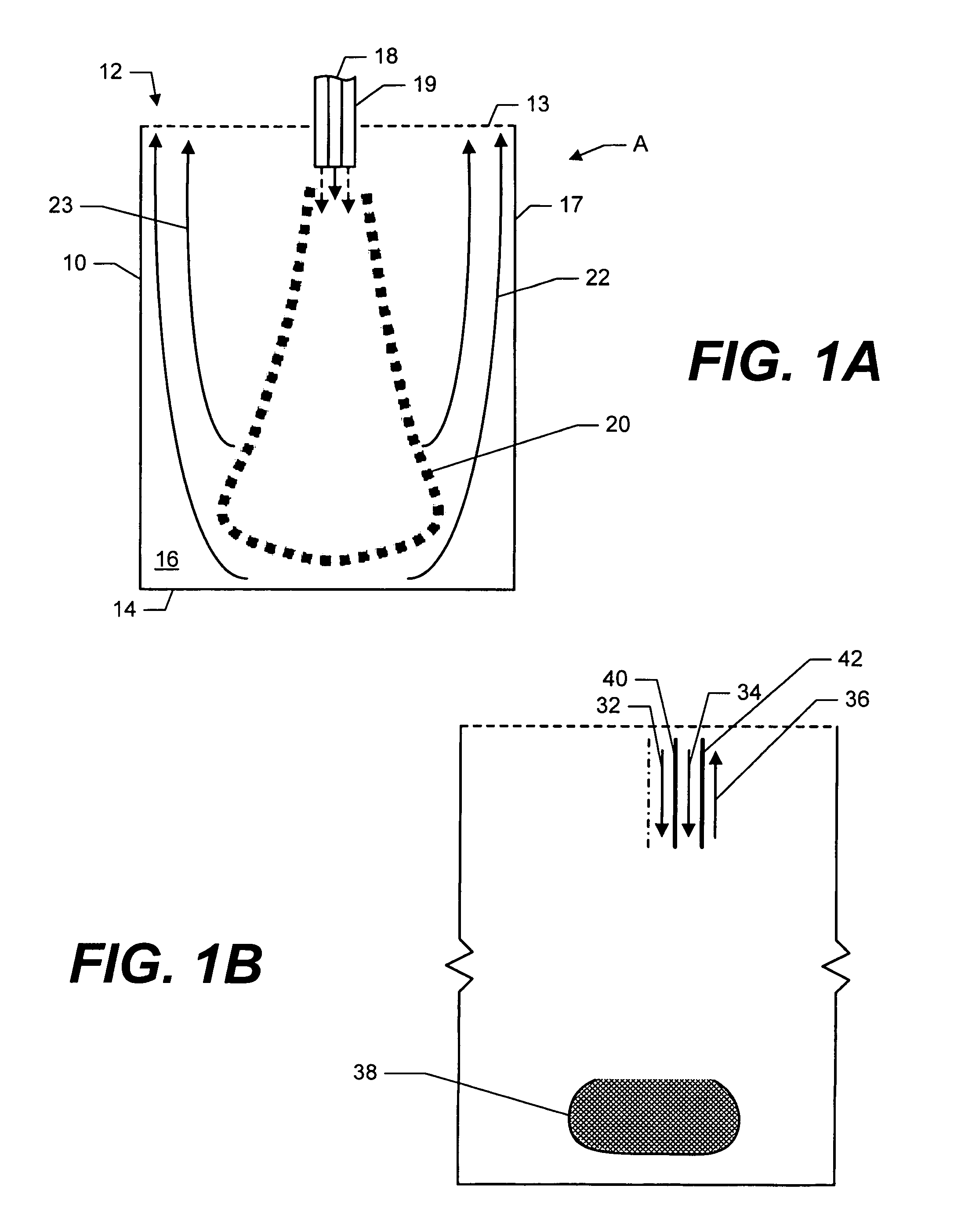

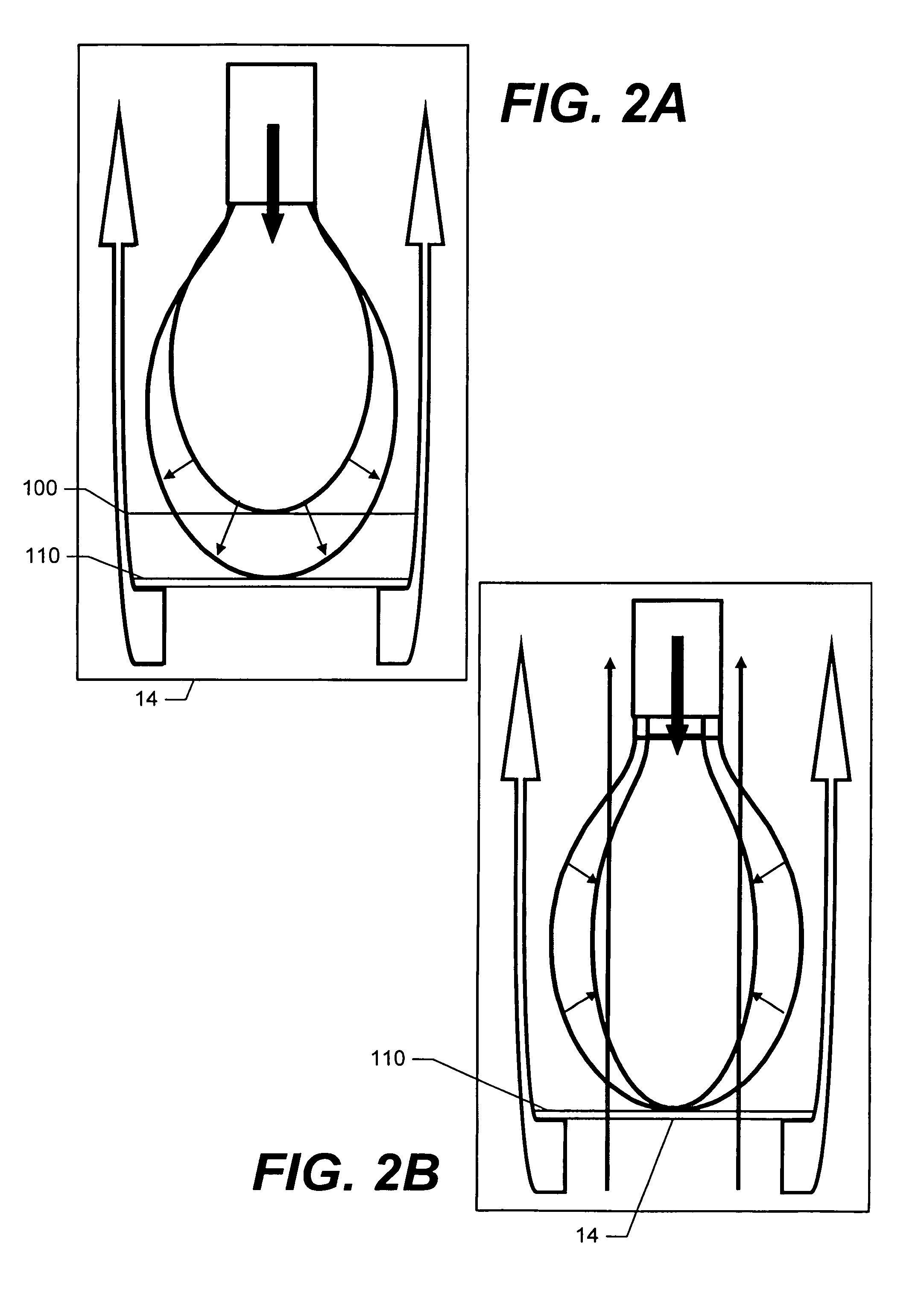

A melter apparatus includes a floor, a ceiling, and a substantially vertical wall connecting the floor and ceiling at a perimeter of the floor and ceiling, a melting zone being defined by the floor, ceiling and wall, the melting zone having a feed inlet and a molten glass outlet positioned at opposing ends of the melting zone. The melting zone includes an expanding zone beginning at the inlet and extending to an intermediate location relative to the opposing ends, and a narrowing zone extending from the intermediate location to the outlet. One or more burners, at least some of which are positioned to direct combustion products into the melting zone under a level of molten glass in the zone, are also provided.

Owner:MANVILLE JOHNS

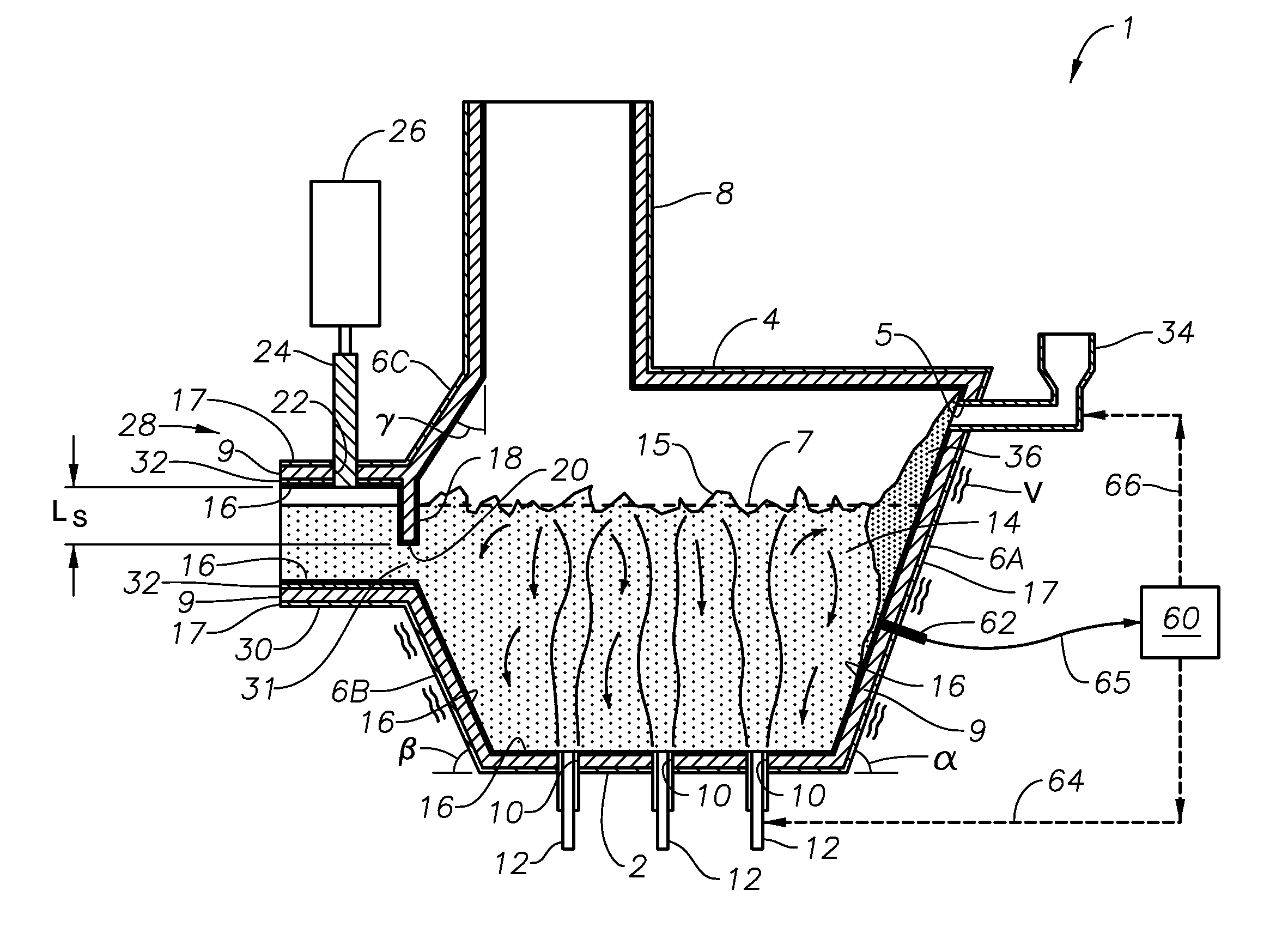

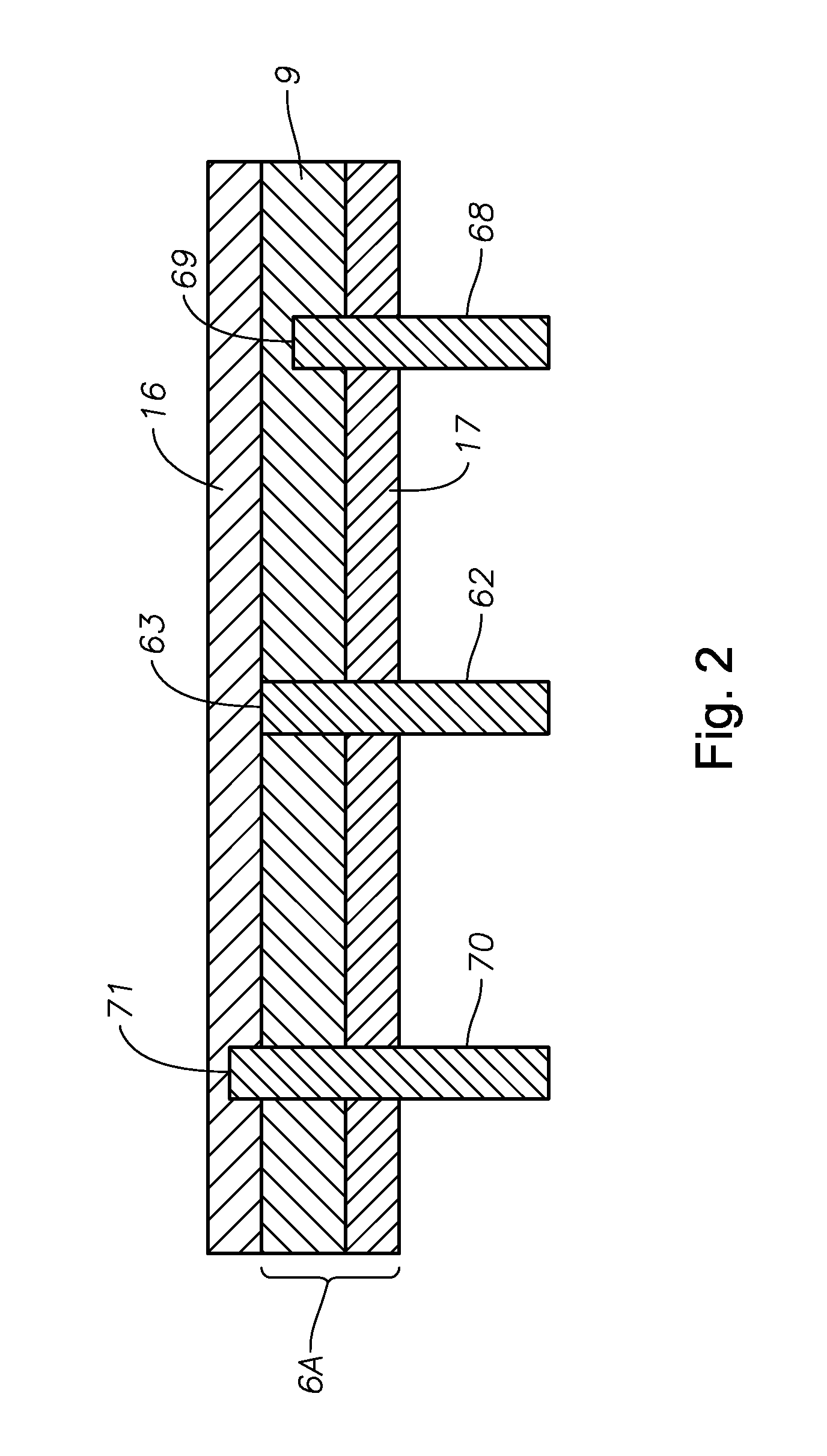

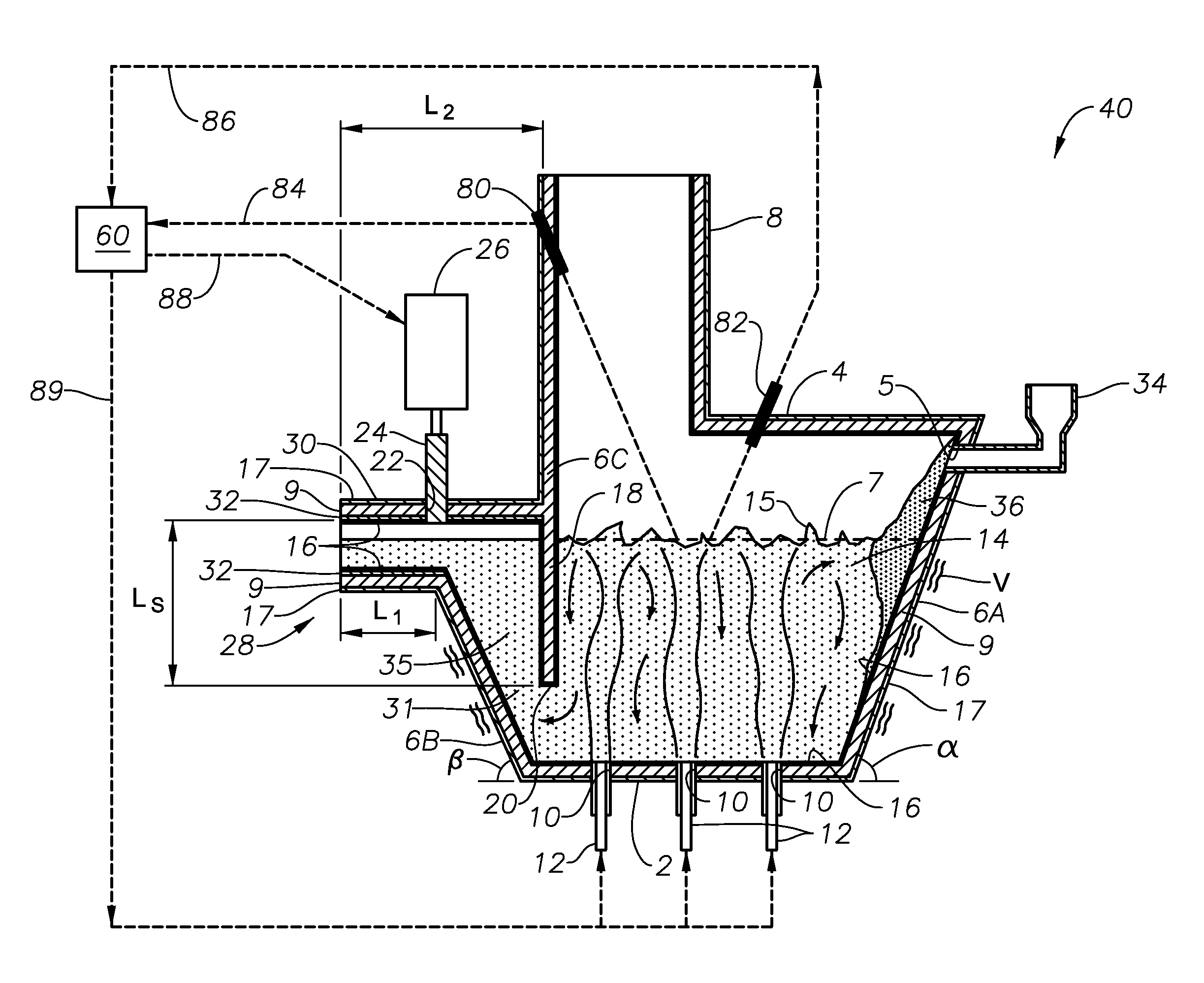

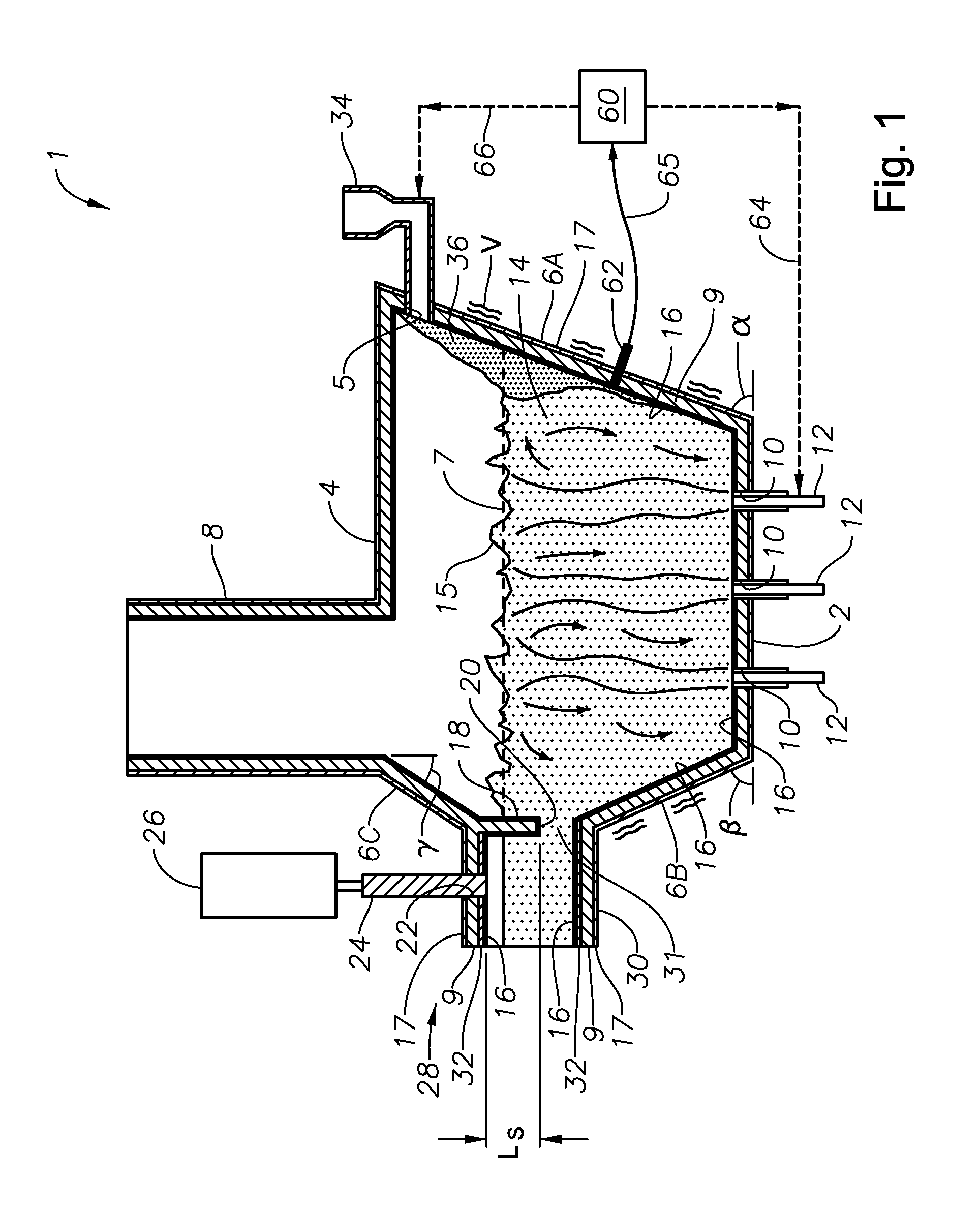

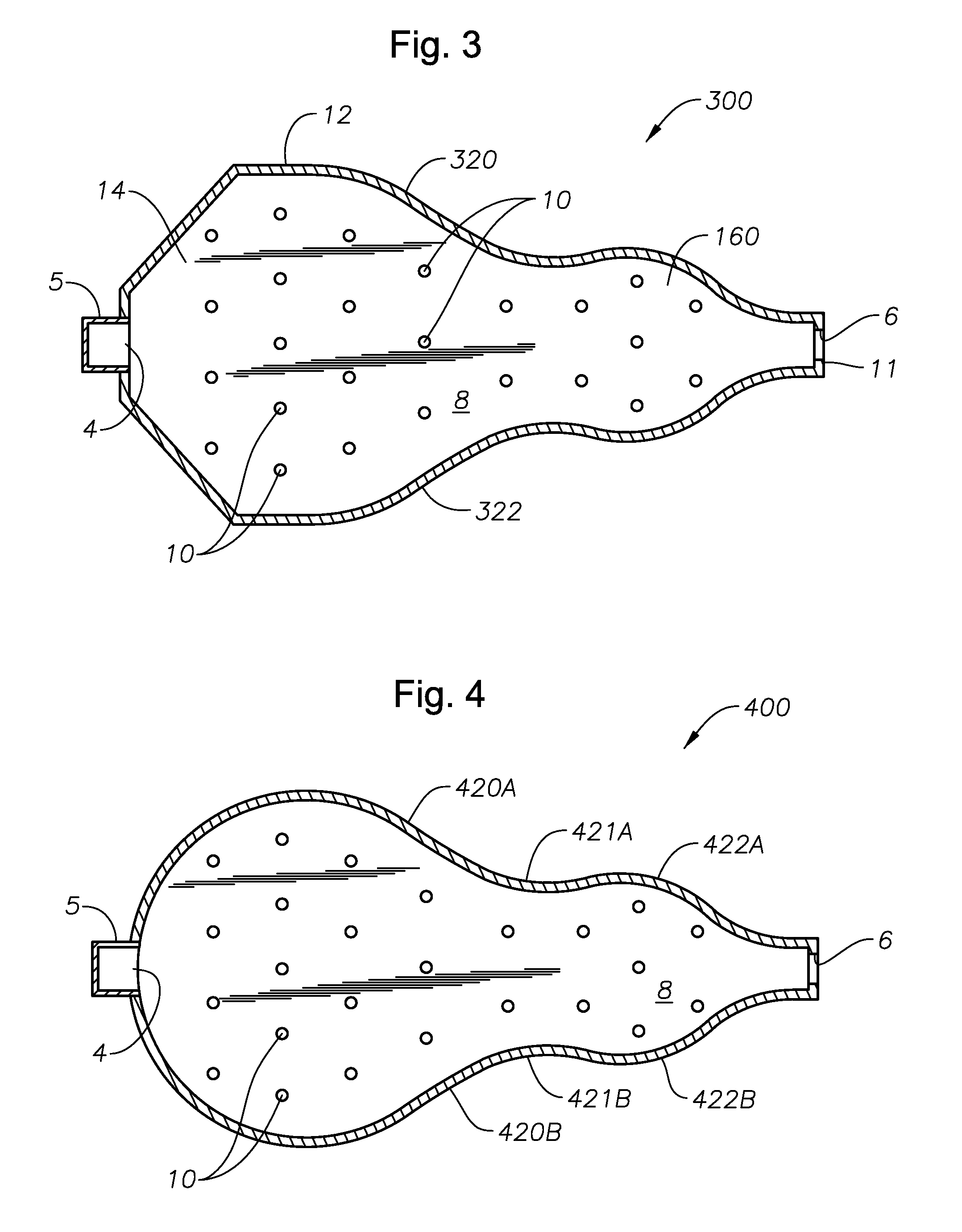

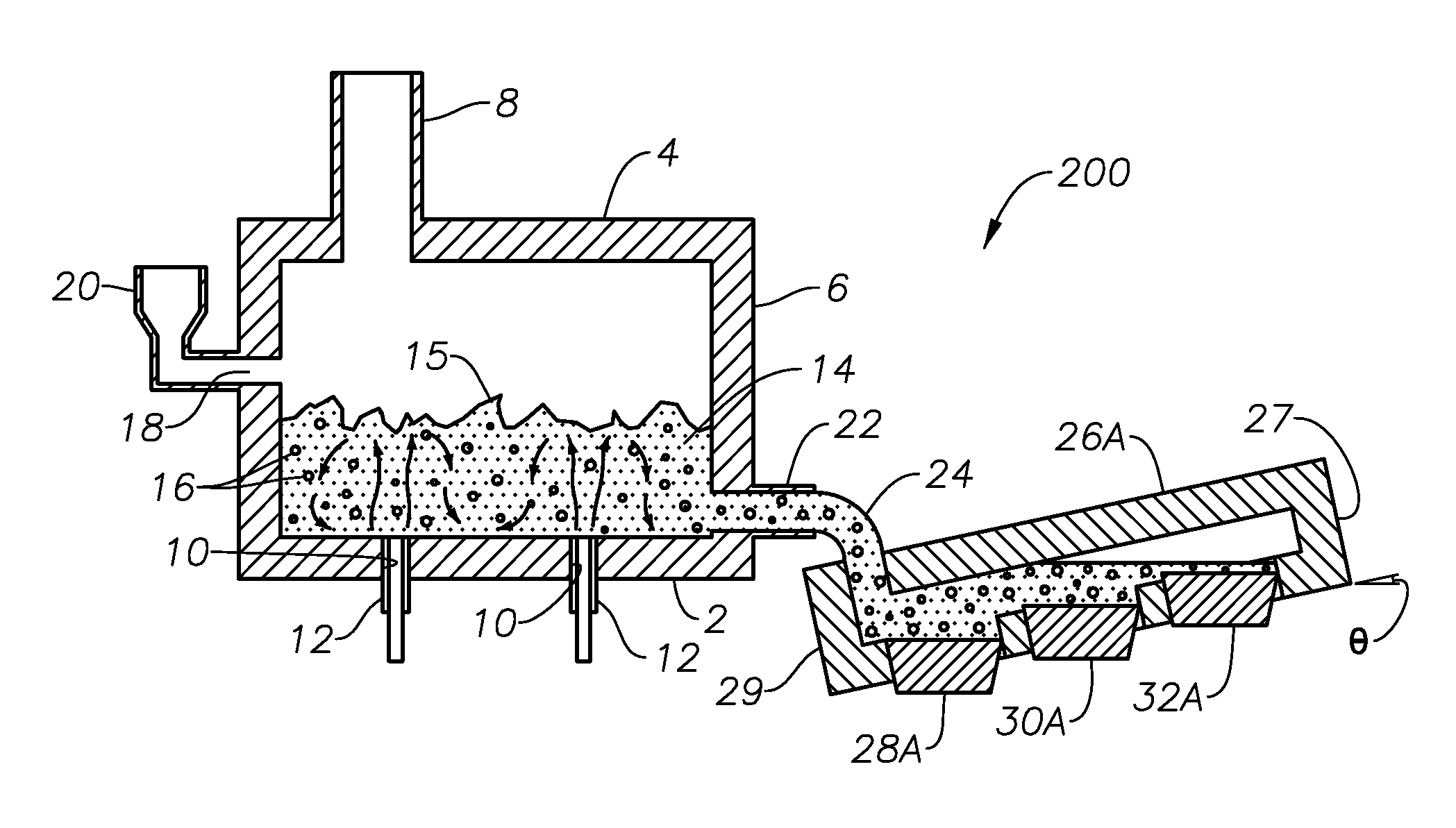

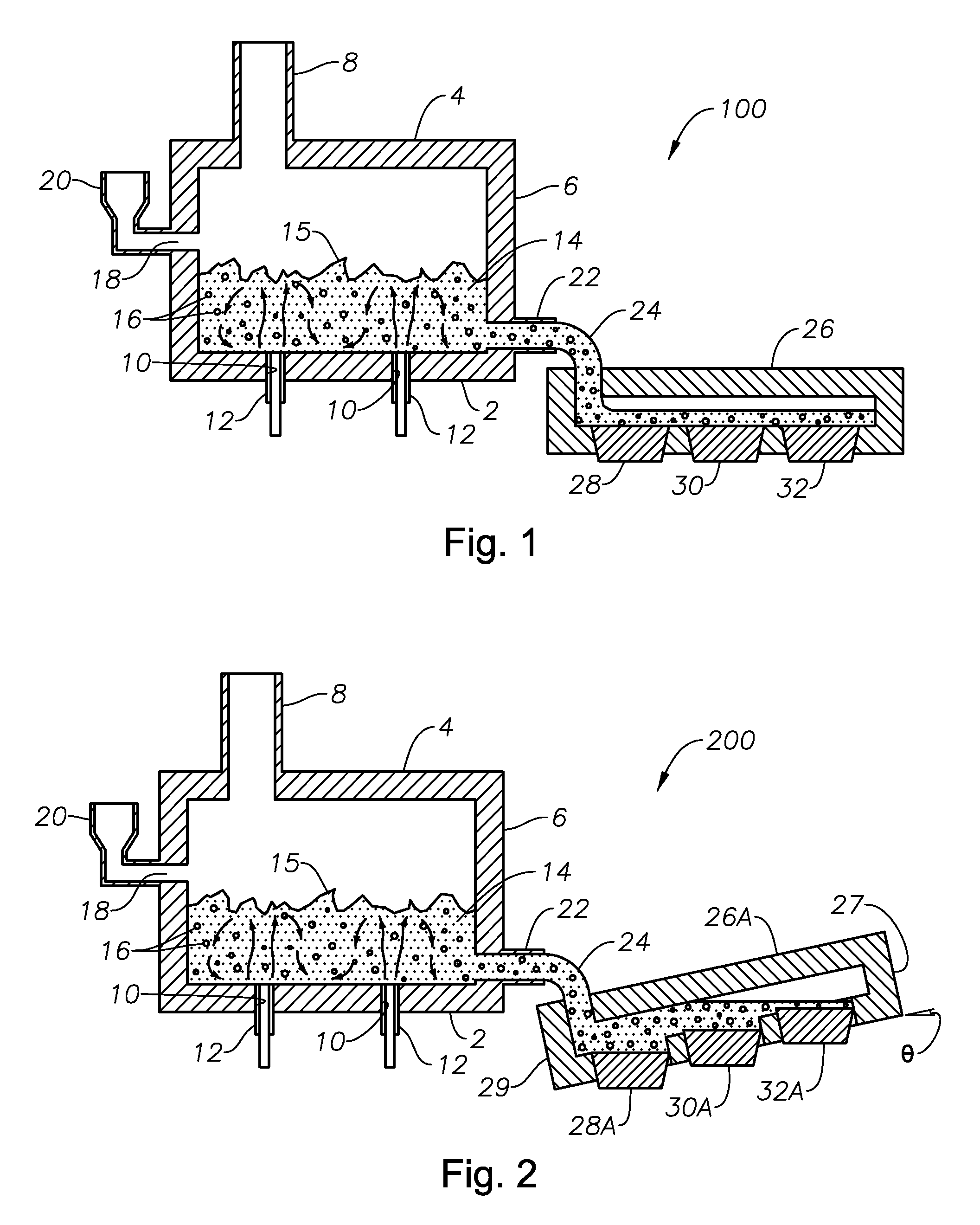

Submerged combustion melting processes for producing glass and similar materials, and systems for carrying out such processes

Processes of controlling submerged combustion melters, and systems for carrying out the methods. One process includes feeding vitrifiable material into a melter vessel, the melter vessel including a fluid-cooled refractory panel in its floor, ceiling, and / or sidewall, and heating the vitrifiable material with a burner directing combustion products into the melting zone under a level of the molten material in the zone. Burners impart turbulence to the molten material in the melting zone. The fluid-cooled refractory panel is cooled, forming a modified panel having a frozen or highly viscous material layer on a surface of the panel facing the molten material, and a sensor senses temperature of the modified panel using a protected thermocouple positioned in the modified panel shielded from direct contact with turbulent molten material. Processes include controlling the melter using the temperature of the modified panel. Other processes and systems are presented.

Owner:JOHNS MANVILLE CORP

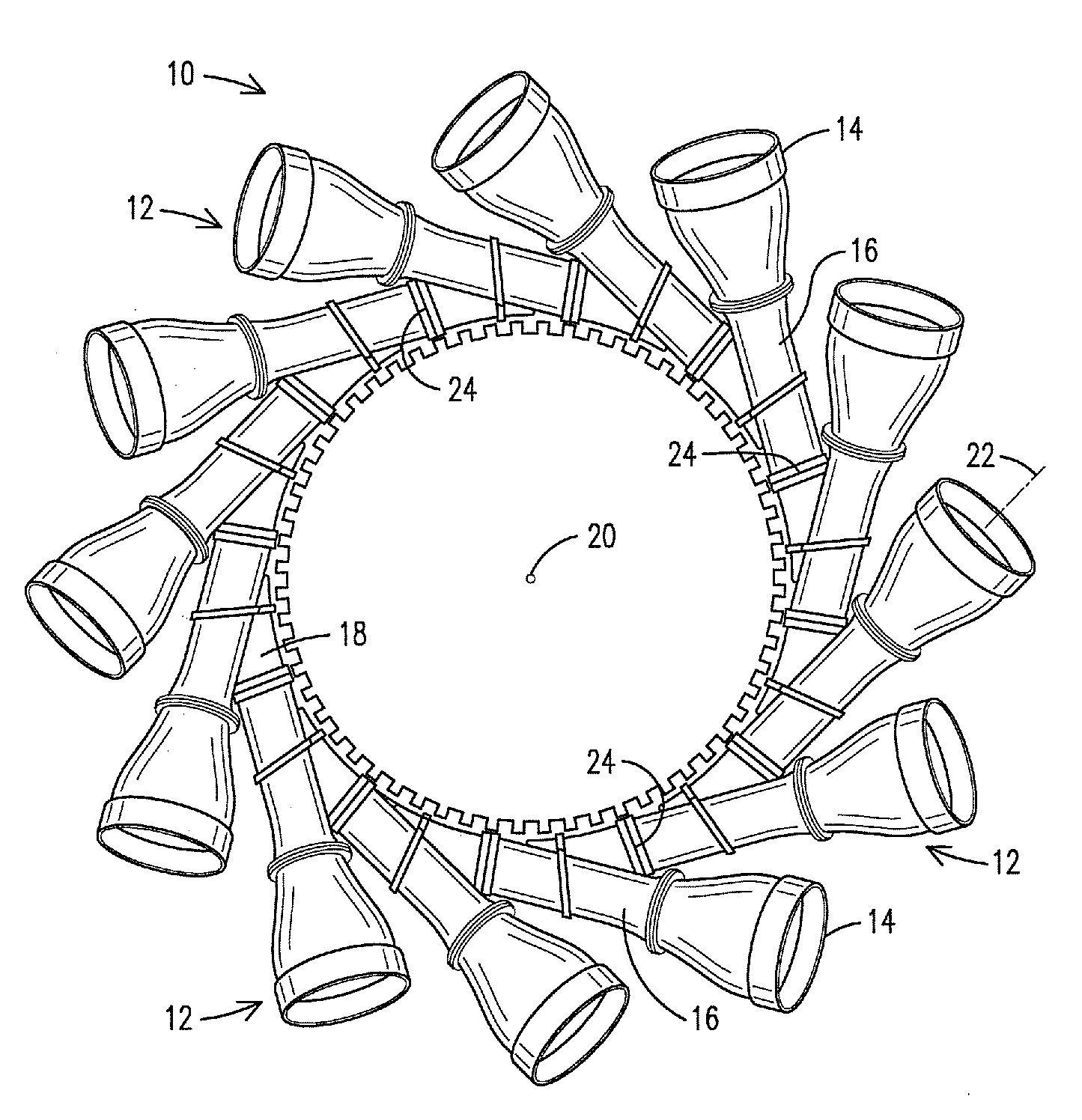

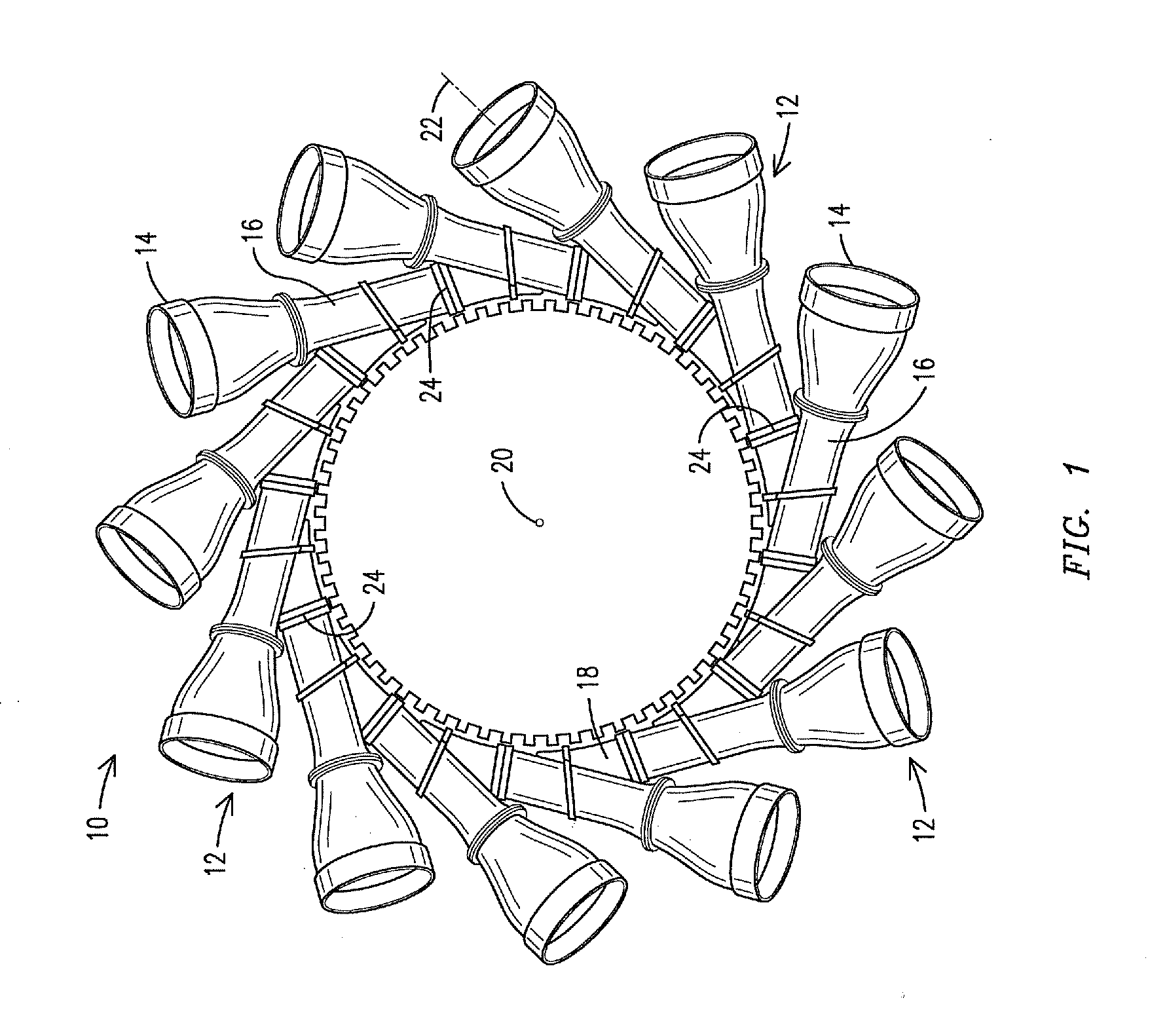

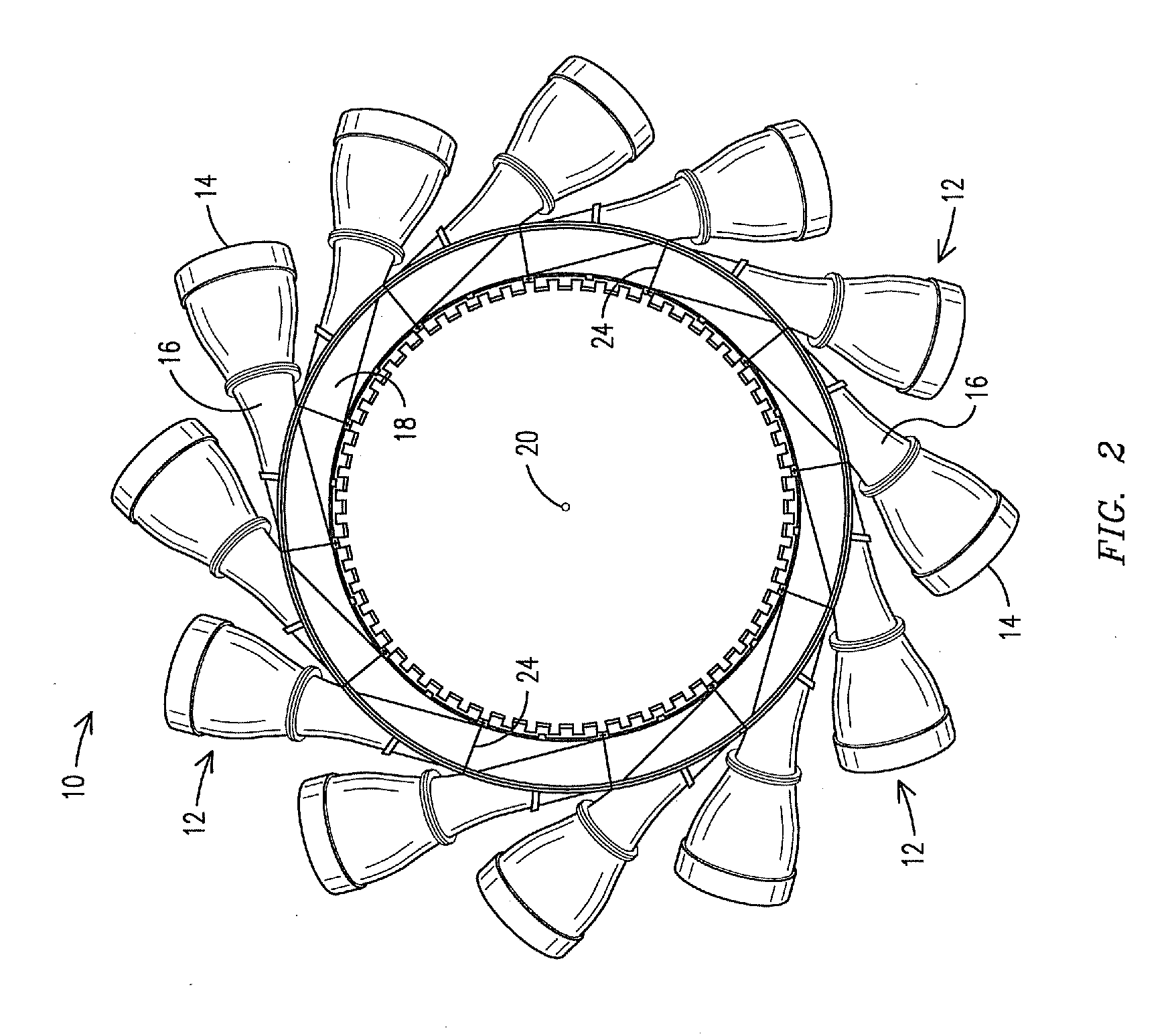

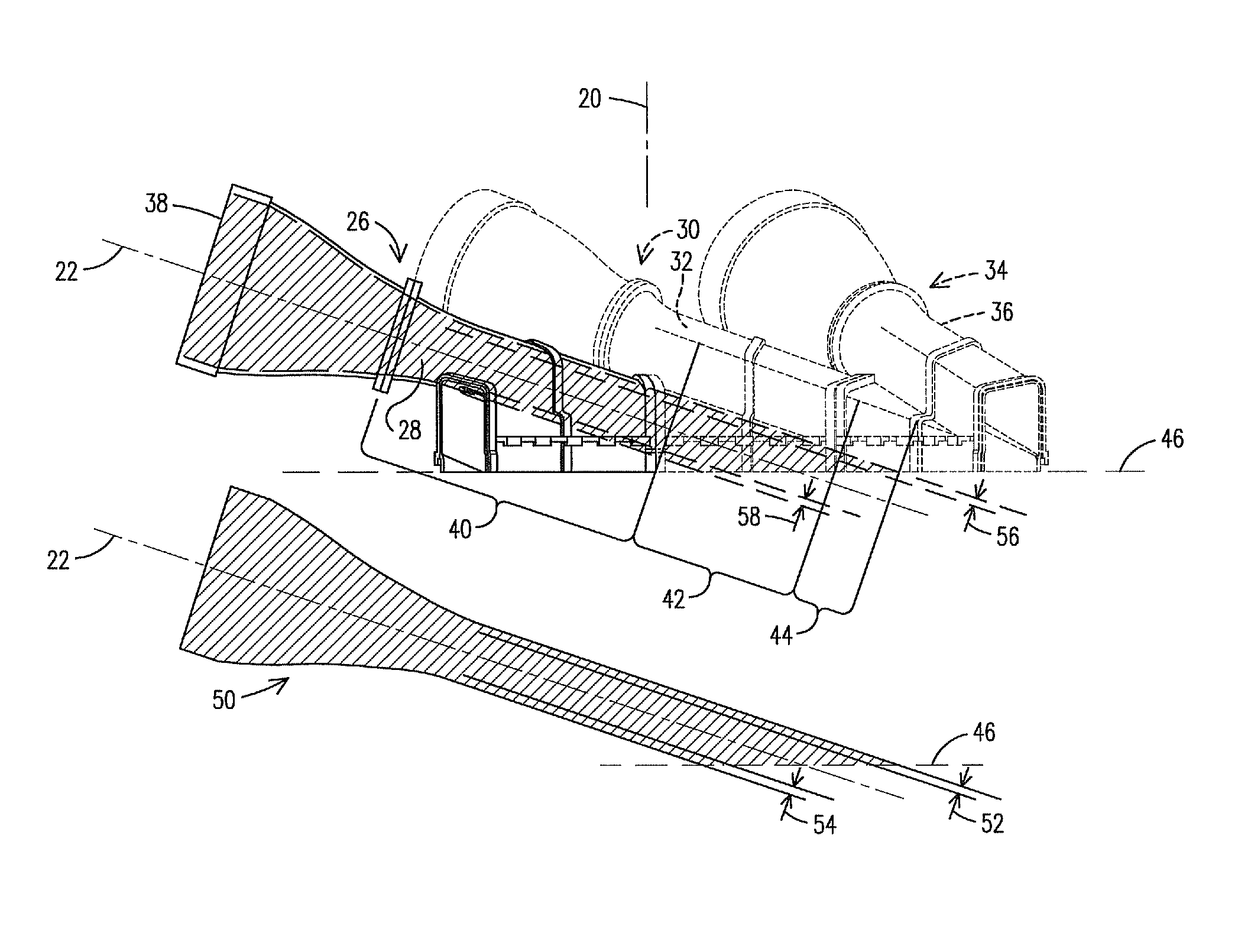

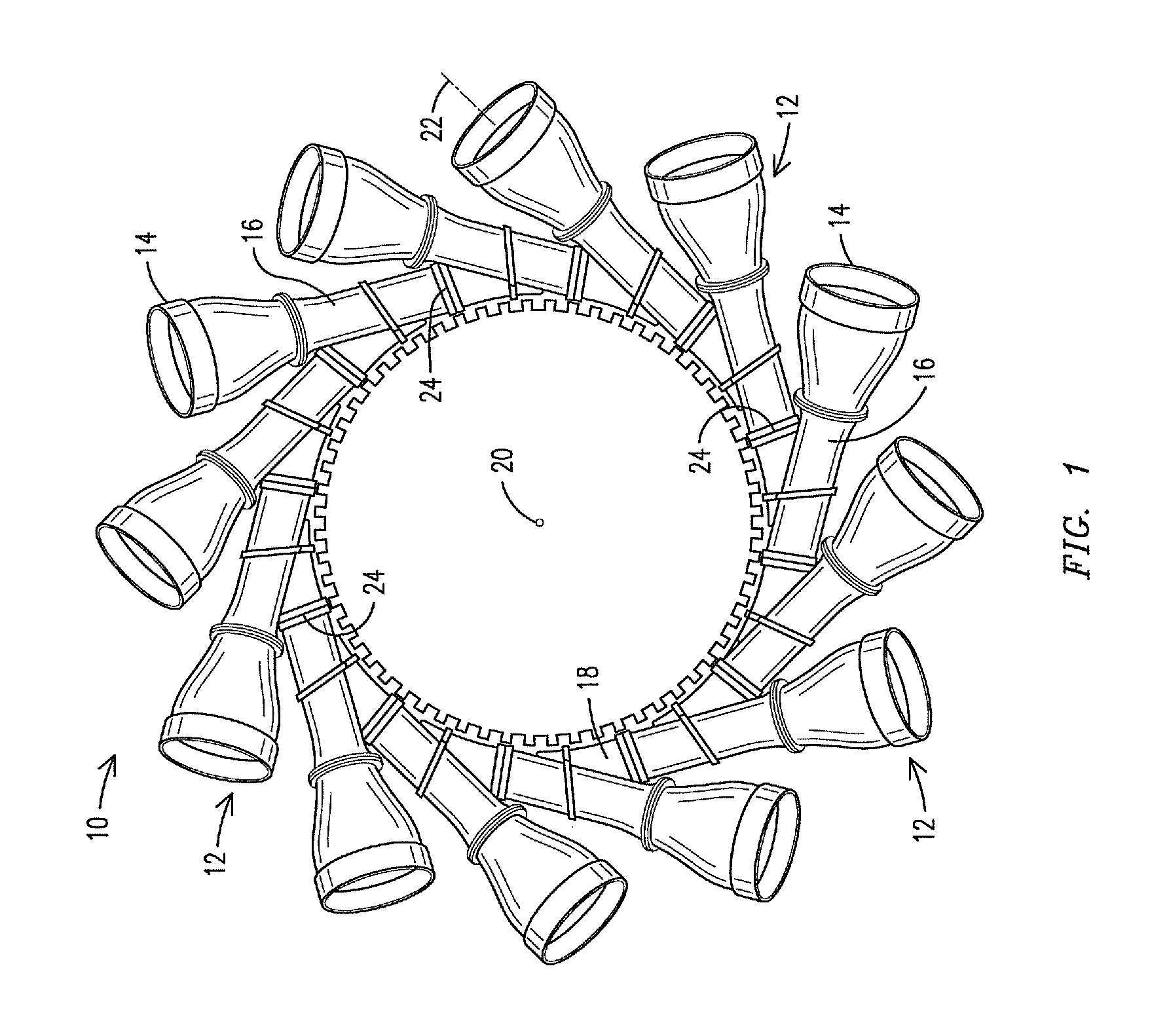

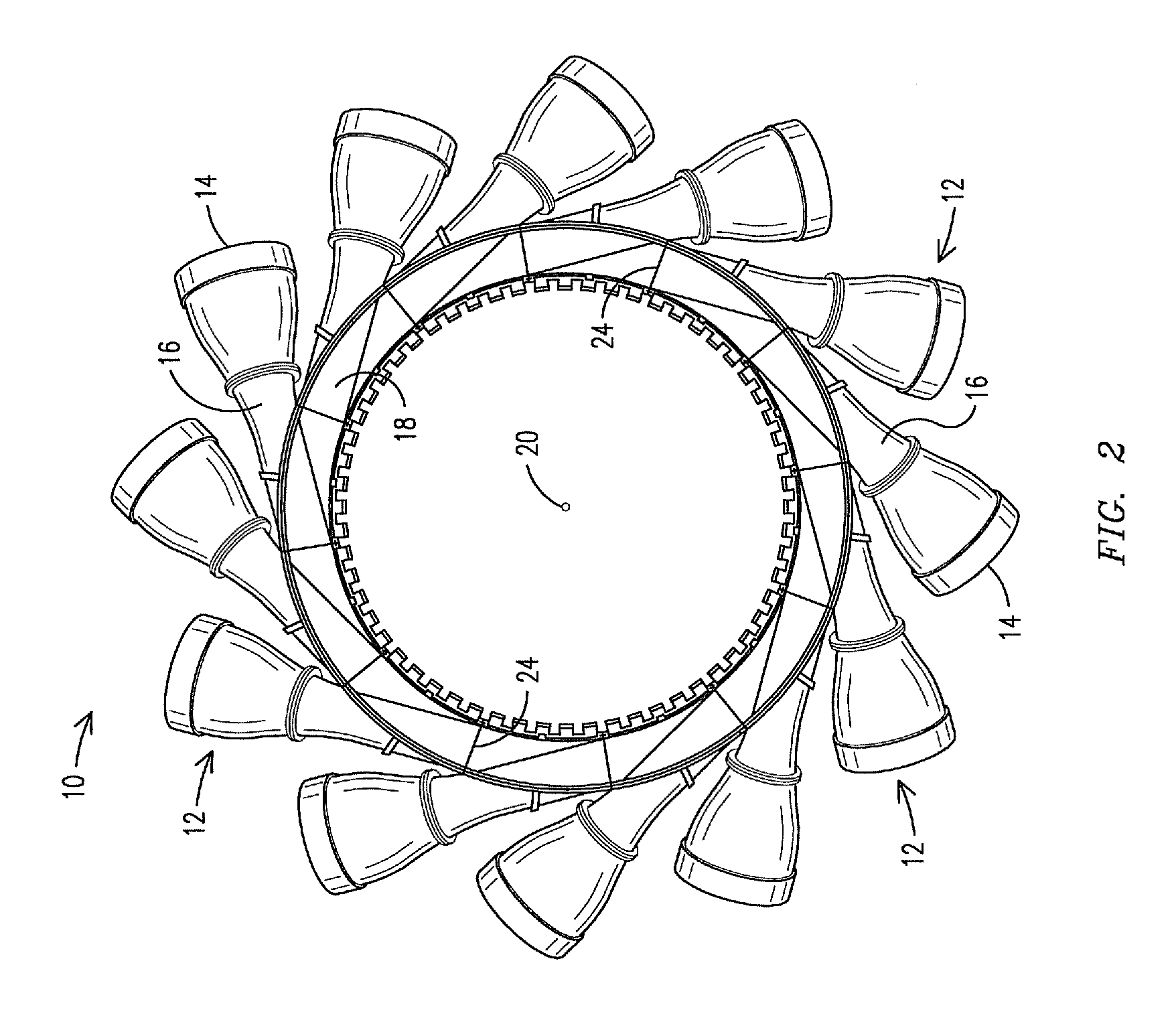

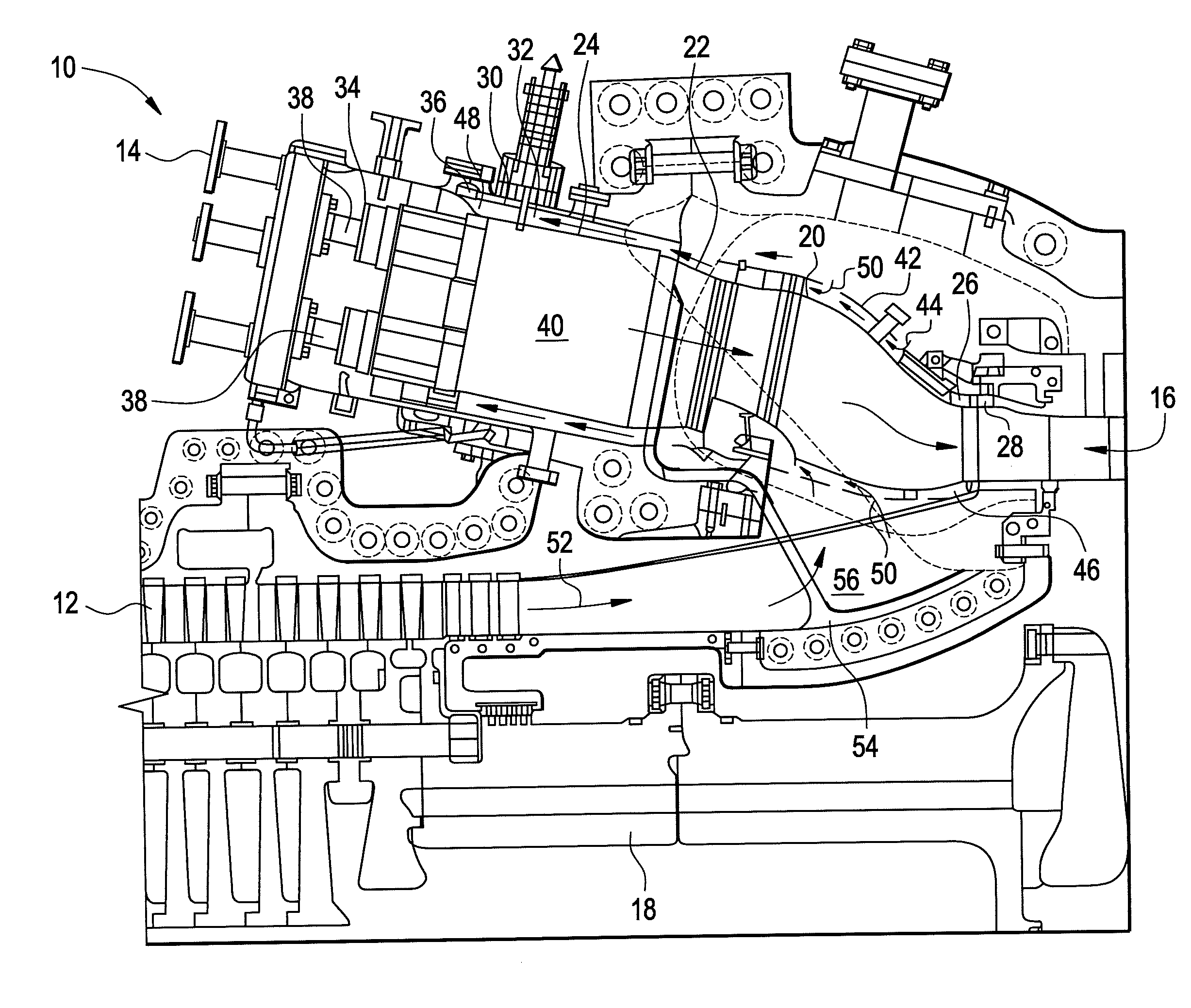

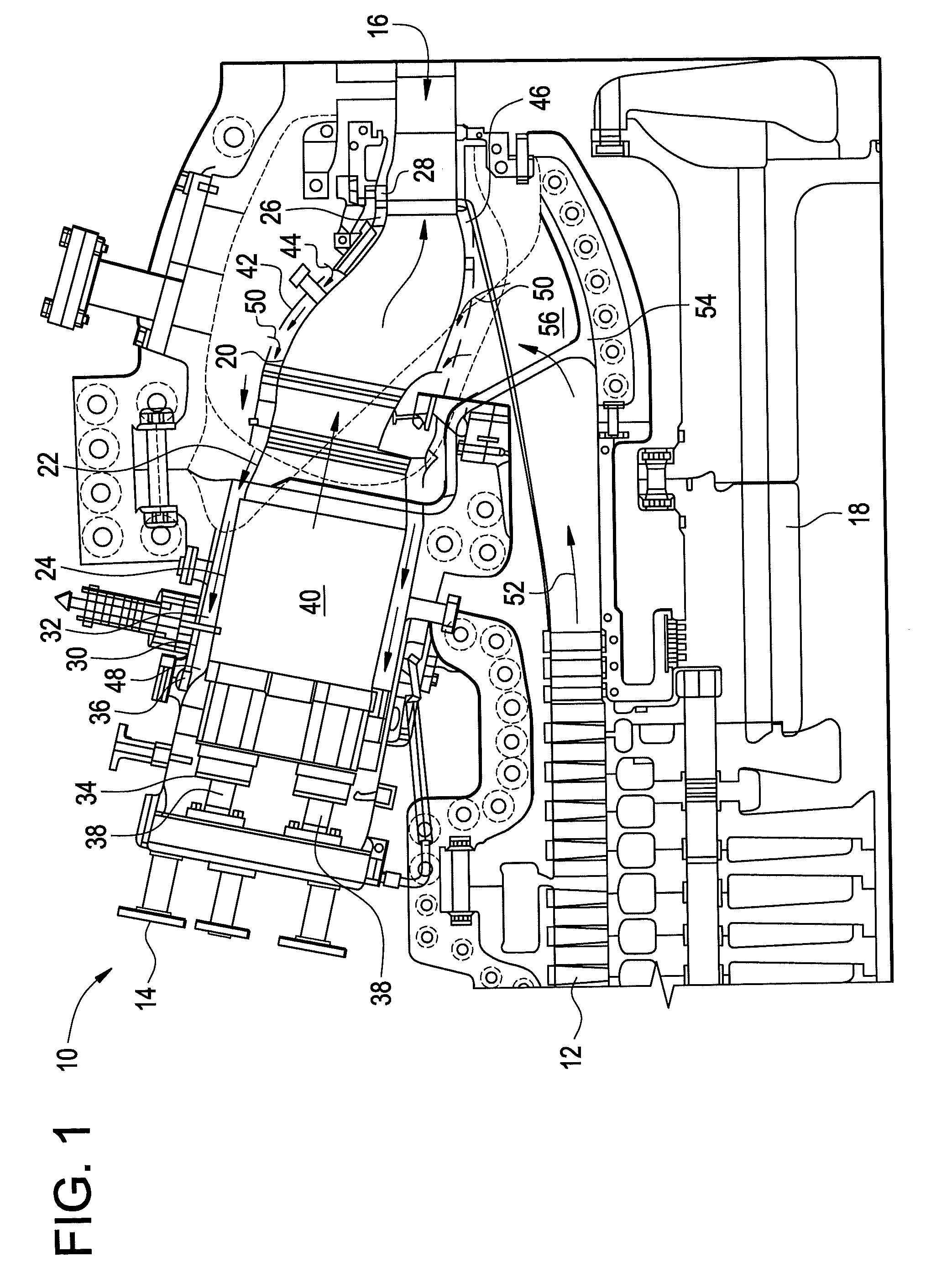

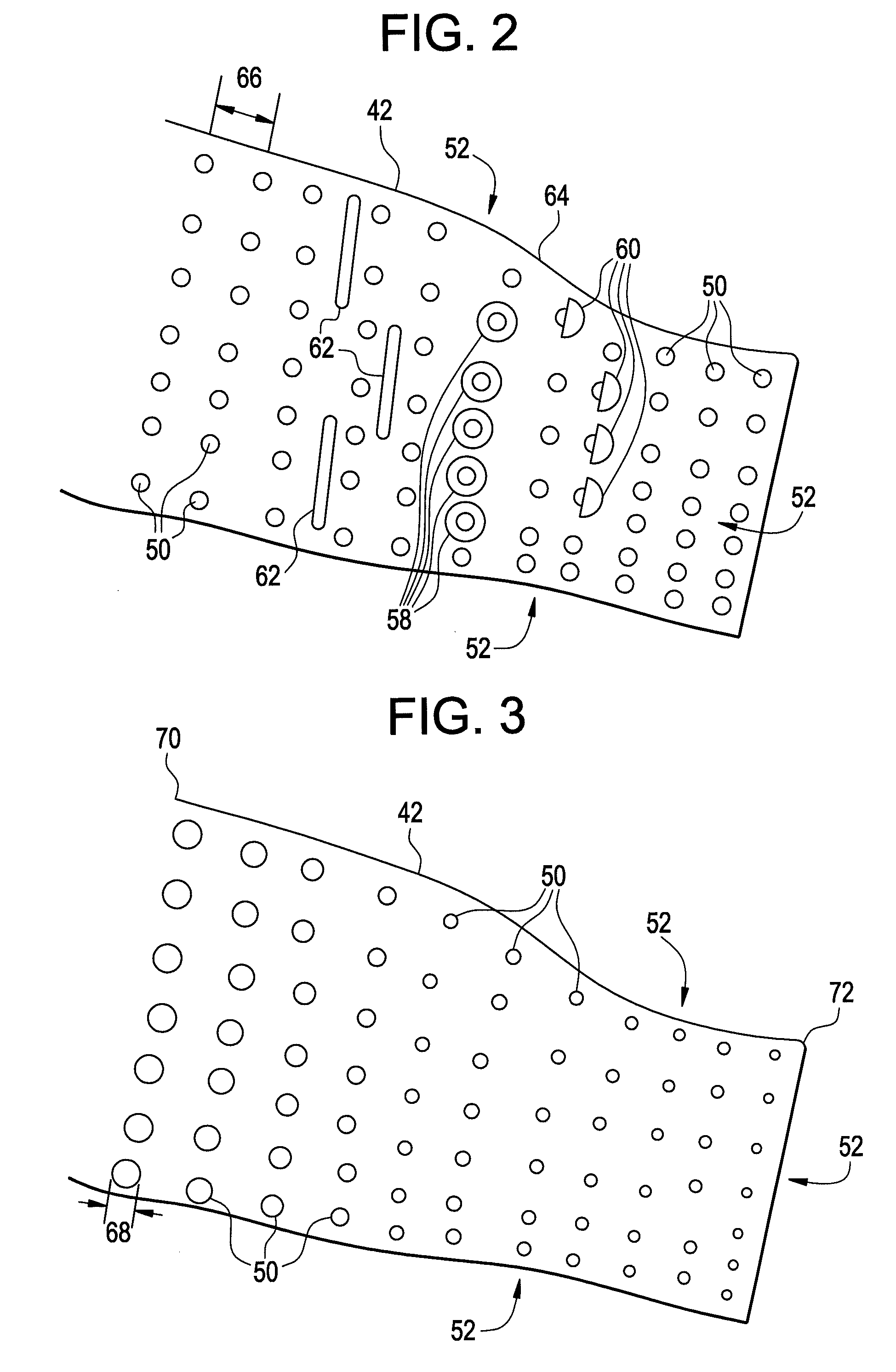

Assembly for directing combustion gas

An arrangement (10) for conveying combustion gas from a plurality of can annular combustors to a turbine first stage blade section of a gas turbine engine, the arrangement (10) including a plurality of interconnected integrated exit piece (IEP) sections (16) defining an annular chamber (18) oriented concentric to a gas turbine engine longitudinal axis (20) upstream of the turbine first stage blade section. Each respective IEP (16) includes a first flow path section (40) receiving and fully bounding a first flow from a respective can annular combustor along a respective common axis (22) there between, and delivering a partially bounded first flow to a downstream adjacent IEP section (42). Each respective IEP further includes a second flow path section (112) receiving a partially bounded second flow from an upstream adjacent IEP (66) and delivering at least part of the second flow to the turbine first stage blade section.

Owner:SIEMENS ENERGY INC

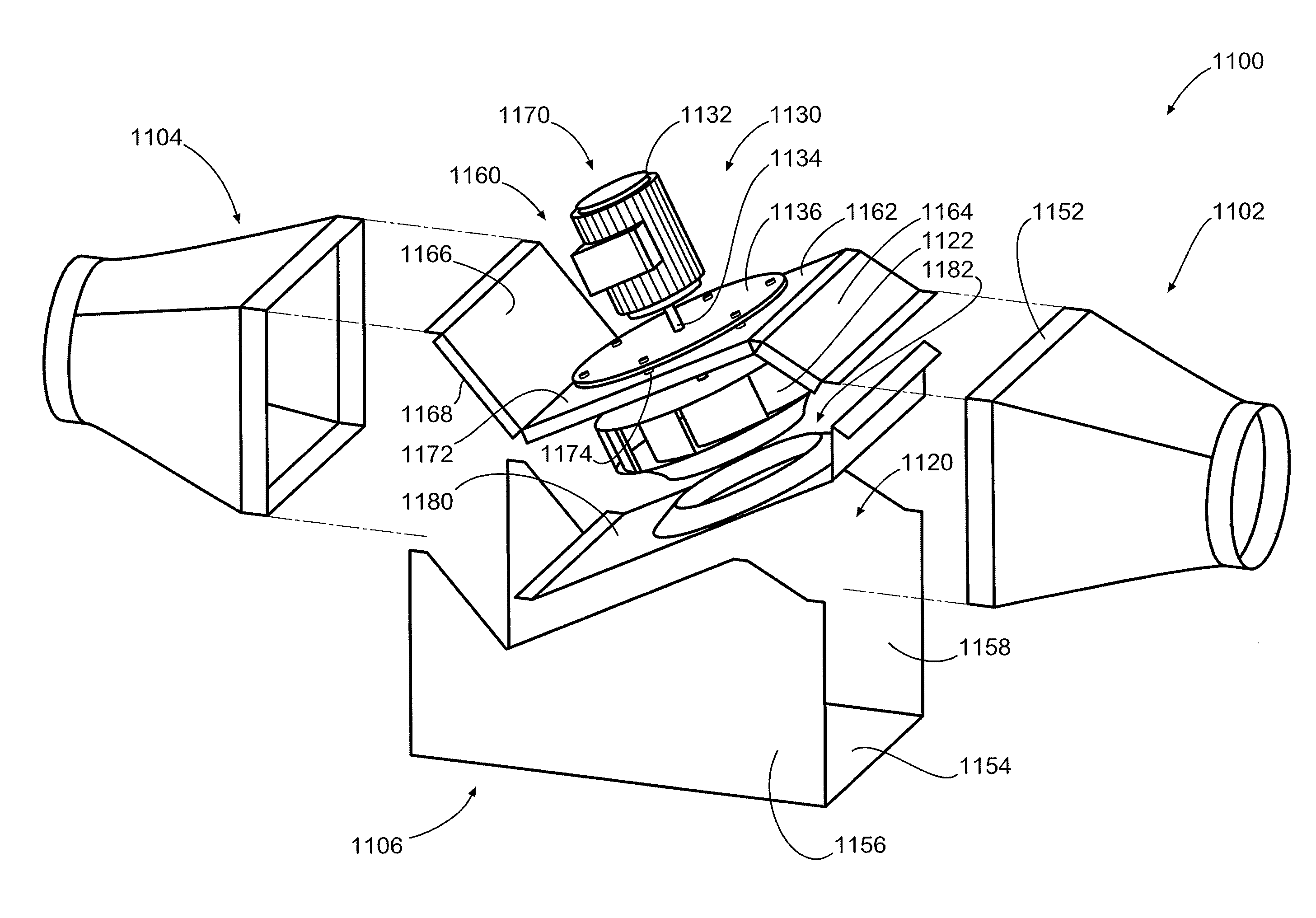

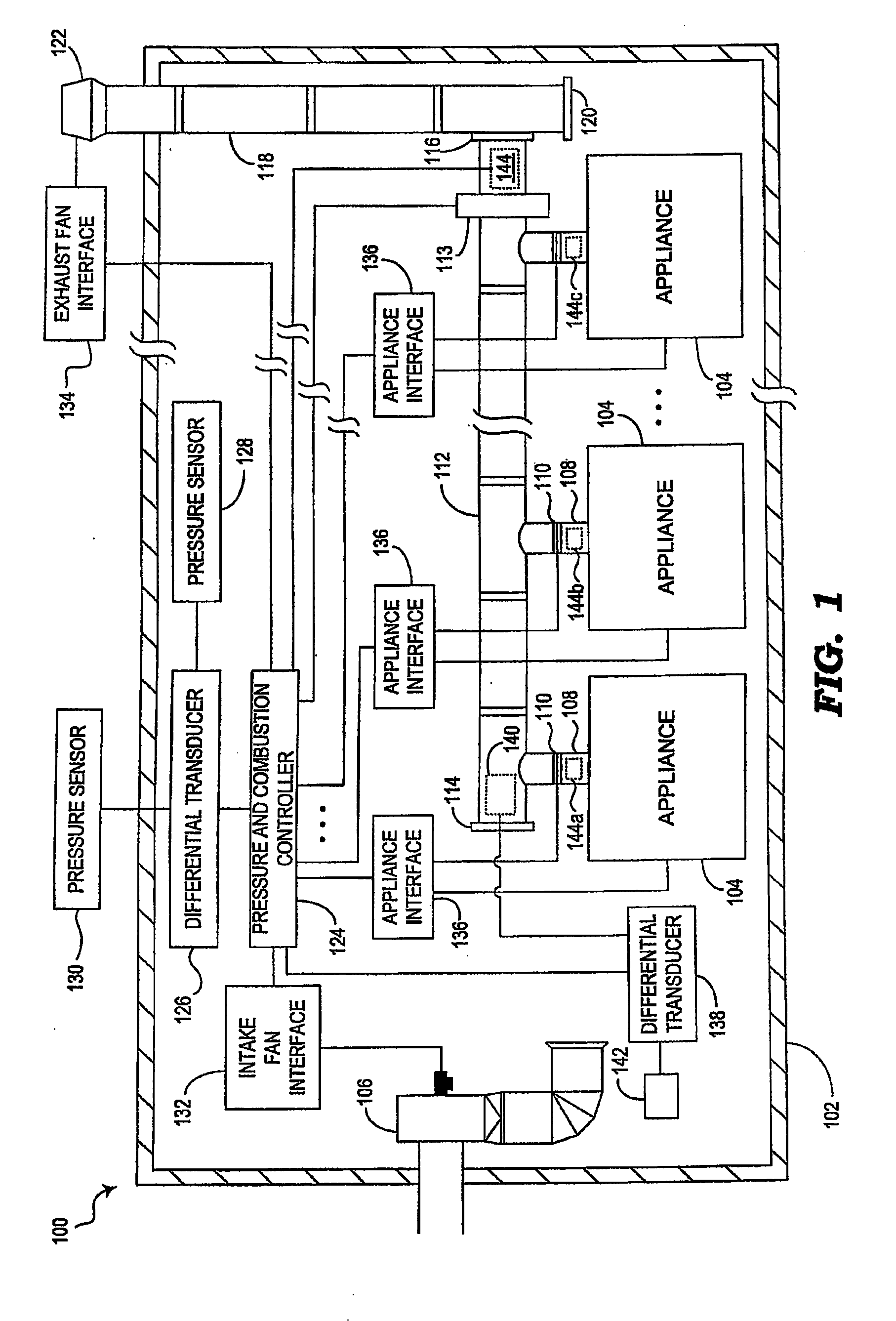

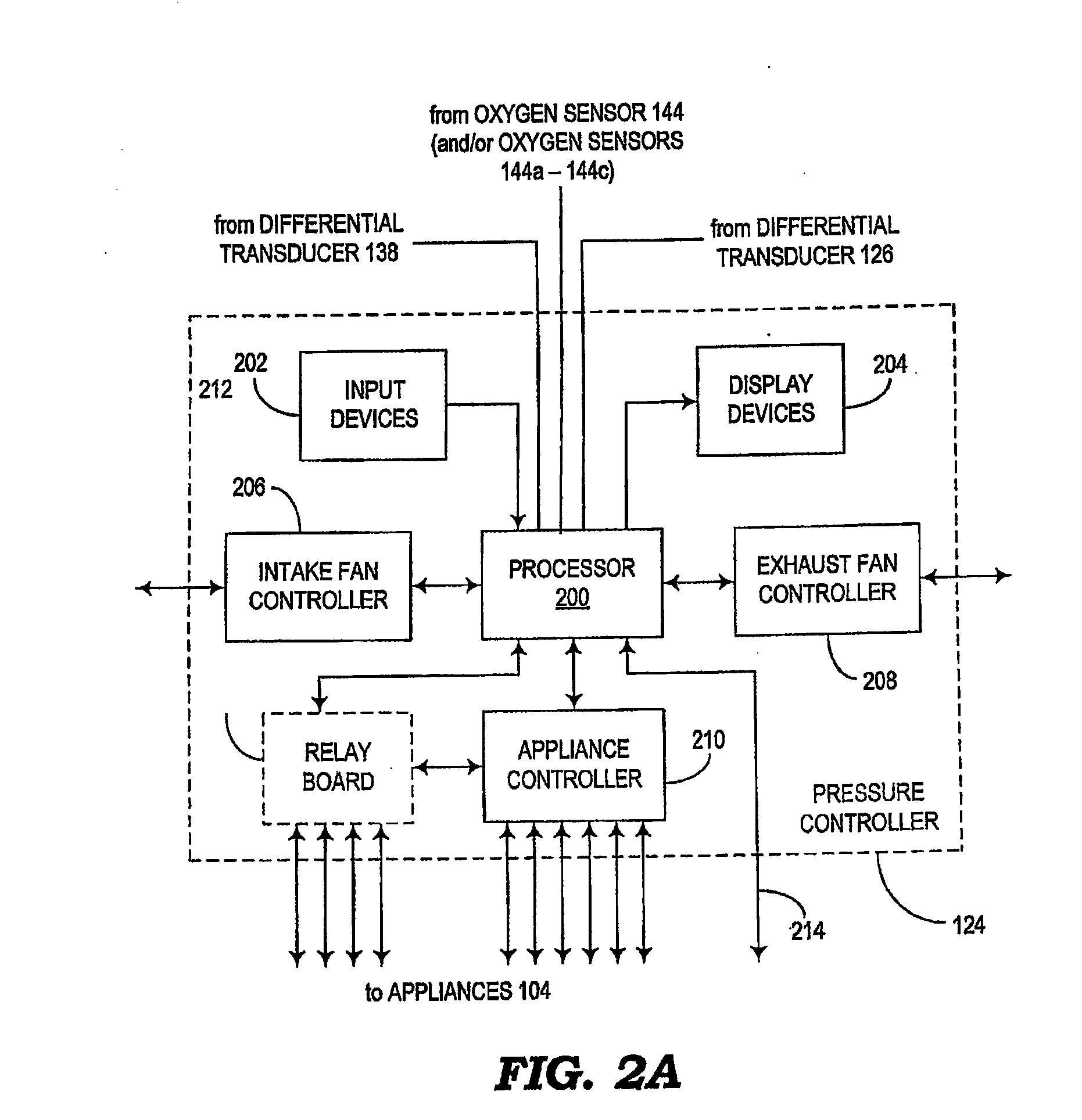

Fan Assemblies, Mechanical Draft Systems and Methods

InactiveUS20090215375A1Facilitate independentFacilitate locally controlled ignitionDomestic stoves or rangesLiquid heating fuelDirect combustionControl theory

Fan assemblies, mechanical draft systems and methods are provided. In this regard, a representative mechanical draft system for use with multiple appliances includes: a chimney operative to direct combustion products from multiple appliances; a chimney fan operative to draw combustion products from the chimney; and a controller operative to adjust an operating speed of the chimney fan such that, responsive to a change in pressure in the chimney, the controller adjusts the operating speed of the chimney fan to maintain a desired pressure in the chimney.

Owner:GREENVEX

Submerged combustion melting processes for producing glass and similar materials, and systems for carrying out such processes

Processes of controlling submerged combustion melters, and systems for carrying out the methods. One process includes feeding vitrifiable material into a melter vessel, the melter vessel including a fluid-cooled refractory panel in its floor, ceiling, and / or sidewall, and heating the vitrifiable material with a burner directing combustion products into the melting zone under a level of the molten material in the zone. Burners impart turbulence to the molten material in the melting zone. The fluid-cooled refractory panel is cooled, forming a modified panel having a frozen or highly viscous material layer on a surface of the panel facing the molten material, and a sensor senses temperature of the modified panel using a protected thermocouple positioned in the modified panel shielded from direct contact with turbulent molten material. Processes include controlling the melter using the temperature of the modified panel. Other processes and systems are presented.

Owner:JOHNS MANVILLE CORP

Panel-cooled submerged combustion melter geometry and methods of making molten glass

ActiveUS8769992B2Small sizeAllows more flexibility in the shape of the melterPulsating combustionGlass furnace apparatusThermodynamicsCombustor

A melter apparatus includes a floor, a ceiling, and a substantially vertical wall connecting the floor and ceiling at a perimeter of the floor and ceiling, a melting zone being defined by the floor, ceiling and wall, the melting zone having a feed inlet and a molten glass outlet positioned at opposing ends of the melting zone. The melting zone includes an expanding zone beginning at the inlet and extending to an intermediate location relative to the opposing ends, and a narrowing zone extending from the intermediate location to the outlet. One or more burners, at least some of which are positioned to direct combustion products into the melting zone under a level of molten glass in the zone, are also provided.

Owner:JOHNS MANVILLE CORP

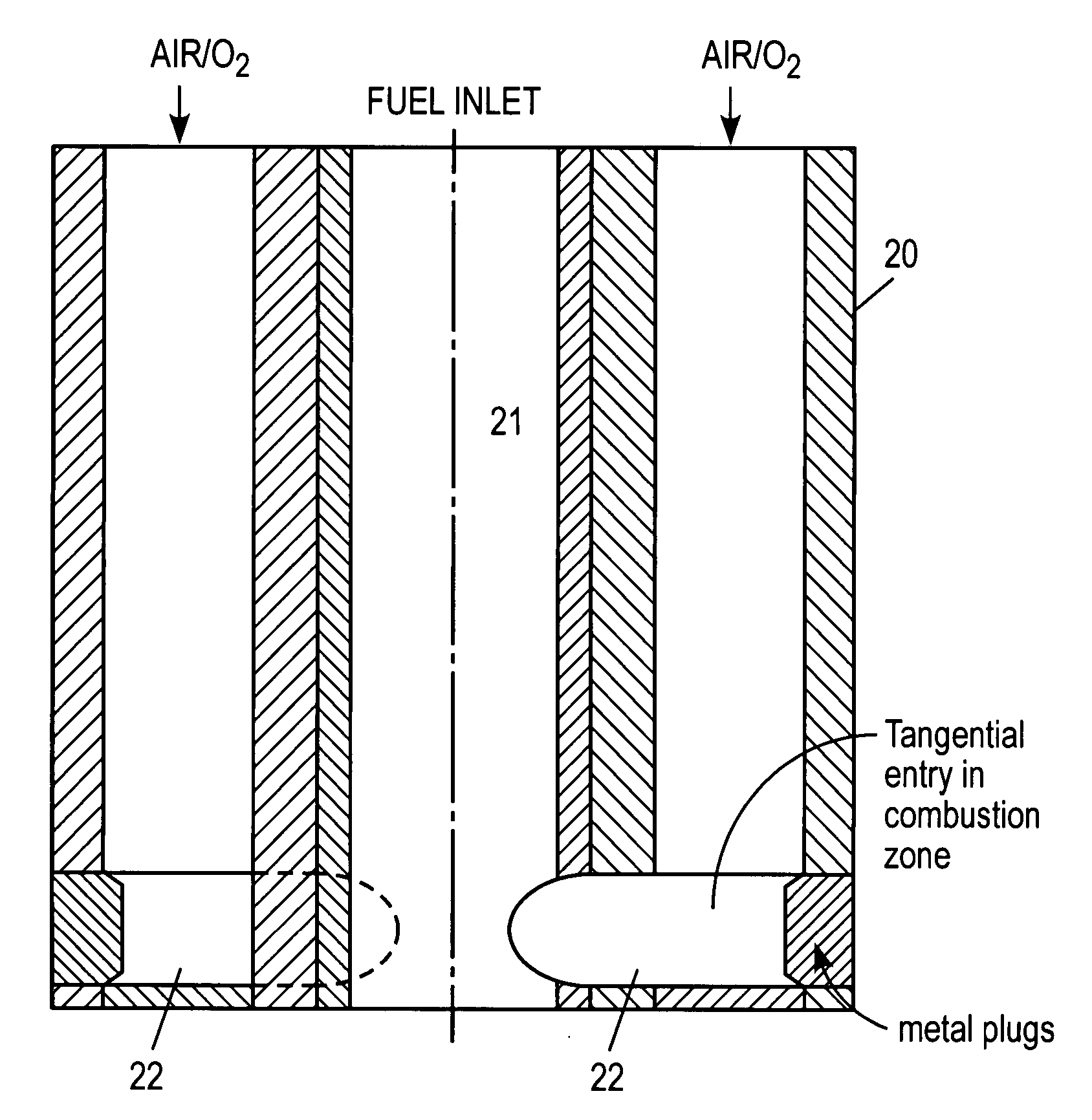

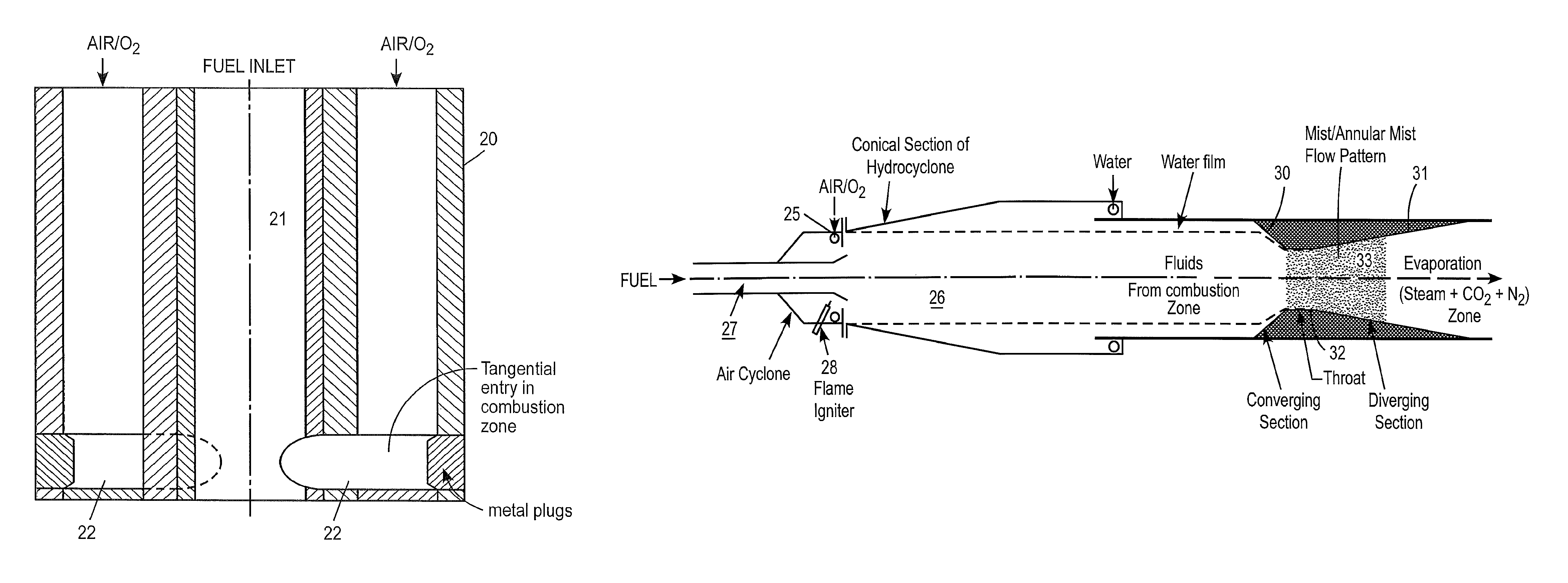

Direct combustion steam generator

ActiveUS20070202452A1Flame stabilizationHigh strengthGas turbine plantsFluid removalDirect combustionProcess engineering

A method and apparatus for generating steam by heating water with a flame is provided. The water is introduced into a vortex sustaining container and flows through the container in a spiraling manner creating a liquid vortex with an open axial core. The flame effects heat transfer and is the product of the ignition of fuel mixed with a tangentially swirling oxygen containing gas.

Owner:DIRECT COMBUSTION TECH

Stagnation point reverse flow combustor

InactiveUS7425127B2Combustion using gaseous and pulverulent fuelContinuous combustion chamberStagnation pointCombustor

A method for combusting a combustible fuel includes providing a vessel having an opening near a proximate end and a closed distal end defining a combustion chamber. A combustible reactants mixture is presented into the combustion chamber. The combustible reactants mixture is ignited creating a flame and combustion products. The closed end of the combustion chamber is utilized for directing combustion products toward the opening of the combustion chamber creating a reverse flow of combustion products within the combustion chamber. The reverse flow of combustion products is intermixed with combustible reactants mixture to maintain the flame.

Owner:GEORGIA TECH RES CORP

Assembly for directing combustion gas

An arrangement (10) for conveying combustion gas from a plurality of can annular combustors to a turbine first stage blade section of a gas turbine engine, the arrangement (10) including a plurality of interconnected integrated exit piece (IEP) sections (16) defining an annular chamber (18) oriented concentric to a gas turbine engine longitudinal axis (20) upstream of the turbine first stage blade section. Each respective IEP (16) includes a first flow path section (40) receiving and fully bounding a first flow from a respective can annular combustor along a respective common axis (22) there between, and delivering a partially bounded first flow to a downstream adjacent IEP section (42). Each respective IEP further includes a second flow path section (112) receiving a partially bounded second flow from an upstream adjacent IEP (66) and delivering at least part of the second flow to the turbine first stage blade section.

Owner:SIEMENS ENERGY INC

Direct combustion steam generator

Owner:DIRECT COMBUSTION TECH

Biomass molding fuels

InactiveCN101899345AEmission reductionImprove effective utilizationBiofuelsSolid fuelsSulfurDirect combustion

The invention discloses biomass molding fuels. The fuels are granulated and molded after biomass material particles and a fuel additive are mixed, wherein, based on the weight of the biomass material particles, the fuel additive comprises the following components in percentages by weight: 0.1-5% of grease, 0.1-2% of sulfur fixation agent and 0.1-0.5% of combustion improver. The biomass molding fuel obtained in the invention is a high grade clean fuel suitable for use in industrial boilers and can be directly burned in various BMF (Biomass molding fuel) boilers.

Owner:GUANGZHOU DEVOTION THERMAL TECH

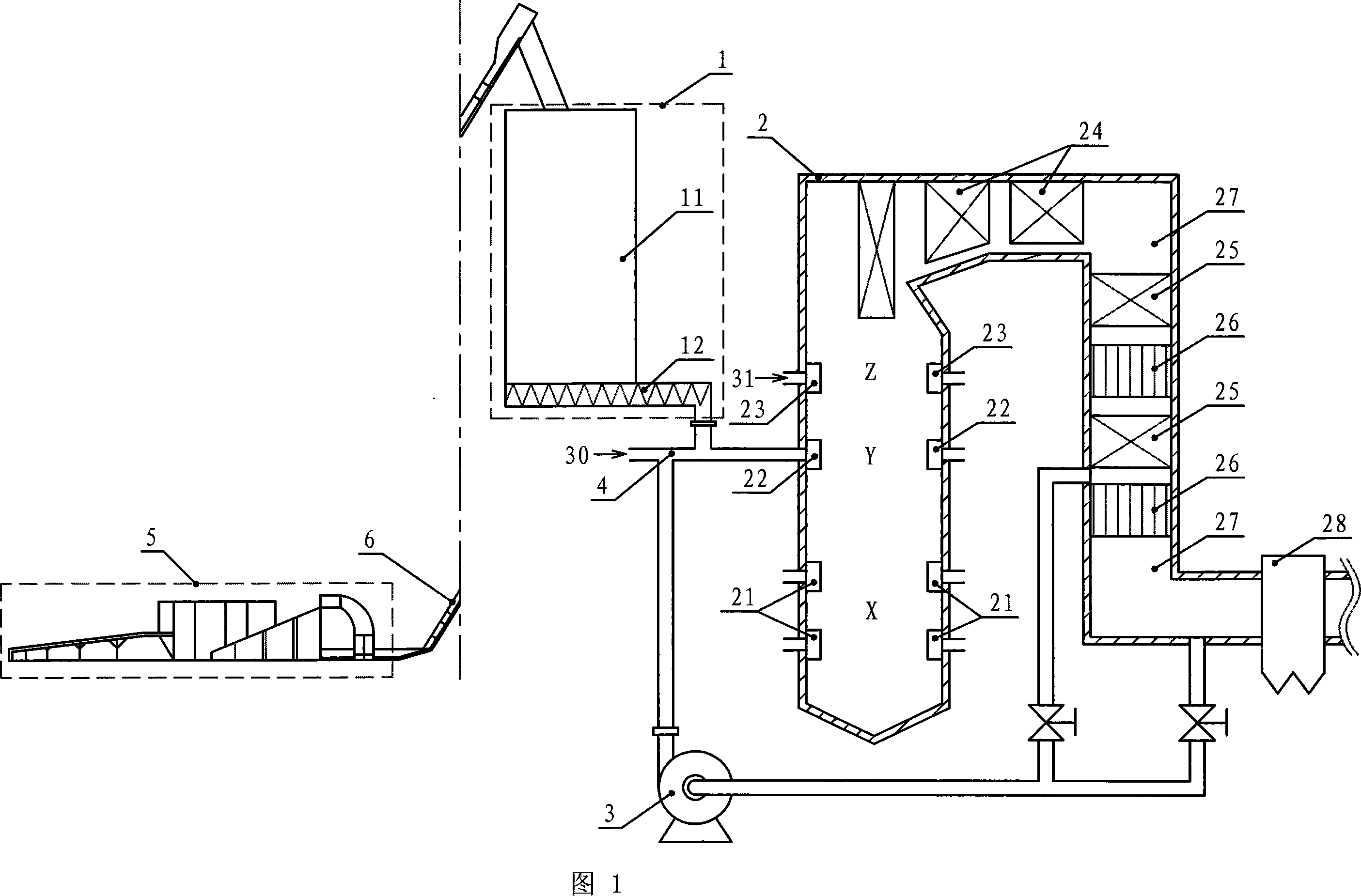

Method and device of denitration utilizing biomass direct burning and re-burning as well as smoke gas recirculating technology

InactiveCN101021316AReduce technical riskLow technical costCombustion apparatusCombustorDirect combustion

The present invention belongs to a denitration method by utilizing biomass direct combustion and secondary combustion and flue gas recirculating process and its equipment, and relates to a coal powder boiler low NOx combustion process and its equipment. The invented method includes the following steps: making coal powder be passed through the combustor of coal powder boiler and fed into main combustion zone to make combustion and form the flue gas containing NOx; utilizing the mixture of once air and recirculating tail portion flue gas to spray biomass particles into secondary combustion reduction zone and make NOx formed in the main combustion zone be reacted and formed into N2; at the same time make the biomass coke ad NOx produce isophase reduction reaction to form Nz; spraying burning air from upper portion of secondary combustion reduction zone to make non-burnt combustible material be burnt up.

Owner:HARBIN INST OF TECH

Combustor structure

InactiveUS20100005804A1Weakening rangeContinuous combustion chamberGas turbine plantsCombustorCombustion chamber

A combustor includes at least one combustor liner defining a combustion chamber capable of directing combustion products toward a turbine. At least one combustor sleeve is located outside of the combustion chamber and is capable of reducing a magnitude of acoustic waves in the combustion chamber. The at least one combustor liner and the at least one combustor sleeve define at least one flow channel therebetween. Further, a combustor includes at least one combustor liner defining a combustion chamber capable of directing combustion products toward turbomachinery. At least one combustor sleeve disposed outside of the combustion chamber and is capable of controlling distribution of fluid flow in the combustor to modify a uniformity of the fluid flow to the combustion chamber.

Owner:GENERAL ELECTRIC CO

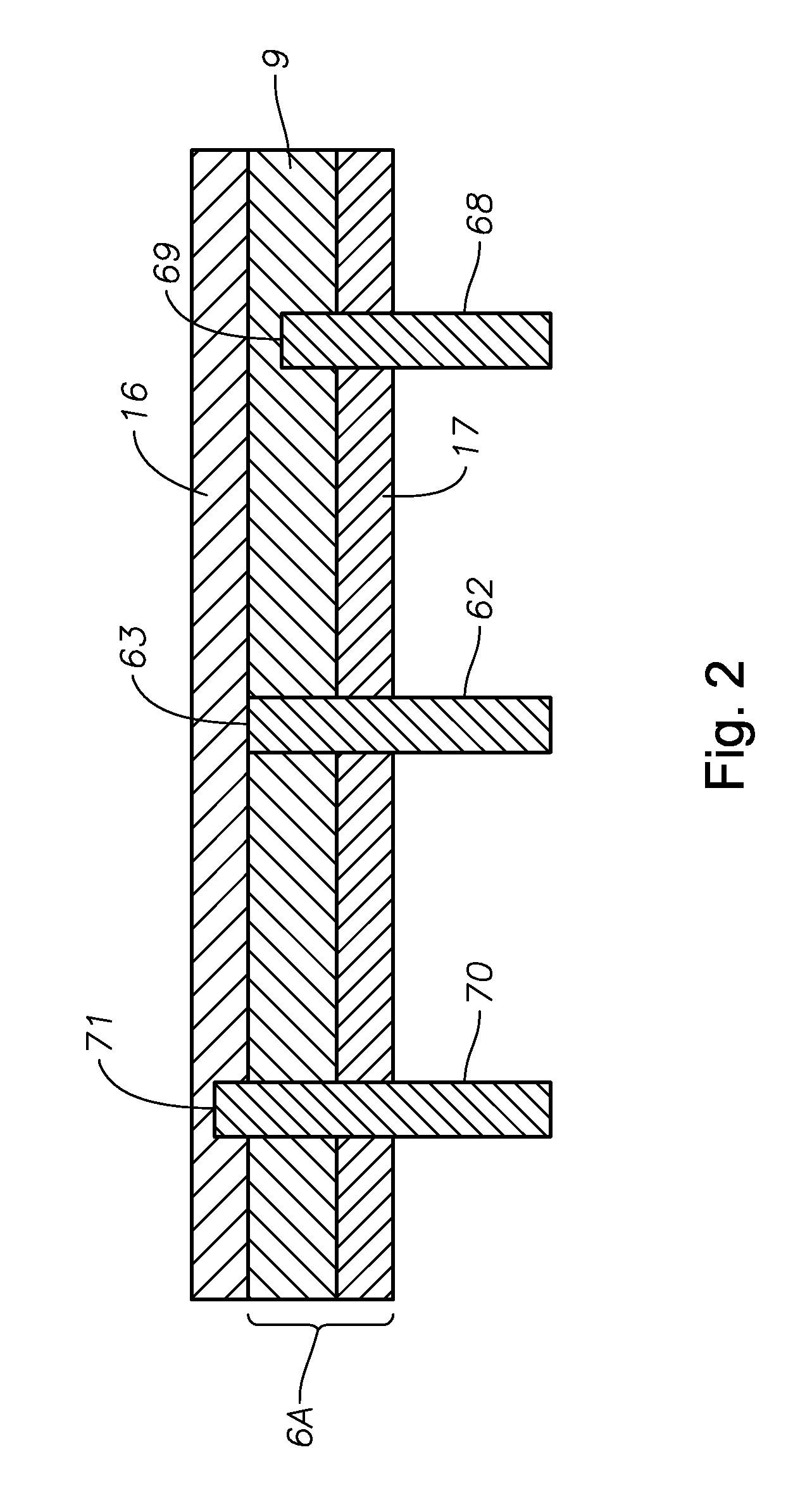

Process of using a submerged combustion melter to produce hollow glass fiber or solid glass fiber having entrained bubbles, and burners and systems to make such fibers

Owner:JOHNS MANVILLE CORP

Process of using a submerged combustion melter to produce hollow glass fiber or solid glass fiber having entrained bubbles, and burners and systems to make such fibers

Processes and systems for producing glass fibers having regions devoid of glass using submerged combustion melters, including feeding a vitrifiable feed material into a feed inlet of a melting zone of a melter vessel, and heating the vitrifiable material with at least one burner directing combustion products of an oxidant and a first fuel into the melting zone under a level of the molten material in the zone. One or more of the burners is configured to impart heat and turbulence to the molten material, producing a turbulent molten material comprising a plurality of bubbles suspended in the molten material, the bubbles comprising at least some of the combustion products, and optionally other gas species introduced by the burners. The molten material and bubbles are drawn through a bushing fluidly connected to a forehearth to produce a glass fiber comprising a plurality of interior regions substantially devoid of glass.

Owner:JOHNS MANVILLE CORP

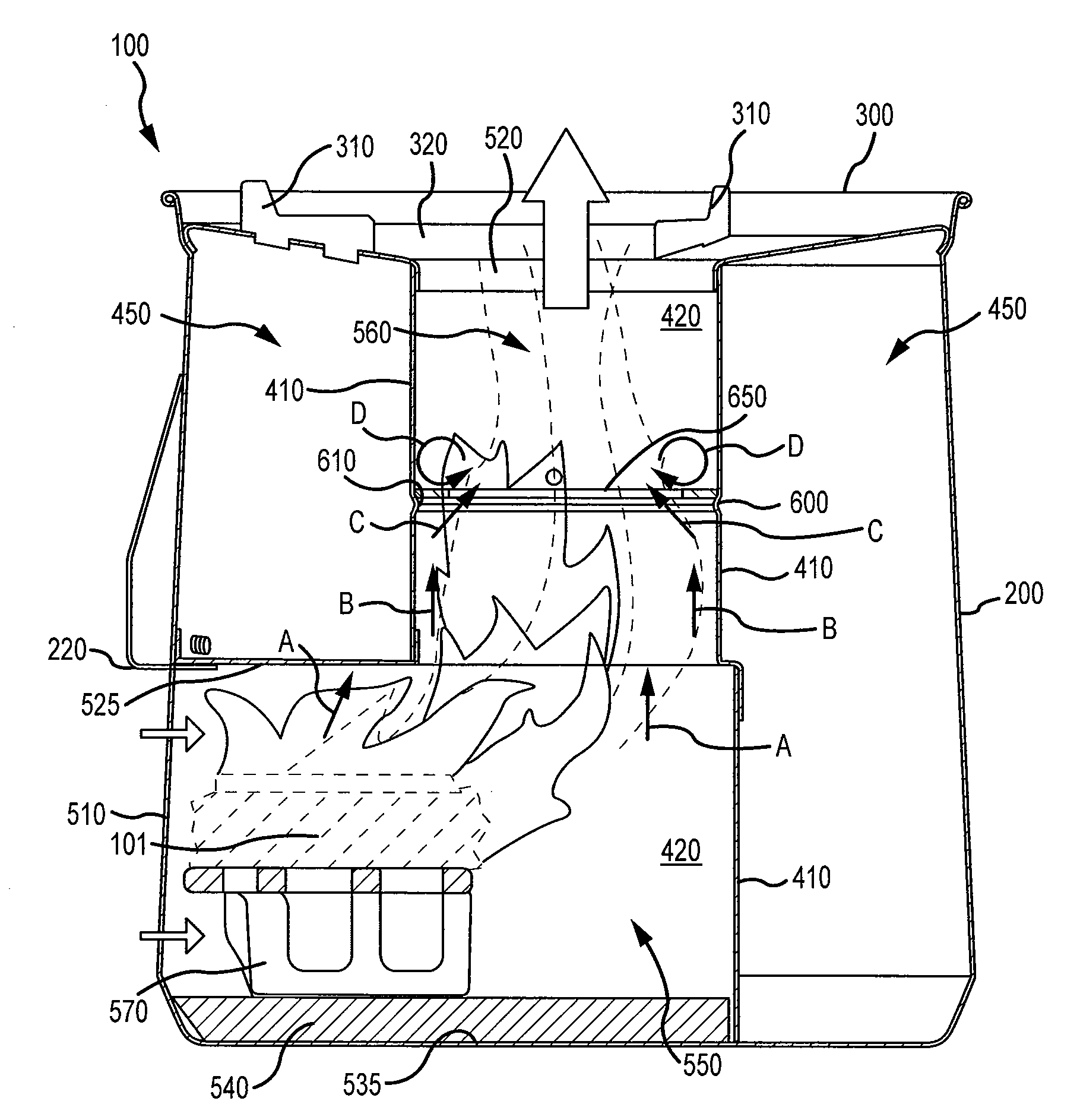

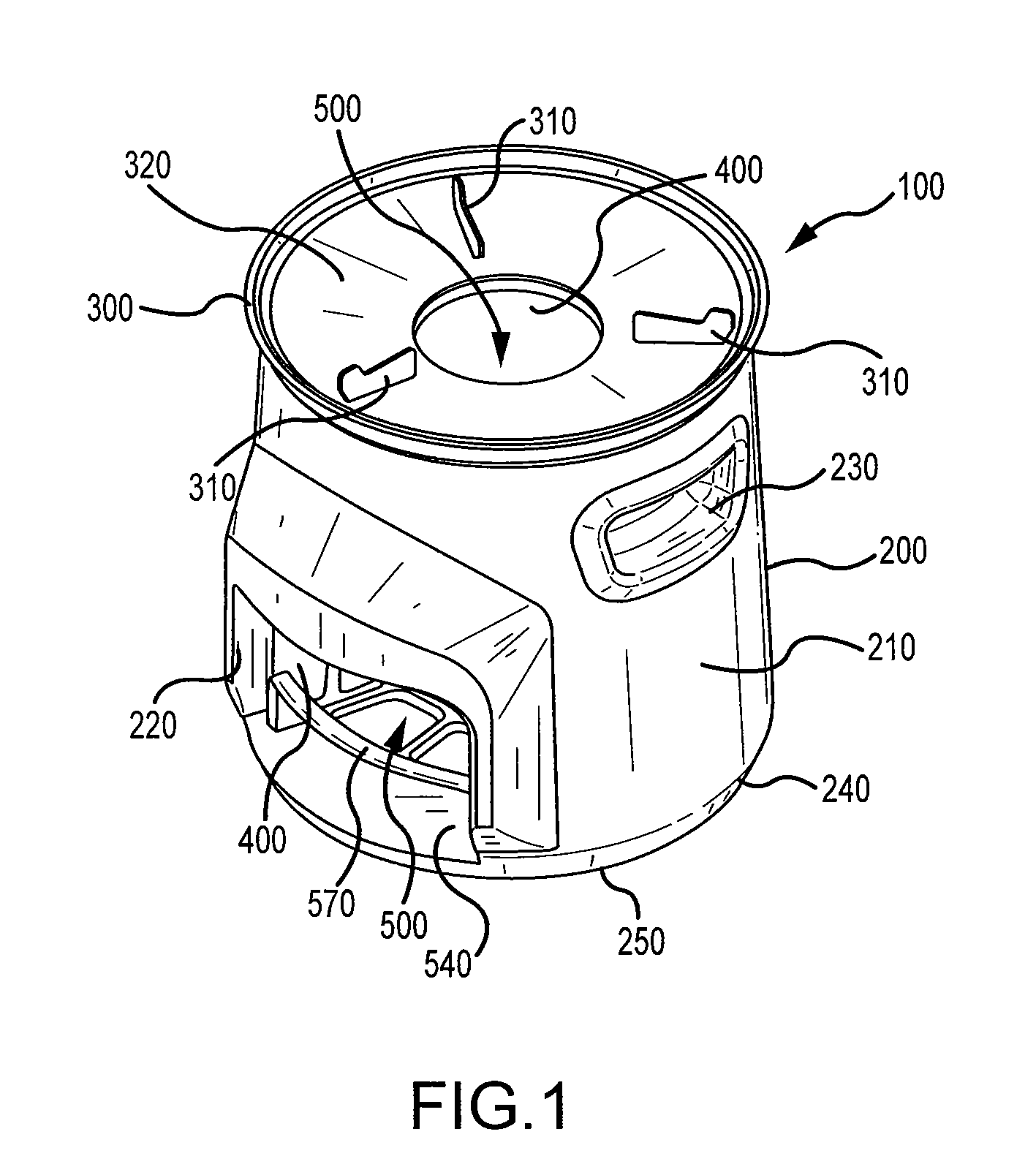

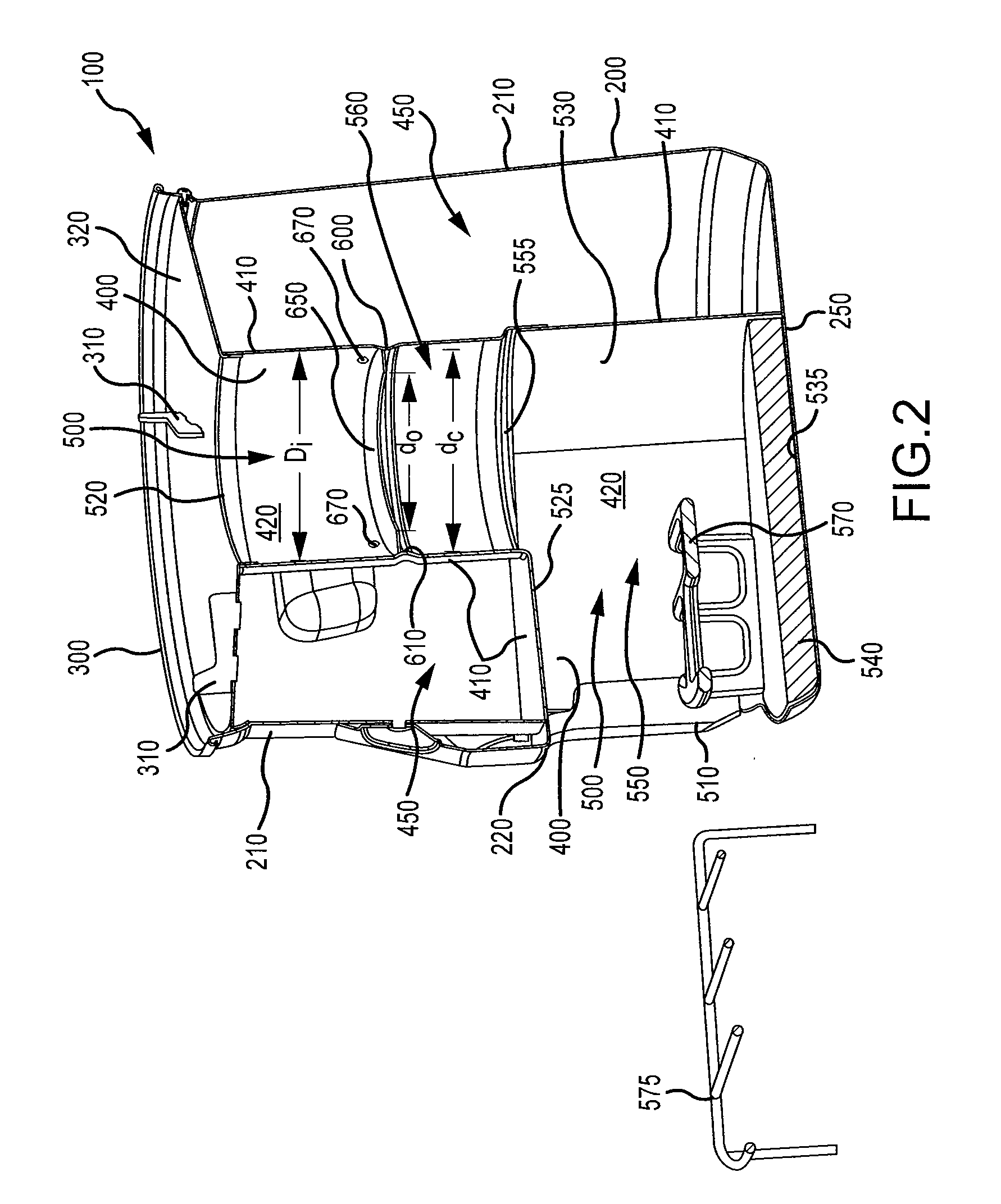

Cook stove assembly

InactiveUS20100258104A1Increase productionReduce productionLighting and heating apparatusCombustion-air/flue-gas circulation for stovesCombustion chamberDirect combustion

A combustion chamber, having an upper part and a lower part, may include an annular constriction, in combination with the combustion chamber, to aid in directing partially combusted gases such as carbon monoxide away from the periphery of the combustion chamber back toward its center, and into the flame front. The annular constriction may also impede the flow of partially combusted gases located at the periphery, thus increasing the time these gases spend within the combustion chamber and increasing the likelihood that any products of incomplete combustion will undergo combustion. The combustion chamber may further comprise a dual burner cooktop for directing combustion gases and exhaust to multiple cooking vessels. In further embodiments, the combustion chamber may be made of, lined, or clad with a metal alloy comprising iron, chromium, and aluminum.

Owner:COLORADO STATE UNIVERSITY +1

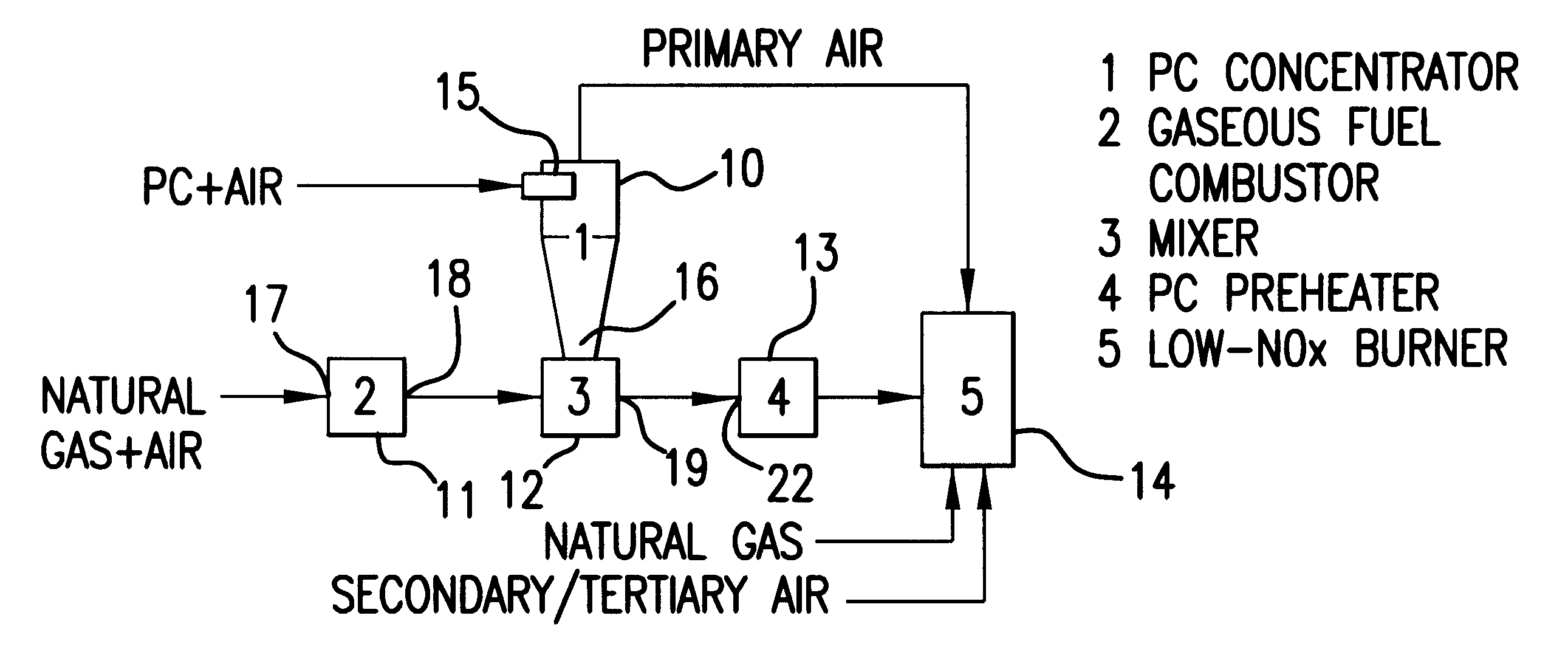

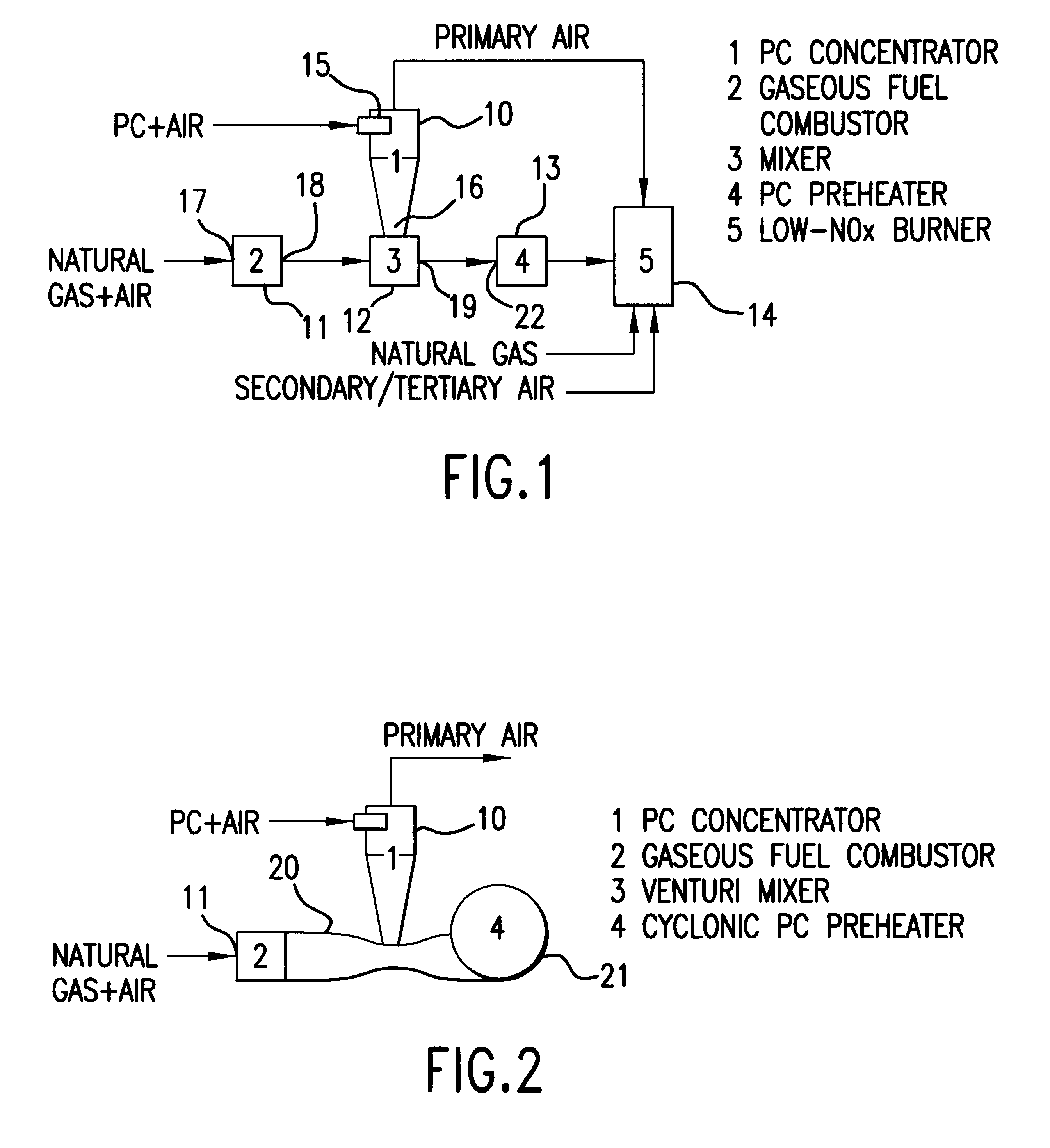

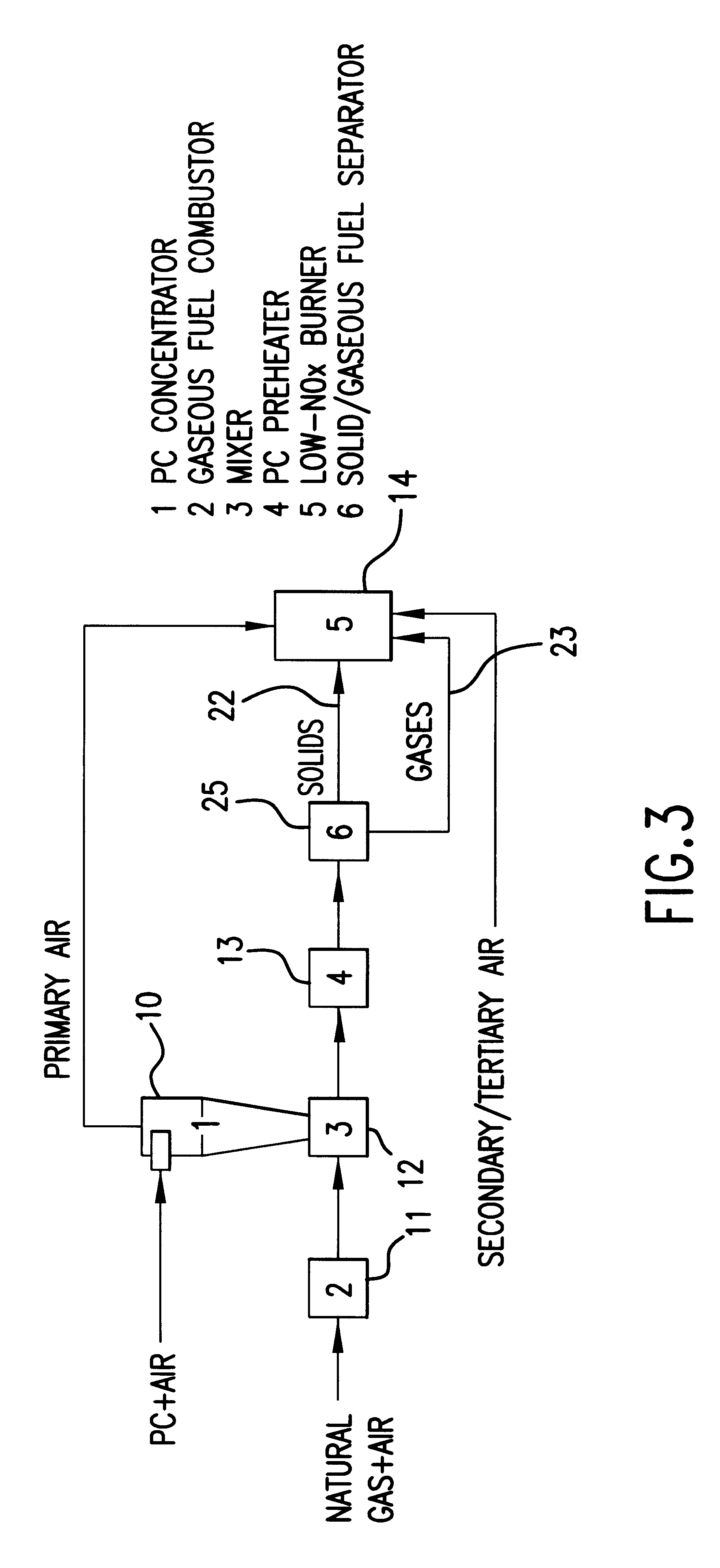

Low NOx pulverized solid fuel combustion process and apparatus

InactiveUS6244200B1Reduce the amount requiredImprove combustion effectCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustion chamberPartial oxidation

A method and apparatus for low-NOx combustion of a pulverized solid fuel in which combustion products from a partial oxidation combustor are mixed with a pulverized solid fuel, thereby preheating the pulverized solid fuel and resulting in devolatilization of at least a portion of the pulverized solid fuel. The preheated pulverized solid fuel and the devolatilization products are then burned in a burner firing directly into a combustion chamber.

Owner:INST OF GAS TECH

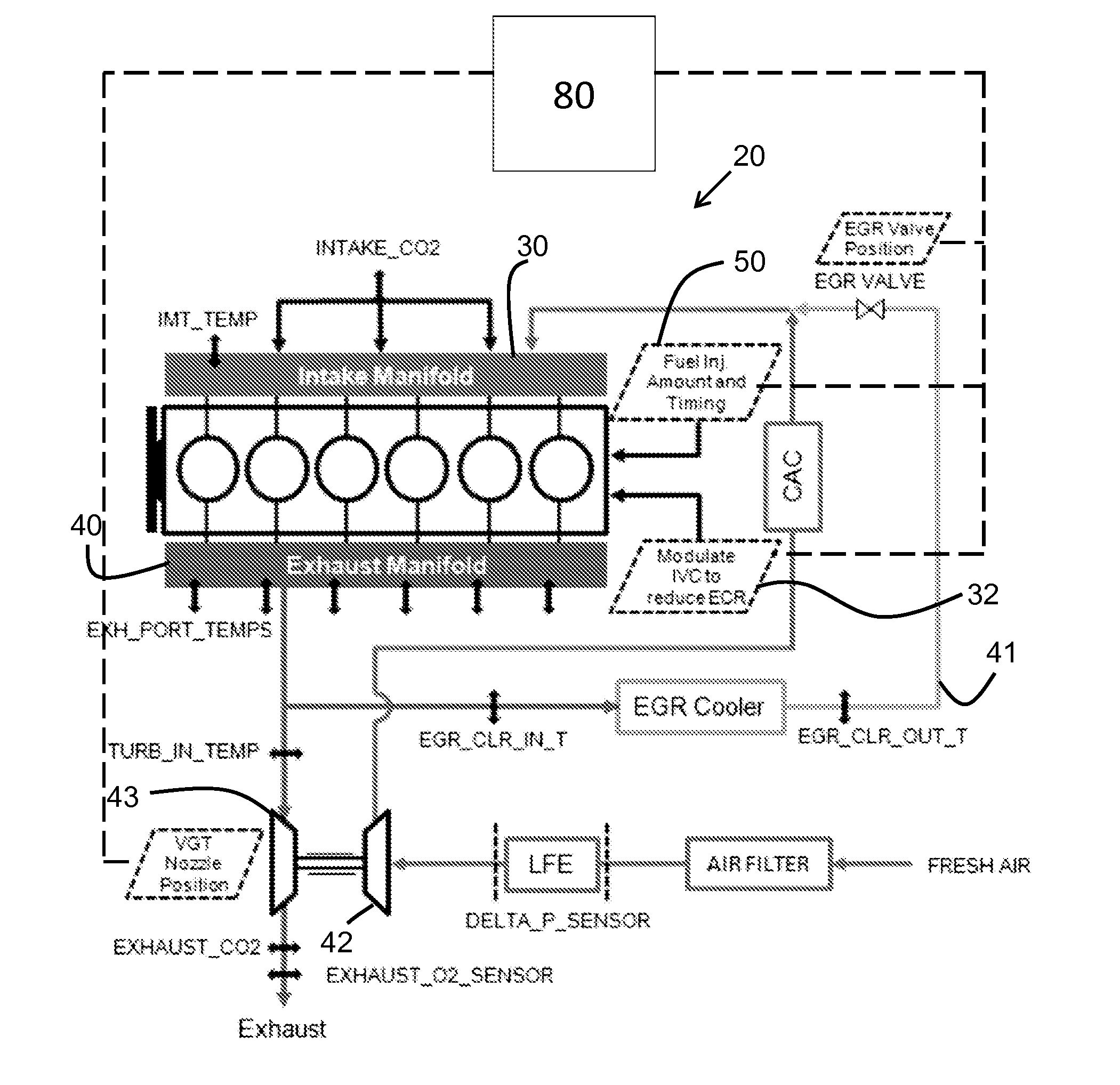

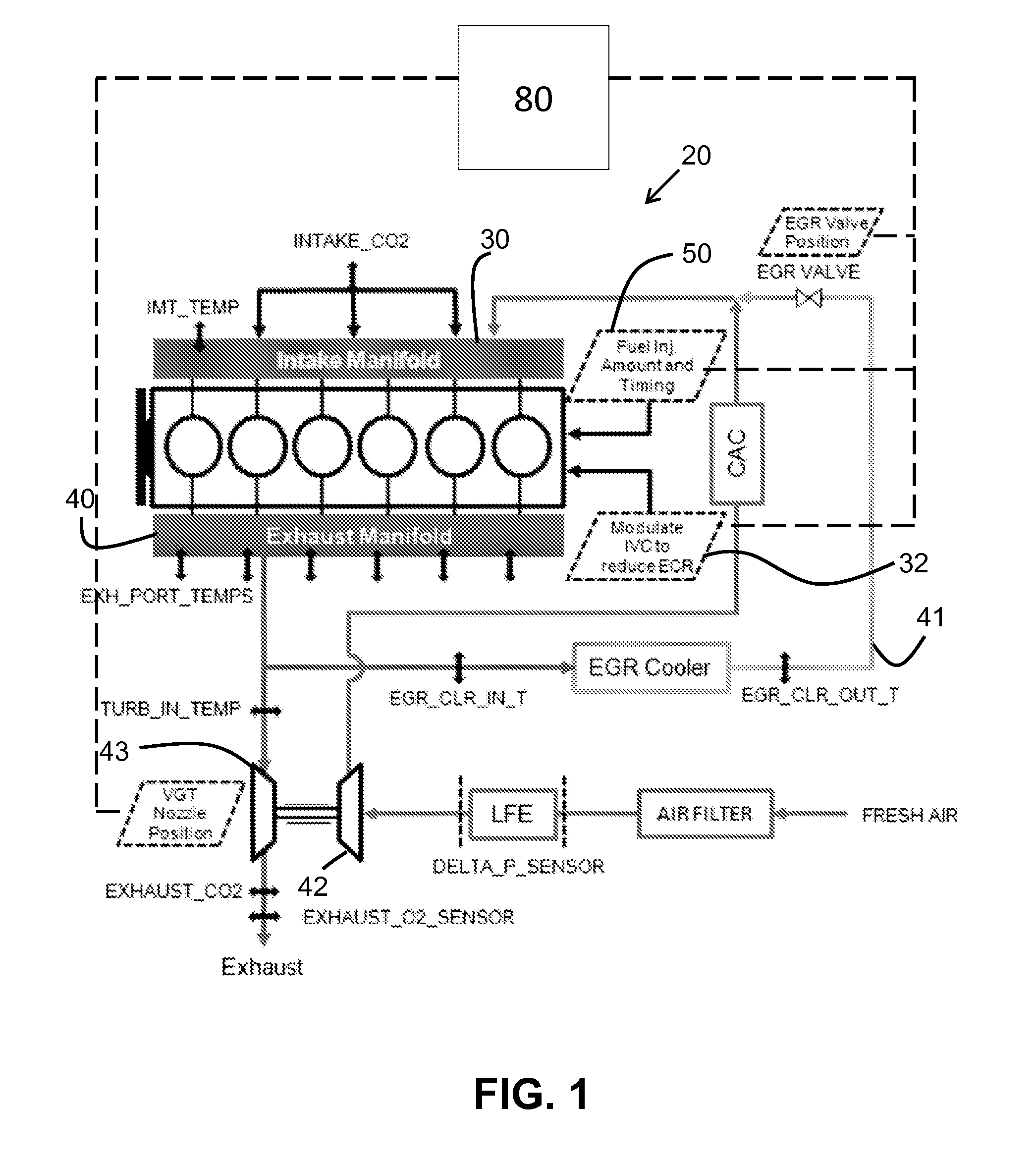

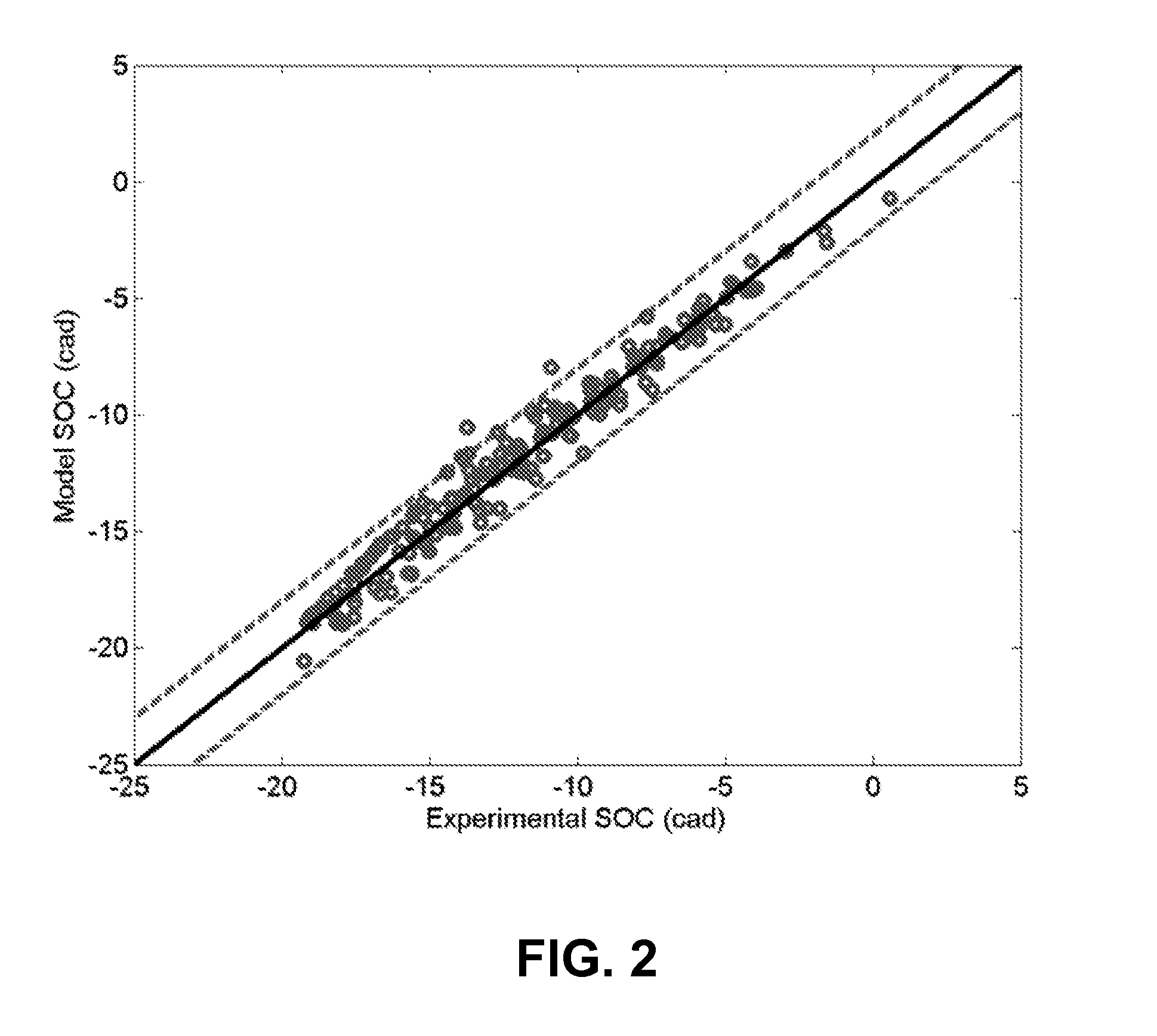

Nonlinear model-based controller for premixed charge compression ignition combustion timing in diesel engines

ActiveUS20150330326A1Electrical controlInternal combustion piston enginesNonlinear modelModel based controller

Advanced combustion modes, such as PCCI, operate near the system stability limits. In PCCI, the combustion event begins without a direct combustion trigger in contrast to traditional spark-ignited gasoline engines and direct-injected diesel engines. The lack of a direct combustion trigger encourages the usage of model-based controls to provide robust control of the combustion phasing. The nonlinear relationships between the control inputs and the combustion system response often limit the effectiveness of traditional, non-model-based controllers. Accurate knowledge of the system states and inputs is helpful for implementation of an effective nonlinear controller. A nonlinear controller is developed and implemented to control the engine combustion timing during diesel PCCI operation by targeting desired values of the in-cylinder oxygen concentration, pressure, and temperature during early fuel injection.

Owner:PURDUE RES FOUND INC

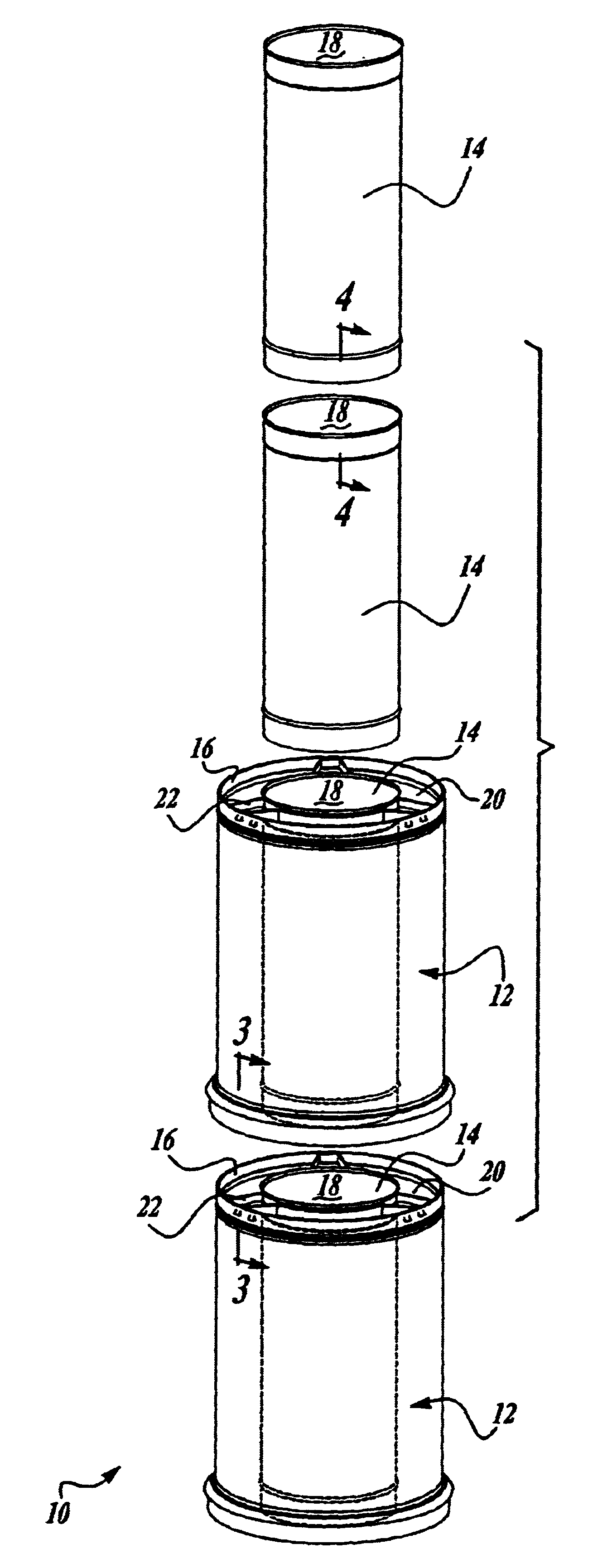

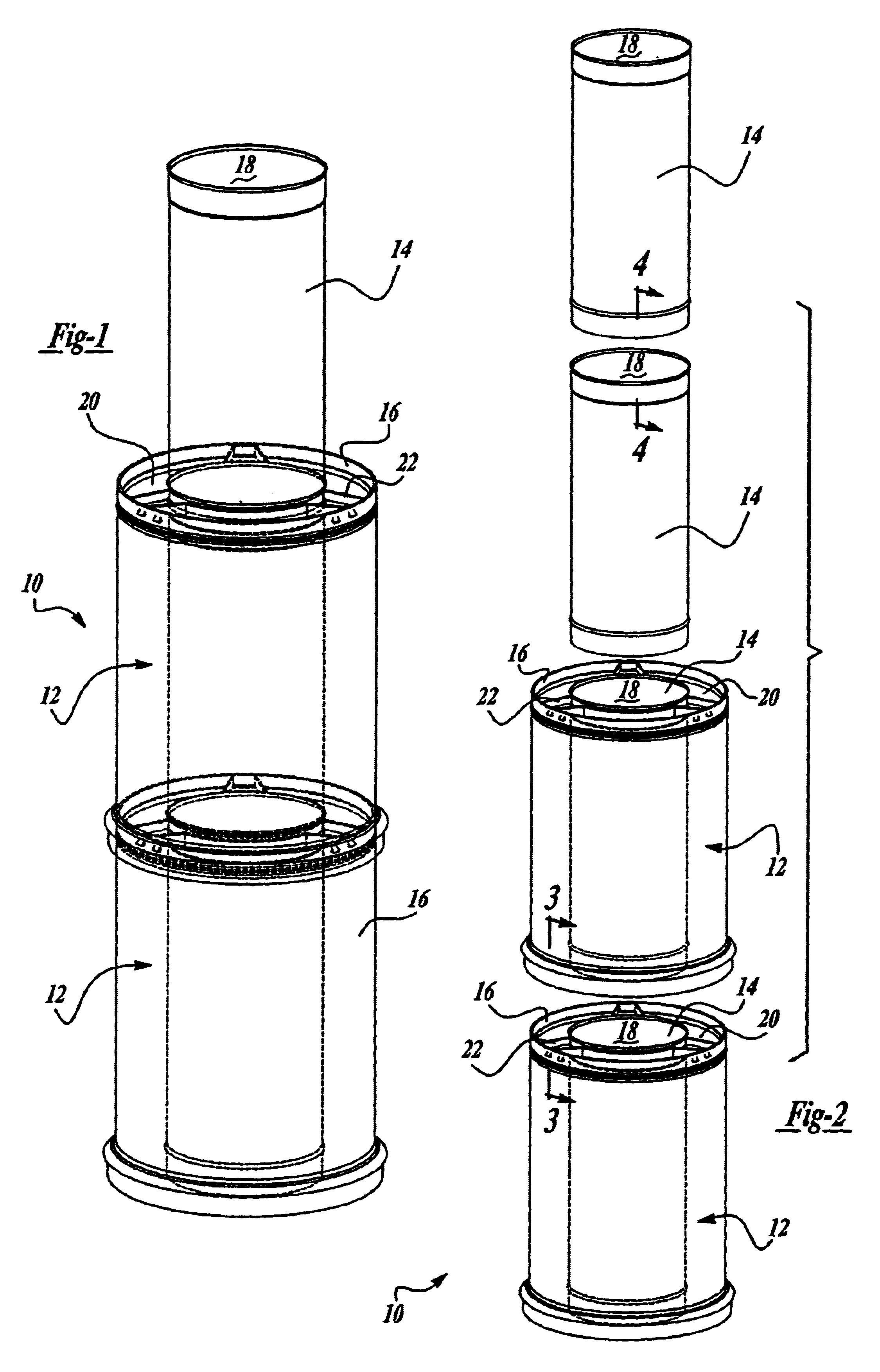

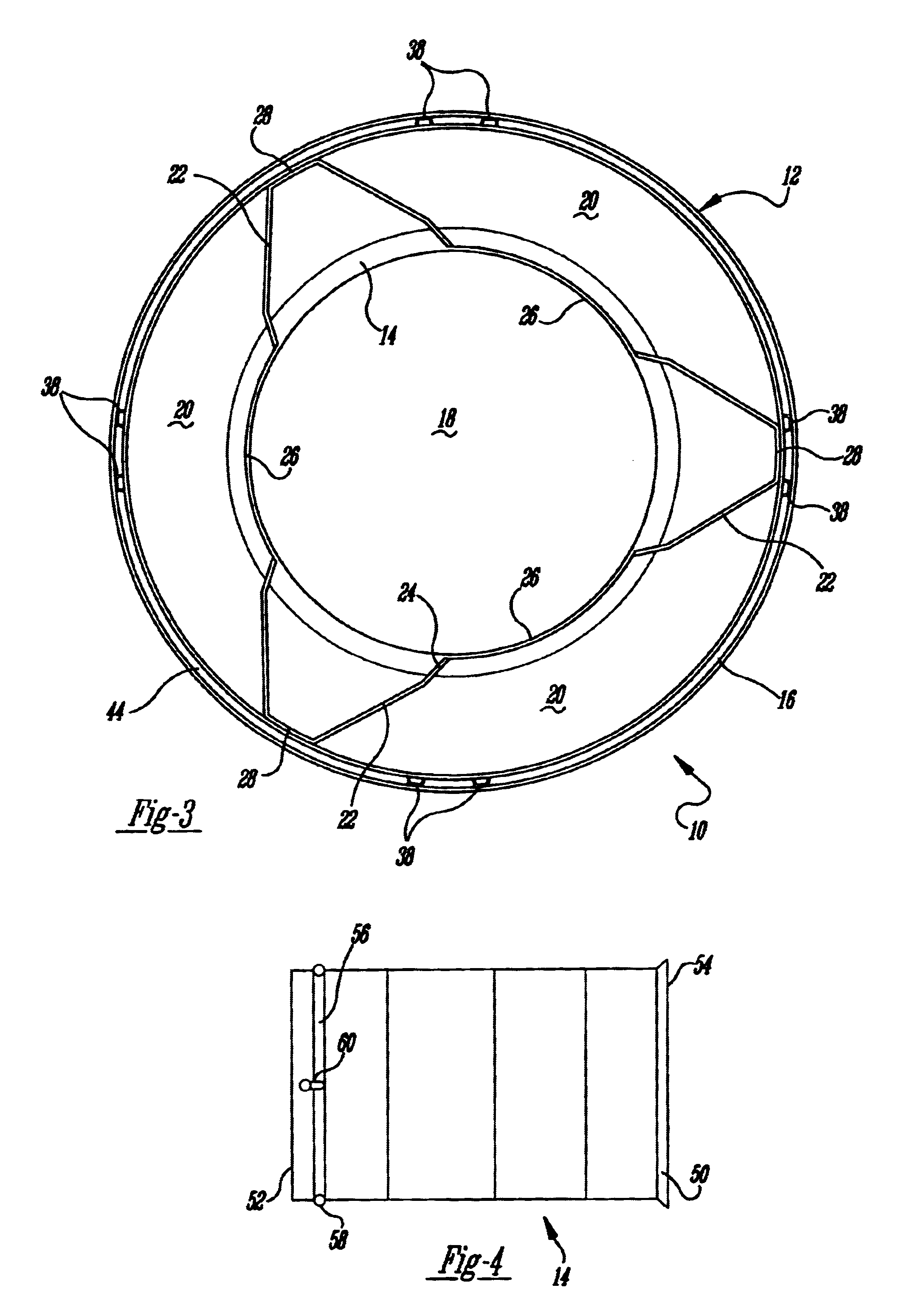

Direct venting vent pipe

InactiveUS6634352B2Facilitate run of unrestricted lengthEfficient combustionPipe supportsDomestic stoves or rangesDirect combustionDouble wall

A venting system for a direct vent fireplace or other direct vent appliance to direct combustion gases to an exterior area. The direct venting vent pipe facilitates unrestricted lengths of pipe installations. The vent pipe has a double wall construction forming an interior axial passageway and a coaxial outer passageway. The double walls are spaced apart by an insert to maintain coaxial spacing. Sections of the vent pipe are lockingly connected to prevent separation and ensure sealing connection between the pipe sections. Elastic seal members are utilized between the matingly connected sections and a mechanical lock assembly prevents separation.

Owner:CARDINAL IP HLDG LLC

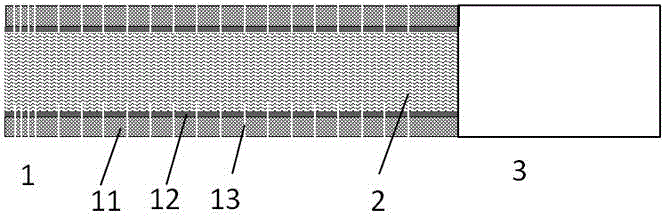

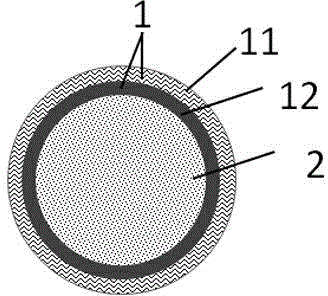

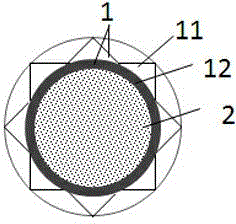

Heating non-combustion type tobacco product heated through paper

The invention relates to a heating non-combustion type tobacco product heated through paper. The heating non-combustion type tobacco product comprises a cut tobacco filler, a wrapping layer wrapping the outside of the cut tobacco and a filter tip. The heating non-combustion type tobacco product is characterized in that the wrapping layer is formed by compounding a cigarette paper combustion layer and an aluminum foil heat conduction layer; the aluminum foil heat conduction layer is in direct contact with the cut tobacco filler; and through holes are formed in the wrapping layer. The heating non-combustion type tobacco product has the beneficial effects that (1) compared with a traditional cigarette, the heating non-combustion type tobacco product is not in direct contact with the combustion cut tobacco filler, and therefore injurious ingredients generated by tobacco high-temperature combustion splitting are greatly reduced; (2) compared with other heating type tobacco products in the literature of the prior art, the heating non-combustion type tobacco product has the advantages of being easy to manufacture and low in cost; as the structure is coincident with that of the traditional cigarette, common cigarette paper only needs to be replaced with the composite wrapping layer, and then the production requirement can be met; and (3) the smoking mode is coincident with a common cigarette smoking mode, and a consumer can easily accept the heating non-combustion type tobacco product.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

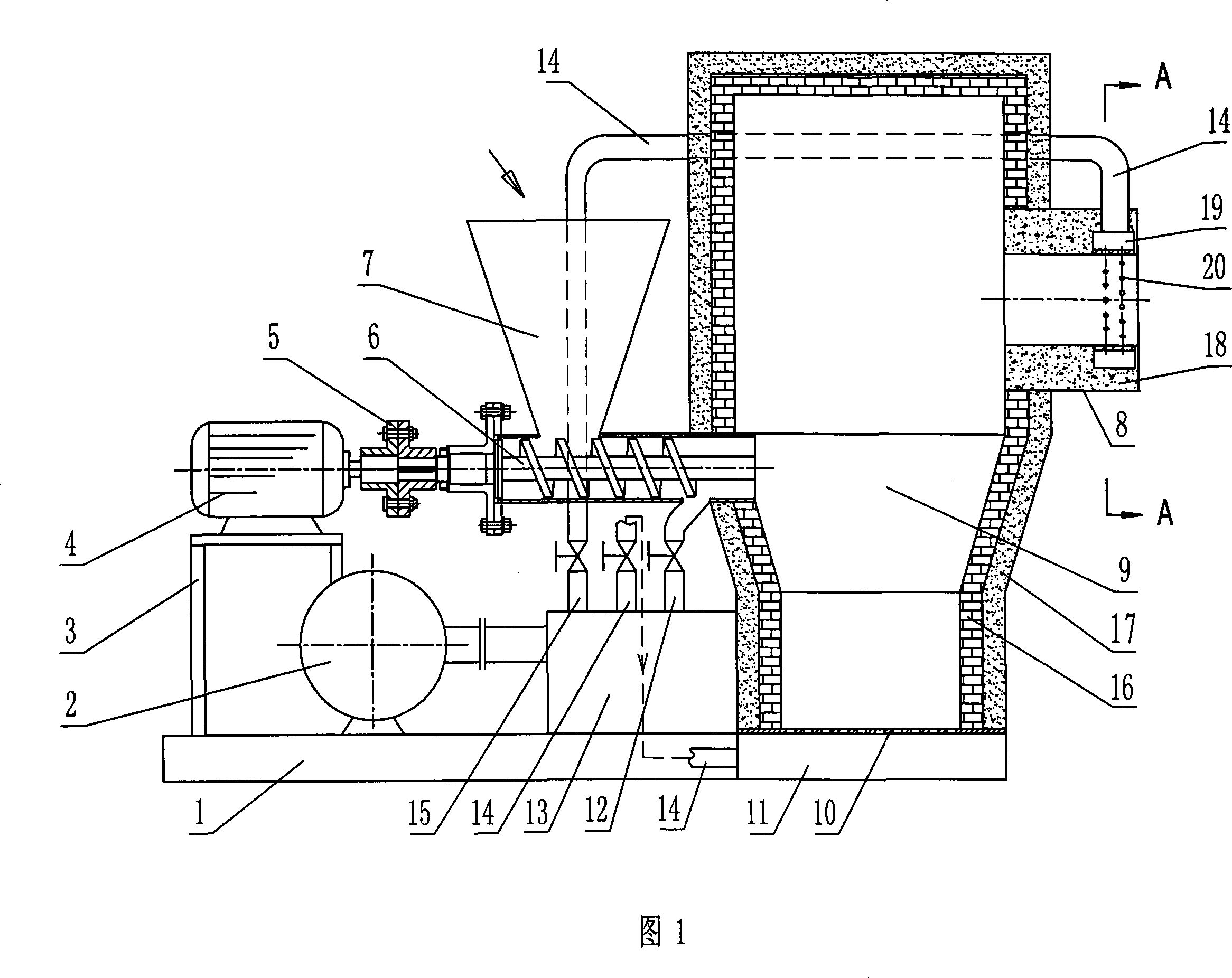

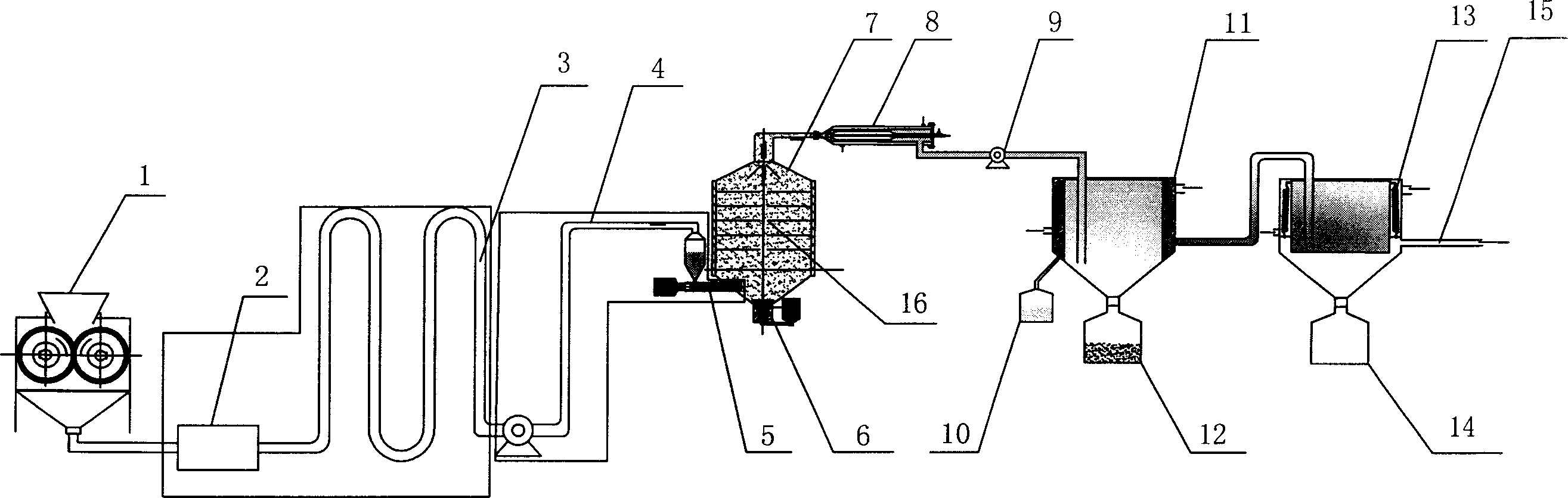

Method and apparatus for biomass ebullition, gasification and combustion

InactiveCN101196296AGuaranteed uptimeImprove combustion performanceFluidized bed combustionApparatus for fluidised bed combustionCombustion chamberDirect combustion

The invention relates to a biomass boiling gasification burning method and device, which is characterized in that: blow the biomass fuel from a material inlet of a gasification firebox to the gasification firebox; the biomass fuel boils under the action of a primary flow raising from the bottom of the gasification firebox; then the biomass fuel burns incompletely under boiling status after lighted up to generate with high temperature combustible gas which can be discharged by a gas burner for direct burning. The boiling gasification burning device comprises a feeding mechanism, an air supply mechanism and the gasification firebox; a gas burner for discharging high temperature fuel gas is arranged at middle upper section of the side wall of the gasification firebox; a discharging opening of the feeding mechanism is positioned on the side wall of the gasification firebox lower than the gas burned and is communicated with the gasification firebox; a wind arrangement device is arranged at bottom of the gasification firebox; the air supply mechanism provides the gasification firebox with the primary flow through the wind arrangement device, which is communicated with the discharging opening of the feeding mechanism through the a feeding air pipe.

Owner:ENERGY RES INST CO LTD HENAN ACADEMY OF SCI

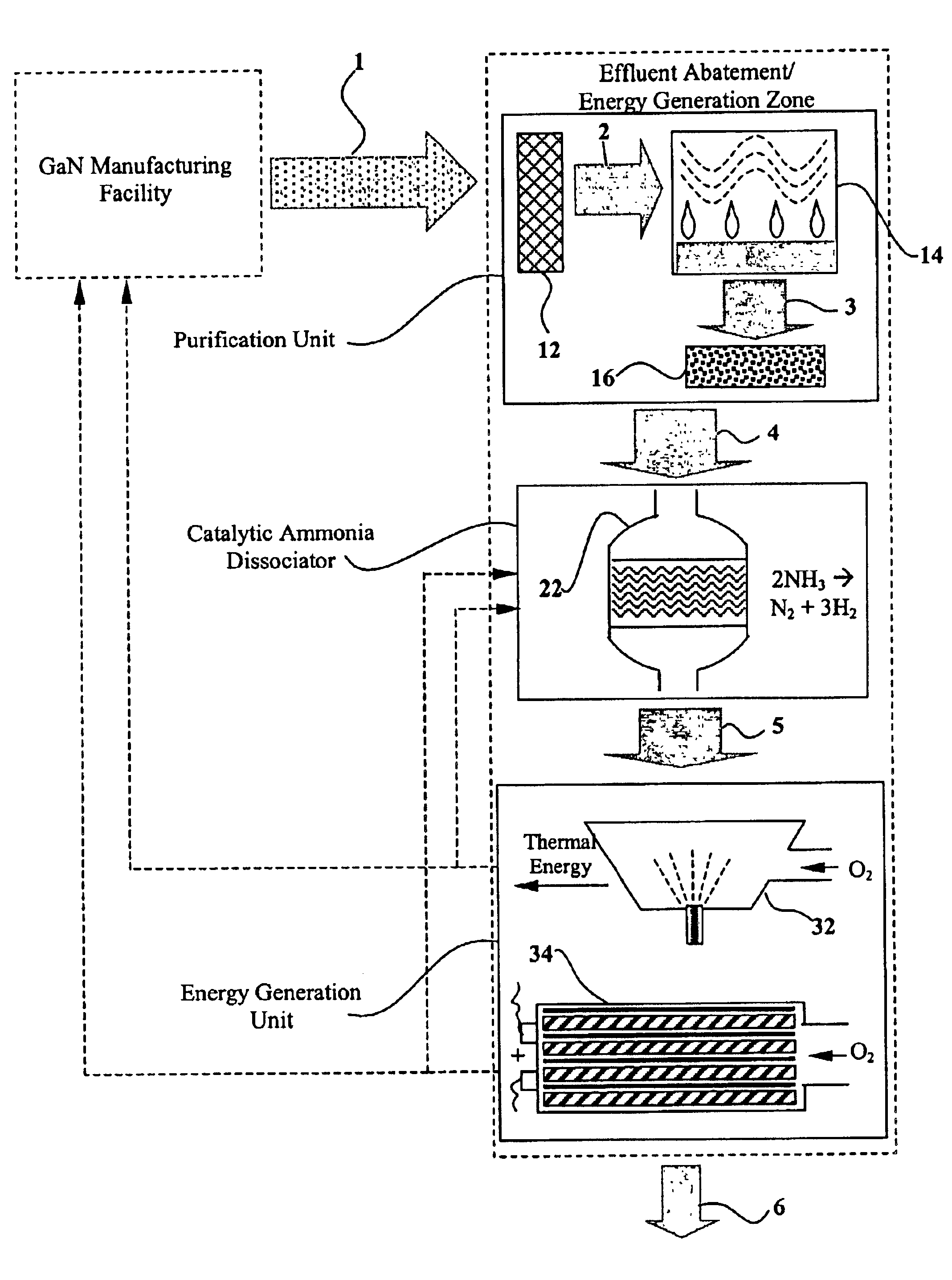

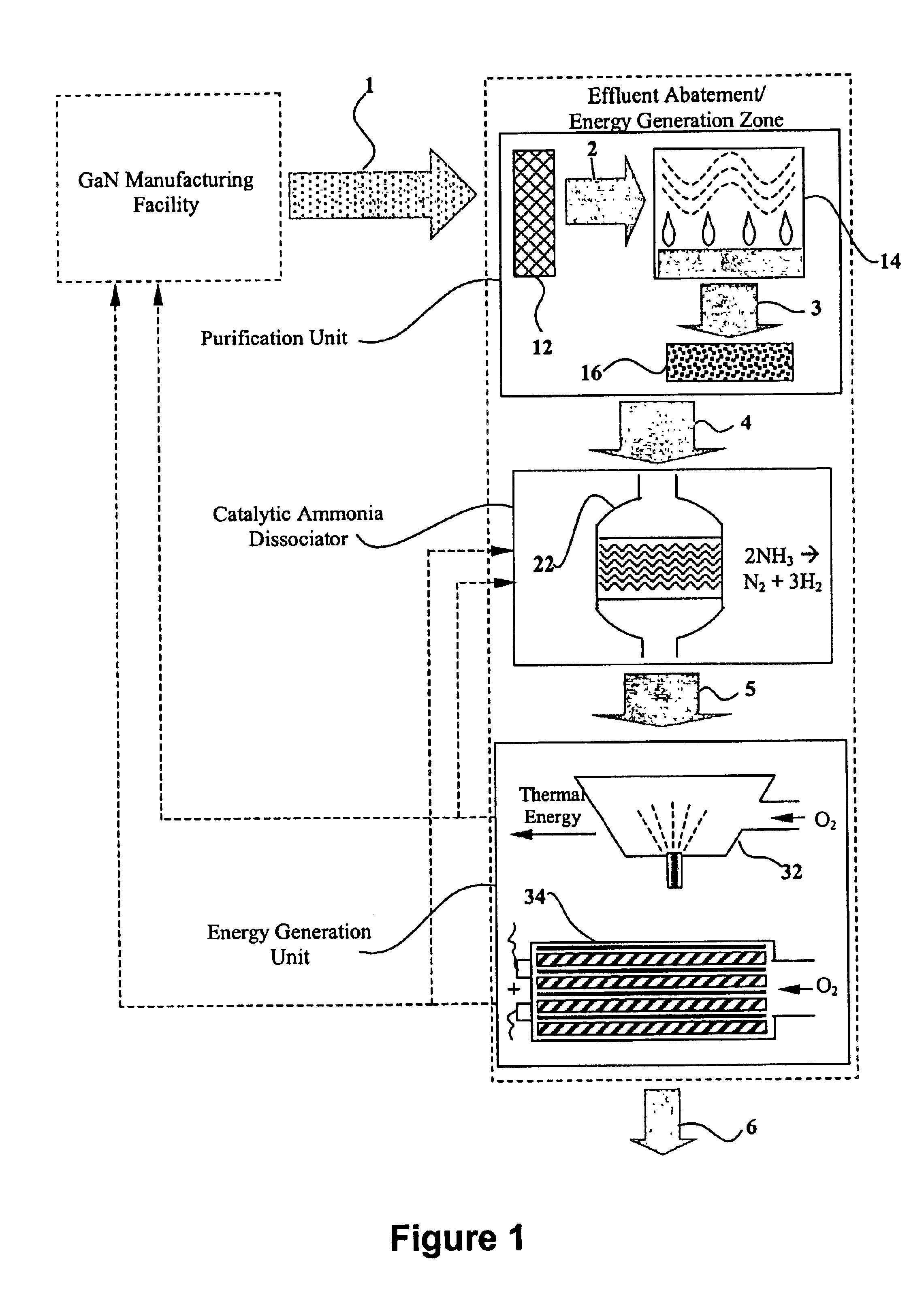

Integrated system and process for effluent abatement and energy generation

The present invention relates to an effluent abatement / energy generation system, as well as a method, for abating a process effluent gas stream that contains one or more target compounds such as hydrogen gas, ammonia gas, isopropanol, and other volatile organic compounds that are readily oxidizable, and for concurrently generating energy using such process effluent gas stream. Such effluent abatement / energy generation system comprises a purification unit for removing components other than such target compounds from the process effluent gas stream, and an energy generation unit for generating thermal and / or electrical energy. Such energy generation unit may comprise a combustion assembly, such as a microturbine, for direct combustion or catalytic combustion of the target compounds to generate thermal and / or electrical energy. Such energy generation unit may also comprise a fuel cell for using the target compounds to generate electrical energy.

Owner:BHT SERVICES PTE LTD

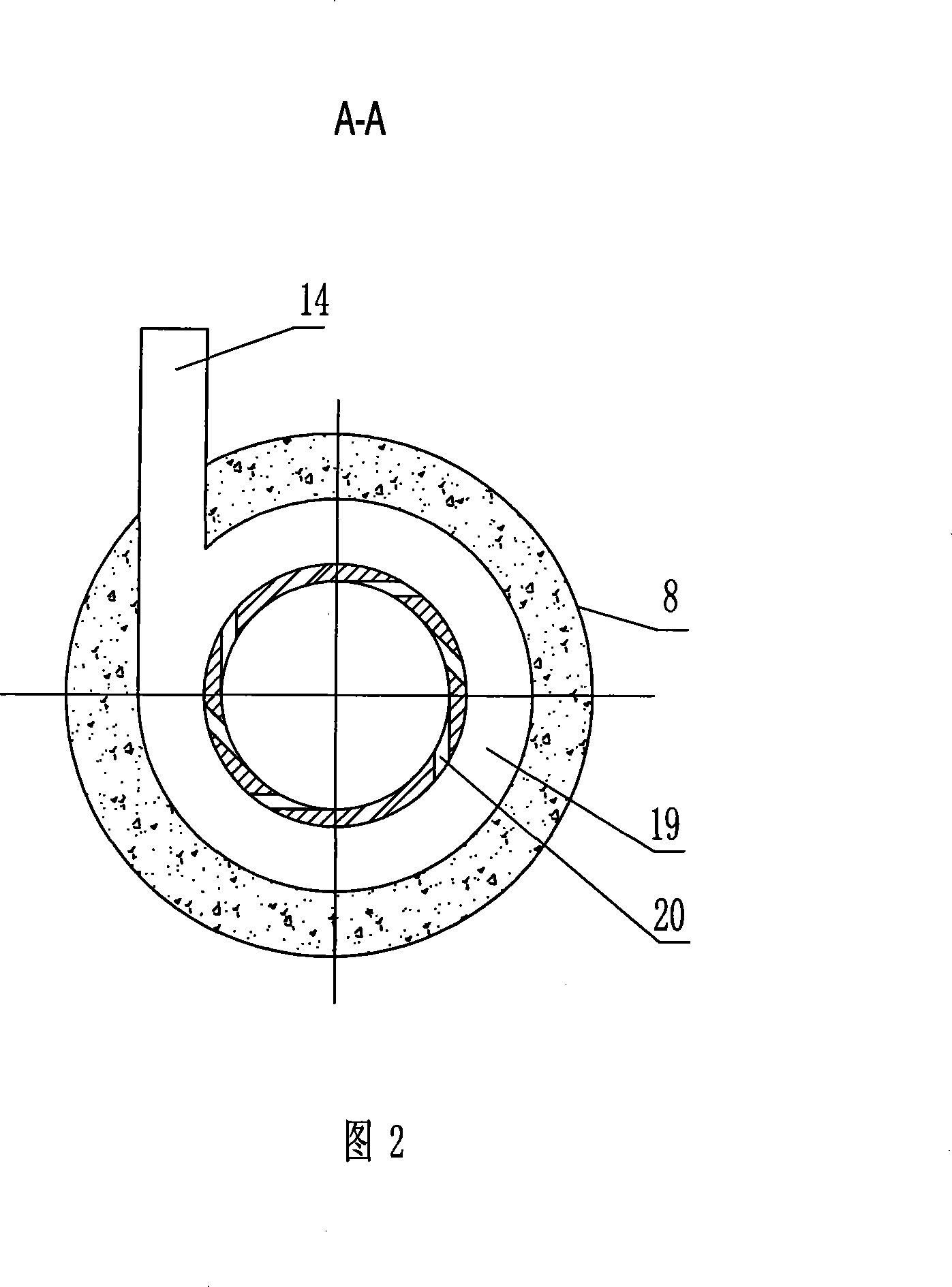

Multifunctional biomass heat conversion equipment and process

InactiveCN102839003AStrong noveltyAdvancedCarbon compoundsIndirect heating destructive distillationTemperature controlDirect combustion

The invention belongs to the technical field of biomass heat conversion, and particularly relates to equipment and a process for carbonizing, activating, pyrolysis gasification, catalytic cracking of a plurality of product roads. The equipment comprises a flue pipe, an activator (gasifying agent) inlet, an auxiliary activator (gasifying agent) inlet, a feeding hole, a feeding cover seal, a forced blanking shoveling board, a gear, a drive and transmission case, heat-insulating cotton, a riding wheel, a barrel angle adjusting bolt, a temperature measuring device, a combustion channel, a product channel, an angle adjusting screw, a discharge cover seal, a lighting-up tuyere, an explosion-proof opening, a combustion-supporting opening (viewing port), a discharge sealing valve and a discharge cooler. According to the invention, the multifunctional biomass heat conversion equipment simultaneously has the functions of carbonizing, activating, pyrolysis gasification, catalytic cracking by changing an inclination angle, a rotating speed and a sealing mode; a traditional direct combustion method is changed into a bolometric method, and the problems of low yield, serious ignition loss, non-uniform reaction, small yield, large consumption and temperature control difficulty in the biomass heat conversion process are solved from the technical aspect.

Owner:秦恒飞

Annealing process for producing cold rolling non-oriented electrical steel

InactiveCN103451399AFunction increaseLower cost of capitalFurnace typesHeat treatment furnacesProduction lineElectrical steel

The invention discloses an annealing process for producing cold rolling non-oriented electrical steel. Band steel continuous annealing and galvanizing common production lines are adopted for the annealing working procedure, and the annealing working procedure comprises the following process conditions: A. preheating stage: preheating band steel to 190 DEG C + / -40 DEG C; B. heating at a direct-combustion stage: heating the band steel at naked flame to 700 DEG C+ / -60 DEG C; C. heating by a radiant tube: continuing heating the band steel by a radiant tube to 780 DEG C+ / -60 DEG C, and controlling the dew point to be less than or equal to minus 40 DEG C; D. soaking stage of the radiant tube: keeping the temperature of the band steel to be 870 DEG C+ / -60 DEG C by the electric radiant tube, and controlling the dew point to be less than or equal to minus 40 DEG C; E. spray cooling stage: introducing compressed air by a spray cooling fan at the spray cooling stage so as to enable the surface of the band steel to be oxidized evenly, and finally cooling the band steel to be 140 DEG C+ / -20 DEG C by the spray cooling fan; and F. discharging from a furnace: cooling the band steel to be 80 DEG C+ / -20 DEG C through a furnace nose, and discharging from the furnace. The process is used for producing the cold rolling non-oriented electrical steel bands by utilizing an existing band steel continuous annealing and galvanizing common production lines of iron and steel enterprises, and the costs of capital, equipment and production are reduced effectively.

Owner:HEBEI IRON AND STEEL

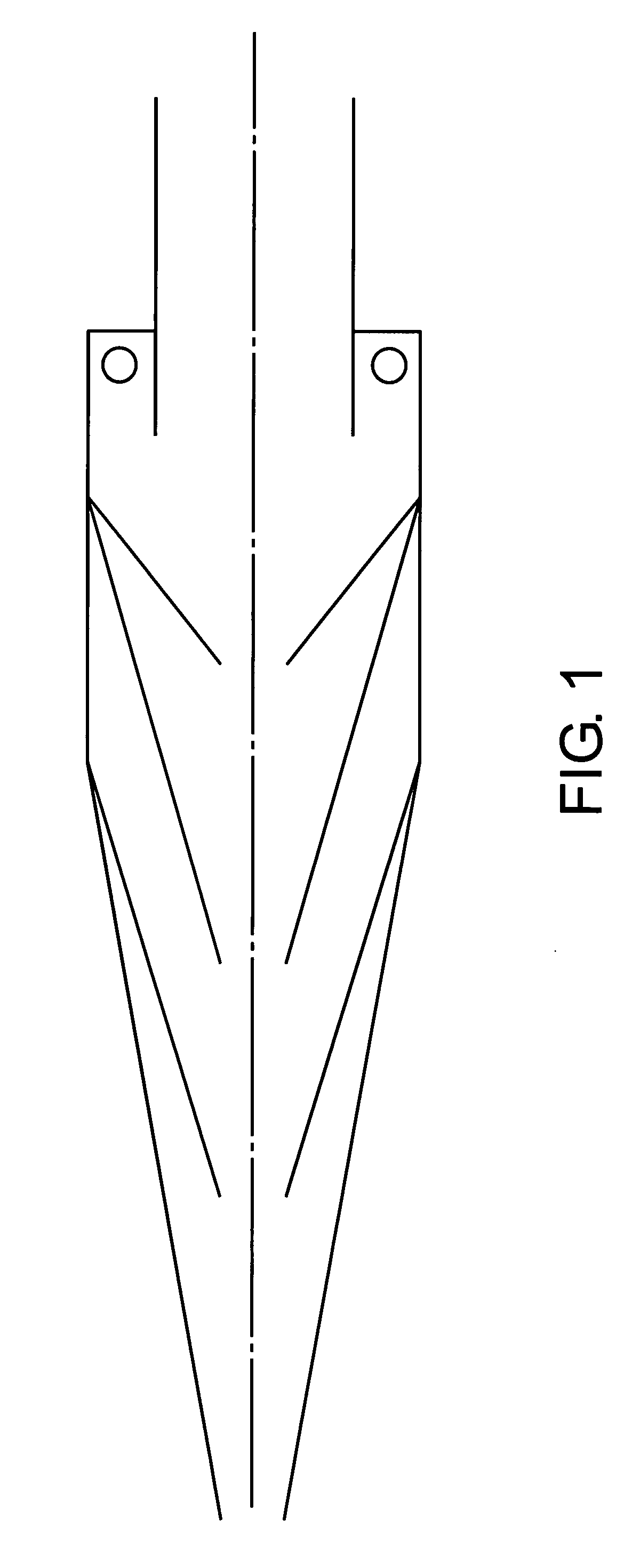

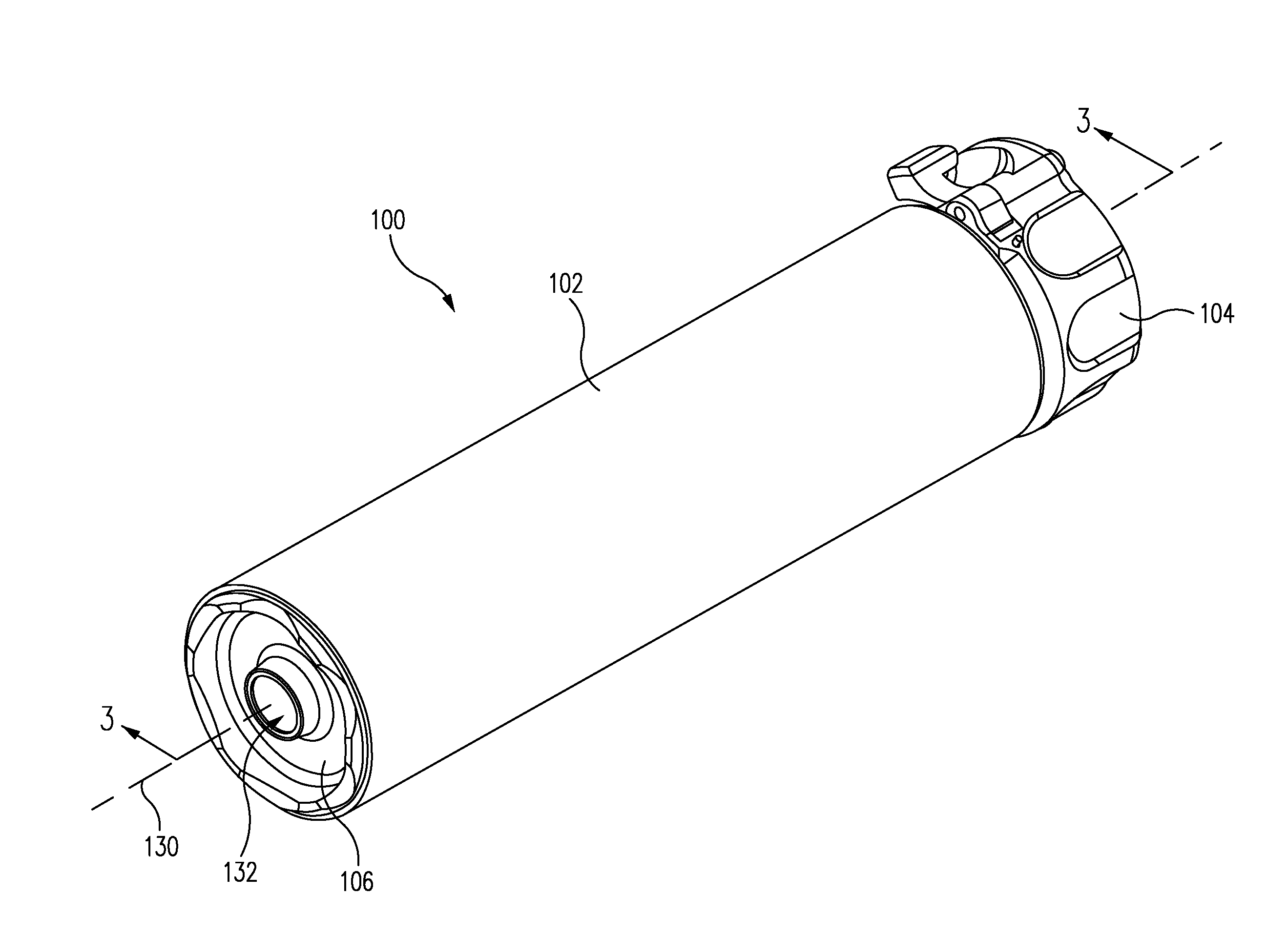

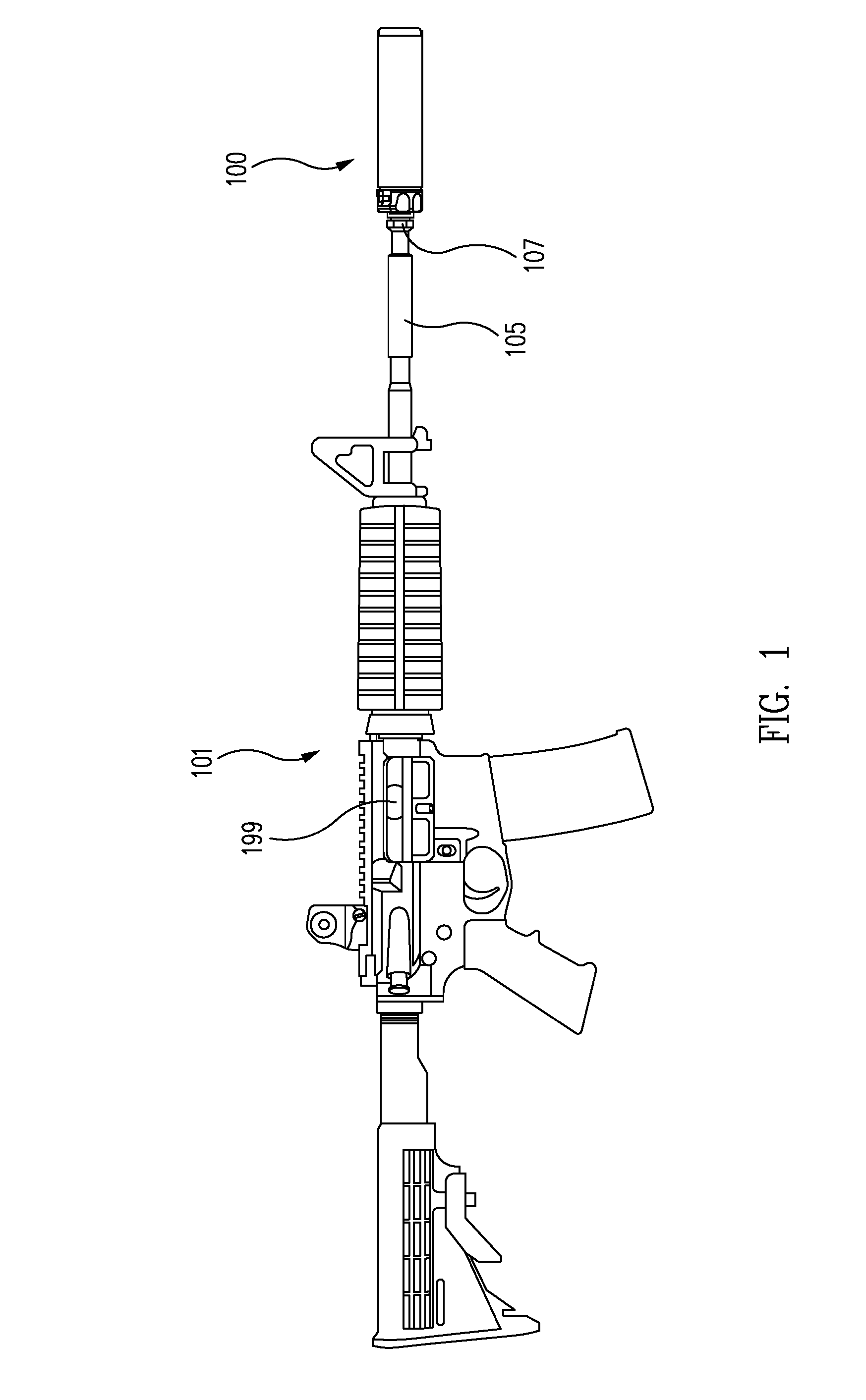

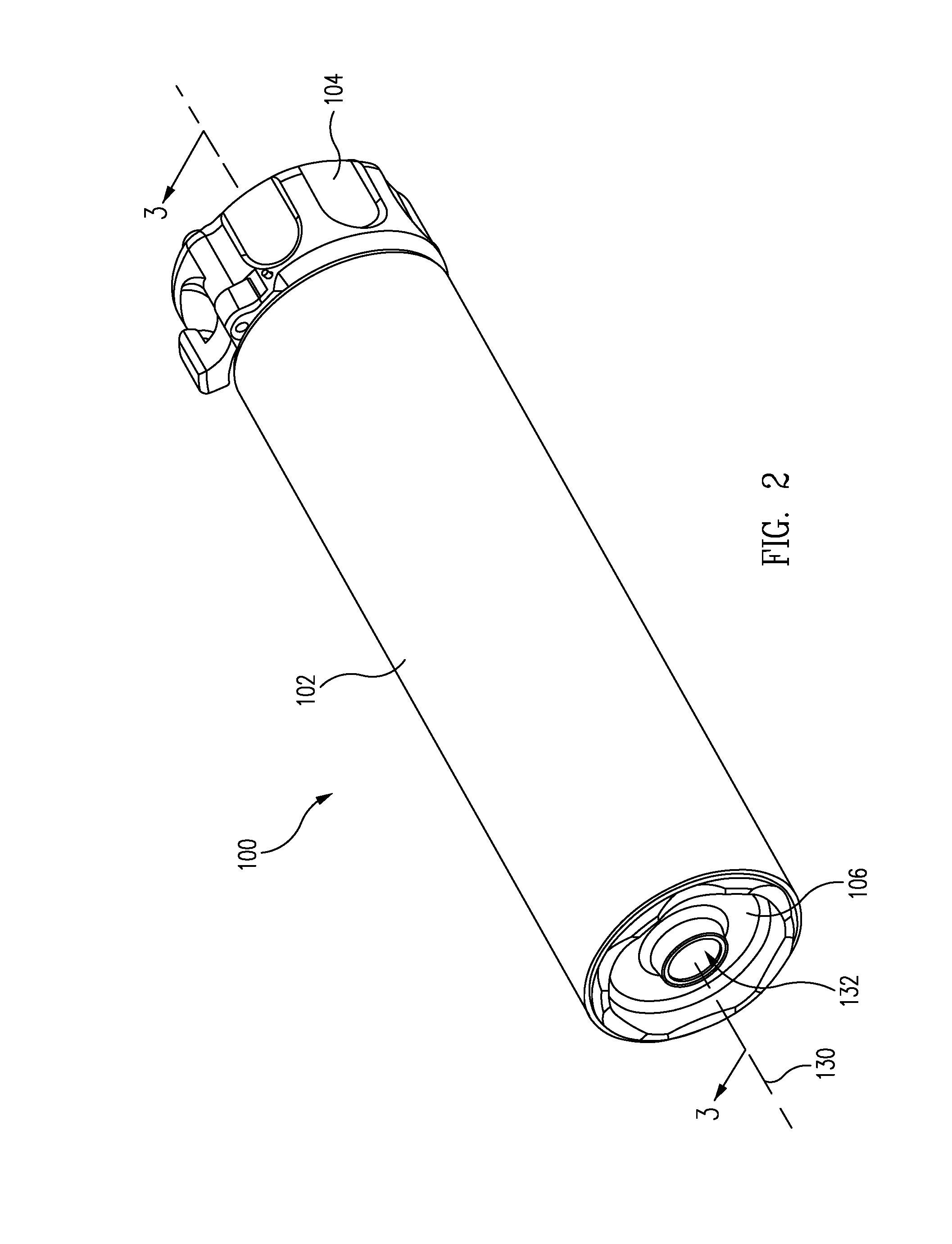

Laser welded firearm sound suppressors

ActiveUS20160209152A1Cost-effectiveReduce ejection port flashElectrical transducersRecord carriersSuppressorDirect combustion

Various techniques are provided to assemble, manufacture, and operate firearm sound suppressors. In one example, a sound suppressor for a firearm includes a baffle; a spacer abutted to the baffle; and a circumferential laser weld joining the baffle and the spacer. In another example, a sound suppressor for a firearm includes a plurality of baffles; a plurality of spacers; a substantially tubular housing surrounding the baffles and the spacers; wherein the housing and the spacers define an annular volume surrounding the spacers; an aperture in a circumfery of at least one of the spacers; and wherein the aperture is adapted to direct combustion gases in a radial direction from within the spacer into the annular volume to reduce ejection port flash of the firearm. Additional suppressor embodiments and related methods are also provided.

Owner:SUREFIRE LLC

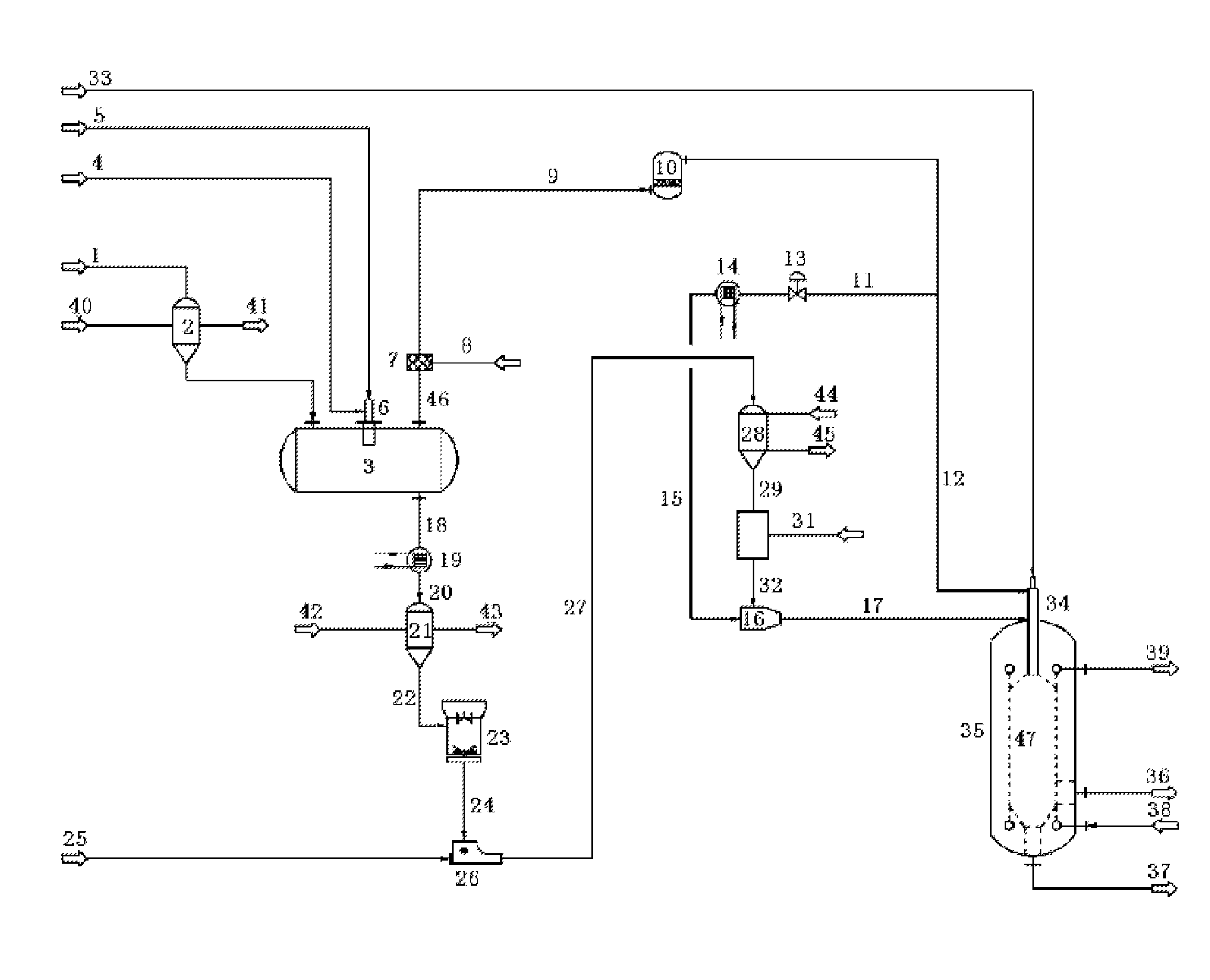

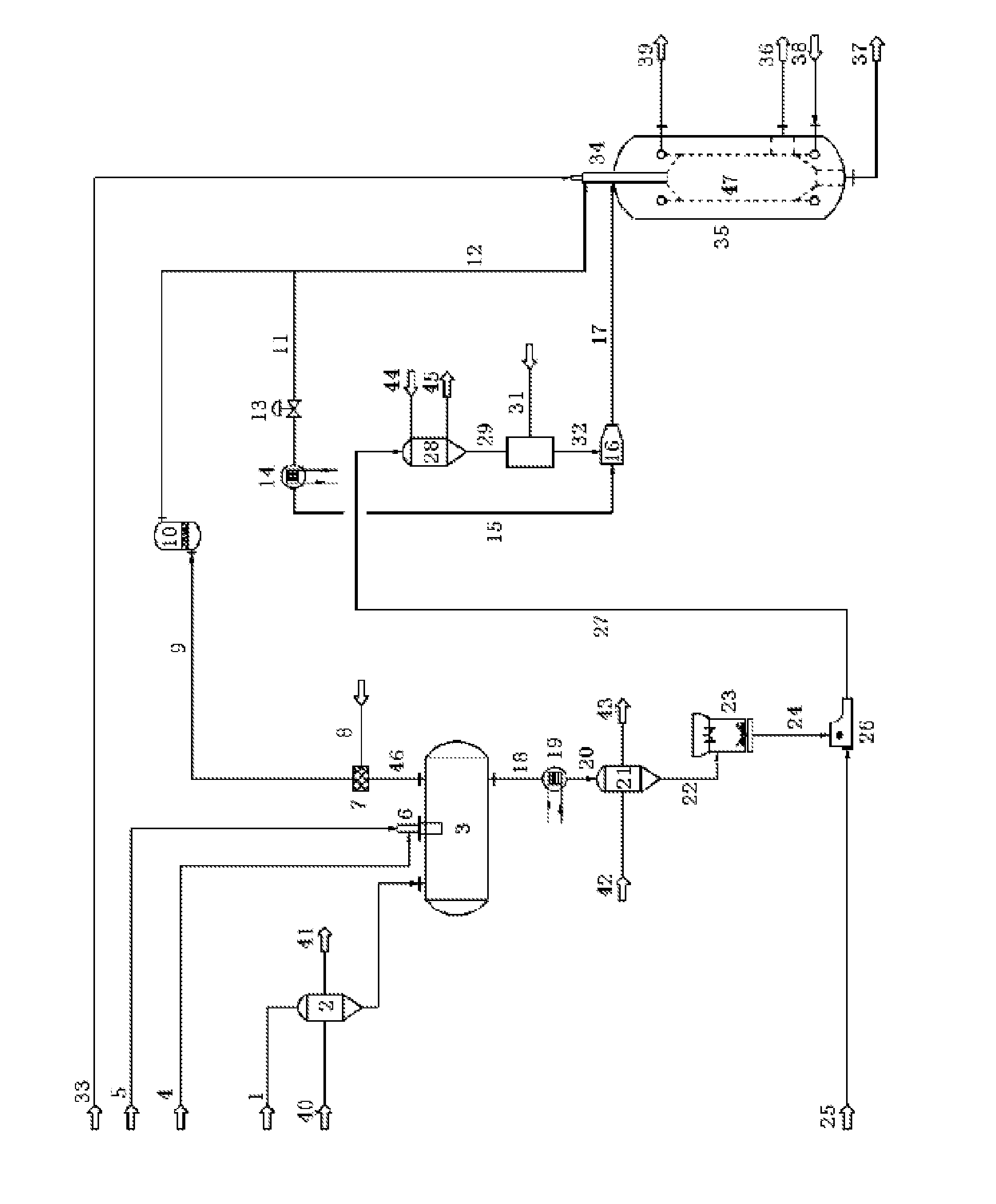

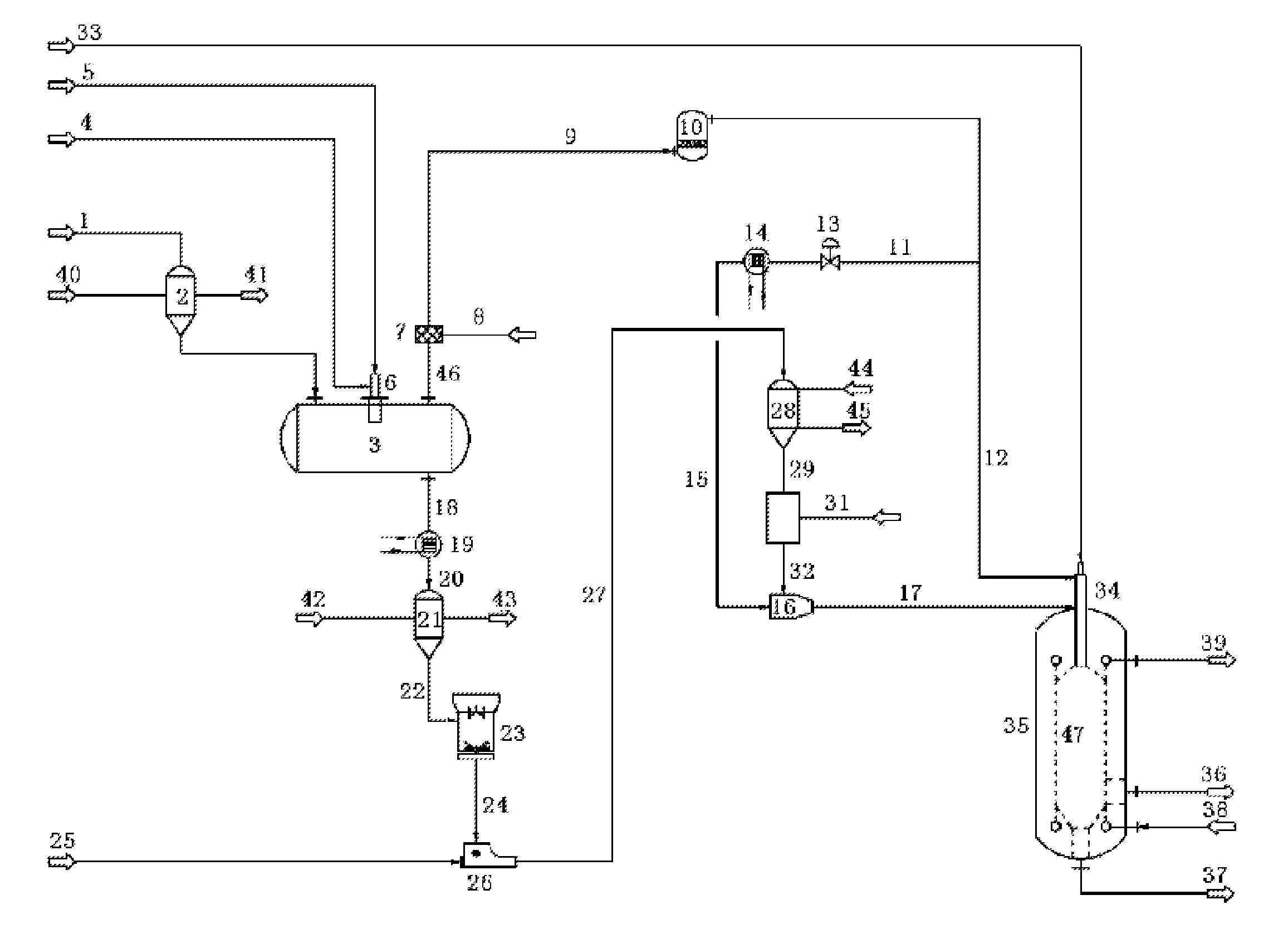

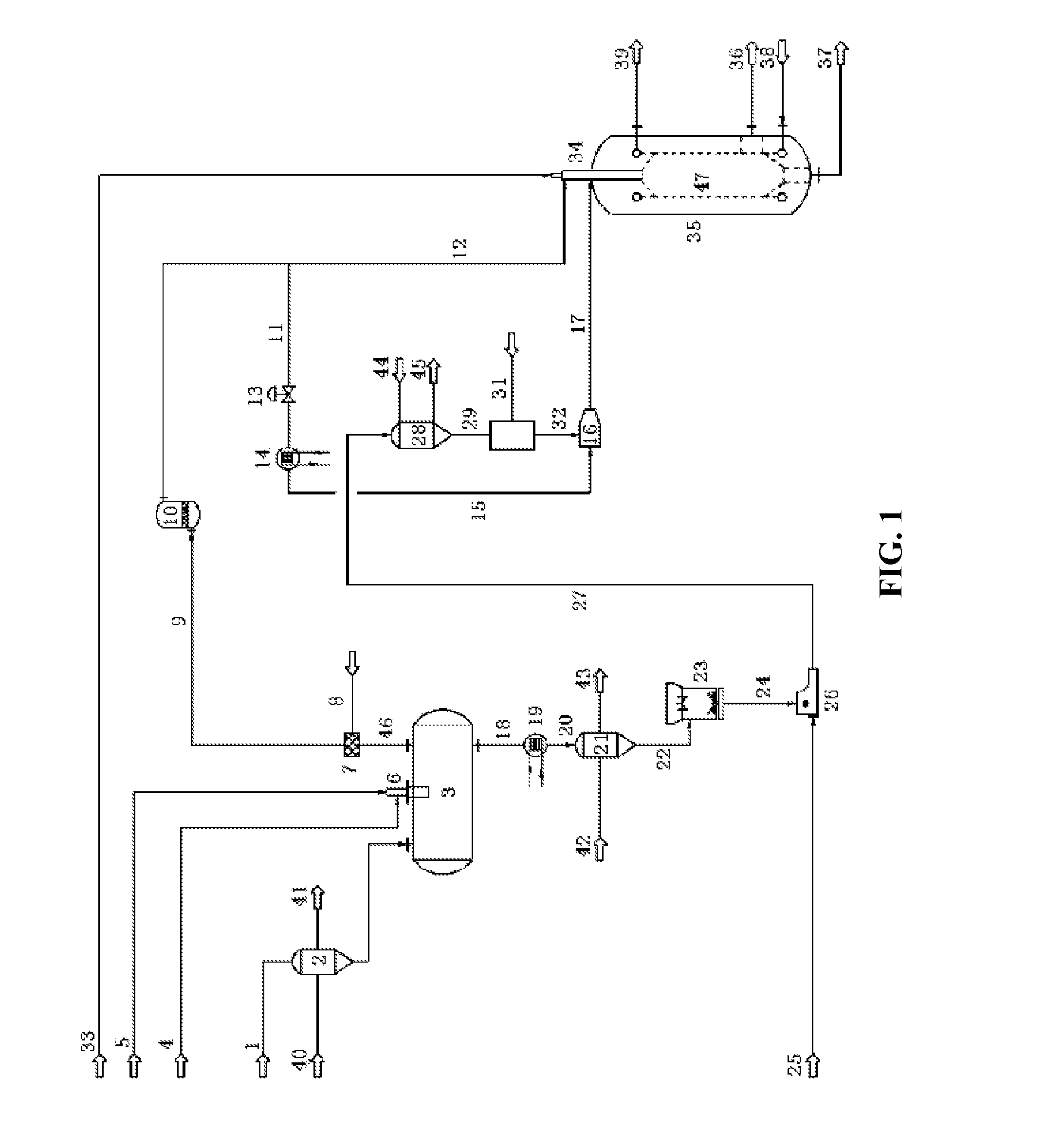

Method and system for producing synthetic gas from biomass by high temperature gasification

A method for producing synthetic gas from biomass by high temperature gasification, by: feeding biomass, carbonizing to yield pyrolysis gas and charcoal, pulverizing the charcoal, and gasifying in a gasifier. The heat source for the carbonizing step comes from a direct combustion reaction between external combustible gas and external oxygen in a carbonization furnace. Also provided is a device for producing synthetic gas from biomass by high temperature gasification, containing at least: a supercharging feeding system for biomass, a carbonization furnace containing at least a burner nozzle, a pulverizing system, a transportation system for charcoal powder, a gasifier, a pneumatic conveying system, and a plurality of connecting pipes therefor; the burner nozzle of the carbonization furnace is connected to an external combustible gas pipe and an external oxygen pipe respectively.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

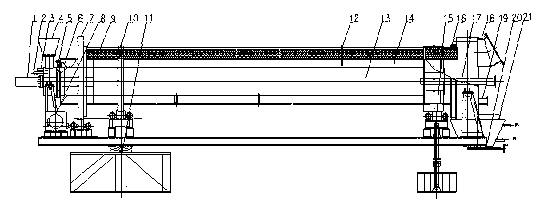

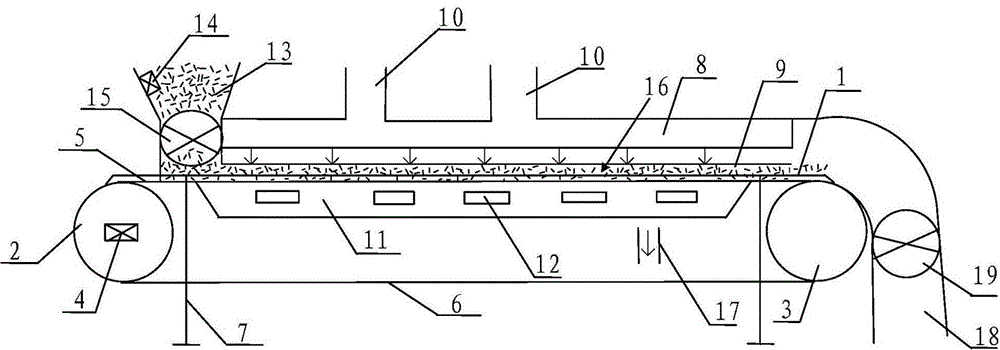

Fuel drying device used for direct combustion biomass power station

InactiveCN104482742ALarge amount of processingMeet fuel needsDrying gas arrangementsDrying machines with progressive movementsCold airPower station

The invention discloses a fuel drying device used for a direct combustion biomass power station. The fuel drying device comprises a conveyor; the conveyor is provided with an upper conveying belt for conveying of an upper layer and a lower conveying belt for conveying of a lower layer; a hot air box is installed above the upper conveying belt; the bottom of the hot air box is installed with a hot air uniform plate; a plurality of hot air inlets are formed in the top of the hot air box; a cold air box is arranged between the upper conveying belt and the lower conveying belt of the conveyor; a feeding hopper is arranged above a head of the conveyor; the rear part of the conveyor is installed with a discharge hopper; and a material layer room is arranged between the hot air uniform plate and the upper conveying belt. The fuel drying device can recycle flue gas waste heat of the power plant to achieve the fuel drying of the direct combustion biomass power station, is energy-saving and environment-friendly; and at the same time, a large amount of fuel can be process, so that the demand for fuel of the power station can be met. The drying device is good in liquidity and has no requirements on the shape of the fuel, and congestion in the drying process is avoided.

Owner:闵公发

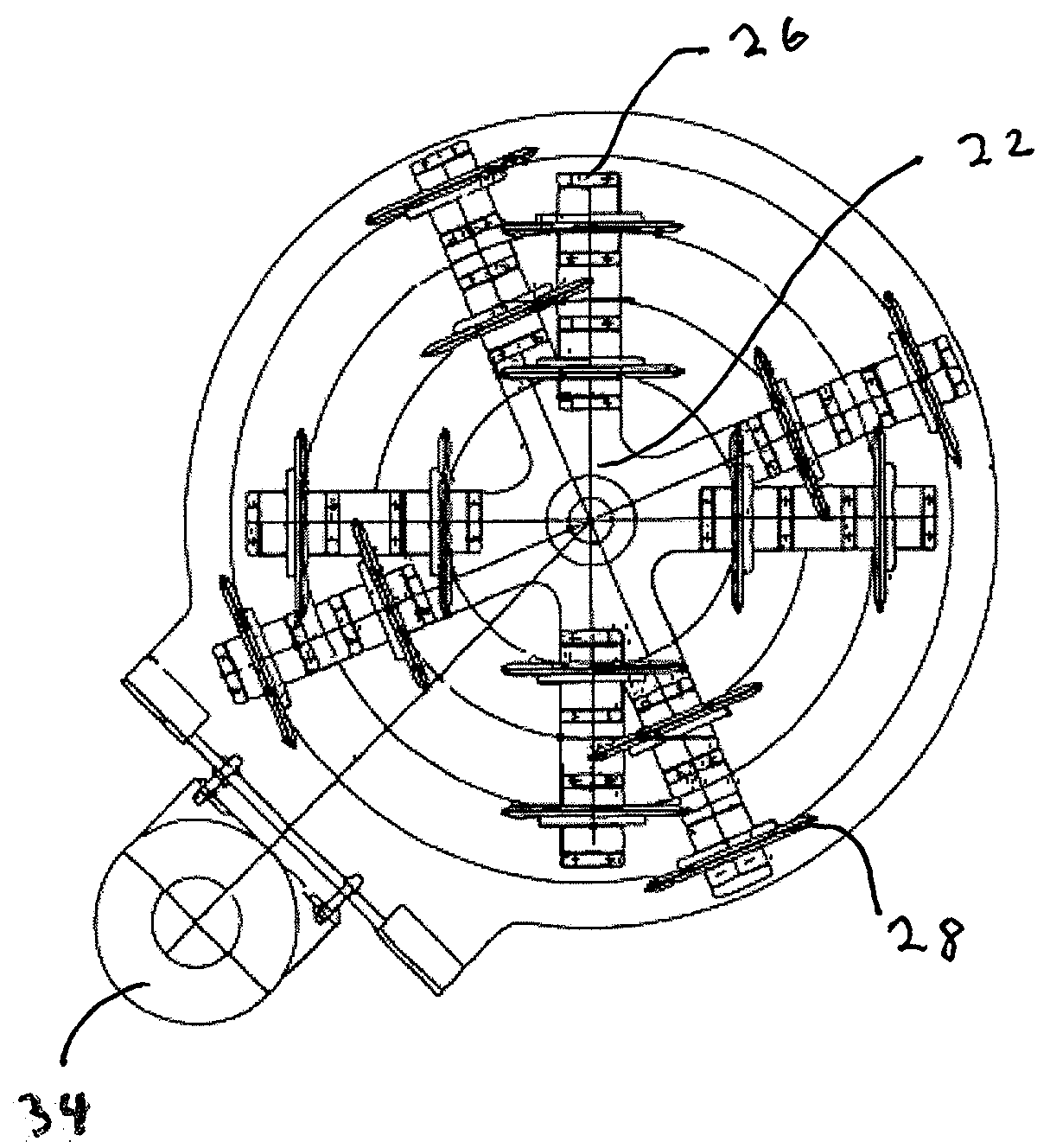

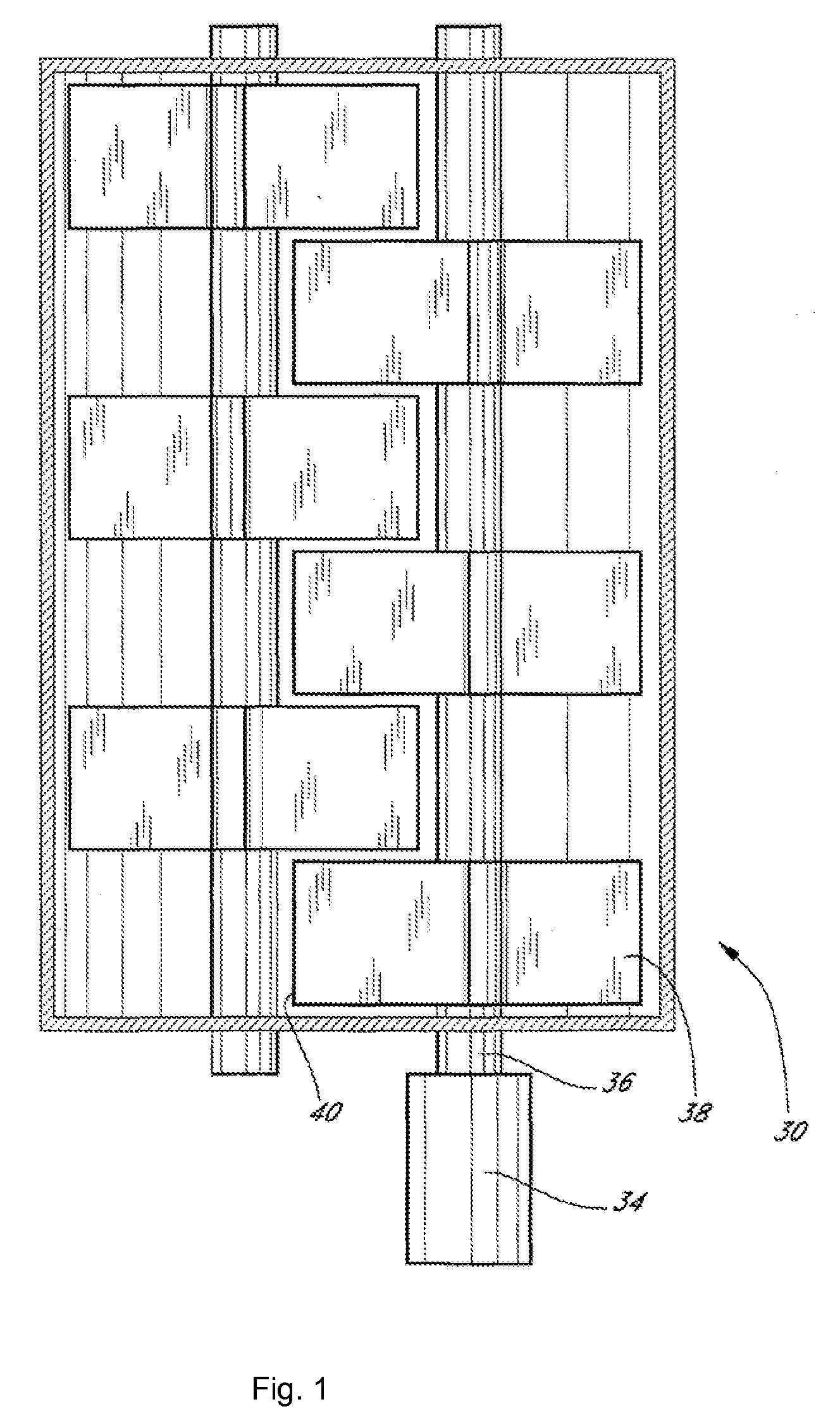

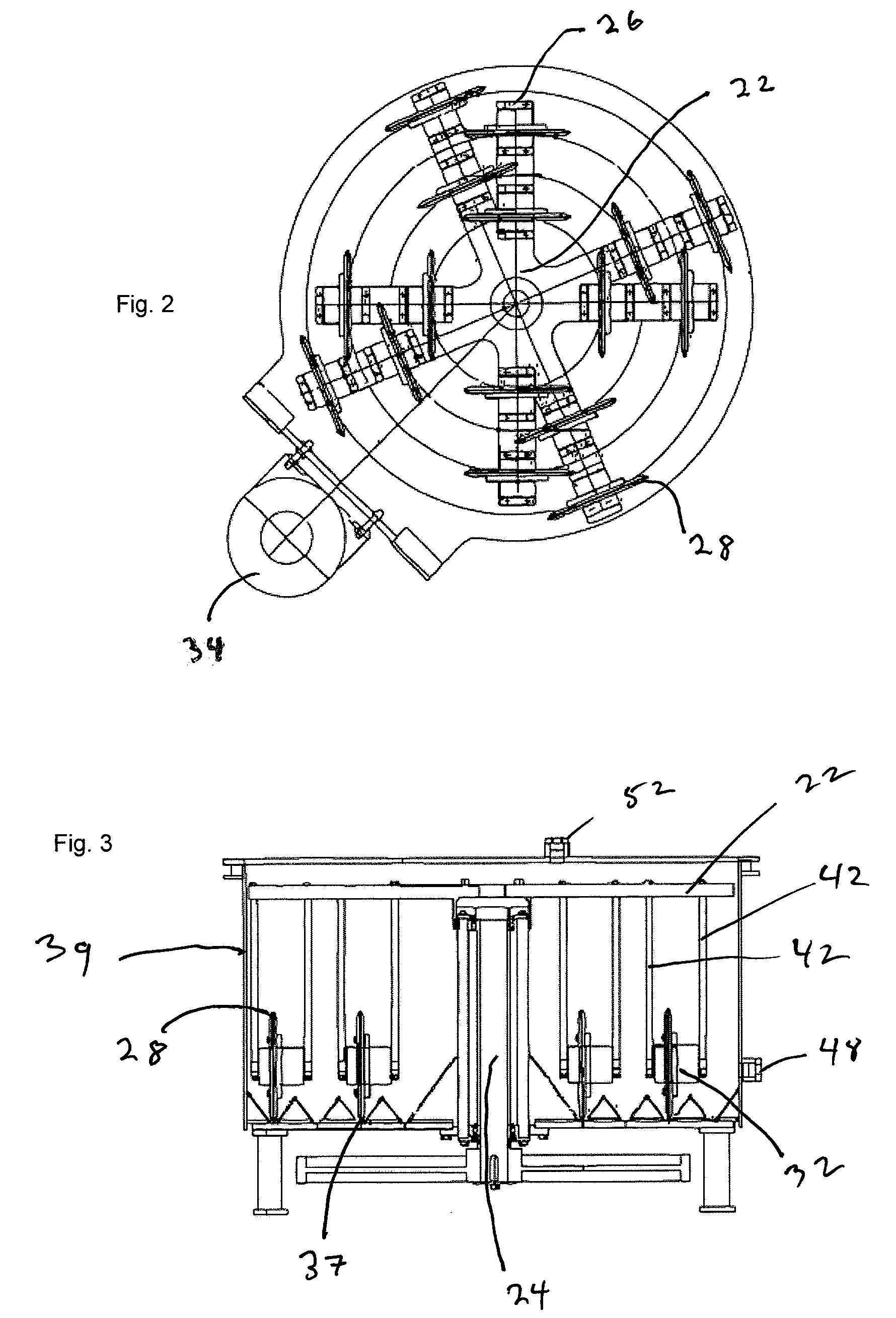

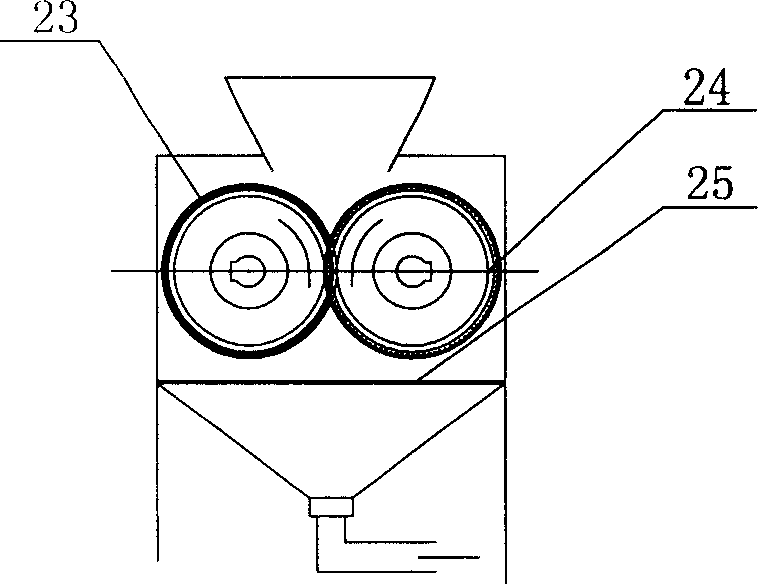

Disruptor System for Dry Cellulosic Materials

ActiveUS20090224086A1Readily hydrolyzableEnhance stirringReed/straw treatmentCocoaMaximum diameterEngineering

Cellulosic biomass is reduced to a micropowder with particles having average diameters below 5-10 micrometers with a significant fraction of the particles have diameters below 1 micrometer. Biomass (e.g., wood, agricultural waste or other plant materials) is first processed into pieces having a maximum diameter of about 10 mm. This is then dried to reduce its water content to no more than about 15% by weight and introduced into a disruptor which reduces the particle size to about 1 mm. Next the biomass is processed with a disc mill where edges of rotating discs travel along a groove pressing and squeezing the biomass, thereby breaking the biomass pieces into smaller and smaller particles. The resulting micropowder is extremely susceptible to enzymatic or chemical hydrolysis into constituent sugars. In addition, the micropowder can be suspended in an air stream and burned directly to provide heat to boilers and similar devices.

Owner:BIOMASS CONVERSIONS LLC

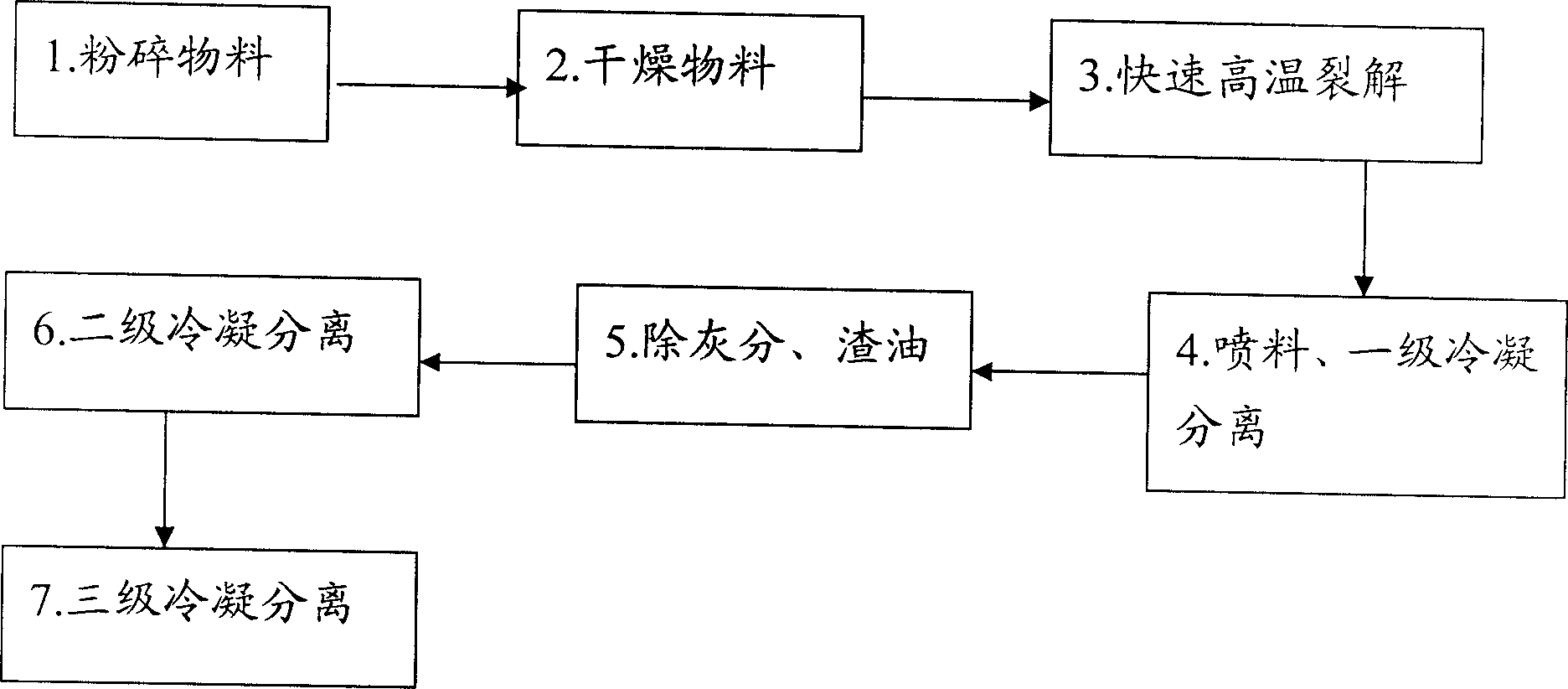

Biomass oil preparing process and device

The invention discloses a technology for preparation of biotic oil with dissimilar components using biomass including crop straw and its devices. The biotic materials produce the biotic oil by disintegrating process, dehydrating process, split process, multi-stage condensing process and disintegrating process and the devices install reducing mechanism for materials, drier installation, feed gear, cracking unit for bulk, multi-stage condensing unit, debonding unit and collecting device corresponding to every process. The invention can be used in preparing biotic oil with a large industrial scale, in which the heavy leavings and solid carbon powder mixed with ashes can be used as fuels of furnace; the elementary biotic oil can directly be used in direct-combustion system including oil-burning boiler and direct-combustion central air-conditioning, which can substitute gasoline and diesel as combustion engine fuel by refining; the biotic oil with low-boiling point and high-quality can substitute liquefied petroleum gas as domestic fuel.

Owner:何仁

Method and system for producing synthetic gas from biomass by high temperature gasification

InactiveUS20100223846A1Improve energy efficiencyEffective controlBiofuelsFuel cellsCombustorDirect combustion

A method for producing synthetic gas from biomass by high temperature gasification, by: feeding biomass, carbonizing to yield pyrolysis gas and charcoal, pulverizing the charcoal, and gasifying in a gasifier. The heat source for the carbonizing step comes from a direct combustion reaction between external combustible gas and external oxygen in a carbonization furnace. Also provided is a device for producing synthetic gas from biomass by high temperature gasification, containing at least: a supercharging feeding system for biomass, a carbonization furnace containing at least a burner nozzle, a pulverizing system, a transportation system for charcoal powder, a gasifier, a pneumatic conveying system, and a plurality of connecting pipes therefor; the burner nozzle of the carbonization furnace is connected to an external combustible gas pipe and an external oxygen pipe respectively.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com