Roller for energy-saving constant-temperature oil heating mangle

A technology of ironing rollers and oil heating, which is applied in the mechanical treatment of leather surface, mechanical treatment of small raw hides/large raw hides/leather/furs, raw hides/leather/furs manufacturing equipment, etc. Problems such as difficulty in replacement, to achieve the effect of uniform heating, uniform temperature conduction, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

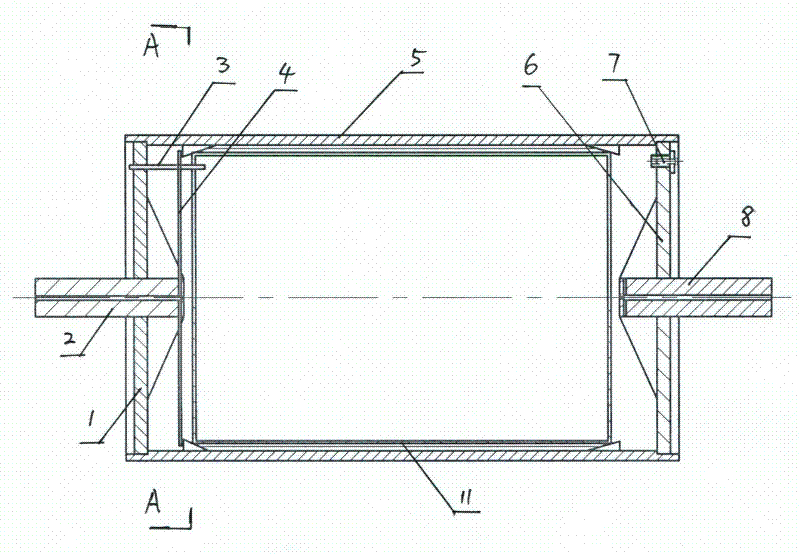

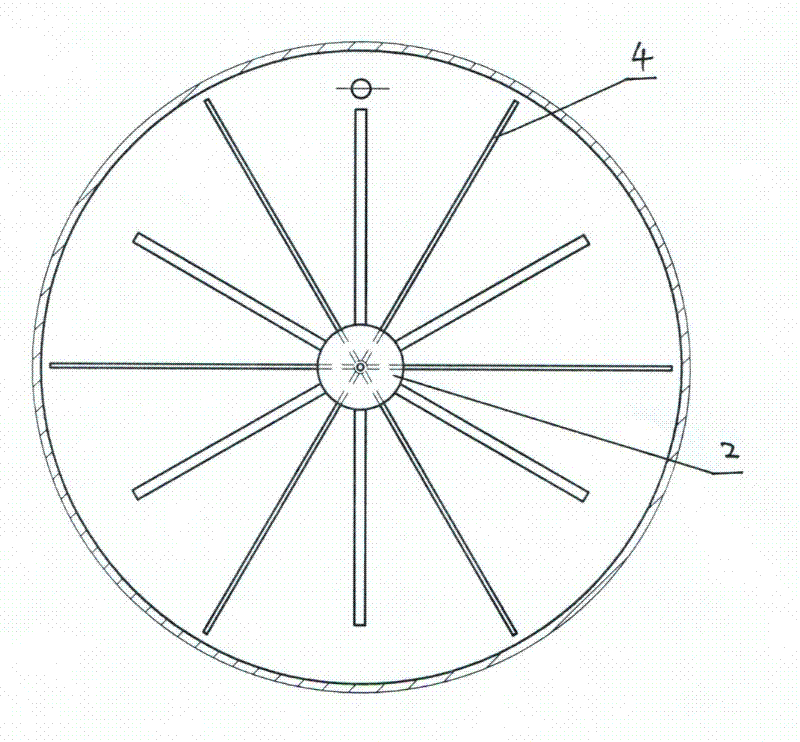

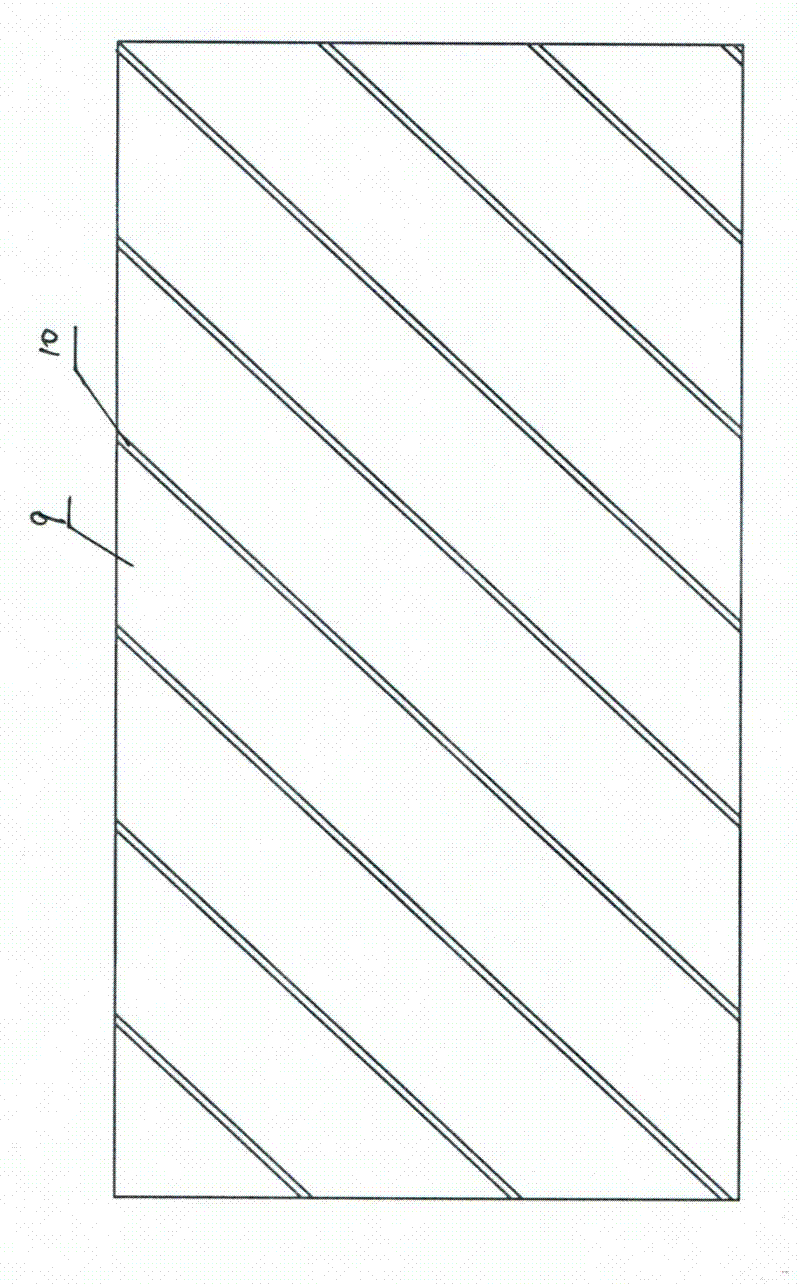

[0014] An energy-saving constant temperature oil heating ironing machine roller, which is provided with a roller shell 5, and the two ends of the roller shell 5 are respectively fixed with an oil inlet end cover 1 and an oil outlet end cover 6, and the oil inlet end cover 1 is provided with an oil inlet shaft The head 2 and the oil outlet end cover 6 are provided with an oil outlet shaft head 8, and a cylindrical inner tank 11 is arranged in the roller shell 5, and an oil inlet chamber is arranged between the oil inlet end cover 1 and the inner tank 11, and the oil outlet There is an oil outlet chamber between the end cover 6 and the inner tank 11, and the oil passage is formed by the annular chamber between the cylindrical surface of the inner tank 11 and the inner wall of the roller shell 5, and several spirals are arranged on the cylindrical surface of the inner tank 11. The guide groove 9 is separated by the spiral guide fins 10 arranged on the cylinder surface of the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com