Patents

Literature

191 results about "Fixation agent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A fixation agent is a chemical that is capable to fixate one substance to another substance that the first substance have little affinity to.

Covalently immobilized protein gradients in three-dimensional porous scaffolds

ActiveUS20070212730A1Bioreactor/fermenter combinationsBiological substance pretreatmentsChemistryFixation agent

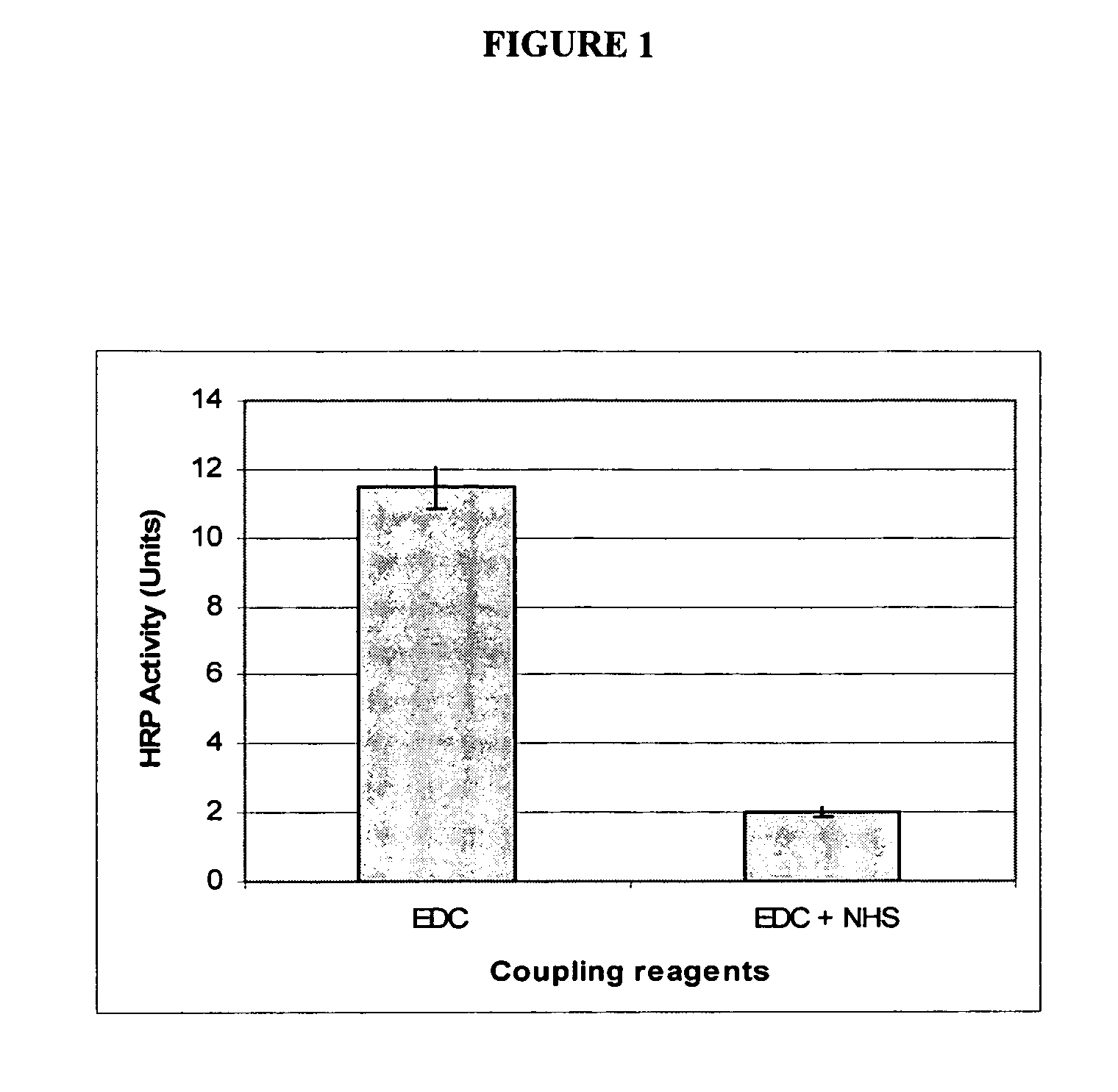

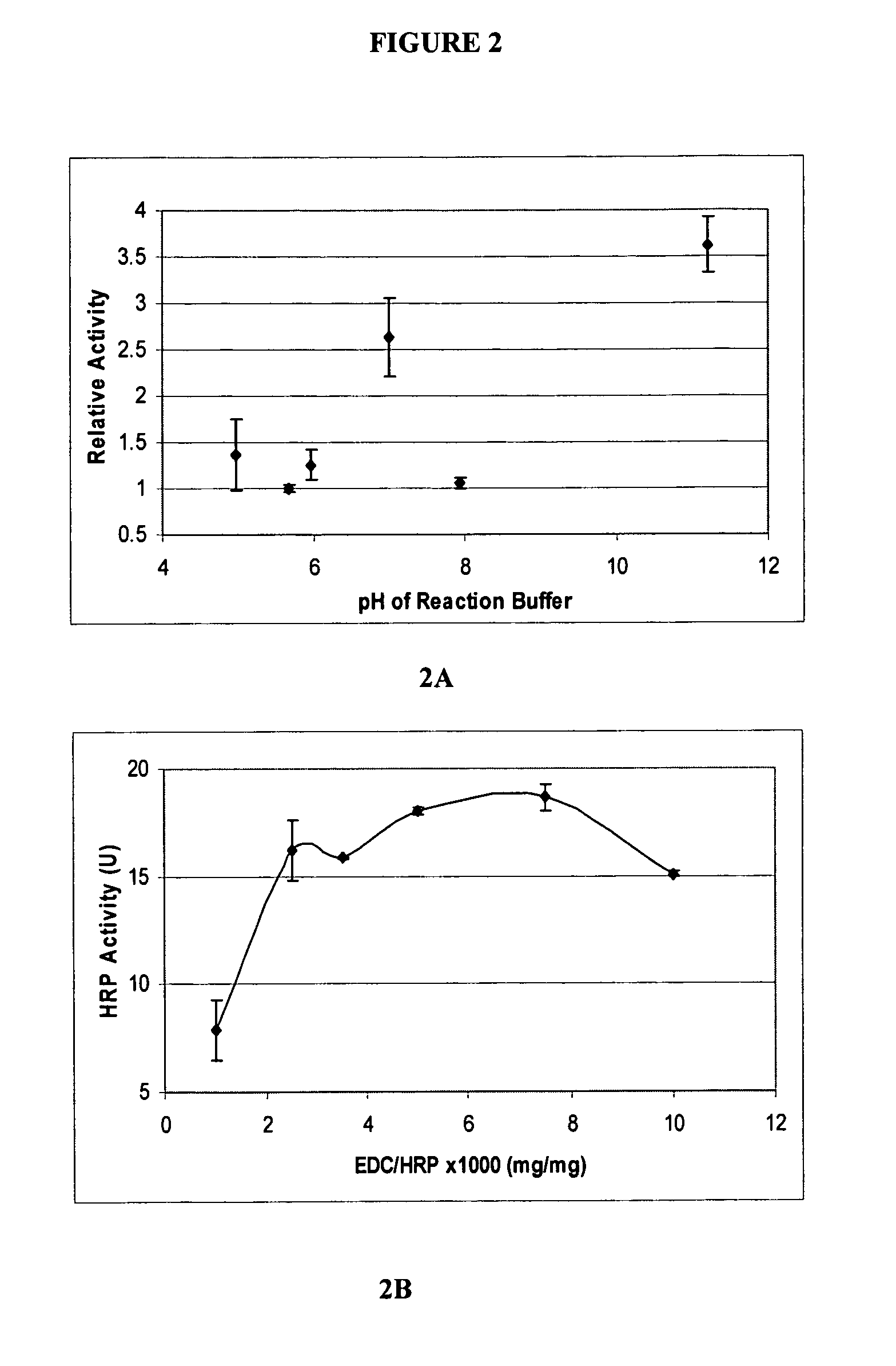

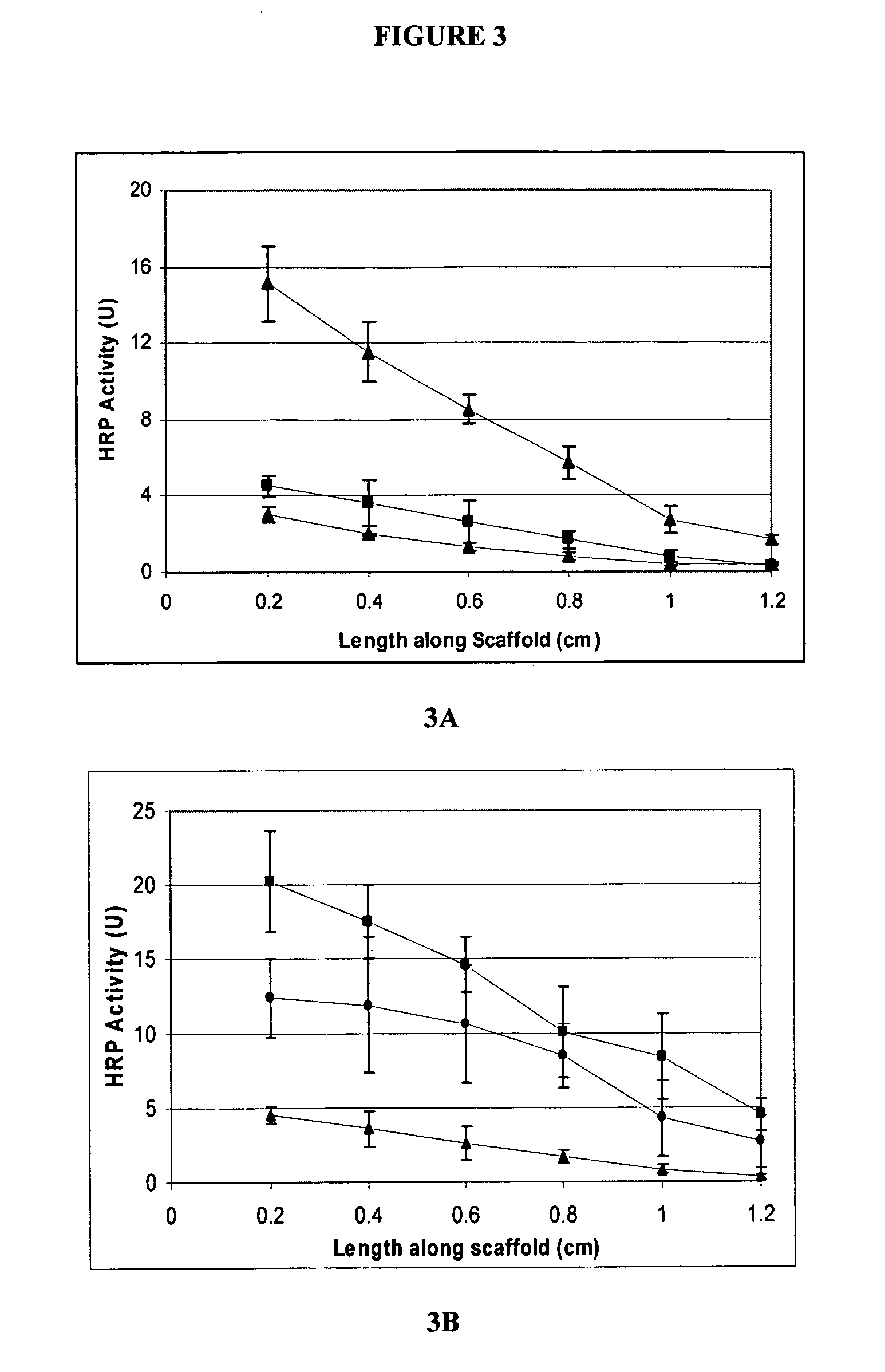

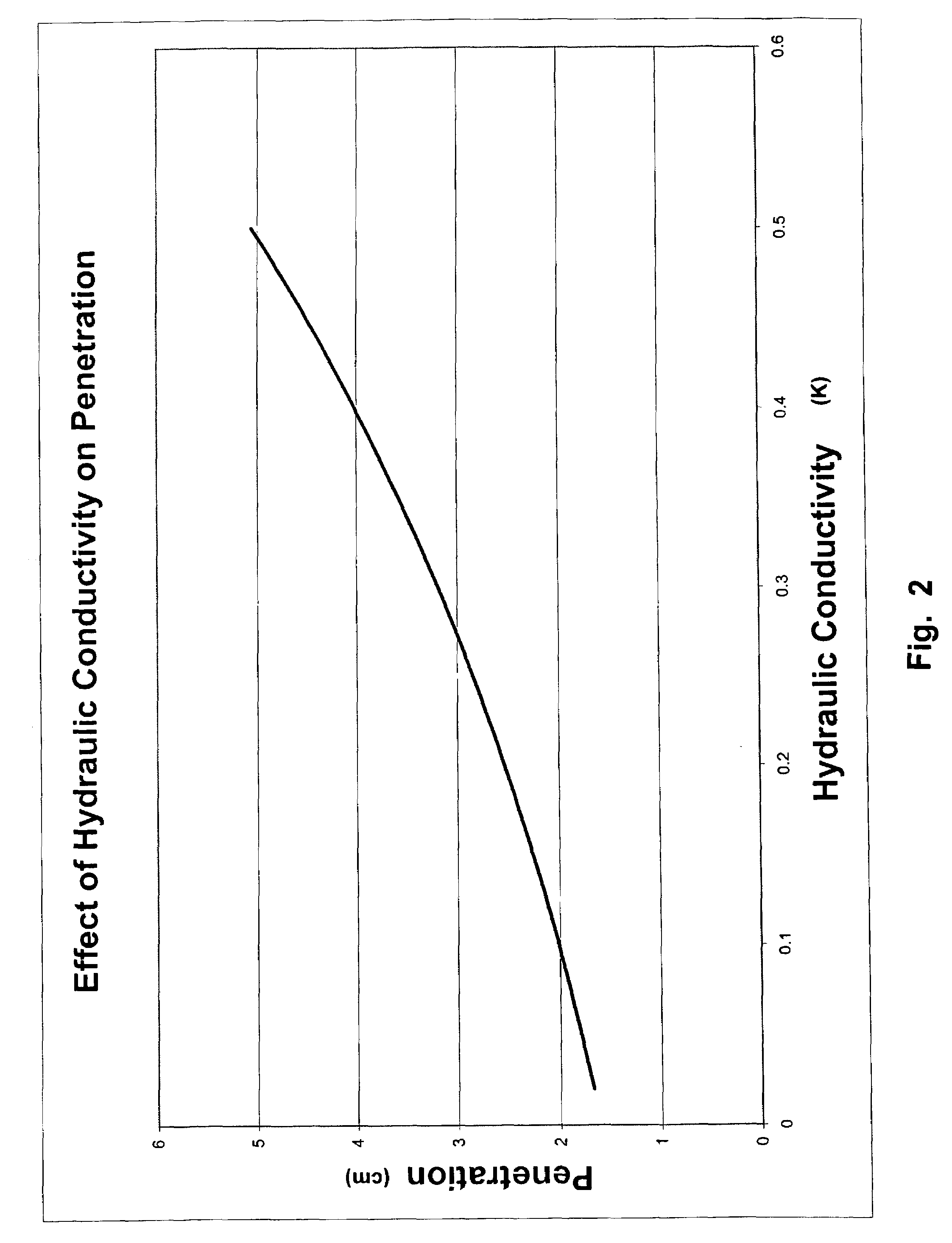

The invention provides a method for forming an immobilized agent gradient within a 3-dimensional porous scaffold. A 3-dimensional scaffold formed from a biocompatible material is provided. The surface of the scaffold and / or the agent is activated so as to allow binding of the agent to the scaffold. The activated scaffold is contacted with a solution containing the agent. Contact with the solution is maintained for a sufficient period of time to allow diffusion of the solution through a portion of the scaffold, thereby forming a desired gradient of the agent through the 3-dimensional scaffold.

Owner:TRUSTEES OF TUFTS COLLEGE TUFTS UNIV +1

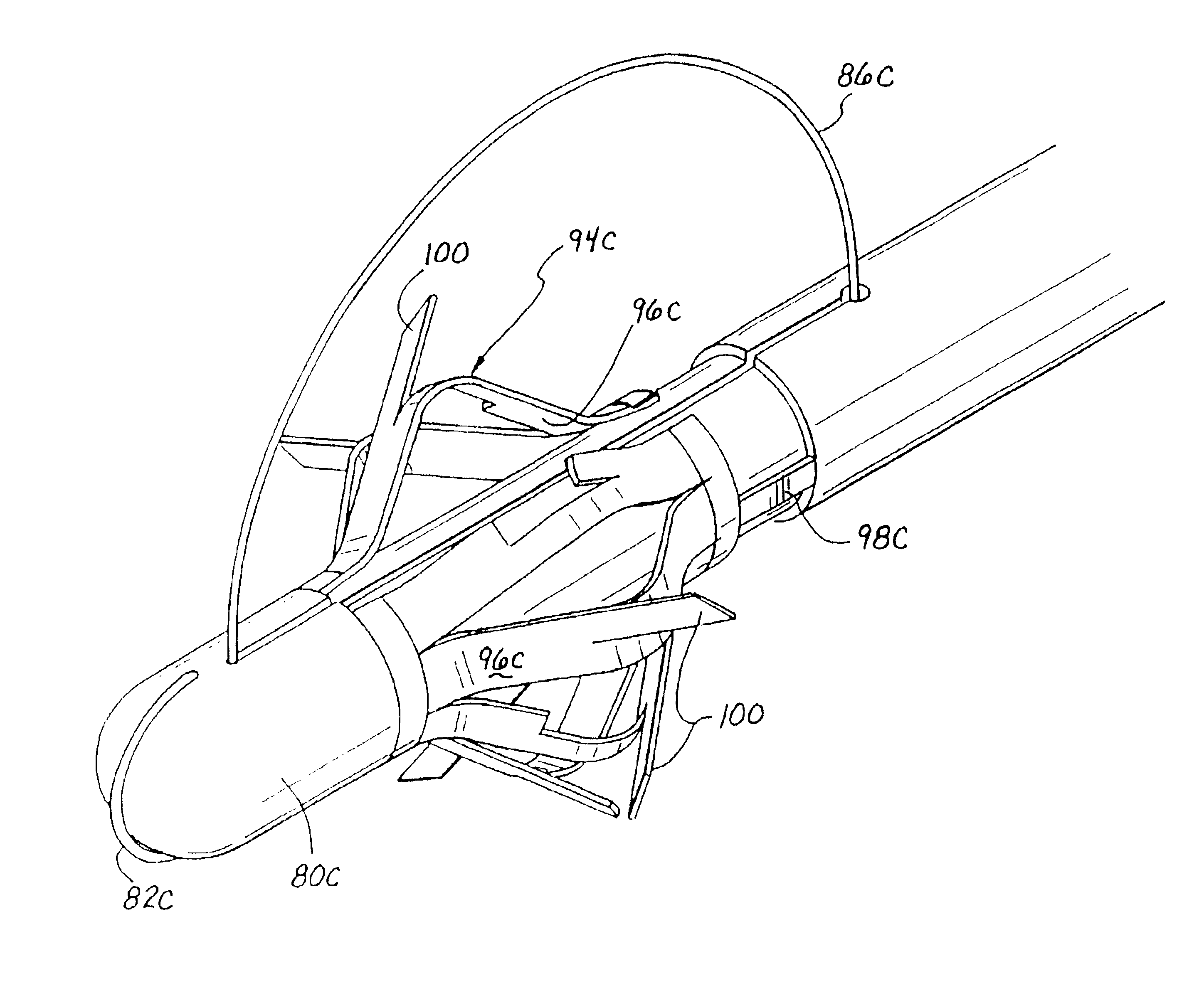

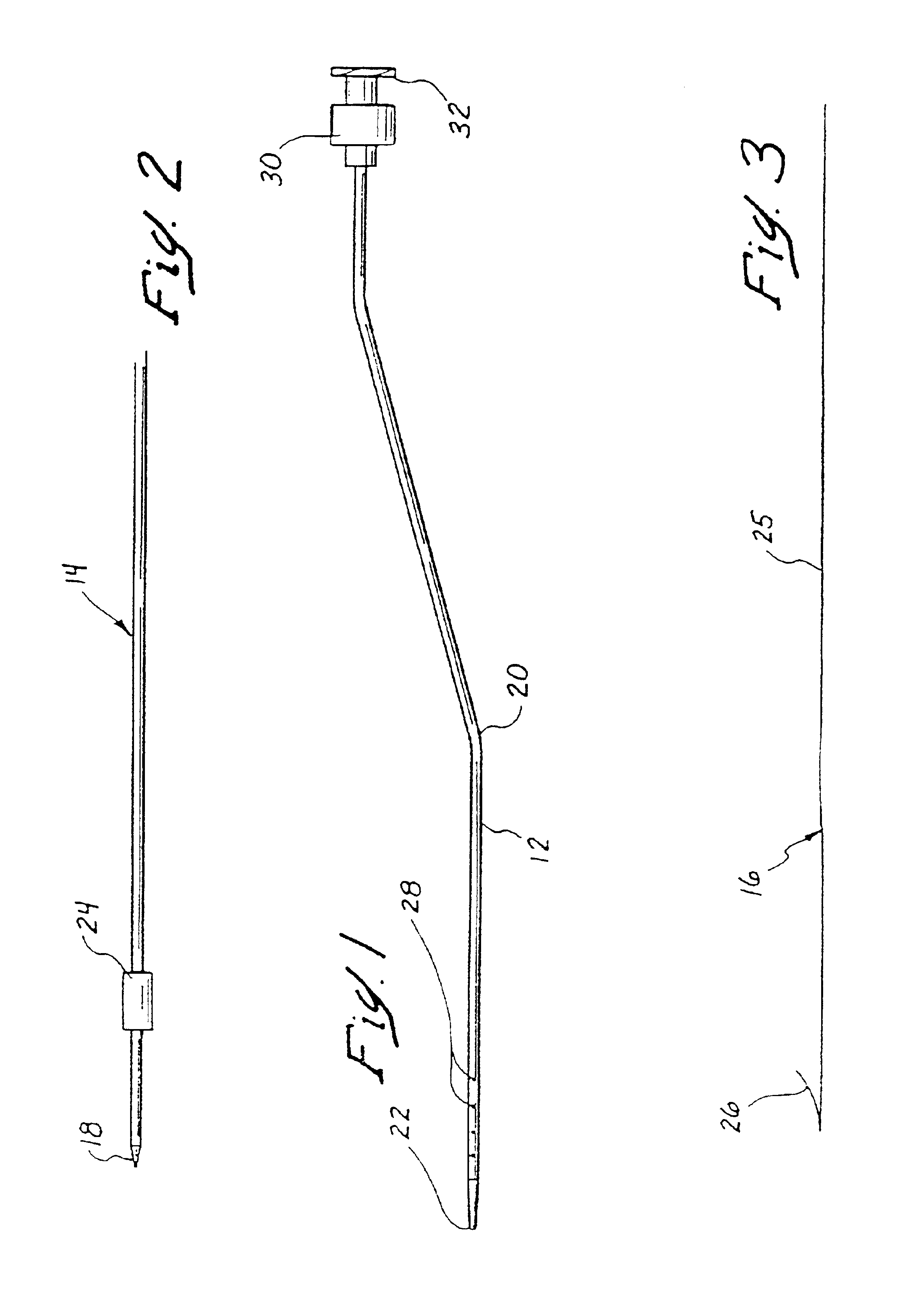

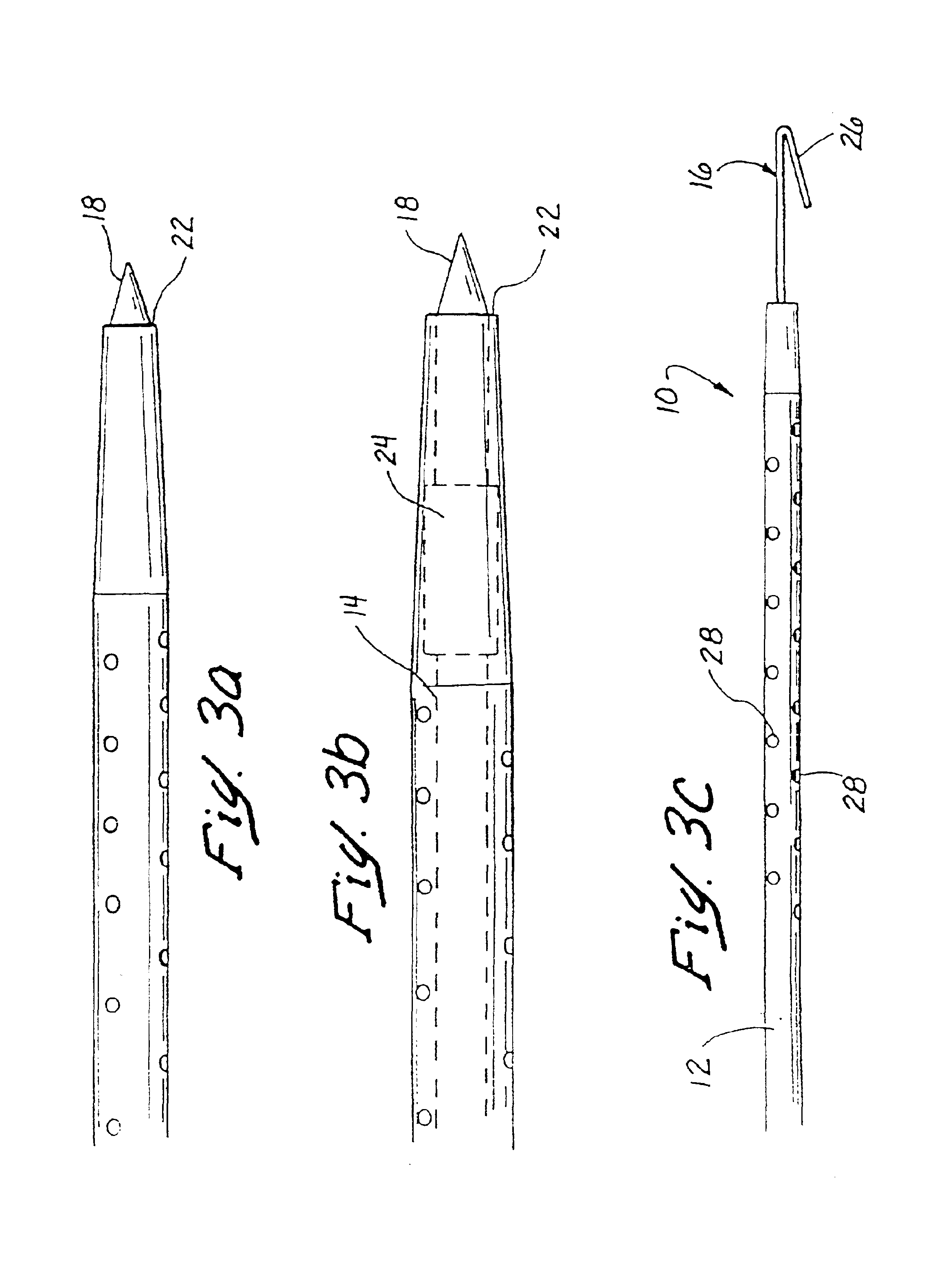

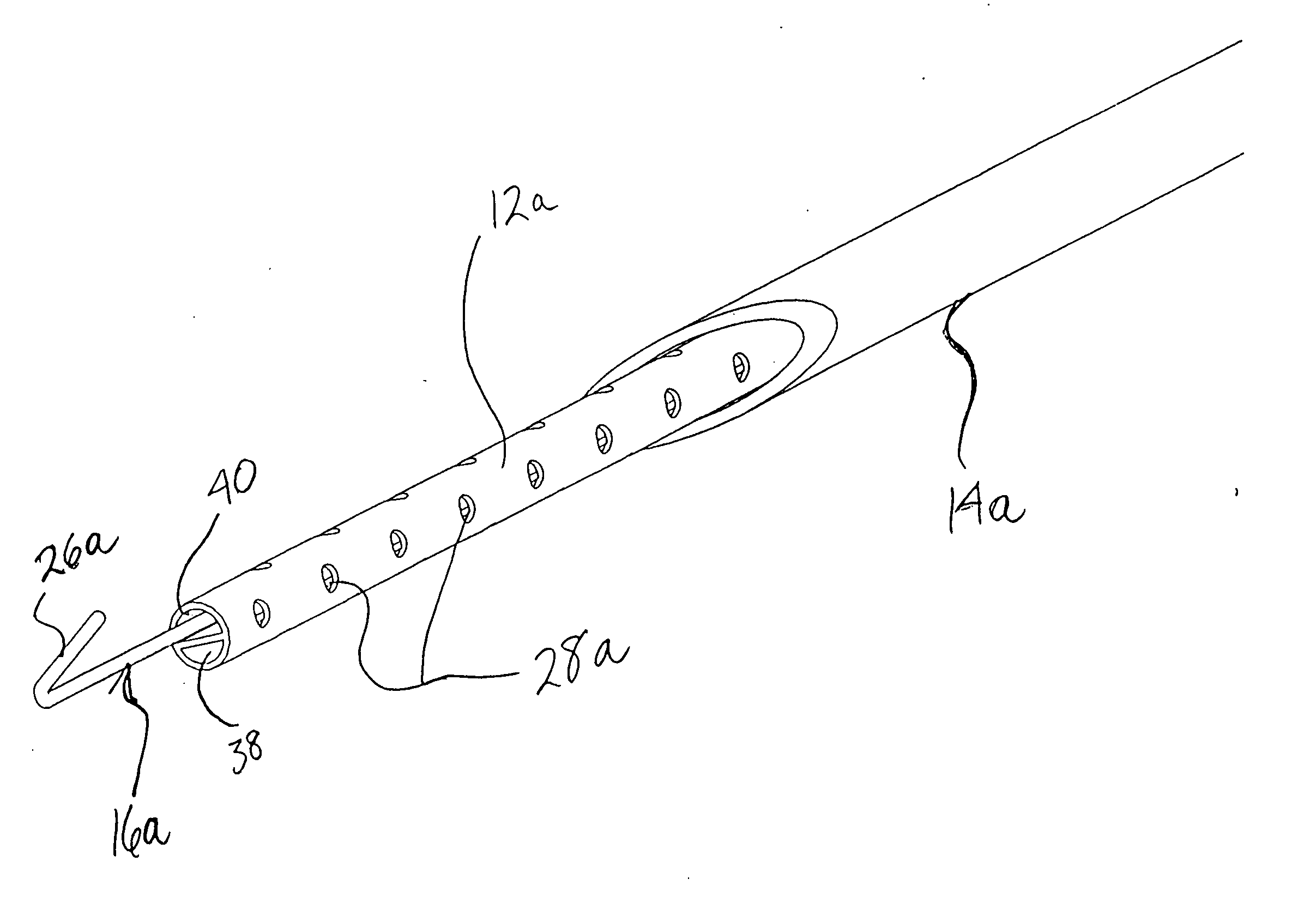

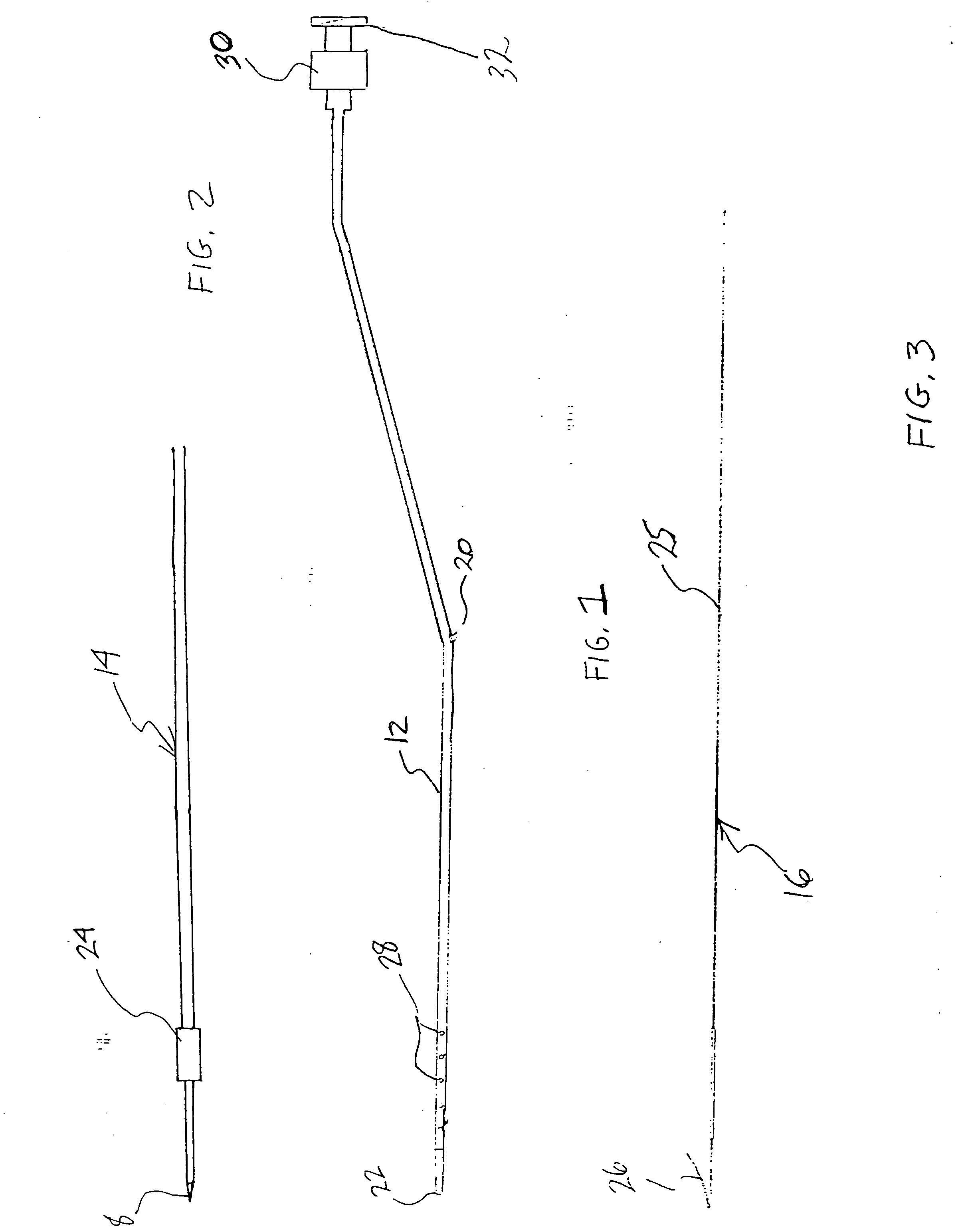

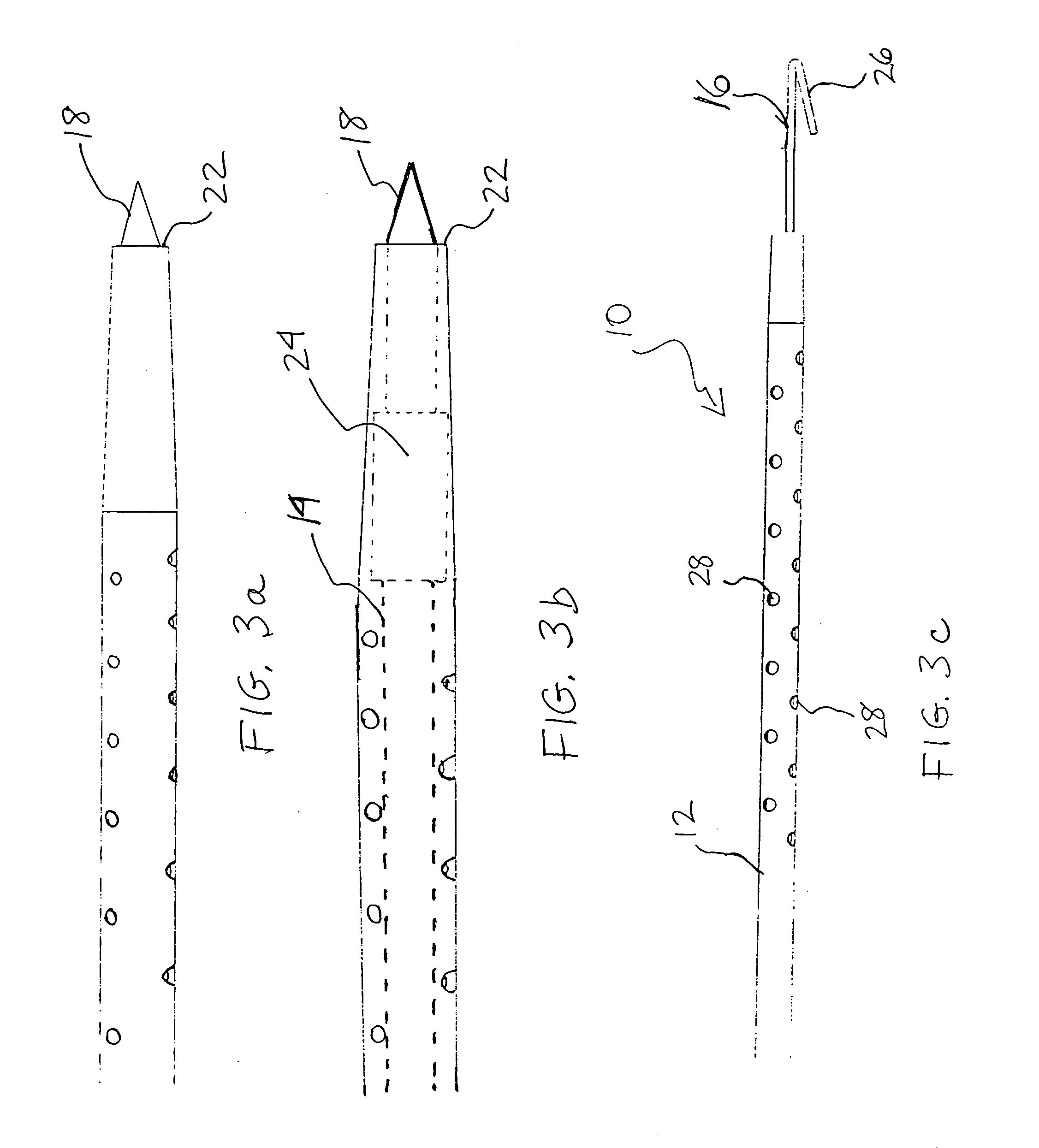

Methods and apparatus for securing medical instruments to desired locations in a patient's body

Devices and methods are provided for securely affixing a medical instrument to desired tissue in a patient's body, using a fixation agent. Such medical instruments may comprise localization wires or tissue acquisition instruments, such as biopsy instruments, for example. In the case of tissue acquisition instruments, the inventors have discovered significant advantages for securely affixing the distal end of the tissue acquisition instrument to a particular tissue target area. For example, such an approach permits the imaging environment to be uncoupled from the procedural environment so that expensive and often unavailable imaging equipment, such as stereotactic imaging equipment, need not be used. In a preferred embodiment, a bonding agent, such as adhesive, surgical glue, or a solvent, is used as the fixation agent.

Owner:SENORX

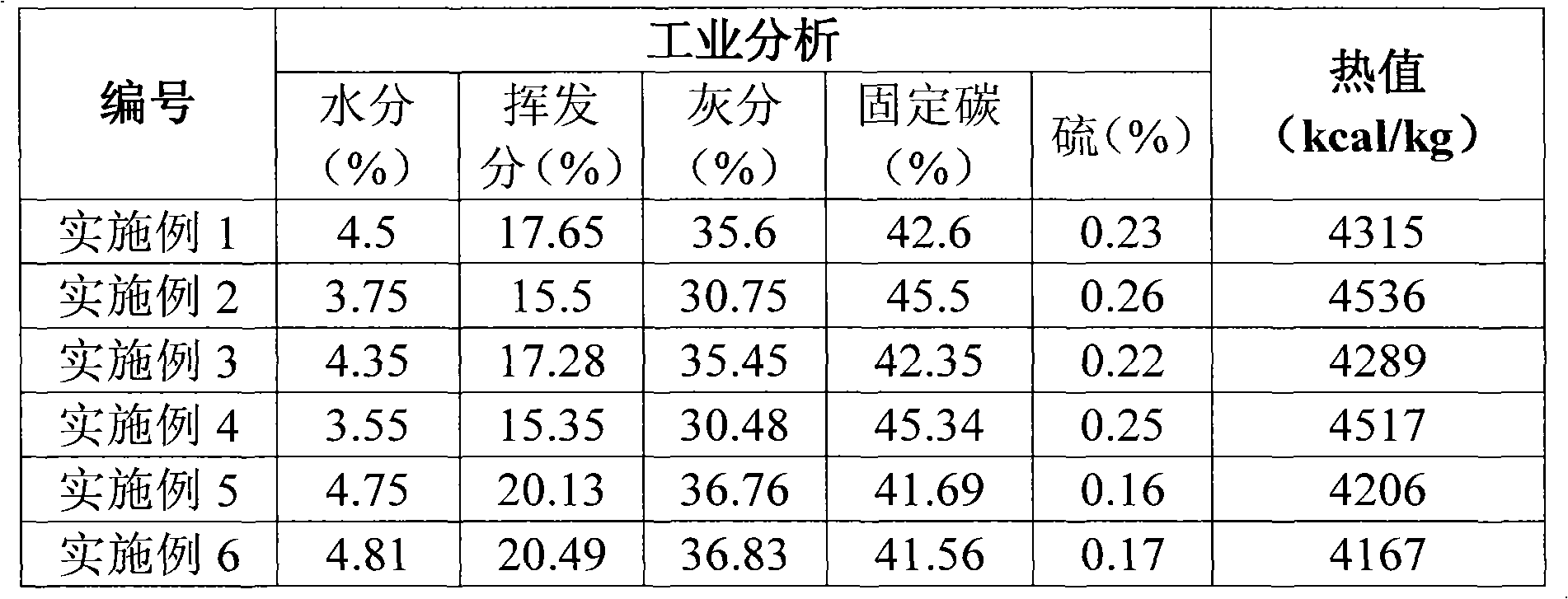

Biomass molding fuels

InactiveCN101899345AEmission reductionImprove effective utilizationBiofuelsSolid fuelsSulfurDirect combustion

The invention discloses biomass molding fuels. The fuels are granulated and molded after biomass material particles and a fuel additive are mixed, wherein, based on the weight of the biomass material particles, the fuel additive comprises the following components in percentages by weight: 0.1-5% of grease, 0.1-2% of sulfur fixation agent and 0.1-0.5% of combustion improver. The biomass molding fuel obtained in the invention is a high grade clean fuel suitable for use in industrial boilers and can be directly burned in various BMF (Biomass molding fuel) boilers.

Owner:GUANGZHOU DEVOTION THERMAL TECH

Silica gel based animal litter

A litter composition comprising a substantially particulate primary absorbent material and a binding agent, the binding agent comprising approximately 0.01%-40% of the litter composition. In one embodiment, the primary absorbent material comprises silica gel and the binding agent comprises a galactomannan. In additional embodiments, the litter composition also includes at least one of the following components: fixing agent, colorant agent, anti-bacterial agent, fragrance and / or supplemental absorbent material.

Owner:THE CLOROX CO

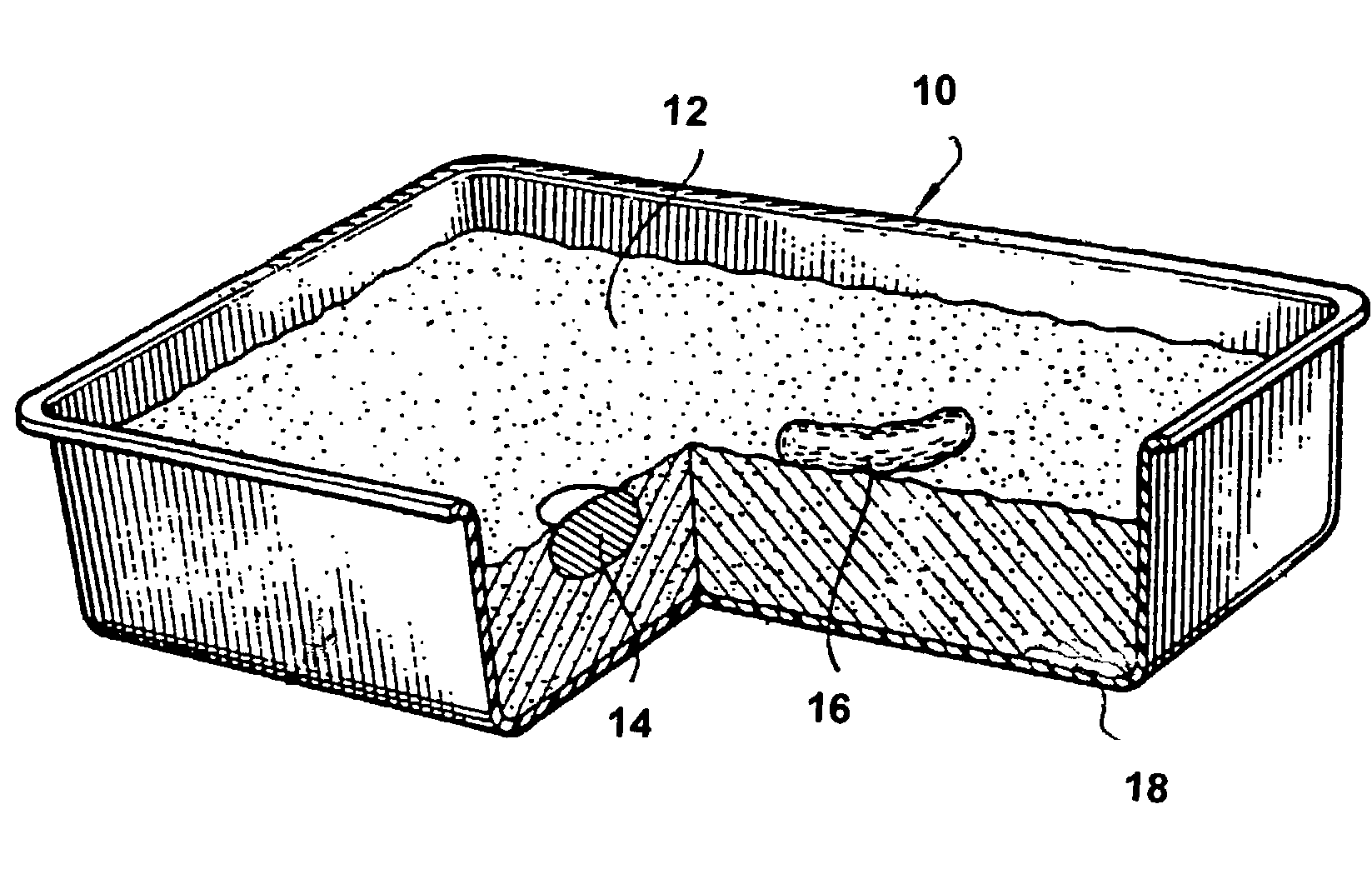

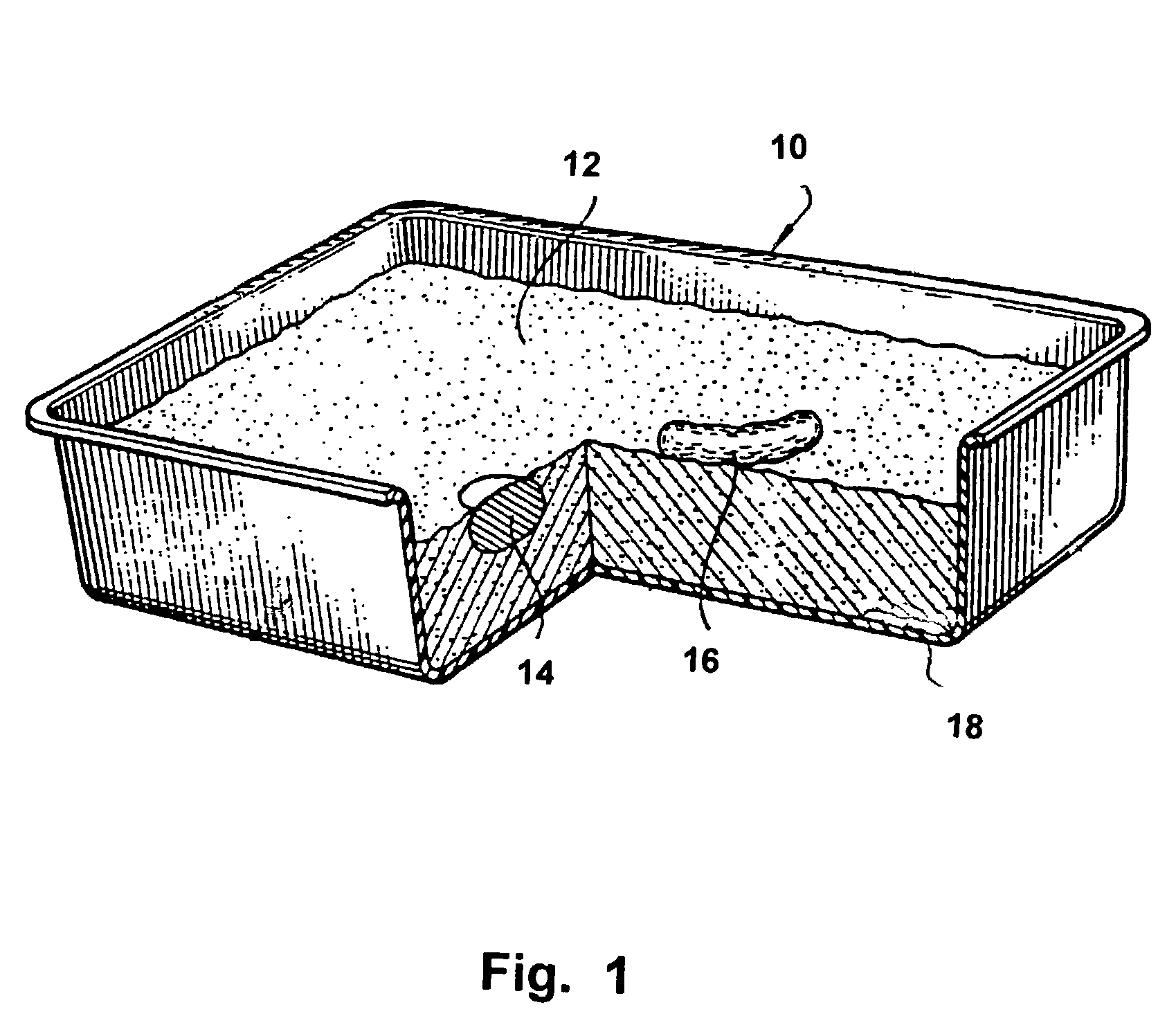

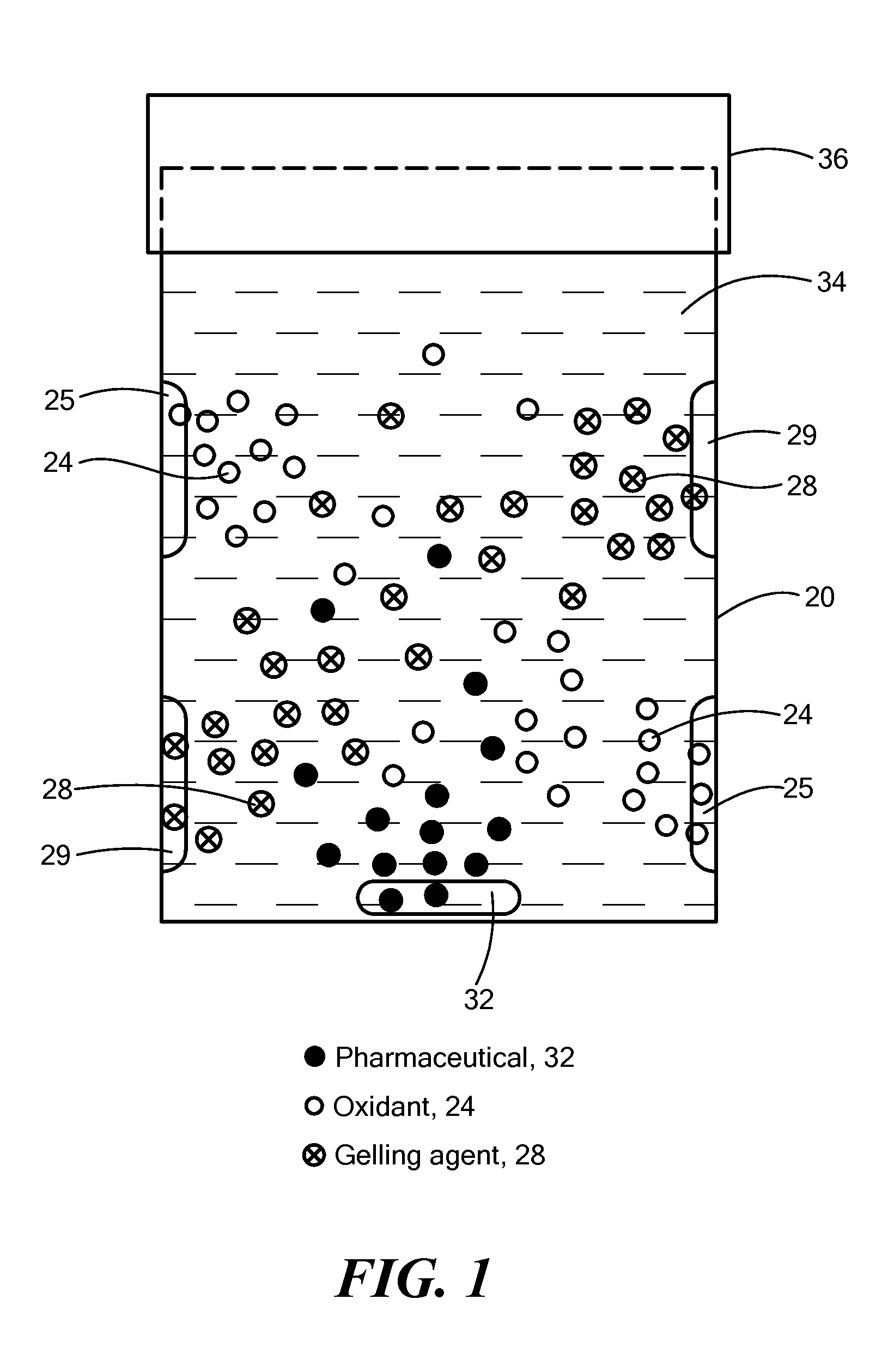

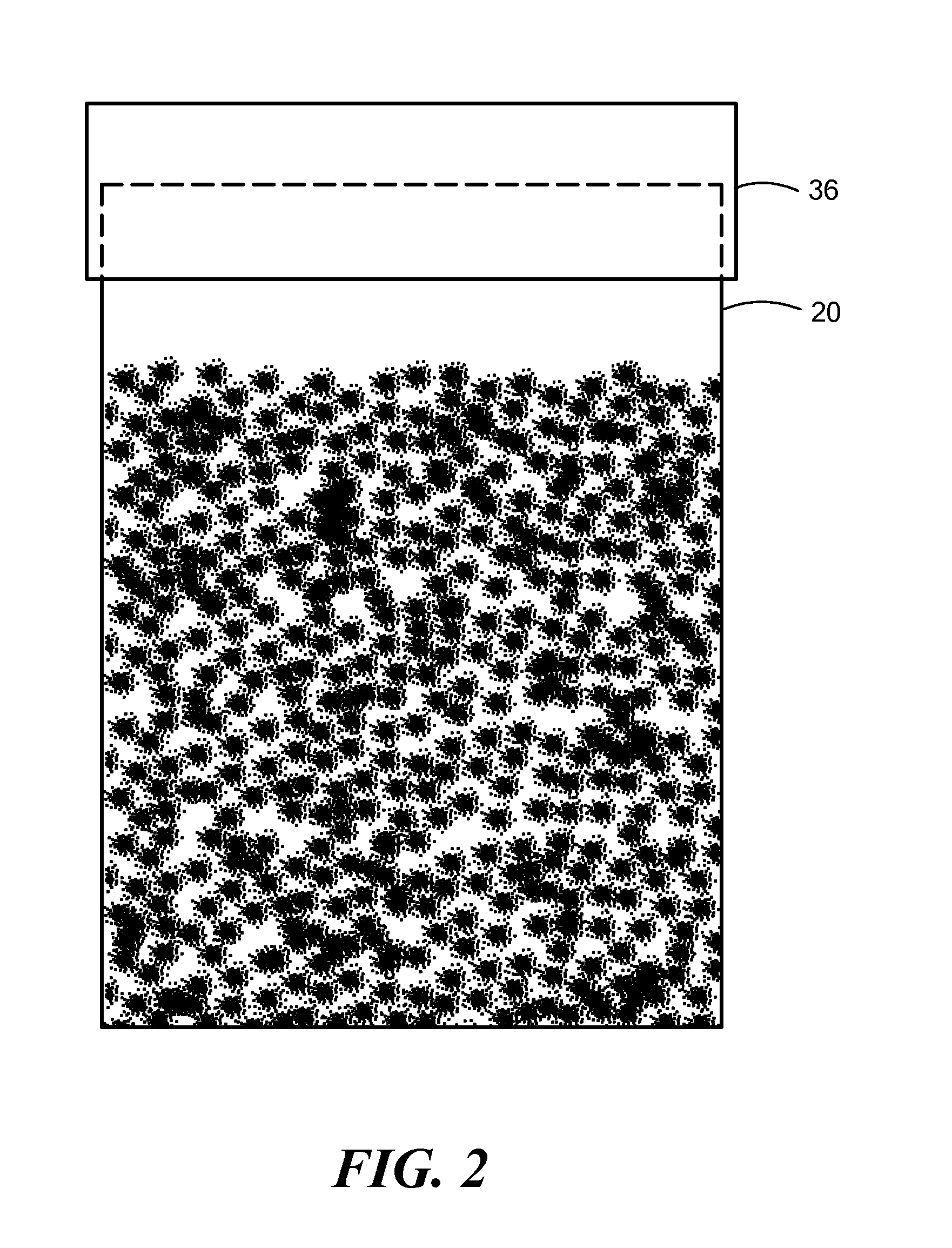

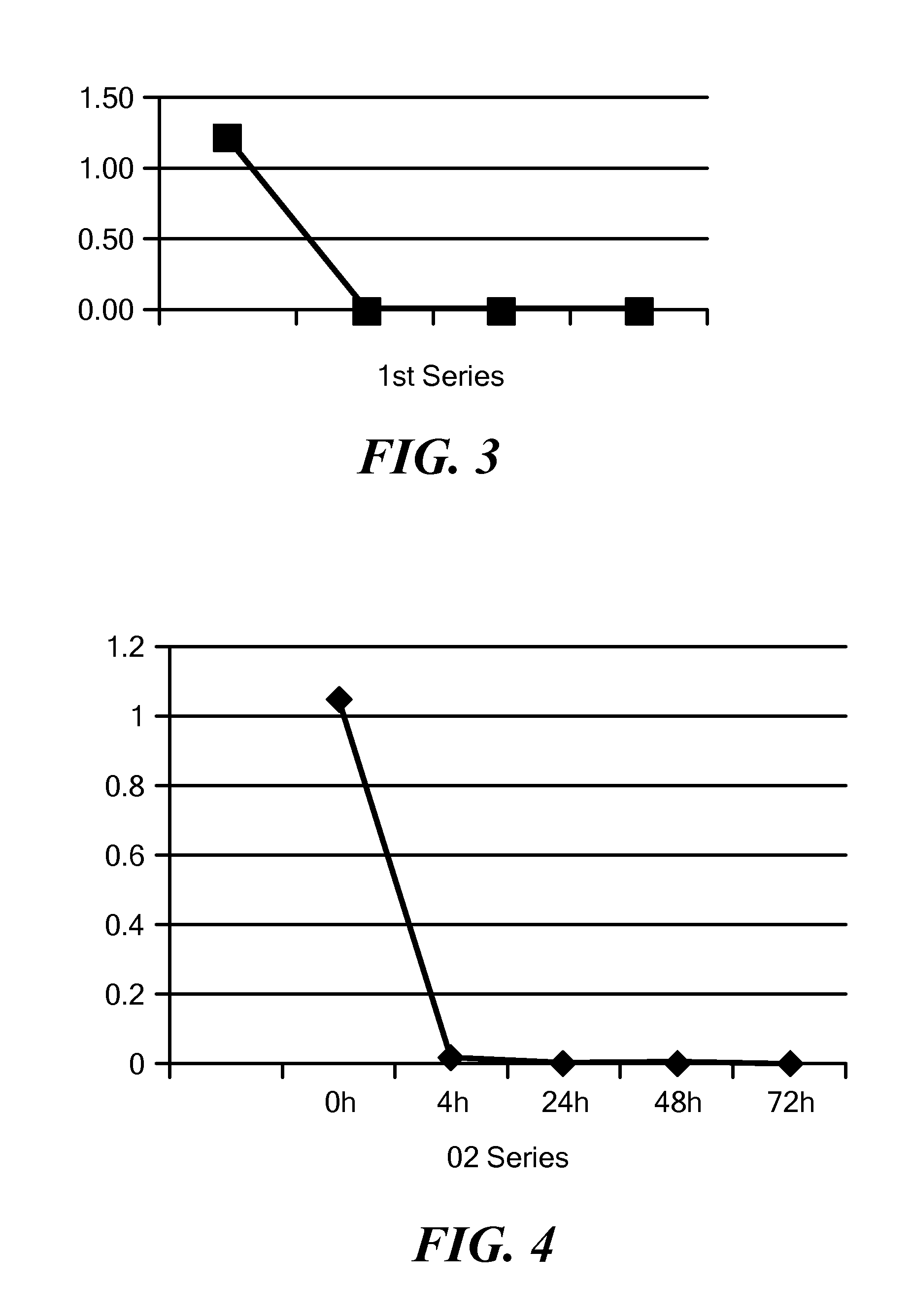

System and Method for Deactivation and Disposal of a Pharmaceutical Dosage Form

A system and method are provided for deactivation and disposal of a pharmaceutical dosage form. The system and method employ an oxidant and an immobilizing agent placed in a container. The pharmaceutical dosage form is placed into the container, and water is added to the container. A rapid chemical deactivation of the active ingredient or ingredients in the pharmaceutical then occurs by a chemical oxidation process. Upon contact with the water, the immobilizing agent swells or expands in volume to form a gel or slurry, binding the other components in the container within the gel or slurry, where they remain after disposal. The system can be in the form of a kit, or can be scaled up for use by municipalities or institutions.

Owner:SARANGAPANI SHANTHA

Hydrogel sheets and shapes for oral care

InactiveUS20070122362A1Enhanced inhibitory effectReduce releaseCosmetic preparationsToilet preparationsCross-linkBeam energy

A hydrogel for use in oral care. The hydrogel is ion beam cross-linked, the hydrogel is adapted to be disposed in the oral cavity and may be adapted to provide a denture fixative or may be loaded with a whitening agent for use in whitening one or more teeth and disposed on or adjacent one or more teeth and the whitening agent is slow-released to whiten the one or more teeth. Other loading materials may include materials for treatment of alveolitis or malodor, inter alia. The present invention is a new hydrophilic oral and dental cohesive hydrogel sheet designed to securely grip and cushion prosthetic devices in the human mouth with the further ability to slow release antimicrobial or other orally desirable agents. Additionally, the invention also provides a method of making an orally cohesive device that: 1) is easily adapted and applied to a removable dental prosthesis; 2) bonds well to alveolar ridge / palatal mucosa and denture acrylic materials; and 3) releases cleanly, with no tacky or thixotropic residue when the prosthesis is removed. The cohesive hydrogel gel device is a hydrogel-forming polymer mixed with water, optionally surrounding an internal scrim, and uses an electron-beam energy source to cause cross-linking. The method does not need any chemical additive to affect the cross-linking. Furthermore the beam energy can be adjusted to optimize the cohesive properties of either side of the device, as well as to compensate for addition of orally active agents, if any are chosen. The hydrogel sheets are pre-cut to fit most sizes of maxillary and mandibular full denture prostheses, but can be easily trimmed with a scissors by the end user for the ideal custom fit of any full or partial denture, in either arch.

Owner:GINIGER MARTIN S +1

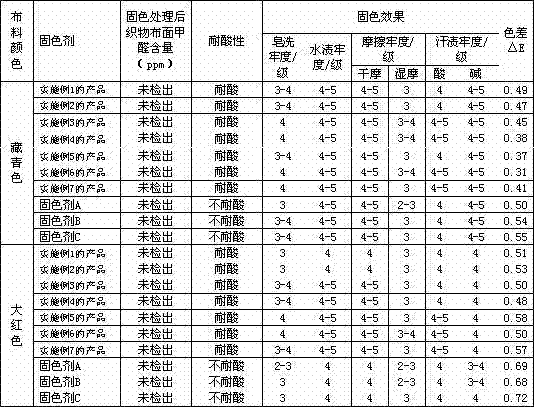

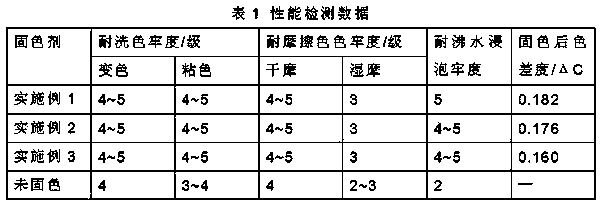

Acid reaction resistant chinlon fixer and application thereof

The invention discloses an acid reaction resistant chinlon fixer. Currently, most chinlon fixer products on the market are not resistant to acid; during a fixation treatment, when the fixer encounters strong acid or concentrated organic acid, a large sum of white precipitates will be produced; and fixer spot is easily generated in the fixation process, leading to generation of inferior-quality products or even waste products. The acid reaction resistant chinlon fixer provided by the invention is prepared by the following method comprising the following steps: subjecting a phenolic compound and two aromatic sulfonic acid compounds to a condensation reaction with formaldehyde in the presence of a complex catalyst; and then adding epichlorohydrin and a modifier to the above reaction system for modification; and finally, adjusting pH value of the modified multielement copolymer aromatic sulfonic acid formaldehyde condensation substance to 2-4 with strong acid or concentrated acid, so as to obtain the acid reaction resistant chinlon fixer. The acid reaction resistant chinlon fixer provided by the invention has acid resistance obviously better than that of a general commercial chinlon fixer, and solves the problem of hard fixation and poor washing fastness of chinlon fabric dyed by acid dyeing.

Owner:传化智联股份有限公司 +1

Composition for the oxidative treatment of hair or skin fixative compostion and method for permanent deformation of hair

InactiveUS20070092471A1Without damaging structureCosmetic preparationsHair cosmeticsAcid derivativeAcoric acid

Cosmetic composition for the oxidative treatment of hair or skin, prepared by mixing of at least two components, in which dehydroascorbic acid or a dehydroascorbic acid salt or a dehydroascorbic acid derivative is generated from ascorbic acid, ascorbic acid derivative and ascorbic acid salt prior to application by an enzyme that catalyzes the enzymatical oxidation of said of ascorbic acid as well as a process for carrying out the oxidative treatment of keratin, particularly for the oxidative post-treatment of reduced hair in the process of permanent deformation of hair using said composition.

Owner:WELLA AG

Preparation method of hydrophilic cationic formaldehyde-free fixing agent

ActiveCN102409568AImprove water absorptionDoes not reduce the color fixing effectDyeing processPolymer scienceEther

The invention relates to a preparation method of a hydrophilic cationic formaldehyde-free fixing agent. The method is characterized by comprising the following steps of: I, dropwise adding 20-70 parts by weight of a quaternizing reagent into 30-60 parts by weight of olefin alkyl amine under the ice-water bath condition, and then stirring; II, adding 60-180 parts by weight of alkylene alcohol polyethenoxy ether, 200-600 parts by weight of alkyl olefin alkyl ammonium chloride, 0.04-0.5 part by weight of a metal ion screening agent and 200-500 parts by weight of water in sequence, and stirring; III, raising the temperature to 60-90 DEG C, dropwise adding 8-20 parts by weight of a water-soluble initiator, preserving heat and reacting for a certain period of time; and IV, after the reaction, regulating the pH value to 5-8 with a caustic soda liquid to obtain the hydrophilic cationic formaldehyde-free fixing agent. Compared with the conventional cationic formaldehyde-free fixing agent, the fixing agent has the advantages of higher hydrophilicity and applicability to fixing for cotton fiber active dyeing.

Owner:江西德盛精细化学品有限公司

Application of coal modifier in shaft kiln incineration and producing technique thereof

A 'SHENZHOUSHENGLONG' coal modifier mainly consists of a grinding aid, a catalyst, an oxidant, a smoke suppressor and combustion improver, a smoke suppressor and igniter, a sulfur fixation agent, a bulking agent, a penetrating agent, etc. The coal modifier is a powdery material and can be added into coal (at a ratio of 0.1% the actual coal weight) to improve the combustion temperature and the combustion speed of the coal, thus achieving catalytic combustion and improving the coal combustion effect as well as the coal utilization rate. Accordingly, the invention performs the functions of saving coal, substituting high-quality coal by poor-quality coal, improving the hourly output of cement clinker stage, improving the grade of cement clinker, fixing sulfur and reducing the discharge of harmful gases such as SO2 in the smoke, thus protecting environment and indeed achieving the green production of cement.

Owner:哈尔滨绿万家环保科技有限公司 +5

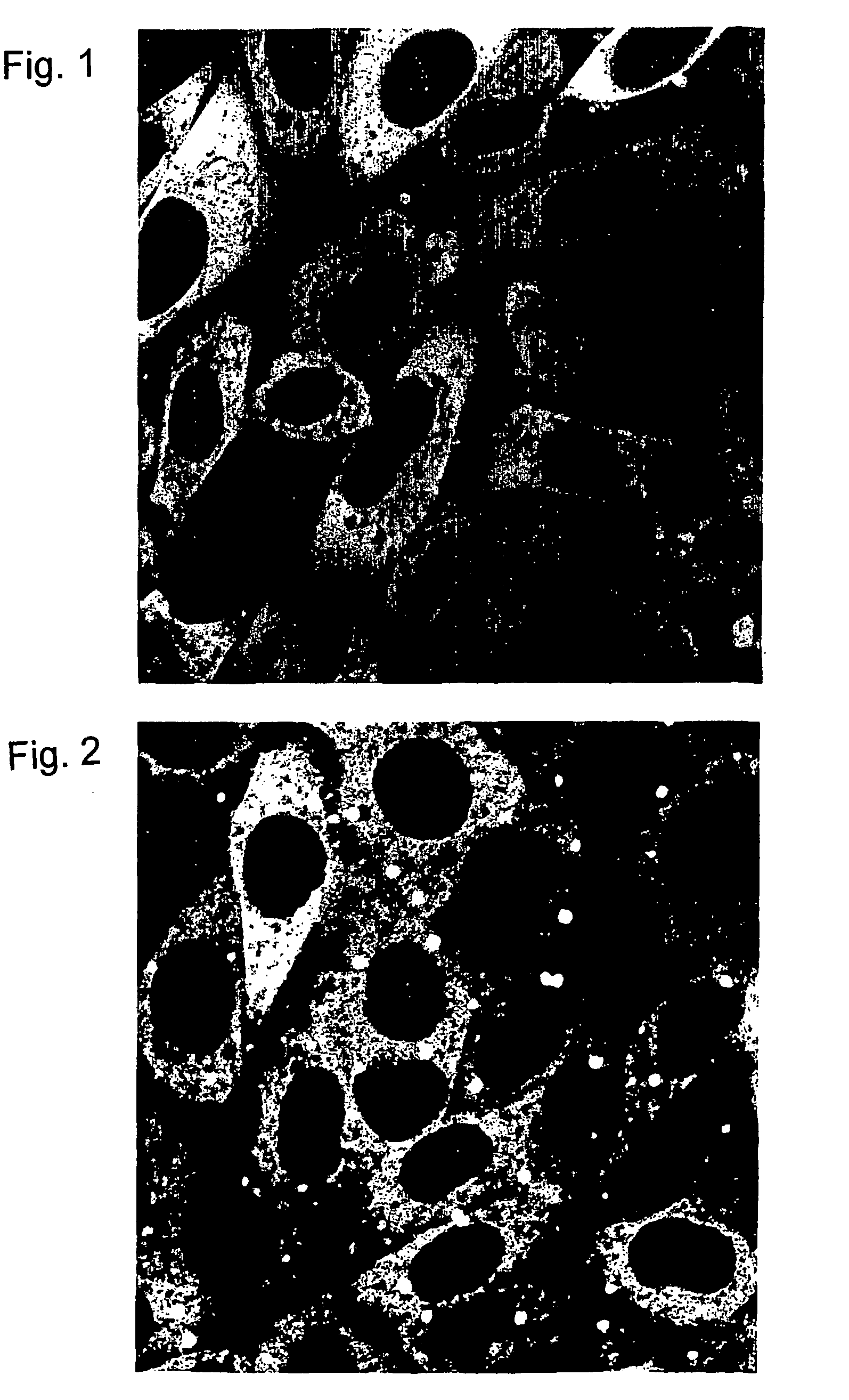

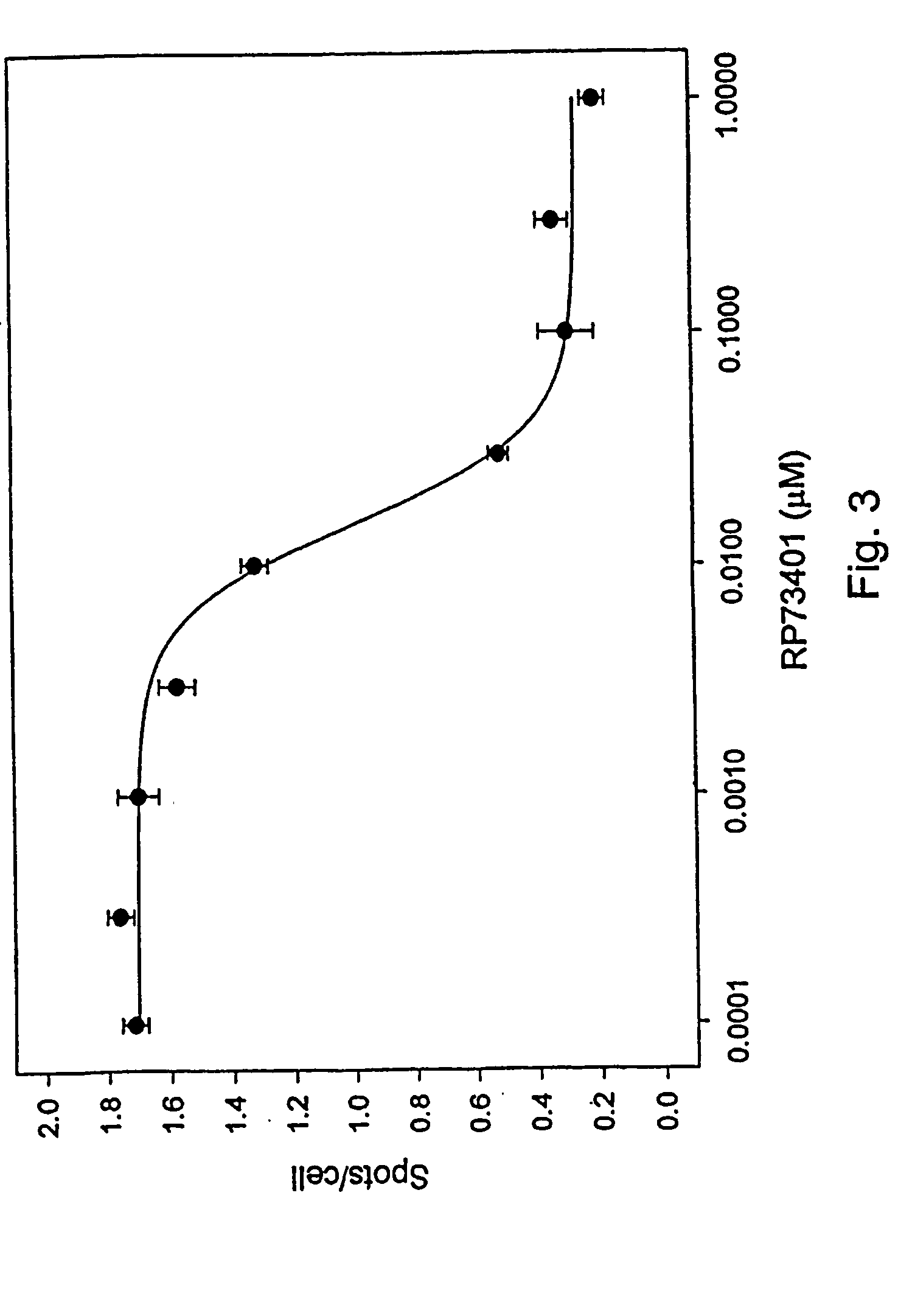

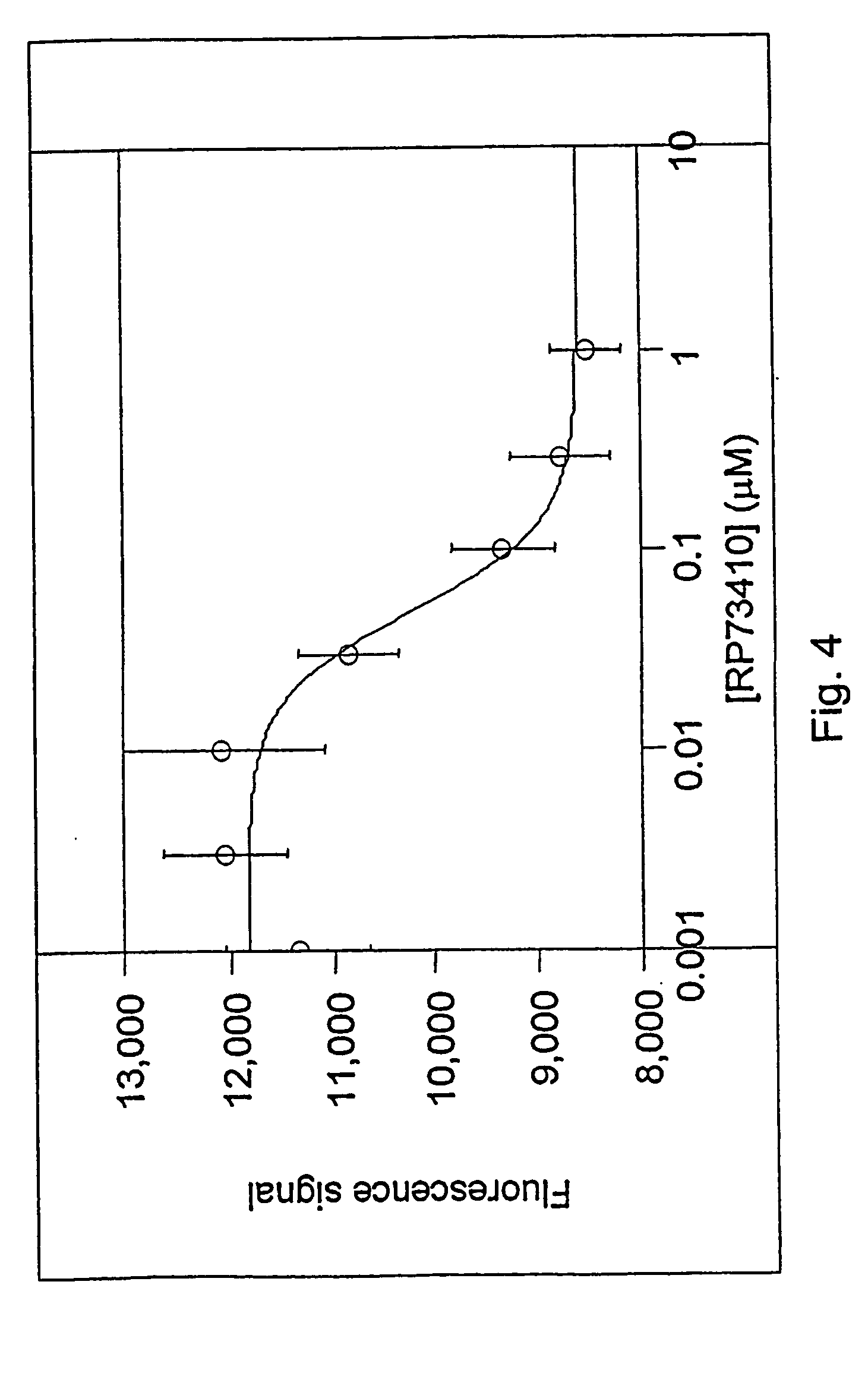

Method for extracting quantitative information relating to interactions between cellular components

A method is described to assay for protein interactions in living cells, e.g. by the introduction of two heterologous conjugates into the cell. The method uses the measurement of cellular distribution of a detectable component (e.g. a GFP-labeled˜fluorescent probe) to indicate the presence or absence of an interaction between that component and a second component of interest. The method uses the knowledge that certain components can be stimulated to redistribute within the cell to defined locations. Inducible redistribution systems make it possible to determine if specific interactions occur between components. Inducible systems are described where it is demonstrated that the redistribution stimuli are essentially “null”, in that they affect no other system in the cell during the assay period, other than the component whose redistribution can be induced. Also described is an extraction buffer which is useful in high throughput screening for drugs which affect the intracellular distribution of intracellular components. The extraction buffer comprises a cellular fixation agent and cellular permeabilisation agent. Optimizing the composition of the extraction buffer and its application to various cell types is described.

Owner:FISHER BIOIMAGE

Sludge heavy metal disposing method in land utilization

InactiveCN1544366AControl Oxidation/Reduction PotentialEasy to handleSludge treatment by de-watering/drying/thickeningSludgeSulfide

The invention relates to a process for treating heavy metal in sludge comprising, using sulfides and lime as fixation agent, aligning formula and charging quantity according to the types and content of the heavy metal in the sludge, weighing and preparing fixation agent according to the weight ratio of sulfide / lime = 0.3-3, charging into sludge according to the percentage by weight of 0.5%-20% in the sludge, agitating homogeneously, stabilization treatment for 2-15 days, thus sludge meeting land use requirements can be obtained.

Owner:TONGJI UNIV

Biomass moulded coal and preparation method thereof

InactiveCN101985575ALow calorific valueLow volatileBiofuelsSolid fuelsFixation agentSodium hydroxide

The invention provides a method for preparing biomass moulded coal by using biomass and inferior smokeless pulverized coal as raw materials. The biomass moulded coal is prepared by uniformly mixing the biomass, the inferior smokeless pulverized coal and additives (a sulfur fixation agent, a biomass binder, an oxidant and a waterproofing agent), and performing low-pressure compression moulding by a wet method, wherein the sulfur fixation agent is calcined lime CaO; the biomass binder is light yellow dope prepared by treating bagasse by using 1 to 2 percent sodium hydroxide solution; the oxidant is potassium permanganate; and the waterproofing agent is tar or a binder. The biomass moulded coal comprises following raw materials in part by mass: 40 to 65 parts of inferior smokeless pulverized coal, 25 to 55 parts of biomass and 5 to 10 parts of additive. The biomass moulded coal has the advantages of low cost, low ignition point, high burn-off rate and integrative desulfurization and water proofing performance, and has great significance of energy conservation and environmental protection.

Owner:SOUTH CHINA UNIV OF TECH

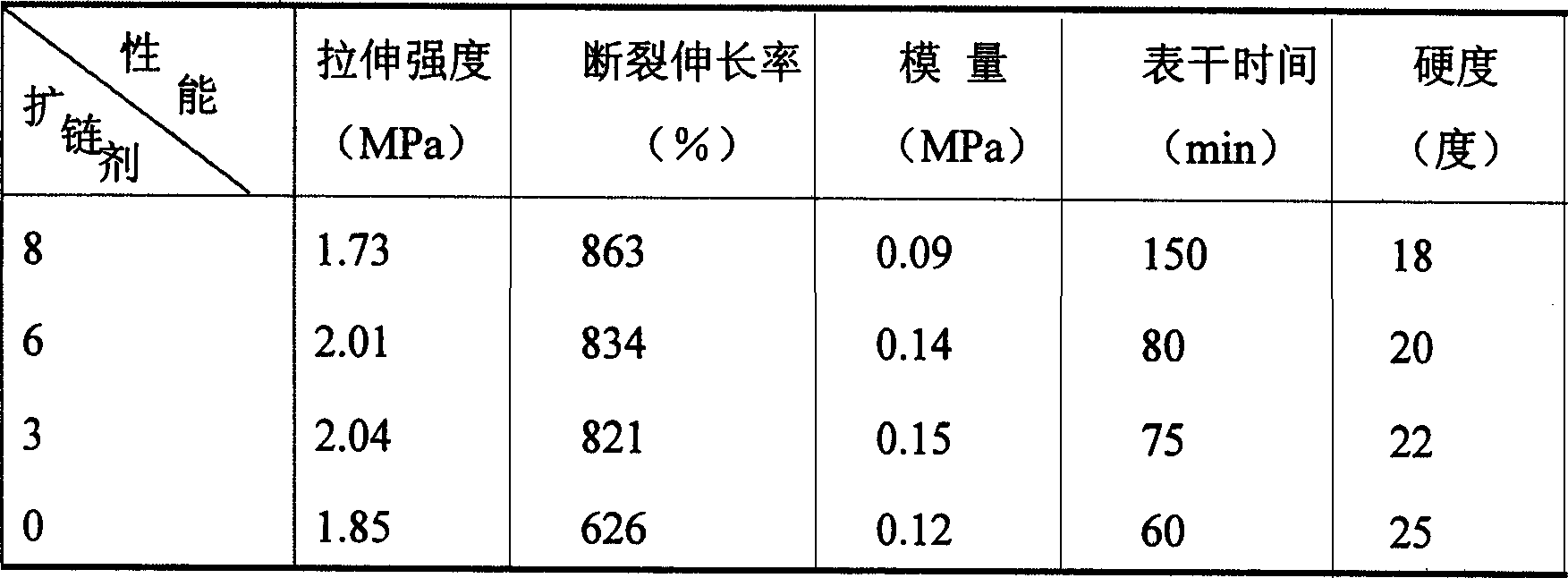

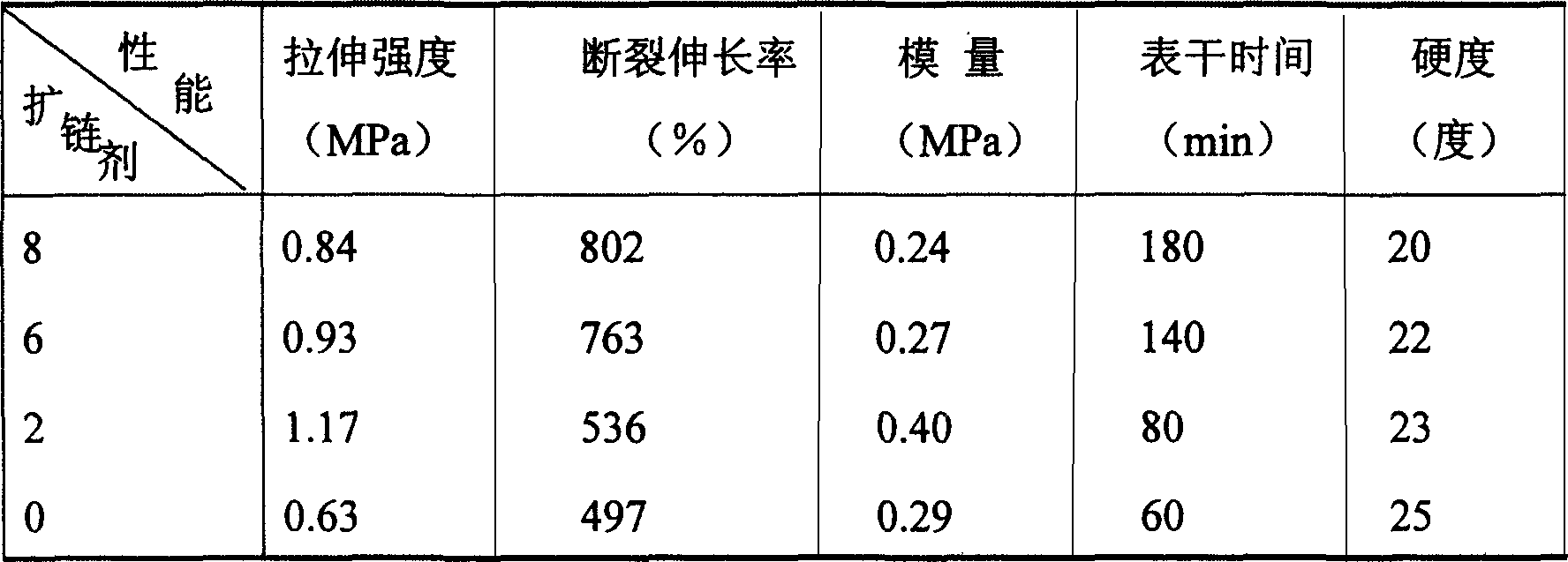

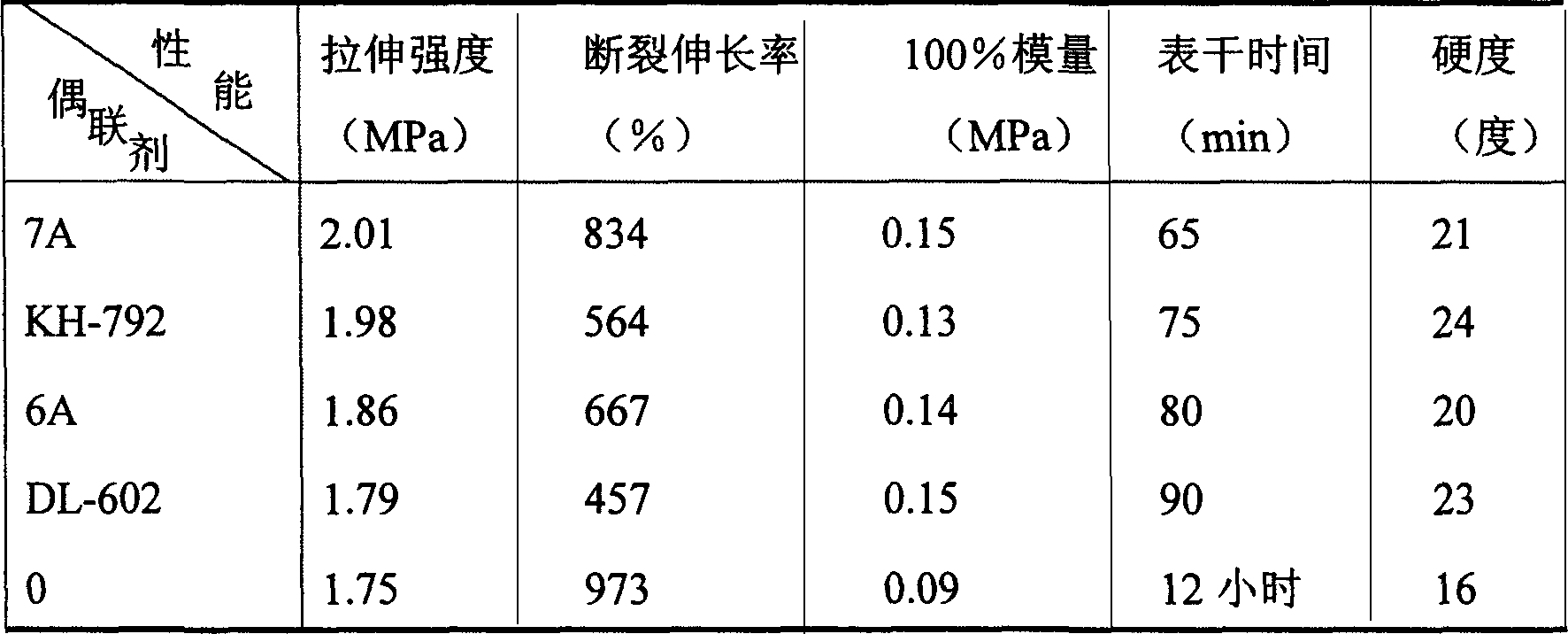

Low-modulus high-elongation high-adhesive-strength organosilicon sealing material and its preparing method

The invention discloses a method to make low modulus high extensibility high strength of bond organic silicon sealed material. The components are poly-organic radical siloxane 100 portions, filling material 50-200 portions, extending agent 1-10 portions, cross linking fixation agent 2-10 portions, activator 0.05-2 portions and silane coupling agent 0.1-5 portions. The sealing material has excellent weathering aging endurance and temperature endurance, good cementing and good water endurance.

Owner:ZHEJIANG UNIV +1

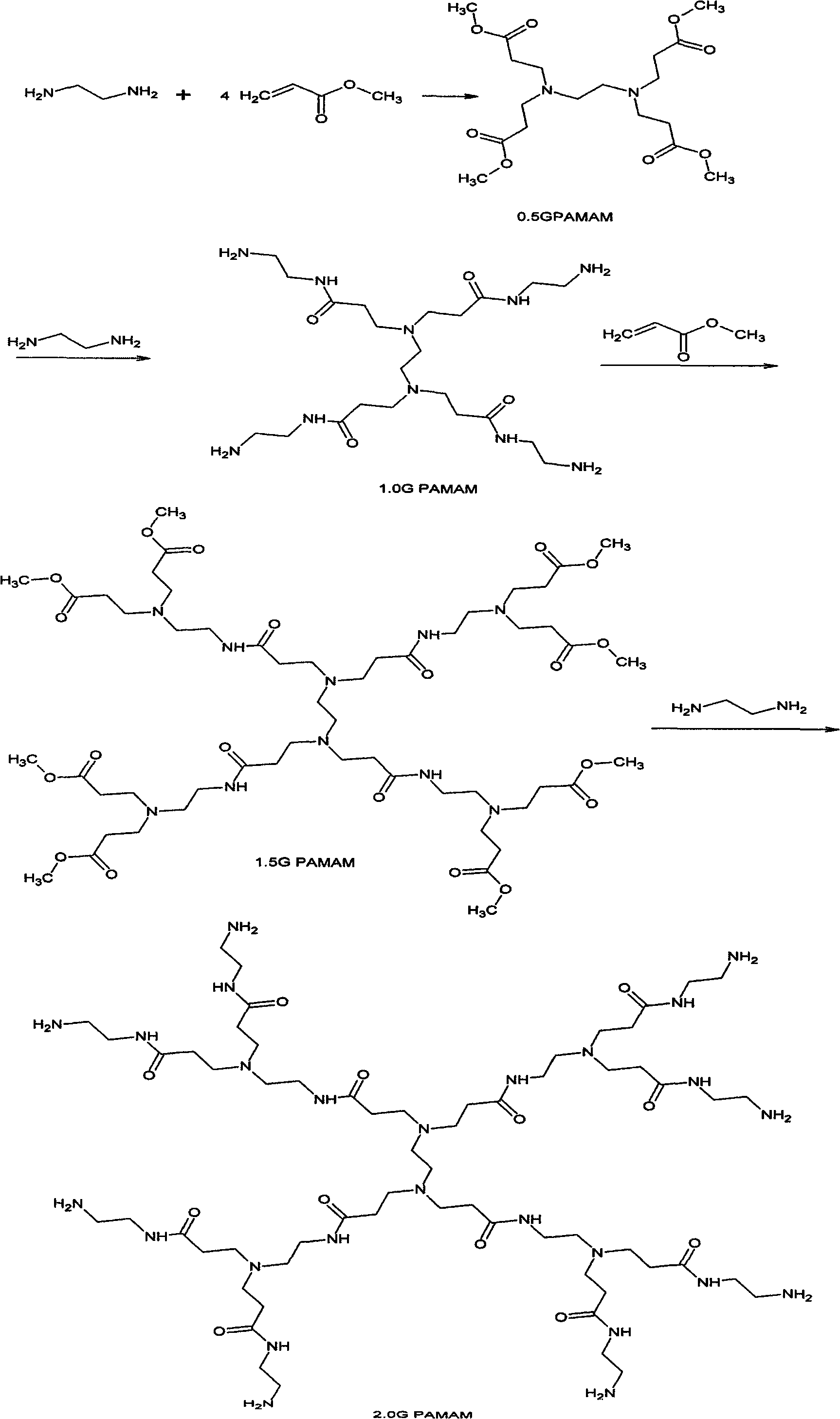

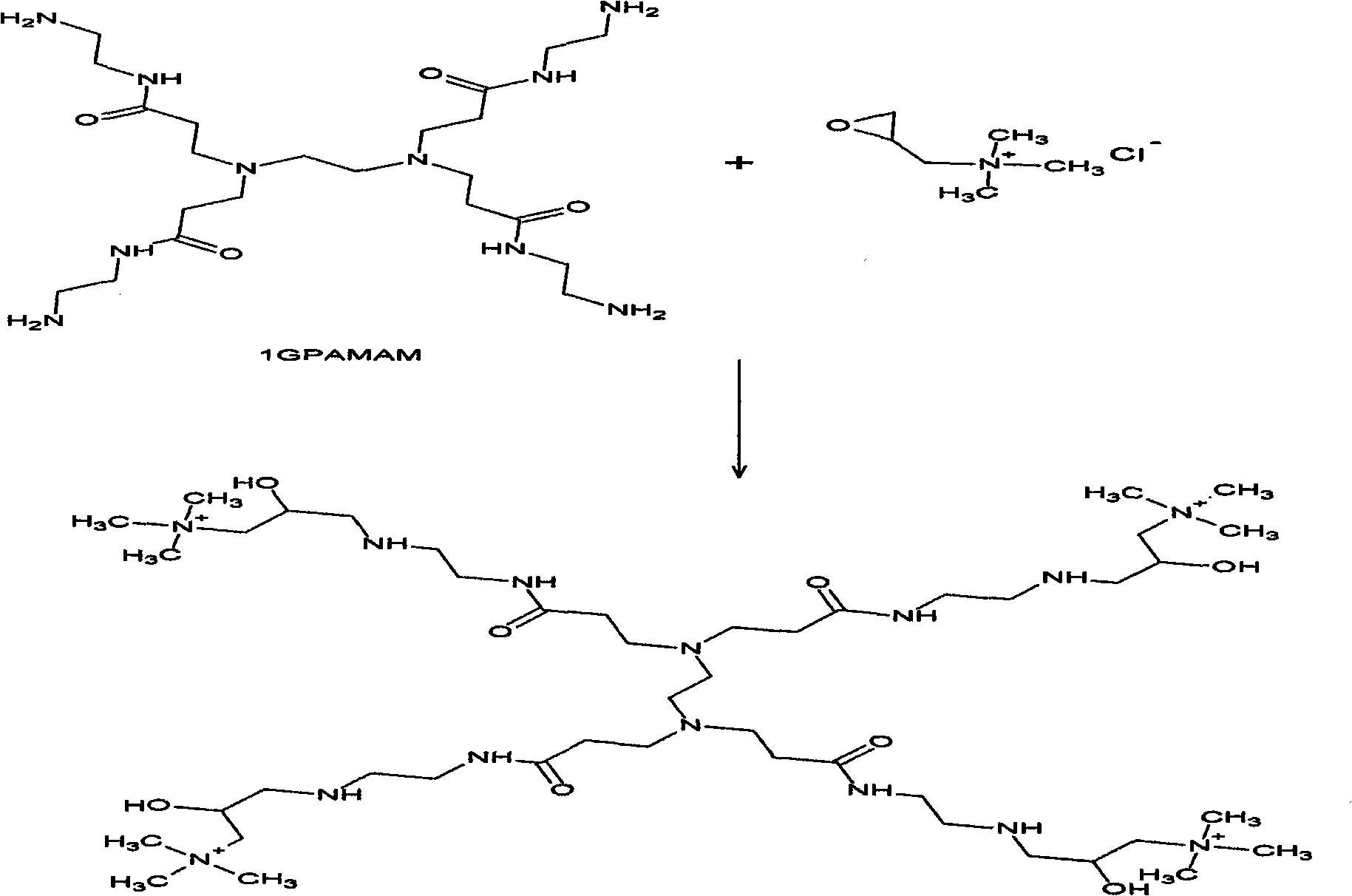

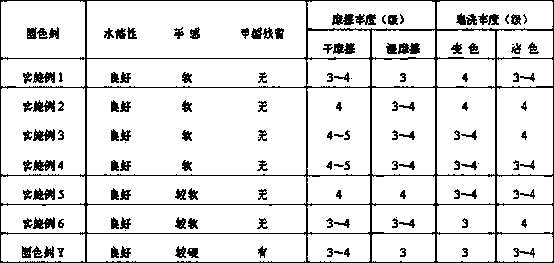

Dendriform cationic leather fixing agent and preparation method thereof

The invention relates to a method for preparing a leather fixing agent, in particular to a dendriform cationic leather fixing agent and a preparation method thereof. To overcome the defects of low activity, high consumption and easily caused grain leather existing in the prior art, the invention adopts a technical scheme that: the method for preparing the dendriform cationic leather fixing agent comprises the following steps: (1) mixing organic amine and acrylic ester, adding a reaction solvent, stirring to react, vacuumizing, distilling by rotating, and removing the solvent and excessive acrylic ester to prepare dendriform PAMAM; and (2) mixing the dendriform PAMAM prepared in the step (1) with a cationic etherifying agent, adding a solvent, adding an extracting agent after reaction, andextracting for multiple times to prepare graft modified dendriform cationic leather fixing agent. Compared with the prior art, the method has the advantages of reducing the hydrolysis effect of dye, improving fastness of leather to wet rubbing, reducing the consumption of the dye, not influencing the hand feeling of the leather, and making the fixing agent biologically degraded easily.

Owner:SHAANXI UNIV OF SCI & TECH

Fabric formaldehyde-free fixing agent

InactiveCN103669050AImprove color fixationHigh color fastnessDyeing processColour fastnessPolymer science

The invention discloses a fabric formaldehyde-free fixing agent. The fixing agent comprises the following raw materials in parts by mass: 10-15 parts of poly dimethyl diallyl ammonium chloride, 15-18 parts of 2-hydroxypropyltrimethyl ammonium chloride chitosan, 25-34 parts of water, 20-25 parts of ethanol and 5-10 parts of fatty alcohol polyoxyethylene ether. The fixing agent disclosed by the invention has an excellent fixation effect, and can effectively improve colour fastness of fabric dyes and wet rubbing fastness in the processes of dyeing and printing. The fabric treated by the fabric formaldehyde-free fixing agent does not discolor.

Owner:NANTONG TONGZHOU DISTRICT CHUANJIANG TOWN SUNWORLD DYNASTY HOME TEXTILE DESIGN STUDIO

Silk fiber knitted fabric dyeing method for achieving fluorescent color

The invention discloses a silk fiber knitted fabric dyeing method for achieving a fluorescent color. The dyeing method comprises the following steps: adding a scoured and bleached silk fiber knitted fabric into a machine, adding water, starting a cycle, adding a wetting agent, adjusting the pH value of a work solution to 4-5 with acetic acid, and starting heating; adding a modifier; heating, wherein a heating rate is 1-2 DEG C / min; carrying out thermal insulation for 30 min, wherein the temperature is 75-80 DEG C; adding soda ash to adjust the pH value of the work solution to 9-10; draining the solution, and carrying out water washing; adding water, acetic acid, a cationic fluorescent dye, and a leveling agent; heating, wherein the heating rate is 1-2 DEG C / min; carrying out thermal insulation; draining the solution, and carrying out water washing; soaping; carrying out water washing; carrying out color fixation, wherein the amount of a color fixation agent is 2-5% owf, and the temperature is 65-70 DEG C; and drying. According to the present invention, the silk fibers are modified, and the existing cationic fluorescent dye is adopted to achieve fluorescent dyeing of the silk fiber knitted fabric, such that the fabric achieves a fluorescent color, and adverse impact of fluorescent coating material dyeing on fabric wearability and the problem of difficulty in achieving industrial production are overcome.

Owner:FOSHAN MINGZHOU TEXTILE

Method for making high-grade cabretta soft leather with defective sheepskin blue plate

InactiveCN1594599AAvoid wastingLow costLeather surface mechanical treatmentLeather surface finishingWaxSheep skin

The invention relates to a method for making high-grade sheep skin soft upper leather from inferior sheep skin, which comprises: dying, polishing leather, spraying sarcenet oil, mending, smoothing, grounding using grounding agent, brushing and scraping using multi-membrane agent several times, plucking skin, beating soft, scraping skin, Spraying surface slurry, spraying fixation agent, spraying hand feeling agent, ironing etc. Grounding agent is formulated by cation compound resin, non-ionic wax, cation color cream and water. Multi-membrane agent is formulated by non-ionic caseose-free color cream, compound resin, small molecule acroleic acid, swelling resin etc. Surface slurry is formulated by color cream, non-ionic wax, compound resin, silicon casein, flexible acroleic acid, paint slurry etc. fixation agent is formulated by water and aqueous gloss oil. Grounding agent is used mechanically and manually in the invention. Multi-membrane agent ,surface slurry and fixation agent have low cost , little pollution and can make high-grade sheep skin soft upper leather from inferior sheep skin.

Owner:孟立君

Methods and apparatus for securing medical instruments to desired locations in a patient's body

Devices and methods are provided for securely affixing a medical instrument to desired tissue in a patient's body, using a fixation agent. Such medical instruments may comprise localization wires or tissue acquisition instruments, such as biopsy instruments, for example. In the case of tissue acquisition instruments, the inventors have discovered significant advantages for securely affixing the distal end of the tissue acquisition instrument to a particular tissue target area. For example, such an approach permits the imaging environment to be uncoupled from the procedural environment so that expensive and often unavailable imaging equipment, such as stereotactic imaging equipment, need not be used. In a preferred embodiment, a bonding agent, such as adhesive, surgical glue, or a solvent, is used as the fixation agent.

Owner:SENORX

Lignin sand-fixation agent

A sand-fixation lignin chemical is prepared from the waste digestion liquid generated in chemical pulping step through reaction on aldehyde compound, adding less cross-linking agent and condensating reaction on urea. It is applied by spraying it on ground surface for preserving water, improving soil and increasing the survival rate of vegetation.

Owner:NANJING FORESTRY UNIV

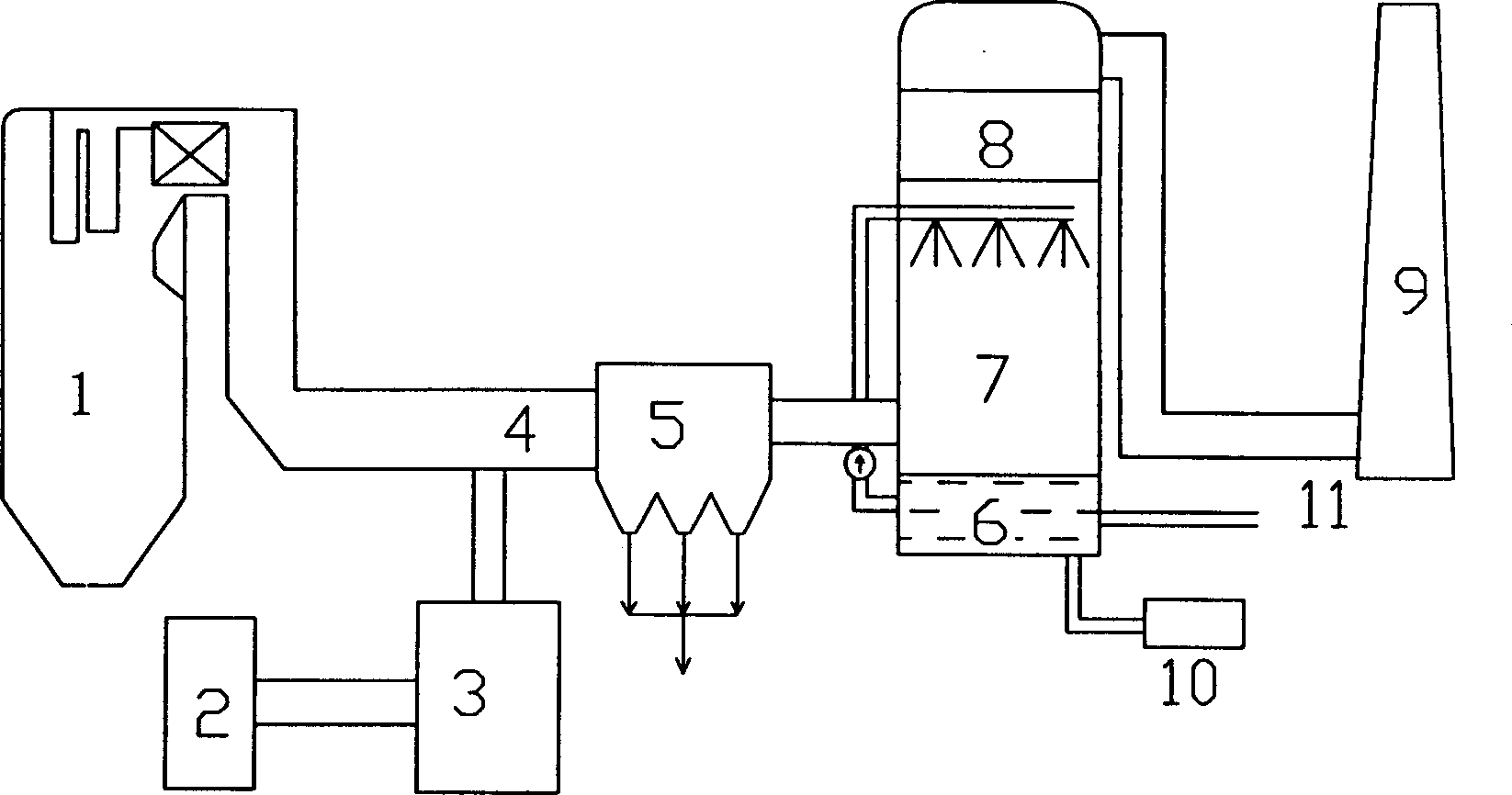

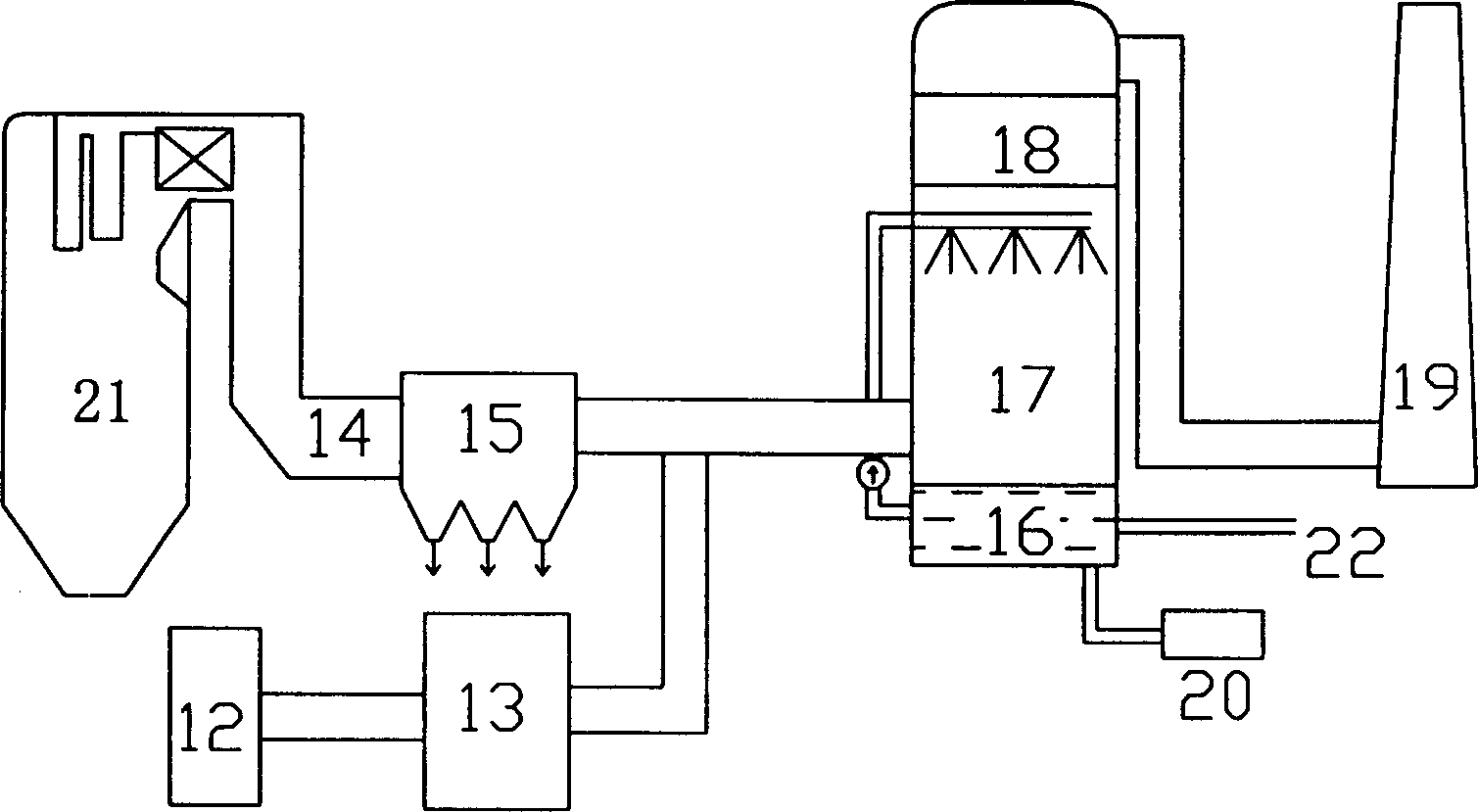

Method for removing hydrargyrum from coal burning boiler flue gas by ozone oxidation

The invention provides a method for controlling the hydrargyrum exhaustion of boiler smoke. The method comprises: ejecting ozone into the low-temperature section of smoke channel of boiler whose temperature ranges from 110-150Deg. C; oxygenizing the nonvalent Hg which is not dissolved in water into bivalent Hg; washing the smoke in the washing tower to dissolve the bivalent Hg in water; adding H2S fixation agent into solution to generate HgS deposition from bivalent Hg. Compared to the Hg exhaustion removing efficiency in present fire coal power station which is lower than 50-50%, the total Hg removing efficiency of said invention can be over 80%.

Owner:ZHEJIANG UNIV

Embedding medium suitable for plant tissue frozen section and frozen section method

InactiveCN102816401AOvercome the problem that it is easily soluble in fixative and cannot be fixed first and then slicedSlice flatDead plant preservationPreparing sample for investigationBiotechnologyCellulose

Owner:HUNAN UNIV OF SCI & TECH

Fabric formaldehyde-free fixing agent and preparation method thereof

ActiveCN103669041AImprove washing fastnessSimple preparation processDyeing processPolymer scienceMeth-

The invention relates to a fabric formaldehyde-free fixing agent, and a preparation method thereof, and belongs to the technical field of textile auxiliary agents. The fixing agent comprises the following components in parts by weight: 15-25 parts of crylic acid butyl ester, 5-9 parts of chitosan hyamine, 6-10 parts of isobornyl acrylate, 7-14 parts of acrylyl oxyethyl acrylate trimethyl ammonium chloride, 8-10 parts of triallylamine, 2-5 parts of organo-siloxane, 3-5 parts of glacial acetic acid, 0.1-1 part of azodiisobutyronitrile and 100-120 parts of deionized water. The fabric formaldehyde-free fixing agent is simple in preparation process, the prepared fixing agent is free of formaldehyde and APEO (Alkylphenol Ethoxylates), static combination of cation groups in fixing agent molecules with anion groups in dye can be achieved, insoluble lake can be formed on the surface of a fabric, and hydrosolvent groups of the dye are sealed up, so that the washing fastness of the colored fabric can be improved.

Owner:JIANGSU ZHONGXIN RESOURCES GRP

Digital printing process for polyester-cotton fabric

InactiveCN107090724ASolve contaminationColorfulDry-cleaning apparatus for textilesGrip property fibresCooking & bakingDisperse dye

The invention relates to a digital printing process for a polyester-cotton fabric. The digital printing process comprises the following process steps: (1) sizing a polyester-cotton fabric; (2) digital printing: carrying out spray printing according to a pattern requirement of rip printing software, generating cyan by virtue of color card generation software (C:100, M:100, Y:100 and K:100), and carrying out unreeling and sequential digital printing on the fabric reeled in the step (1), wherein a printer comprises a first spray head and a second spray head, the first spray head is used for spraying and printing disperse dye ink, the second spray head is used for spraying and printing active dye ink, and a printing condition is that bidirectional four channels are adopted; (3) high-temperature baking: baking the digital-printed fabric in the step (2) at 180-190 DEG C for 40-50 seconds; (4) cotton-cloth steaming; (5) a washing and soaping process: carrying out open-width washing on the fabric processed in the step (4); and (6) shaping and drying: adding a softening agent and a color fixation agent into the fabric processed in the step (5) for shaping, and drying at a temperature of 150-160 DEG C, wherein the speed of a drying vehicle is 40m / min-50m / min.

Owner:杭州科迈数码纺织技术有限公司

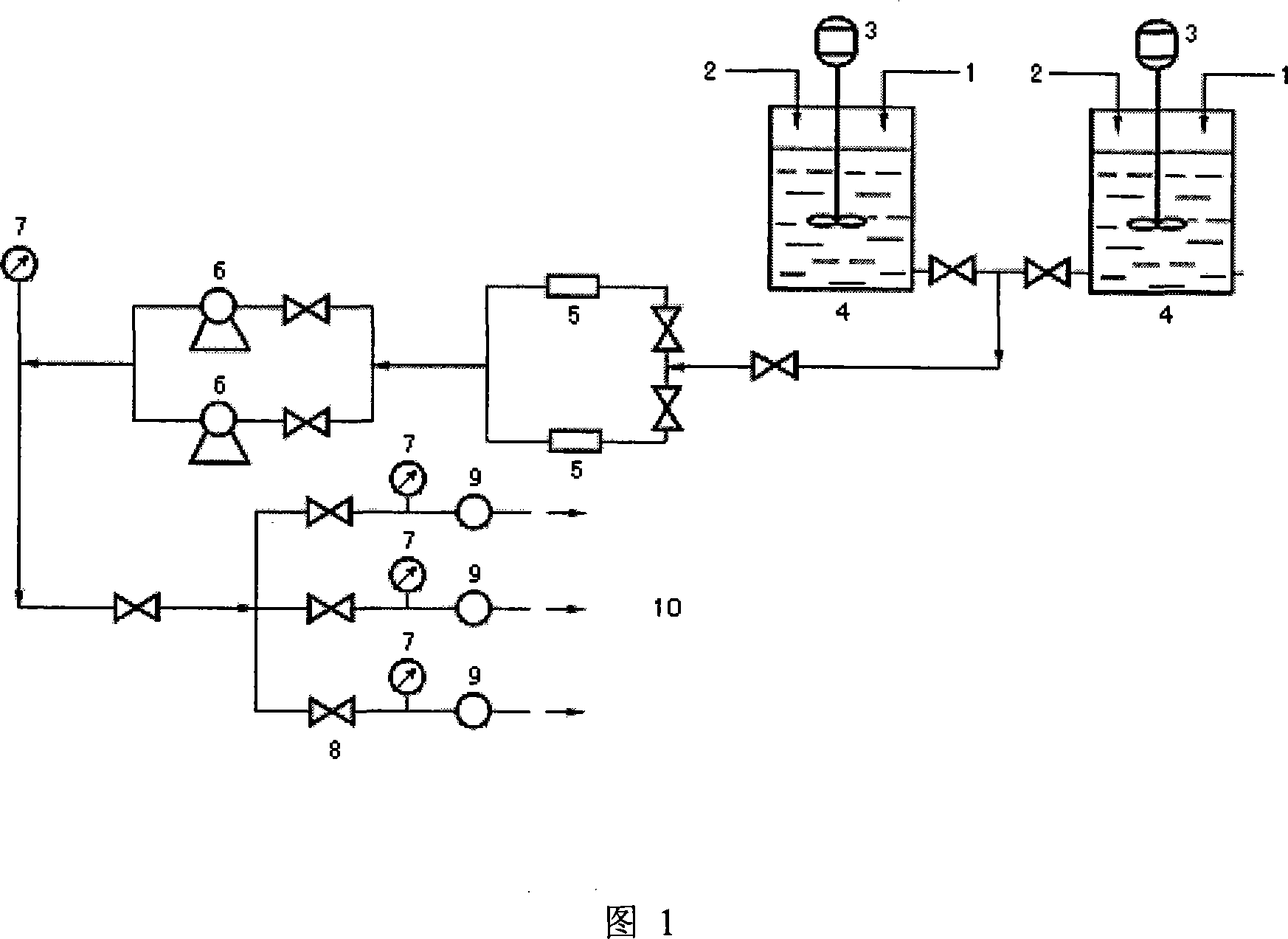

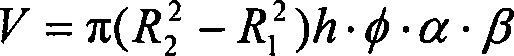

Preparation method of cationic organic silicon modified poly(diallyldimethylammonium chloride) fixing agent

ActiveCN103709326AHigh positive charge densityImprove water resistanceDyeing processNitrogen gasFixation agent

The invention relates to the technical field of fixing agent, and provides cationic organic silicon modified poly(diallyldimethylammonium chloride) fixing agent and a preparation method thereof. The preparation method comprises the following main steps: uniformly mixing dimethyl diallyl ammonium chloride, an organic silicon monomer, chelator and deionized water; and introducing nitrogen gas to expel oxygen, then adding initiator, and performing free radical polymerization to obtain the cationic organic silicon modified poly(diallyldimethylammonium chloride) fixing agent. The fixing agent prepared through the method provided by the invention is used for finishing after dyeing, the dry and wet rubbing fastness (especially wet rubbing fastness) of anionic dye for dyeing can be enhanced, the shade is not influenced, and the feeling of textile can be kept soft; and the fixing agent prepared through the preparation method is free of formaldehyde, non-toxic and environment-friendly, and is novel dyeing and printing auxiliary agent.

Owner:FUJIAN QINGYUAN TECH

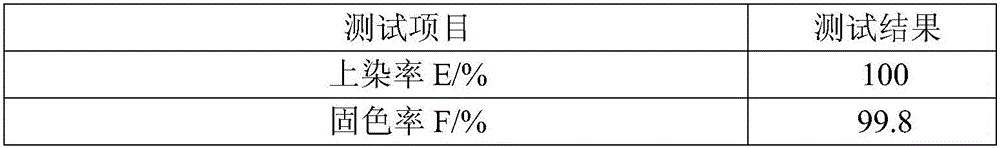

Non-aqueous solvent dyeing method of washing-free reactive dye

The invention provides a non-aqueous solvent dyeing method of a washing-free reactive dye. The non-aqueous solvent dyeing method comprises the following steps: mixing pre-treated loose fibers, yarns, fabric or clothes with an reactive dye, a micro-molecular quaternary ammonium salt and a good solvent of the reactive dye, so as to form a mixing system; raising the temperature of the mixing system; adding a bad solvent of the reactive dye into the mixing system before raising the temperature or in a temperature rising process; keeping the heat after raising the temperature to a dyeing temperature, wherein the volume ratio of the good solvent of the reactive dye and the bad solvent of the reactive dye is 1 to (3-30), the ratio of the volume of the good solvent of the reactive dye to the mass of the loose fibers, the yarns, the fabric or the clothes is (0.8-10)mL to 1g, and the mass ratio of the micro-molecular quaternary ammonium salt to the reactive dye is (0.1-0.5) to 1; and then drying and putting into a color fixation solution and carrying out color fixation treatment, wherein the color fixation solution contains a 5-100g / L color fixation agent.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Dyeing and finishing process for modal fabric

InactiveCN104975499AReduce pollutionAvoid damageBiochemical fibre treatmentHeating/cooling textile fabricsInorganic saltsProcess engineering

The invention discloses a dyeing and finishing process for modal fabric. The process comprises the procedures of pretreatment, pre-setting, modification treatment, dyeing, soaping, fixation, after-finishing, drying, sizing, calendering and rolling. According to the invention, pretreatment is carried out by adopting ultrasonic wave, and a step of modification treatment is added; in the dyeing procedure, a base substituent SA is used, use of a large quantity of alkaline substances and inorganic salt is avoided, nature dye is adopted, and colophony powder is added as a fixing agent, so that the color fixing effect is enhanced, environmental pollution is avoided, and the requirement of green environmental protection is met; furthermore, montmorillonoid is adopted to carry out modification treatment and flame retardant treatment on the fabric, so that the flame retardancy of the fabric is high. According to the invention, a yellowing-resisting reagent is used in the procedures of pre-setting, sizing and after-finishing, so that the final fabric cannot become yellow easily.

Owner:TAICANG CHENGLE CHEM FIBER

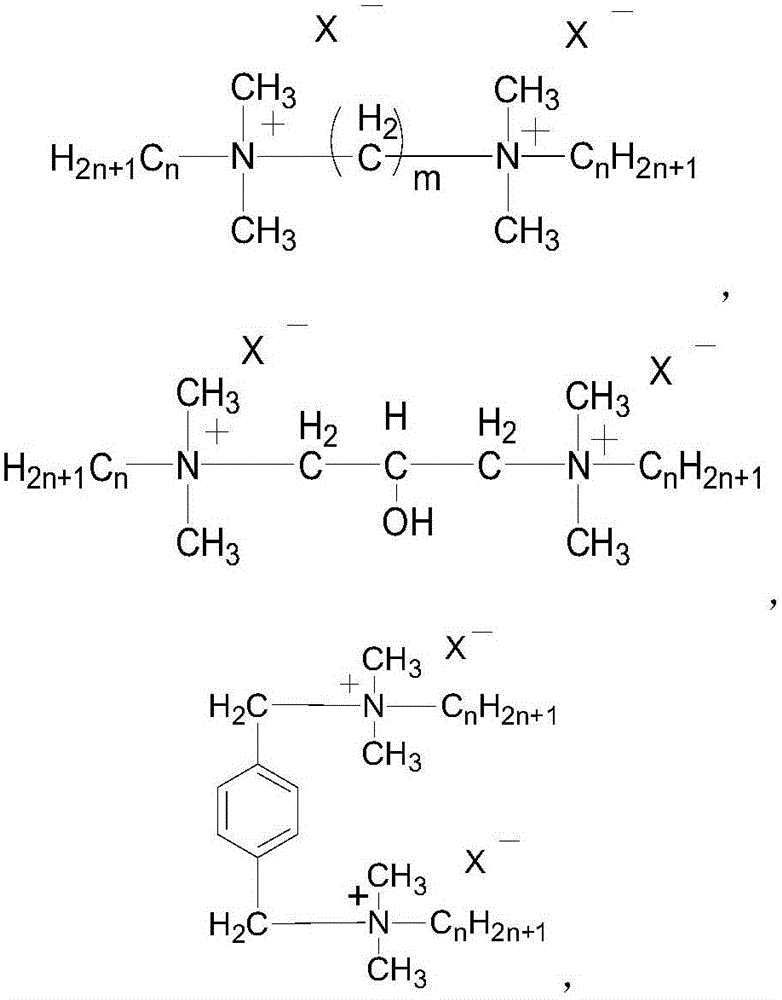

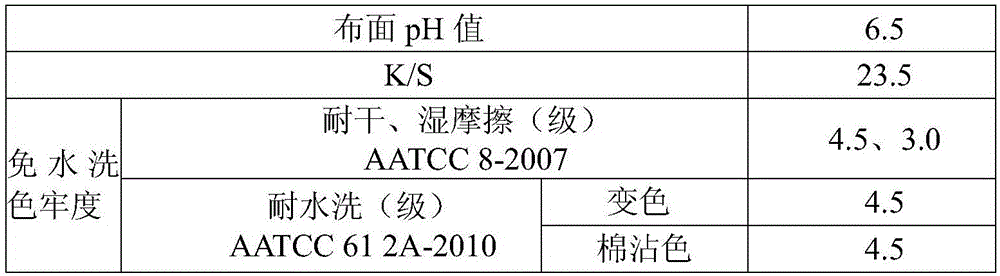

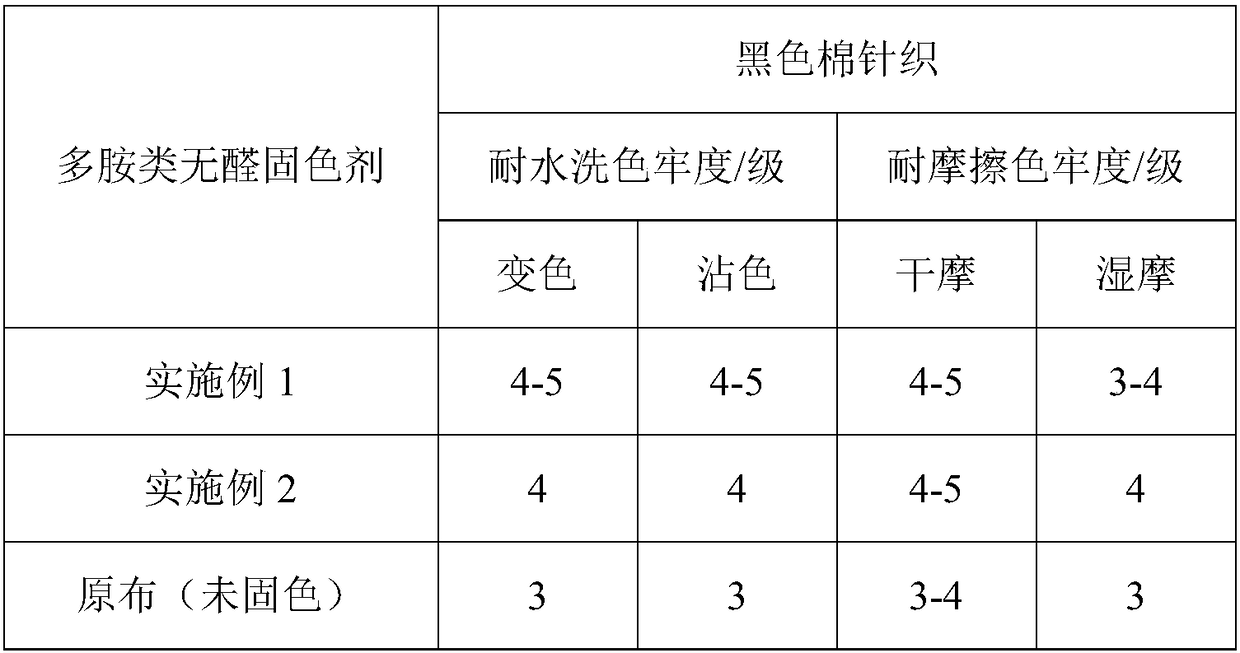

Polyamine formaldehyde-free fixing agent as well as preparation and application method thereof

InactiveCN108660810APrevent falling offImprove color fastnessDyeing processQuaternary ammonium surfactantIon

The invention provides a polyamine formaldehyde-free fixing agent as well as preparation and application method thereof. The polyamine aldehyde-free fixing agent is prepared from the following components in parts by weight: 8 to 15 parts of organic amine monomer, 5 to 15 parts of N-aminoethyl piperazine, 10 to 20 parts of quaternary ammonium cationizing agent, 15 to 25 parts of dicyandiamide, 2 to5 parts of organic acid, 8 to 15 parts of organic solvent, 5 to 15 parts of epichlorohydrin, 10 to 20 parts of cationic etherifying agent, 5 to 10 parts of polyvinyl alcohol (PVA) and 40 to 60 partsof deionized water. The polyamine formaldehyde-free fixing agent provided by the invention is green and environmentally friendly, and can eliminate reddish color produced during dyeing while fixing, thus avoiding repairing dyeing, and effectively improving various color fastnesses of fabrics, such as washing fastness, friction fastness and boiling water fastness.

Owner:苏州联胜化学有限公司

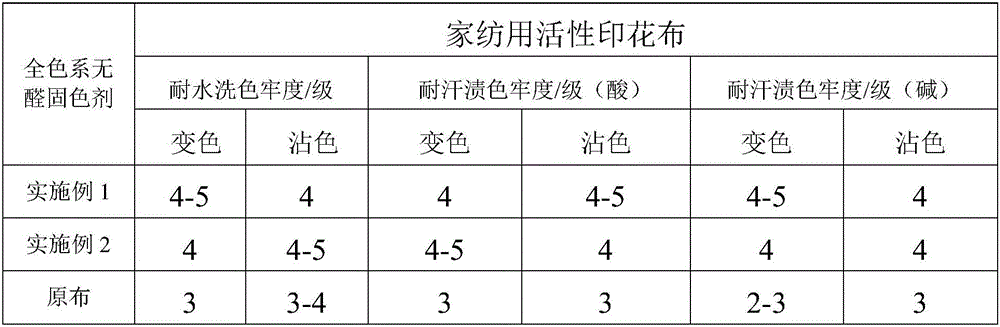

Formaldehyde-free fixing agent for all-color-series reactive dyes as well as preparation method and use method of formaldehyde-free fixing agent

The invention provides a formaldehyde-free fixing agent for all-color-series reactive dyes as well as a preparation method and a use method of the formaldehyde-free fixing agent. The formaldehyde-free fixing agent is formed by compounding a first fixing agent and a second fixing agent in a ratio being (1-3):(2-4) in parts by weight. According to the formaldehyde-free fixing agent for all-color-series reactive dyes, two different types of fixing agents are compounded, so that the formaldehyde-free fixing agent contains quaternary ammonium salt cation groups and reactive groups, the groups can have a certain synergistic effect, and the fixing performance of the formaldehyde-free fixing agent is more outstanding.

Owner:苏州联胜化学有限公司

Re-use agent for polymer after driving and injecting method thereof

InactiveCN101058723AChange flow directionEnhanced overall recoveryFluid removalDrilling compositionFixation agentPolymer

The invention discloses a reusing agent of residual ground polymer driven by polymer as well as injecting method, which is characterized by the following: adopting double-liquid method fixation agent and modified calcium soil as flocculant; allocating the fixation agent with 0. 09%-0. 54% Na2Cr2O7 solution and 0. 16%-0. 96% Na2SO3 solution with bulk rate at (0. 8-1. 2):1; making the flocculant as modified calcium soil added by Na2CO3 and NaHCO3. The injecting method comprises the following steps: injecting Na2Cr2O7 solution first and insulating liquid separately; injecting Na2SO3 solution and flocculant; injecting water normally. The invention can do deep adjusting and dissect for residual ground polymer, which can change the flowing direction of ground flow effectively and improves the recovery efficiency after driving by polymer.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com