Patents

Literature

623results about "Leather surface mechanical treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

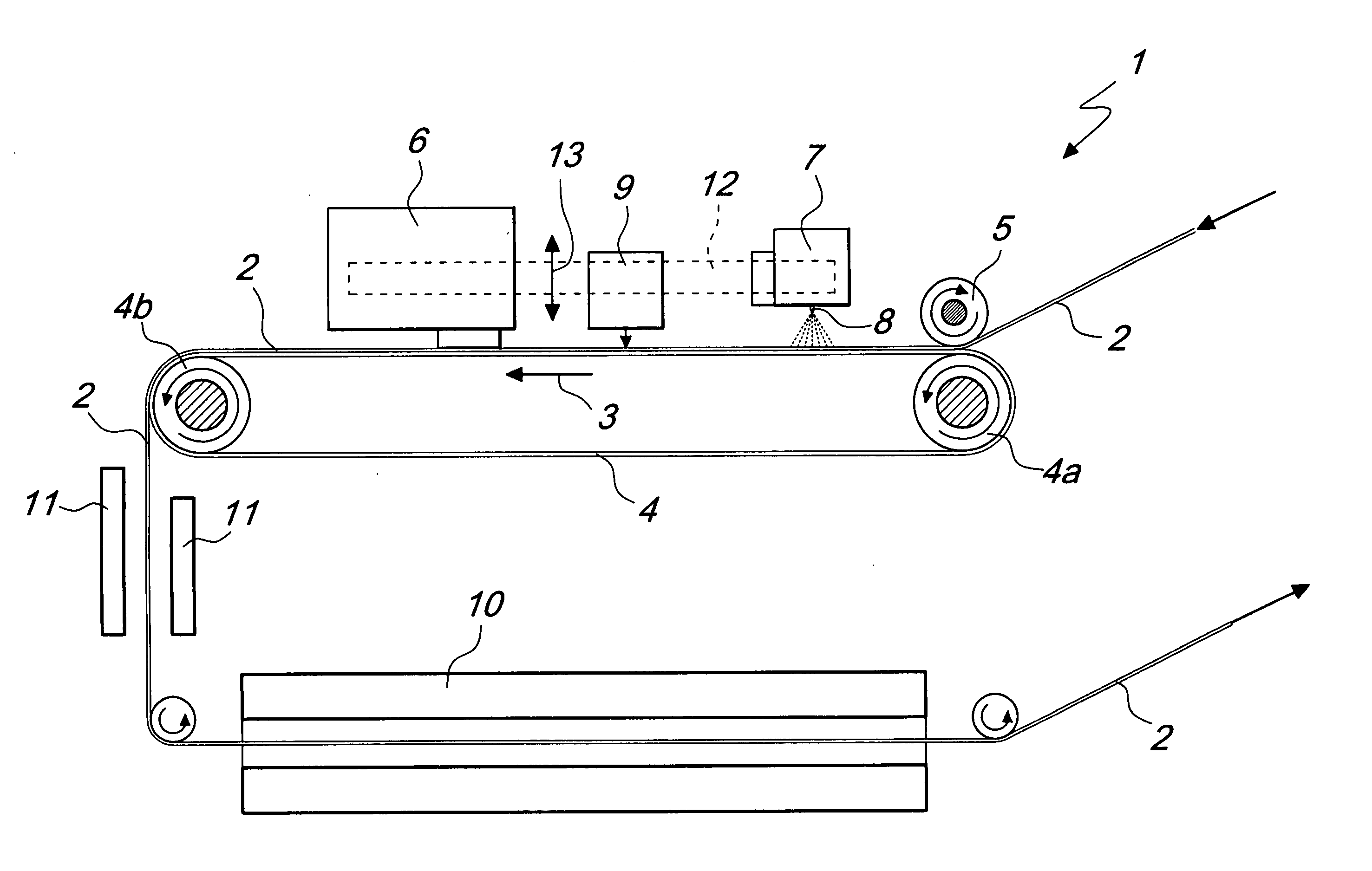

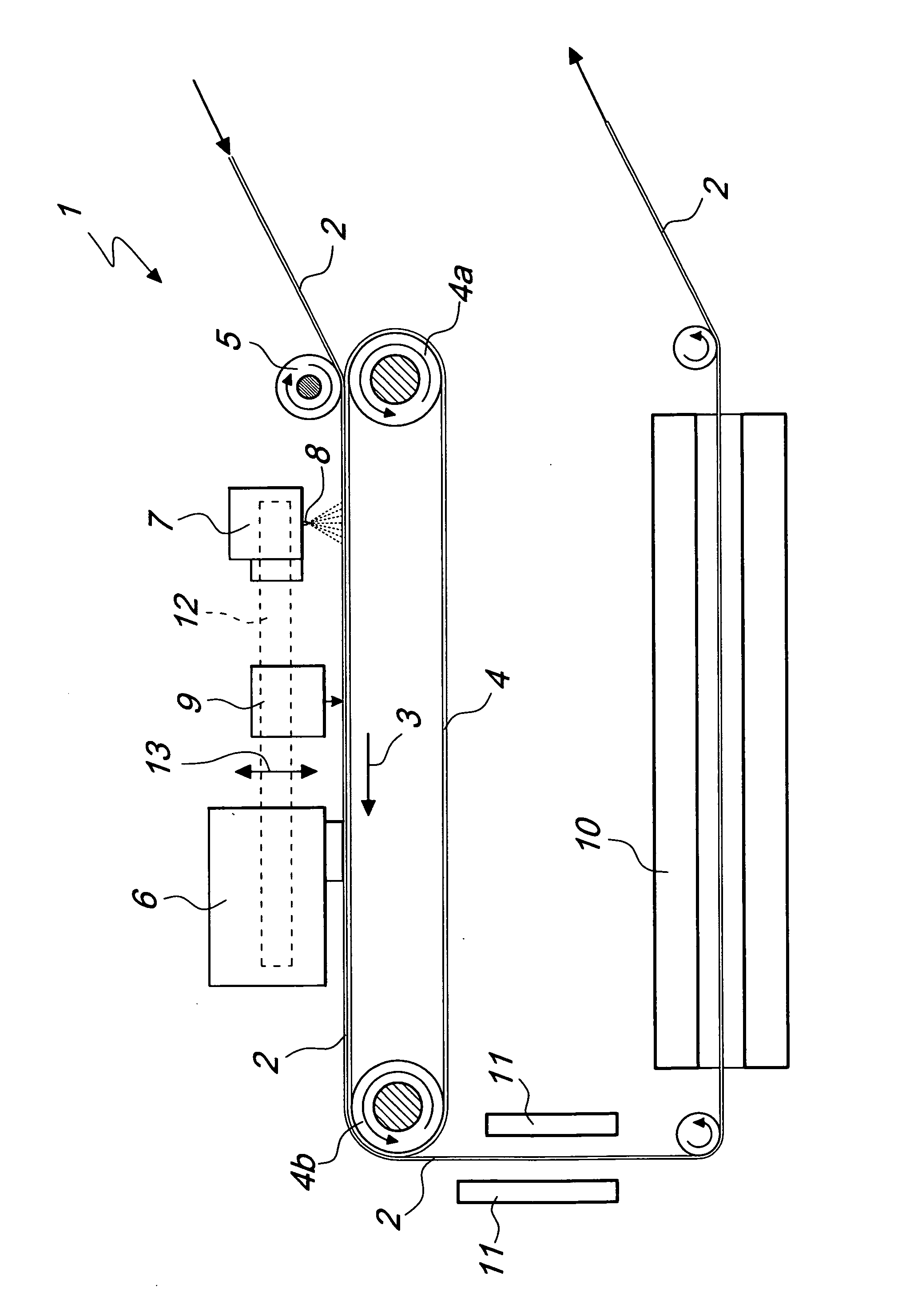

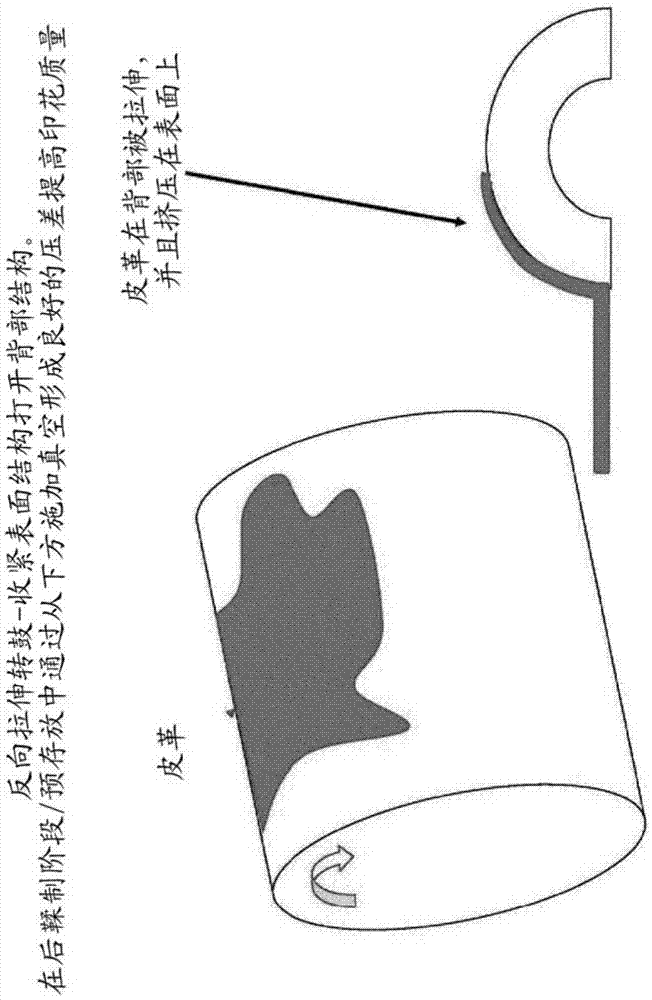

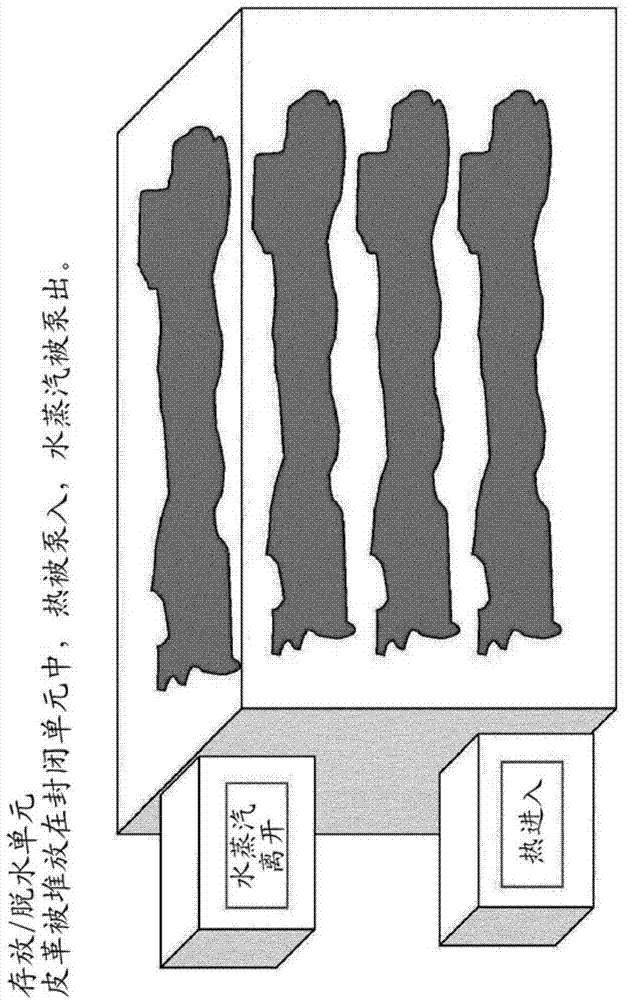

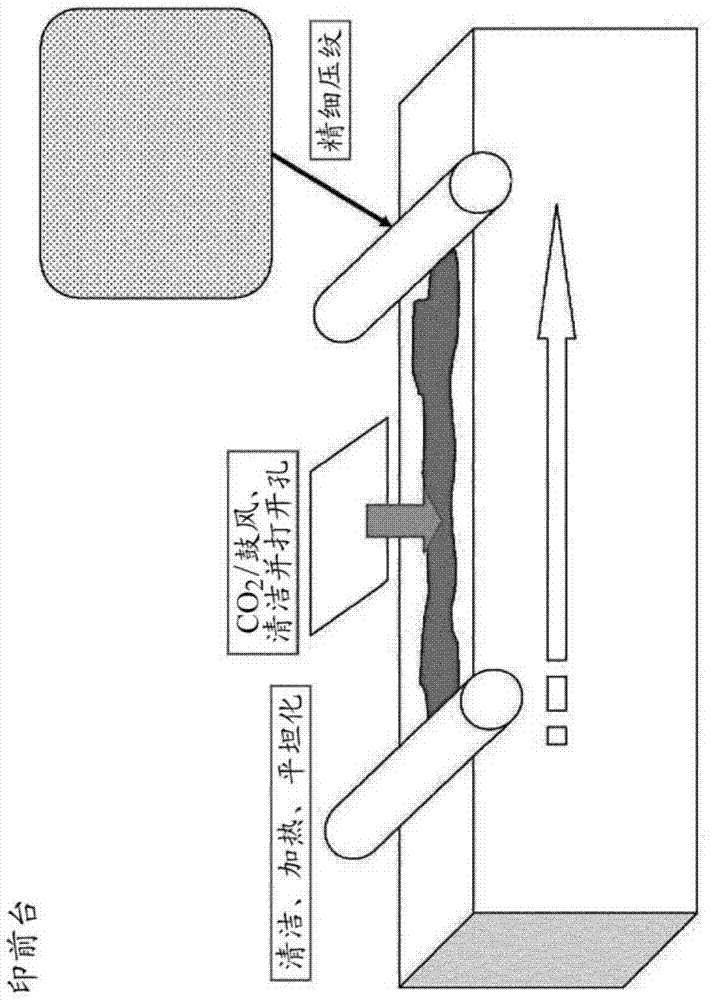

Method and apparatus for digital inkjet printing of materials, particularly sheet-like materials such as fabrics, hides or the like

InactiveUS20050206711A1Low costDuplicating/marking methodsTypewritersEngineeringMechanical engineering

Owner:MILINI PAOLO

Method for manufacturing washable cow split leather

ActiveCN107502685AFully rehumidifiedImprove washing resistanceTanning treatmentPre-tanning chemical treatmentSofteningChemistry

The invention relates to a method for manufacturing washable cow split leather and belongs to the technical field of manufacture of leather. The method comprises the following steps: taking a cow split leather blank subjected to wringing and shaving, and sequentially performing re-wetting, primary washing, retanning, neutralizing, secondary washing, filling, dyeing, stuffing, acid solidification, thrice washing, fixing, quartic washing, drying, hanging and airing, vibratory softening, leather fluffing and milling. The washable cow split leather manufactured by the method has favorable washability, and is high in leather yield.

Owner:漳州香洲皮革有限公司

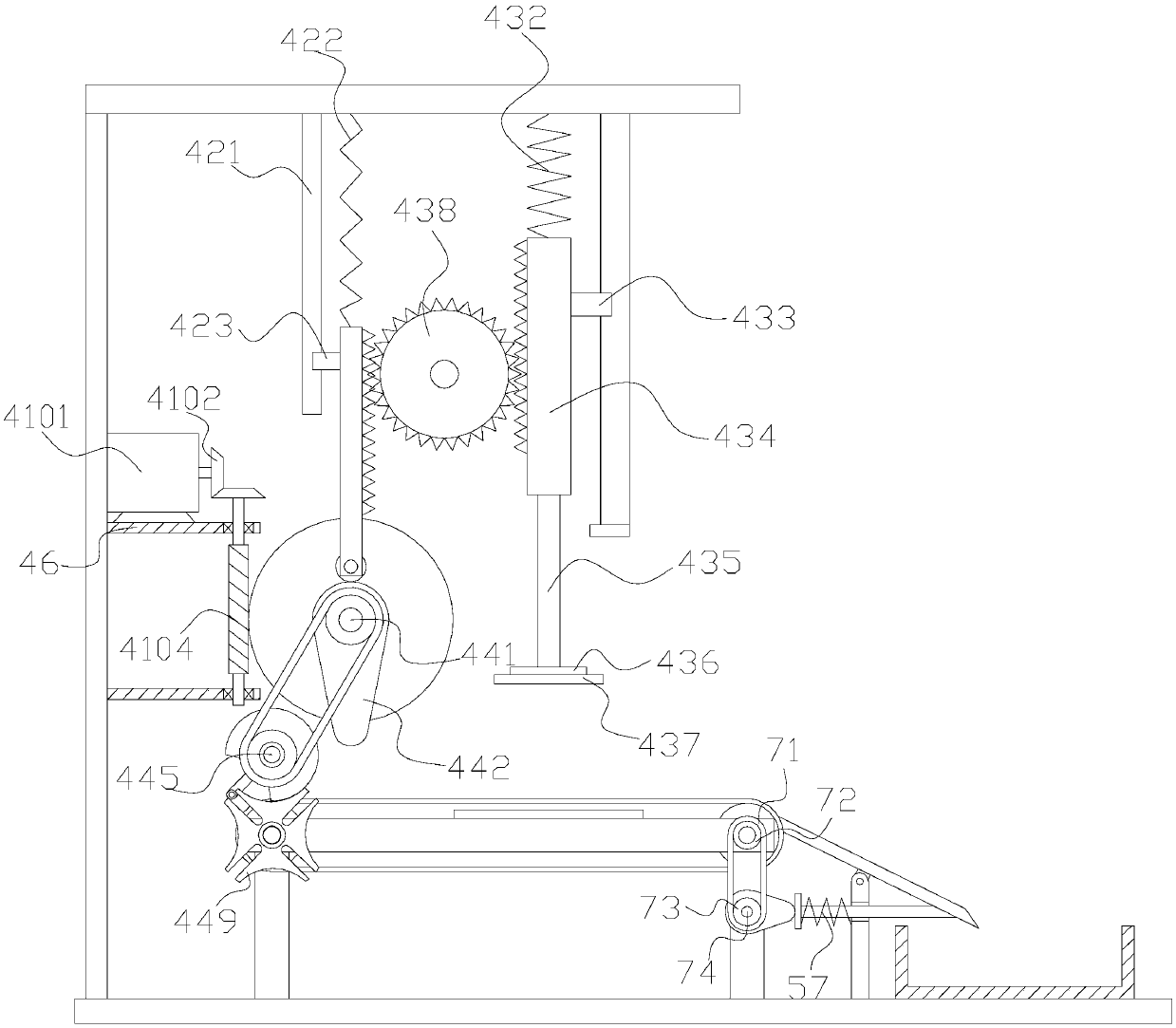

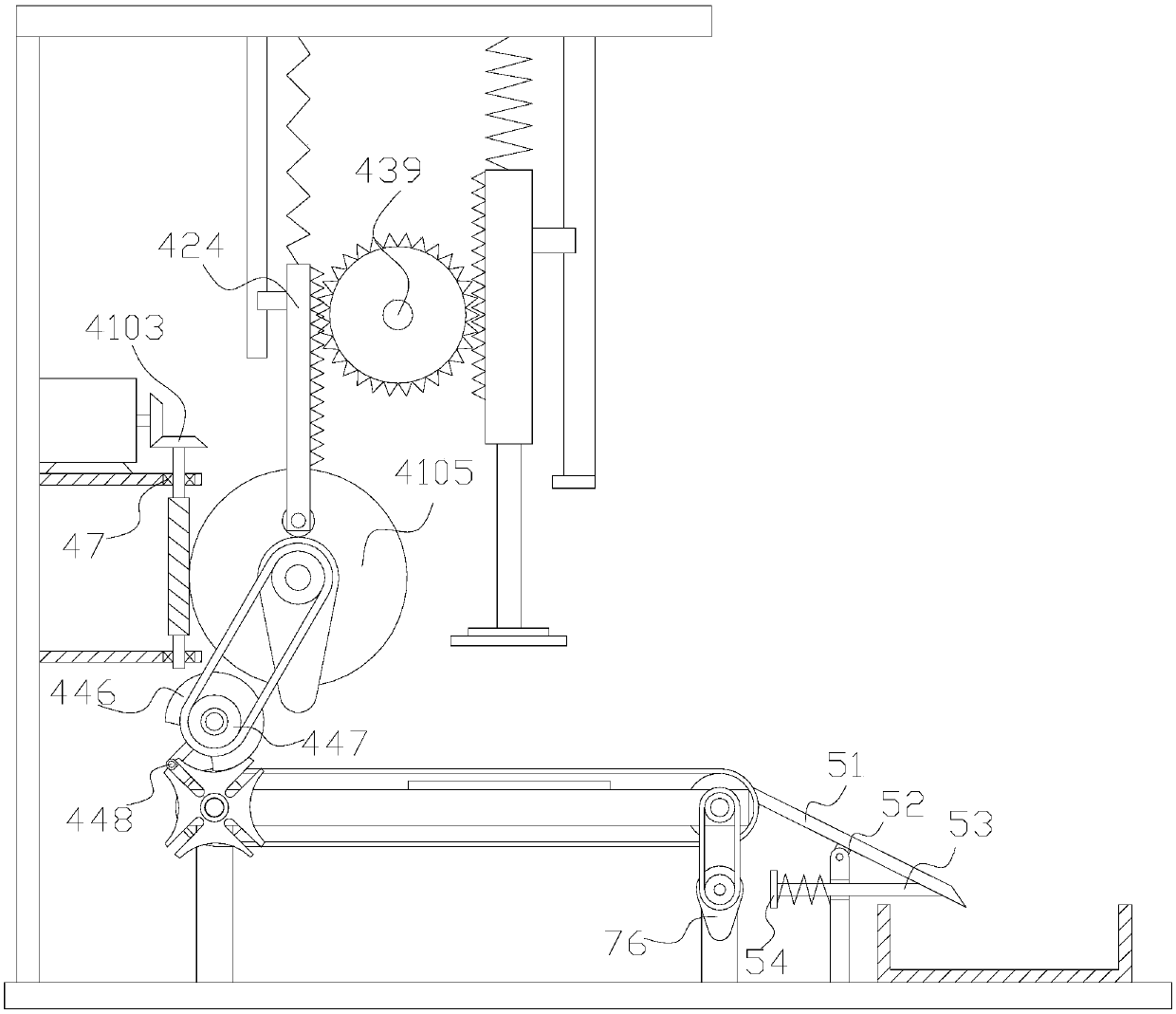

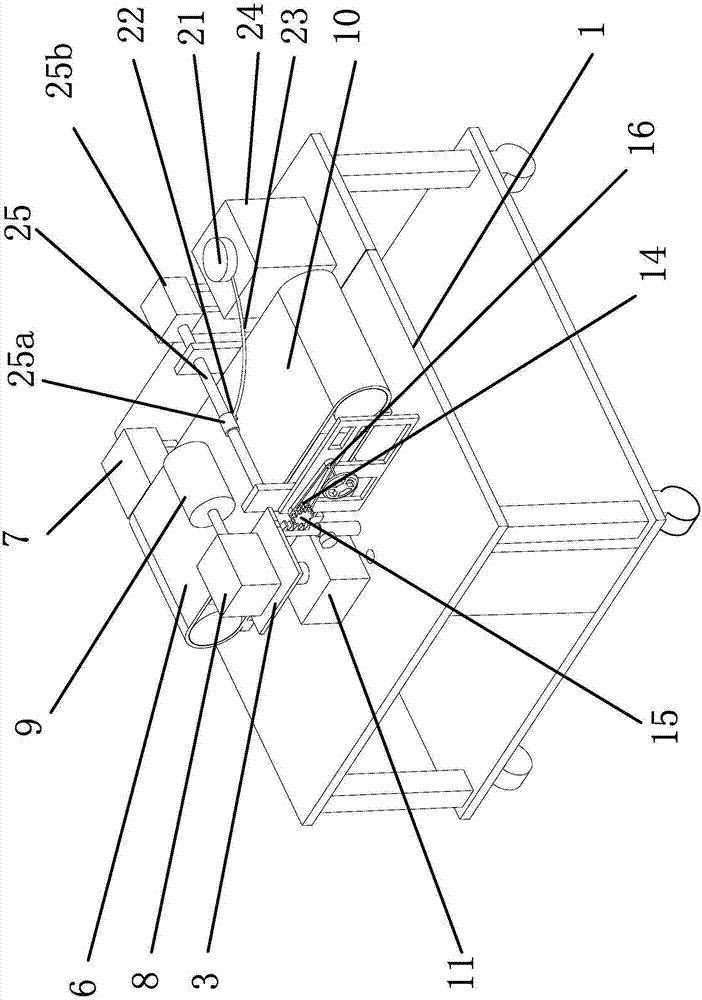

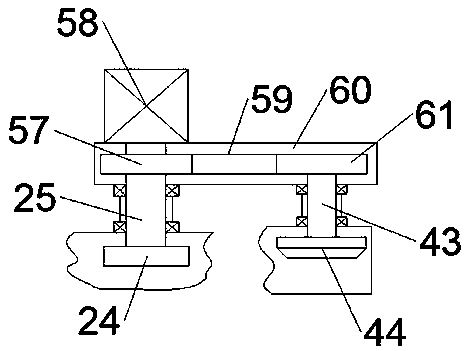

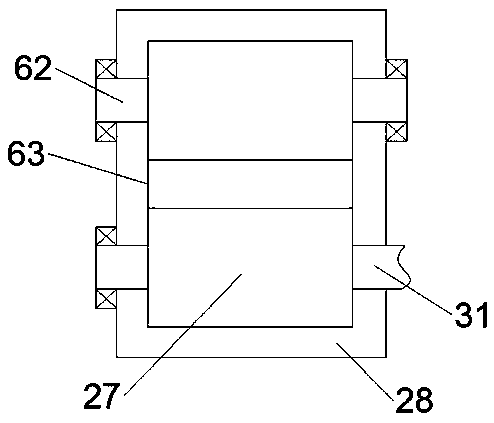

Leather embossing device for basketball manufacture

InactiveCN108676929AImprove work efficiencyAvoid accidental injurySkins/hides/leather/fur manufacturing apparatusBall sportsConveyor belt

The invention discloses a leather embossing device for basketball manufacture. The structure of the device comprises a bottom plate, a left side plate, a top plate, an embossing mechanism, a materialshaking device, a collecting frame and a rotating device; and the bottom of the left side plate is vertically arranged at the left side of the top of the bottom plate by means of welding connection, the top is vertically mounted at the left end of the bottom of the top plate by means of welding connection, the embossing mechanism is arranged below the top plate, and the top of the bottom plate isprovided with the material shaking device and the collecting frame from left to right in order; the embossing mechanism and a conveyor belt move in a clearance fit movement, when the embossing mechanism embosses on the basketball leather, the embossing mechanism is raised, the conveyor belt starts to transport the next piece of leather to be embossed to lower part of the embossing mechanism, and during the processing process of the embossing mechanism, the conveyor belt is in a stopped state. This automatic feeding method can replace the manual picking method, which can be used for continuousproduction in order to improve work efficiency, and at the same time, accidental injury during manual picking can be avoided.

Owner:曾培玉

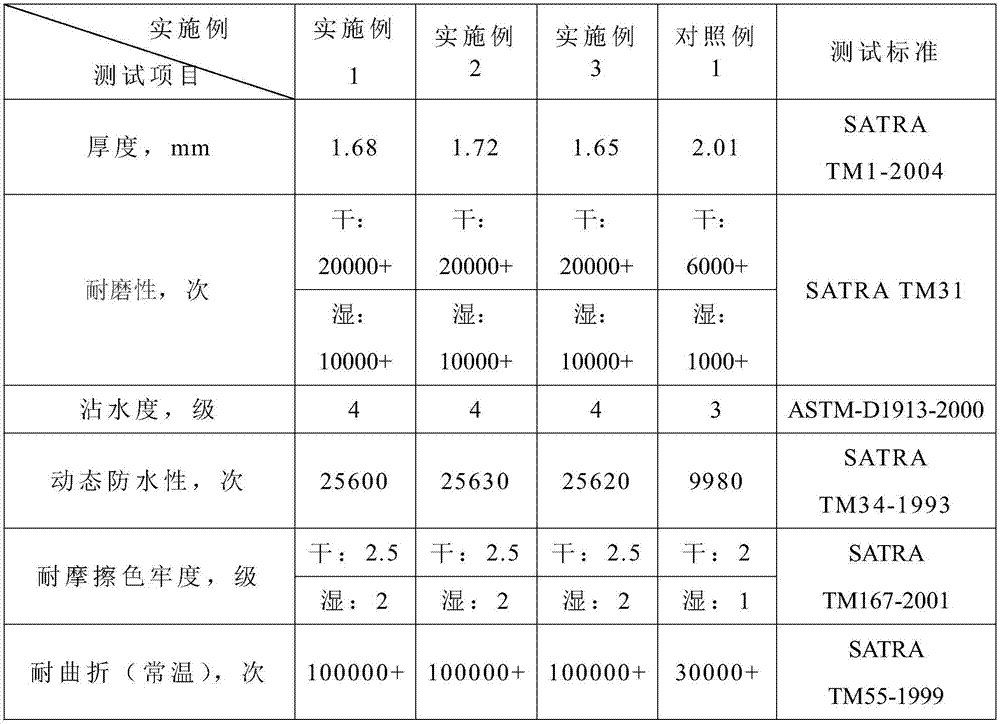

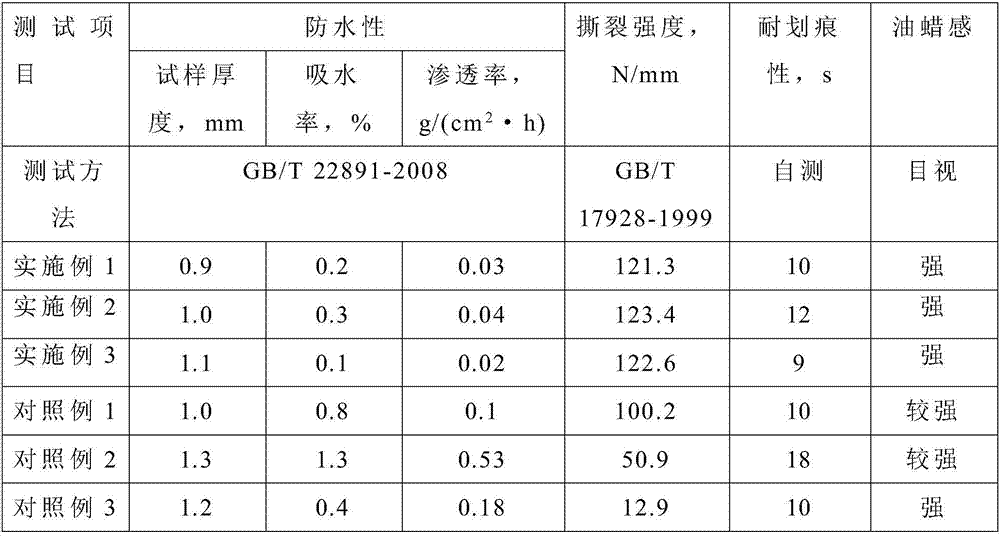

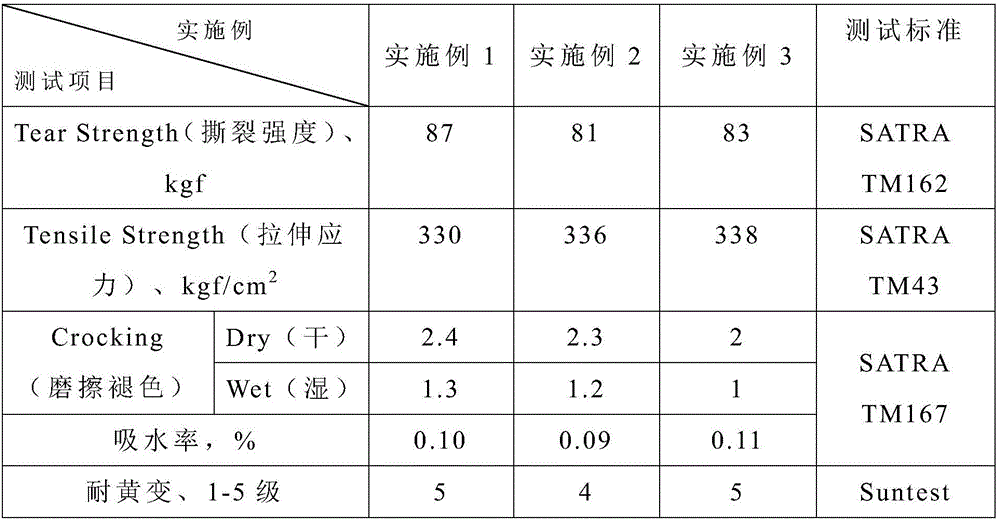

Production method for split-layer oil wax waterproof leather

ActiveCN106957932AImprove waterproof performanceHigh tear strengthLeather softeningLeather surface mechanical treatmentMaterials science

The invention relates to a production method for split-layer oil wax waterproof leather and belongs to the technical field of leather. The production method for the split-layer oil wax waterproof leather includes the following steps that a split-layer leather blank is taken, dried and then subjected to leather grinding, first time of milling, spraying, oil wax roll painting, roll finishing, secondary milling and feeling agent spraying, and then the split-layer oil wax waterproof leather is obtained. The split-layer oil wax waterproof leather prepared through the production method has good waterproof performance and wet rubbing resistance and meanwhile has relatively high tearing strength; in addition, the split-layer oil wax leather prepared through the production method is relatively high in oil wax sense and chromatic aberration sense, the antiquing effect of the leather is effectively improved, scratching resistance of the leather is good, and scratches can disappear by themselves once happening to the surface of a leather material; and the performance of the split-layer oil wax waterproof leather prepared through the production method can rival the performance of top layer oil wax leather.

Owner:漳州香洲皮革有限公司

Leather surface coating and finishing process

InactiveCN102690904ALeather softeningLeather surface mechanical treatmentSurface coatingCeramic materials

The invention provides a leather surface coating and finishing process. The process comprises the following steps: a, resin impregnation: a leather is impregnated in a resin impregnation liquid consisting of a resin emulsion and an impregnating agent to make the resin impregnation liquid permeates deep parts of the leather; b, primary coating: surfaces of the leather are coated with a primary coating liquid; c, first mechanical finishing: surface finishing is performed on the primary-coated leather; d, middle coating: the surfaces of the first mechanical-finished leather are coated with a middle coating liquid; e, second mechanical finishing: polishing, patterning and coloring finishing are performed on the middle-coated leather in turn; f, final coating: the surfaces of the second mechanical-finished leather are coated with a final coating liquid; g, third mechanical finishing: brightness adjustment and surface hand-feel adjustment are performed on the final-coated leather; h, ironing; i, softness finishing: hand-feel finishing is performed on the ironed leather by using a vibration machine for softening leathers. The process consumes less chemical raw materials, has advantages of low pollution and environmental protection, and can improve quality of the leather significantly.

Owner:赣州华坚鞋业集团有限公司

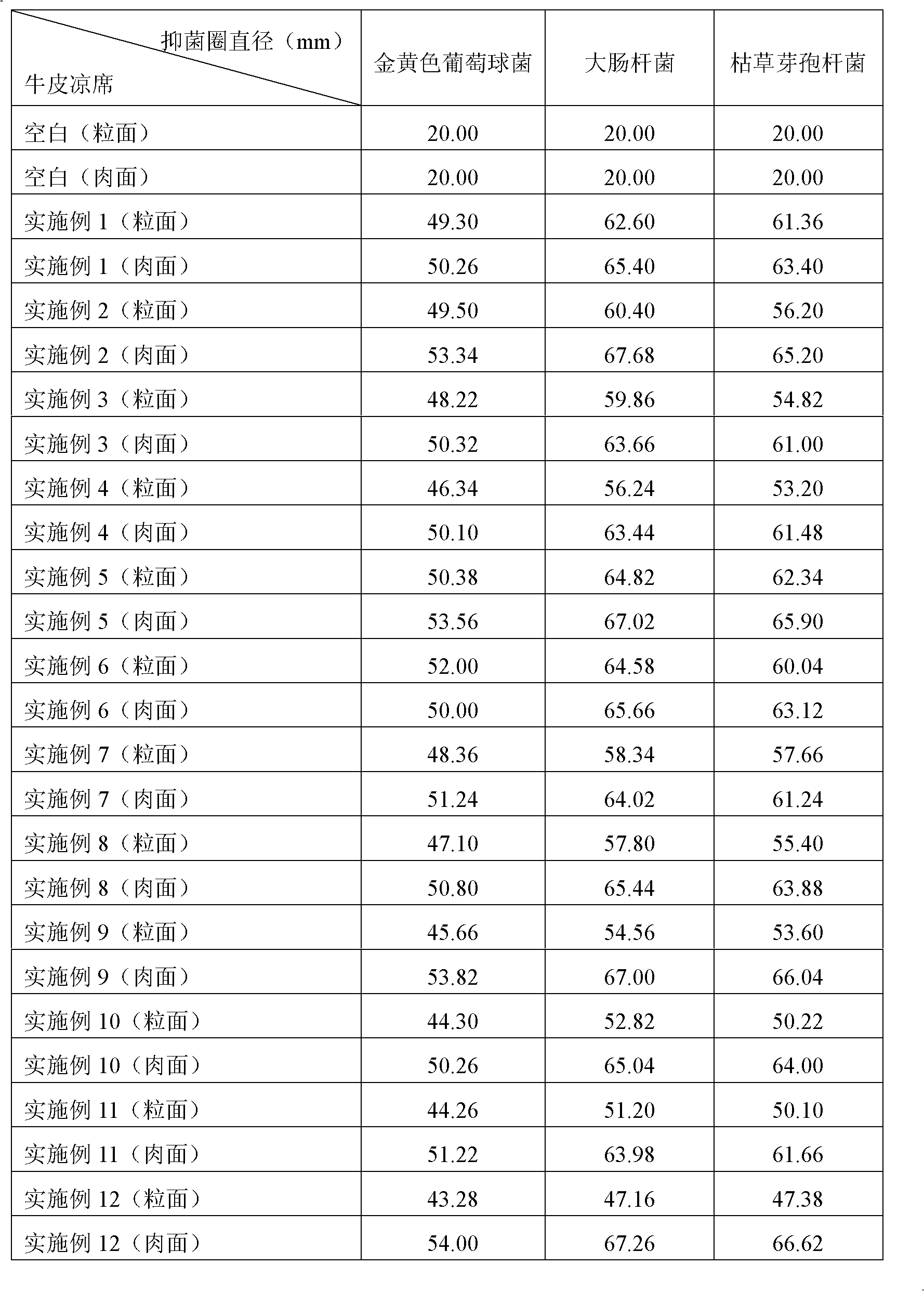

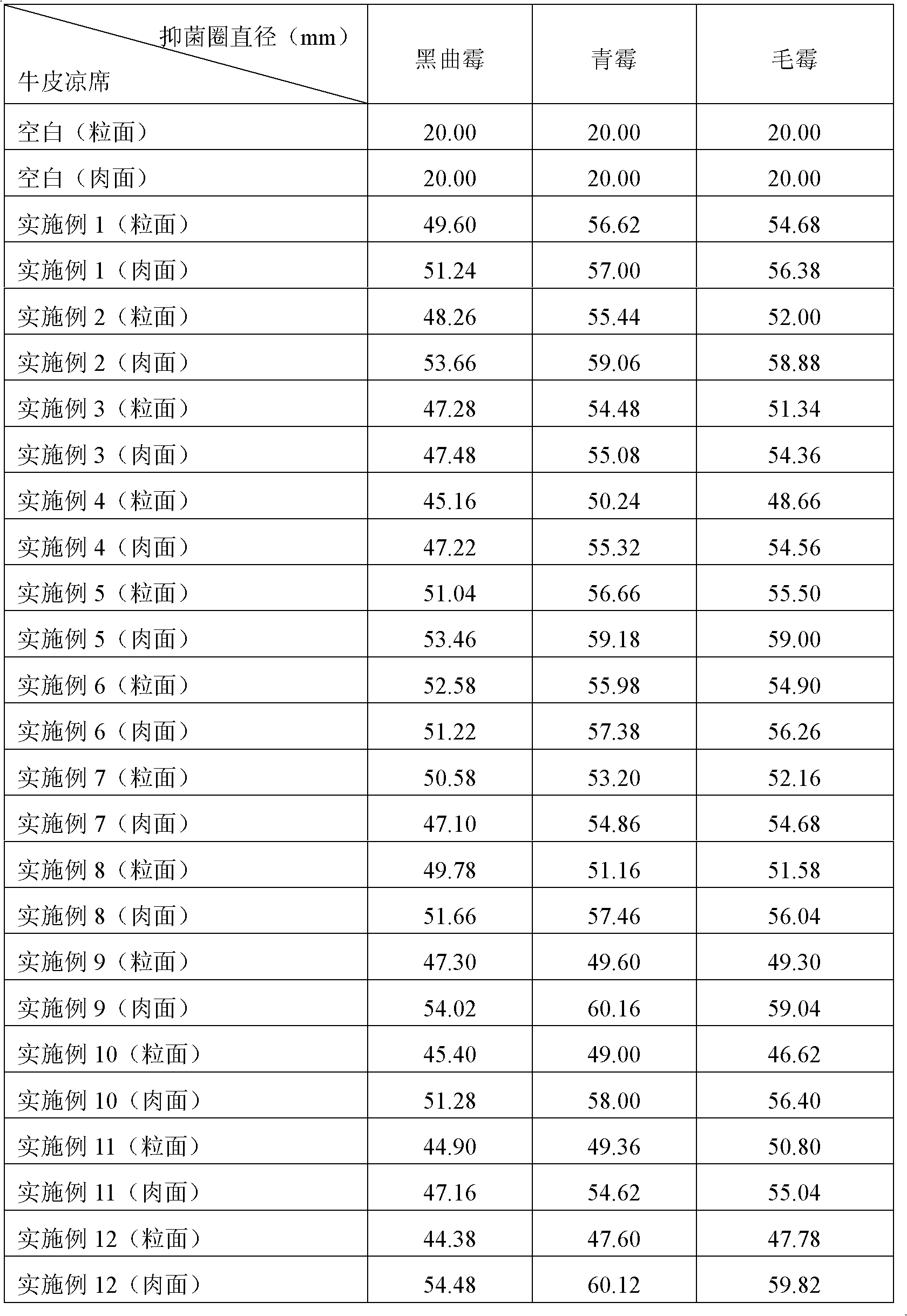

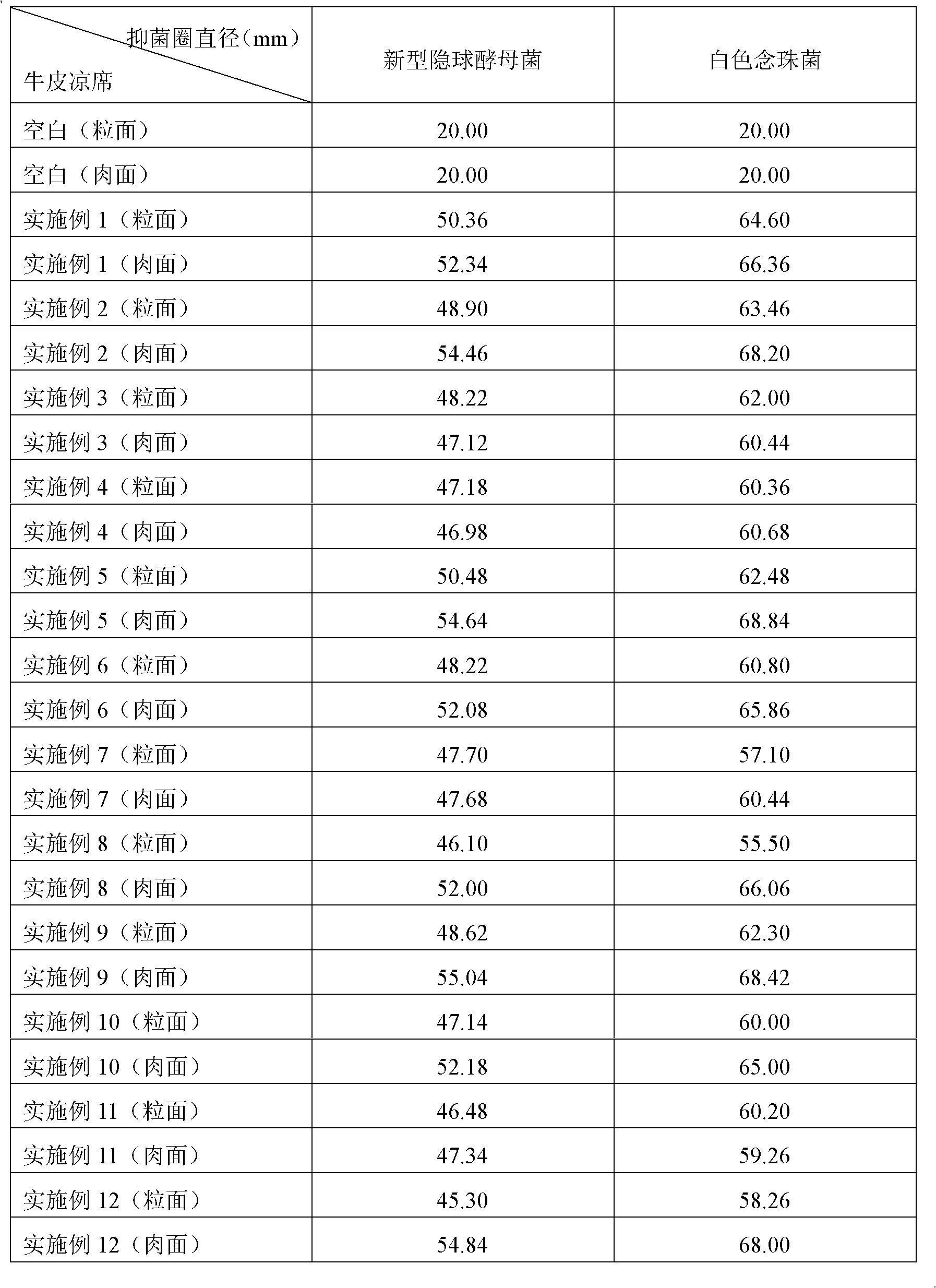

Cow leather mat with anti-bacterial function and preparation method thereof

InactiveCN102670007AEnhanced inhibitory effectLow toxicityLeather surface mechanical treatmentBed-coversInhibition zoneAgricultural science

The invention discloses a cow leather mat with an anti-bacterial function. The cow leather mat is characterized in that a grain side and a flesh side of the cow leather mat simultaneously comprises a nano-silver and isothiazolinone antibacterial agent; the inhibition zone of the nano-silver and isothiazolinone antibacterial agent to staphylococcus aureus, colon bacillus, bacillus subtilis, Aspergillus niger, blue mould, hair mould, cryptococcus neoformans, candida albicans is 43.28 to 68.84mm; the dry wipe resistance level is 4 to 5 level or 5 level; the wet wipe resistance level is 3 to 4 level or 4 level; and folding resistance fastness is 1 level. The invention also discloses a preparation method of the cow leather mat. The cow leather mat not only has good inhibit function to bacterium and fungus, but also has durable antibacterial property; the preparation method is skillful, the only thing to do is to add antibacterial treatment after a middle layer is coated, additional investment cannot be increased, the process is simple to operate, and the cow leather mat is applicable to industrial application.

Owner:SICHUAN UNIV

Method for making high-grade cabretta soft leather with defective sheepskin blue plate

InactiveCN1594599AAvoid wastingLow costLeather surface mechanical treatmentLeather surface finishingWaxSheep skin

The invention relates to a method for making high-grade sheep skin soft upper leather from inferior sheep skin, which comprises: dying, polishing leather, spraying sarcenet oil, mending, smoothing, grounding using grounding agent, brushing and scraping using multi-membrane agent several times, plucking skin, beating soft, scraping skin, Spraying surface slurry, spraying fixation agent, spraying hand feeling agent, ironing etc. Grounding agent is formulated by cation compound resin, non-ionic wax, cation color cream and water. Multi-membrane agent is formulated by non-ionic caseose-free color cream, compound resin, small molecule acroleic acid, swelling resin etc. Surface slurry is formulated by color cream, non-ionic wax, compound resin, silicon casein, flexible acroleic acid, paint slurry etc. fixation agent is formulated by water and aqueous gloss oil. Grounding agent is used mechanically and manually in the invention. Multi-membrane agent ,surface slurry and fixation agent have low cost , little pollution and can make high-grade sheep skin soft upper leather from inferior sheep skin.

Owner:孟立君

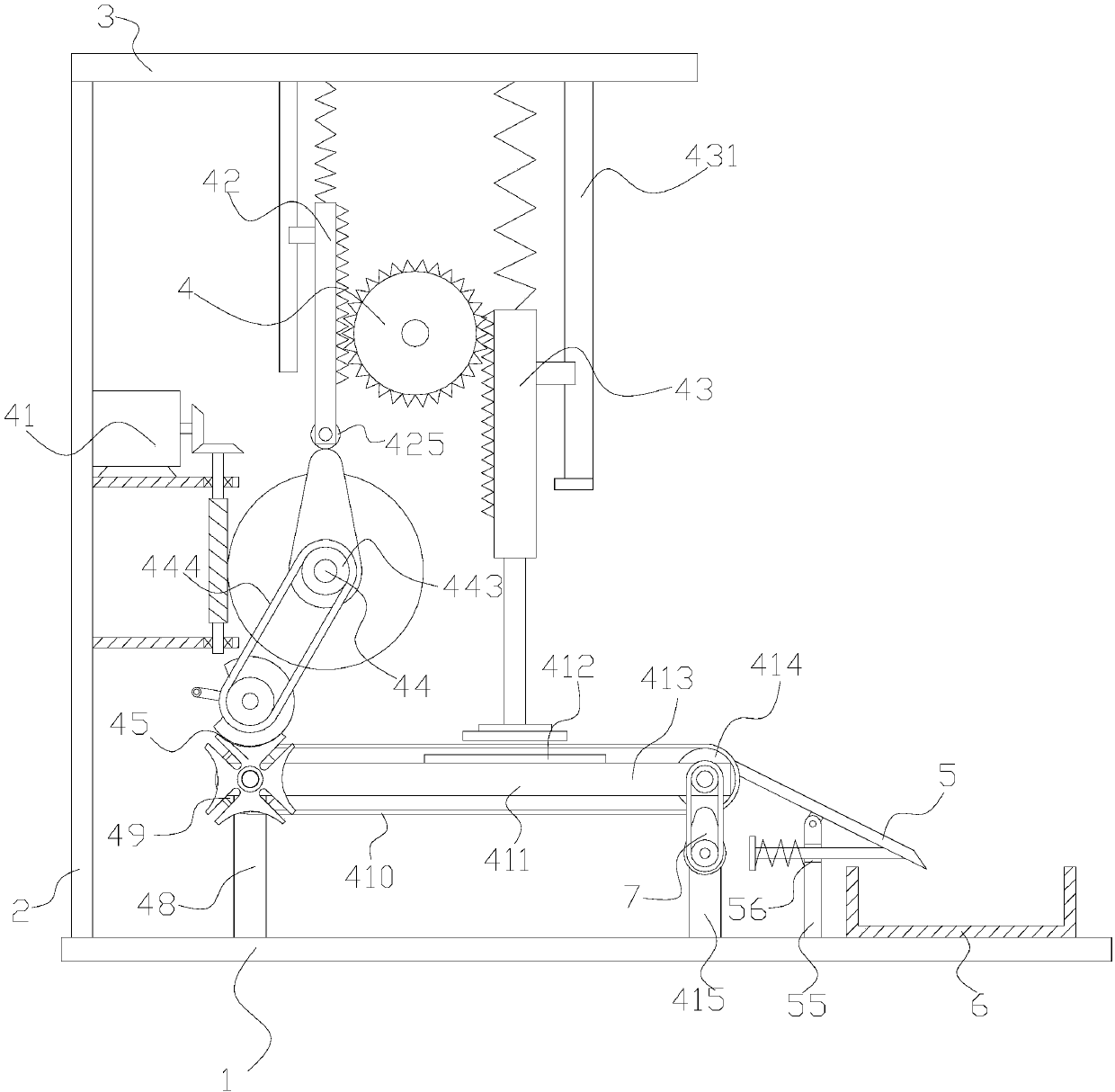

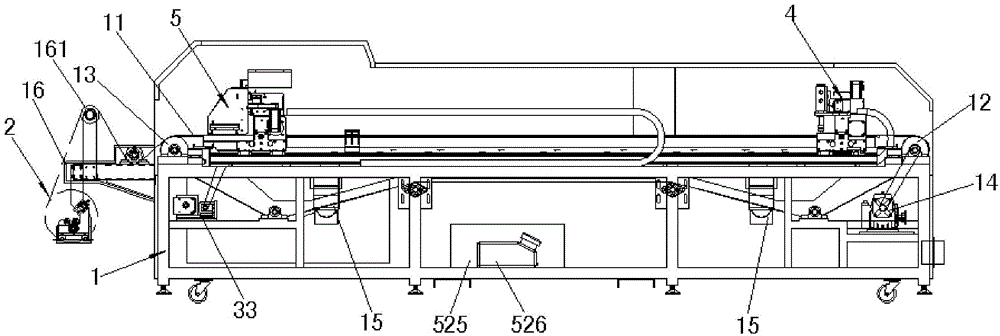

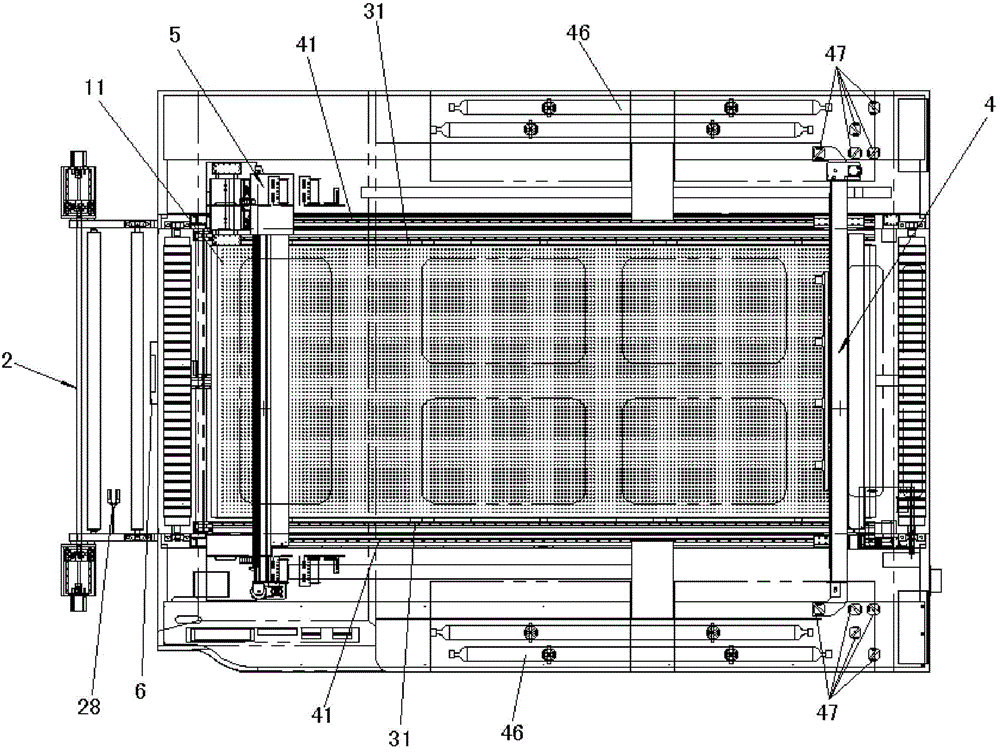

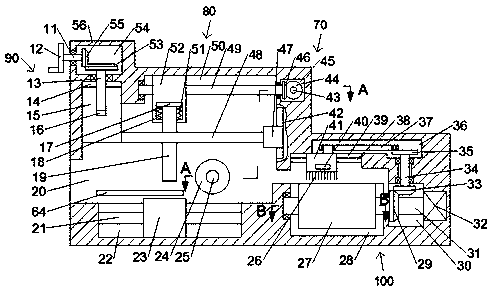

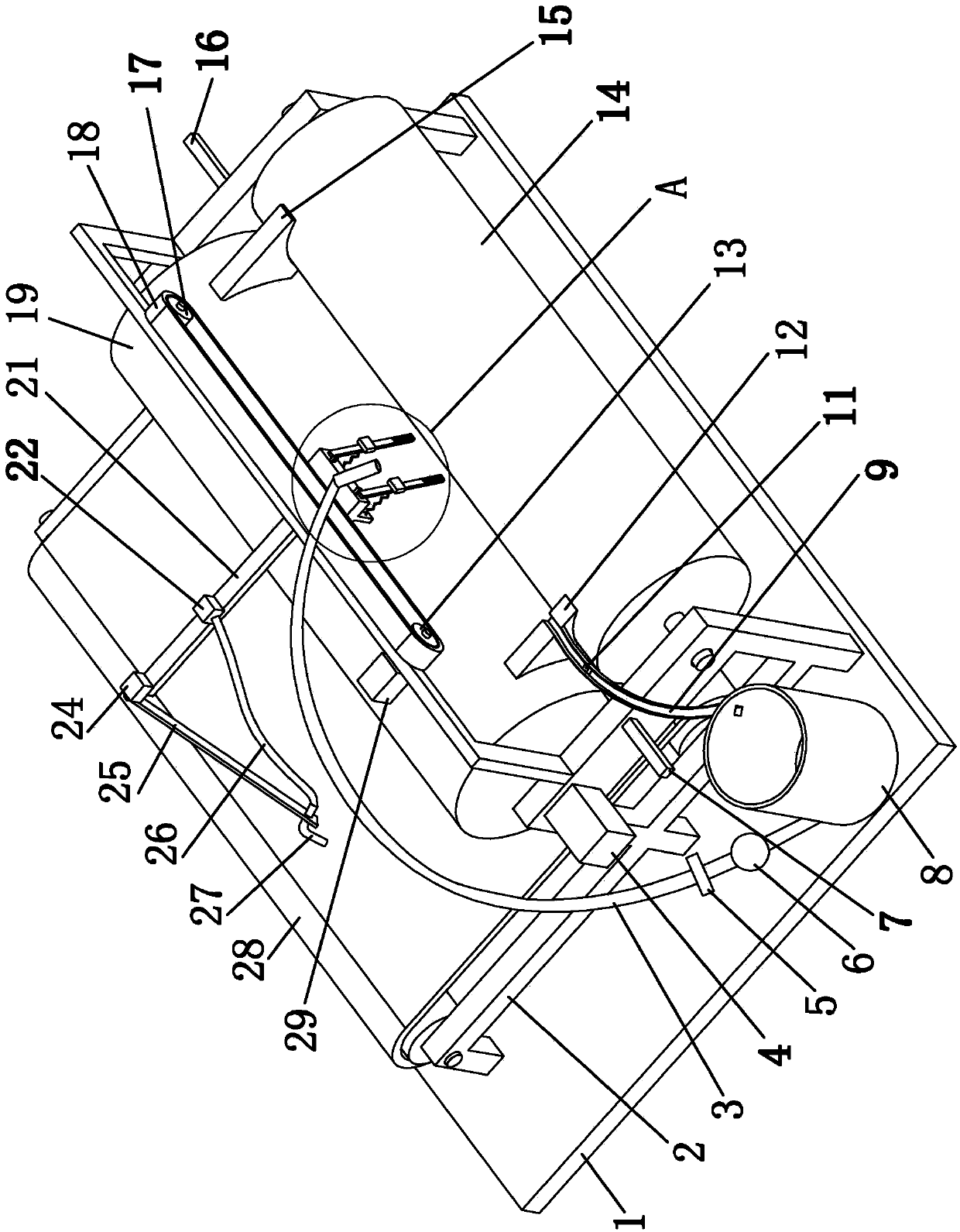

Full-automatic leather printing and cutting machine and printing and cutting method implemented by same

InactiveCN104818350ASolve processabilitySolve the large number of laborLeather clicking/perforating/clickingTypewritersComputer control systemGraphics

The invention discloses a full-automatic leather printing and cutting machine which comprises a framework, an automatic rectifying mechanism, an automatic feeding manipulator, an automatic laser cutting mechanism, an automatic printing mechanism and a control system. A frame and a frame shaft are arranged at the front end of the framework, the frame shaft is arranged on the frame, the automatic rectifying mechanism is arranged at the front end of the framework, the automatic feeding manipulator, the automatic laser cutting mechanism and the automatic printing mechanism are arranged on the framework, and the control system is arranged in the framework and is connected with the automatic feeding manipulator, the automatic laser cutting mechanism and the automatic printing mechanism. The full-automatic leather printing and cutting machine has the advantages that manual production can be truly replaced by machines, accordingly, the leather processing efficiency and processing precision can be greatly improved, and the processing cost can be reduced; optional patterns can be accurately printed by the printing mechanism by the aid of the computer control system, and the problem of asymmetric pattern printing in existing leather processing procedures can be effectively solved.

Owner:DONGGUAN DEL LASER TECH

Engineered leather and methods of manufacture thereof

Owner:MODERN MEADOW INC

Leather bronzing technique

InactiveCN101570800AImprove adhesionStrong three-dimensional senseTransfer printingDuplicating/marking methodsPowder coatingBronzing

The invention discloses a leather bronzing technique, which can thermally print gold powder coating on the leather surface, can ensure the lasting adhesion of the gold powder and further improve the third dimension of thermally printed patterns. The leather bronzing technique overprints embossing with convex and concave feelings on the leather via a template, before overprinting, silver paper coated with gold powder is paved on the leather, during overprinting, the gold powder on the silver paper is thermally printed onto the embossing surface by the template to form a gold powder coating. The technique combines bronzing and overprinting, overprints the patterns or decorative designs on the template onto the leather surface to form embossing with convex and concave feelings, and simultaneously thermally prints the gold powder coating on the silver paper onto the embossing surface under certain pressure and temperature, thus can transfer and print the gold powder coating onto the leather surface according to pictures and texts on the template and ensure lasting adhesion of the gold powder, meanwhile, the thermally printed patterns have great third dimension and lustre sensation, thus greatly improving the visual effect of leather products.

Owner:杨洪

Leather carving process

InactiveCN101279567AReduce production processReduce manufacturing costLamination ancillary operationsDecorative surface effectsManufacturing technologySurface layer

The invention relates to a skin sculpture process, which is characterized in that the process comprises the following steps: a corresponding punch is manufactured according to a selected pattern, a concave die is replaced by a soft polyamine lipid plate without the need for manufacturing the concave die, and the punch and the soft polyamine lipid plate are combined into a die; a PVC sheet is pasted on the back of leather; the die is put on a hydraulic press and a leather product after adhesion is placed between the punch and the soft polyamine lipid plate; the front of the leather is tightly attached to the soft polyamine lipid plate and the PVC sheet faces to the punch; hot pressing die assembly is carried out rapidly, the temperature of the hydraulic press is 80 to 90 DEG C, the pressure is 5 to 10MPa, and the die is opened 5 seconds later for cooling; a polishing machine is used for polishing: the color on the surface layer of the leather is polished, the ground color is exposed and a comparison pattern between the bottom color and the color on the surface layer is formed; the convex combination effect of the pattern and the leather can acquire the required relief pattern on the leather. Compared with the prior art, the skin sculpture process has the following advantages that: 1. as the concave die is free from manufacture but substituted for by the soft polyamine lipid plate, the manufacturing technology is reduced and production cost is reduced; 2. manufacturing temperature is reduced; as the punch can be made from non-metallic material instead of metallic material, the production cost is further reduced and the processing is easy; 3. as for the leather, double-colored or multi-colored leather is adopted and for hot pressing and polished for forming the relief pattern with rich pattern hue.

Owner:熊银昌

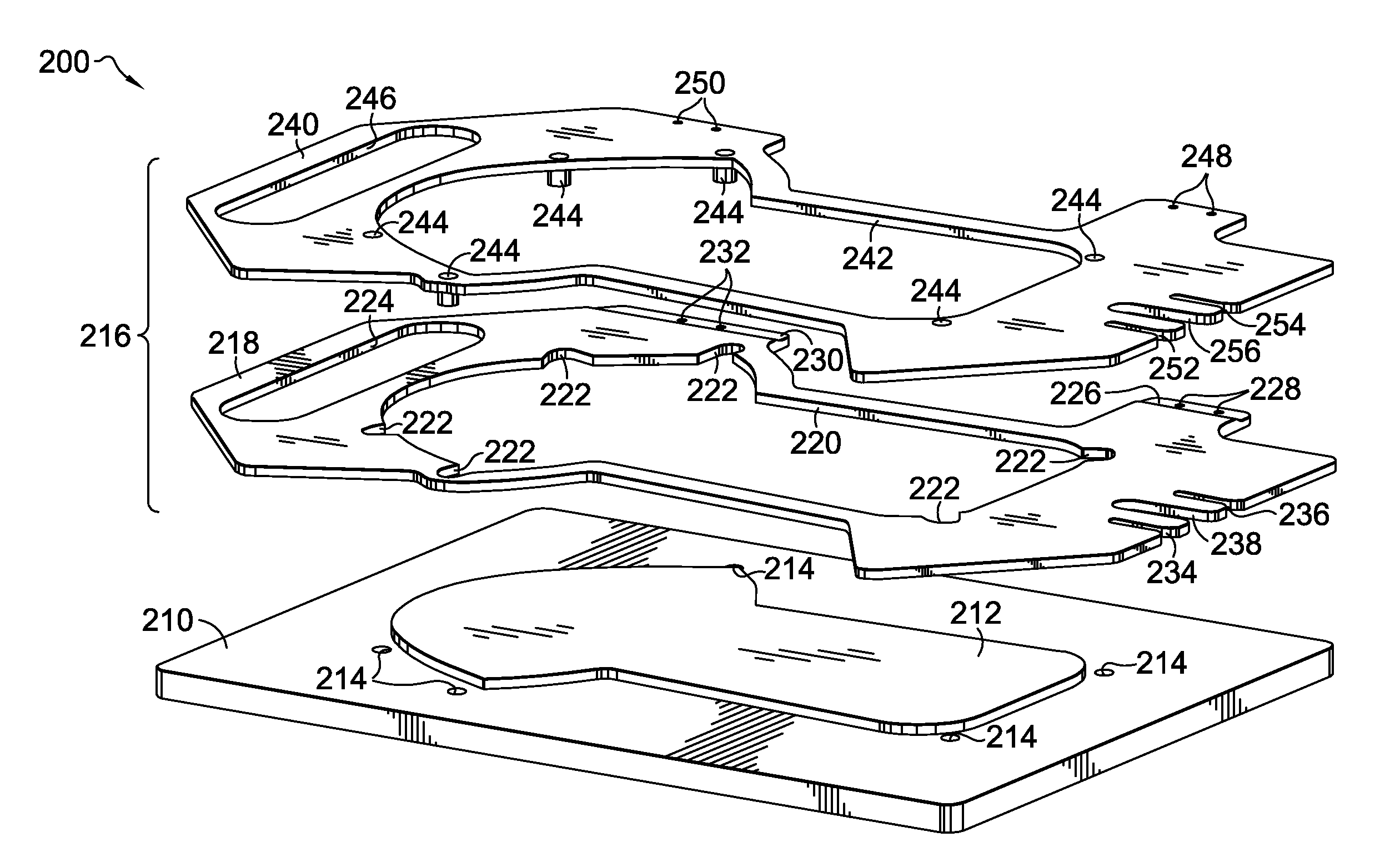

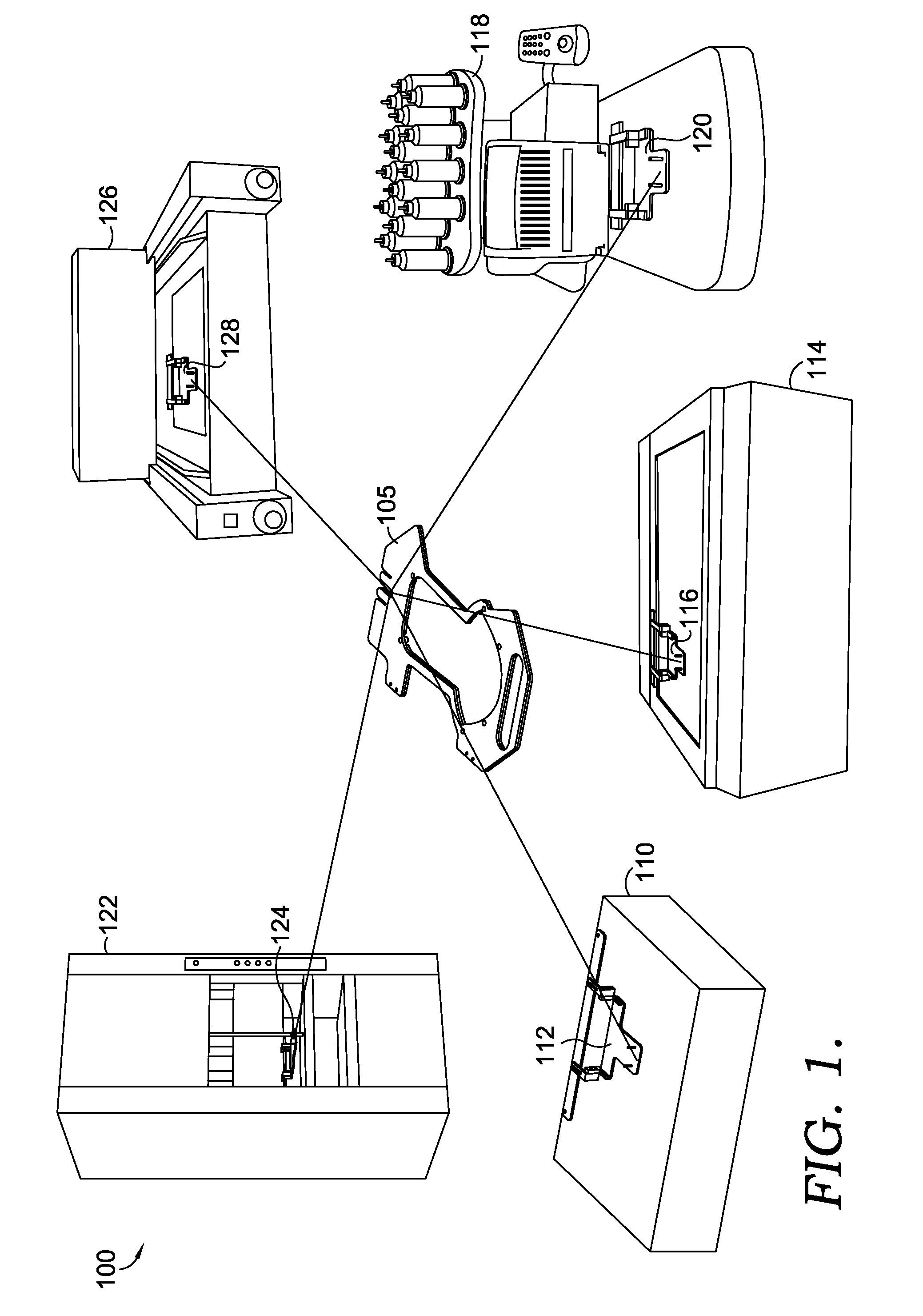

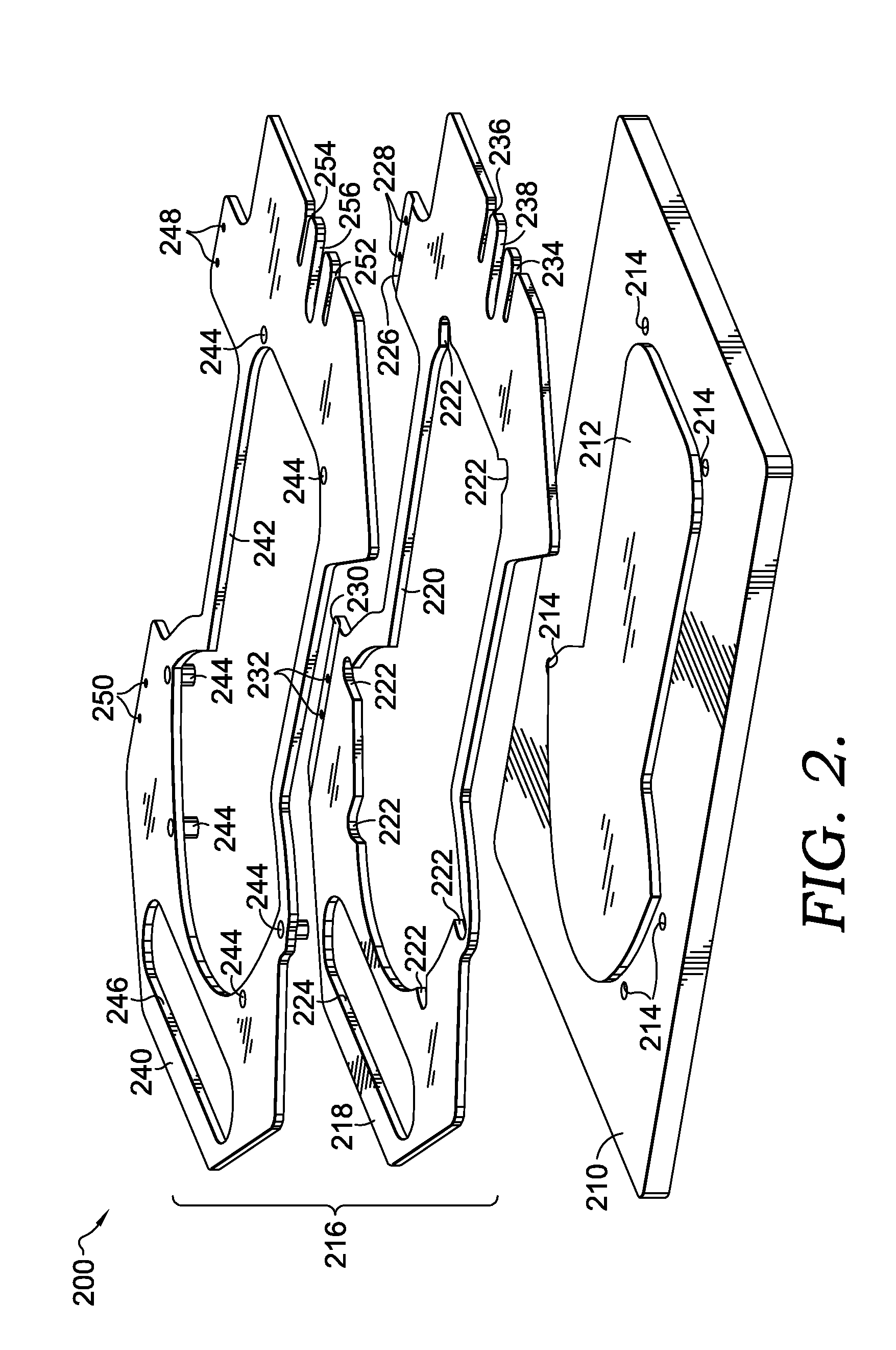

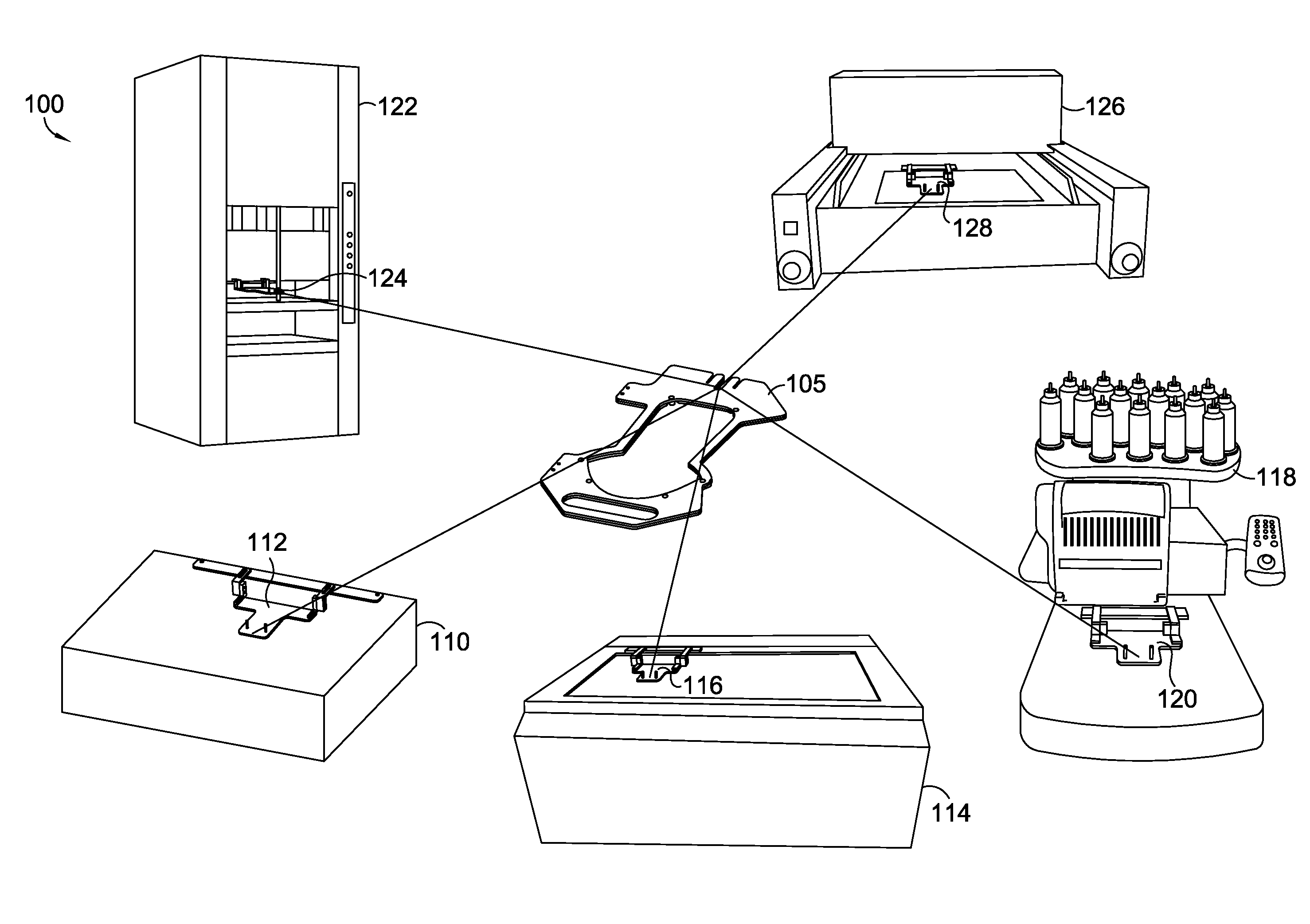

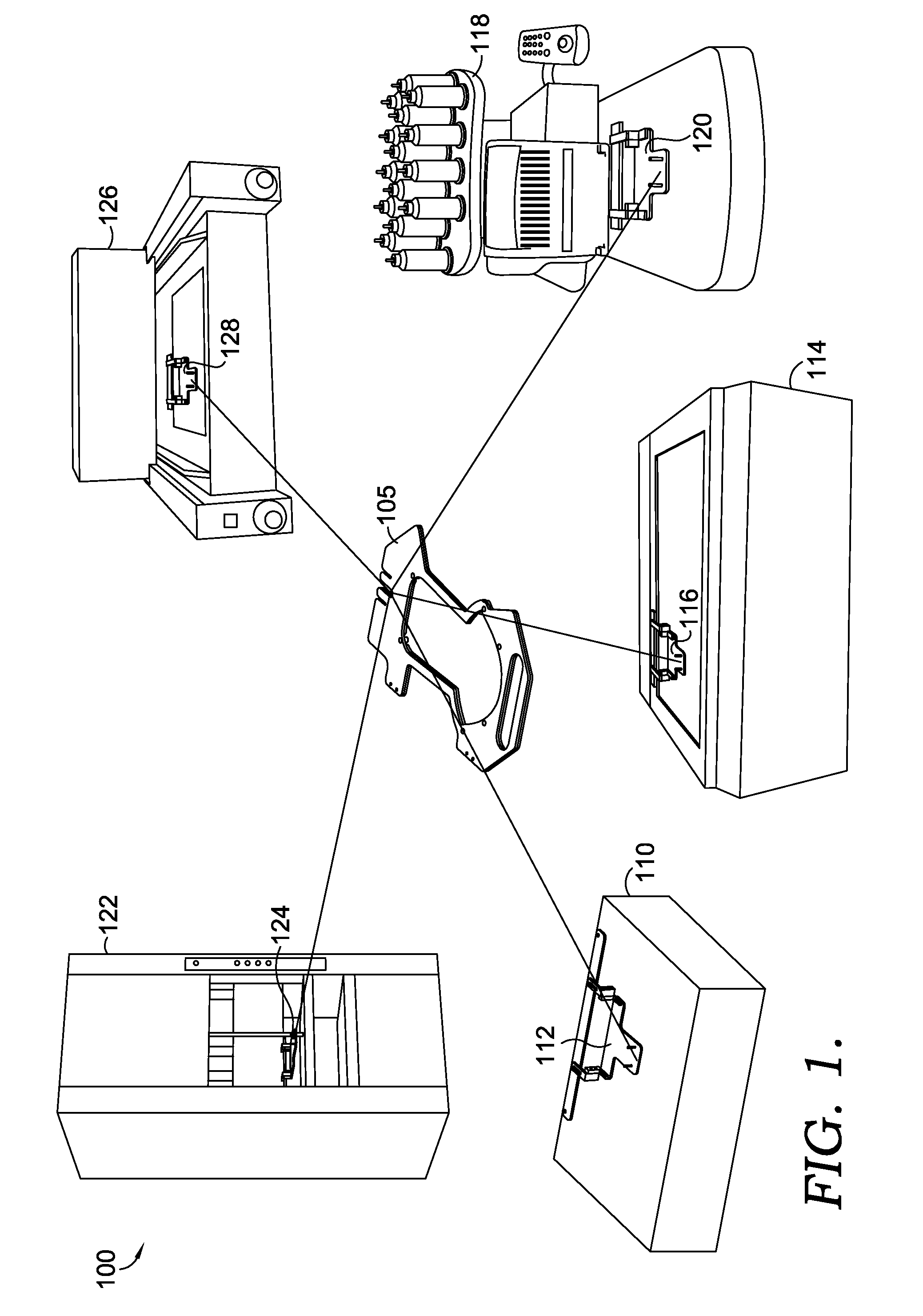

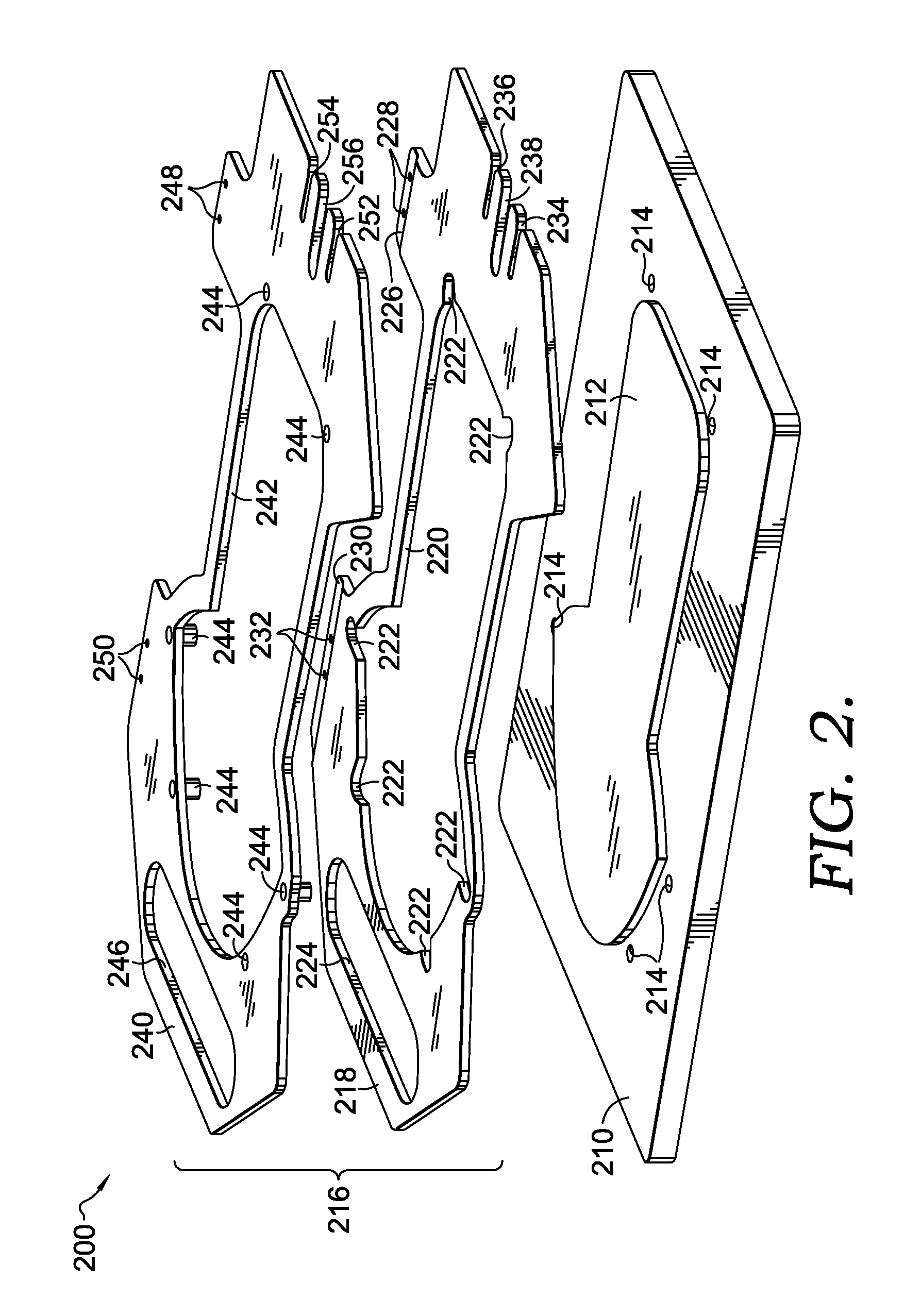

Unitary Multi-Use Alignment Fixture For Shoe Production

ActiveUS20120272463A1Eliminate variationMinimizing operation interactionShoemaking devicesLastingEngineeringEquipment use

A system for manufacturing shoes is provided that includes two or more pieces of equipment used in the customization and manufacturing of shoes and an alignment fixture that may engage with each piece of equipment by way of an alignment mounting member. The alignment fixture may secure to it a portion of a shoe, such as an upper portion, wherein the shoe portion remains in a flat position, and in a fixed relationship to the alignment fixture, throughout the various processes performed by the pieces of equipment. These processes may include, for example, printing, laser, embroidery, forming, cutting, or the like.

Owner:NIKE INC

Method for performing antique treatment on leather surface

InactiveCN101892331AAchieve antique effectLeather surface mechanical treatmentLeather surface finishingColor effectWax

The invention relates to a method for performing antique treatment on a leather surface. Mixed polish is utilized to treat the leather surface and comprises shellac, rosin and alcohol in a weight ratio of 5-25:5-15:100, preferably 20:5:100. The method comprises the following steps of: a, polishing the surface of animal skin blank into a plush shape; b, expanding the animal skin blank, spraying the mixed polish on the animal skin blank, and then performing air drying; c, moving the air-dried animal skin blank to a drying room and roasting for 2 to 3h at the temperature of between 42 and 47 DEG C; d, coloring effect under colors on the animal skin blank at normal temperature; e, moving the colored animal skin blank to the drying room for drying; f, treating cracks of the animal skin blank; g, coloring effect colors on the animal skin blank by using a mixed pigment, and then spraying a layer of the mixed polish on the animal skin blank uniformly; h, moving the animal skin blank to the drying room for drying; i, pulling the cracks of the animal skin blank out, and polishing and burnishing; k, moving the burnished animal skin blank to the drying room and roasting for 5 to 7h at the temperature of between 30 and 40 DEG C; and j, cooling the product, coating leather protective wax on the product to obtain the finished product.

Owner:廖顺南

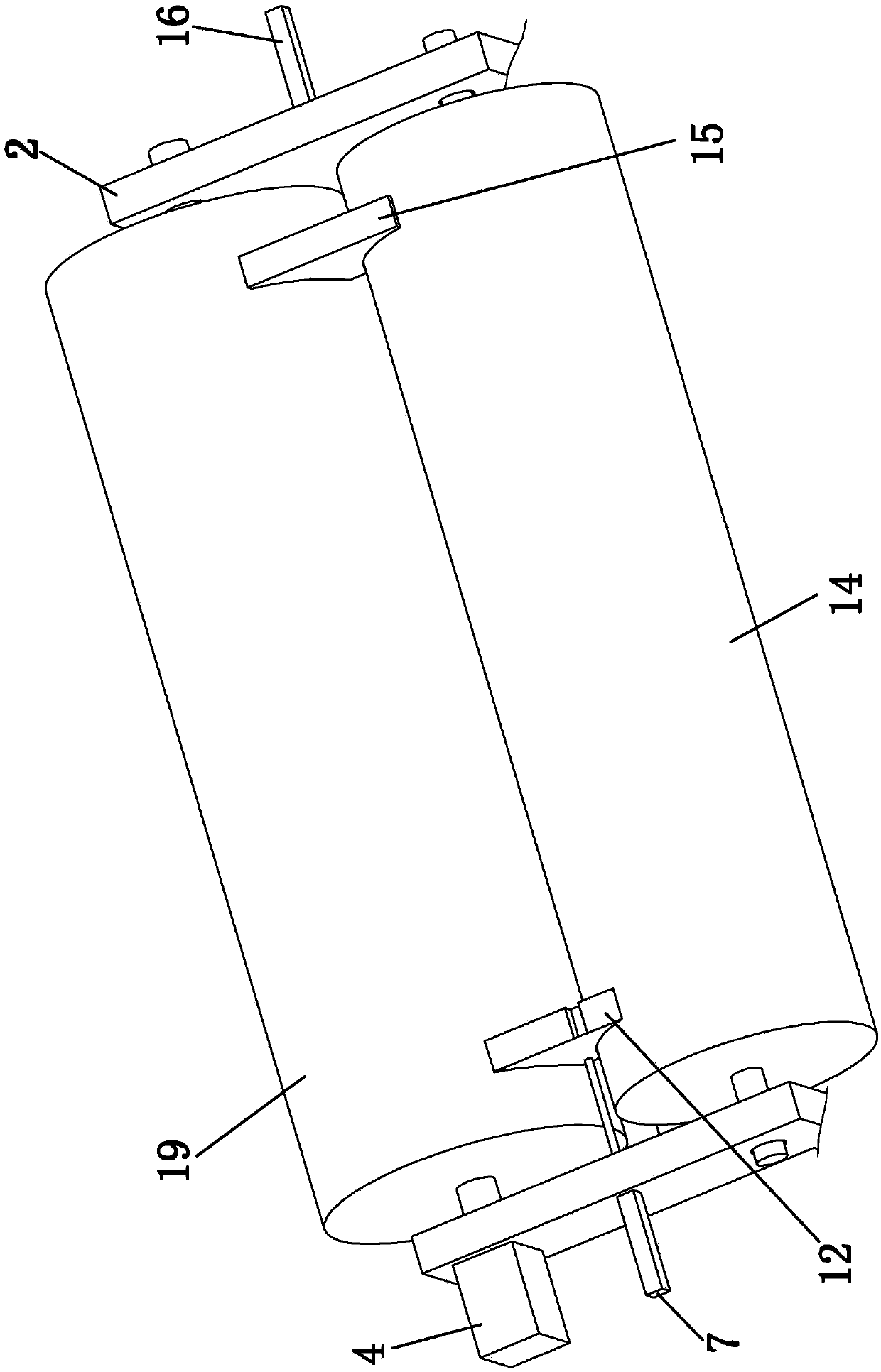

Waxing device for production of sofa leather

InactiveCN110643751AImprove uniformityGuaranteed stabilitySkins/hides/leather/fur manufacturing apparatusLeather/skins/hides/pelt chemical treatment apparatusMechanical engineering

The present invention discloses a waxing device for production of sofa leather. The device includes a feeding box provided with a feeding chamber therein; the feeding chamber is open upward and is provided with a feeding device for transporting leather; the upper side end face at the rear side of the feeding chamber is fixedly connected with a fixed plate; the front side end face of the fixed plate is provided with a spraying device; the spraying device cleans the leather with an air flow, and sprays wax to the leather; a lifting device located at the right side of the spraying device is disposed on the front side end face of the fixed plate; the lifting device is provided with a waxing device for waxing and polishing therein; and the lifting mechanism of the present invention can drive the waxing mechanism to move up and down so as to realize self-adaptation for waxing of the leather of different thicknesses, realize automatic removing of liquid wax inside a spraying pipe and preventthe cured liquid wax from blocking the spraying pipe and affecting subsequent processing.

Owner:PANAN LINSI LEATHER IND RES CO LTD

Leather printing

An apparatus for printing leather including an ink acceptor applicator that applies ink directly onto a surface of the leather; an ink applicator that applies ink to the ink acceptor and / or the leather surface; an additive applicator that applies additive onto the ink acceptor, the ink and / or the leather surface; a barrier having a surface configured to contact the acceptor, ink and additive on the leather surface; and a heater that heats the surface of the barrier to a predetermined temperature or a temperature within a selected temperature range such that the barrier, which is substantially impervious to the ink and has a melting point higher than the select temperature range, contacts at least the acceptor ink and additive on the surface directly to liquify the acceptor ink and additive into the leather and the acceptor, ink and additive fuses and penetrates into the leather.

Owner:AGFA NV

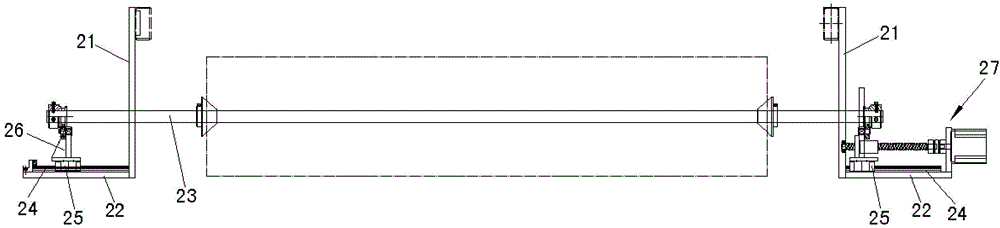

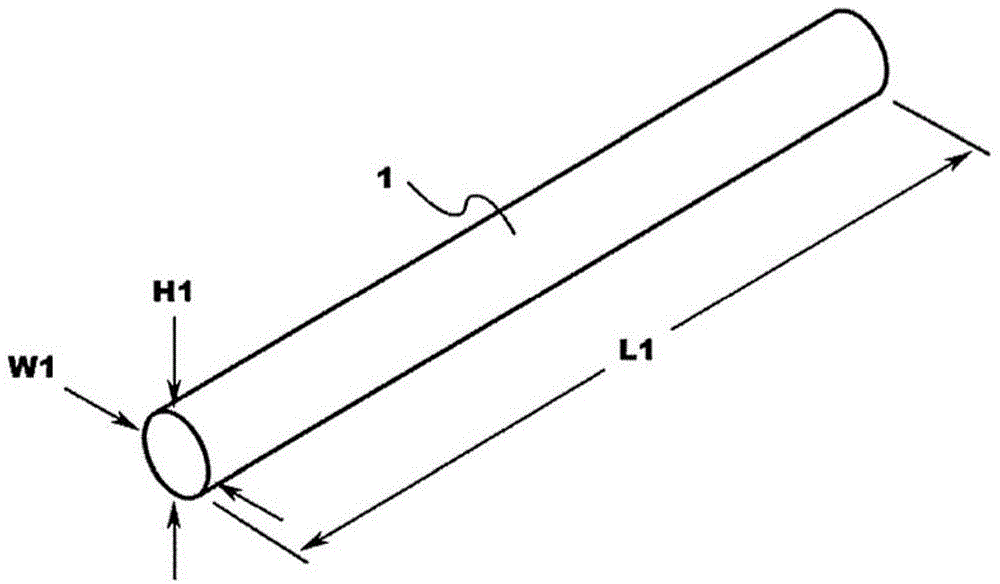

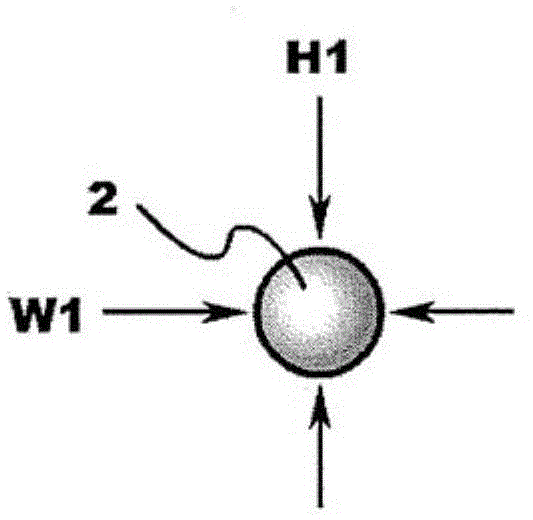

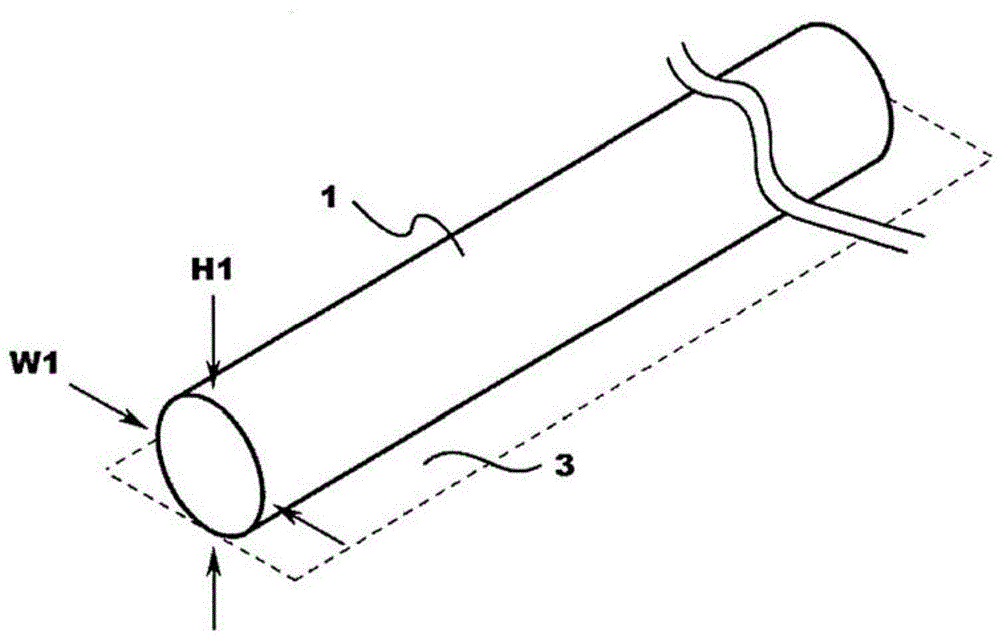

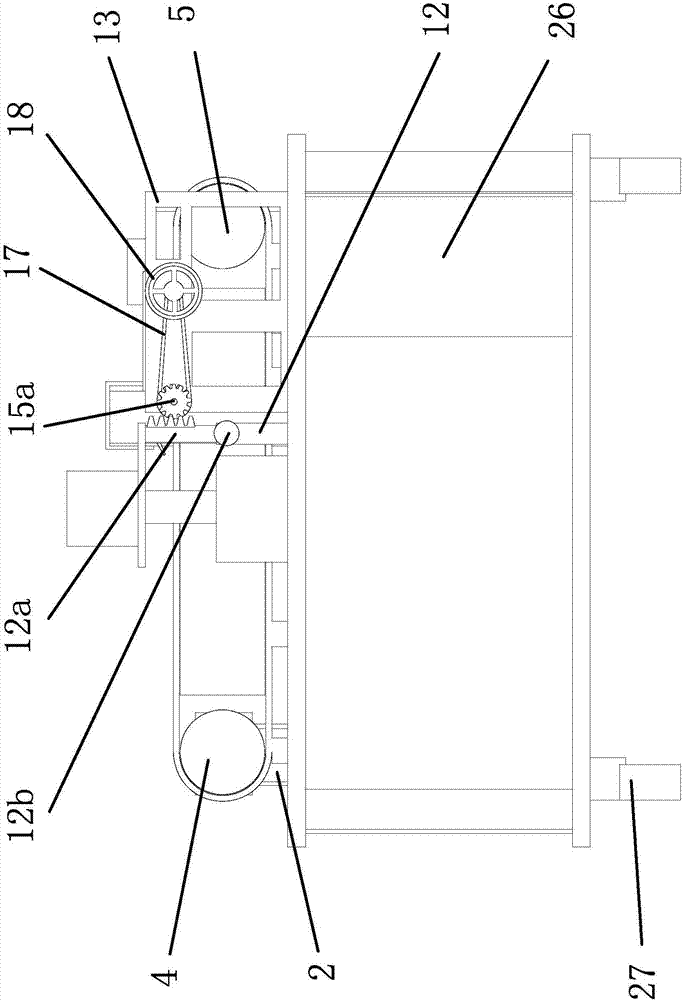

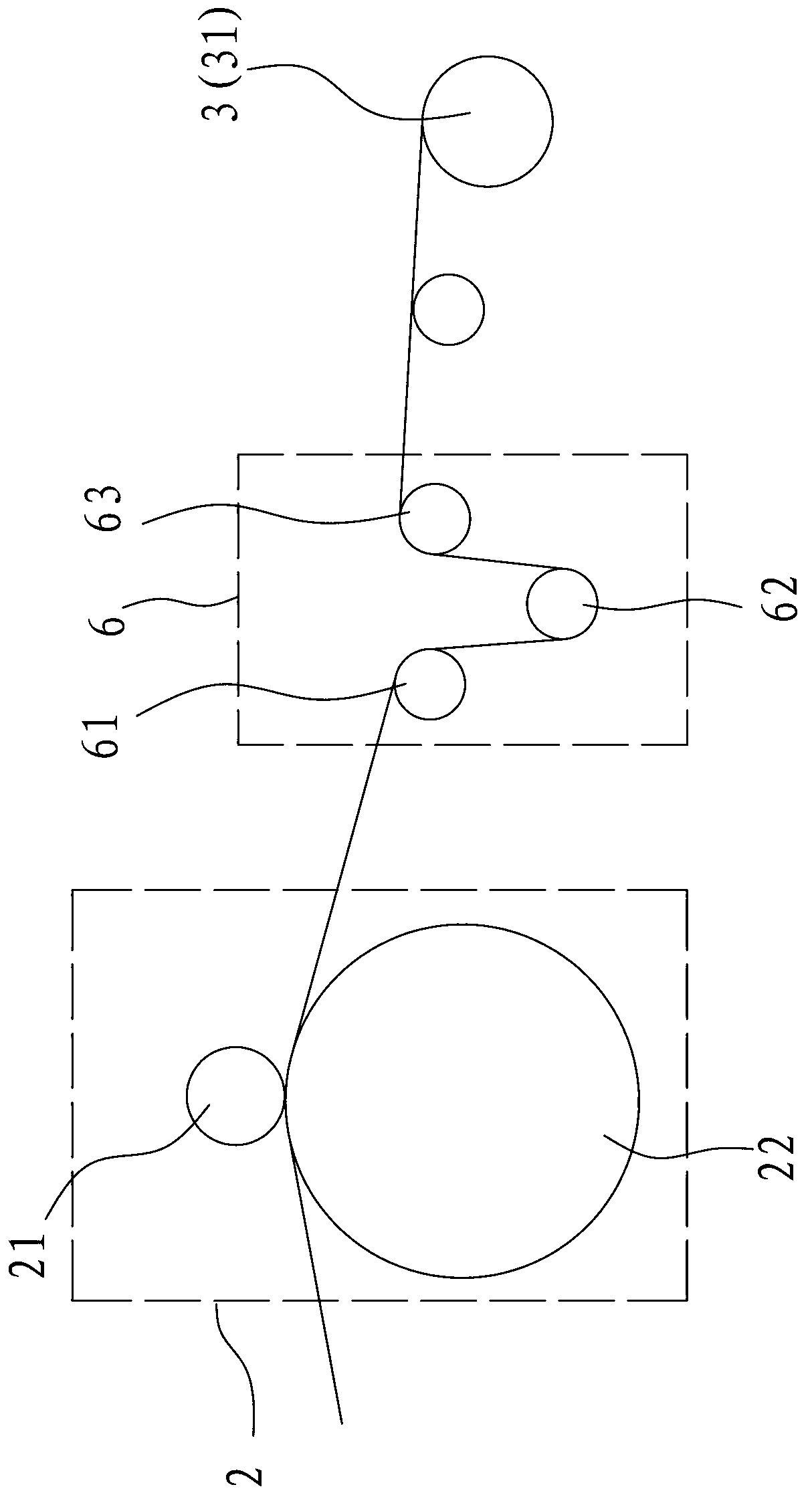

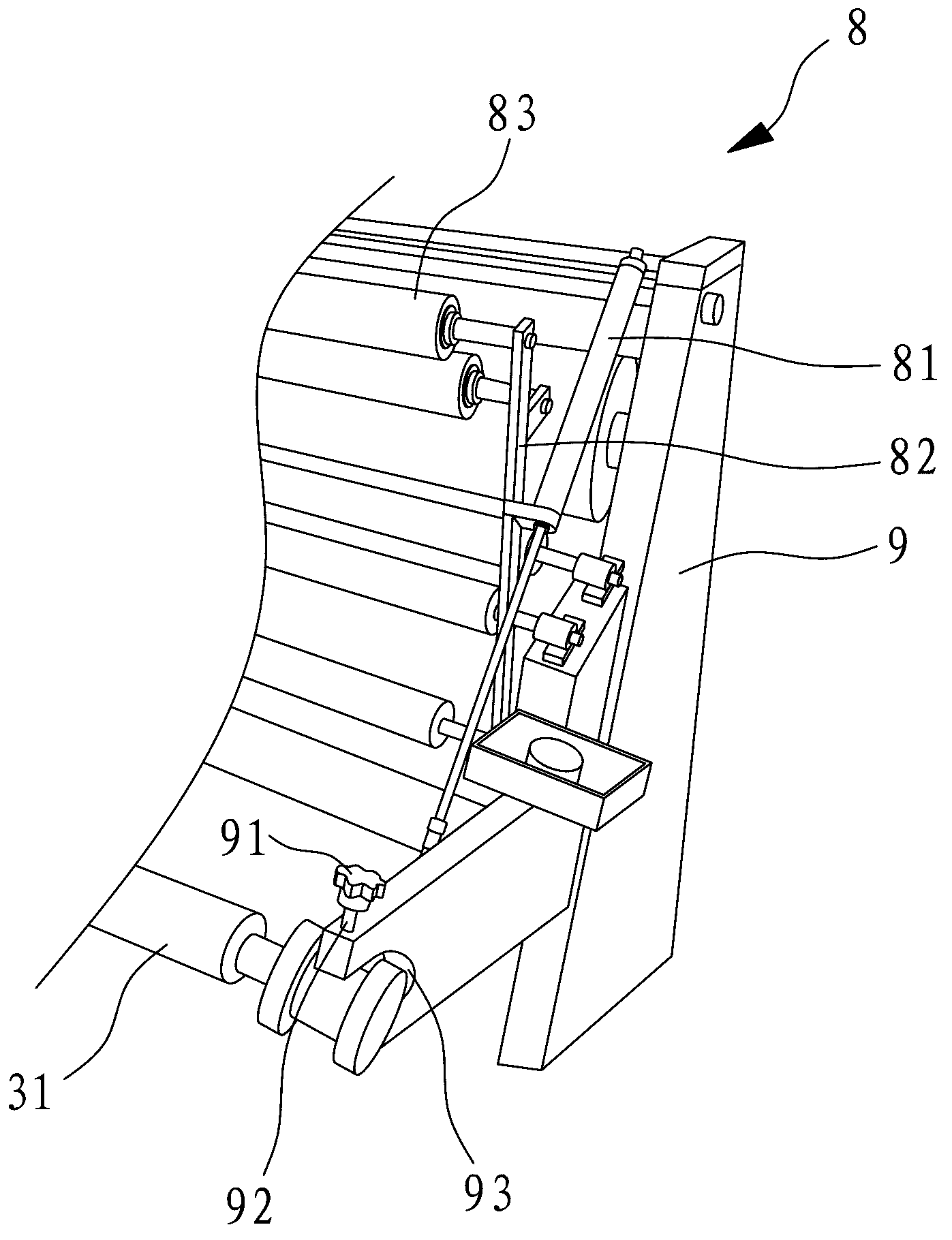

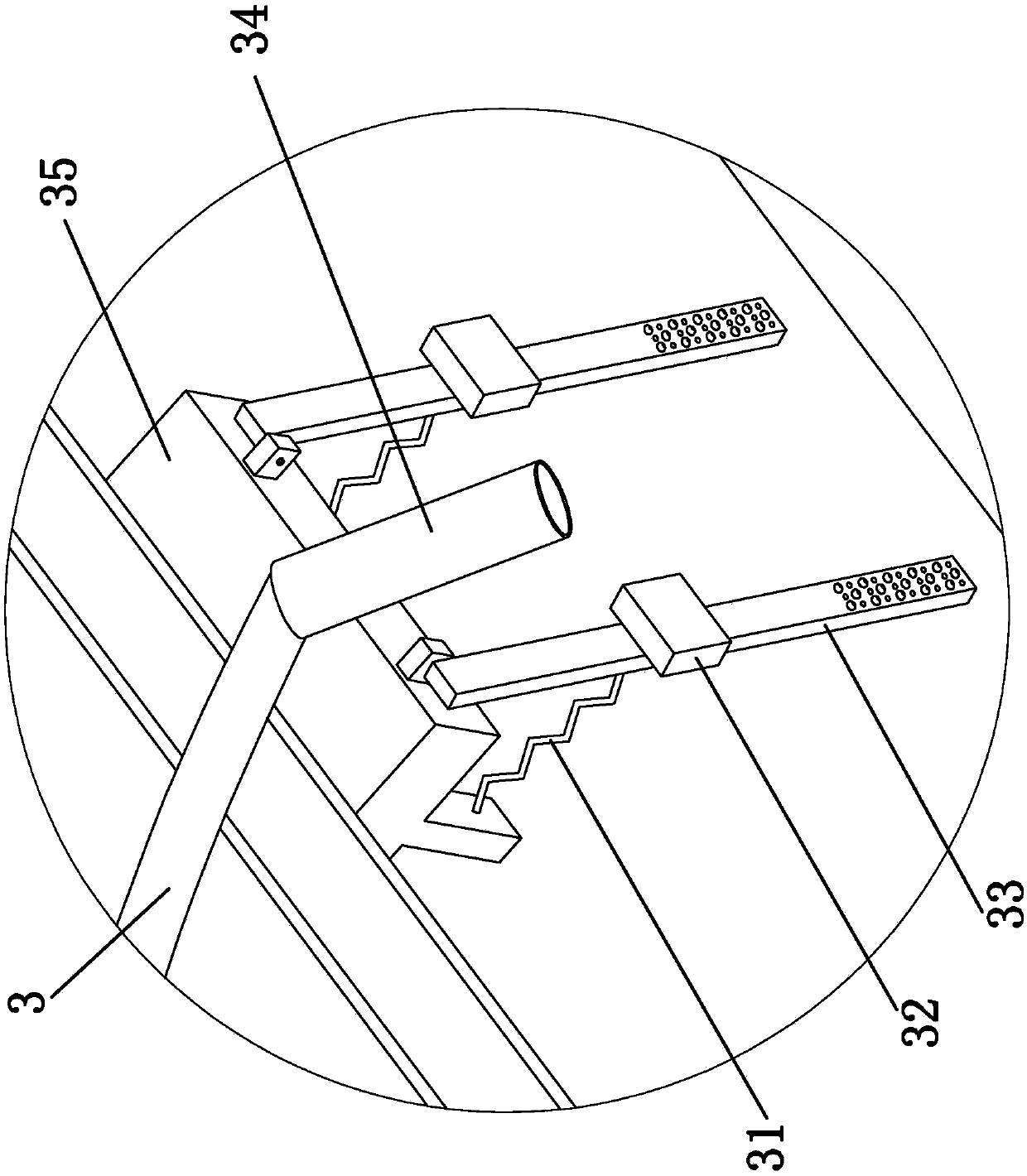

Leather grinding machine

ActiveCN107164574AAdjust the grinding degree at any timeAdjust the degree of sandingSkins/hides/leather/fur manufacturing apparatusLeather surface mechanical treatmentEngineeringMechanical engineering

The invention provides a leather grinding machine, and belongs to the technical field of machines. The technical problems that an existing leather grinding machine is huge in size and cannot be conveniently used by research personnel are solved. The leather grinding machine comprises a base, a fixed table arranged on the base, and a movable table arranged on the base. The leather grinding machine is characterized in that the fixed table is provided with a first roller and a second roller which are parallel; the first roller and the second roller are arranged on the fixed table in a circumferential rotation and axial fixing manner; a conveying belt is arranged between the first roller and the second roller in a sleeving manner, and the first roller is driven by a first motor; the movable table is located on one side of the fixed table, and the base is provided with a lifting mechanism pushing the movable table to ascend and descend up and down; and a limiting mechanism used for limiting the lowest height of the movable table is further arranged between the movable table and the base. The leather grinding machine has the beneficial effects that the mechanical structure is simple, and the leather grinding precision is high.

Owner:浙江深梦皮革科技有限公司

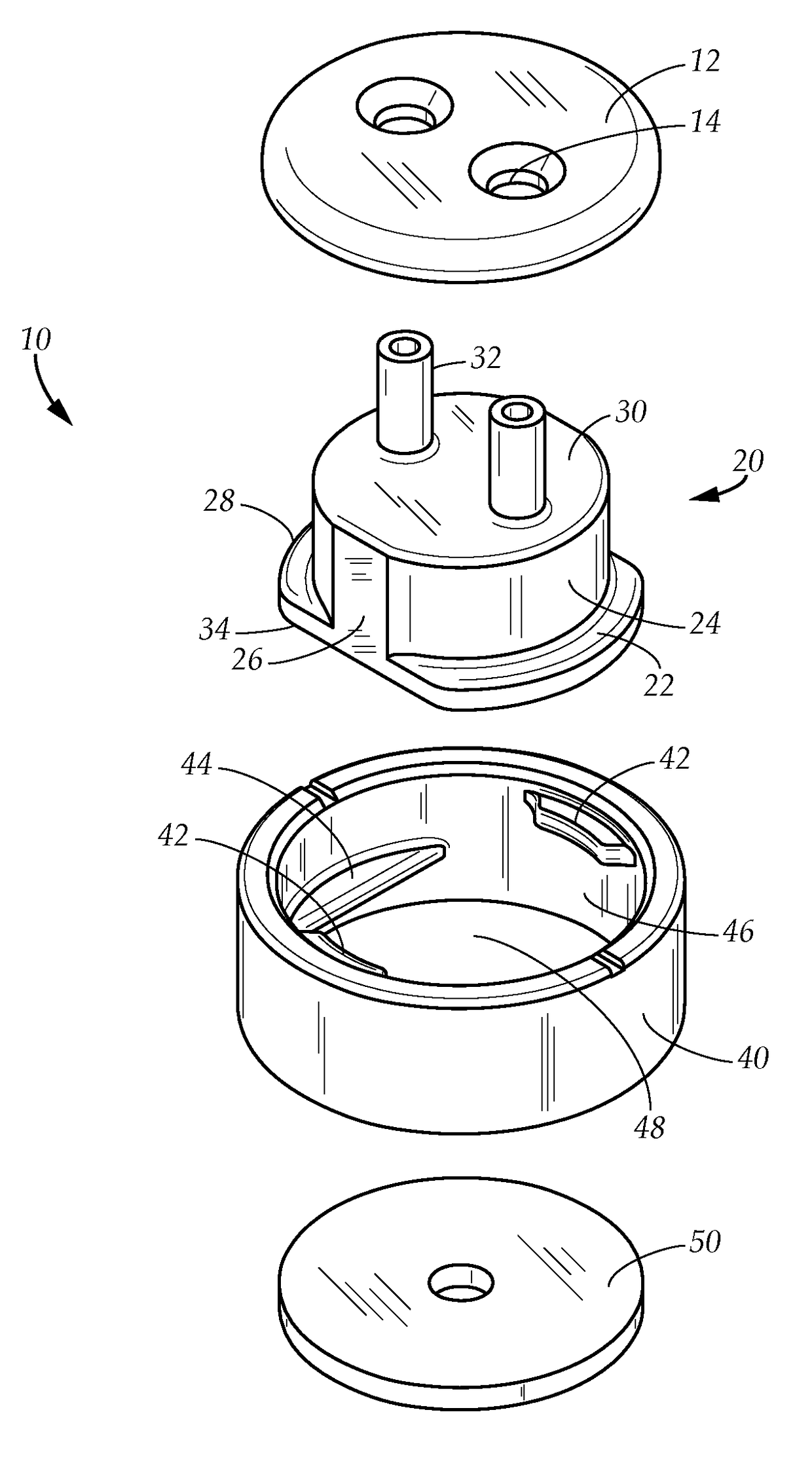

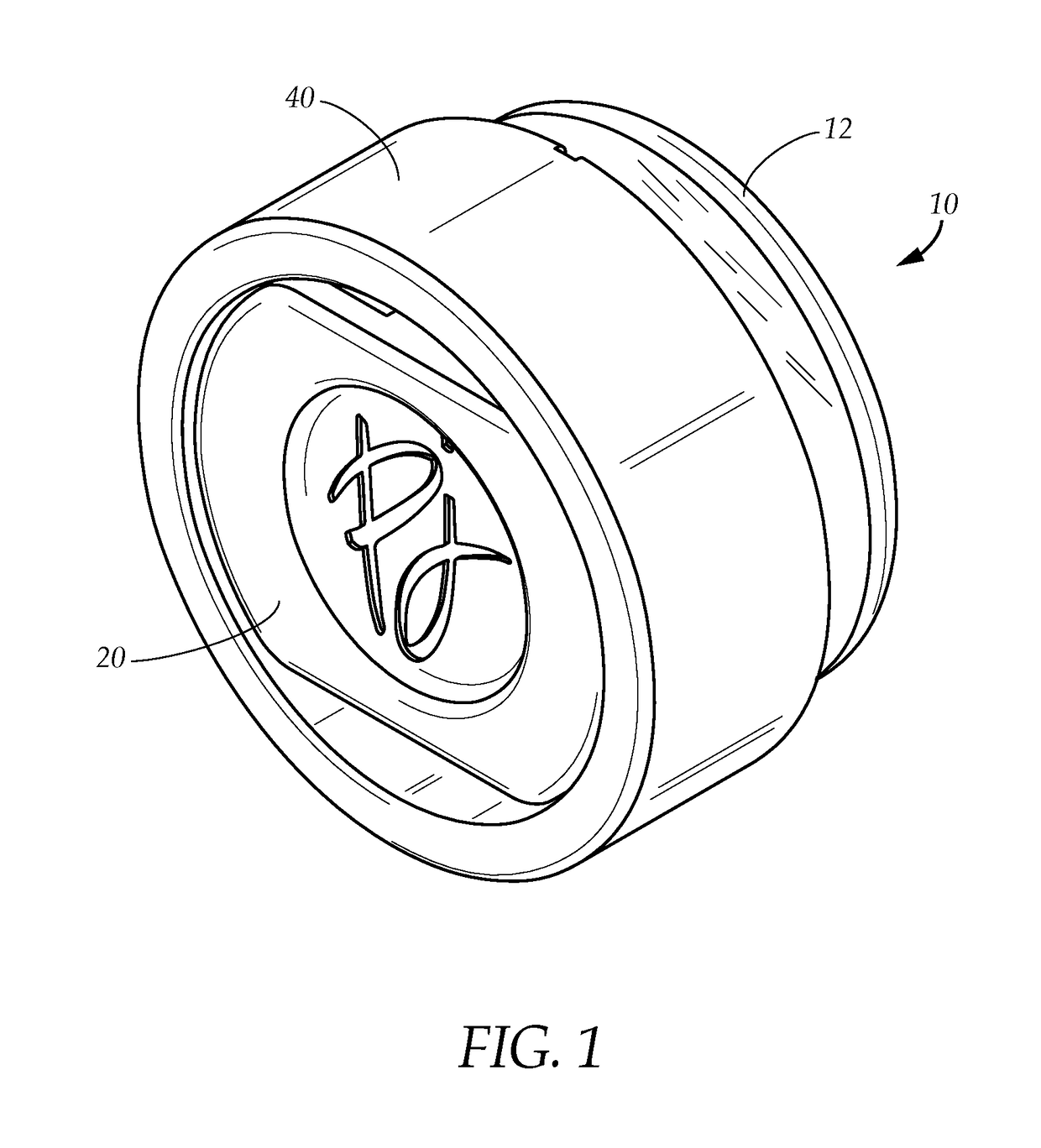

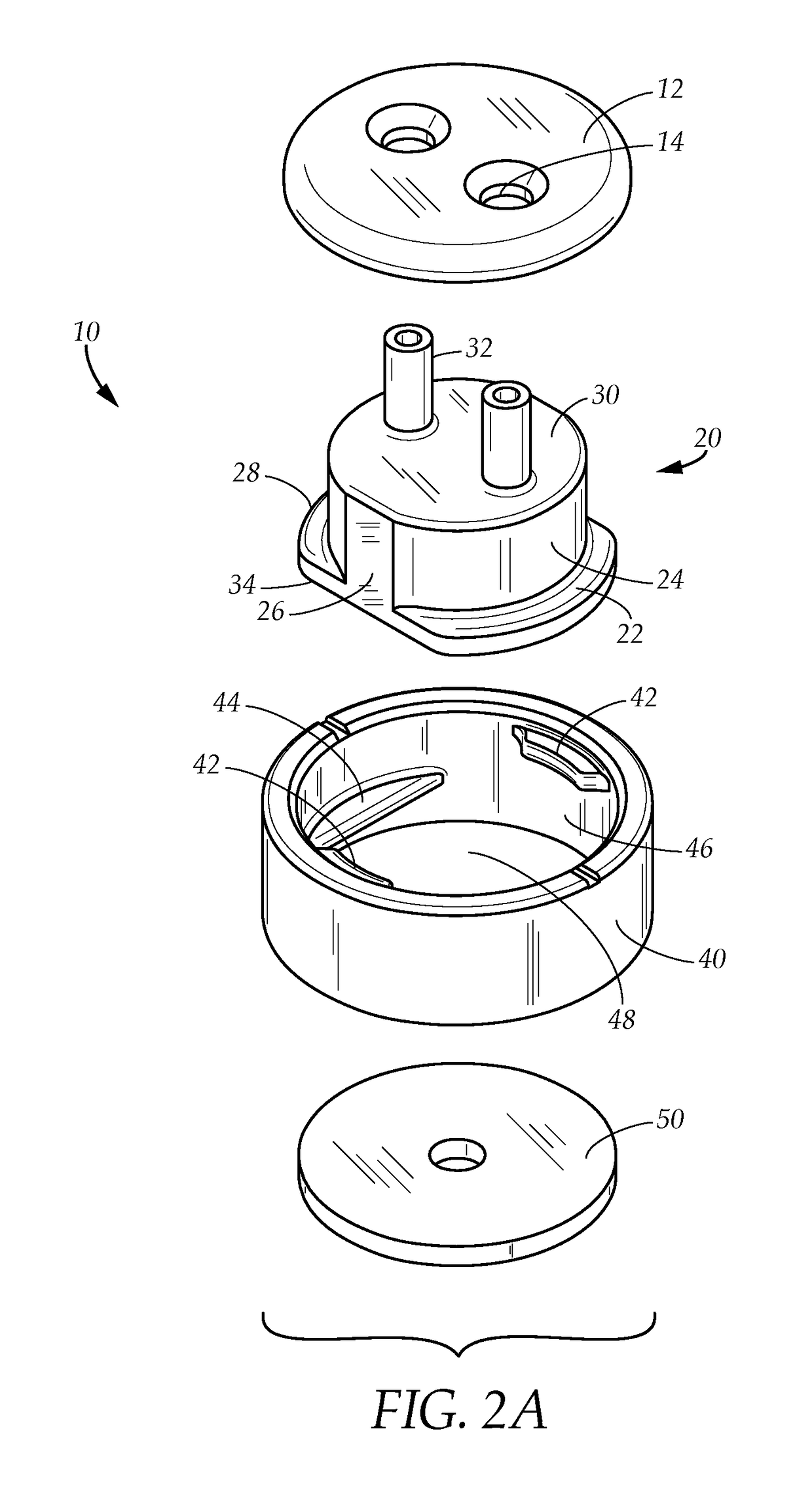

Pop-twist lock fastener

A fastener assembly that allows a user to change the appearance of a leather good such as clothing or an accessory by interchangeably attaching ornamentation to clothing or accessory, changing the appearance of the leather good. The fastener assembly is easy to use and only requires a user to place an ornament having an anchor attached over a base attached to a leather good and rotating to lock the ornament in place. The fastener assembly has a plurality of flanges on the anchor that prevent the ornament from rotating and falling off the base. A disk magnet inside the anchor further locks the ornament onto the base. The fastener assembly is useful for a wide variety of clothing and accessories made of leather or leather-like materials. The style of ornament is without limit.

Owner:PHOEBE JAMES INC

Preparation method for half-vegetable tanning knurled soft leather

ActiveCN103805721AUniform thicknessImprove dyeing uniformityTanning treatmentPre-tanning chemical treatmentMaterials scienceDyeing

The invention relates to a preparation method for leather and provides a preparation method for half-vegetable tanning knurled soft leather which is high in finished leather area yield, uniform in thickness and high in leather production performance. The soft leather prepared by adopting the preparation method disclosed by the invention has natural lines; the loose surface rate is reduced, the using amount of grease is lowered, and the leather production cost can be effectively reduced; the finished leather area yield is increased, and the leather production economical benefit is improved. The preparation method comprises the following technical steps of (1) preparing blue wet leather; (2) treating the blue wet leather; (3) performing preliminary uniform cutting; (4) performing bleaching and preliminary retanning dyeing; (5) performing secondary cutting; (6) performing secondary retanning dyeing; (7) performing aftertreatment.

Owner:XINGYE LEATHER TECH CO LTD

Leather wallet material processing device

ActiveCN110172533AGuaranteed smooth grindingSimple structureEdge grinding machinesGrinding drivesEdge surfaceBristle

The invention discloses a leather wallet material processing device. The leather wallet material processing device comprises a processing box. The processing box is internally provided with a transmission cavity. A grinding threaded rod rotates to drive a grinding threaded block to move left and right. The grinding threaded block moves to drive a pressure rod to move. The moving mechanism drives the pressure rod to move up and down to adjust the position and press leather. A main motor of a transmission mechanism provides power to drive the pressure rod to move left and right and drive a grinding stone to rotate to conduct grinding on the edge of the leather. The leather wallet material processing device grinds the edge surface of the leather smooth. An auxiliary motor in a waxing mechanism provides power to drive a brush block to move left and right to conduct waxing on the surface of the leather automatically through bristles.

Owner:义乌市玉刚箱包有限公司

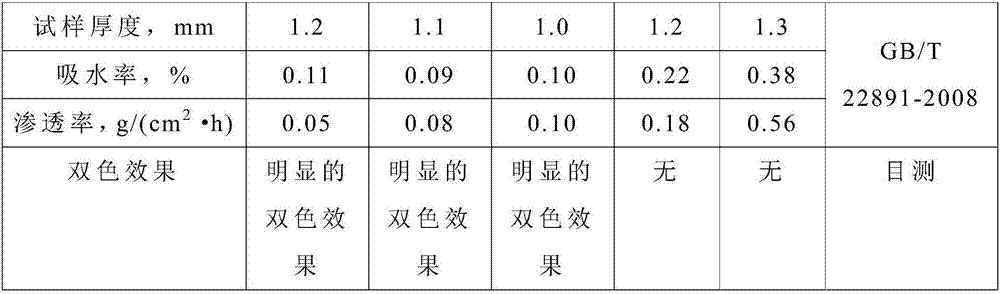

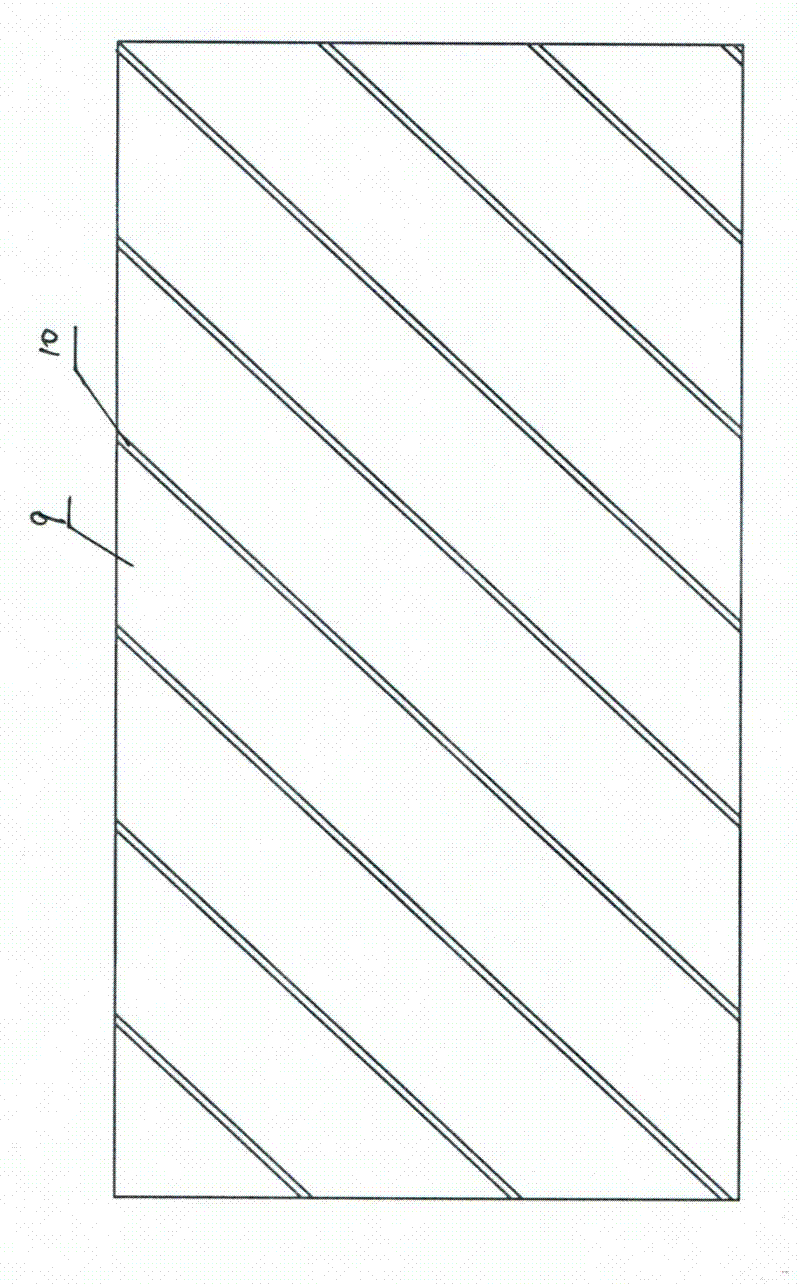

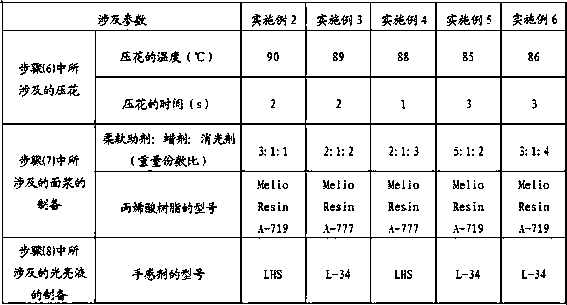

Manufacturing method of bicolor wax-texture crack split leather

ActiveCN107236833AStrong two-color contrast effectImprove performanceLeather/skins/hides/pelt chemical treatment apparatusLeather softeningWaxCrazing

The invention relates to a manufacturing method of bicolor wax-texture crack split leather and belongs to the technical field of leather. The manufacturing method of the bicolor wax-texture crack split leather comprises the following steps that processed and dyed split leather is obtained, dried, ground, milled, sprayed for the first time, roll-finished, sprayed for the second time, vibration-softened, rolled with oil wax and milled in sequence, and thus the bicolor wax-texture crack split leather is obtained. According to the manufacturing method of the bicolor wax-texture crack split leather, the processed and dyed split leather is dried, ground, milled, sprayed for the first time, roll-finished, sprayed for the second time, vibration-softened, rolled with the oil wax and milled, and the technological conditions of the steps and the chemical therapy ratio are strictly controlled and optimized, so that the low-level split leather is manufactured into the high-level crack leather with the wax texture, and the crack leather further has the strong bicolor contrast effect.

Owner:漳州香洲皮革有限公司

Production technique of semi-vegetable tanning cowhide pattern-marking upper leather

InactiveCN101709337ALight colorEasy to dyeTanning treatmentLeather surface mechanical treatmentPulp and paper industryDyeing

The invention relaters to a production technique of semi-vegetable tanning cowhide pattern-marking upper leather, comprising the technical steps of: a, retanning by using a vegetable tanning agent; b, folding and extruding a leather billet to form patterns, fixing in a wooded frame, and then placing the leather billet and the wooded frame into a flat-bed marking device together for pattern marking; c, taking the leather billet out of the wooden frame after the pattern marking, unfolding through milling and toggling, and then manufacturing a cowhide upper pattern-marking leather product with stereoscopic patterns through coating and trimming. The invention firstly marks the patterns in the purpose-made wooded frame with certain height, the pattern-marking leather is higher than the wooded frame, and then the wooded frame and the pattern-marking leather are placed into the flat-bed marking machine together for the pattern marking so that the leather with the special patterns is obtained; in addition, the invention uses the natural vegetable tanning agent birch bark tanning extracts for retanning, is safe, environmental-friendly, light in color and beneficial to dyeing and has larger using amount, enhanced formed effect, protruded leather upper patterns, unique and natural patterns, strong stereoscopic impression and good visual effect.

Owner:甘肃宏良皮业股份有限公司

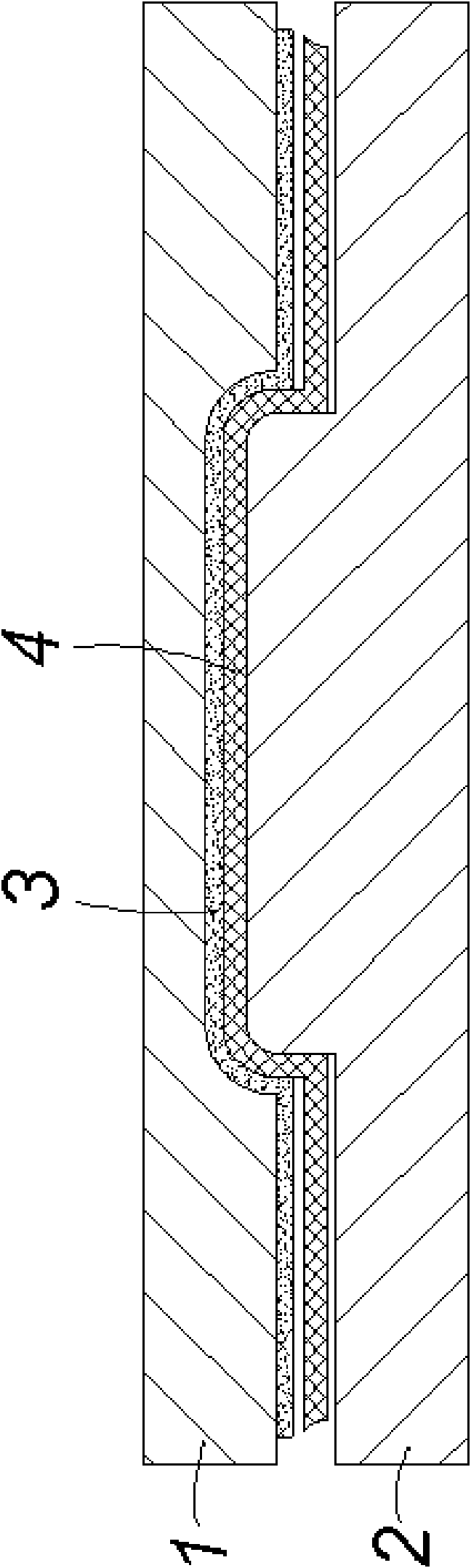

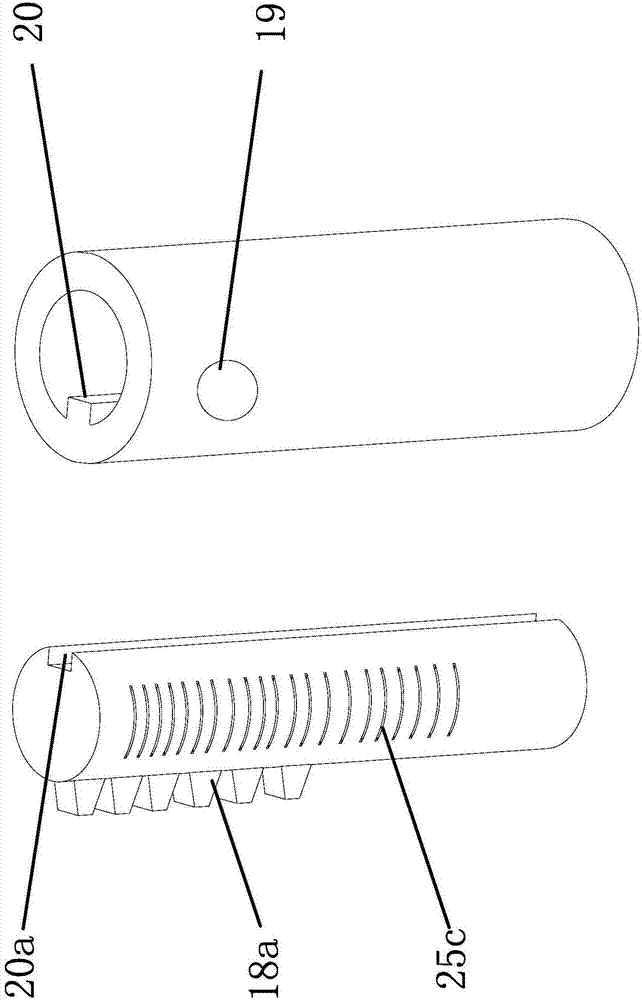

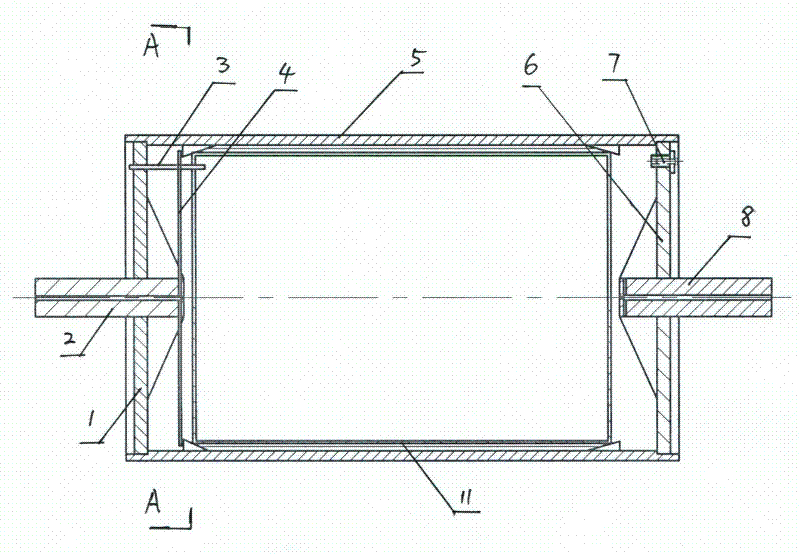

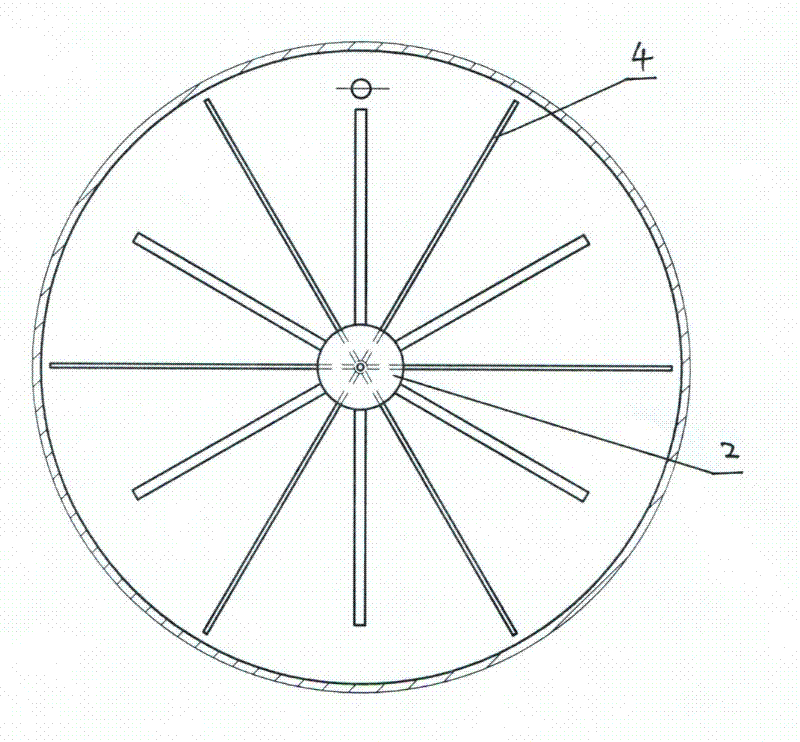

Roller for energy-saving constant-temperature oil heating mangle

InactiveCN102505051AUniform temperature conductionHeating evenlySkins/hides/leather/fur manufacturing apparatusLeather surface mechanical treatmentSpiral flowExhaust pipe

The invention discloses a roller for an energy-saving constant-temperature oil heating mangle, which comprises a roller body; spindle noses are fixed at two ends of the roller body; the roller body is provided with a roller shell; an oil inlet end cap and an oil outlet end cap are respectively fixed at two ends of the roller shell; an oil inlet spindle nose is arranged on the oil inlet end cap; an oil outlet spindle nose is arranged on the oil outlet end cap; a cylindrical inner container is arranged in the roller shell; an oil inlet cavity is arranged between the oil inlet end cap and the inner container; an oil outlet cavity is arranged between the oil outlet end cap and the inner container; an annular cavity between the cylindrical surface of the inner container and the inner wall of the roller shell forms an oil passage; a plurality of spiral flow guide grooves are arranged on the cylindrical surface of the inner container; the flow guide grooves are formed by the diversion of spiral flow guide fins on the cylindrical surface of the inner container; the rotation angle of the flow guide fins from the oil inlet end to the oil outlet end of the oil passage is 160-200 degrees; the distance between the cylindrical surface of the inner container and the inner wall of the roller shell is 10-12mm; and the height of each flow guide fin is 5-6mm. The inner container is provided with an exhaust pipe which is communicated with the outside. By using the heat guide oil to transfer heat, the roller is even in heating and accurate in temperature regulation and control.

Owner:HIGH TECH RES INST NANJING UNIV LIANYUNGANG

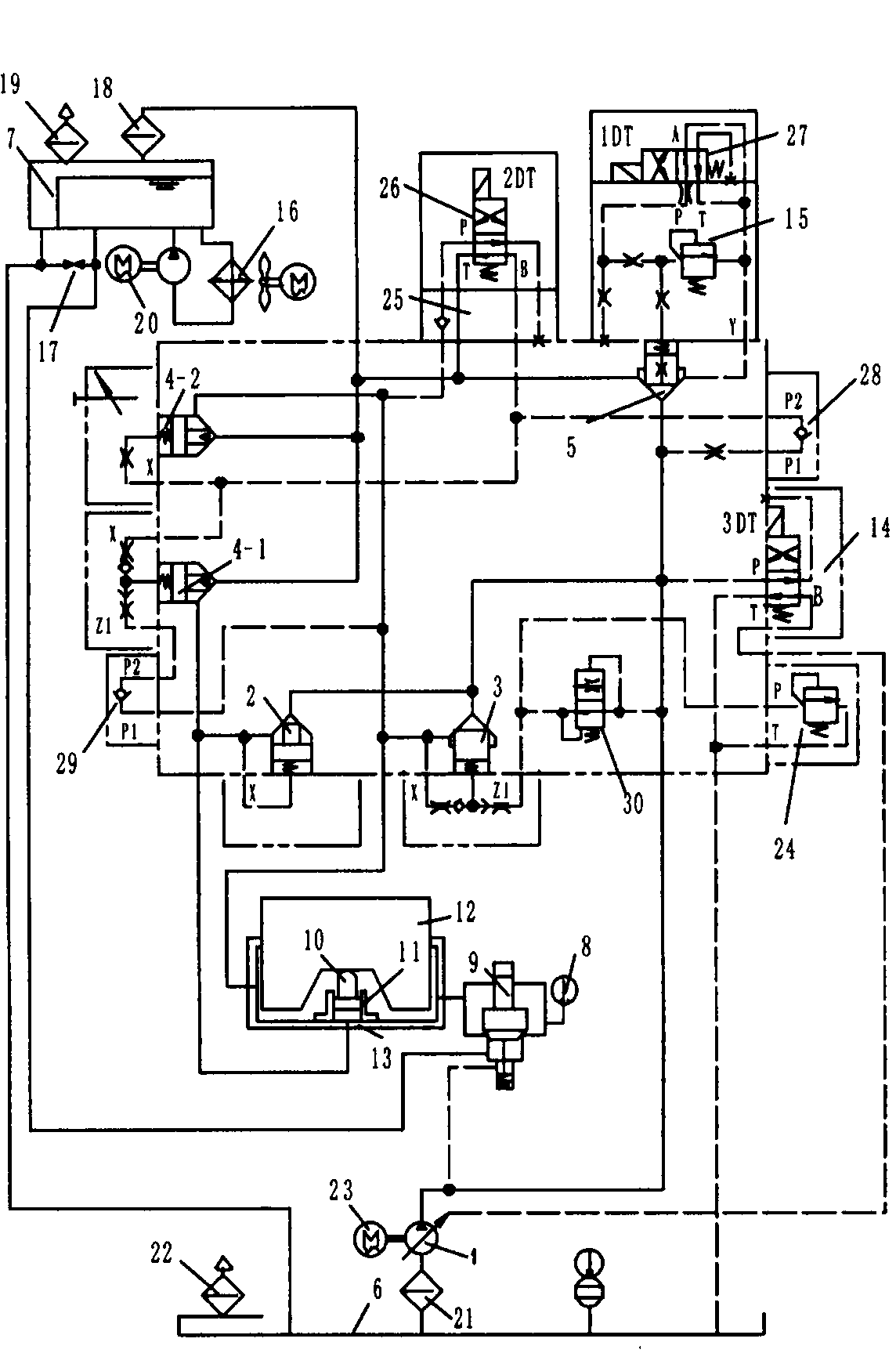

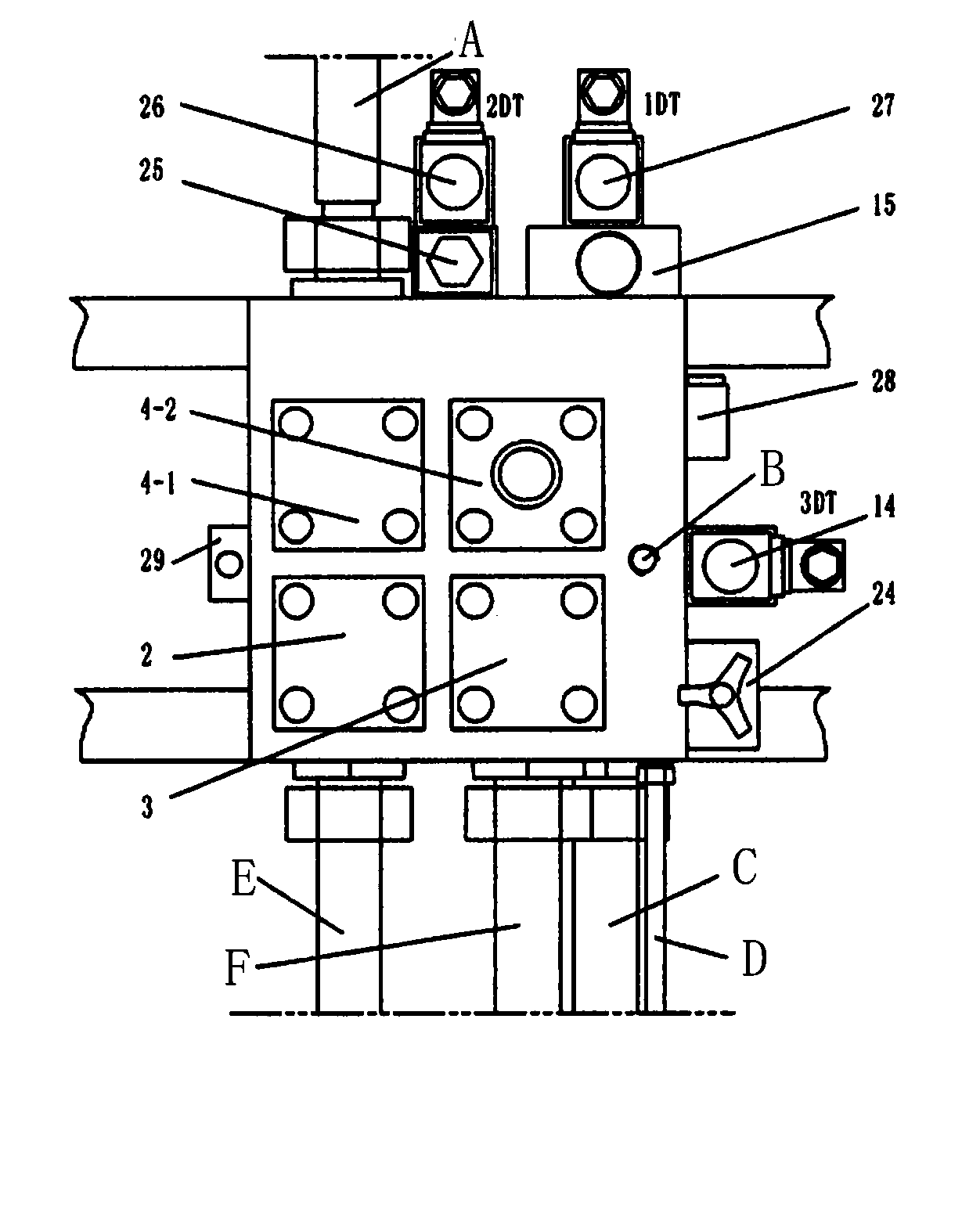

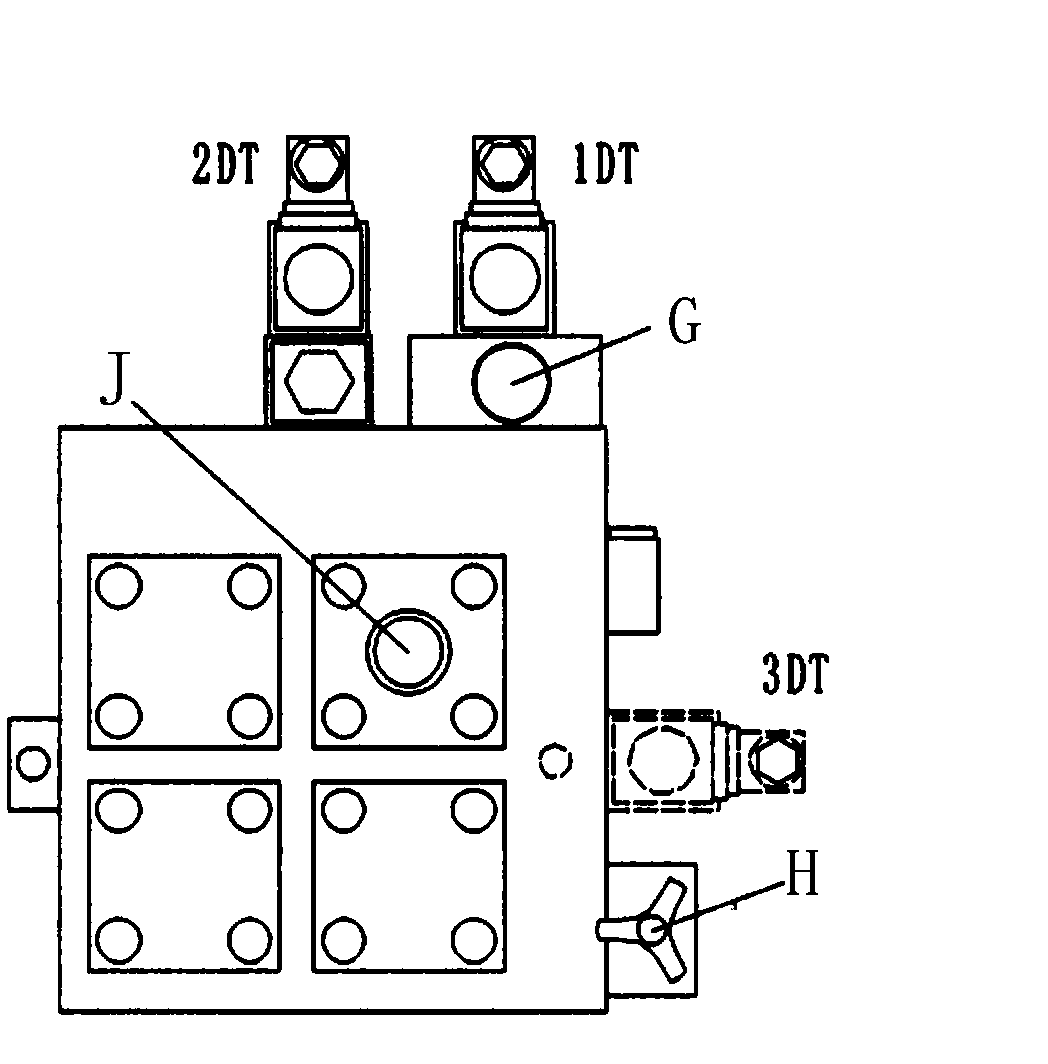

Hydraulic transmission and control system for press machine

ActiveCN104074815AImprove reliabilityImprove liquidityServomotor componentsServomotorsEngineeringMechanics

The invention provides a hydraulic transmission and control system for a press machine. The system is characterized by comprising a centralized-control combined valve block, as well as a small hydraulic cylinder, a large hydraulic cylinder, a main oil tank and a sub oil tank which are connected with the centralized-control combined valve block. The system thoroughly changes the traditional hydraulic transmission and control system for a press machine; the original pressure applying / pressure maintaining valve block and sequence control valve are combined into a uniform 'combined valve block'; the traditional slide valve control is changed into advanced cartridge valve control; the original speed regulation-free / throttling speed regulation feeding is changed into volume speed regulation; according to the system provided by the invention, an oil temperature is regulated in an air-cooling manner for replacing water-cooling regulation.

Owner:沈阳中大机械有限公司

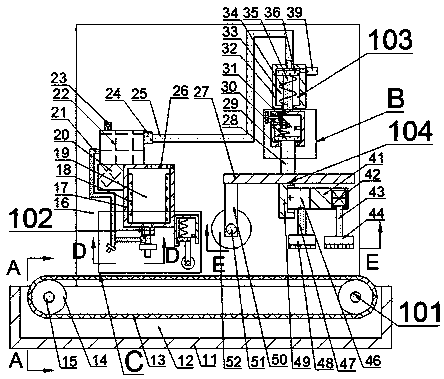

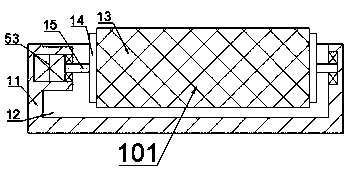

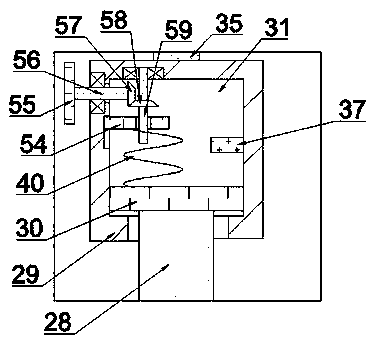

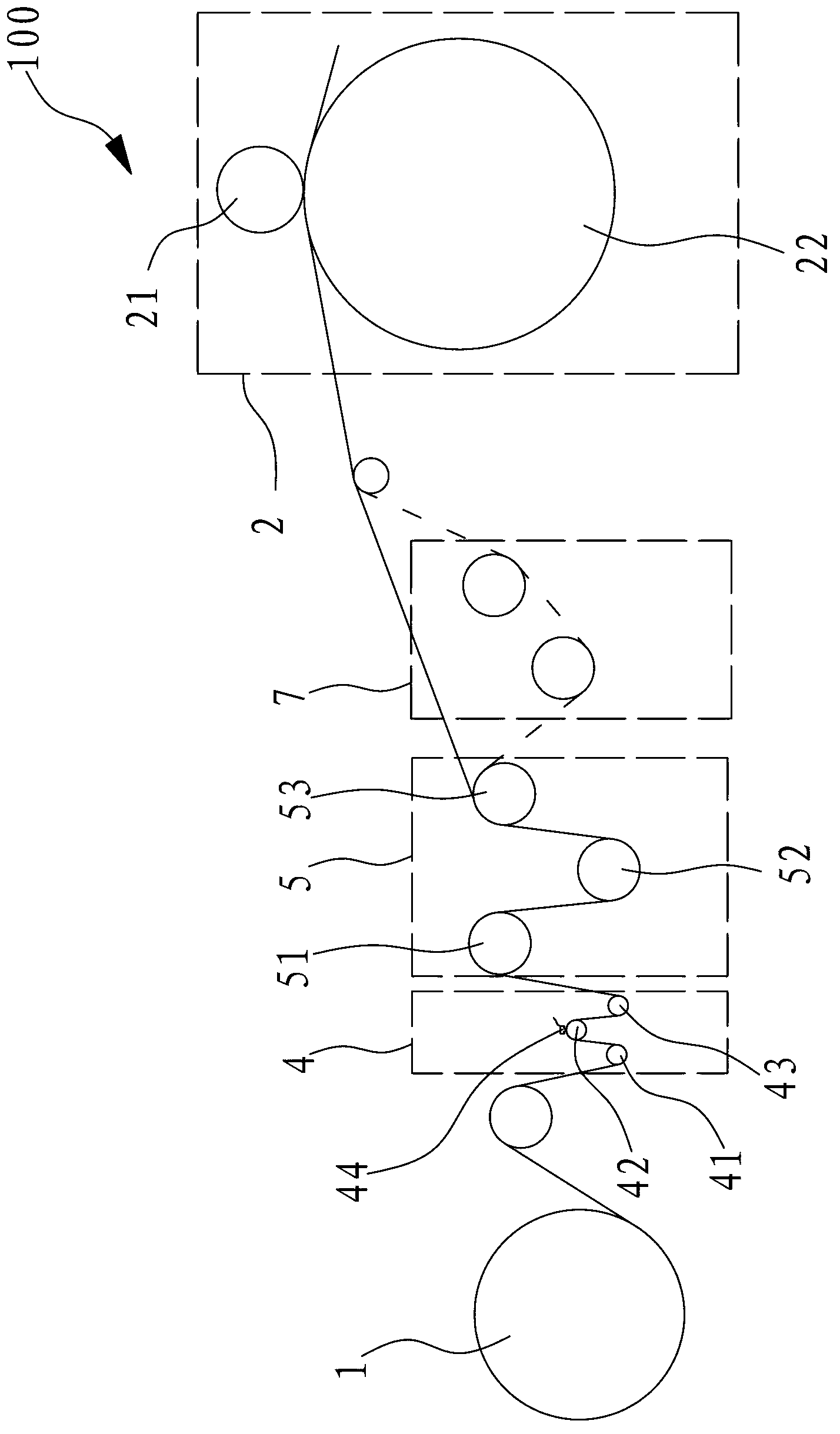

Automatic embossing machine

InactiveCN102839230AHigh speedHigh precisionMechanical working/deformationSkins/hides/leather/fur manufacturing apparatusTrademarkEngineering

The invention discloses an automatic embossing machine which comprises a feeding device, an embossing device and a receiving device which are sequentially arranged along the moving direction of materials. The embossing device is provided with a pattern roller, a hard roller and a hydraulic mechanism; the pattern roller is positioned above the hard roller and is tangential to the hard roller; the hydraulic mechanism is connected with the pattern roller and can be used for changing the acting force between the pattern roller and the hard roller. Furthermore, the automatic embossing machine also comprises a positioning device and a constant tension device. Compared with the prior art, any materials can have stereoscopic aesthetic perception on the automatic embossing machine, so that the effects of preventing the counterfeiting and protecting trademarks are achieved; and moreover, on the basis of the positioning device and the constant tension device, the positioning speed and accuracy also can be improved, materials are saved and the winding operation is ensured stable, reliable, rapid and efficiently.

Owner:SHISHI XINGGANG PLASTIC PACKAGING

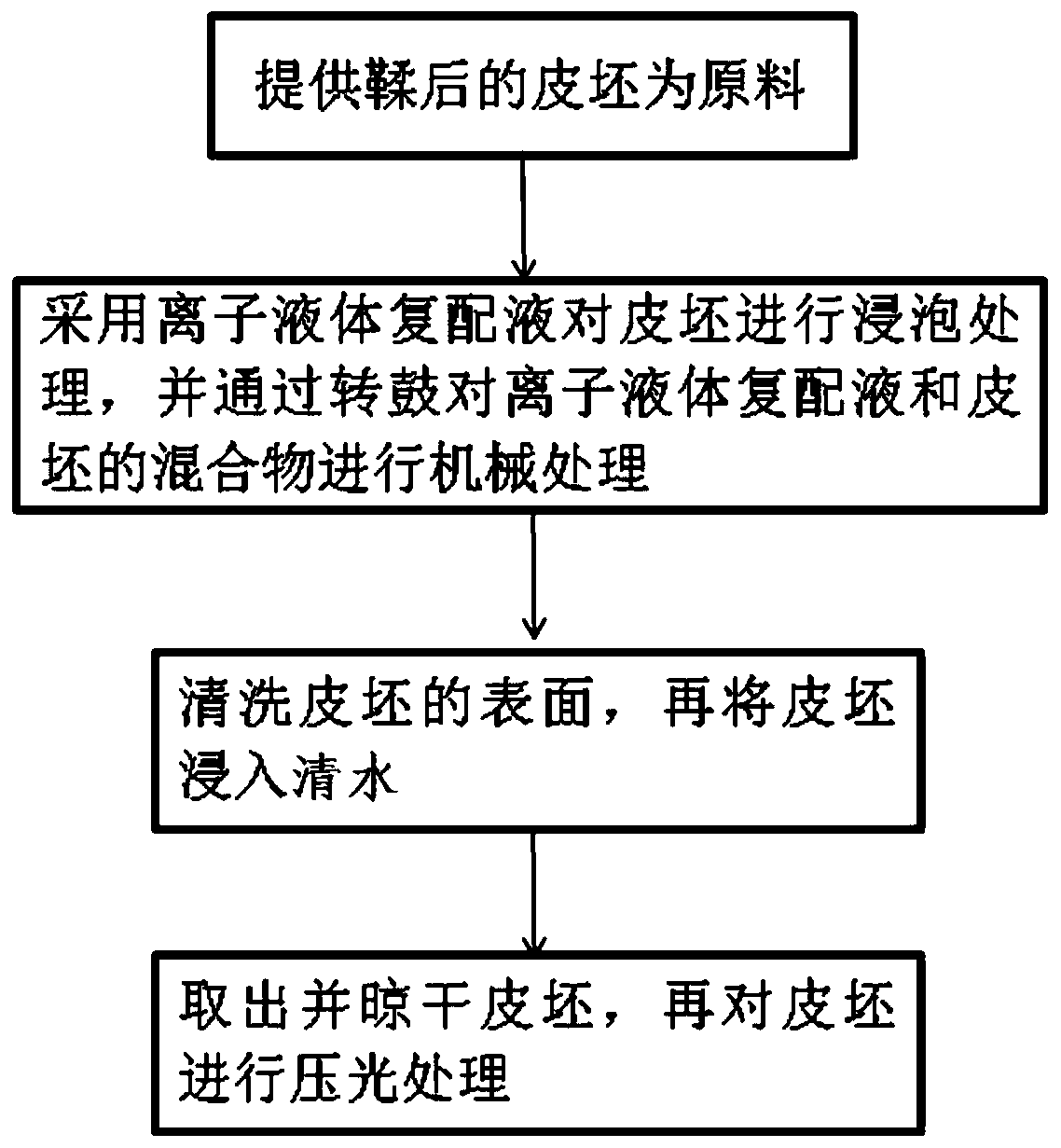

Transparent leather and preparation method thereof

ActiveCN110184398AIncrease shrinkage temperatureKeep natural propertiesLeather/skins/hides/pelt chemical treatment apparatusLeather surface mechanical treatmentIonic liquidRaw material

The invention relates to transparent leather, wherein transparency of the transparent leather is 46-74%, the shrinkage temperature is 90-110 DEG C, and the thickness is 0.4-1.4 mm. The invention further provides a preparation method of the transparent leather. The preparation method comprises the following steps: providing a tanned leather blank as a raw material; carrying out immersion treatmenton the leather blank by adopting an ionic liquid compound liquid, and carrying out mechanical treatment on the mixture of the ionic liquid compound liquid and the leather blank through a rotary drum;cleaning the surface of the leather blank, and then soaking the leather blank into clear water; and taking out the leather blank, airing the leather blank, and then carrying out calendering treatmenton the leather blank.

Owner:浙江通天星集团股份有限公司

Manufacturing method of sofa leather

ActiveCN107937632AAchieve preparationEasy to manufactureLeather softeningLeather surface mechanical treatmentKnurlingEngineering

The invention provides a manufacturing method of sofa leather, and solves the technical problems of more complicated steps, need of spending a lot of manufacturing time, complicated manufacturing andthe like in a traditional manufacturing method. The manufacturing method of the sofa leather comprises the following steps: (a) a leather blank is flatly paved on a passing water extruder to for waterextrusion to remove 78-96% of water in the leather blank; (b) the leather blank is dried through a drying device; (c) a repair agent is coated on the leather blank; (d) the leather blank is polishedthrough a leather polishing machine; (e) the leather blank is sized through a roller coating device; (f) paint is sprayed to the leather blank through a spraying device to obtain leather; (g) the leather is embossed or printed by two modes of knurling and plate pressing; (h) fall softening or pull softening is performed by a pull softening machine and a fall softening rotating drum; (i) the leather is ironed through high temperature to obtain finished sofa leather; and (j) the leather is measured, detected and warehoused. The manufacturing method of the sofa leather has the advantage of convenience to manufacture.

Owner:德州兴隆皮革制品有限公司

Suede leather production method

ActiveCN108165678AEnhance the feelImprove fullnessTanning treatmentPre-tanning chemical treatmentPhosphateTannin

The invention provides a suede leather production method. Suede leathers are obtained through performing water leaching, ash leaching, ash removal, acid leaching, tanning, uniform turning, retanning,neutralization, dyeing and degreasing and drying on leathers. The retanning process comprises the following steps: after 2% of acid-resistance acrylic acid and 0.5% of acid-resistance grease are usedfor treatment, pH is controlled as 3.0; and a chromium retanning agent is added for treatment. The neutralization process comprises the following steps: 150% of water, 2% of sodium formate and 2% of neutralization auxiliary are added; a rotating drum is rotated by 60 min; then, water washing is performed by 10 min; and the temperature is increased to 60 DEG C. The dyeing and greasing process comprises the following steps: 150% of water with a temperature of 40 DEG C, 1.5% of dicyandiamide tannin, 2% of amphoteric synthesized tannin, 4% of tannin extract and 2% of dye are added; the rotating drum is rotated by 50 min; 2% of sulfonated oil, 2% of phosphate and 5% of synthesized oil are added; the rotating drum is rotated by 50 min; 0.8% of formic acid is added; and the drum is stopped by 3 hours. The retanning, neutralization and greasing processes are improved to improve uniformity, hand feel, fullness, reading-writing effect and mercerization of the suede leathers.

Owner:NINGXIA JINHAI LEATHER IND

Production technique of xanthochromia-resisting and illumination-resisting two-layer leather

ActiveCN107523655AEnhanced yellowing resistance and light resistanceEasy to stretchTanning treatmentPre-tanning chemical treatmentSofteningXanthochromia

The invention relates to a production technique of xanthochromia-resisting and illumination-resisting two-layer leather, and belongs to the technical field of leather. The production technique of the xanthochromia-resisting and illumination-resisting two-layer leather includes steps of taking two-layered leathers, and orderly performing rewetting, retanning, alkali extraction, neutralizing, dyeing, fat liquoring, fixation, drying, softening, leather grinding, milling to obtain the xanthochromia-resisting and illumination-resisting two-layer leather. The xanthochromia-resisting and illumination-resisting two-layer leather has the advantages of being excellent in stretching performance, good in wear and fading resistance, good in waterproof property, and excellent in xanthochromia resistance and illumination resistance.

Owner:漳州香洲皮革有限公司

Unitary multi-use alignment fixture for shoe production

ActiveUS8850678B2Eliminate variationMinimal operator interactionLastingShoemaking devicesEngineeringMechanical engineering

A system for manufacturing shoes is provided that includes two or more pieces of equipment used in the customization and manufacturing of shoes and an alignment fixture that may engage with each piece of equipment by way of an alignment mounting member. The alignment fixture may secure to it a portion of a shoe, such as an upper portion, wherein the shoe portion remains in a flat position, and in a fixed relationship to the alignment fixture, throughout the various processes performed by the pieces of equipment. These processes may include, for example, printing, laser, embroidery, forming, cutting, or the like.

Owner:NIKE INC

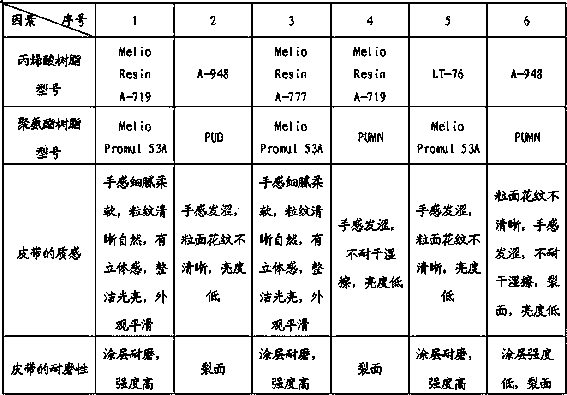

Method for producing double-smooth surface belt by utilizing cattle vegetable tanned harness leather

ActiveCN103642950ASmooth appearanceGood lookingPolyurea/polyurethane coatingsLeather surface mechanical treatmentChemistrySmooth surface

The invention discloses a method for producing a double-smooth surface belt by utilizing cattle vegetable tanned harness leather. The method comprises the steps of strip cutting, splitting, grinding, scraping and leveling, secondary grinding, embossing, surface paste spraying, bright layer spraying, holing, buckle arrangement and the like. According to the method, a production process is simple, the problem that only one surface can be coated when the cattle vegetable tanned harness leather is used for producing a belt is solved, and the double surfaces of the belt are endowed with the characteristics of cleanliness, brightness, smooth appearance, abrasion resistance of coatings, strong strength and the like by technical processing; the method is applied to the production of the belt.

Owner:JIHUA 3514 LEATHER & FOOTWARE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com