Patents

Literature

2830 results about "Steam heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

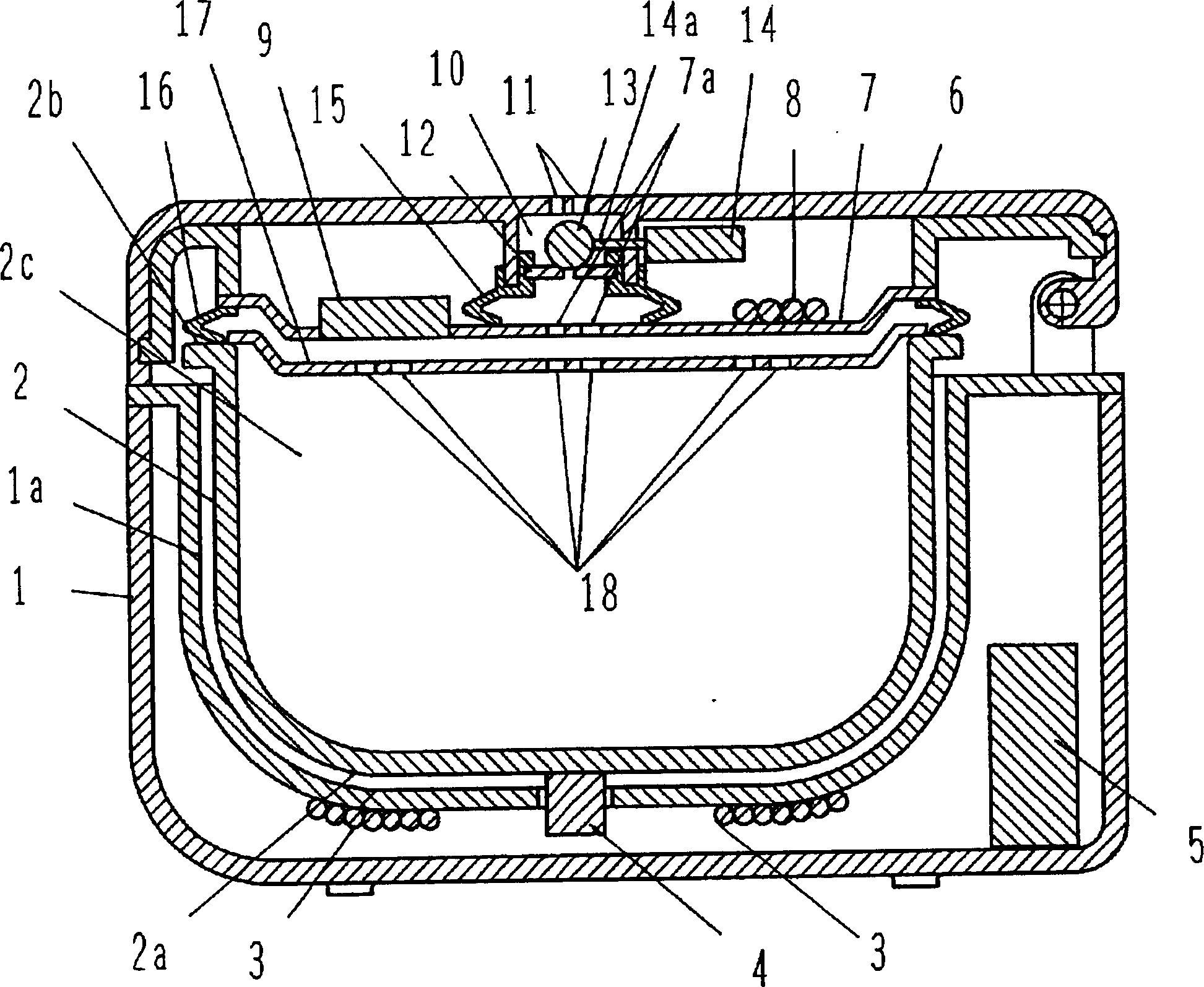

Steam pressure cooker

The invention relates to a household drinking appliance, in particular to a steam pressure cooker, which comprises a main pot body. The upper end of the main pot body is connected with a selective laminated pot body and a pot lid, the bottom of the main pot body is connected with a steam-heating plate, and the shell of the main pot body is connected with a water accumulation core and a handle; and the water accumulation core is connected with one end of the steam-heating plate through a water supply pipe, the steam-heating plate can boil water through an external heating source to generate steam, and one end of the steam-heating plate is also connected with an air delivery pipe and an anti-spillage box and extends into the main pot body. The invention has the advantages that the drink-steaming speed is high, the adoption of the steam-heating plate can realize the water boiling within a short term due to the clearance cooking in the small space, and the generated heat can be used for steaming and cooking food; and the thermal energy transmitted from a heat source can be utilized more completely and more directly due to the fin type heat transfer block of the steam-heating plate technology.

Owner:戴文育

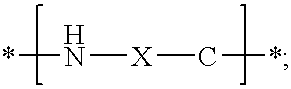

Polyamide composition

InactiveUS6887930B2Low water absorptionOvercome lack of heat resistanceCarboxylic acidTerephthalic acid

A polyamide composition comprising 50 to 90 parts by weight of (A) semiaromatic polyamides having dicarboxylic acid units containing 60 to 100 mole % of terephthalic acid units and diamine units containing 60 to 100 mole %, in total, of 1,9-nonanediamine units and / or 2-methyl-1,8-octanediamine units, and 50 to 10 parts by weight of (B) aliphatic polyamides in which the average of total carbon atoms of dicarboxylic acid units and diamine units per one amide group is 7 to 12; having excellent moldability, toughness, light-weightness, hot water and steam resistance, heat resistance, mechanical characteristics, low water absorption, chemical resistance and melt stability; and are applicable for molding at low temperature with a conventional steam-heating or a conventional hot-water-heating type mold to give molded articles having sufficient heat resistance, rigidity at high temperature and dimensional stability.

Owner:KURARAY CO LTD

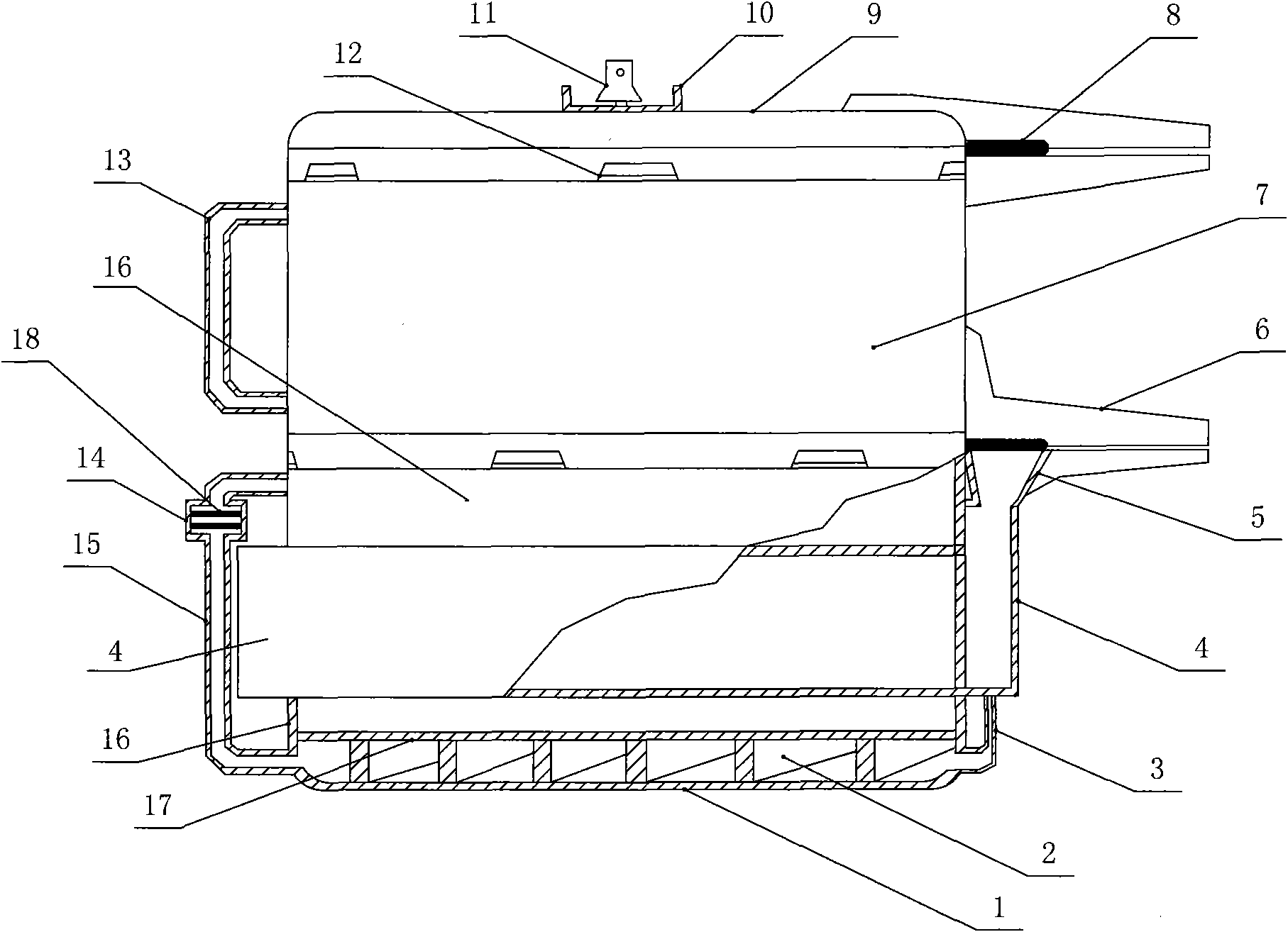

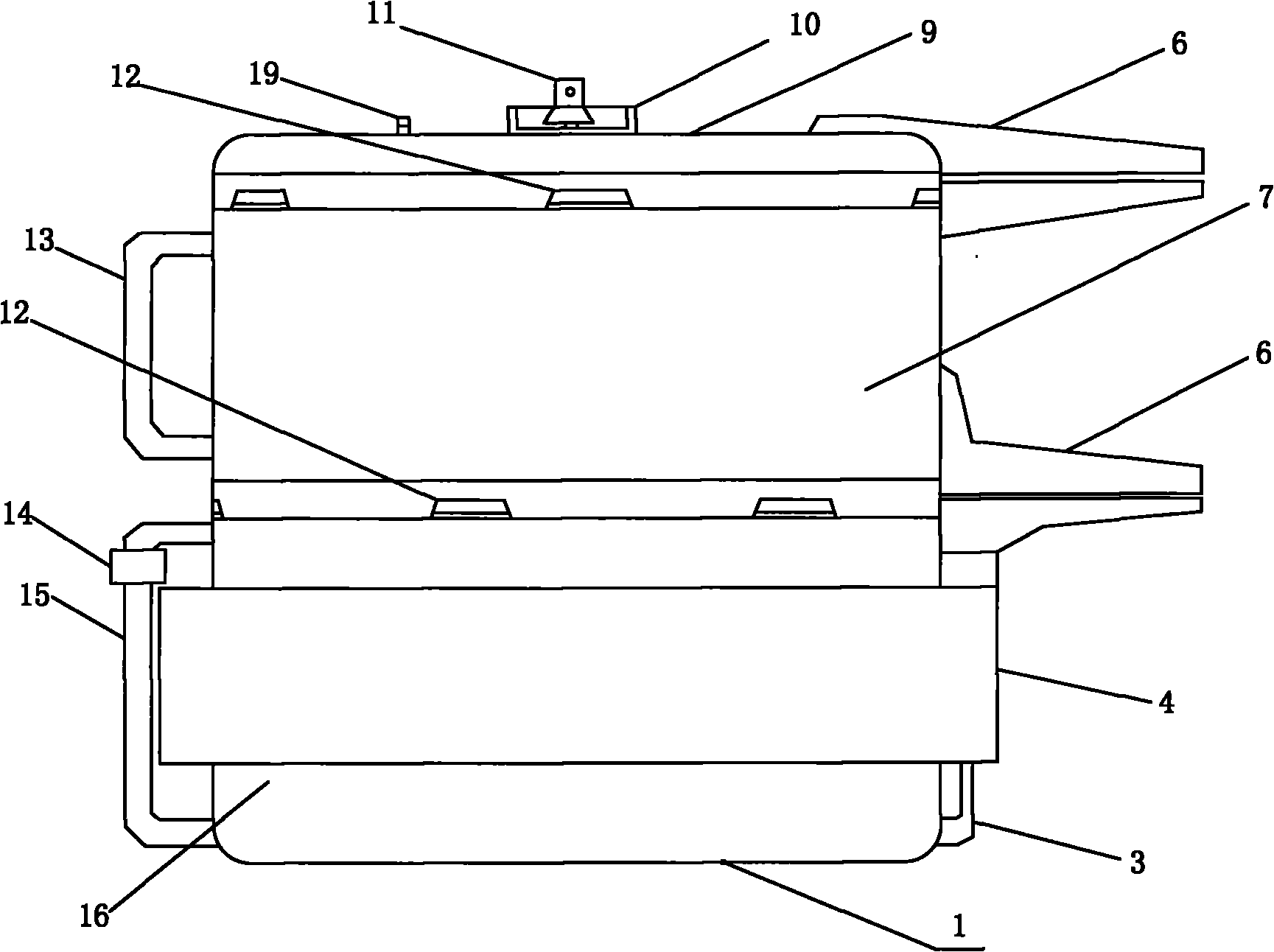

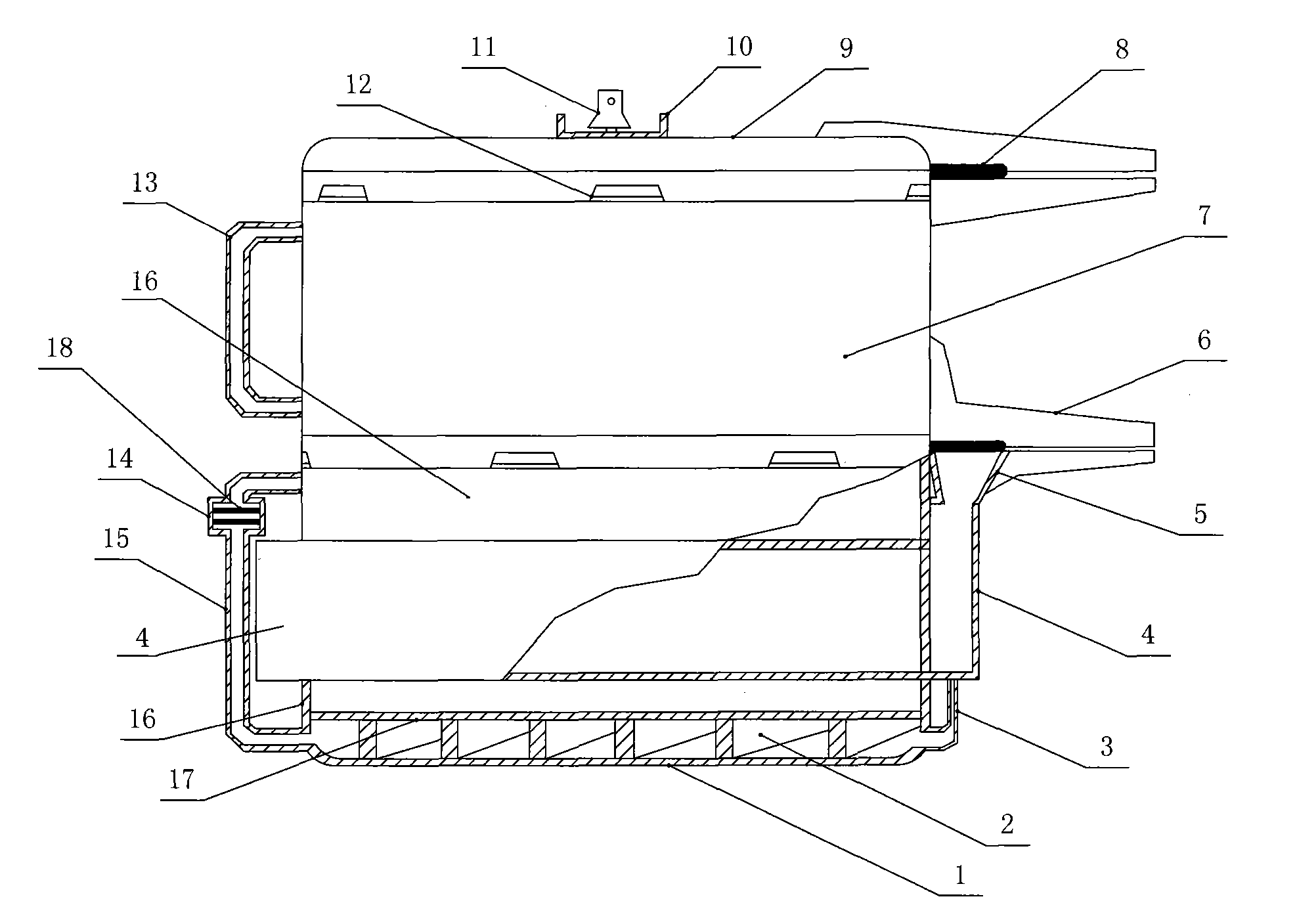

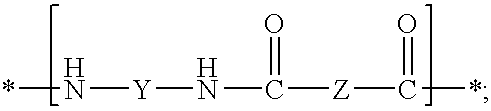

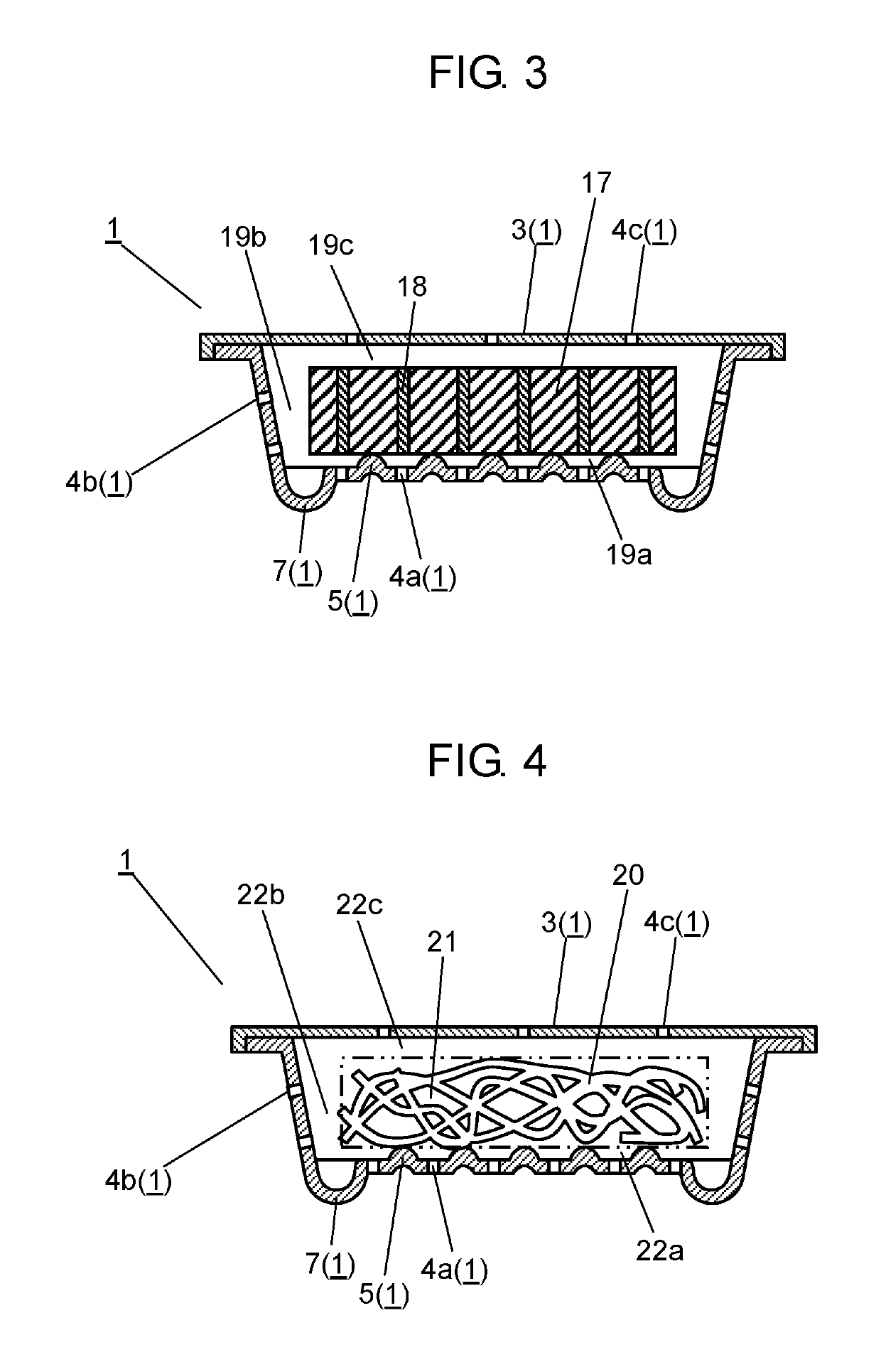

Electric cooker

InactiveCN1820685AImprove gelatinizationReduce power consumptionPressure-cookersEngineeringElectric power

The electric rice cooker includes one cooker body, one detachable pot, one cover, one pressure regulator for maintaining certain pressure inside the pot, one sealing unit to seal the opening of the pot, and one steam heater to heat the generated steam into high temperature steam for cooking rice. The electric rice cooker has reduced steam heating time, capacity of cooking delicious rice and effect of promoting water absorption. In addition, it has no special steam generator, and this results in reduced cooker size, low power consumption for generating steam and reduced total power consumption.

Owner:PANASONIC CORP

Processing method of ultrafine green tea powder

A superfine green tea powder is prepared from fresh tea leaves through choosing, spreading, adding green protector, steam heating, lossening, cooling, kneading, drying and superfine pulverizing.

Owner:TEA RES INST CHINESE ACAD OF AGRI SCI

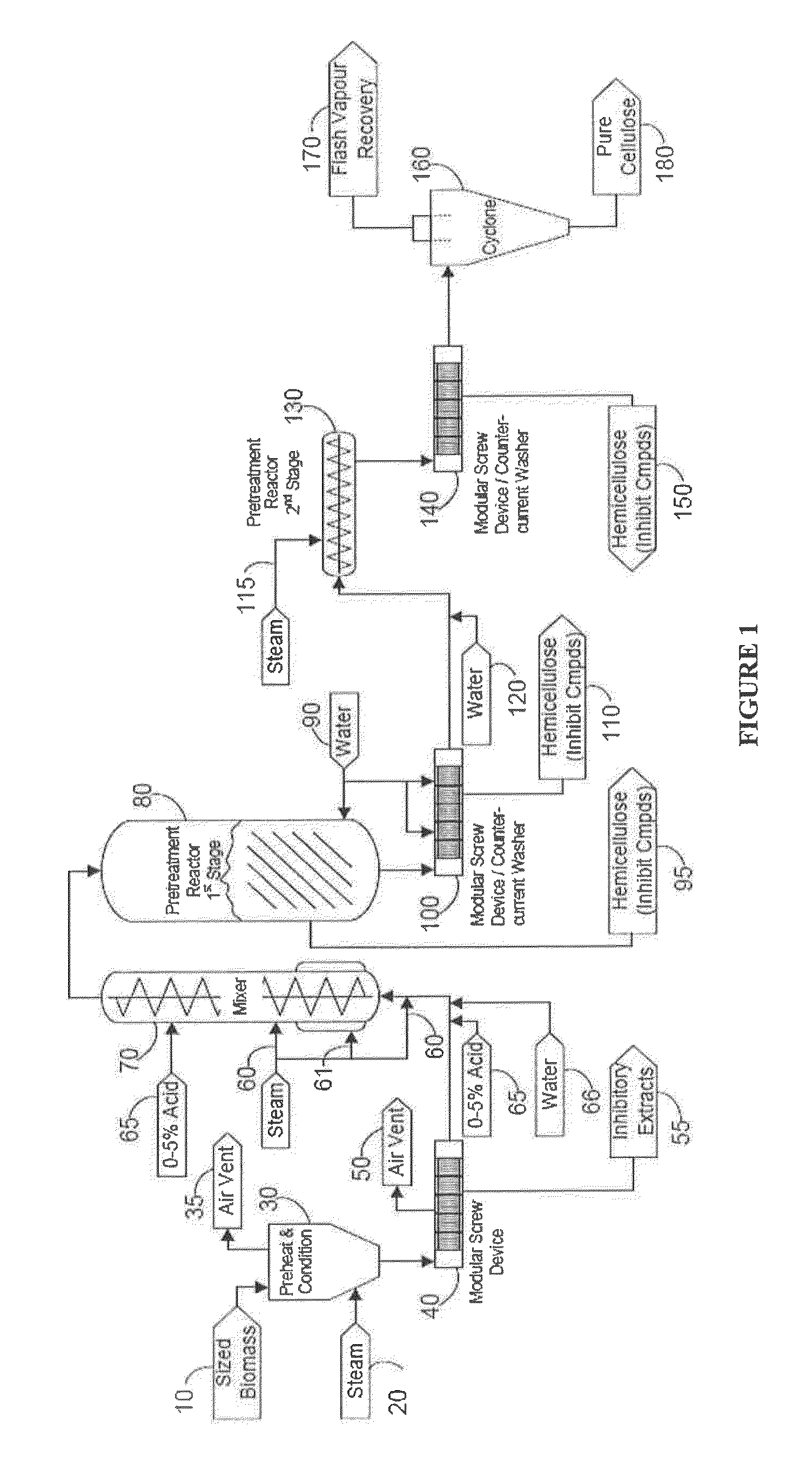

Two stage continuous pre-treatment of lignocellulosic biomass

InactiveUS20130029406A1Improve disadvantagesBiofuelsWaste based fuelLignocellulosic biomassEnvironmental engineering

Disclosed is a method of pretreating biomass in two pretreatment stages as part of a biofuel production process. The first stage pretreatment is carried out by heating the biomass to a first stage temperature of 140° C. to 180° C. for a first stage time of 30 minutes to 2 hours at a first stage pressure of 105 to 150 psig; and the second stage is carried out by heating the biomass to a second stage temperature of 190° C. to 210° C. for a second stage time of 2 to 10 minutes at a second stage pressure of 167 to 262 psig. The biomass may be initially conditioned prior to the first pretreatment stage by atmospheric steam heating and adjusting the moisture content of the biomass. Hemicellulose and inhibitors (inhibitory compounds) to downstream hydrolysis and fermentation are preferably removed between the first and second pretreating stages, more preferably after each pretreatment stage.

Owner:GREENFIELD SPECIALTY ALCOHOLS

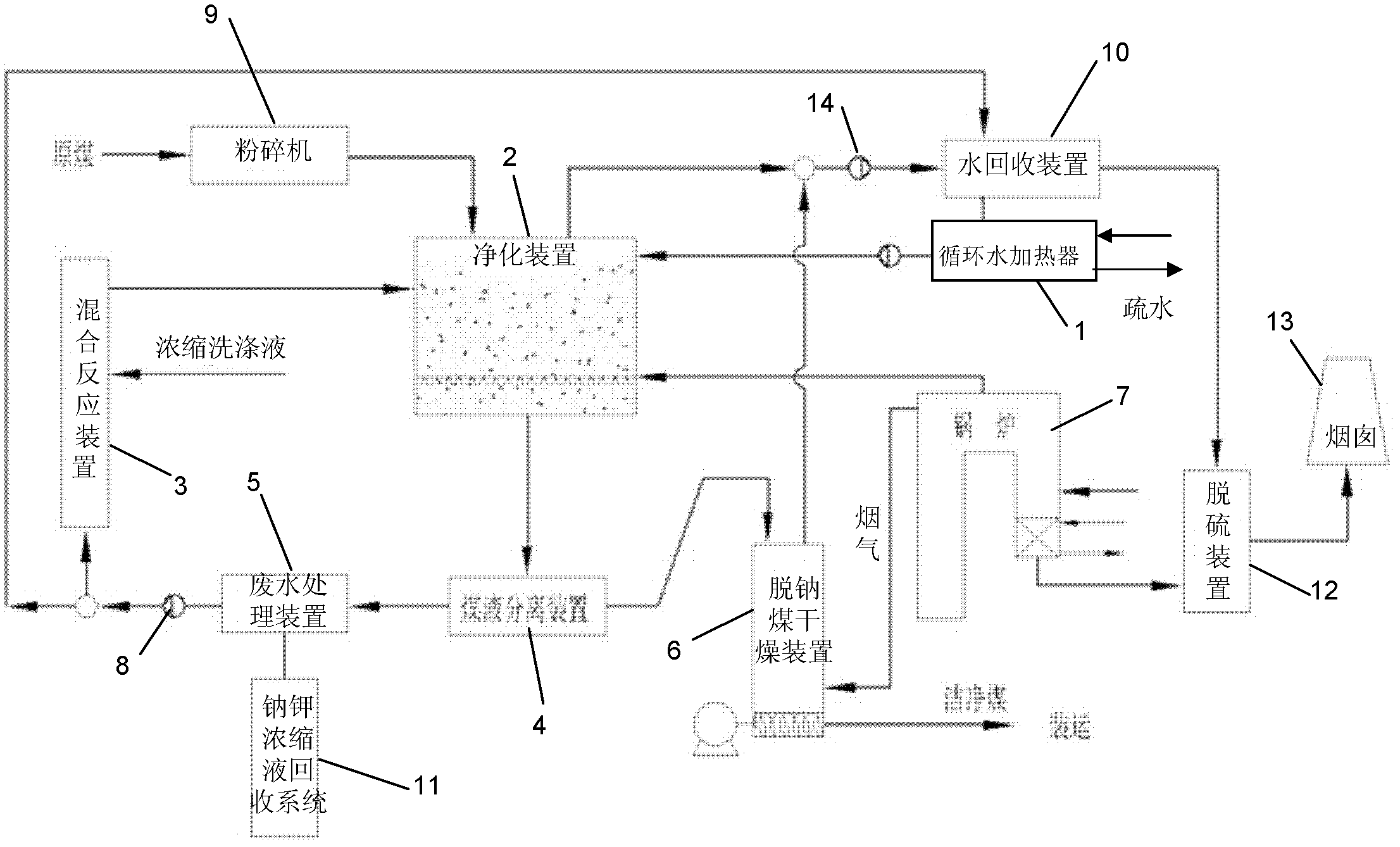

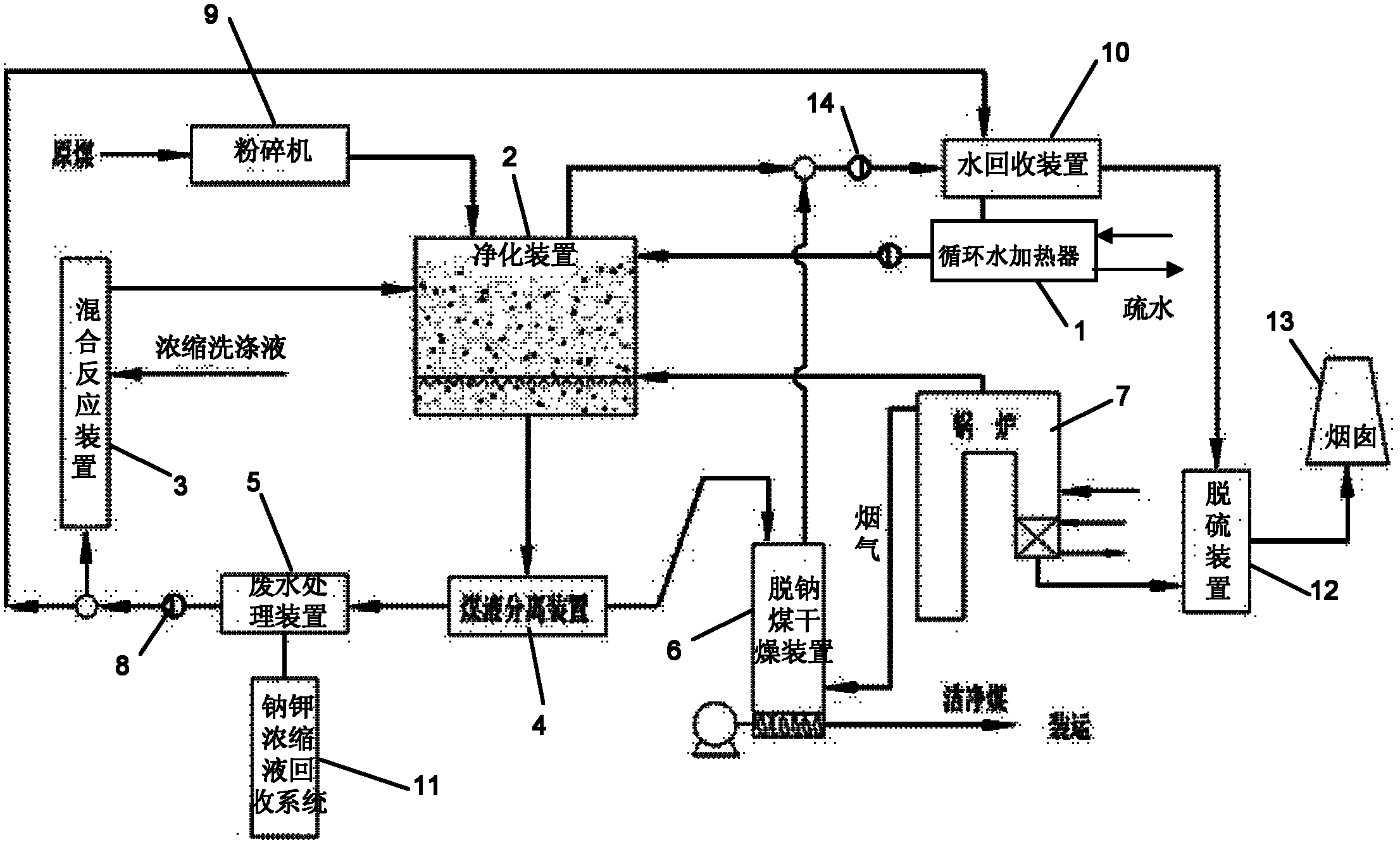

Sodium-removing purification cyclic system of high-sodium coal

InactiveCN102533383AReduce alkali metal contentSimple processSolid fuelsHigh sodiumWater circulation

The invention discloses a sodium-removing purification cyclic system of high-sodium coal. The system comprises a circulating water heater, a raw coal purification device, a mixing reaction device, a coal liquid separation device, a wastewater treatment device, a sodium-removing coal drying device and a steam heating source. The cyclic system heats water by utilizing a power plant heat source, andpurification and sodium removal are carried out on the raw coal through water circulation, thus good coal quality is reached, and the effects of saving water and the like are reached.

Owner:SHANGHAI YUANMENG ELECTRIC POWER ENERGY TECH CONSULTING CENT

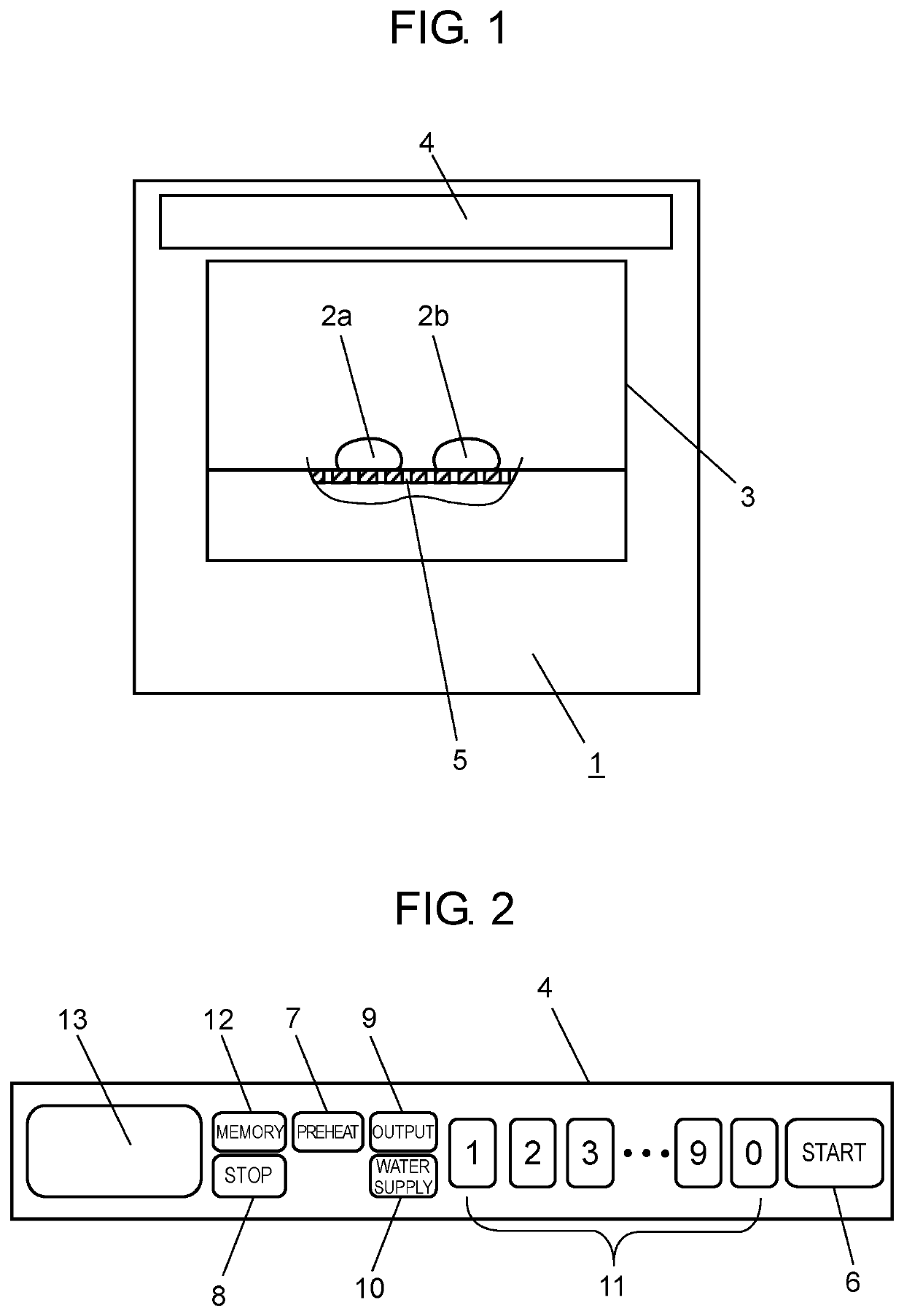

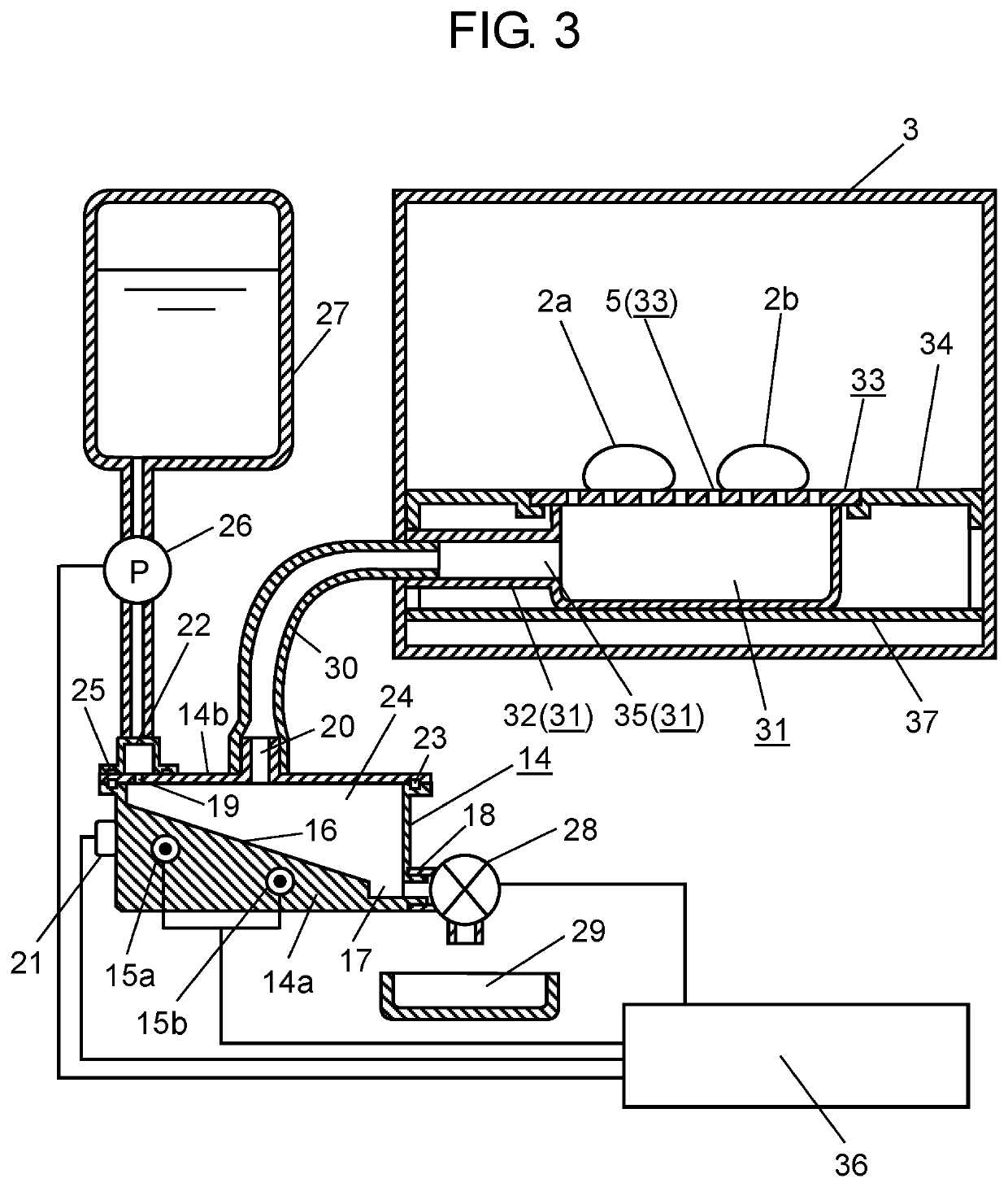

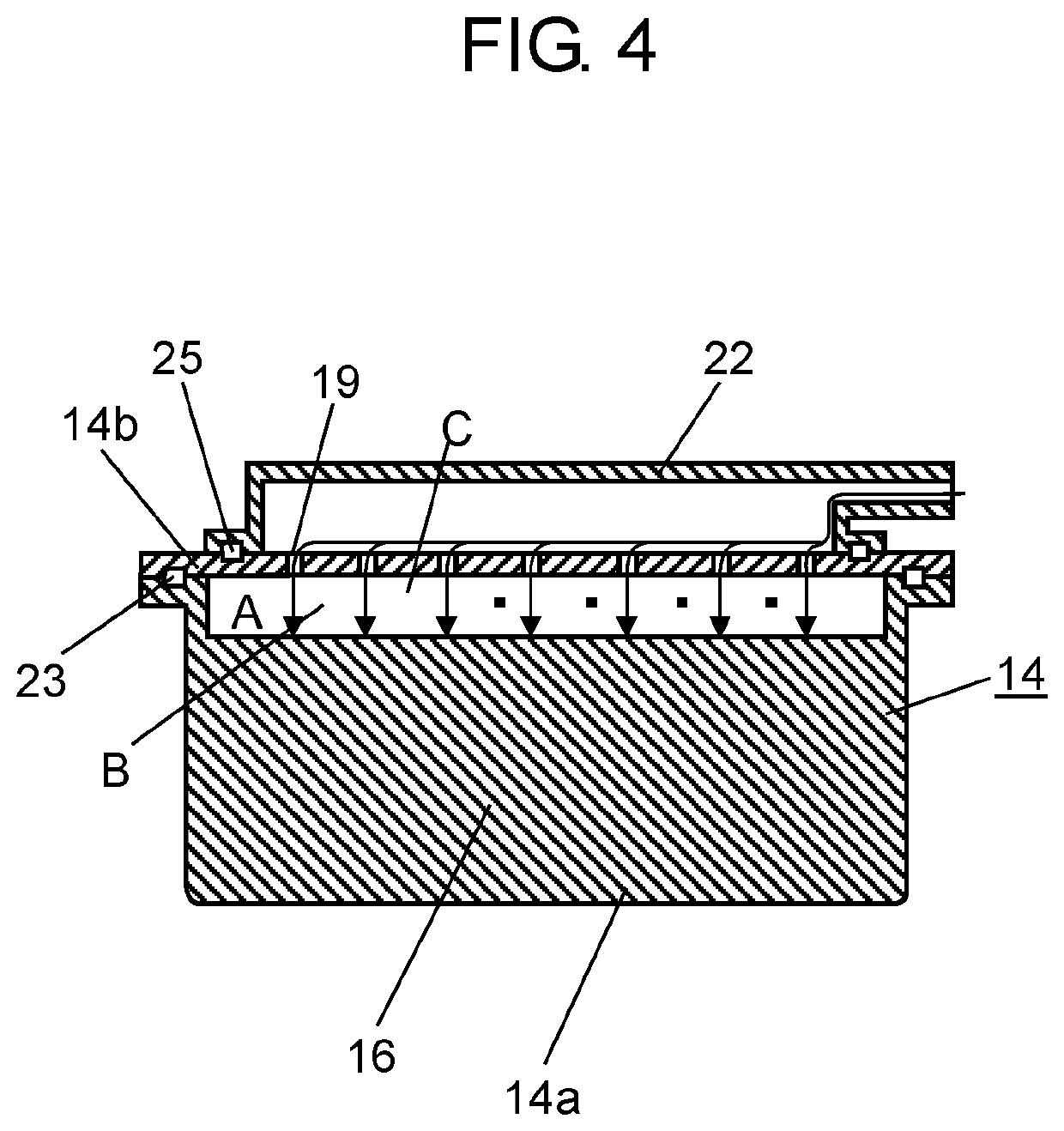

Method and apparatus for quickly cooking comestibles

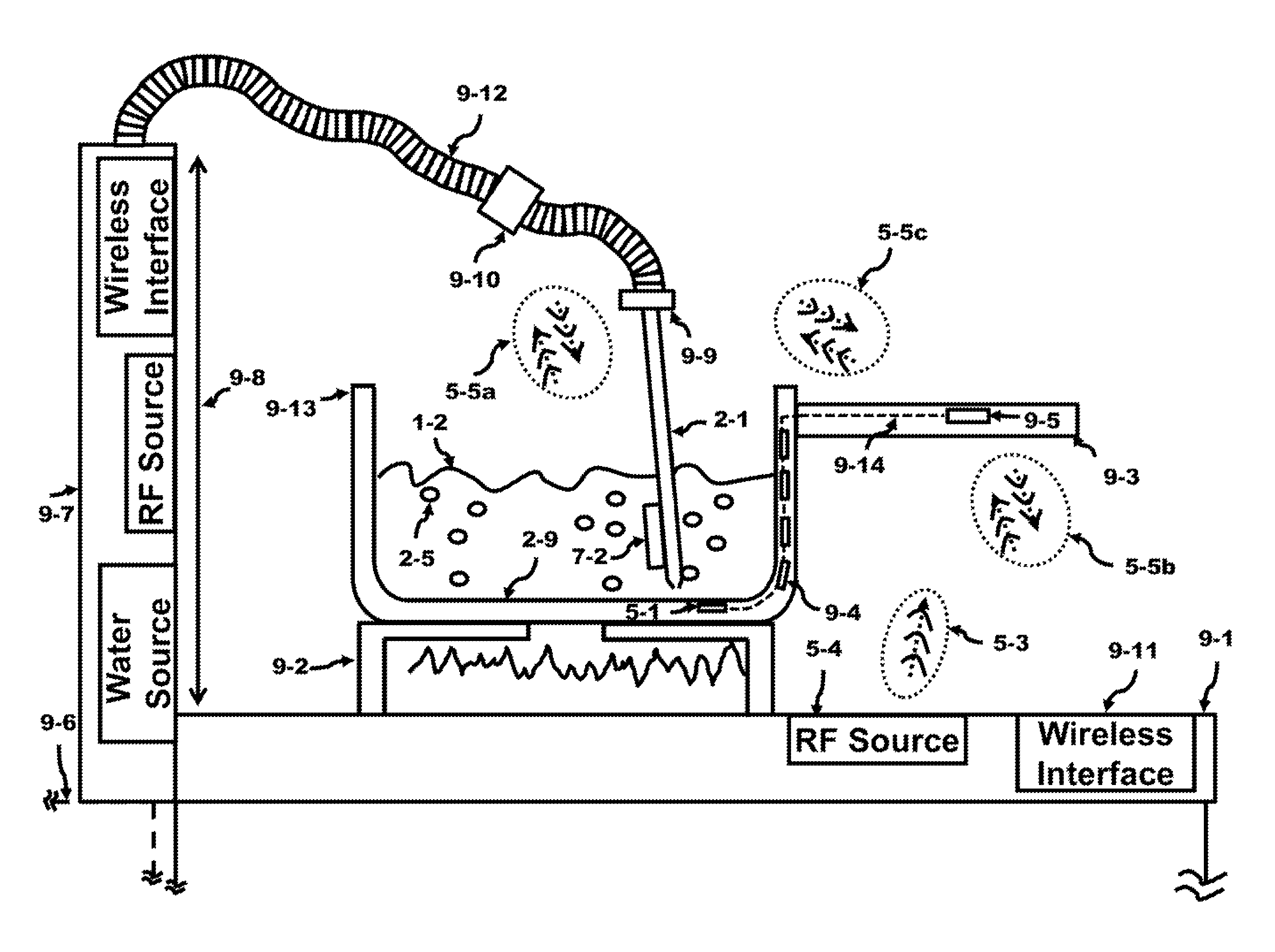

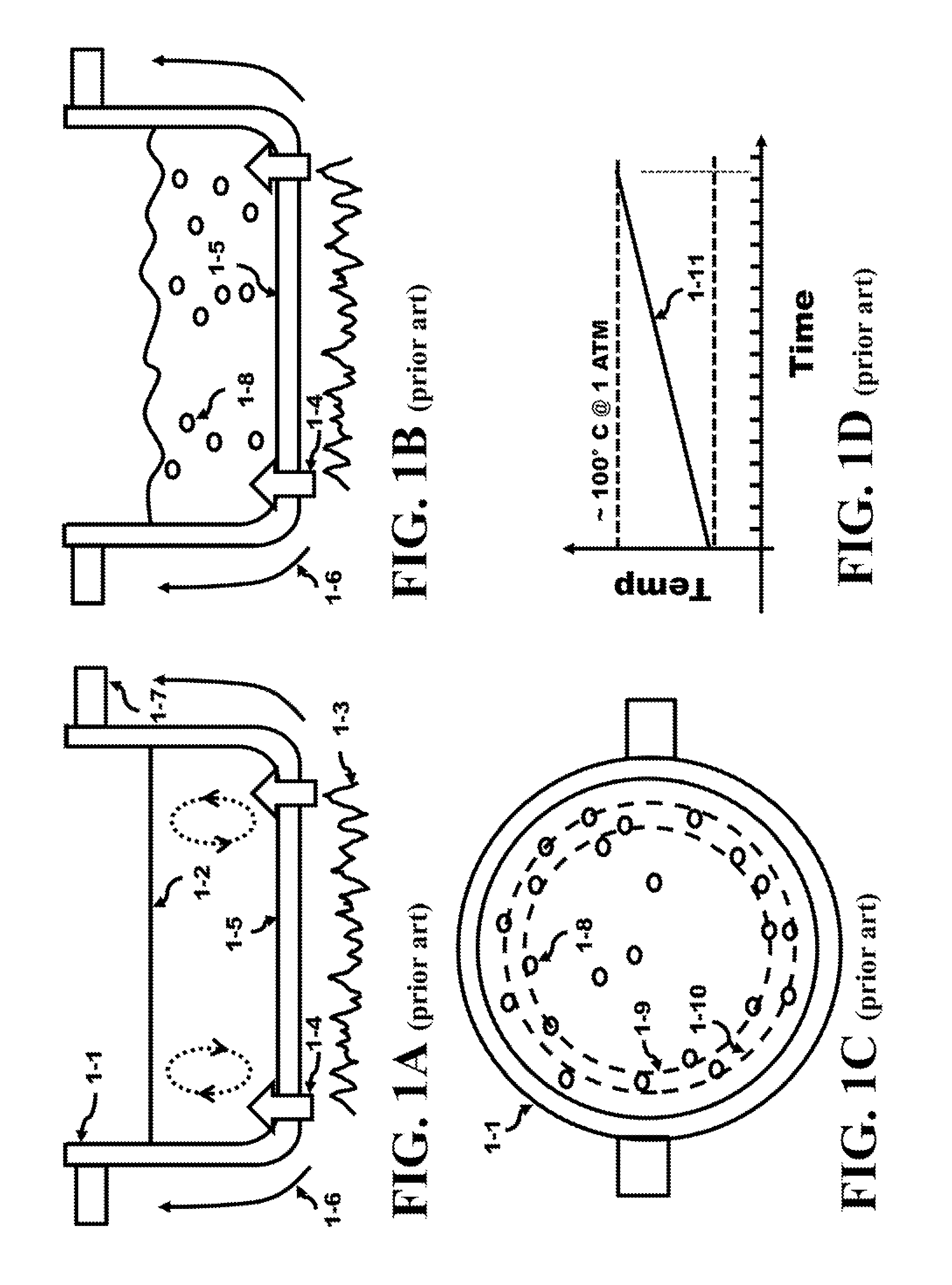

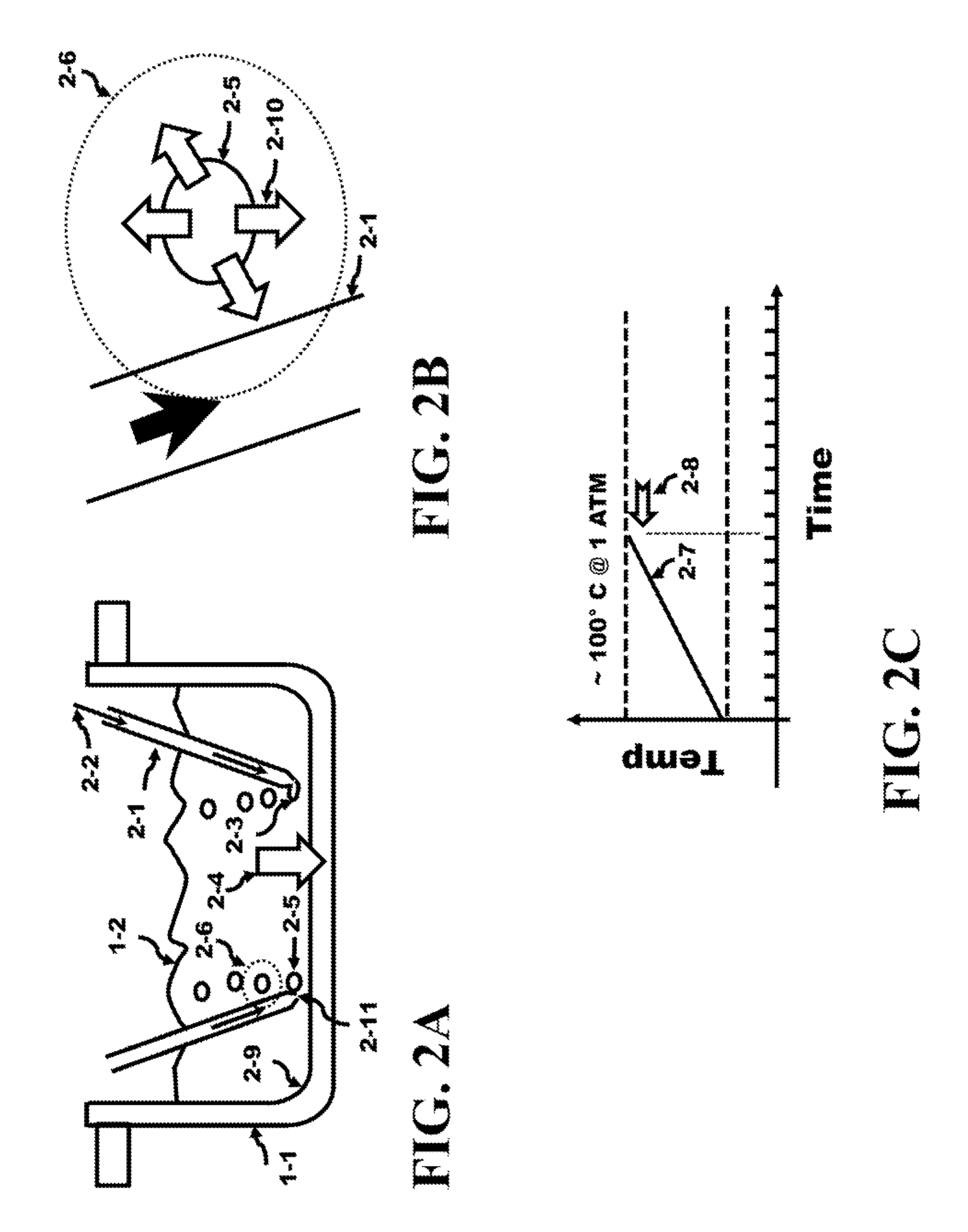

ActiveUS9545168B2Maximize cooking without losing significant nutrients of the comestiblesConcern for seepage is reducedBoiling over preventionWater-bath cooking vesselsRadio frequency energyThermodynamics

Steam heating used with conventional heating techniques achieves a rapid boiling point. An intelligent electronic control system which uses sensors placed at various points in the system to monitor and / or control cooking, interacts with the Internet to determine cooking steps, powers embedded electronics in vessels by RF energy, and adjusts the heating temperatures of the contents of the vessel as a function of time. A stove will provide configurable tubes with a coupling unit at their end to attach various steam wands easily moved into position that provide this steam to vessels placed on a grill. Delicate cooking of comestibles can be achieved by maintaining a controlled temperature or cycling the temperature to maximize cooking without losing significant nutrients of the comestibles. Small coupling holes introduce steam at the bottom surface of a vessel to efficiently cook comestibles. The coupling holes have a radius which stratifies the Young-Laplace equation.

Owner:TRACKTHINGS

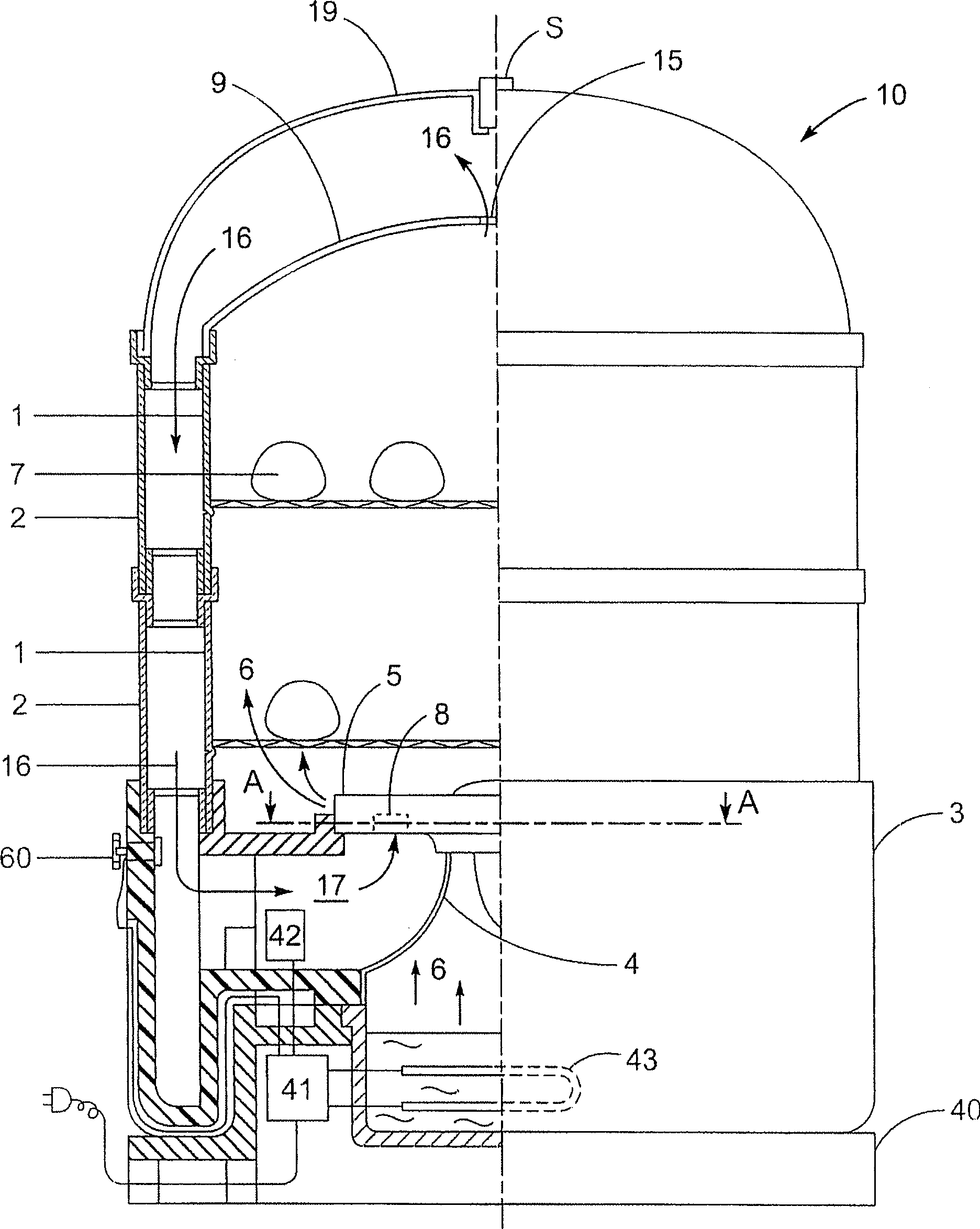

Vapor cooker

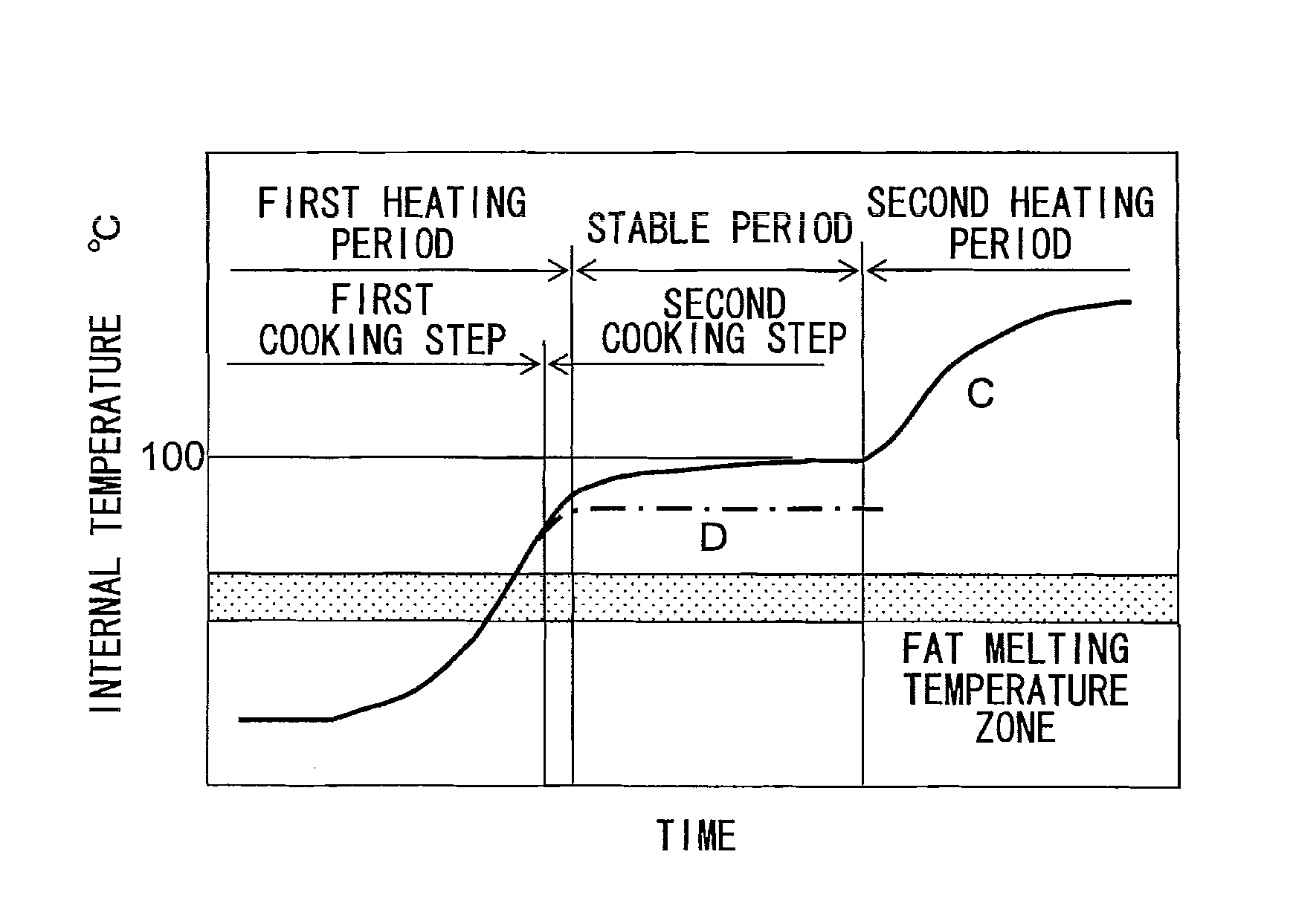

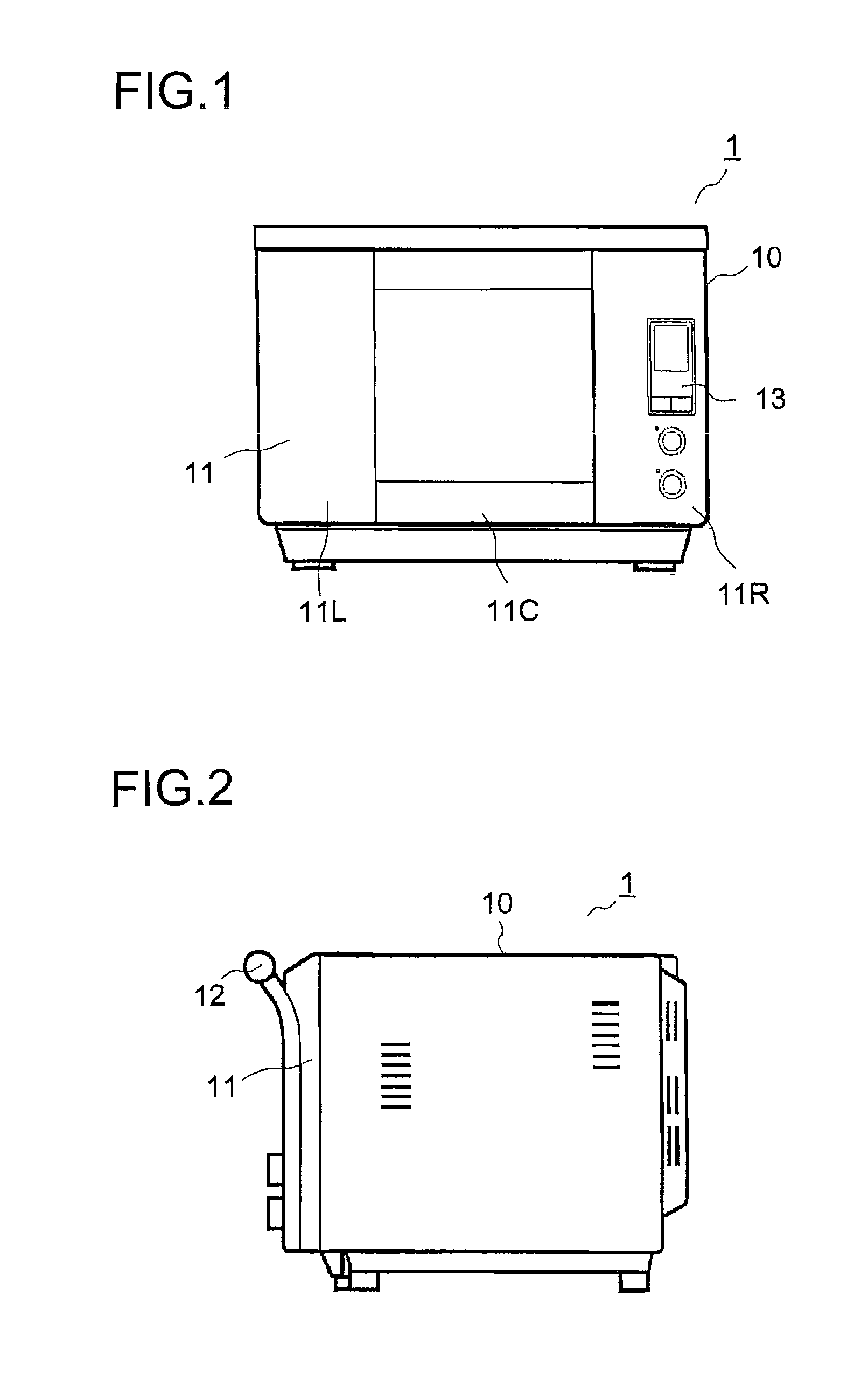

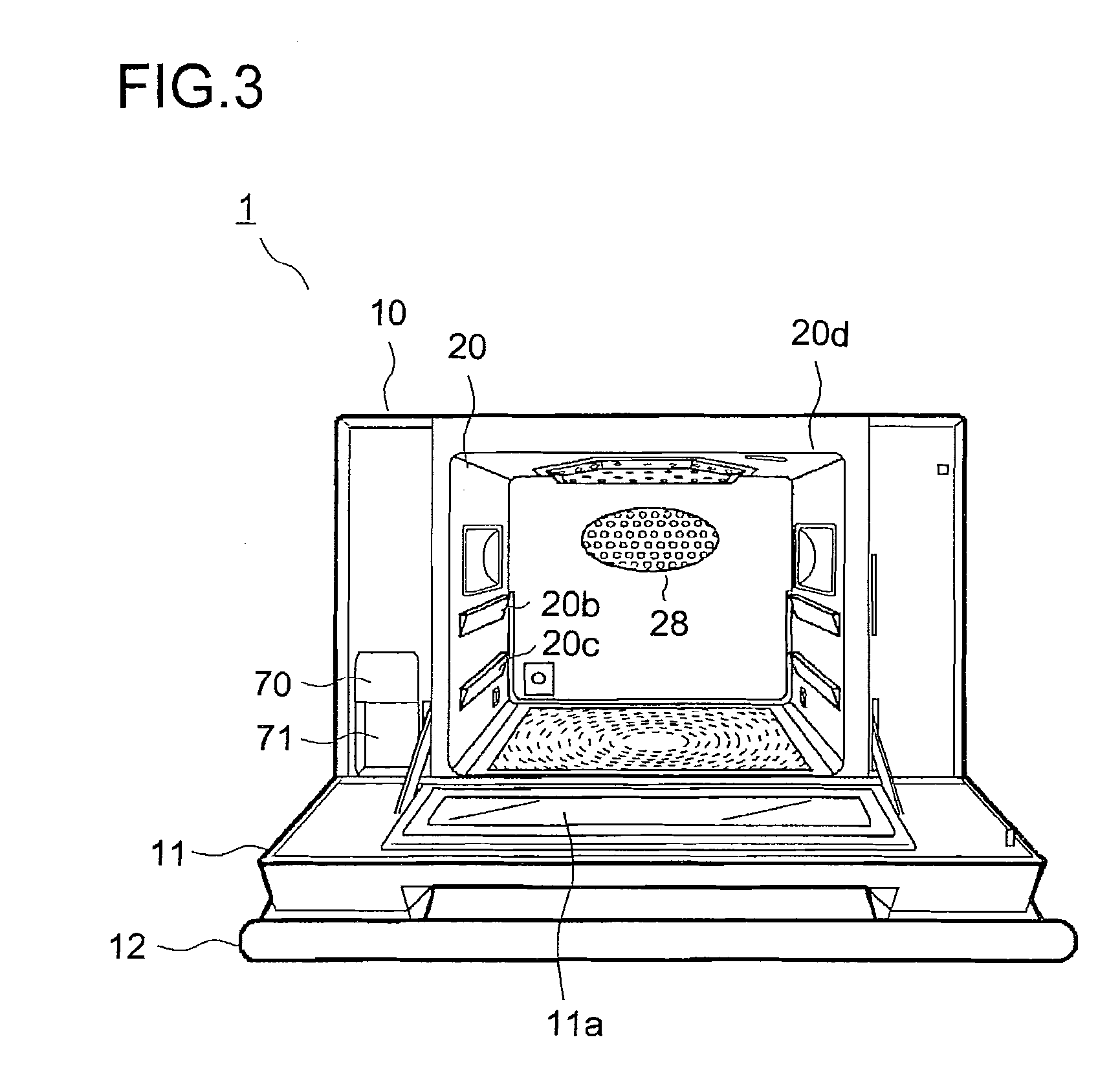

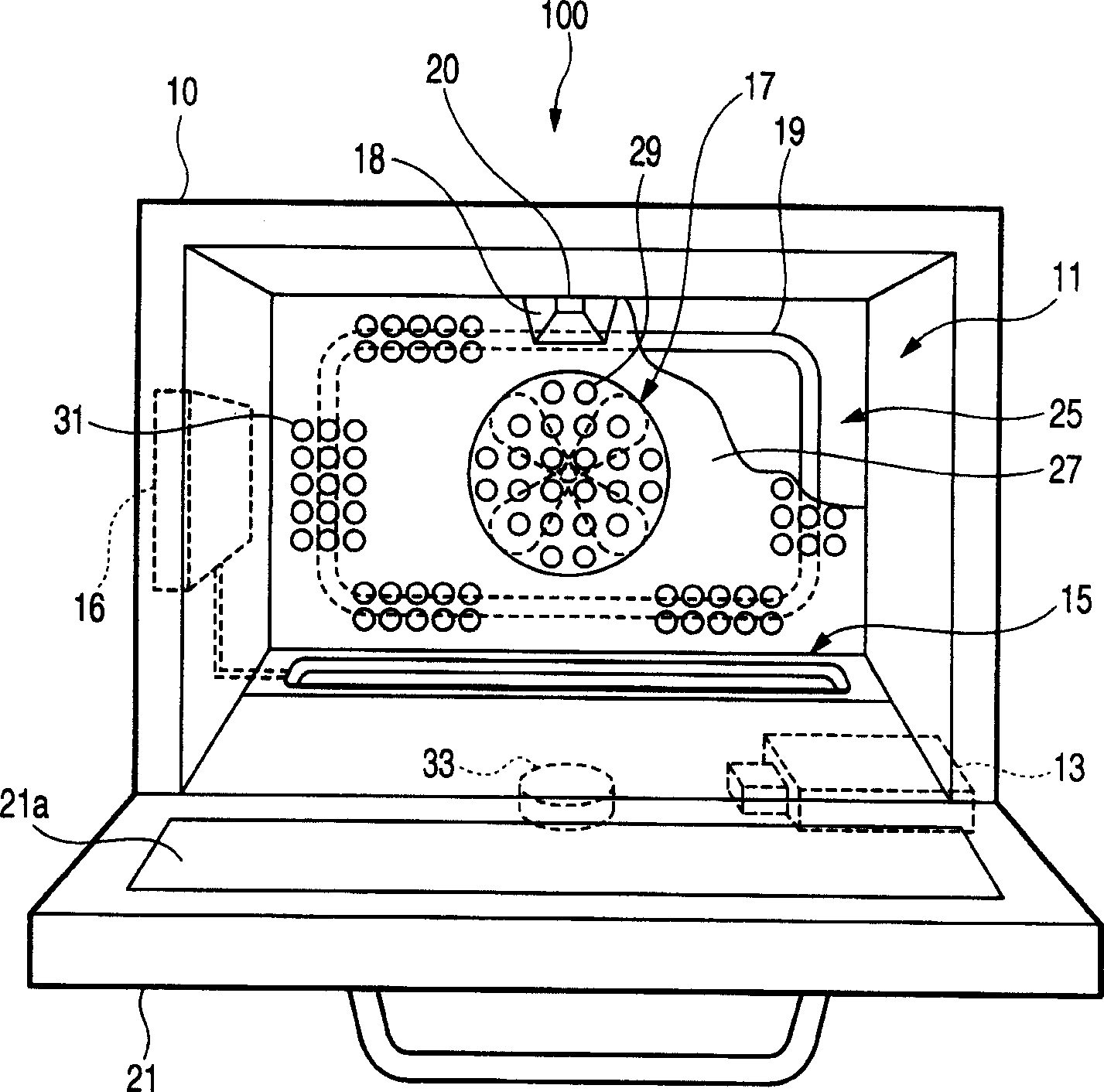

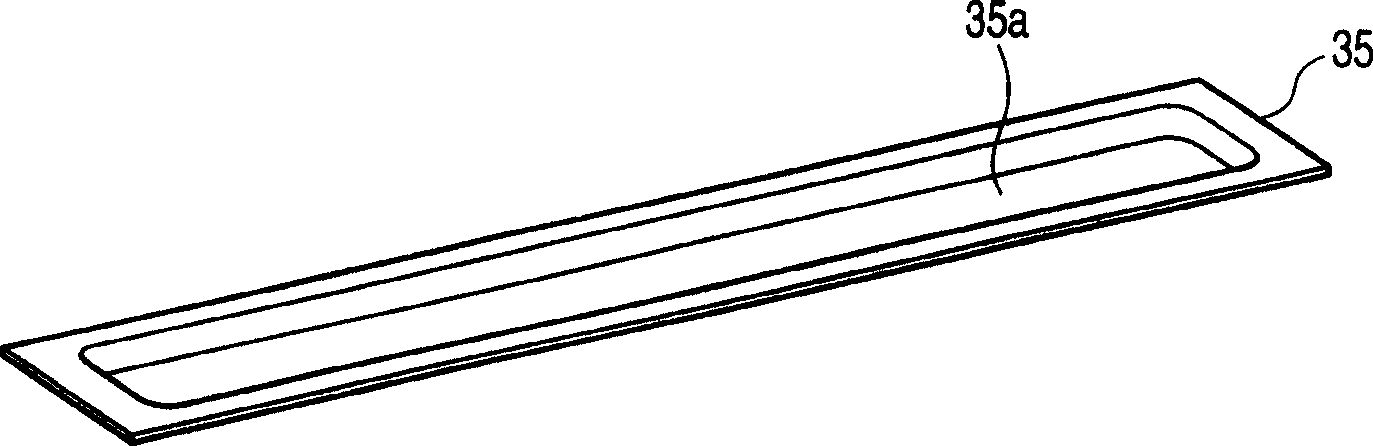

ActiveUS8420983B2Increase temperatureKeep for a long timeOven air-treatment devicesElectric heating for furnacesEngineeringSuperheated steam

A steam cooker 1 has: a steam generation heater 52 generating steam; and a steam heating heater 41 heating the steam generated by the steam generation heater 52 to generate overheated steam and heating steam in a heating chamber 20 through circulation, an-article-to-be-heated F being cooked by use of steam fed into the heating chamber 20. The steam cooker 1 has: a first cooking step in which the article-to-be-heated F is cooked with supply of electric power to the steam generation heater 52 being larger than that to the steam heating heater 41; and a second cooking step in which the article-to-be-heated F is cooked with supply of electric power to the steam generation heater 52 being smaller than that to the steam heating heater 41. When the temperature of the article-to-be-heated F exceeds the fat melting temperature zone but is less than or equal to 100° C., the first cooking step is switched to the second cooking step.

Owner:SHARP KK

High frequency heating apparatus and control method thereof

The invention relates to a high-frequency heating device with steam generation function and a control method thereof. When the high-frequency heating process using high frequency and the steam heating process using steam generated in the heating chamber are performed independently or simultaneously in order to heat the object to be heated, the air in the heating chamber is stirred at the same time to circulate the air in the heating chamber. . Corresponding to the type of items to be heated, the appropriate heating program is automatically selected to implement the heating process.

Owner:PANASONIC CORP

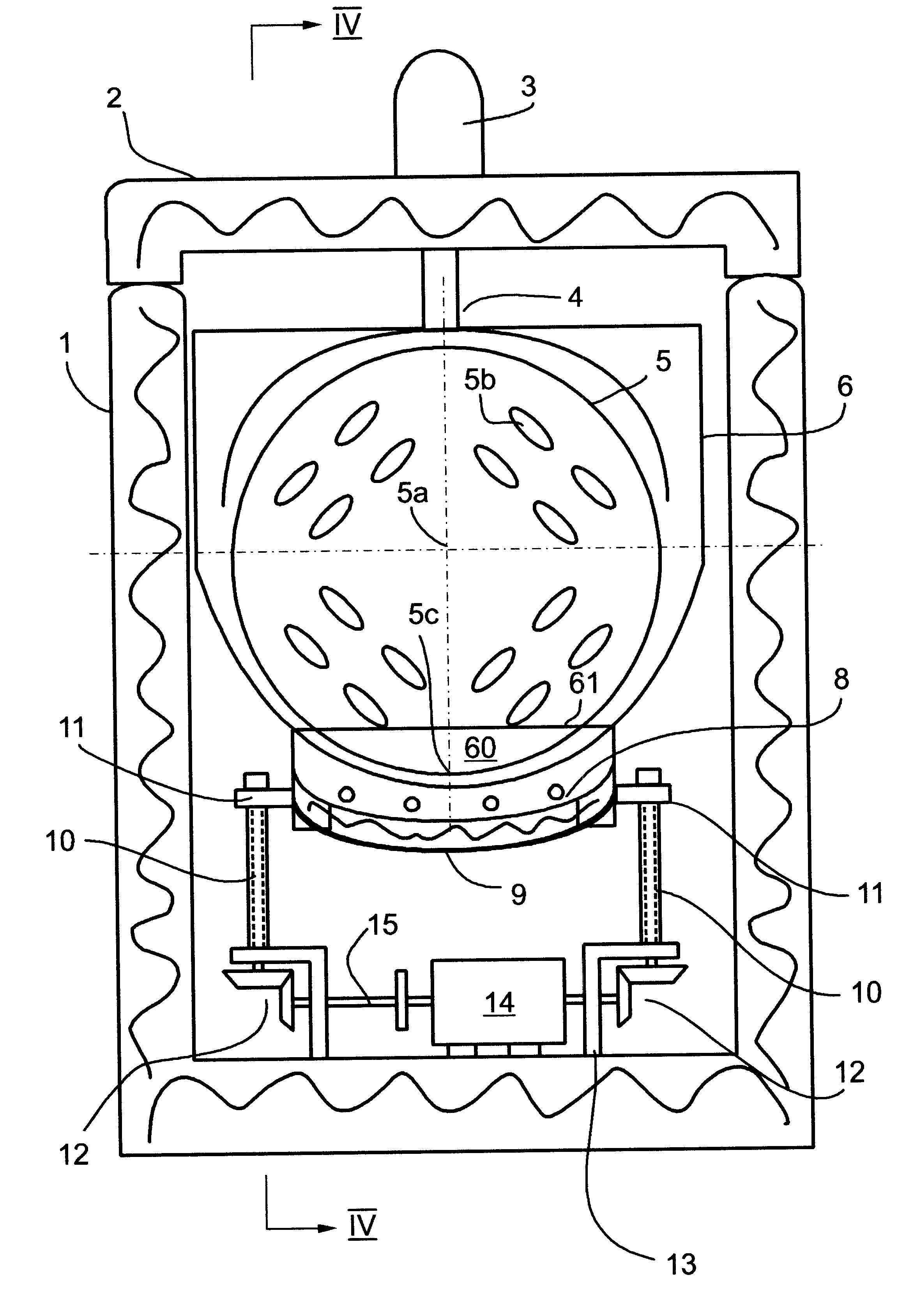

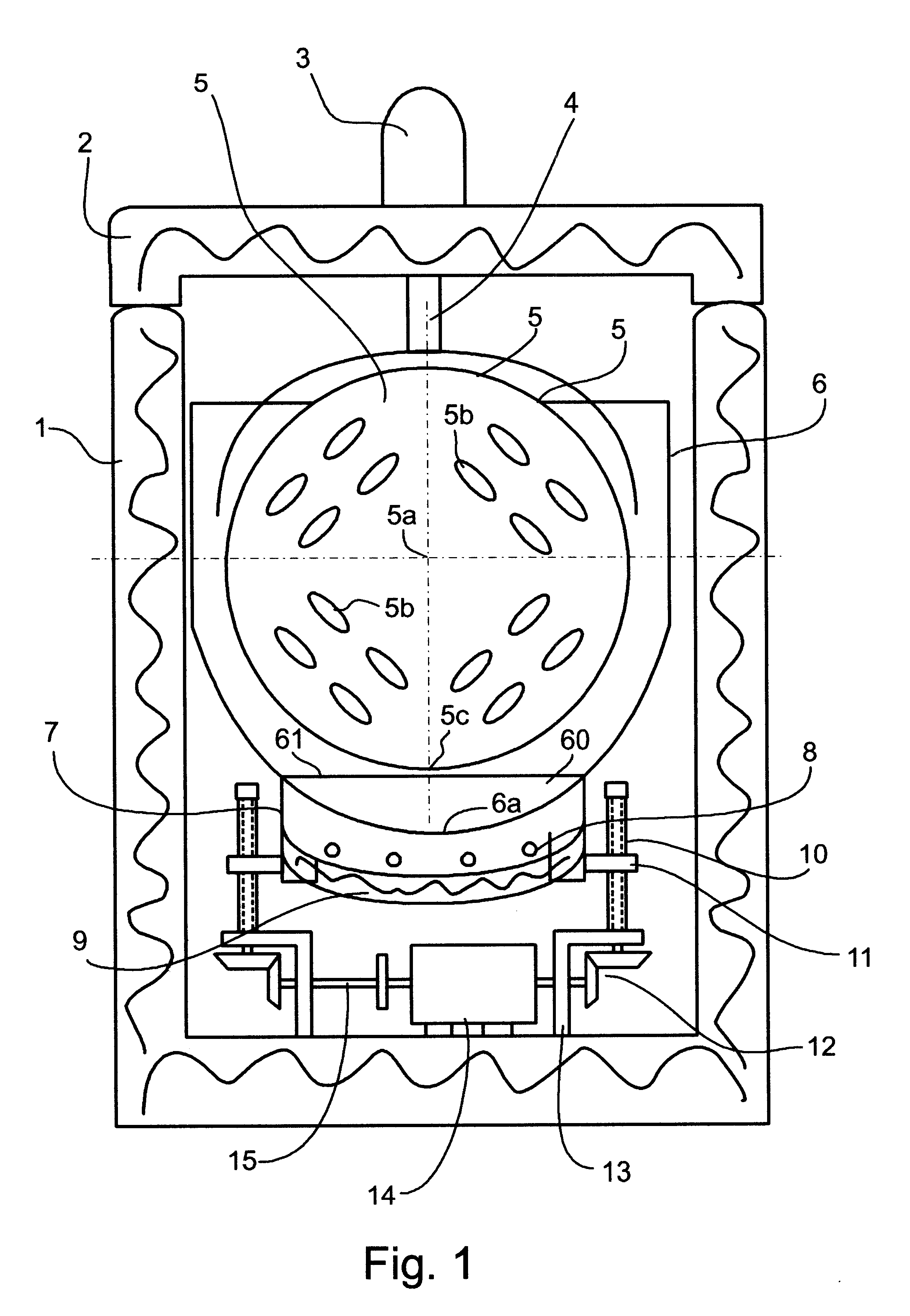

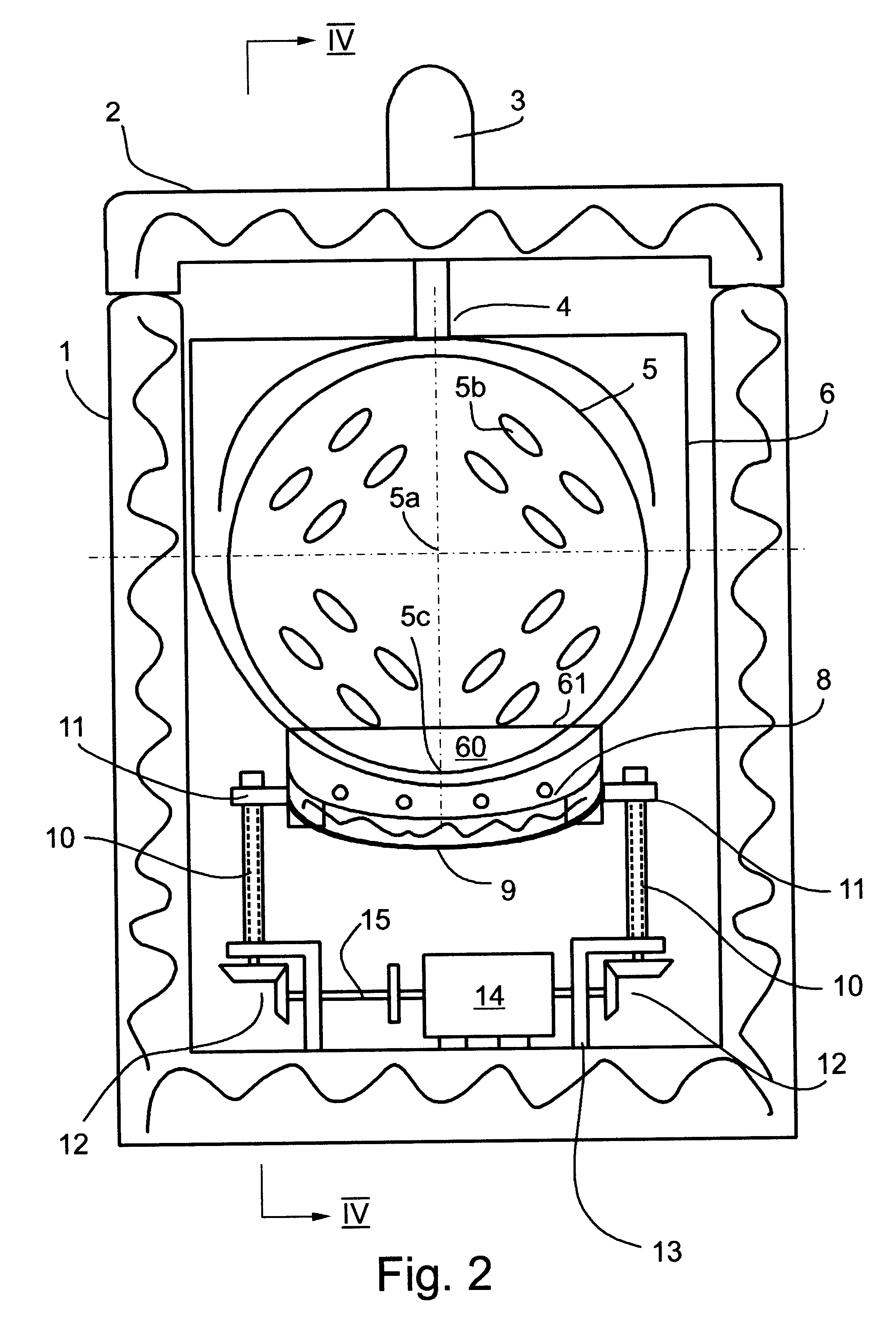

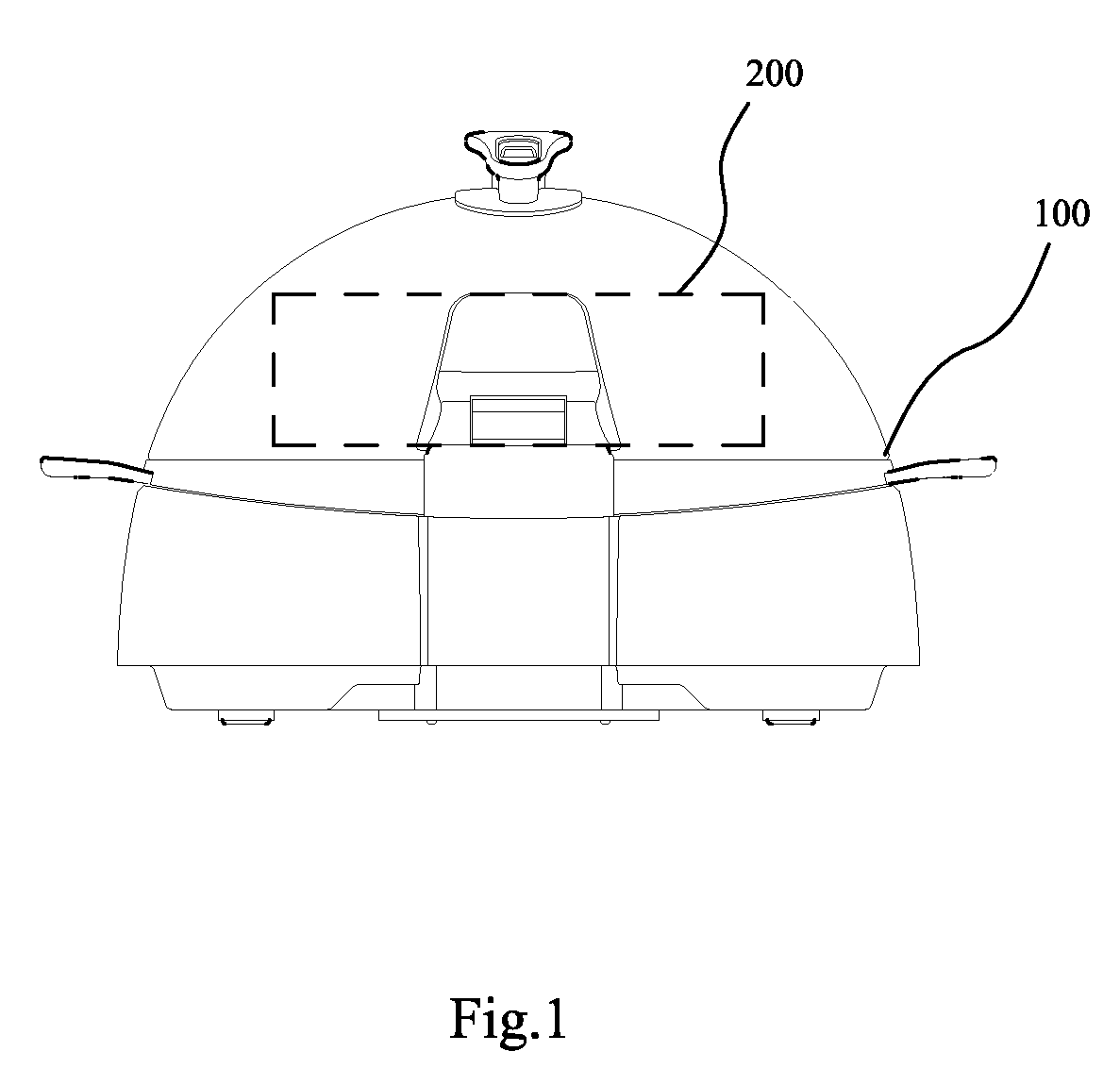

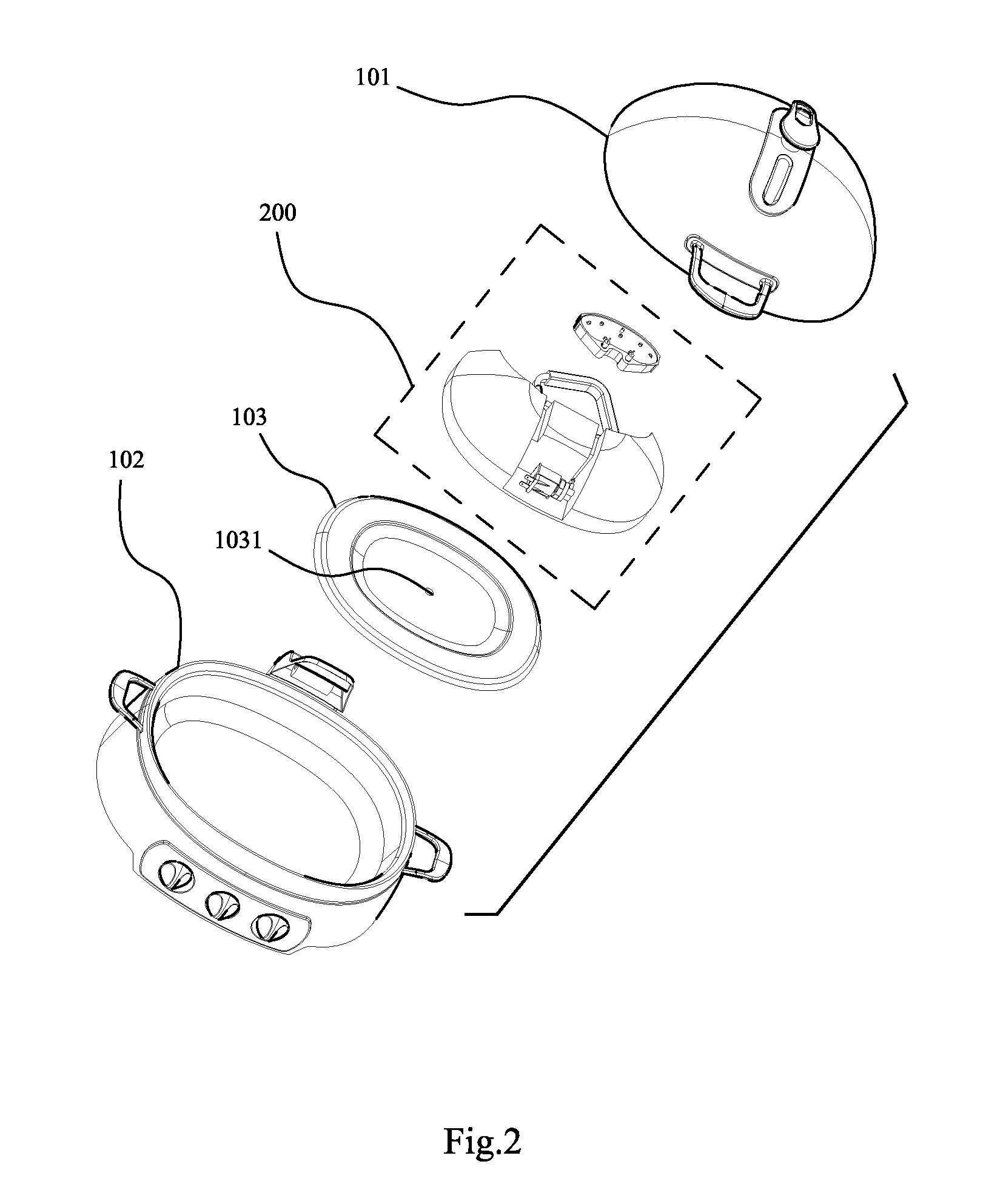

Appliance for cooking food articles

InactiveUS6453801B1Quantity minimizationReduce temperature differenceSteam cooking vesselsRoasting apparatusEngineeringElectrical drive

A cooking appliance and method for cooking food articles by means of a heated cooking liquid, includes a liquid container for receiving a quantity of the cooking liquid; an electrical heater for heating the cooking liquid; a perforated rotary drum for receiving the food articles to be cooked; and an electrical drive for rotating the rotary drum. The liquid container is selectively movable to a raised position, wherein the cooking liquid therein directly contacts food articles in the drum, or to a lowered position wherein the cooking liquid therein is spaced below the food articles in the drum. The lowered position of the liquid container may be used for steam-heating the food articles, or for pre-heating the food articles before being fried by moving the liquid container to its raised position.

Owner:DIME GROUP

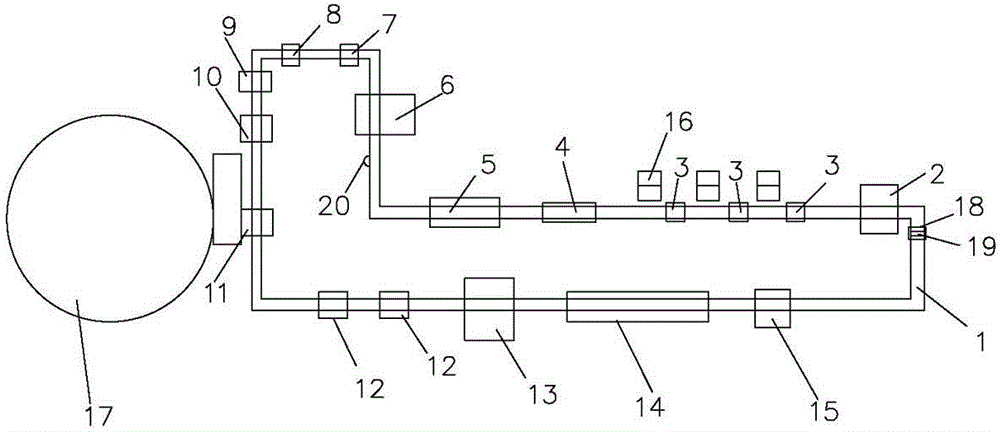

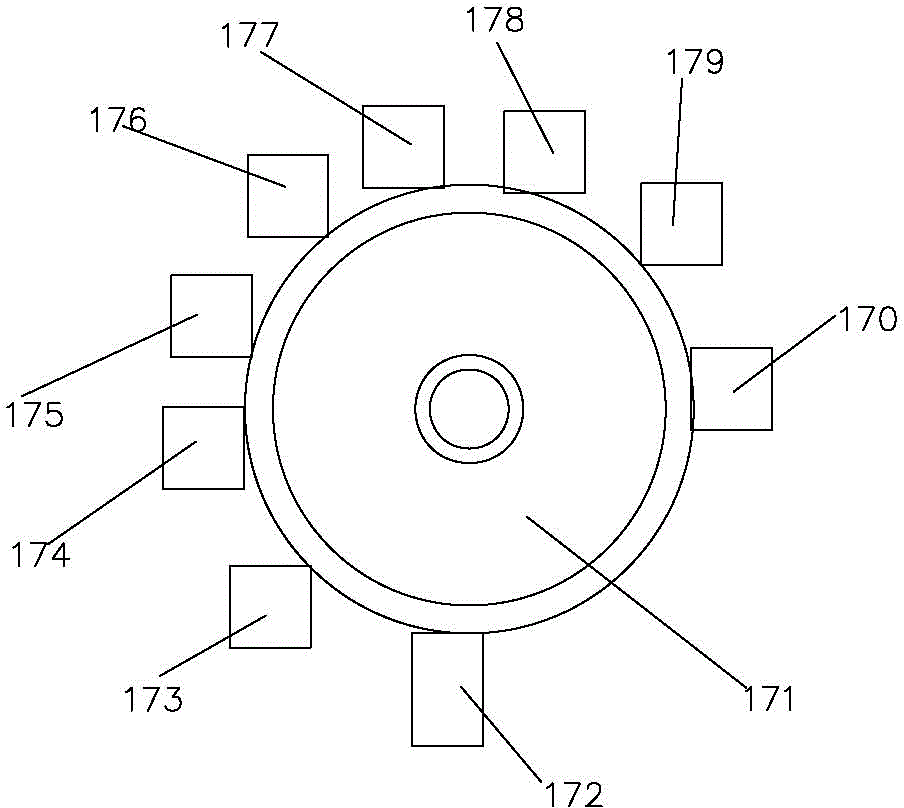

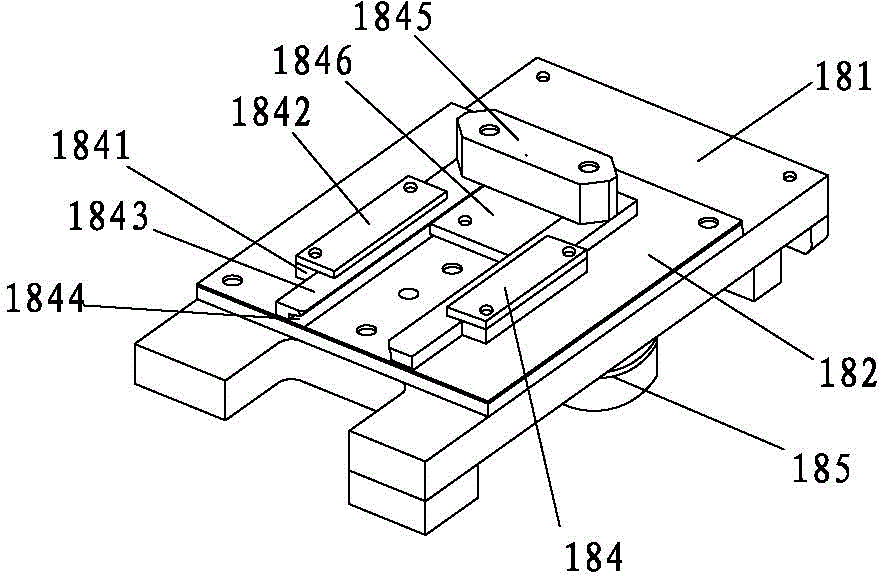

Automatic shoemaking production line for injection moulded shoes

ActiveCN103330337AStructural standardizationGuaranteed stabilityShoemaking devicesLastingCircular discProduction line

The invention discloses an automatic shoemaking production line for injection moulded shoes. The automatic shoemaking production line comprises a conveyor line, wherein at least one shoe last pallet is arranged on the conveyor line; a shoe last is arranged on the shoe last pallet; a first manipulator lubricant spraying work platform, a shoe last work platform, a steam heating box, a first baking oven, a second manipulator roughing platform, a latex spraying platform, an outsole processing elastic piece platform, a compressing platform, a rough selvedge firing platform, a third manipulator carrying platform, a finished product flashing platform, a fourth manipulator paint spraying platform, a freezer and an outsole cutting processing platform are arranged on the conveyor line at an internal in sequence from an input end to an output end of the conveyor line; a disc injection molding device is arranged on one side of the third manipulator carrying platform. According to the automatic shoemaking production line for injection moulded shoes, the mechanical automation and the mechanical semi-automation are adopted by each manufacturing procedure; each manufacturing procedure is operated by one person; the whole automatic shoemaking production line structure is standardized through the cooperating production of each heating device and the cooling device; the stability of the shoe quality is guaranteed.

Owner:JIESHENG INTELLIGENT TECH CO LTD

Rose essential oil and rose pure dew extraction equipment

InactiveCN101353611AAvoid direct accessInhibition of dissolutionEssential-oils/perfumesDistillationEngineering

The invention discloses extraction equipment for rose essential oil and rose hydrosol which mainly includes a distillation still, a steam conduit, a condenser and an oil-water separator, wherein, the distillation still is connected with the oil-water separator by the steam conduit and the condenser; the lower end of the interior of the distillation still is provided with a steam heating coil; and the upper part of the steam heating coil is provided with a transverse plate sieve which can be opened freely. An adsorption plant is arranged between the top of the distillation still and the steam conduit and internally filled with active ceramic rings serving as an absorbent. The extraction equipment of the invention has the advantages of simple operation, convenient use and high production efficiency, and can greatly enhance the quality of the rose essential oil and the rose hydrosol.

Owner:许向梅

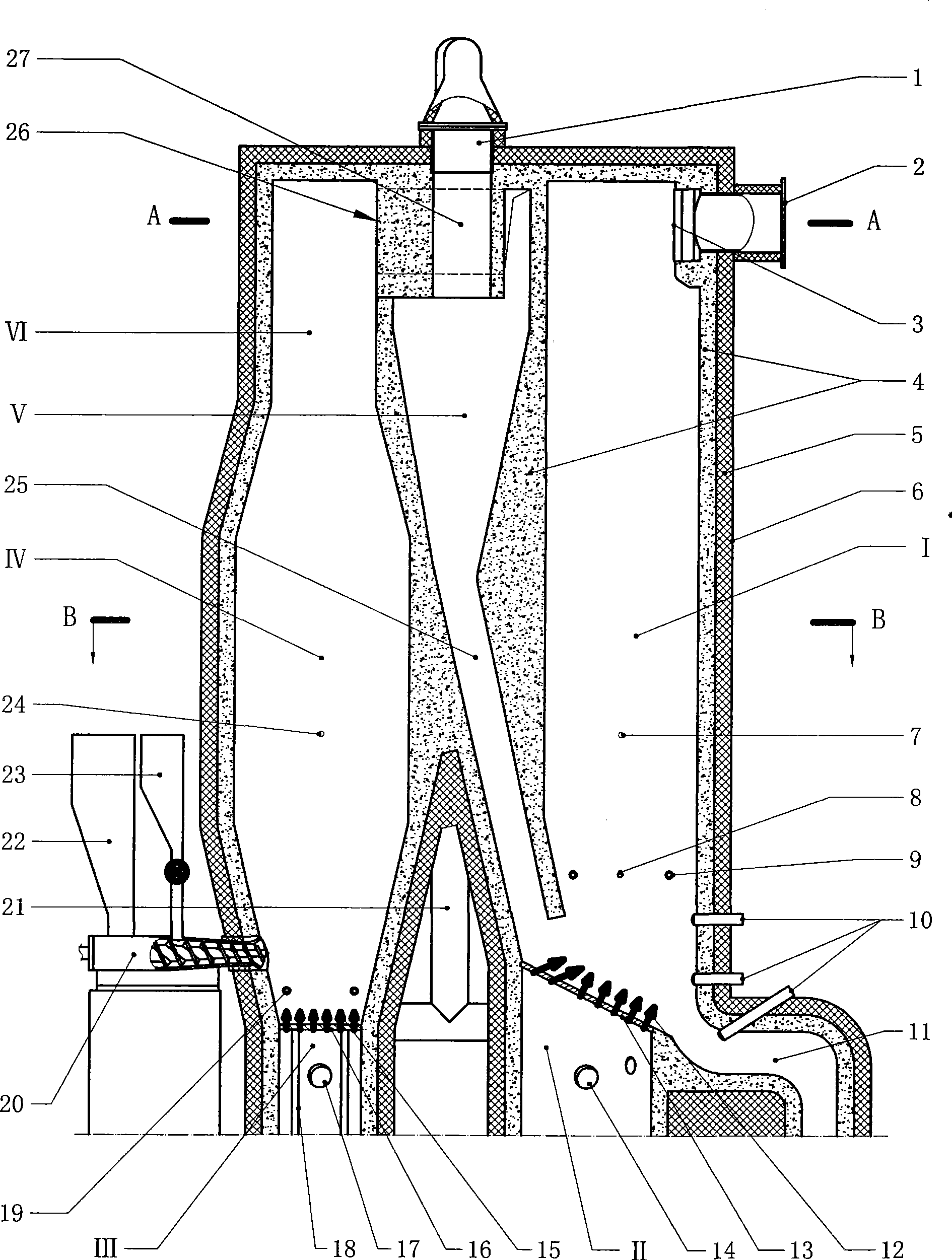

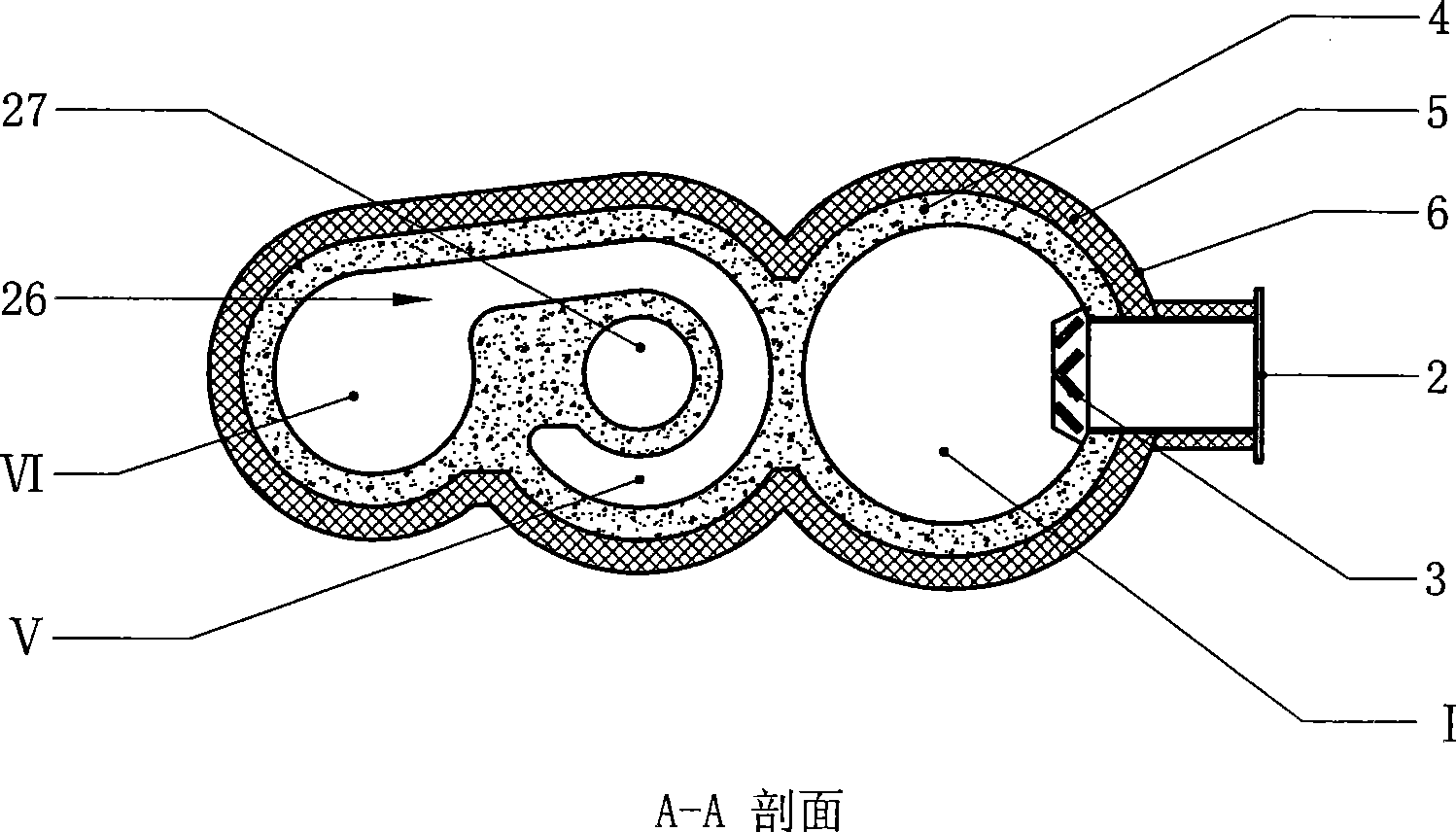

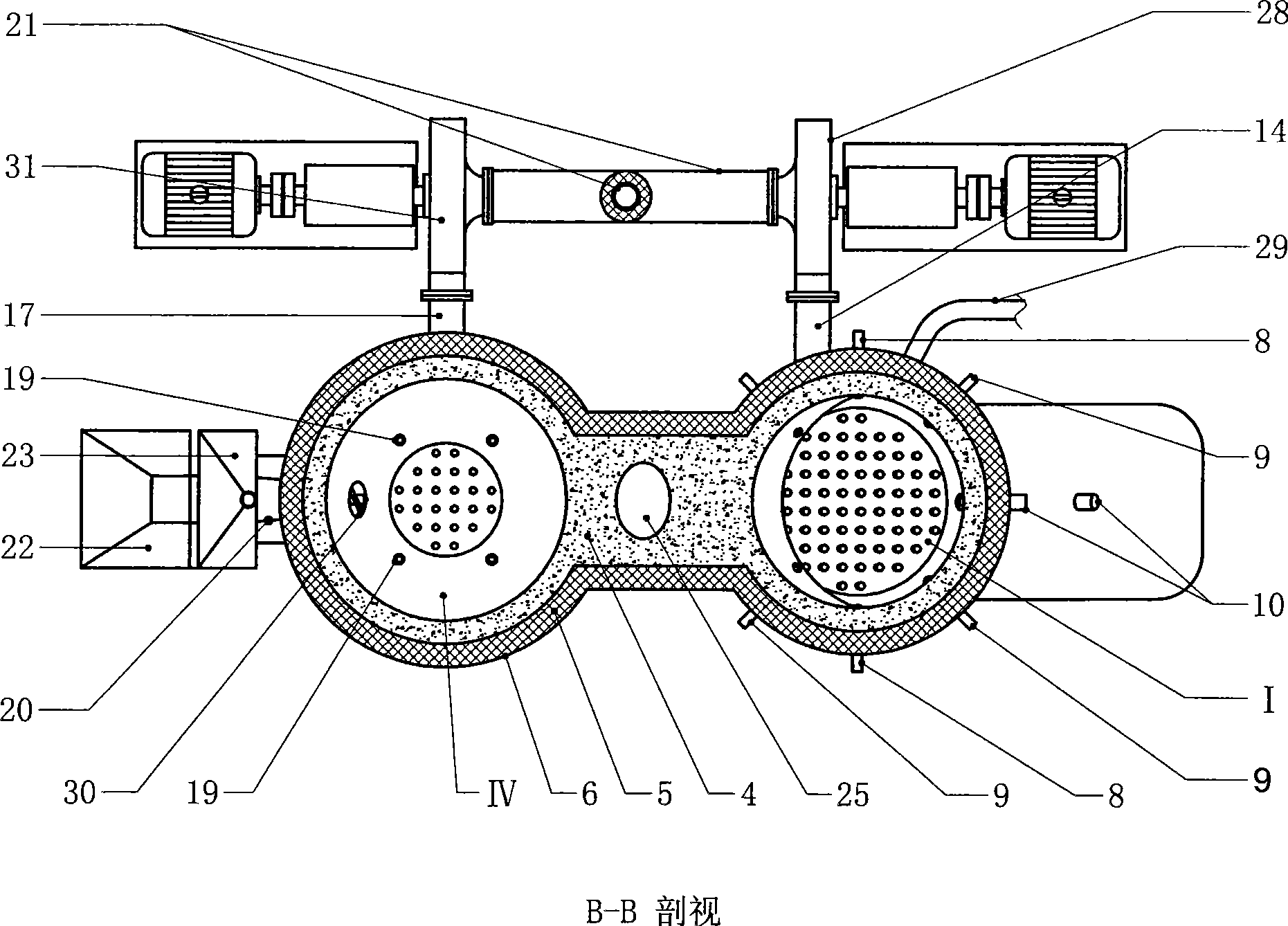

Plasma and calcium oxide cooperation-gasified rubbish biomass gasification method and equipment

InactiveCN101469865AReduce contentHigh calorific valueSpecial form destructive distillationIncinerator apparatusNew energyWater vapor

A method and apparatus for gasifying a plasma and calcium oxide cooperating with gasified rubbish biomass, relating to the rubbish processing and new energy resource field, characterized in that, the rubbish biomass is fed into a suspending fluidized bed thermal decomposition furnace, meanwhile, the heated fluidization material is circularly fed into the thermal decomposition furnace and is mixed with the raw materials to transfer heat, so that the rubbish biomass raw material is heated to decompose, and then the thermal decomposed gas and solid carbocoal is fed into a turbulent fluidized bed gasification furnace, the water vapor is heated over 3100 DEG C and is sprayed into the gasification furnace by a plasma spray gun, the water vapor is reacted with the solid carbocoal to generate carbon monoxide and hydrogen gas, the required heat of the gasification reaction in the gasification furnace can be provided by the plasma spray gun and an exothermal reaction of the calcium oxide absorbing the carbon dioxide. According to the invention, synthesis gas can be produced by rubbish and biomass raw materials under the condition without air or oxygen, the main ingredients of the synthesis gas are hydrogen gas and carbon monoxide which can be directly used for city gas or producing hydrogen gas, methanol and dimethyl ether and so on clean energies.

Owner:衢州市广源生活垃圾液化技术研究所

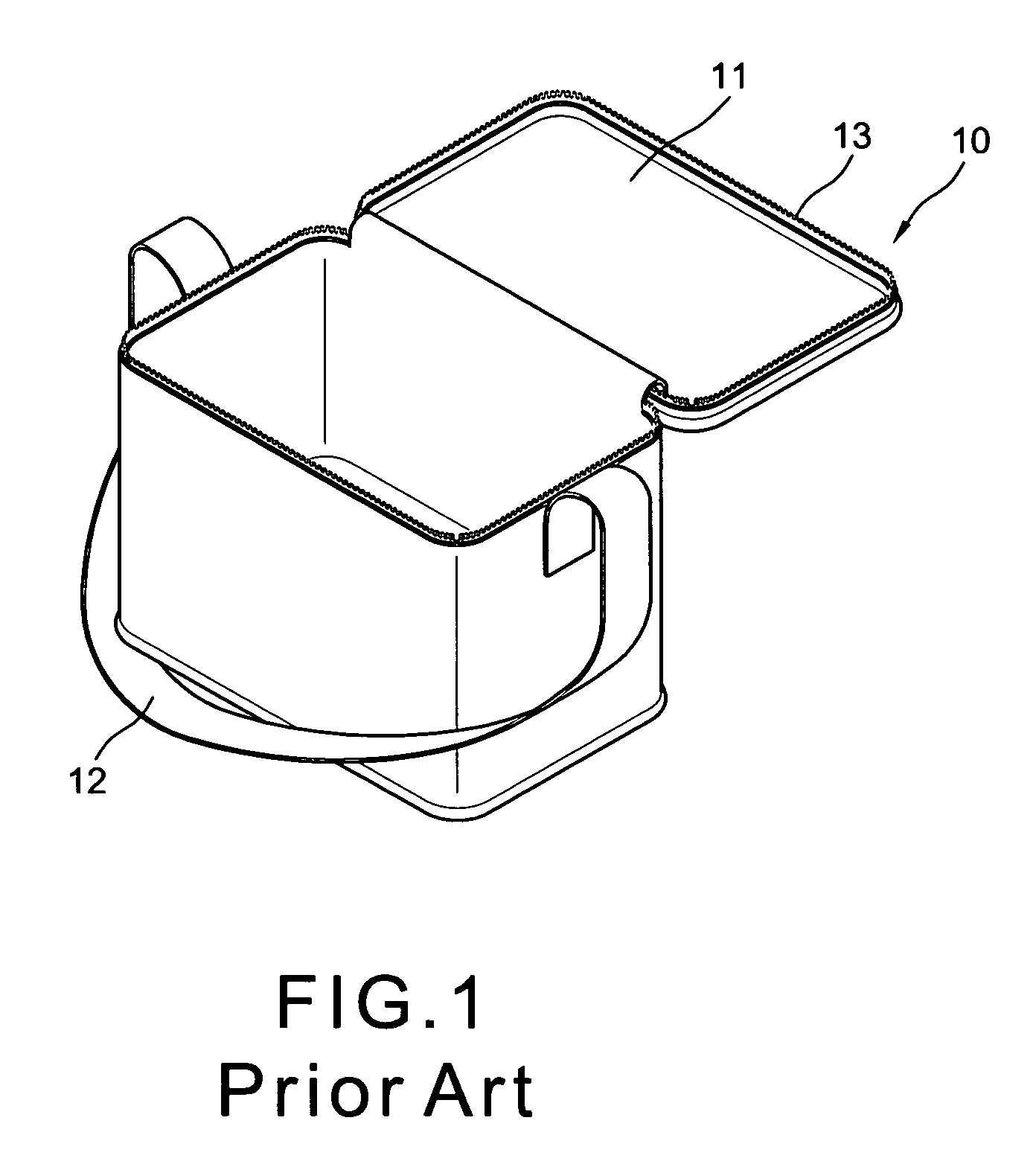

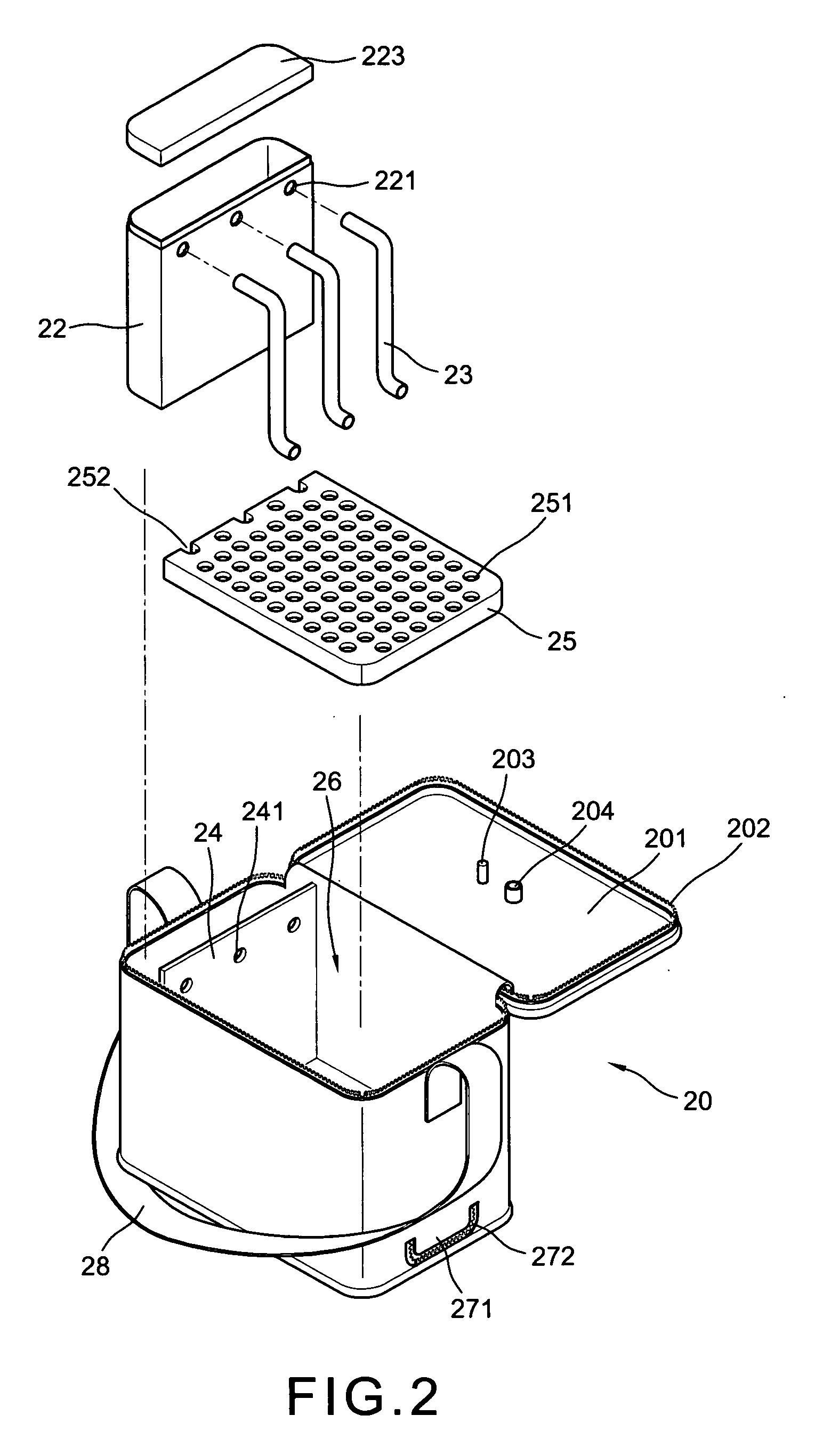

Portable warm bag having steam heating device

A portable warm bag having steam heating device includes a rectangular bag having a pressure sensor, a pressure releasing valve, a switch bottom and a valve cover on both sides of the upper lid, a partition vertically disposed in the bag adjacent a lateral side thereof to define a gap therebetween to receive a vapor creater therein which supplies the vapor into the food containing space via a hose and through a perforated plate above the bottom of the bag, a power source compartment under the bottom of the bag containing a plurality of rechargeable batteries therein for heating a heating bar in the vapor creater to boil the water to create vapor to into the bag to establish a heating circulation into the food which is kept at constant temperature eatable to the user.

Owner:YEH YIN TING

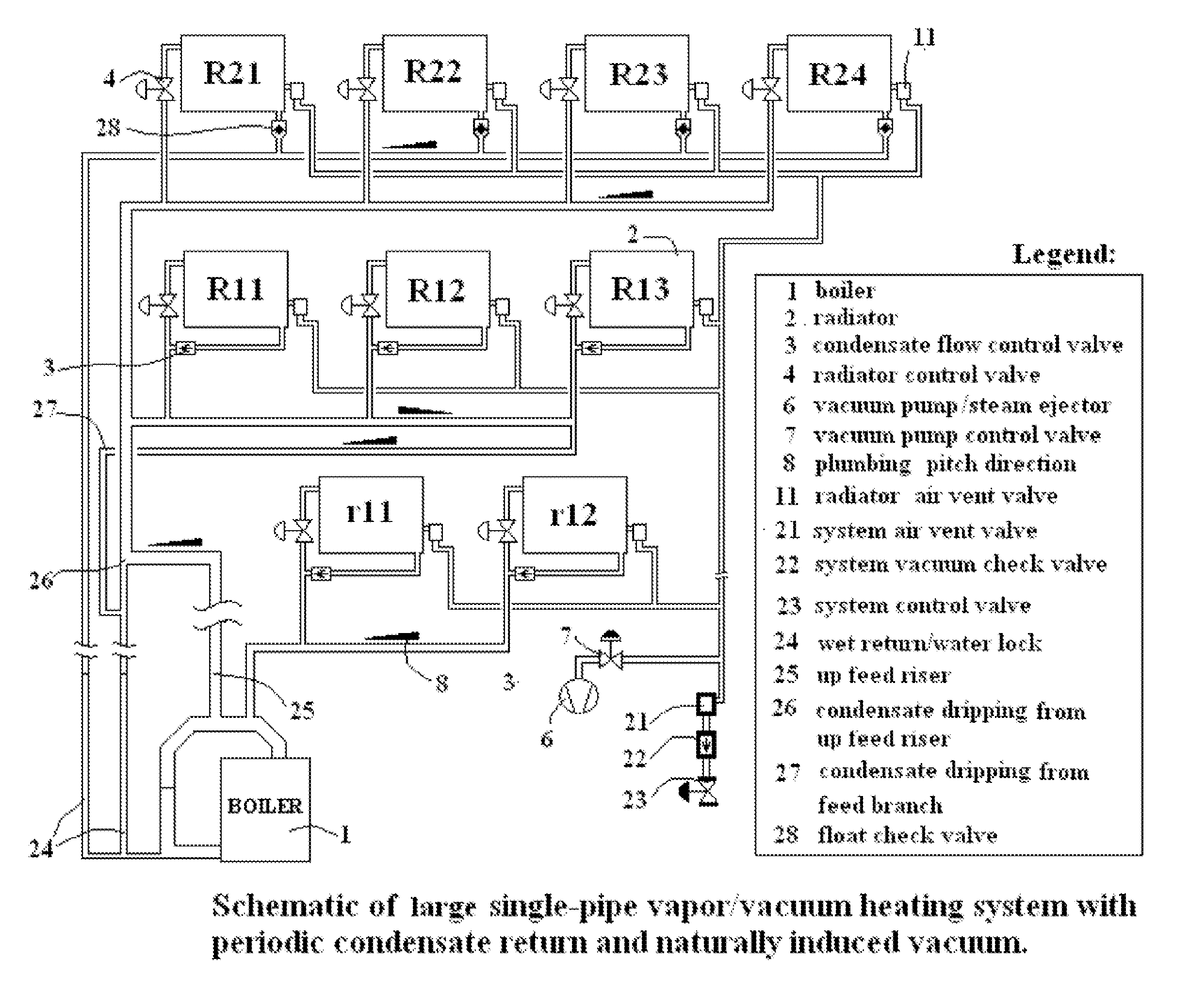

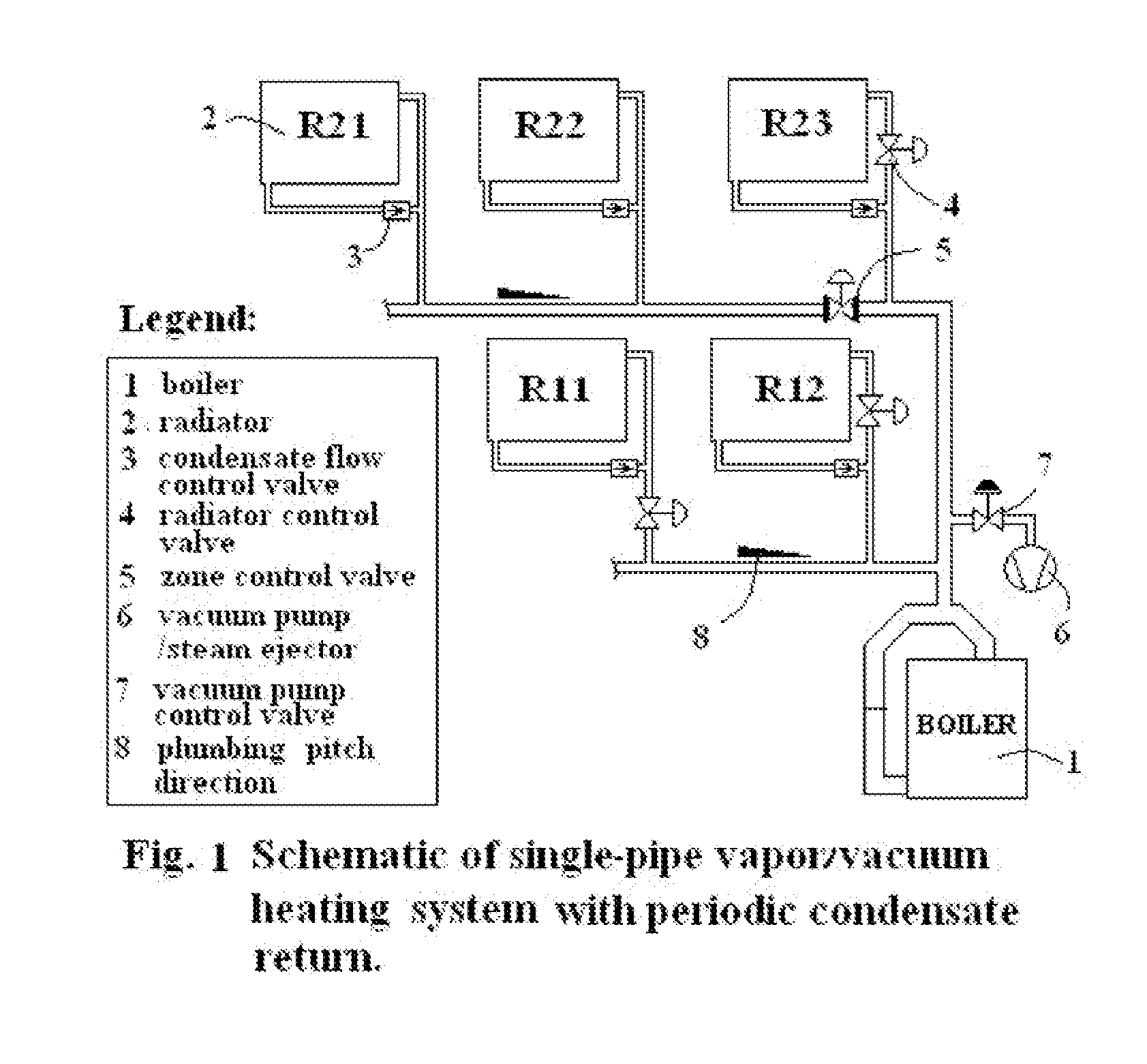

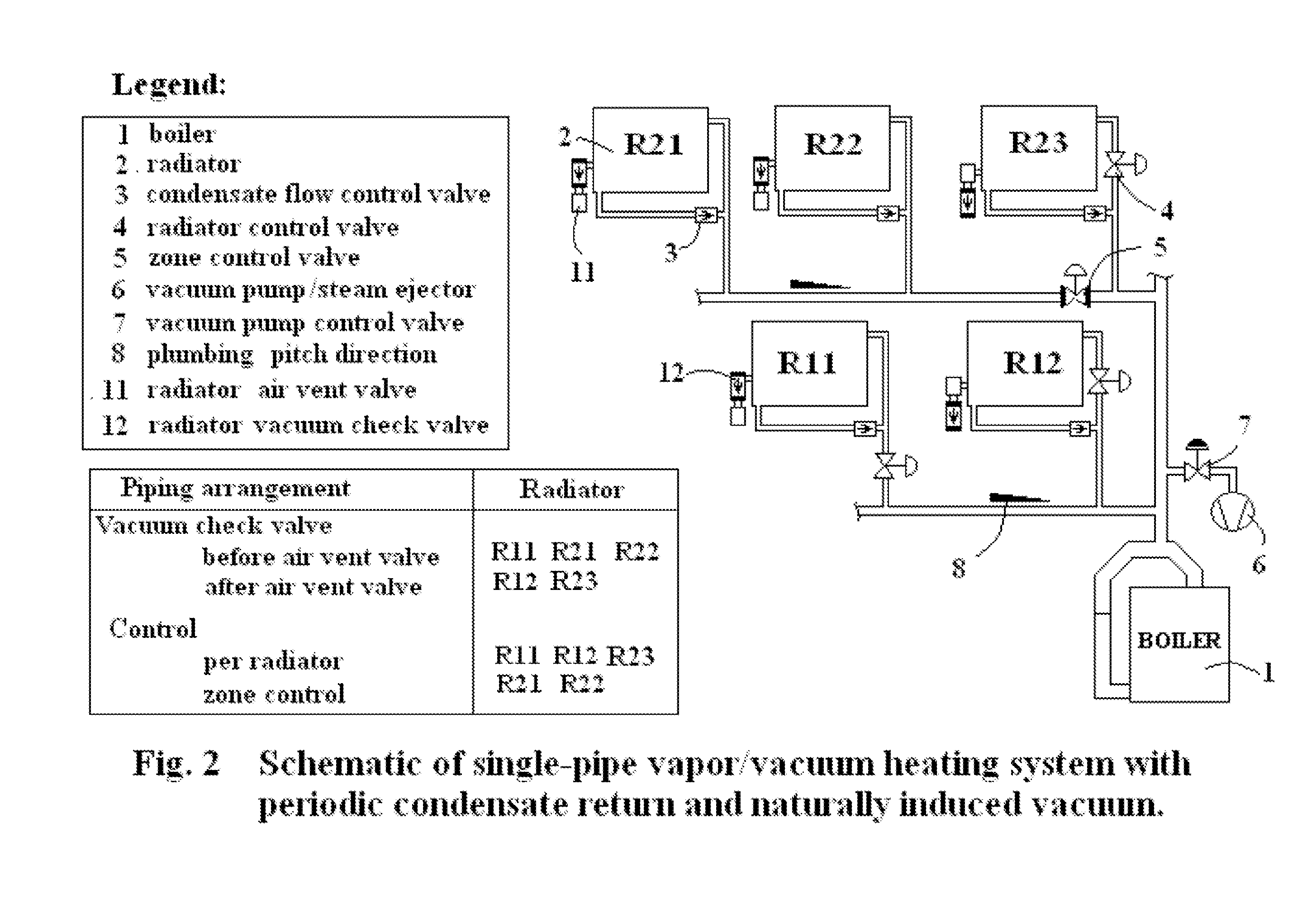

Vapor/vacuum heating system

InactiveUS20110198406A1Prevent hammeringEliminate rustAir-treating devicesCentral heating componentsTemperature conditioningEngineering

A building heating system with cycling steam source used for plurality of radiators is provided. During heating cycle condensate is retained in radiators and released later through steam supply line. Such condensate and steam flows alternation eliminates water hammering and justify usage of smaller diameter tubes and new radiator design. When air is evacuated, system operates like branched heat pipe with periodic condensate return. System may include vacuum check valve on air vent lines and operational procedure to create vacuum naturally by steam condensing in a closed space after complete air purging from the system. Steam / vapor source's cut off pressure can be adjusted to regulate the vapor's temperature depending on the outside temperature. Method is proposed for conversion of the existing steam heating systems into a vapor / vacuum system with naturally induced vacuum.

Owner:ZHADANOVSKY IGOR

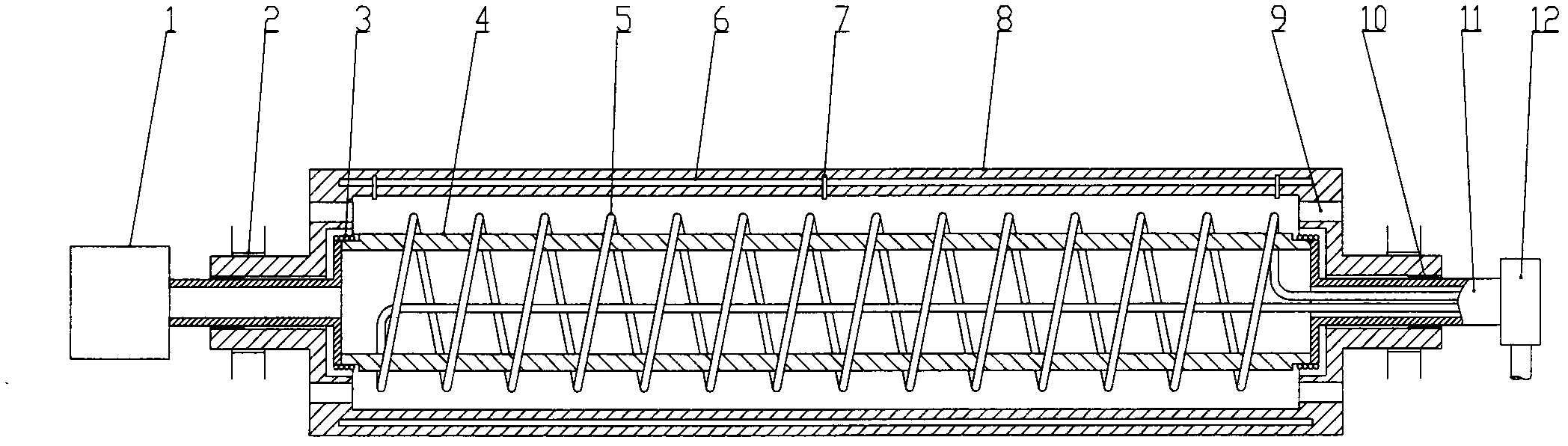

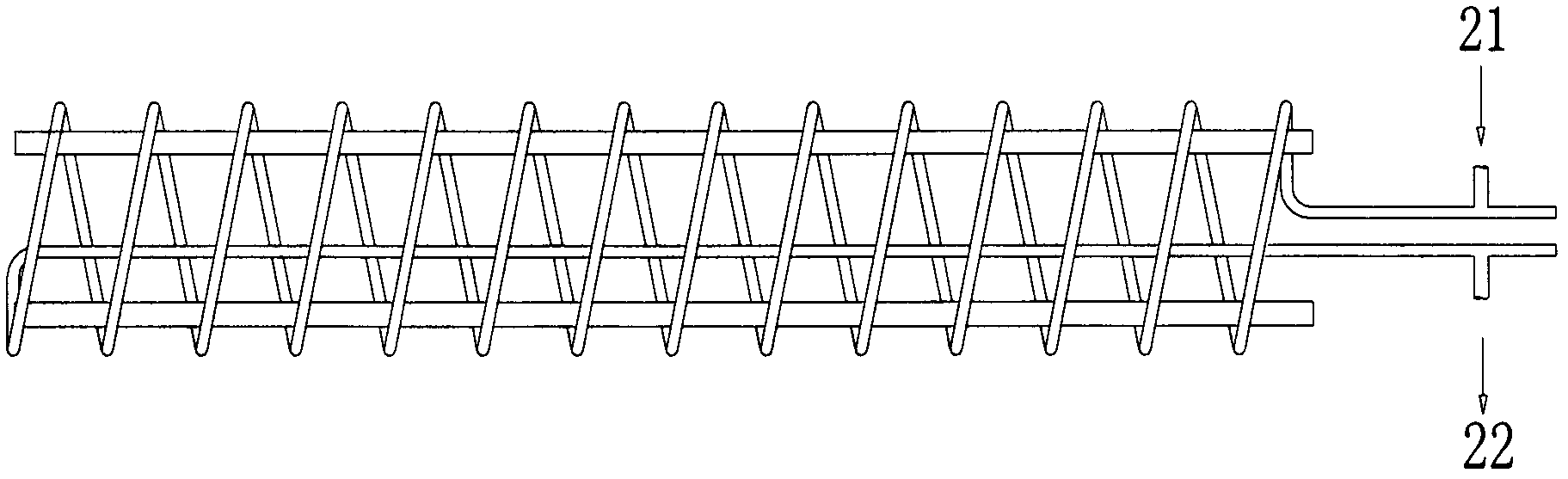

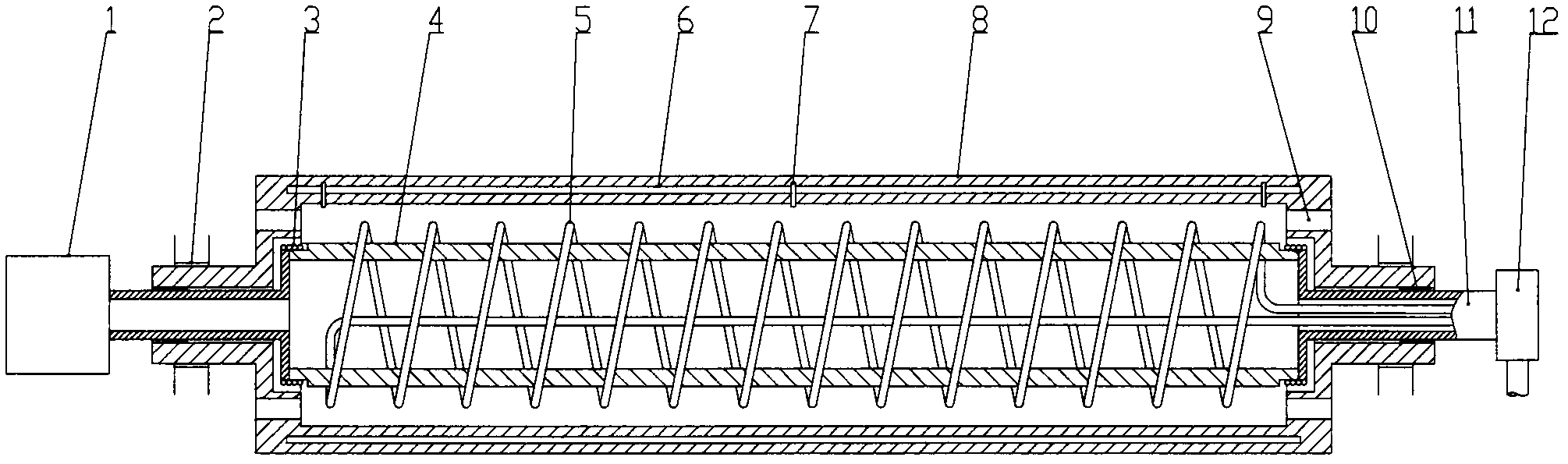

Electromagnetic induction heating roller

InactiveCN102325395AReduce pollutionReduce fireCoil arrangementsInduction heating apparatusElectricityKerosene

The invention discloses an electromagnetic induction heating roller in which high-frequency electromagnetic induction coils are arranged. The main body is a hollow roller body; a magnetism conductive iron core is arranged in the roller body; one end of the magnetism conductive iron core is connected with a cable connector through a half shaft; a heating coil wound on the magnetism conductive iron core is led into the roller body via the cable connector; a compensative heating coil wound on both ends of the magnetism conductive iron core is led into the roller body via the cable connector; a layer of water-filled isolating cavity is arranged in the wall of the roller body; and the surfaces of both ends of the roller body are respectively provided with a plurality of air holes for exhausting heat. The heating roller which is produced by utilizing the electromagnetic induction heating principle can replace various other heating rollers which are still used in a large quantity at present. Compared with the currently used steam heating, resistance wires, electric heating tubes or method for heating the surface of the heating roller with hot kerosene, the electromagnetic induction heating roller can save more electricity consumption and increase the temperature stability and precision of the roller surface.

Owner:张家港市弘扬机械设备有限公司

Preparation method of polystyrene foam board

The invention provides a production method of a polystyrene foam board. The method comprises the following steps: (1) prefoaming and curing expandable polystyrene particles; (2) steeping cured polyphenyl particles in a flame-retardant water solution, and then fishing out and drying; (3) mixing connection resin with flame-retardant inorganic material powder, and fully stirring evenly; (4) mixing the obtained materials, fully stirring evenly, adding a curing agent, and quickly stirring evenly; and (5) transferring the materials to a molding machine, heating and molding by steam, wherein the steam pressure is 0.01-0.15MPa, the steam heating time is 5-20s, thus obtaining the polystyrene foam board. The polystyrene foam board produced by the method disclosed by the invention has relatively low fire retardant content and relatively high flame retardant property.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

Method and apparatus for managing hydrogen sulfide tail gas

InactiveCN1745877AAvoid pollutionEasy to operateDispersed particle separationSodium hydrosulfideProduct gas

A process for treating the tail gas containing hydrogen sulfide includes such steps as introducing said tail gas to the solution of sodium hydroxide, reacting at 50-80 Deg C. until the sodium hydroxide and hydrogen sulfide become saturated solution of sodium thiohydride for recovering it, and condensing CS2 gas into liquid in condenser for recovering it. Its apparatus is composed of a stage-one reactor with tail gas inlet and outlet tubes, liquid draining valve and steam heating tube, a stage-two reactor with tail gas inlet and outlet tubes, liquid draining valve and water jetter, and a condenser between said two reactors.

Owner:XINXIANG CHEM FIBER

Fused salt heat accumulating peak regulating system for heat-engine plant heating by means of main steam

PendingCN108548168AGet the most out of your utilizationImprove economyLiquid degasificationSteam generation plantsEngineeringHigh pressure

The invention relates to a fused salt heat accumulating peak regulating system for a heat-engine plant heating by means of main steam and belongs to the technical field of heat accumulating peak regulating of heat-engine plants. The system comprises a main steam regulating valve, a high pressure steam-fused salt heat exchanger, a reheated steam regulating valve, a high temperature fused salt tank,a high pressure fused salt pump, a low temperature fused salt tank, a low temperature fused salt pump, a throttling valve, a high pressure heater, a water delivery pump, a deaerator, a boiler, a highpressure cylinder and a medium pressure cylinder. When the electrical load is reduced, the utilization ratio of the boiler is fully exerted; a fused salt heat accumulating system is additionally arranged to store heat of residual stem of the boiler in the high temperature fused salt through the high pressure steam-fused salt heat exchanger; in the electrical peak stage, the high temperature fusedsalt is extracted from the fused salt tank to be fed to the high pressure steam-fused salt heat exchanger again to heat the boiler feed water and generate high temperature high pressure steam and issent to a turbine to increase the generating capacity of the turbine and play a peak regulating role on a unit. Residual steam generated by the boiler can be recovered when the electrical load is relatively low, so that the utilization ratio and the operating safety of the boiler are improved, and the purpose of being energy-saving is achieved.

Owner:BEIJING UNIV OF TECH

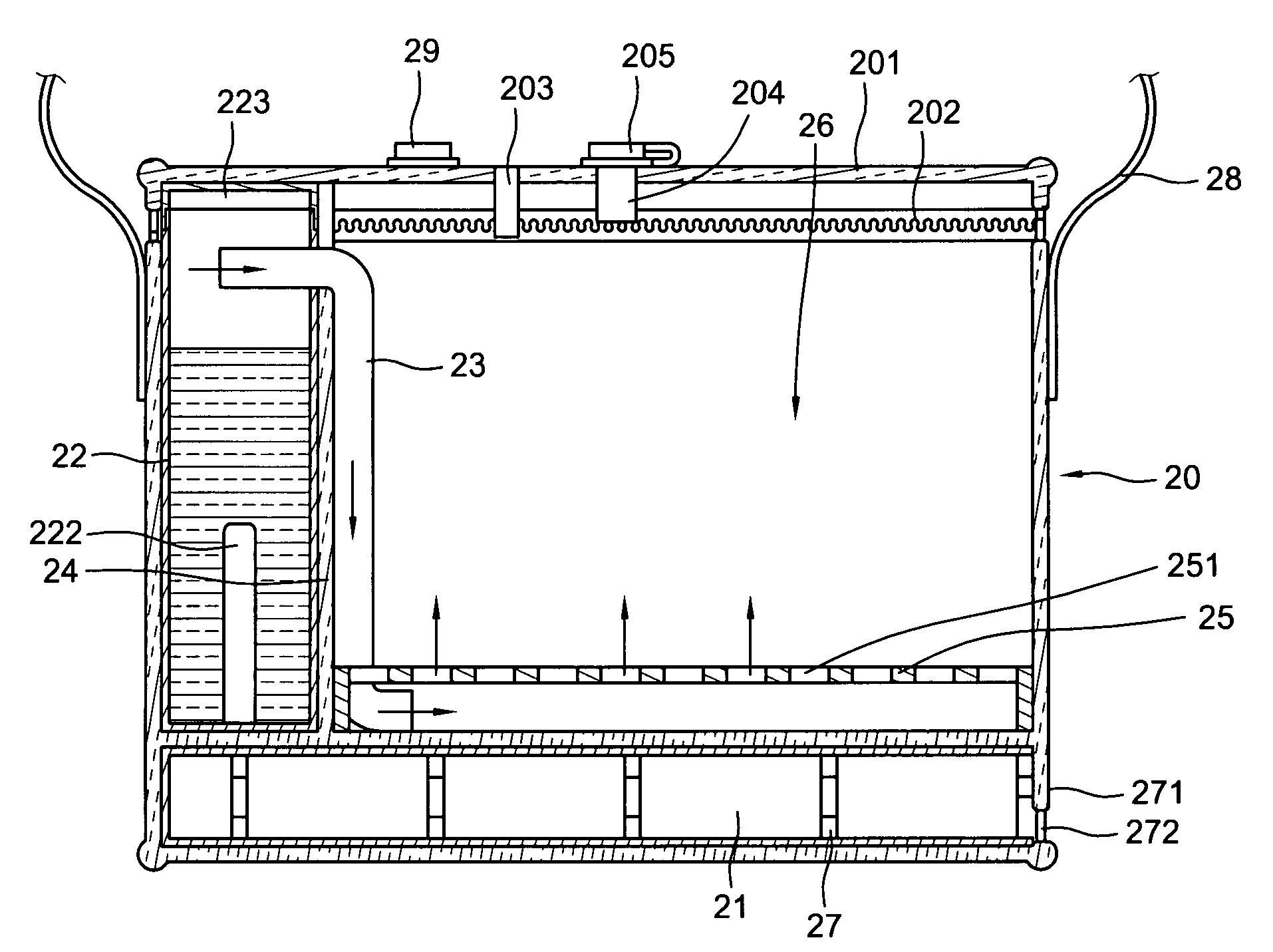

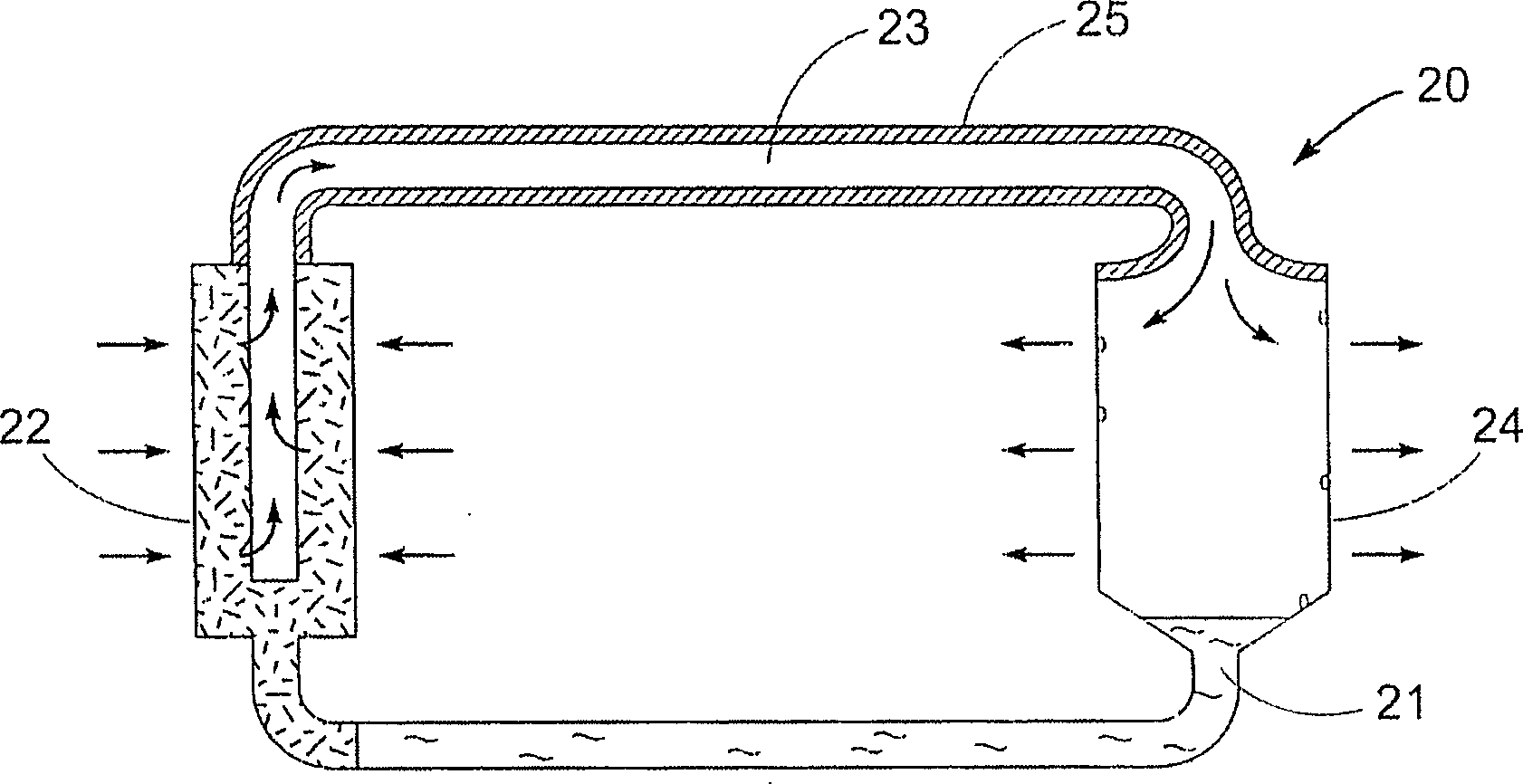

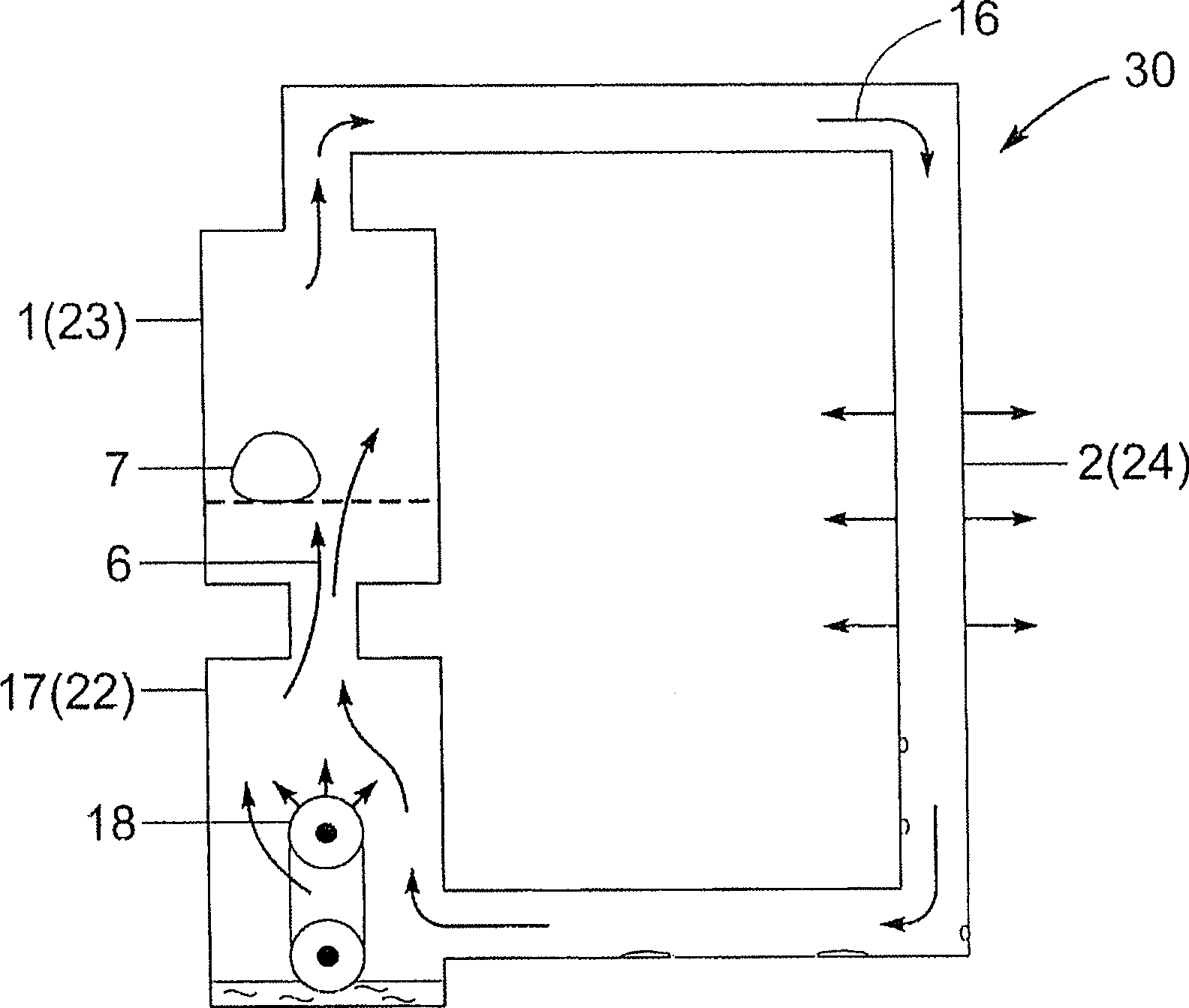

Hot pipe type food steamer and control method thereof

InactiveCN101375767AImproved steam issuesSimple structureStorage heatersSteam cooking vesselsGreenhouseEngineering

The invention relates to a heat pipe-type steamer and a control method thereof. The heat pipe-type steamer comprises a main body, a steam recovery device and a recovered steam heating chamber, which are in the end-to-end connection to form a heat pipe loop using the steam as heat-transfer medium. The recovered steam heating chamber is the heat pipe heat-absorbing end. The steam recovery device is the heat pipe heat-dissipating end. The main body is the heat pipe body. A built-in heat source is arranged inside the recovered steam heating chamber. The steam of the heating chamber is heated by the built-in heat source, then flows through the heat pipe body and reaches the heat pipe heat-dissipating end, and finally flows back to the recovered steam heating chamber and is heated by the built-in heat source again. In the heat pipe loop, the steam is circulated by the convection and upward-floating and the food inside the main body is heated by the circulated steam. In the control method, the cooking process is set in a heat pipe-type steam circulation mode and a steam jet driving mode. When the steam inside the steamer is insufficient, the cooking process is completed in the steam jet driving mode. After the steam is supplemented and the steam temperature reaches the upper limit for cooking, the cooking process is completed in the heat pipe-type steam circulation mode. The food is heated in the two modes alternately.

Owner:徐佳义

Grilling device

ActiveUS8604394B2Fast heatingMore nutritiousLighting and heating apparatusWater heating stoves/rangesEngineeringCooked food

The present invention relates to a grilling device, especially relates to a steam grilling device. It comprises a main body and a steam generator disposed on the main body. Compared to the conventional technique, by adding a steam generator on the main body of grilling device, the grilling device will has not only a general grilling function, but also has the steam heating function, so the heating of the grilling device will speed up, the loss of the nutrition of the food will be eliminated, and it also has effects such as degreasing and freshen, so the cooked food will be more nutritious and healthy.

Owner:TSANN KUEN ZHANGZHOU ENTERPRISE CO LTD

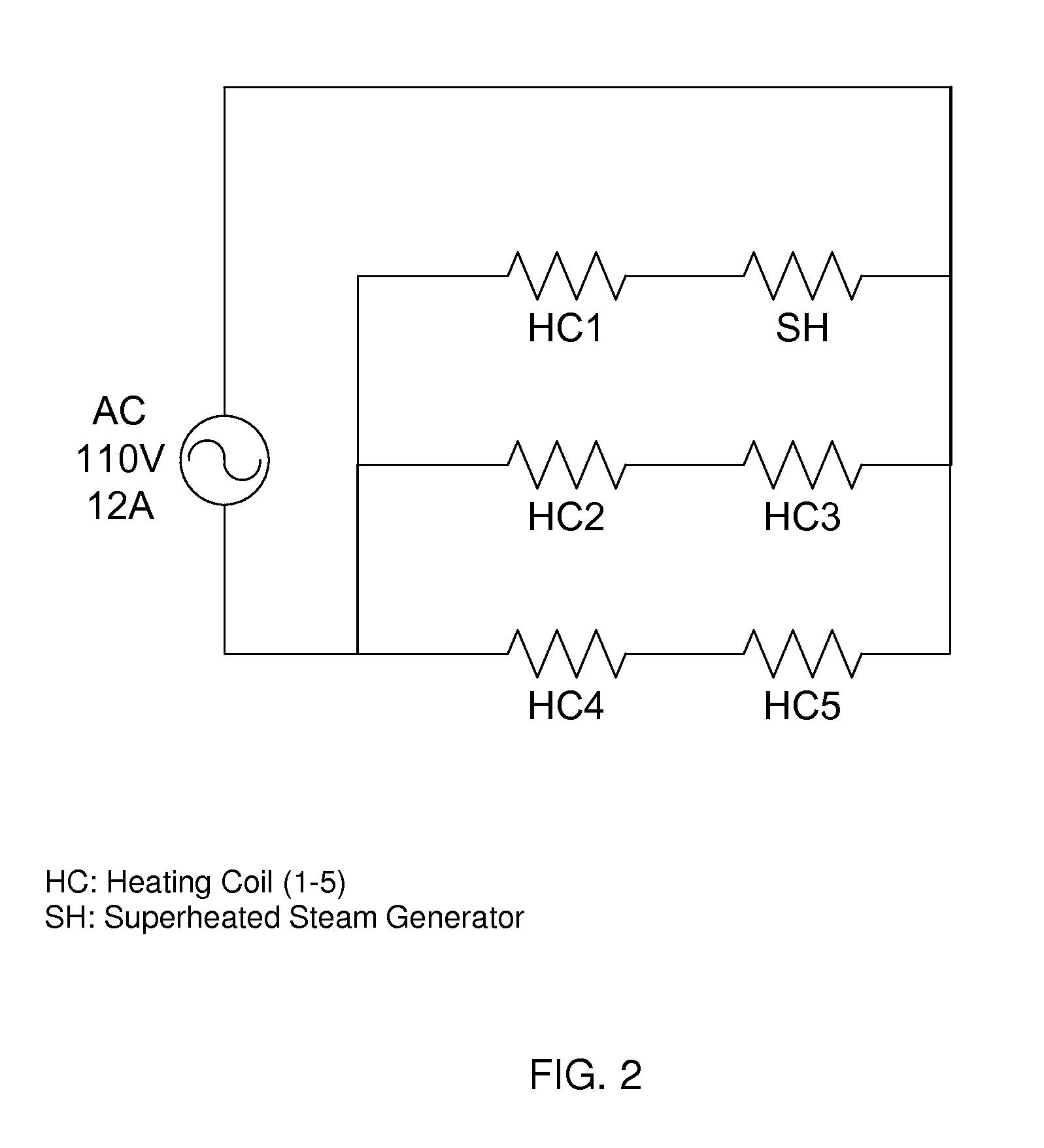

Compact steamer

InactiveUS20160018100A1Minimizing damageHigh enthalpySteam generation heating methodsHand ironHand heldEngineering

A compact steaming device, which may be handheld, and method for the generation at one atmosphere and projection of superheated steam over objects and surfaces for the elimination and control of unwanted microorganisms and pests including, but not limited to bedbugs, fleas, ants, lice and mites. A preferred embodiment of such a compact device comprises a vessel, a base, heating coils, a superheated steam generator and an external power supply for the initial boiling of a liquid to vapor and for subsequent heating of the vapor to superheated temperatures. The device and method allow for the generation of steam or gas and subsequent superheating to be accomplished safely at one atmosphere. The preferred embodiment allows for the free flow of the gas through and out of the compact device safely and effectively relieving any resulting pressure. A multi-watt embodiment is also envisioned which may be handheld or stationary.

Owner:MICROPYRETICS HEATERS INT

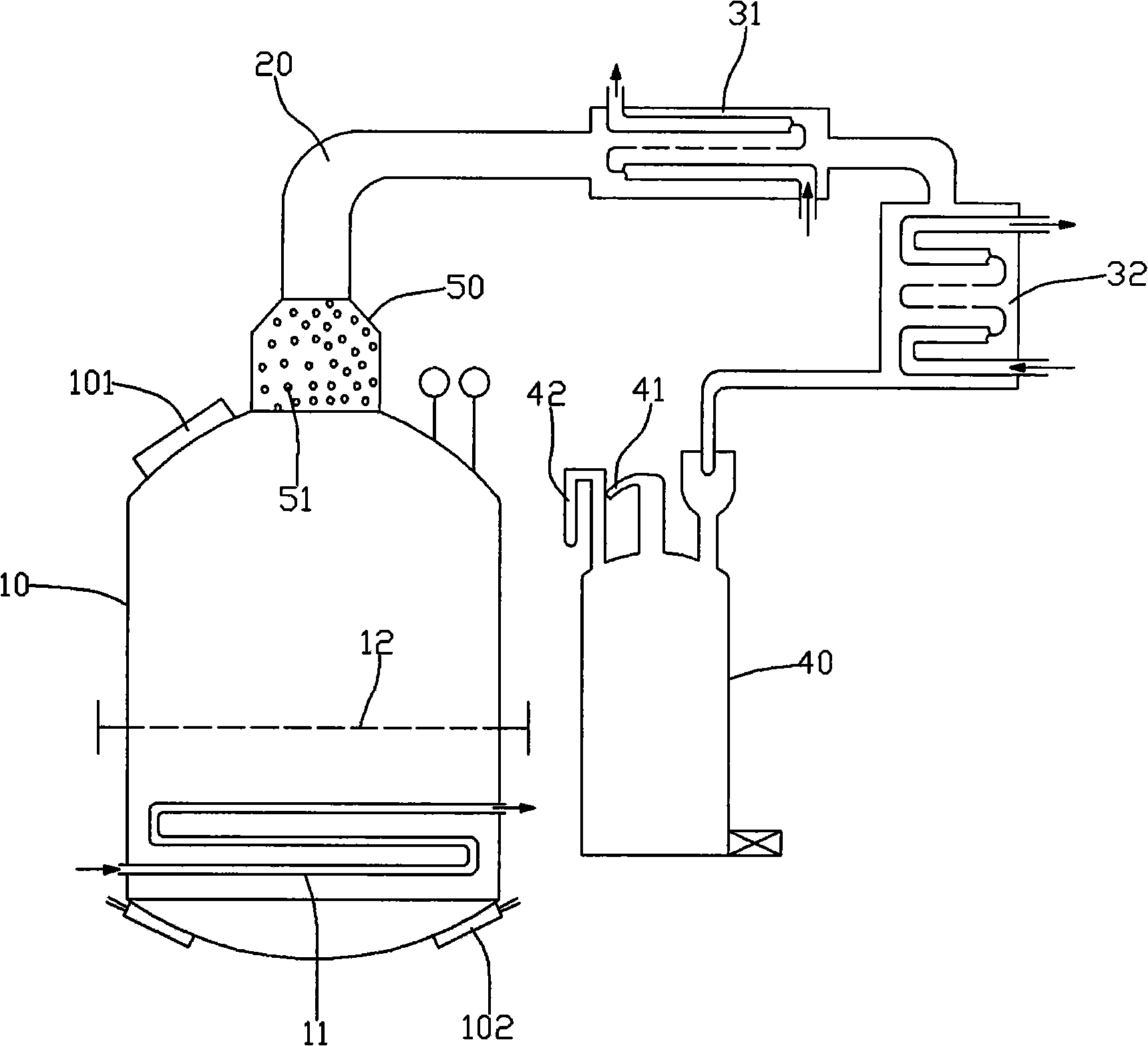

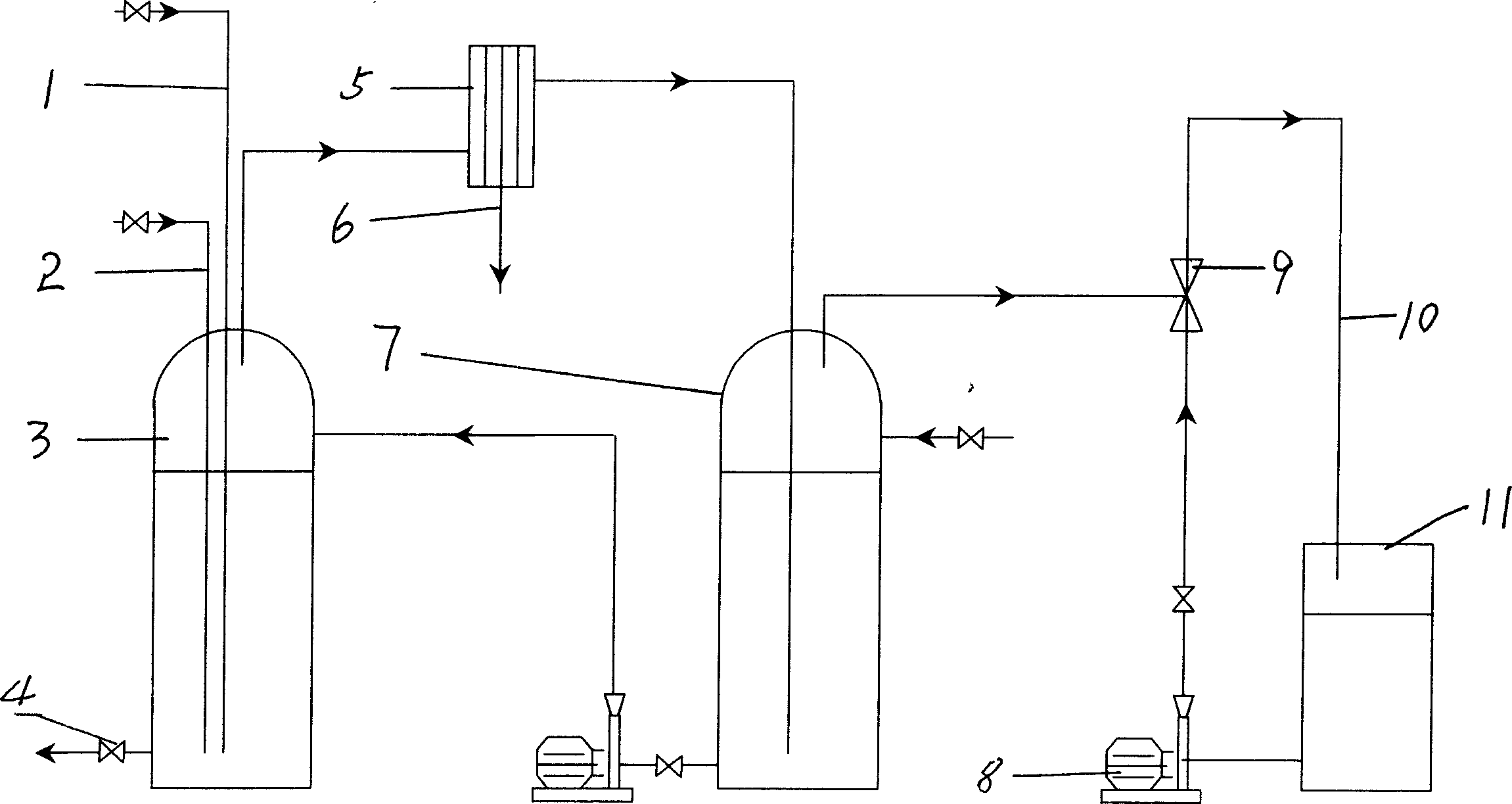

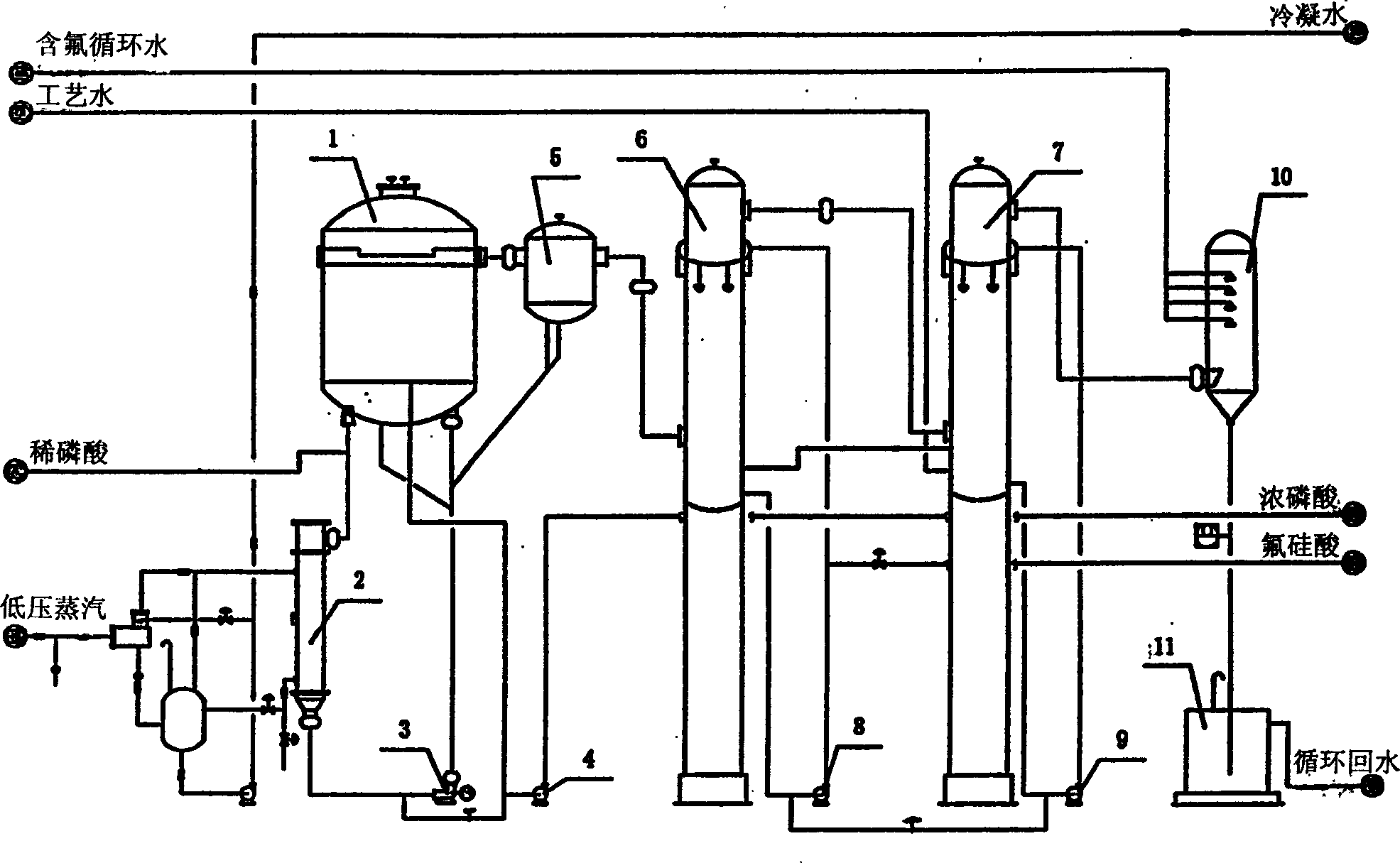

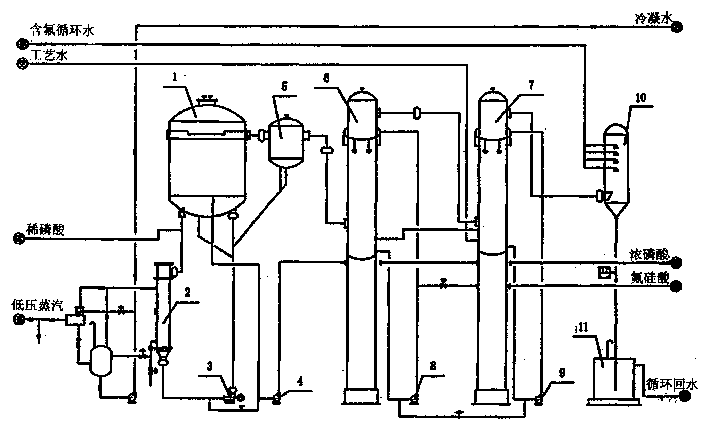

Method for producing phosphoric acid by adopting steam heating forced circulation concentration wet process and its equipment

InactiveCN1460636ALess process equipmentCompact layoutSilicon halogen compoundsPhosphorus compoundsGas phasePhosphoric acid

The phosphoric acid can be circularly heated and concentrated in a circulating loop formed from flash chamber, graphitic heat exchanger and axial-flow circulating pump, the diluted phosphoric acid can be added into the circulating loop from outlet pipe of graphitic heat exchanger, and the evaporated steam can be passed through the entrainment eliminator to remove entrained acid foam, then the steam is more passed through two-stage fluorine absorbing tower, sprayed and washed so as to recover fluoride in the gas phase. The vacuum required for flash chamber is provided by atmosphere condenser. Said invention can make wet phosphoric acid be concentrated to 48-50% P2O5 from 20-25% P2O5.

Owner:EAST CHINA ENG SCI & TECH

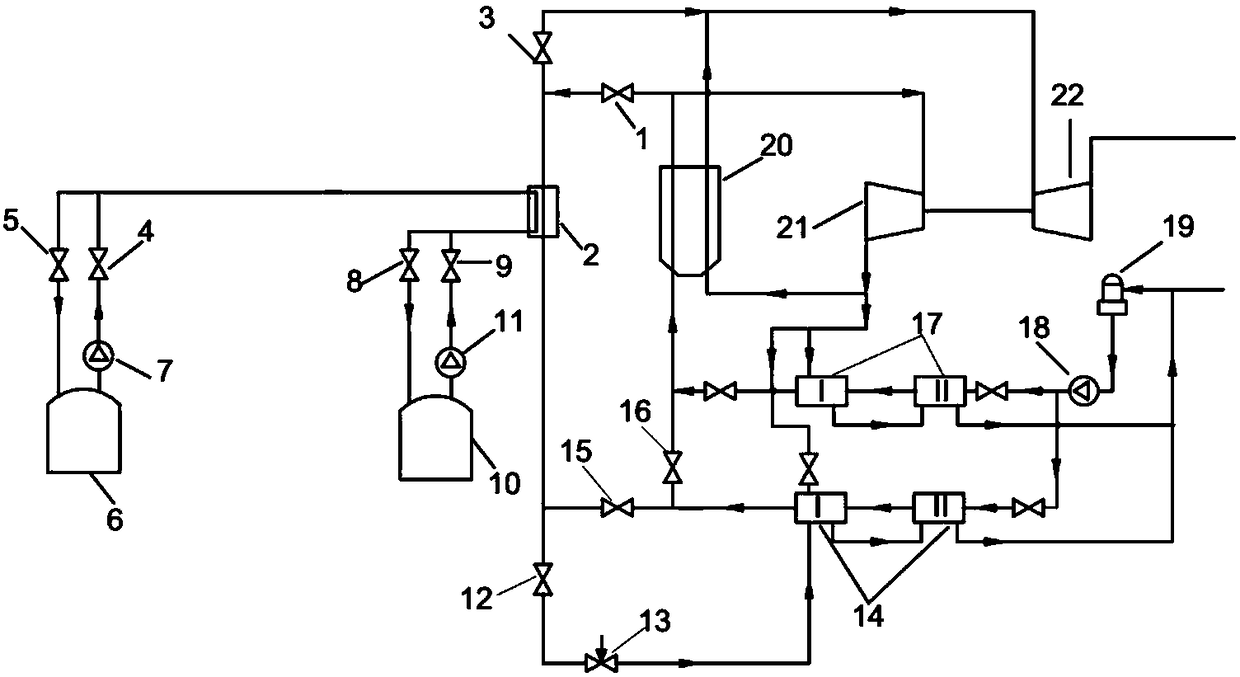

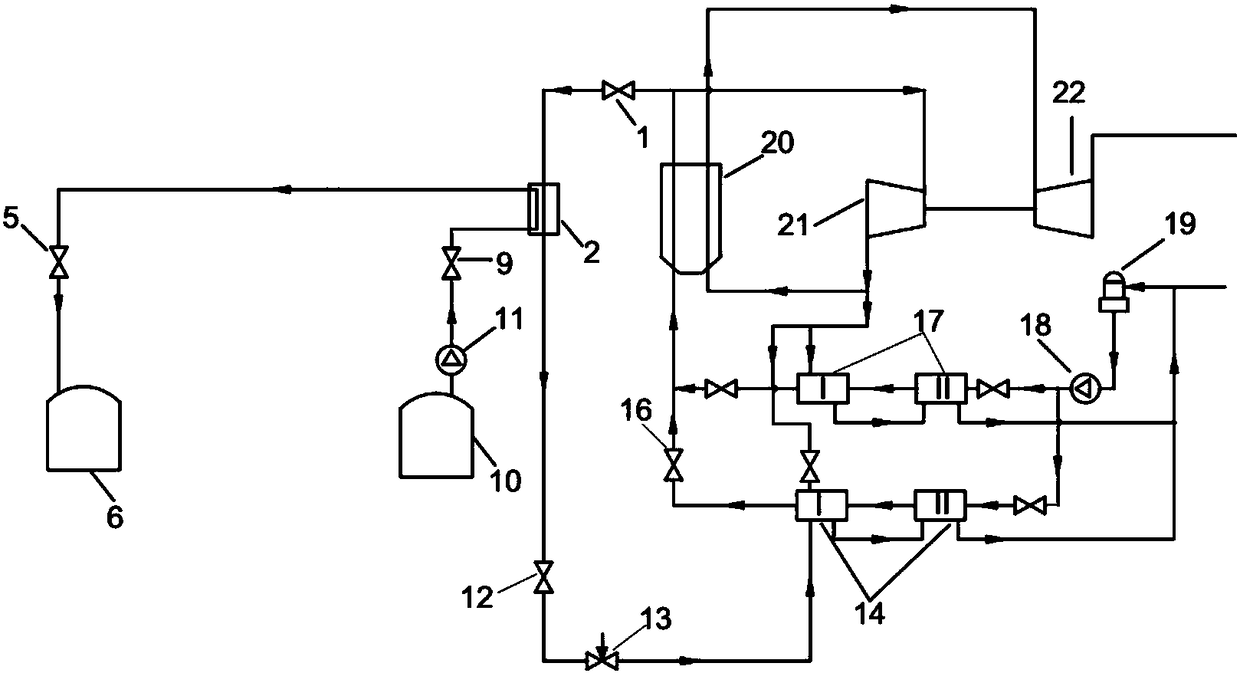

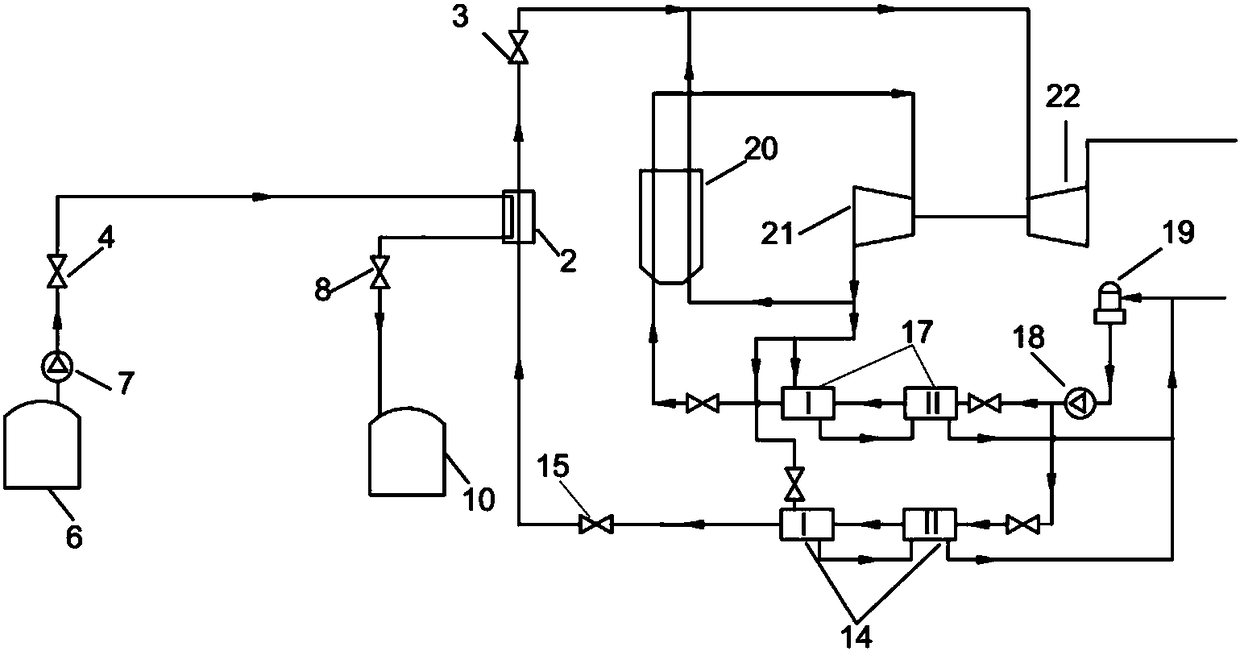

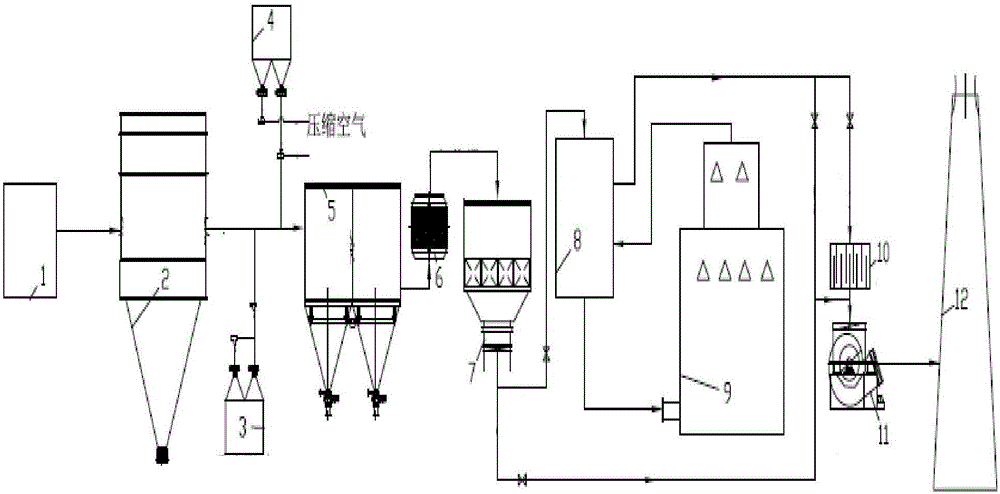

Waste incineration flue gas purifying treatment system

InactiveCN106215563AOptimize process flowMeet ultra-low emission requirementsGas treatmentDispersed particle filtrationActivated carbonBaghouse

The invention provides a waste incineration flue gas purifying treatment system. The waste incineration flue gas purifying treatment system comprises SNCR denitration, semi-dry-process deacidification, dry-process deacidification and cooling, activated carbon adsorption, cloth bag dust removal, steam heating, low-temperature SCR denitration, flue gas heat exchange, wet-process deacidification and flue gas white mist removal which are sequentially implemented, wherein the SNCR denitration is performed in an SNCR device, the semi-dry-process deacidification is performed in a semi-dry-process reaction tower, the dry-process deacidification and cooling are performed in the dry-process deacidification tower, the activated carbon adsorption and the cloth bag dust removal are performed in a cloth bag dust remover, the steam heating is performed in a steam heater arranged between the cloth bag dust remover and a low-temperature SCR device, the low-temperature SCR denitration is performed in the low-temperature SCR device, flue gas heat exchange is performed in a flue gas / flue gas heat exchanger arranged between the low-temperature SCR device and a wet-process scrubbing tower, the wet-process deacidification is performed in the wet-process scrubbing tower, and the flue gas white mist removal is performed in another steam heater. The particulate matter, dioxin, heavy metals and acidic gas in flue gas are removed to the most degree, and the ultra-low emission requirements are met.

Owner:EVERBRIGHT ENVIRONMENTAL PROTECTION TECH RES INST SHENZHEN CO LTD

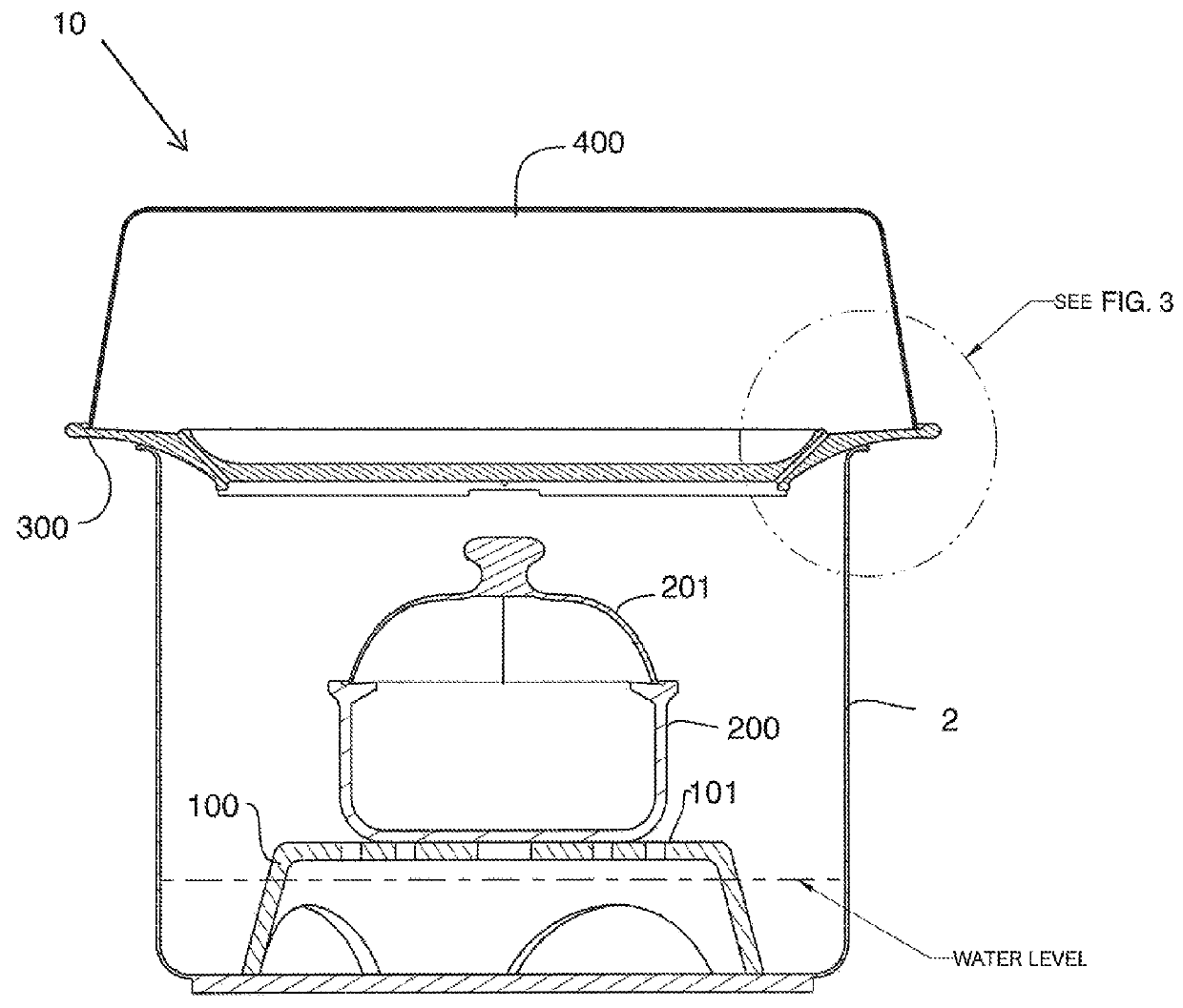

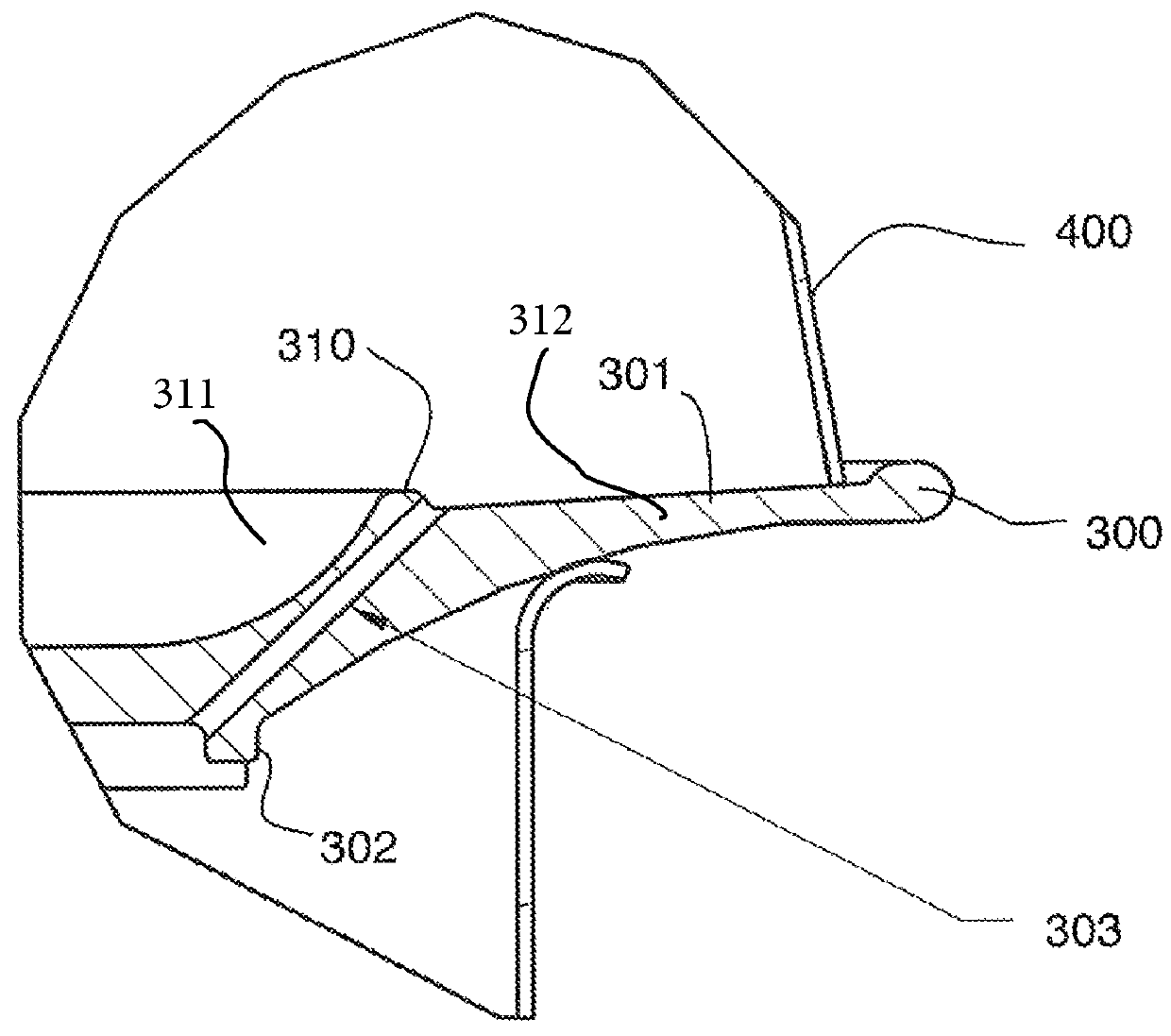

Steam cooking apparatus and method of use

ActiveUS9961929B2Heated quicker and moreFood contentMultiple-unit cooking vesselsSteam cooking vesselsSteam cookingEngineering

The present invention provides an apparatus for the steaming heating of food. The apparatus is designed for placement within and onto an outer vessel. The apparatus including a steaming pedestal, bowl, bowl lid, steaming platform, lid, bowl plate, and under plate. The steaming platform including a plurality of venting / draining apertures and flange.

Owner:OLSSON MATTHEW K

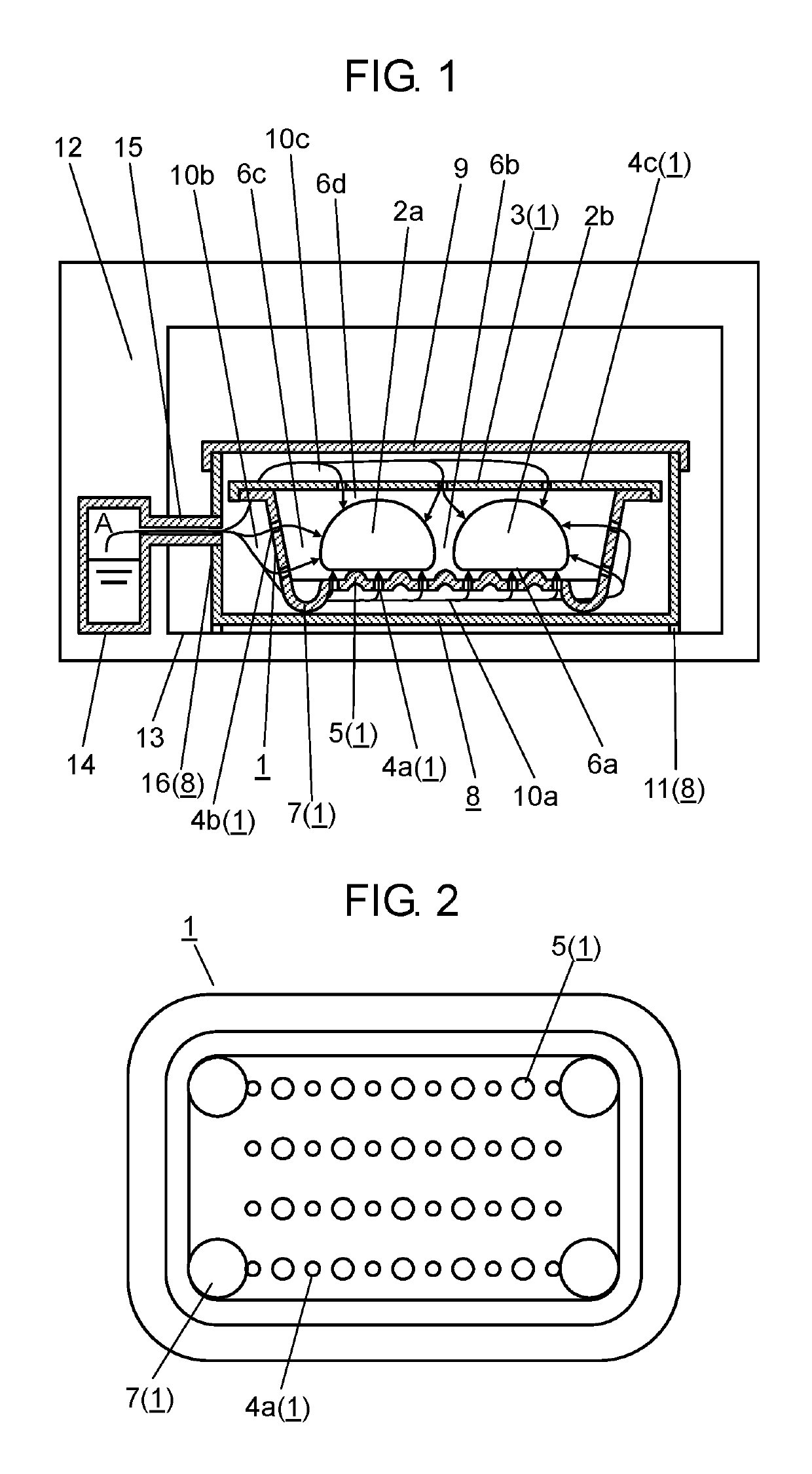

Foods in food container, and heating device for foods in food container

ActiveUS10368681B2Easy to reachQuickly subjected to steam heatingFood preservationCooking vesselsFood contact materialsEngineering

A heating device for a food item in a food container includes the food container that contains the food items, a cooking container that contains the food container, and a steam generation device that supplies steam into the cooking container. The food container has an opening hole that communicates with an internal space and an external space, and at least one of a food surrounding space provided between an inner wall of the food container and the food items, and between the food items. The food surrounding space and the external space are communicated with each other through the opening hole, and steam is supplied into the cooking container to heat the food items by the steam. Thereby, the heating device for a food item in a food container that can subject the food item in the cooking container to steam heating can be provided.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Formula and process for producing polymeric aluminum chloride

InactiveCN101531388AReduce moisture contentAchieve reuseAluminium chloridesWater/sewage treatment by flocculation/precipitationAluminium chlorideAluminium chlorohydrate

The invention relates to a formula and a process for producing polymeric aluminum chloride. 5 tons of running water are added into a reaction tank and 14.2 tons of 31 percent hydrochloric acid are added into the reaction tank at the same time, and stirring is started for uniformly mixing; steam heating is started, 4.25 tons of bauxite are put at the same time, the timing is started when the temperature reaches 95 DEG C, and the reaction time is 40 to 60 minutes; after the reaction completes, the temperature is kept above 75 DEG C, 5 tons of calcium aluminum powder are put when 8 tons of running water are added, and the temperature is kept above 95 DEG C after the addition of the running water and the calcium aluminum powder completes for reaction for 2 hours; after the reaction completes, 5 tons of running water are added, and after the aluminum oxide content is adjusted to 10.0 percent, the mixture in the reaction tank is transferred to a sedimentation tank to allow large sludge particles to settle; after the content of the polymeric aluminum chloride water insoluble matters in the sedimentation tank reach 2.0 percent, the sludge is furthered removed to form a qualified product through the treatment of sludge-removing equipment; and water content in the sludge is reduced and the COD removal rate is improved.

Owner:DONGYING HUATAI FINE CHEM

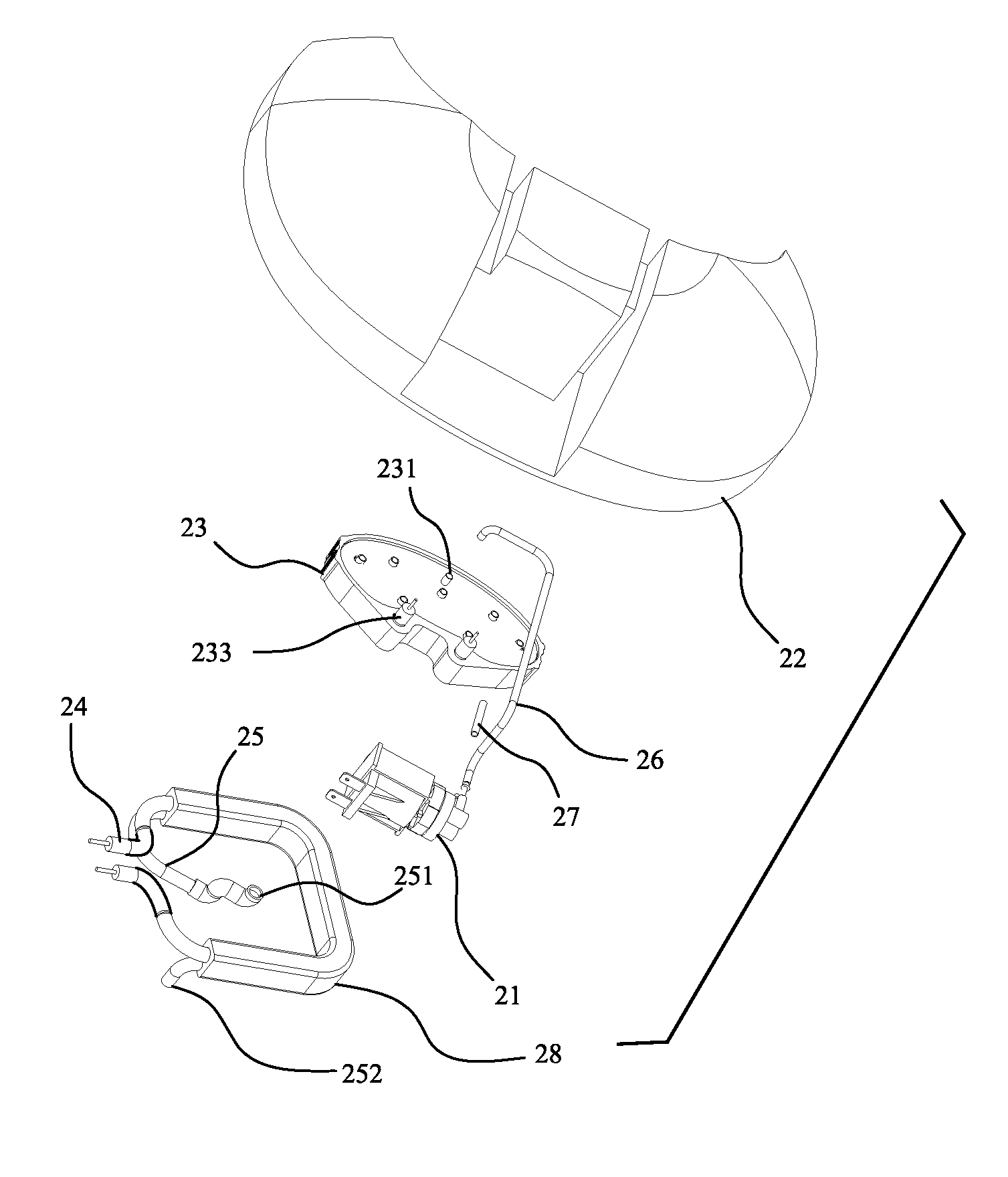

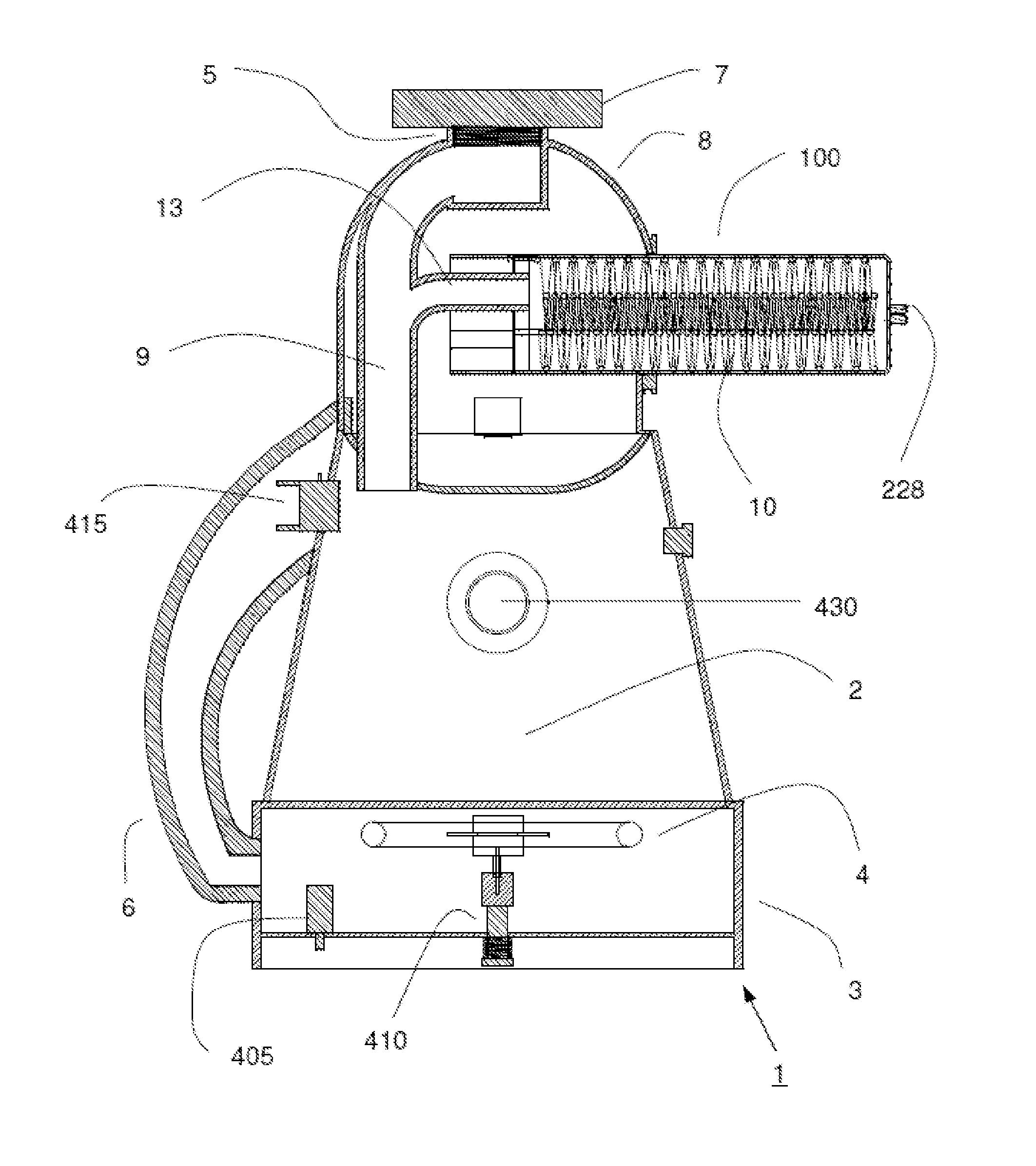

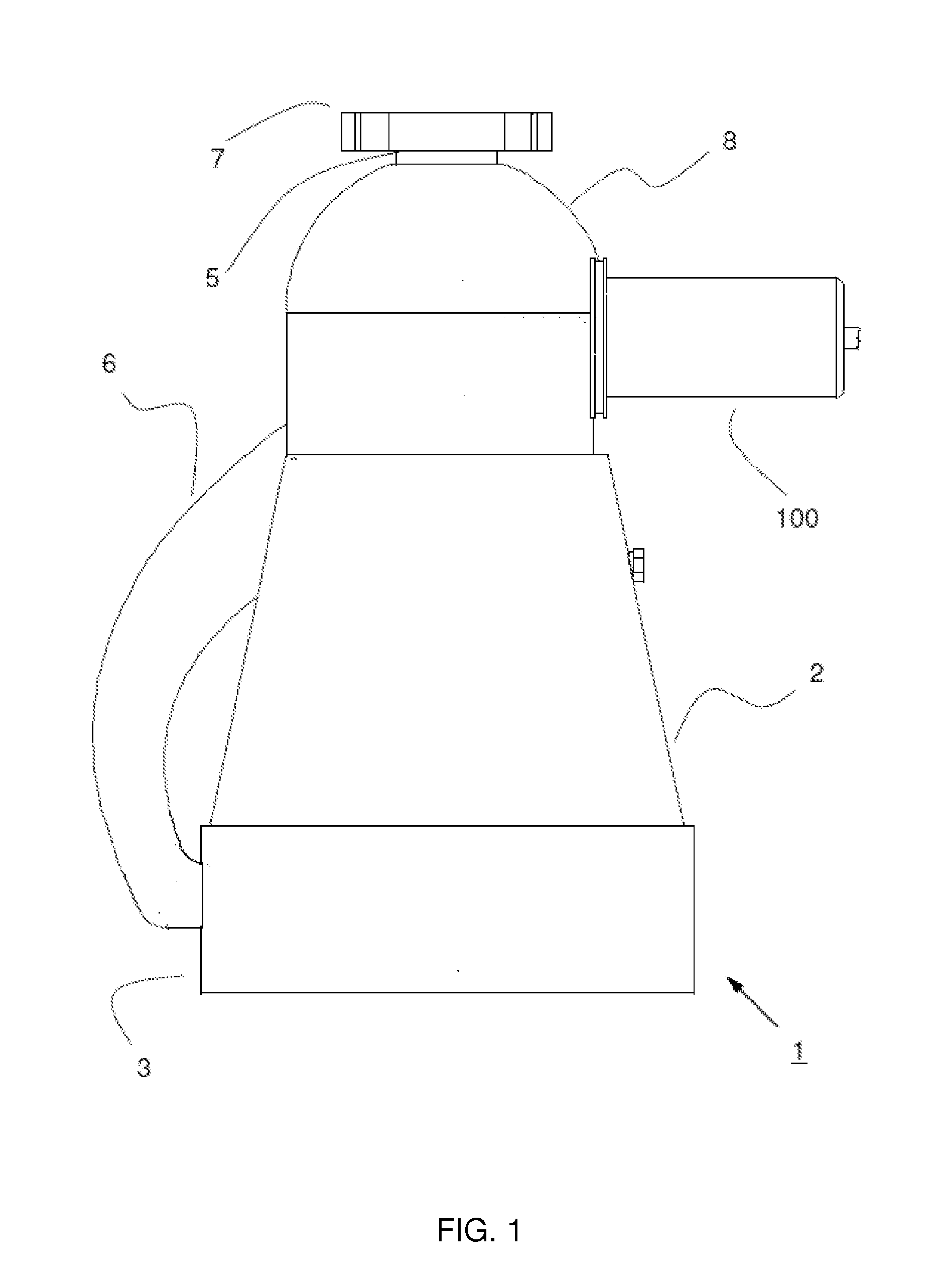

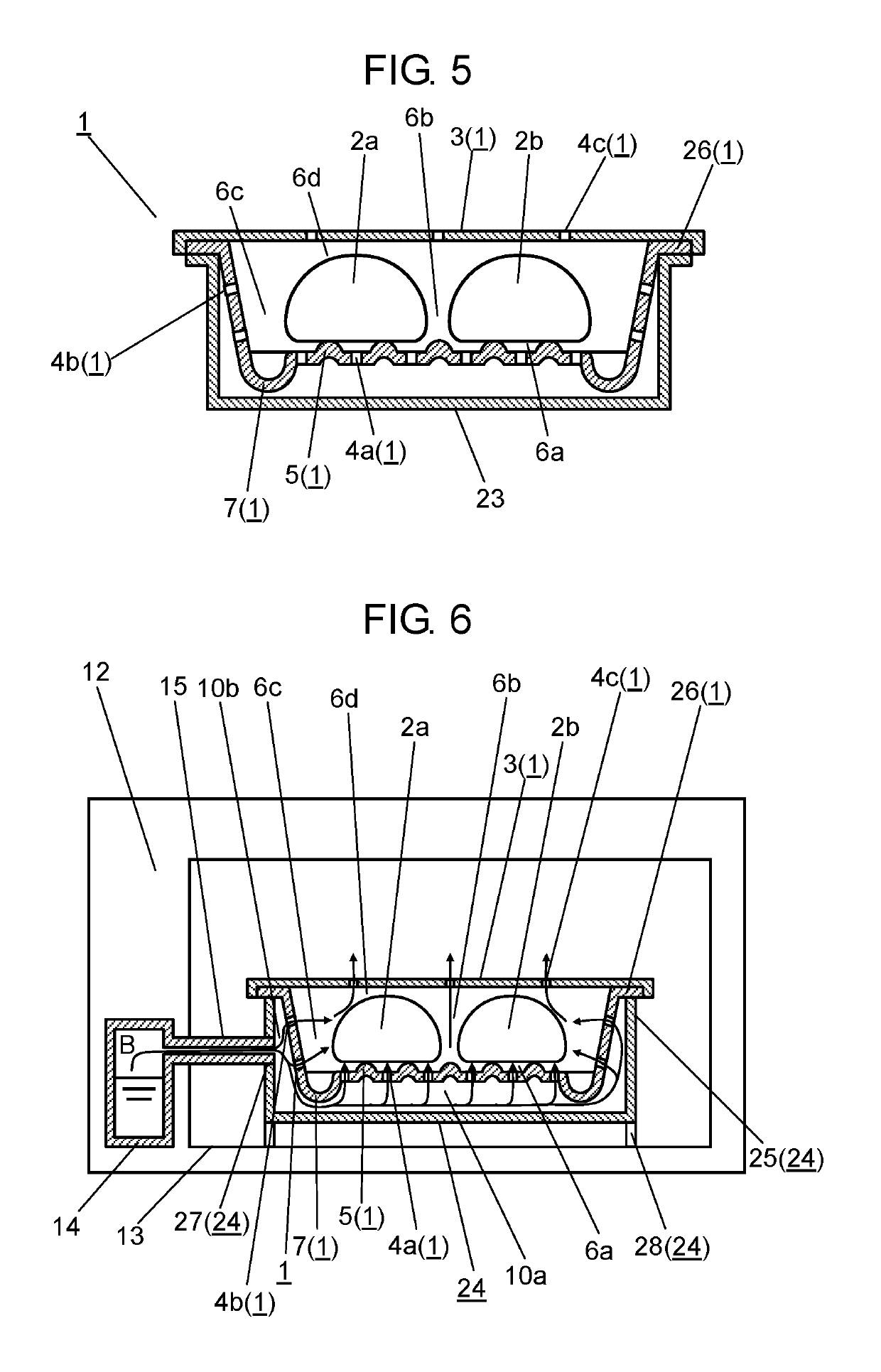

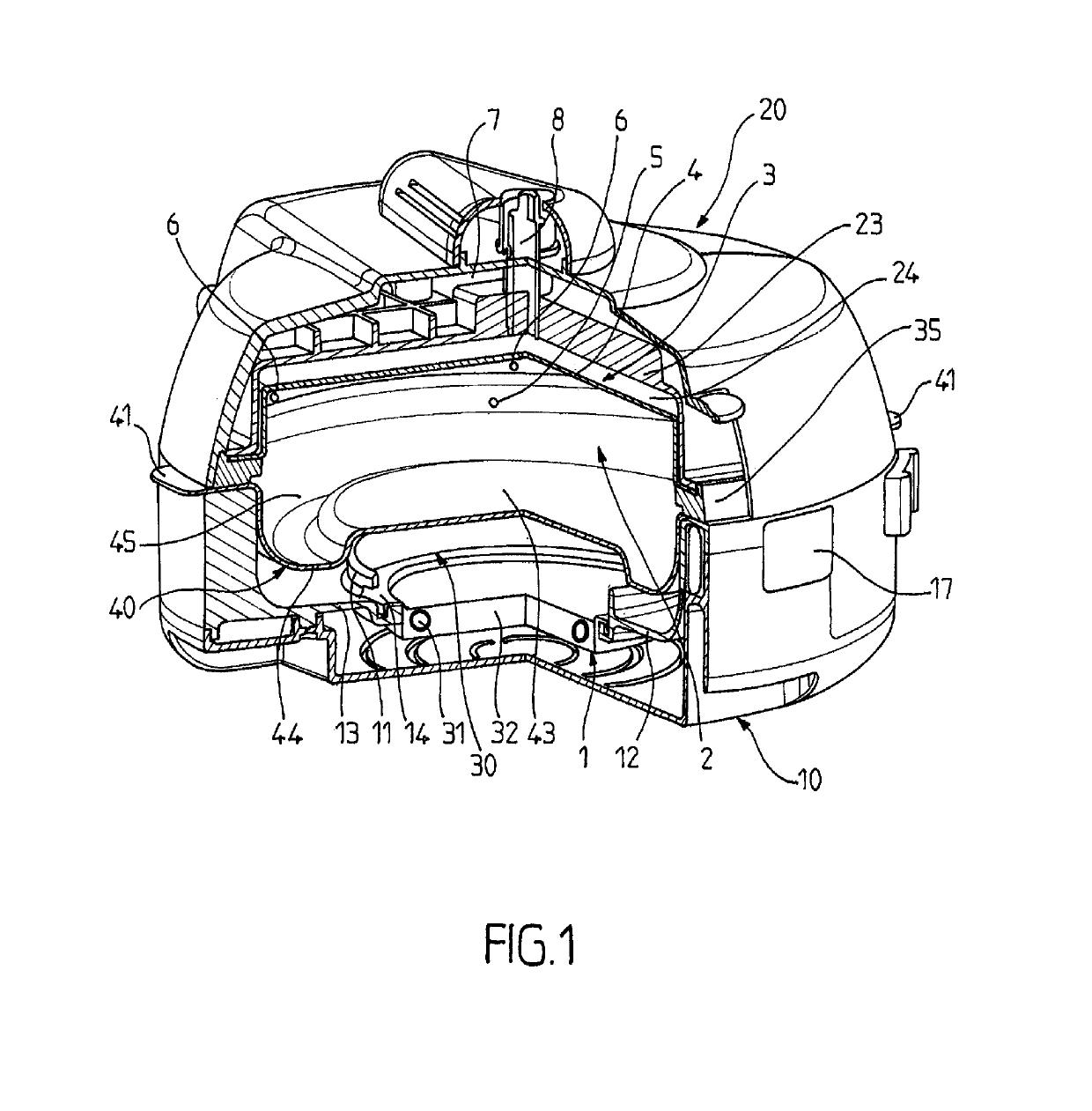

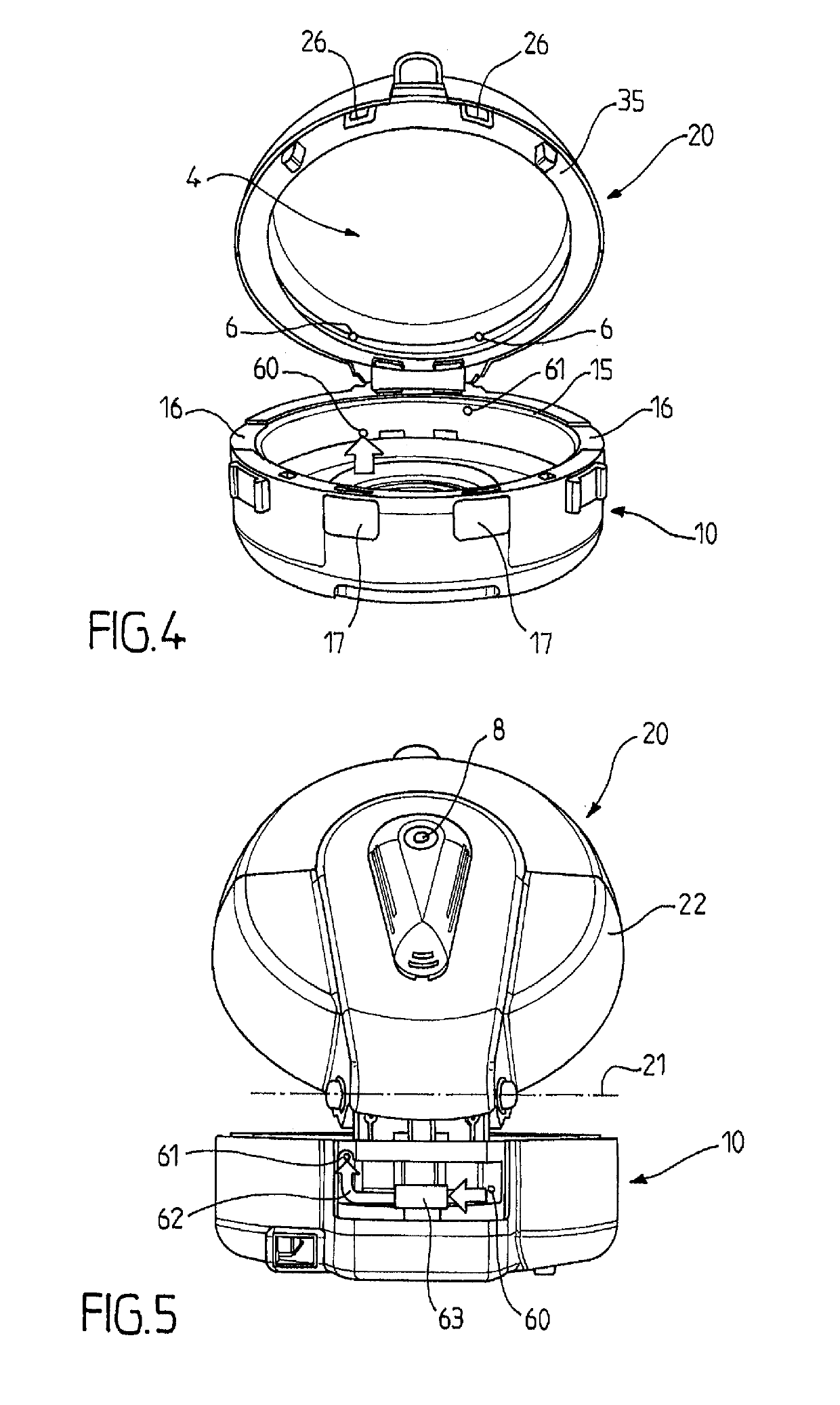

Electric appliance for heating and/or cooking food with steam

ActiveUS10499760B2Easy constructionTime period is limitedBoiling over preventionSteam cooking vesselsEngineeringExpansion chamber

Provided is a food cooking and / or heating appliance including an enclosure (2) including a reservoir (40) and a cover (20), and a steam production device. The cover (20) is equipped with a steam expansion chamber (3) supplied with steam by the steam production device (1). The steam expansion chamber (3) includes a containment wall (4) delimiting part of the enclosure (2) and the containment wall (4) can move in relation to the reservoir (40) when the cover (20) closes the enclosure (2).

Owner:SEB SA

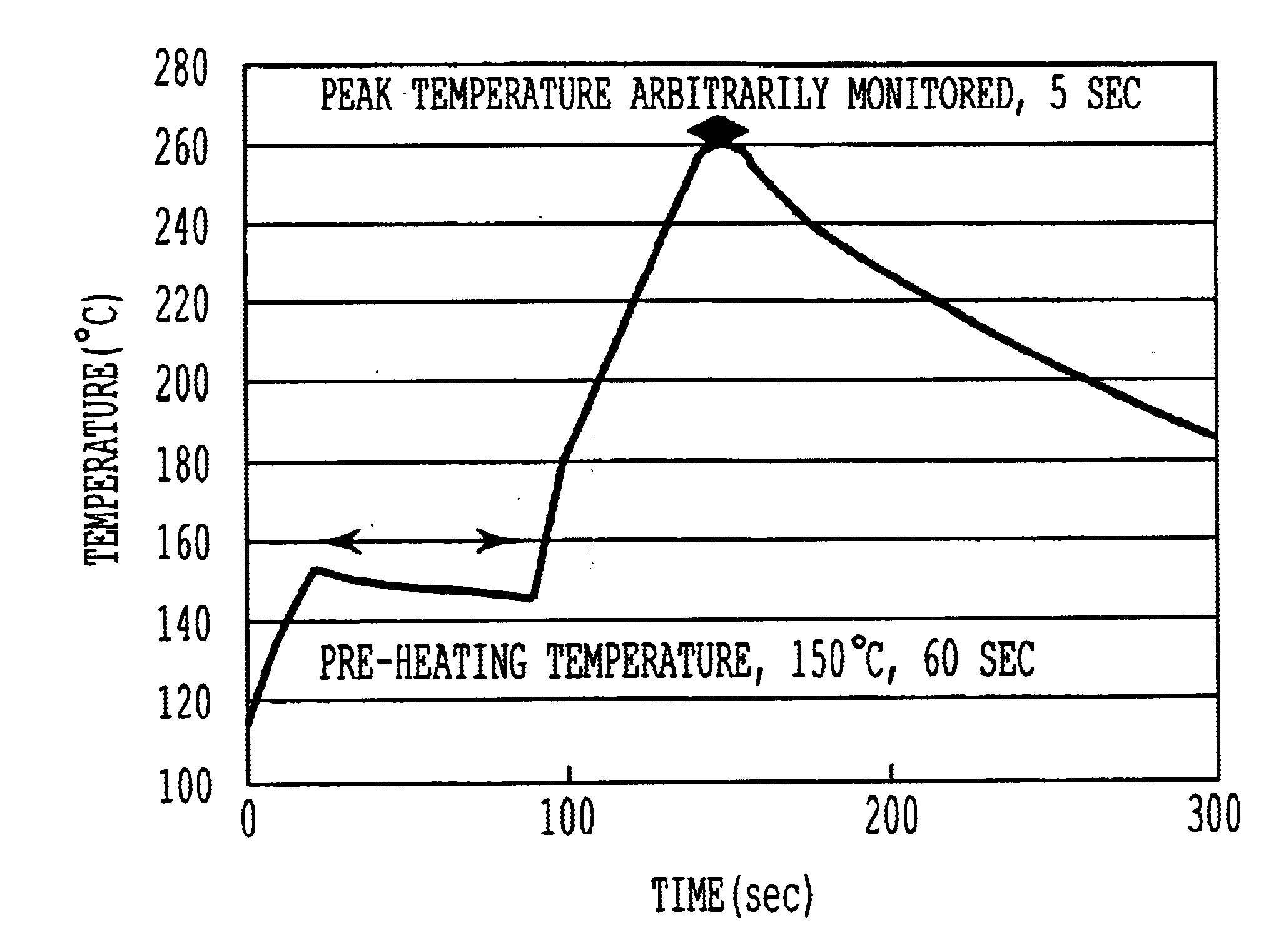

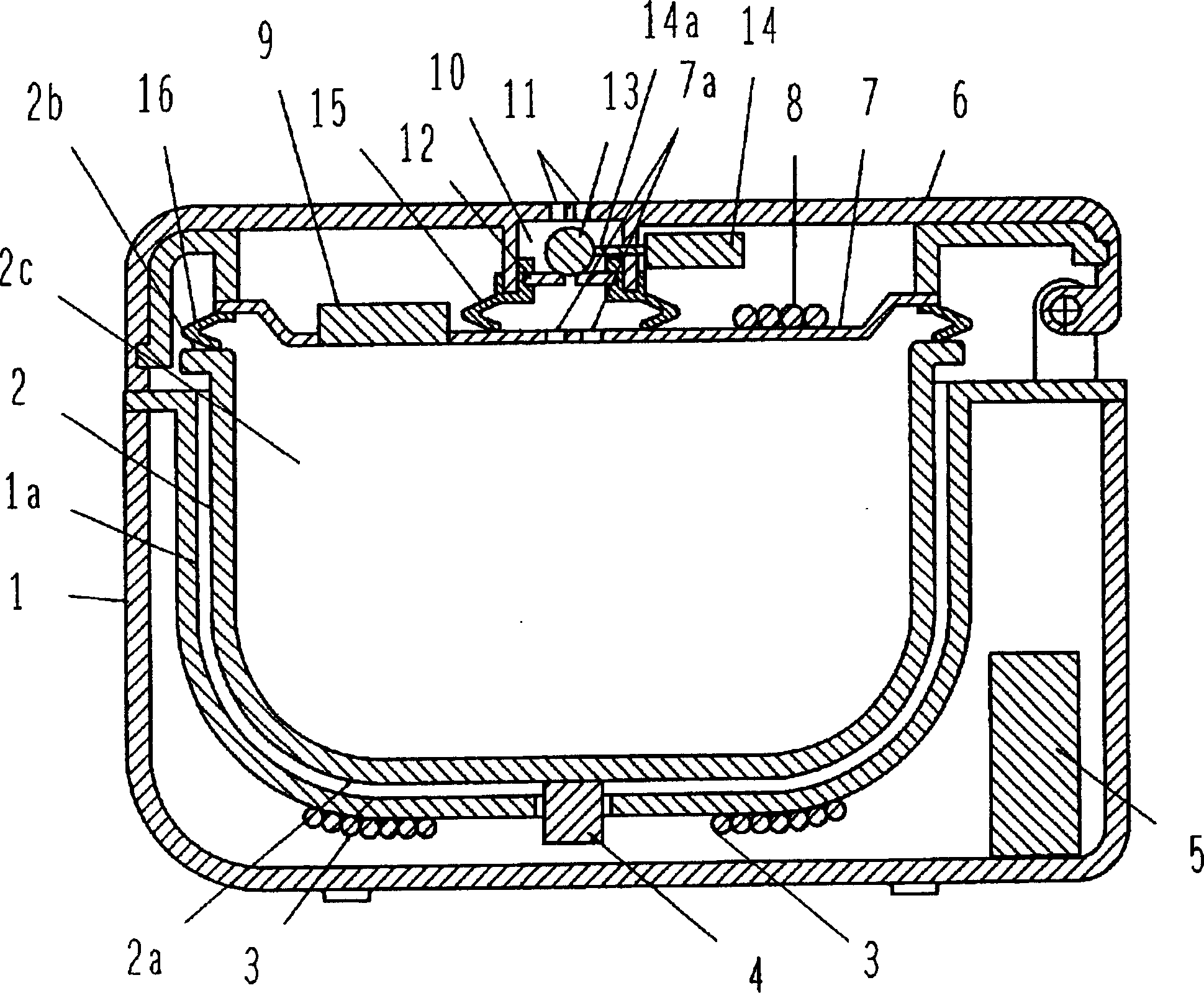

Heating cooker

ActiveUS10638869B2Shorten the timeGreat effortDomestic stoves or rangesLighting and heating apparatusThermodynamicsSteam pressure

By preheating temperature raising unit of a steam and hot water generating device beforehand to a predetermined temperature, and supplying water in an amount equal to or more than predetermined amount V (per unit time) to the temperature raising unit, a large amount of steam is instantaneously generated. At this time, hot water adhered to the temperature raising unit rises along with the steam, and the steam and hot water flowed through a steam hole, a relay tube, and a steam chamber are caused to eject instantaneously with accumulated steam pressure from a steam and hot water discharging port. The steam and hot water then hit and heat food products accommodated in a cooking chamber. Thus, a heating cooker capable of promptly heating a food product with steam can be provided.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

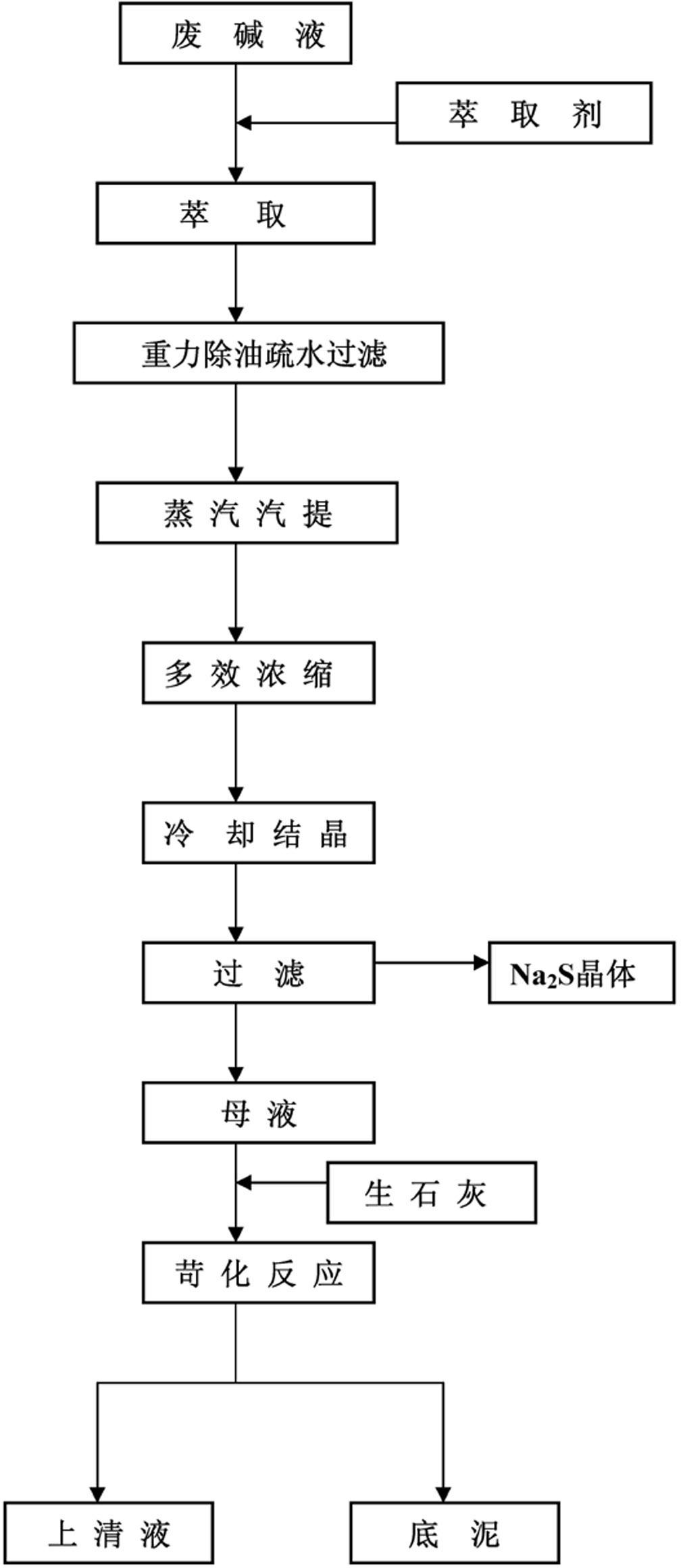

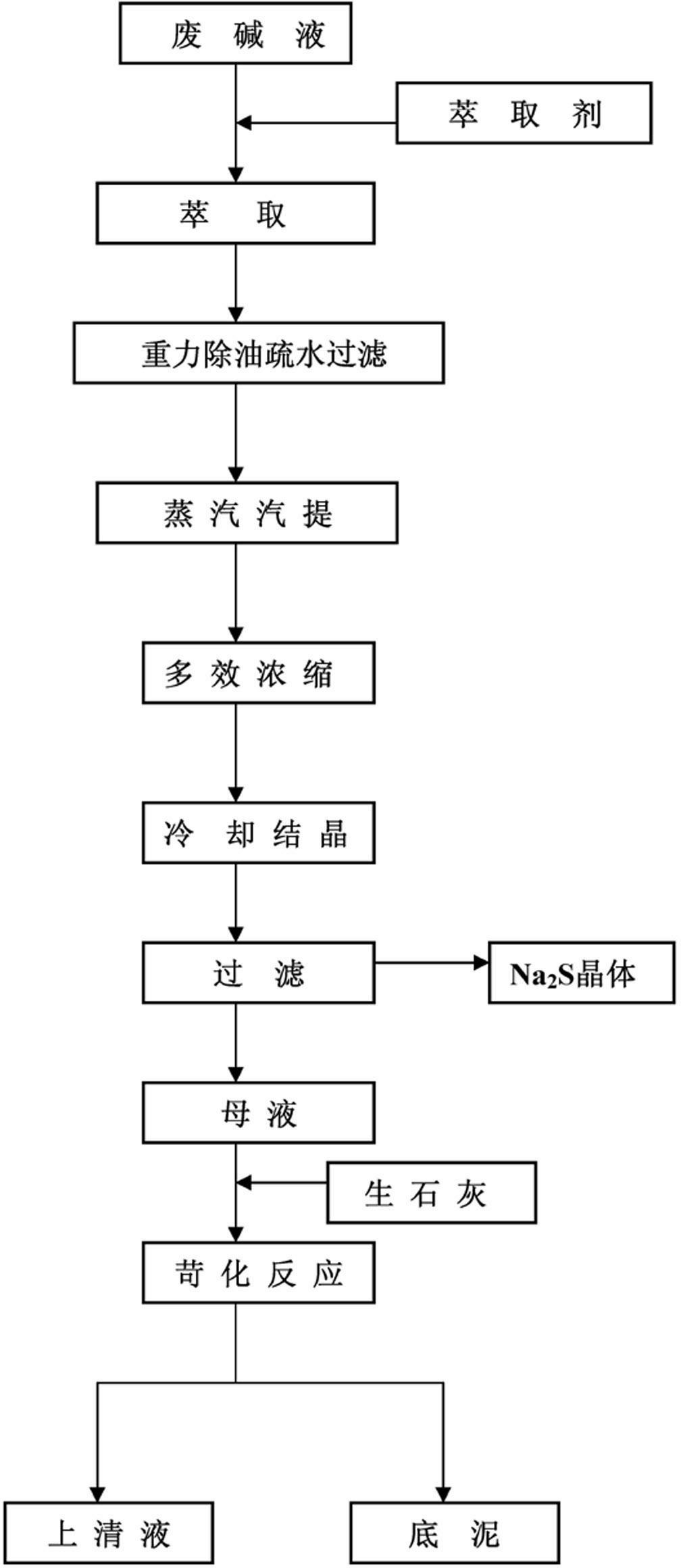

Circular and comprehensive utilization method for ethylene alkali waste liquid

ActiveCN102424498AEfficient use ofAchieving zero emissionsMultistage water/sewage treatmentWater/sewage treatment by heatingCement factoryEnvironmental engineering

The invention relates to a circular and comprehensive utilization method for ethylene alkali waste liquid. The method is characterized in that oil in waste alkali is extracted by an extractant firstly, a hydrophobic type filtering gravity oil removal tank is used for removing a oil-containing suspended substance in alkali waste liquid, hydrocarbons substances dissolved in the alkali waste liquid can be steamed by selecting an indirect steam heating stripping method, then the alkali waste liquid is evaporated and concentrated so that the Na2S concentration in the alkali liquid can reach more than 15%, and the Na2S is precipitated through cooling and crystallizing, crystals can be filtered to obtain mother liquor, the mother liquor is carried out causticizing reaction by adding quicklime, precipitated to obtain a supernatant and bottom mud, the supernatant is returned for ethylene circular and comprehensive utilization, the obtained bottom mud can be used as a raw material for cement mill. The method of the invention solves four problems of oil substances (comprising suspended substances) removal, residual alkali comprehensive disposal, sulfide treatment and dissolved organic matterdegradation in circular and comprehensive utilization of the ethylene alkali waste liquid, the ethylene alkali waste liquid treatment realizes sewage zero-discharge, saves resource and energy, and accords with circular economy idea.

Owner:珠海横琴恒生源环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com